Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1940results about "Loaders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Substrate processing apparatus

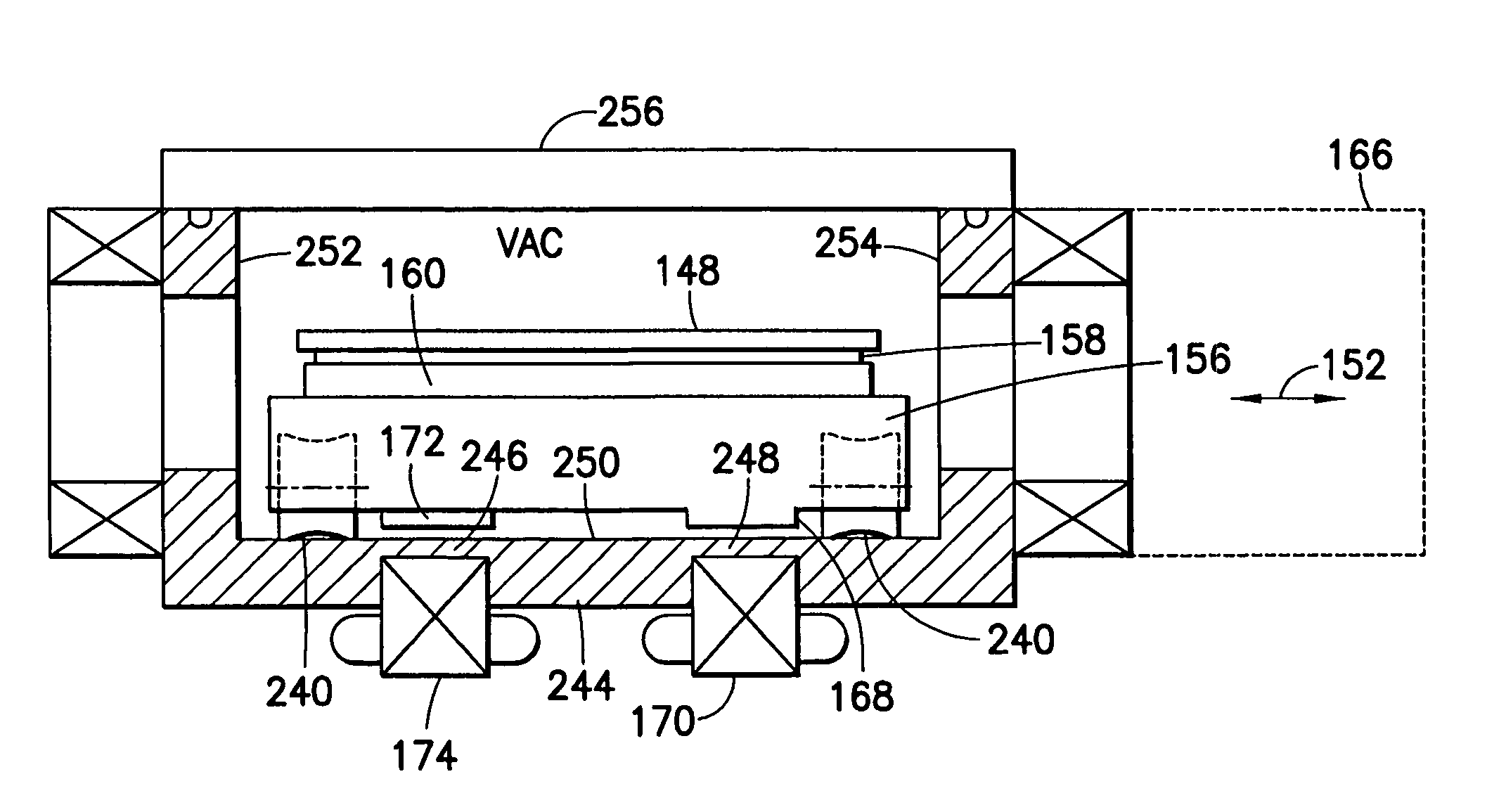

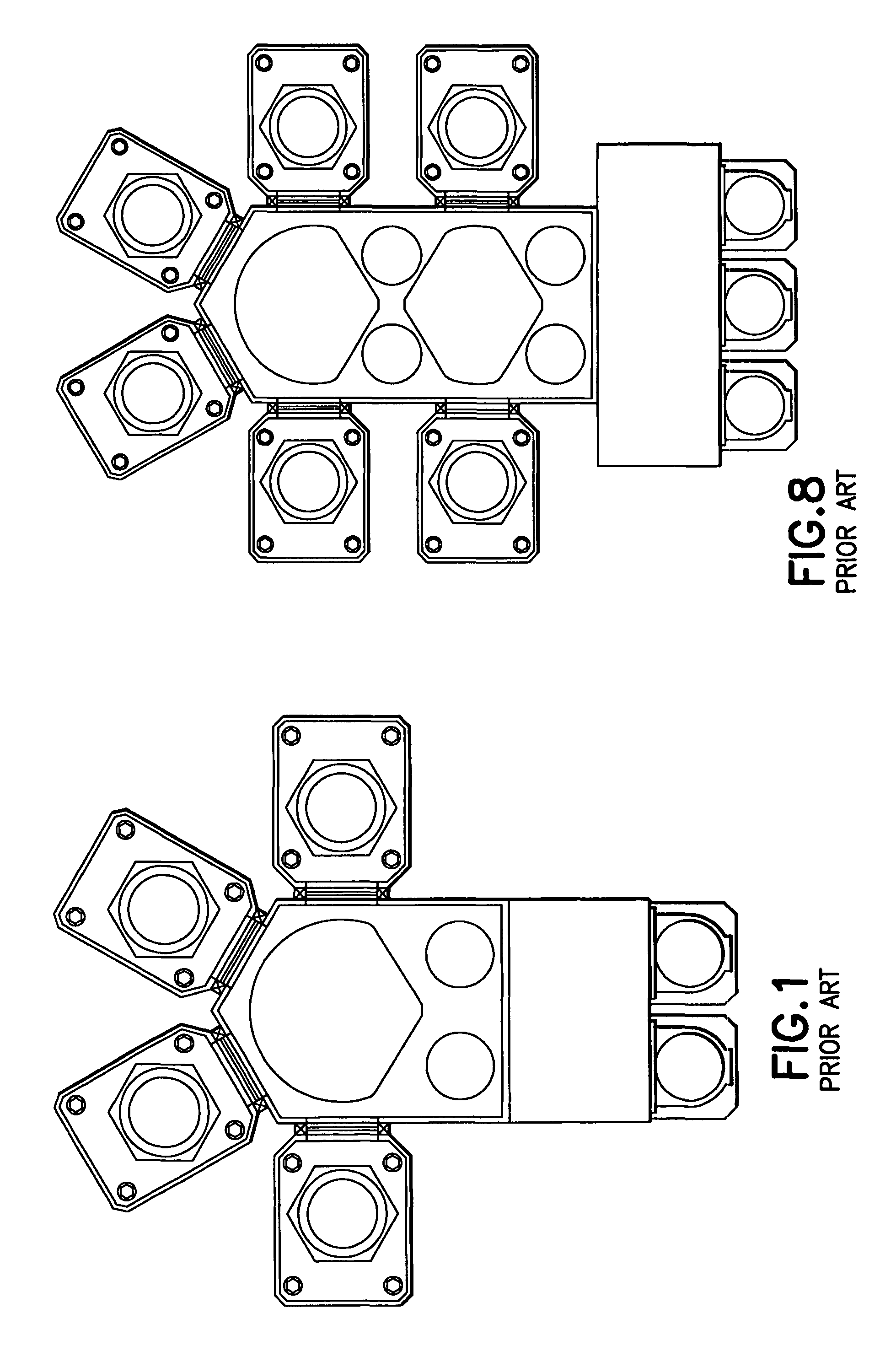

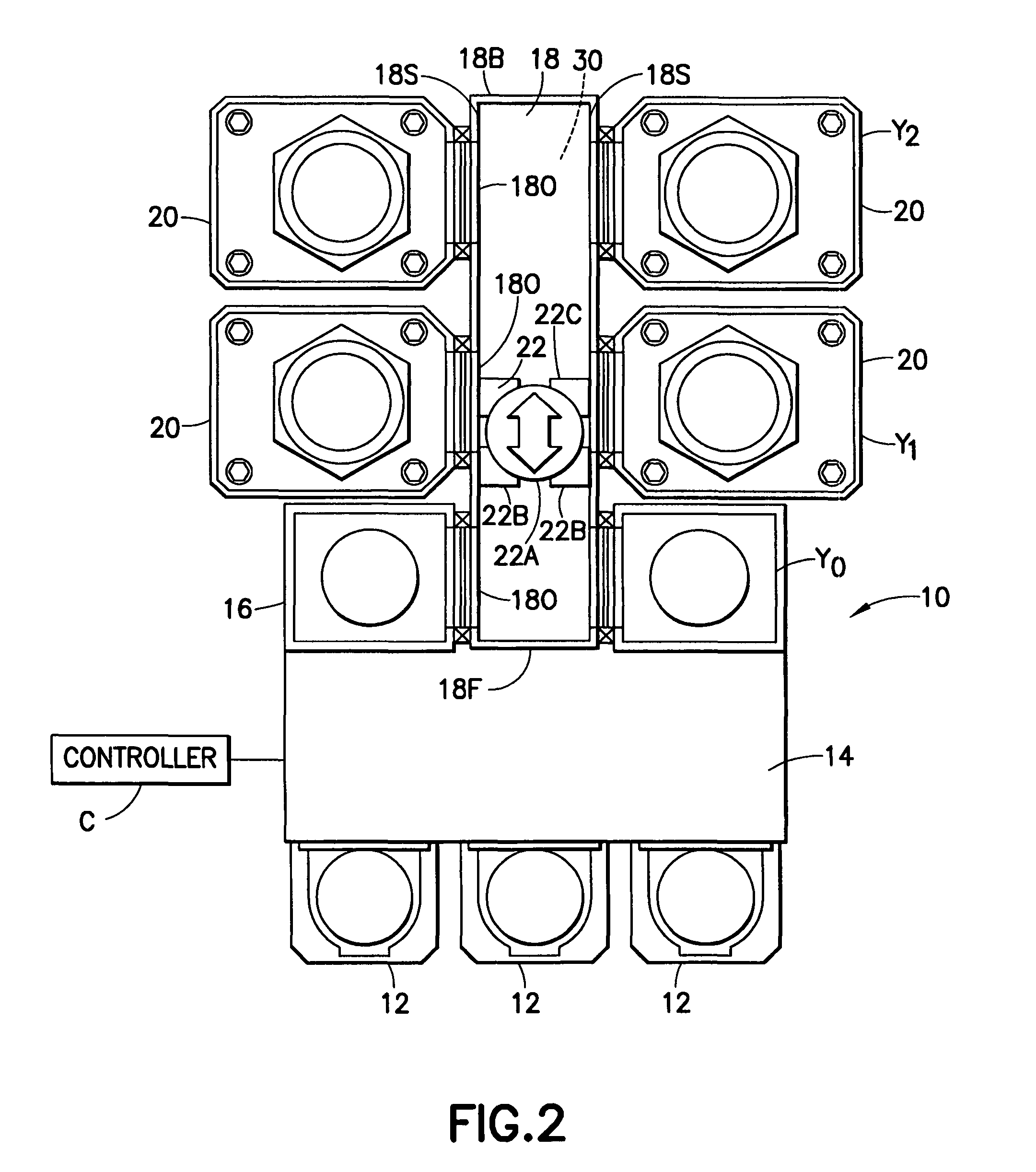

Substrate processing apparatus having a chamber, a generally linear array of process modules, a substrate transport, and a drive system. The chamber is capable of being isolated from the outside atmosphere. Each process module of the array is communicably connected to the chamber to allow a substrate to be transferred between the chamber and process module. The substrate transport is located in and is movably supported from the chamber. The transport is capable of moving along a linear path defined by the chamber for transporting the substrate between process modules. The drive system is connected to the chamber for driving and moving the transport along the linear path. The chamber comprises a selectable number of chamber modules serially abutted to defined the chamber. Each module has an integral portion of the drive system.

Owner:BOOKS AUTOMATION US LLC

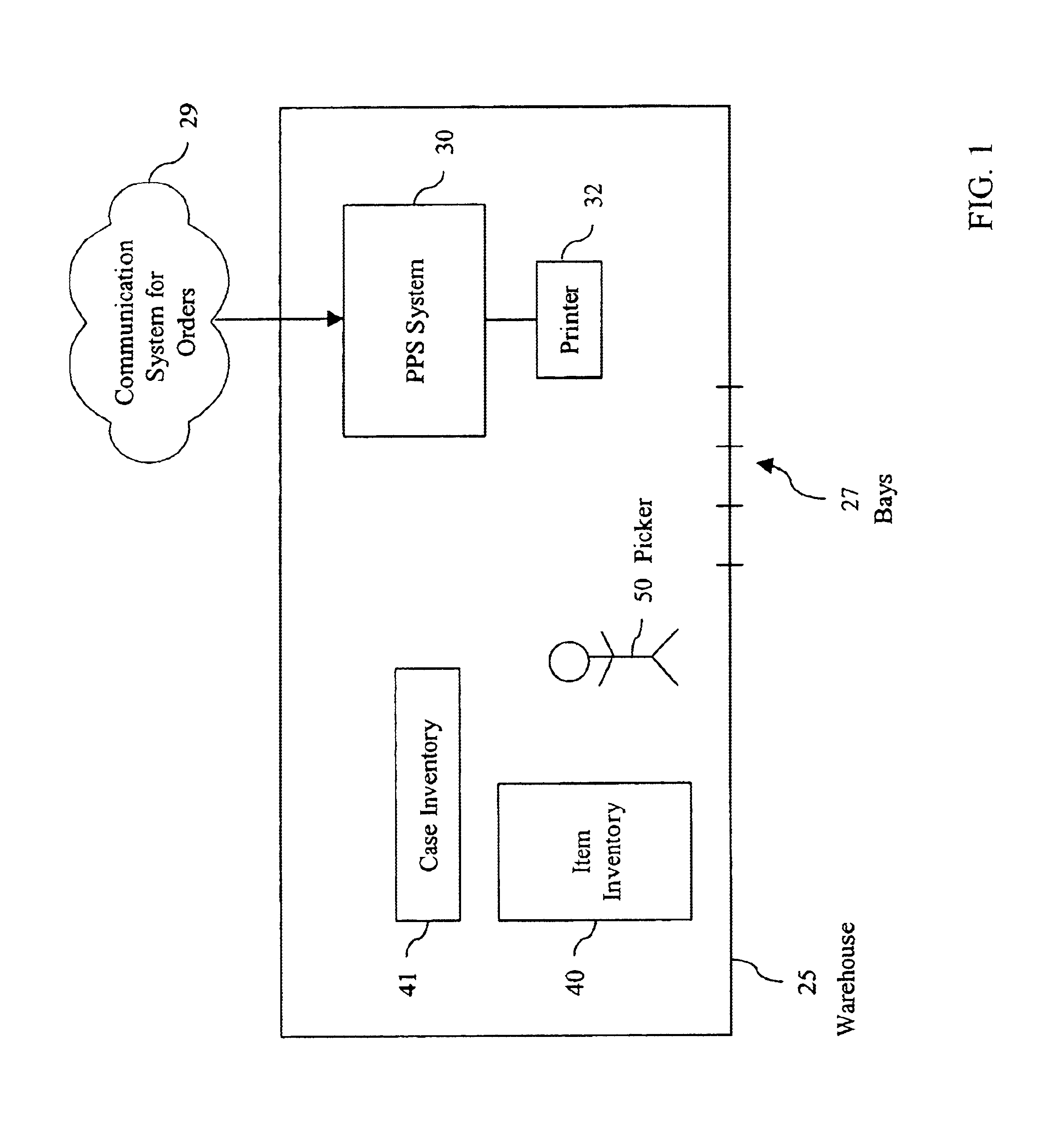

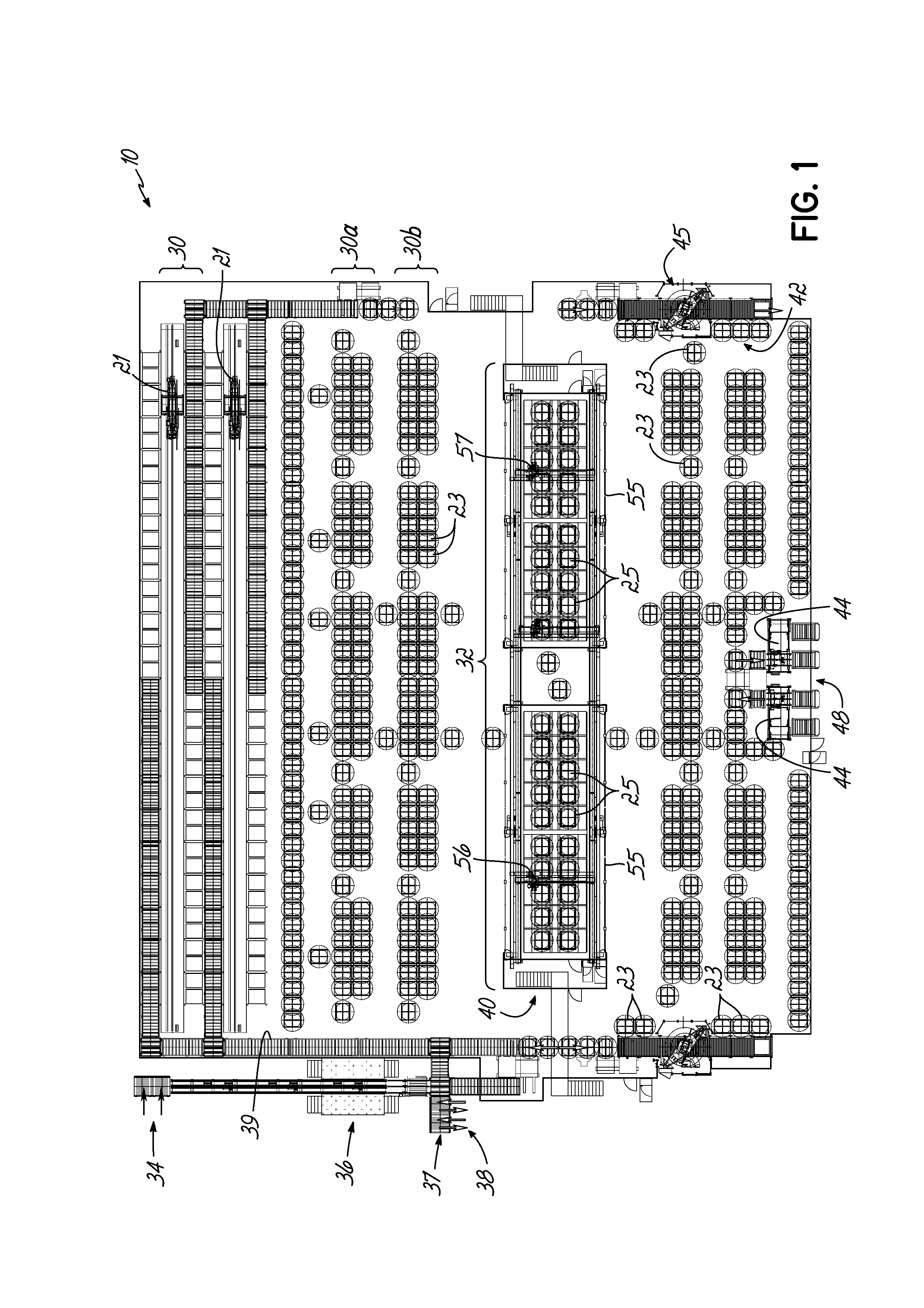

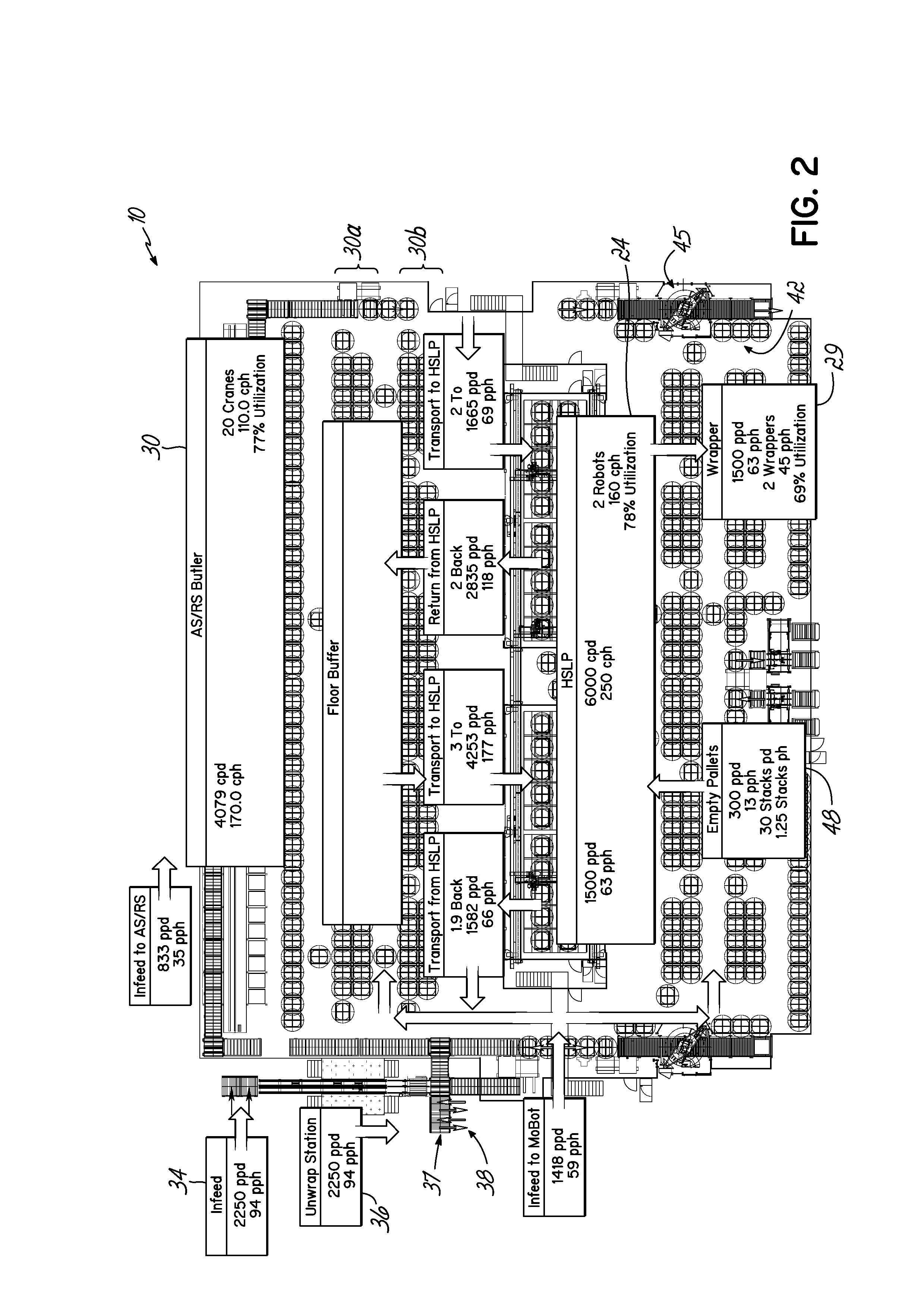

Palletizing systems and methods

InactiveUS20080131255A1Increase order filling efficiencyImprove filling efficiencyLoadersPackagingCustomer orderAutomatic guidance

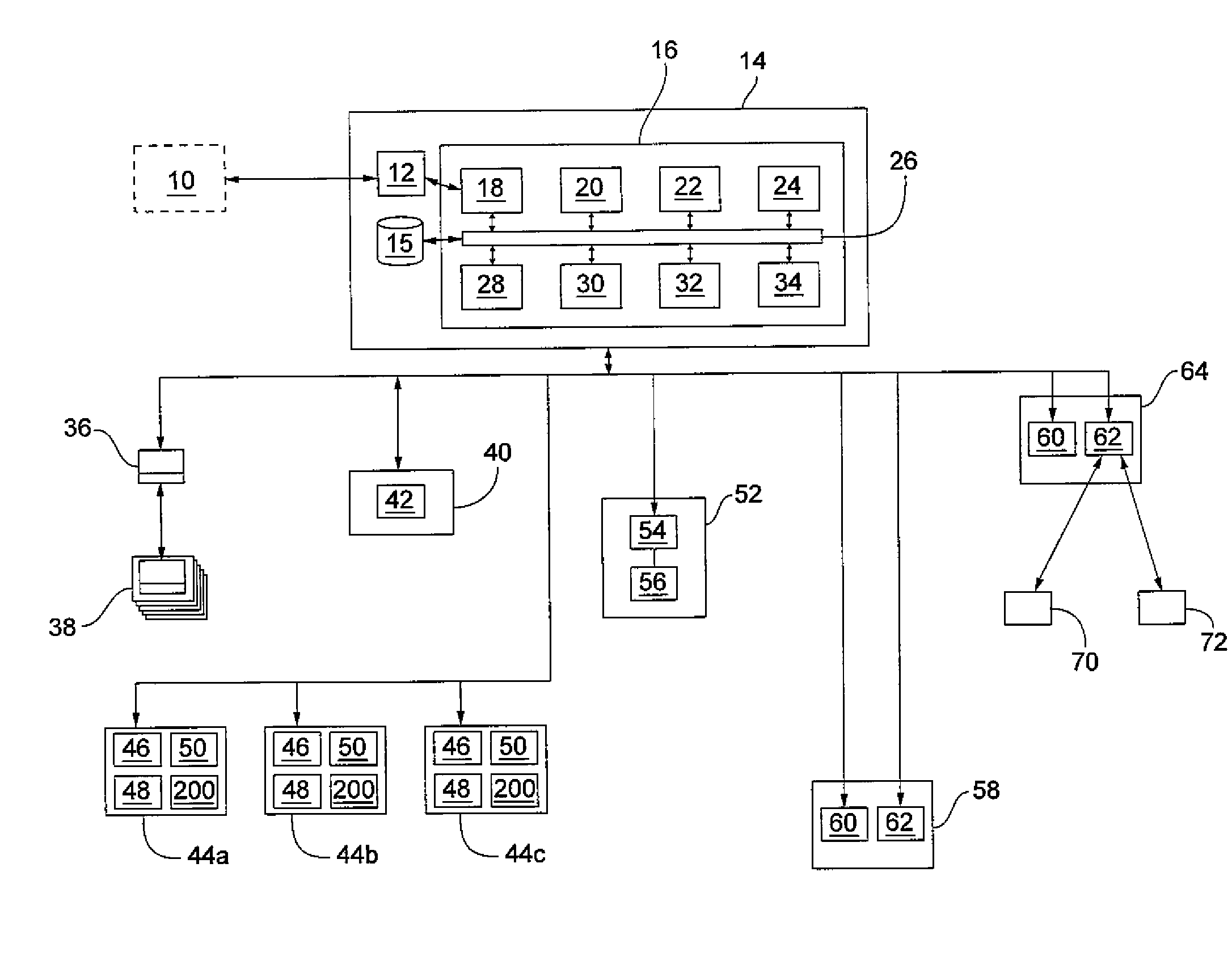

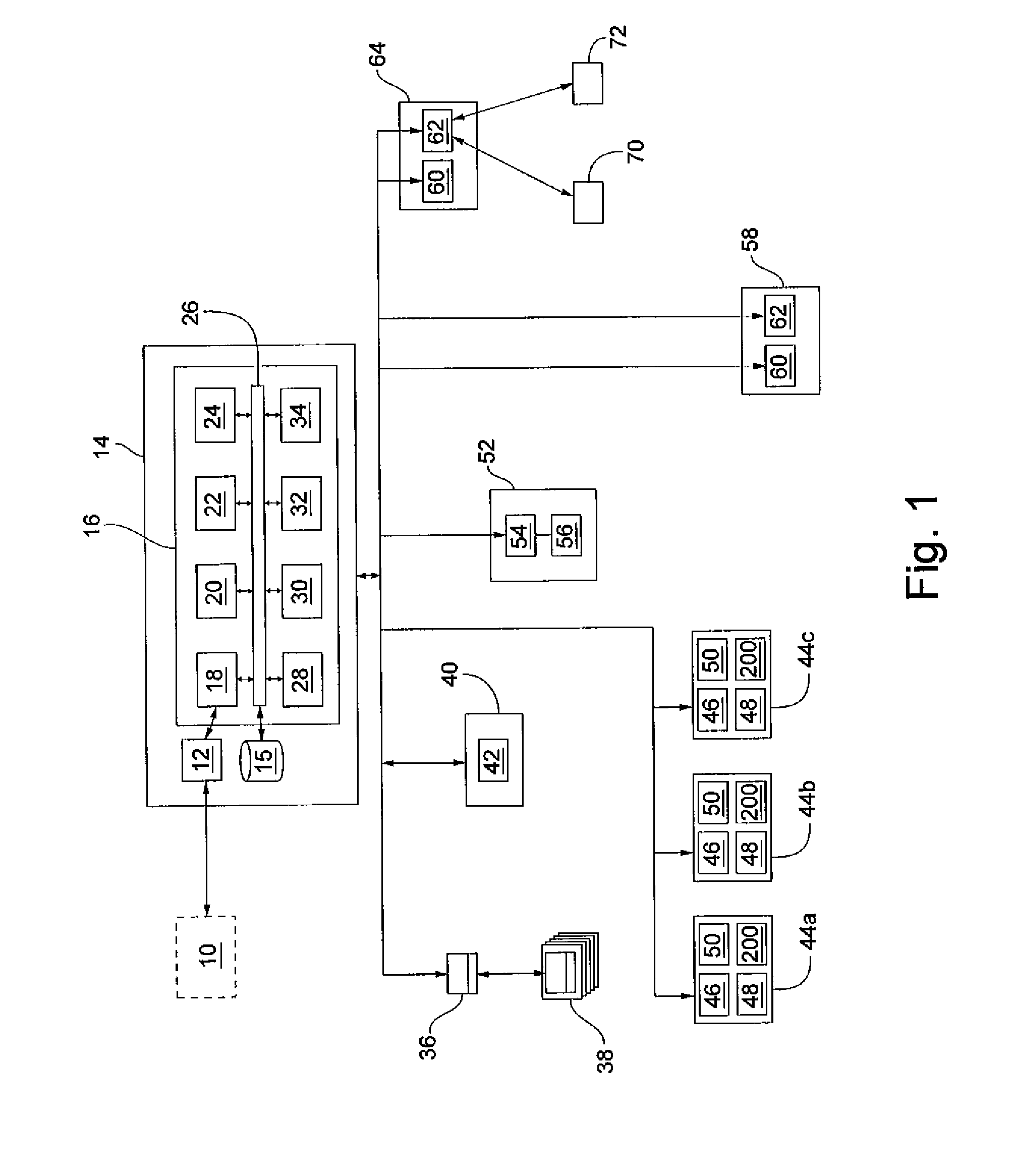

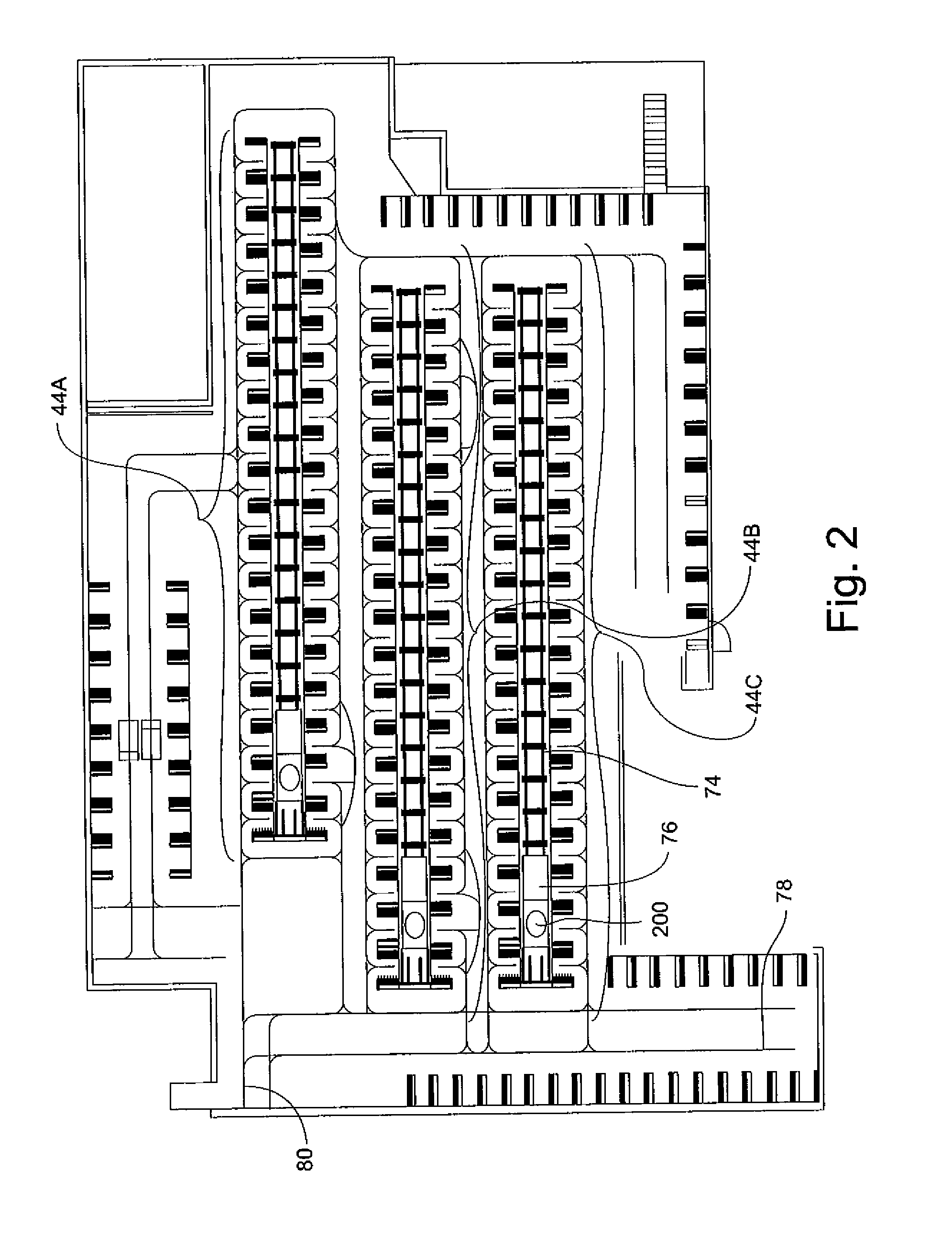

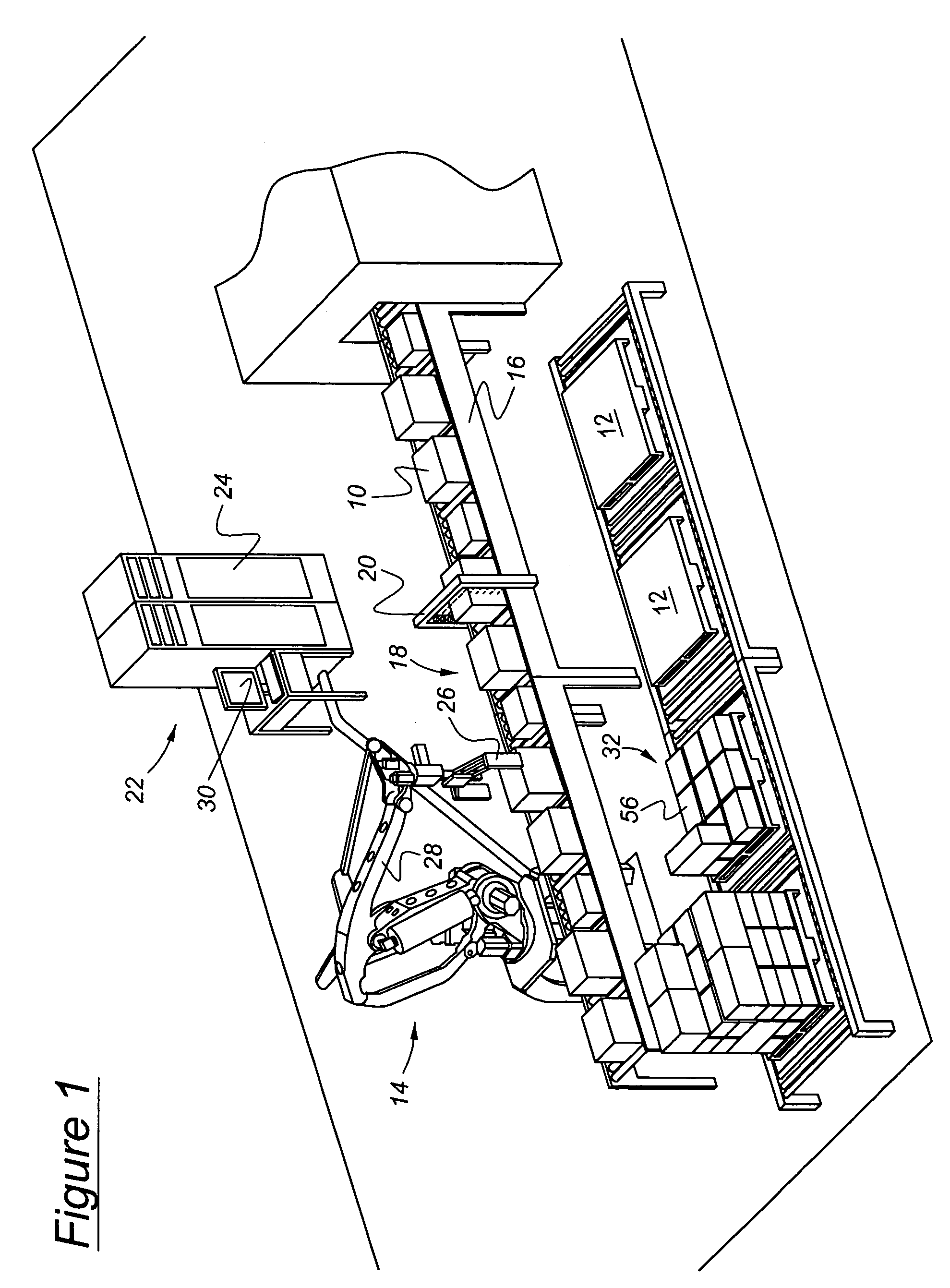

Palletizing systems and methods increasing the efficiency at which pallets of mixed products are built. The systems and methods include a pallet building module for receiving customer orders and generating pallet building instructions for arranging the products on the pallets, among other functions. The pallet building module is in communication with a number of robot cells that include source products and pallet building robots for building pallets based upon instructions generated by the pallet building module. The system includes other modules for system control including conveyor controllers, forklift controllers, and automatic guided vehicle controllers, among other controllers. Methods for building pallets of mixed product from source products within more than one robot cell.

