Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "High insulation breakdown voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

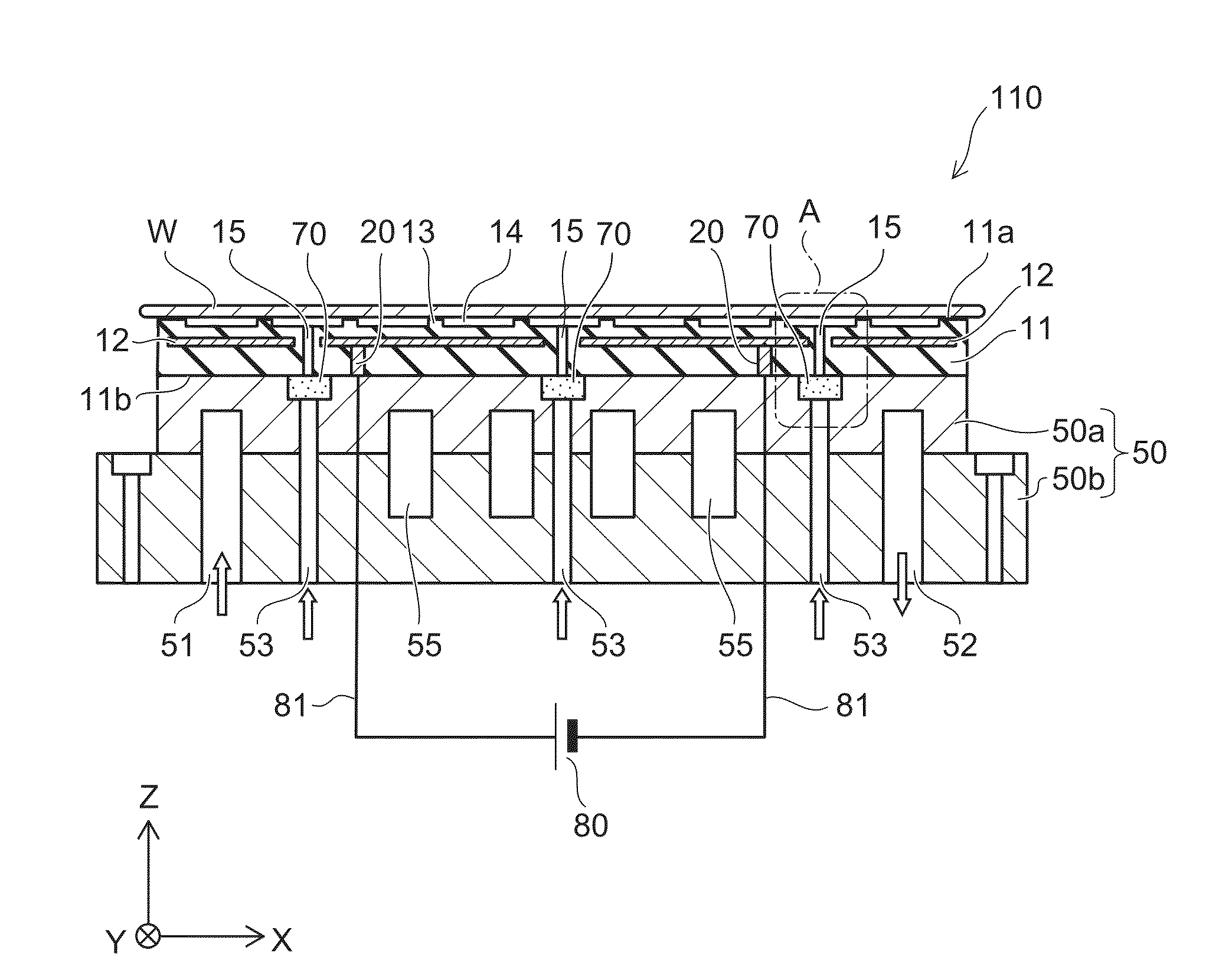

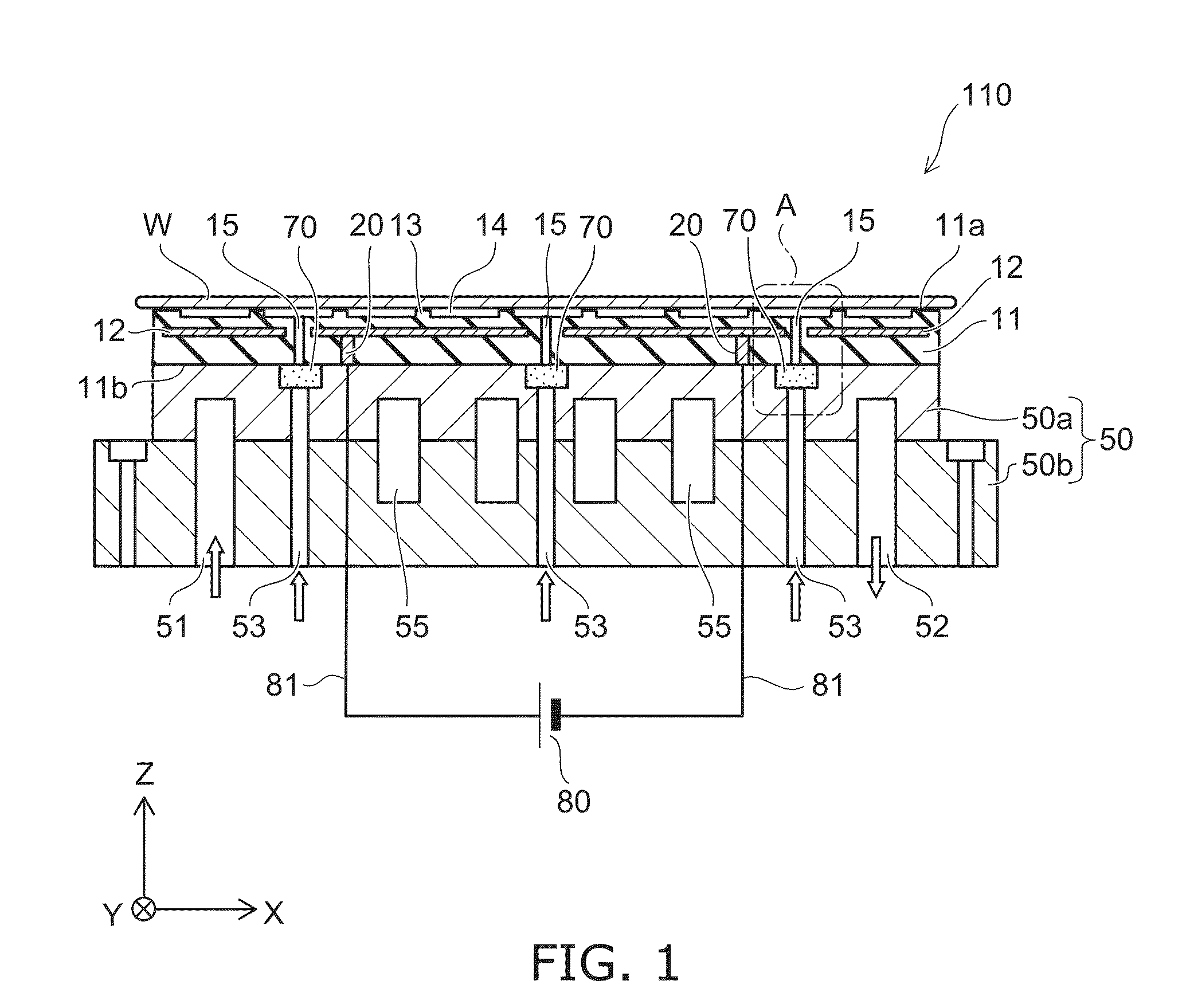

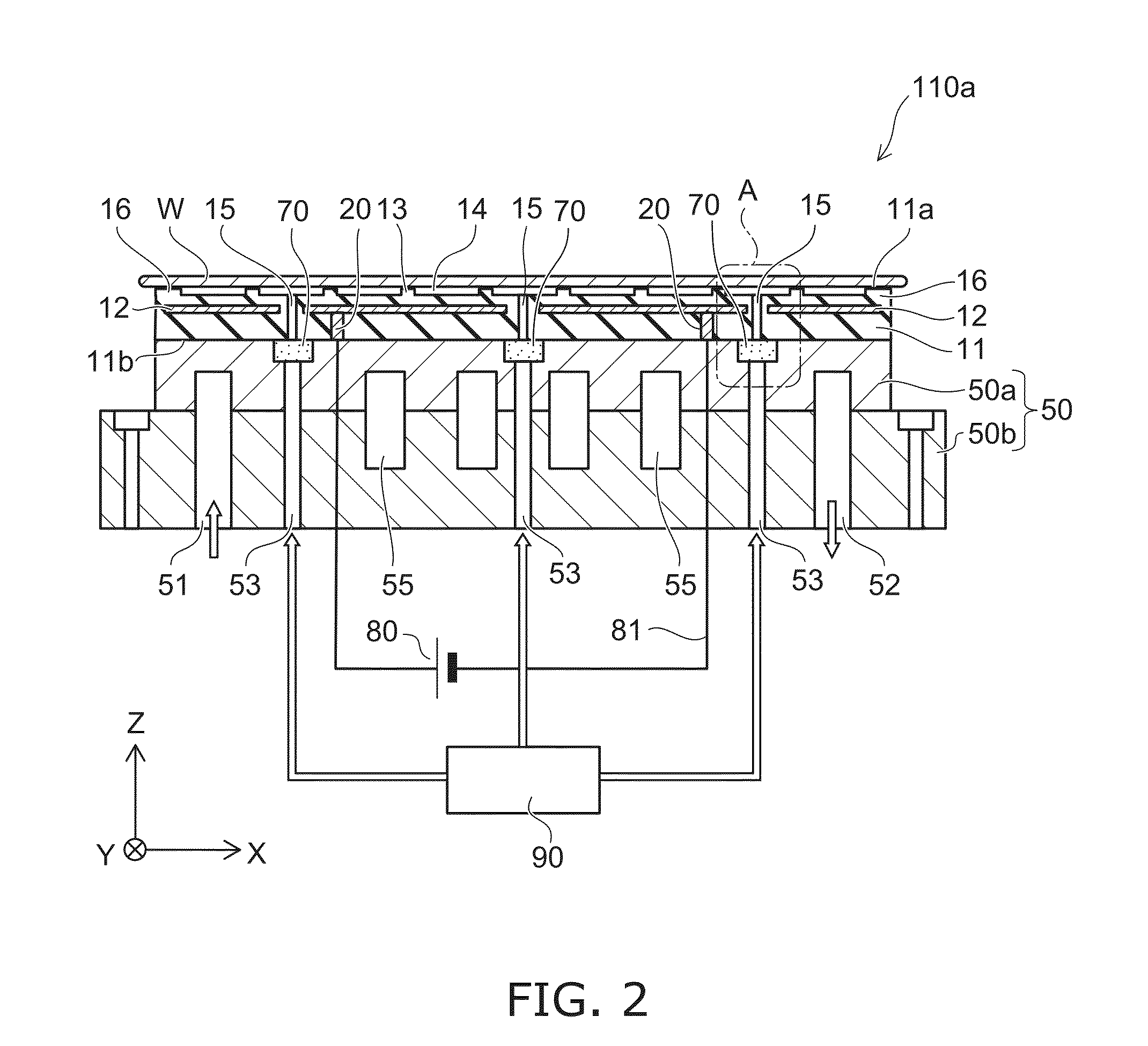

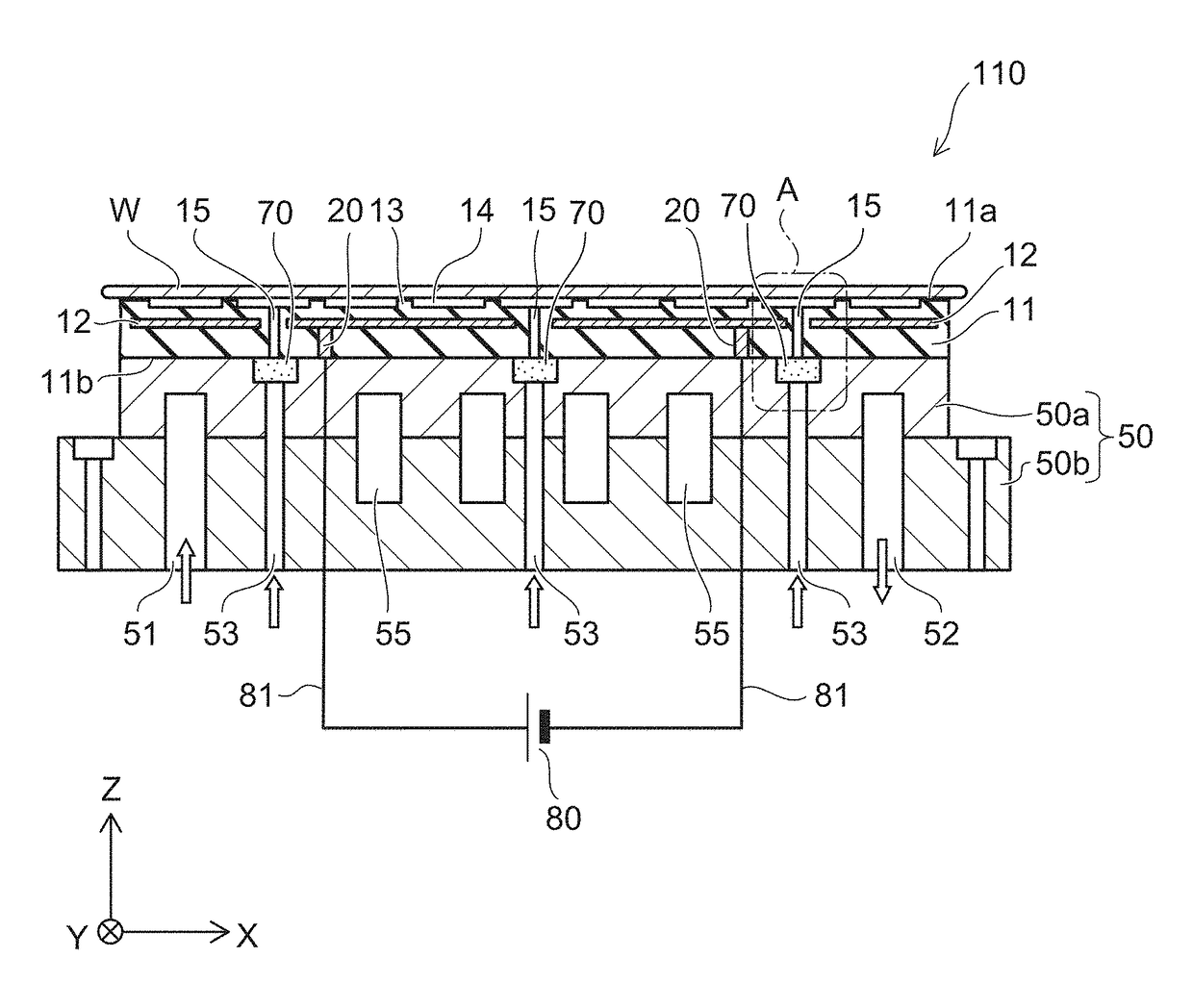

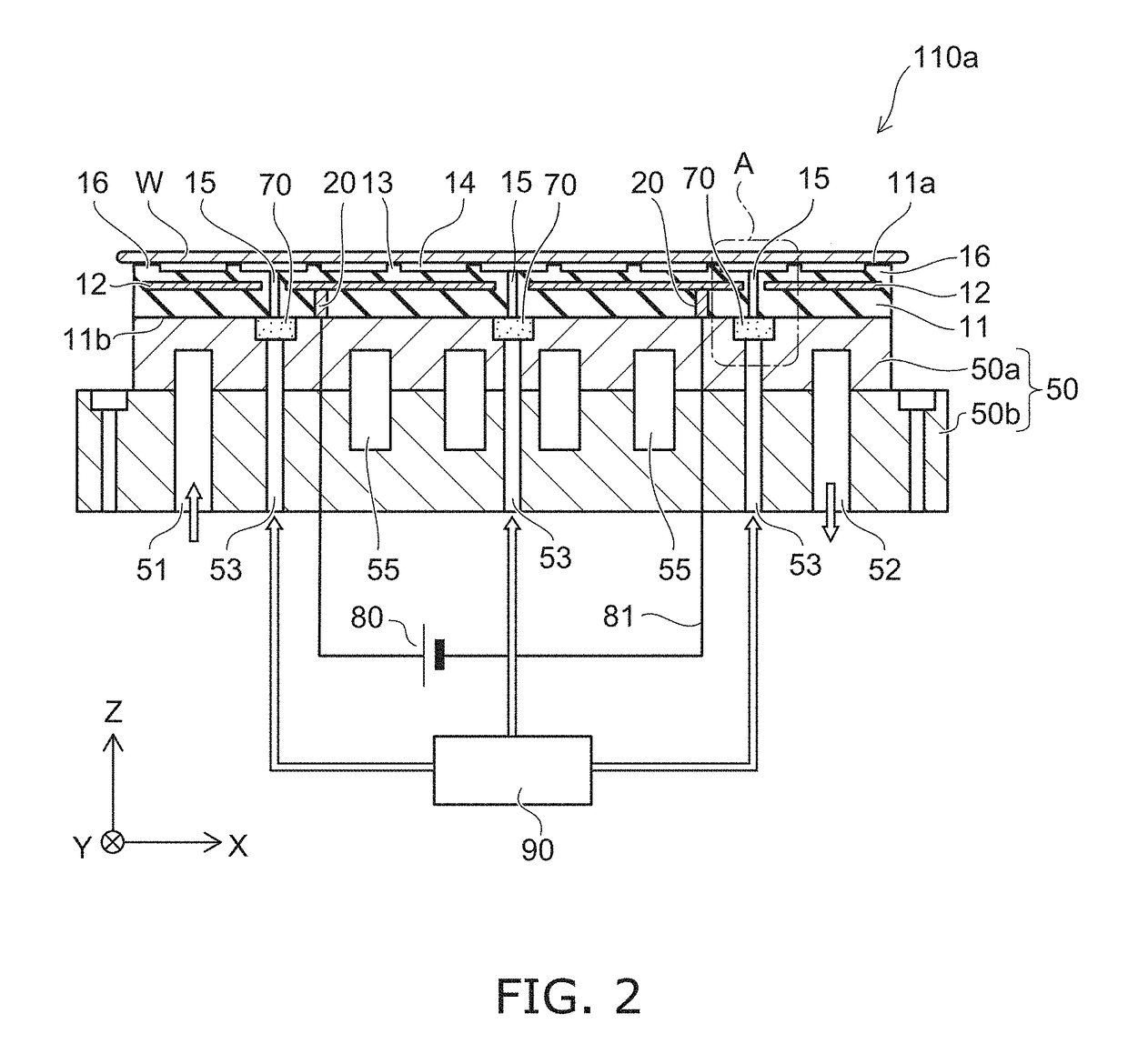

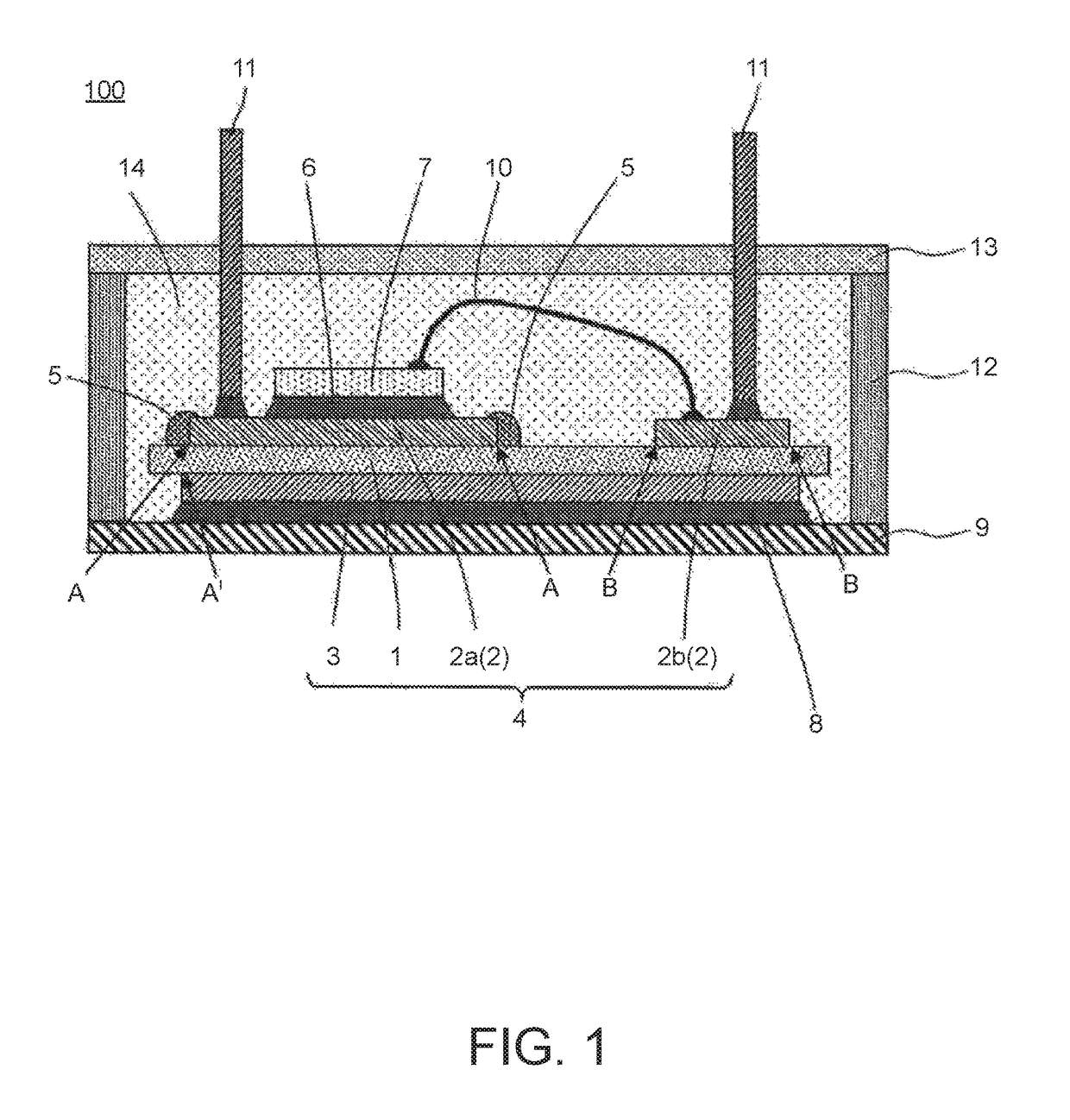

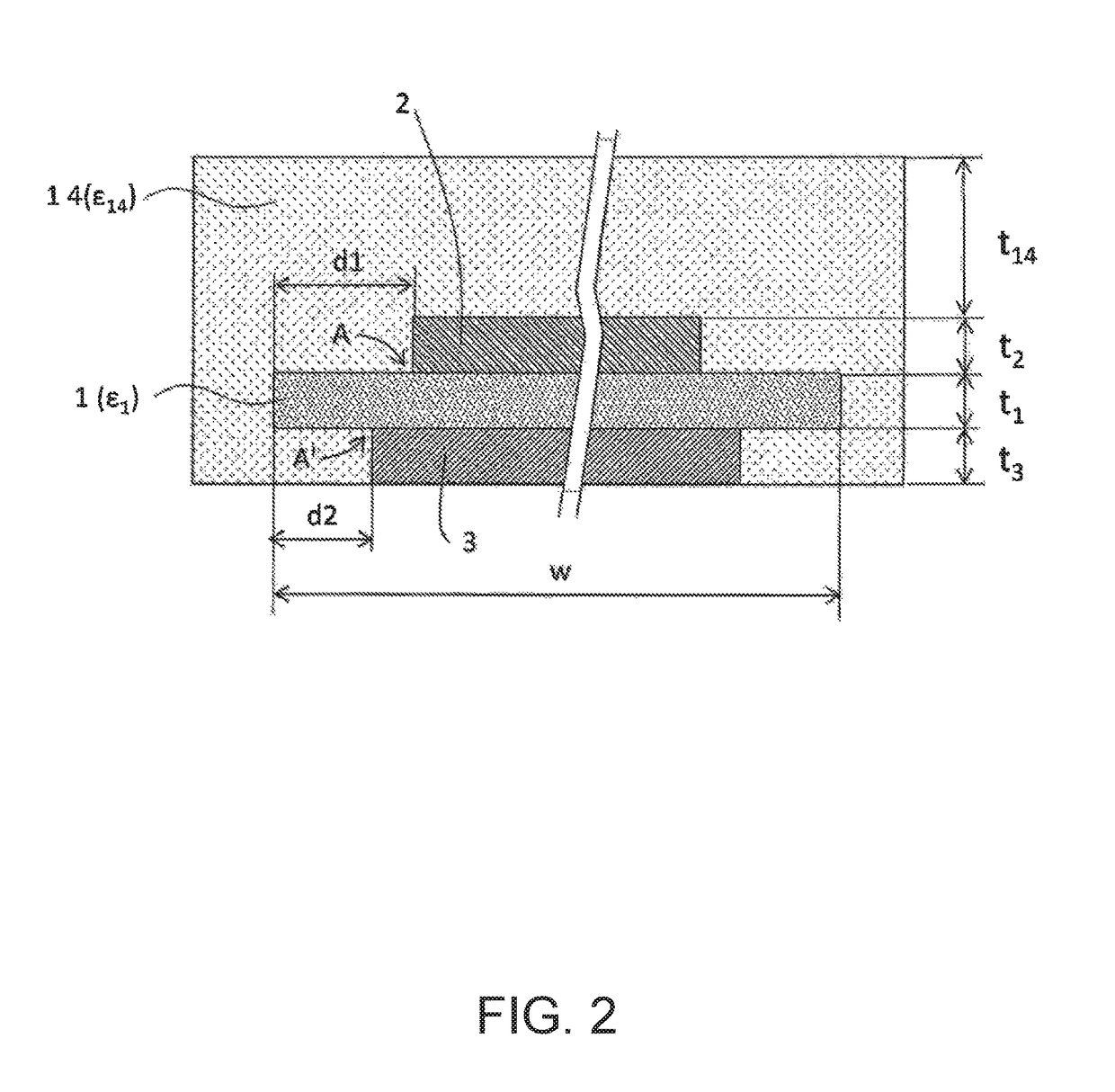

Electrostatic chuck

ActiveUS20160276198A1High insulation breakdown voltageImprove temperature uniformitySleeve/socket jointsSemiconductor/solid-state device manufacturingMetallurgyDielectric substrate

According to an aspect of an embodiment of the invention, there is provided an electrostatic chuck including: a ceramic dielectric substrate including a first major surface for mounting a clamped target, a second major surface on opposite side from the first major surface, and a through hole provided from the second major surface to the first major surface; a metallic base plate supporting the ceramic dielectric substrate and including a gas feed channel communicating with the through hole; and an insulator plug including a ceramic porous body provided in the gas feed channel and a ceramic insulating film provided between the ceramic porous body and the gas feed channel and being denser than the ceramic porous body, the ceramic insulating film biting into the ceramic porous body from a surface of the ceramic porous body.

