Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

117results about How to "Improve withstand voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

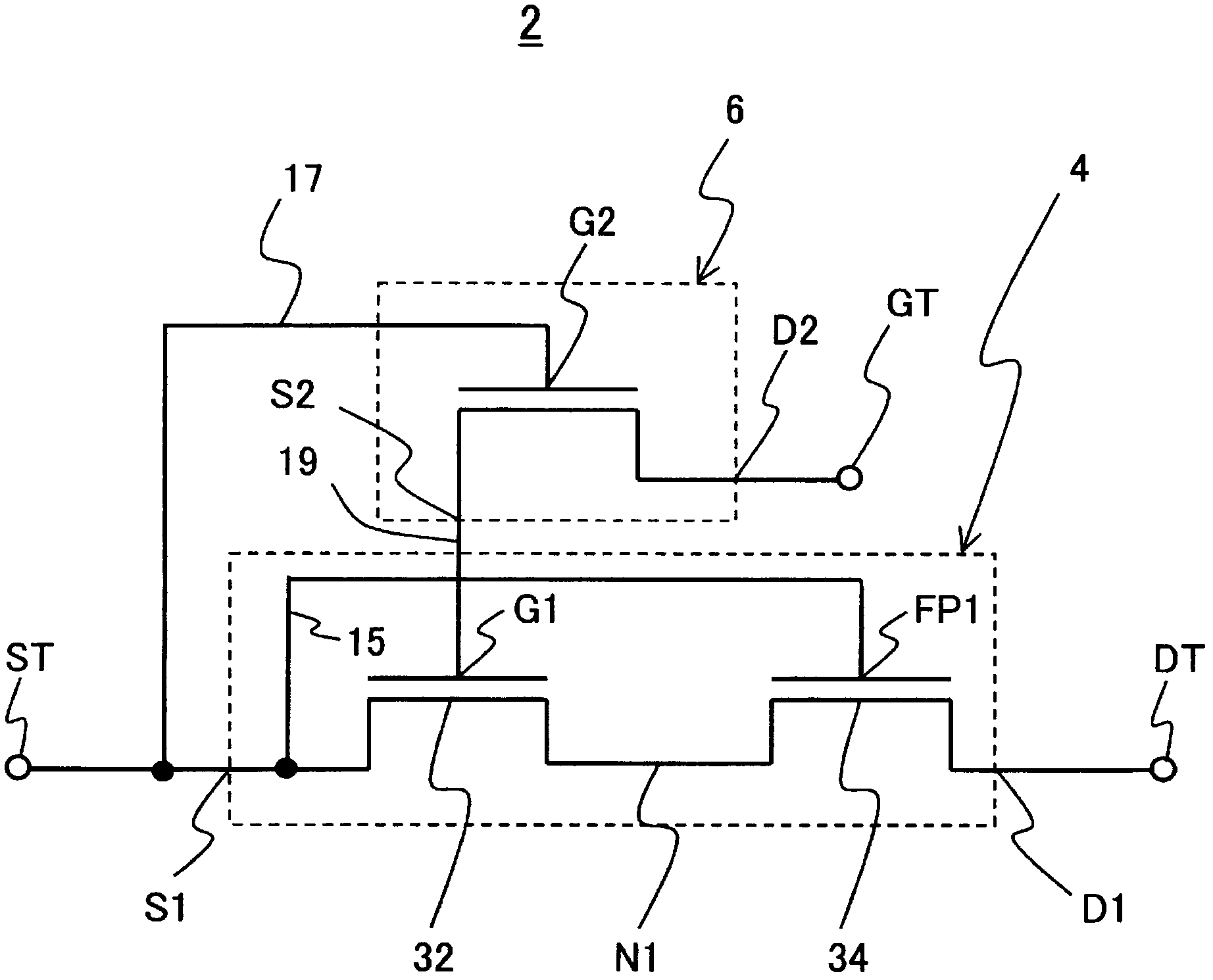

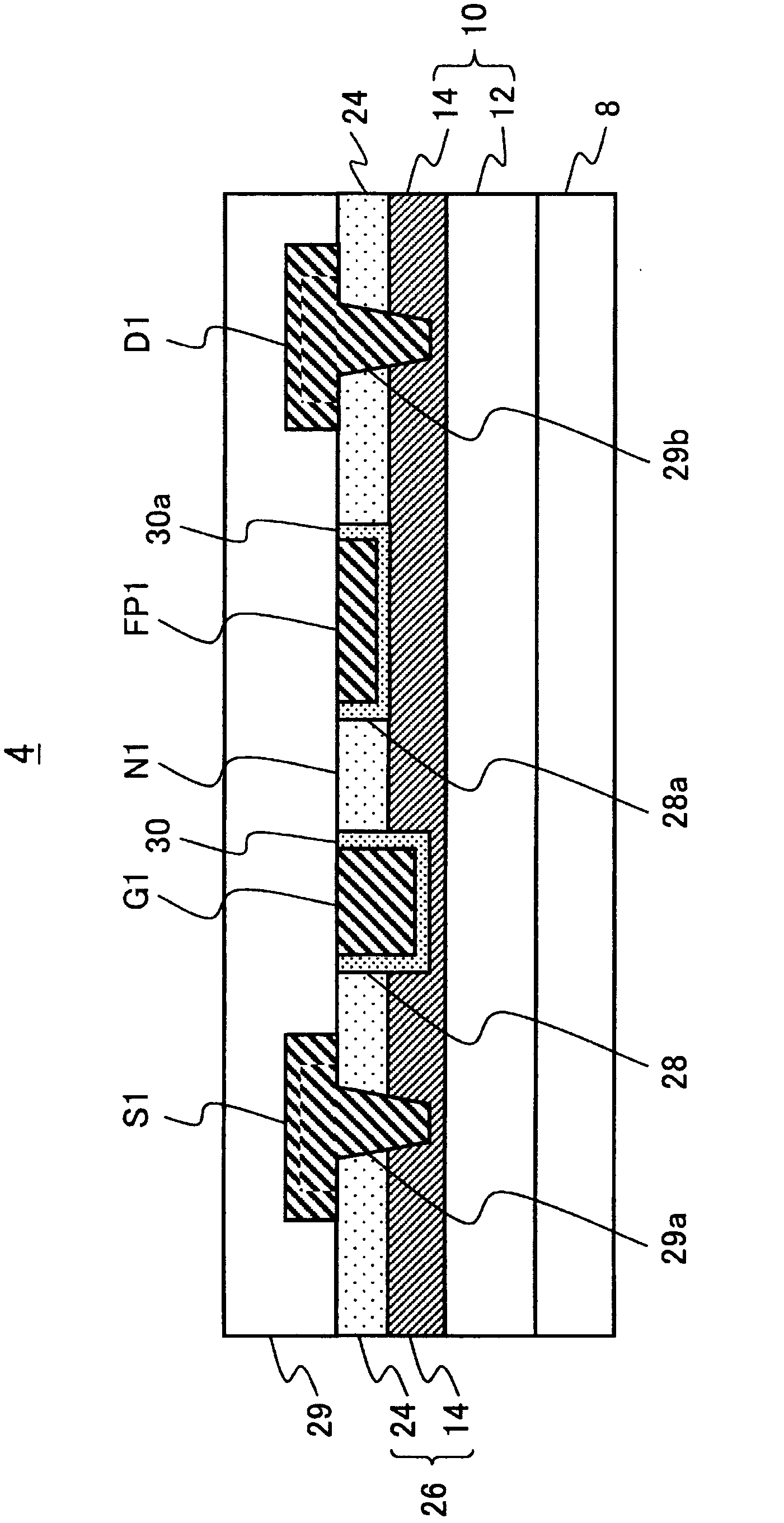

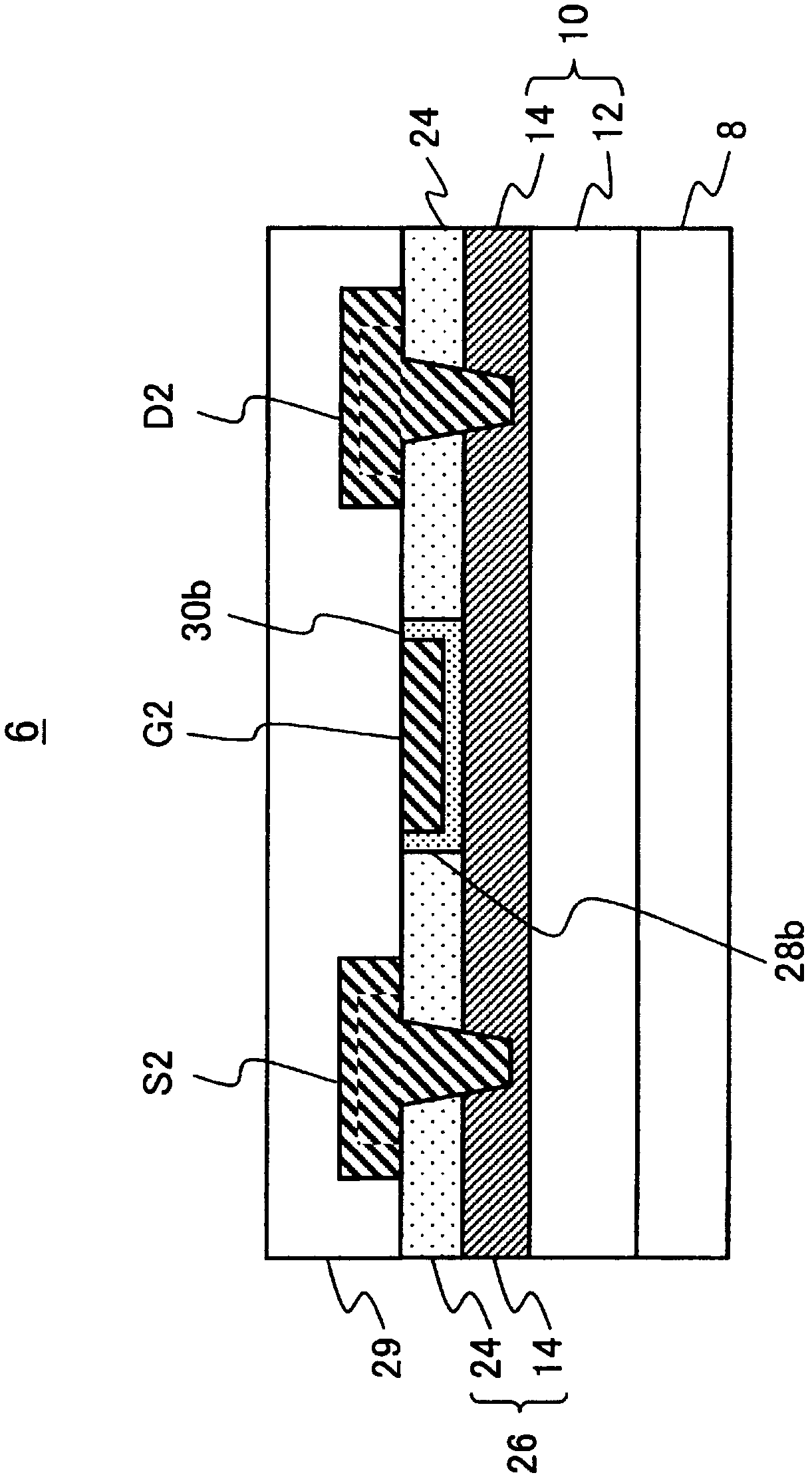

Semiconductor device, manufacturing method and transistor circuit

InactiveCN102683405AImprove withstand voltageSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceTransistor circuits

A transistor circuit includes a first high electron mobility transistor and a second high electron mobility transistor having a negative threshold voltage, wherein a source of the second high electron mobility transistor is coupled to a gate of the first high electron mobility transistor, and a gate of the second high electron mobility transistor is coupled to a source of the first high electron mobility transistor. The invention enables the withstand voltages of the high electron mobility transistors to be improved.

Owner:TRANSPHORM JAPAN

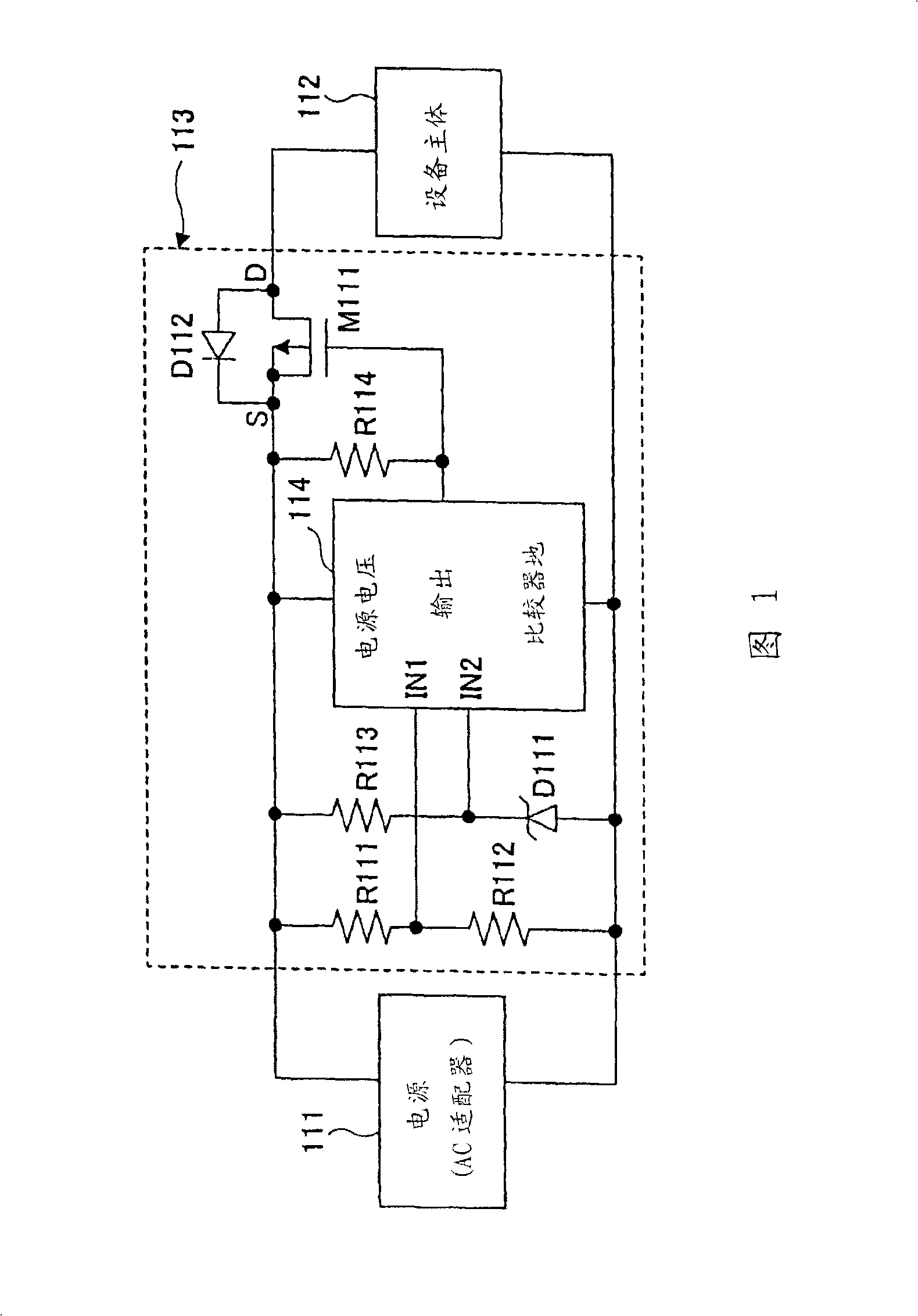

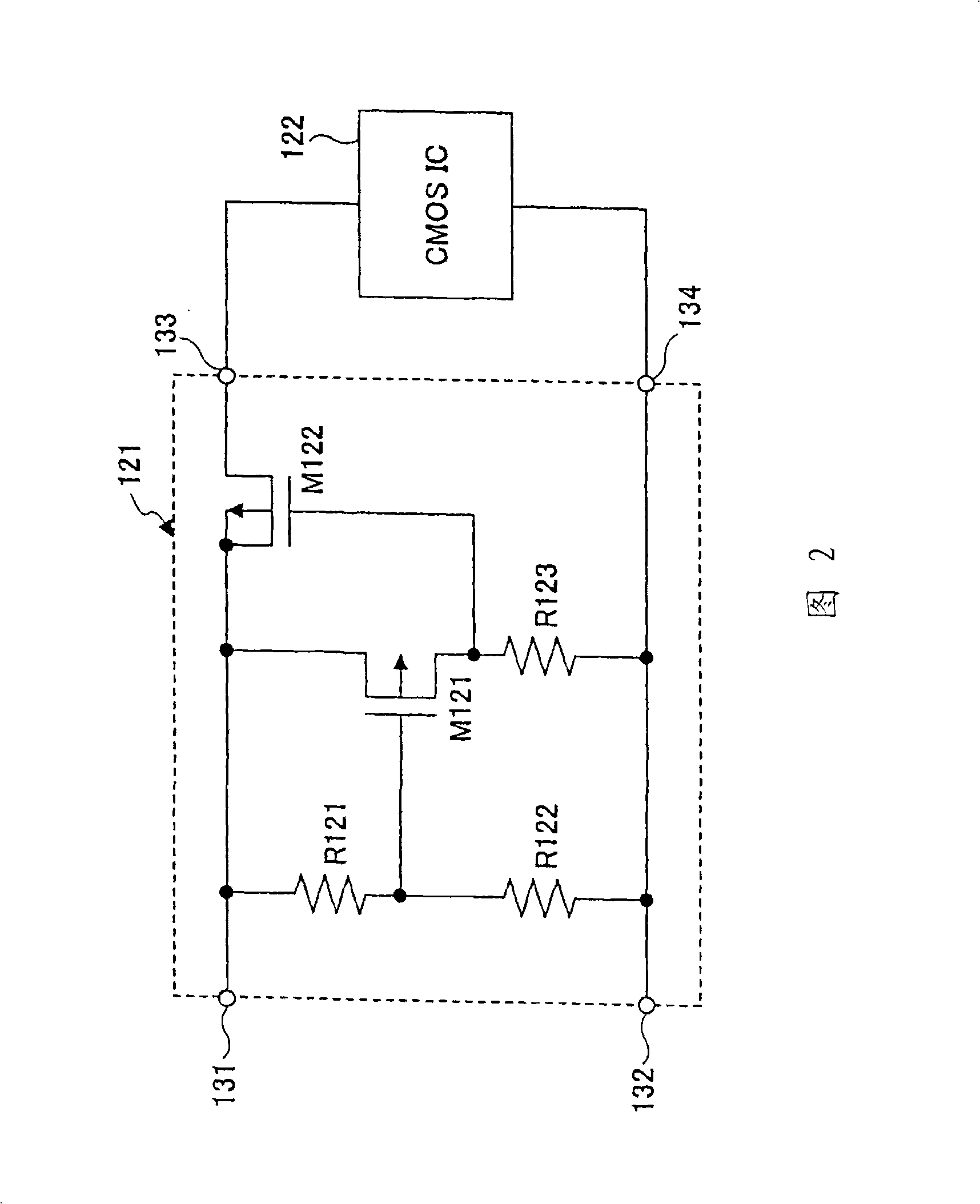

Excess voltage protection circuit, method of protecting a circuit from excess voltage, and semiconductor apparatus having the excess voltage protection ciruit

InactiveCN101346865AReduce withstand voltageSmall sizeTransistorDc-dc conversionSemiconductorResistor

In a disclosed excess voltage protection circuit, when the input voltage equal to or higher than a predetermined maximum voltage is detected by an excess voltage detection circuit, a switching element is shut off so as to prevent the input voltage being output from the excess voltage protection circuit. A voltage obtained by dividing the input voltage using resistors is output from the excess voltage protection circuit.