Owner:TRANSBOTICS CORPORATION

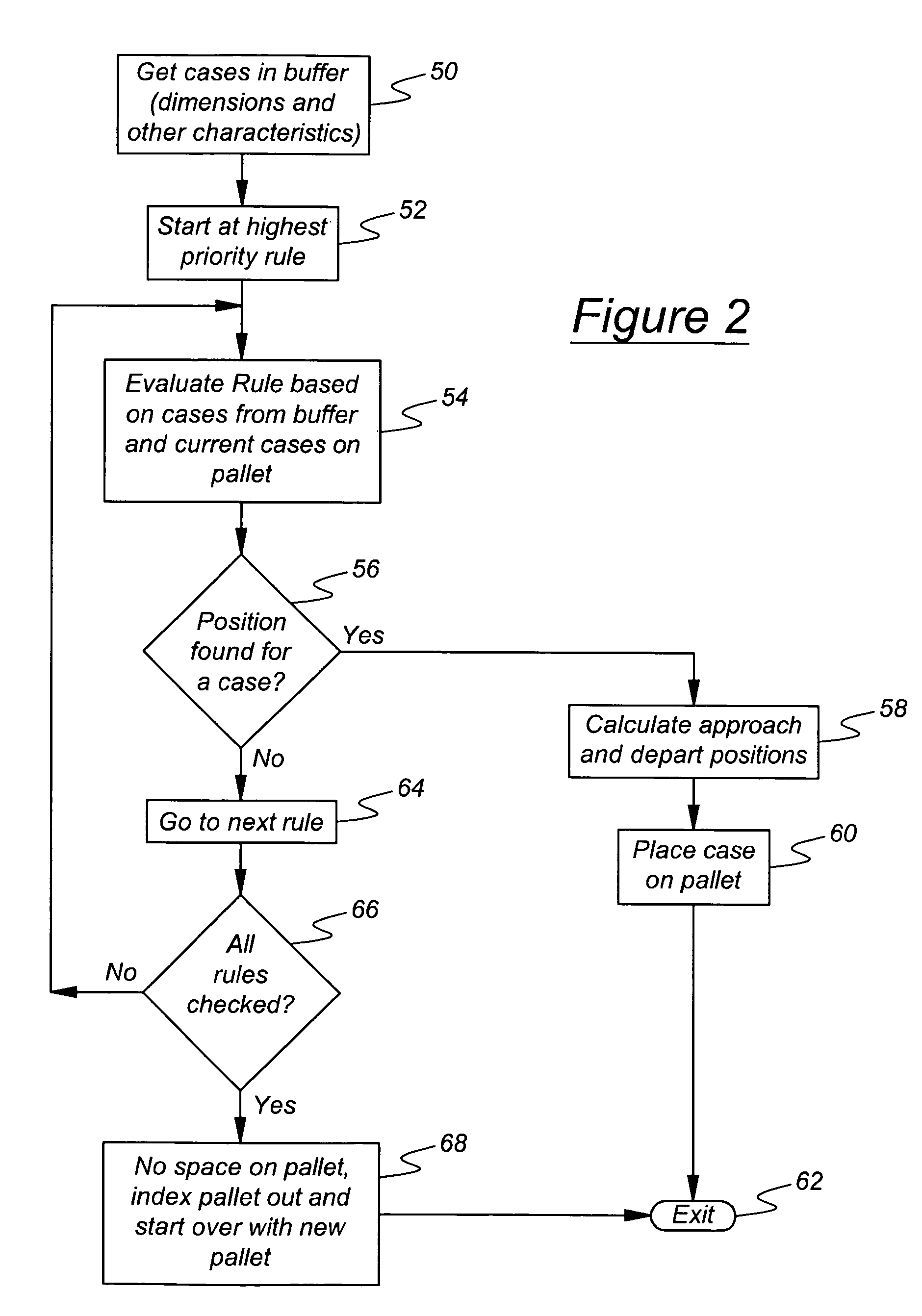

Automated palletizing cases having mixed sizes and shapes

InactiveUS7266422B1Increase the use of spaceGuaranteed smooth progressProgramme controlProgramme-controlled manipulatorEngineeringPallet

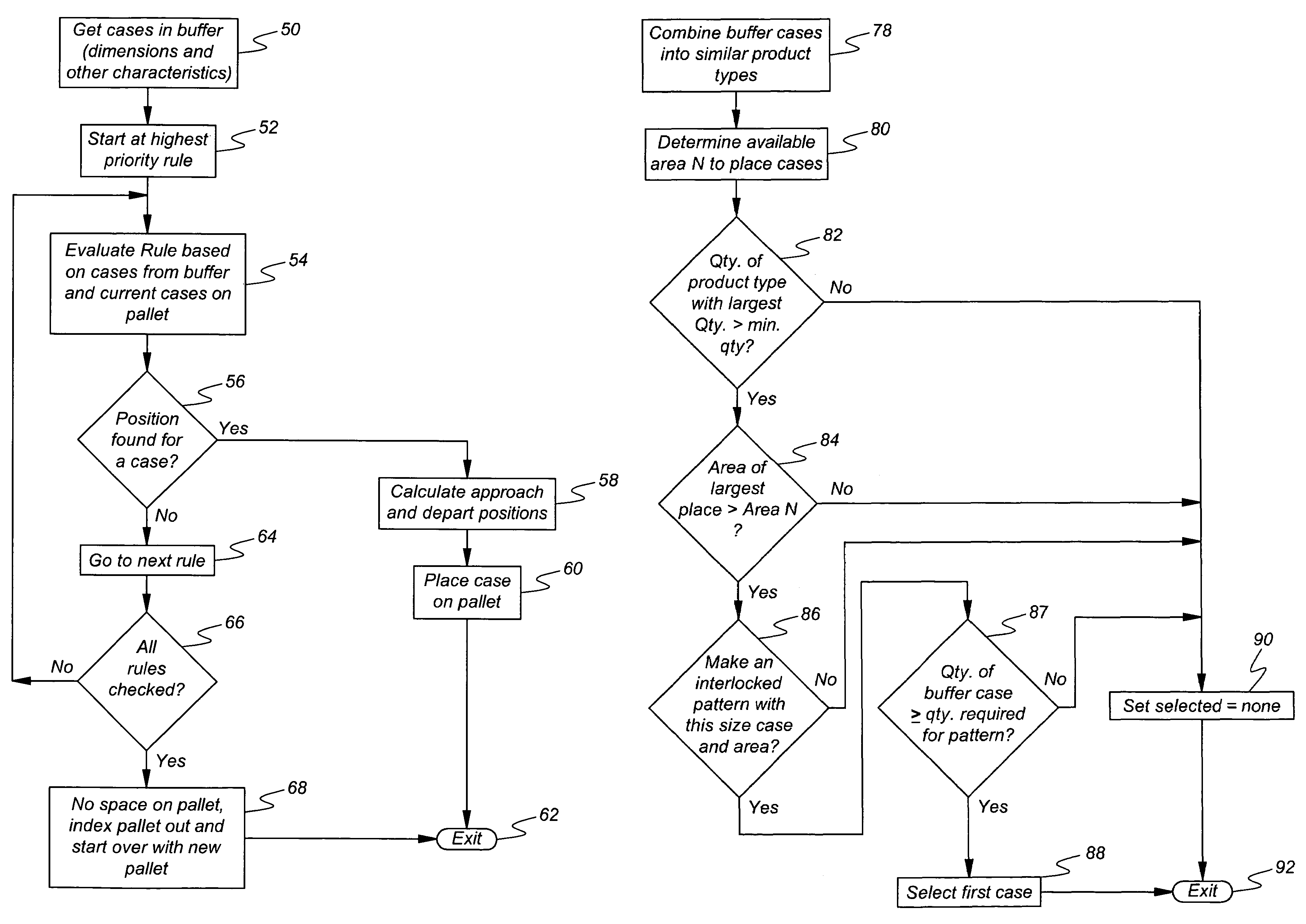

A method for stacking cases on a pallet includes supplying cases to a buffer, determining physical characteristics of buffer cases including dimensions of a case base and case height, and determining available positions on the pallet where a buffer case can be placed. Rules for selecting a case from the buffer for placement on the pallet are applied to at least a portion of the buffer cases to identify a selected buffer case that satisfies at least one of the rules and a corresponding place on the pallet for the selected case. Then the selected case is removed from the buffer and placed on the pallet in the corresponding place by an industrial robot.

Owner:FANUC ROBOTICS AMERCA

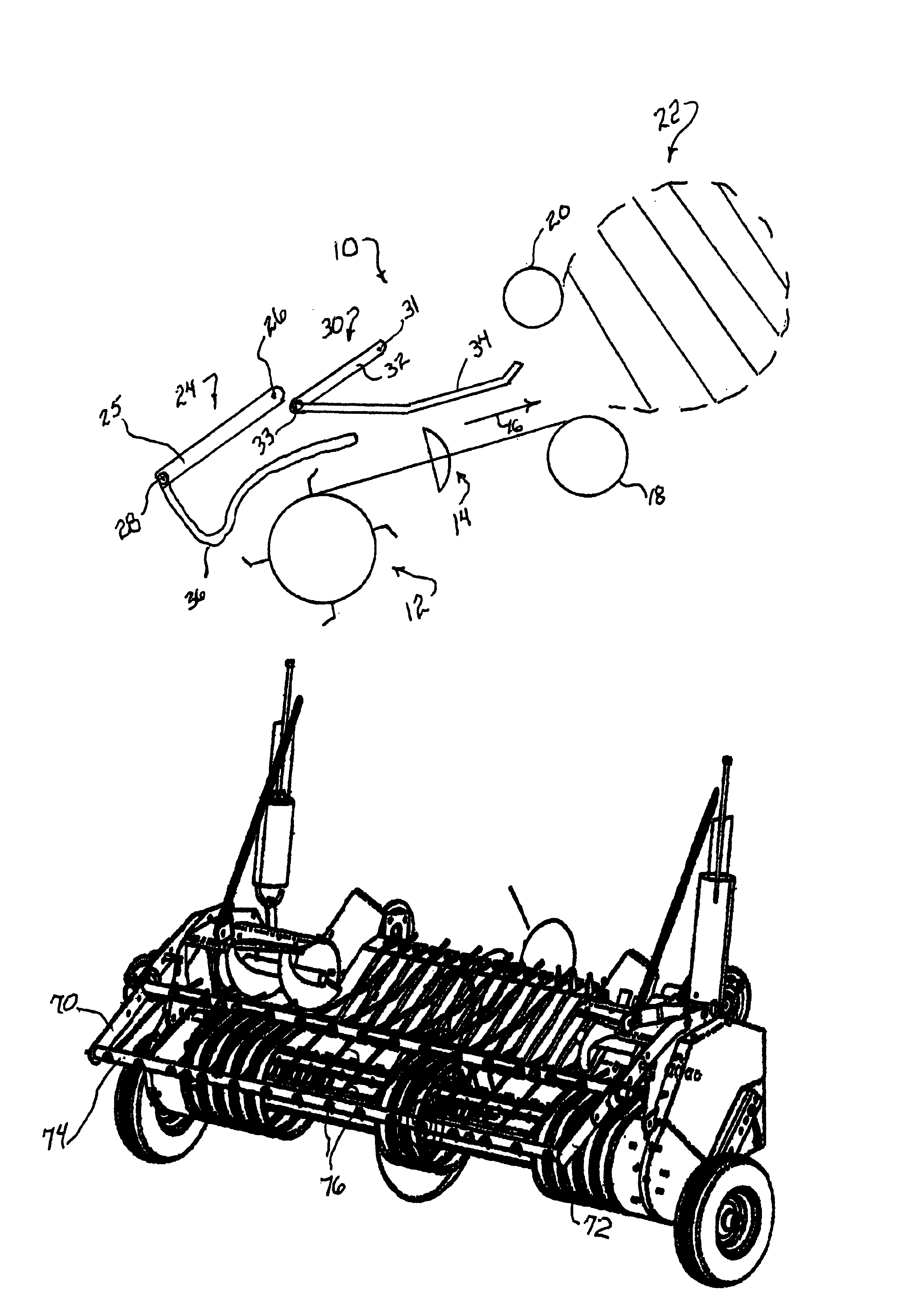

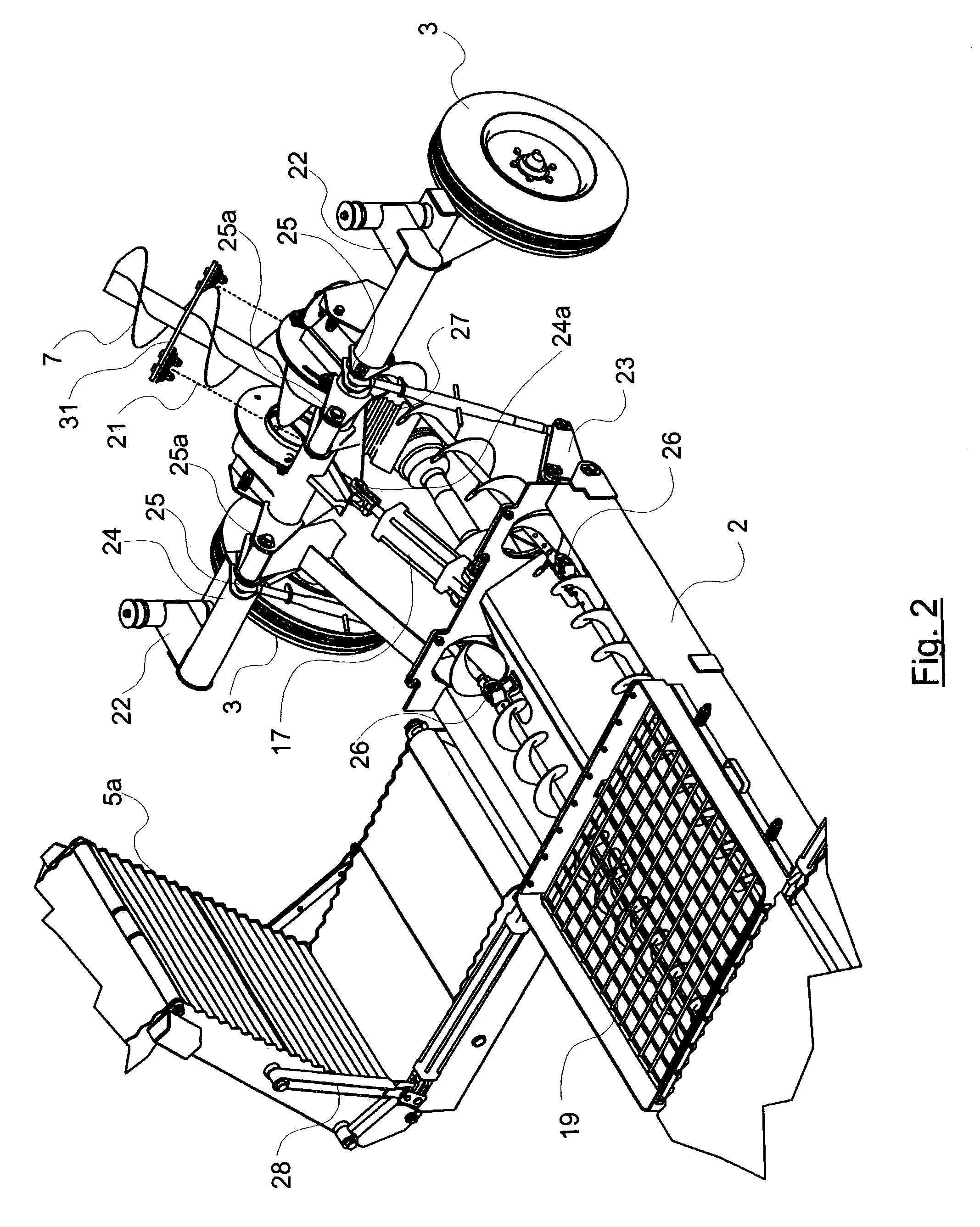

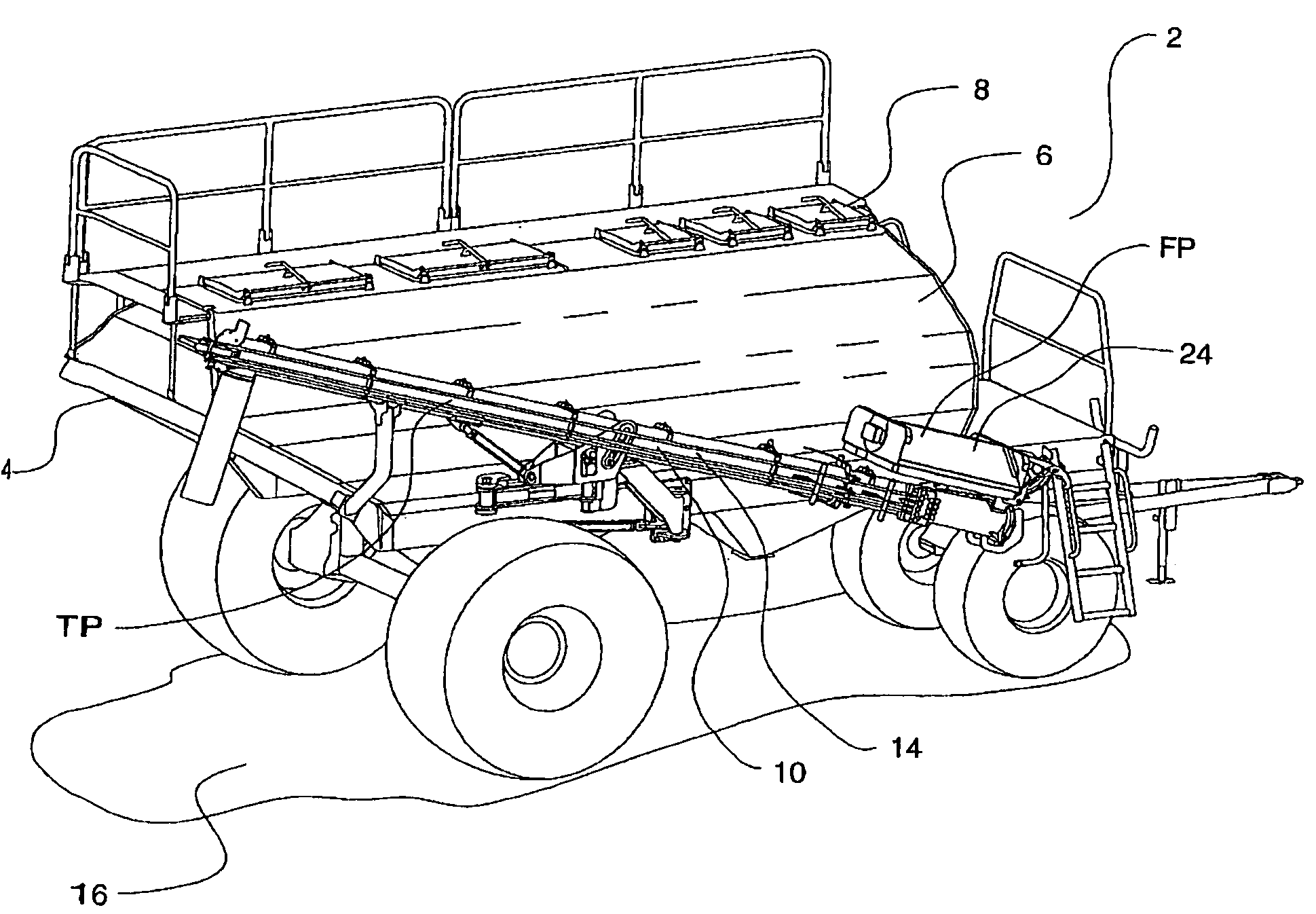

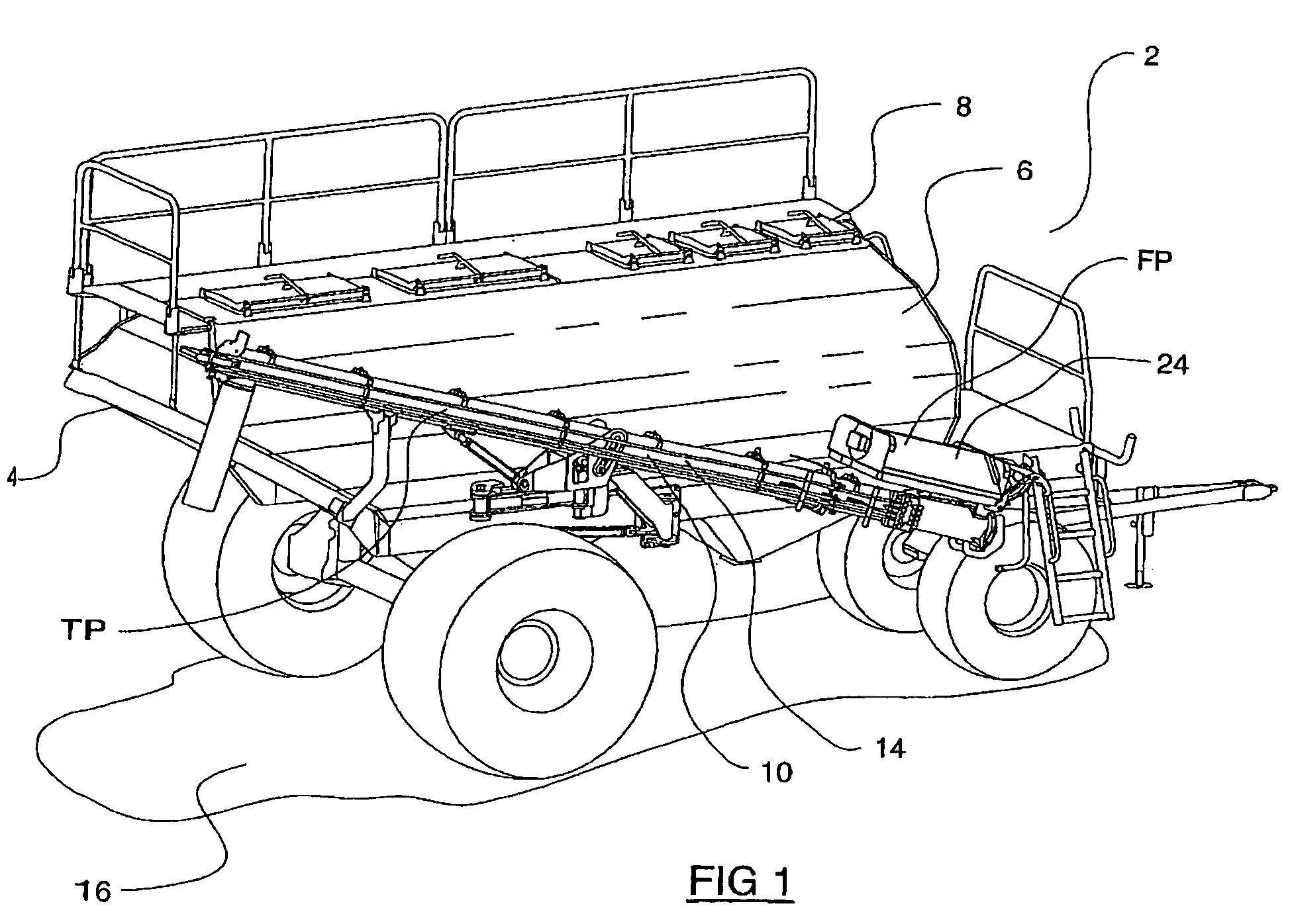

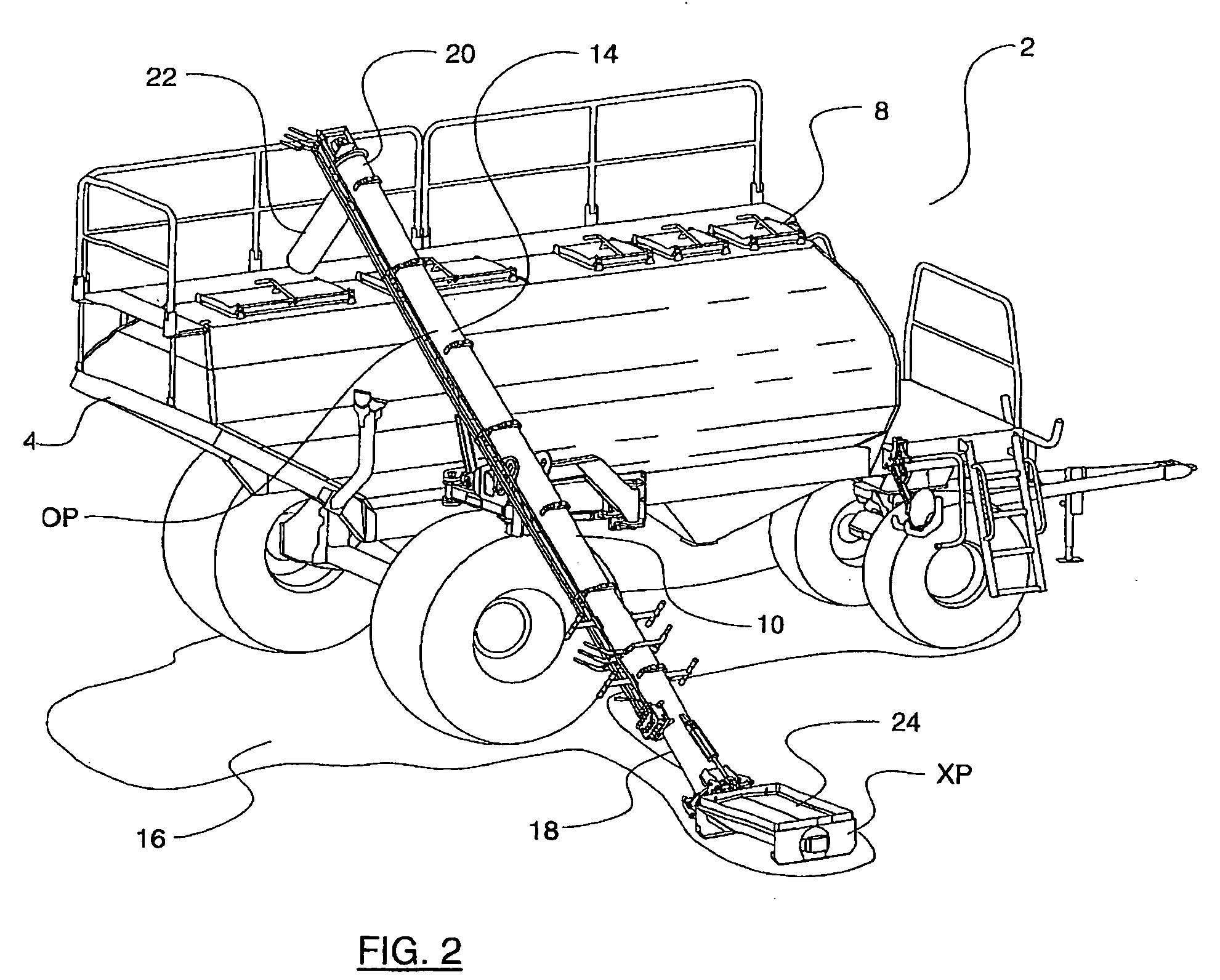

Windguard for round baler

ActiveUS6877304B1Improve versatilityEfficiently and effectively assembleLoadersMowersElectrical and Electronics engineering

