Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3710results about "Cycle brakes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

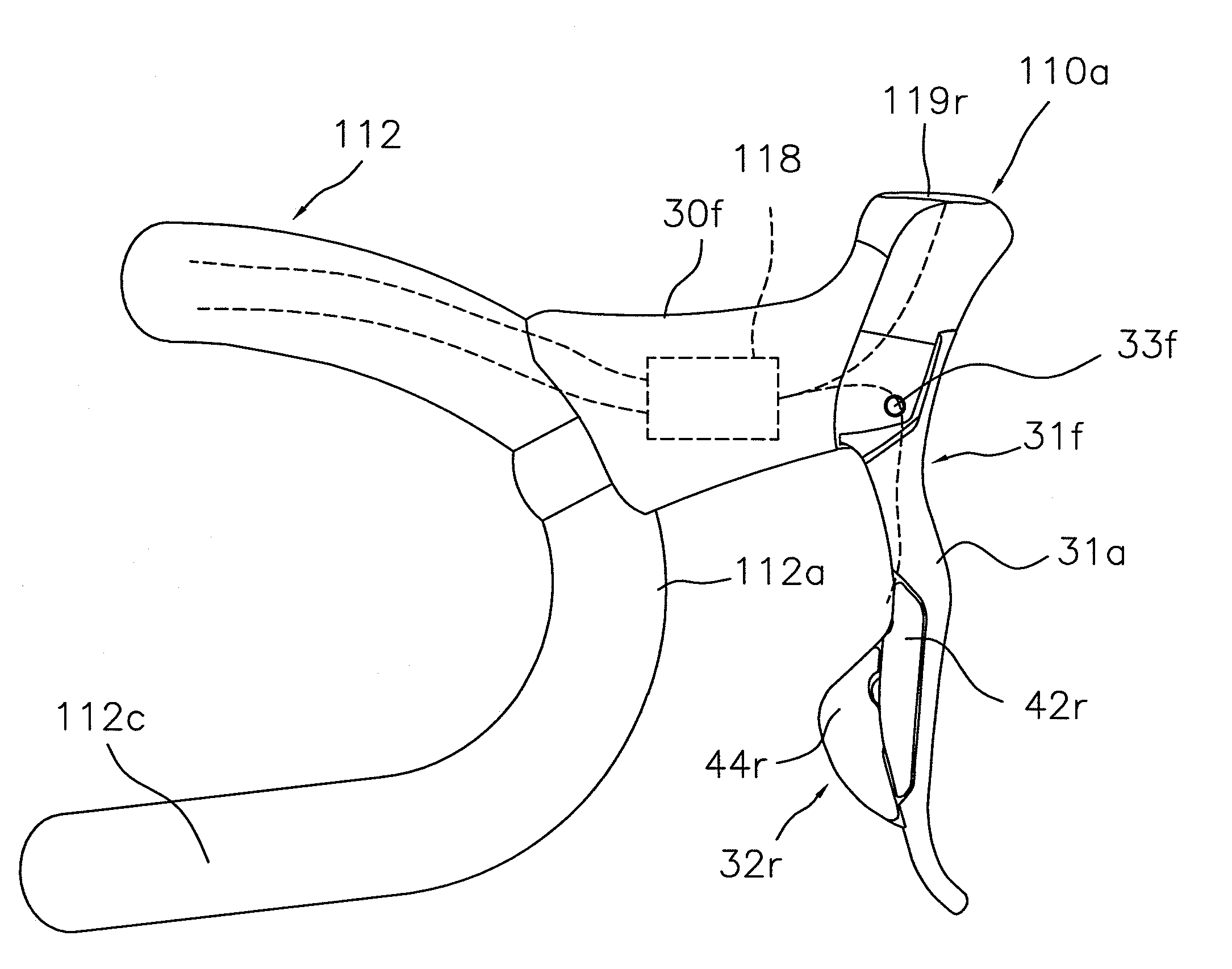

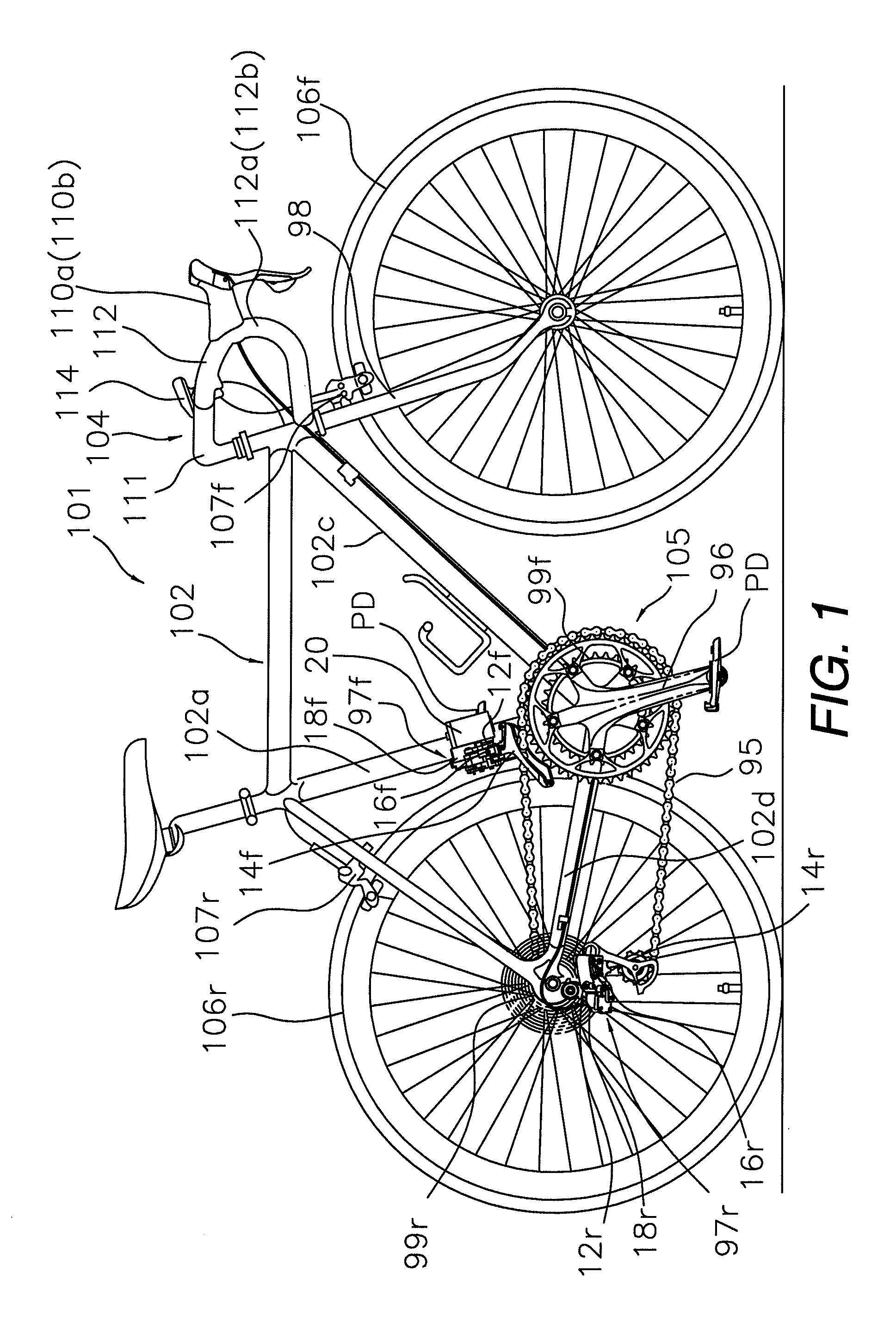

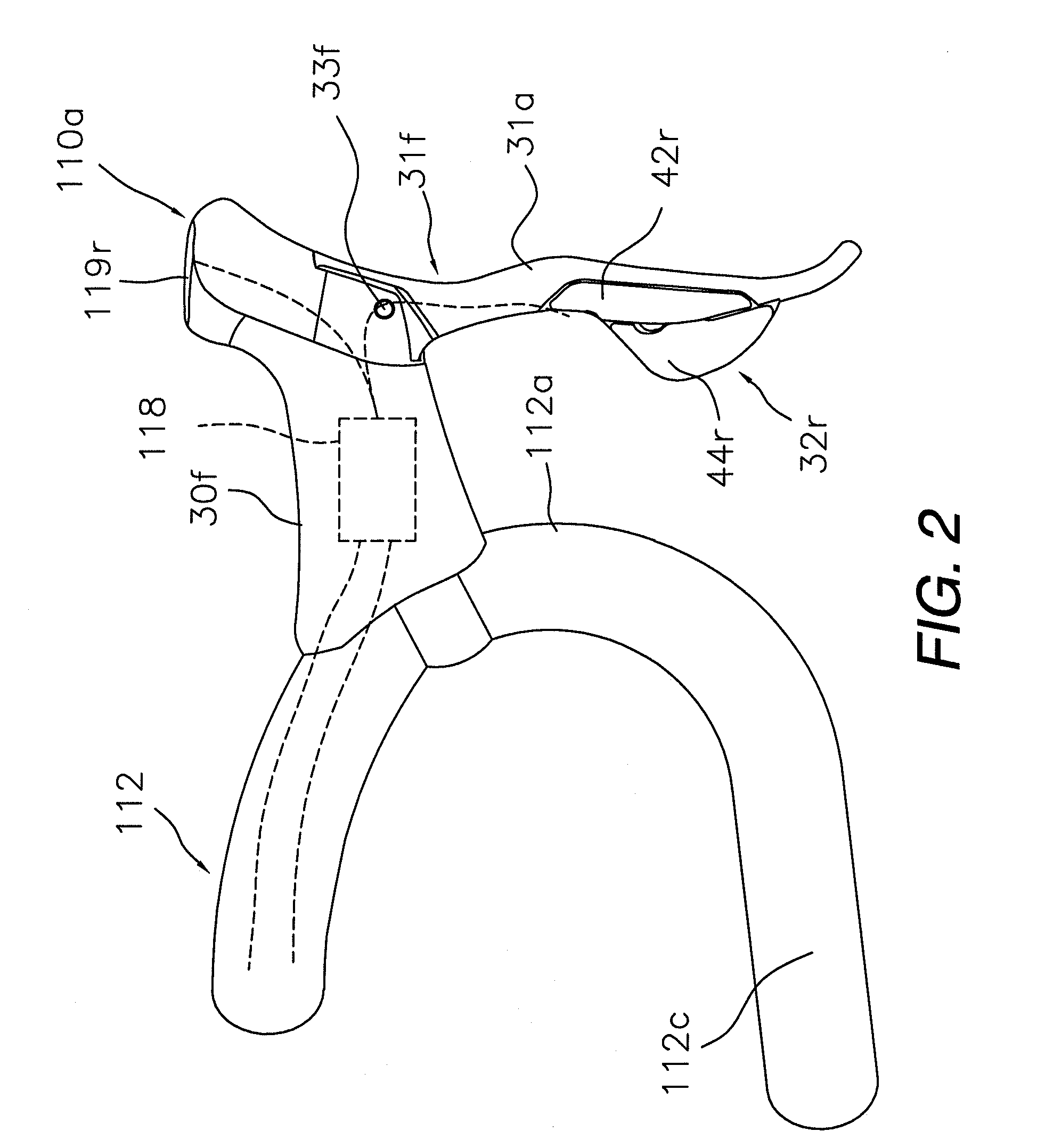

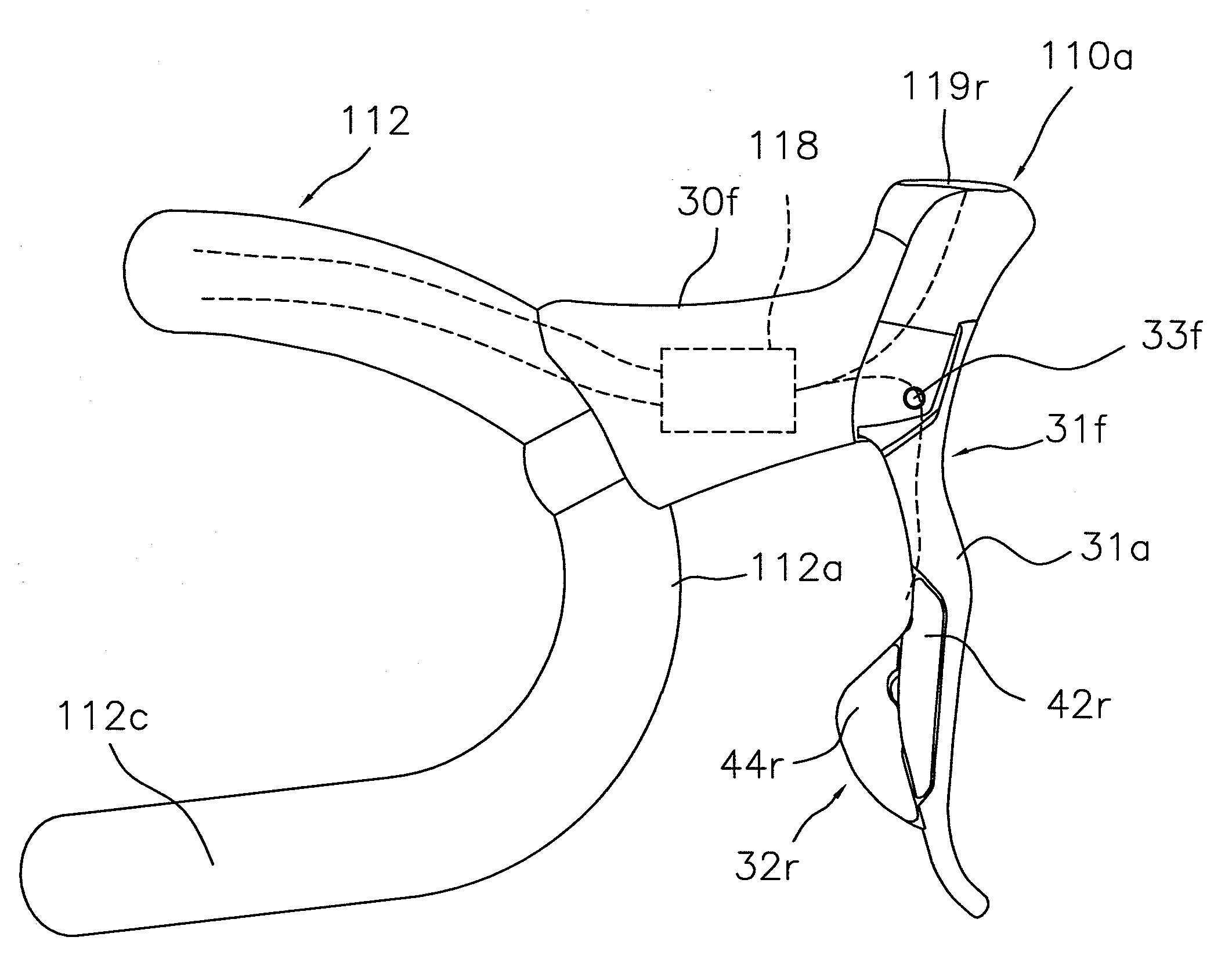

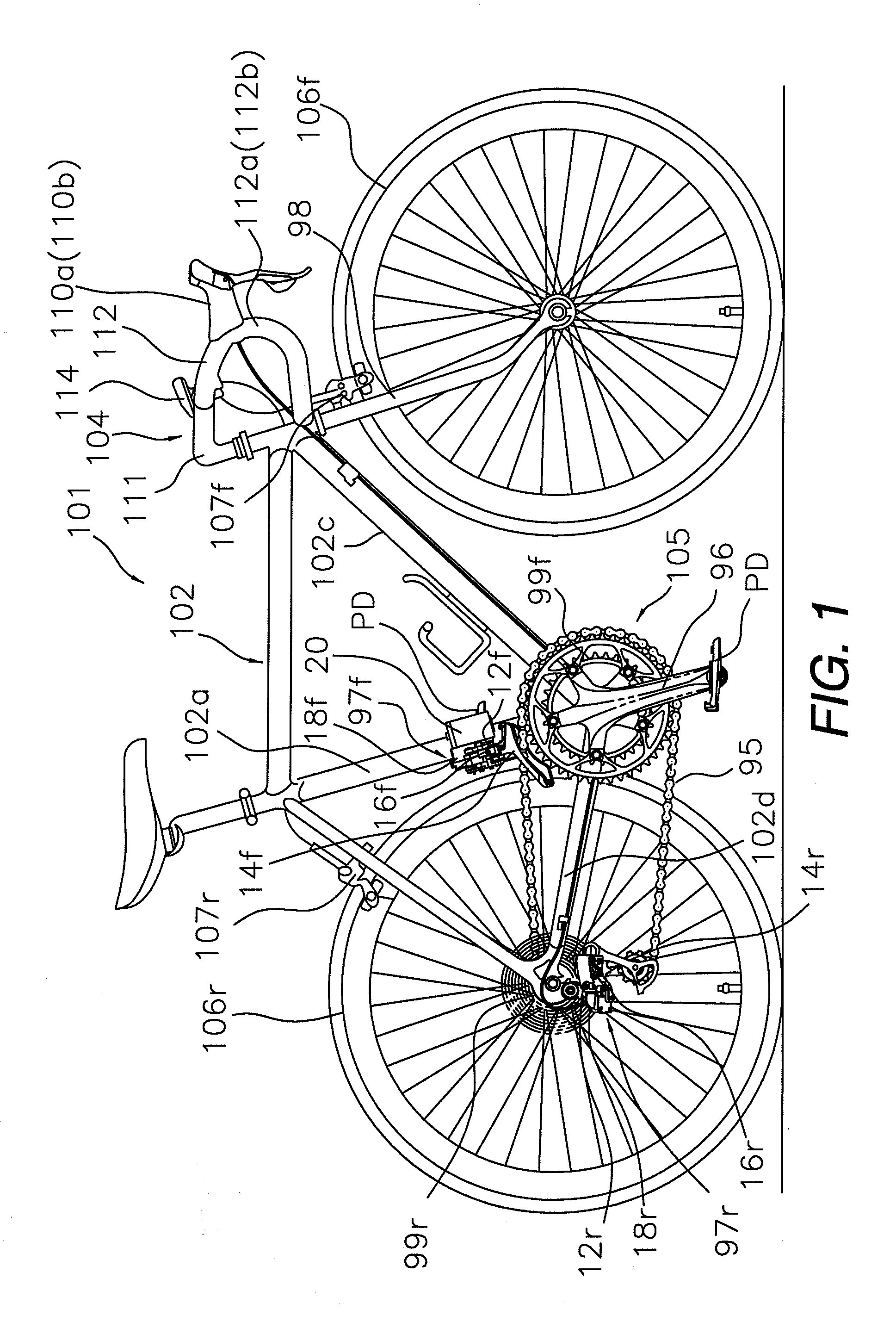

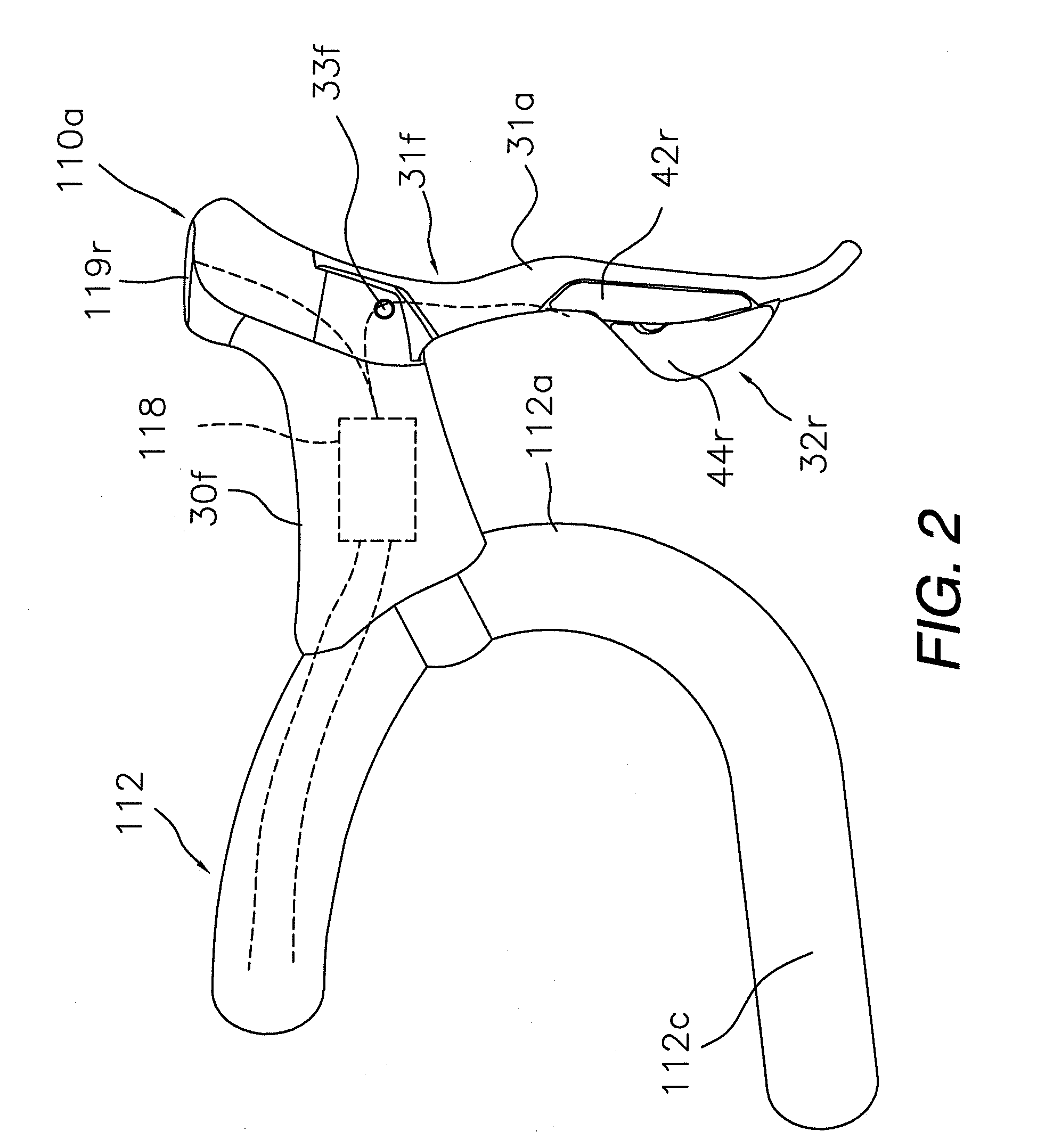

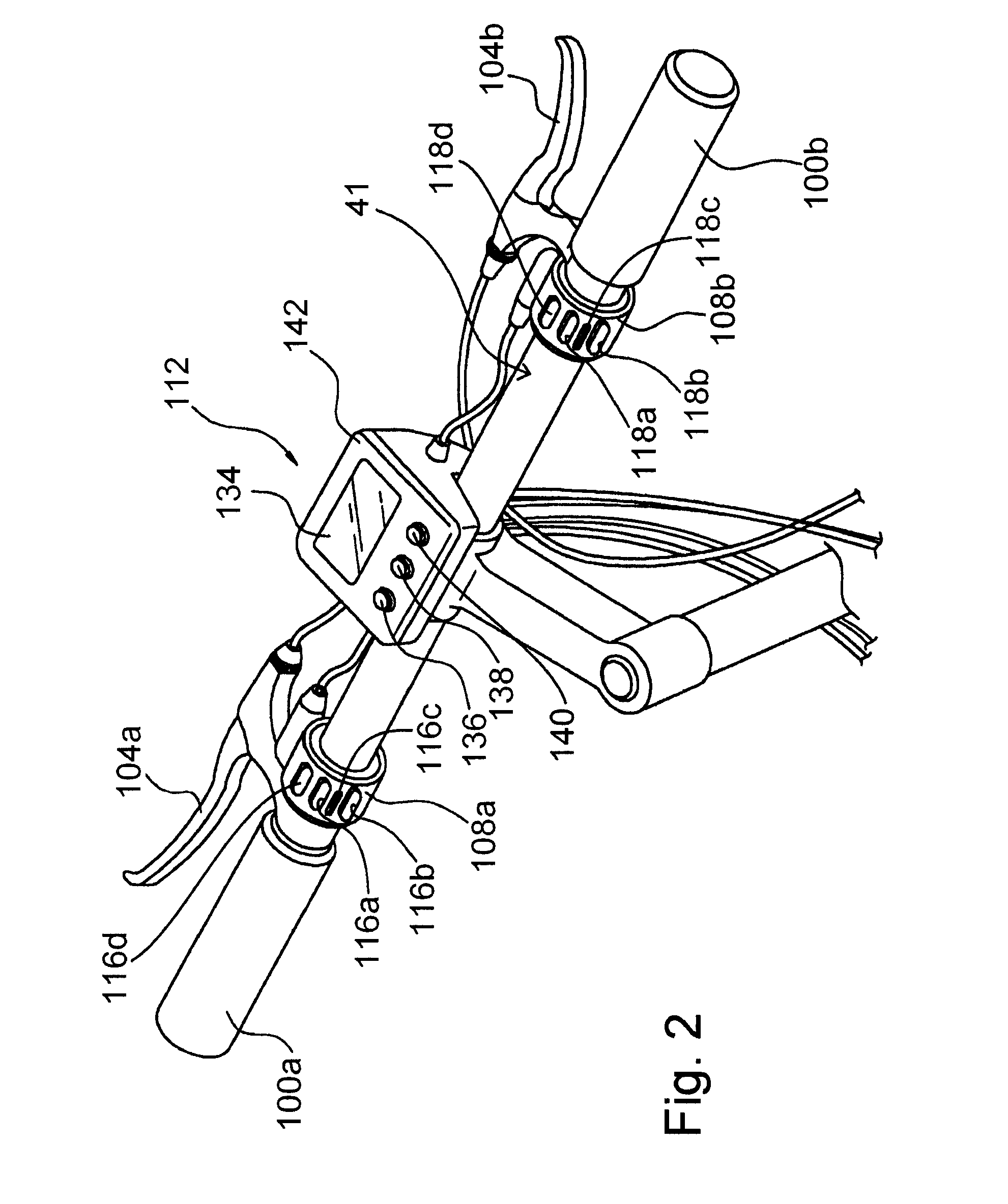

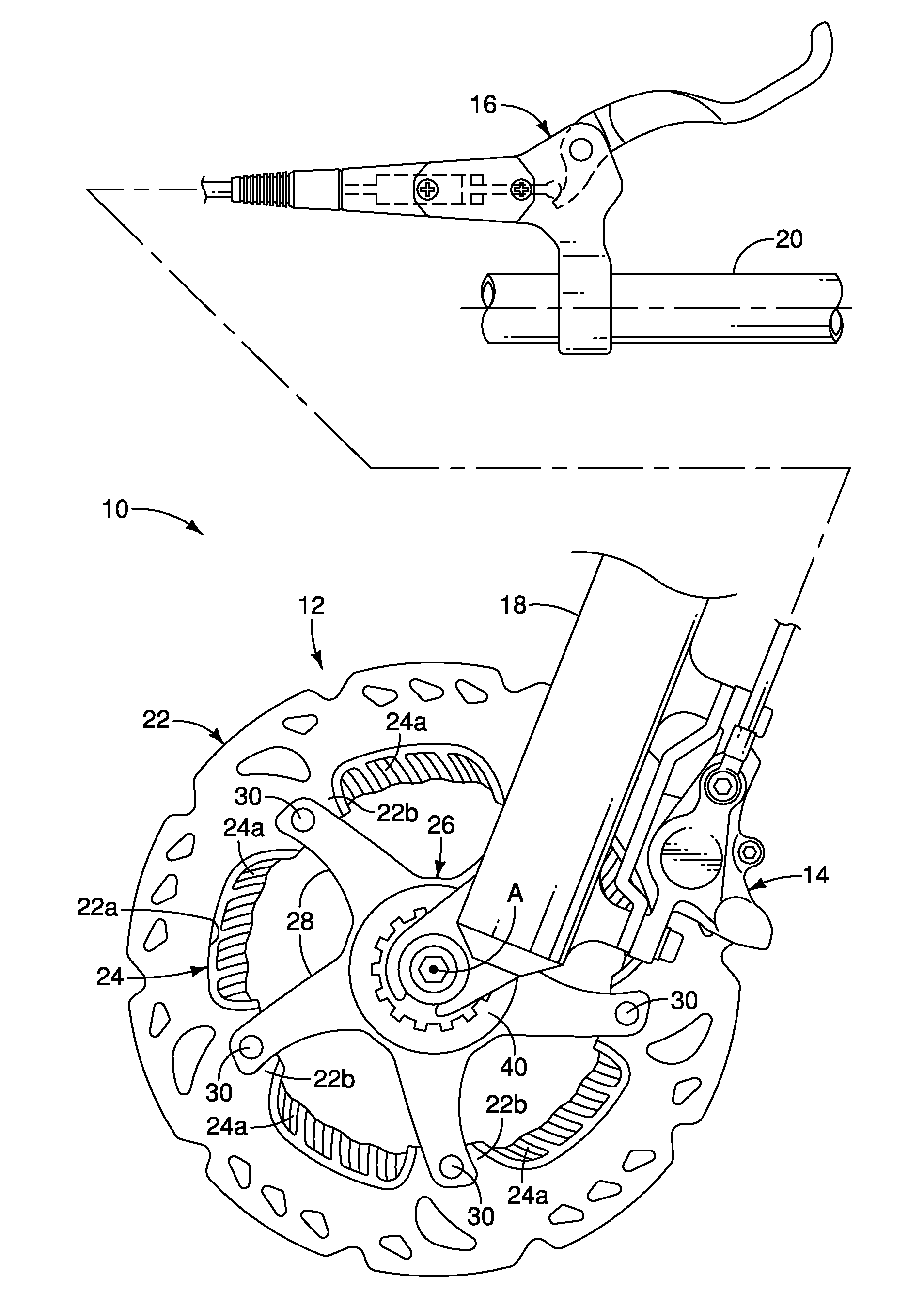

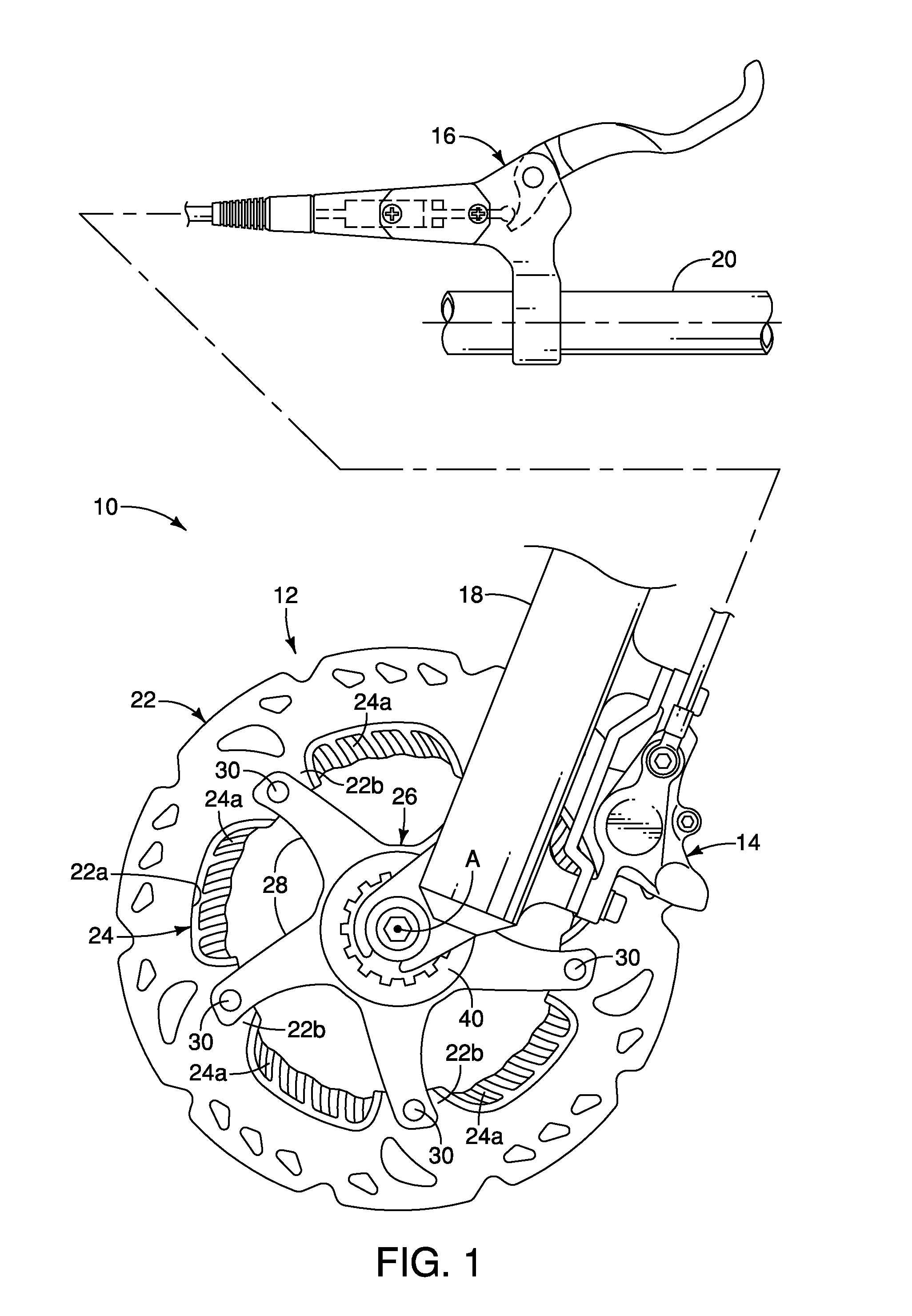

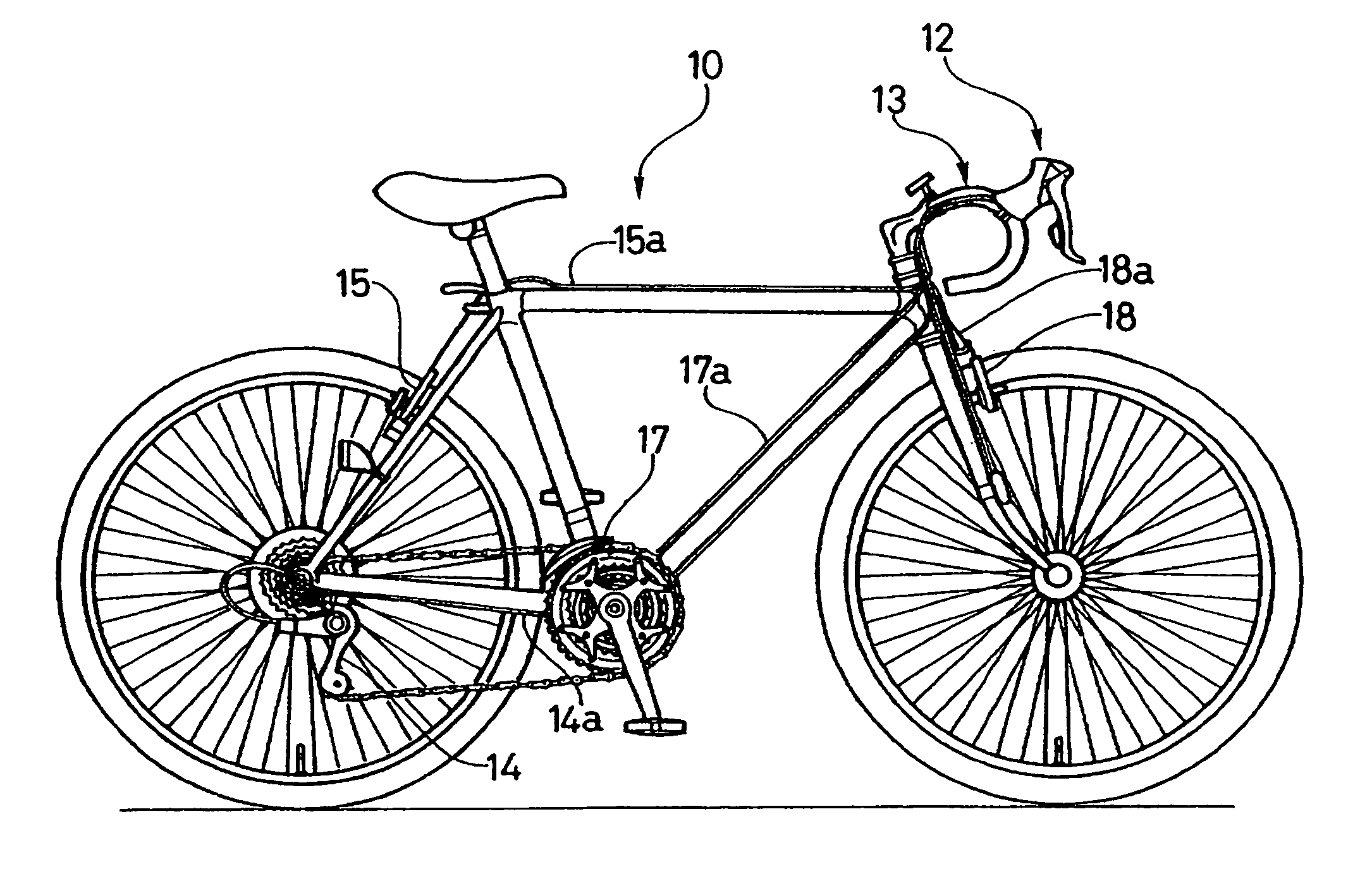

