Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

577results about How to "Load large" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of communicating packet multimedia to restricted endpoints

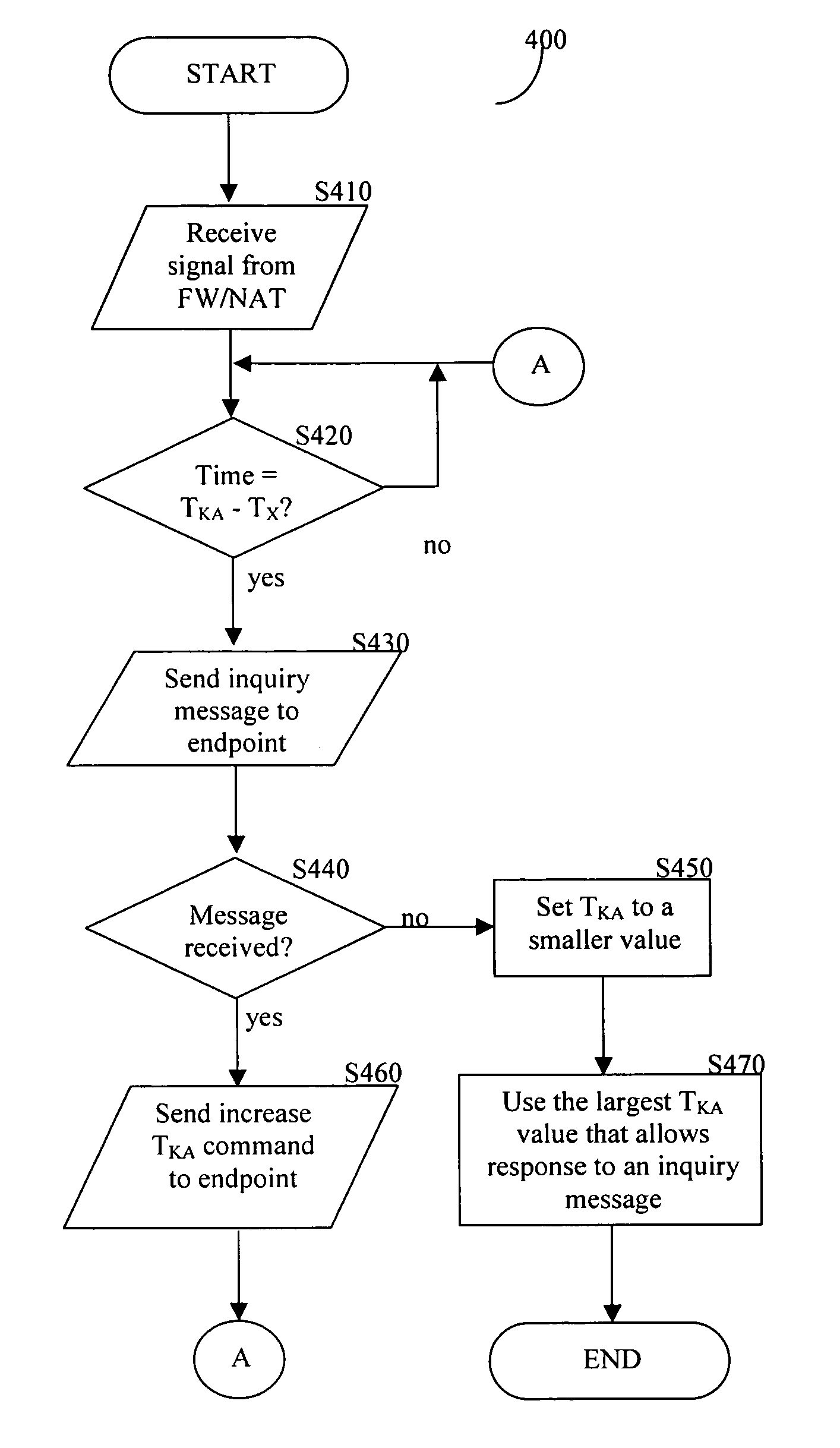

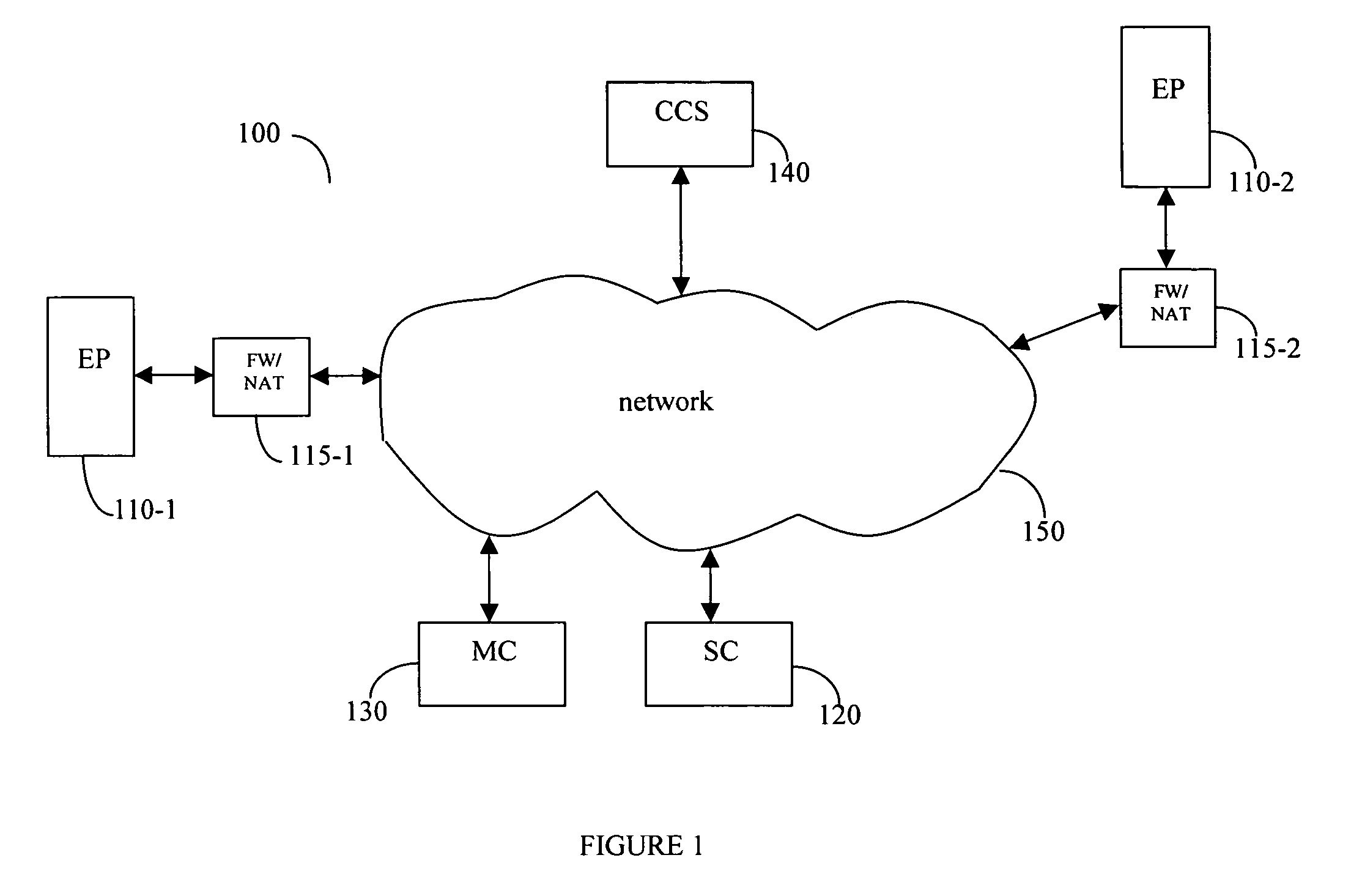

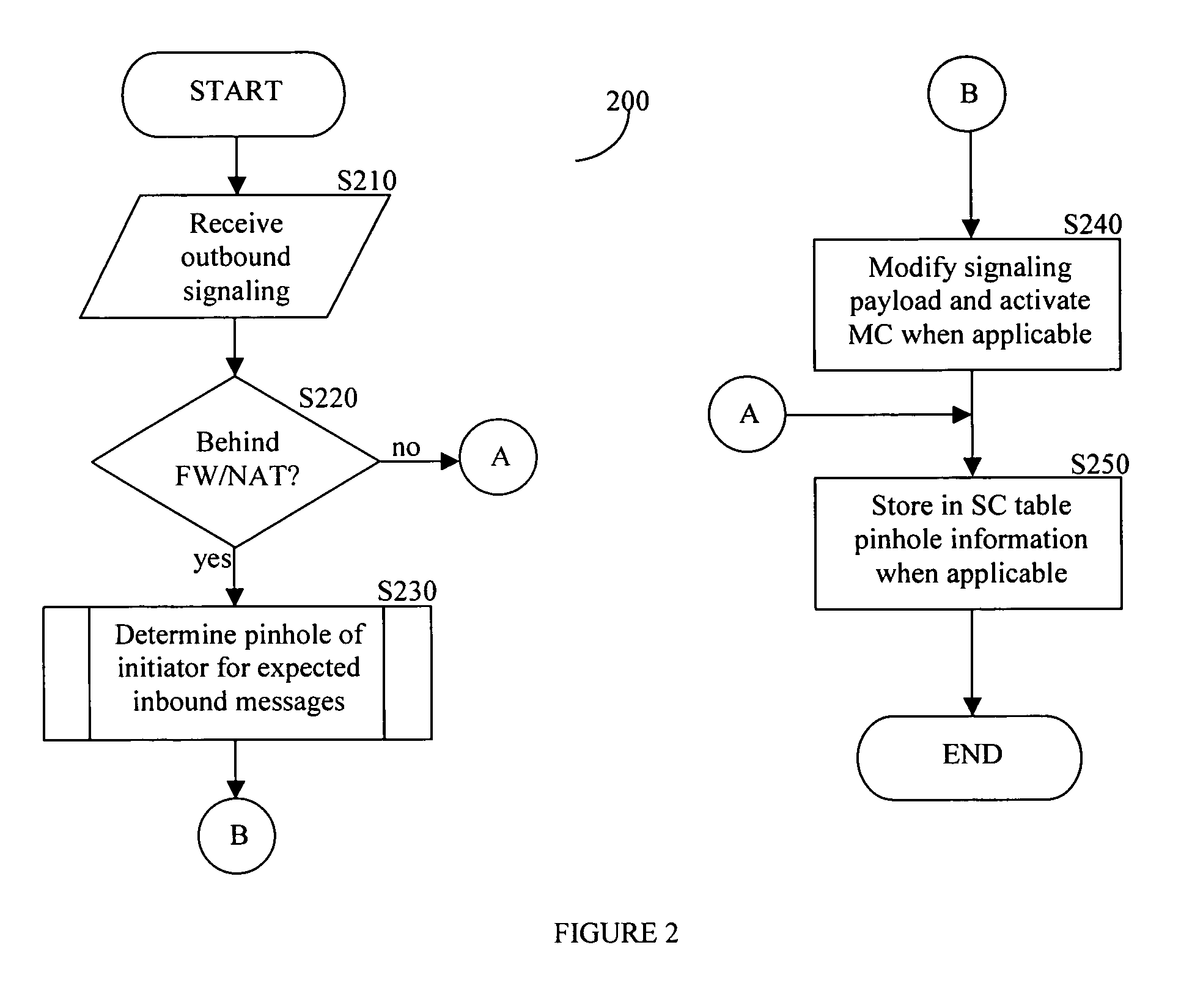

ActiveUS7483437B1Minimize the numberLoad largeData switching by path configurationNetwork packetNetwork element

A method, performed in a network element, for communicating packet multimedia data between a first endpoint and a second endpoint, the method comprising the machine-implemented steps of receiving an outbound multimedia data packet; determining if the outbound multimedia data packet originated from a first endpoint that is logically behind a security device; determining and storing information identifying a logical pinhole in the security device, wherein the logical pinhole is associated with expected inbound multimedia data packets directed to the first endpoint; performing an action that keeps the logical pinhole open during all of a communication session between the first endpoint and the second endpoint; and forwarding inbound multimedia data packets directed from the second endpoint to the first endpoint via the logical pinhole.

Owner:JUMIPER NETWORKS INC

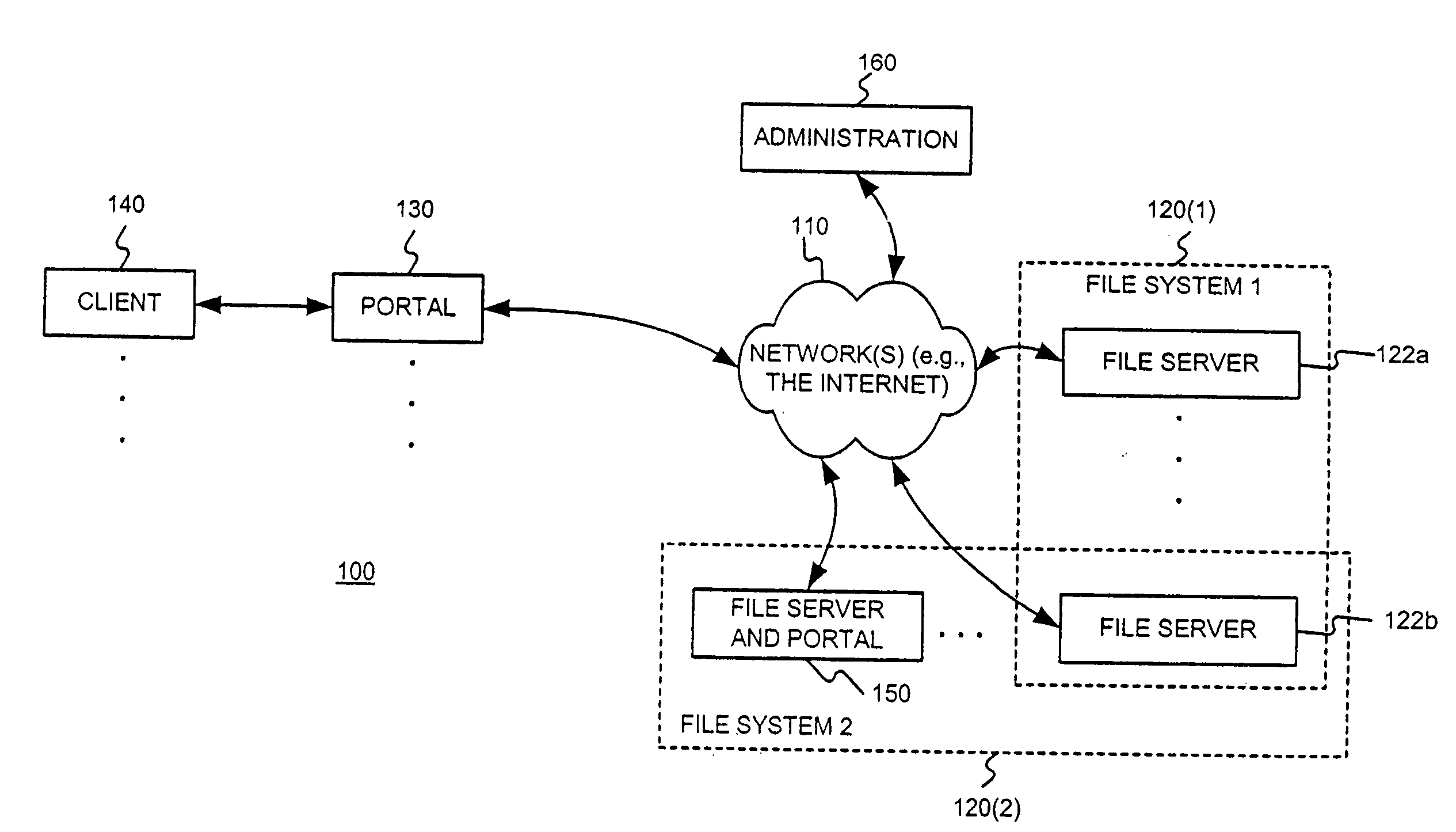

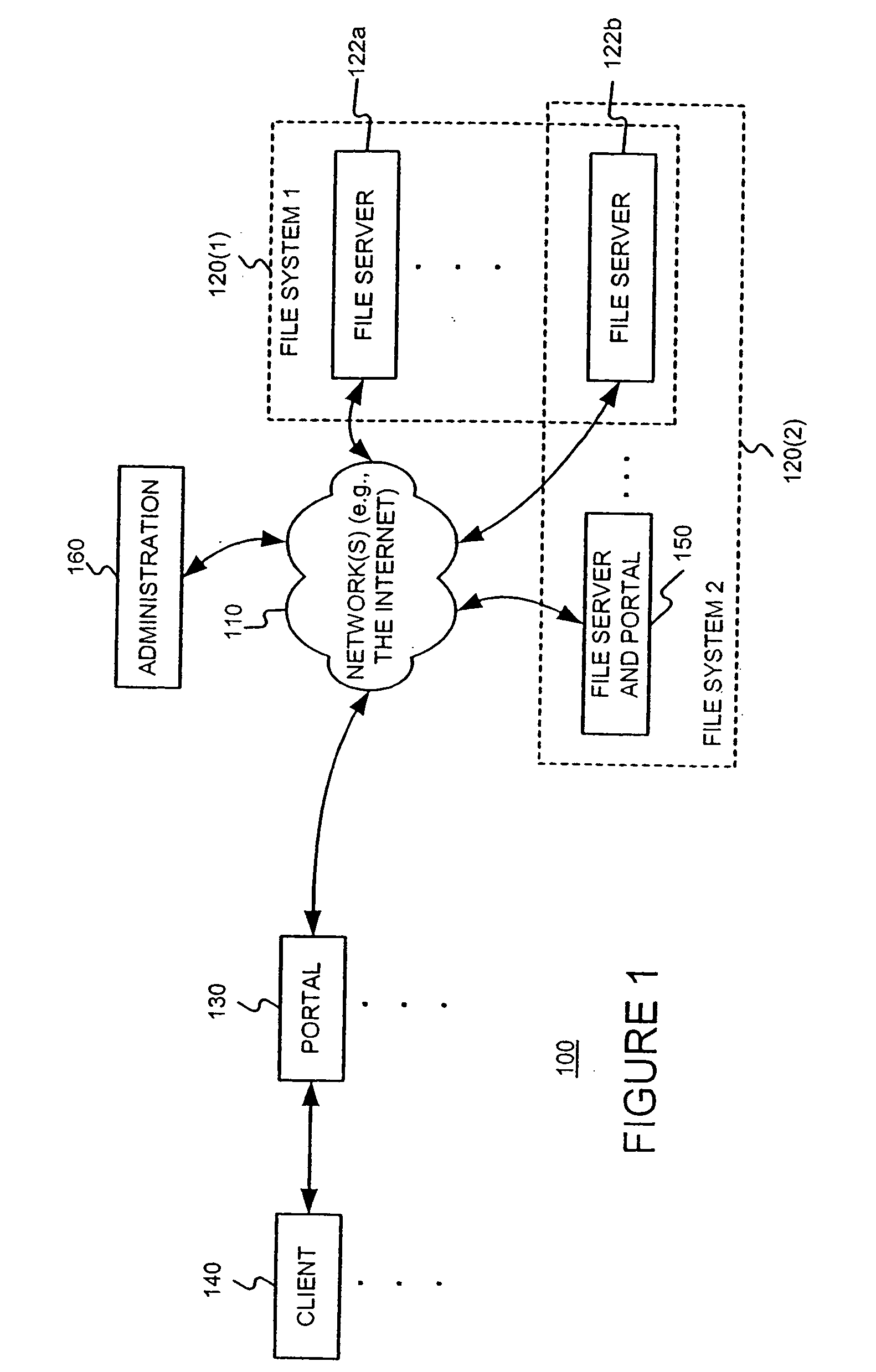

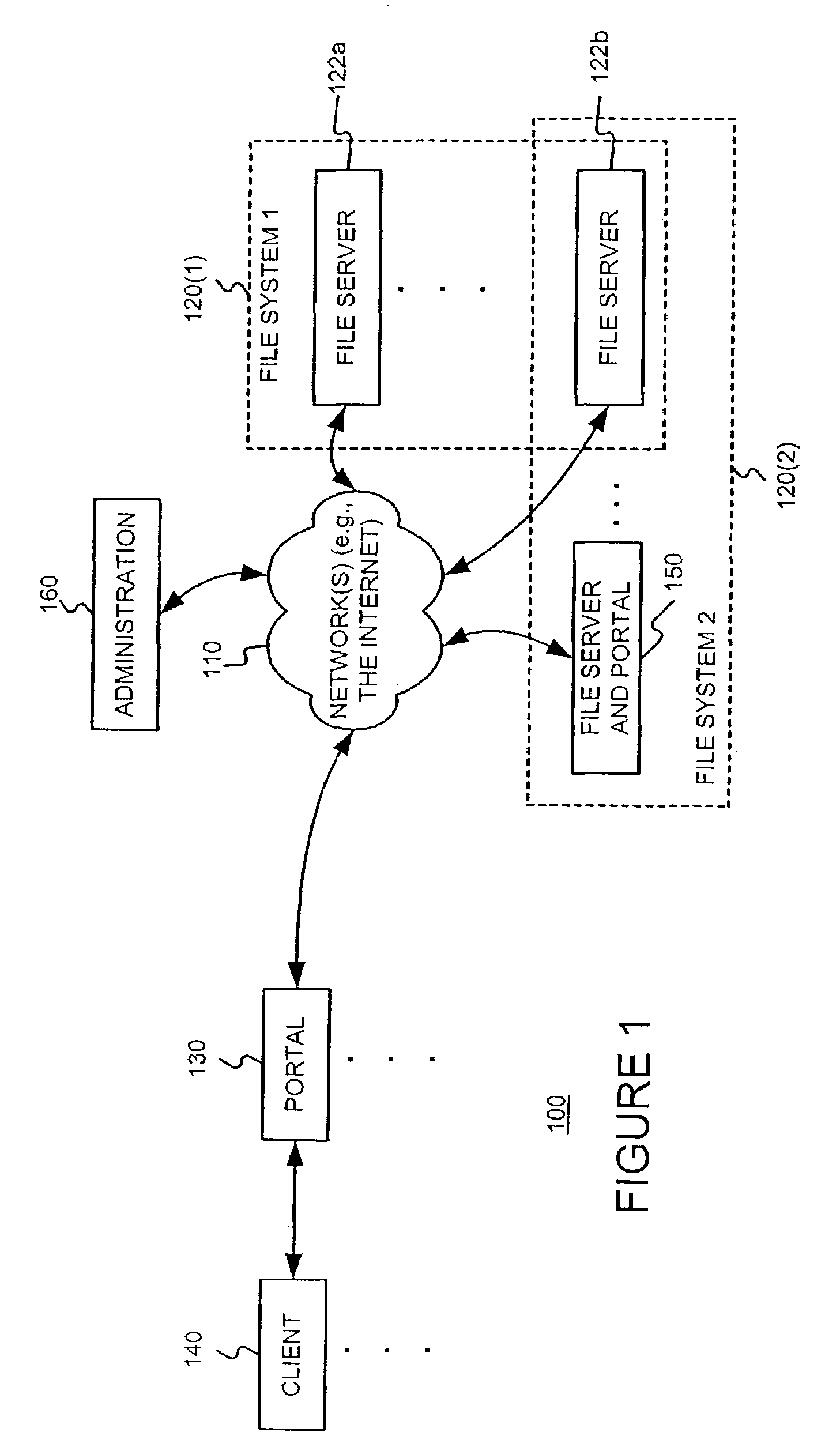

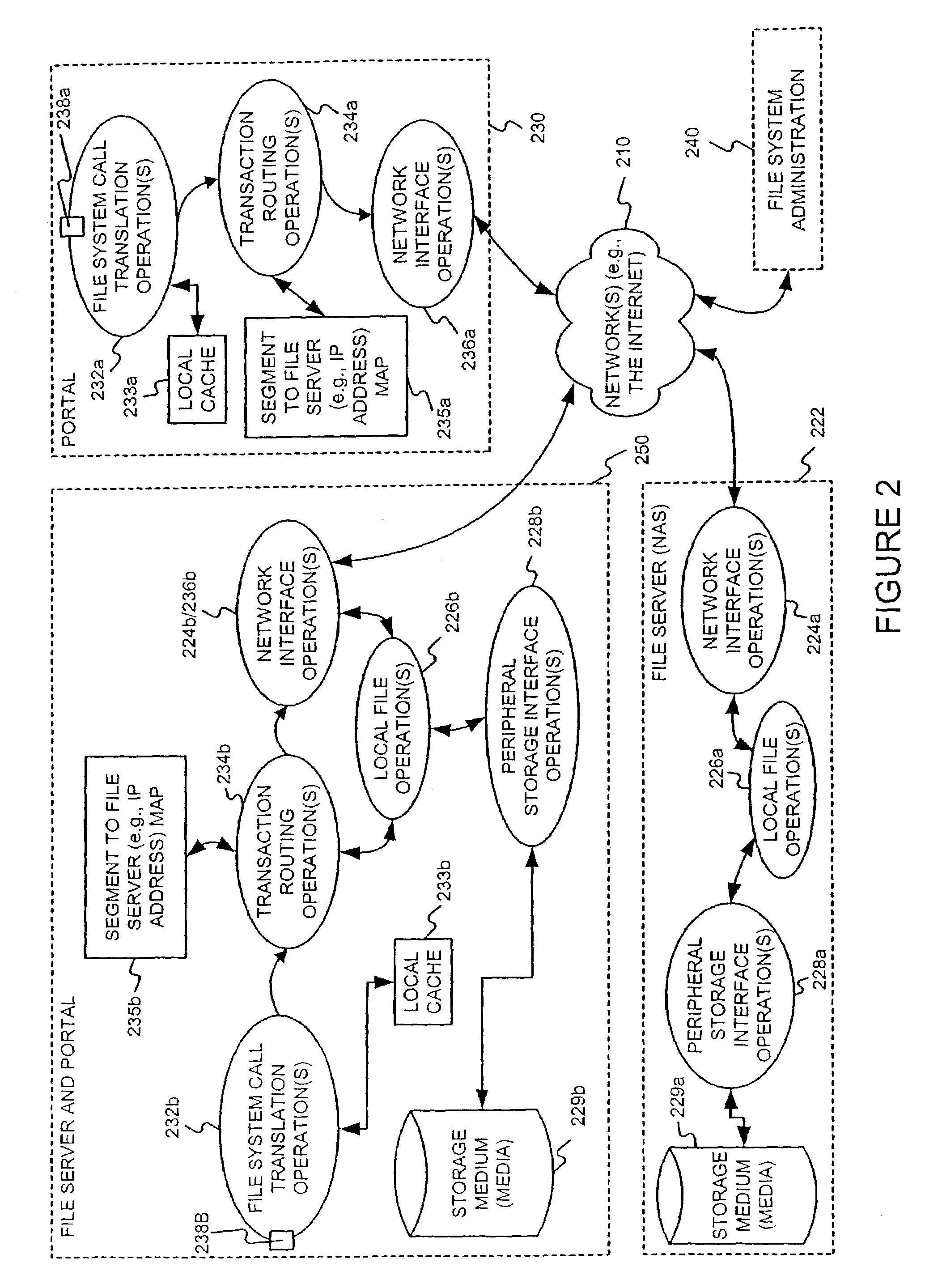

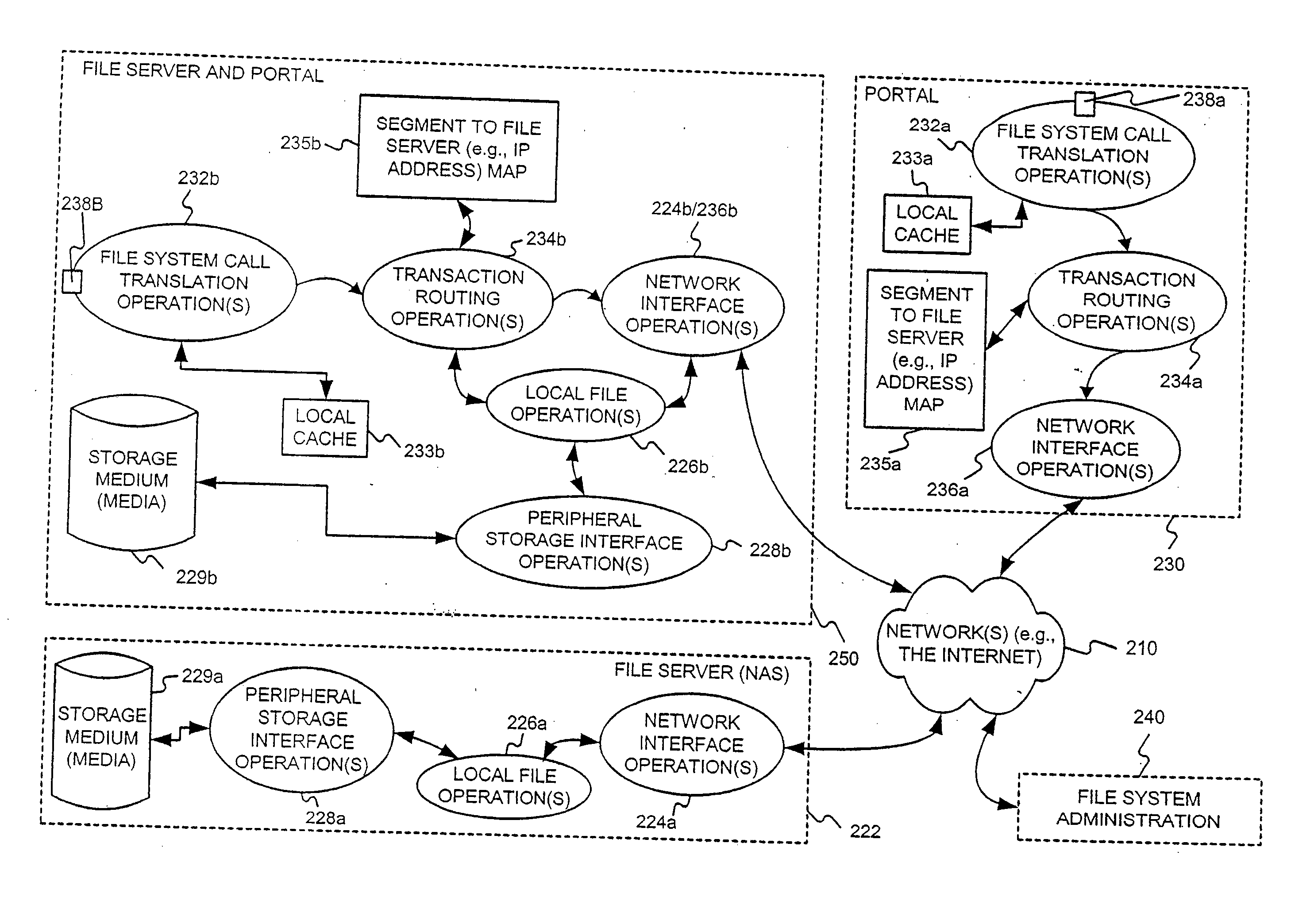

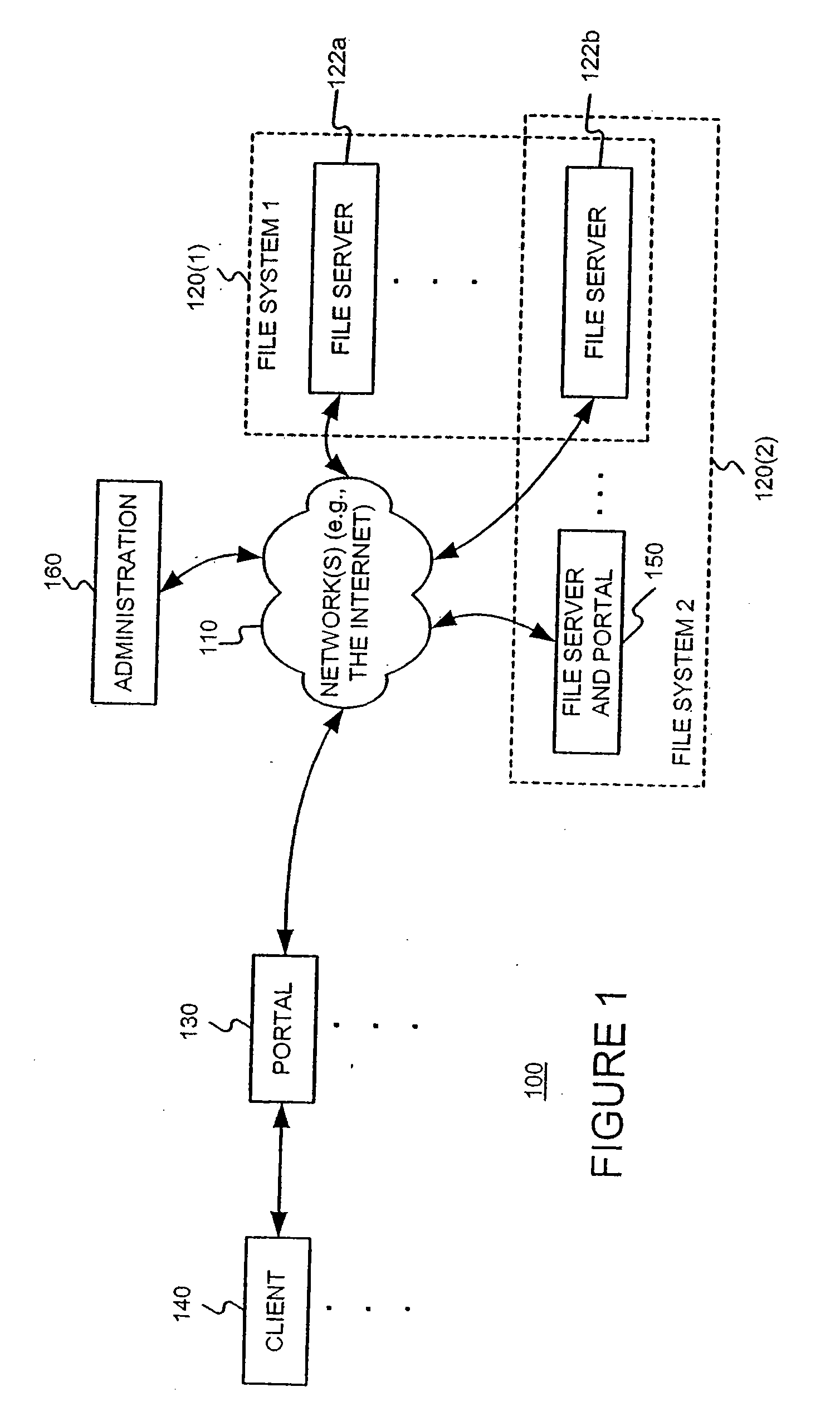

Migration of control in a distributed segmented file system

InactiveUS20040236798A1Efficient executionStorage capacity can be easilyTransmissionWeb data navigationDistributed File SystemFile system

A method of managing segments in a distributed-file system implemented by a plurality of file servers includes determining a segment of the distributed-file system controlled by a first file server for which control is to be migrated, selecting a second file server, that is different from the first file server, to take control of the segment, and moving control of the segment from the first file server to the second file server.

