Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

152 results about "Bag-in-box" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bag-in-box or BiB is a type of container for the storage and transportation of liquids. It consists of a strong bladder (or plastic bag), usually made of several layers of metallised film or other plastics, seated inside a corrugated fiberboard box. The bag is supplied to the company which will fill it as an empty pre-made bag. The company filling the bag with its product generally removes the tap, fills the bag (with wine, juice or other liquid) and replaces the tap and then the bag is placed in the box. The bags are available as singles for semi-automatic machines or as web bags, where the bags have perforations between each one. These are used on automated filling systems where the bag is separated on line either before the bag is automatically filled or after. Depending on the end use there are a number of options that can be used on the bag instead of the tap. The bags can be filled from chilled product temperatures up to 85 degrees Celsius.

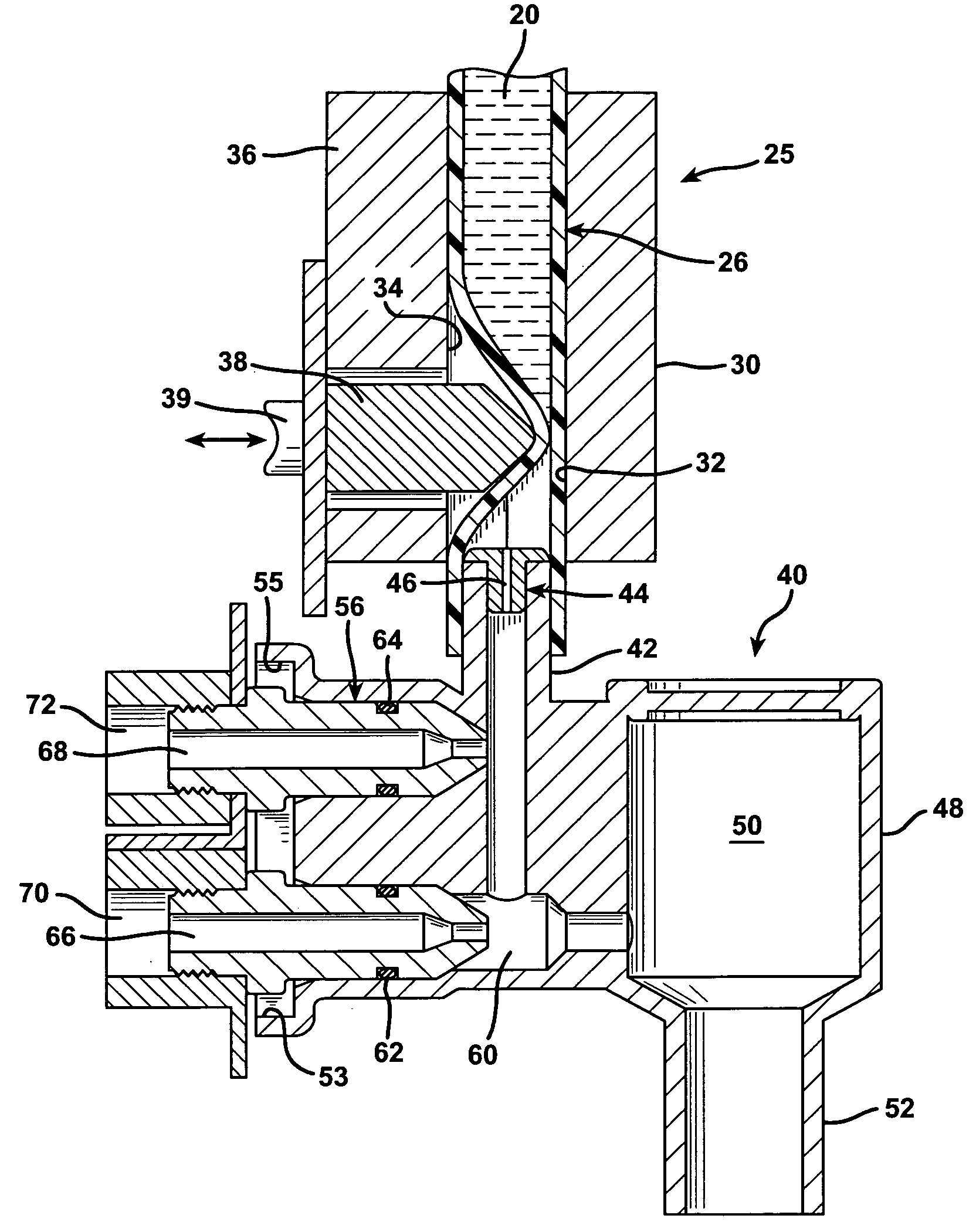

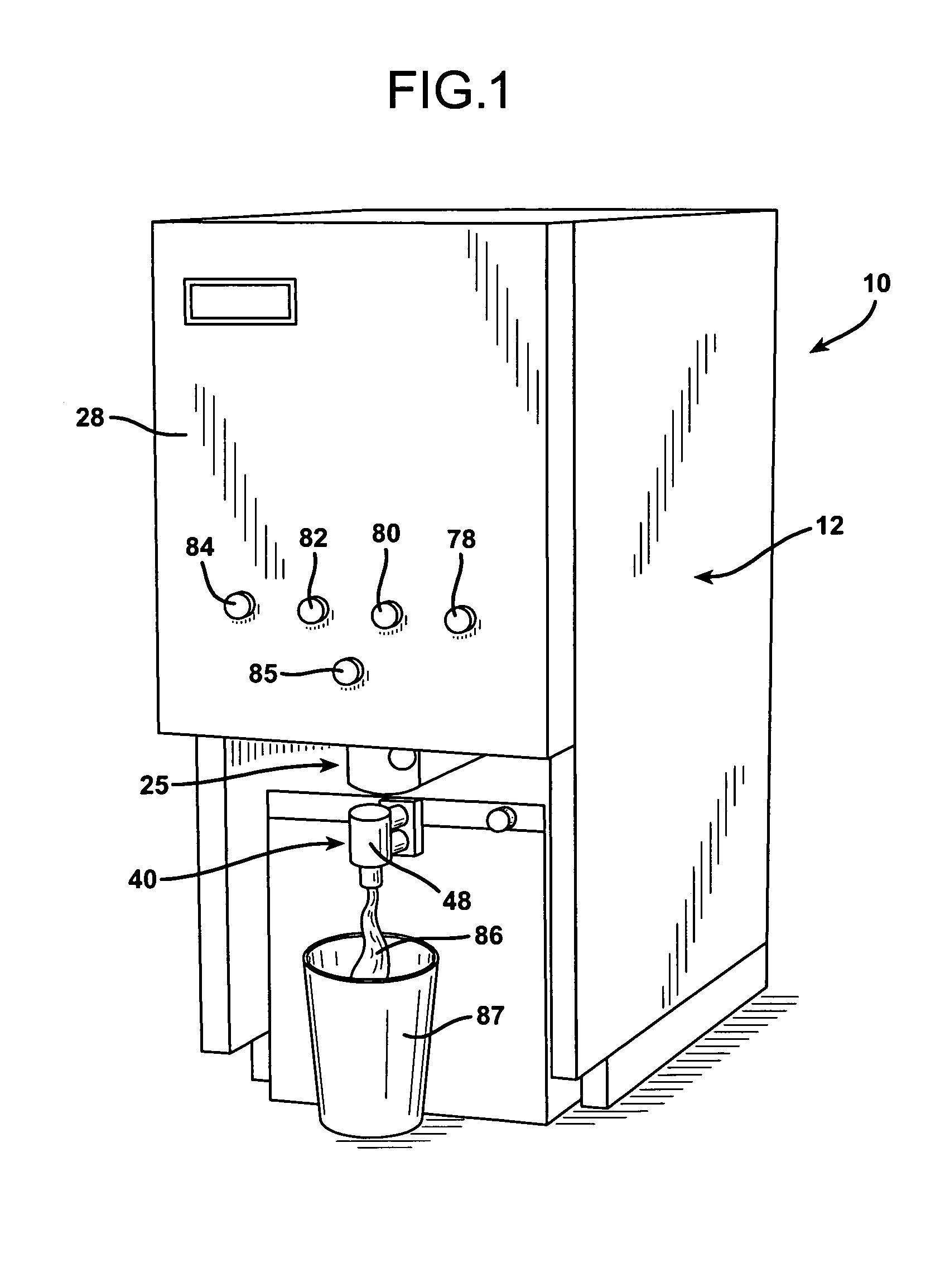

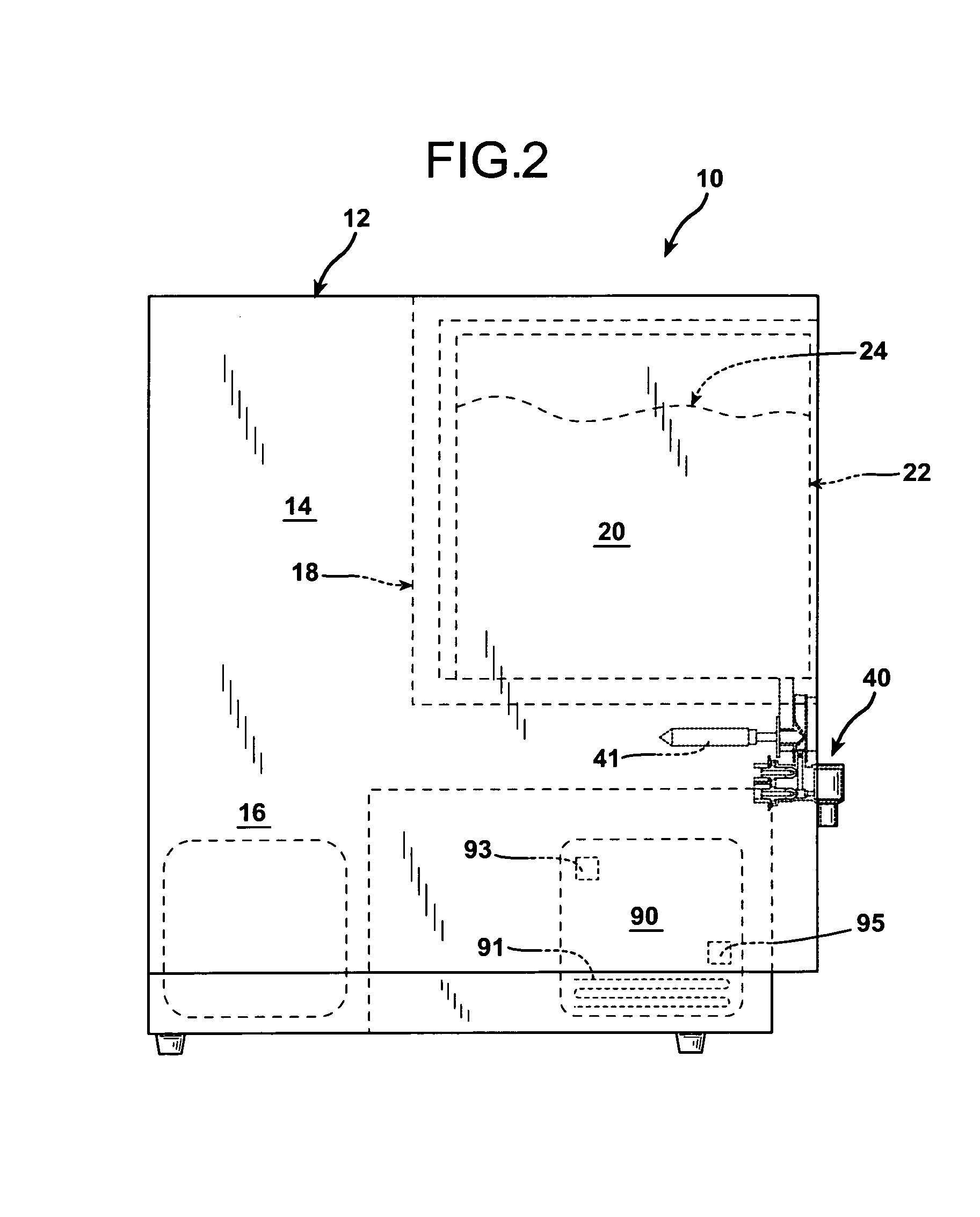

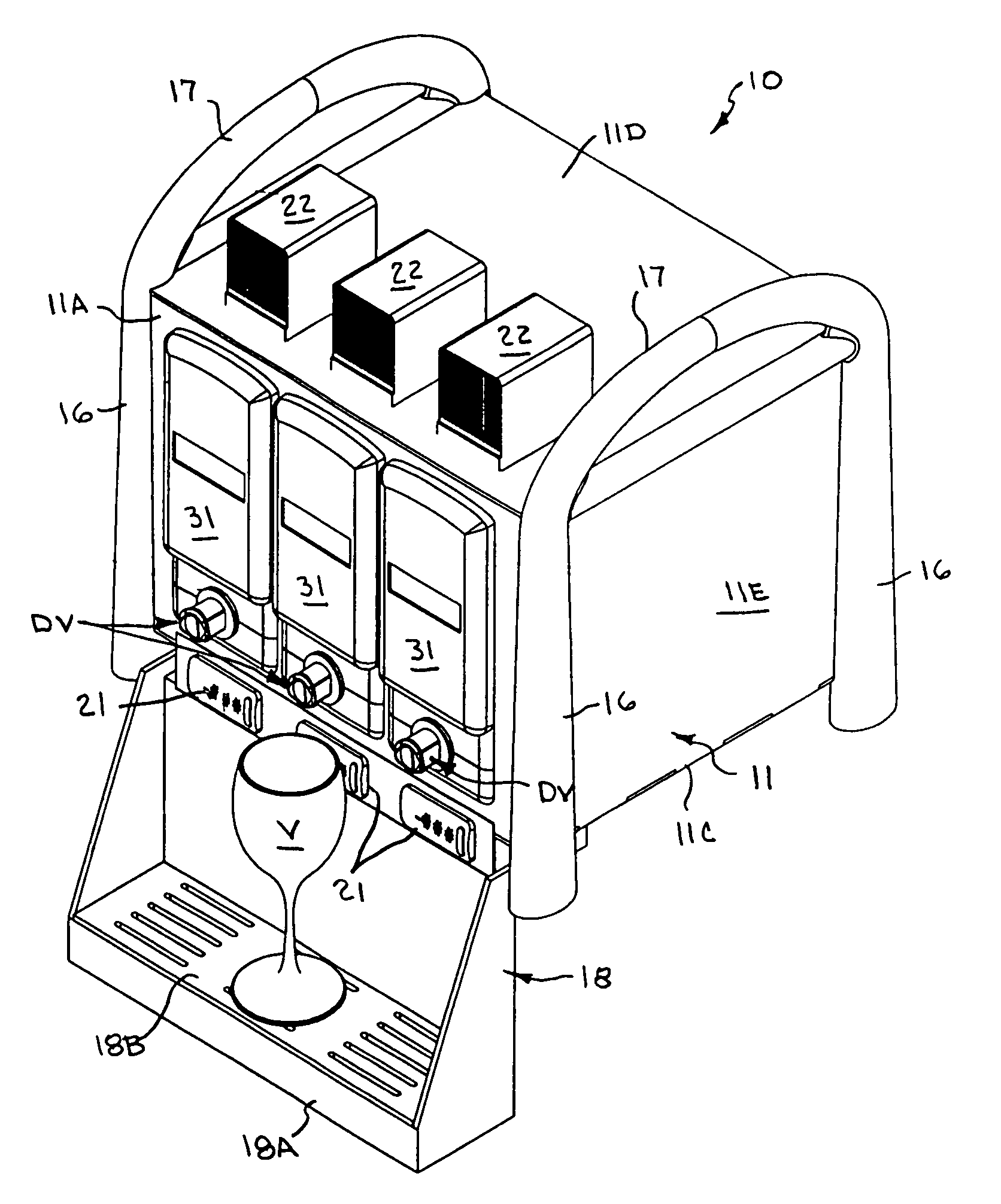

Hot dairy-based beverage dispenser

InactiveUS7021206B2Reduce eliminateConstant flowLighting and heating apparatusUsing liquid separation agentPinch valveEngineering

A dispensing unit for dispensing hot, dairy-based beverages has a self-contained refrigerated unit located above a venturi-type emulsification foaming head. The dispensing unit has particular applicability to the dispensation of foamy, hot milk for use in beverages such as cappuccino and nonfoamy, hot milk for use in beverages such as coffee latte, hot chocolate, and other hot dairy-based beverages. The refrigeration unit accommodates a “bag in box” cold milk storage container of the type widely used in food service establishments. The dispensing unit employs a pinch valve that avoids direct contact between the milk and the valve components. The refrigerated milk is stored above the level of the foamer head so that the flow of milk results partially from gravitational force on the milk, and is not totally dependent upon venturi suction created in the foamer head.