Owner:RICOH MICROELECTRONICS CO LTD

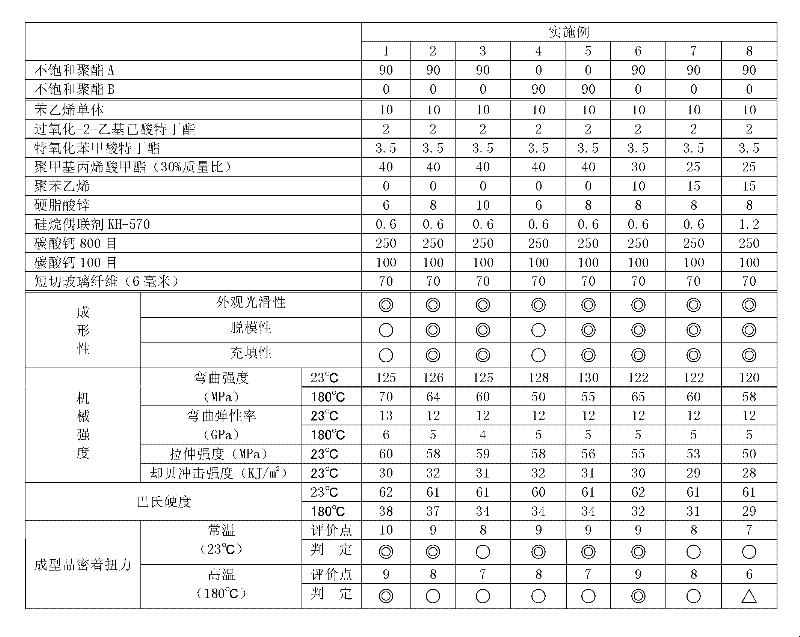

Unsaturated polyester bulk molding compound as well as method and application thereof

The invention relates to the technical field of a bulk molding compound for metal bonding, and specifically relates to an unsaturated polyester bulk molding compound as well as a method and application of the bulk molding compound. The bulk molding compound is prepared from the following raw materials in parts by weight: 8-20 parts of unsaturated polyester, 5-15 parts of low shrink agent, 55-70 parts of inorganic filler, 0.8-1.8 parts of internal demolding agent, 6-20 parts of fiber-reinforced material, 0.3-0.7 parts of curing agent, 0-3 parts of styrene, and 0.05-0.3 part of coupling agent. According to the invention, after the bulk molding compound (BMC) is molded, fast setting is realized and the appearance is excellent; and when used for electric tool and motor loop sealing and other fields, the bulk molding compound has excellent bonding property and torsion to the metal surface at normal temperature and high temperature, excellent resistance to impact, and excellent voltage withstand performance, conforms to the reliability required by product use, and fills up the blank of the field.

Owner:SHANGHAI SHOWA HIGHPOLYMER CO LTD

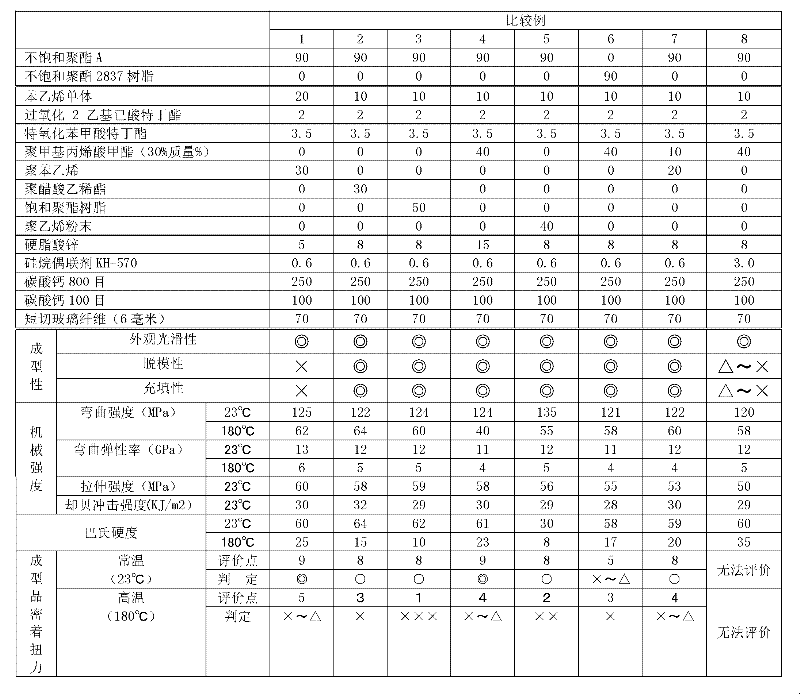

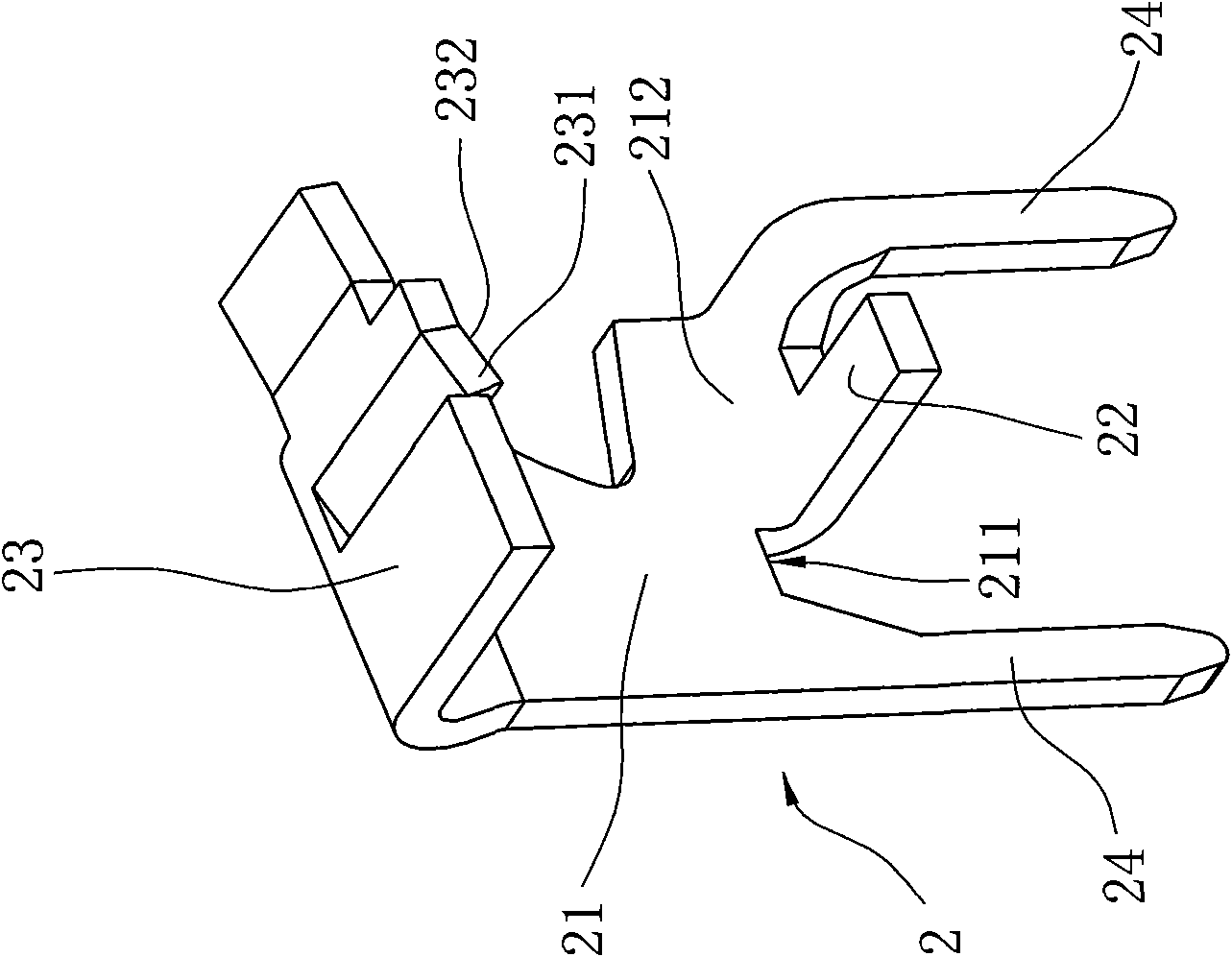

Electric connector

ActiveCN101562282AIncreased current carrying areaImprove conductivityCoupling device connectionsContact member manufacturingElectricityState of art

The invention provides an electric connector. The electric connector comprises an insulating base, a solder terminal fixedly arranged in the insulating base and an elastic plate comprising a free end and a fixed end, wherein the free end always keeps the trend of pressing against the solder terminal; the fixed end is fixedly connected with the solder terminal; and the bottom end of a button connected with the upper part of the base is pressed against the free end of the elastic plate. The electric connector is characterized in that the solder terminal comprises a current carrying main board, and a support plate pressed against the bottom of the fixed end extends out of the lower part of the current carrying main board and the upper edge of the current carrying main board is bended outwards to form a capped edge pressed against the top of the free end; the current carrying main board, the support plate and the capped edge of the solder terminal form a C-shaped cross section; and the bottom of the solder terminal is also provided with two solder legs which are one-piece formed, arranged on both sides of the support plate respectively and staggered front and back. Compared with the prior art, the electric connector has the advantages that the current carrying area of the solder terminal is larger, and the conductivity of the solder terminal is improved; and because the solder legs are staggered front and back, the creepage distance is increased, the withstand voltage value of the electric connector is improved, and the electric strength of the product is further improved.

Owner:NINGBO DEGSON ELECTRONICS CO LTD

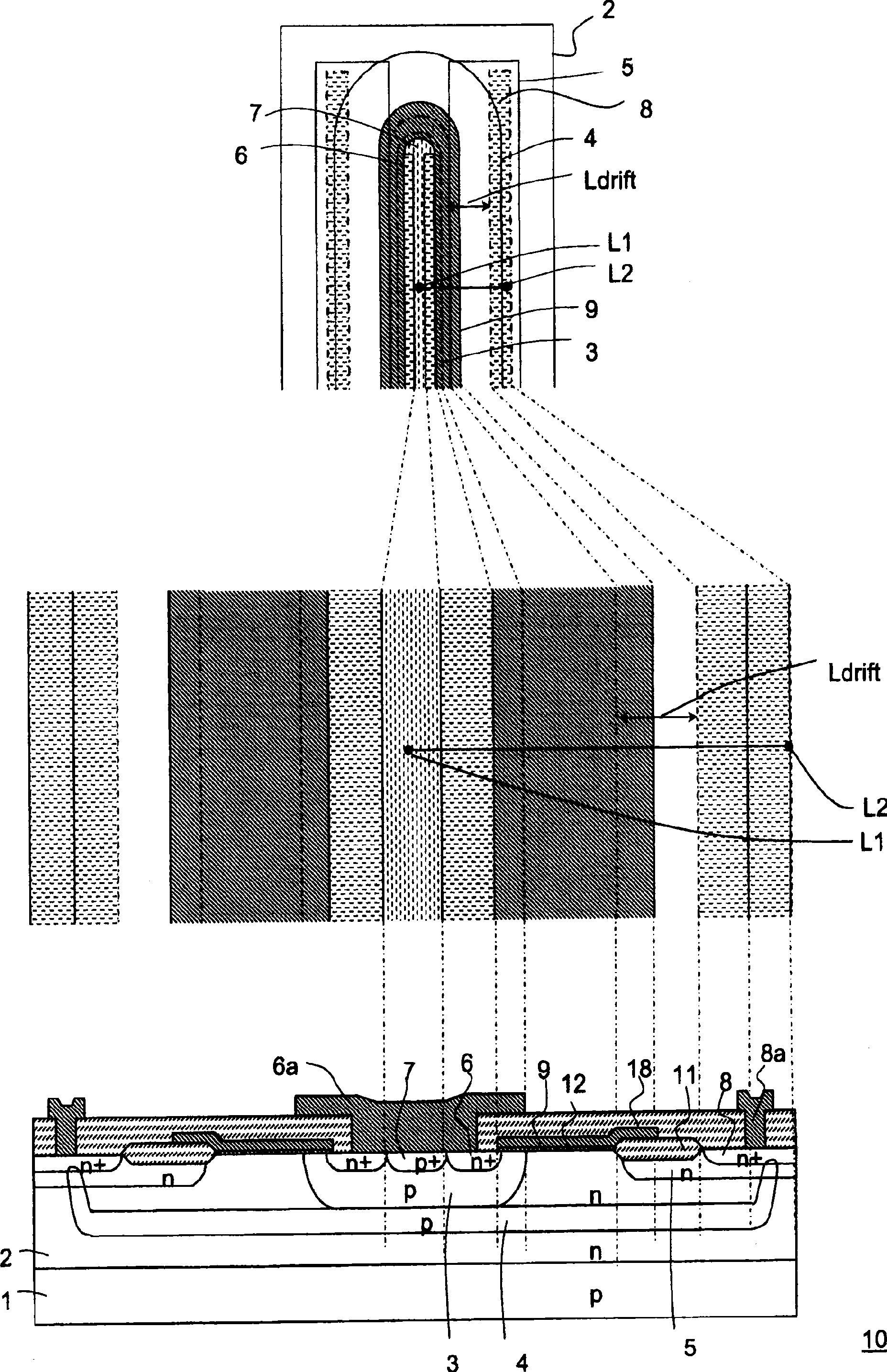

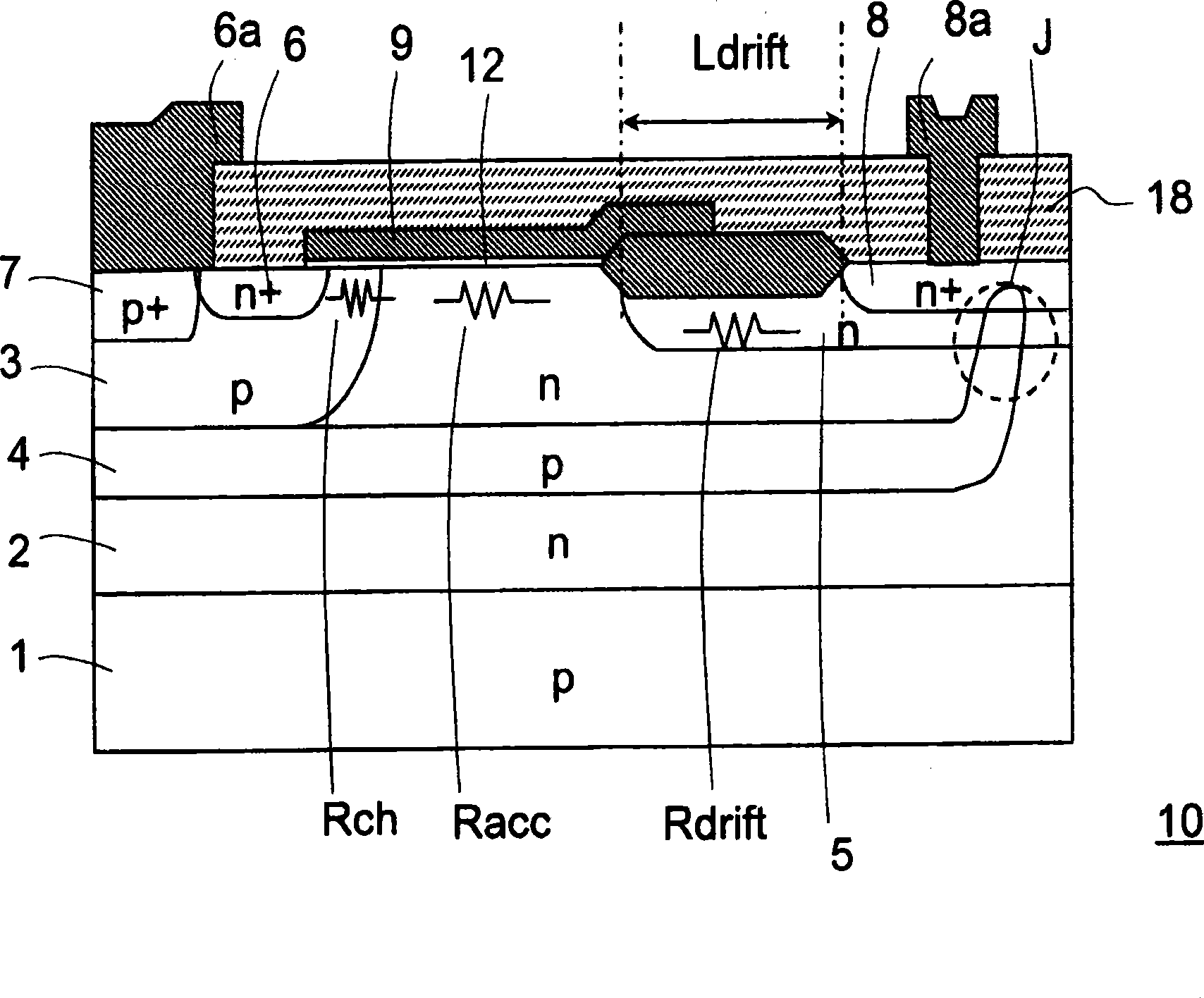

Semiconductor device and its manufacturing method

InactiveCN101465378ALower on-resistanceImprove withstand voltageSemiconductor/solid-state device manufacturingSemiconductor devicesBody areaSource area

Provided are a semiconductor device which can be manufactured at low cost and has a low on-resistance and a high withstand voltage, and its manufacturing method. The semiconductor device comprises an N-type well area (2) formed on a P-type semiconductor substrate (1), a P-type body area (3) formed within the well area (2), an N-type source area (6) formed within the body area (3), an N-type drain area (8) formed at a distance from the body area (3) within the well area (2), a gate insulating film (12) formed so as to overlay a part of the body area (3), a gate electrode (9) formed on the gate insulating film (12) and a P-type buried diffusion area (4) which makes contact with the bottom of the body area (3) and extends to an area beneath the drain area (8) in a direction parallel to the surface (1) of the semiconductor substrate within the well area (2).