Owner:HEWLETT PACKARD CO

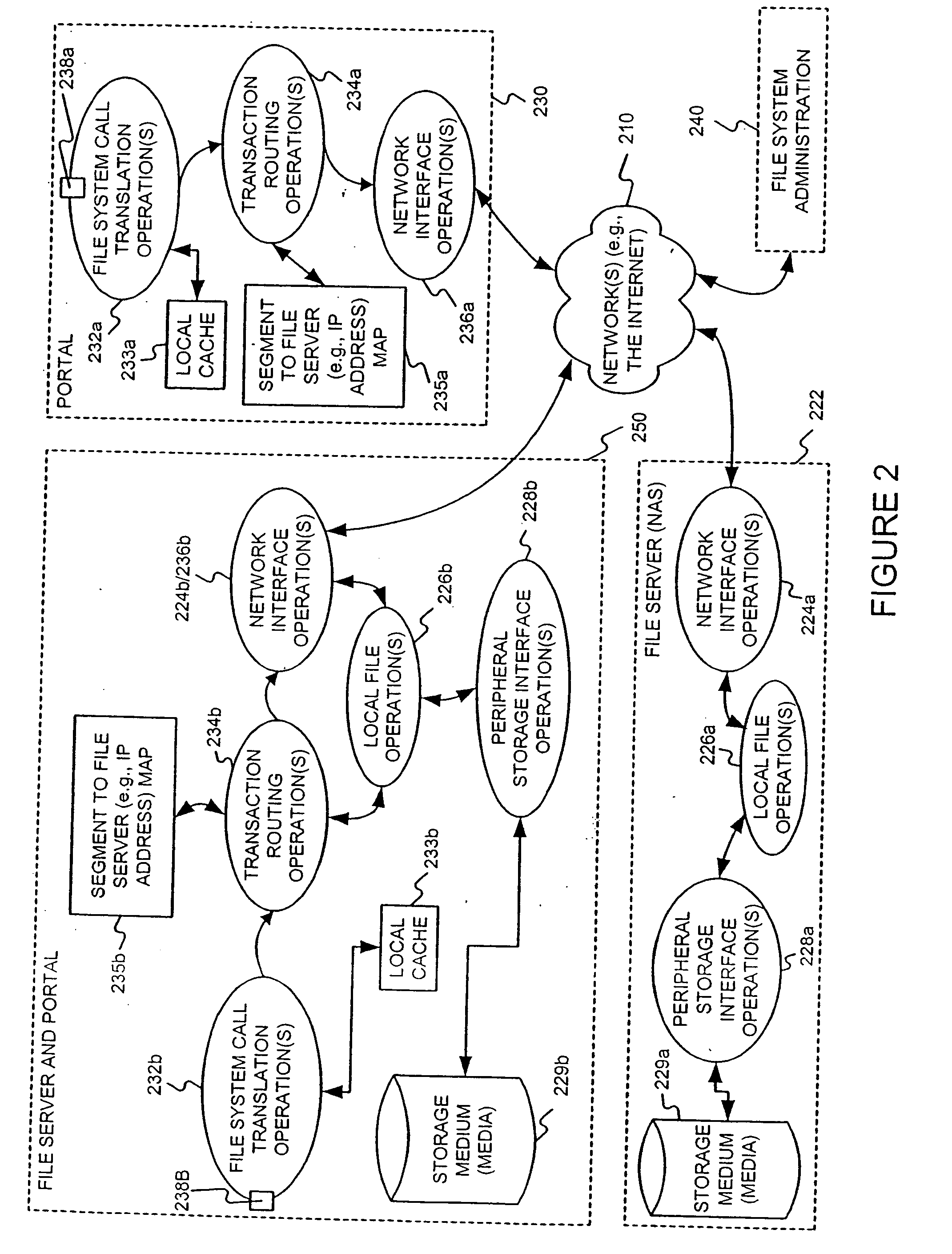

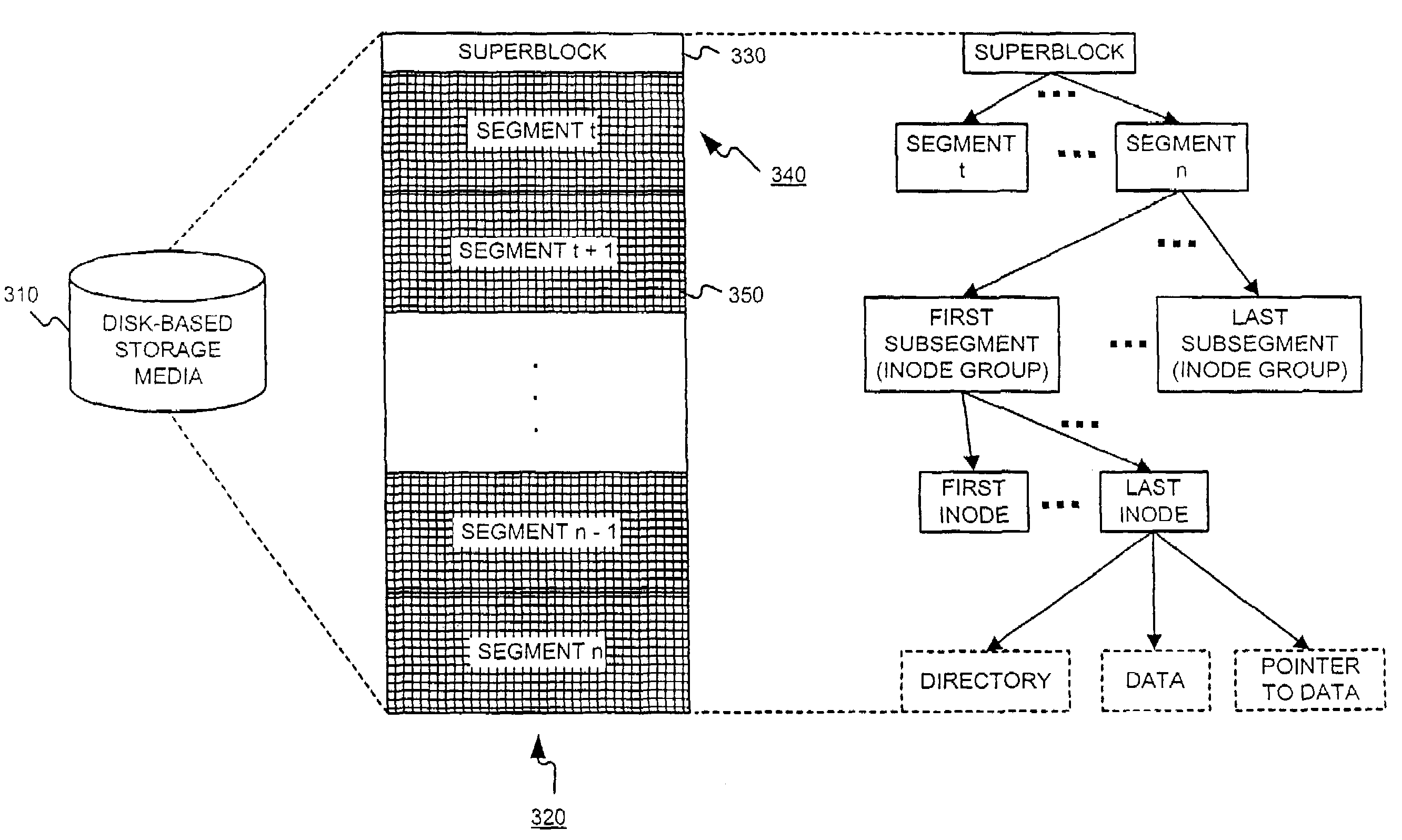

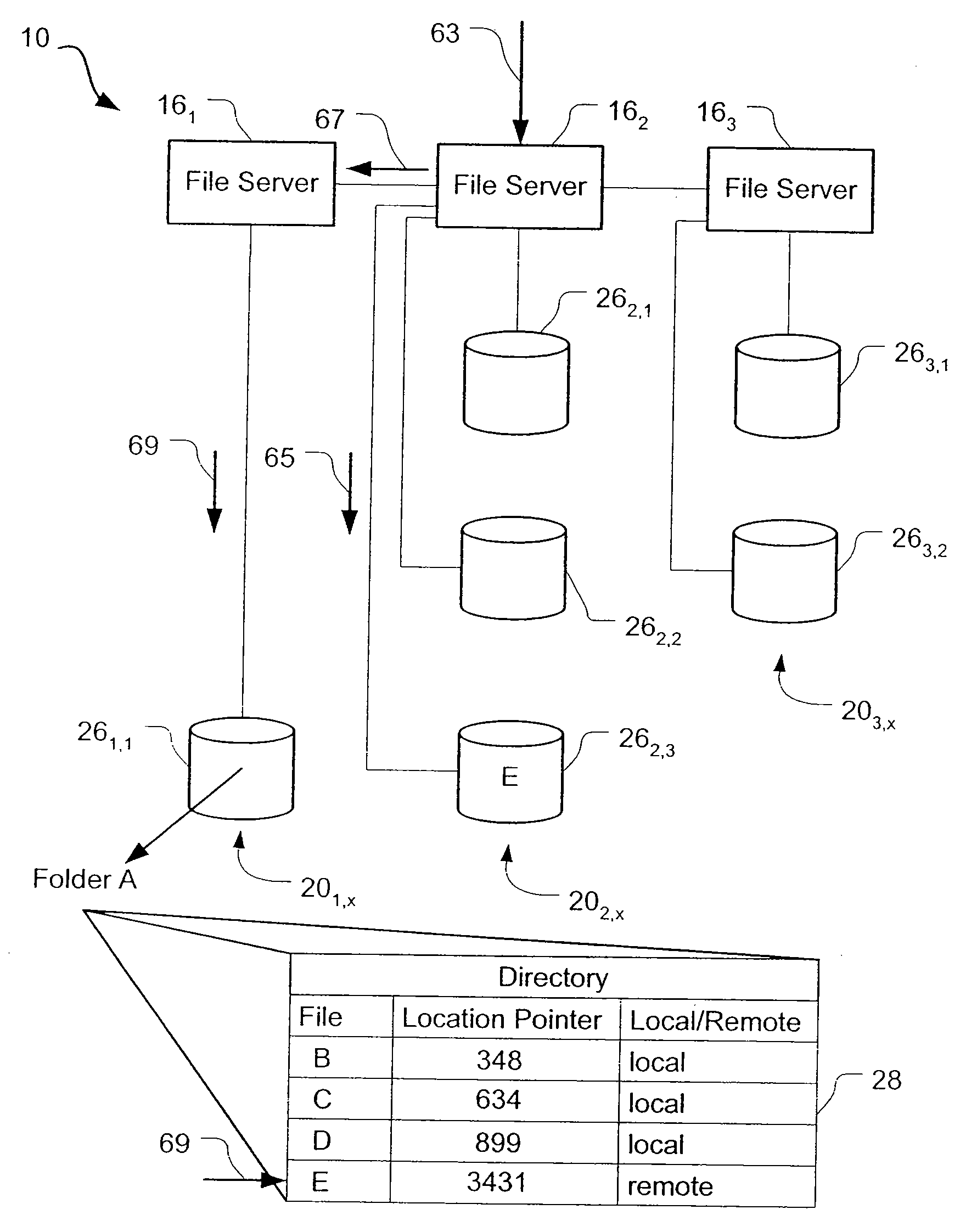

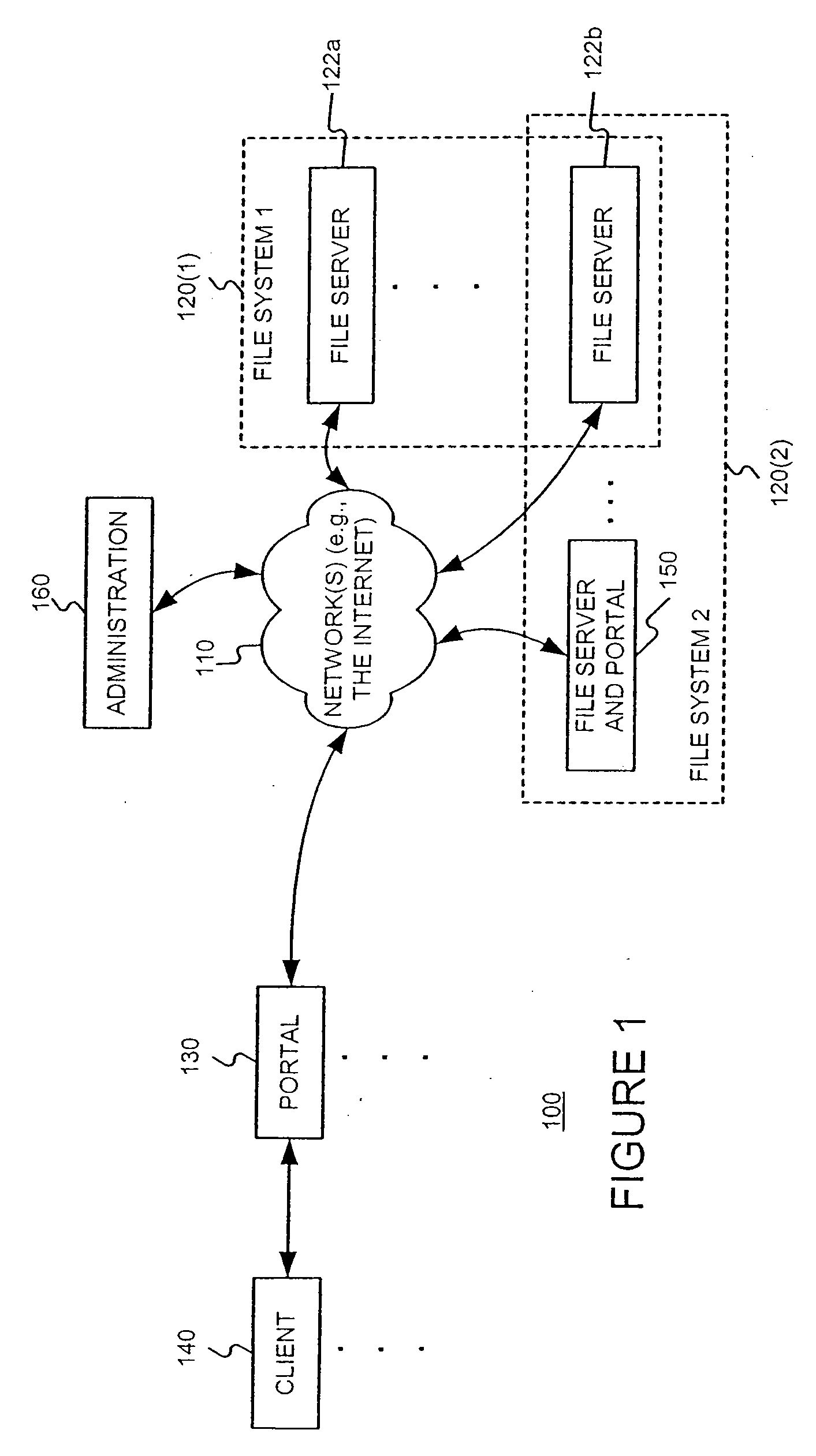

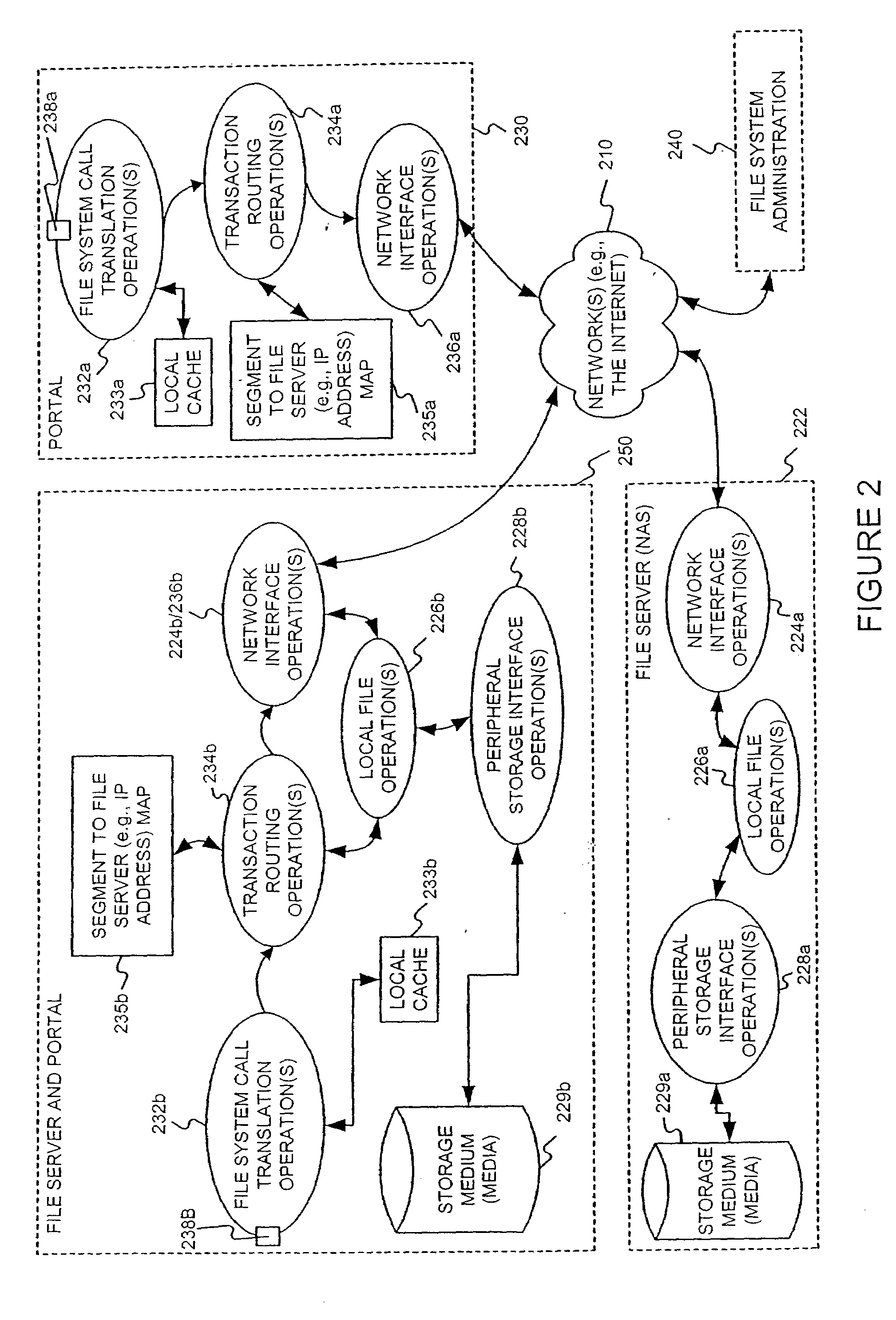

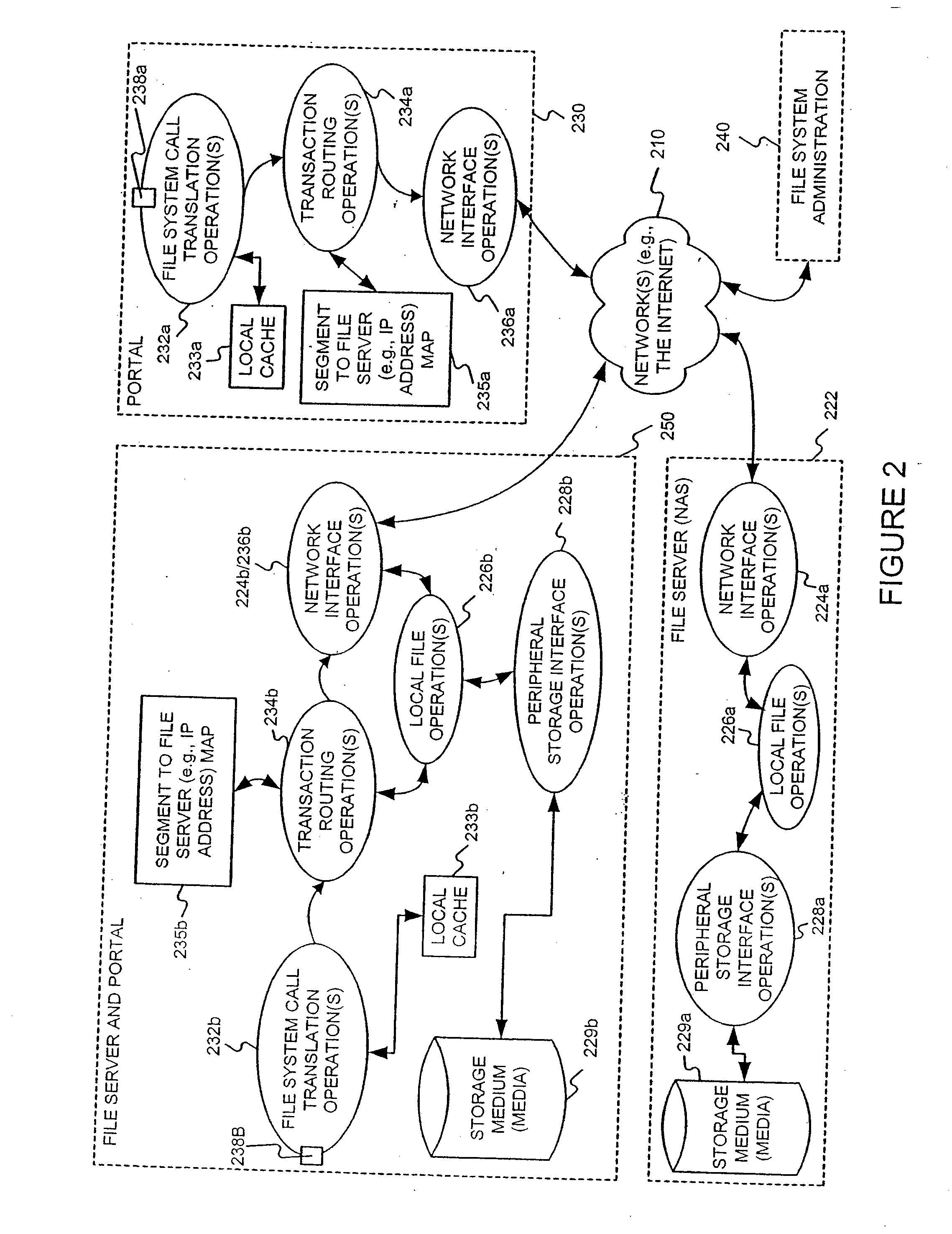

Storage allocation in a distributed segmented file system

InactiveUS7406484B1Efficient executionStorage capacity can be easilyData processing applicationsTransmissionInodeData sharing

A file system (i) permits storage capacity to be added easily, (ii) can be expanded beyond a given unit, (iii) is easy to administer and manage, (iv) permits data sharing, and (v) is able to perform effectively with very large storage capacity and client loads. State information from a newly added unit is communicated (e.g., automatically and transparently) to central administration and management operations. Configuration and control information from such operations is communicated (e.g., automatically) back down to the newly added units, as well as existing units. In this way, a file system can span both local storage devices (like disk drives) and networked computational devices transparently to clients. Such state and configuration and control information can include globally managed segments as the building blocks of the file system, and a fixed mapping of globally unique file identifiers (e.g., Inode numbers) and / or ranges thereof, to such segments.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

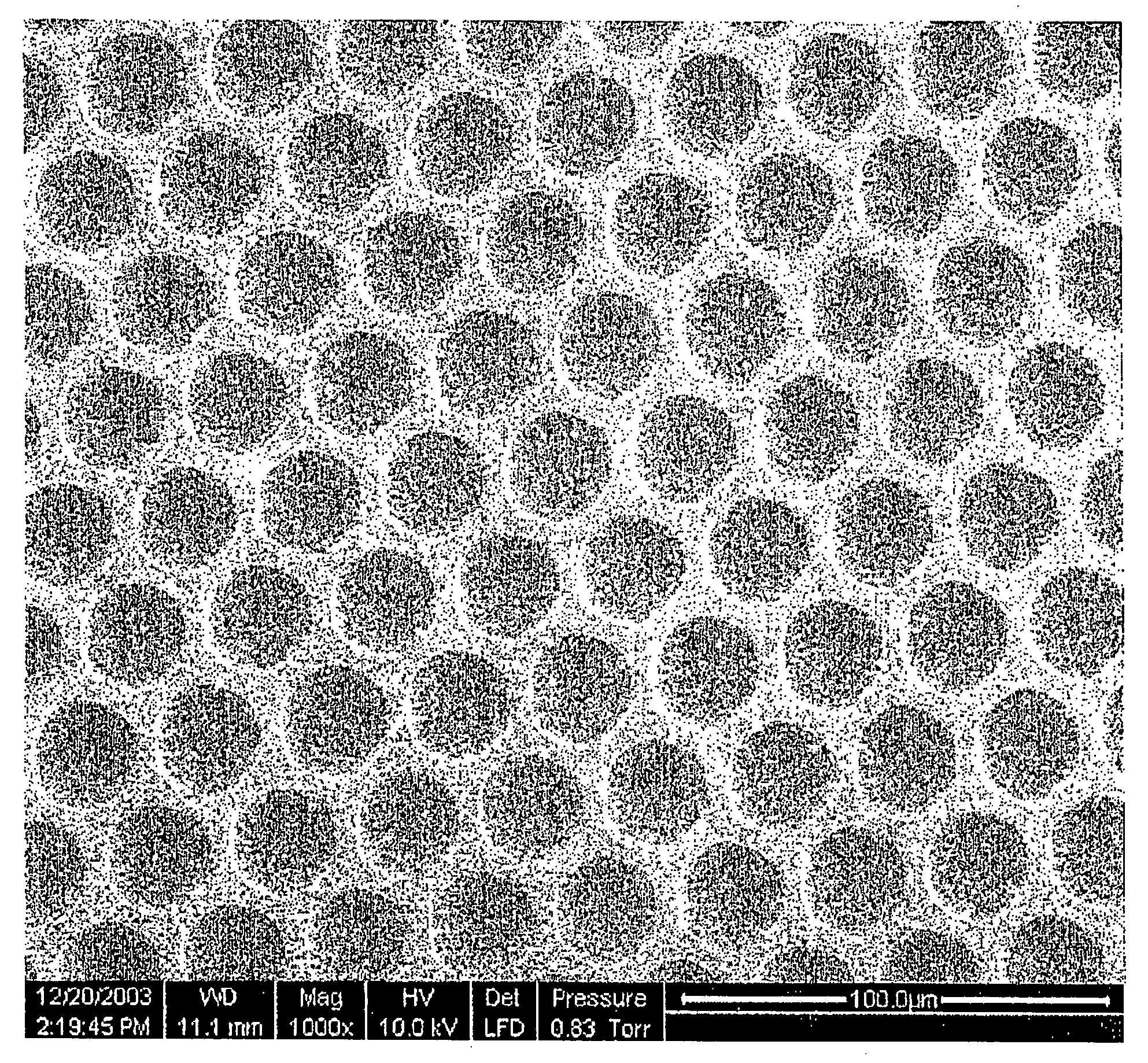

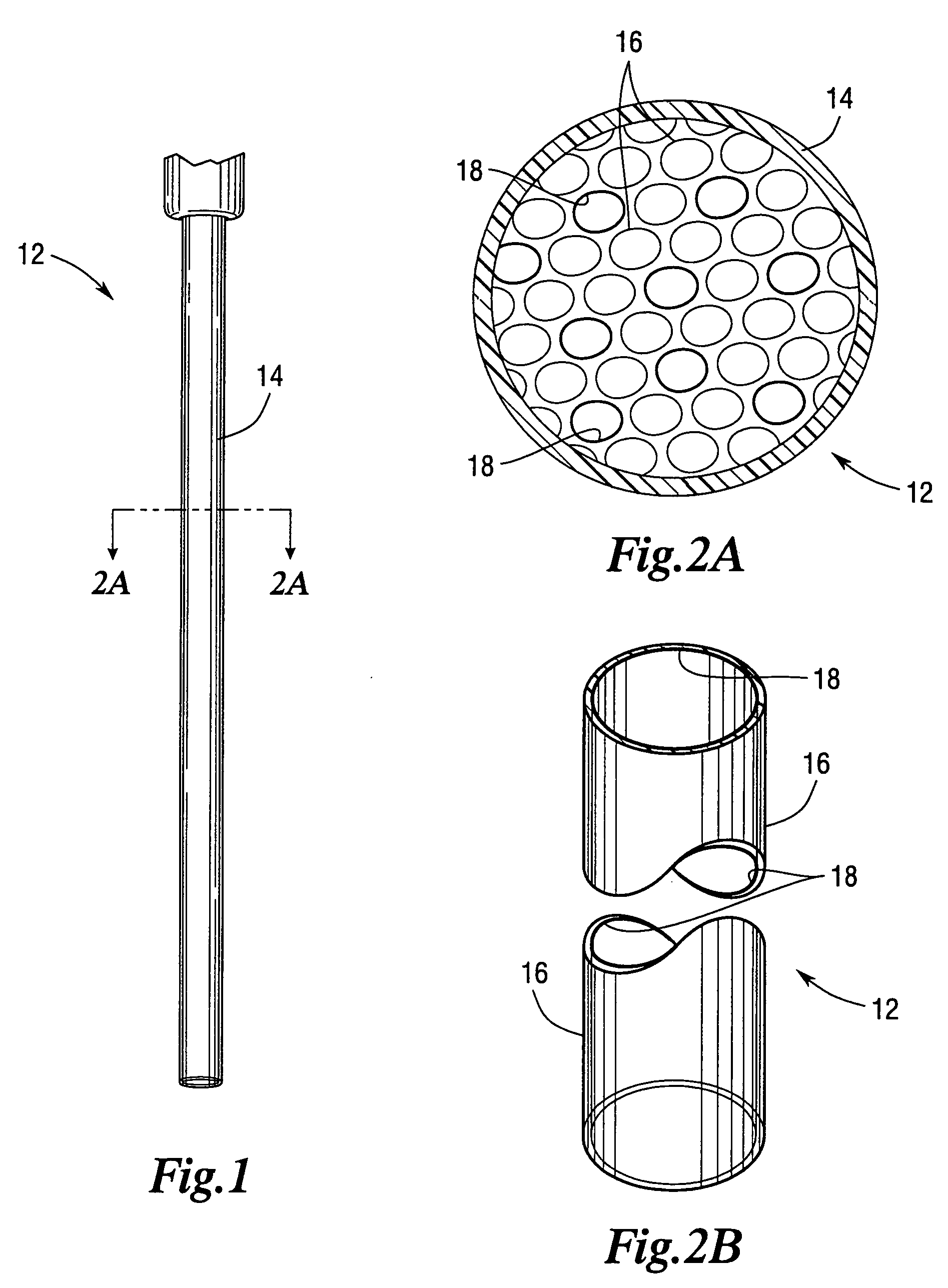

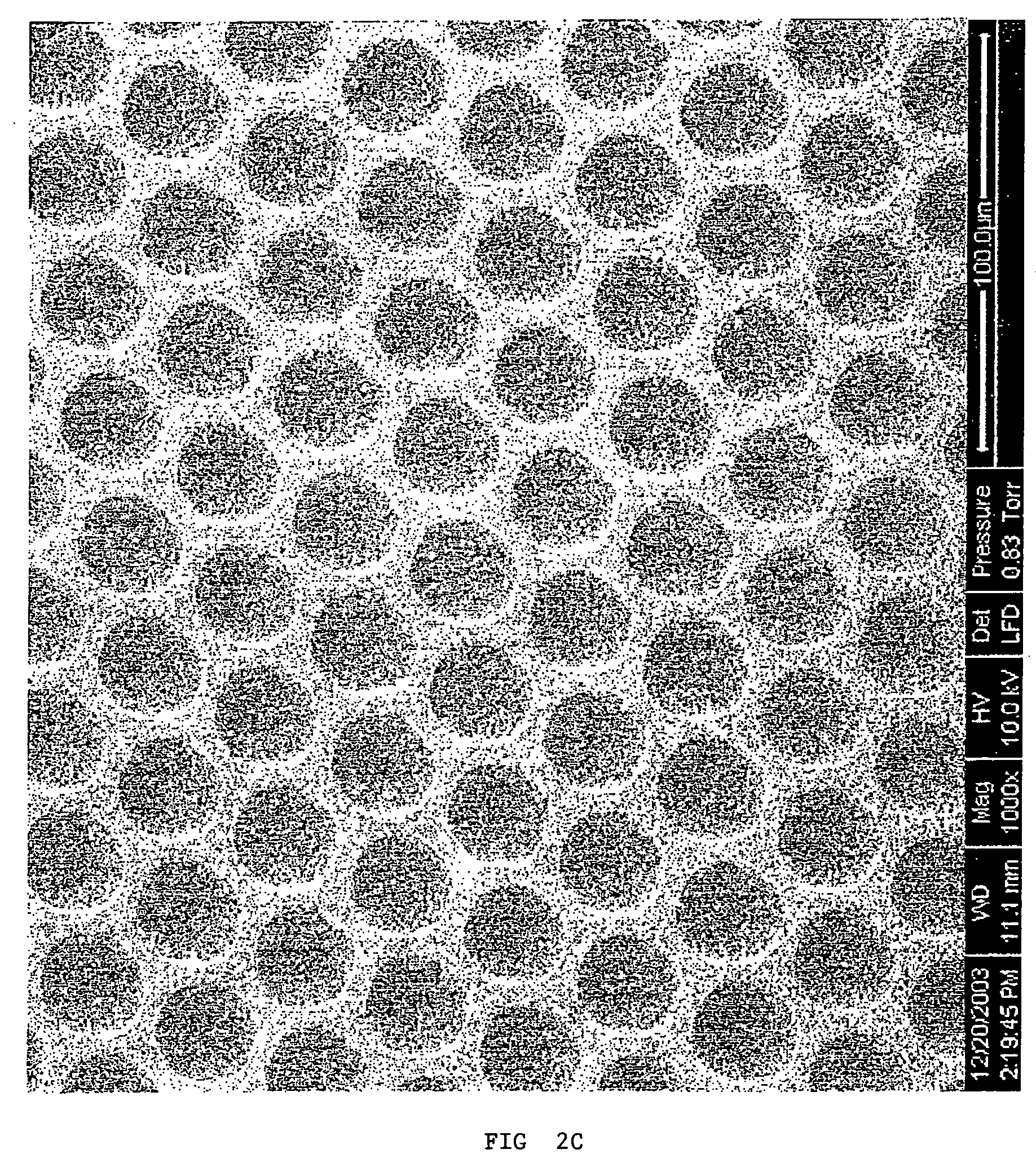

Multicapillary device for sample preparation

InactiveUS20070017870A1Large specific surface areaLoad largeIon-exchange process apparatusComponent separationStationary phaseMICRO PIPETTE

A multicapillary sample preparation device, especially useful for handling biological samples, comprising a plurality of uniform capillary tubes coated with a stationary phase, and arranged in a monolithic element. The multicapillary device is suitable for attachment to a pipette, micropipette, syringe, or other analytical or sample preparation instrument.

Owner:BIOEDGE

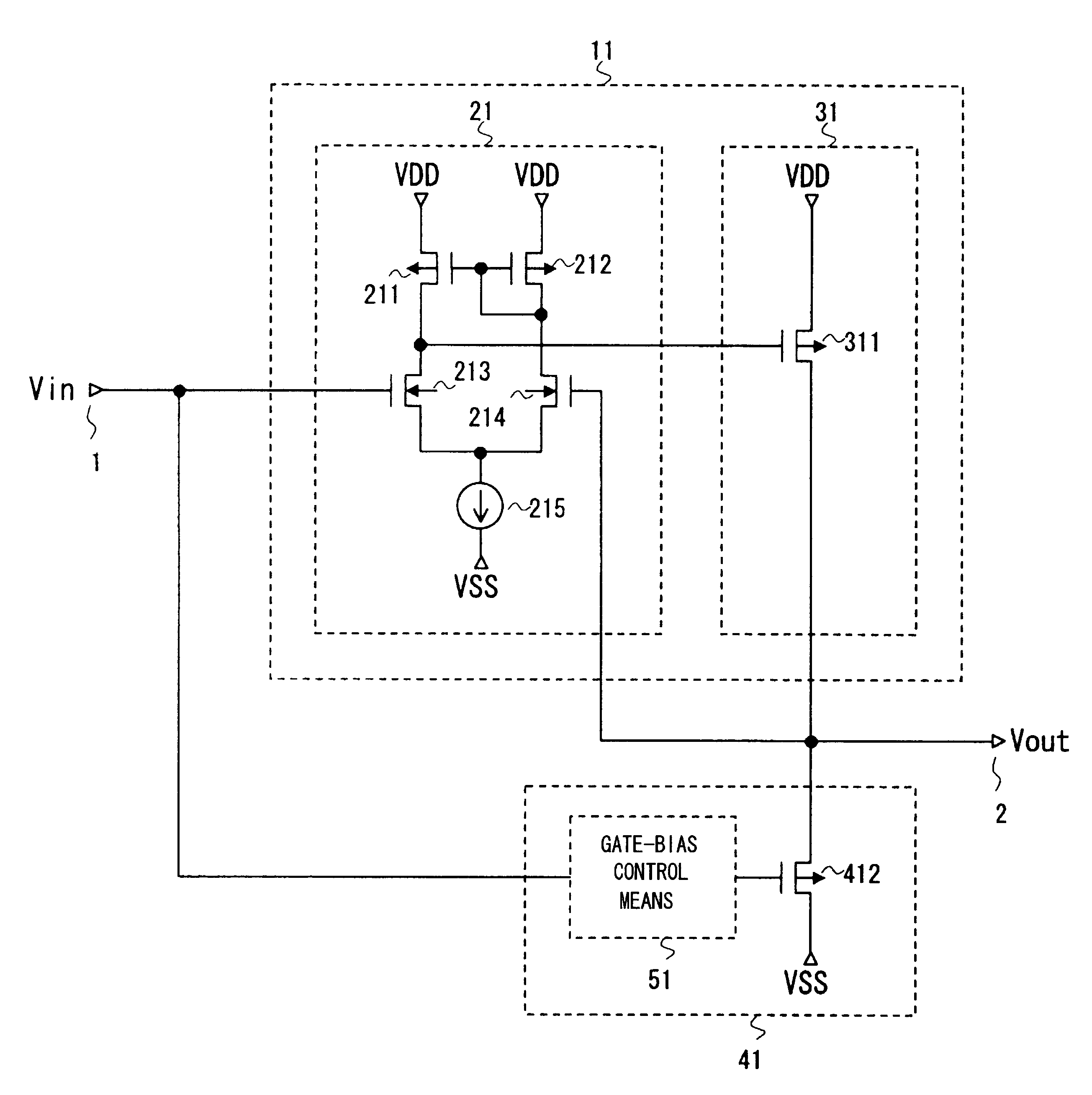

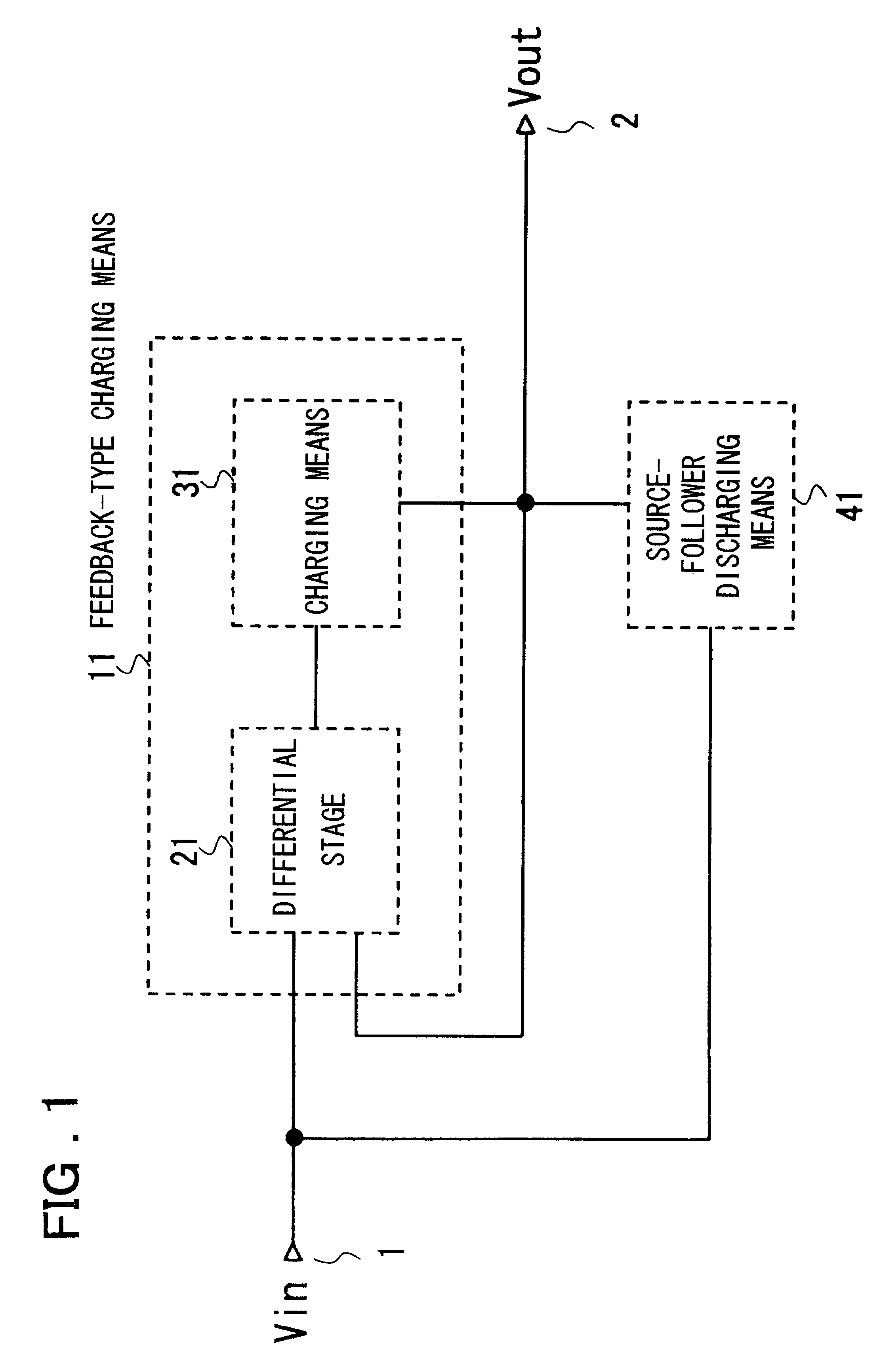

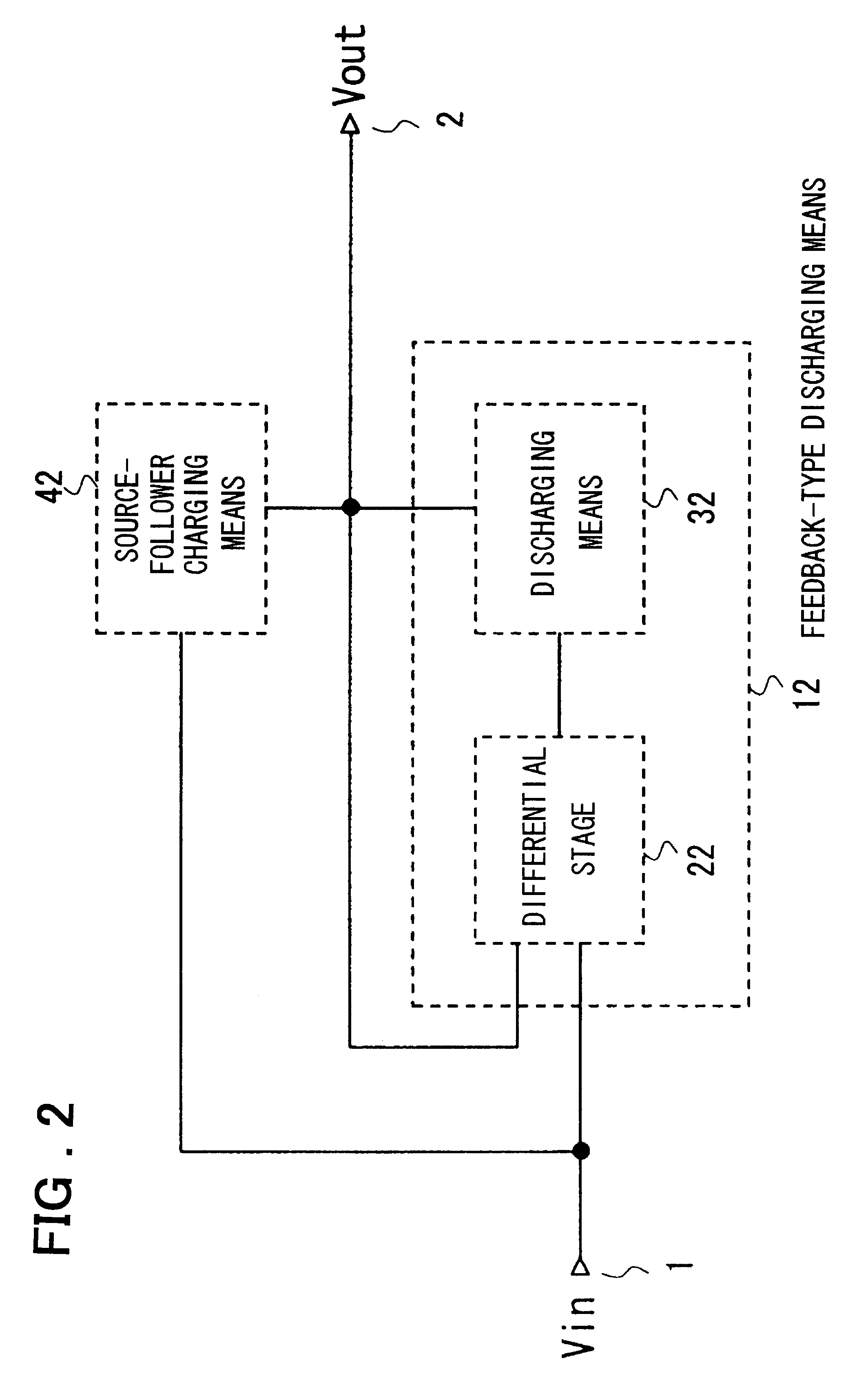

Feedback-type amplifier circuit and driver circuit

InactiveUS6614295B2Guaranteed uptimeIncrease computing speedAmplifier modifications to reduce non-linear distortionStatic indicating devicesDriver circuitAudio power amplifier

Disclosed is a feedback-type amplifier circuit including feedback-type charging means, which operates as a voltage follower, having a differential stage which receives an input-terminal voltage and an output-terminal voltage differentially as inputs and charging means for performing a charging operation at the output terminal based upon an output from the differential stage; and follower-type discharging means for performing a discharging operation at the output terminal by follower operation of an active element in accordance with a voltage difference between the input-terminal voltage and the output-terminal voltage.

