Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

113 results about "Cycle rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cycle rate is the selected number of system cycles per hour at 50% load. If the cycle rate were set to 3, each ON/OFF cycle would be 20 minutes long when operating at 50% load. The total ON and/or OFF times depends on the actual indoor space load.

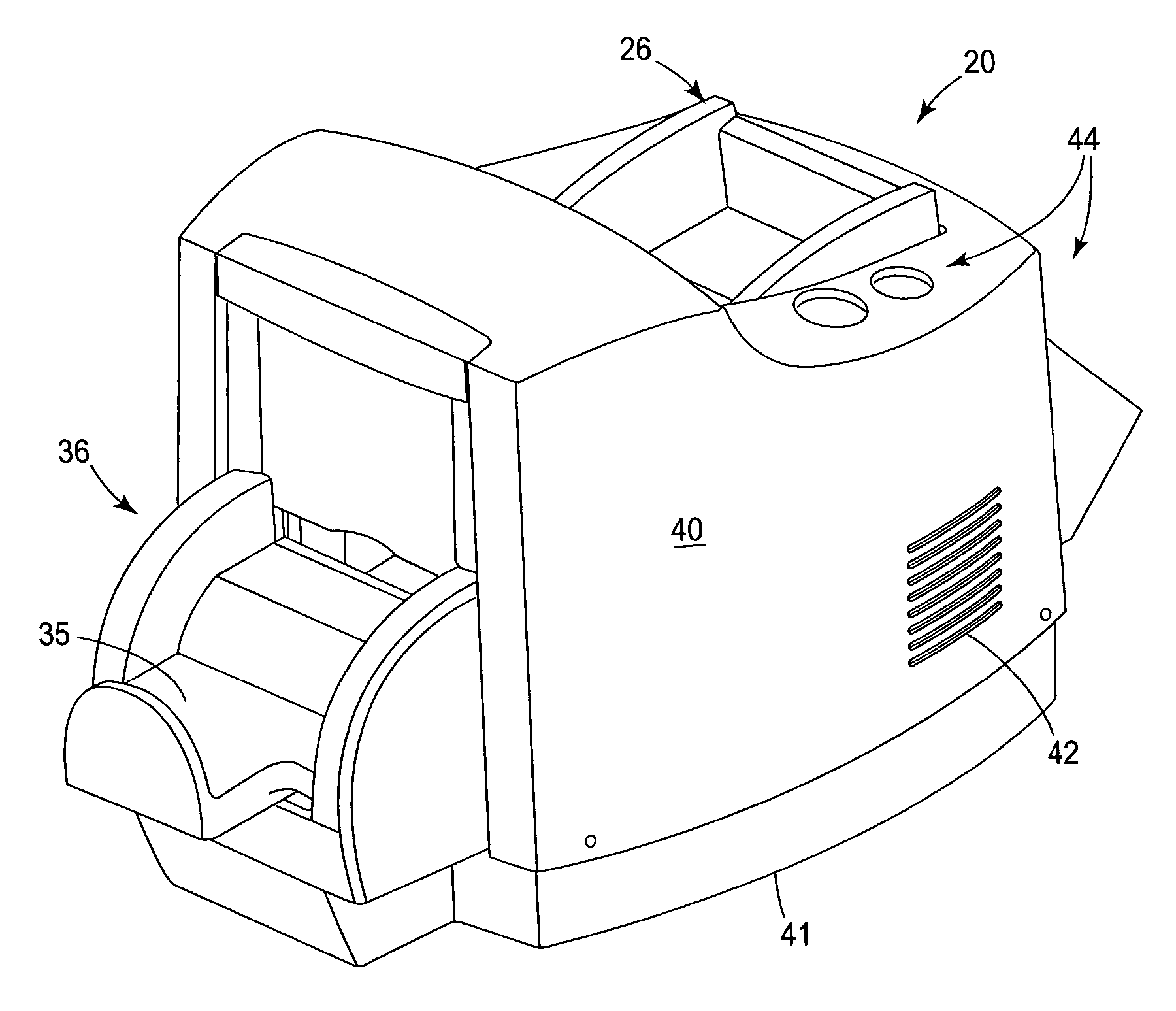

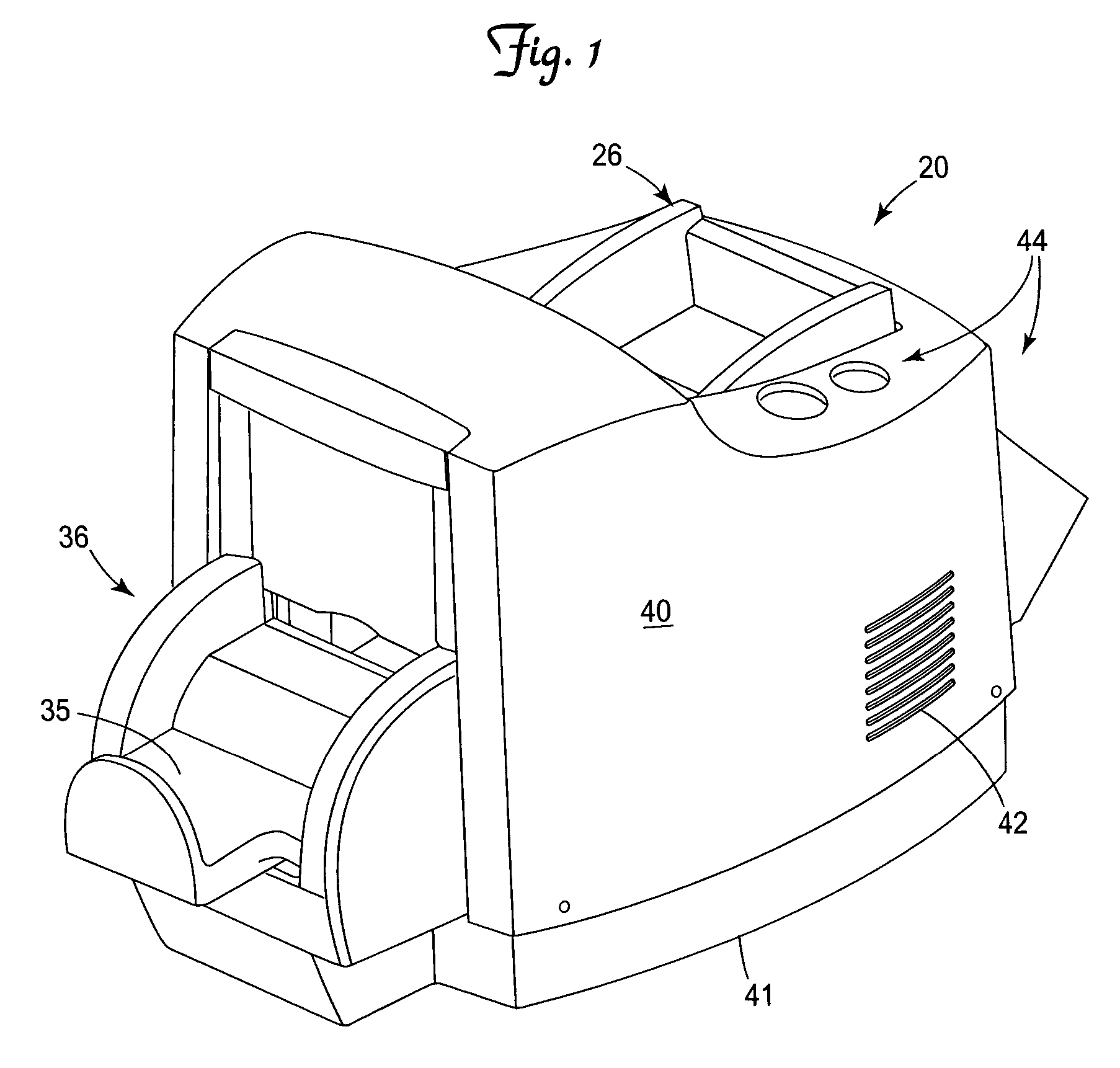

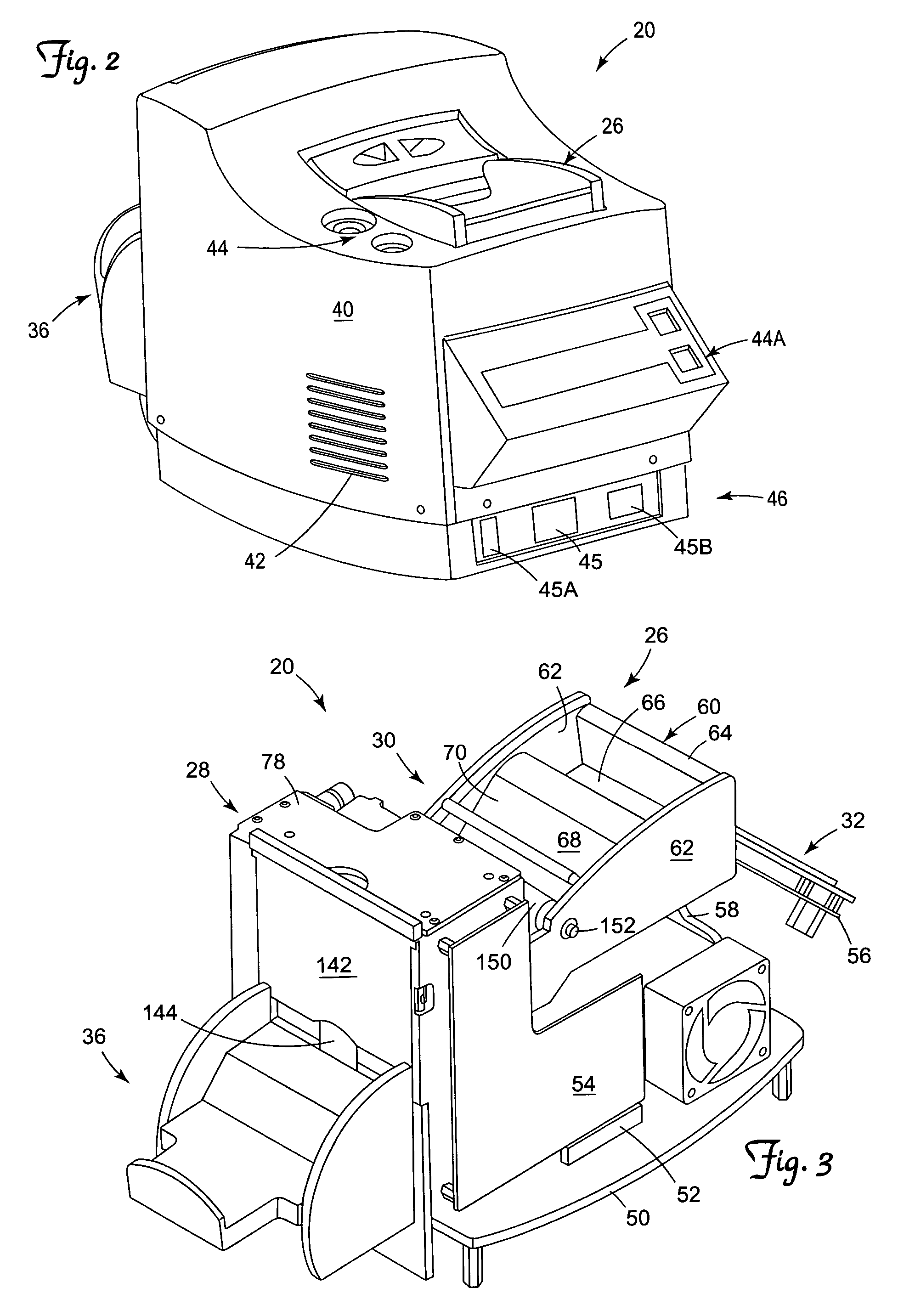

Playing card shuffler with differential hand count capability

A programmable card handling machine with a display and appropriate inputs for adjusting the machine to any of a number of games comprises inputs including a number of cards per hand selector, a card game selector, a number of hands delivered selector and a trouble-shooting input. These features also provide for interchangeability of the apparatus for many different games, for many types of cards or decks and in different locations thereby reducing the number of back-up machines or units required at a casino. The display may include a game mode or game selected display, and use a cycle rate and / or hand count monitor and display for determining or monitoring the usage of the machine. The card-handling machine is capable of randomly selecting numbers of cards to be delivered in a hand of cards to players and the dealer during a round of a casino table card game.

Owner:LNW GAMING INC

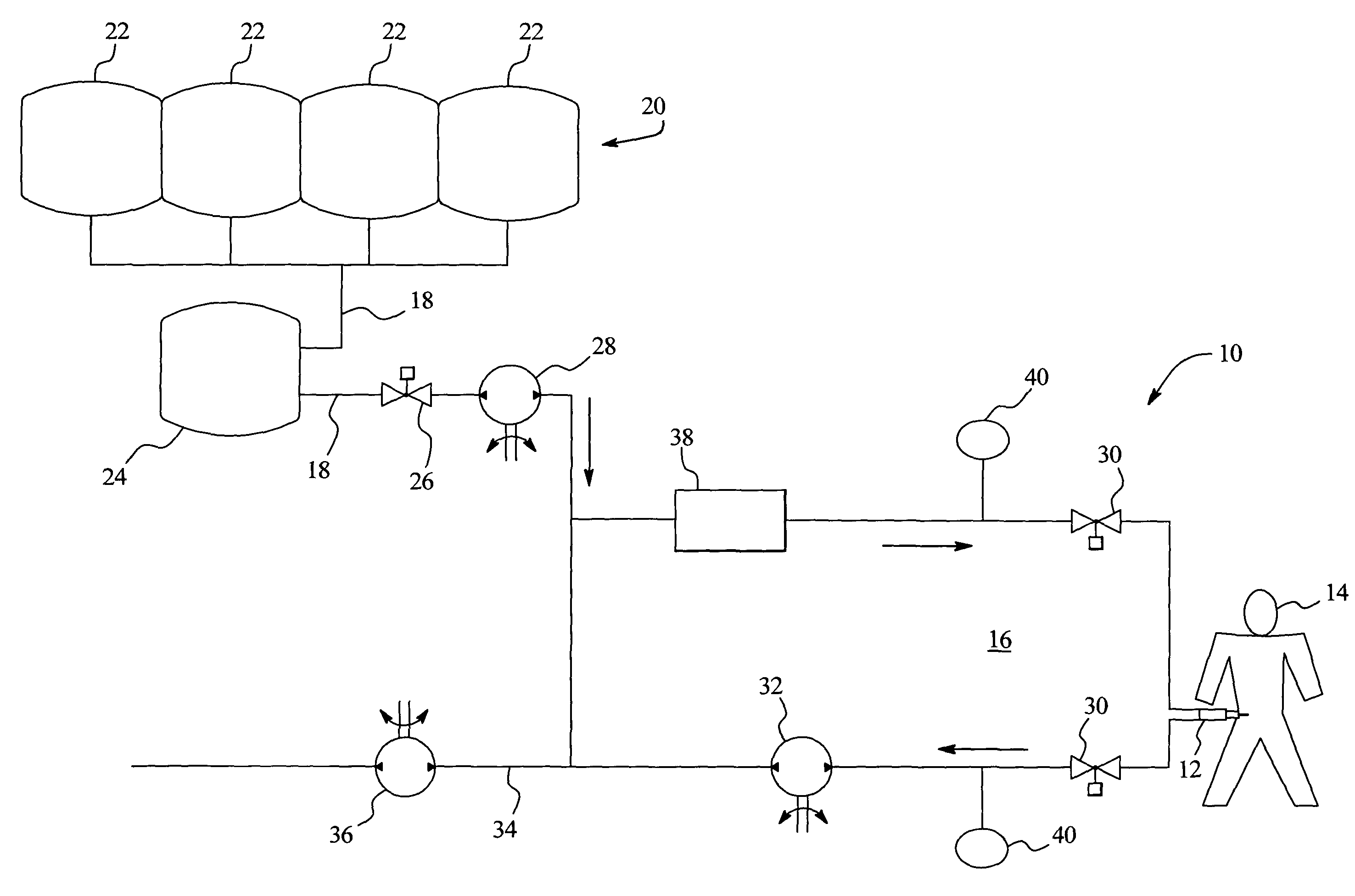

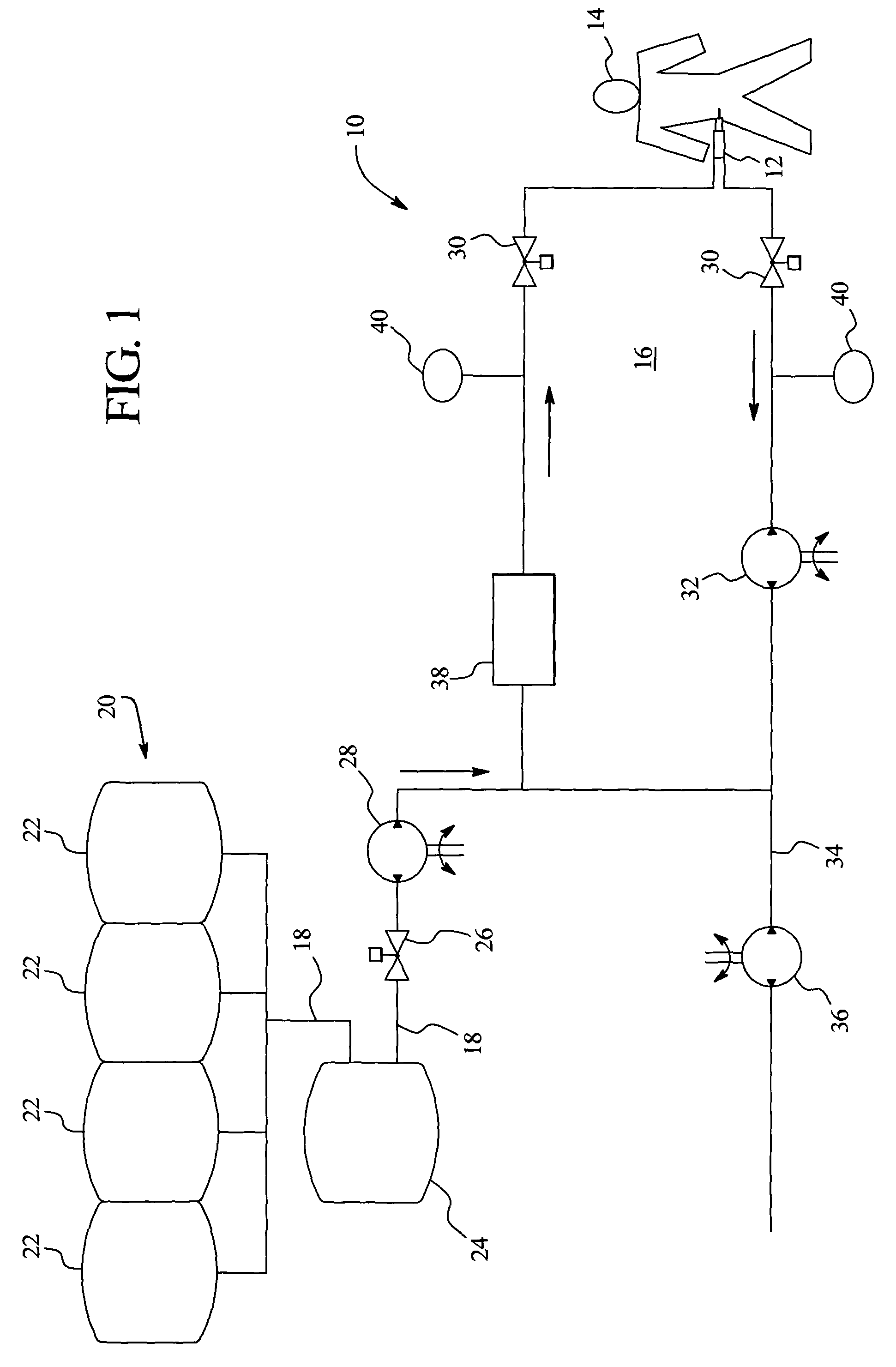

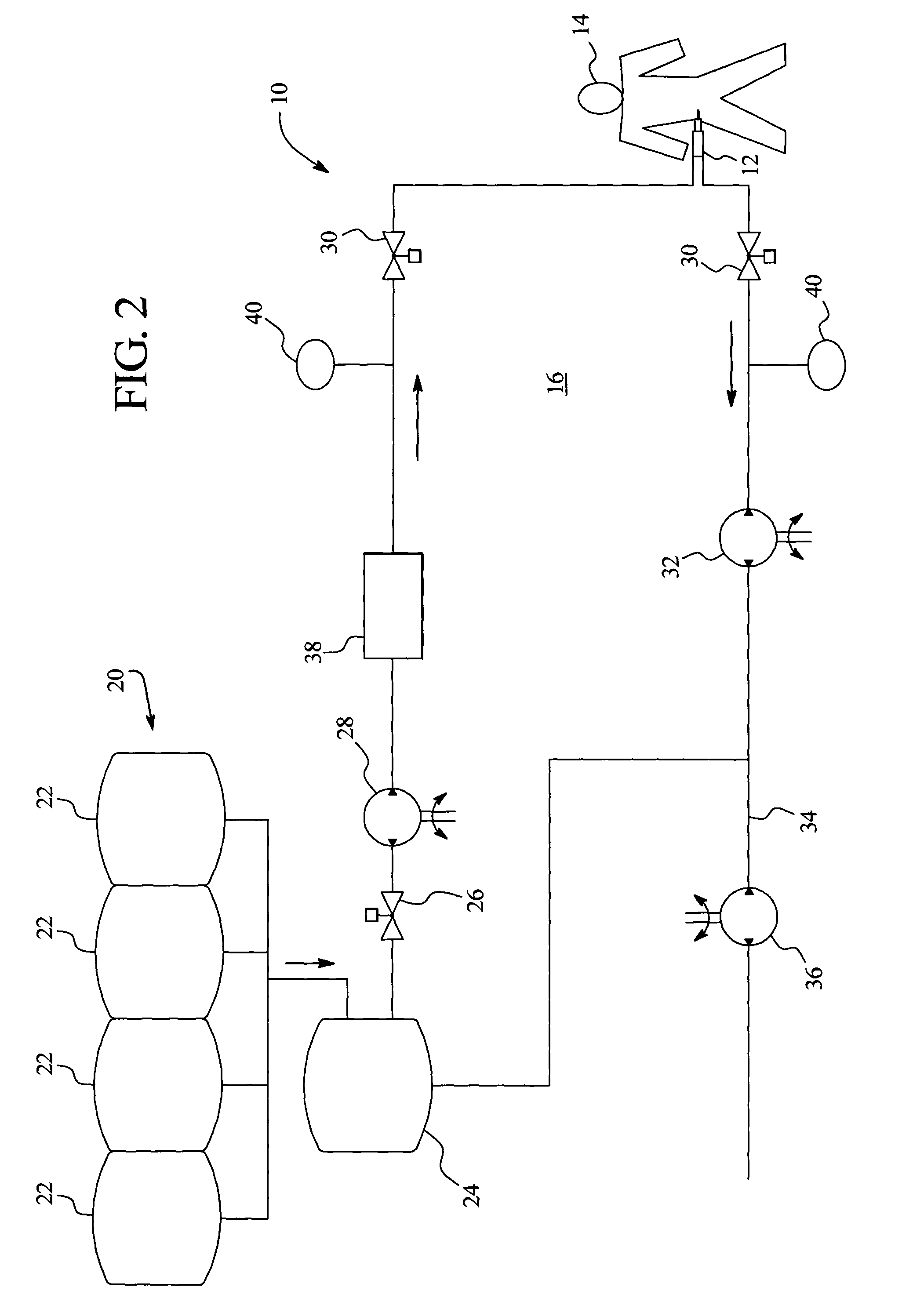

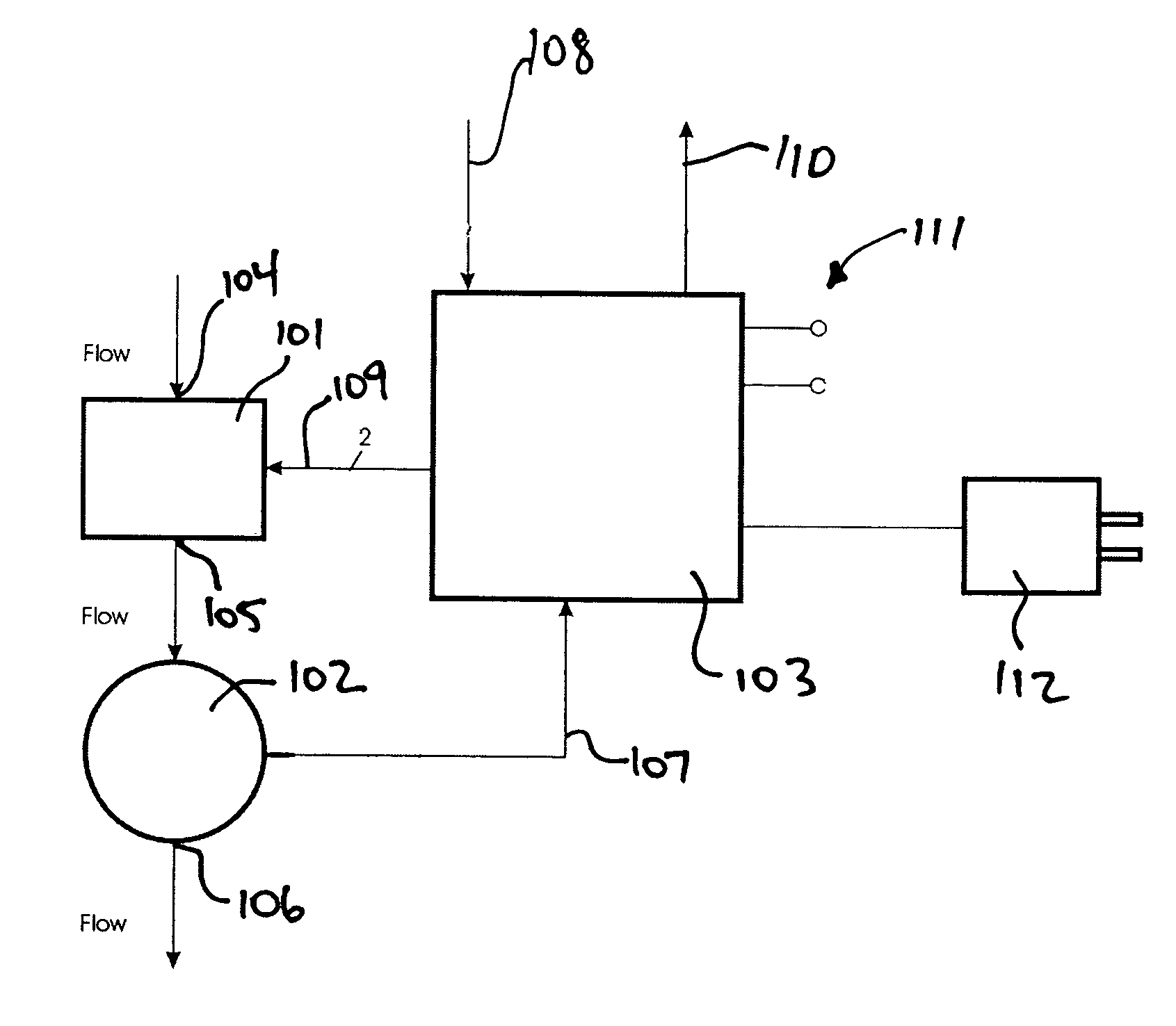

Systems and methods for performing peritoneal dialysis

ActiveUS7922686B2Strengthen the systemImprove methodPeritoneal dialysisProsthesisCycle rateContinuous flow

Systems and methods for providing multiple pass continuous flow dialysis therapy are provided. The present invention includes a fluid circuit connected to a patient via a catheter thereby defining a fluid loop along which a therapy fluid including a dialysate can be continuously circulated into, through and out of a peritoneal cavity of a patient to remove a therapeutically effective amount of excess water and solutes including uremic toxins. The feed rate and discharge rate of therapy fluid into the fluid loop can be controllably regulated in proportion to the circulation rate of fluid in the fluid loop such that the therapy fluid can pass a multiple number of times along the fluid loop prior to discharge.

Owner:BAXTER INT INC +1

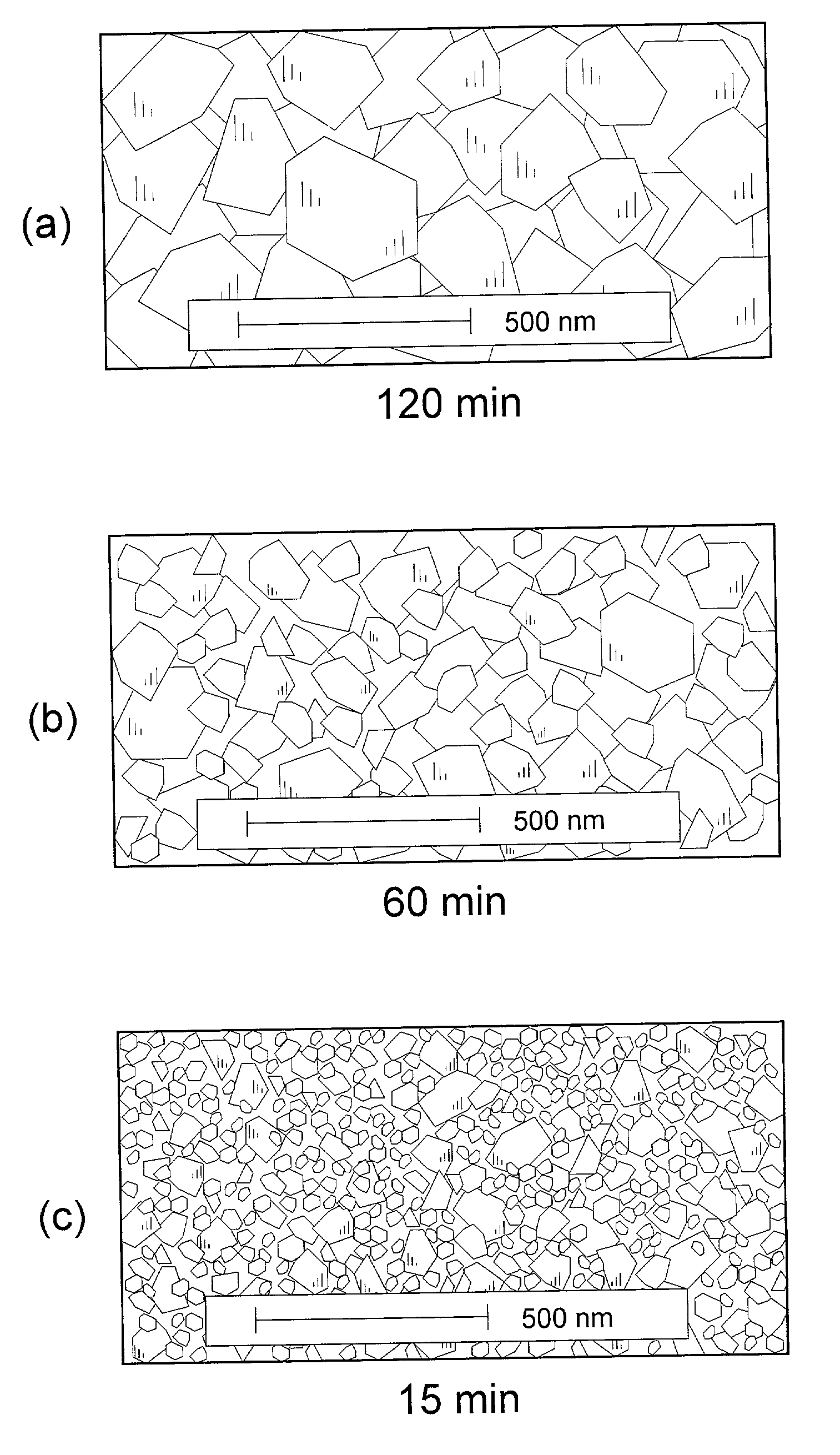

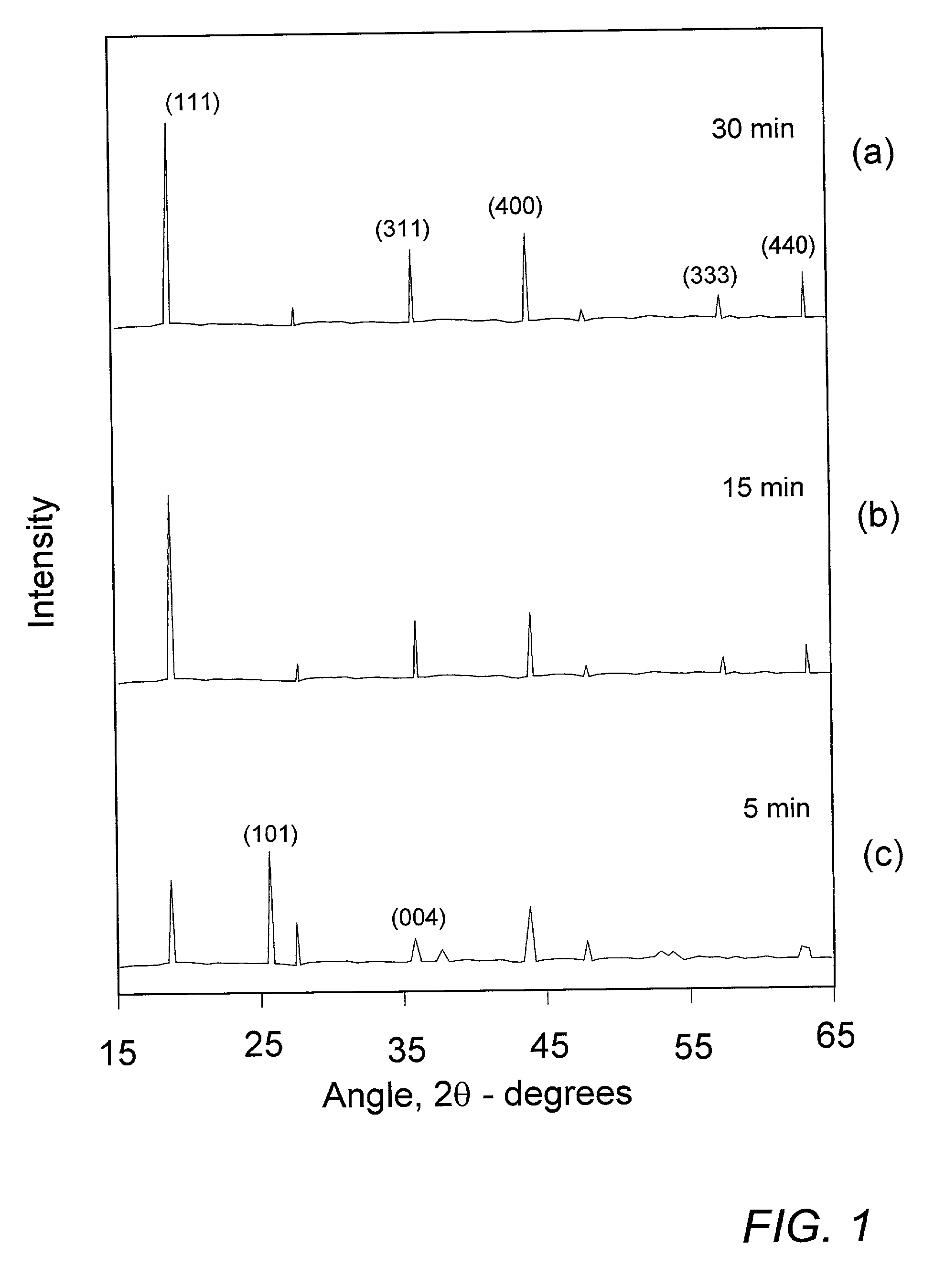

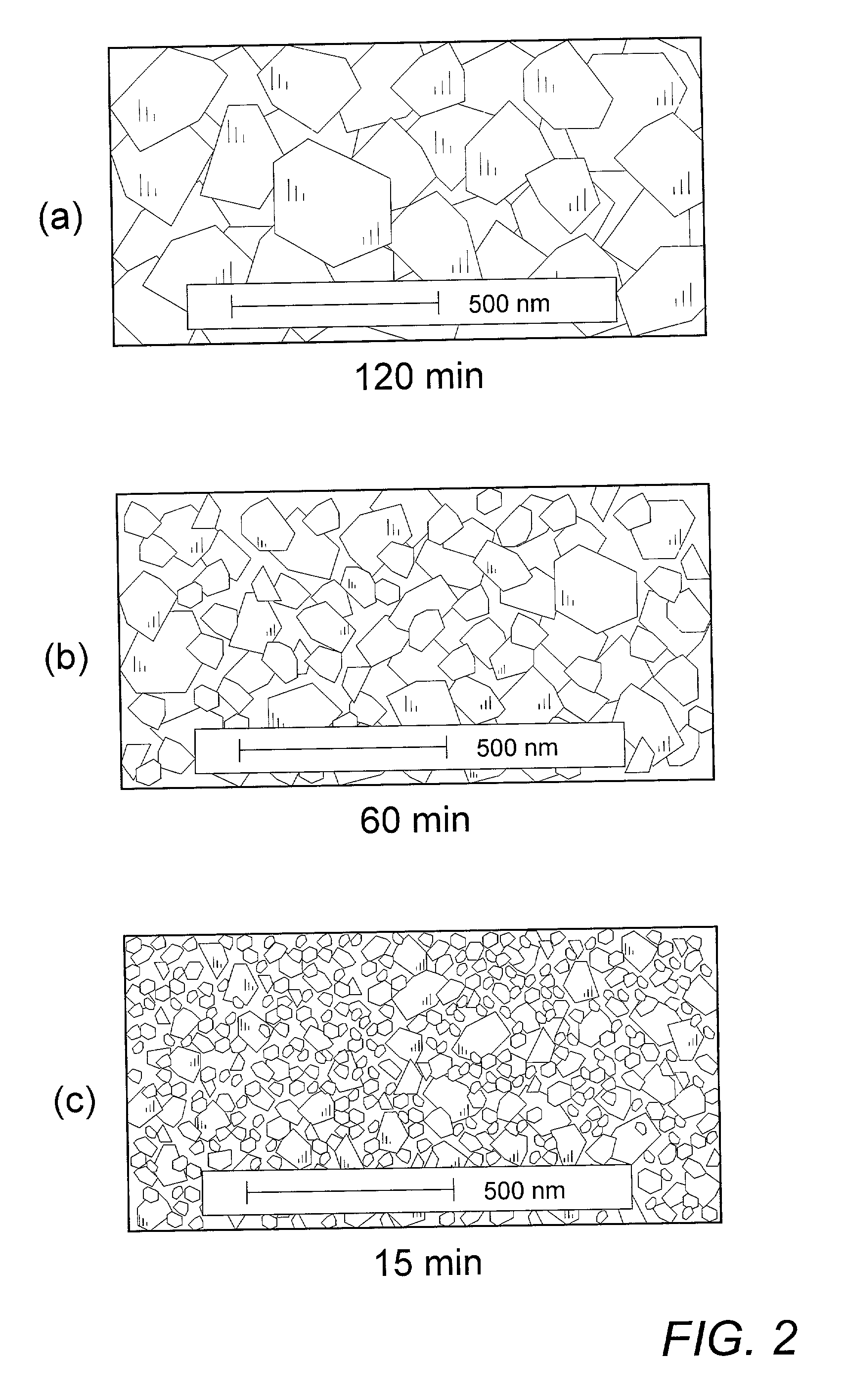

Nanostructure lithium titanate electrode for high cycle rate rechargeable electrochemical cell

Rechargeable electrochemical cells, such as lithium batteries and asymmetric hybrid battery / supercapacitor systems, exhibiting exceptional specific capacity levels and stability over extended high-rate recharge cycling comprise nanostructure zero strain Li4Ti5O12 intercalation electrode material synthesized in a short duration process of annealing mixed TiO2 and Li-source precursor compounds at about 800° C. for a time of about 15–30 min which is not substantially longer than that required to effect maximum available reaction between the precursors, thereby substantially eliminating the growth of synthesized Li4Ti5O12 particles beyond nanostructure size. The process reduces by order of magnitude the time and energy required for synthesis of the active electrode material and fabrication of utilizing cell devices, and provides such nanostructure material which enables repeated, high-rate recharge cycling without loss of cell capacity or efficiency.

