Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

153results about How to "Improve thermal deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

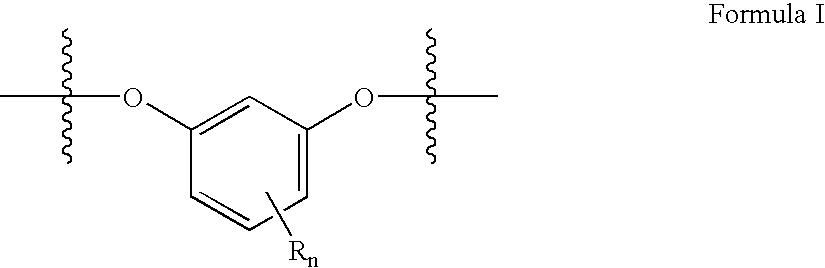

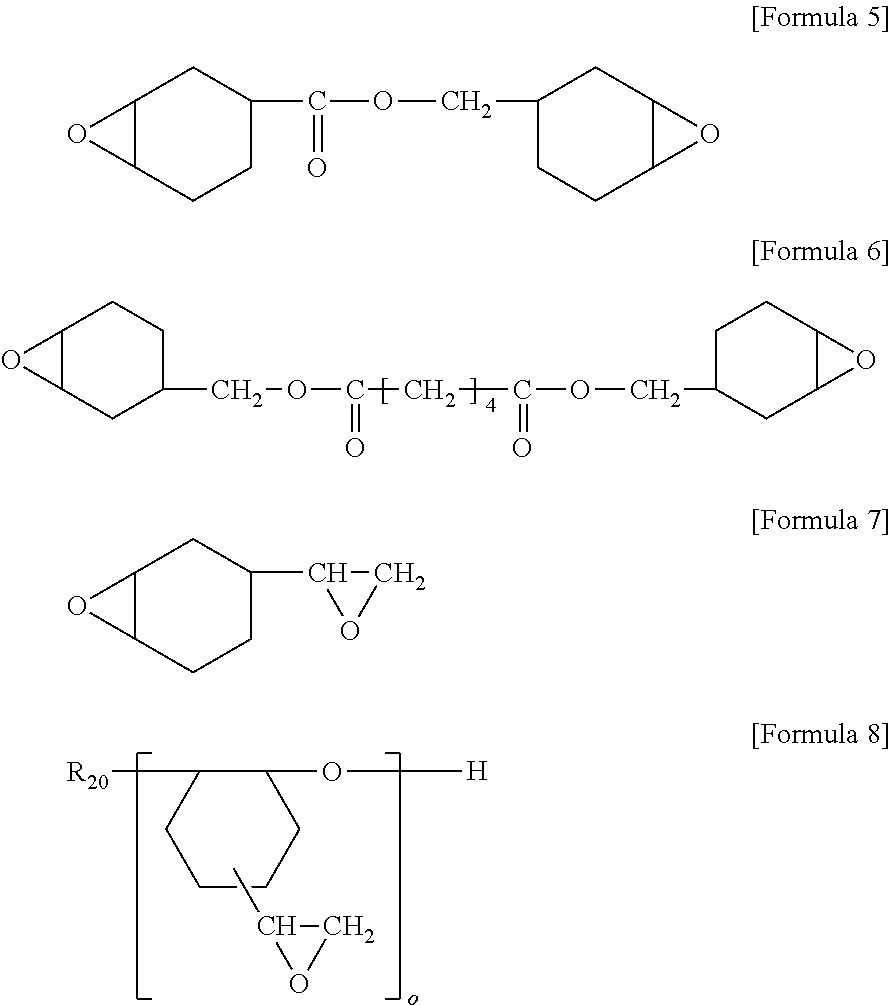

Stereolithographic resins with high temperature and high impact resistance

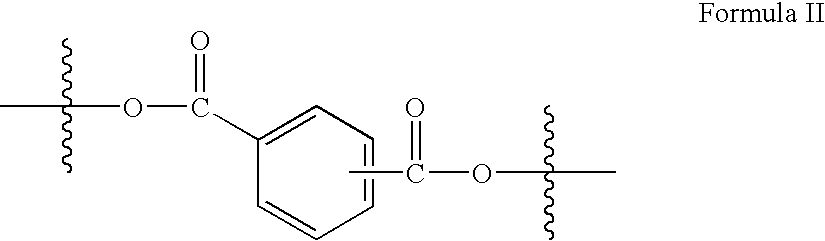

InactiveUS6989225B2High modulusHigh elongation at breakAdditive manufacturing apparatusImpression capsMeth-Cationic polymerization

A liquid radiation-curable composition that comprises(A) at least one polymerizing organic substance comprising a mixture of(1) at least one alicyclic epoxide having at least two epoxy groups; and(2) at least one difunctional or higher functional glycidylether of a polyhydric compound;(B) at least one free-radical polymerizing organic substance comprising a mixture of(1) optionally, at least one trifunctional or higher functional (meth)acrylate compound; and(2) at least one aromatic di(meth)acrylate compound;(C) at least one cationic polymerization initiator;(D) at least one free-radical polymerization initiator;(E) optionally, at least one hydroxyl-functional aliphatic compound; and(F) at least one hydroxyl-functional aromatic compound;wherein the concentration of hydroxyl groups in the radiation-curable composition is at least about 1.1 equivalent OH groups per kilogram;wherein the concentration of epoxy groups in the radiation-curable composition is at least about 5.5 equivalent epoxy groups per kilogram; andwherein the amount of trifunctional or higher functional (meth)acrylate compound (B)(1) is from 0% to about 3% of the composition and the amount of aromatic di(meth)acrylate compound (B)(2) is at least 10% of the composition.

