Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

916 results about "Vegetable fibers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

It swells as it absorbs water. Some vegetables that have soluble fiber include peas, with 8.8 grams of fiber per cup, carrots, 1.7 grams each, psyllium, 16 grams per ounce, and black beans, with 10.4 grams per cup. Insoluble fiber, also called roughage, does not dissolve in the digestive tract.

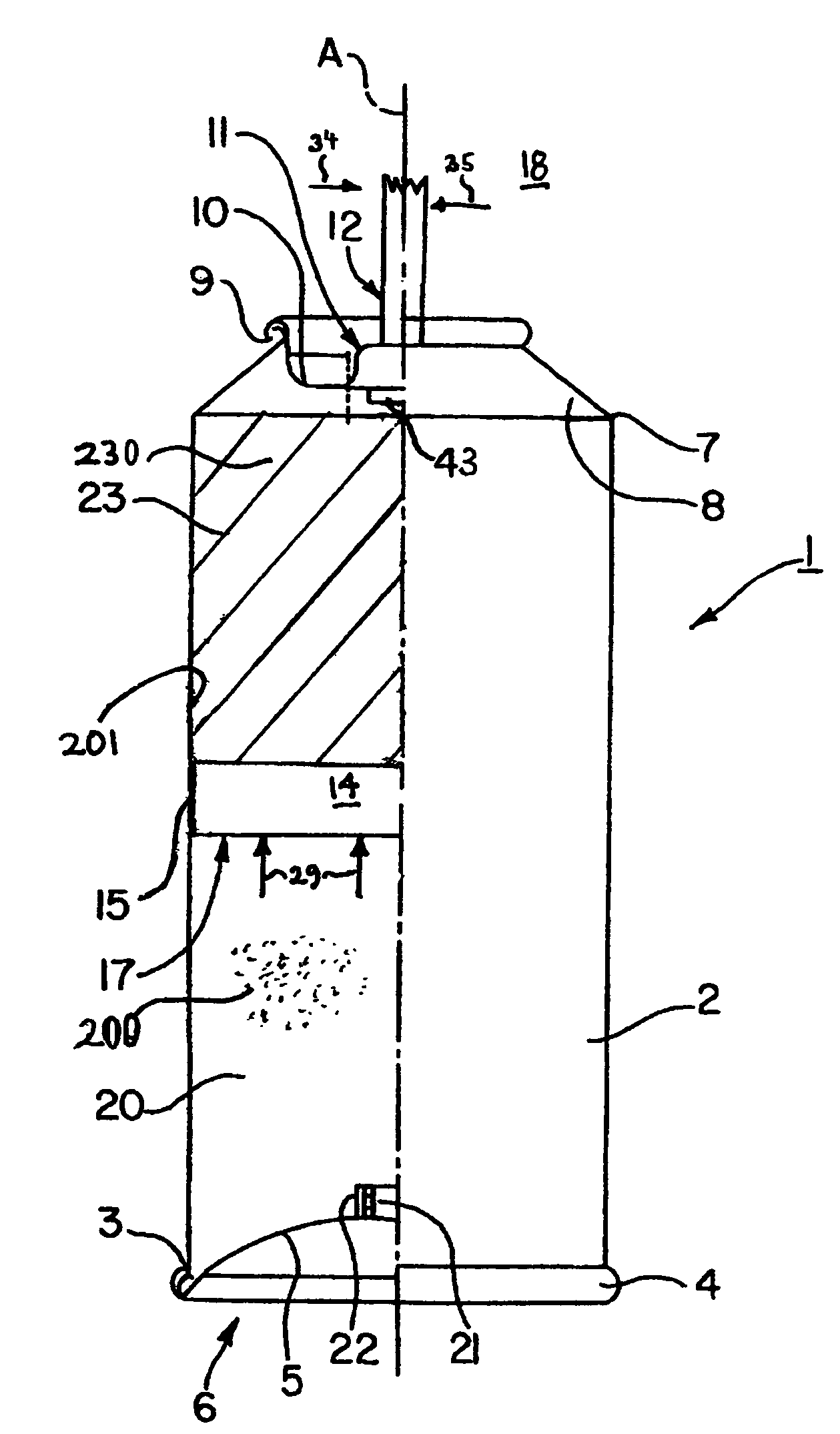

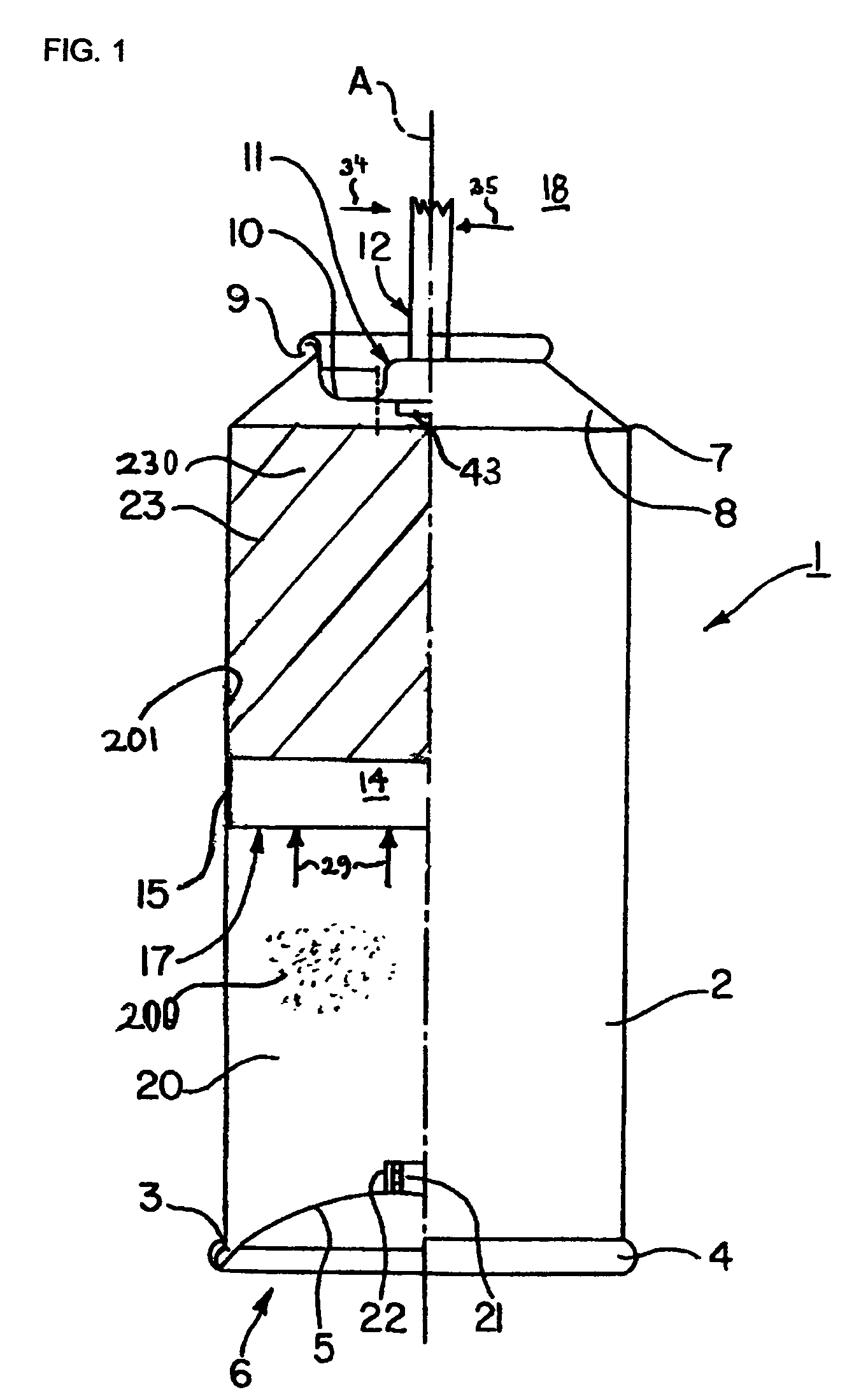

Breed-specific canine food formulations

InactiveUS6156355AUnique shapeManaged fat levelMilk preparationAnimal feeding stuffFood formulationAdditive ingredient

Breed-specific dog food formulations that comprise chicken meat as the major ingredient, rice as the predominant (or sole) grain source, fruit and / or vegetable fiber as the primary or sole fiber source, unique fat and antioxidant blend, vitamins, herbs and spices, carotenoids, and no corn or artificial colors, preservatives, flavors or sugars are provided.

Owner:BIG HEART PET INC

PVC fine foaming wood-plastic coiled material and method of preparing the same

The invention discloses a PVC micro-foaming wood-plastic coiled material, including the following materials by weight portion:100 portions of PVC, 70-80 portions of waste vegetable fibers, 10-30 portions of CaCO3, 1-4 portions of coupling agent, 2-8 portions of heat stabilizer, 3-9 portions of lubricant, 7-12 portions of toughening agent, 3-7 portions of plasticizer, 0.6-1.2 portions of composite foaming agent and 2-3 portions of titanium pigment powder. Compared with the prior art, the composite material prepared by the method has high toughness, the disadvantages of high resin content, little filler and high cost of common PVC coiled materials are avoided. The coiled materials can be used as the coating materials of indoor floor, peripheries and walls with sophisticated shapes.

Owner:HUANGSHAN HUASU NEW MATERIAL SCI & TECH CO LTD +1

Styrene-based non-halogen flame-retardant injection-grade wood-plastic composite material and preparation method thereof

ActiveCN101864118AImprove liquidityGive full play to the flame retardant effectBuilding productHalogen

The invention discloses a styrene-based non-halogen flame-retardant injection-grade wood-plastic composite material and a preparation method thereof. The wood-plastic composite material comprises the following components by mass percentage: 25% to 60% of styrene-based resin, 5% to 50% of vegetable fiber, 0.5% to 20% of compatibilizer, 0% to 30% of toughener, 0.5% to 8% of dispersant, 5% to 40% offlame retardant and flame-retardant synergist and 0% to 1% of antioxidant. Compared with the existing wood-plastic composite material, the styrene-based non-halogen flame-retardant injection-grade wood-plastic composite material prepared by the invention has the characteristics of simple production procedure, lower flame-retardant consumption, good non-halogen flame-retardant effect and wide range of forming manners. Therefore, the invention is suitable for various injection-molded parts, such as the housing of electrical products, furnishings, automobile materials, artworks, complex-structured building products and the like.