Owner:RUTGERS THE STATE UNIV

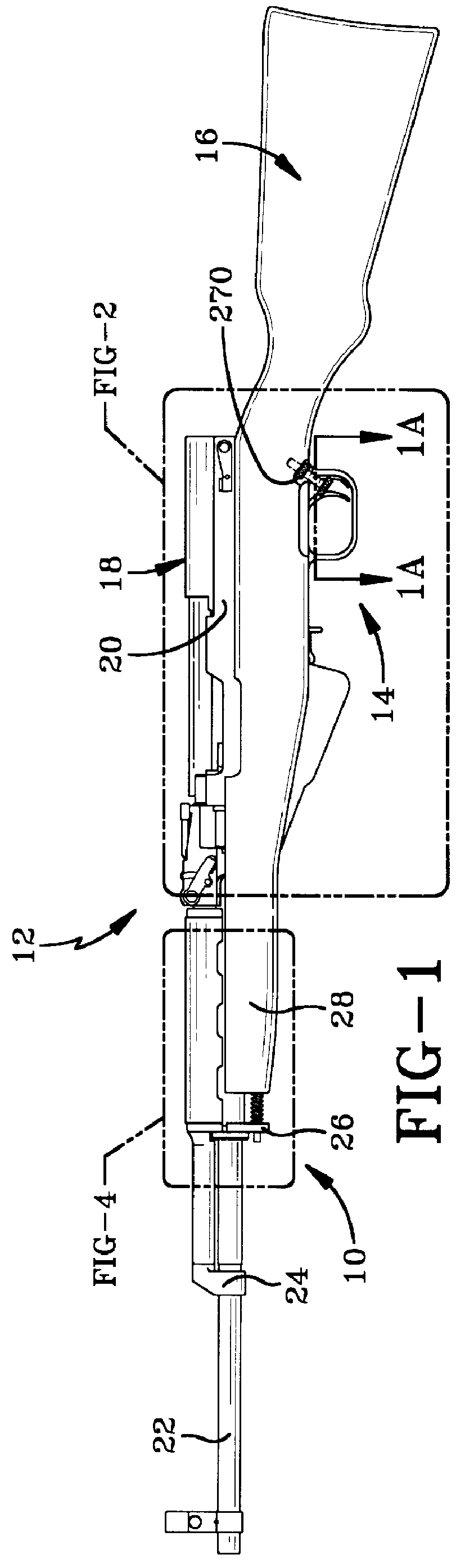

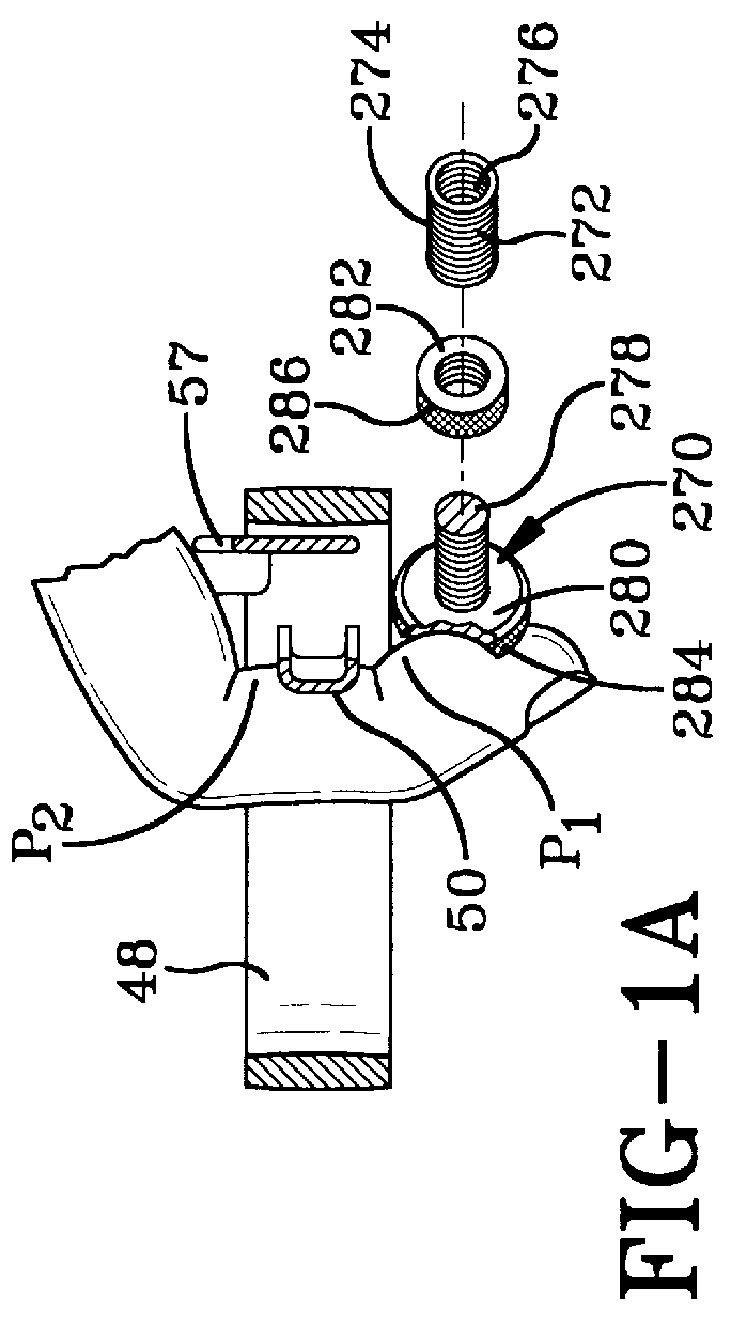

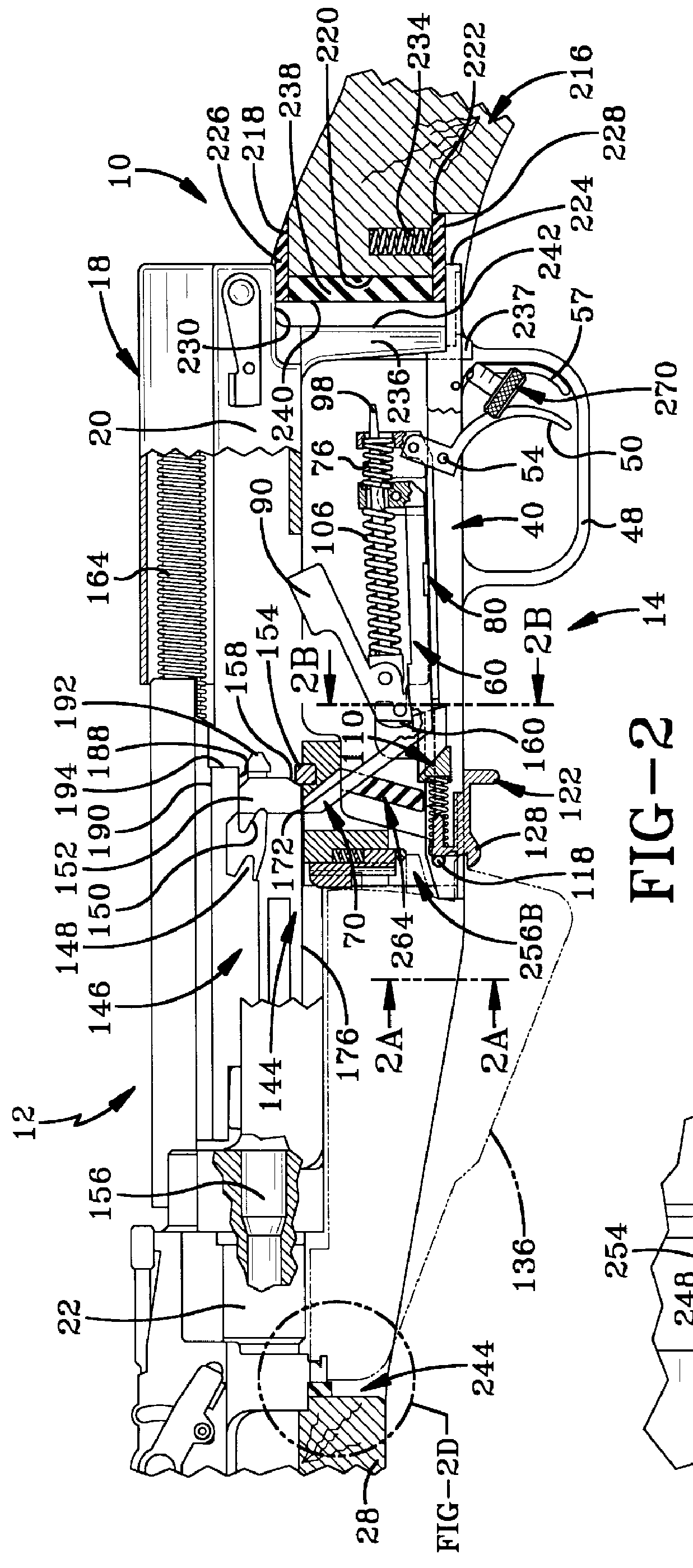

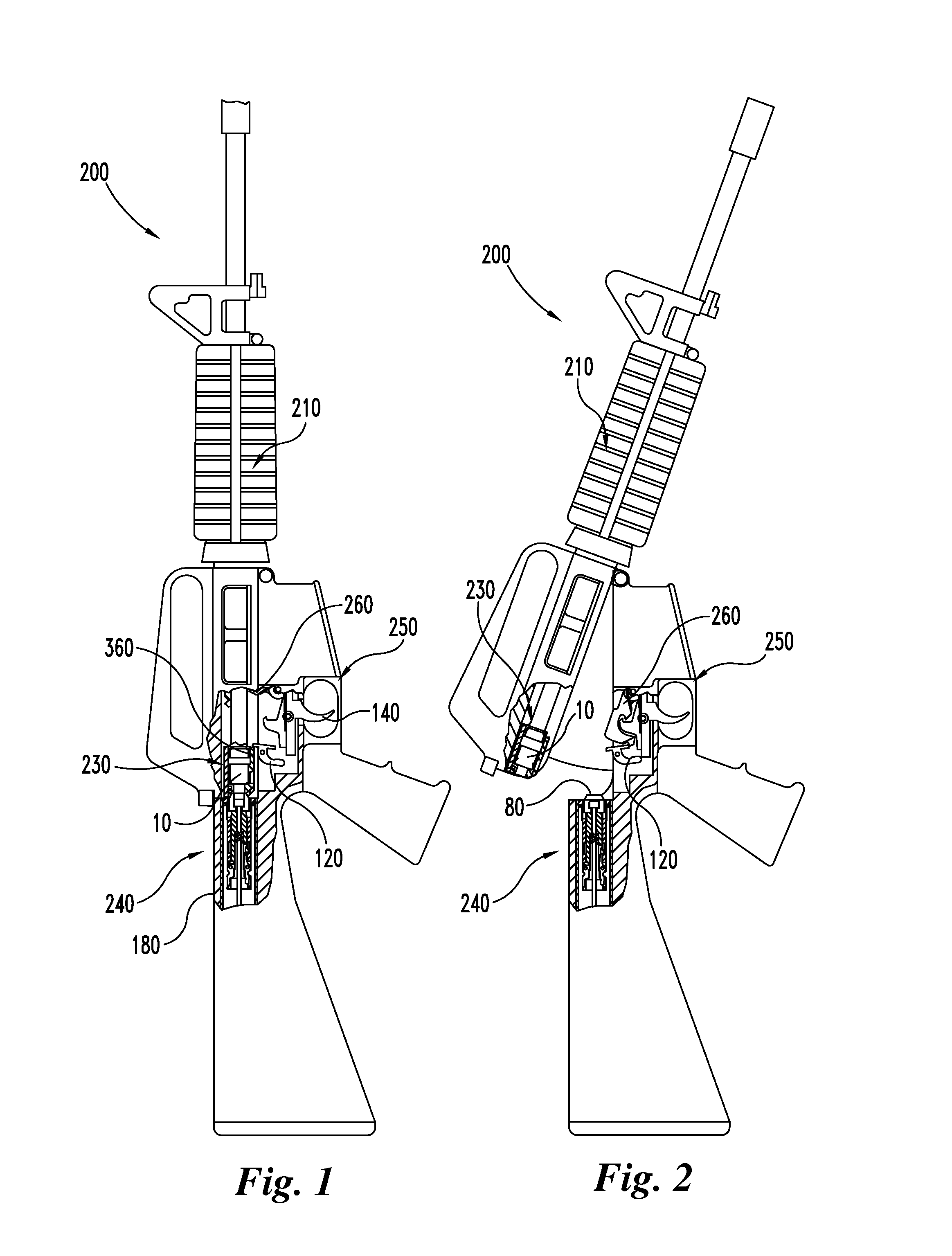

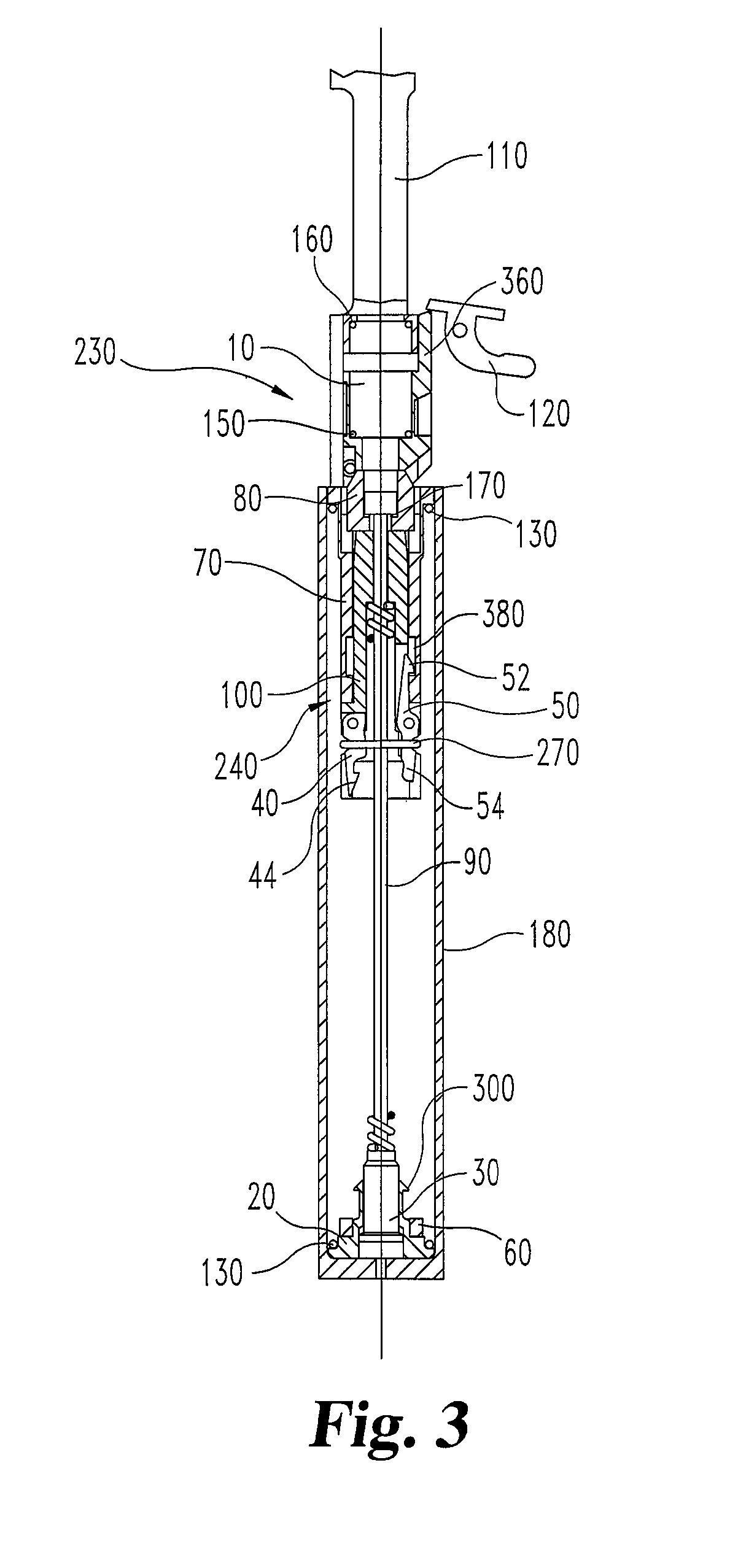

Method and apparatus for accelerating the cyclic firing rate of a semi-automatic firearm

An accelerating assembly effectively to increase the cyclic rate at which the trigger of a semi-automatic firearm can be actuated to discharge the weapon. The firearm has a supporting device, a receiver housing supported from the supporting device, a trigger and trigger mechanism secured to the receiver housing. The accelerating mechanism incorporates structure that permits the receiver and the trigger to translate rearwardly a predetermined distance with respect to the supporting device in response to the recoil imparted by the discharge of the semi-automatic firearm. A biasing arrangement continuously urges the receiver, and trigger, to translate forwardly with respect to the supporting device substantially that same predetermined distance. A locating stop is mounted on the supporting device. The locating stop is disposed to be engaged by the shooter's finger after the trigger has been actuated to fire the semi-automatic weapon. That engagement of the shooter's trigger finger with the locating stop effectively immobilizing the shooter's trigger finger with respect to the supporting device until the shooter releases the trigger. The method of the present invention operates by depressing the trigger with a shooter's trigger finger in order to discharge the firearm. The shooter's finger is then immobilized in the position it has assumed to discharge the firearm. The trigger is translated away from the immobilized trigger finger to effect a total disengagement therebetween. Sequentially thereafter the trigger is biased into engagement with the immobilized trigger finger to effect successive discharges of the firearm.

Owner:SLIDE FIRE SOLUTIONS

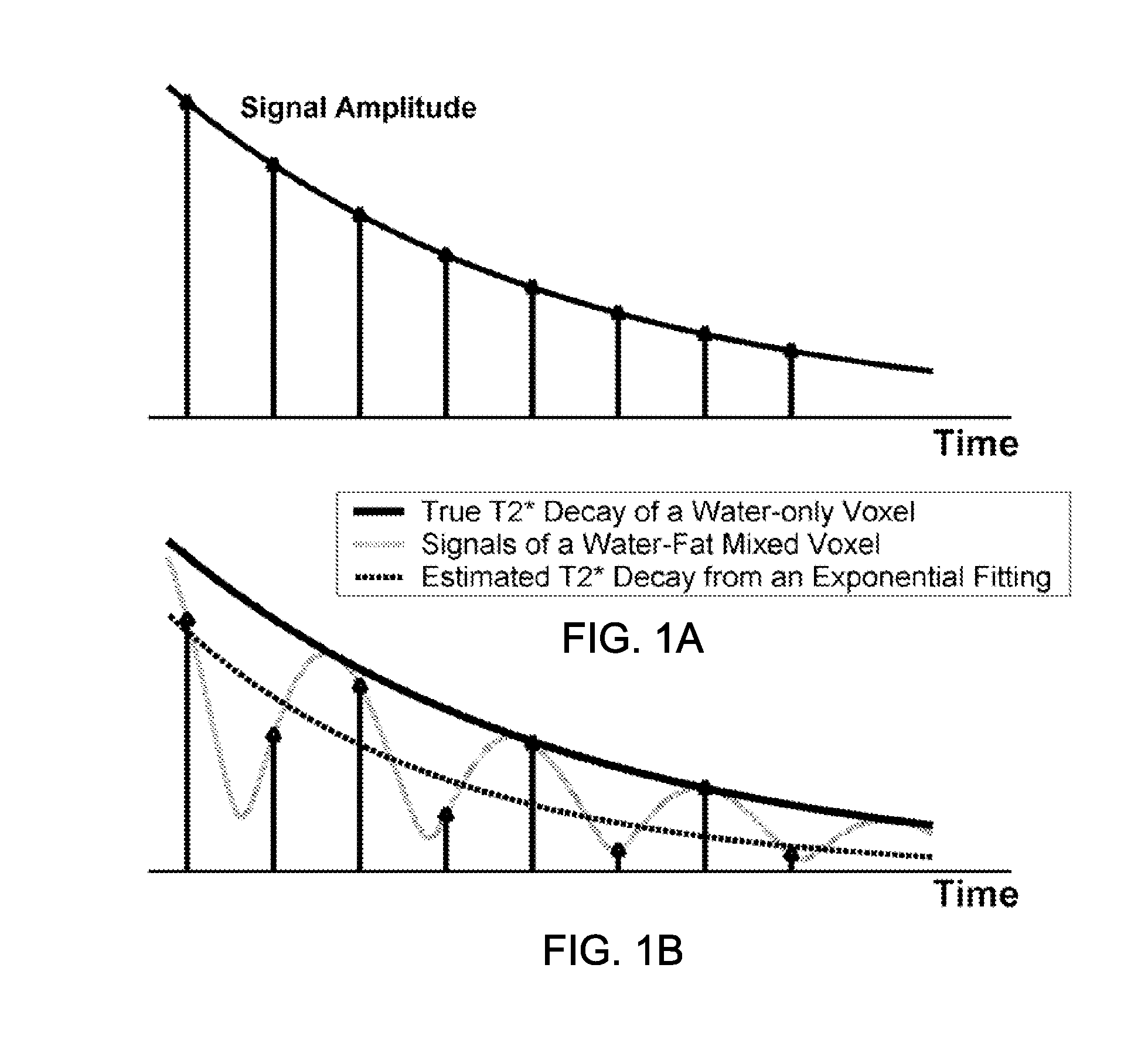

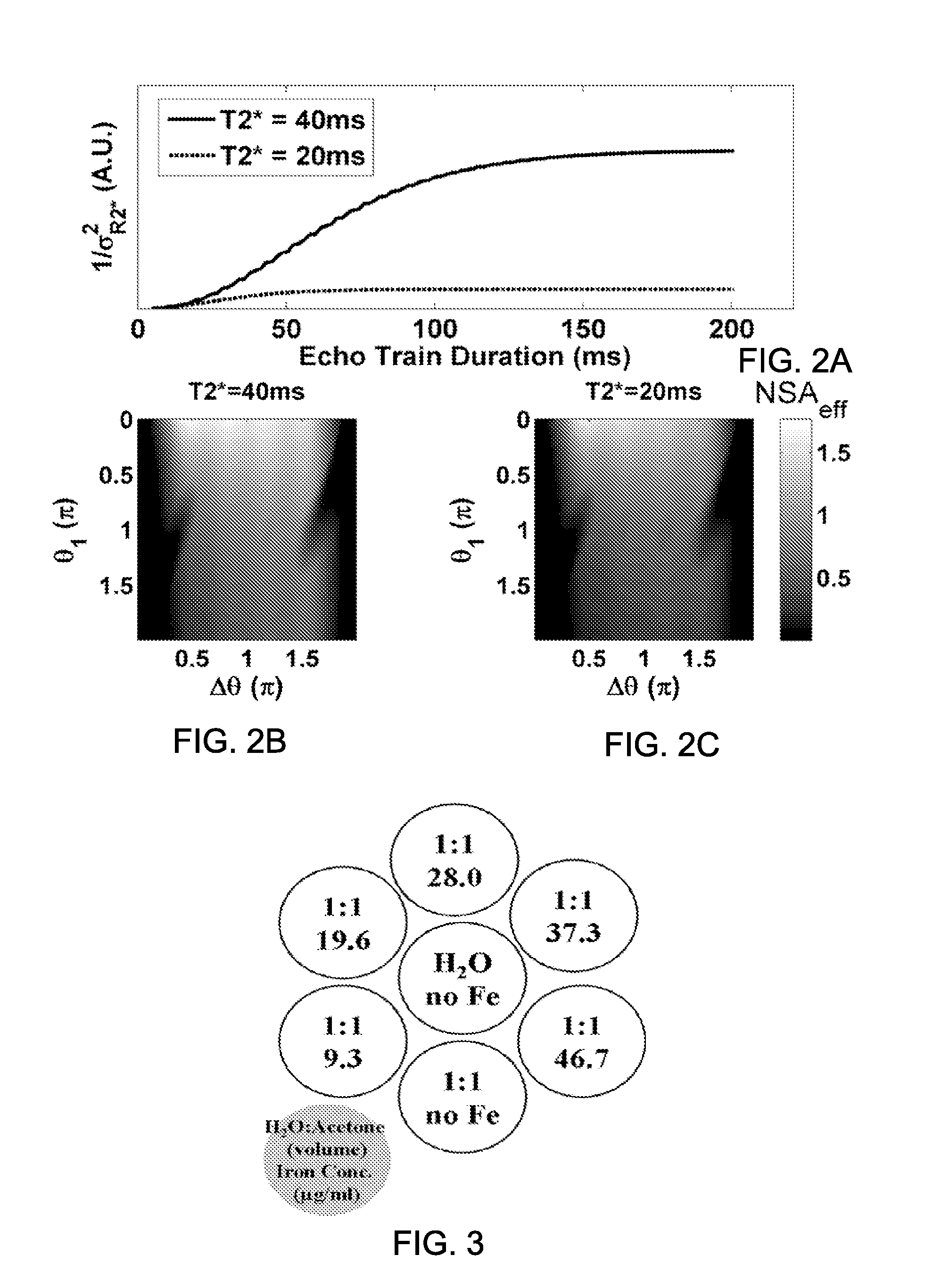

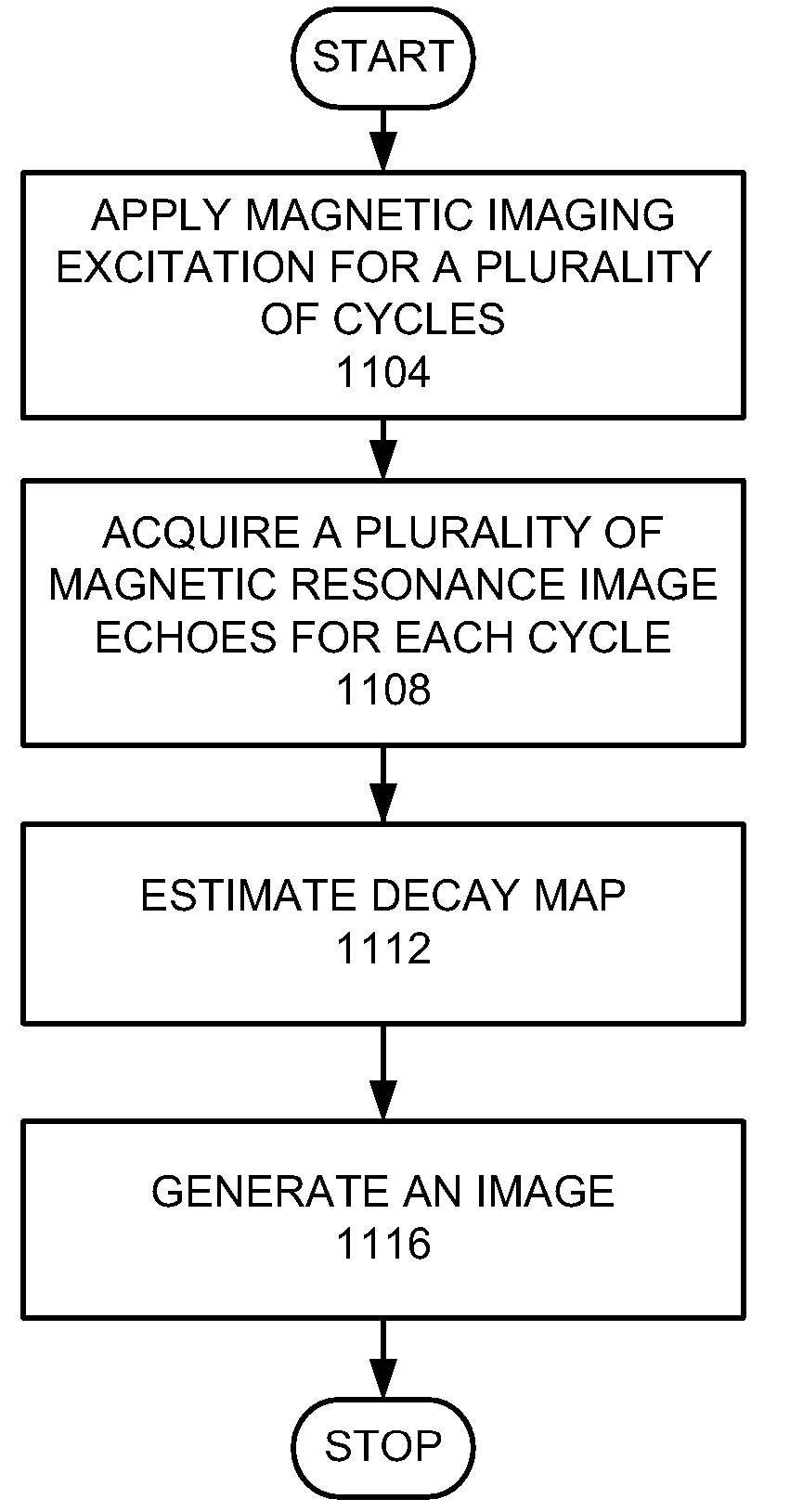

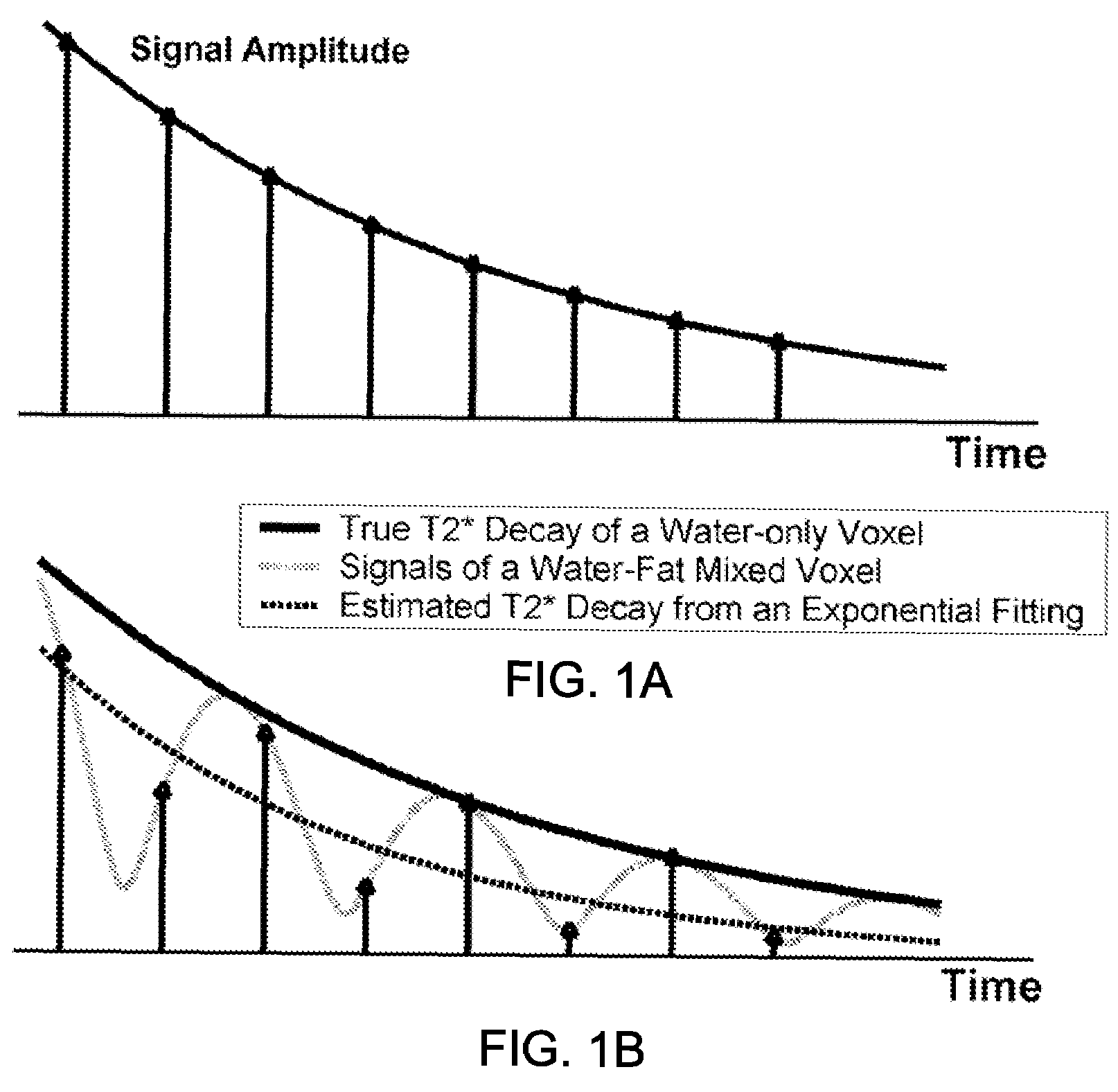

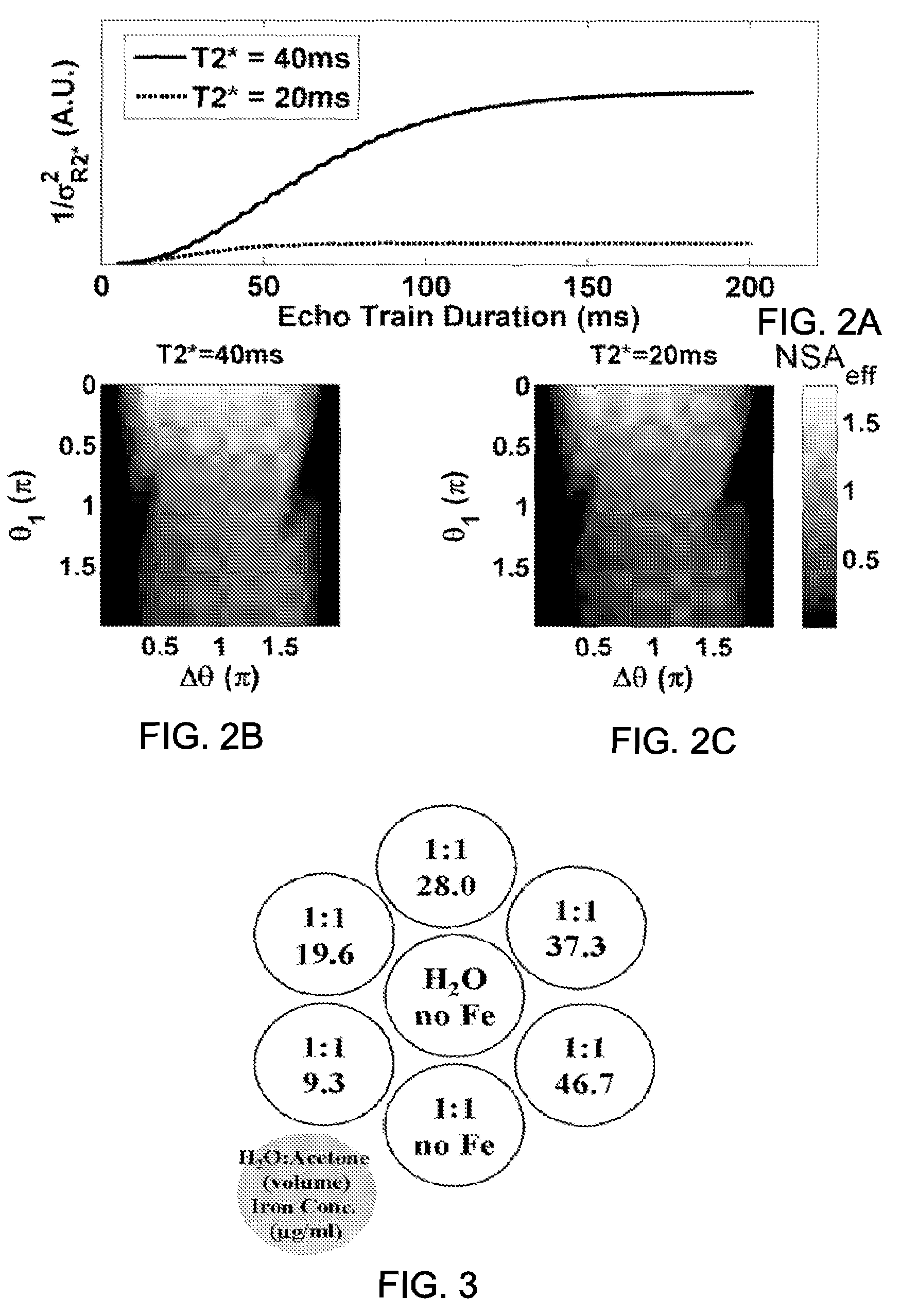

Simultaneous chemical species separation and t2* measurement using MRI

ActiveUS20070247153A1Measurements using NMR imaging systemsAnalysis using nuclear magnetic resonanceCycle rateChemical species

A method for generating a magnetic resonance image is provided. A magnetic resonance imaging excitation is applied for a plurality of cycles at a cycle rate. A plurality of magnetic resonance image echoes is acquired for each cycle. A decay map is estimated from the plurality of magnetic resonance image echoes for each cycle. The estimated decay map is used to generate an image for at least two different species.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

