Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1611 results about "Ramie" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ramie (/ˈreɪmi/, RAY-mee) is a flowering plant in the nettle family Urticaceae, native to eastern Asia. It is a herbaceous perennial growing to 1.0–2.5 m (3 ft 3 in–8 ft 2 in) tall; the leaves are heart-shaped, 7–15 cm (2.8–5.9 in) long and 6–12 cm (2.4–4.7 in) broad, and white on the underside with dense, small hairs—this gives it a silvery appearance; unlike stinging nettles, the hairs do not sting. The true ramie or China grass is also called Chinese plant or white ramie.

Hemostatic textile

ActiveUS20070160653A1Quick activationNon-adhesive dressingsPeptide/protein ingredientsLactideSisal fiber

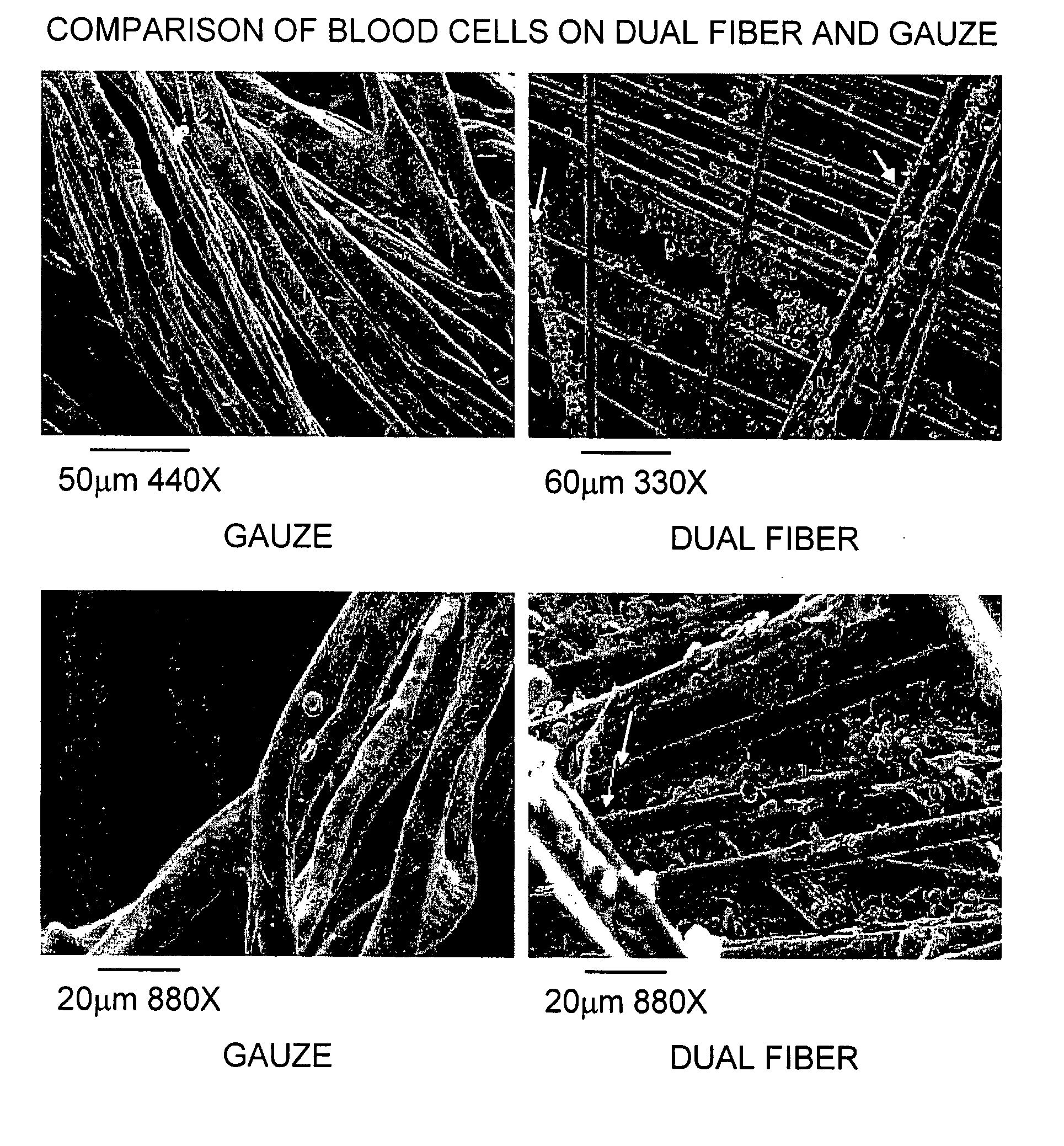

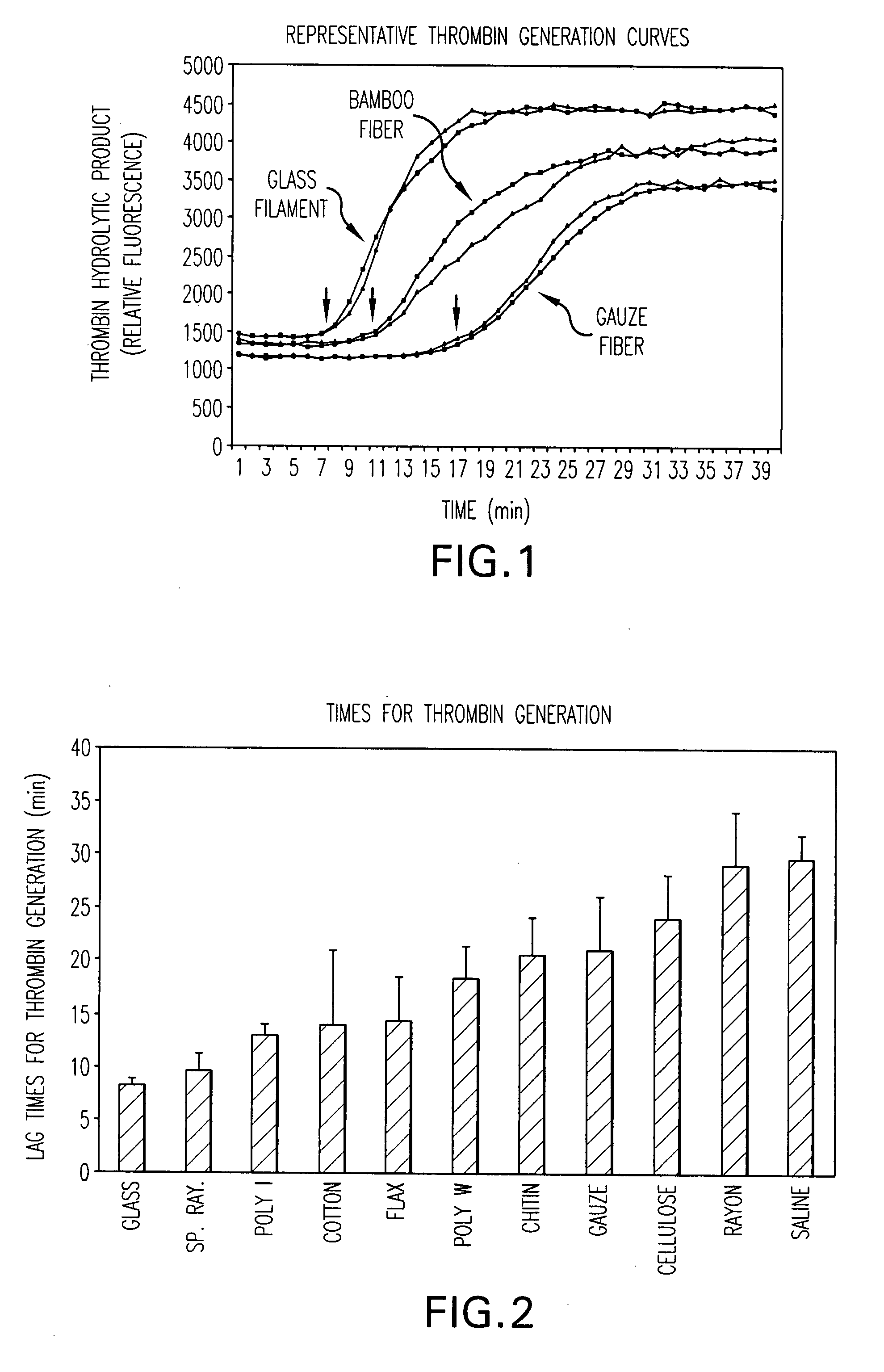

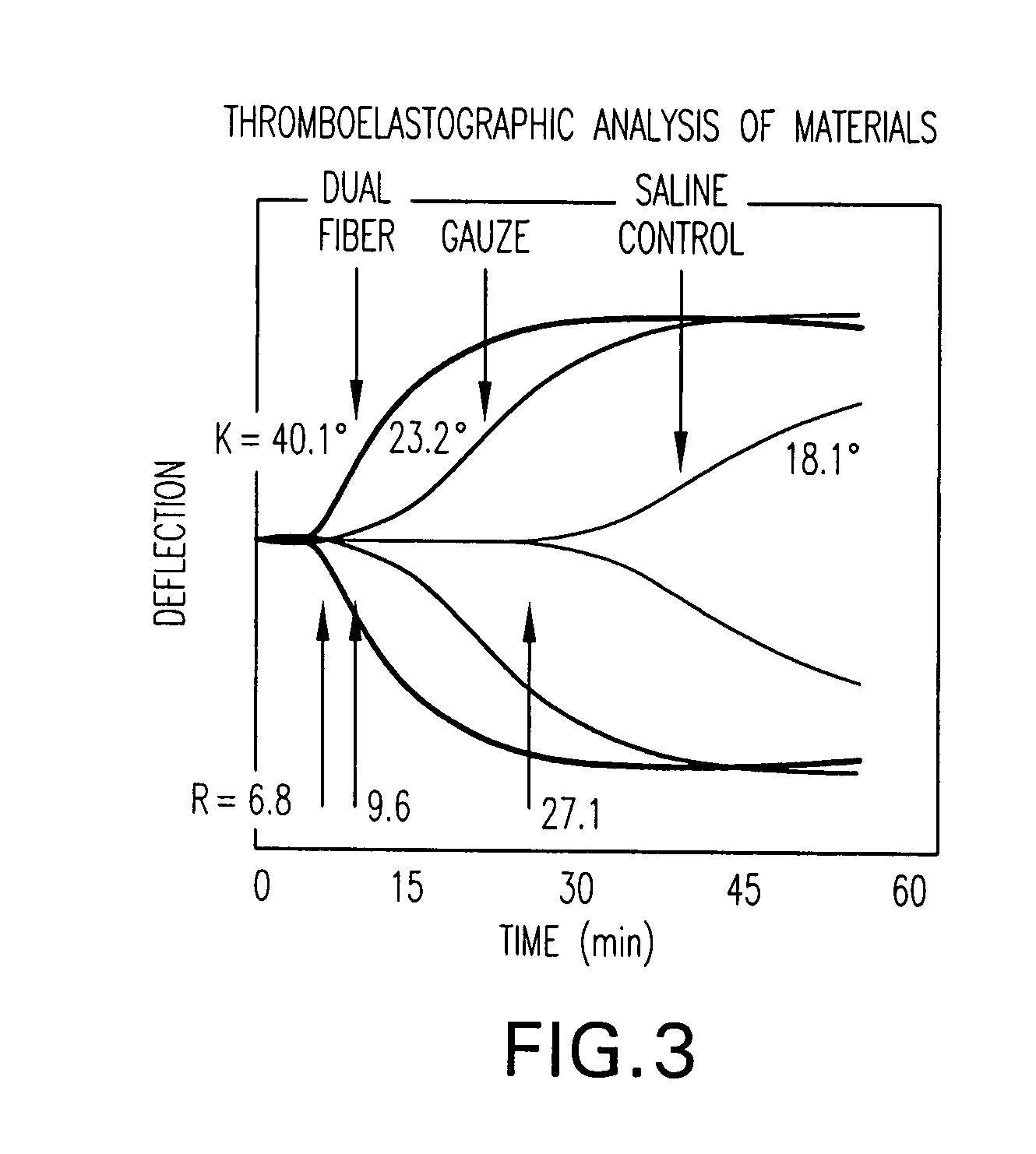

The present invention is directed to a hemostatic textile, comprising: a material comprising a combination of glass fibers and one or more secondary fibers selected from the group consisting of silk fibers; ceramic fibers; raw or regenerated bamboo fibers; cotton fibers; rayon fibers; linen fibers; ramie fibers; jute fibers; sisal fibers; flax fibers; soybean fibers; corn fibers; hemp fibers; lyocel fibers; wool; lactide and / or glycolide polymers; lactide / glycolide copolymers; silicate fibers; polyamide fibers; feldspar fibers; zeolite fibers, zeolite-containing fibers, acetate fibers; and combinations thereof; the hemostatic textile capable of activating hemostatic systems in the body when applied to a wound. Additional cofactors such as thrombin and hemostatic agents such as RL platelets, RL blood cells; fibrin, fibrinogen, and combinations thereof may also be incorporated into the textile. The invention is also directed to methods of producing the textile, and methods of using the textile to stop bleeding.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL +1

Technological process of ramie bast fiber

ActiveCN101824658AImprove processing uniformityImprove qualityCombing machinesDrafting machinesBiochemical engineeringCombing

The invention relates to a technological process of a ramie bast fiber, which comprises a basic degummed ramie production route: raw ramie skin-sorting and derooting-mechanical ungluing-cage loading-biological ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-radio frequency drying- degummed ramie. Long ramie can be growth through the mechanical hemp oiling- infiltration and health care-stretch breaking and carding-pre-gilling-combing and sorting-final gilling of the degummed ramie. Short ramie can be produced through the combing and the sorting of combed noil. Oakum can be produced through biological ungluing-high-temperature stewing and ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-dehydration and drying-radio frequency drying-mechanical hemp oiling- infiltration and health care-opening and edulcoration- combing and sorting. Improving methods are adopted for the mechanical ungluing, biological ungluing, high-temperature rinsing, sub-fiber washing, stretch breaking and carding, combing and sorting and the like. The preparation process has the advantages of short process, high production efficiency, high mechanical automation degree, stable product quality, excellent fiber quality and strong operability of fiber length and fineness, and can be used in the production processes of various bast fiber raw material, gramineae fiber raw material, leaf fiber raw material and other fibers.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

Method of preparing fiber for weave by peroxide degumming method

InactiveCN1924120APractical degummingPractical methodFibre treatment to obtain bast fibreHydrogenRamie

This invention relates to one fabric fiber method for oxidation glue removing, which uses ramie plant oxidation as oxidation agent and forms glue removing process liquid composed of chelant, hydrogen bonding destroy agent, anti-deposition agent, lignin removal agent and water under certain temperature for removing glue and bleaching. This invention can integrate glue removing and bleaching into one process for simplifying process.

