Dielectric films and electronic components

A dielectric film, X-ray technology, applied in fixed capacitor parts, fixed capacitor dielectrics, electrical components, etc., can solve the problem of difficult to respond to miniaturization requirements, and achieve high Q value, high relative permittivity, high The effect of insulation breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1>< comparative example 1

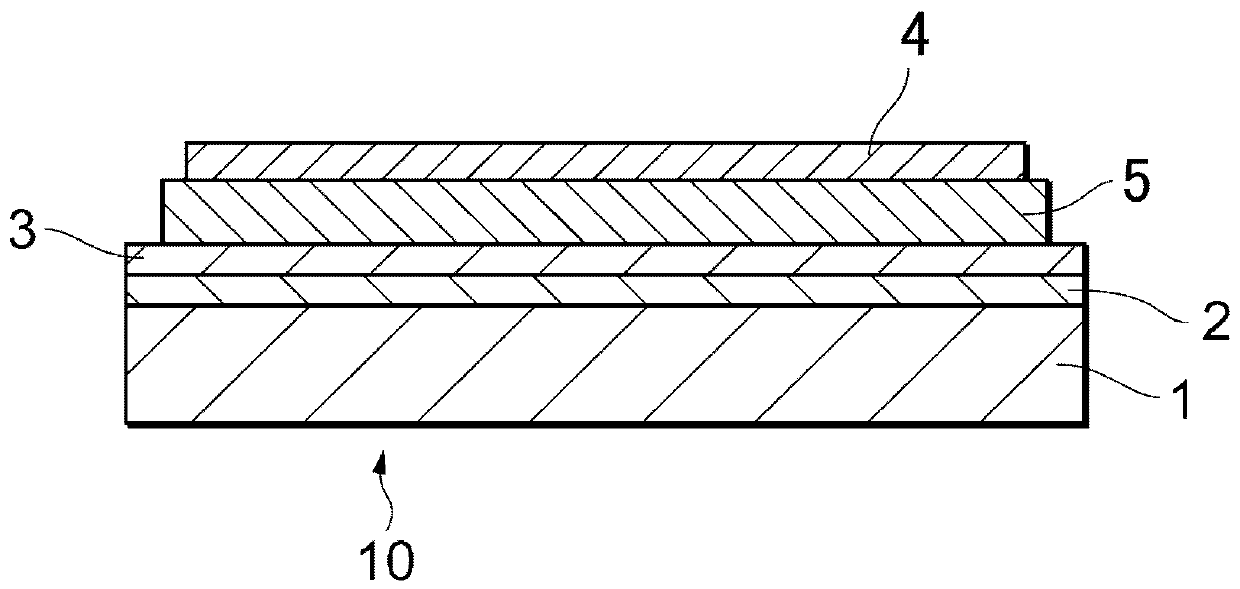

[0063] First, 6 μm thick SiO on the surface of 350 μm thick Si 2 On the surface of the 10 mm×10 mm square support substrate of the insulating layer, a Cr thin film as an underlayer was formed so as to have a thickness of 20 nm by a sputtering method.

[0064] Next, on the base layer of the Cr thin film formed above, a Cu thin film as a lower electrode was formed by sputtering so as to have a thickness of 100 nm.

[0065] For the formed Cr / Cu thin film, the heating rate is set to 10°C / min, the holding temperature is set to 150°C, the temperature holding time is set to 0.5 hours, and the atmosphere is set to a nitrogen atmosphere. Carry out heat treatment.

[0066] A sputtering method was used for the formation of the dielectric film. The target required for forming the dielectric film was produced as follows.

[0067]First, MgCO was carried out so that the amounts of Mg, Ca, Sr, Ba, Ta, Nb, V, Hf, Zr, Ti, and Zn in Sample No. 1 to Sample No. 47 shown in Table 1 were obtained...