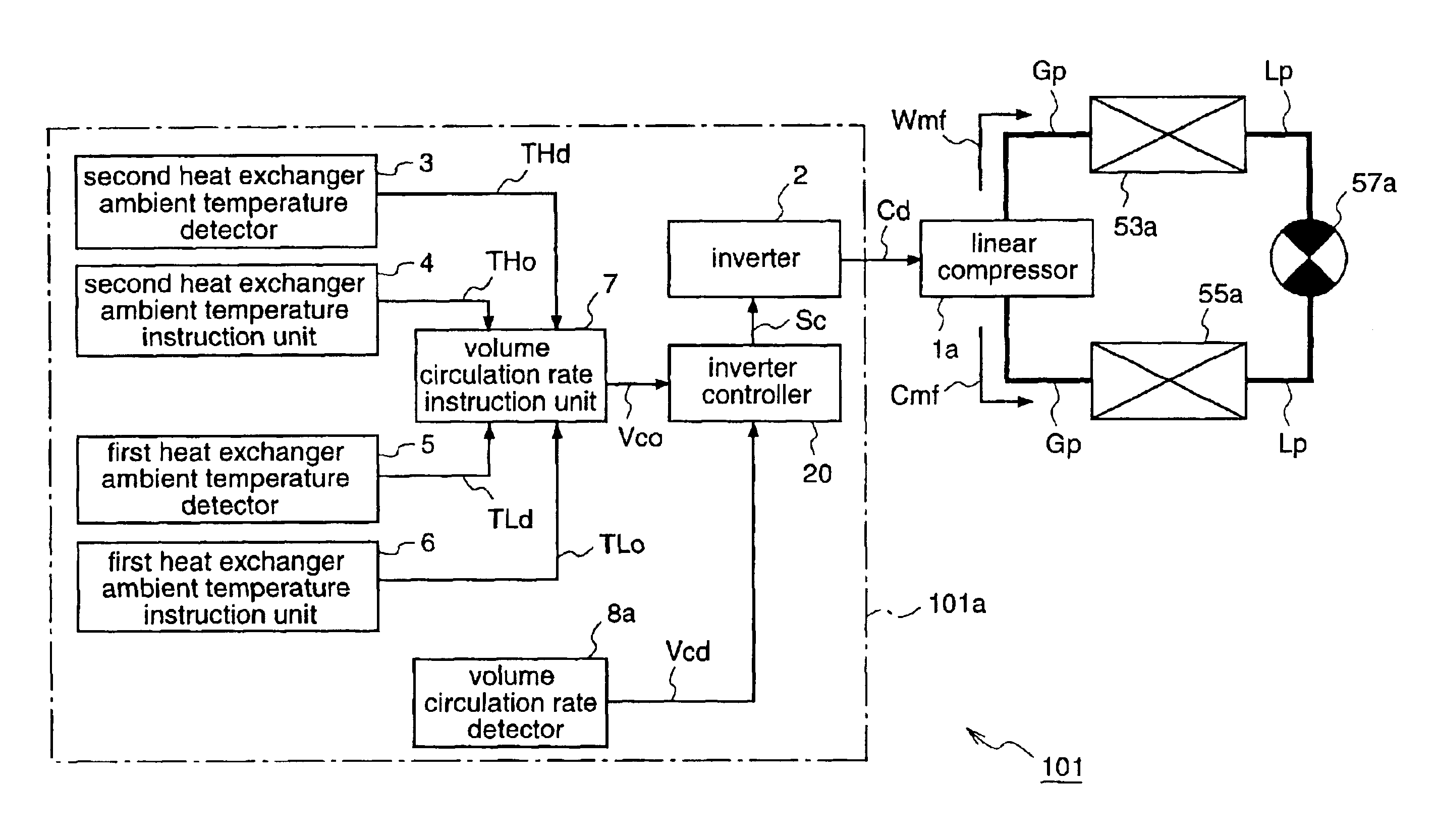

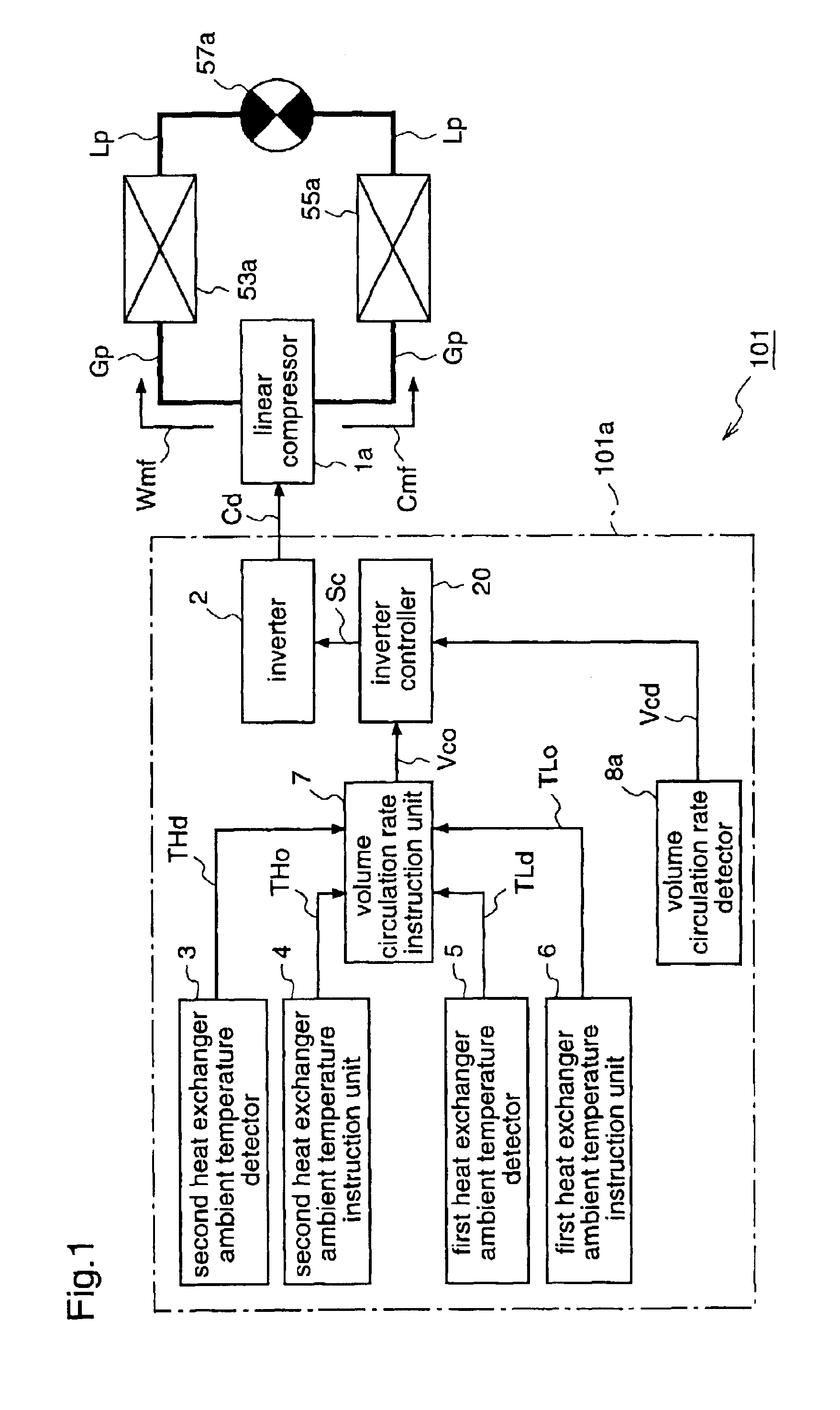

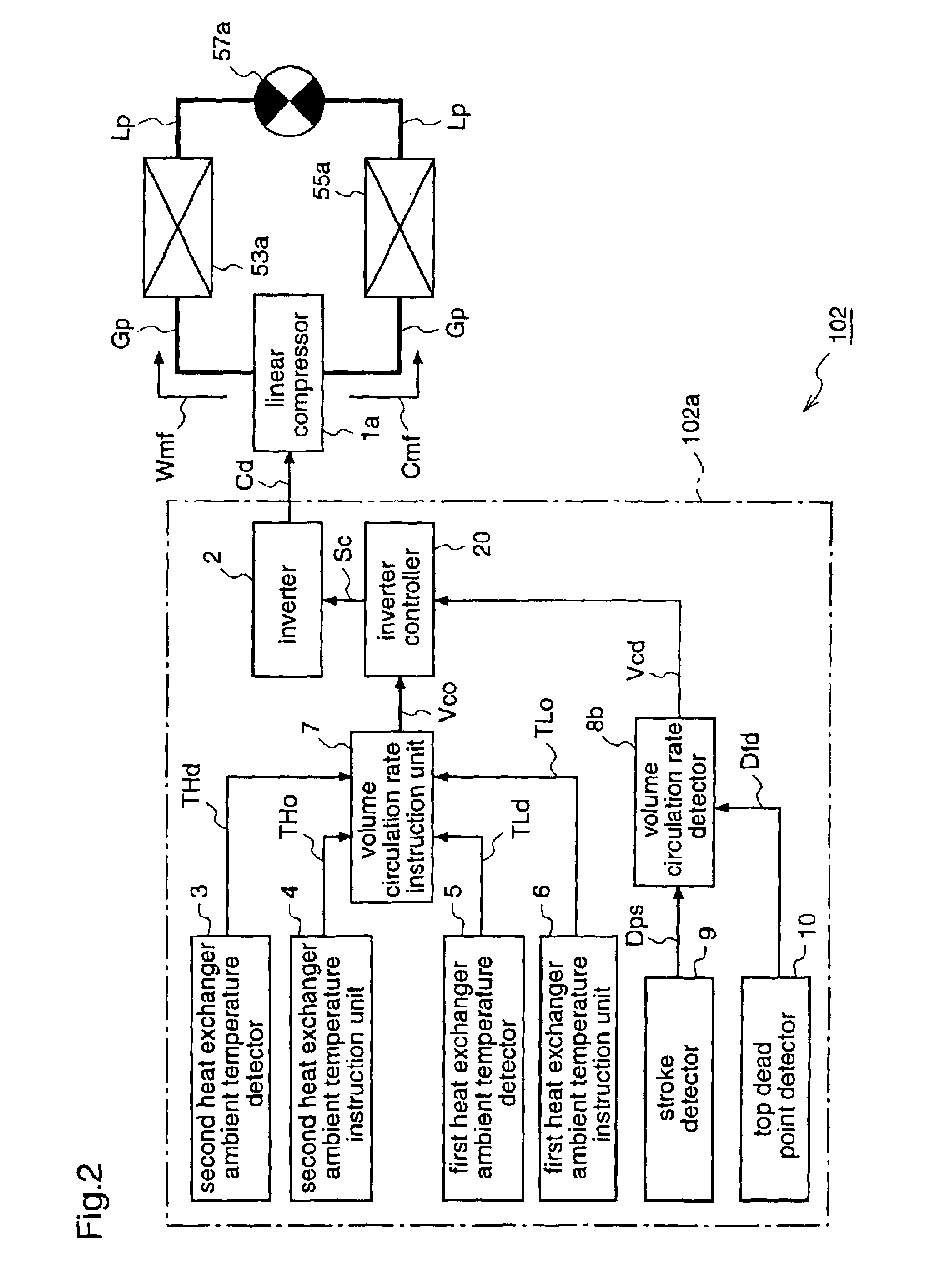

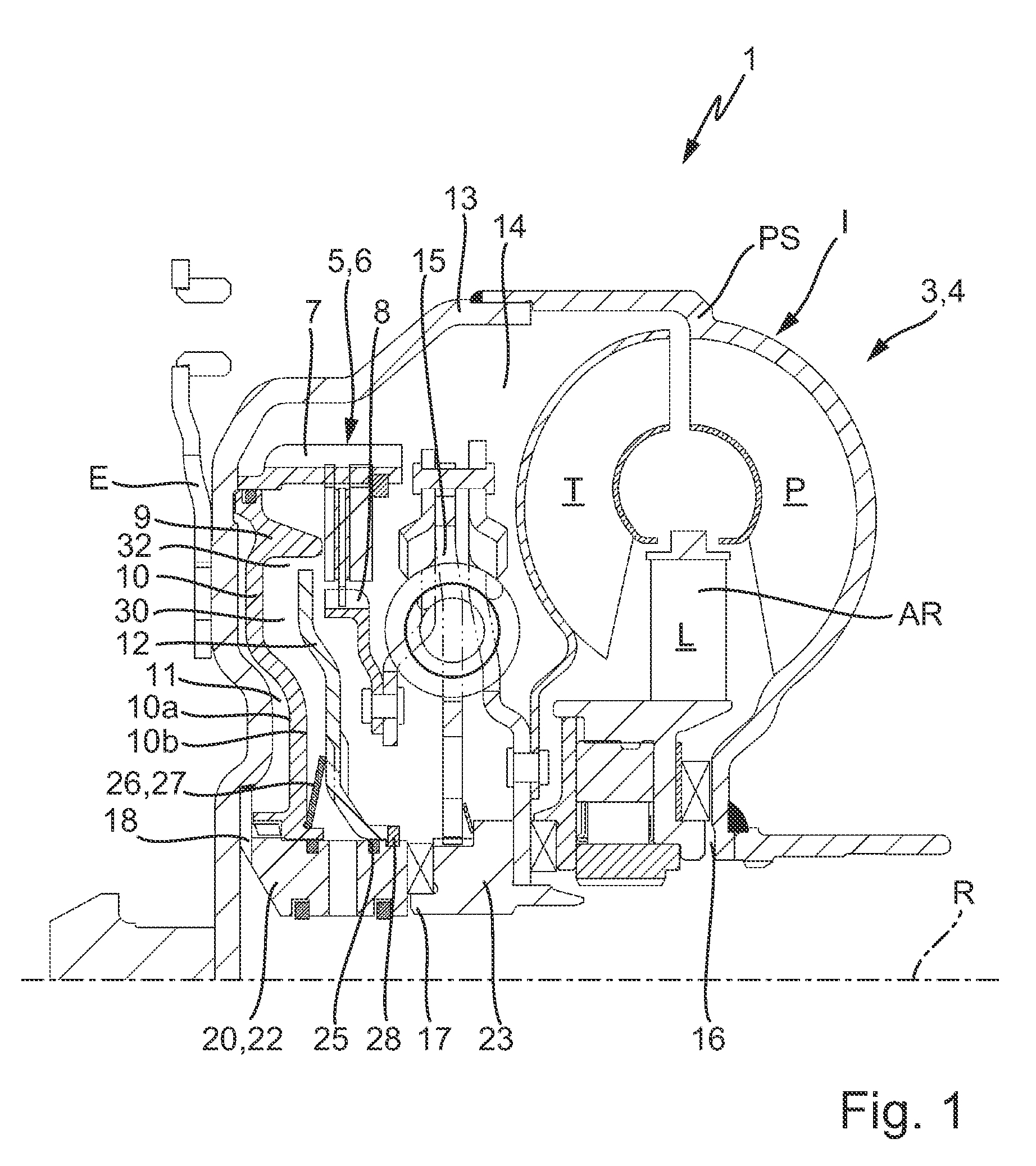

Refrigeration cycle apparatus

InactiveUS6868686B2Improve efficiencyShort timeHeat pumpsCompression machines with non-reversible cycleCycle rateInstruction unit

A refrigeration cycle apparatus having a linear compressor is provided with a volume circulation rate instruction unit for obtaining a volume circulation rate Vco of a refrigerant in accordance with refrigerating capacity required of the refrigeration cycle apparatus, on the basis of an ambient temperature of an indoor heat exchanger (evaporator), a target temperature set on the evaporator by the user, and an ambient temperature of an outdoor heat exchanger (condenser). A volume circulation rate detector is provided for detecting a volume circulation rate Vcd of the refrigerant that actually circulates in a refrigerant circulation path of the refrigeration cycle apparatus; and an inverter is provided for generating an AC current for driving the linear compressor. The inverter is controlled so as to decrease a difference between the volume circulation rate Vco and the volume circulation rate Vcd.

Owner:PANASONIC CORP

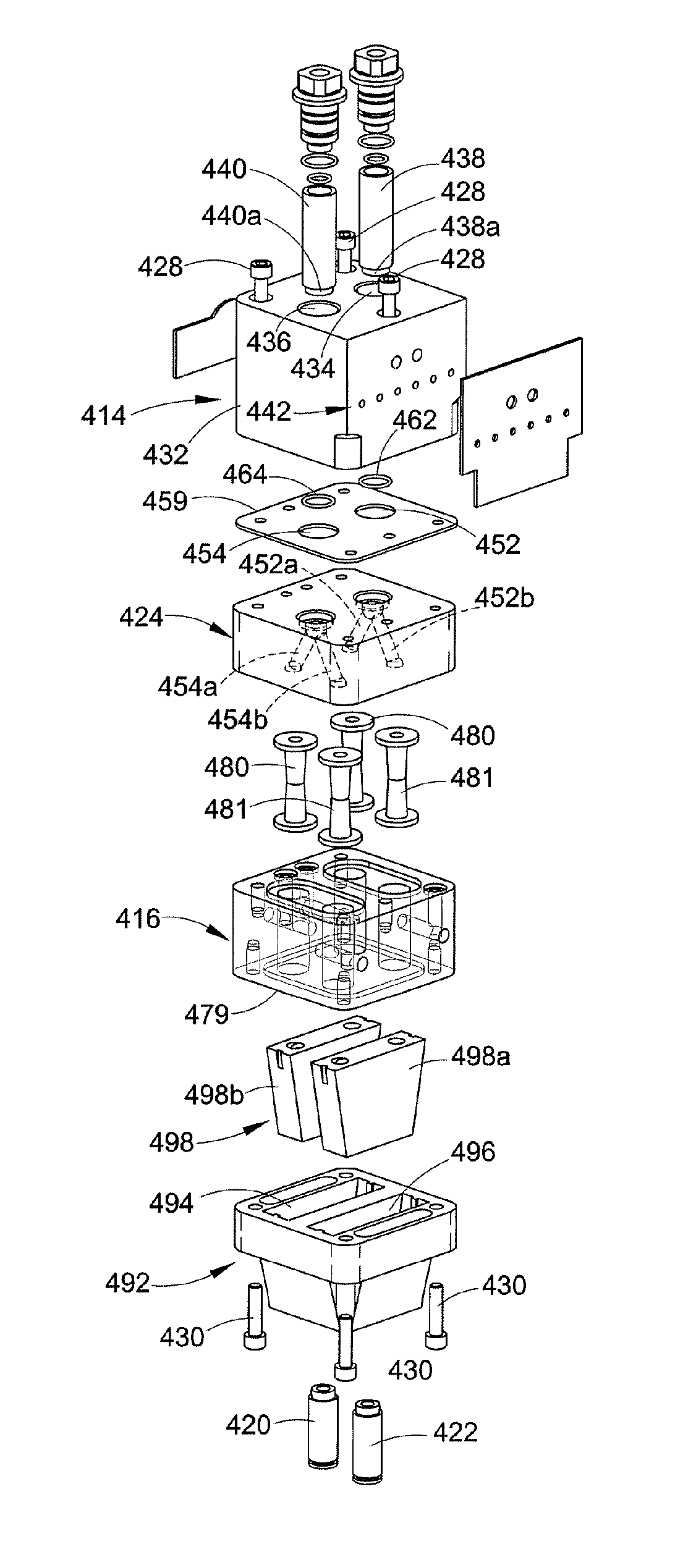

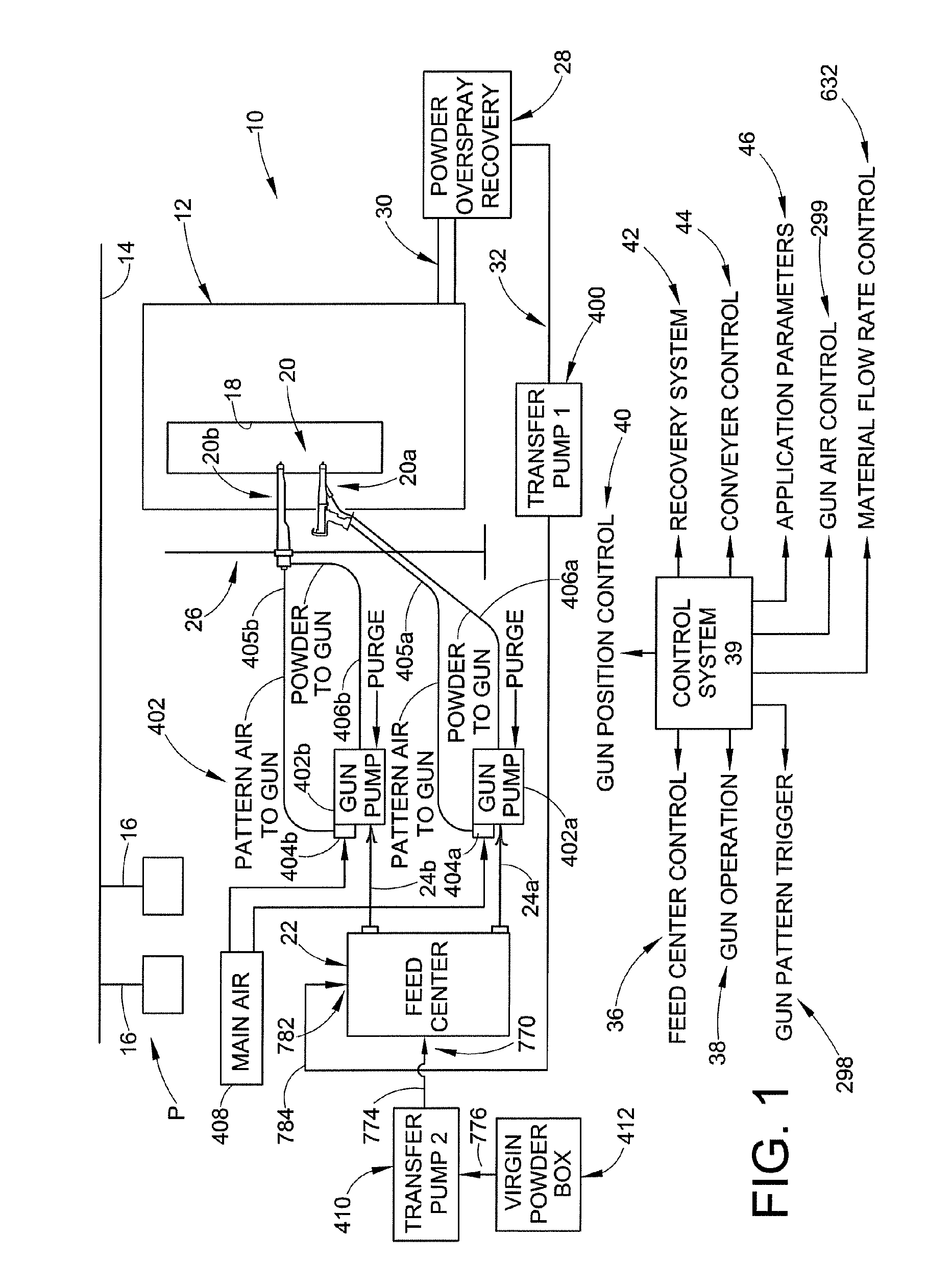

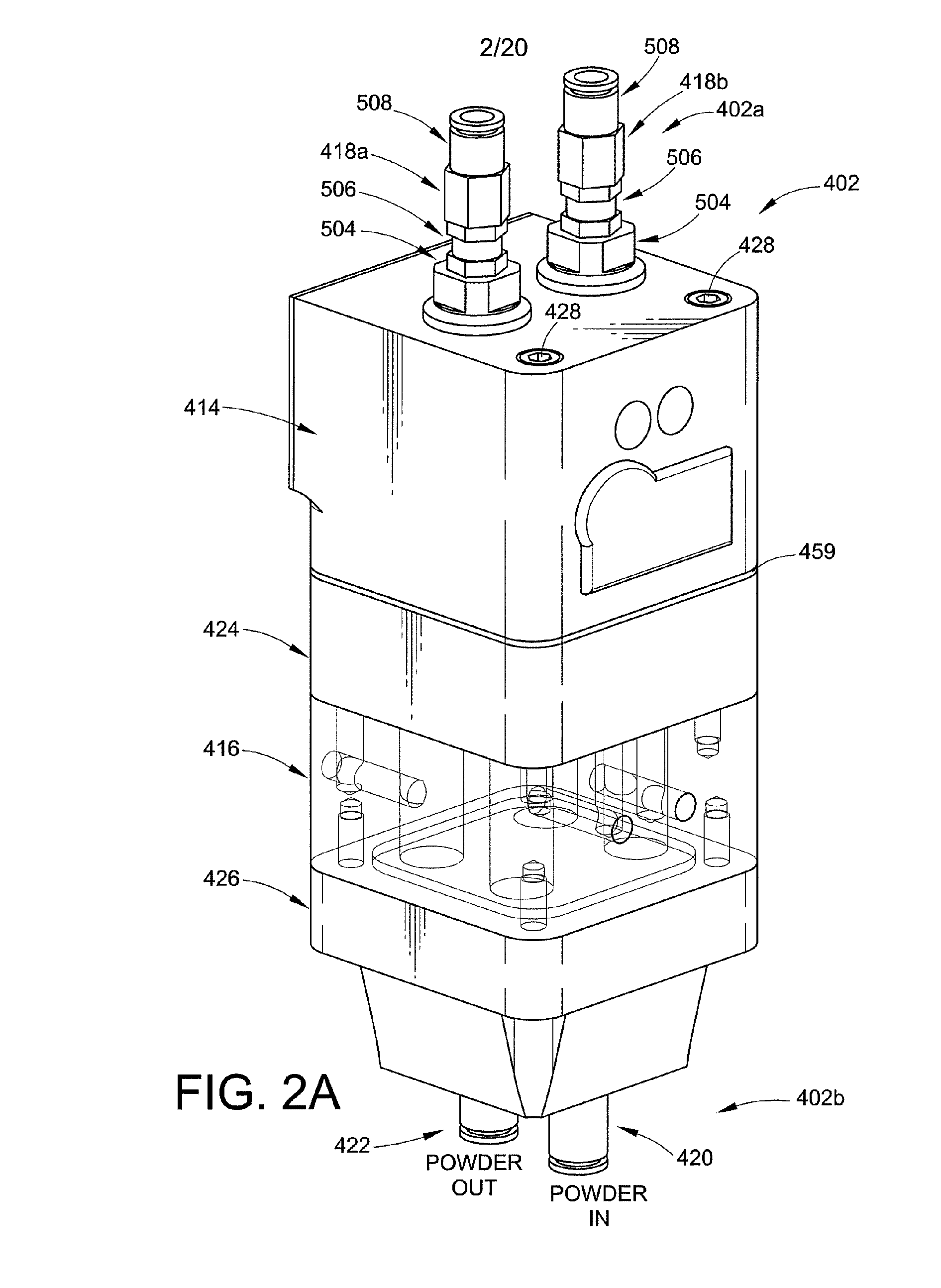

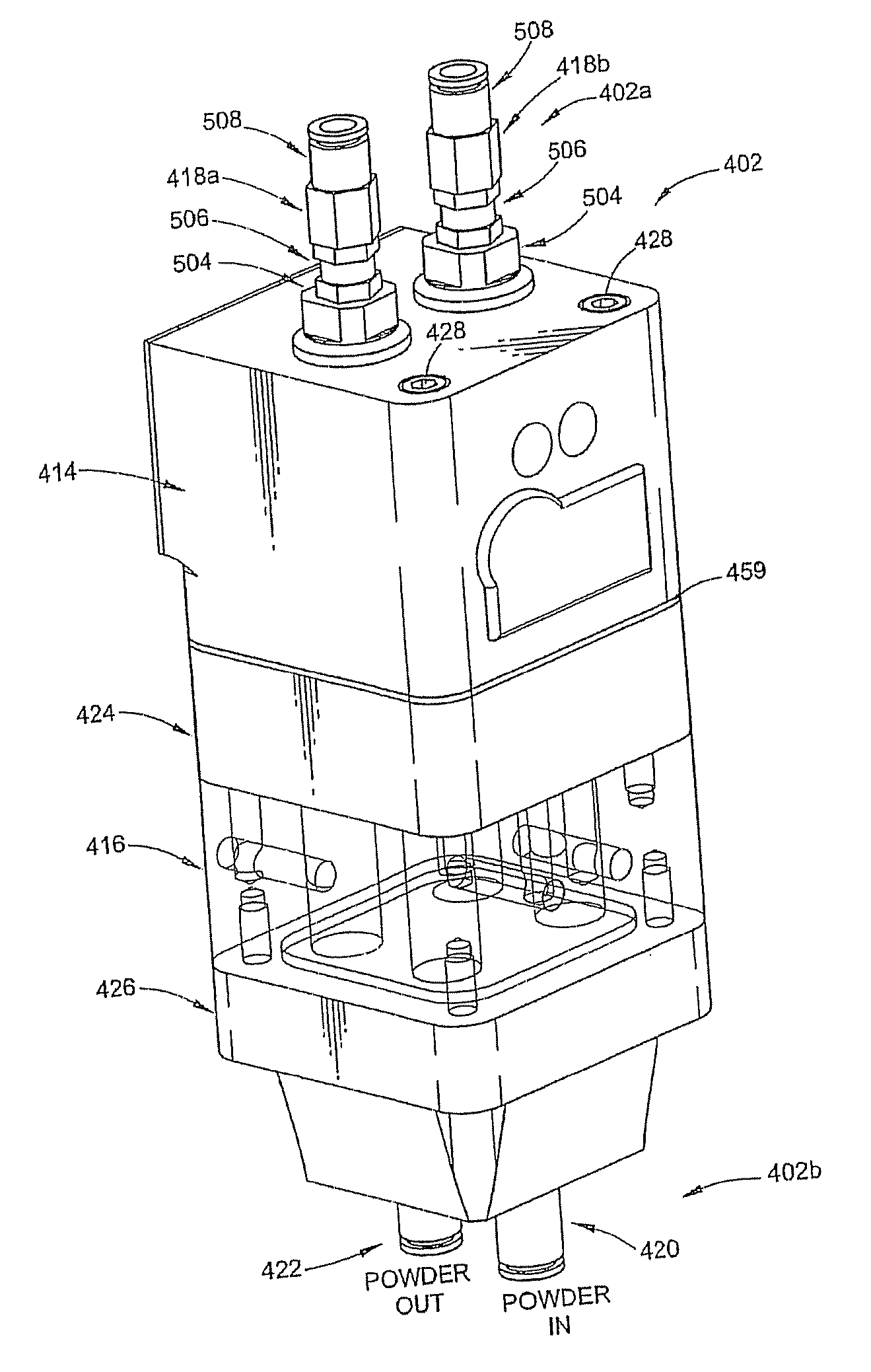

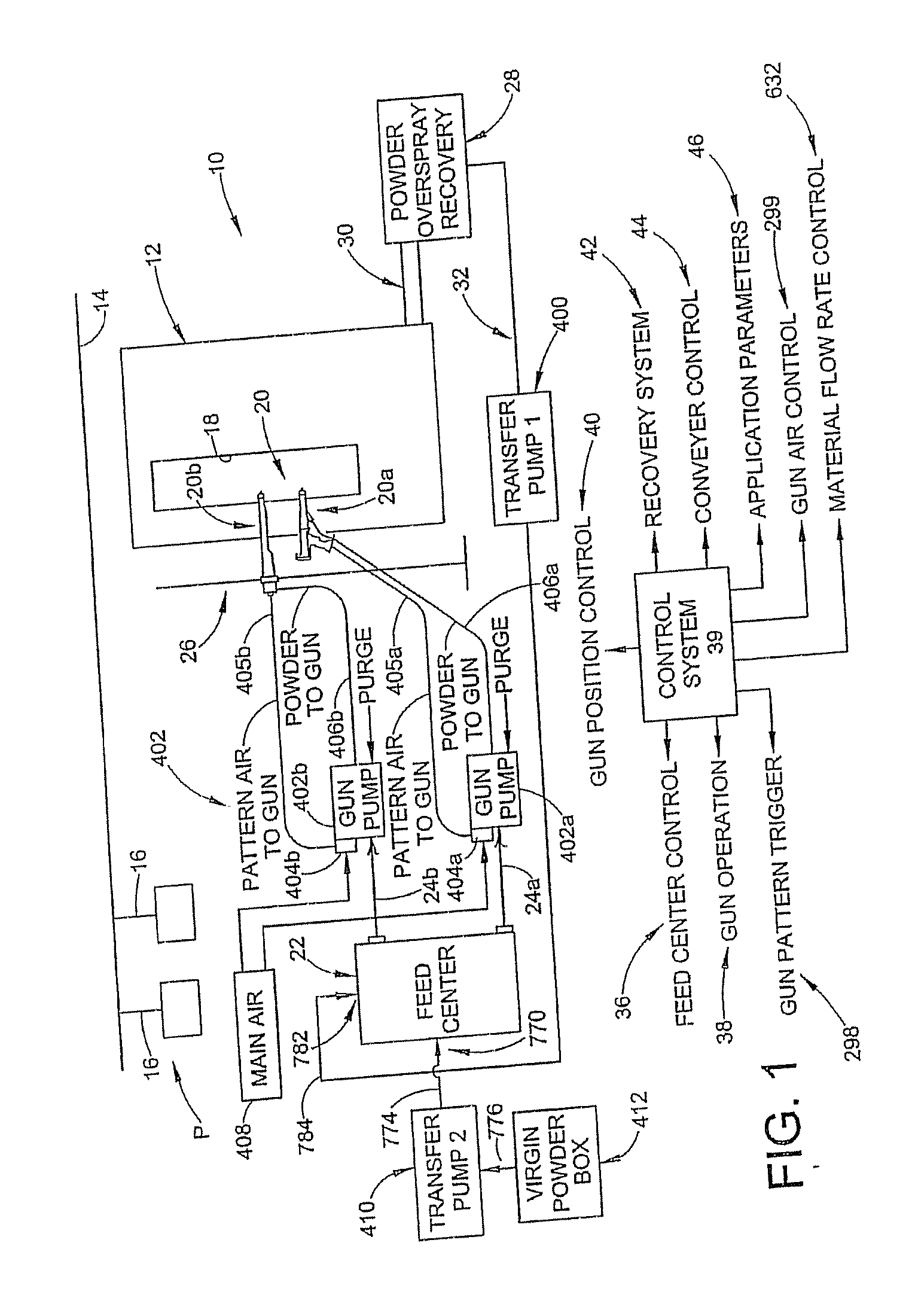

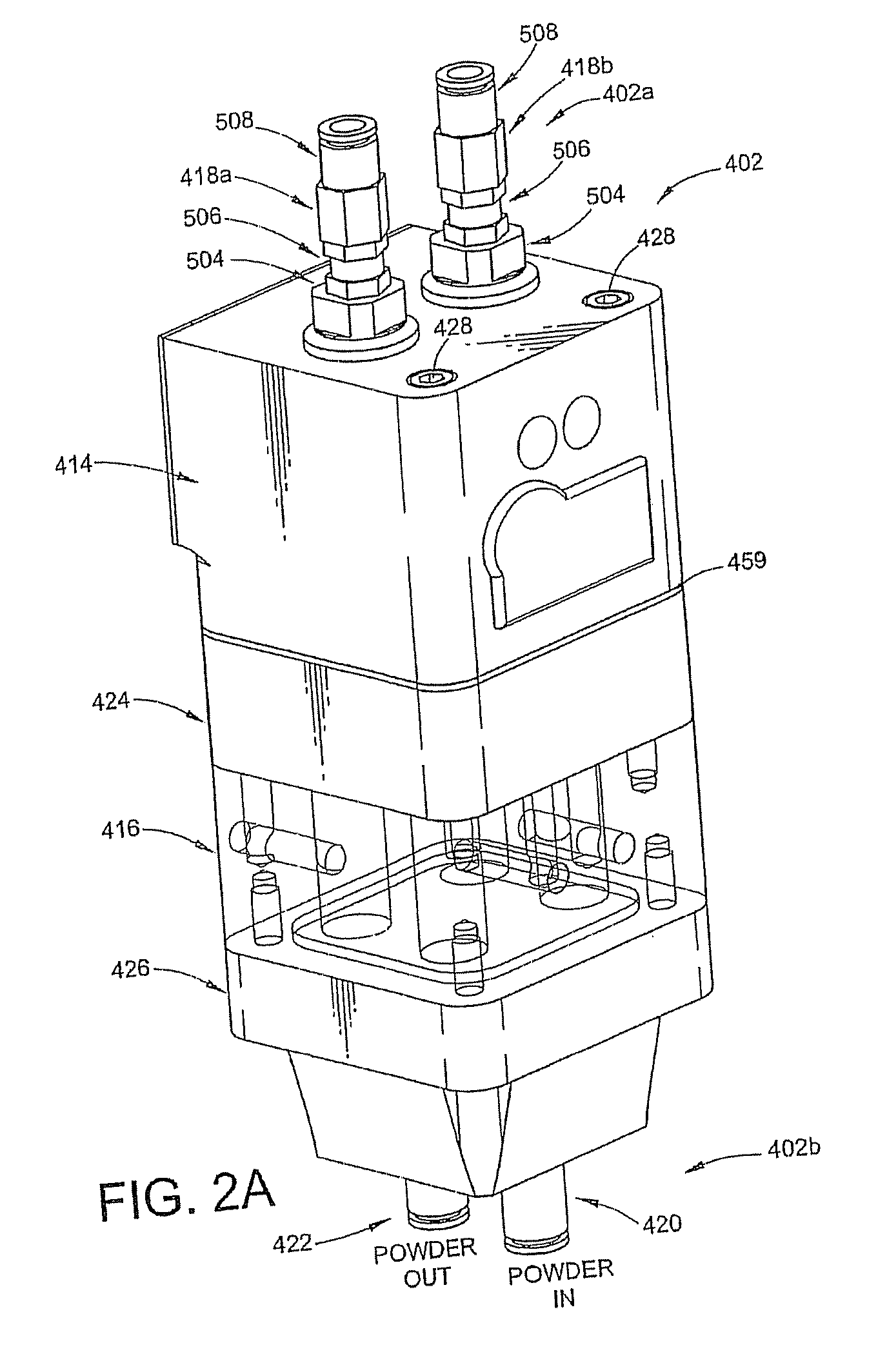

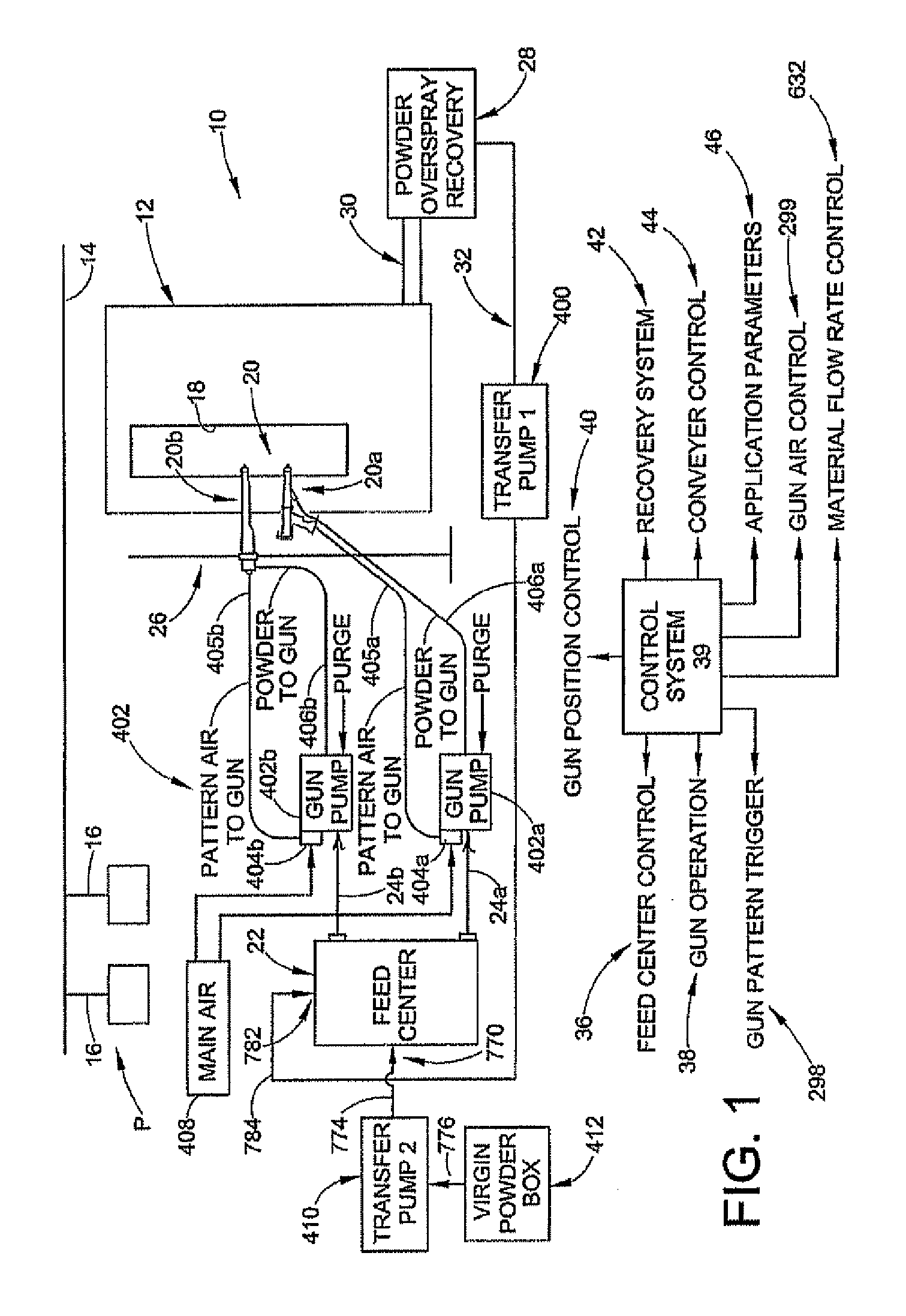

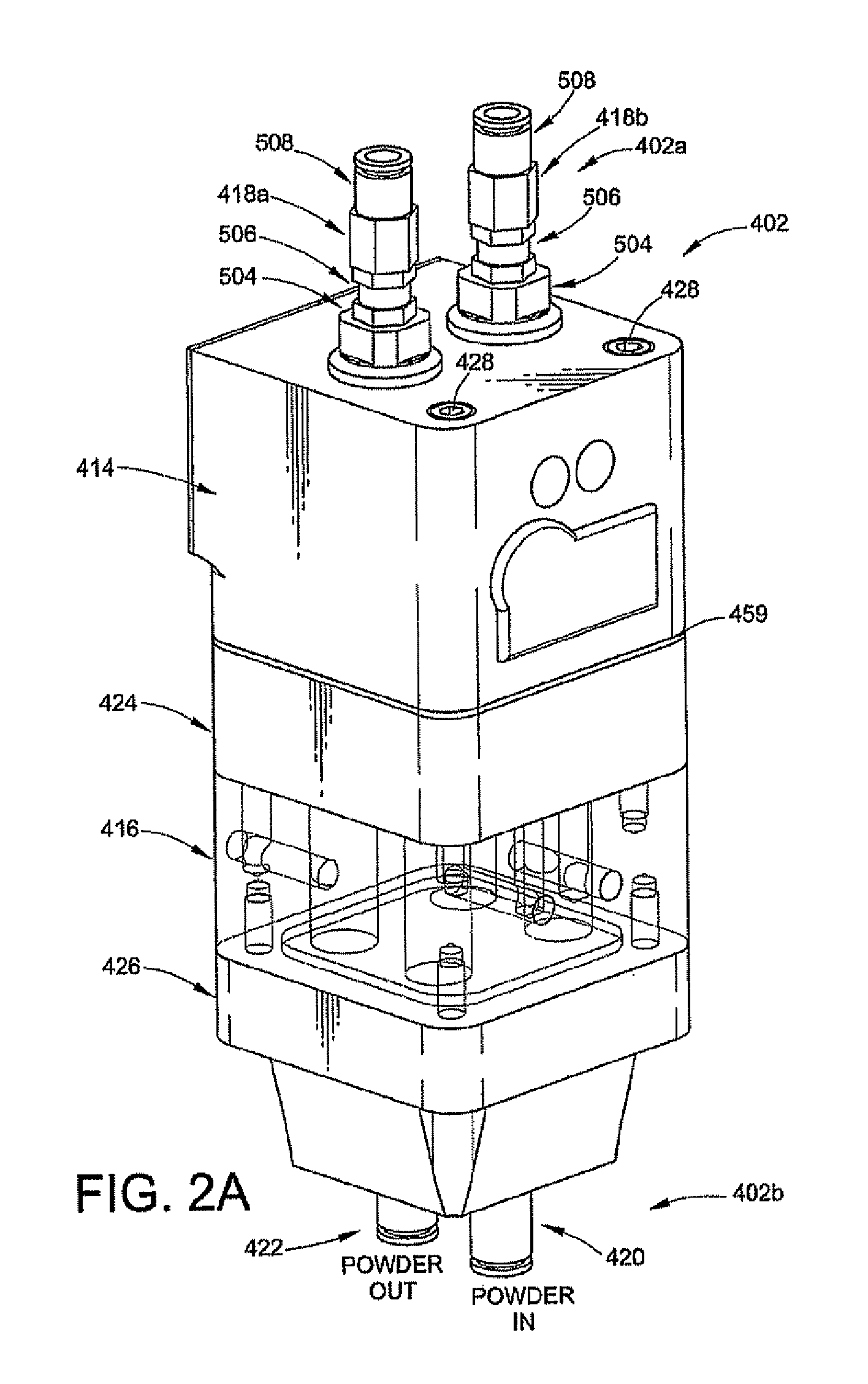

Dense phase pump for dry particulate material

InactiveUS20050158187A1Improve cleanabilityImprove serviceabilityLiquid surface applicatorsPositive displacement pump componentsCycle ratePump chamber

A dense phase pump for particulate material includes a pump chamber wherein material flows into the pump chamber under negative pressure and flows out of the pump chamber under positive pressure. A plurality of pinch valves are provided to control flow of material into and out of the pump chamber. The pinch valves are operated independent of each other and of the pump cycle rate. A modular design of the pump is provided.