Owner:3D SYST INC

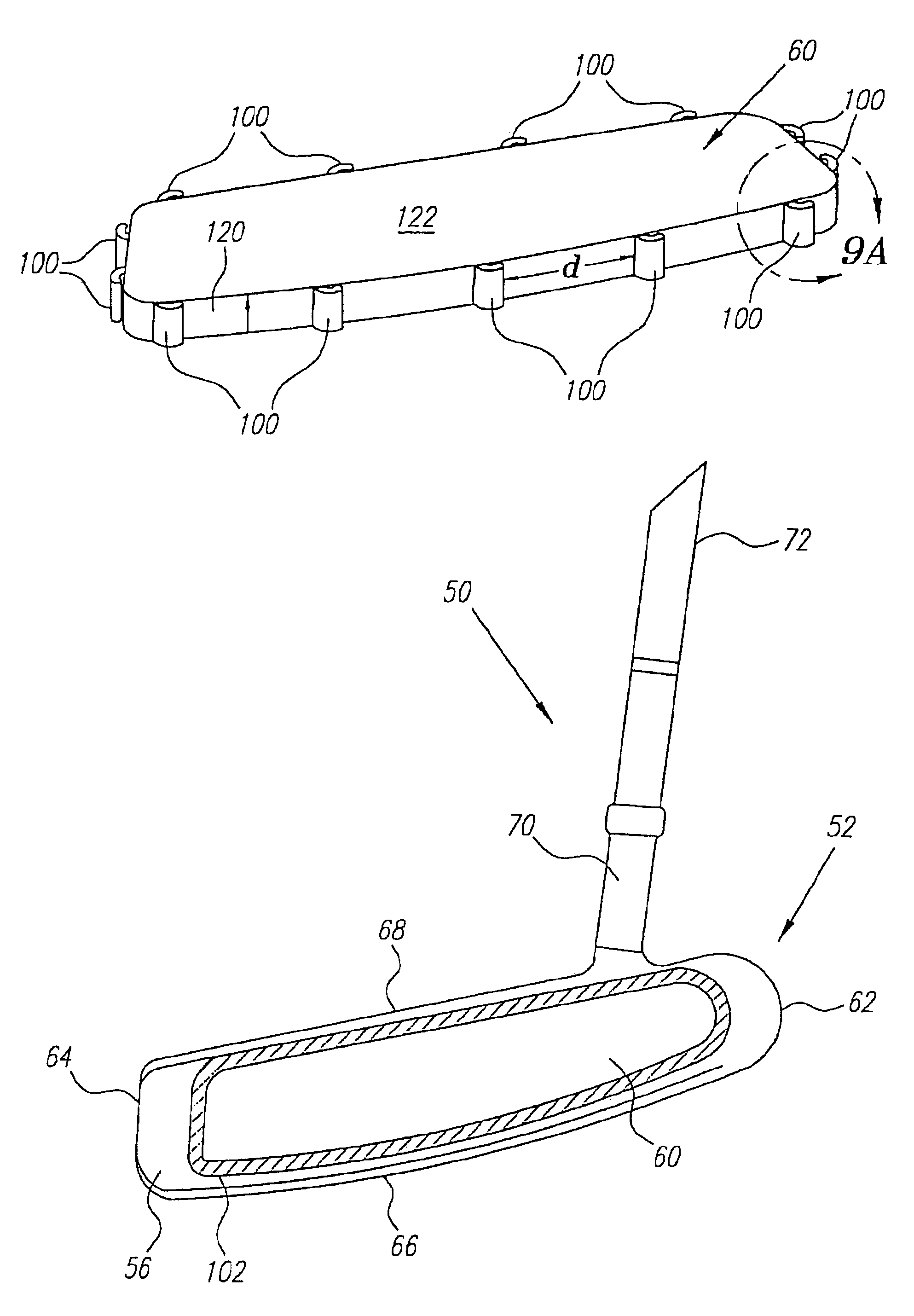

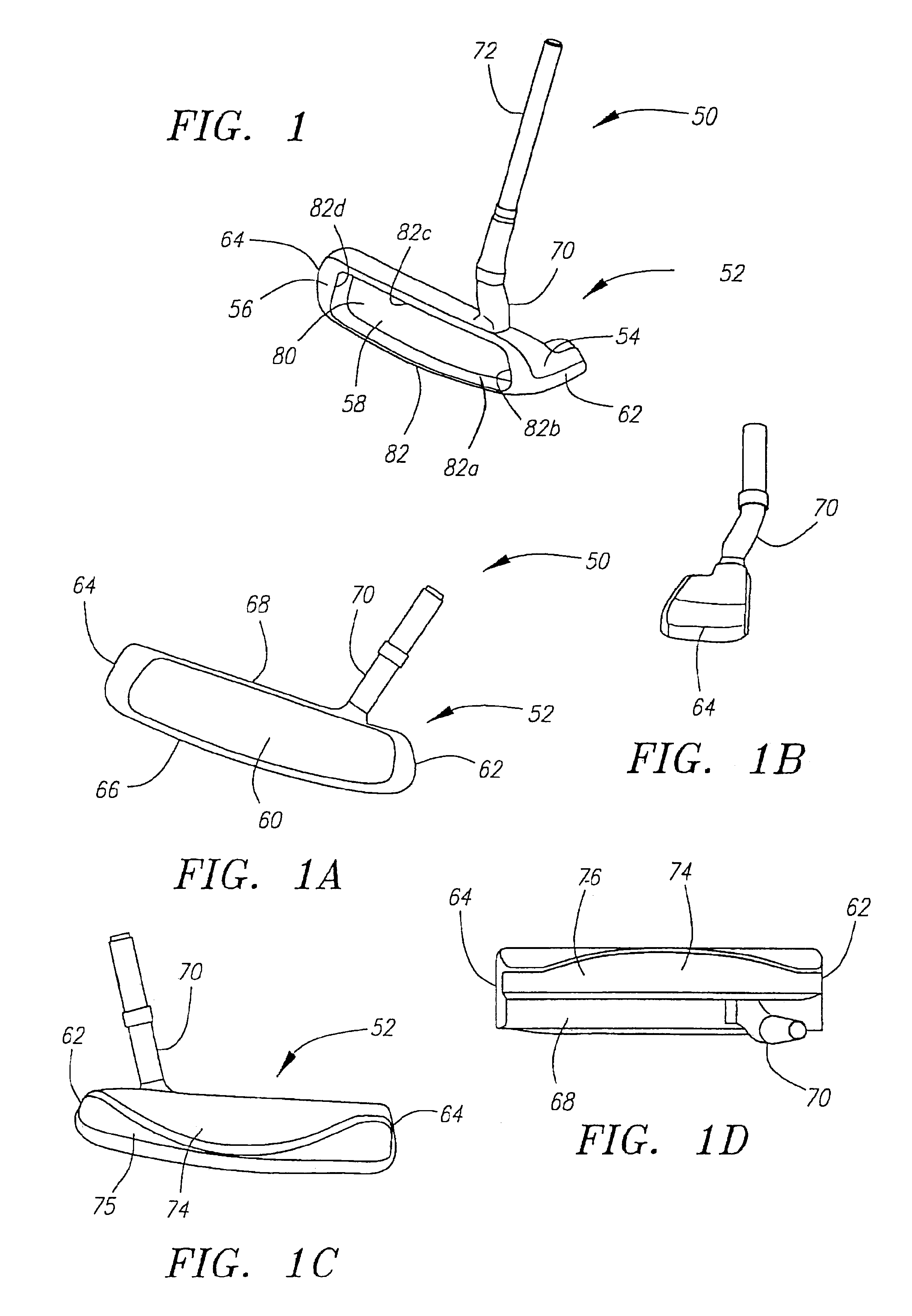

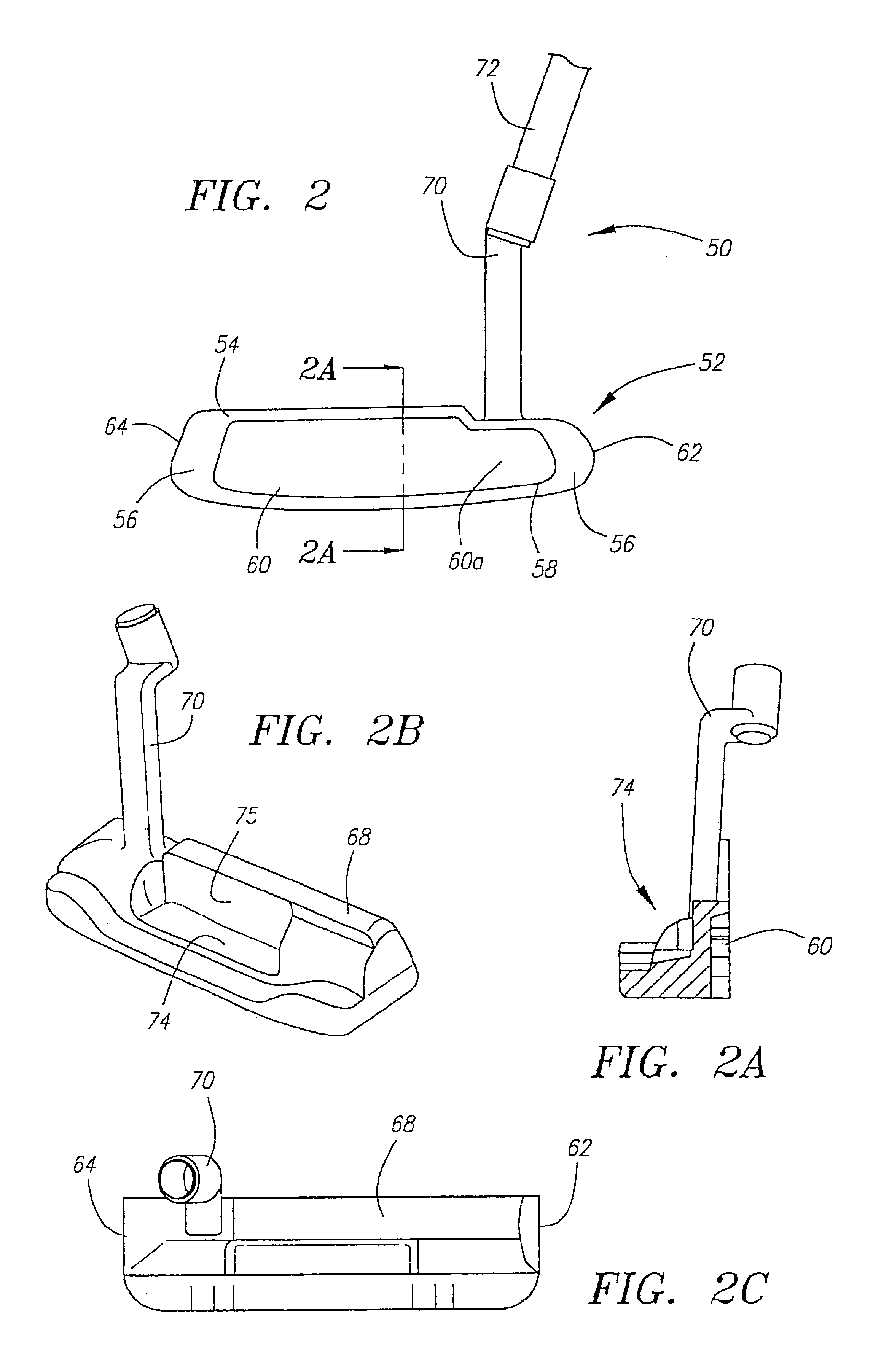

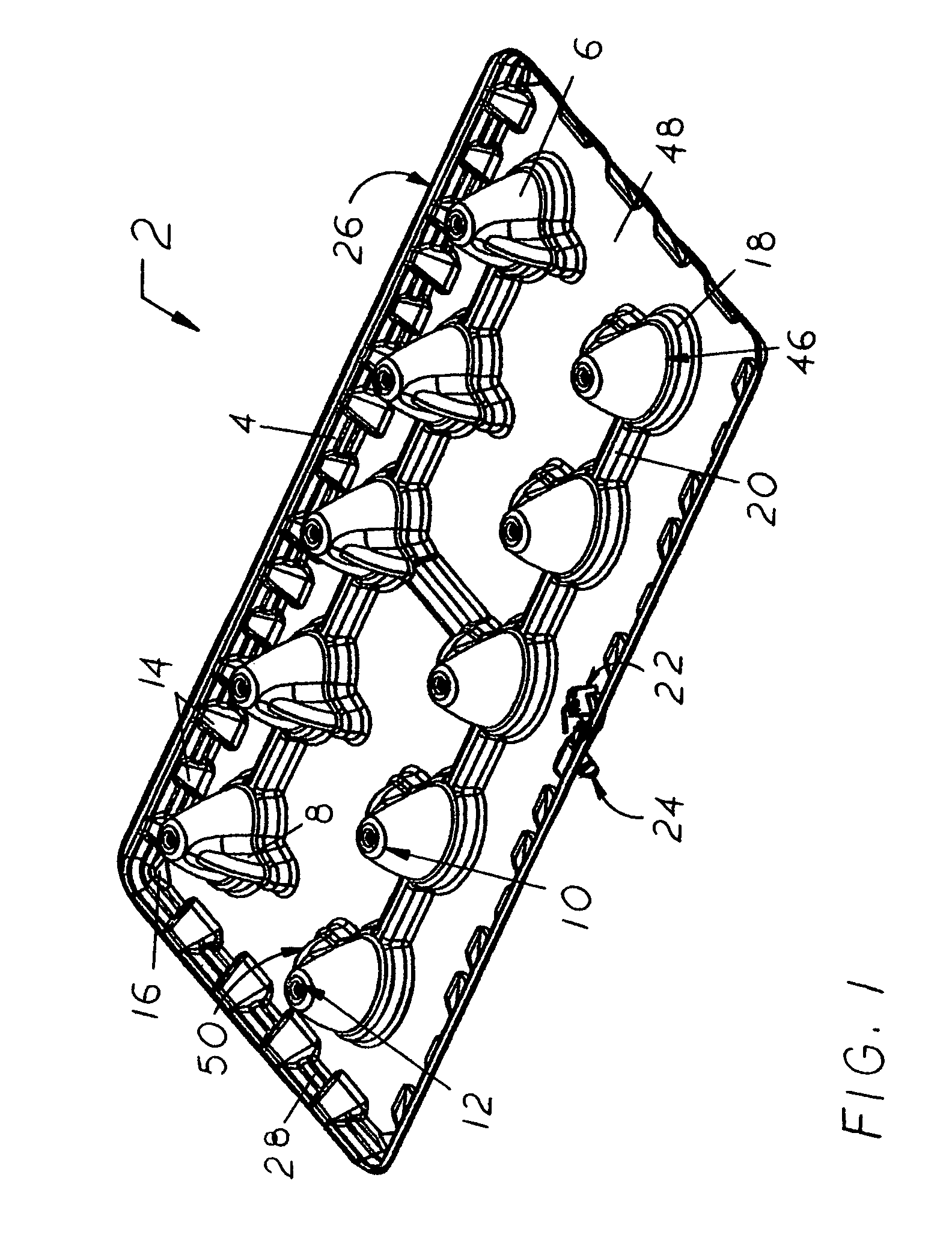

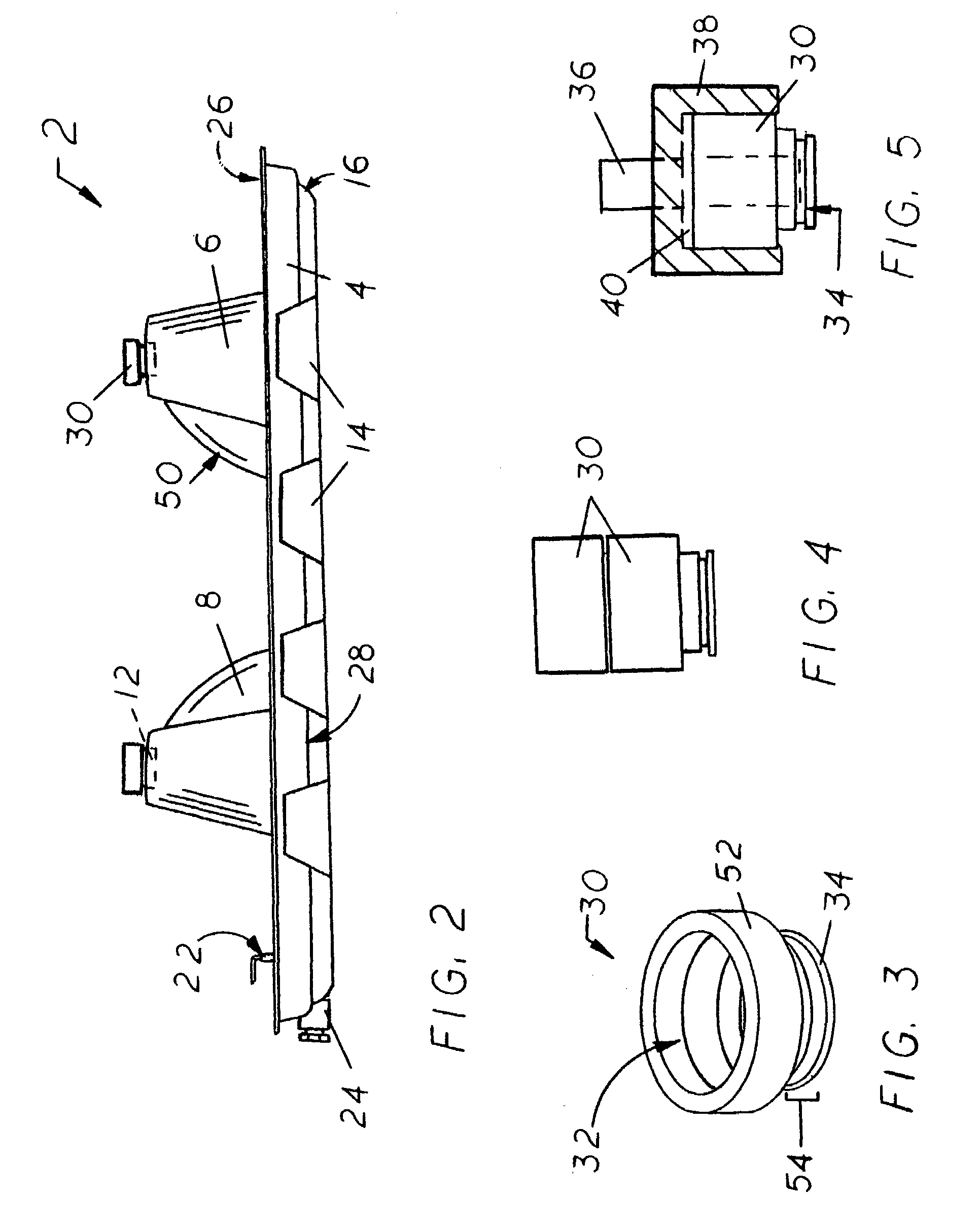

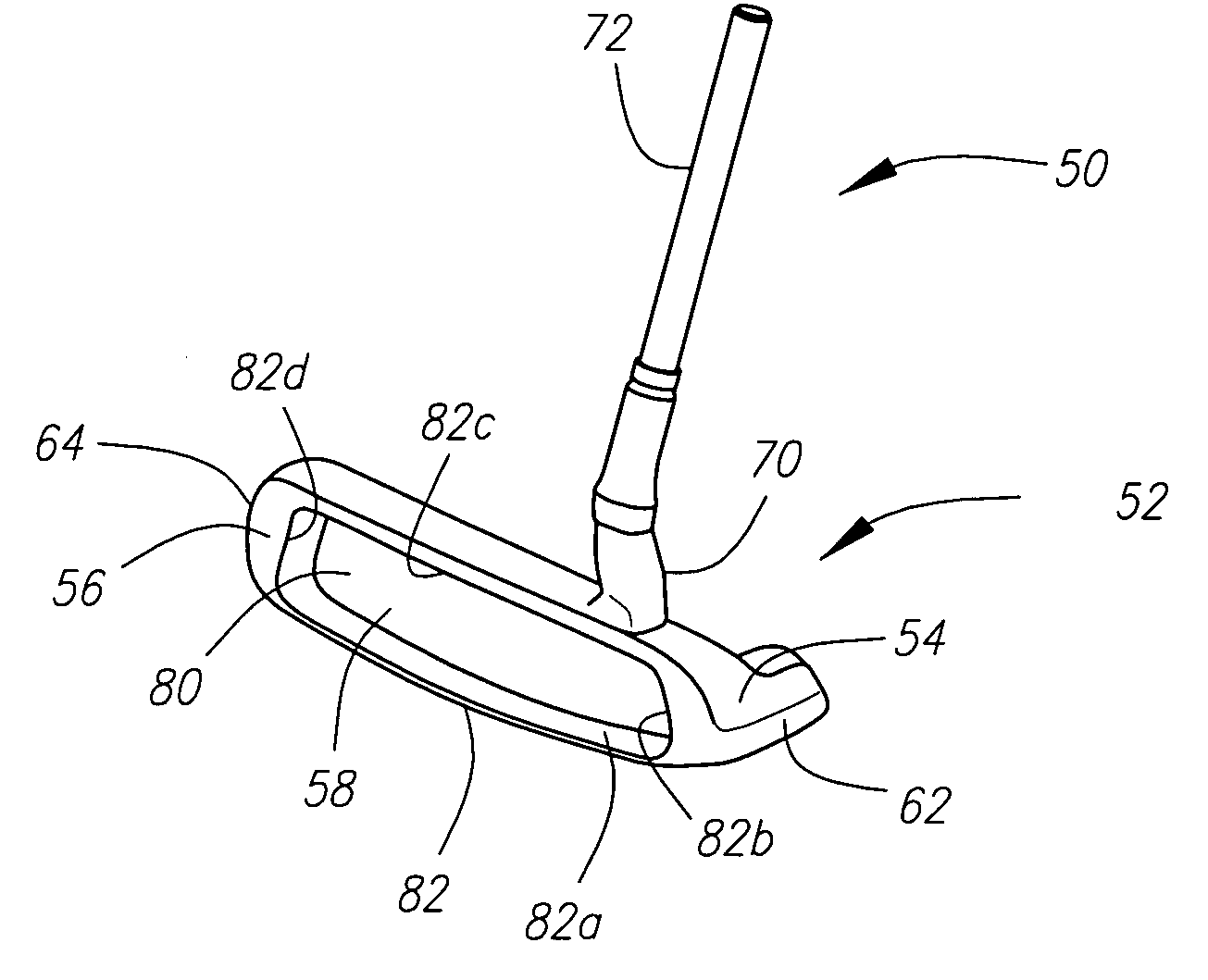

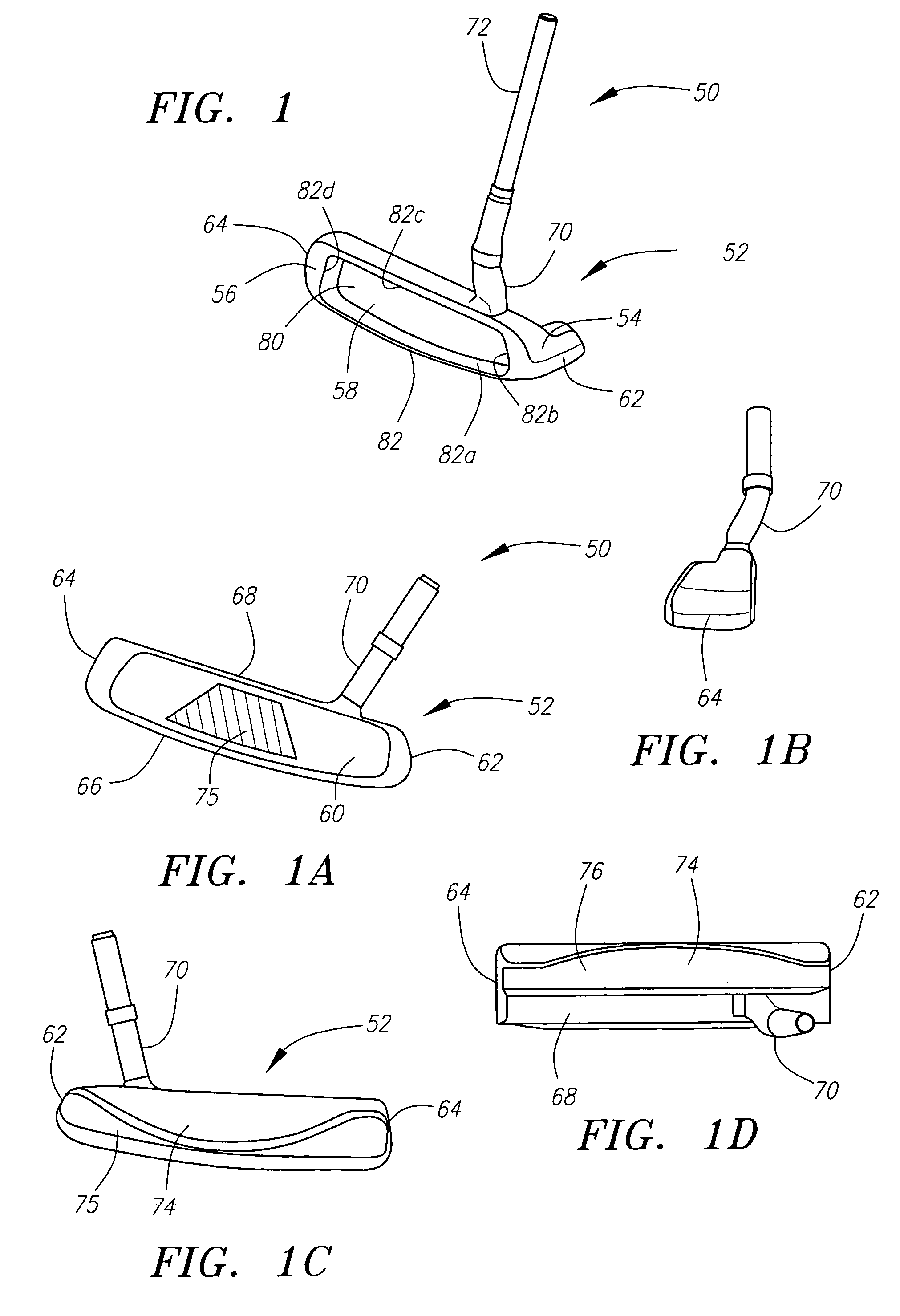

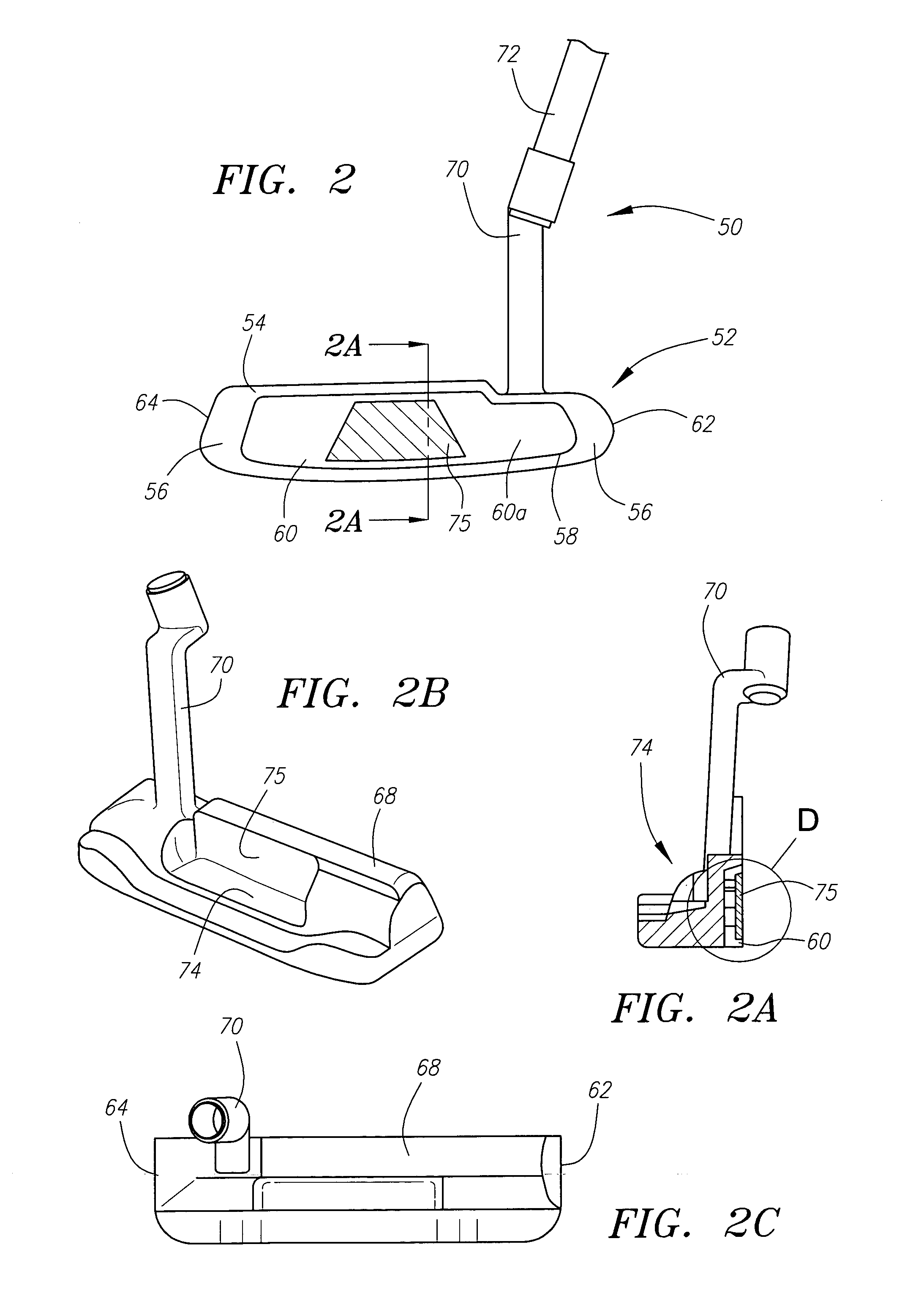

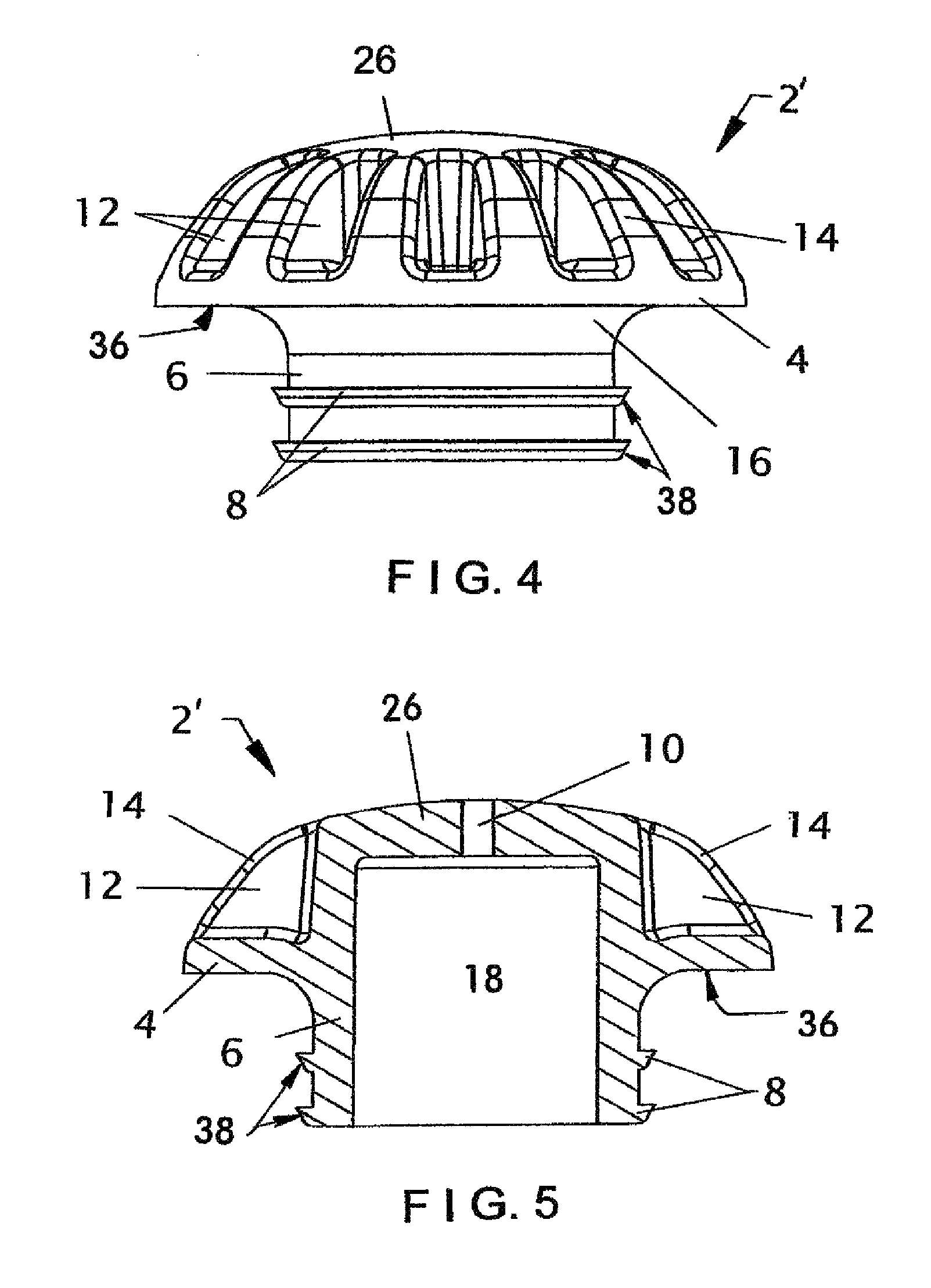

Insert for golf club head

InactiveUS6971960B2Easy to manufactureImprove thermal deformationGolf clubsAdhesiveThermoplastic polyurethane

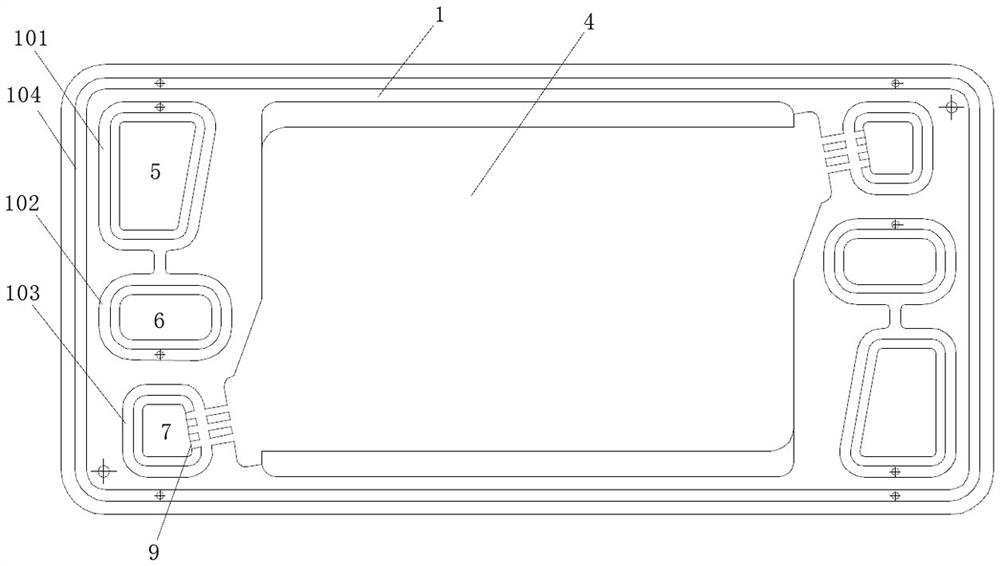

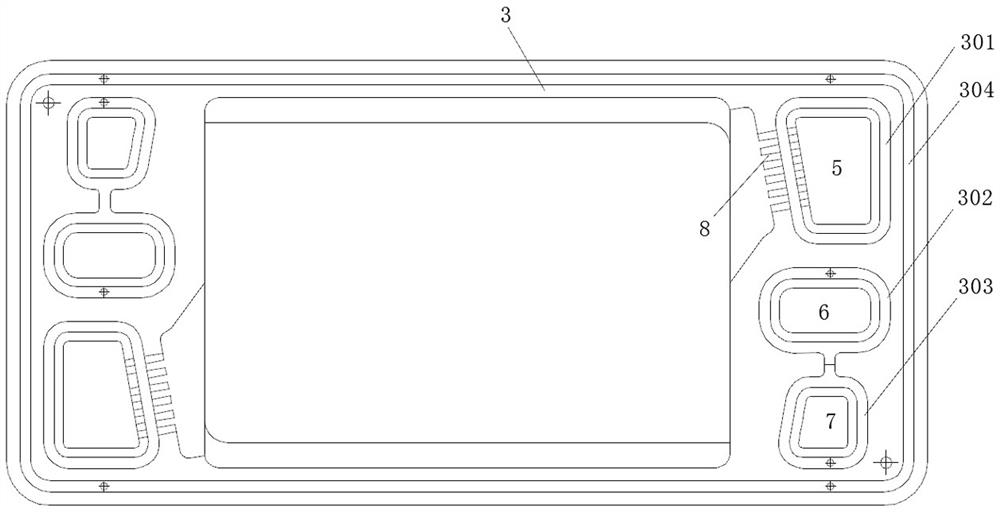

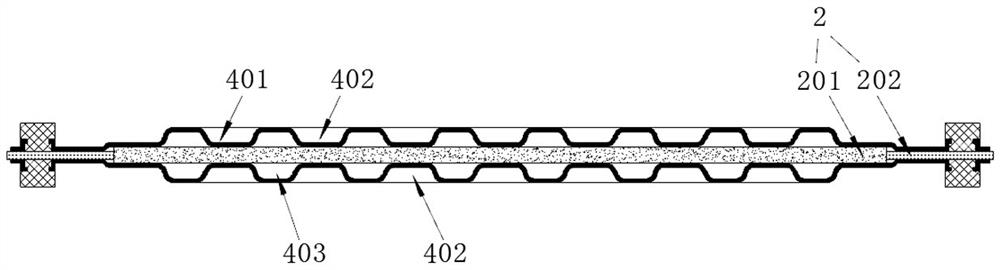

An insert composed of a thermoplastic polyurethane materials is disclosed herein. The thermoplastic polyurethane insert is disposed in a recess of the club head in which the recess has a depth that is greater than the thickness of the insert. The thermoplastic polyurethane insert preferably has a plurality of tabs on its perimeter to engage the recess walls to allow the insert to essentially float within the recess. An adhesive is disposed between the rear wall of the recess and an interior surface of the insert. Further, an adhesive is applied between the plurality of tabs, and preferably over the exterior surface of each of the plurality of tabs.

Owner:TOPGOLF CALLAWAY BRANDS CORP

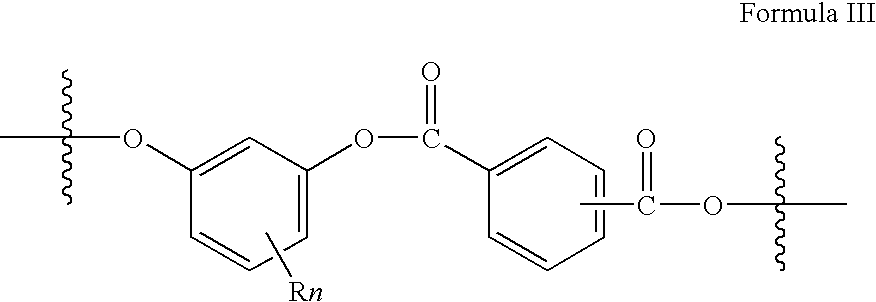

Release agent for transparent polymide blends

Compositions made from a polyarylate or polyester carbonate containing greater than about 50 mole % resorcinol based ester linkages give miscible blends with polyimide resins, addition of alkyl amide compounds improves mold release and melt flow while maintaining transparency. The blends also have high refractive index and low haze.