Owner:ECKENHAUSEN ROLAND B +1

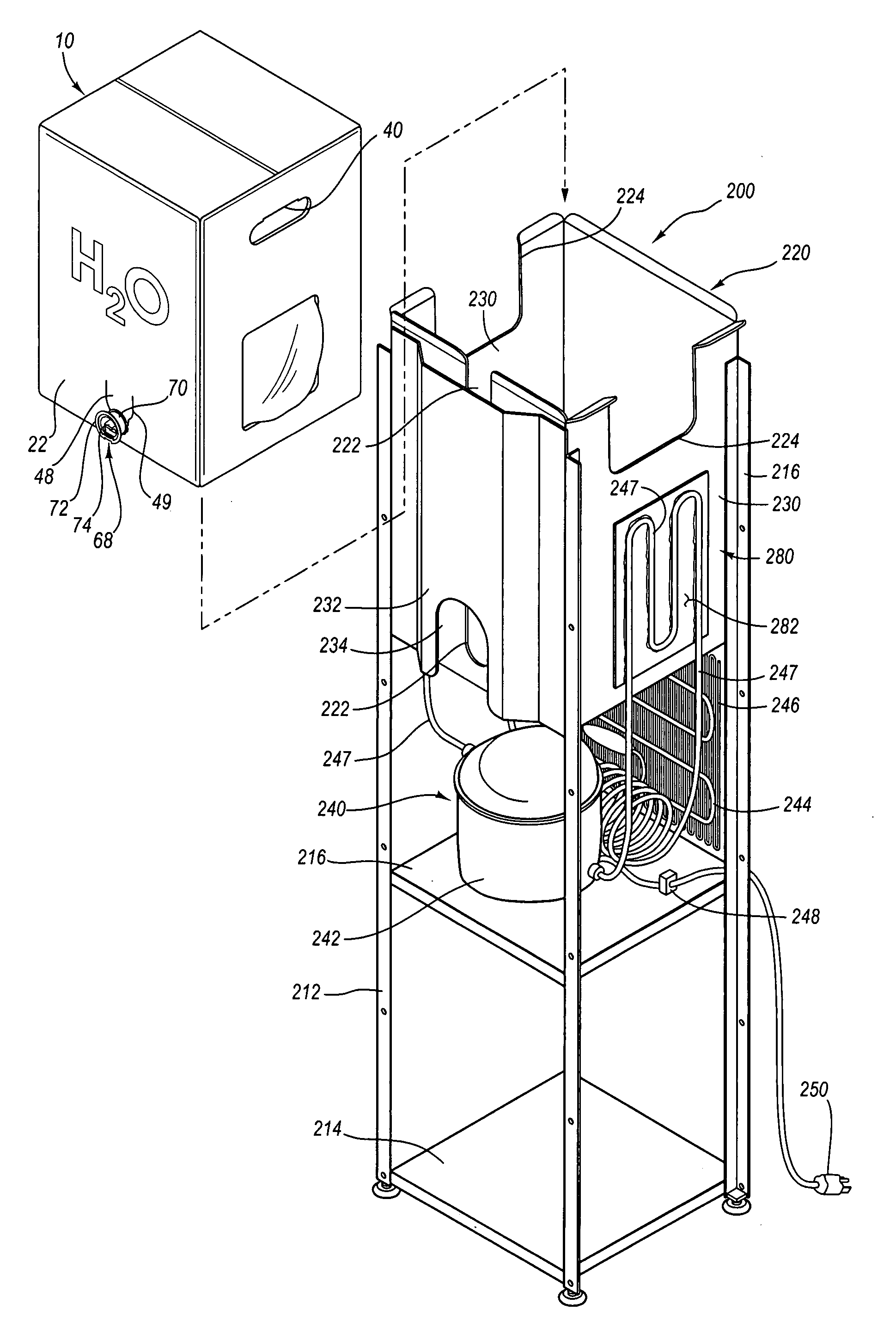

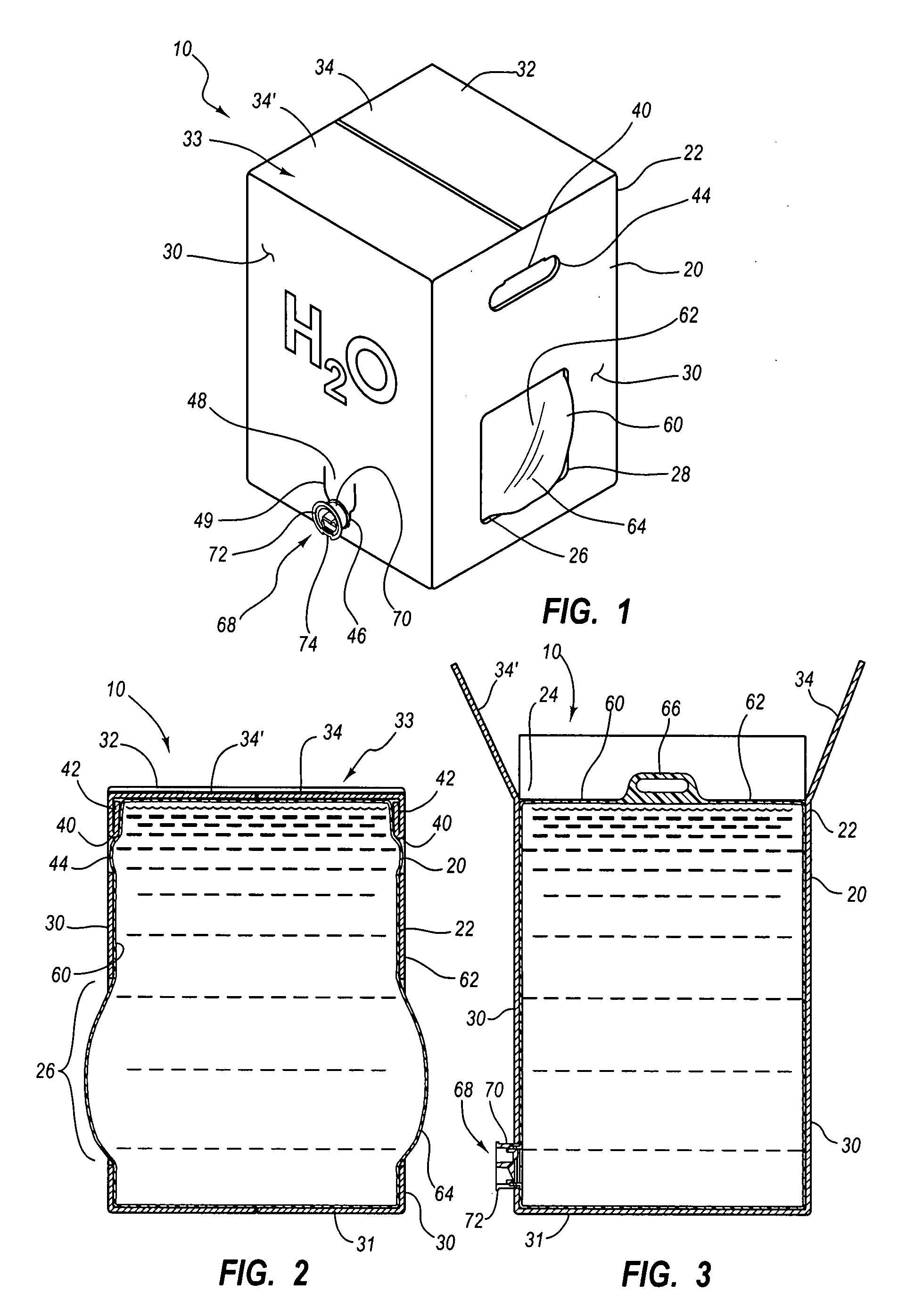

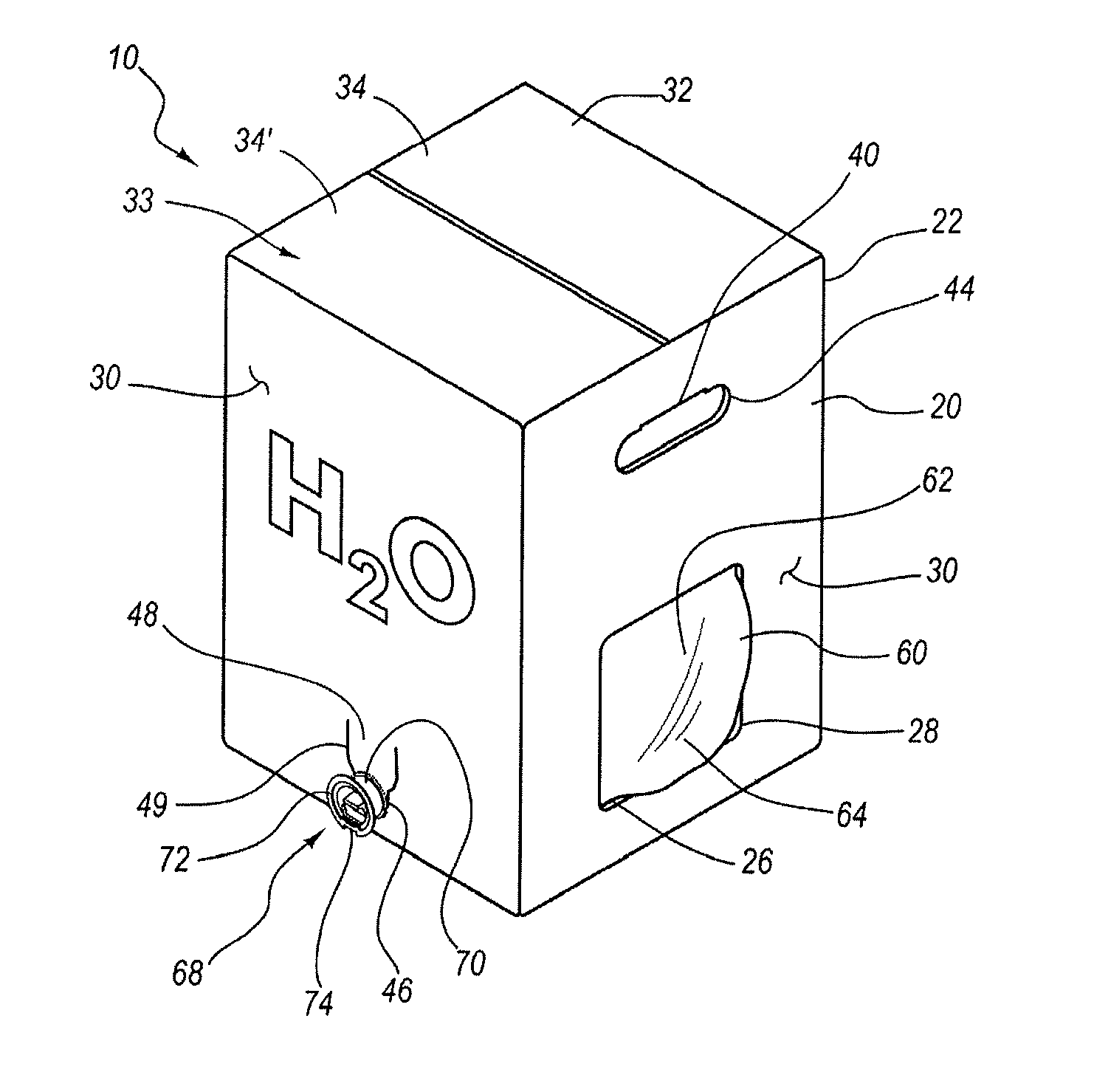

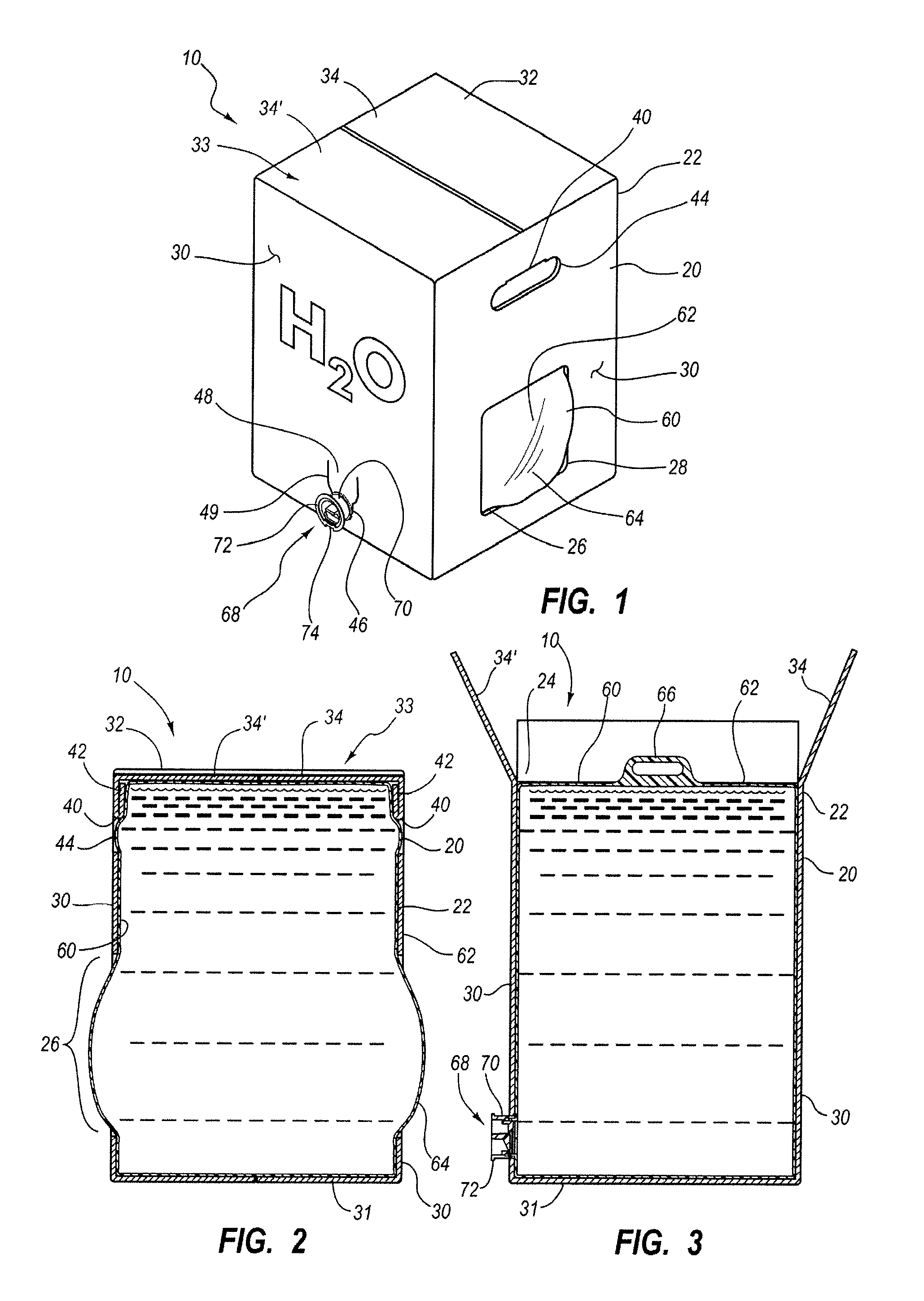

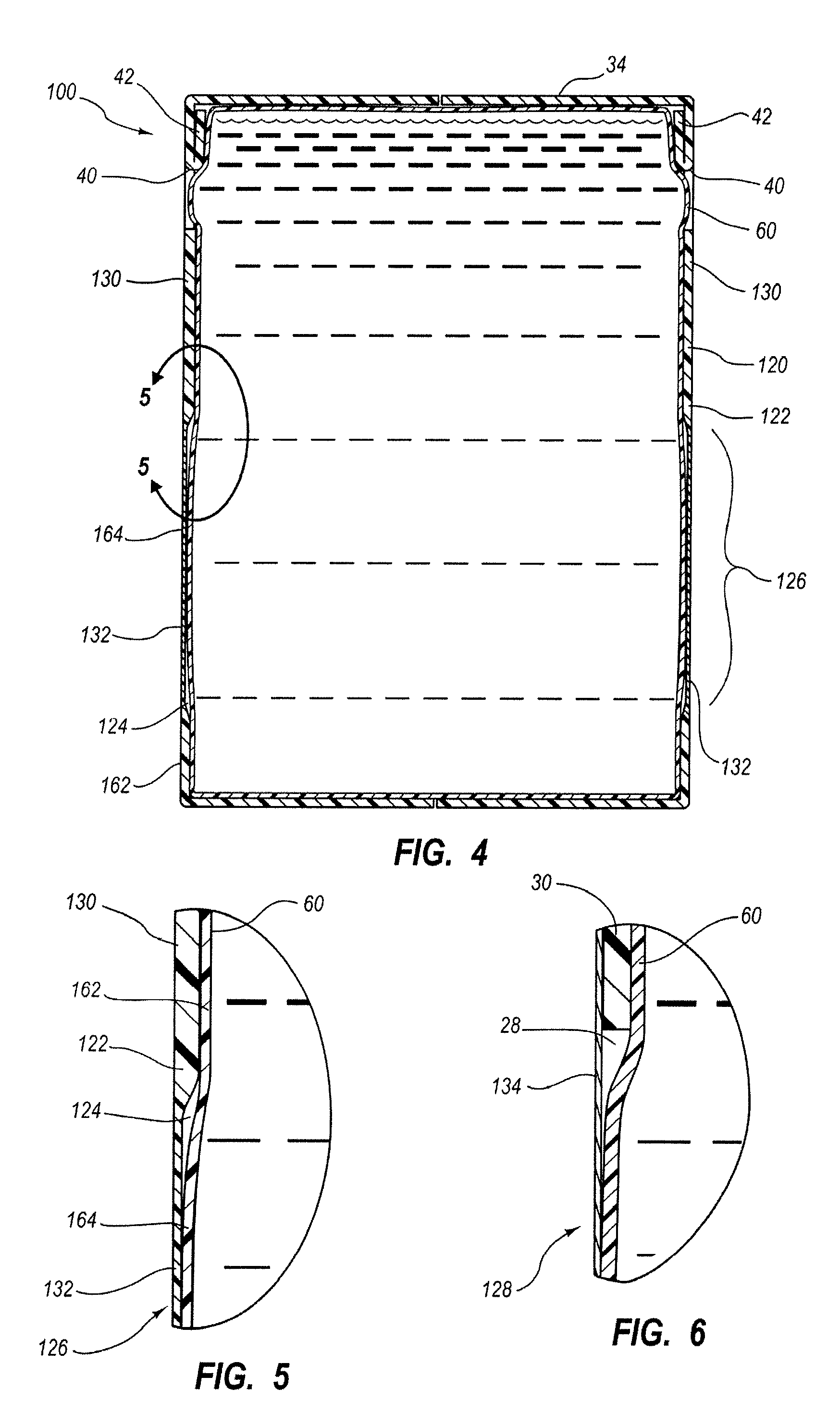

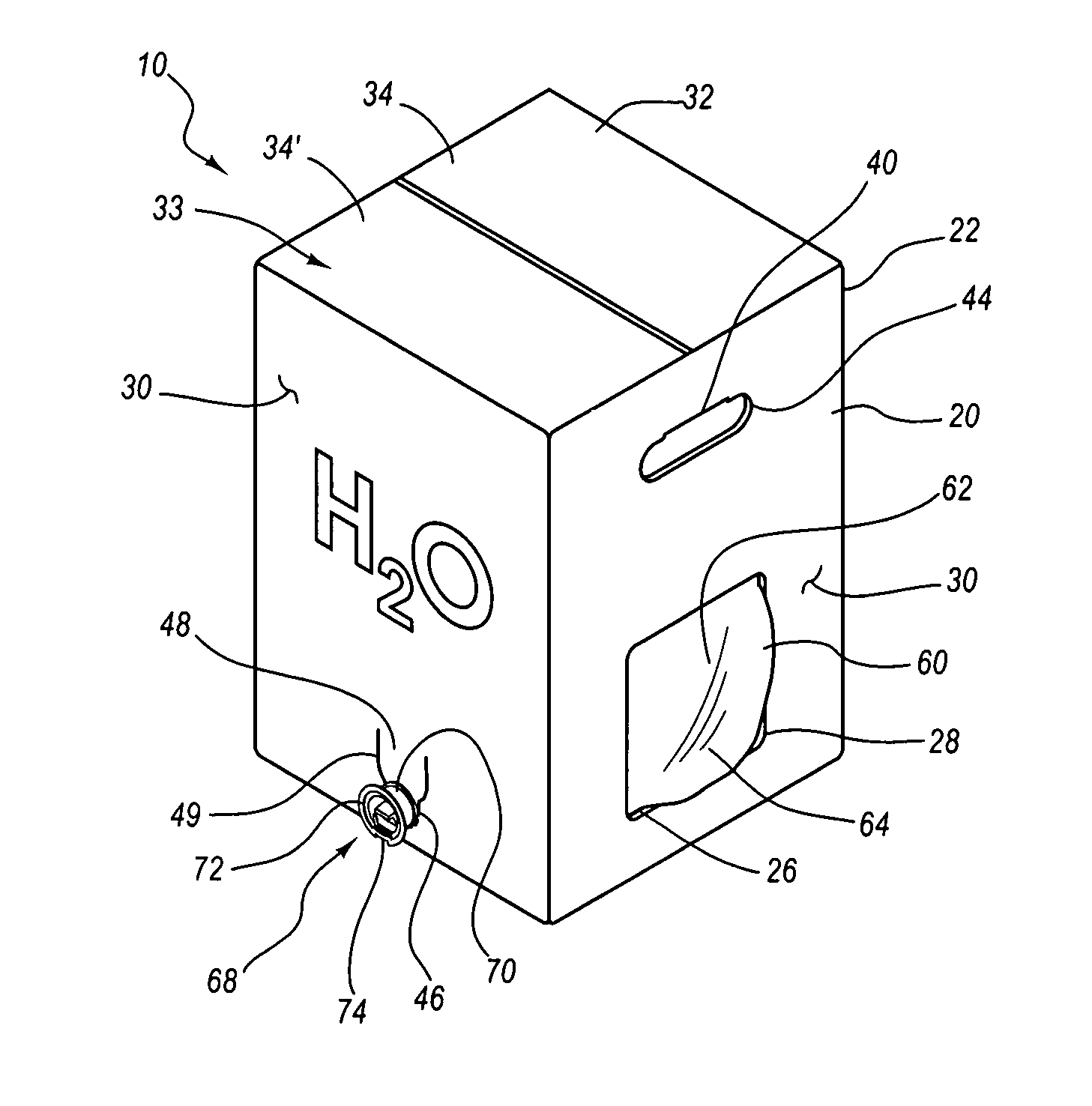

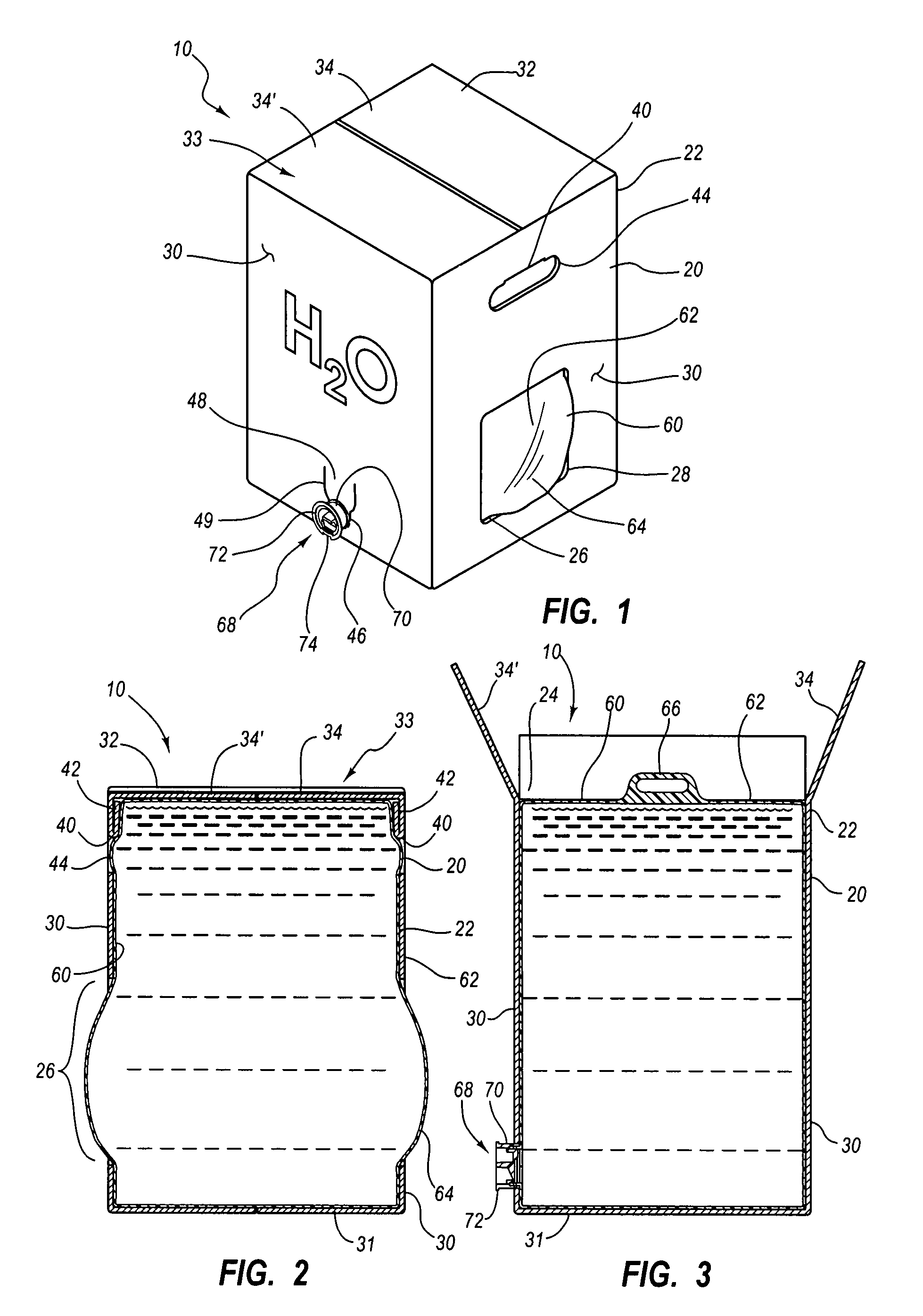

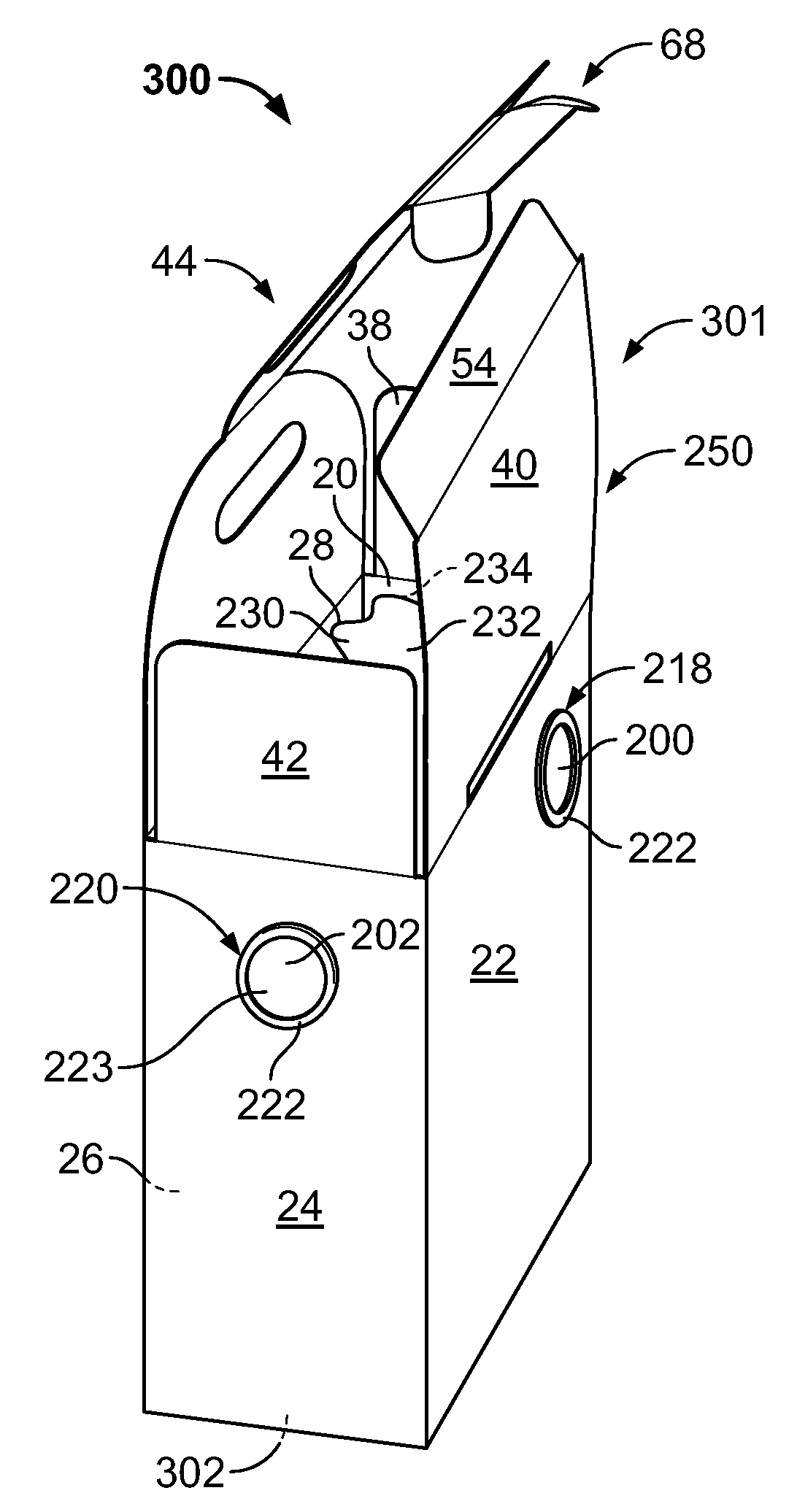

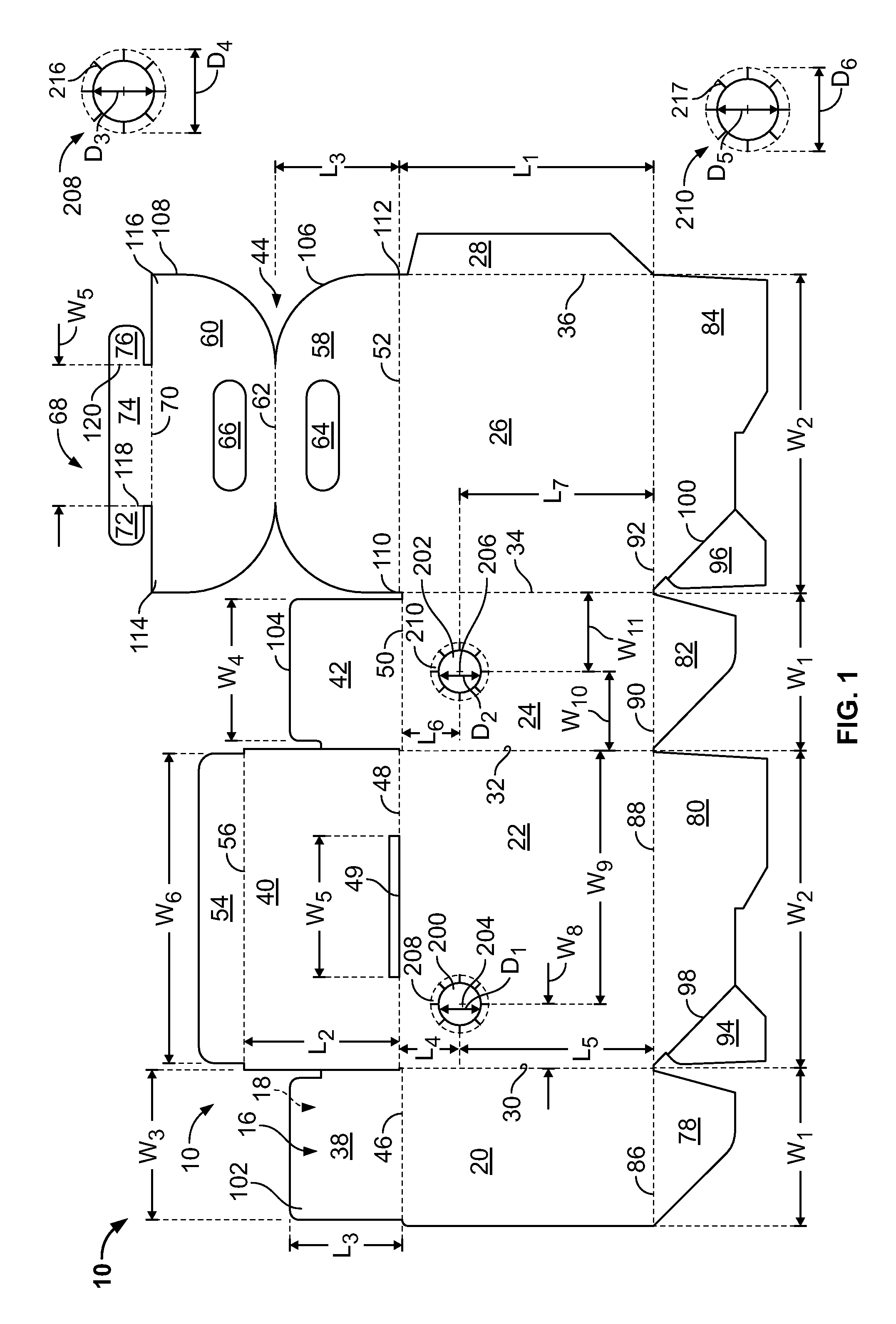

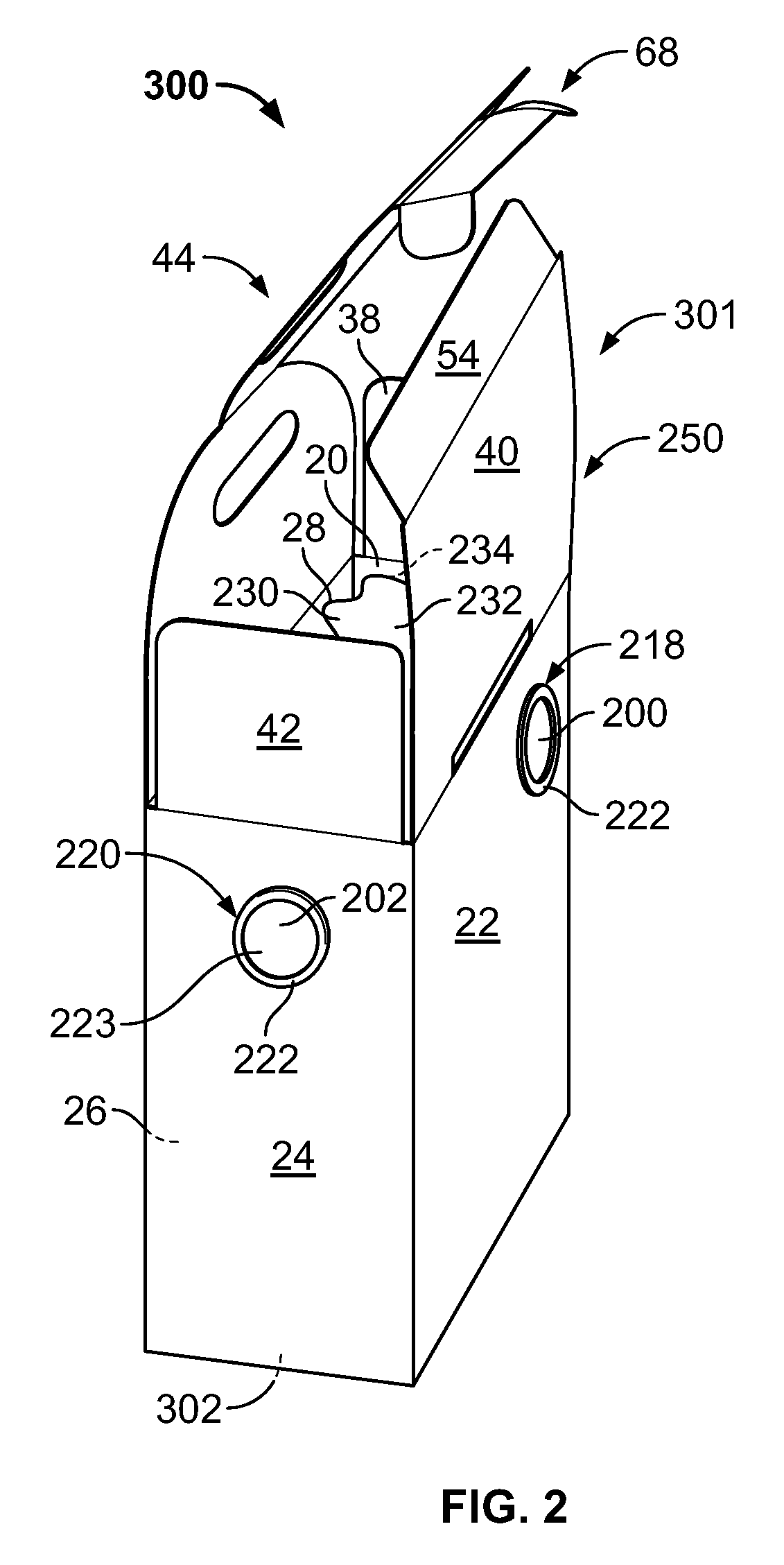

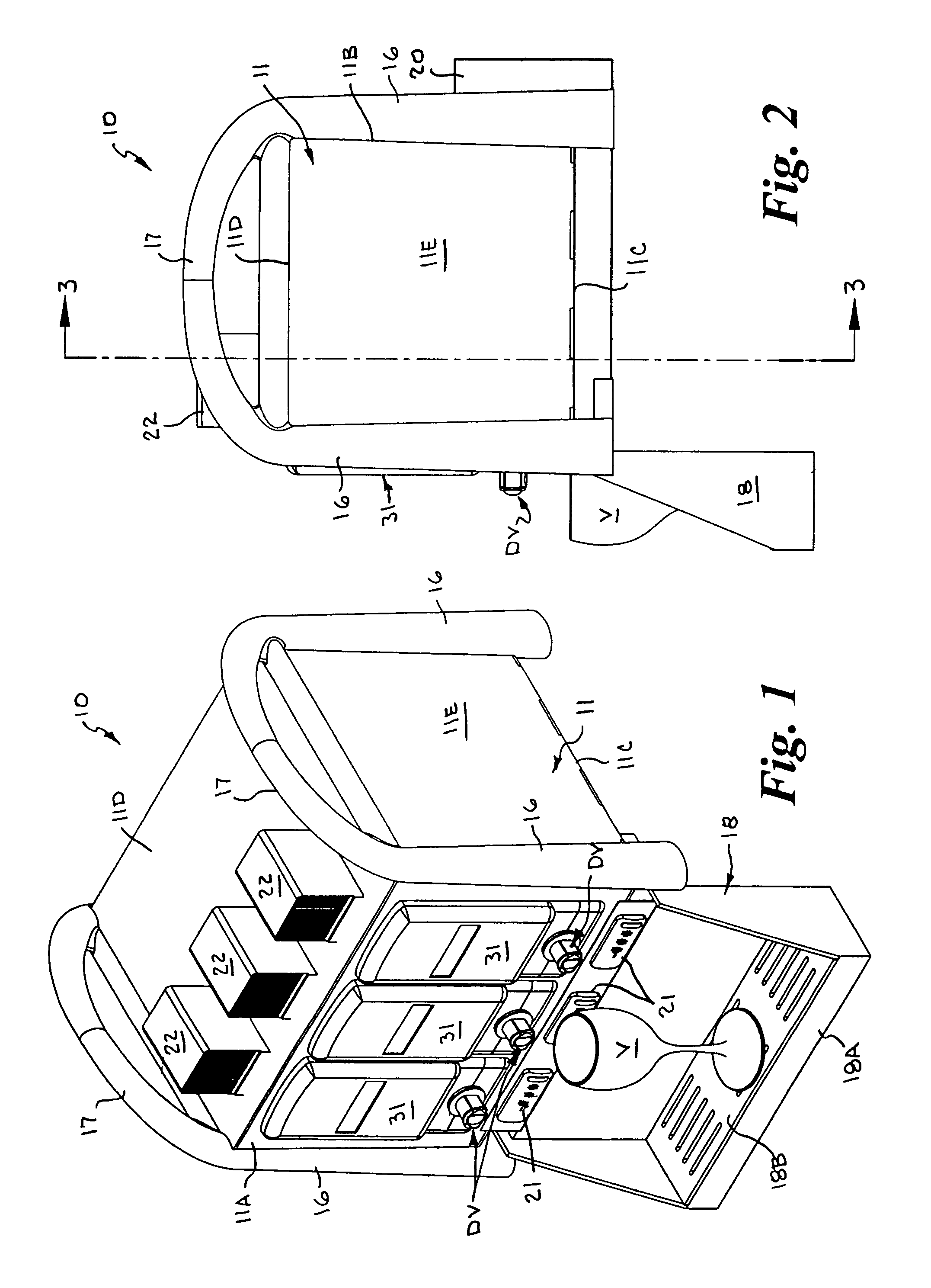

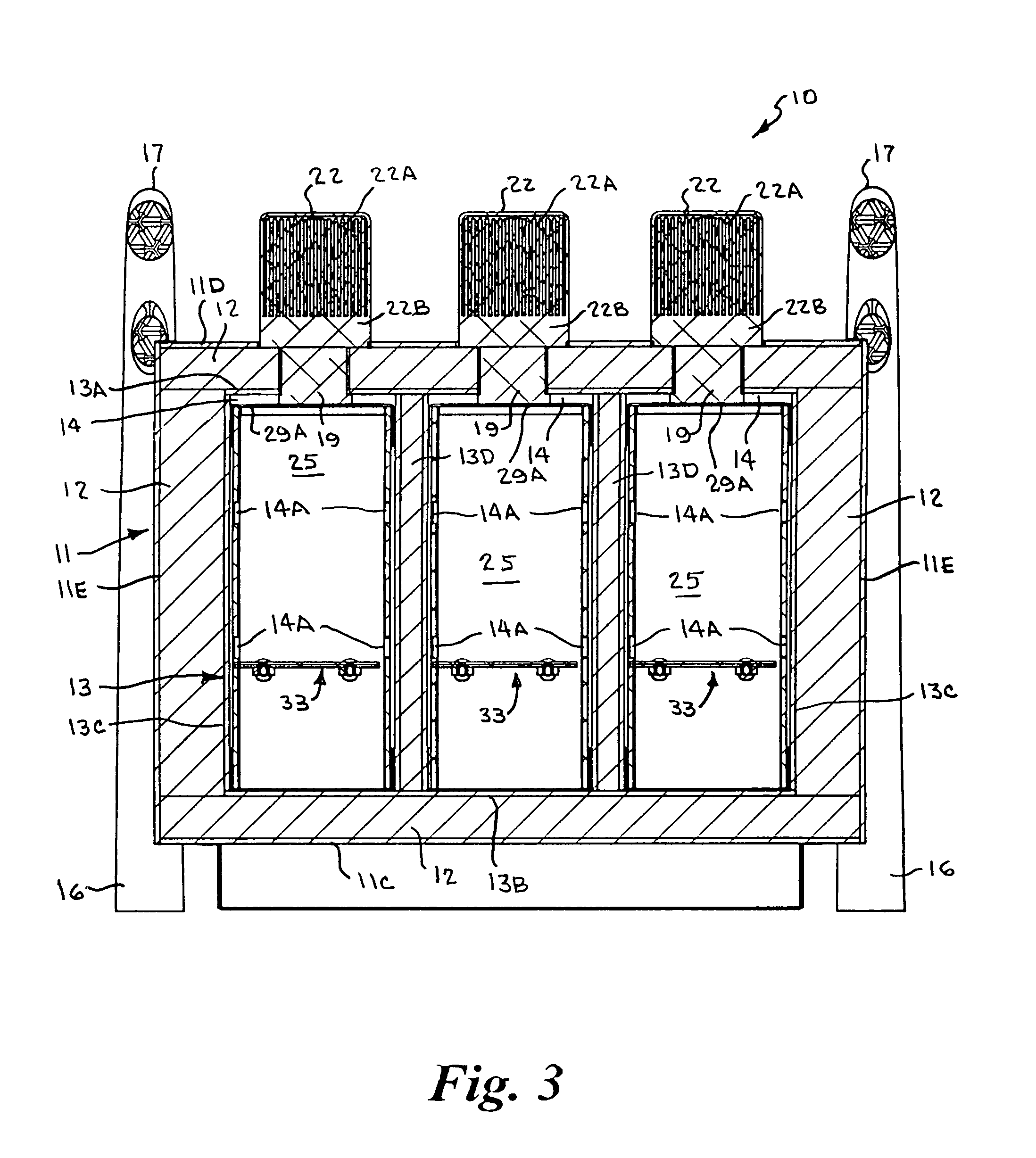

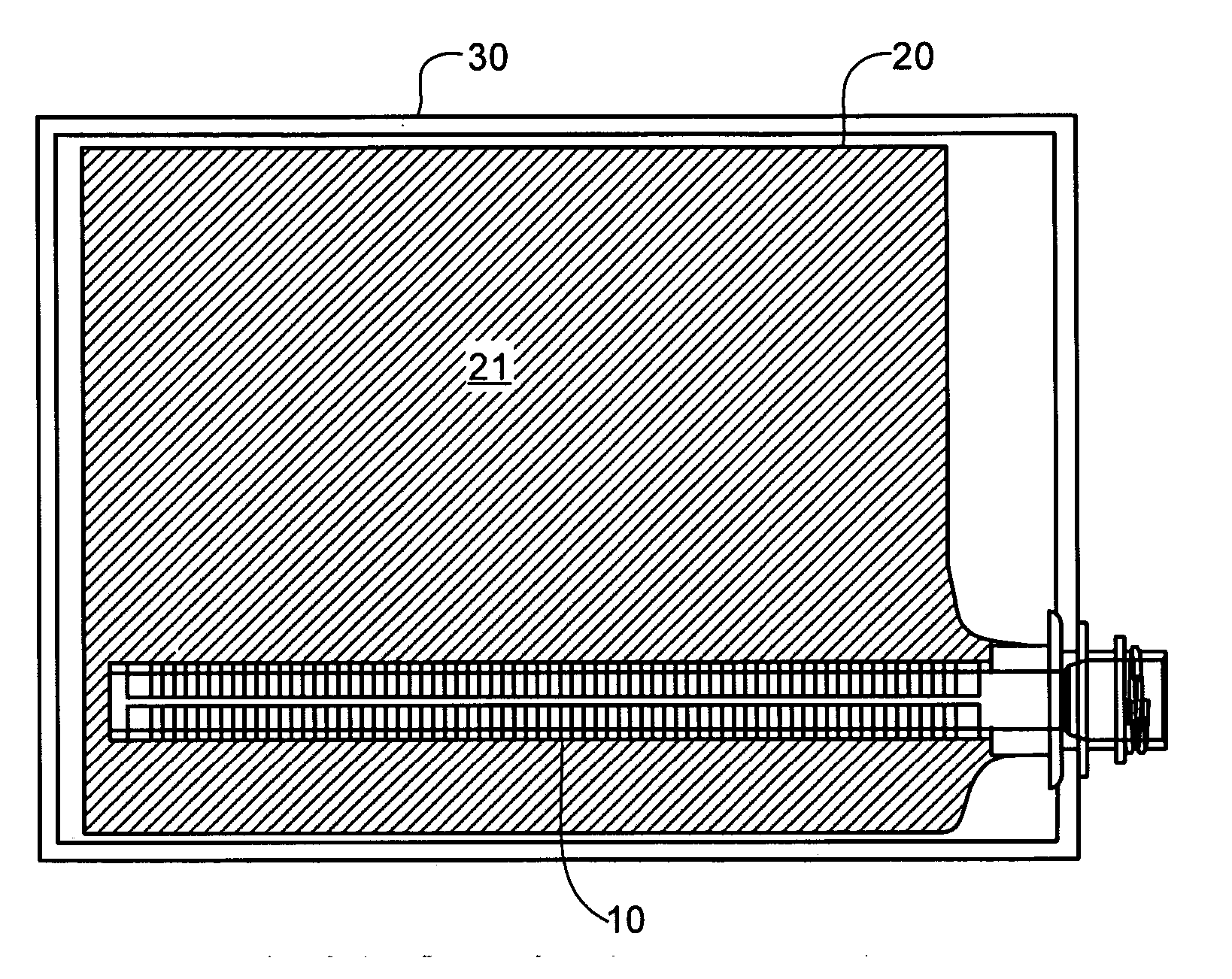

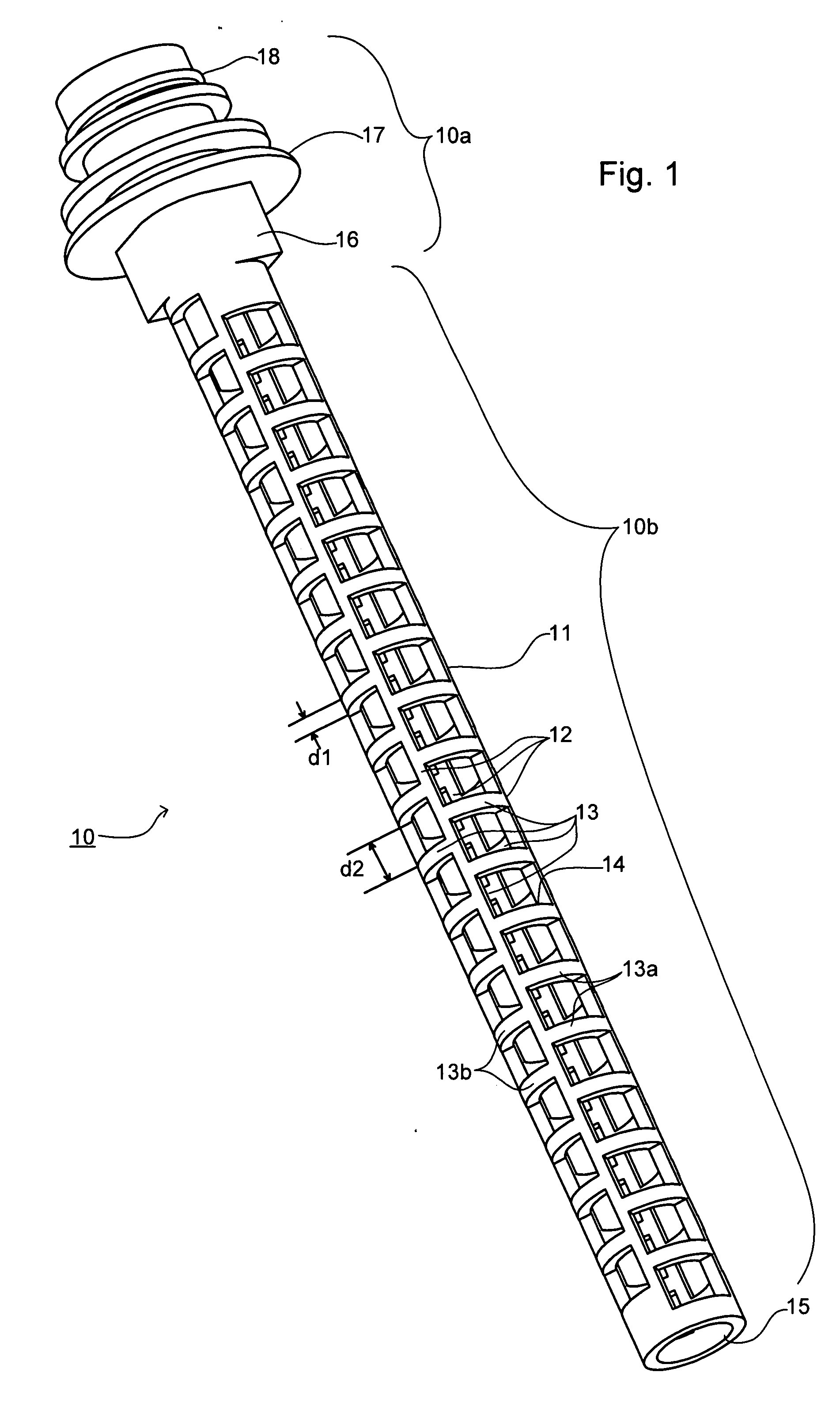

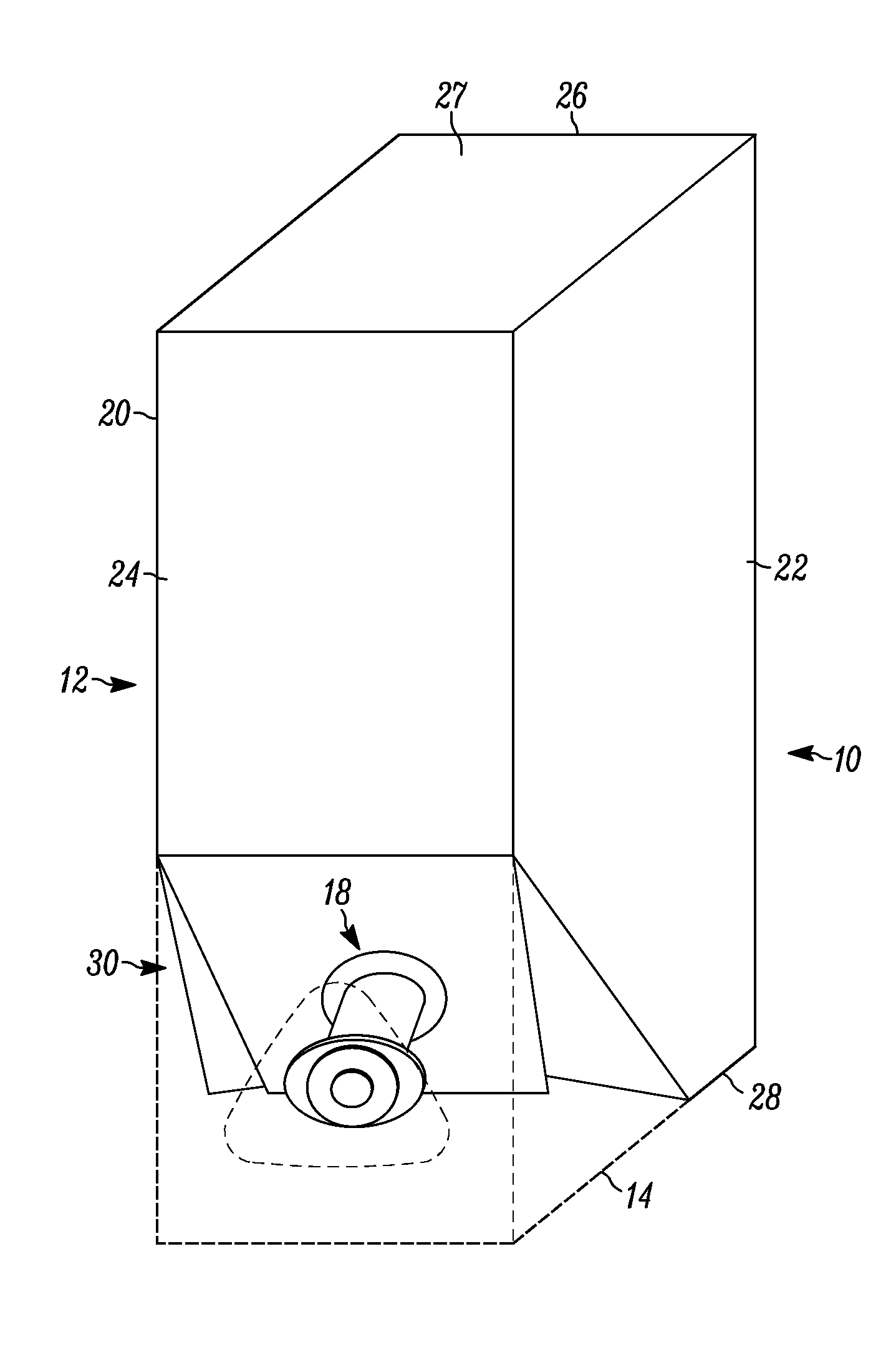

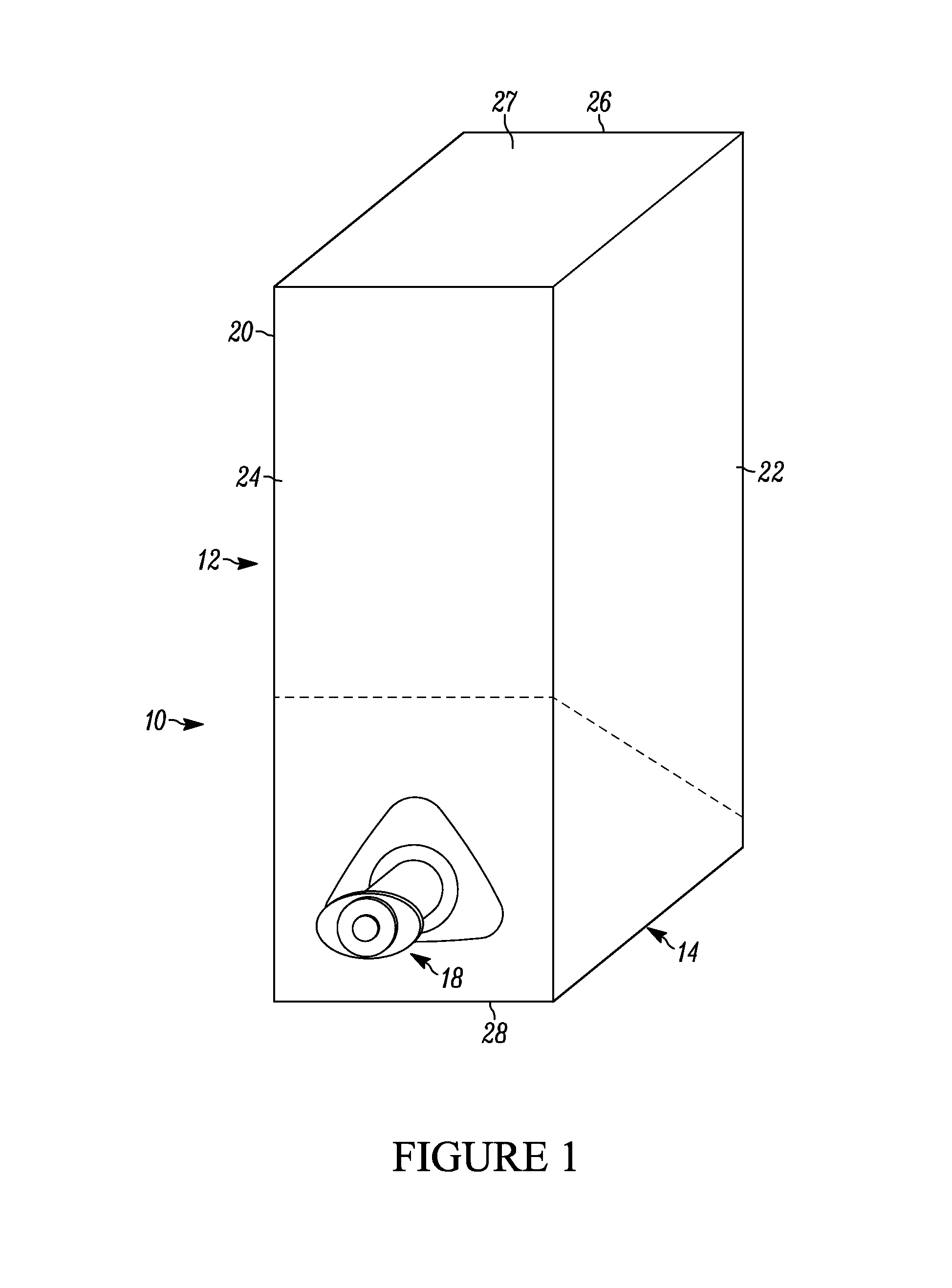

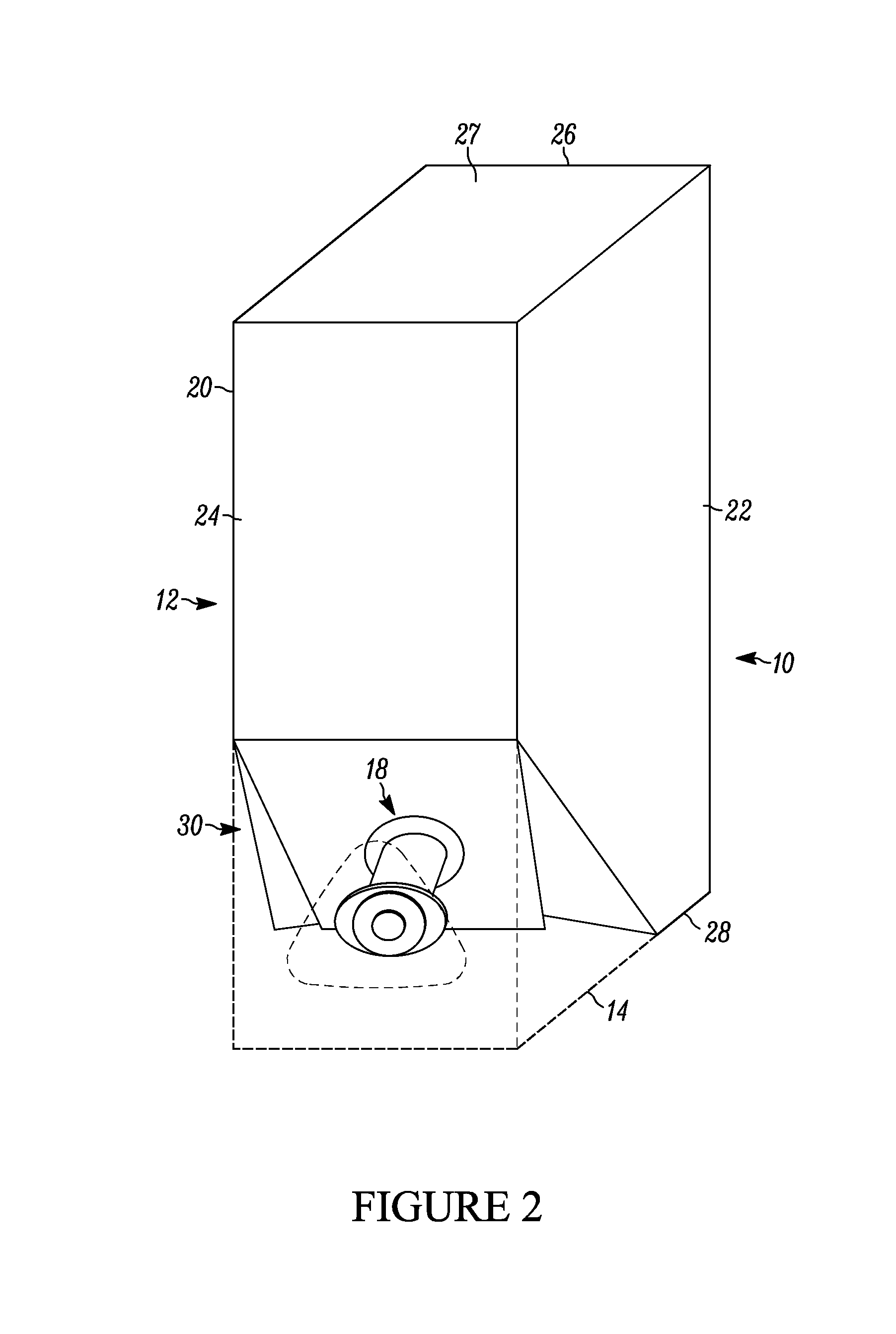

Temperature controlled liquid dispenser, containers therefore, and bag-in-box container construction

InactiveUS20080277417A1Improve thermal conductivityThermal energy is effectively and efficiently transferredDomestic cooling apparatusLiquid flow controllersTemperature controlThermal energy

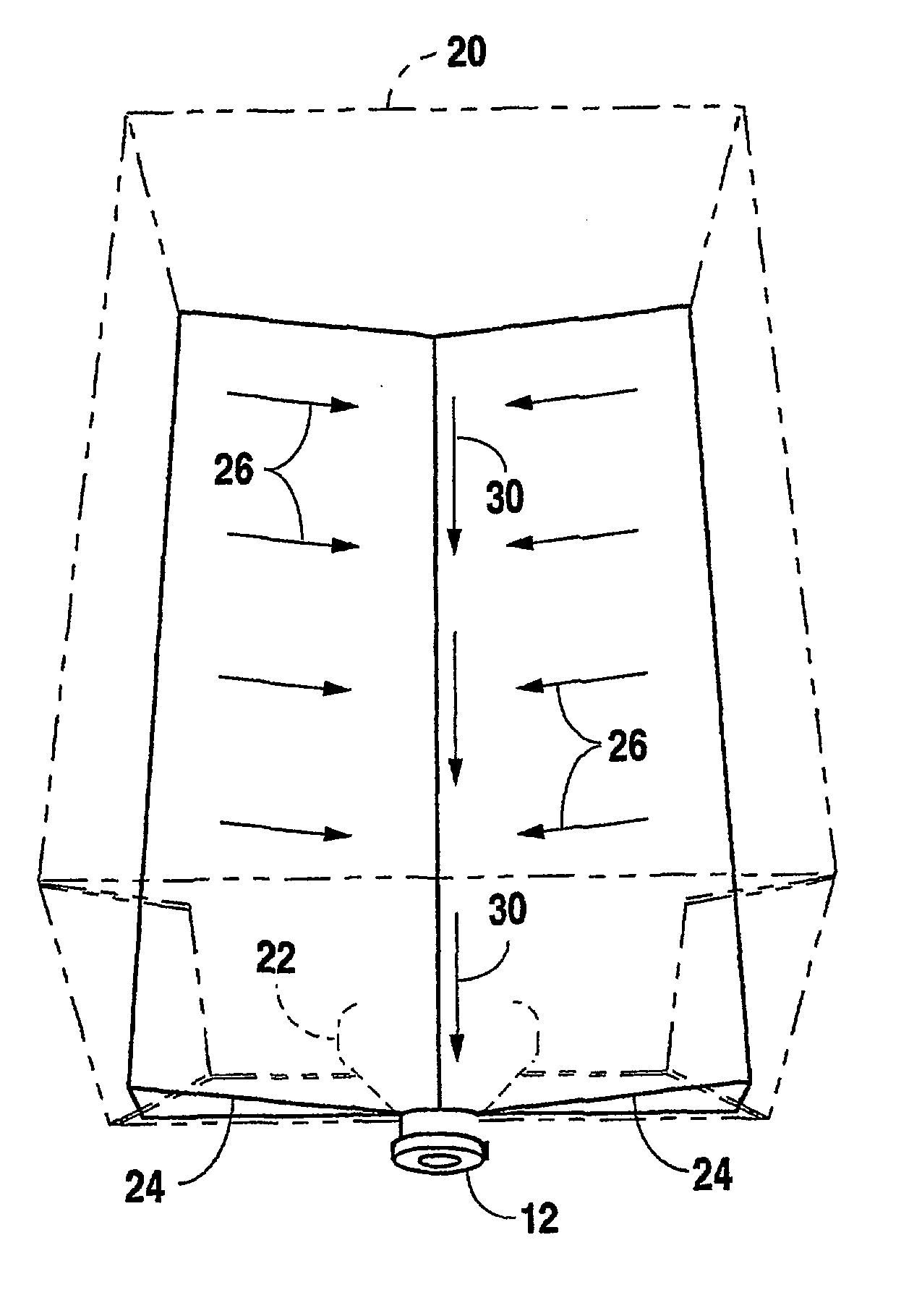

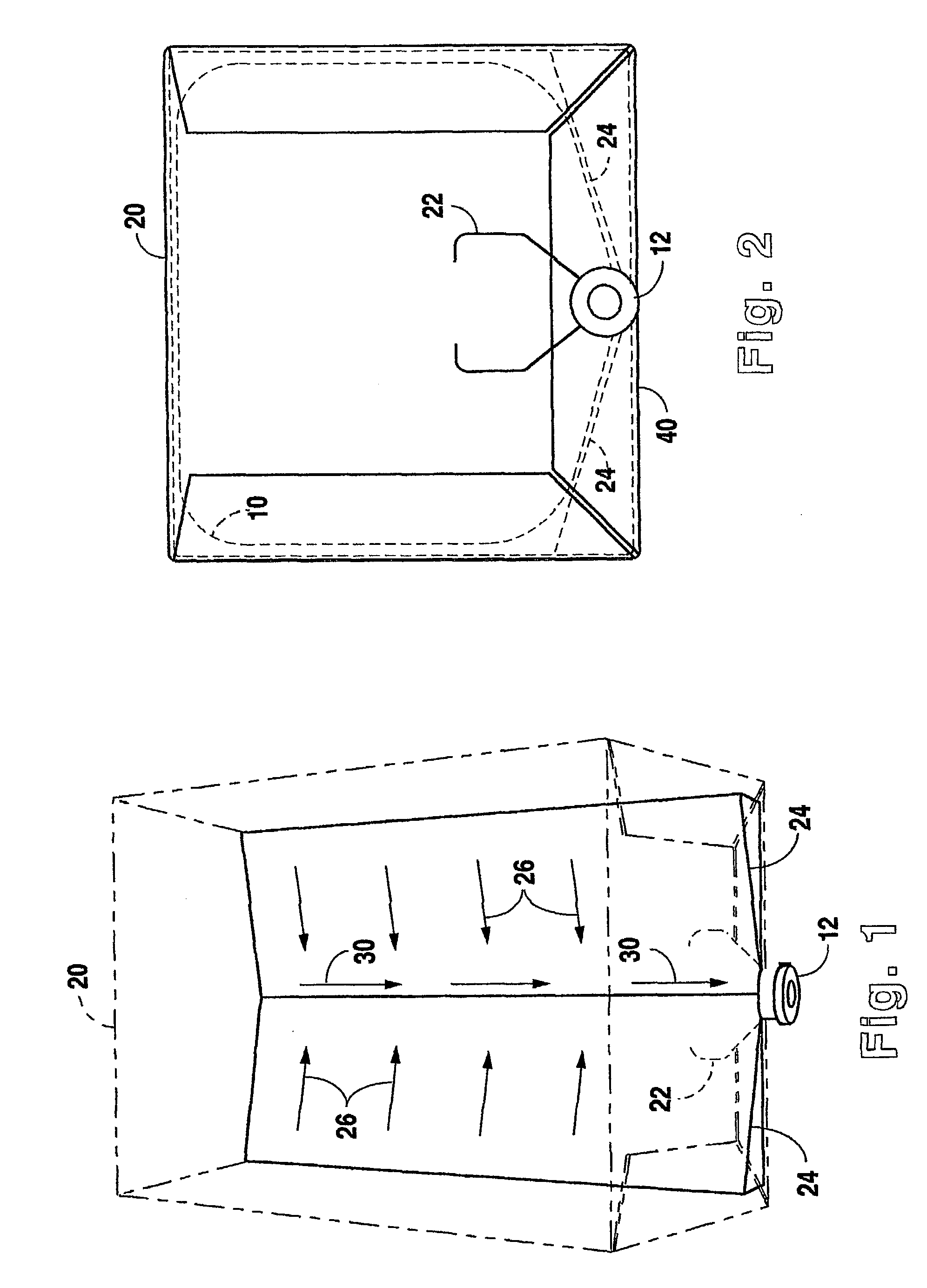

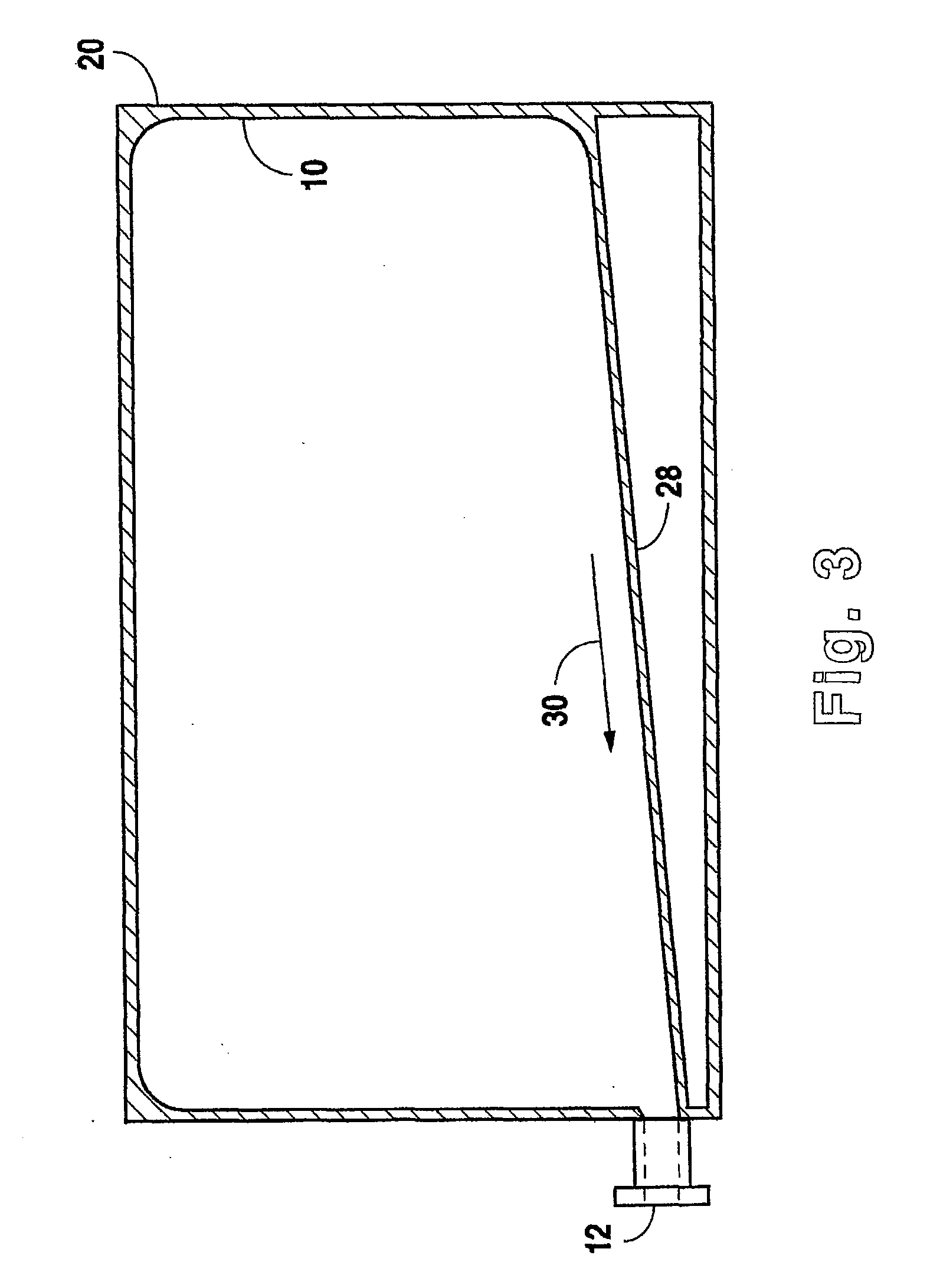

A dispenser for relative rapid cooling or heating of the contents of a liquid storage container provides a receptacle for receiving the liquid storage container therein and positioning a thermal transfer portion of the liquid storage container in thermal conductive relationship with a thermal conduction pad associated with the receptacle. Thermal energy is effectively and efficiently transferred from the thermal conduction pad to the liquid in the liquid storage container. The thermal conduction pad is controlled to provide and maintain the desired temperature to the