Owner:BLUE LEAF I P INC +1

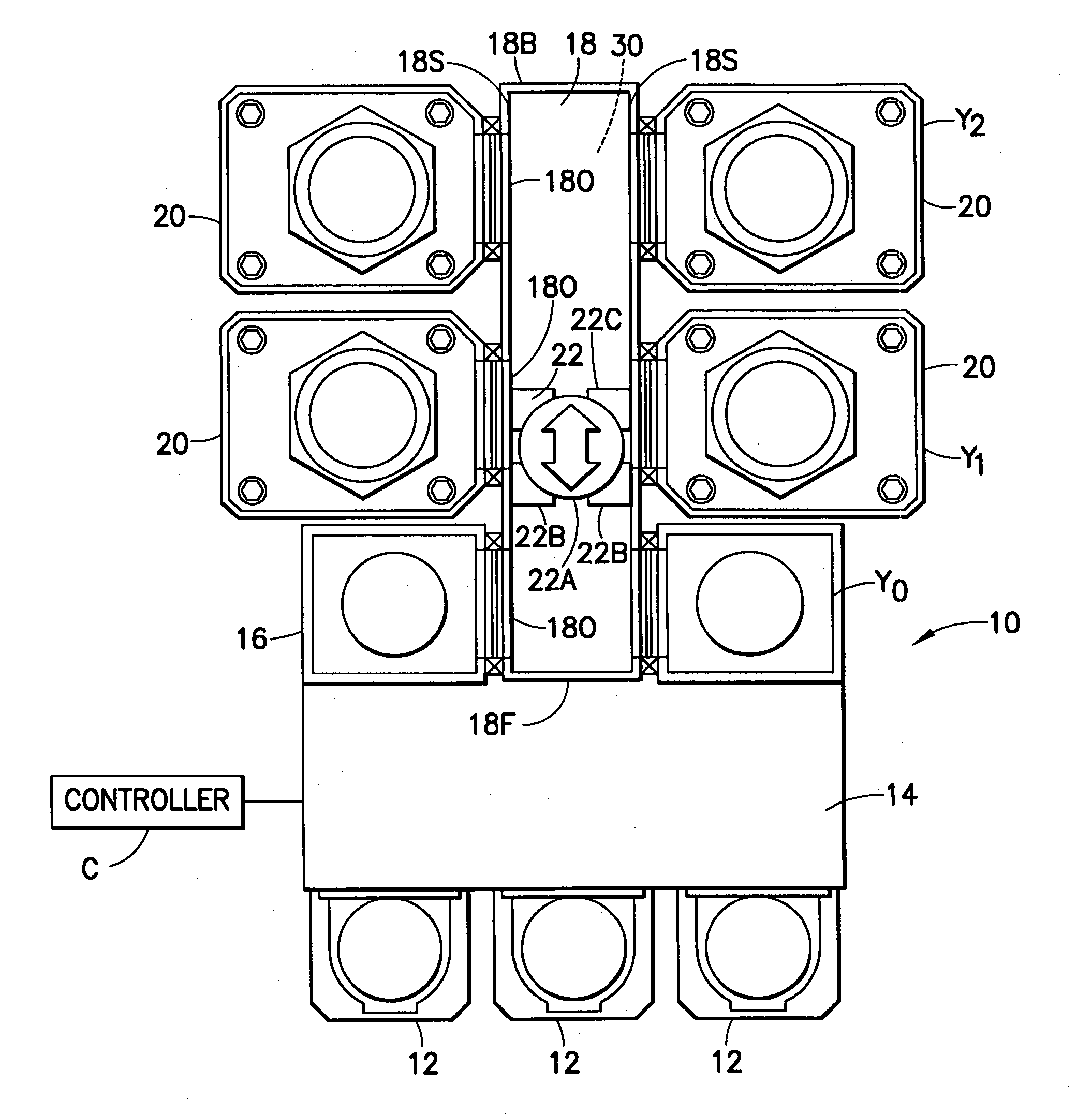

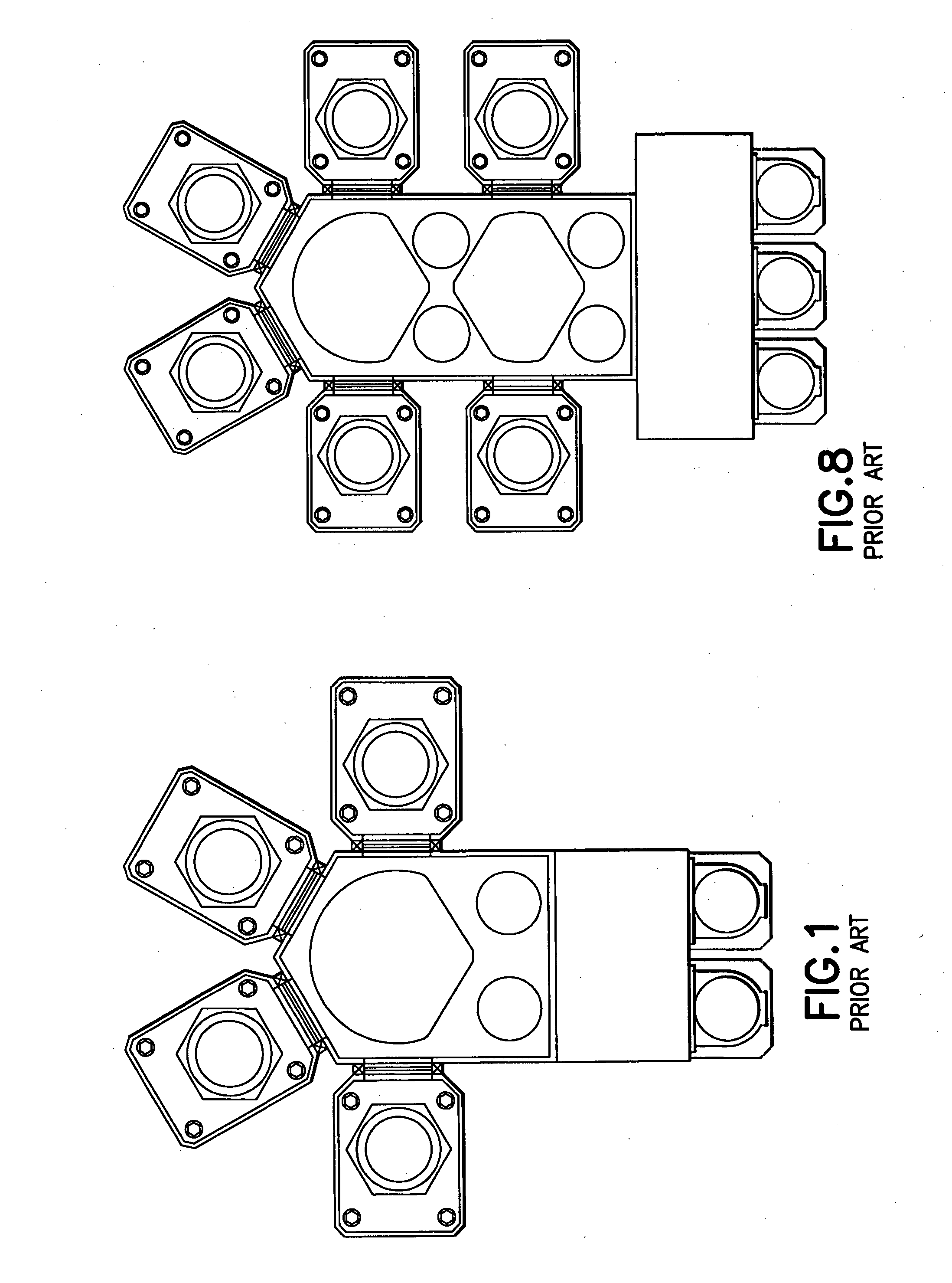

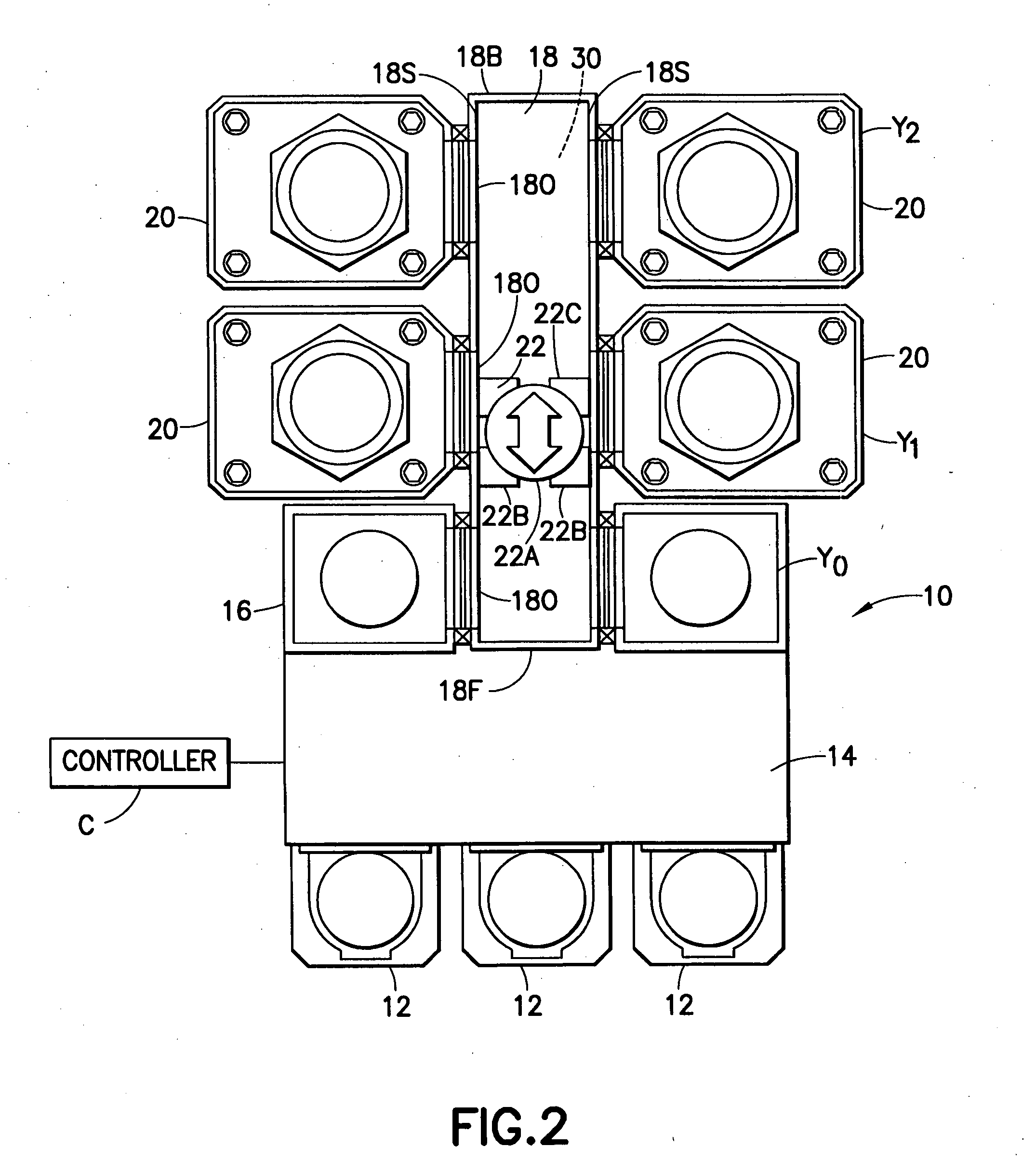

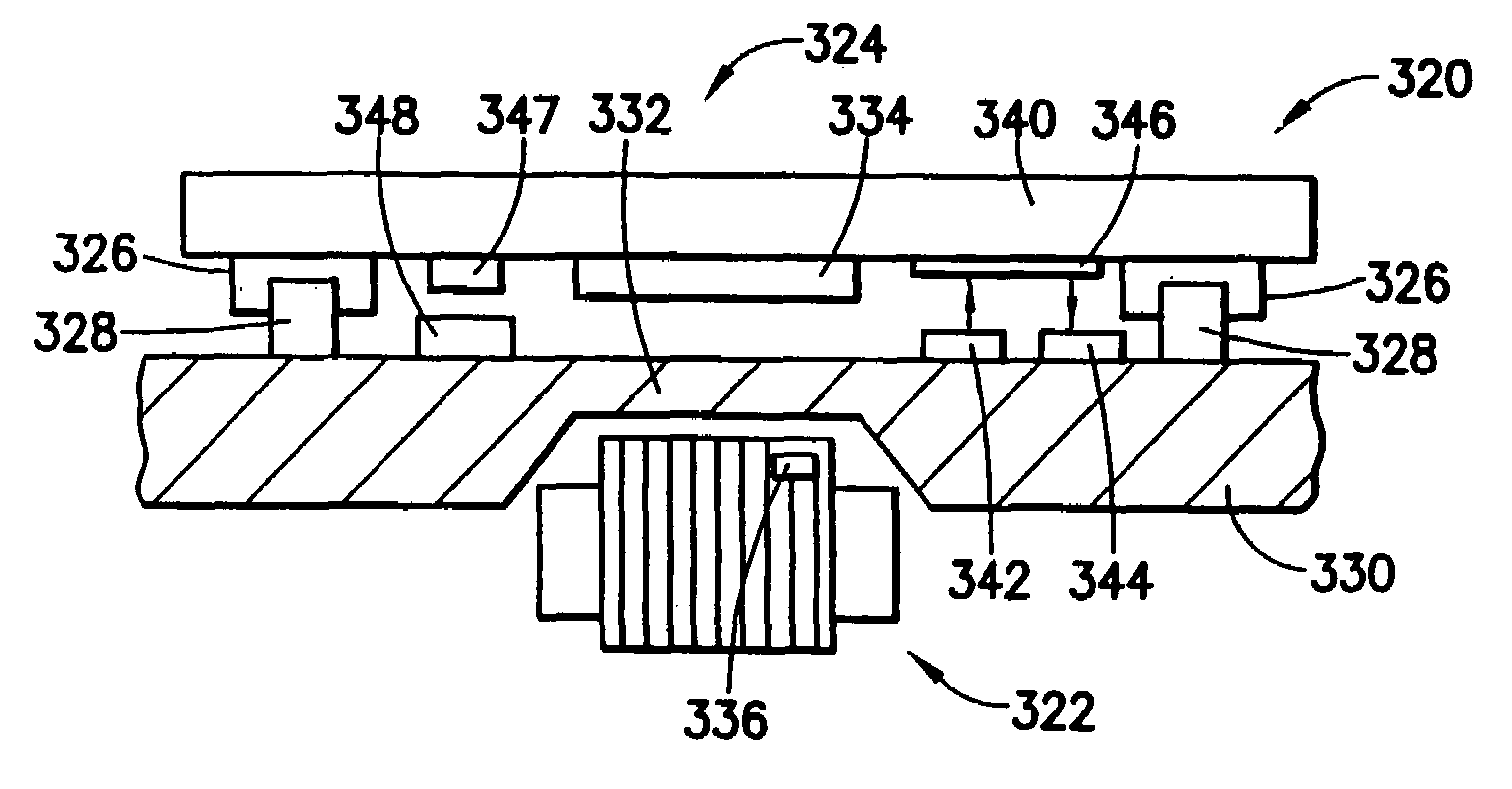

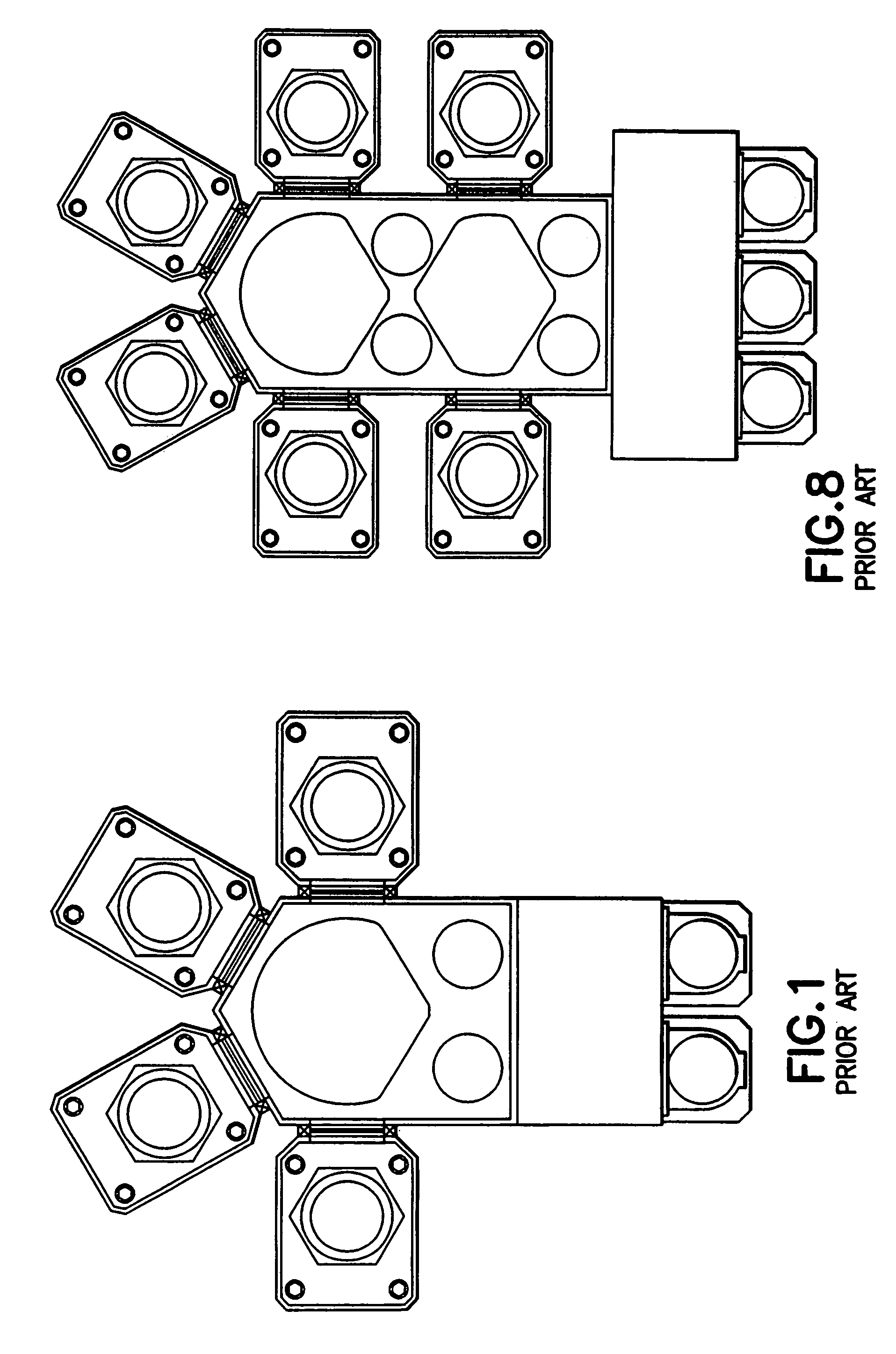

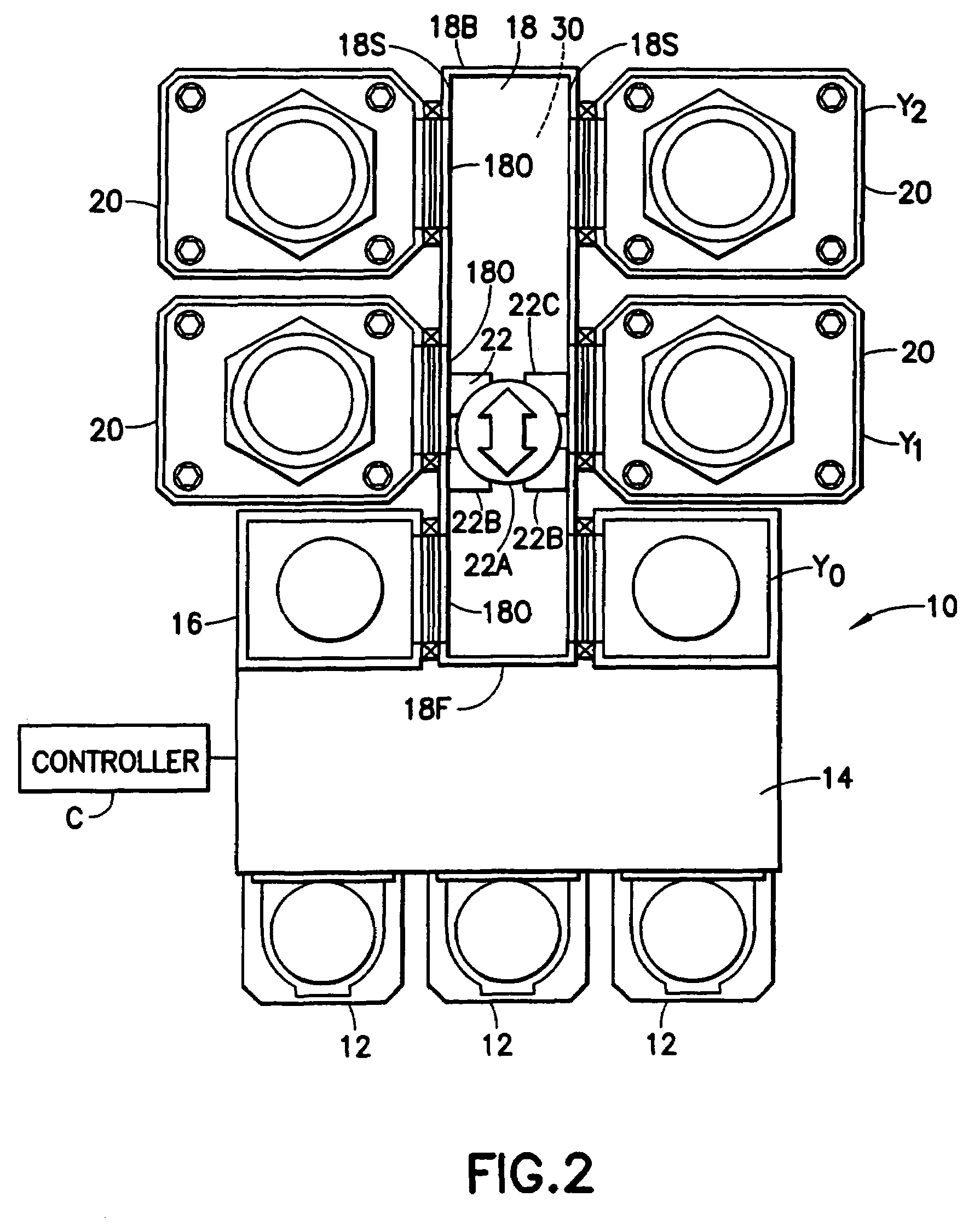

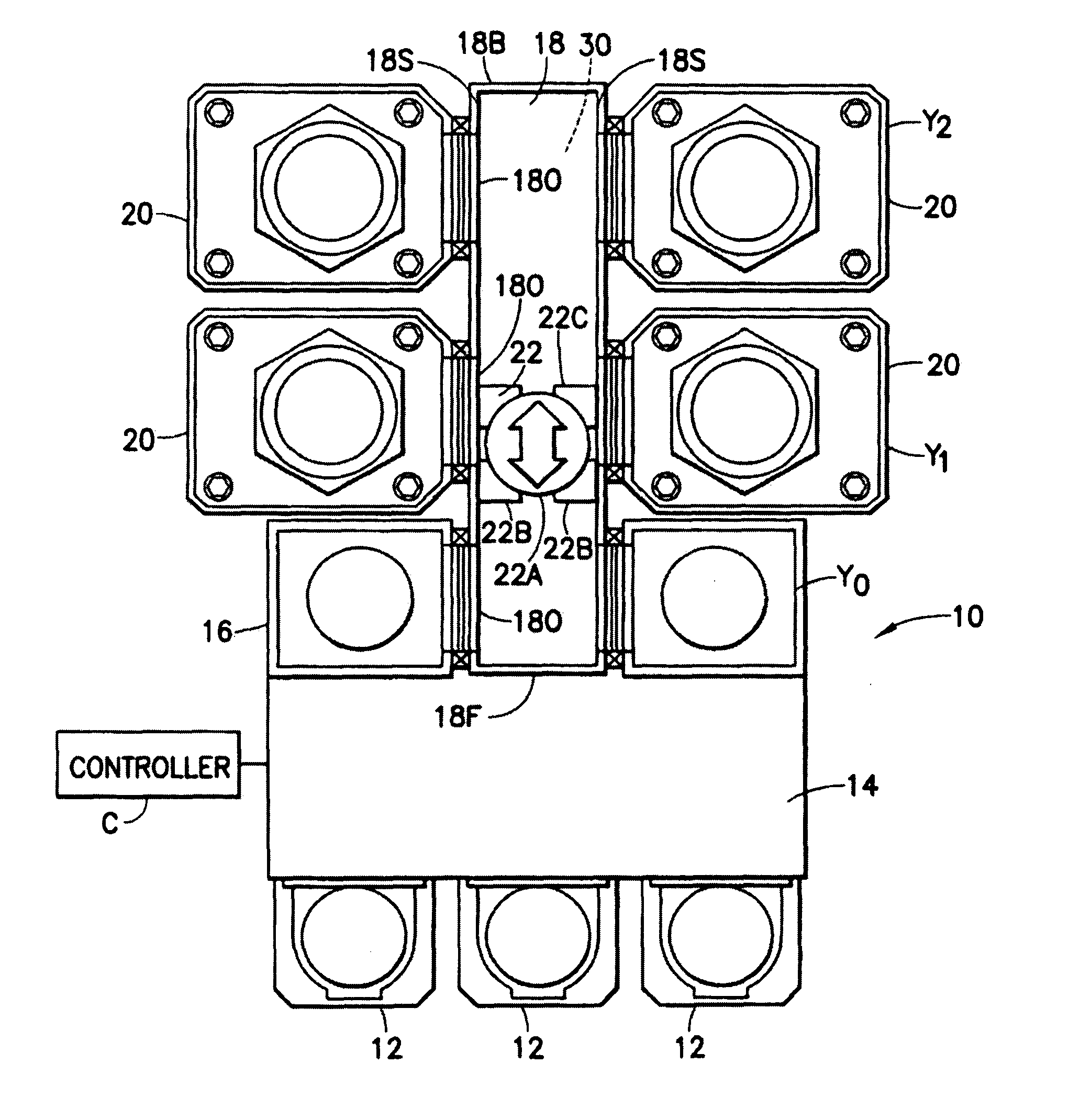

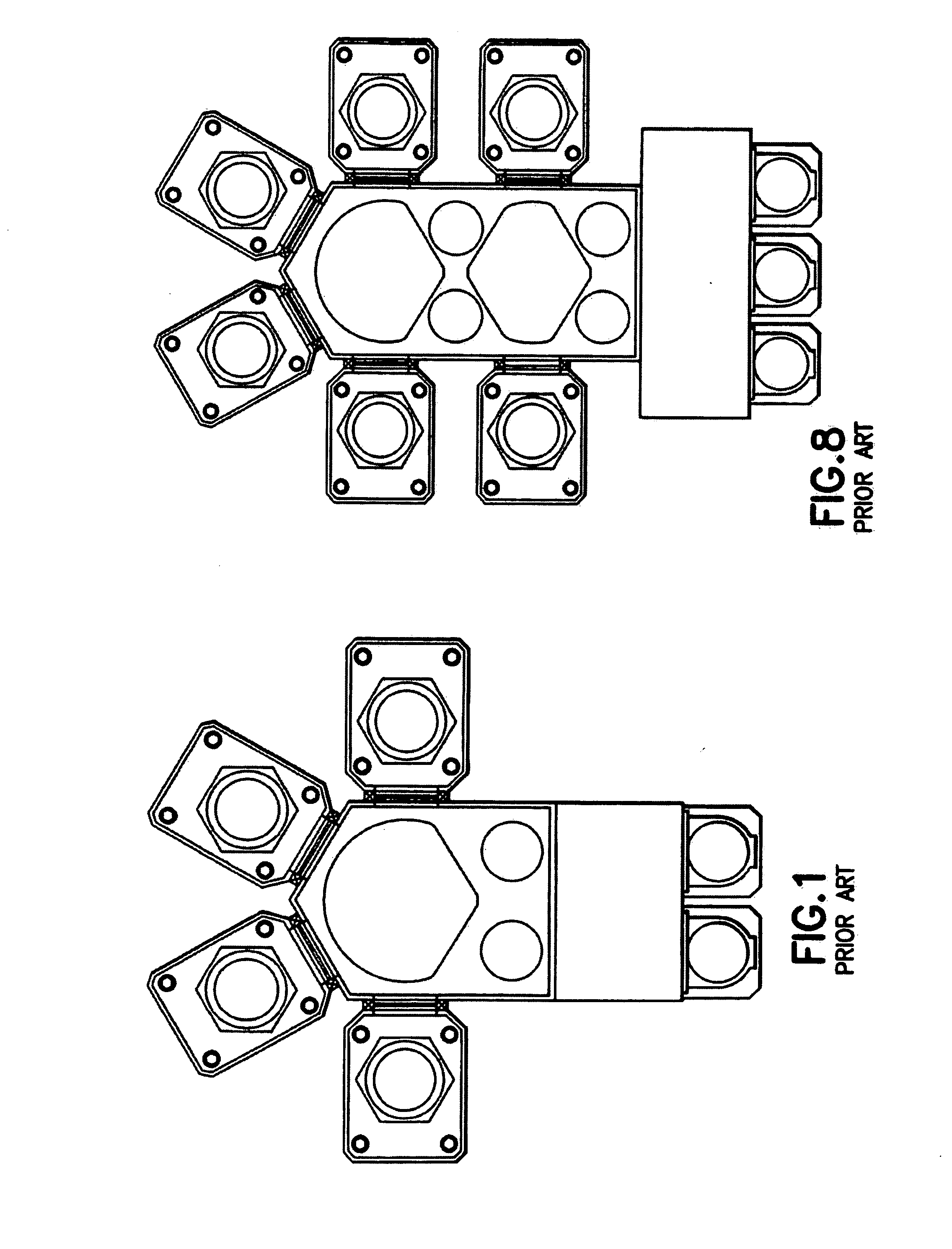

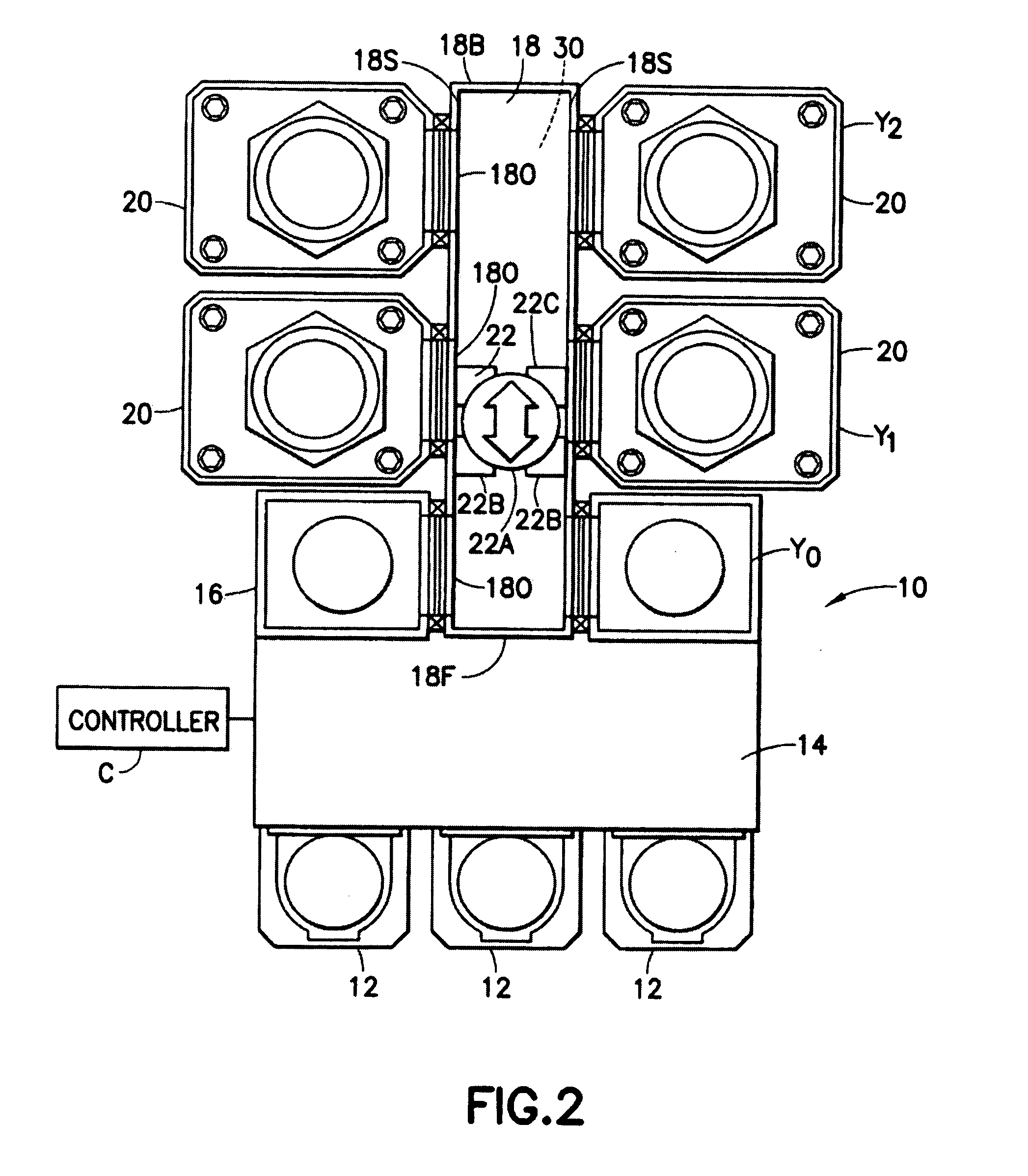

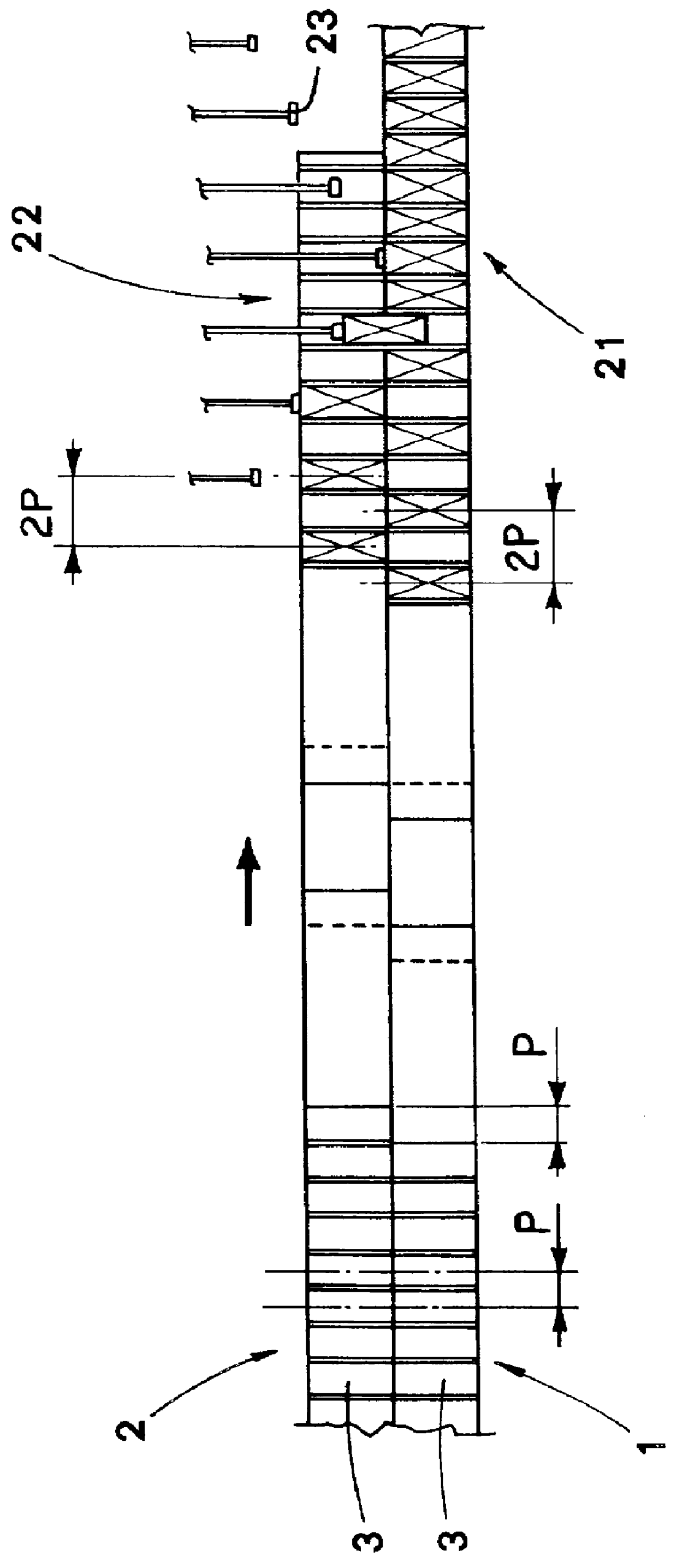

Linear substrate transport apparatus

Substrate processing apparatus having a chamber, a generally linear array of process modules, a substrate transport, and a drive system. The chamber is capable of being isolated from the outside atmosphere. Each process module of the array is communicably connected to the chamber to allow a substrate to be transferred between the chamber and process module. The substrate transport is located in and is movably supported from the chamber. The transport is capable of moving along a linear path defined by the chamber for transporting the substrate between process modules. The drive system is connected to the chamber for driving and moving the transport along the linear path. The chamber comprises a selectable number of chamber modules serially abutted to defined the chamber. Each module has an integral portion of the drive system.

Owner:BOOKS AUTOMATION US LLC

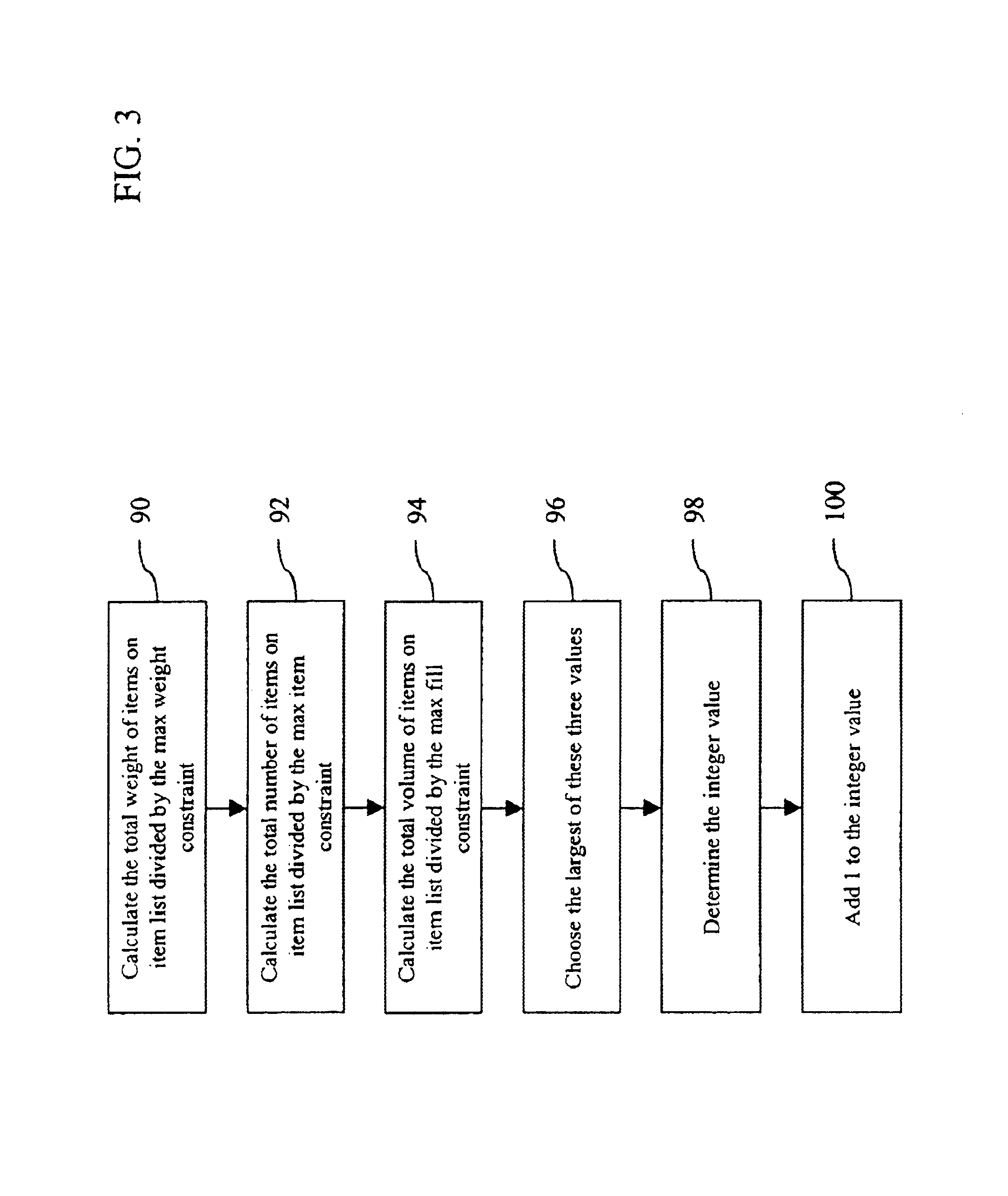

Method and system of optimized sequencing and configuring of items for packing in a bounded region

The present invention includes methods of selecting cases in which to pack items in an item order and selecting the sequence and configuration of placement of items into the selected cases. One such method includes examining an order comprising a list of items to be packed, determining the cases available for packing, determining the minimum number of cases required for packing the items in the list of items to be packed, selecting a case to be packed with one or more of the items in the list of items to be packed, wherein said selecting a case comprises determining a desired average volume per case and selecting the smallest of the cases available to be packed that comprises a volume in excess of the average volume per case, and determining the configuration of placement in the case to be packed of items in the list of items to be packed. Such steps may be repeated until all items in the item list are selected and configured for packing.

Owner:NEW BREED

Substrate processing apparatus

A semiconductor workpiece processing apparatus having a first chamber, a transport vehicle, and another chamber. The first chamber is capable of being isolated from an outside atmosphere. The transport vehicle is located in the first chamber and is movably supported from the first chamber for moving linearly relative to the first chamber. The transport vehicle includes a base, and an integral semiconductor workpiece transfer arm movably mounted to the base and capable of multi-access movement relative to the base. The other chamber is communicably connected to the first chamber via a closable opening of the first chamber. The opening is sized to allow the transport vehicle to transit between the first chamber and the other chamber through the opening.

Owner:BOOKS AUTOMATION US LLC

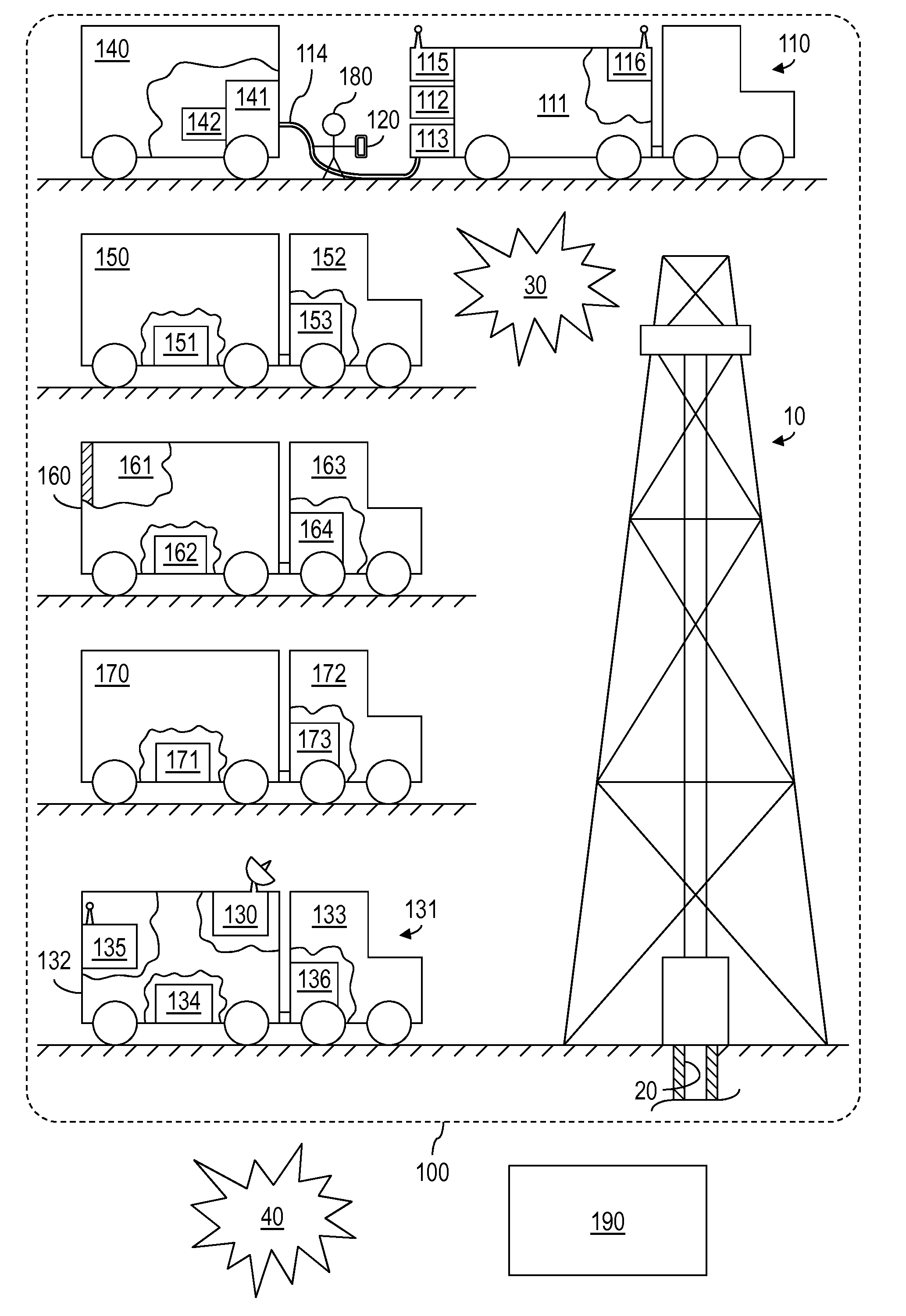

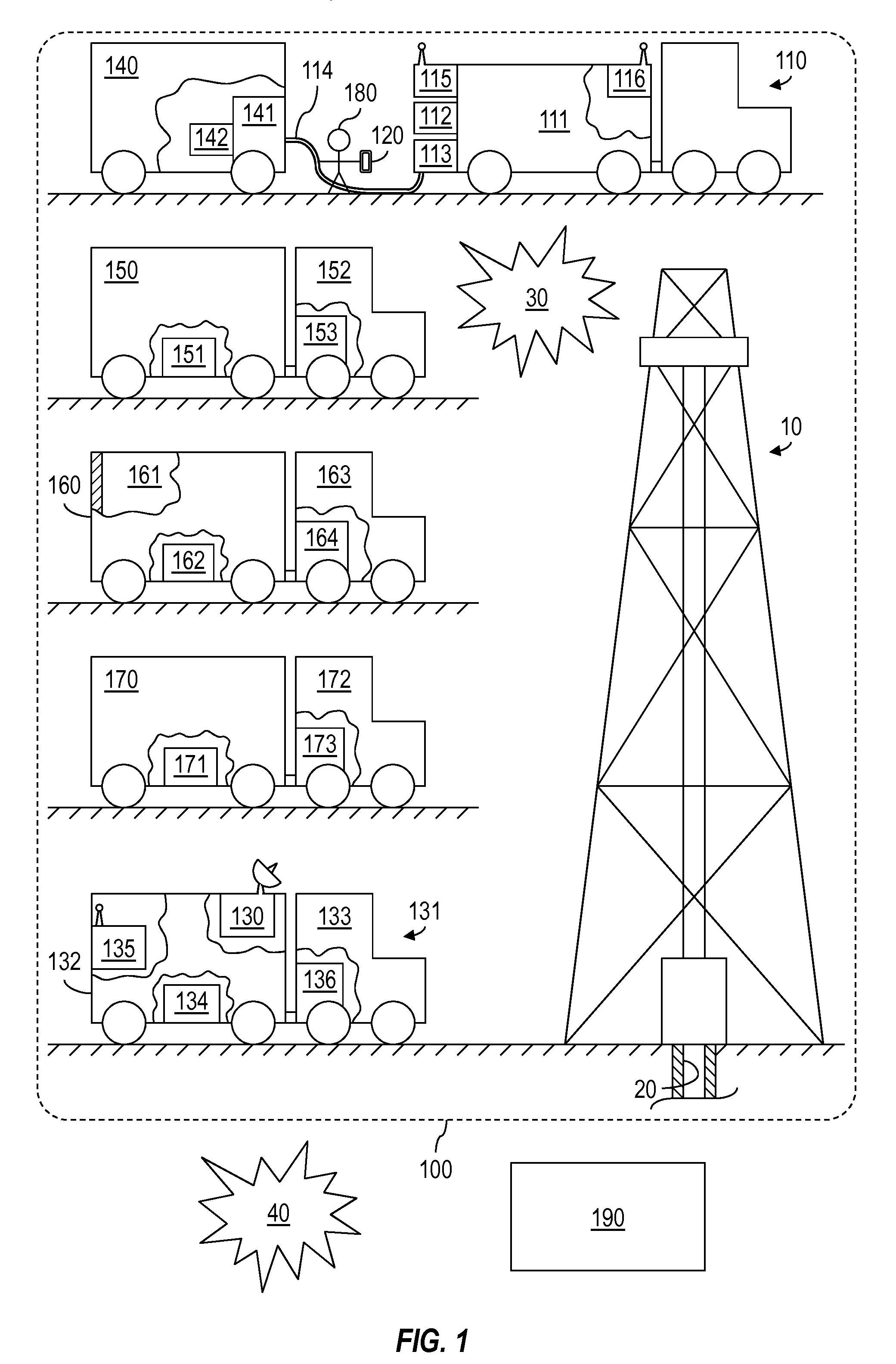

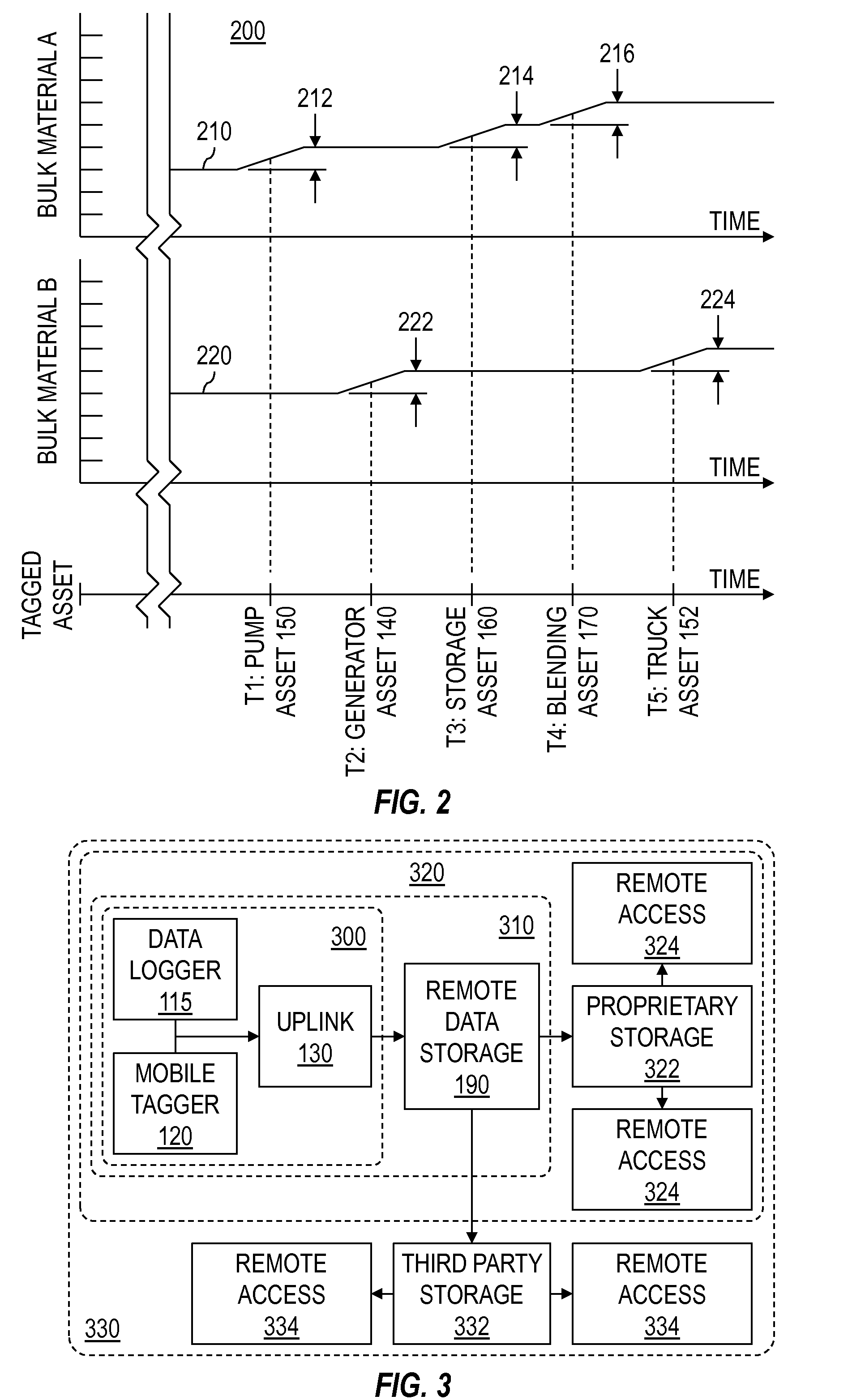

Remote wellsite material tracking

A wellsite system that includes a bulk material transporter, a mobile tagger, and an uplink. The bulk material transporter includes a supply of a bulk material, a meter to measure output from the supply, and a data logger to log the output as a function of a predetermined parameter. The mobile tagger assigns transfer parameters to each transfer of the bulk material from the supply to one of multiple assets located at the wellsite, including the output measured by the meter. The uplink wirelessly transmits data from the log and the transfer parameters to remote data storage not located at the wellsite.