Owner:SHPP GLOBAL TECH BV

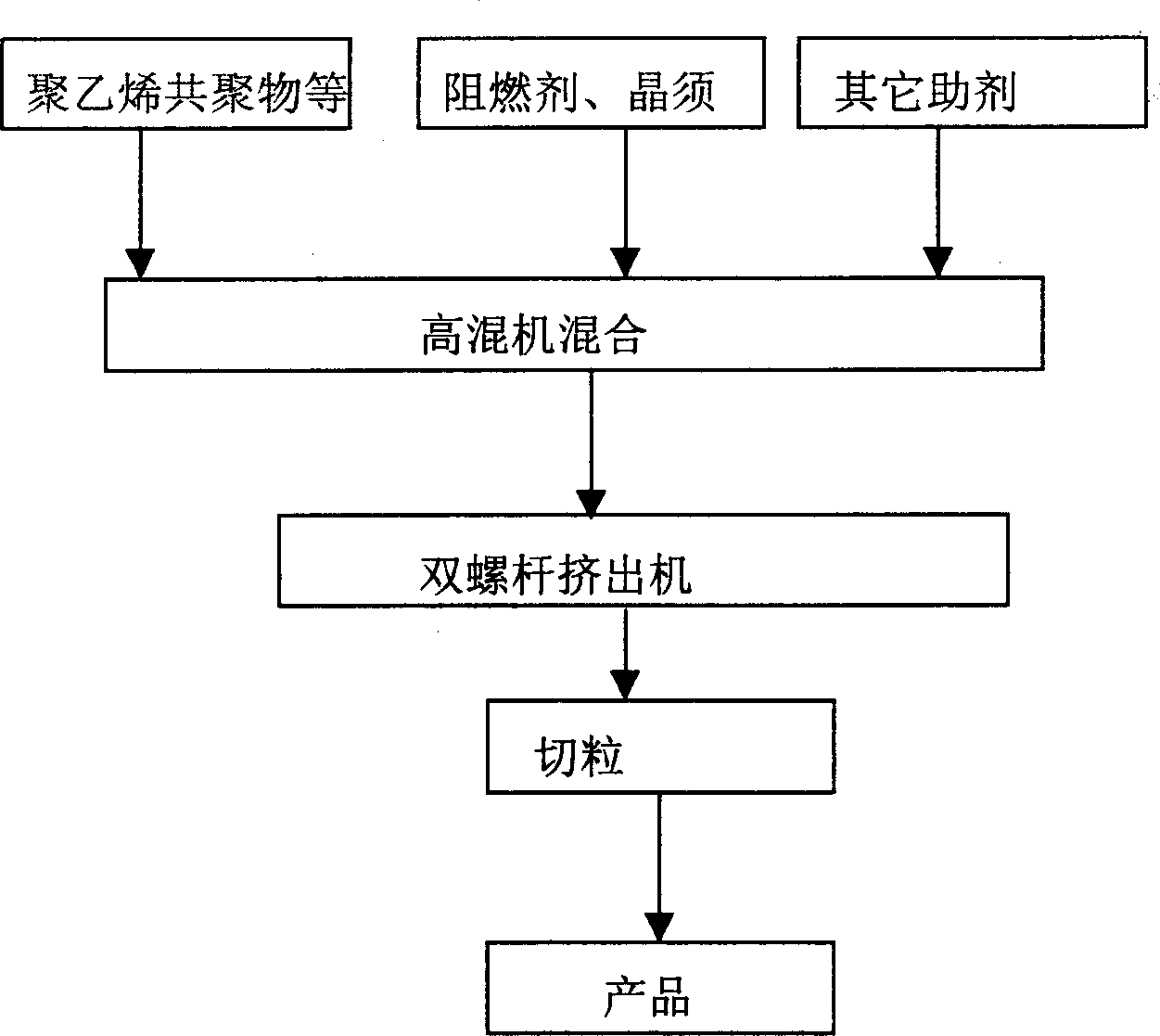

Thermoplastic non-halogen low fume fire resistant cable isolation material and processing tech. thereof

InactiveCN1787120AGood mechanical propertiesExcellent processing performanceRubber insulatorsPlastic/resin/waxes insulatorsInorganic crystalsMagnesium

The invention relates to a formula design for a thermoplastic halogen-free low-smoke flame-retardant cable insulating material and the manufacturing process thereof, concretely, using polyethene copolymer and / or modified ethylene-propylene rubber as a substrate, adding in halogen-free and nontoxic flame-retardant agent (nano magnesium hydroxide or aluminum hydroxide) and inorganic crystal whisker strengthening material as primary components, and adding in proper assistant, proportioning, mixing, plasticizing and making grains to make the insulating material. Its technical characters: not containing halogen, P, Al and other heavy metals; having god mechanical property, machining property and superior flame retardancy and having excellent thermal deforming, thermal ageing and thermal shock properties. The made cables have high safety and reliability. It is applied to the cables operating at 70 deg.C-105 deg.C long time, such as ship cables, cables for nuclear power plants, power and control cables for high-rise buildings, etc.

Owner:大连圣迈化学有限公司

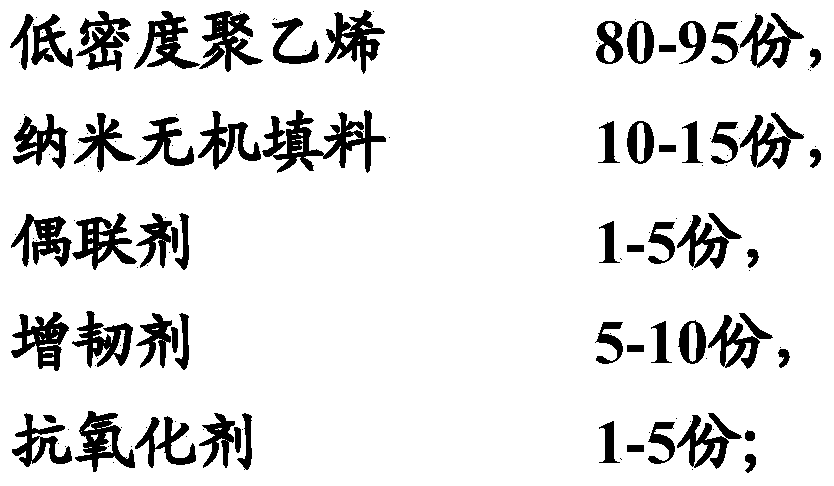

Modified low density polyethylene nanocomposite material used for 3D printing, and preparation method thereof

ActiveCN103992548AStay specialImprove thermodynamic performanceLow-density polyethyleneHeat resistance

A modified low density polyethylene material used for 3D printing comprises, by weight, 80-95 parts of low density polyethylene, 1-10 parts of an inorganic nanoparticle filler, 1-5 parts of a coupling agent, 5-10 parts of a flexibilizer, and 1-5 parts of an antioxidant. The modified low density polyethylene material has the advantages of very good fusion viscosity, very good fluidity, very good heat resistance and very good wear resistance, accords with the characteristics a 3D printing material, and has a wide application prospect in the 3D printing technology.

Owner:INST OF CHEM CHINESE ACAD OF SCI

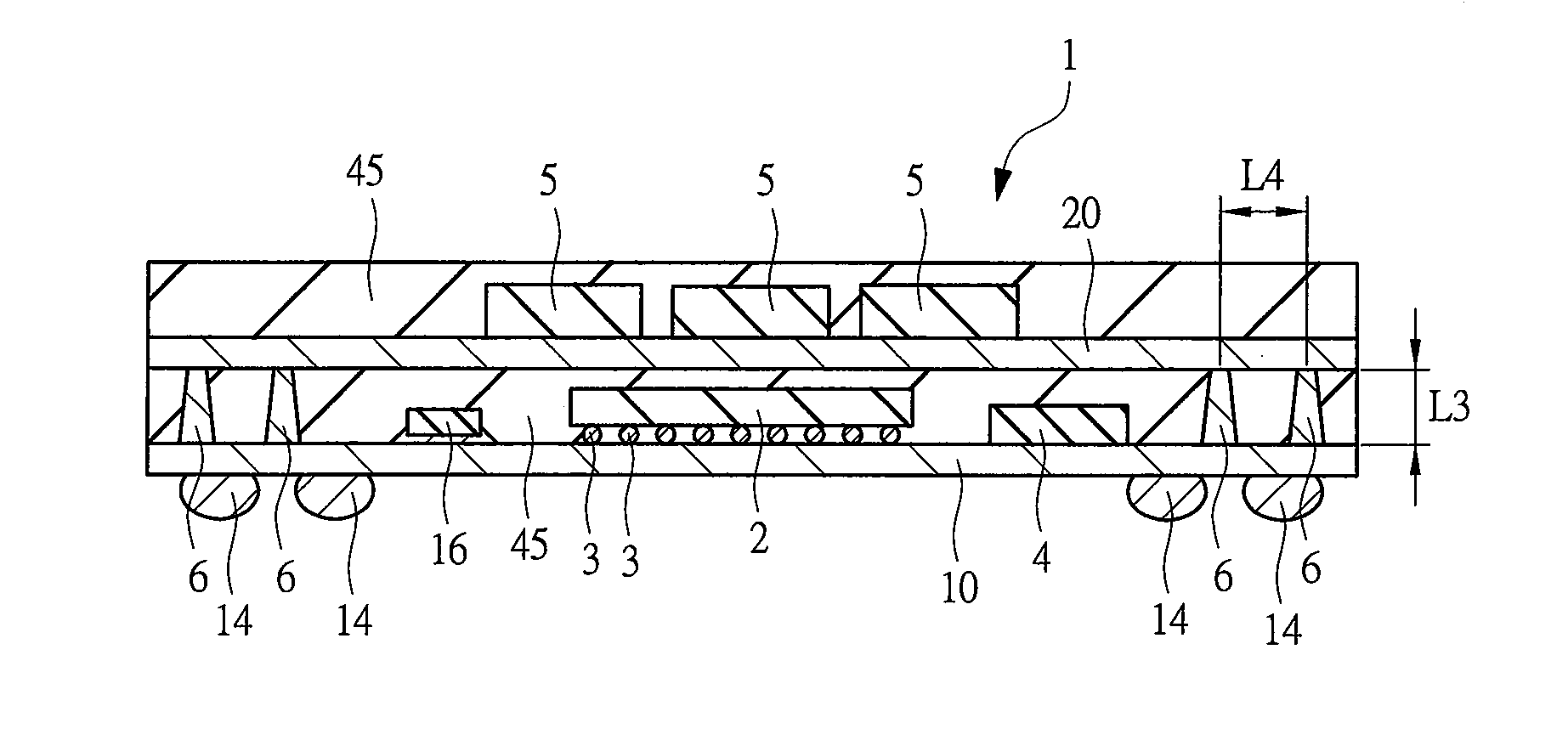

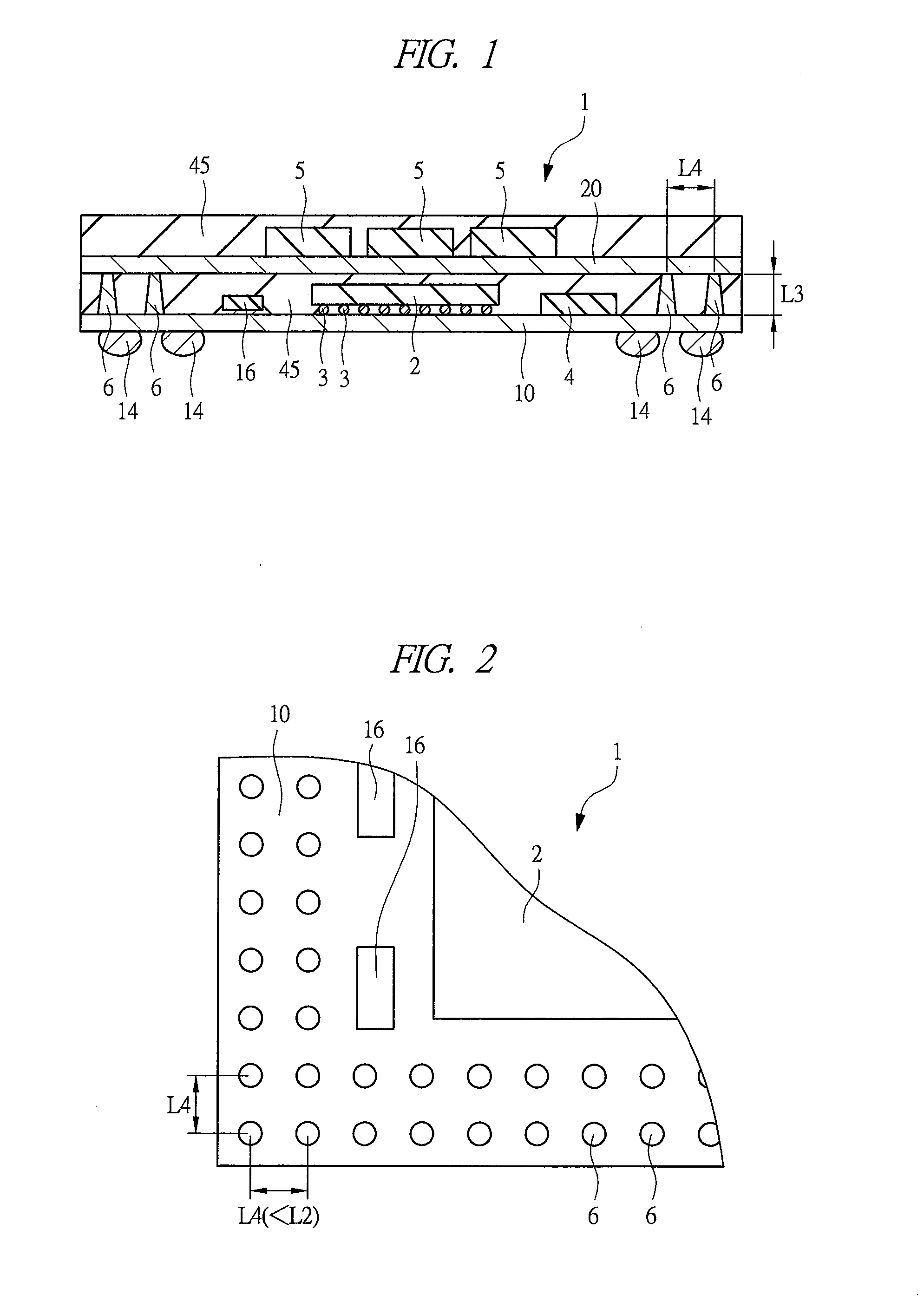

Semiconductor device and method of manufacturing the same

ActiveUS20110128713A1Downsizing and thinningLower Reliability RequirementsSemiconductor/solid-state device detailsPrinted circuit aspectsElectrical connectionSolder ball

In a semiconductor device in which a plurality of wiring substrates each mounting an electronic component are stacked and sealed by a resin, the semiconductor device can be downsized, thinned, and highly reliable, and its manufacturing cost can be reduced. By using a metal paste for electrical connection between the stacked lower-layer side wiring substrate and upper-layer side wiring substrate, a connecting pitch can be smaller than that in a connecting method of using a solder ball including Cu core, and the connection at low temperature can be achieved. Also, by coating a metal paste by a print-coating method or a dispense-coating method, manufacturing steps are simplified, so that the manufacturing cost is reduced.

Owner:RENESAS ELECTRONICS CORP

Honing strip and manufacturing method thereof

The invention provides a honing strip and a manufacturing method thereof. The method comprises the following steps of: mixing first metal powder prepared from components in a predetermined proportion and nonmetal powder such as graphite, Fe3O4 or MoS2 to form a bonding agent, adding a predetermined amount of abrasive such as diamond or cubic boron nitride (CBN for short) into the bonding agent, and performing granulation to obtain working layer granules; performing granulation on second metal powder to obtain transition layer granules; arranging the working layer granules in a first die to form a working layer of the honing strip, arranging the transition layer granules in the first die and on the working layer to form a transition layer, and pressing the first die to form a preformed honing strip; and charging the preformed honing strip into a second die, and performing hot pressing forming to obtain the honing strip. The honing strip has the characteristics of good exposure effect, low grinding resistance, low heating deformation of a honing head, long durability, high precision of machined workpieces, good finishment and the like.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