liquid. The liquid is dispensed directly from the container. Various types of containers can be used in the dispenser, with a special bag-in-box container having a inner container and outer box with thermal conduction windows in the box to provide good heat transfer between the thermal conduction pads and the inner container constituting an aspect of the invention. A special rigid container can also be used.

Owner:GROESBECK R CLAY

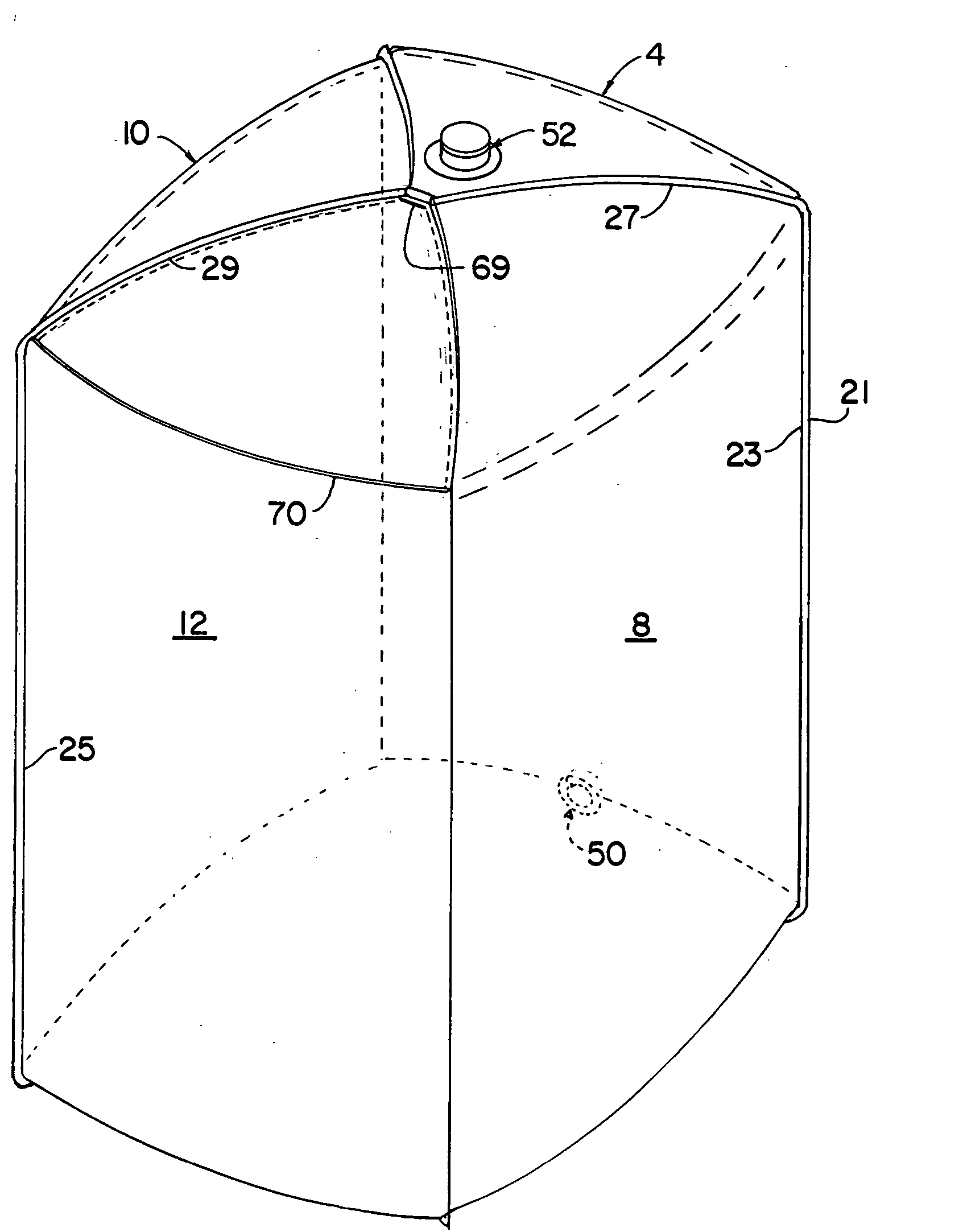

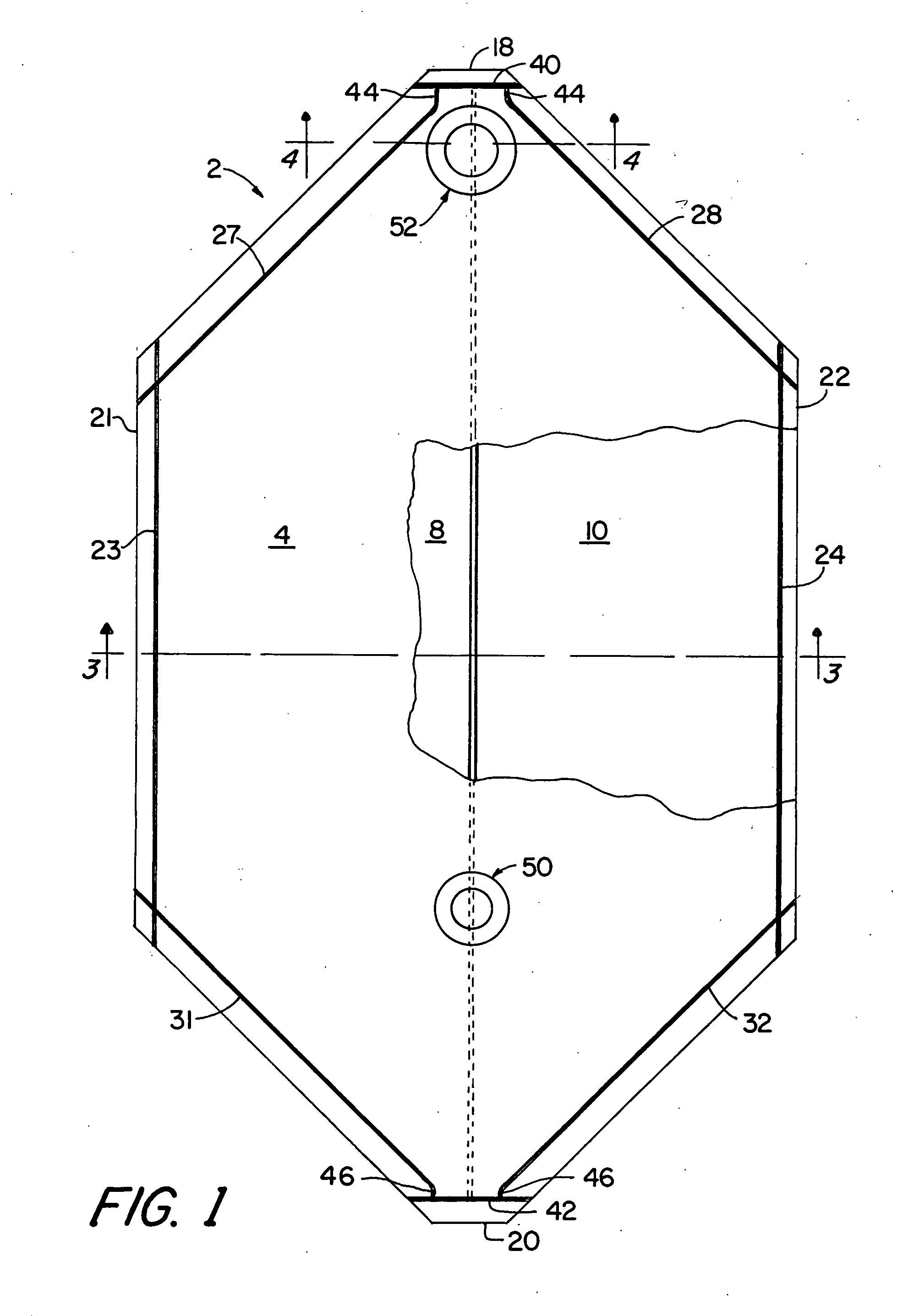

Flexible liner for FIBC or bag-in-box container systems

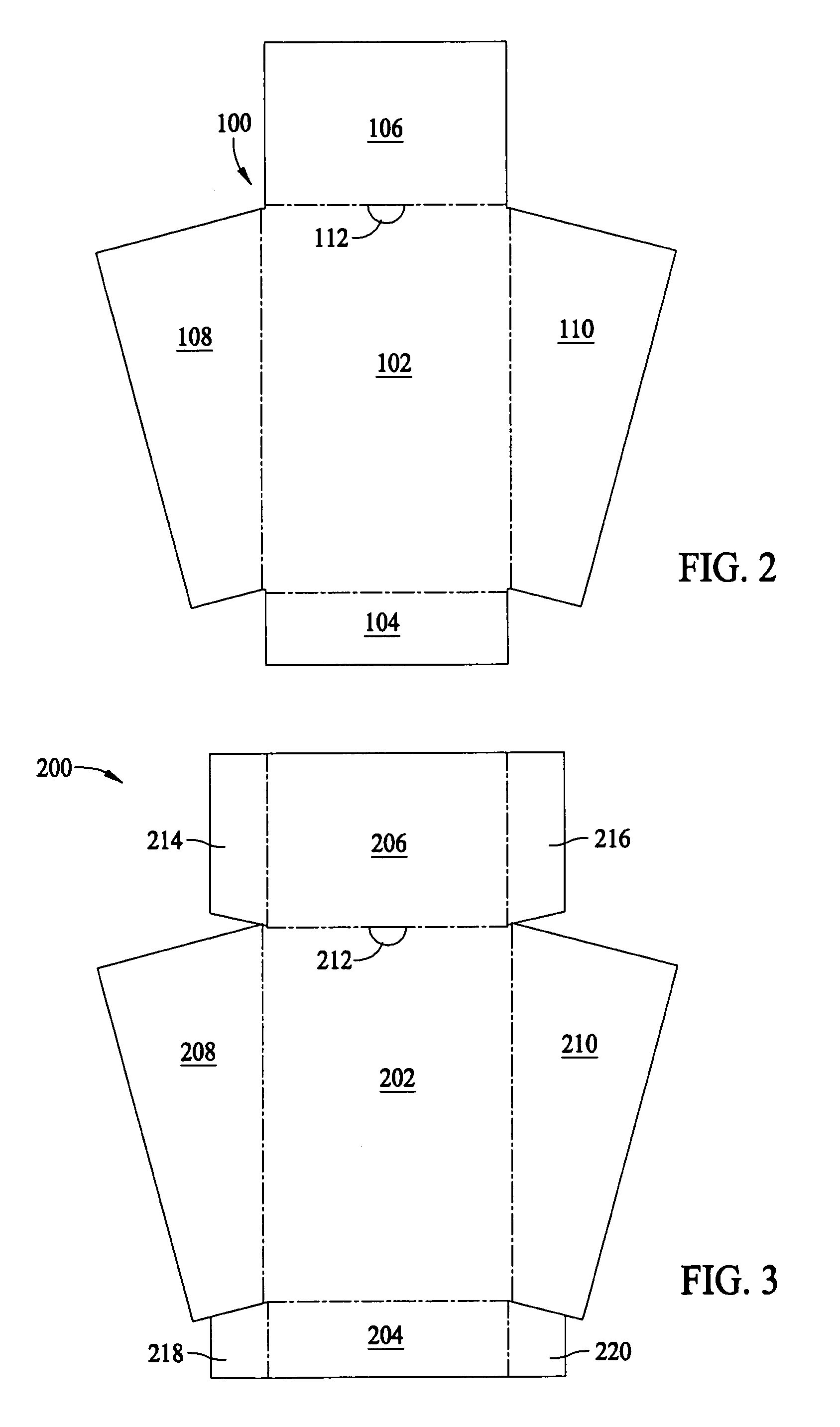

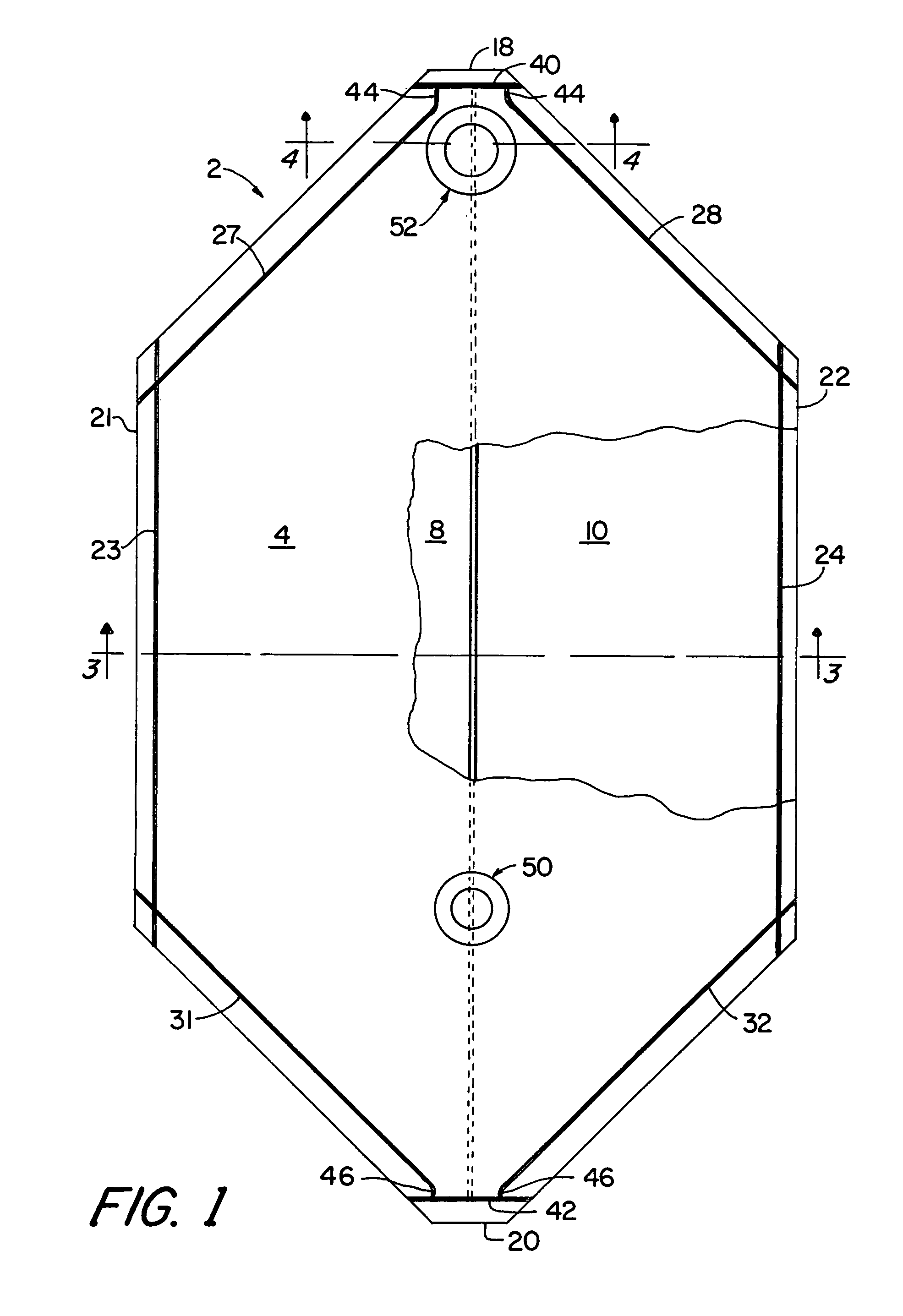

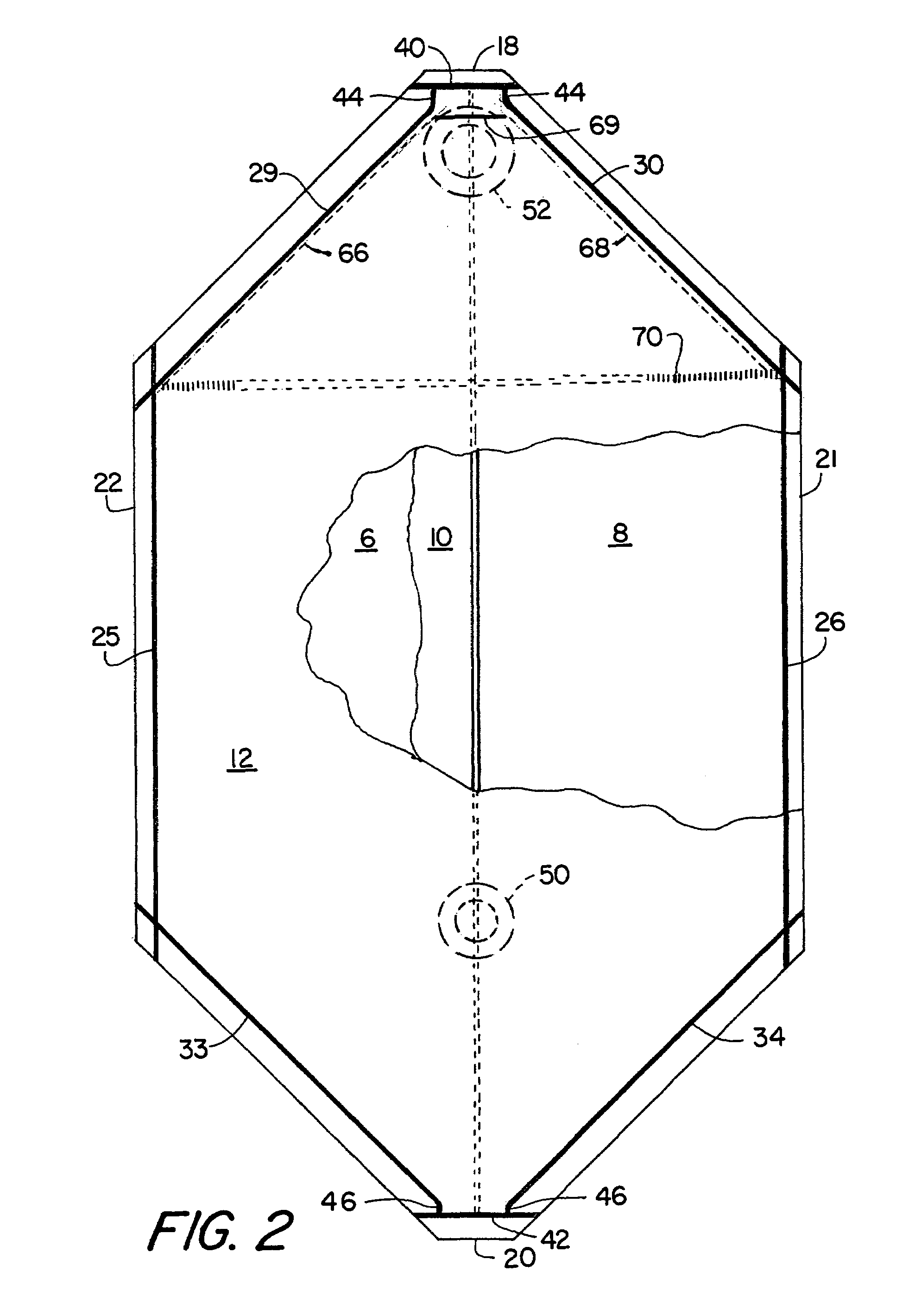

The present invention is a collapsible liner for use in a bulk container. The liner comprises a first flexible panel, a second flexible panel, a first seal, a second seal, and a tab. The first flexible panel includes a first longitudinal edge. The second flexible panel includes a second longitudinal edge. The first seal joins the first and second panels near the first and second longitudinal edges and runs generally parallel to the first and second edges. The second seal joins the first and second panels and is generally oblique to the first seal. At least one of the panels extends across at least one of the seals to form the tab, which includes an attachment feature. The attachment feature may be a piece of tape affixed to the tab. The attachment feature may be a strip of fabric or other reinforcement material melted into the tab, sealed within the tab or affixed to the tab via an adhesive. The attachment feature may be a hole with sealed or unsealed edges. The attachment feature may be a grommet or a loop for receiving a hook.