Owner:DONGHUA UNIV

Plant restoration method for heavy metal pollution of soil

InactiveCN1593797AImprove extraction efficiencyNo secondary pollutionContaminated soil reclamationRestoration methodSoil heavy metals

Owner:SOUTH CHINA UNIV OF TECH

Ramie combine harvester

InactiveCN101518182AReduce impurityIncrease productivityHarvestersMechanical fibre separationEngineeringMechanical equipment

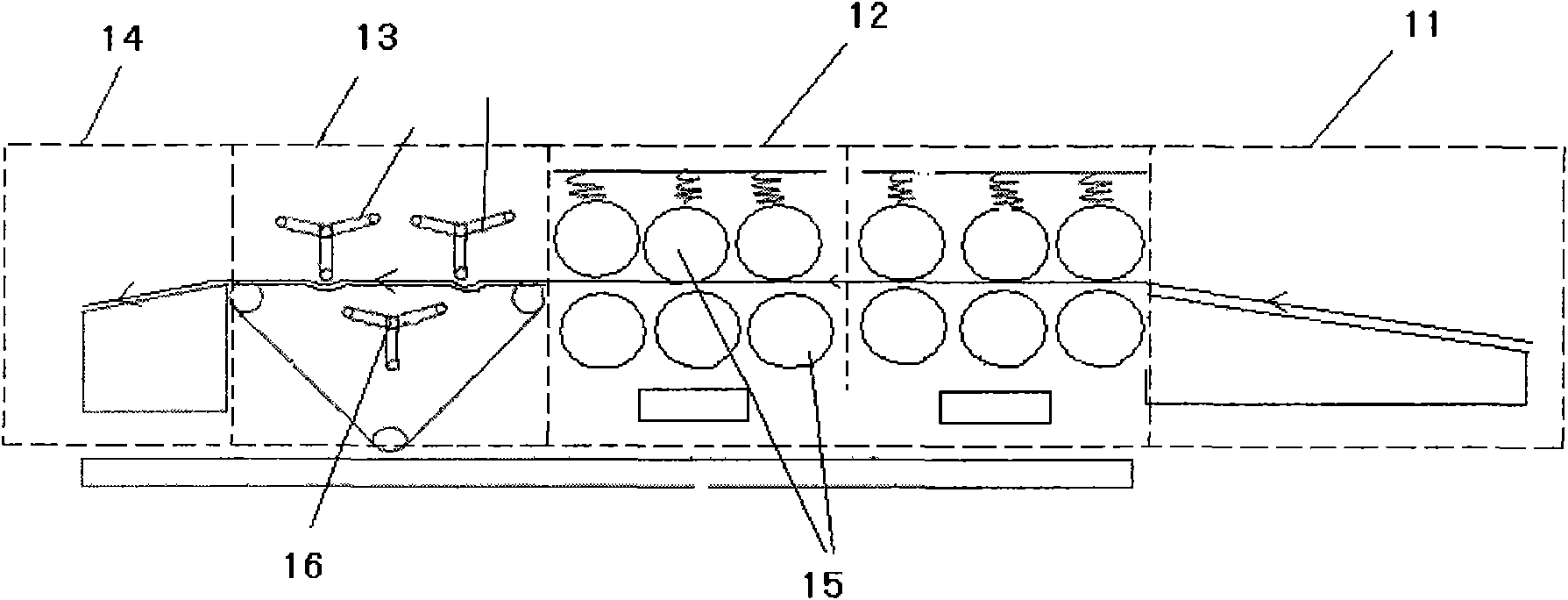

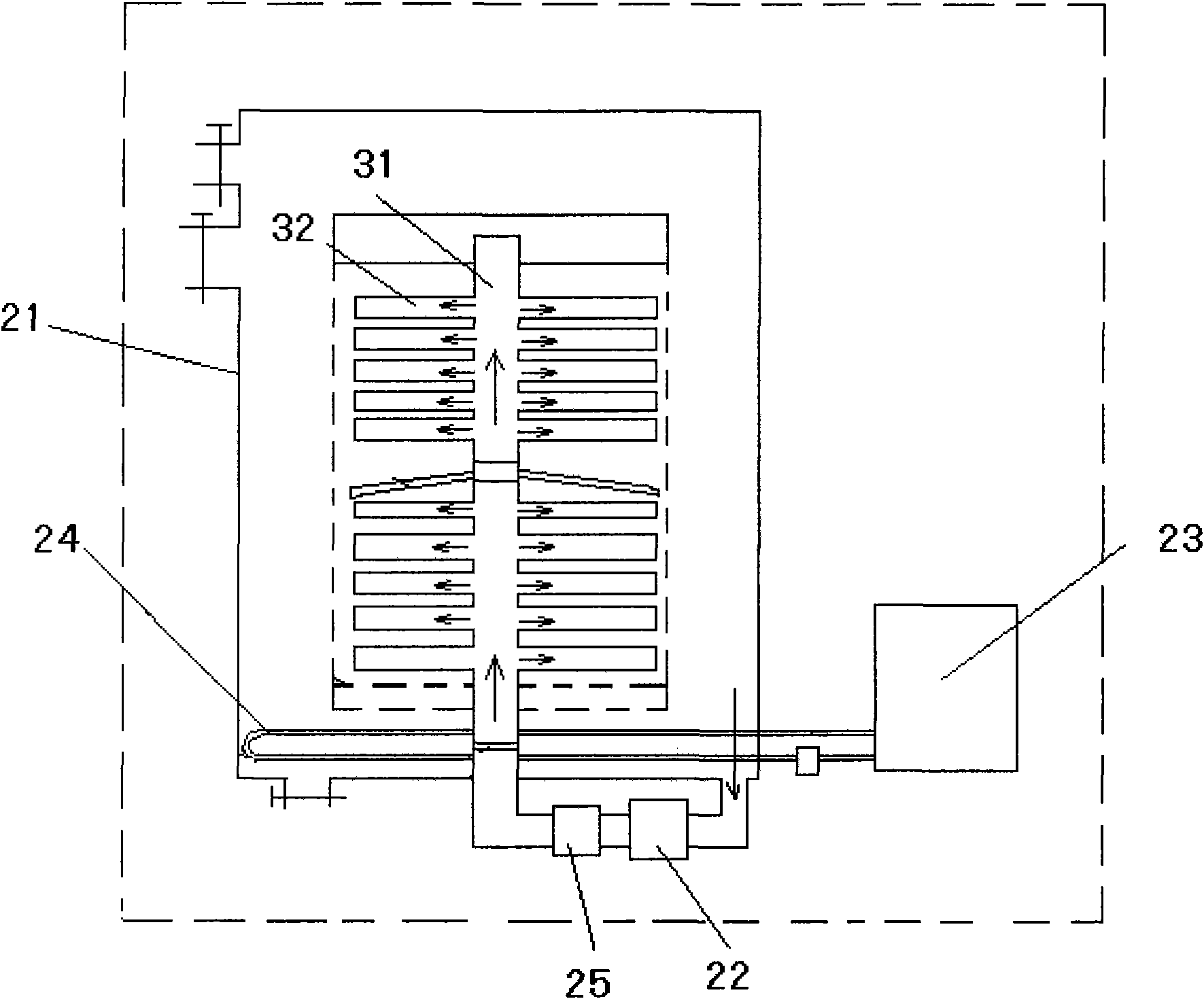

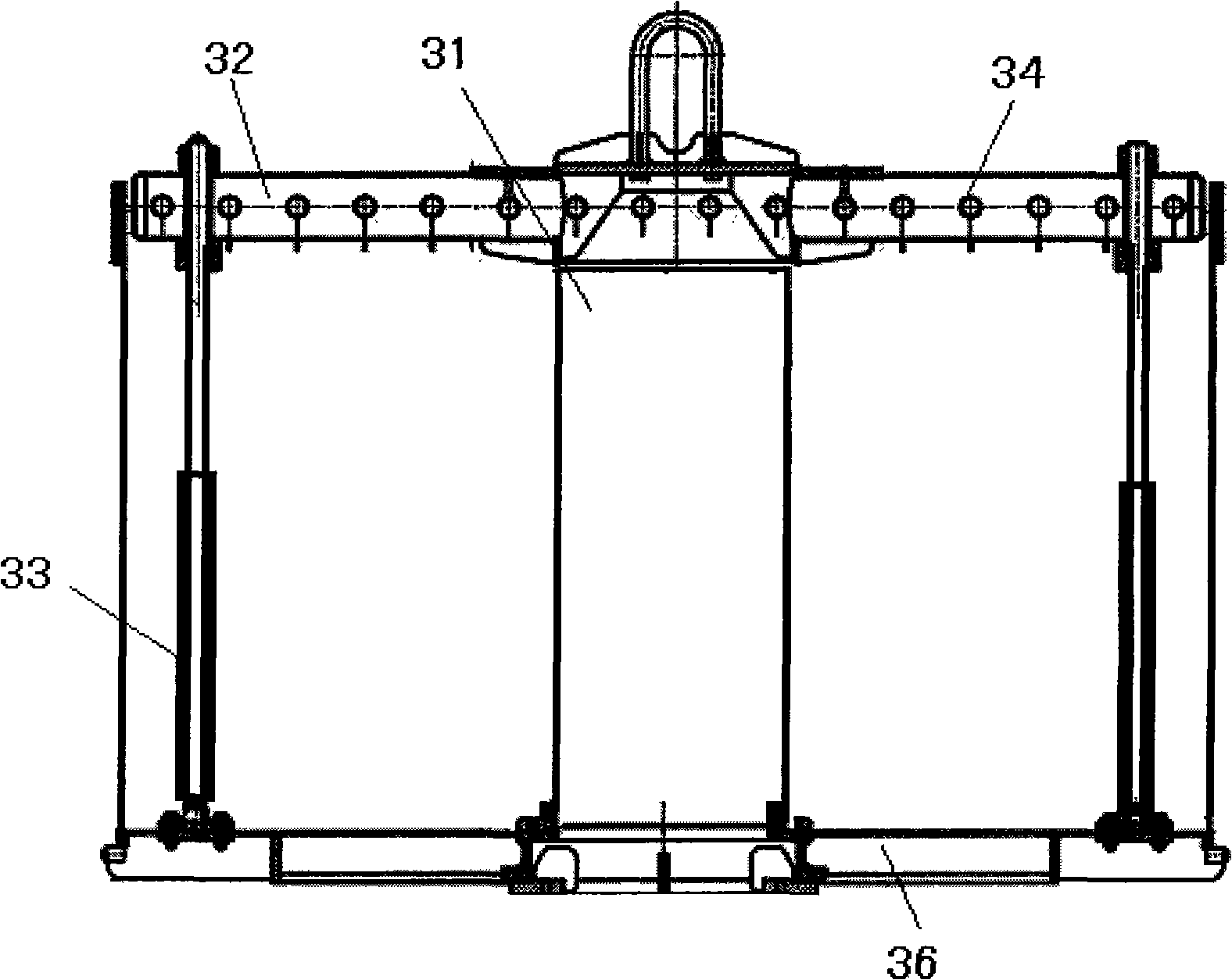

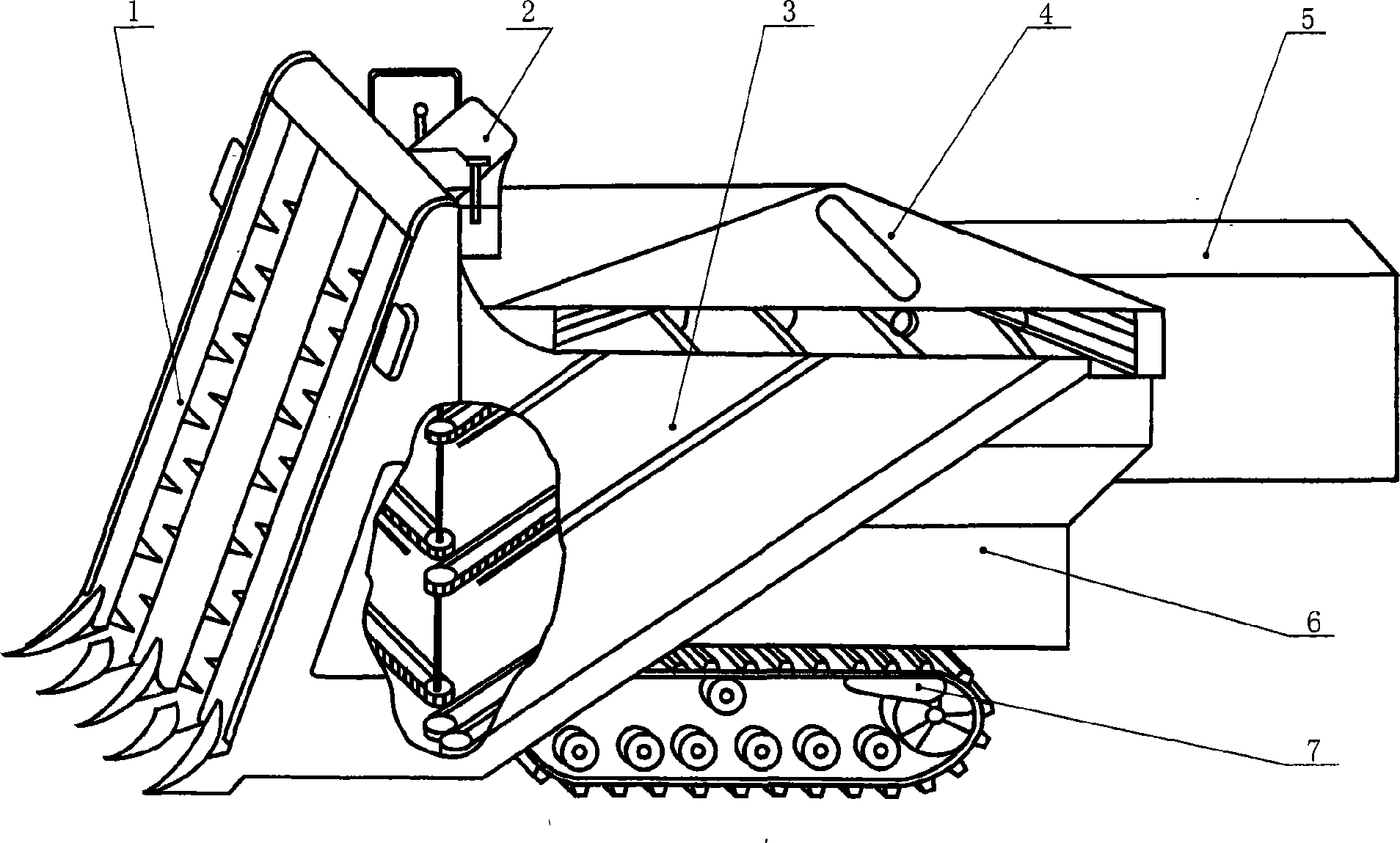

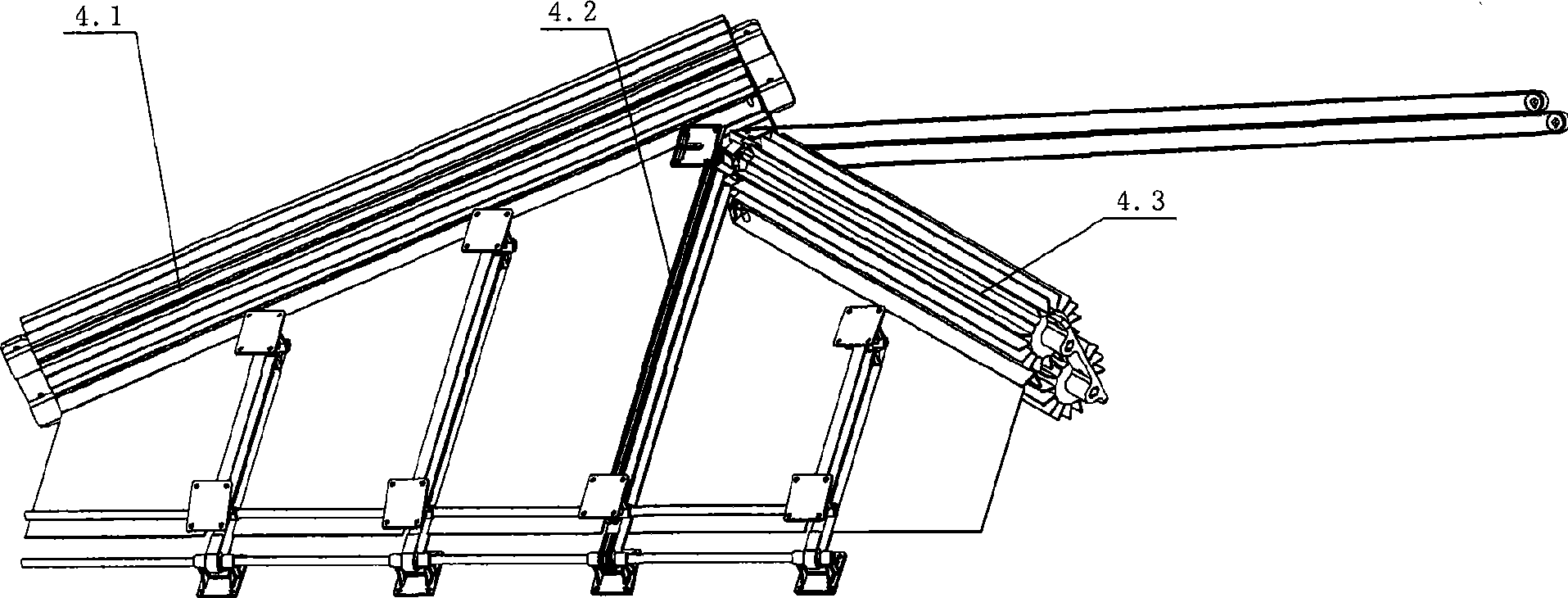

The invention relates to a ramie combine harvester which is applicable to combining harvest of ramie, namely completes ramie cutting and fiber primary processing by one time continuously, belonging to agricultural mechanical equipment. The ramie combine harvester consists of a vertical cutting table, an operating mechanism, a middle conveyor, a two-way automatic ramie removing machine, a mechanism which integrates ramie bin, power and transmission mechanism and a walking device. A bottom plate part is universal with a half head-feed grain combine harvester. A holding conveying belt is a synchronous belt; and the outer surfaces of the two belts are coupled with a longitudinal convex-concave bar groove, one belt at the inner side is a fixed support and the other belt is an elastic pressing support. The two-way ramie removing machine has two sets of ramie removing mechanisms at the front and back which are arranged in a reversed-V shape. After being cut, the ramie stalks are conveyed in a vertical and lateral mode, conveyed by a holding base part in a rotatable and upward mode, continuously fed into two sets of ramie removing mechanism for processing the base part and the tip part in a horizontal mode and the obtained ramie stalks are wound at a ramie blocking pin with an extruding and scratching machine at the tail ends of the ramie removing mechanisms, and the fiber is drawn, thus realizing removing of skin, skeleton and glue. The mechanical equipment has high production efficiency and good ramie removing quality and thoroughly solves the scutching difficulty which restricts the development of the ramie industry.

Owner:咸宁市农业机械化研究所

Process for the extraction and preparation of bast fibers, bast fibers obtained therefrom and their use

ActiveUS7481843B2Good bulkinessEasy crimpingBleaching apparatusDetergent compounding agentsYarnPolymer science

The present invention generally relates to a process for the extraction and preparation of bast fibers with high quality and high counts. The process is suitable for ramie, hemp and flax. The present invention also relates to bast fibers with high counts produced according to the process, as well as pure yarns and mixed, blended yarns made from said bast fibers.

Owner:XU MEIRONG

Manufacturing method of ramie based on sectioned circulation

ActiveCN101624727AGet rid of dependenceReduce dosageMechanical treatmentBacteriological rettingChemical treatmentCarding

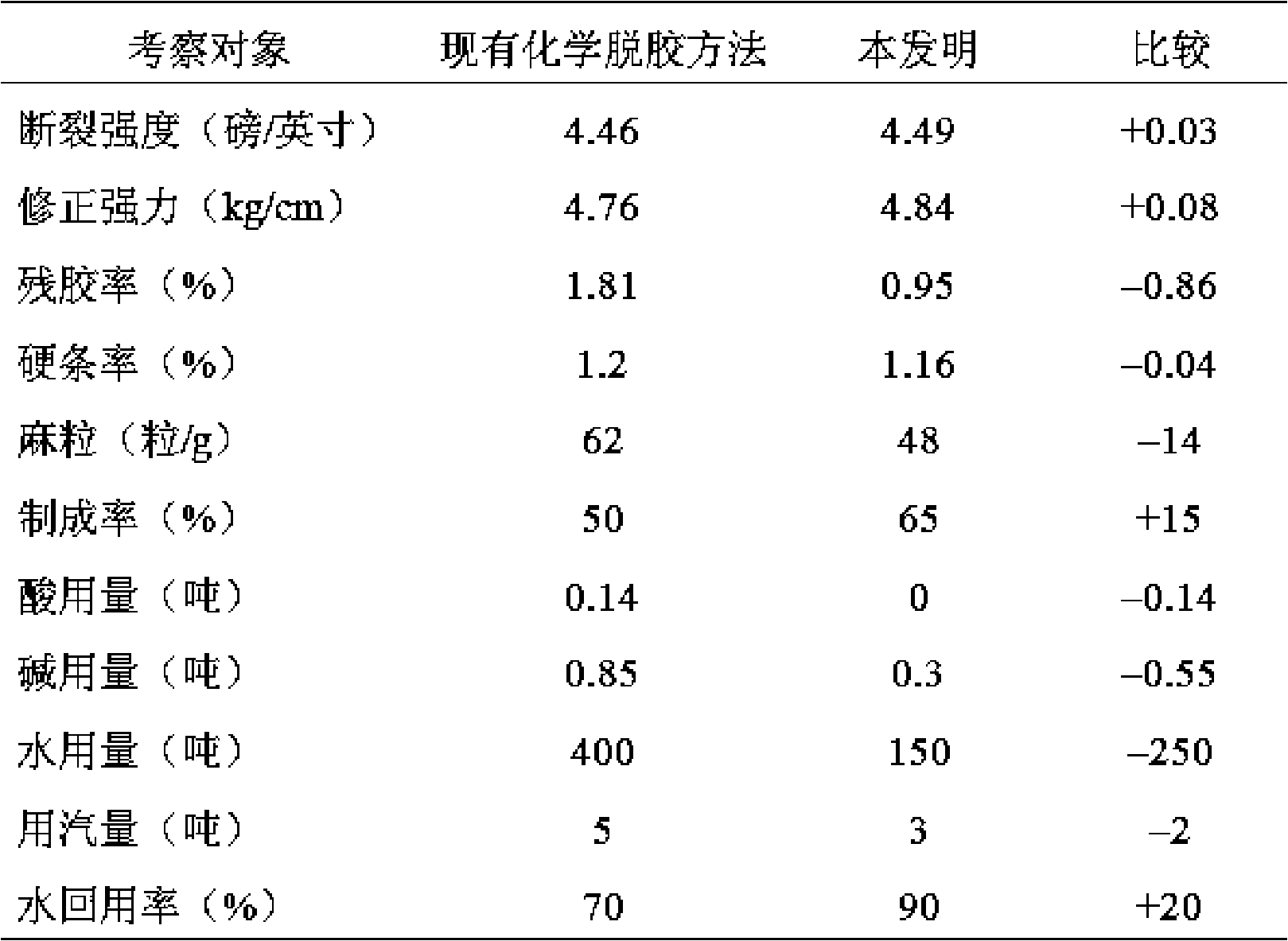