Owner:KINGFA SCI & TECH CO LTD +2

Paper-imitating biodegradable resin and preparation method

ActiveCN101914294AAvoid pollutionAvoid degradationInorganic fibres/flakesPaper/cardboardBiopolymerVegetable fibers

The invention discloses a paper-imitating biodegradable resin and a preparation method. For improving the degradability and natural recoverability of paper-imitating materials and making the paper-imitating materials have similar lightness, foldability and printing and writing performance as the conventional paper. The paper-imitating biodegradable resin uses mineral fibers, vegetable fibers and starch fibers as main components, and concretely comprises the following components in part by weight: 40 to 70 parts of mineral fibers, 10 to 30 parts of vegetable fibers, 5 to 20 parts of starch fibers, 5 to 15 parts of biopolymer, 3 to 5 parts of modifier, 3 to 5 parts of compatibilizer and 3 to 8 parts of processing assistant. The mineral fibers, vegetable fibers and starch fibers are interweaved through thermoplastic processing, and the preparation process is clear and pollution-free. The paper-imitating biodegradable resin can be processed into various paper-imitating products by hot plasticizing equipment, and the products, when discarded, can be swallowed and decomposed by microbes without polluting the environment.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Heavy metal-contaminated soil solidifying agent and application method thereof

ActiveCN103833274AHigh strengthReduce risk of leachingSolid waste managementOrganic fertilisersDry weightChemical reaction

The invention discloses a heavy metal-contaminated soil solidifying agent and an application method thereof. The solidifying agent comprises the following components by mass: on the basis of the dry weight of heavy metal-contaminated soil, 10 to 15% of a binding material, 5% of biochar, 10% of vegetable fiber and 1% of a stabilizing agent. The components are added according a sequence of the stabilizing agent-the biochar-the vegetable fiber-the binding material. Addition of the chemical stabilizing agent and the biochar in the process of stabilization enables heavy metals to be absorbed and passivated and to lose mobility; preparation of heavy metal-contaminated soil slurry provides conditions for a later chemical reaction; the whole processing process is free of dust pollution and discharging of unwanted sewage. Addition of the vegetable fiber enables cracking of heavy metal-contaminated soil solidified by using a conventional solidifying agent to be effectively prevented and endurance of a solidified body to be improved. The method provided by the invention has the advantages of strong operability, low cost, extensive applicability, a high resource utilization rate, low environmental risk and easy large-scale popularization.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Process for treating restaurant-kitchen garbage by utilizing Hermitia illucens

ActiveCN102350433AQuickly continue workingContinuous operationSolid waste disposalAnimal feeding stuffBioprocessorMass ratio

The invention discloses a process for treating restaurant-kitchen garbage by utilizing Hermitia illucens, which comprises the following steps of: carrying out solid-liquid separation on restaurant-kitchen garbage, wherein, the water content is 65-85%; crushing the restaurant-kitchen garbage into grains with the grain diameter of 2-50mm; adding auxiliary materials in the restaurant-kitchen garbageto form a treating material, wherein, the mass ratio of the restaurant-kitchen garbage to the auxiliary materials is 1: (0.25-1); adding 5,000,000-12,000,000 Hermitia illucens larvas which are 3-6 days old in per ton of processing material to form a mixture, wherein, the auxiliary materials are vegetable fiber auxiliary materials; adding the mixture into a barrel of a drum-type Hermitia illucens bioprocessor; leading the temperature of the mixture in the barrel to be 32-42 DEG C, and the relative humidity to be 35-75%; unloading after 3-5 days; sieving to separate the Hermitia illucens larvasand the treating remnants; and drying and smashing the treating remnants to be used as a feed. In the process provided by the invention, the treating period is controlled within 72 hours on the ideal condition, thus the restaurant-kitchen garbage can be transformed into a finished product of the feed, thus providing good guarantee for the continuous operations of restaurant-kitchen garbage treatment plants; and the space and resources are saved for the smaller inventory, and the potential pollution risks are avoided.

