Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

379 results about "Pinch valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pinch valve is a full bore or fully ported type of control valve which uses a pinching effect to obstruct fluid flow.

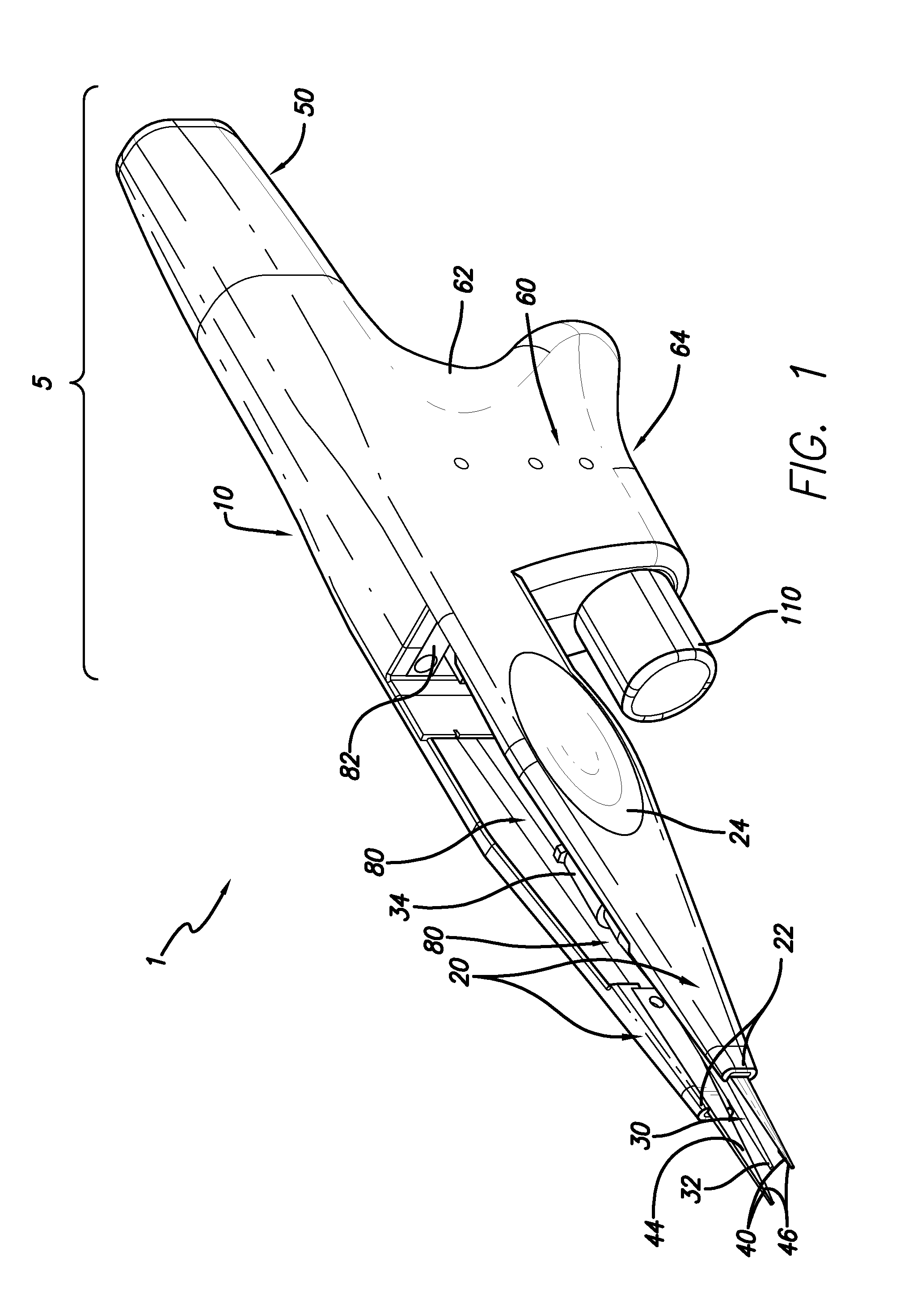

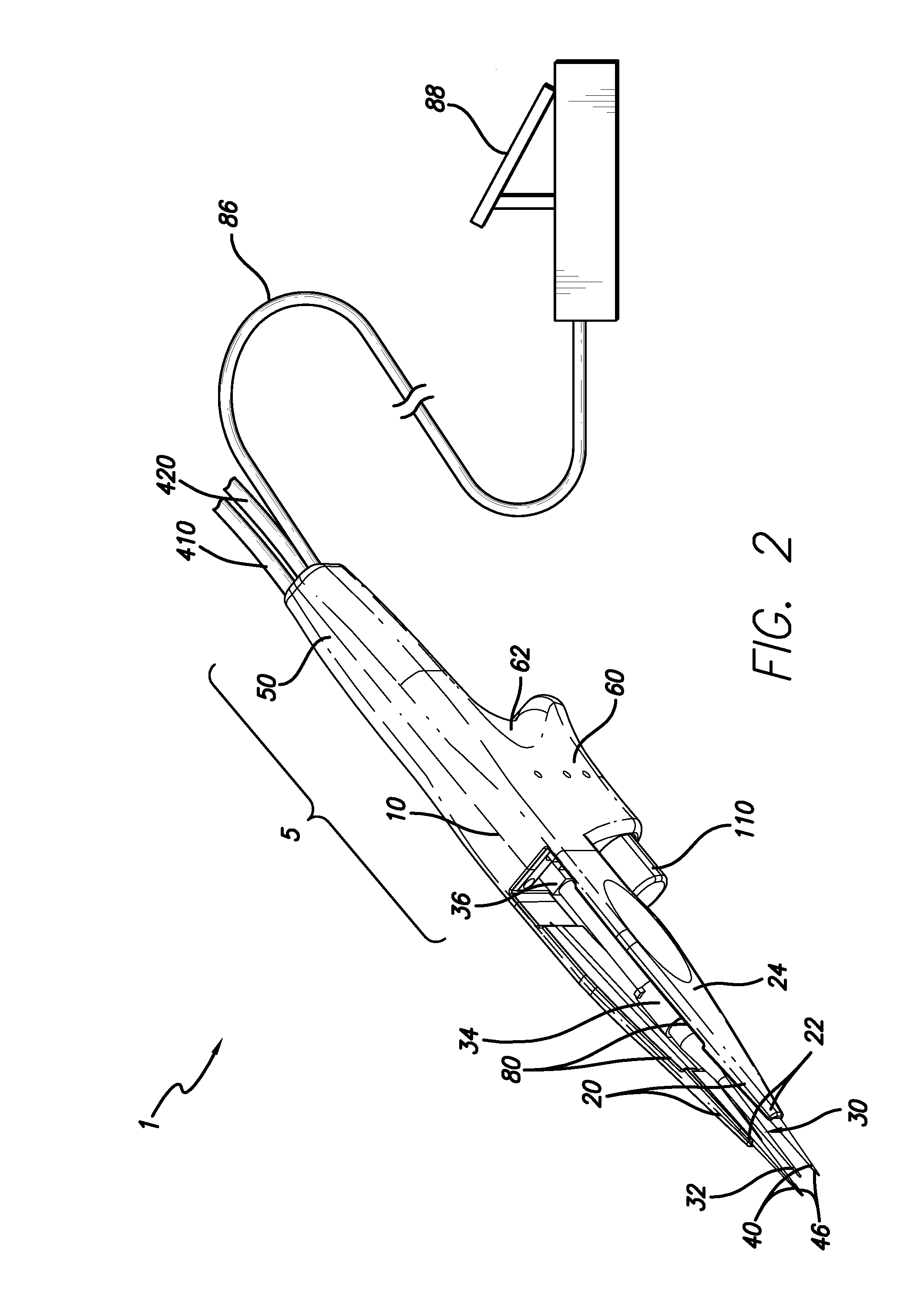

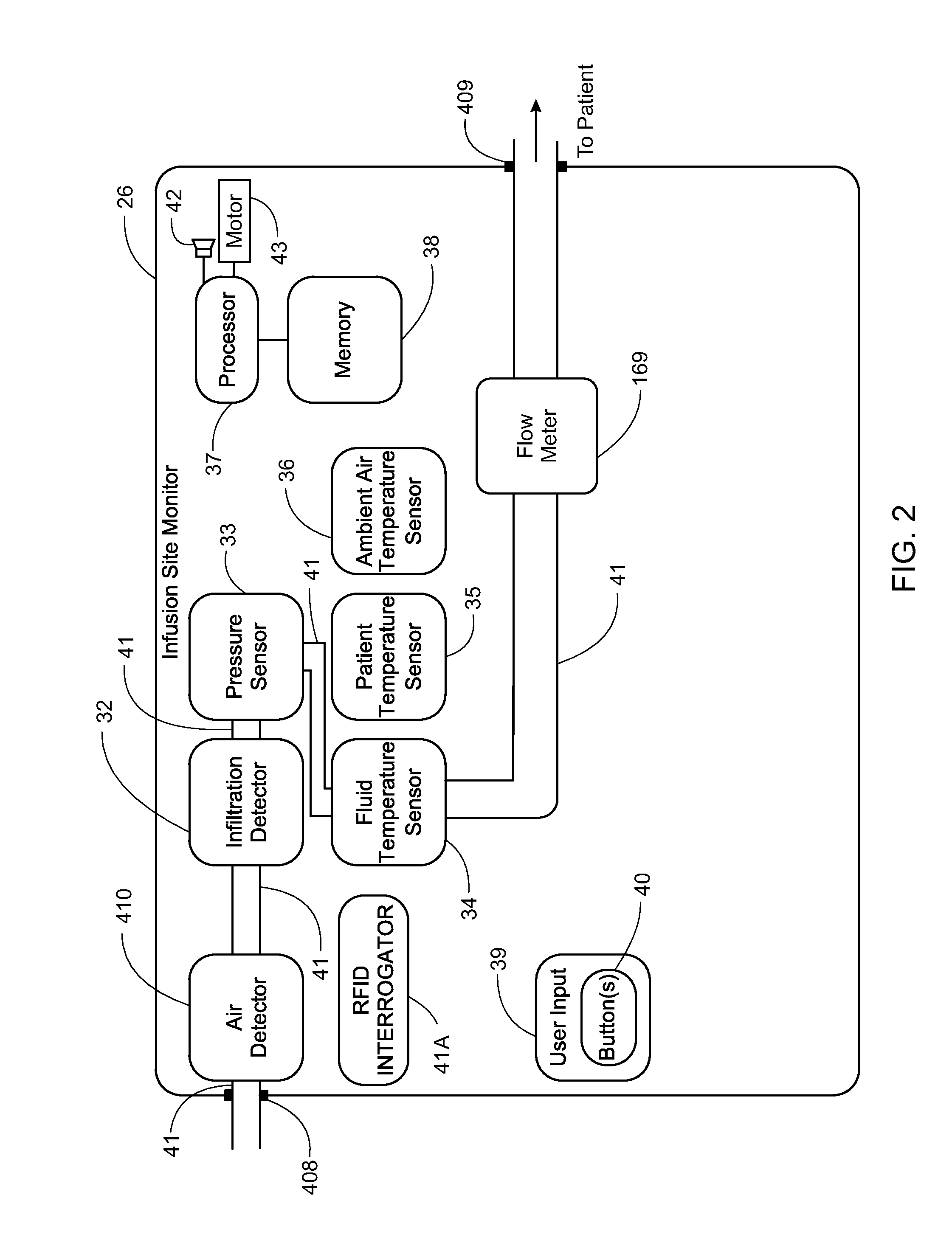

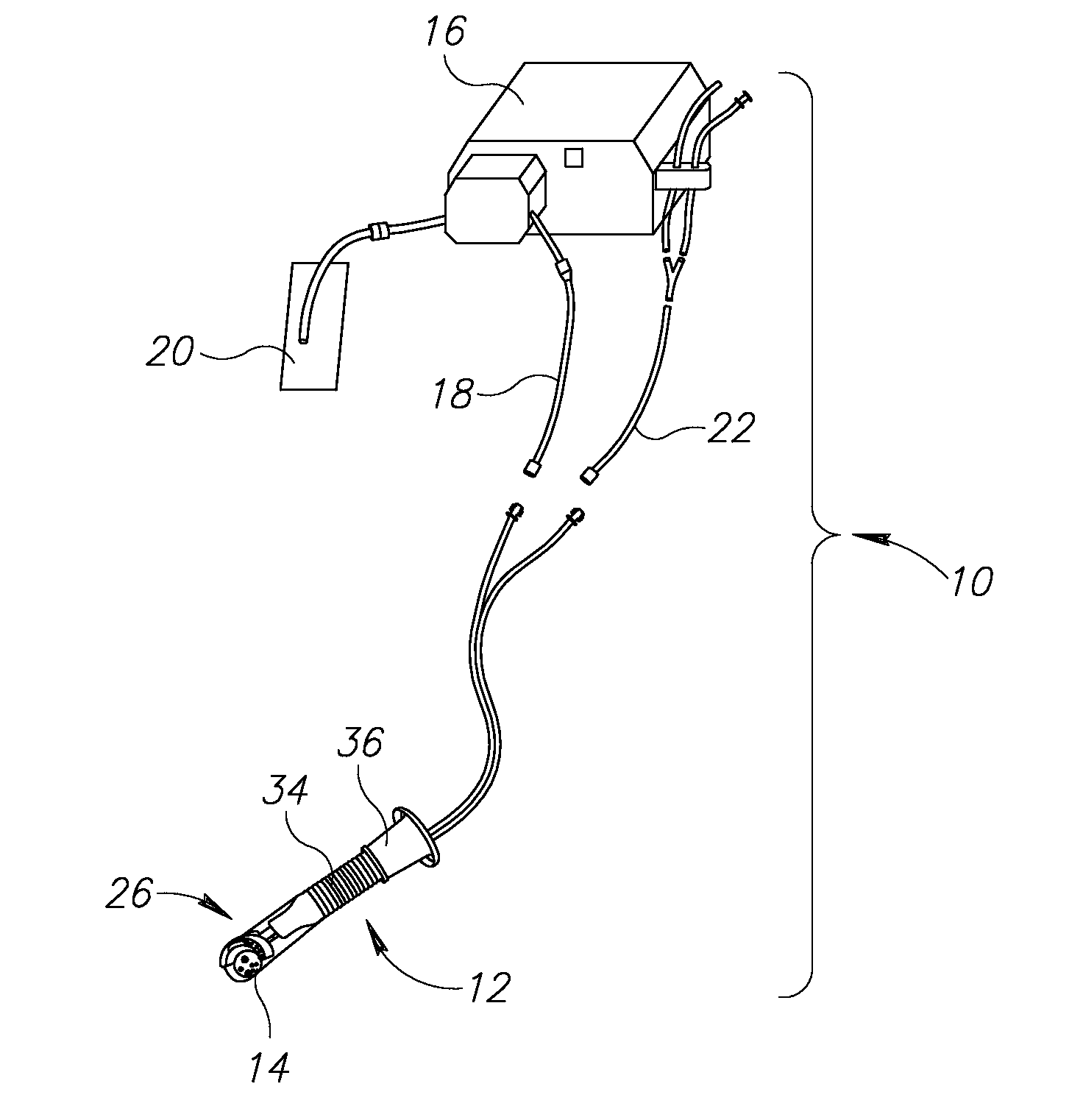

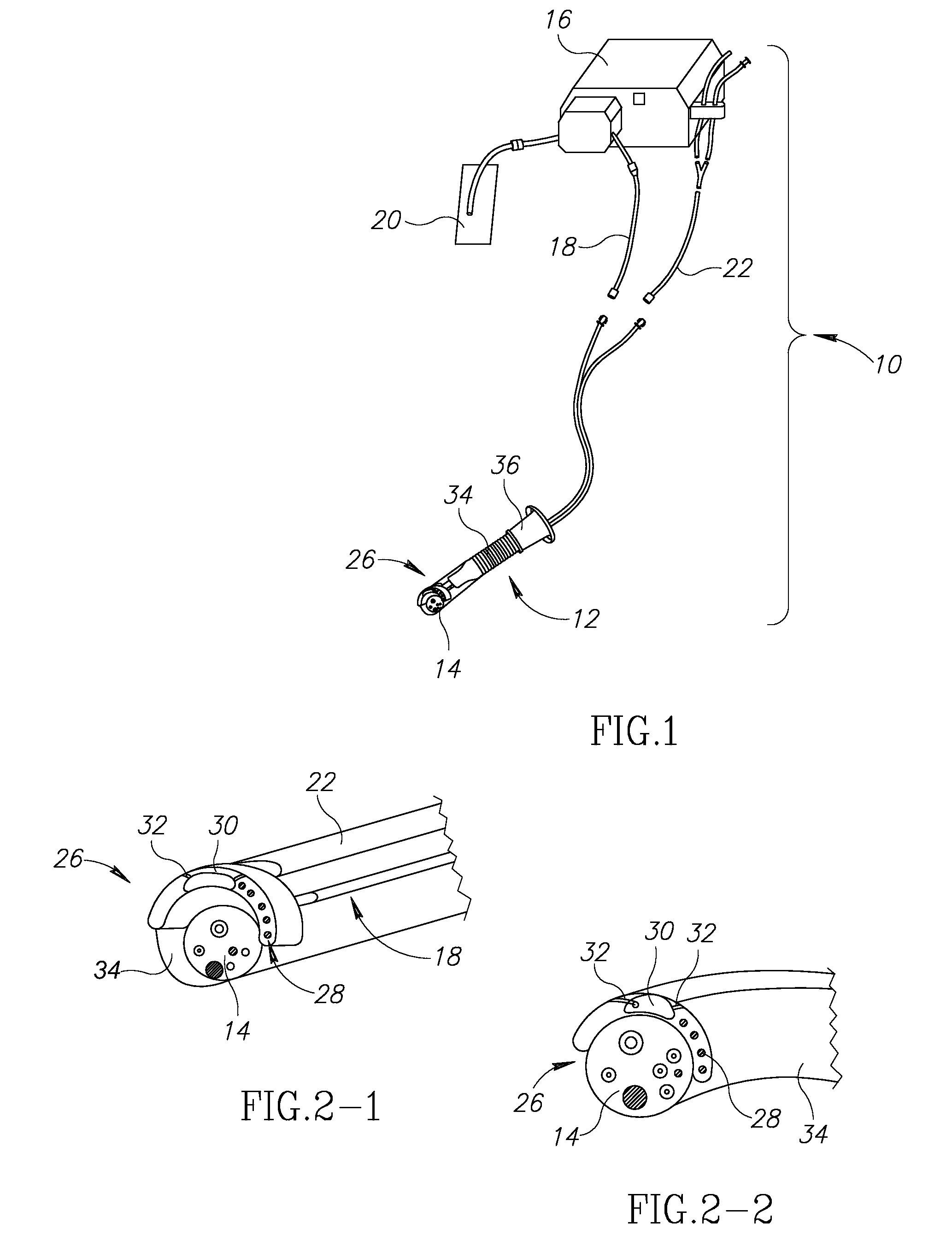

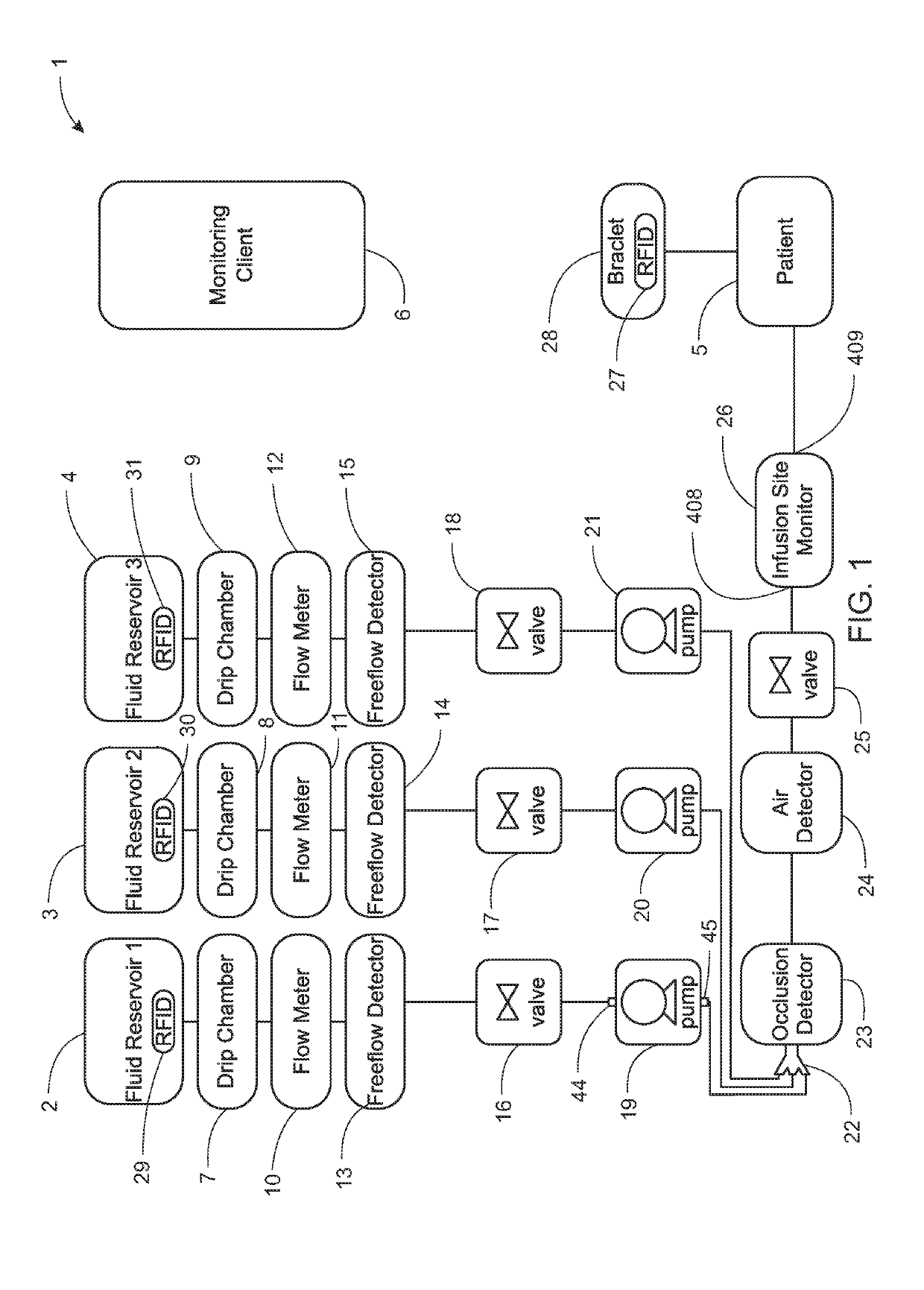

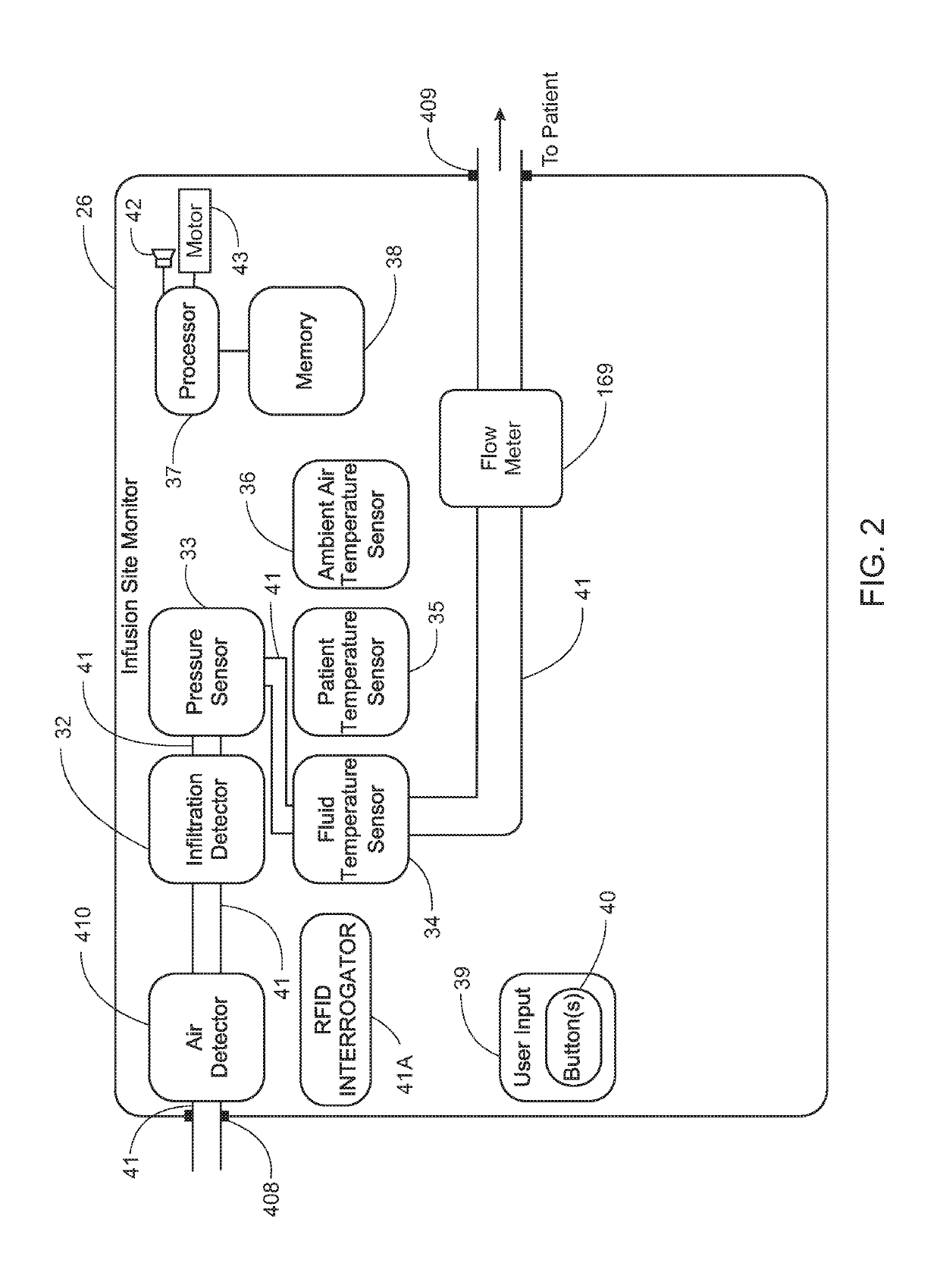

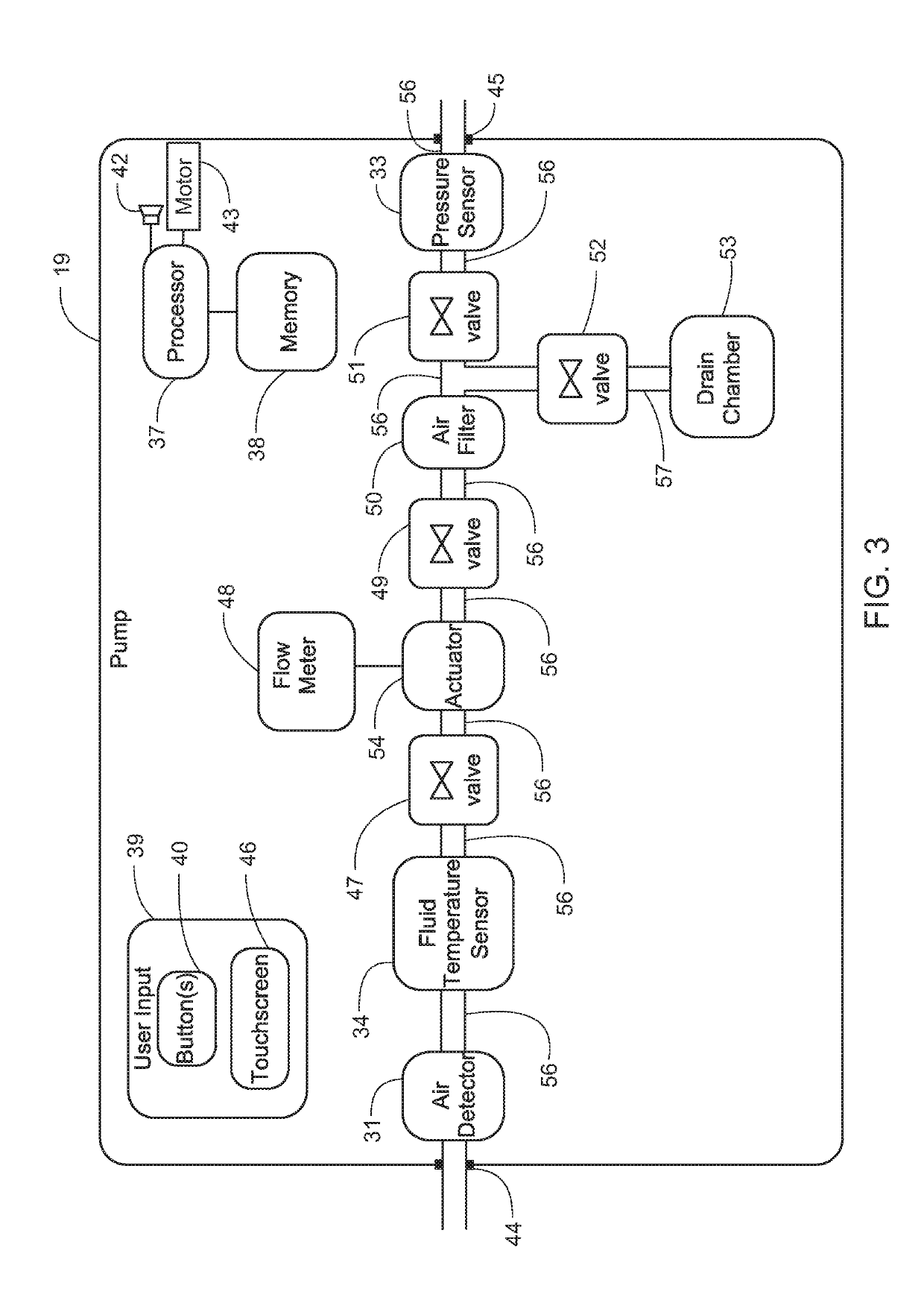

System, Method, and Apparatus for Infusing Fluid

ActiveUS20130177455A1Reduce peak torqueDrug and medicationsFlexible member pumpsPeristaltic pumpPinch valve