Owner:NORDSON CORP

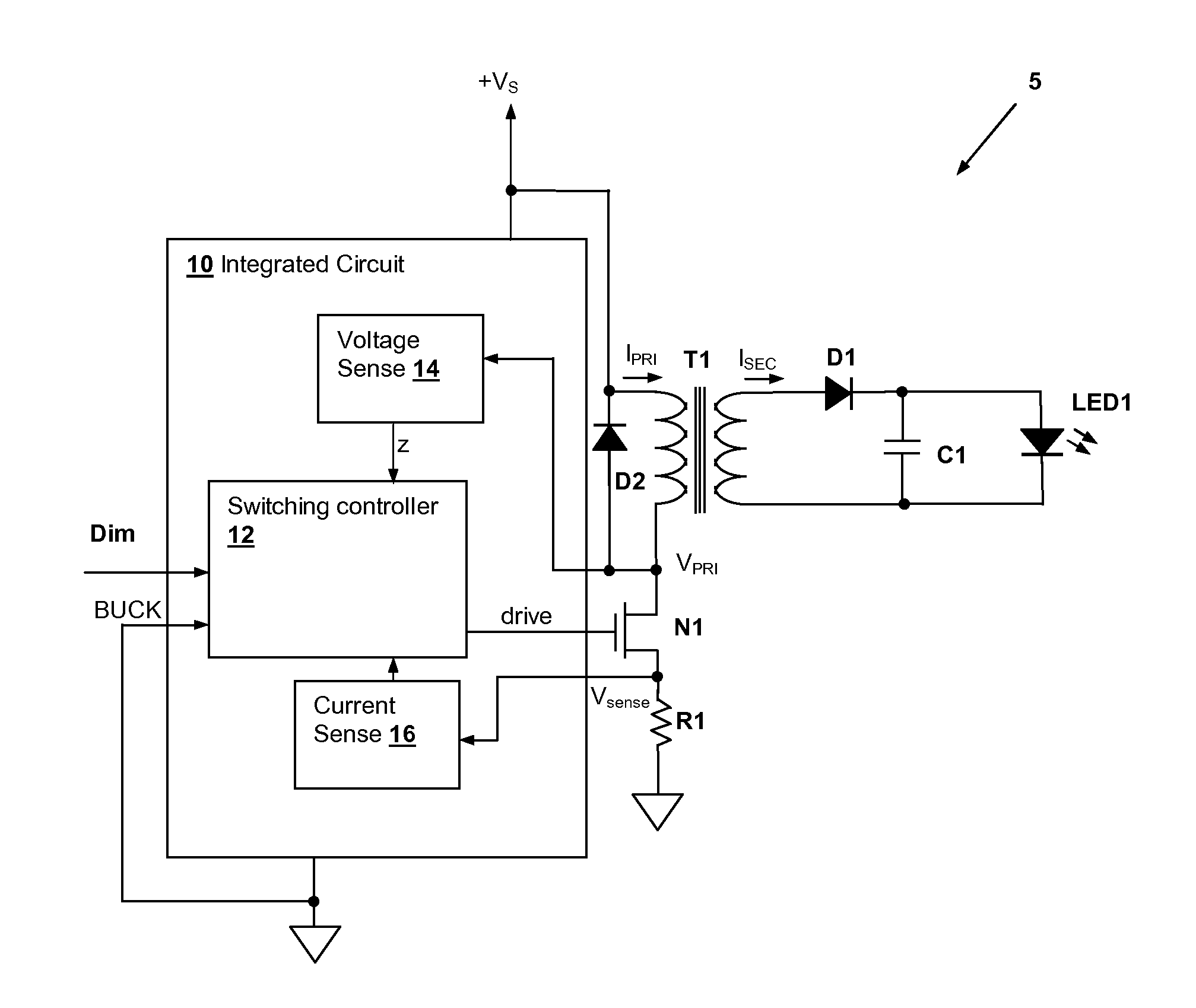

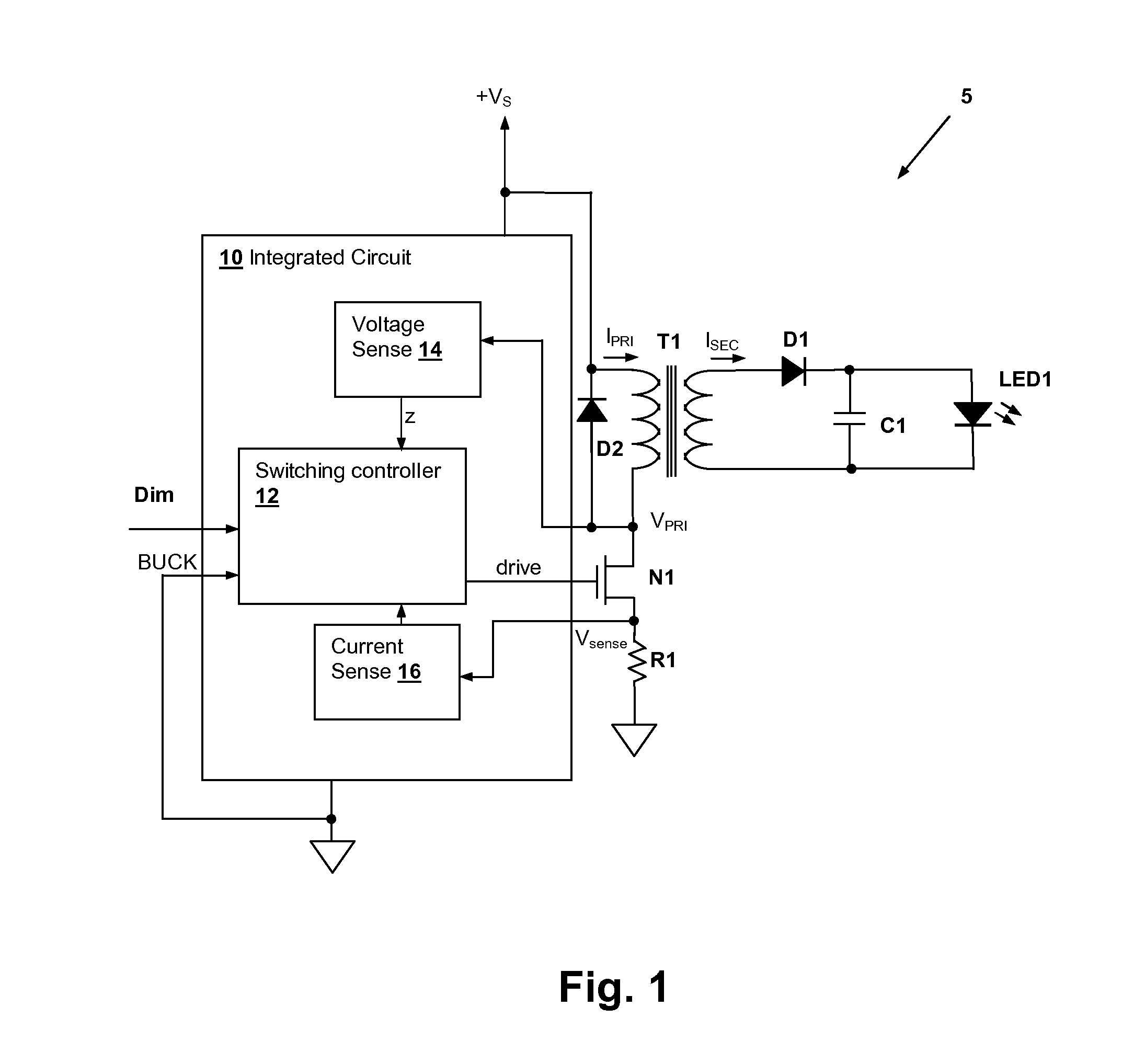

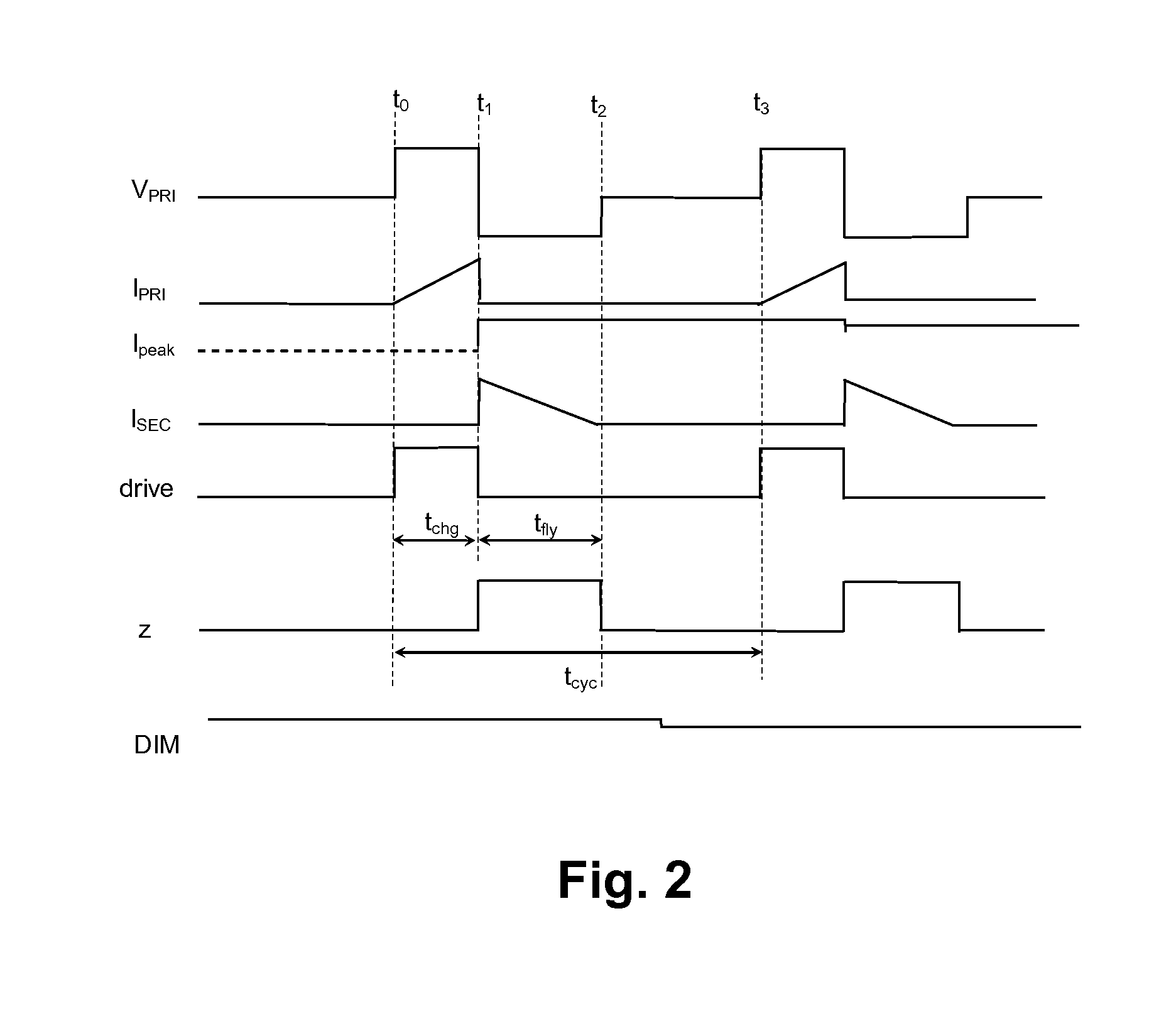

Integrated circuit switching power supply controller with selectable buck mode operation

An integrated circuit (IC) controller for a switching power supply has a selectable operating mode for supporting multiple switching power supply topologies. The IC controls current by controlling a cycle rate of the switching power supply to provide a constant or variable output current, which may be provided to lighting devices such as light-emitting diodes (LEDs). The selectable operating mode includes at least a buck converter operating mode and another operating mode, which may be a flyback converter operating mode.

Owner:SIGNIFY HLDG BV

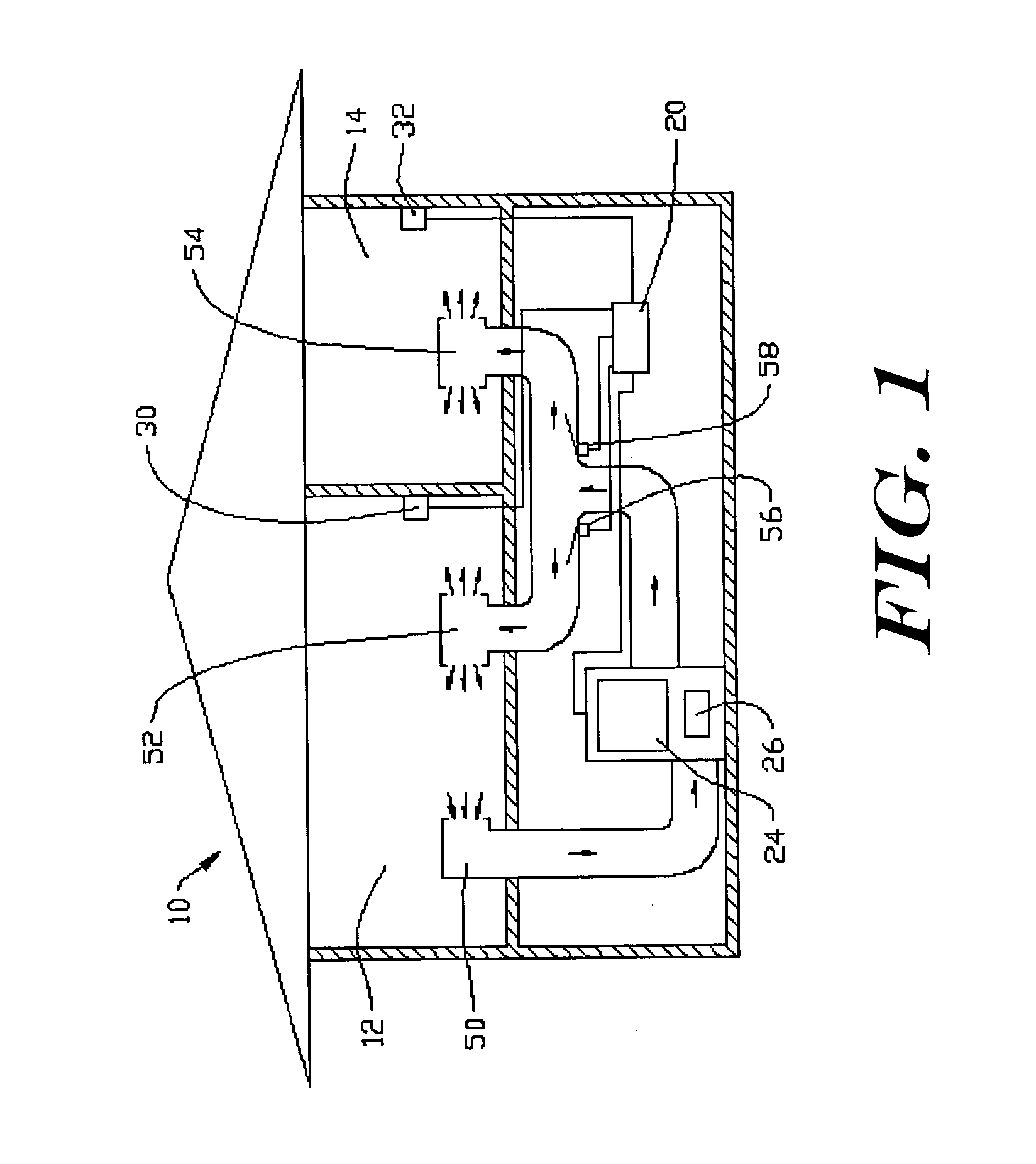

Method and apparatus for controlling humidity with an air conditioner

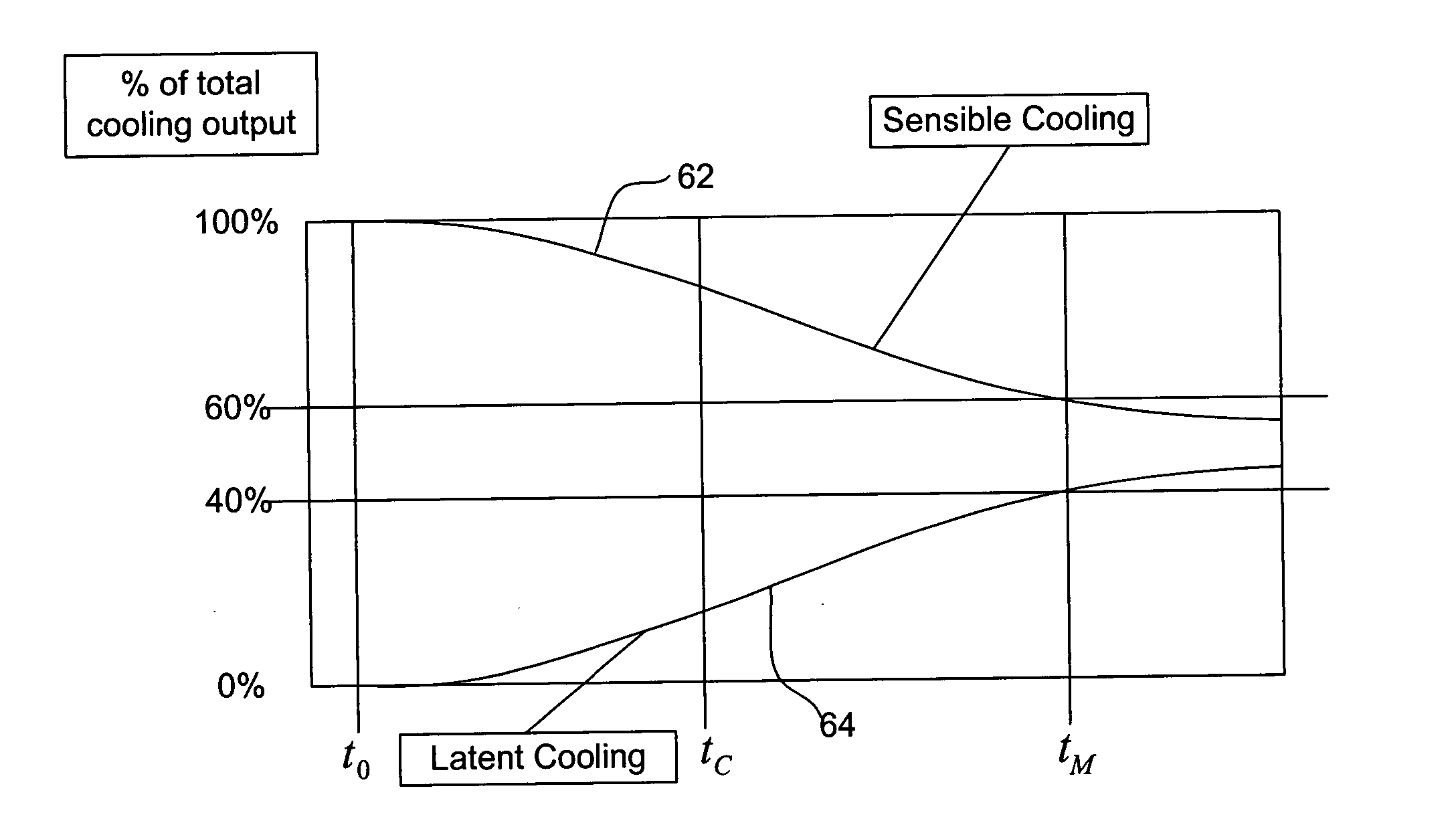

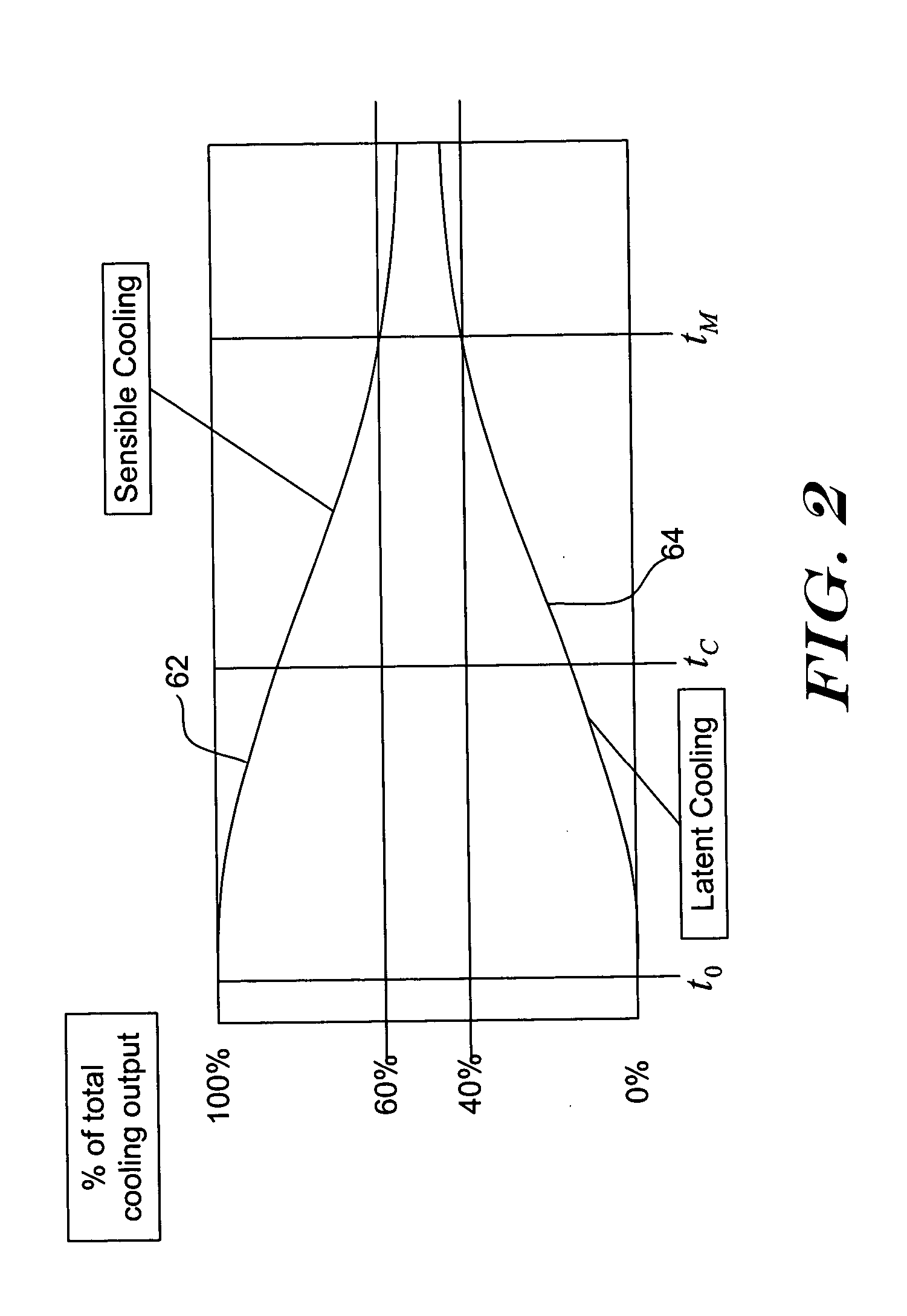

InactiveUS20050016189A1Effectively humiditySpace heating and ventilation safety systemsSpace heating and ventilation control systemsCycle rateInterior space

Methods and apparatus for more effectively managing humidity of an inside space using an air conditioner are provided. In one illustrative embodiment, the system determines whether the humidity level in an inside space is above a predetermined humidity threshold, and if so, changes a control parameter such as a minimum “on” time for the air conditioner. If the humidity level in the inside space is not above the predetermined humidity threshold, the control parameter is not changed, or changed less than when the humidity level is above the predetermined humidity threshold. Rather than changing (i.e. increasing) the minimum “on” time, it is contemplated that any control parameter that increases the “on” time of the air conditioner may be used including, for example, changing (i.e. decreasing) the maximum cycle rate allowed for the air conditioner.

Owner:HONEYWELL INT INC

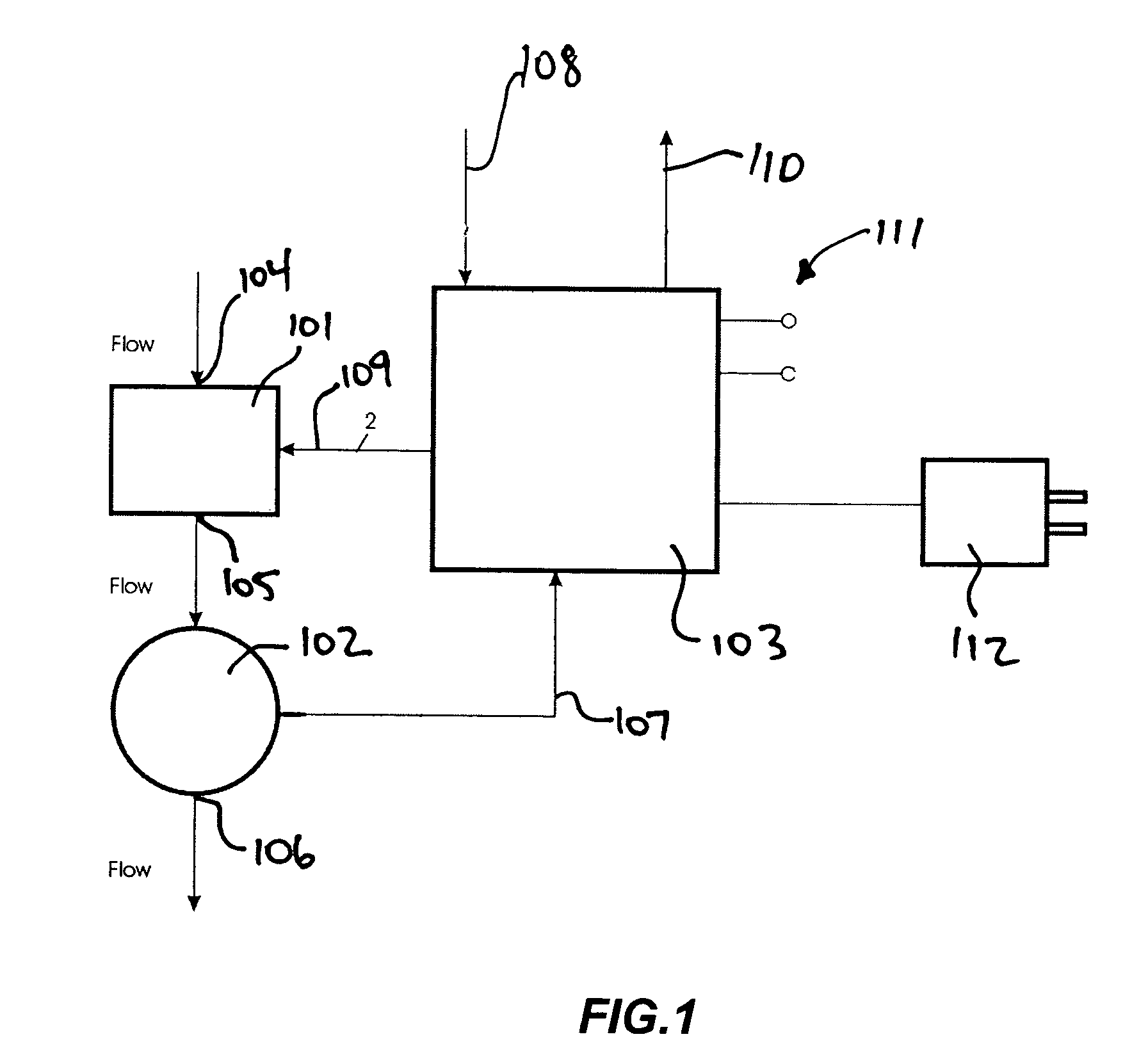

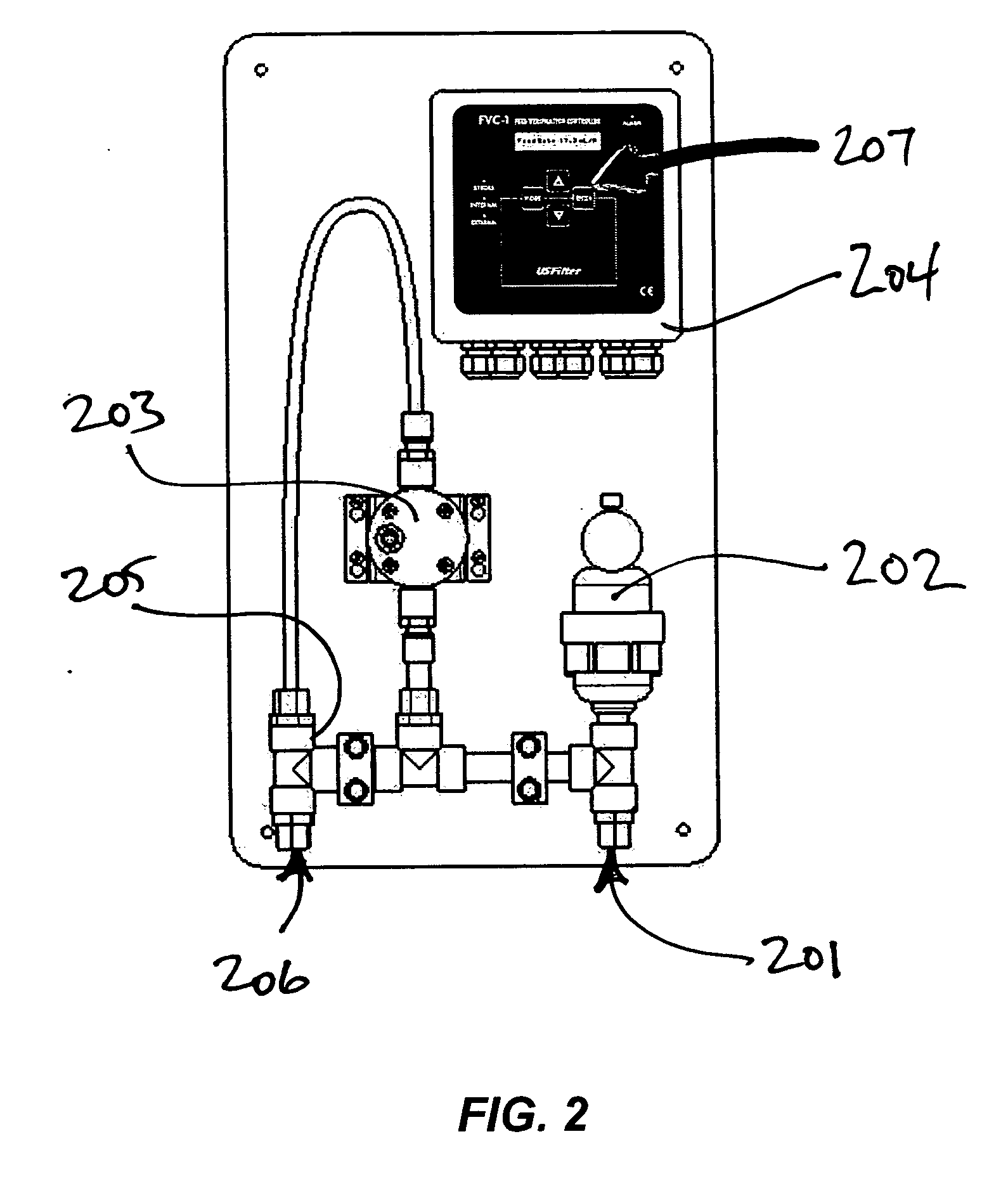

Method of controlling fluid flow

According to various aspects of embodiments of the invention, the actual flow rate produced by a metering pump is continuously measured using a positive displacement flow meter. Based on the flow rate reported by the meter, the output of the metering pump is continuously adjusted via a pump controller to achieve a desired set point flow rate. The operator sets a desired flow rate, rather than setting the pump cycle rate, or the output rating per pump cycle to produce an approximate output flow rate. According to some embodiments of aspects of the invention, a fluid feed system commanded to a fluid flow rate set point by a set point signal includes: a metering pump receiving a control signal directing a cycle rate for the metering pump; a fluid flow meter connected to measure a fluid flow rate produced by the metering pump and which provides a fluid flow rate signal; and a metering pump controller responsive to the set point signal and the fluid flow rate signal to adjust the control signal to direct a cycle rate which produces a fluid flow rate equal to the fluid flow rate set point. According to other embodiments of aspects of the invention, there is a method of controlling a fluid flow rate, comprising: displacing an approximately defined quantity of fluid at a rate determined by a control signal; measuring an actual flow rate; and adjusting the control signal to produce a rate of displacing the approximately defined quantity of fluid such that the actual flow rate matches a desired flow rate. According to yet other embodiments of aspects of the invention, a metering pump may be constructed and / or controlled as described above, in a chemical processing facility or a fluid dispenser. The variations described may be interchanged and combined in any suitable manner determined by one implementing an embodiment of the invention.

Owner:SIEMENS WATER TECH HLDG CORP

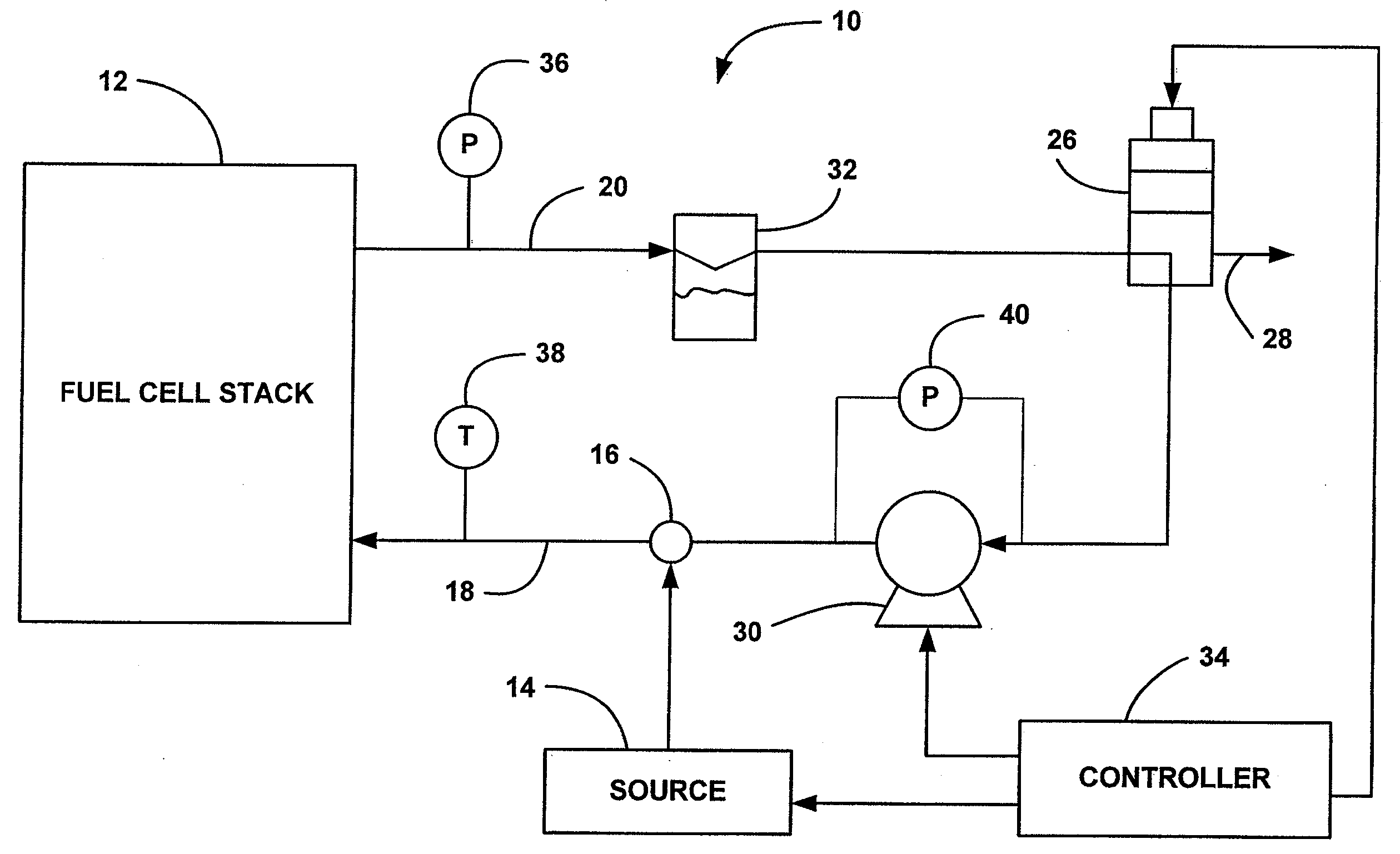

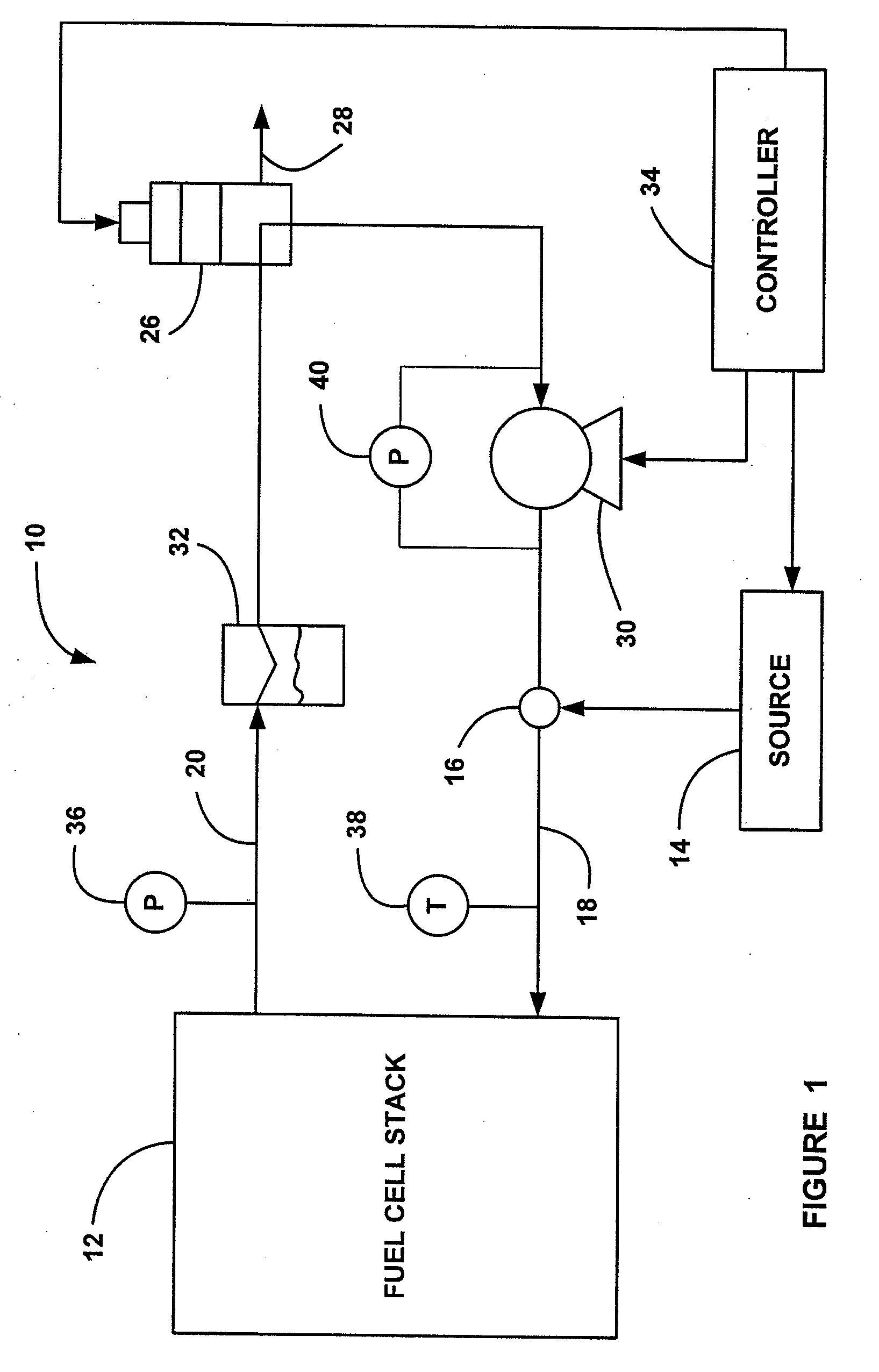

System and method for controlling an anode side recirculation pump in a fuel cell system

ActiveUS20090280373A1Accurate valueFuel cell auxillariesDigital computer detailsCycle rateFuel cells

A system and method for controlling the speed of a recirculation pump in an anode recirculation loop of a fuel cell system based on a predetermined ratio of fresh hydrogen to recirculated anode gas. The system uses a model to determine the volume flow of the recirculated gas through a fuel cell stack to determine the recirculation rate based on a measured temperature of the recirculated gas, a measured pressure drop across a recirculation pump, a pressure drop across the anode inlet and outlet of the stack, a percentage of hydrogen in the recirculated gas, and the density of the recirculated gas.

Owner:GM GLOBAL TECH OPERATIONS LLC

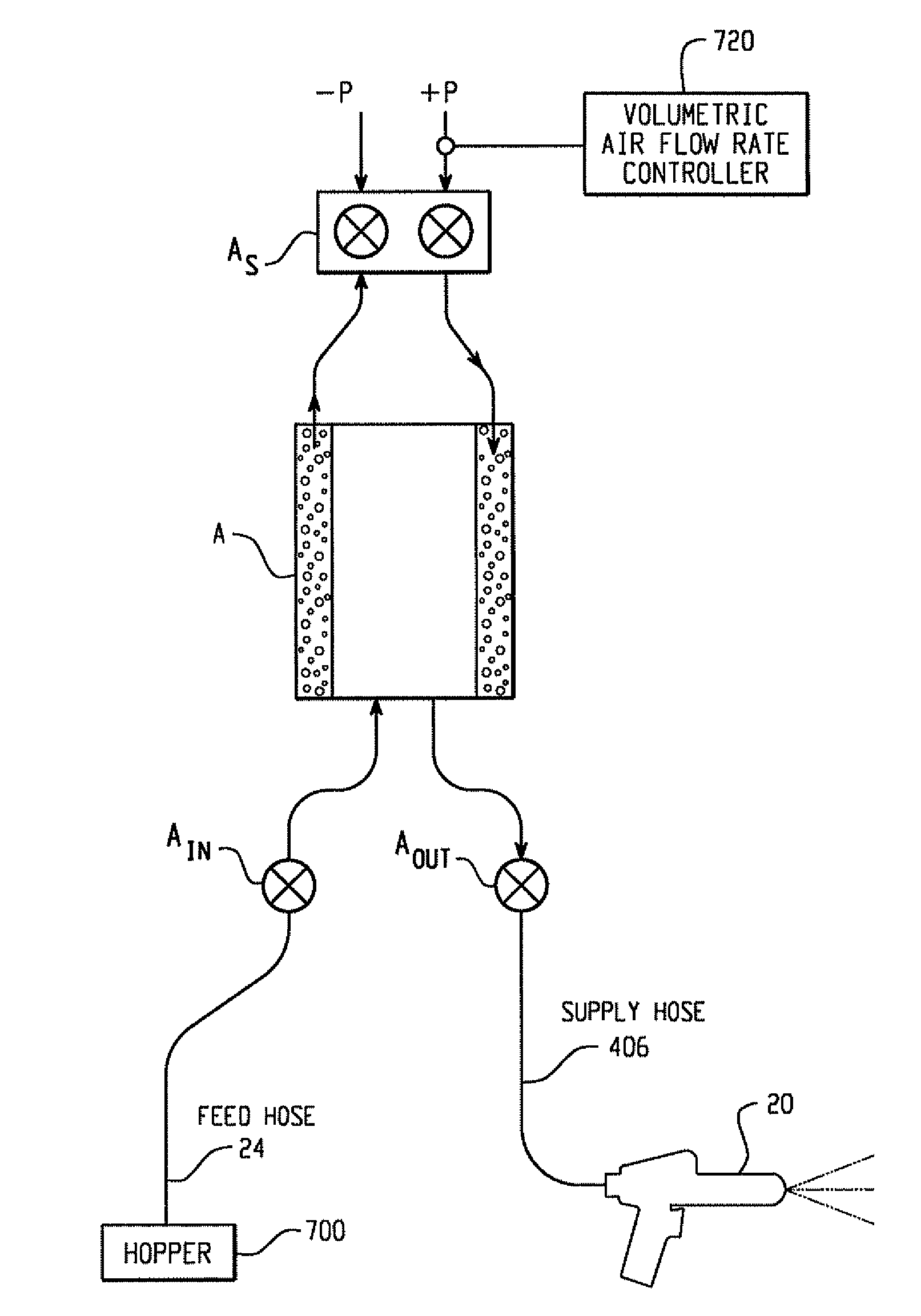

Pump with Suction and Pressure Control for Dry Particulate Material

A pump for particulate material includes a pump chamber wherein material flows into the pump chamber under negative pressure and flows out of the pump chamber under positive pressure. A plurality of pinch valves are provided to control flow of material into and out of the pump chamber. The pinch valves are operated independent of each other and of the pump cycle rate. A modular design of the pump is provided. A pump control feature is provided for air flow rate control during positive and negative pressure conditions.