Owner:RENESAS ELECTRONICS CORP

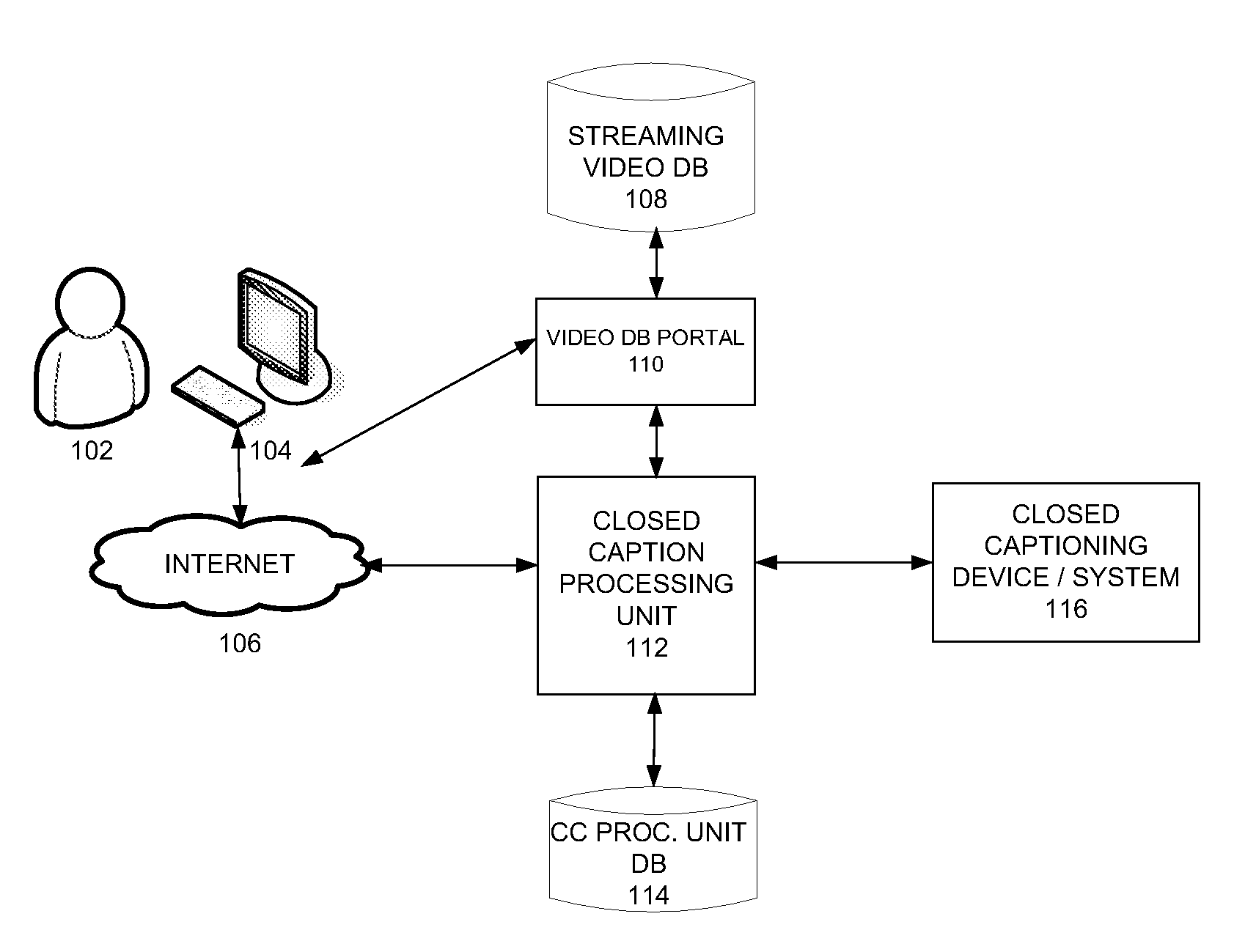

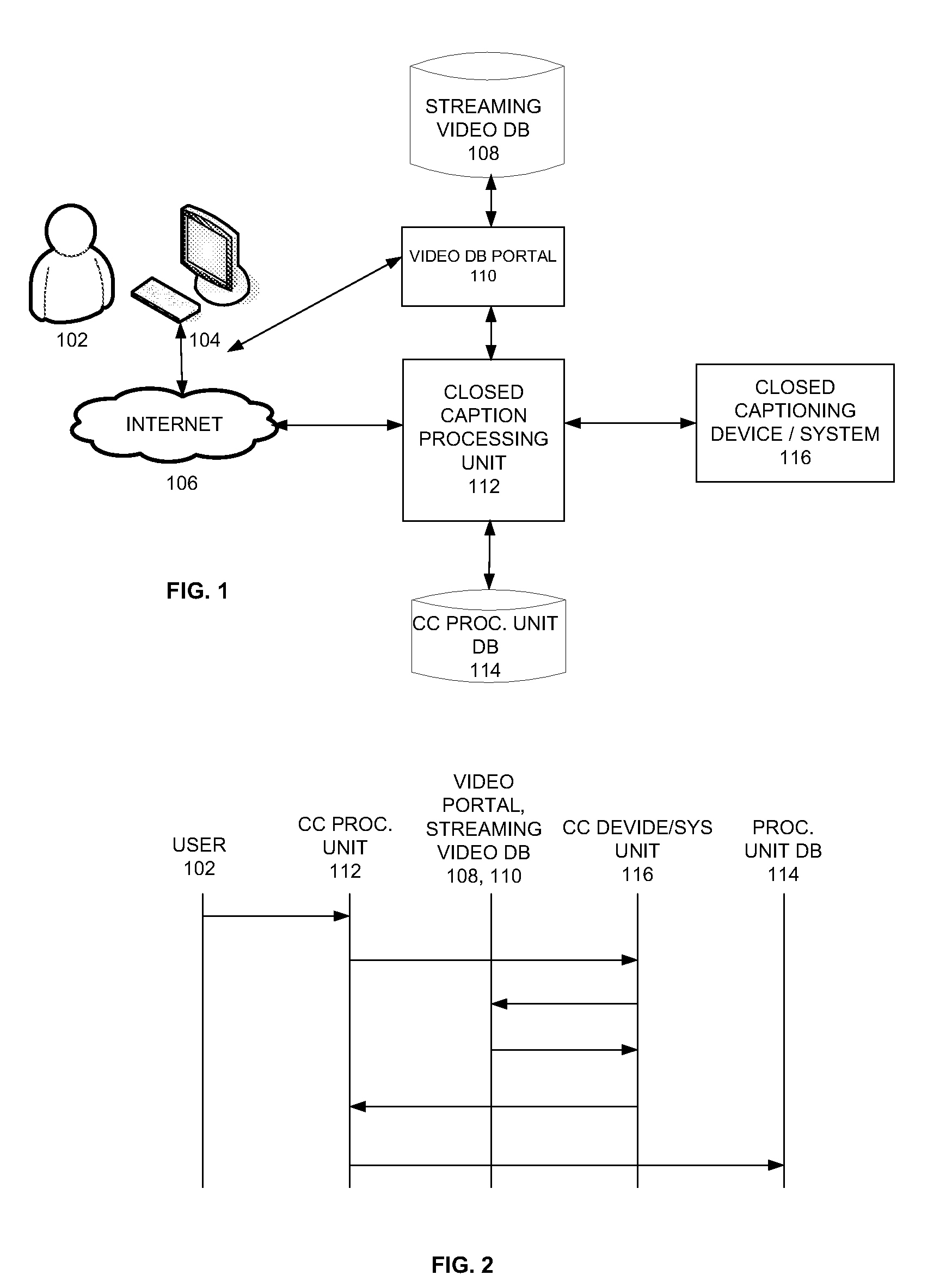

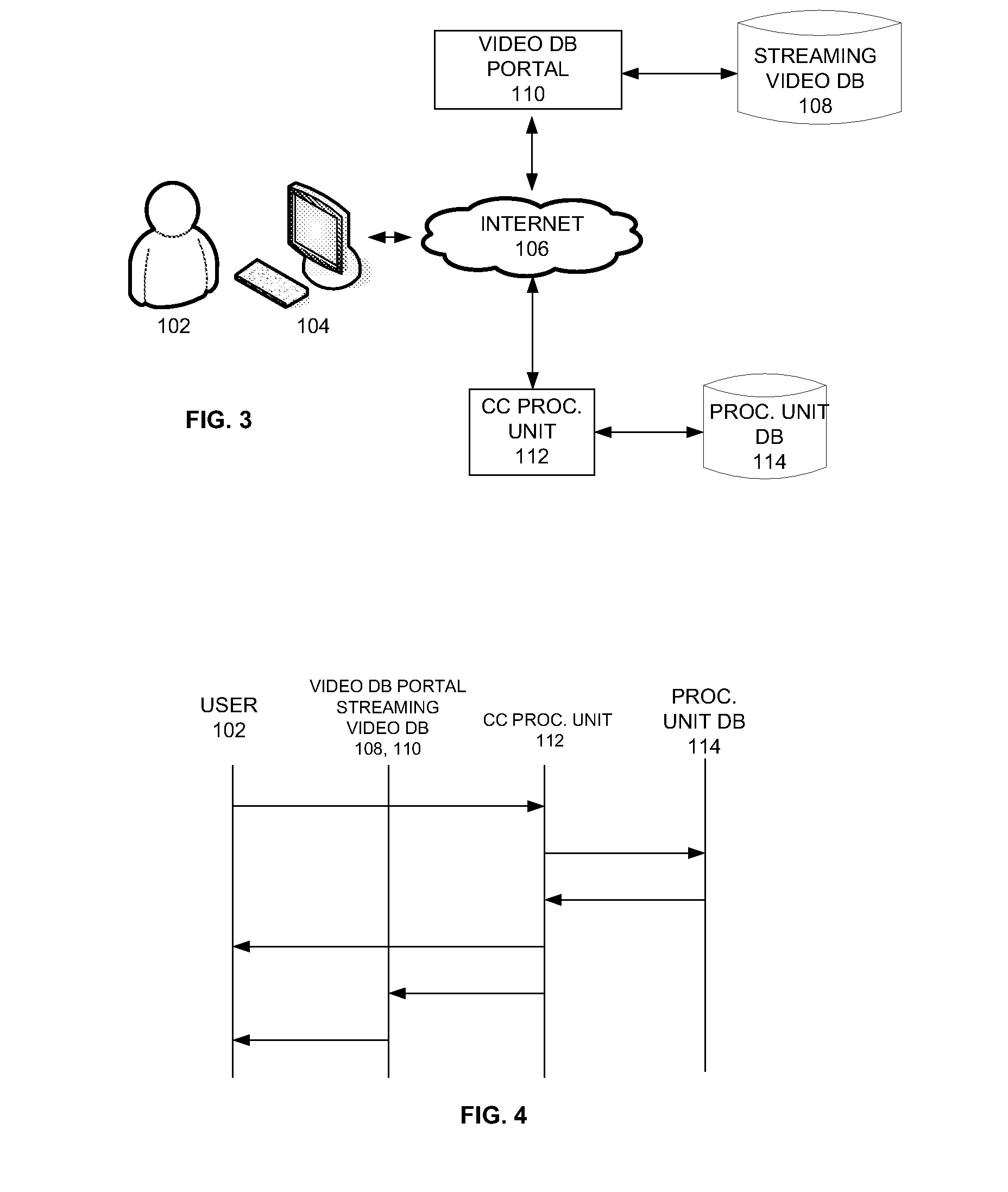

Text data for streaming video

InactiveUS20080284910A1Load largeTelevision system detailsPicture reproducers using cathode ray tubesClosed captioningText string

In a system and method providing a video with closed captioning, a processor may: provide a first website user interface adapted for receiving a user request for generation of closed captioning, the request referencing a multimedia file provided by a second website; responsive to the request: transcribe audio associated with the video into a series of closed captioning text strings arranged in a text file; for each of the text strings, store in the text file respective data associating the text string with a respective portion of the video; and store, for retrieval in response to a subsequent request made to the first website, the text file and a pointer associated with the text file and referencing the text file with the video; and / or providing the text file to an advertisement engine for obtaining an advertisement based on the text file and that is to be displayed with the video.

Owner:ERSKINE JOHN +2

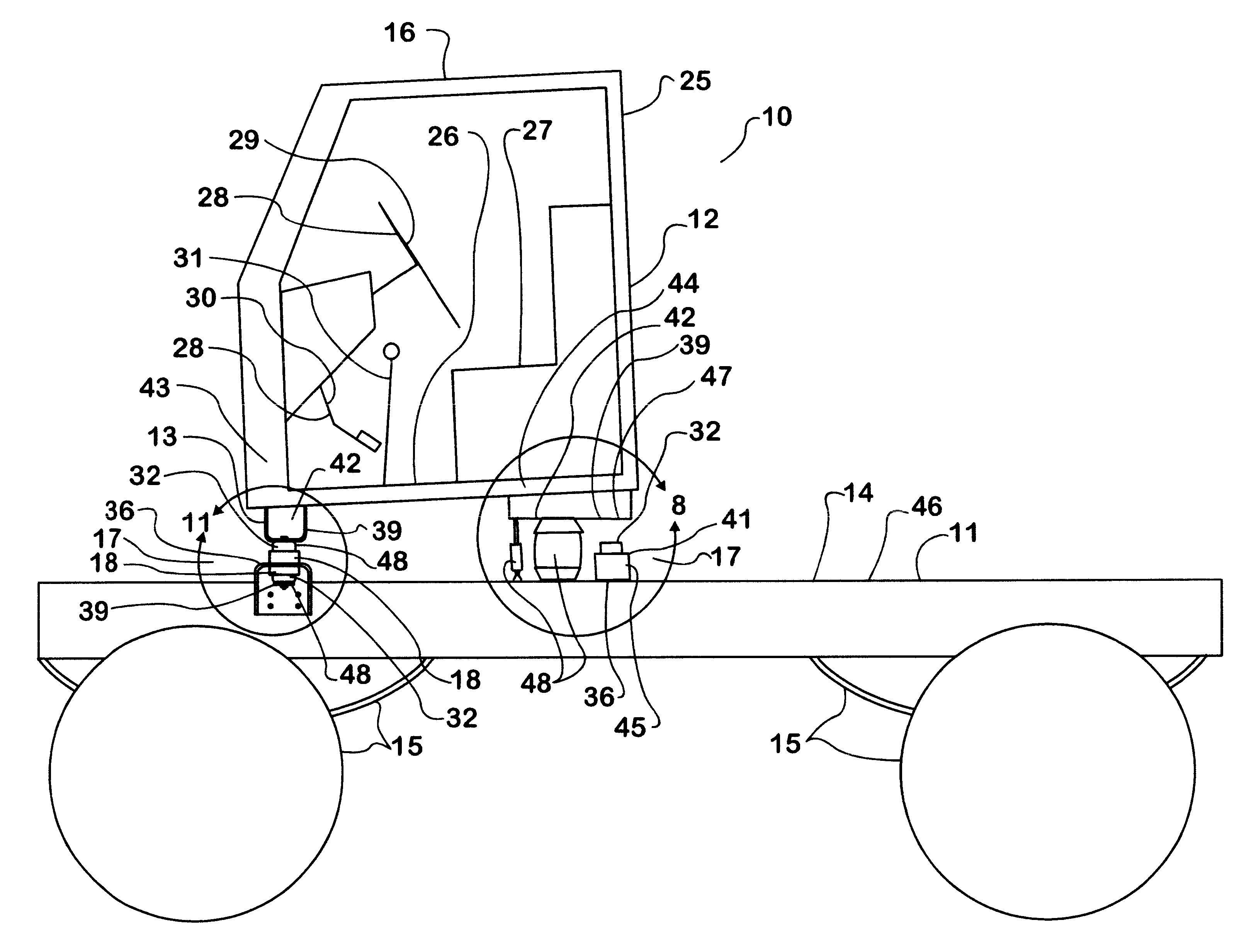

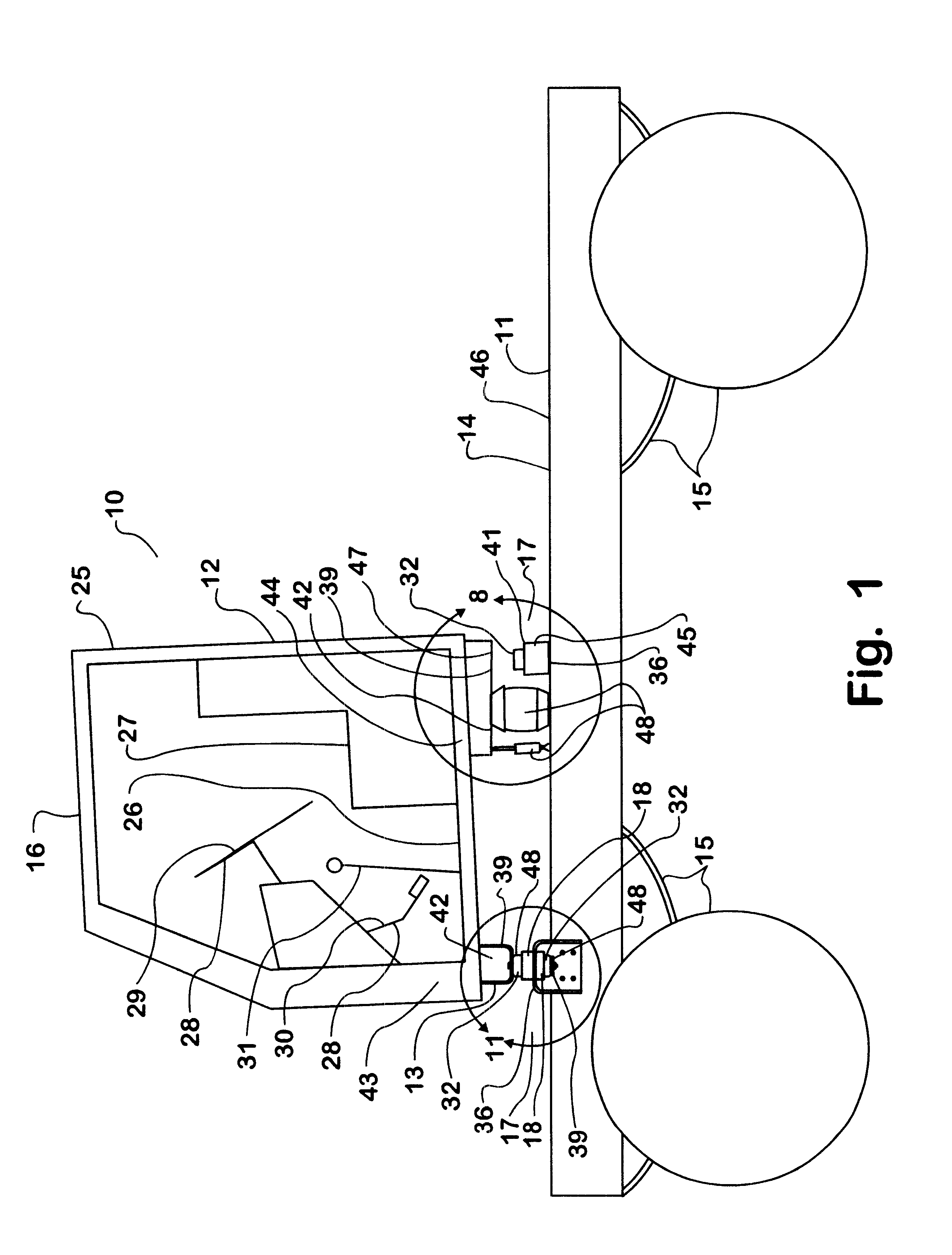

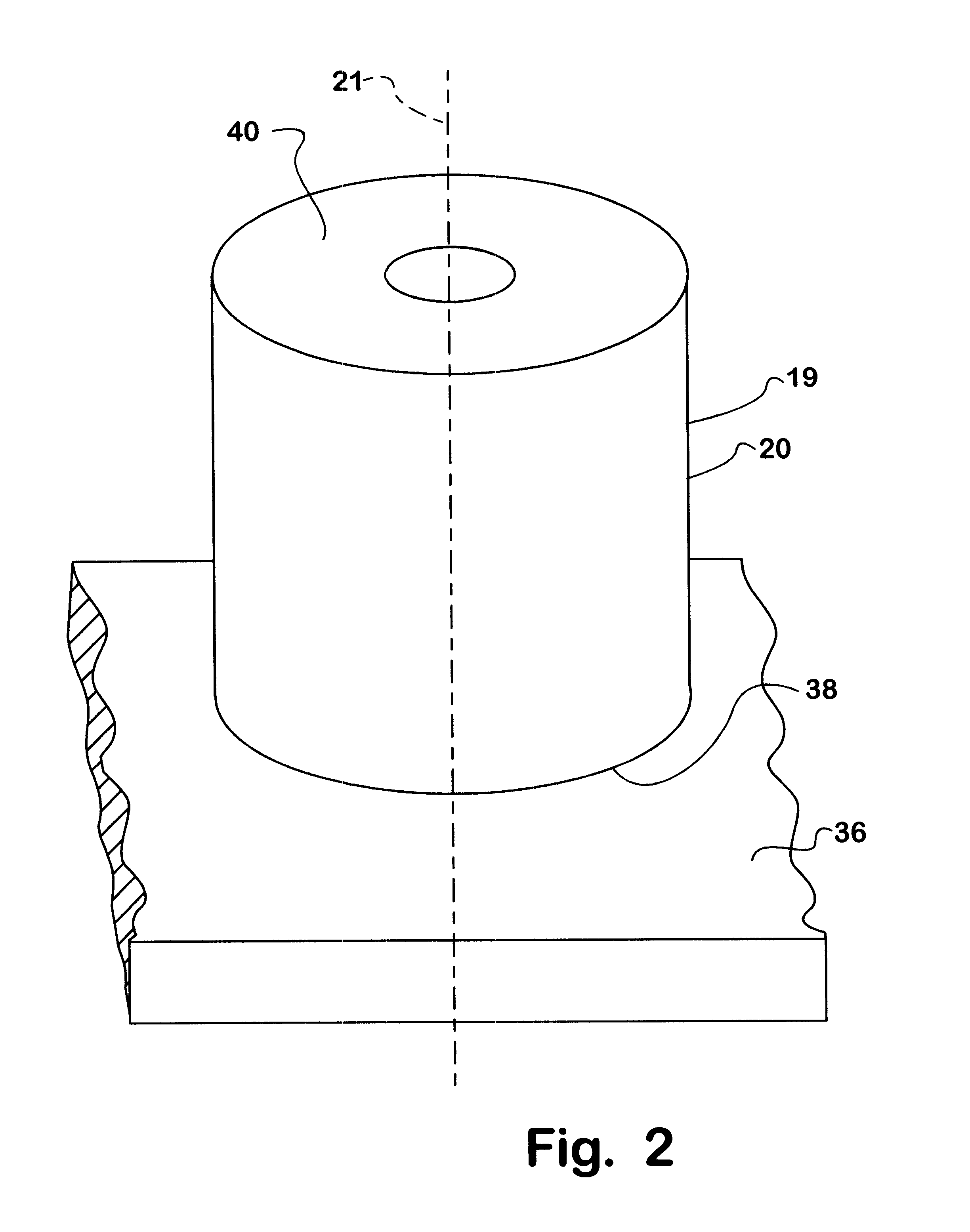

Vehicle body suspension system

A vehicle includes a body structure that is suspended from a chassis of the vehicle by a vehicle body suspension system. The vehicle body suspension system is constructed in a manner to allow relative movement to occur between the suspended body structure and the chassis in such a manner to at least partially isolate the suspended body structure from the vibrations and accelerations of the chassis. The vehicle body suspension system includes one or more spring / damper components that comprise an elastomer body that is surrounded and, therefore, reinforced by a reinforcing wall constructed of a relatively rigid material. The vehicle body suspension system may utilize one or more of the reinforced elastomer block spring / damper components as bump stops and / or primary spring / damper components.

Owner:NAVISTAR CANADA

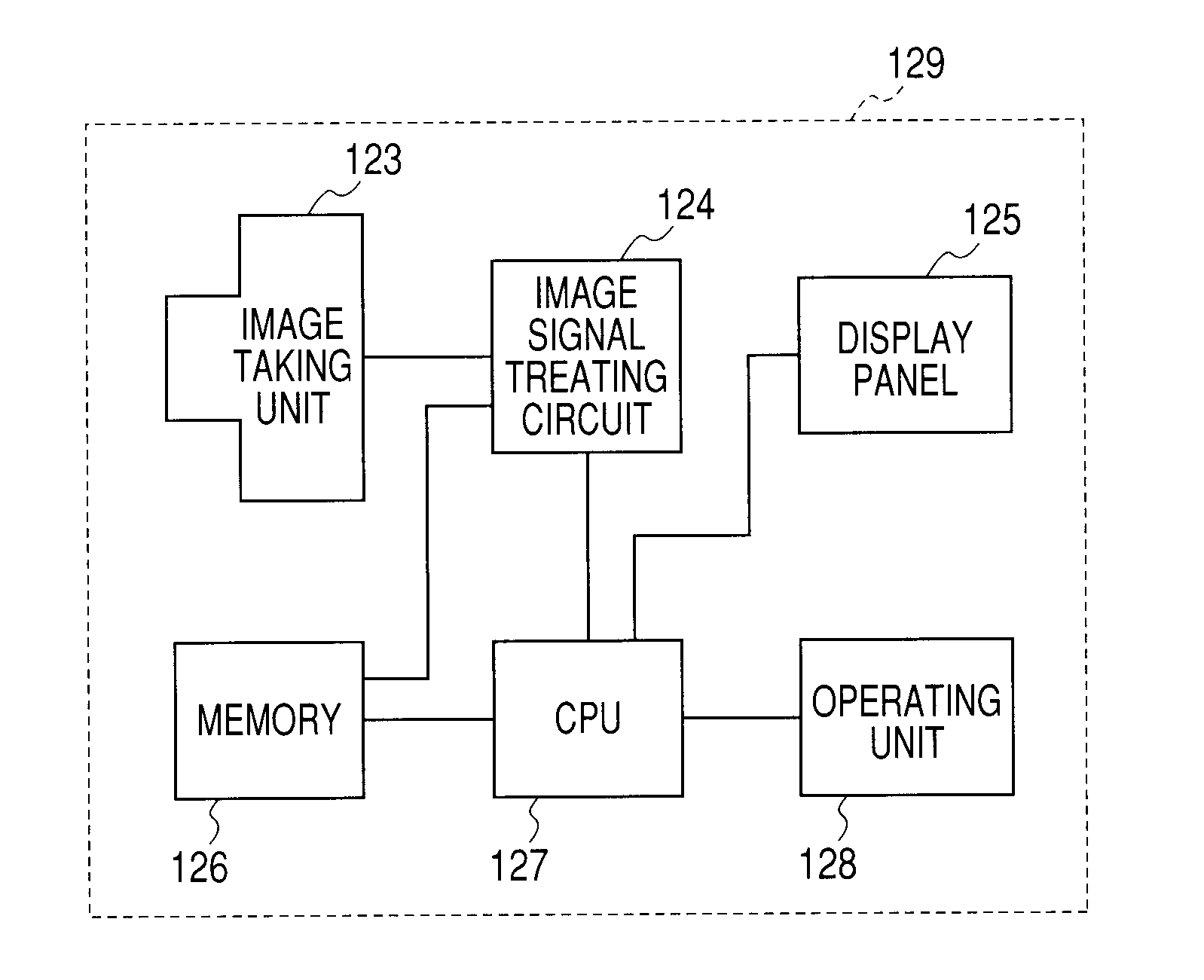

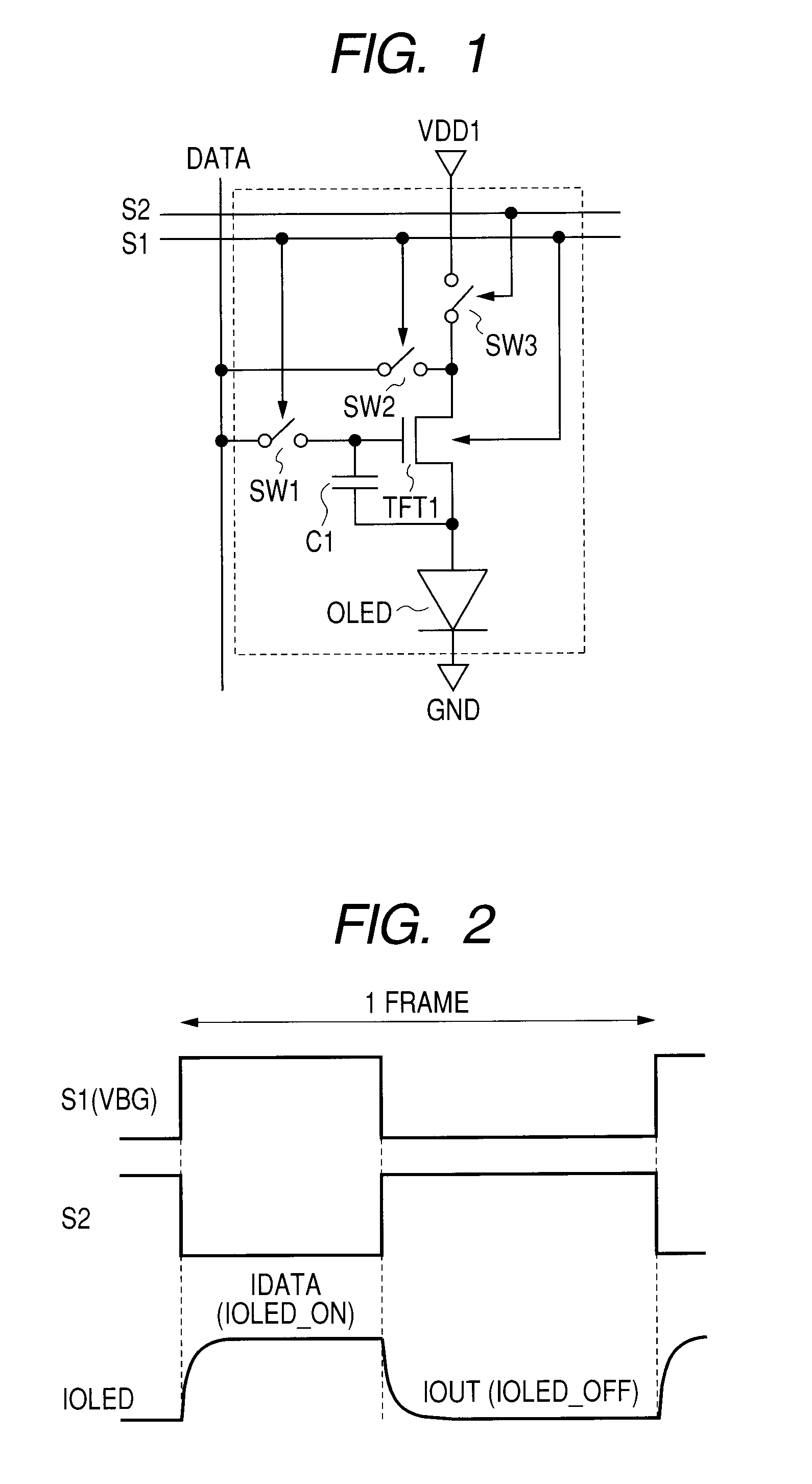

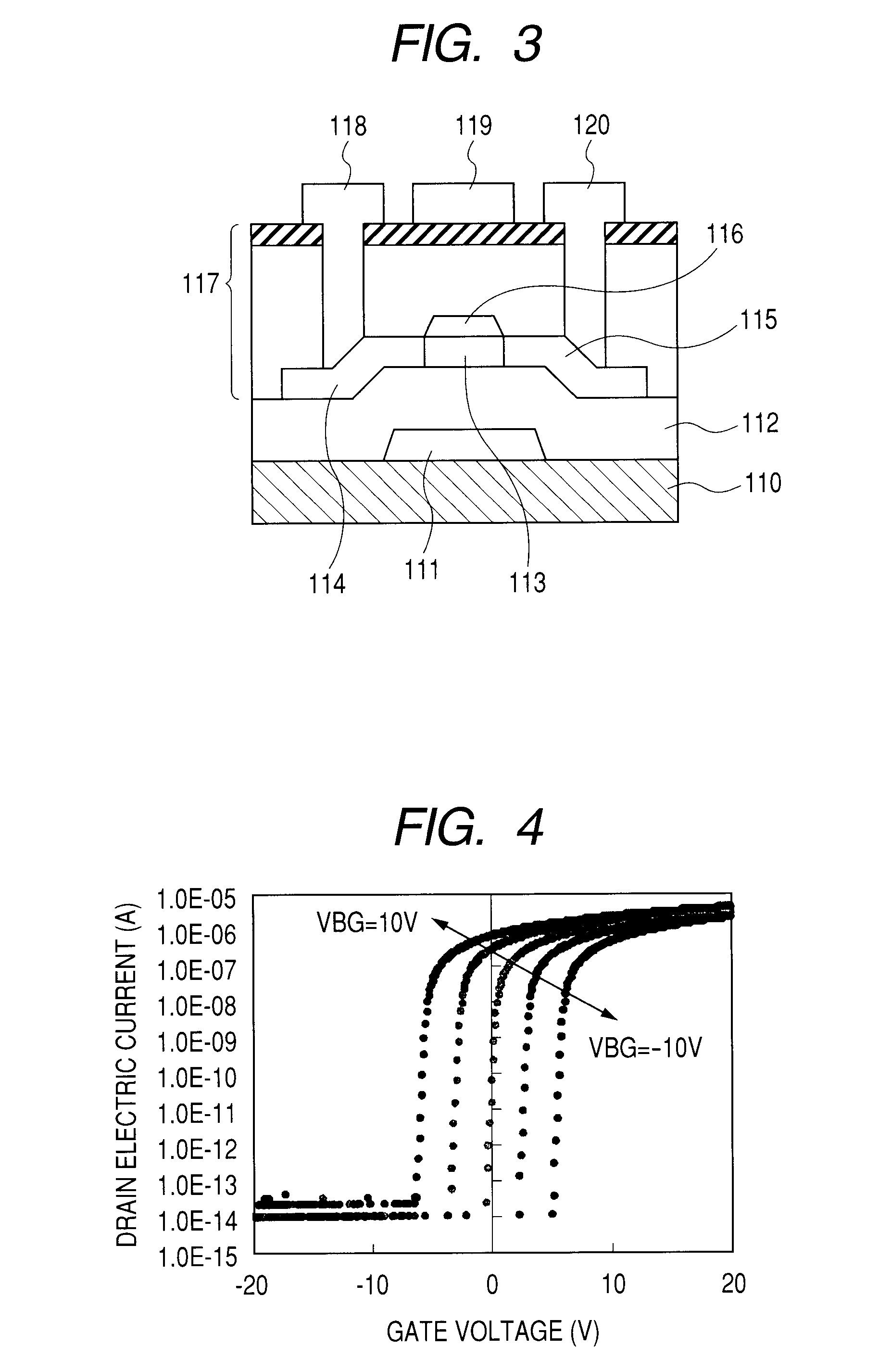

Pixel circuit, light emitting display device and driving method thereof

InactiveUS20100053041A1High quality displayLoad largeTelevision system detailsStatic indicating devicesDisplay deviceGate voltage

A pixel circuit including at least a light emitting element, and a thin film transistor that supplies to the light emitting element a first current controlling a gray scale according to luminance-current characteristics of the light emitting element, wherein the thin film transistor has a back gate electrode, at least a driving period in which the thin film transistor supplies the first current to the light emitting element, and a writing period in which a second current is written to the thin film transistor before the driving period in order to pass the first current to the thin film transistor during the driving period are included, and by changing voltages which are applied to the back gate electrode in the driving period and the writing period, current capability to a gate voltage of the thin film transistor is made to differ.

Owner:CANON KK

Storage allocation in a distributed segmented file system

InactiveUS20080222223A1Storage capacity can be easilyEfficient executionData processing applicationsTransmissionInodeData sharing

A file system (i) permits storage capacity to be added easily, (ii) can be expanded beyond a given unit, (iii) is easy to administer and manage, (iv) permits data sharing, and (v) is able to perform effectively with very large storage capacity and client loads. State information from a newly added unit is communicated (e.g., automatically and transparently) to central administration and management operations. Configuration and control information from such operations is communicated (e.g., automatically) back down to the newly added units, as well as existing units. In this way, a file system can span both local storage devices (like disk drives) and networked computational devices transparently to clients. Such state and configuration and control information can include globally managed segments as the building blocks of the file system, and a fixed mapping of globally unique file identifiers (e.g., Inode numbers) and / or ranges thereof, to such segments.

Owner:HEWLETT PACKARD DEV CO LP

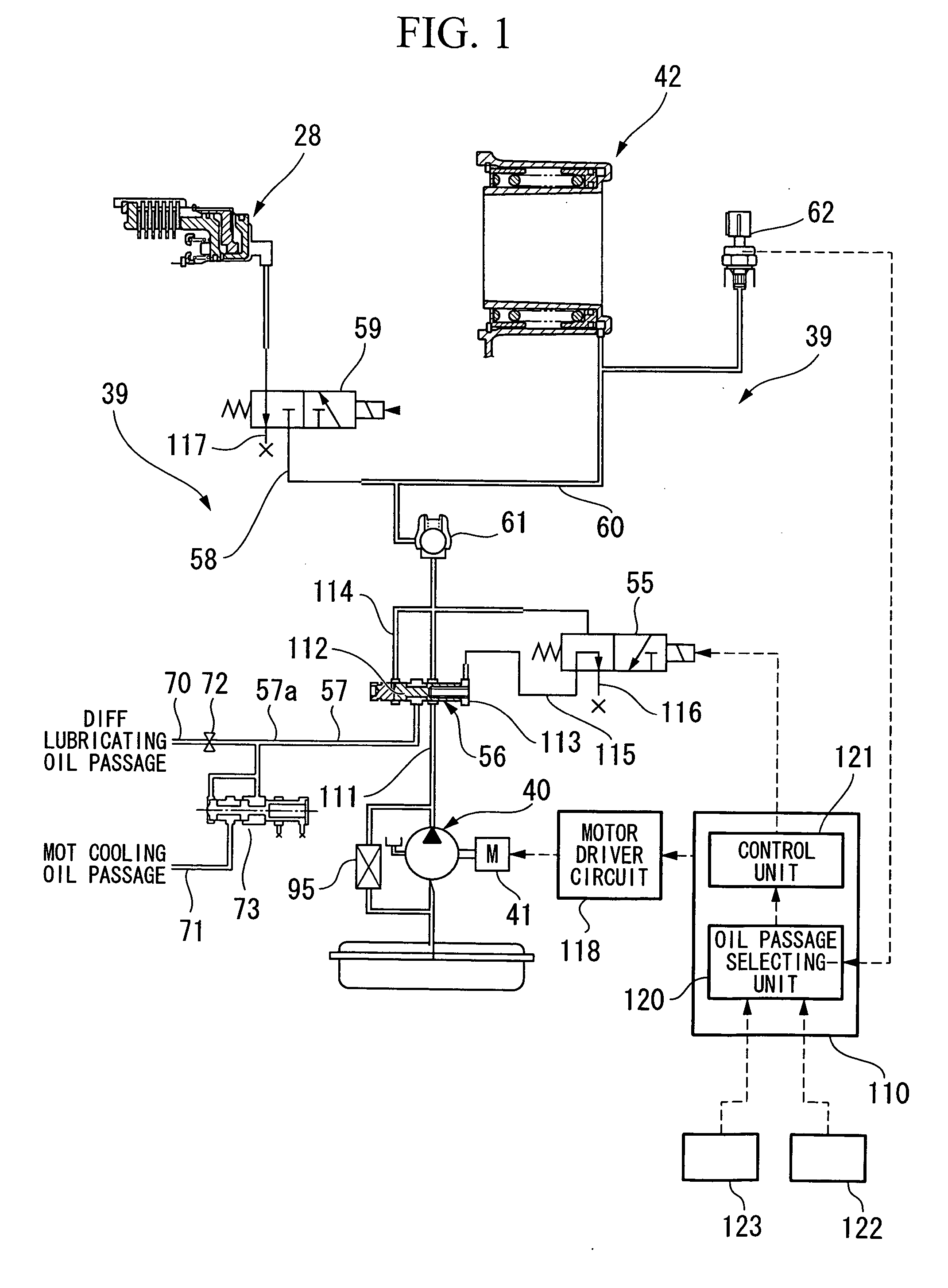

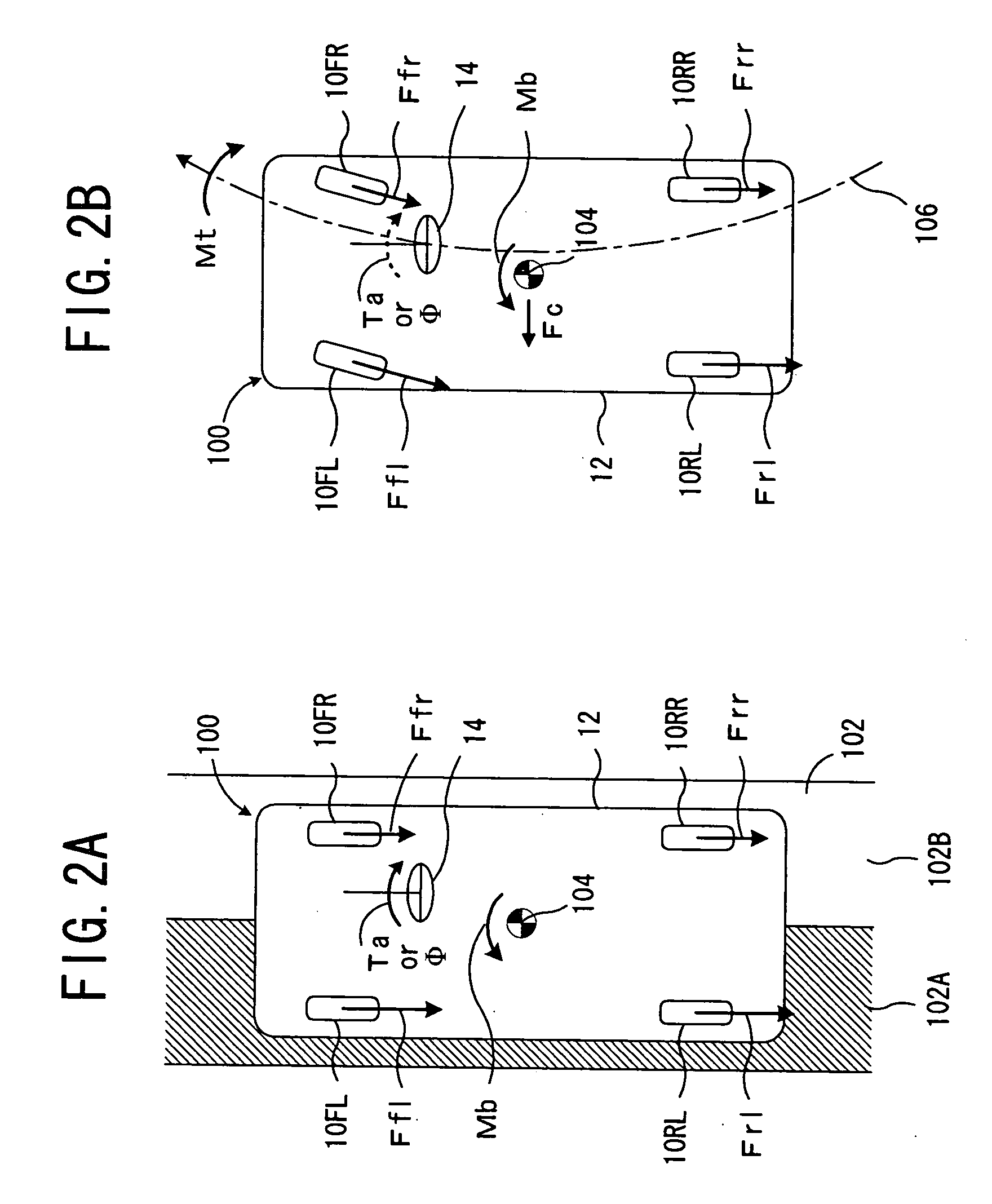

Hydraulic circuit control device

InactiveUS20060223670A1Reduce stressIncrease heightServomotorsGear lubrication/coolingHydraulic circuitControl mode

A hydraulic circuit control device that selectively supplies oil to a first oil passage and a second oil passage by an oil pump, the control device includes: an oil passage switching unit adapted to connect the oil pump to either the first oil passage or the second oil passage; a control mode switching unit adapted to switch the control mode of the electric motor to either a torque control mode or a speed control mode; an oil passage selecting unit adapted to select whether to connect the oil pump to the first oil passage or the second oil passage; and a control unit adapted to perform control so that the control mode switching unit switches the control mode to the torque control mode when the first oil passage has been selected, and perform control so that the control mode switching unit switches the control mode to the speed control mode when the second oil passage has been selected.