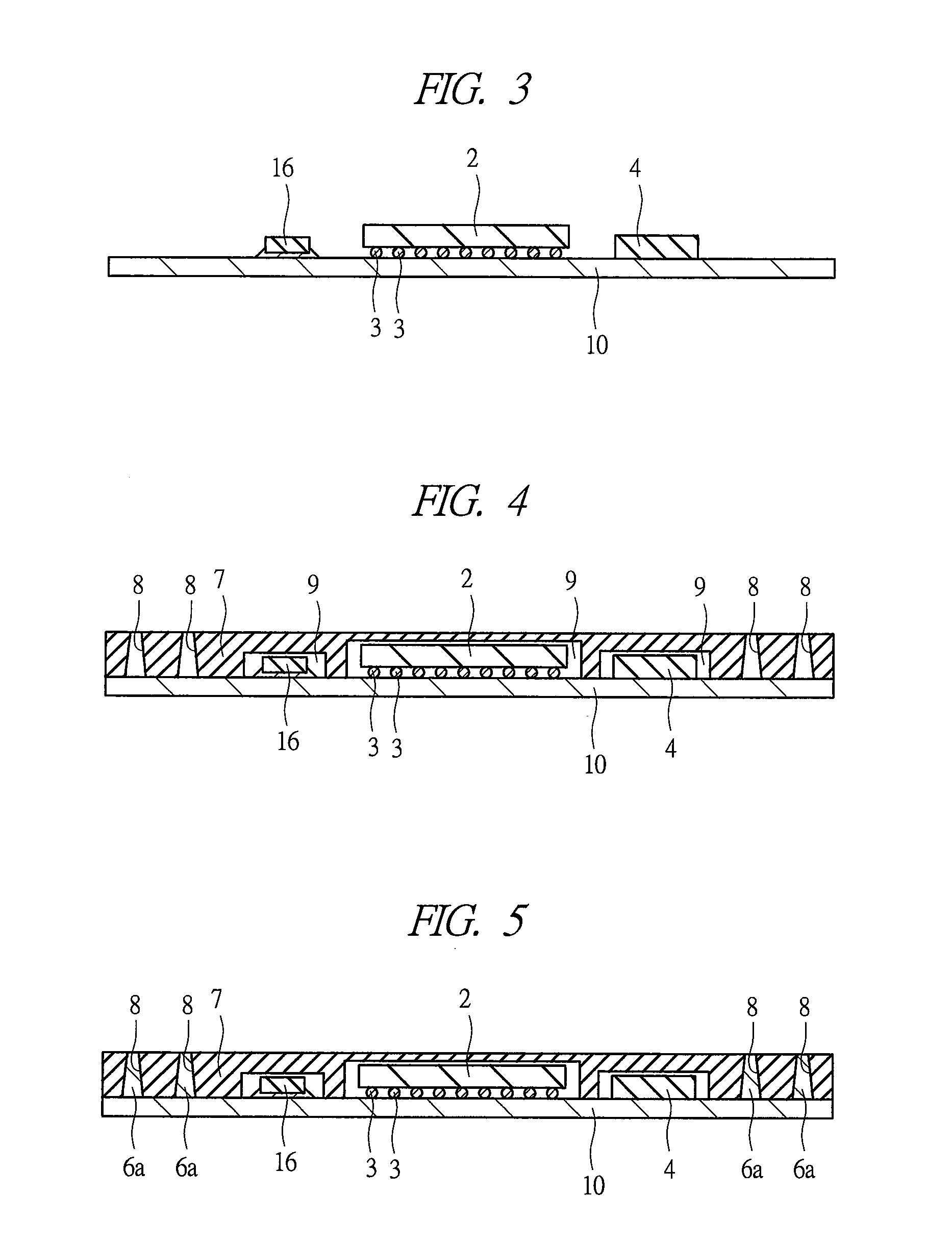

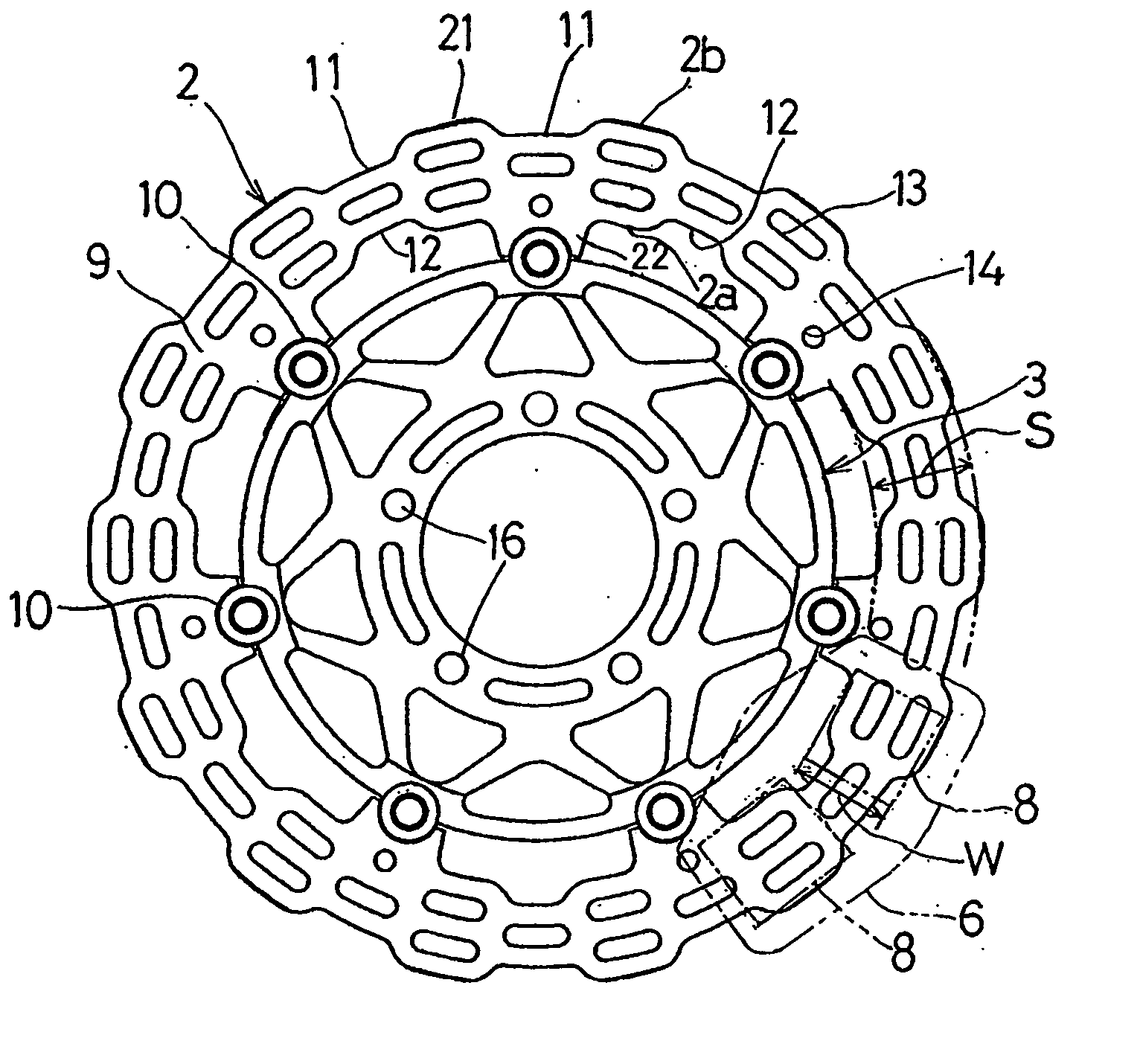

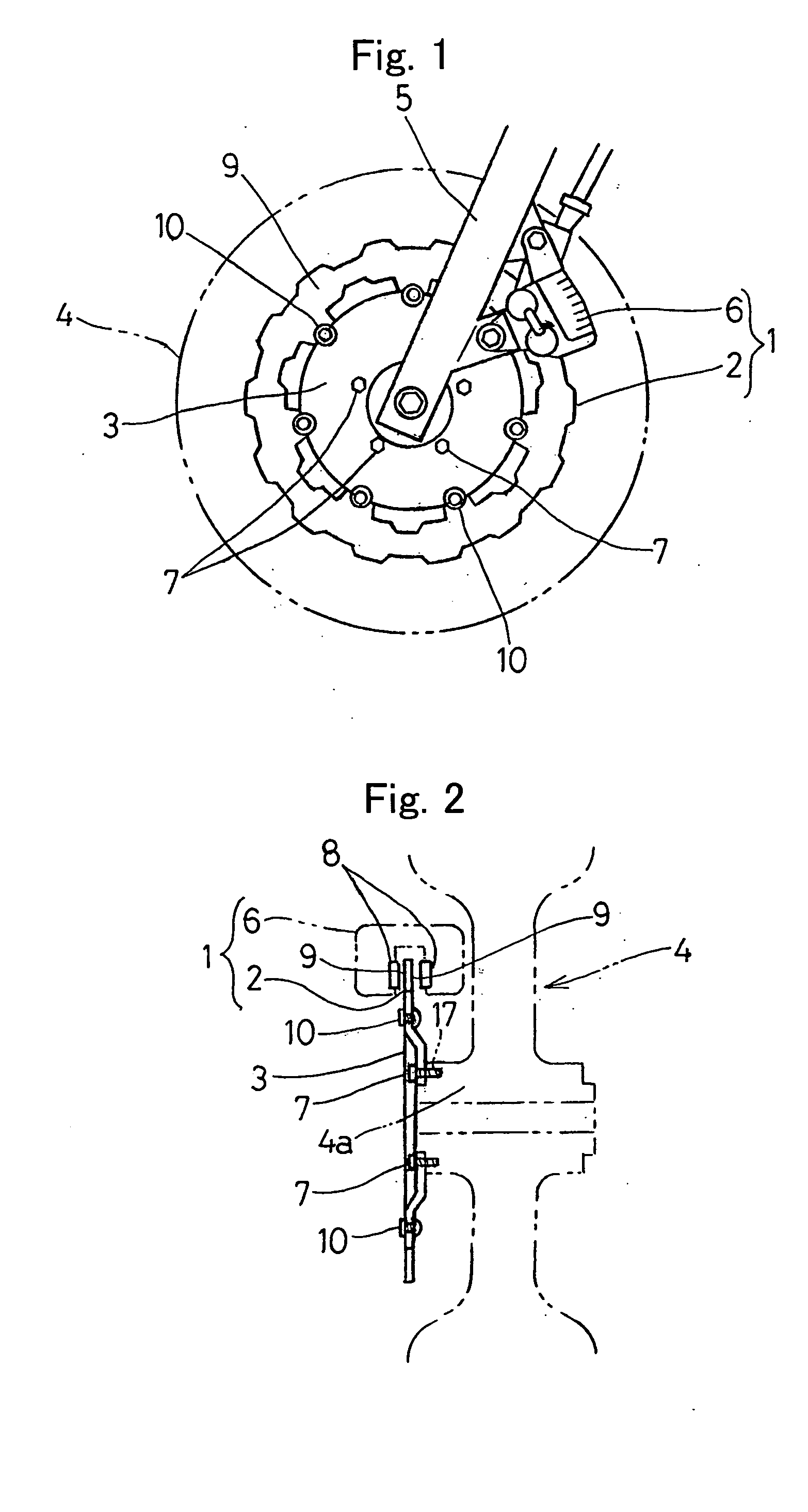

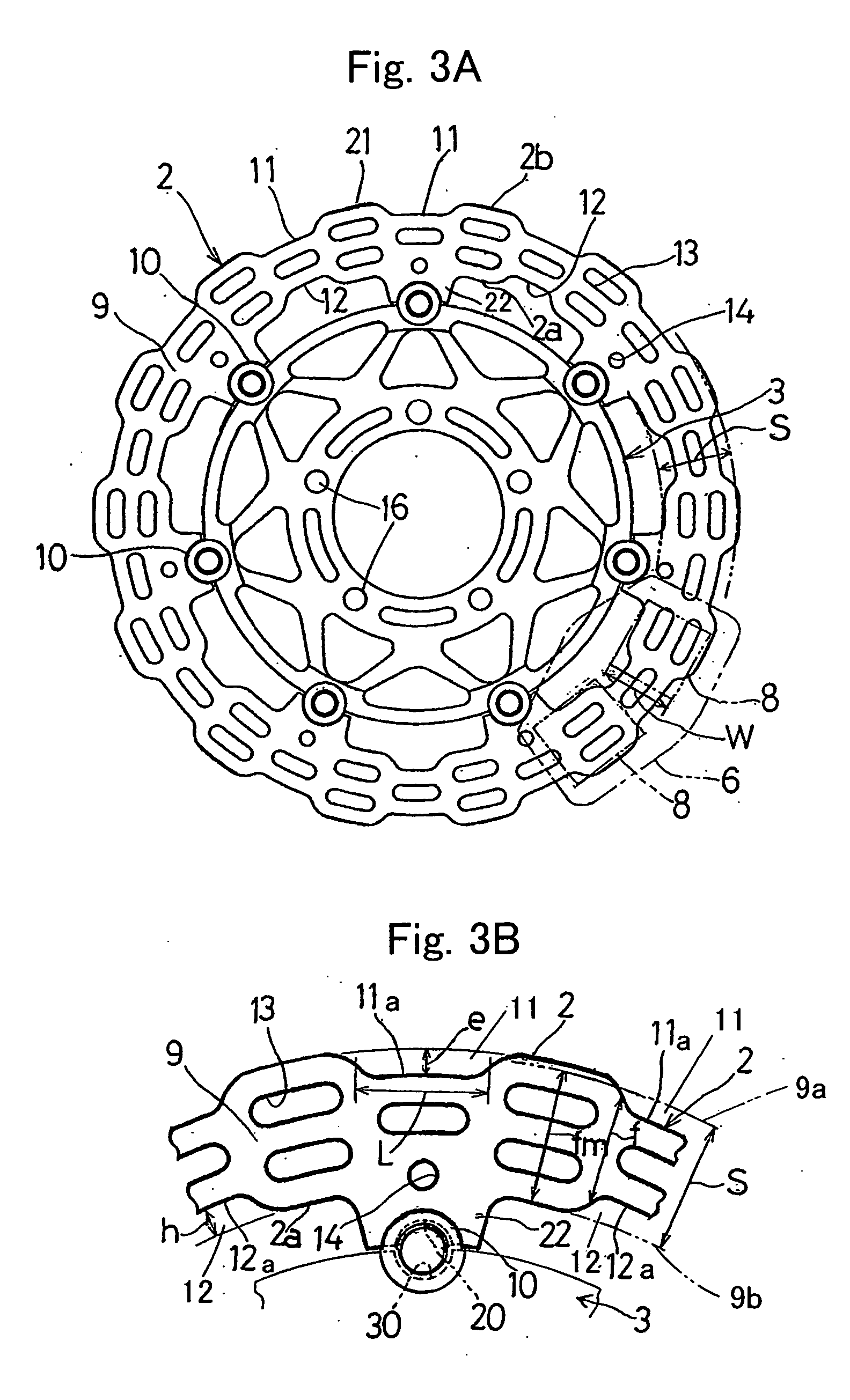

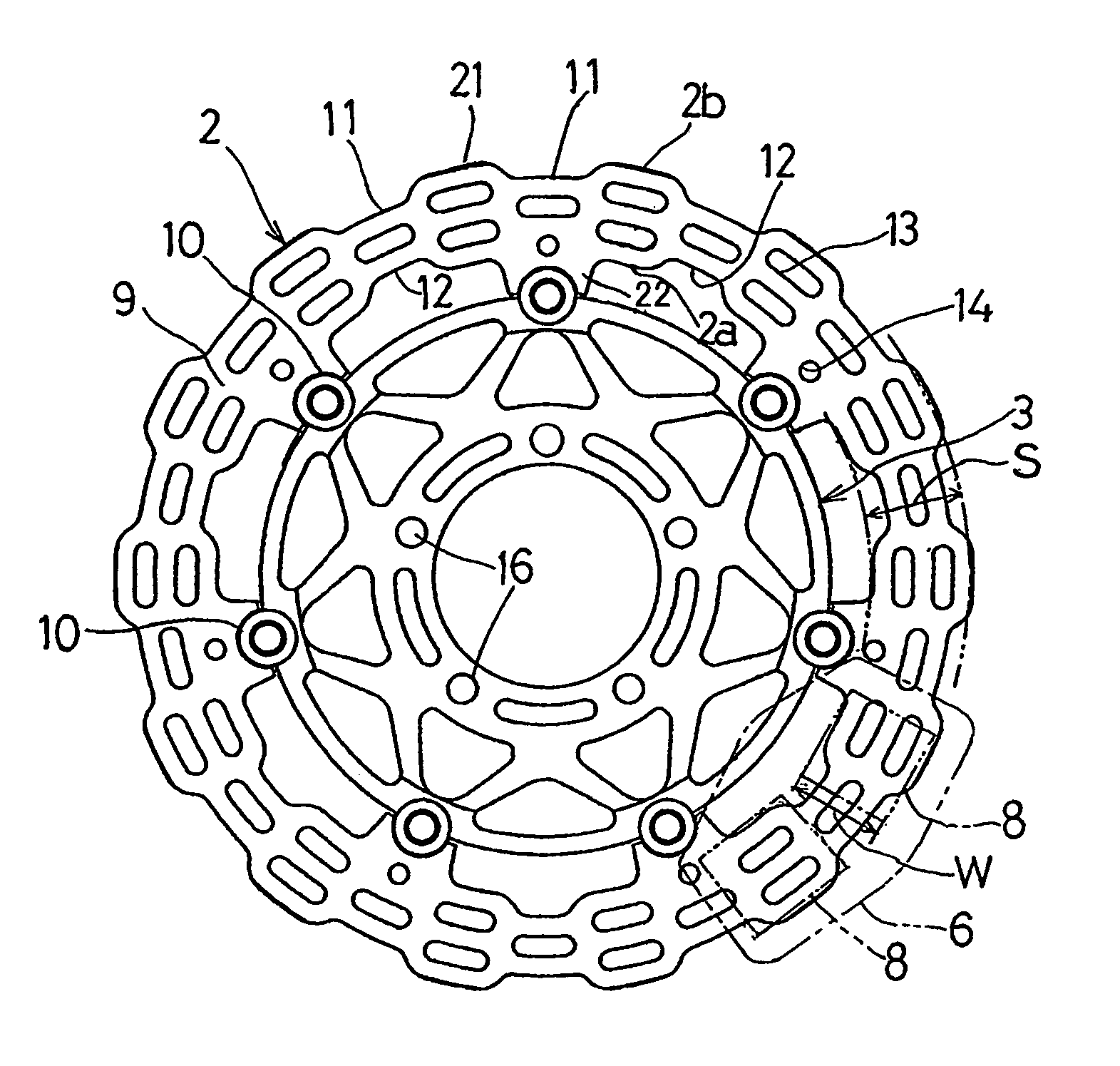

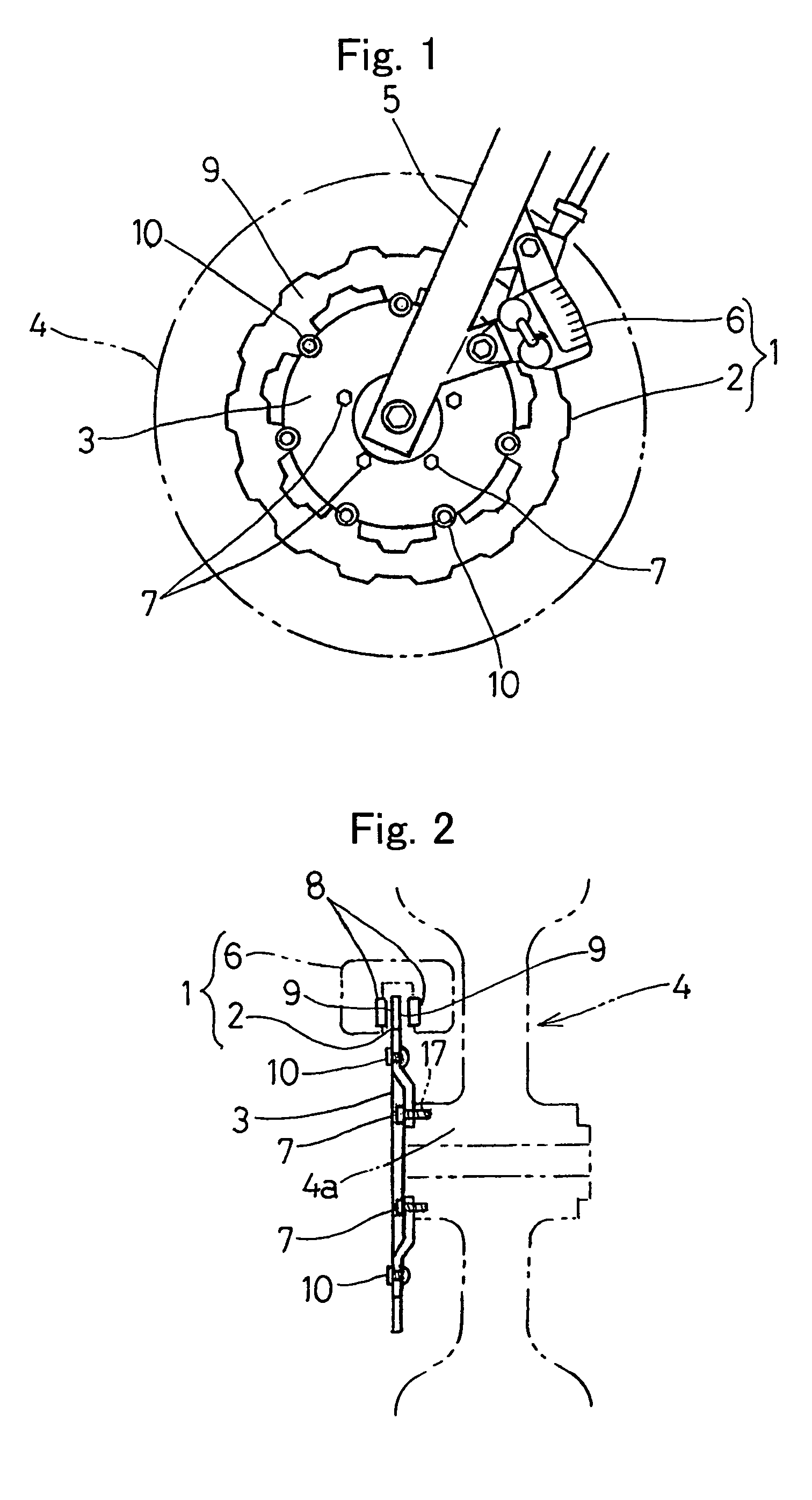

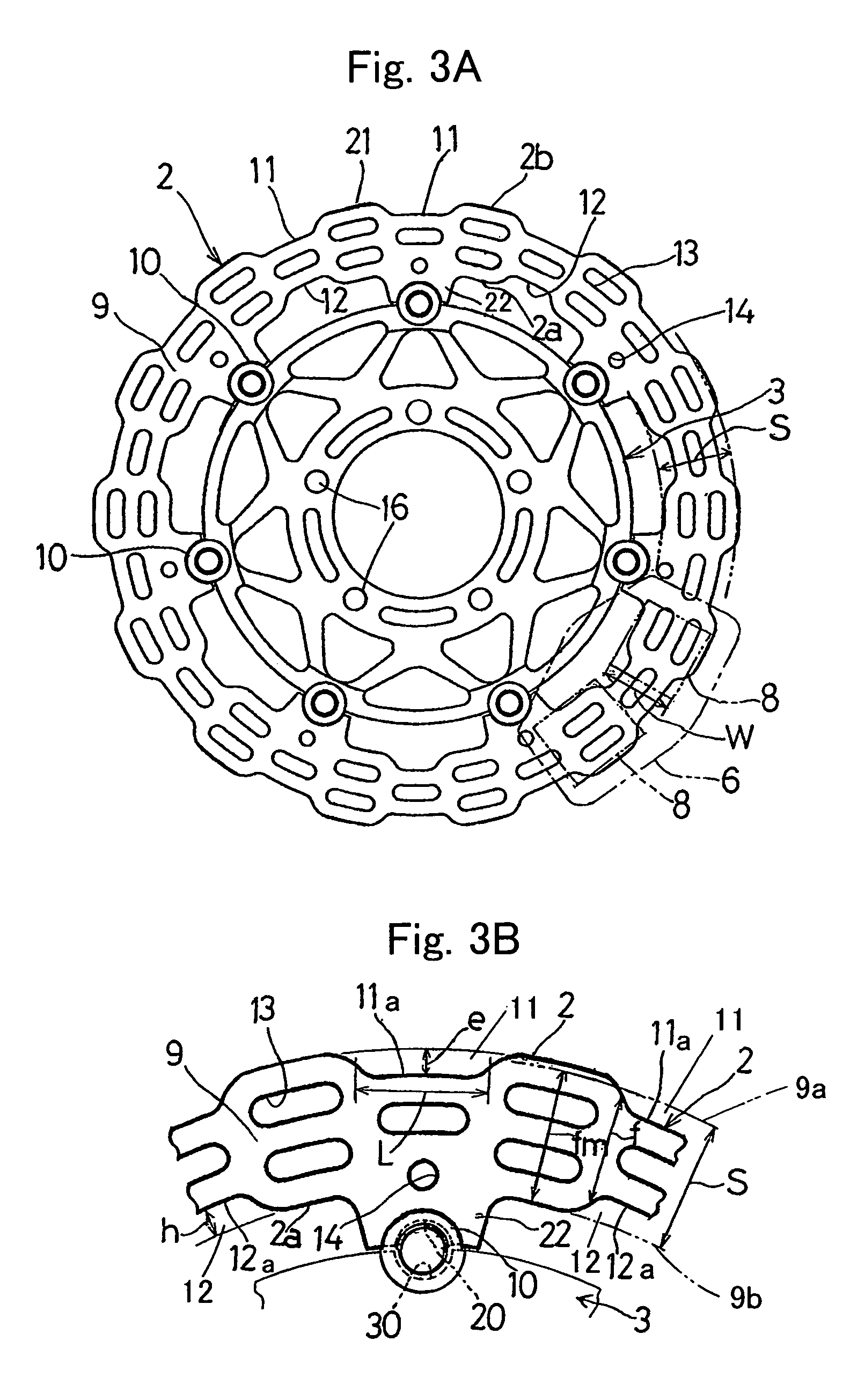

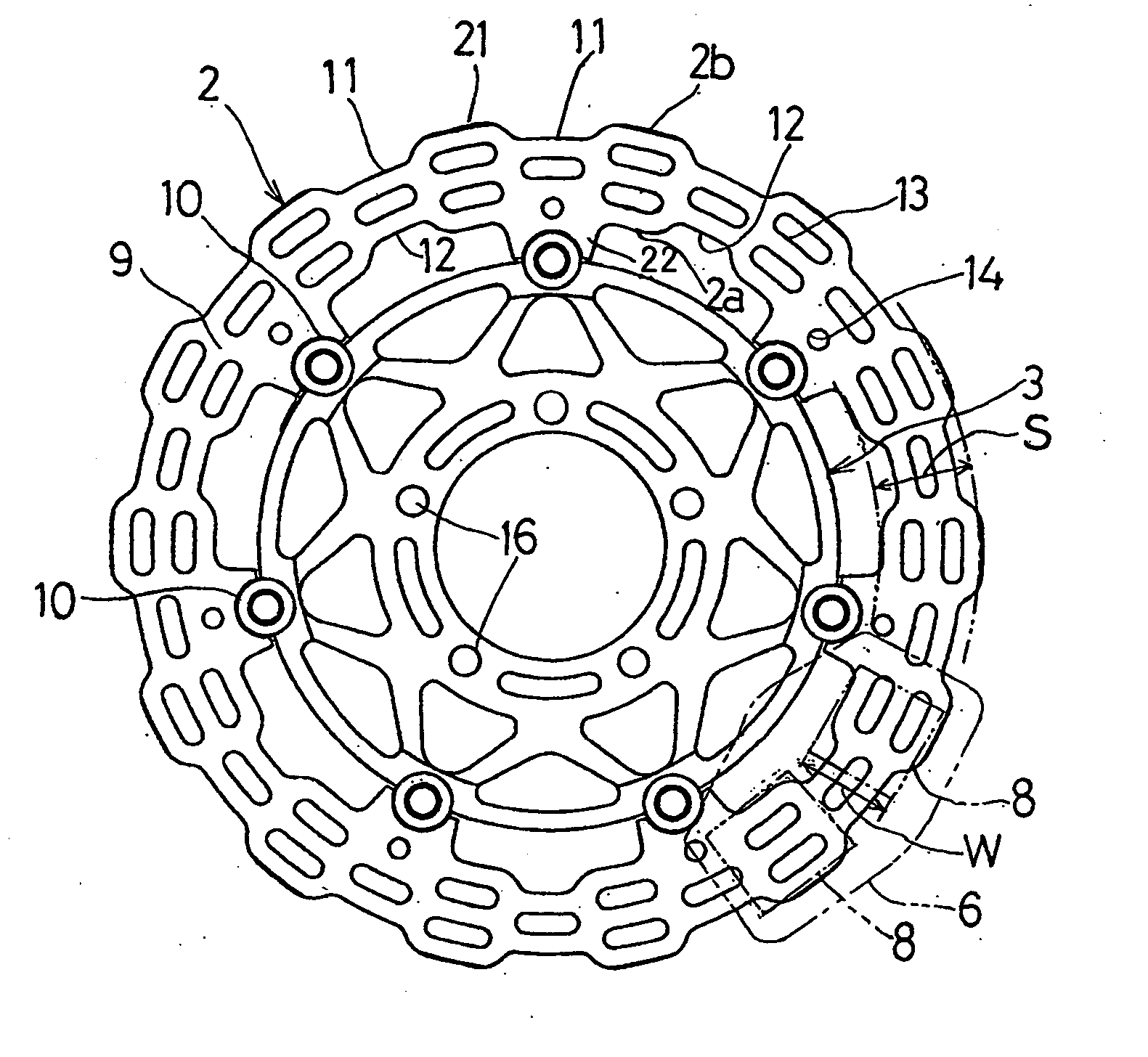

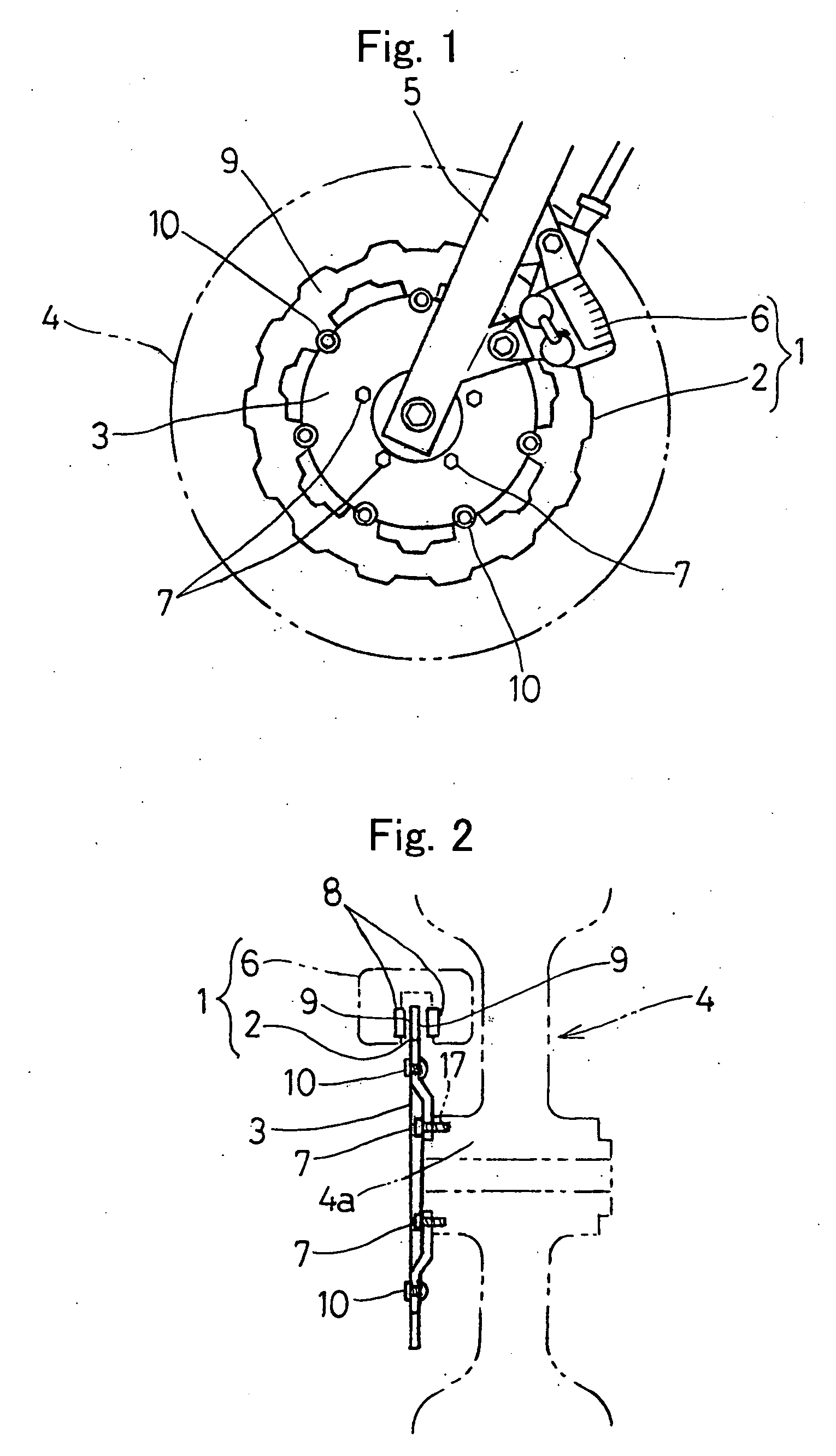

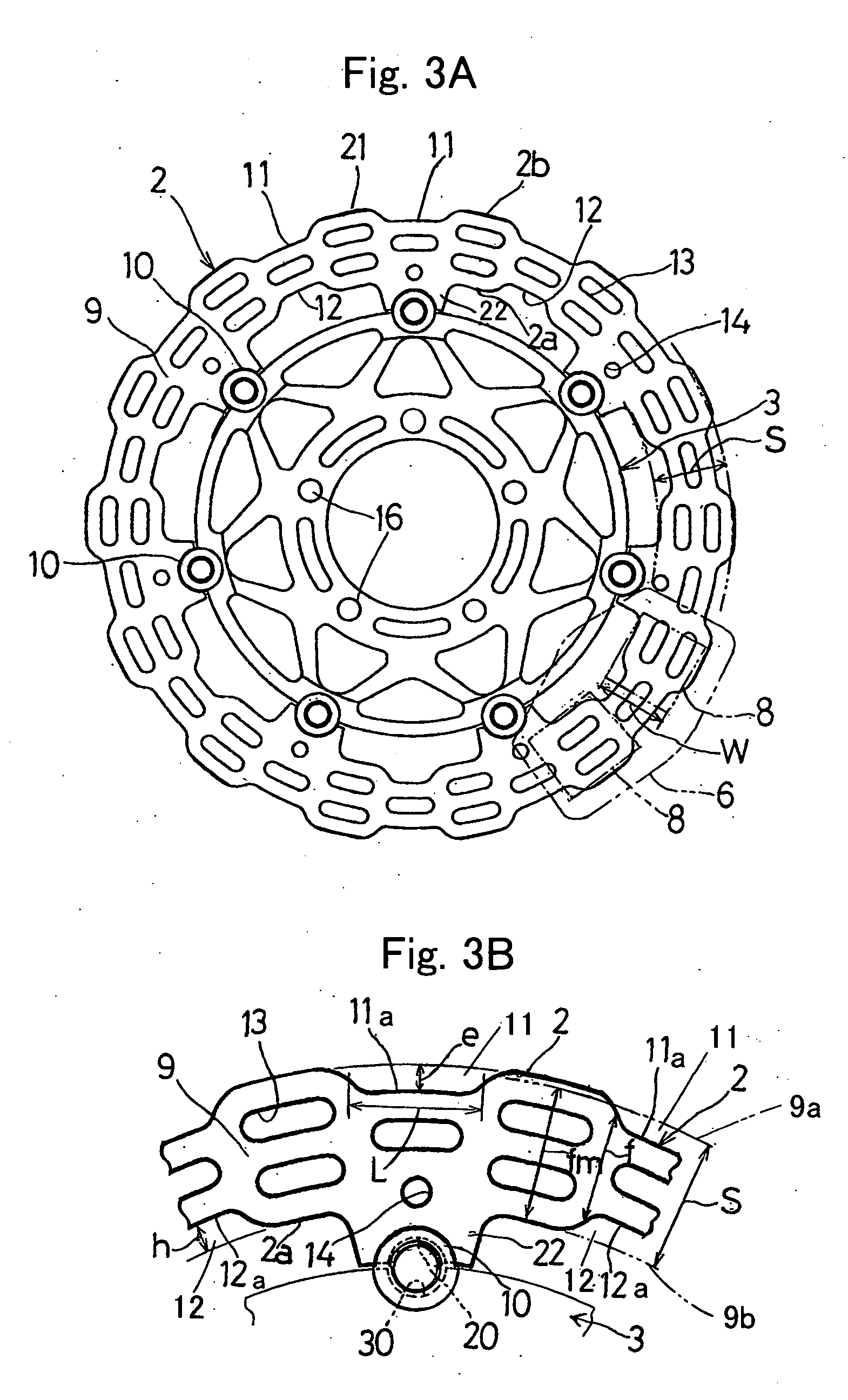

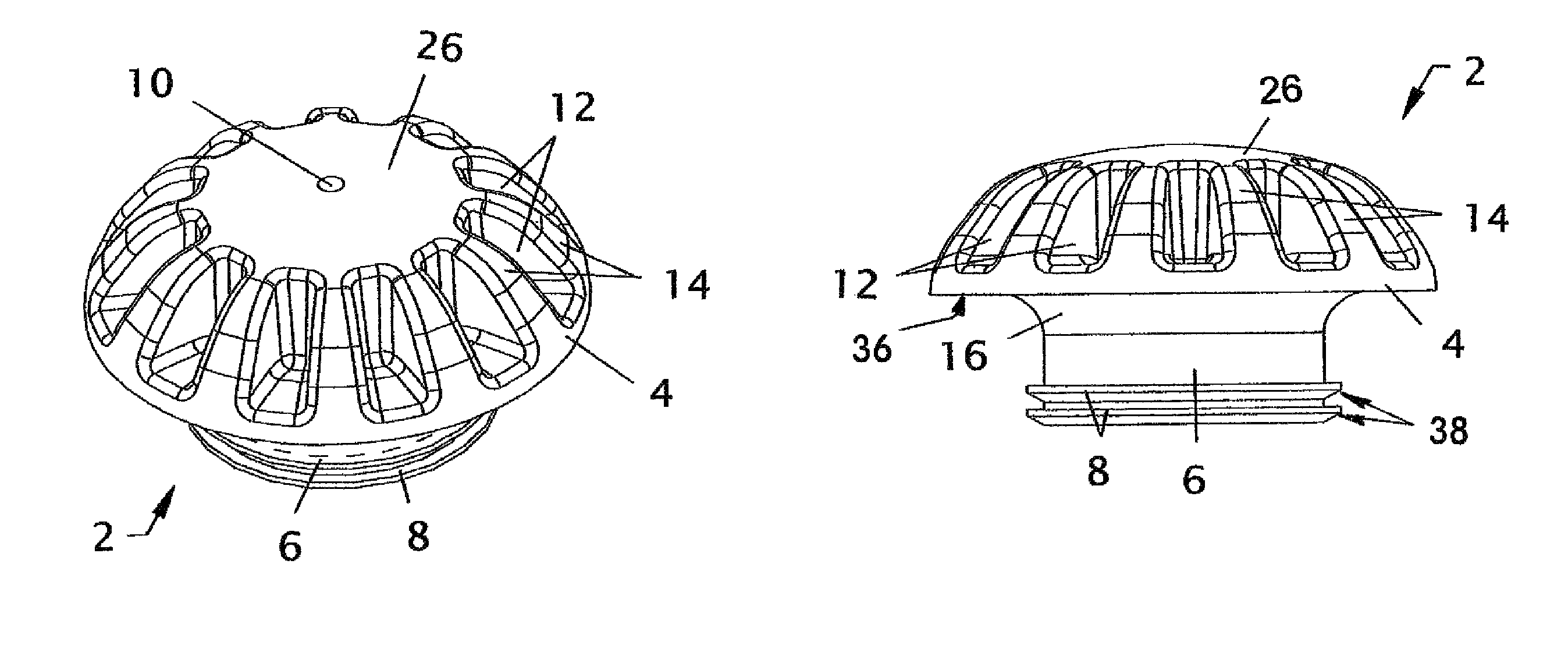

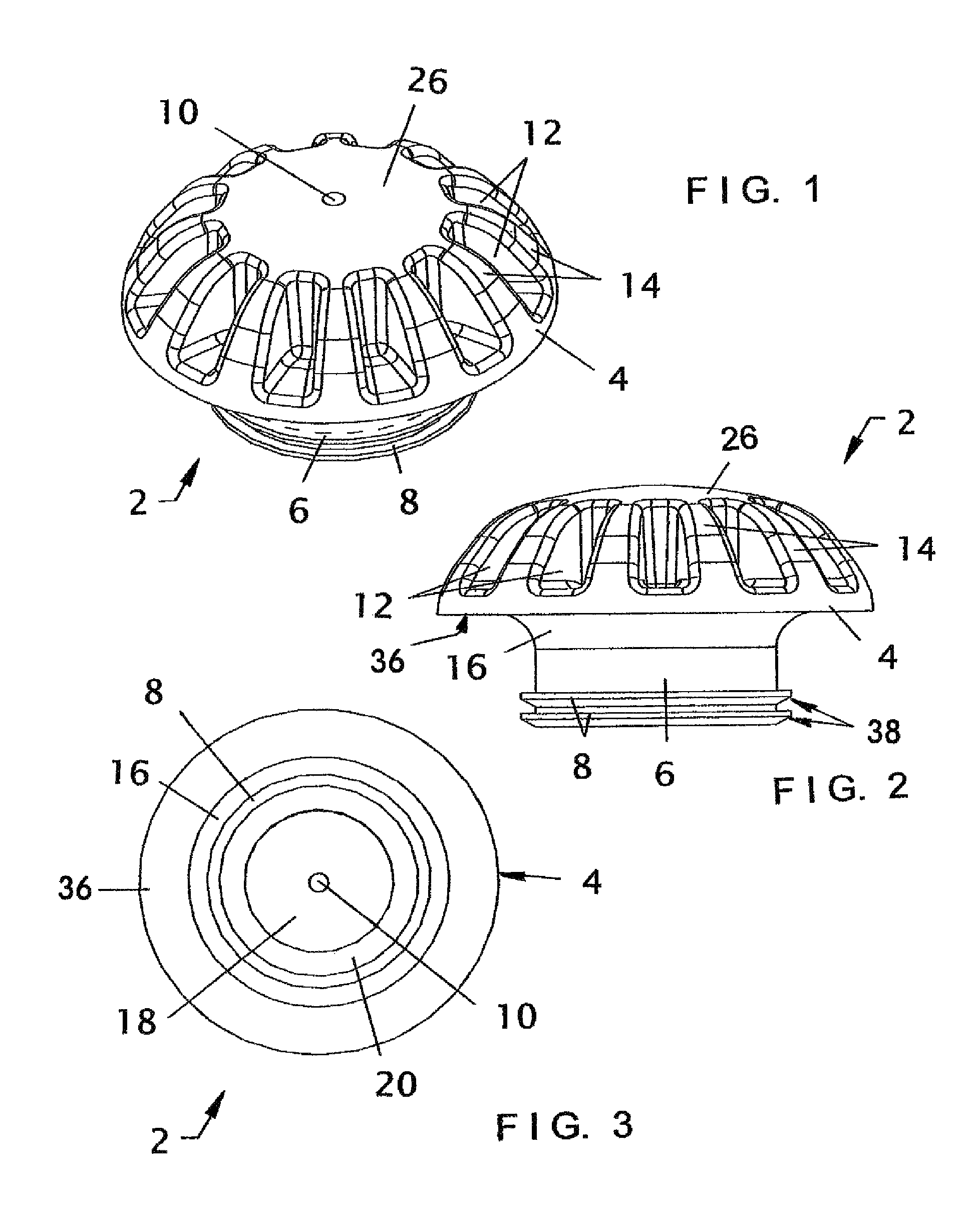

Brake disc for automotive disc brake assembly

ActiveUS20050092561A1Prevent thermal deformationPrevent brake noiseBraking discsCycle brakesThermal deformationEngineering

There is provided a brake disc in a disc brake for a vehicle, which can be manufactured lightweight, suppress the thermal deformation and is effective to prevent the brake noises. This brake disc (2) is supported by a wheel 4 through a plurality of support members (10) and is operable to exert a braking force when sandwiched by frictional pads (8, 8). The brake disc (2) has an outer peripheral face (2b) formed with a plurality of outer recesses (11) deploying in a circumferential direction. Accordingly, the radial width (f) of the braking surfaces (9), with which the frictional pads (8) is engageable, varies in a direction circumferentially thereof.

Owner:KAWASAKI MOTORS LTD

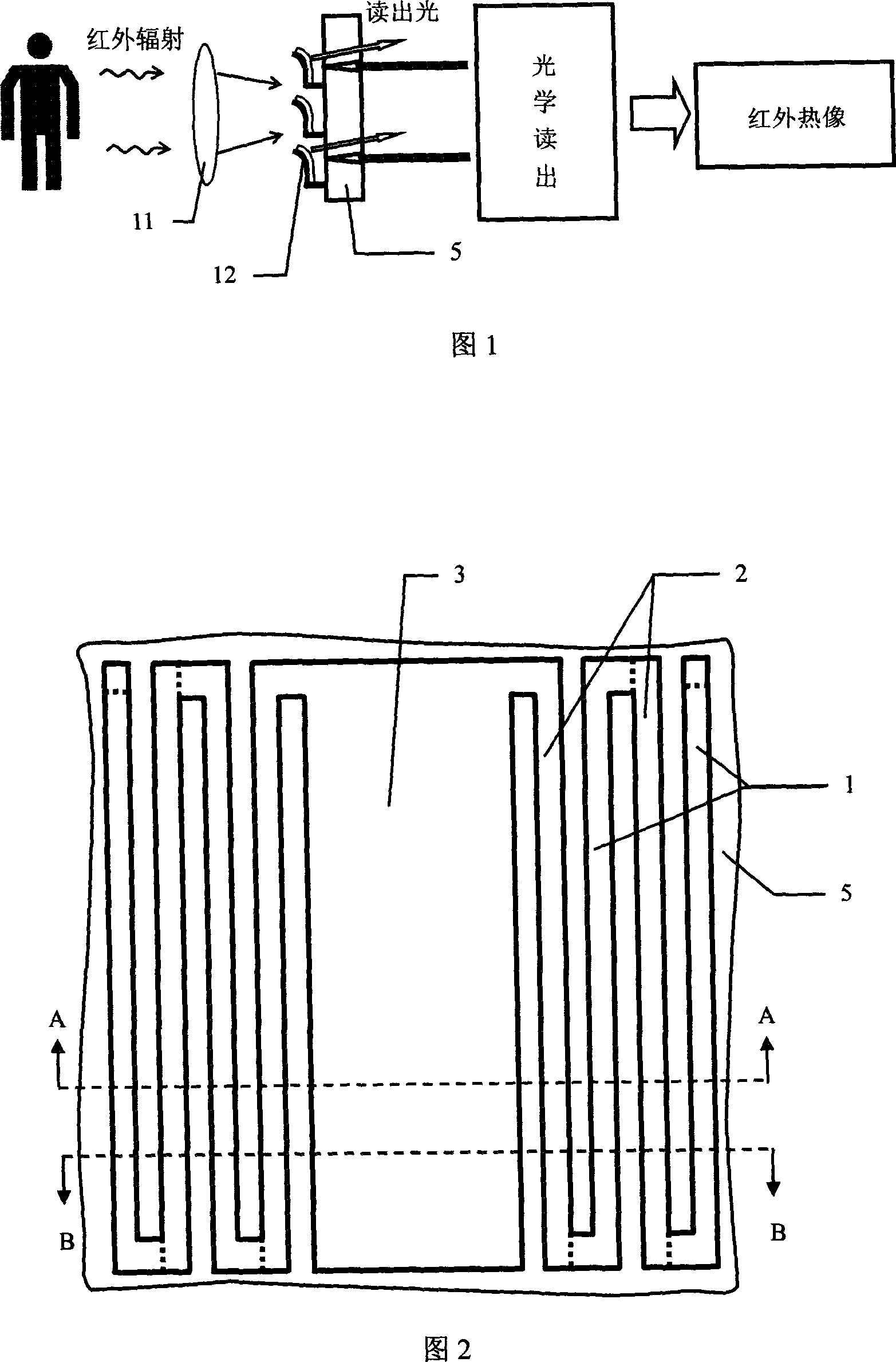