Owner:SHARP KK

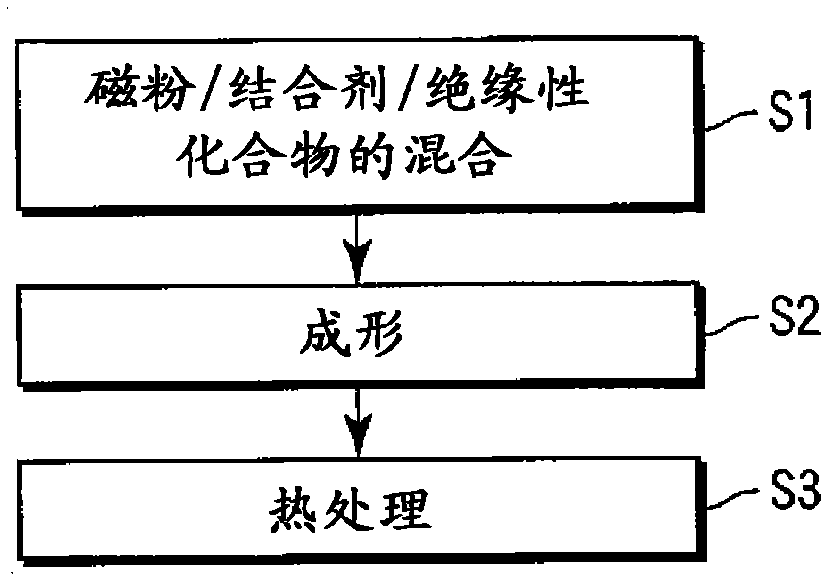

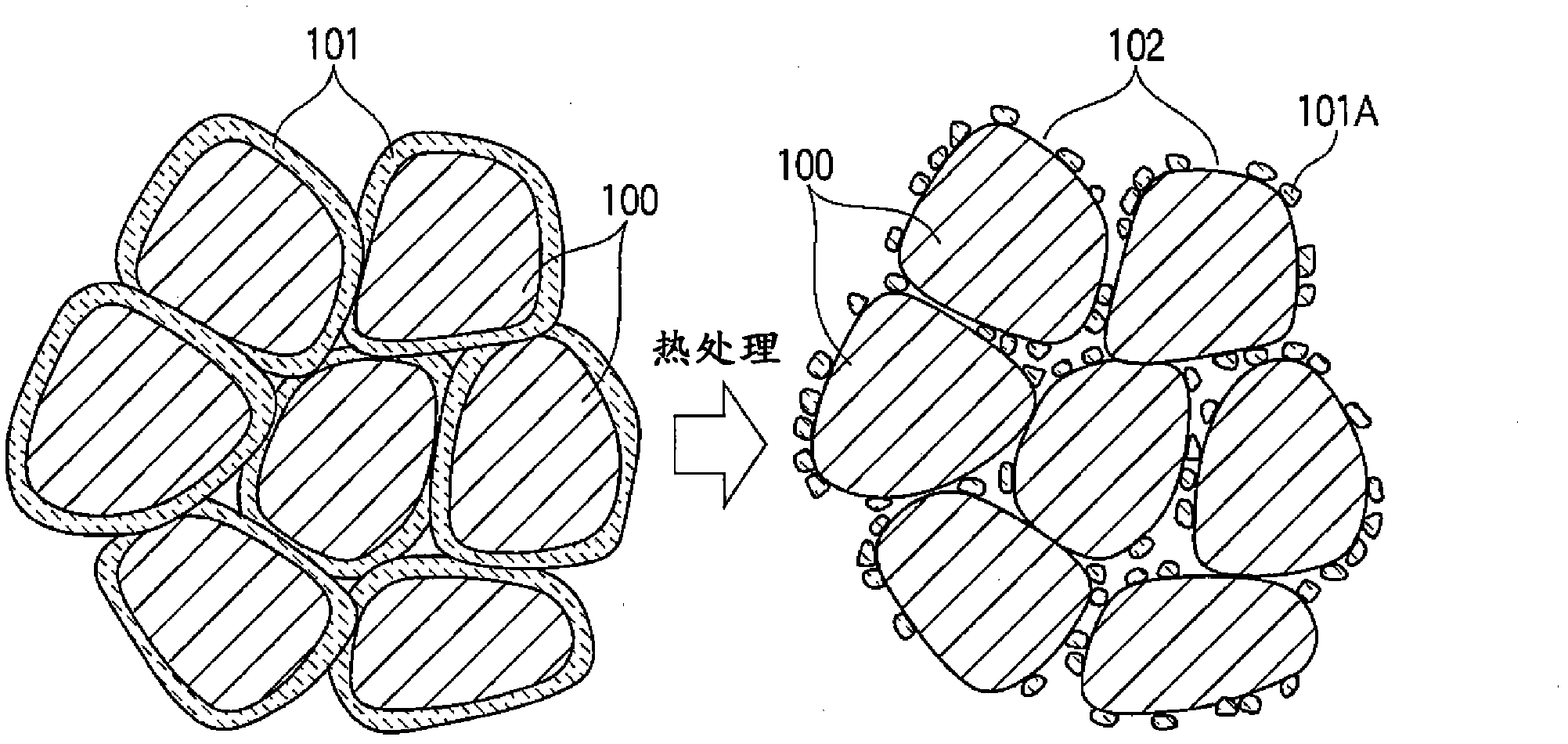

Method of producing composite magnetic material and composite magnetic material

InactiveCN102007550AImprove insulation performanceImprove withstand voltageTransportation and packagingMetal-working apparatusNon magneticMetal powder

Disclosed is a method for producing a composite magnetic material which has high magnetic permeability and low core loss, while securing high insulation and high withstand voltage. A composite magnetic material produced by the method is also disclosed. Specifically, a nonmagnetic binding material containing an insulating lamellar compound is mixed with a soft magnetic metal powder, then the resulting mixture is formed into a desired shape, and then the shaped body is subjected to a heat treatment under predetermined conditions. Consequently, a thin insulating layer composed of the insulating lamellar compound is formed on the surface of the soft magnetic metal powder.

Owner:TOHO ZINC

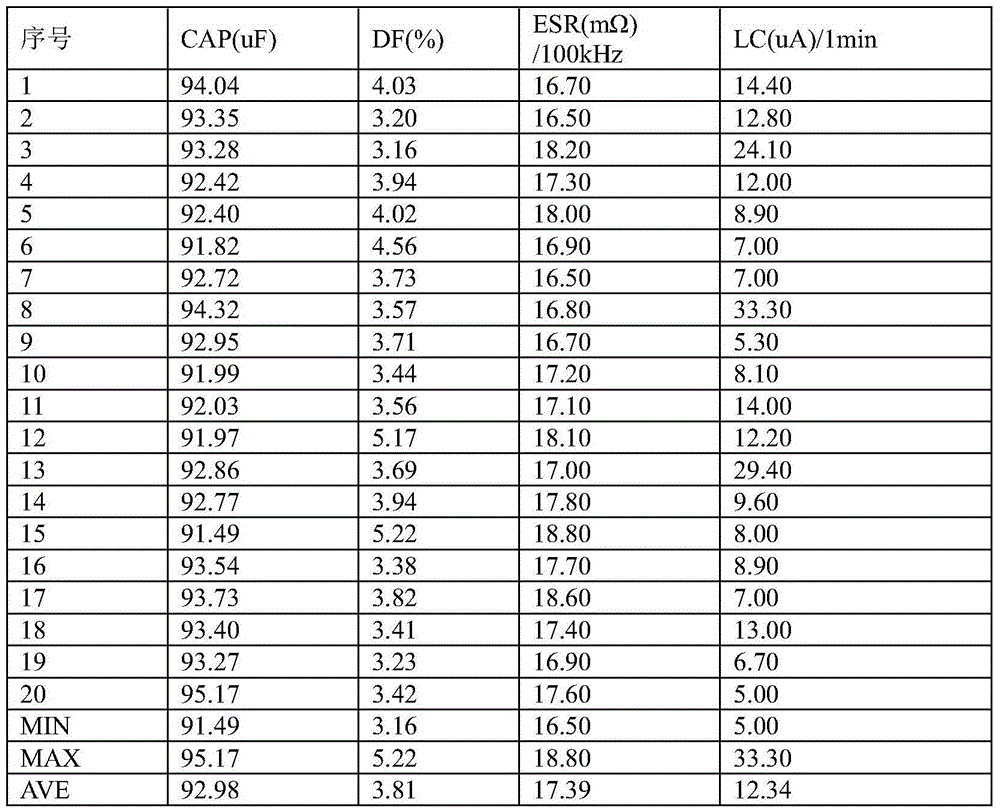

Manufacturing method for high-voltage solid electrolyte aluminum electrolytic capacitor

ActiveCN104637687AFully generatedImprove electrical performanceSolid electrolytic capacitorsCapacitor electrolytes/absorbentsConductive polymerOptoelectronics

The invention discloses a manufacturing method for a high-voltage solid electrolyte aluminum electrolytic capacitor. The manufacturing method comprises the following steps: firstly, welding a core cladding on an iron bar, applying voltage for formation, and then performing cleaning and drying; secondly, immersing the dried core cladding in a dispersoid A for 1-30 minutes; thirdly, moving the core cladding out of the dispersoid A, vacuumizing the core cladding and then immersing the core cladding into the dispersoid A for 1-10 minutes; fourthly, retaining the core cladding in the dispersoid A, breaking vacuum and then pressurizing, and maintaining the immersion time for 1-10 minutes; fifthly, retaining the core cladding into the dispersoid A, deflating to normal voltage and maintaining the immersion time for 1-10 minutes; sixthly, taking out the core cladding, placing the core cladding at the temperature 65-100DEG C and drying for 20-60 minutes, placing the core cladding at the temperature of 135-165DEG C and drying for 20-60 minutes; seventhly, at least repeating the third step to the sixth step once; eighthly, placing the treated substance in a casing, sealing and performing ageing treatment, wherein the dispersoid A is a dispersoid containing conducting polymer. According to the manufacturing method, a solid-state capacitor with a lower ESR (Equivalent Series Resistance) value and a higher voltage resisting value can be obtained; meanwhile, lower leak current is obtained.

Owner:ZHAOQING BERYL ELECTRONICS TECH

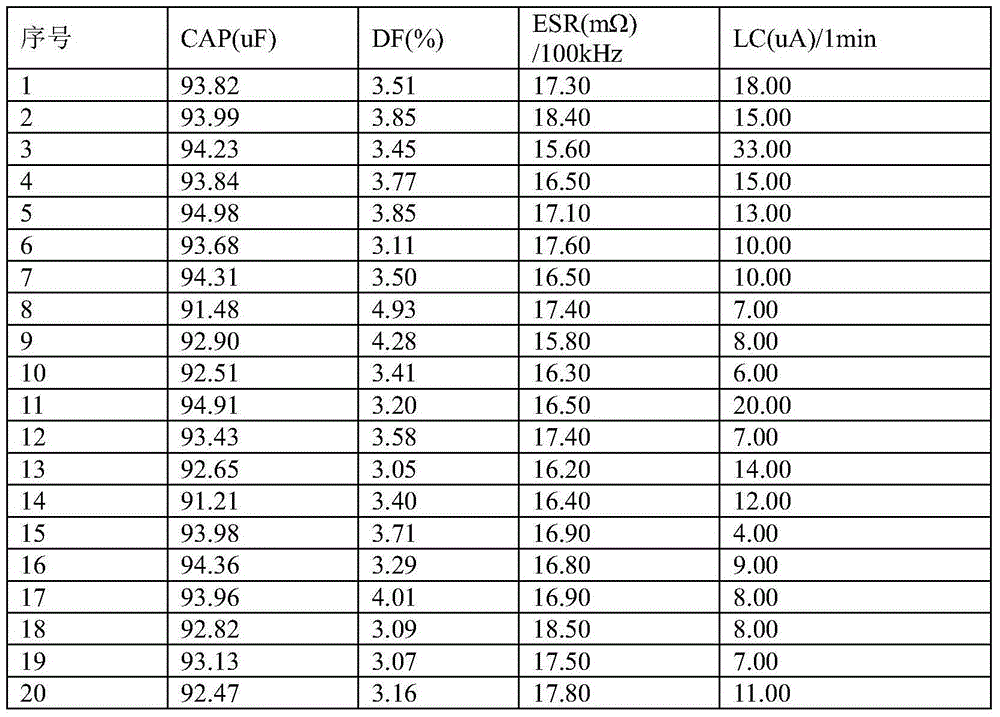

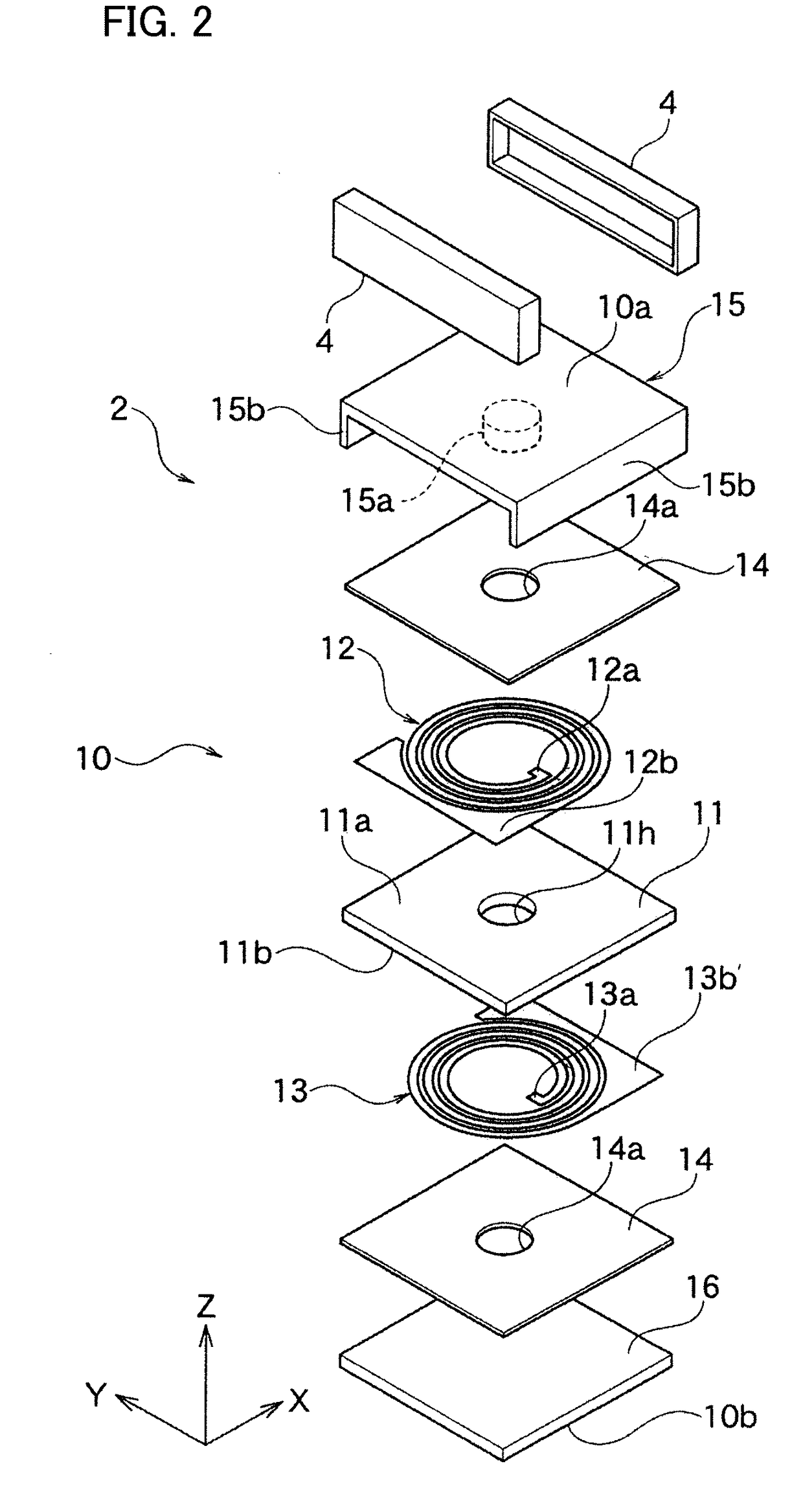

Coil device

ActiveUS20170154720A1Excellent initial magnetic permeabilityExcellent core lossTransformers/inductances casingsTransformers/inductances coils/windings/connectionsMetal powderFerric

A coil device comprising a coil, and a magnetic metal powder containing resin covering said coil. Said magnetic metal powder comprises at least two types of magnetic metal powders with different D50. The magnetic metal powder having larger D50 is defined as a large diameter powder, and the magnetic metal powder having smaller D50 is defined as a small diameter powder among the two types of said magnetic metal powder. Said large diameter powder is made of iron or iron based alloy. Said small diameter powder is made of Ni—Fe alloy. Said small diameter powder has D50 of 0.5 to 1.5 μm. Said large diameter powder and said small diameter powder respectively comprises an insulation coating layer.