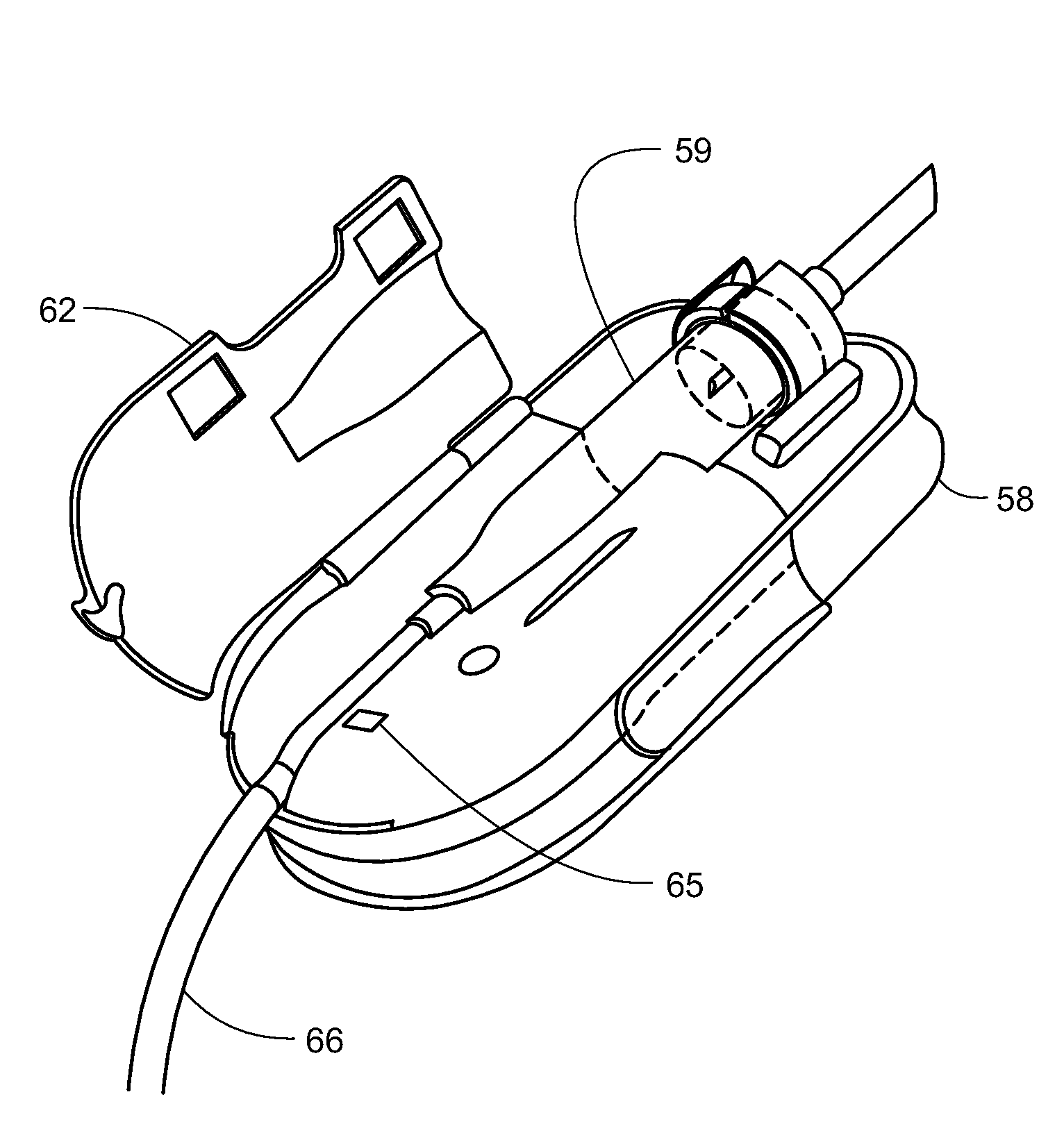

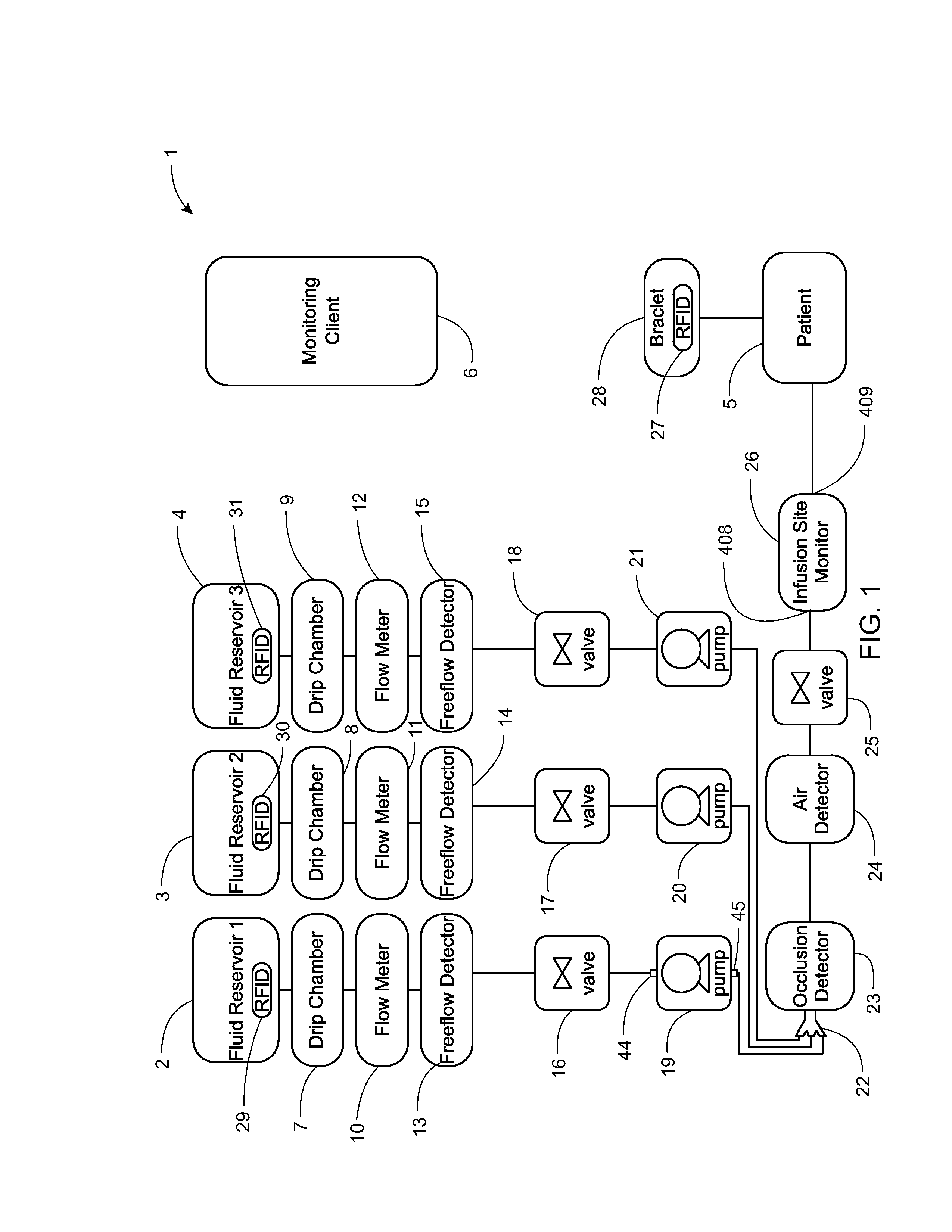

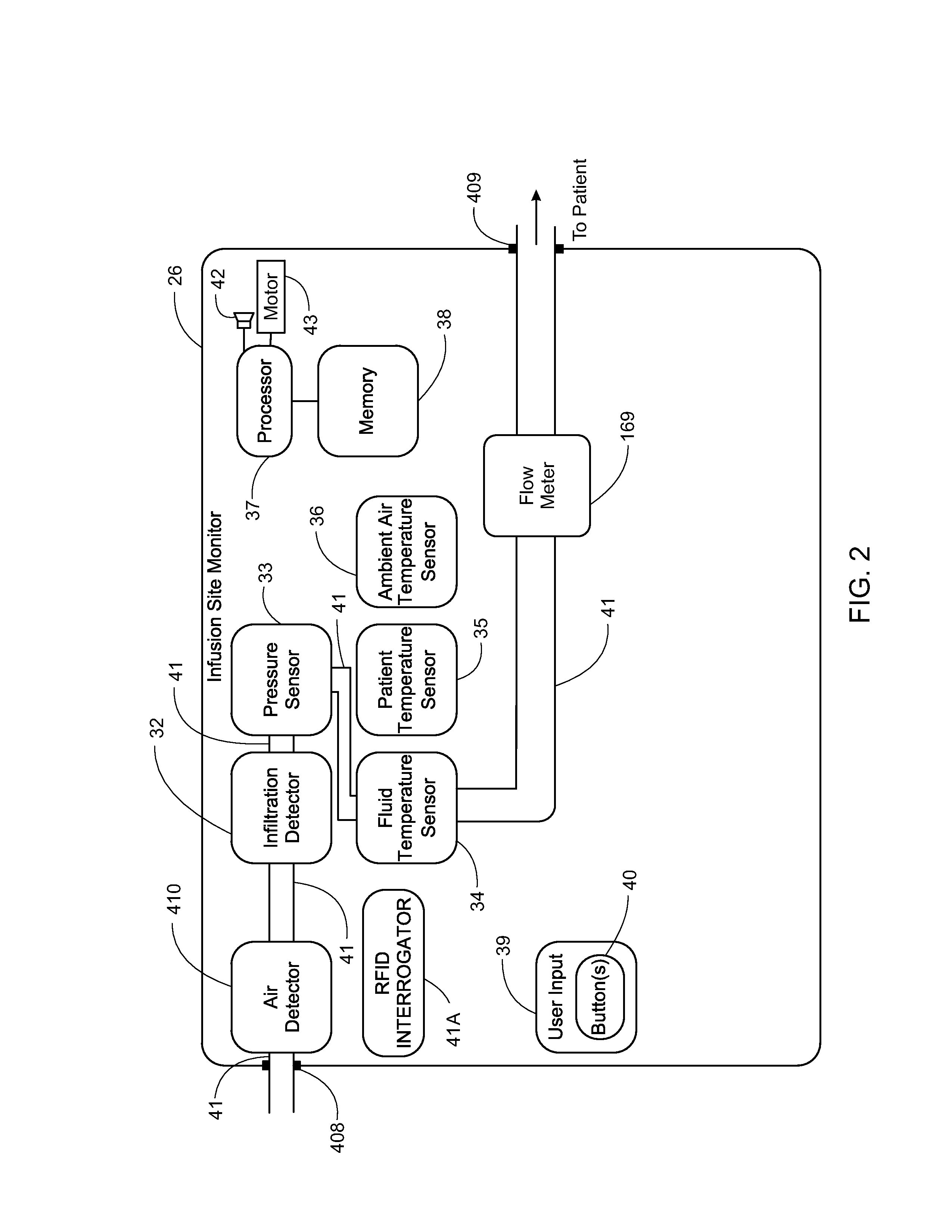

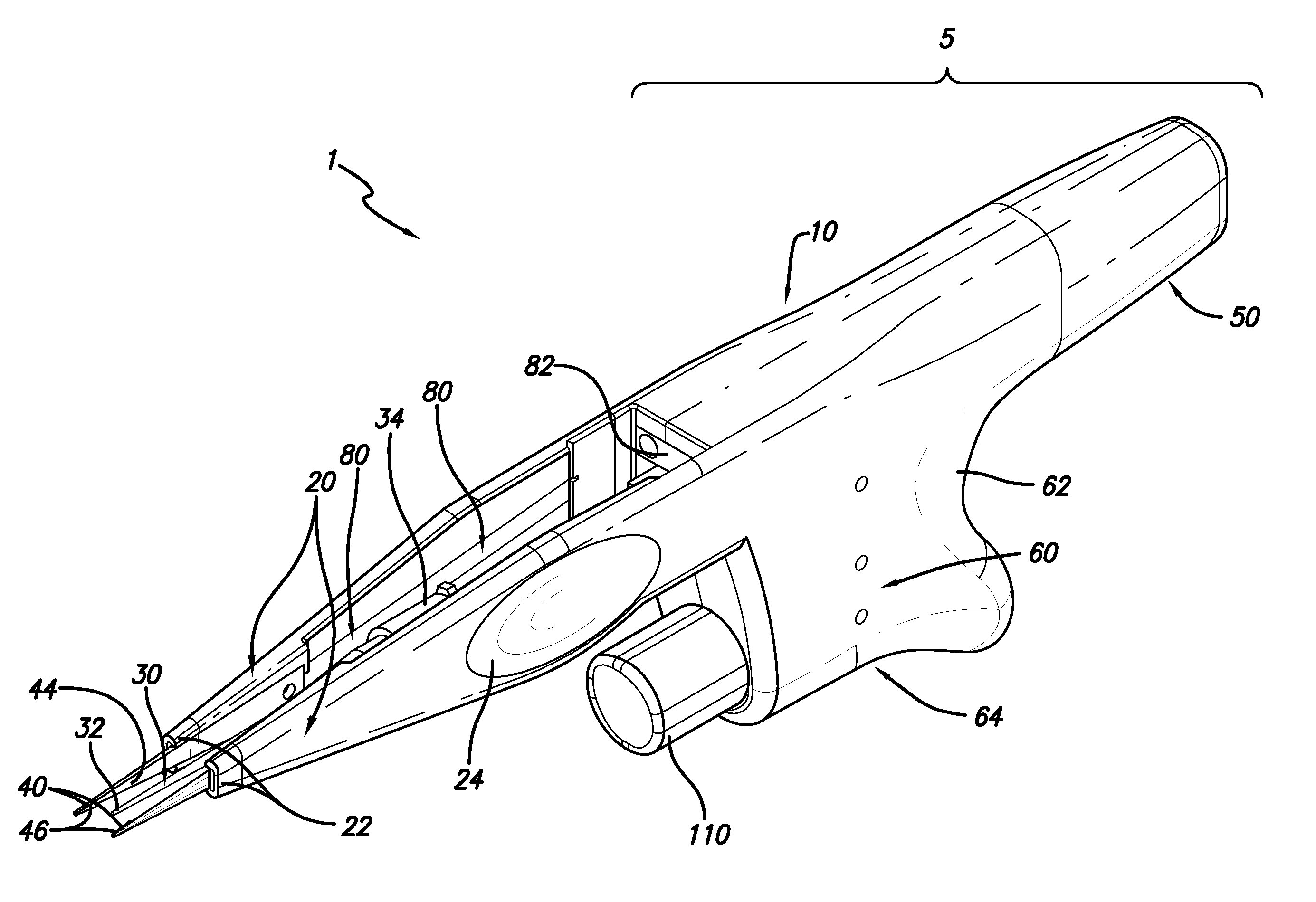

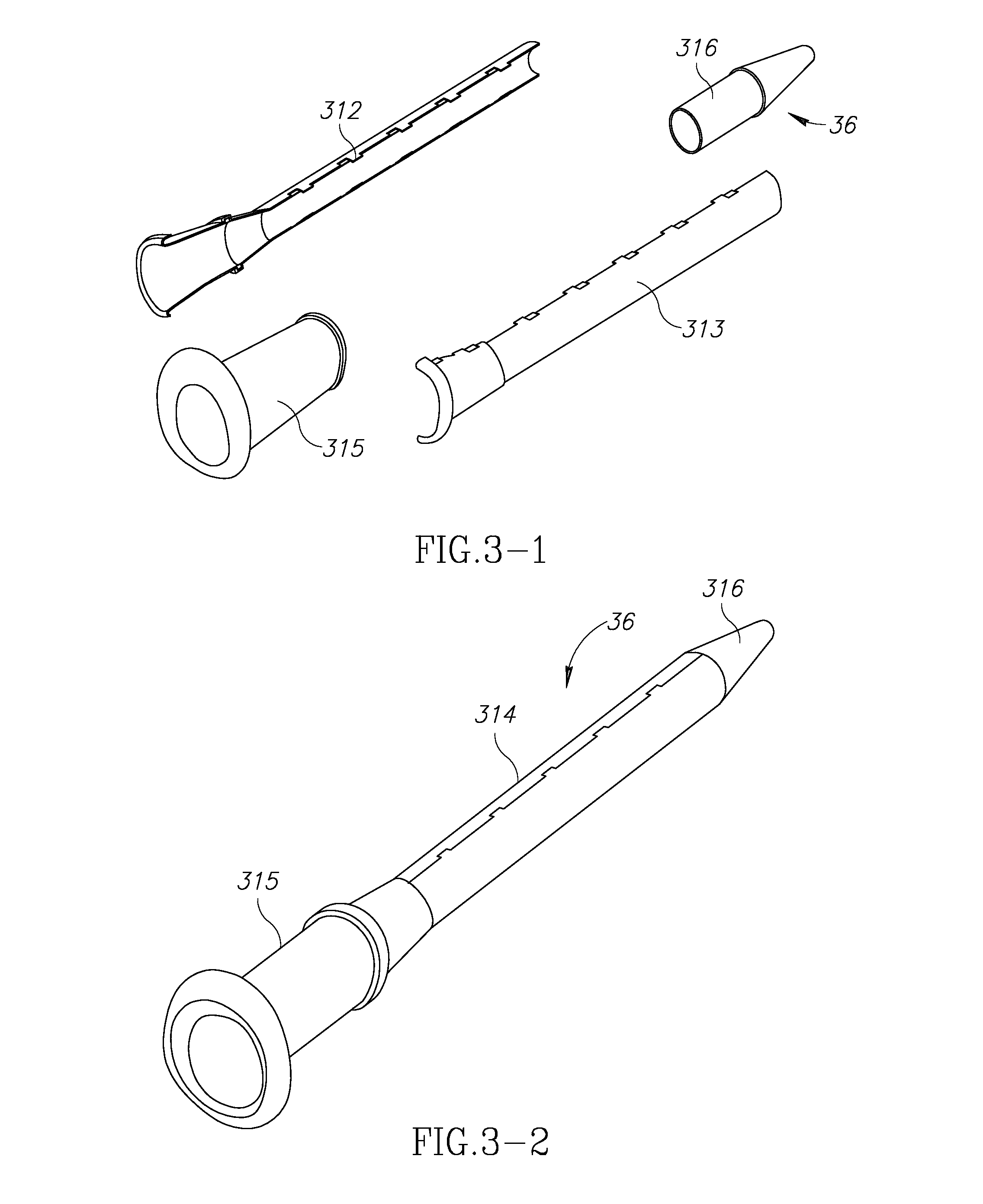

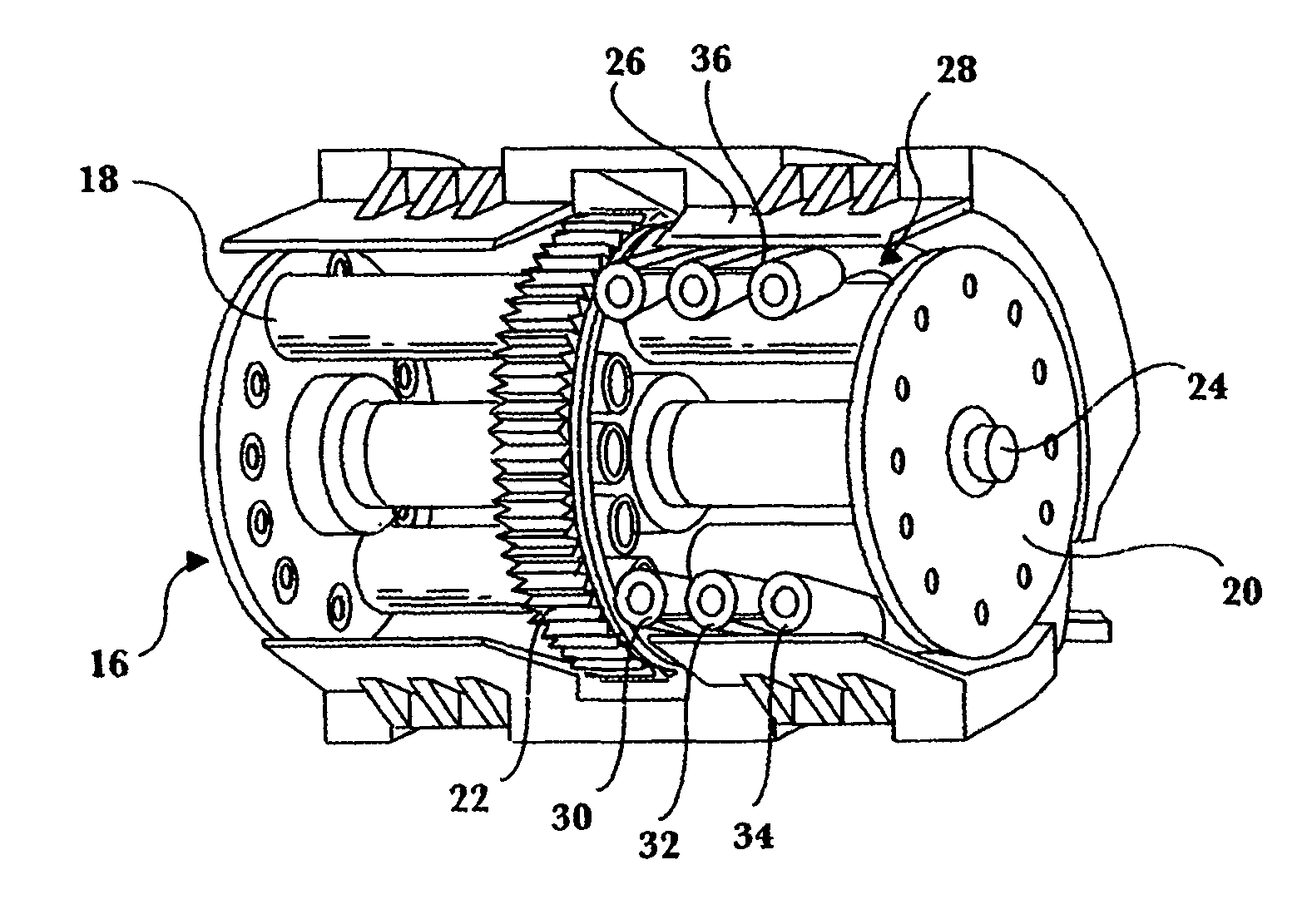

A peristaltic pump, and related system method are provided. The peristaltic pump includes a cam shaft, first and second pinch-valve cams, first and second pinch-valve cam followers, a plunger cam, a plunger-cam follower, a tube receiver, and a spring-biased plunger. The first and second pinch-valve cams are coupled to the cam shaft. The first and second pinch-valve cam followers each engage the first and second pinch-valve cams, respectively. The plunger cam is coupled to the cam shaft. The plunger-cam follower engages the plunger cam. The tube receiver is configured to receive a tube. The spring-biased plunger is coupled to the plunger-cam follower such that the expansion of the plunger cam along a radial angle intersecting the plunger-cam follower as the cam shaft rotates pushes the plunger cam follower towards the plunger and thereby disengages the spring-biased plunger from the tube. A spring coupled to the spring-biased plunger biases the spring-biased plunger to apply the crushing force to the tube.

Owner:DEKA PROD LLP

Four function surgical instrument

Owner:INASURGICA

System, Method, and Apparatus for Infusing Fluid

ActiveUS20160097382A1Reduce peak torqueFluid parameterData processing applicationsPeristaltic pumpPinch valve

A peristaltic pump, and related system method are provided. The peristaltic pump includes a cam shaft, first and second pinch-valve cams, first and second pinch-valve cam followers, a plunger cam, a plunger-cam follower, a tube receiver, and a spring-biased plunger. The first and second pinch-valve cams are coupled to the cam shaft. The first and second pinch-valve cam followers each engage the first and second pinch-valve cams, respectively. The plunger cam is coupled to the cam shaft. The plunger-cam follower engages the plunger cam. The tube receiver is configured to receive a tube. The spring-biased plunger is coupled to the plunger-cam follower such that the expansion of the plunger cam along a radial angle intersecting the plunger-cam follower as the cam shaft rotates pushes the plunger cam follower towards the plunger and thereby disengages the spring-biased plunger from the tube. A spring coupled to the spring-biased plunger biases the spring-biased plunger to apply the crushing force to the tube.

Owner:DEKA PROD LLP

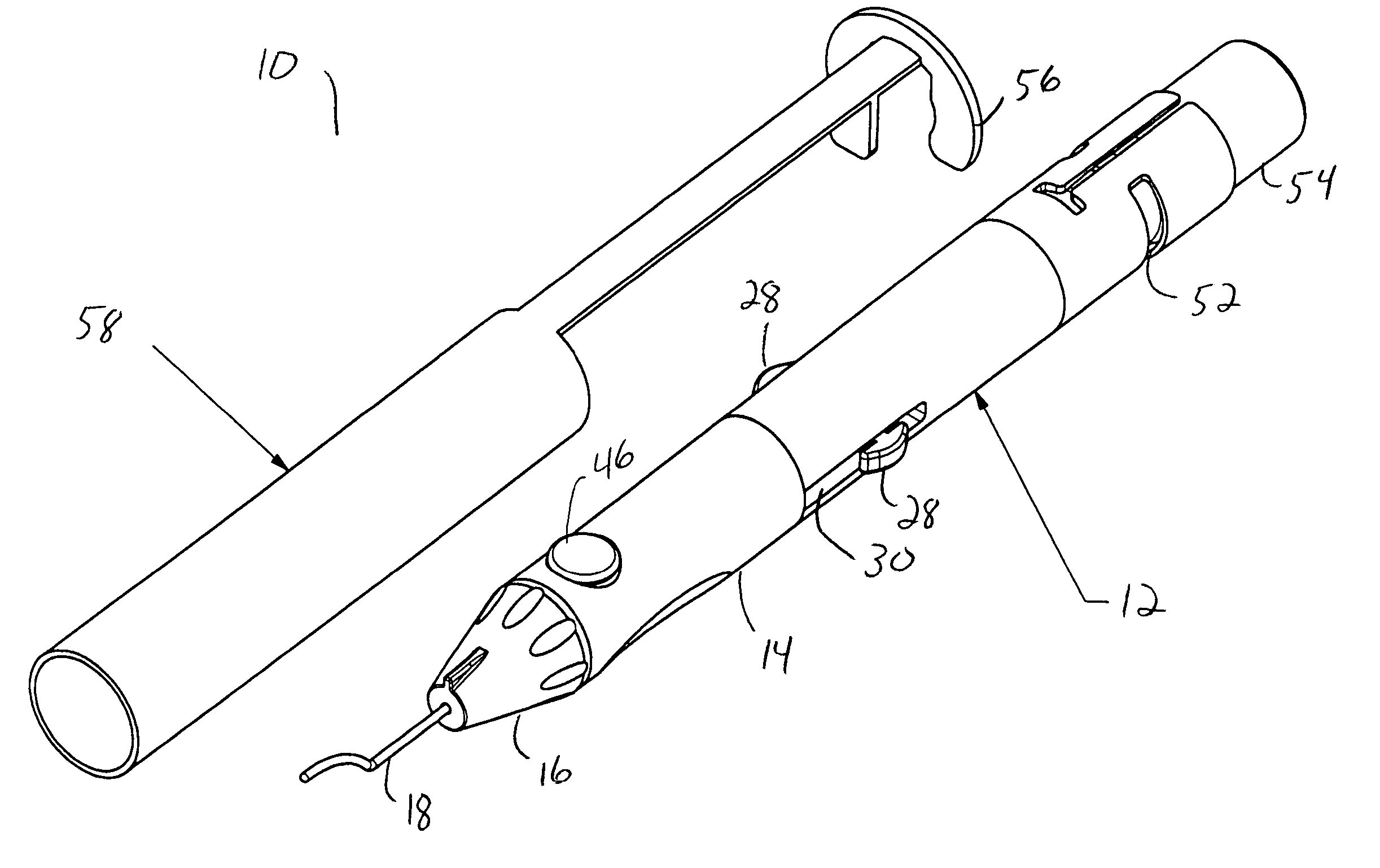

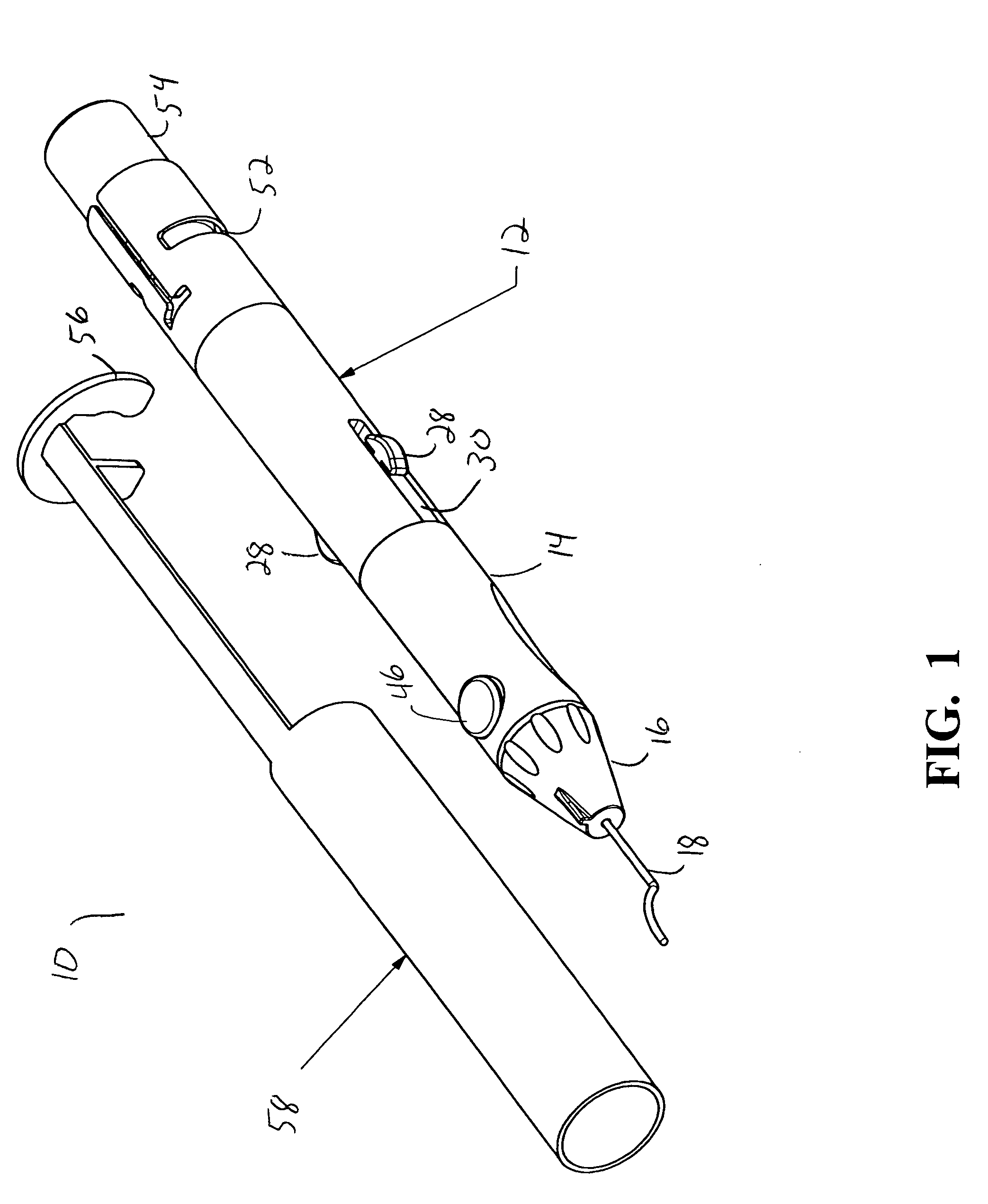

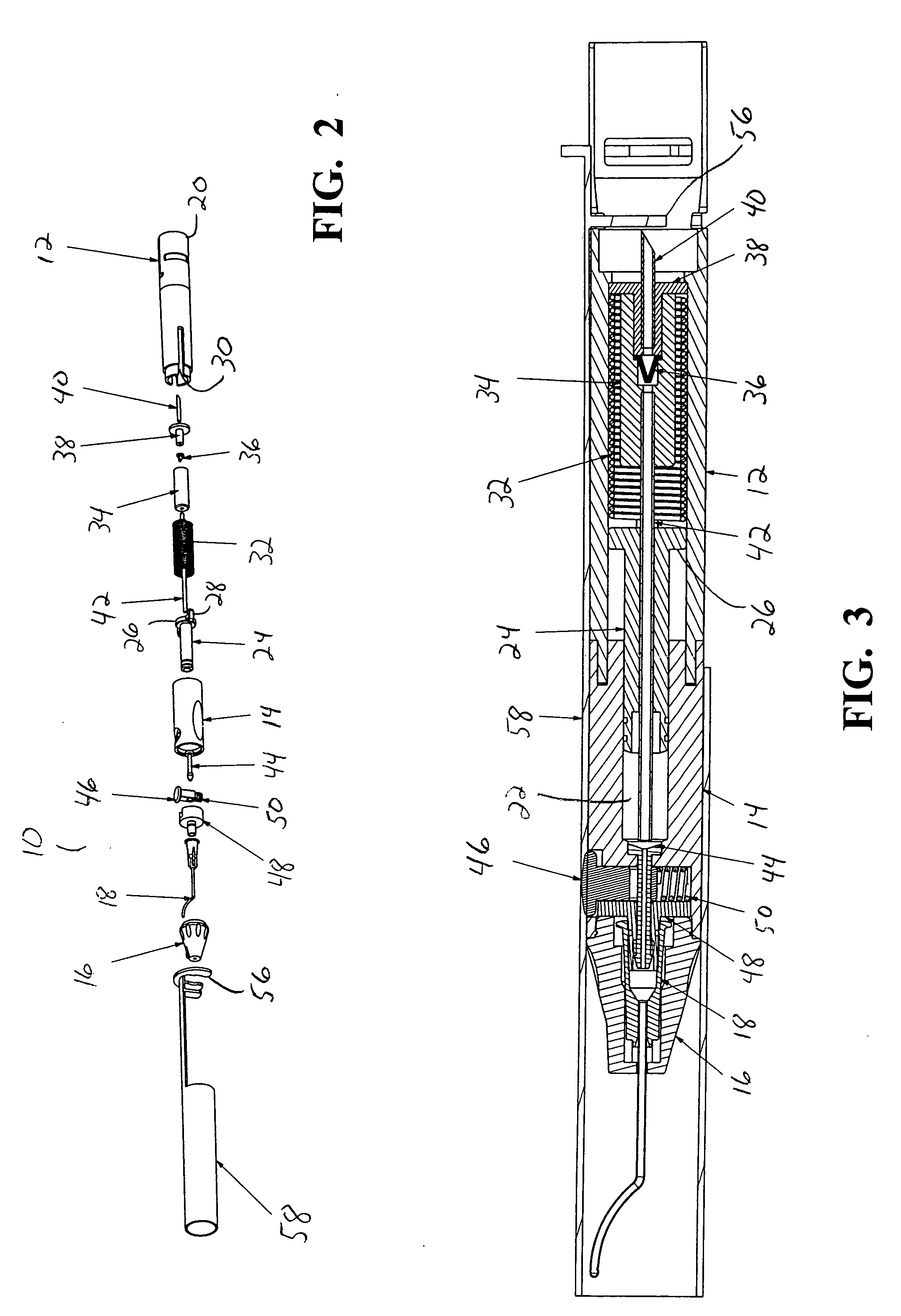

Fluid delivery device

A syringe-like device having a chamber in which a pressurizing piston reciprocates. The chamber is connected on one end to a vial containing a drug to be delivered to an eye and on the other end to a needle or cannula for administering the drug to an eye. Pulling proximally backwards on the piston creates a vacuum in the chamber and draws the drug out of the vial. Upon release of the piston, a spring pushes the piston forward, pressurizing the chamber and forcing the drug out of the cannula. A one-way valve prevents the drug from being expelled back into the vial. A pinch valve between the chamber and the cannula allows the flow of the drug out of the cannula to be stopped. The flow rate of the drug out of the cannula can be controlled by varying the size of the chamber, piston and spring.