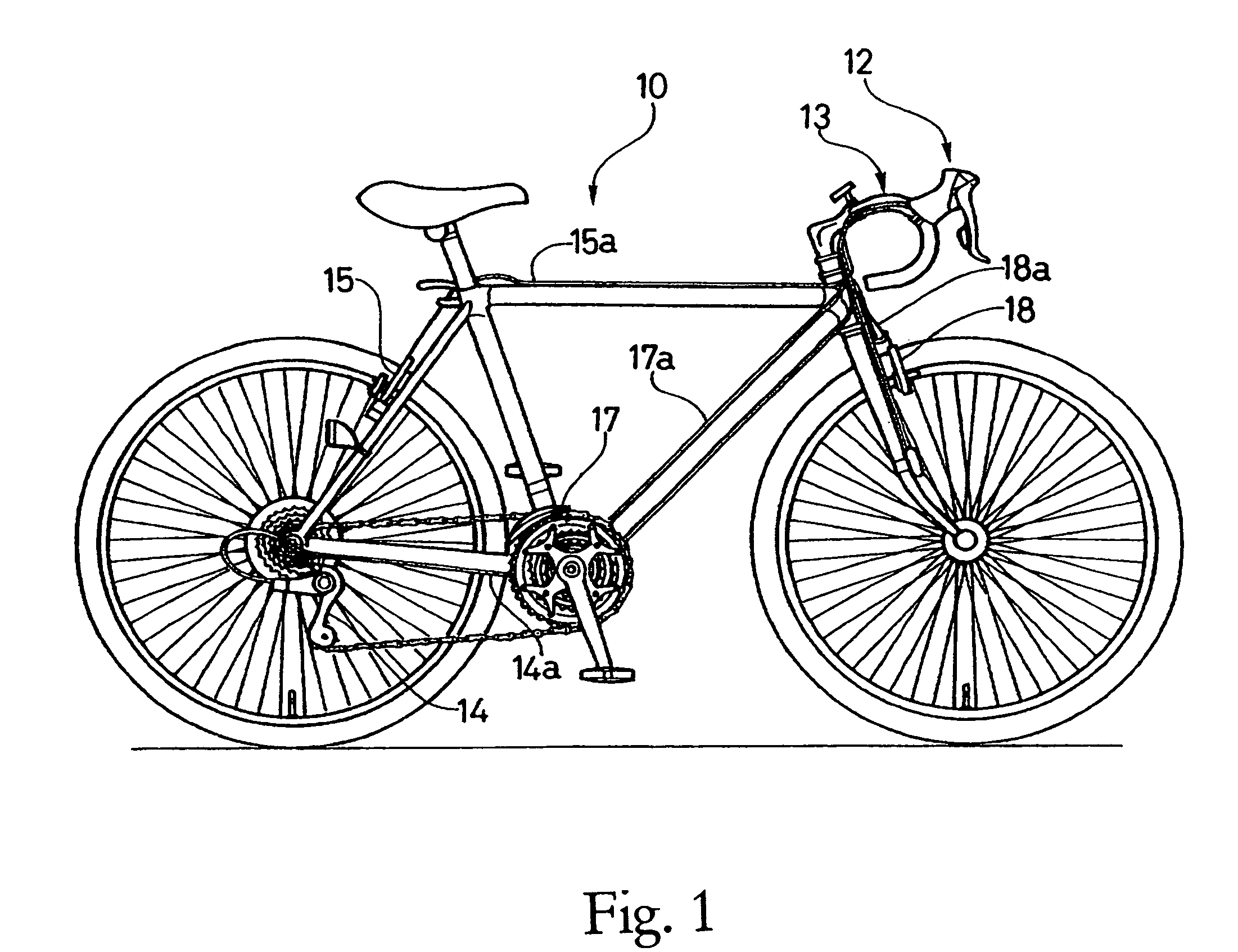

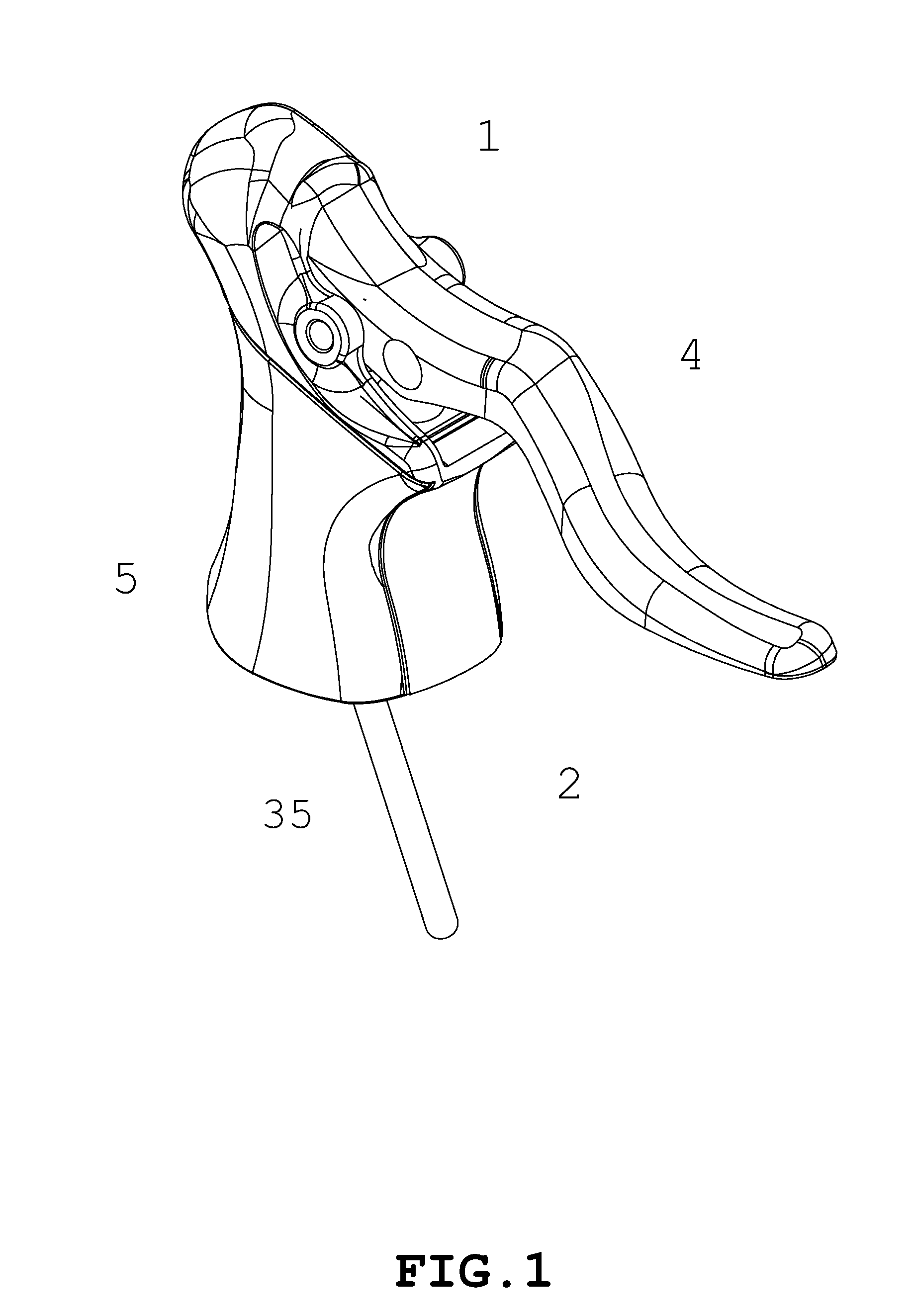

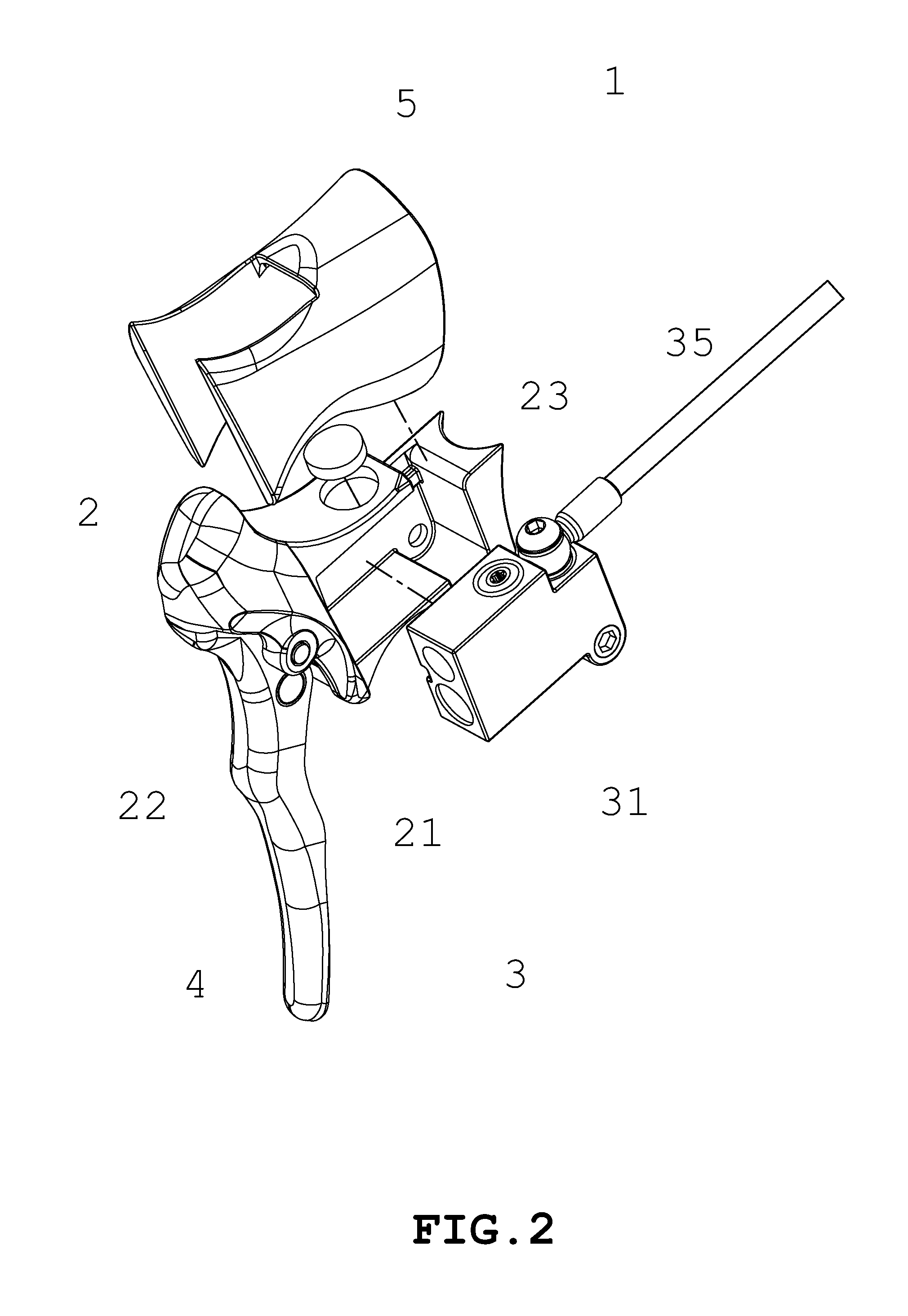

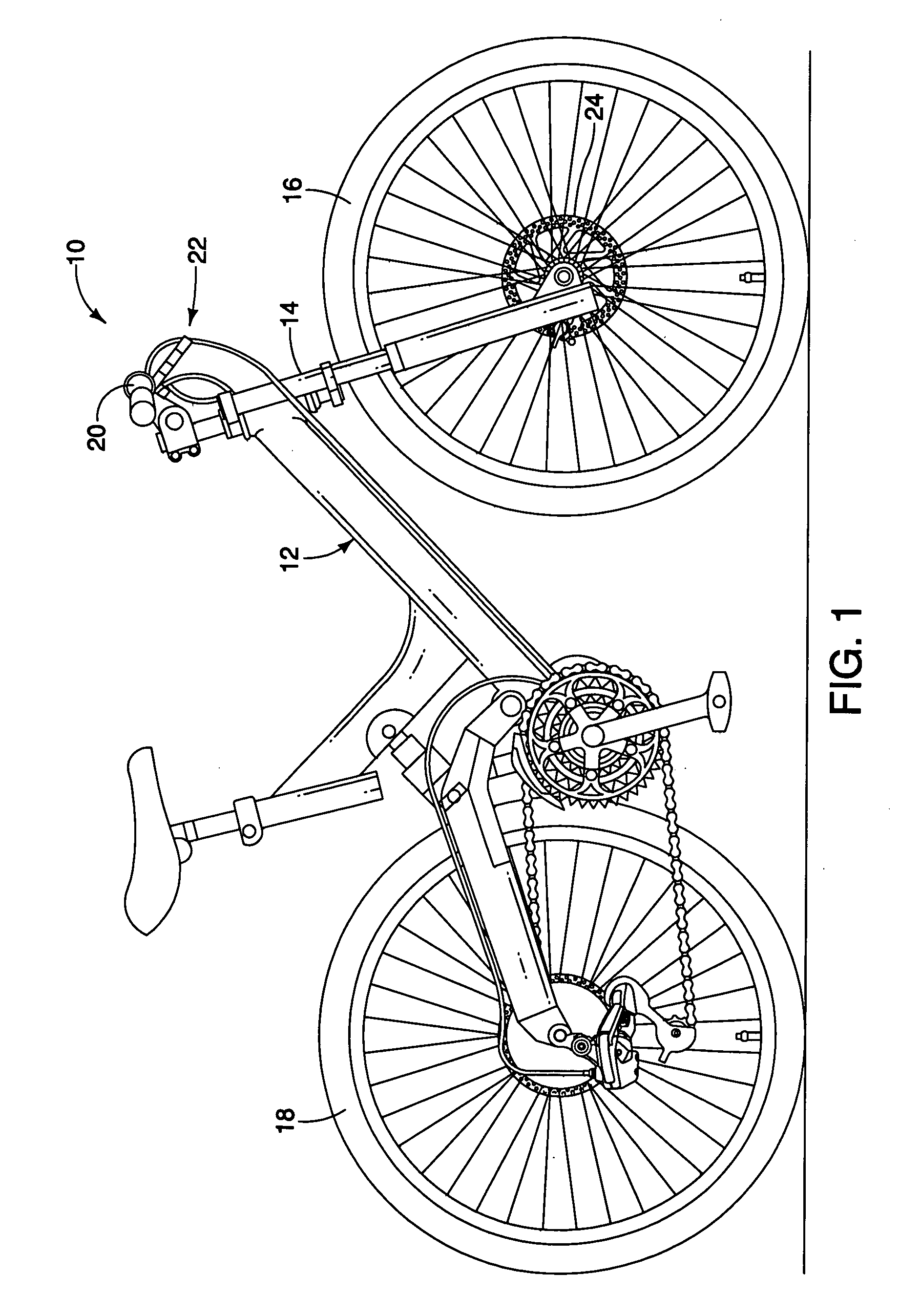

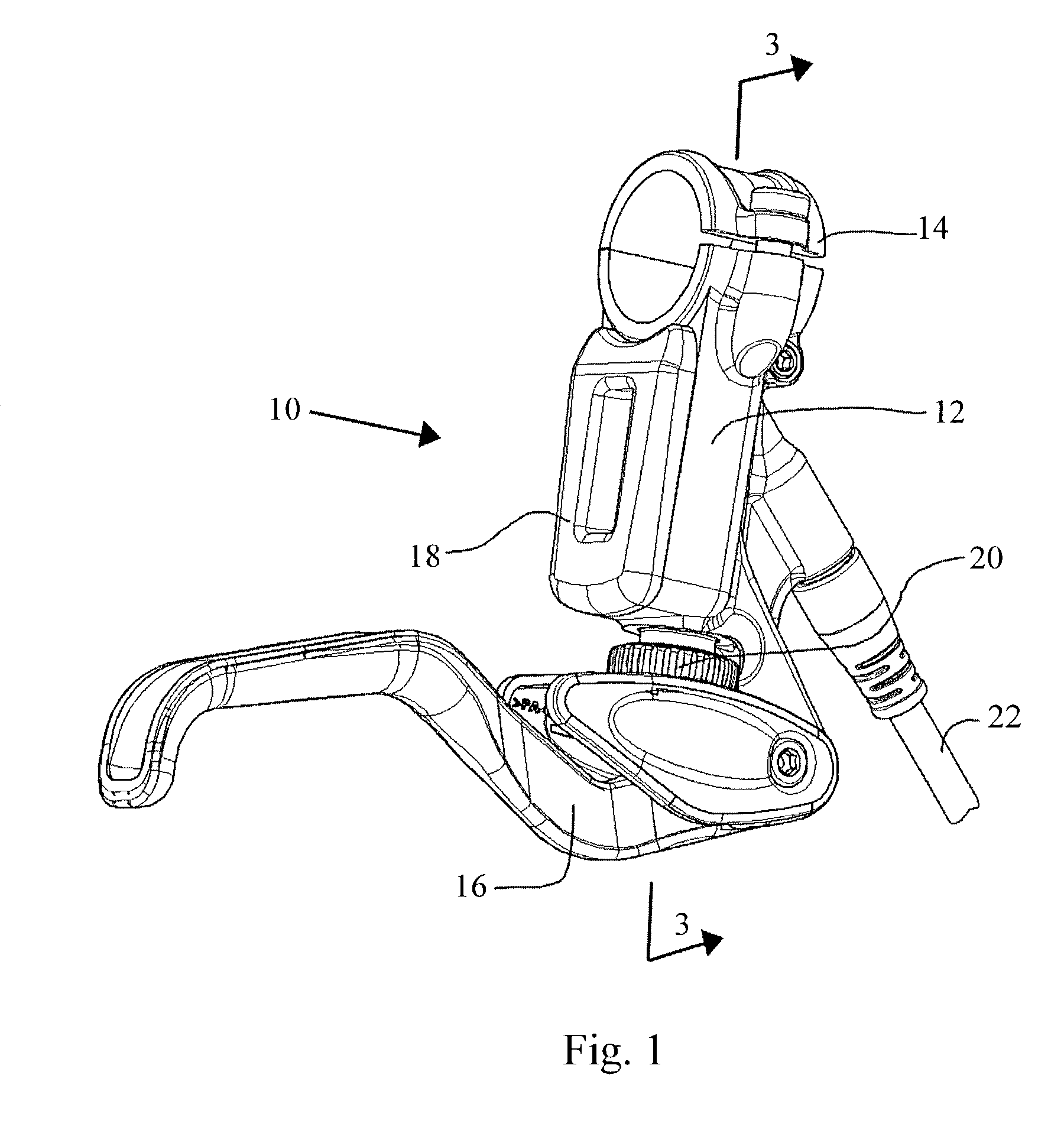

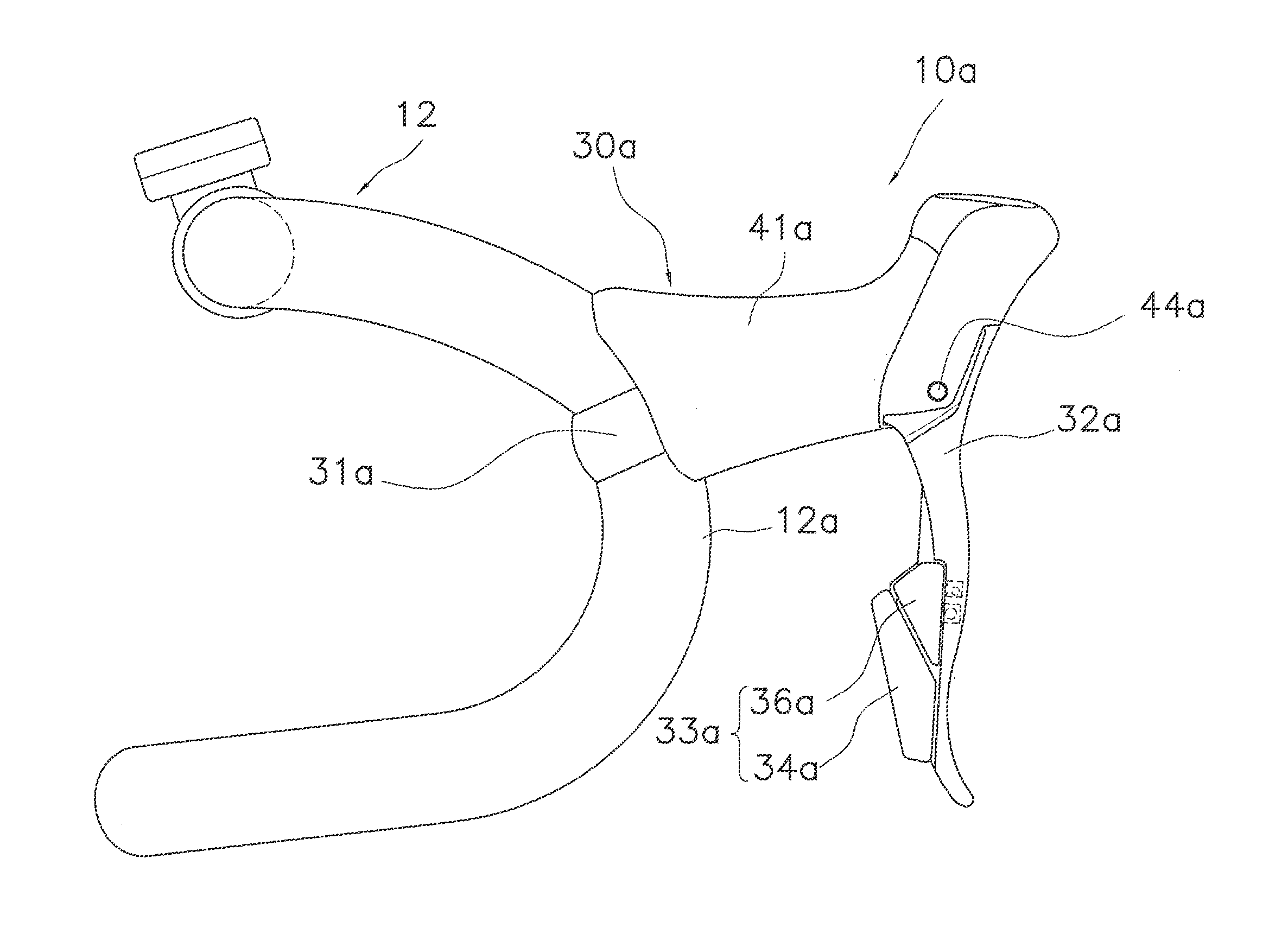

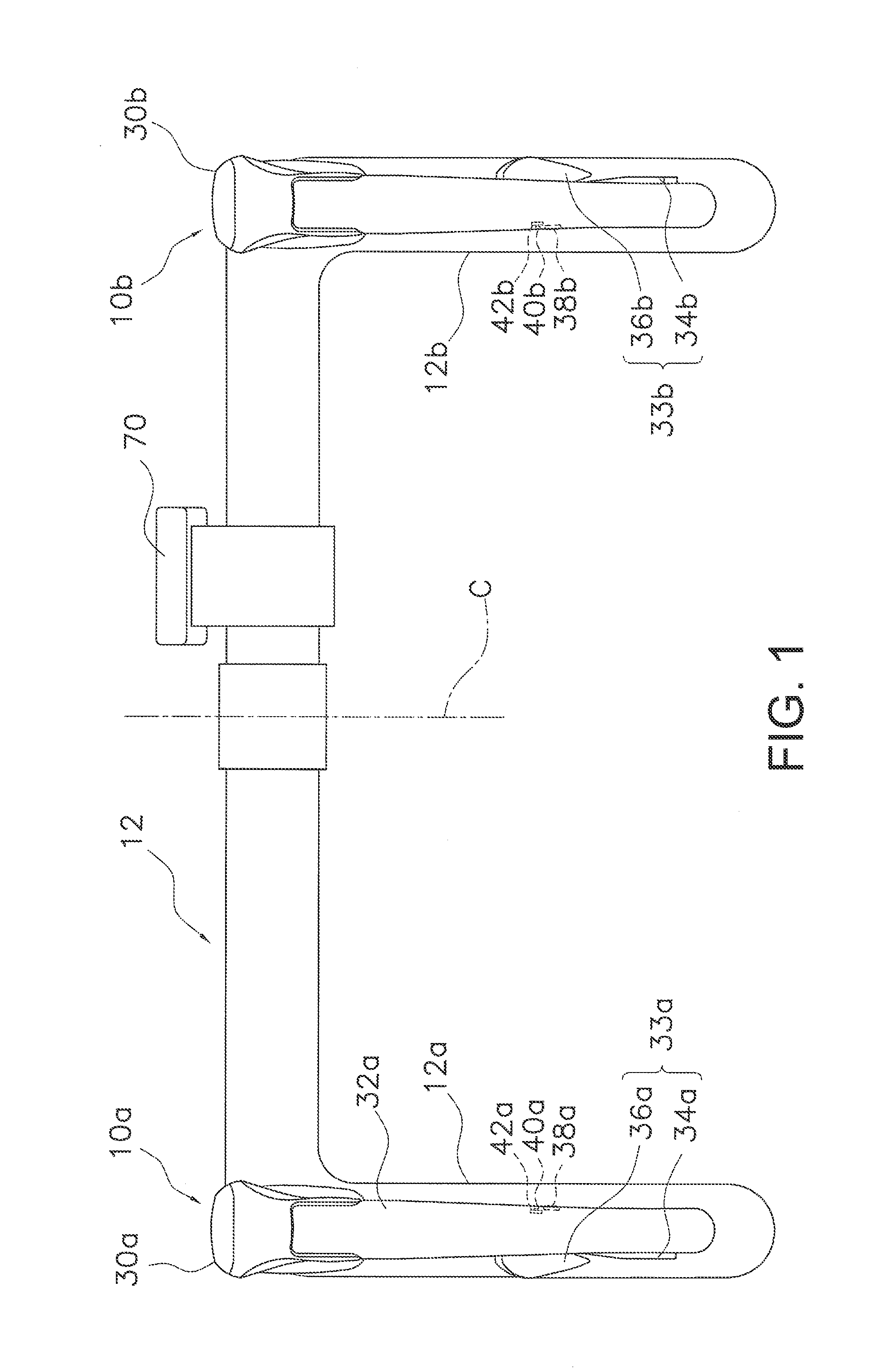

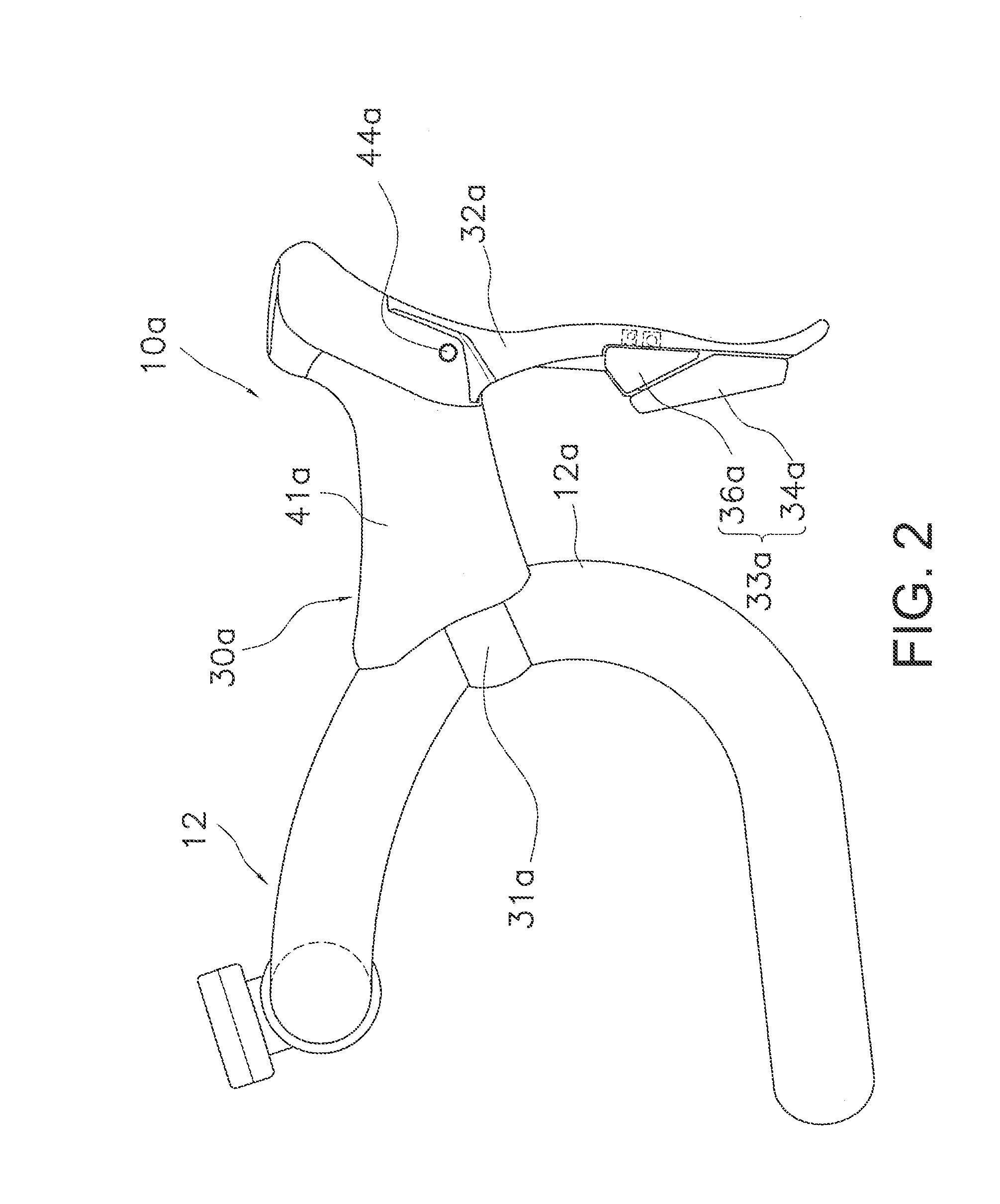

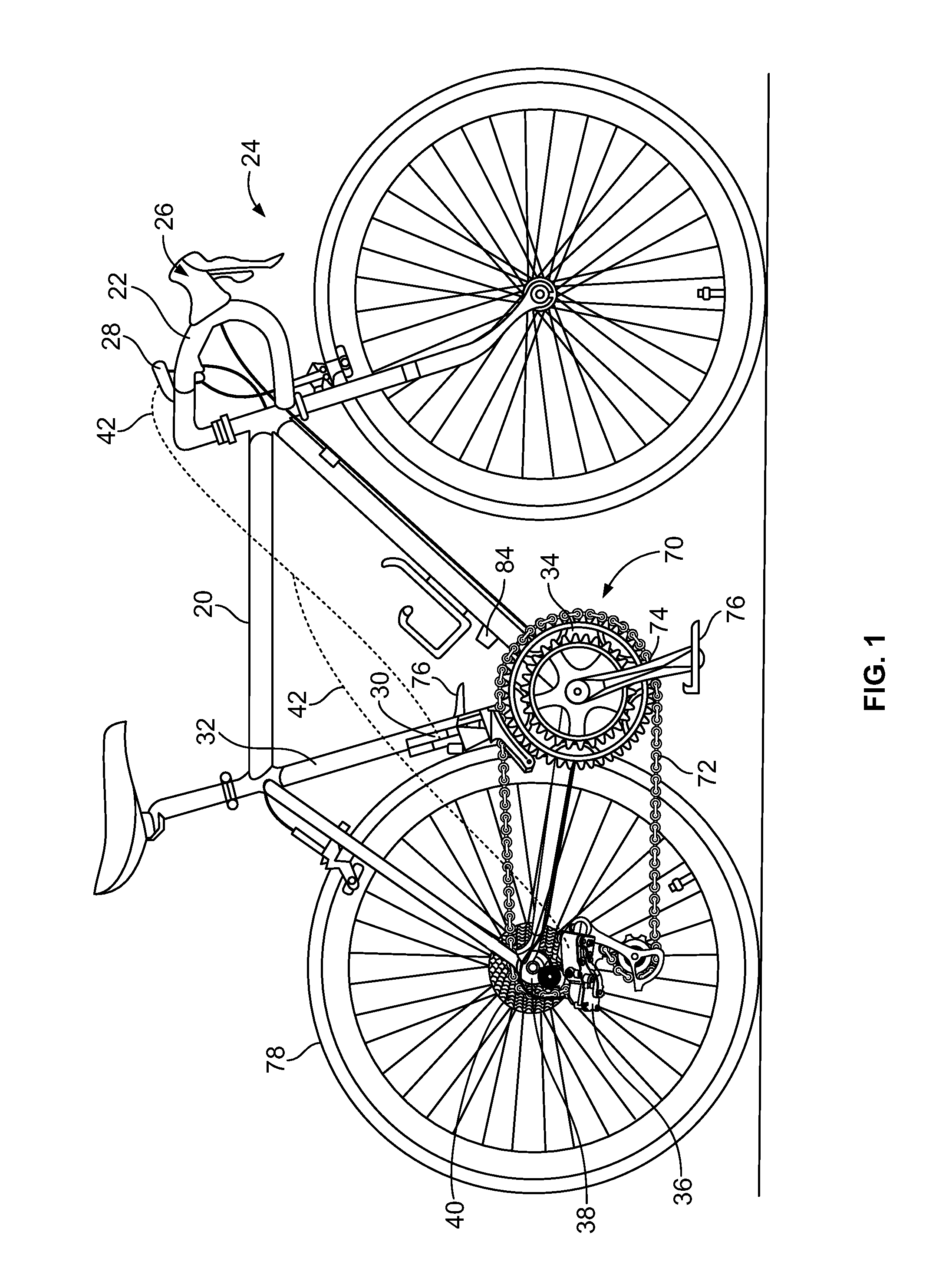

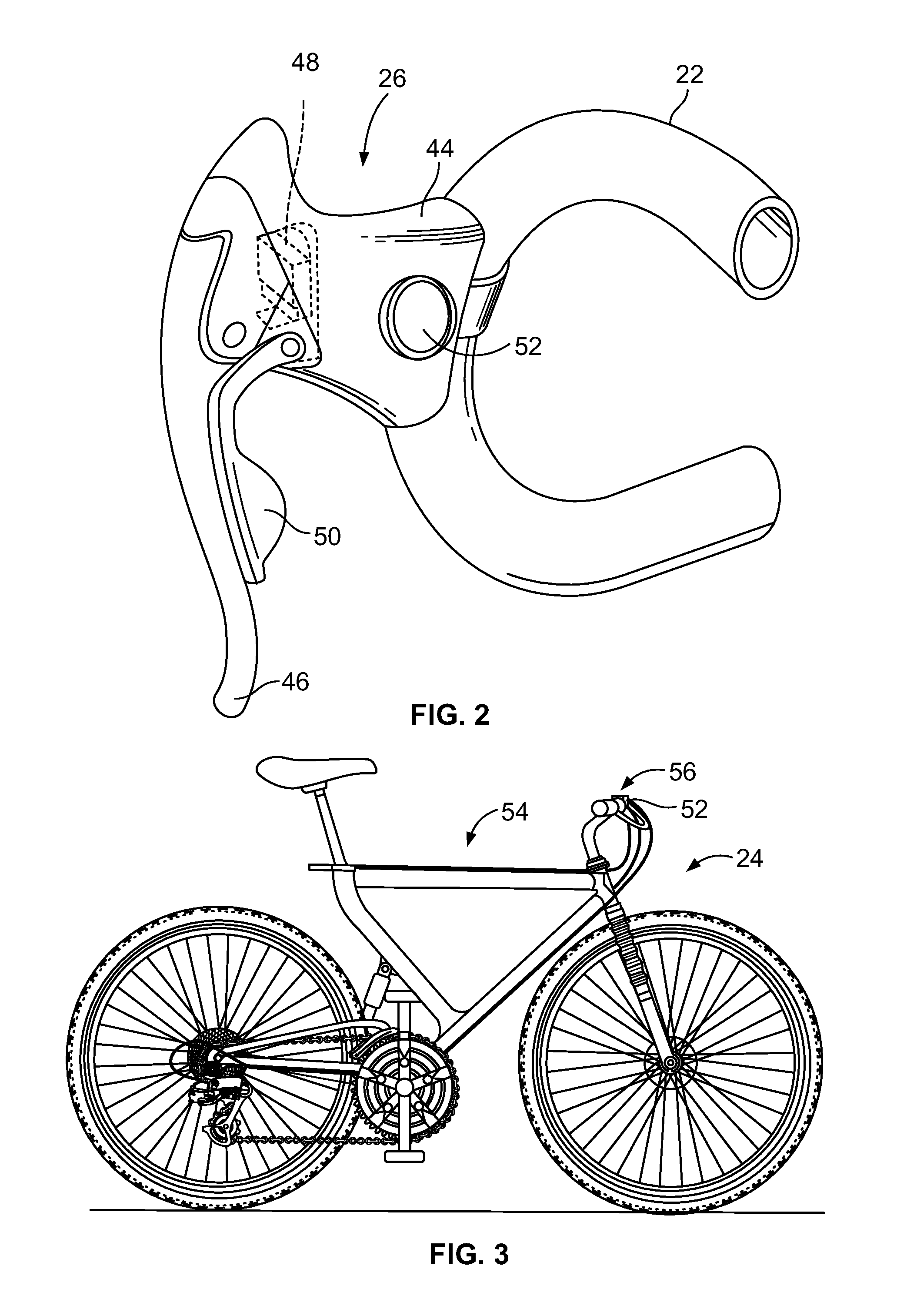

Bicycle control device

ActiveUS7854180B2Avoid it happening againSimple to executeCycle control systemsAxle suspensionsEngineeringElectrical and Electronics engineering

