Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4426results about "Continuous wound-up machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

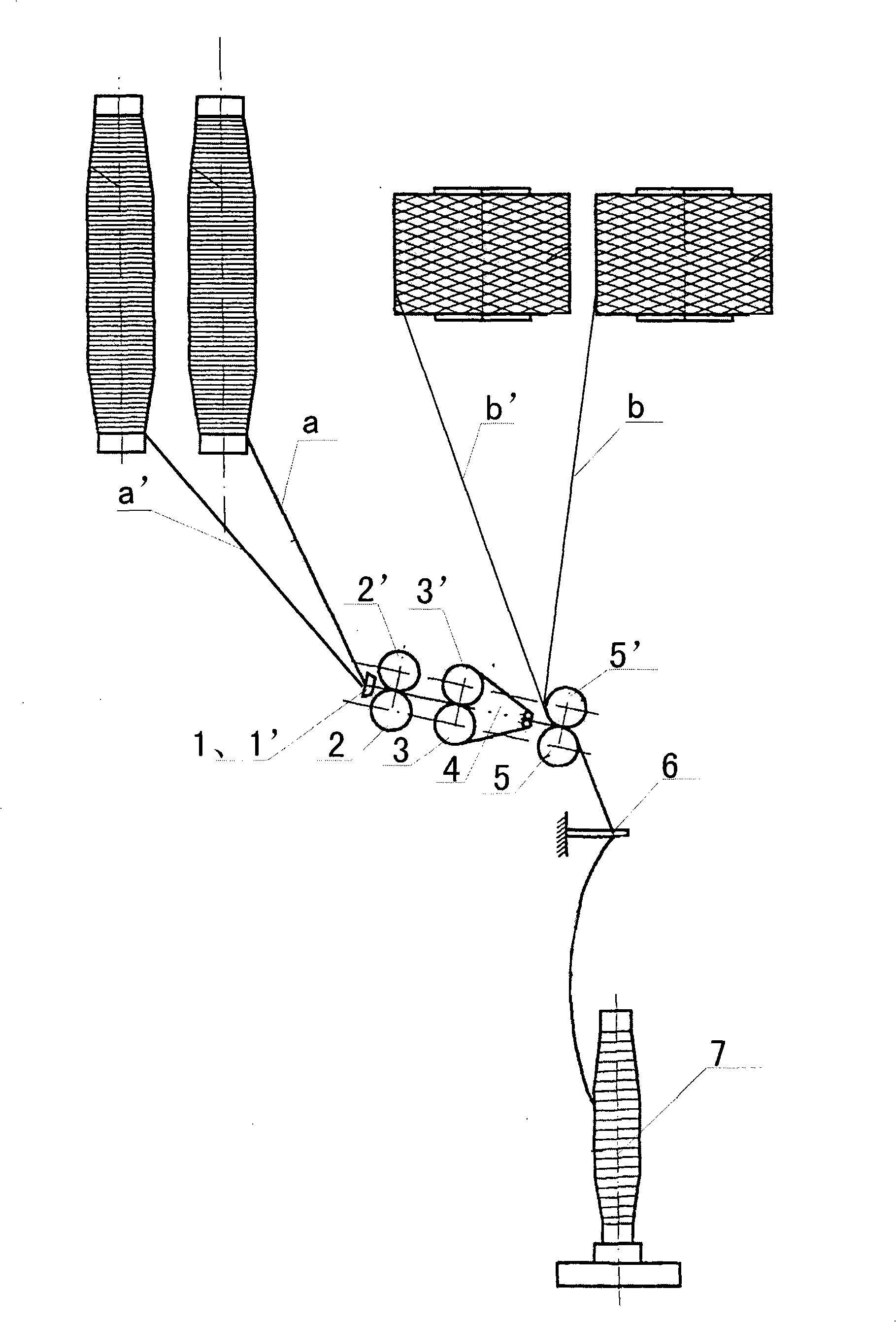