Owner:TOTO LTD

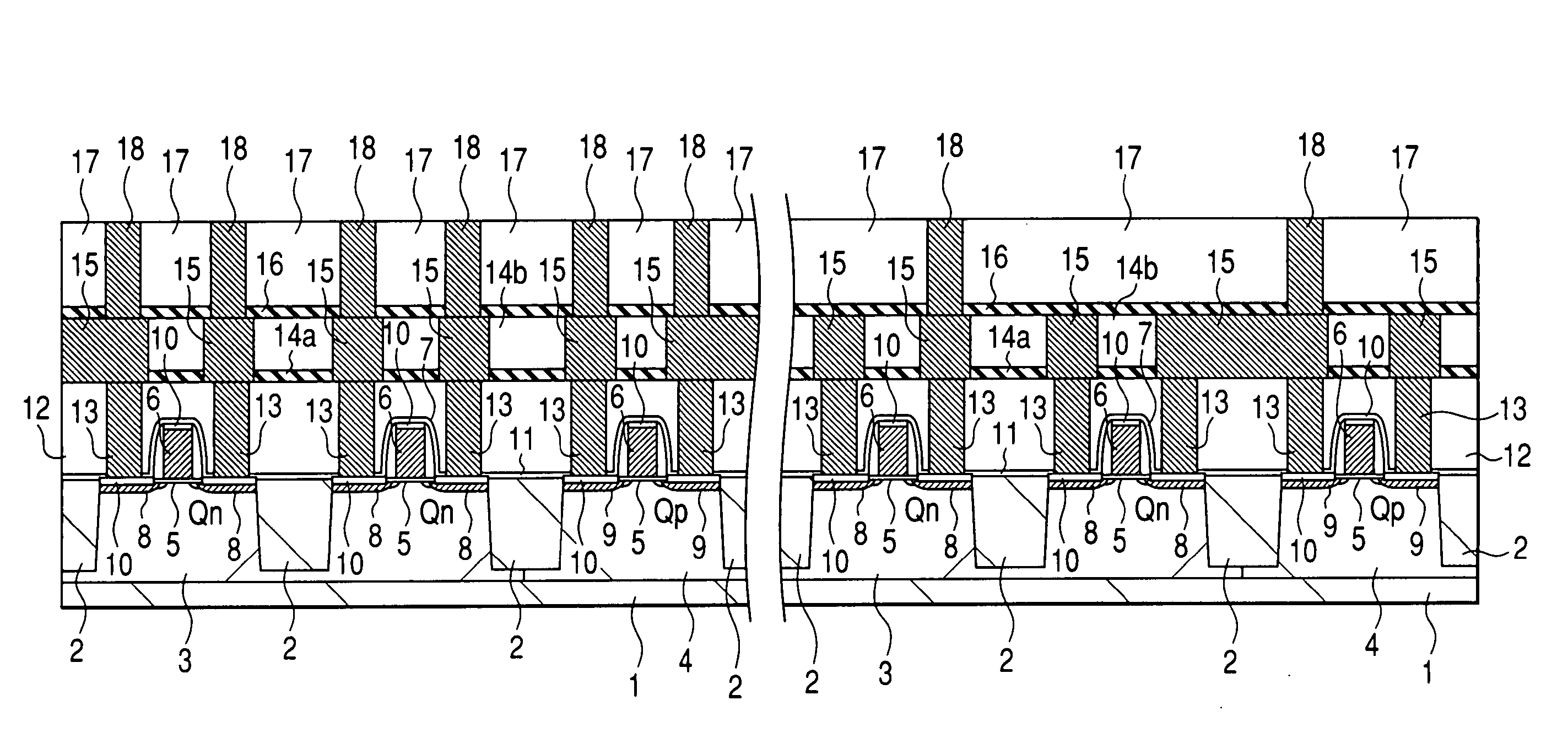

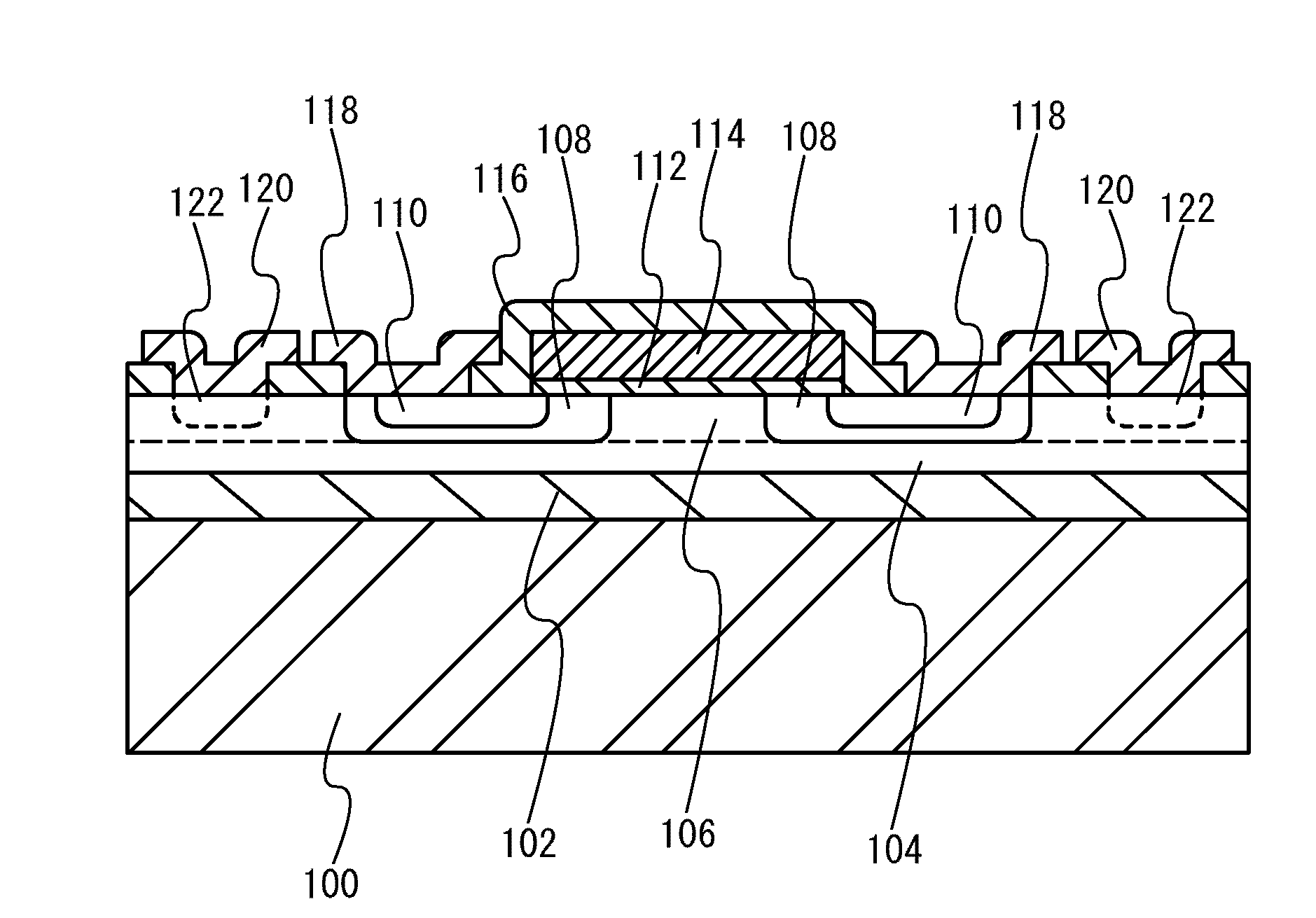

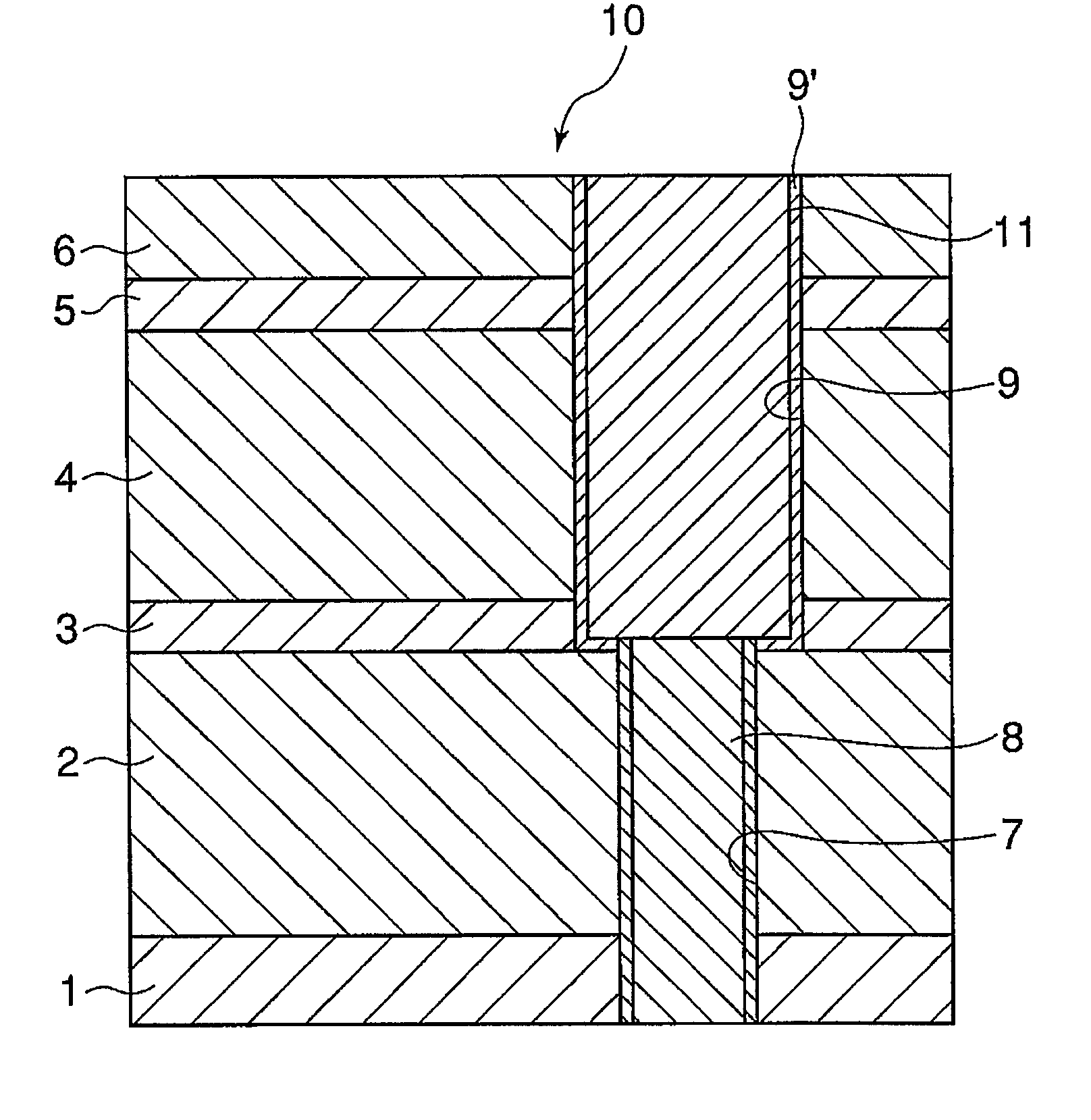

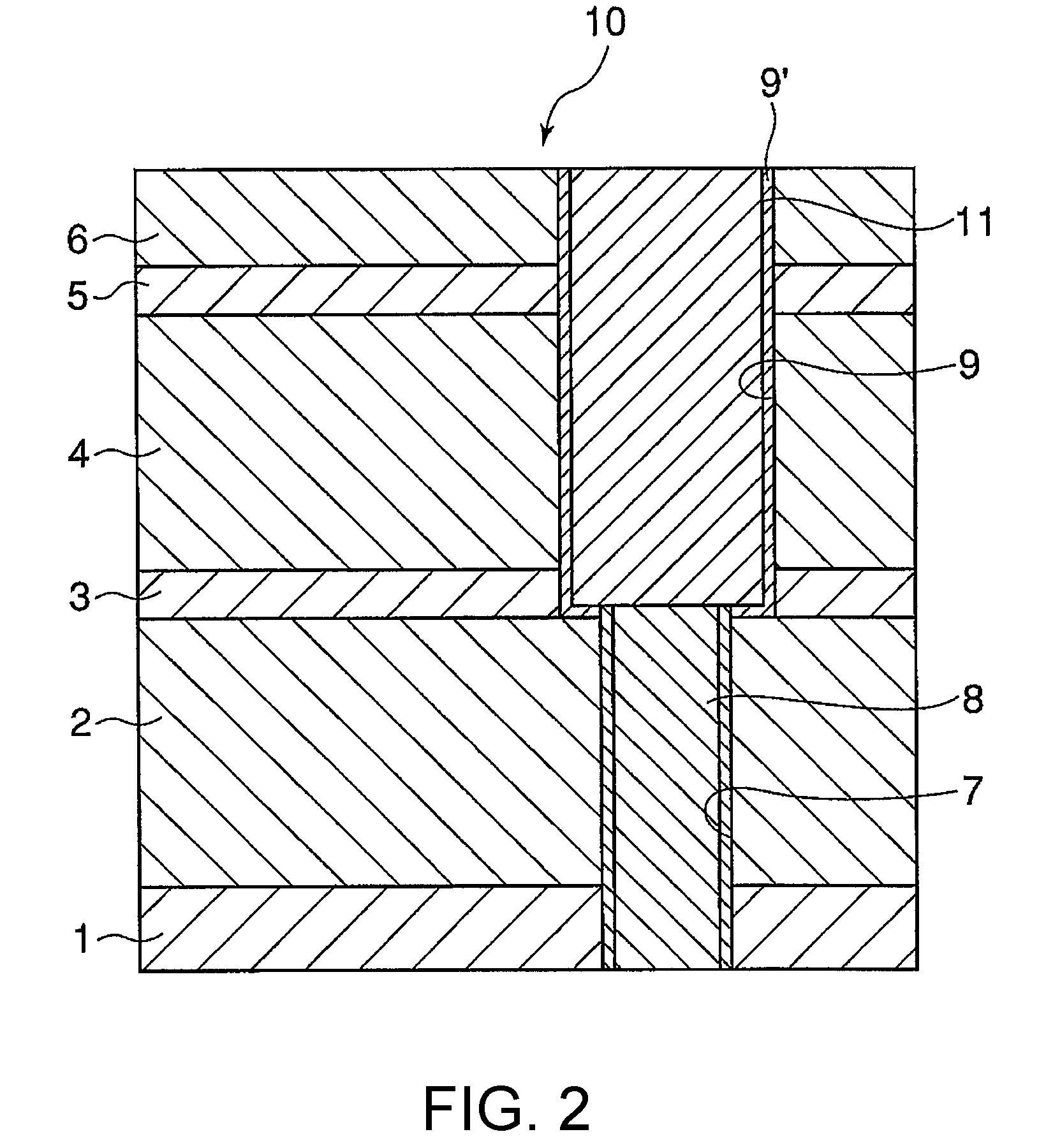

Semiconductor device and manufacturing method of the same

ActiveUS20060281298A1CapacitanceReduce capacitanceSemiconductor/solid-state device manufacturingLow-k dielectricCapacitance

In a semiconductor device, capacitance between copper interconnections is decreased and the insulation breakdown is improved simultaneously, and a countermeasure is taken for misalignment via by a manufacturing method including the steps of forming an interconnection containing copper as a main ingredient in an insulative film above a substrate, forming insulative films and a barrier insulative film for a reservoir pattern, forming an insulative film capable of suppressing or preventing copper from diffusing on the upper surface and on the lateral surface of the interconnection and above the insulative film and the insulative film, forming insulative films of low dielectric constant, in which the insulative film is formed such that the deposition rate above the opposing lateral surfaces of the interconnections is larger than the deposition rate therebelow to form an air gap between the adjacent interconnections and, finally, planarizing the insulative film by interlayer CMP.

Owner:KOKUSA ELECTRIC CO LTD

Semiconductor device and manufacturing method of the same

ActiveUS7501347B2High insulation breakdown voltageCapacitanceSemiconductor/solid-state device manufacturingCapacitanceCountermeasure

In a semiconductor device, capacitance between copper interconnections is decreased and the insulation breakdown is improved simultaneously, and a countermeasure is taken for misalignment via by a manufacturing method including the steps of forming an interconnection containing copper as a main ingredient in an insulative film above a substrate, forming insulative films and a barrier insulative film for a reservoir pattern, forming an insulative film capable of suppressing or preventing copper from diffusing on the upper surface and on the lateral surface of the interconnection and above the insulative film and the insulative film, forming insulative films of low dielectric constant, in which the insulative film is formed such that the deposition rate above the opposing lateral surfaces of the interconnections is larger than the deposition rate therebelow to form an air gap between the adjacent interconnections and, finally, planarizing the insulative film by interlayer CMP.

Owner:KOKUSA ELECTRIC CO LTD

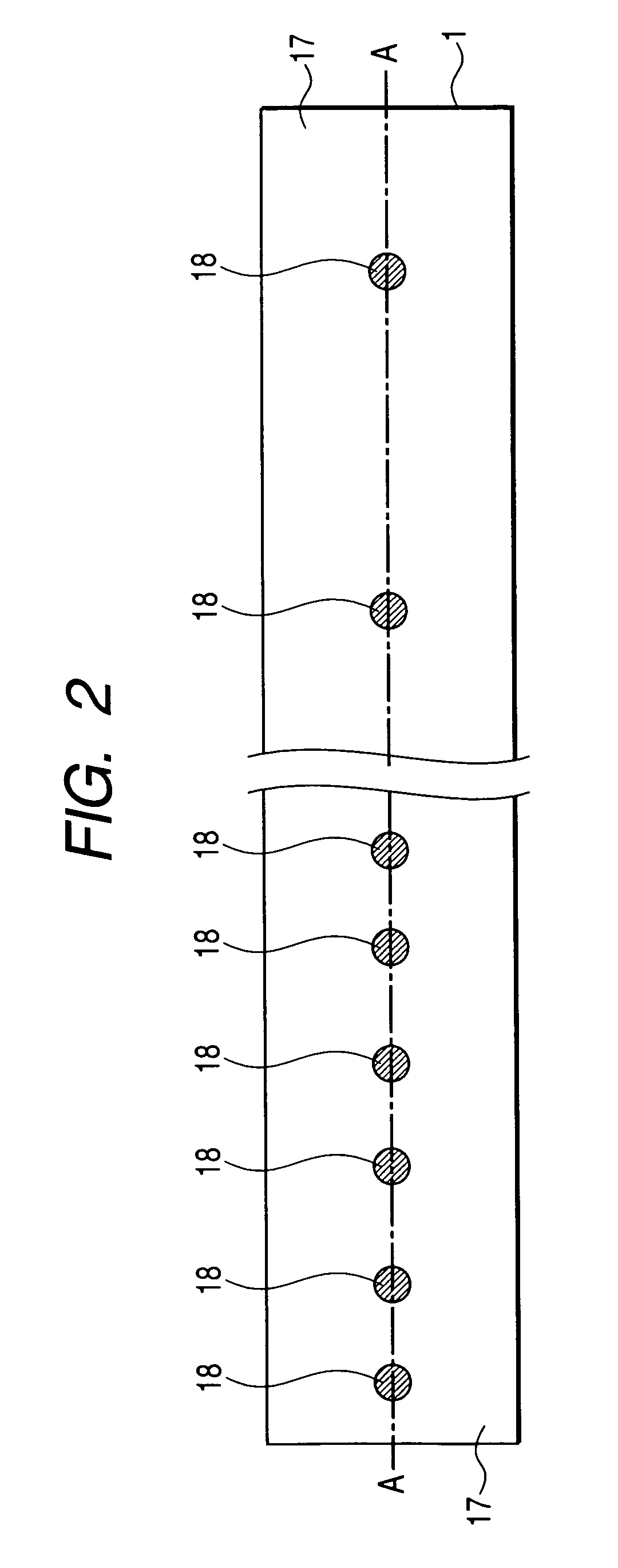

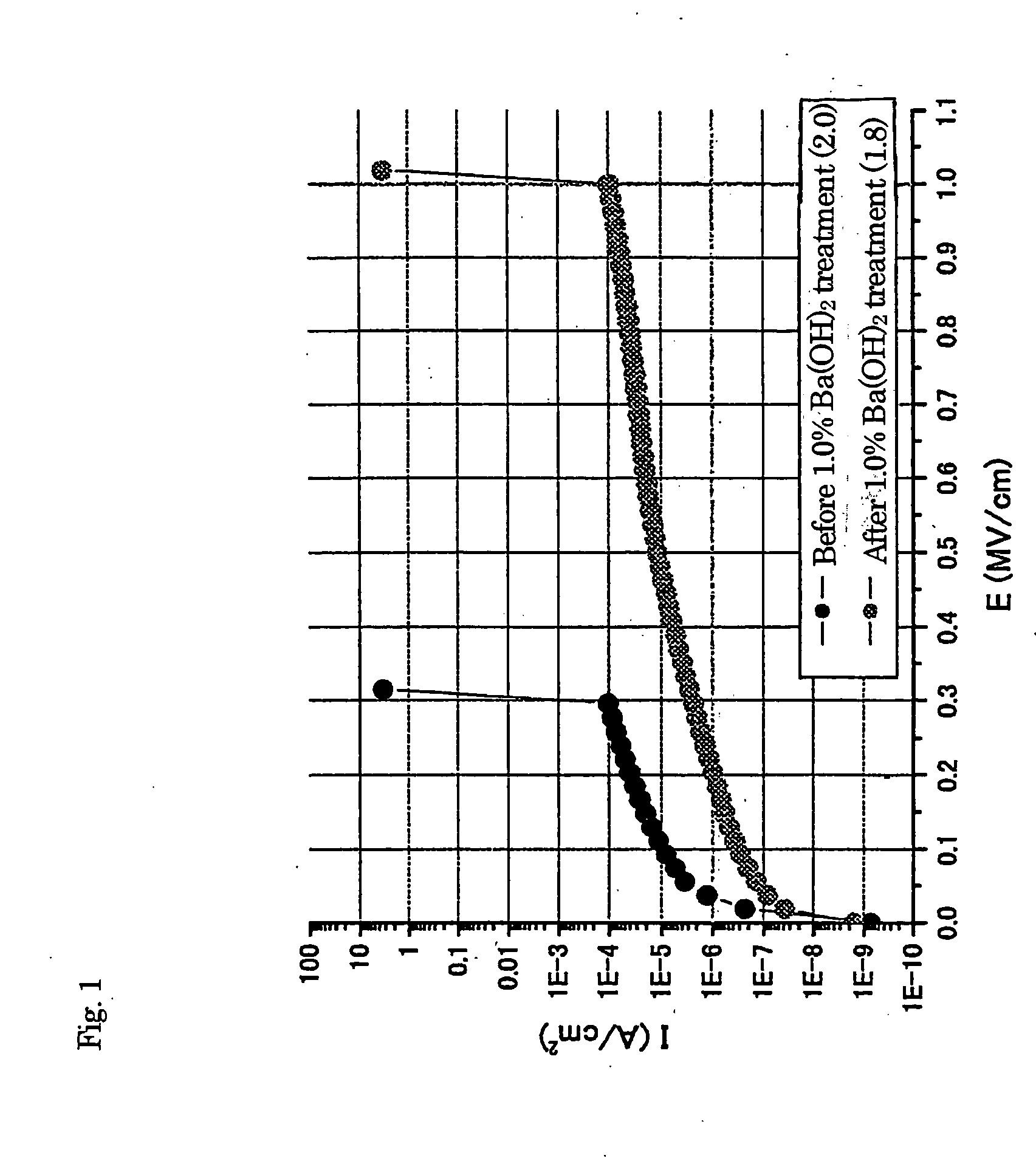

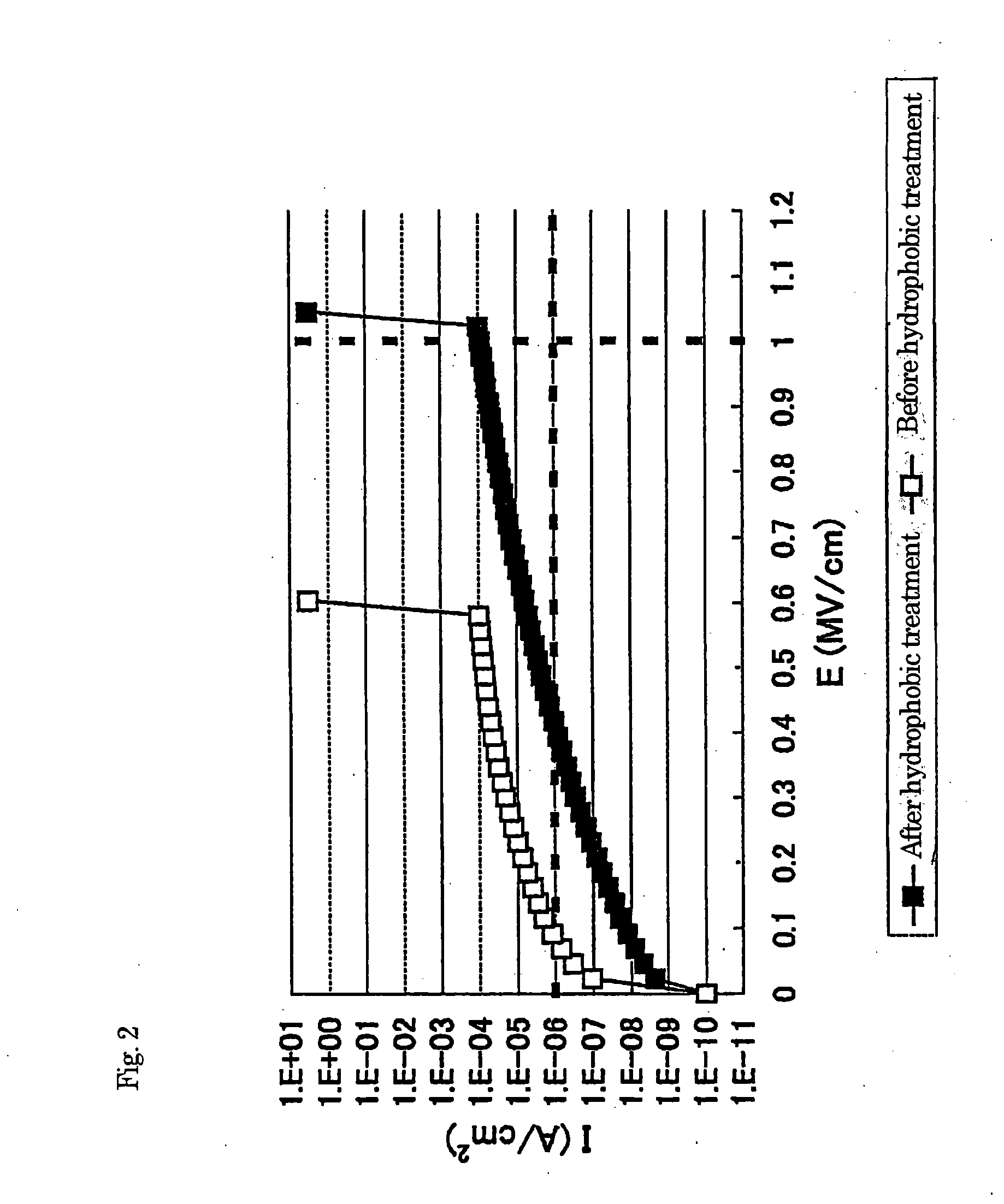

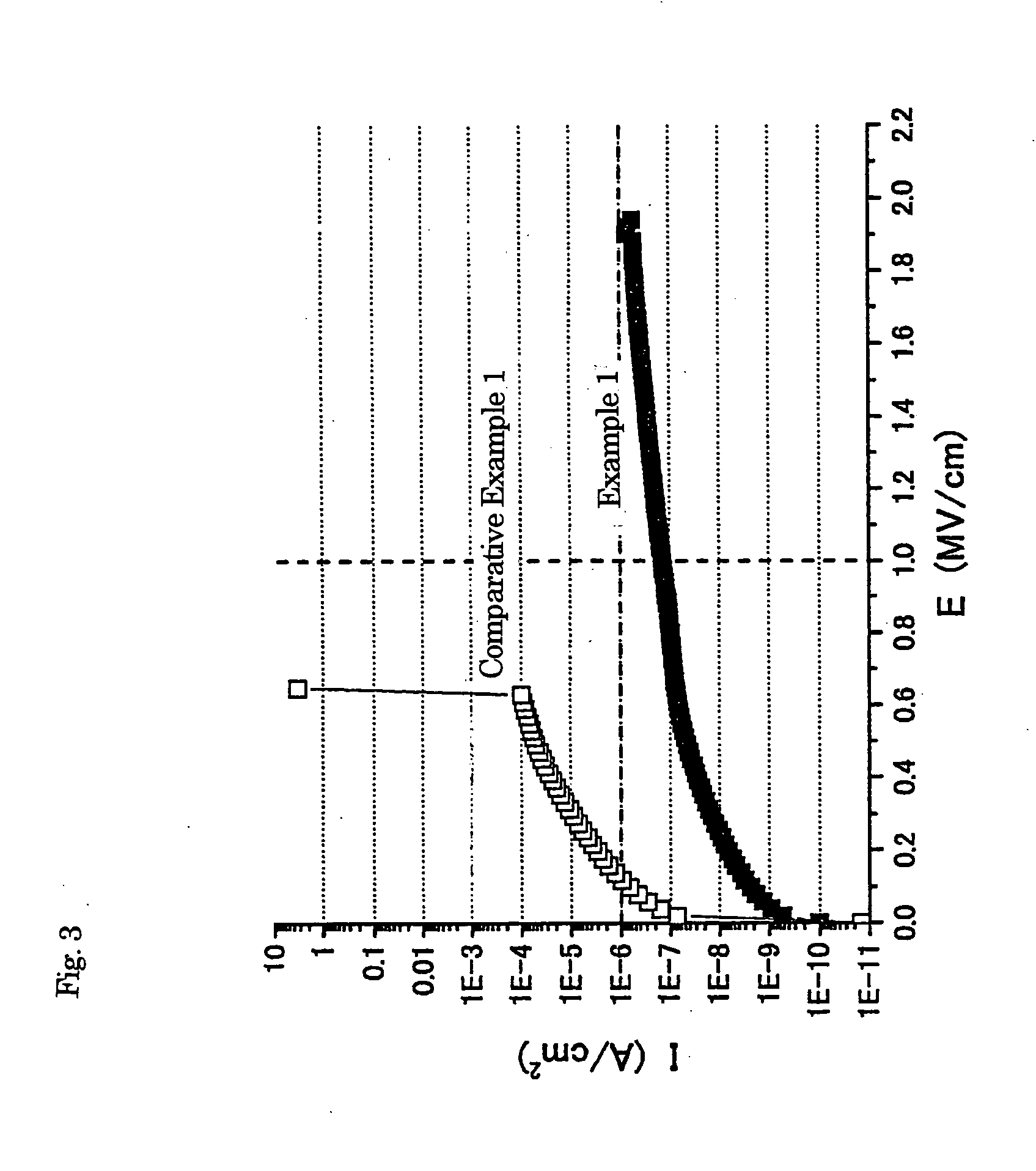

Low-dielectric films, and manufacturion method thereof, and electronic component using it

InactiveUS20060244034A1High insulation breakdown voltageGuaranteed functionTransistorSemi-permeable membranesDisiloxaneIntegrated circuit

While a fine porous diamond particle film has been known as a high heat resistant and low dielectric constant film and also has high mechanical strength and heat conductivity, and is expected as an insulating film for multi-layered wirings in semiconductor integrated circuit devices, it is insufficient in current-voltage characteristic and has not yet been put into practical use. According to the invention, by treating the fine porous diamond particle film with an aqueous solution of a salt of a metal such as barium and calcium, the carbonate or sulfate of which is insoluble or less soluble, and a hydrophobic agent such as hexamethyl disilazane or triethyl monochlolo silane, as well as a reinforcing agent containing one of dichlorotetramethyl disiloxane or dimethoxytetramethyl disiloxane, thereby capable of putting the dielectric breakdown voltage and the leak current within a specified range of a practical standard.

Owner:RORZE CORP

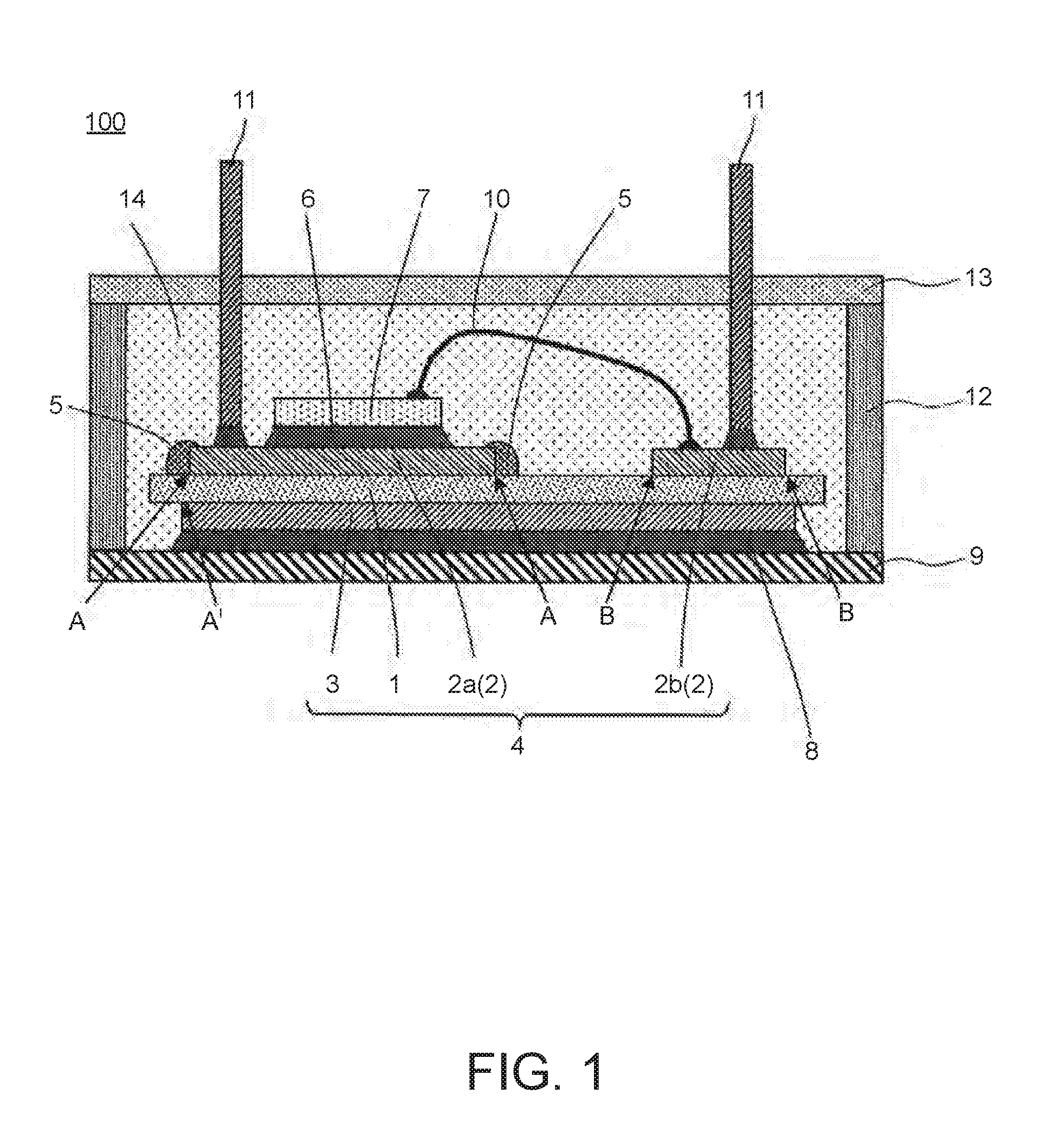

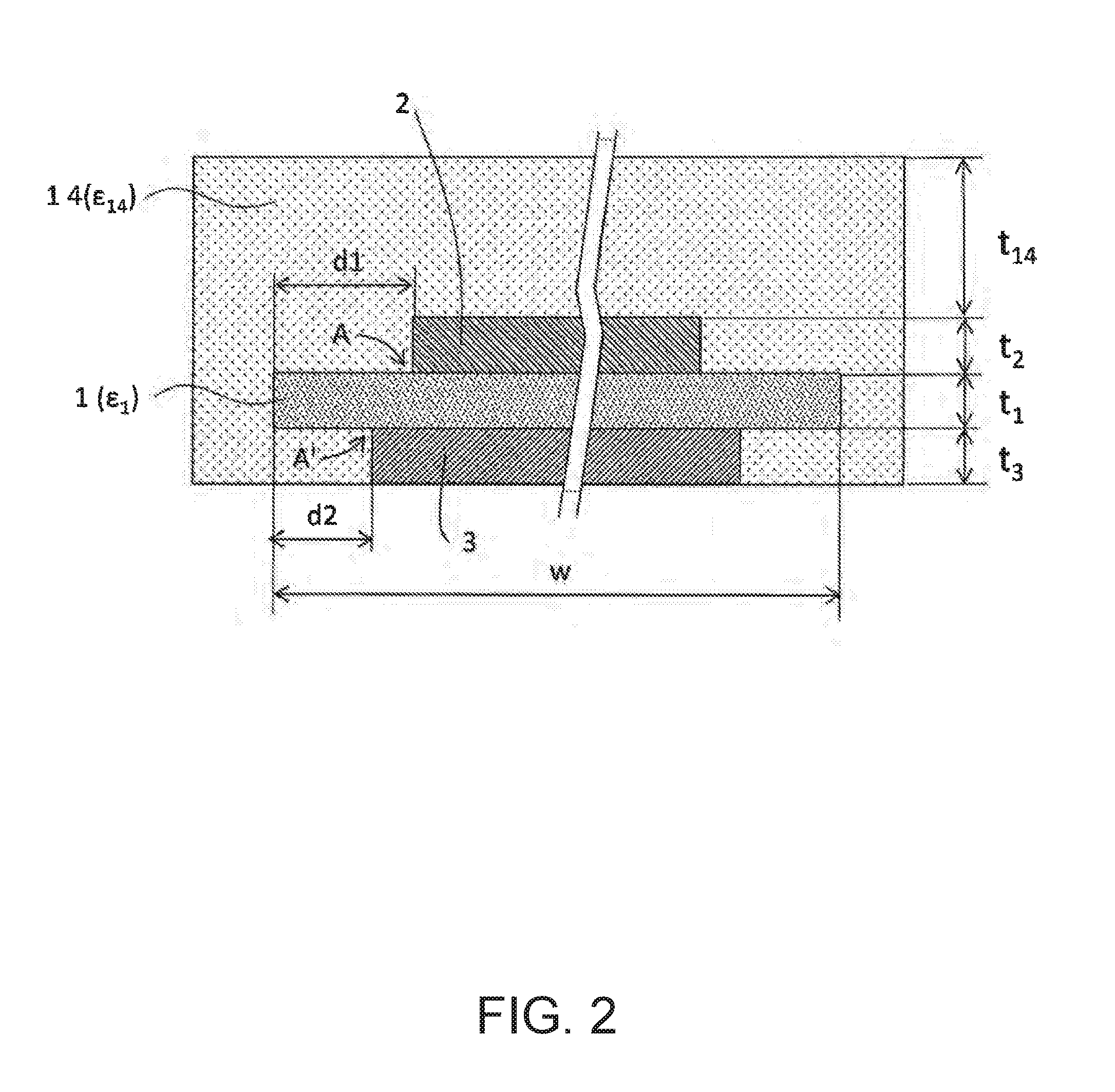

Semiconductor module and method of manufacturing semiconductor module

ActiveUS20170025344A1Weakening rangeIncrease production costSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A semiconductor module includes an insulated circuit board that includes an insulating substrate, a first conductive plate arranged on a first principal surface of the insulating substrate and within the outer edges of the insulating substrate, and a second conductive plate arranged within the outer edges of the insulating substrate on a second principal surface of the insulating substrate that faces the first principal surface. Furthermore, boundary edges between the first principal surface of the insulating substrate and the side faces of the first conductive plate are covered by an ion gel that contains an ionic liquid.