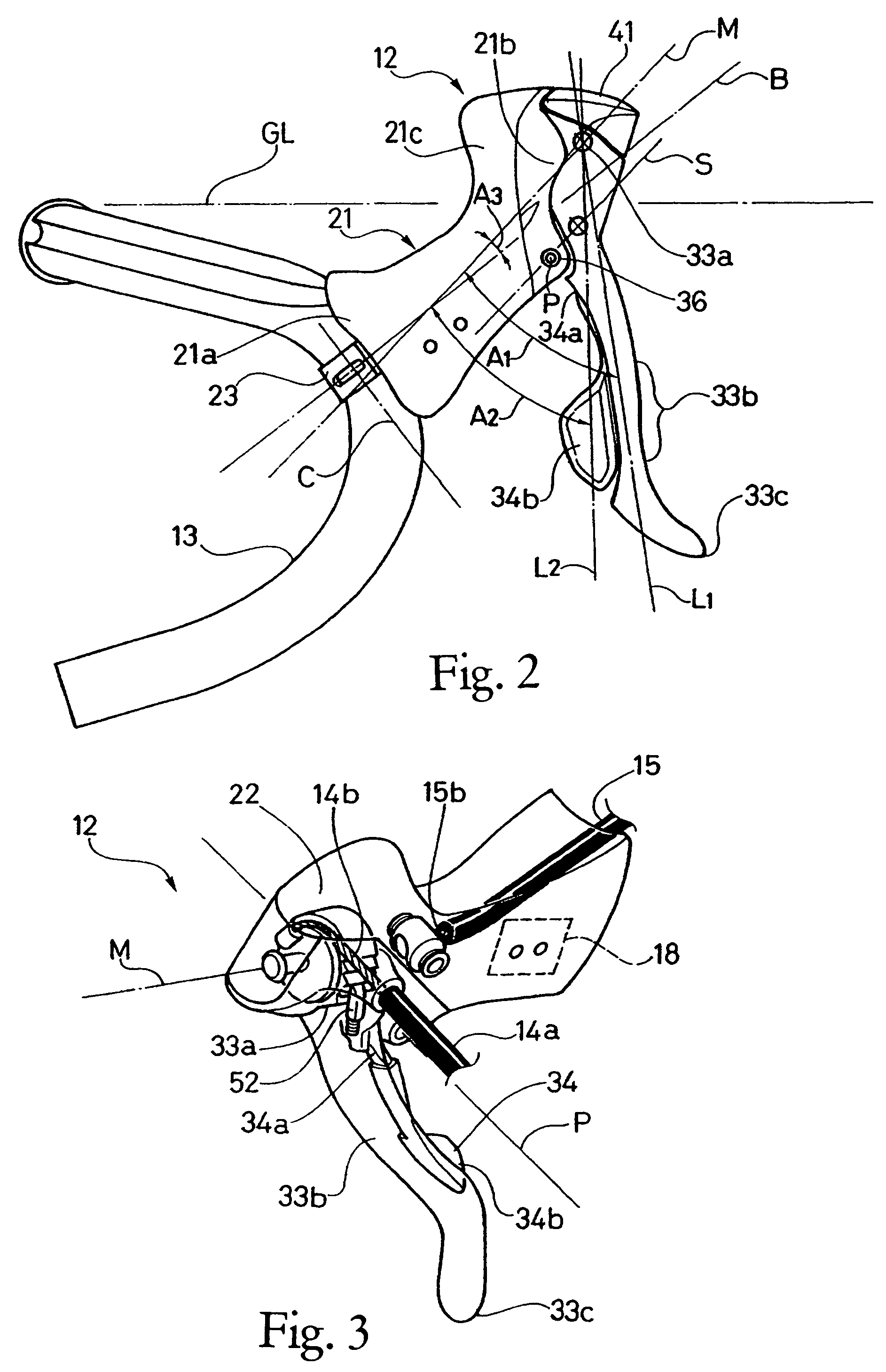

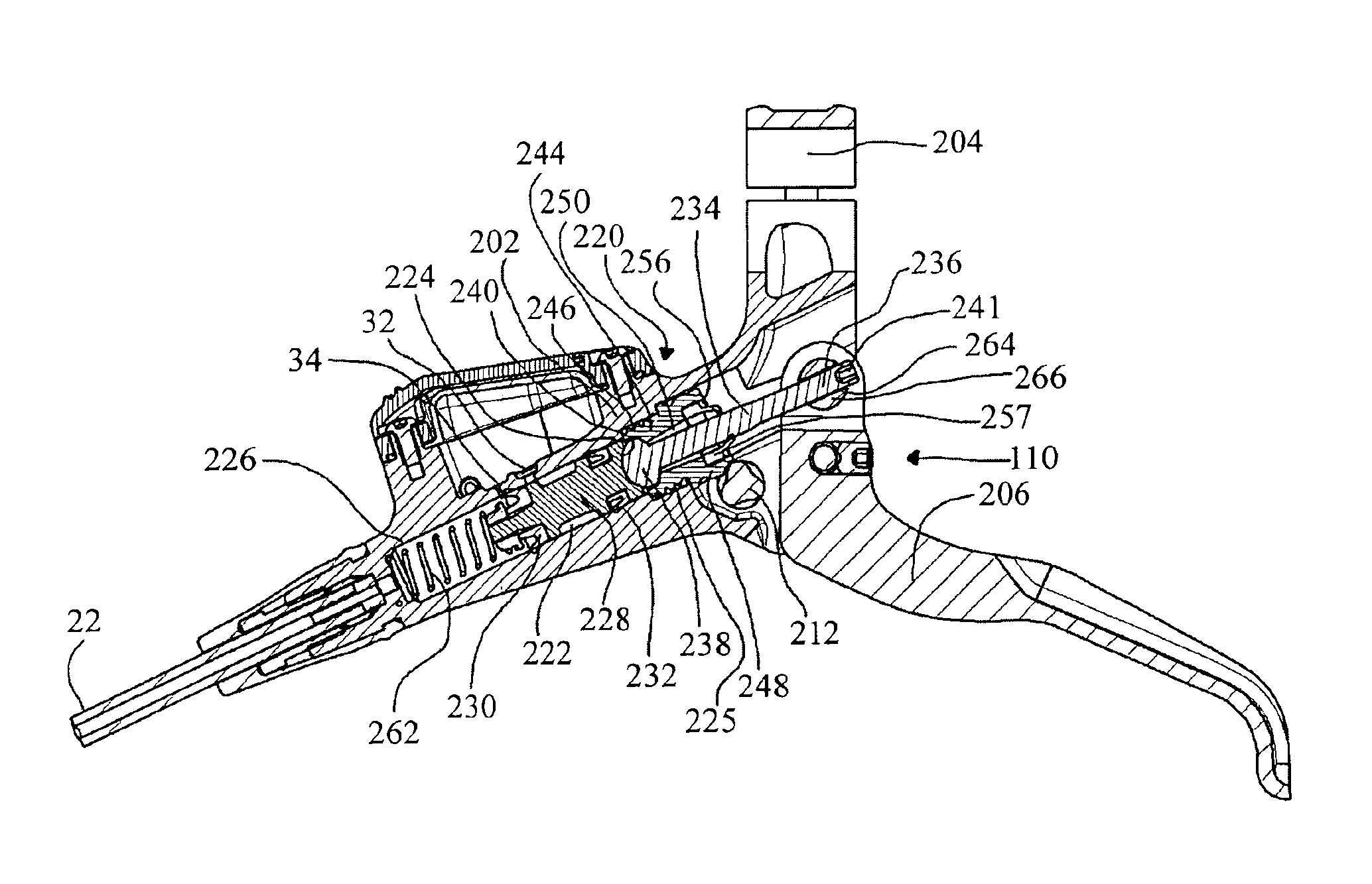

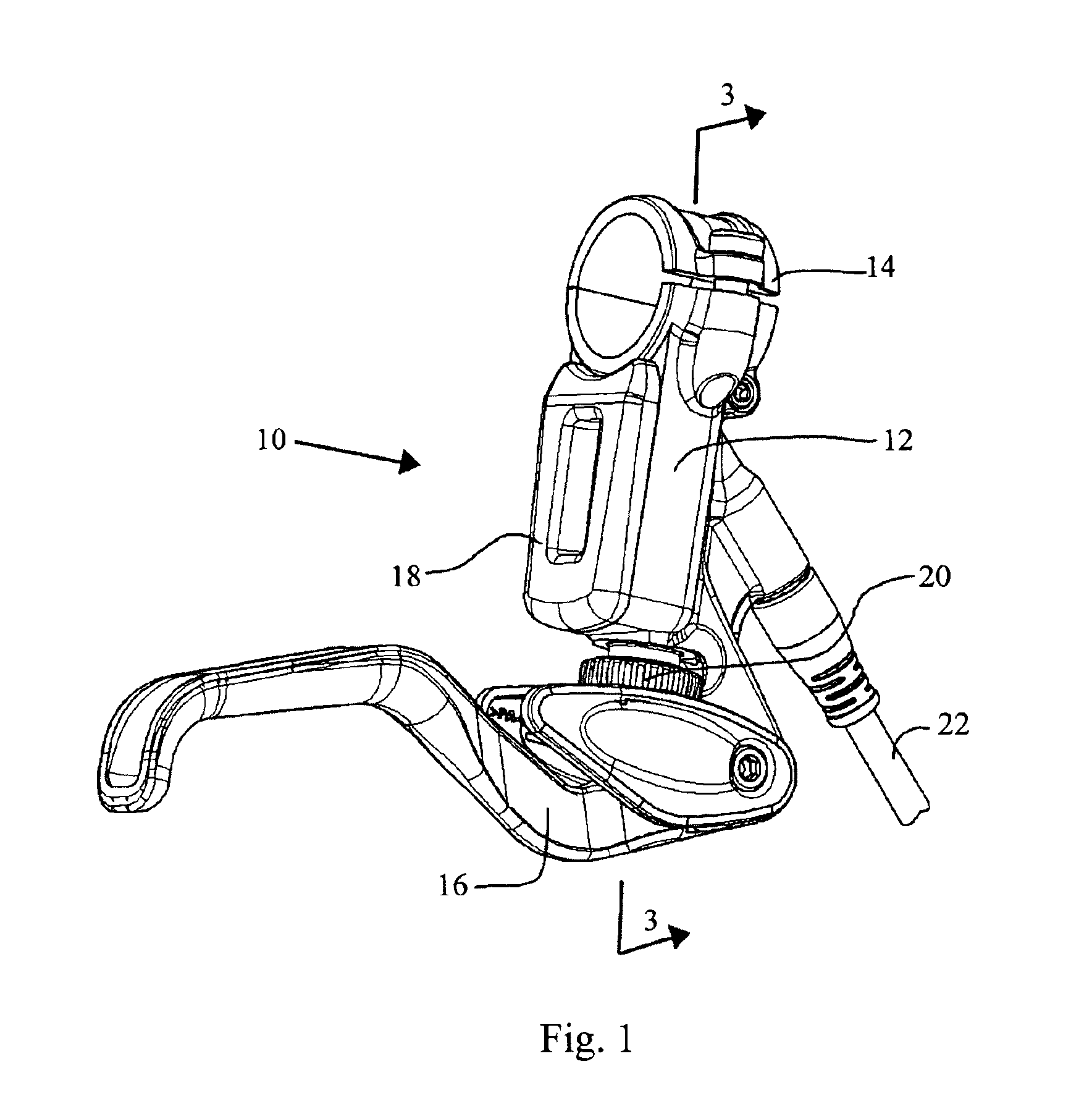

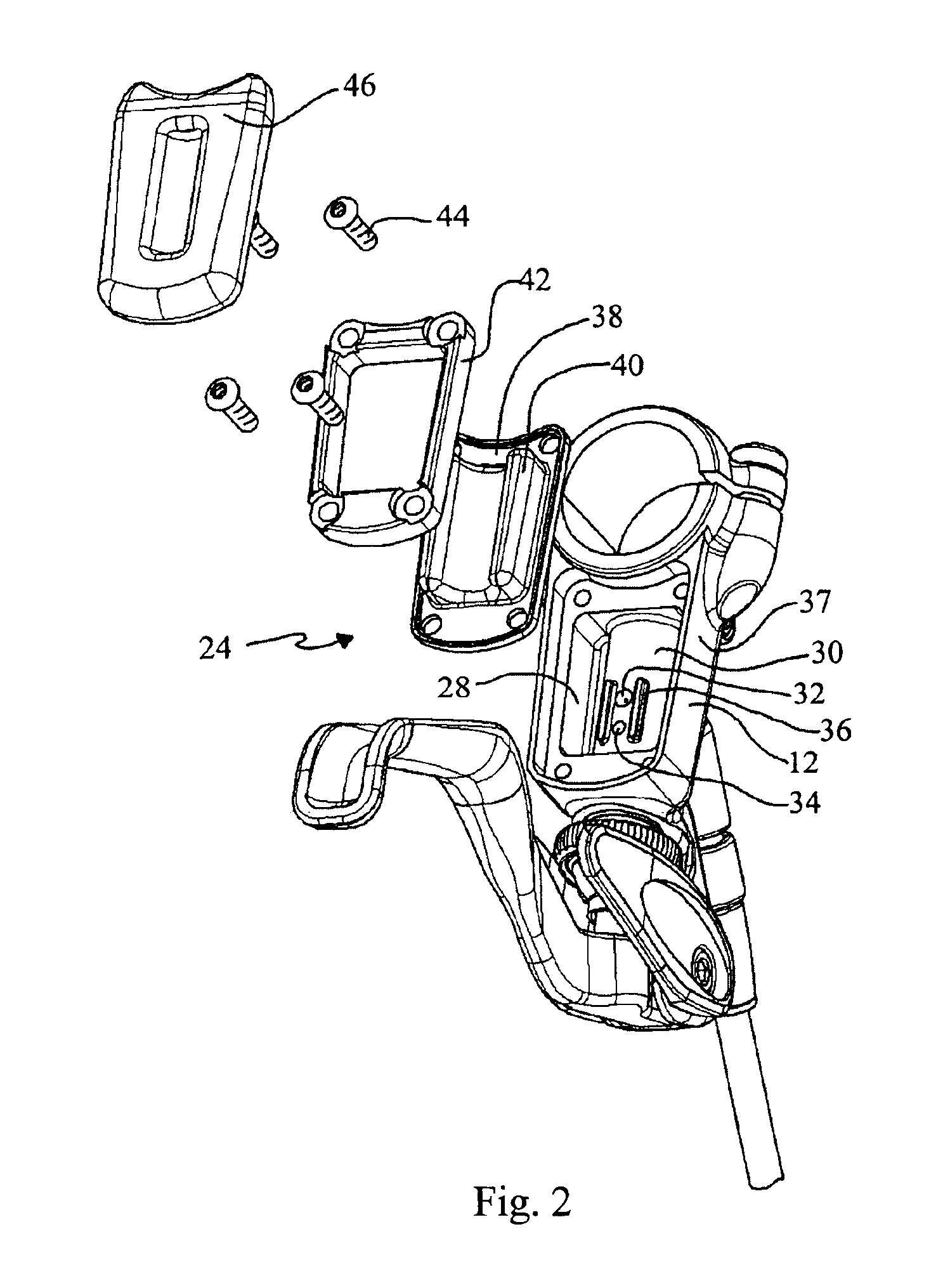

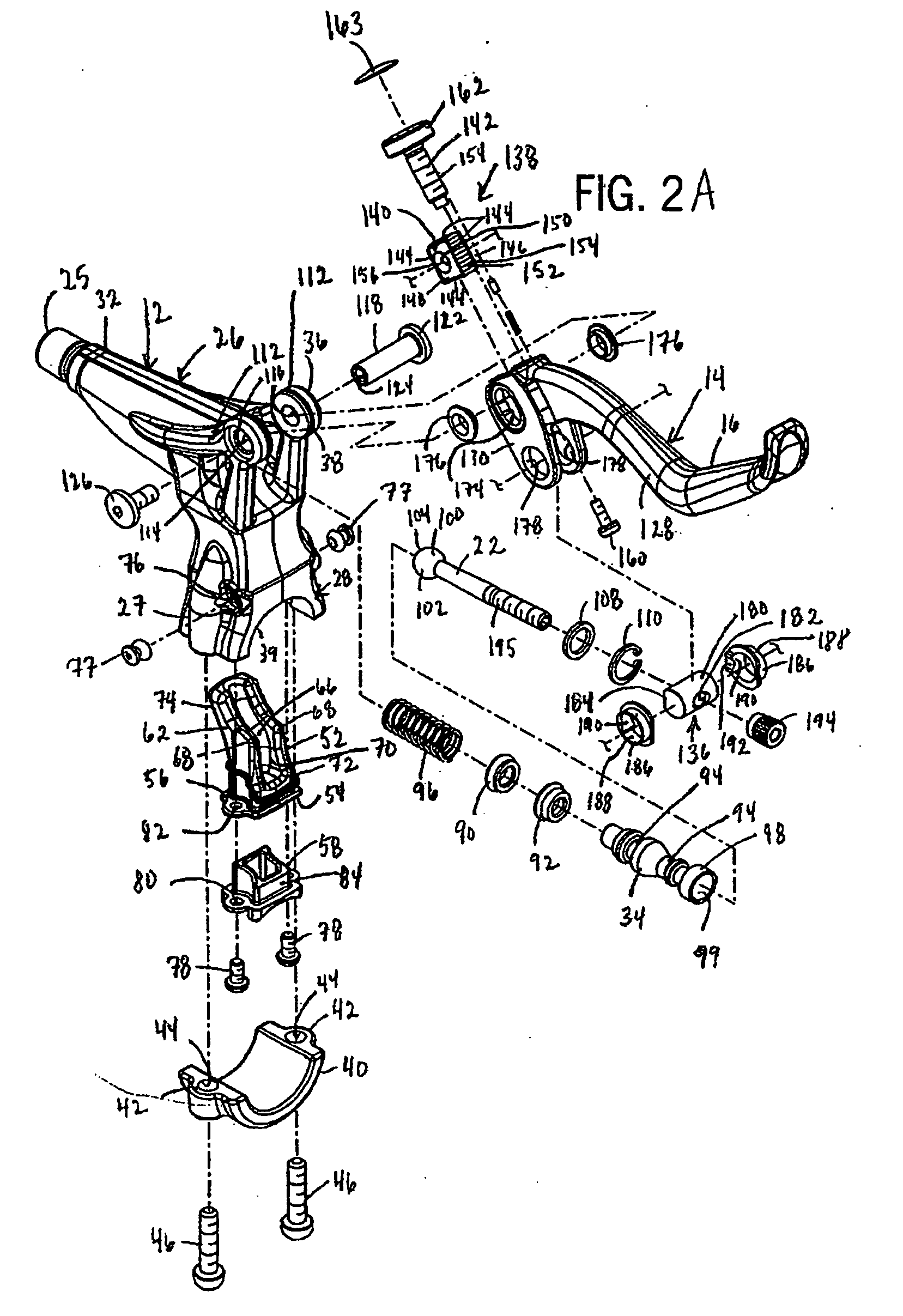

A bicycle control device is provided with a brake bracket, a brake lever, a first gearshift operating part, a second gearshift operating part, a first electrical switch, and a second electrical switch. The brake bracket is mountable to a handlebar. The brake lever is pivotally mounted to the brake bracket. The first gearshift operating part is movable relative to the brake lever. The second gearshift operating part is separate from the first gearshift operating part and movable relative to the brake lever. The first electrical switch is operated with the first gearshift operating part. The second electrical switch is operated with the second gearshift operating part. The second gearshift operating part is arranged such that when the first gearshift operating part is moved relative to the brake lever, the second gearshift operating part moves relative to the brake lever along with the first gearshift operating part.

Owner:SHIMANO INC

Bicycle control device

A bicycle control device is provided with a brake bracket, a brake lever, a first gearshift operating part, a second gearshift operating part, a first electrical switch, and a second electrical switch. The brake bracket is mountable to a handlebar. The brake lever is pivotally mounted to the brake bracket. The first gearshift operating part is movable relative to the brake lever. The second gearshift operating part is separate from the first gearshift operating part and movable relative to the brake lever. The first electrical switch is operated with the first gearshift operating part. The second electrical switch is operated with the second gearshift operating part. The second gearshift operating part is arranged such that when the first gearshift operating part is moved relative to the brake lever, the second gearshift operating part moves relative to the brake lever along with the first gearshift operating part.

Owner:SHIMANO INC

Apparatus for controlling multiple bicycle operating characteristics

Owner:SHIMANO INC

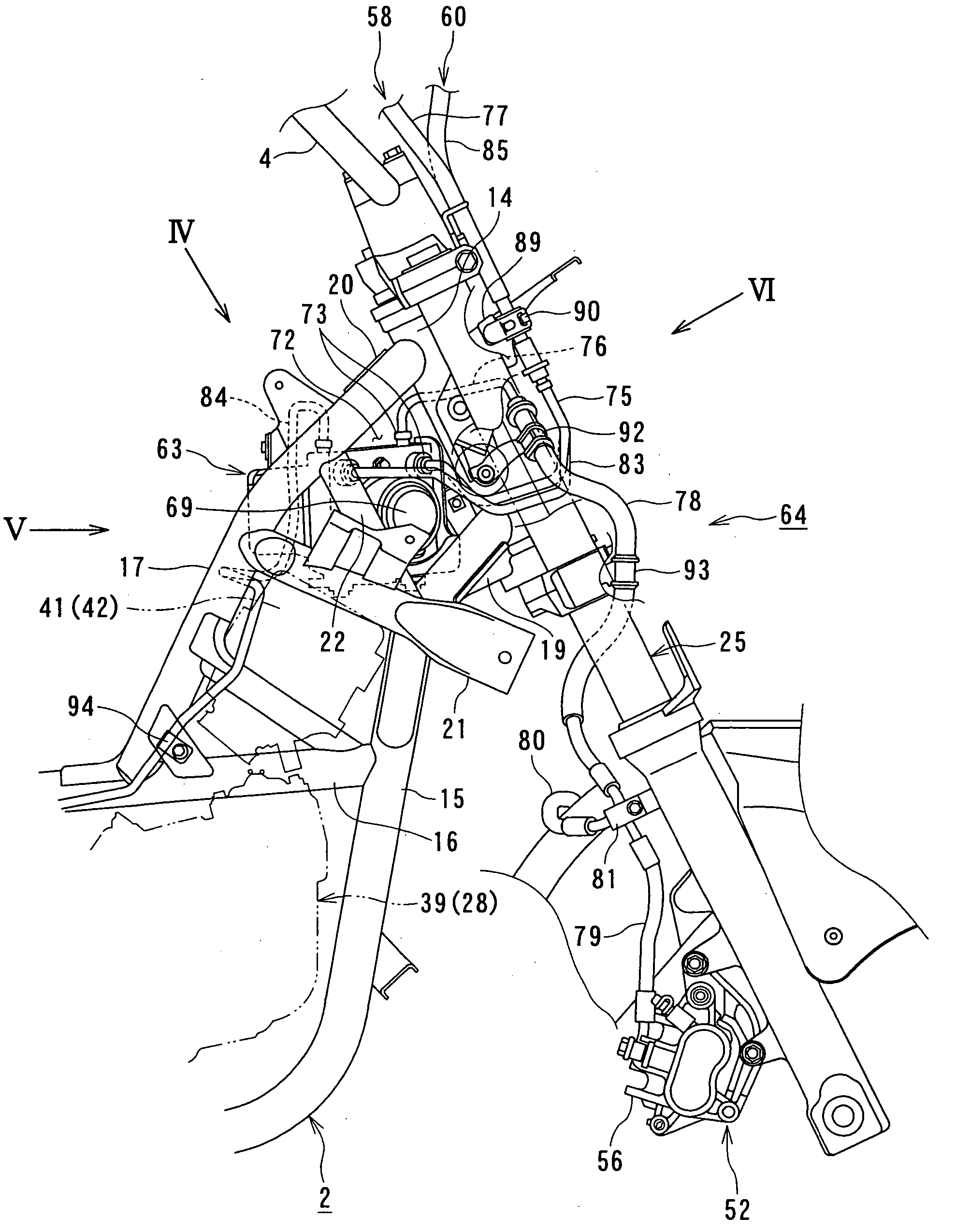

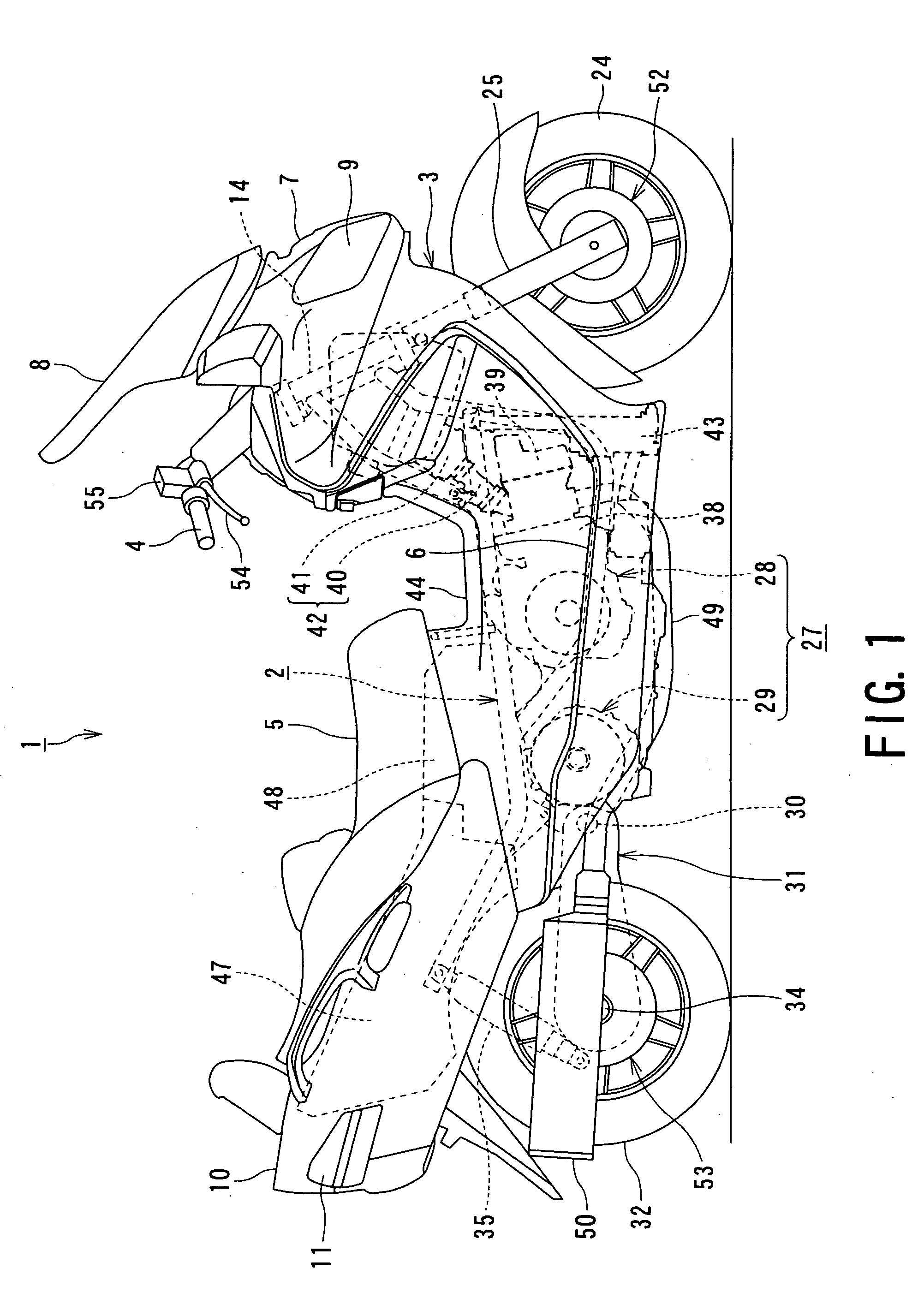

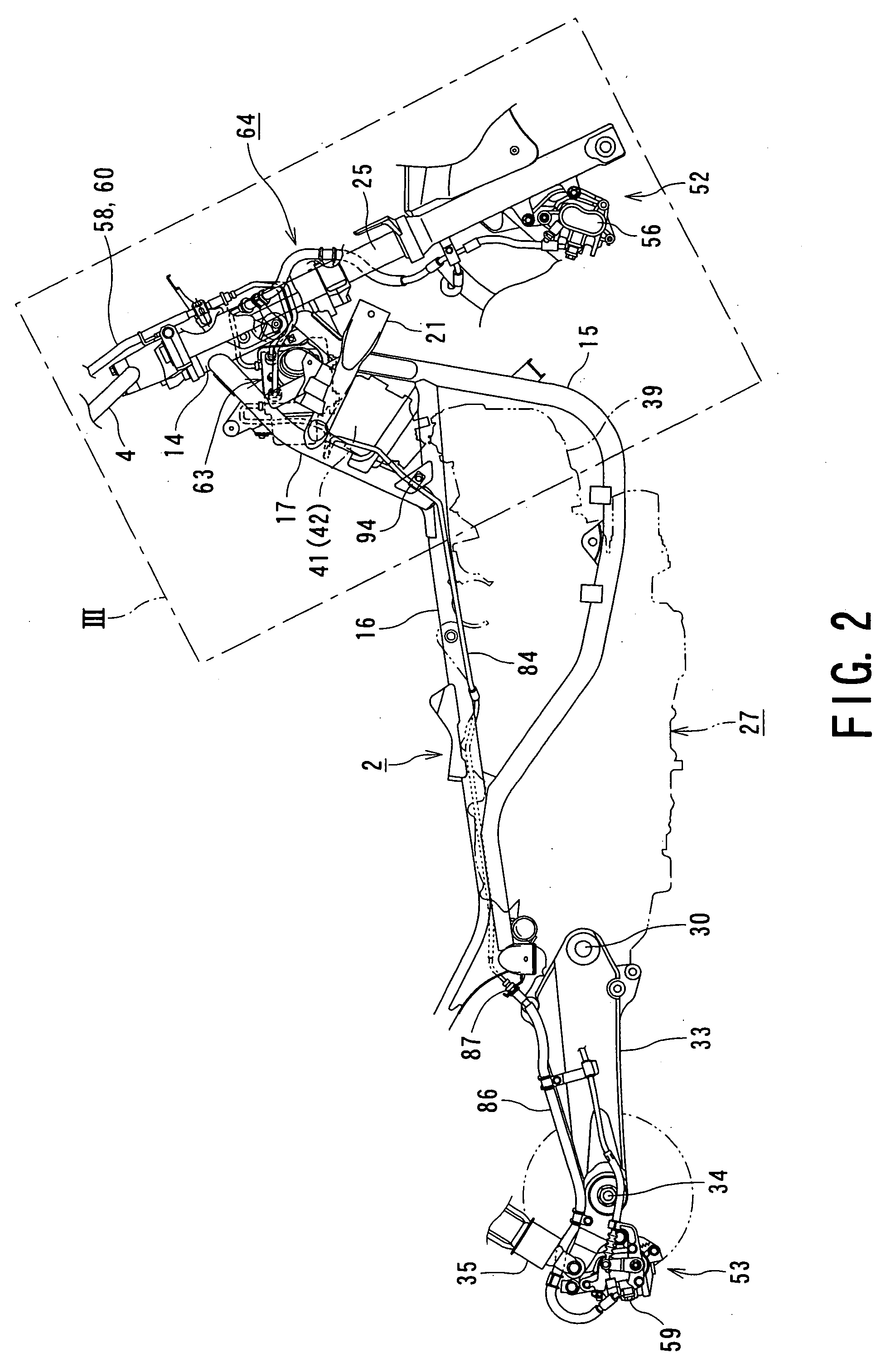

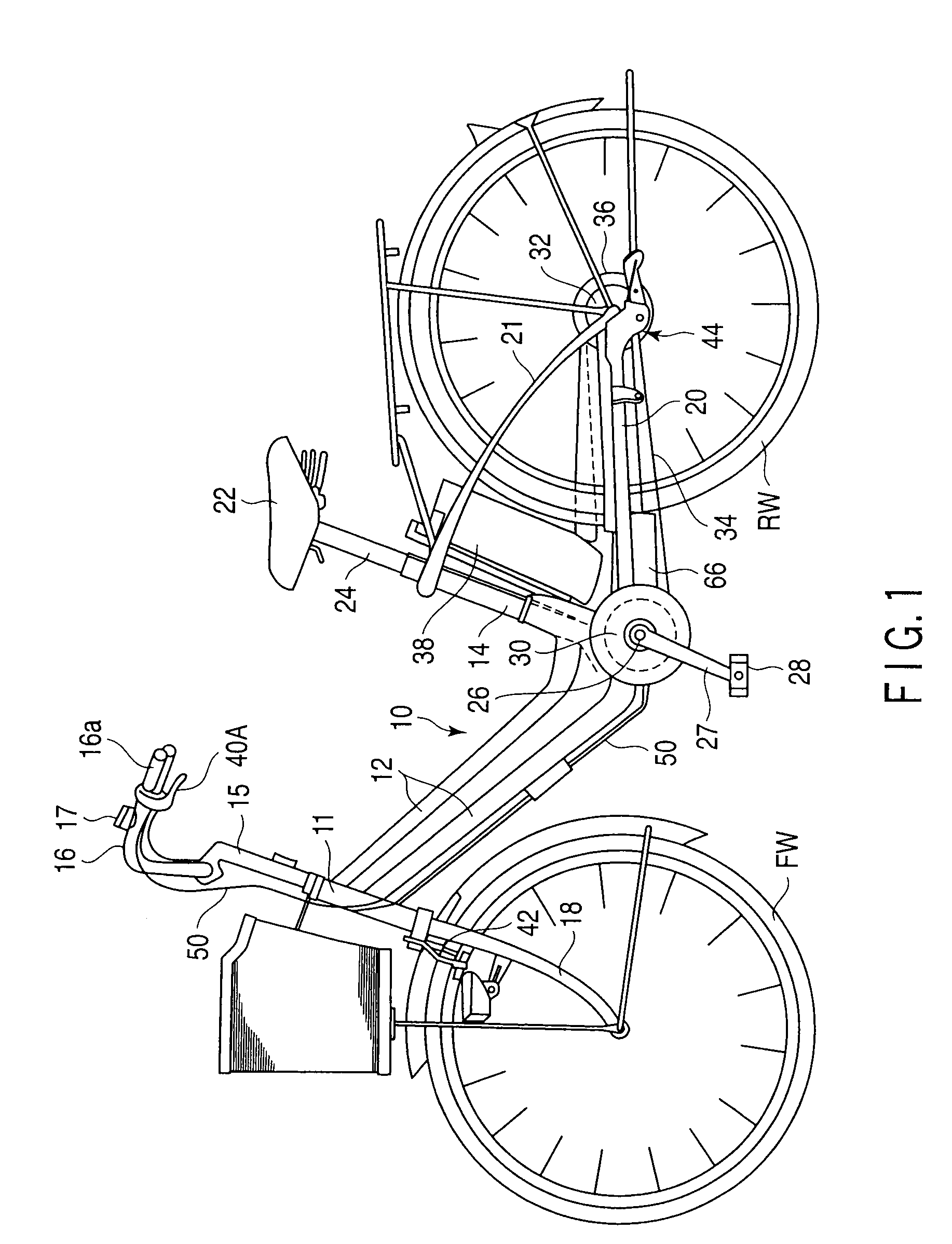

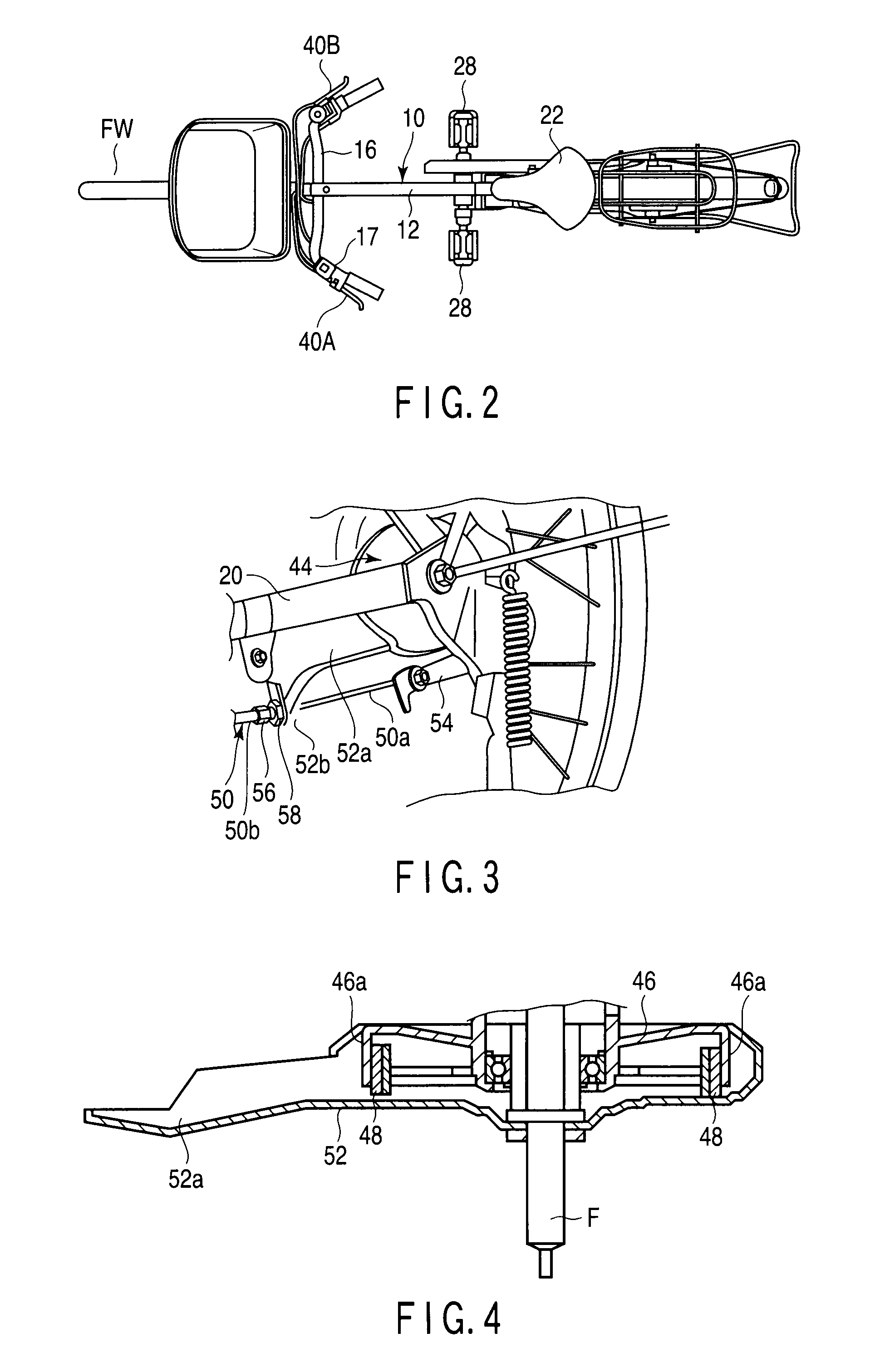

Motorcycle with antilock brake system

ActiveUS20050134114A1Improve braking performanceImprove engine performanceElectric propulsion mountingGas pressure propulsion mountingMaster cylinderEngineering

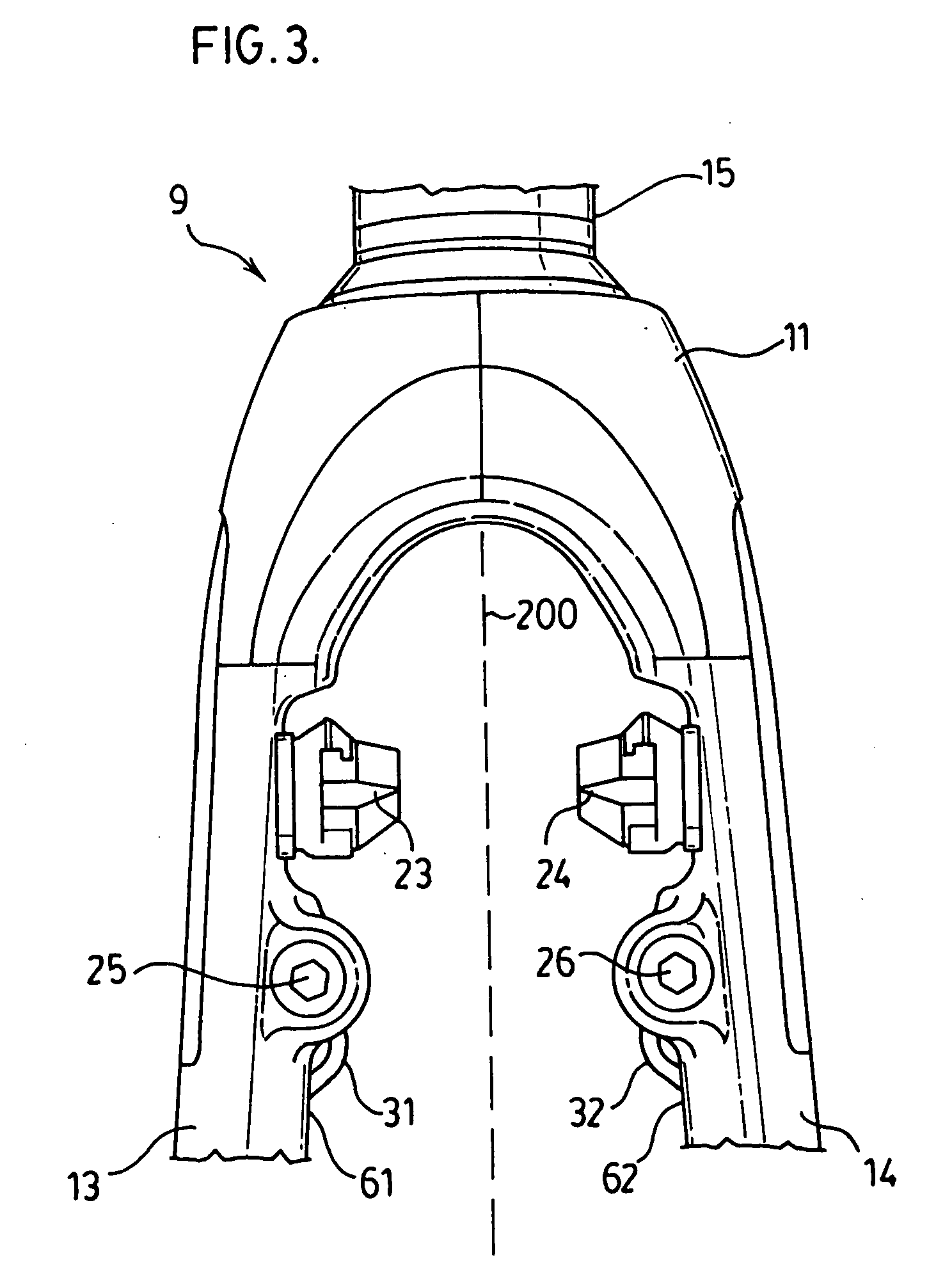

In a motorcycle provided with an antilock brake system, a front fork supporting a front wheel of a motorcycle is supported to be rotatable by a head pipe which is located at the front end portion of a body frame of a motorcycle, a handle-bar is secured to an upper end portion of the head pipe, master cylinders attached to the handle-bar are connected to hydraulic wheel brakes, respectively, via brake pipes. An antilock brake system includes an ABS-unit for antilock control disposed in an intermediate portion of the brake pipes. The ABS-unit is disposed immediately behind the head pipe and between a pair of body frame components disposed on both lateral sides of the motorcycle body and extending, from the head pipe, obliquely downward and backward, while extending outward in directions opposite to each other in the width direction of the motorcycle body.

Owner:SUZUKI MOTOR CORP

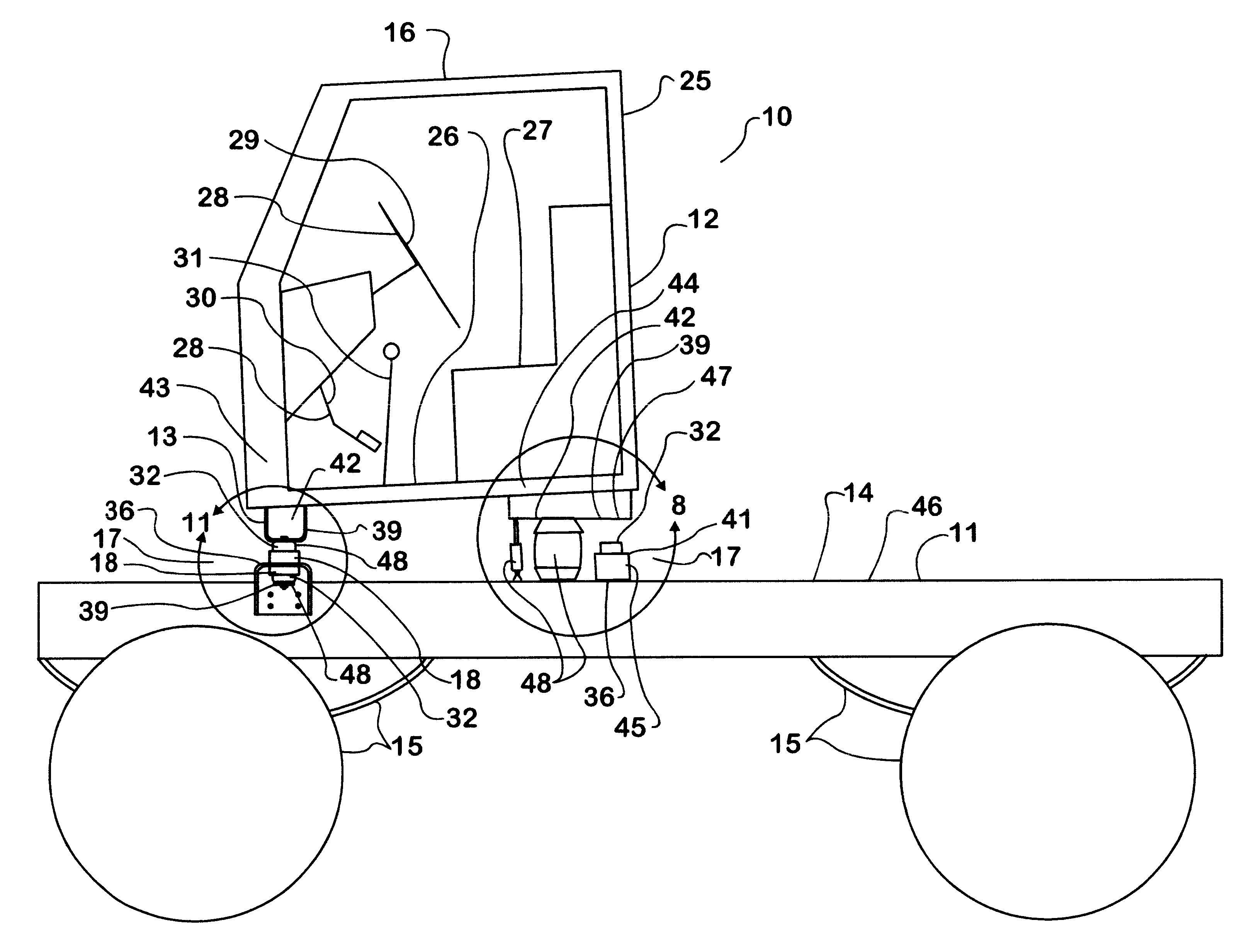

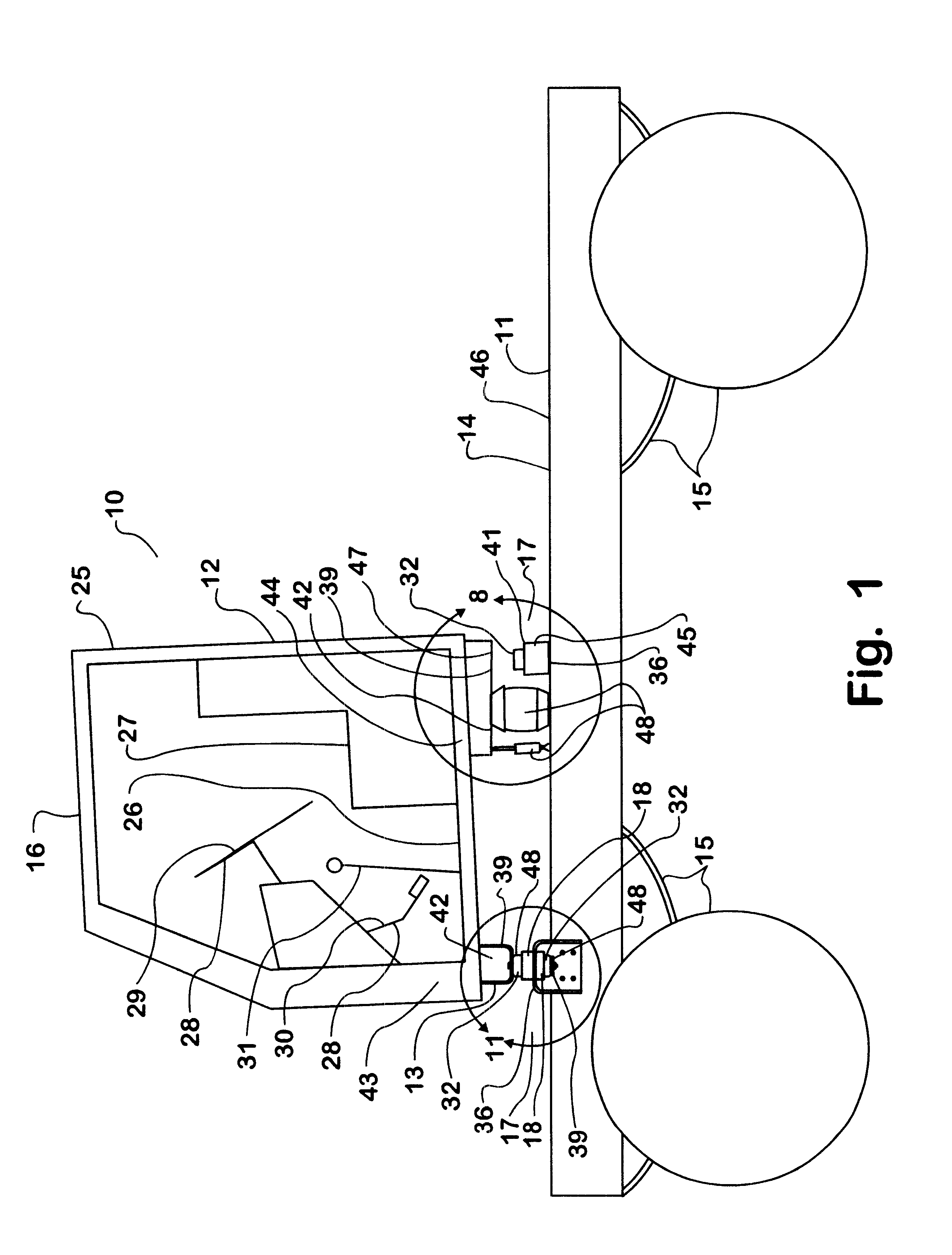

Vehicle body suspension system

A vehicle includes a body structure that is suspended from a chassis of the vehicle by a vehicle body suspension system. The vehicle body suspension system is constructed in a manner to allow relative movement to occur between the suspended body structure and the chassis in such a manner to at least partially isolate the suspended body structure from the vibrations and accelerations of the chassis. The vehicle body suspension system includes one or more spring / damper components that comprise an elastomer body that is surrounded and, therefore, reinforced by a reinforcing wall constructed of a relatively rigid material. The vehicle body suspension system may utilize one or more of the reinforced elastomer block spring / damper components as bump stops and / or primary spring / damper components.