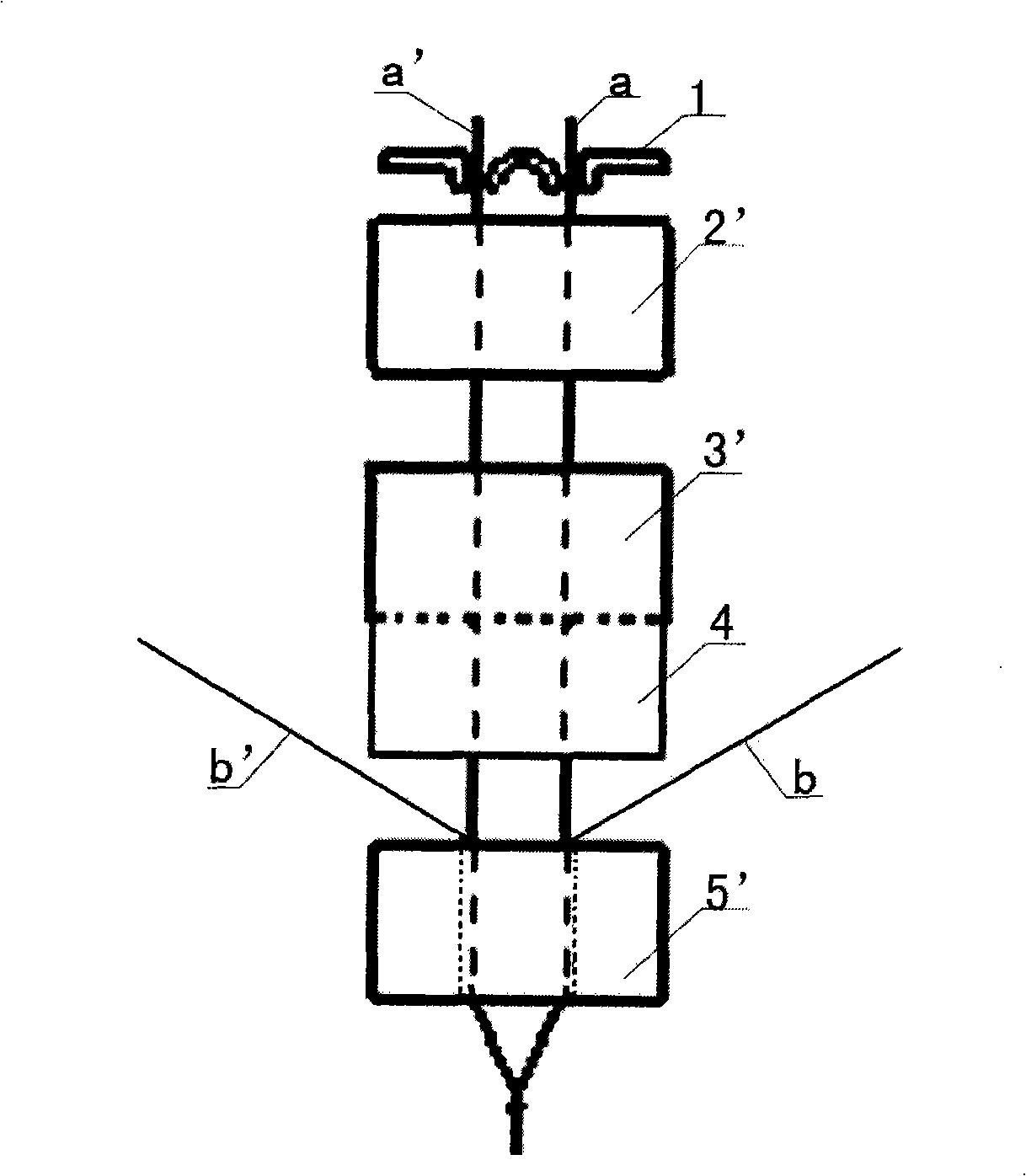

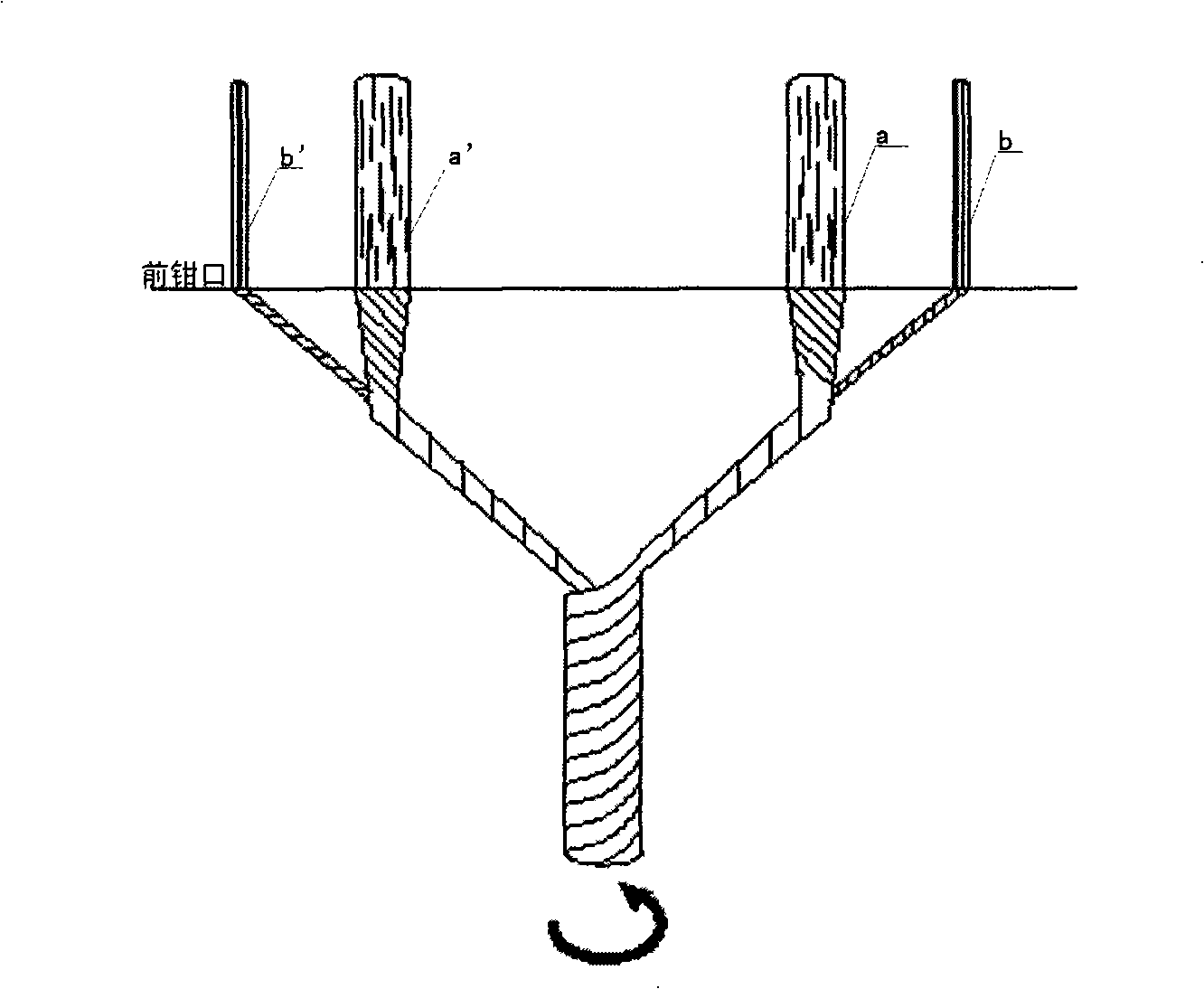