The invention discloses a manufacturing method of ramie based on sectioned circulation, belonging to the manufacturing method of textile fibre and solving the problems that the prior method has a large quantity of waste water, serious pollution and high cost. The method comprises following steps: pretreatment of primary ramie, chemical treatment, biological treatment and post treatment; the pretreatment improves the degree of looseness of the primary ramie through beating, ultrasound or extraction; the biological treatment degrades pectin, hemicellulose and others impurities through bio-enzyme or microbial fermentation; the chemical treatment further degrades residual pectin and others impurities through alkali boil-off; the post treatment obtains refined dry ramie by beating, whitening, water scrubbing, dehydration, oil feeding, drying, carding and baking. The quality of the product meets the requirements of first-class GB / T 20793-2006, the degumming yield rate is improved by 15%, the water consumption is reduced by at least 60%, the method is free from using acid, the alkali charge is reduced by 65%; water, the alkali and the bio-enzyme used in each step are recyclable; the byproducts can be recycled in time, the sewage quantity is small and the pollution level is low.

Owner:HUAZHONG UNIV OF SCI & TECH

Natural vegetable fiber reinforced fully-degradable polymer composite material and preparation method thereof

The invention refers to a full-degradable polymer composite material strengthened by the natural plant fiber and the preparing method. It adopts India plant fiber-Hildegardia populifolia, sisal fiber, ramee, wood fibre and so on as the fiber raw material, tand the degradable plastic-the poly-methyl ethyl carbonic acid resin as the basic body, and smelts and commixes the filling and the basic body on the existent / nonexistent condition of the coupling agent to make the composite material. The weight percent content of the fiber is 5-80%, the better fiber 10-40%.

Owner:SUN YAT SEN UNIV

Method for producing antimicrobial calcium alginate fiber

ActiveCN101381907AEvenly distributedImprove antibacterial propertiesAlginate artificial filamentsAbsorbent padsCalcium alginateMechanical property

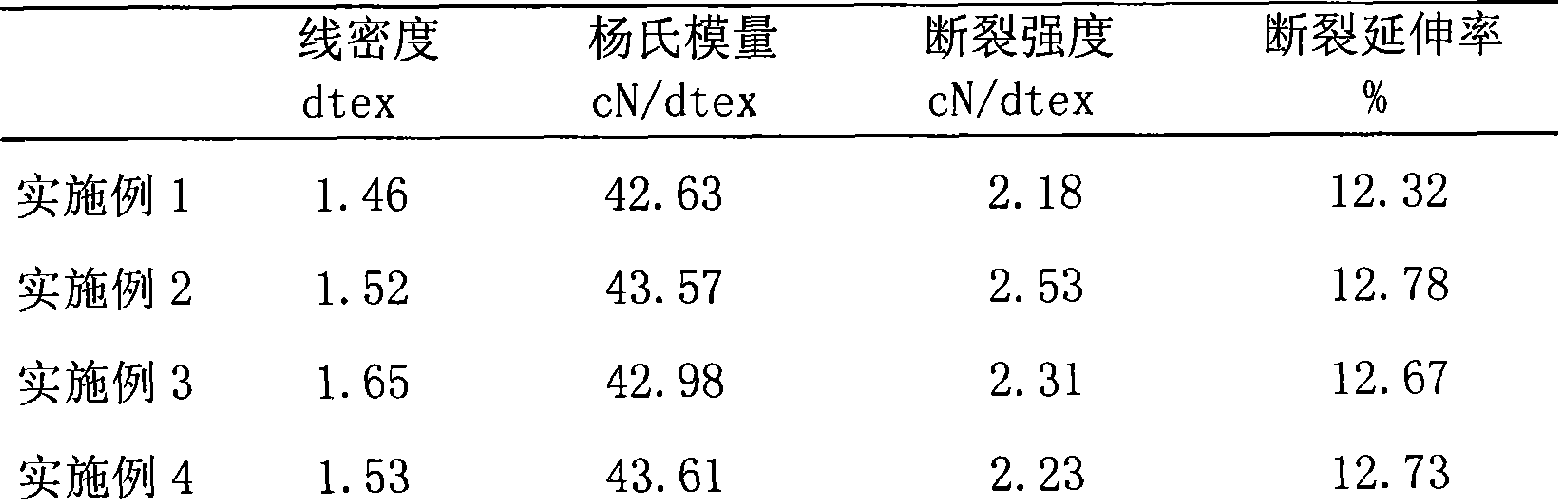

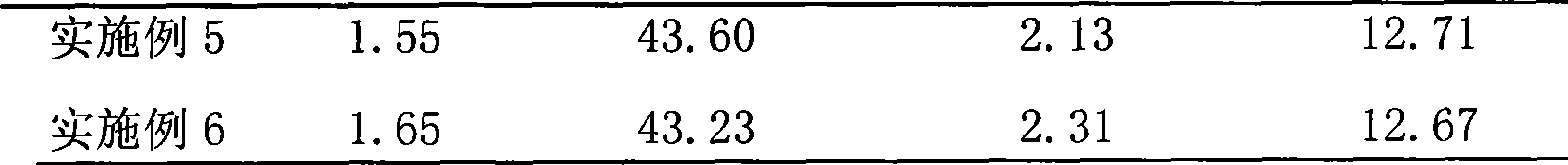

The invention discloses a method for manufacturing an antimicrobial calcium alginate fibre. A sodium alginate is used as spinning stock solution; in a solidification bath containing an antimicrobial agent, the antimicrobial calcium alginate fibre is obtained by a wet-method spinning process; and the antimicrobial agent is a cationic compound which is combined with large molecules of the calcium alginate fibre through ionic bonds. The antimicrobial calcium alginate fibre obtained by the method has no toxicity and no side effect on human body; the antimicrobial agent and the large molecules of the fibre are combined by the ionic bonds in order that the antimicrobial agent has long-lasting antimicrobial function; in addition, the fibre retains the excellent quality of the calcium alginate fibre, has excellent hygroscopic property and good mechanical property, can be used for manufacturing medical dressings, has the advantages of convenient use, comfortable application and good ventilation, the acceleration of the healing of wound, the relieving of the pains of patients and the like, can be also used for manufacturing clothing and industrial textiles by pure spinning or blended spinning with cotton, mucilage glue, bamboo pulp, fur, ramie, soybean protein fibre and the like.