Owner:FUJI ELECTRIC CO LTD

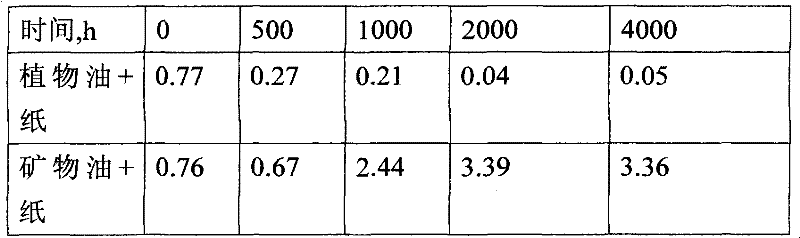

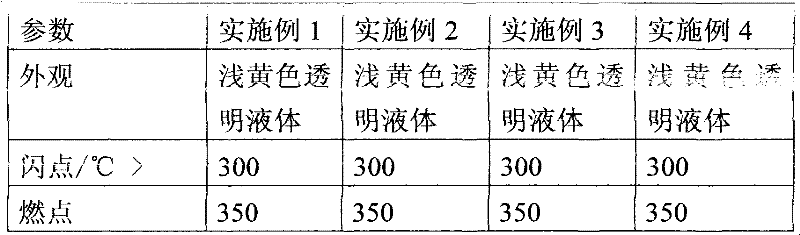

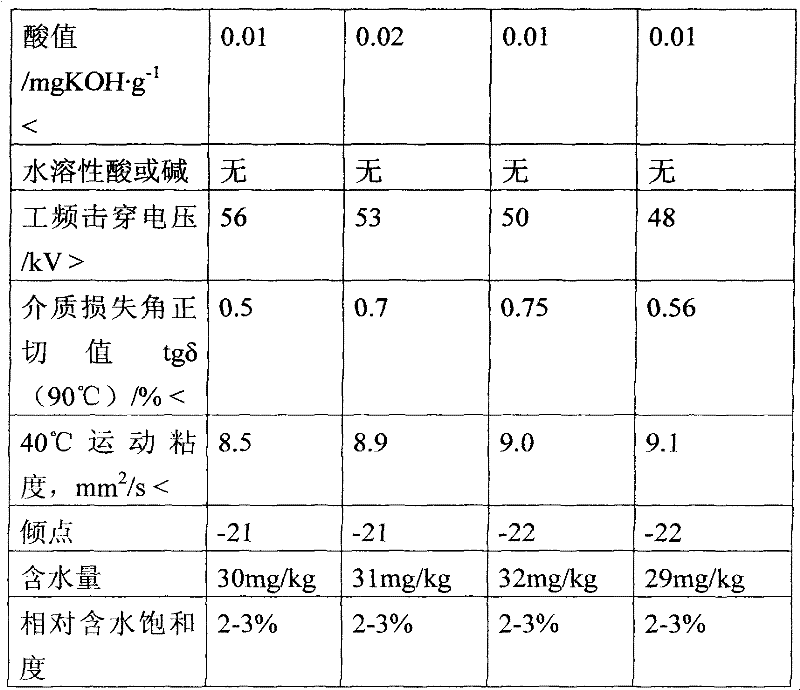

Vegetable insulating oil and preparation method thereof

InactiveCN102543262AGreenLow-carbon and energy-savingLiquid organic insulatorsTransformers/inductances coils/windings/connectionsVegetable oilTransformer

The invention discloses vegetable insulating oil, which is mainly prepared from the following raw materials in percentage by weight: 90 to 95 percent of vegetable oil and 2 to 5 percent of antioxidant. The invention also provides a method for preparing the vegetable insulating oil. The product is a novel vegetable insulating oil, is insulating oil for a transformer, is a high-performance insulating material extracted from renewable plants, and has the characteristics of environment friendliness, safe operation, long service life, high overload capacity, low carbon, energy saving and the like.

Owner:GUANGDONG JOOYN NEW MATERIAL TECH CO LTD

Semiconductor device and manufacturing method of the same

ActiveUS20100213470A1Without decreasing productivityHigh voltageSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialSemiconductor

At least part of a semiconductor layer or a semiconductor substrate includes a semiconductor region having a large energy gap. The semiconductor region having a large energy gap is preferably formed from silicon carbide and is provided in a position at least overlapping with a gate electrode provided with an insulating layer between the semiconductor region and the gate electrode. By making a structure in which the semiconductor region is included in a channel formation region, a dielectric breakdown voltage is improved.

Owner:SEMICON ENERGY LAB CO LTD

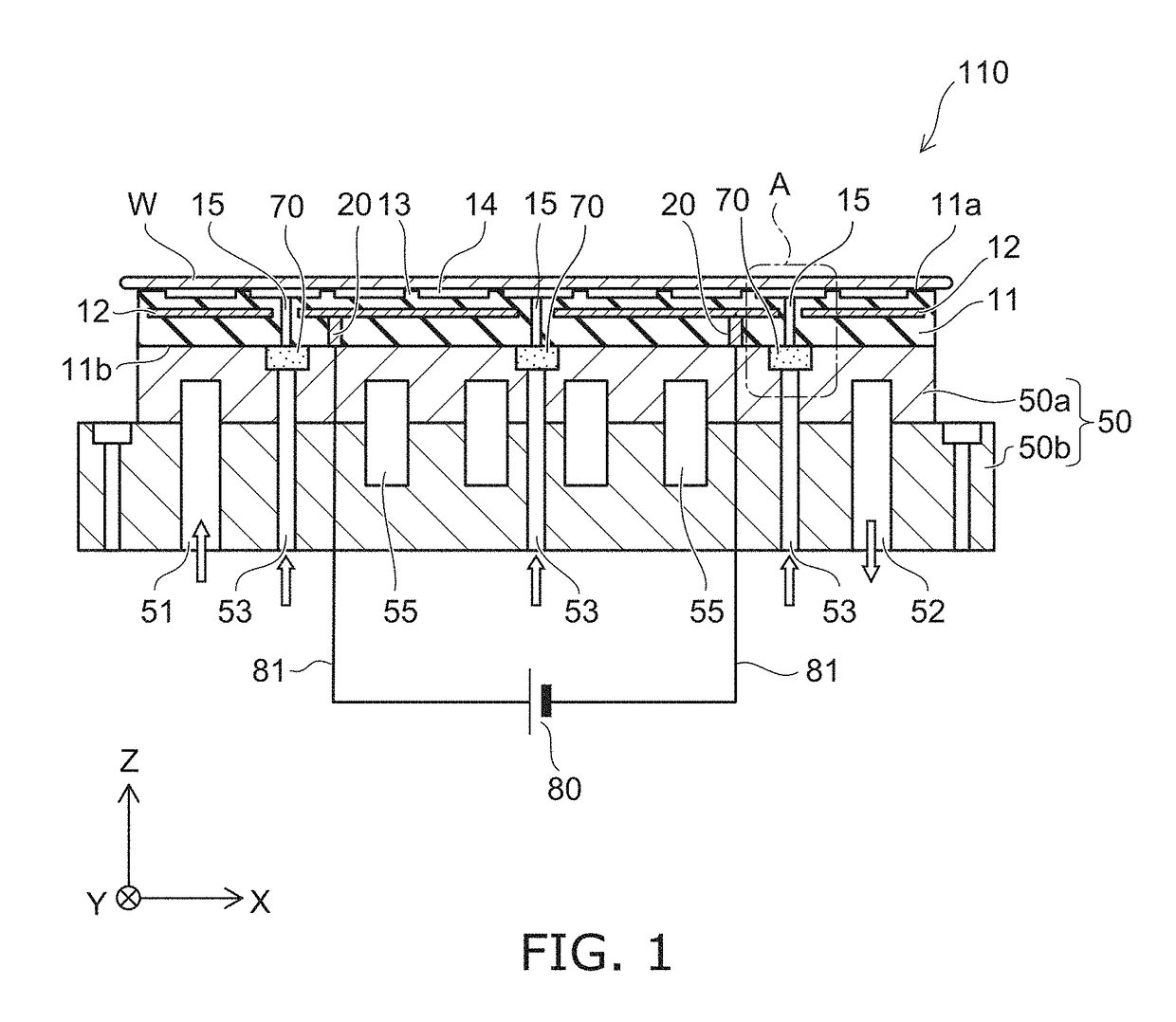

Electrostatic chuck

ActiveUS9960067B2High insulation breakdown voltageHigh wafer temperature uniformitySleeve/socket jointsSemiconductor/solid-state device manufacturingDielectric substrateMetal

According to an aspect of an embodiment of the invention, there is provided an electrostatic chuck including: a ceramic dielectric substrate including a first major surface for mounting a clamped target, a second major surface on opposite side from the first major surface, and a through hole provided from the second major surface to the first major surface; a metallic base plate supporting the ceramic dielectric substrate and including a gas feed channel communicating with the through hole; and an insulator plug including a ceramic porous body provided in the gas feed channel and a ceramic insulating film provided between the ceramic porous body and the gas feed channel and being denser than the ceramic porous body, the ceramic insulating film biting into the ceramic porous body from a surface of the ceramic porous body.

Owner:TOTO LTD

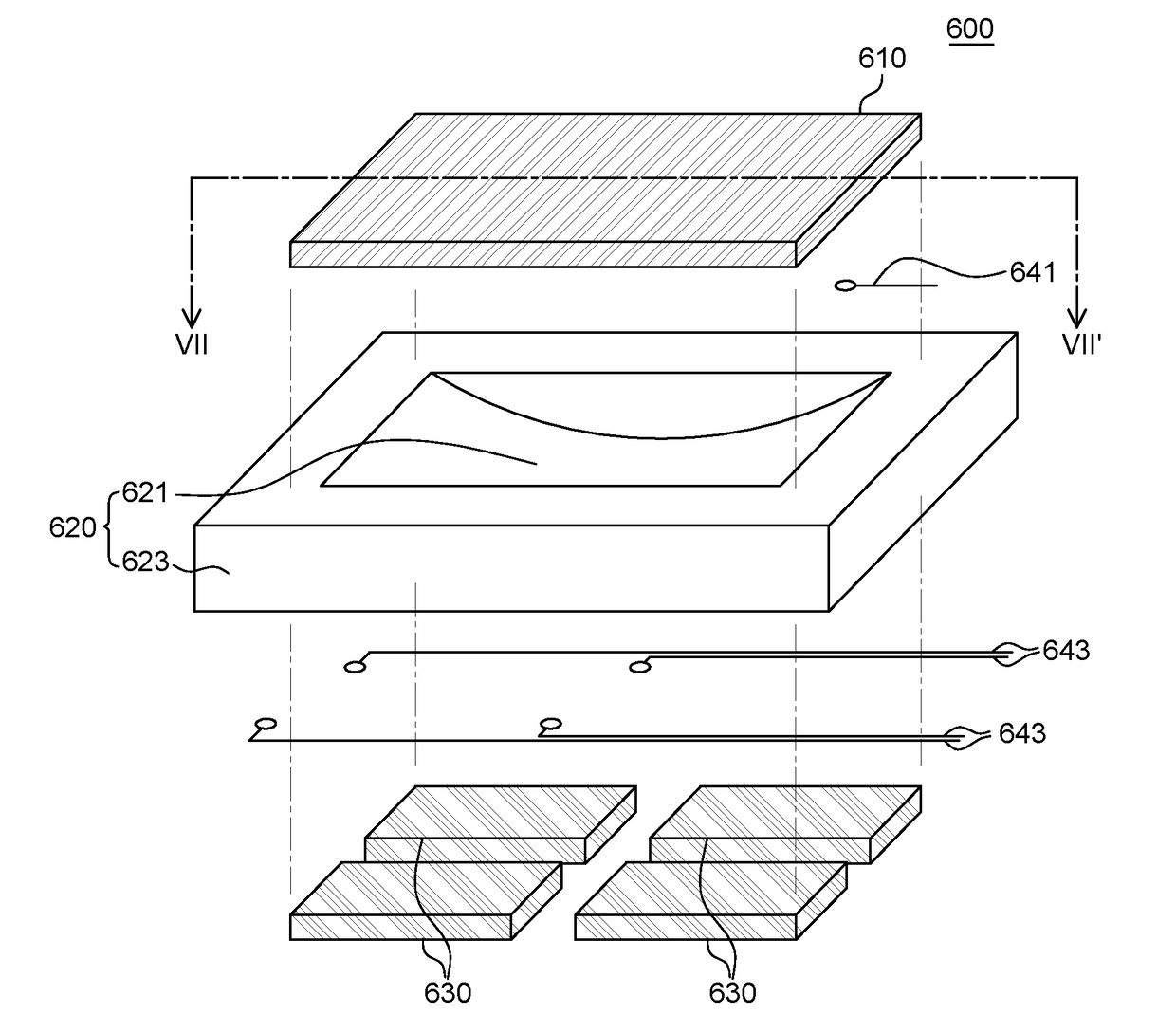

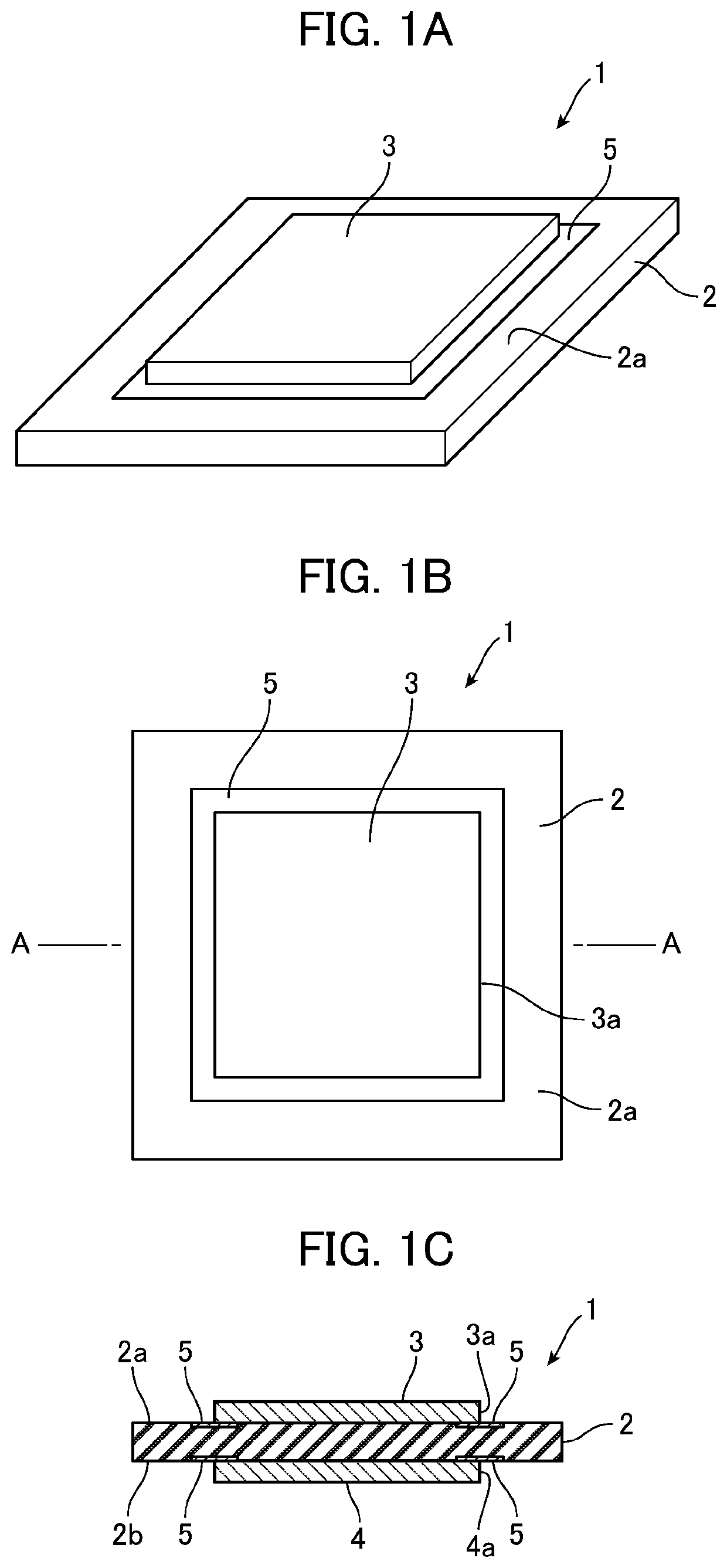

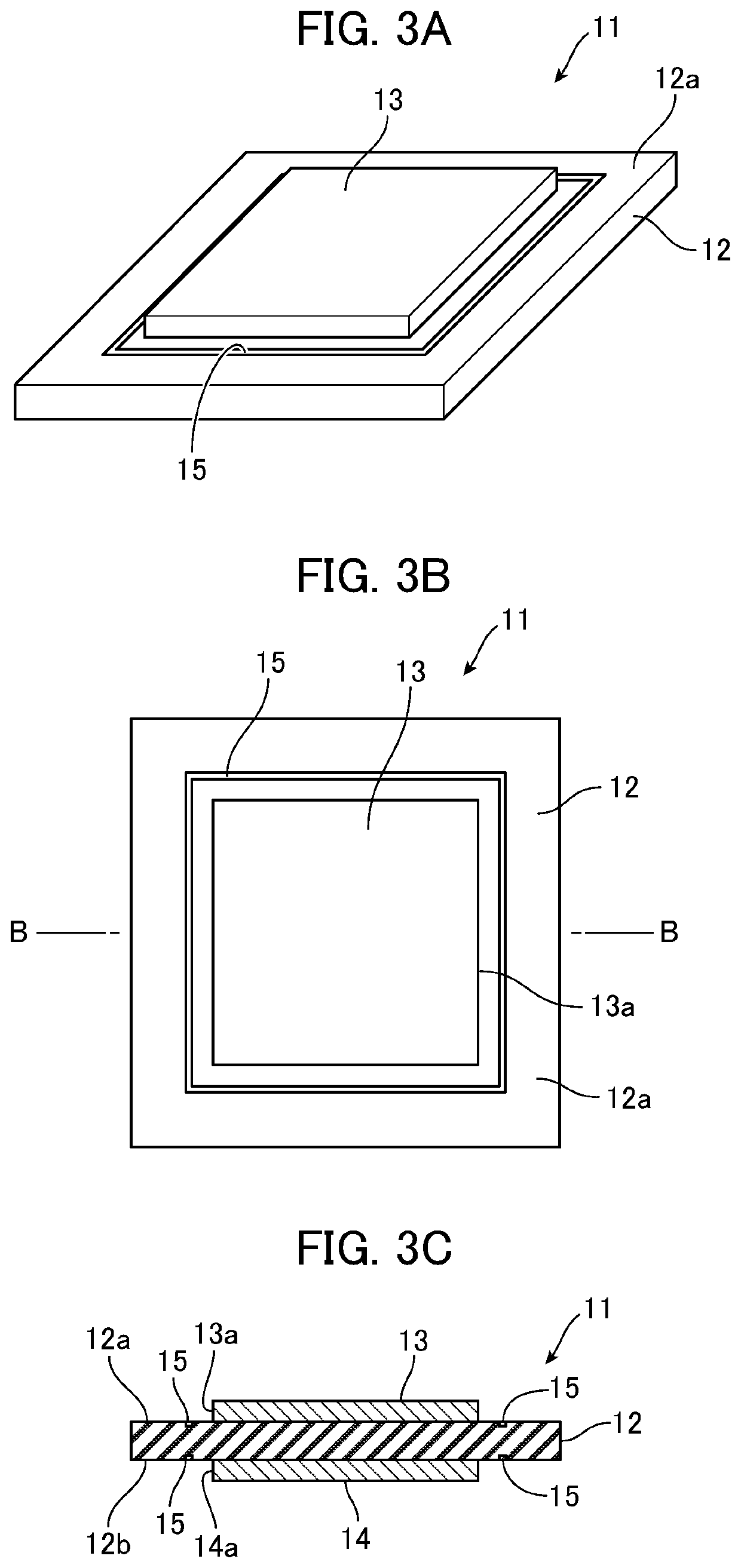

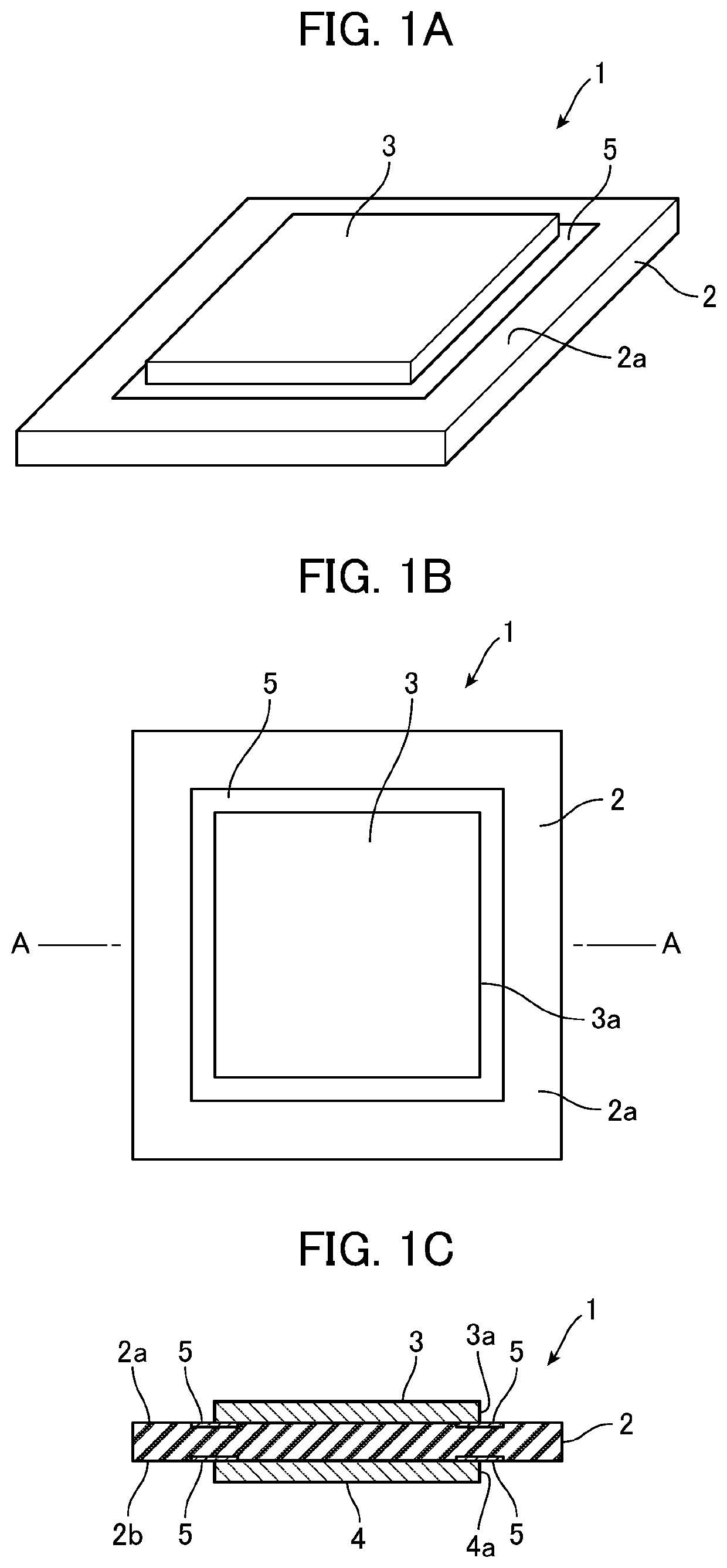

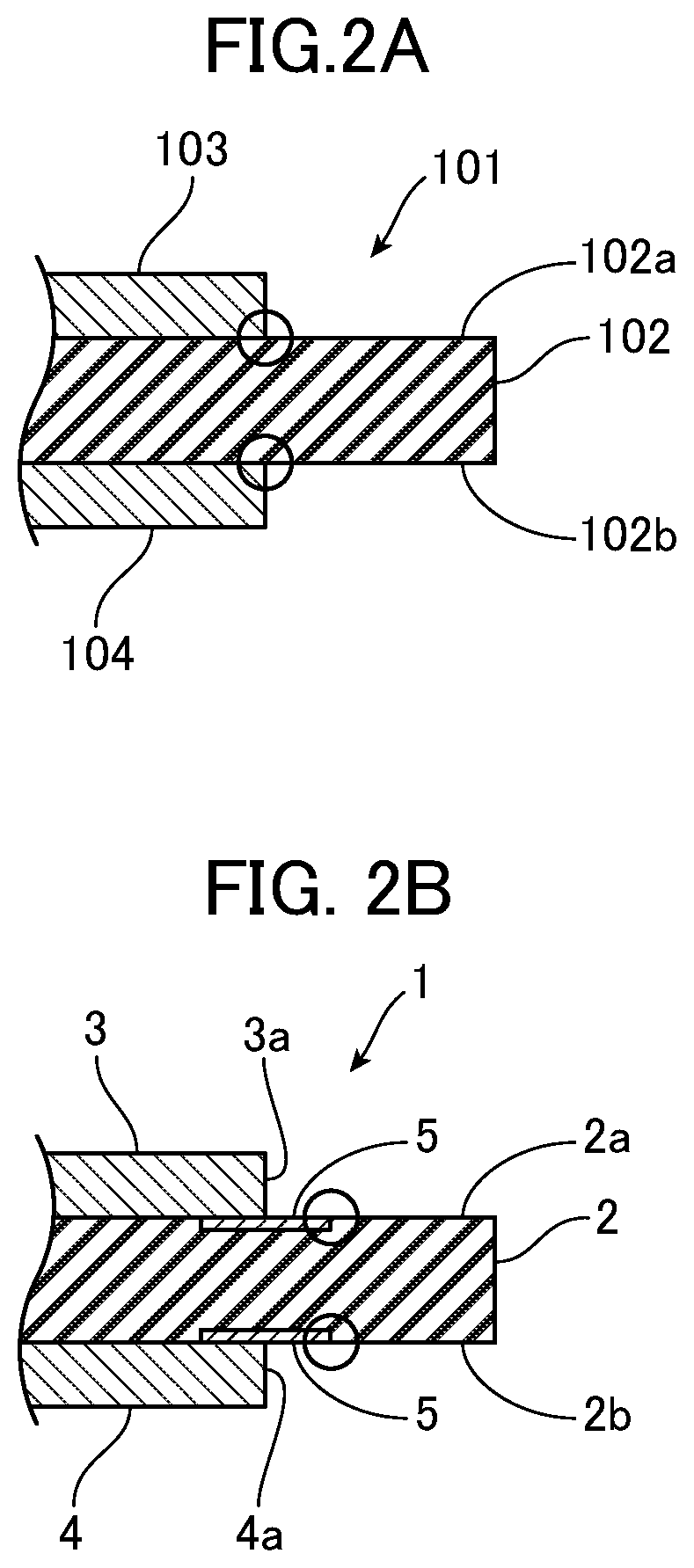

Touch Sensitive Element and Display Device Including the Same

ActiveUS20180120942A1Small thicknessIncrease vibration intensityInput/output for user-computer interactionSolid-state devicesDisplay deviceBiomedical engineering

There is provided a touch sensitive element including an electroactive layer, and an electrode disposed on at least one surface of the electroactive layer. The electroactive layer has a first portion having a first thickness and a second portion which has a second thickness different from the first thickness and is in contact with the first portion at an outside of the first portion.

Owner:LG DISPLAY CO LTD

Interlayer insulating film, wiring structure and electronic device and methods of manufacturing the same

InactiveUS20100032844A1Low dielectric constantImprove featuresSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorNitrogen

A wiring structure of a semiconductor device or the like includes an interlayer insulating film having a fluorocarbon film formed on an underlayer, and a conductor buried in the interlayer insulating film. The fluorocarbon film contains nitrogen and is low in dielectric constant, excellent in reproducibility and stable.