Owner:深圳市腾浪再生资源发展有限公司

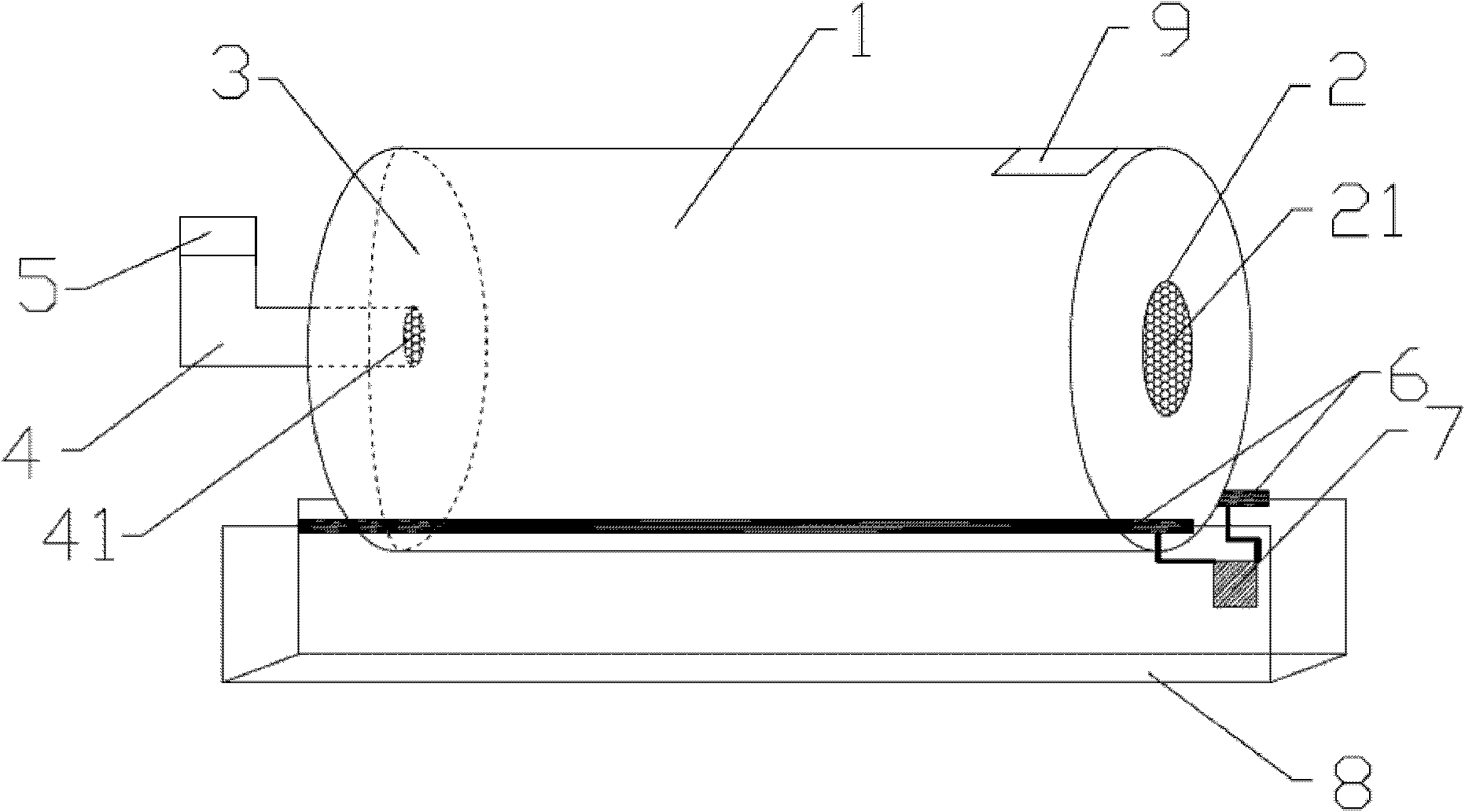

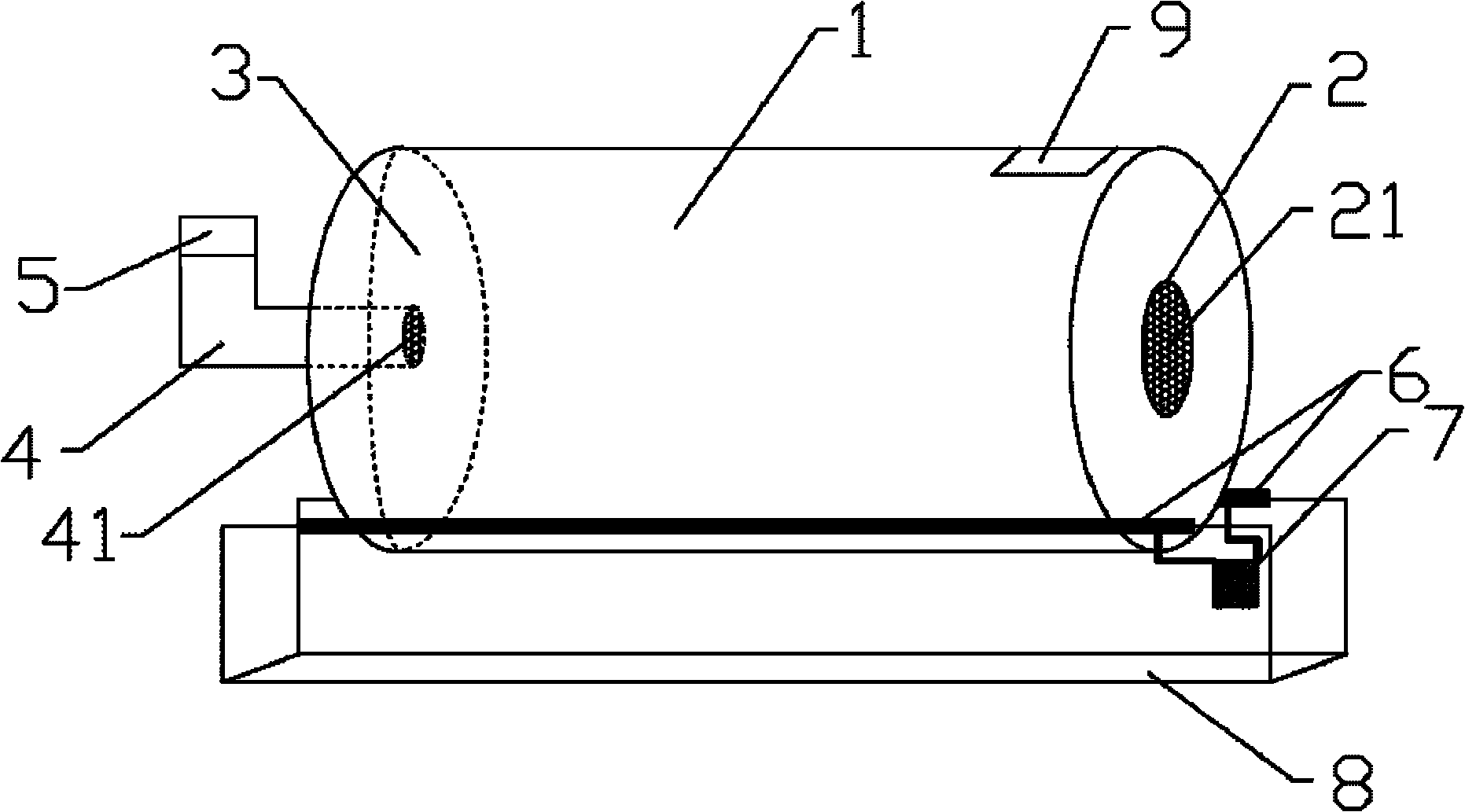

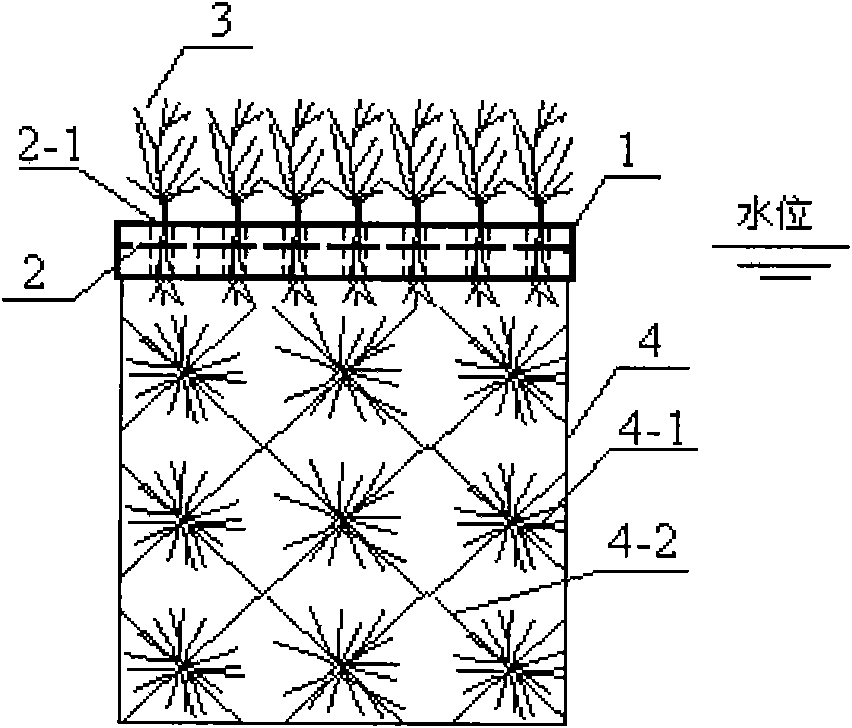

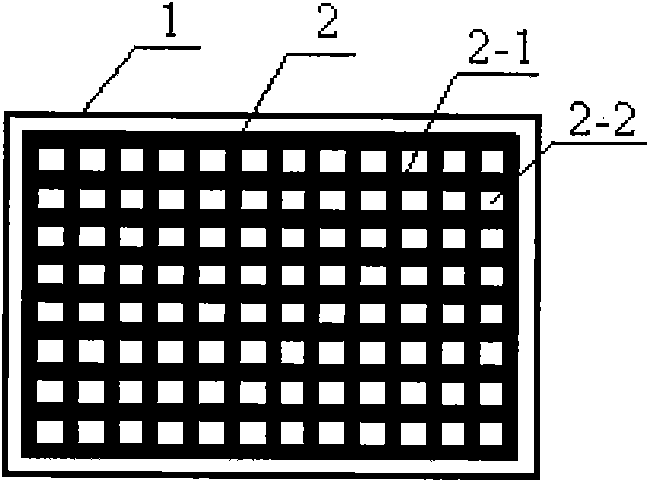

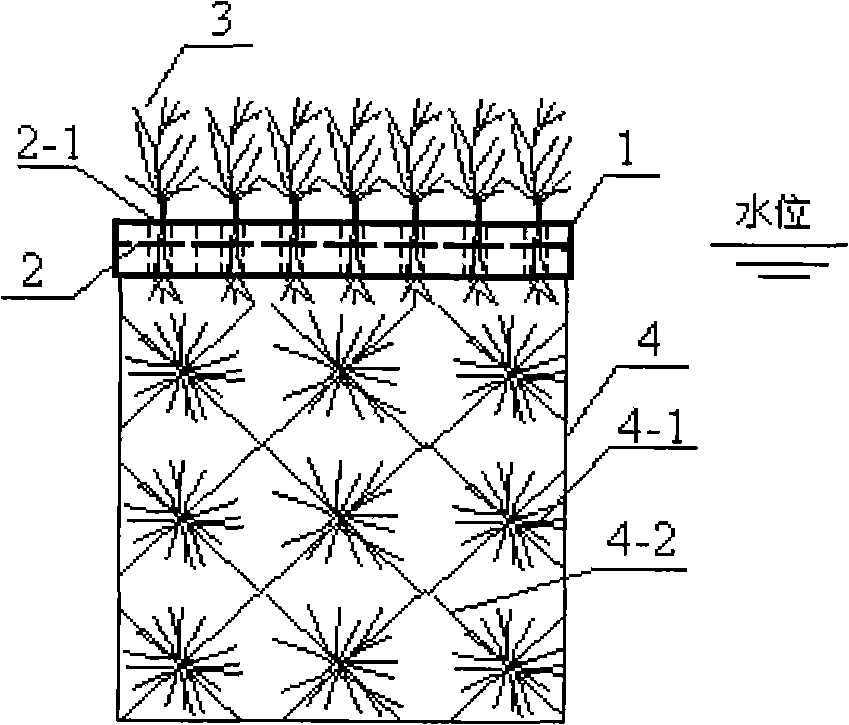

Combined type ecological floating bed water purifying device

InactiveCN101851024AFavorable for attachment growthAvoid the disadvantages of churnBiological water/sewage treatmentEutrophicationWater quality

The invention relates to a combined type ecological floating bed water purifying device used for in-situ purification treatment of polluted water in rivers and lakes. A floating body frame of a floating bed is provided with a grid-like bamboo charcoal floating bed main board made of bamboo charcoal pieces which are processed intensely by a compound enzyme biological promoter before being used, and when the bamboo charcoal pieces are used, the bamboo charcoal pieces can quite well adsorb nitrogen and phosphorus in the water and effectively promote the attached growth of indigenous microorganisms in the water; grid holes on the bamboo charcoal floating bed main board are used as planting holes of plants, and various aquatic plants or economic plants with water purification function can be mixedly planted; and biological fillers are arranged on the lower part of the floating bed, and biomass-based materials which are natural vegetable fibers are used by biofilm formation of microorganisms. The device can greatly improve the capability of removing nitrogen, phosphorus and organic matters from the eutrophication water of the ecological floating bed device and has the characteristics of simple structure, convenient mounting and control, high water flow impact resistance and the like, so that the device is quite suitable to be used for the in-situ purification treatment of water in natural rives, lakes and reservoirs and scenic water.

Owner:TONGJI UNIV

Wood-plastic composite material and method of preparing the same

The invention discloses a wood-plastic composite material and a preparation method thereof. The composite material includes the following materials by the weight portion: 100 portions of reclaimed plastic particles, 80-100 portions of bamboo powder, 80-100 portions of inorganic filler, 1-2.5 portions of titanic acid ester, 1-5 portions of compatibilizing agent, 8-10 portions of lubricant and 1-2 portions of functional auxiliary agent. Compared with the prior art, the invention integrates the advantages of inorganic filler and bamboo fiber, reduces the dosage of vegetable fiber in the traditional wood-plastic formula, and increases the dosage of inorganic filler; the composite material prepared by the method has higher toughness and rigidity, lower water absorption rate and smaller molding shrinkage; and the pollution of waste plastics and vegetable fibers to the environment is reduced.

Owner:HUANGSHAN HUASU NEW MATERIAL SCI & TECH CO LTD +1

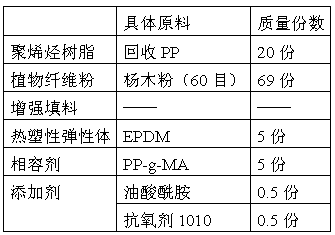

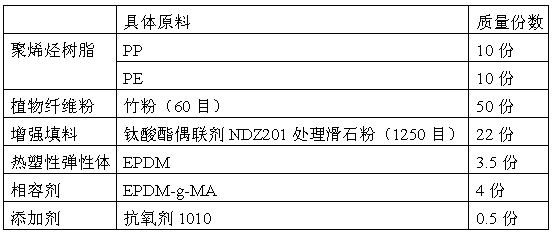

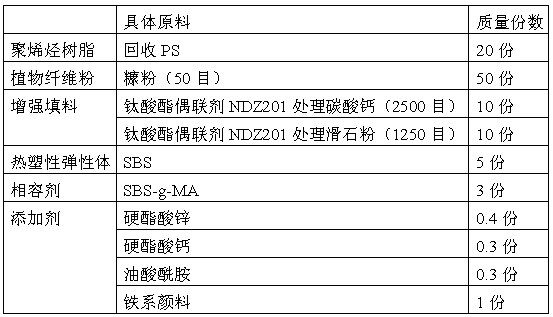

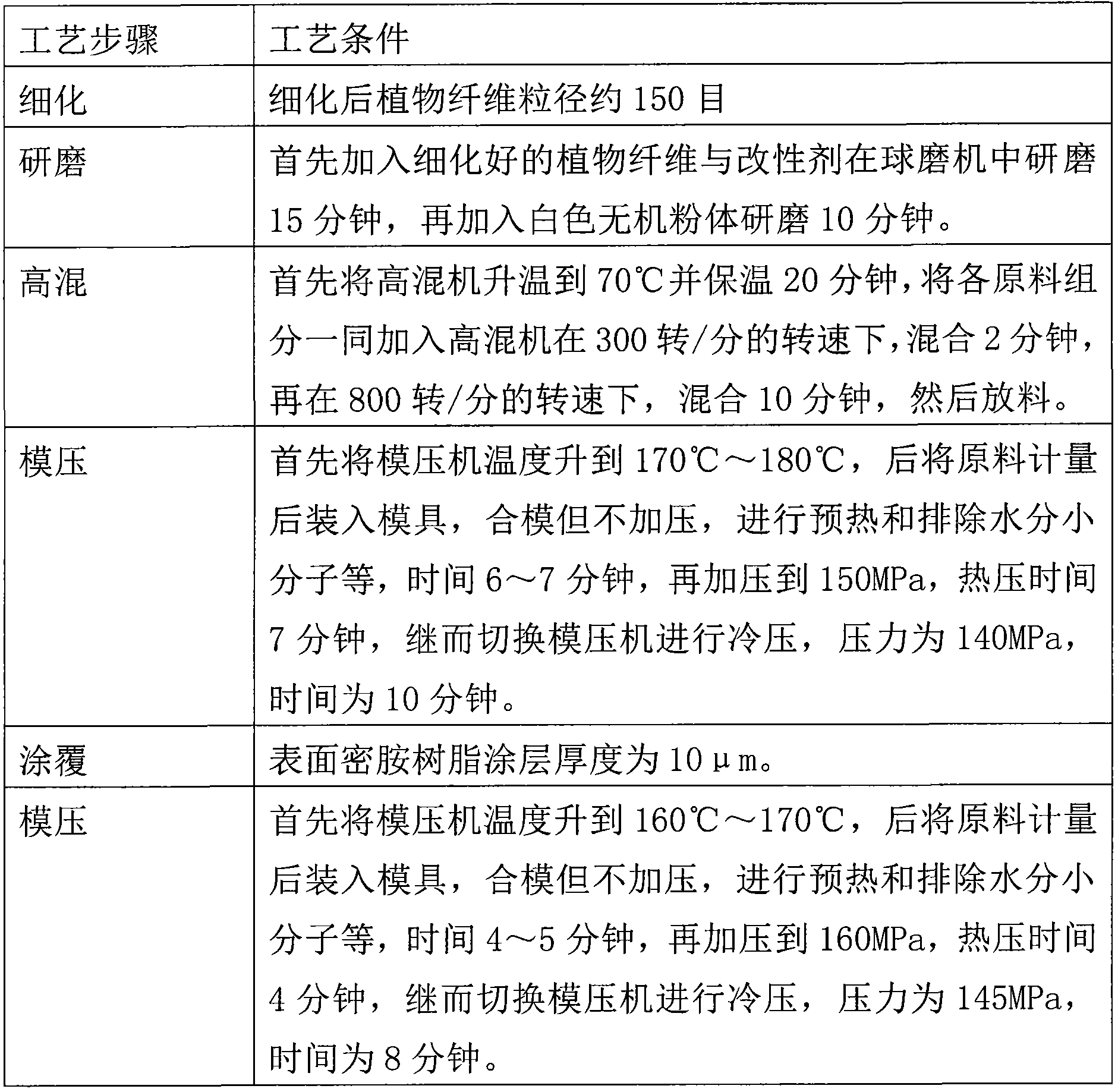

Elastomer toughening wood-plastic composite material and preparation method thereof

An elastomer toughening wood-plastic composite material is composed of, by mass percentage, 15-30% of polyolefin resin, 40-70% of plant fiber powder, 0-30% of reinforcing filler, 1-5% of thermoplastic elastomers, 2-5% of compatilizer, and 0-2% of additives. According to the elastomer toughening wood-plastic composite material and a preparation method of the elastomer toughening wood-plastic composite material, the high fiber content, mechanical strength and rigidity of the wood-plastic composite material are kept, and meanwhile, toughness of the wood-plastic composite material is improved. The cracking and fractured rate of the wood-plastic composite material during the processing and using processes is lowered, and the service life of the wood-plastic composite material is prolonged.

Owner:WUXI SHUNXUAN NEW MATERIALS +1

Seashell-diatom ooze wall surface decoration wall material and production and construction method thereof

The invention discloses a seashell-diatom ooze wall surface decoration wall material and a production and construction method thereof. The decoration wall material comprises: 20 to 98 parts of shell powder, 8 to 30 parts of silica, 4 to 100 parts of kieselguhr, 2 to 20 parts of medical stone, 3.8 to 48 parts of mica powder, 2 to 10 parts of magnesium-rich silicate, 6 to 26 parts of scolecite, 1.5to 36 parts of hydrosilicate, 0 to 50 parts of titanium dioxide powder, 2 to 50 parts of calcium carbonate, 0.1 to 0.3 part of vegetable fiber, 1 to 30 parts of pigment, 4.8 to 40 parts of kelp powder, 1 to 30 parts of cold soluble polyvinyl alcohol powder and 1 to 20 parts of hydroxypropyl methyl cellulose. The production and construction method comprises: placing the raw material components into a stirrer for uniform stirring; filling the mixture in bags, packing the bags in boxes, sealing the boxes and storing the boxes in a storehouse; adding water into the mixture and stirring the mixture uniformly; and pasting the mixture on a wall surface to be decorated to make various texture patterns. The seashell-diatom ooze wall surface decoration wall material has the advantages of: (1) soft texture and no toxicity, fading nor stripping; (2), characteristics of eliminating indoor pollution, regulating indoor humidity, eliminating odor, isolating noises and offering high skin texture feel; (3) fire proofing and flame retarding; and (4) rich color.