Owner:NORDSON CORP

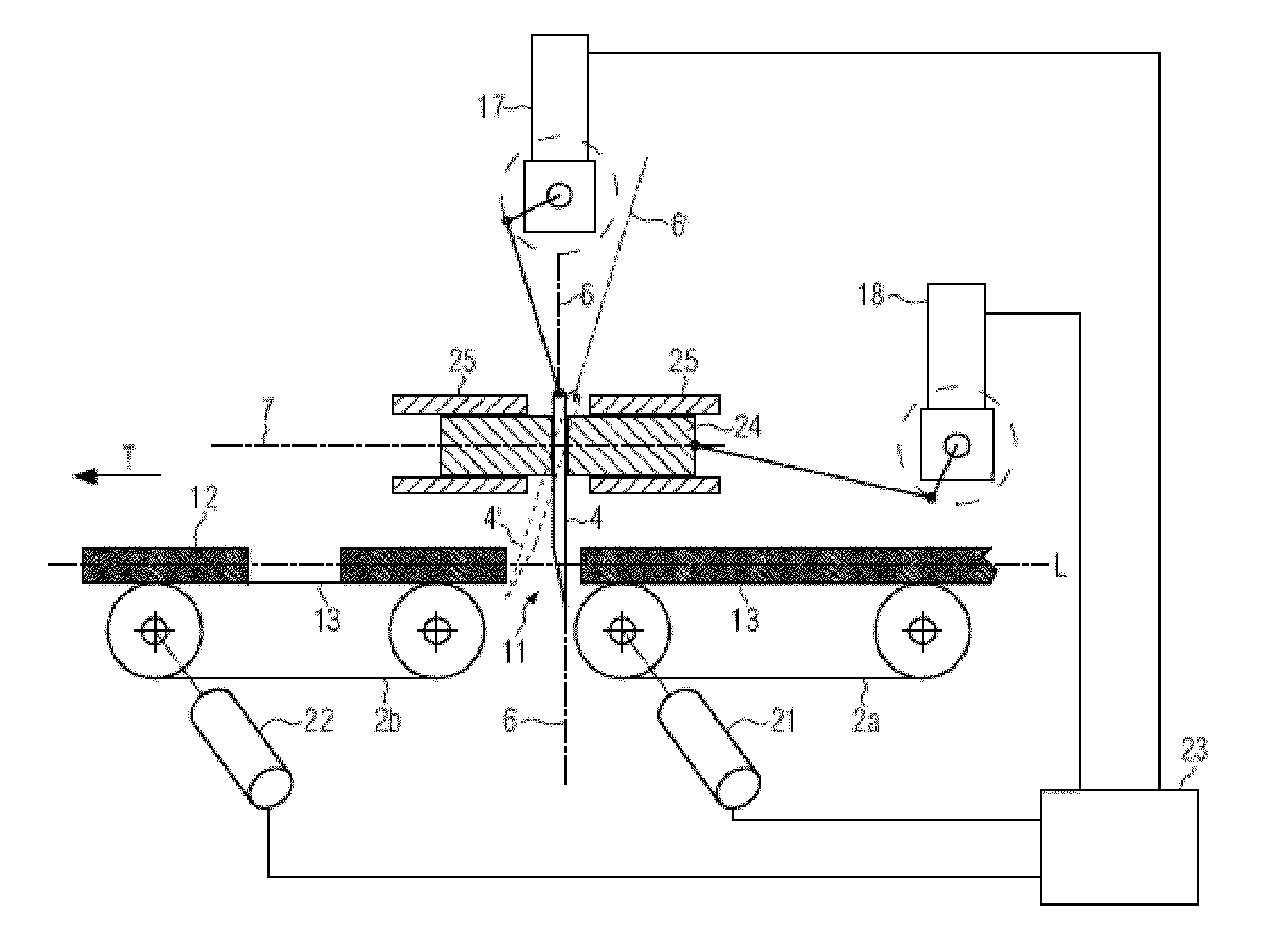

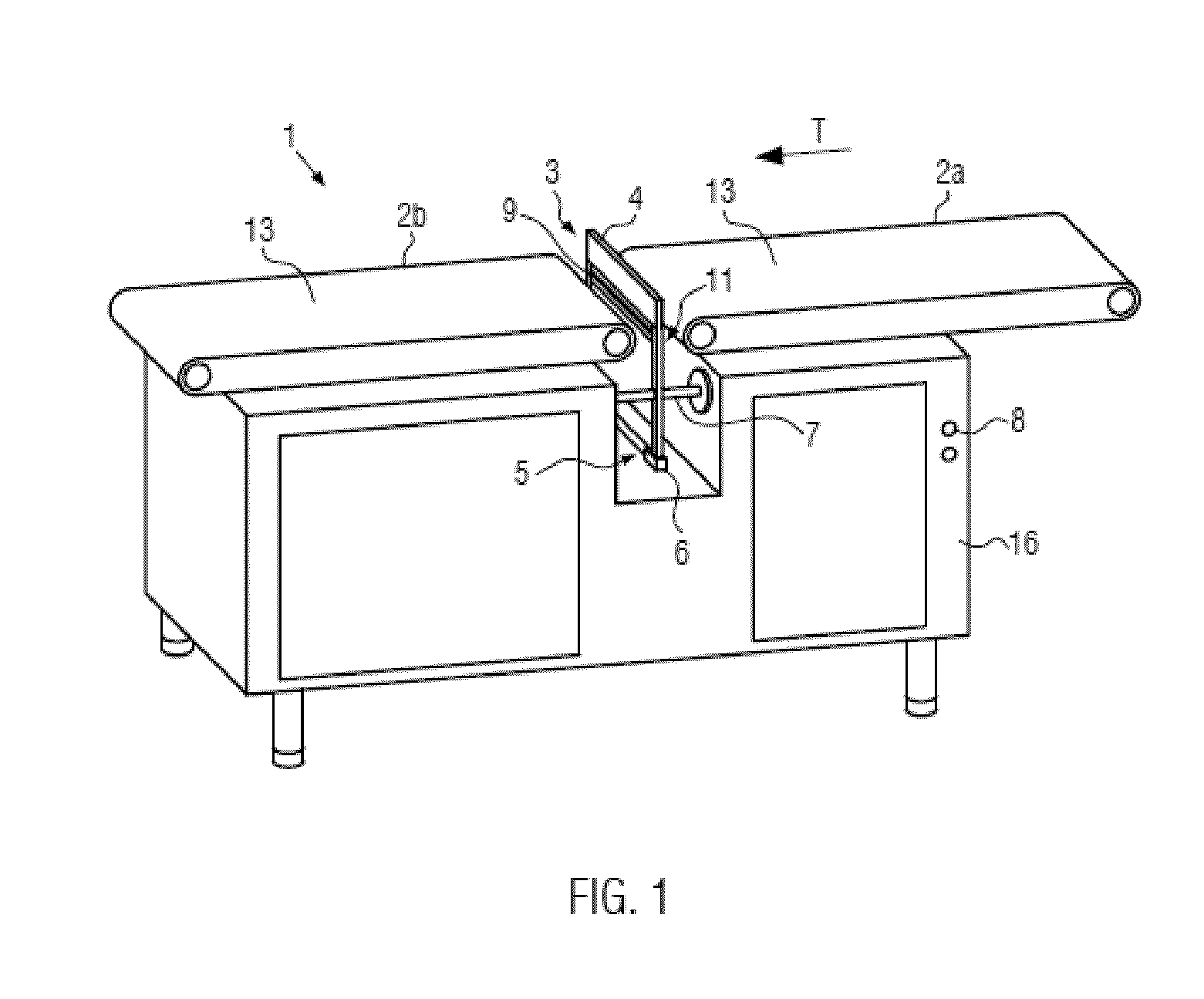

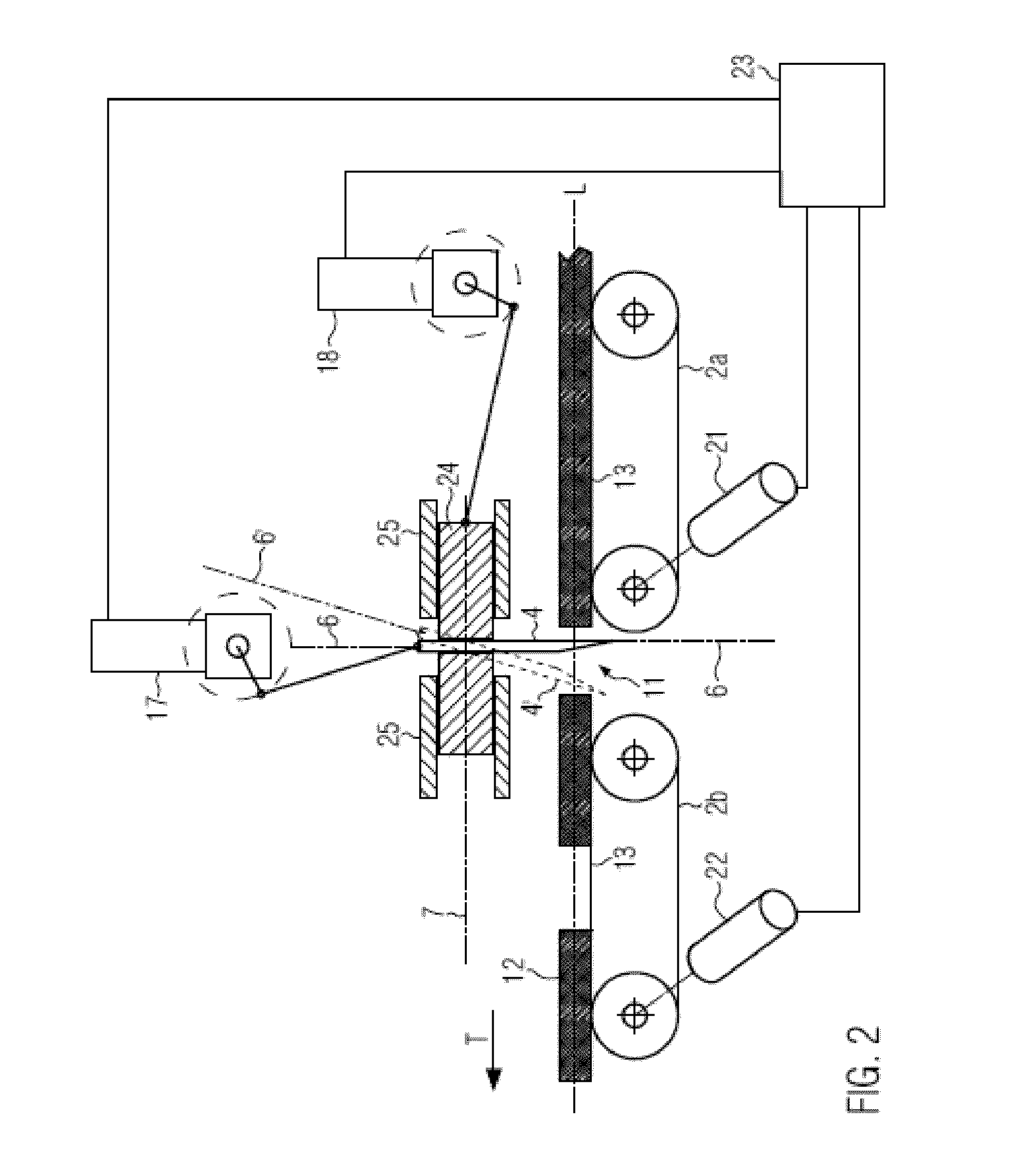

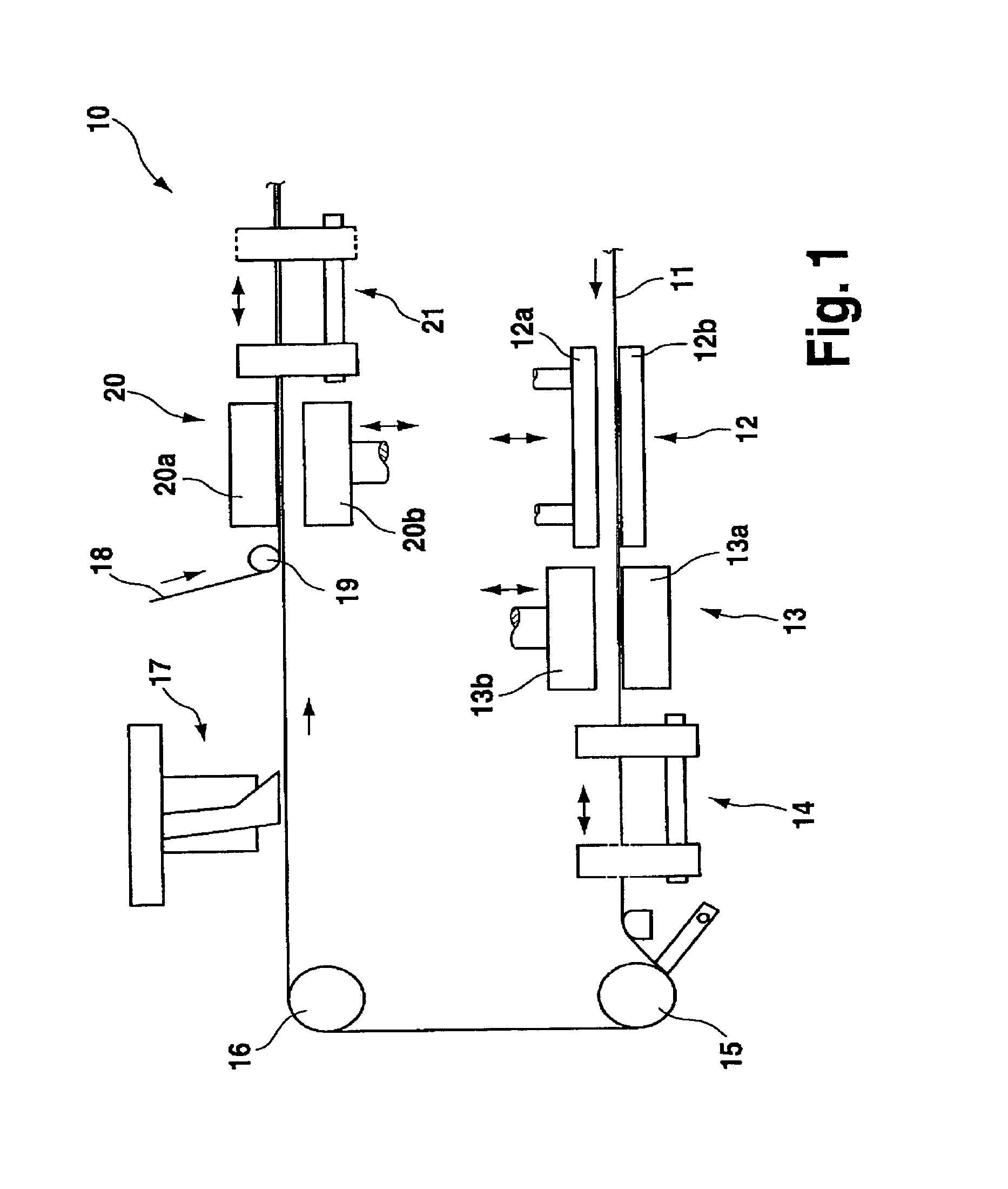

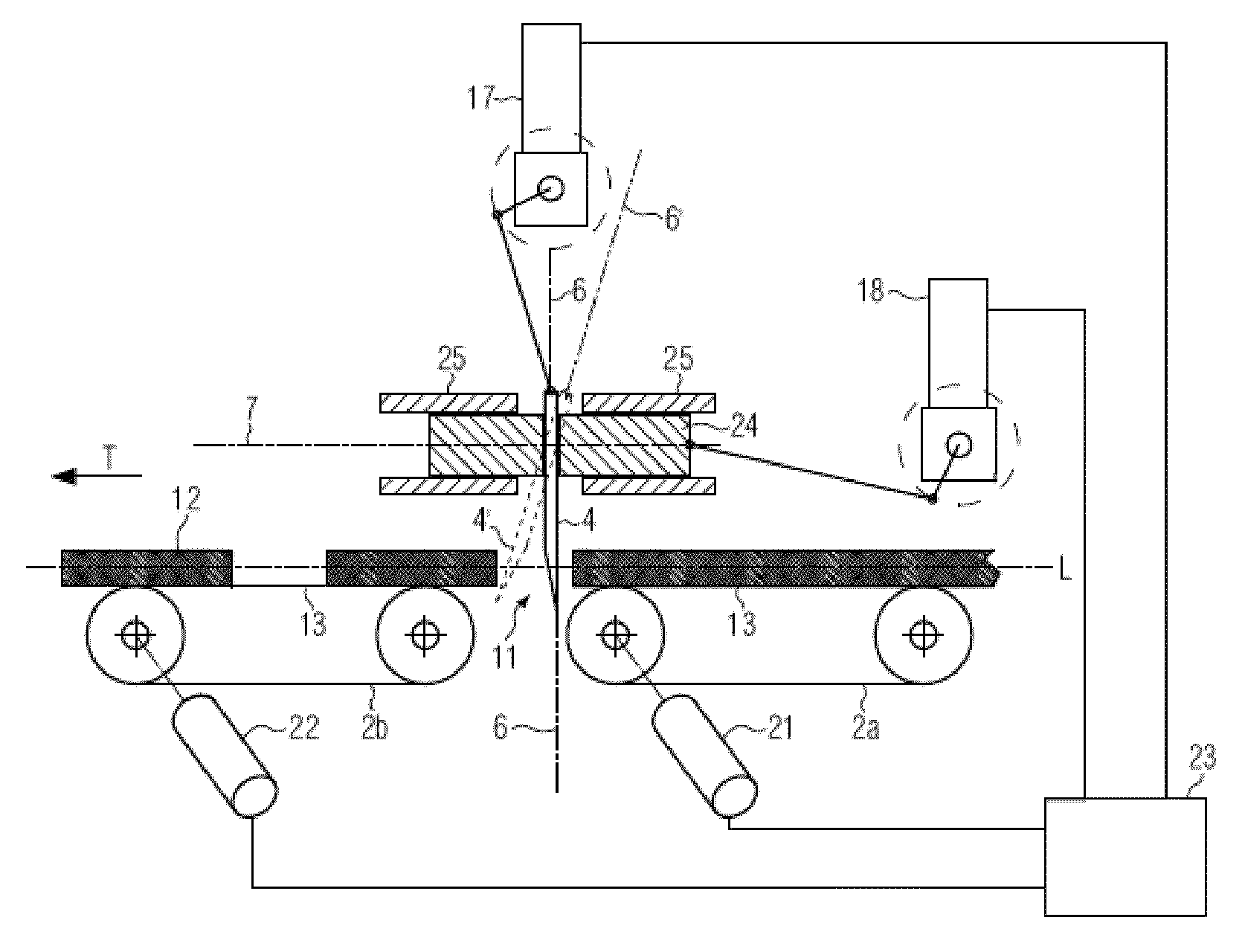

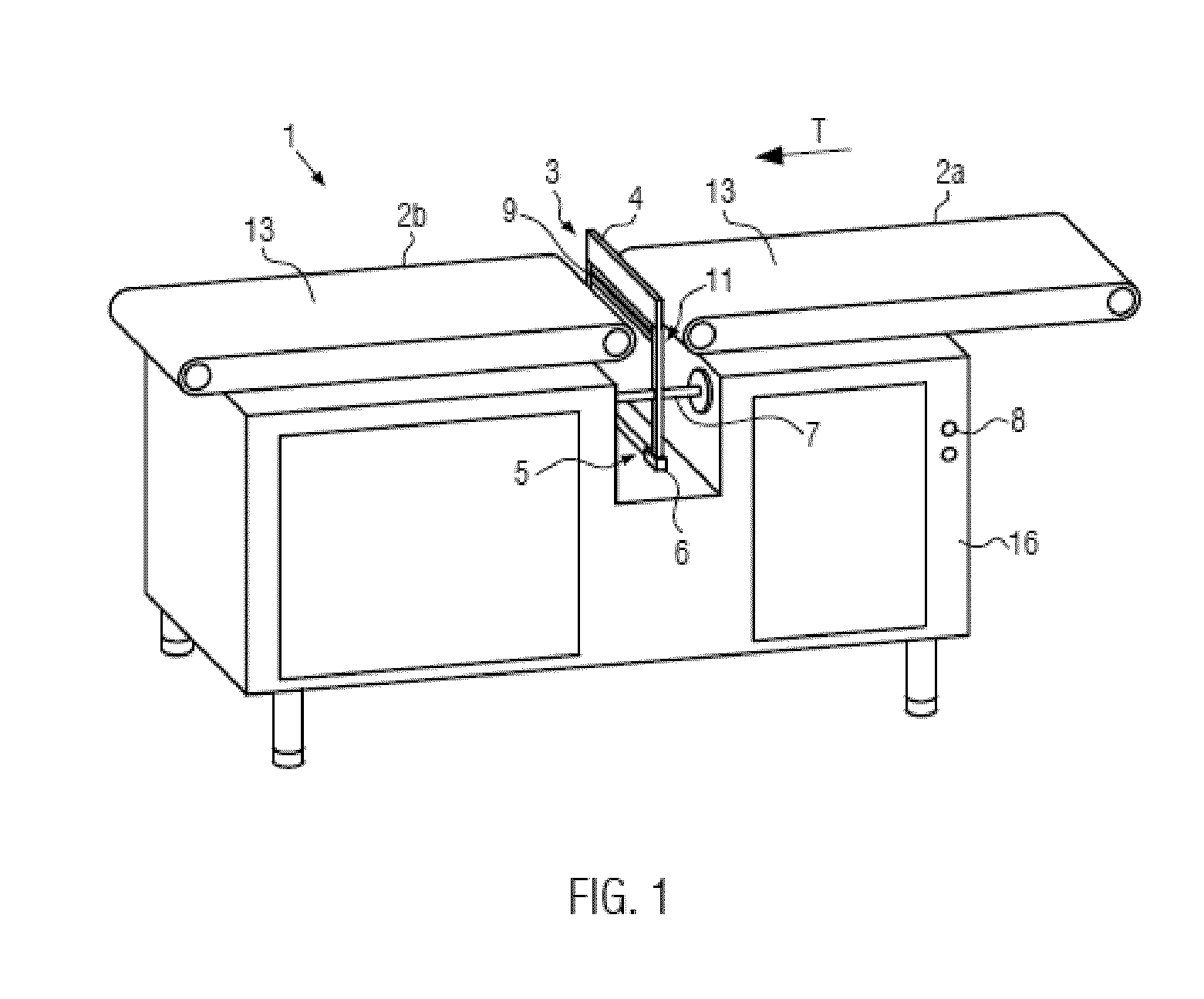

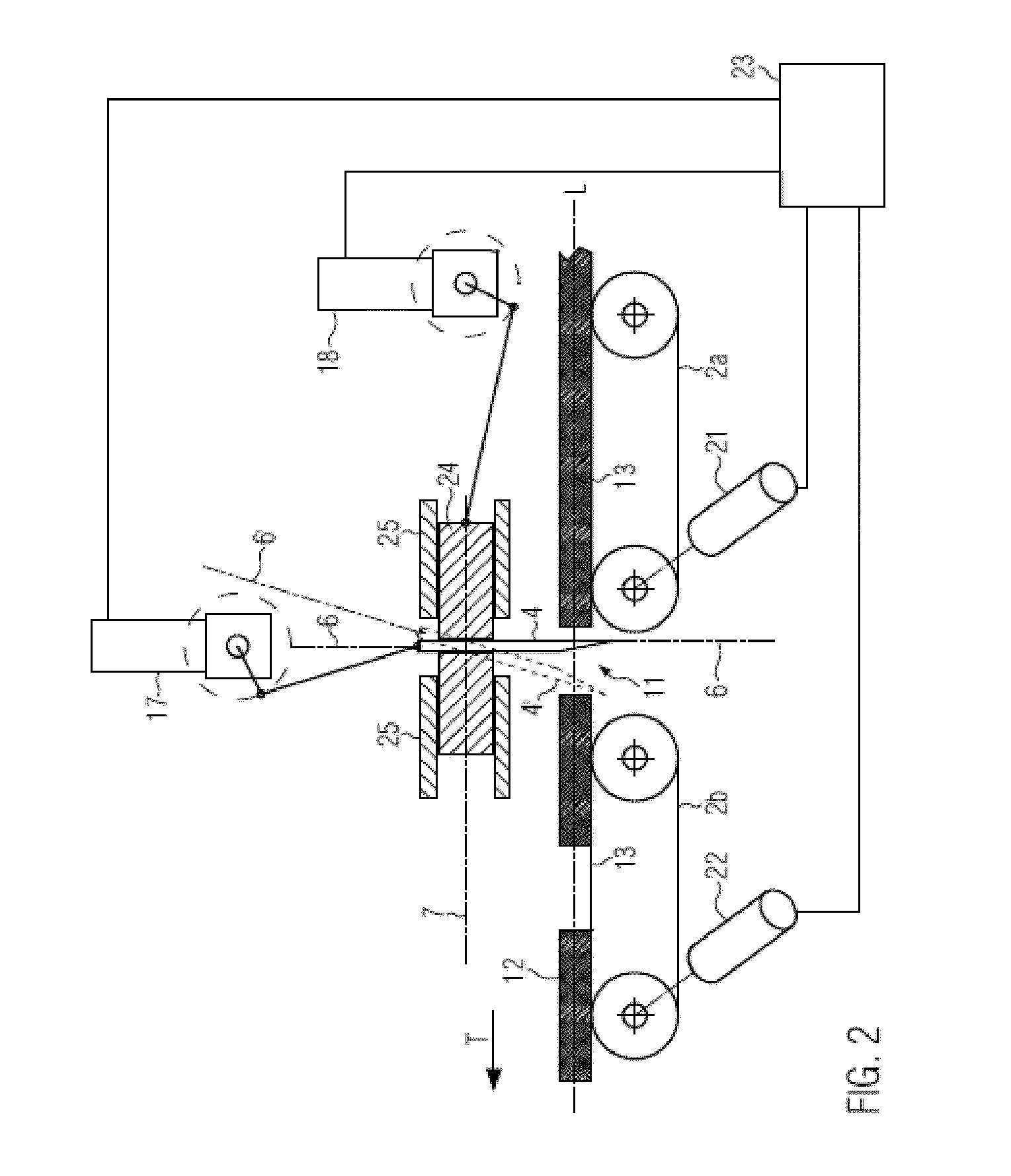

Method and device for separating products

ActiveUS20130205961A1Exact weight precisionIncrease cycle rateStock shearing machinesMetal working apparatusCycle rateEngineering

A method and a device for separating food products, including to permit a straight cut at high cycle rates, the food product is conveyed by a conveying device in the direction of transport. The food product is cut through, where a cutting element is moved in the direction of transport and transverse to the direction of transport, wherein the motion of the cutting element transverse to the direction of transport is controlled independently of its motion in the direction of transport and the food product does not rest on the cutting area on the conveying means.

Owner:ALBERT HANDTMANN MASCHFABRICK

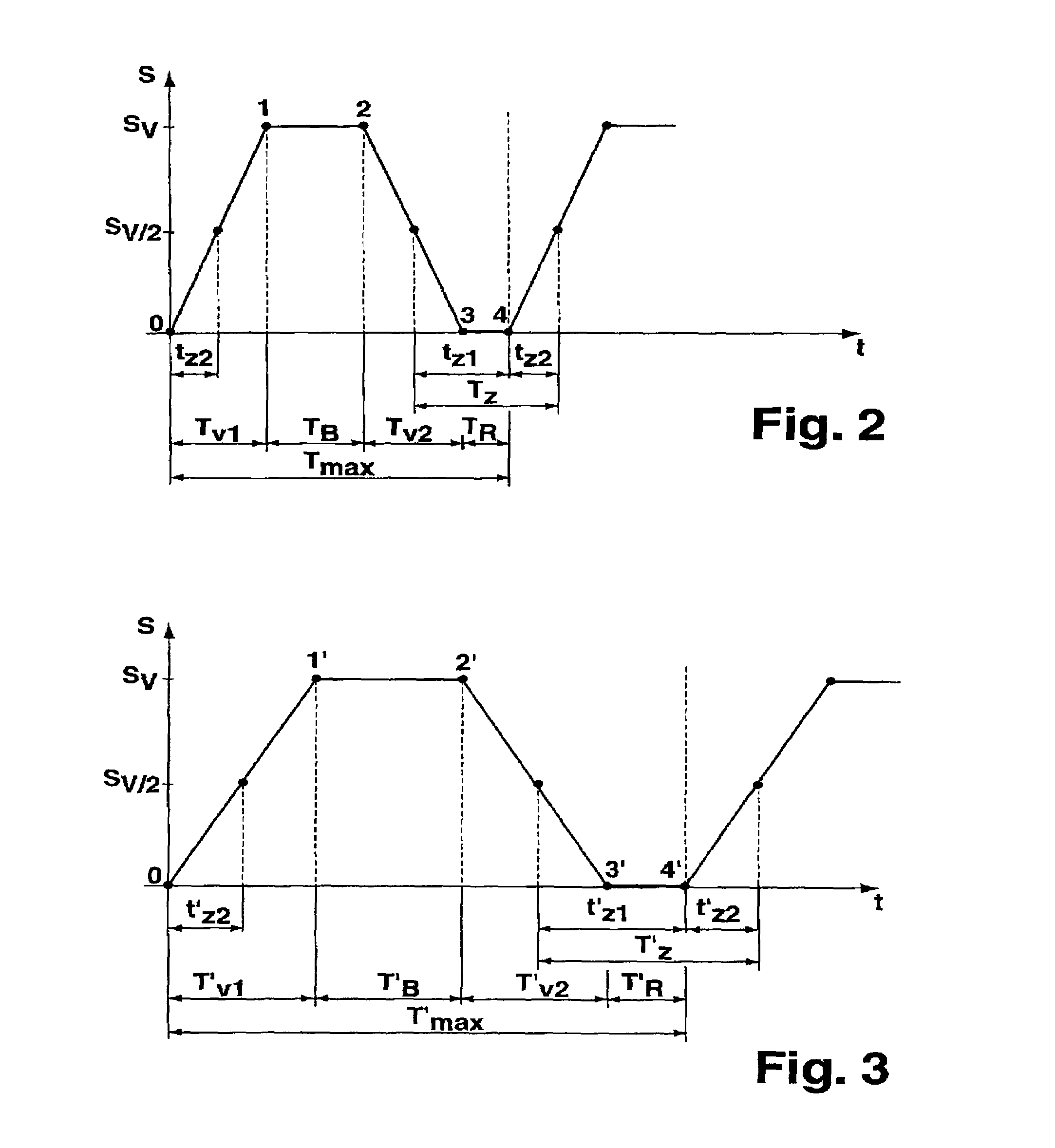

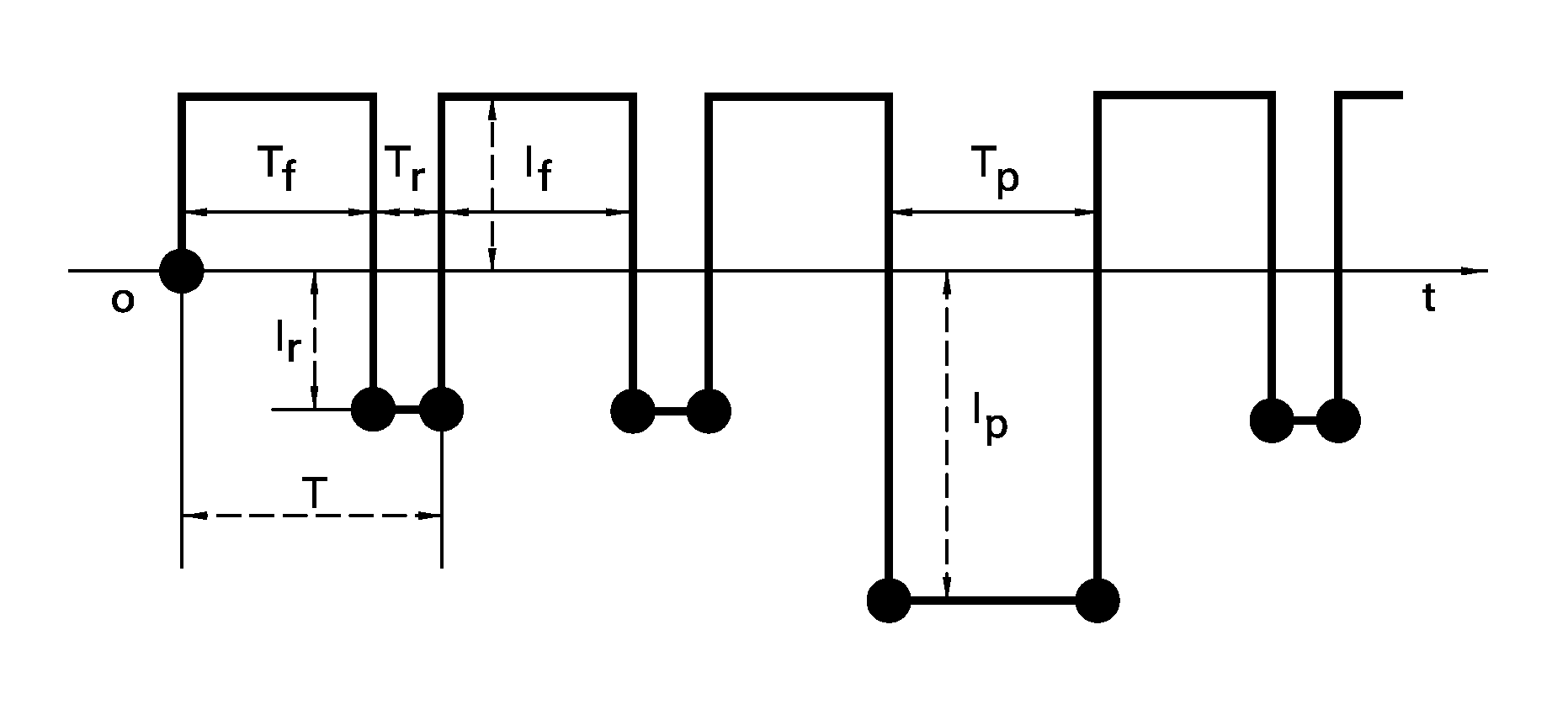

Method for controlling a blister packaging machine

InactiveUS7055296B2Good body shapeHigh process reliabilityWrappers shrinkagePackaging automatic controlCycle rateWork cycle

A method for controlling a blister packaging machine has a work station which at least operates in cycles and which performs at least one first adjusting motion for a time period TV1 during one work cycle, followed by a treatment state for a time period TB, in which a product and / or material is treated. A second adjusting motion is then performed for a time period TV2 followed by a resting state for a time period TR. The time periods TV1, TB, TV2 and TR and a cycle rate R (=cycles / min) of the packaging machine are preset and at least the cycle rate R can be changed to a different cycle rate RV using an input device. A cycle time difference ΔT which results from the changed cycle rate RV is substantially used to change the duration TR of the resting state. The time periods TV1, TB and TV2 preferably remain unchanged when entering a different cycle rate RV.