Owner:HONDA MOTOR CO LTD

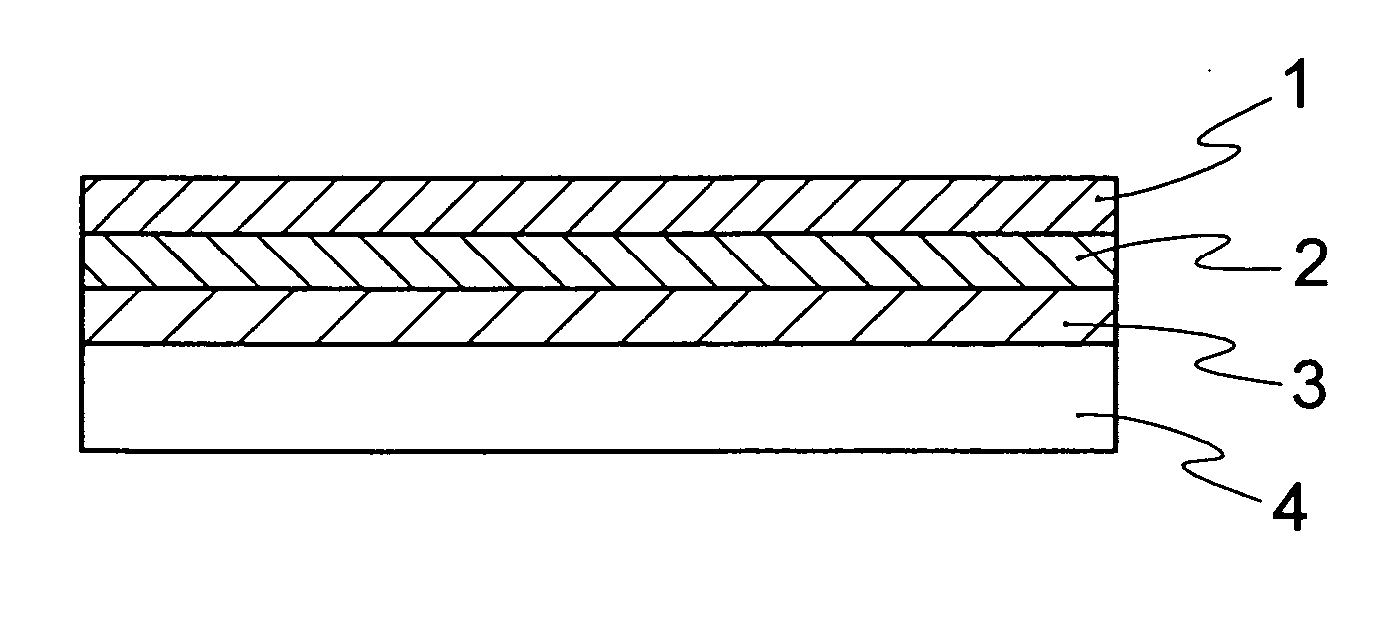

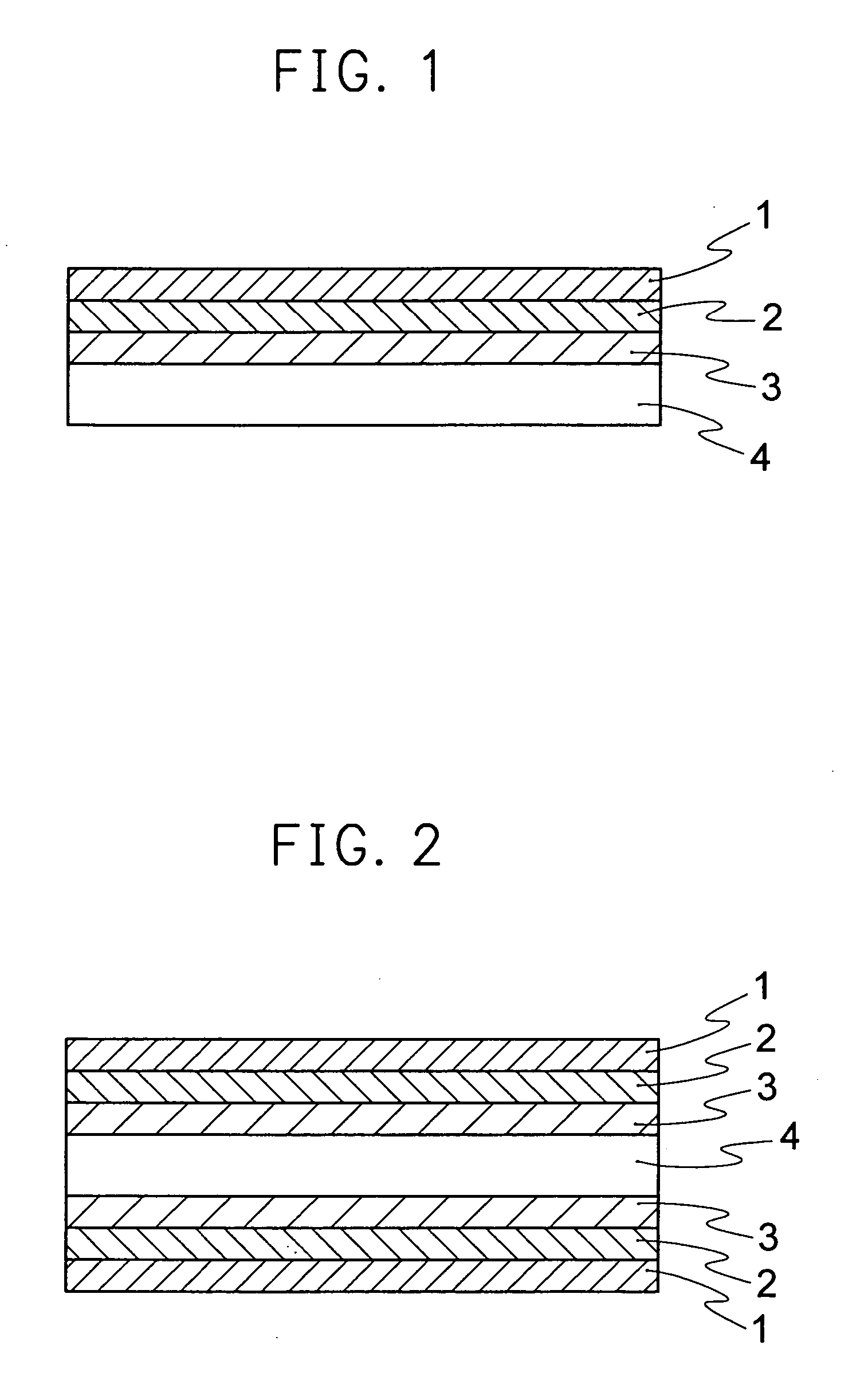

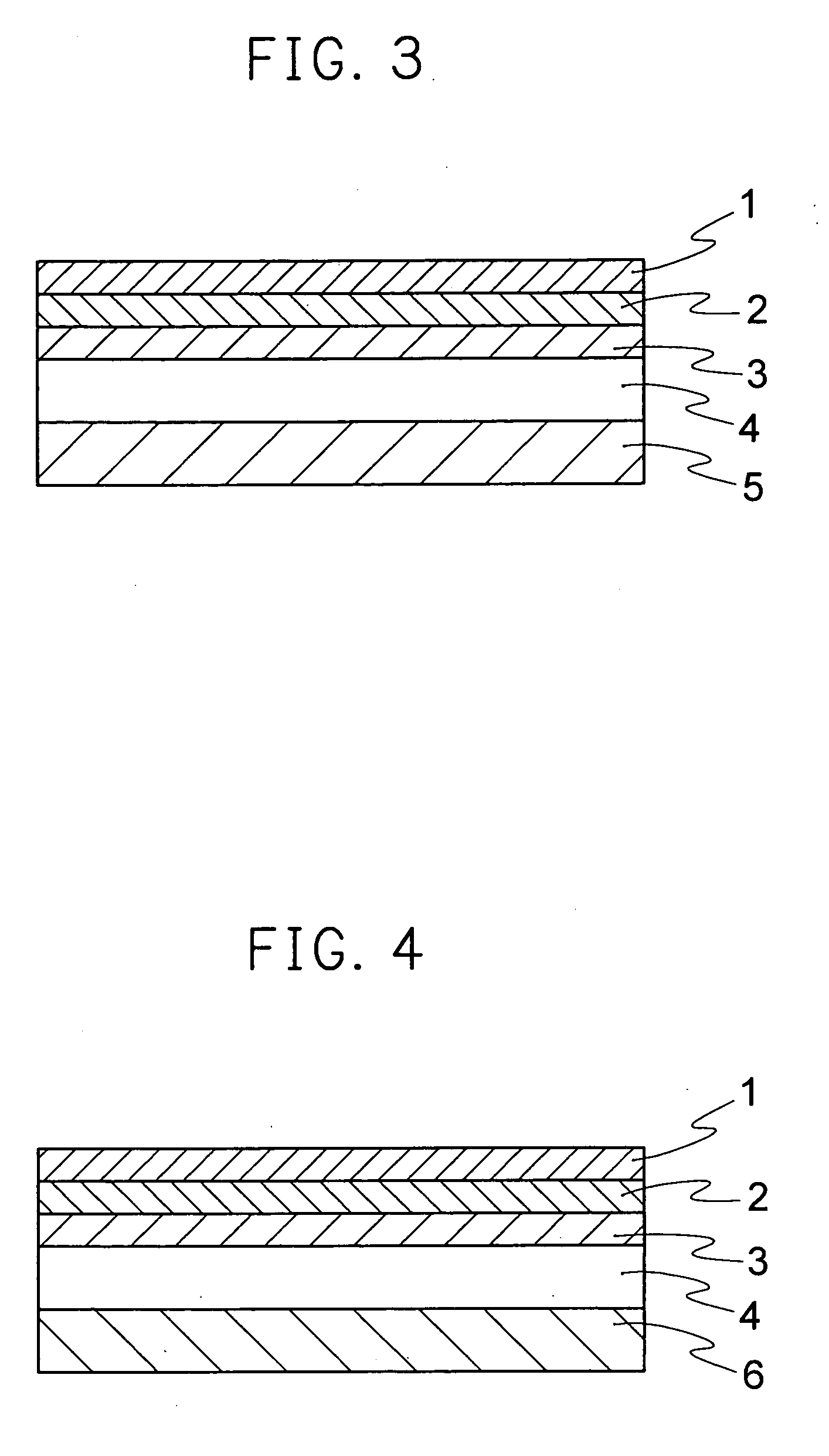

Laminate, printed circuit board, and preparing method thereof

InactiveUS20060048963A1Improve adhesion stabilityAchieve adhesion propertyInsulating substrate metal adhesion improvementMagnetic/electric field screeningHigh densityPrinted circuit board

A laminate which comprises a thermoplastic polyimide layer and a metal layer, or comprises a non-thermoplastic polyimide film layer and, formed on one or both surfaces, a thermoplastic polyimide layer and a metal layer; and a printed wiring board comprising the laminate. The laminate can be used for forming a high density circuit thereon, exhibits good resistance to further processing such as desmearing and excellent adhesion, and is excellent in adhesion reliability in a high temperature atmosphere.

Owner:KANEKA CORP

Migration of control in a distributed segmented file system

InactiveUS20070226331A1Storage capacity can be easilyEfficient executionDigital data processing detailsDigital computer detailsFile systemDistributed File System

A method of managing segments in a distributed-file system implemented by a plurality of file servers includes determining a segment of the distributed-file system controlled by a first file server for which control is to be migrated, selecting a second file server, that is different from the first file server, to take control of the segment, and moving control of the segment from the first file server to the second file server.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP +1

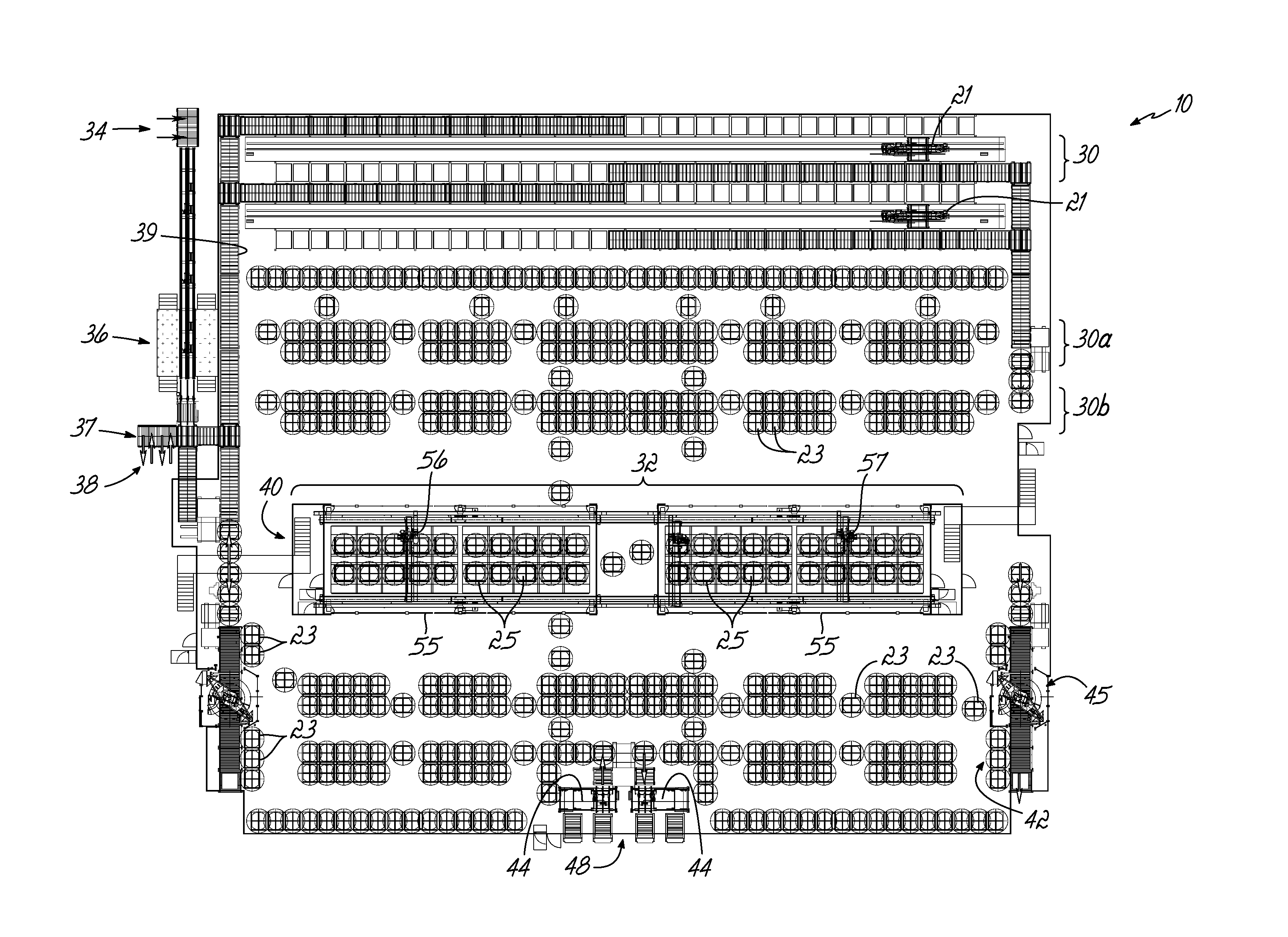

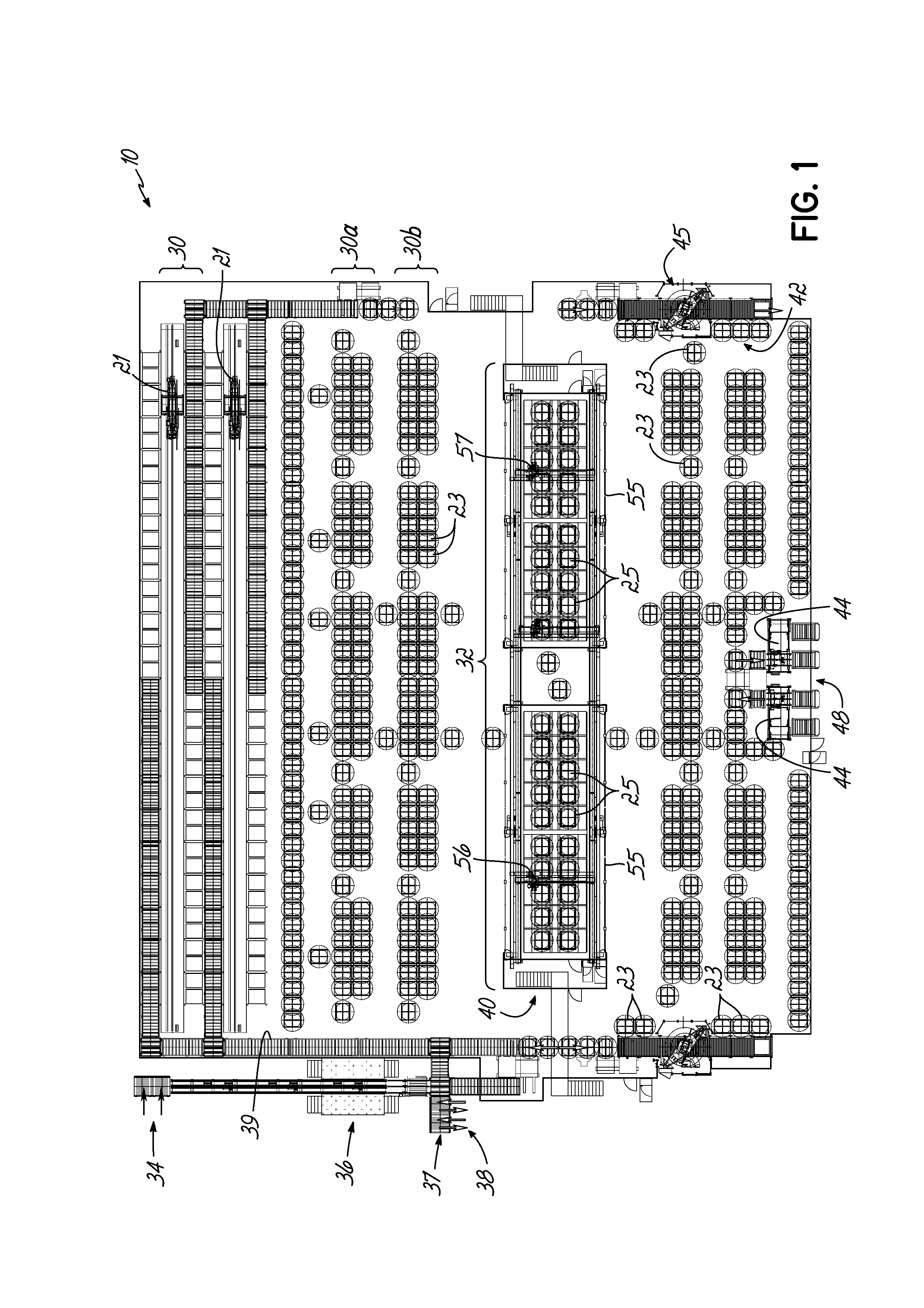

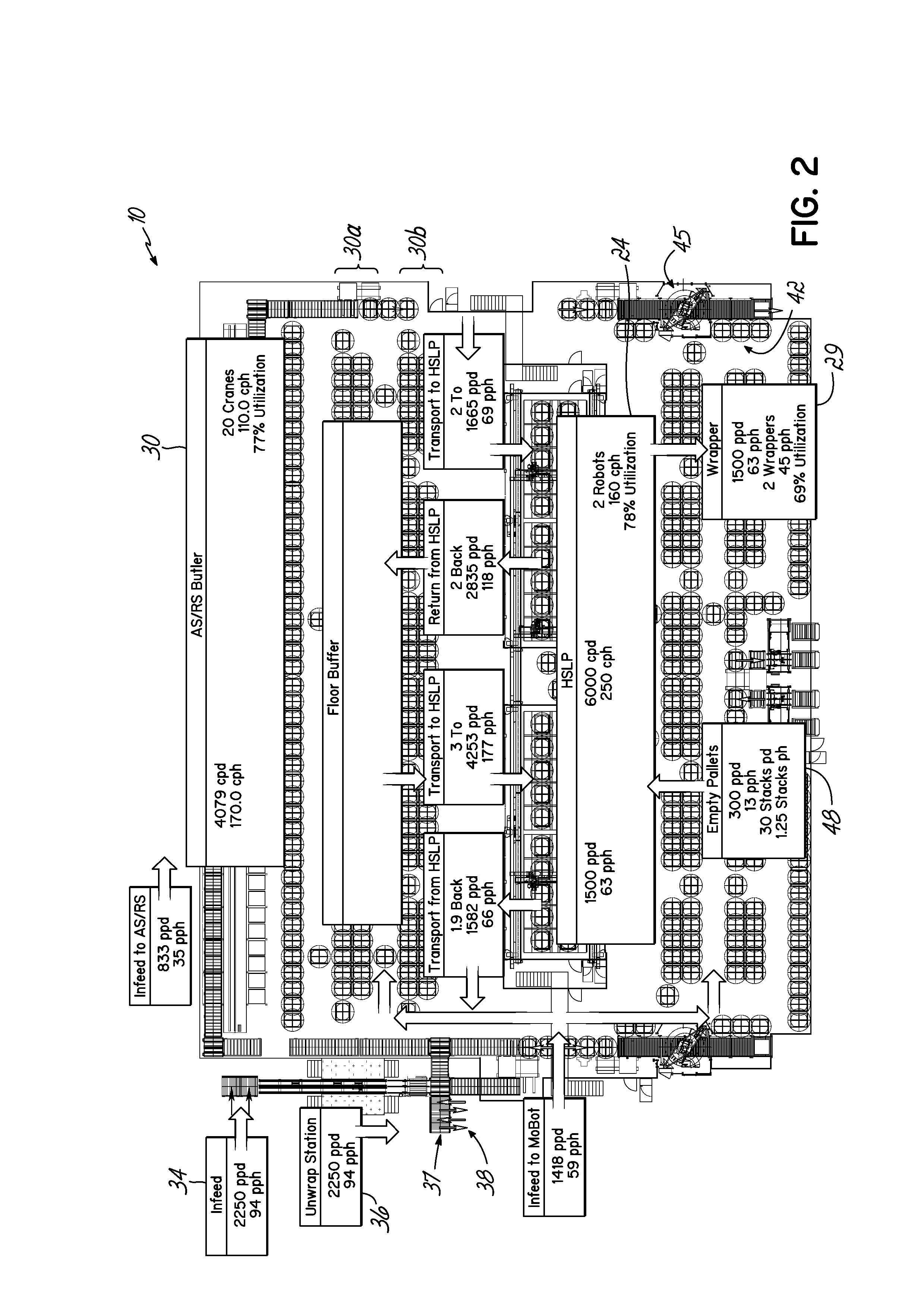

Automated layer picking and storage system

InactiveUS20130177379A1Reduce distanceLoad largeLoadersSemiconductor/solid-state device manufacturingOrder formEngineering

A material handling storage, retrieval and load building system receives source pallets, bearing product loads in full or partial layers, stores them in a variety of locations depending on the frequency of demand for products thereon and builds homogeneous product or similar product full or partial layers on target or order pallets, in both single and multiple layer picks, from products on the source pallets, to order after retrieving the source pallets to a building pallet location. Pallets are transferred within the system on pallet stands which are selectively coupled to automatically guided vehicles, thus providing significant flexibility in the pallet storage locations and in the transfer distance within the system. Apparatus and methods are disclosed.

Owner:KUKA SYST NORTH AMERICA LLC

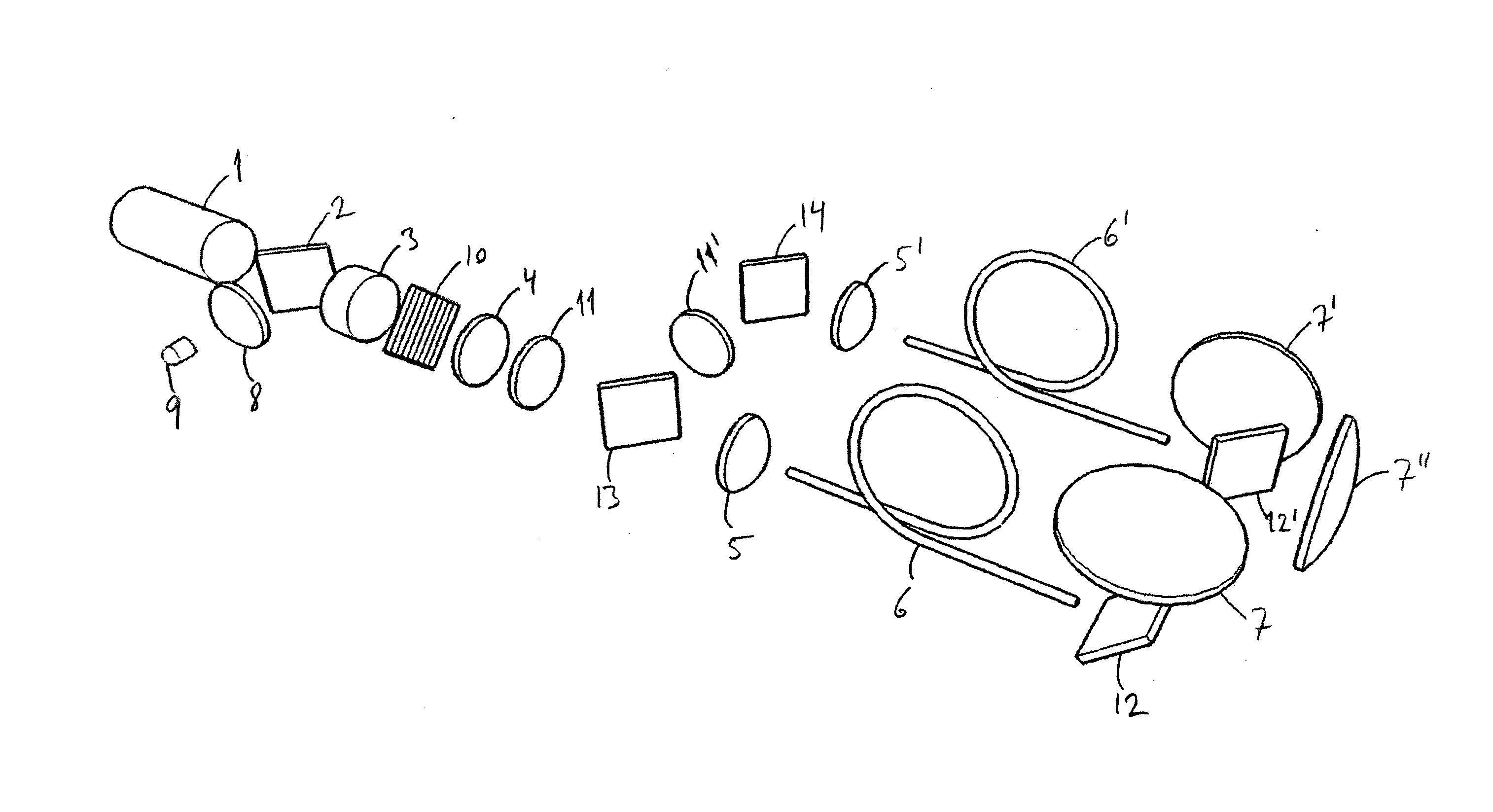

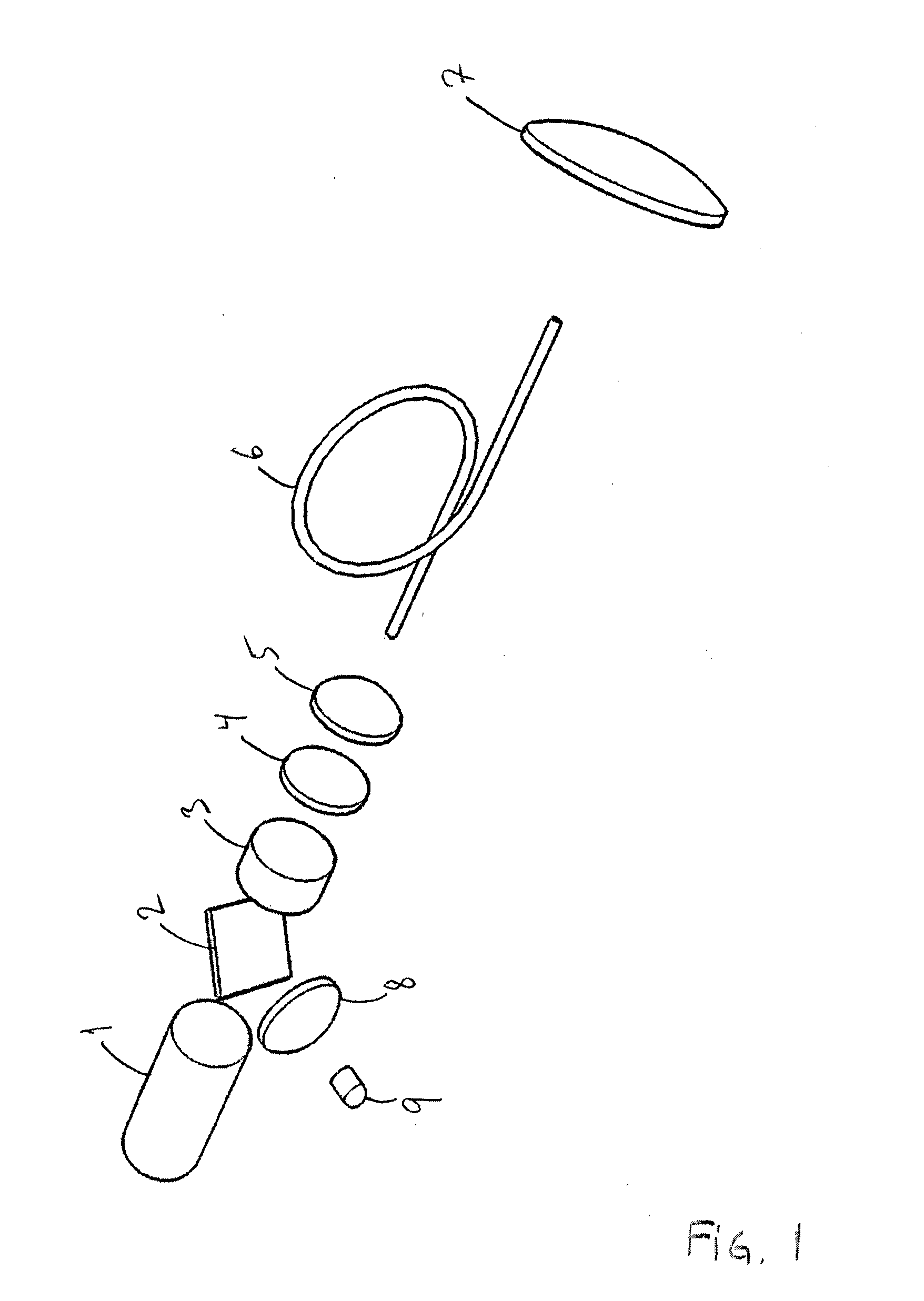

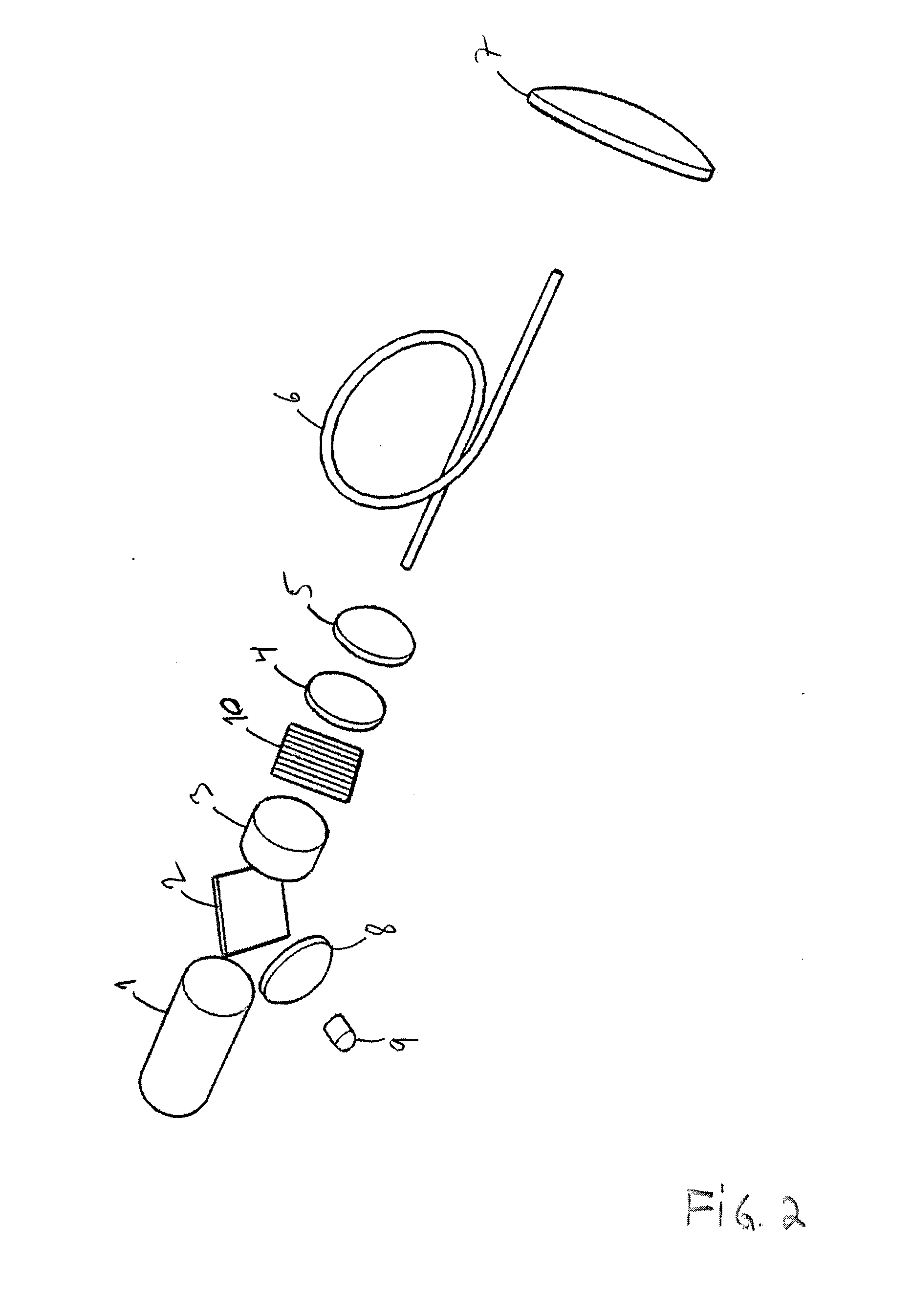

Multiple Directional LIDAR System

ActiveUS20150055115A1Improve performanceIncrease capacityOptical rangefindersElectromagnetic wave reradiationBeam steeringBeam splitter

The present invention relates to a low-cost LIDAR system. The system may be integrated in a wind turbine for measurement of the approaching wind field. One embodiment relates to a LIDAR system comprising a beam generating section adapted for generating a substantially linearly polarized output beam, and a beam steering section comprising a first optical device for controllably altering the polarization of the output beam, said first optical device in optical connection with a first polarizing beam splitter, said beam steering section adapted for directing the outputbeam interchangeably between a first direction and a second direction.