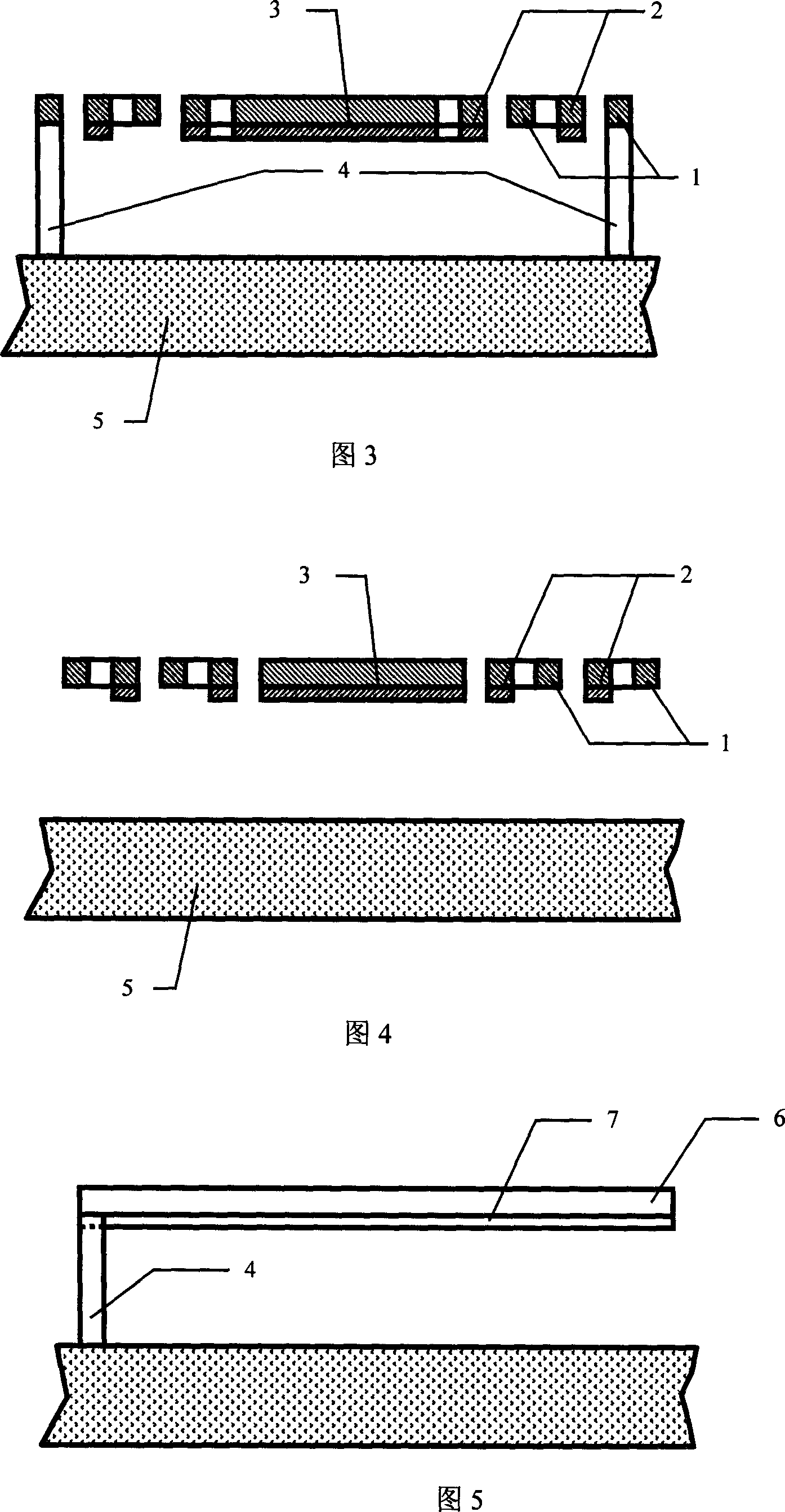

Glass substrate optical display infra-red sensor

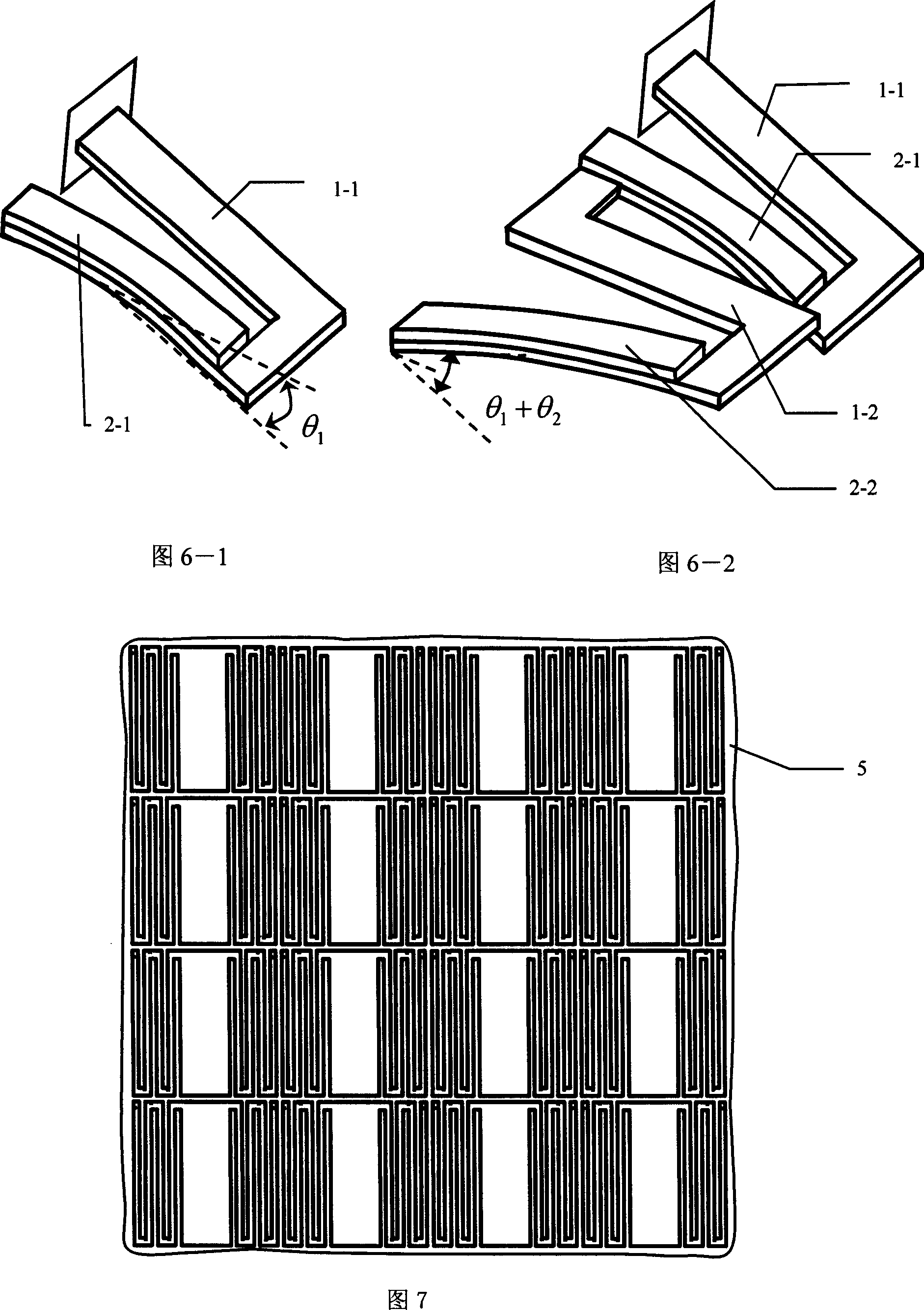

InactiveCN1970430AAvoid lossIncrease the areaTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesInfraredThermal deformation

The glass substrate optical reading infrared sensor features in the light through but infrared blocked glass substrate, side support flat beam unit with two sets of thermal deformation mechanism at both sides of the infrared absorbing plate, baffling distributed through the heat insulation beam and thermal deformation beam. The thermal deformation mechanism connected to both sides of the infrared absorbing plate with its inner side, with the outside end beam fixed on the glass substrate through the anchor erect. The heat insulation beam is nonmetallic film, the heat deformation beam is dual material beam formed on the nonmetallic film coated on the metal film, infrared absorbing plate having its reflective surface facing the glass substrate, visible light passing through the glass substrate projected on the reflective surface, with the infrared light directly projecting on the other side. It eliminates the frame structure, alleviates the dimensional conflict on the same flat layer due to the heat deformation mechanism and the infrared absorbing plate, effectively improving the super infrared detection sensitivity.