Owner:NAVISTAR CANADA

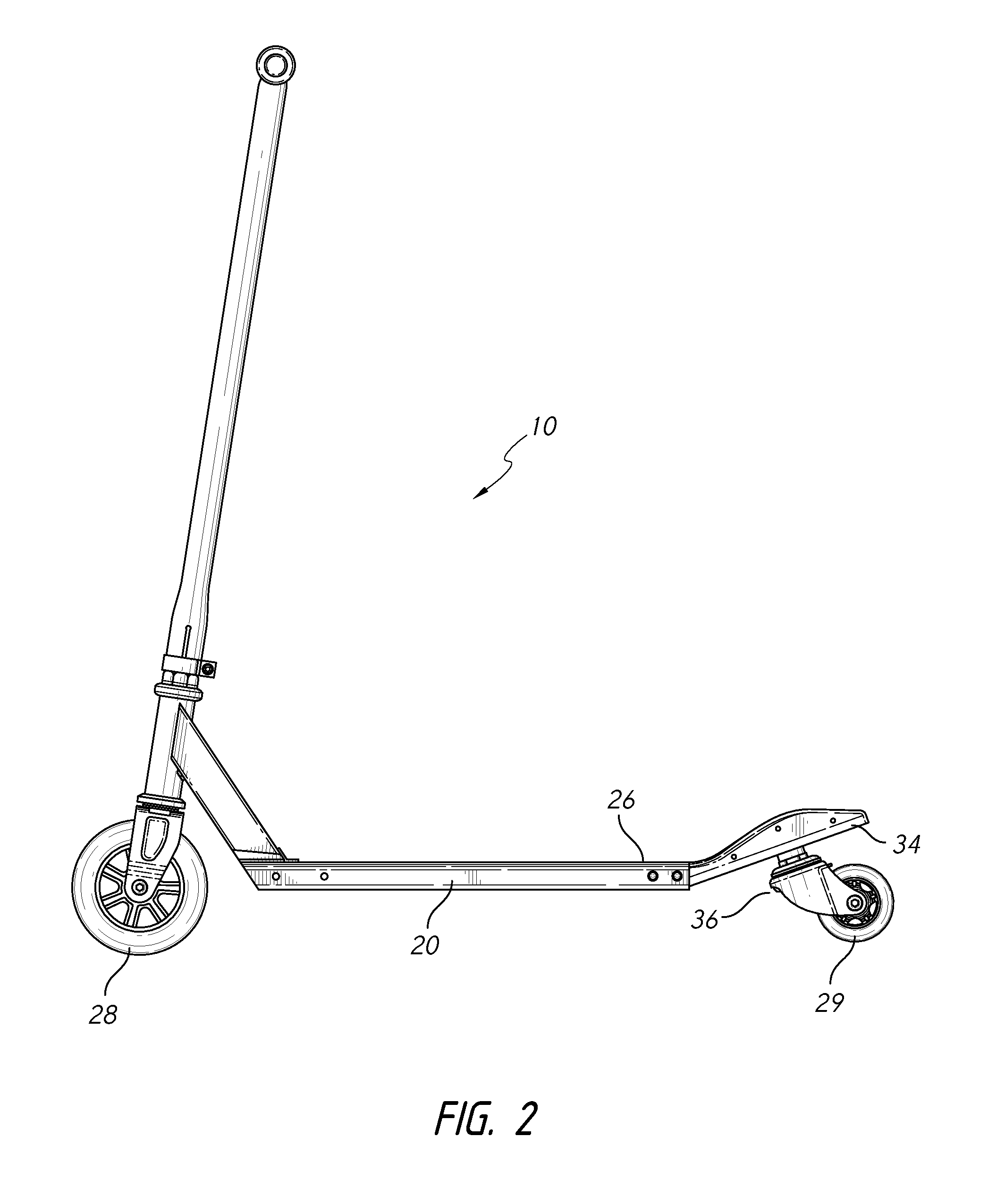

Scooter

Owner:EARTH TOOL L L C

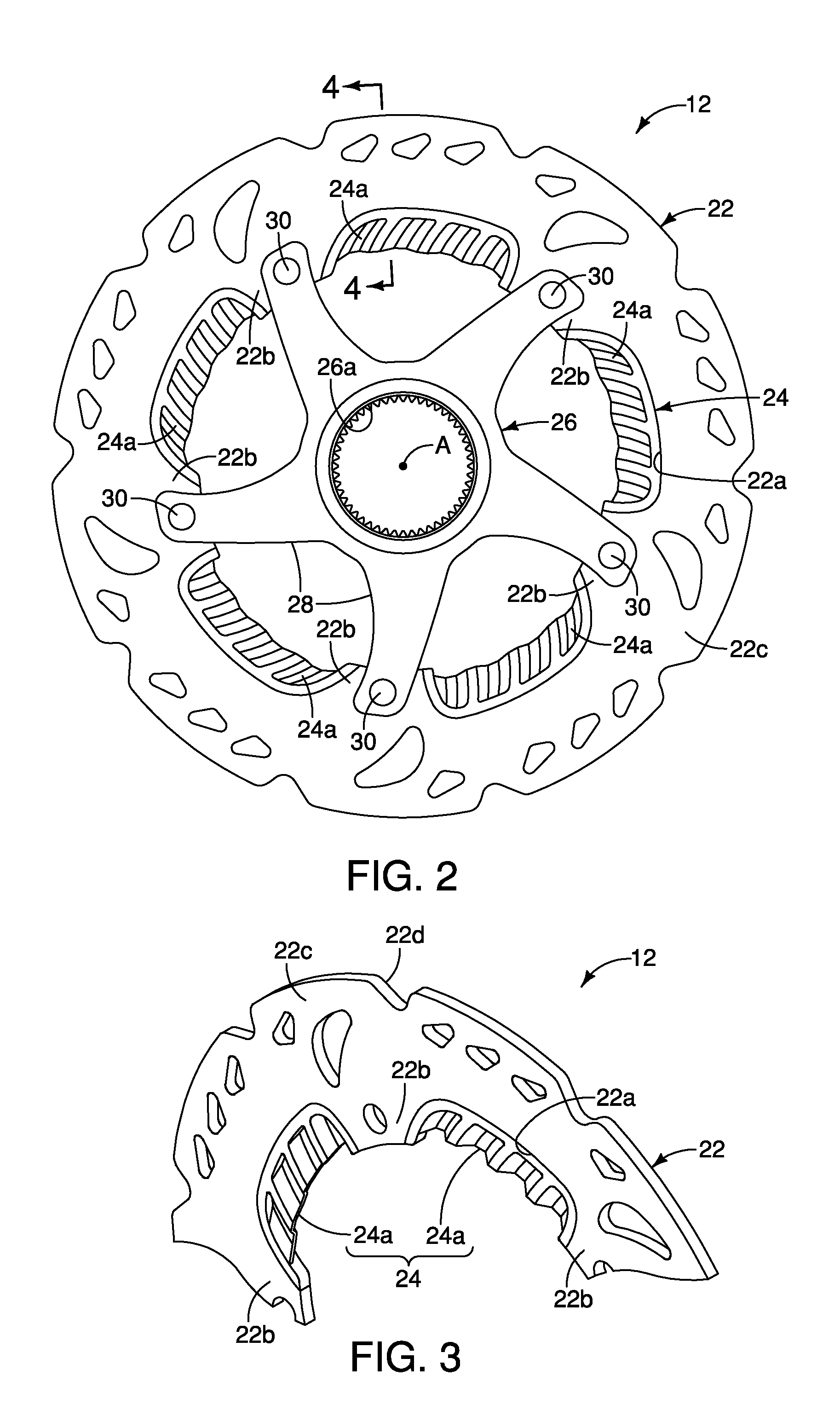

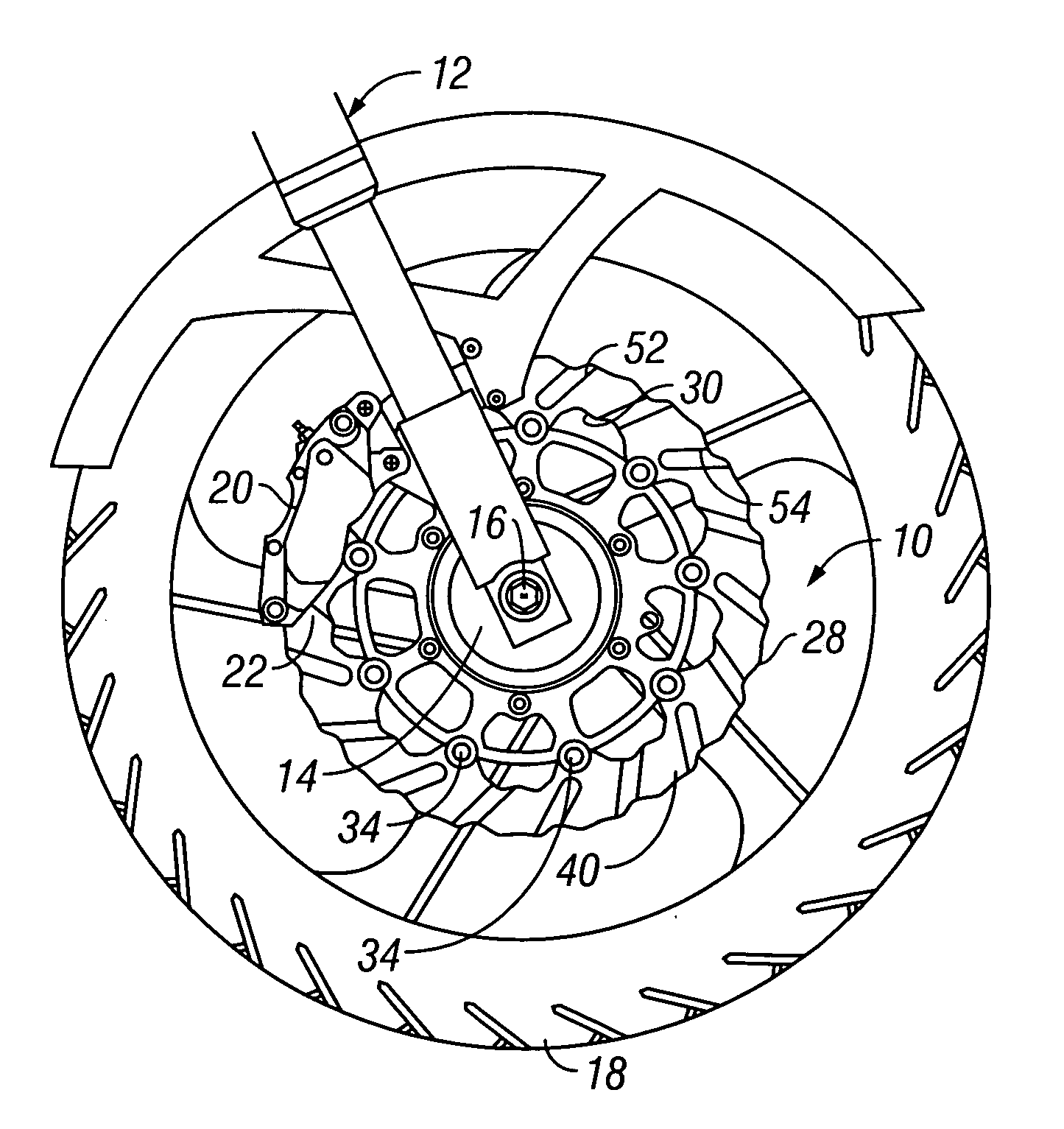

Bicycle disc brake rotor

ActiveUS20130168193A1Improve performanceEffective coolingAxially engaging brakesBraking discsEngineeringMechanical engineering

A bicycle disc brake rotor basically has an outer portion and a cooling fin. The outer portion has first and second base surfaces facing in opposite axial directions. The cooling fin is disposed radially offset from at least one of the first and second braking surfaces.

Owner:SHIMANO INC

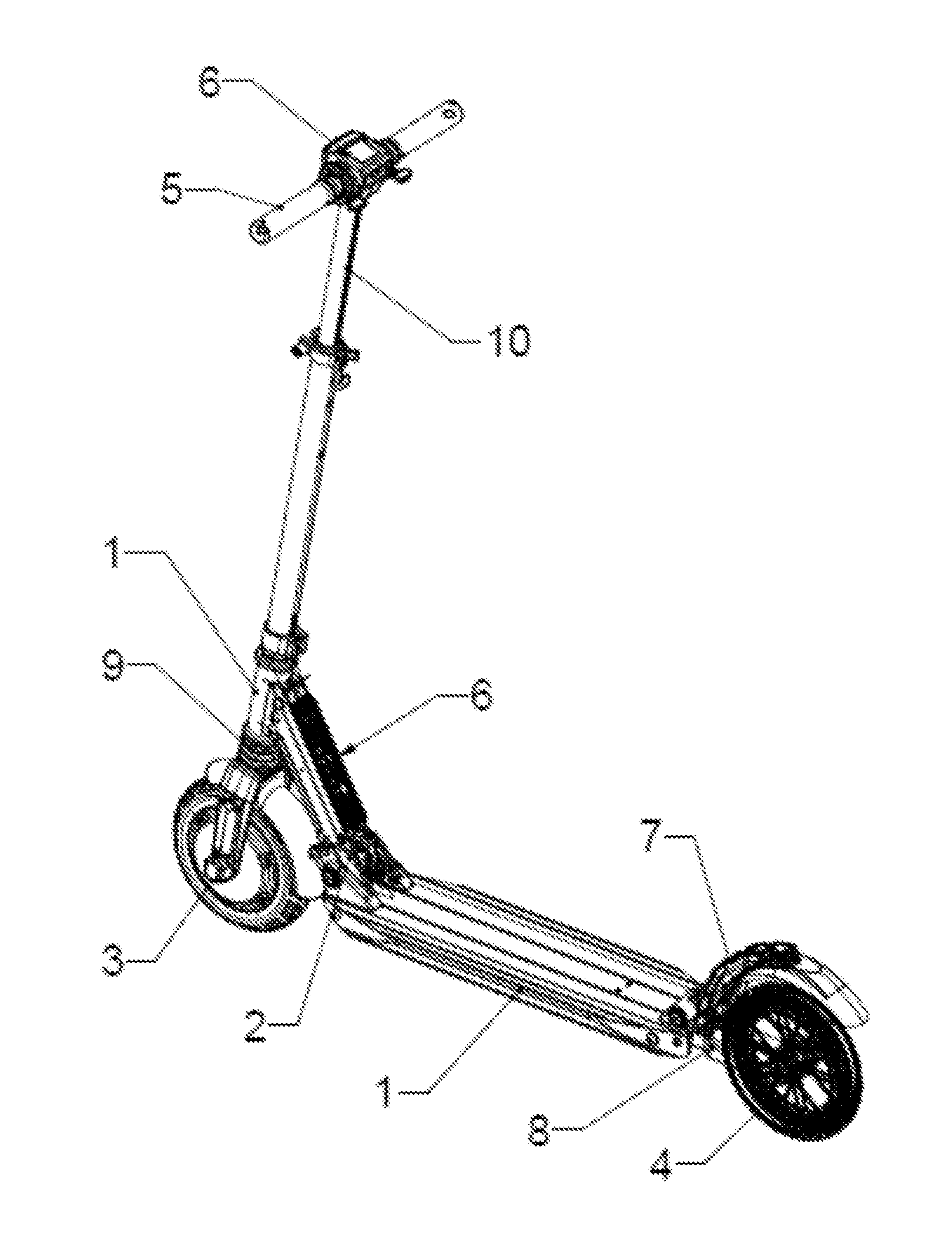

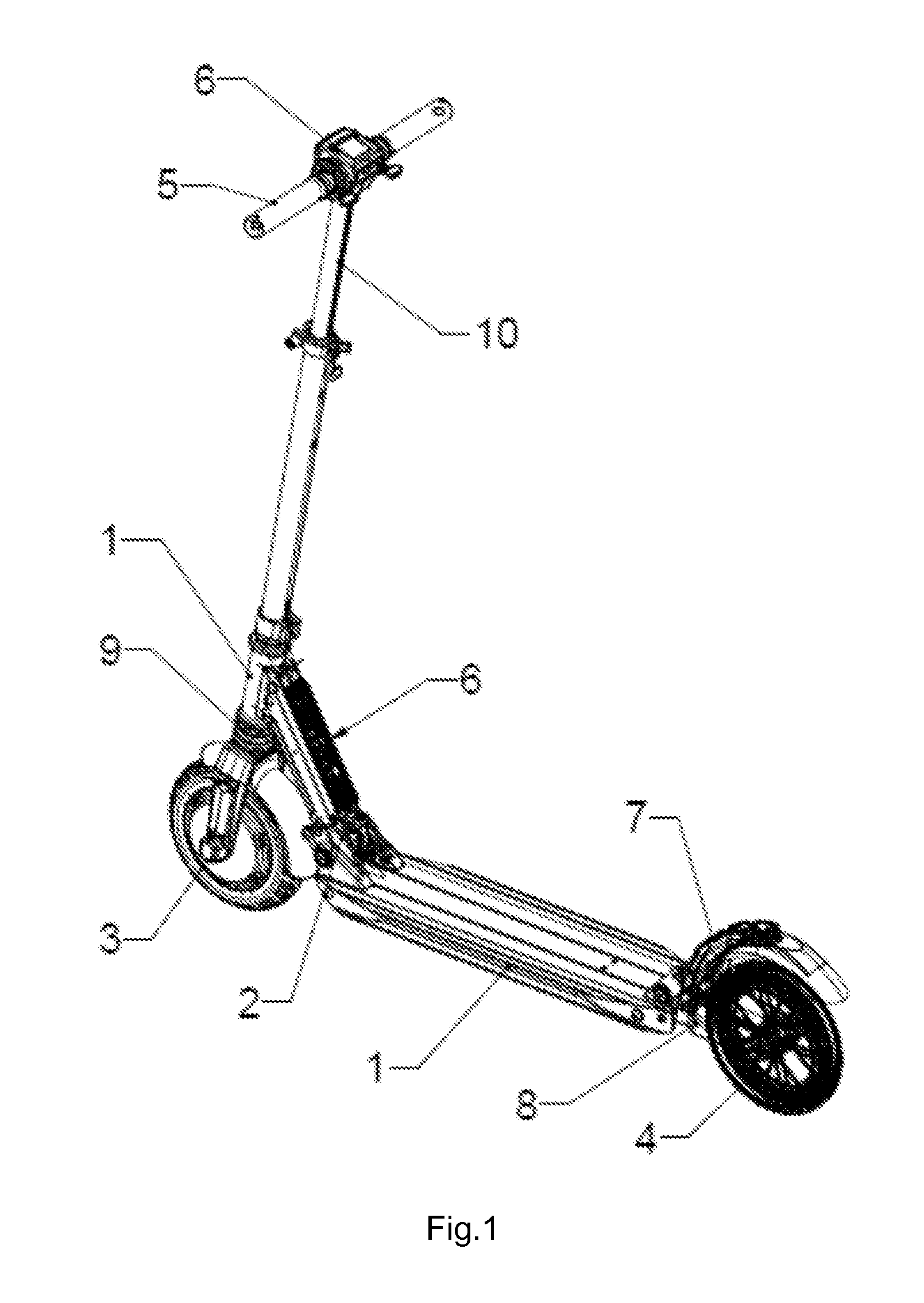

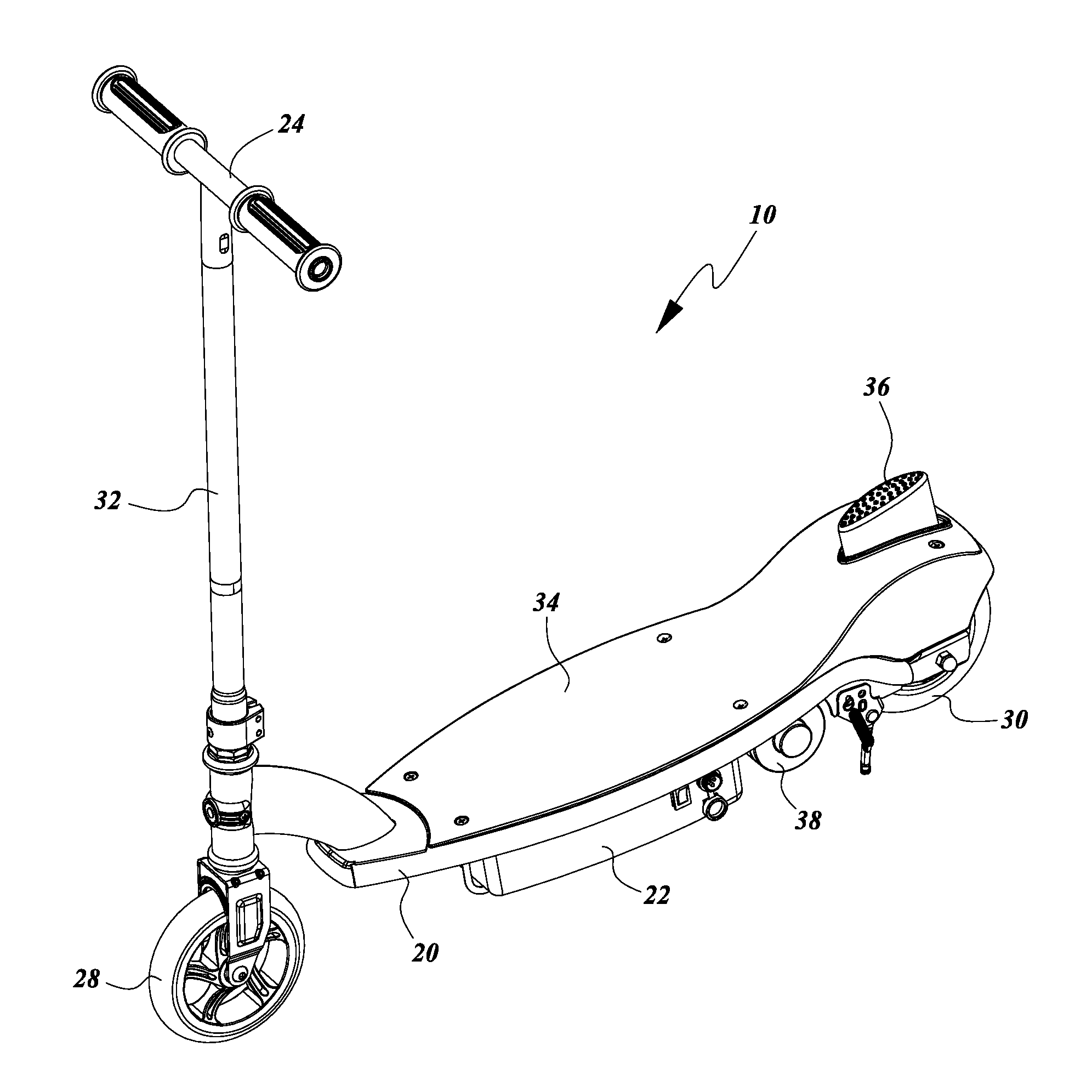

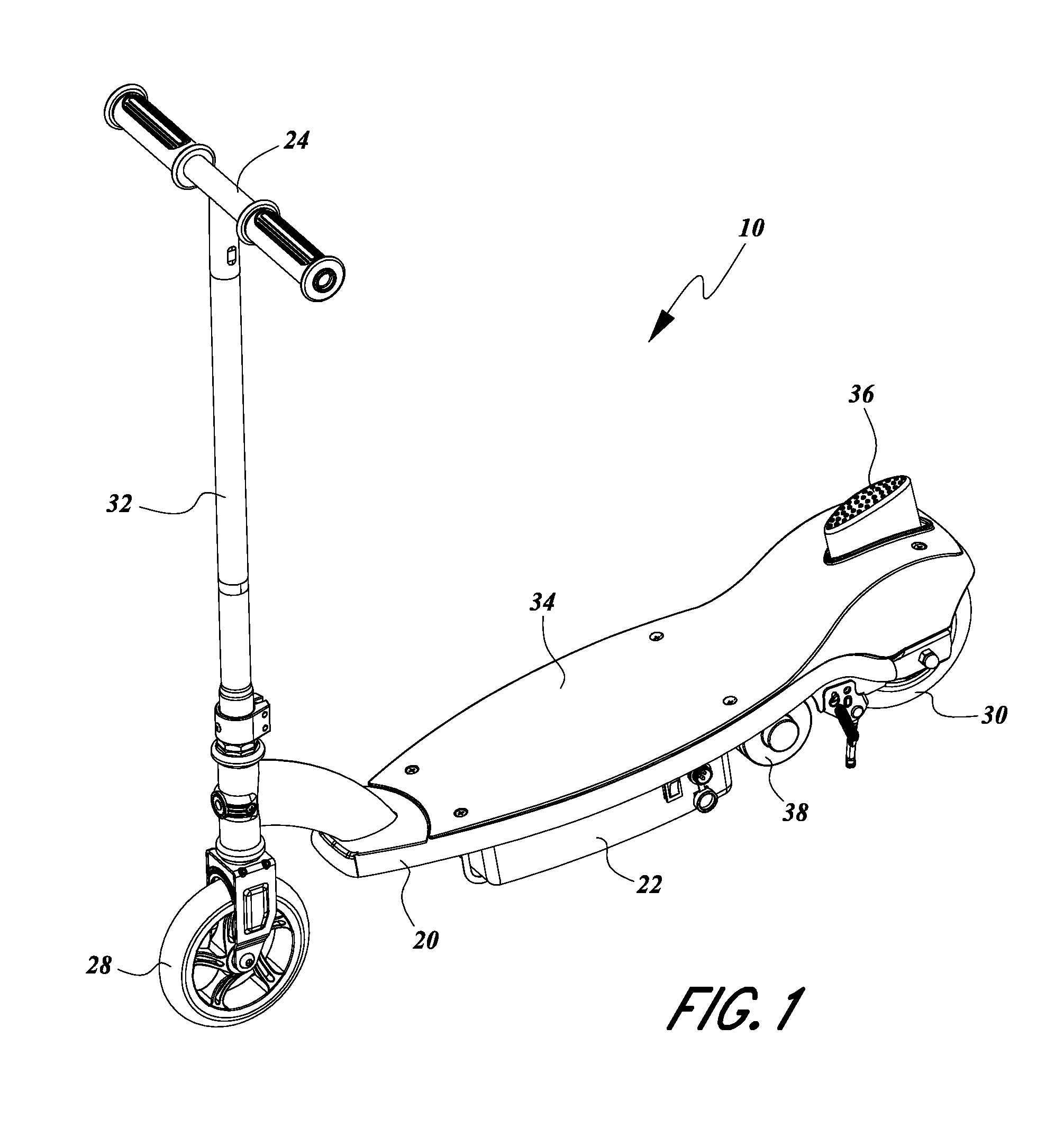

Foldable and portable electric vehicle

InactiveUS20160009332A1Small sizeReduce weightMechanical apparatusMotorised scootersSteering columnElectric vehicle

A foldable and portable electric vehicle for the transport of a single person comprises a foldable chassis with a support plate, a folding system for folding the chassis, a front driving wheel, a rear wheel, a foldable handlebar, an integrated system of command, control, monitoring and signaling, a mechanical brake on the rear wheel, a suspension on the rear wheel and a suspension on the front wheel, and a steering column.

Owner:NEXTROM IND SRL

Bicycle control device

A control device is configured to be attached to the handlebar of a bicycle for controlling a brake mechanism and change speed mechanism. The control device comprises a bracket fixed to the handlebar, a brake lever pivotally coupled crosswise relative to the bracket and a release lever. The brake mechanism is controlled by fore and aft pivotal movement of the brake lever, while the change speed mechanism is controlled by sideways pivotal movement of the brake lever and the release lever. The brake lever and the release lever are further configured relative to the bracket for smooth easy operation by the rider.

Owner:SHIMANO INC

Fork with integrated braking system

InactiveUS20080035431A1Reduce resistanceIncrease its aerodynamic effectPassenger cyclesChildren cyclesAerodynamic dragEngineering

A cycle with a wheel-supporting structure comprising a crown section and a pair of forklegs, a brake assembly with lever arms mounted at least partially within cavity openings within each fork leg to reduce aerodynamic drag.

Owner:WHITE PHILIP G & ANNA DOPICO AS TRUSTEES OF +1

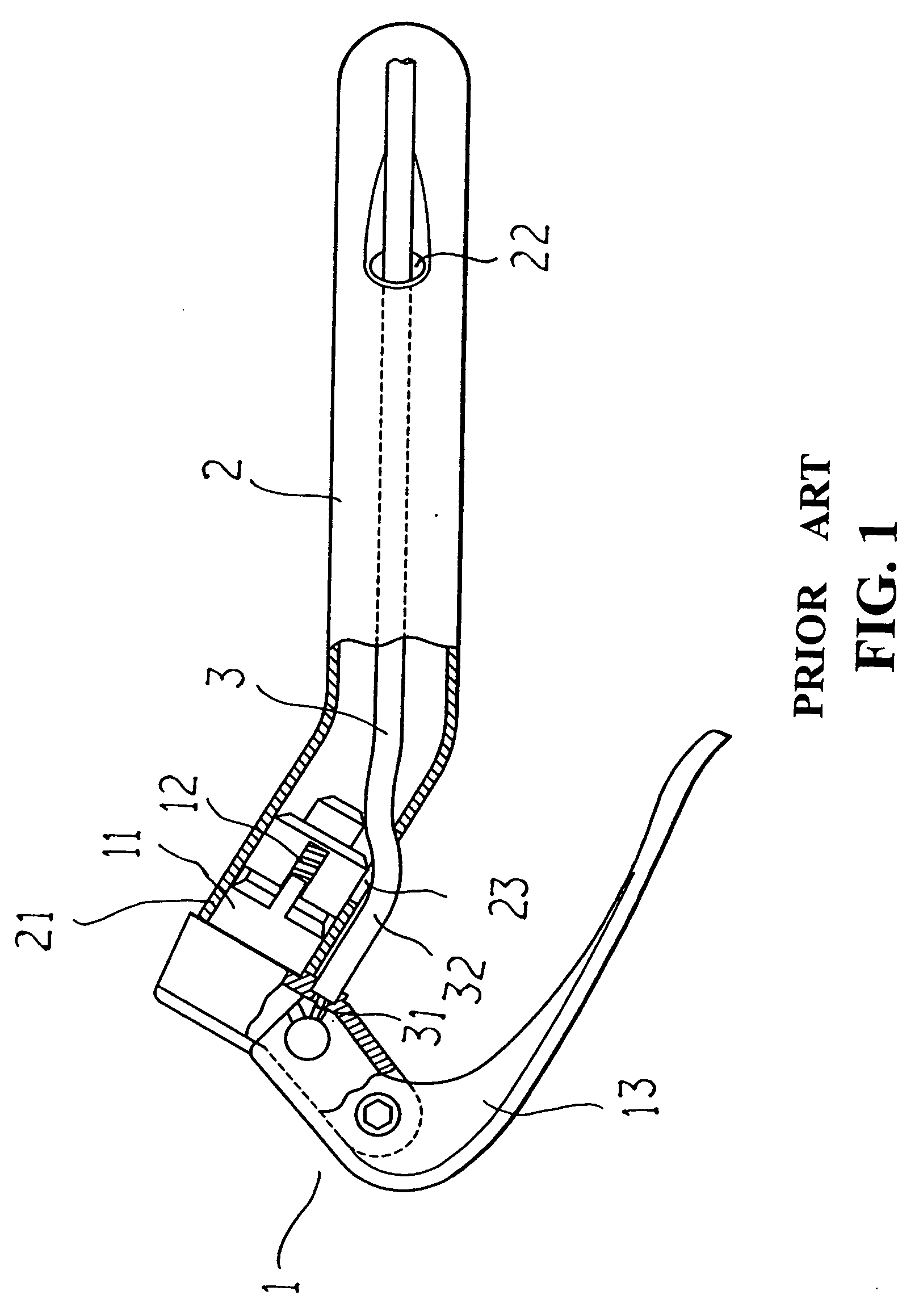

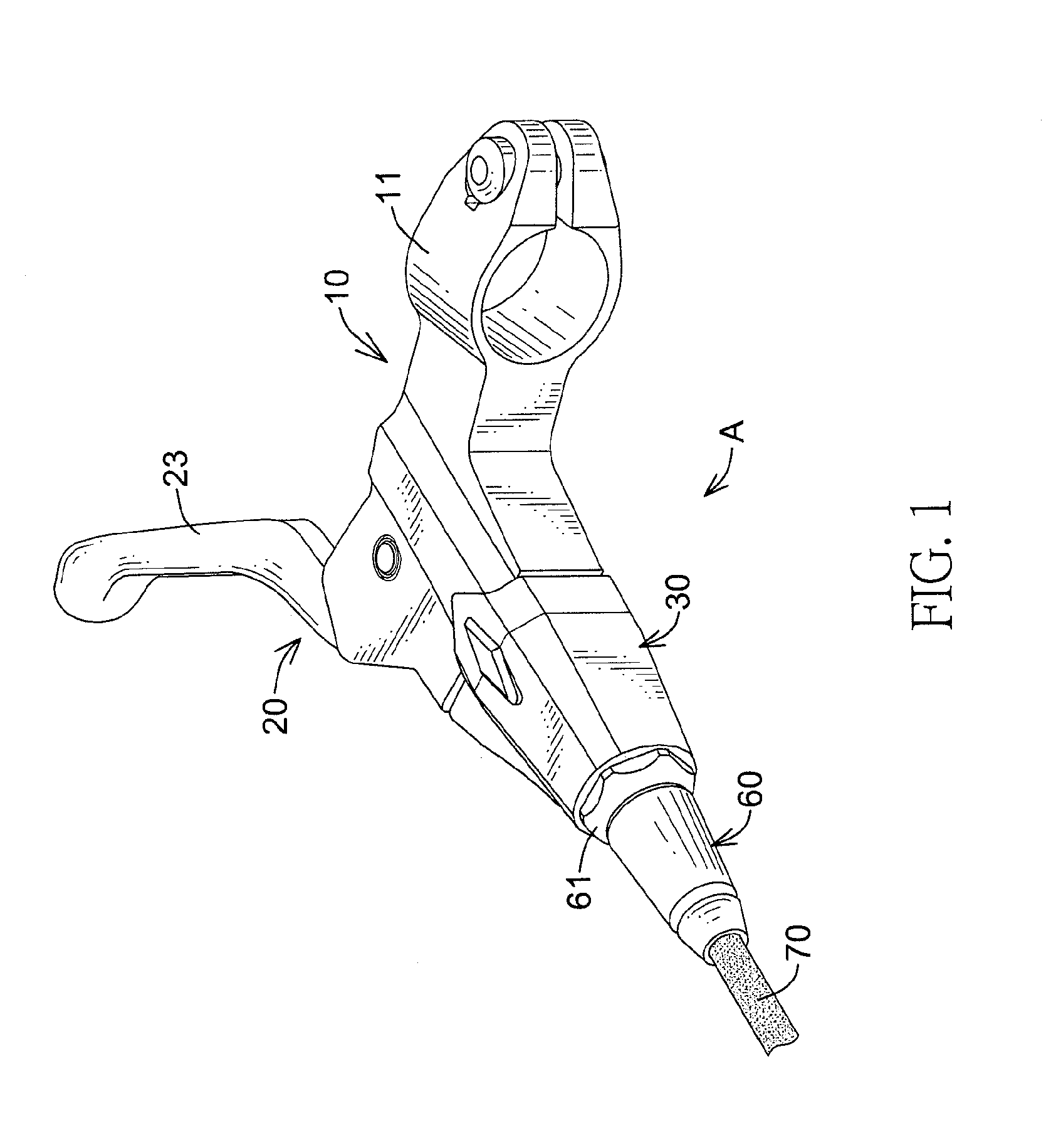

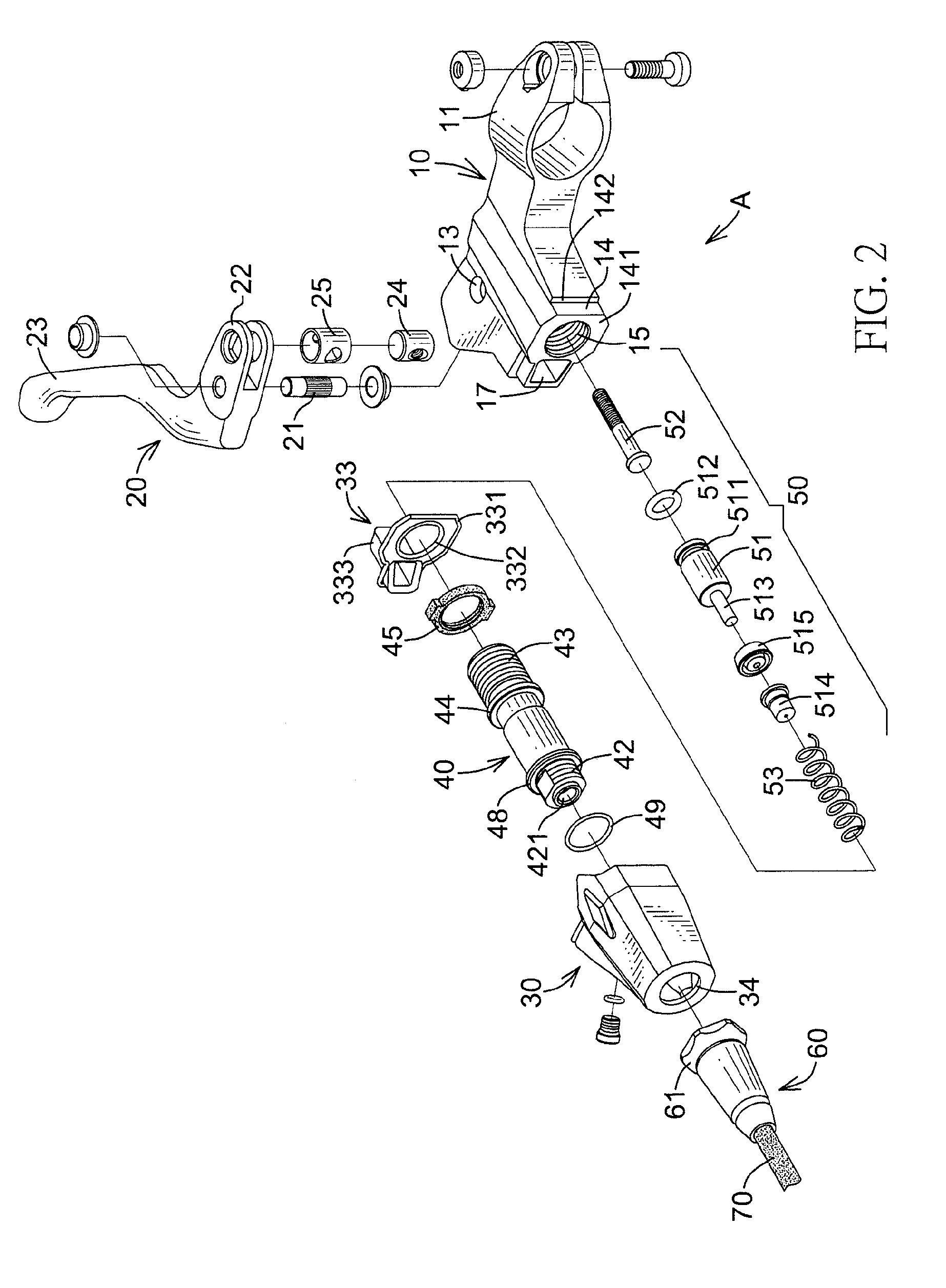

Hydraulic brake lever for a bicycle

InactiveUS6883647B1Mitigate and obviate disadvantageEasy to operateEngine sealsBraking action transmissionHydraulic brakeHydraulic pressure

A hydraulic brake lever for a bicycle, comprising a main body, a pull handle, and an adjusting mechanism. Thus, the hydraulic brake lever can be operated conveniently and smoothly, thereby facilitating the rider operating the hydraulic brake lever. In addition, the hydraulic brake lever is sensitive, thereby protecting the rider's safety. Further, the operation stroke of the brake can be changed and adjusted conveniently, so as to adjust the sensitivity of the brake to the optimum state.