Owner:ALCON INC

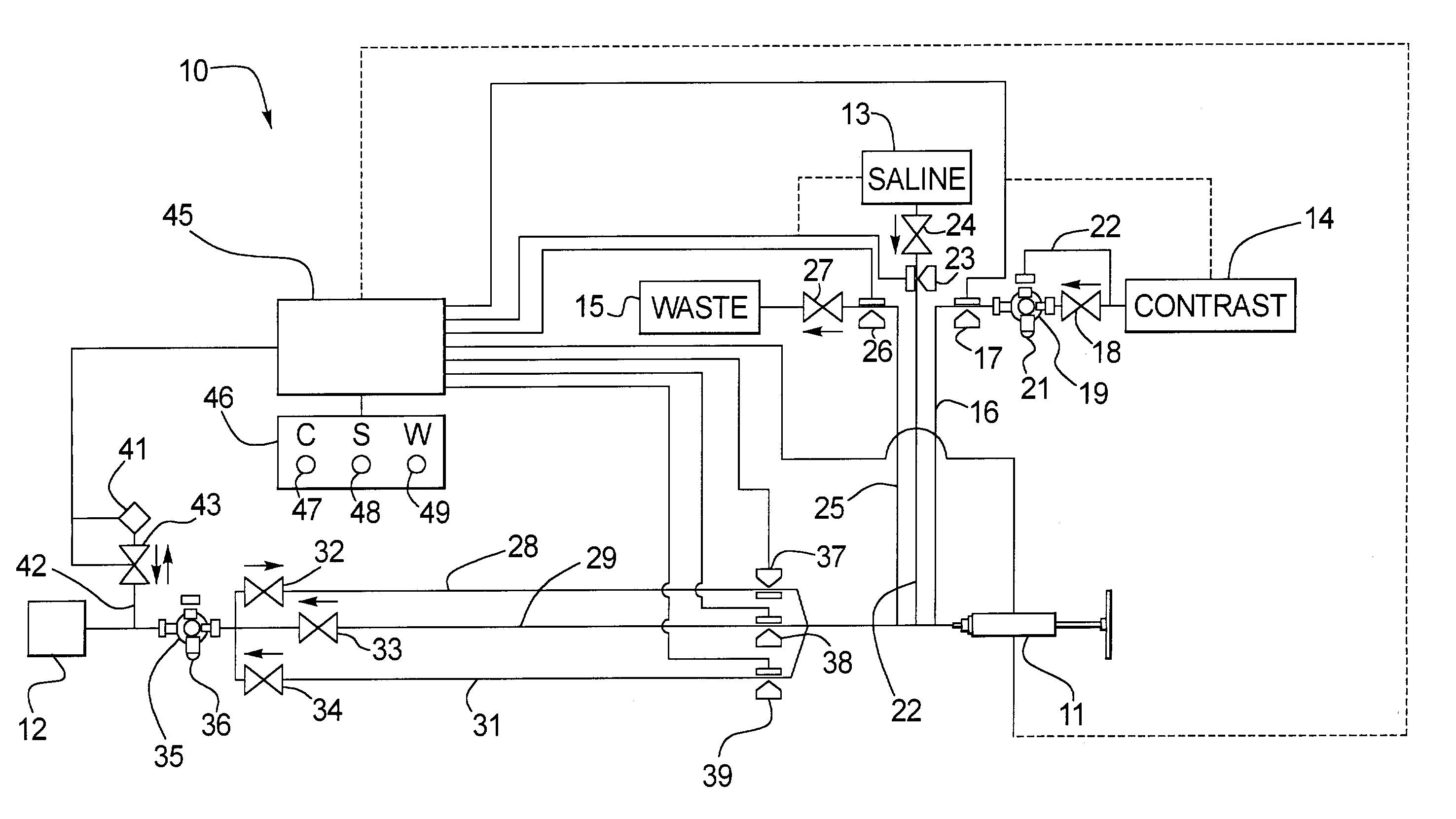

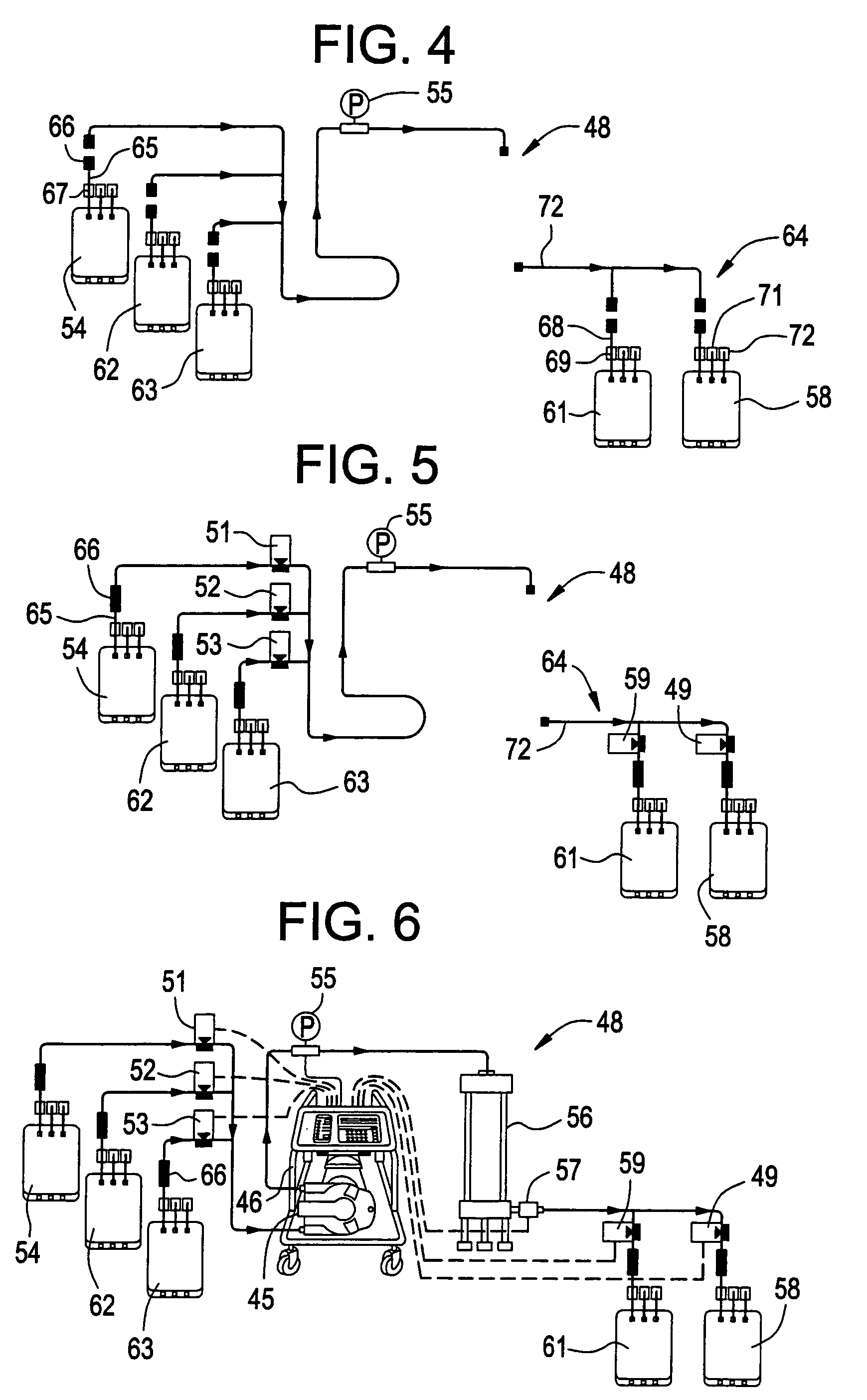

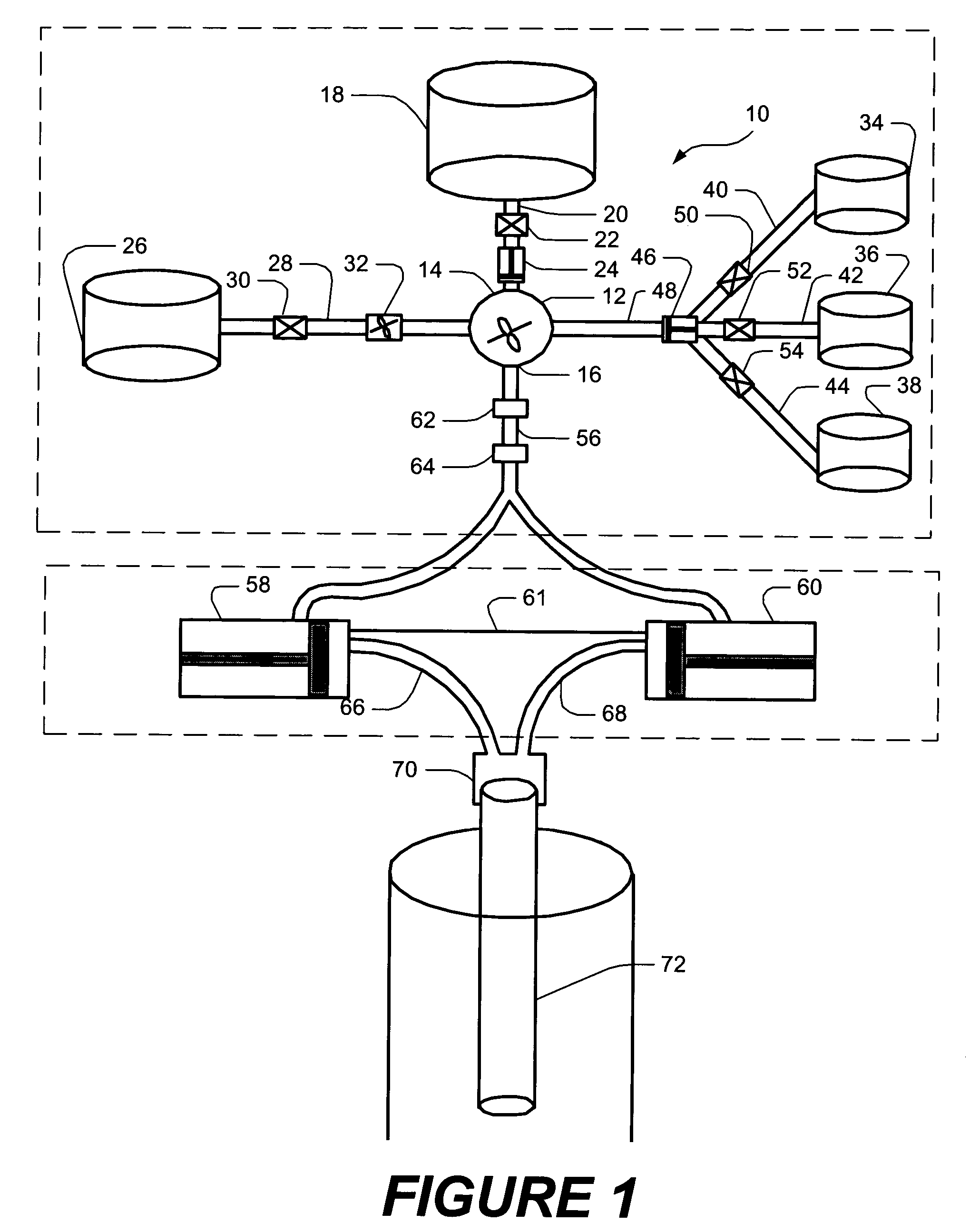

Angiographic fluid control system

An automated fluid control system for controlling fluid flow between a catheter, a saline supply, a contrast supply and an injector is disclosed. Pinch valves are provided in the saline input and output lines and contrast input and output lines. A controller is linked to the pinch valves to sequentially open and close the pinch valves during functions which include contrast injection and saline injection.

Owner:MEDLINE INDUSTRIES

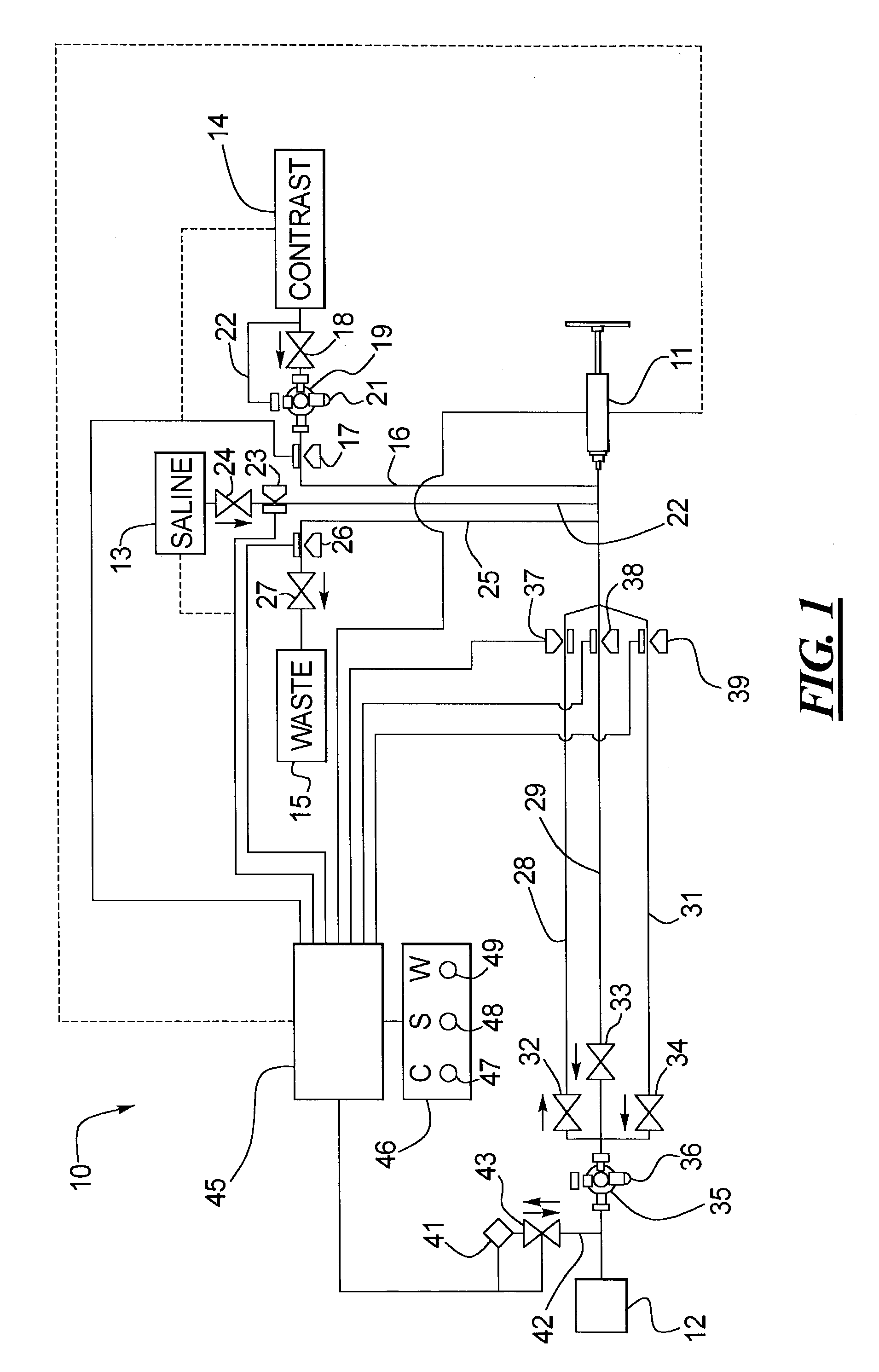

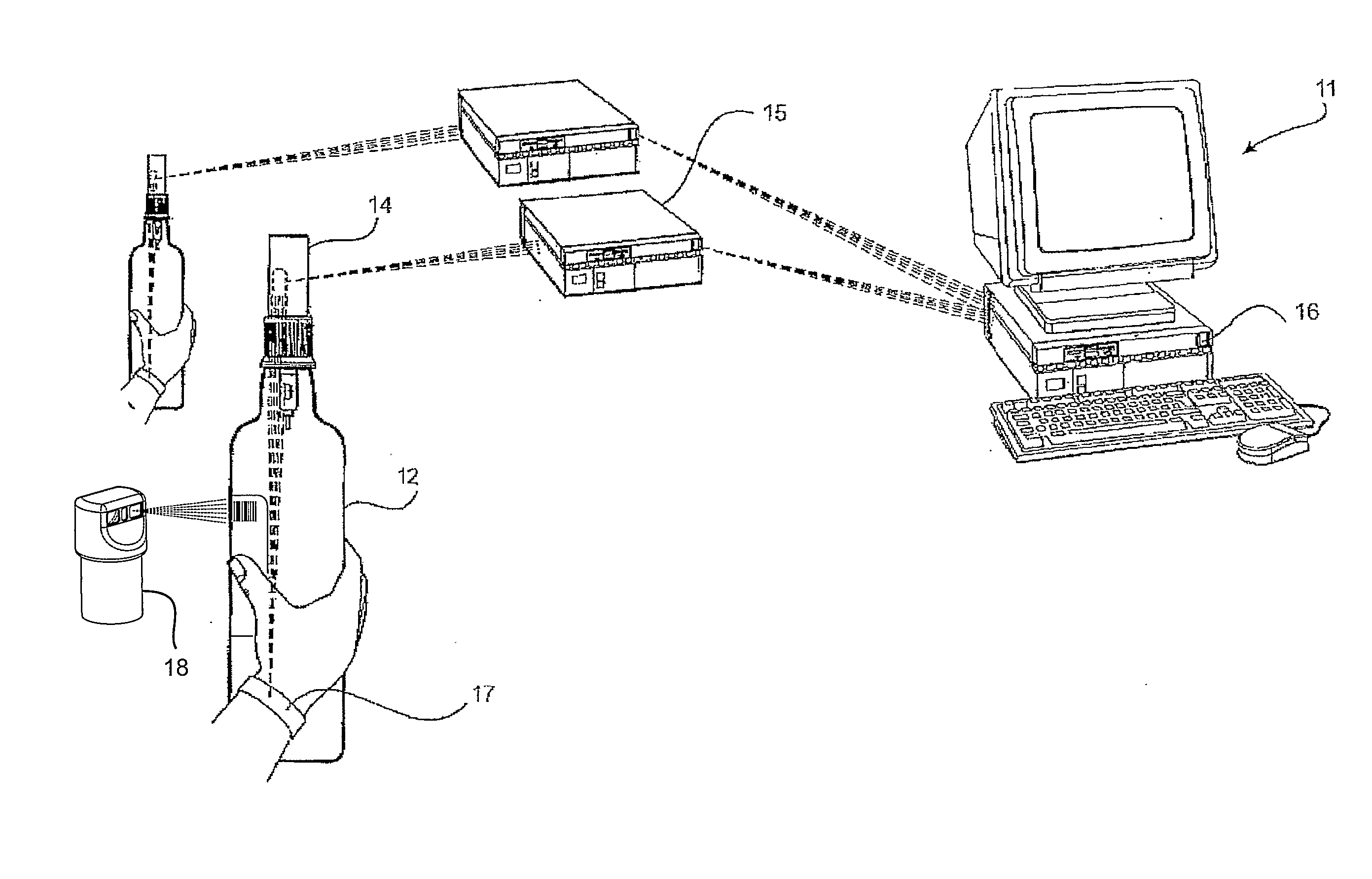

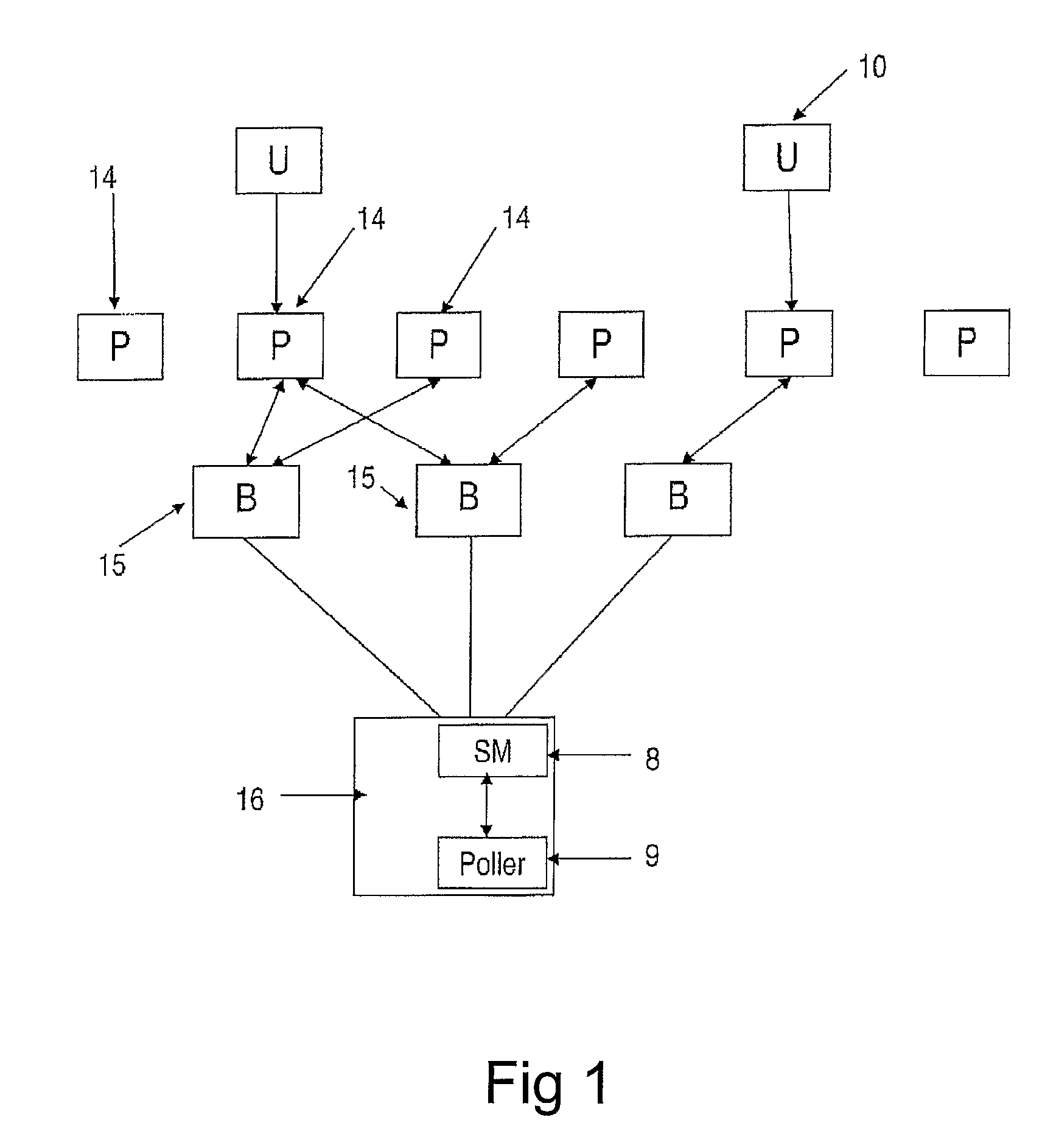

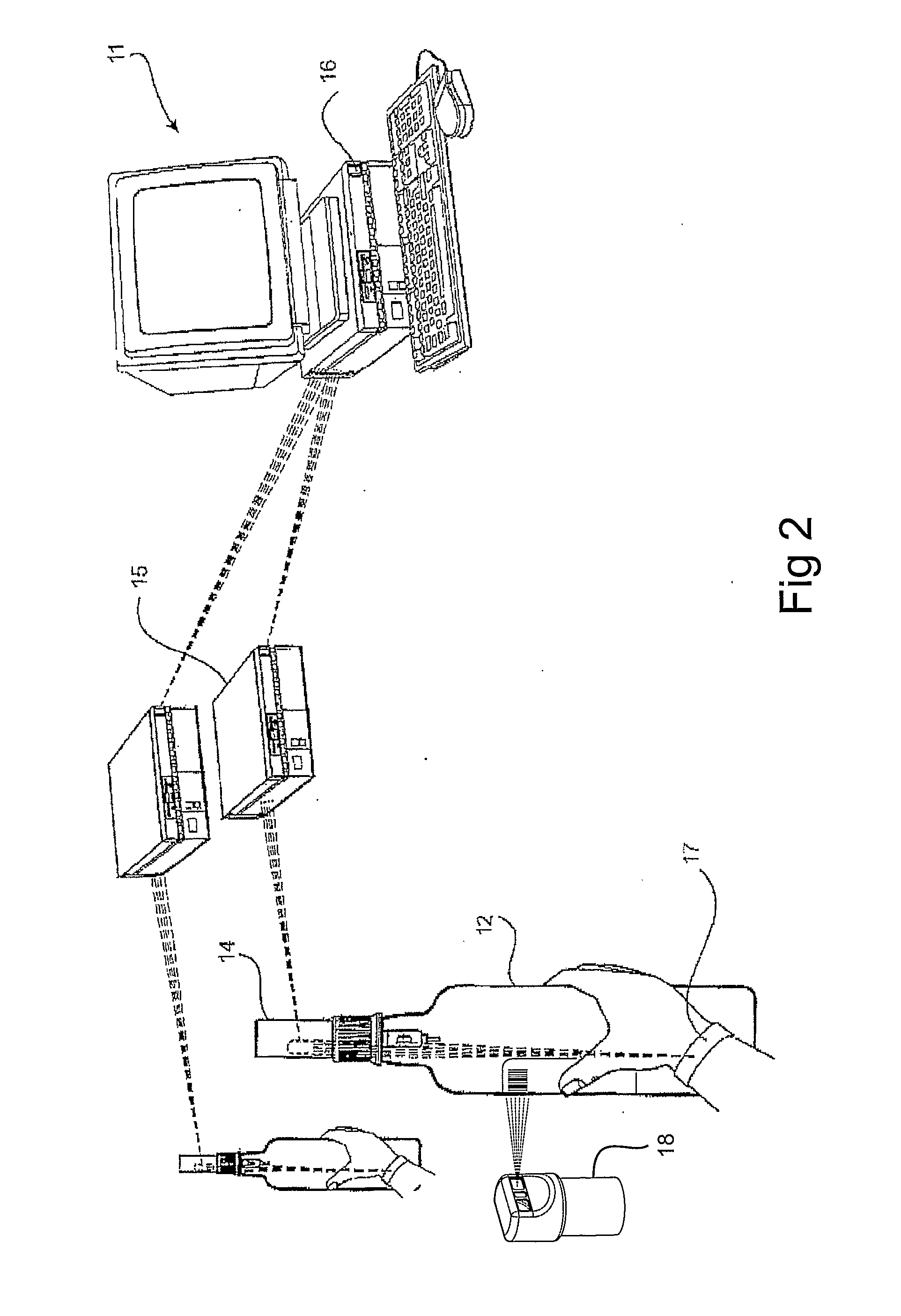

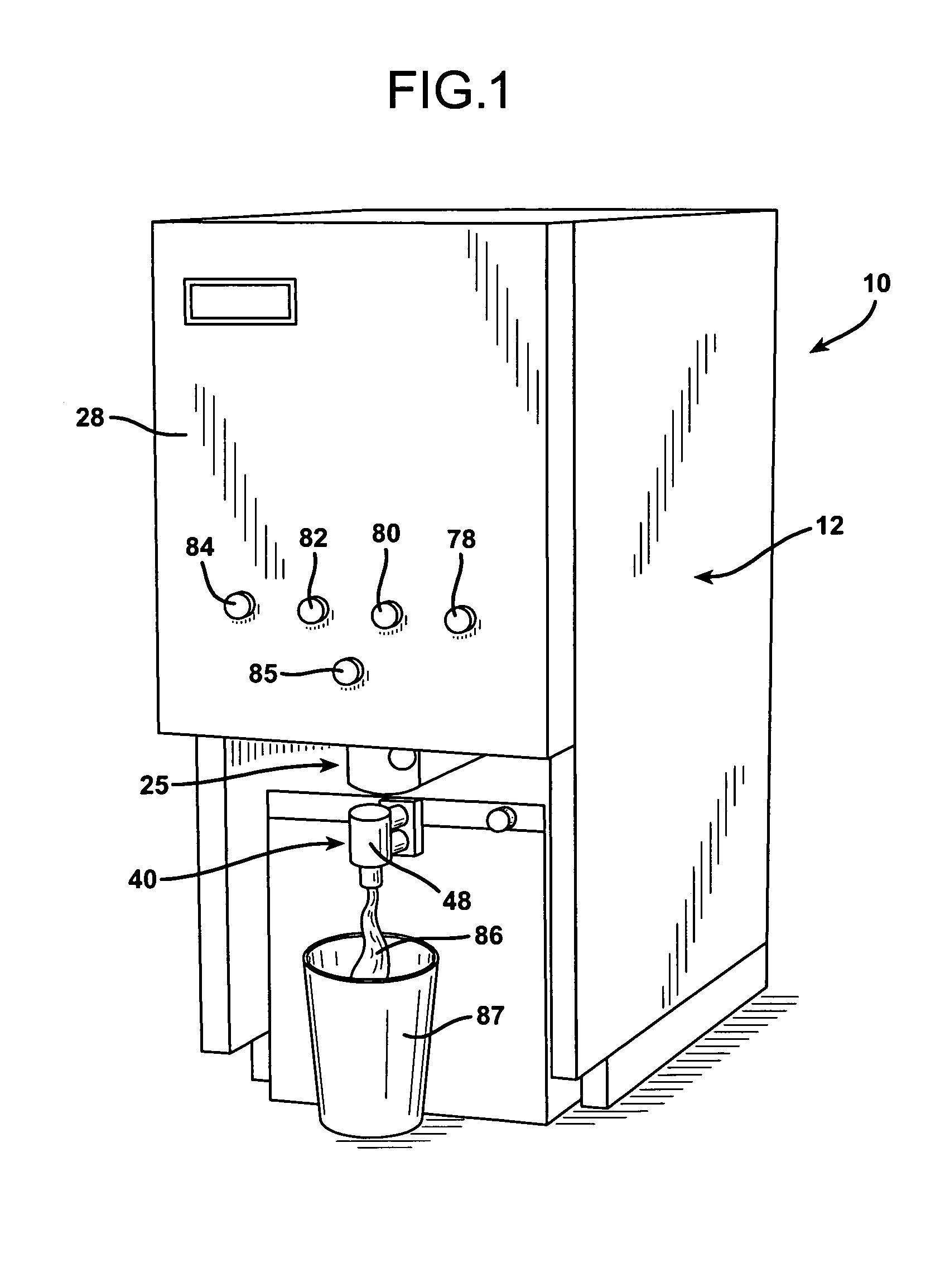

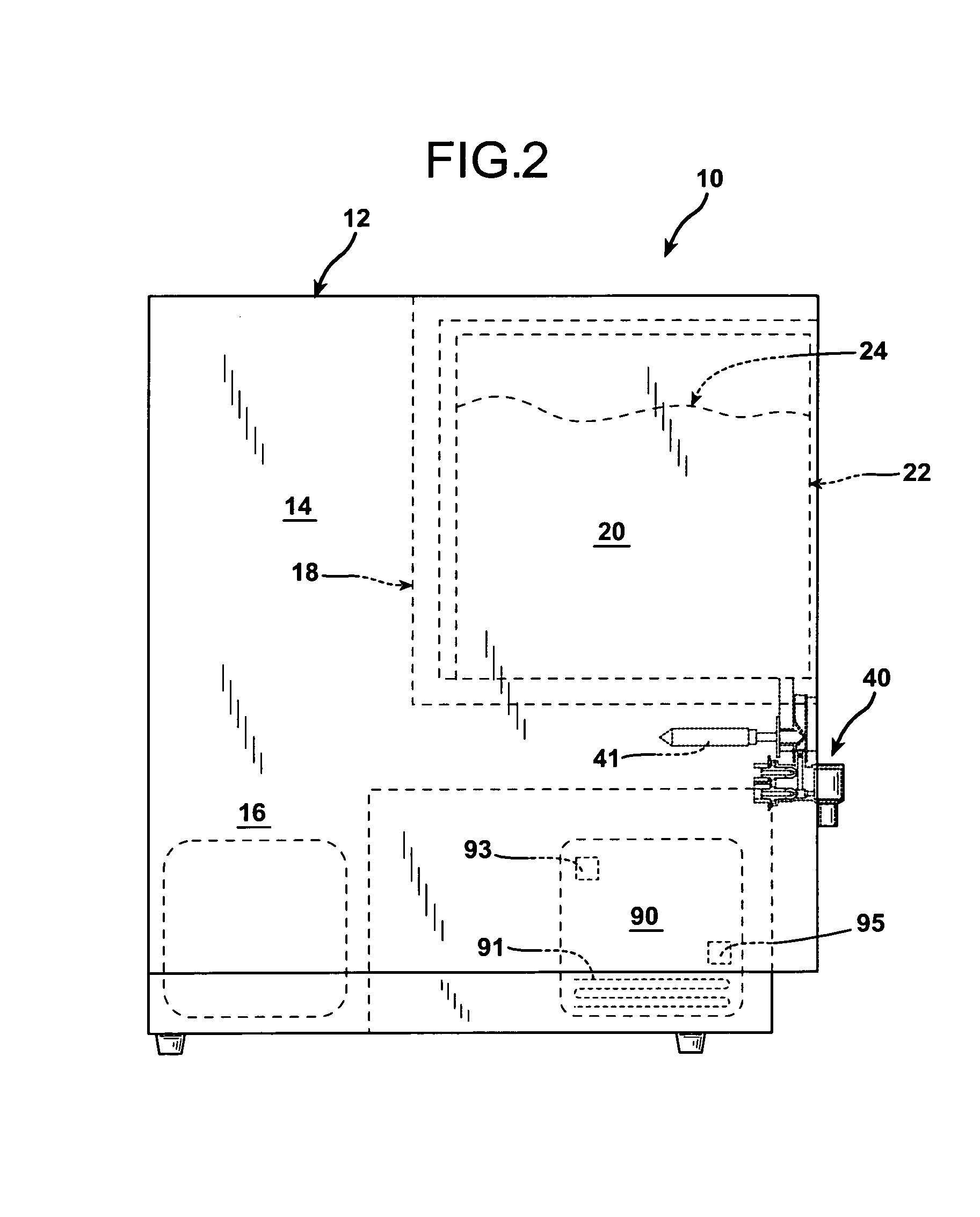

Beverage Control System

InactiveUS20080195251A1Prevent rotationOpening closed containersBottle/container closureDistribution controlPinch valve

Pourer (14) including a beverage dispensing controller (23) including a pinch valve solenoid (40, 83) to control the dispensing of a beverage; a cap (21) includes a locking system to releasably secure the cap to a beverage container (12). The cap has a cap body (31) having an outer duct (43), and the locking system includes a collar (32) with a central aperture for receiving and allowing the collar (32) to pass over the outer duct, and a locking tab located on the cap body. A clamp (34) is engaged by a slide (33) to thereby secure the cap to the container (12) and a locking pin (38) which when engaged acts to prevent rotation of the collar (32). Also, disclosed is a system (FIG. 2) that includes the pourer (14) having a unique identification (ID) and can trasmit wireless signals to a base station (15) about the amount of beverage dispensed; a personal identification unit (17) such as a passive RFID tag to identify the barman pouring the beverage; and an infra-red sensor (7) to allow the pourer (14) to communicate with a container scanner (18) that reads the barcode on the container.