Owner:SCHLUMBERGER TECH CORP

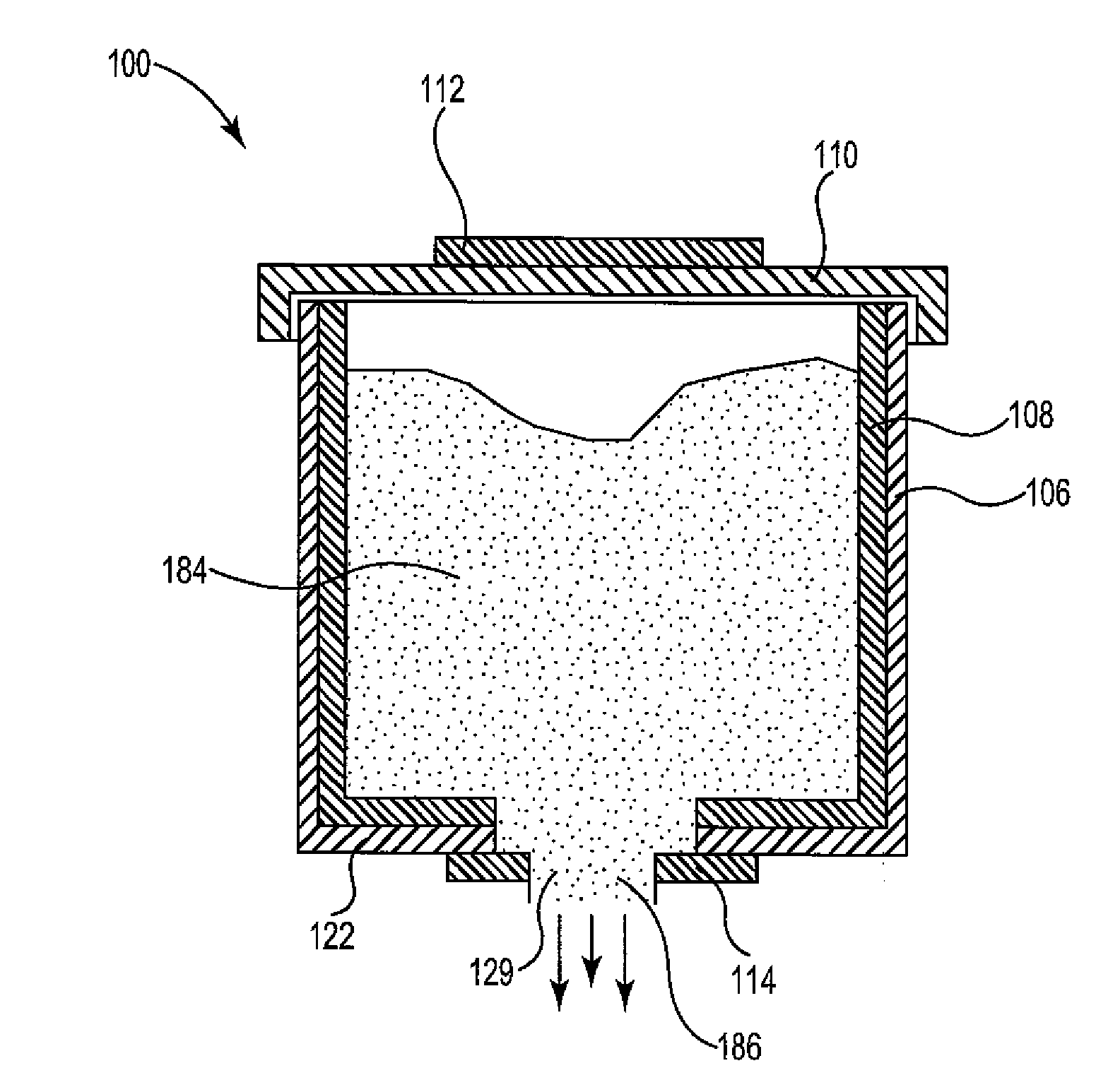

Container system for hydraulic fracturing proppants

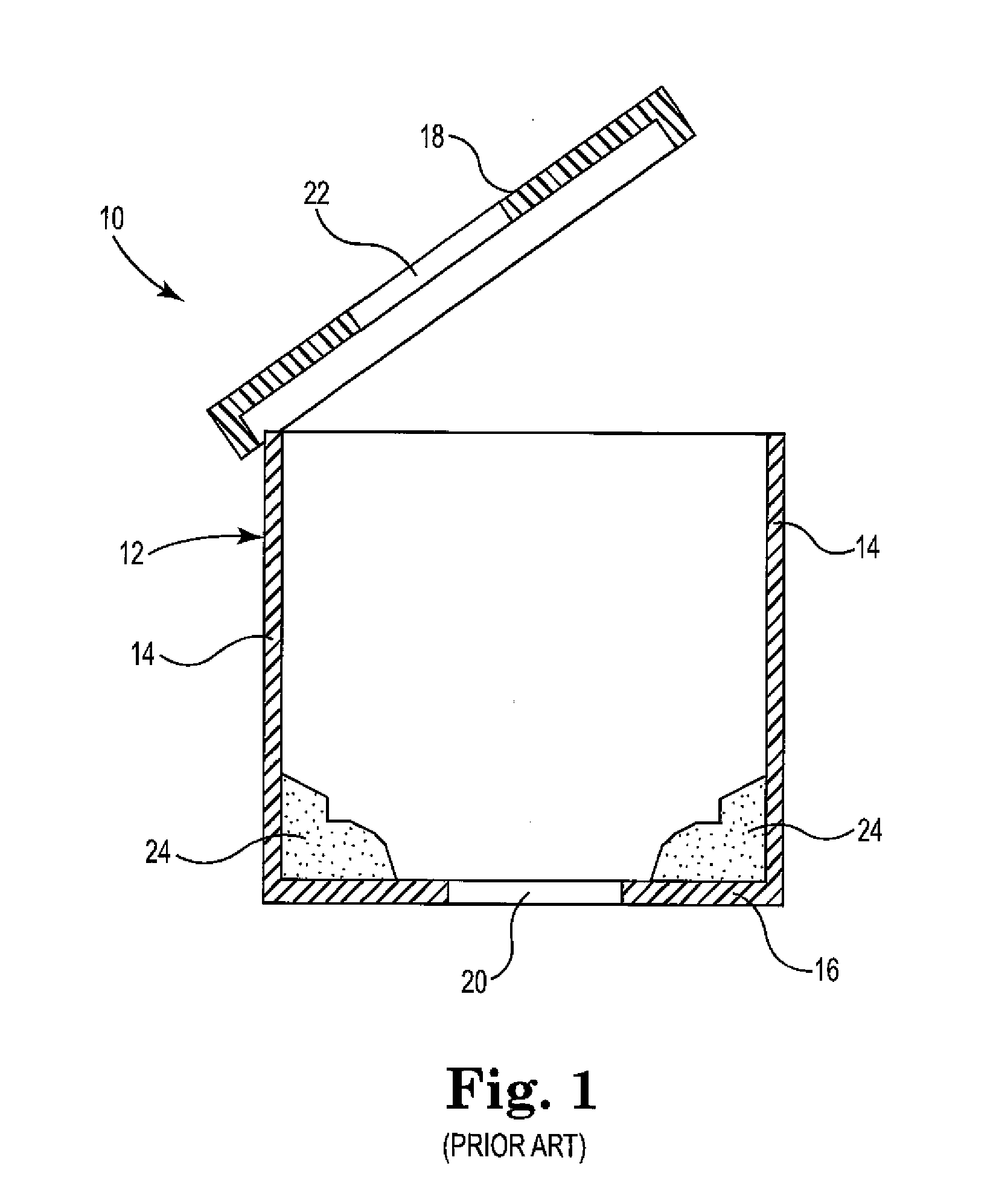

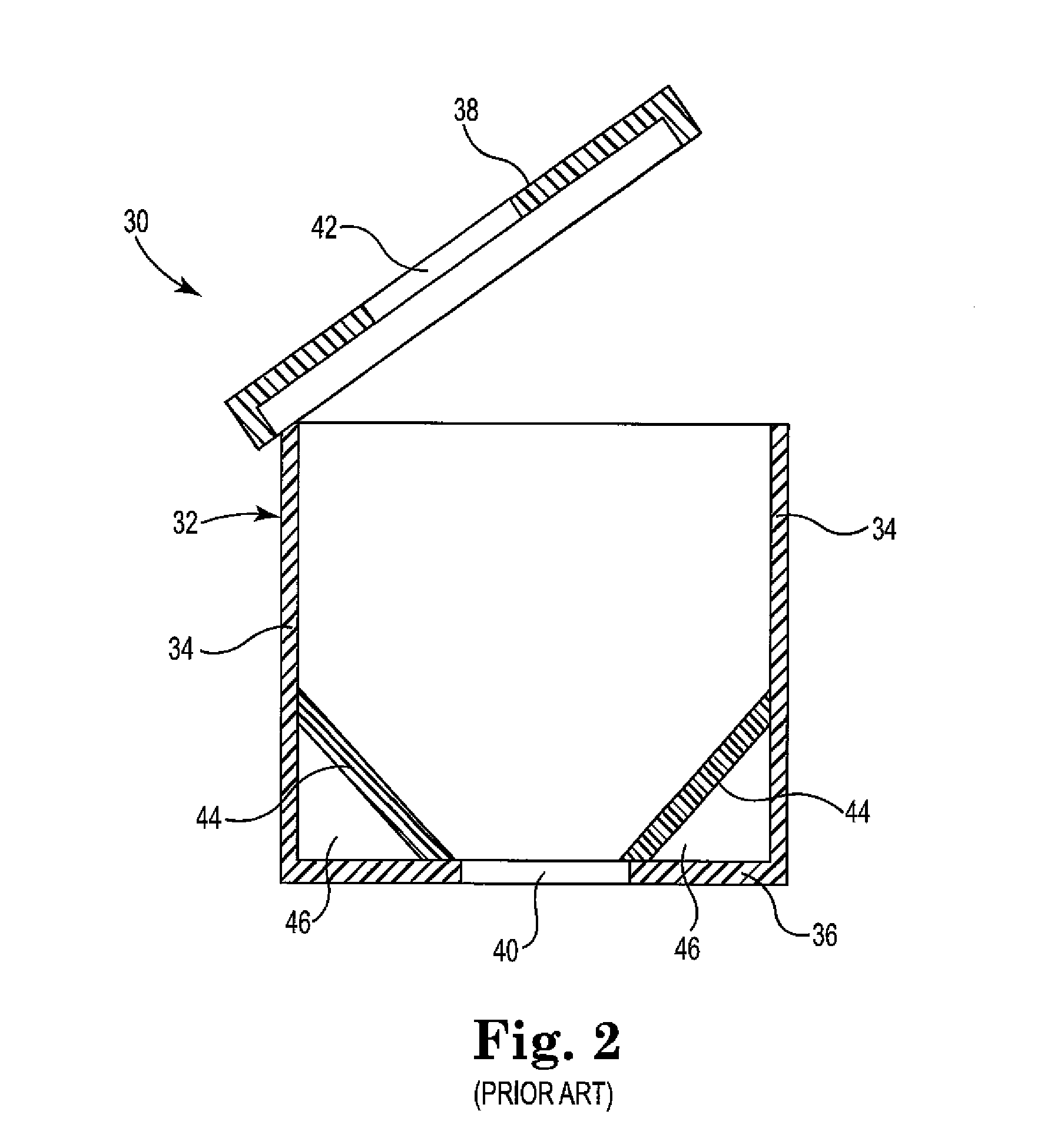

InactiveUS20150086307A1Large storage capacityIncrease storage capacityLoadersLarge containersEngineeringHydraulic fracturing proppants

Described herein is an improved container for storing, shipping, and dispensing proppant materials used in hydraulic fracturing operations. The container systems incorporate stretchable hopper structures in the container. The hopper expands and contracts responsive to the amount of proppant material held in the container. When the container is filled with a sufficient amount of proppant, the hopper stretches to expand the storage volume. When the sufficient amount of proppant material is dispensed from the container, the hopper contracts to lift and dispense the container contents.

Owner:PROPPANT EXPRESS SOLUTIONS LLC

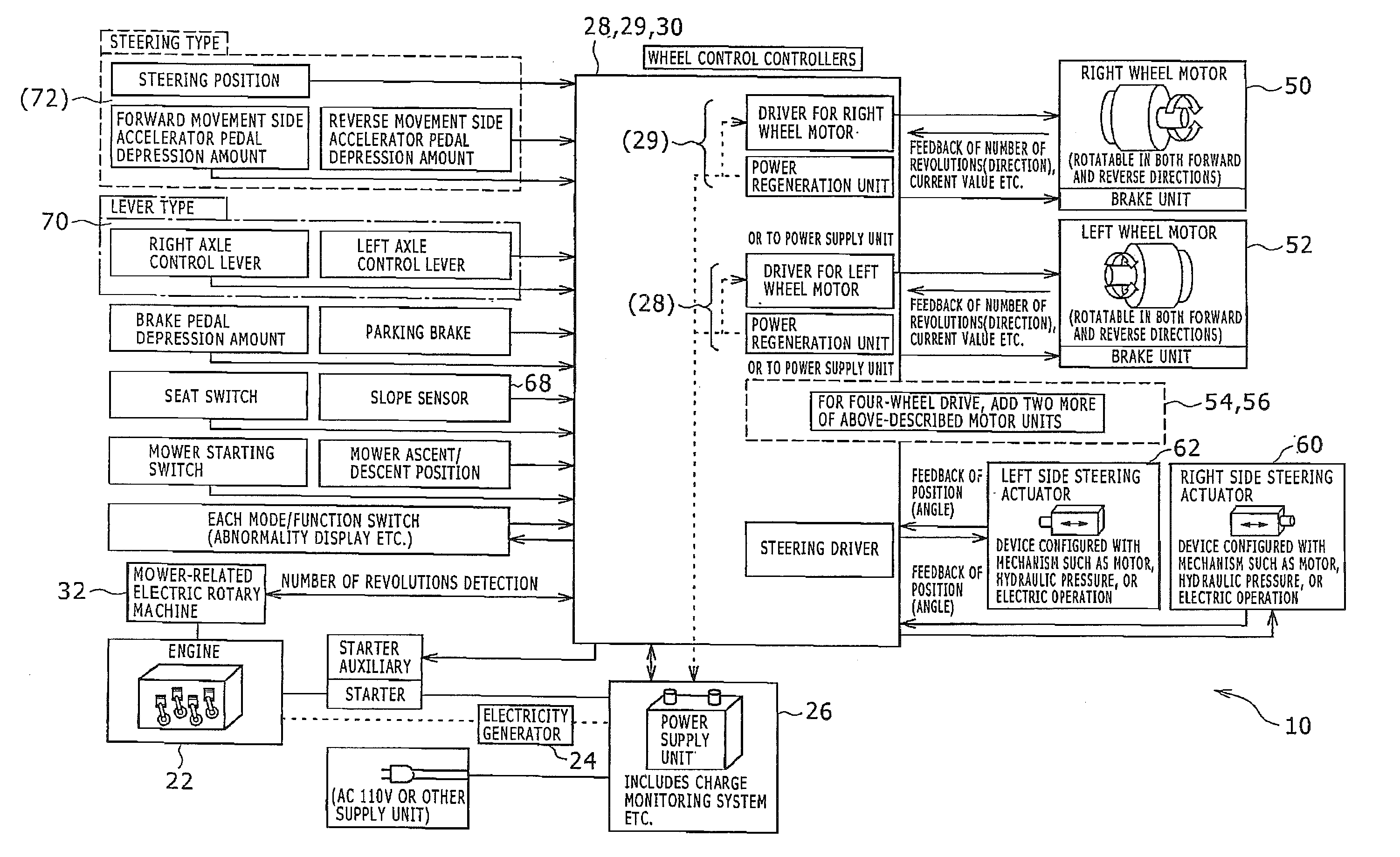

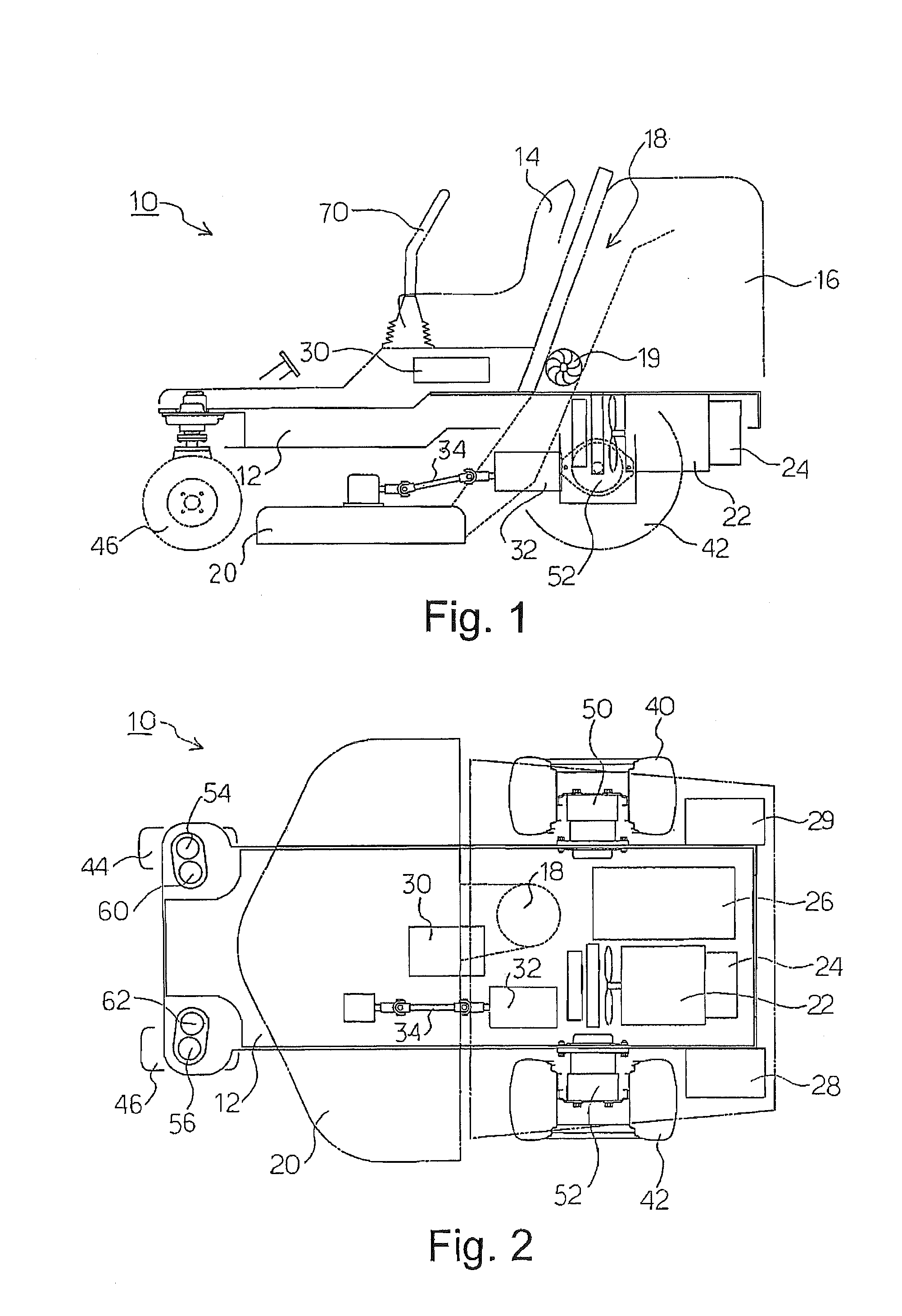

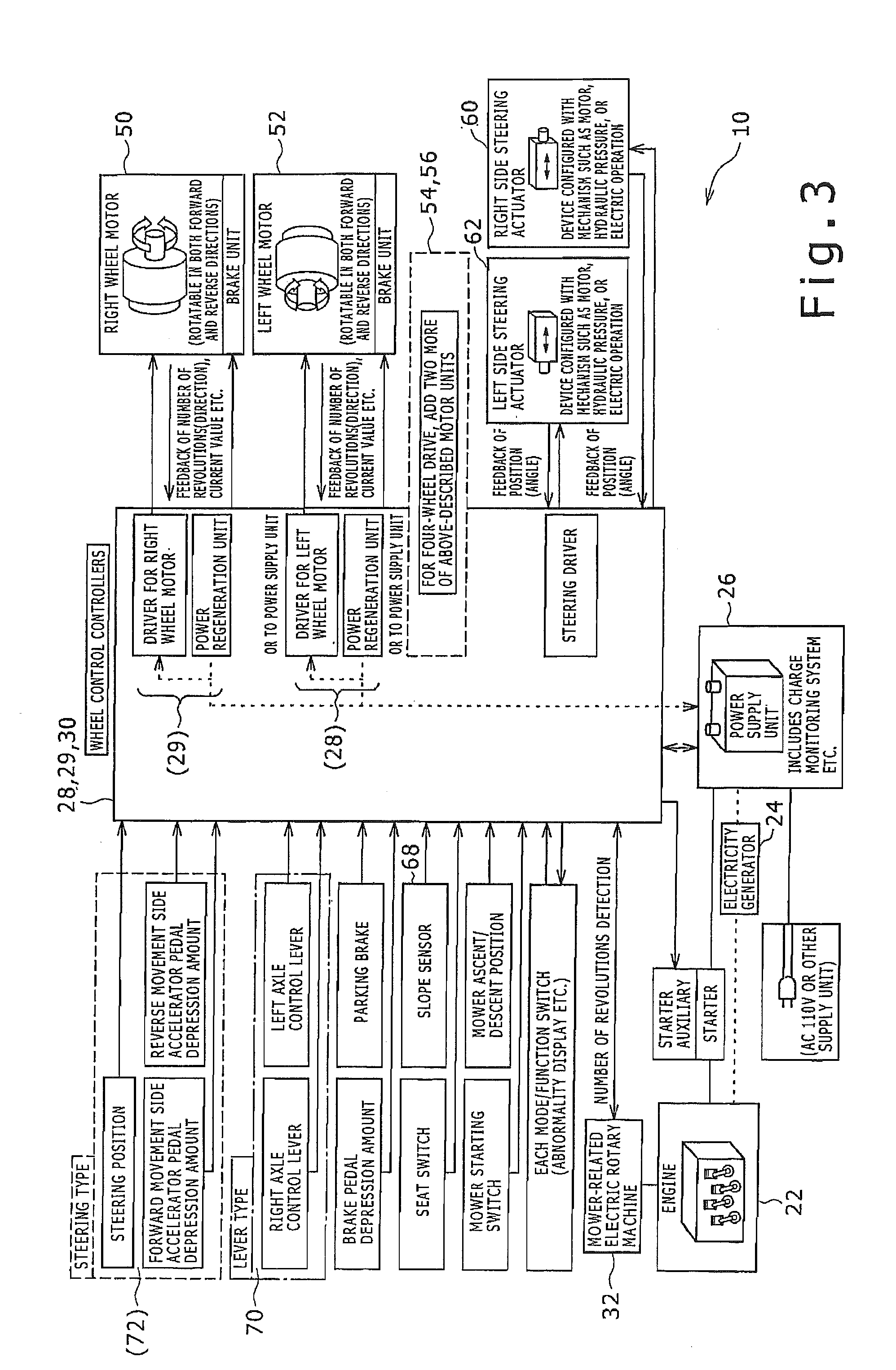

Control sysytem for motor-driven lawnmower vehicle

A control system for an engineless, motor-driven lawnmower vehicle includes electric motors and controllers. At least one of the electric motors is an electric drive motor connected to a drive wheel of the lawnmower vehicle to enable transmission of motive power. At least one other electric motor is a mower-related electric motor connected to a lawnmower rotary tool to enable transmission of motive power. At least one of the controllers is a drive wheel controller which includes a drive wheel driver and which controls operation of the electric drive motor in response to a signal from at least one operator sensor for detecting an operation amount of at least one operator. At least one controller controls to activate or stop the mower-related electric motor. At least one controller is connected to the drive wheel controller and transmits a control signal thereto in response to a signal from the operator sensor.

Owner:KANZAKI KOKYUKOKI MFG

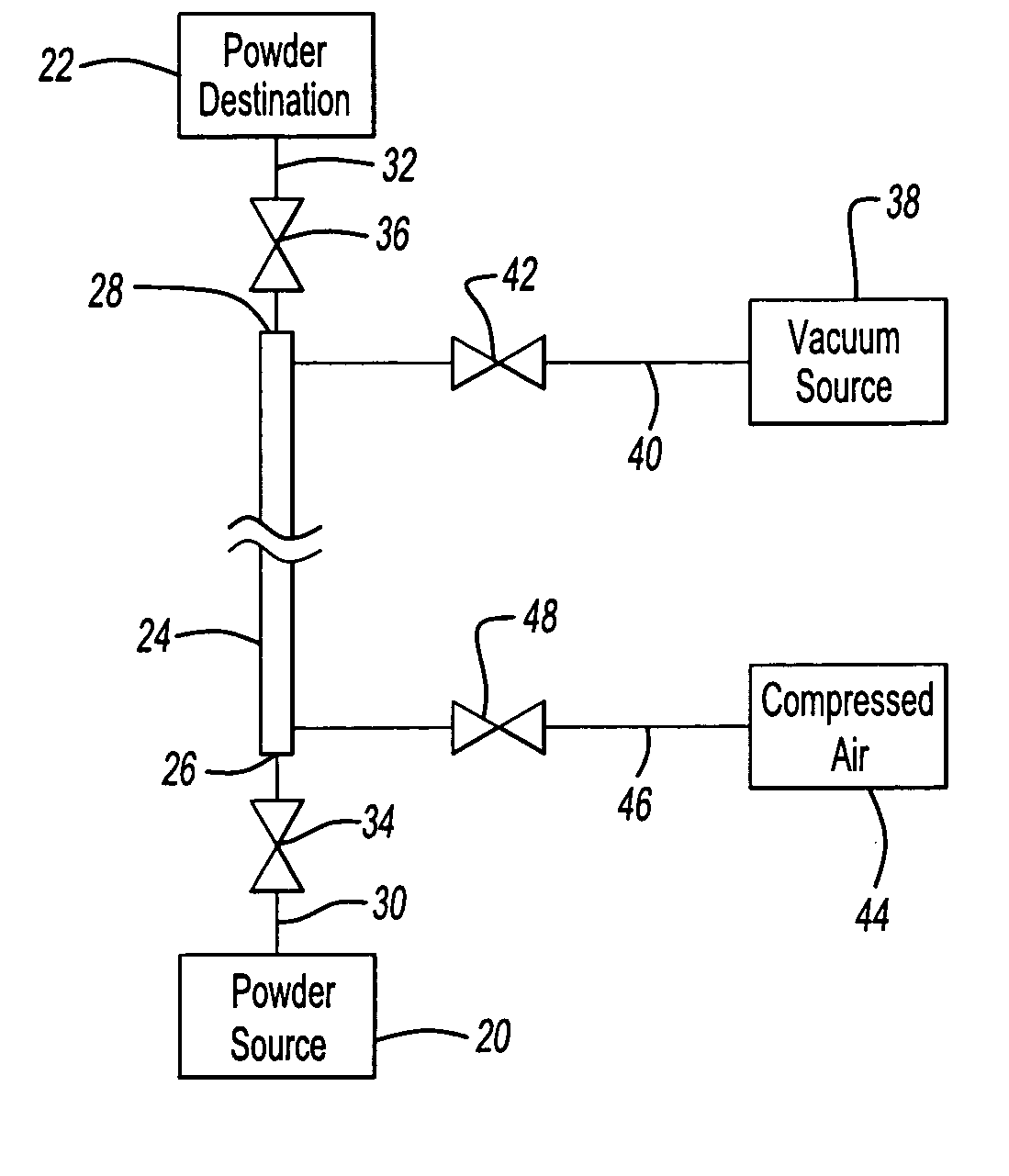

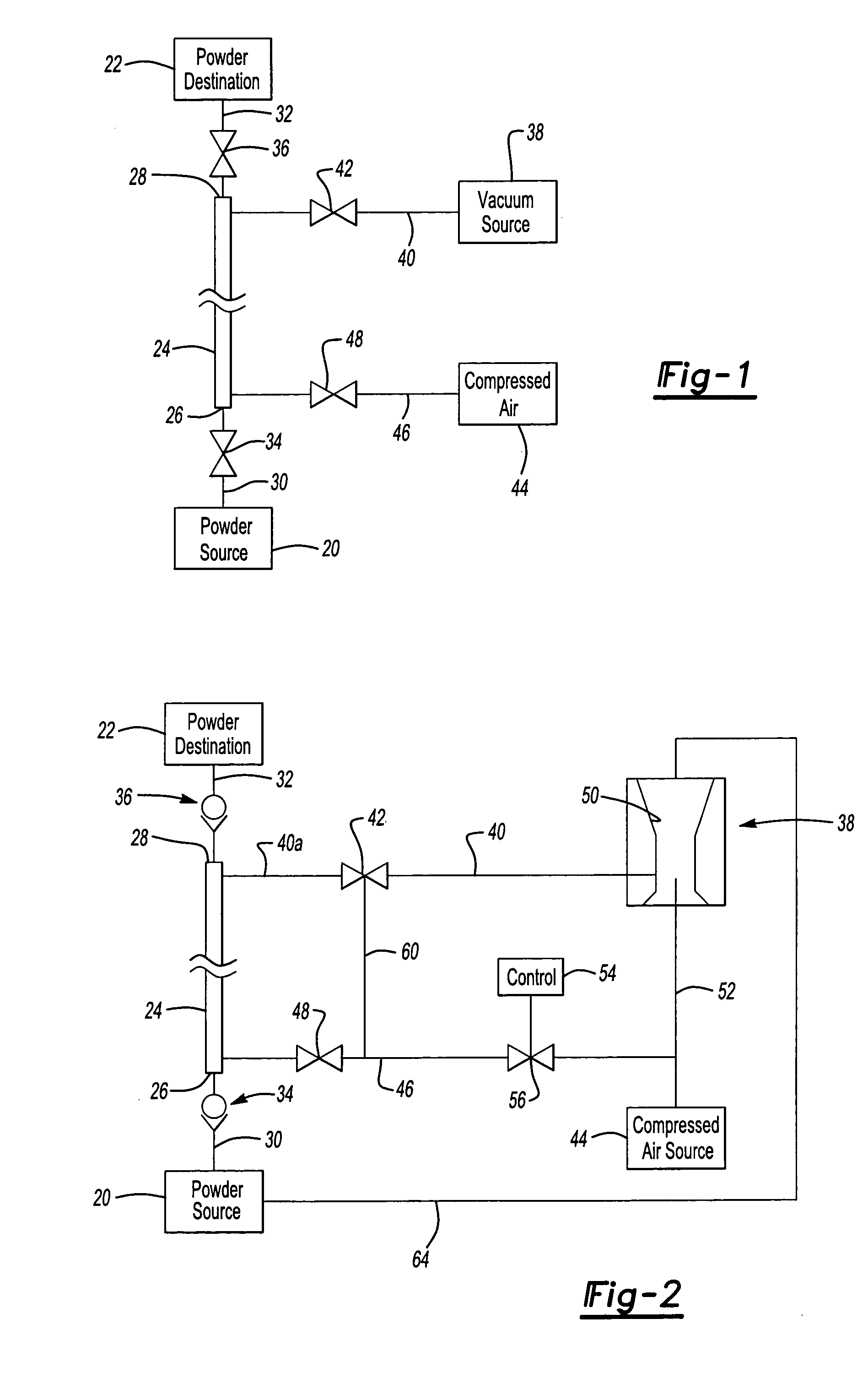

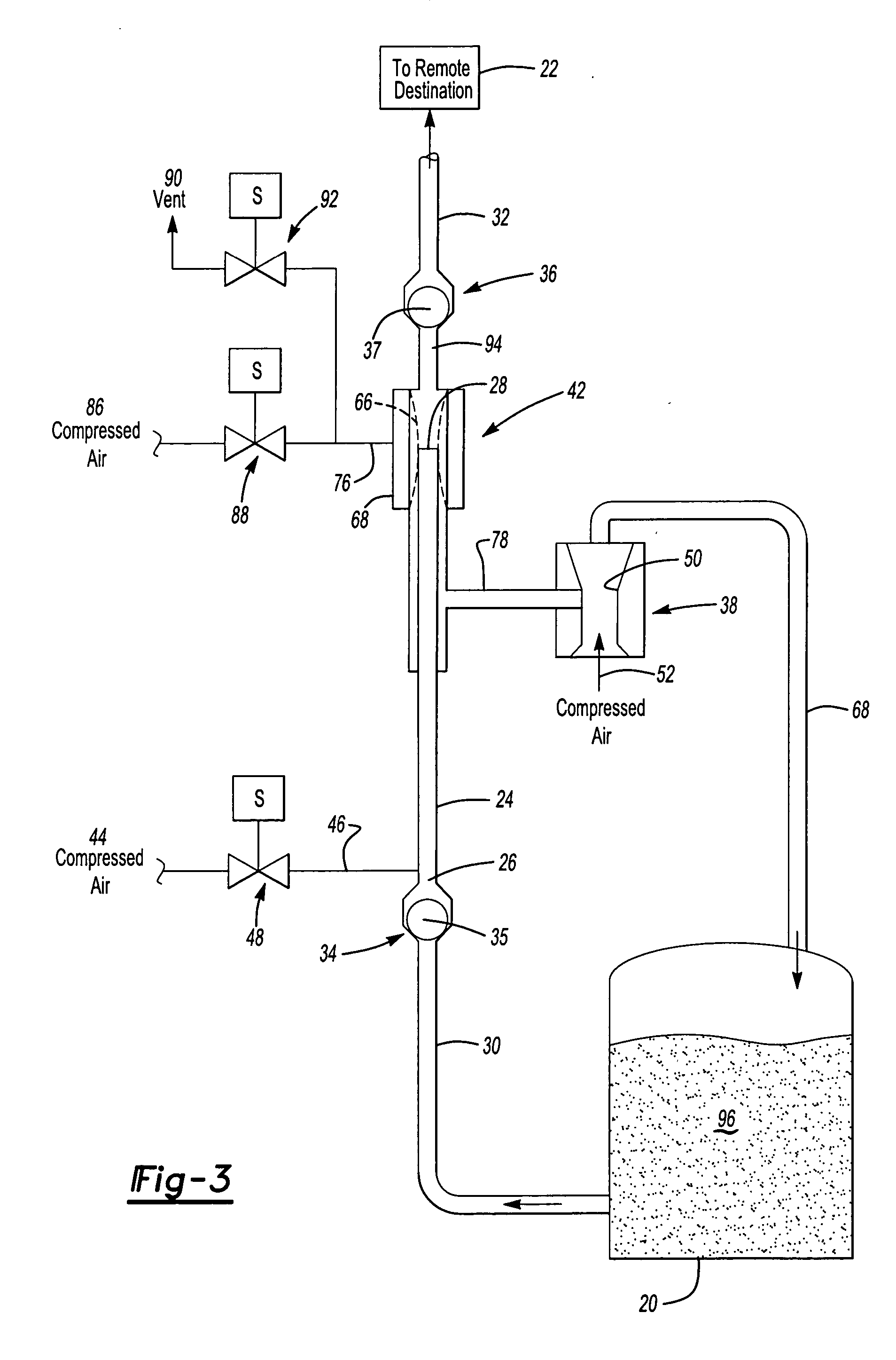

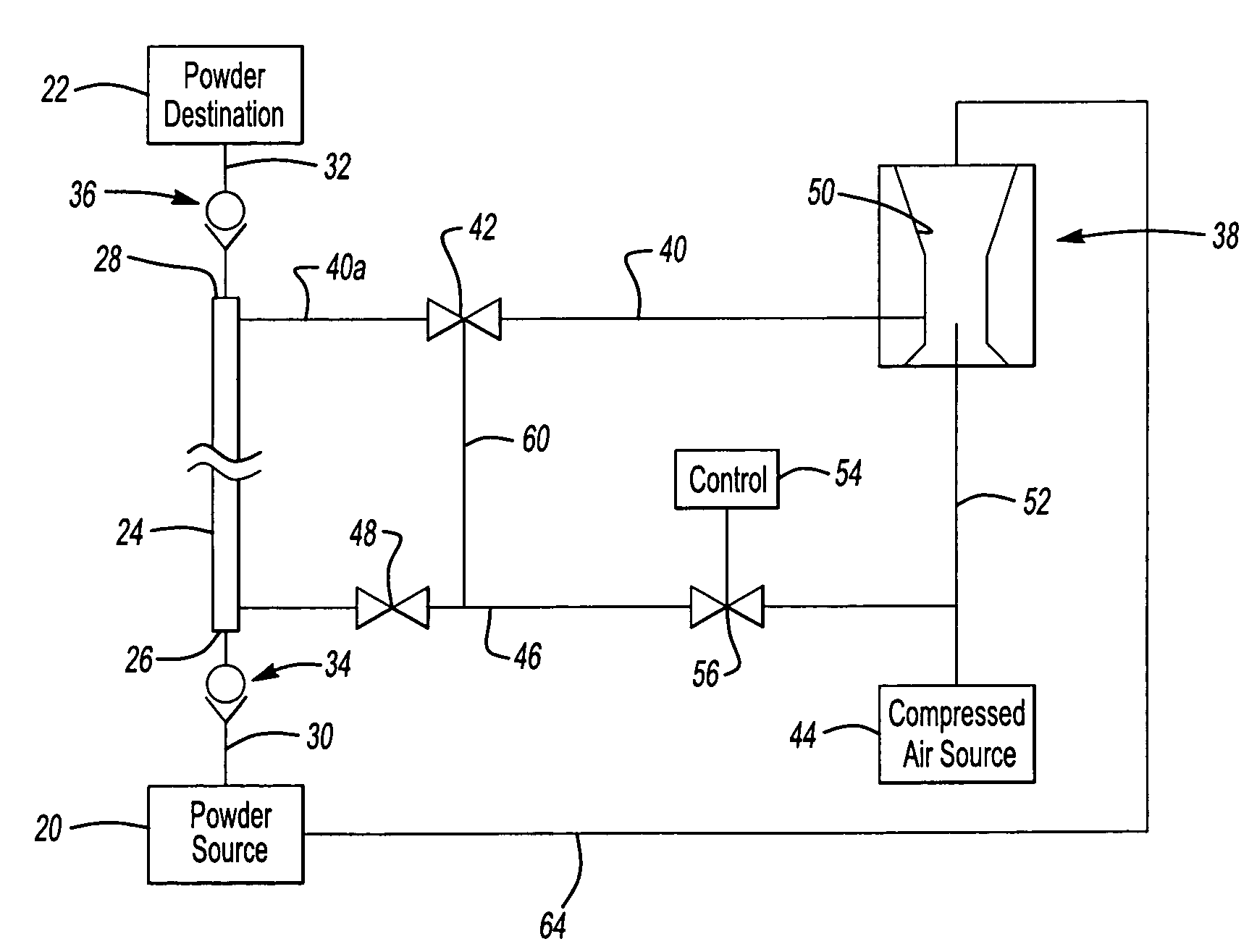

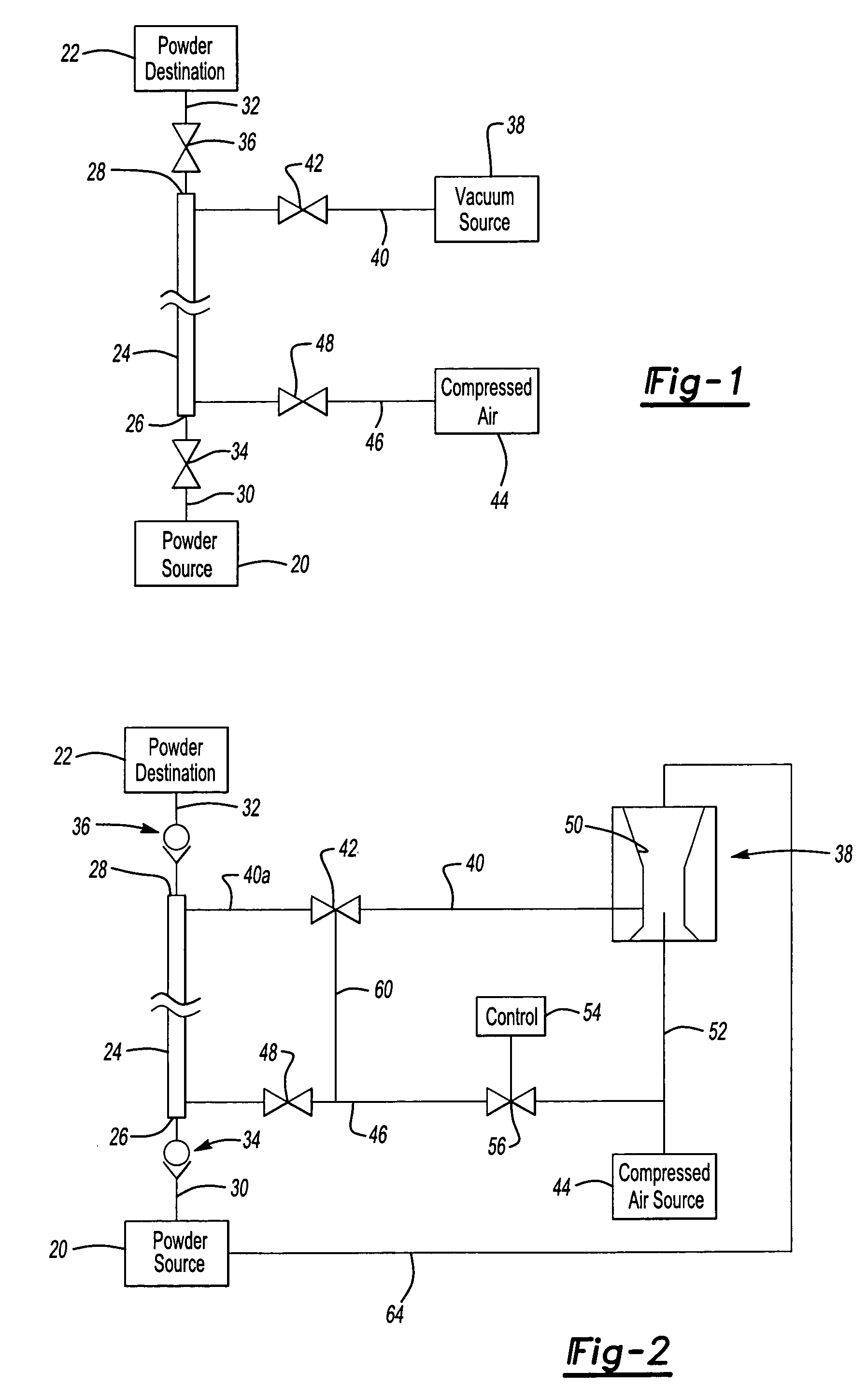

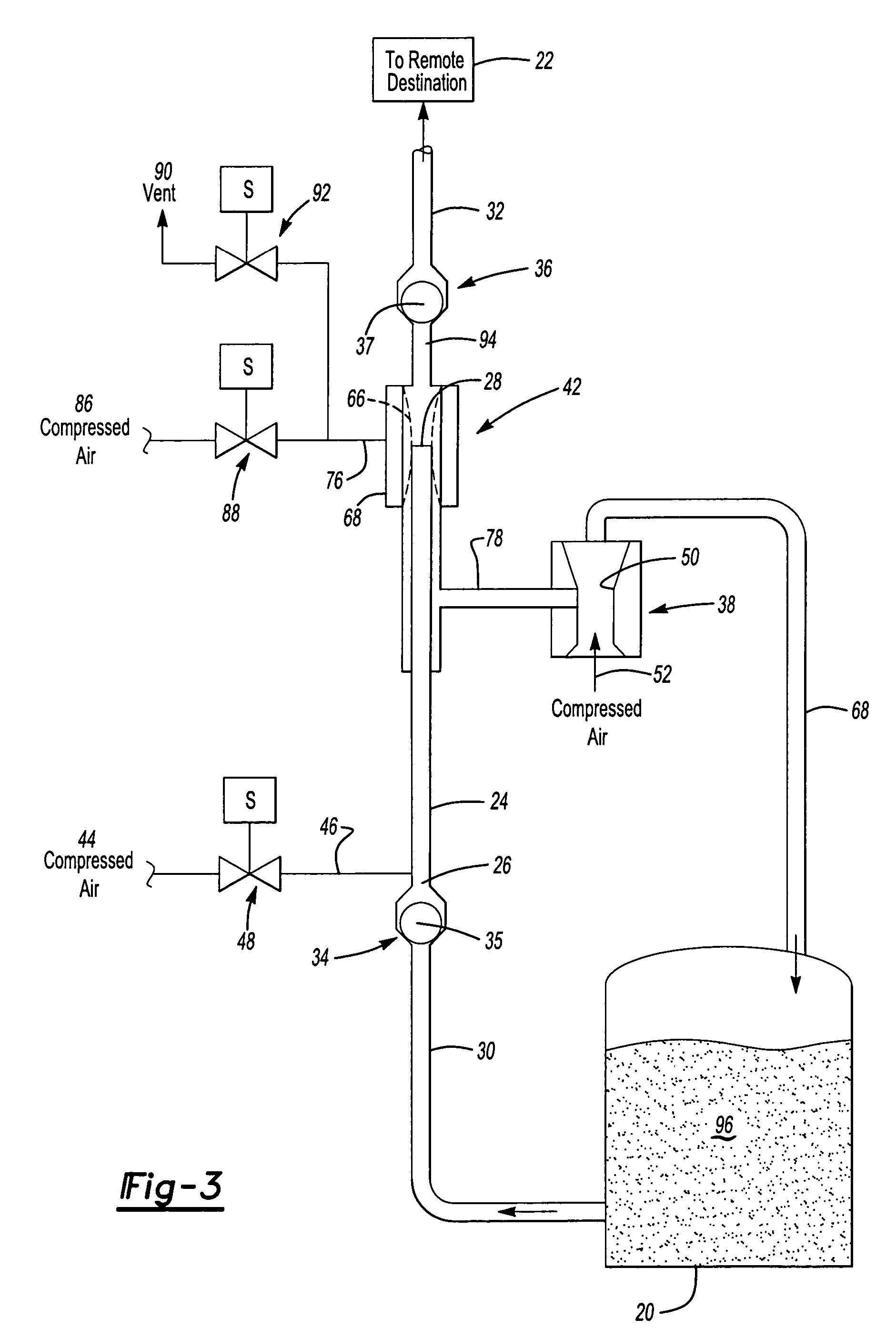

Pump for transferring particulate material

A pump for transferring particulate material from a source to a remote location, including a particulate chamber having open ends, check valves at the open ends, a vacuum source connected to the chamber adjacent one end, a gas source at the opposed end of the chamber and a control which alternatively connects the vacuum to the chamber to draw particulate material from the source to the chamber and connecting the gas under pressure to drive the particulate material to the remote location. In a preferred embodiment, the chamber has a cylindrical inner diameter and the source of vacuum is a venturi pump connected to a pinch valve permitting overflow of particulate material through the pinch valve and venturi pump, which is returned to the source. In one embodiment, the pinch valve surrounds an open end of the chamber permitting overflow while avoiding agglomeration of the particulate material.

Owner:DURR SYST INC

Substrate processing apparatus

A semiconductor workpiece processing apparatus having a first chamber, a transport vehicle, and another chamber. The first chamber is capable of being isolated from an outside atmosphere. The transport vehicle is located in the first chamber and is movably supported from the first chamber for moving linearly relative to the first chamber. The transport vehicle includes a base, and an integral semiconductor workpiece transfer arm movably mounted to the base and capable of multi-access movement relative to the base. The other chamber is communicably connected to the first chamber via a closable opening of the first chamber. The opening is sized to allow the transport vehicle to transit between the first chamber and the other chamber through the opening.