Owner:WEN CHUN TE

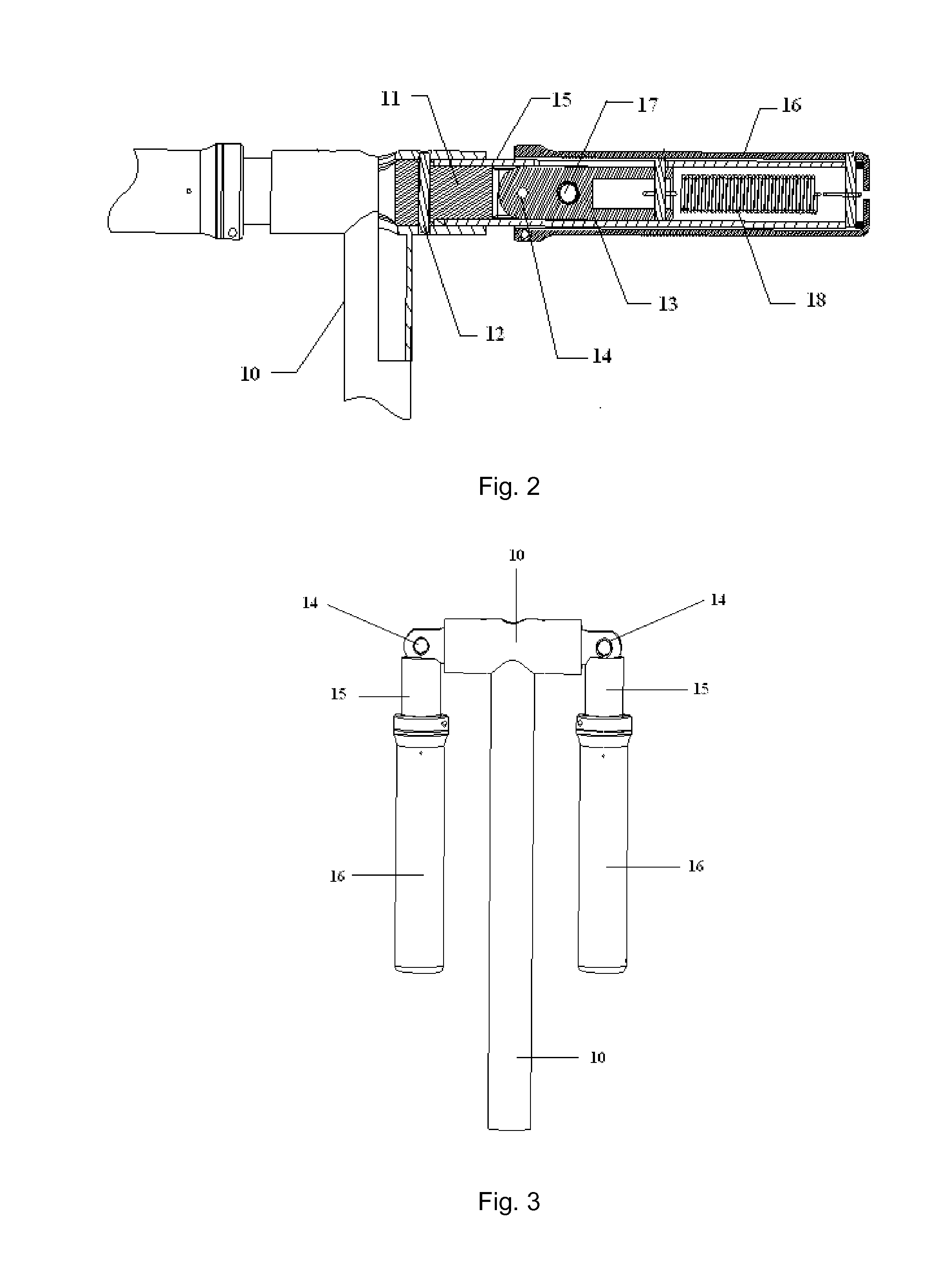

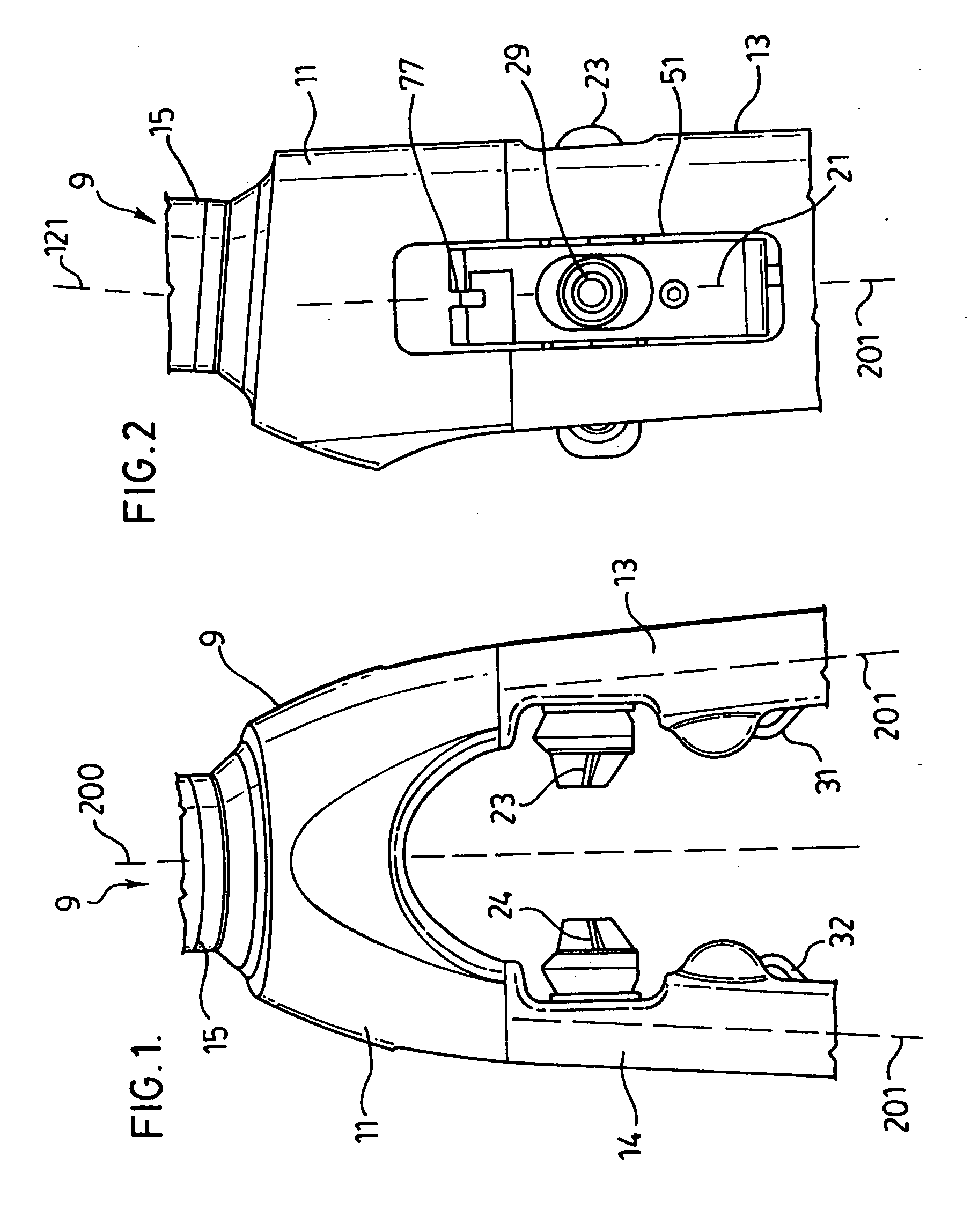

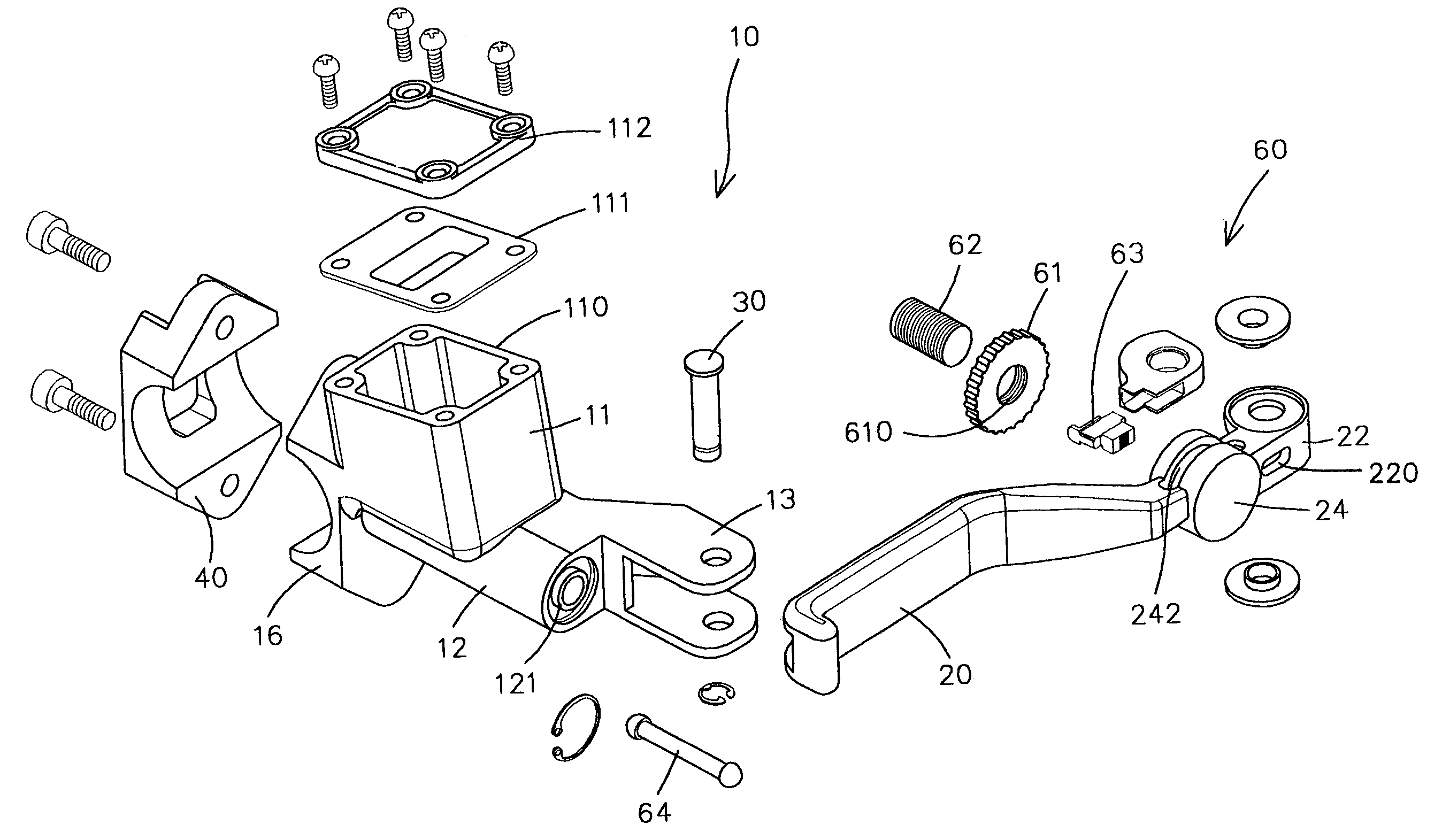

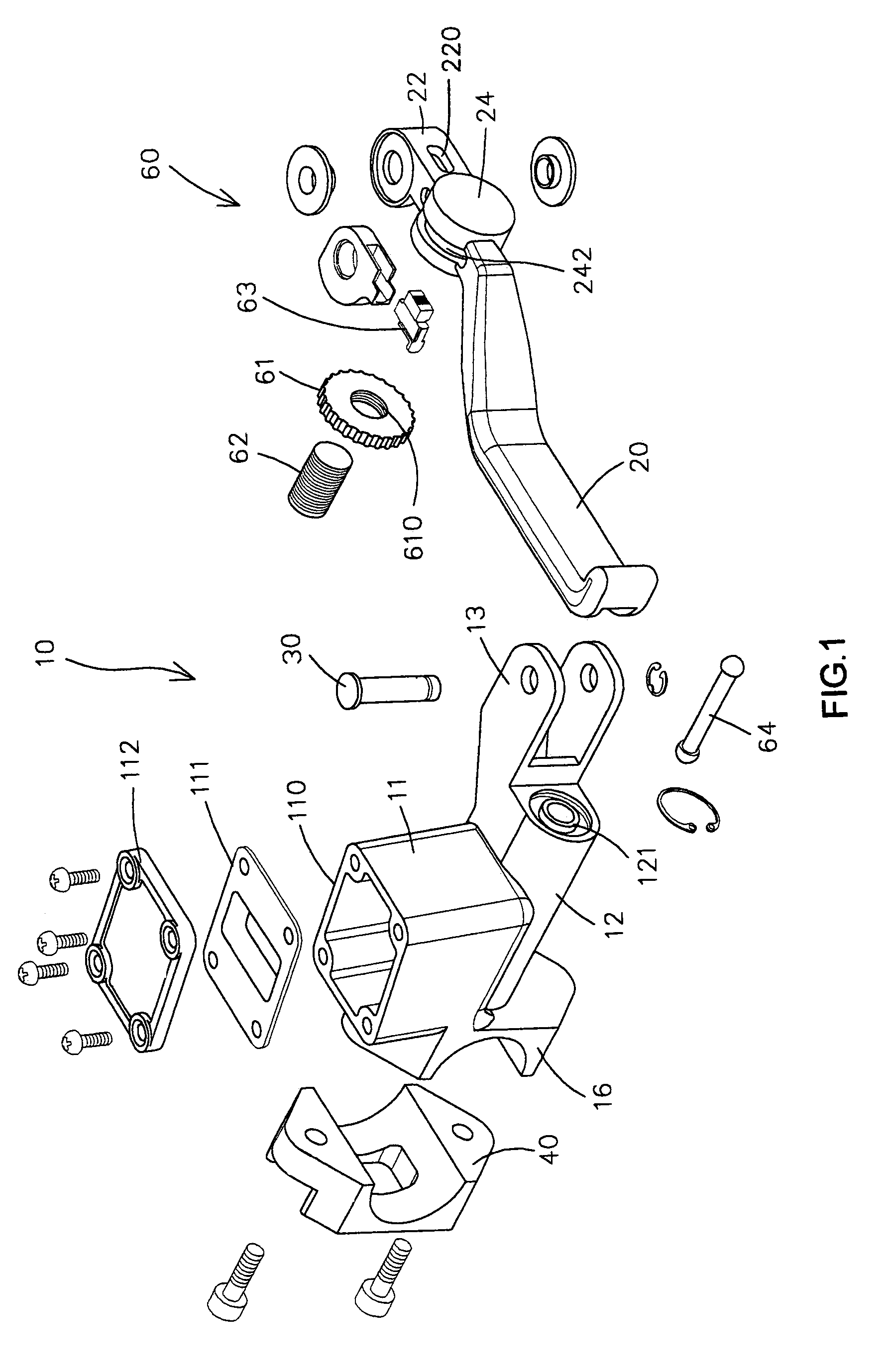

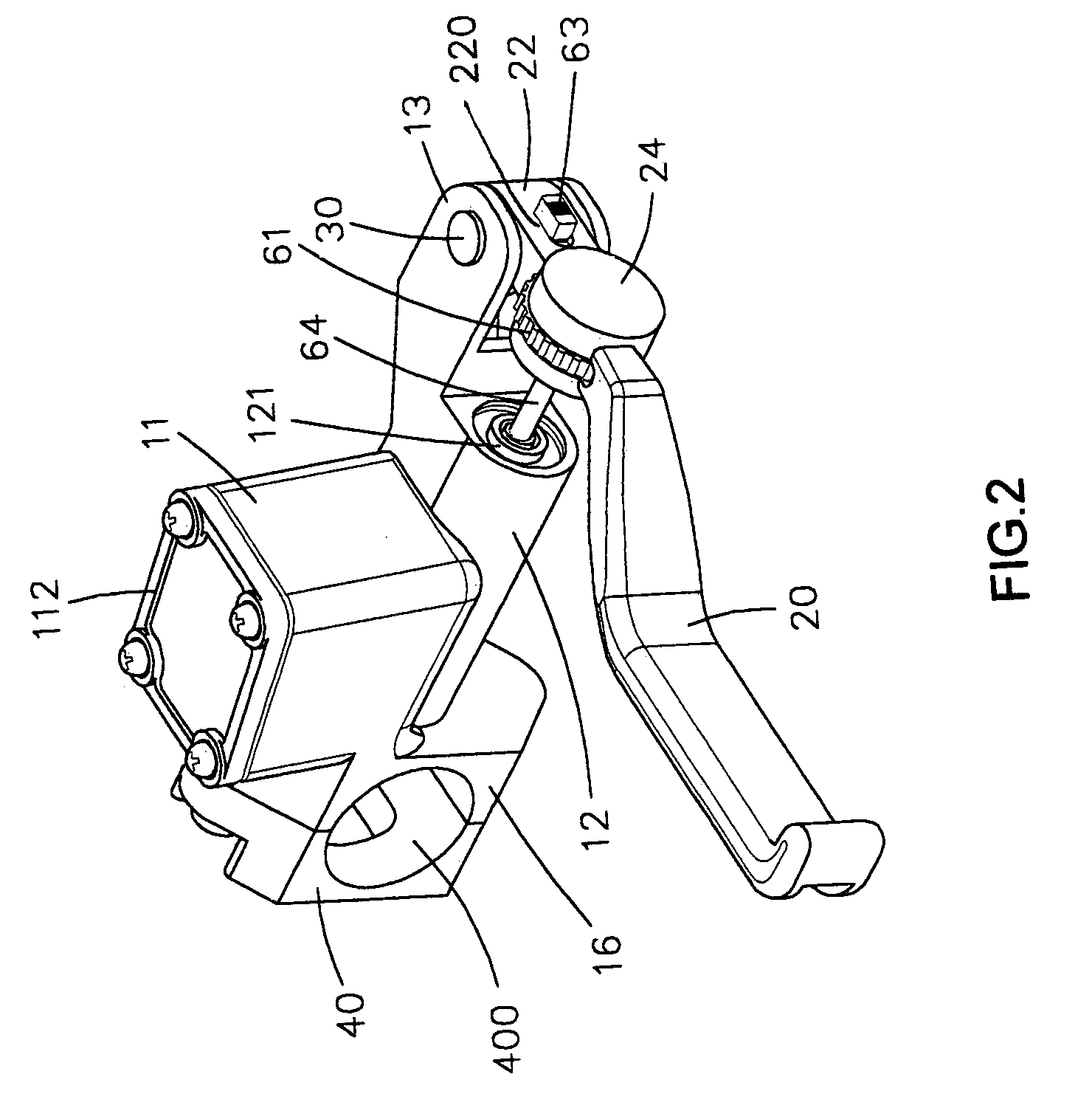

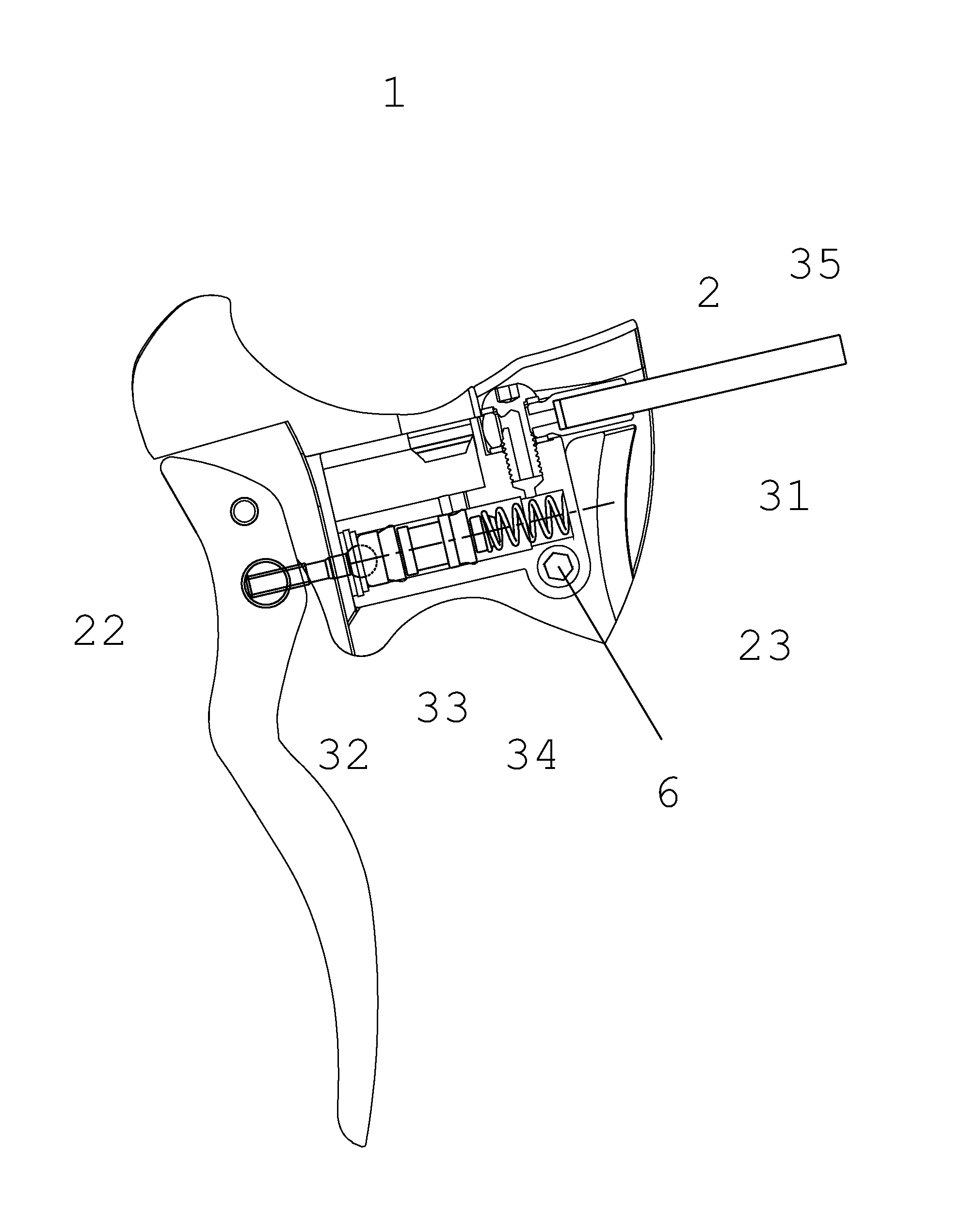

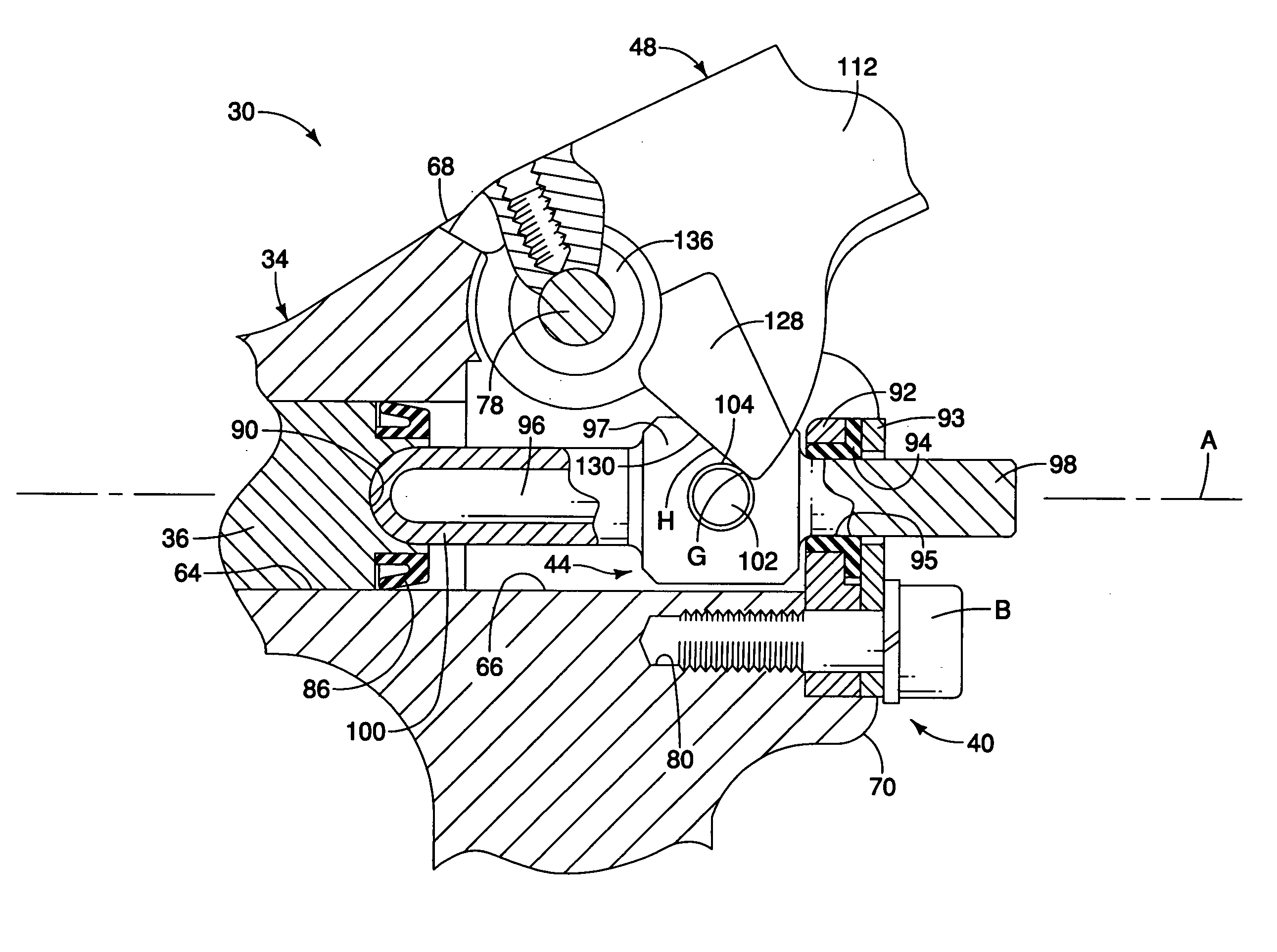

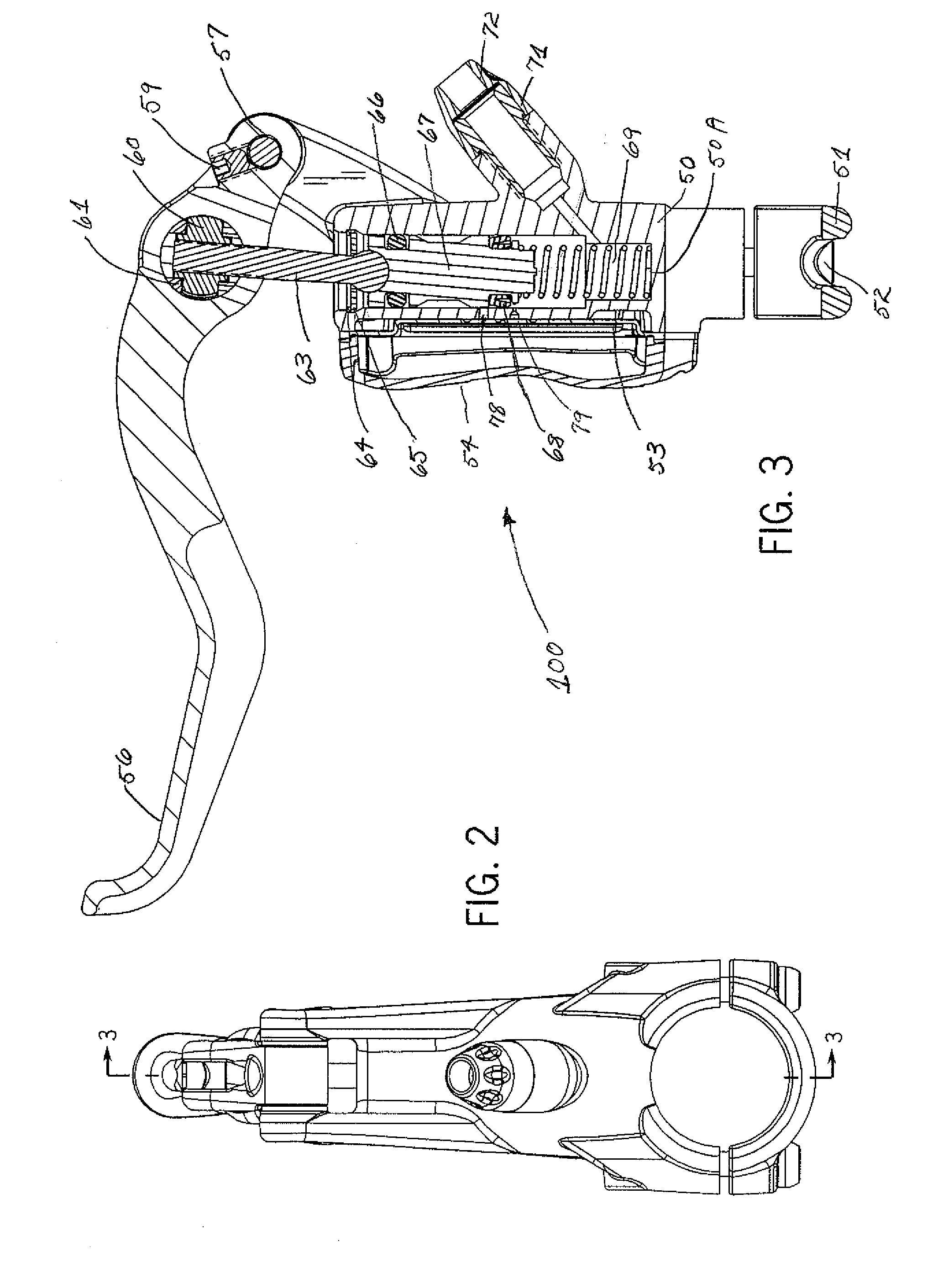

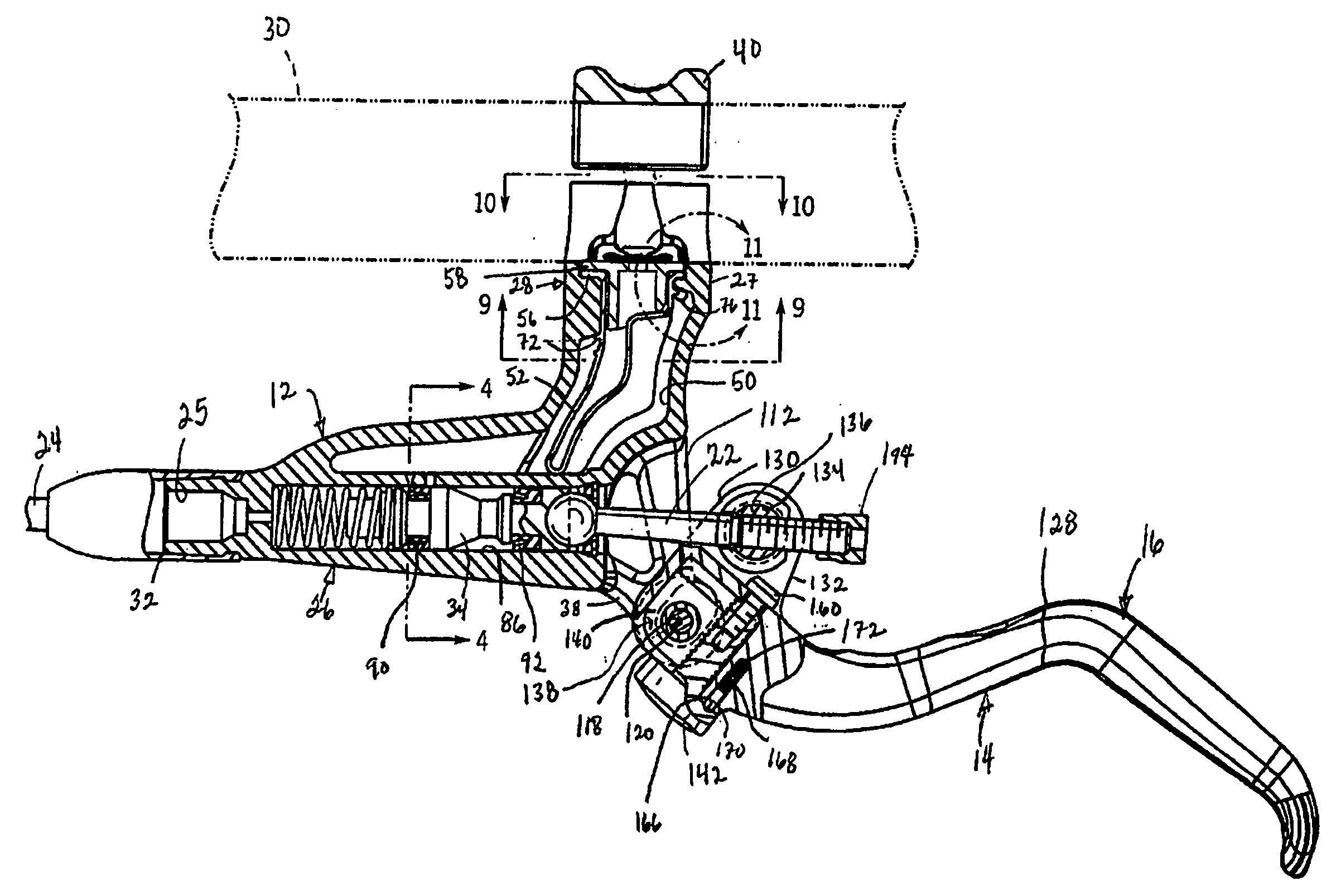

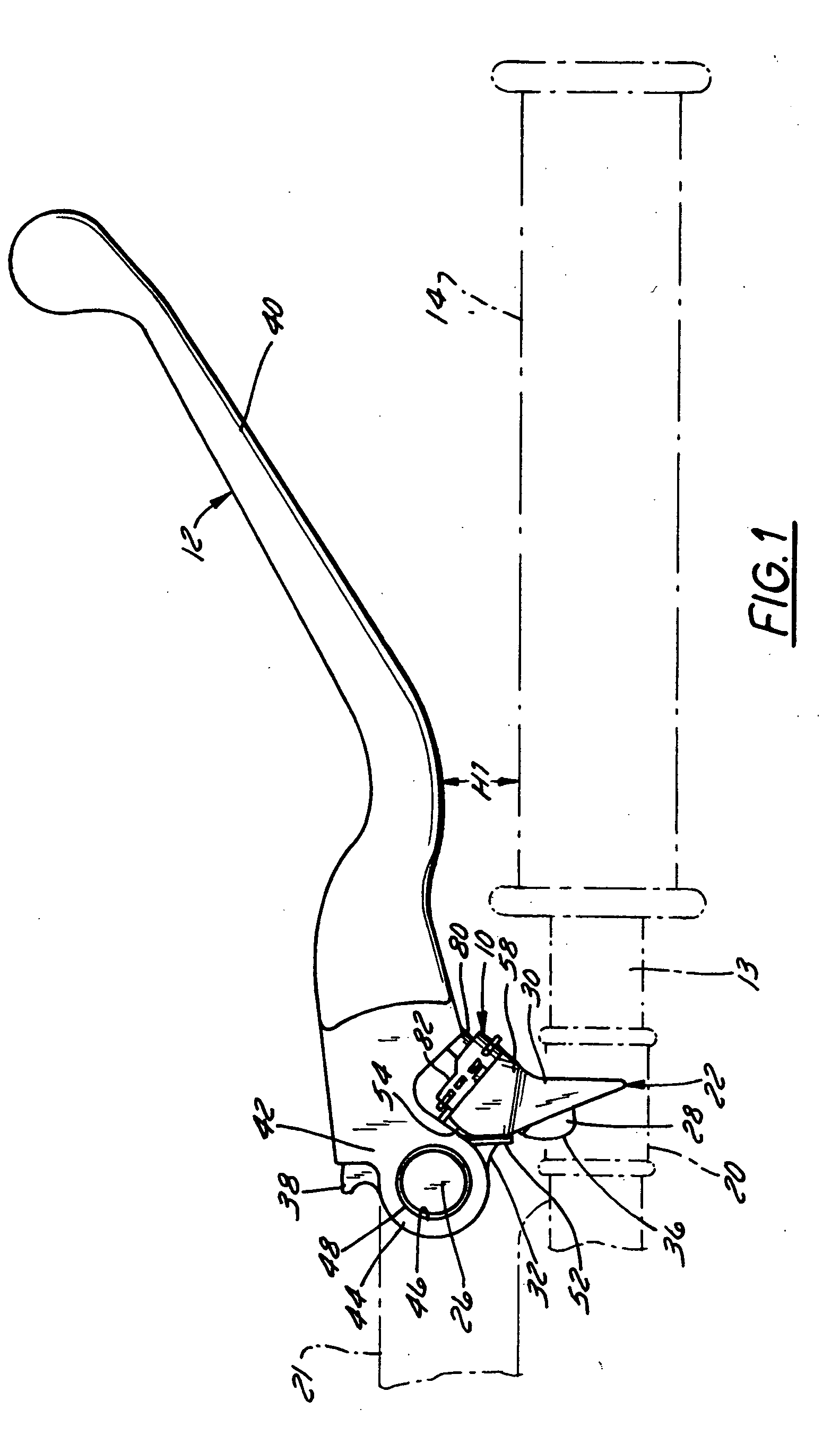

Reach adjustment mechanism for a master cylinder lever of a hydraulic disc brake

InactiveUS6957534B2Prevent unwanted changesIncreasing costControlling membersRotary clutchesRest positionMaster cylinder

A master cylinder for a hydraulic disc brake includes a housing defining a cylinder, the cylinder having a first and second end along its axis. A piston is received in the cylinder and has a radial seal between the piston and the cylinder. A lever is pivotably associated with the housing for pivoting between a rest position and an actuated position relative to the housing. A push rod is operatively associated with the piston and the lever to move the piston axially within the cylinder as the lever is actuated between the rest and actuated positions. A threaded engagement between a first end of the push rod and the lever is configured to cause movement of the rest position of the lever relative to the housing when a rotating force is applied to the push rod causing axial rotation of the push rod. An indexing structure is operatively associated with the push rod for providing index axial rotation of the push rod upon application of the rotating force to the push rod causing axial rotation of the push rod.

Owner:SRAM CORPORATION

Braking device with hidden hydraulic cylinder

InactiveUS20120240715A1Save spacePrevent leakageControlling membersMechanical apparatusHydraulic cylinderAlloy

A braking device with a hidden hydraulic cylinder has a hydraulic cylinder hidden inside a body of the braking device and further protected by a casing made of plastics, rubber or light alloy. Thereby, the space can be saved and any leakage due to unexpected collision. A tube is mounted to the hydraulic cylinder at any angle, preventing any wear or breaks due to frequent use. Therefore, the braking device of this invention is particularly suitable to the road bicycle.