Owner:TOHOKU UNIV +1

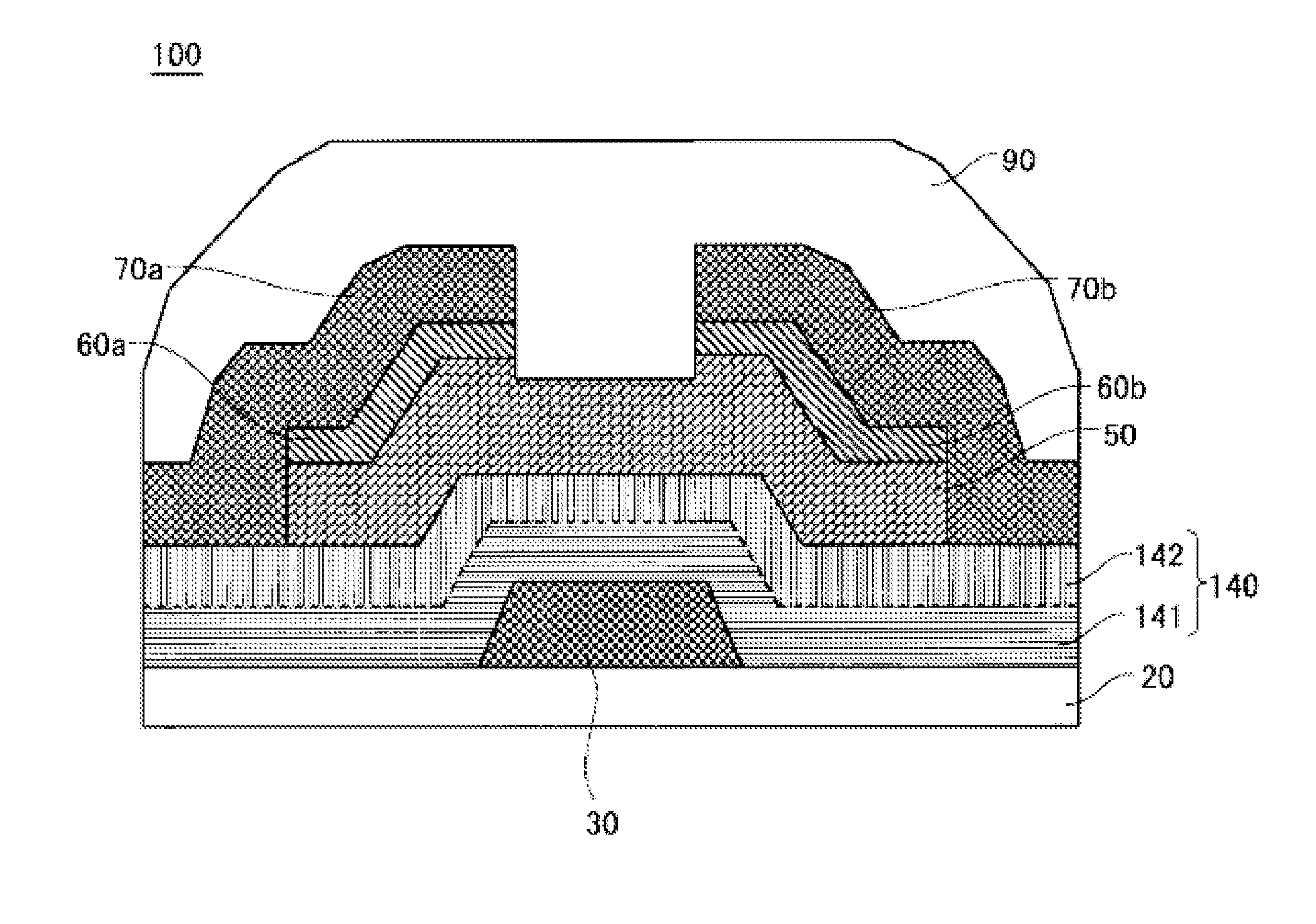

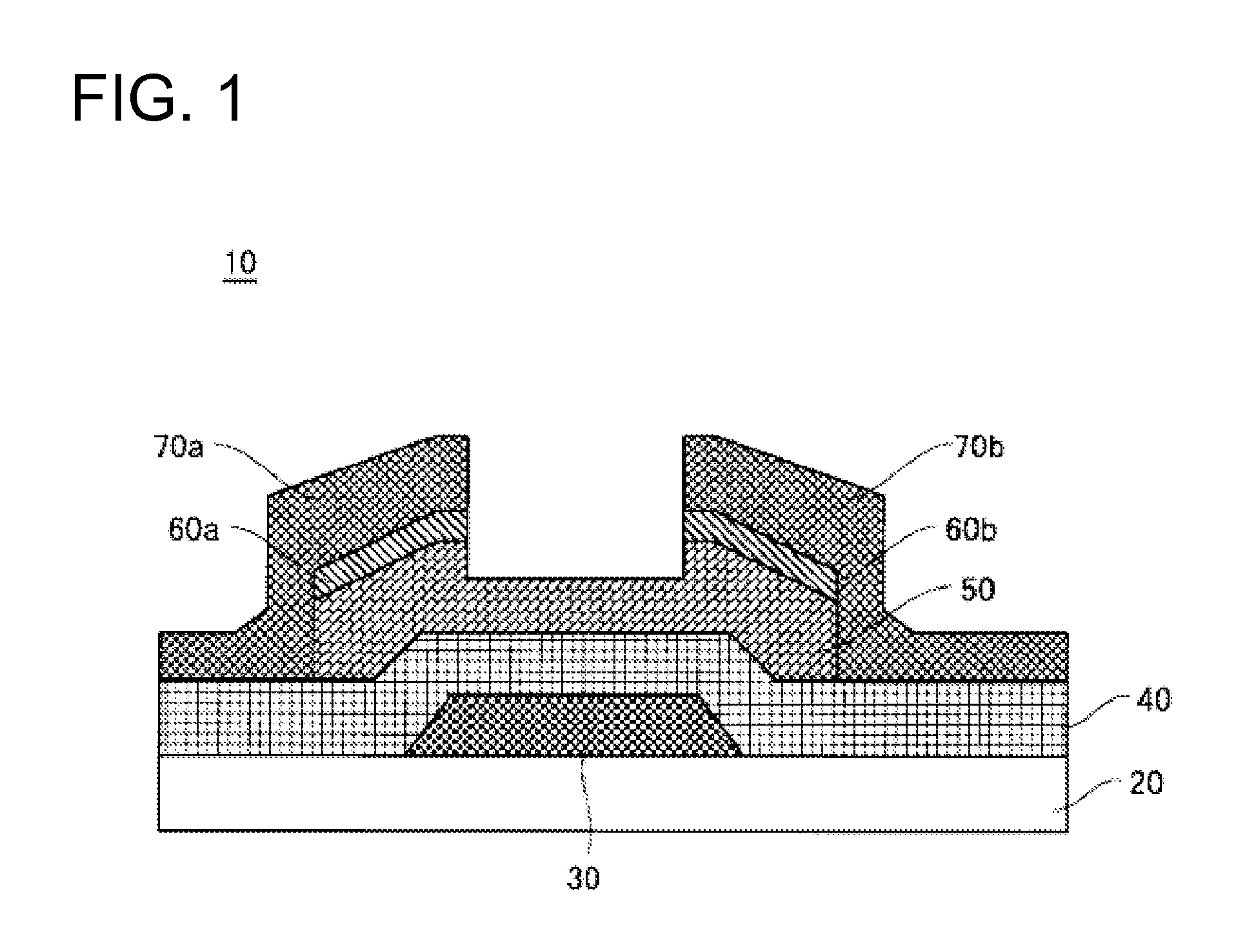

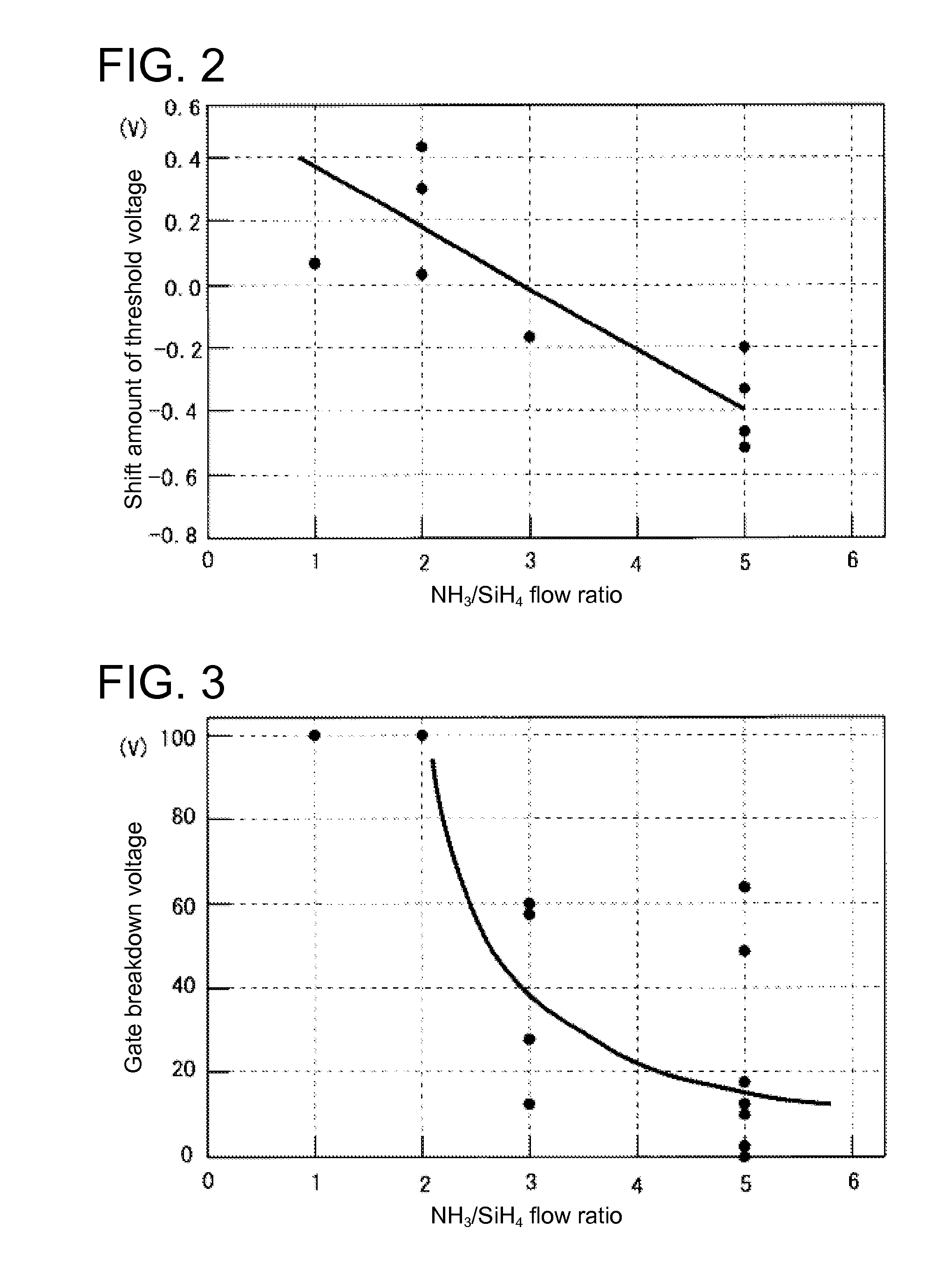

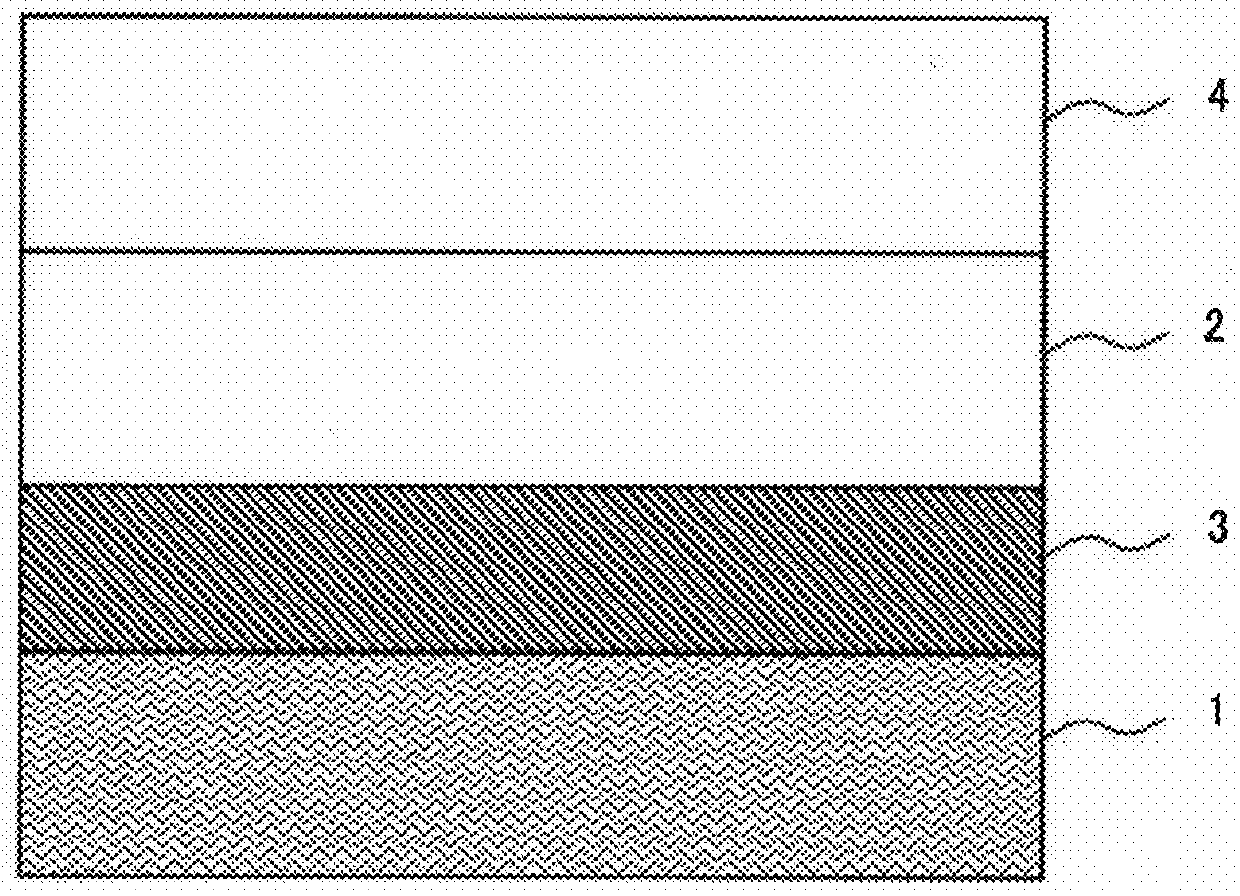

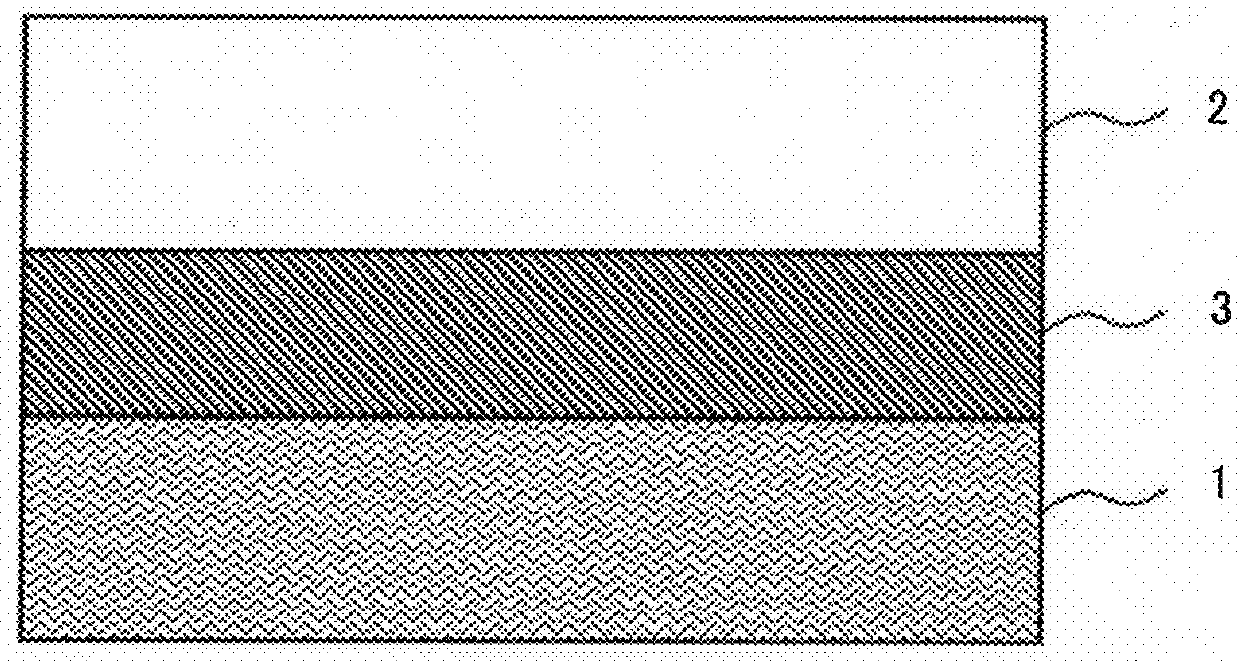

Thin film transistor and method for producing the same

InactiveUS20120104403A1Increase in amount of threshold can be suppressedHigh dielectric breakdown voltageTransistorSemiconductor/solid-state device manufacturingBlock effectNitrogen

An object of the present invention is to provide a thin film transistor having a gate insulating film for suppressing a shift amount of a threshold voltage generated by use under a high temperature environment. In a thin film transistor having a channel layer made of microcrystalline silicon, a gate insulating film 140 is a film obtained by laminating a first silicon nitride film 141 having a nitrogen concentration of 6×1021 atoms / cc or less and a second silicon nitride film 142 having a nitrogen concentration higher than 6×1021 atoms / cc. Therefore, the second silicon nitride film 142 increases the blocking effect against mobile ions entering from a glass substrate 20 to make the mobile ions less likely to be stored in an interface with a channel layer 50. The first silicon nitride film 141 increases the dielectric breakdown voltage of the gate insulating film 140.

Owner:SHARP KK

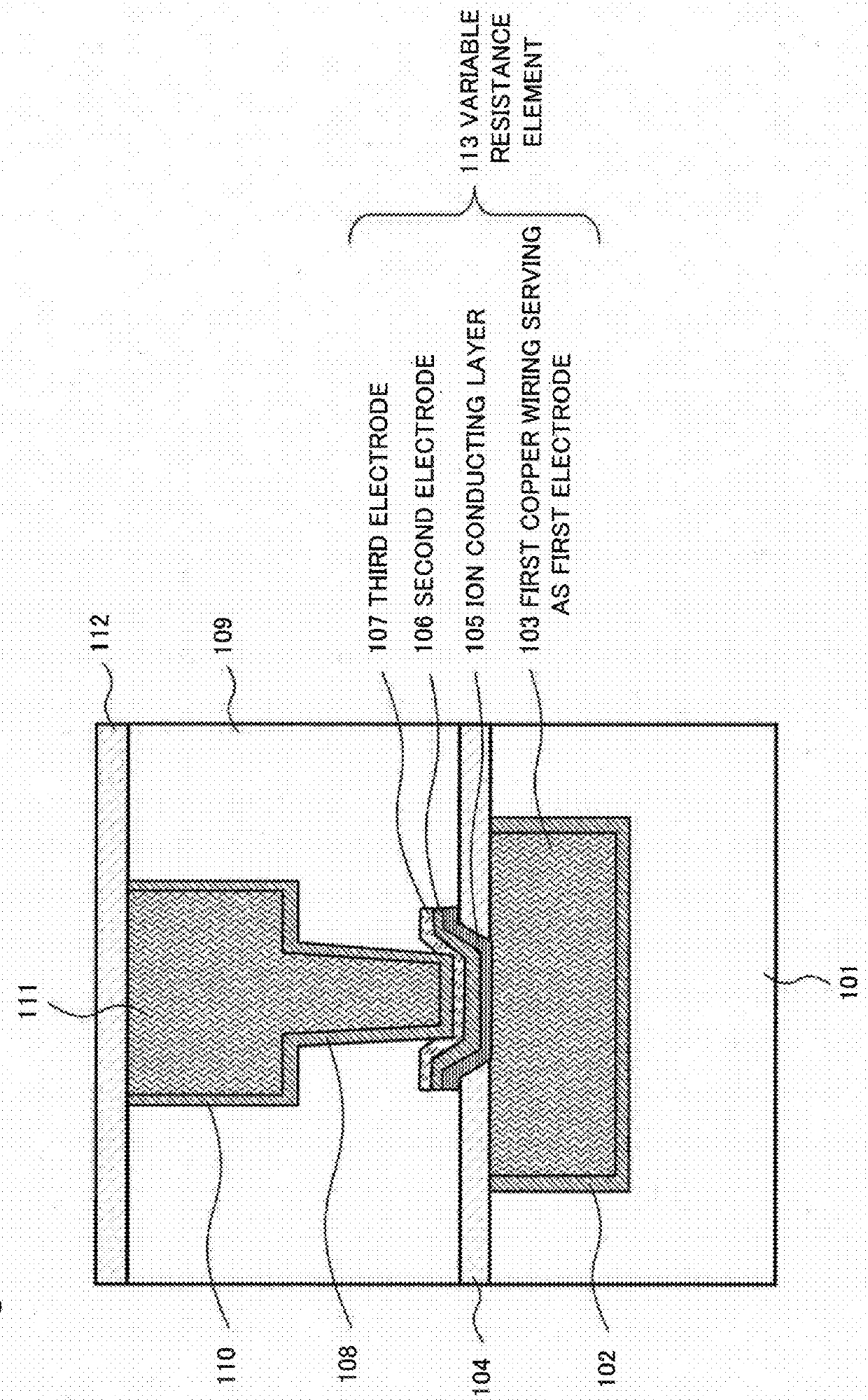

Variable resistance element and method for producing variable resistance element

ActiveUS20180166630A1High insulation breakdown voltageElectrical apparatusStatic storageNitrogenCopper

In order to improve the number rewrites by improving the dielectric breakdown resistance of an ion conducting layer in a variable resistance element, this variable resistance element is provided with: a first electrode that contains at least copper; a second electrode that contains at least Ru, nitrogen and a first metal; and an ion conducting layer that is positioned between the first electrode and the second electrode.