Owner:IWK VERPACKUNGSTECHN

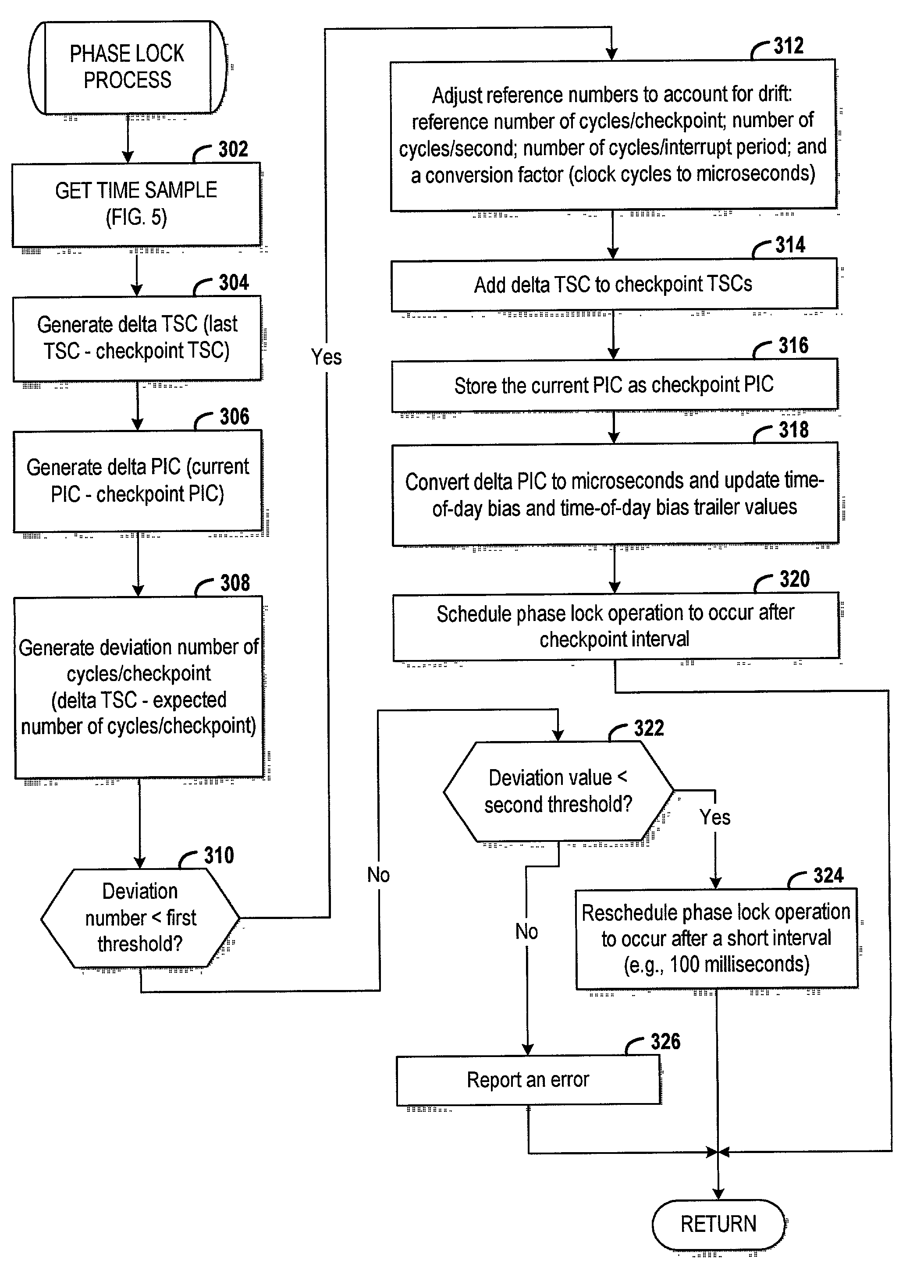

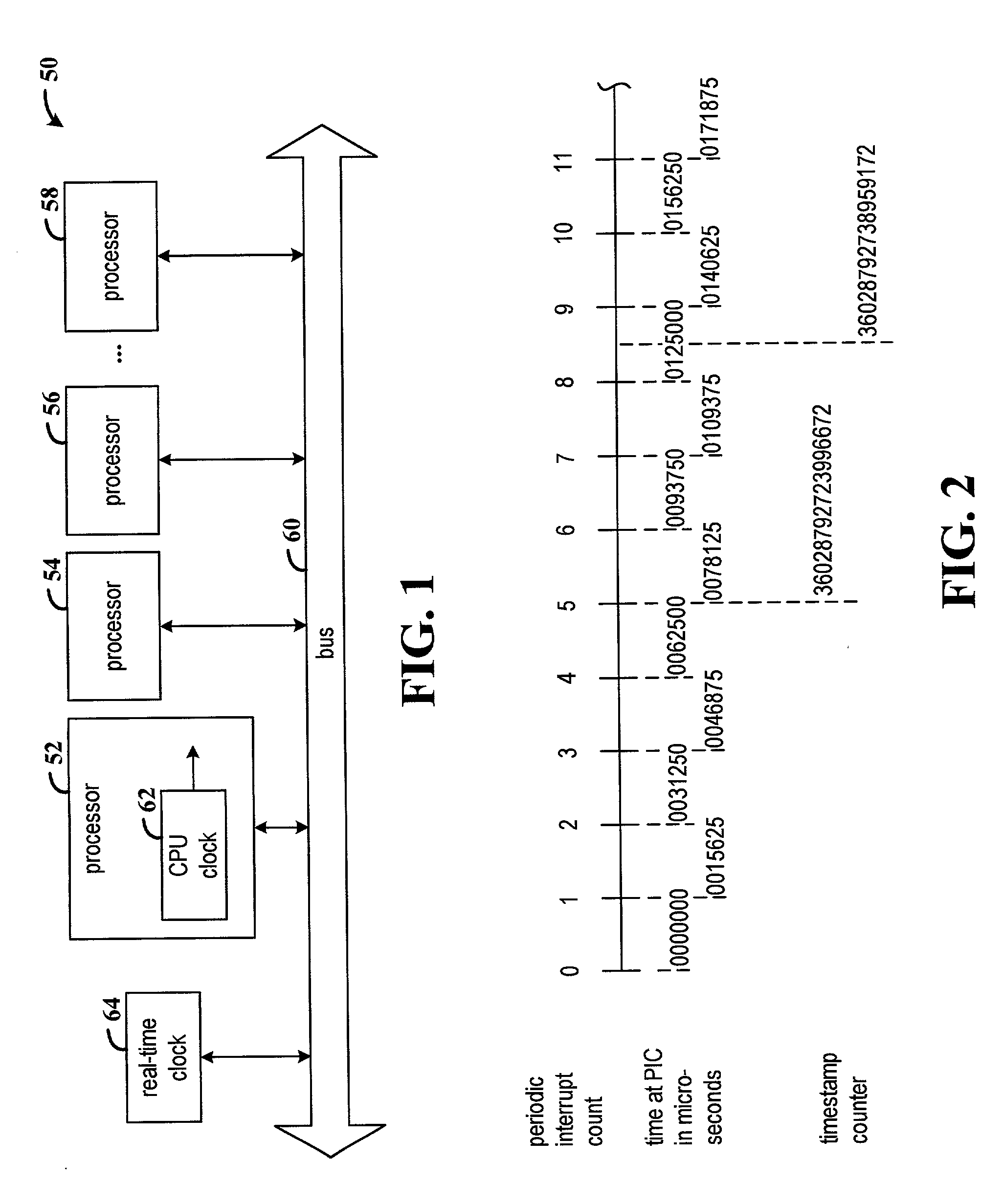

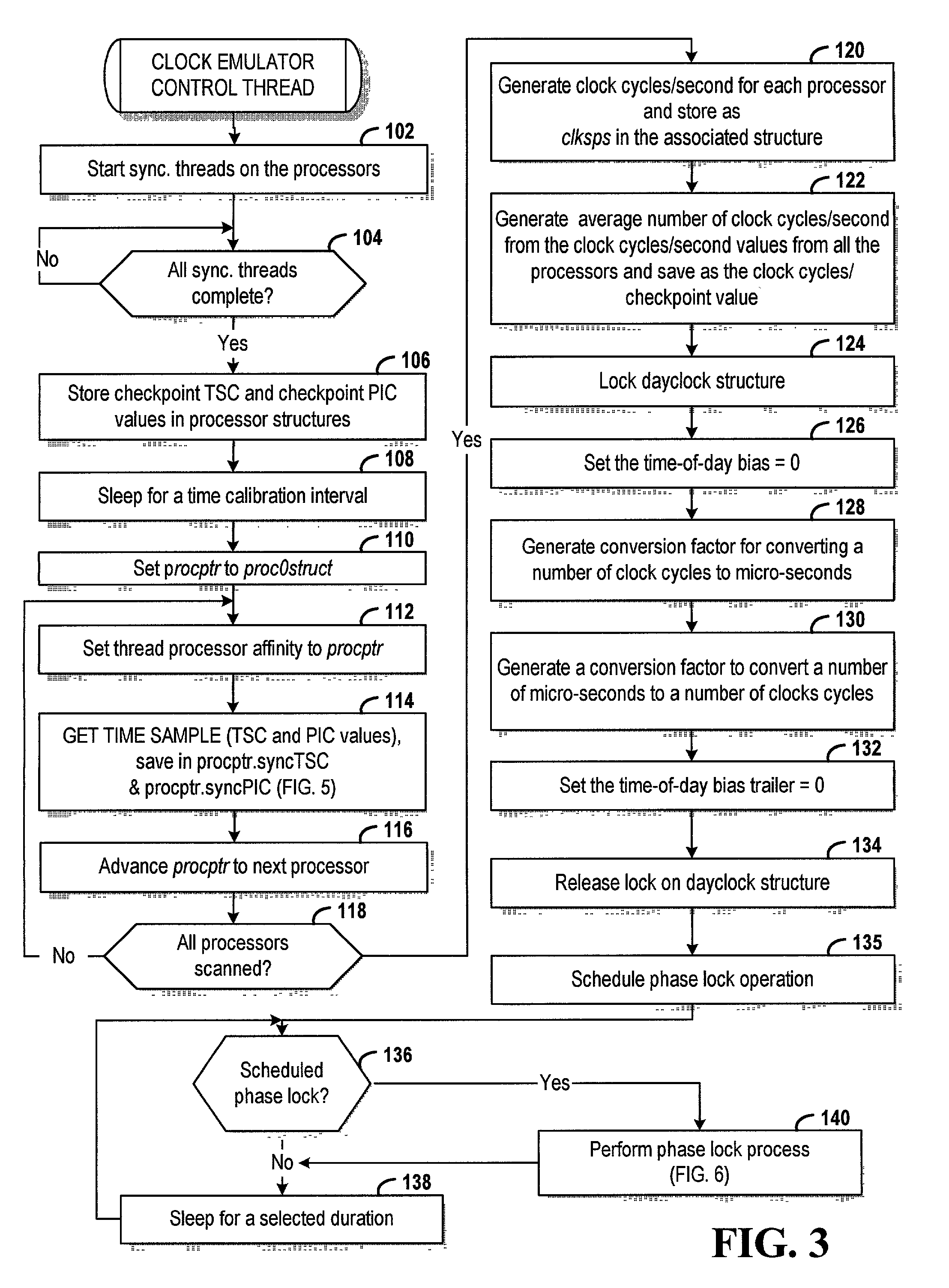

Emulation of a high-speed, high-stability clock

A method and apparatus for emulating a high-precision, high-accuracy clock. In one embodiment, two clocks are used in the emulation. The first clock has precision greater than precision of the second clock and accuracy less than accuracy of the second clock. A checkpoint time relative to elapsed cycles of the second clock and a checkpoint cycle count of cycles of the first clock are periodically stored relative to a checkpoint period that lasts for a selected number of cycles of the second clock. A reference cycle rate of the first clock is calculated relative to the cycle rate of the second clock. The current time is determined as a function of the checkpoint time, a number of cycles of the first clock elapsed since storing the most recent checkpoint cycle count, and the reference cycle rate of the first clock.

Owner:UNISYS CORP

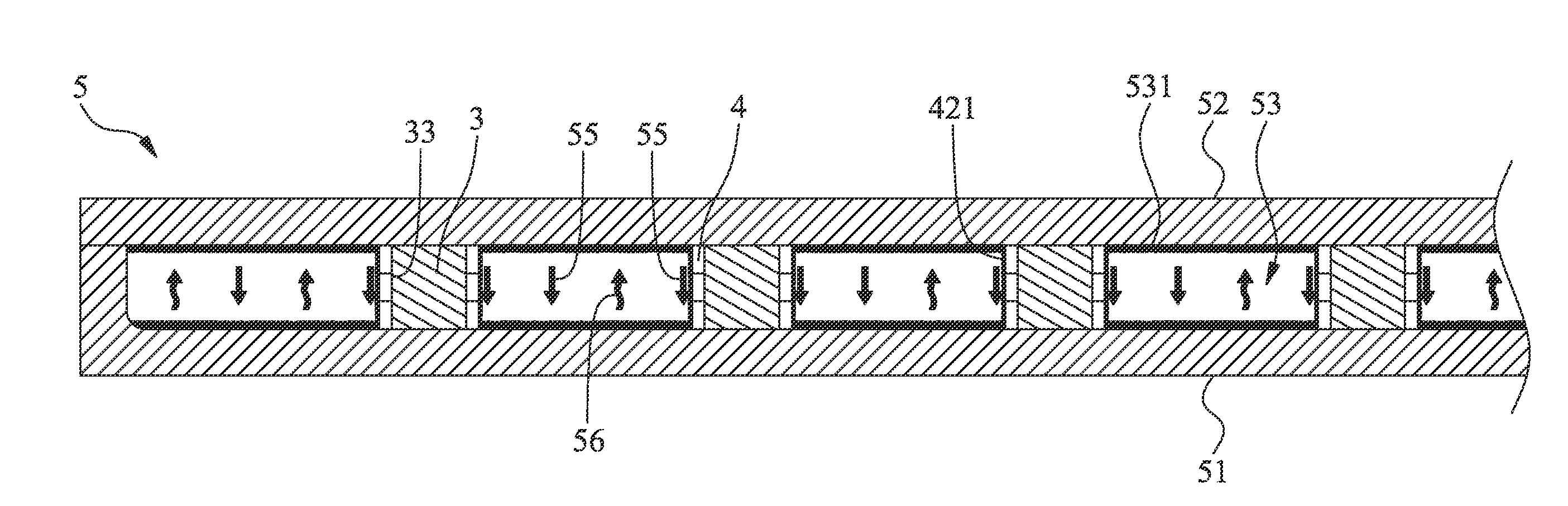

Support structure for flat-plate heat pipe

InactiveUS20110088873A1Improve cooling effectImprove thermal uniformityIndirect heat exchangersHeat exchanger casingsCycle rateWorking fluid

A support structure for flat-plate heat pipe, including a main body and a fitting body. The fitting body has at least one open side and a first side section connected with the open side. The first side section has a capillary structure formed on a periphery of the first side section. The first side section and the open side together define a space for fixedly fitting the main body therein. By means of the capillary structure of the first side section of the fitting body, the circulating rate of a working fluid flowing within the flat-plate heat pipe is increased to achieve better heat dissipation effect and better thermal uniformity.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

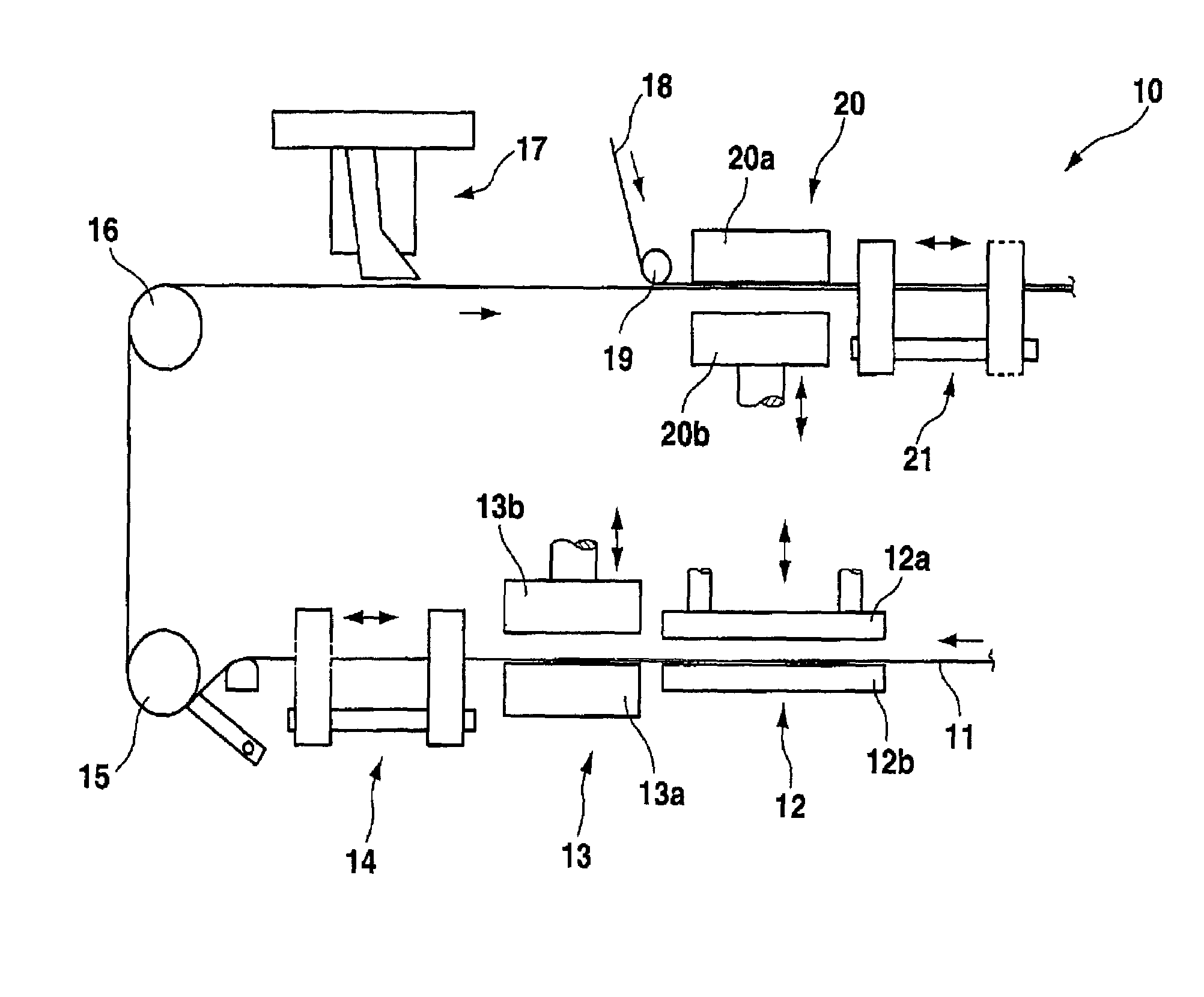

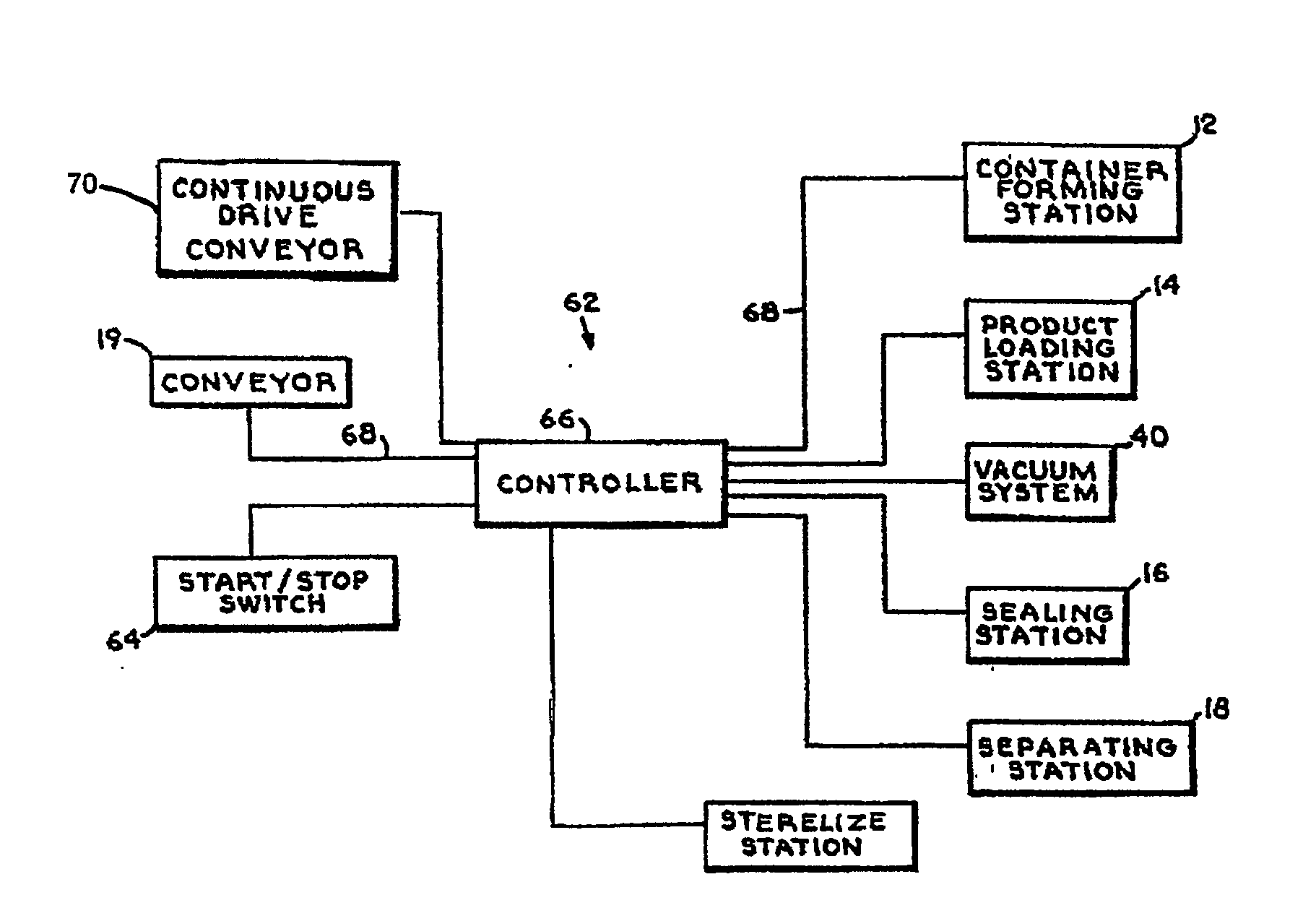

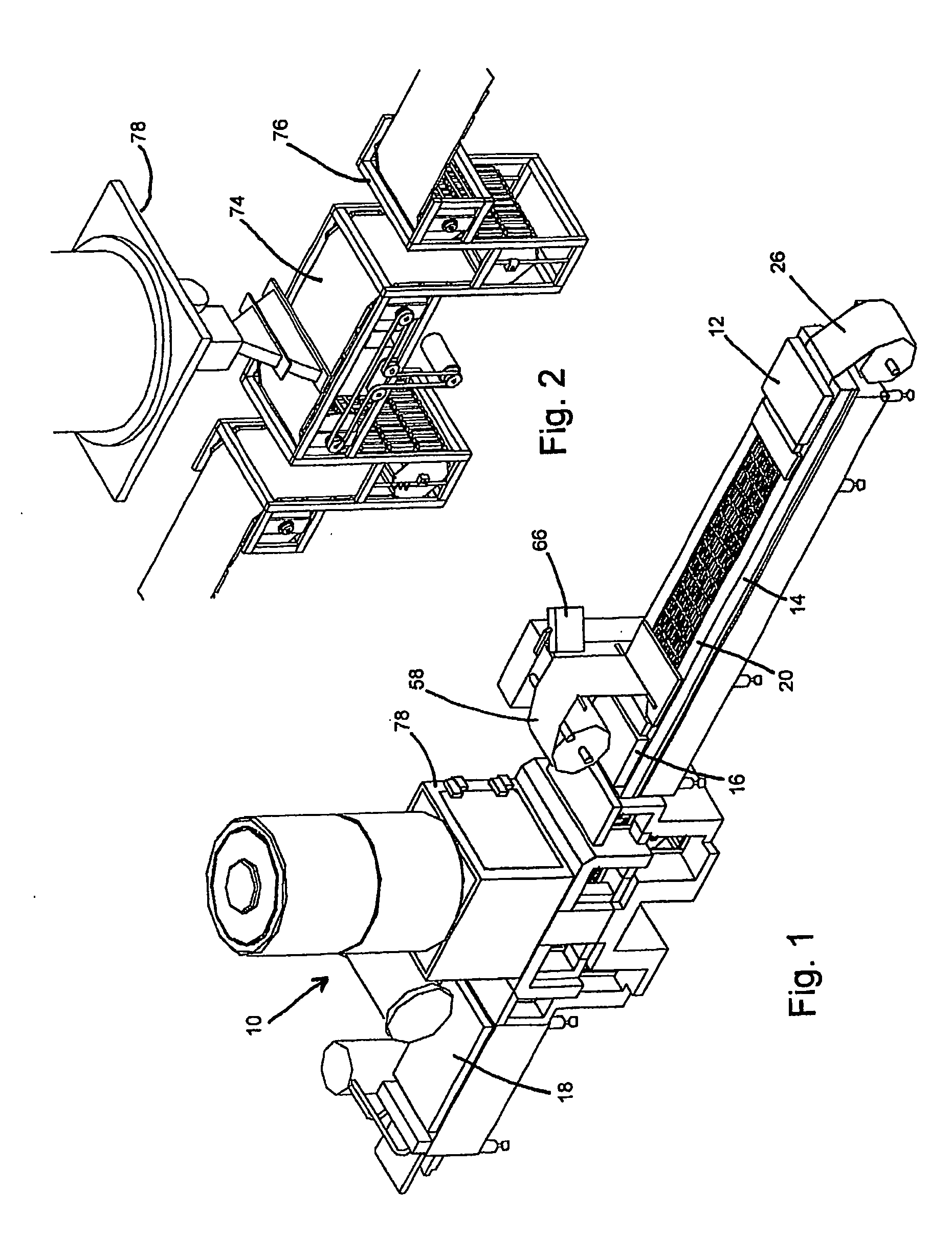

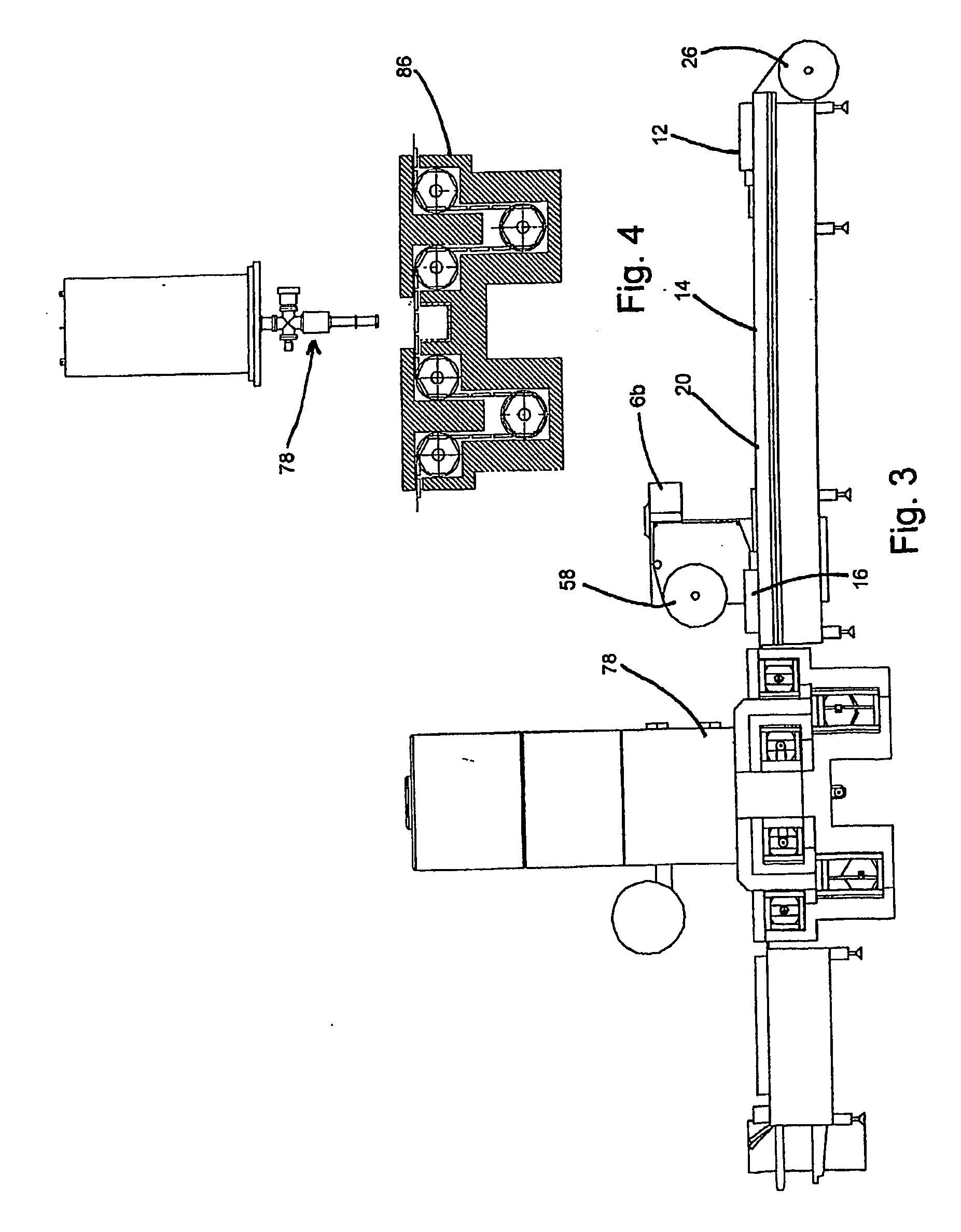

Inline processing and irradiation system

InactiveUS20090173039A1Mechanical integritySave energyPackage sterilisationMaterial analysis by optical meansCycle rateProcess engineering

A stream of products is packaged and biologically treated by the system. The system has an index conveyor with a filling station and a packaging station. Discrete packages are filled with the stream of products, sealed and moved on an index conveyor. The system moves the discrete packages an irradiation chamber at a steady rate on a continuous speed conveyor. A controller matches the cyclical rate of the index conveyor with the steady rate of the continuous speed conveyor and uses a buffer to transition from the cyclical rate to the steady rate.

Owner:RDI IBA TECH GROUP +1

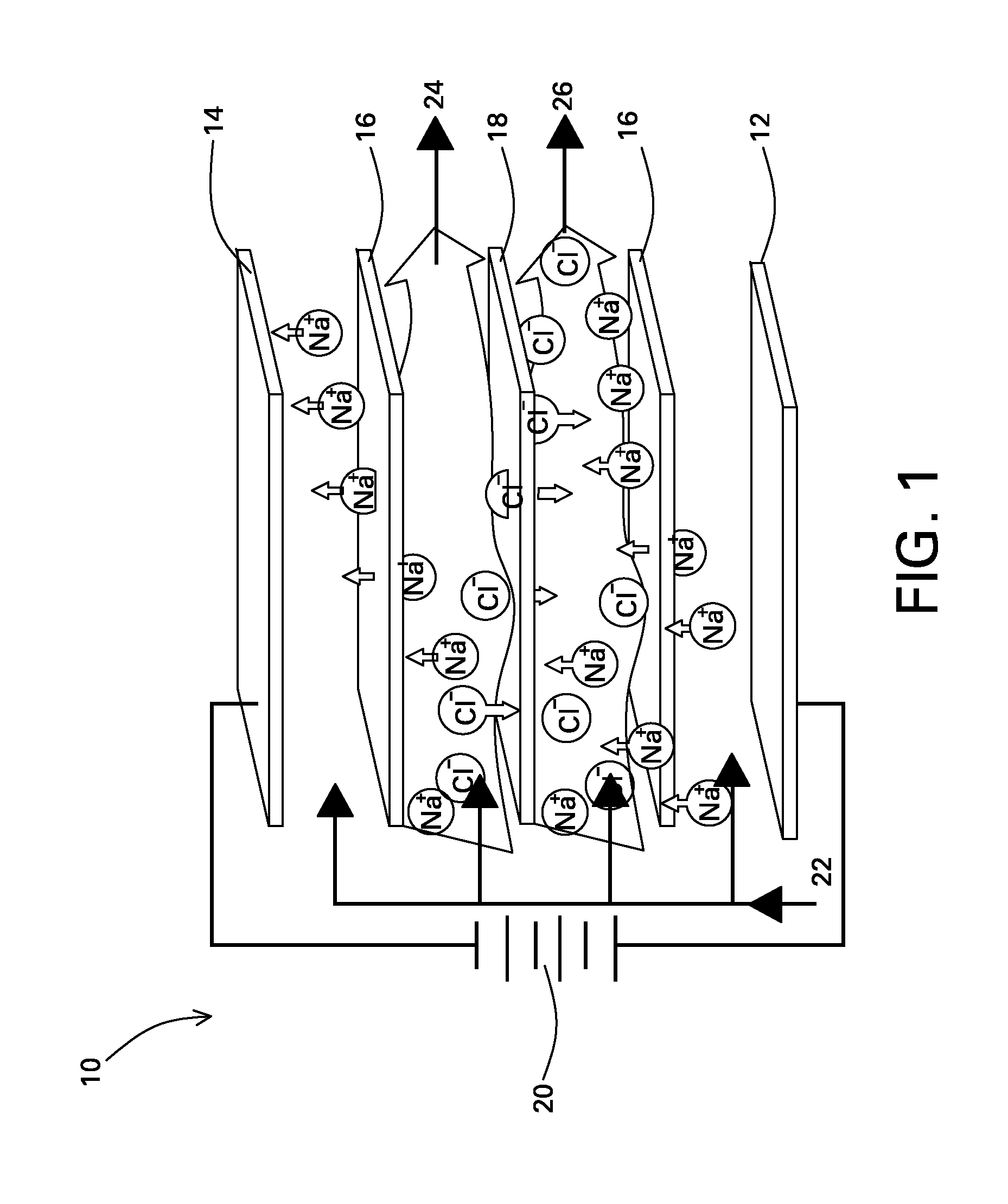

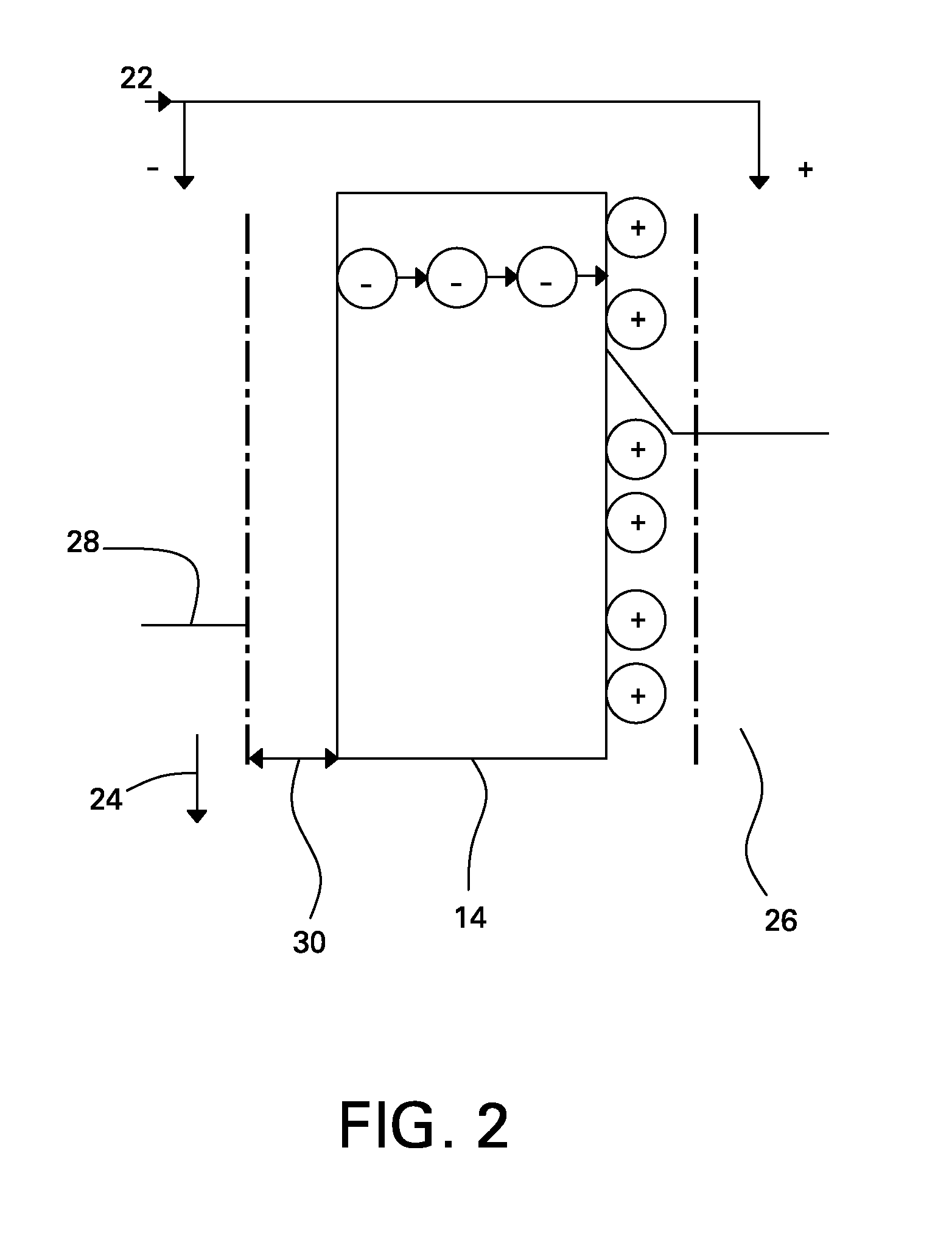

Electrodialysis device and process

A device includes a first electrode and a second electrode spaced from the first electrode to define a volume. An anion exchange membrane and a cation exchange membrane are disposed within the volume. A controller controls a supply of electrical current from an electrical source to the first electrode and to the second electrode. The electrical current supply is controlled to switch from a first mode of operation to a second mode of operation providing electrical current having a reverse polarity during each cycle. The electrical current is supplied at a controlled cycle rate and for a controlled duration. The cycle rate is greater than about 100 hertz and less than about 10 kilohertz.

Owner:BL TECH INC

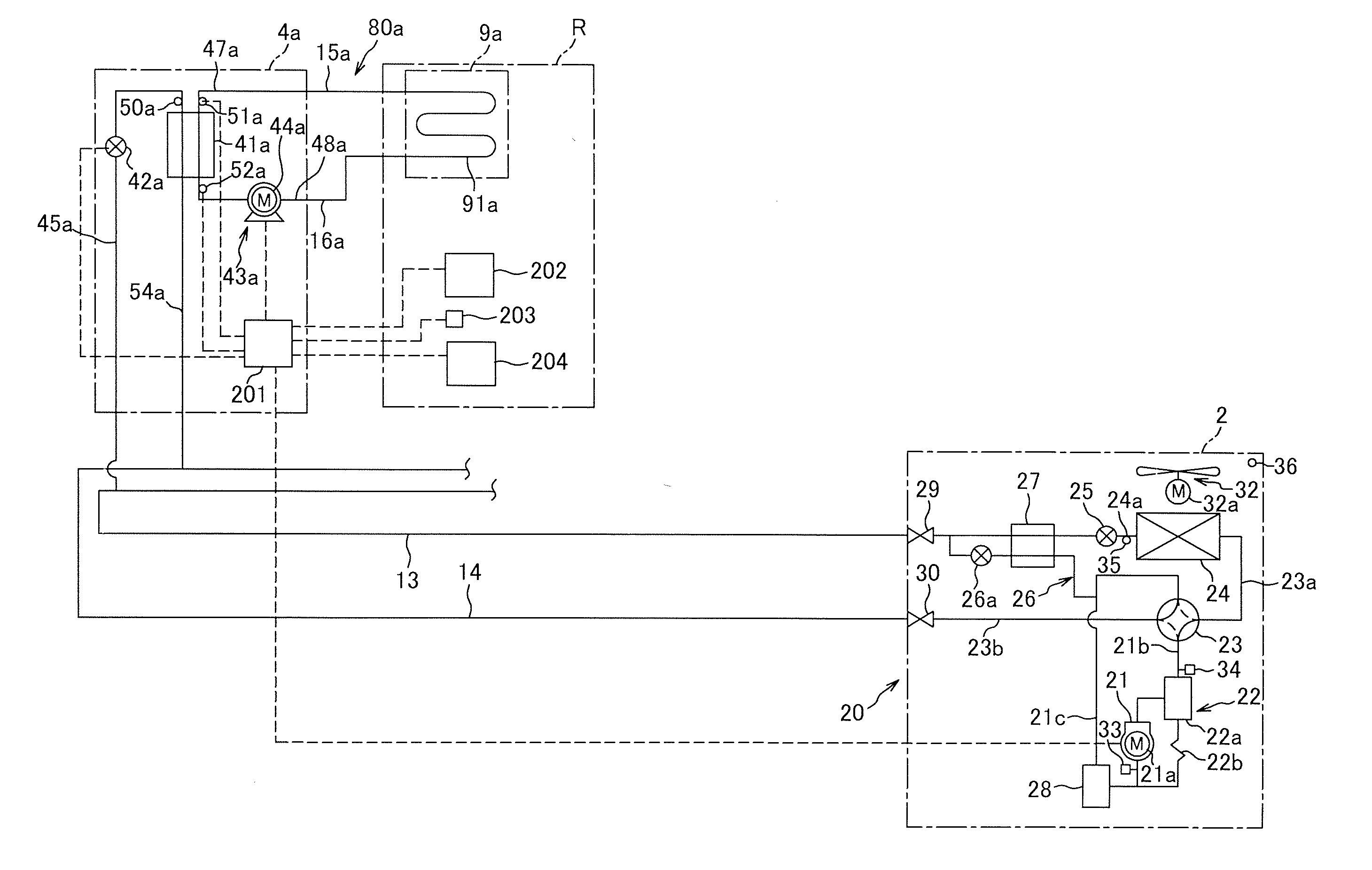

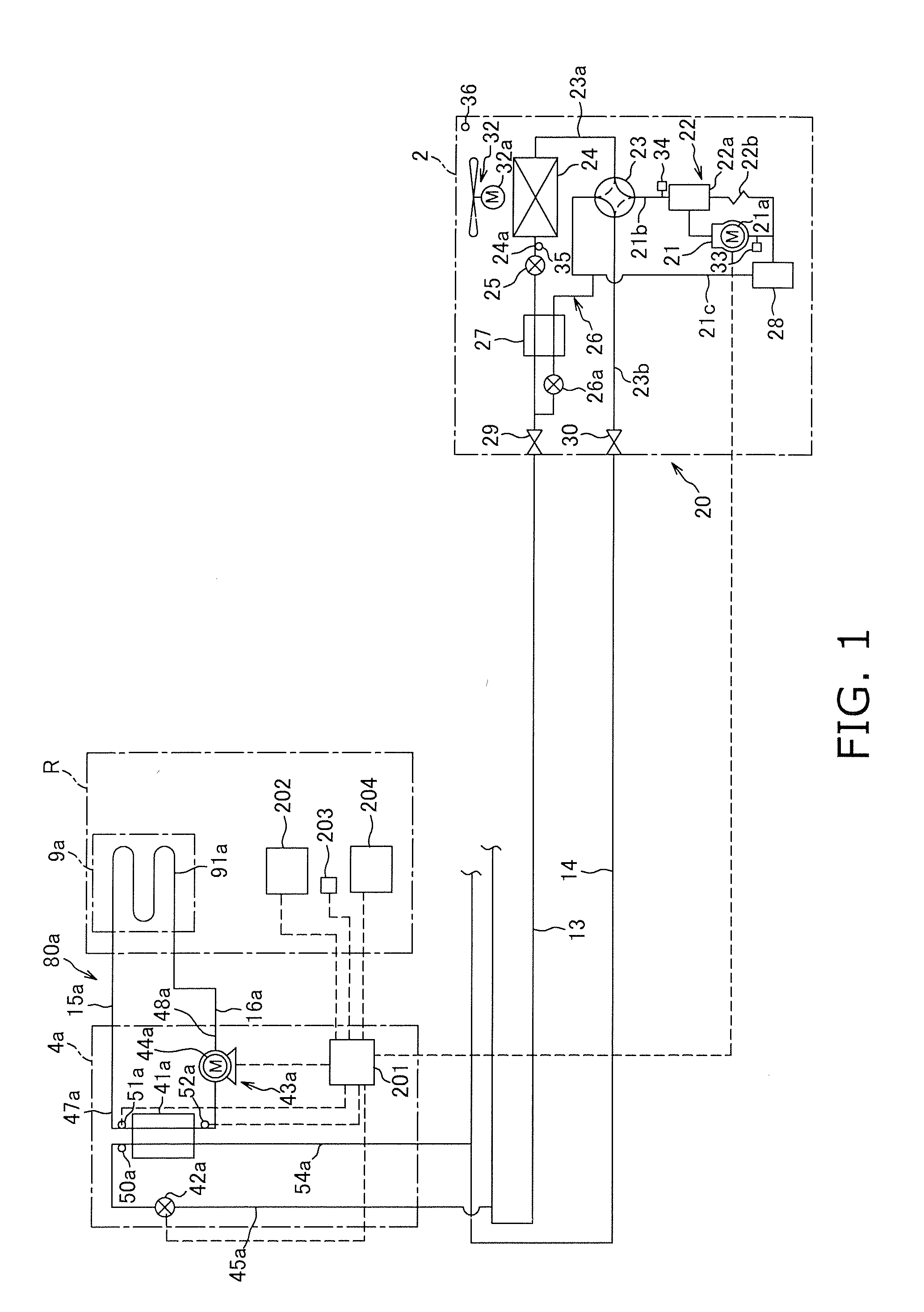

Heat pump system

InactiveUS20110302947A1Excessive temperature rise can be more preventedAvoid excessive heatHeating fuelHeat pumpsCycle rateEngineering

A heat pump system includes a refrigerant circuit, an inlet temperature sensor measuring a heat exchanger inlet temperature of an aqueous medium in a usage-side heat exchanger of the refrigerant circuit, an outlet temperature sensor measuring a heat exchanger outlet temperature of the aqueous medium in the usage-side heat exchanger, a variable-capacity circulating pump circulating the aqueous medium inside a hot-water circuit of a loop, and a controller. The controller controls refrigerant-side circulation rate in the refrigerant circuit to bring a temperature of the aqueous medium at the outlet of the usage-side heat exchanger to a targeted first target temperature, and operating capacity of the circulating pump to bring a medium temperature differential of the aqueous medium between the outlet and the inlet of the usage-side heat exchanger to a targeted second target temperature differential.