Owner:青岛泉佳美硅藻泥科技有限公司

Liquid ammonia modified method of cotton fibriia and yarn

InactiveCN101413213AGood flexibilityImprove curling effectLiquid/gas/vapor removal by centrifugal forceTextile treatment by pouringYarnVegetable fibers

The invention provides a method for modifying cotton and long vegetable fiber or yarn by ammonia liquid, which comprises the following steps: firstly, drying pre-treatment of raw materials; secondly, ammonia leaching of the raw materials in a hermetical treatment tank; thirdly, spin-drying of the raw materials subjected to ammonia leaching when a creel is twirled; fourthly, drying of the raw materials subjected to spin-drying by ammonia flow when the creel rotates slowly; fifthly, flushing of the raw materials which are dried by the ammonia flow by airflow when the creel rotates slowly; and so on. The method keeps the inherent advantages of the cotton, the long vegetable fiber and the yarn, overcomes the defects of the cotton, the long vegetable fiber and the yarn, increases softness, crimp tendency and fluffiness of the cotton, the long vegetable fiber and the yarn, improves the dye-uptake rate, the leveling property and the showy dye level, and further solves the problems of energy conservation, efficiency improvement and environmental protection.

Owner:上海业安纺织科技有限责任公司

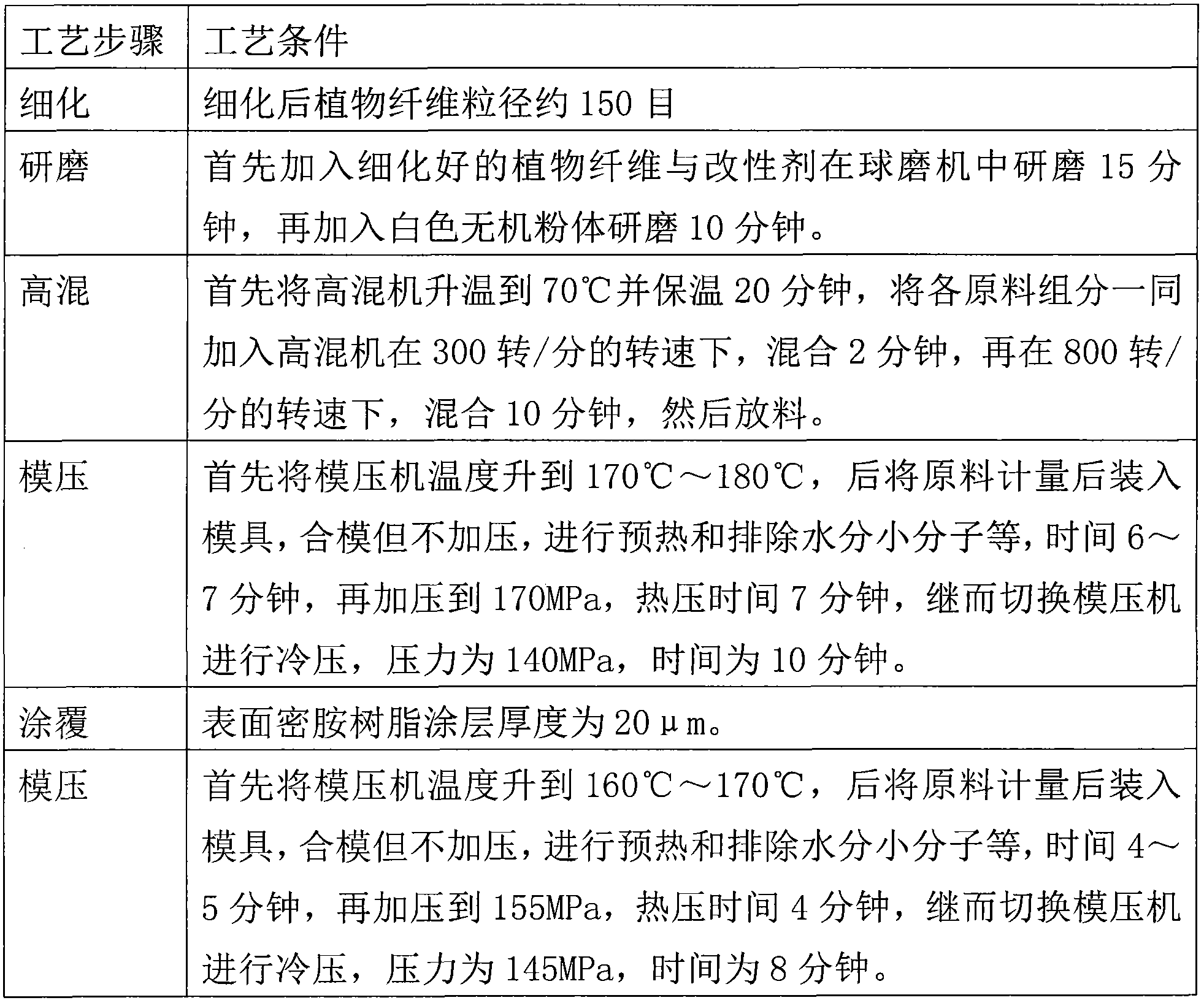

Manufacturing method for vegetable fiber compound tableware

ActiveCN102794803AControlled high temperature oxidative degradationControllable DurabilityWood compressionAviationHusk

The invention belongs to the technical field of vegetable fiber compound tableware and specifically relates to a manufacturing method for the vegetable fiber compound tableware. The manufacturing method specifically comprises seven steps. The production cost of the vegetable fiber compound tableware is obviously lower than that of the traditional metal, ceramic and melamine tableware; the traditional metal, ceramic and melamine tableware can be replaced by the vegetable fiber compound tableware; a large quantity of vegetable fibers, such as, crop straws, rice husks, cobs, sawdust, and the like, are effectively utilized; the atmospheric pollution caused by vegetable fiber burning is effectively prevented and the waste is turned into the wealth; the main products are as follows: basins, bowls, cups, dishes, trays, snack boxes, soup ladles, soup spoons, chopsticks, aviation meal boxes, and the like; and the products have the characteristics of high ceramic simulating strength, good natural texture, clear and gorgeous grains, and the like.

Owner:安徽绿之态秸秆制品有限公司

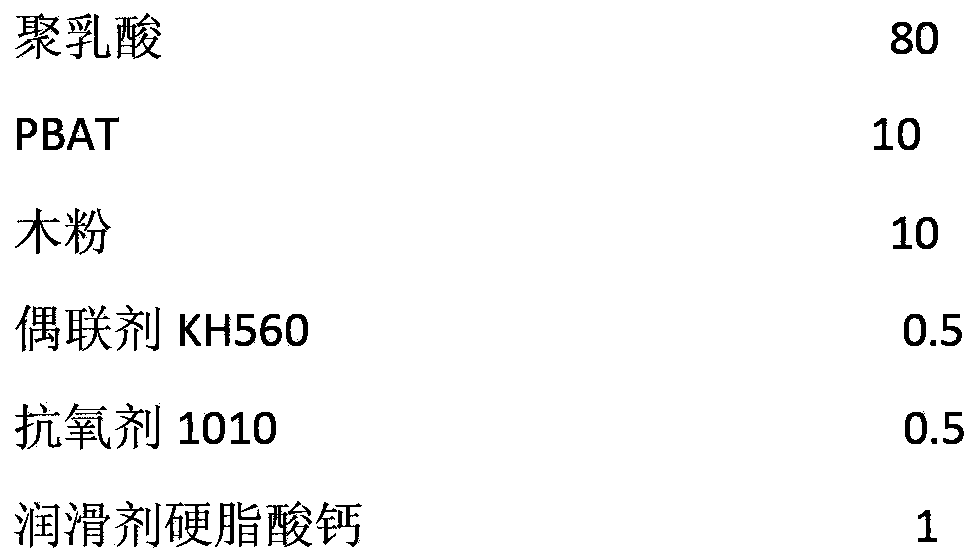

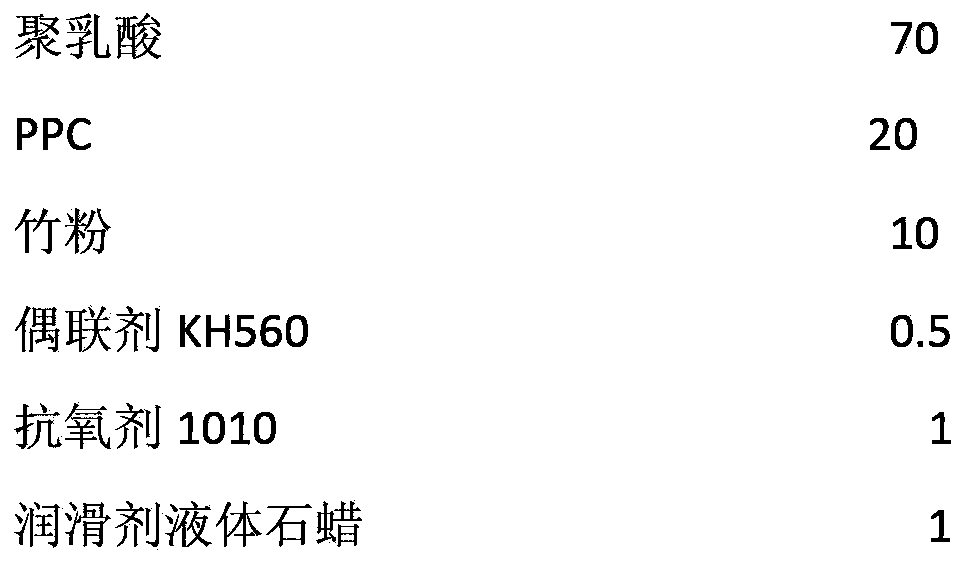

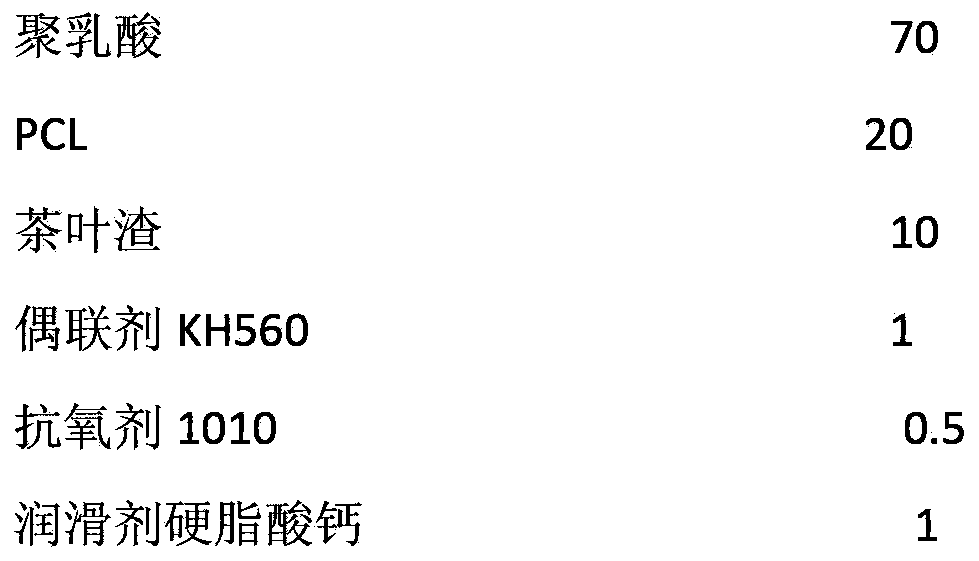

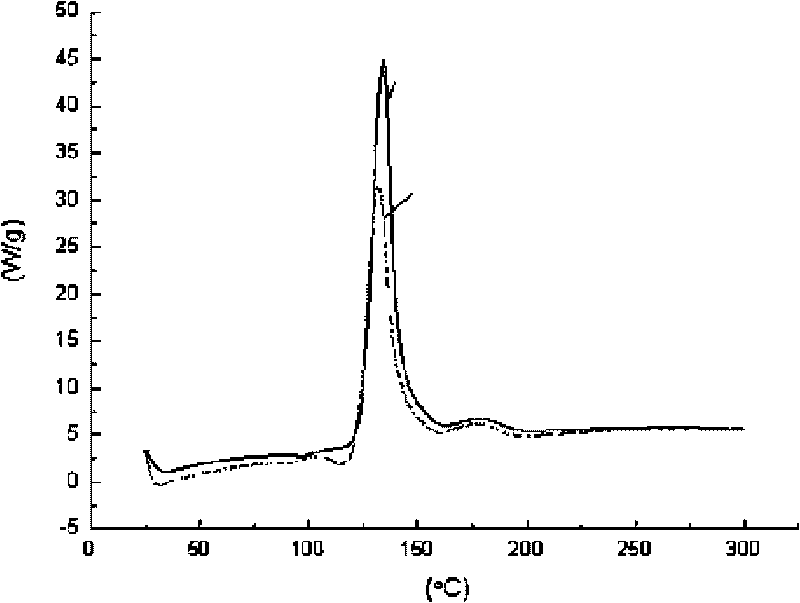

High temperature resistant and degradable polylactic acid wood plastic material and preparation method thereof