Owner:NANOBRIDGE SEMICON INC

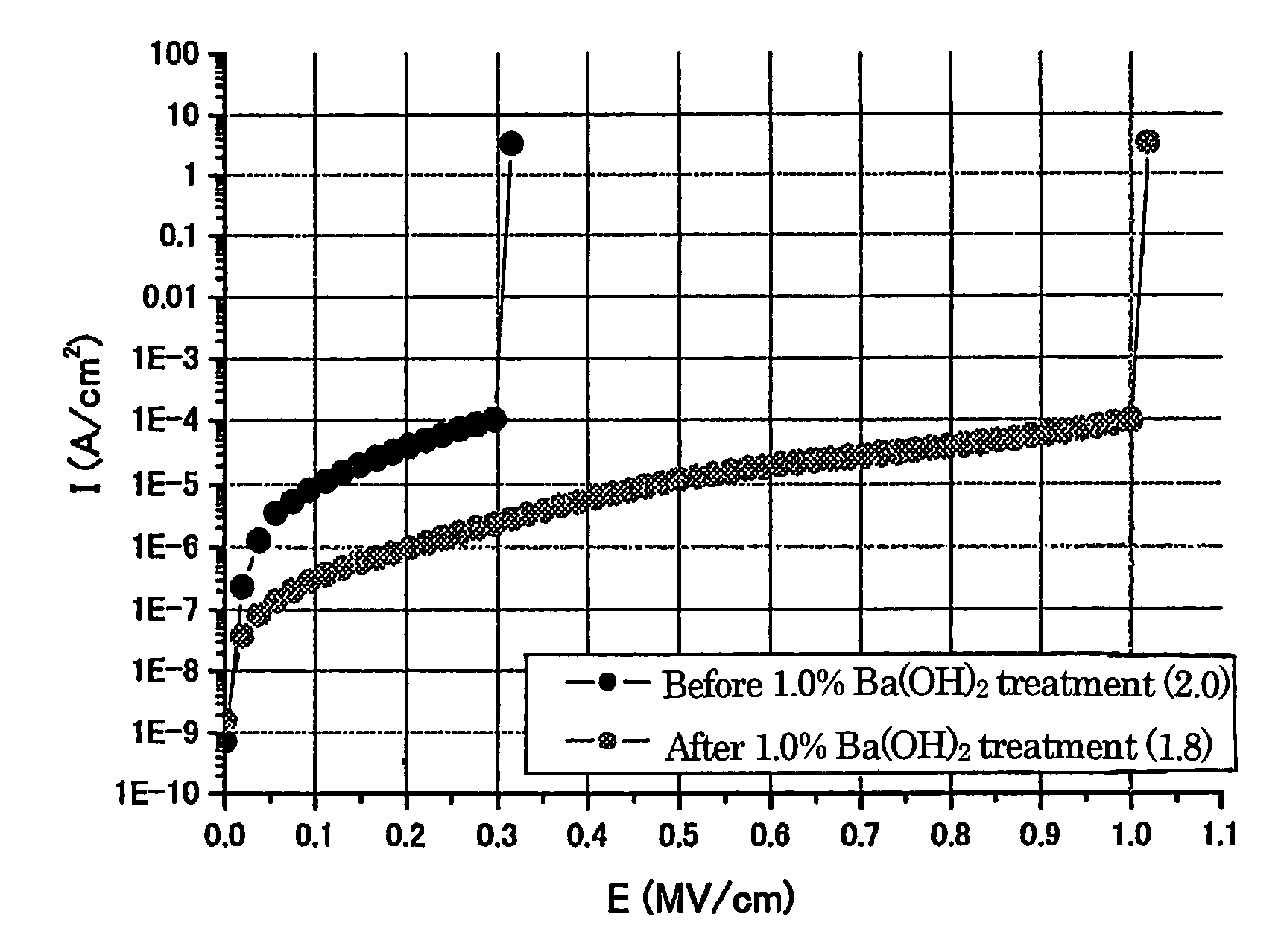

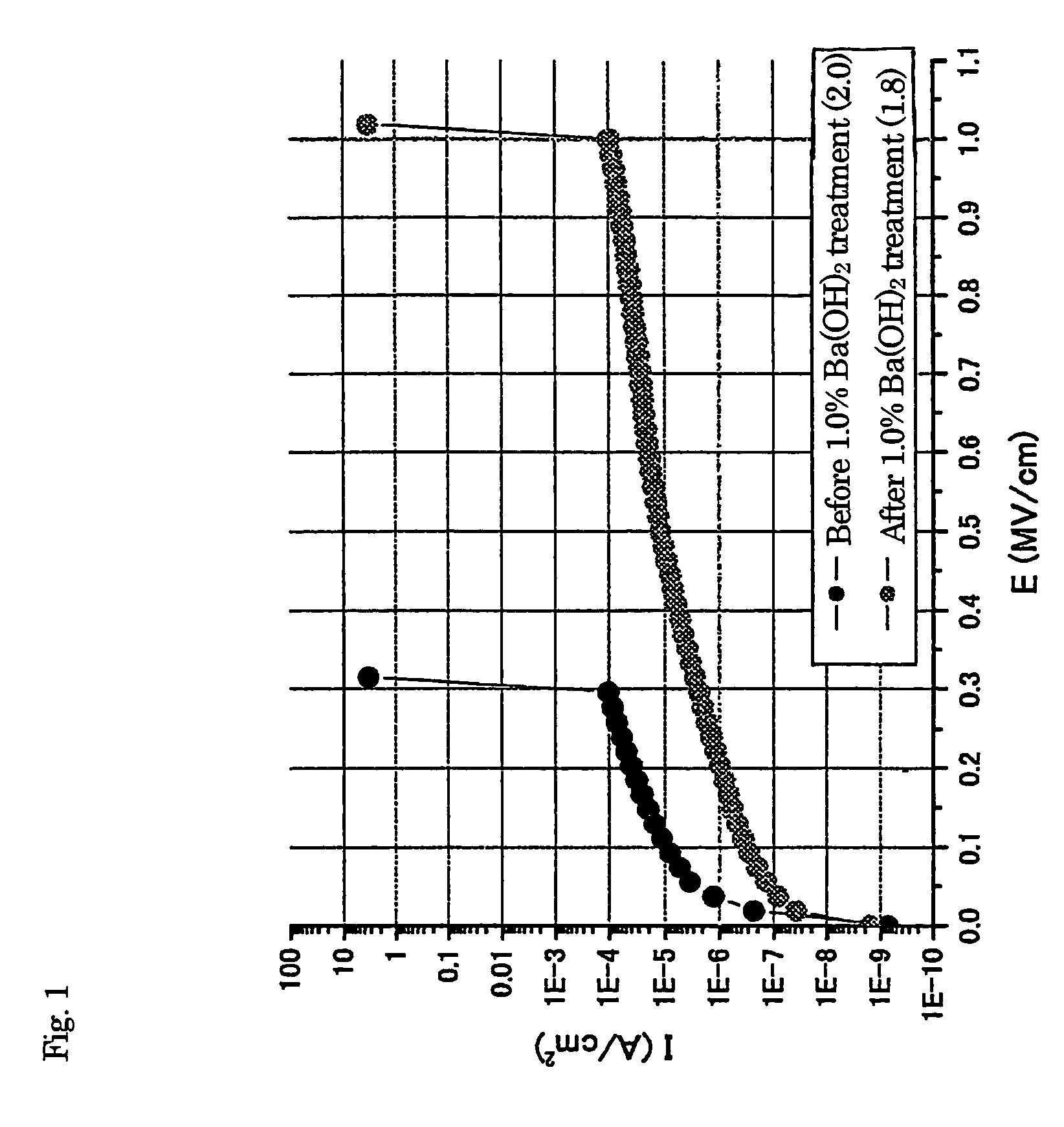

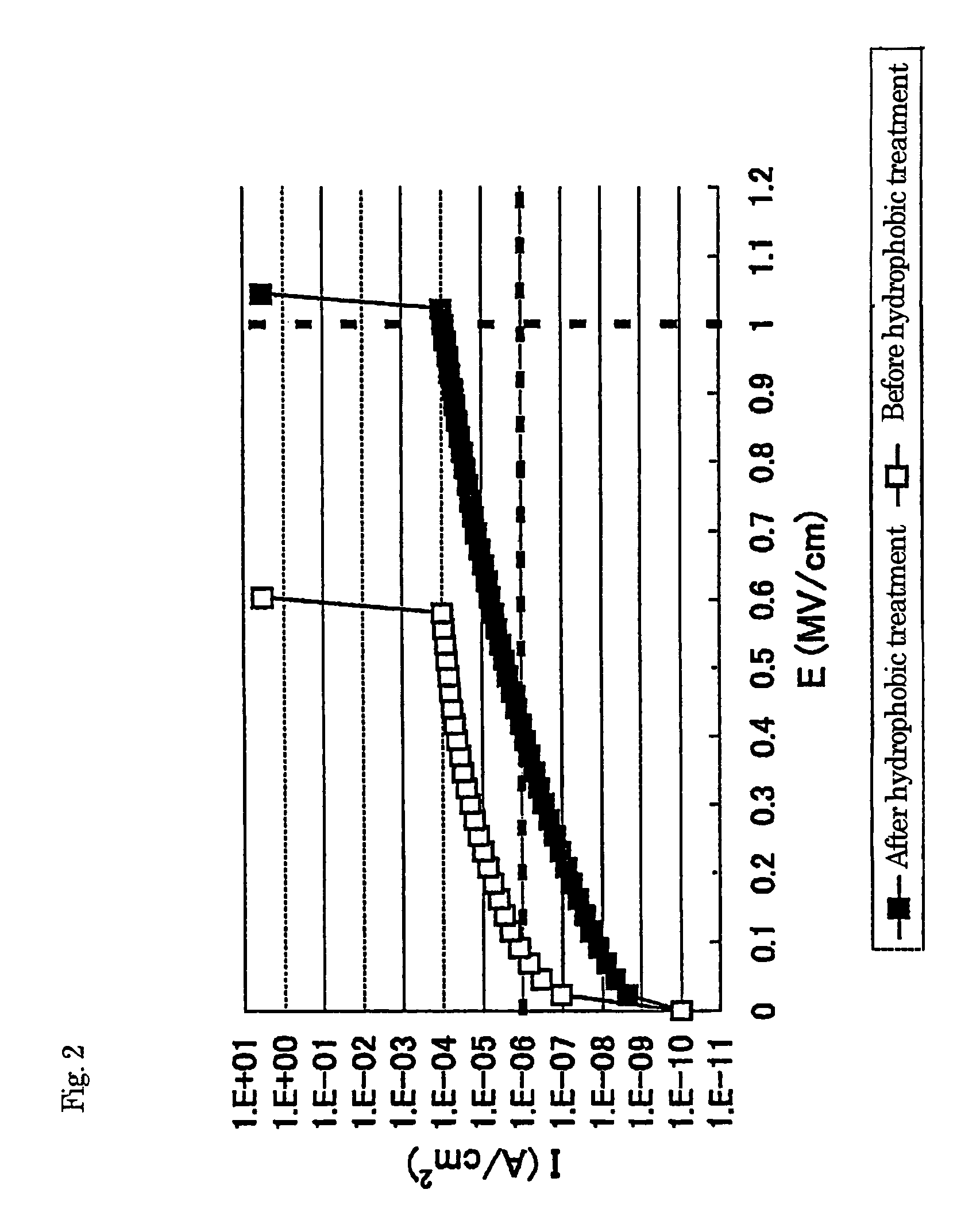

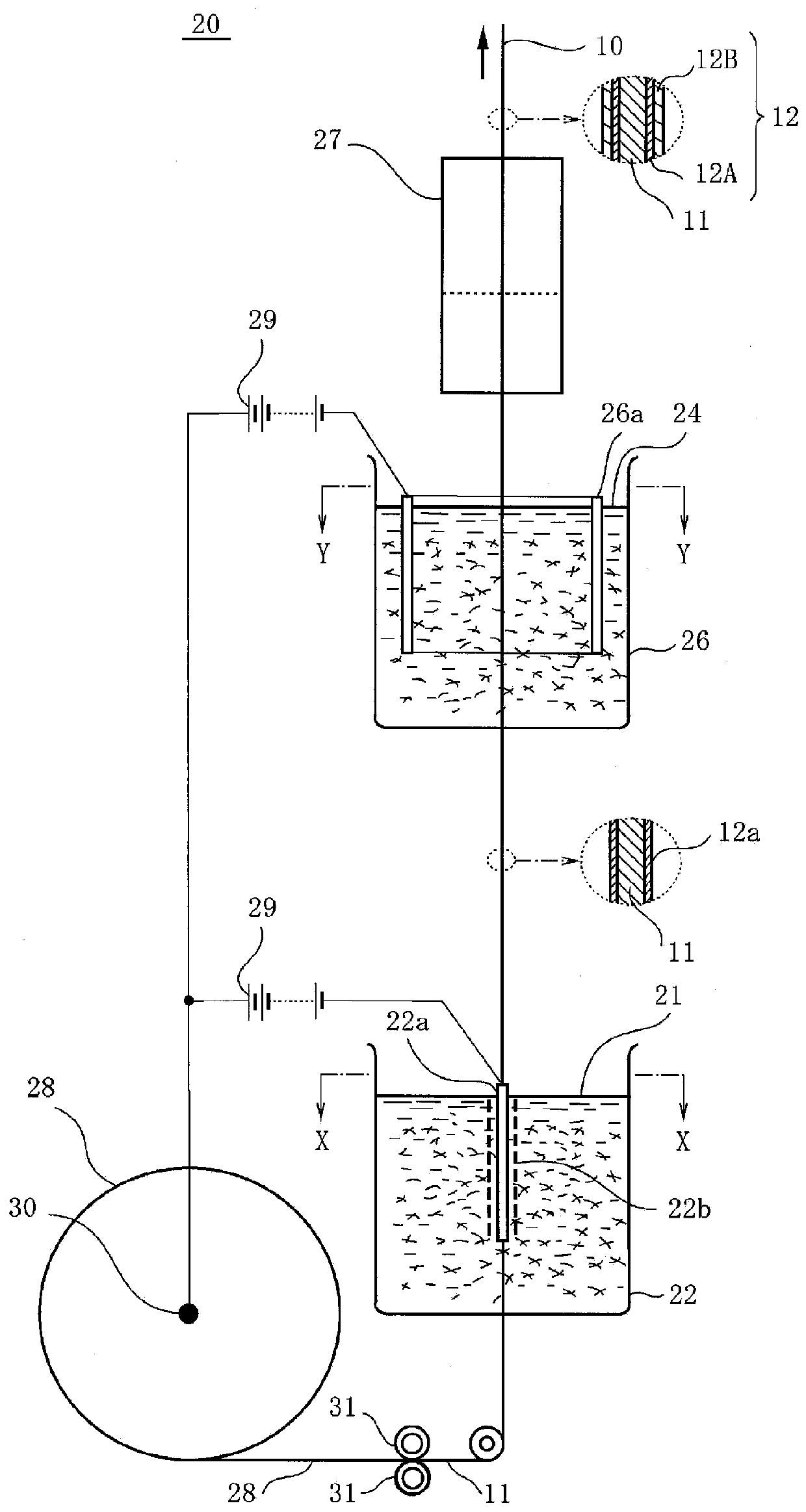

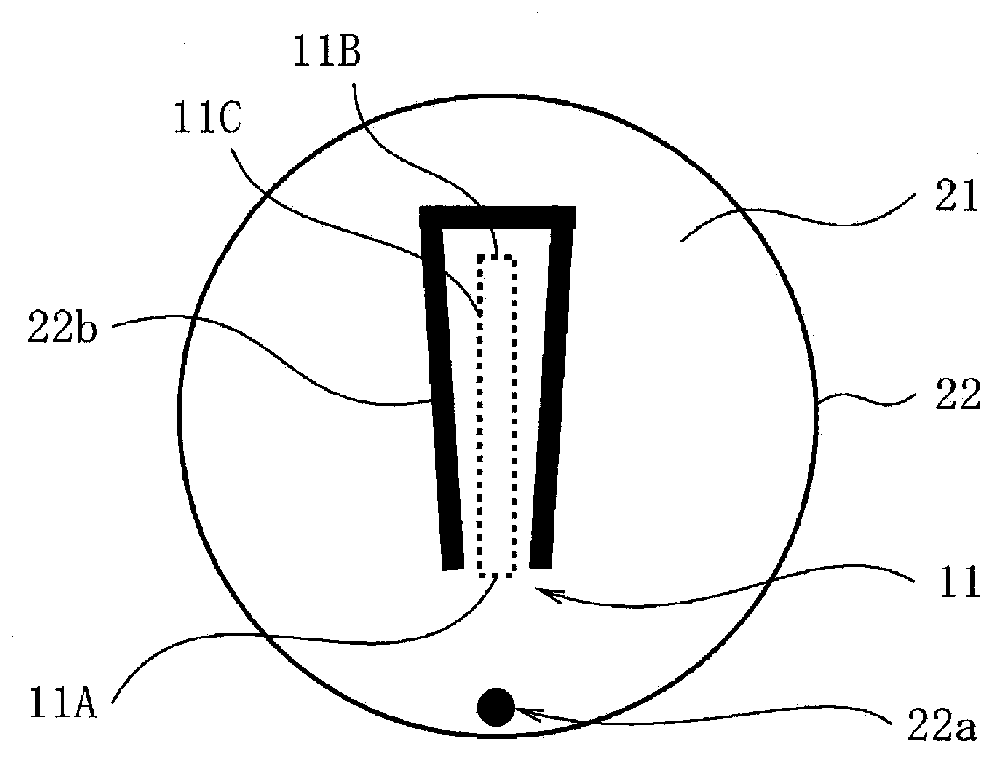

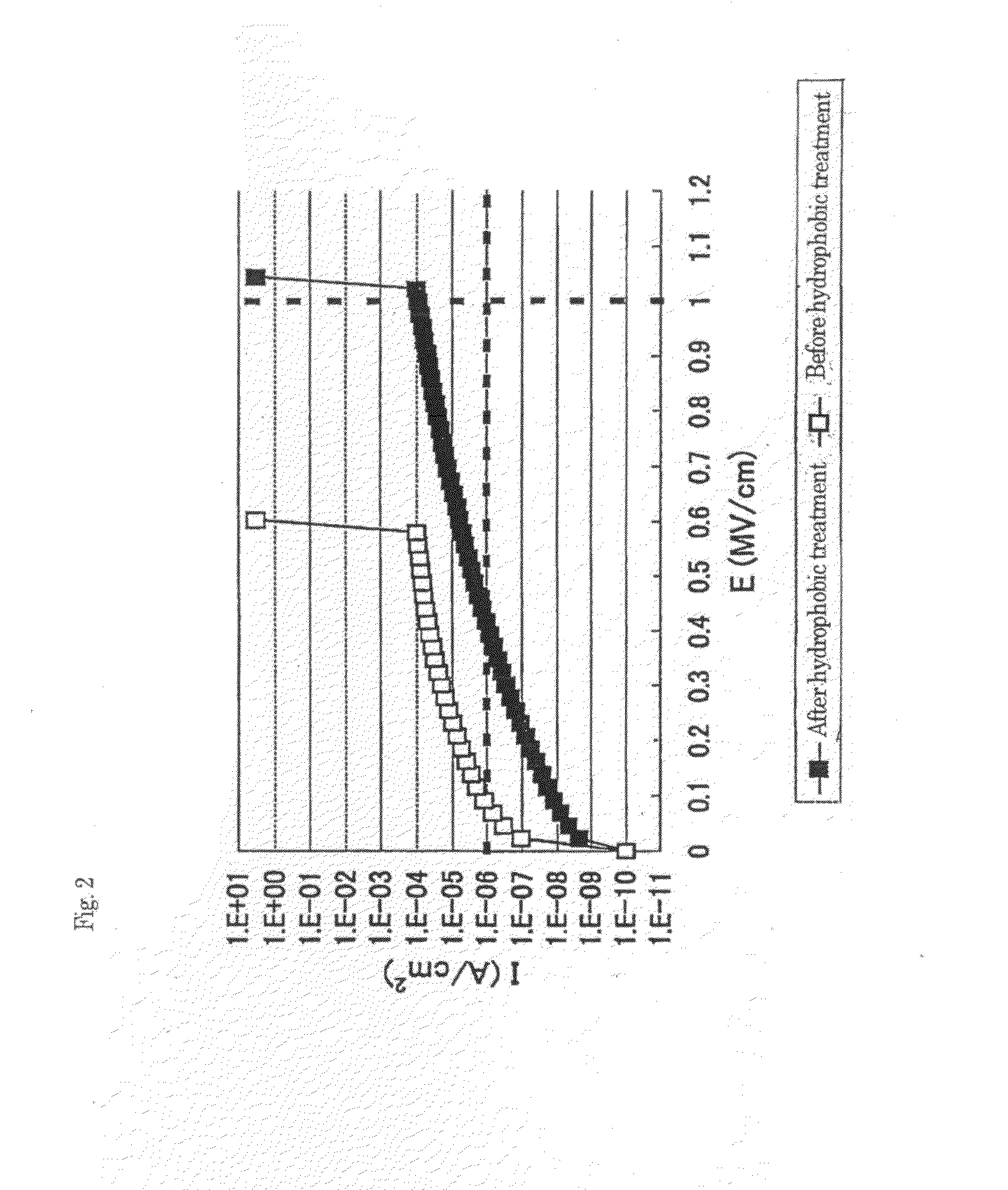

Low dielectric constant films and manufacturing method thereof, as well as electronic parts using the same

InactiveUS7749920B2Guaranteed functionImprove thermal conductivityTransistorSemi-permeable membranesDisiloxaneSilanes

While a fine porous diamond particle film has been known as a high heat resistant and low dielectric constant film and also has high mechanical strength and heat conductivity, and is expected as an insulating film for multi-layered wirings in semiconductor integrated circuit devices, it is insufficient in current-voltage characteristic and has not yet been put into practical use. According to the invention, by treating the fine porous diamond particle film with an aqueous solution of a salt of a metal such as barium and calcium, the carbonate or sulfate of which is insoluble or less soluble, and a hydrophobic agent such as hexamethyl disilazane or triethyl monochloro silane, as well as a reinforcing agent containing one of dichlorotetramethyl disiloxane or dimethoxytetramethyl disiloxane, thereby capable of putting the dielectric breakdown voltage and the leak current within a specified range of a practical standard.

Owner:RORZE CORP

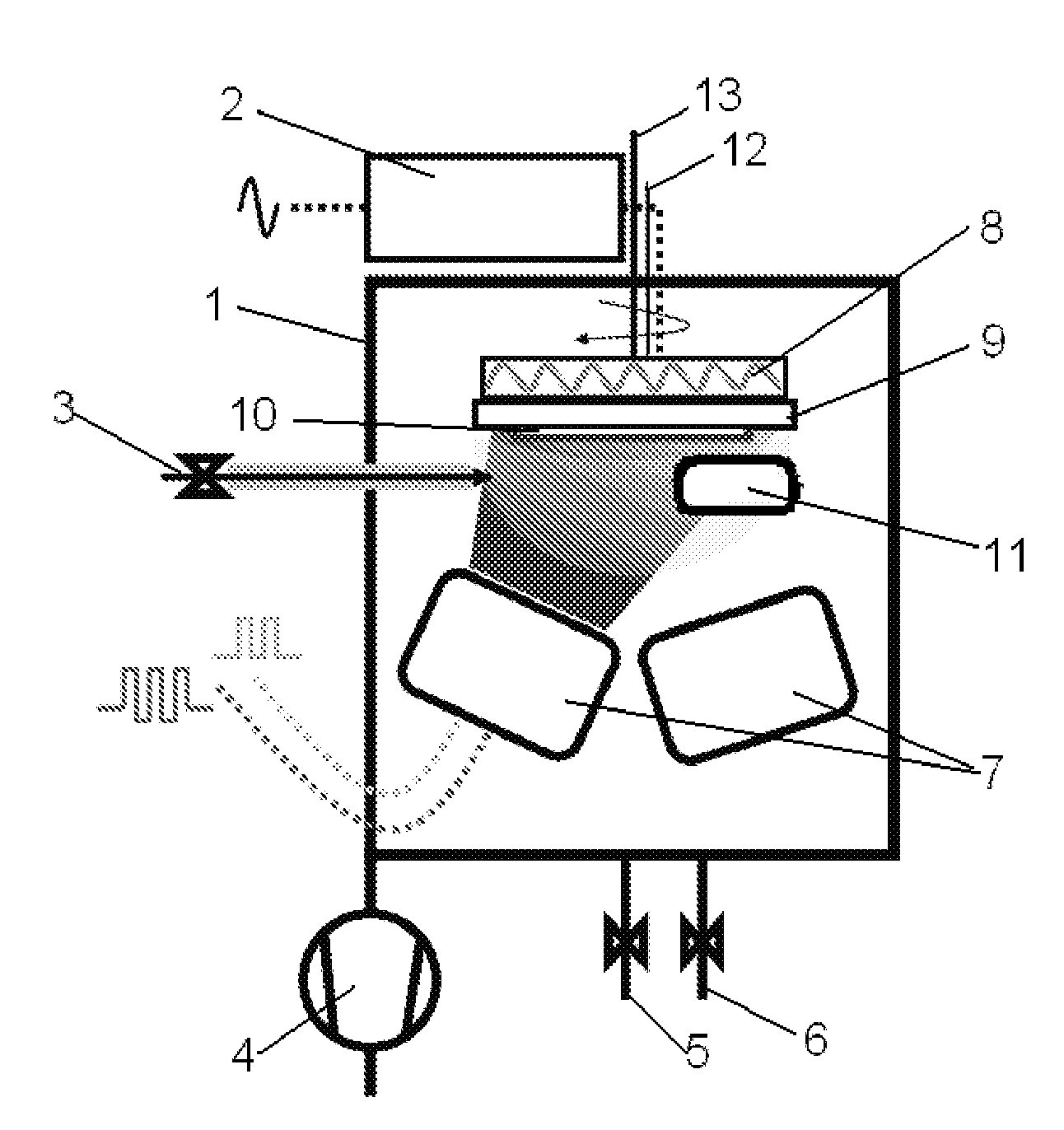

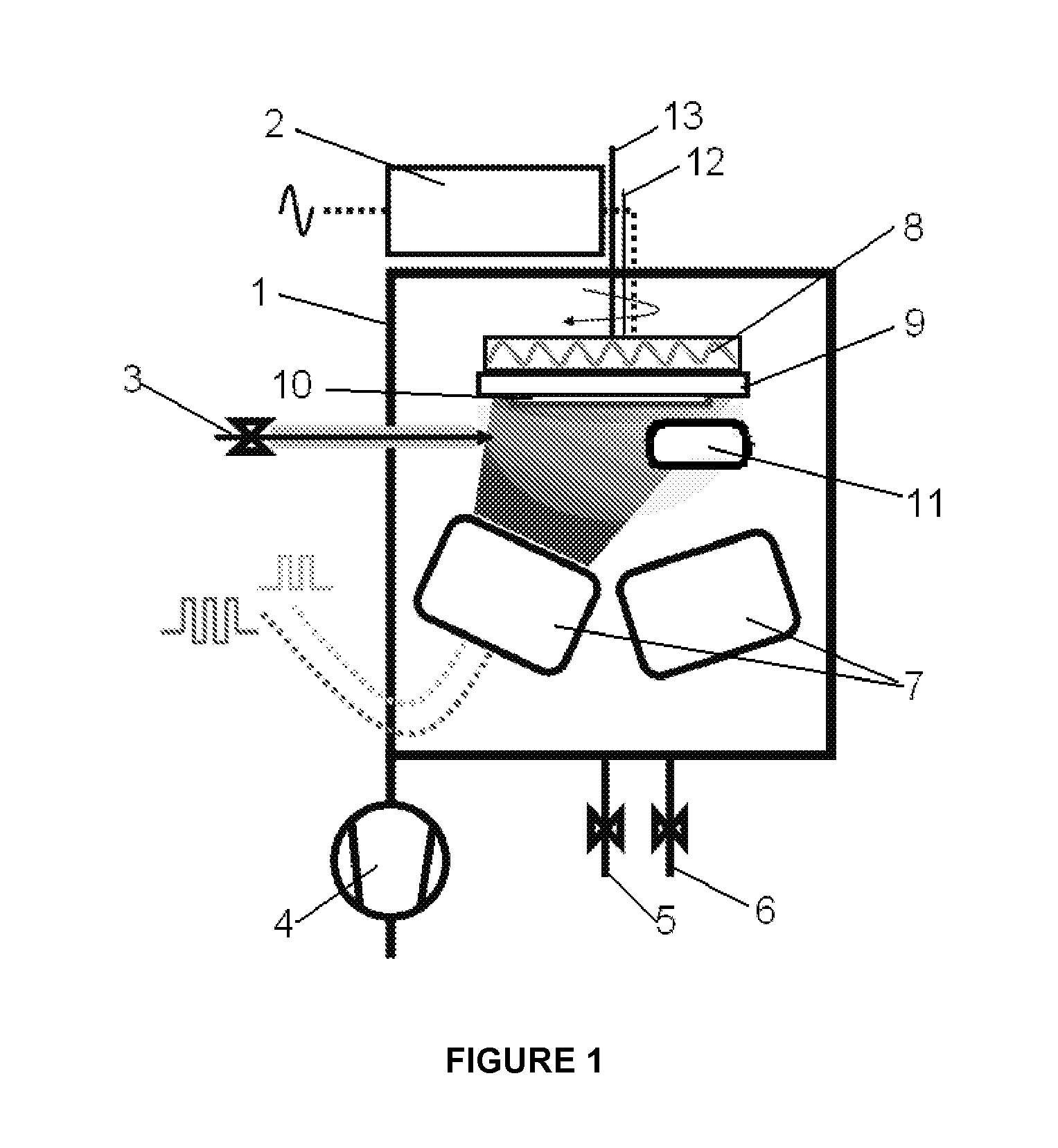

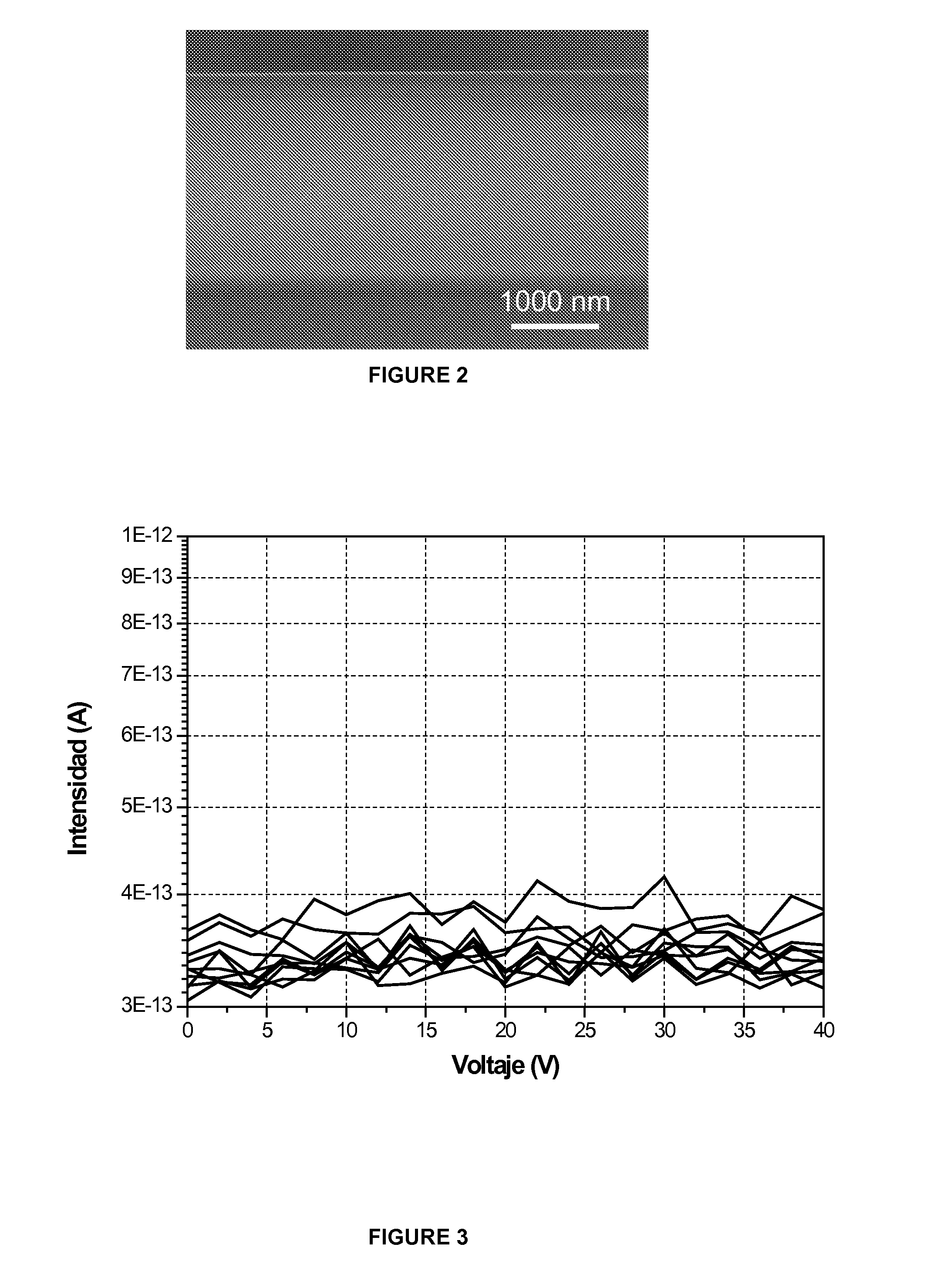

Method for producing a dielectric and/or barrier layer or multilayer on a substrate, and device for implementing said method

InactiveUS20150325418A1Improve featuresImprove efficiencySilicaFinal product manufactureReactive gasDecomposition

The present invention relates to the procedure for the preparation of barrier and / or dielectric layers on a substrate, characterized in that it comprises the following stages: (a) cleaning the substrate, (b) placing the substrate on a sample holder and the introduction thereof into a vacuum chamber, (c) dosage of said vacuum chamber with an inert gas and a reactive gas, (d) injection into the vacuum chamber of a volatile precursor that has at least one cation of the compound to be deposited, (e) activation of a radio frequency source and activation of at least one magnetron, (f) decomposition of the volatile precursor using plasma, the reaction between the cation of the volatile precursor and the reactive gas occurring at the same time that the reaction between the reactive gas contained in the plasma and the cation from the target by sputtering takes place, thus leading to the deposition of the film onto the substrate. The device for carrying out said method is also object of the invention.

Owner:ABENGOA SOLAR NEW TECH SA

6-series aluminum alloy surface insulation oxidation method

InactiveCN110241449AQuality improvementPrevent contamination of oxidation bathAnodisationAnodic oxidationBenzene

The invention belongs to the technical field of metal surface treatment, and relates to a 6-series aluminum alloy surface insulation oxidation method. The 6-series aluminum alloy surface insulation oxidation method comprises the steps of deoiling, alkali corrosion, dusting, anodizing and hole sealing, wherein the anodizing technique is characterized in that a dusted aluminum alloy section is placed in an electrolytic cell containing 160-220 g / L sulfuric acid electrolyte for electrolysis; the density of current is 1.3-2.0 A / dm<2>; the electrolysis oxidation time is 20-50 min; the electrolysis temperature is 18-22 DEG C; the hole sealing technique is characterized in that the anodized aluminum alloy section is soaked in a sealing agent mixed solution of which the PH value is 5.5-6.0 for sealing treatment for 8-30 min; moisture on the surface of the section is drained off; the main solution of the sealing agent mixed solution is 1-10 g / L nickel fluoride, 0.1-5 g / L benzene sulfonic acid and 0.1-5 g / L EDTA disodium; the sub solution is glacial acetic acid and ammonia water which are used for adjusting the PH value of the sealing agent mixed solution; electric insulated shoes made of the aluminum alloy section oxidation film which is sealed with the sealing agent mixed solution are greatly improved; and the insulation breakdown voltage is far higher than that of a sulfuric acid anodizing film layer manufactured in a traditional technique.

Owner:CHINA ZHONGWANG

Semiconductor module and method of manufacturing semiconductor module

ActiveUS9818687B2Reduce concentrationHigh insulation breakdown voltageSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

Owner:FUJI ELECTRIC CO LTD

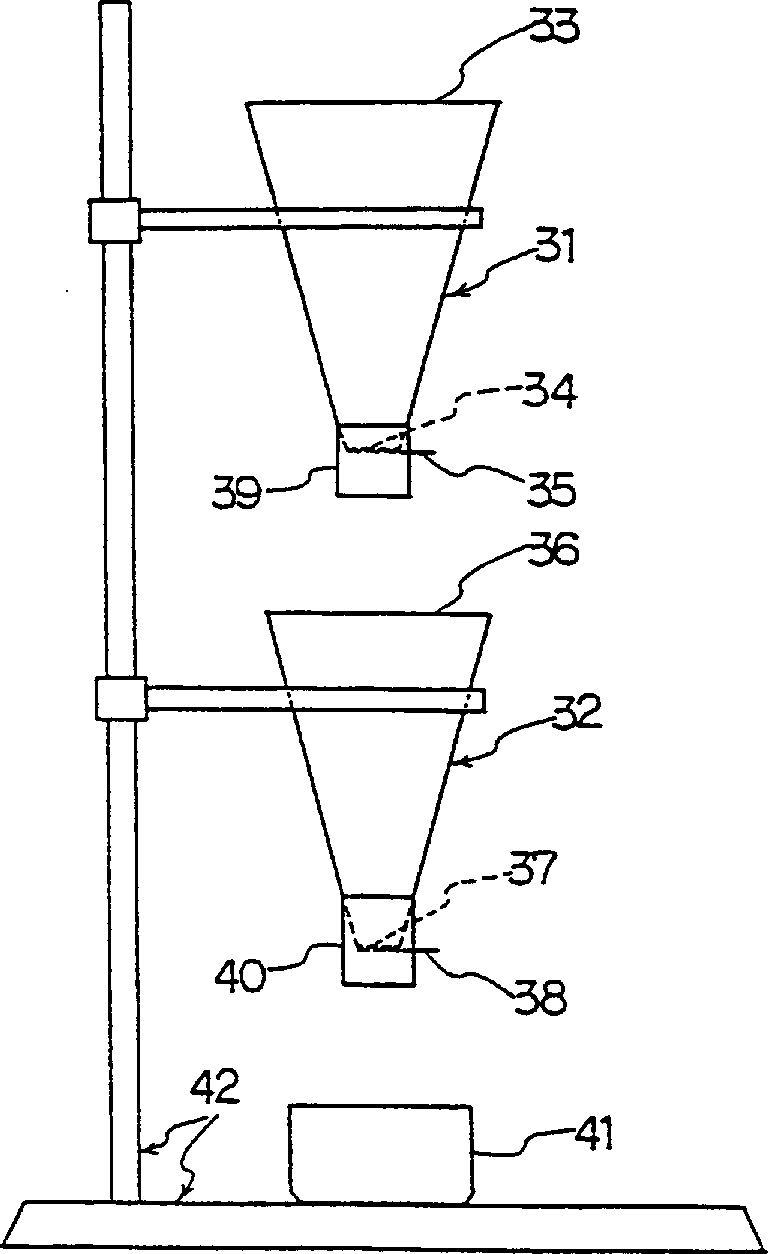

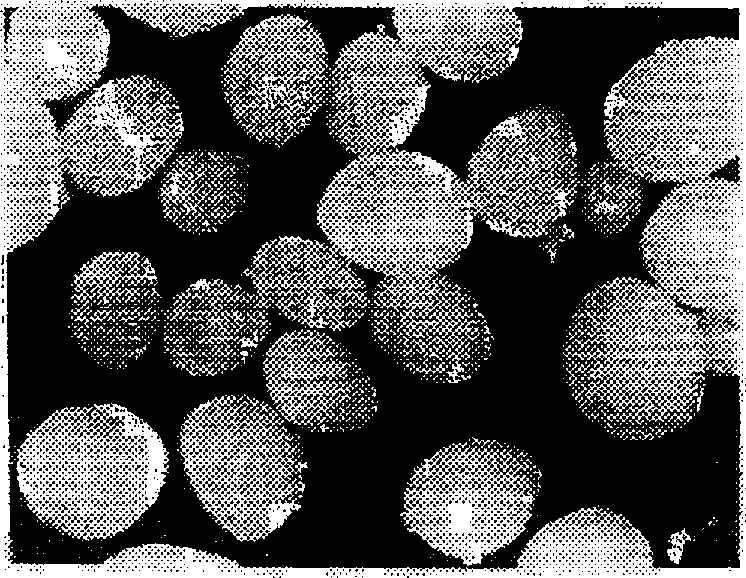

Granular powder of modified polytetrafluoroethylene

InactiveCN1249767AHigh apparent densitySteep particle size distributionApparent densityPolymer science

A granular powder of a modified PTFE, which has a high apparent density, a small average particle diameter, a narrow particle size distribution, a charge amount of substantially zero, and a small angle of repose and is excellent in powder flowability and especially powder stability. A powder of a modified PTFE is granulated by stirring the PTFE in water in the presence of both an organic fluid forming a liquid-liquid interface with water and a nonionic surfactant comprising a segmental polyalkylene glycol having at least one hydrophobic segment and at least one hydrophilic segment. The granular powder can give molded articles having excellent tensile strength and elongation, a reduced surface roughness, and a high breakdown voltage and a high whiteness (Z value).