Owner:TEKTRO TECH

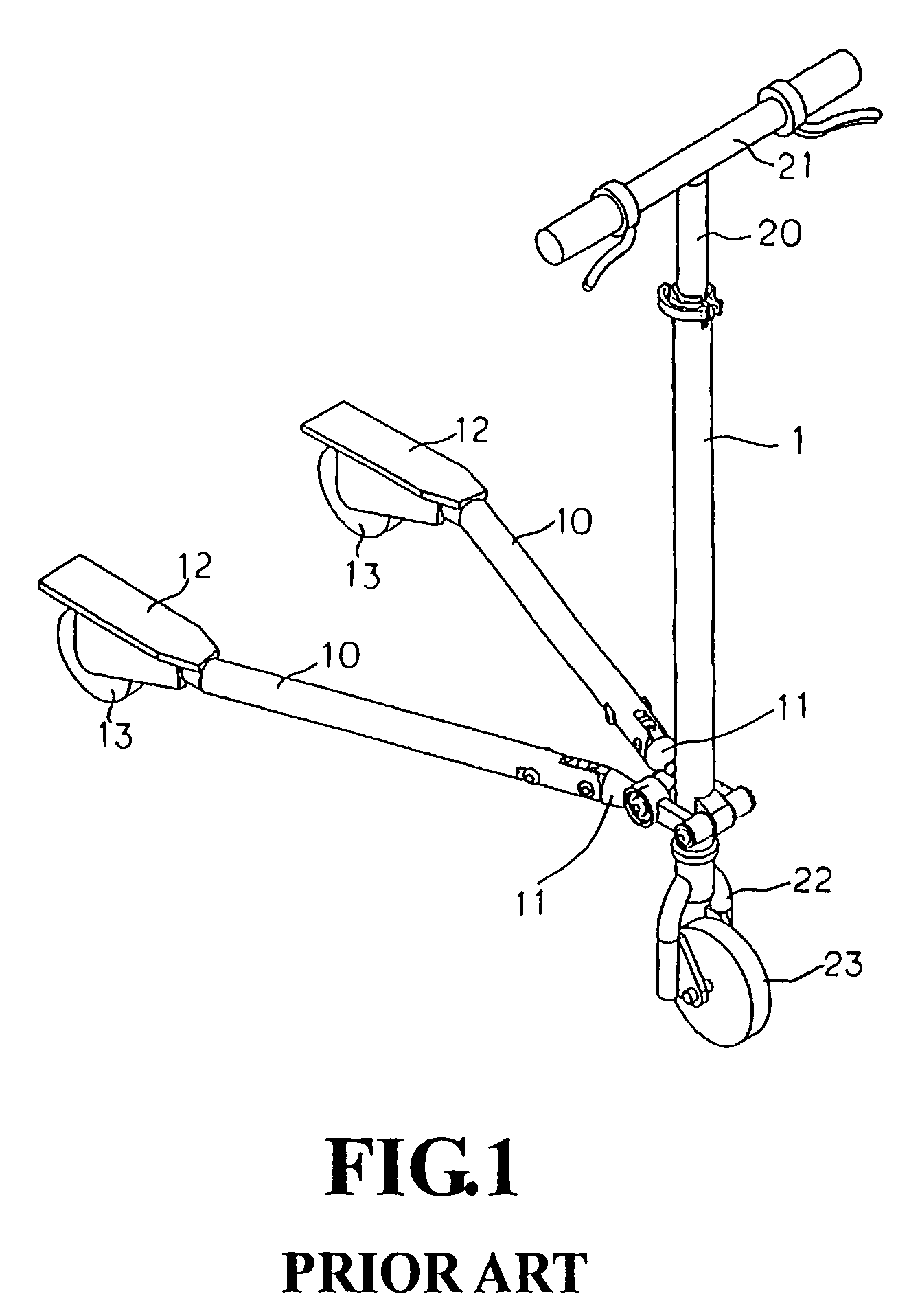

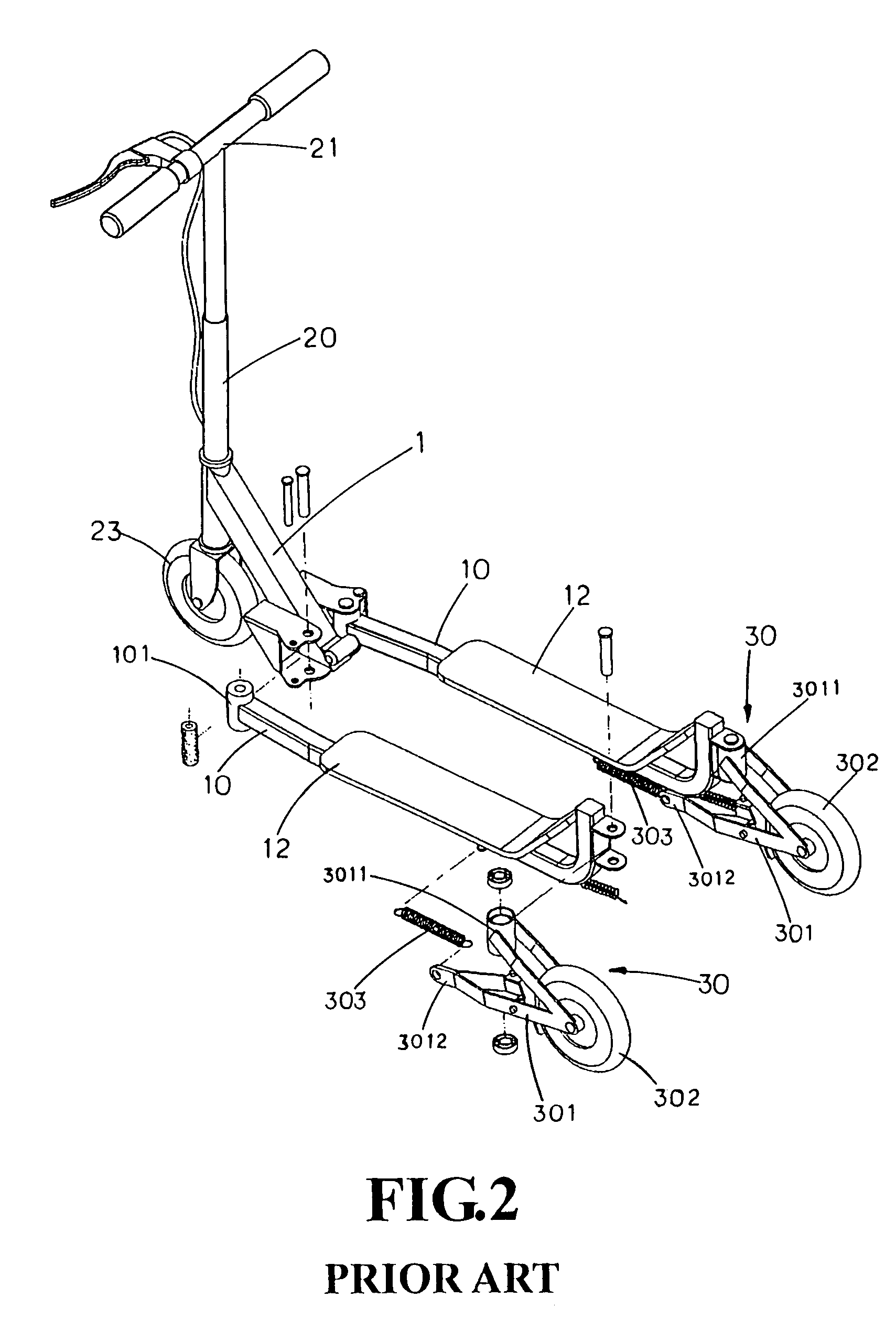

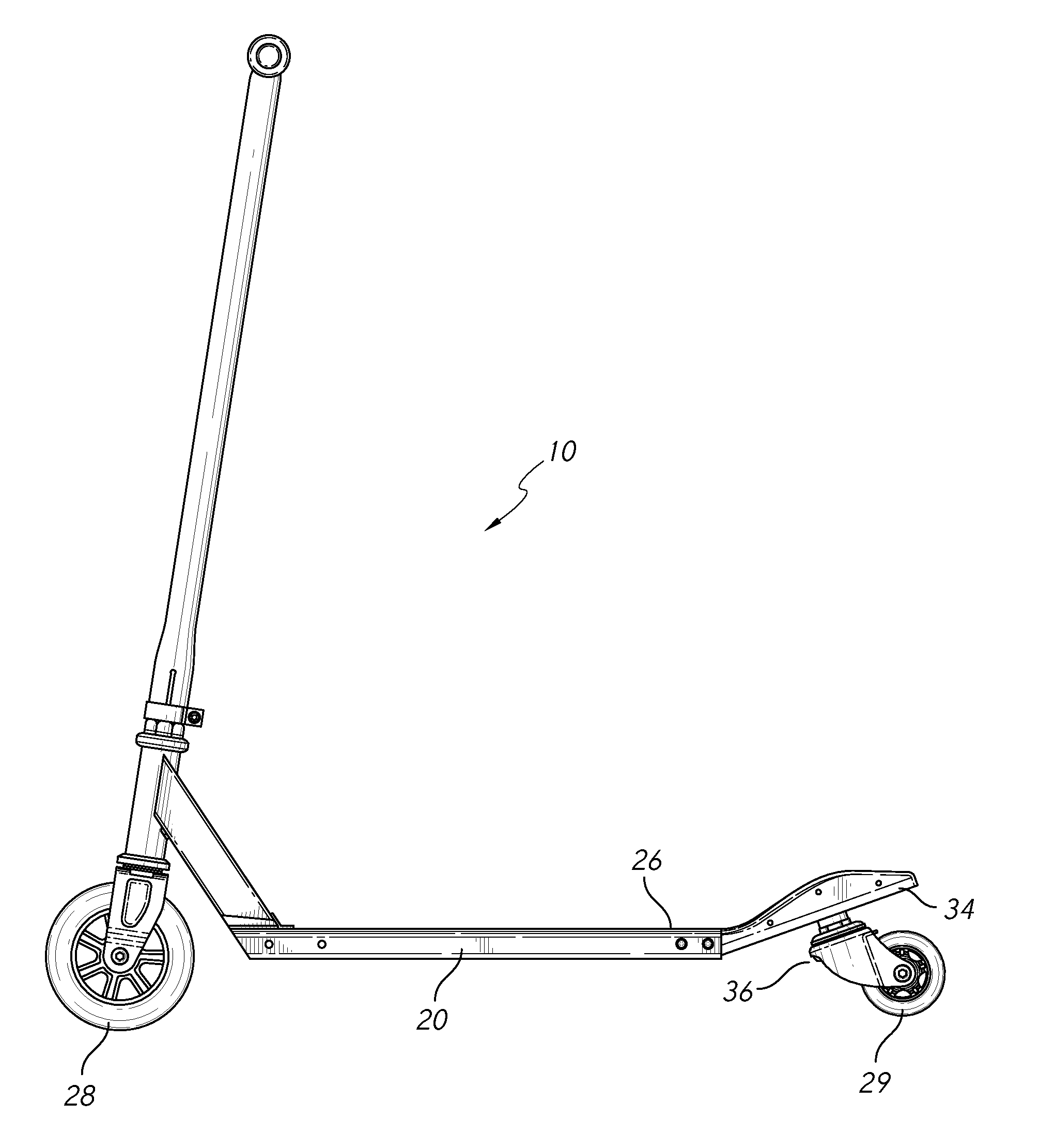

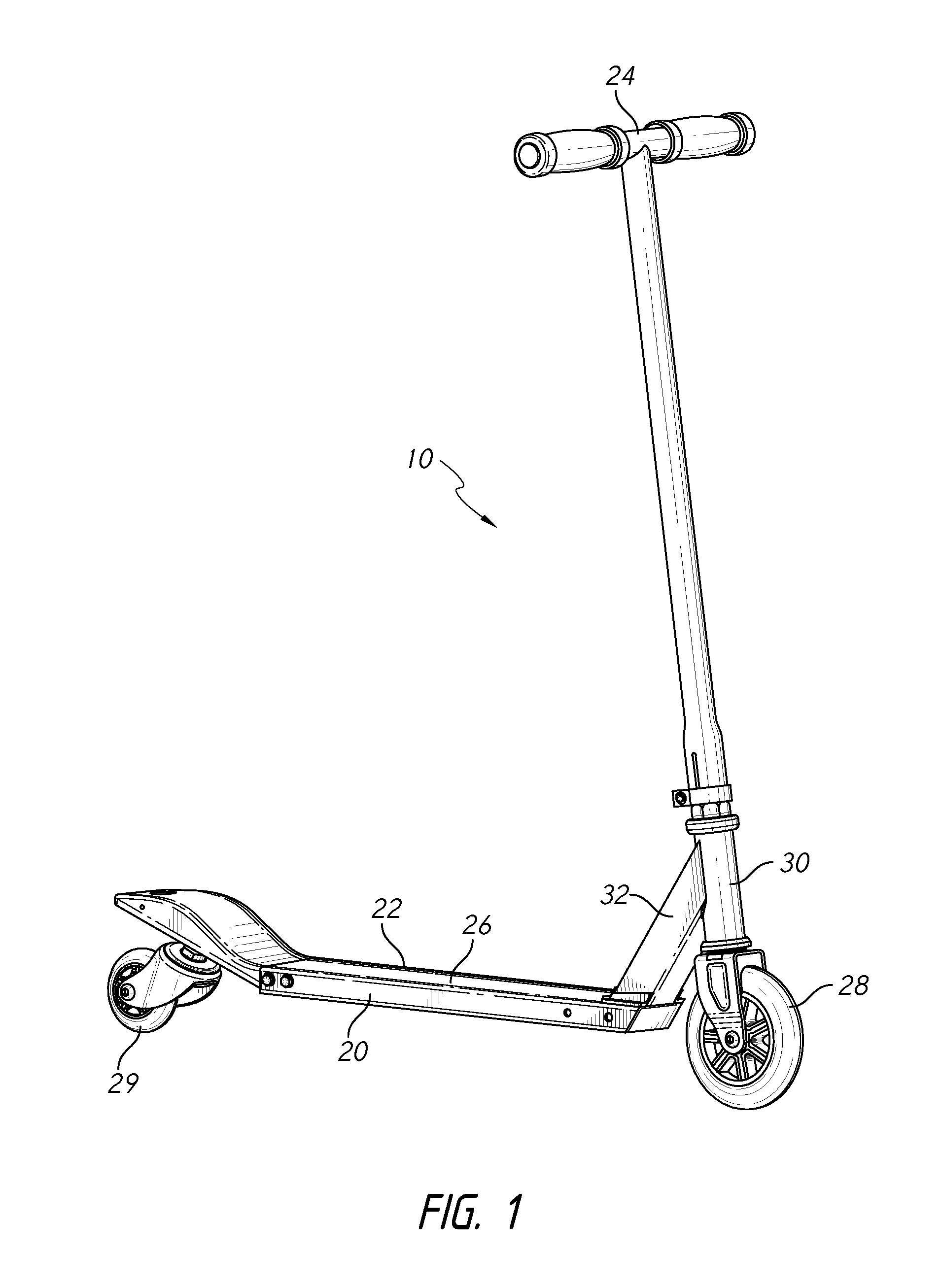

Scooter with rear swivel wheel

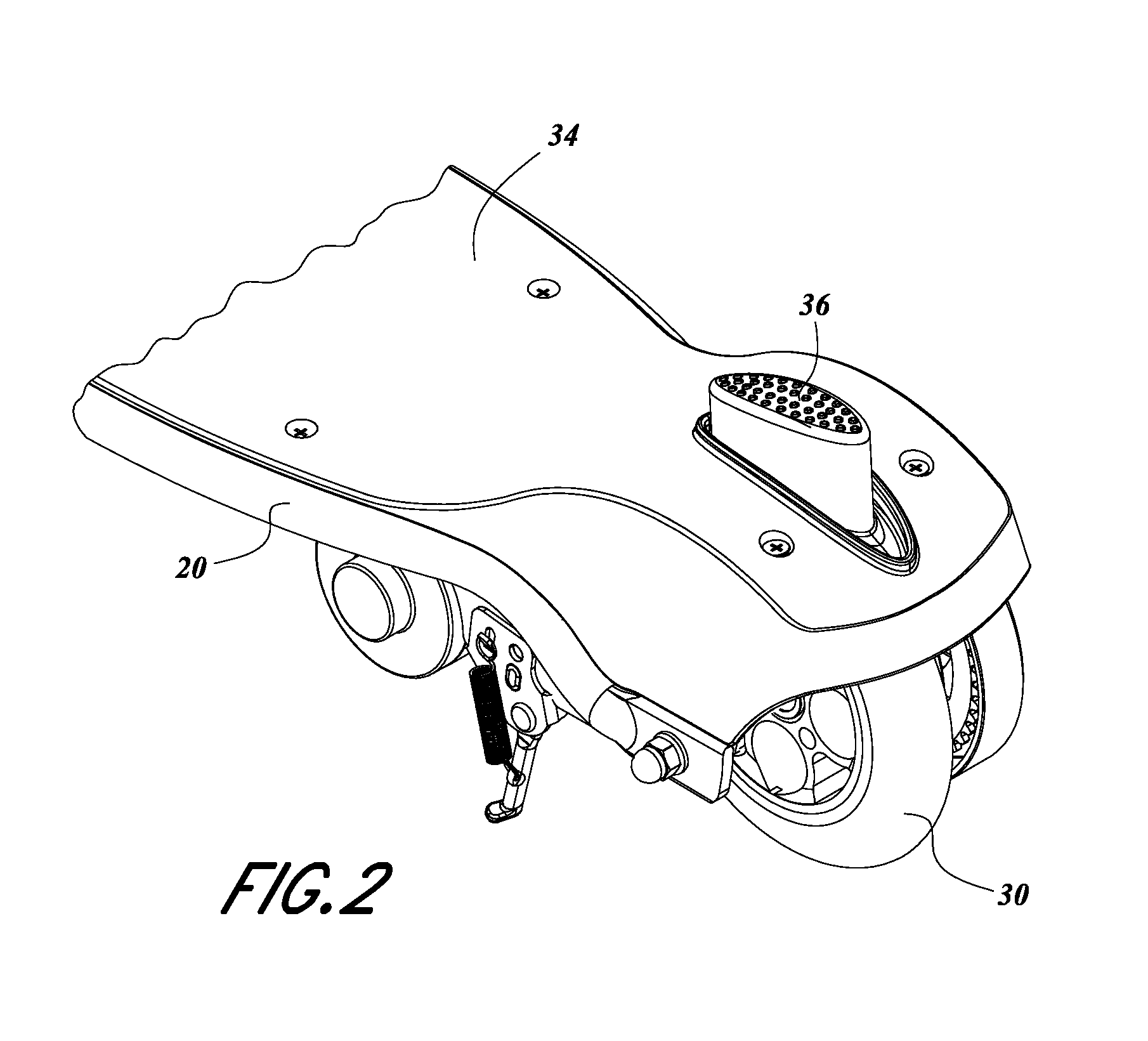

ActiveUS8870200B2Increase the user's enjoymentImprove abilitiesSteering deviceFoldable cyclesBrake forceFootplate

Owner:RAZOR USA

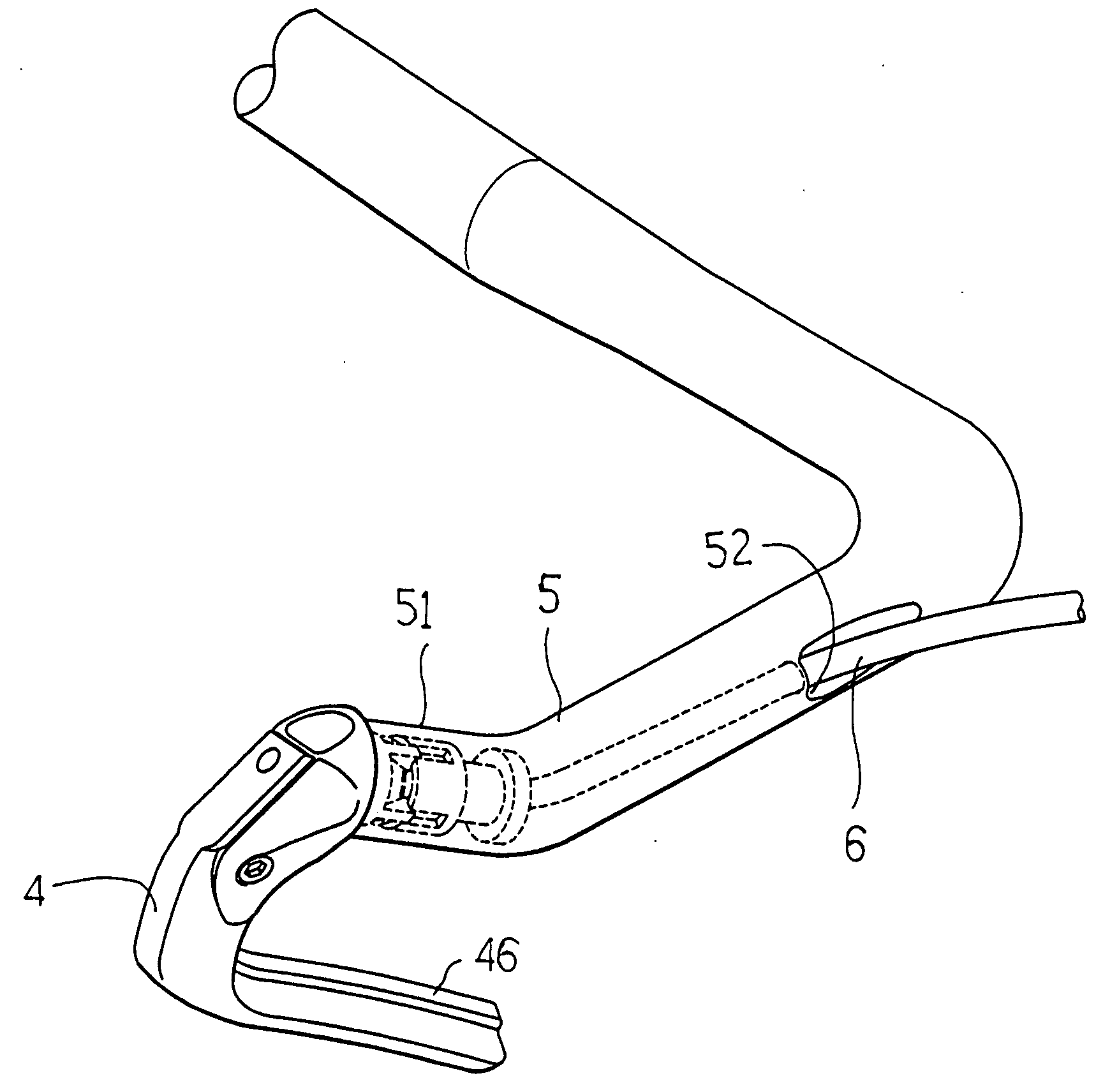

Embedding typed handbrake operating device

ActiveUS20060266594A1Efficient and effectiveCycle control systemsBrake actuating mechanismsExtremity PartMechanical engineering

An embedding typed handbrake operating device is disclosed herein, which mainly contains a positioning seat to which an operating lever is pin-joined. A stopping ring, a spring, and a locking seat are sequentially joined to the positioning seat through a locking bolt. The brake sleeve of a brake cable is threaded into the tubular body of the end section of the handlebar via a cable entrance hole and then into the locking seat. A brake wire is threaded through the operating lever, an axial through hole of the locking bolt, and into the brake sleeve connected to the locking seat, and finally to the handbrake assembly.

Owner:TEKTRO TECH

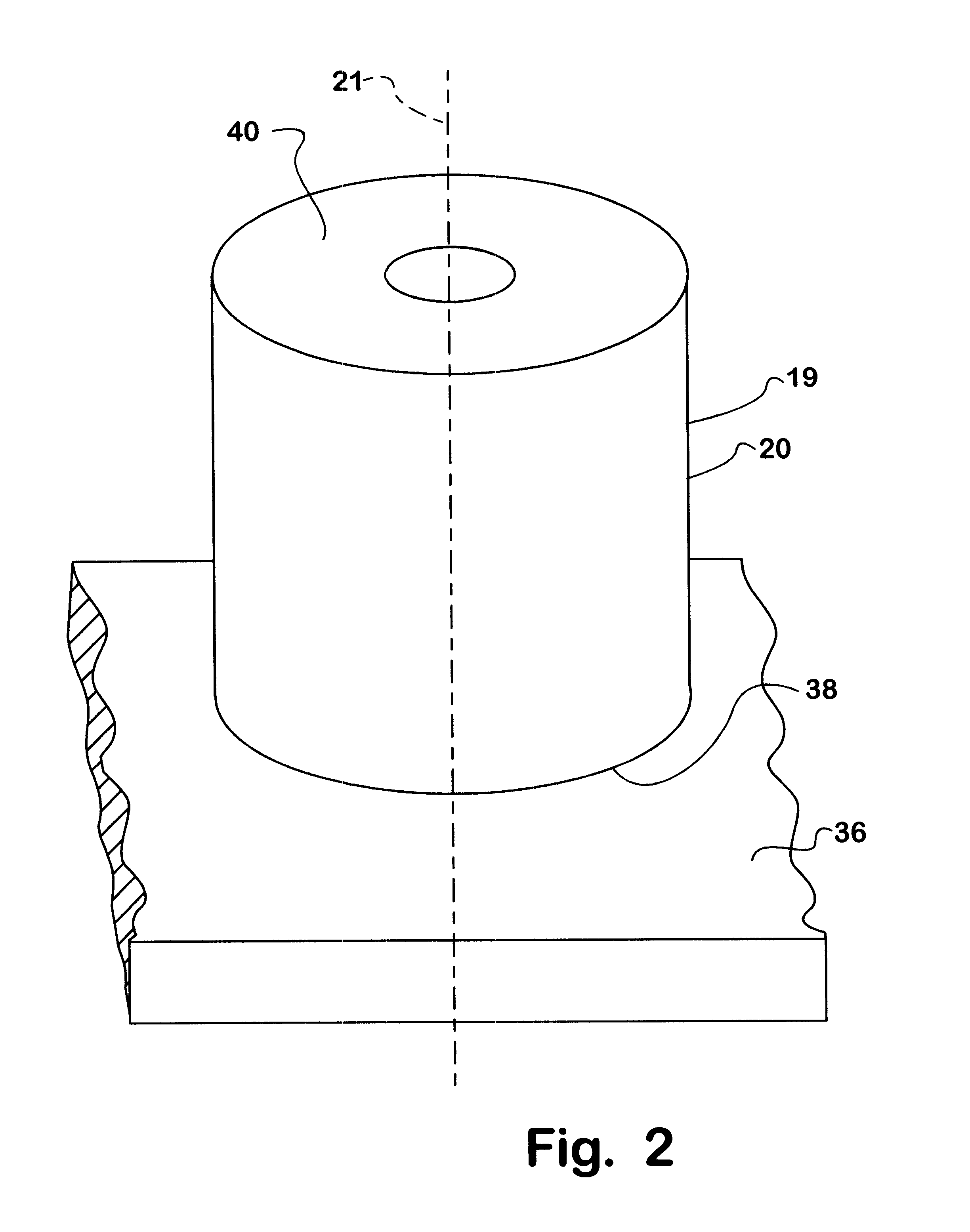

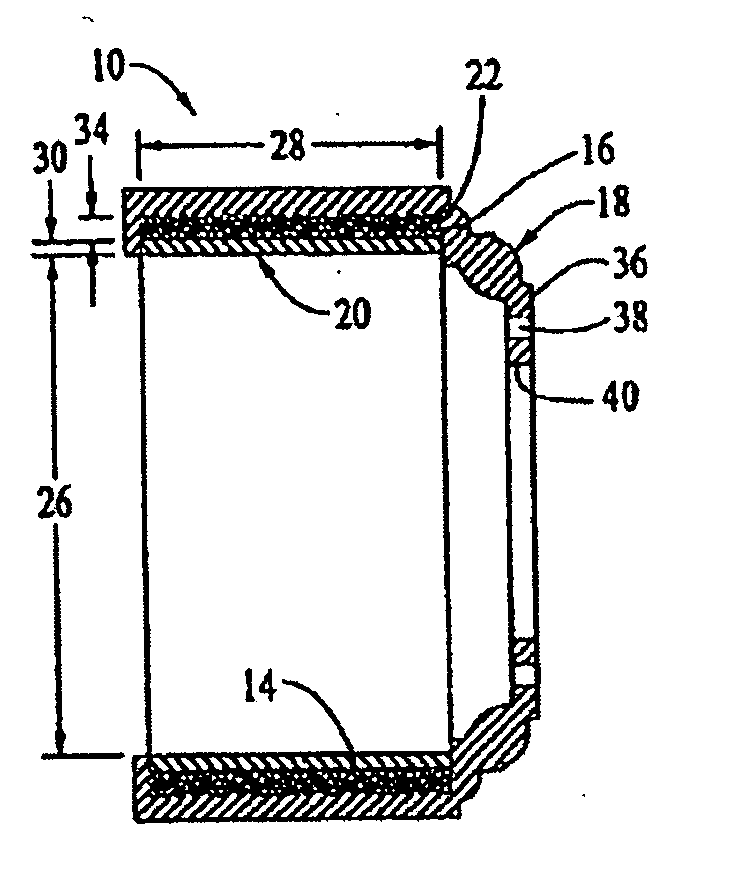

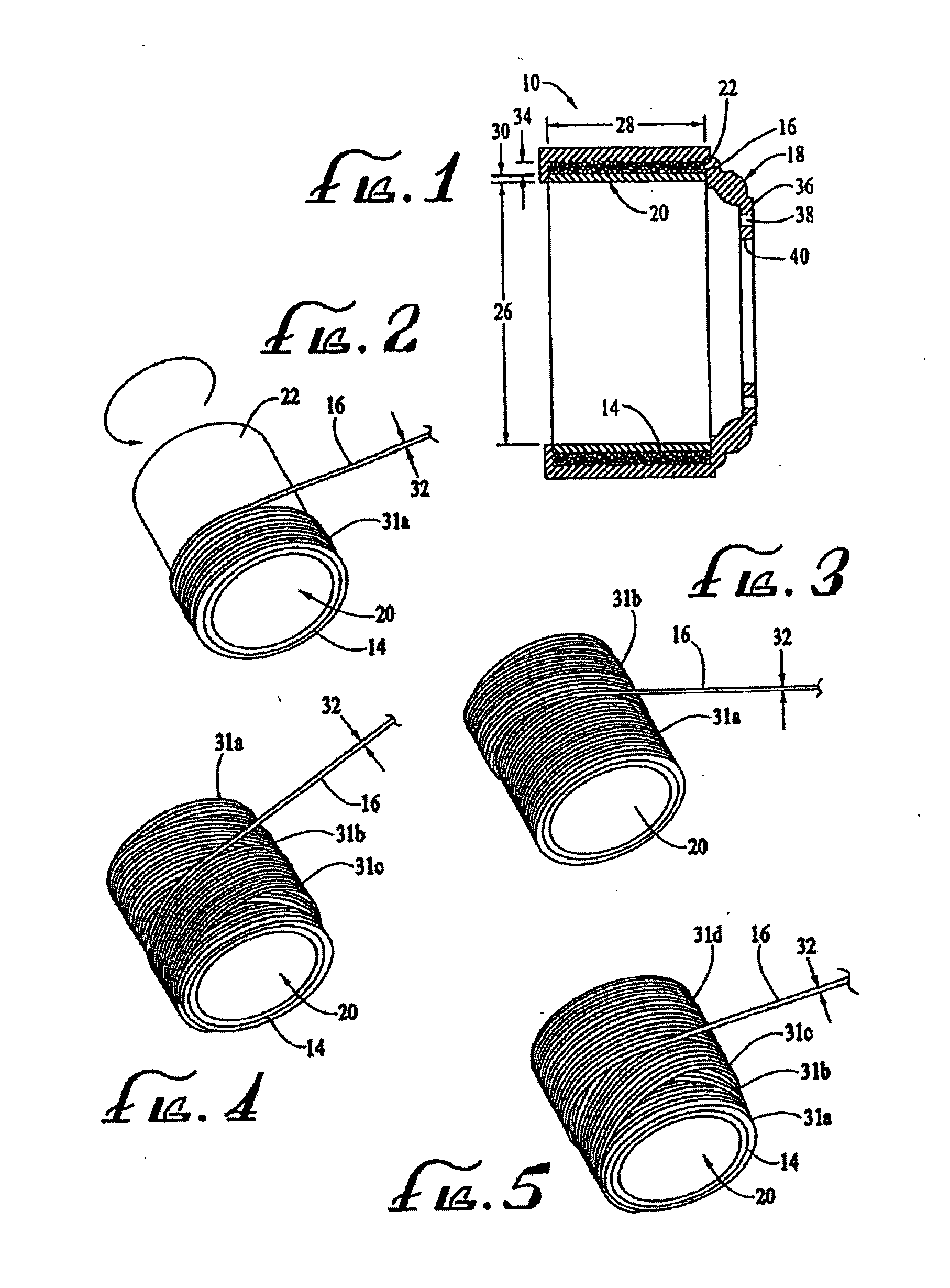

Lightweight reinforced brake drum and method for making same

InactiveUS20050217950A1Reduce manufacturing costAdd supportBraking drumsCoatingsCarbon graphiteEngineering

The invention provides a lightweight brake drum (10) comprising a lightweight, tubular inner member (14) having a reinforcement wrapping retention pattern (e.g., groove) cast in the exterior surface thereof, a length of reinforcement material (e.g., wrapped wire, cable, mesh, fibers, etc.) (16) in communication with a reinforcement retention pattern (e.g., a groove around the inner member) (14), the drum including an outer shell (18). The inner member (14) and the outer shell (18) are made of lightweight materials. Single, or multiple layers of reinforcement material (e.g. wrapping) are applied (e.g., wrapped) around the inner member (14) to support and inhibit expansion of the inner member (14). Because the reinforcement material (16) provides support against expansion, the inner member (14) and the outer shell (18) can be made of lightweight materials. In preferred embodiments, a bonding layer (66) is applied to the exterior surface of the inner member prior to application of the reinforcement material thereon. In preferred embodiments the reinforcement material comprises a low-impedance material such as copper along with another material that has good tensile strength characteristics (e.g., steel, composite fibers, Basalt-fibers, etc.). Preferably, the inner member comprises at least one material selected from the group consisting of a aluminum-based metal matrix composite (MMC) with a particulate reinforcement, ceramic matrix composite (CMC), and carbon graphite foam.

Owner:BENMAXX

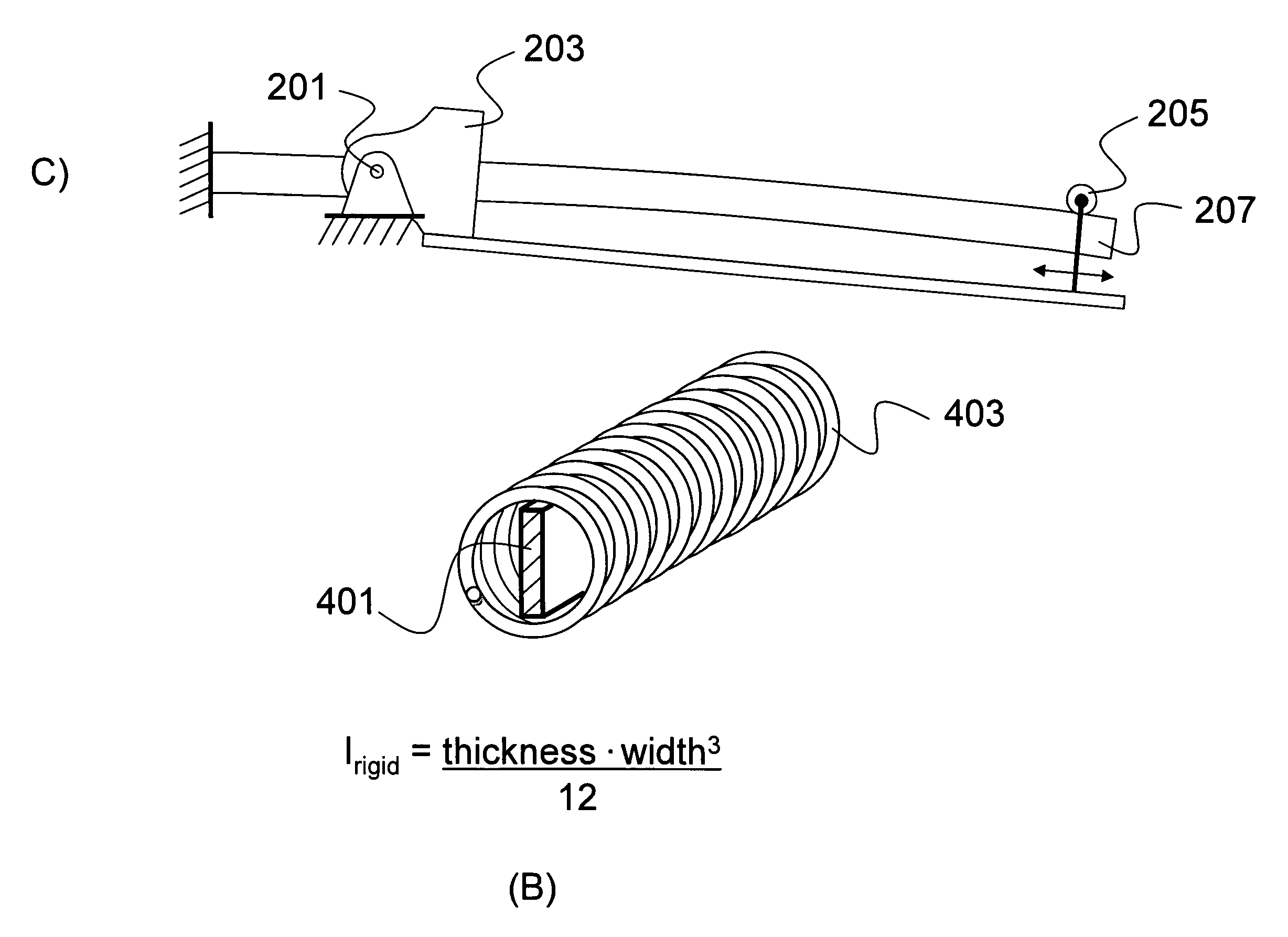

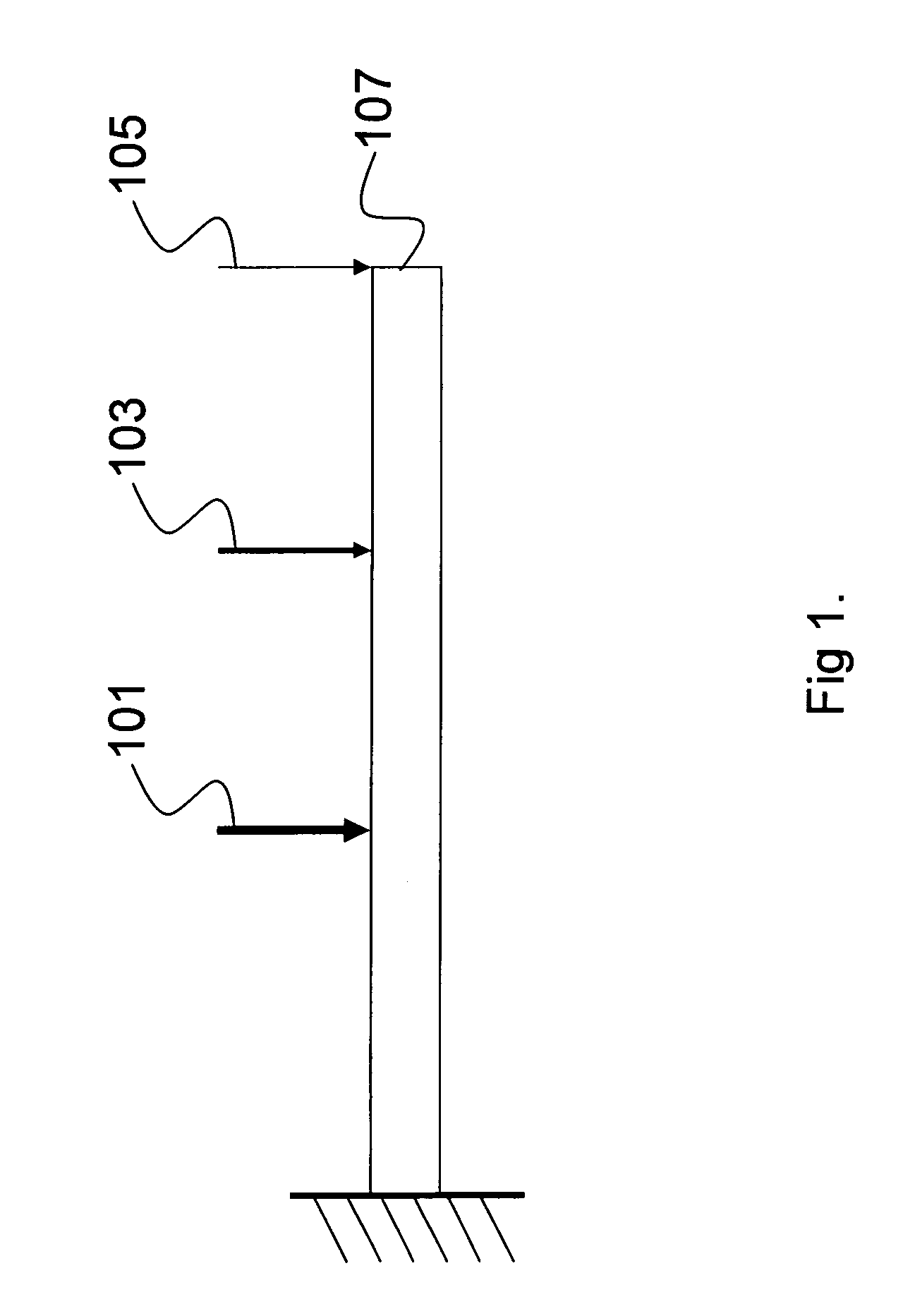

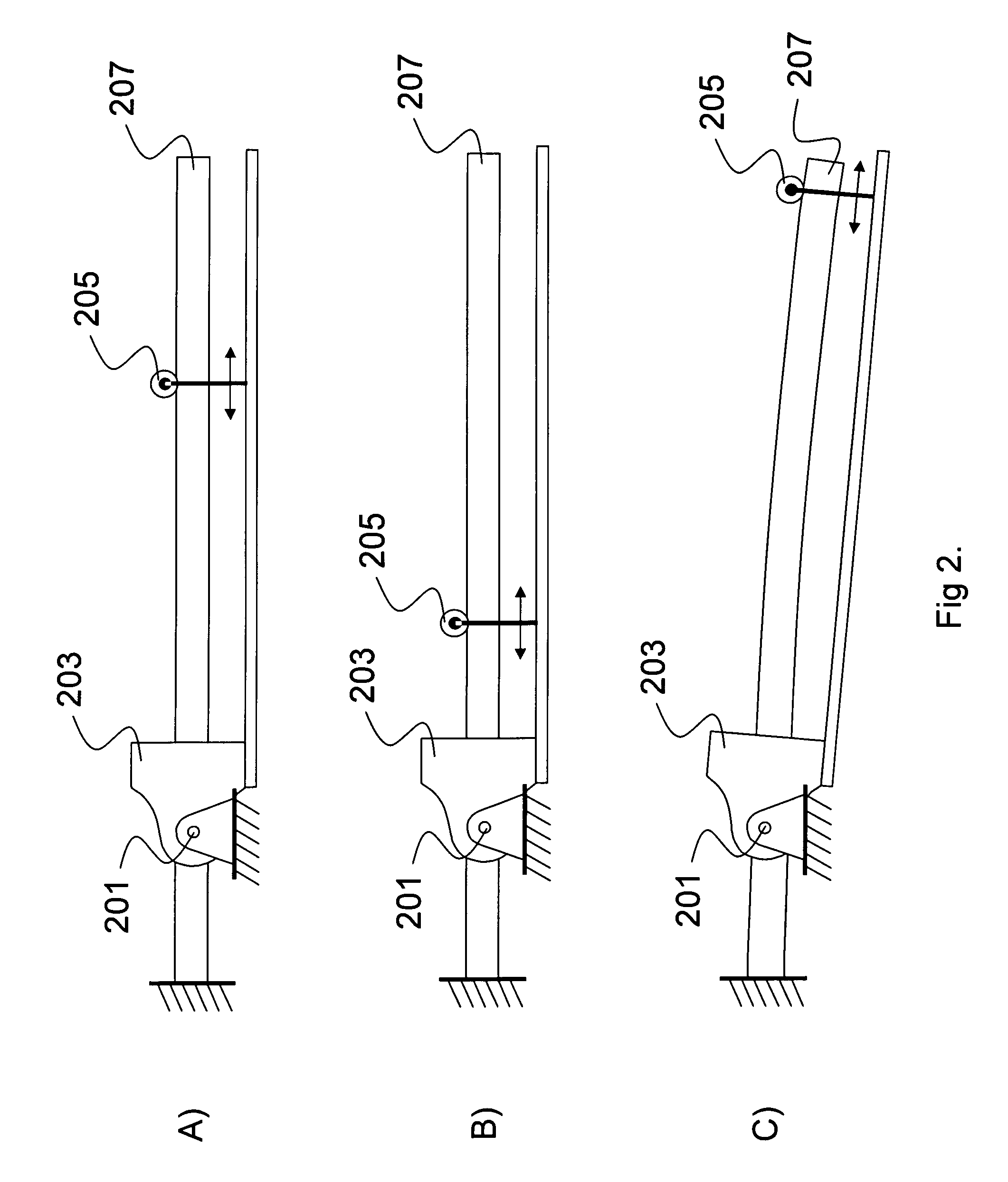

Adjustable stiffness leaf spring actuators

The present invention is a spring based actuator with a leaf spring having a length, width and thickness and a coil spring positioned over the leaf spring. The coil spring further comprises: a first end; a second end; and at least one force generator acting on either the first end of the coil spring and the second end of the coil spring to deflect the coil spring and the leaf spring.