Owner:BOOKS AUTOMATION US LLC

Pump for transferring particulate material

A pump for transferring particulate material from a source to a remote location, including a particulate chamber having open ends, check valves at the open ends, a vacuum source connected to the chamber adjacent one end, a gas source at the opposed end of the chamber and a control which alternatively connects the vacuum to the chamber to draw particulate material from the source to the chamber and connecting the gas under pressure to drive the particulate material to the remote location. In a preferred embodiment, the chamber has a cylindrical inner diameter and the source of vacuum is a venturi pump connected to a pinch valve permitting overflow of particulate material through the pinch valve and venturi pump, which is returned to the source. In one embodiment, the pinch valve surrounds an open end of the chamber permitting overflow while avoiding agglomeration of the particulate material.

Owner:DURR SYST INC

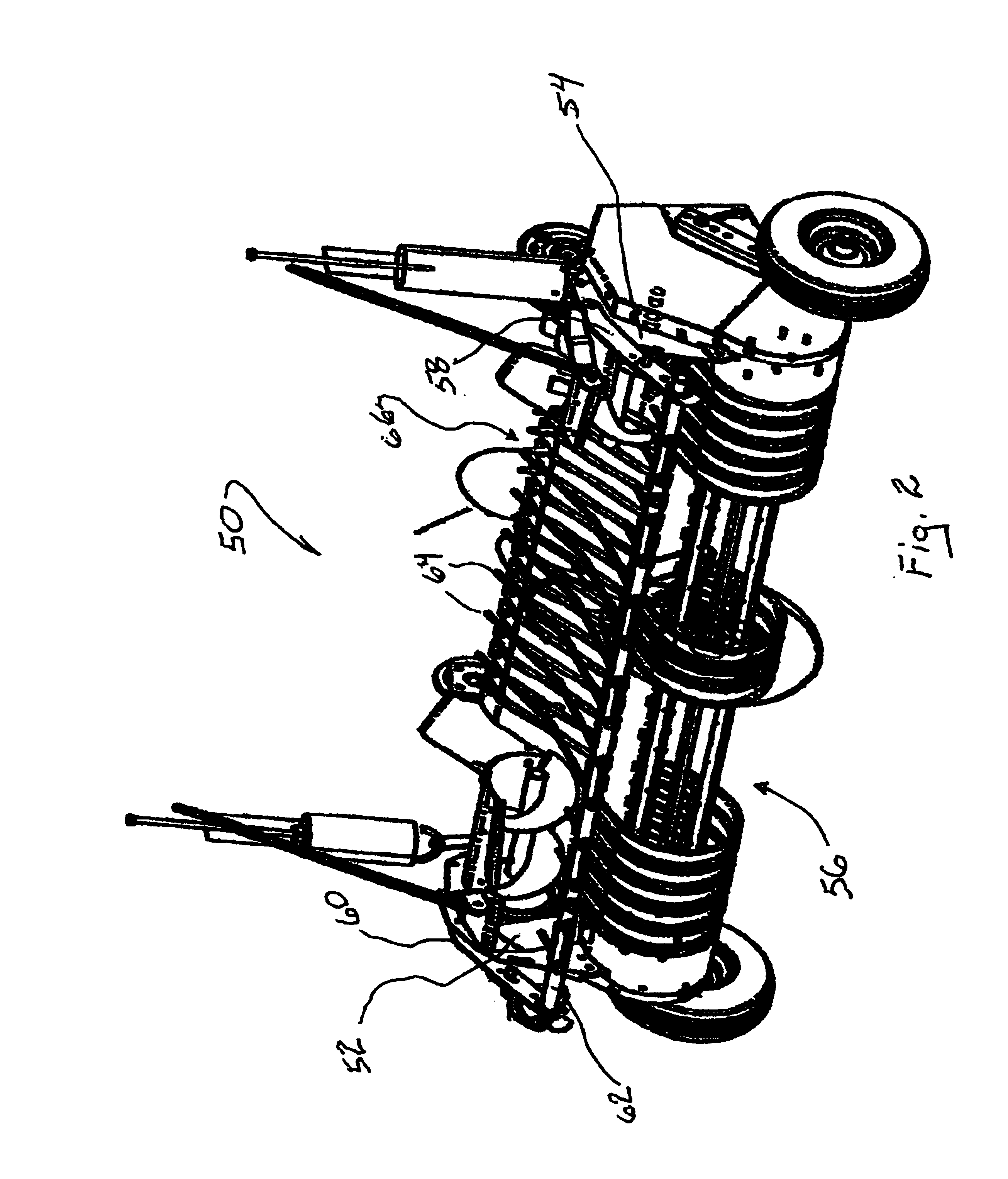

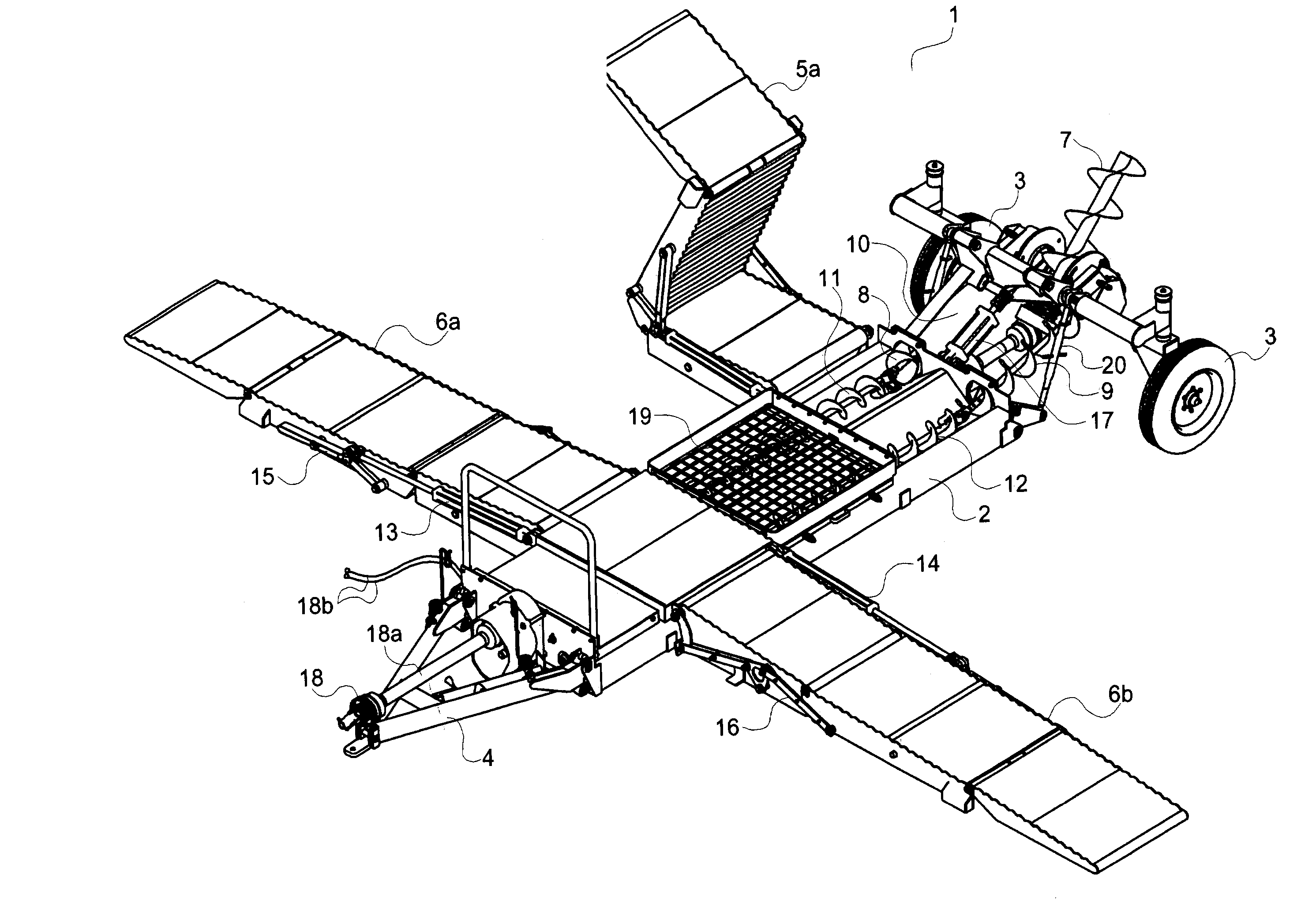

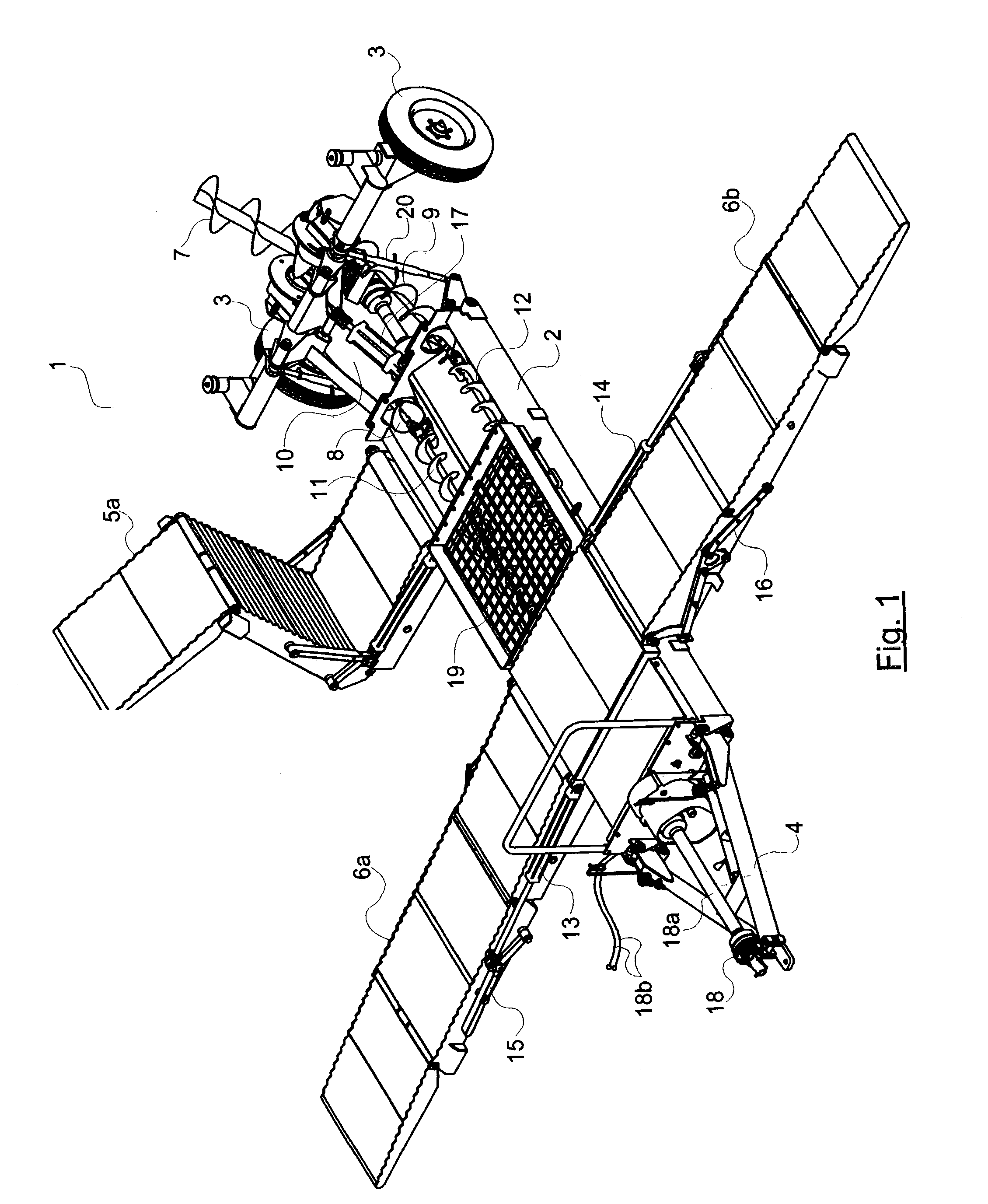

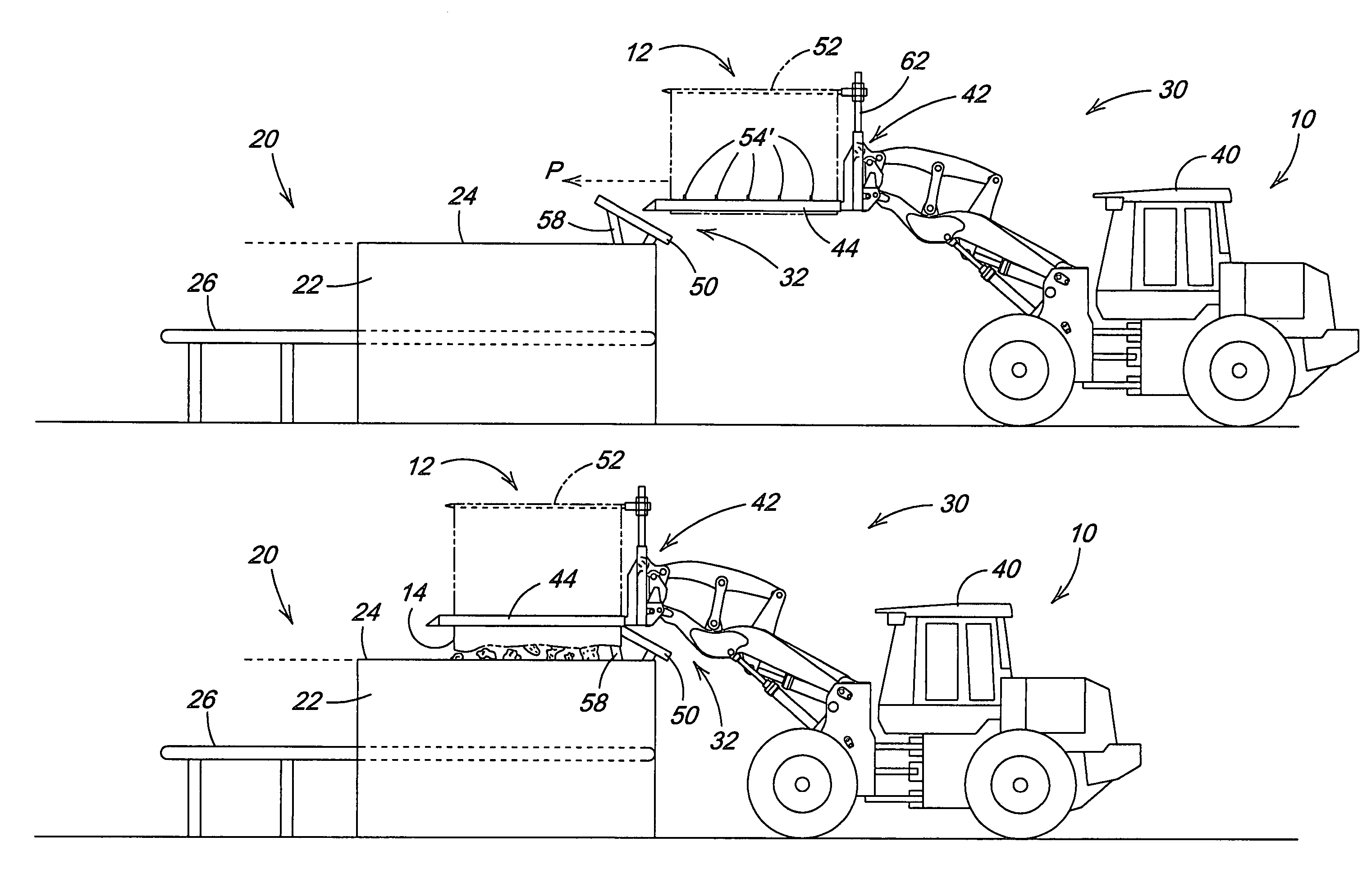

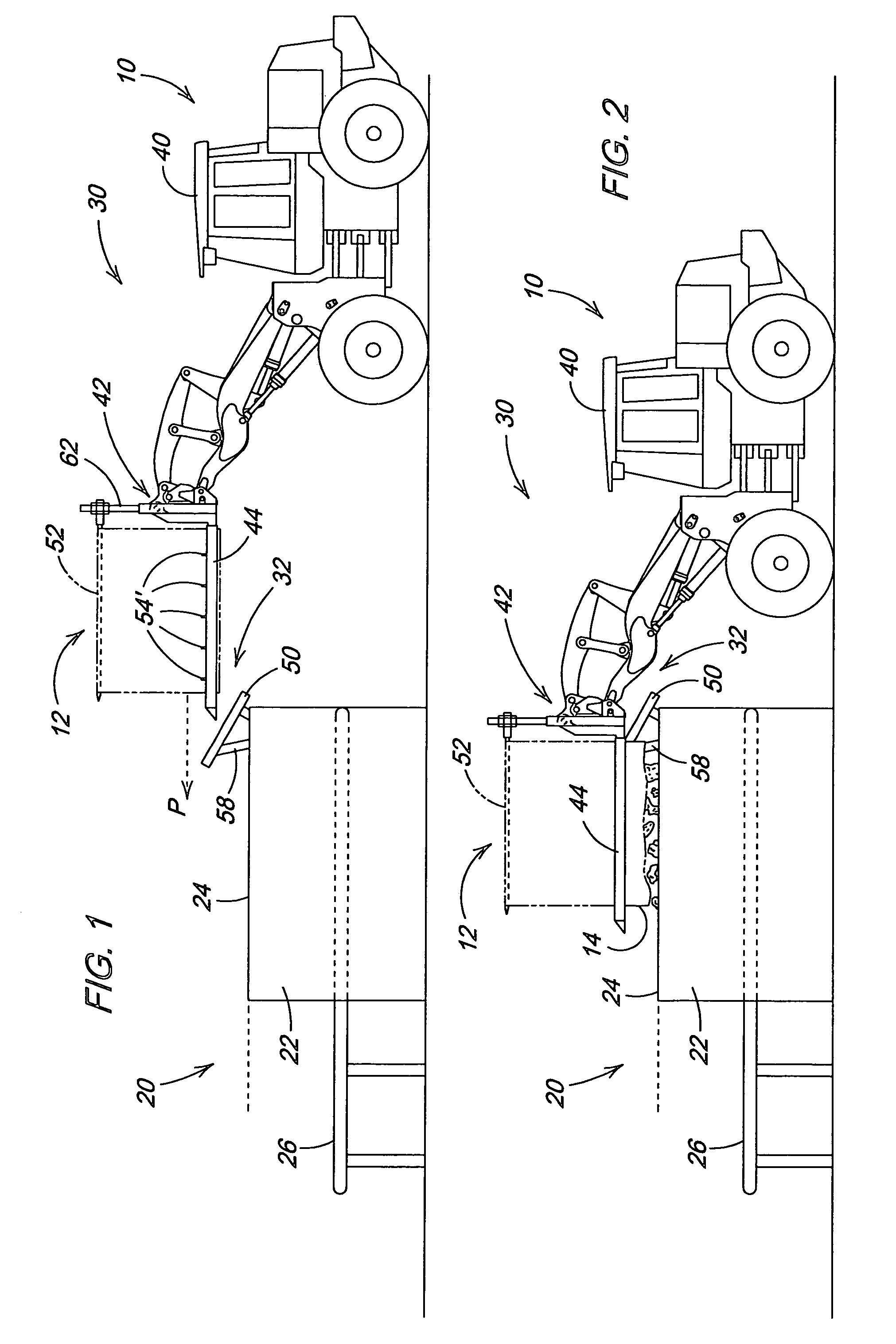

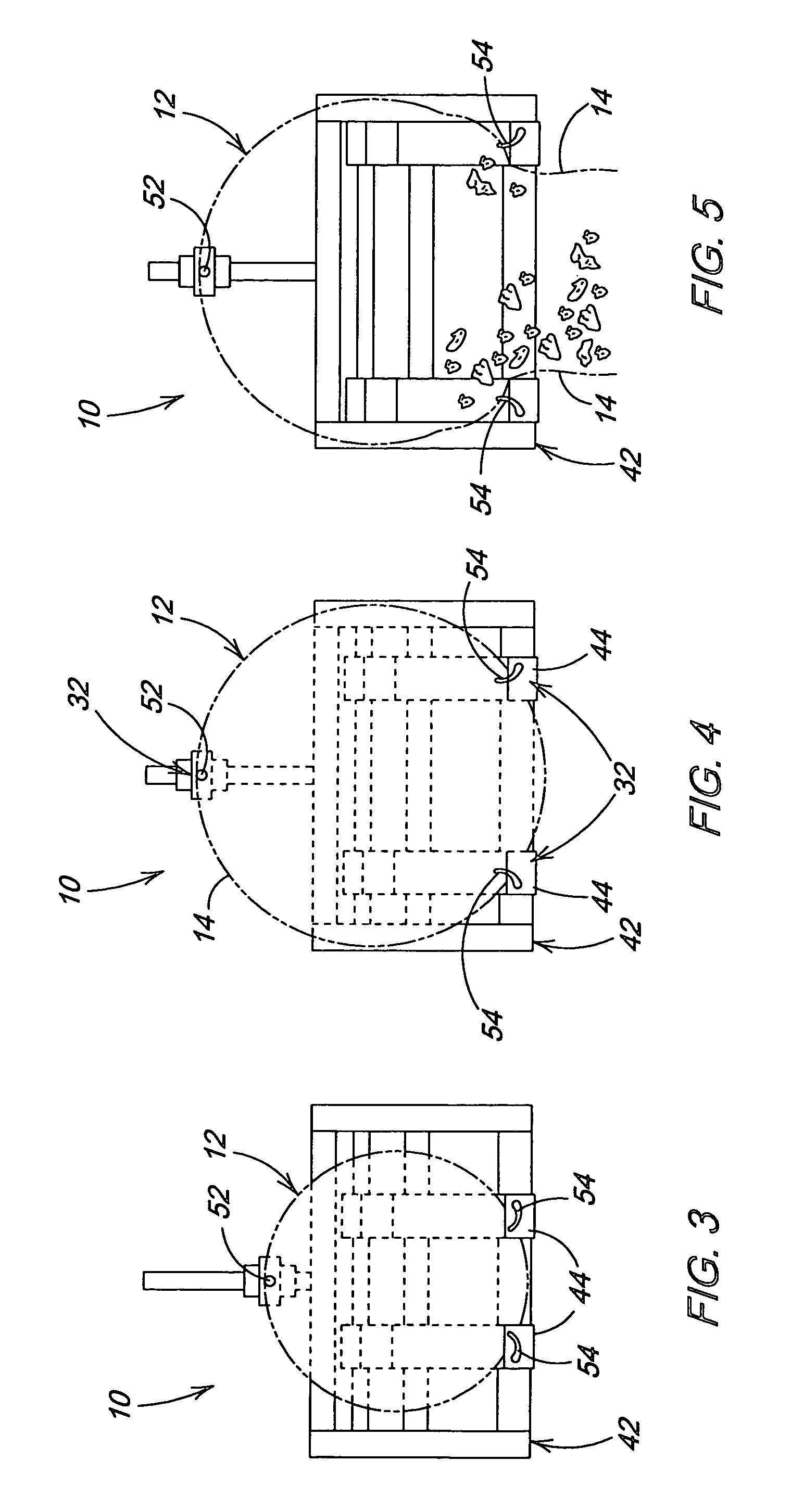

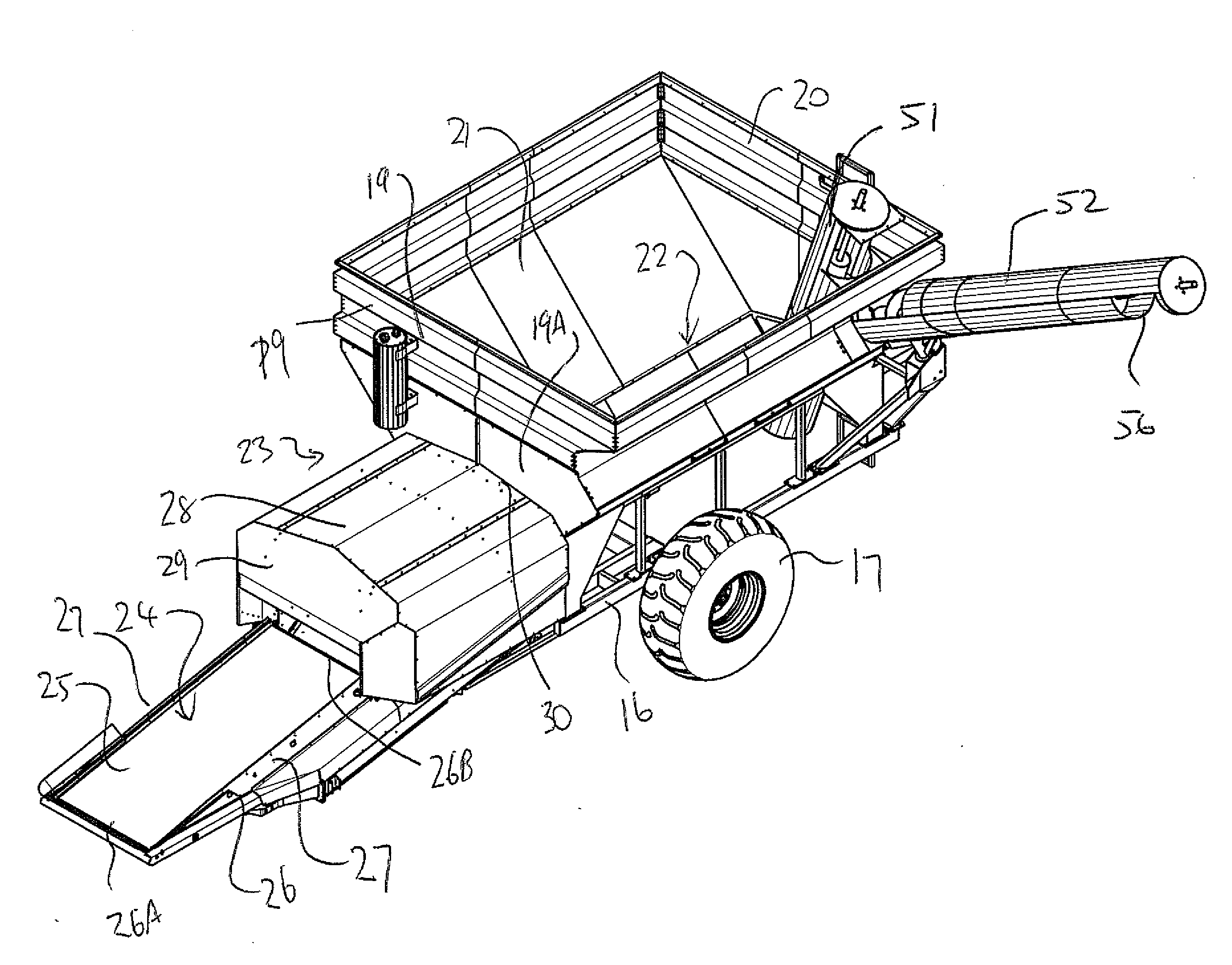

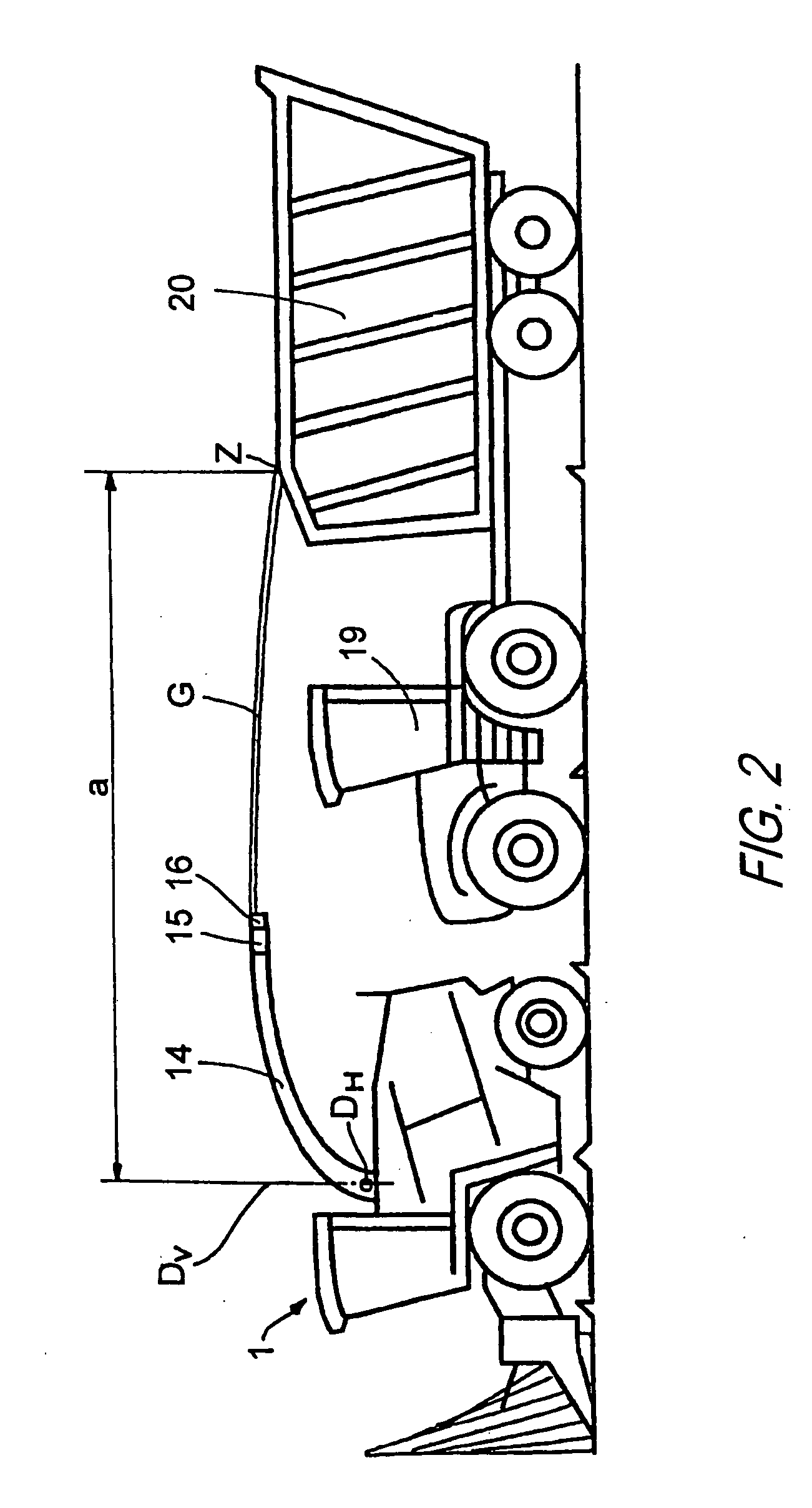

Unloading system for particulate material

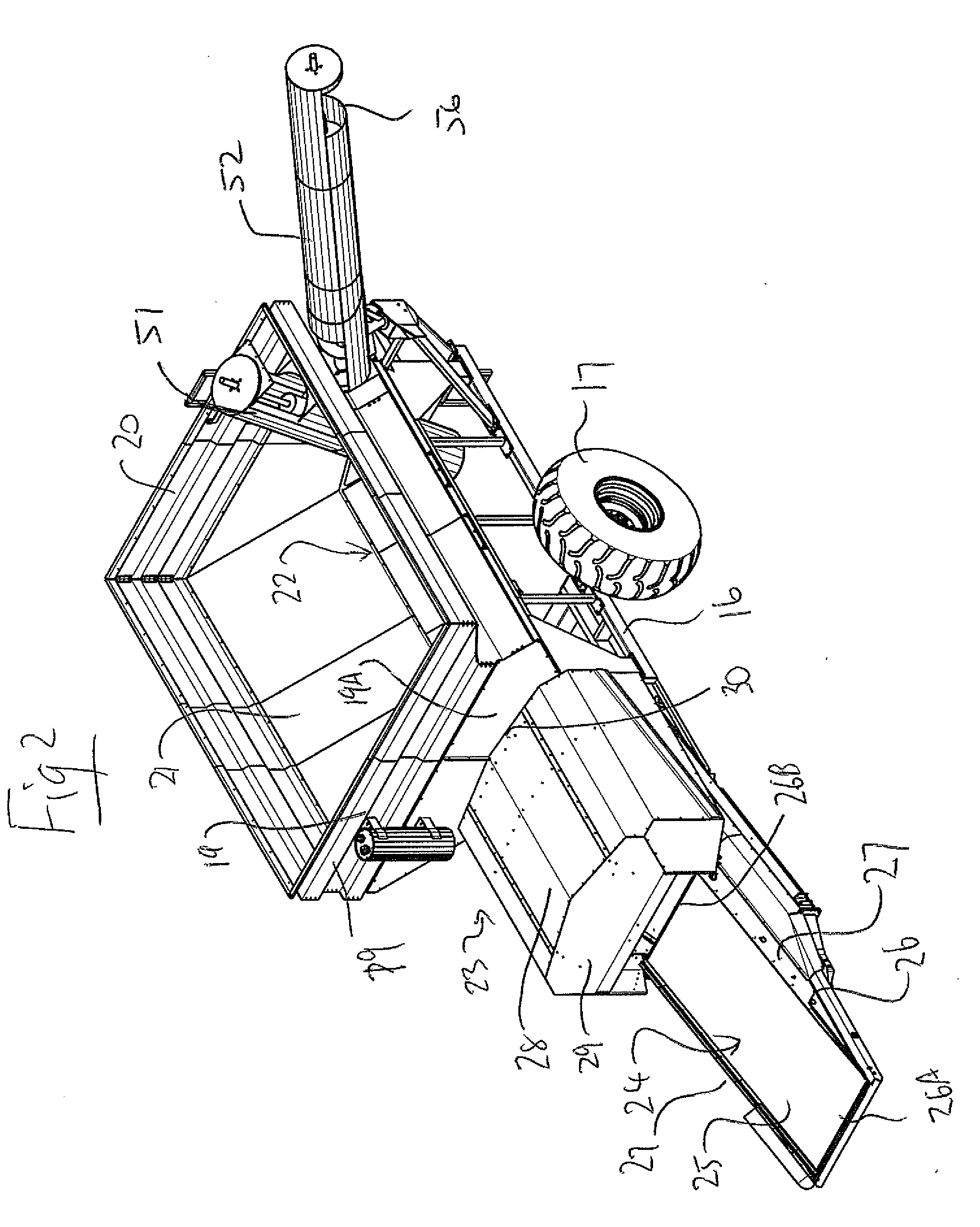

InactiveUS7090066B2Precise positioningLoadersRefuse transferringAgricultural engineeringParticulate material

This invention concerns a new grain unloading system using an integrated ramp, horizontal transfer conveyor and elevating system. The unit is towed, positioned and powered by an agricultural tractor.

Owner:BOURGAULT INDS

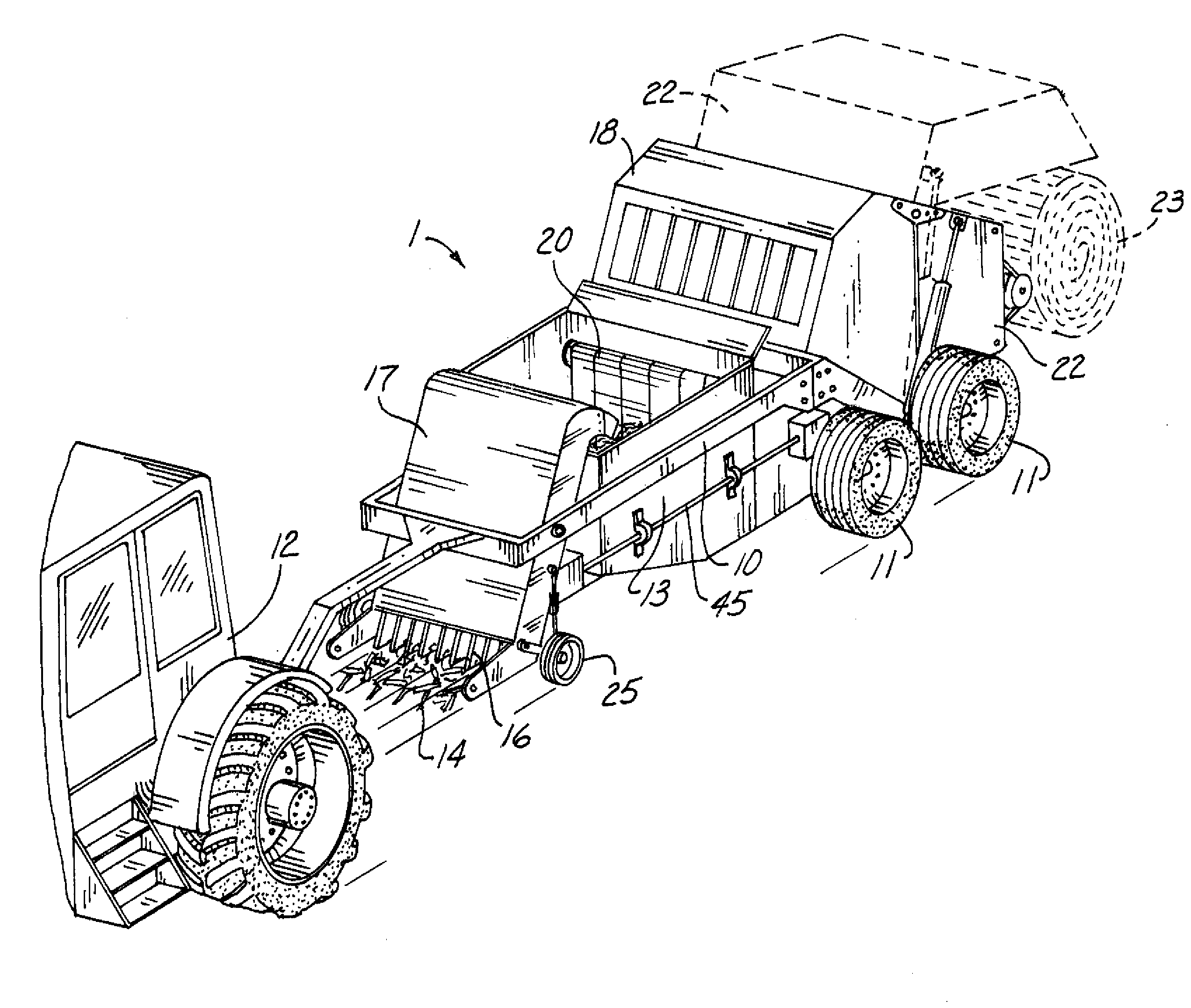

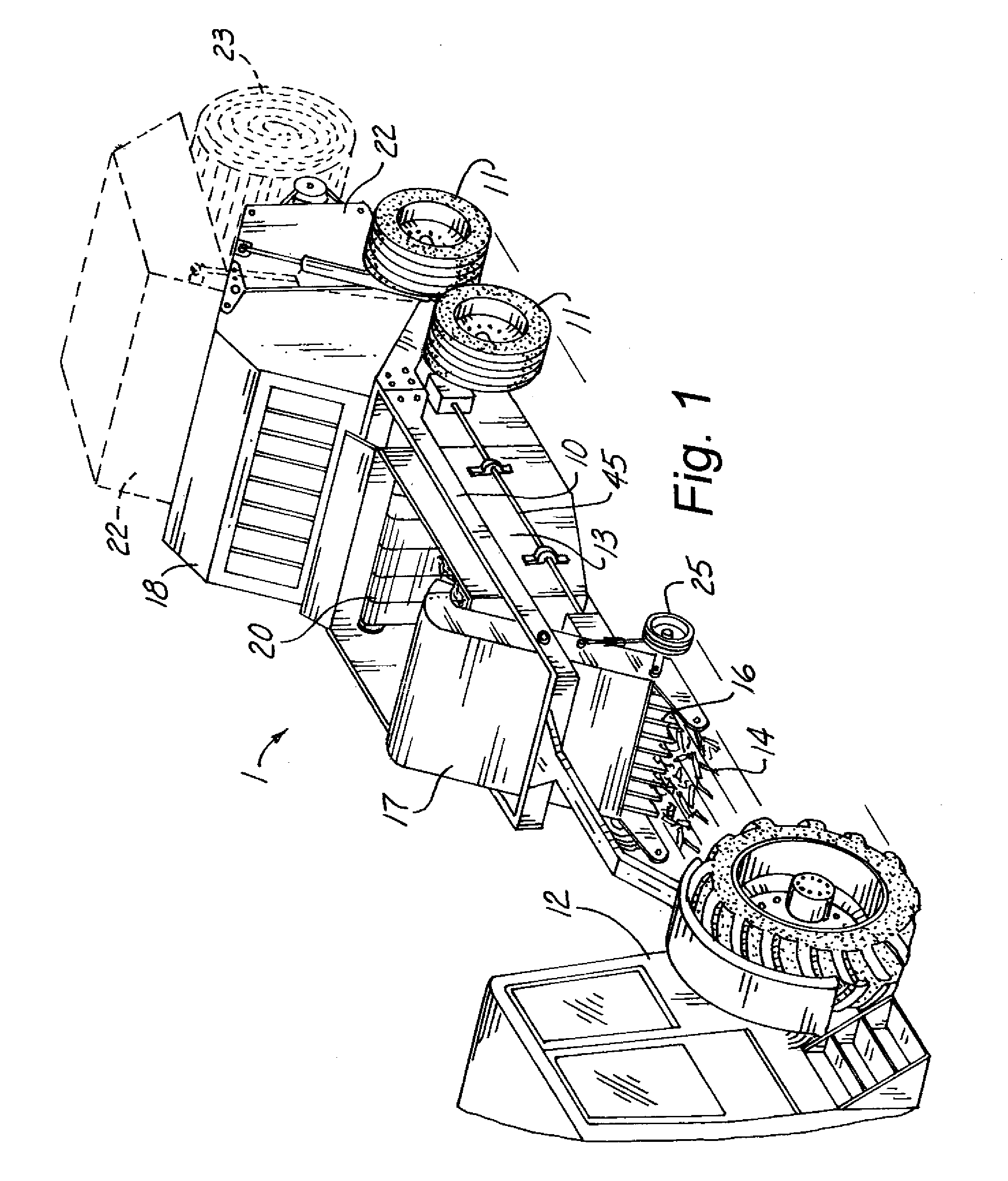

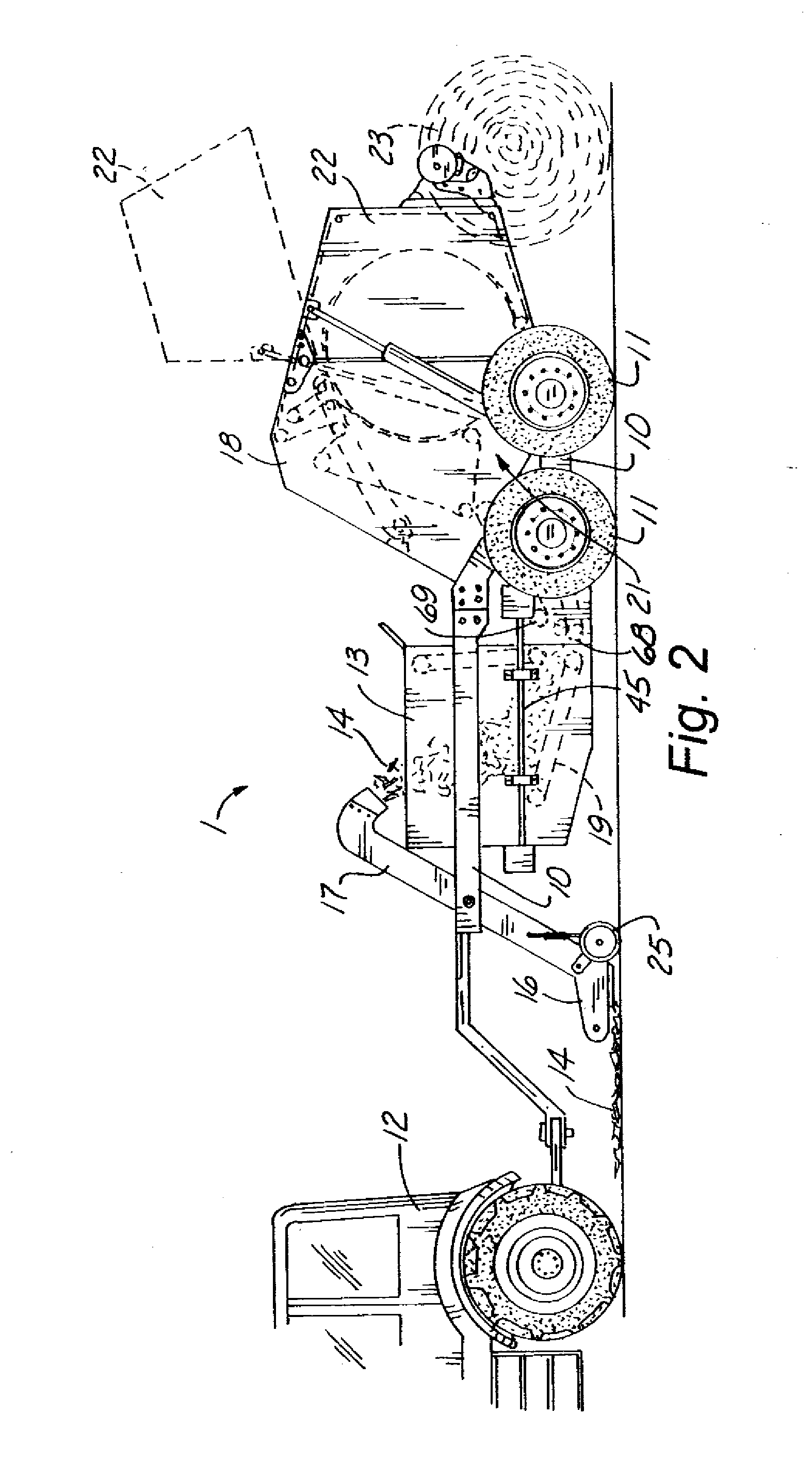

Corn Stalk Baling Method and Apparatus

A method and apparatus for baling a crop with stiff stalks such as corn stalks has a frame with a front and a rear. At least one ground engaging wheel operatively attached to the frame for facilitating movement of the frame in a forward direction. An accumulator is operatively attached to the frame for holding the crop in various amounts. A pickup is operatively attached to the front of the frame for picking up the crop from a field and transferring the crop into the accumulator. A baler is operatively attached to the frame behind the accumulator for transforming a crop into a bale. A transfer mechanism such as a conveyor is provided in the accumulator for moving the crop in the accumulator to the inlet of the baler. In another embodiment, a pickup of a first predetermined width is provided for picking up the crop from a field and transferring the crop into the accumulator. The baler has an inlet and a baling chamber of a second predetermined with that is significantly larger than the first predetermined width of the pickup so that a larger bale can be made. The transfer mechanism can be in segments which are independently operable.