Owner:DAIKIN IND LTD

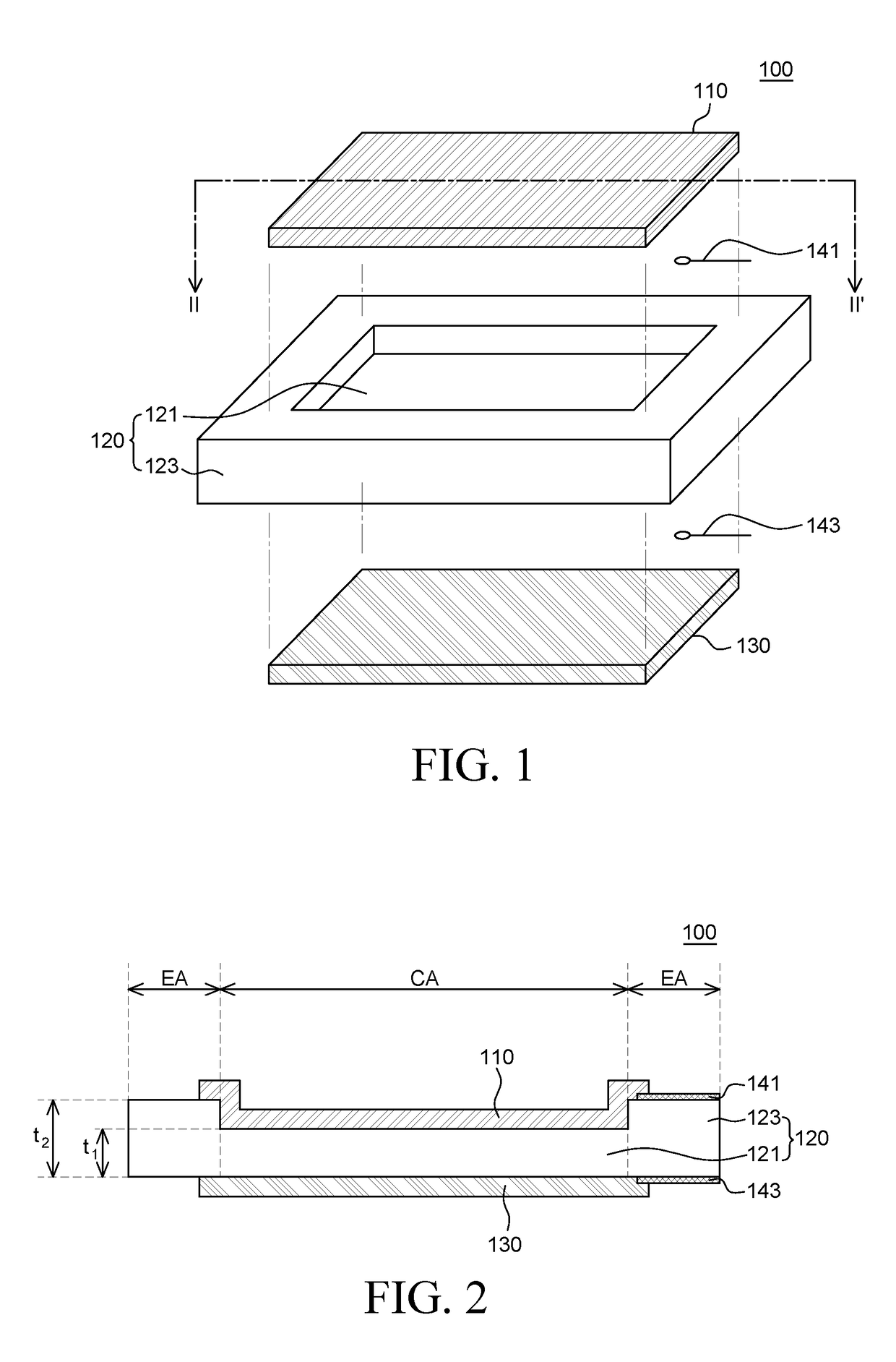

Insulated electric wire, production method therefor, coil and coil production method using same

ActiveCN110352463APrevent peelingAvoid wrinklesTransformers/inductances coils/windings/connectionsElectric machinesElectrical conductorEngineering

This insulated electric wire comprises an insulation coat covering a flat rectangular conductor wire whereof the transversal cross-sectional shape is rectangular. The insulation coat comprises an inner layer covering the surface of the flat rectangular conductor wire, and an outer layer covering the surface of the inner layer. In the rectangular transversal cross section of the flat rectangular conductor wire, among two short sides opposing one another and having an identical length, one of the short sides is covered by the inner layer whereof the thickness (t1) is greater than the thickness (t2) of the inner layer covering the other short side (which includes t2=0). The elastic modulus of the inner layer is smaller than the elastic modulus of the outer layer, or the yield stress of the inner layer is smaller than the yield stress of the outer layer. Alternatively, the elastic modulus and the yield stress of the inner layer are both smaller than the elastic modulus and the yield stressof the outer layer.

Owner:MITSUBISHI MATERIALS CORP

Low dielectric constant films and manufacturing method thereof, as well as electronic parts using the same

InactiveUS20100237476A1Guaranteed functionImprove thermal conductivitySilicon organic compoundsSemiconductor/solid-state device detailsDisiloxaneSilanes

While a fine porous diamond particle film has been known as a high heat resistant and low dielectric constant film and also has high mechanical strength and heat conductivity, and is expected as an insulating film for multi-layered wirings in semiconductor integrated circuit devices, it is insufficient in current-voltage characteristic and has not yet been put into practical use. According to the invention, by treating the fine porous diamond particle film with an aqueous solution of a salt of a metal such as barium and calcium, the carbonate or sulfate of which is insoluble or less soluble, and a hydrophobic agent such as hexamethyl disilazane or trimethyl monochlolo silane, as well as a reinforcing agent containing one of dichlorotetramethyl disiloxane or dimethoxytetramethyl disiloxane, thereby capable of putting the dielectric breakdown voltage and the leak current within a specified range of a practical standard.

Owner:RORZE CORP

Interlayer insulating film, wiring structure and electronic device and methods of manufacturing the same

InactiveUS7923819B2Improve featuresLow dielectric constantSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorNitrogen

A wiring structure of a semiconductor device or the like includes an interlayer insulating film having a fluorocarbon film formed on an underlayer, and a conductor buried in the interlayer insulating film. The fluorocarbon film contains nitrogen and is low in dielectric constant, excellent in reproducibility and stable.

Owner:TOHOKU UNIV +1

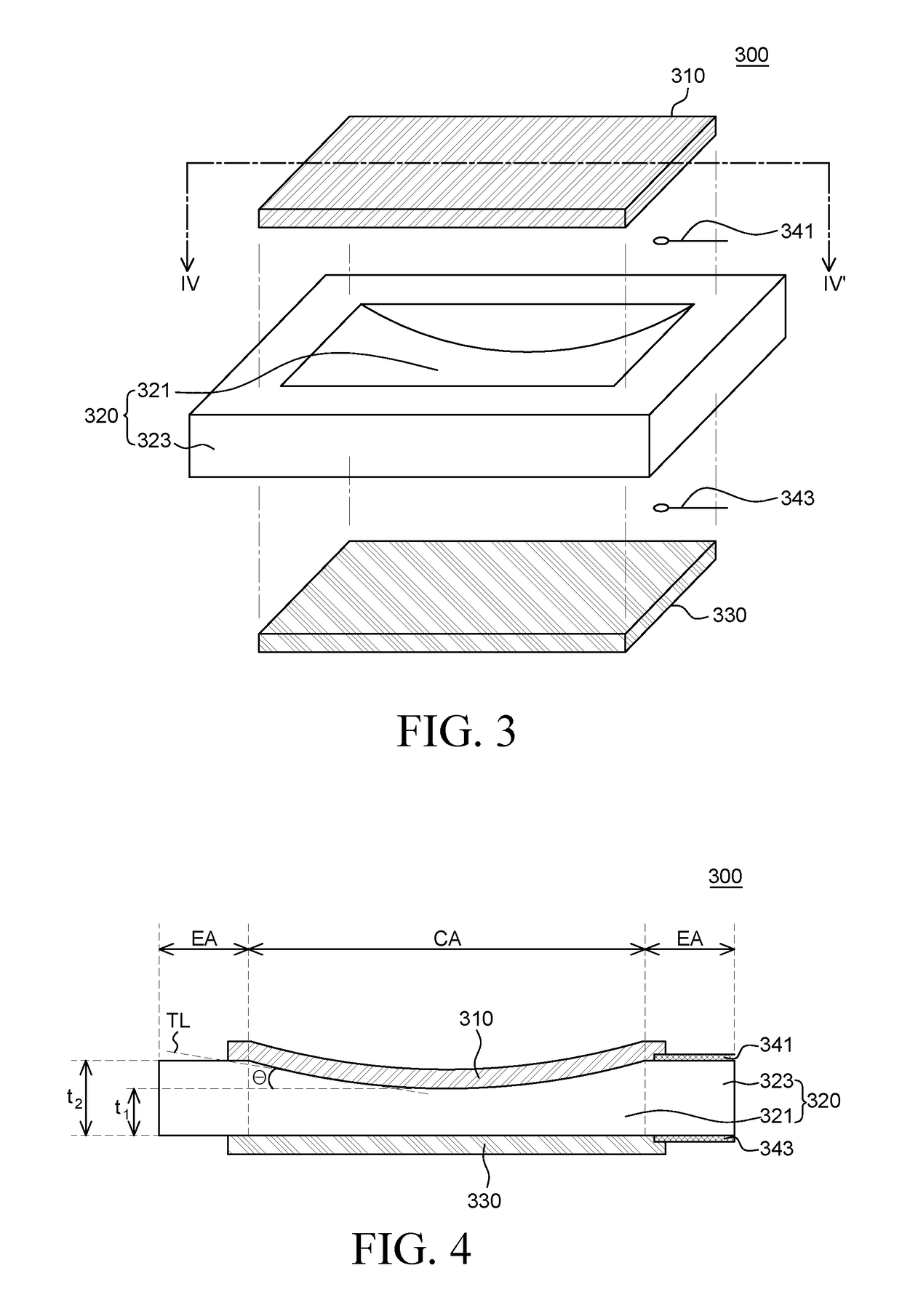

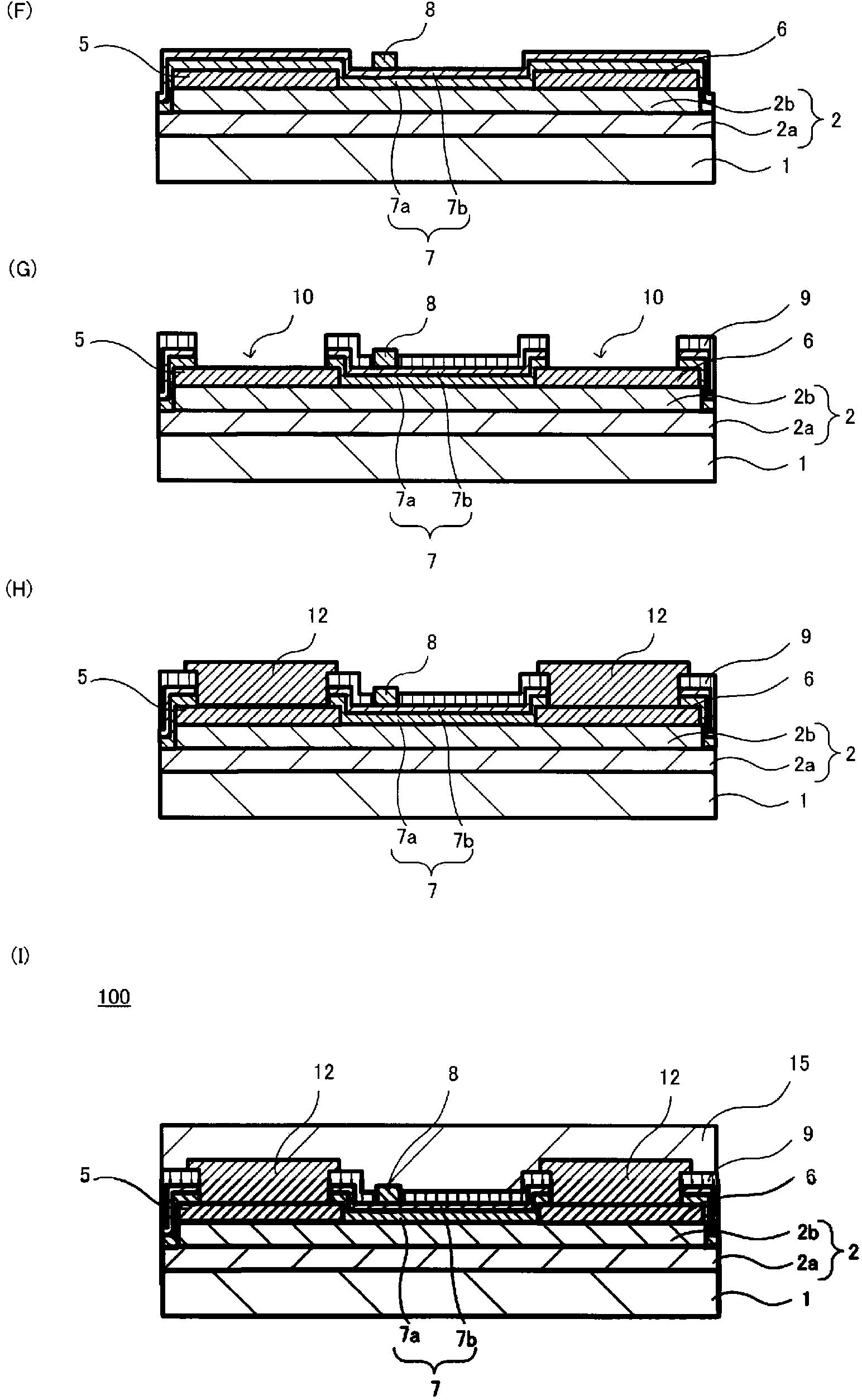

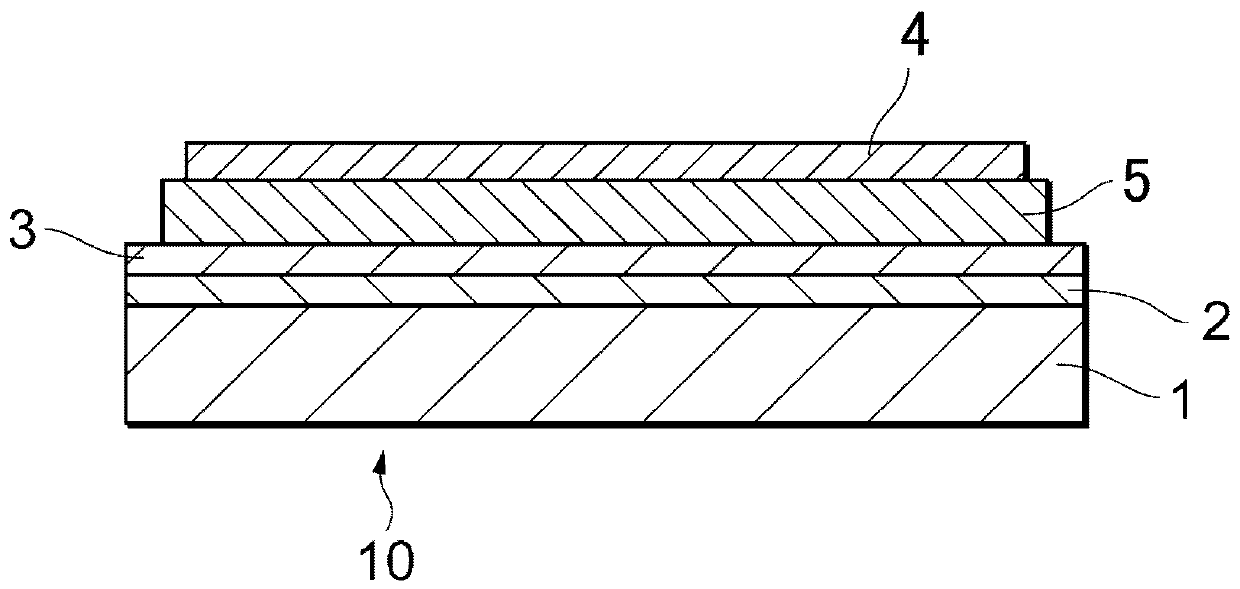

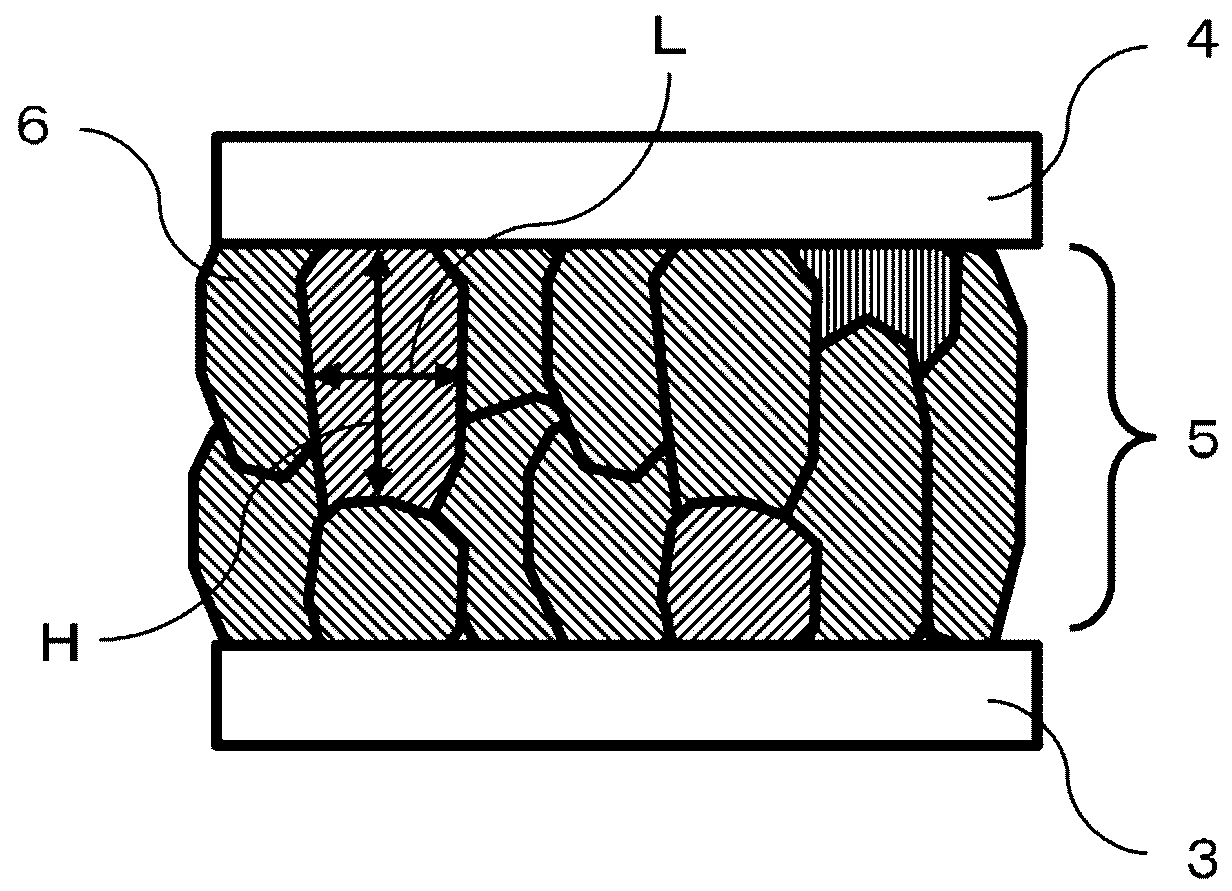

Method of producing laminated substrate, method of producing semiconductor module, laminated substrate, and semiconductor module

ActiveUS11004807B2High insulation breakdown voltageHigh voltageSemiconductor/solid-state device detailsSolid-state devicesLaser processingEngineering

Owner:FUJI ELECTRIC CO LTD

Method of producing laminated substrate, method of producing semiconductor module, laminated substrate, and semiconductor module

ActiveUS20200043872A1High insulation breakdown voltageHigh voltageSemiconductor/solid-state device detailsSolid-state devicesLaser processingSemiconductor

A method of manufacturing a laminated substrate including an insulation substrate comprised of ceramic, and a front electrode formed on a front surface of the insulation substrate, a semiconductor element being mountable on a front surface of the front electrode, including forming the front electrode on the front surface of the insulation substrate, and before or after the forming the front electrode, applying laser processing to the front surface of the insulation substrate at an outer peripheral area of the front electrode to modify a conductive property of the front surface of the insulation substrate to have electrical conductivity.