Owner:山东康康新材料科技有限公司

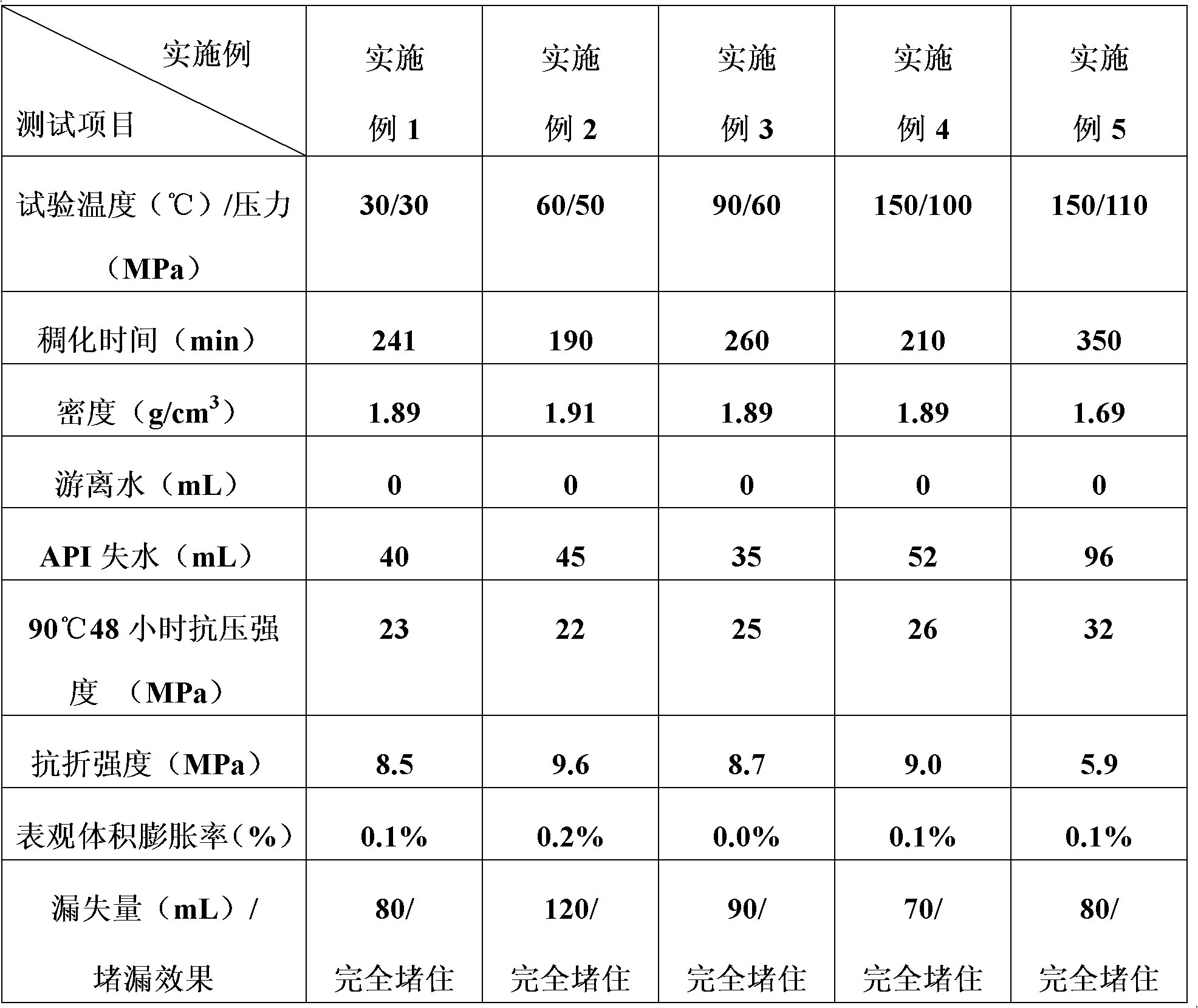

Leaking stoppage cement slurry for well cementation and preparation method thereof

InactiveCN101857800AGood high temperature application performanceEvenly dispersedDrilling compositionCementation processSodium sulfate

The invention relates to leaking stoppage cement slurry for well cementation and a preparation method thereof. The leaking stoppage cement slurry consists of the following components in parts by weight: 100 parts of oil-well cement, 50-150 parts of water, 0.01-8 parts of fibrilia, 1-20 parts of dispersing agent, 1-20 parts of filtrate reducer, 5-50 parts of alkali regulator, 1-10 parts of retarder and 0-1 part of defoaming agent, wherein the dispersing agent is lauryl sodium sulfate or sodium hexametaphosphate; the filtrate reducer is 2-acrylamide-2-methylpropanesulfonic acid or hydroxyethylcellulose; the alkali regulator is silicon powder; the retarder is sodium lignin sulfonate or citric acid; the defoaming agent is dimethyl silicon oil or tributyl phosphate; and the fibrilia is one or the mixture of two or more of jute, flax, hemp, ramie and sisal. The invention effectively solves the problem of leakage loss of cement slurry and inherent brittleness of set cement in the well cementation process on the premise of meeting various engineering performances required by the well cementation and provides the guarantee for subsequent operation of oil well gas.

Owner:SOUTHWEST PETROLEUM UNIV

Moisture-absorbing and perspiring anti-bacterial fabric and preparation technology thereof

InactiveCN105421055AImprove antibacterial propertiesSoft and wear-resistantBiochemical fibre treatmentLiquid/gas/vapor removalWater basedMoisture

The invention relates to a moisture-absorbing and perspiring anti-bacterial fabric and a preparation technology thereof. The moisture-absorbing and perspiring anti-bacterial fabric is blended and weaved by the following raw materials in parts by weight: 40 to 80 parts of bamboo fibers, 40 to 80 parts of long staple, 10 to 30 parts of ramie, 10 to 30 parts of coolmax fibers, 10 to 20 parts of corn fibers, 10 to 20 parts of Delight fibers, and 5 to 20 parts of Tancel, and then is treated by anti-bacterial finishing liquid; the anti-bacterial finishing liquid comprises 5 to 10 parts of chitosan, 5 to 10 parts of silk fibroin, 0.5 to 3 parts of butyl ricinoleate sodium sulfate, 0.5 to 3 parts of lemon acid, 0.5 to 2 parts of butyl methacrylate, 5 to 8 parts of dodecyl diphenyl ether sodium disulfonate, 5 to 10 parts of hydroxypropyl methyl cellulose, 5 to 10 parts of polyhexamethylene biguanidine, 5 to 15 parts of organosilicon quaternary ammonium salt, 3 to 8 parts of dodecyl trimethyl ammonium chloride, and 5 to 10 parts of water-based polyurethane. The moisture-absorbing and perspiring anti-bacterial fabric has the advantages that the anti-bacterial property is higher, the moisture-absorbing, perspiring, anti-pilling and air-ventilation properties are realized, the softness is realized, and the abrasion is resisted; the moisture-absorbing and perspiring anti-bacterial fabric is particularly suitable for being applied to the fields of underwear, overwear, sportswear and bedding articles.

Owner:杜名胜

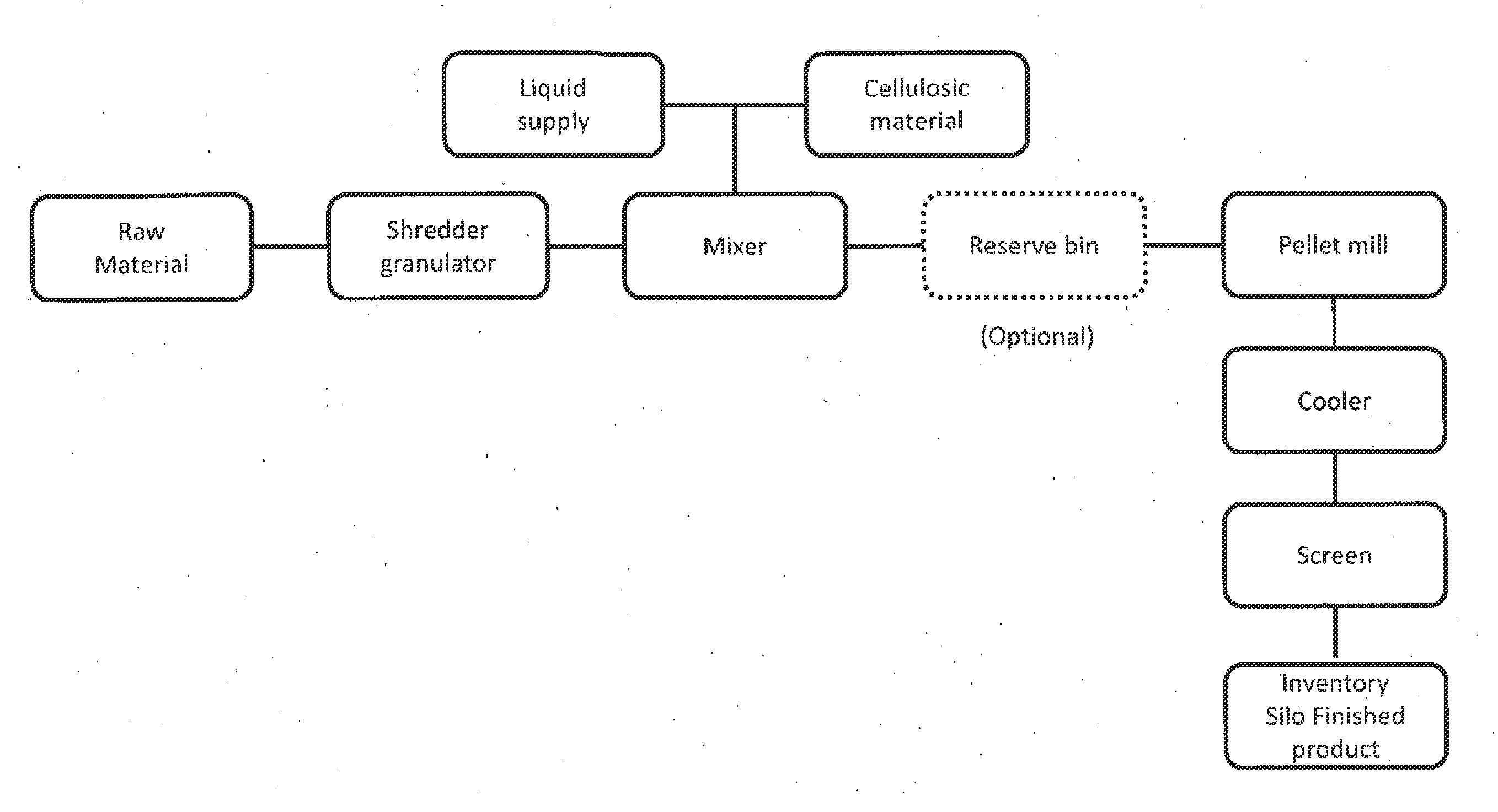

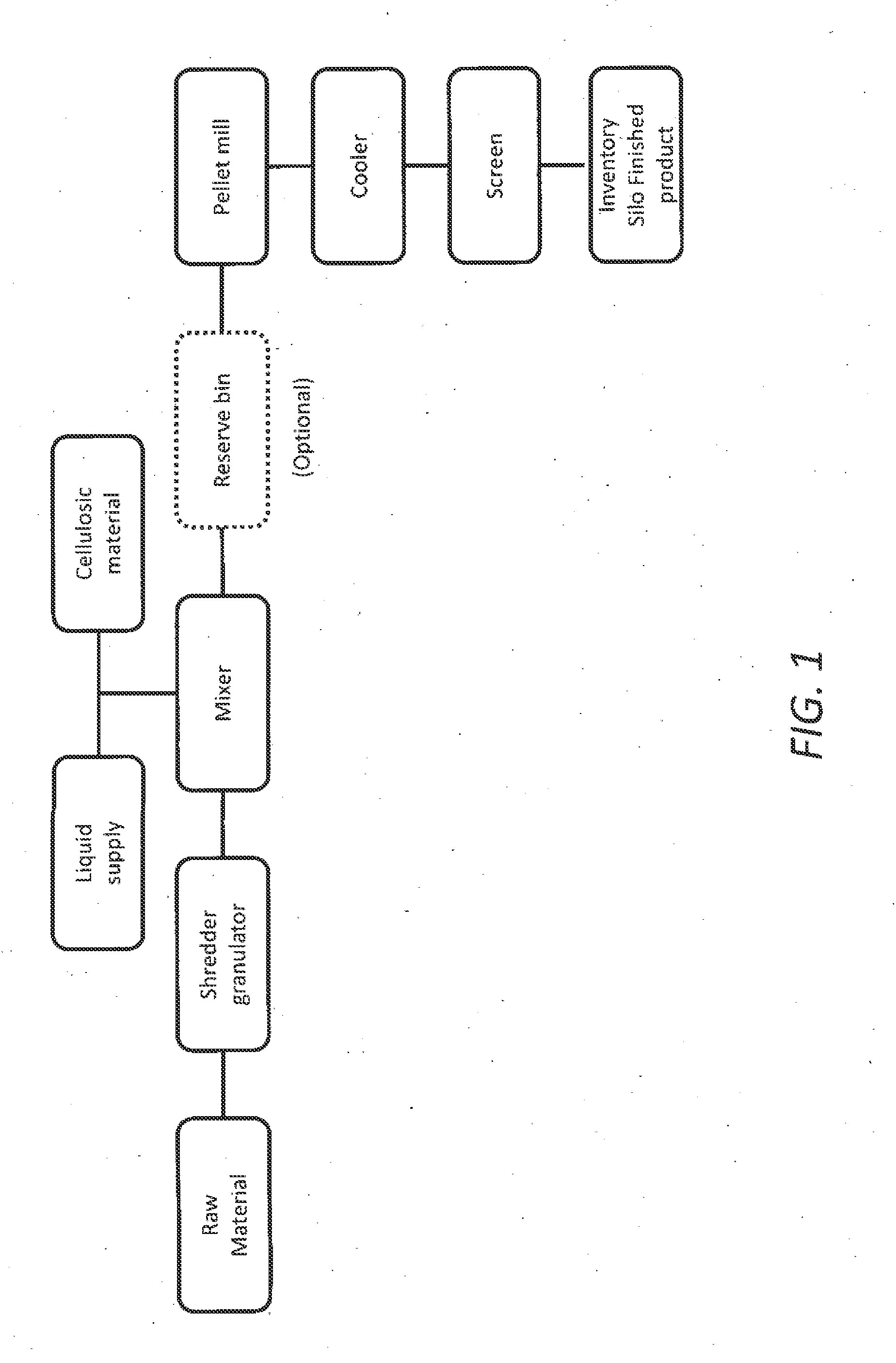

Multipurpose pellets and method of making same

A multipurpose pellet is provided comprising: from about 0.1% to about 100% by weight of a vegetable fiber chosen from cotton, bamboo fiber, rice fiber, esparto, papaya, coir, sisal, kapok, jute, ramie, flax, roselle hemp, hemp, kenaf, abaca, soybean fiber, okra fiber, vine fiber, banana fiber, rattan and nettlesjute; and from about 99.9% to about 0% by weight of cellulosic material.

Owner:LEFEBVRE ROBERT

Hemp fiber degumming boiling-off additive, preparing method and application thereof

InactiveCN101550607AConvenient lengthImprove finenessFibre treatment to obtain bast fibreWastewaterSURFACTANT BLEND

The present invention discloses a hemp fiber degumming boiling-off additive, a preparing method and the application thereof. The invention is characterized in that the additive is composed of two parts of organic surfactant and inorganic boiling-off additive. The additive I and the additive II are prepared through compounding the organic surfactant and inorganic boiling-off additive. Furthermore the additive I and the additive II are applied for the chemical degumming of raw hemp ramie. When the additive I and the additive II according to the invention are applied to the industrial process of chemical boiling-off degumming, not only are the xylogen content and residual adhesive rate reduced, but also the degumming effect is increased. Furthermore the boiling-off time is shortened. The dosage of NaOH and the discharge amount of polluted wastewater are reduced. Additionally, the adding of the additive according to the invention increases the whiteness and plasticity of degummed ramie. The hemp fiber degumming boiling-off additive has excellent application value.