Owner:MILNER ANDREW

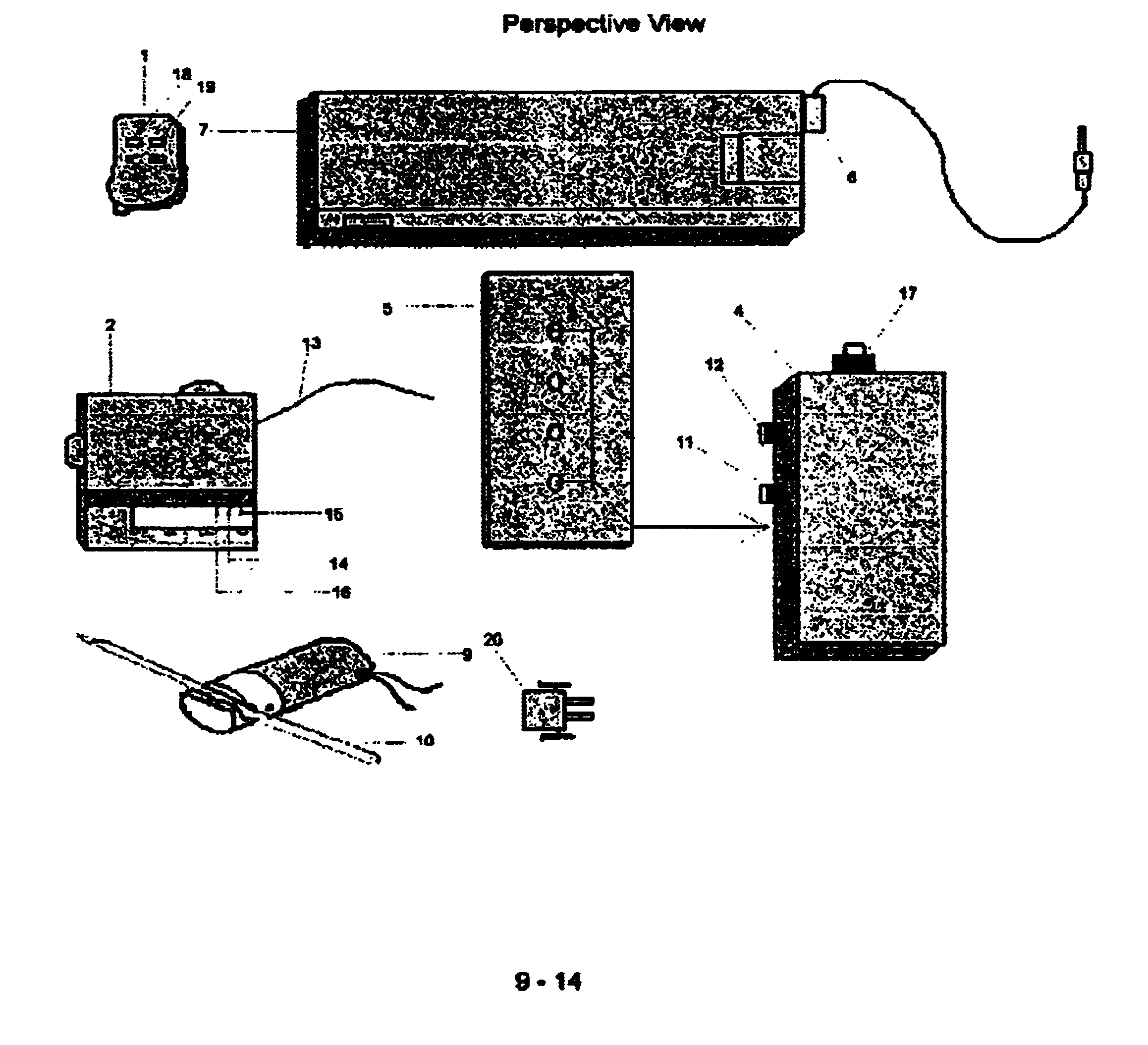

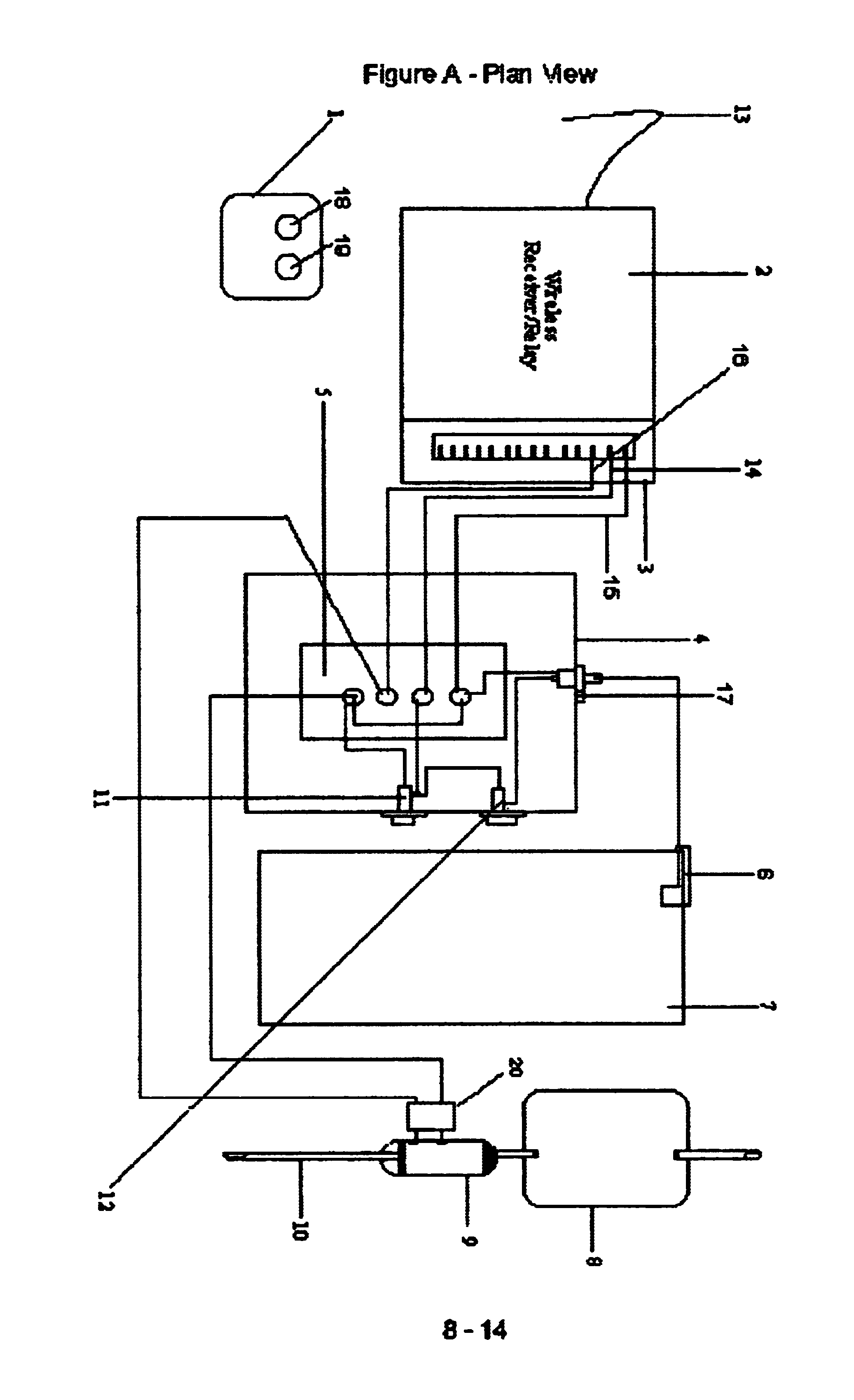

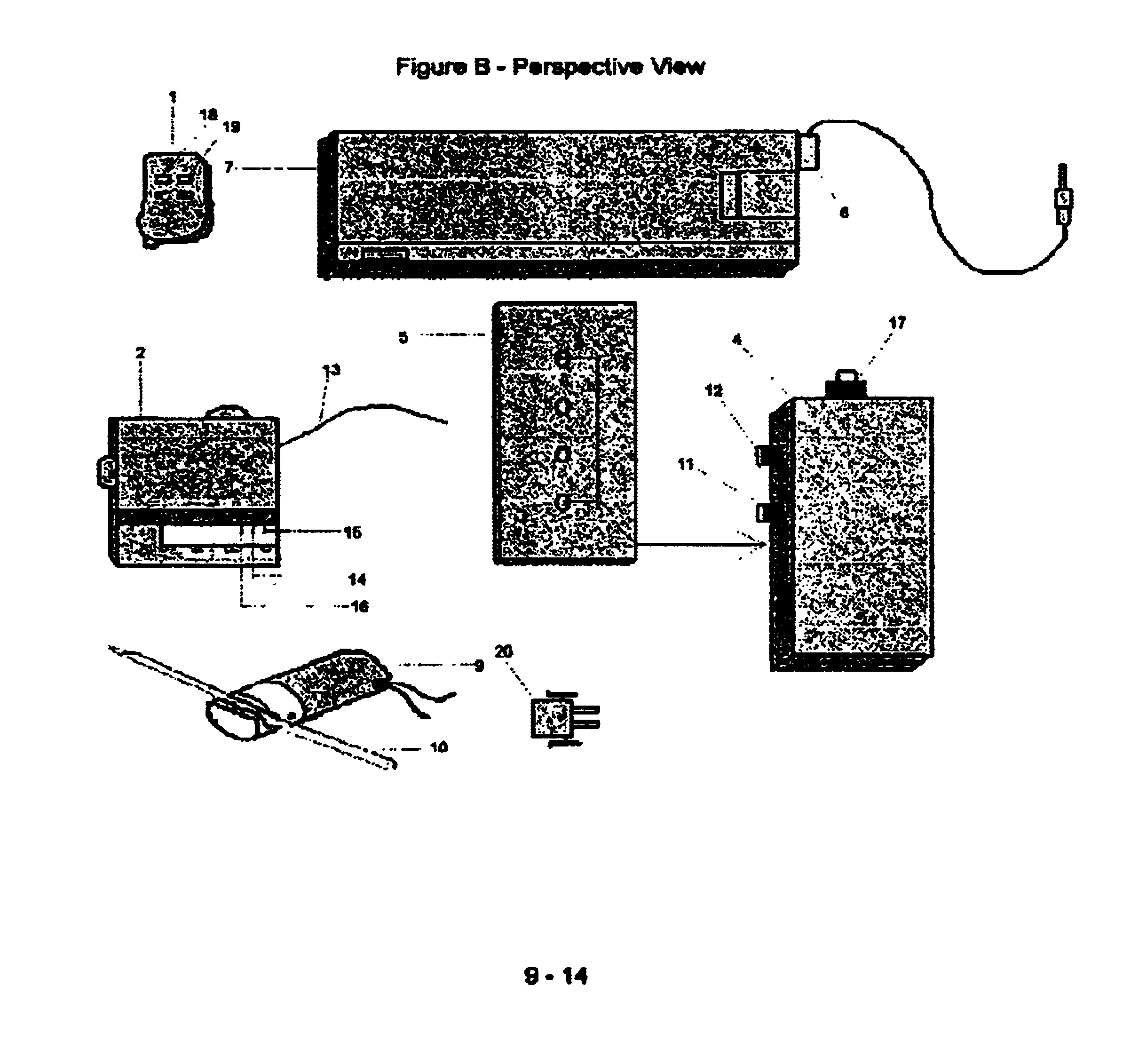

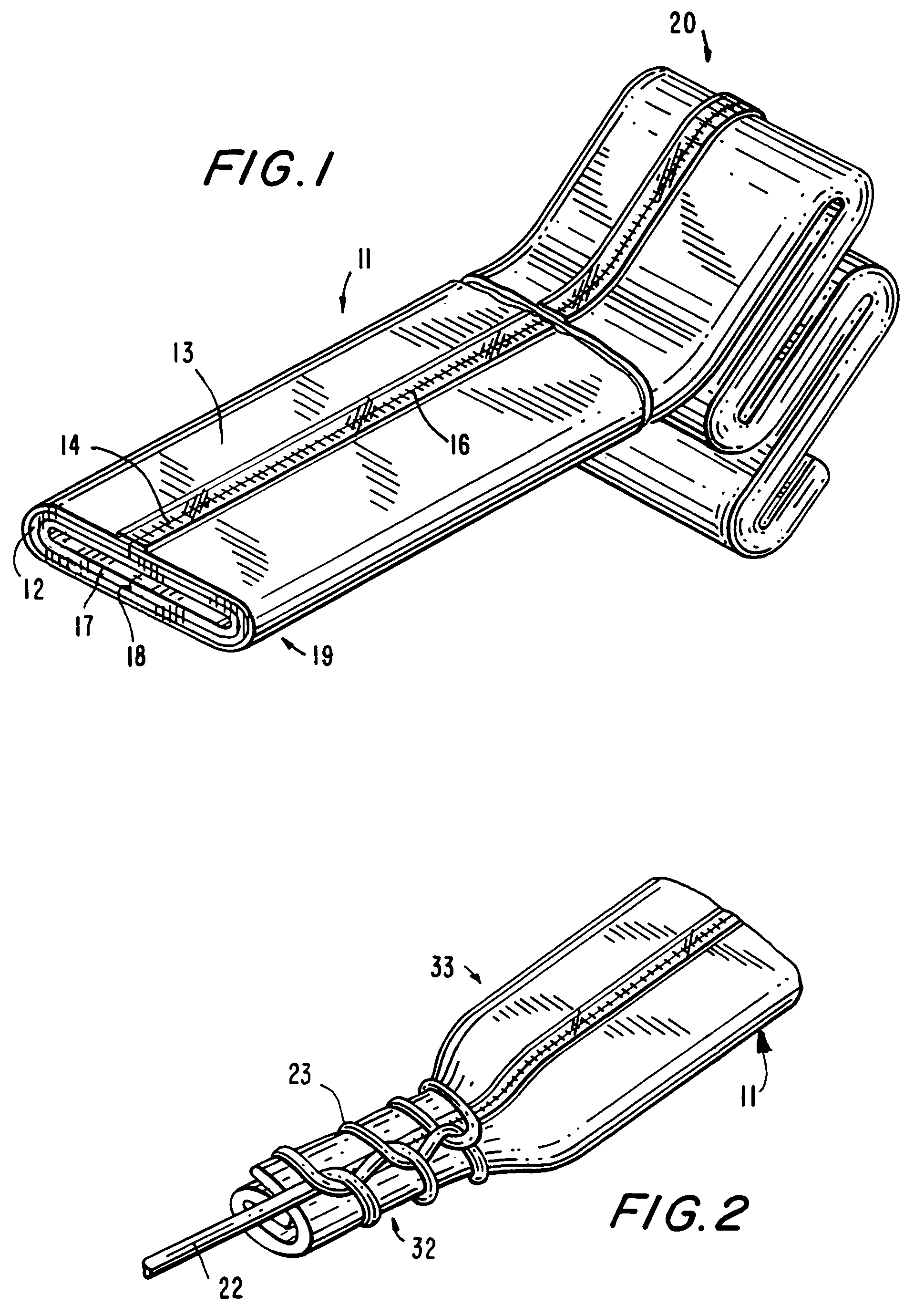

Remote controlled urinary leg/bed bag drain valve

InactiveUS6945965B2Increasing good healthImprove comfortMedical devicesNon-surgical orthopedic devicesPinch valveRemote control

An apparatus designed to empty a urinary drain bag having a battery powered wireless remote transmitter that activates a wireless remote controlled receiv r relay connected to a battery powered solenoid operated pinch valve that is attached to a flexible drain tube, attached to an outlet of a urine drain bag to an “on” position, allowing the bag to drain for a designated period of time after which time the solenoid returns to a closed or “off” position, stopping the draining of the bag.

Owner:WHITING HOWARD ANTHONY

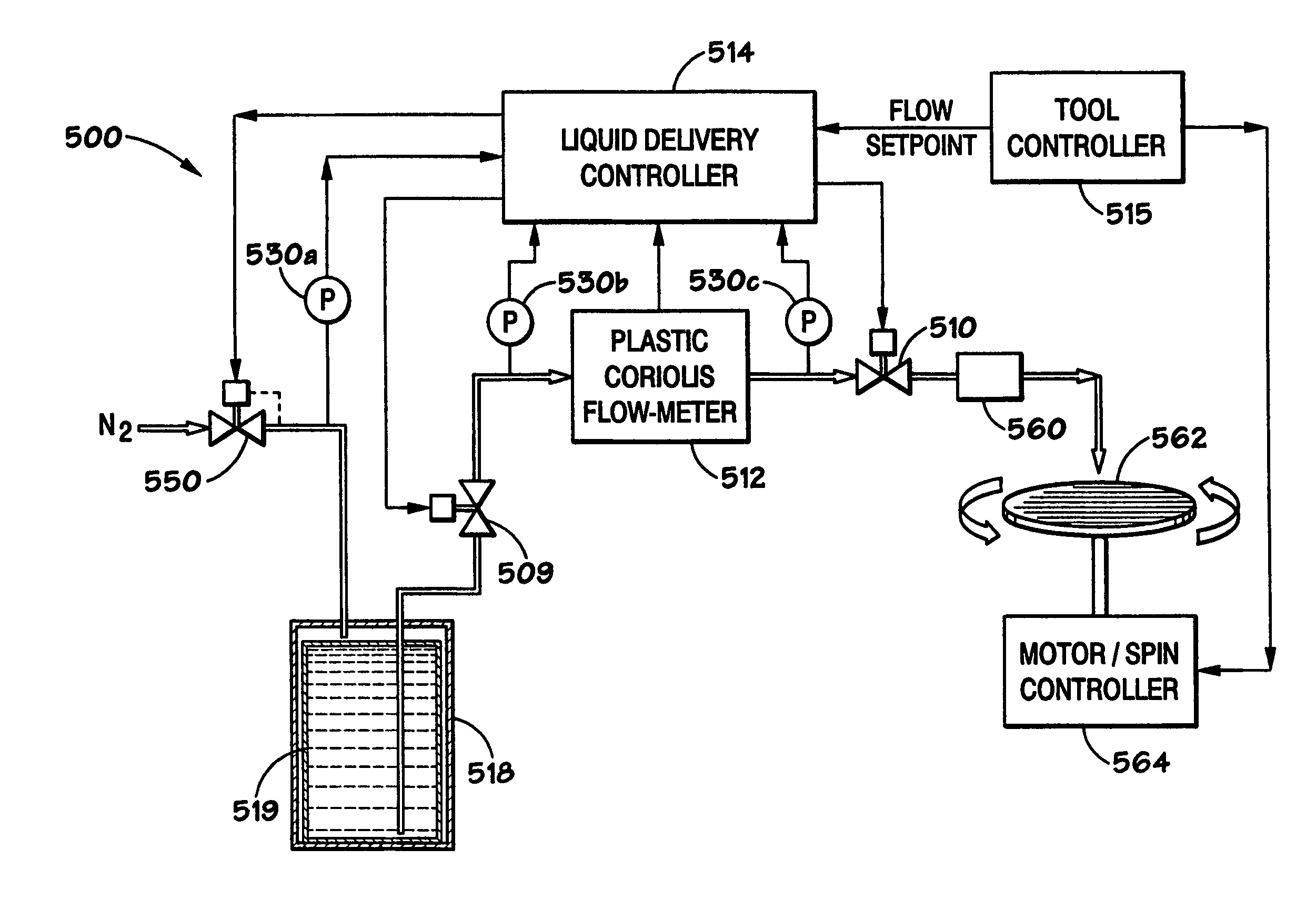

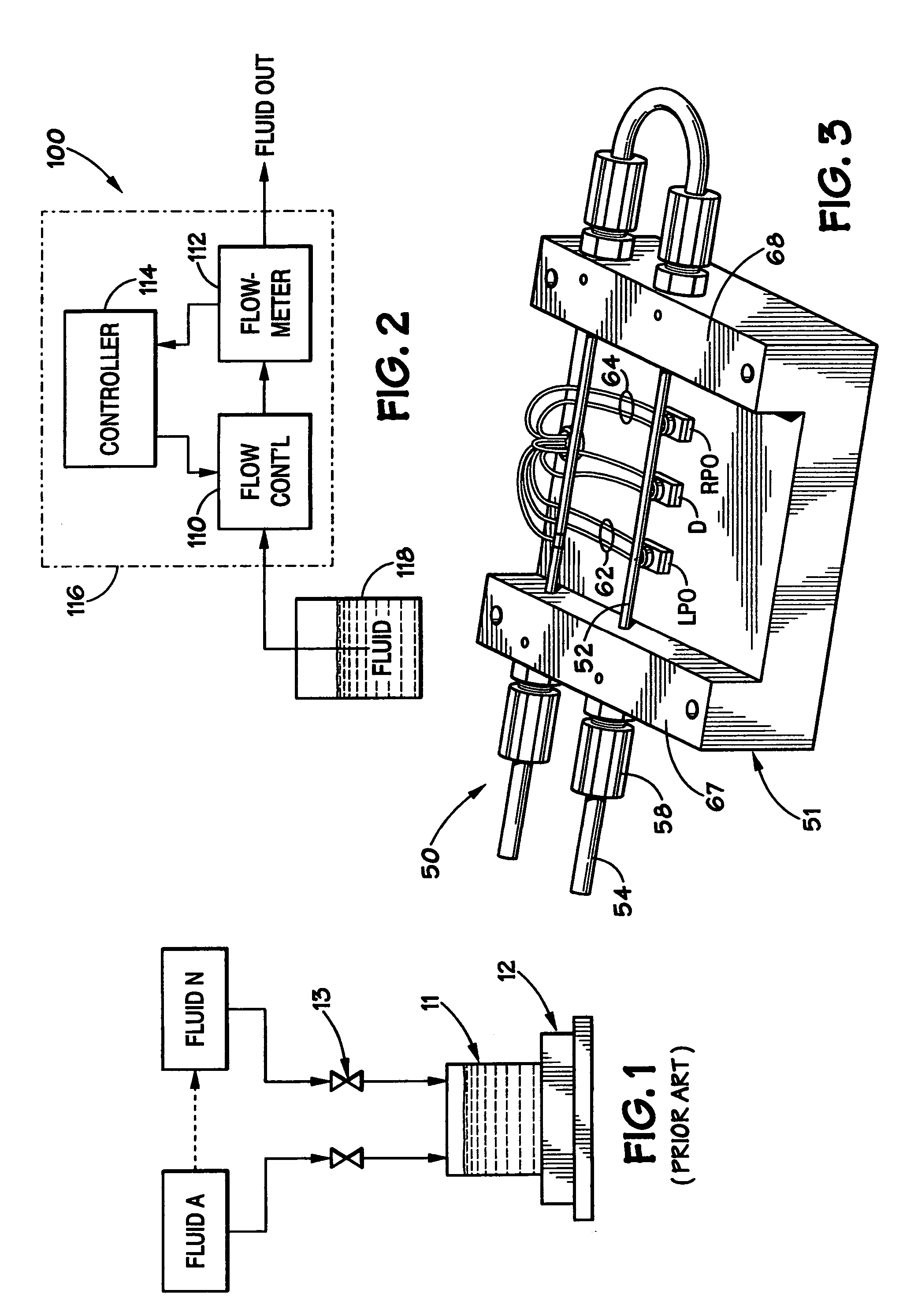

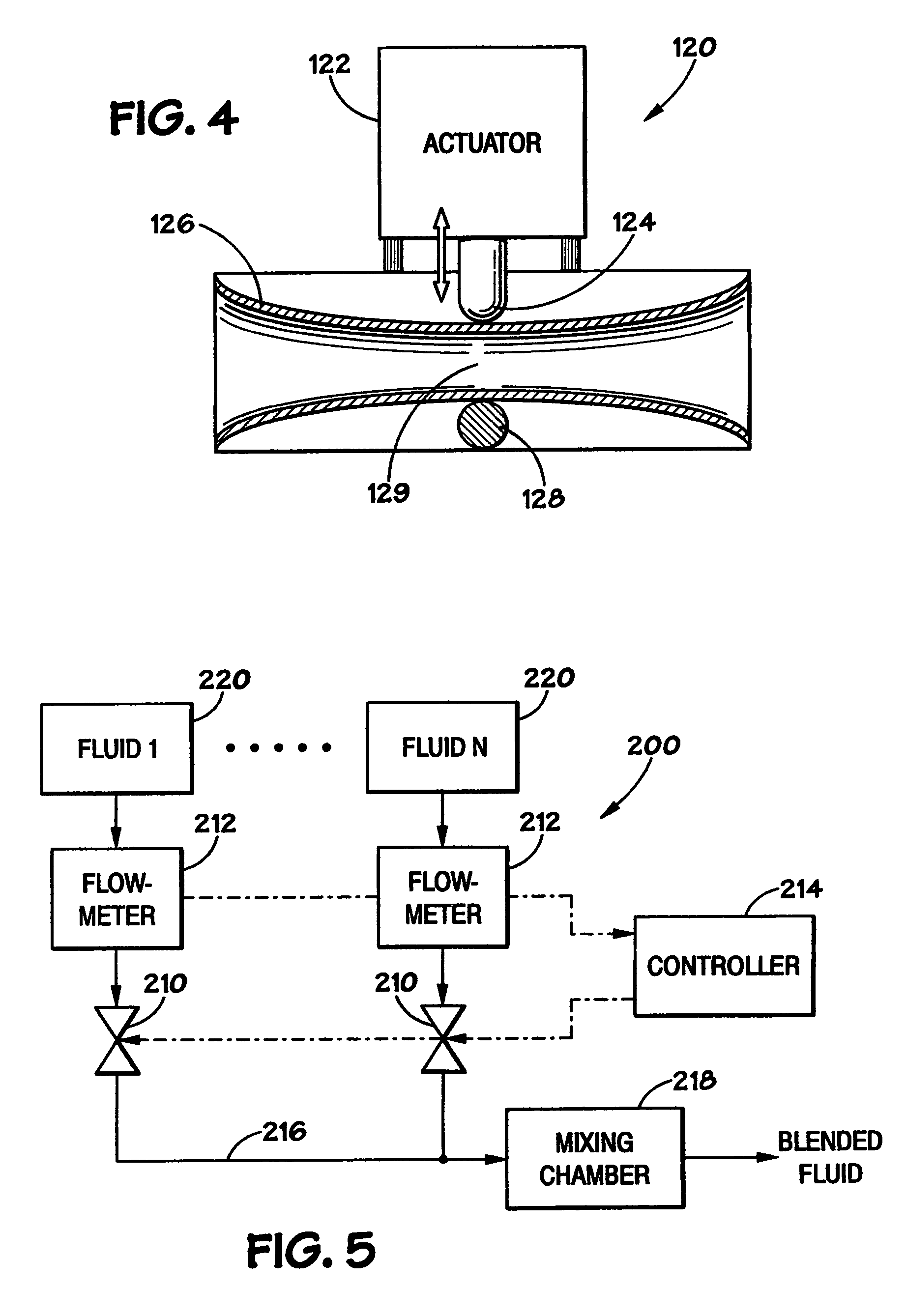

High purity fluid delivery system

InactiveUS7114517B2Operating means/releasing devices for valvesFlow control using electric meansPlastic materialsPinch valve

A fluid delivery system includes a flow control device and a Coriolis mass flowmeter in fluid communication with the flow control device. The Coriolis flowmeter has a flow-tube made of a high-purity plastic material, such as PFA, making the delivery system suitable for high purity applications. A controller provides a control output signal to the flow control device, which may comprise a pinch valve, so as to vary the flow control device output in response to a setpoint signal and measurement signals received from the flowmeter.