The invention discloses a high temperature resistant and degradable polylactic acid wood plastic material and a preparation method thereof. The polylactic acid wood plastic material is prepared through the following steps: uniformly mixing the following ingredients by mass: 50%-70% of polylactic acid, 10%-20% of toughening component, 10%-40% of vegetable fiber, and 1%-3% of other auxiliaries, preparing the polyblend master batch through an extruding machine, and preparing polylactic acid wood plastic material through the extruding machine. According to the invention, polylactic acid is used as basal body resin material, flexible and biologically degradable plastic is used as a toughening component, vegetable fiber is used as an intensifier, and a coupling agent, an anti-oxidant, a lubricant and other auxiliaries are added to realize the modification for polylactic acid wood in heat resistance and tenacity; compared with conventional petroleum based macro molecule material, the polylactic acid wood plastic material is environmental-friendly and reproducible; compared with conventional polylactic acid material, the polylactic acid wood plastic material has excellent tenacity and heat resistance.

Owner:SOUTH CHINA UNIV OF TECH

Biodegradable oil-water separation net film with super-hydrophobic and super-oleophylic properties and preparation method thereof.

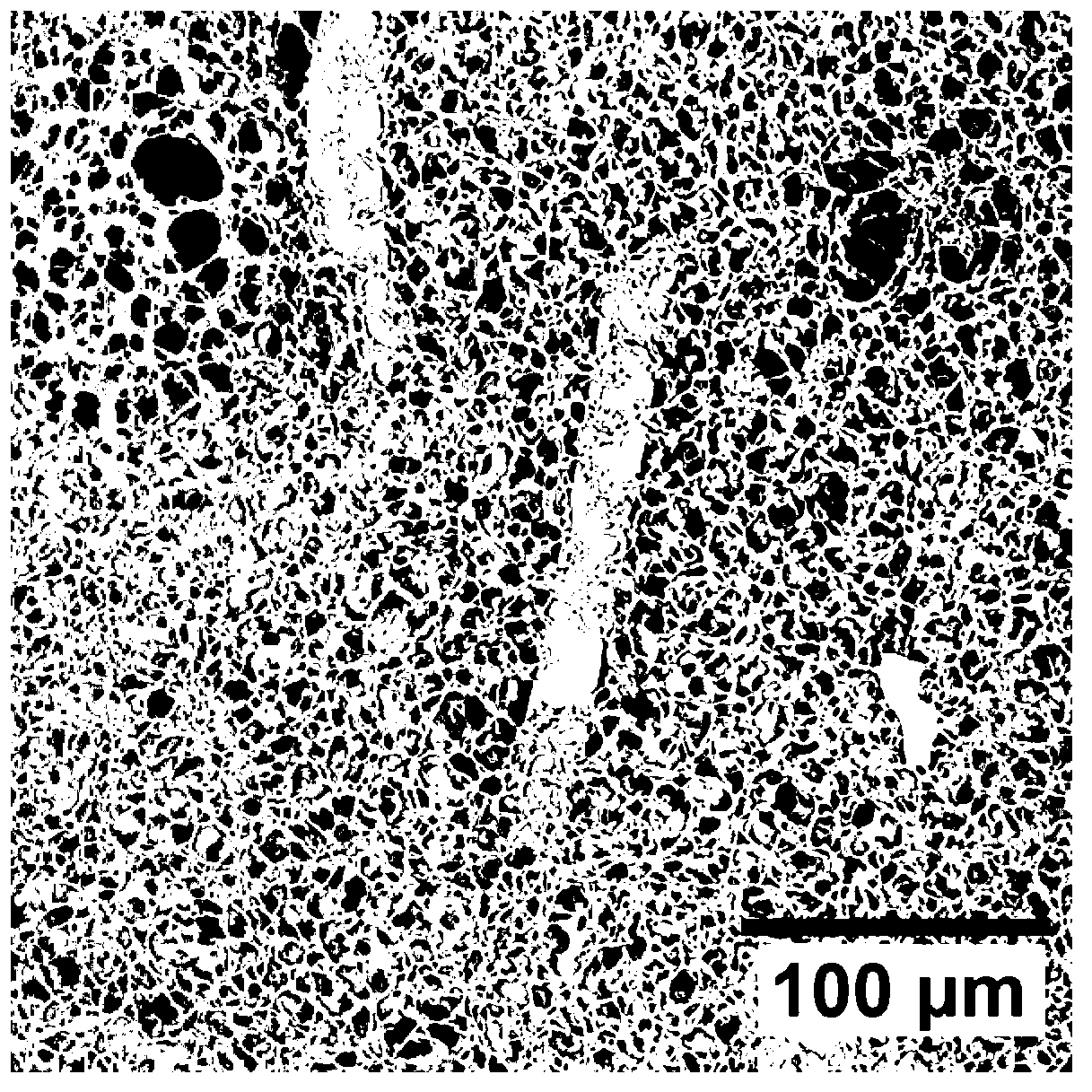

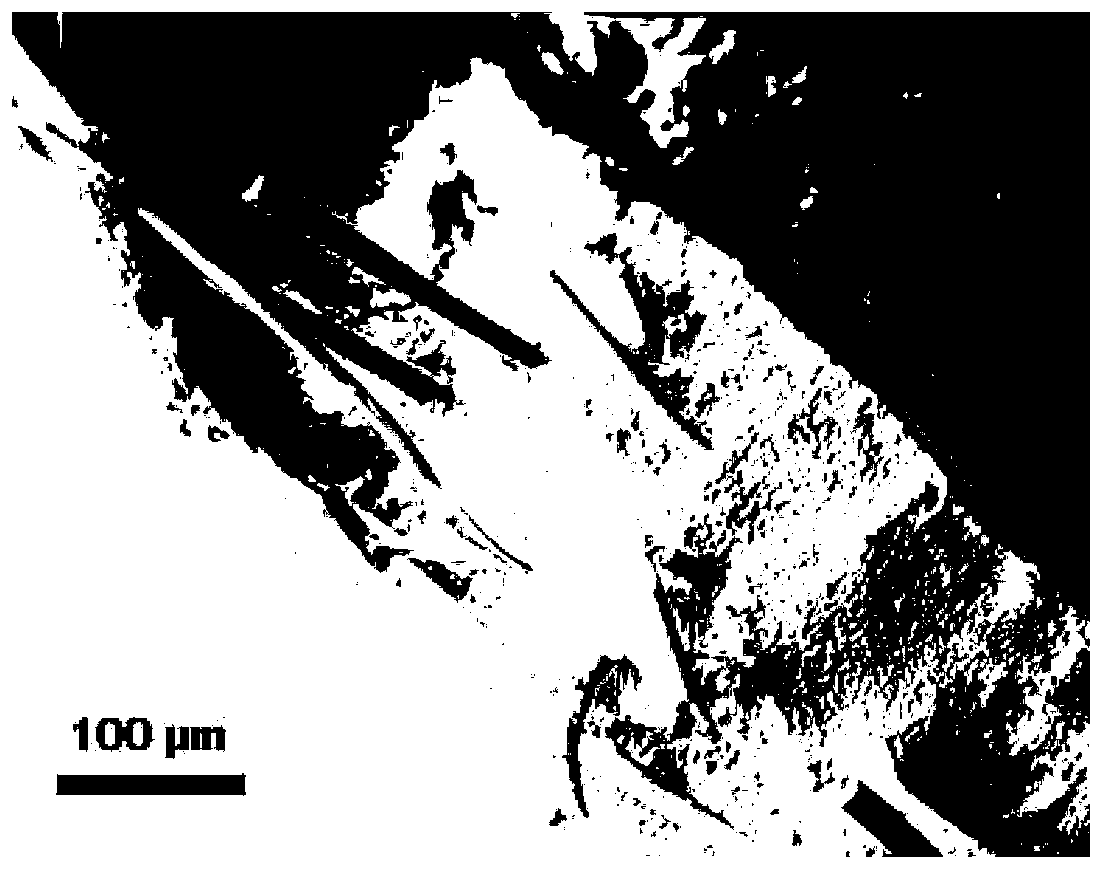

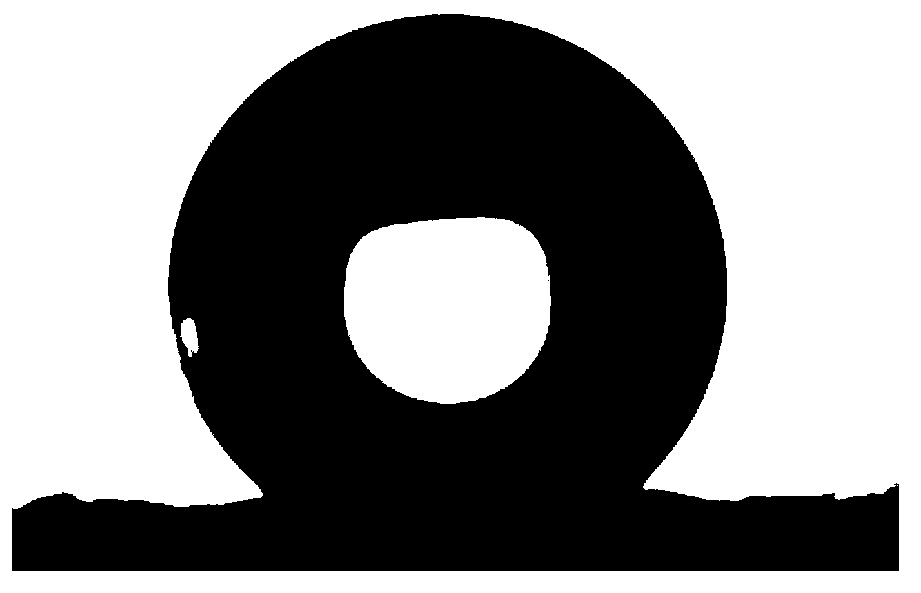

ActiveCN103157392ANo pollution in the processGood biocompatibilitySemi-permeable membranesFatty/oily/floating substances removal devicesOrganic solventVegetable fibers

The invention discloses a biodegradable oil-water separation net film with super-hydrophobic and super-oleophylic properties and a preparation method of the biodegradable oil-water separation net film. The preparation method comprises the following steps of: dissolving the separation net film in an organic solvent by adopting PLA (Poly Lactic Acid) as a unique or main material, adding a vegetable fiber material, immersing a poor solvent of the PLA after mixing uniformly, preparing and obtaining a micronan composite net-shaped porous structure by phase separation and forming the biodegradable oil-water separation net film with the super-hydrophobic and super-oleophylic properties after drying. The biodegradable oil-water separation net film disclosed by the invention has the advantages that the super-hydrophobic and super-oleophylic special wettability is achieved, the contact angle to water in the air is larger than 150 degrees, the contact angle to oil is near 0 degree, and the oil-water separation effect is good. The biodegradable oil-water separation net film disclosed by the invention also has the advantages of high separation speed, good separation effect, simple preparation method, no need of other chemical additives, wide material source and biodegradability, and can be prepared on large scale for the aspects of oily sewage treatment and water-body purification and the like.