Owner:WINDAR PHOTONICS

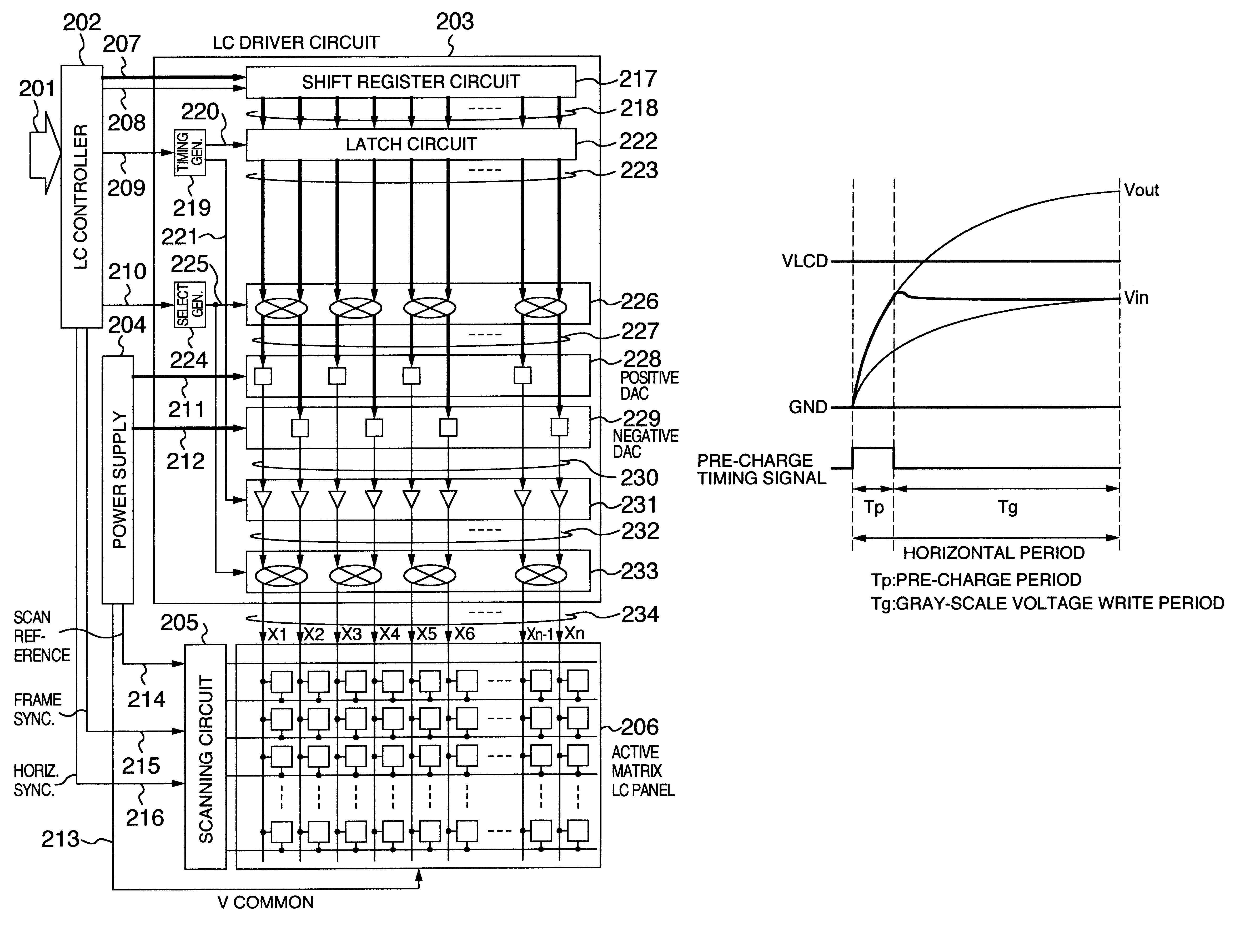

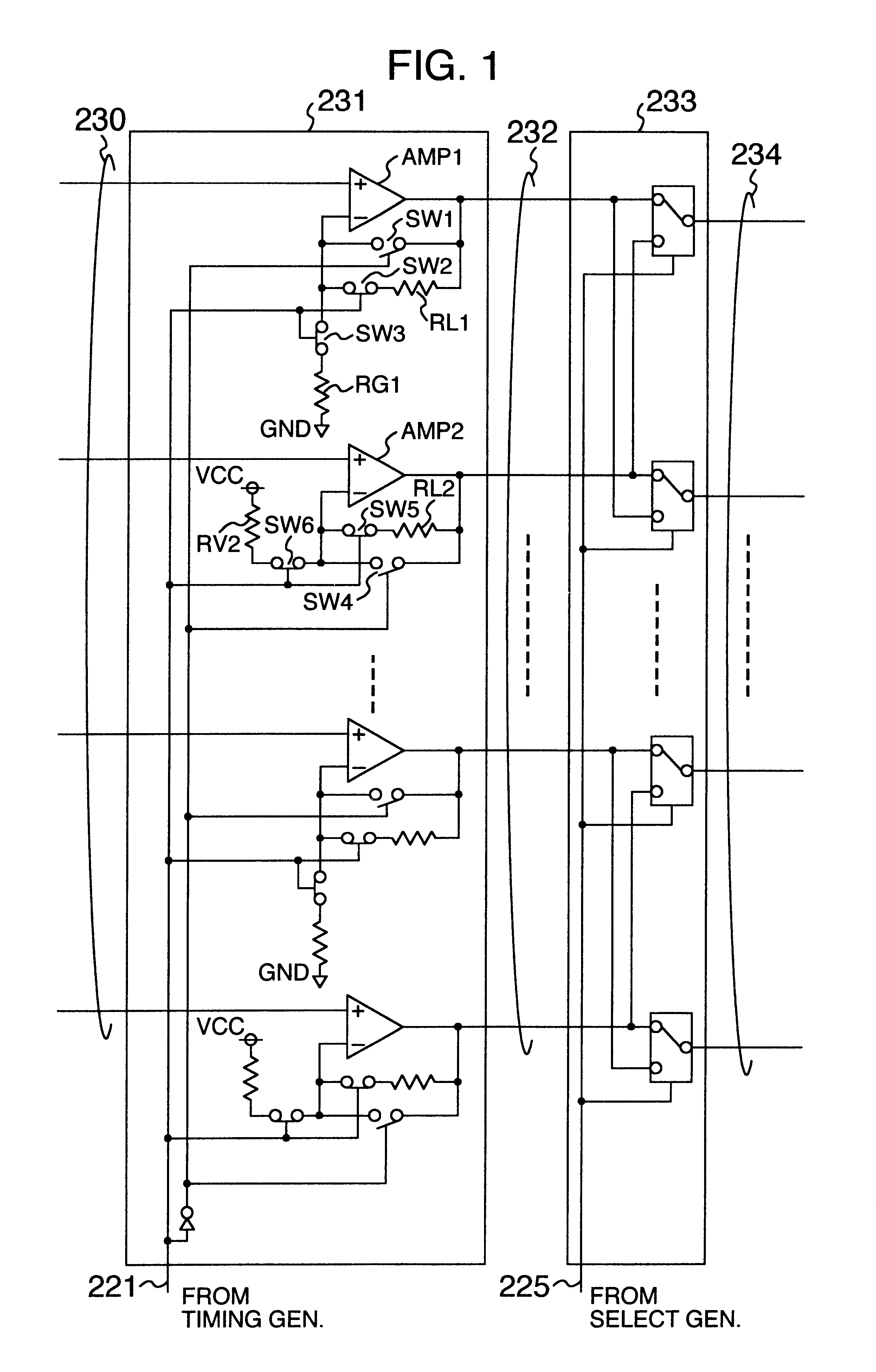

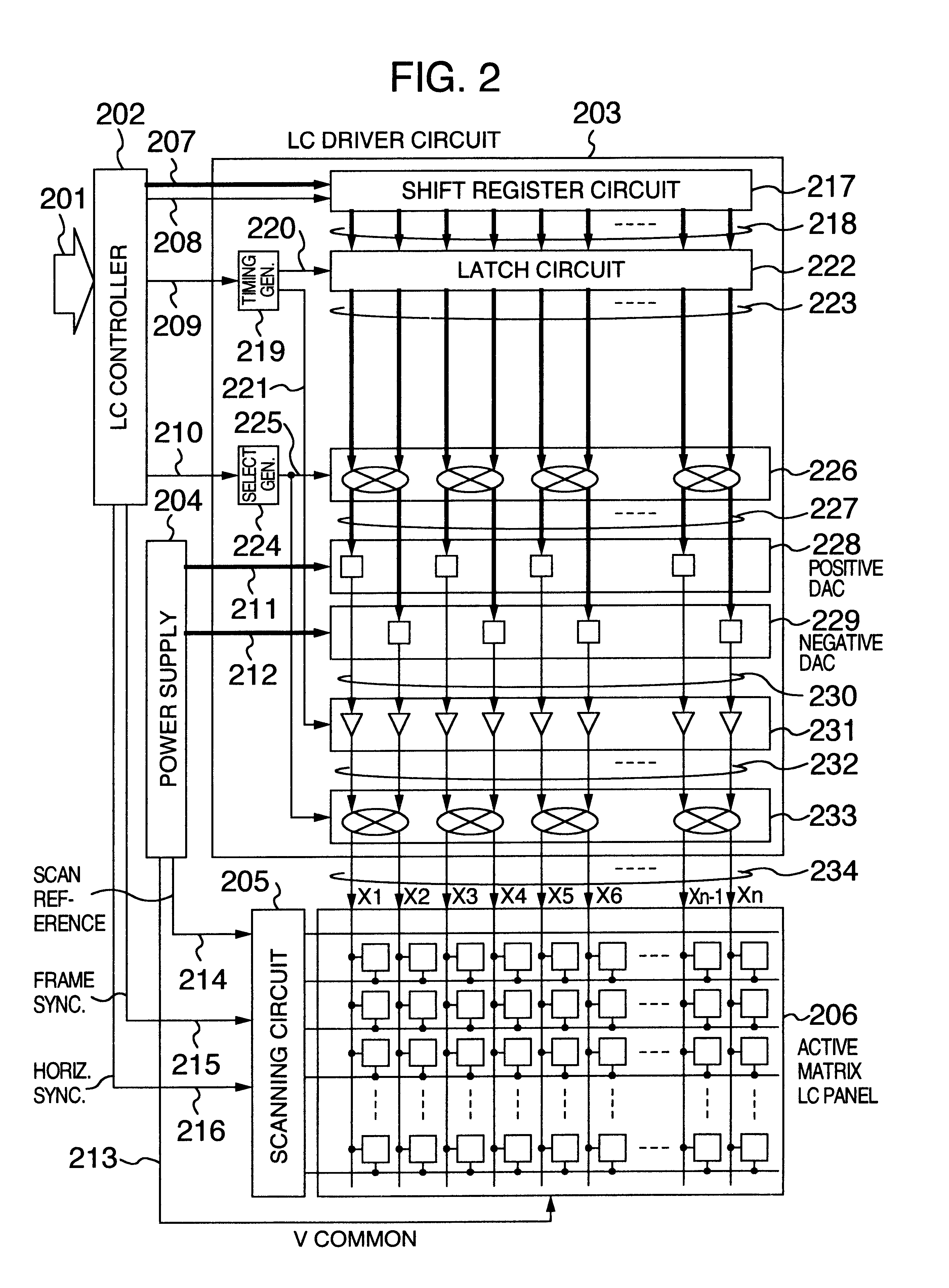

Liquid crystal driver circuit and LCD having fast data write capability

InactiveUS6661402B1Shorten charging timeReduce loadStatic indicating devicesDriver circuitAudio power amplifier

A fast-write, high picture-quality LCD (Liquid Crystal Display) compatible with a high-resolution, large-sized liquid crystal panel. An output amplifier circuit of a liquid crystal driver circuit includes an amplifier configuration, which functions as an amplifier that amplifies the predetermined gray-scale voltage for output and as an amplifier that buffers the predetermined gray-scale voltage and outputs with no amplification, and a circuit for switching the above two types of amplifiers. In each horizontal period, a liquid crystal panel is driven by the amplified output for a predetermined period and by the buffered output for the rest of the period. A pre-charge control circuit is provided to check whether the gray-scale voltage is to be amplified depending upon display data.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

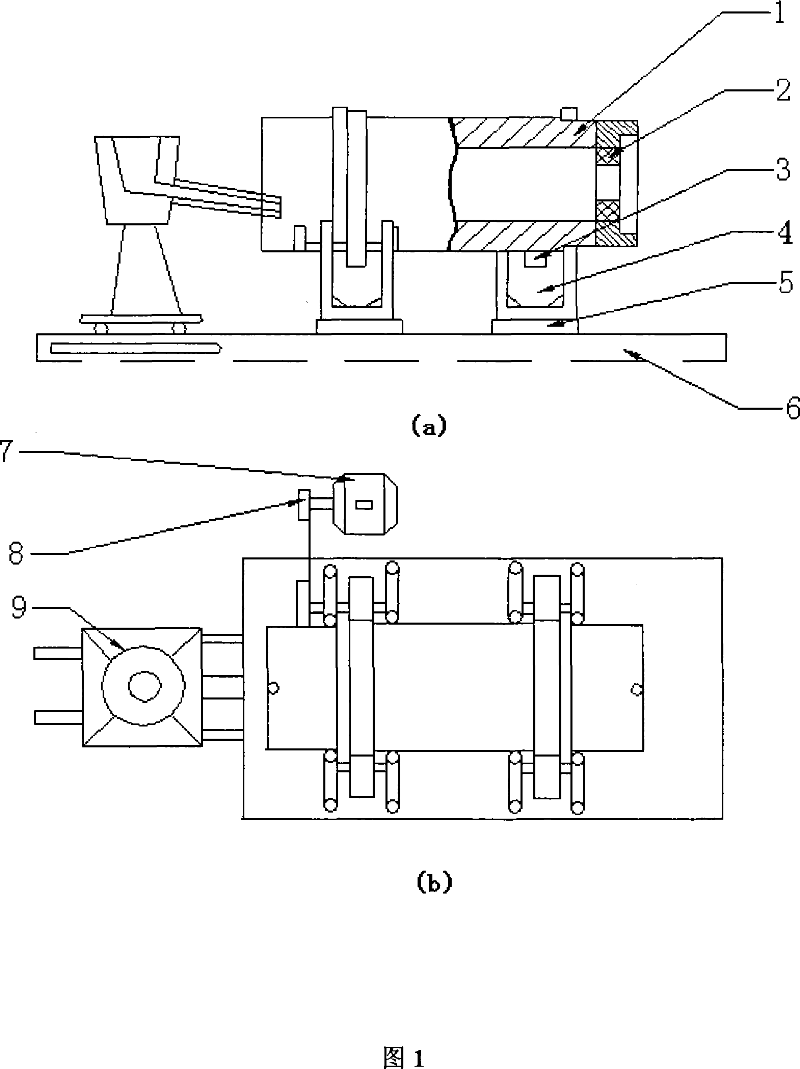

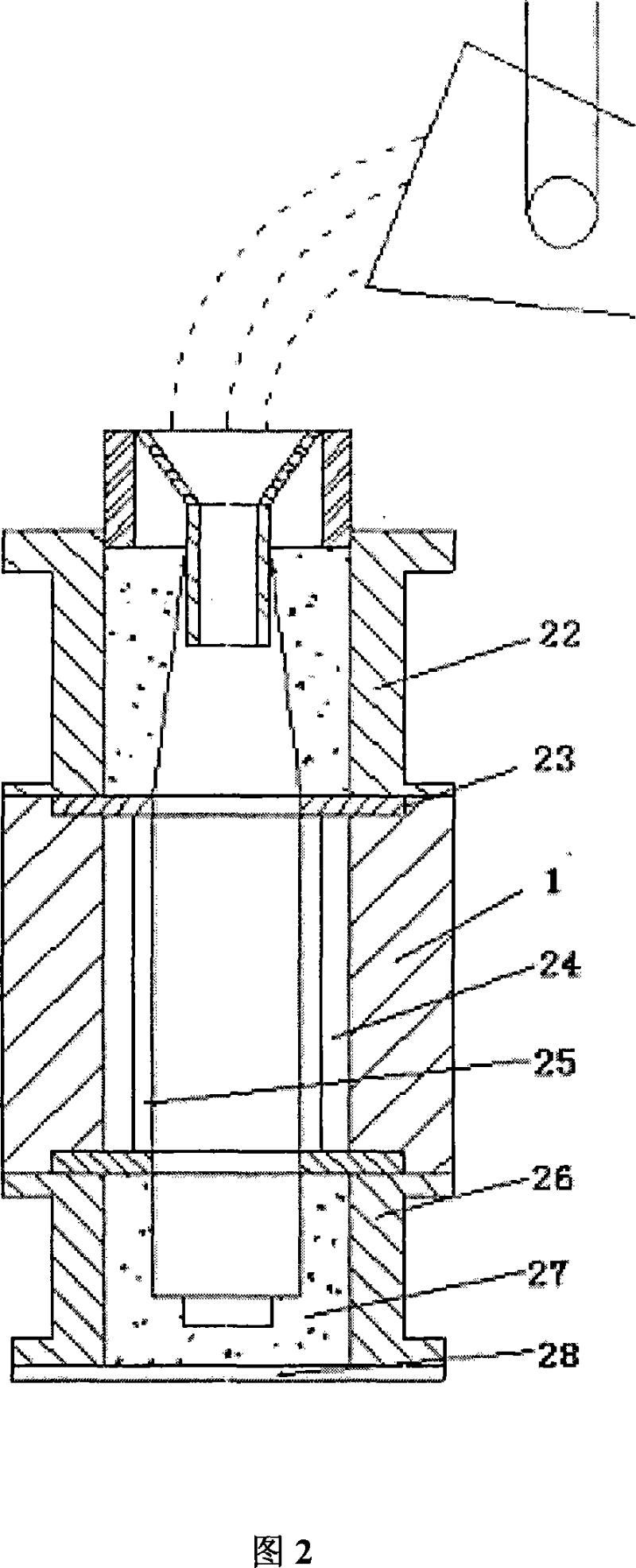

Low-aliquation high-speed steel roll and the preparing method

The invention discloses a low segregation centrifugal casting high speed steel roll and the method. The roll is constituted by high speed steel roll body and alloy ductile ion roll core. The roll is produced by electric furnace. The high speed steel roll body is cast on horizontal centrifuge. As the liquid steel is cast iron powder suspension concentrate with 4%-6% by weight of liquid steel is added. After the liquid steel is cast glass waste sludge is added and then it is cooled by spraying water to form the model. Meanwhile the rotate speed of casting model is changed continuously and finally the ductile ion roll core is cast at the top statically. There is no obvious element segregation in radial section of high speed steel roll manufactured in invention. The macro hardness of roll is high and can achieve 63-65HRC. The difference of roll face hardness is less than 2HRC. The hardness fall of roll along the radial direction is small. The tensile strength of roll body is more than 600MPa and the elongation of roll core is more than 3%. The service life is improved by 5-8 times than high chromium cast iron roll and is improved by 35%-48% than common high speed steel roll. It can decrease the producing cost of rolling steel and prolong roll changing period.

Owner:XI AN JIAOTONG UNIV

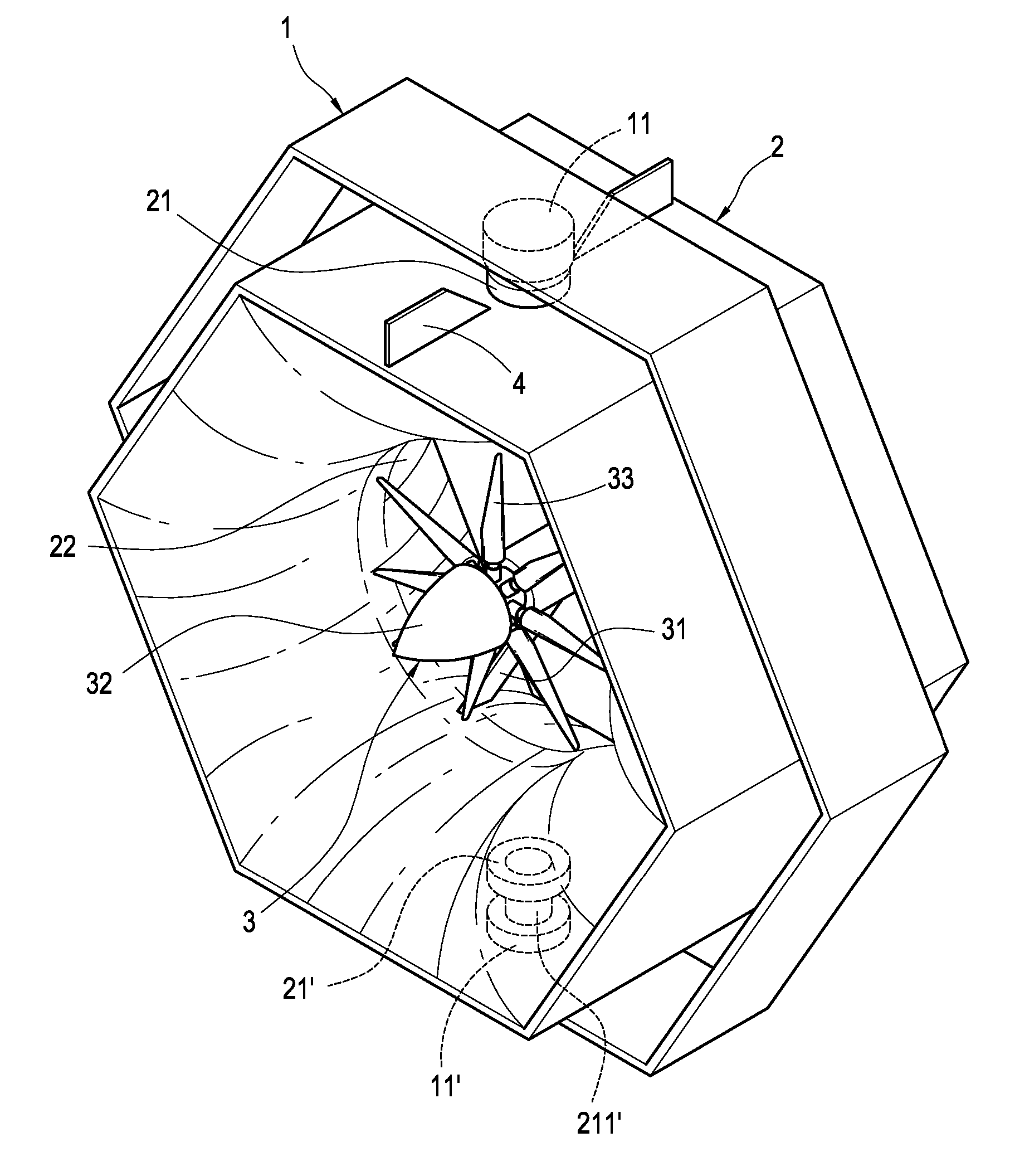

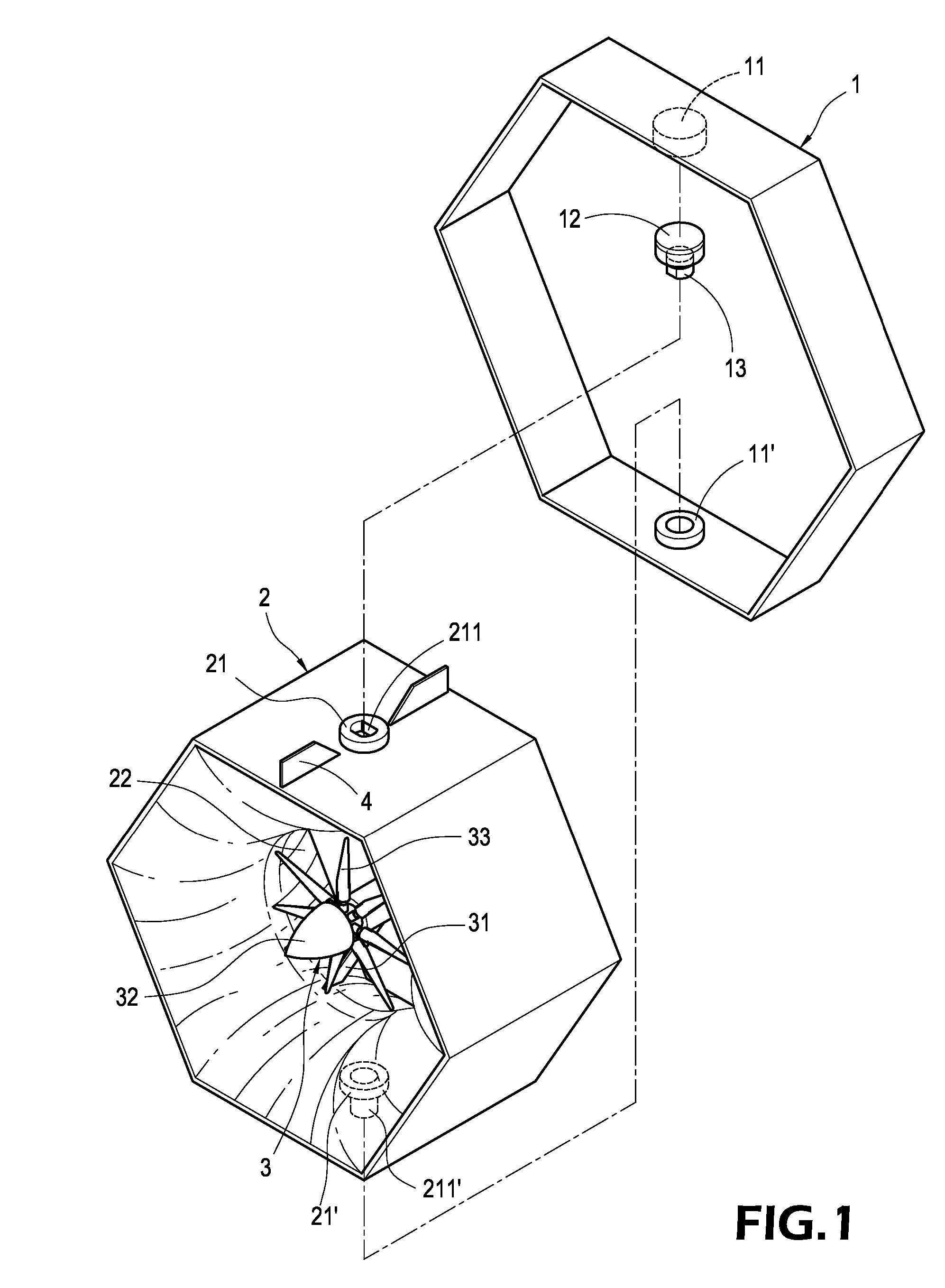

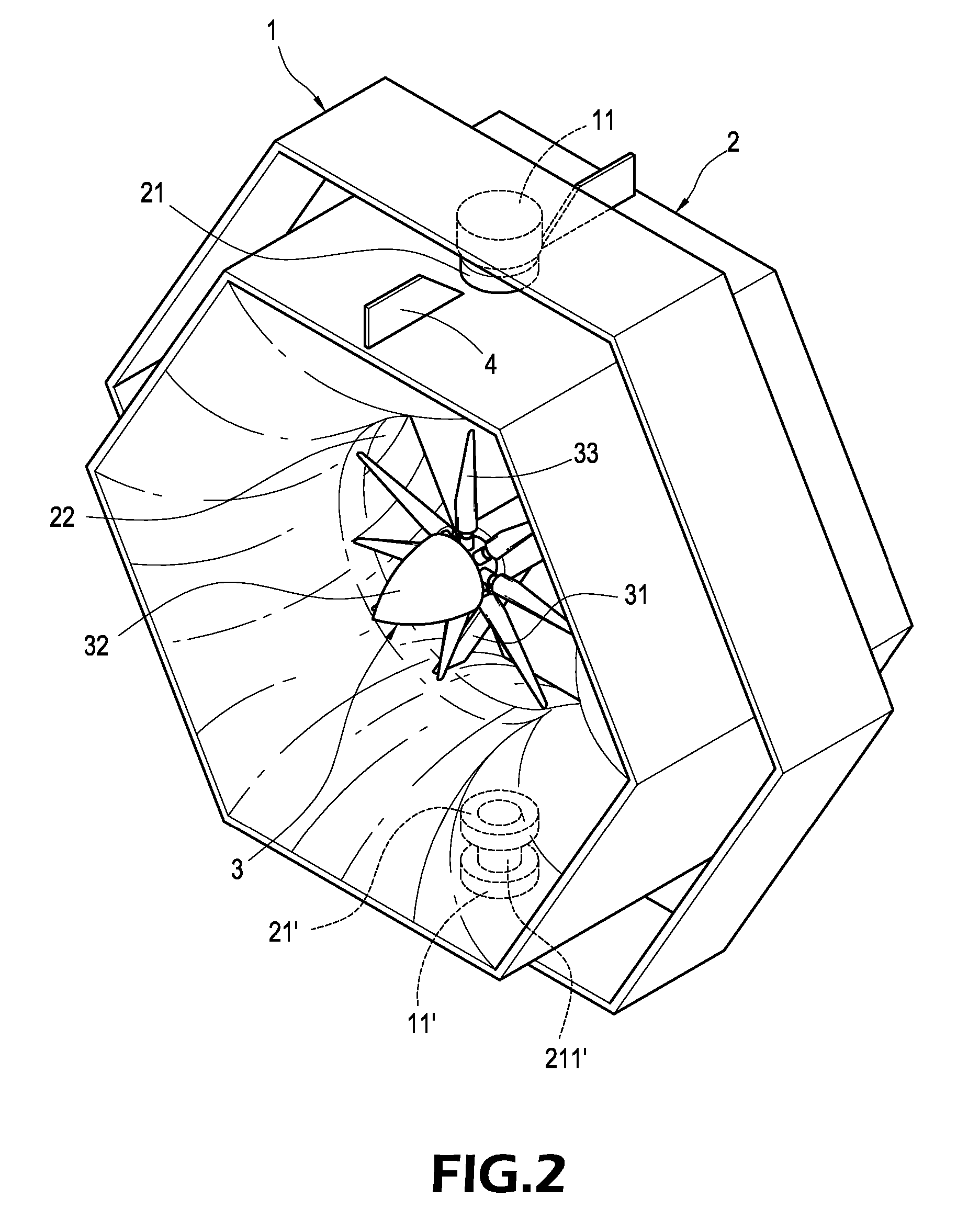

Wind Guiding Hood Structure For Wind Power Generation

A wind guiding hood for wind power generation includes a frame, a wind guiding hood, a turbine and a wind direction detector. The turbine is installed in the wind guiding hood, and the wind guiding hood is pivotally connected into the frame. After the wind direction detector installed on the wind guiding hood detects a change in wind direction, a correct wind direction signal is transmitted to an actuator installed on the frame to drive the actuator to control the turning direction of the wind guiding hood and adjust the wind surface, so that the wind guiding hood can obtain a larger wind load for the turbine to generate electric power.

Owner:JETPRO TECH

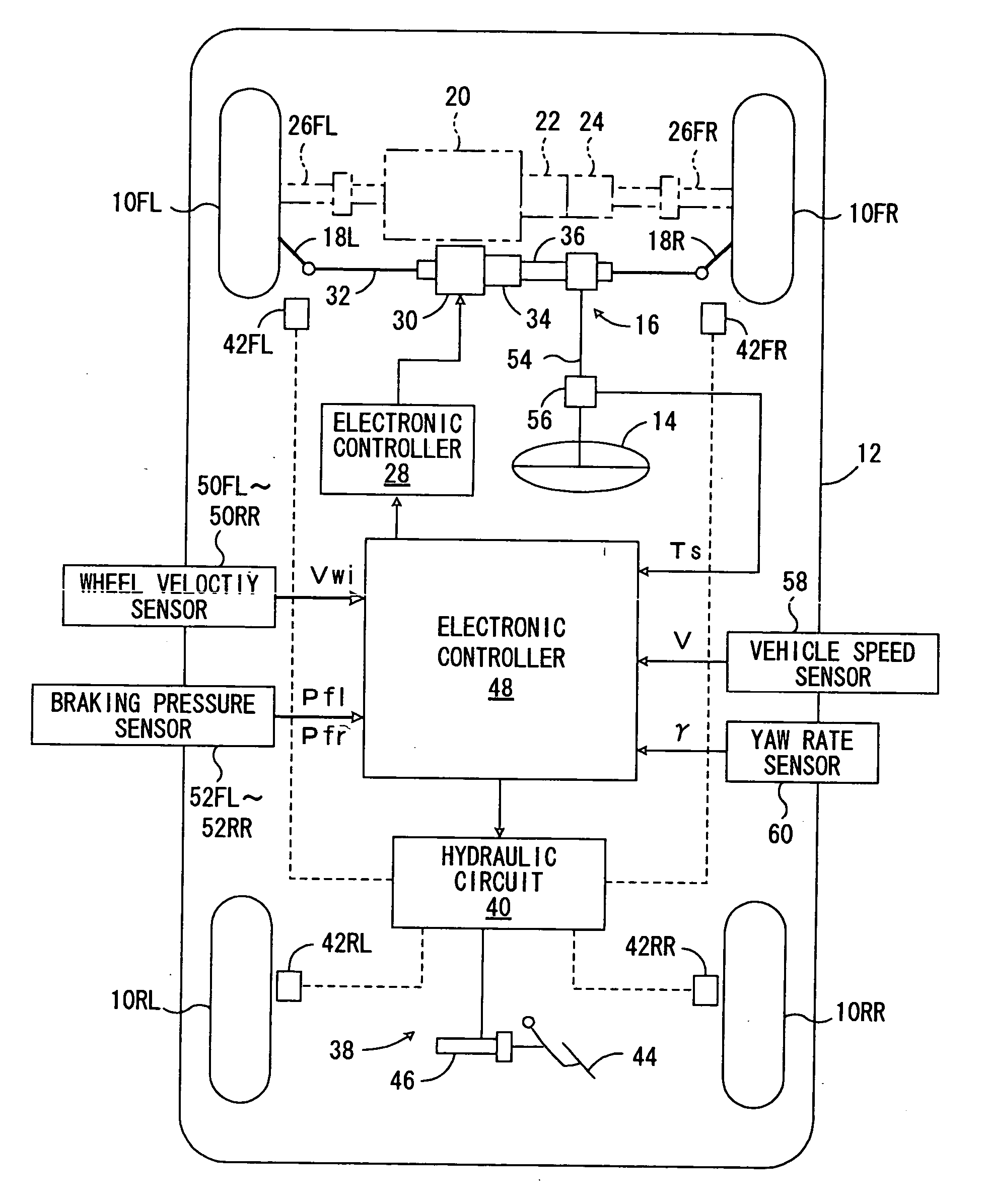

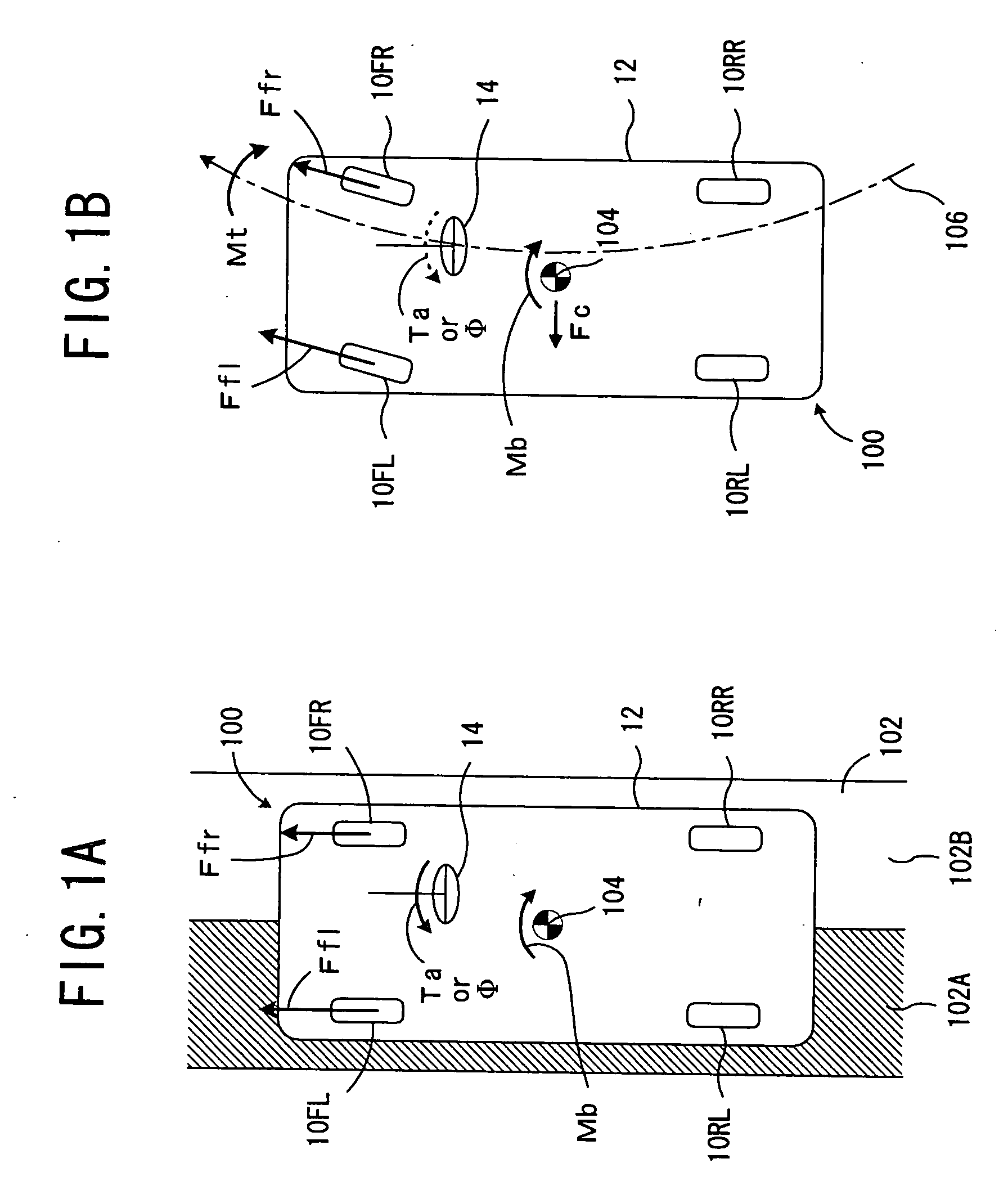

Vehicle steering control device

InactiveUS20040099469A1Restricting undesirableRestricting unexpected modificationHand manipulated computer devicesBrake system interactionsSteering angleFrictional coefficient

A new and novel device for controlling a steering characteristic of a vehicle such as automobile so as to enhance an effect of suppressing a change in a behavior of the vehicle body due to a difference between driving and braking forces on the left and right wheels is characterized in that the device makes an amount of controlling the steering characteristic smaller as an index indicating an amount of a shift of vertical loads between the left and right wheels is increased. The steering characteristic is modified through controlling steering assist torque or a steering angle of the steered wheels. The steering assist by the steering control device is fully effective when the vehicle is running on a straight road having surfaces of different frictional coefficients while less effective on a curved road having a uniform frictional surface, preventing undesirable and unexpected modification of the steering characteristic during turning of the vehicle.