Owner:EMERSON ELECTRIC CO

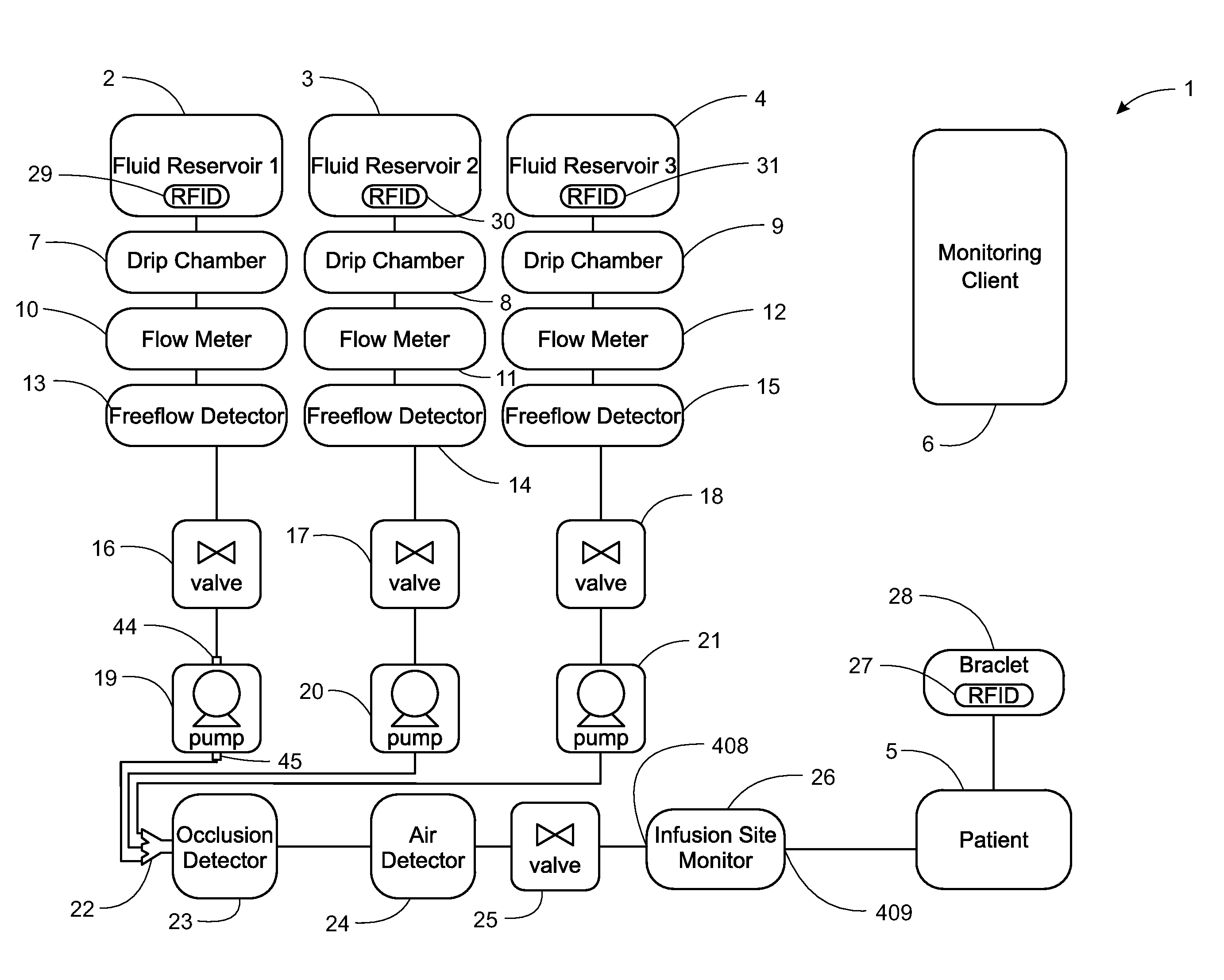

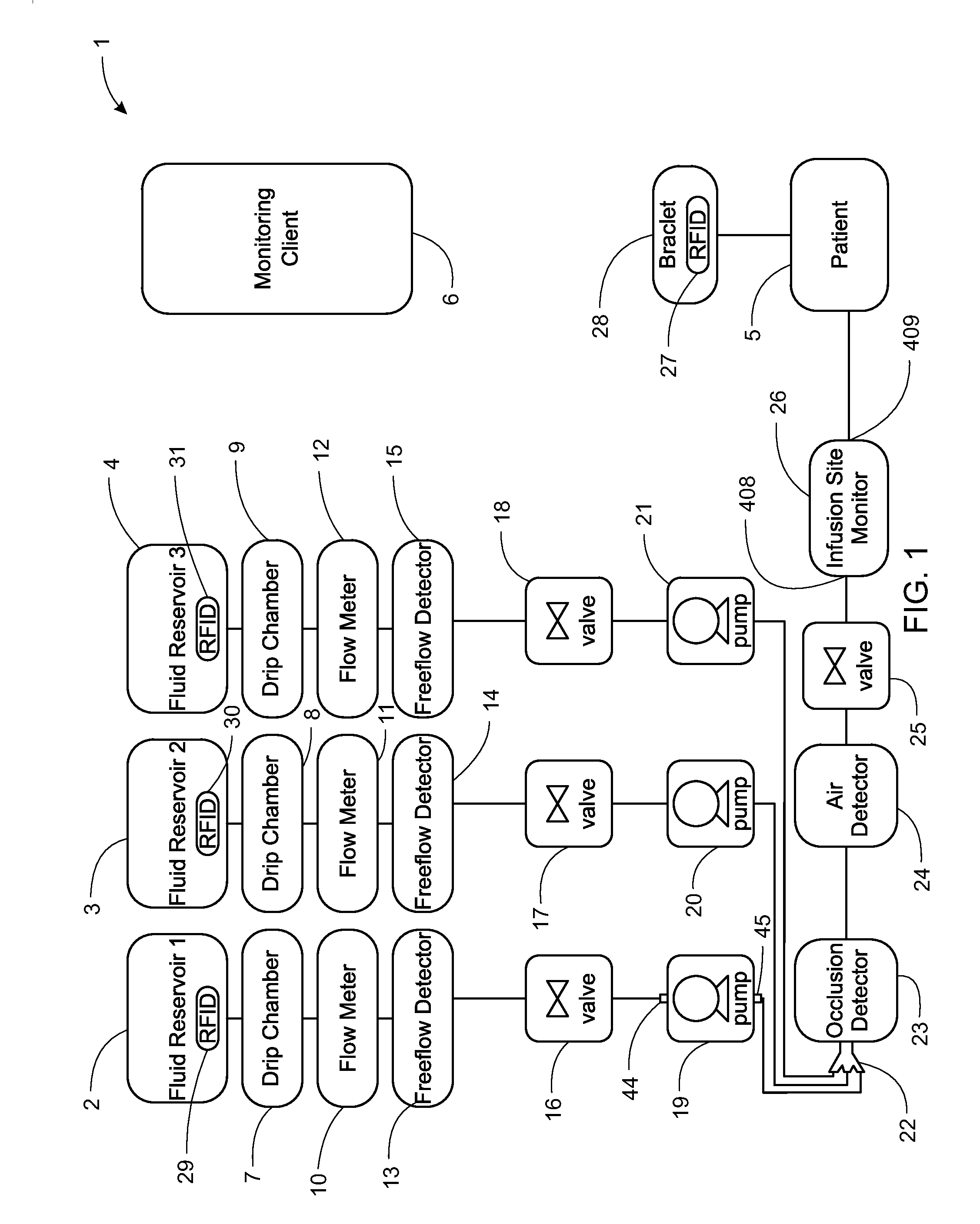

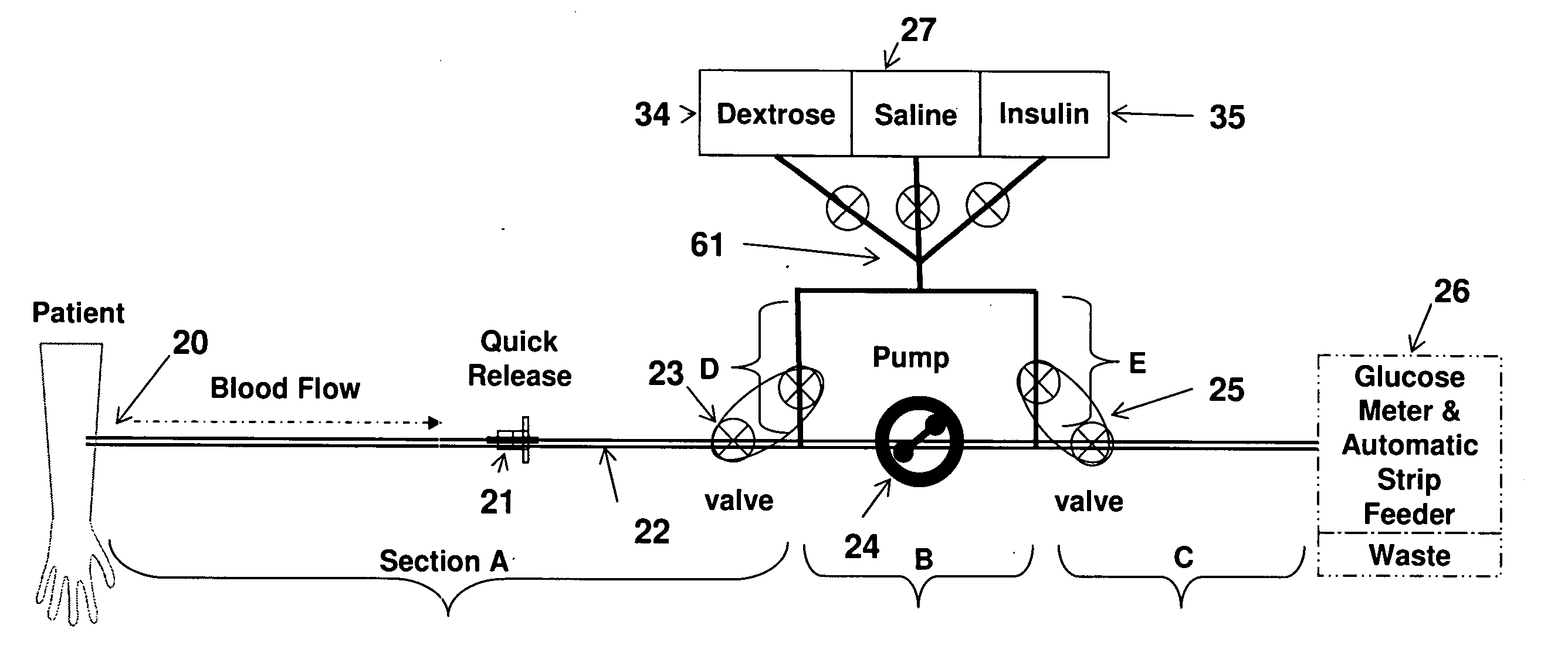

Automated Blood Sampler and Analyzer

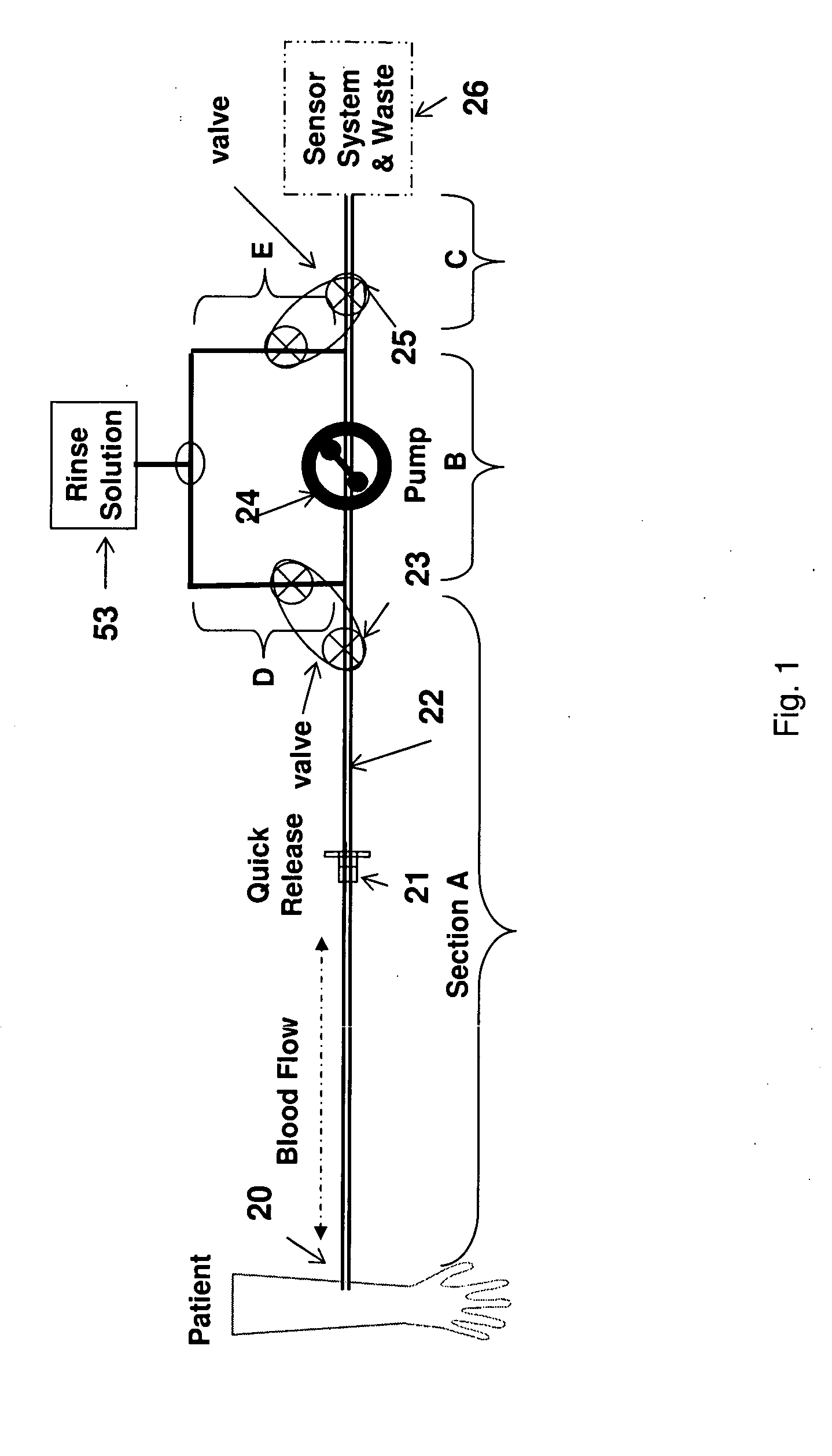

ActiveUS20100137778A1Eliminate riskEliminate the risk of contaminationBioreactor/fermenter combinationsBiological substance pretreatmentsPeristaltic pumpVein

An automated blood sampler integratable with a glucose monitor comprises a catheter connected to a tube-set forming a single blood passageway; a clamp-on air-bubble sensor and a occlusion sensor externally attached to the tube set; a single peristaltic pump and two 3-way pinch valves attached to the tube set and control fluid flow. The sampler draws blood from a stationary patient, samples the blood for analytical measurement of blood parameters; after which the passageway is rinsed, the blood re-infused, and slow saline infusion prevents vein collapse. The cycle repeats at user or predefined intervals. In another preferred embodiment, blood is not re-infused, and only one 3-way pinch valve is used.

Owner:CASCADE METRIX LLC

Single-use manifold for automated, aseptic transfer of soulutions in bioprocessing applications

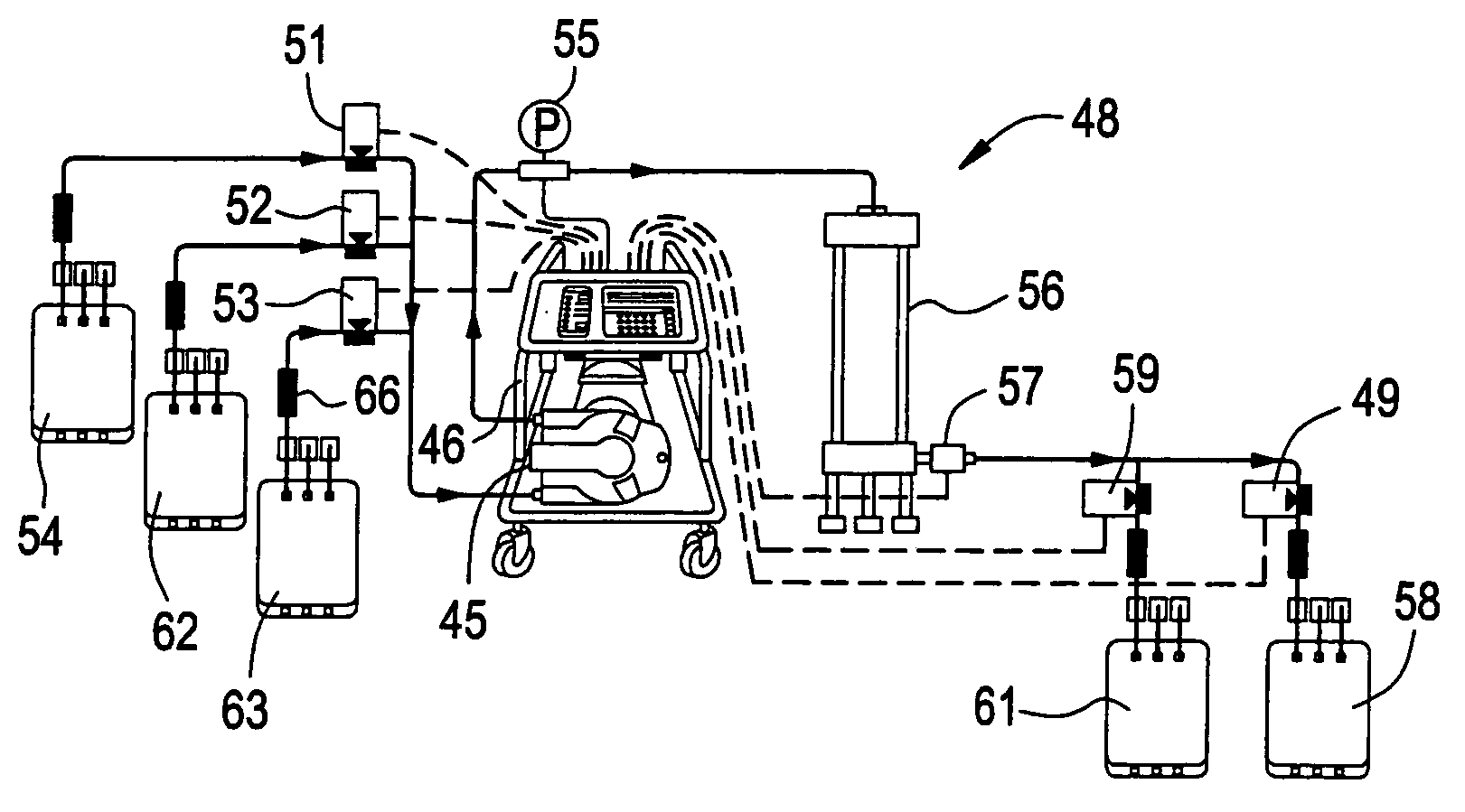

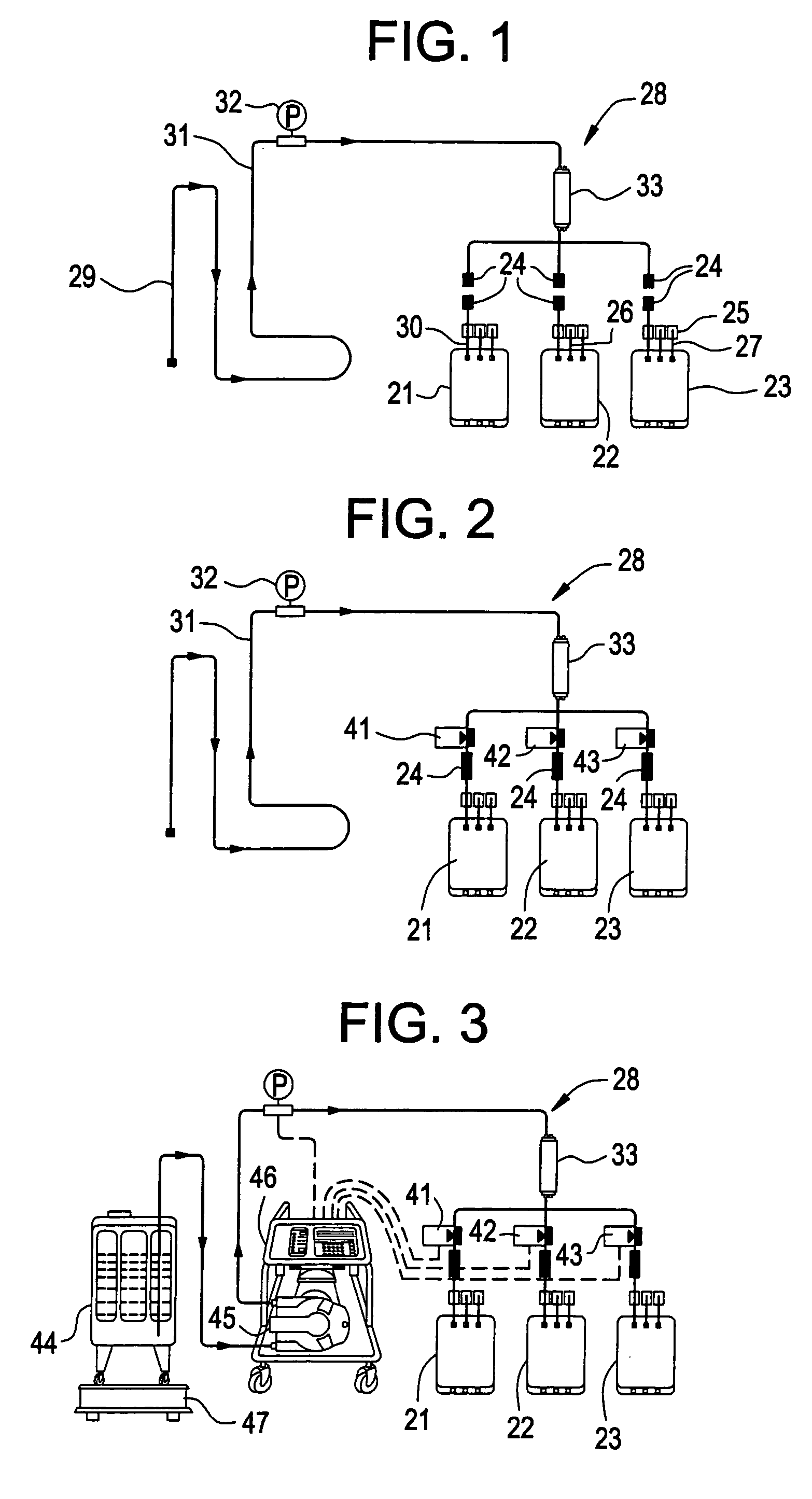

InactiveUS7052603B2Reduce expenditure of resourceReduce time expenditureIon-exchanger regenerationUltrafiltrationPinch valveQuality assurance

Presteralized manifolds are provided which are designed for sterile packaging and single-use approaches. Disposable tubing and flexible-wall containers are assembled via aseptic connectors. These manifolds interact with at least one remotely controlled pinch valve which engages only the outside surface of the manifold tubing. Such manifold and pinch valve systems can be used in conjunction with a peristaltic type of pump, which, together with the remotely operated pinch valve, can be operated by a controller which provides automated and accurate delivery of biotechnology fluid in an aseptic environment while avoiding or reducing cleaning and quality assurance procedures.

Owner:PARKER INTANGIBLES LLC

Hot dairy-based beverage dispenser

InactiveUS7021206B2Reduce eliminateConstant flowLighting and heating apparatusUsing liquid separation agentPinch valveEngineering

A dispensing unit for dispensing hot, dairy-based beverages has a self-contained refrigerated unit located above a venturi-type emulsification foaming head. The dispensing unit has particular applicability to the dispensation of foamy, hot milk for use in beverages such as cappuccino and nonfoamy, hot milk for use in beverages such as coffee latte, hot chocolate, and other hot dairy-based beverages. The refrigeration unit accommodates a “bag in box” cold milk storage container of the type widely used in food service establishments. The dispensing unit employs a pinch valve that avoids direct contact between the milk and the valve components. The refrigerated milk is stored above the level of the foamer head so that the flow of milk results partially from gravitational force on the milk, and is not totally dependent upon venturi suction created in the foamer head.

Owner:ECKENHAUSEN ROLAND B +1

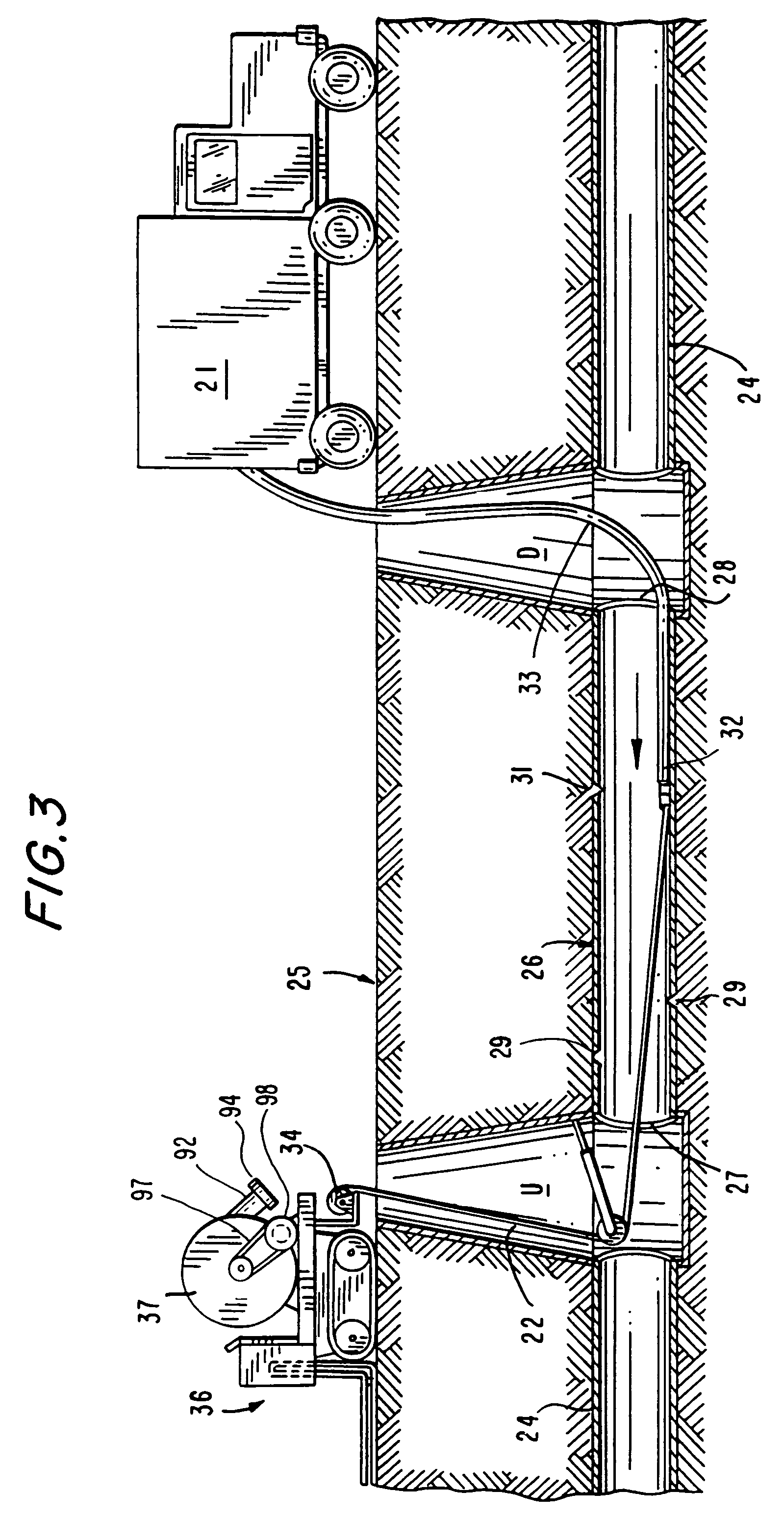

Low cost method and apparatus for fracturing a subterranean formation with a sand suspension

The present invention is directed to a low cost method and apparatus for fracturing a subterranean formation. The invention involves using a centrifugal pump to combine a fracture fluid, a sand suspension and liquid additive and discharge a mixture of these components into a high pressure pump that injects the mixture into the subterranean formation. The apparatus employs a control pinch valve to precisely control the amount of sand suspension being added to the mixture. The apparatus eliminates the need for expensive blenders, other equipment and associated personnel and provides a low cost means of fracturing the subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