Owner:TAIYUAN UNIV OF TECH +1

Bamboo fibre and ramie hemp blended yarn and production method thereof

InactiveCN101041916AEliminate the disadvantages of low count, poor spinnability, itchy wearing, etc.Easy to takeYarnYarnRamie

The invention discloses a blended yarn of bamboo fiber and ramie fiber, and relative production, characterized in that it uses bamboo fiber and ramie fiber as materials, while their ratio is 25-90:10-75 at 6s-23s to be prepared into bars and spin. The invention combines the characters of bamboo fiber and ramie fiber, to use the antibiosis, damp absorption characters of fiber, and eliminate the defects as lower ramie fiber number, bad spinning property and bad feeding, or the like, while the product can be used in knitted product and weaving product, with smooth and beautiful appearance.

Owner:湖南瑞亚高科集团有限公司

Bamboo fibre and ramie fibre mixed spinning fabric and method for production thereof

The invention discloses a blended face fabric and manufacturing method of bamboo fiber and ramie hemp, which is characterized by the following: adopting bamboo fiber and ramie hemp at 25-90:10-75 with 38-90 root per time for warp set, 34-80 root per time for weft density and 6s-32s count; slivering; spinning; warping, sizing; denting; weaving. The invention improves antibiotic, moisture-discharging property due to ramie, which is comfortable to wear.

Owner:湖南瑞亚高科集团有限公司

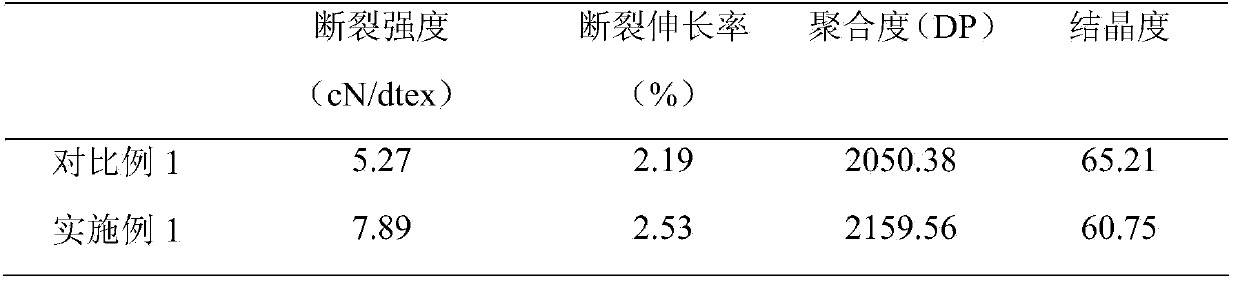

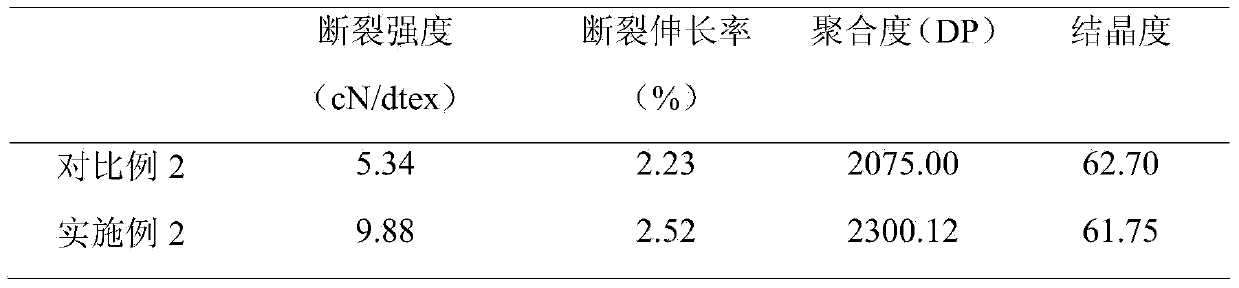

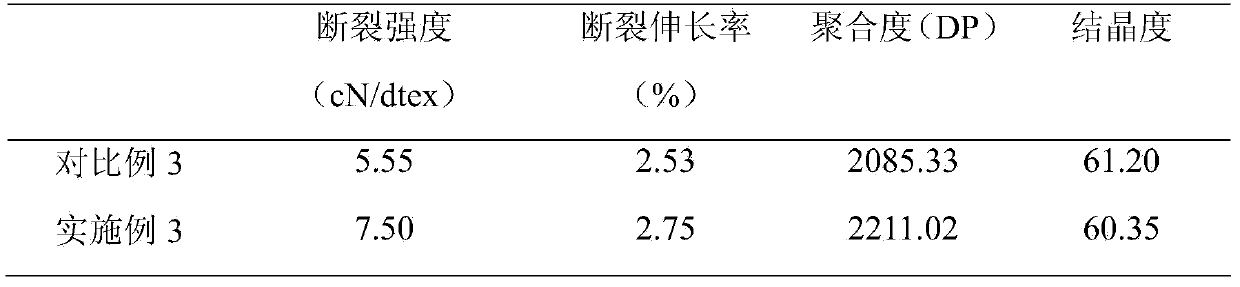

Method for enhancing property of ramie fiber through oxidative degumming

ActiveCN103993364AGood extensibilityHigh elongationFibre treatment to obtain bast fibreActive agentPhysical chemistry

The invention relates to a method for enhancing the property of a ramie fiber through oxidative degumming. The method comprises the following steps of mixing original ramie and a peroxide degumming solution according to mass ratio being 1 to 10, boiling for 40-60 minutes under the condition of 80-85 DEG C, wherein with respect to the weight percent of the original ramie, the peroxide degumming solution comprises the following components by weight percent: 1%-4% of sodium hydroxide, 3%-8% of peroxides, 0.5%-4% of quinones compounds, 1%-6% of a metal ion chelating agent, 2%-4% of a peroxide stabilizing agent, 2%-6% of a surface active agent and the balance being water; adding sodium hydroxide, boiling for 1-1.5 hours under the condition of 100 DEG C to obtain treated ramie; boiling the treated ramie and a reducing solution at 60-100 DEG C for 40-90 minutes, then applying oil, and drying. According to the method disclosed by the invention, needed degumming time is short and the efficiency is high and the bleaching and the degumming can be completed together; the prepared ramie fiber has good tensile property.

Owner:DONGHUA UNIV

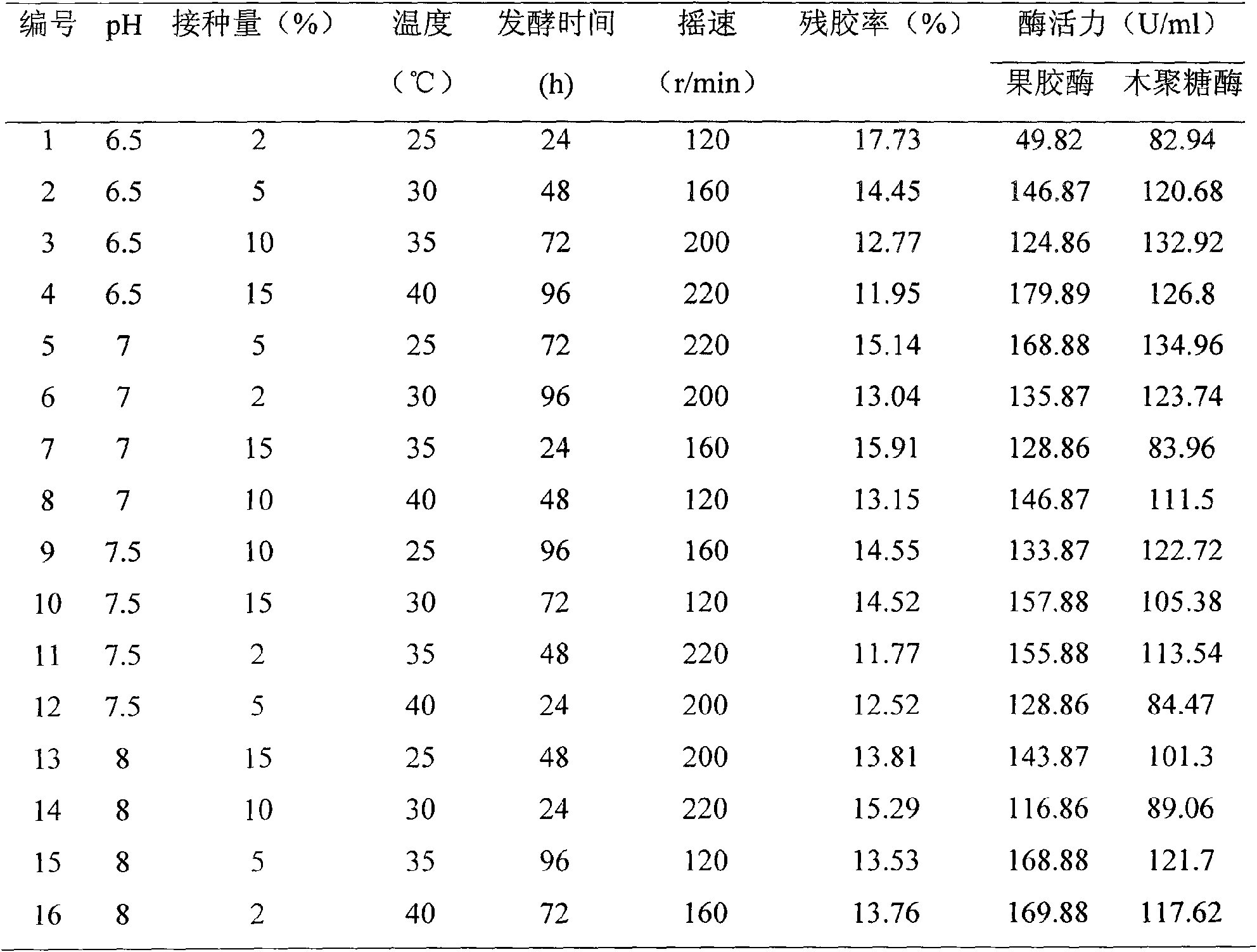

Industrial fermentation ramee rapid extraction technique for Erwinia

ActiveCN101235357AReduce technical difficultyImprove activation process parametersBacteriaMutant preparationAnimal ForagingHigh pressure

The invention discloses a technique for rapidly extracting ramie hemp erwinia bacterium factory production fermentation, the technique comprises preprocessing material, immersing or sprinkling and inoculating, immersing or fermenting, deactivating with hot water, and the procedure of circulation washing, water dressing and fiber finish, erwinia bacterium which has broad-spectrum and high effective to degumming, pulping and saccharifying of herb fiber material, and bacterial agent preparation and activated technical parameter. The erwinia bacterium addicts the mannose, the peak for secreting non-cellulose to degrade key enzyme (pectic enzyme, beta-mannase and xylanase) can be achieved through purely culturing for 7h to 9h. Bacterial agent is inoculated on herb fiber material such as ramie and the like for activating the bacterial agent for 5h-6h, fermentation forage fodder turns to blue after fermenting for 5h-6h, pectine, hemicellulose and partial lignin which are partially degraded and associated in fiber cell are stripped, non-cellulose residues which are absorbed on fiber can be removed by means of the flushing of high-pressure flushing, and the purpose of extracting net fiber can be reached.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

Processing method for cotton/hemp blended knitted fabric

InactiveCN101200845AEliminate internal stressReduce heavy metal contentWeft knittingBiochemical fibre treatmentYarnBoiling process

The invention discloses a processing method of cotton / ramie blended knitting fabric which adopts processing equipment of a cotton mill and adds yarn boiling and demineralizing processes before a weaving process. The whole technological process is from yarn boiling, demineralizing, weaving, mercerizing, bleaching and boiling, biological enzyme washing, and dyeing, softening, dehydration, width opening, drying and setting to preshrinking. The yarn boiling temperature in the yarn boiling process is 80 to 130 DEG C and the time is 10-30m. The demineralizing temperature in the demineralizing process is 30 to 90 DEG C and the time is 10-30m. In the demineralizing treatment, acid demineralizing agent and refining agent are used to remove heavy metal ions in cotton / ramie blended yarn. The invention has the advantages of ensuring the neat surface of the knitting fabric, comfort handle, light shrinkage and distortion and good durability with the added yarn boiling and demineralizing processes, eliminating the internal stress of the cotton / ramie blended yarn through the yarn boiling process, improving the toughness and the weaving efficiency of the knitting fabric, improving the insurance coefficient of the boiling and bleaching process through the demineralizing process and providing a guarantee for the strength of the knitting fabric.

Owner:宁波雅戈尔日中纺织印染有限公司

Polymeric materials incorporating core-shell silica nanoparticles

InactiveUS20110263037A1VersatileAnalysis using chemical indicatorsChemical analysis using titrationPolyesterCellulose acetate

Fibers, fabrics and textiles in which core-shell silica nanoparticles are incorporated are provided. The fibers, fabrics and textiles can be polymeric materials or natural cellulose-based or protein-based materials in which core-shell silica nanoparticles are incorporated. A variety of polymeric and natural materials can be employed, such as cellulose acetate, nylon, rayon, modacrylic, olefin, acrylic, polyester, polylactic acid, polylactic-co-glycolic acid (PLGA), polyurethane, aramid, wool, cotton, ramie, milk protein, soy protein, bamboo, etc. The core-shell silica nanoparticles can incorporate sensing, magnetic, thermal, electrical, chemical or RFID properties that can be imparted to the materials and that allow the materials to sense one or more conditions of interest, making them ideal for in situ sensing, treatment, or security applications.