Owner:CDF CORP

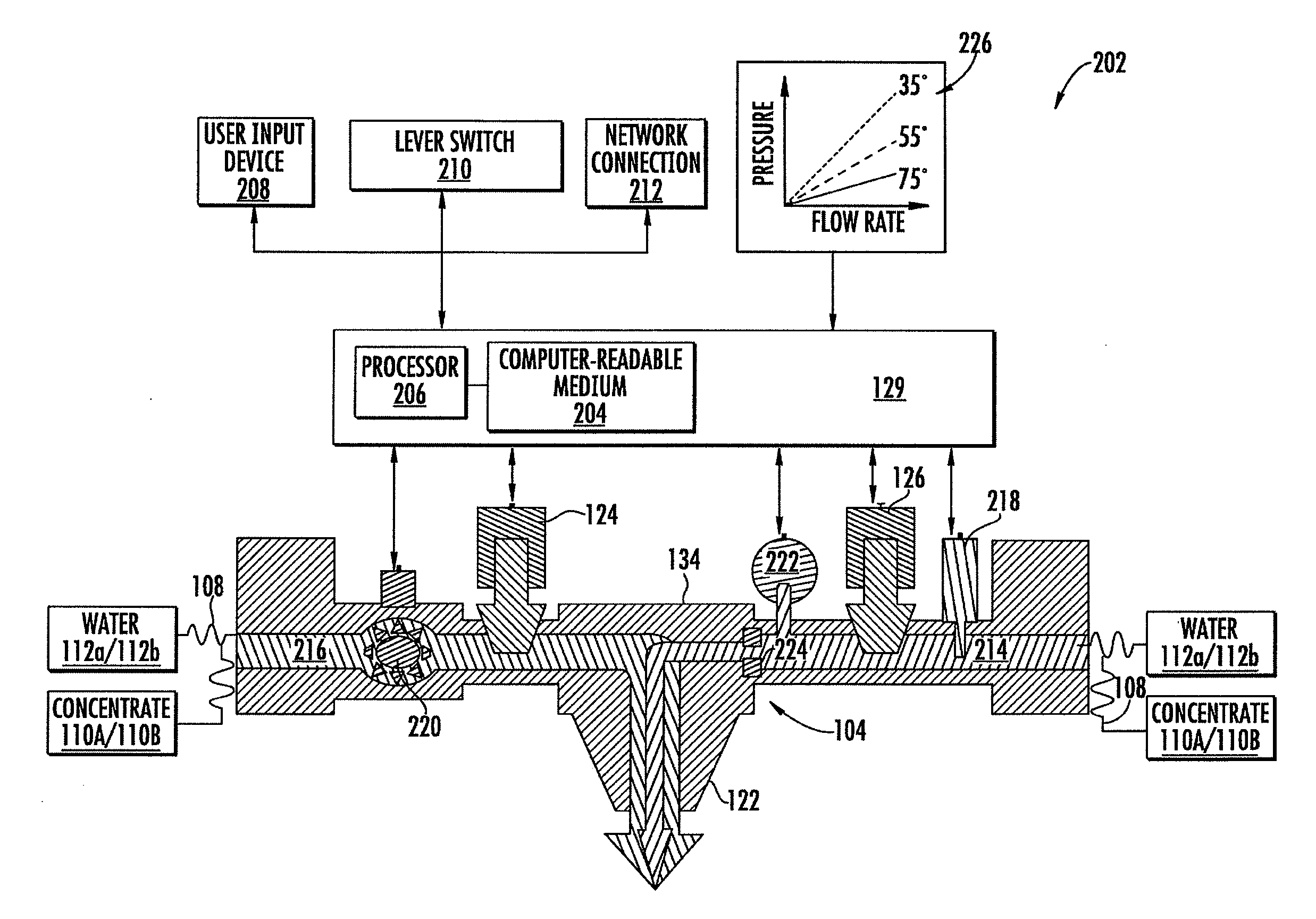

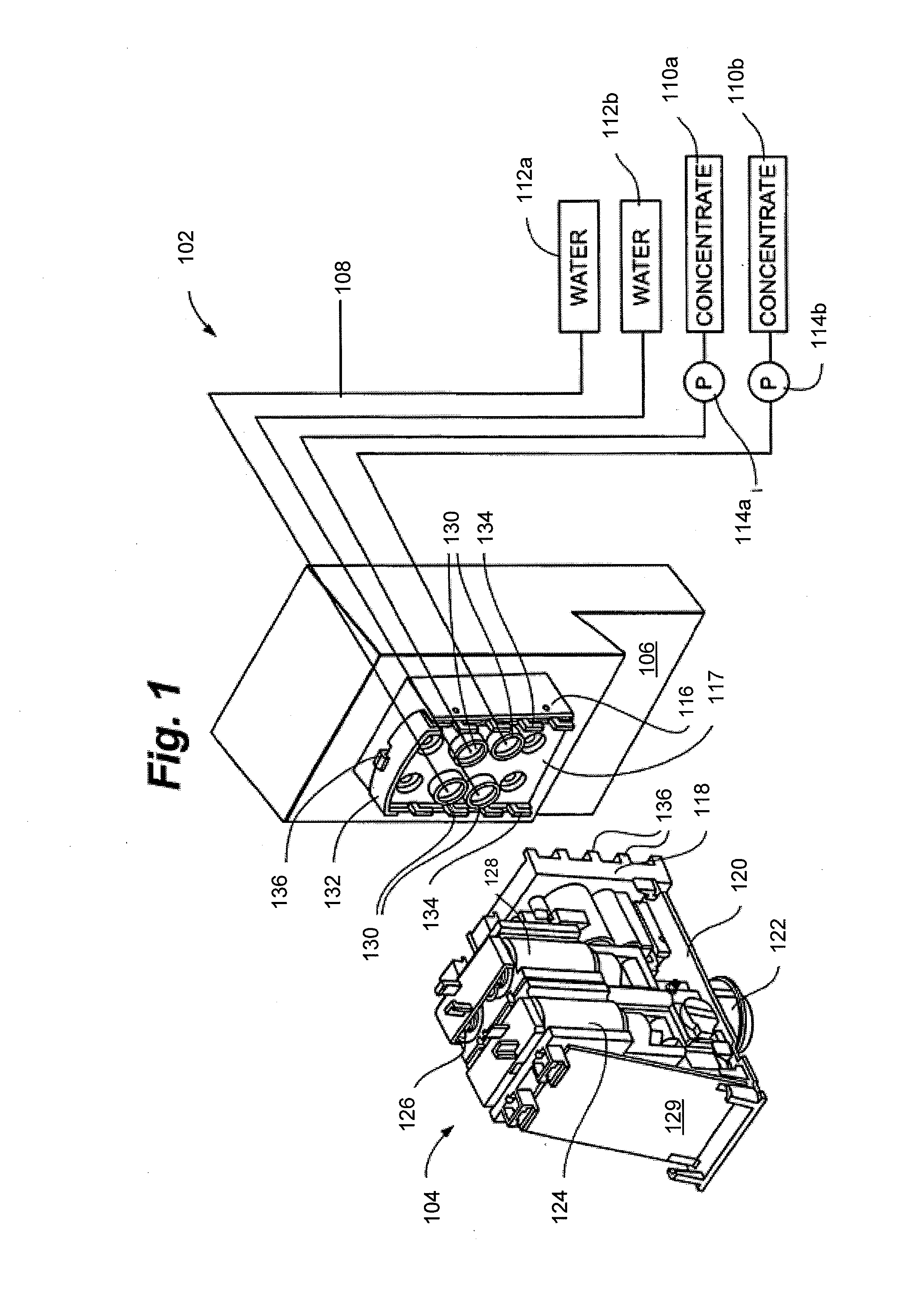

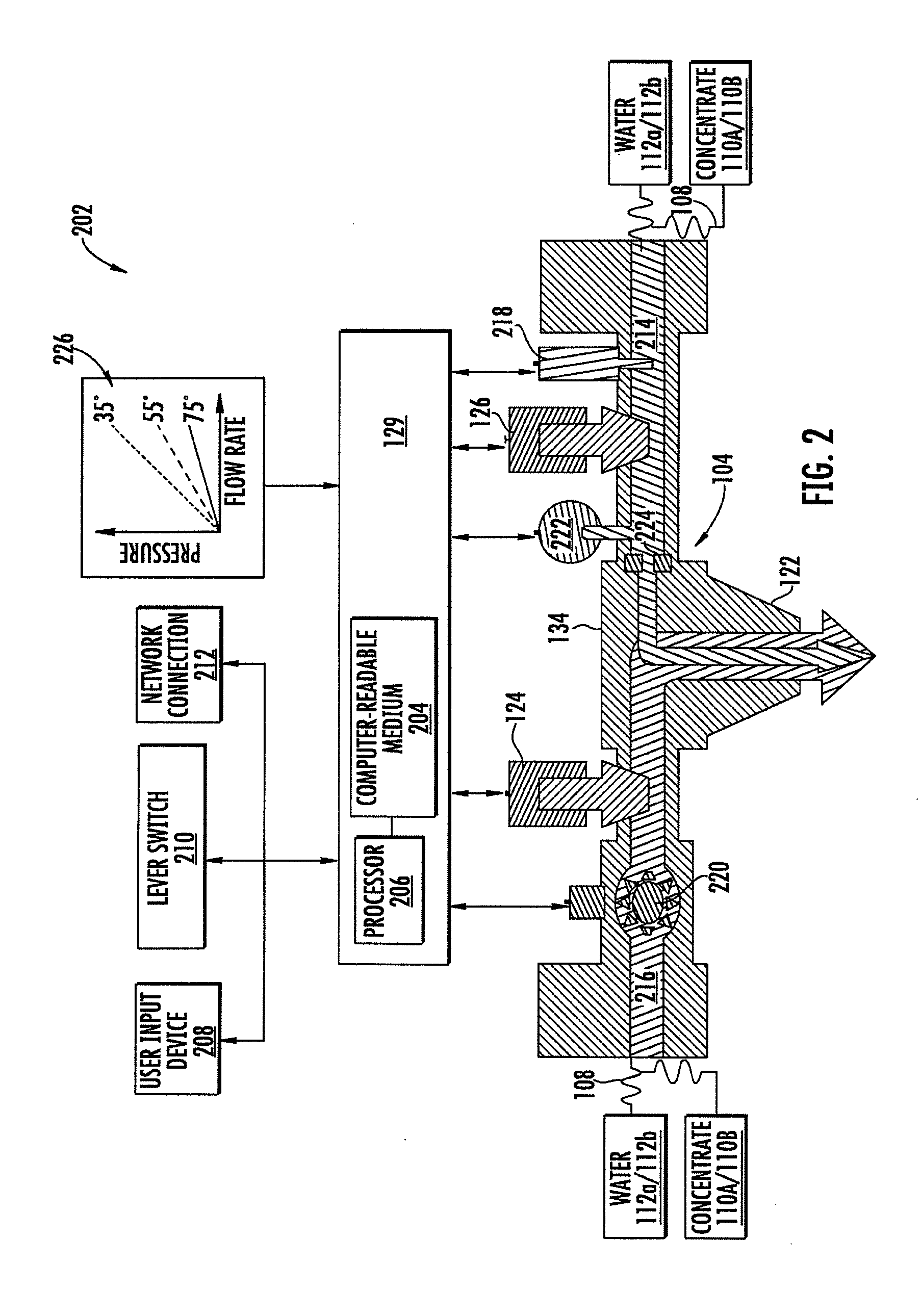

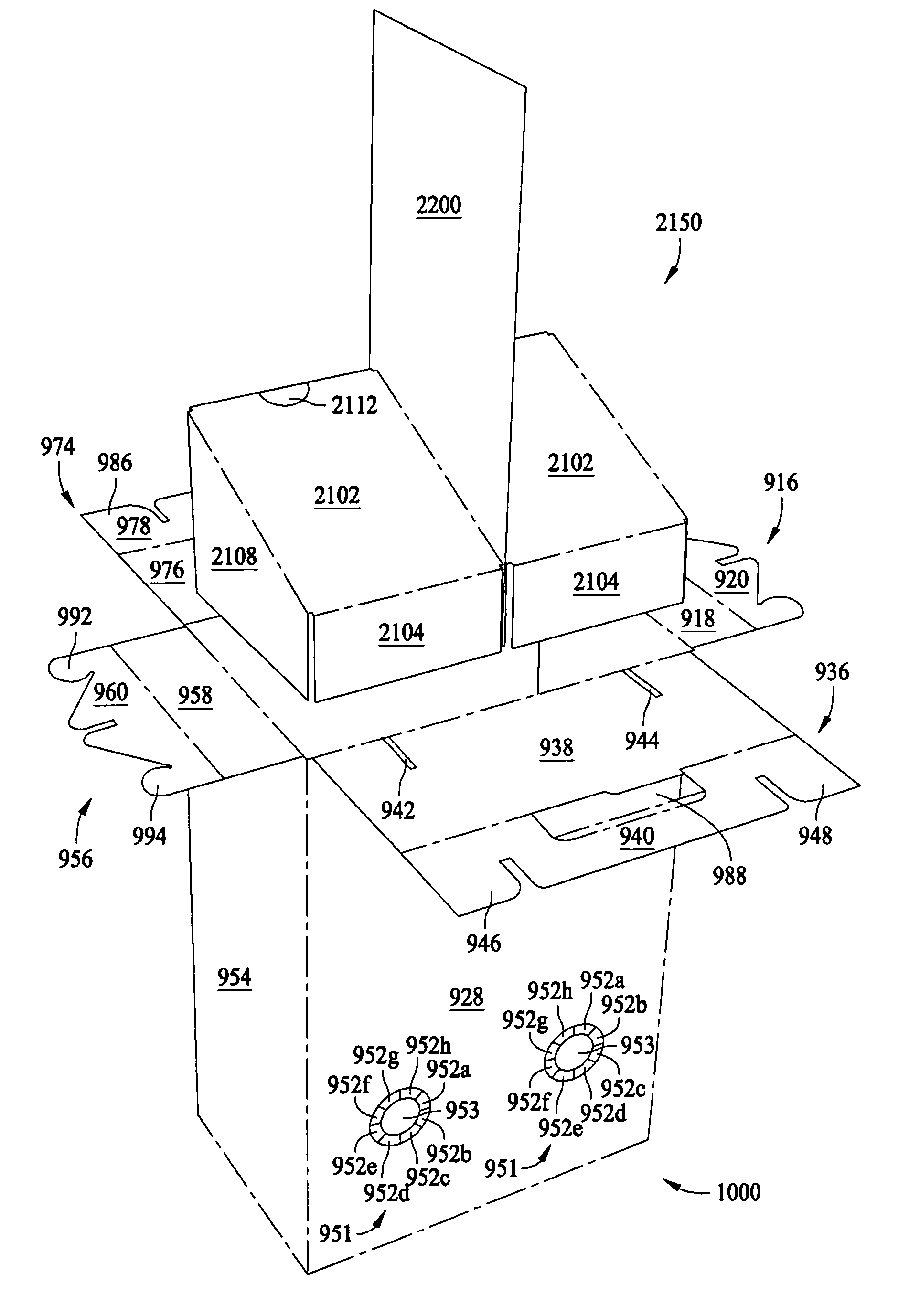

Bag-in-Box Pump System

Systems and methods for packaging beverage components and dispensing beverages are provided. Bag-in-box packages include connectors that contain rotary pumps. Each rotary pump includes a resiliently deformable housing and a rotor that form a plurality of chambers. The bag-in-box package may be incorporated into a dispenser system that includes a touch screen that allows users to input beverage selections.