Owner:VERMEER MFG CO

Loading conveyor with folding hopper for agricultural commodity carts

ActiveUS7267519B2Increase capacityShorten the lengthLoadersFertiliser distributersHydraulic cylinderEngineering

Owner:BOURGAULT INDS

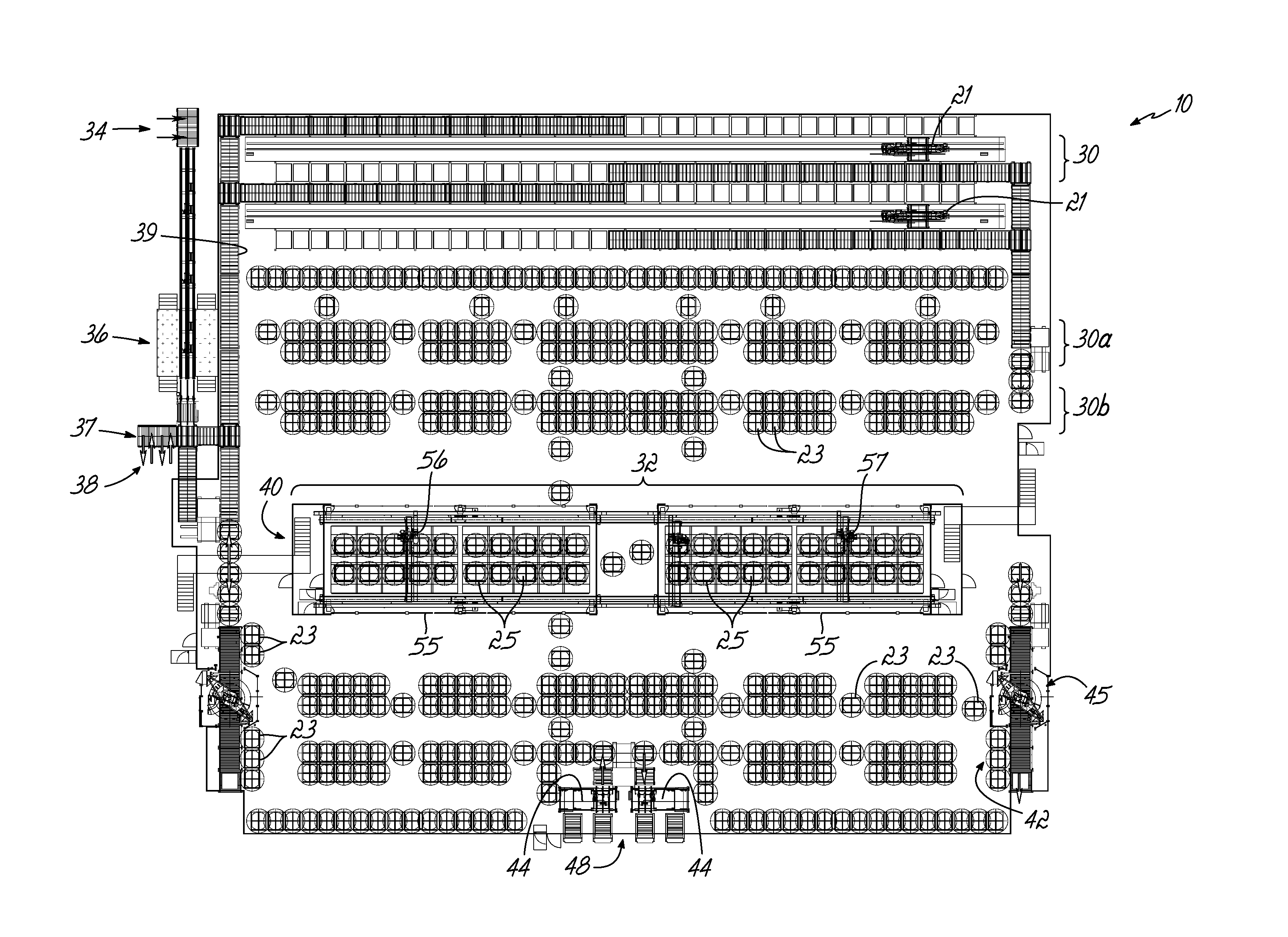

Automated layer picking and storage system

InactiveUS20130177379A1Reduce distanceLoad largeLoadersSemiconductor/solid-state device manufacturingOrder formEngineering

A material handling storage, retrieval and load building system receives source pallets, bearing product loads in full or partial layers, stores them in a variety of locations depending on the frequency of demand for products thereon and builds homogeneous product or similar product full or partial layers on target or order pallets, in both single and multiple layer picks, from products on the source pallets, to order after retrieving the source pallets to a building pallet location. Pallets are transferred within the system on pallet stands which are selectively coupled to automatically guided vehicles, thus providing significant flexibility in the pallet storage locations and in the transfer distance within the system. Apparatus and methods are disclosed.

Owner:KUKA SYST NORTH AMERICA LLC

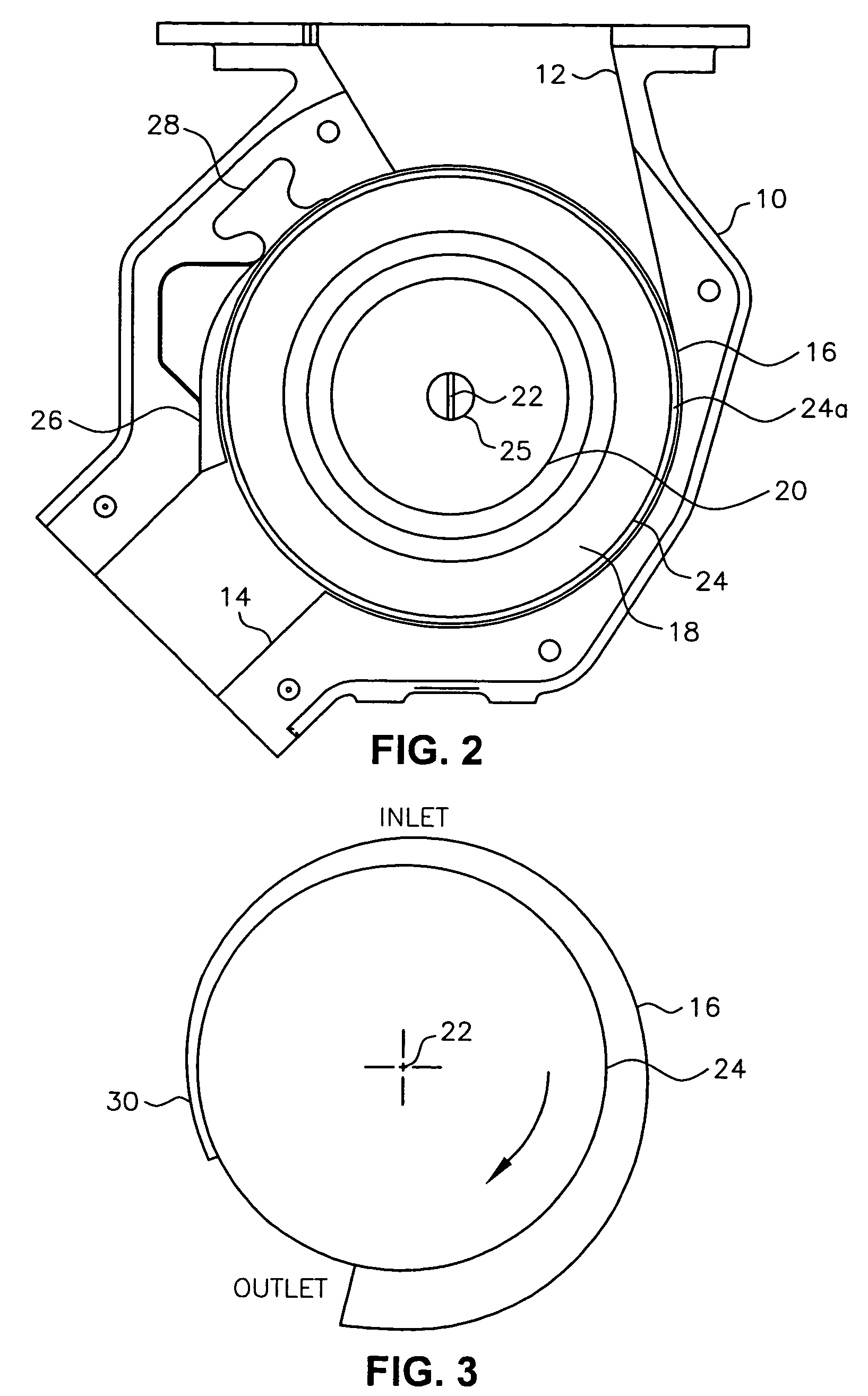

Bulk material pump feeder with reduced disk jamming

A bulk materials pump feeder having a housing and a rotating drive rotor for transferring material from an inlet to an outlet of the housing. The drive rotor has a hub. Drive disks extend away from the hub toward a housing inner wall. Three structural features of the feeder reduce the tendency of material to jam between the drive rotor and the housing or other stationary parts. First, the distance between the circumferential edges of the drive disks and the housing inner wall increases from the inlet to the outlet in the direction of rotation of the drive rotor. Second, a low-friction brush seal disposed on the periphery of the drive disks seals the area between the periphery of the drive disks and the inner wall. Finally, a materials scraper having a flexible tip is mounted in the housing and extends into the drive rotor between the drive disks.

Owner:K TRON TECH INC

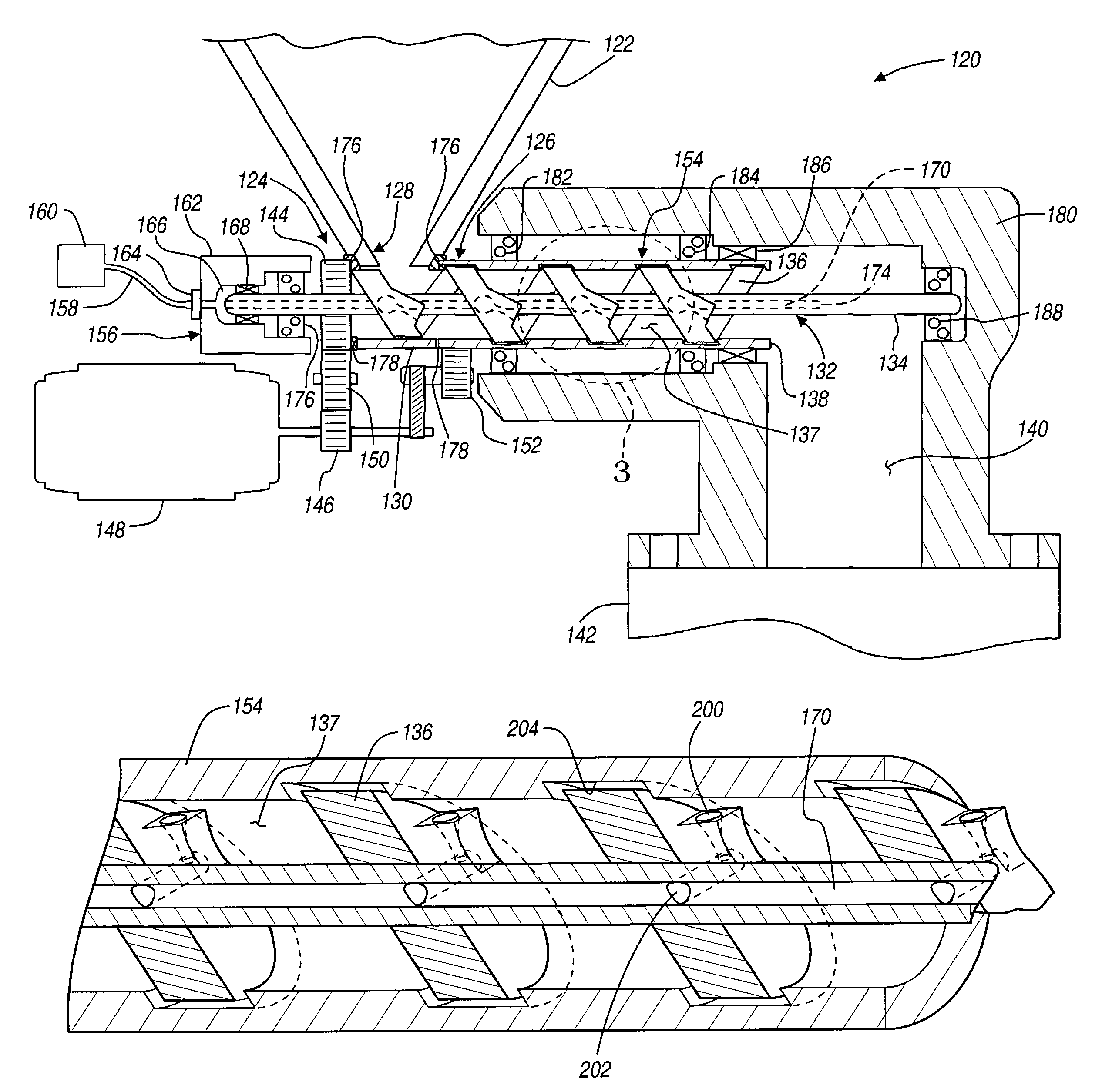

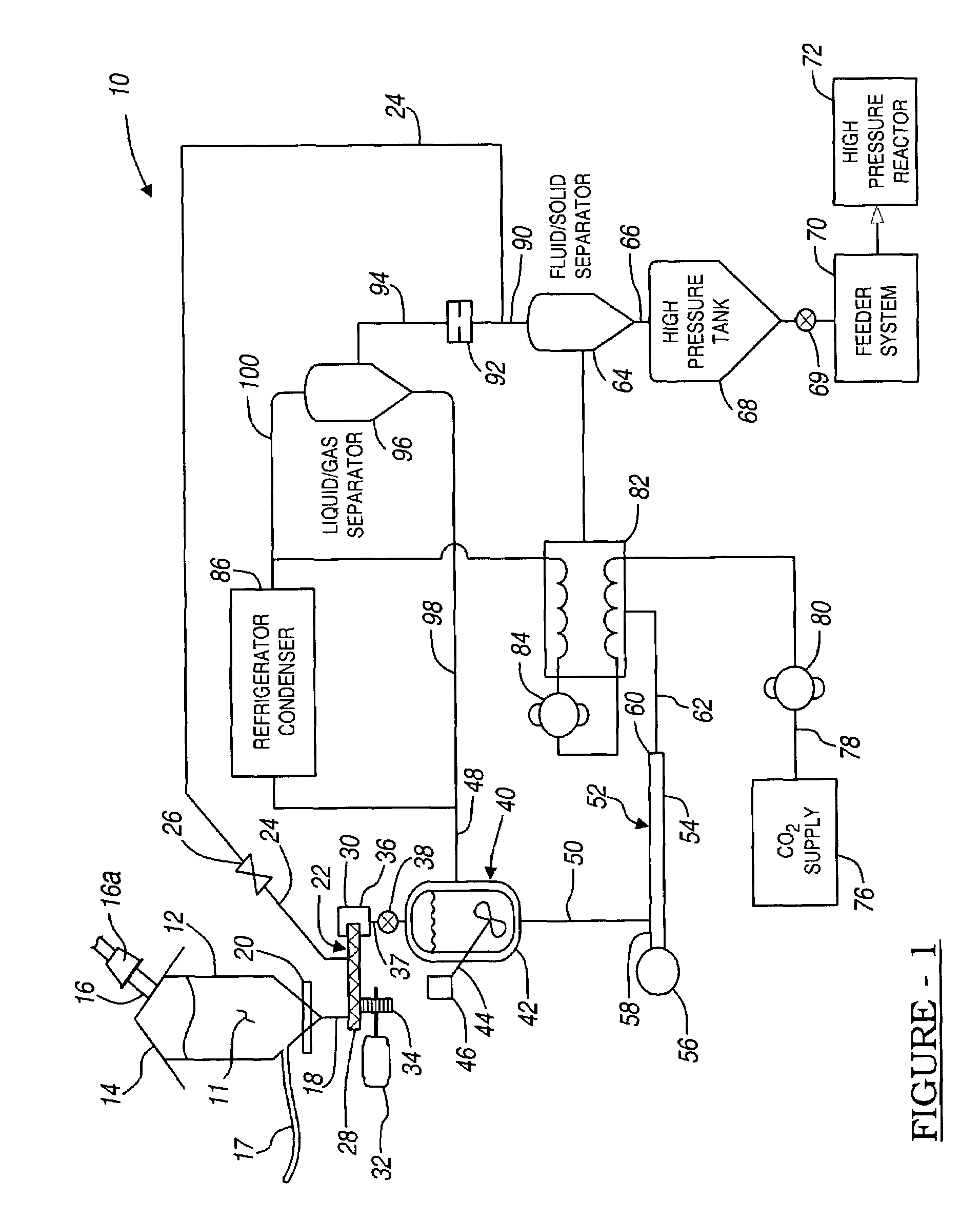

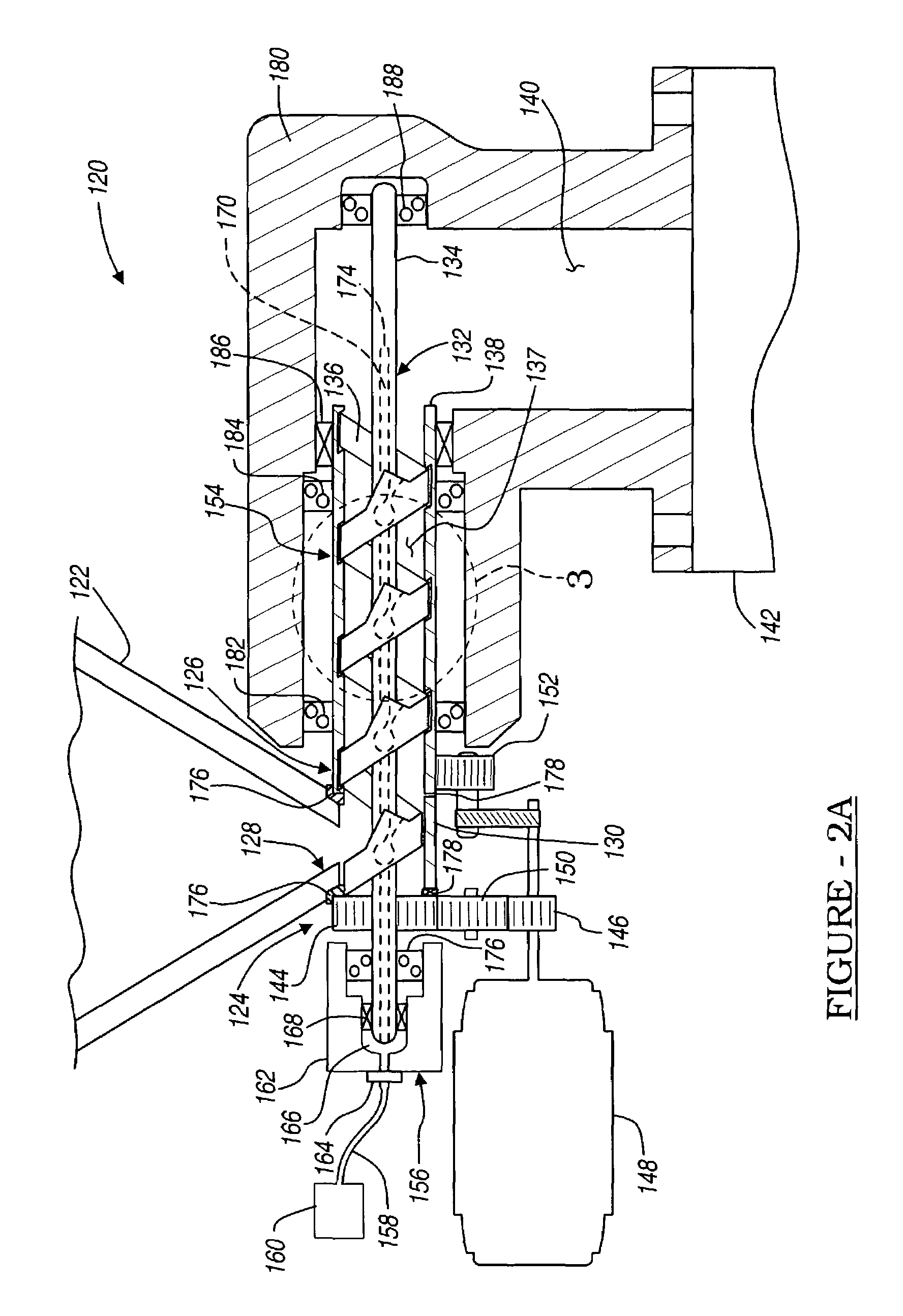

Method and apparatus for continuously feeding and pressurizing a solid material into a high pressure system

A system for substantially continuously providing a solid material, for example pulverized coal, to a pressurized container. The system provides the solid material to a first container of a first pressure elevated above an initial pressure of the solid material. Generally, a screw conveyor augmented with a jet port is used to move the material where the jet port provides a gas to provide a make-up volume of the solid material. The system also provides the material to a second high pressure container after the material has been formed into a slurry. Therefore, the solid material may be substantially continuously provided in a system to a high pressure container.