Owner:TDK CORPARATION

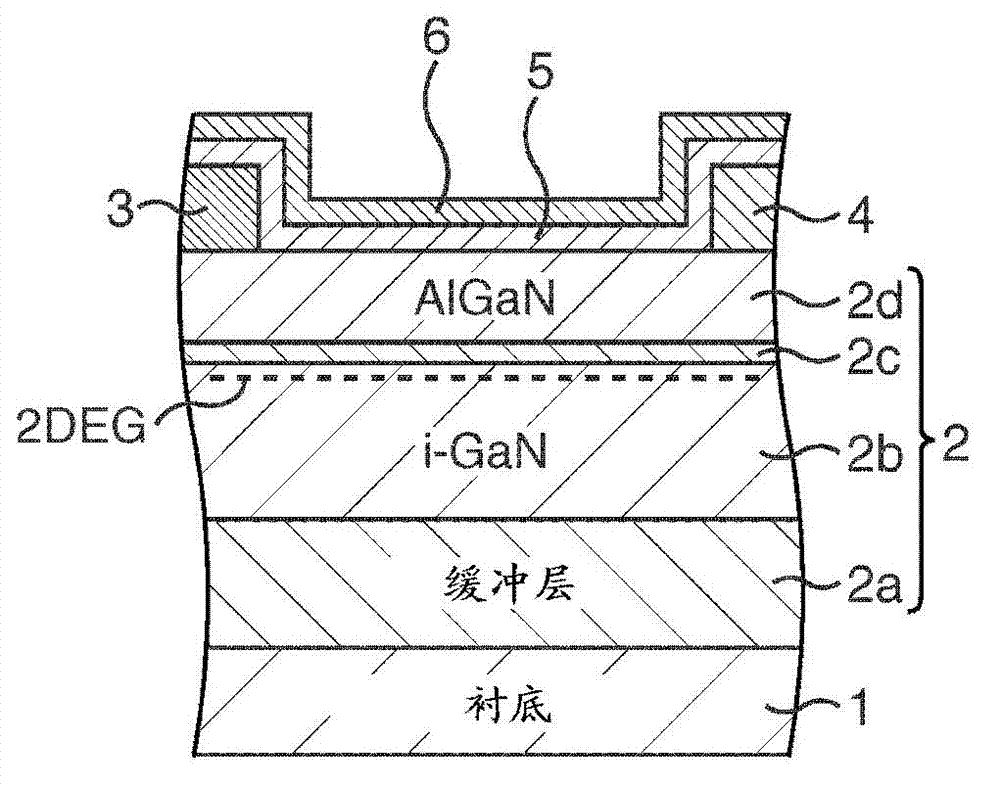

Compound semiconductor device and method of manufacturing the same

ActiveCN103035683AInhibition of collapseImprove withstand voltageSemiconductor/solid-state device manufacturingSemiconductor devicesOxygenSemiconductor device

A HEMT has a compound semiconductor layer, a protection film which has an opening and covers an upper side of the compound semiconductor layer, and a gate electrode which fills the opening and has a shape riding on the compound semiconductor layer, wherein the protection film has a stacked structure of a lower insulating film not containing oxygen and an upper insulating film containing oxygen, and the opening includes a first opening formed in the lower insulating film and a second opening formed in the upper insulating film and wider than the first opening, the first opening and the second opening communicating with each other.

Owner:FUJITSU LTD

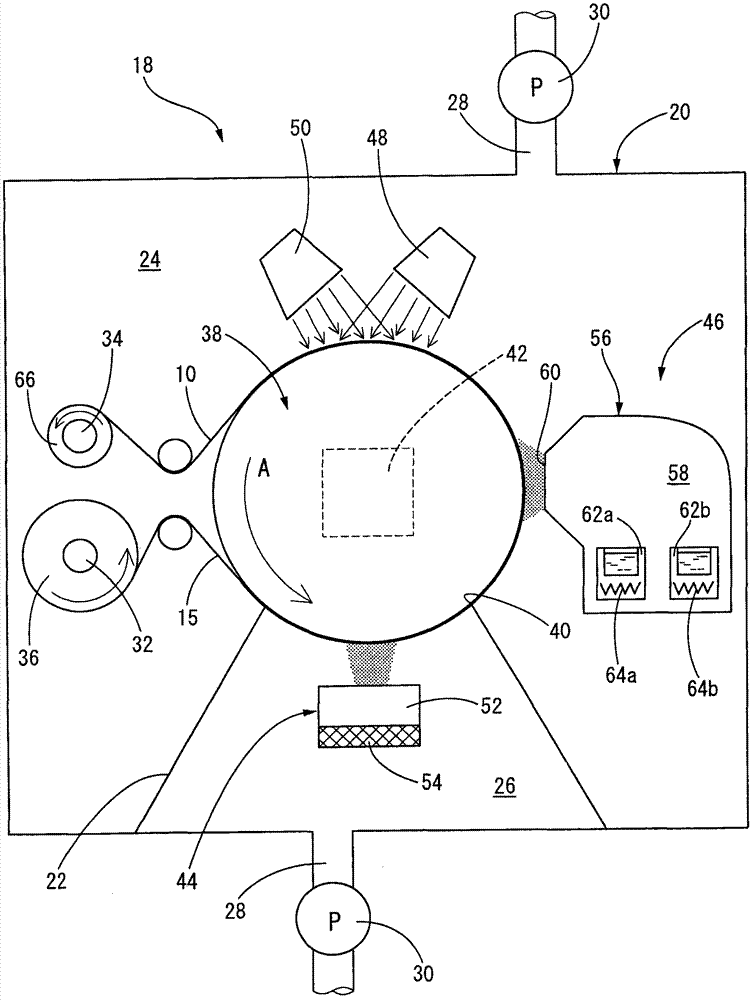

Photomultiplier tube

ActiveCN101814413AAvoid incidenceImprove withstand voltageMutiple dynode arrangementsPhotocathodeDynode

Electrons are prevented from being made incident onto an insulation part between dynodes to improve a withstand voltage. The photomultiplier tube is provided with a casing having a glass substrate on which a main surface made with an insulating material is formed, dynodes constituted with a 1st stage to an Nth stage (N denotes an integer of 2 or more) which are arrayed so as to be spaced away sequentially from a first end side to a second end side on the main surface, a photocathode which is installed on the first end side so as to be spaced away from the 1st stage dynode to emit photoelectrons, and an anode part which is installed on the second end side so as to be spaced away from the Nth stage dynode, taking out multiplied electrons as a signal, in which a groove, the surface of which is made with an insulating material, is formed between two adjacent dynodes on the main surface of the glass substrate, and the 1st stage to the Nth stage dynodes are fixed on raised parts 45 adjacent to the grooves on the glass substrate.

Owner:HAMAMATSU PHOTONICS KK

Electrolytic condenser

InactiveCN1381854AReduce leakage currentImprove withstand voltageCapacitor electrolytes/absorbentsOrganic acidCapacitance

The invention discloses an electrolytic capacitor, which is characterized in that conductive polymers and organic acid complex salts are used as electrolytes. The electrolytic capacitor has the following effects: (1) the leakage current is small, and the withstand voltage value is increased; (2) the impedance characteristic is excellent; (3) the stability is excellent; (4) it can be manufactured under simple engineering.

Owner:SANYO CHEM IND LTD +1

Dry-type transposed conductor air reactor for pre-burying optical fiber Bragg optical grating temperature measuring shape-changing sensor

ActiveCN103839654AGuaranteed safe operationTimely discovery of potential safety hazardsThermometer detailsThermometers using physical/chemical changesFiberGlass fiber

A dry-type transposed conductor air reactor for pre-burying an optical fiber Bragg optical grating temperature measuring shape-changing sensor comprises the optical fiber Bragg optical grating temperature measuring shape-changing sensor, a dry-type air reactor common inter layer structure, a transposed conductor coil winding, a glass fiber packaging layer (a glass-fiber-added cotton belt) and an epoxy glue layer. The dry-type transposed conductor air reactor is characterized in that the optical fiber Bragg optical grating temperature measuring shape-changing sensor is pre-buried in the dry-type air reactor based on the transposed conductor technology, the coil winding of the dry-type air reactor is formed by winding a flat aluminum stranded conductor, and a reactor coil is packaged through glass fiber of the glass-fiber-added cotton belt immersed by epoxy resin. By means of the dry-type transposed conductor air reactor, the high-voltage-resisting level can be improved, temperature rising can be reduced, and the safety of high-voltage power transmission and distribution is improved.

Owner:YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST +1

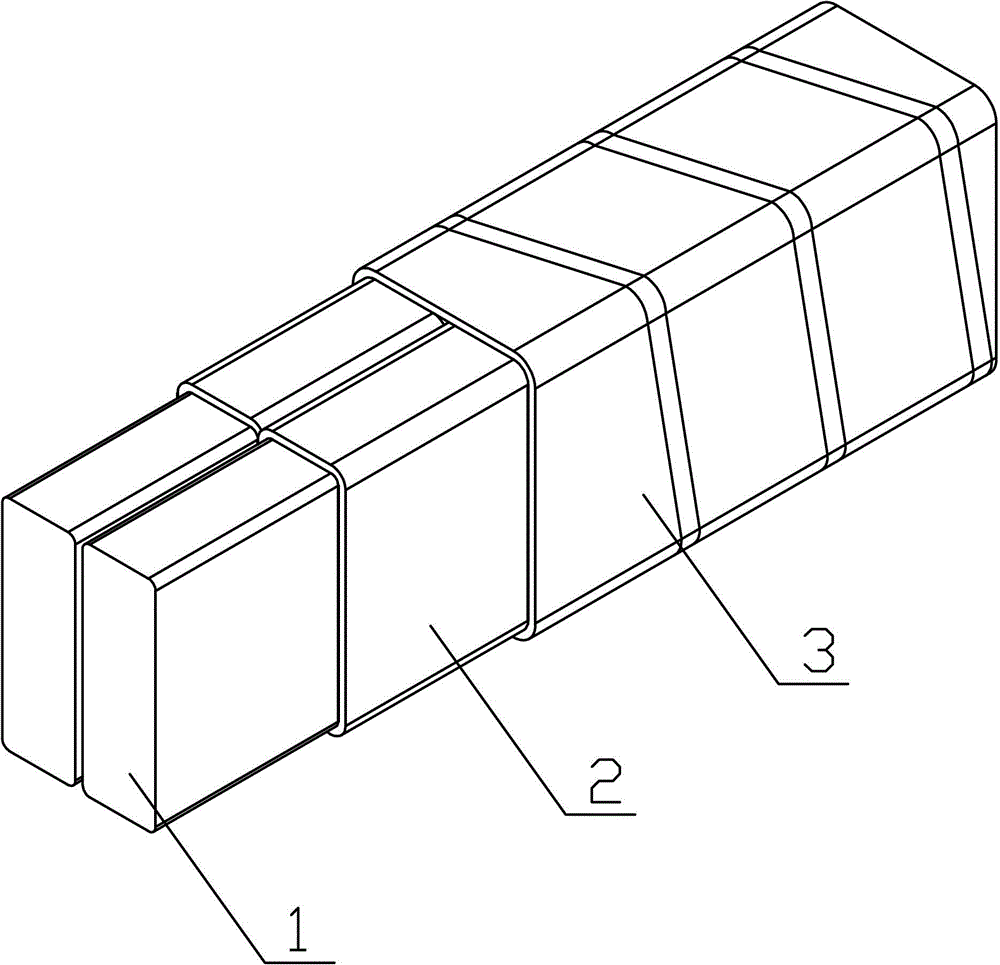

Film capacitor element, film capacitor, and method of producing the film capacitor element

InactiveCN102737843ALess impuritiesImprove withstand voltageThin/thick film capacitorFixed capacitor dielectricDielectricVapor deposition polymerization

A film capacitor element is provided which has a smaller size and higher capacity while securing the sufficient withstand voltage at a high level and which can be efficiently produced. The film capacitor element including a laminated body including at least one dielectric film and at least one metal deposition film. The at least one dielectric includes at least one vapor-deposited polymer film. The at least vapor-deposited polymer film is formed by a deposition polymerization of a plurality of monomers each having a structure in which two benzene rings are linked via a linking group.

Owner:KOJIMA PRESS IND CO LTD

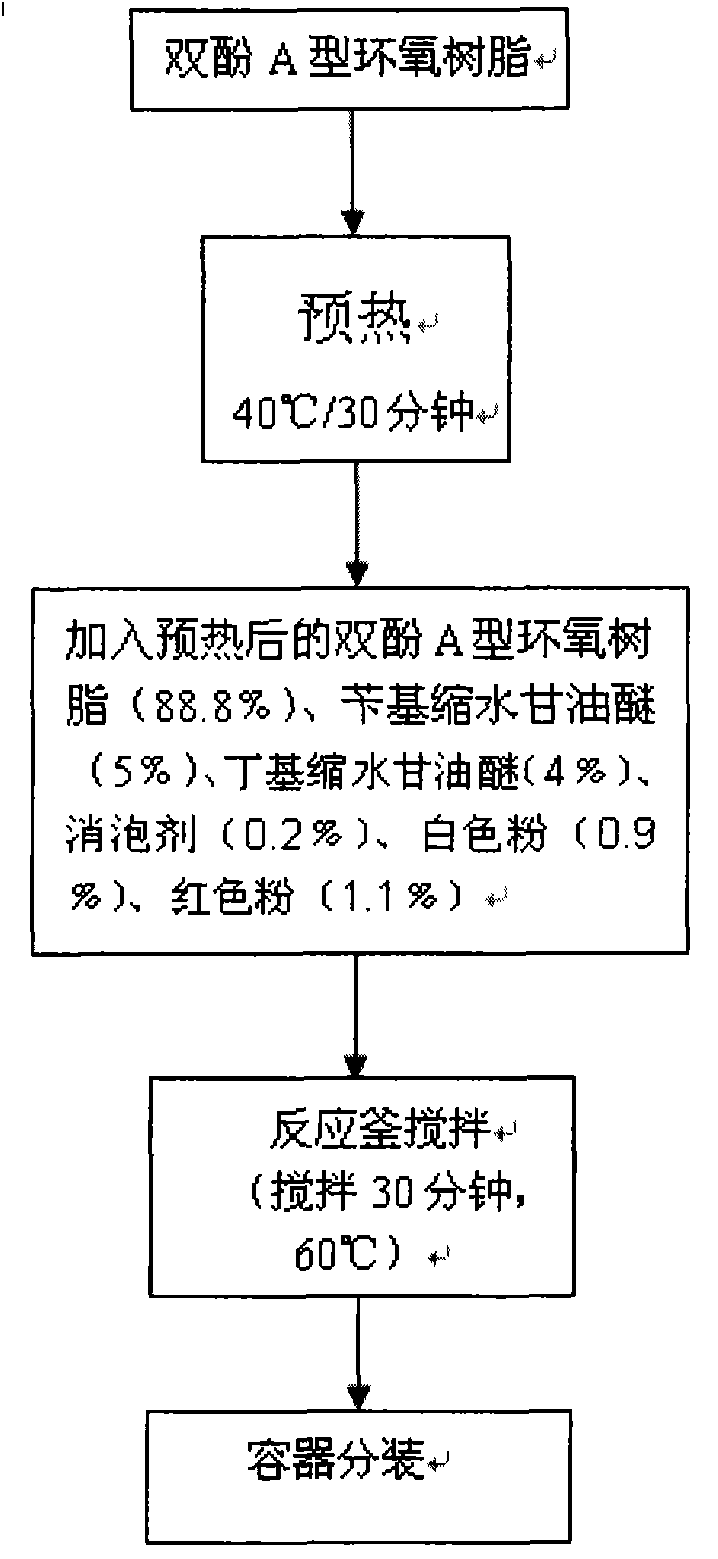

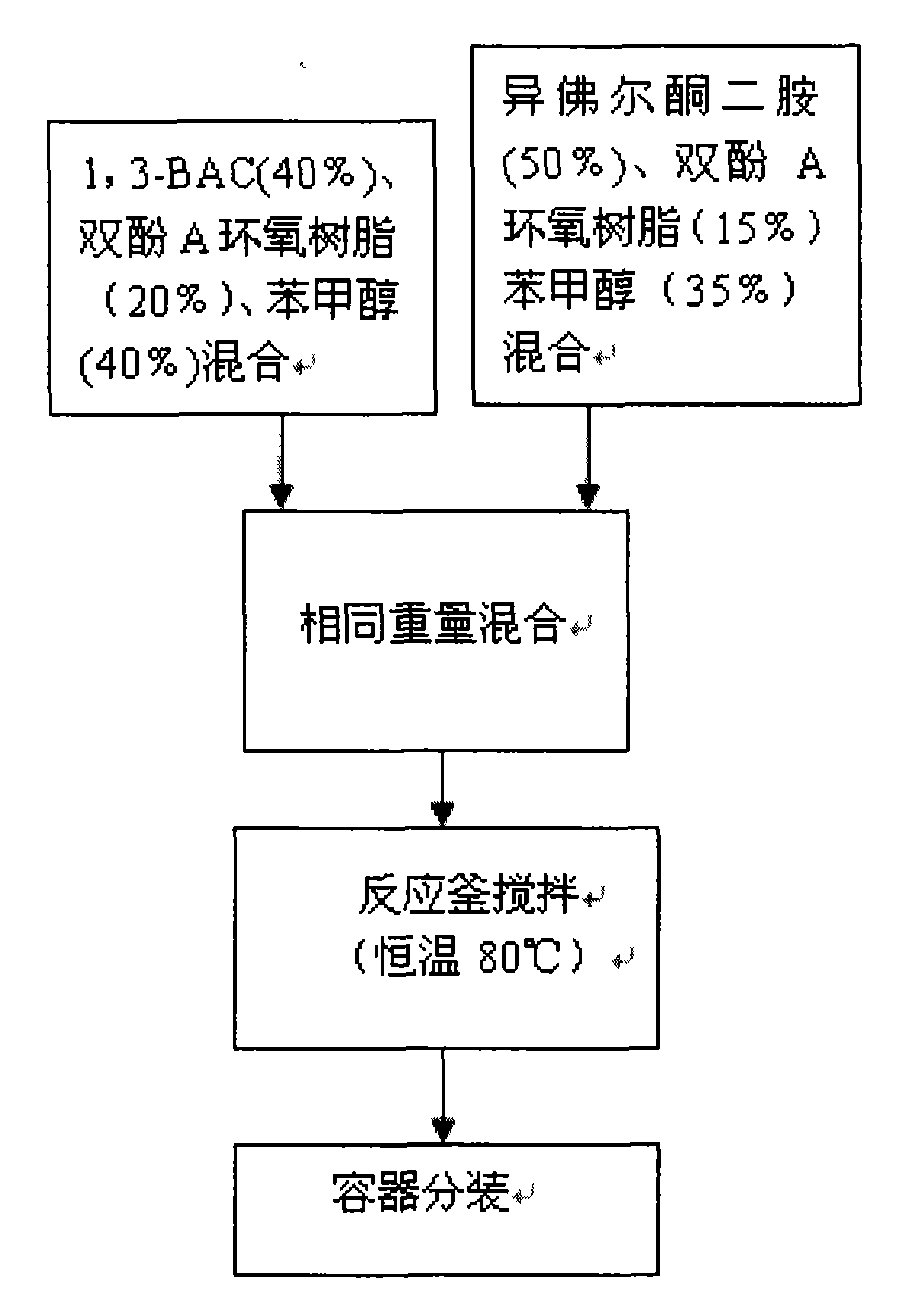

Epoxy resin pouring sealant

InactiveCN103361019AHigh hardnessImprove thermal deformationNon-macromolecular adhesive additivesEpoxy resin adhesivesLower limitThermal deformation

The invention discloses an epoxy resin pouring sealant. The epoxy resin pouring sealant comprises the component A--an epoxy resin and the component B--a curing agent. The component A comprises, by weight, 85 to 89% of a bisphenol A epoxy resin, 3 to 13% of a diluent and 0.15 to 0.25% of a defoaming agent. The component B comprises a first raw material and a second raw material, wherein the first raw material comprises, by weight, 40% of 1,3-BAC, 20% of the bisphenol A epoxy resin and 40% of benzyl alcohol, the second raw material comprises, by weight, 50% of isophorone diamine, 15% of the bisphenol A epoxy resin and 35% of benzyl alcohol, and the first raw material and the second raw material with same weight are mixed and stirred to obtain the component B. A weight ratio of the component A to the component B is 2: 1. The sum of the upper limit value of any component of the component A and the lower limit value of the rest components is no more than 100%, and the sum of the lower limit value of any component of the component A and the upper limit value of the rest components is no less than 100%. The epoxy resin pouring sealant provided by the invention has improved hardness, thermal deformation, voltage resistance, etc.