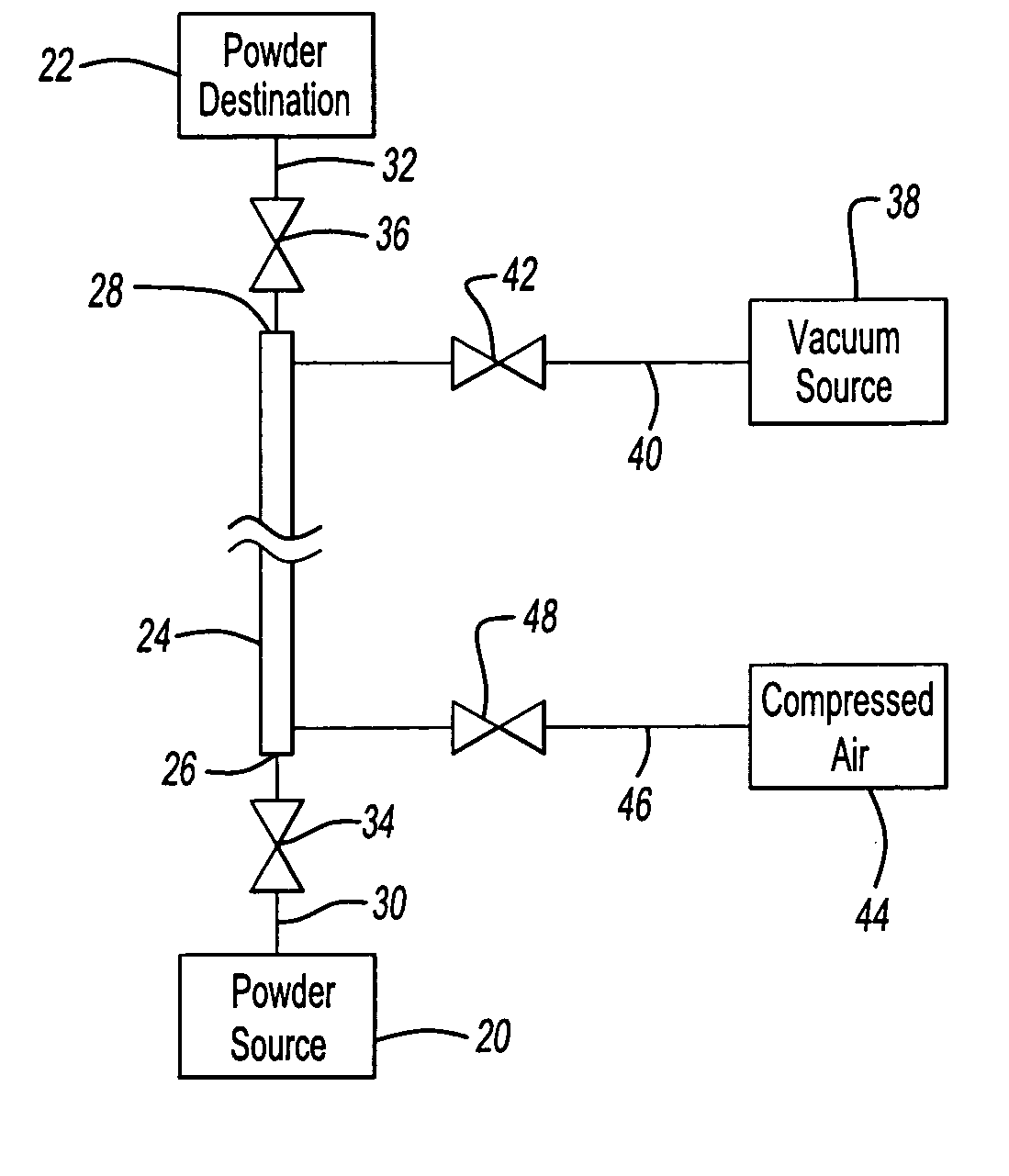

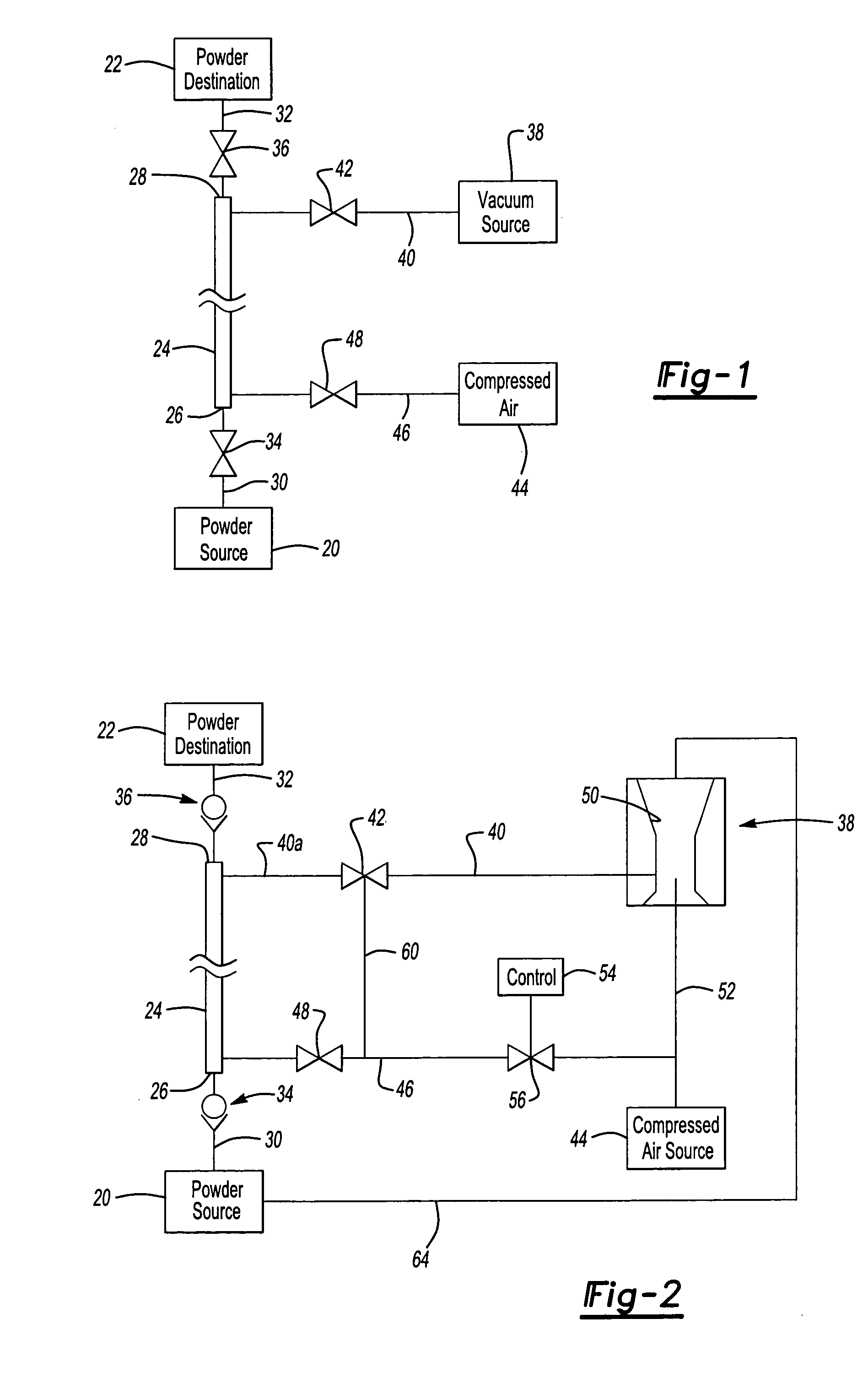

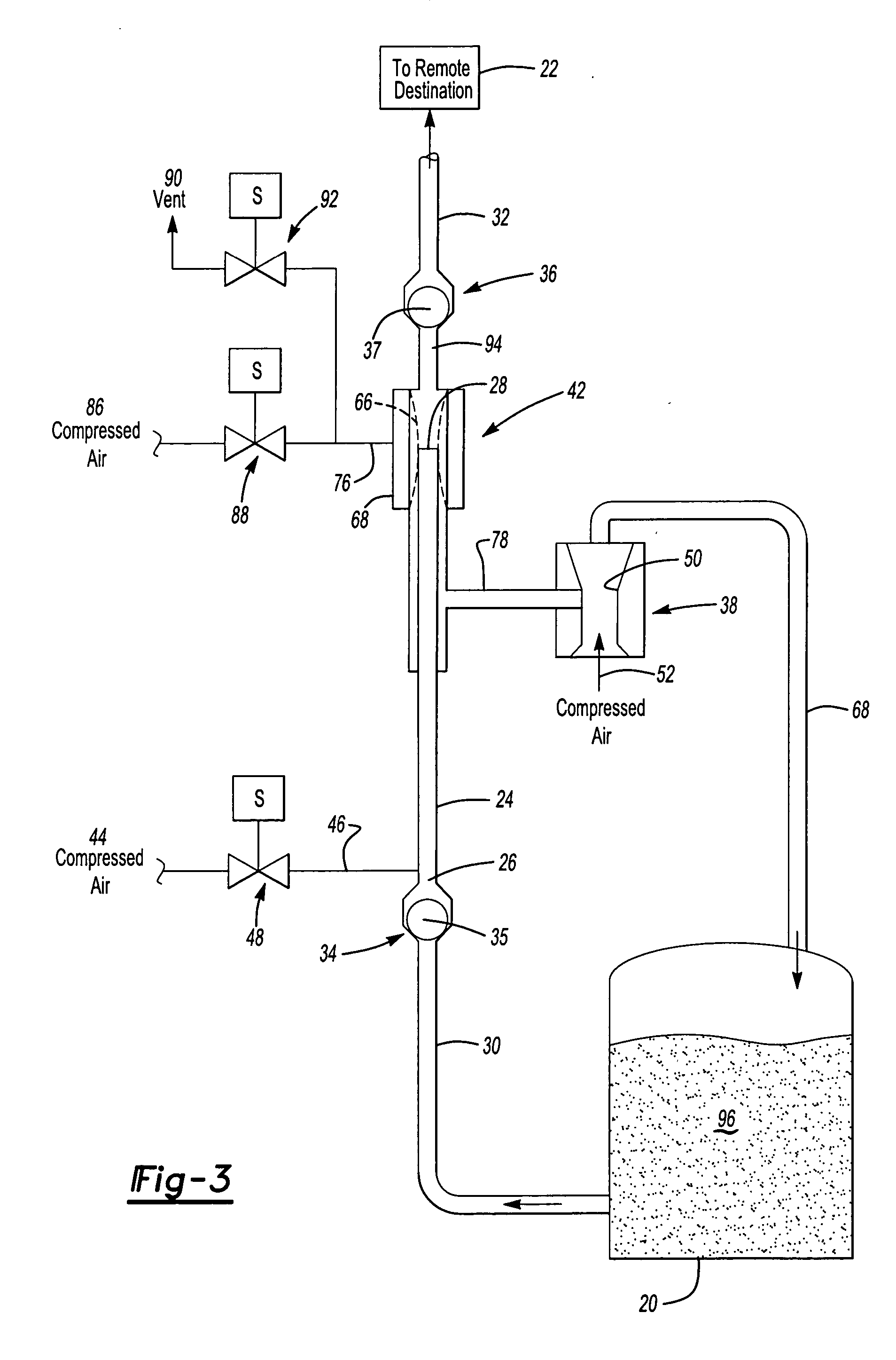

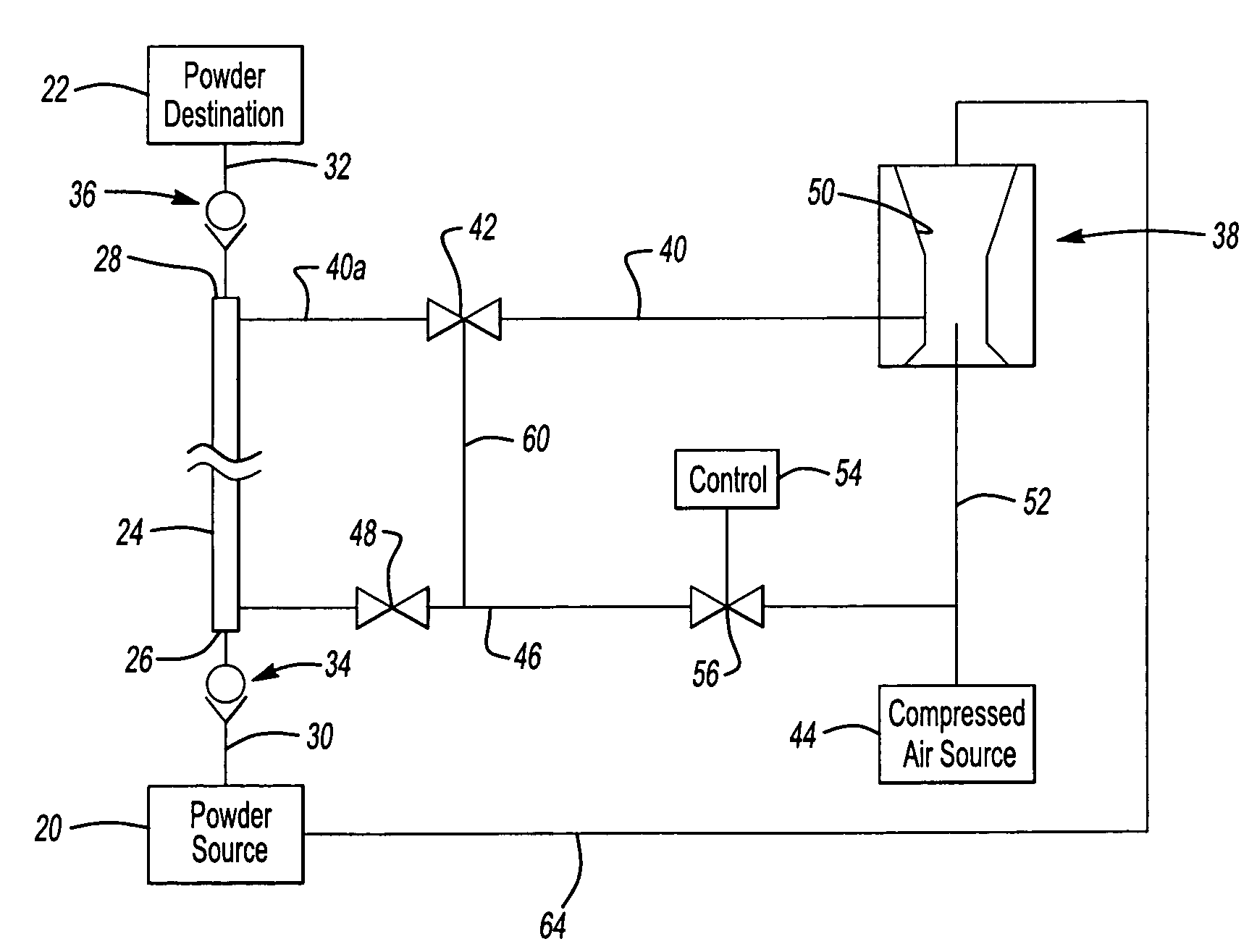

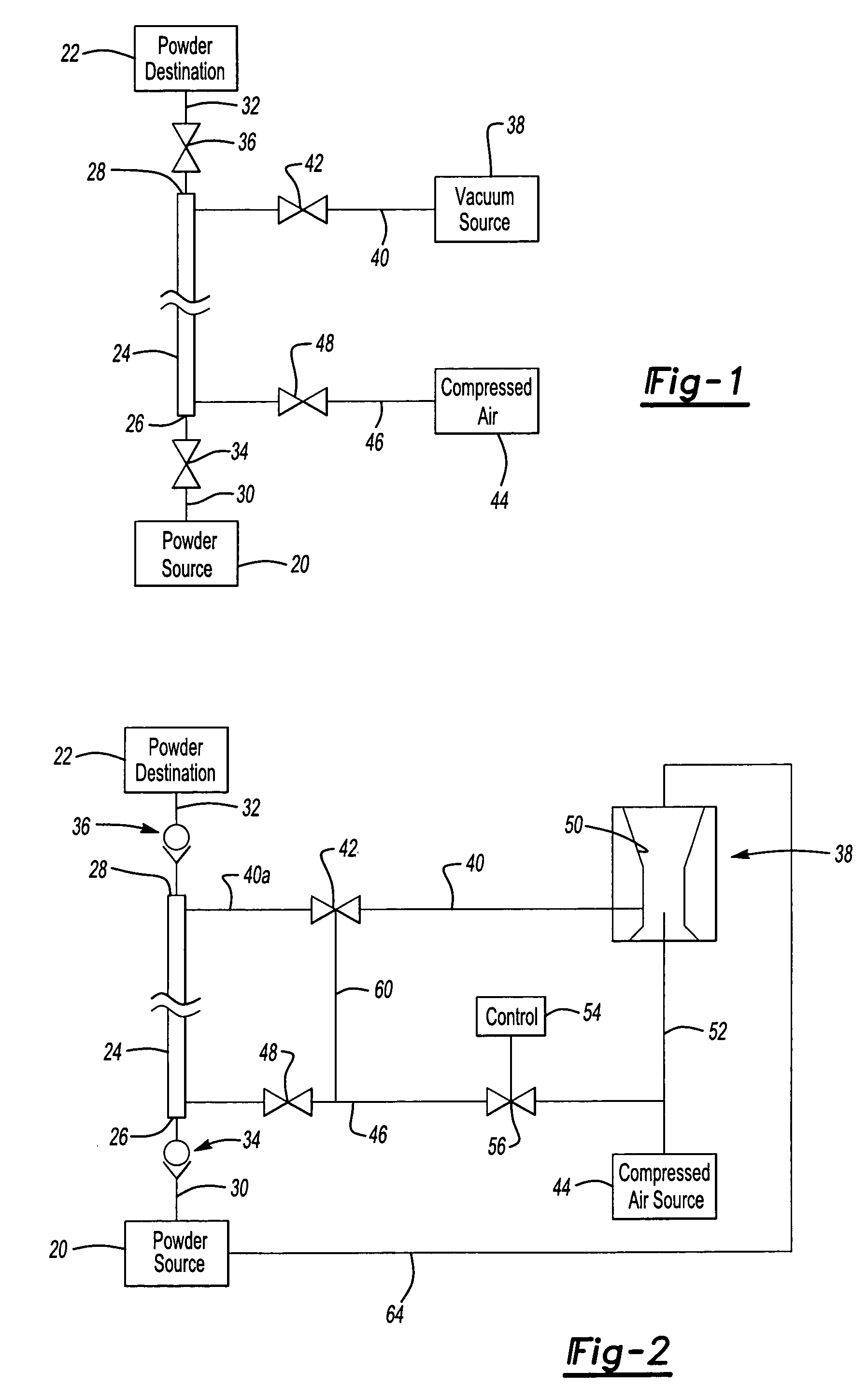

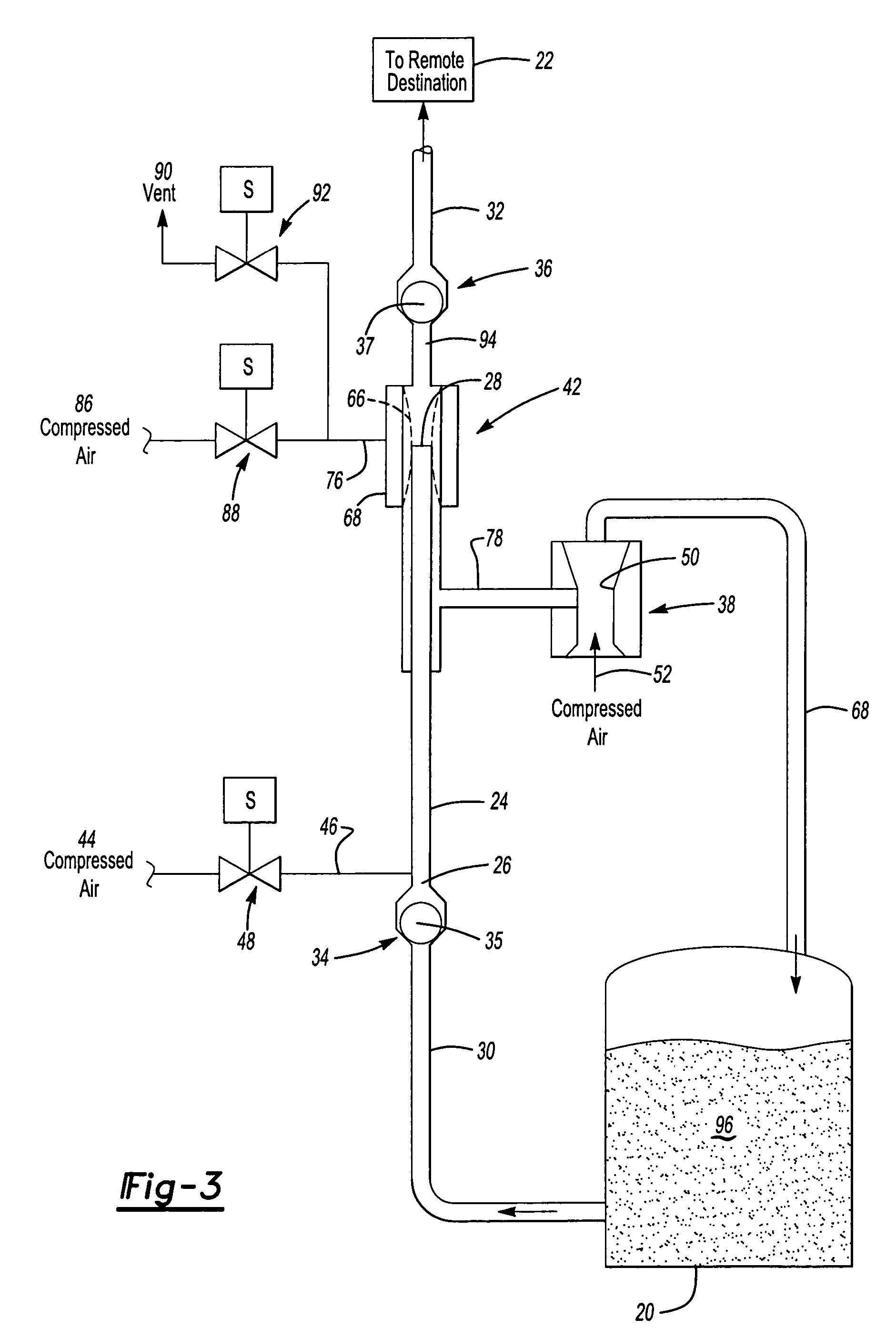

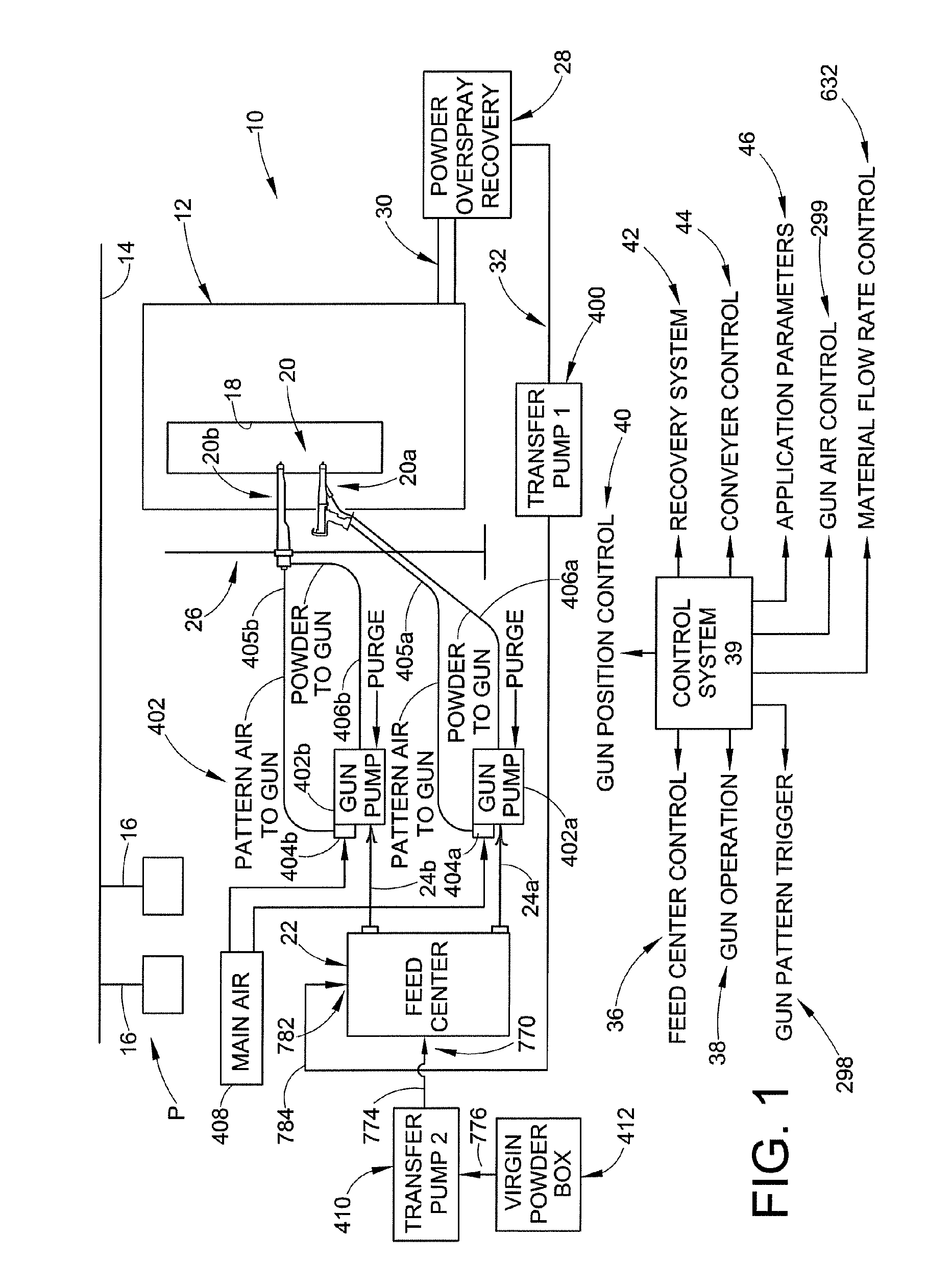

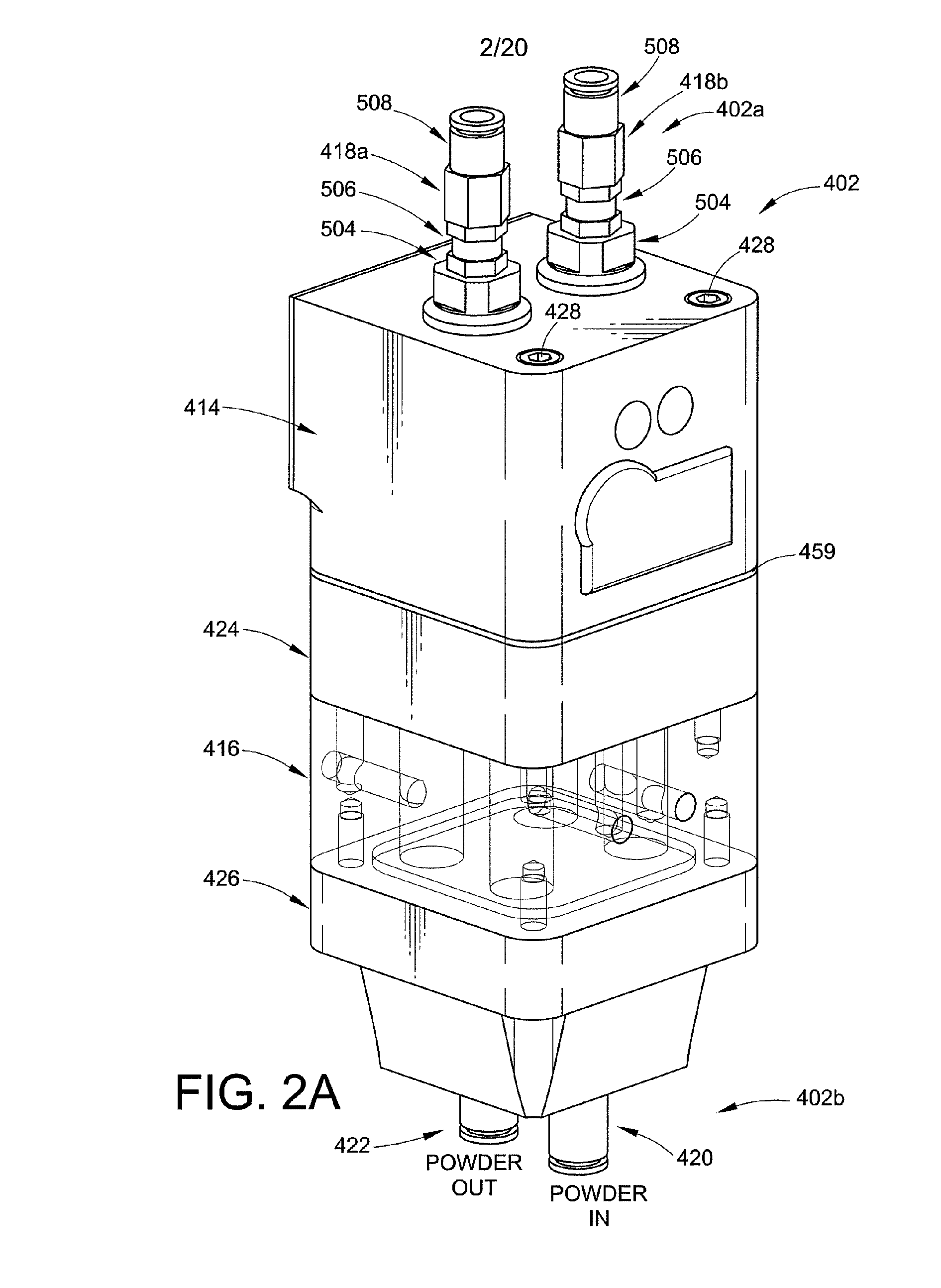

Pump for transferring particulate material

A pump for transferring particulate material from a source to a remote location, including a particulate chamber having open ends, check valves at the open ends, a vacuum source connected to the chamber adjacent one end, a gas source at the opposed end of the chamber and a control which alternatively connects the vacuum to the chamber to draw particulate material from the source to the chamber and connecting the gas under pressure to drive the particulate material to the remote location. In a preferred embodiment, the chamber has a cylindrical inner diameter and the source of vacuum is a venturi pump connected to a pinch valve permitting overflow of particulate material through the pinch valve and venturi pump, which is returned to the source. In one embodiment, the pinch valve surrounds an open end of the chamber permitting overflow while avoiding agglomeration of the particulate material.

Owner:DURR SYST INC

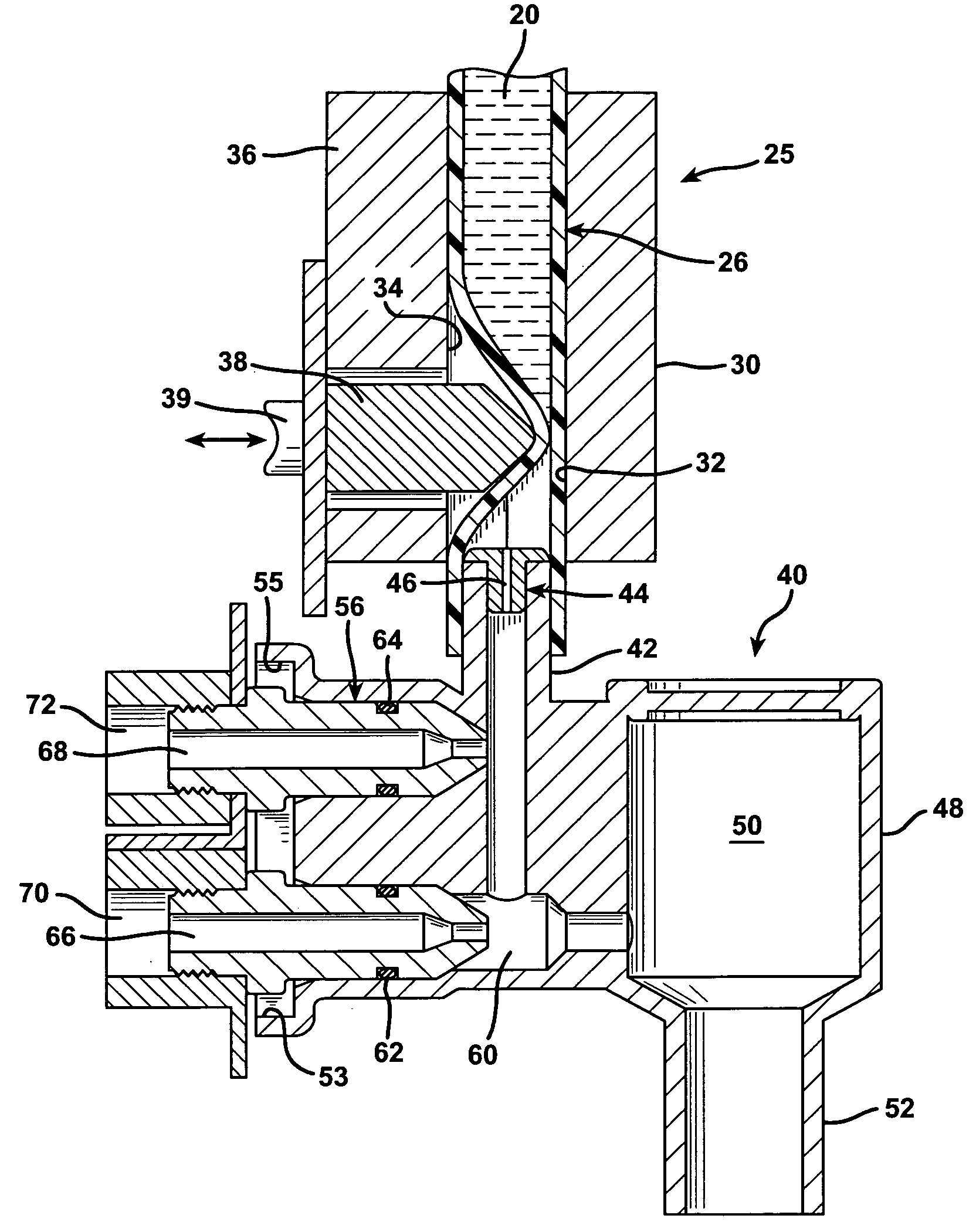

Pinch valve

ActiveUS7104275B2Reduce errorsDiaphragm valvesOperating means/releasing devices for valvesPinch valveControl valves

A control valve includes an elastomeric flow tube, a plunger having first and second ends, and a pinch member connected to the first end of the plunger. The pinch member is situated adjacent the flow tube. A reference surface is positioned generally opposite the pinch member such that the elastomeric tube is squeezable between the pinch member and the reference surface to control fluid flow through the flow tube. A first guide spring is situated between the pinch member and the first end of the plunger, and a second guide spring is situated adjacent the second end of the plunger. A damper may be connected to the plunger. Further, a pressure containing member may situated about at least a portion of the flow tube.

Owner:EMERSON ELECTRIC CO

Pump for transferring particulate material

A pump for transferring particulate material from a source to a remote location, including a particulate chamber having open ends, check valves at the open ends, a vacuum source connected to the chamber adjacent one end, a gas source at the opposed end of the chamber and a control which alternatively connects the vacuum to the chamber to draw particulate material from the source to the chamber and connecting the gas under pressure to drive the particulate material to the remote location. In a preferred embodiment, the chamber has a cylindrical inner diameter and the source of vacuum is a venturi pump connected to a pinch valve permitting overflow of particulate material through the pinch valve and venturi pump, which is returned to the source. In one embodiment, the pinch valve surrounds an open end of the chamber permitting overflow while avoiding agglomeration of the particulate material.

Owner:DURR SYST INC

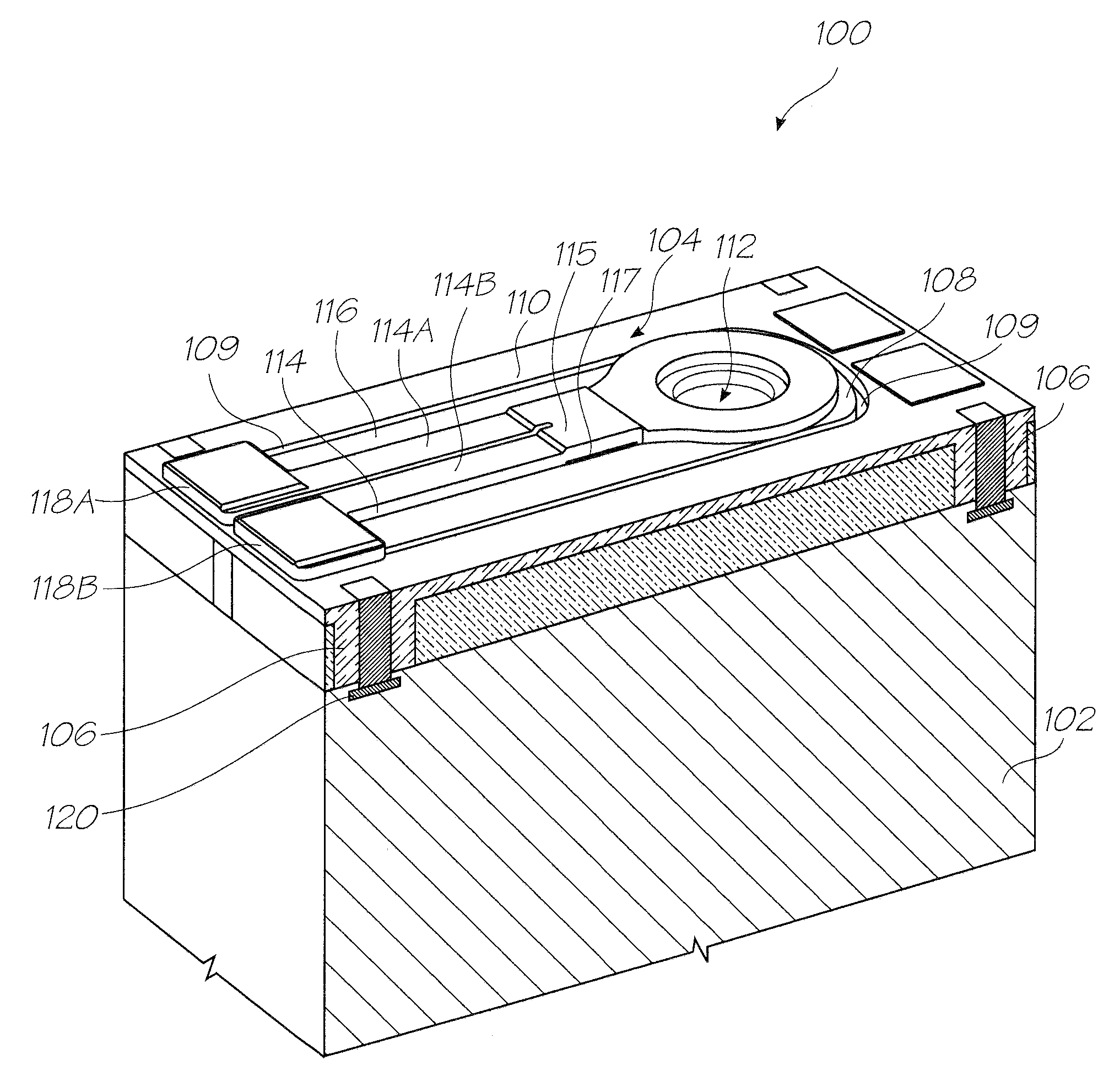

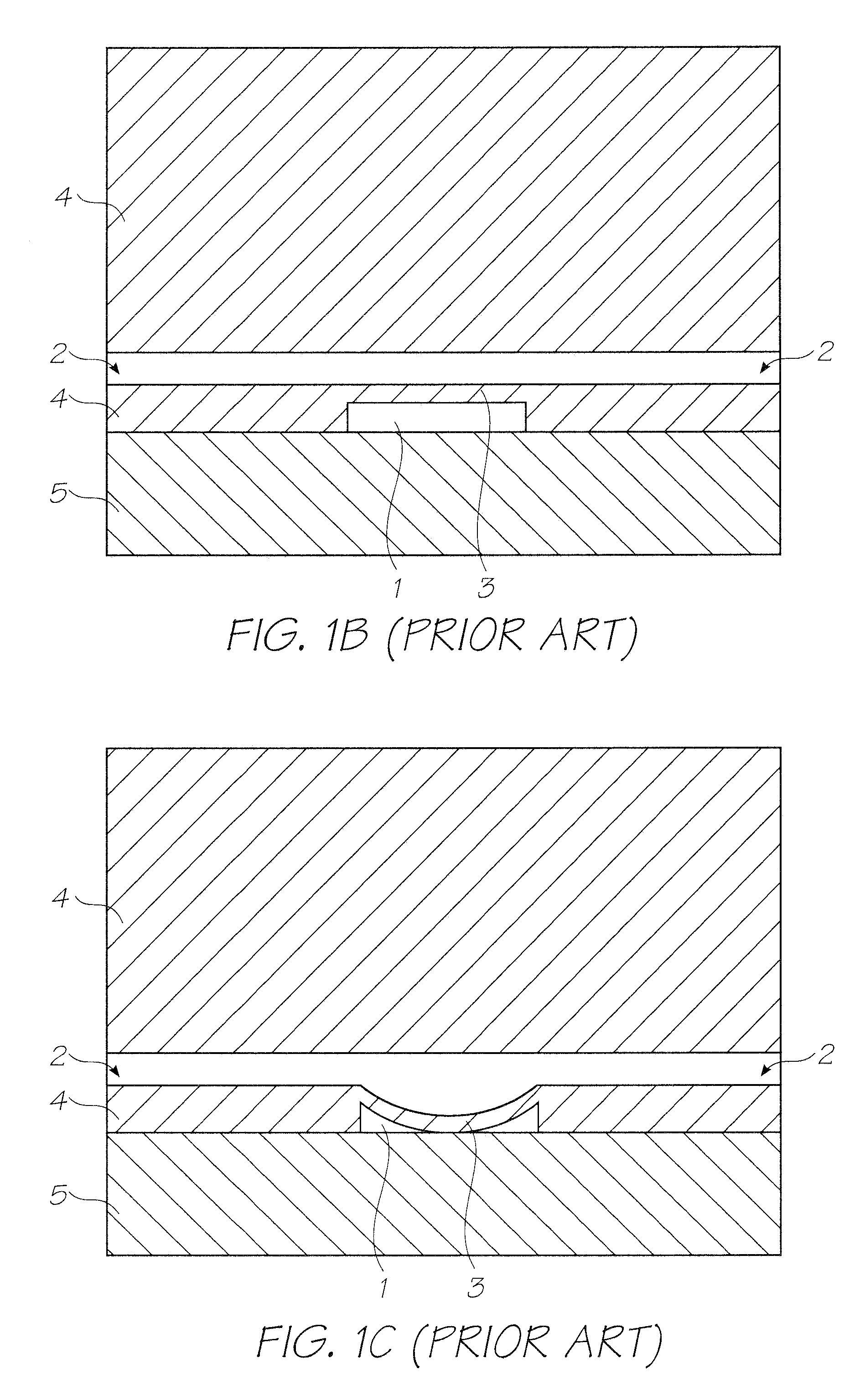

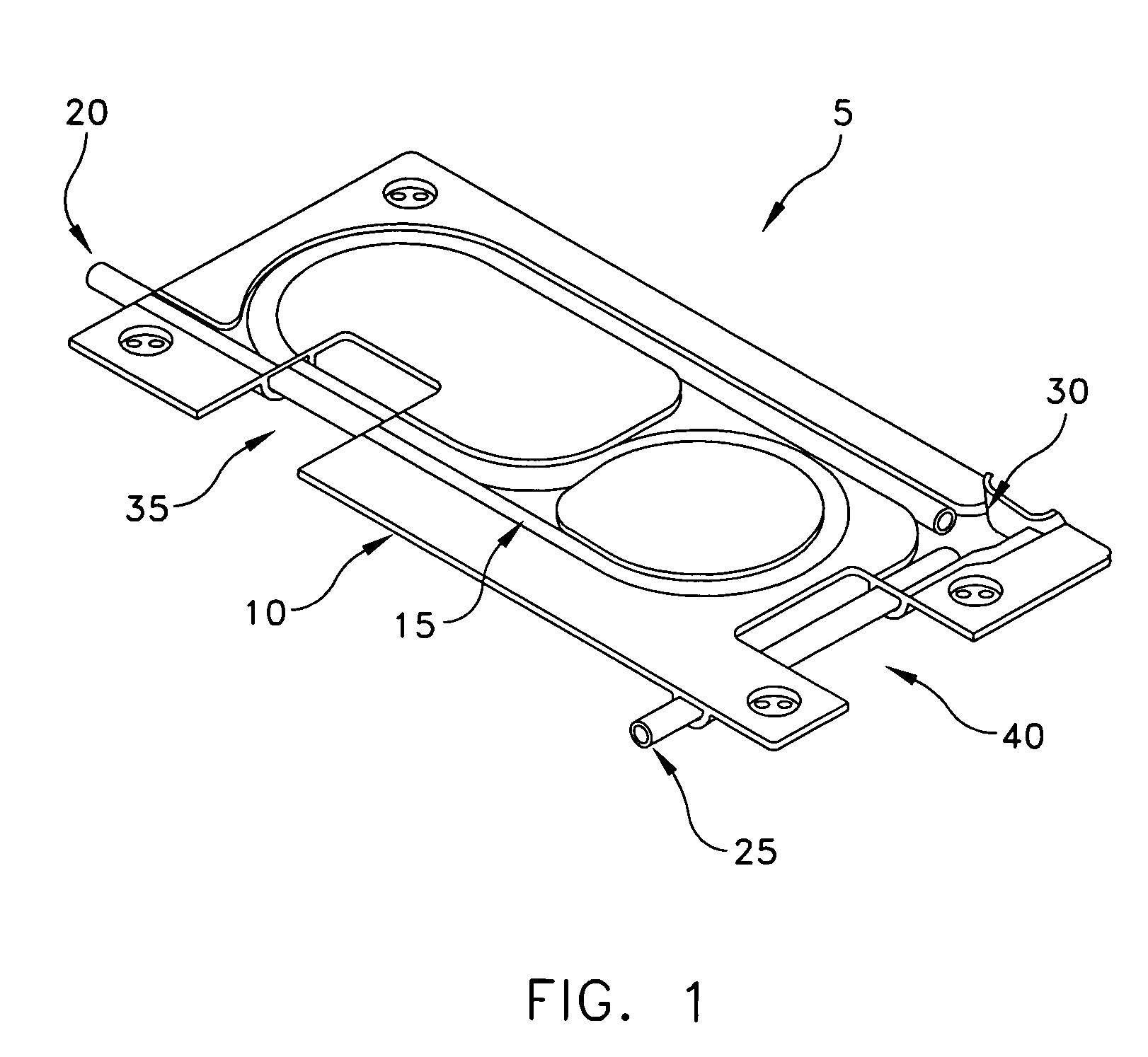

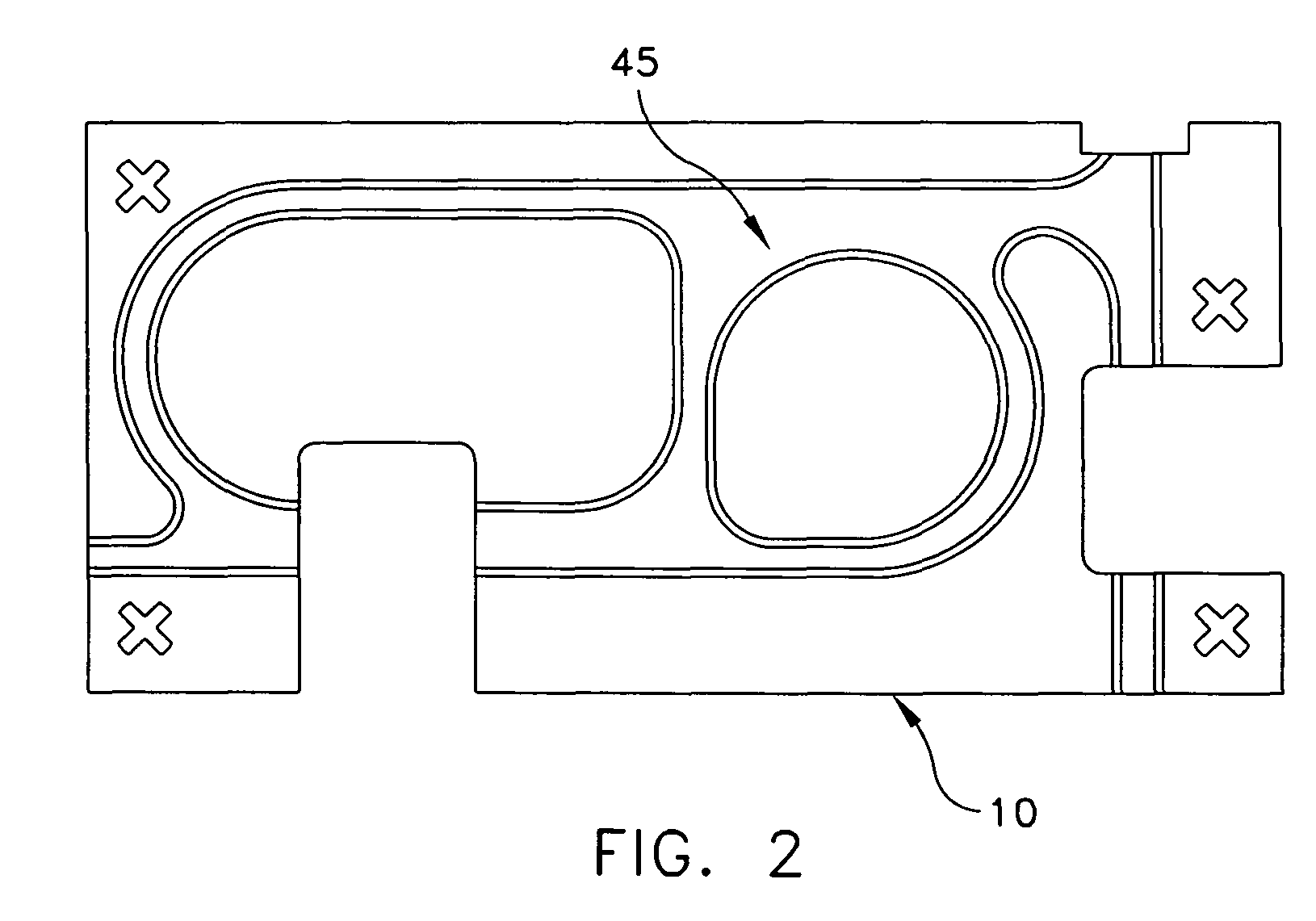

Mechanically-Actuated Microfluidic Pinch Valve

A microfluidic pinch valve. The valve comprises a microfluidic channel defined in a compliant body; a valve sleeve defined by a section of the microfluidic channel, the valve sleeve having a membrane wall defining part of an outer surface of the body; a compression member for pinching the membrane wall against an opposed wall of the valve sleeve; and a thermal bend actuator for moving the compression member between a closed position in which the membrane wall is sealingly pinched against the opposed wall, and an open position in which the membrane wall is disengaged from the opposed wall.