Owner:UNIV OF SCI & TECH OF CHINA

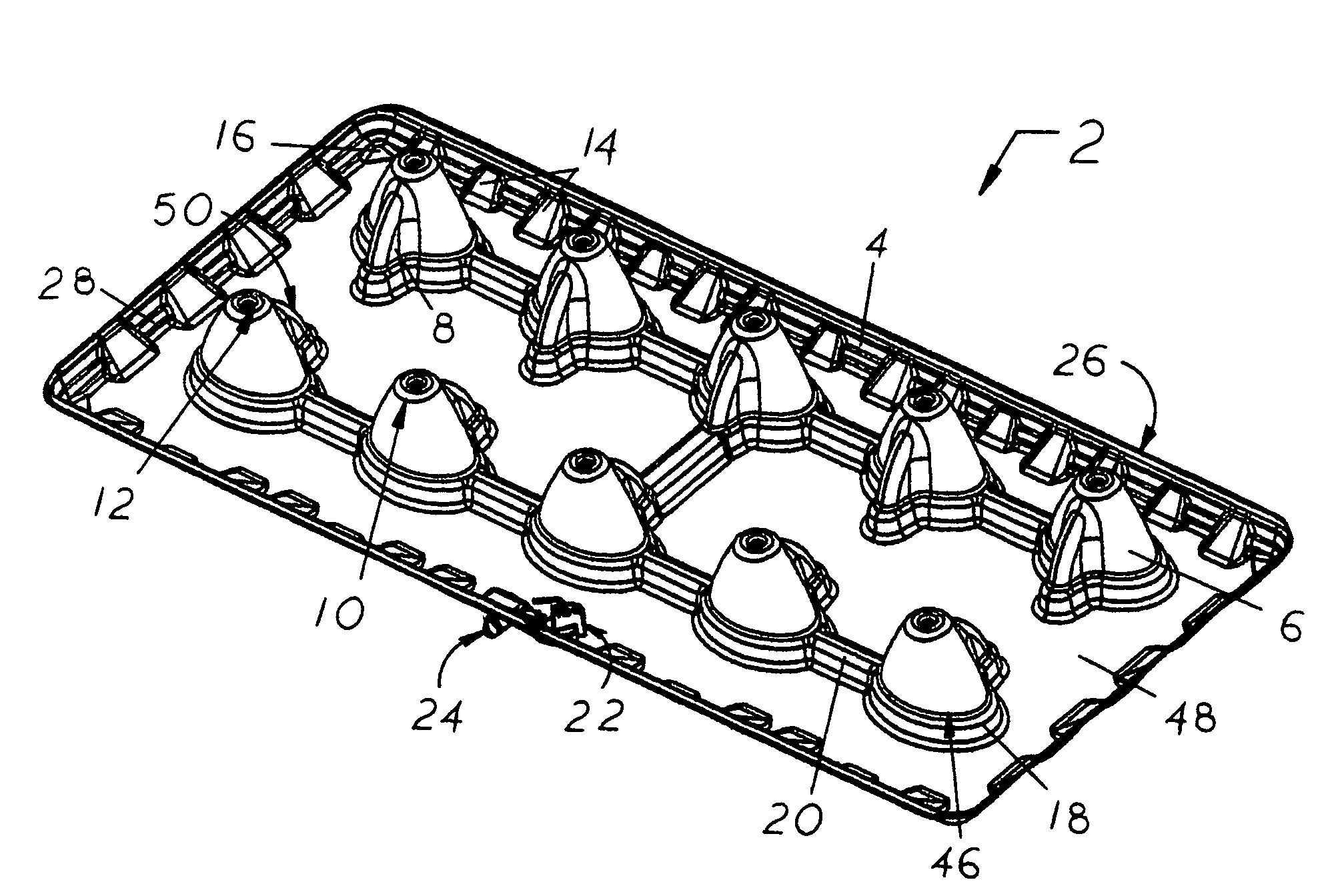

Pan with integrated egg-shaped supports

ActiveUS7673646B1Weight distributionReduce morbidityLighting and heating apparatusCombustion enginesMechanical engineeringWeight distribution

A fluid-collection pan configured for supporting a unit or system responsible for fluid damage risk to its surroundings. Multiple large egg-shaped supports upwardly extend from the pan's bottom surface and are integrated with it. They also each have an arcuate top surface that is transformed into an elliptical base as it meets the pan's bottom surface. Each support also has an upwardly-tapering protrusion with a convexly-shaped top edge that extends centrally from one of the longer sides of the elliptical base toward the support's top surface. The protrusion and the narrow sides of the elliptical base form a substantially triangular shape, which broadens the weight distribution of the supported fluid-causing unit across the pan's bottom surface. The top surface of each support also has a central indentation configured for receipt of a vibration isolator that provides contact with the supported unit. Optional stress-transmitting ribs may extend between adjacent egg-shaped supports.

Owner:RECTORSEAL LLC

Putter-type golf club head with an insert

A method for manufacturing a golf club head with an insert having a face plate is disclosed herein. The insert is disposed in a recess of the club head in which the recess has a depth that is greater than the thickness of the insert. The insert is preferably composed of a thermoplastic polyurethane material formed from a polytetramethylene ether glycol terminated hexamethylene diisocyanate prepolymer having a NCO group content of 8.0% to 12.0%, and a 1,4 butane diol. An adhesive is preferably disposed between the rear wall of the recess and an interior surface of the insert. Further, an adhesive is applied between the plurality of tabs, and preferably over the exterior surface of each of the plurality of tabs.

Owner:TOPGOLF CALLAWAY BRANDS CORP

Aluminum alloy section for automobile bumper as well as preparation method of aluminum alloy section

ActiveCN104404322AGood thermal deformationExcellent corrosion resistance and welding performanceCorrosionThermal deformation

The invention discloses an aluminum alloy section for an automobile bumper. The aluminum alloy section comprises the following elements in percentage by mass: 6.0-6.5% of Zn, 0.8-1.0% of Mg, 0.2-0.3% of Mn, 0.1-0.2% of Cu, 0.2-0.3% of Ti and the balance of Al and inevitable impure elements; a preparation method of the aluminum alloy section comprises the following steps: (1) smelting, (2) refining, (3) casting, (4) homogenizing and extruding, and (5) quenching and aging, so as to obtain an aluminum alloy section finished product. The aluminum alloy section prepared by the invention is good in thermal deformation and machinability and excellent in corrosion resistance and welding property, and the produced automobile bumper is light in weight and can better absorb collision impact energy; the aluminum alloy section achieves various technical indexes of the automobile bumper speculated by the nation in performance, and further meets the development tendency of light weight of modern automobiles.

Owner:南通佳坤新材料科技有限公司

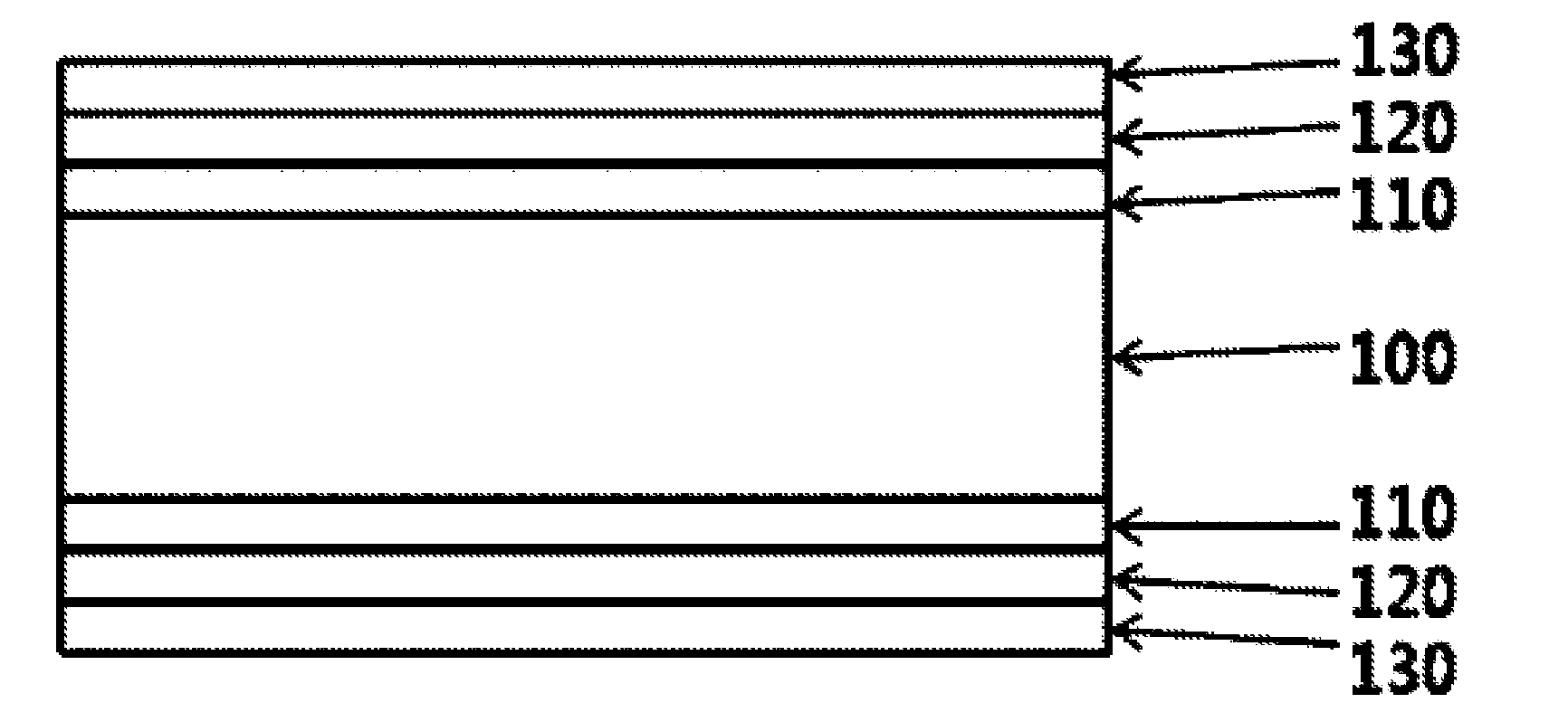

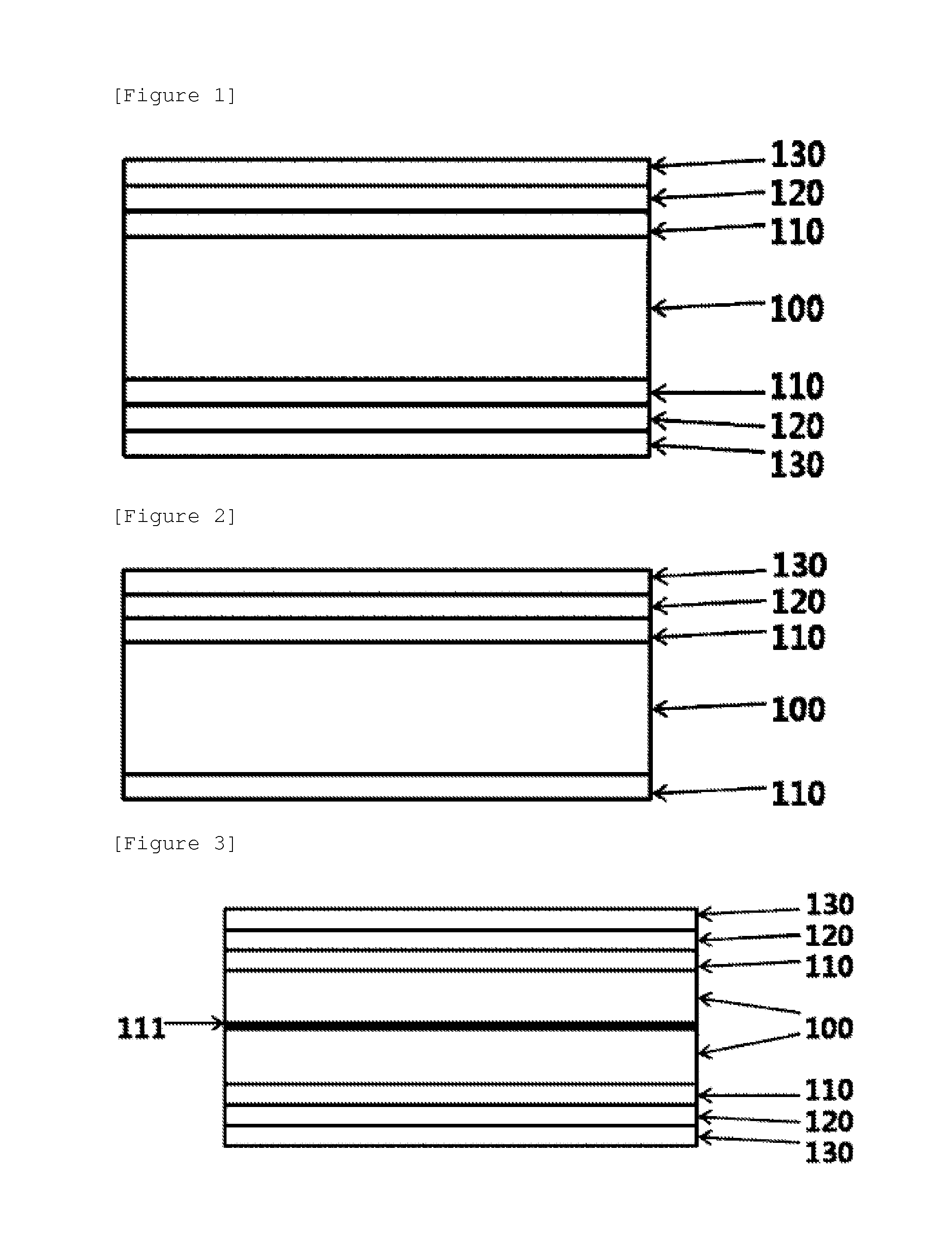

Laminated plastic substrate, and a production method for the same

ActiveUS20110287233A1Improvement in high-temperature thermal deformationExcellent gas barrier performanceMaterial nanotechnologyDecorative surface effectsThermal deformationLinear expansion coefficient

The present invention provides a multilayered plastic substrate that simultaneously satisfies improvement in high temperature thermal deformation according to low linear expansion coefficient and excellent dimensional stability and excellent gas barrier property, and is capable of being used instead of a glass substrate that has brittleness and heavy disadvantages without a problem caused by a difference in linear expansion coefficient between layers, and a method for manufacturing the same.

Owner:LG CHEM LTD

Alkali-free short glass fiber reinforced nylon material and preparation method

InactiveCN104046000ASmall water absorptionGood dimensional stabilityHeat deflection temperatureAlkali free

The invention belongs to the field of a composite high-molecular material and relates to an alkali-free short glass fiber reinforced nylon material and its preparation method. The alkali-free short glass fiber reinforced nylon material is prepared from the following components, by weight, 40-70 parts of nylon, 20-50 parts of alkali-free short glass fiber, 3-8 parts of a lubricant and 2-7 parts of an antioxidant. In comparison with the prior art, the preparation technology is simple; the material has advantages of low water absorption, superior stability and high thermal deformation temperature; the added alkali-free short glass fiber undergoes silane coupling agent surface treatment and has good caking property with a resin matrix; the length of the added glass fiber is short such that the glass fiber is uniformly dispersed in the resin matrix; and after injection moulding, the material is surface-brightening and there is no glass fiber flow liner or exposure.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Brake disc for automotive disc brake assembly

InactiveUS7331433B2Prevent thermal deformationAvoid noiseBraking drumsBraking discsThermal deformationEngineering

Owner:KAWASAKI MOTORS LTD

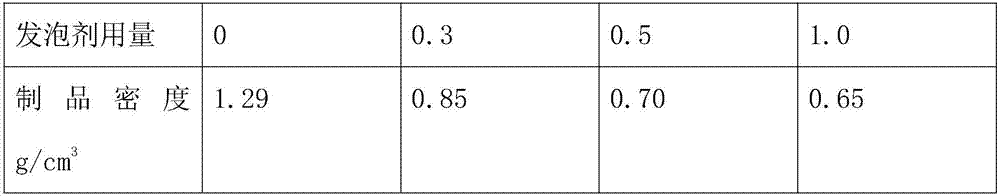

Wood plastic composite section bar and production technology thereof

InactiveCN107501805AImprove mechanical propertiesReasonable formula designProduction rateFoaming agent

The invention discloses a wood plastic composite section bar and a production technology thereof. The wood plastic composite section bar comprises the following raw materials in parts by weight: 40-60 parts of PVC, 10-15 parts of wood powder, 20-30 parts of CACO3, 1-3 parts of a stabilizer, 1-2 parts of a foaming agent, 1-2 parts of a lubricating agent and 4-6 parts of processing additives. The wood plastic composite section bar is reasonable in formula design, has a coupling toughening function, is capable of promoting the mechanical properties of material, is beneficial to the promotion of rigidity and thermal deformation of products and is available for indoor and outdoor wood plastic products and products with higher requirement on thermal deformation; a toughening agent CPE is added, so that the toughness of the product is higher; the wood plastic composite section bar has high heat stability, weather fastness and anti-ultraviolet function; the section bar is high in compatibility with resin, high in dispersibility, and capable of increasing production rate and promoting the surface glossiness of products; the wood plastic composite section bar has anti-fogging and antistatic functions; the wood plastic composite section bar is suitable for production wood plastic skirting lines, door pocket lines, sill lines, ecological wood, hollow panels, floor boards, stair railings, ventilated windows, micro-foamed cabinet panels, wave panels, and other products.

Owner:安徽淮宿建材有限公司

Chlorinated propylene random copolymer and compositions containing the same

A novel binder resin which attains good adhesion to various substrates such as polyolefin resins, vinyl chloride resins, polycarbonate resins, polyethylene terephthalate resins, acrylonitrile / butadiene / styrene resins, and nylon resins even by low-temperature baking and is excellent in solvent solubility. Namely, a chlorinated propylene random copolymer produced by subjecting a propylene random copolymer which is obtained by copolymerizing propylene with other alpha-olefin by using a metallocene catalyst as the polymerization catalyst and which has a melting point (Tm) of less than 115 DEG C as determined with a differential scanning calorimeter (DSC) to degradation by heat preferably at a temperature ranging from the melting point of the copolymer to 350 DEG C and chlorination successively.

Owner:NIPPON PAPER CHEM

Brake disc for automotive disc brake assembly

InactiveUS20050161296A1Prevent thermal deformationPrevent brake noiseBraking element arrangementsBraking discsThermal deformationEngineering

There is provided a brake disc in a disc brake for a vehicle, which can be manufactured lightweight, suppress the thermal deformation and is effective to prevent the brake noises. This brake disc (2) is supported by a wheel 4 through a plurality of support members (10) and is operable to exert a braking force when sandwiched by frictional pads (8, 8). The brake disc (2) has an outer peripheral face (2b) formed with a plurality of outer recesses (11) deploying in a circumferential direction. Accordingly, the radial width (f) of the braking surfaces (9), with which the frictional pads (8) is engageable, varies in a direction circumferentially thereof.

Owner:KAWASAKI HEAVY IND LTD

Method for manufacturing CNT (carbon nanotube) composite transmission conductor

InactiveCN101948988AImprove mechanical propertiesImprove thermal performanceSingle bars/rods/wires/strips conductorsInsulated cablesMultiwalled carbonThermal deformation

The invention discloses a method for manufacturing a CNT (carbon nanotube) composite transmission conductor, which comprises the following steps: filling MCNT (multiwalled carbon nanotube) powder accounting for 1 to 7 percent of the total mass into small holes uniformly drilled on electrotechnical aluminium blocks; stacking two aluminium blocks in which the MCNT powder has been filled inversely by using a blind-hole method; after the two aluminium blocks are prepared into composite materials through a friction extrusion process, carrying out tandem rolling and drawing on the composite materials so as to prepare the composite materials into required CNT / aluminum based composite material round wires; and finally, stranding the round wires by a wire twisting machine, then through a back-twisting stress eliminating device, obtaining a single-stranded CNT composite transmission conductor. The method of the invention has the advantages: 1) the coefficient of linear expansion of the conductor is small, and the thermal deformation resistance performance is strong, the method can reduce the influence of the temperature on sag change, improve the sag characteristics, improve the security of overhead lines, and reduce the construction cost of the lines; 2) the method is helpful to improve the conductivity of the conductor along the line, and further reduce the transmission losses; and 3) the process is relatively simple, and the loosening and skid phenomenon and the like of composite cores and aluminium strands due to various reasons do not exist.