Owner:HOLLANDER KEVIN +1

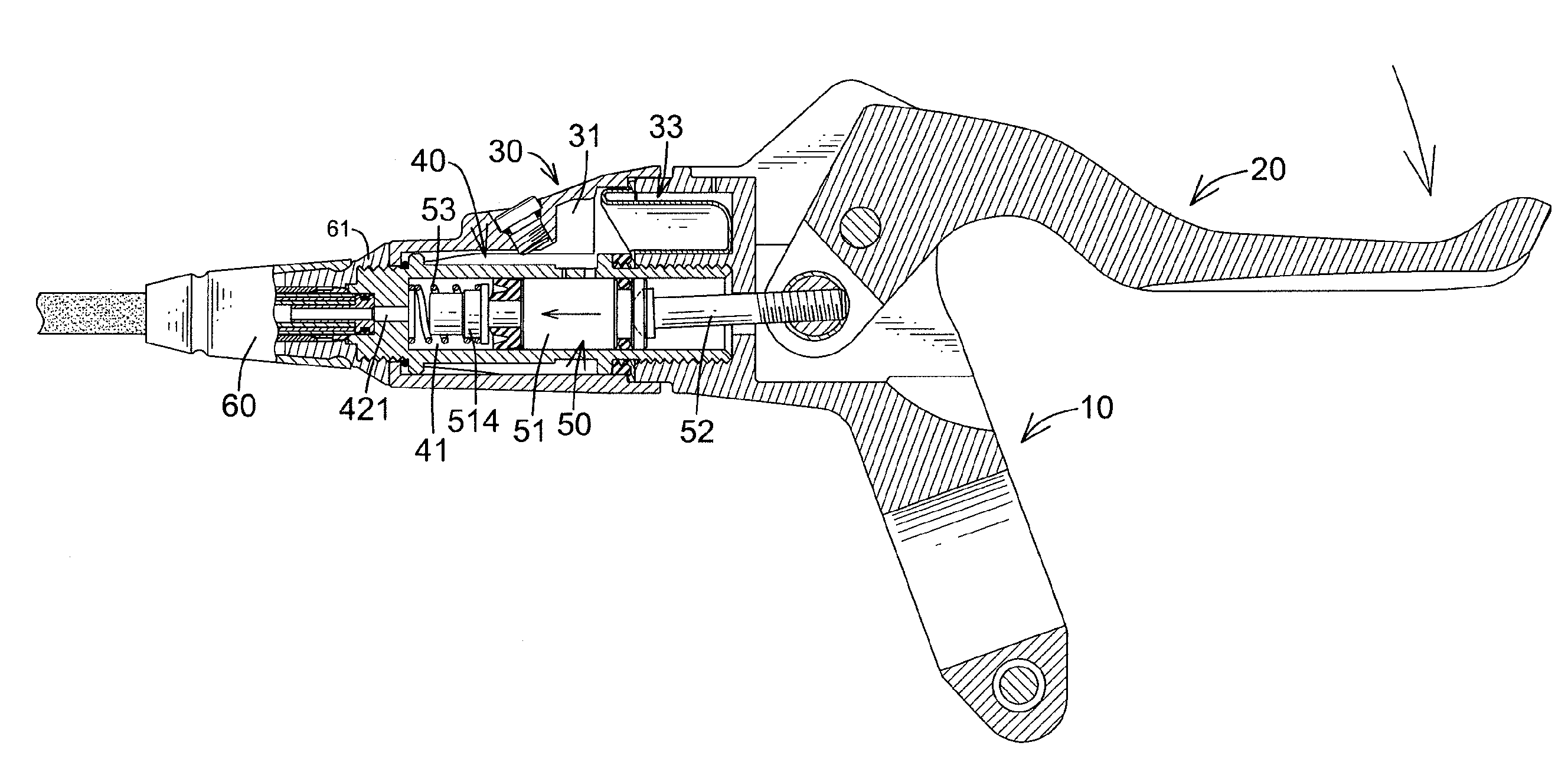

Bicycle hydraulic brake accentuate device

ActiveUS20070283692A1Improved master piston movement responseImproved brake responseRotary clutchesTelemotorsRest positionMaster cylinder

A bicycle hydraulic brake actuation device includes a hydraulic master cylinder housing having a bore and a push rod guide surface, a master piston and a radial seal received in the bore, a push rod and a lever. The push rod is supported by the push rod guide surface for sliding movement within the hydraulic master cylinder housing. The push rod is configured to move the master piston and the radial seal from a neutral position to a braking position. The lever is pivotally attached to the housing for pivotal movement between an at rest position and a brake actuation position. The lever is also configured and arranged to move the push rod and the master piston from the neutral position toward the braking position as the lever is pivoted between the at rest position and the brake actuation position.

Owner:SHIMANO INC

Hydraulic brake lever

InactiveUS20090120751A1Reduce stressManufacturing limitationCycle control systemsHand actuated initiationsHigh pressureMechanical engineering

A hydraulic brake lever includes a body having a bladder chamber, a cavity and a flexible separator mounted between the bladder chamber and the cavity. The flexible separator holds hydraulic oil in a front section of the body and prevents a rear section of the body from contacting with the pressurized hydraulic oil. A cylinder is mounted in the cavity of the body and accommodates a piston set. Thus, a high pressure is kept in the cylinder and is not applied directly on the body. Due to the separating design, the hydraulic oil applied a low pressure on the body. Thus, manufacturing the body is less limited and a manufacturing cost is reduced.

Owner:LEE CHI ENTERPRISES

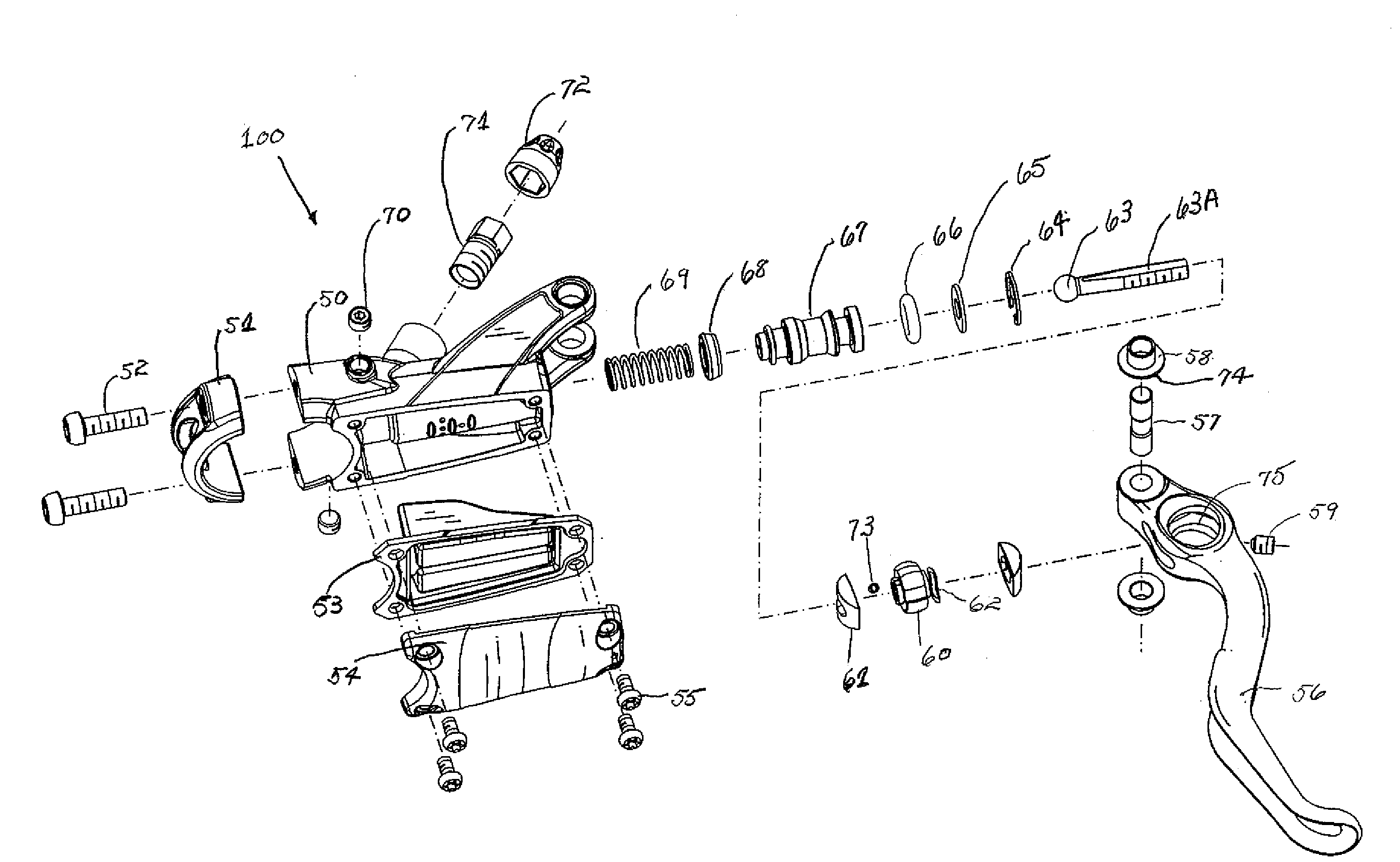

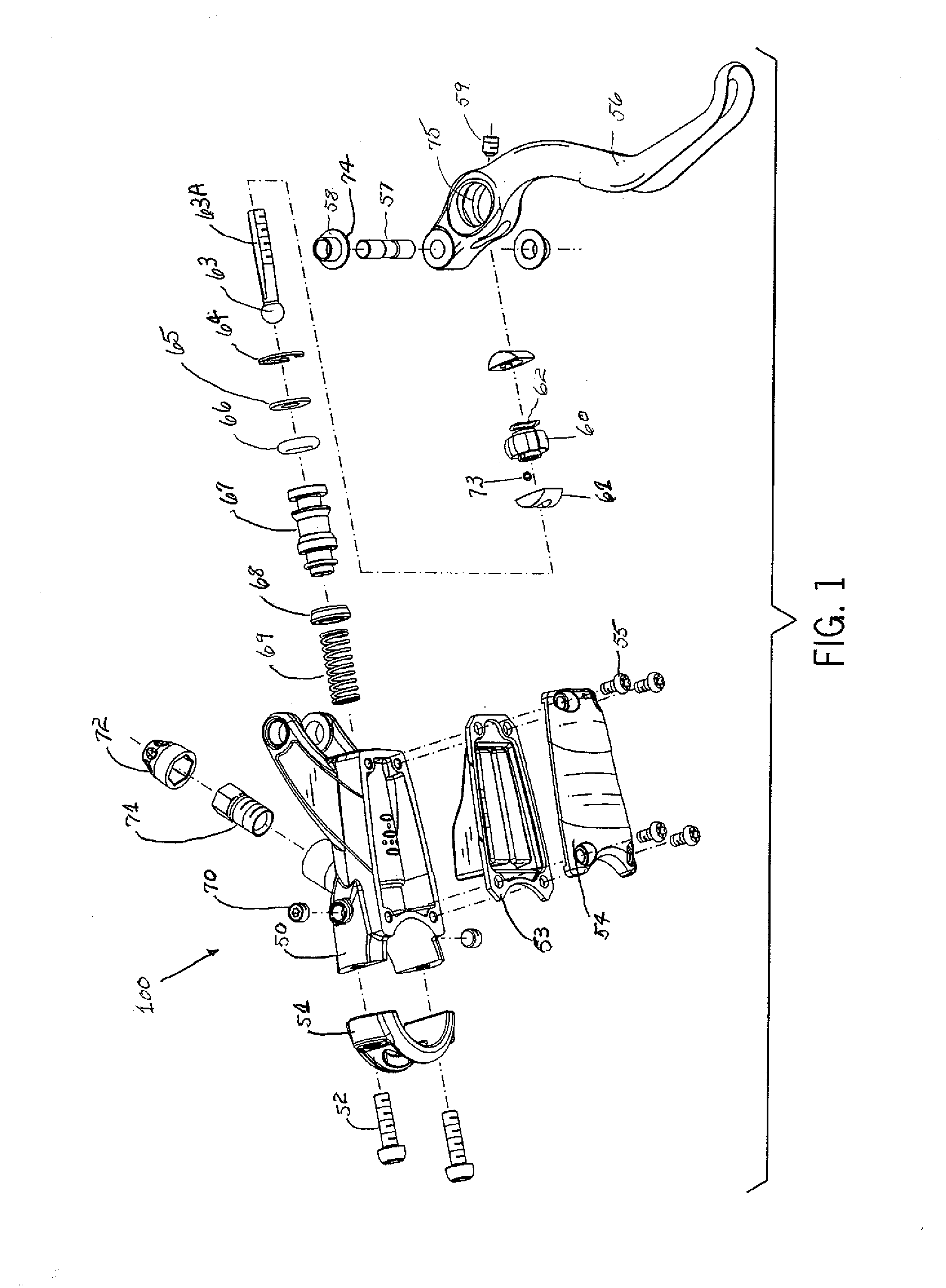

Hydraulic Brake Master Cylinder

A hydraulic brake master cylinder is provided that is compact and light in weight. The master cylinder has a reservoir shape that provides increased reservoir expansion volume. The master cylinder also provides gear shifter operation clearance and a comfortable lever that allows easy adjustment without the use of tools. The lever has defined increments of adjustment which make it easy to use. The invention also includes a method of bleeding air from the system without requiring reorientation of the master cylinder. The retention methods for the various lever embodiments shown allow for easy and inexpensive retention of the lever and also provide for reduced overall weight and cost.

Owner:HAYES BICYCLE GROUP

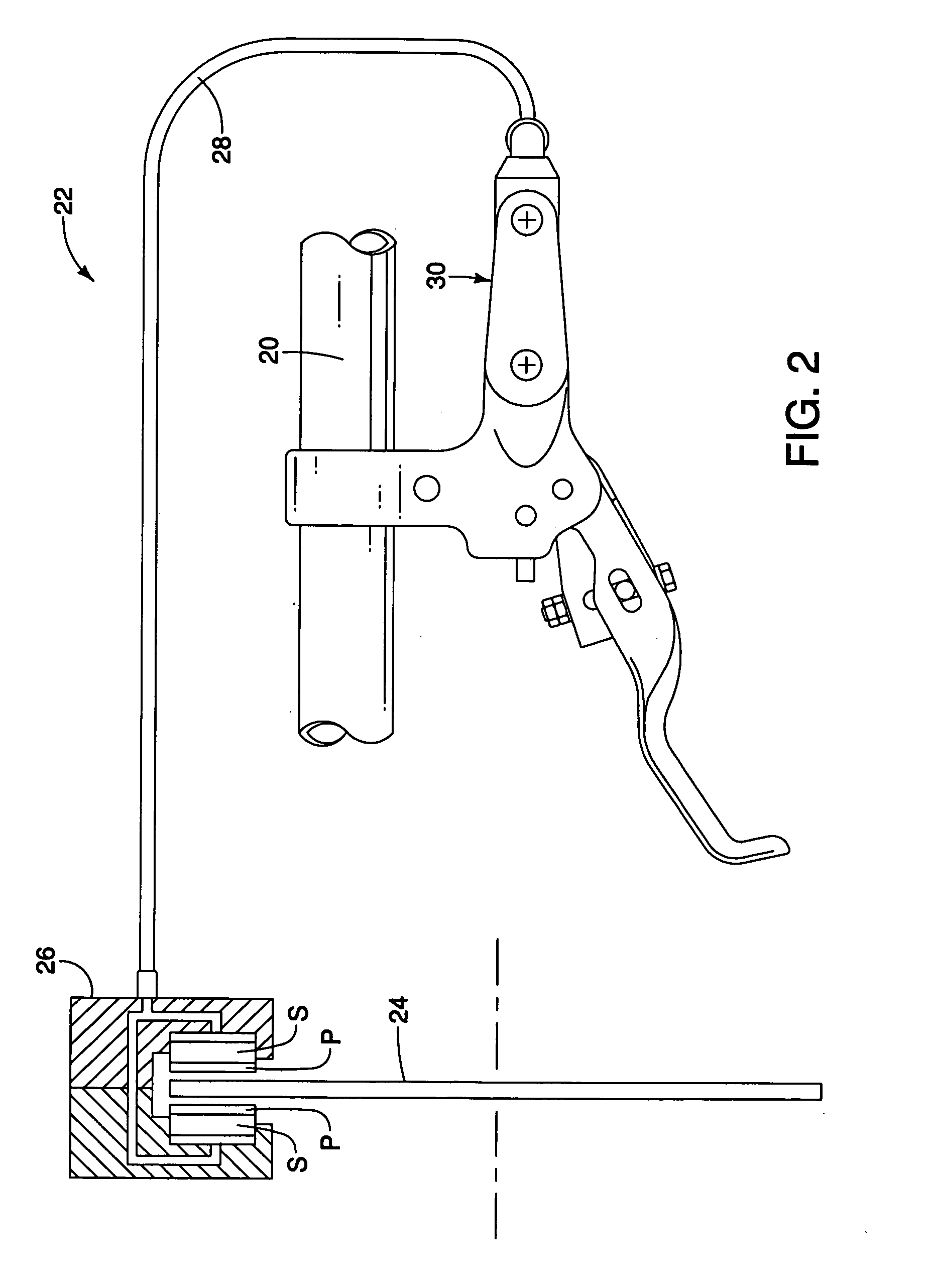

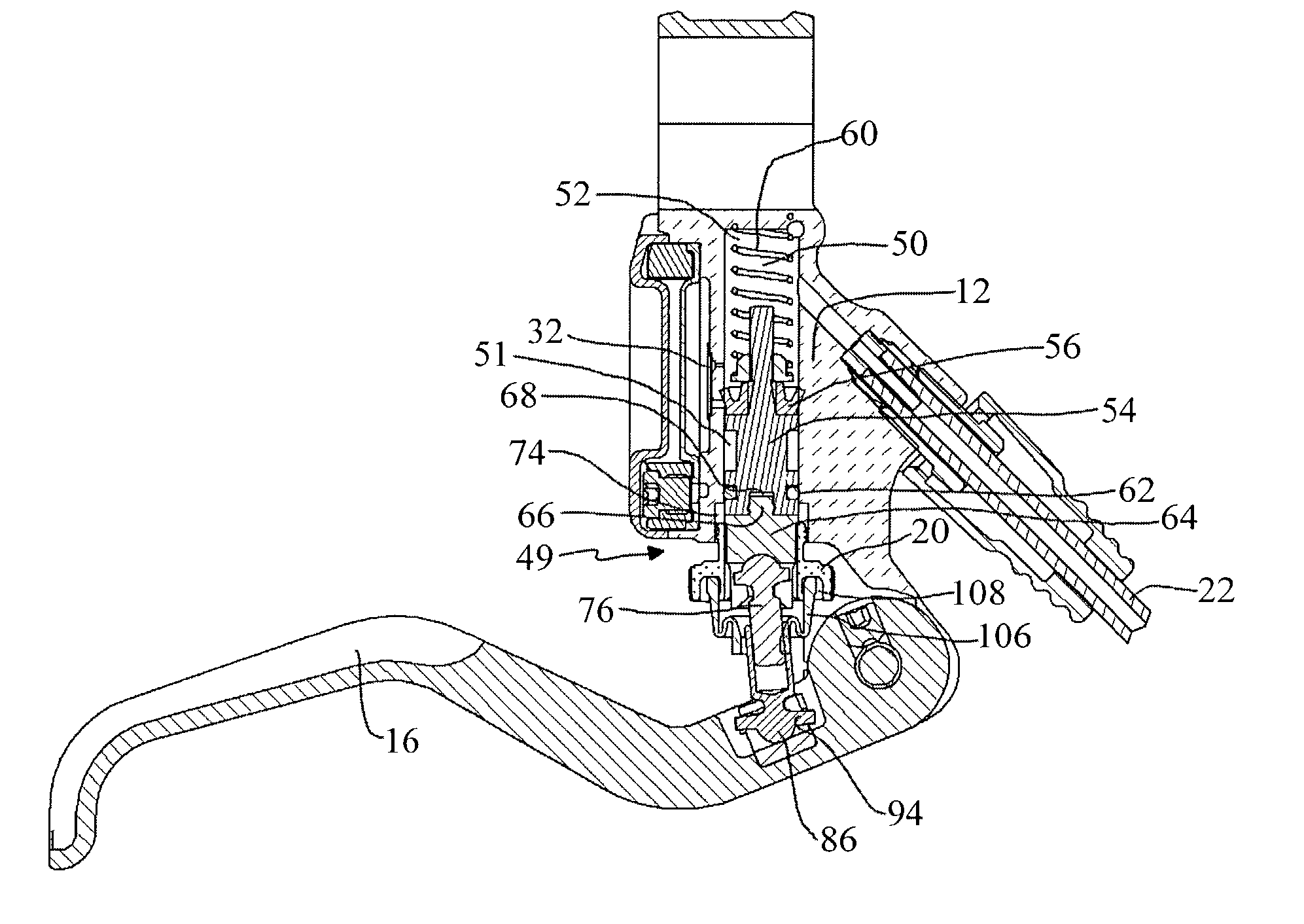

Master cylinder lever for a hydraulic disc brake having favorable handle pivot geometry

ActiveUS7204350B2Increased mechanical advantageImprove production safetyFluid braking transmissionCycle brakesMaster cylinderEngineering

A bicycle hydraulic disc brake master cylinder includes a housing having a bar clamp at one end configured for fastening the housing to a bicycle handle bar, the bar clamp receiving the handle bar along a clamp axis. A handle is pivotably connected to the housing to pivot about a pivot axis in operative association with a piston train to impart a drive force on the piston train. The handle defines a finger receptacle receiving at least one finger of a user defining an effective force point at a select distance from a distal end of the handle. A select ideal finger actuation path for the at least one finger of a user begins at a start point at the effective finger force point with the handle at an engagement point where the handle begins to drive the piston train against operative fluid resistance and extends along a line from the start point at a select angle relative to the clamp axis. A pivotable connection is provided between the handle and the housing and is located on the housing relative to the clamp axis so that with the handle actuated by a force applied to the effective finger force point along this select ideal actuation path, a mechanical advantage to the user resulting from the handle actuation does not diminish more than three percent as the handle is pivoted between the engagement point and a fully actuated position.

Owner:SRAM CORPORATION

Control device

ActiveUS20140352478A1Increase in sizeMechanical apparatusCycle control systemsCommunication unitEngineering

A control device is configured to be installed on a handlebar of a bicycle and configured to operate a brake device on the bicycle. The control device basically includes a bicycle attachment member, a brake operating member and at least one of a wireless communication unit and a notification unit. The brake operating member is pivotally coupled to the attachment member to pivot about a first axis. The least one of the wireless communication unit and the notification unit is disposed on the brake operating member.

Owner:SHIMANO INC

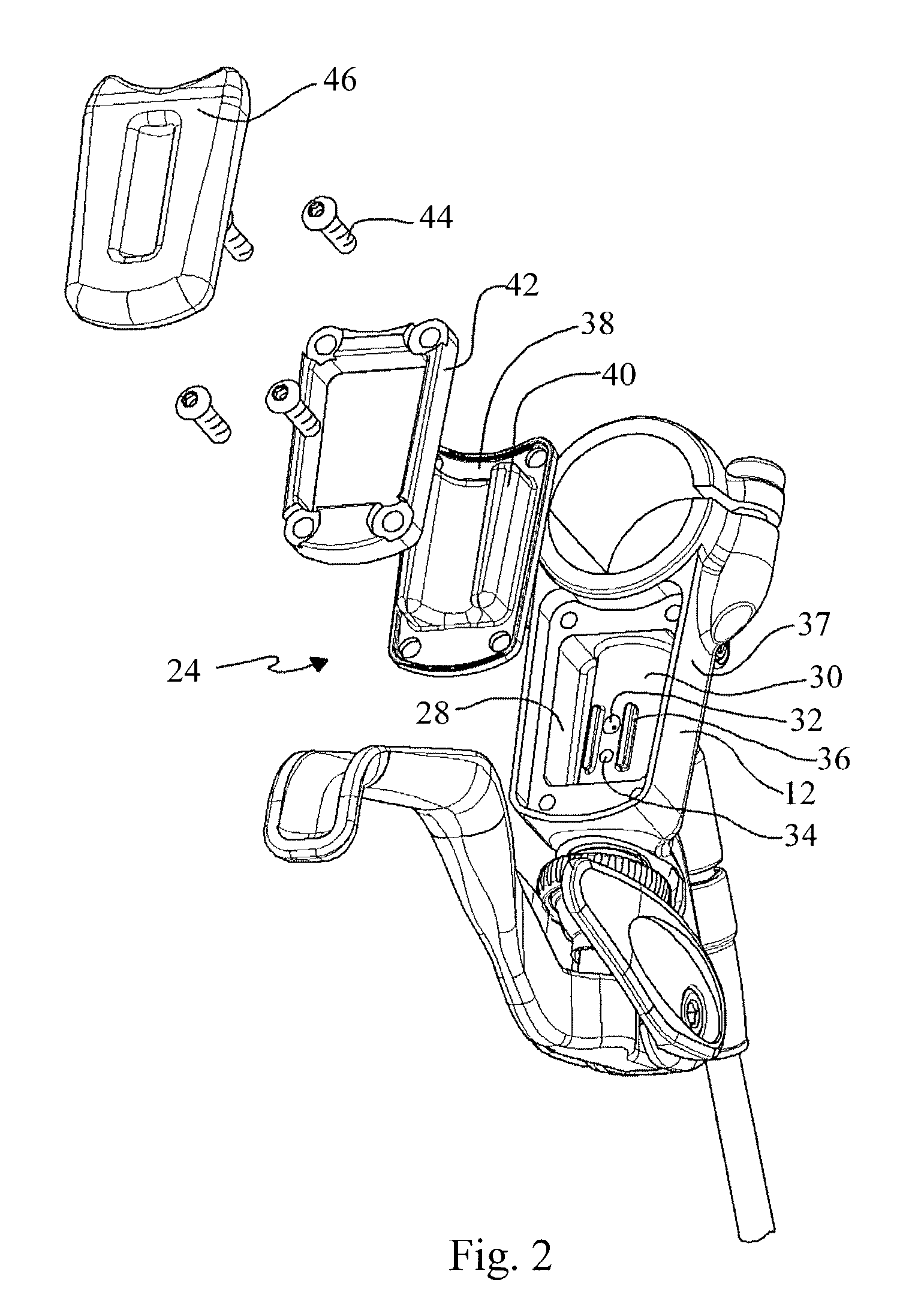

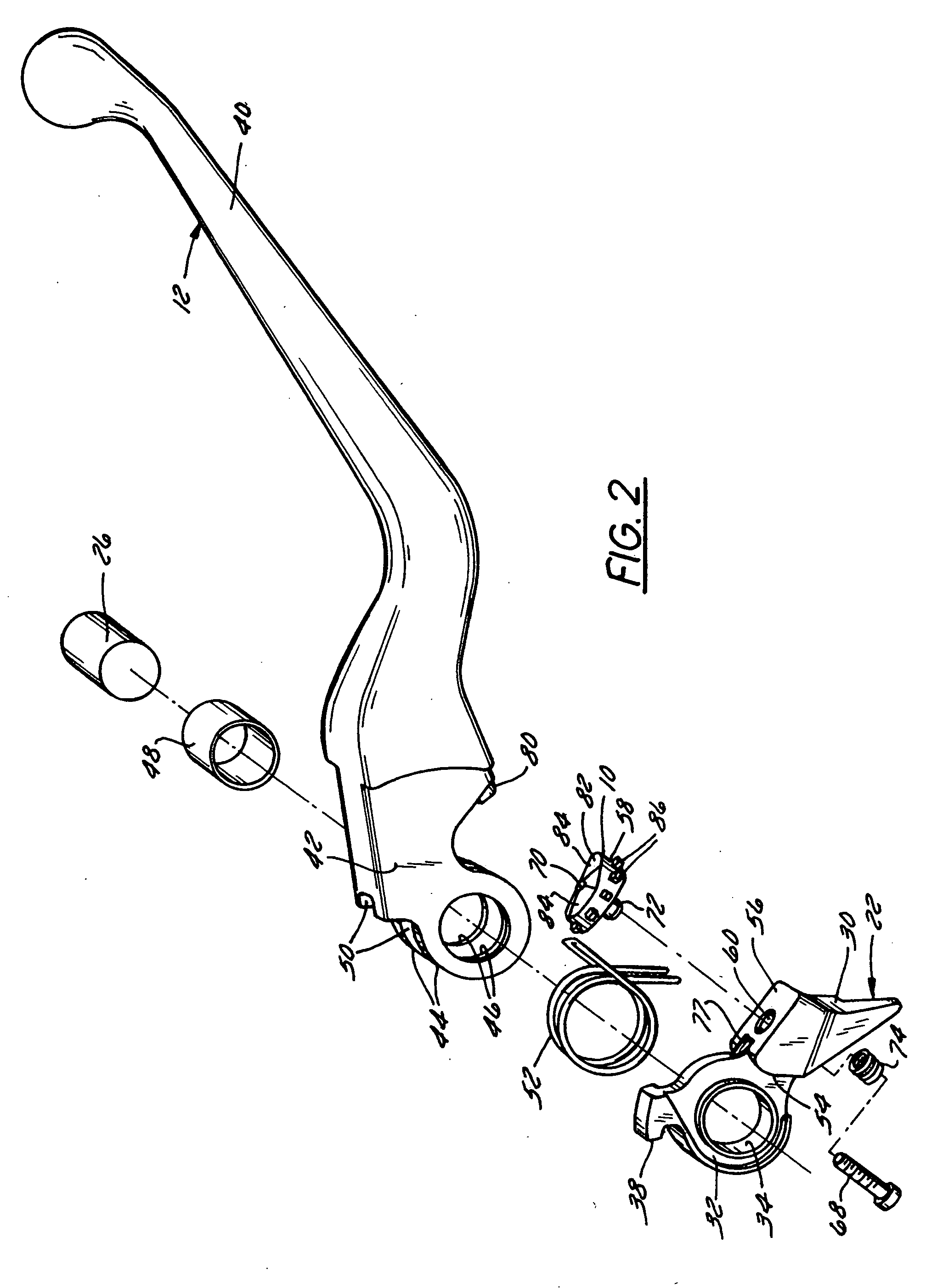

Lever assembly and master cylinder

ActiveUS20050199450A1Reduce weight and sizeHand actuated initiationsFluid braking transmissionMaster cylinderEngineering

A lever assembly and a master cylinder are provided. The lever assembly includes a lever and an adjuster mechanism that changes the mechanical advantage of the lever. The reach of the lever relative to a handlebar can be adjusted. Both the mechanical advantage and reach of the lever can be adjusted without tools and while a vehicle including the same is operated. The master cylinder includes a reservoir in a clamp area. A reservoir bladder fits into the reservoir. A cover encloses the bladder and includes a vent opening making the bladder at atmospheric pressure such that air can move into the bladder and out of the bladder. The master cylinder can be bled without reorienting the master cylinder. A method of adjusting a mechanical advantage of a lever and a method of bleeding a braking system without reorienting the master cylinder are also provided.

Owner:HAYES BICYCLE GROUP

Brake and clutch lever height adjusters

A brake or clutch lever comprises a lever that pivots about an axis, a lever mounting structure from which the lever extends, and a thumbwheel having a cam thereon. The cam is disposed directly between the lever and the lever mounting structure. The thumbwheel rotates about an axis that is perpendicular to the axis of lever pivoting. Also provided is a method of adjusting a height of a brake or clutch lever. A grip portion of a brake or clutch lever is lifted away from a handlebar. A thumbwheel having a cam thereon is rotated about an axis that is perpendicular to a pivot axis of the brake or clutch lever. The brake or clutch lever is lowered toward the handlebar. A method of assembling a brake or clutch lever height adjuster is also provided.