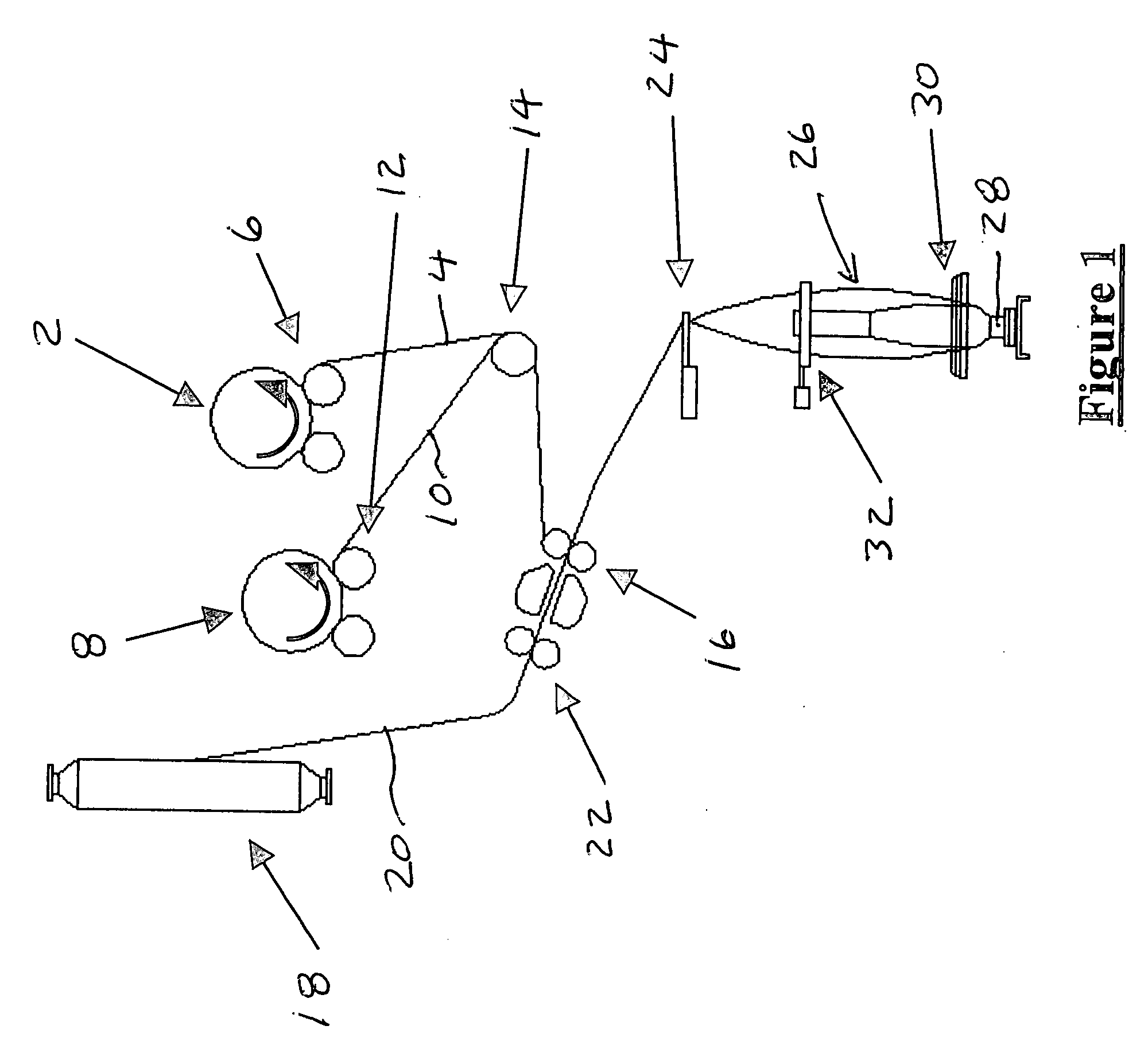

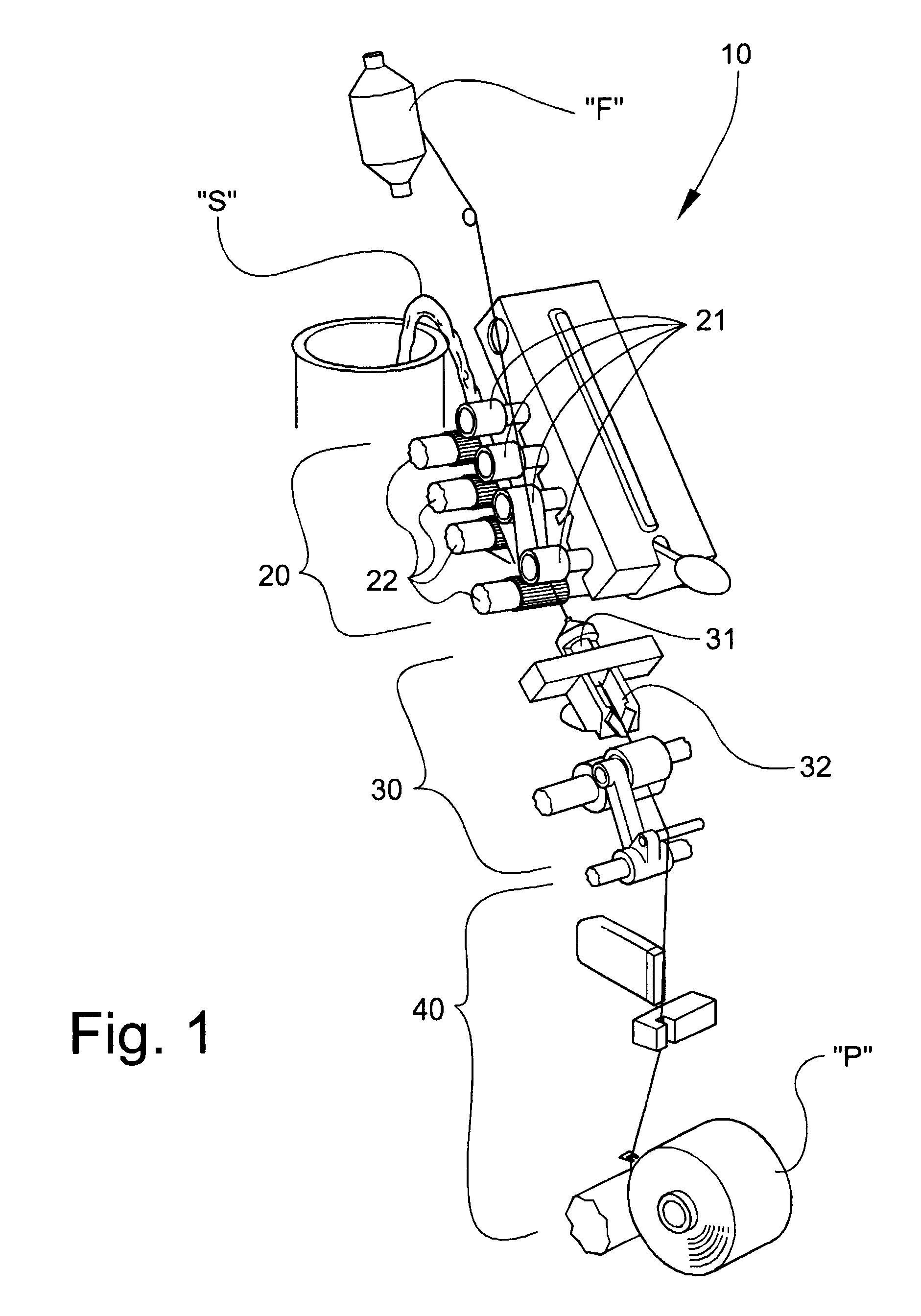