Owner:FUJI ELECTRIC CO LTD

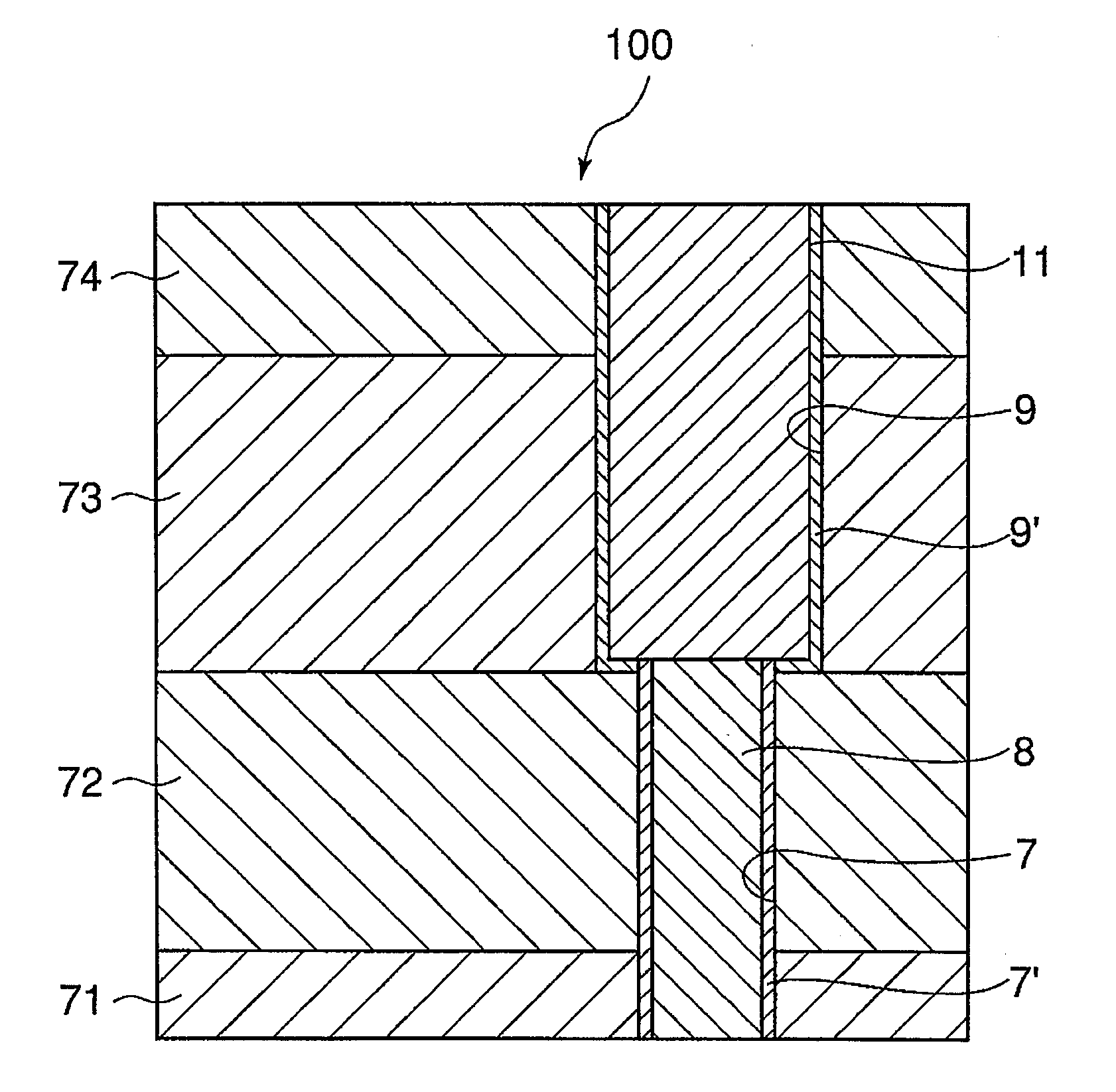

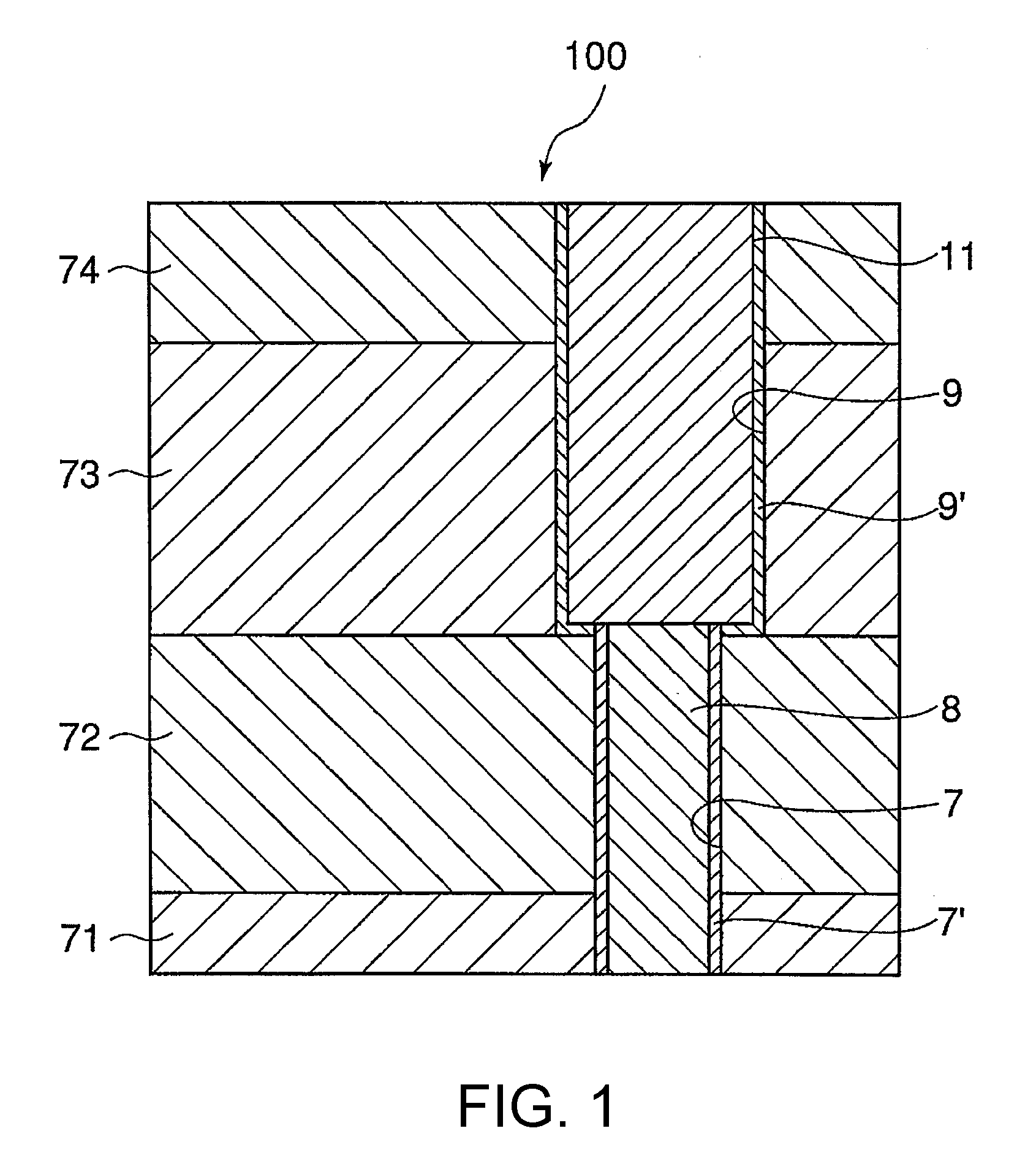

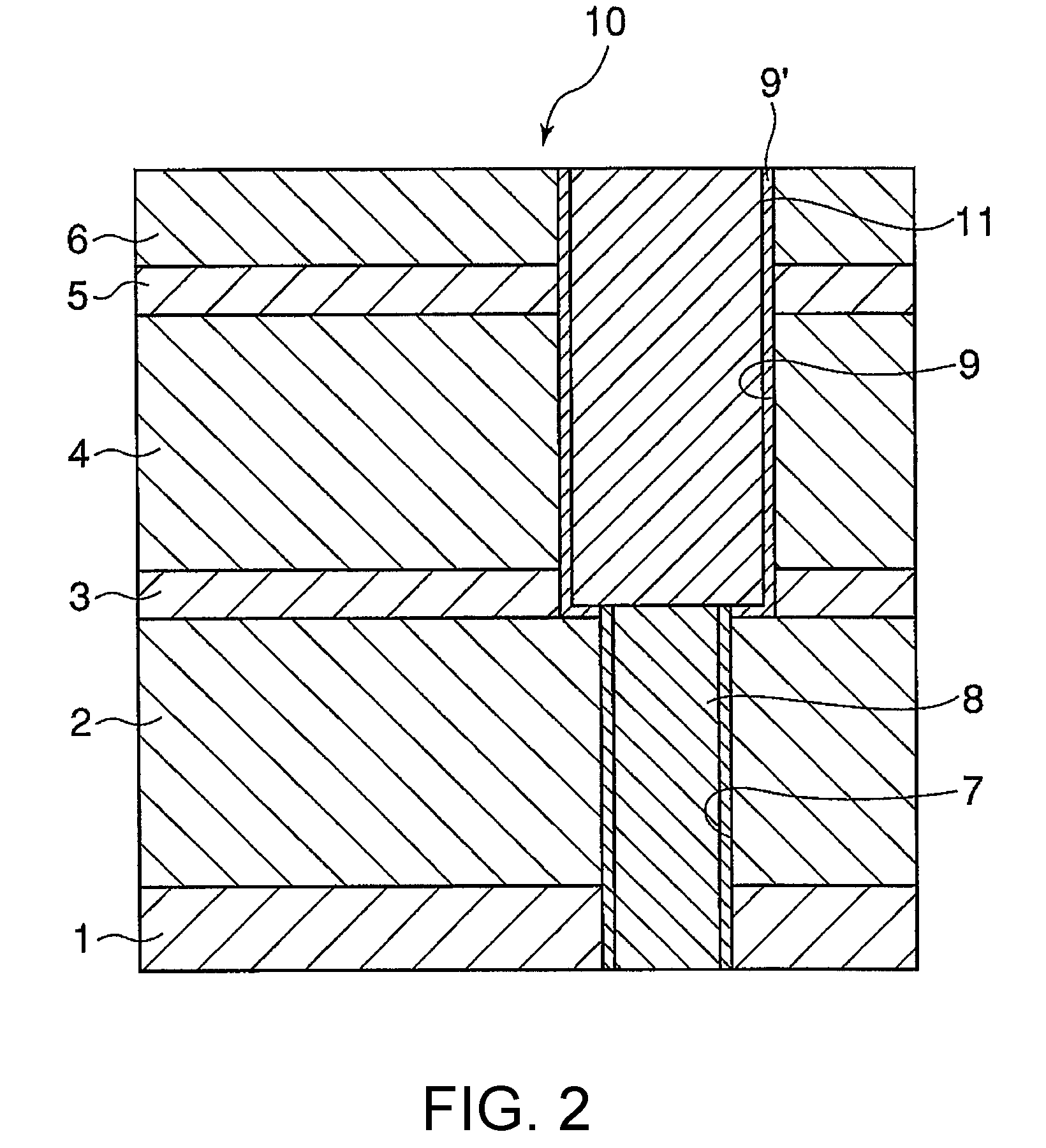

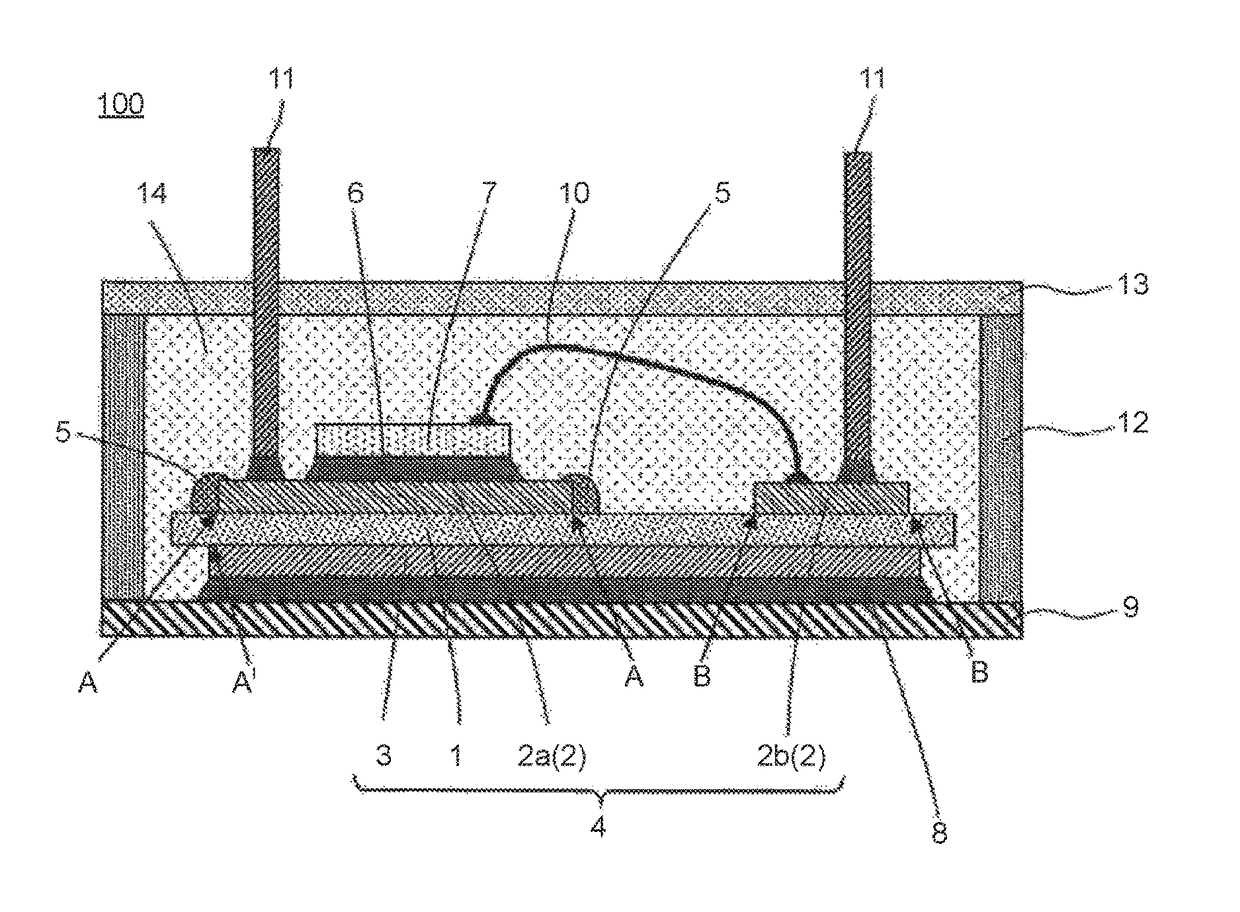

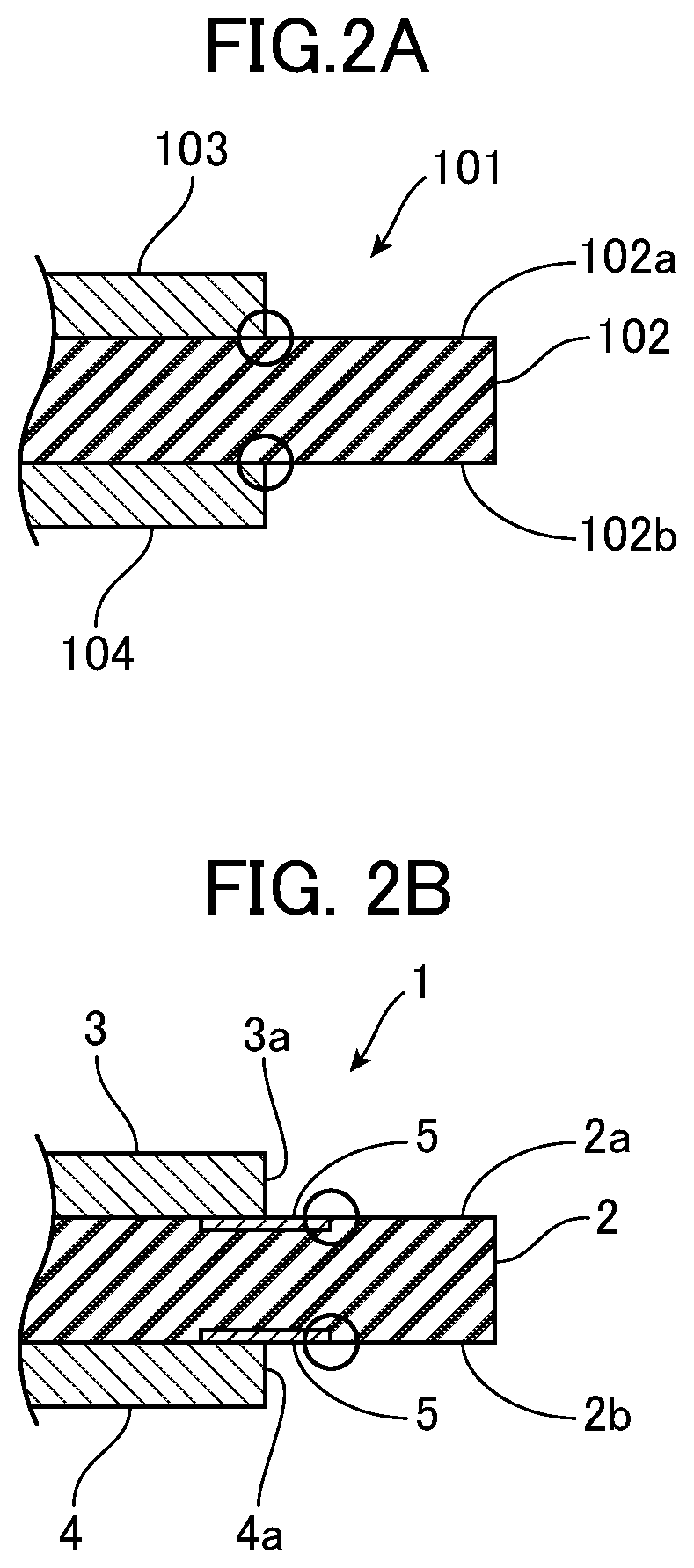

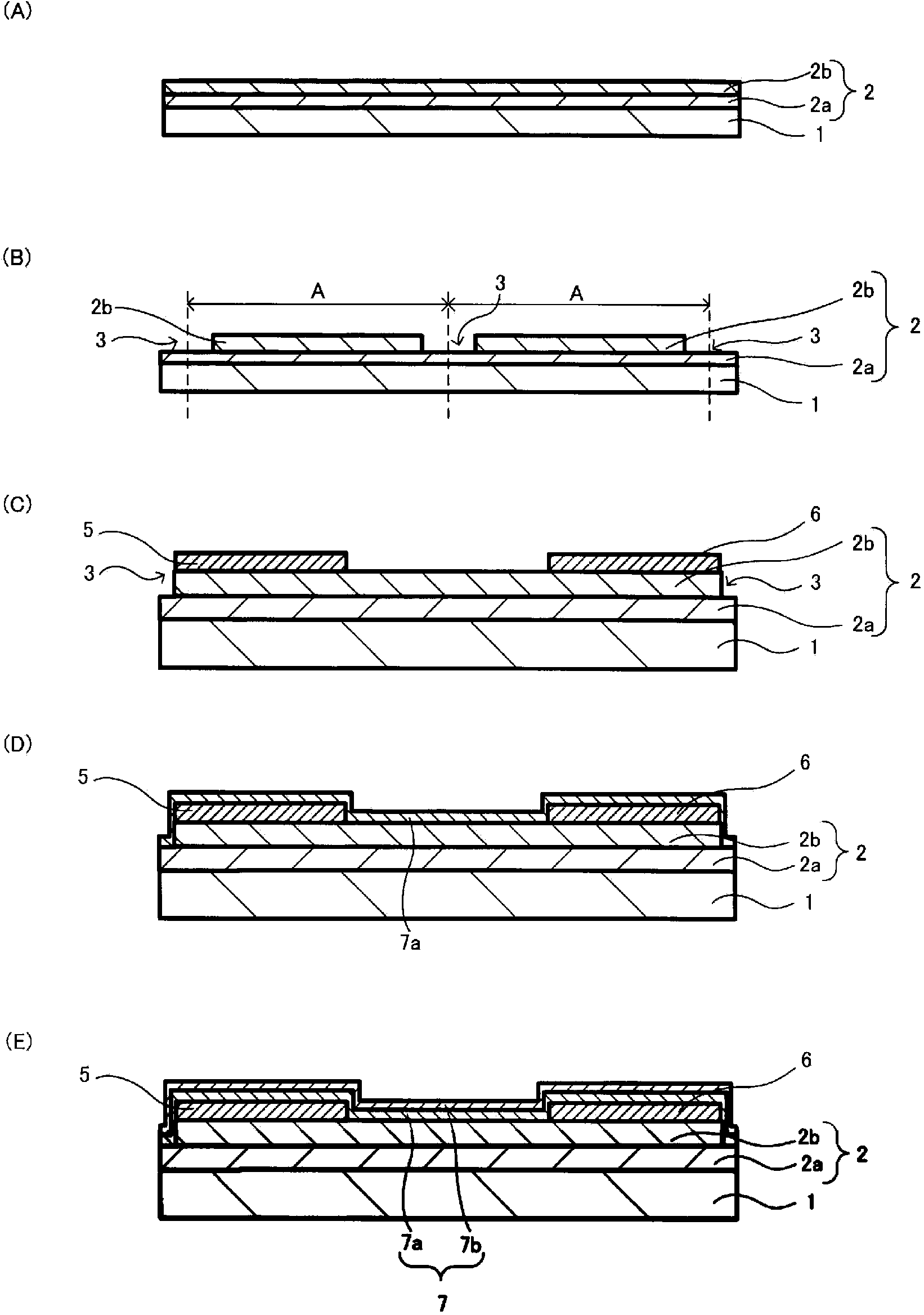

Transistor and transistor manufacturing method

InactiveCN104395992AHigh insulation breakdown voltageSmall currentTransistorSemiconductor/solid-state device detailsImpuritySemiconductor

The purpose of the present invention is to provide a transistor, which has a high breakdown voltage of a gate insulating film, while suppressing deterioration of a current flowing between drain / source electrodes. A transistor (100) is characterized in being provided with: a semiconductor layer (2); a gate insulating film (7) formed on the semiconductor layer (2); a gate electrode (8) formed on the gate insulating film (7); and a source electrode (5) and a drain electrode (6), which are formed on the semiconductor layer (2) with the gate electrode (8) sandwiched between the electrodes. The transistor is also characterized in that the concentration of an impurity contained in the gate insulating film (7) is reduced toward the gate insulating film (7) surface on the gate electrode (8) side from the gate insulating film (7) surface on the semiconductor layer (2) side.

Owner:MURATA MFG CO LTD

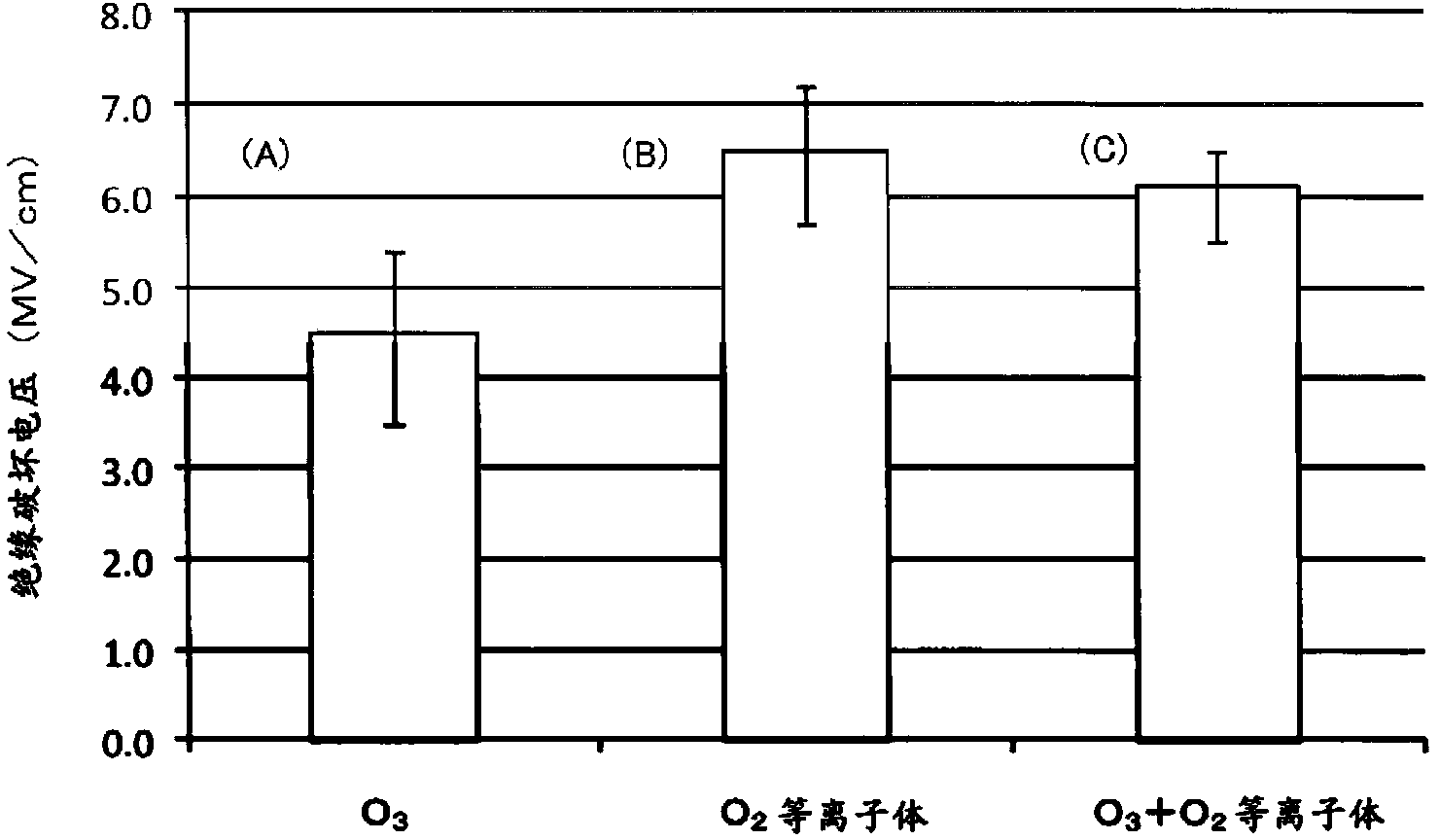

Epoxy resin composition for coil impregnation, method for producing coil product, and ignition coil

An epoxy resin composition for coil impregnation contains (A) epoxy resin, (B) acid anhydride, (C) curing accelerator, and (D) spherical cristobalite.

Owner:KYOCERA CORP

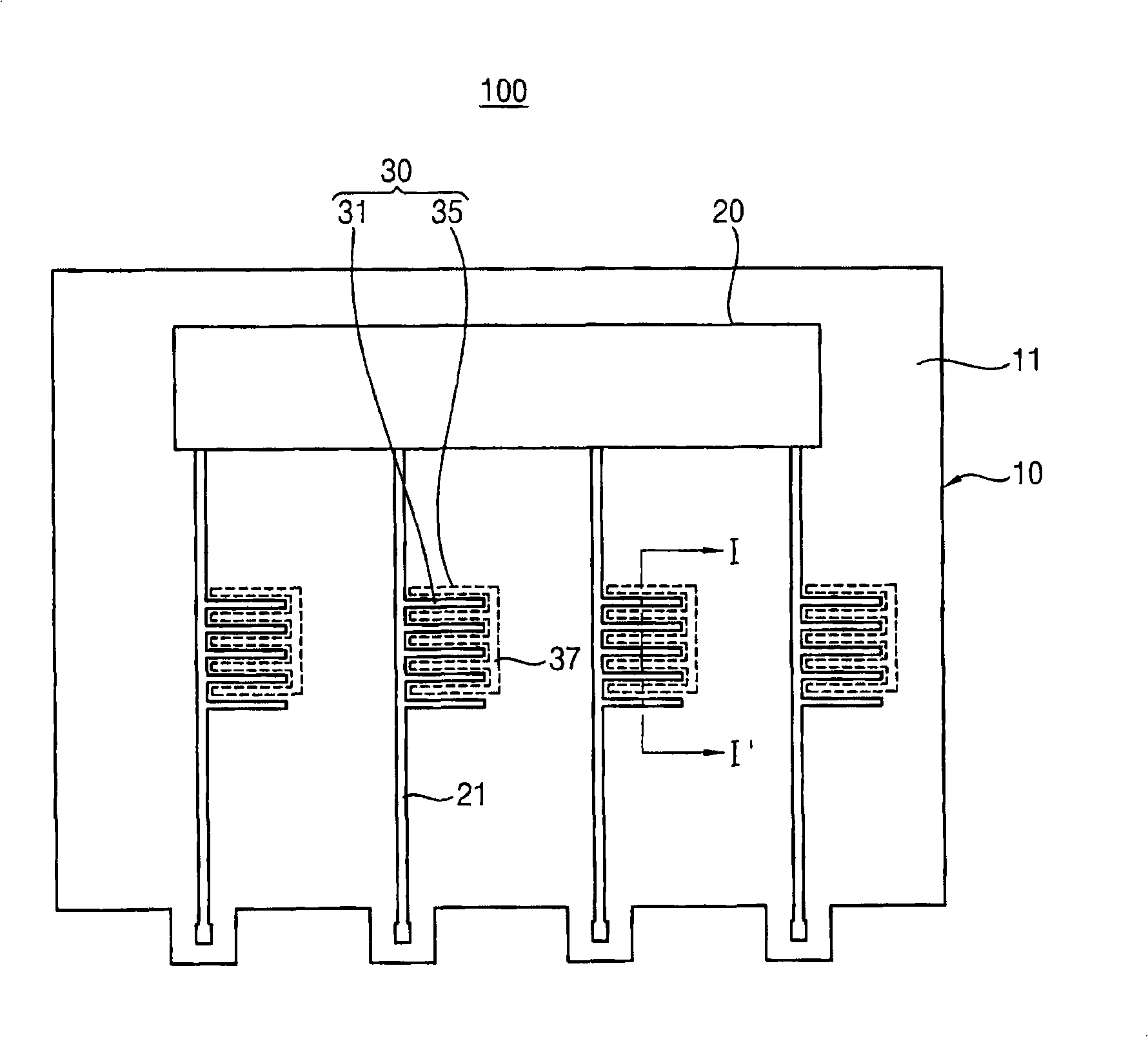

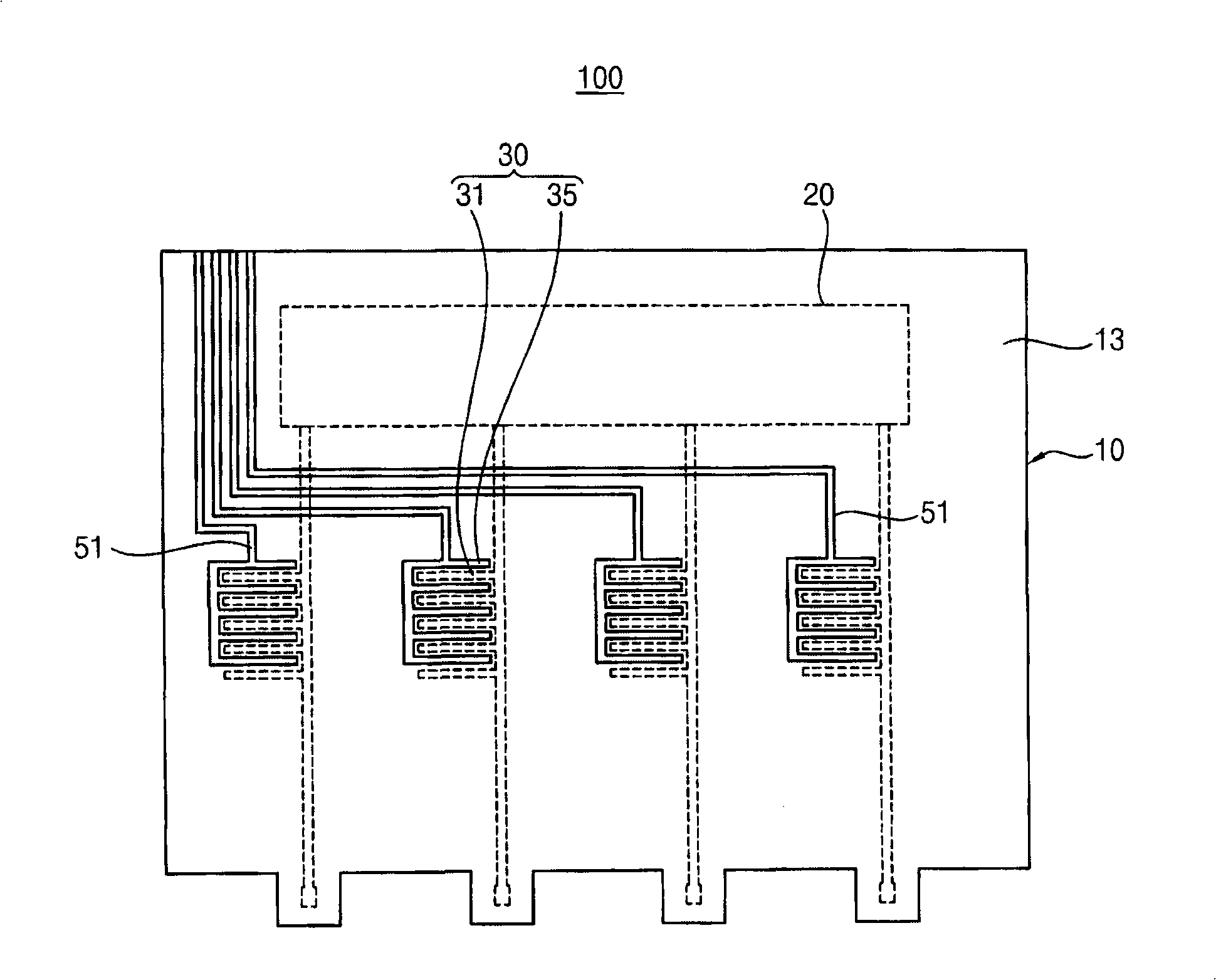

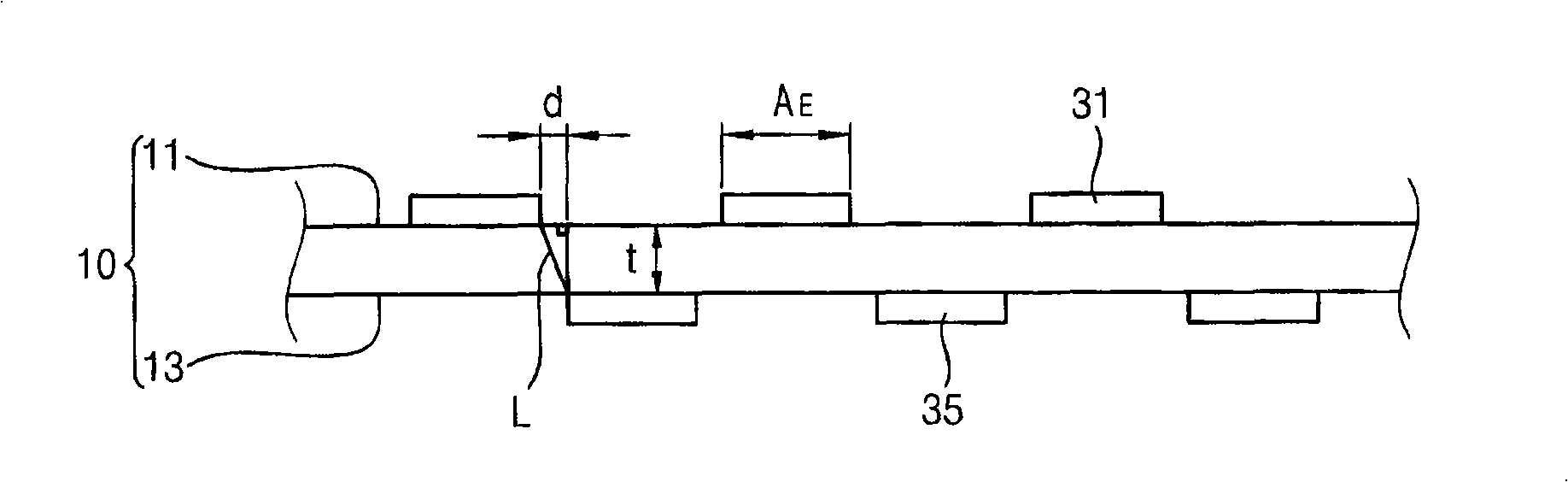

Voltage supply module and backlight assembly having the same

InactiveCN101494943AImprove electrical stabilityHigh insulation breakdown voltageStatic indicating devicesCross-talk/noise/interference reductionCapacitanceTransverter

In a voltage supply module and a backlight assembly having the same, a converter is disposed on a first face of a board and converts basic voltage into driving voltage. A capacitor includes at least one first electrode connected to an output line of the converter and at least one second electrode disposed to be spaced apart from the first electrode along a direction substantially parallel with the first face. A plurality of the second electrodes are disposed on the board between the first electrodes. The first and second electrodes form a ballast capacitance.