Owner:TSINGHUA UNIV

Preparation method of diatomite ceramic particles or ceramic plates

InactiveCN102093033AIncrease contentImprove adsorption capacityClaywaresExpanded clay aggregateVegetable fibers

The invention relates to a preparation method of diatomite ceramic particles or diatomite ceramic plates. The preparation method of the diatomite ceramic particles comprises the following steps: grinding diatomite, adding cosolvent, mineral powder and vegetable fiber powder to mix evenly and grind; and adding water to mix, shaking to obtain diatomite ceramic particles, and roasting to obtain the finished diatomite ceramic particles. The preparation method of the ceramic plates comprises the following steps: using evenly mixed powder to perform dry pressing with a pressure forming machine, or using mud with the water content of 15-25wt% to perform extrusion forming; and roasting to obtain the diatomite ceramic plates. The formed and dried diatomite ceramic plates or diatomite ceramic particles are soaked in slurry prepared from anatase titanium dioxide nanometer powder or metatitanic acid powder and then dried and roasted to obtain diatomite ceramic particles or diatomite ceramic plates with photochemical activity. In the invention, the low temperature sintering method is adopted to prepare the diatomite diatomite ceramic plates and ceramic particles which have high diatomite content and good adsorption property and water resistance and can be combined with various functional components on the surface. The diatomite ceramic products in the invention are convenient to use and have simple production technology and cheap and easy available raw materials.

Owner:JILIN UNIV +1

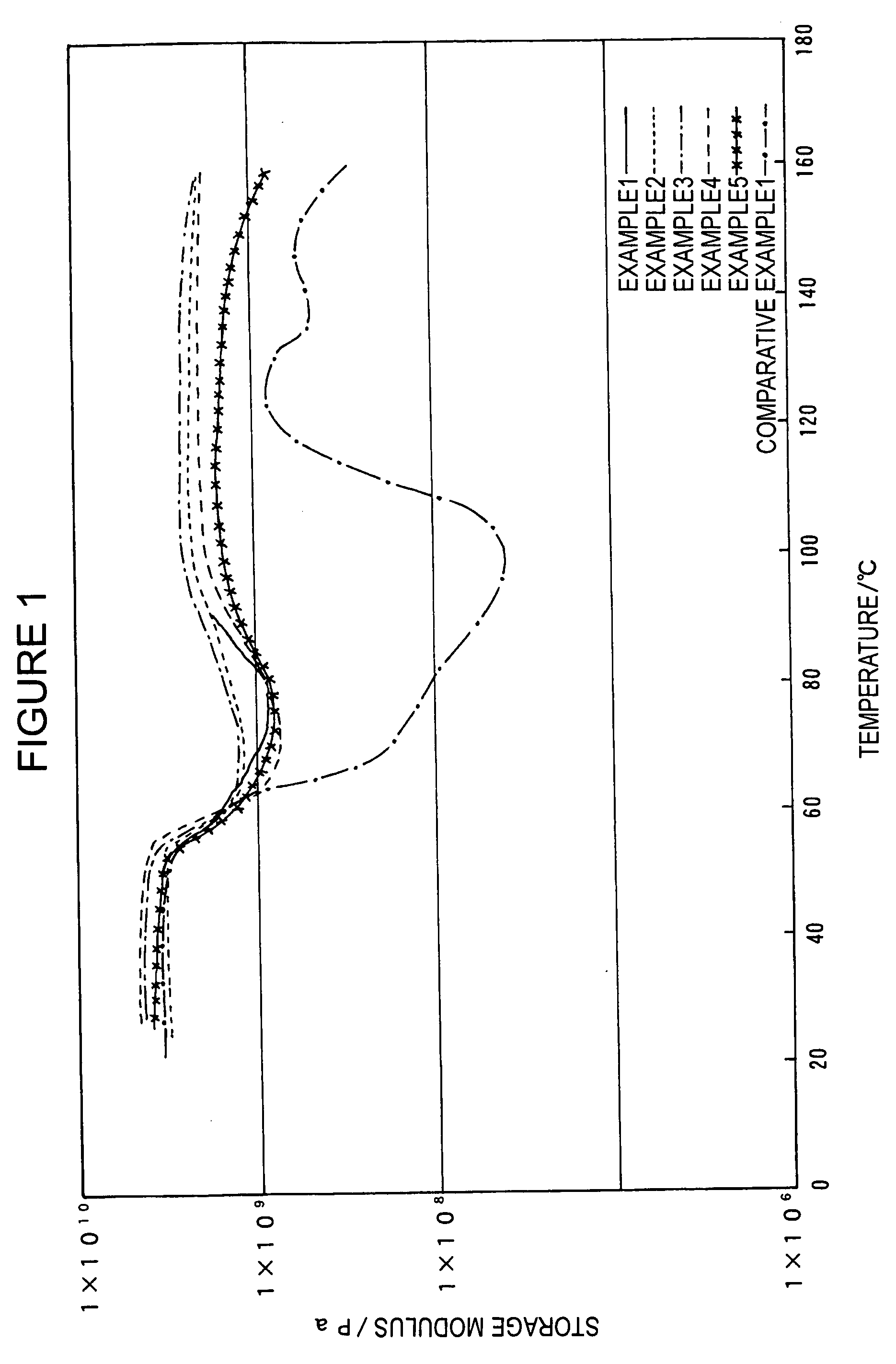

Molding material containing unsaturated polyester resin and microfibrillated plant fiber

ActiveUS20110263756A1High mechanical strengthGood effectCeramic shaping apparatusVegetable fibersHemicellulose

The present invention relates to a molding material comprising an unsaturated polyester resin and microfibrillated plant fibers, the microfibrillated plant fibers comprising cellulose and hemicellulose, and having a specific surface area of 5 to 20 m2 / g; a method of producing the molding material; a molded article obtained by curing the molding material; and a method of producing an unsaturated polyester resin molded article comprising microfibrillated plant fibers.

Owner:DAINIPPON INK & CHEM INC +1

Composite composition and molding using the same

A composite composition includes at least one organic polymer compound having biodegradability, vegetable fibers, and a hydrolysis inhibitor for the organic polymer compound having biodegradability.

Owner:SONY CORP

Natural vegetable fiber reinforced fully-degradable polymer composite material and preparation method thereof

The invention refers to a full-degradable polymer composite material strengthened by the natural plant fiber and the preparing method. It adopts India plant fiber-Hildegardia populifolia, sisal fiber, ramee, wood fibre and so on as the fiber raw material, tand the degradable plastic-the poly-methyl ethyl carbonic acid resin as the basic body, and smelts and commixes the filling and the basic body on the existent / nonexistent condition of the coupling agent to make the composite material. The weight percent content of the fiber is 5-80%, the better fiber 10-40%.

Owner:SUN YAT SEN UNIV

Edible spread composition and packaged product

Owner:KRAFT FOODS GRP BRANDS LLC

Fiber reinforcement fire-proof thermal insulation plate and preparation process thereof

InactiveUS20150345132A1Low production costResistance to crackingSolid waste managementClimate change adaptationThermal insulationCalcium formate

The present invention discloses a fiber reinforcement fire-proof thermal insulation plate, which is prepared by raw materials having the following weight portions: 80-100 portions of fly ash, 30-50 portions of expanded perlite, 10-20 portions of haydite, 10-20 portions of vegetable fiber, 5-10 portions of winnowing beads, 5-8 portions of sepiolite, 3-5 portions of sodium fluorosilicate, 3-5 portions of calcium formate, 3-5 portions of flame-retardant, 0.1-0.5 portion of triisopropanolamine loeate and 0.1-0.3 portion of dimethoxy-ethane. According to the present invention, industrial production wastes are adopted as main raw materials, so that the production cost is reduced; and defects in the existing building thermal insulation plates can be effectively overcome through the cooperation effect produced by organic combination of the fly ash, light aggregates and additives.