Owner:CORNELL UNIVERSITY

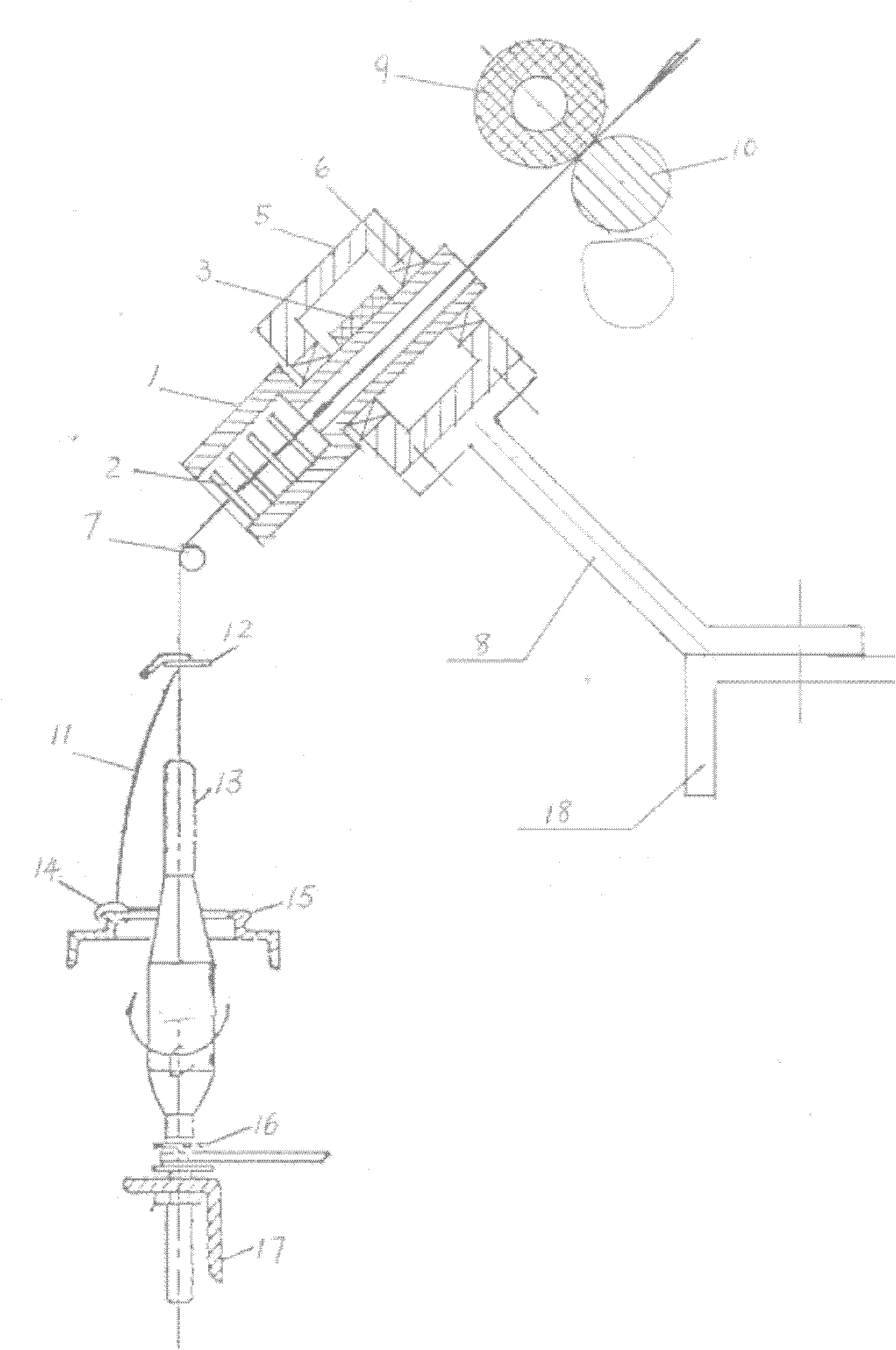

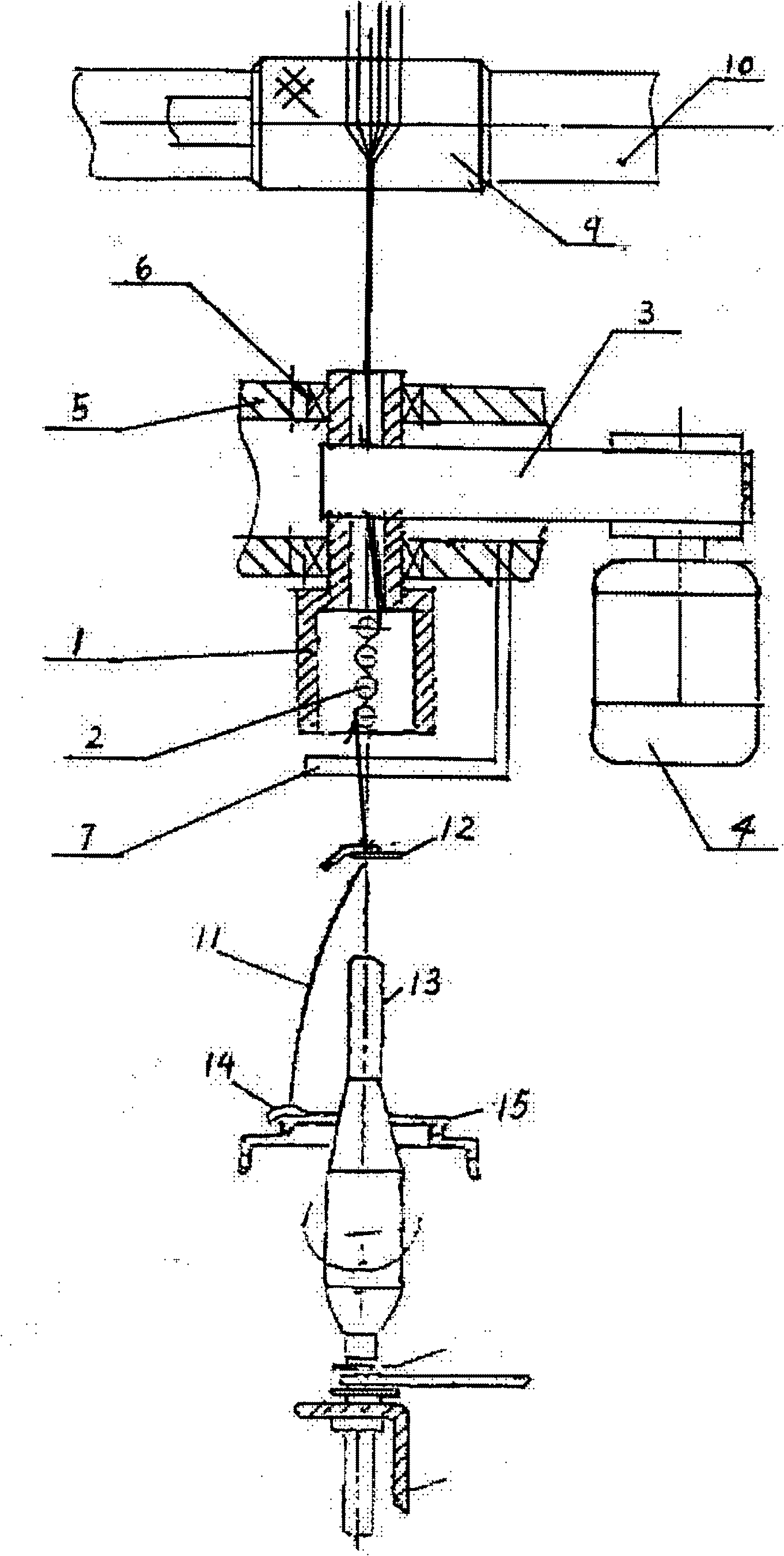

High-tenacity and low-tension spinning device

ActiveCN101892533AHigh strengthReduce spinning tensionDrafting machinesContinuous wound-up machinesEngineeringHardness

The invention relates to a high-tenacity and low-tension spinning device, which is used for ring spinners in textile industry. In the invention, a frame member is arranged along the length direction of a ring spinner in the middle of a spinning section between a front jaw and a yarn guide hook, a false twisting unit arranged corresponding to a spindle is fixed on the two borders of the frame member by two bearings and makes tangential transmission by a driving belt driven by a motor, and a yarn tension damping needle rod is arranged in the false twisting unit. By using the invention, the spinning tenacity is greatly improved, the spinning tension is reduced, and the spinning tension difference of large cop, middle cop and small cop is reduced, thereby realizing low-tension spinning; yarn filoplume is reduced, rubber roller is not wound by fibre frequently, and flyings are reduced, thereby improving spinning environment and spinning quality; heavy twist torsional moment is featured, the device can be applied to yarn with bigger hardness and cruder fibre, fibre material scope is enlarged, and raw material cost is reduced; and installation of the low-tension spinning device keeps the mechanism of the traditional ring spinners unchanged and is fit for modification of ring spinners for cotton / yarn / ramie / silk spinning.

Owner:SHANGHAI TEXTILE GRP DETECTION STANDARD CO LTD

High-efficiency multifunctional water-base fire resistant fluid and preparation method thereof

InactiveCN101560400AGood water solubilityImprove solubilityFibre treatmentPaper/cardboardWater basedPolyester

The invention provides a high-efficiency multifunctional water-base fire resistant fluid and a preparation method thereof. The high-efficiency multifunctional water-base fire resistant fluid is characterized by comprising the following raw materials in portion by mass: 10 to 20 portions of ammonium phosphate salts, 4 to 8 portions of boron compounds, 1 to 3 portions of tri-n-butylamine, 2 to 8 portions of glucose, 3 to 5 portions of tertiary amine, 3 to 5 portions of urea, 1 to 3 portions of penetrant, 1 to 2 portions of surfactant, 0 to 1 portion of softener and 40 to 80 portions of water. The high-efficiency multifunctional water-base fire resistant fluid has the characteristics of clearness, achromatism, transparency, neutrality, low smoke, non-toxicity, nonirritant, noncorrosiveness, low cost and high efficiency. Inflammable materials such as polyester-cotton blend, cotton fabrics, ribless corduroy, bourette, silk-ramie, knitgoods, canvases, paper sheets, cartons and the like with hygroscopicity become fire-resistant materials after being treated by the high-efficiency multifunctional water-base fire resistant fluid, and reach the fire-resistant B1 standard stated by the country. The high-efficiency multifunctional water-base fire resistant fluid can be widely used for top-grade indoor finishing such as curtains, carpets, wall paper, paper-based finishing, wooden furniture, ceiling and the like, simultaneously has the advantages of simple construction and low cost, is a new generation of high-tech environment-friendly product, and has wide market prospect.

Owner:KUNMING UNIV OF SCI & TECH

Method for treating soil heavy metal combined pollution

InactiveCN101797579AImprove conductivityPromote absorptionContaminated soil reclamationEnvironmental effectSoil heavy metals

The invention relates to a method for treating soil heavy metal combined pollution. Simultaneously the earthworms are bred and the ramie is planted in the soil. The part of the ramie on the ground is regularly harvested in the planting process of the ramie and the underground part of the ramie continuously grows so as to circularly harvest the part on the ground. The introduction amount of the earthworms is over 10,000. A repair method provided by the invention can realize the repair for the combined pollution of various heavy metals in the soil. Moreover, the method can maintain the long-term continuous plant in-situ growth repair. The used economic crops also can produce great economic value, cannot generate secondary pollution by the food cycle, achieves the win-win aim of the environmental effect and the economic benefit and is easy to popularize and use.

Owner:SUN YAT SEN UNIV

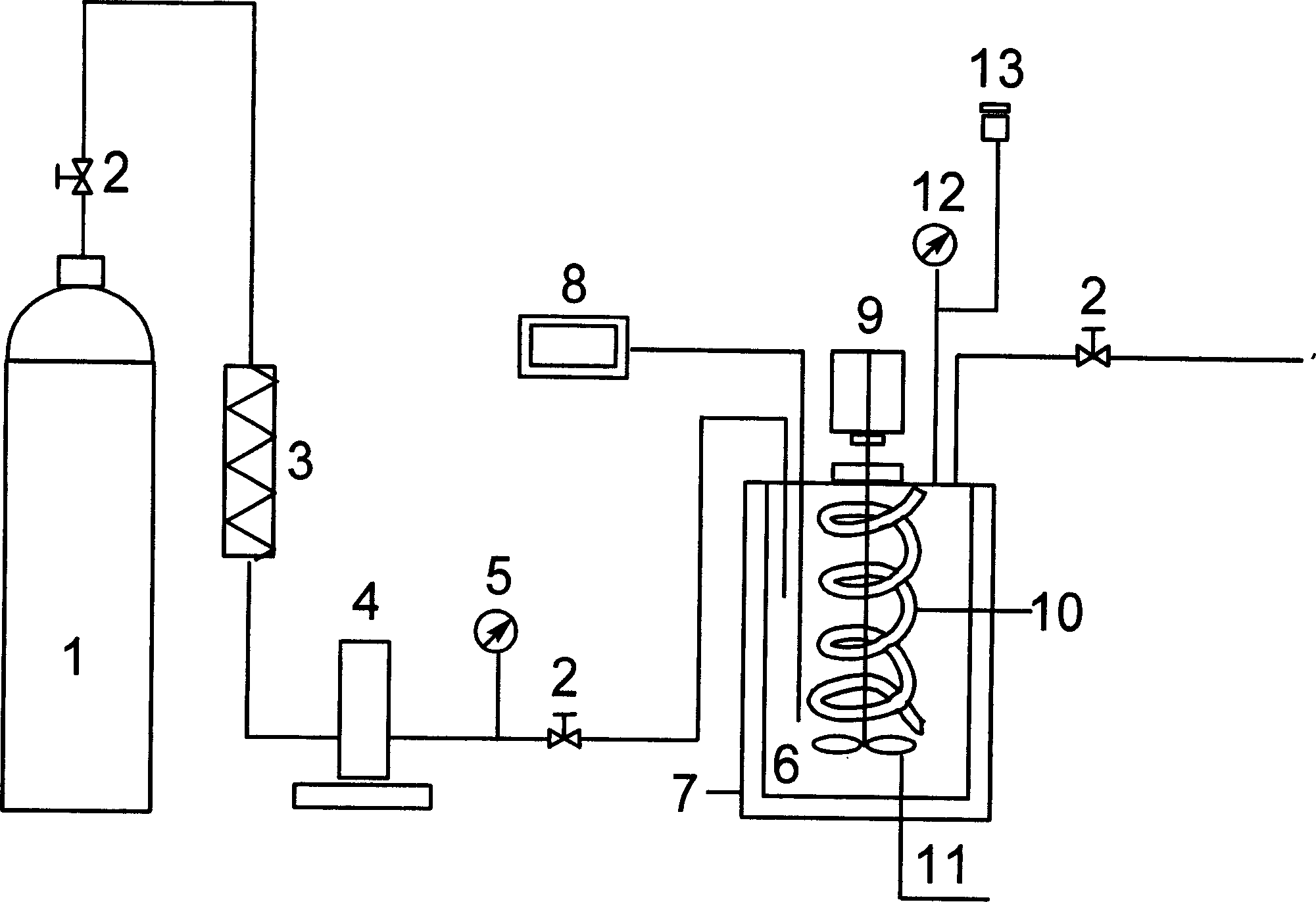

Technology for dyeing ramie fiber with overcritical carbon dioxide method

The invention relates to a new process of supercritical CO2 dyeing of ramie fiber, using ramie fiber as raw material, swelling by NaOH solution and modifying by benzoyl chloride, and dyeing with dispersive dye in supercritical CO2 medium by supercritical fluid technique. And its advantages: it is a clean producing process; the dyed ramie fiber has characters of bright color, short dyeing flow, dyeing uniformity, good color intensity, low synthetic cost, and remarkable economic and environmental protection benefits. And it also reveals a process device implementing the dyeing method, suitable to spread and apply in spinning and weaving, and printing and dyeing enterprises.