Owner:PEPSICO INC

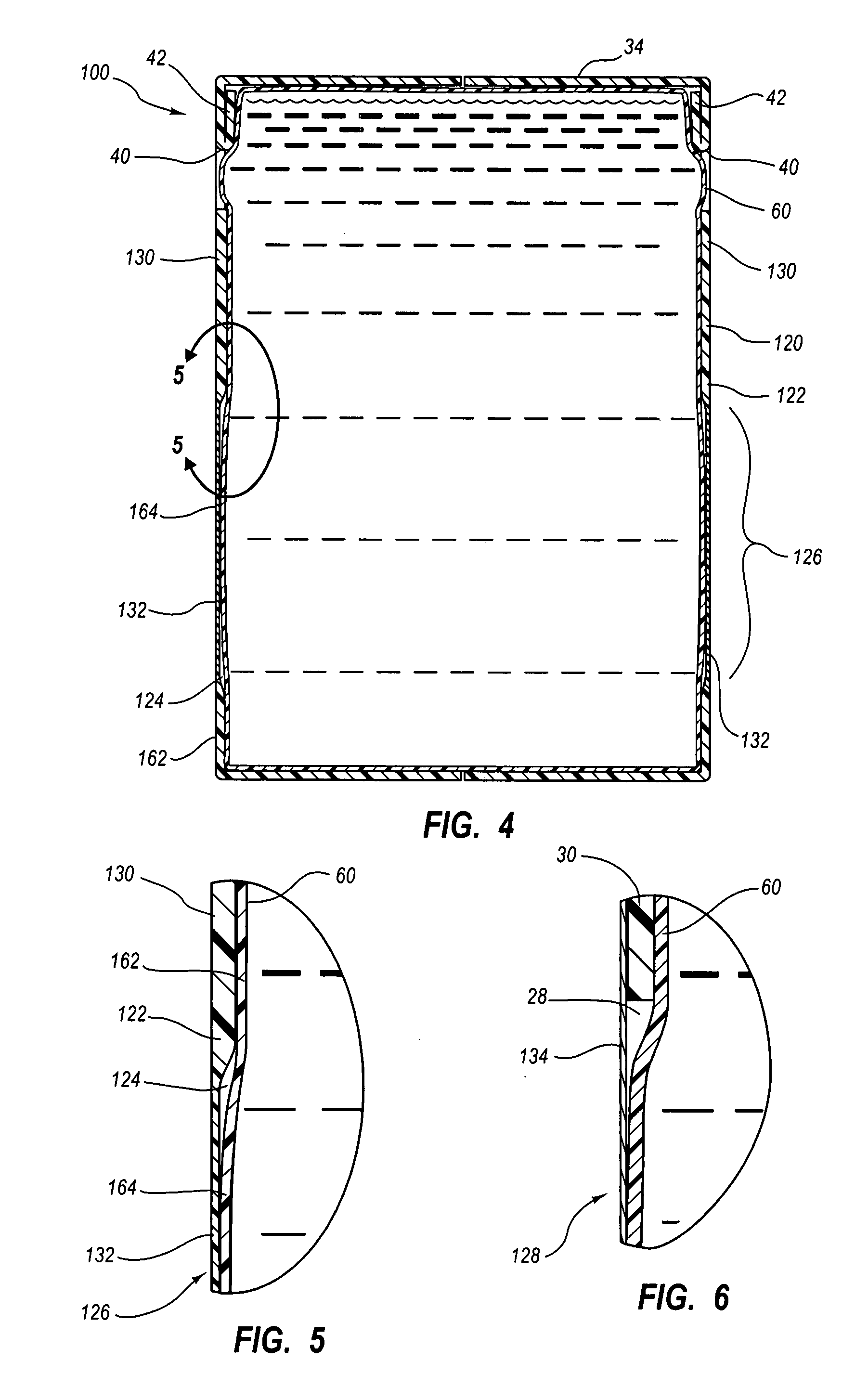

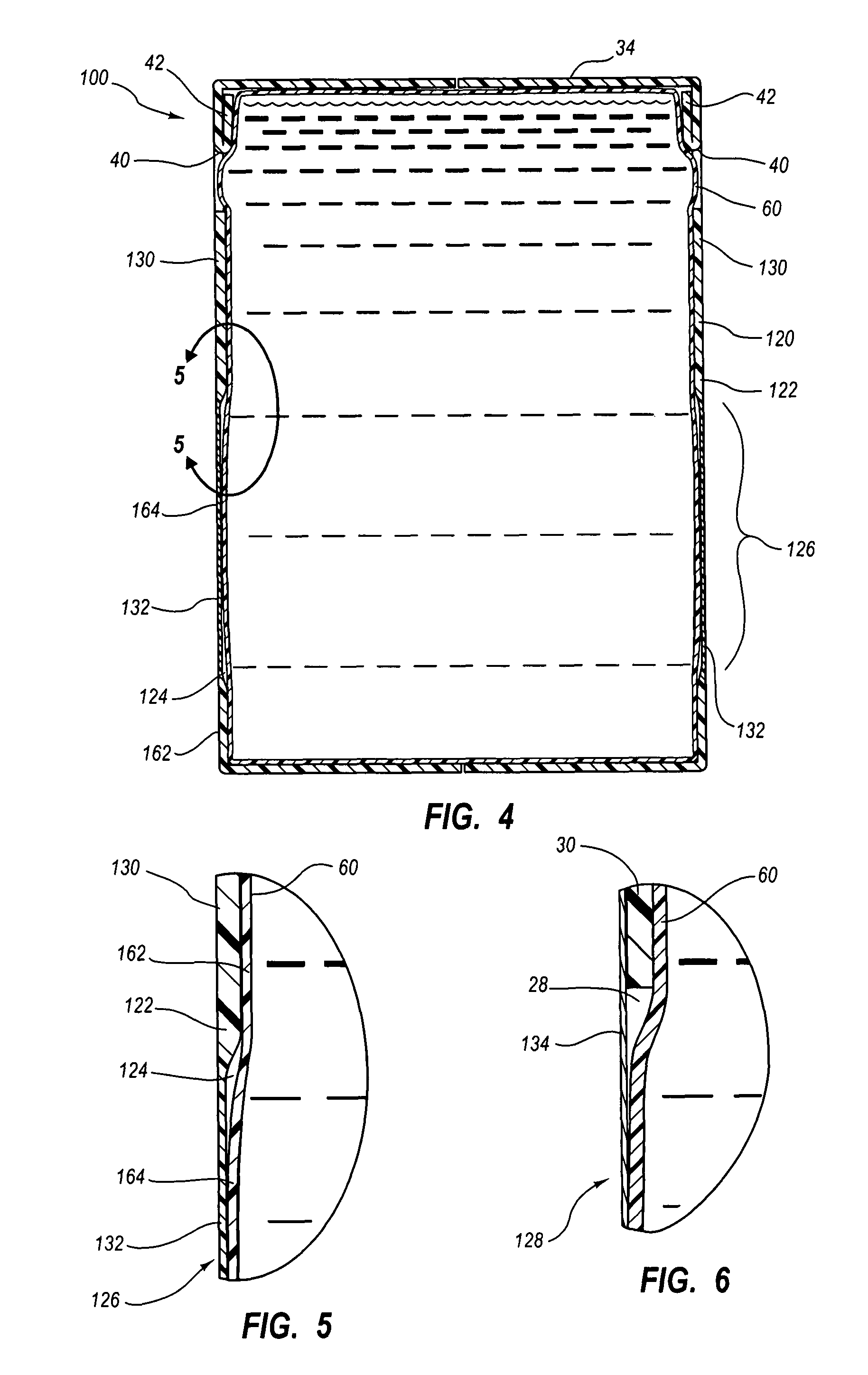

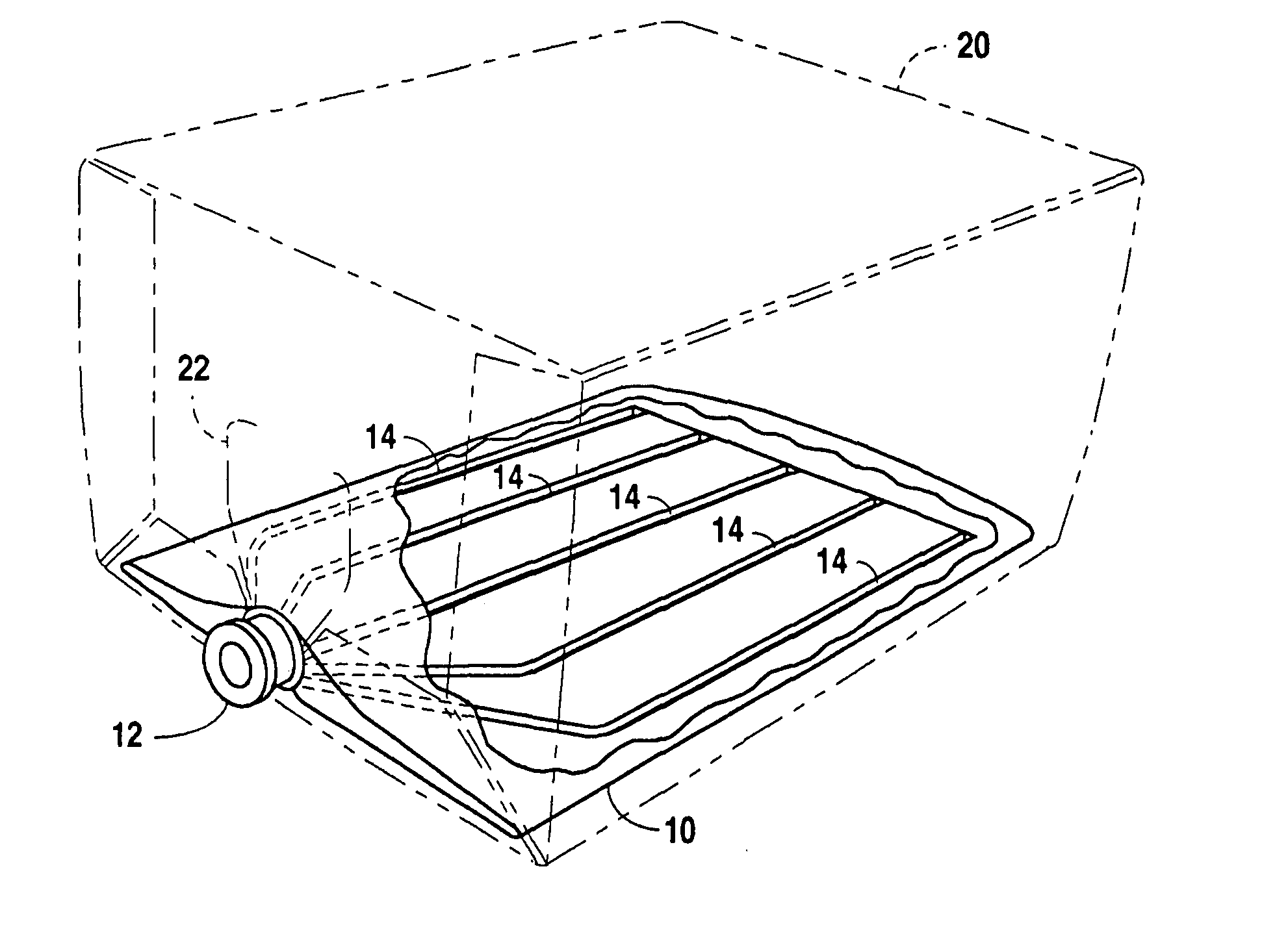

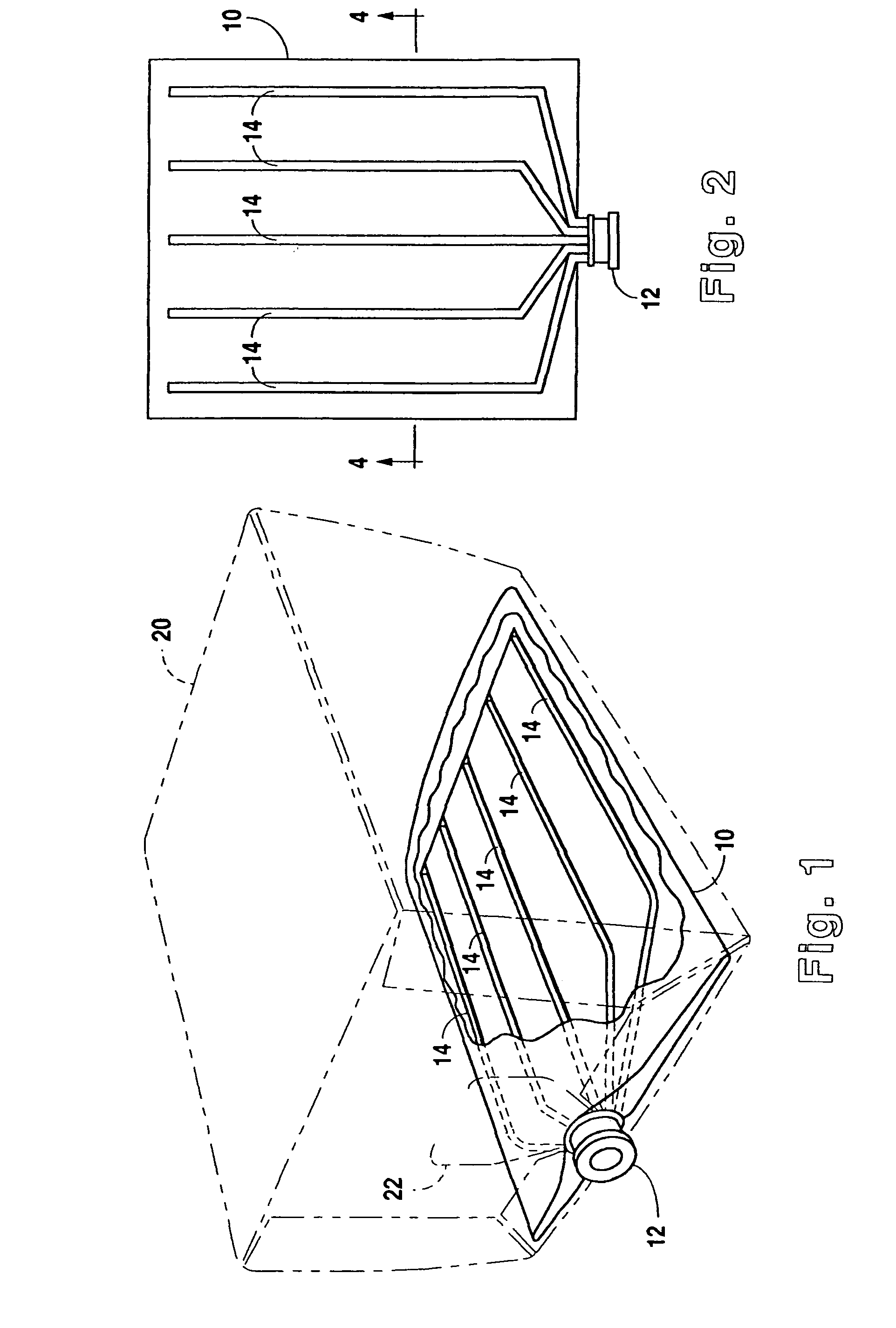

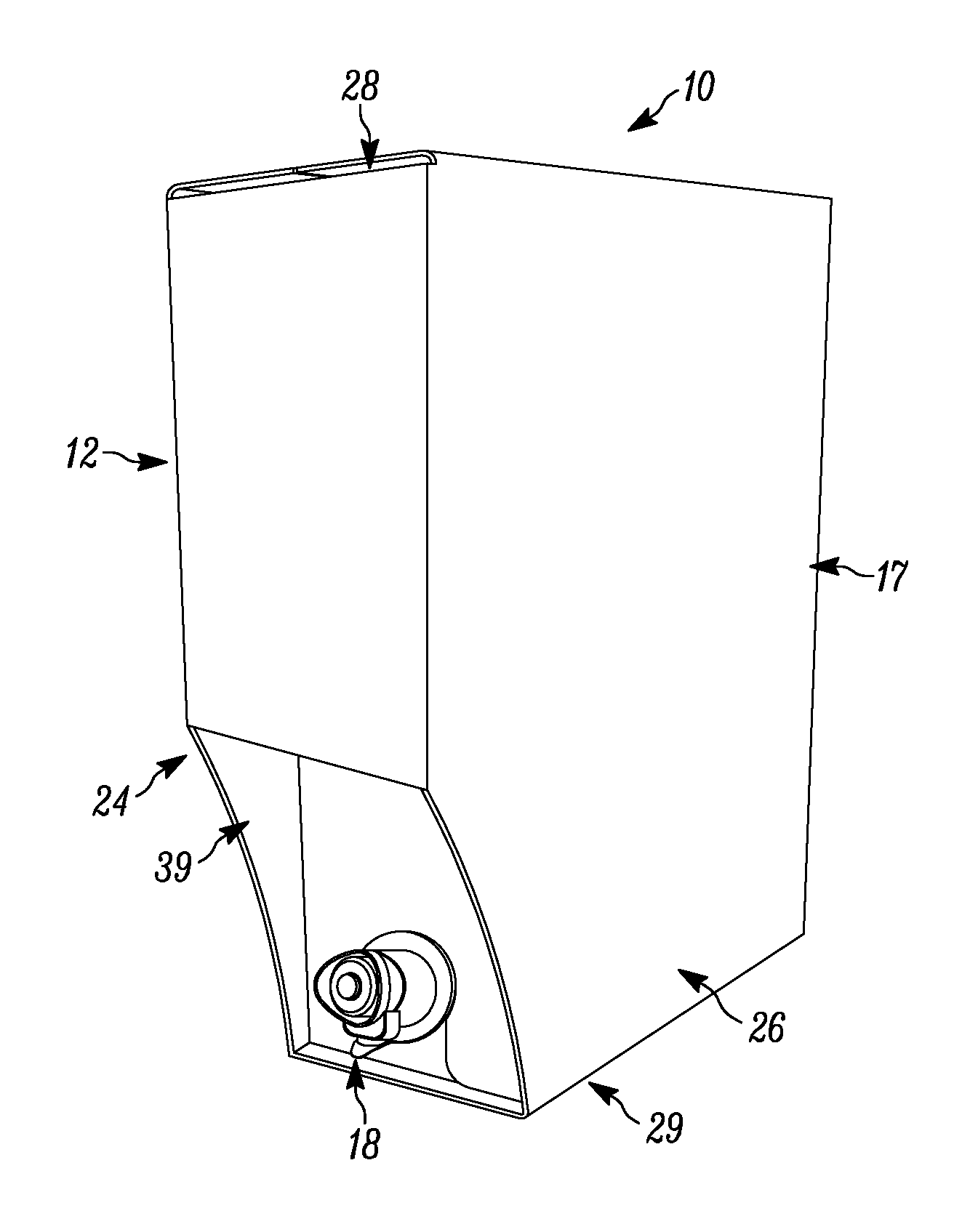

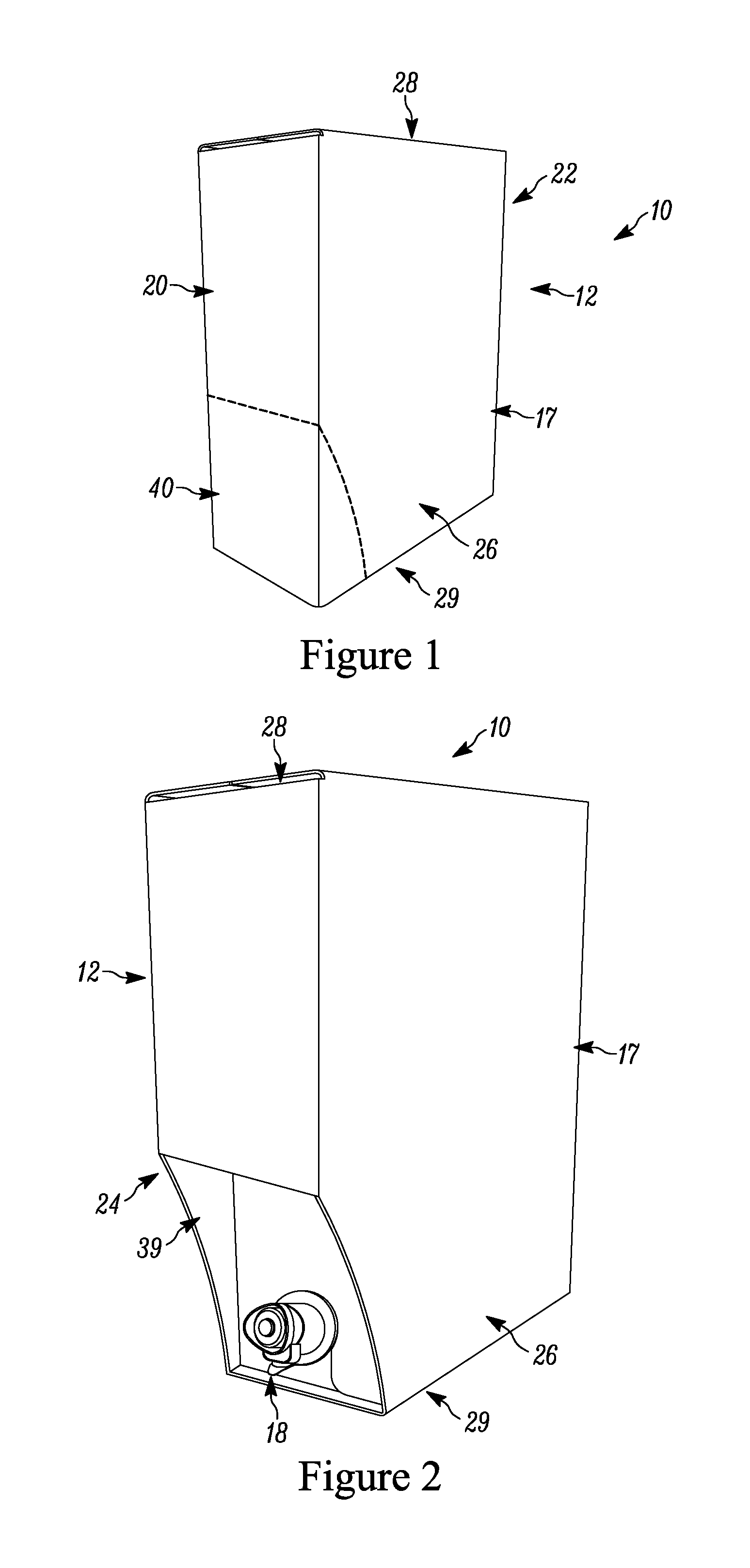

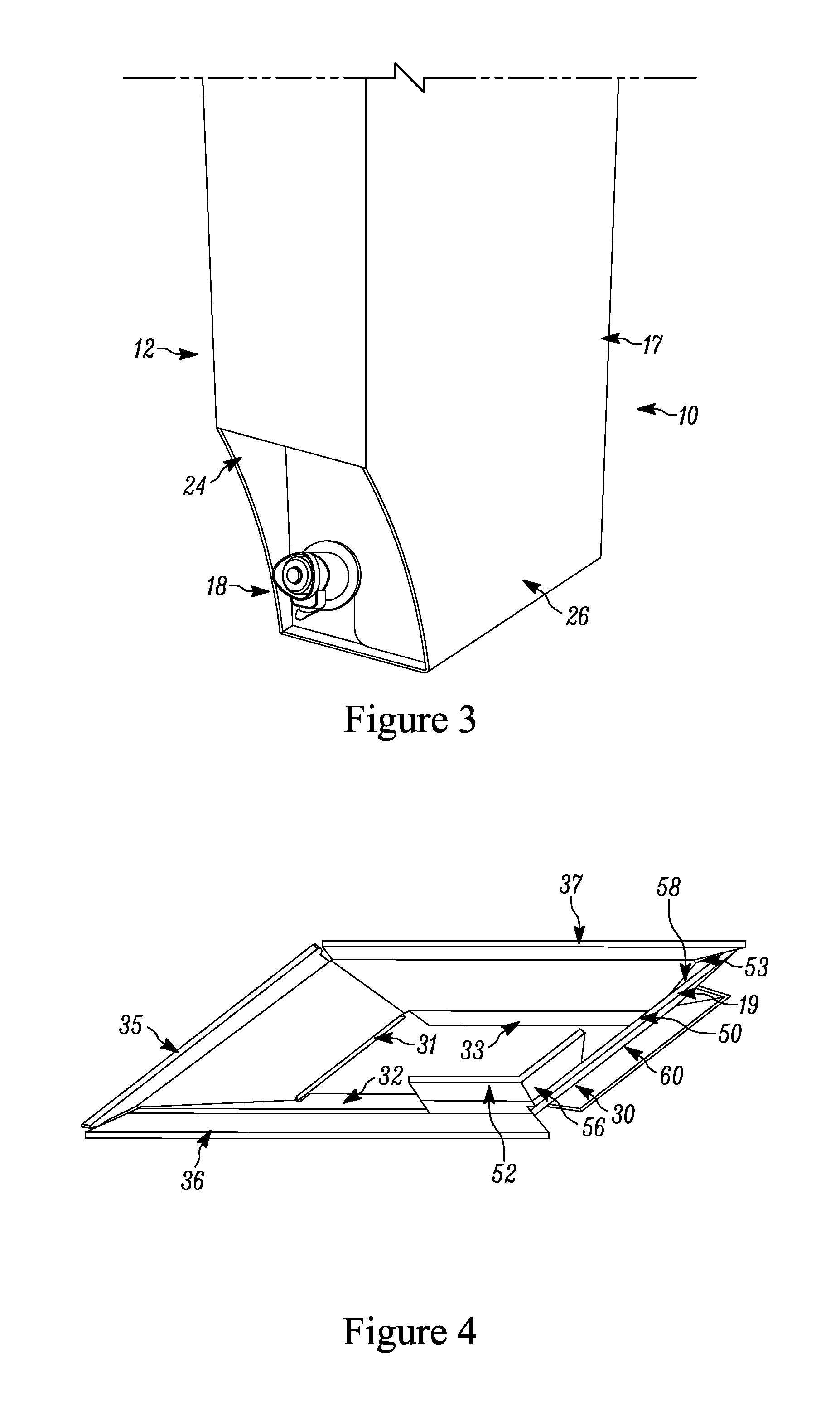

Bag-in-box container for liquids

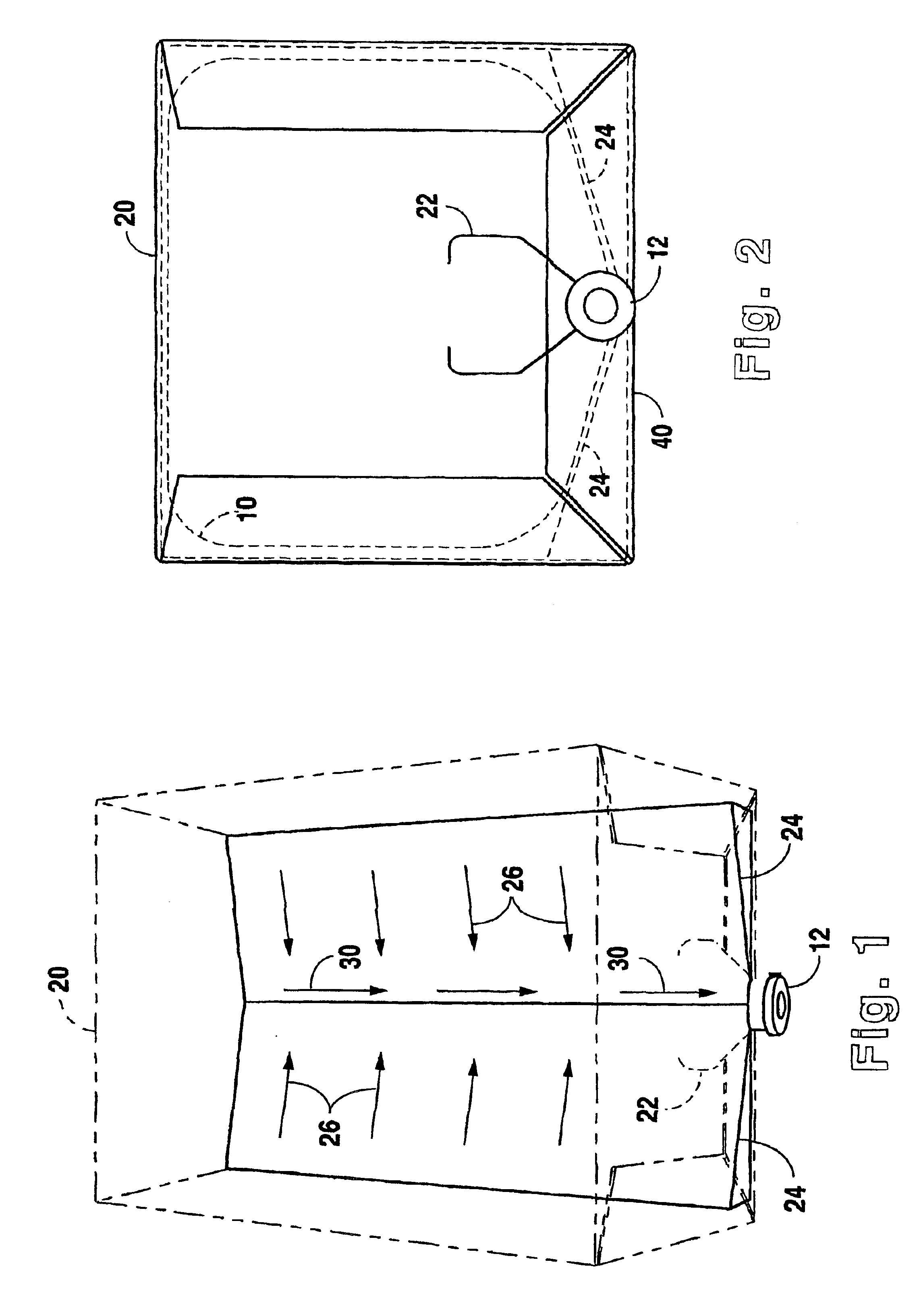

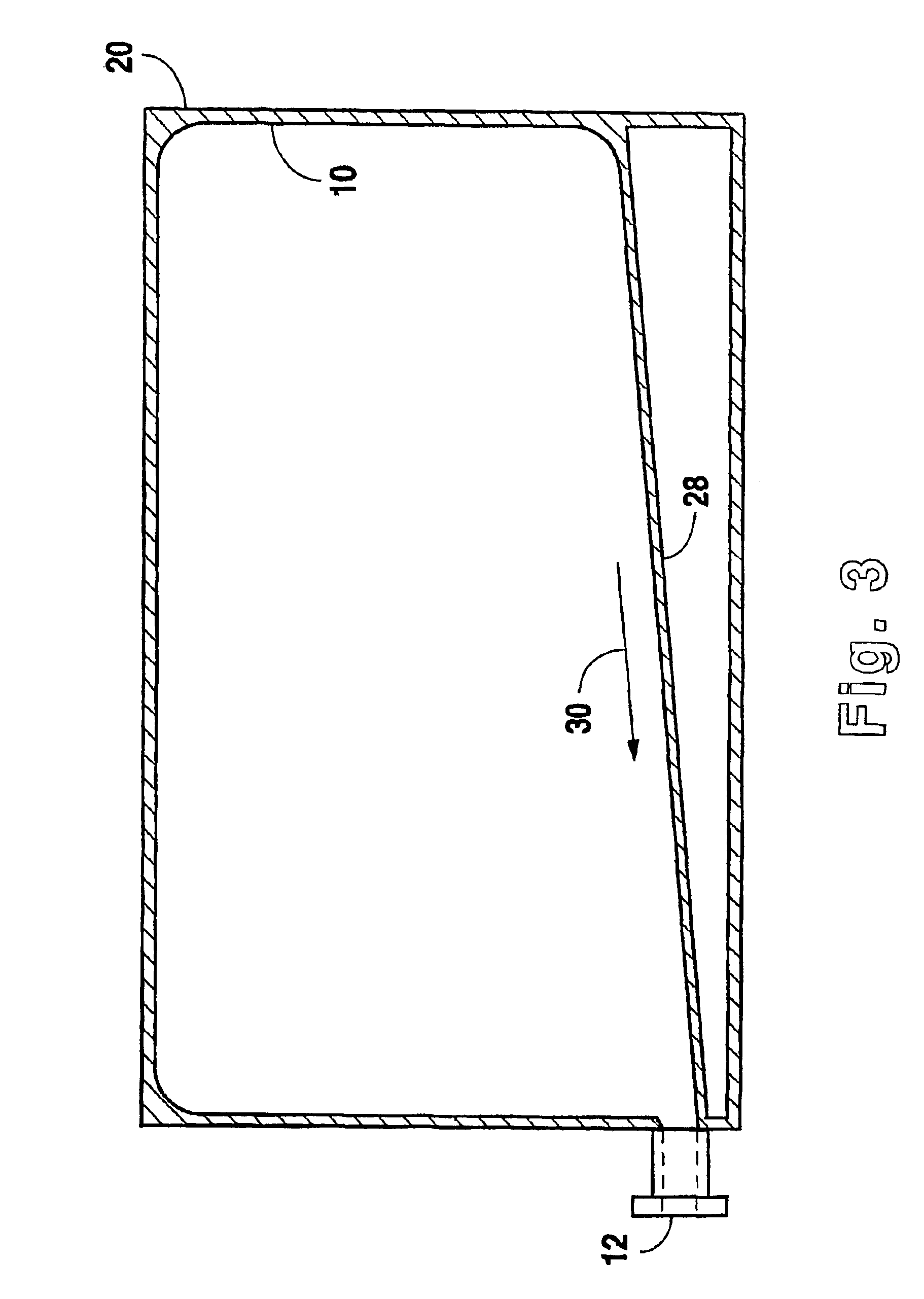

This invention is directed to an improved bag-in-box apparatus for containing and dispensing liquids such as beverages. The interior surface of the bottom of the box (20) is preferably sloped downward toward the spout (12) of the bag (10) such that gravity helps feed the liquid toward the spout (12). In lieu of or in conjunction with slopes, the interior bottom surface of the box (120, 130, 150, 140, 160) may have terraces (34), curves (132, 134), corrugations (152), fan-like ridges (142), or beams (162). The present invention thereby reduces the amount of residual liquid as the liquid is withdrawn from the bag (10) without the need for an evacuation strip or a special slanted rack. Although the primary intended application of the present invention is in bag-in-box packages for containing and dispensing beverages, this invention may also be used to advantage in other liquid dispensing applications.

Owner:DR PEPPER SEVEN UP

Bag-in-box beverage container

InactiveUS7571835B2Increase temperatureReduce heatFlexible containersPliable tubular containersPlastic materialsCarton

Owner:WESTROCK SHARED SERVICES LLC

Evoh resin composition, and molded article and multilayer structure both comprising same

Provided is an EVOH resin composition suitable for use as a multilayer structure serving as a material for molded articles, in particular, liquid container such as bags for bag-in-boxes. The EVOH resin composition has such flexibility that even when used in applications where the resin composition is repeatedly folded or deformed over a long period, the resin composition does not develop pinholes or the like, and further has excellent gas barrier properties and melt molding stability.

Owner:MITSUBISHI CHEM CORP

Seashell-diatom ooze wall surface decoration wall material and production and construction method thereof

The invention discloses a seashell-diatom ooze wall surface decoration wall material and a production and construction method thereof. The decoration wall material comprises: 20 to 98 parts of shell powder, 8 to 30 parts of silica, 4 to 100 parts of kieselguhr, 2 to 20 parts of medical stone, 3.8 to 48 parts of mica powder, 2 to 10 parts of magnesium-rich silicate, 6 to 26 parts of scolecite, 1.5to 36 parts of hydrosilicate, 0 to 50 parts of titanium dioxide powder, 2 to 50 parts of calcium carbonate, 0.1 to 0.3 part of vegetable fiber, 1 to 30 parts of pigment, 4.8 to 40 parts of kelp powder, 1 to 30 parts of cold soluble polyvinyl alcohol powder and 1 to 20 parts of hydroxypropyl methyl cellulose. The production and construction method comprises: placing the raw material components into a stirrer for uniform stirring; filling the mixture in bags, packing the bags in boxes, sealing the boxes and storing the boxes in a storehouse; adding water into the mixture and stirring the mixture uniformly; and pasting the mixture on a wall surface to be decorated to make various texture patterns. The seashell-diatom ooze wall surface decoration wall material has the advantages of: (1) soft texture and no toxicity, fading nor stripping; (2), characteristics of eliminating indoor pollution, regulating indoor humidity, eliminating odor, isolating noises and offering high skin texture feel; (3) fire proofing and flame retarding; and (4) rich color.

Owner:青岛泉佳美硅藻泥科技有限公司

Temperature controlled liquid dispenser, containers therefore, and bag-in-box container construction

ActiveUS8459503B2Improve thermal conductivityThermal energy is effectively and efficiently transferredDomestic cooling apparatusLighting and heating apparatusLiquid liquid partitionThermal energy

A dispenser for relative rapid cooling or heating of the contents of a liquid storage container provides a receptacle for receiving the liquid storage container therein and positioning a thermal transfer portion of the liquid storage container in thermal conductive relationship with a thermal conduction pad associated with the receptacle. Thermal energy is effectively and efficiently transferred from the thermal conduction pad to the liquid in the liquid storage container. The thermal conduction pad is controlled to provide and maintain the desired temperature to the liquid. The liquid is dispensed directly from the container. Various types of containers can be used in the dispenser, with a special bag-in-box container having a inner container and outer box with thermal conduction windows in the box to provide good heat transfer between the thermal conduction pads and the inner container constituting an aspect of the invention. A special rigid container can also be used.

Owner:GROESBECK R CLAY

Bag with flap for bag-in-box container system

InactiveUS20050220369A1Facilitate complete emptying of its contentsBagsSacksBag-in-boxSheet material

A bag for storing material in liquid or particulate form, comprising four side walls and top and bottom walls that are integral extensions of the four side walls, is characterized by an additional single or multi-ply sheet that overlies and is sealed to one side of said bag, said sheet material being adapted to be partially separated from itself so as to form a flap at the top end of the bag that can be gripped for use in supporting the bag as it is being drained of its contents via a drain located at the bottom end of the bag.

Owner:CDF CORP

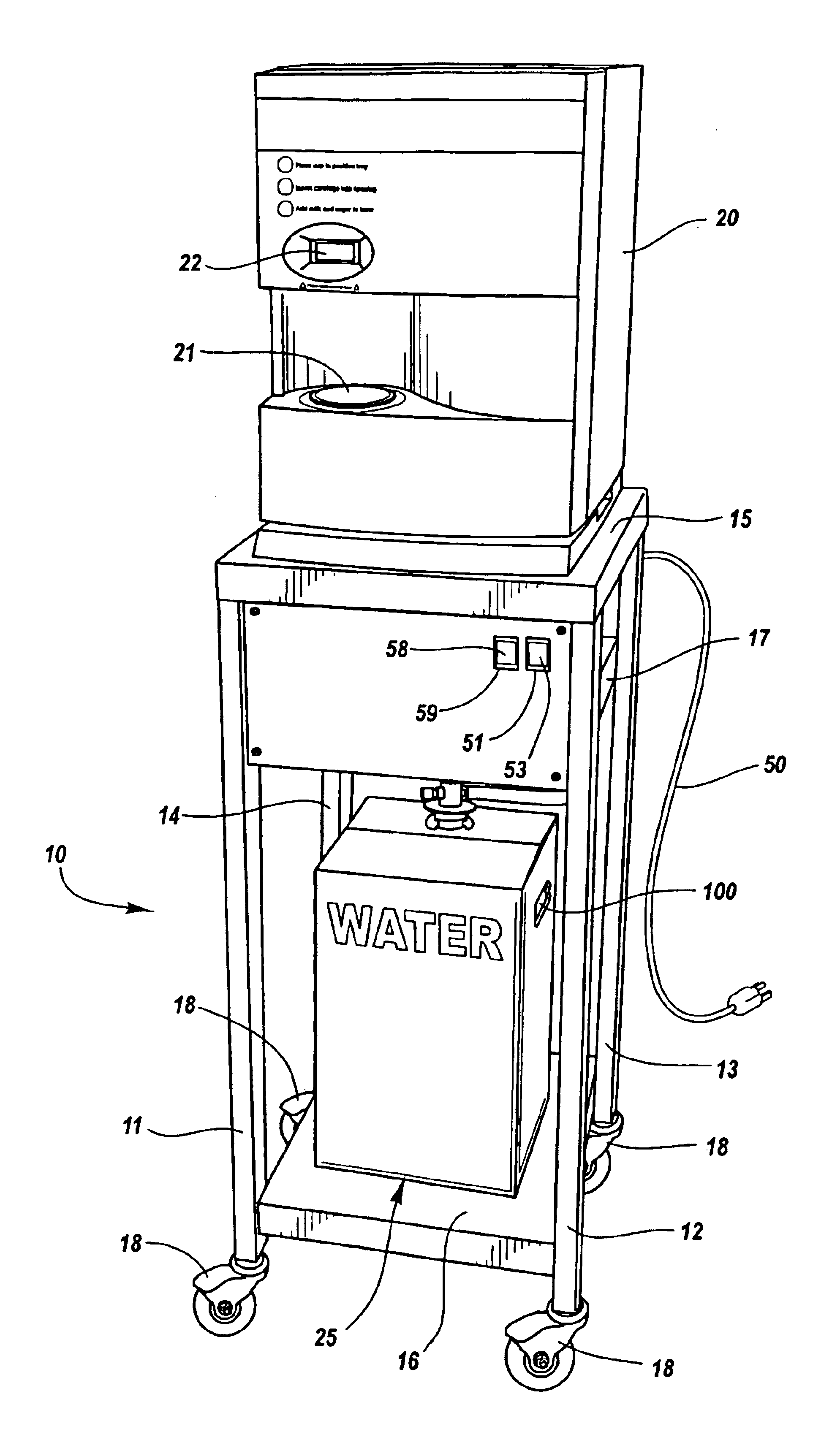

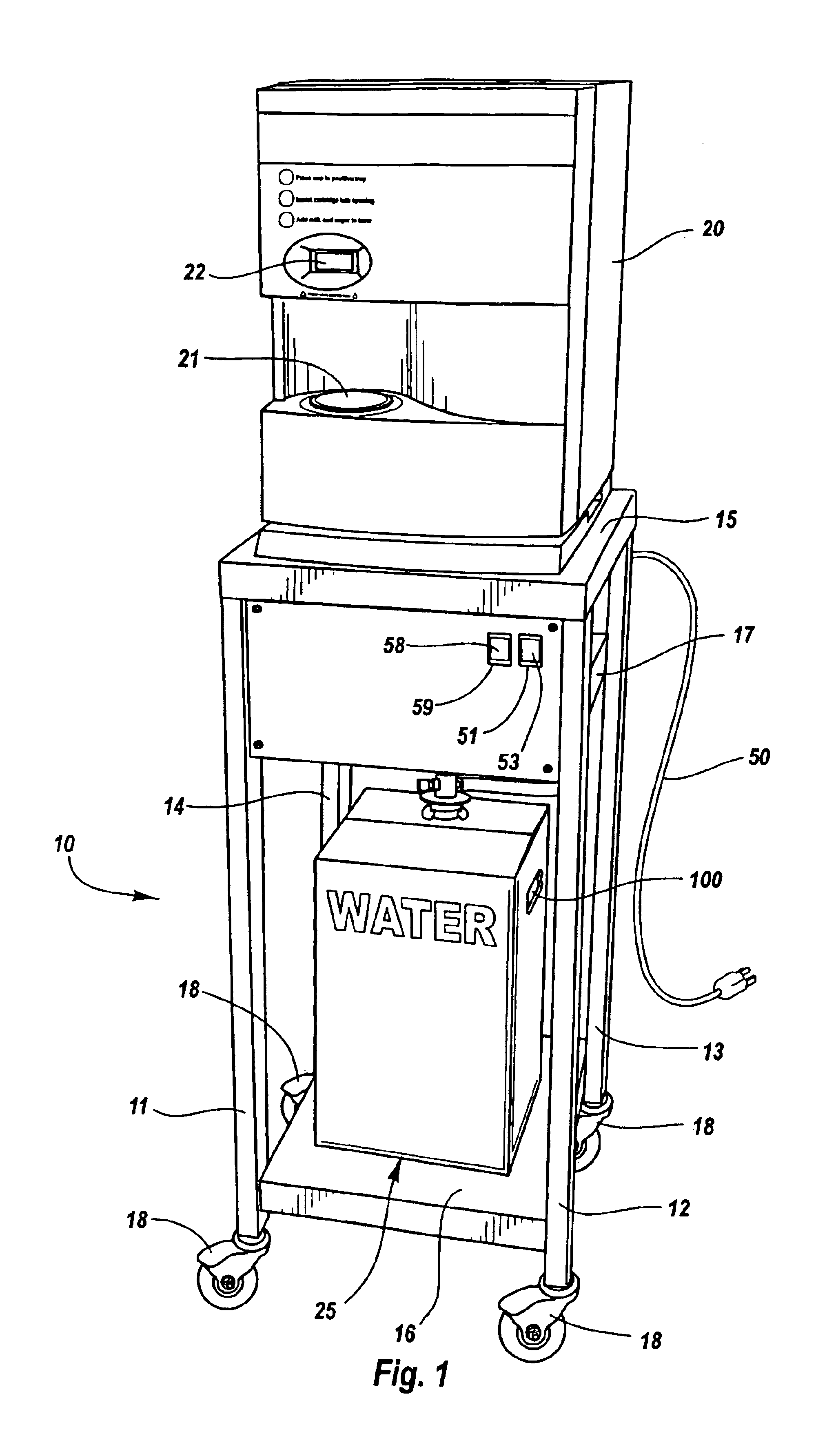

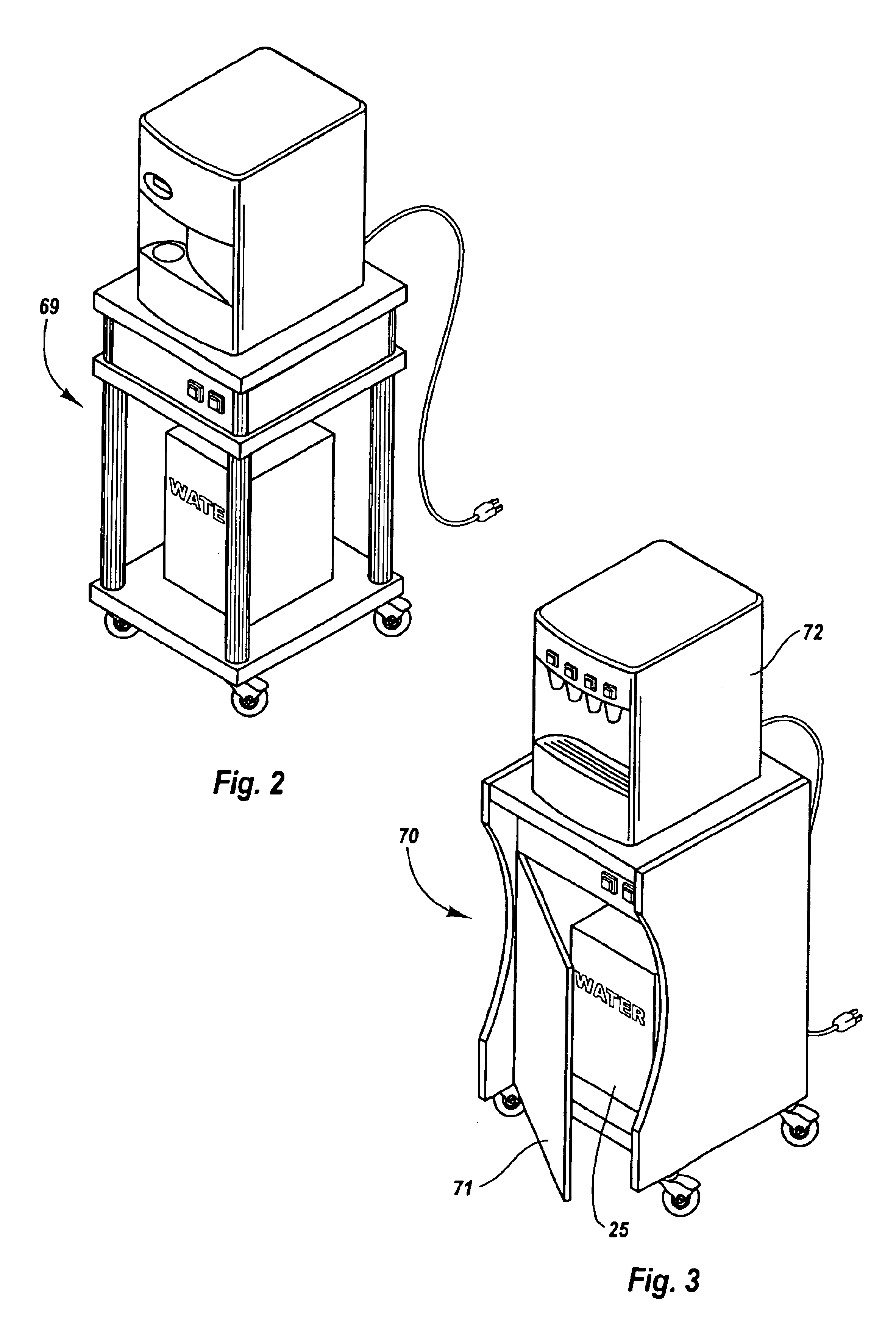

Drink dispensing cart and water packaging and supply system

InactiveUS6926170B2Eliminate storageEliminate needTank vehiclesLiquid transferring devicesLine tubingTime delays

A drink dispensing cart includes a drink dispensing machine that is normally plumbed directly into a municipal water pipe at a fixed location. The cart includes a container of water, preferably a disposable container of water such as a bag-in-box container of water, and a pump to pump water from the container of water to the drink dispensing machine. A controller controls operation of the pump to operate the pump only when water is needed by the drink dispensing machine and to provide an indication when the container of water is empty and needs changing. A pressure sensor in an outlet line extending between the pump and drink dispensing machine senses when water is needed by the dispenser and a pressure sensor in an inlet line extending between the pump and the container of water senses when the container of water is empty and needs replacing. A time delay circuit delays start of operation of the pump when water is needed by the drink dispenser to avoid pulsing of the pump. The bag-in-box container of water is sized for efficient packing and shipping.