Owner:THE BOEING CO +1

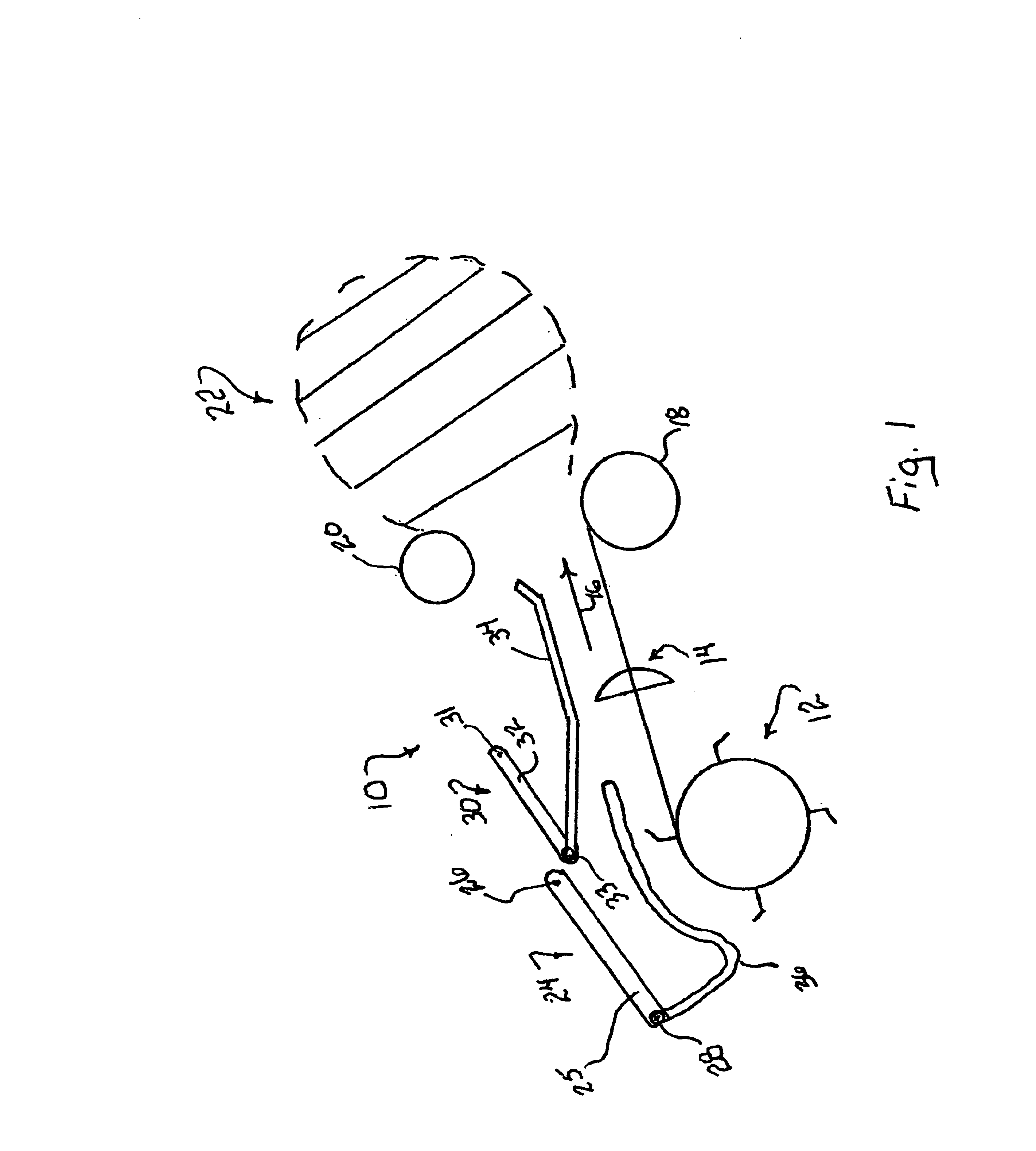

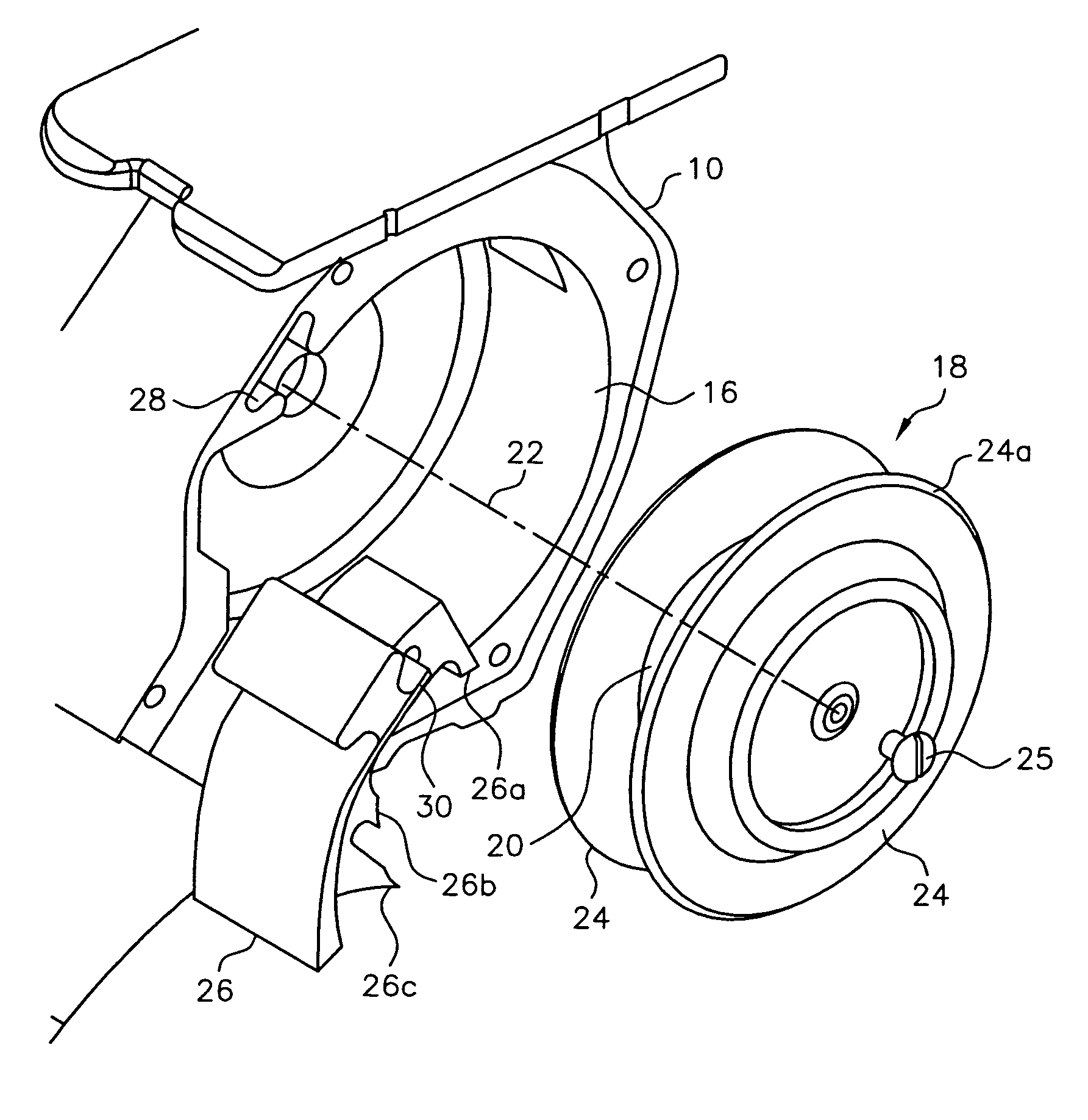

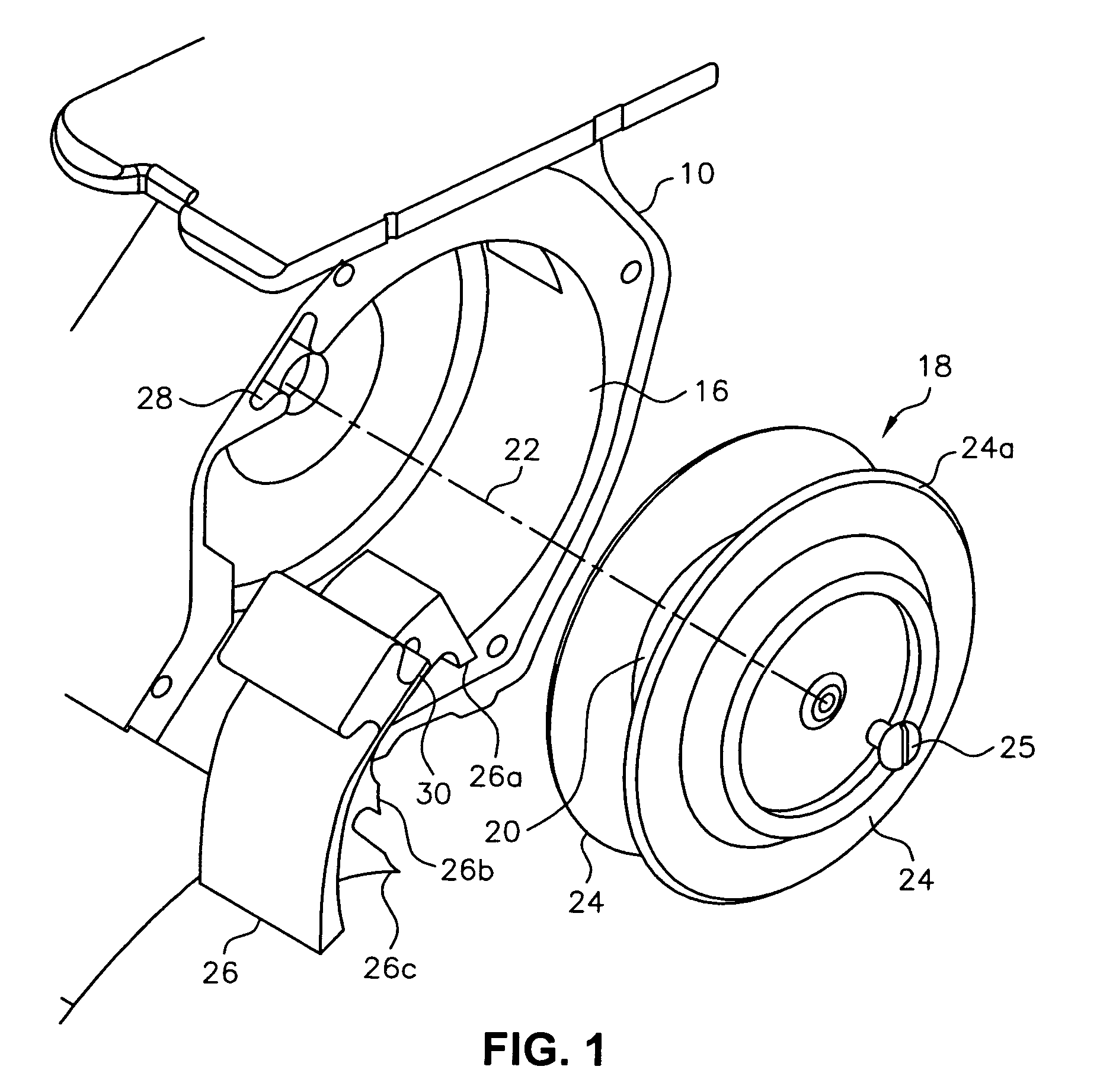

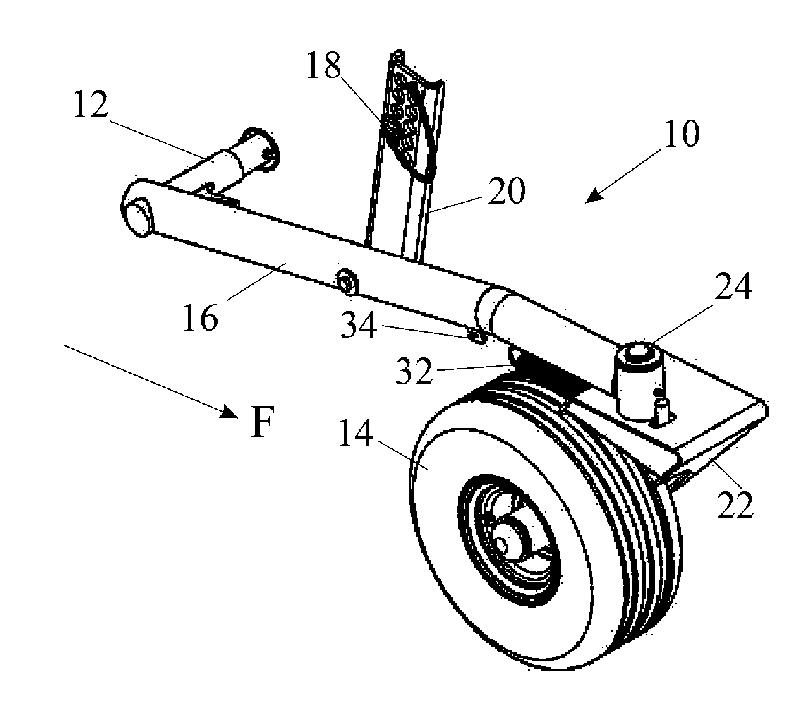

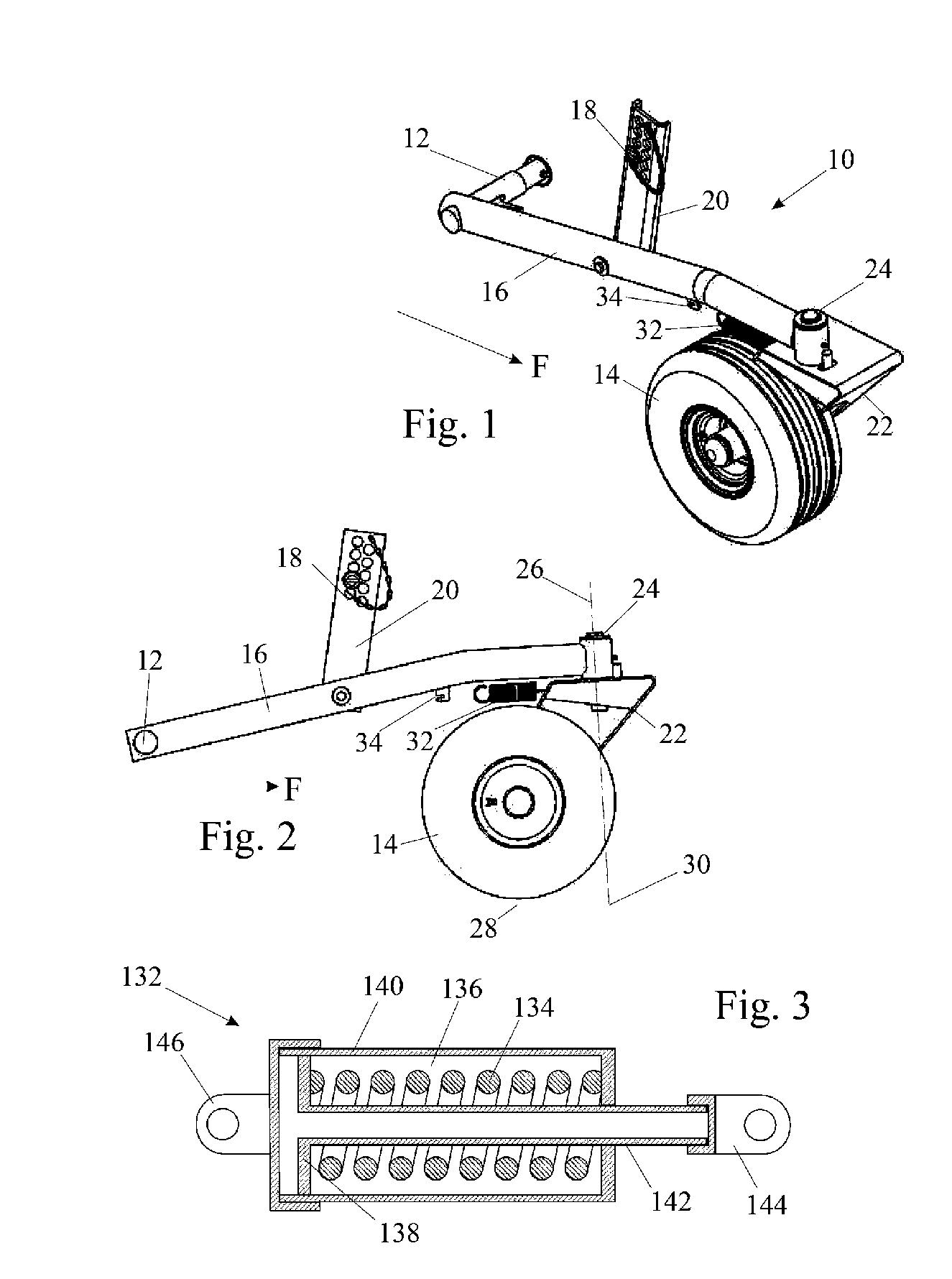

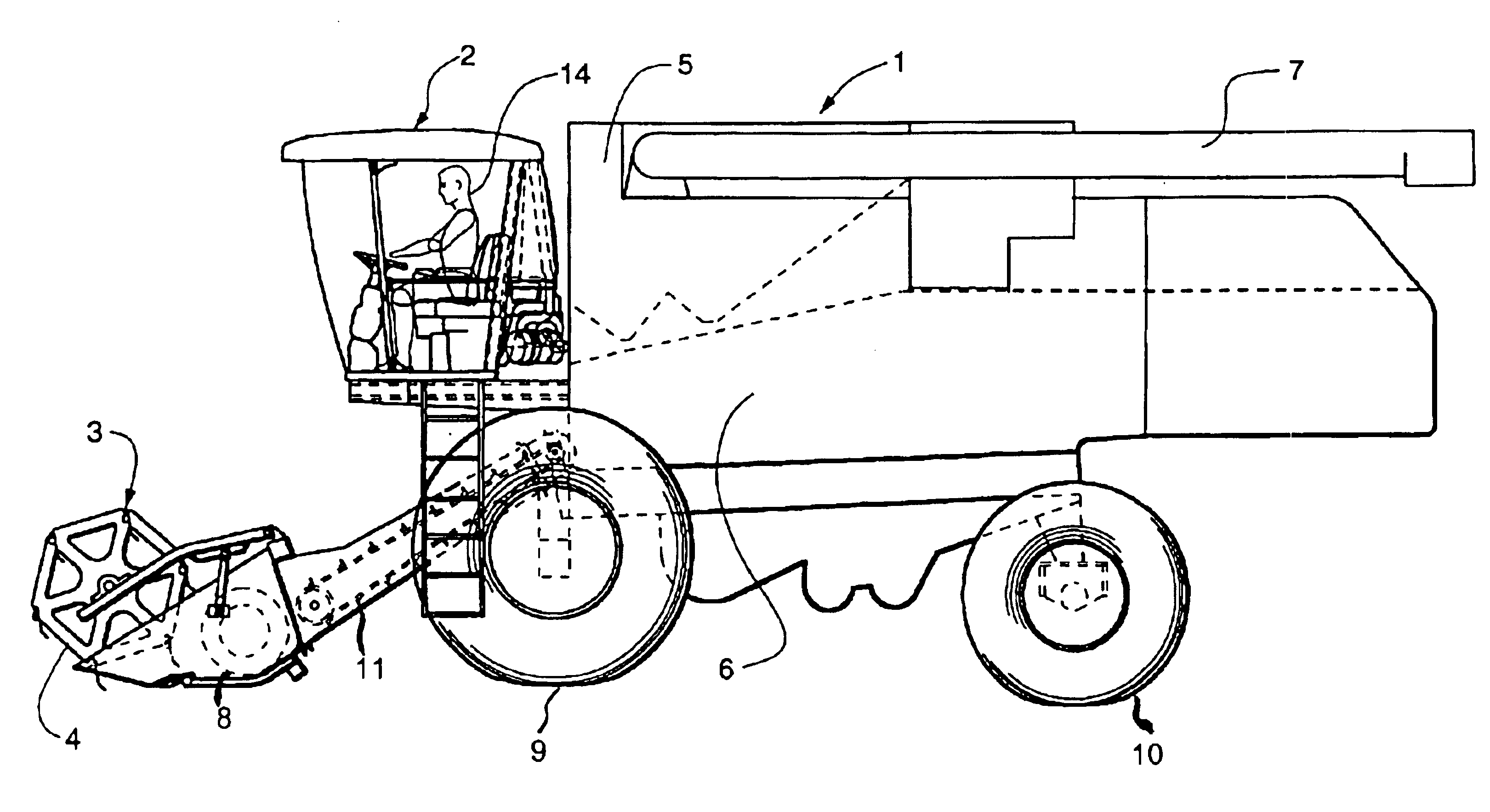

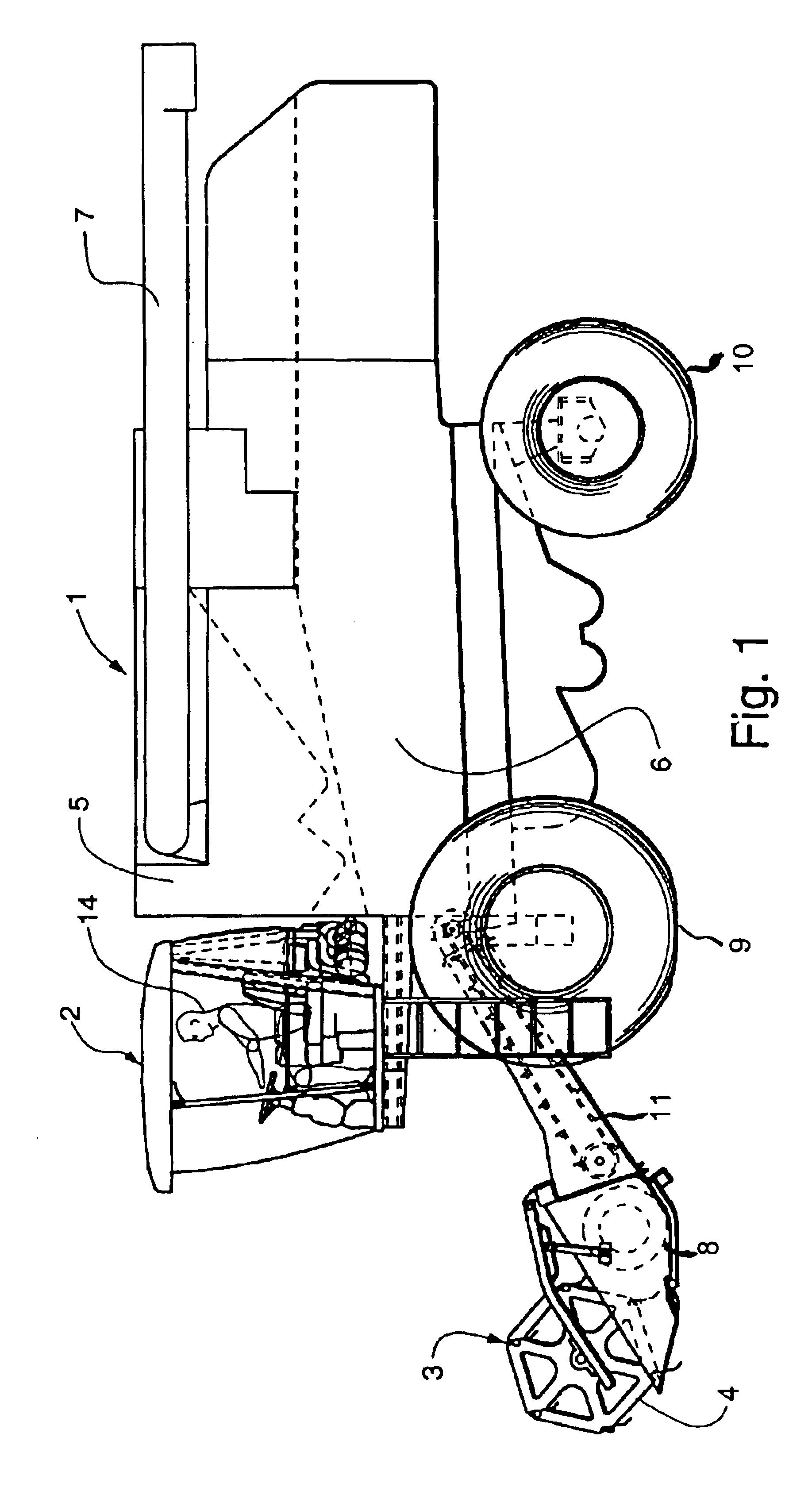

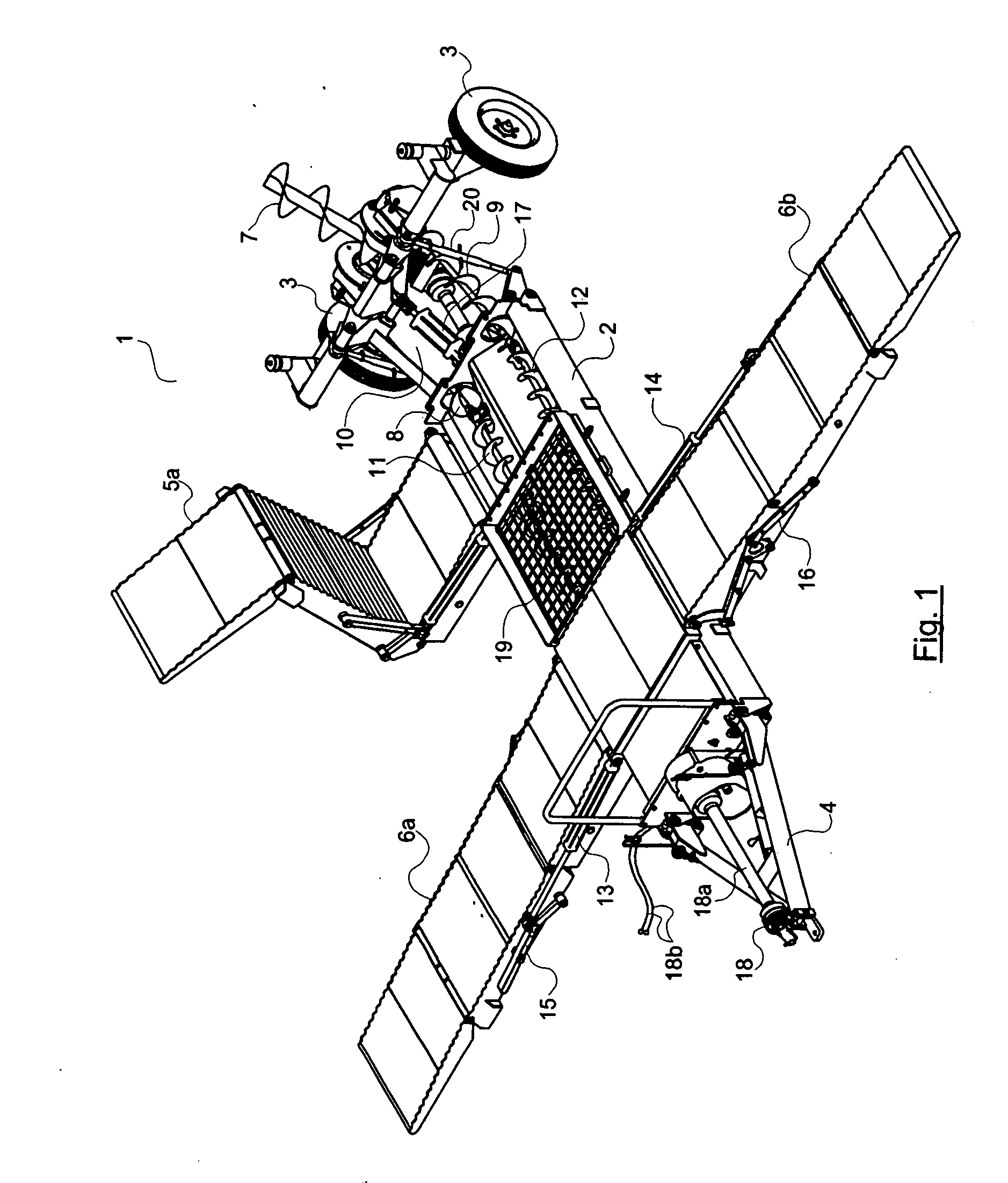

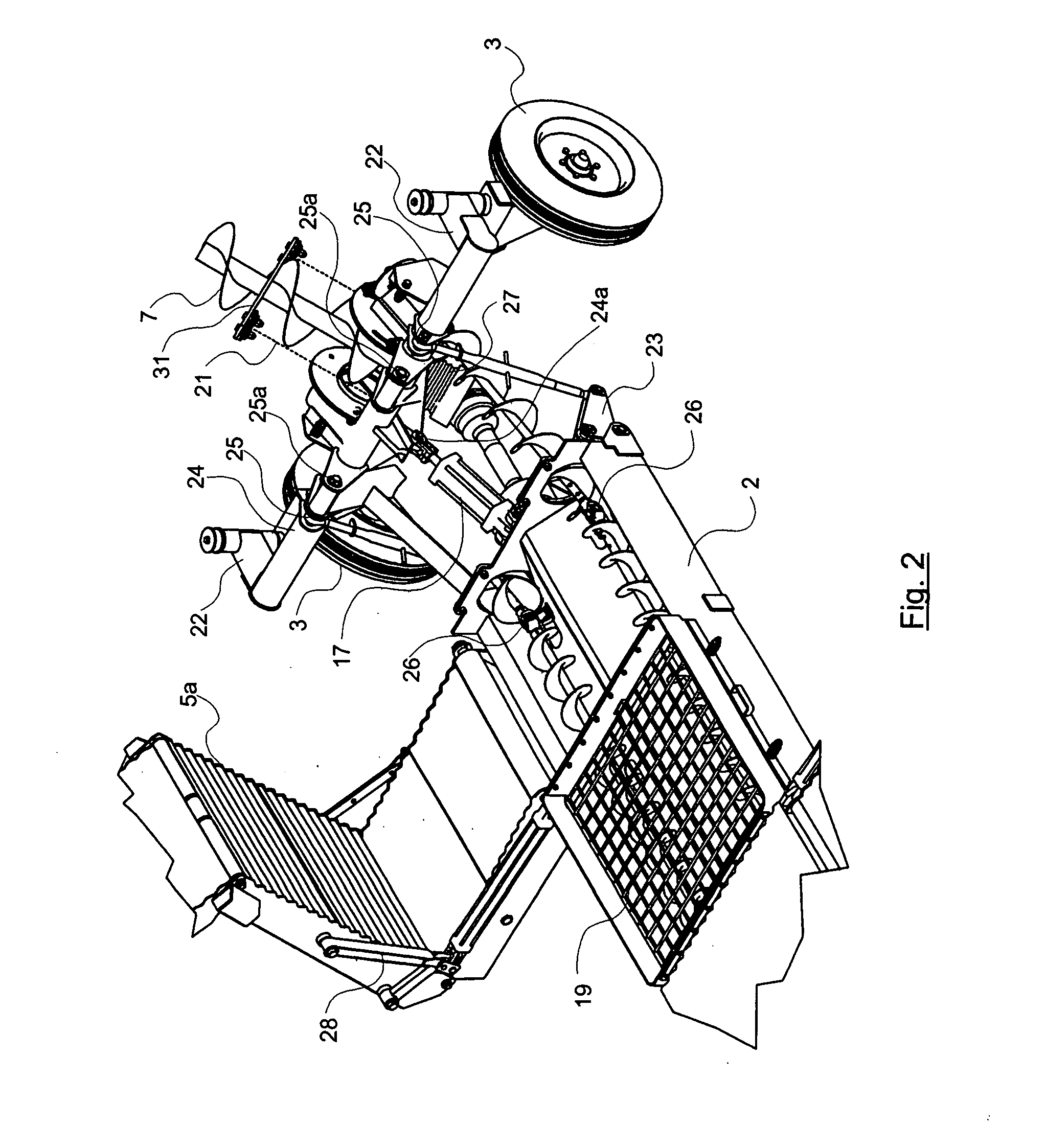

Pickup for an Agricultural Machine

ActiveUS20130305683A1Prevent uncontrolled oscillationConsume energyLoadersMowersAgricultural engineeringAgricultural machinery

An agricultural machine having a frame carrying a crop pickup mechanism and supported on the ground by means of two support wheels. Each support wheel is rotatably mounted on a carrier that is connected to the frame of the pickup for rotation about a caster axis. Each wheel carrier is connected by a respective spring to a point fixed relative to the frame of the pickup. The spring biases the carrier to cause the support wheel to park in a predetermined direction relative to the frame of the pickup.

Owner:BLUE LEAF I P INC

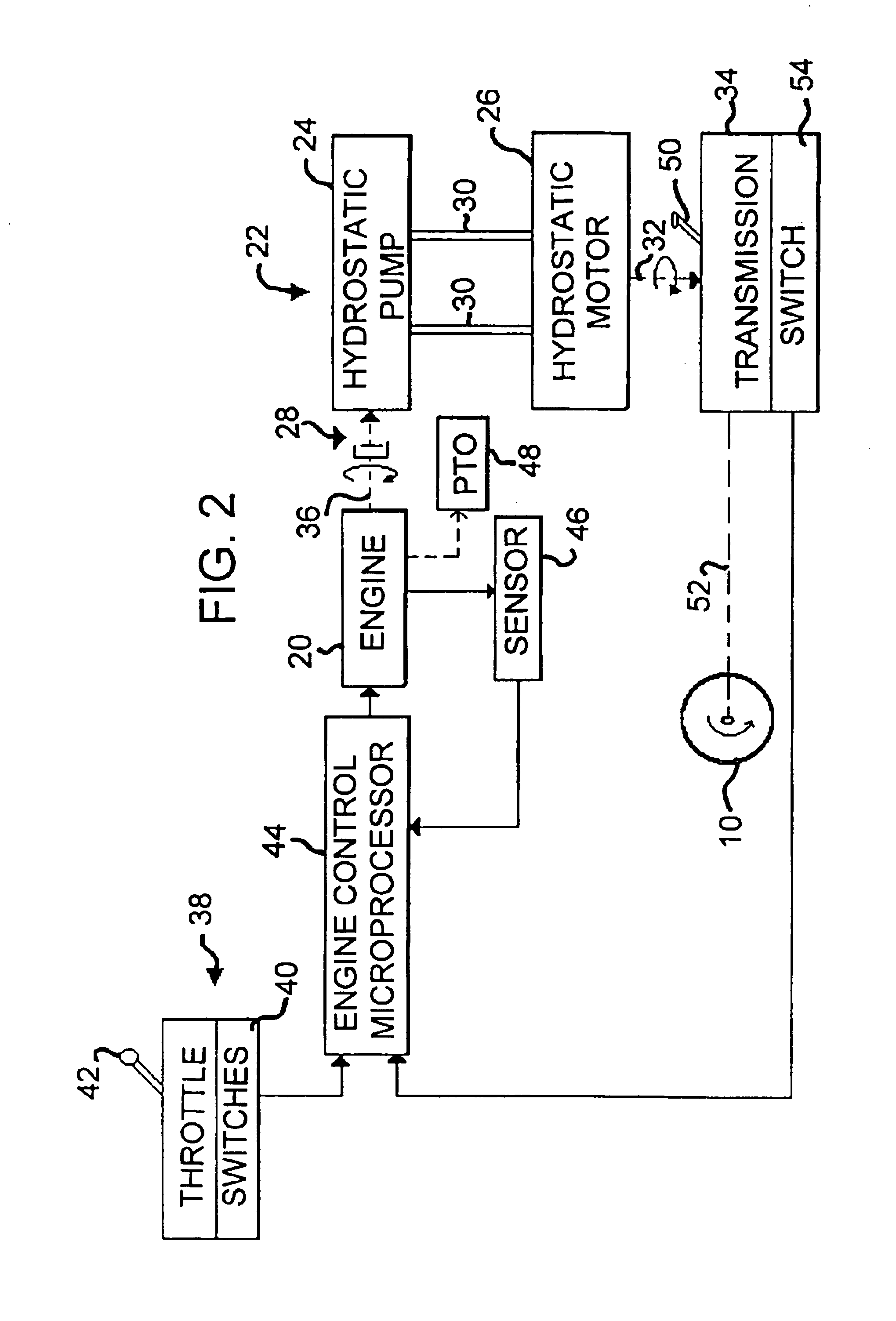

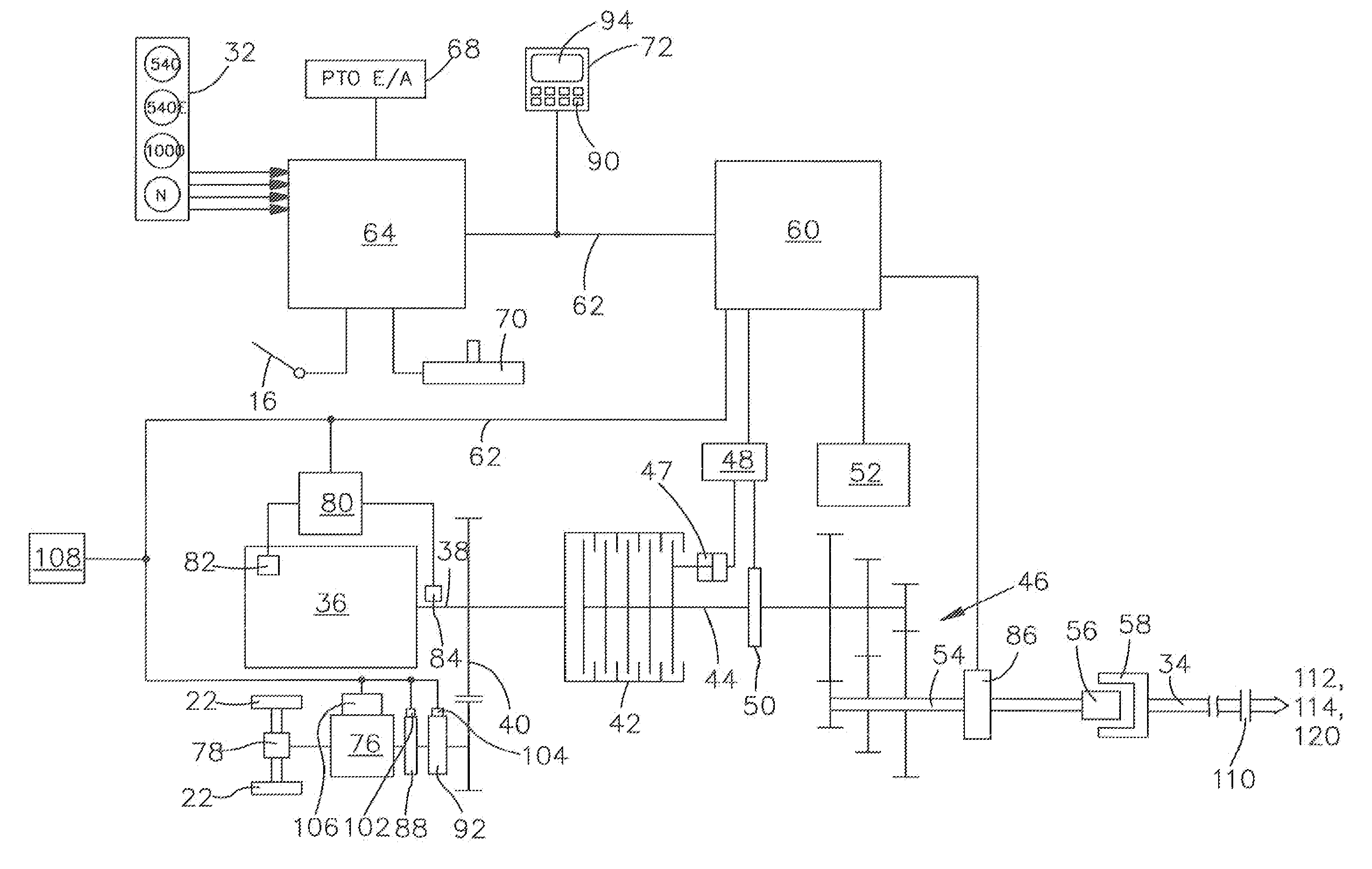

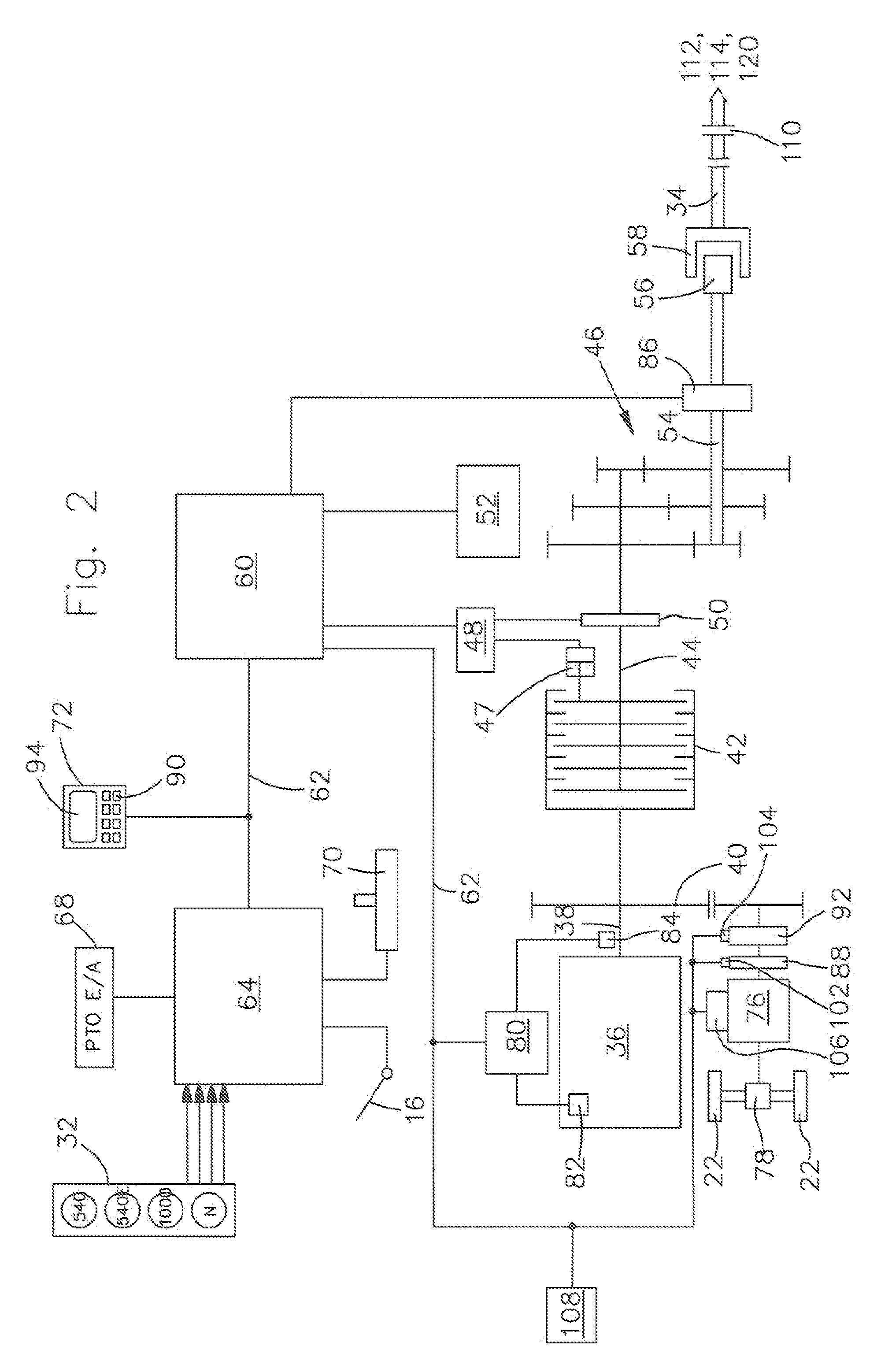

Combine power selection system

InactiveUS6865870B2Increase engine speedAvoid efficiencyAgricultural machinesVehicle fittingsThrottle controlRoad surface

A system for propelling a combine over the ground and driving other components of the combine includes an engine driving a transmission via a hydrostatic drive system. A microprocessor stores a work table and a road table for controlling engine speed. A gear selector operates a switch to select one of the tables and a throttle control operates switches to select a speed value from the selected table. When working a field, the work table is selected so that the engine runs at speeds in a range suitable for driving the other components. For transport of the combine the road table is selected so that the engine may run at a speed higher than speeds suitable for driving the other components. For a given setting of the throttle control, the engine is controlled to run at either a first or second speed depending on the setting of the gear select lever.

Owner:BLUE LEAF I P +1

Seed cotton handling system

InactiveUS7165928B2Effective conveying and wrap cutting systemEconomical and easy to useLoadersLifting devicesHandling systemCantilever

Owner:DEERE & CO

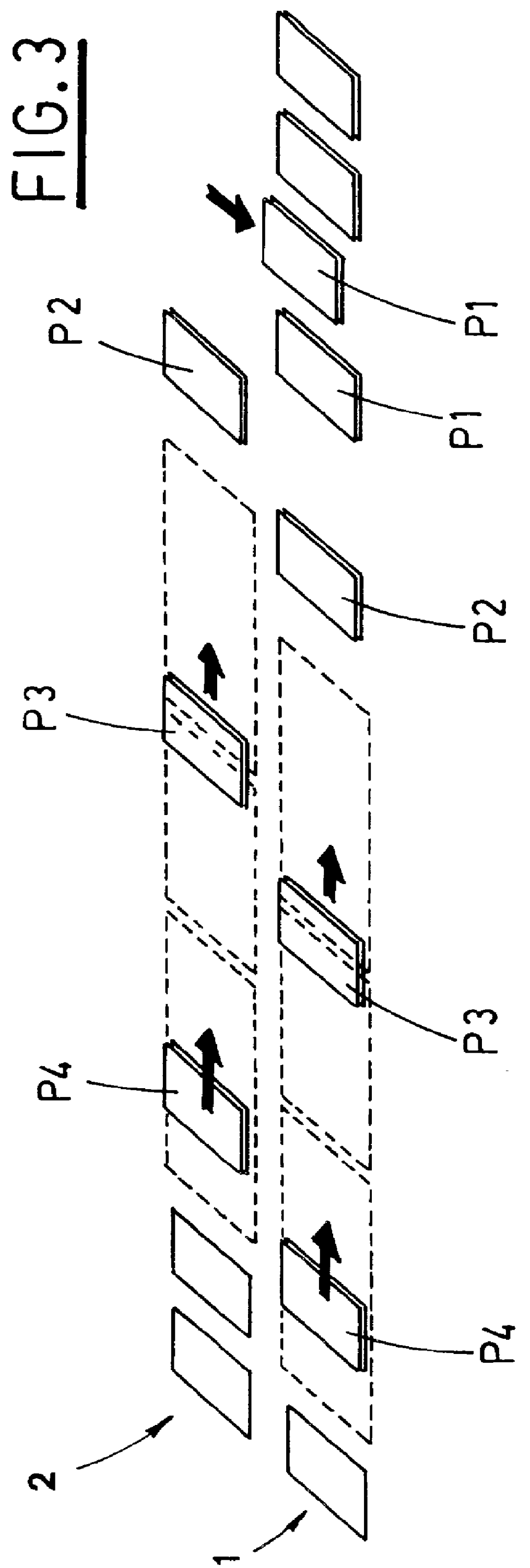

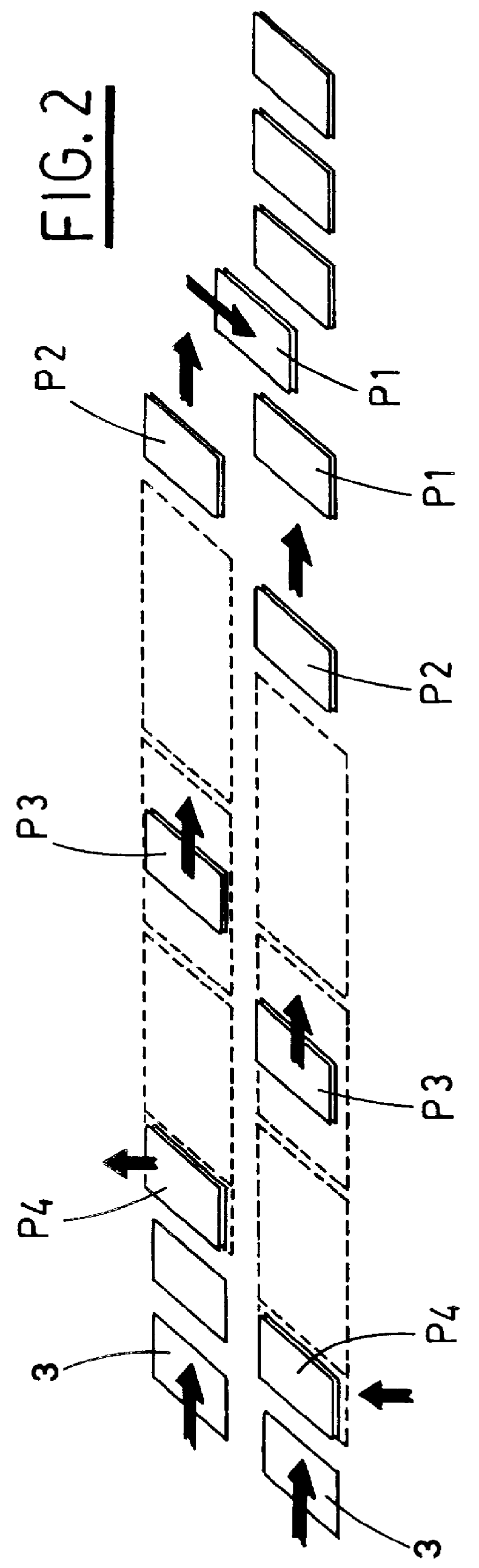

Method and apparatus for taking over and piling articles supplied in a plurality of rows and for conveying obtained piles of articles to a packaging line

PCT No. PCT / IB97 / 00036 Sec. 371 Date Jul. 21, 1998 Sec. 102(e) Date Jul. 21, 1998 PCT Filed Jan. 17, 1997 PCT Pub. No. WO97 / 27108 PCT Pub. Date Jul. 31, 1997The present invention describes an apparatus which carries out a method for taking and piling articles supplied in a plurality of rows for transferring the obtained piles of articles to a packaging line. The articles are moved along at least two working lines arranged side by side and parallel to each other. The articles are piled in piling stations which are staggered apart by a predetermined step. The obtained piles of articles are transferred, also staggered by a predetermined step, to a packaging line where a first conveyer moves the piles from the piling member, to other conveying devices which move the piles to a packaging line in which the piles are arranged in a single row.

Owner:IMA IND MASCH AUTOMATICHE SPA

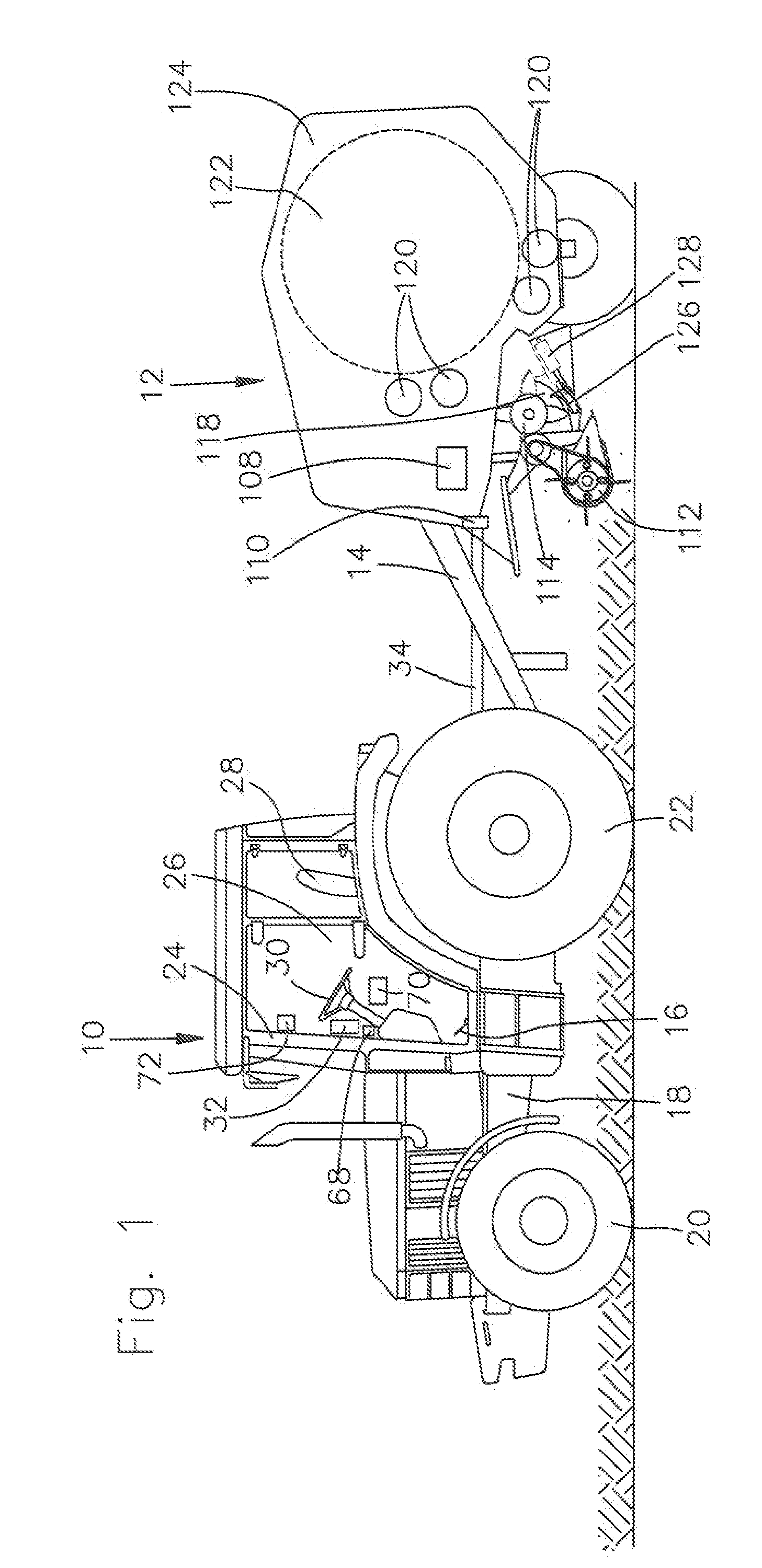

Drive Arrangement And Process For The Drive Of An Agricultural Implement

ActiveUS20100036569A1Eliminate overloadProcess safetyAgricultural machinesLoadersActuatorControl theory

A drive arrangement for the drive of an agricultural implement is provided that includes a drive engine that can be brought into a drive connection over a separable power take-off shaft clutch with a power take-off shaft output. A drive line of the operating implement is connected with the power take-off shaft output, with an overload clutch, and a control arrangement. The control arrangement is connected to a sensor arranged for the detection of the torque at the power take-off shaft output and, in normal operation, permits an actuator to disengage the power take-off shaft clutch as soon as the torque detected by the sensor reaches or exceeds a first threshold value, that corresponds to a torque that is smaller than the cut-off torque of the overload clutch. Immediately following, the control arrangement orders the actuator to engage the power take-off shaft clutch and when the power take-off shaft clutch is disengaged permits a torque at the power take-off shaft output that is greater than the cut-off torque of the overload clutch.

Owner:DEERE & CO

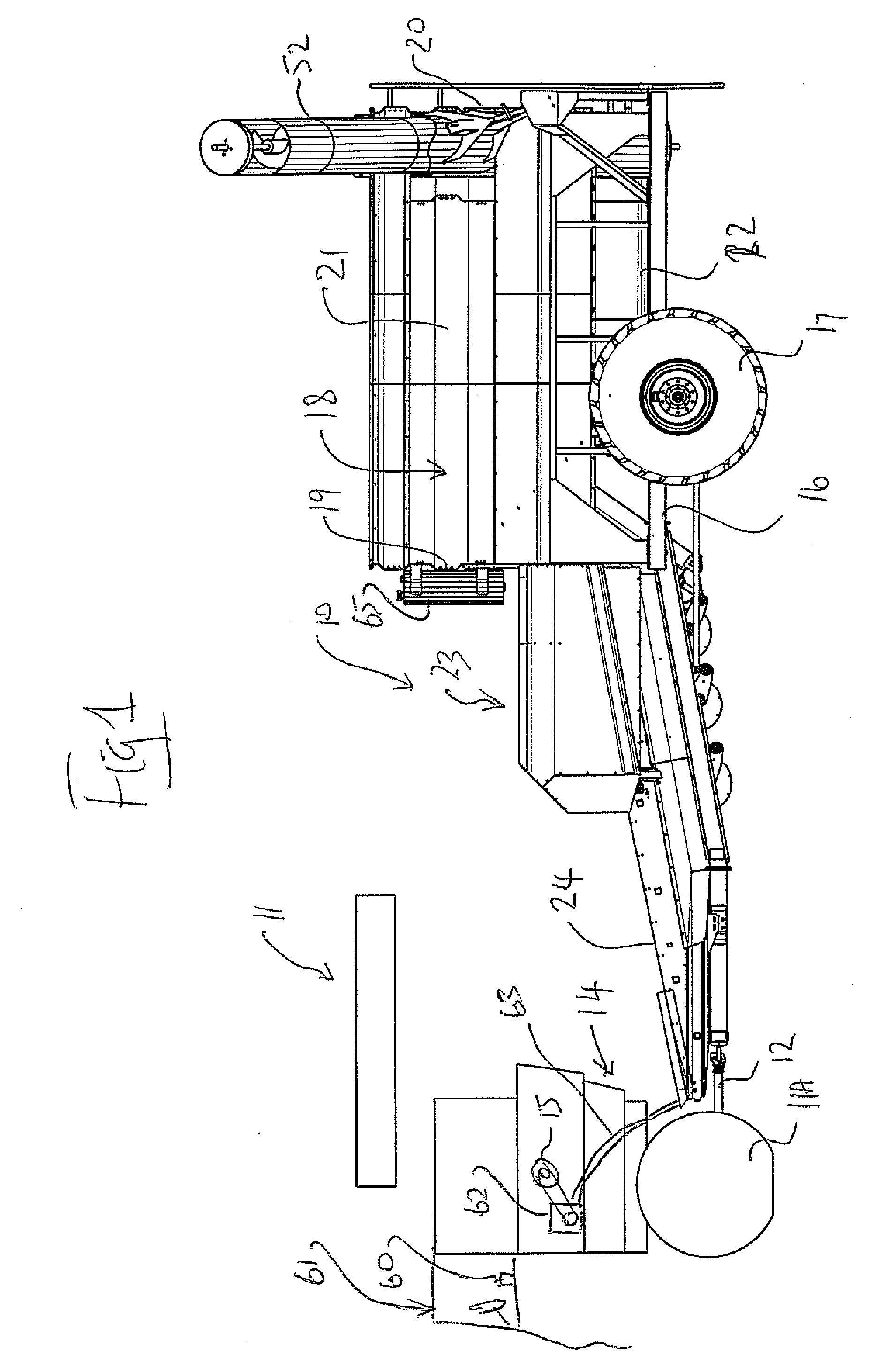

Harvesting corn cobs

A cart is towed behind a combine harvester for collecting corn cobs and includes a conveyer belt feeding into a system for separating cobs from residue to be discharged and a tank for receiving and transporting the cobs. An unload auger is provided from the tank to one side of the cart while the cart moves forward. Power for driving the cart is obtained from a chopper drive of the combine harvester. The separating arrangement includes a series of sequential blower fans for blowing air through the discharged material as it is discharged from a conveyor and into a spreading guide disperses the residue. The cobs are conveyed using a series of augers where the auger to flight distance is at least 2 inches and particularly a pair of augers feed the cobs through a front wall of the tank so as to push cobs upwardly into the tank.