Owner:ANHUI KANGRUIXIN ELECTRONICS TECH

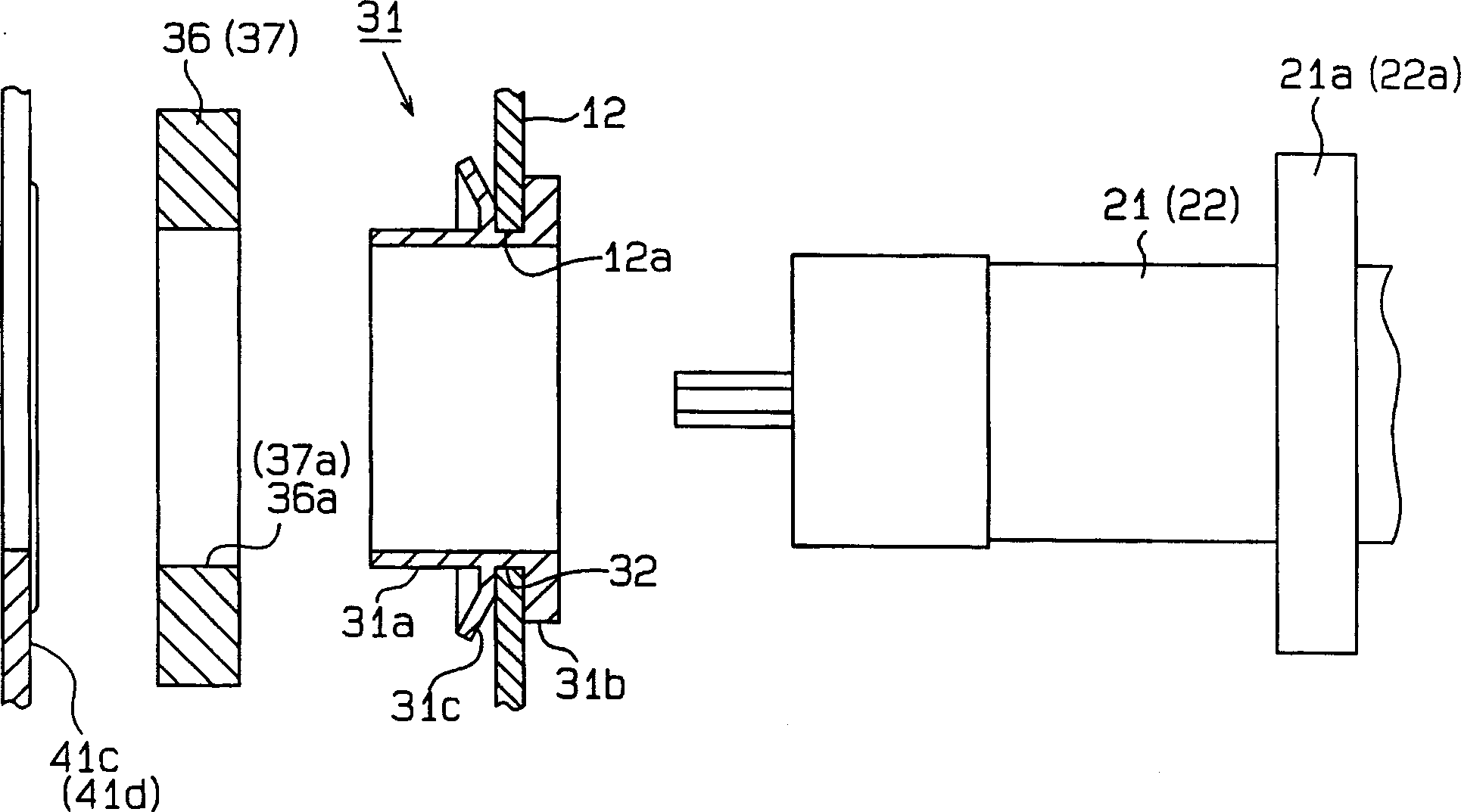

Switch

InactiveCN1341943AImprove withstand voltagePrevent movementSwitches with movable electrical contactsHigh-tension/heavy-dress switchesSet screwZero phase

A switch, wherein an encased zero-phase current transformer (36) and a cut-off relay (37) are fitted into the inside edges of both bushings (21, 22). Between each of the zero phase sequence current transformer (36) and the cut-off relay (37) and an unit casing, an elastic pressing element (31c) is provided that presses both the zero phase sequence current transformer (36) and the cut-off relay (37) in the inside direction of the casing. The movement of the zero phase sequence current transformer (36) and the cut-off relay (37) toward the inside of the casing is restricted by an insulating barrier (41). This structure makes it unnecessary to set screws into the inside surface of the casing and improve withstand voltage between the switch and ground.

Owner:ENERGY SUPPORT CORP

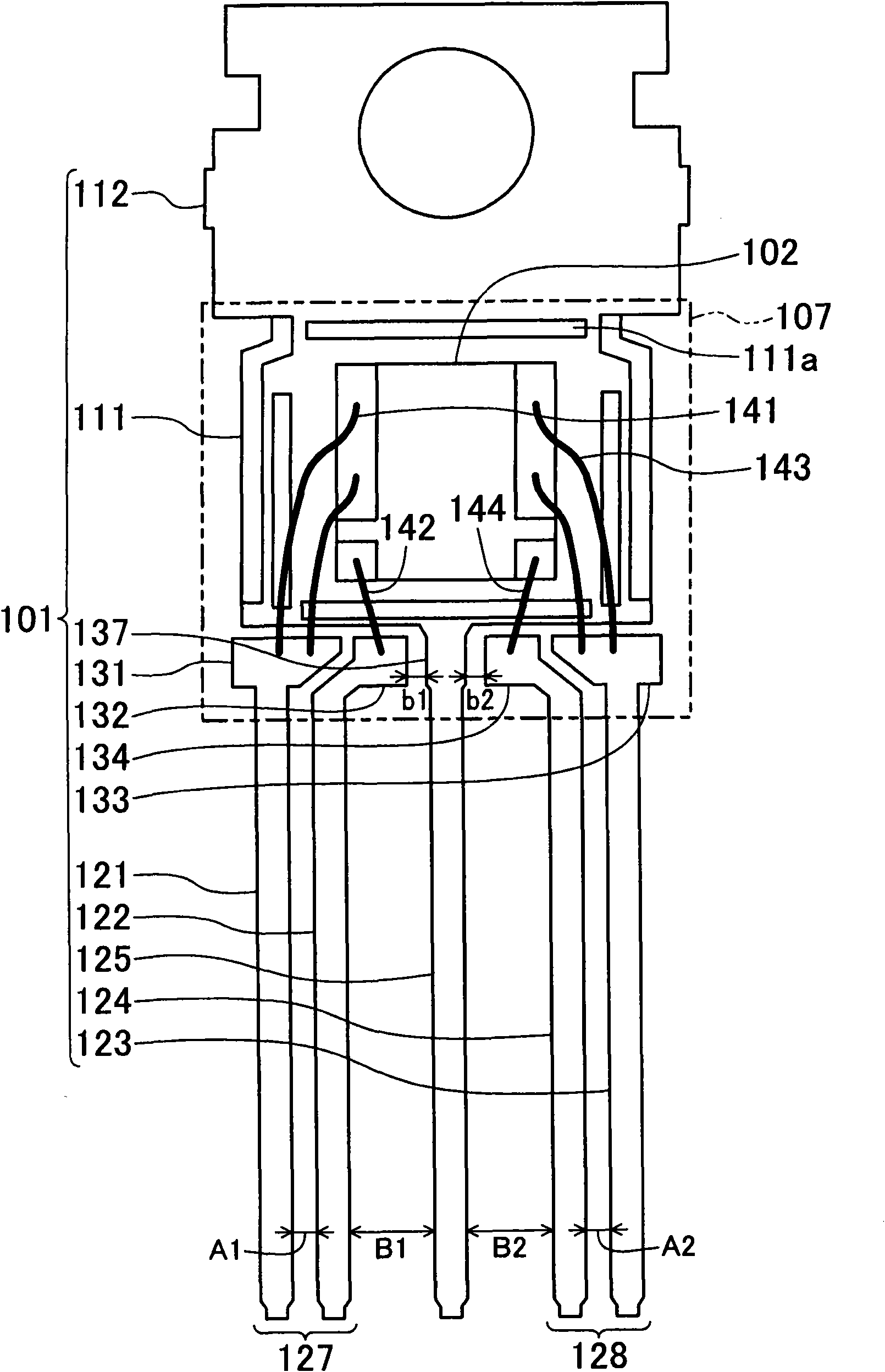

Semiconductor device and lead frame thereof

InactiveCN102074538AImprove withstand voltageIncrease the shortest distance in spaceSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor devicePower flow

An objective of the present invention is to implement a small-sized semiconductor device that satisfies clearances required to secure the dielectric strength and allows flow of a large current. The semiconductor device includes a semiconductor element (102) and a lead frame (101). The lead frame (101) includes a first lead (121), a second lead (122), a third lead (123), a fourth lead (124), and a fifth lead (125) placed parallel to one another. The first and second leads are placed adjoining to each other and constitute a first lead group(127), and the third and fourth leads are placed adjoining to each other and constitute a second lead group(128). The spacing between the first lead group and the fifth lead, the spacing between the second lead group and the fifth lead, and the spacing between the first lead group and the second lead group are larger than the spacing between the first lead and the second lead and the spacing between the third lead and the fourth lead.

Owner:PANASONIC CORP

Winding wire for SF6 gas insulated transformer

ActiveCN102915791AHigh mechanical strengthImprove high temperature resistanceInsulated cablesInsulated conductorsElectrical conductorTransformer

The invention relates to a winding wire (PET film and aluminum combined wire) for an SF6 gas insulated transformer, which comprises aluminum flat wire conductors, PET film insulated layers of individual aluminum flat wires, PET film insulated layers of aluminum combined wires; individual PET film bands outside the aluminum flat wire conductors are overlapped and wound to form the PET film insulated layers of the individual aluminum flat wires; and a plurality of layers of PET film band outside the PET film insulated layers of the individual aluminum flat wires are overlapped and wound to form the PET film insulated layers of the aluminum combined wires. According to the invention, plastic films with very high mechanical intensity, insulation capacity and high sealing performance serve as an insulation material, and the PET film and aluminum combined wire made of the insulation material is anti-high temperature, voltage resistant and good in mechanical intensity and heat conduction performance.

Owner:WUXI TOLY ELECTRIC WORKS

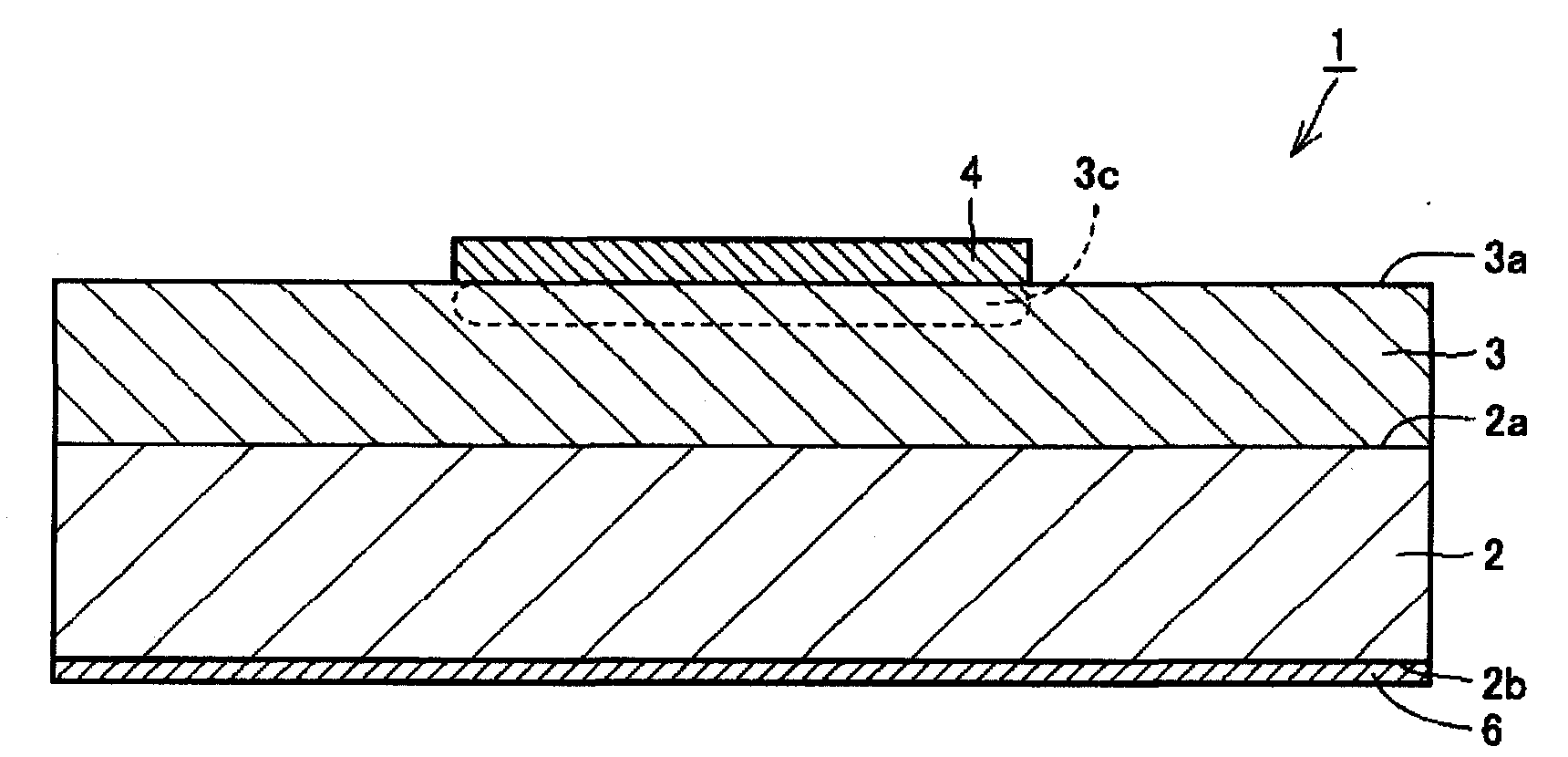

Schottky barrier diode and method for manufacturing schottky barrier diode

InactiveCN102119443AReduce dislocation densityReduce reverse leakage currentSemiconductor devicesSchottky barrierAlloy

Disclosed is a method for manufacturing a schottky barrier diode (11), comprising the following steps. A GaN substrate (2) is first provided. A GaN layer (3) is formed on the GaN substrate (2). A schottky electrode (4) is formed that includes a first layer which is formed of Ni or a Ni alloy and formed in contact with the top of the GaN layer (3). The step of forming the schottky electrode (4) comprises the step of forming a metal layer to serve as the schottky electrode (4) and the step of heat treating the metal layer. The dislocation density of a region, in the GaN layer (3), which is in contact with the schottky electrode (4) is not more than 1 108 cm-2.

Owner:SUMITOMO ELECTRIC IND LTD

Non-aqueous electrolyte for lithium secondary cell or lithium-ion capacitor, and lithium secondary cell or lithium-ion capacitor in which same is used

ActiveCN108140895AExcellent withstand voltageLow freezing pointHybrid capacitor electrolytesHybrid capacitor electrodesSolventLithium-ion capacitor

Disclosed is a non-aqueous electrolyte for a lithium secondary cell or a lithium-ion capacitor in which a lithium salt is dissolved at a specific amount in a non-aqueous solvent, wherein: the non-aqueous solvent contains specific amounts of ethylene carbonate, propylene carbonate, dimethyl carbonate, methylethyl carbonate, and a fluorinated chain ester; the total amount of ethylene carbonate and propylene carbonate contained in the non-aqueous solvent is in a specific range; the total amount of dimethyl carbonate and the fluorinated chain ester contained is in a specific range; and the non-aqueous electrolyte has a flash point of 20 DEG C or higher. Also disclosed is a non-aqueous electrolyte for a lithium secondary cell or a lithium-ion capacitor in which a lithium salt is dissolved at aspecific amount in a non-aqueous solvent, wherein: the non-aqueous solvent contains specific amounts of ethylene carbonate, propylene carbonate, dimethyl carbonate, methylethyl carbonate, and ethyl propionate; the total amount of ethylene carbonate and propylene carbonate contained in the non-aqueous solvent is in a specific range; the total amount of dimethyl carbonate and ethyl propionate contained is in a specific range; and the non-aqueous electrolyte has a flash point of 20 DEG C or higher.