Owner:SAMSUNG DISPLAY CO LTD

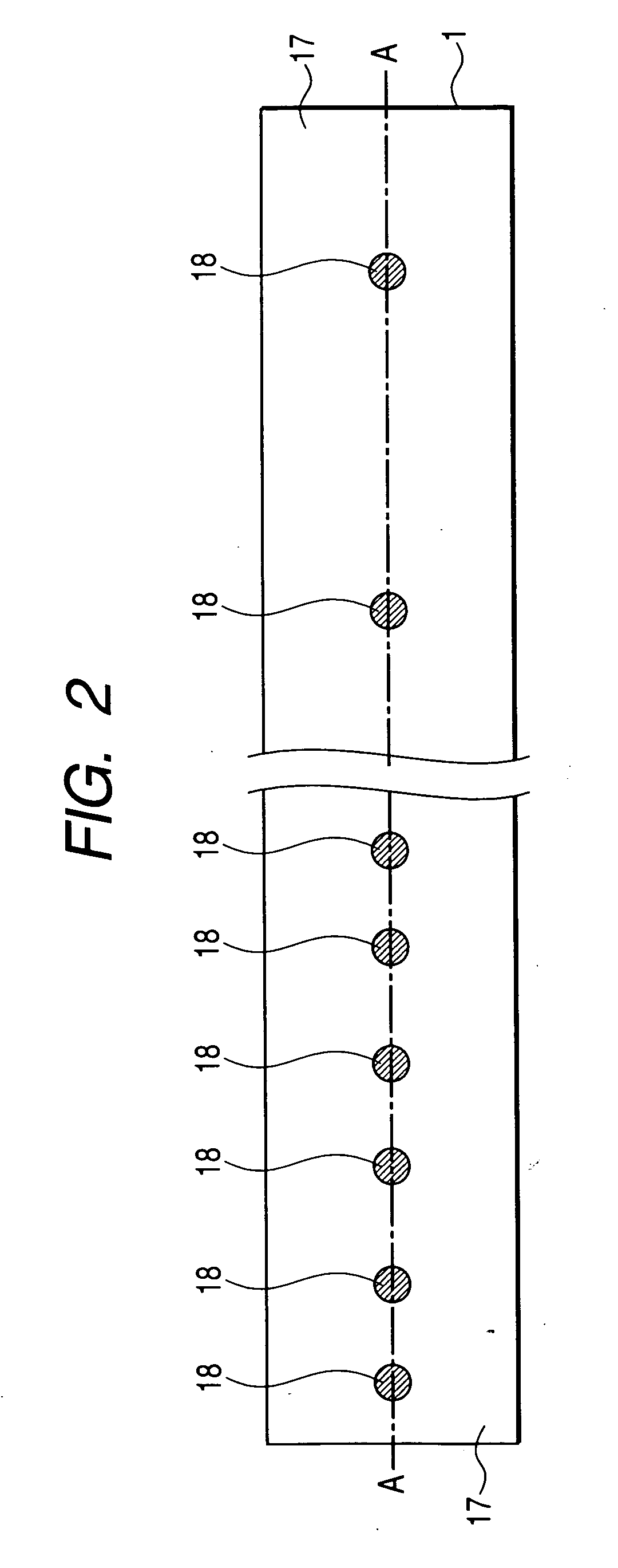

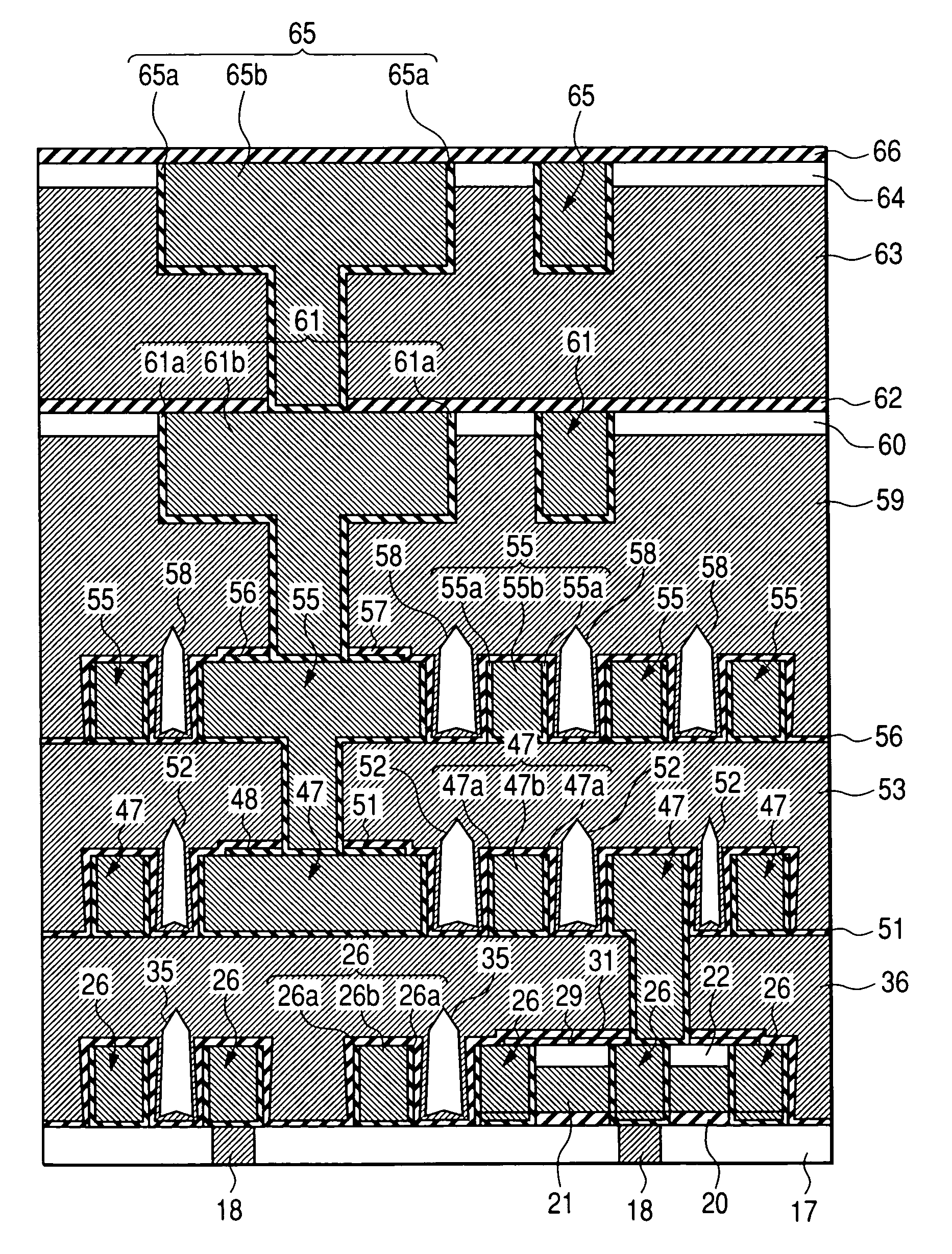

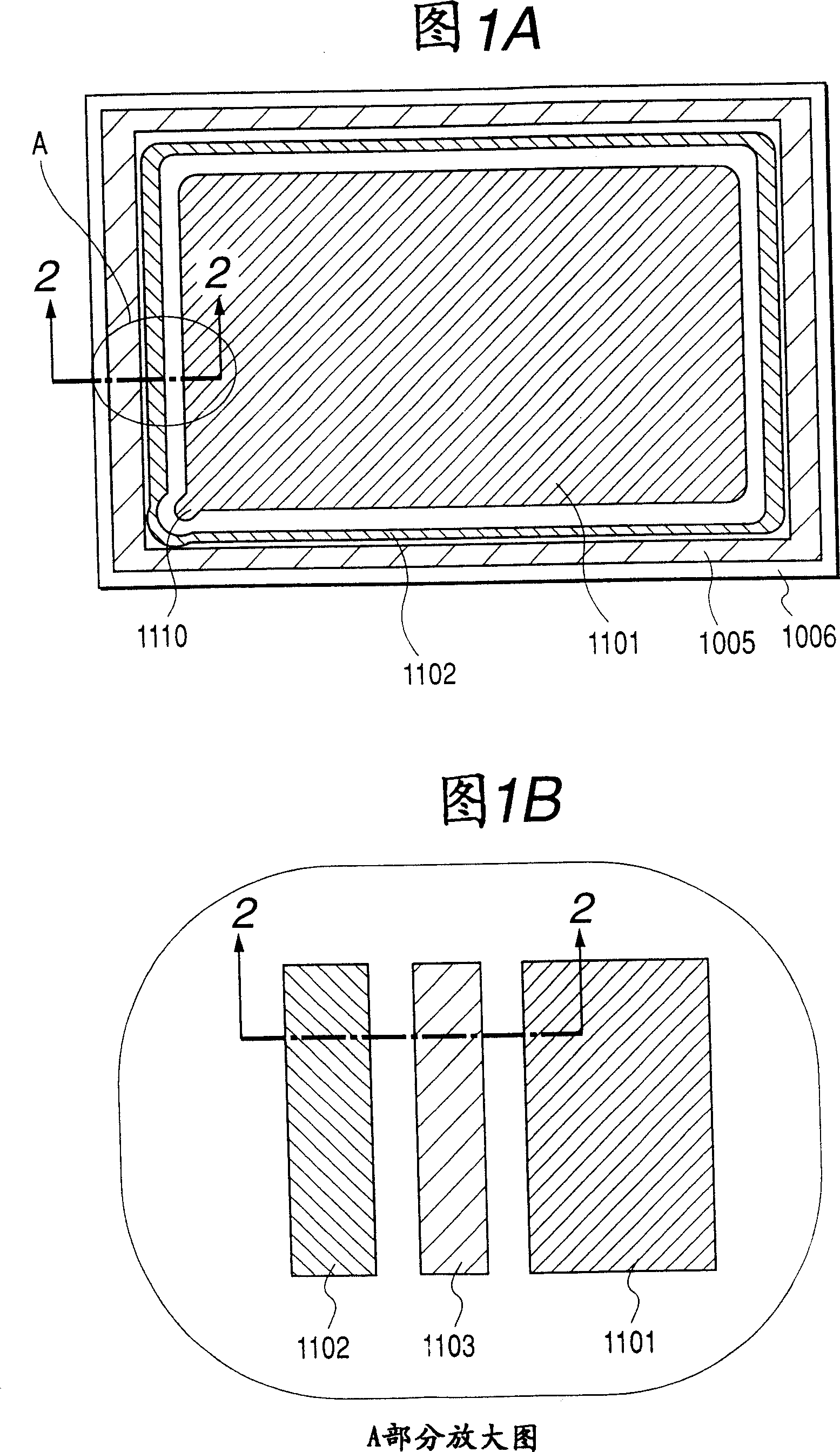

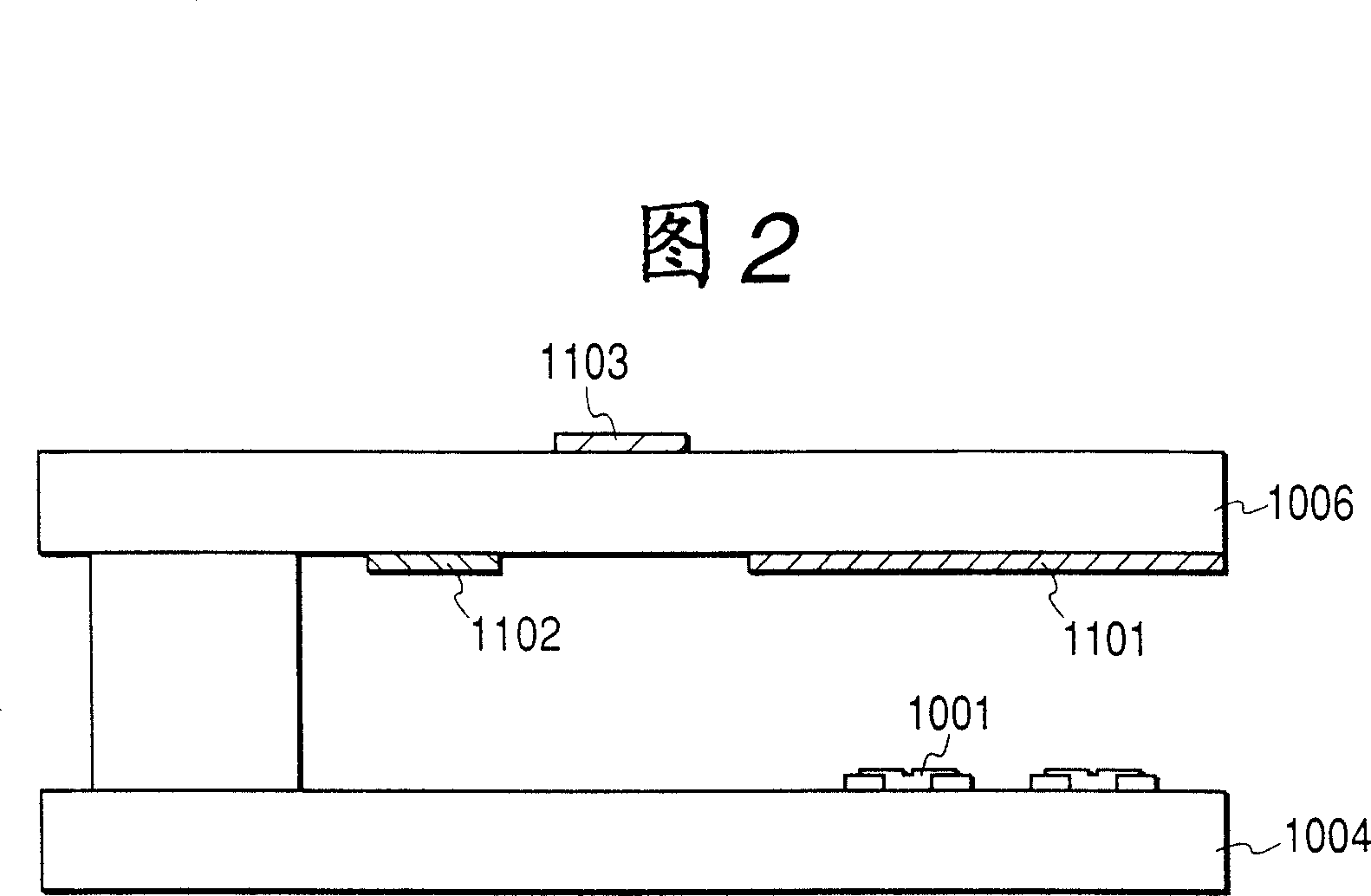

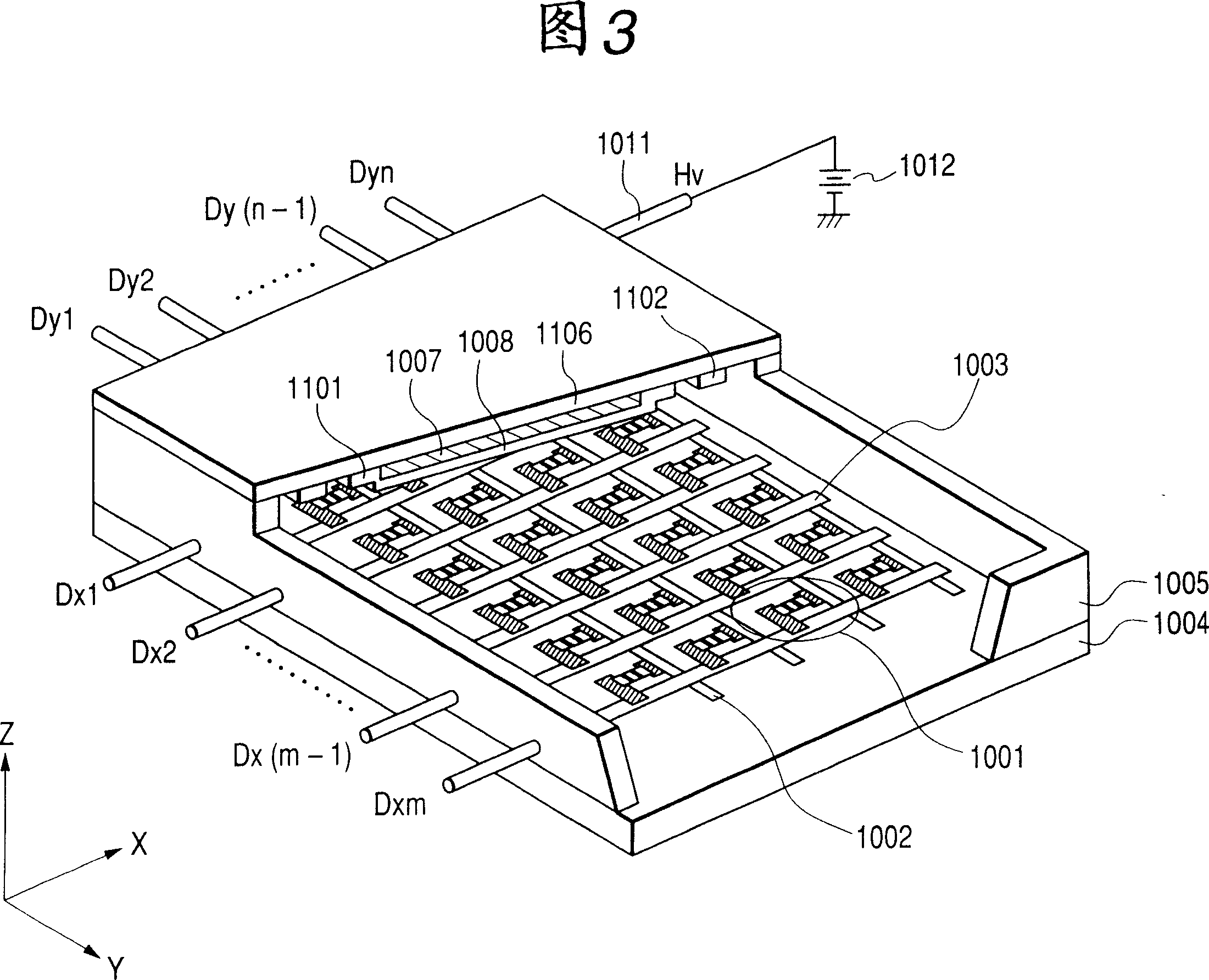

Image display device

InactiveCN100372045CReduce depthReduce border areaDischarge tube luminescnet screensCathode-ray/electron-beam tube vessels/containersBeam sourceDisplay device

An image display device is provided which is capable of increasing a dielectric voltage while reducing a depth and a frame region. The image display device is provided with a rear plate having surface conduction electron-emitting devices that are electron beam source and a faceplate having an anode electrode and a first potential regulating member on an identical surface. The anode electrode and the first potential regulating member are arranged separately from each other. The anode electrode is regulated to an electron accelerating potential. The first potential regulating member is regulated to a potential lower than that of the anode electrode. A second potential regulating member regulated to a potential lower than that of the anode electrode is provided at least in the vicinity of an end of the first potential regulating member on the anode electrode side on a surface on the opposite side of a surface having the first potential regulating member of the faceplate.

Owner:CANON KK

Dielectric films and electronic components

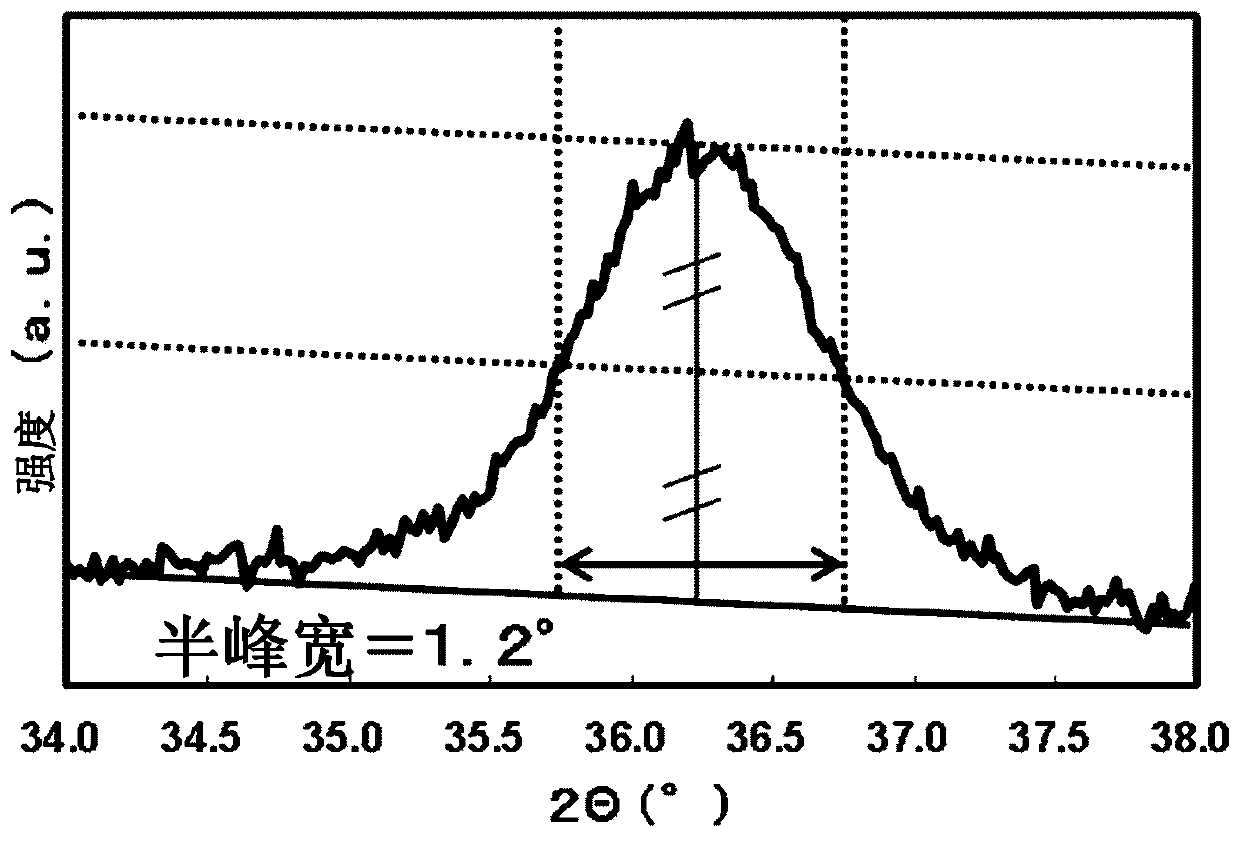

ActiveCN107221430BHigh relative permittivityHigh Q valueThin/thick film capacitorFixed capacitor dielectricX-rayElectron

An object of the present invention is to provide a dielectric film having a high relative permittivity, Q value, and dielectric breakdown voltage, and an electronic component using the dielectric composition. The dielectric film is characterized in that the dielectric film is mainly composed of an alkaline earth metal oxide having a NaCl-type crystal structure, the dielectric film has a columnar structure with (111) orientation in the normal direction, and the dielectric film has a In the Cu-Kα X-ray diffraction diagram, the half-maximum width of the diffraction peak of (111) is 0.3°-2.0°.

Owner:TDK CORPARATION

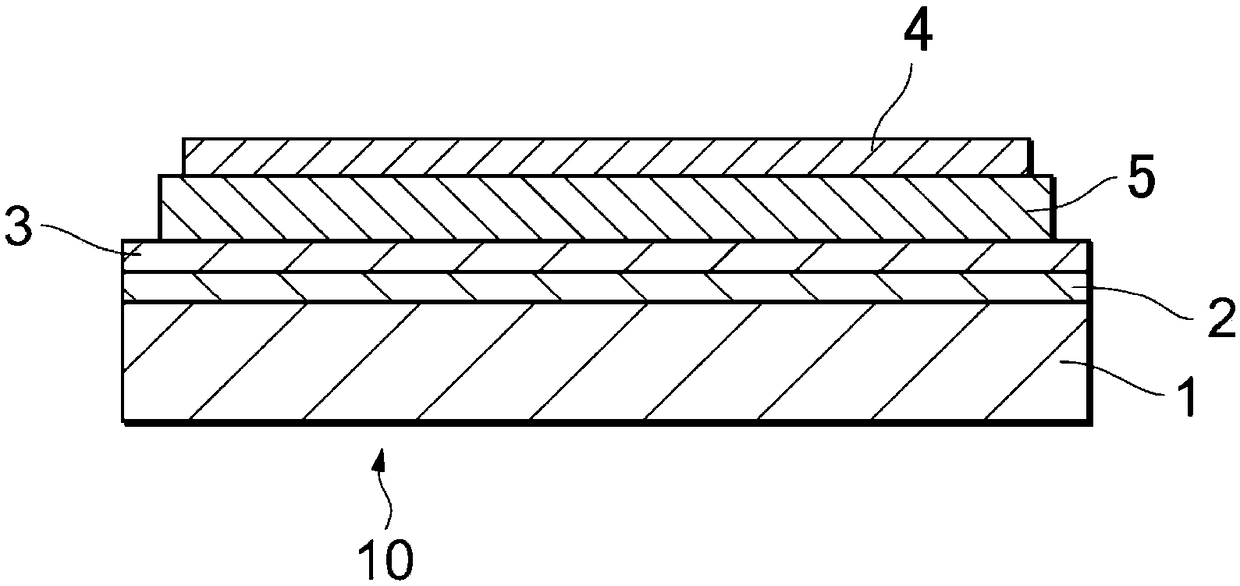

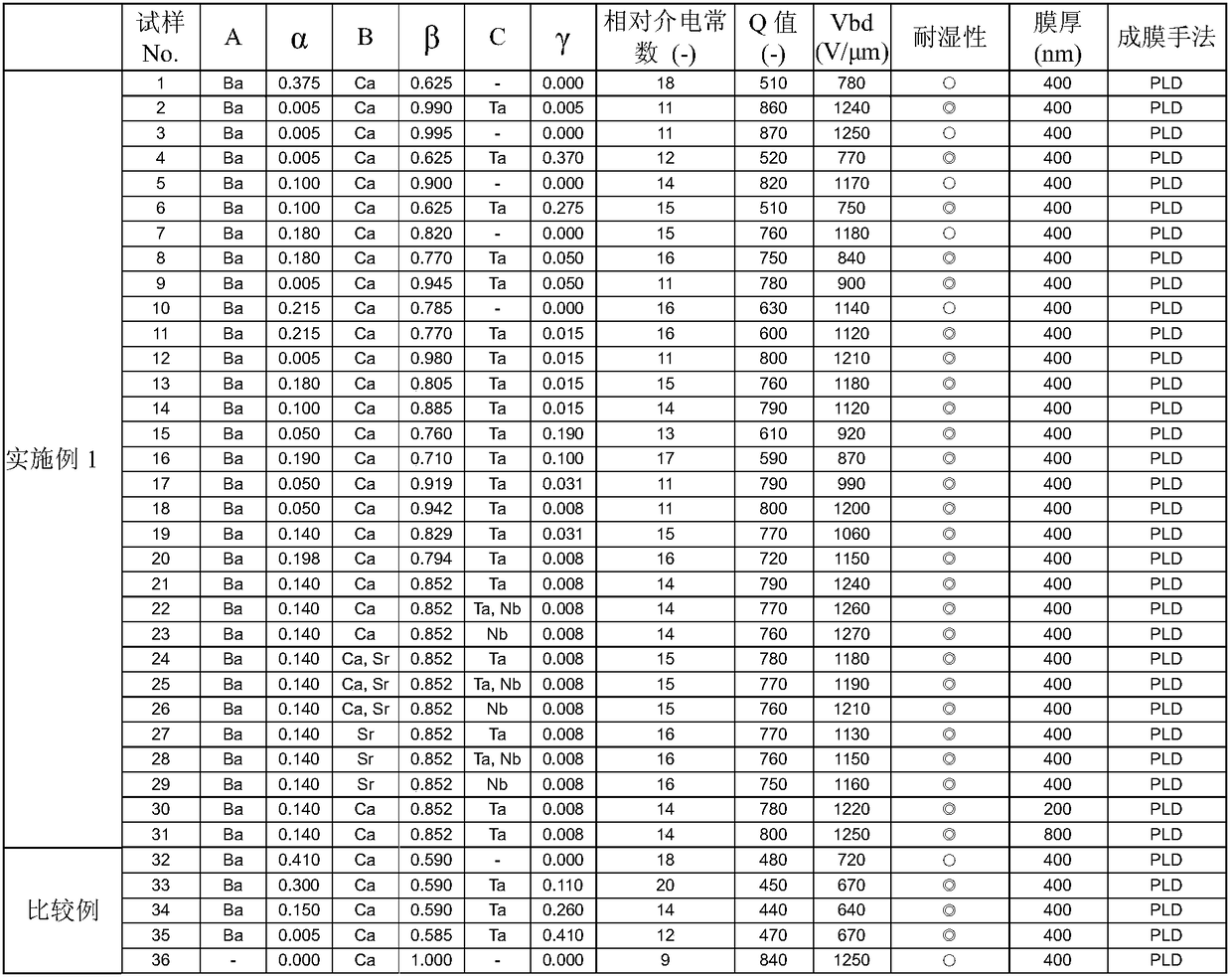

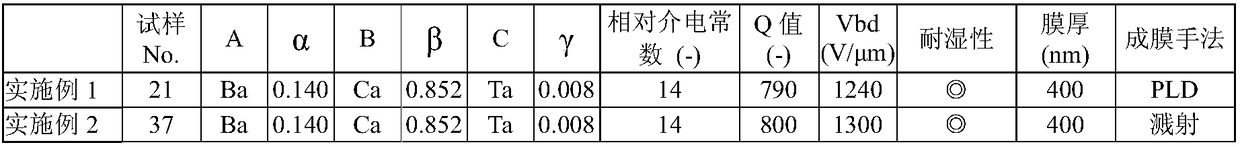

Dielectric composition and electronic component

ActiveCN106960726BHigh relative permittivityHigh Q valueThin/thick film capacitorTantalum compoundsDielectric lossPhysical chemistry

The purpose of the present invention is to provide a dielectric composition with a high relative permittivity and small dielectric loss, that is, a high Q value and a high dielectric breakdown voltage even when used at a high frequency (2 GHz), and a dielectric composition using the same Dielectric composition for electronic components. The dielectric composition involved in the present invention is characterized in that: as the main component, it contains the chemical formula AαBβC2γOα+β+5γ (A is Ba element, B is at least one element selected from Ca or Sr, C is selected from Ta or Nb For composite oxides represented by at least one element), the relationship between α, β, and γ satisfies α+β+γ=1.000; 0.000<α≤0.375; 0.625≤β<1.000; 0.000≤γ≤0.375.

Owner:TDK CORPARATION

Semiconductor device

InactiveCN1131548CAvoid pollutionEasy to moveSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorOhmic contact

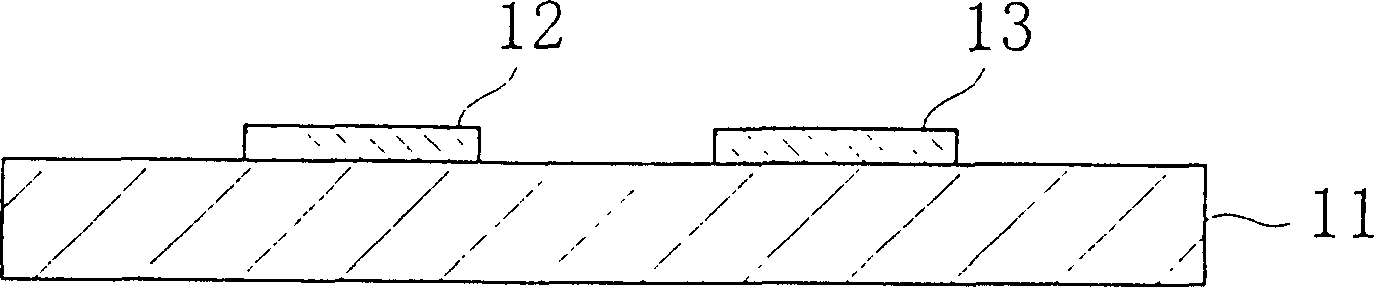

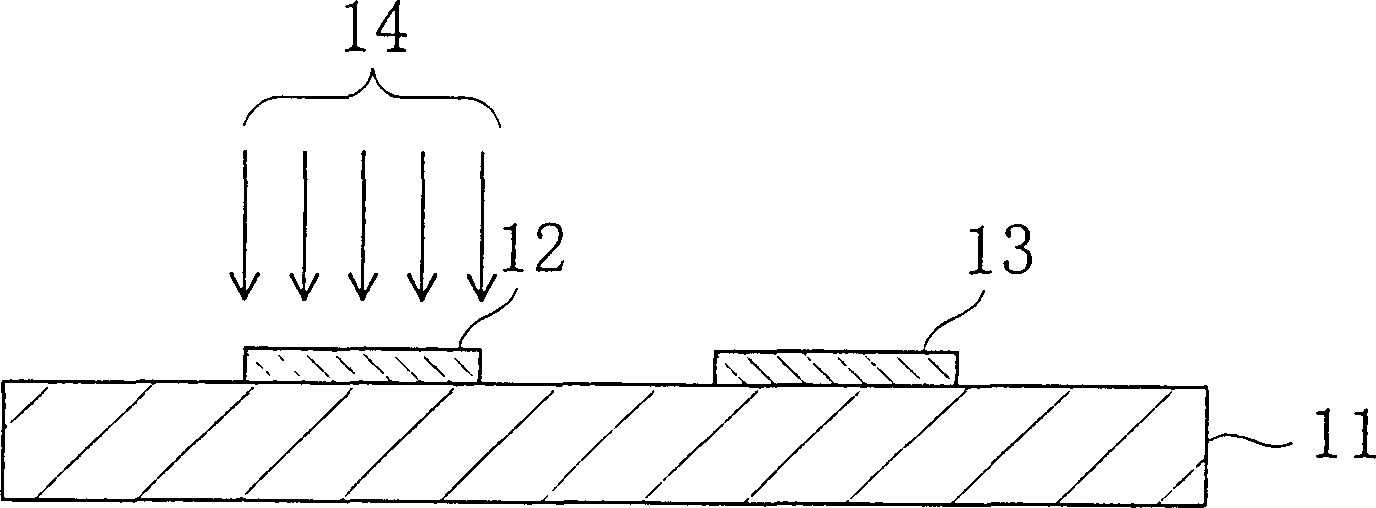

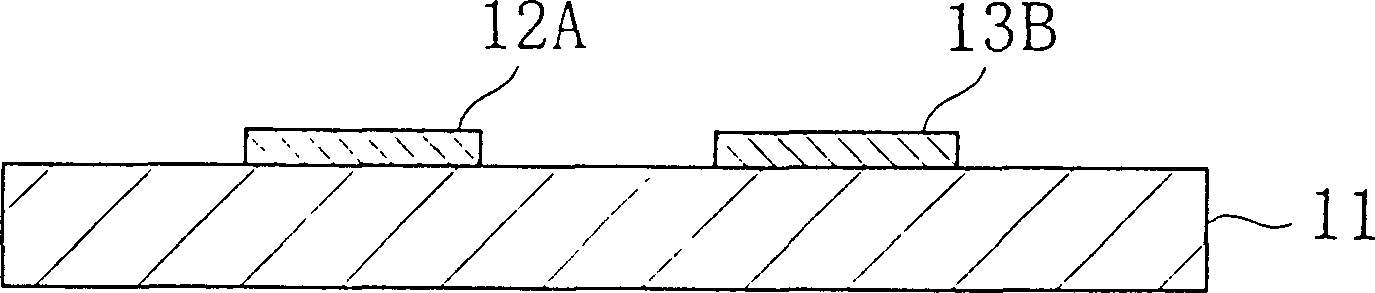

A first metal film and a second metal film, both of which are made of Ni or the like, are deposited on the upper surface of a substrate made of SiC. In such a state, the interface between the first metal film and the substrate and the interface between the second metal film and the substrate both form a Schottky contact. Next, laser light is irradiated from above the upper surface of the substrate only onto the first metal film on the substrate after the diameter of the top end of the laser light has been reduced. Thus, since the metal-semiconductor interface between the first metal film and the substrate is turned into an alloy owing to the energy of the laser light without heating the entire substrate, an ohmic contact can be formed in the interface between the first metal film and the substrate. As a result, an ohmic electrode can be constituted by the first metal film.

Owner:PANASONIC CORP

Electrodeposition solution and method for producing conductor with insulating film using same

PendingCN110234717AAvoid foamingHigh insulation breakdown voltagePlastic/resin/waxes insulatorsElectrophoretic coatingsPolymer scienceElectrical conductor

An electrodeposition solution comprises a dispersion medium (13) and a solids fraction (11). The solids fraction (11) includes polyimide resin particles (11a) and fluorine resin particles (11b). Also,the content ratio of fluorine resin particles (11b) in the solids fraction (11) is 20-70 mass%. In addition, the median diameter of the polyimide resin particles (11a) is 50-400 nm.

Owner:MITSUBISHI MATERIALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com