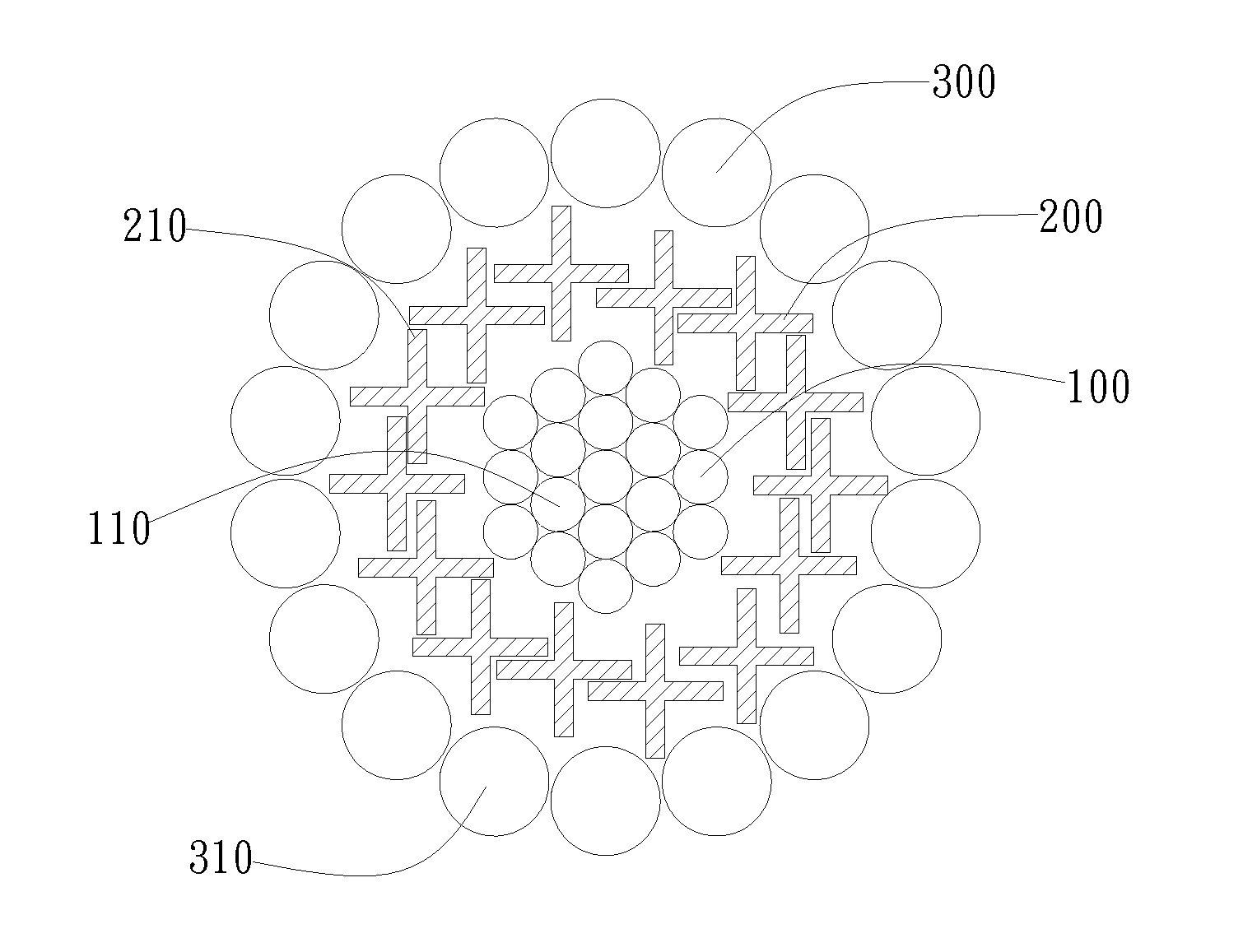

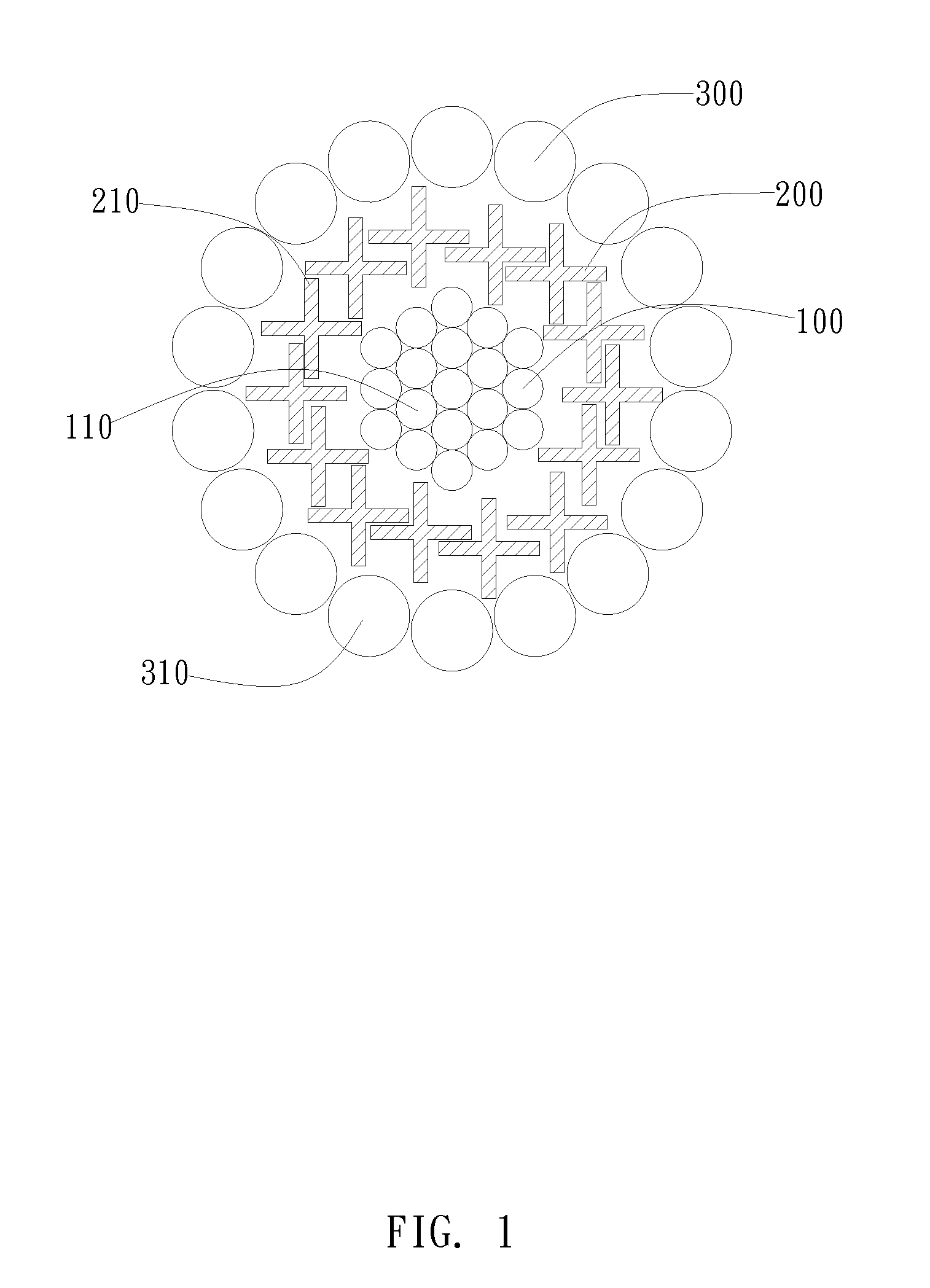