Owner:MU电解液株式会社

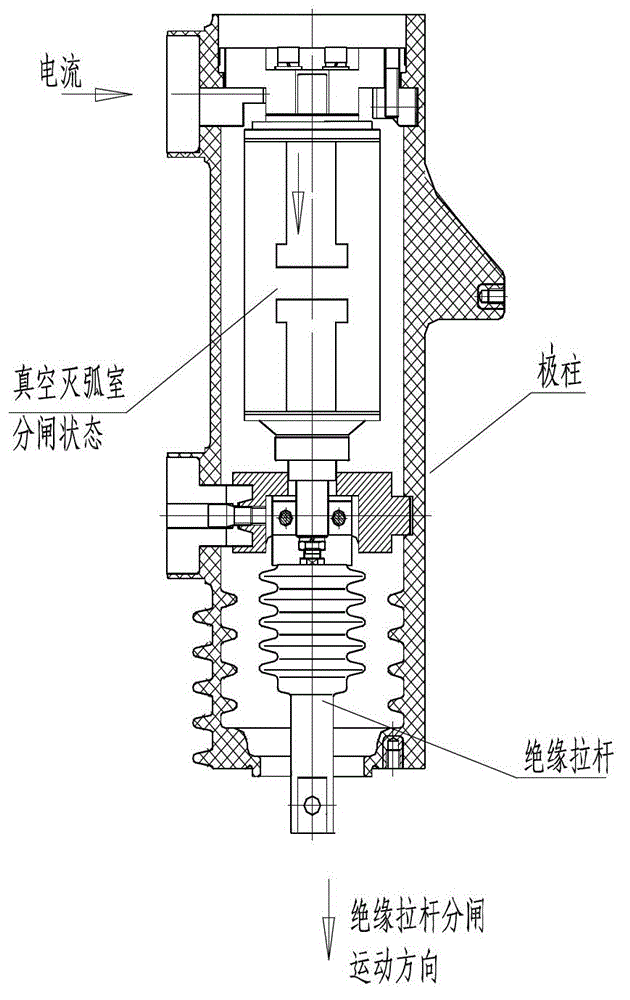

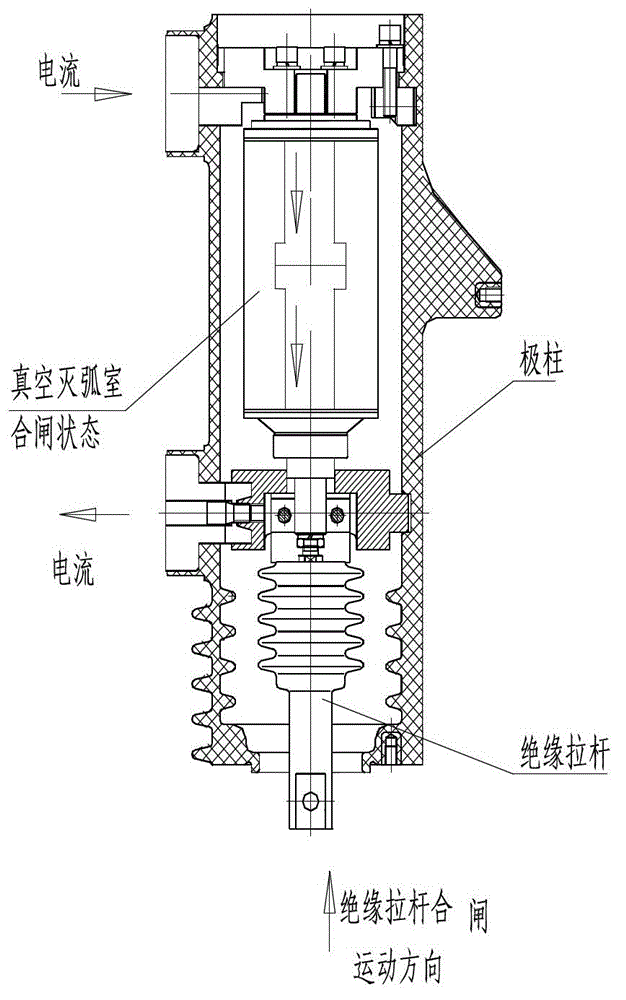

Lumbar-support rotary-type voltage-sharing grounding shielding high-voltage vacuum arc extinguishing chamber solid-sealed polar pole

ActiveCN104064397AImprove safety and reliabilitySimplify the layout processHigh-tension/heavy-dress switchesAir-break switchesIntegrated operationsThree-phase

The invention relates to a lumbar-support rotary-type voltage-sharing grounding shielding high-voltage vacuum arc extinguishing chamber solid-sealed polar pole. A conductive seat, a vacuum arc extinguishing chamber and a conductive tube are electrically connected to form a high-voltage circuit and also integrally packaged with a coaxial cylindrical grounding shielding tube through a solid insulating material. Rotary moving contact fingers are installed at the two ends of the solid-sealed polar pole. A slide spring contact finger and a direct-acting disc spring cylinder assembly rod piece are installed in the conductive tube. The solid-sealed polar pole is fixed through lumbar support and wires enter and exit at the two ends of the solid-sealed polar pole. Under alternative linear and rotary driving of a four-station integrated operation mechanism of a high-voltage vacuum isolation circuit breaker, the vacuum arc extinguishing chamber in the solid-sealed polar pole can be enabled to switch on or switch off so that a circuit breaker function is realized and positive and reversed 90-degree rotation can also be carried out so that the three-phase polar pole of the high-voltage vacuum isolation circuit breaker is enabled to realize switching of a work position and an isolation position and thus a disconnecting switch function is realized and a clear and visible double-isolation fracture is arranged at the isolation position. The product design has the advantages of being compact in structure, small in size, free from maintenance, mixed in use and reliable in operation and the like.

Owner:广东维能电气有限公司

MEMS sensing device for electric field measurement based on piezoelectric-magnetic anisotropy coupling structure

ActiveCN109212329AReduce volumeSimple structureElectromagentic field characteristicsElectric field sensorElectricity

The invention discloses a MEMS sensing device for electric field measurement based on a piezoelectric-magnetic anisotropy coupling structure. The device comprises piezoelectric materials. The bottom surface of the piezoelectric materials adheres to a bottom metal, and the top surface of the piezoelectric materials adheres to a ferromagnetic membrane and a metal electrode. The beneficial effect isthat: the device has a large measuring range, a high sensitivity, a fast transient response speed, an electric field measurement range with a wide band and a high field strength, a good temperature stability, a high integration degree and a small size; the device provides a high-performance, low-cost, safe and reliable electric field sensor for the fields of electric power systems, aerospace, meteorological monitoring and the like.

Owner:TSINGHUA UNIV

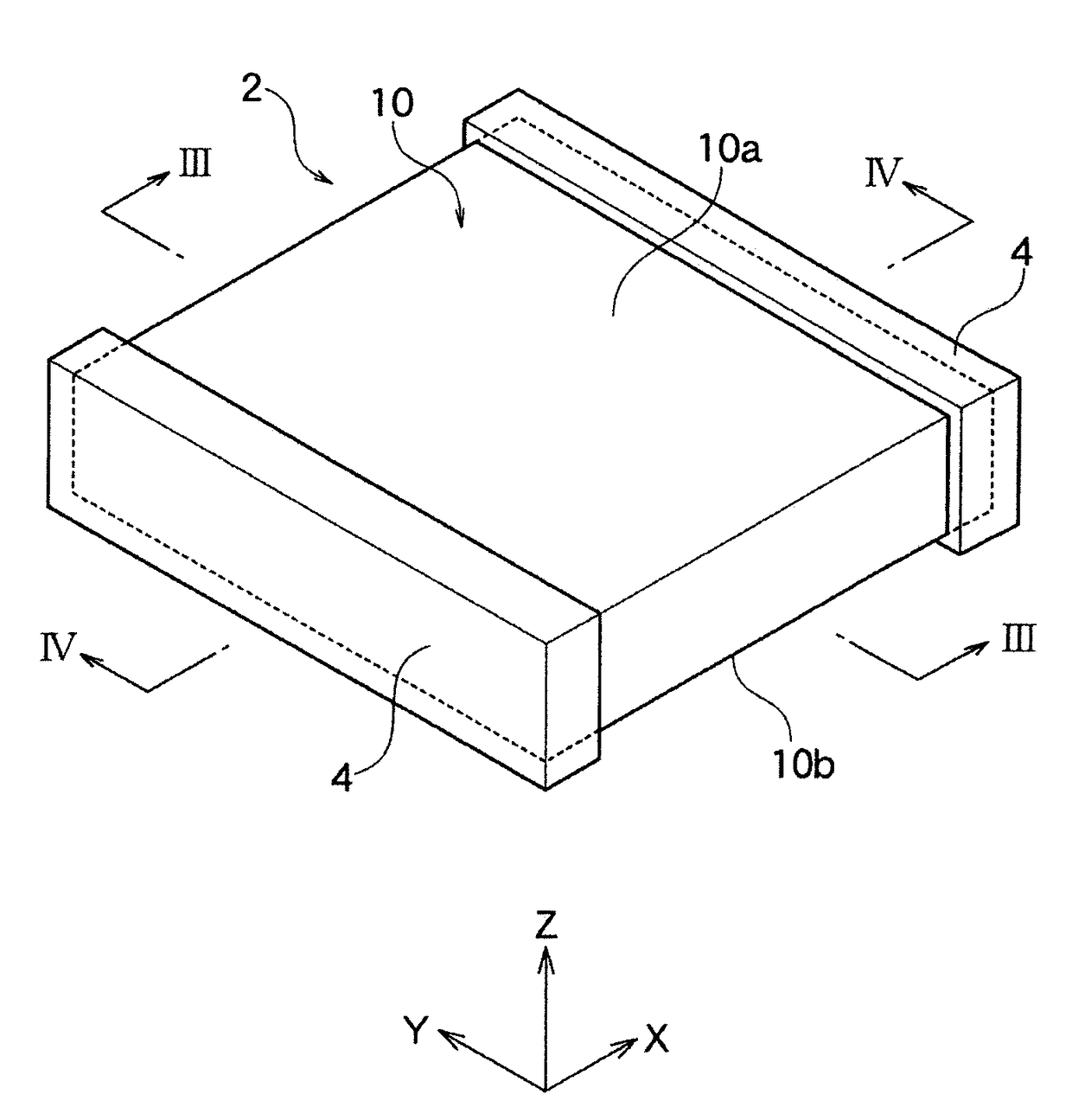

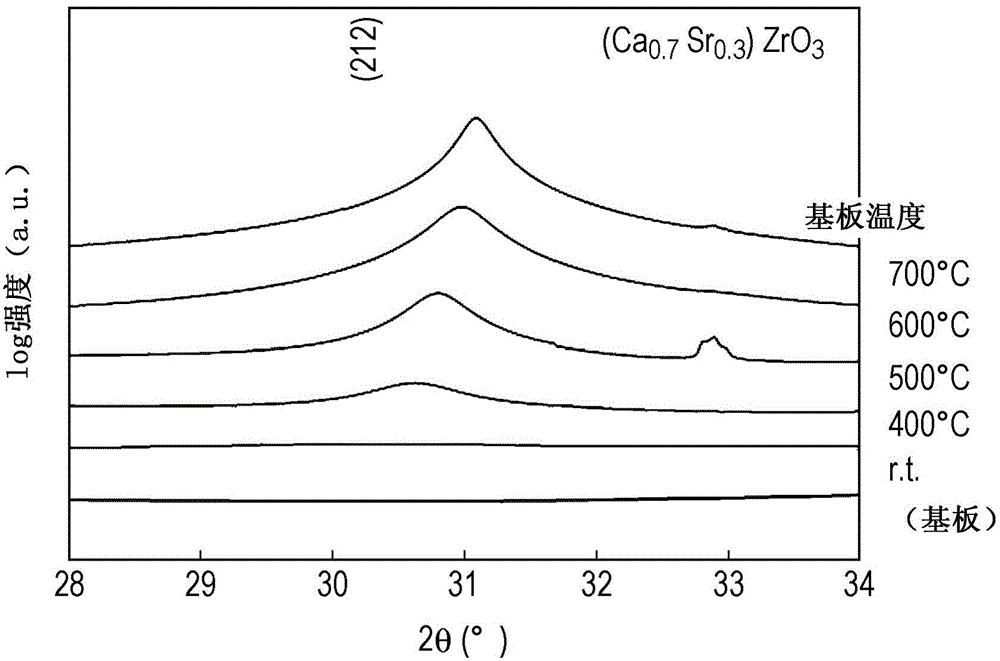

Dielectric composition and electronic component

ActiveCN104952617AImprove withstand voltageHigh relative permittivityThin/thick film capacitorFixed capacitor dielectricElectronic componentMaterials science

A dielectric composition contains major components that are an A-group containing major components that are at least two selected from the group consisting of Ba, Ca, and Sr and a B-group which contains a major component that is selected from Zr and Ti and which contains at least Zr. The dielectric composition contains an amorphous substance containing the A-group and the B-group and a crystalline substance containing the A-group and the B-group. In the dielectric composition, the inequality 0.5 ‰¤ ± ‰¤ 1.5 holds, where ± is the molar ratio of the A-group to the B-group.