Embodiment 2

[0101] Except for changing the thickness of the dielectric film, a sample was prepared in the same manner as in Example 1, Sample No. 29, and the same evaluation as in Example 1 was performed. The results are shown in Table 3.

[0102] [table 3]

[0103]

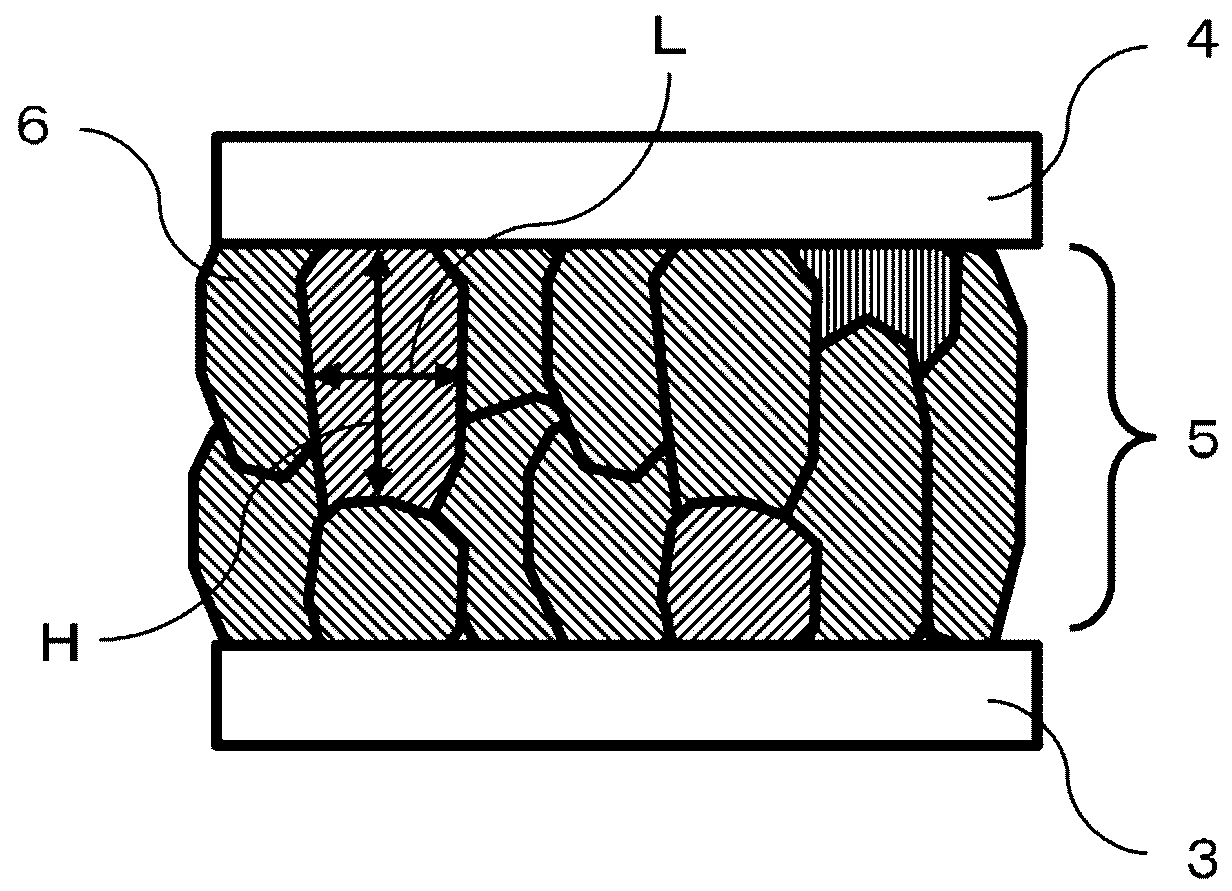

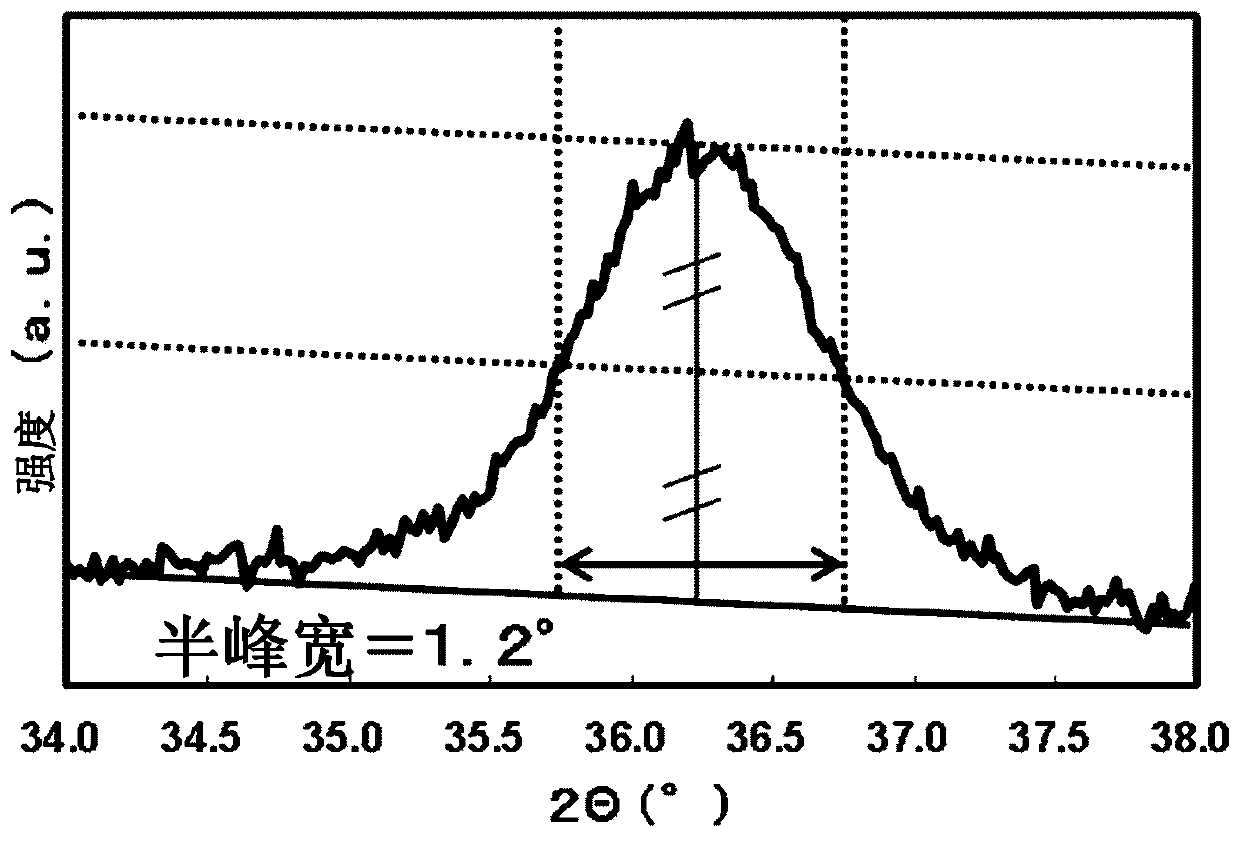

[0104] Sample No.48~Sample No.50

[0105] From Table 3, it can be confirmed that even if the film thickness of the dielectric film is different, as long as the dielectric film has an alkaline earth metal oxide having a NaCl-type crystal structure as the main component, and the dielectric film has a (111) orientation in the normal direction In the Cu-Kα X-ray diffraction pattern of the above-mentioned dielectric film, the characteristic dielectric film with a half width of the diffraction peak (111) of 0.3° to 2.0° exhibits substantially the same characteristics even when the film is thinned to 50 nm. . That is, it was confirmed that as long as the dielectric film has the characteristics of the present invention, even i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com