Owner:GROESBECK R CLAY

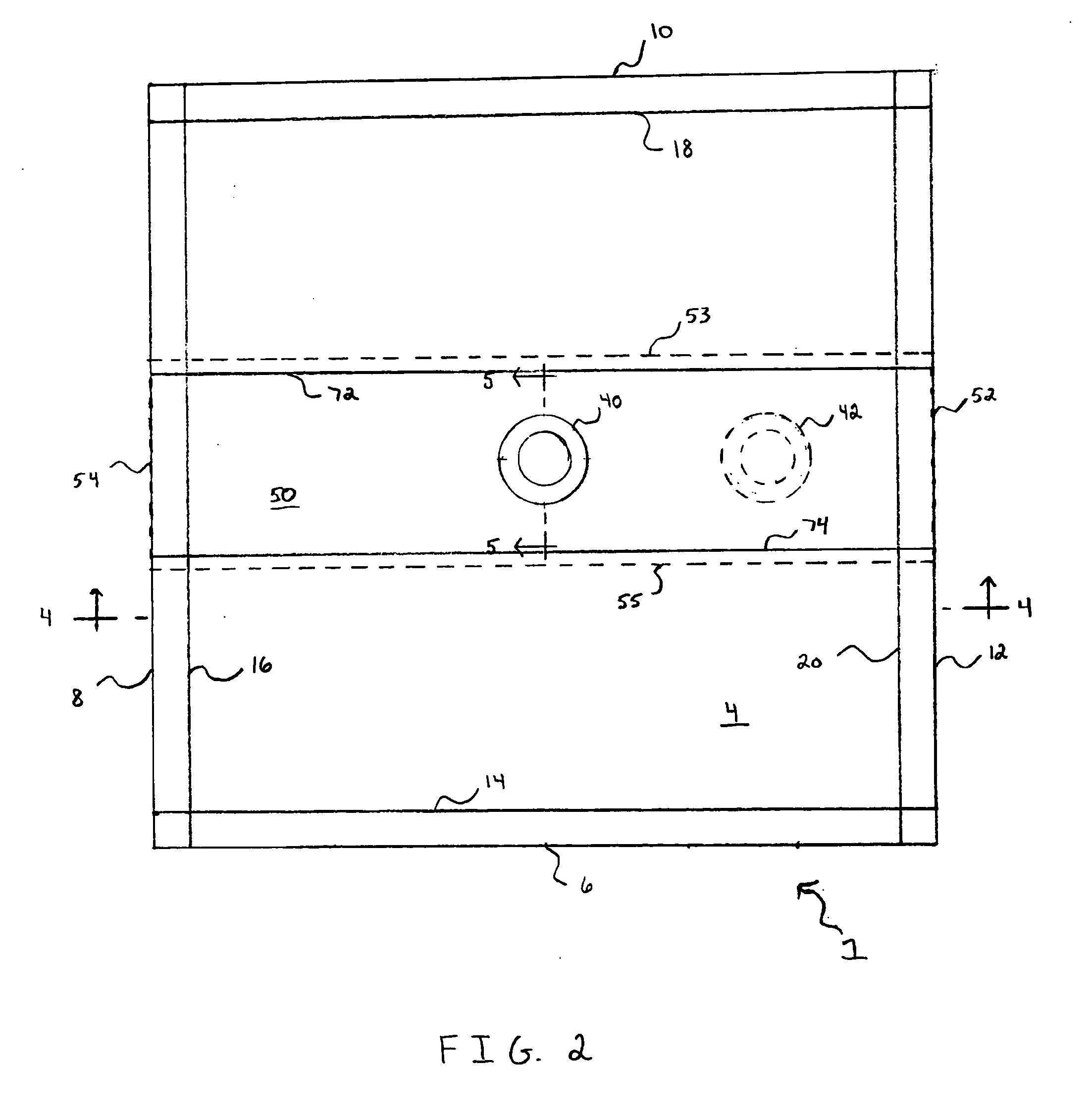

Temperature controlled liquid dispenser, containers therefore, and bag-in-box container construction

InactiveUS7975879B2Improve thermal conductivityThermal energy is effectively and efficiently transferredDomestic cooling apparatusLiquid flow controllersTemperature controlThermal energy

Owner:GROESBECK R CLAY

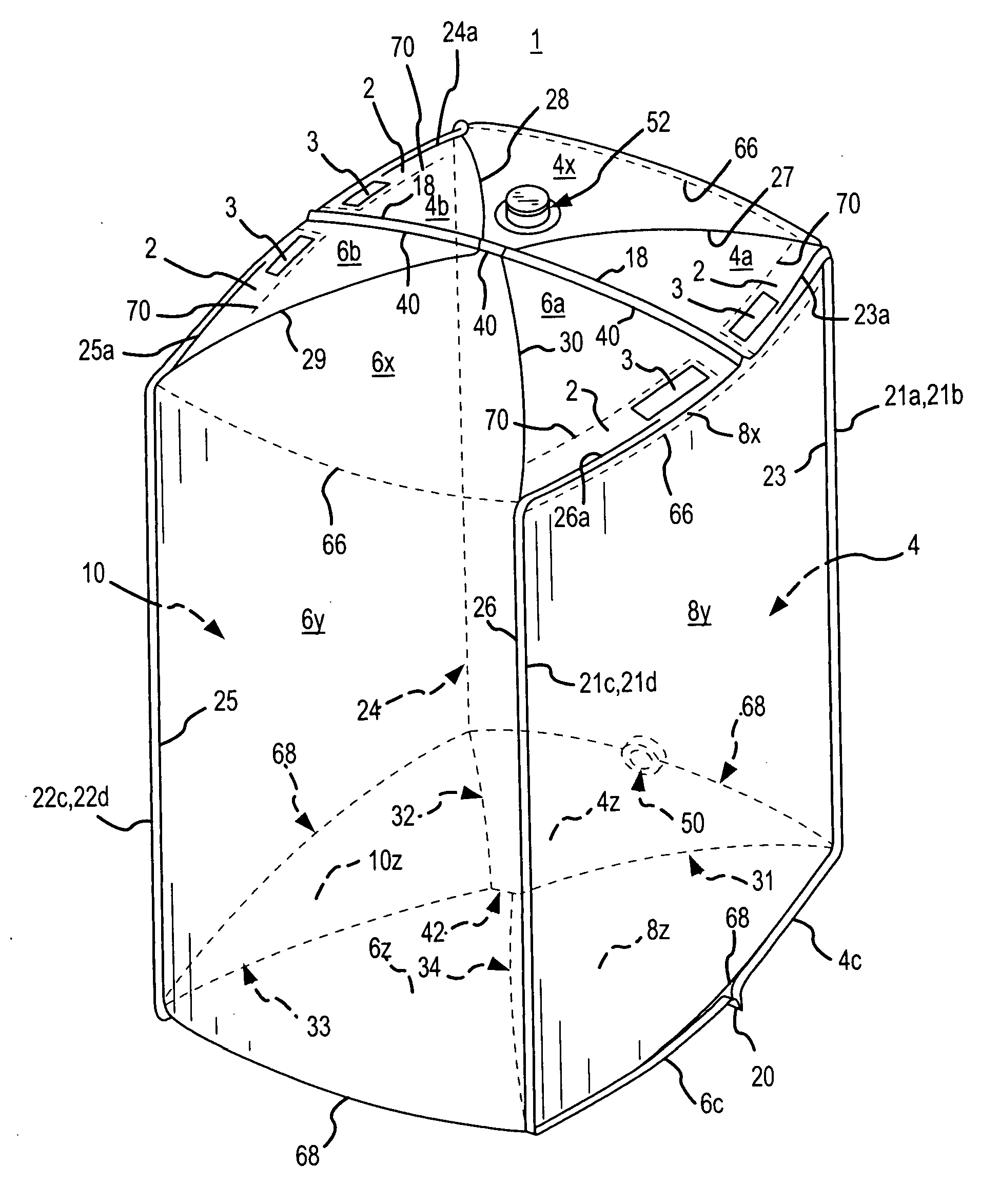

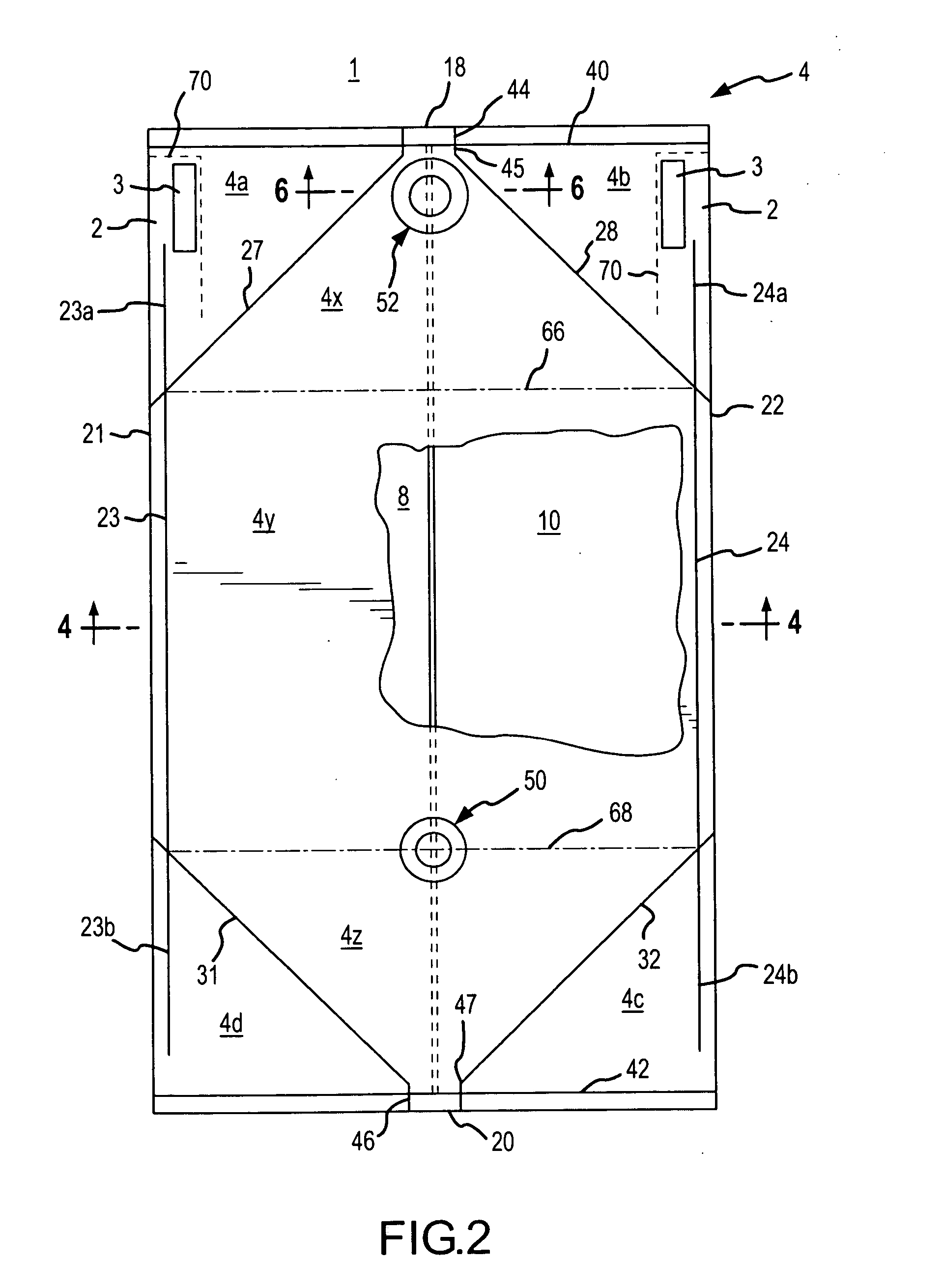

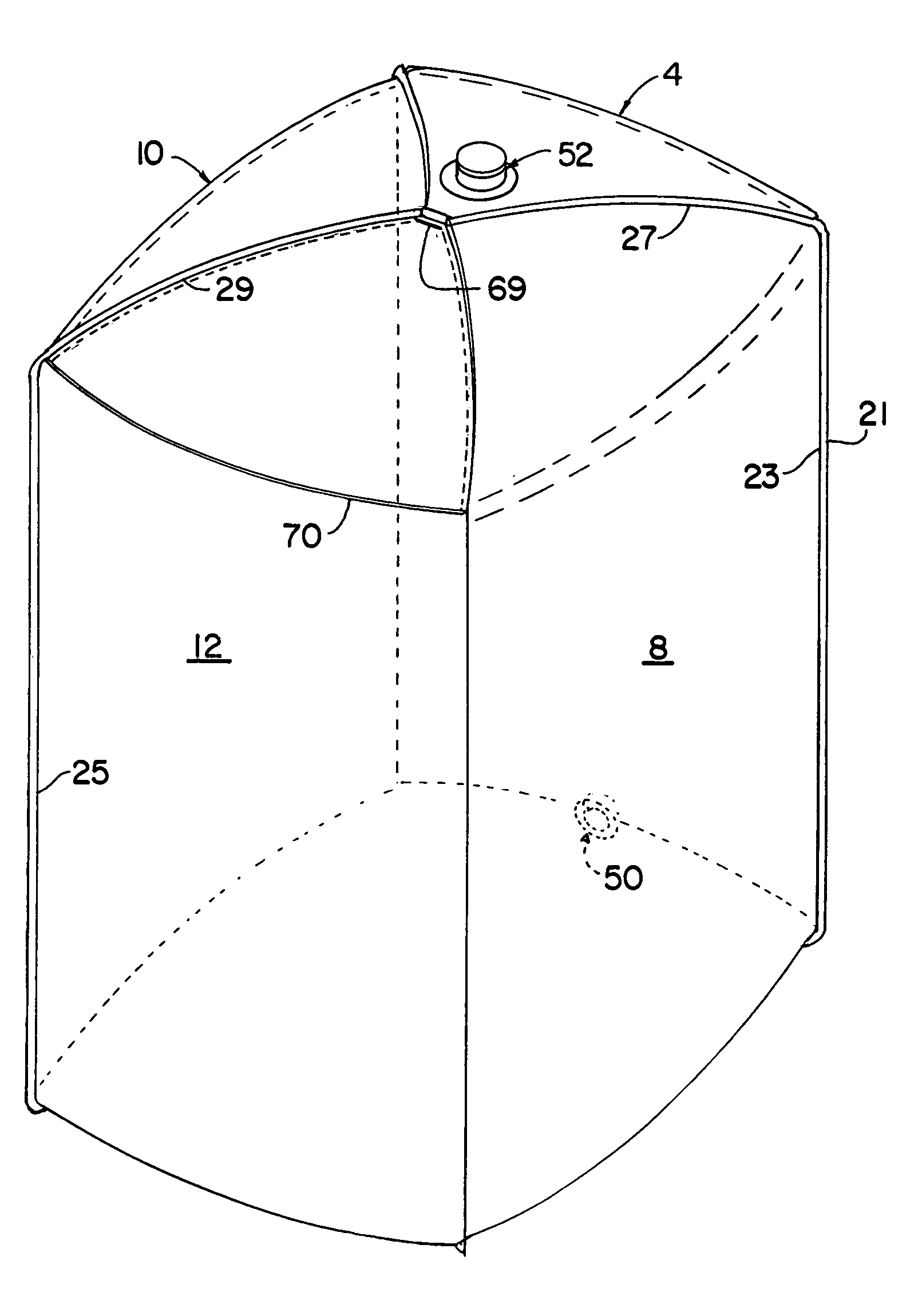

Bag-in-box container and method of constructing the same

A bag-in-box container for storing and dispensing liquids is provided. The container includes an outer box including two opposing end walls, two opposing side walls, a bottom wall, a top wall, a fill opening, and a dispensing opening. The container further includes an inner, liquid-impermeable bag stored within the outer box. The bag includes a first opening, a filling fixture coupled to the first opening, a second opening, and a dispensing fixture coupled to the second opening. The filling fixture extends through the fill opening and defines a first fluid passageway extending from outside of the box to an internal cavity of the bag. The dispensing fixture extends through the dispensing opening and defines a second fluid passageway extending from the bag internal cavity to outside of the box.

Owner:ROBERT BOSCH GMBH +1

Flexible liner for FIBC or bag-in-box container systems with improved flex crack resistance

Owner:CDF CORP

Thermoelectric wine bag cooler/dispenser

InactiveUS8820094B1Maintenance contentEasy constructionLiquid flow controllersMachines using electric/magnetic effectsThermoelectric coolingEngineering

A thermoelectric wine pouch cooler / dispenser apparatus powered by household current has a thermally insulated cabinet that sits on a countertop or other flat surface and has a thermoelectric cooling system. The cabinet has at least one thermally insulated compartment that receives a removable bag support housing containing a collapsible flexible wine-filled bag from a “bag-in-box” wine container and its dispensing valve. The bag support housing includes a spring biased plate to facilitate emptying of the contents of the bag. The temperature of each compartment is individually controlled by a digital temperature controller and a thermoelectric cooling assembly which includes a fan and a cold plate engaged on a thermally conductive heat transfer block at the top of each compartment which engages the bag support housing.

Owner:CASHER CALVIN +1

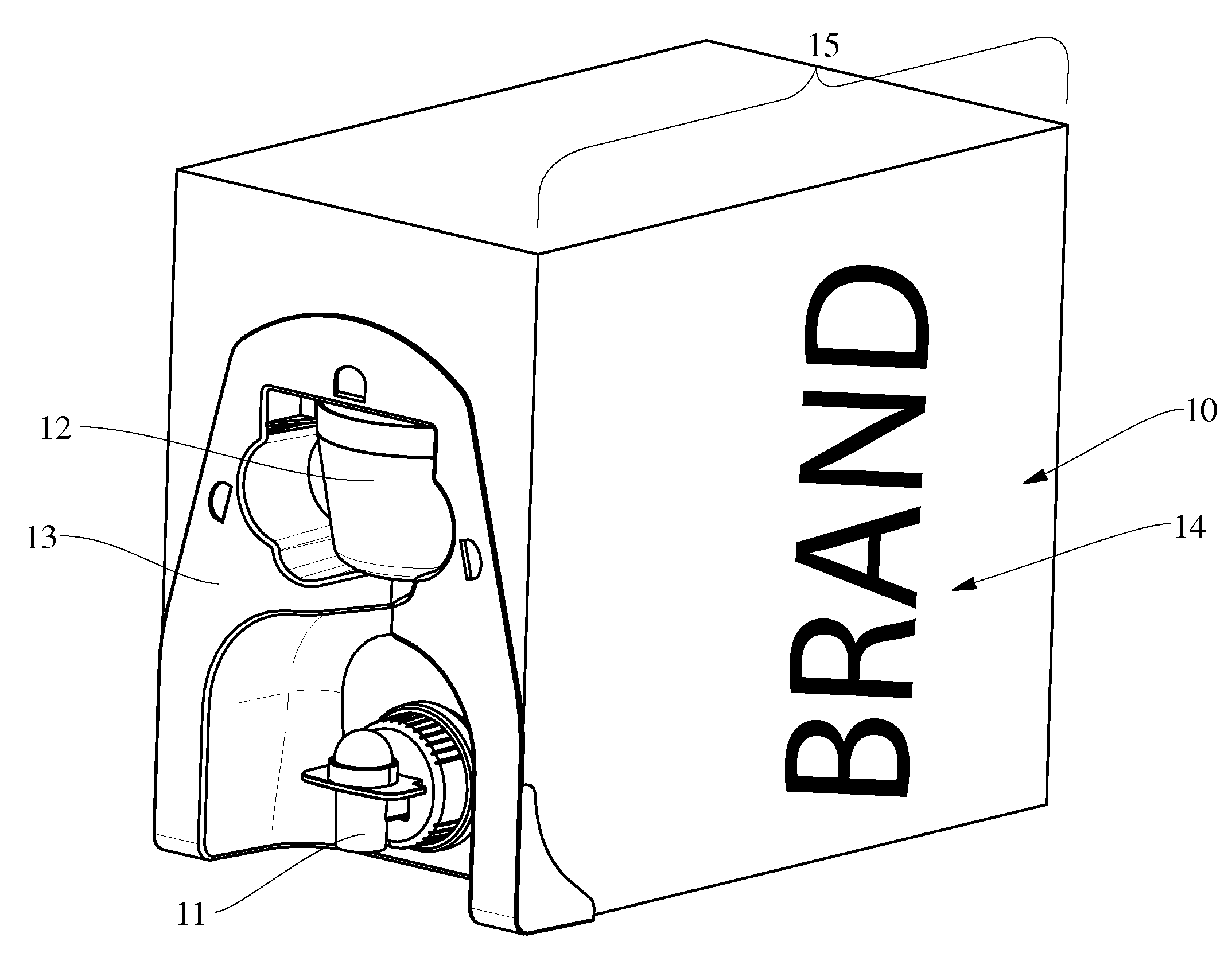

Bag-In-Box Package with Integrated Cup

InactiveUS20110031303A1Easy to useKeep the structure stableFlexible containersPliable tubular containersBiomedical engineeringBag-in-box

Fabric care products having a package useful for storing, dispensing, and / or measuring flowable compositions, including at least one inner container; an outer container at least partially encompassing the inner container; a dispensing means operatively attached to the inner container; and a vessel.