Owner:GUANGDONG NO 1 CONSTRUCTION ENGINEERING CO LTD

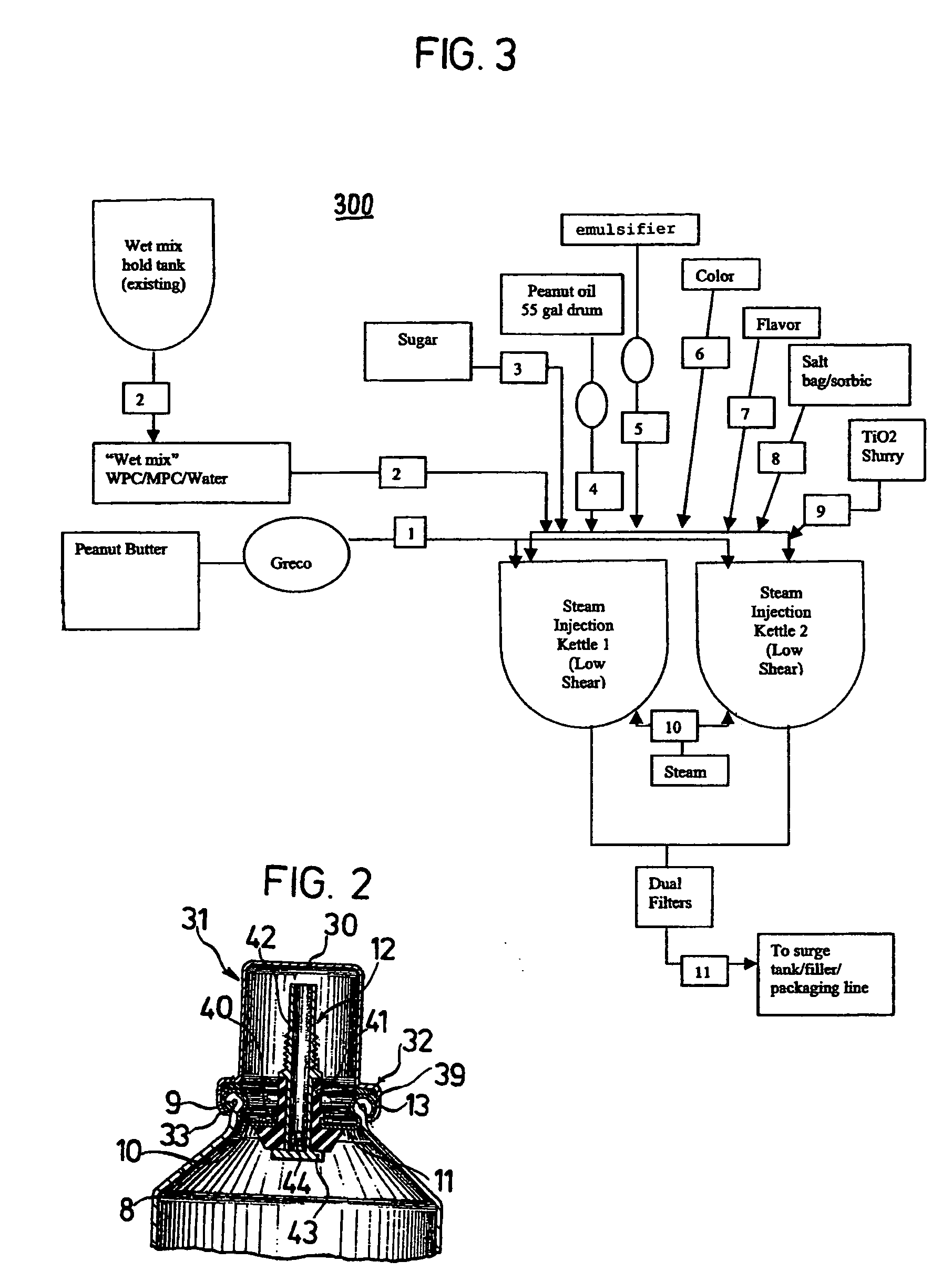

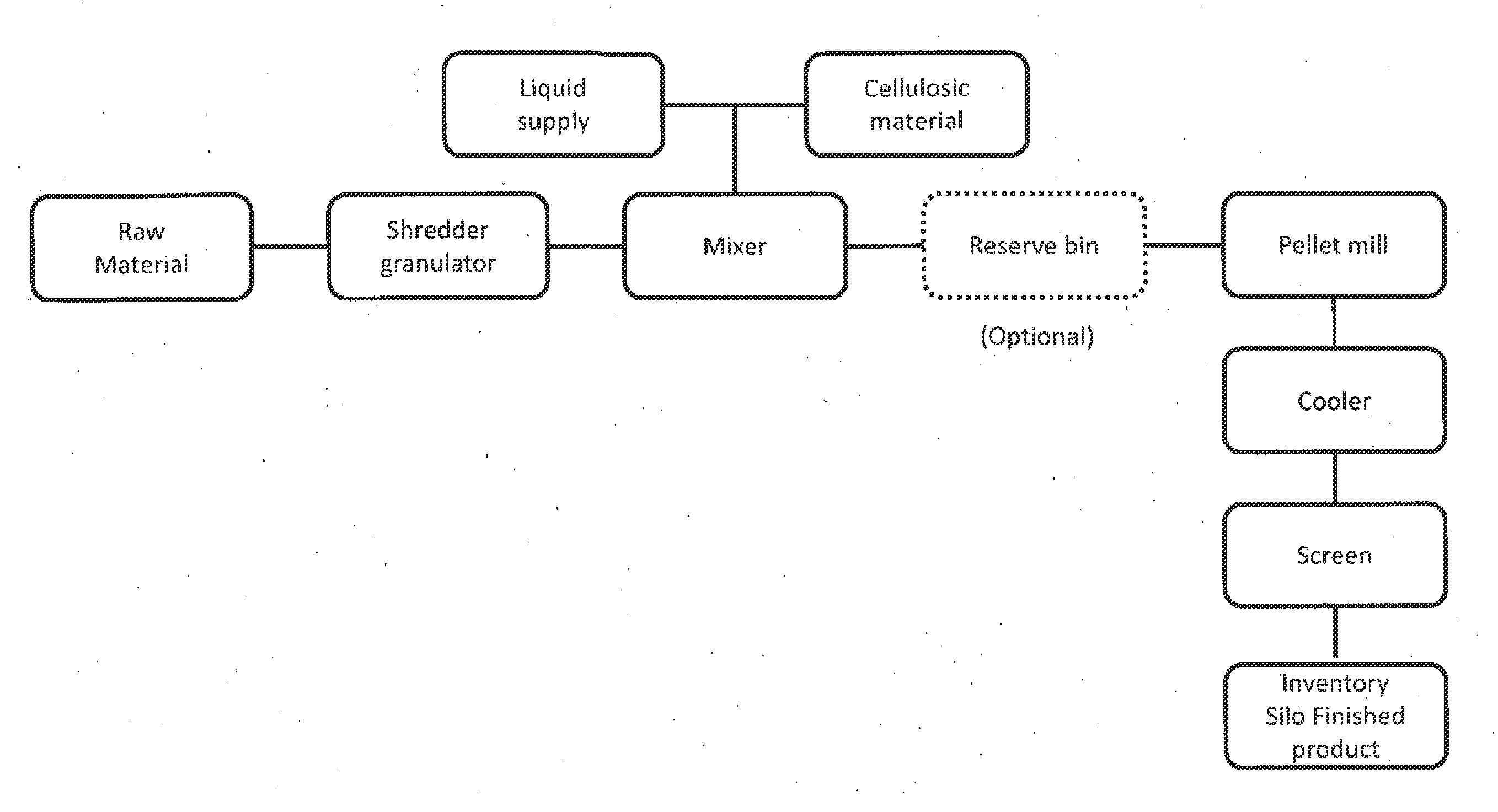

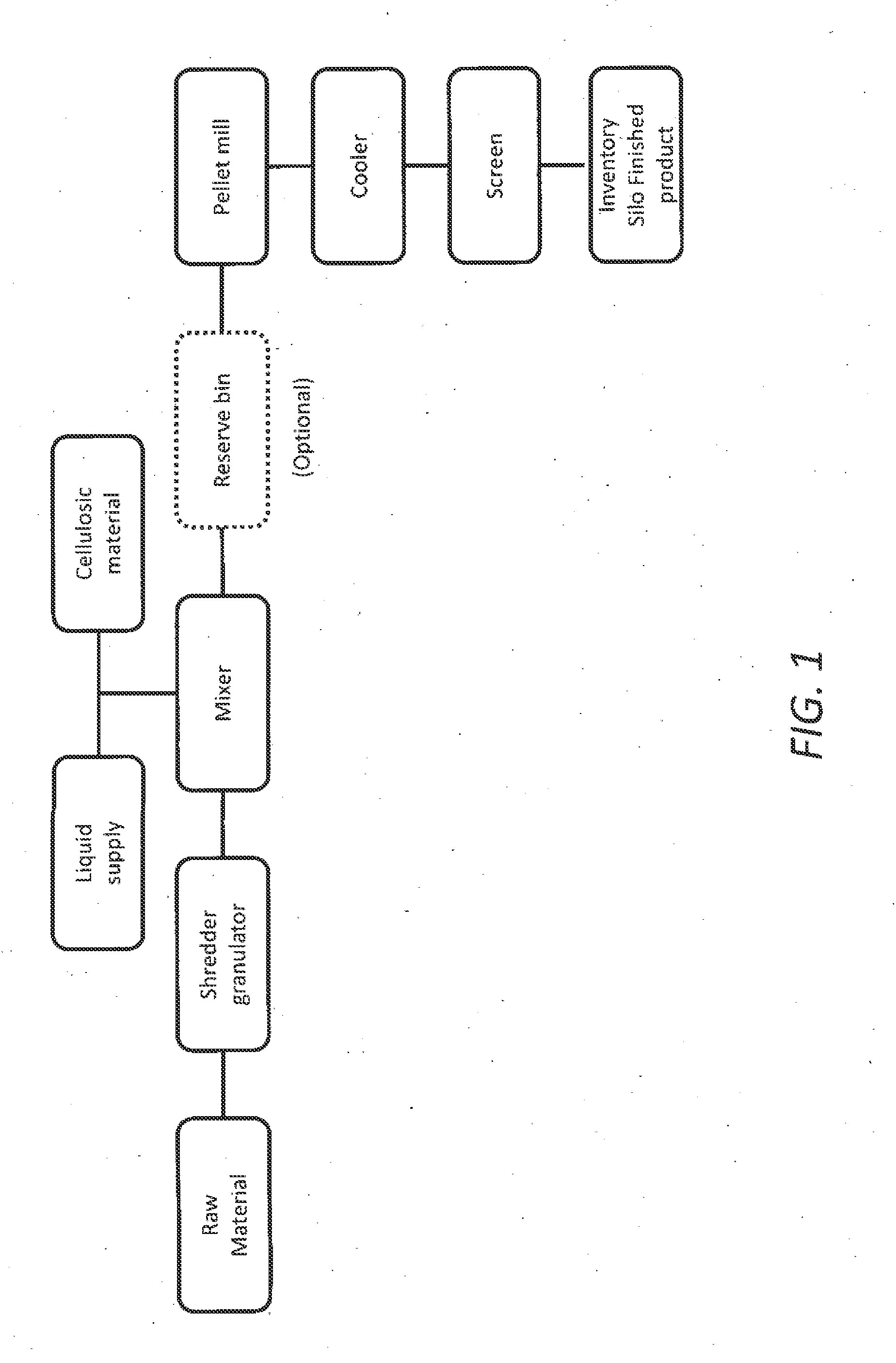

Multipurpose pellets and method of making same

A multipurpose pellet is provided comprising: from about 0.1% to about 100% by weight of a vegetable fiber chosen from cotton, bamboo fiber, rice fiber, esparto, papaya, coir, sisal, kapok, jute, ramie, flax, roselle hemp, hemp, kenaf, abaca, soybean fiber, okra fiber, vine fiber, banana fiber, rattan and nettlesjute; and from about 99.9% to about 0% by weight of cellulosic material.

Owner:LEFEBVRE ROBERT

Method for car clutch face sheet production

InactiveCN101429977ALow priceImprove adsorption capacityAldehyde/ketone condensation polymer adhesivesFriction clutchesAdhesiveFilling materials

The invention relates to a method for producing automobile clutch facing patches, which adopts an organic vegetable fiber and other fibers to weave the organic vegetable fiber and other fibers into twill fabrics as a framework material, simultaneously mixes and stirs bonding materials such as water soluble phenol resin, filling materials and water to be prepared into slurry. The method utilizes a natural wood vegetable fiber to replace an inorganic fiber material, and the natural wood vegetable fiber is reproducible and has no pollution. The water soluble phenol resin is used to replace rubber and is taken as a bonding adhesive for preparing the clutch facing patches. Industrial naptha is not used any more. Therefore, compared with the prior art, the method has the following advantages: firstly, the method has the characteristic of environmental protection; and secondly, the method is favorable for reducing the production cost of the automobile clutch facing patches, and solving the problem of product performance fluctuation.