Owner:TDK CORP

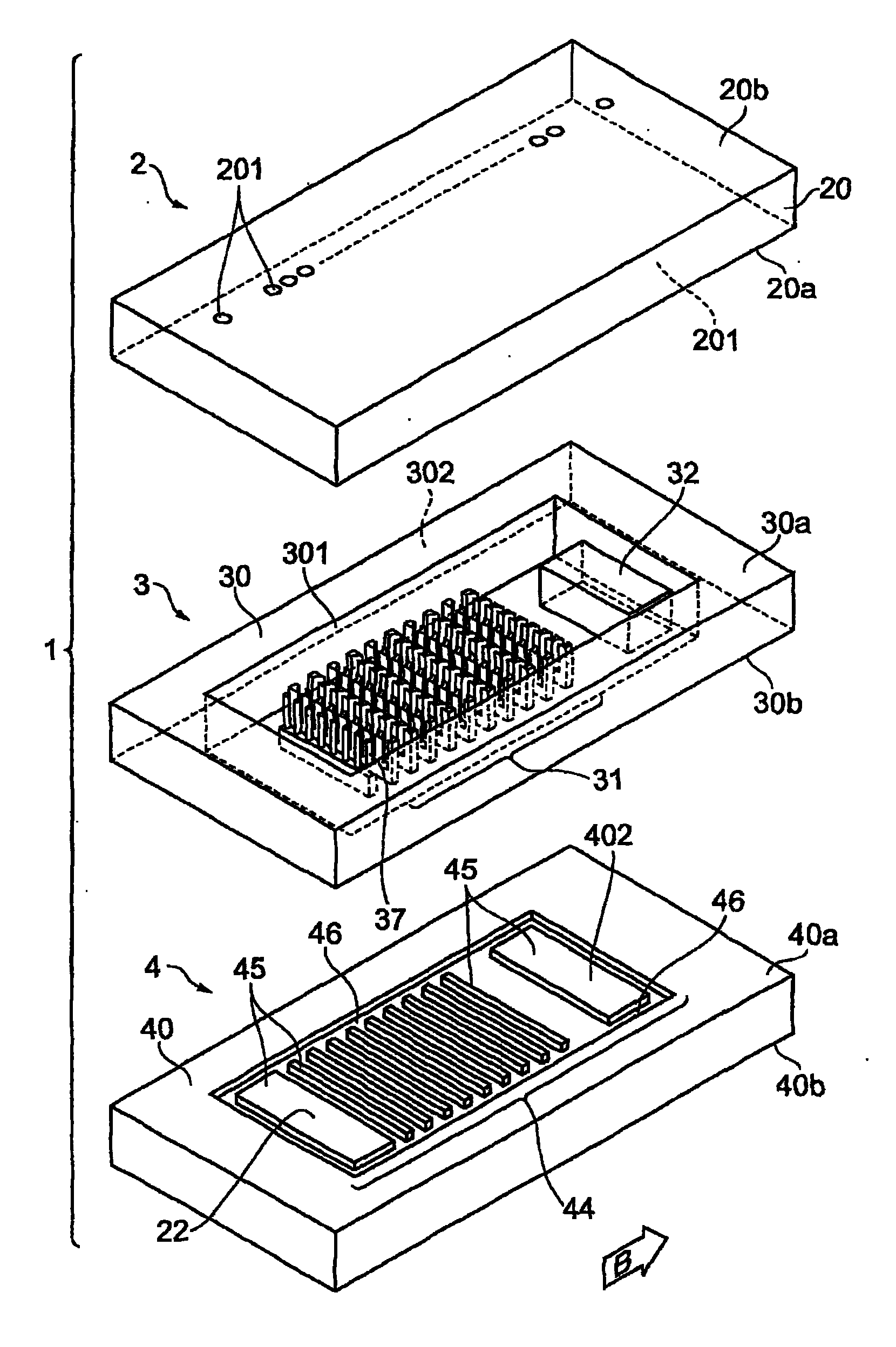

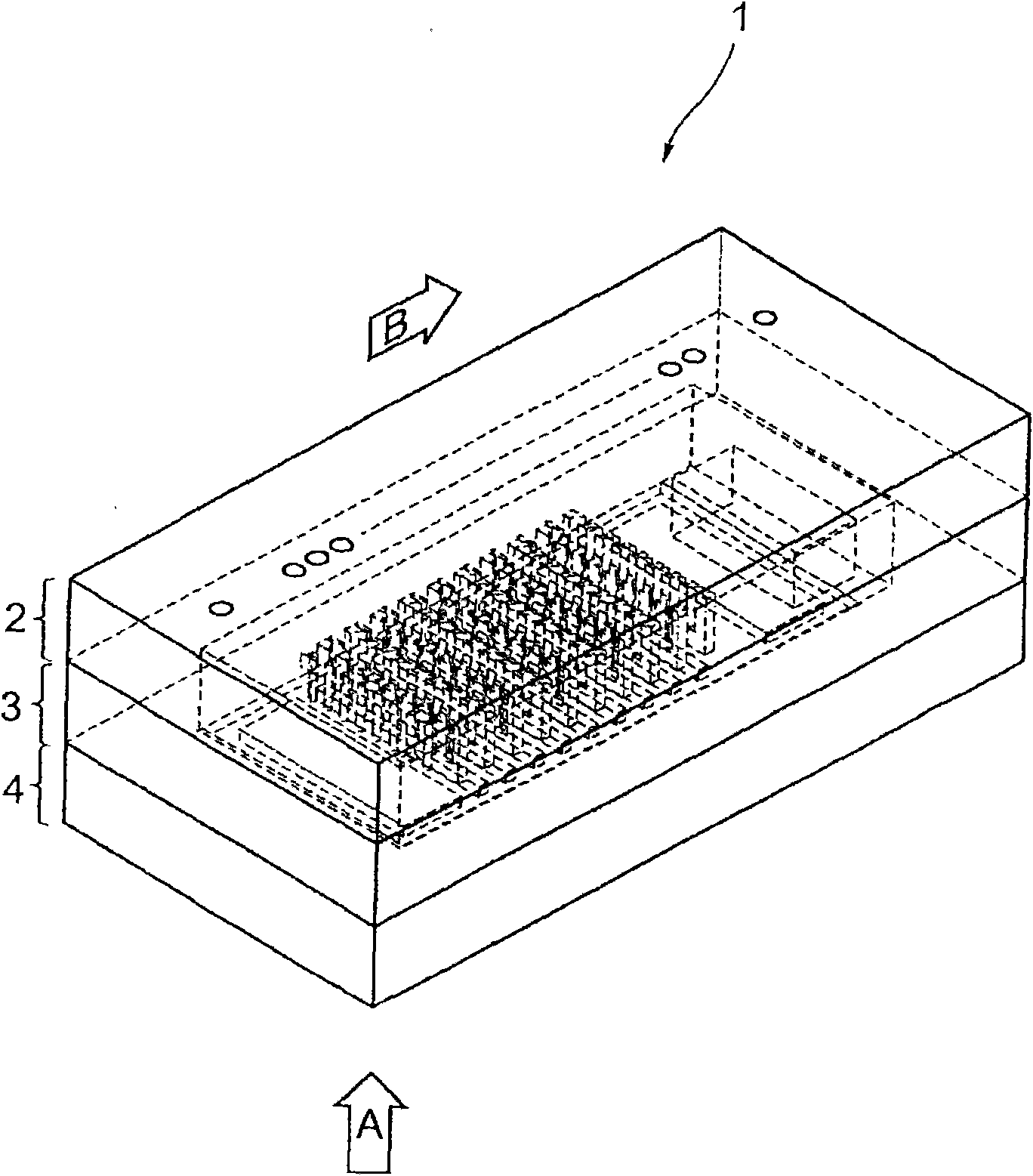

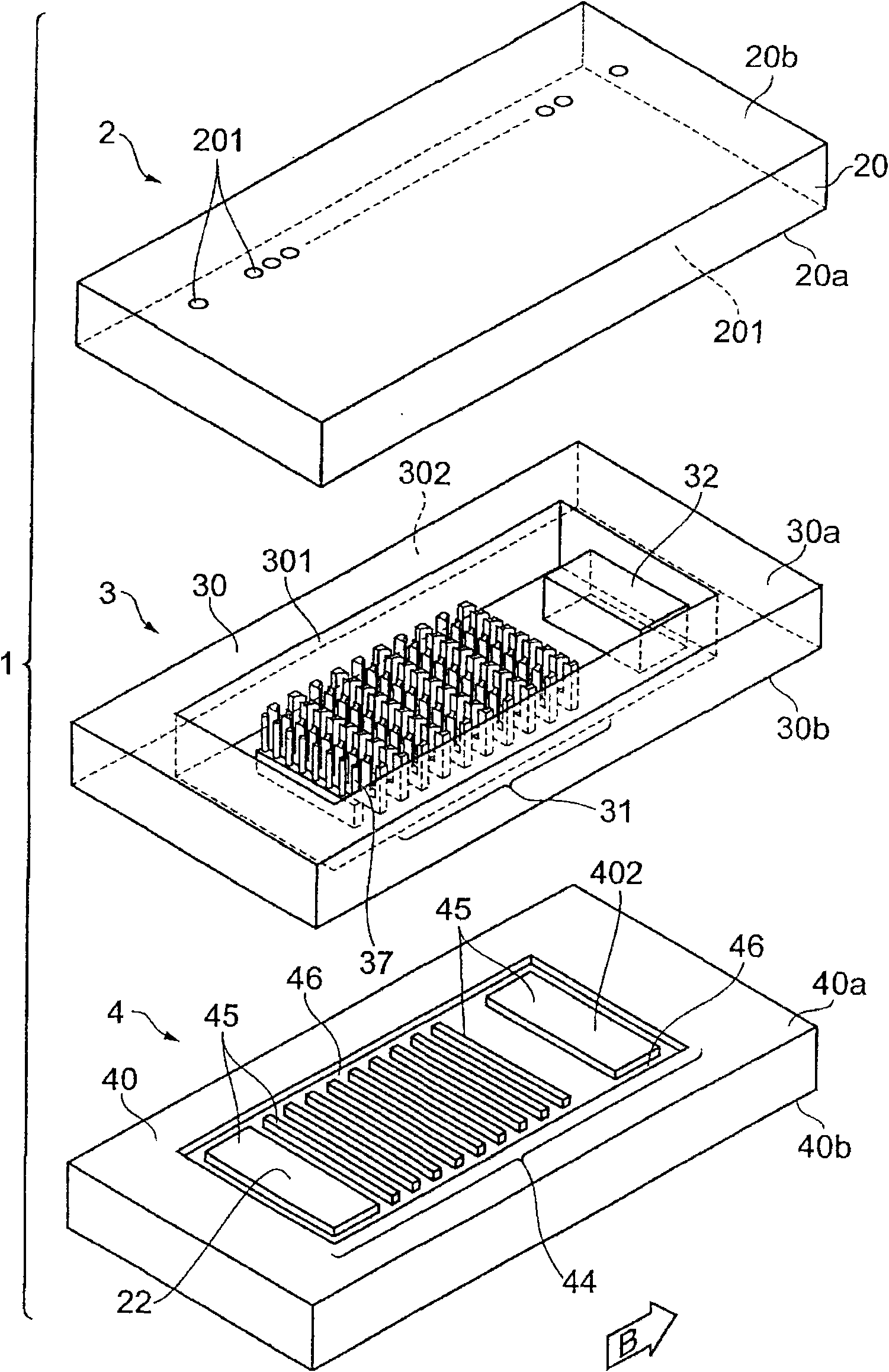

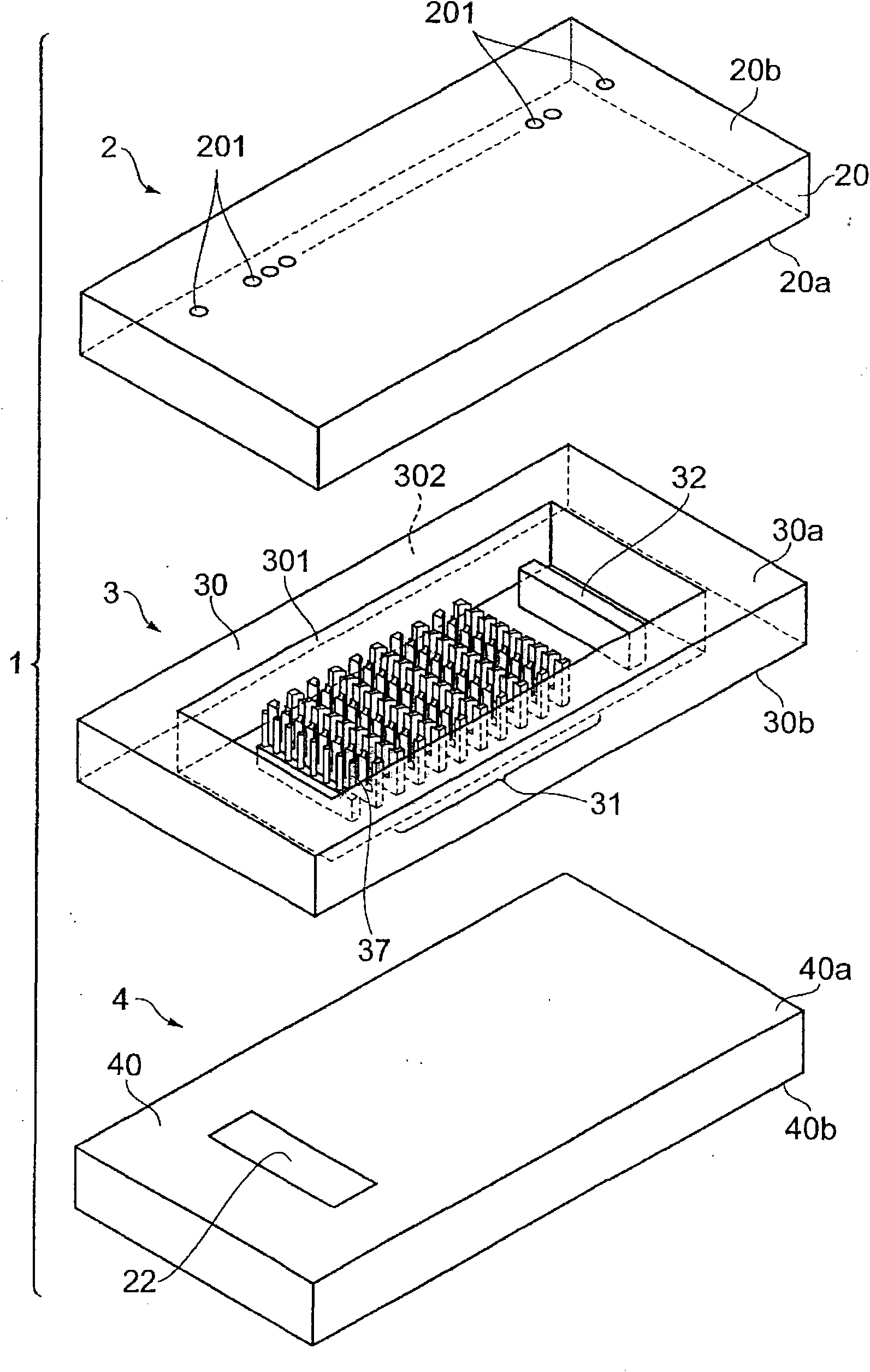

Photomultiplier tube

ActiveCN101814414AAvoid incidenceImprove withstand voltageMutiple dynode arrangementsMultiplier dynodesPhotocathodeDynode

Electrons are prevented from being made incident onto an insulation part of a casing between dynodes to improve a withstand voltage. The photomultiplier tube (1) is a photomultiplier tube which is provided with substrates (20, 40) arranged so as to oppose each other, with the respective opposing surfaces (20a, 40a) made with an insulating material, a substrate (30) constituting a casing together with the substrates (20, 40), dynodes 31a to 31j arrayed on an opposing surface (40a) on the substrate (40) so as to be spaced away sequentially from a first end side to a second end side, a photocathode (22) installed so as to be spaced away from the dynode (31a) to the first end side, and an anode part (32) installed so as to be spaced away from the dynode (31j) to the second end side, in which the opposing surface (20a) of the substrate (20) is formed so as to cover the dynodes (31a to 31j), and a plurality of conductive layers (21a to 21j) set equal in potential to dynodes (31a to 31j) which are electrically independent from each other are installed at sites opposing individually the dynodes (31a to 31j) on the opposing surface (20a).

Owner:HAMAMATSU PHOTONICS KK

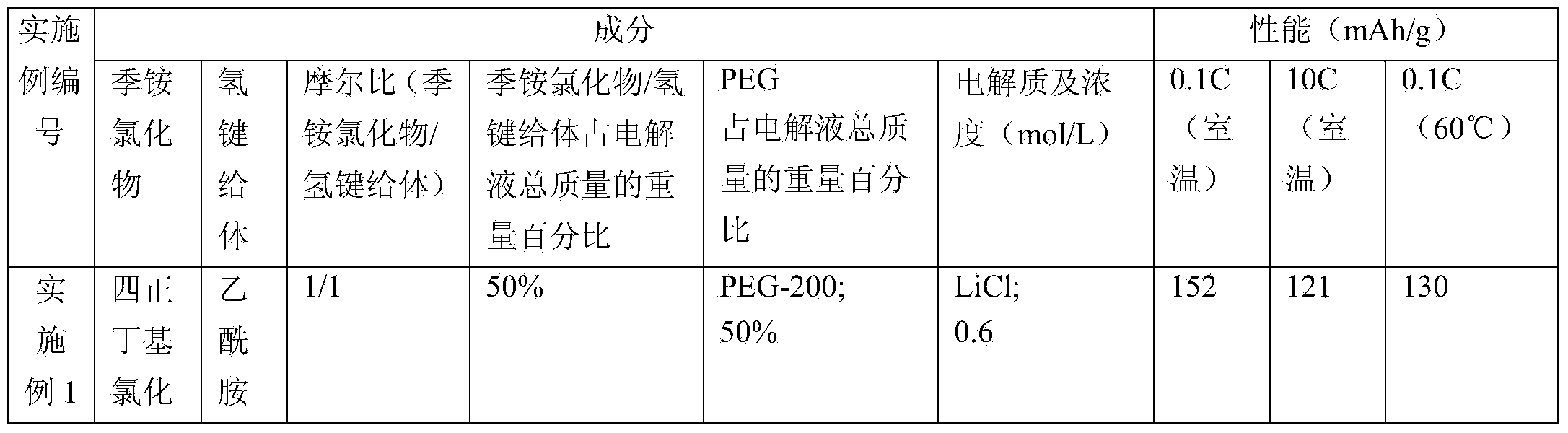

Lithium-ion power battery electrolyte

ActiveCN103956516AImprove securityImprove flame retardant performanceSecondary cellsOrganic electrolytesElectrolysisElectrical battery

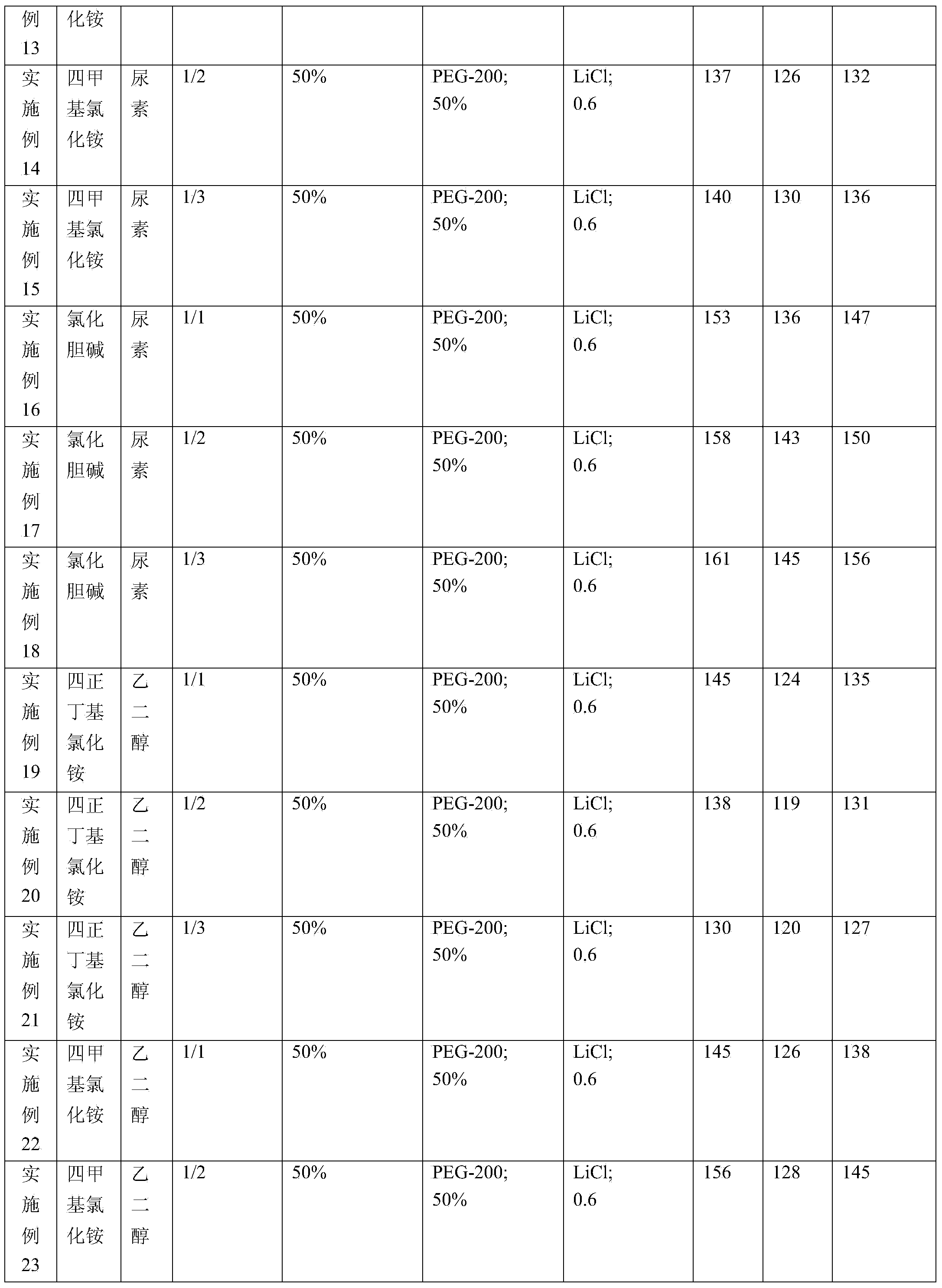

The invention relates to a lithium-ion power battery electrolyte. The lithium-ion power battery electrolyte comprises four components, namely, quaternary ammonium chloride, a hydrogen bond donor, lithium salt electrolyte and polyethylene glycol PEG, wherein the mole ratio of the quaternary ammonium chloride and the hydrogen bond donor is (1 to1)-(1to3); the concentration of the lithium salt electrolyte in the electrolyte is 0.1-3.0mol / L, and the PEG is 0.1%-90% of total mass of the electrolyte. On one hand, an ionic liquid guarantees the high security and fire resistance of electrolysis, on the other hand, and the price of the lithium-ion power battery electrolyte is low; meanwhile, a PEG component is added in the electrolyte, the compatibility of an electrolyte and a lithium-ion battery material is improved, and the property of electrolyte is improved. The lithium-ion power battery electrolyte provided by the invention has properties of good security property, fire resistance, high temperature characteristic and withstand voltage property and the like.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