Owner:SHAANXI NORMAL UNIV

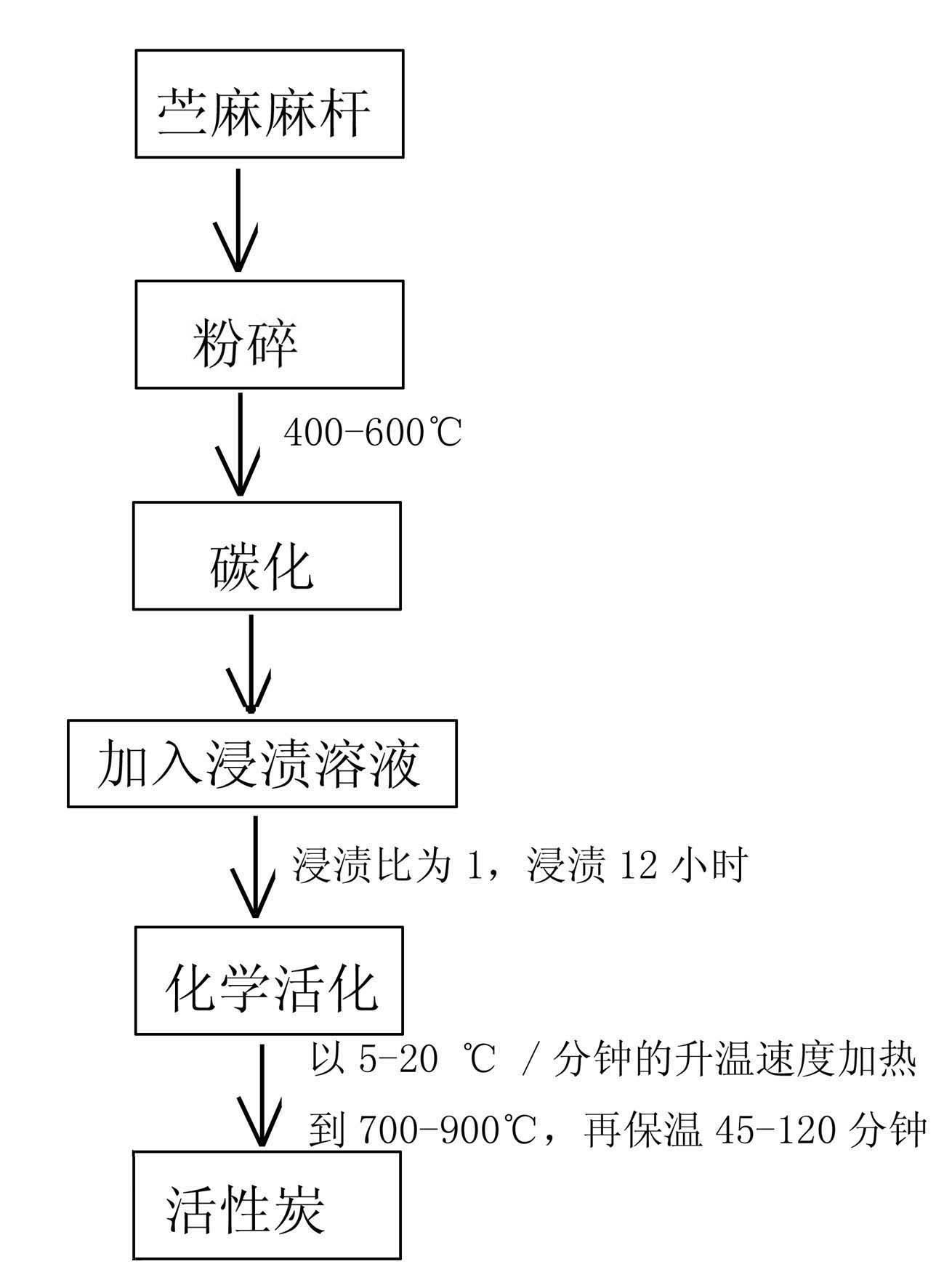

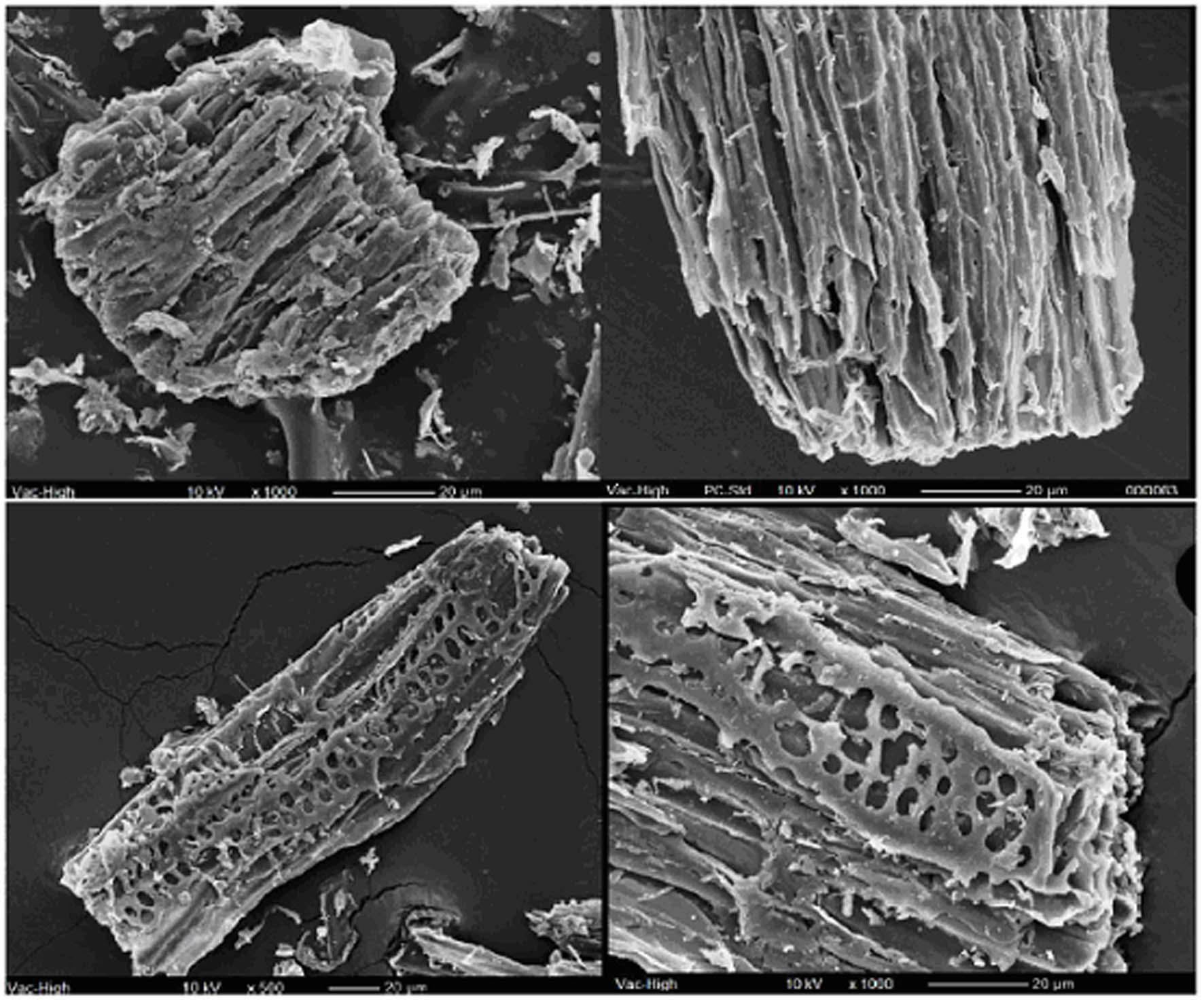

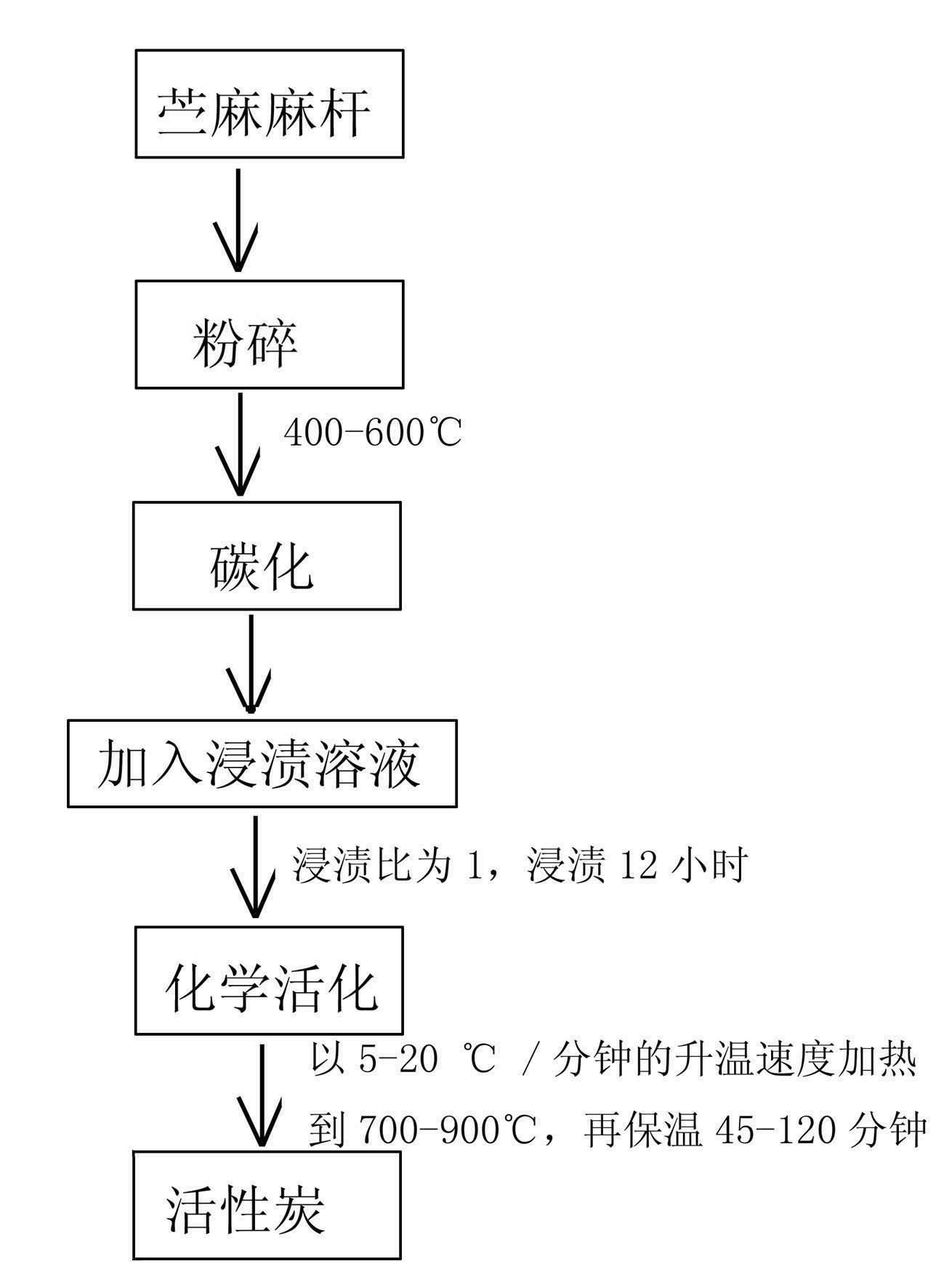

Method for preparing active carbon from ramie stalks

The invention relates to a method for preparing active carbon from ramie stalks. The method is simple, economical and environmentally-friendly, and the obtained active carbon has well-developed mesopores, high iodine adsorption value and high methylene blue adsorption value. The method comprises the following specific steps of: (1) smashing ramie stalks into particles of between 50 meshes and 200 meshes, carbonizing at the temperature of between 400 DEG C and 600 DEG C for 60-120 minutes, cooling to room temperature and extracting the particles out to obtain primary carbon; (2) putting the primary carbon into a soaking solution with the concentration of between 30 percent by mass and 70 percent by mass for soaking in the soaking ratio of between 1 and 4 for 12 hours, and dehydrating by using a centrifuge to obtain ramie stalk carbonized particles; and (3) putting the carbonized particles into a tubular carbonization furnace, heating to 700-900 DEG C at the temperature raising speed of between 5 DEG C per minute and 30 DEG C per minute, preserving heat for 45-120 minutes, cooling to room temperature, extracting the carbonized particles out, neutralizing with acid or alkali, cleaning with pure water until the pH value is between 6.5 and 7, and drying to obtain active carbon taking the ramie stalks as a raw material.

Owner:WUHAN TEXTILE UNIV

Forage suitable for growth of hybridized boars

The invention discloses forage suitable for the growth of hybridized boars. The forage is made by the following raw materials by weight percentage: 40-50% of concentrated forage and 50-60% of green forage, wherein the concentrated forage consists of corn flour, rice bran, wheat bran, corn lug cakes, bean pulp and tofukasu; and the green forage consists of one or more of alligator alternanthera, grassiness, ramie leaves, ryegrass, grain tree leaves, sweet potato vines and leaves, kudzu roots, vines and leaves and mulberry leaves. The forage is good in palatability; active ingredients of the forage can be preserved effectively; immune functions of the hybridized boars can be improved; the consumption of the concentrated forage can be reduced; and the cost is saved. The hybridized boars fed by the forage are good in growth vigor and shining in hair; the characteristics of the original boar meat such as less fat, high nutrition value and rich venison are kept; and the boar meat is safe and reliable to eat, meets the requirements of people on green pork, and has greater competitiveness in the market. In addition, the forage is wide in raw material source and low in cost; and food can be saved.

Owner:钱信美

Semi-durable ramie nonwoven material for home textiles and production method thereof

InactiveCN102220674AGood for healthImprove protectionPattern makingNon-woven fabricsUltraviolet lightsNonwoven fabric

At present, natural fibrilia non-woven fabric materials are partial to a heavy type, and are mainly applied to the field of materials for automobiles, but the application of the natural fibrilia non-woven fabric materials to the field of home textiles is limited. The invention provides a semi-durable ramie nonwoven material for the home textiles, which comprises a matrix material and a surface modification layer formed by padding the matrix material in finishing liquid, wherein the matrix material comprises the following components in percentage by mass: 80 to 90 percent of ramie combed noil fibers and 10 to 20 percent of polylactic acid bi-component fibers; the finishing liquid comprises the following components in percentage by mass: 97.5 to 99.4 percent of polyacrylate bonding agent, 0.2 to 1.5 percent of hydrophilic organic silicon softening agent and 0.1 to 0.5 percent of penetrating agent; and the thickness of the ramie nonwoven material for the home textiles is between 0.5 and 1.5 millimeters, and the weight is between 60 and 120 grams / square meter. The semi-durable ramie nonwoven material has the functions of light weight, thinness, washability, antibacterium, acarid prevention, static resistance and ultraviolet light prevention, is soft in handfeel, and can be degraded completely after being discarded.