Owner:ZHEJIANG DUALRAY FRICTION MATERIAL

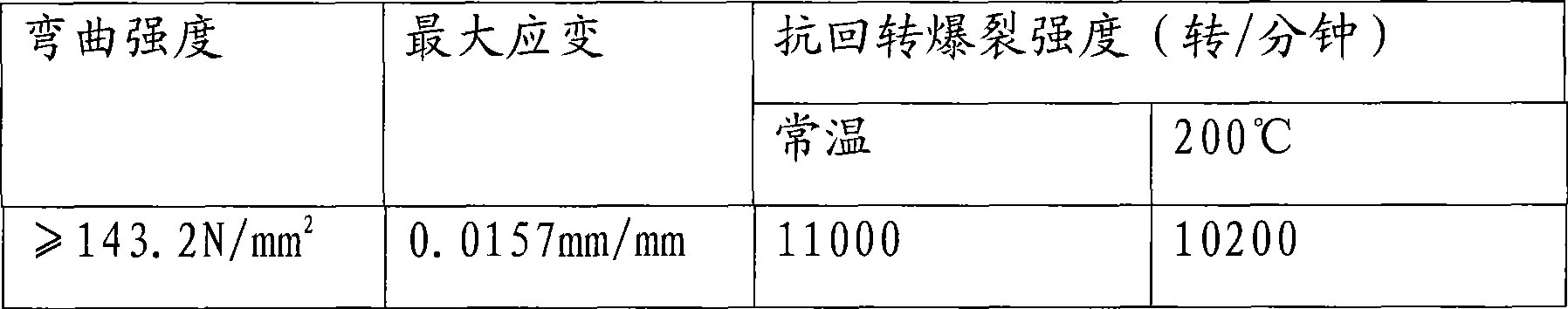

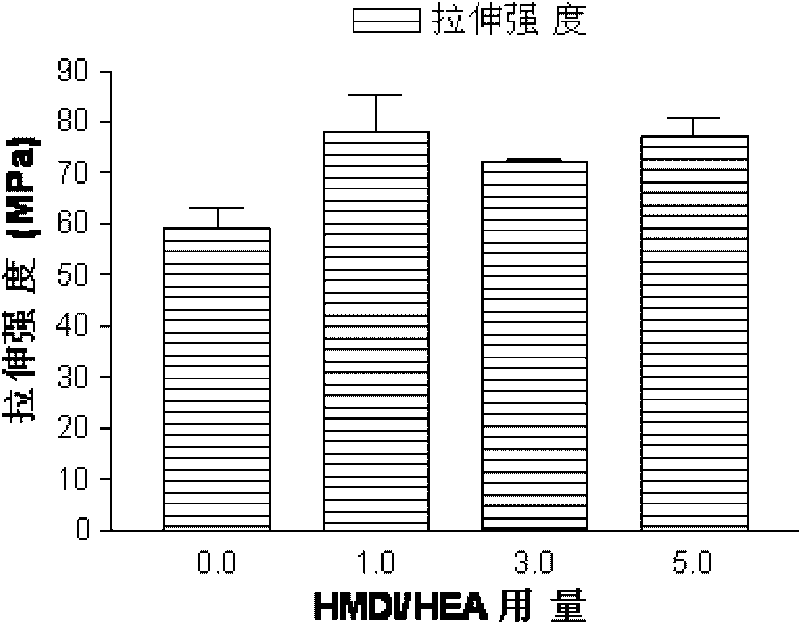

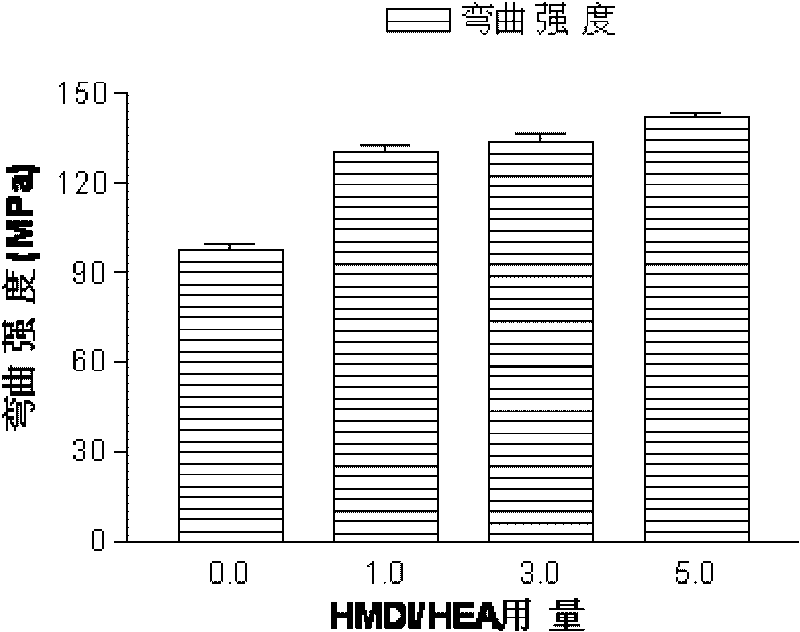

Modified bamboo fiber composite material and preparation method thereof

The invention aims at providing a modified bamboo fiber composite material and a preparation method thereof, which solve the problems of poor mechanical property, low tensile strength, low bending strength and the like of the prepared composite material caused by low interface combination strength of the vegetable fiber and plastics in the prior art. The bamboo fiber composite material of the invention adopts the bamboo fiber, the unsaturated polyester and the evocating agents for hot press molding to obtain the bamboo fiber composite material. After the modified bamboo fiber composite material of the invention adopts a modifying agent for the modification, the modified bamboo fiber, the unsaturated polyester and the evocating agents carry out hot press molding to obtain the modified bamboo fiber composite material. Both the bamboo fiber composite material and the modified bamboo fiber composite material prepared by the method of the invention have good tensile strength, bending strength and flexural modulus.

Owner:惠州绿能实业有限公司

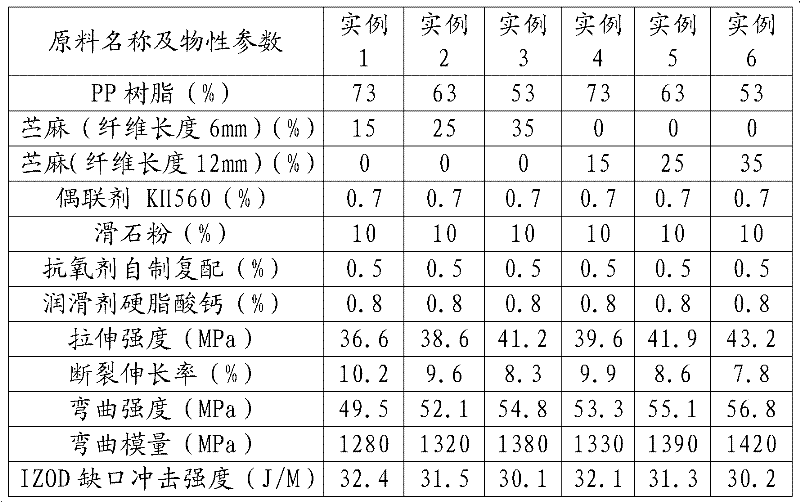

Fiber reinforced polypropylene (PP) automobile interior decoration material and preparation method thereof

The invention discloses a fiber reinforced PP automobile interior decoration material and a preparation method thereof. The fiber reinforced PP automobile interior decoration material comprises, by weight, 40-70% of a PP resin, 10-40% of a vegetable fiber, 5-20% of a filler, 0.3-0.8% of a coupling agent, 0.2-0.6% of an antioxidant and 0.3-1.0% of a lubricant. The vegetable fiber reinforced PP automobile interior decoration material is prepared by weighing above raw materials according to above proportions, mixing the raw materials for 3-5min in a mixer, putting the mixed raw materials in a parallel double screw extruder, and carrying out melt extrusion and granulation on the mixed raw materials. The vegetable fiber reinforced PP automobile interior decoration material which is obtained in the invention, adopts vegetable fiber reinforcement and has the advantages of excellent mechanical property, recoverability, small density, high impact resistance, and good energy absorption property accords with development trends of environmental protection, lightweight and sustainability of the automobile industry.

Owner:SHENZHEN KEJU NEW MATERIAL

Granulated powder containing vegetable proteins and fibers, process for producing same, and use thereof

InactiveUS20110311599A1Inorganic/elemental detergent compounding agentsCosmetic preparationsBiotechnologyVegetable fibers

The present invention concerns a granulated powder containing at least one vegetable protein and at least one vegetable fiber, characterized in that it has a laser volume mean diameter D4,3 of between 10 μm and 500 μm, preferably between 50 μm and 350 μm, and even more preferably between 70 μm and 250 μm, and a dry matter content, determined after stoving at 130° C. for 2 hours, of greater than 80%, preferably greater than 85%, and even more preferably greater than 90%. The present invention also concerns a process for manufacturing this granulated powder as well as its use in various industrial field, and more particularly in the food-processing field, where it is used as a functional agent such as an emulsifying, overrun, stabilizing, thickening and / or gelling agent, in particular for totally or partially replacing certain animal proteins in the preparation of food products.

Owner:ROQUETTE FRERES SA

Novel Chinese herbal medicine tobacco sheet and preparation method thereof

The invention discloses a novel Chinese herbal medicine tobacco sheet and a preparation method thereof. The method comprises steps as follows: tobacco stems, tobacco powder, milkvetch roots, mulberry bark, pueraria roots, liquorice roots, ginkgo leaves, mulberry leaves and eucommia leaves are selected, washed clean and placed together to be cooked, and insoluble solids and a mixed solution are obtained; the insoluble solids are ground and evenly mixed with non-tobacco plant fiber pulp and water, and final pulp is obtained; papermaking, long-net water filtration, vacuum dehydration, squeezing and drying are performed on the final pulp, and a shaped tobacco sheet is obtained; a seasoning flavor is added to the mixed solution, the mixture is evenly mixed and then sprayed onto the tobacco sheet, the tobacco sheet is dried and sliced, and then the Chinese herbal medicine tobacco sheet is obtained. According to the novel Chinese herbal medicine tobacco sheet, the preparation process is simple and easy to implement, utilization rates of raw materials are high, and tar and harm can be reduced effectively; the finished product is mellow in taste, soft in smoke, little in miscellaneous gas and capable of regulating blood lipids, promoting blood circulation, eliminating blood stasis, clearing away heat and toxic materials, tonifying livers and kidneys, relieving coughs and asthma, enhancing human immunity and inhibiting human cardiovascular and cerebrovascular diseases and respiratory tract diseases.

Owner:陈五桂

Inorfil softening intensifier and preparation thereof

InactiveCN101503280AGood flexibilityHigh strengthInorganic fibres/flakesGlass fiberPolyvinyl alcohol

The invention relates to an inorganic fiber softening reinforcing agent and a preparation method thereof. The method is to lead H2O2, polyvinyl alcohol and potassium hydroxide to react for 2 to 4 hours at a temperature between 50 and 60 DEG C, adds an etherifying agent after the reaction to react for 4 to 8 hours at a temperature between 50 and 70 DEG C, and regulates the pH value of the solution to 7 to 8 so as to obtain the inorganic fiber softening reinforcing agent. The softening reinforcing agent is applicable to various inorganic fiber materials produced by physical or hot melt method, including basalt fibers, aedelforsite fibers, meerschaum fibers, gypsum fibers, flyash fibers and glass fibers. The softening reinforcing agent can improve the softness and strength of inorganic fibers, improve the defect of easy fracture of the inorganic fibers in processes of pulping, dispersing and transporting, change the charge property of the inorganic fiber surface, reinforce the bonding force of the inorganic fibers and plant fibers, and greatly improve application performance of the inorganic fibers in making paper, insulating wool boards and the like by wet method.

Owner:鹤壁洁联新材料科技有限公司

Dynamic hot water reaction hard microporous fiber calcium silicate board and manufacturing method thereof

InactiveCN101838131AHigh hardnessHigh strengthSolid waste managementCeramic materials productionCalcium silicateSodium Bentonite

The invention relates to a dynamic hot water reaction hard microporous fiber calcium silicate board which is characterized in that a board body is obtained through a reaction of ingredients and water in the weight ratio of 1:4. The ingredients comprise the following components in proportion (molar ratio): 45-47 percent of siliceous material, 40-42 percent of calcareous material, 7 percent of fiber and 6-7 percent of reaction promoter, wherein the siliceous material is one or a mixture of diatomaceous earth, quartz powder, glass dust, opoka and river sand powder; the calcareous material is lime and / or cement; the fiber is one or a mixture of mineral fiber, vegetable fiber and polymer fiber; and the reaction promoter is water glass and / or bentonite. The ingredients which do not contain toluene, formaldehyde or radioactive substances are adopted to react with water in the invention, so that no harmful gas is produced. The finished product has fire prevention, moisture prevention, mold prevention, high tensile strength, high flexural strength and good temperature resistance, and is a multipurpose product suitable for internal walls, external walls and ground surfaces.

Owner:陈耀强

Completely degradable vegetable fiber product and manufacturing method thereof

InactiveCN101525494AImprove use valueReduce pollutionWood working apparatusDomestic articlesMicrowave ovenAdhesive

The invention relates to a completely degradable product and a manufacturing method thereof. The product comprises the compositions in percentage by weight: 40 to 80 percent of vegetable fiber powder, 2 to 40 percent of adhesive, 5 to 15 percent of release agent and 5 to 40 percent of starch. Preferably, the product also contains 1 to 2 percent of toner. The technology can make full use of various natural vegetable fiber materials and increases the using value of raw materials while reducing environmental pollution; the manufactured product is completely biodegradable and nontoxic; moreover, the product has lower manufacturing cost and different types and is suitable for daily use. The manufacturing method essentially and structurally changes the configuration of vegetable fiber and ensures that each composition has excellent processing flowability. Technically, the manufactured product reaches relevant international testing standards (such as American / European food testing standards) and can be tested through dishwasher and microwave oven; therefore, the product is applicable for industrial automatic production.

Owner:艾唐贸易(深圳)有限公司 +1

Biodegradable material and preparation method and application thereof

The invention relates to the field of biodegradable materials, in particular to a biodegradable material and a preparation method and application thereof. The biodegradable material at least comprises the following components in parts by weight: 100 parts of a carrier, 10-50 parts of a bio-based material, 5-20 parts of a compatilizer, 1-12 parts of a photodegradation agent, 5-20 parts of a filler and 0.01-5 parts of an aid, wherein the carrier is polyolefin resin; the bio-based material is any one or more of starch and natural plant fibers; the compatilizer is a mixture of glycidyl methacrylate and modified cyclodextrin, wherein the mass ratio of glycidyl methacrylate to modified cyclodextrin is 1:(0.1-1); the photodegradation agent is any one or more of anatase TiO2, a benzophenone compound, a transition metal compound or complex and rare earth carboxylate; and the aid is any one or more of an initiator, a plasticizer, a slipping agent, a dispersant and styrene.

Owner:浙江苏达山新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com