Owner:DAIKIN IND LTD +1

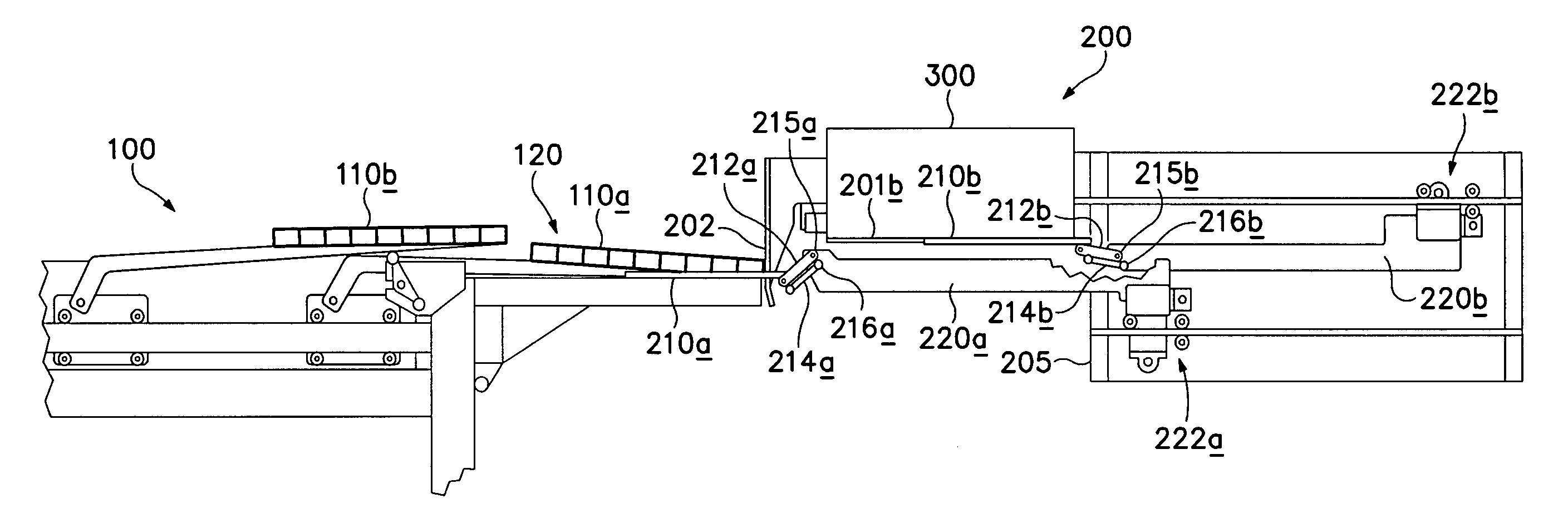

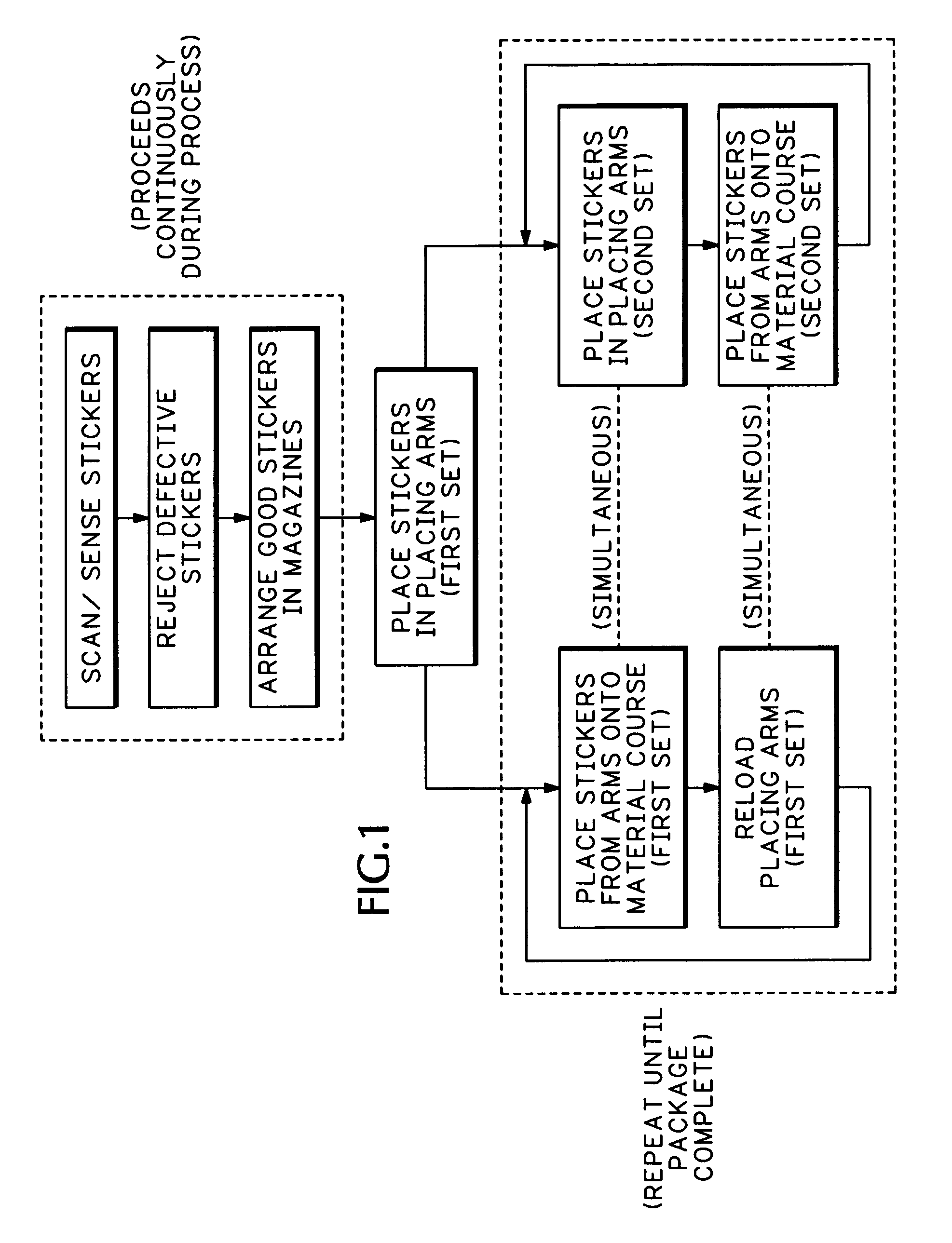

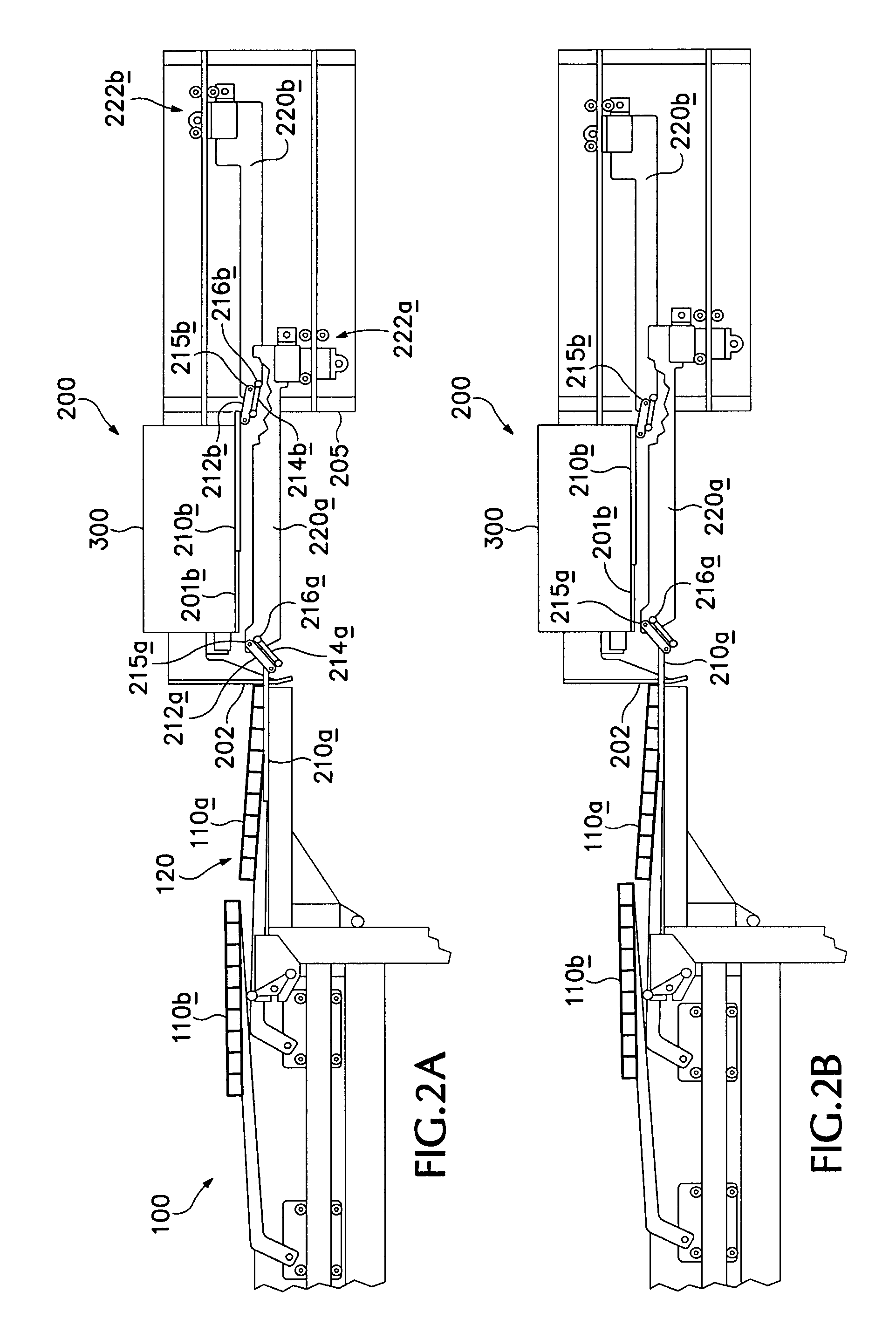

High speed sticker placer having horizontal and vertical positioning

InactiveUS7547182B2Few timing and maintenance issueStay competitive and efficientConveyorsStacking articlesCycle rateEngineering

A slat positioning and placing machine is preferably configured to place slats on top of or between accumulated material layers. A set of actuating arms preferably includes complementary operating slat holding holders, such as pans or other holding devices. As a first slat holder is inserting a slat into a material package being formulated, a second slat holder is preferably positioned to receive a slat. As the second slat holder is being positioned to insert the slat into the package, the first slat holder is preferably being cycled back to receive a slat. A controls methodology preferably electronically profiles the forward and rearward movement of the actuating arms. The raising and lowering functions can also be electronically profiled. The profiles can also preferably be adjusted to increase the cycle rates for various lengths being processed, and various cycling and positioning methods are contemplated. Sticker rake-off fingers can also be provided that move from a non-obstructing position to a rake-off position to help position stickers in the material package being formed.

Owner:HOGUE INDS

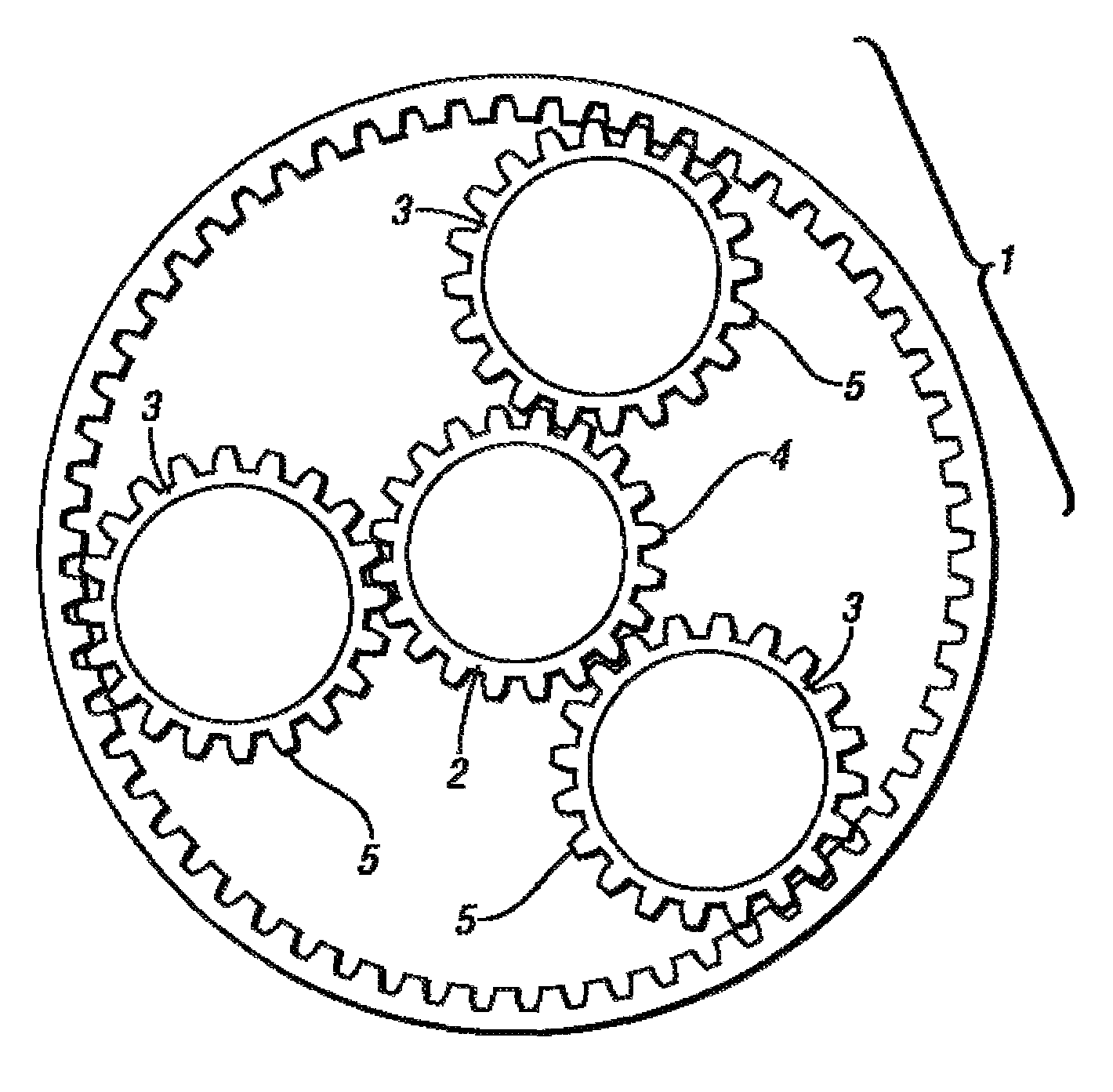

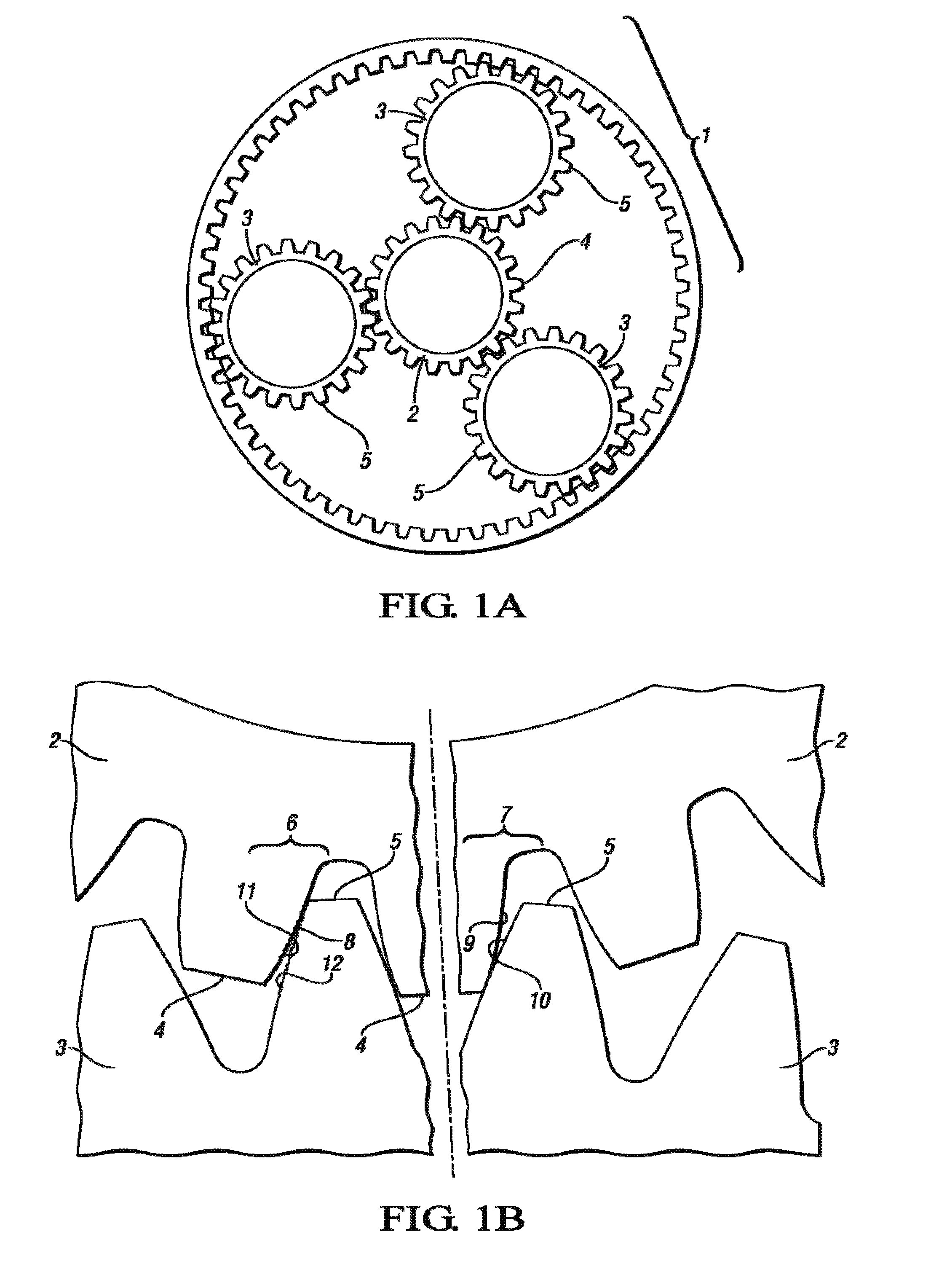

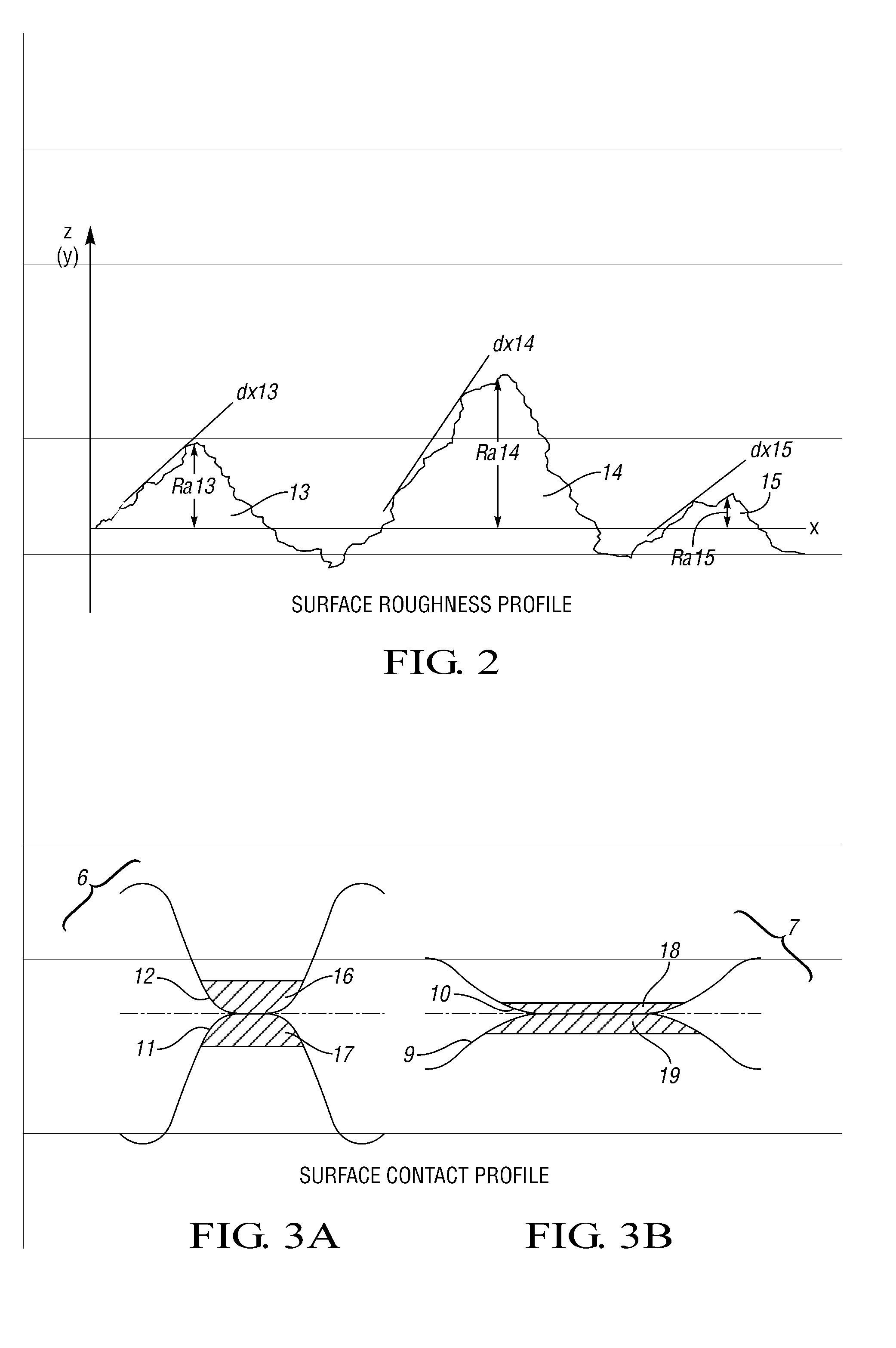

Apparatus and method of using a hardness differential and surface finish on mating hard gears

An apparatus and method for finishing the mating surfaces of a gear set or gear train includes at least a first and a second rotatably connected gear element in dynamic, lubricated contact and rotating at different cycle rates. A hardness differential is employed between mating gear surfaces to balance surface damage imparted by friction and plastic deformation. The mating surfaces are of a hardness of at least approximately 70 on the Rockwell superficial hardness scale (70HR-30N), and are subjected to a polishing process, such as isotropic chemical finishing, to shape the surface asperity profile, thereby reducing accumulative damage due to friction and plastic deformation.

Owner:GM GLOBAL TECH OPERATIONS LLC

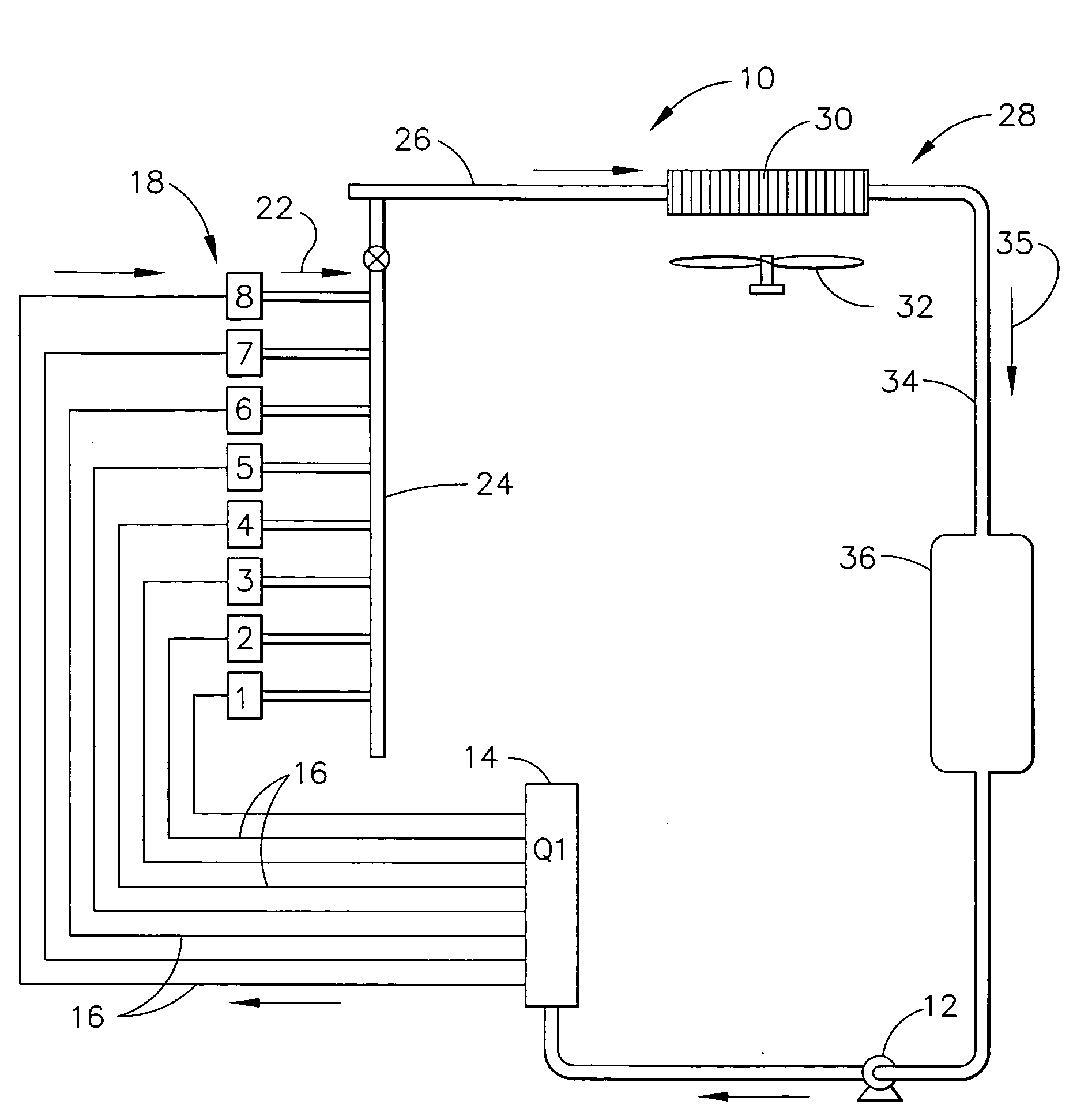

System and method for controlling the cooling of variable heat loads in heat generating devices

InactiveUS20090158757A1Quick changeSemiconductor/solid-state device detailsCompression machines with non-reversible cycleCycle rateEngineering

The present invention offers an improvement over prior art cooling systems by accounting for rapid changes in thermal load. The circulation rate of refrigerant in a cooling cycle is set so that the two phase mixture exiting the cold plate evaporator device stays within a saturation dome of all mixtures between a saturated liquid and a saturated vapor. Furthermore, the two phase mixture exiting the cold plate evaporator device is allowed to move within the saturation dome so that the exit quality of the two phase mixture leaving the cold plate evaporator device changes with the heat load being removed. In this way, rapid changes in heat load are removed from the component or components in contact with the cold plate evaporator device without having to change the circulation rate of refrigerant in the cycle. Only the exit quality of the vapor leaving the cold plate / evaporator changes.