Owner:ELECTRIC POWER RES INST STATE GRID JIANGXI ELECTRIC POWER CO +1

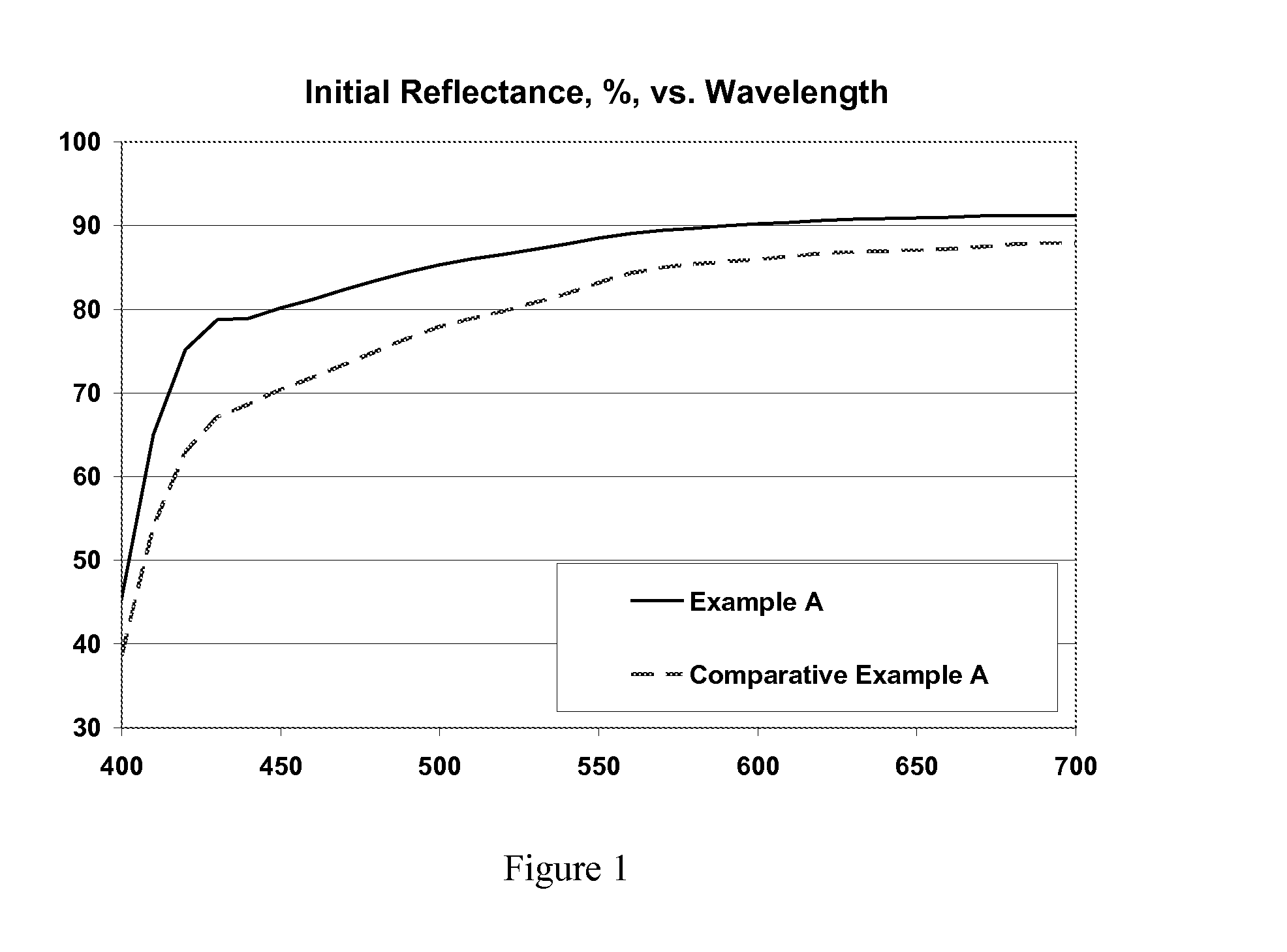

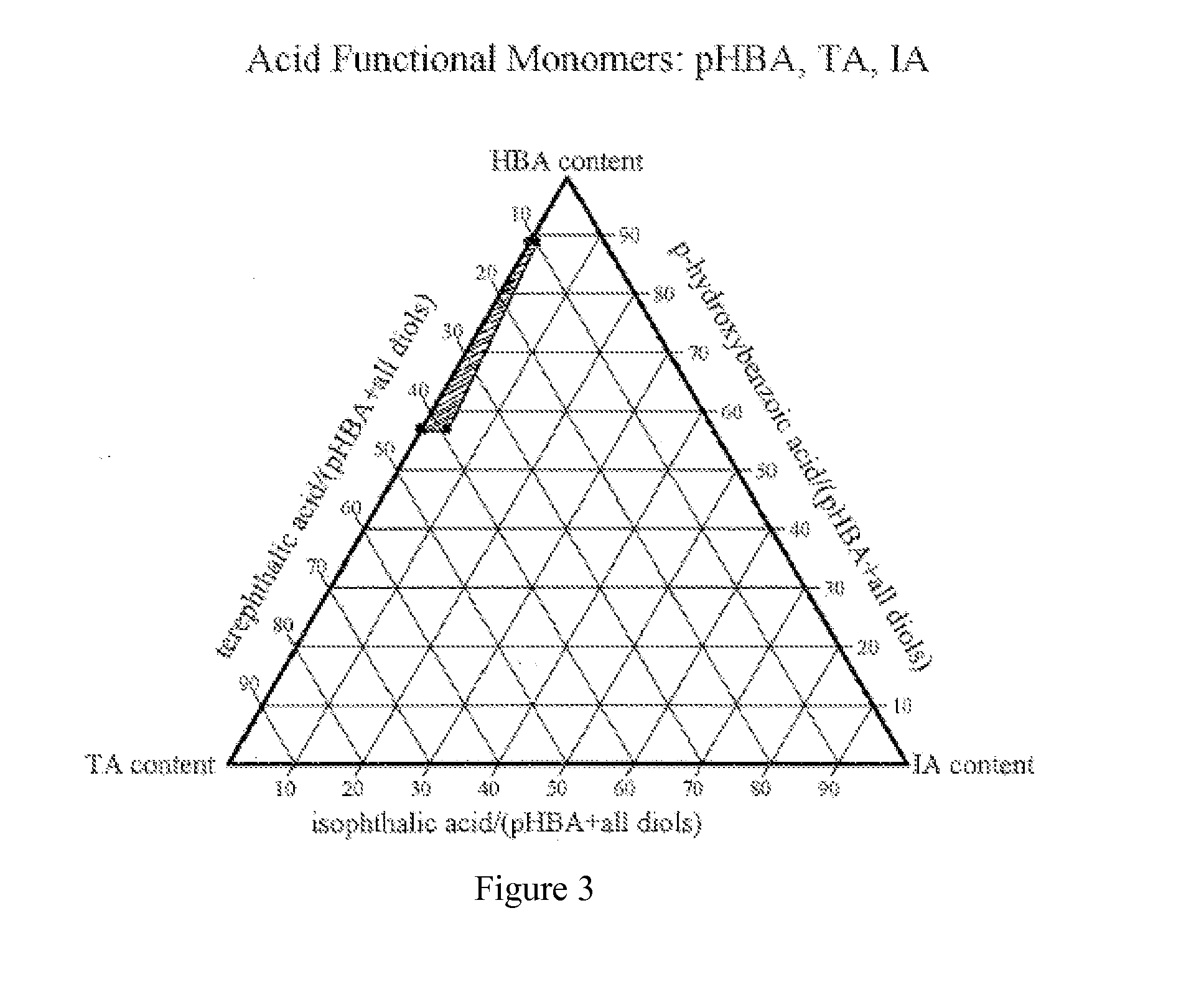

Hydroquinone-containing polyesters having improved whiteness

InactiveUS20110213077A1Exceptional whitenessExceptional whiteness propertyLiquid crystal compositionsSolid-state devicesPolymer scienceHeat resistance

A polyester containing polymerized units of hydroquinone; 4,4′-biphenol; and hydroxybenzoic acid; terephthalic acid and optionally isophthalic acid. A method of forming a polyester including first acylating a mixture of hydroquinone; 4,4′-biphenol; terephthalic acid and optionally isophthalic acid; and hydroxybenzoic acid; and then polycondensing the resulting acylated mixture. The polyester is suitable for uses such as lighting where high whiteness, high reflectivity and high heat resistance are desirable.

Owner:SOLVAY ADVANCED POLYMERS LLC

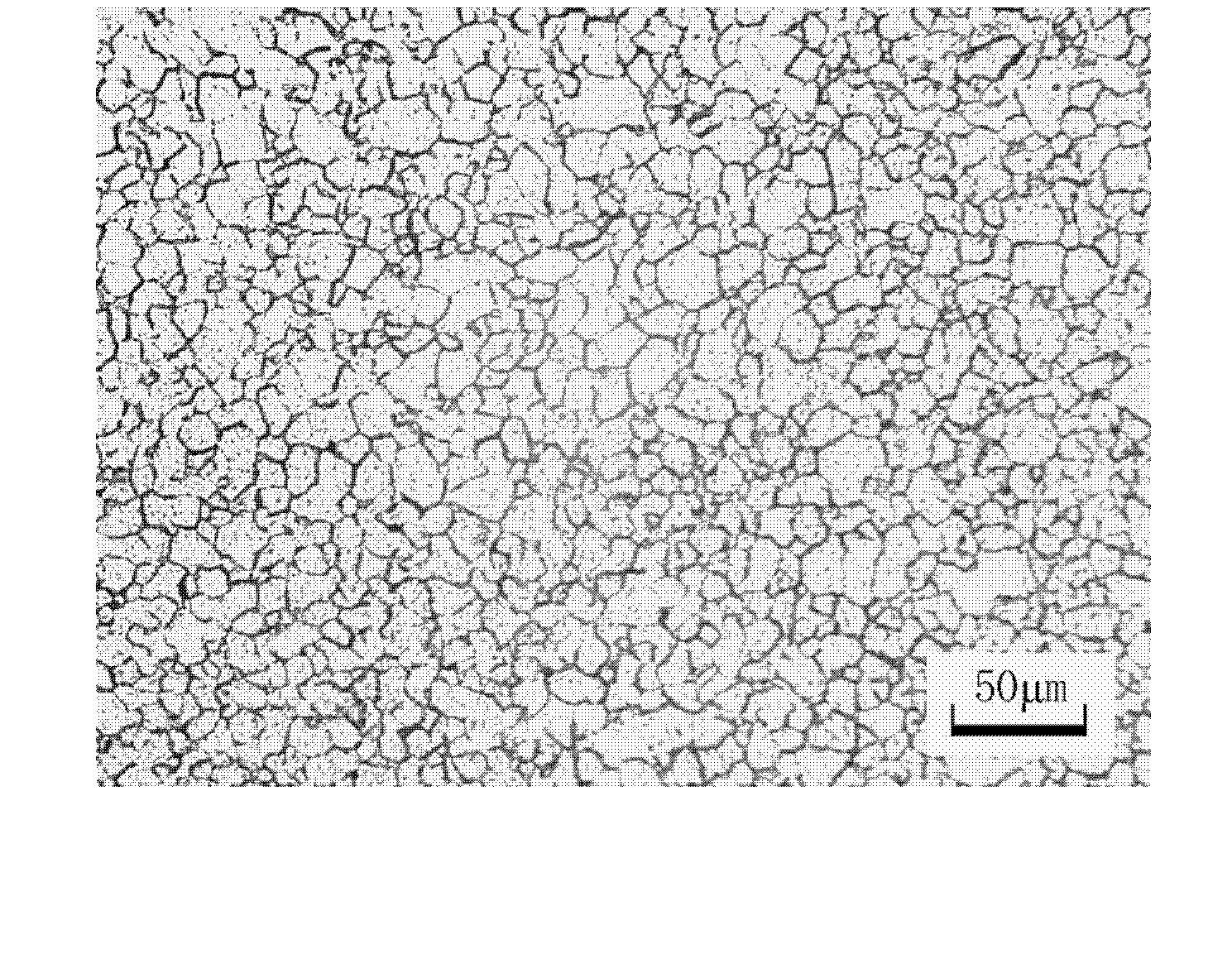

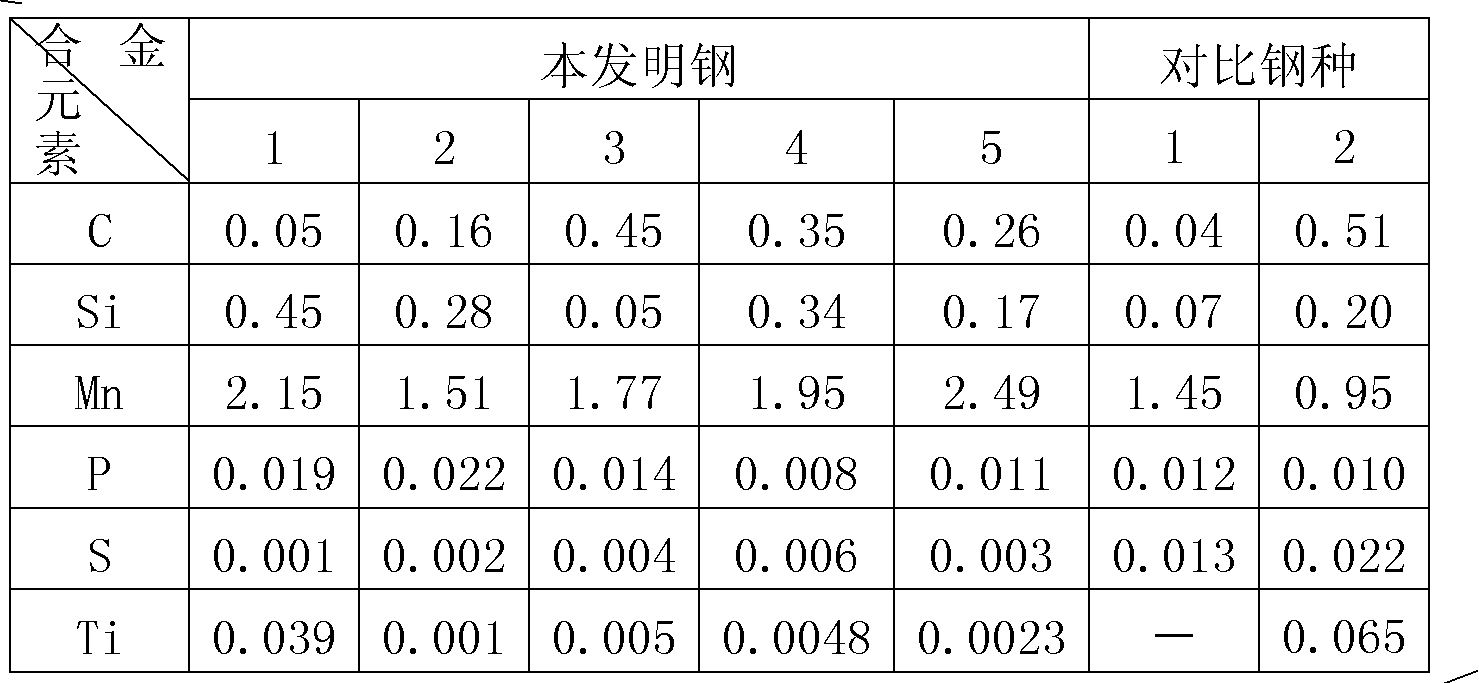

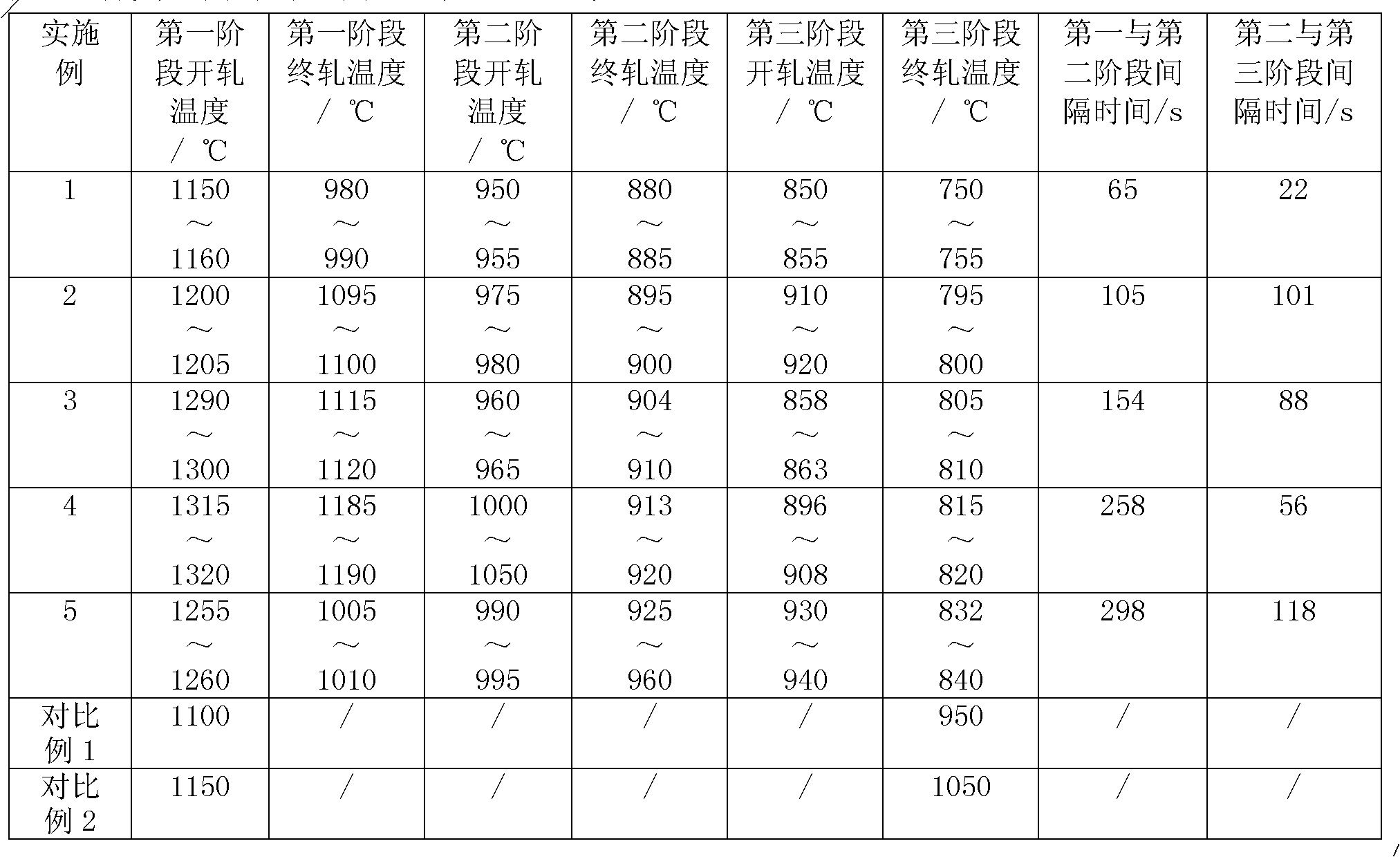

Seawater corrosion resistant structural steel with uniform metallographic structure and production method thereof

InactiveCN102534378AIncreased resistance to marine corrosionHigh strengthSheet steelMicroscopic observation

The invention relates to seawater corrosion resistant structural steel with the uniform metallographic structure and a production method thereof. The seawater corrosion resistant structural steel comprises the following compositions according to percentages by weight: 0.05-0.45% of C, 0.05-0.45% of Si, 1.50-2.50% of Mn, less than or equal to 0.025% of P, less than or equal to 0.006% of S, 0.001-0.0048% of Ti and the rest of Fe and inevitable impurities. The production method comprises the following steps of: smelting, and carrying out vacuum treatment and continuous casting to form a blank; conventionally heating and soaking the casting blank; carrying out subsection rolling, i.e. casting-state structure rolling, rolling of refining grains and homogenization rolling of grain sizes; naturally cooling till reaching room temperature, and setting aside for application. According to the observation of the structural steel by using a 200-times metallographic microscope, in a finished product steel plate, the grains with the size of 10-25mum accounts for 80%-90%, the grains with the size of greater than 25mum is less than or equal to 5%, and the size of the rest of grains is less than 10mum; the seawater corrosion resistant of the steel plate is increased by at least 45%; and the steel plate has good strength and toughness and excellent cold and hot deformation and welding performance.

Owner:武汉钢铁有限公司

Vibration isolator

ActiveUS8317169B1Improve vibration reductionReduce material costsPortable framesStands/trestlesAir movementEngineering

A generally mushroom-shaped vibration isolator having a broad cap and a smaller diameter stem that is used for safety enhancement between a heavy furnace, air conditioning unit, storage hot water heater tank, or other fluid-producing unit, and a fluid-collecting pan positioned under it. Vibration isolator stems are placed within indentations in raised areas of the pan and comprise highly impact-resistant materials, temperature-resistant materials, provide enhanced air movement and heat deflection around a furnace / unit / tank, reduce after-installation furnace / unit / tank movement, and meet furnace non-combustible clearance requirements. The cap has a broad underside surface, top surface radially-extending ribs and cutouts, and may have a slightly convex top, while the stem has at least one outwardly-depending wedge-shaped projection that is sufficiently flared-out to flip over as it is inserted into an indentation for a tight fit within several sizes of indentation, as well as removal resistance. A tapered connection also exists between cap and stem.