Owner:SILVERBROOK RES PTY LTD

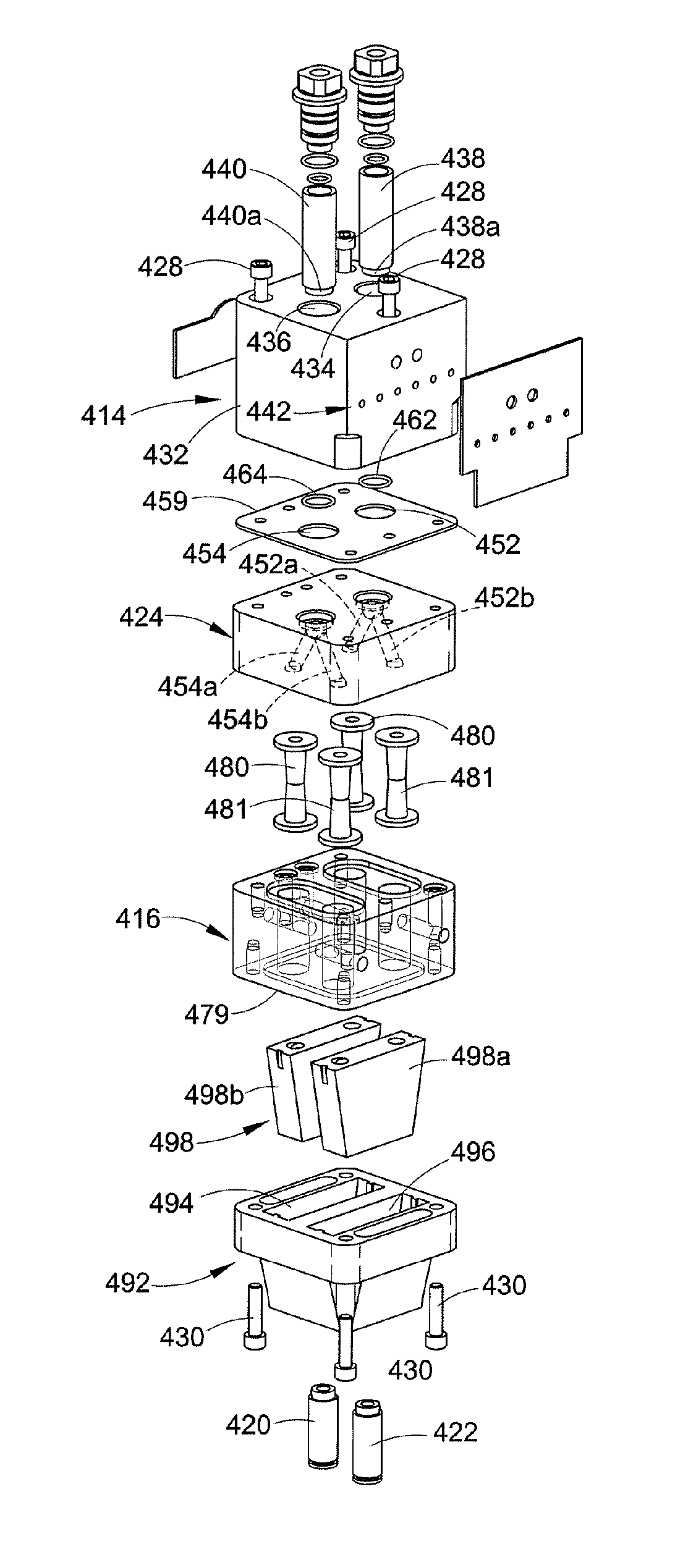

Dense phase pump for dry particulate material

InactiveUS20050158187A1Improve cleanabilityImprove serviceabilityLiquid surface applicatorsPositive displacement pump componentsCycle ratePump chamber

A dense phase pump for particulate material includes a pump chamber wherein material flows into the pump chamber under negative pressure and flows out of the pump chamber under positive pressure. A plurality of pinch valves are provided to control flow of material into and out of the pump chamber. The pinch valves are operated independent of each other and of the pump cycle rate. A modular design of the pump is provided.

Owner:NORDSON CORP

Low cost method and apparatus for fracturing a subterranean formation with a sand suspension

The present invention is directed to a low cost method and apparatus for fracturing a subterranean formation. The invention involves using a centrifugal pump to combine a fracture fluid, a sand suspension and liquid additive and discharge a mixture of these components into a high pressure pump that injects the mixture into the subterranean formation. The apparatus employs a control pinch valve to precisely control the amount of sand suspension being added to the mixture. The apparatus eliminates the need for expensive blenders, other equipment and associated personnel and provides a low cost means of fracturing the subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

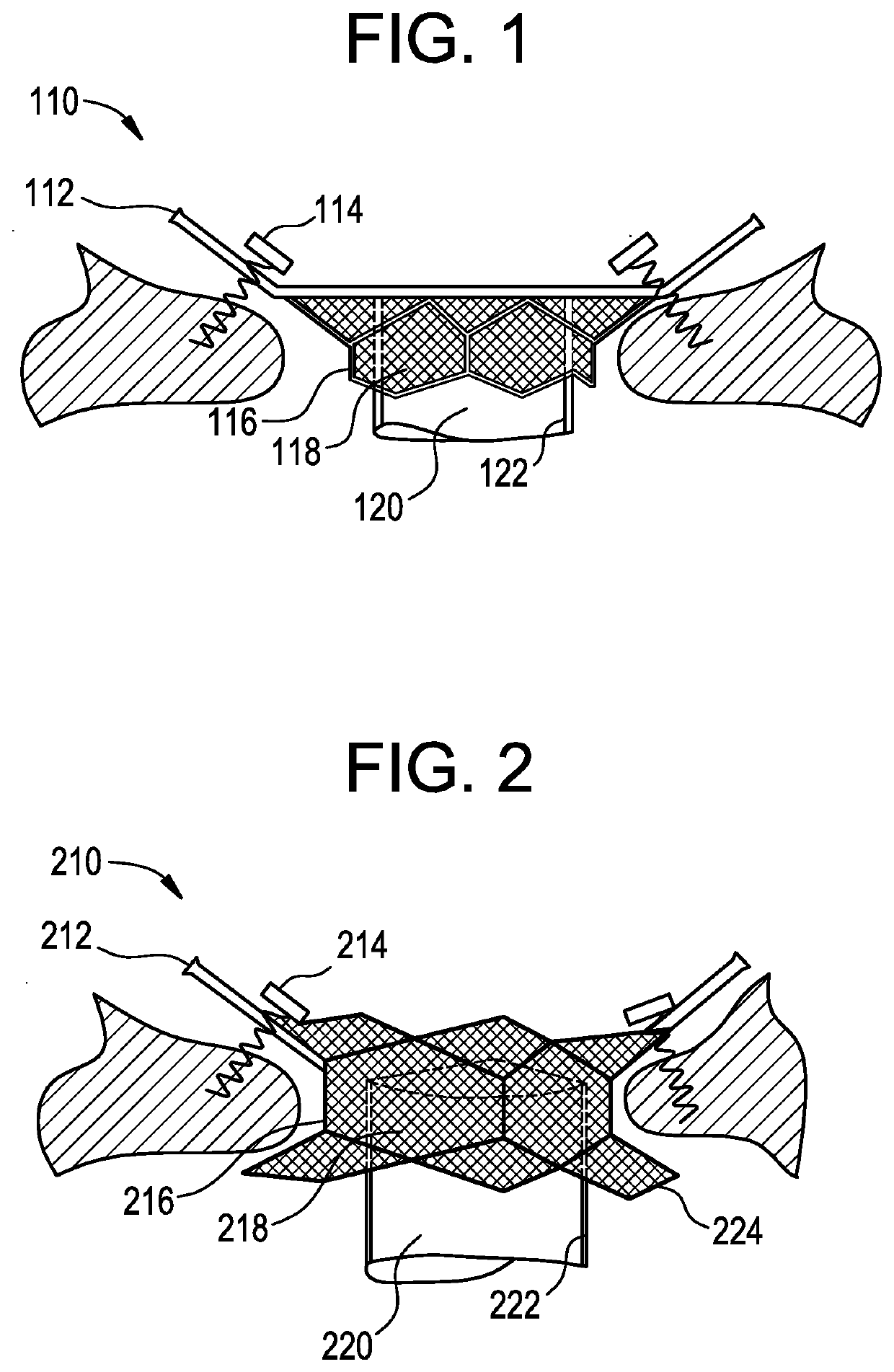

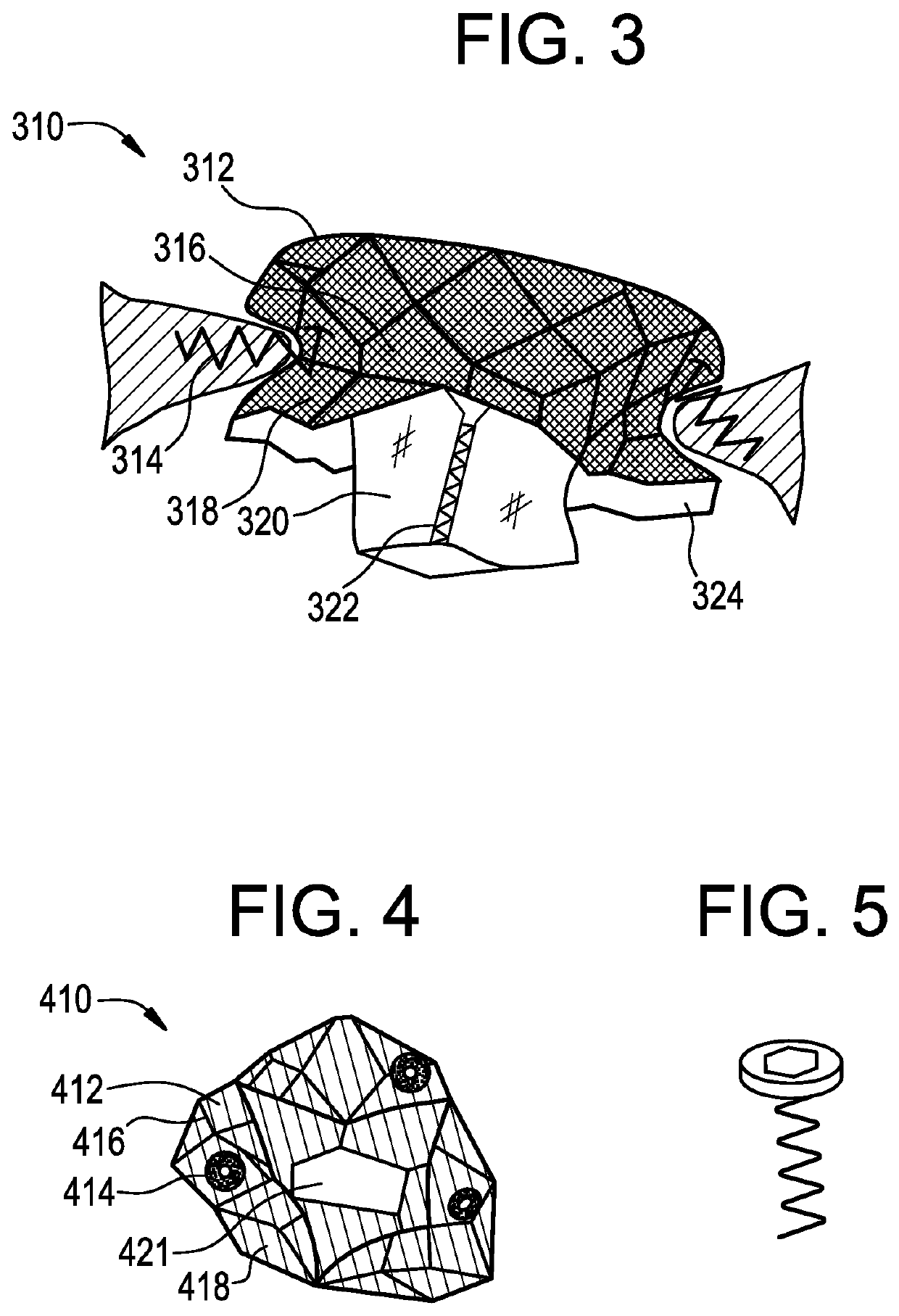

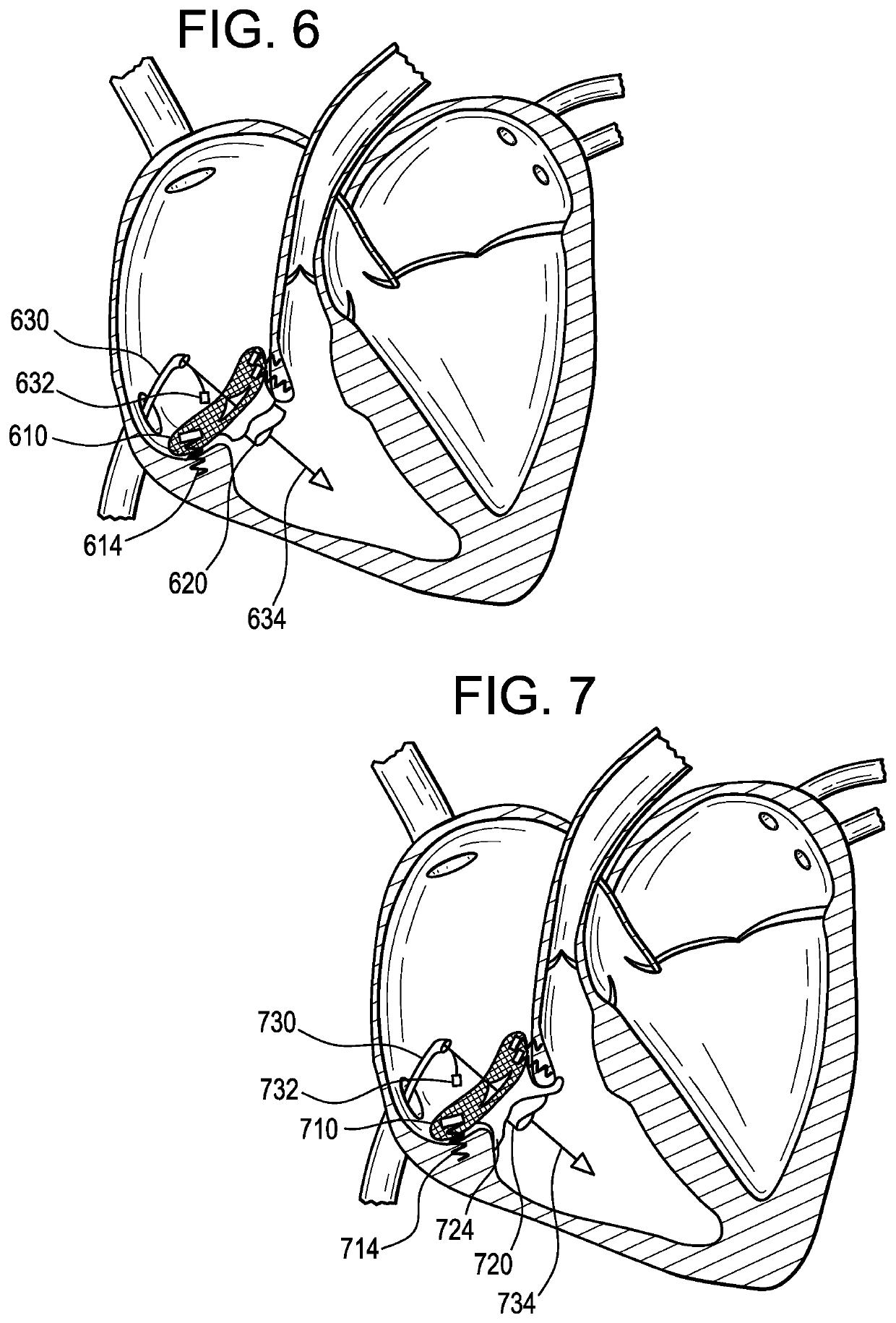

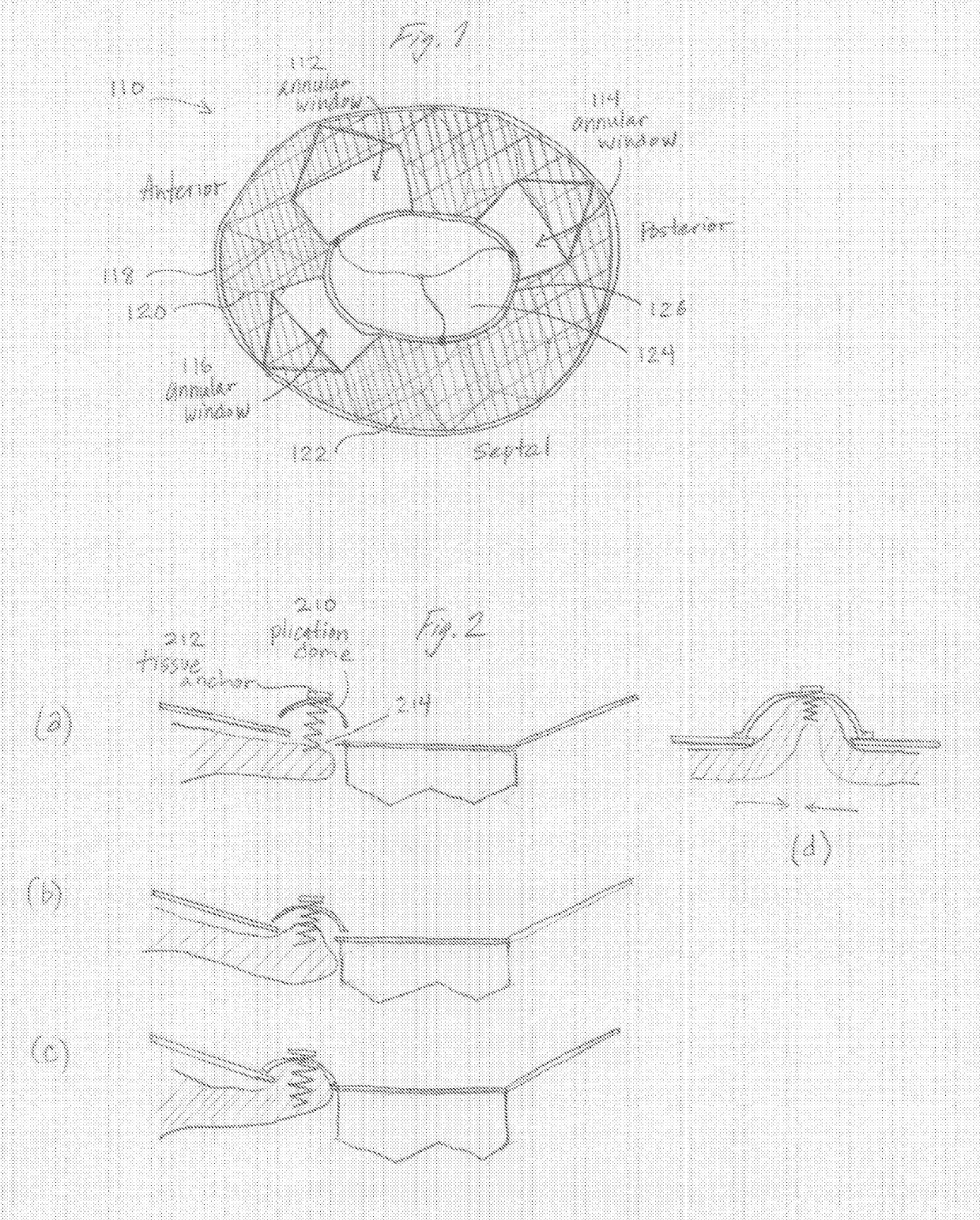

Transcatheter Heart Valve with Plication Tissue Anchors

The invention relates to a transcatheter heart valve replacement (A61F2 / 2412), and in particular a device and method for percutaneous annular plication and heart valve deployment for mounting a pressure actuated flow control sleeve, a pinch valve, as a replacement device for a heart valve, whereby the prosthesis has an atrial annular flange or cuff having one or more integral plication tissue anchors for engaging the valve annulus, wherein the is a reciprocating mechanical member that is compressed by pressurized working fluid within the heart during ventricular systole.

Owner:VDYNE INC

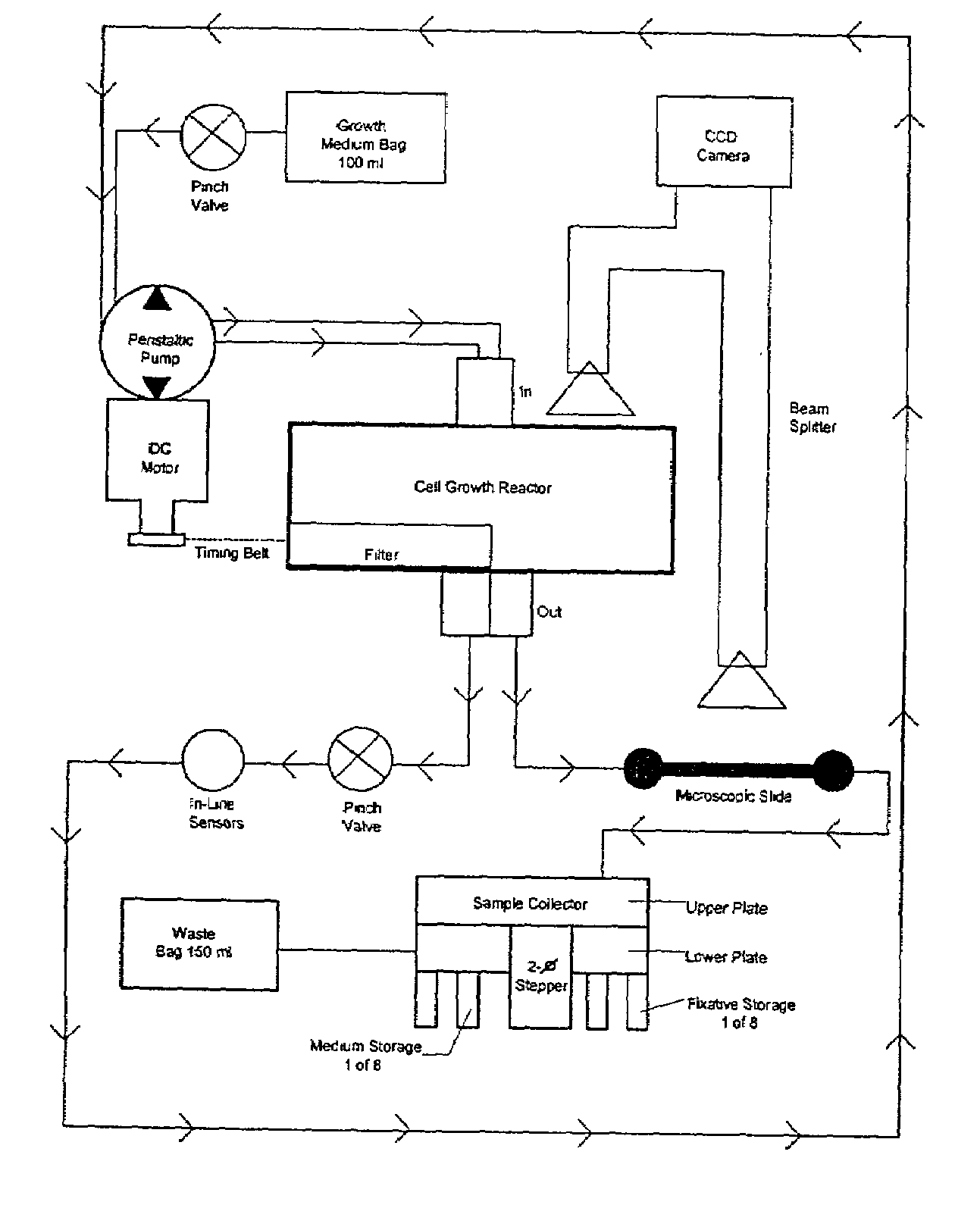

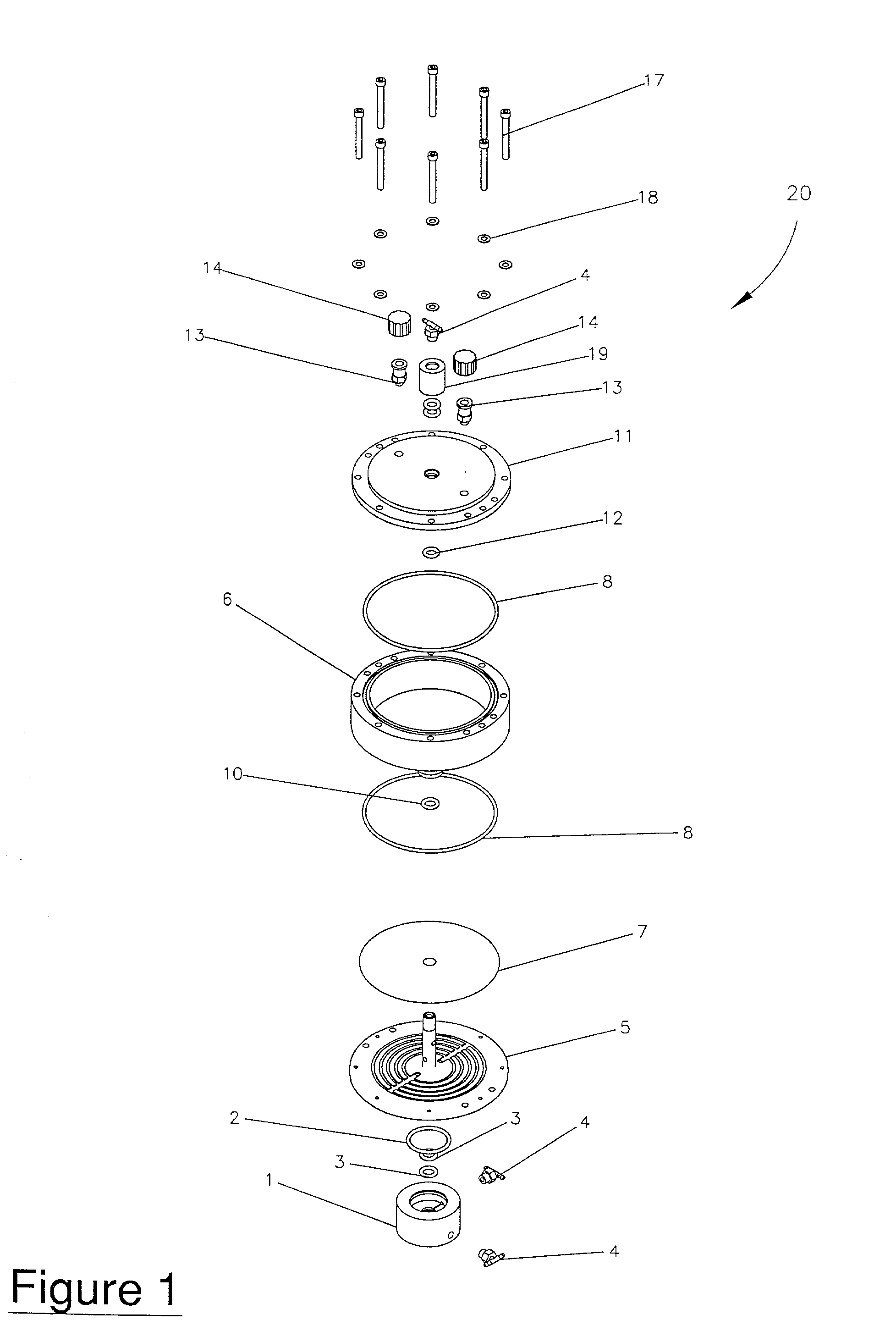

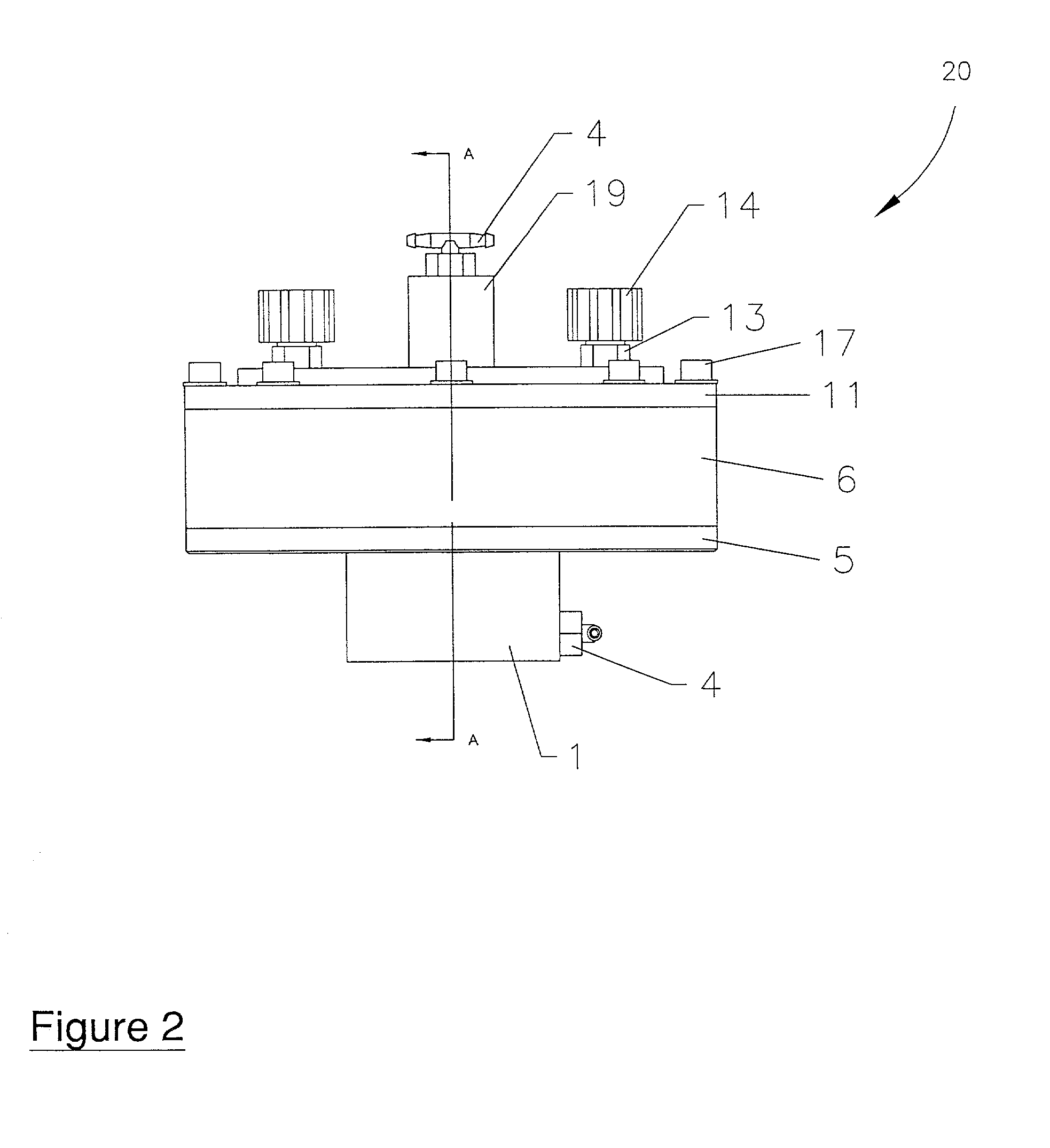

Bioreactor apparatus and cell culturing system

InactiveUS7198940B2Minimized pressure dropLarge filter areaBioreactor/fermenter combinationsBiological substance pretreatmentsCell free supernatantPeristaltic pump

A bioreactor apparatus and cell culturing system is provided for the automated cultivation and processing of living cells remotely both on earth and in low gravity which utilizes a generally cylindrical reactor vessel that may be optionally rotated about its cylindrical axis while allowing the entrance of fresh or recycled fluid and the removal, optionally, of spent medium, medium to be recycled or filtered or unfiltered medium for the collection of samples. A method of exchanging gases between the culture medium and ambient gases is provided. A fresh-medium storage bag and peristaltic pump is used for batch feeding, perfusion or sample collection. An enclosure and manifold representing an additional level of chemical containment and a series of pinch valves for the periodic collection of samples of suspended cells or cell-free medium is disposed therein together with a humidity control system. The bioreactor is computer controlled in order to control all functions including rotation of the reactor vessel, feeding fresh medium, perfusing the reactor vessel, timed collection of samples of fluid from the reactor, selecting between collecting cells or cell-free supernatant. A sealed compartment for sample-collection bags provides a level of chemical containment for safety. A sealed external housing is used for all components of the device except the power supply and computer. An external loop and electronic video microscope provides real-time and recorded and / or transmitted observation of cells in the suspension.