Owner:THE PROCTER & GAMBLE COMPANY

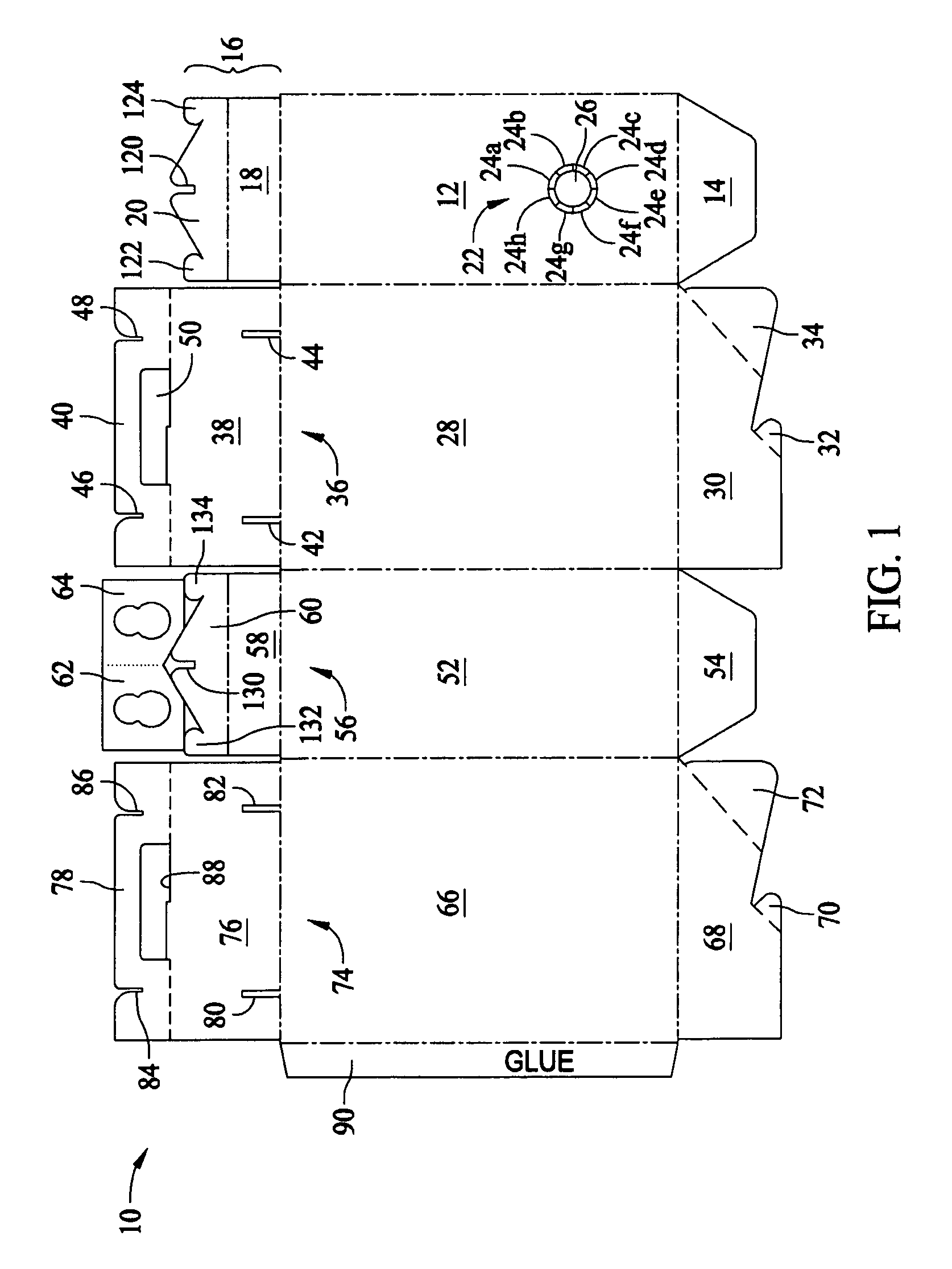

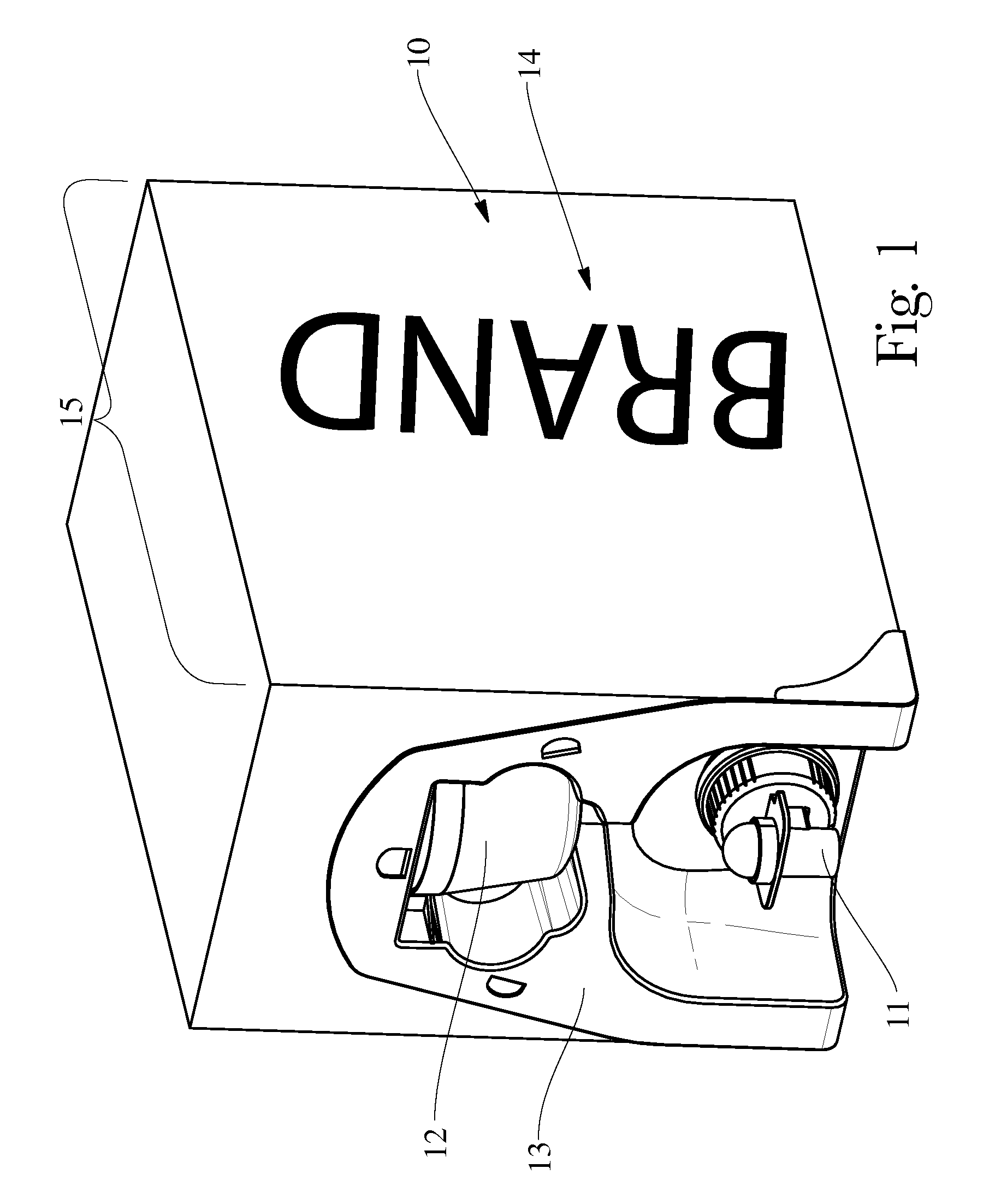

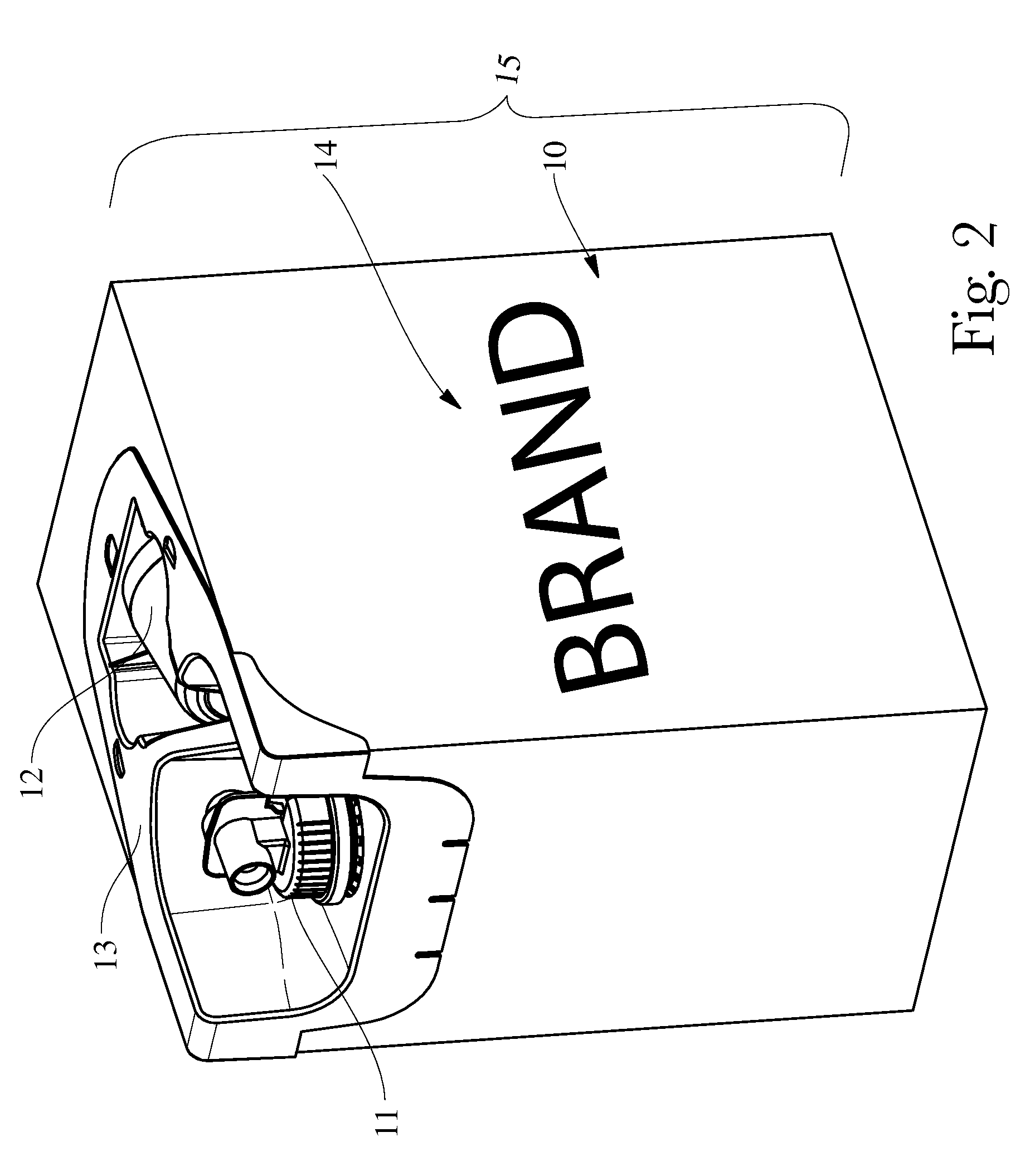

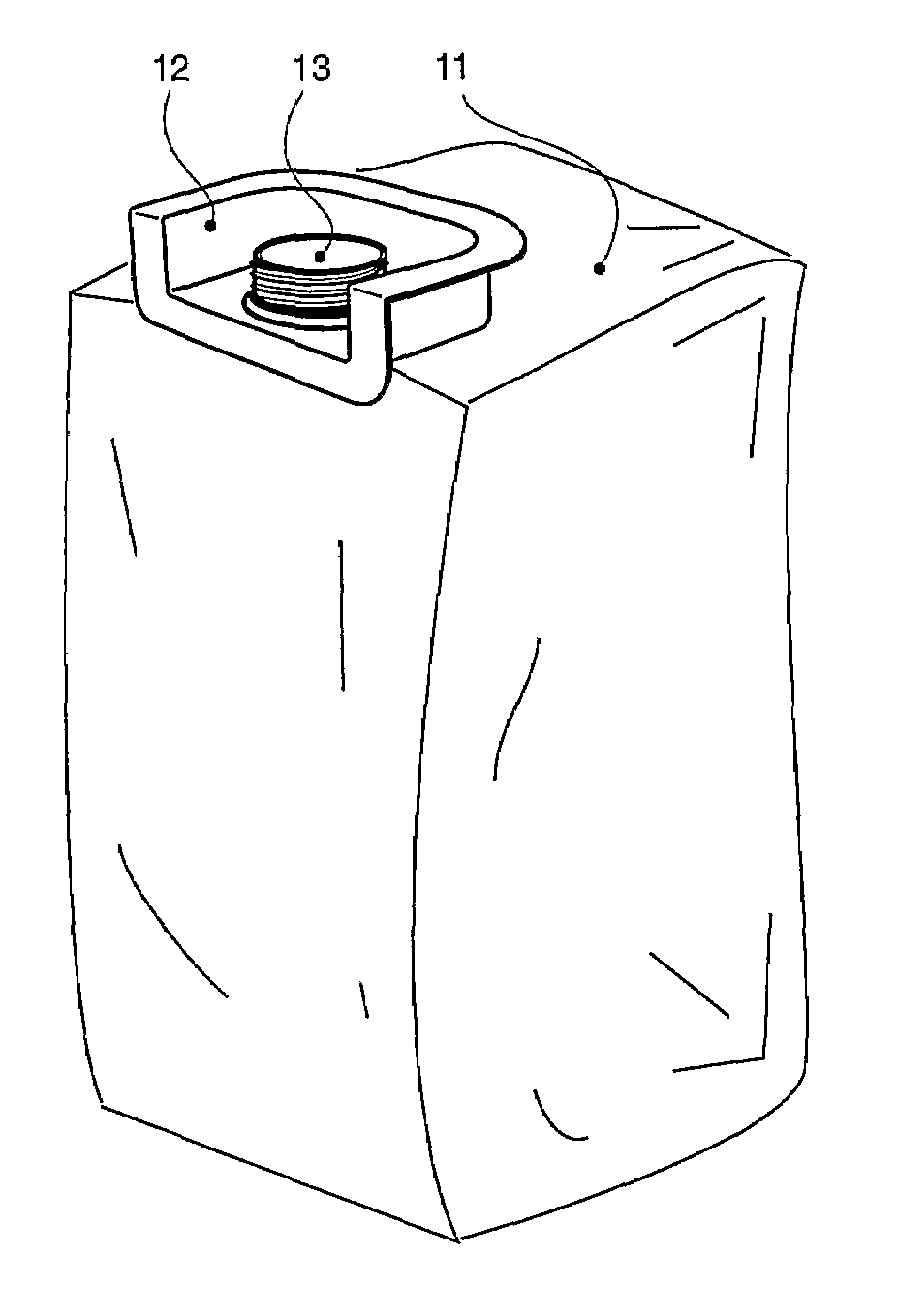

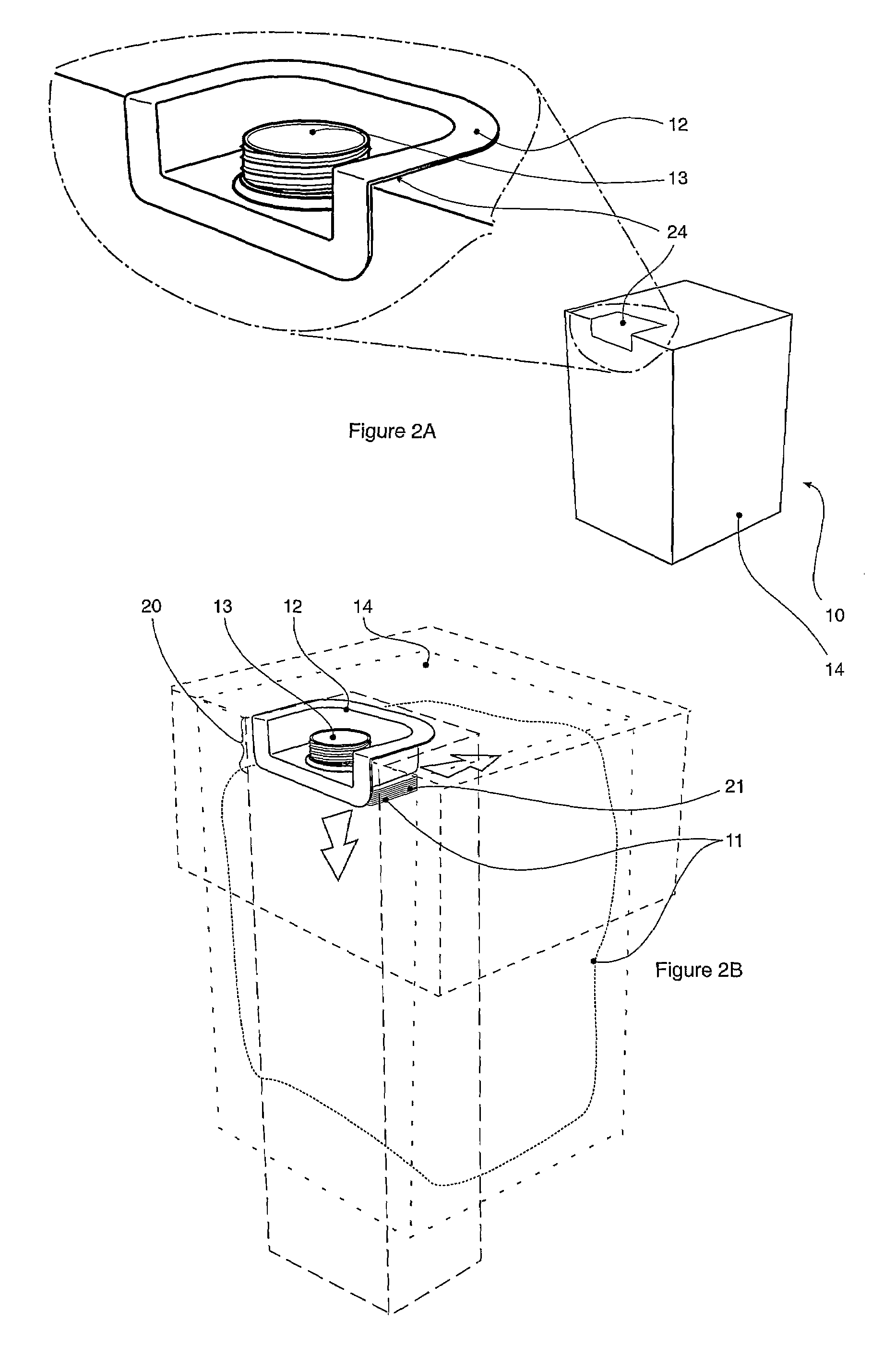

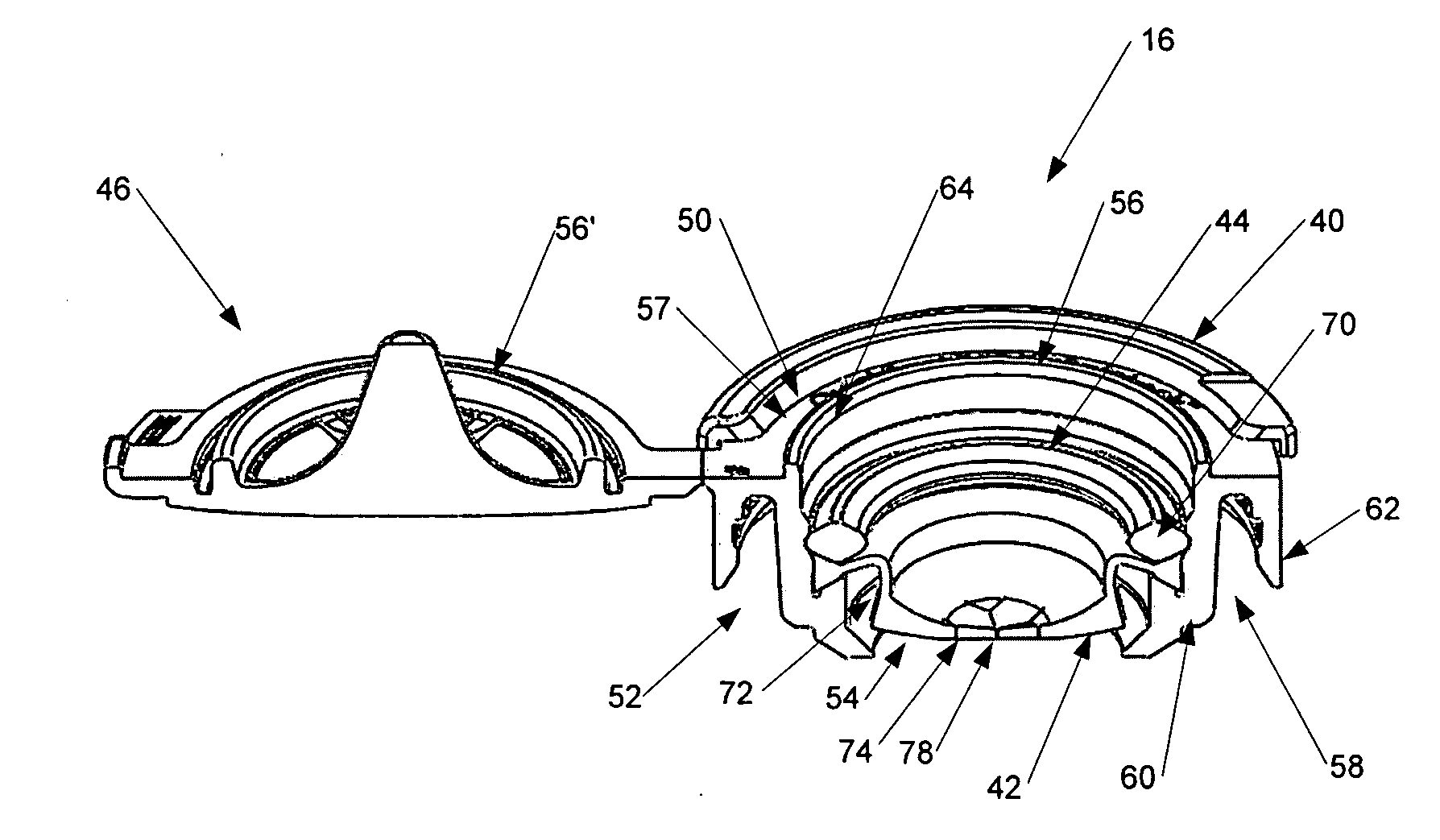

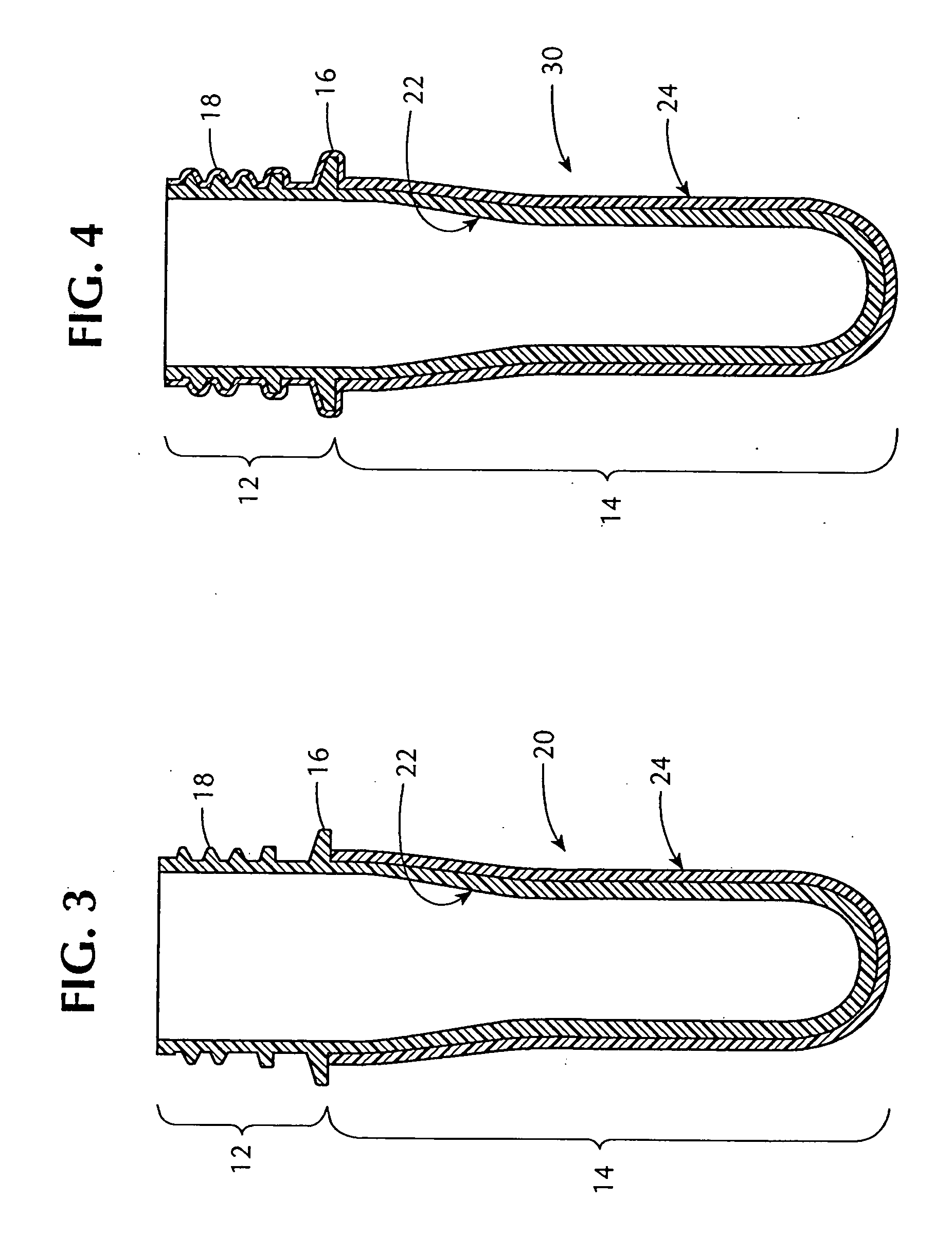

Bag Cartridge with Anti-Torque Collar

A collapsed bag cartridge (20) for Bag-in-Box (BIB) carton packaging, is configured for installation as a self-contained module in an aperture (24) in a pre-assembled carton wall; the bag cartridge features a collapsed bag in a compact folded format (21) with a locating and retention collar (12) upon a bag neck (13) of complementary profile to the carton aperture; with complementary inter-fitting ribs and slots (18), in collar aperture rim upstand (17) and bag neck (13) for closure anti-torque action.

Owner:STEPHENSON JOHN

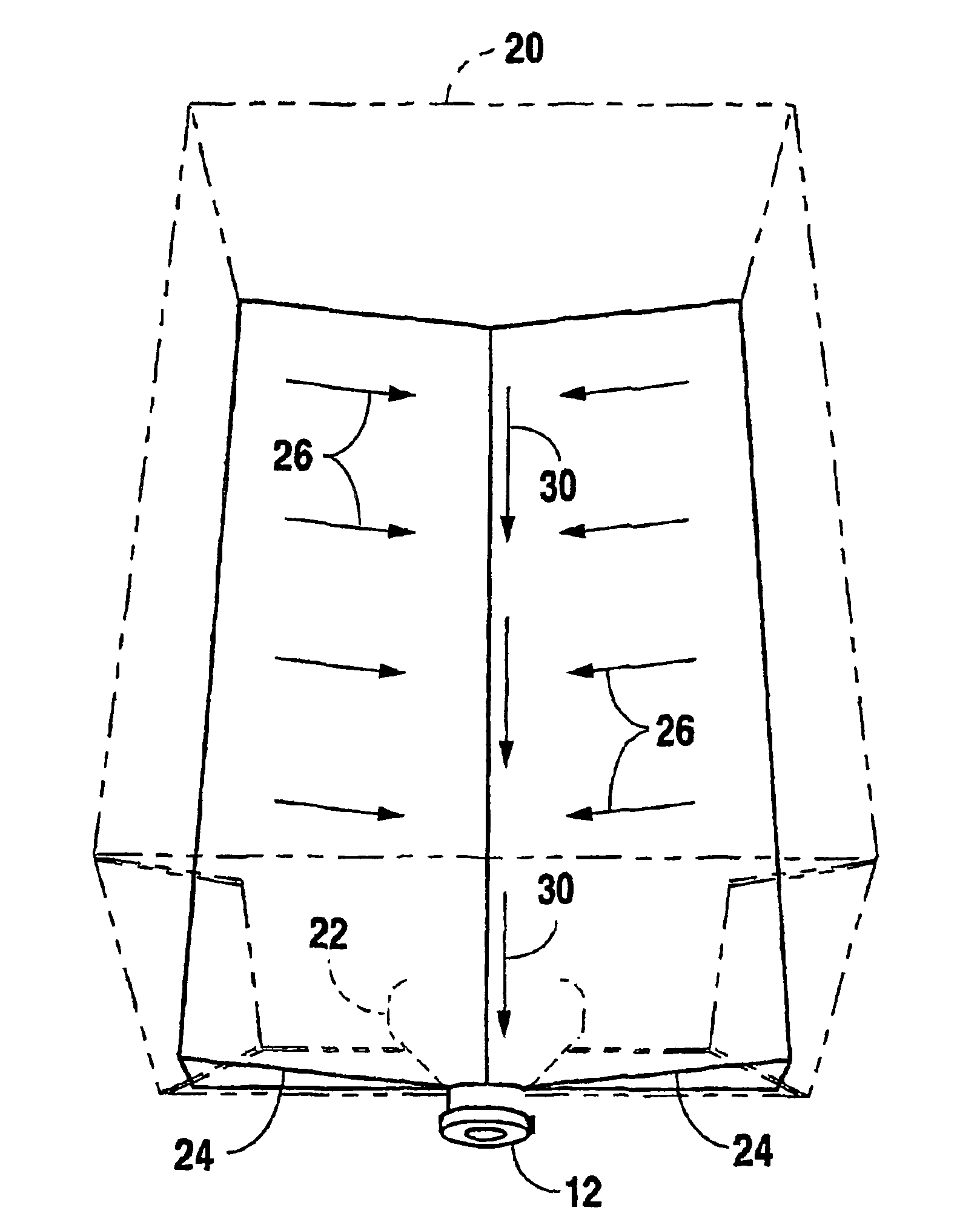

Bag-in-box container for liquids

This invention is directed to an improved bag-in-box apparatus for containing and dispensing liquids such as beverages. The interior surface of the bottom of the box (20) is preferably sloped downward toward the spout (12) of the bag (10) such that gravity helps feed the liquid toward the spout (12). In lieu of or in conjunction with slopes, the interior bottom surface of the box (120, 130, 150, 140, 160) may have terraces (34), curves (132, 134), corrugations (152), fan-like ridges (142), or beams (162). The present invention thereby reduces the amount of residual liquid as the liquid is withdrawn from the bag (10) without the need for an evacuation strip or a special slanted rack. Although the primary intended application of the present invention is in bag-in-box packages for containing and dispensing beverages, this invention may also be used to advantage in other liquid dispensing applications.

Owner:DR PEPPER SEVEN UP

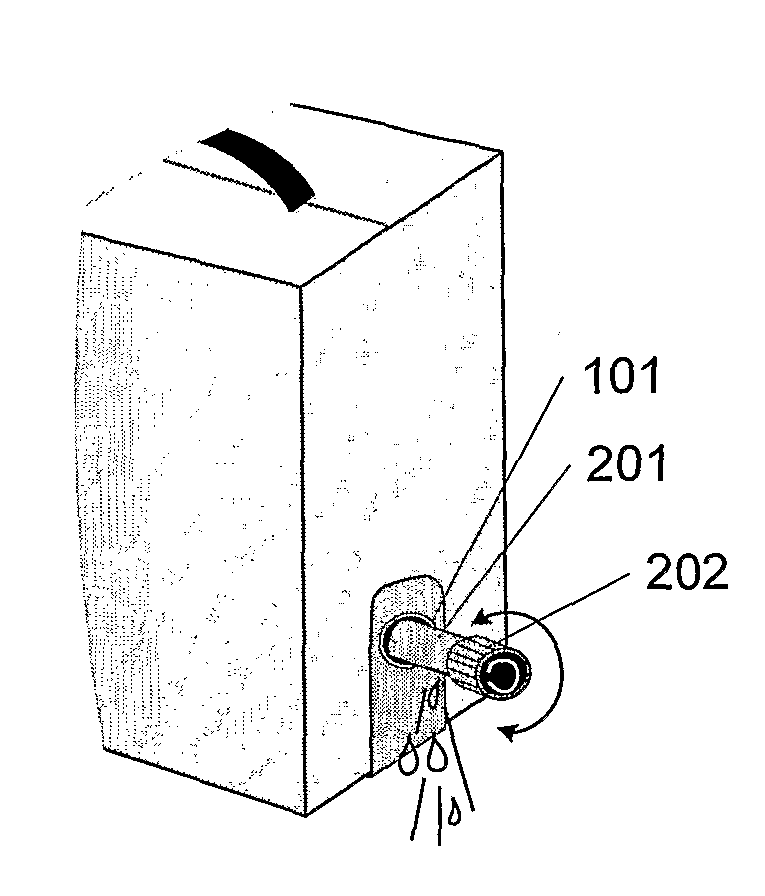

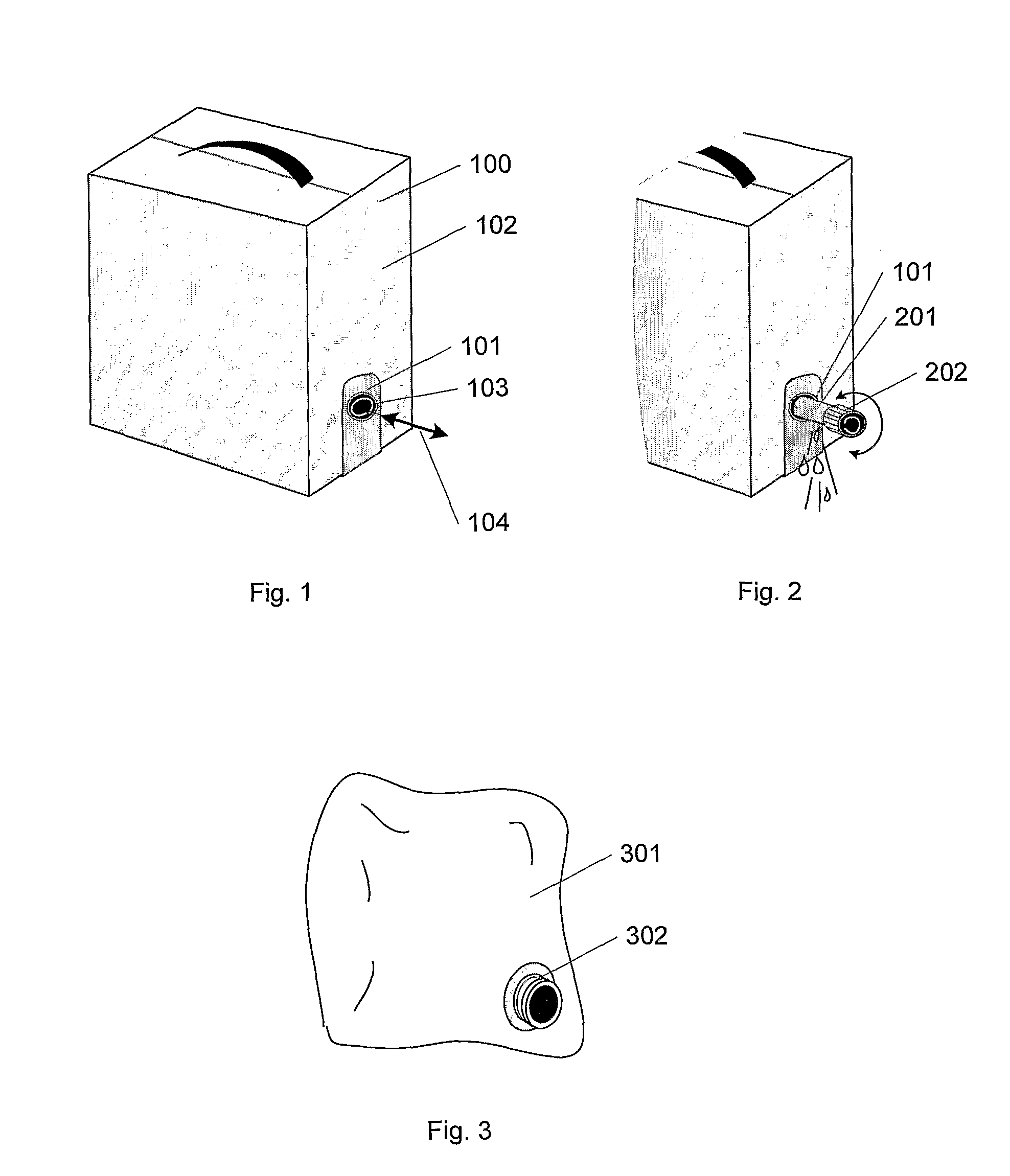

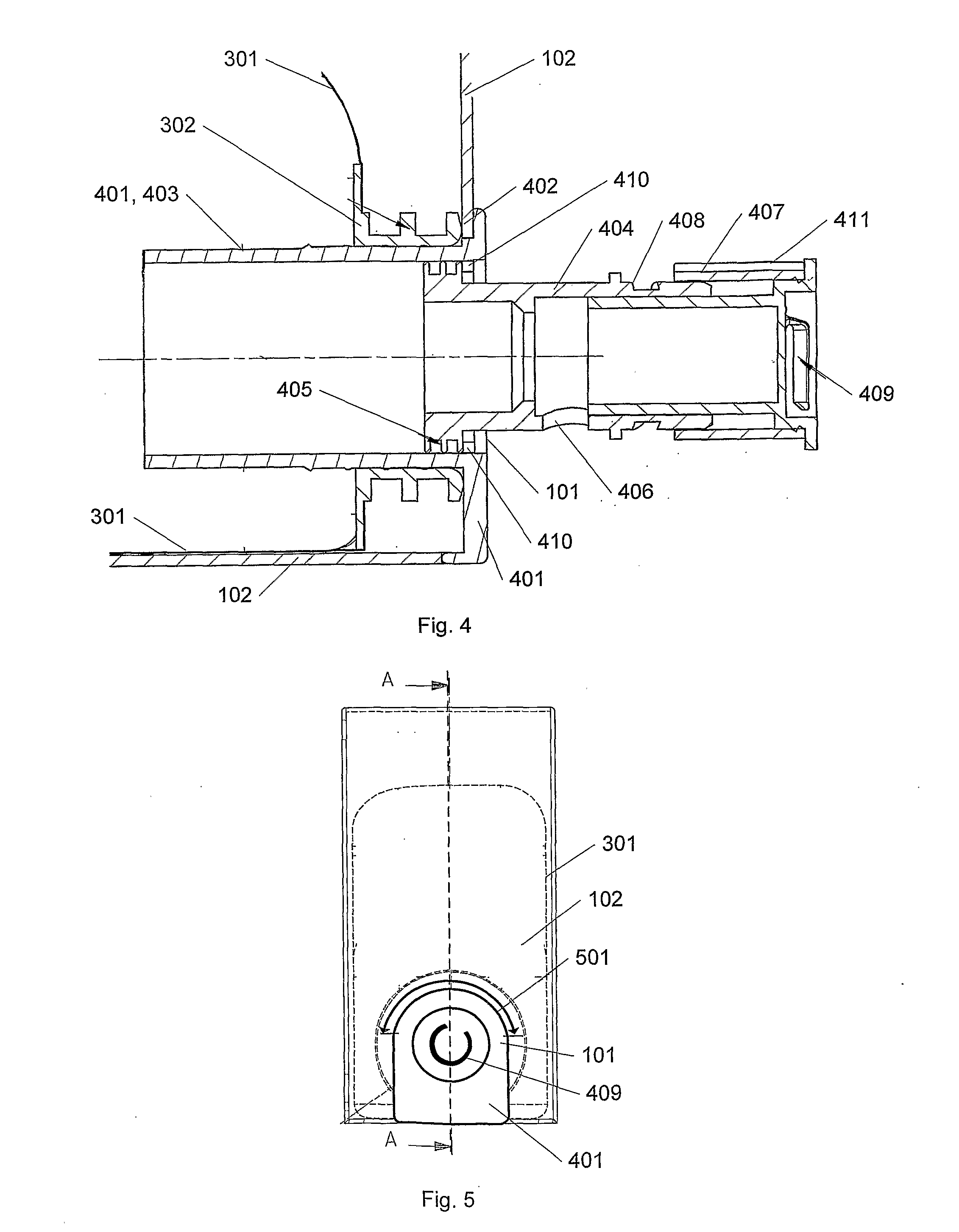

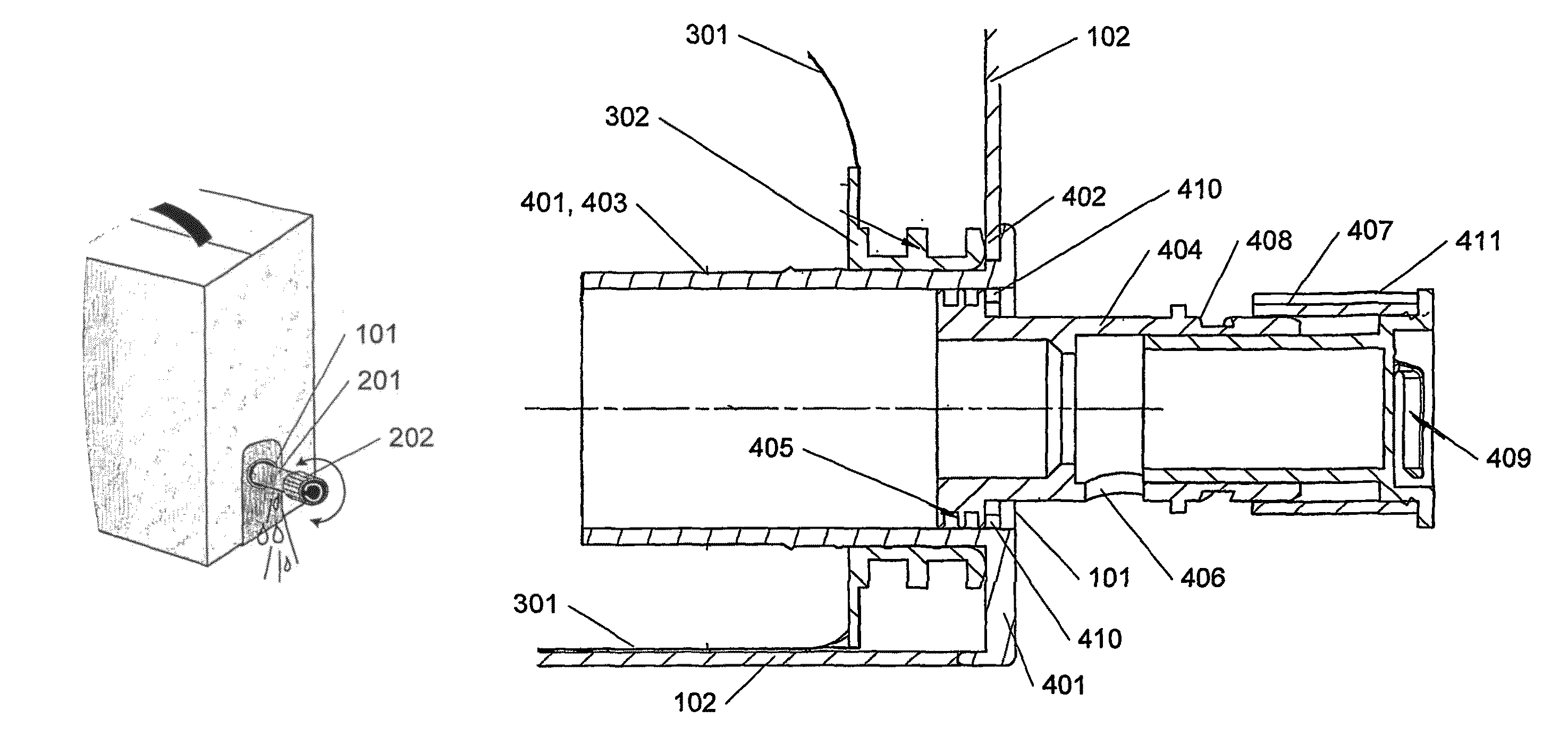

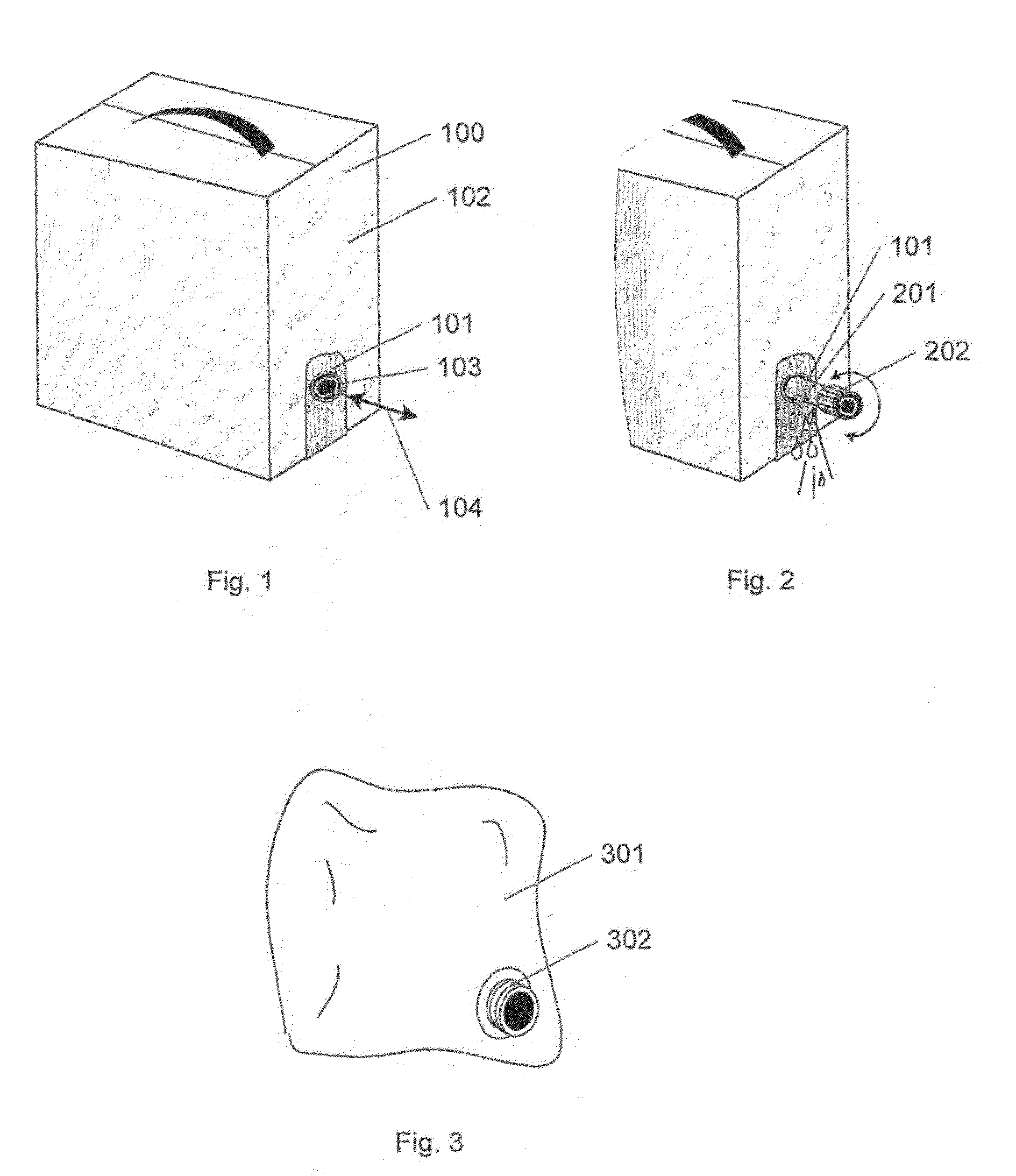

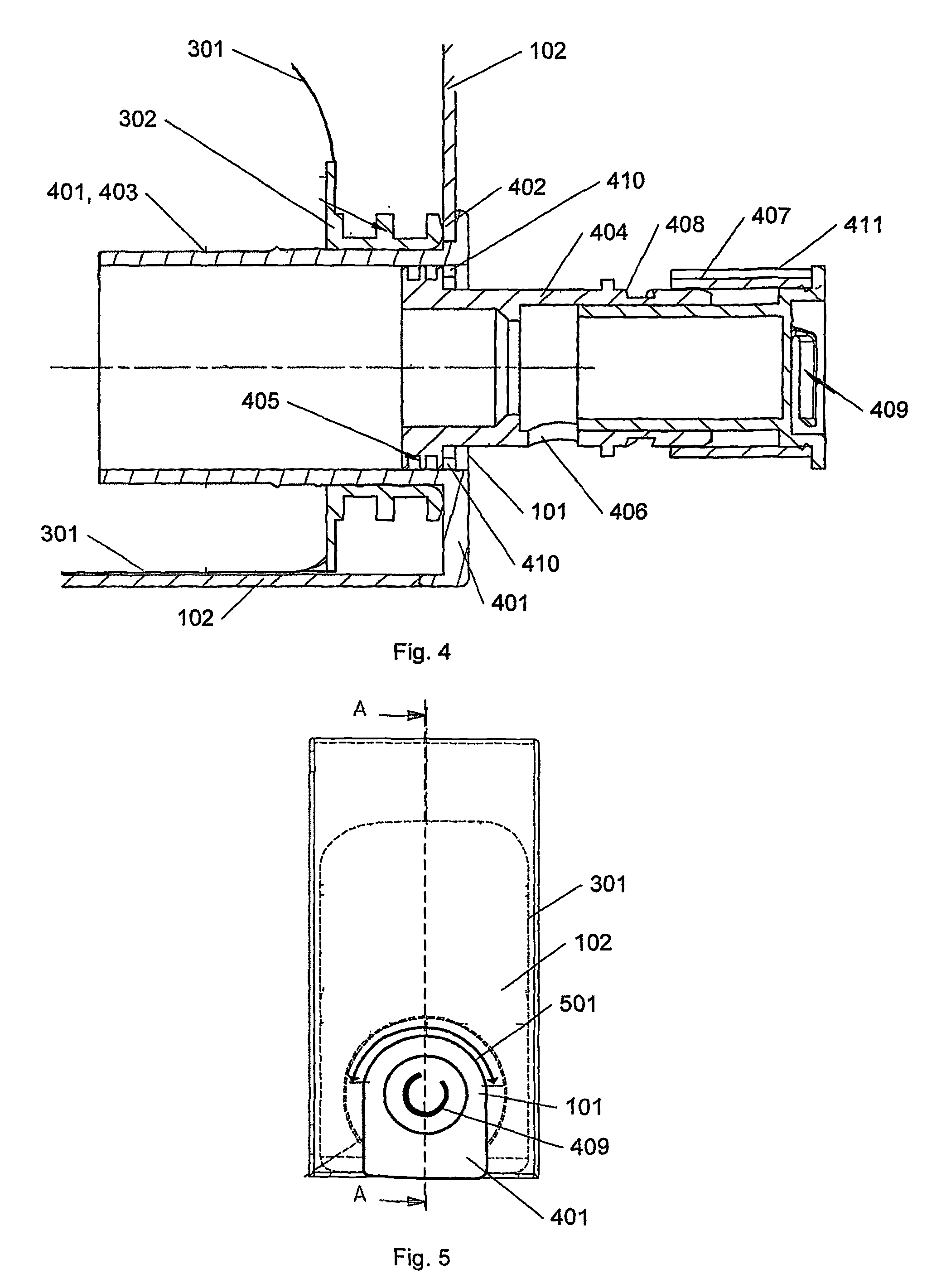

Tap for a Bag-in-Box

ActiveUS20090159594A1Low production costSimple methodBagsLiquid flow controllersEngineeringBag-in-box

This invention relates to a telescope tap to be used for the tapping of liquid from a bag-in-box where a bag containing the liquid and equipped with a spout is placed inside a box. The telescope tap comprises a base member which engages with the spout and with the box wall, a telescope pipe placed sliding extractable in the base member, a handle to extract the telescope pipe from inside the box, a knob for opening and closing the outlet in the telescope pipe, and a gap around a part of the telescope tap for slidably receiving the box wall when sliding the telescope tap into the box. The invention furthermore concerns a method of filling a bag-in-box with a fluid, where a bag with a spout is filled with a fluid, a telescope tap is placed in the spout thereby closing the bag, a cut is made in the box, and the bag then is slid into the box with the tap fitting the cut in the box.