Owner:RECTORSEAL LLC

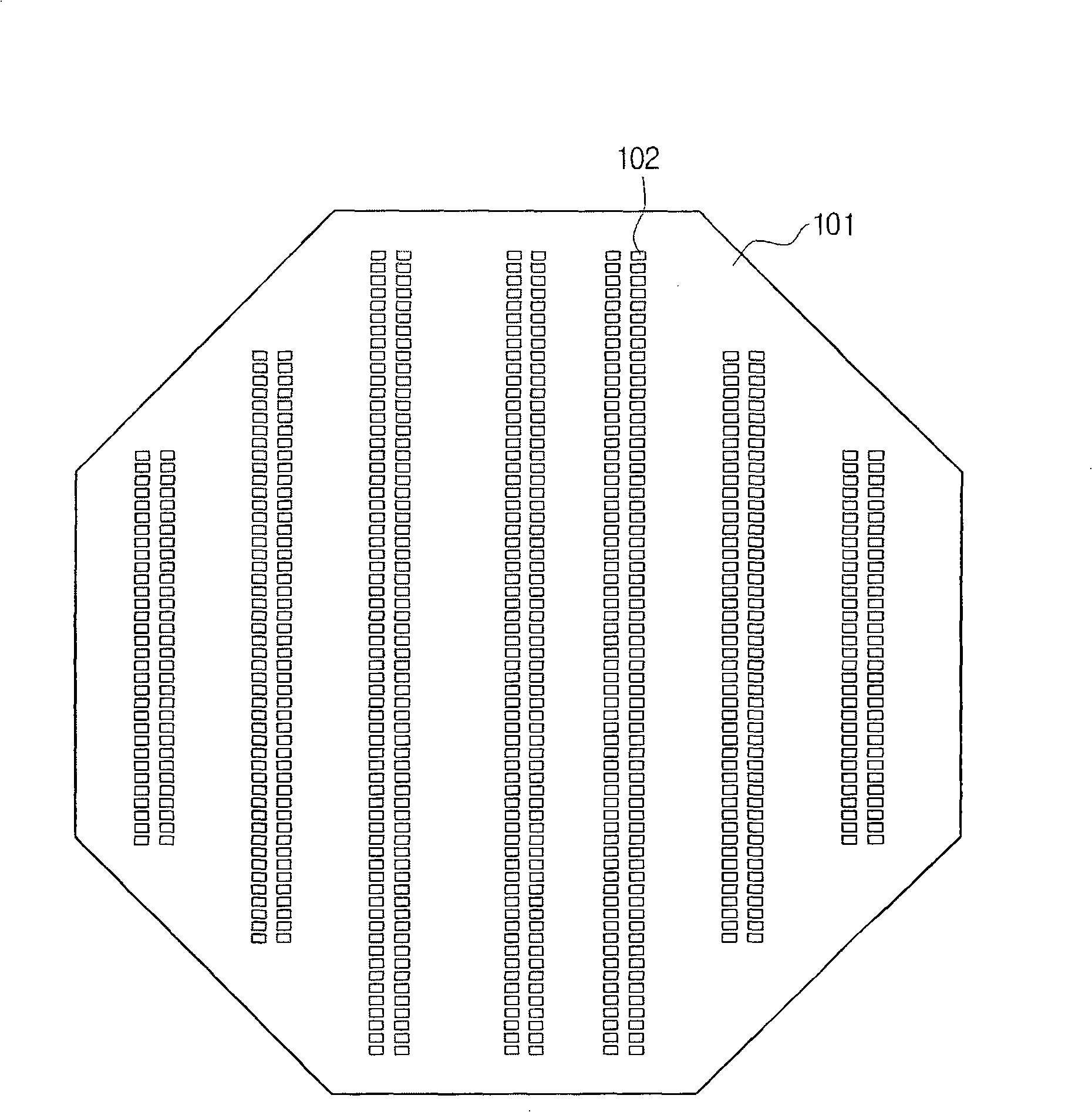

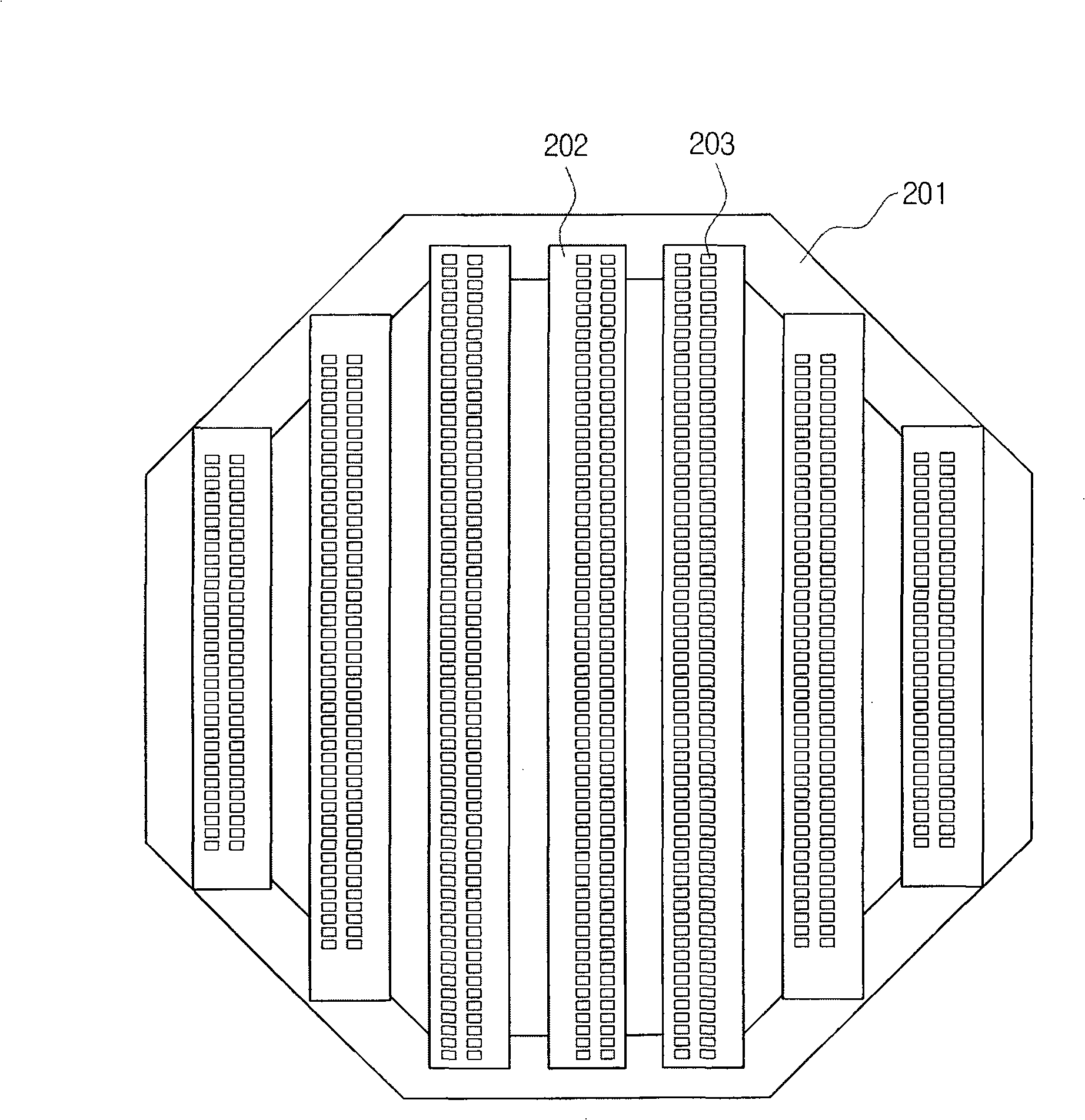

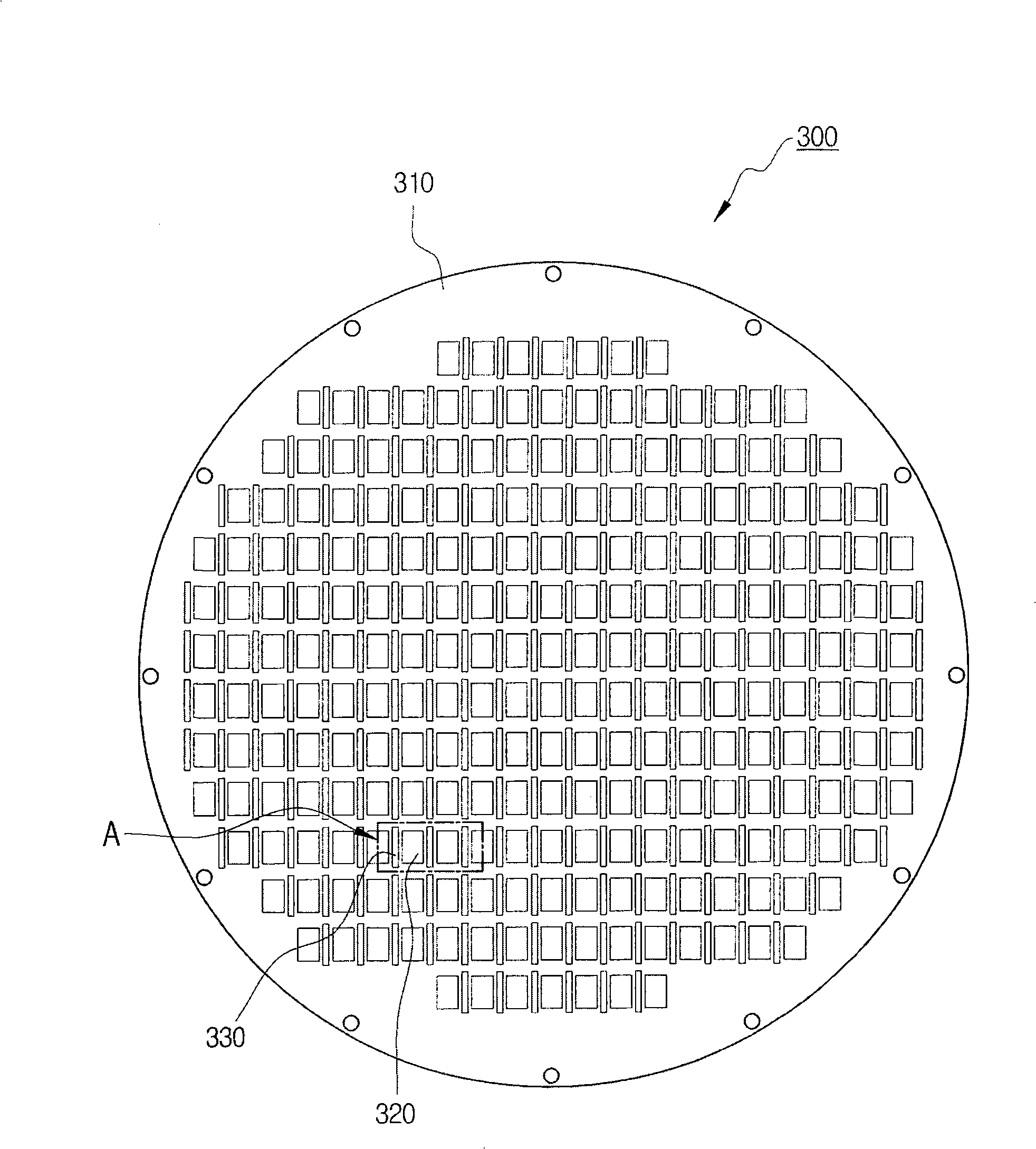

Probe card and method for fabricating the same

ActiveCN101303371AMinimize process defectsImprove thermal deformationSemiconductor/solid-state device testing/measurementElectronic circuit testingElectricityProbe card

The present disclosure relates to a probe card for testing semiconductor chips on a semiconductor wafer comprising: a circuit board receiving electrical signals from outside; a plurality of unit probe modules contacting the semiconductor chips on the wafer to transfer the electrical signals; a space transformer having the plurality of probe modules seated on the upper portion thereof and electrically connected to the circuit board, wherein the respective probe modules are arranged at intervals from each other on the space transformer and the space transformer has vertical apertures penetrating through it up and down;and at least one vertical conductive medium electrically connecting the respective unit probe modules and the circuit board, wherein the vertical conductive medium is arranged in the vertical apertures provided in the space transformer and the respective unit probe modules are arranged at positions spaced from the vertical conductive medium.

Owner:AMST CO LTD

Alloy steel for low temperature vacuum carburizing

The present invention relates to an alloy steel for low temperature vacuum carburizing, and more particularly, to an alloy steel for low temperature vacuum carburizing, wherein, where the thermal processing of carburizing and quenching is performed at 810° C. or so of an available minimum carburizing temperature of a conventional vacuum carburizing furnace, it is able to securing an adequate ferrite phase (α) to improve the thermal distortion according to the thermal processing of an annulus gear, and to satisfying shape restrictions such as a roundness or a cylindricity of the annulus gear to be manufactured. An alloy steel for a low temperature vacuum carburizing according to the present invention, the alloy steel is composed of a chief element of Fe, wherein the alloy steel is formed so that dissolved oxygen (DO) is 10 ppm or less in an alloy system which comprises 0.17˜0.24 weight percent of C, 0.8˜1.2 weight percent of Cr, 0.4˜0.8 weight percent of Mn, 0.80˜1.20 weight percent of Si, 0.020 weight percent or less of P, 0.020 weight percent or less of S, 0.015˜0.045 weight percent of V, and the remaining weight percent of Fe.

Owner:HYUNDAI MOTOR CO LTD +1

Sealing structure and sealing method of non-welded metal plate single battery

PendingCN112701315AReduce manufacturing costImprove yieldSealing/support meansStructural engineeringBattery cell

The invention relates to a sealing structure and a sealing method of a non-welded metal plate single cell, the sealing structure comprises a single cell formed by stacking an anode plate, a membrane electrode and a cathode plate together, an air main channel is communicated with a cathode flow field through an air side air inlet duct and a negative plate air side boss, and a hydrogen main channel is communicated with an anode flow field through a hydrogen side gas inlet duct by penetrating through a hydrogen side boss of an anode plate; the anode plate air side boss is communicated with the anode plate water side boss through a first channel, a first communication hole is formed in a membrane electrode frame between the anode plate water side boss and the cathode plate water side boss, and the cathode plate water side boss is communicated with the cathode plate hydrogen side boss through a second channel; and sealing rings are formed in the anode plate air side boss, the first channel, the anode plate water side boss, the cathode plate water side boss, the second channel and the cathode plate hydrogen side boss through integrated glue injection. The sealing structure and the sealing method are high in reliability, low in production cost and high in production efficiency.

Owner:FUJIAN YANAN ELECTRIC MACHINE

Aluminum alloy for special high-pressure oil pump shell and preparation method thereof

InactiveCN103103409AImprove high temperature performanceImprove thermal deformationFree coolingIngot

The invention relates to an aluminum alloy for a special high-pressure oil pump shell and a preparation method thereof. The alloy comprises the ingredients by weight percent: 5-7% of Si, 1.3-1.7% of Cu, 0.4-0.7% of Mg, 0.1-0.35% of Mn, 0.2-0.3% of Ti, 0.4% or less of Fe, 0.01% or less of Sn, 0.01% or less of Pb, 0.03% or less of Ca, 0.05% or less of single impurity, and the balance of aluminum, wherein the total impurities are 0.15% or less. The preparation method comprises the following steps of: smelting at 755-765 DEG C; spraying a common refining agent by argon at 745-755 DEG C; evenly scattering a sodium modifier under the temperature which is 740 DEG C at least, standing for 10-20 minutes; casting by a semi-continuous direct water cooling method; homogenizing a cast ingot, naturally cooling after discharging from a furnace; and carrying out heat treatment quenching after extruding and molding the homogenized cast ingot, and finally carrying out precipitation heat treatment. The aluminum alloy has the beneficial effects of good high temperature performance, thermal deformability, abrasive resistance, gas tightness and the like, is good in casting and extruding properties, and can be well applied to the special high-pressure oil pump shell.

Owner:龙口市丛林铝材有限公司

Method for preparing NdFeB/SmCo5 composite permanent magnet doped with PrCu alloy by adopting thermal deformation method

InactiveCN106298136AReduce interdiffusionWeaken the exchange coupling effectInorganic material magnetismInductances/transformers/magnets manufactureMagnetic phaseThermal deformation

The invention relates to a method for preparing an NdFeB / SmCo5 composite permanent magnet doped with PrCu alloy by adopting a thermal deformation method and belongs to the technical field of magnetic materials. The ratio of the weight of PrCu alloy powder for doping to the weight of total powder is 2-15 weight percent. The deformation quantity of the composite magnet is 60-90 percent. The SPS technology thermal deformation method is adopted for preparing the NdFeB / SmCo5 thermal deformation composite rare earth permanent magnet doped with the PrCu alloy; in the process of thermal deformation, as a boundary phase, a PrCu phase can isolate two hard magnetic phases, so that the mutual diffusion is reduced, an exchange coupling effect between the two phases is weakened, and the coercive force is improved; in the process of thermal deformation, after being liquefied, the PrCu phase is diffused at a crystal boundary and can also coordinate the thermal deformation of the two phases to promote the thermal deformation of the two phases; the obtained nanocrystalline NdFeB / SmCo5 composite magnet doped with the PrCu alloy has good magnetic property, thermal stability, corrosion resistance and mechanical property.

Owner:BEIJING UNIV OF TECH

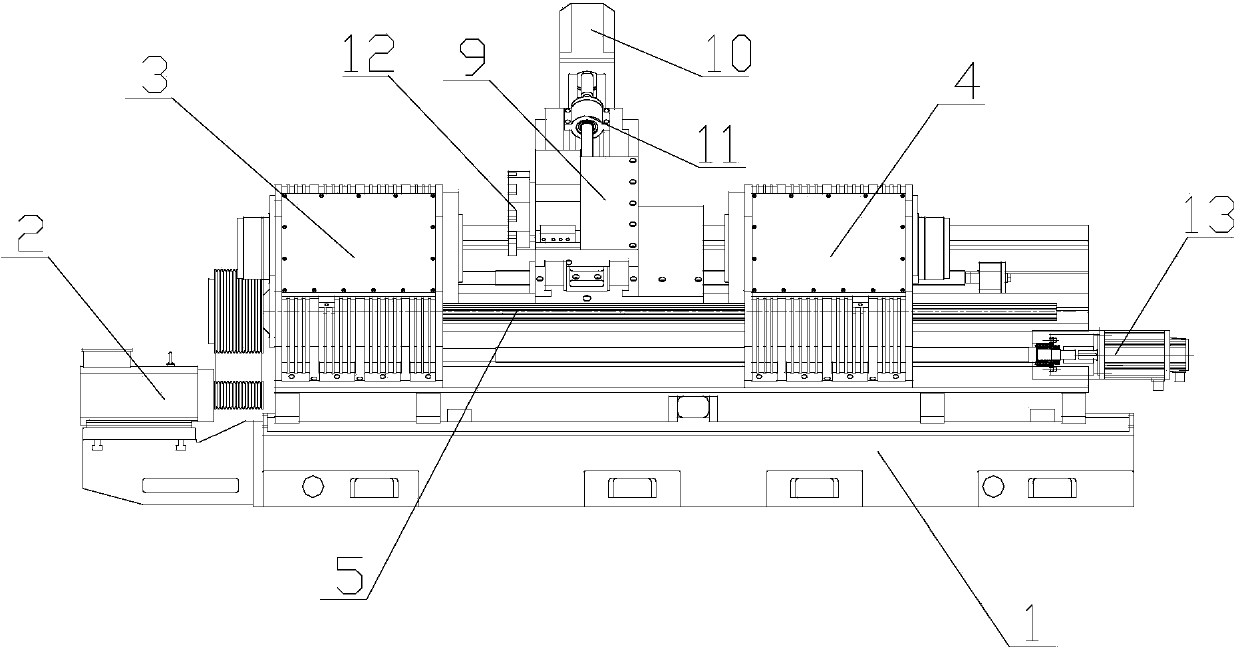

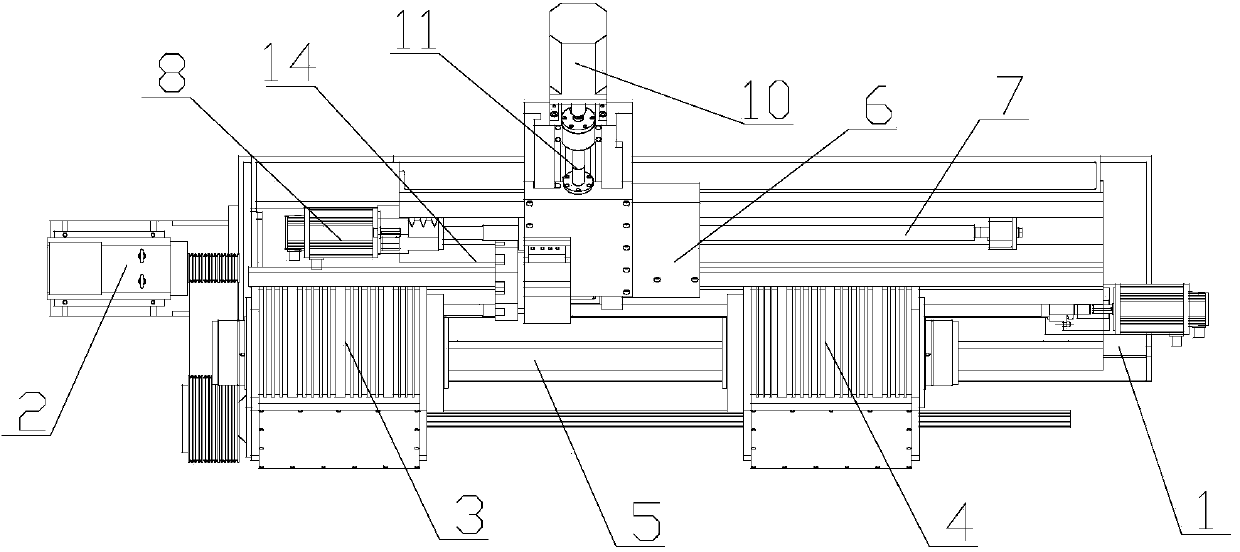

Synchronous double-spindle-box numerically controlled lathe

InactiveCN104190954AReduce coefficient of frictionIncrease coefficient of frictionAutomatic/semiautomatic turning machinesBall screwLong axis

The invention discloses a synchronous double-spindle-box numerically controlled lathe. The synchronous double-spindle-box numerically controlled lathe comprises a lathe body and a main motor arranged on one side of the lathe body, wherein a left spindle box and a right spindle box are arranged at the two ends of the lathe body, a synchronous shaft is arranged between the left spindle box and the right spindle box, the lathe body is provided with a lathe saddle, the lathe saddle is provided with a ball screw a, a servo driving motor a is arranged on one side of the lathe saddle, a middle supporting plate is arranged on the lathe saddle, a servo driving motor b is arranged on one side of the middle supporting plate, a ball screw b is arranged in the middle supporting plate, and an electric tool tower is arranged on the middle supporting plate. When the lathe machines a long-axis-class workpiece, the two ends of the workpiece can be clamped and rotate synchronously, multiple times of machining can be carried out on the workpiece through one time of clamping, and production efficiency is improved. Thus, the dimensional accuracy of the workpiece is guaranteed, the automation degree is high, the productivity efficiency is improved by 6-8 times, and the labor cost is largely reduced.

Owner:LIUAN RUIPU NC MACHINERY

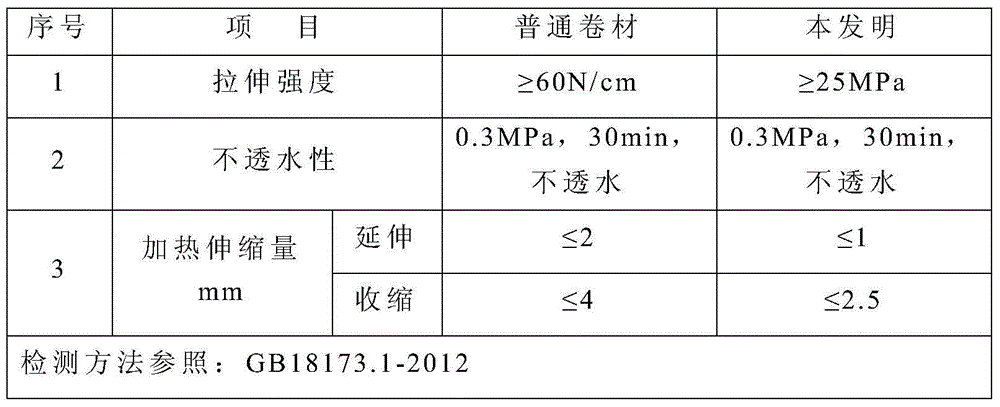

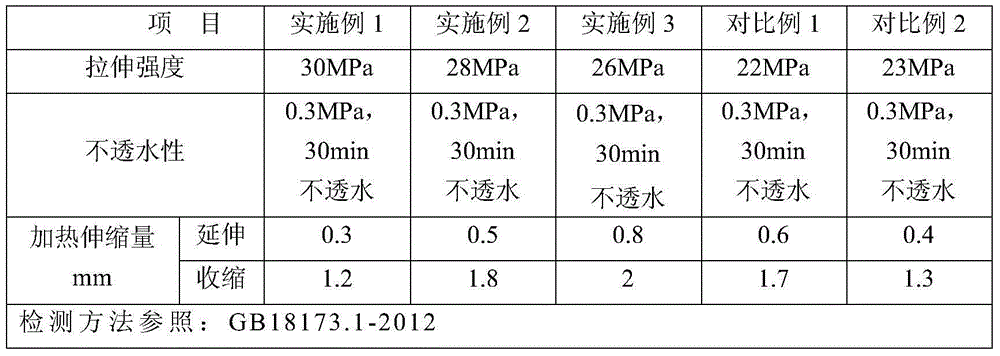

Carbon fiber reinforced polyethylene waterproof roll and preparation method thereof

ActiveCN104893084AImprove waterproof performanceGood physical and mechanical propertiesLow-density polyethyleneFiber

The invention provides a carbon fiber reinforced polyethylene waterproof roll and a preparation method thereof. The preparation method comprises the steps of fully mixing 56-90 parts of linear low density polyethylene (LLDPE) resin, 9-40 parts of chopped carbon fiber, 0.1-0.2 part of an antioxidant and 0.1-0.2 part of white oil, and then granulating; and mixing 95-100 parts of a granulated product, 3-5 parts of carbon black, 0.1-0.2 part of an antioxidant and 0.1-0.2 part of white oil, then plasticizing, extruding, shaping and cooling to obtain the final product. The carbon fiber reinforced polyethylene waterproof roll provided by the invention can overcome adverse effects caused by differences between interlayer structures, and the strength of the carbon fiber reinforced polyethylene waterproof roll is greatly improved.

Owner:天津市禹红建筑防水材料有限公司

Corrosion resistance aluminum alloy plate for aviation and preparation method of corrosion resistance aluminum alloy plate

InactiveCN111926225AImproves corrosion performance and toughnessGood overall performanceCorrosionAluminium alloy

The invention relates to the technical field of aluminum alloy processing, in particular to a preparation method of an aluminum alloy plate for aviation. The aluminum alloy comprises the following chemical components of, in percentage by mass, 0.05%-0.2% of zirconium, 0.05%-0.2% of scandium, 3.0%-6.0% of zinc, 3.0%-6.0% of magnesium, 3.0%-4.0% of copper, 0.2%-0.4% of silver, 0.05%-0.2% of lithium,1.0%-1.5% of manganese, 0.8%-1.5% of silicon, 0.20%-0.40% of titanium, 0.05%-0.1% of ruthenium, and the balance aluminum and inevitable impurities, and the content of the impurities is controlled tobe 0.15% or below; and an aluminum alloy melt is prepared according to pre-prepared materials, ultrasonic vibration is adopted in a refining process to refine grains, and then the aluminum alloy platefor the aviation is obtained through pouring, homogenization, extrusion, solid solution treatment, pre-stretching and three-stage aging treatment. According to the corrosion resistance aluminum alloyplate for the aviation and the preparation method of the corrosion resistance aluminum alloy plate, the Vickers hardness of the prepared aluminum alloy plate ranges from 175 Hv to 190 Hv, the yield strength ranges from 520 MPa to 562 MPa, the tensile strength ranges from 605 MPa to 656 MPa, the elongation ranges from 9.4% to 12%, the overall performance is excellent, and the aluminum alloy plateis particularly suitable for being used in the aerospace field.

Owner:湖南恒佳新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com