Owner:TECHSHOT INC

Valve mechanism for infusion fluid systems

InactiveUS7306736B2Prevent backflowLow costLiquid separation auxillary apparatusSolvent extractionWhole blood productPinch valve

A method and an apparatus are provided for preventing retrograde flow of fluid, e.g., blood products, into a source of sterile substitution fluid (50). The apparatus of the present invention includes a controllable pinch valve member (110) that is placed on a section of a conduit (90) which carries sterile substitution fluid to an extracorporeal circuit (30). In one embodiment, control over the valve member (110) is based on a control unit (120) using fluid pressures that are sensed upstream and downstream of the valve member (110) by upstream sensor (121) and downstream pressure (122) respectively. The valve member (110) is preferably opened only when the upstream pressure is greater than the downstream pressure. This assures that the substitution fluid flows only in a single direction when the pinch valve member (110) completely occludes the conduit (90) when in a closed position. Therefor, blood will not contaminate the sterile fluid by being drawn into the conduit (90) due to pressure differences.

Owner:LAMBDA INVESTORS

Transcatheter Heart Valve with Plication Window and Tissue Anchors

The invention relates to a transcatheter heart valve replacement (A61F2 / 2412), and in particular a device and method for percutaneous annular plication and heart valve deployment for mounting a pressure actuated flow control sleeve, a pinch valve, as a replacement device for a heart valve, whereby the prosthesis has an atrial annular flange or cuff having one or more integral plication windows connected to a pressure actuated flow control sleeve extending into the ventricle, wherein the is a reciprocating mechanical member that is compressed by pressurized working fluid within the heart during ventricular systole.

Owner:VDYNE INC

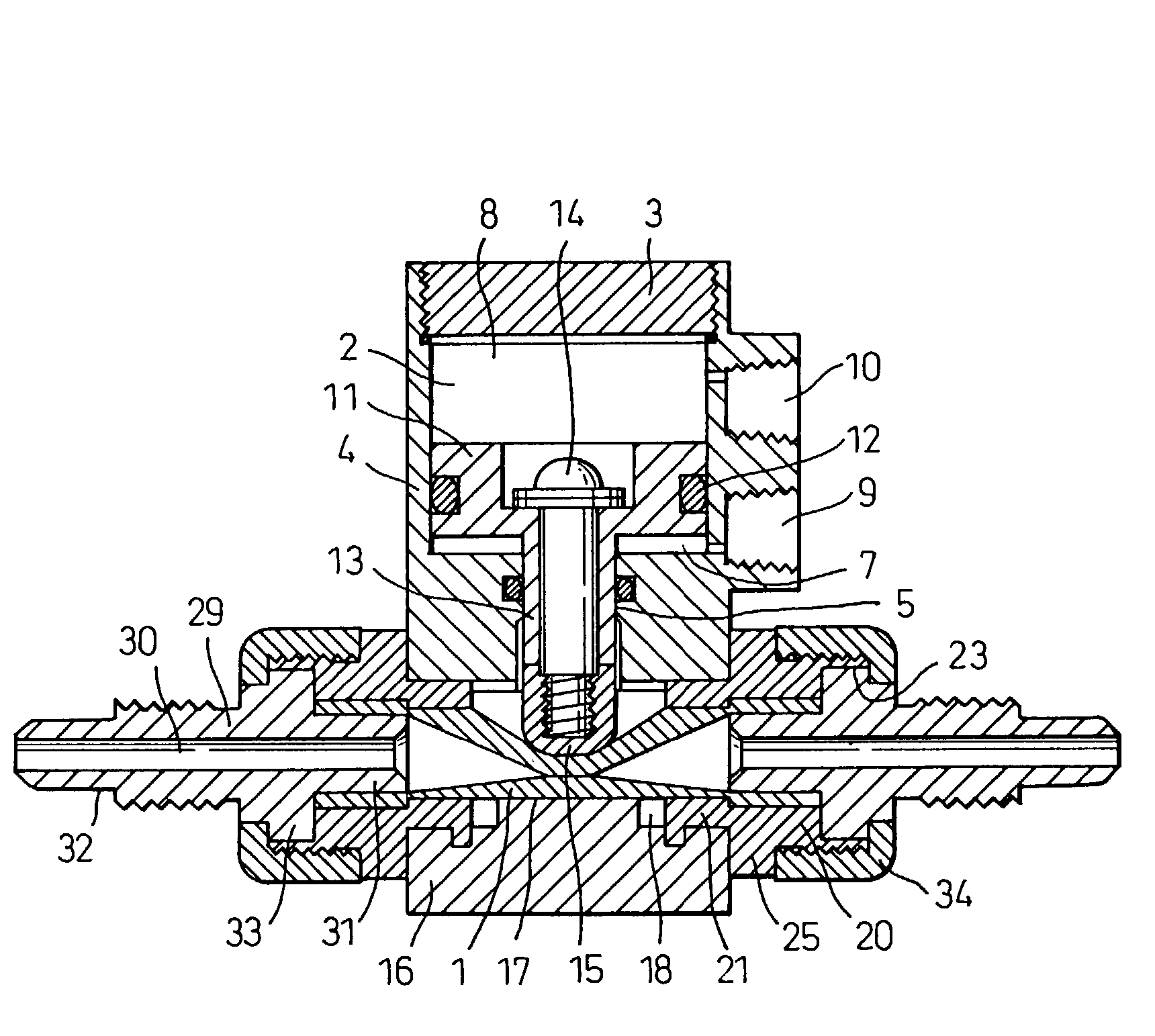

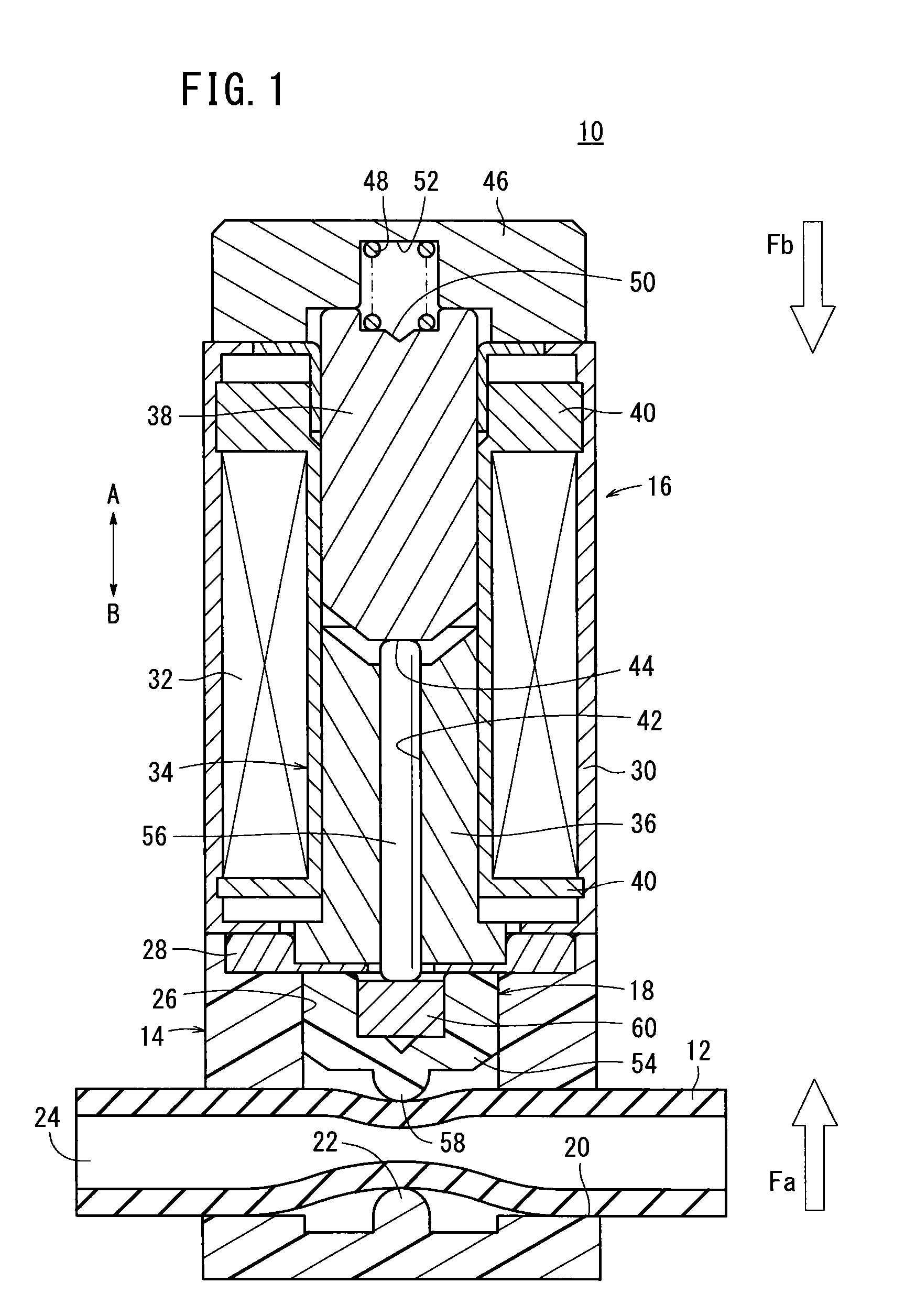

Pinch valve

InactiveUS20030010946A1Increased durabilitySmall flow rateDiaphragm valvesOperating means/releasing devices for valvesPinch valveCylinder block

A pinch valve of the invention comprising an elastic tube body 1, a cylinder body 4 having a cylinder portion 2 and a cylinder cover 3, a piston 11 sliding on the inner periphery of the cylinder body, a pressing piece 15 fixed to a connecting portion 13 suspended from the piston, a body 16 joined to the cylinder body and having a groove 17 receiving the tube body 1, a pair of connecting body carriers 20 engaged with grooves of the body and having a through-hole 26 receiving the tube body 1, a first and a second space portions 8, 7 formed above and under the piston 11, respectively, and a pair of air ports 10, 9 respectively communicating with the first and second space portions 8, 7. The whole pinch valve is made compact in construction.

Owner:ASAHI YUKIZAI KOGYO CO LTD

Wastewater flow control system

A sewage pumping apparatus is provided for delivering sewage collected by gravity in a wet well to a force main. The sewage pumping apparatus comprises a motor controlled pump in fluid communication with the wet well for supplying sewage to the force main via a pinch valve. A fluid parameter sensing device is provided at the outlet of the pump for producing an electrical signal output proportional to the sensed fluid parameter (pressure or flow rate). A Digital Process Controller (DPC) receives and compares the electrical signal from the fluid parameter sensing device to a system setpoint and produces a signal outputs to open or throttle the pinch valve in accordance with the desired system backpressure to prevent overloading or cavitation of the pump and to clear blockages in the system.

Owner:FLOW CONTROL SYST

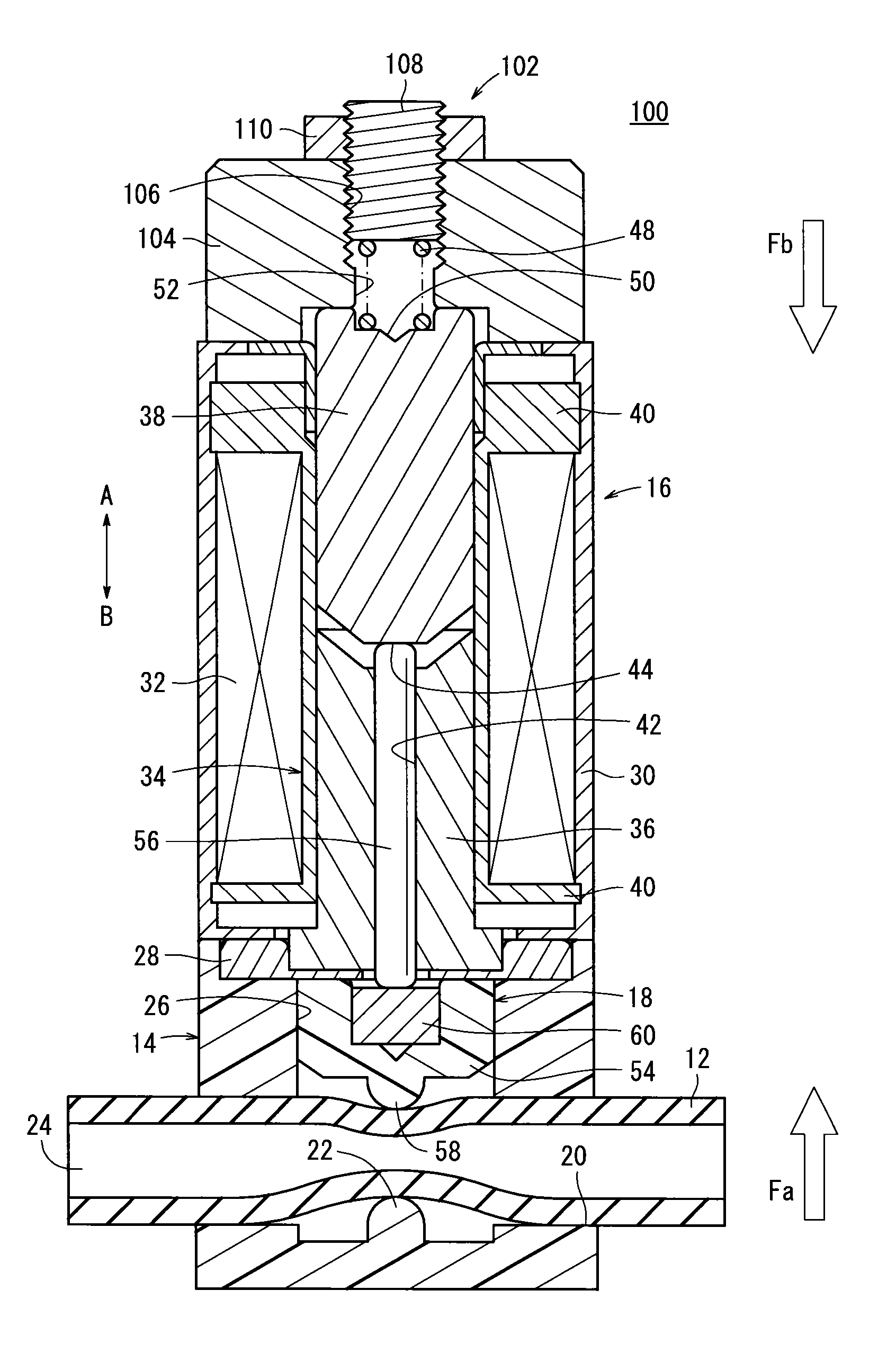

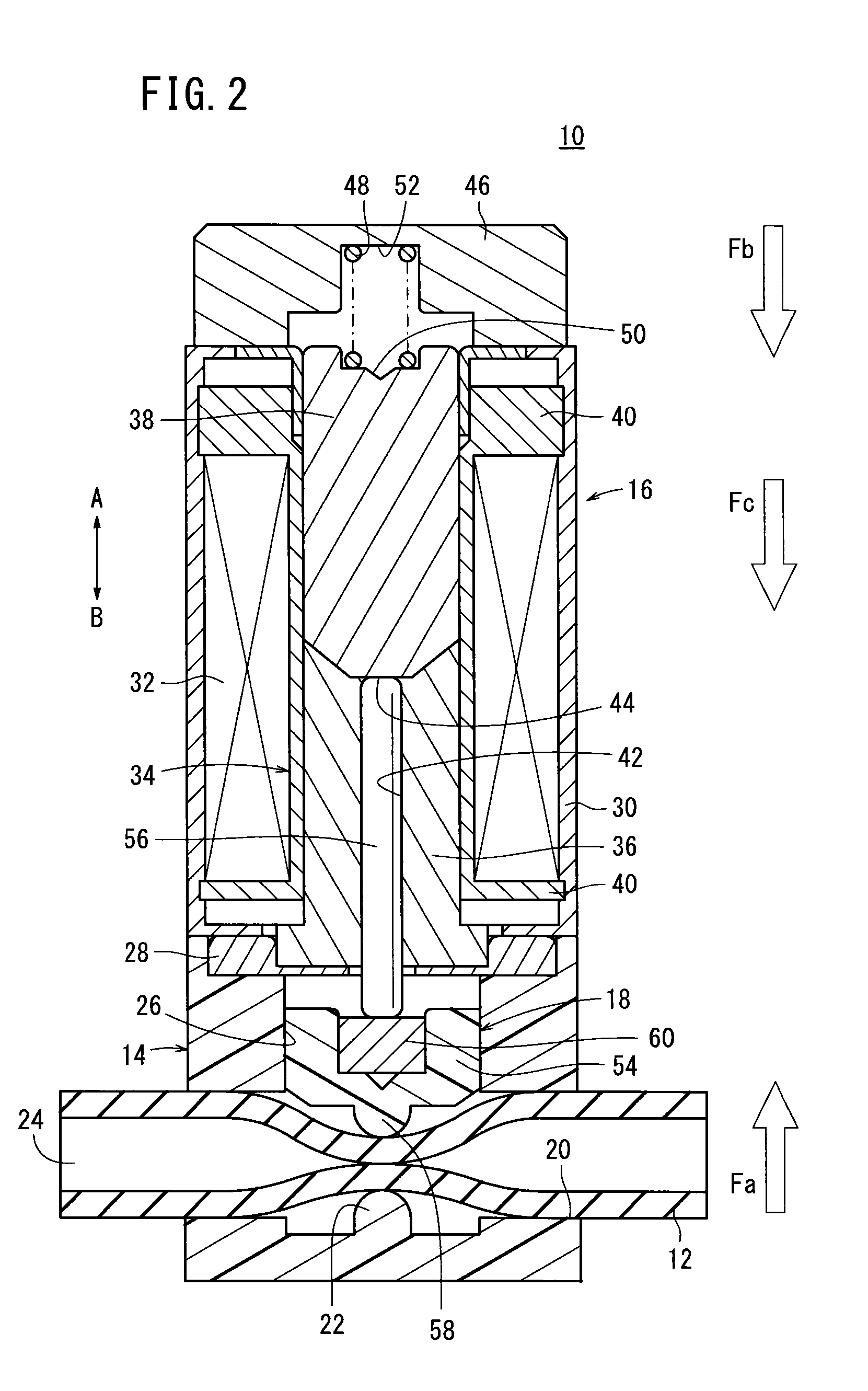

Pinch valve

ActiveUS8622365B2Quick switchLight weightDiaphragm valvesOperating means/releasing devices for valvesExcited statePinch valve

Owner:SMC CORP

Endoscopic system with fluid cleaning

An endoscopic system for use with an endoscope, including an irrigation tube that provides a flow of irrigation fluid for cleaning a body lumen, and a suction tube for sucking material from the body lumen, wherein the suction tube is connected to a branch connector and one branch of the branch connector is connected to a suction source tube which is connected to a suction source and another branch of the branch connector is connected to a vent tube, and wherein the suction source tube and the vent tube pass through a double pinch valve.

Owner:NOVOGI

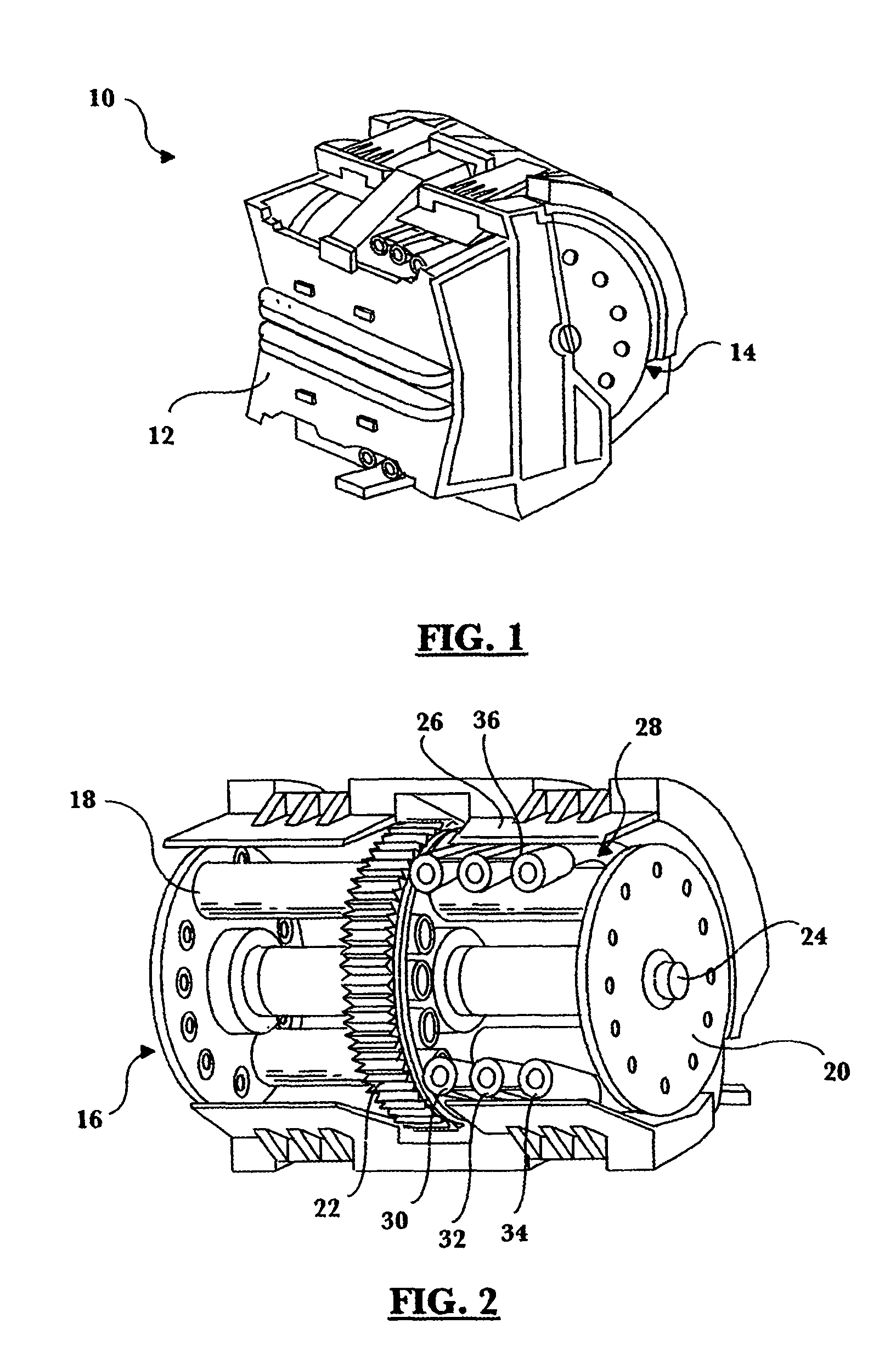

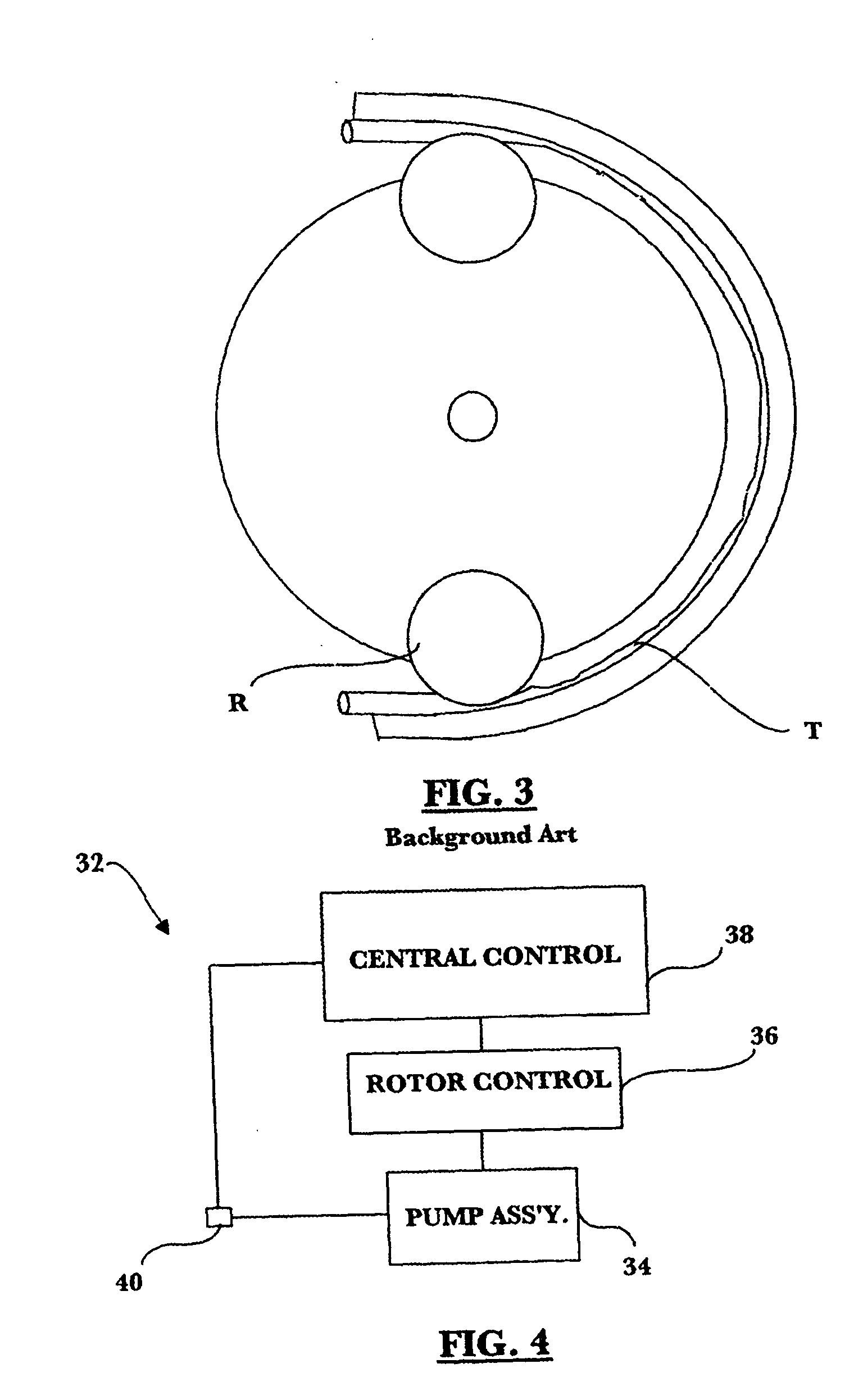

Peristaltic pump with roller pinch valve control

A pump having a rotary portion which compels the movement of a fluid by peristaltic compression of resilient tubing containing the fluid includes a roller assembly having at least one roller mounted in the rotary portion of the pump for contact with the resilient tubing. The roller has a range of rotation in contact with the tubing during pump operation. A roller control mechanism is adapted and constructed to stop the roller at a single, predetermined location on the tubing when the pump operation is stopped.

Owner:HEWLETT PACKARD DEV CO LP

System, Method, and Apparatus for Infusing Fluid

ActiveUS20190154026A1Reduce peak torqueDrug and medicationsVolume/mass flow measurementPeristaltic pumpPinch valve

A peristaltic pump, and related system method are provided. The peristaltic pump includes a cam shaft, first and second pinch-valve cams, first and second pinch-valve cam followers, a plunger cam, a plunger-cam follower, a tube receiver, and a spring-biased plunger. The first and second pinch-valve cams are coupled to the cam shaft. The first and second pinch-valve cam followers each engage the first and second pinch-valve cams, respectively. The plunger cam is coupled to the cam shaft. The plunger-cam follower engages the plunger cam. The tube receiver is configured to receive a tube. The spring-biased plunger is coupled to the plunger-cam follower such that the expansion of the plunger cam along a radial angle intersecting the plunger-cam follower as the cam shaft rotates pushes the plunger cam follower towards the plunger and thereby disengages the spring-biased plunger from the tube. A spring coupled to the spring-biased plunger biases the spring-biased plunger to apply the crushing force to the tube.

Owner:DEKA PROD LLP

System for detecting and removing a gas bubble from a vascular infusion line

System for detecting and removing gas bubbles from a vascular infusion line, including a cassette adapted for disposition intermediate the fluid line, the cassette including a flexible tube having an inlet port for connection to a supply side of the fluid line, an outlet port configured for connection to a patient side of the fluid line, and a purge port intermediate the inlet and outlet ports, and a base unit adapted to receive the cassette and monitor fluid flow through the tube, the base unit including a sensor to detect the presence of a gas bubble in the fluid flow, a pinch valve adapted to stop the flow of fluid, and a control unit adapted to operate the base unit so that (i) fluid is permitted to flow past the pinch valve when no gas bubble is detected; and (ii) fluid flow is arrested when a gas bubble is detected.

Owner:CLEARLINE MD LLC

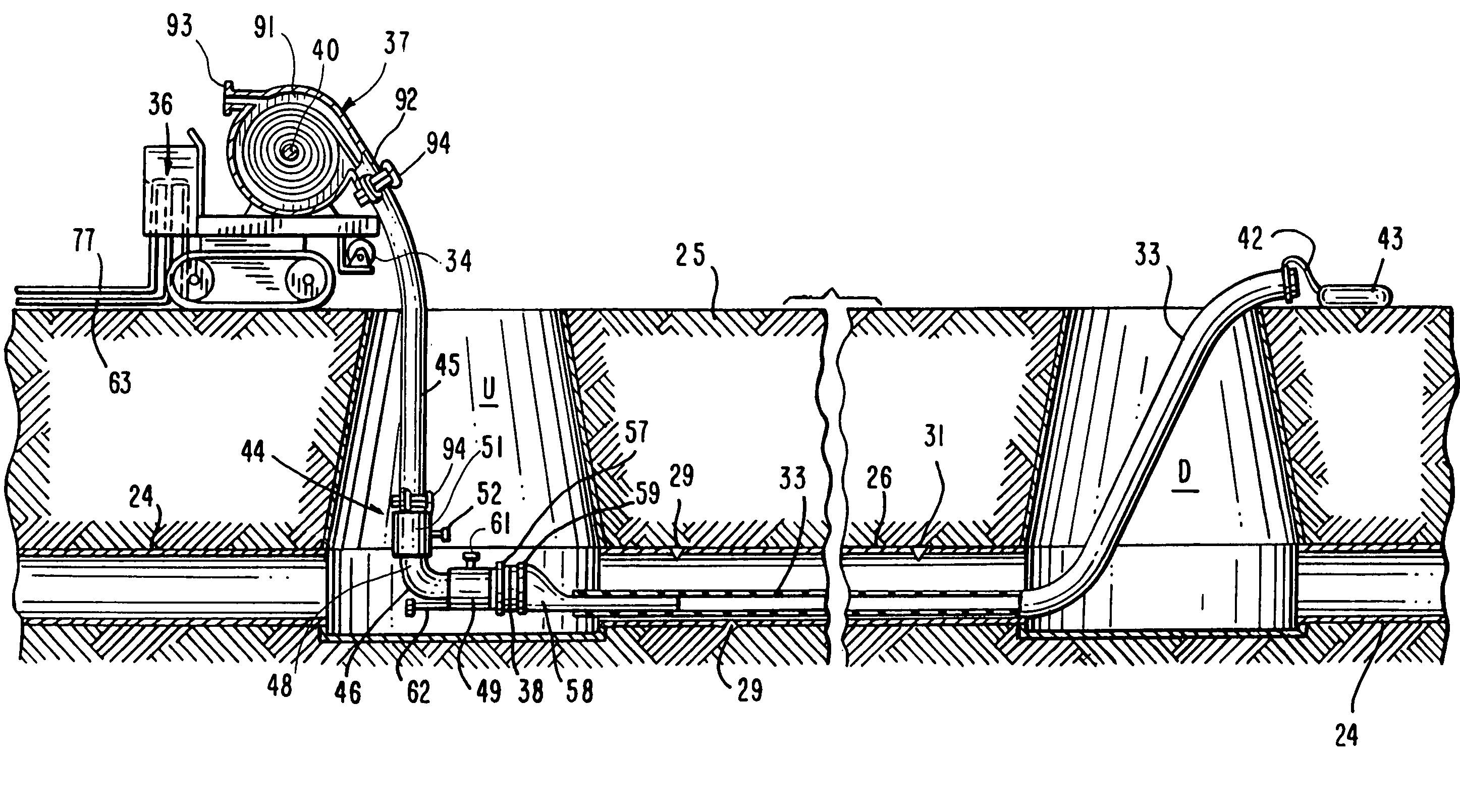

Pressurized bladder canister for installation of cured in place pipe

InactiveUS6969216B2Simple methodMaximize coolingUnderground chambersLaminationPinch valveEngineering

A process for lining an existing pipeline or conduit with a flexible resin impregnated cured in place liner by pulling in the liner and inflating an eversion bladder with air and curing the liner with flow-through steam without loss of pressure is provided. The bladder is stored in a pressure bladder canister coupled to a pressurized downtube and eversion elbow. The bladder is everted by introducing pressurized air into the canister As the bladder reaches the distal manhole, it enters a receiving canister where it is punctured while maintaining air pressure within the bladder a pinch valve between the downtube and elbow isolates the inverted bladder so that steam can be introduced into the bladder to cure the resin and exhaust through the receiving canister. The bladder is then removed and lateral service reinstated.

Owner:INA ACQUISITION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com