Owner:TOYOTA JIDOSHA KK

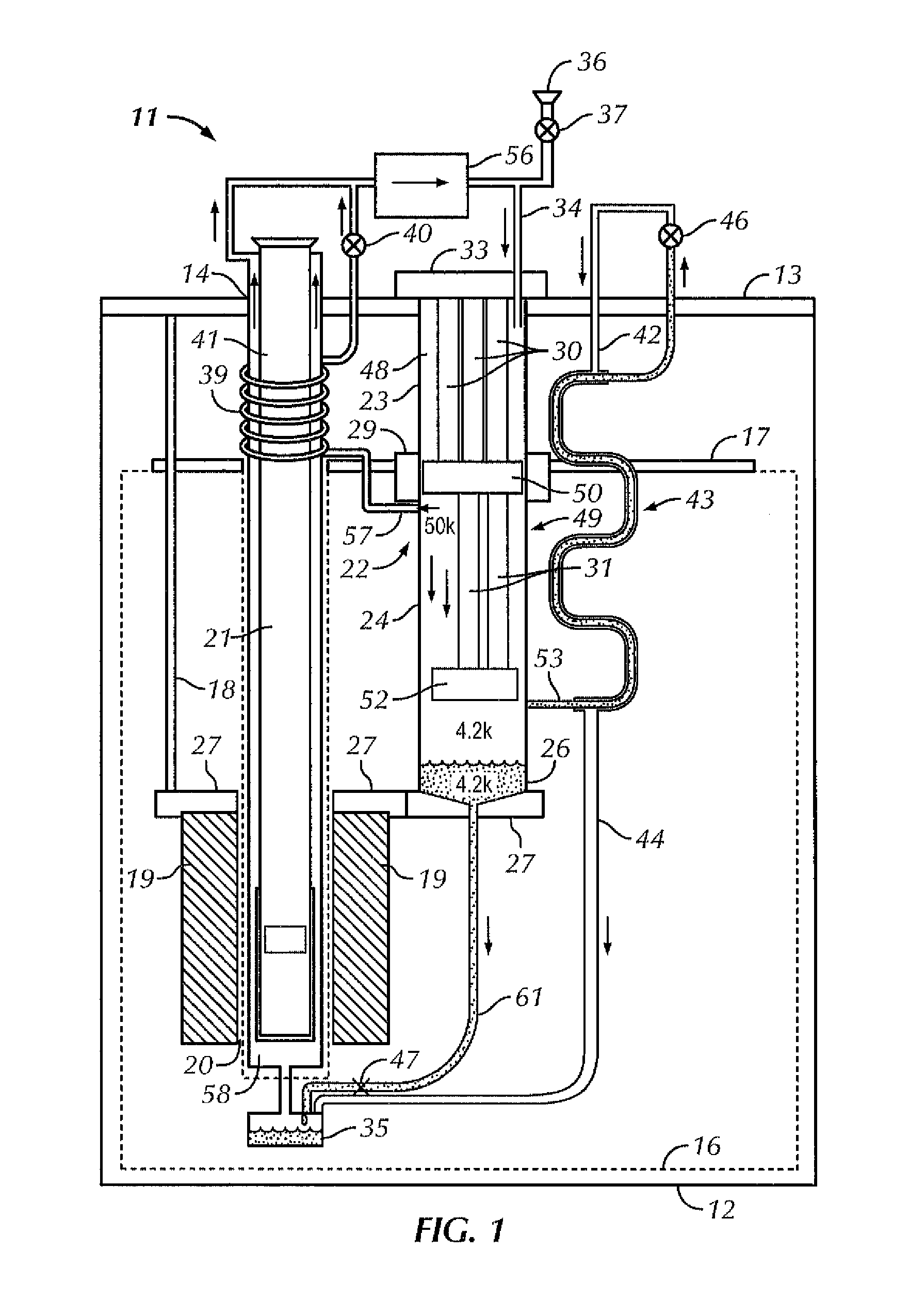

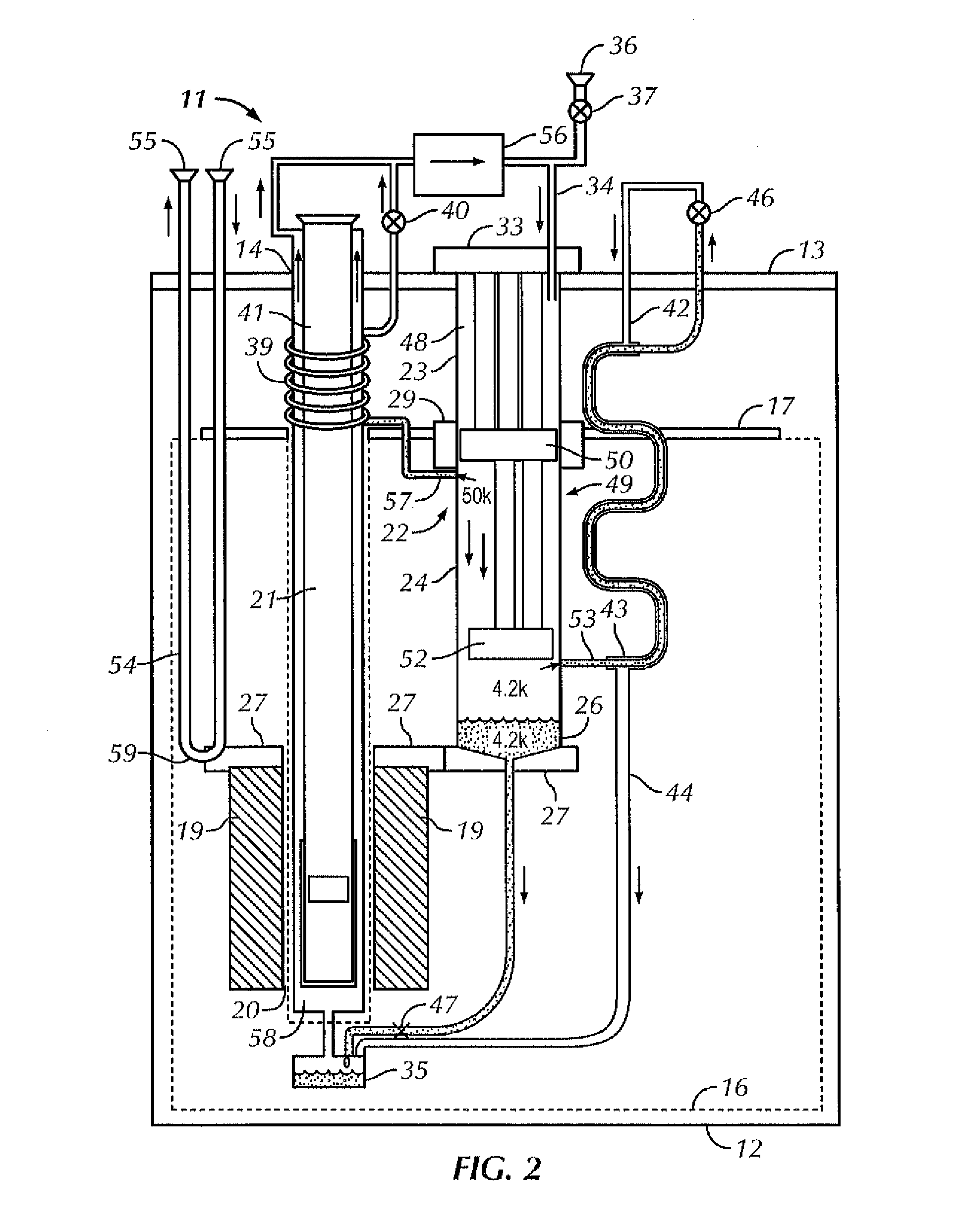

Method and apparatus for controlling temperature in a cryocooled cryostat using static and moving gas

ActiveUS20110219785A1Rapid initial cool-downMinimal, if any, helium replenishmentSolidificationLiquefactionCounter flowTemperature conditioning

A cryostat for providing temperature regulation, one purpose being measuring physical properties of materials, the cryostat employing a superconducting magnet assembly for generating variable magnetic field in the sample space and a cryogenic cooler for cooling the sample space. The cryogenic cooler chamber configuration provides for efficient heat exchange between different stages of the cryogenic cooler without the need for physical heat links. This construction enables selective delivery of cooling power from the cryogenic cooler to the desired areas within the cryostat without using flexible physical thermal links. A counter flow exchanger and ambient temperature valves facilitate efficient use of the cryogenic cooler stages. The removal of large heat load generated by the superconducting magnet while operating in the sweeping mode is achieved, in part, by employing a solid plate thermal coupling element between the cryogenic cooler chamber and the magnet assembly.

Owner:QUANTUM DESIGN

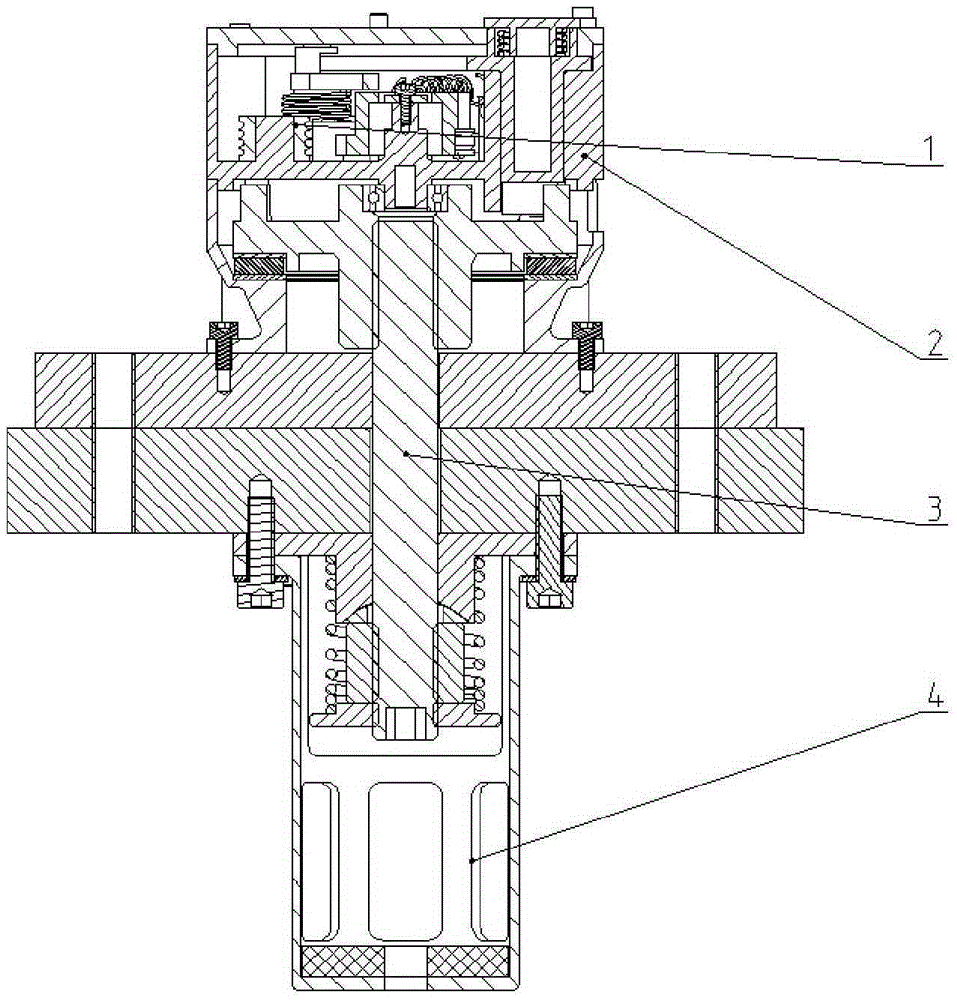

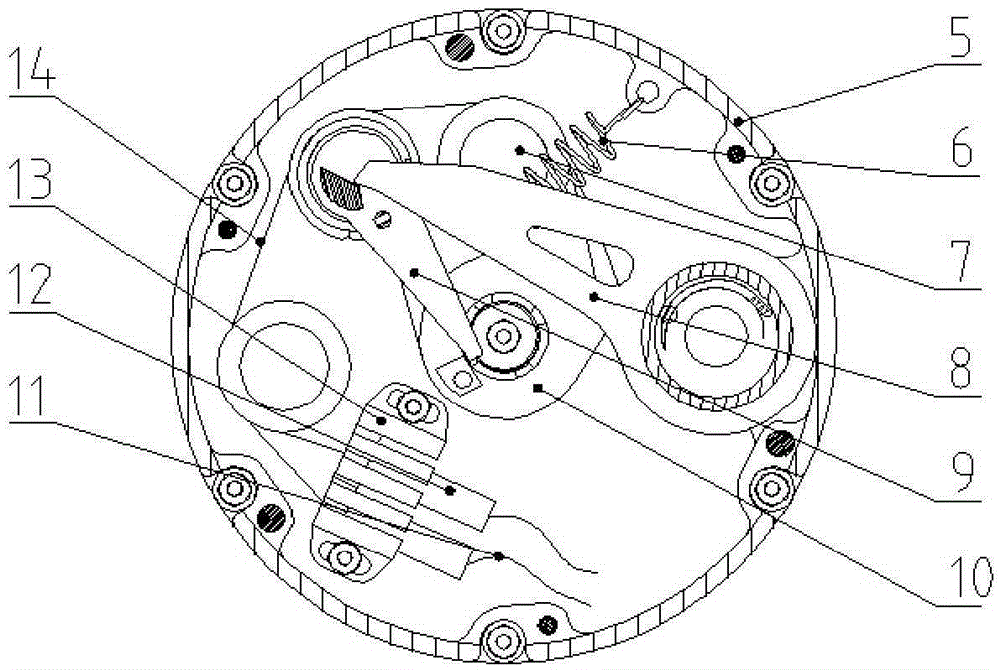

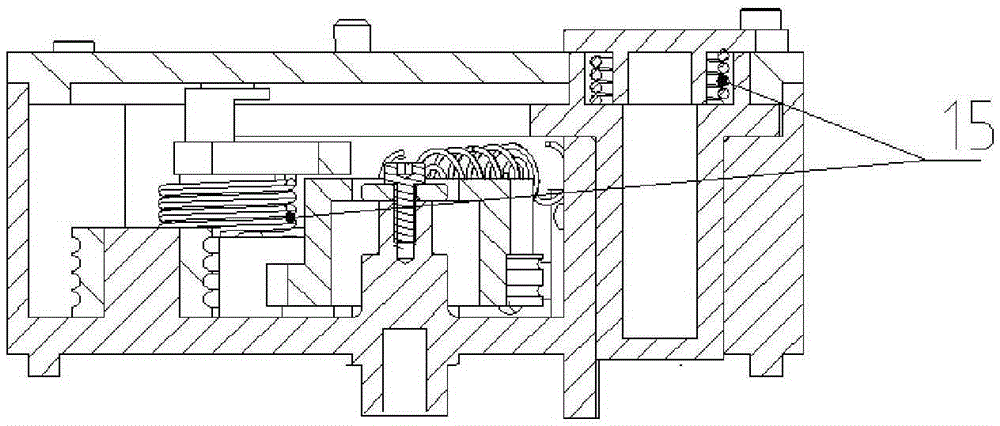

Large-bearing low-impact connecting and separating device based on memory alloy driving

A large-bearing low-impact connecting and separating device based on memory alloy driving comprises a memory alloy driving assembly (1), a deblocking transmission assembly (2), a connecting and separating assembly (3) and a buffering capturing assembly (4), wherein the memory alloy driving assembly (1) can overcome pulling force of a tension spring (6) after being charged with electricity to drive a triggering shaft (10) to rotate, so as to relieve limitation on a primary swinging arm (9); the primary swinging arm (9) rotates to relieve limitation on a secondary swinging arm (8); the secondary swinging arm (8) rotates to relieve limitation on a main force transmission nut (17); the main force transmission nut (17) rotates to enable a bearing rod (22) to conduct linear motion along a center hole of a guide seat (23), so as to realize deblocking separation. The large-bearing low-impact connecting and separating device can realize firm connection and deblocking separation of star arrows as well as stars and load, and has the characteristics of being large in bearing, low in impact, high in reliability and reusable.

Owner:BEIJING SATELLITE MFG FACTORY

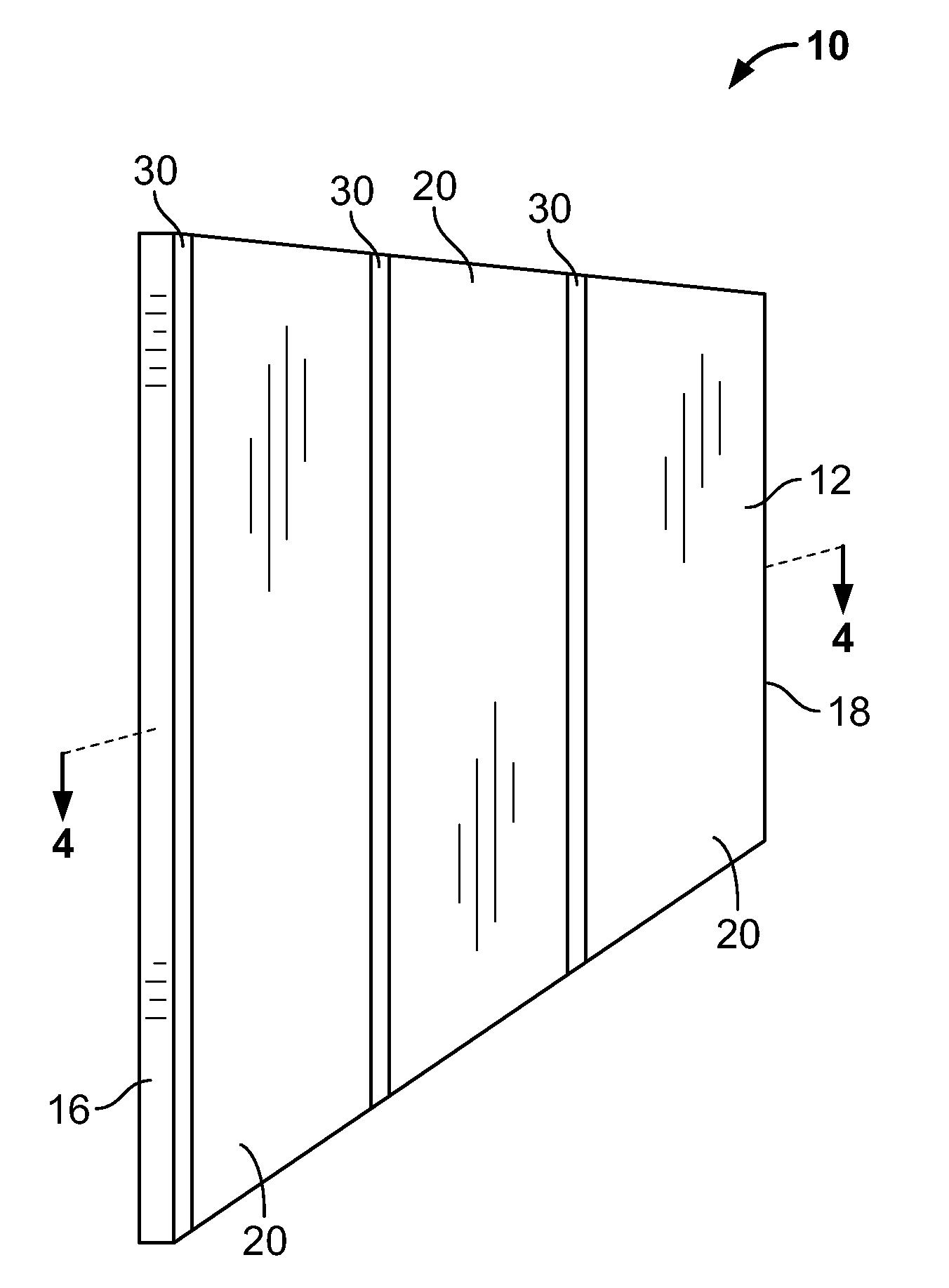

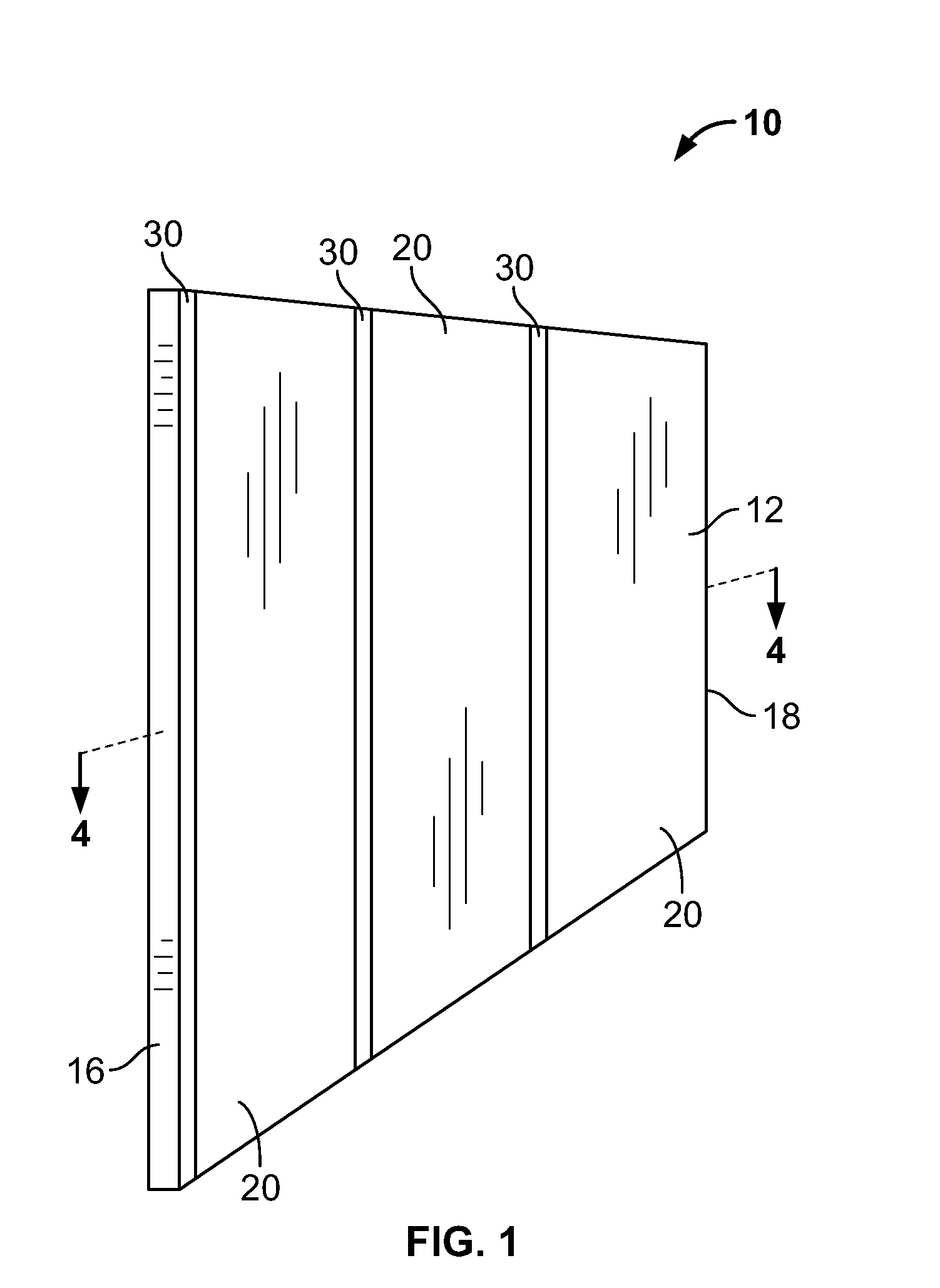

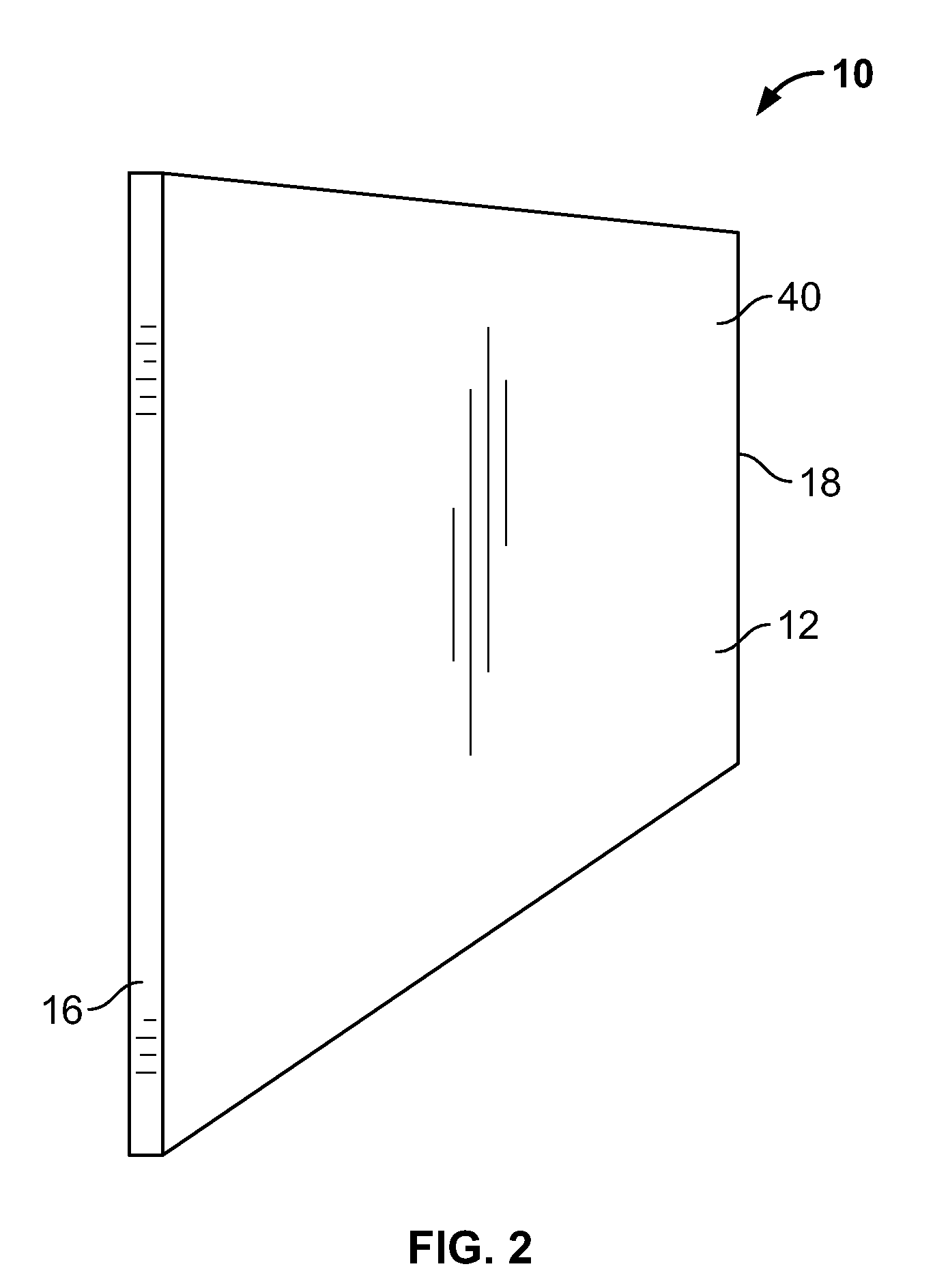

High-strength insulated building panel with internal stud members

InactiveUS20110047908A1Accommodating large shear loadLoad largeConstruction materialWallsHigh intensityStructural integrity

The invention is directed to a building panel which has structural integrity. A plurality of stud members with opposed side surfaces and opposed end surfaces extend from a first face of the panel toward a second face. The plurality of stud members are spaced from each other and extend in a direction which is essentially parallel to each other. A rigid foam fills the volume of the panel which is not filled by the plurality of stud members. The rigid foam is bonded to at least one side surface of each of the plurality of stud members. The bonding of the rigid foam to the plurality of stud members results in a stable and strong panel which is capable of accommodating large shear loads.

Owner:BRUSMAN BRYAN DANIEL +1

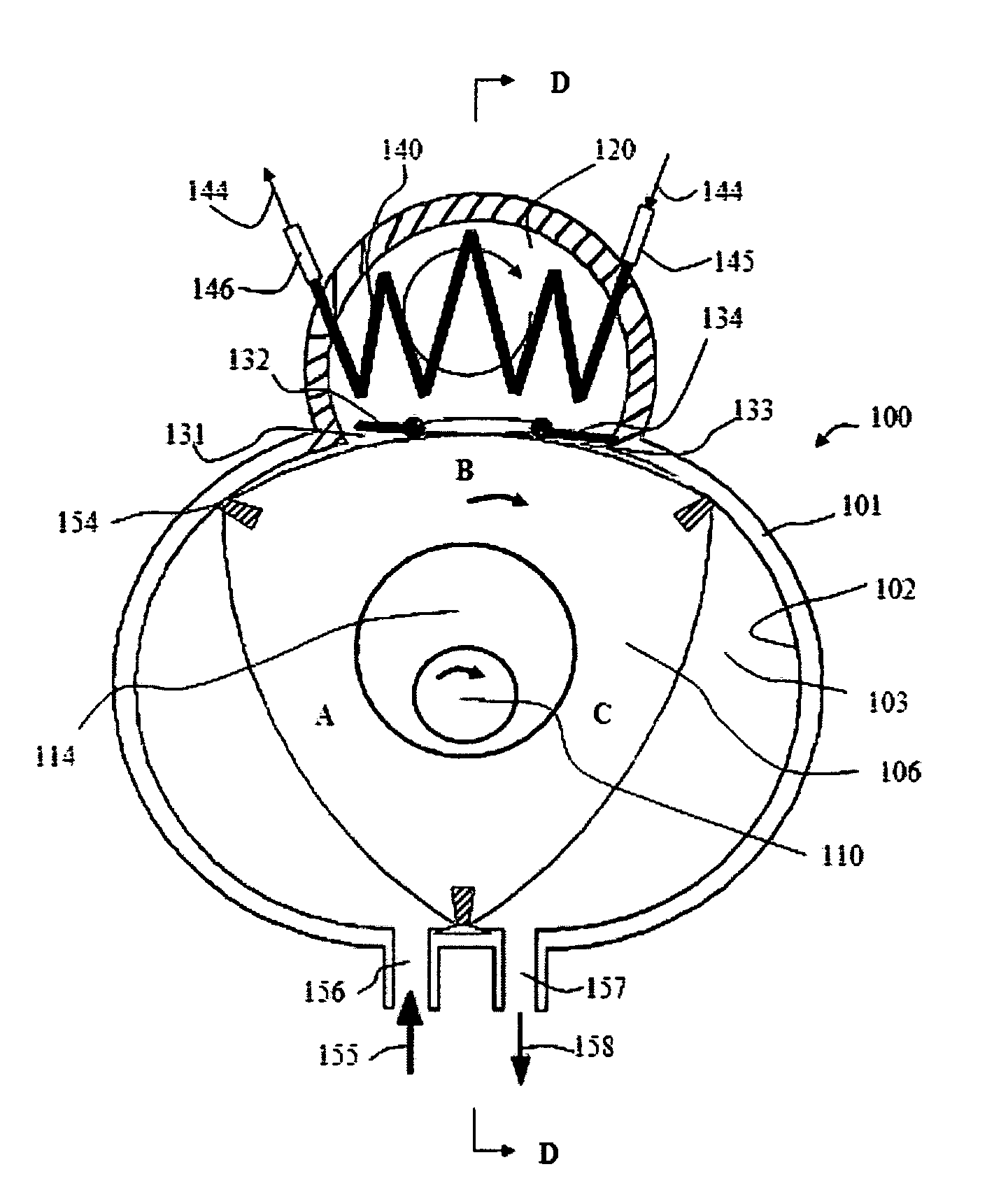

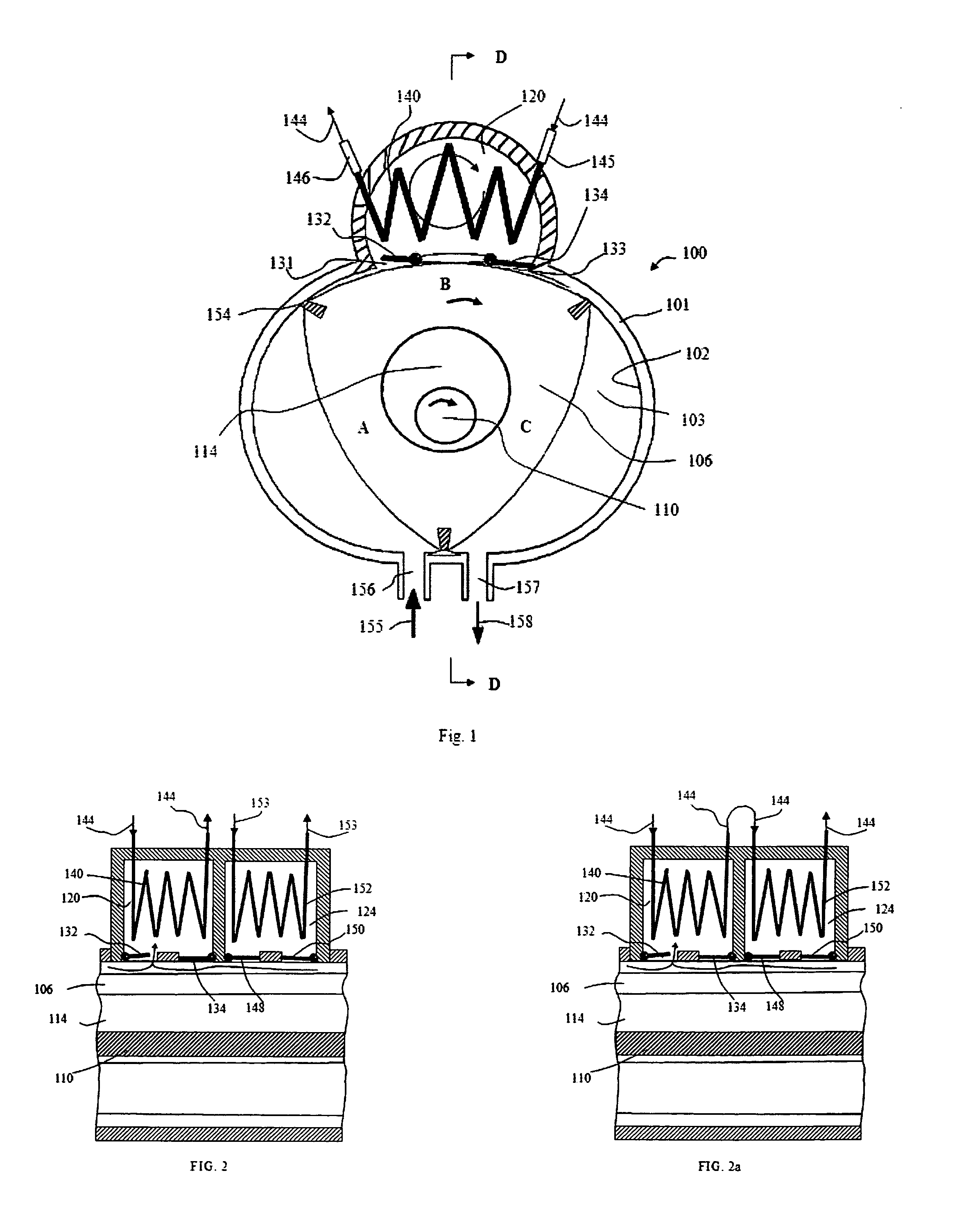

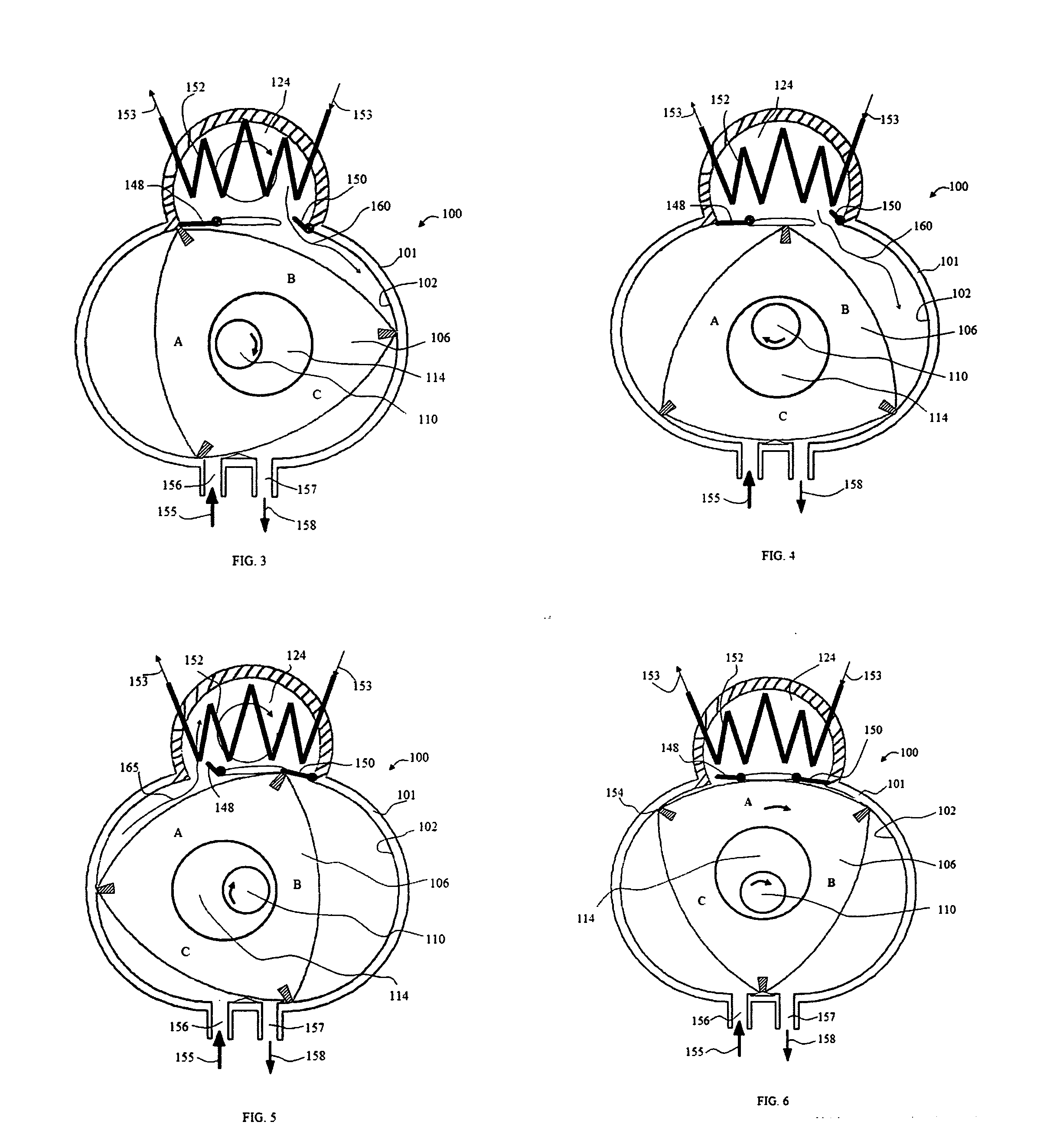

Cao heat engine and refrigerator

InactiveUS20100089062A1Increase the number ofExtended durationAuxillary drivesInternal combustion piston enginesThermal energyAir cycle machine