Owner:JIAXING UNIV

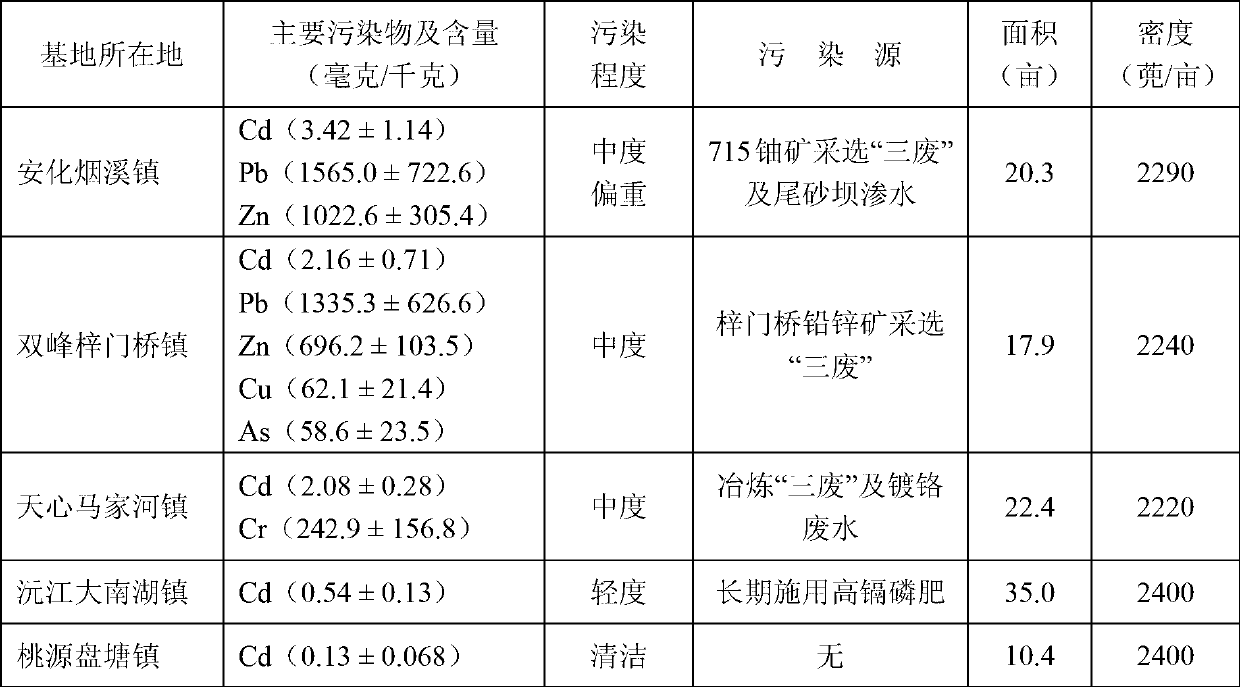

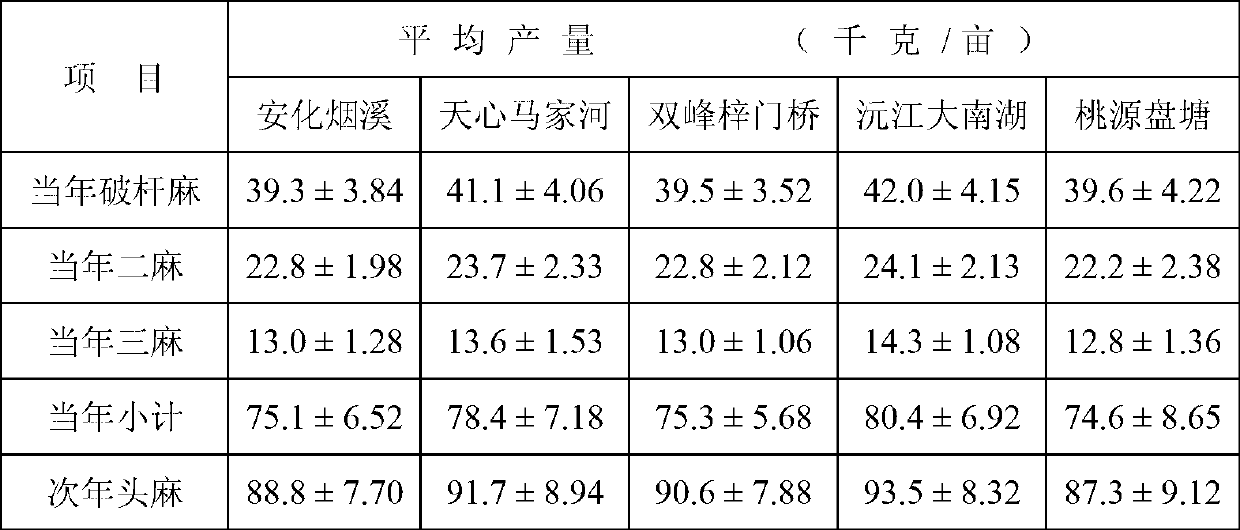

Method for planting ramie in middle-level heavy metal contaminated soils

ActiveCN102919040AStrong resistance to heavy metal pollutionNormal growth cycleHorticultureHigh resistanceShoot

The invention discloses a method for planting ramie in middle-level heavy metal contaminated soils. The method comprises the following steps: A, selecting a specific variety of ramie with high resistance against heavy metal contamination and cultivating strong ramie seedlings by using a young shoot cottage propagation technique; B, constructing a ramie garden and applying a passivator to reduce the activity of heavy metal in soils; C, transplanting in right time and carrying out rational close planting; D, scientifically carrying out cross dressing and cracking stems in right time; and E, preventing and controlling insect disease prevention in time and strengthening winter cultivation management of the garden. Practical results show that the yields of the newly planted ramie garden in the current year and the next year are respectively 75.1-78.4kg / mu and 88.8-91.7kg / mu which are the same as or even higher than those of the newly planted ramie garden with clean soils at the same term; moreover, the heavy metal content of raw ramie can be controlled in a range specified in related standard, and the safe and efficient agricultural utilization of middle-level heavy metal contaminated soils is realized. The method is simple and convenient in technique and easy to implement; moreover, the effect of the method is even higher if applied to the mild heavy metal contaminated soils. The method has a broad application prospect in mass areas with heavy metal contaminated soils.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

Environment-friendly braking friction material and preparation method thereof

The invention provides an environment-friendly braking friction material containing natural plant fiber, natural mineral fiber, natural mineral powder and cardanol-based benzoxazine modified phenolic resin and a preparation method thereof. The natural plant fiber is one or a plurality of flax, ramie, jute, hemp and sisal processed by a chemical method (alkali and acid) and a physical method (high-pressure steam), the natural mineral fiber comprises needle-like limestone and basalt fiber, and the natural mineral powder comprises zircon, barite, vermiculite and graphite. The invention also provides a preparation method of the natural mineral powder and cardanol-based benzoxazine pellet and a preparation method of cardanol-based benzoxazine in-situ toughening phenolic resin.

Owner:BEIJING UNIV OF CHEM TECH

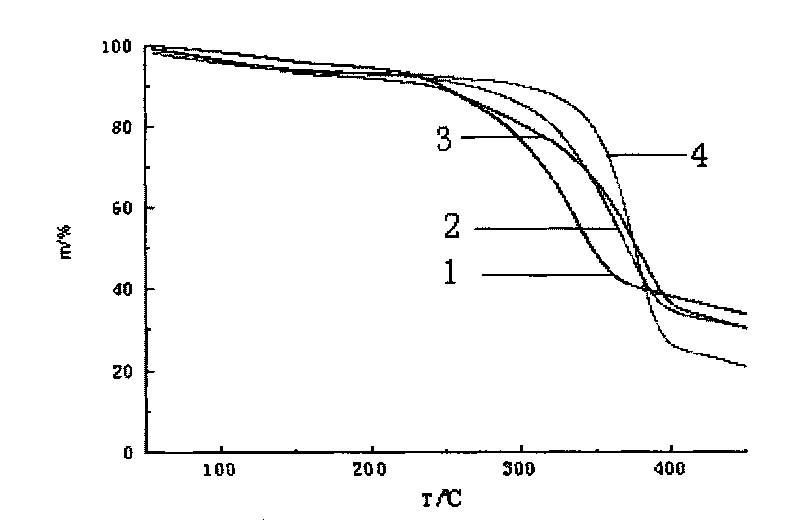

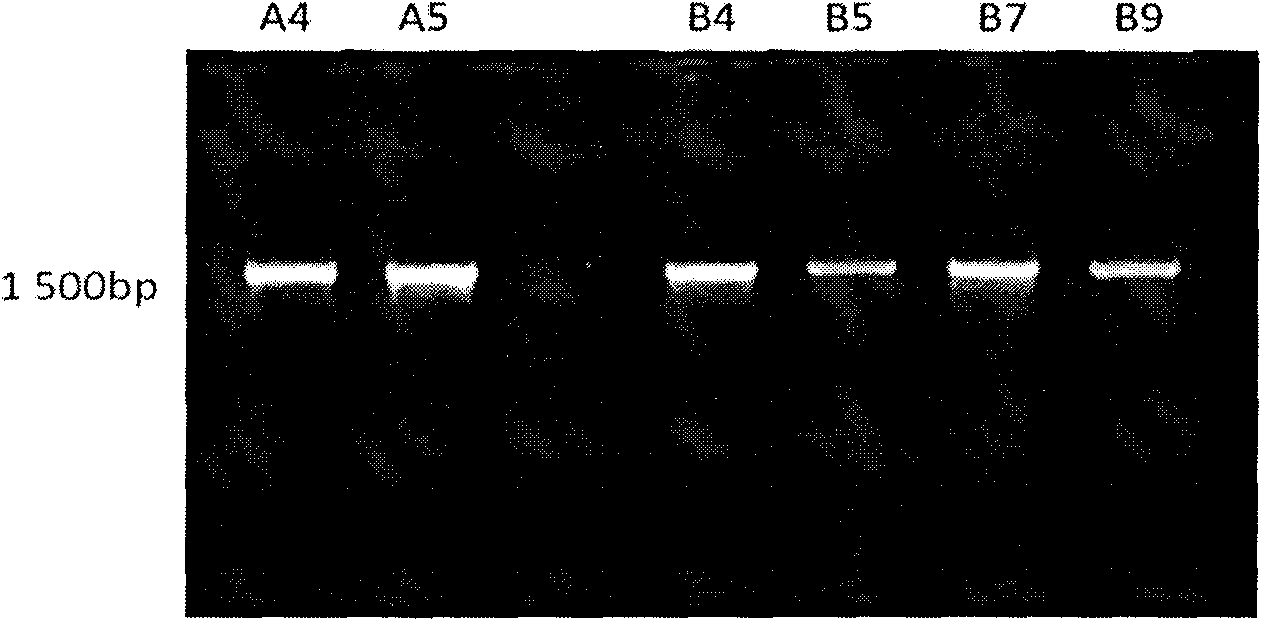

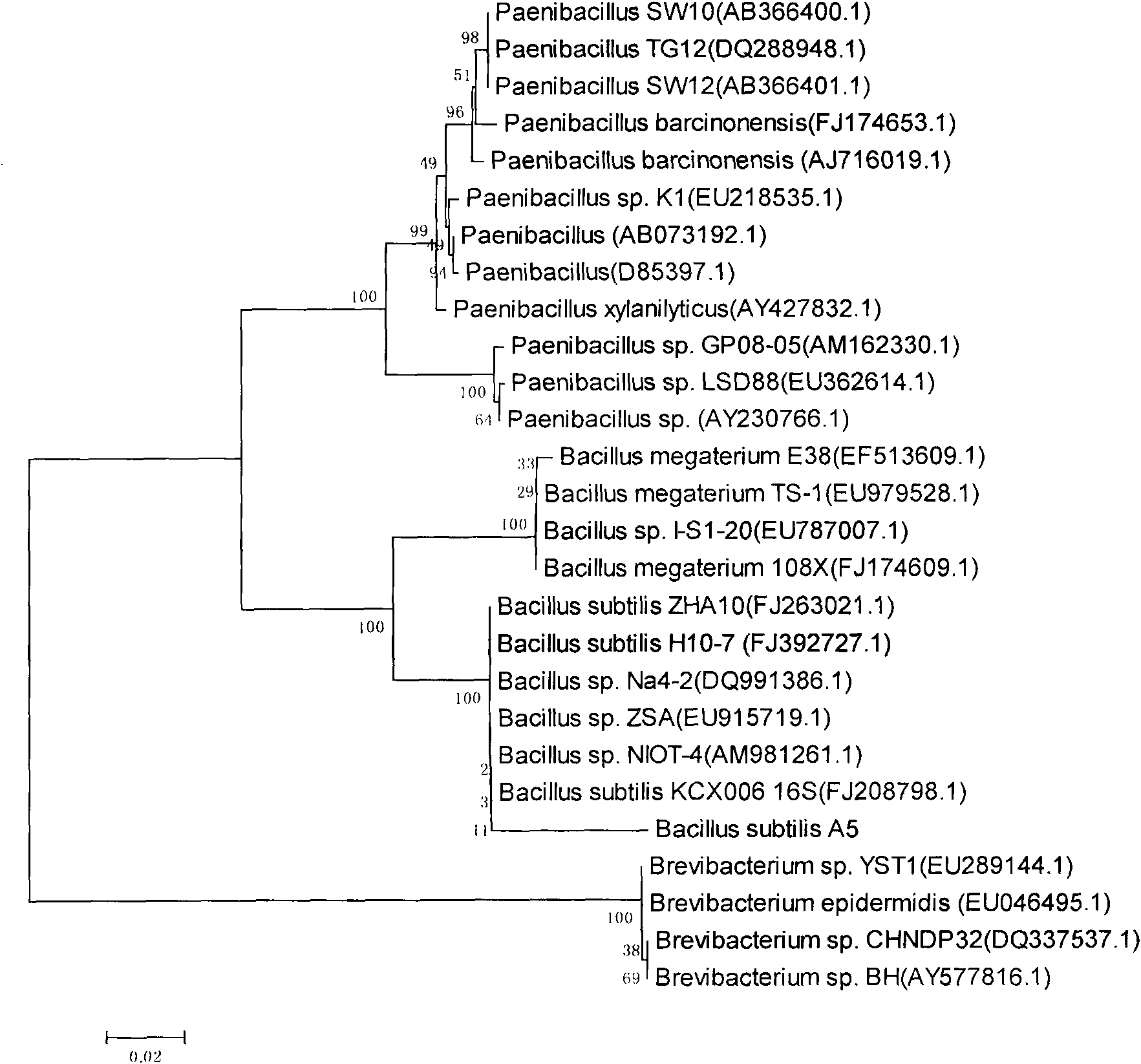

Bacillus subtillis strain containing ramie degumming activity, preparation and application thereof

InactiveCN101654660ANot easy to polluteNo pollution in the processBacteriaMicrobiological testing/measurementPectinaseBiotechnology

The invention relates to a bacillus subtillis strain containing ramie degumming activity, preparation and application thereof, which uses a system taking the strain as the core for ramie degumming. The strain of the system has high reproductive rate, high yield of pectase and xylanase, short production period, strong contamination resistance and favorable heat-resistant quality. The system and thecultivating process are safe to operate, have no toxicity and pollution no environment. Compared with the prior art, the invention has simple technology, is suitable for large-scale industrial production and the like. When the system is used for ramie degumming, degumming time is short, the dispersion coefficient of ramie fiber can reach 100%, degumming ratio can reach above 90%, and the qualityof refined dry ramie can reach the standard of chemical degumming.

Owner:DONGHUA UNIV

Method for preparing micro-fibrillated nanocellulose by use of degummed ramie

InactiveCN103938477ALow priceReduce negative impactPaper material treatmentDistilled waterUltra fine

The invention relates to a method for preparing micro-fibrillated nanocellulose by use of degummed ramie. The degummed ramie is used as a raw material and is crushed into short fibers by a physical-mechanical method, then the short fibers are soaked with distilled water, and then are prepared into cellulose pulp by a beating machine; the cellulose pulp is ground continuously in a reciprocating manner by an ultra-fine refiner to enable the cellulose to be stressed in a refining manner to obtain suspension liquid; and finally, the nanocellulose and water are separated by a centrifugal washing method, and drying is carried out by a vacuum freezing method to finally obtain the powdery micro-fibrillated nanocellulose. The method is simple, has high efficiency, raw material price is low, no chemical agent needs to be added, the energy consumption is low, pollution is slight, the control is easy, and the prepared micro-fibrillated nanocellulose has high yield, good repeatability and good performances and has important scientific significance and considerable application prospect.

Owner:DONGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com