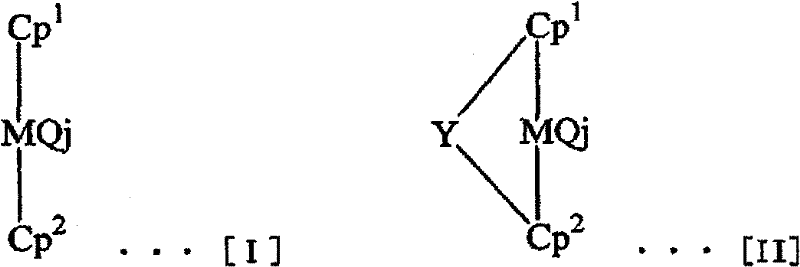

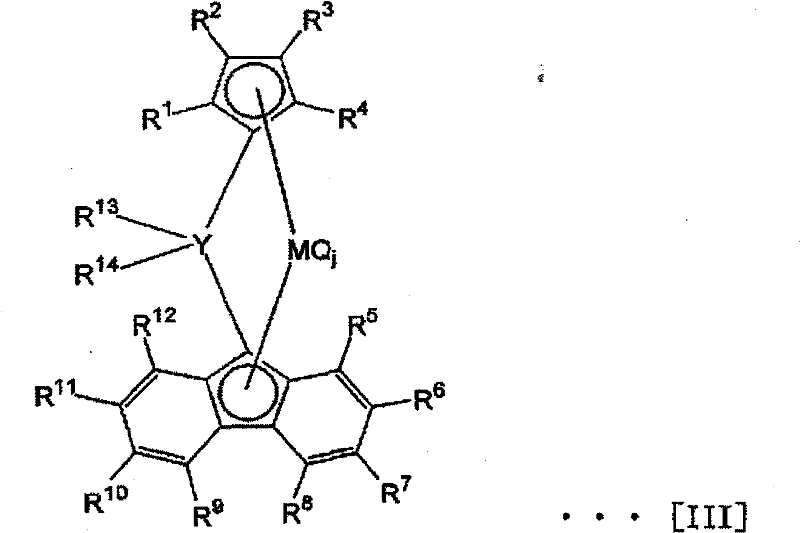

Propylene Homopolymer for Capacitors

Provided is a propylene homopolymer suitably usable in a film for condensers having a high voltage resistance. Also provided is an oriented film obtained by orienting said propylene homopolymer. A propylene homopolymer for condensers satisfies the following requirements (i) to (v) and (ix)that : (i) the MFR is 1-10 g / 10 min; (ii)the mesopentad fraction (mmmm) measured by 13C-NMR is 0.940-0.995; (iii) the integrated elution amount measured by CFC at 90 DEG C is less than or equal to 0.5% by weight; (iv) the melting point measured by DSC is higher than or equal to 152 DEG C; (v) the chlorine content is less than or equal to 2 ppm by weight; and (ix) the peak half-width of eluted component amount to elution temperature measured by cross fractionation chromatography (CFC) with the use of o-dichlorobenzene is lower than or equal to 7.0 DEG C and the peak top temperature being 105-130 DEG C.

Owner:MITSUI CHEM INC +1

High-tension transformer

InactiveCN1497620AReduce distributed capacitanceReduce the numberTransformers/inductances coils/windings/connectionsFixed transformers or mutual inductancesBobbinEngineering

A high-voltage transformer includes a bobbin that holds a core at its center. This bobbin has eight winding grooves arrayed along the central axis of the core. A primary coil is wound around each of two outermost winding grooves with a predetermined number of turns. A secondary coil is wound around the six winding grooves near the center with a predetermined number of turns, which are distributed among these winding grooves. The cathode of a diode is connected through a terminal to one end of the secondary coil where the winding starts, while the anode of another diode is connected through another terminal to the other end of the secondary coil where winding ends.

Owner:MURATA MFG CO LTD

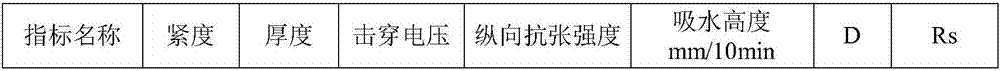

Method of preparing voltage-resistant electrolytic capacitor paper through in-machine coating

InactiveCN108004827AHigh strengthStrong water absorptionSpecial paperPulp beating methodsElectrolysisMass ratio

The invention relates to electrolytic capacitor paper and a preparation method thereof. Raw paper pulp of voltage-resistant electrolytic capacitor paper is composed of low-beating-degree sisal pulp and high-beating-degree sisal pulp according to a mass ratio of 20-40:80-60, beating degree of the low-beating-degree sisal pulp is 20-60 degrees SR while wet weight of the same is 2-16g, and beating degree of the high-beating-degree sisal pulp is 60-98 degrees SR while wet weight of the same is 2-10g; the raw paper pulp is formed and composited through the twin-cylinder net, coating liquid is coated on the surface of paper after pressing and drying, coating amount is 0.2-1.2g / m2, and the coating liquid is composed of nano cellulose and carboxy modified PVA according to a mass ratio of 4:3-1:10.The electrolytic capacitor paper has high strength, good water absorbing performance, low loss and excellent voltage resistance, and voltage resistance value is increased by more than 80V.

Owner:ZHEJIANG KAN SPECIAL PAPER CO LTD +1

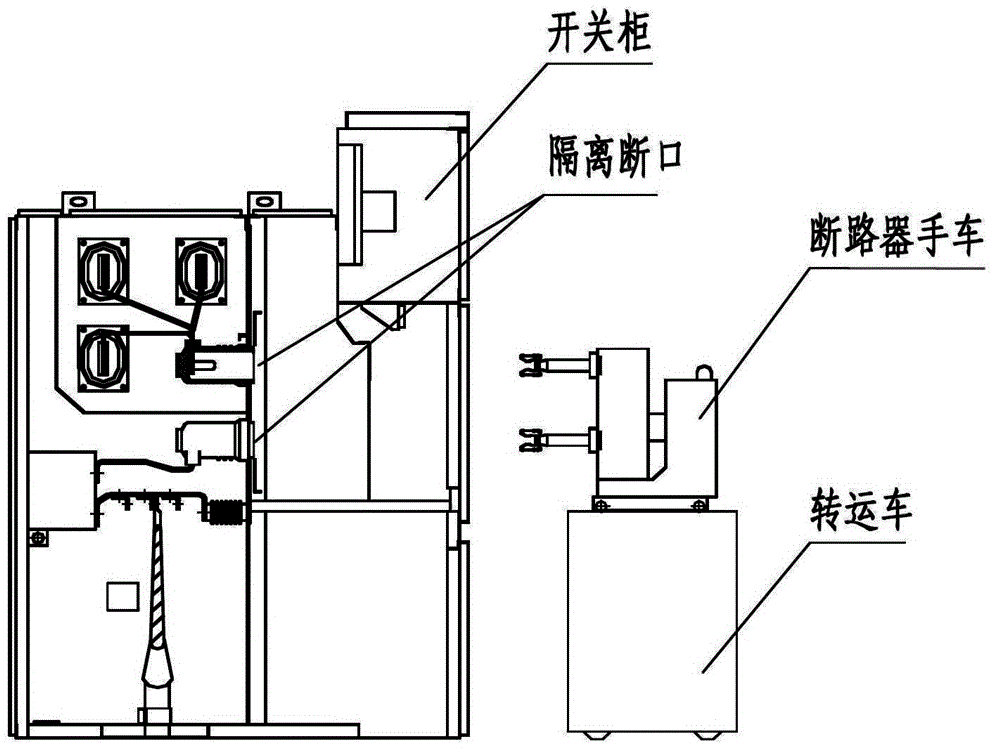

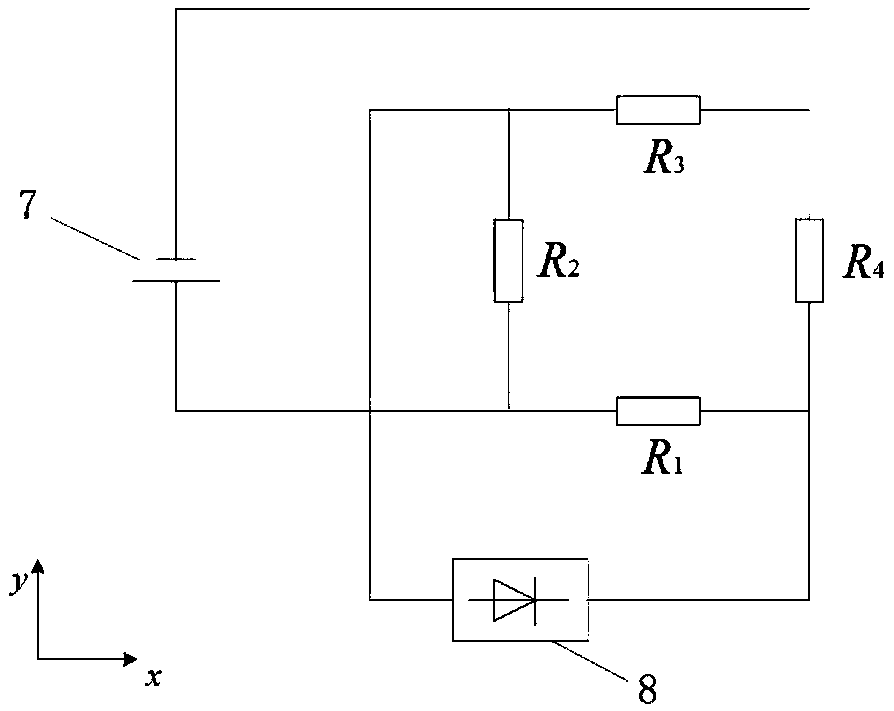

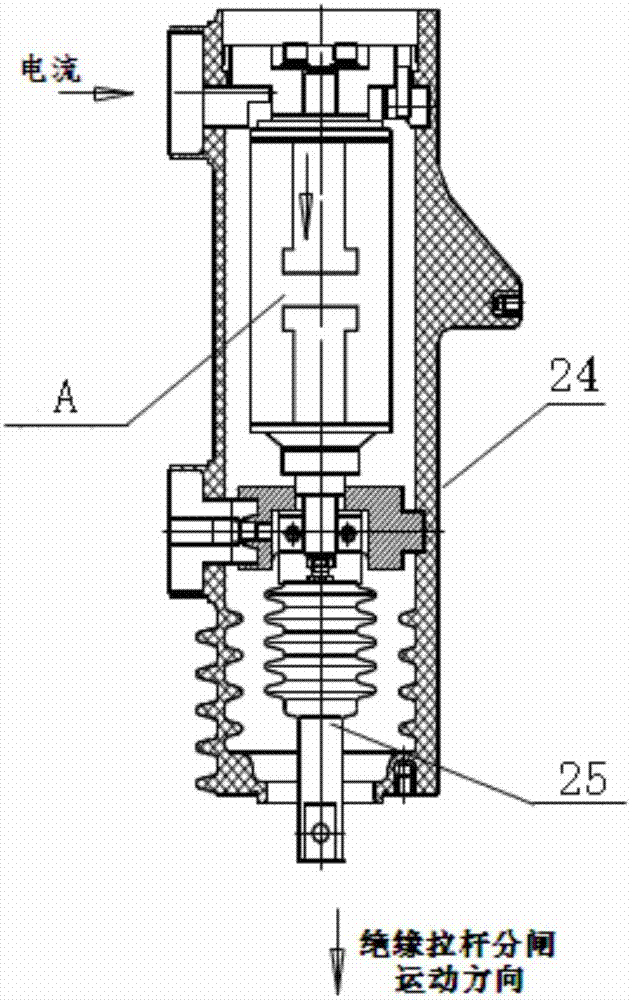

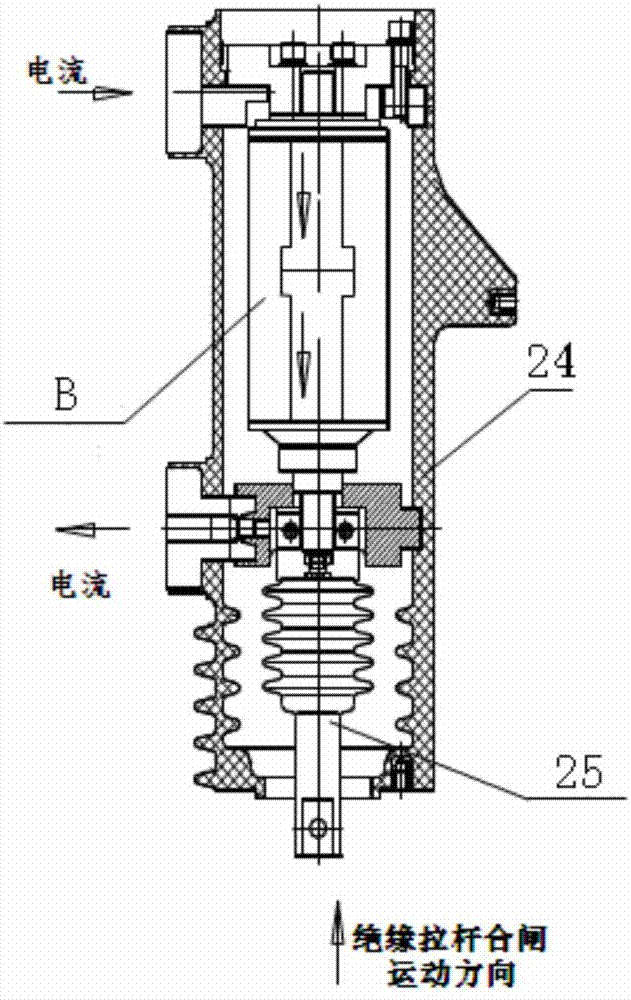

Ultra-high-speed mechanical switch

ActiveCN103578877ASimple structureImprove conductivitySwitch power arrangementsProtective switch operating/release mechanismsUltra high speedDc circuit breaker

The invention discloses an ultra-high-speed mechanical switch, and belongs to the technical field of high-voltage direct current transmission. The ultra-high-speed mechanical switch can be applied to + / -200kV mixed type high-voltage direct-current breakers. The ultra-high-speed mechanical switch comprises a composite insulating sleeve provided with a conductive rod, a basin-type insulator, an upper contact base, a lower contact base, a bridge-connection conductive rod, a composite wedge-shaped contact structure, a transversely-moving-type movable contact system, an insulating pull rod, a bottom tank, a bridge-connection tank, a vertical tank and an ultra-high-speed hydraulic spring operation mechanism. The ultra-high-speed mechanical switch has the advantages of being simple in structure, small in fracture number, high in mechanical reliability, high in withstand voltage, high in switching-on and switching-off operation action and good in synchronism, and can meet the matching requirements of the + / -200kV mixed type high-voltage direct-current breakers.

Owner:SHENYANG POLYTECHNIC UNIV

Waist-supported rotary pressure equalization with grounding shield High-voltage vacuum interrupter solid-sealed pole

ActiveCN104064397BImprove safety and reliabilitySimplify the layout processHigh-tension/heavy-dress switchesAir-break switchesThree-phaseEngineering

The invention relates to a lumbar rotary type pressure equalizing belt grounding shielding high-voltage vacuum interrupter solid-sealed pole, which is electrically connected to a high-voltage conductive circuit by a conductive seat, a vacuum interrupter, and a conductive cylinder, and is grounded with a coaxial cylindrical The shielding cylinder is integrally packaged with solid insulating material, and the two ends of the solid-sealed pole are equipped with rotating movable contact fingers, and the conductive cylinder is equipped with a sliding spring contact finger and a direct-acting disc spring cylinder combination rod. The solid-sealed pole is fixed for the lumbar support, and the wires enter and exit at both ends. Under the linear and rotary alternate driving of the four-station integrated operating mechanism of the high-voltage vacuum isolation circuit breaker, the vacuum interrupter in the solid-sealed pole can be opened or closed to realize the function of the circuit breaker, and it can also be positive and negative. The reverse 90° rotation enables the three-phase pole of the high-voltage vacuum isolation circuit breaker to realize the conversion between the working position and the isolation position, and realizes the function of the isolation switch. There are clearly visible double isolation fractures in the isolation position. The product design has the advantages of compact structure, small size, maintenance-free, multiple functions, and reliable operation.

Owner:广东维能电气有限公司

Voltage-resistant electrolyte-resistant termination adhesive tape and copolymer for termination adhesive tape

ActiveCN114057929AReduce polarityReduce movementNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerElectrolytic agent

The invention discloses a voltage-resistant electrolyte-resistant termination adhesive tape and a copolymer used for the termination adhesive tape. The structure of the copolymer is poly(octadecylacrylate / random 2-ethylhexyl acrylate / random 4-hydroxybutyl acrylate / random 4-((adamantan-1-ylcarbamoyl)oxy)butyl acrylate / random-N,N-dimethylacrylamide). According to the invention, 4-((adamantan-1-ylcarbamoyl)oxy)butyl acrylate is introduced into a side chain of a polyacrylate colloid, so the polarity of a polyacrylate molecular chain is effectively reduced, a free volume is increased, charge movement among molecules is reduced, and voltage resistance is improved; the copolymer is cross-linked with a hydroxyl-containing elastomer and a polyfunctional isocyanate curing agent to form an interpenetrating-polymer-network three-dimensional cross-linked structure, so an obtained adhesive maintains the same good adhesive force as a polyacrylate system and also shows excellent voltage resistance and electrolyte resistance; and the termination adhesive tape prepared from the adhesive can be suitable for high-energy-density lithium ion batteries.

Owner:佛山市顺德区永创翔亿电子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com