Owner:CAO YIDING

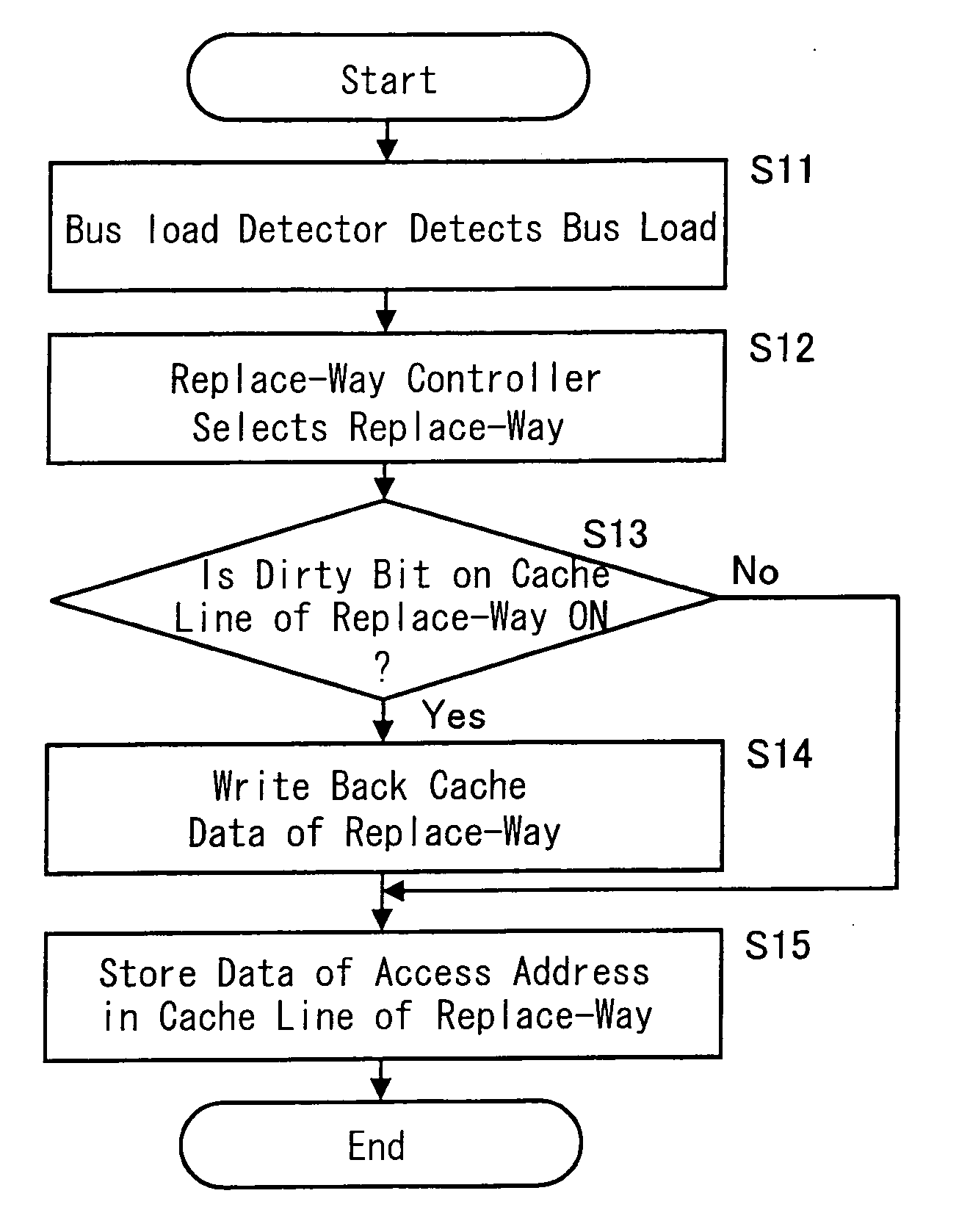

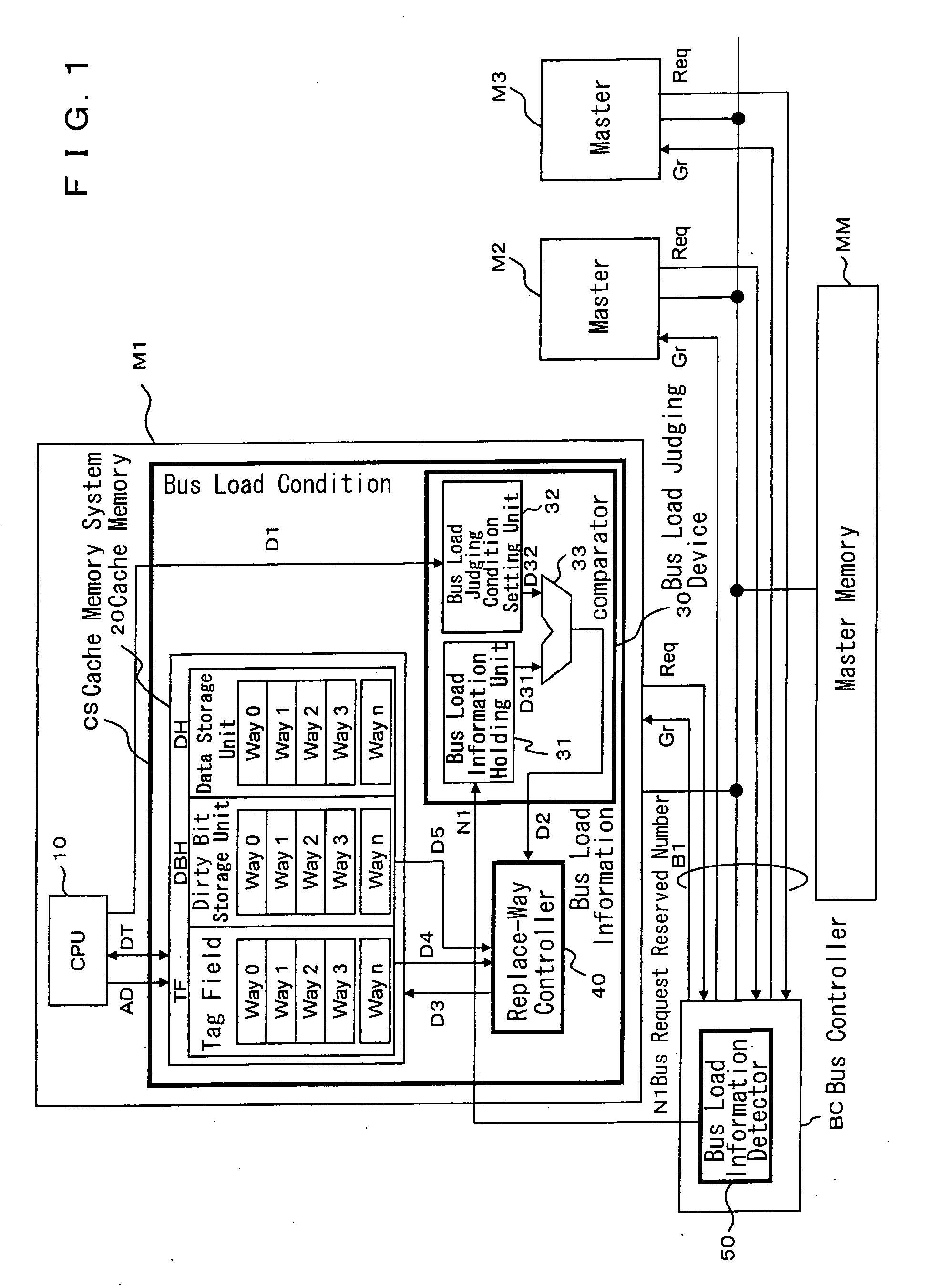

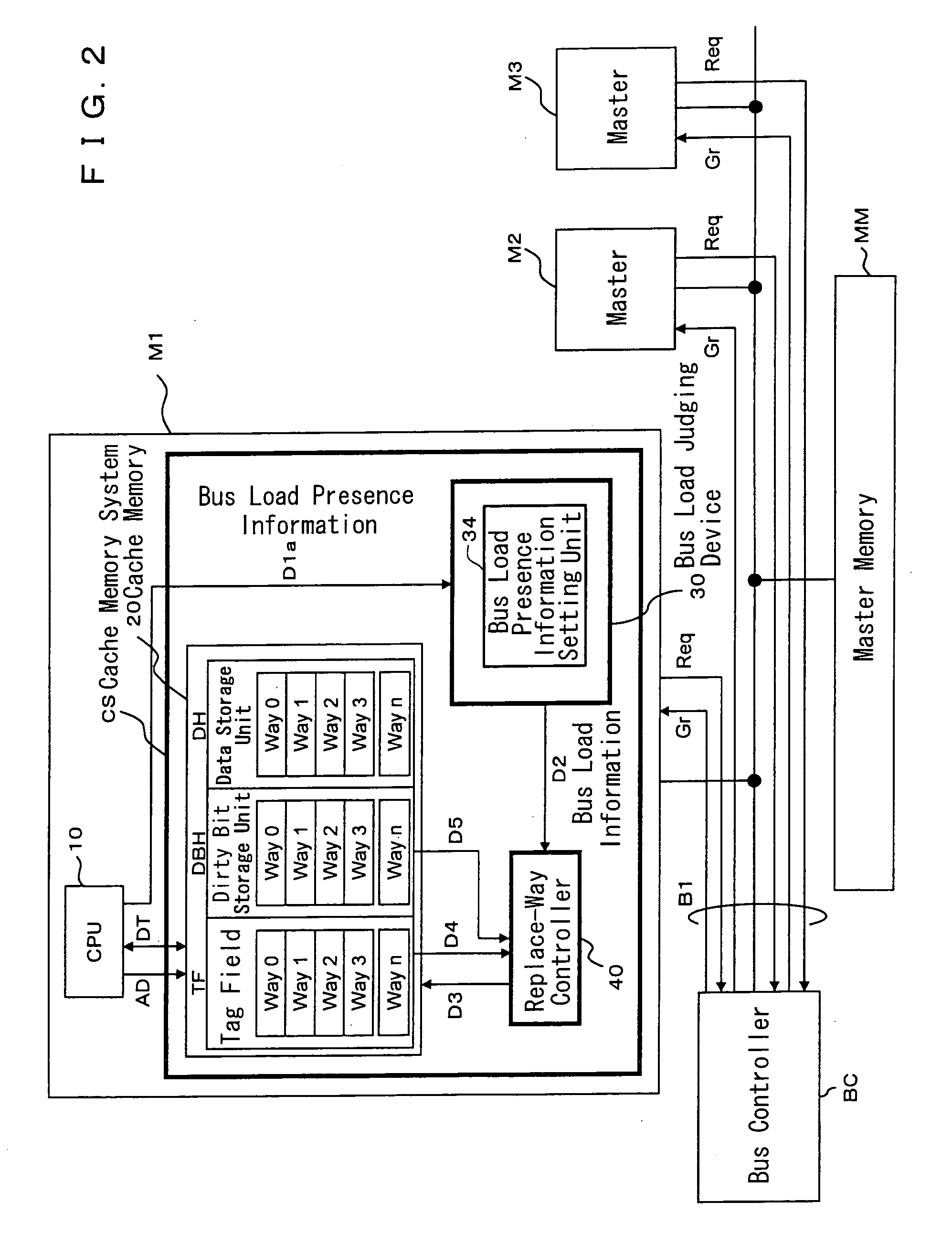

Cache memory system

InactiveUS20060085600A1Load largeBus can be effectively utilizedMemory systemsParallel computingMemory bus

Provided is a cache memory system which, in a system having a plurality of masters, effectively utilizes a bus band. The cache memory system comprises: a cache memory; a bus load judging device for performing judgment of a state of a bus that is connected to a recording device in which cache-target data of the cache memory is stored; and a replace-way controller for controlling a replacing form of the cache memory according to a result of judgment performed by the bus load judging device.

Owner:PANASONIC CORP

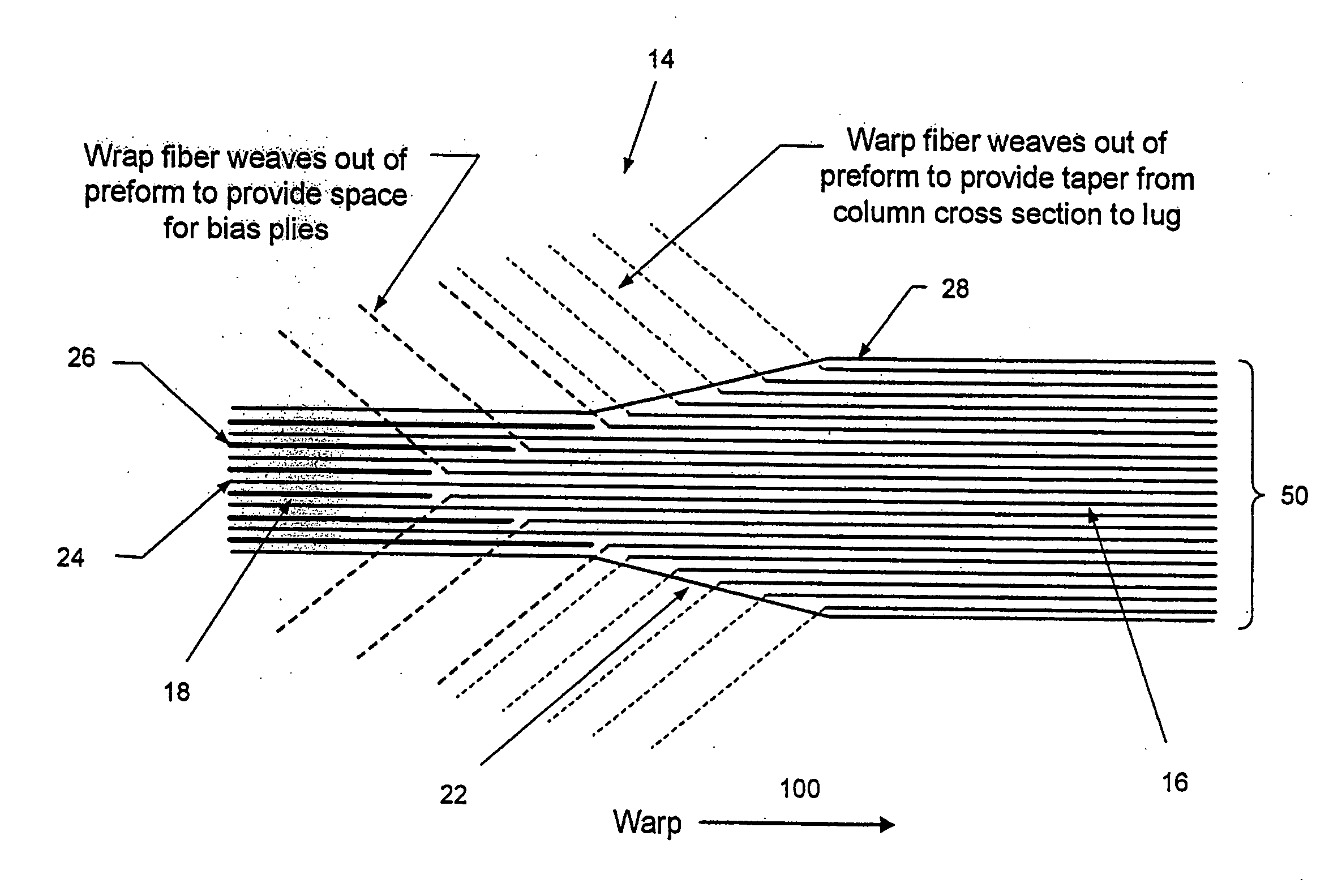

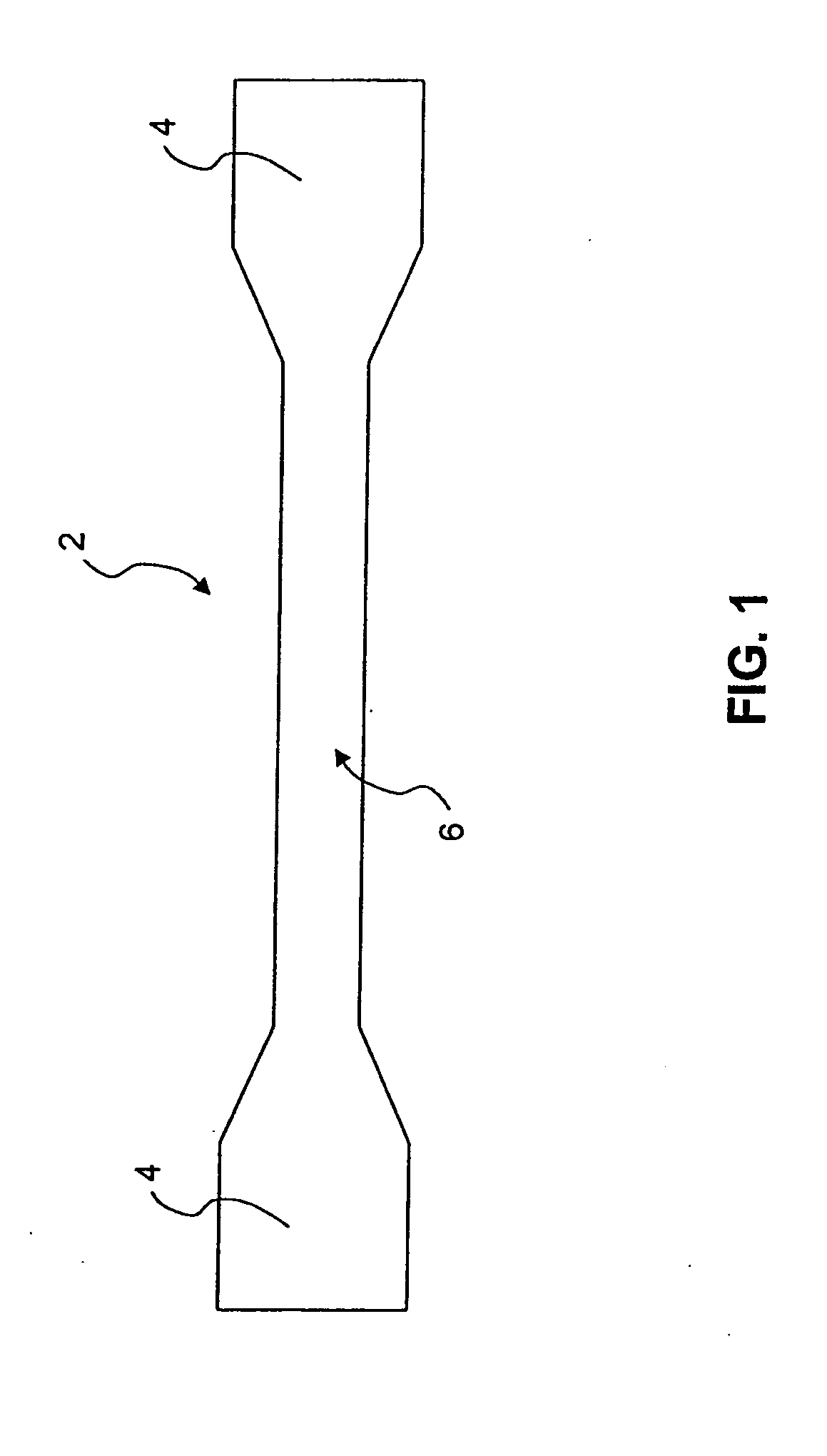

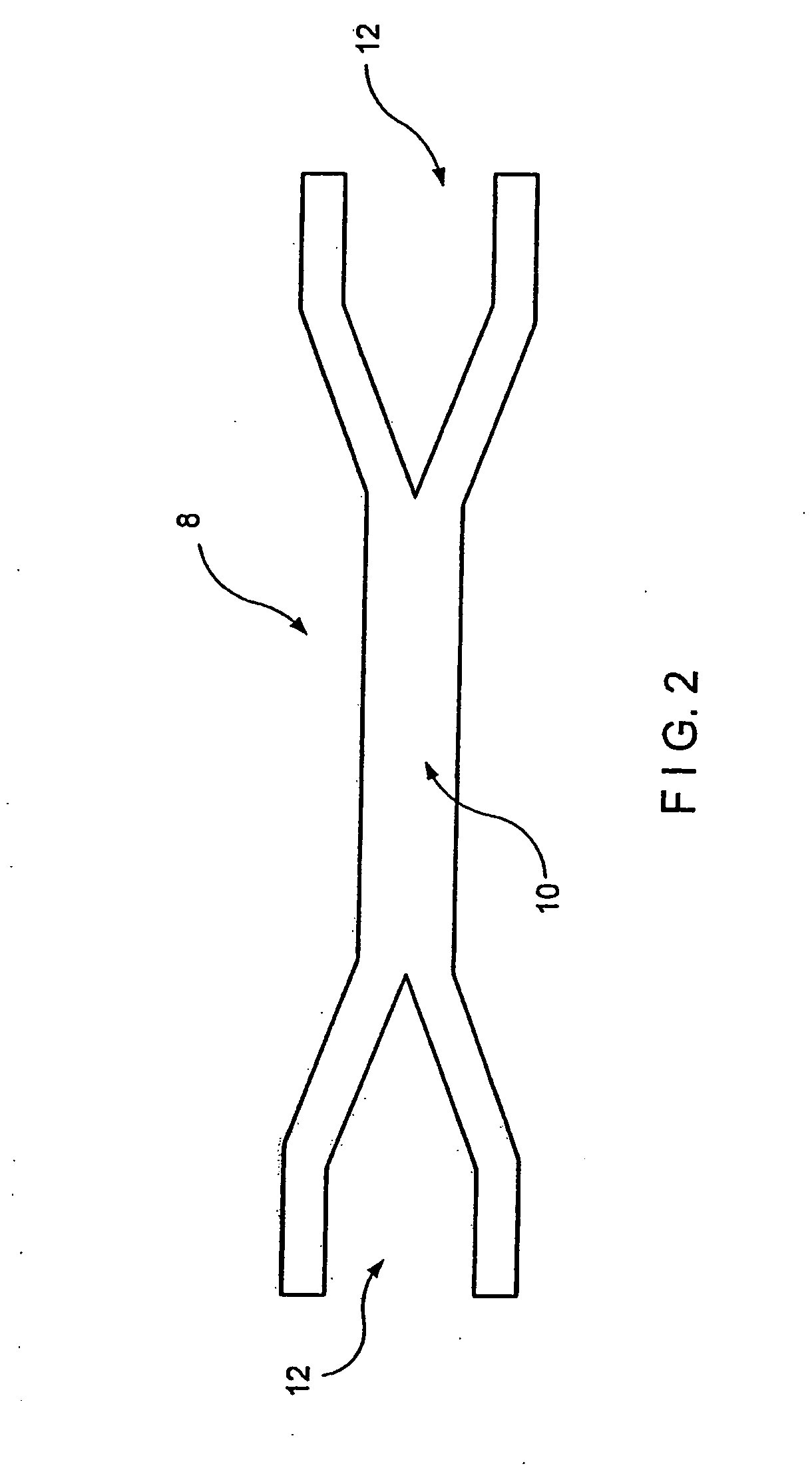

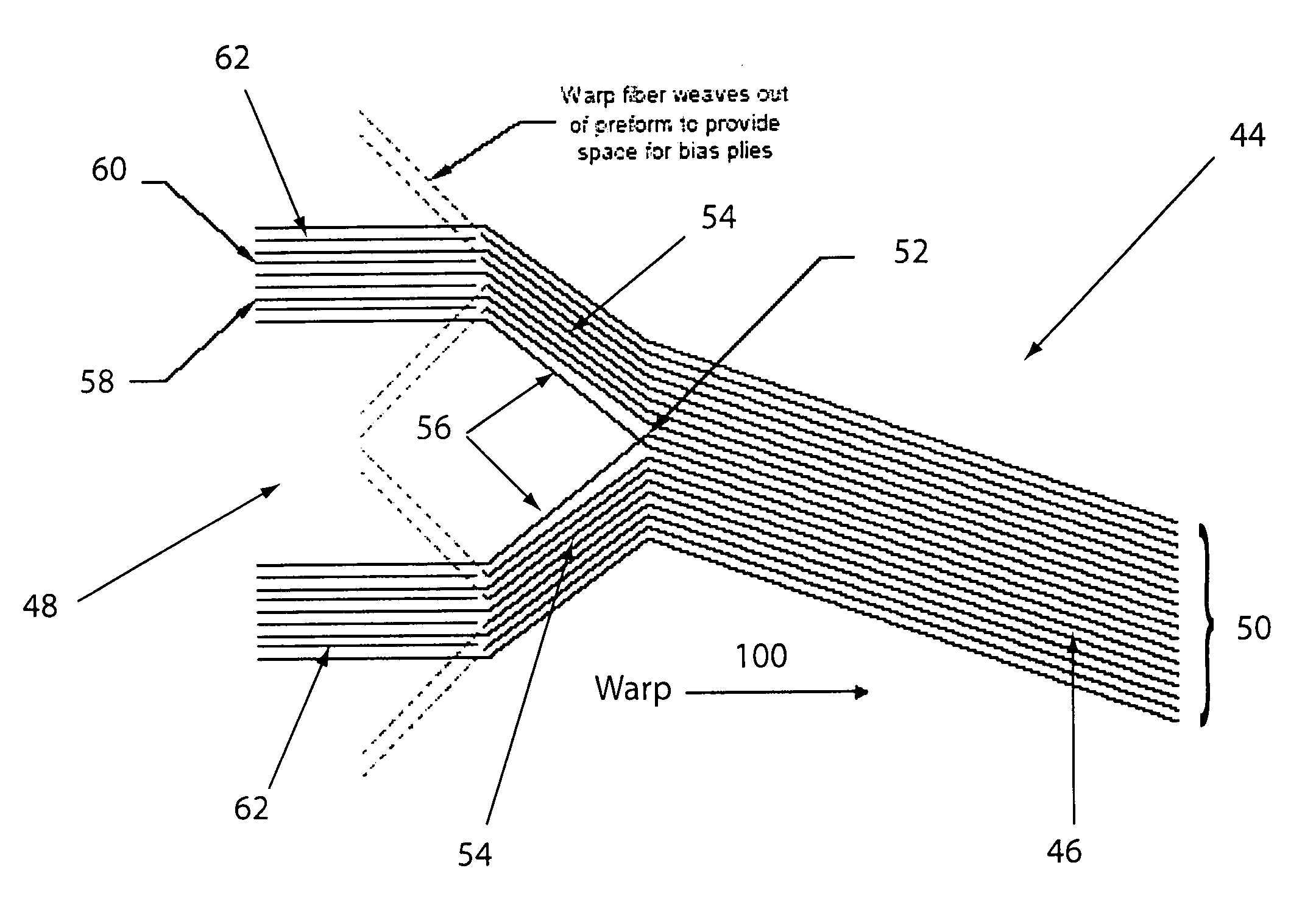

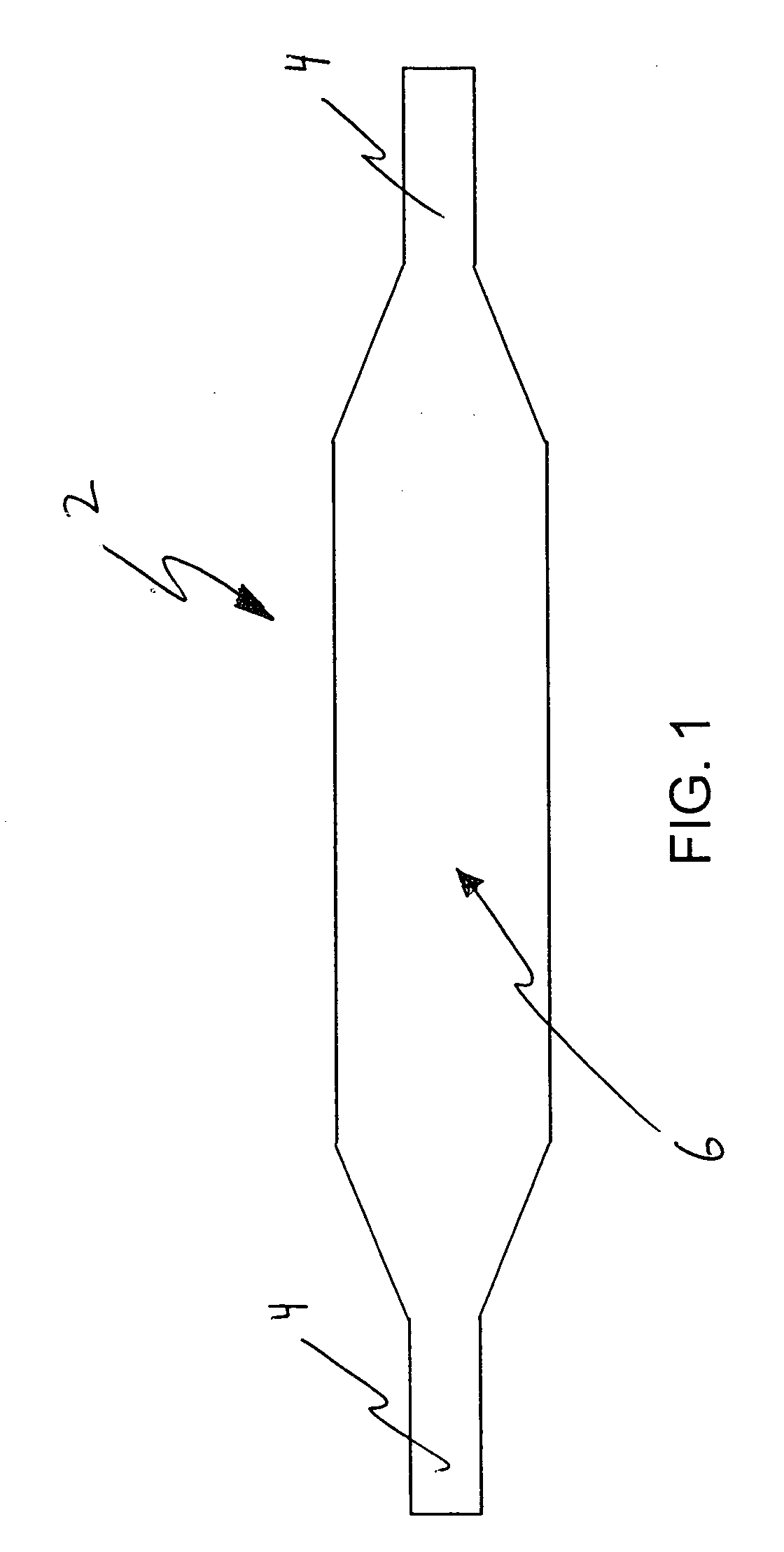

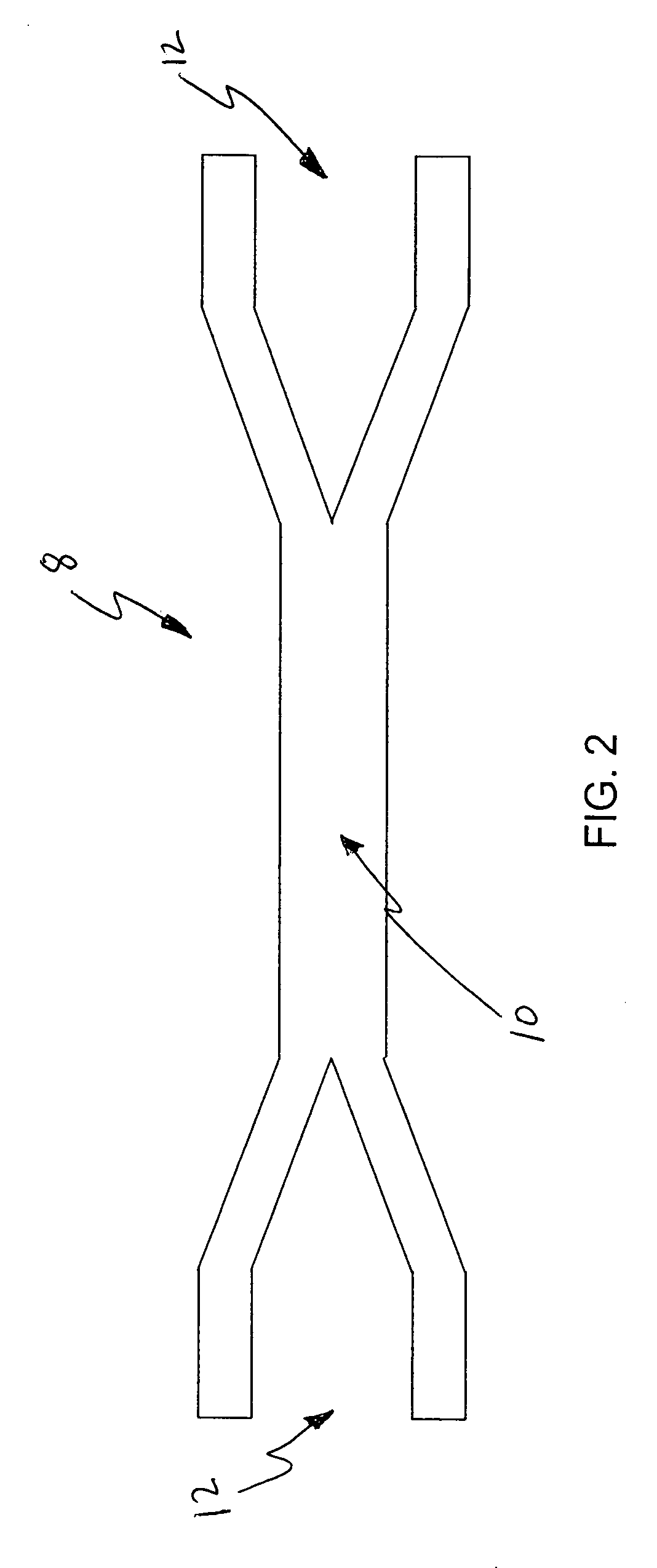

Hybrid Three-Dimensional Woven/Laminated Struts for Composite Structural Applications

ActiveUS20080261474A1High damage toleranceImprove through thickness propertySewing-machine elementsLoomsFiberEngineering

A woven preform used to reinforce a composite structure which includes a central portion having a plurality of interwoven layers. The preform also includes first and second end portions having a plurality of independent woven layers that are integrally woven with the plurality of interwoven layers in the central portion and which extend along the entire length the preform. Interspersed between the plurality of independent woven layers in the first and second end portions are bias plies. The first and second end portions can have through thickness reinforcements comprising reinforcement fibers that traverse through the independent woven layers and the bias plies, locking them together.

Owner:ALBANY ENGINEERED COMPOSITES

Hybrid three-dimensional woven/laminated struts for composite structural applications

ActiveUS20090311462A1Load largeLoomsCellulosic plastic layered productsMechanical engineeringComposite structure

A woven preform used to reinforce a composite structure which includes a central portion having a plurality of interwoven layers. The preform also includes first and second end portions having a plurality of independent woven layers that are integrally woven with the plurality of interwoven layers in the central portion and which extend along the entire length the preform. Interspersed between the plurality of independent woven layers in the first and second end portions are bias plies.

Owner:ALBANY ENGINEERED COMPOSITES

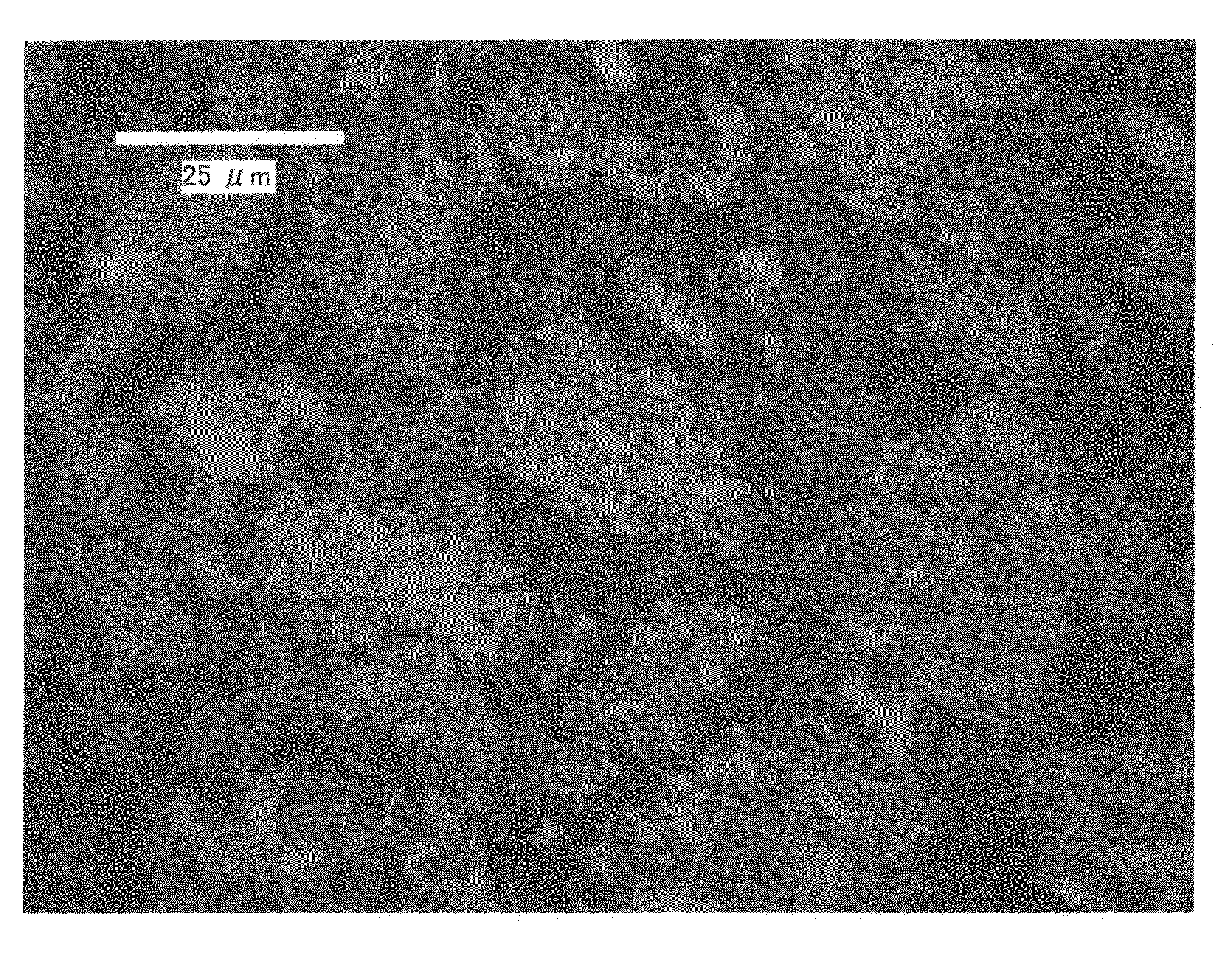

Graphite material, carbonaceous material for battery electrodes, and batteries

InactiveUS8372373B2Large capacityImprove efficiencyGraphiteCell electrodesCurrent loadElectrical battery

Provided are a graphite material suitable as an electrode material for nonaqueous electrolyte secondary batteries, a carbonaceous material for battery electrodes, and secondary batteries which exhibit excellent charge-discharge cycle characteristics and excellent severe-current-load characteristics. A graphite material which has specific sizes of optically anisotropic and isotropic structures, a specific content ratio between both structures, and various orientation of crystallization; and a carbonaceous material for battery electrodes which is made using the graphite material and which exhibits a large discharge capacity and a small irreversible capacity with the severe-current-load characteristics and cycle characteristics being kept at high levels.

Owner:SHOWA DENKO KK

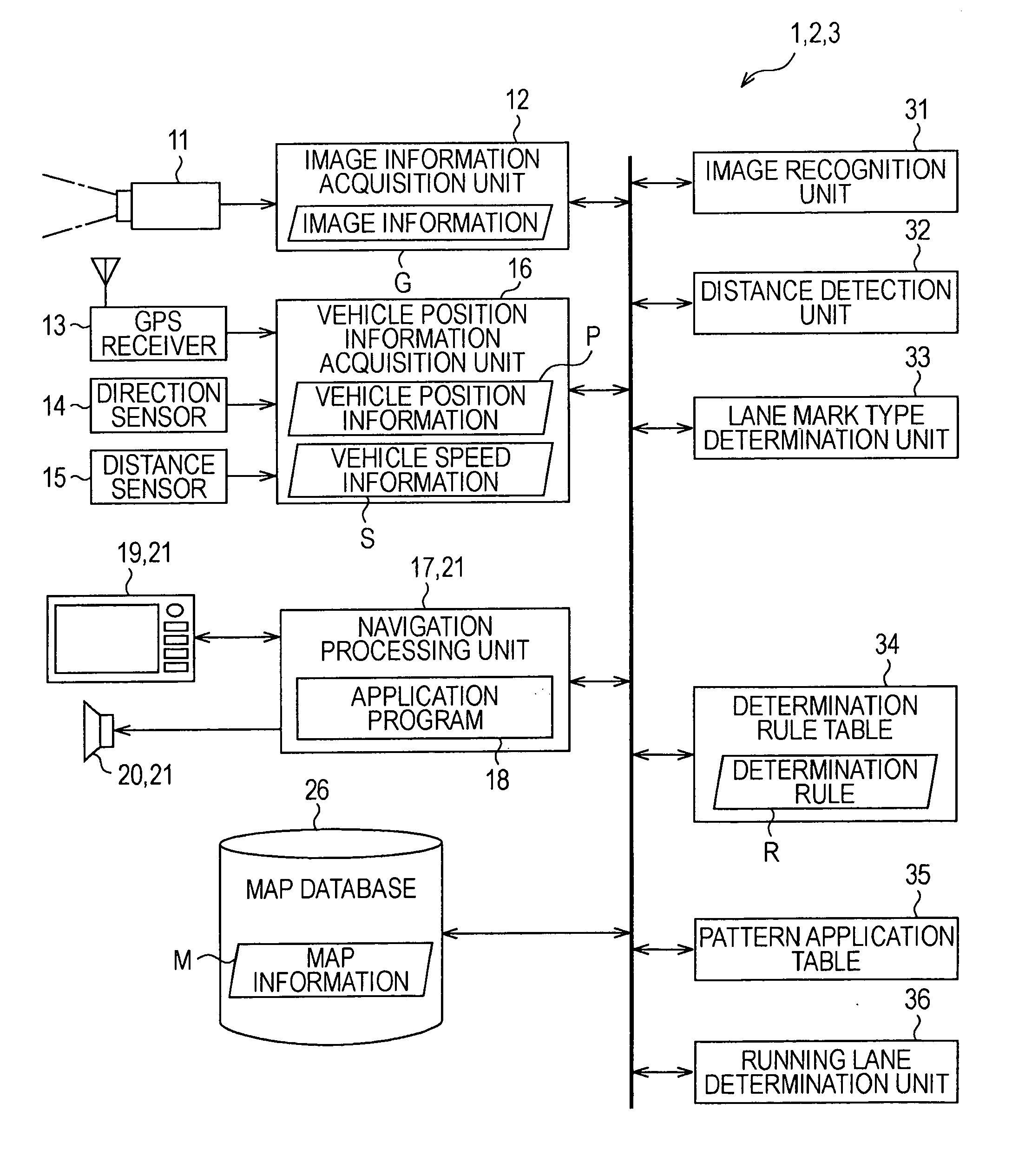

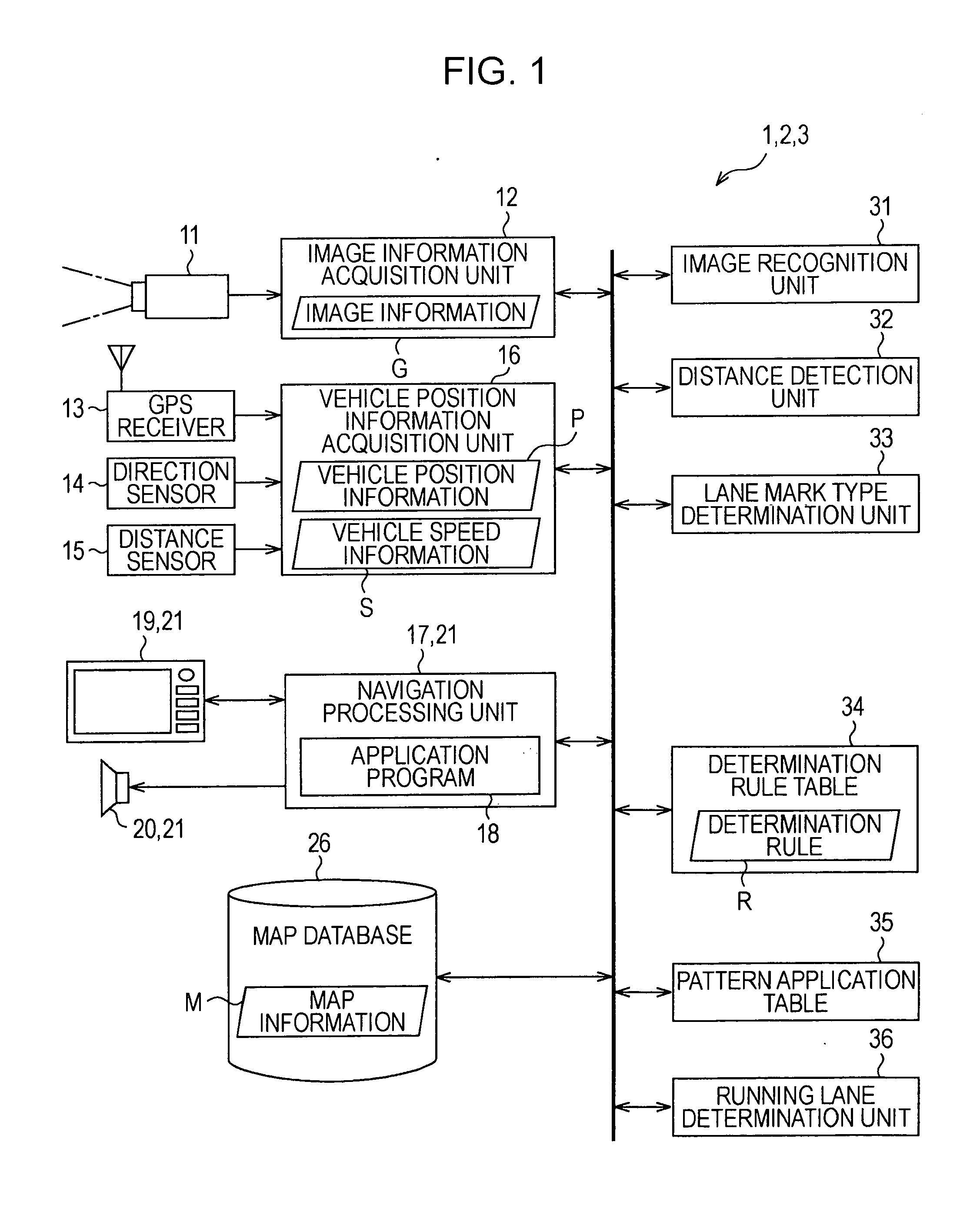

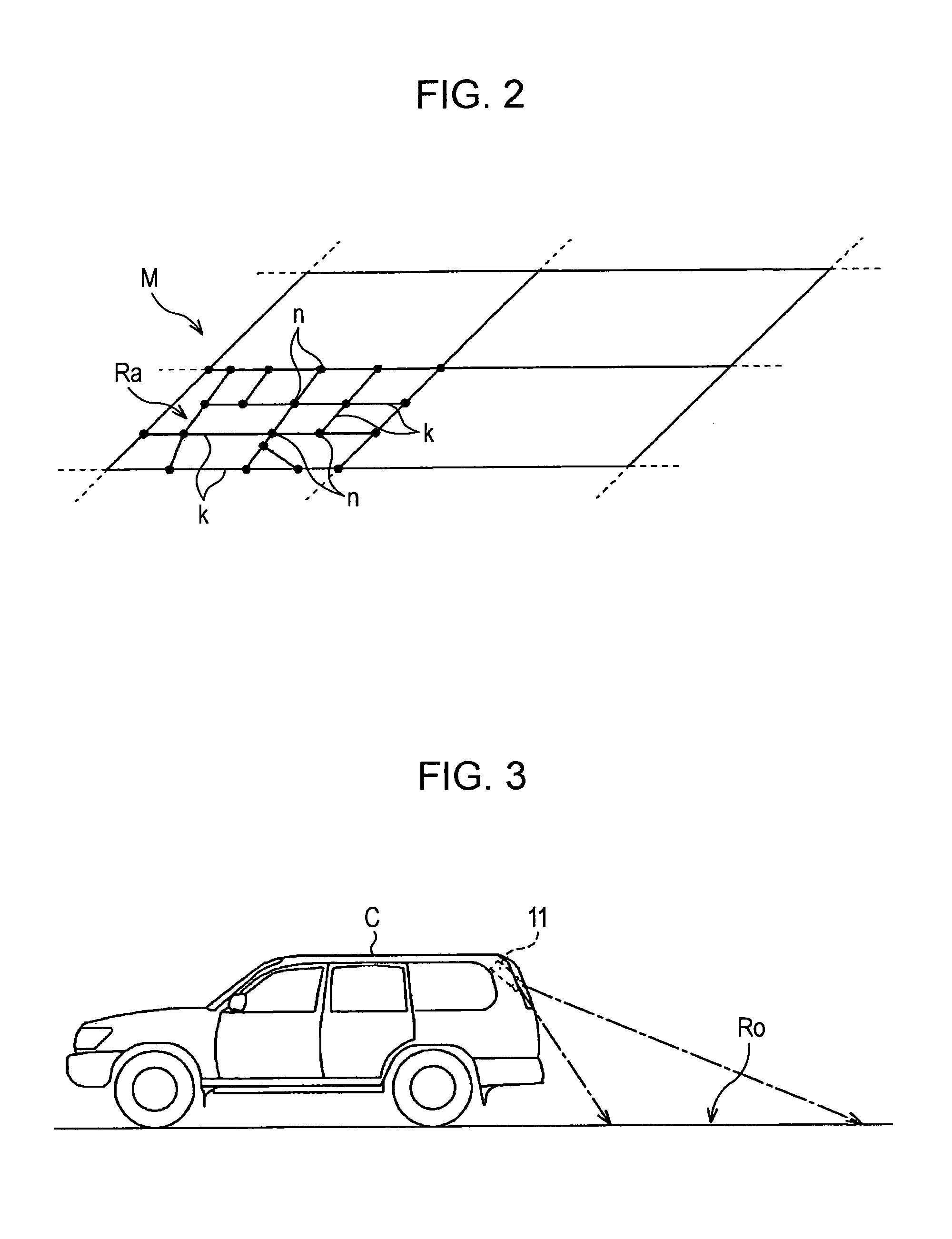

Image recognition apparatuses, methods and programs

InactiveUS20090174577A1Reduce processing latencyImprove processing speedDetection of traffic movementAnti-collision systemsComputer graphics (images)Information device

Image information apparatuses, methods, and programs acquire image information of a plurality of frames of images sensed at predetermined regular time intervals. The apparatuses, methods, and programs detect a leading and trailing end of a lane mark included in a detection area defined in each frame of the image information. The apparatuses, methods, and programs detect a detected distance from one of the leading and trailing end of the lane mark to the other one as a detected distance based on the speed of the vehicle and the number of frames between a frame in which one of the leading end and the trailing end of the lane mark is detected and a frame in which the other one of the leading end and the trailing end of the lane mark is detected and determine a lane mark type of the lane mark on the basis of the detected distance.