Owner:REDEKOP ENTERPRISES

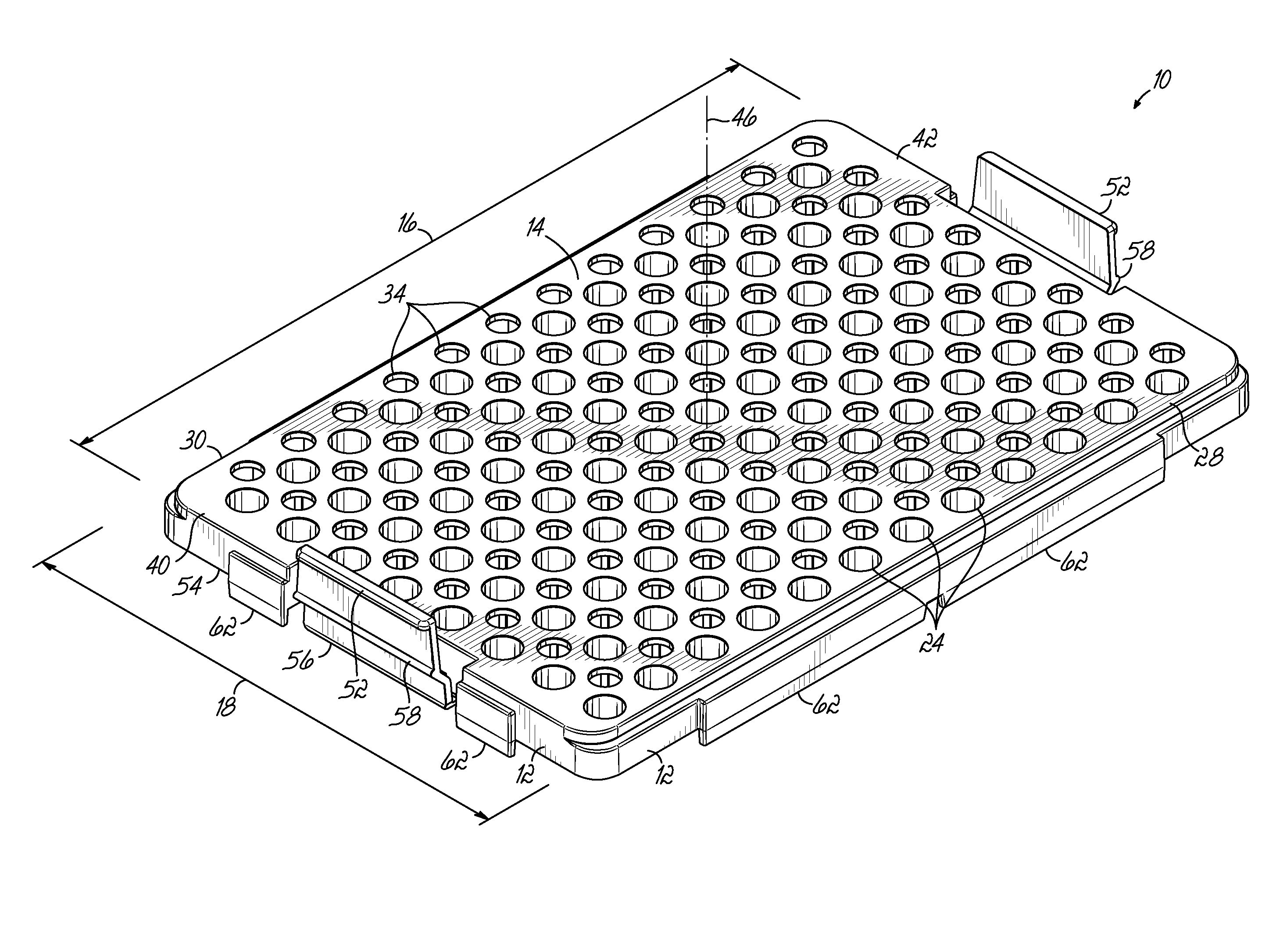

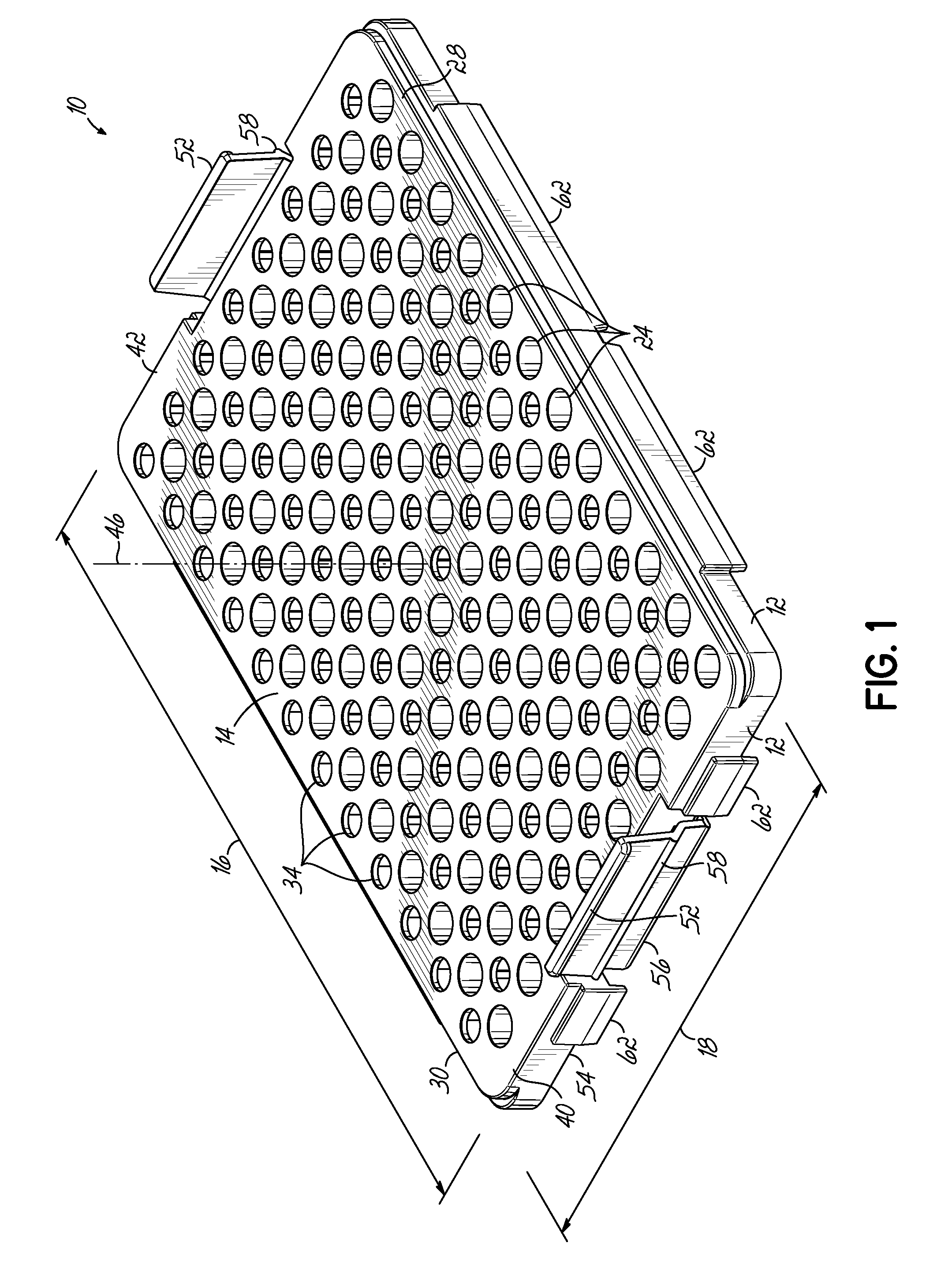

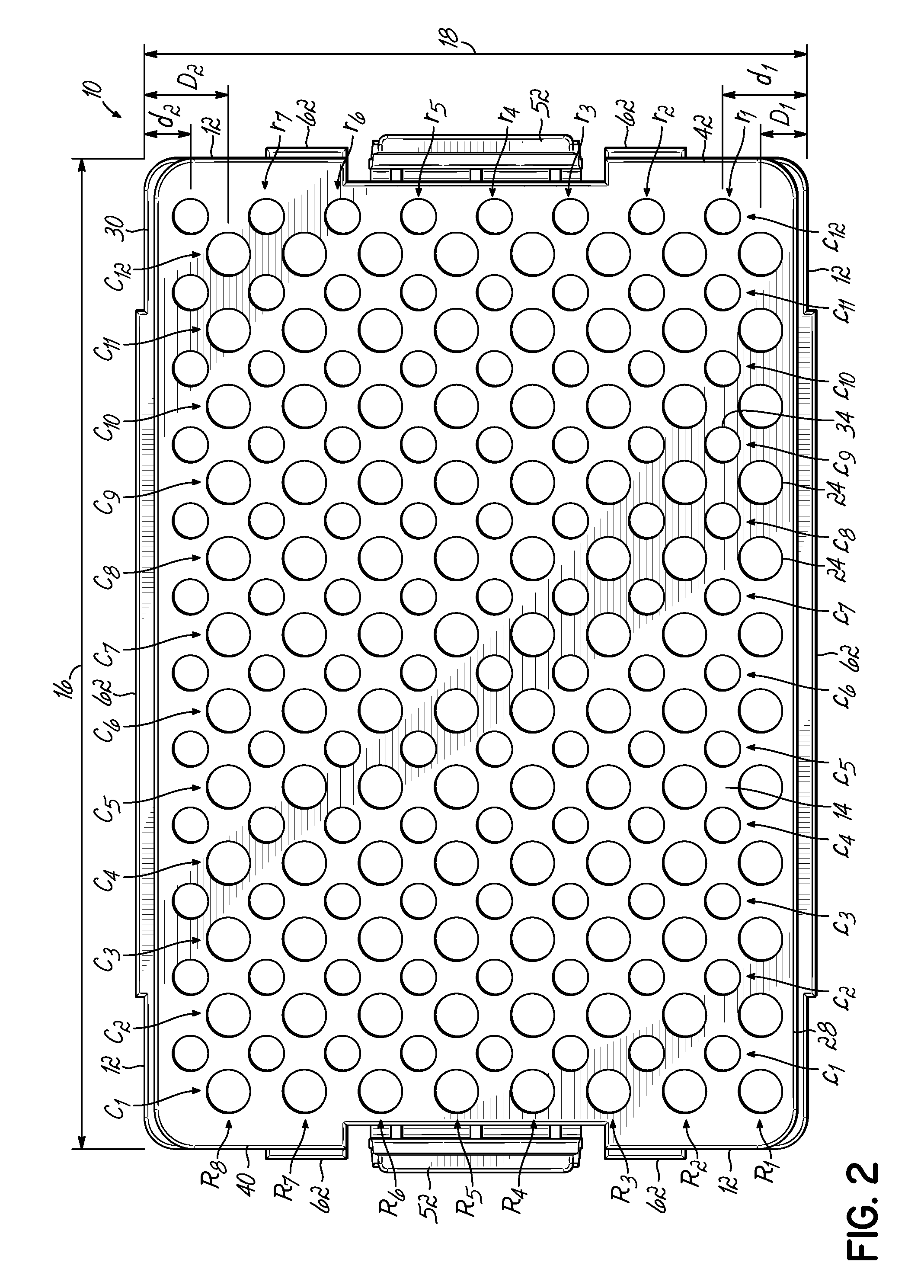

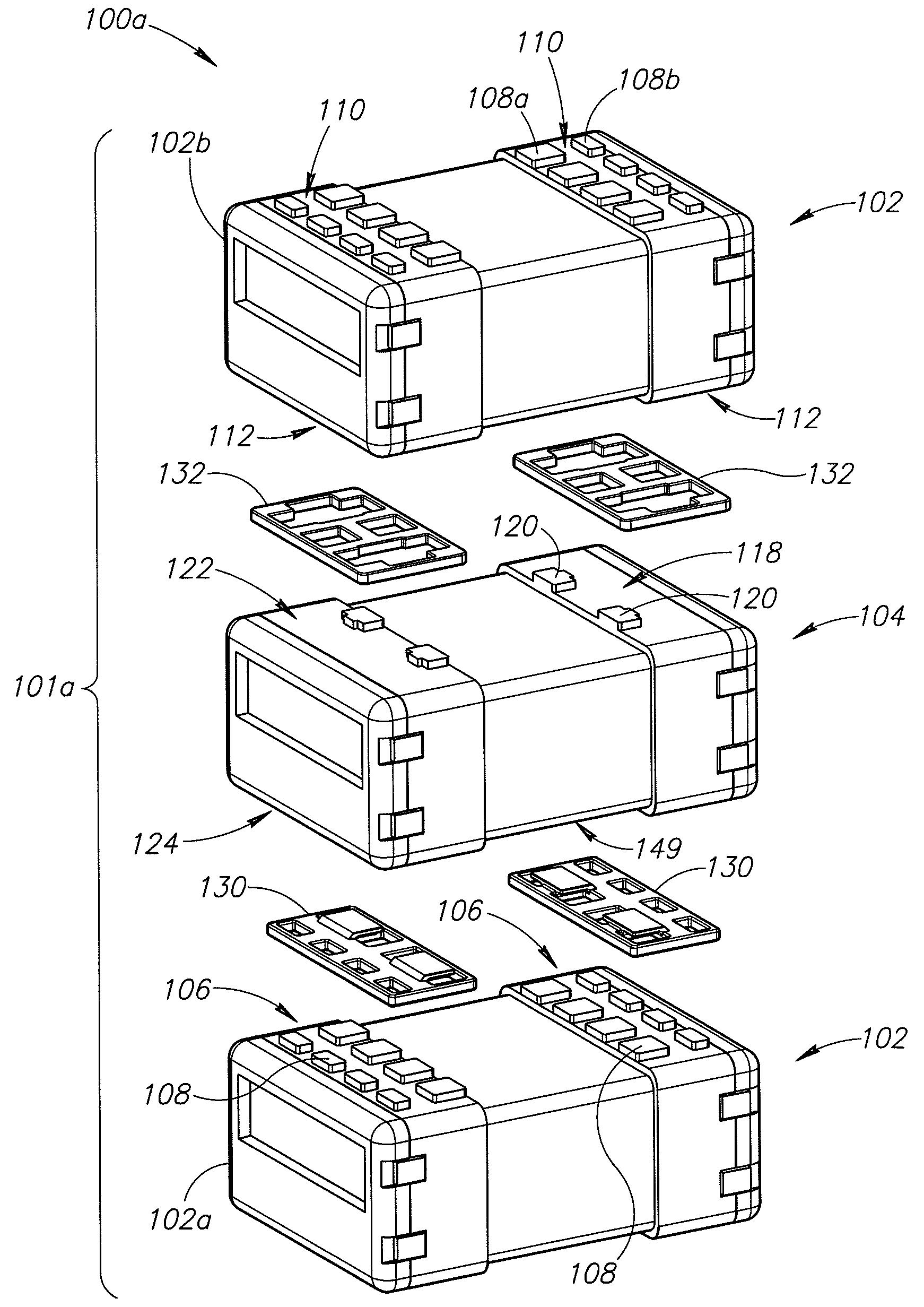

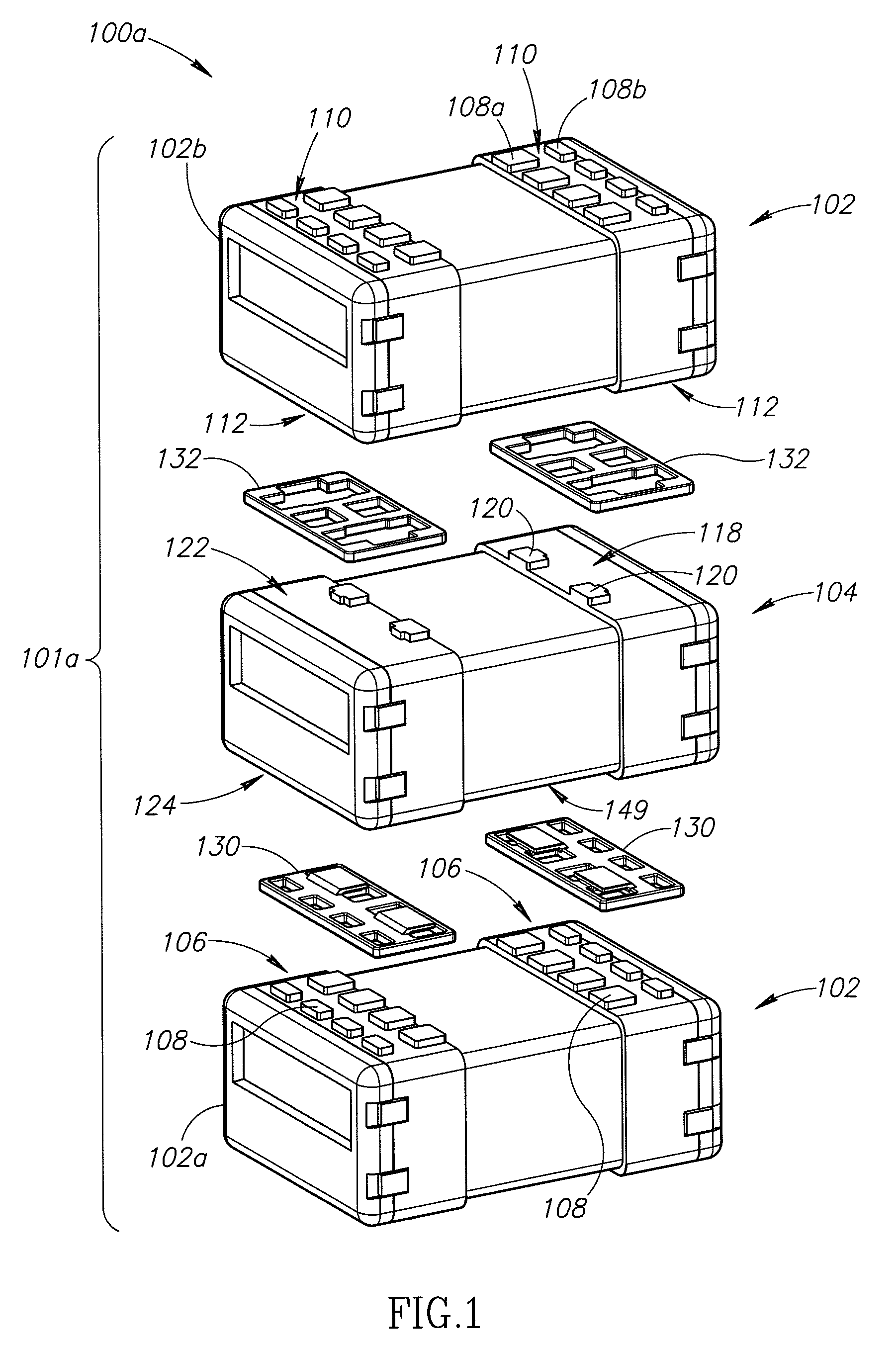

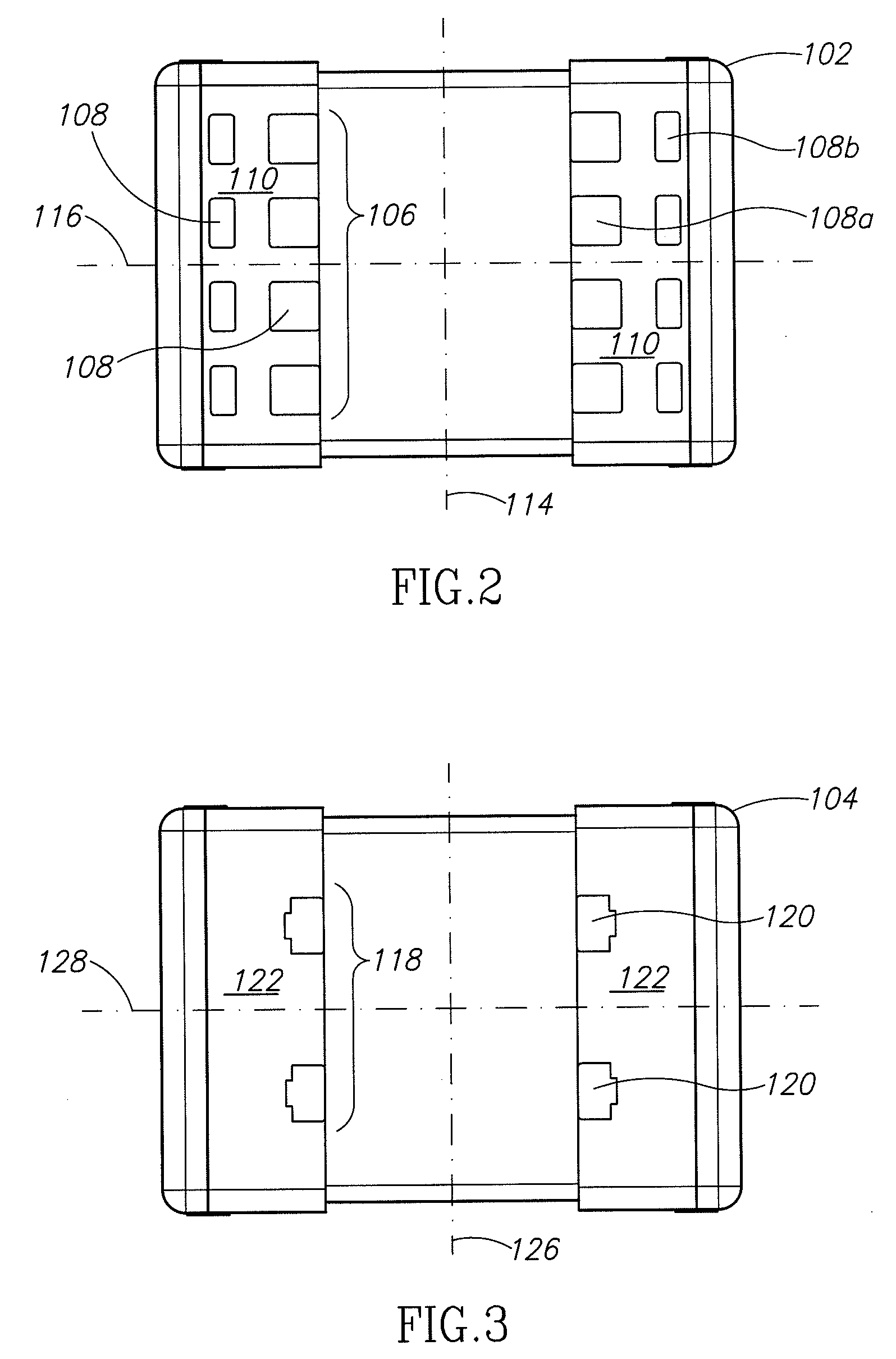

Pipette Tip Stacking Tray

A stackable pipette tip tray is described. The pipette tip tray includes a deck having first and second opposing longitudinal side edges. A plurality of shaft apertures is arranged into a plurality of longitudinal rows on the deck. Each of the shaft apertures has a first size or shape configured to receive a shaft of a pipette tip. The deck also includes a plurality of tip apertures that is also arranged into a plurality of longitudinal rows such that at least one of the longitudinal rows of tip apertures is located between an adjacent pair of longitudinal rows of shaft apertures. Each of the plurality of tip apertures has a second size or shape, different from the first size or shape, and is configured to receive a distal tip end of a pipette tip when one tray of pipette tips is stacked above another tray of pipette tips. The plurality of longitudinal rows of shaft apertures is further arranged such that an outer one of the plurality of longitudinal row of shaft apertures adjacent the first side edge of the deck is positioned closer to the first side edge than an outer one of the plurality of longitudinal row of shaft apertures adjacent the second side edge of the deck is positioned relative to the second side edge.

Owner:MOLECULAR BIOPROD

Container stacking system with universal members

Owner:BECKLIN HLDG

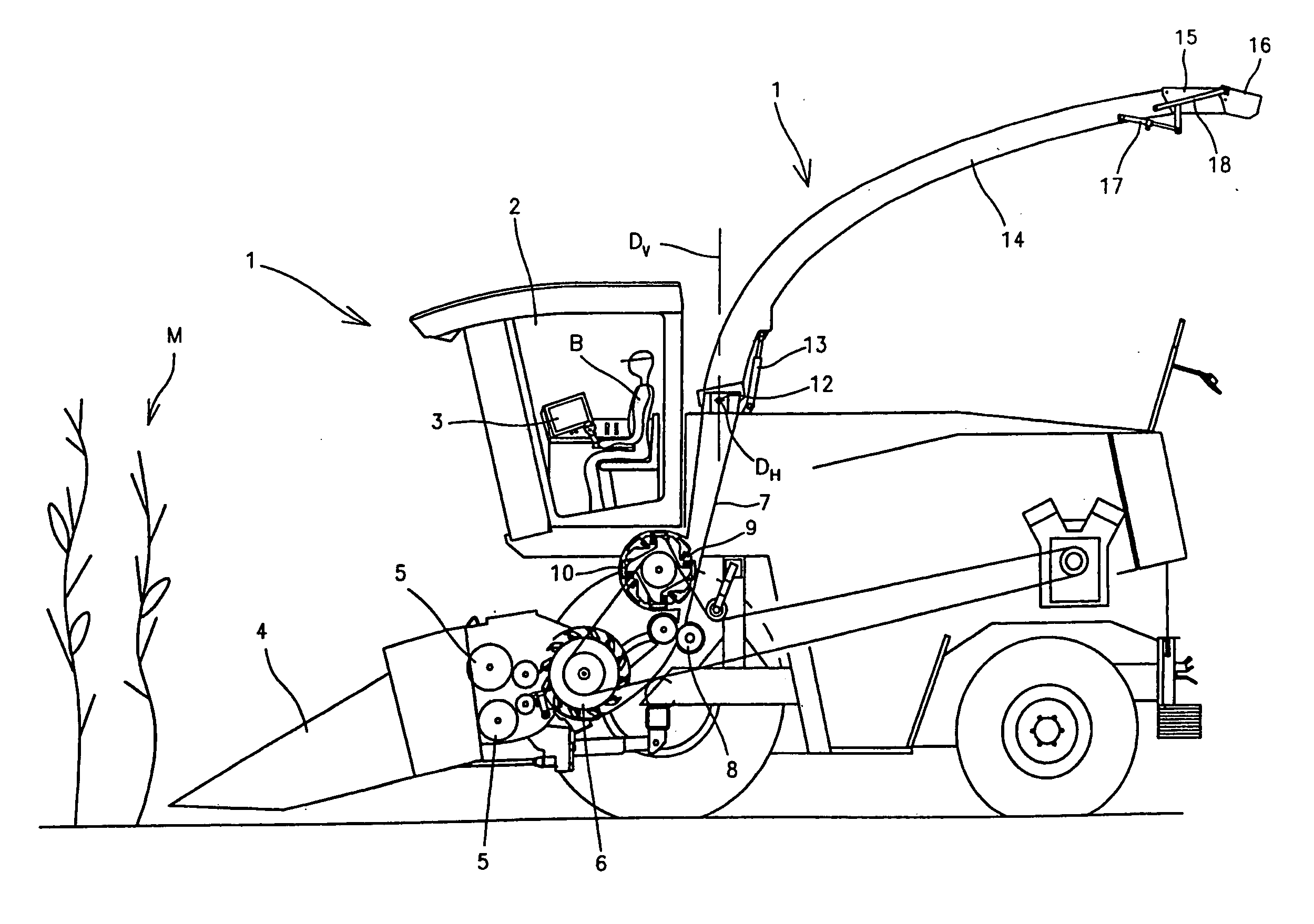

Method for transferring crop material

ActiveUS20070037621A1Improve energy efficiencyLarge transmission distanceLoadersMowersEngineeringThrough transmission

In a method for transferring crop material from a harvesting machine to a hauling vehicle, with which the crop material is accelerated and ejected through a conveyor chute of a transfer device to a target point on the transport vehicle, the acceleration of the crop material to be transferred is controlled as a function of at least one parameter that represents a transfer distance. A corresponding control unit for a harvesting machine, and a harvesting machine with a control unit of this type are also provided.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

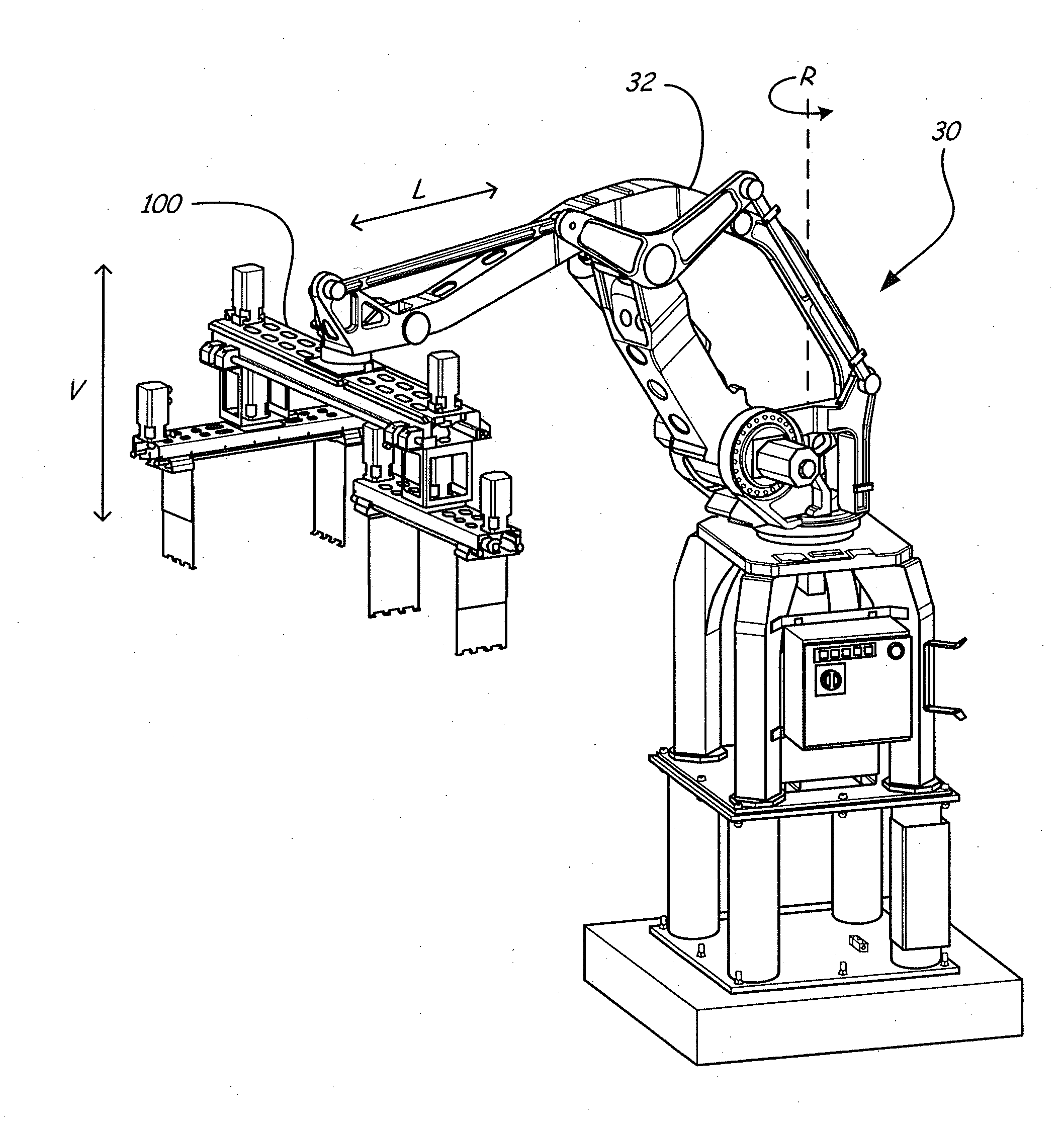

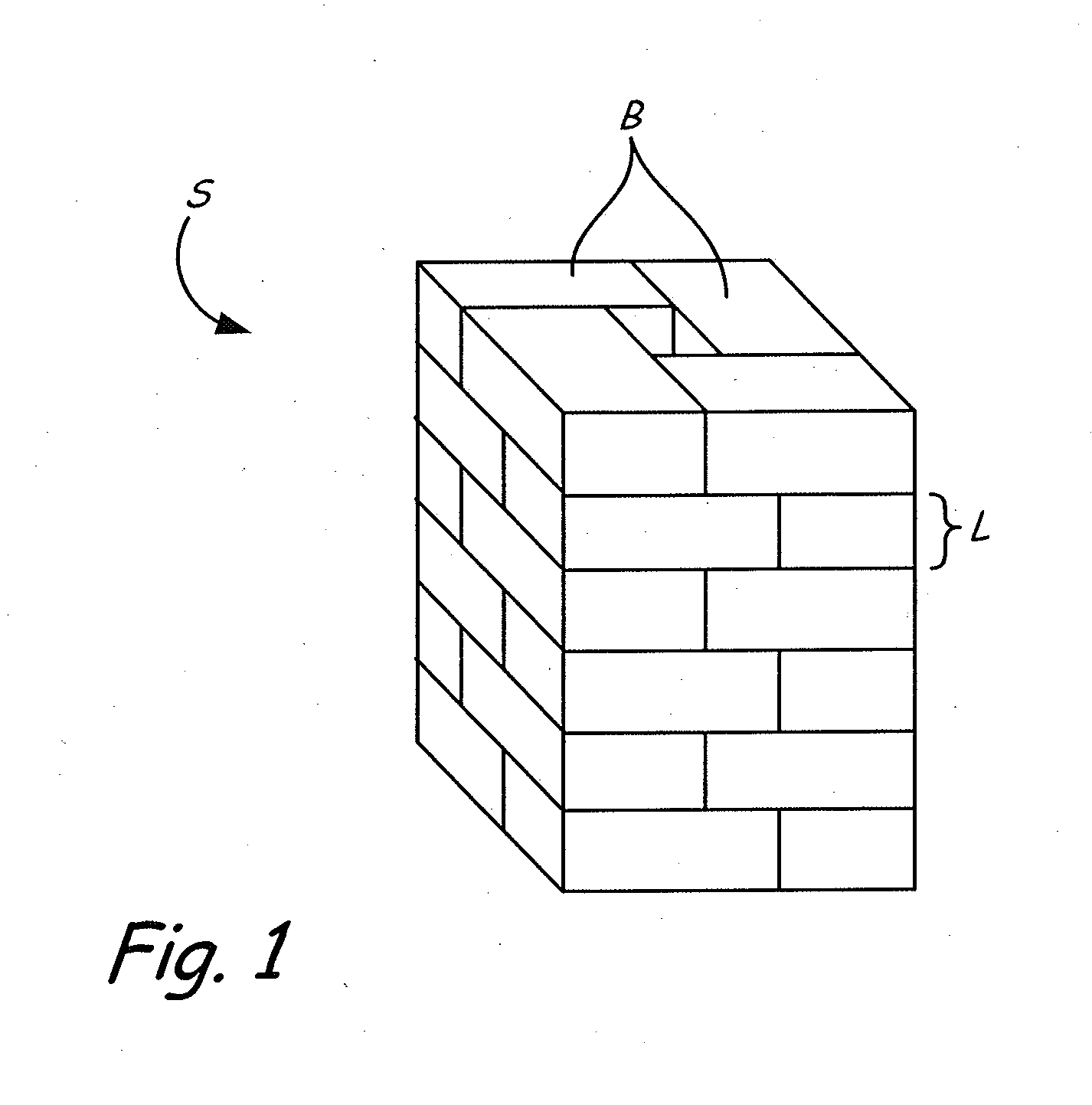

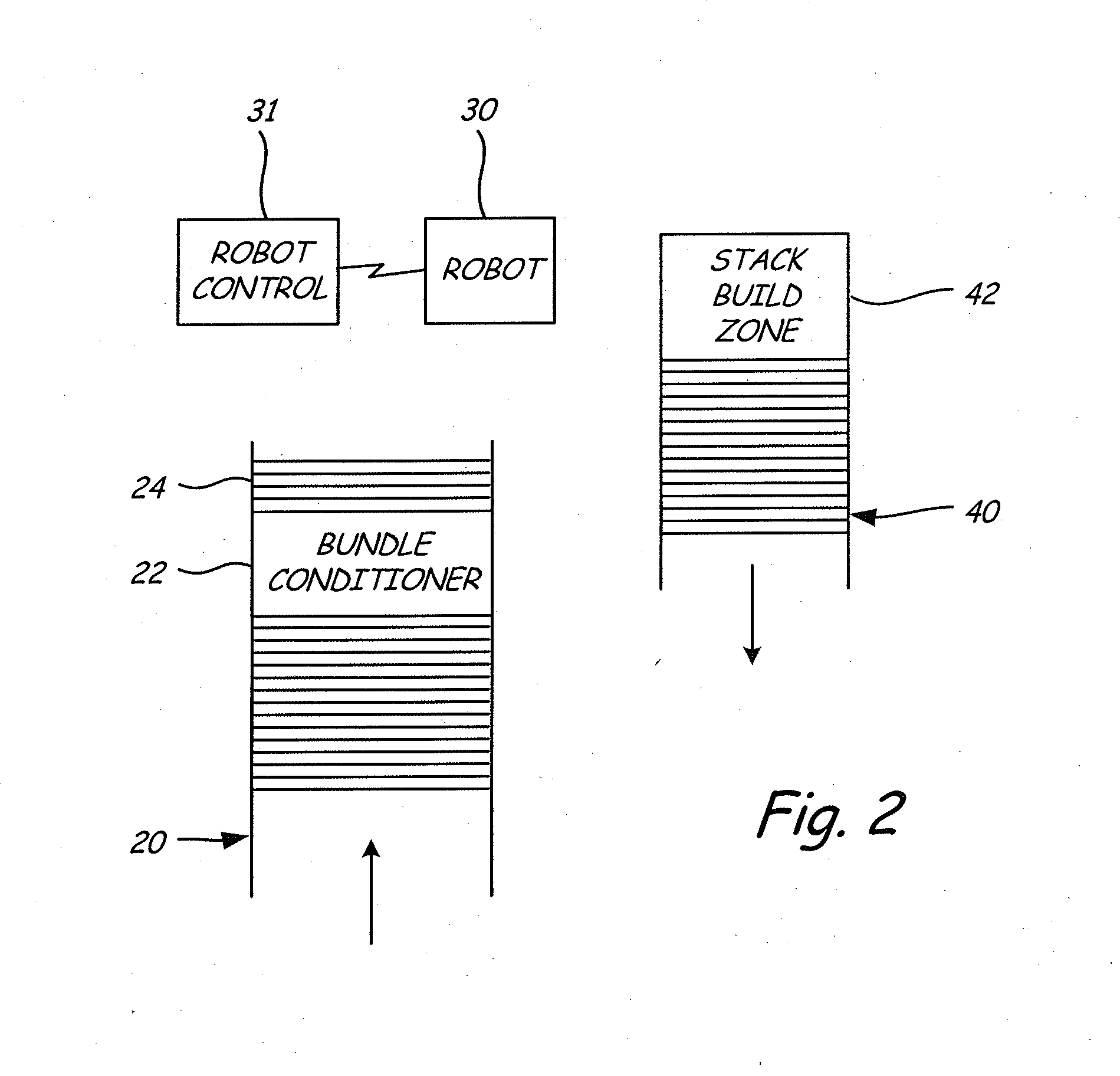

System and methods for forming stacks

A method of forming layered stacks of bundles includes providing a gripping appliance comprising a first gripping assembly and a second gripping assembly. The first gripping assembly is configured for grasping one or more first bundles and the second gripping assembly is configured for grasping one or more second bundles. The first and second gripping assemblies are configured such that first and second bundles grasped thereby may be reoriented relative to one another. The method further includes retrieving from a first location one or more first bundles with the first gripping assembly and one or more second bundles with the second gripping assembly and transporting the first and second bundles to a second location, During transport of the first and second bundles, the bundles are reoriented relative to one another. The bundles are deposited at a selected position in the second location to form at least a partial layer of a layered stack of bundles.

Owner:ALLIANCE MACHINE SYST INTENAT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com