High-tenacity and low-tension spinning device

A low-tension, high-strength technology, applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problem of increased yarn breakage, improved ring-spun yarn quality, and ring-spun yarn Problems such as strong and weak rings can be solved to achieve the effect of reducing spinning tension fluctuations, reducing phenomenon and fly, and improving the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

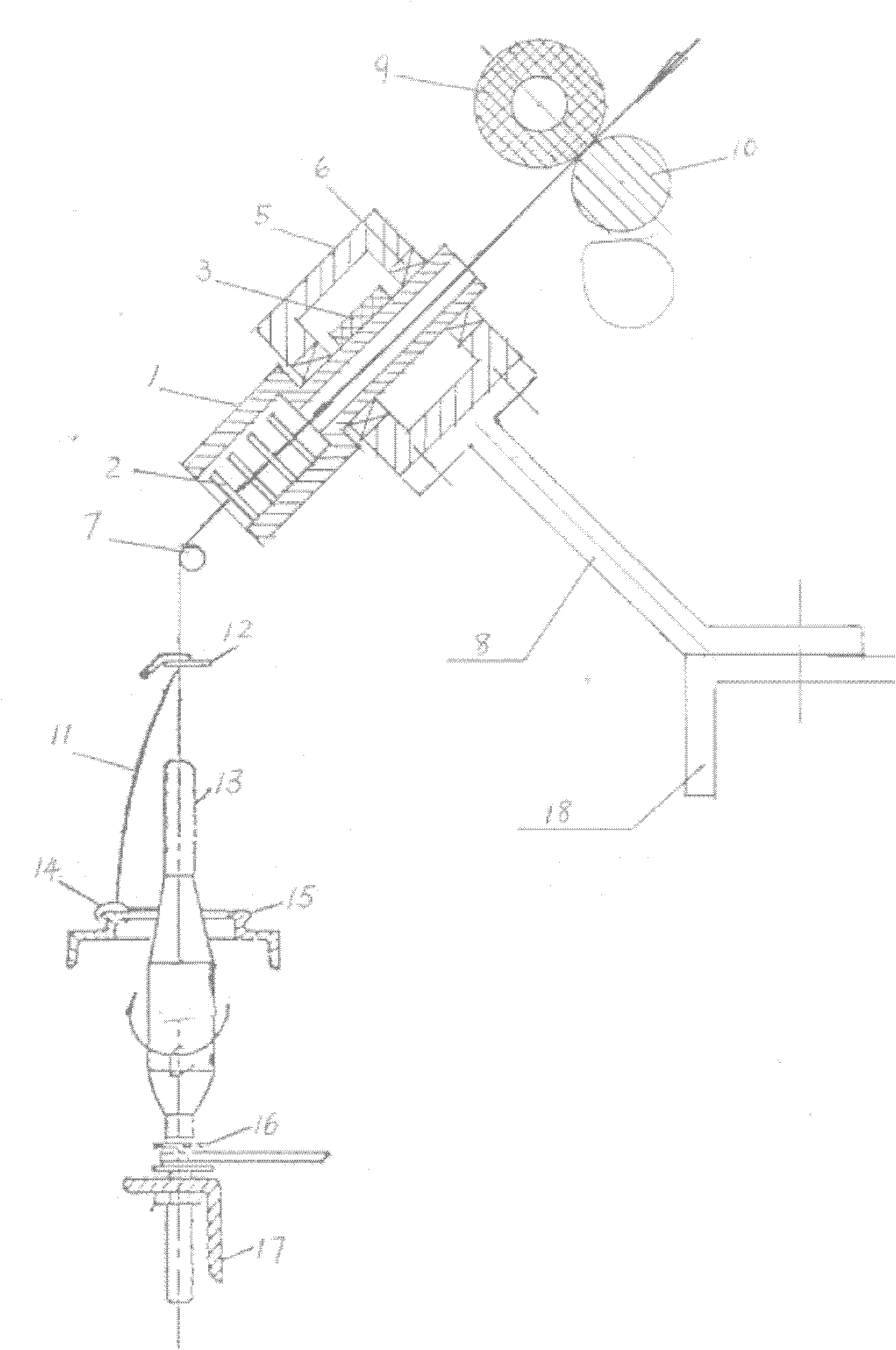

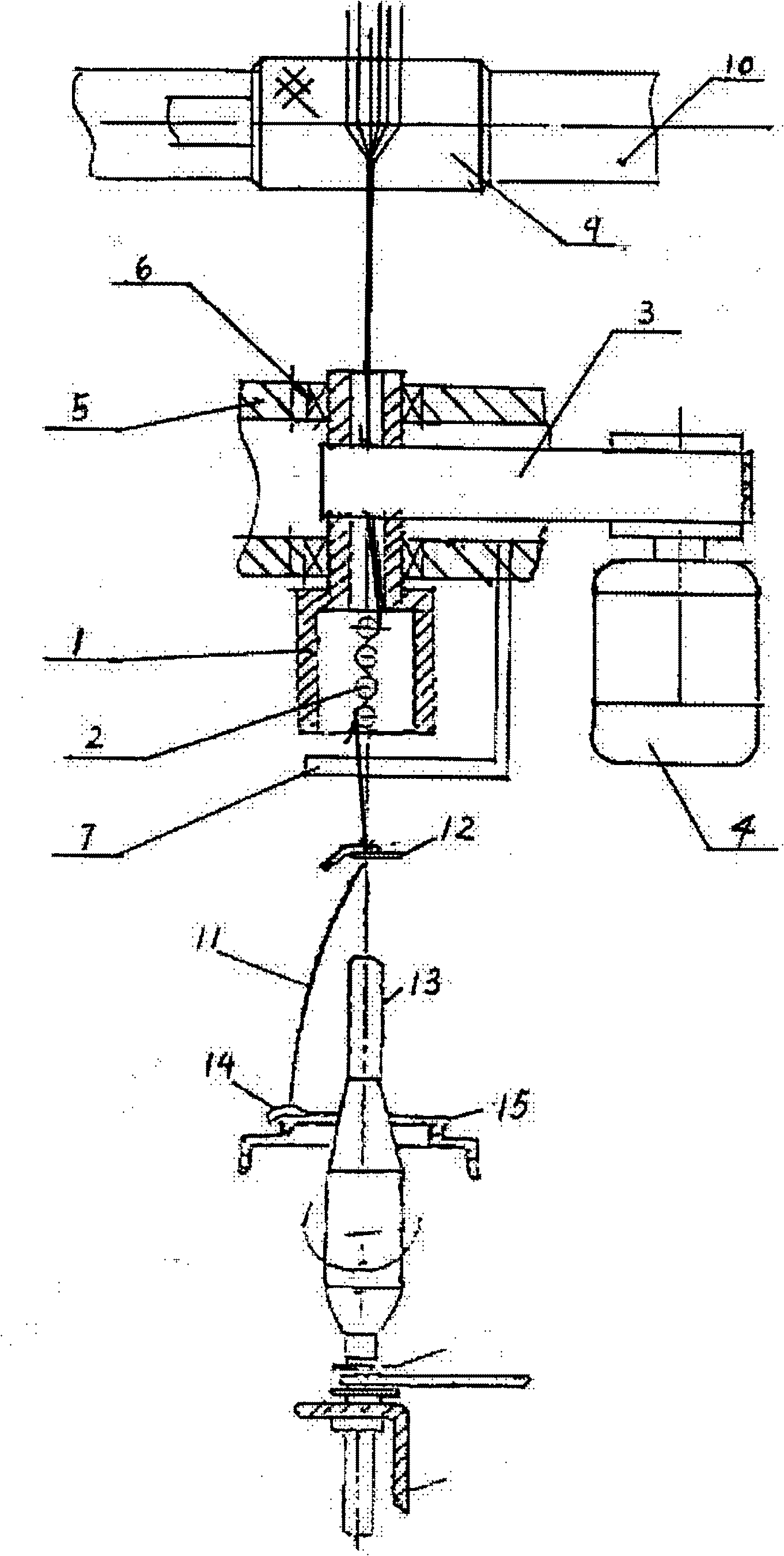

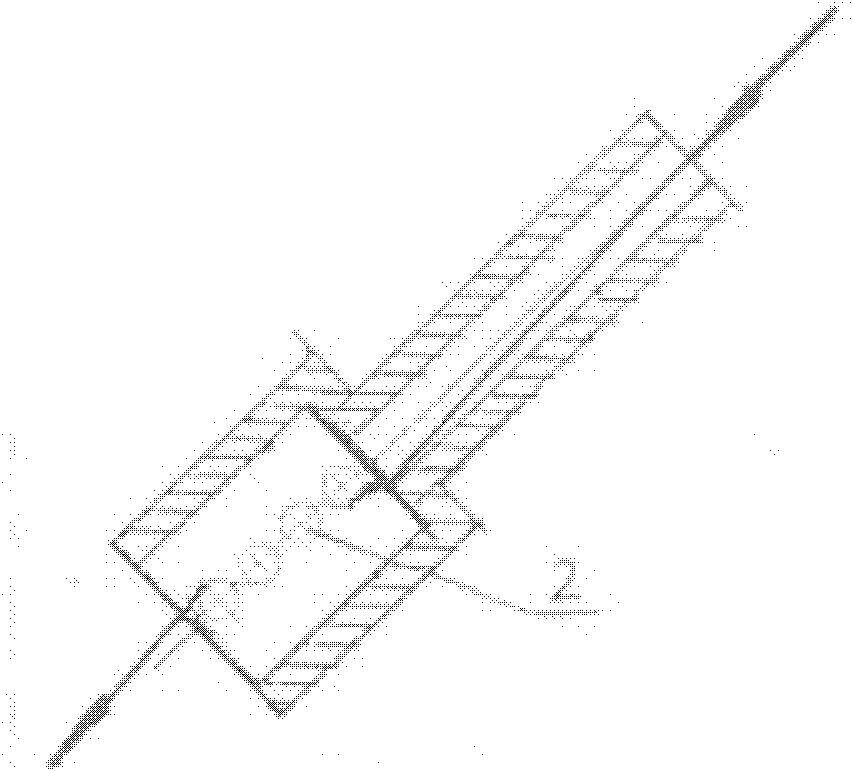

[0043] The frame member 5 arranged along the length direction of the ring spinning machine is fixed on the car panel 18 by the connector 8, the motor 4 is fixed on the car head, and the transmission belt 3 passes through the middle of the frame member 5 and cuts the axis of the false twister 1. to contact. The false twister 1 is fixed on the two frames of the frame member 5 through two bearings 6, and four tension damping needle bars 2 are provided.

[0044] During the production process, the roving fiber bundle output from the front nip composed of the front rubber roller 9 and the front roller 10 enters the false twister 1, and is wrapped around the tension damping needle bar 2 at the lower end of the false twister 1, and then output, through The yarn guide rod 7 and the yarn guide hook 12 are wound on the bobbin 13 afterward.

[0045] The tension damping needle bar 2 plays the following two functions:

[0046]One is to use its axial frictional resistance to the yarn 11 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com