Owner:AISIN AW CO LTD +1

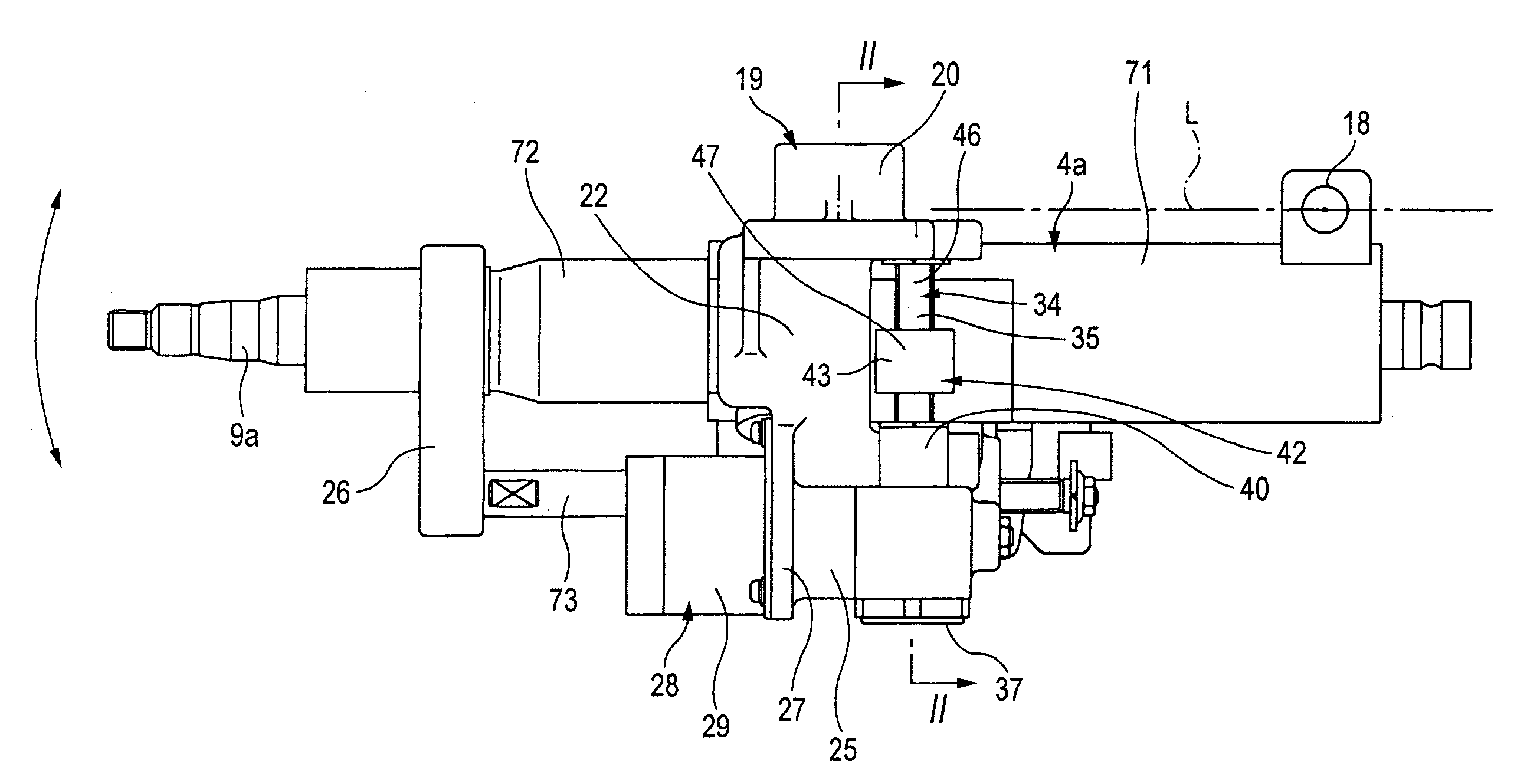

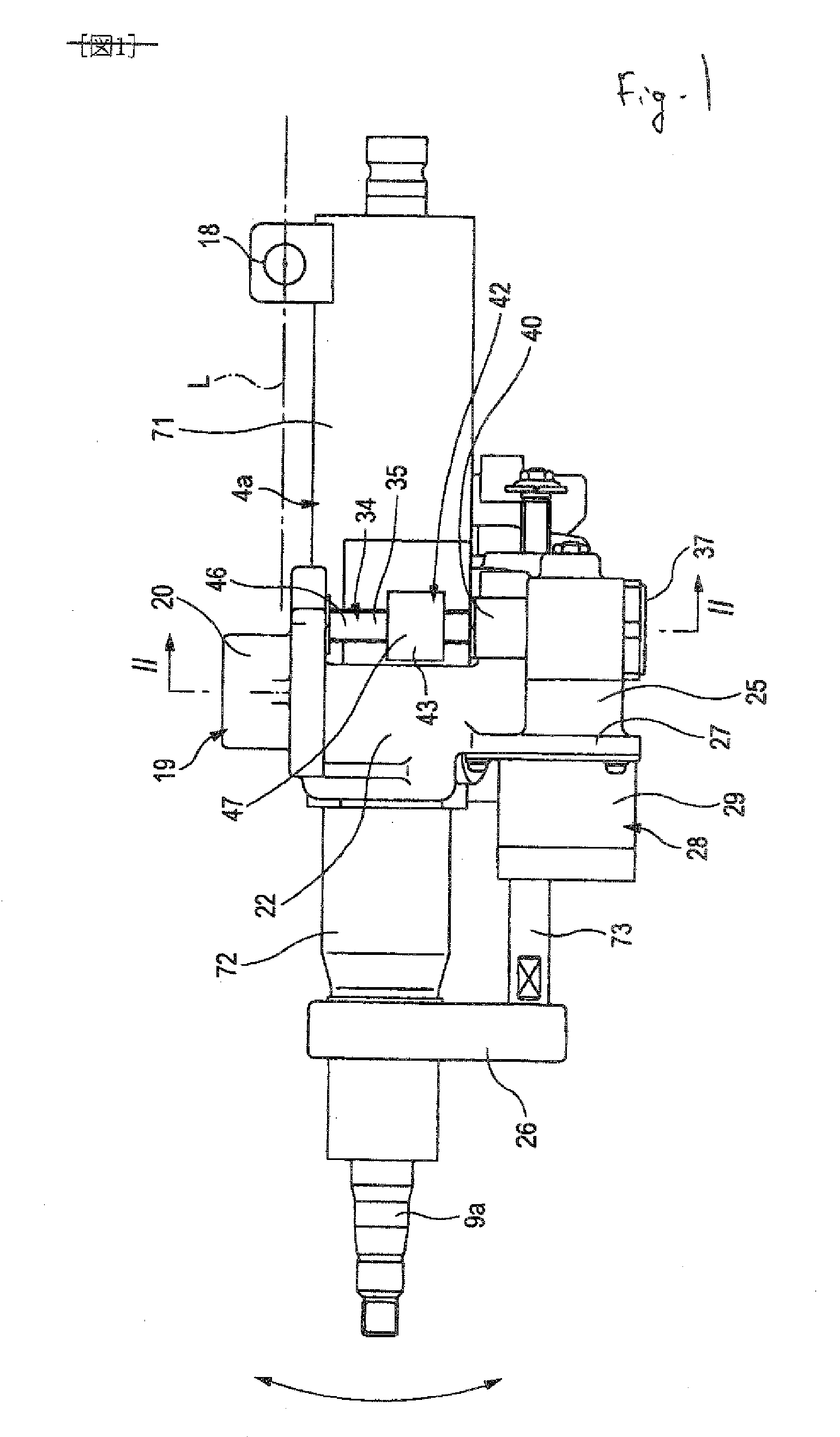

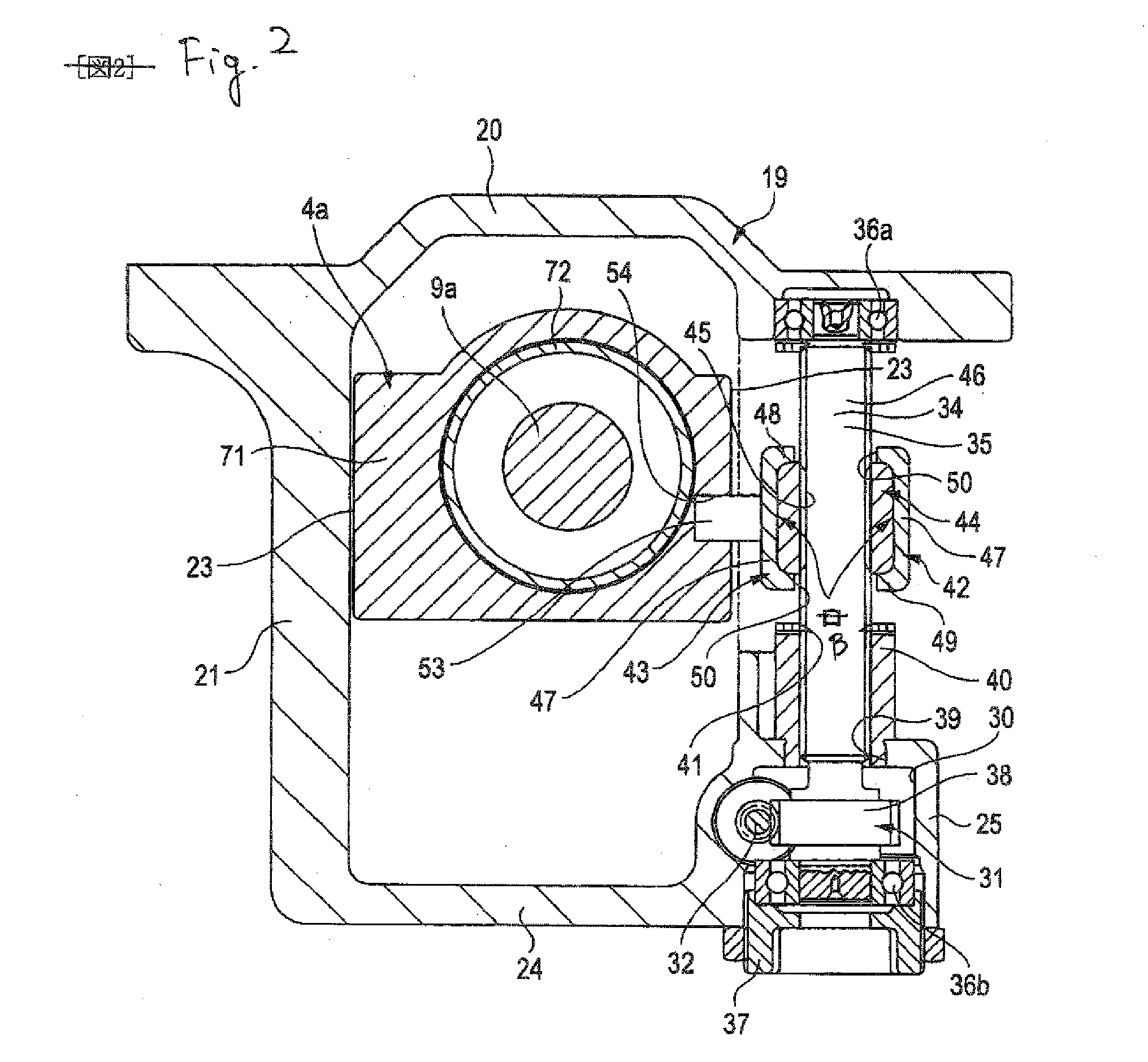

Steering Apparatus

InactiveUS20080216597A1Generation can be preventedSize of apparatus be reducedSteering columnsSteering columnEngineering

Both ends of a screw shaft 35 are supported on a vehicle body side bracket 19 so that only rotation is allowed. The screw shaft 35 is rotated by an electric motor 28. A nut member 44 is threadedly engaged with an intermediate portion of the screw shaft 35. The nut member 44 is held on inside of a nut holder 43. The nut holder 43 and nut member 44 are allowed to be shifted each other in longitudinal direction of the nut holder 43 which is perpendicular to both the shaft portion extending parallel to oscillation center axis of a steering column 4a and the axial direction of the screw shaft 35. The nut holder 43 is supported on the steering column 4a so as to be rotated about the shaft portion of the nut holder 43 relative to the steering column 4a.

Owner:NSK LTD

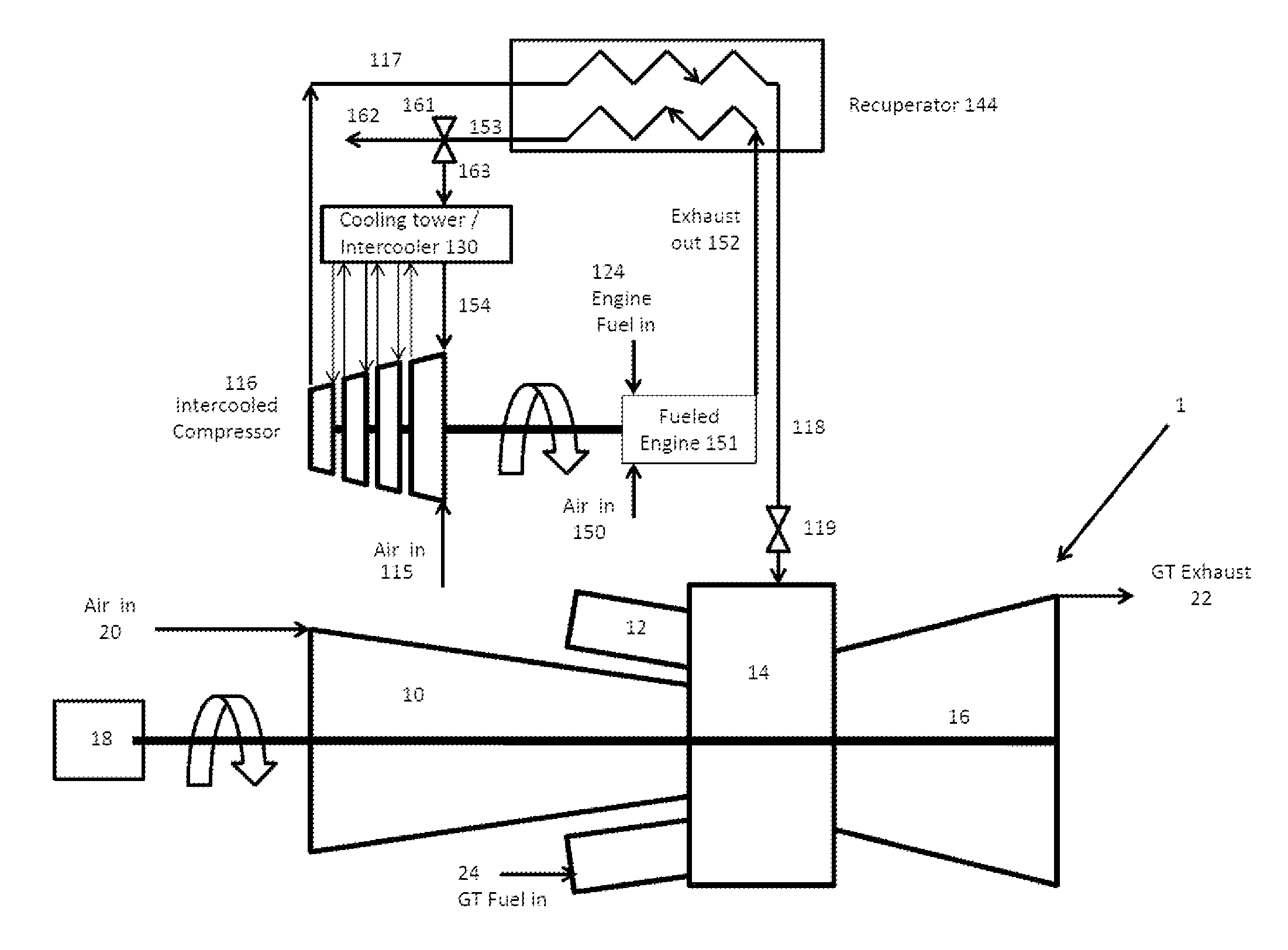

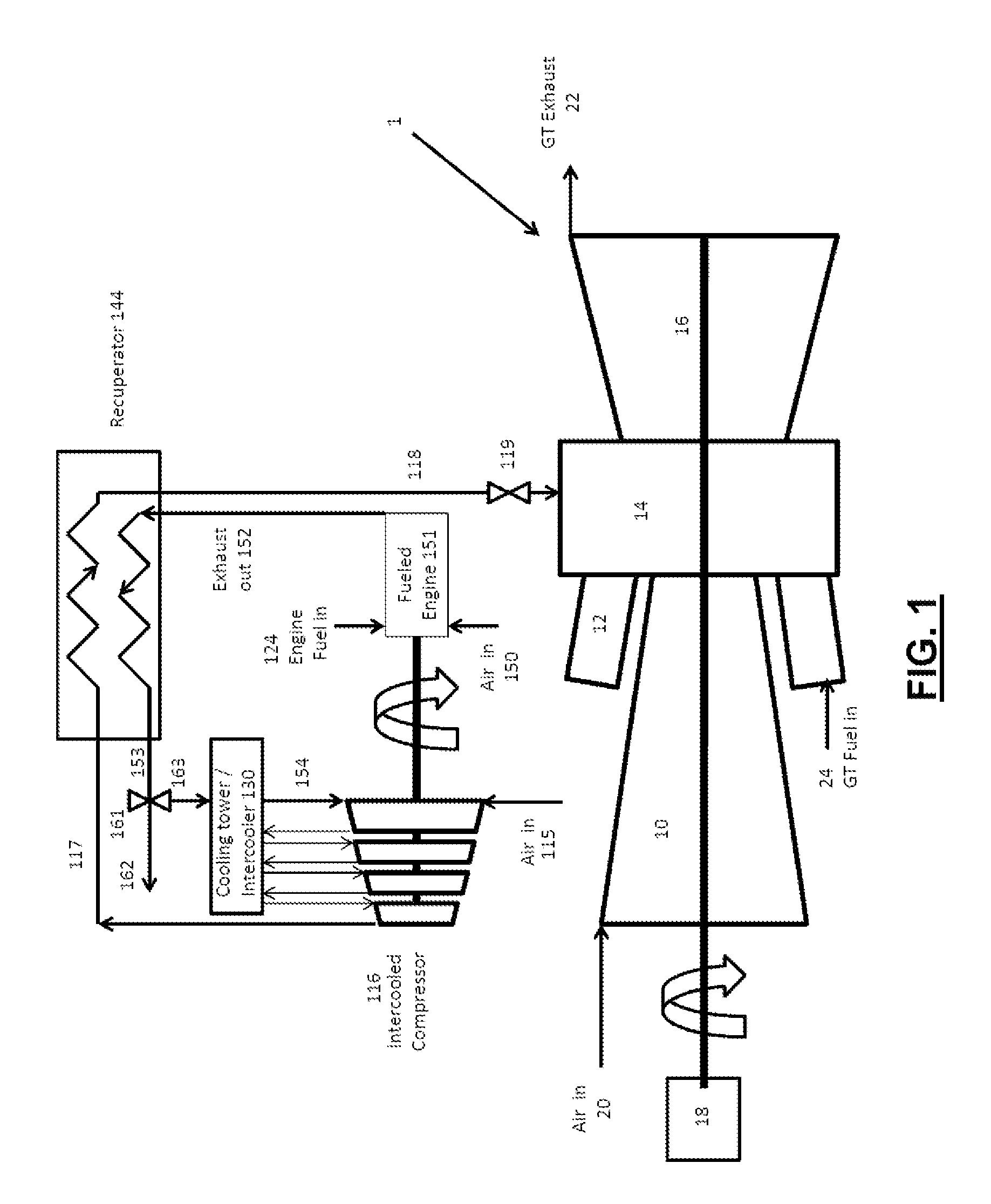

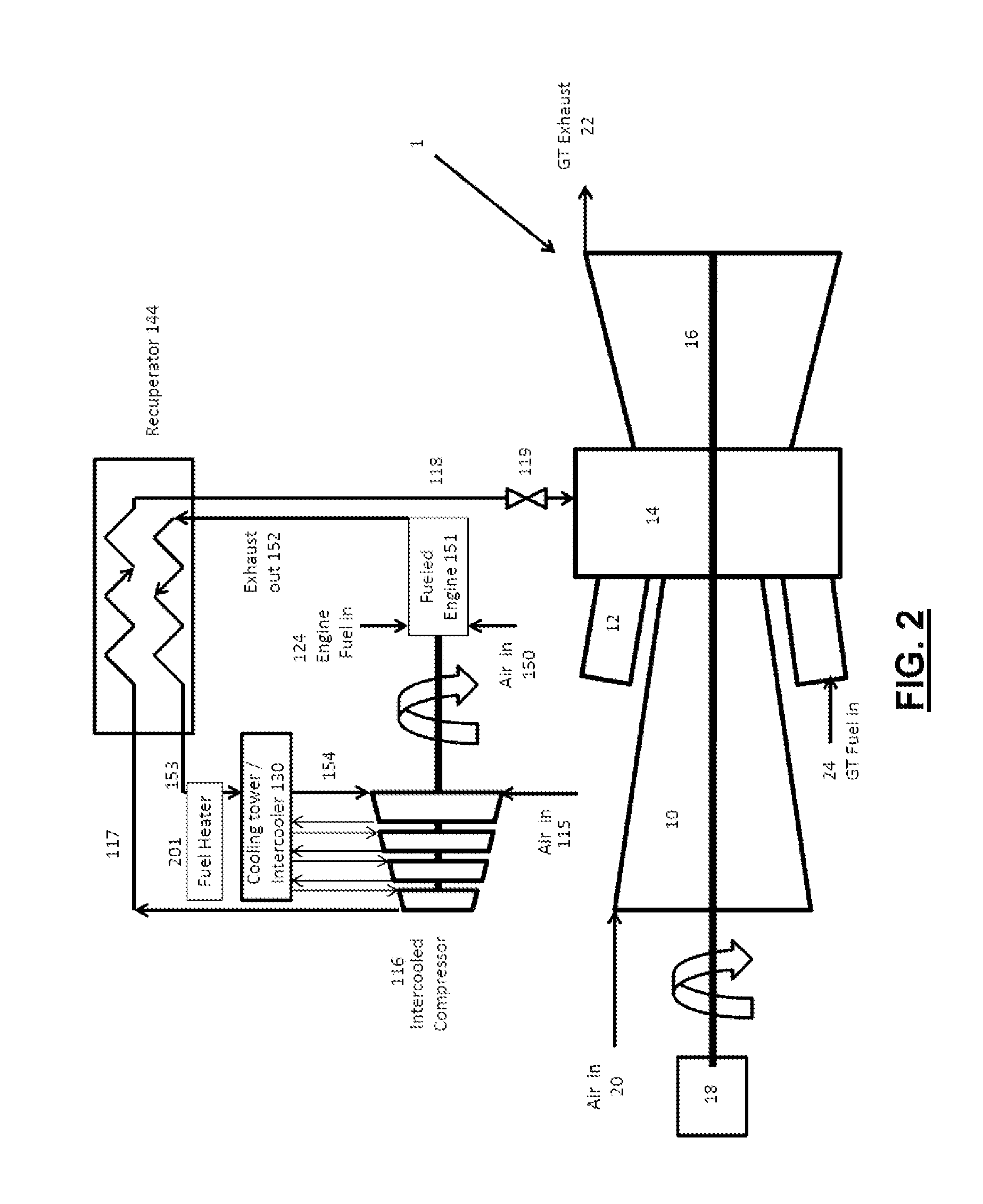

Gas Turbine Energy Supplementing Systems and Heating Systems, and Methods of Making and Using the Same

ActiveUS20150233296A1Increase capacityIncreasing regulation capabilityTurbine/propulsion engine ignitionTurbine/propulsion engine startersElectric power systemEngineering

Electrical power systems, including generating capacity of a gas turbine, where additional electrical power is generated utilizing a separately fueled system during periods of peak electrical power demand.

Owner:POWERPHASE

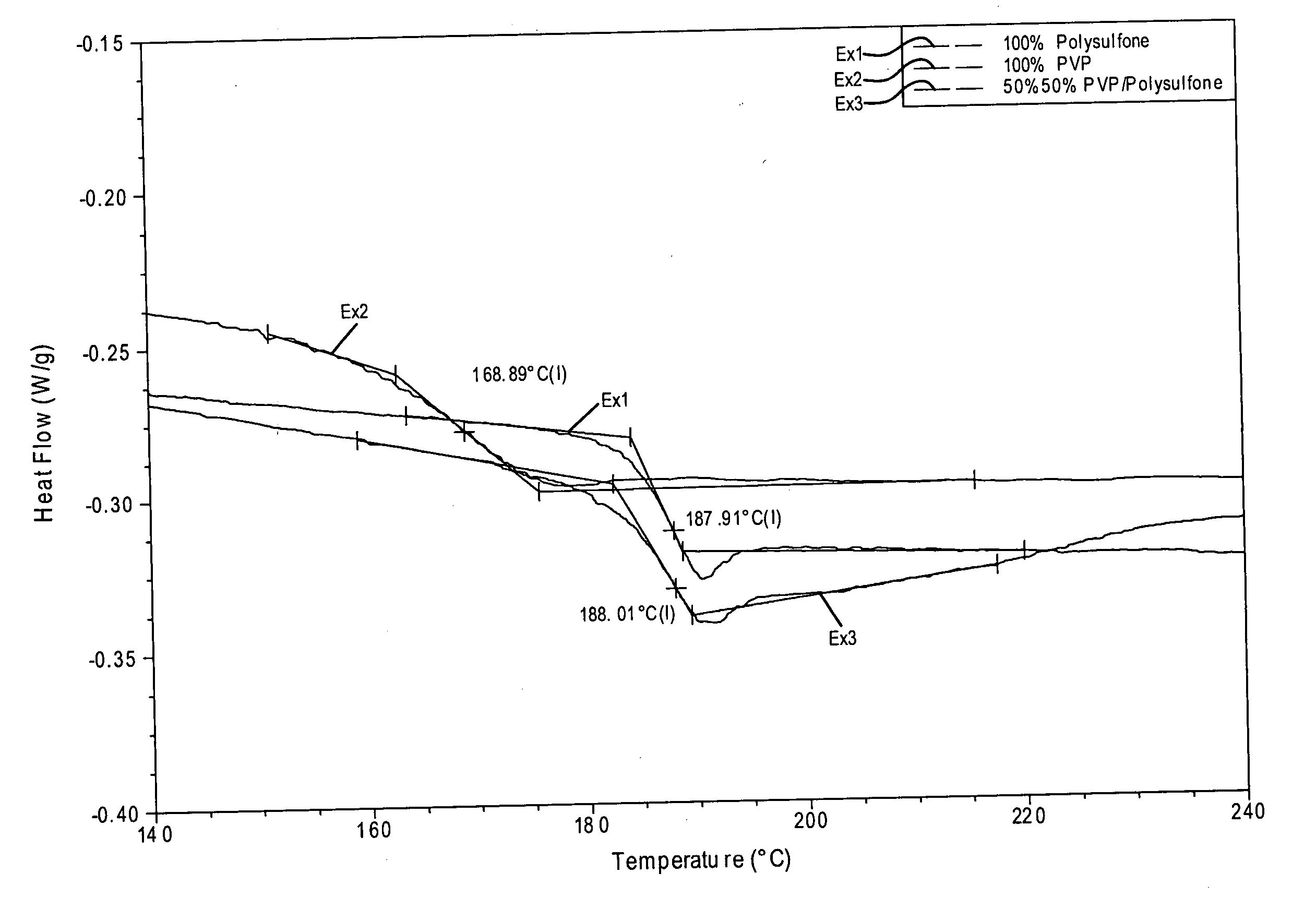

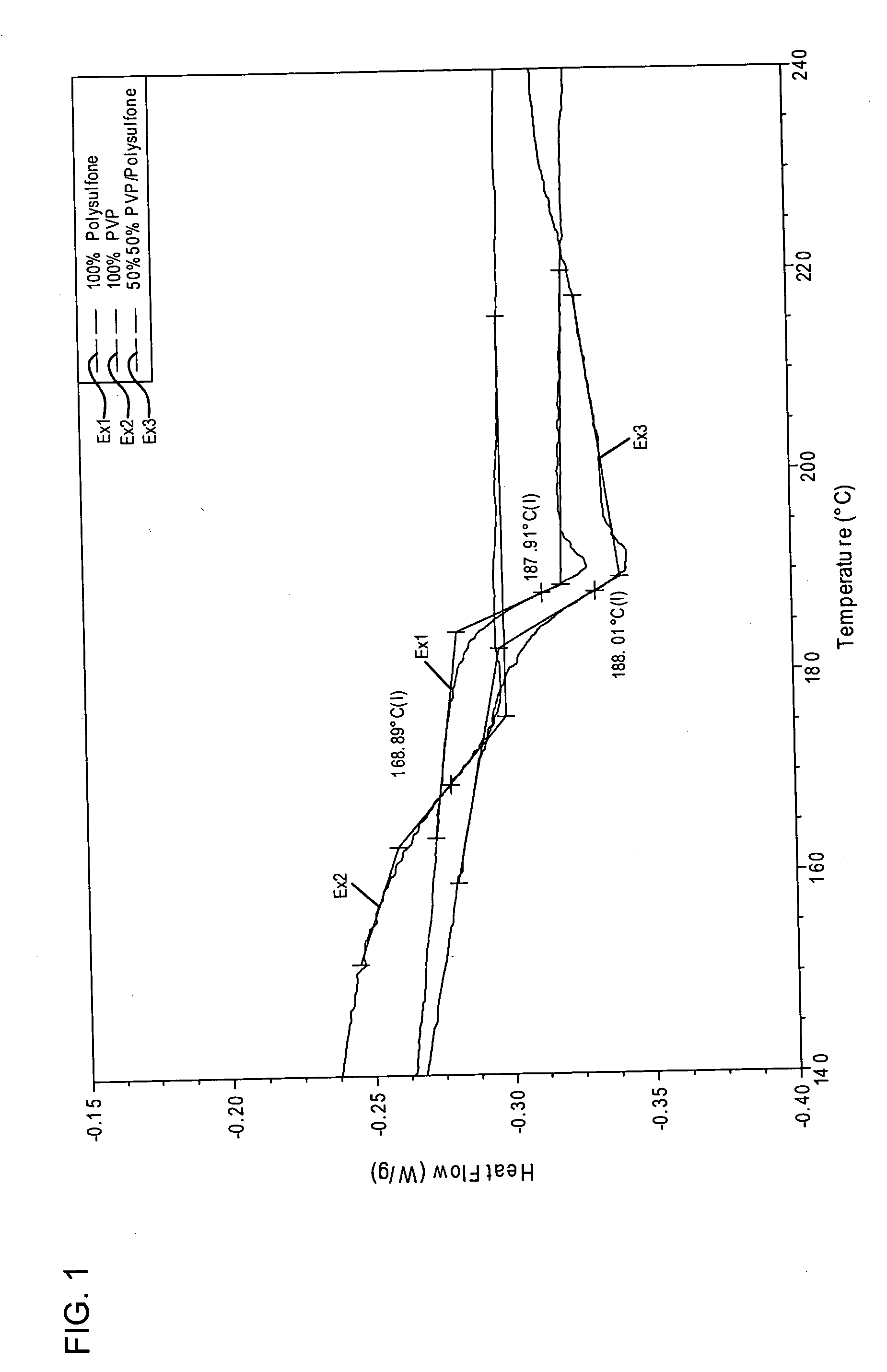

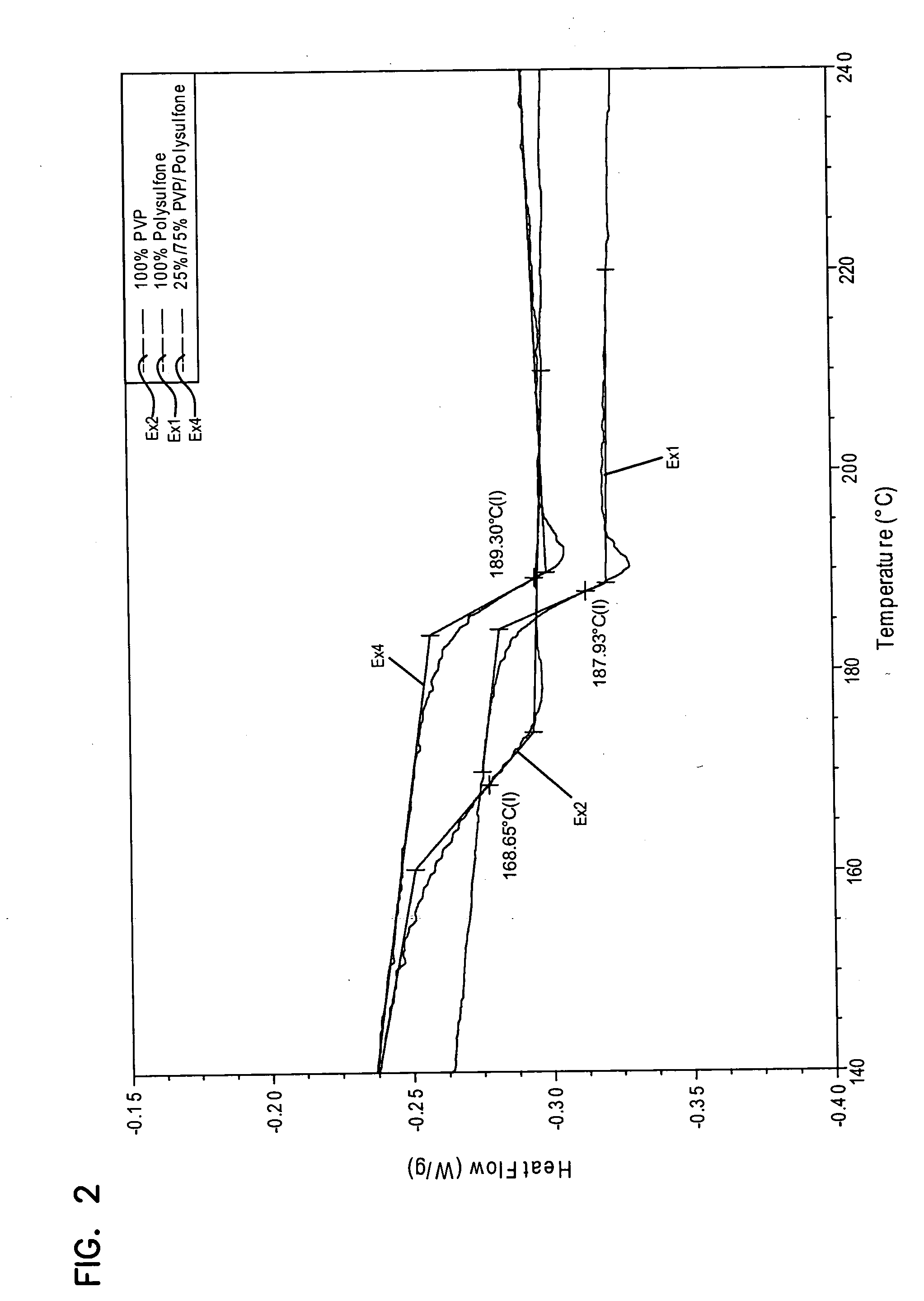

Polysulfone and poly(N-vinyl lactam) polymer alloy and fiber and filter materials made of the alloy

ActiveUS20070102372A1Substantial surface loadingHigh initialSemi-permeable membranesDispersed particle filtrationPolymer sciencePolymer alloy

Owner:DONALDSON CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com