Owner:PERFORMANCE SYST

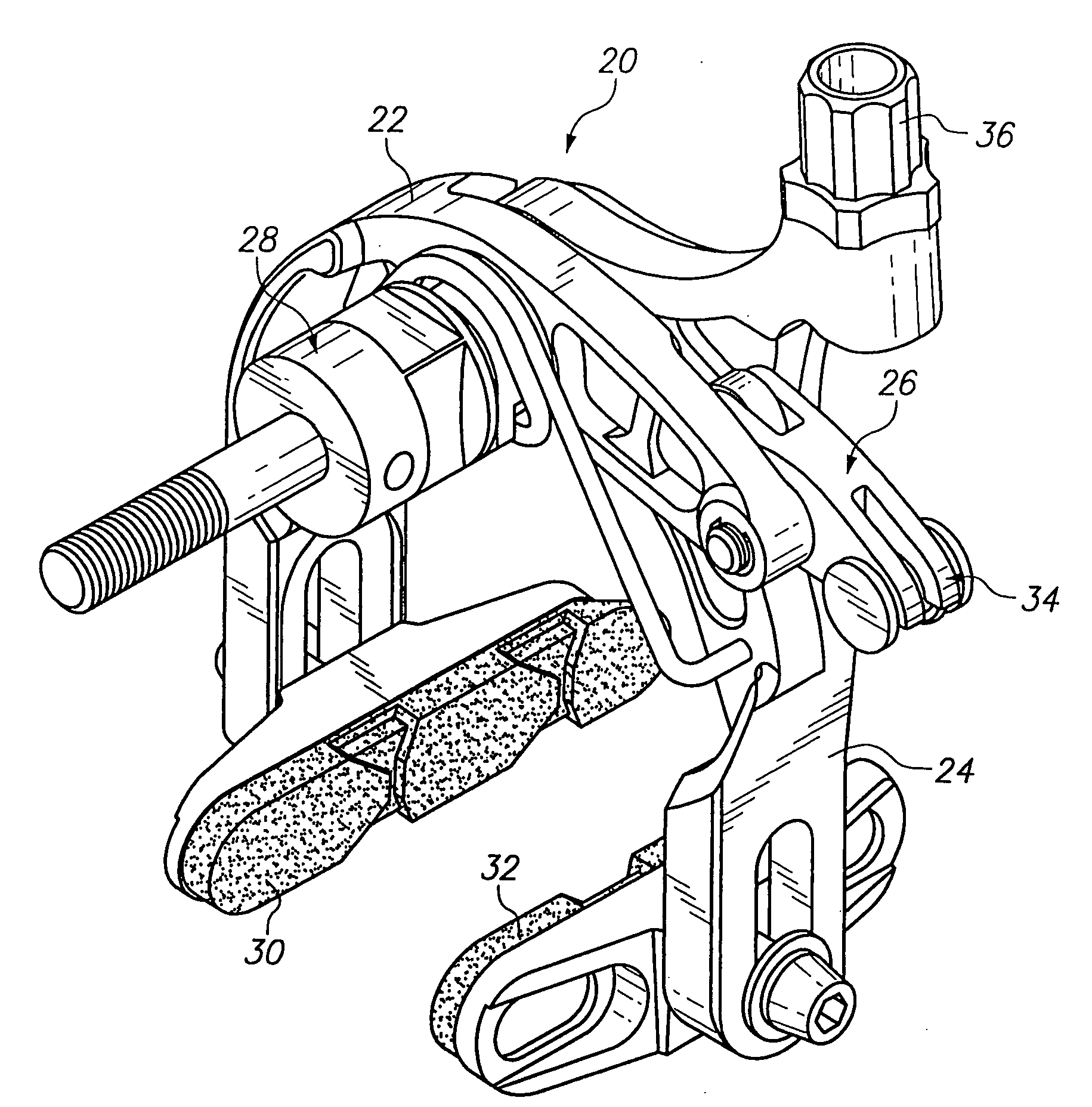

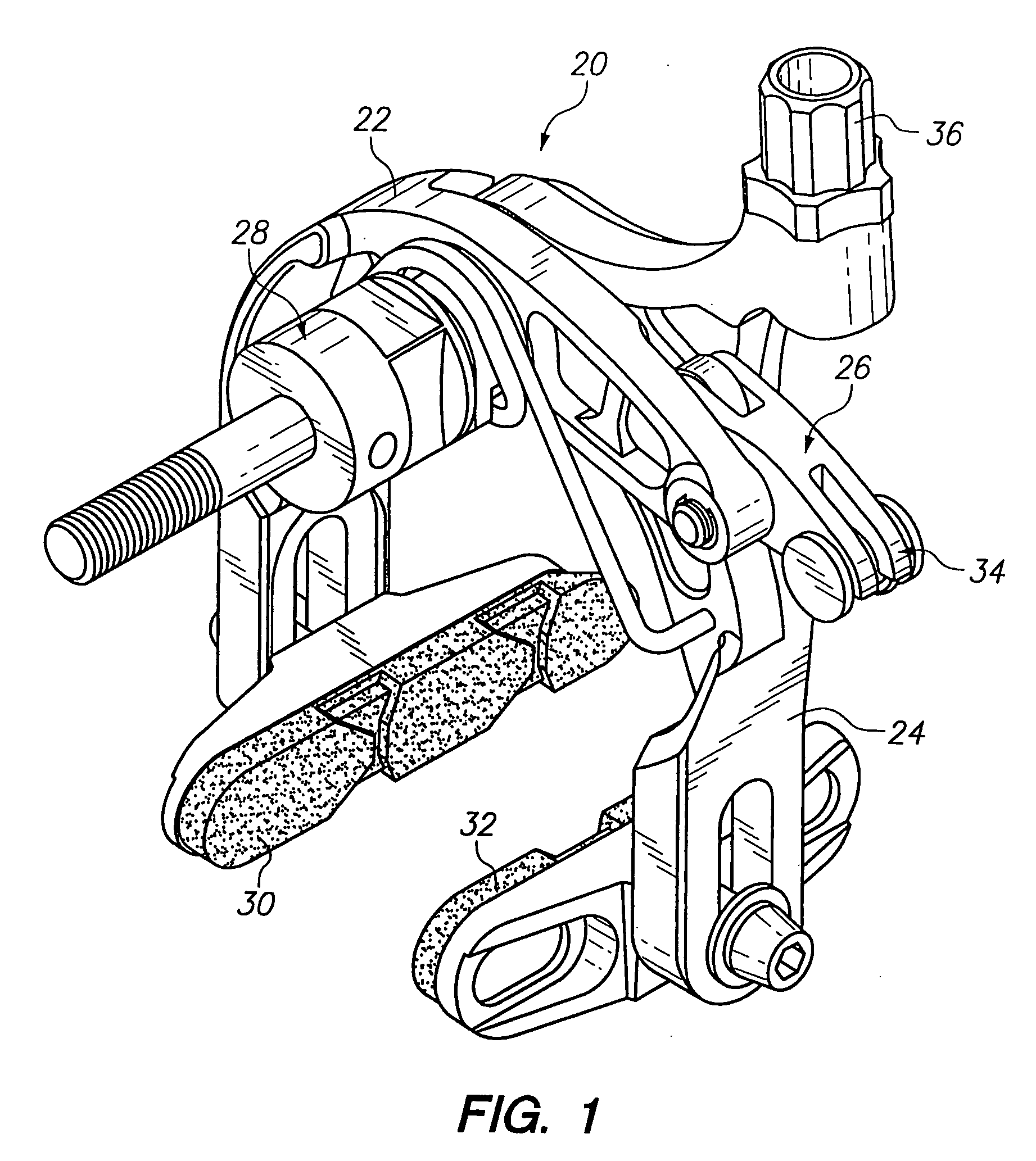

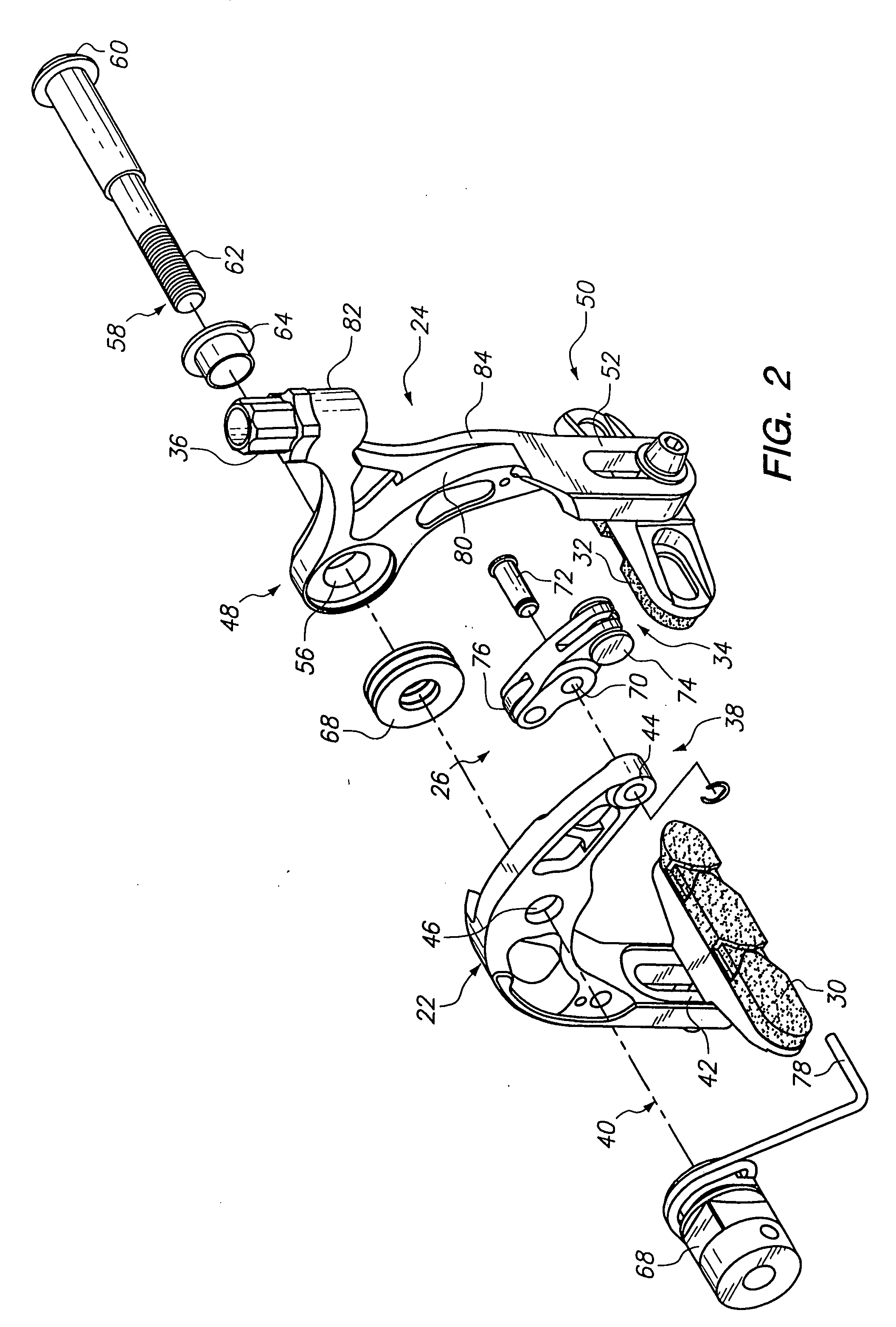

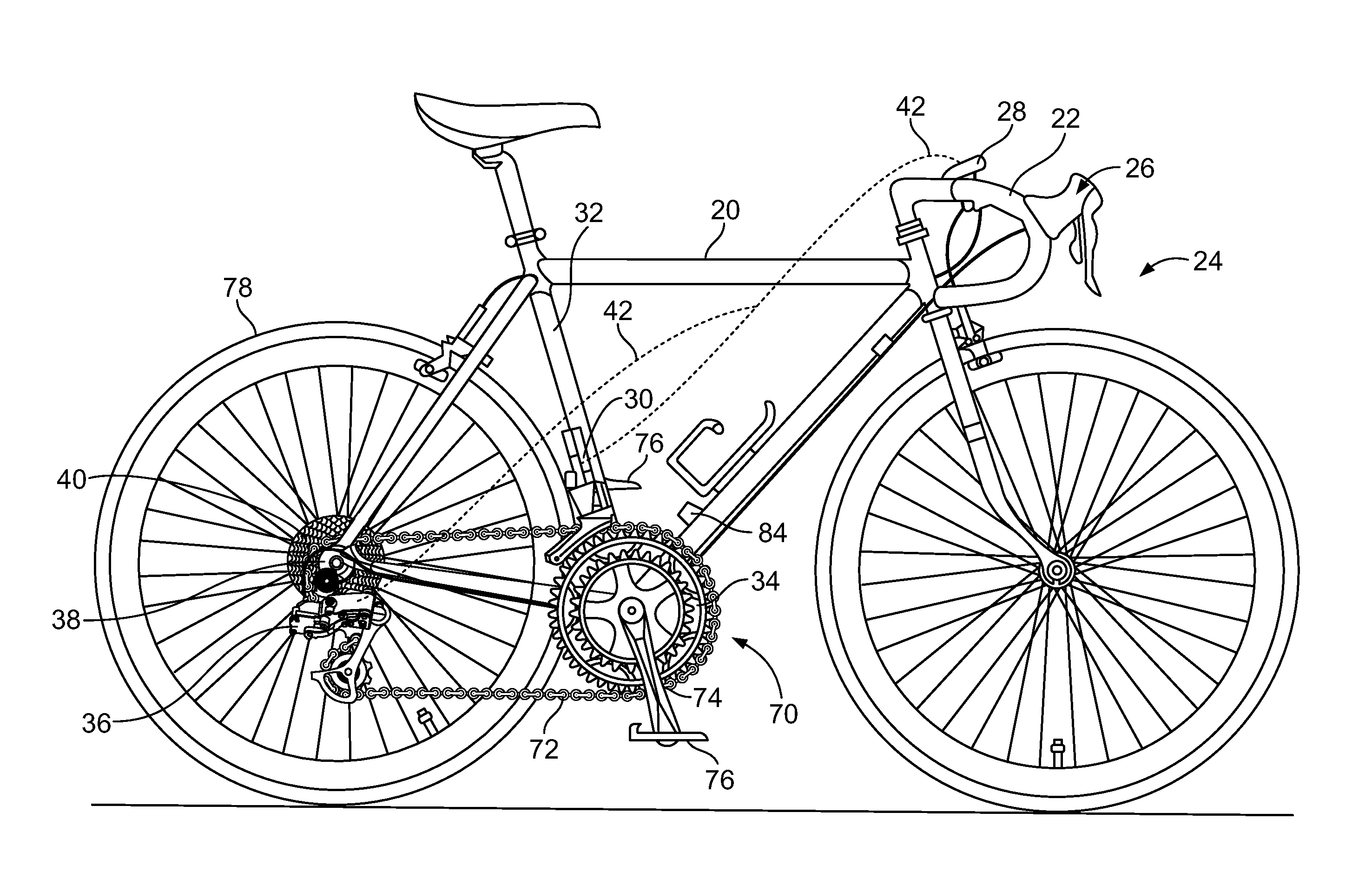

Cam activated bicycle wheel brake

InactiveUS20090038894A1Maximizes braking effectMaximize the effectCycle brakesCamMechanical engineering

A wheel brake for a bicycle or other vehicle has a pair of pivoting arms. Each arm is configured to support a brake pad. A first arm pivotally supports a cam. A second arm defines a cam surface and a cable guide. The cam has a first end for mounting of a cable and a second end having a roller which rests on the cam surface. When the cable is actuated, the cable pulls the first end of the cam, causing the cam to pivot and causing the second end of the cam to roll along the cam surface. Force applied by the cam compresses the arms, causing associated brake pads to move inwardly into engagement with the wheel. The brake is compact and efficient in design.

Owner:LIU ROBERT Z +1

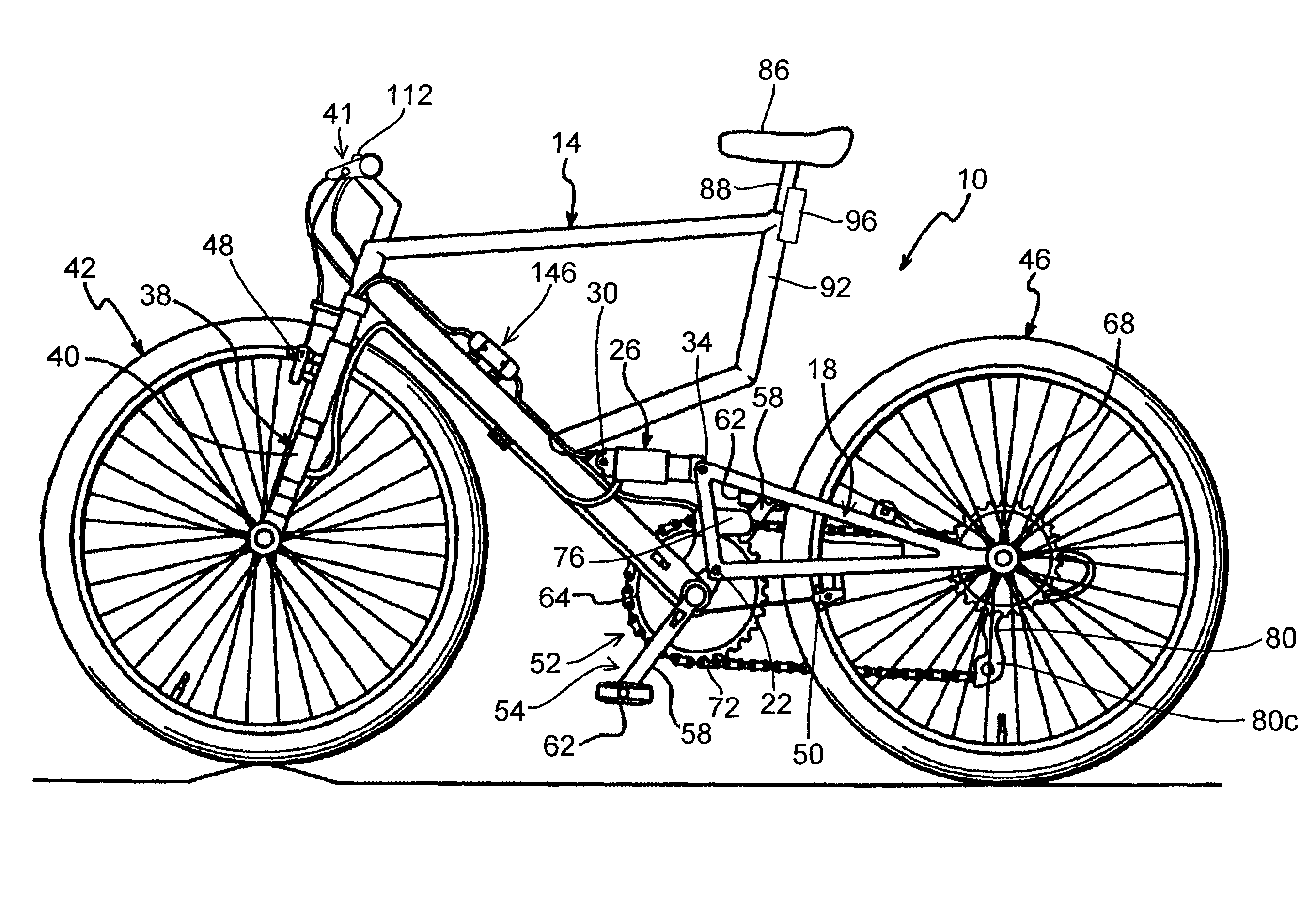

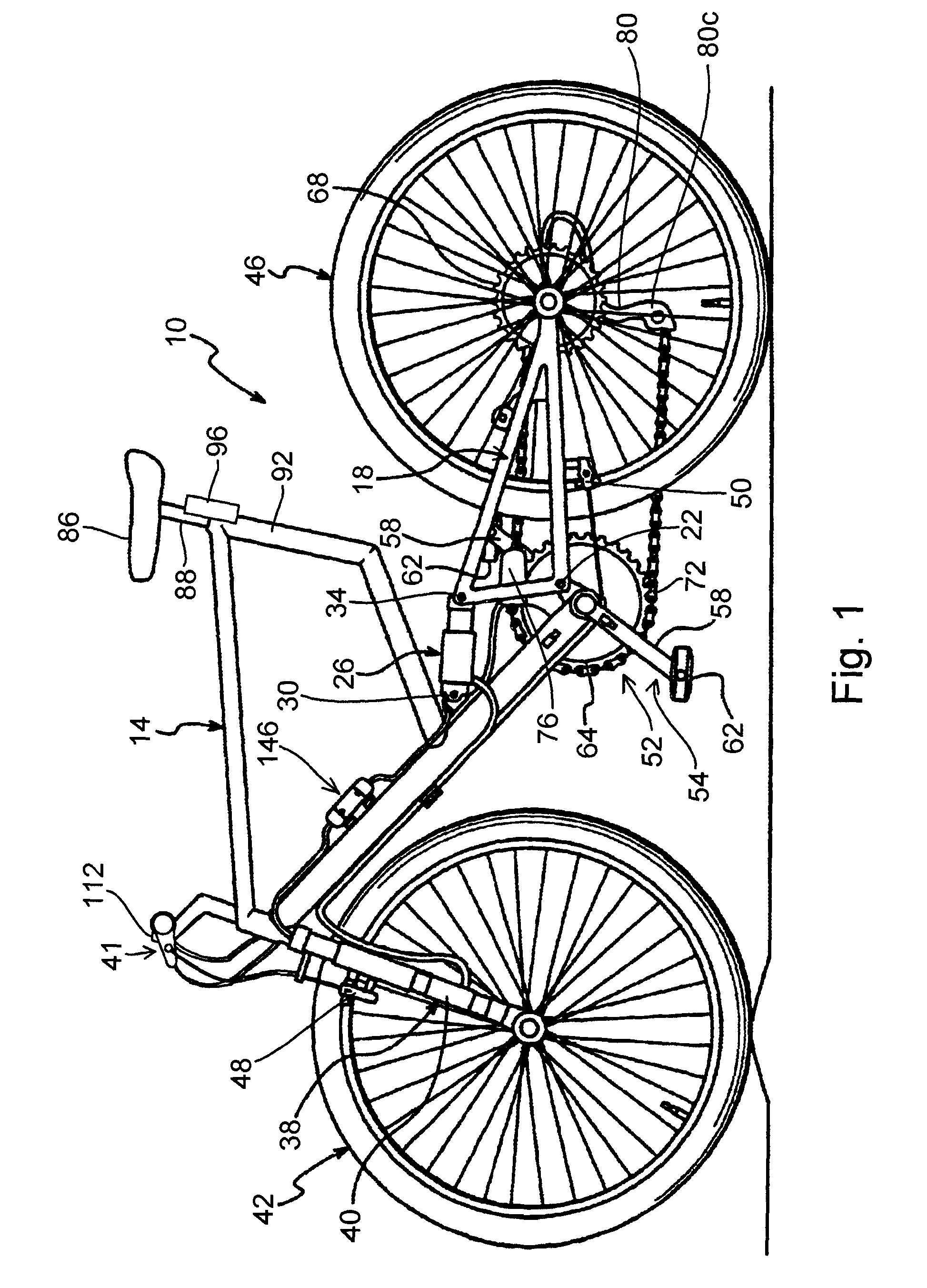

Bicycles with electronic shifting systems and methods

ActiveUS20130061705A1Reduce the possibilityChain/belt transmissionCycle control systemsElectrical and Electronics engineering

Owner:SRAM CORPORATION

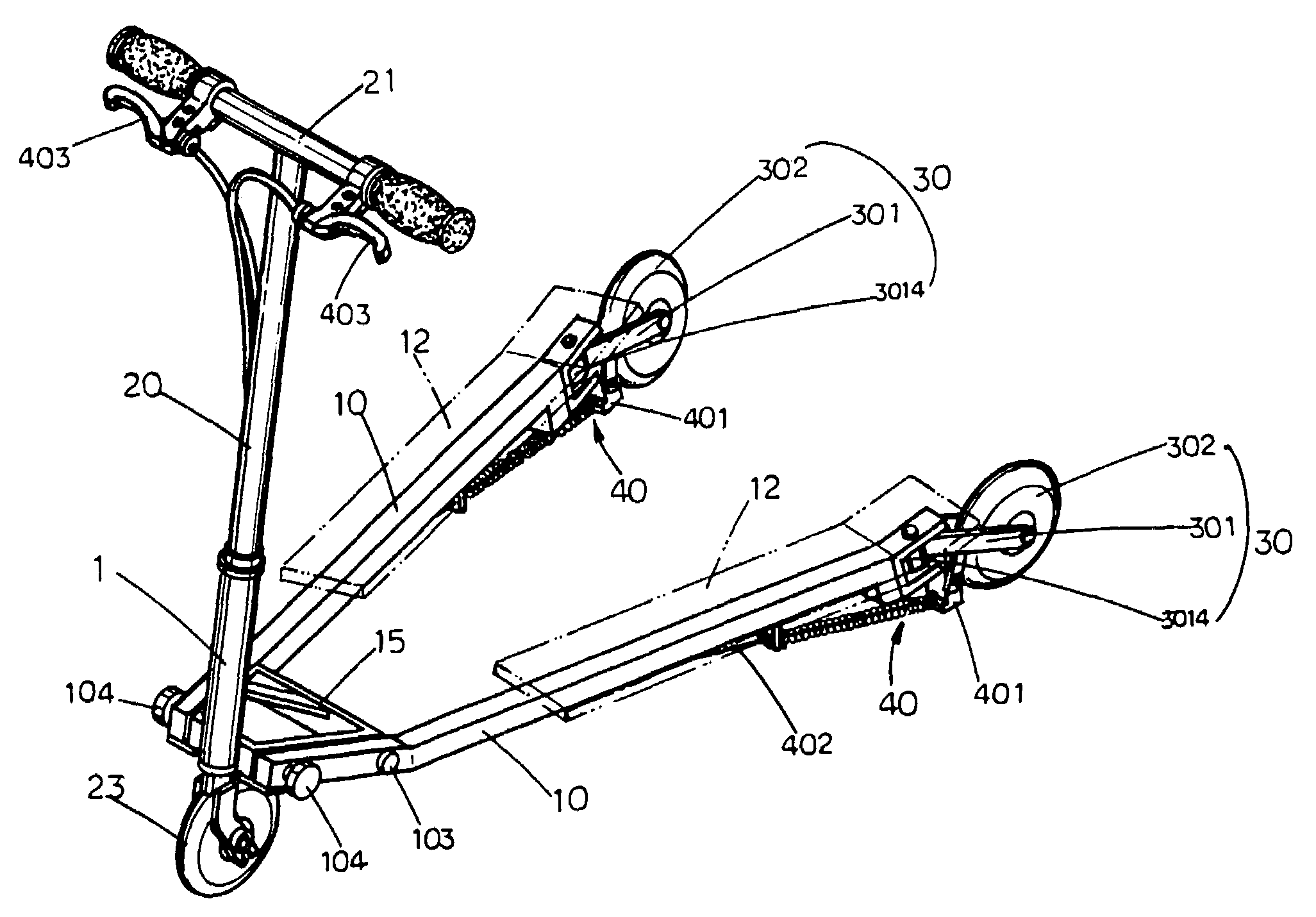

Braking device for a personal mobility vehicle

ActiveUS8813892B2Increased complexityLow priceMotorised scootersCycle control systemsDrive wheelPersonal mobility

A personal mobility vehicle, such as a scooter, includes at least one battery and motor for powering at least one driven wheel. The vehicle also includes a braking assembly configured to isolate the motor from the at least one driven wheel such that power is terminated from the motor to the at least one wheel in response to a user engaging a braking assembly of the vehicle. The vehicle can include a switch or position sensor that interacts with the braking assembly to initiate the isolation of the motor from the at least one driven wheel and the switch or position sensor preferably is inaccessible to the foot of the user.

Owner:RAZOR USA

Brake disk for vehicles

InactiveUS20050056495A1Improve cooling effectEasy to wearBraking discsFriction liningLeading edgeEngineering

An brake disk (10) is provided for use in installation on vehicles (12) or transrotary systems for use in conjunction with brake pads (22). The disk (10) includes an obverse side (40) and a reverse side (42) each of which is provided with a series of alternating protruding segments (44) and indented segments (46). The indented segments (46) on one side of the disk (10) are situated axially opposite protruding segments (44) on the other side. Each protruding segment (44) includes a leading edge (52) for engaging the brake pads (22). The particular shapes and relative circumferential widths of the alternating segments vary depending on particular usage.

Owner:BRAKING ITALA

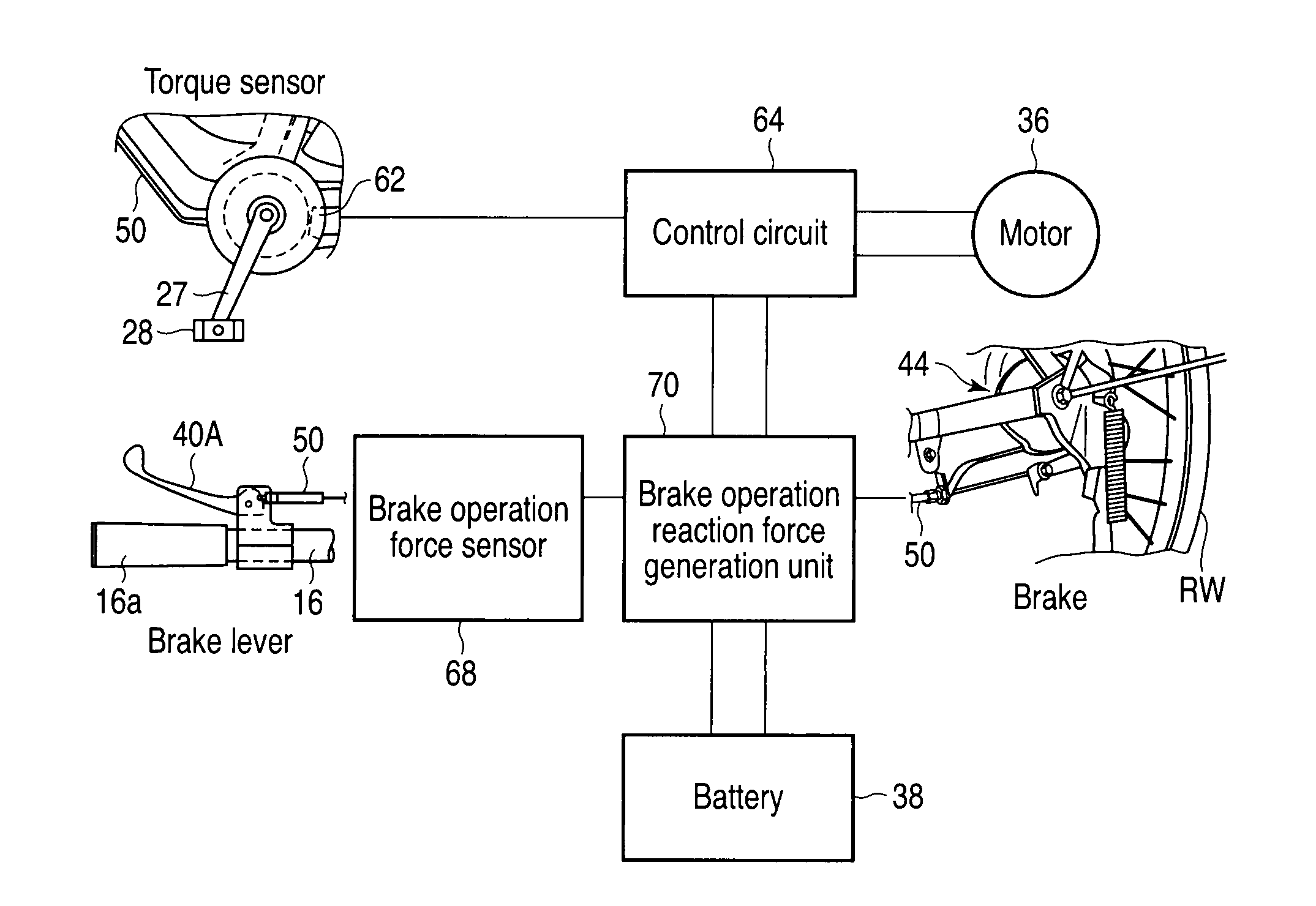

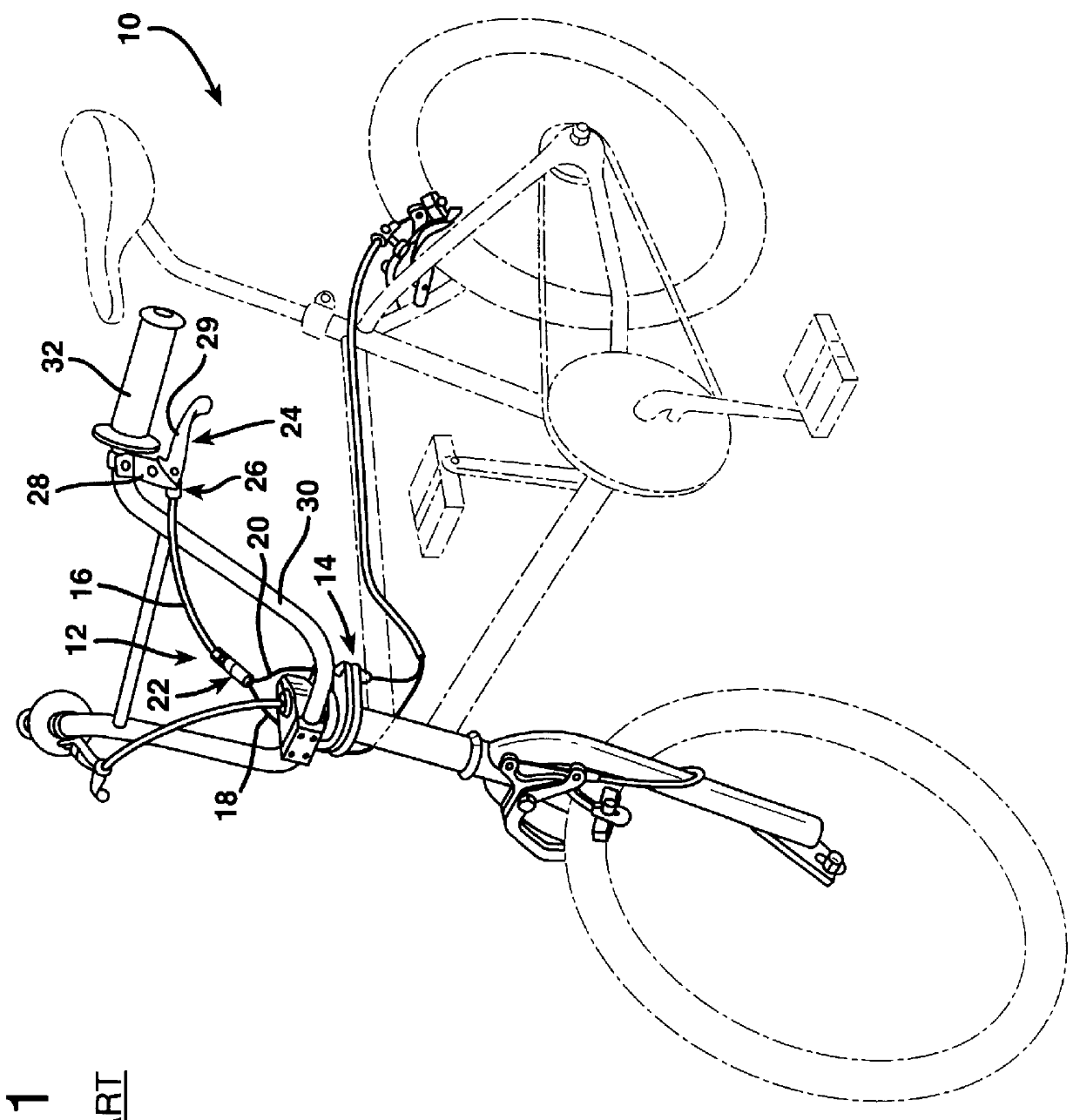

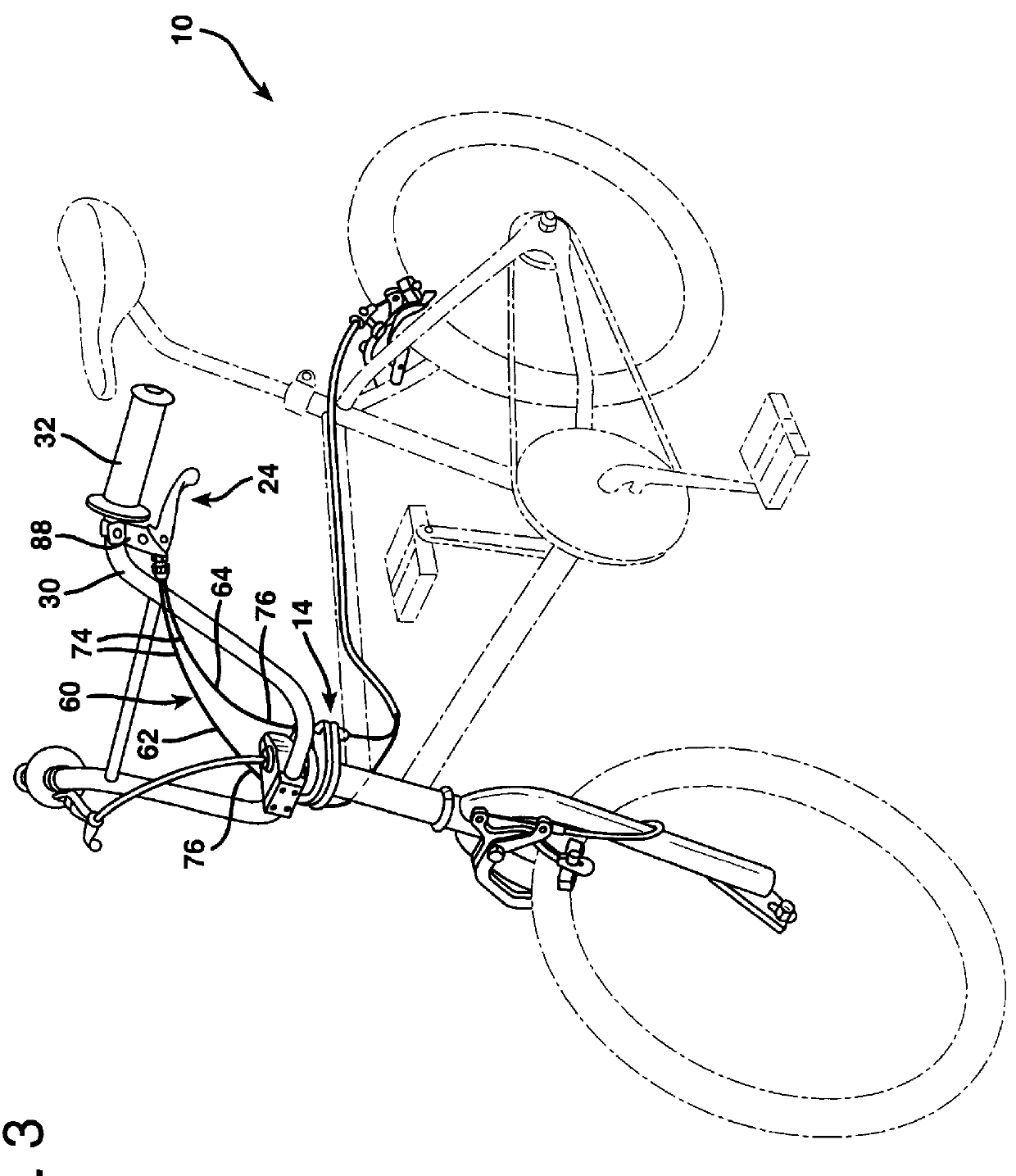

Regenerative braking device and vehicle provided with regenerative braking device

InactiveUS20100252345A1Easy to adjustAuxillary drivesElectrodynamic brake systemsRegenerative brakeForce sensor

Owner:KK TOSHIBA

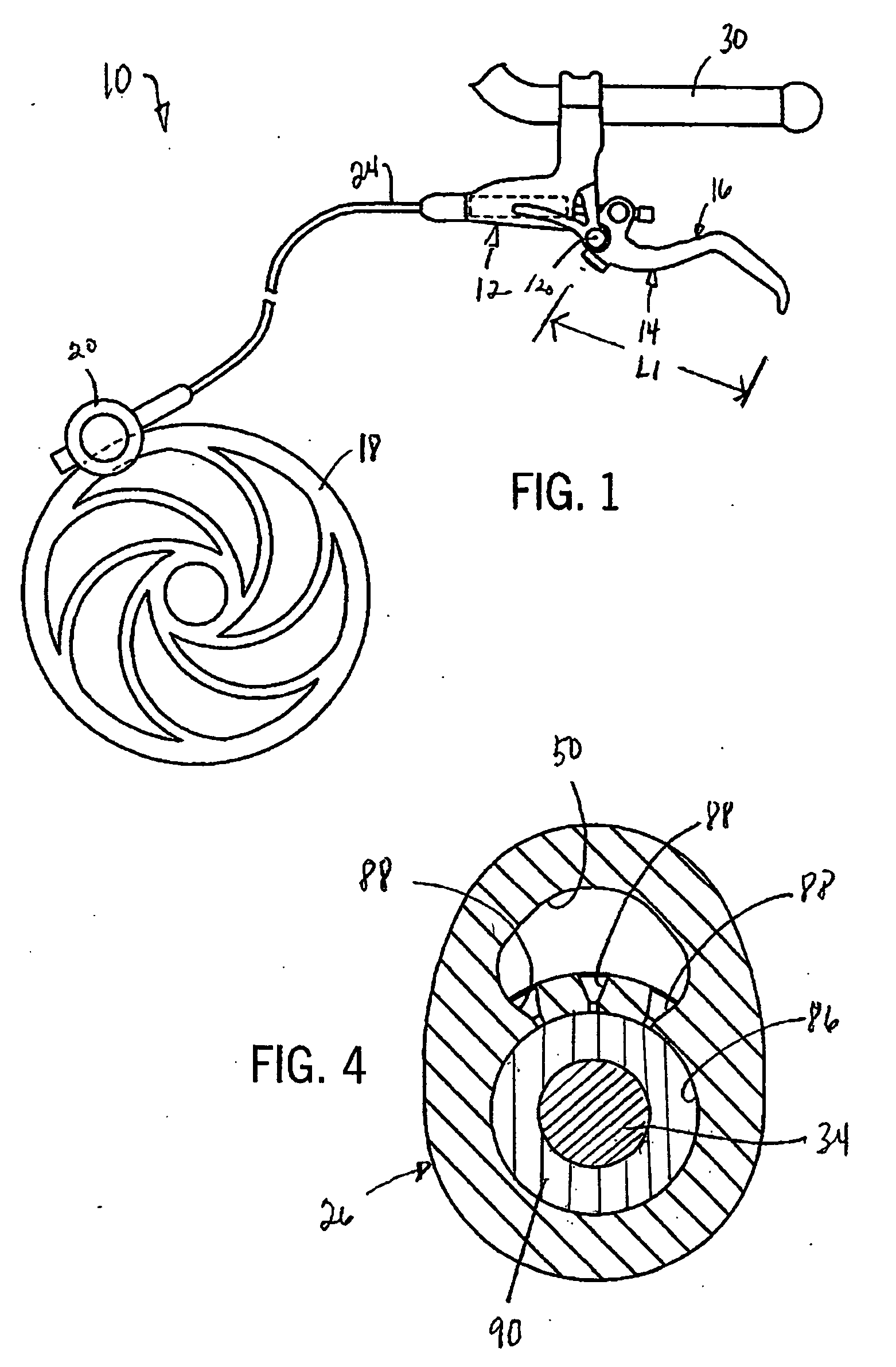

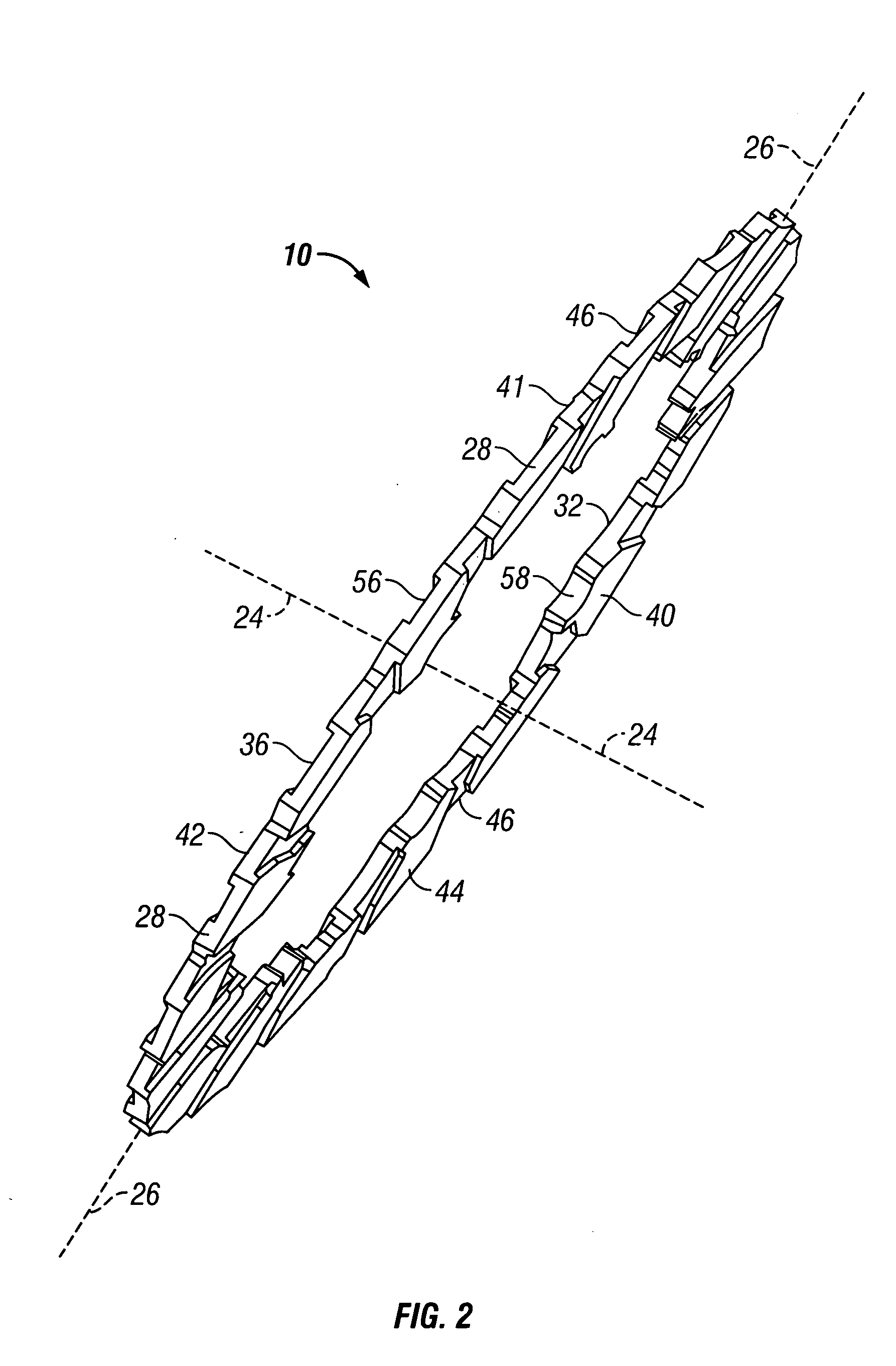

Bicycle brake cable system

InactiveUS6085611AEliminate requirementsLess lateral flexing of the brake lineRoad vehiclesShaft for linear movementCouplingEngineering

A bicycle brake cable system has a brake cable coupling arrangement in which a plurality of branches are provided from a single brake lever force application lug. Splitting of the brake cable is performed within the structure of a brake barrel adjuster. The barrel adjuster is provided with a cylindrical cavity that receives a rotatable coupler therewithin. The interface ends of the force transmission cable segments are terminated in the coupler, which is free to rotate relative to the barrel adjuster. As a consequence, the barrel adjuster may be threadably advanced to either increase or decrease brake tension by rotation relative to its threaded connection to the brake lever assembly body. By providing a coupler that is rotatable relative to the barrel adjuster, the barrel adjuster can be rotated in both directions to increase or reduce brake tension. The relative rotation between the coupler and the threaded nipple of the barrel adjuster allows the force transmission segments of the brake cable to remain stationary relative to the handlebars, while still permitting tension adjustment on the brake cable.

Owner:BEARCORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com