Owner:AMKA

Temperature Controlled Liquid Dispenser, Containers Therefore, and Bag-In-Box Container Construction

ActiveUS20110266287A1Improve thermal conductivityThermal energy is effectively and efficiently transferredDomestic cooling apparatusLighting and heating apparatusThermal energyTemperature control

A dispenser for relative rapid cooling or heating of the contents of a liquid storage container provides a receptacle for receiving the liquid storage container therein and positioning a thermal transfer portion of the liquid storage container in thermal conductive relationship with a thermal conduction pad associated with the receptacle. Thermal energy is effectively and efficiently transferred from the thermal conduction pad to the liquid in the liquid storage container. The thermal conduction pad is controlled to provide and maintain the desired temperature to the liquid. The liquid is dispensed directly from the container. Various types of containers can be used in the dispenser, with a special bag-in-box container having a inner container and outer box with thermal conduction windows in the box to provide good heat transfer between the thermal conduction pads and the inner container constituting an aspect of the invention. A special rigid container can also be used.

Owner:GROESBECK R CLAY

Collapsible container for liquids

Owner:DR PEPPER SEVEN UP

Self sealing bag in box cap assembly

A cap assembly comprising a body, a sealing membrane and a retaining ring. The body includes a top surface, a bottom surface. A spout engagement channel is positioned on the bottom surface. An opening is provided through the body and includes a recessed circumferential channel and a membrane engaging flange positioned proximate the recessed circumferential channel. The sealing membrane covers the opening and includes a body engaging flange and a pierceable surface. The sealing membrane is positioned upon the membrane engaging flange so that the body engaging flange and the membrane engaging flange are in overlying engagement. The retaining ring includes a tab, a sealing membrane engagement surface and an inner wall structure opposite the sealing membrane engagement surface. The retaining ring is positioned with the sealing membrane engagement surface in overlying engagement with the sealing membrane. Extension of the tab into the recessed circumferential channel of the body releasably maintains said overlying engagement and biases the retaining ring against the membrane. The inner wall structure of the retaining ring extends radially inward beyond the membrane engaging flange of the sealing membrane, to in turn, protect the membrane.

Owner:SCHOLLE IPN CORP

Depletion device for bag in box containing viscous liquid

Owner:G R ADVANCED MATERIALS

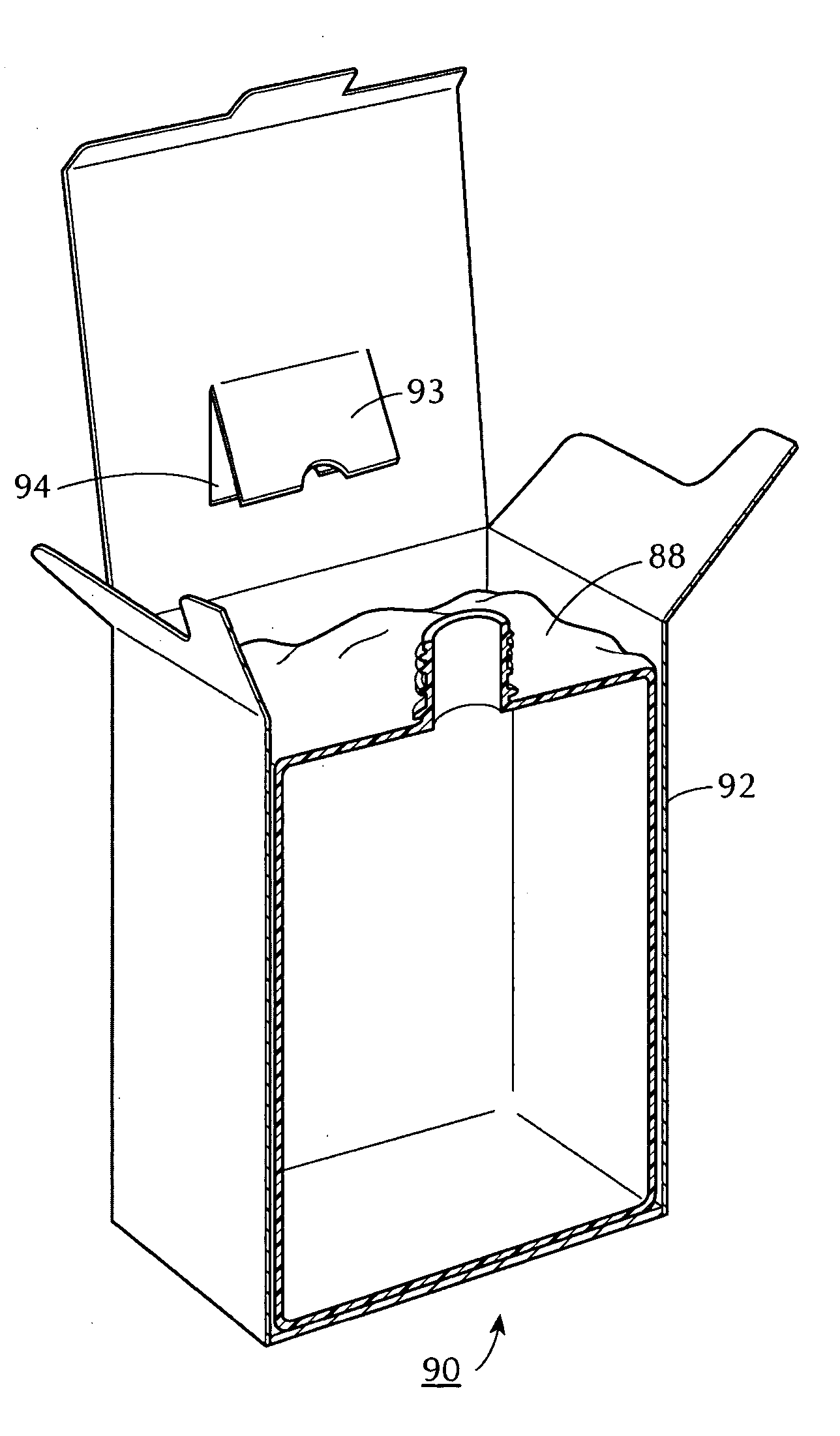

Bag in box packaging having an inserted panel for receiving a spout of the bag

A bag in box packaging including a flexible bag and an outer carton. The flexible bag defines a cavity, with a spout coupled thereto providing access to the cavity. The outer carton has a first sidewall and a second sidewall opposite the first side wall. A front wall extends therebetween. The inner spout retaining member further includes an inner spout retaining member. The inner spout retaining member includes a first panel that extends between the first sidewall and the second sidewall and is spaced apart from the front wall. The first panel includes a spout receiving slot extending thereinto. The spout of the bag is positionable within the spout receiving slot of the first panel, so as to position the spout between the first panel and the front wall. A spout locking member is structurally configured to maintain the spout within the spout receiving slot of the first panel.

Owner:SCHOLLE IPN CORP

Dispensing package

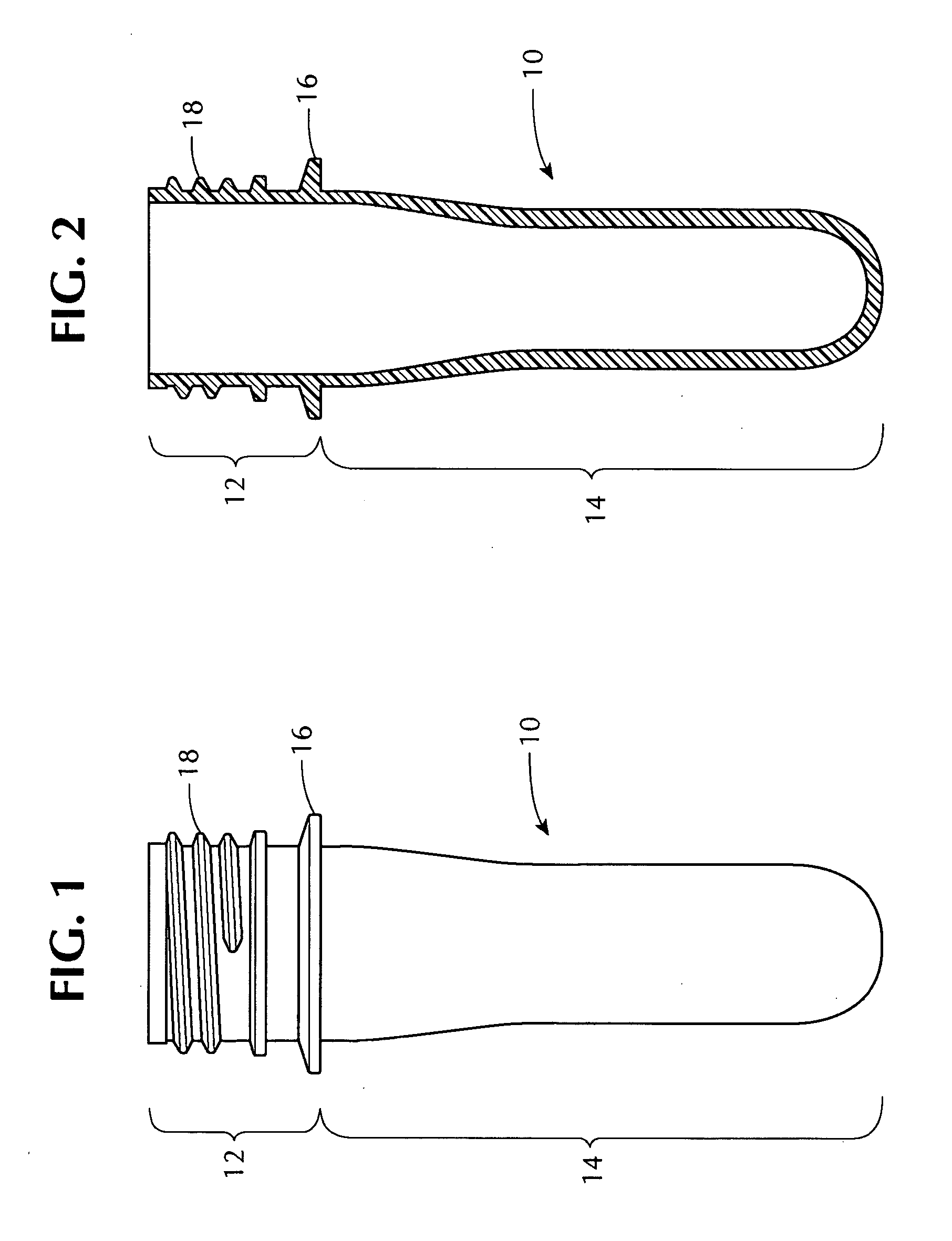

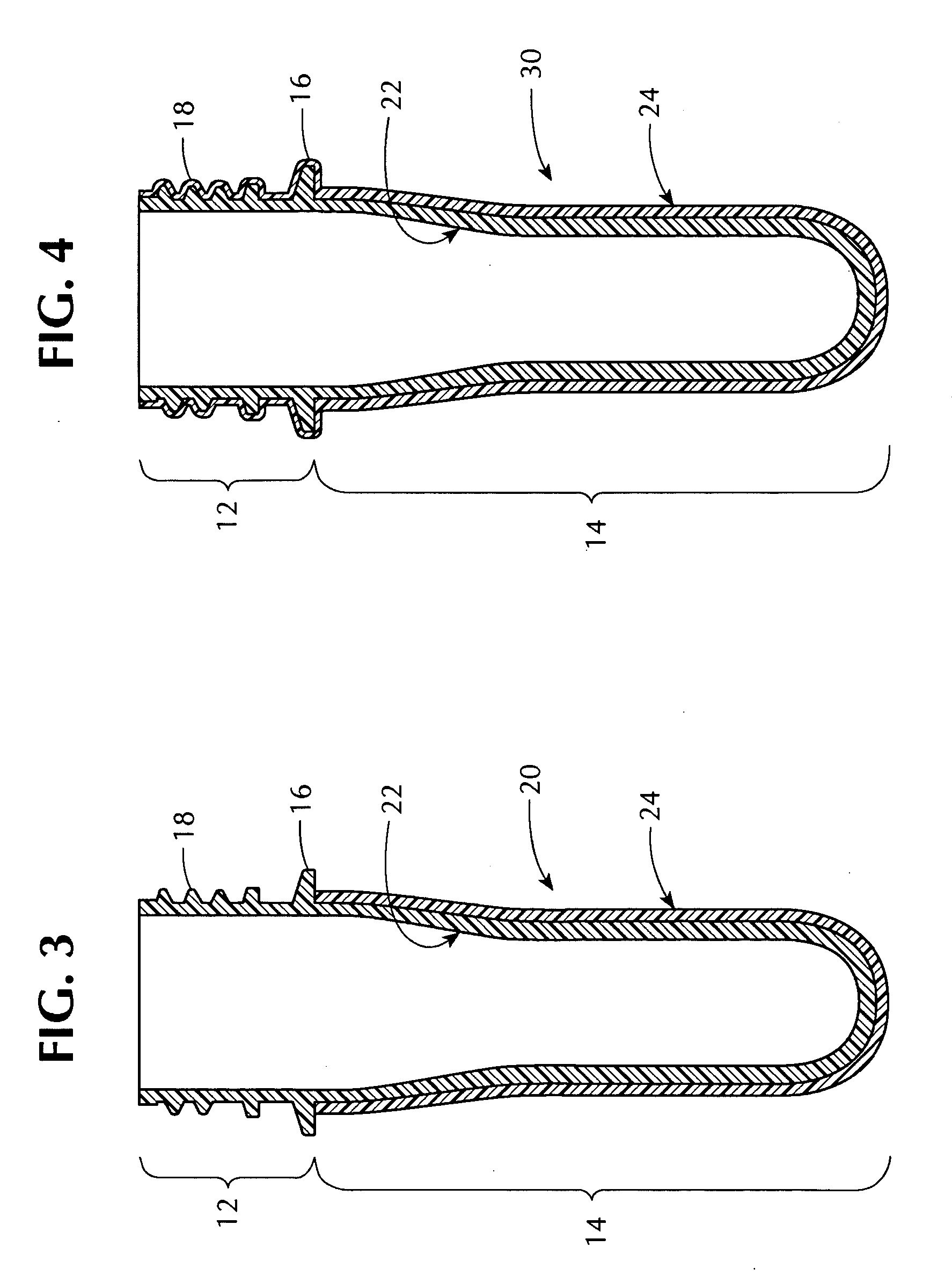

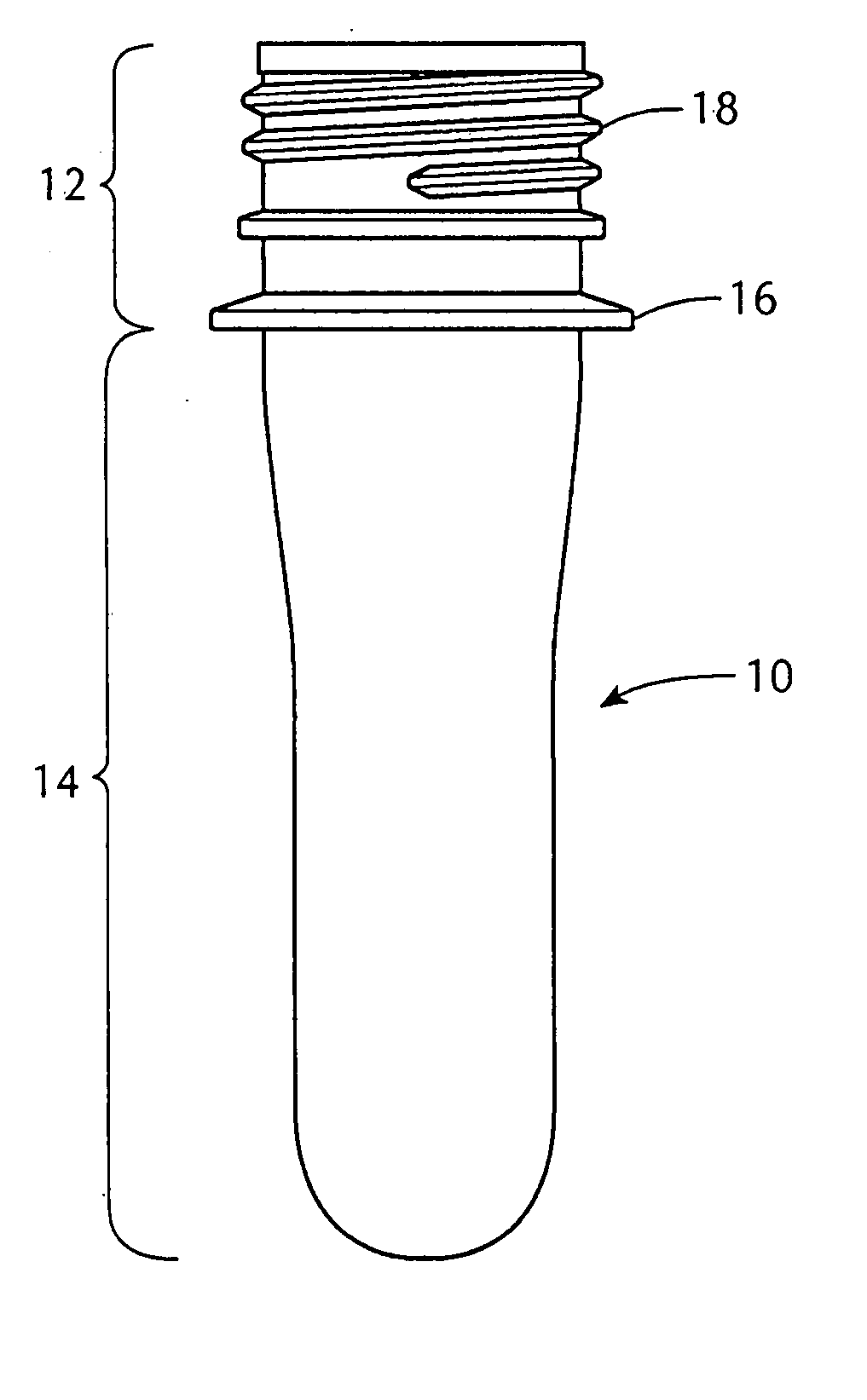

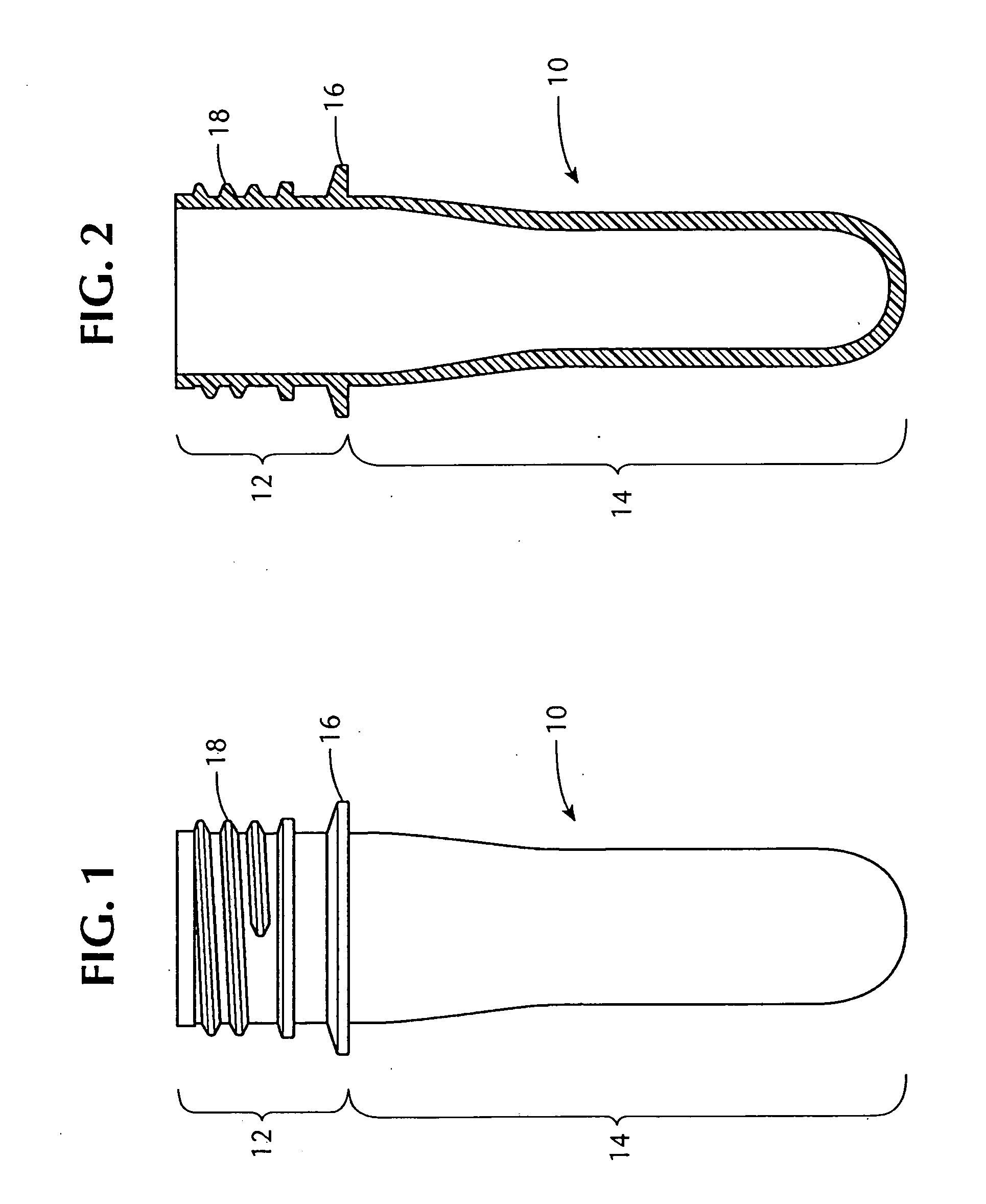

ActiveUS20050133578A1Overcome deficienciesOther chemical processesBottlesCartonThermoplastic materials

A seamless collapsible container has a molded finish, configured and adapted for sealing with a closure and, optionally, for attachment to a dispensing apparatus, and a seamless, blow molded body portion, comprising an inner surface, an outer surface, and a wall, where the wall is sufficiently thin to allow the body portion to collapse, and the molded finish and at least an inner layer of the body portion together comprise a seamless, single piece of thermoplastic material. The seamless collapsible container may be used in such applications as a bag-in-box, a carton liner, and a beverage pouch.

Owner:PEPSICO INC

Dispensing package

A seamless collapsible container has a molded finish, configured and adapted for sealing with a closure and, optionally, for attachment to a dispensing apparatus, and a seamless, blow molded body portion, comprising an inner surface, an outer surface, and a wall, where the wall is sufficiently thin to allow the body portion to collapse, and the molded finish and at least an inner layer of the body portion together comprise a seamless, single piece of thermoplastic material. The seamless collapsible container may be used in such applications as a bag-in-box, a carton liner, and a beverage pouch.

Owner:PEPSICO INC

Bag In Box Packaging

ActiveUS20140076927A1Increase effective widthFlexible containersPliable tubular containersWebbingBag-in-box

An outer box for a bag in box packaging includes a plurality of walls and an articulatable portion. The articulatable portion is hingedly coupled to each of the dispensing wall, the first sidewall and the second sidewall. The articulatable portion also includes a front portion, a first side webbing and a second side webbing. Inward rotation of the front portion causes the first and second panels of each of the first and second side webbing to rotate about a respective one of the central folds thereof. An outer surface of each of the first and second panels face each other, with the articulated portion overlying a portion of the first panel of each of the first side webbing and second side webbing.

Owner:SCHOLLE IPN CORP

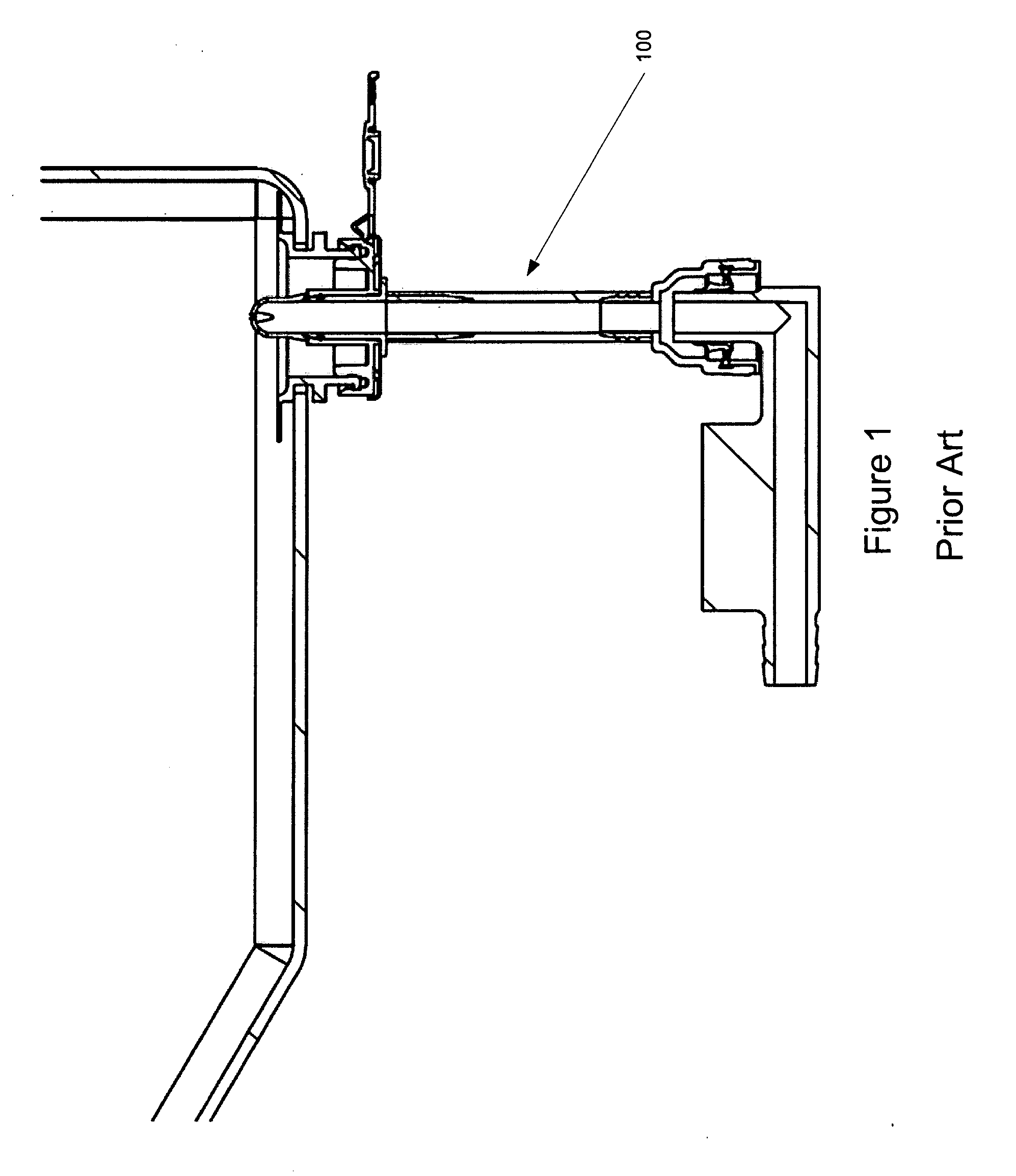

Tap and liquid dispenser for a bag-in-box

This invention relates to a telescope tap to be used for the tapping of liquid from a bag-in-box where a bag containing the liquid and equipped with a spout is placed inside a box. The telescope tap comprises a base member which engages with the spout and with the box wall, a telescope pipe placed sliding extractable in the base member, a handle to extract the telescope pipe from inside the box, a knob for opening and closing the outlet in the telescope pipe, and a gap around a part of the telescope tap for slidably receiving the box wall when sliding the telescope tap into the box. The invention furthermore concerns a method of filling a bag-in-box with a fluid, where a bag with a spout is filled with a fluid, a telescope tap is placed in the spout thereby closing the bag, a cut is made in the box, and the bag then is slid into the box with the tap fitting the cut in the box.

Owner:AMKA

Bag with flap for bag-in-box container system

A bag for storing material in liquid or particulate form, comprising four side walls and top and bottom walls that are integral extensions of the four side walls, is characterized by an additional single or multi-ply sheet that overlies and is sealed to one side of said bag, said sheet material being adapted to be partially separated from itself so as to form a flap at the top end of the bag that can be gripped for use in supporting the bag as it is being drained of its contents via a drain located at the bottom end of the bag.

Owner:CDF CORP

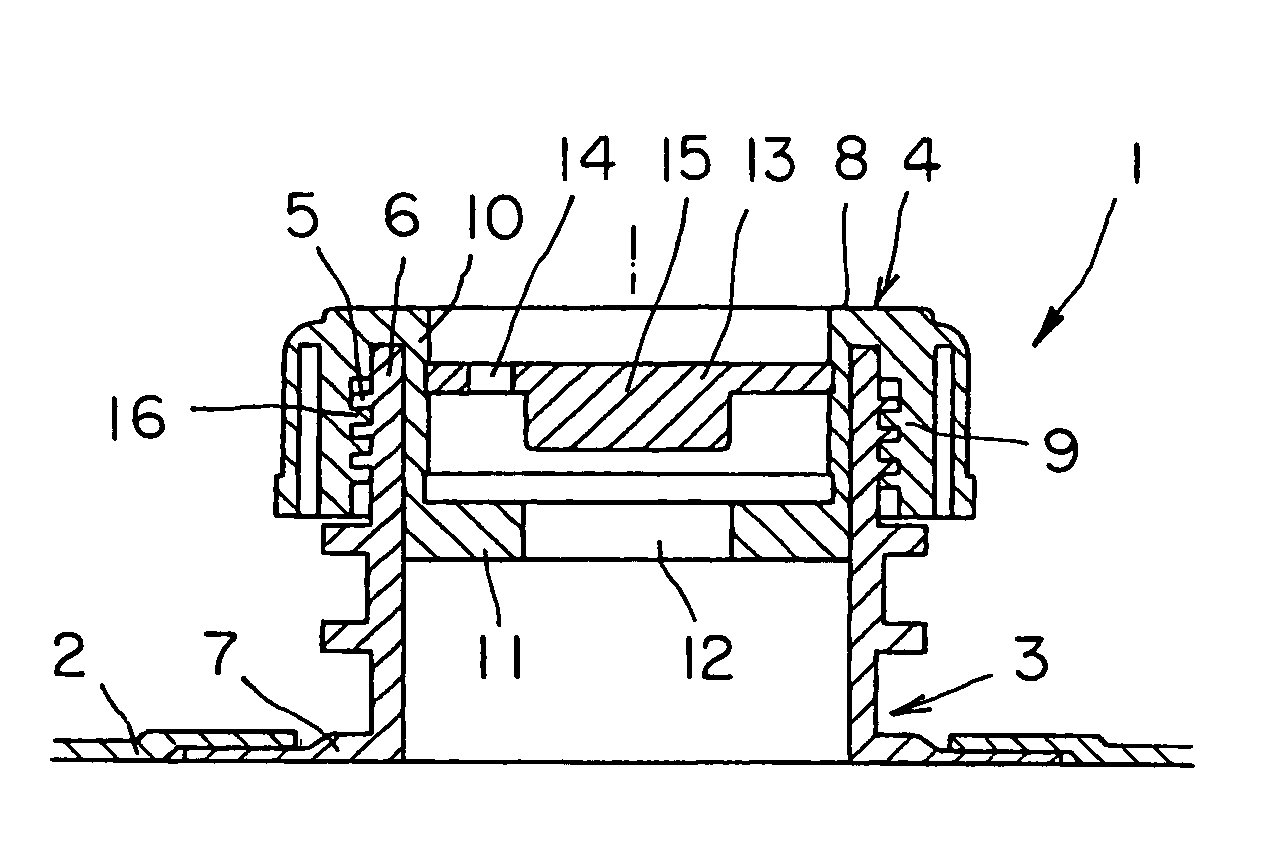

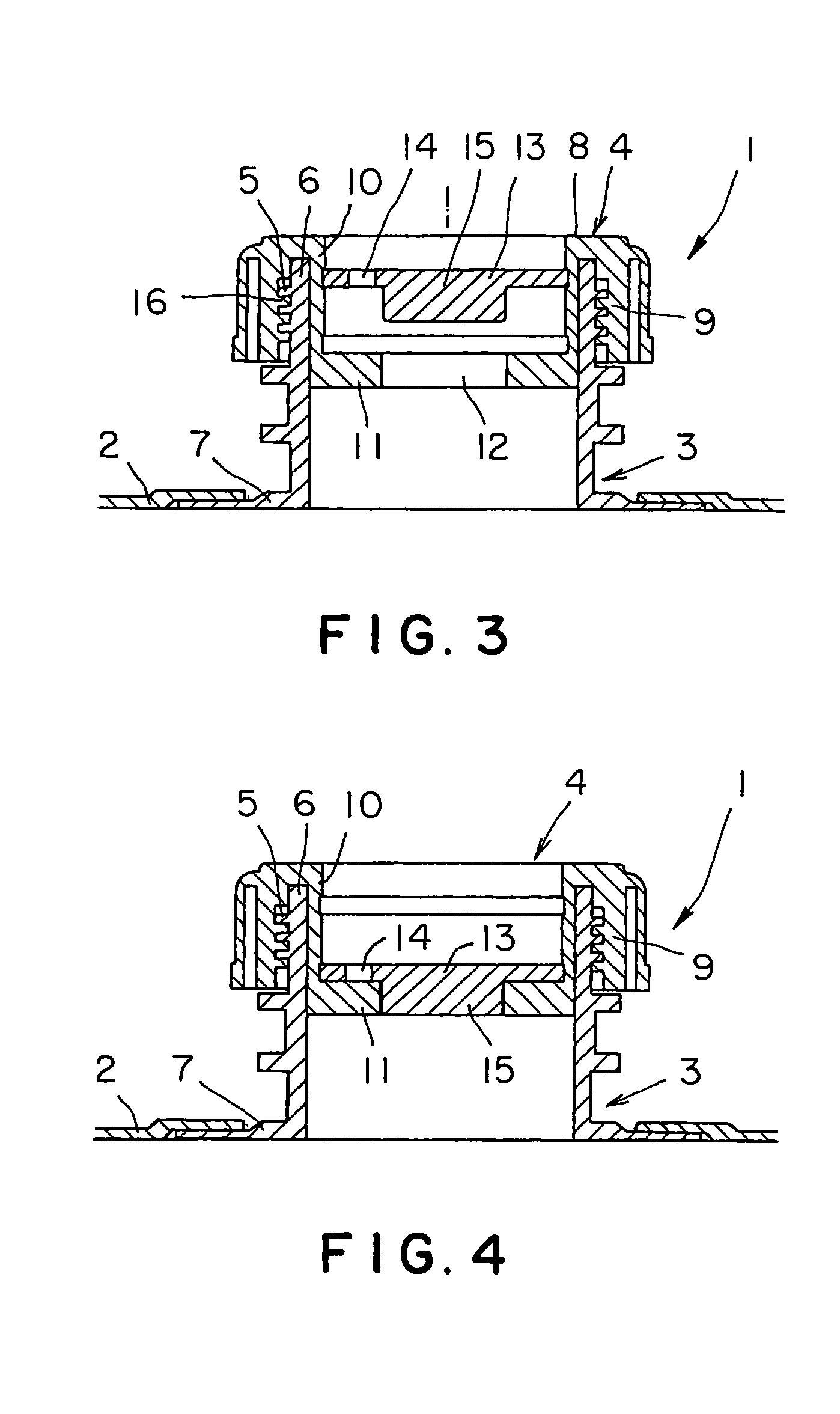

Spouting structure for liquid container and bag-in-box container

A spouting structure includes a spout attached to the liquid container and having a mouthpiece, a cap screwed on the spout and having a top wall and a cylindrical protrusion protruding from a central part of the top wall having a bottom wall provided with an opening and defining a cylindrical bore, and a round plate axially movably fitted in the cylindrical bore of the cylindrical protrusion. The cylindrical protrusion protrudes downward from the top wall and is fitted in the mouthpiece of the spout. The round plate is provided with at least one opening in its peripheral part, has a plugging part formed in a central area of the lower surface thereof and capable of being plugged closely in the opening formed in the bottom wall of the cylindrical protrusion of the cap.

Owner:HOSOKAWA YOKO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com