Owner:MARSALA JOSEPH

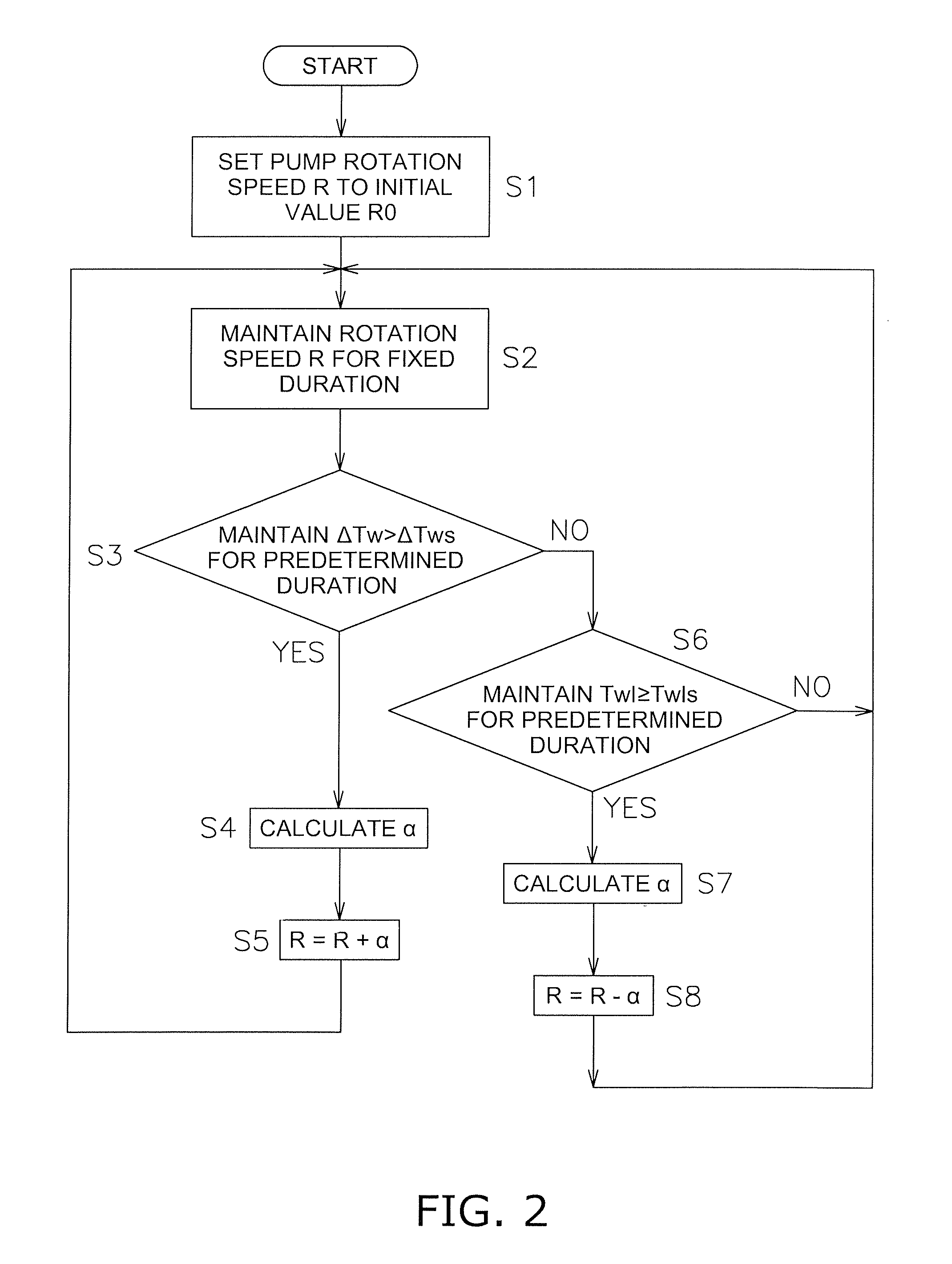

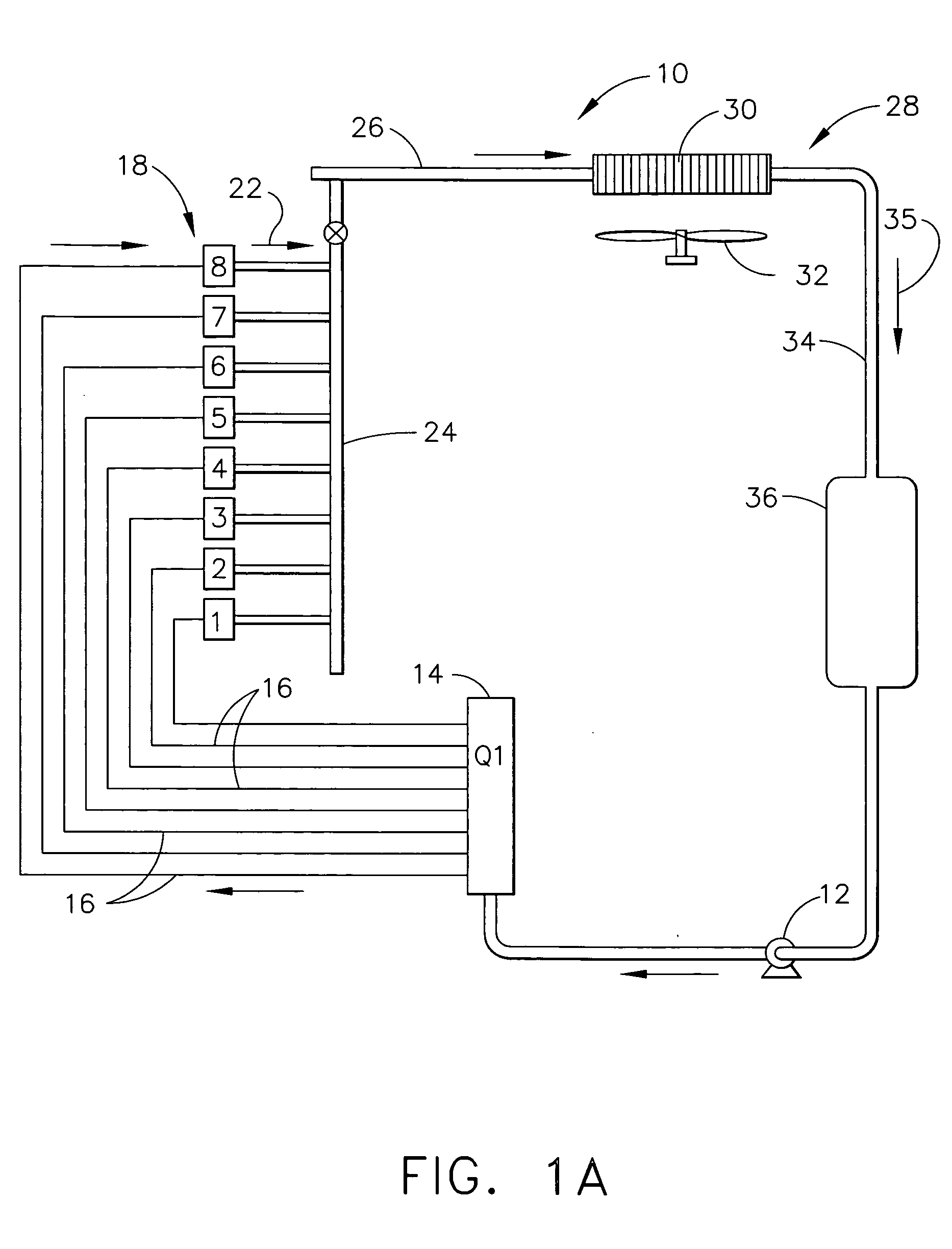

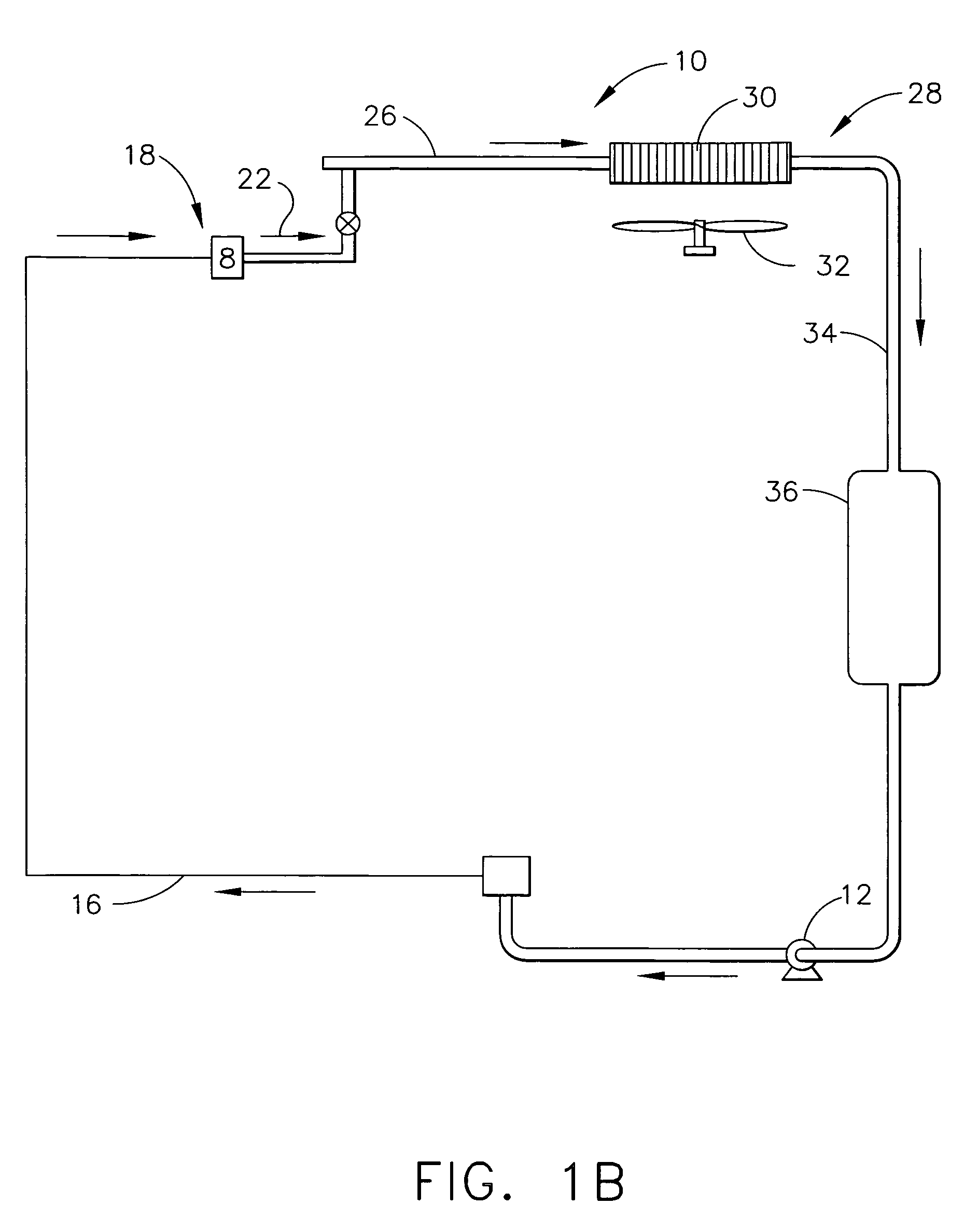

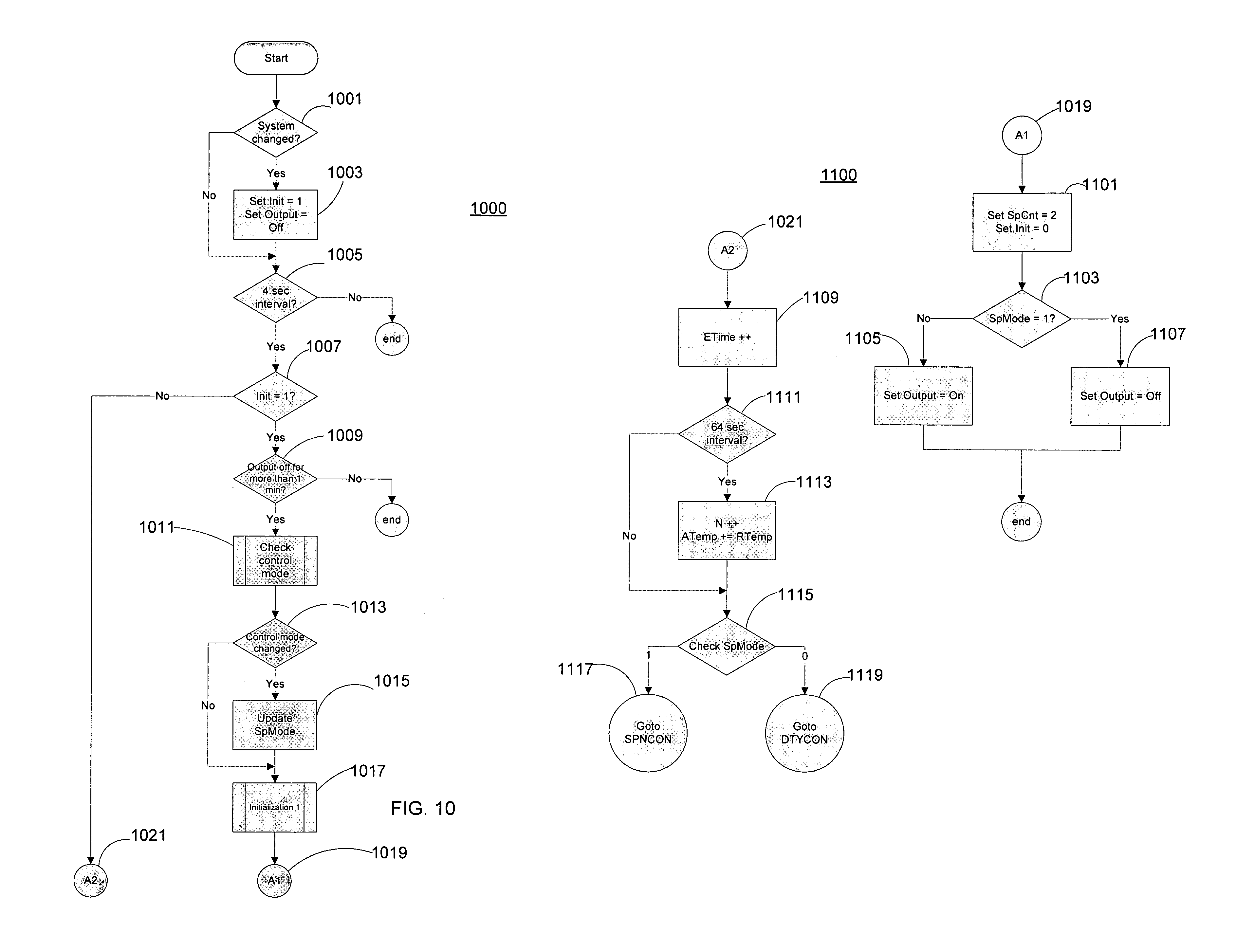

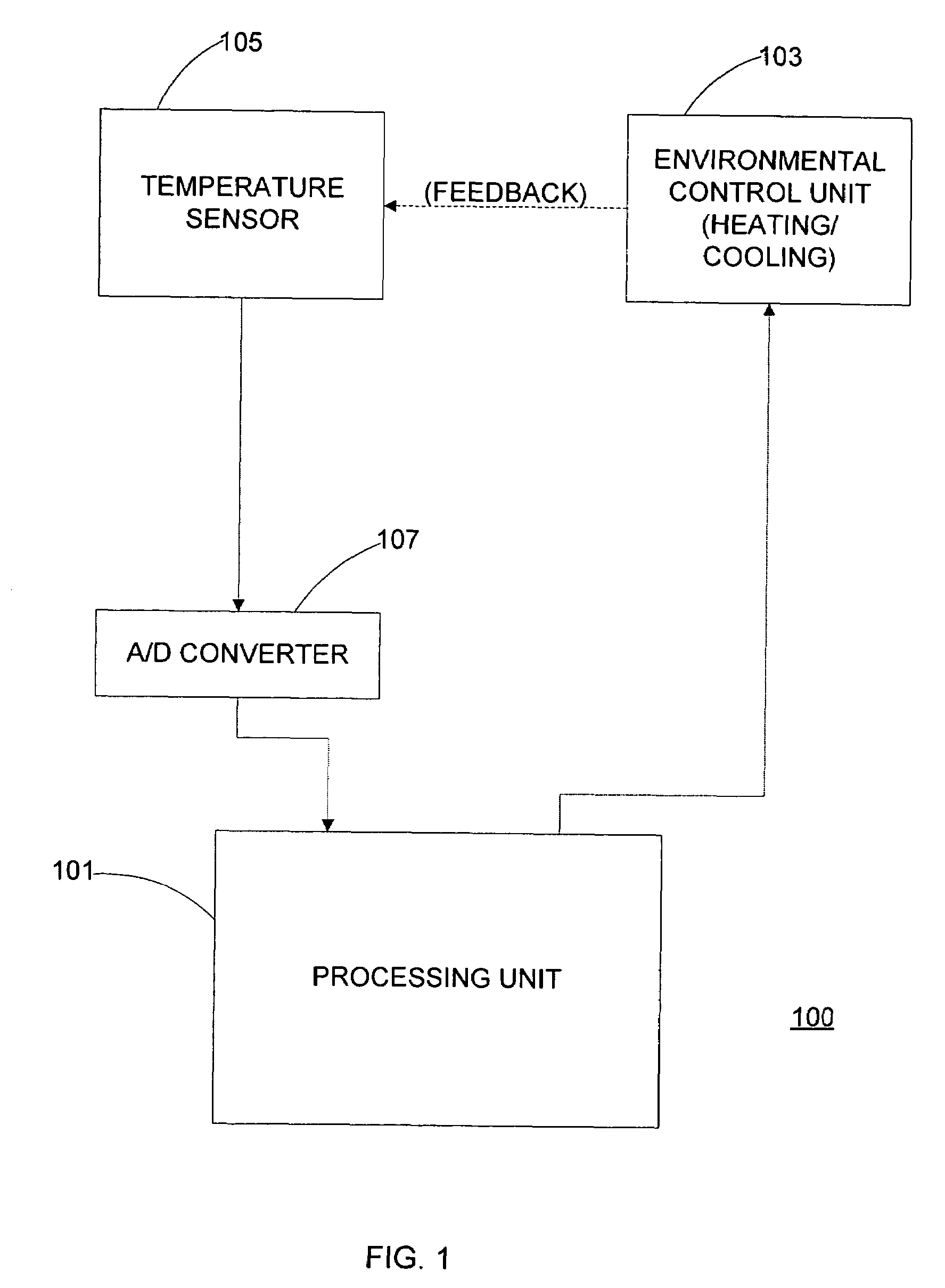

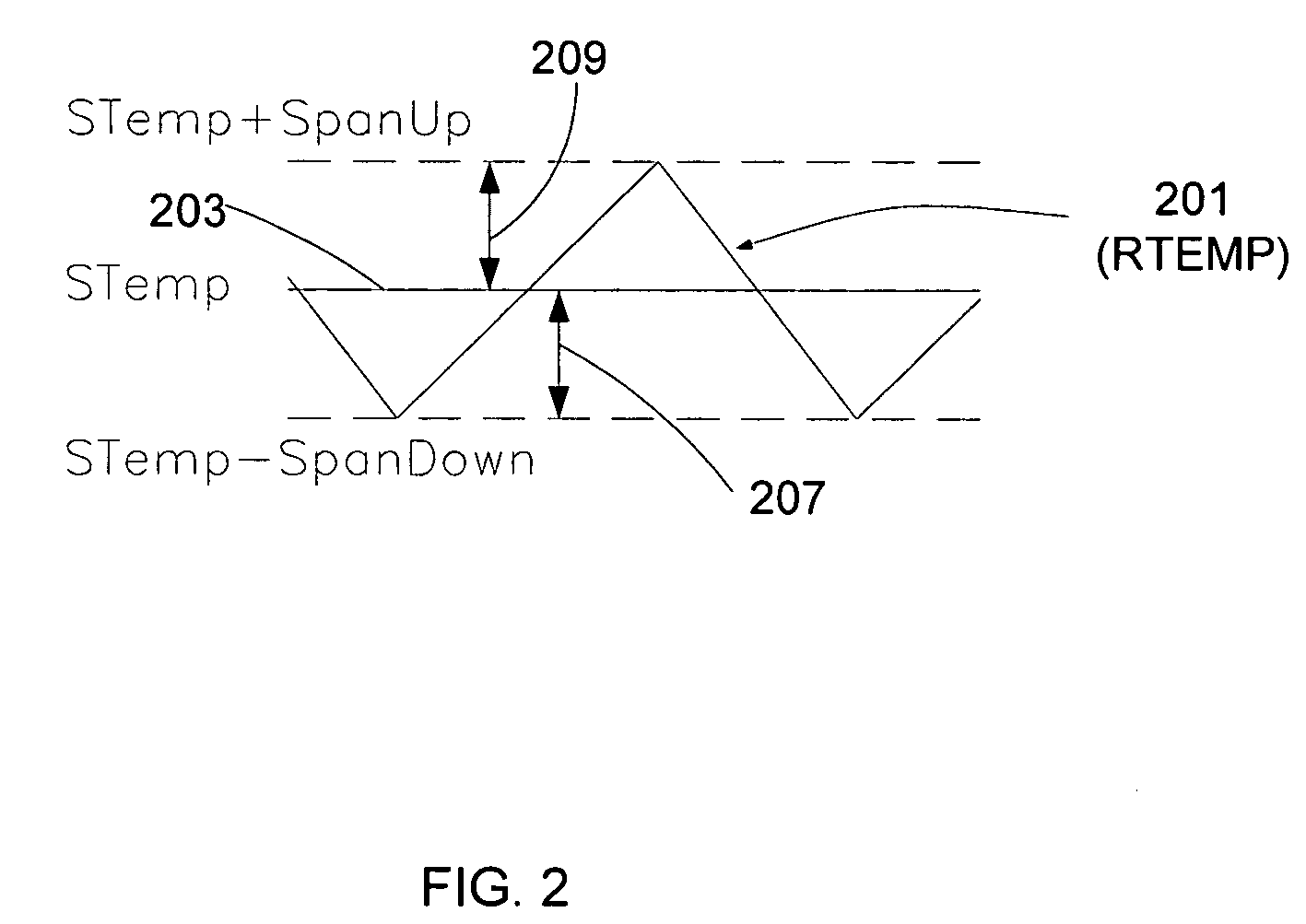

Apparatus for temperature control using a cycle rate control algorithm

The present invention controls a room temperature by controlling an environmental control unit. A total span about a setpoint temperature is adjusted in accordance with a previous total span and a multiplicative factor. The multiplicative factor is periodically updated from a desired cycle time and a previous cycle time. The room temperature may also be controlled by adjusting a duty cycle for controlling an environmental control unit. The duty cycle is adjusted based on an error associated with a previous control cycle and an attenuation factor. A new control cycle may be started by cutting the previous control cycle or a current control cycle may be extended if a predetermined condition is detected. The control mode is selected based on environmental characteristics and room characteristics. The control mode may include a span control mode and a duty cycle control mode that is selected from the cycle rate.

Owner:COMPUTIME LTD

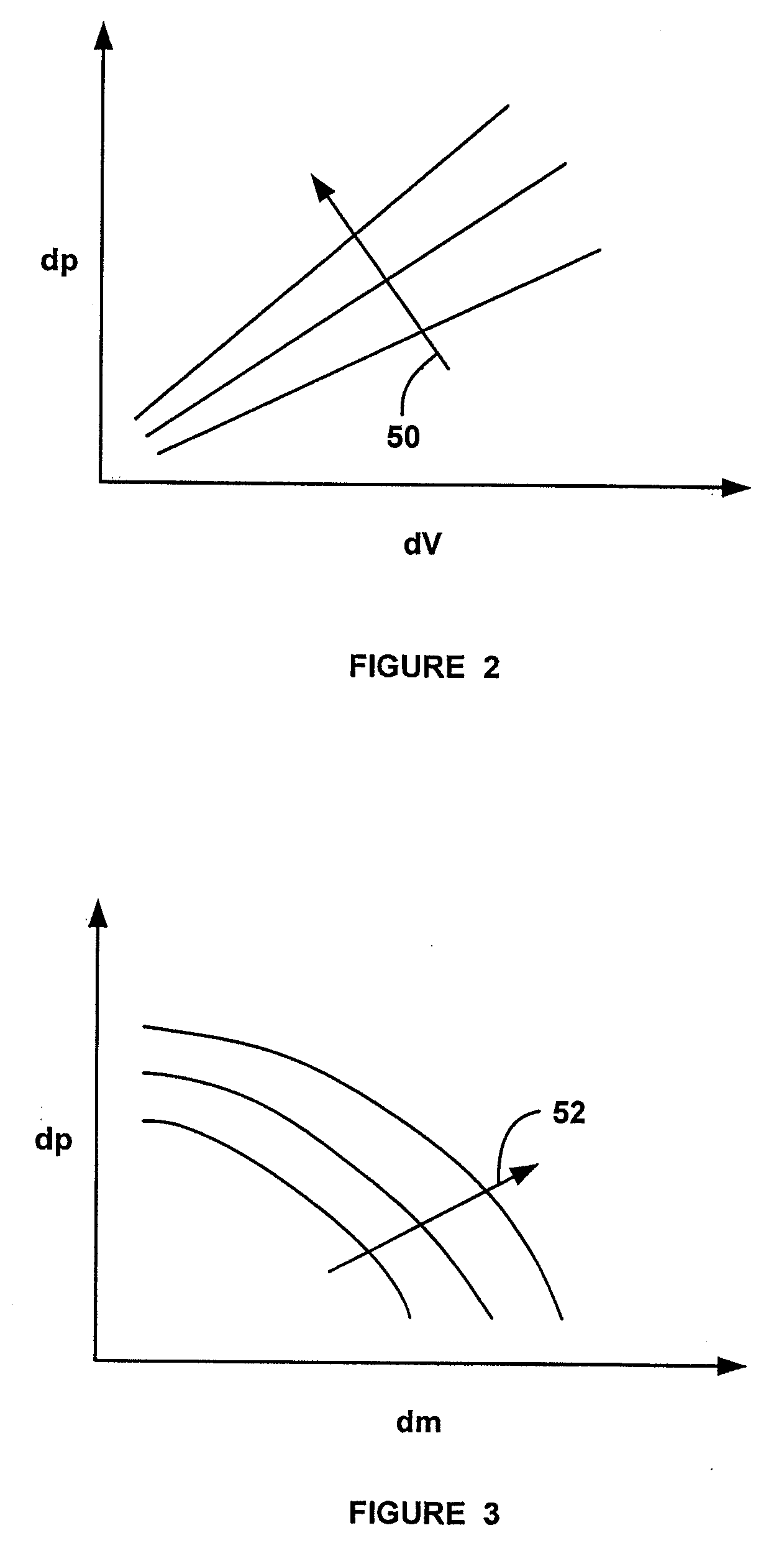

Dense phase pump with open loop control

Owner:NORDSON CORP

Method and device for separating products

ActiveUS8997614B2Exact weight precisionIncrease cycle rateStock shearing machinesMetal working apparatusCycle rateEngineering

A method and a device for separating food products, including to permit a straight cut at high cycle rates, the food product is conveyed by a conveying device in the direction of transport. The food product is cut through, where a cutting element is moved in the direction of transport and transverse to the direction of transport, wherein the motion of the cutting element transverse to the direction of transport is controlled independently of its motion in the direction of transport and the food product does not rest on the cutting area on the conveying means.

Owner:ALBERT HANDTMANN MASCHFABRICK

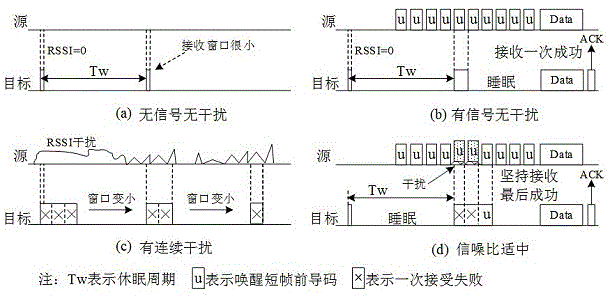

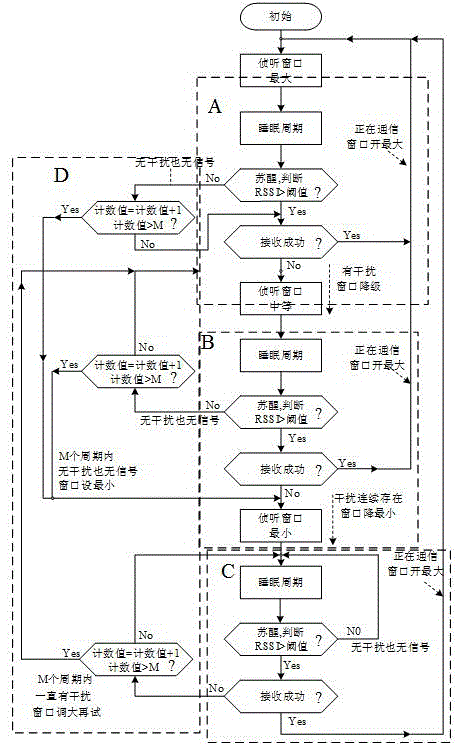

Self-adaptive monitor matching anti-interference method of wireless sensor network

InactiveCN105657804ASize adjustmentSolve consumptionPower managementNetwork topologiesCycle rateWireless mesh network

The invention discloses a self-adaptive monitor matching anti-interference method of a wireless sensor network. The self-adaptive monitor matching anti-interference method adopts a 'self-adaptive monitor matching window' flexibly adjustable in receiving window size to receive data information transmitted from a source node. A receiving monitor window is maximum in size in an initial state, and a received signal strength indicator measures the strength of wireless signals. When the signal strength is lower than a set threshold value, a cycle rate counter adds 1. When the signal strength is higher than the set threshold value, signal receiving starts. When signal receiving succeeds, a communication window is adjusted to be maximum in size and returns to the initial state. If the receiving fails, the window size is decreased. In the monitoring process, if no interference signal or normal signal is found in M cycles, the size of the receiving monitor window is minimum. When the monitor window is in a minimum state, interference signals always exist in the M cycles, and the window is adjusted to be in an intermediate state. By the adoption of the self-adaptive monitor matching anti-interference method, monitor errors between a transmitting node and a receiving node in a wireless interference environment is effectively decreased, and unnecessary energy consumption and lost data packets are reduced.

Owner:SHANGHAI UNIV

Simultaneous chemical species separation and T2* measurement using MRI

ActiveUS7468605B2Measurements using NMR imaging systemsAnalysis using nuclear magnetic resonanceCycle rateChemical species

A method for generating a magnetic resonance image is provided. A magnetic resonance imaging excitation is applied for a plurality of cycles at a cycle rate. A plurality of magnetic resonance image echoes is acquired for each cycle. A decay map is estimated from the plurality of magnetic resonance image echoes for each cycle. The estimated decay map is used to generate an image for at least two different species.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Specimen for Evaluating Pressure Pulse Cavitation in Rock Formations

ActiveUS20170067808A1Material analysis using sonic/ultrasonic/infrasonic wavesElectric discharge heatingCycle rateWorking fluid

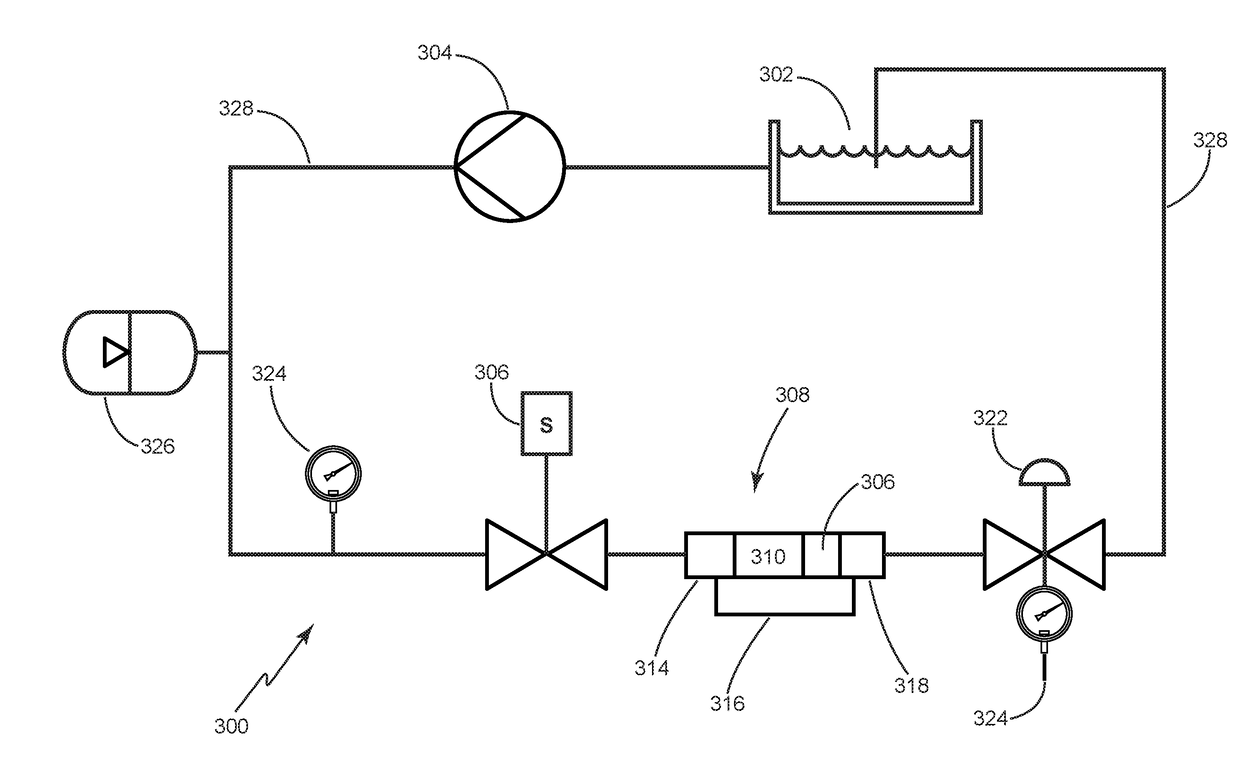

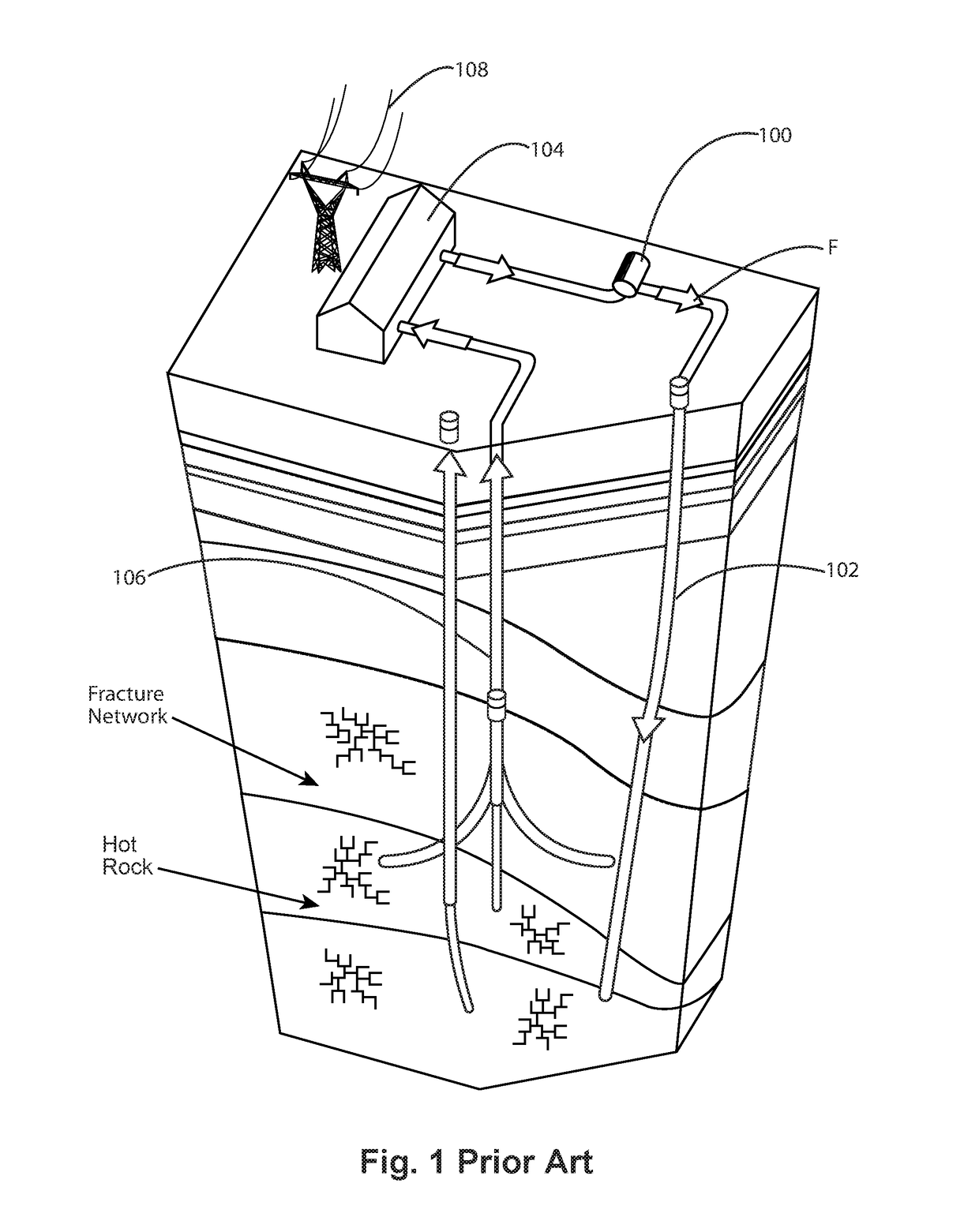

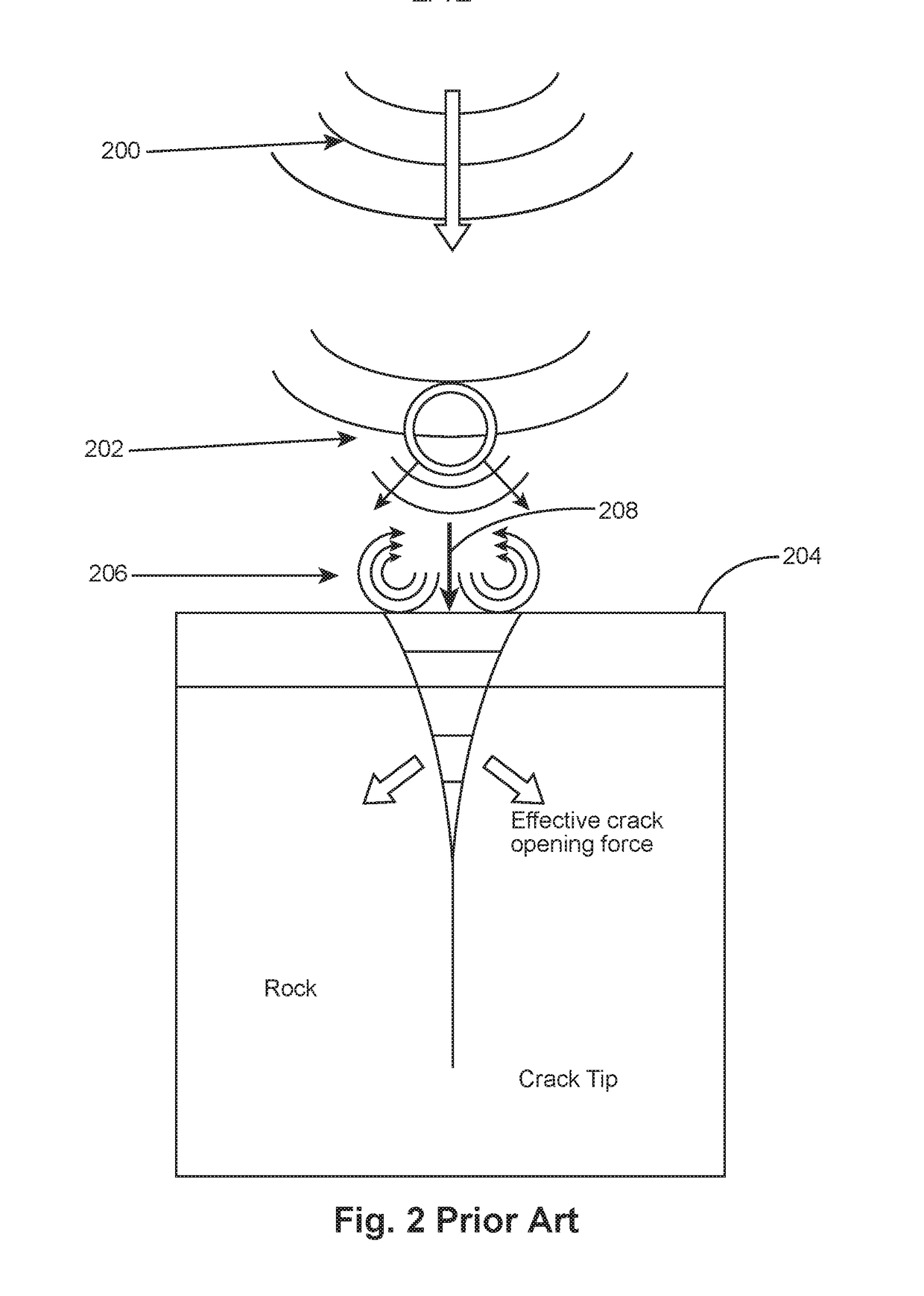

An apparatus 300 for simulating a pulsed pressure induced cavitation technique (PPCT) from a pressurized working fluid (F) provides laboratory research and development for enhanced geothermal systems (EGS), oil, and gas wells. A pump 304 is configured to deliver a pressurized working fluid (F) to a control valve 306, which produces a pulsed pressure wave in a test chamber 308. The pulsed pressure wave parameters are defined by the pump 304 pressure and control valve 306 cycle rate. When a working fluid (F) and a rock specimen 312 are included in the apparatus, the pulsed pressure wave causes cavitation to occur at the surface of the specimen 312, thus initiating an extensive network of fracturing surfaces and micro fissures, which are examined by researchers.

Owner:UT BATTELLE LLC

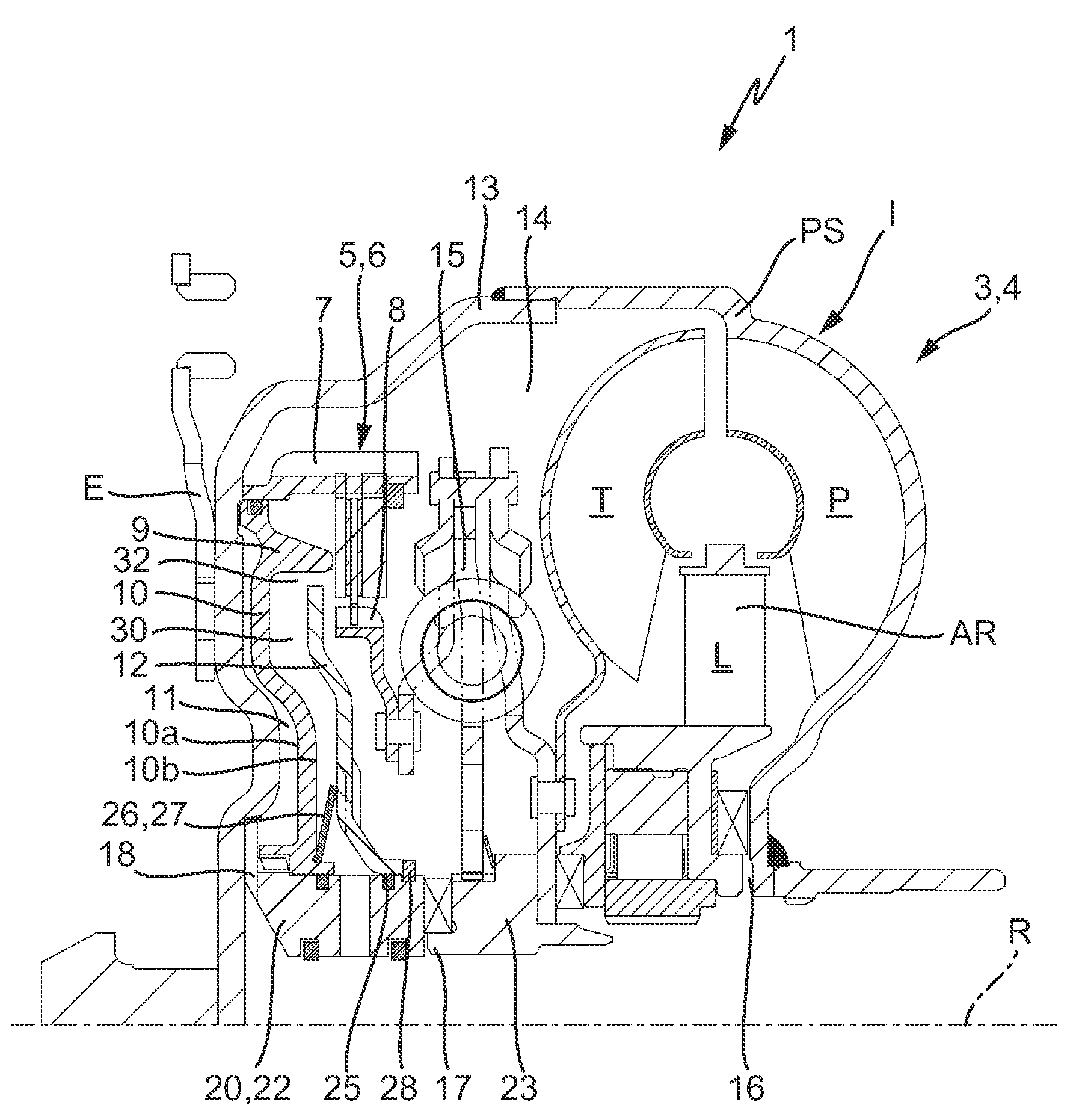

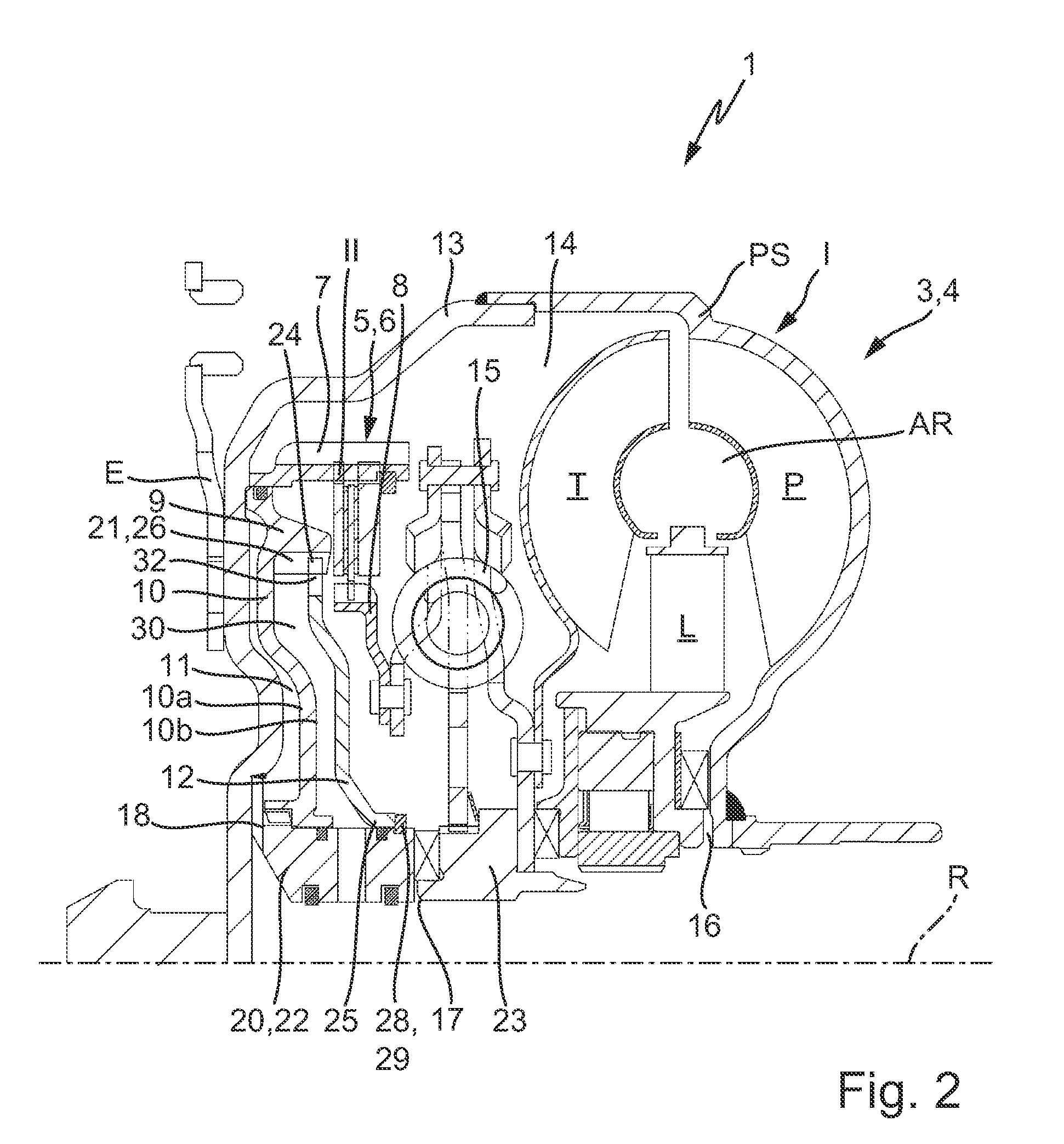

Power transmission device

InactiveUS20100084238A1Improvement of actuation behaviorReduction of hydrodynamic influenceRotary clutchesFluid actuated clutchesCycle rateImpeller

A power transmission device for power transmission between an engine and a power output, comprising at least an input and an output, a hydrodynamic component with an impeller- and a turbine wheel and a device for partially bypassing at least the hydrodynamic component with a servo unit featuring a piston element that can be pressurized with hydraulic medium and having means for influencing the circulation rate difference of flow media on both sides of the piston element, wherein the means comprises rotary synchronism with the piston element of the servo unit, a further rotatable piston element disposed in axial direction with a spacing from the piston element of the servo unit.

Owner:SCHAEFFLER TECH AG & CO KG

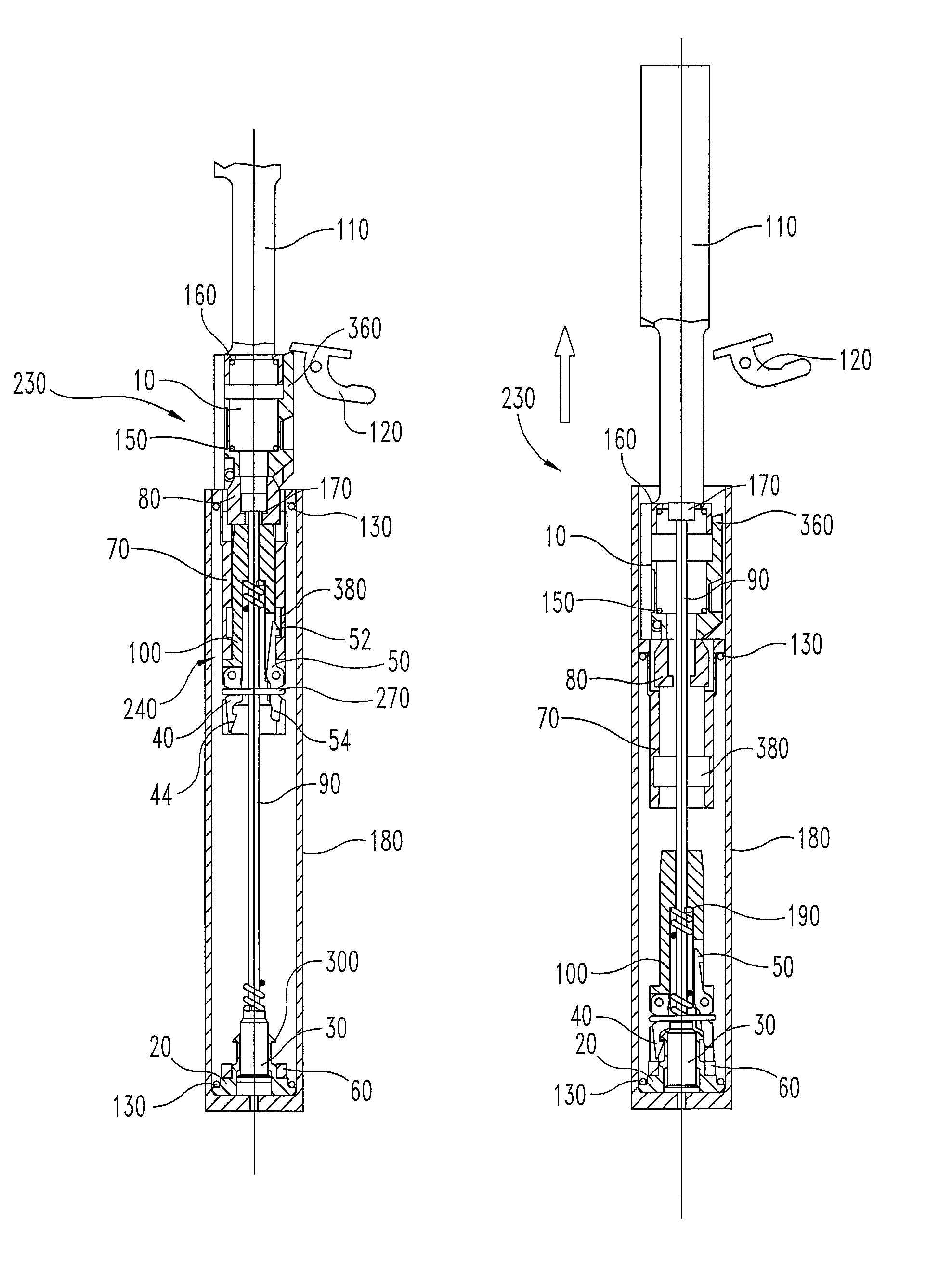

Rate control mechanism

Certain embodiments disclose rate reducer systems and methods to reduce the cyclic rate of self-powered firearms. The reduction in cyclic rate is achieved by mechanically delaying the firing step in the cycle of functioning. This delay is achieved by temporarily latching an inertia weight at the rear of the recoil stroke while the recoiling parts return to battery (i.e. a firing position). When the recoiling parts go into battery, the inertia weight is released and urged forward. At the forward end of its travel, the inertia weight actuates the firing mechanism.

Owner:REYNOLDS S PAUL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com