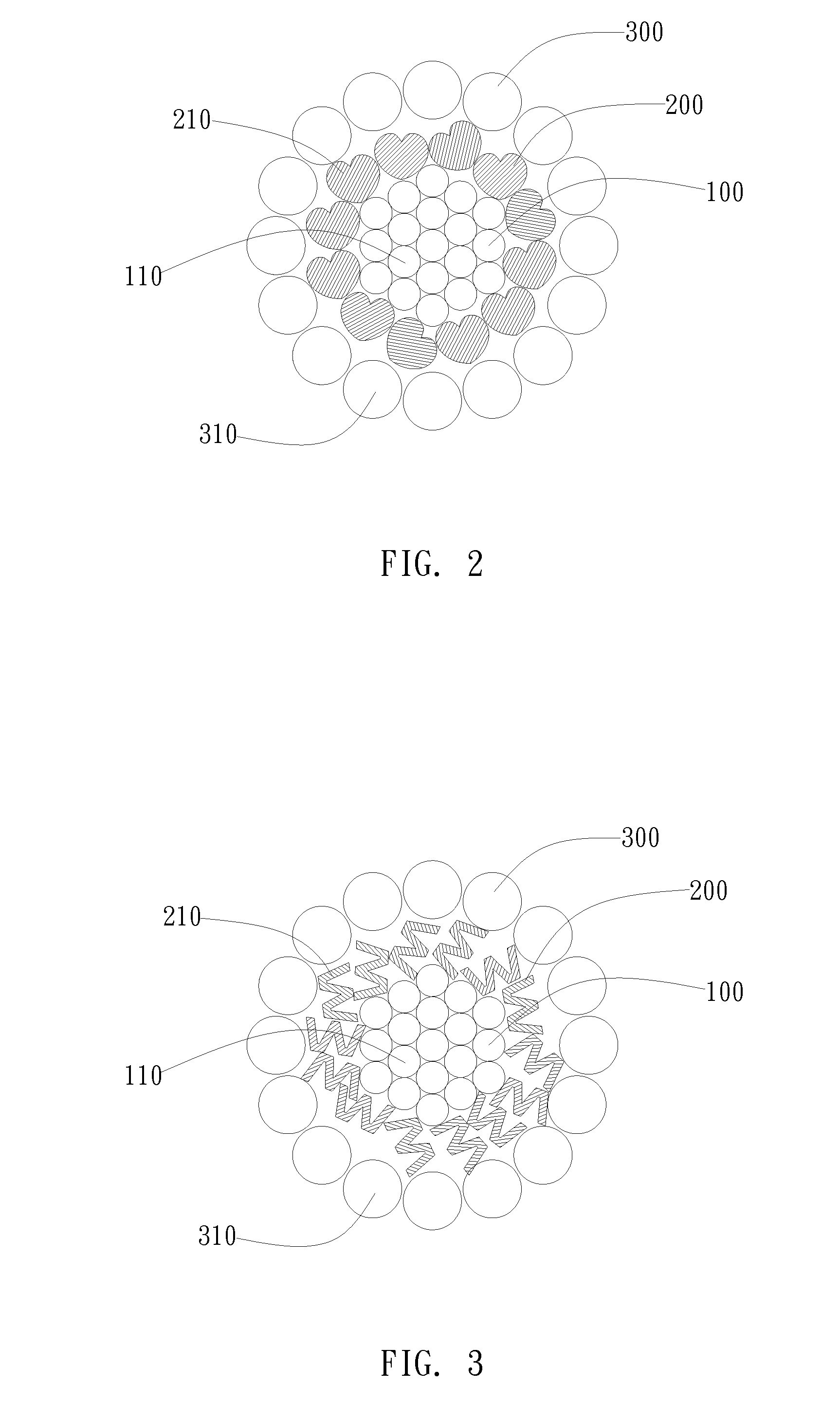

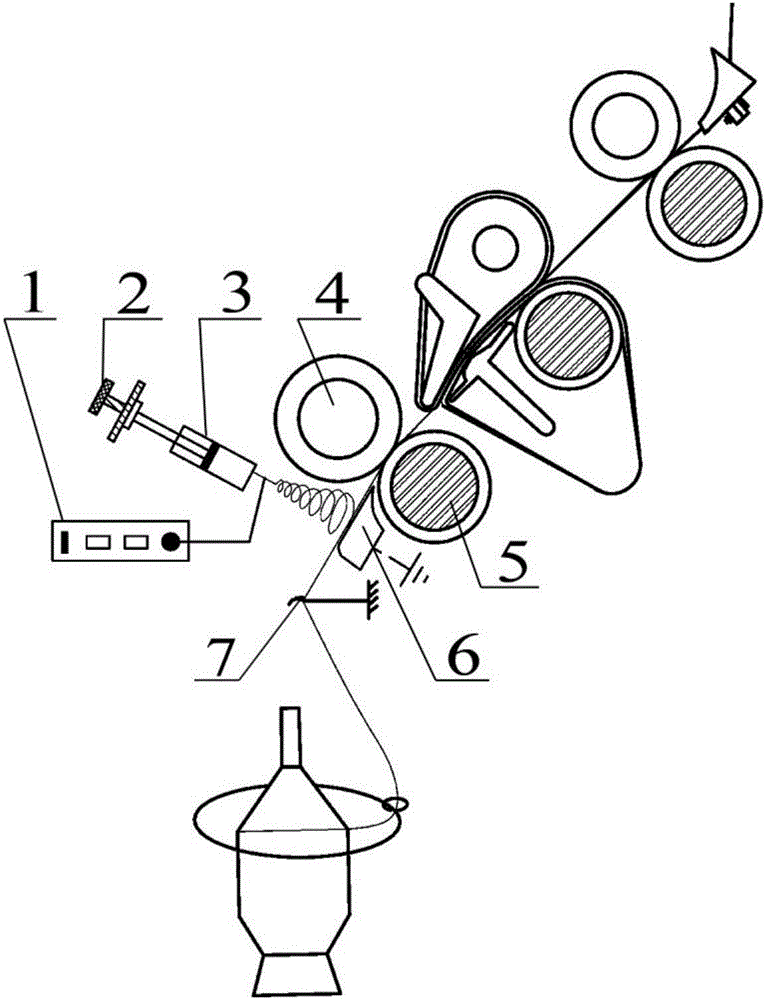

Positioning spinning method of embedded system

InactiveCN101492843ACompact structurePlay a reinforcing roleDrafting machinesContinuous wound-up machinesYarnFiber

Owner:WUHAN TEXTILE UNIV +2

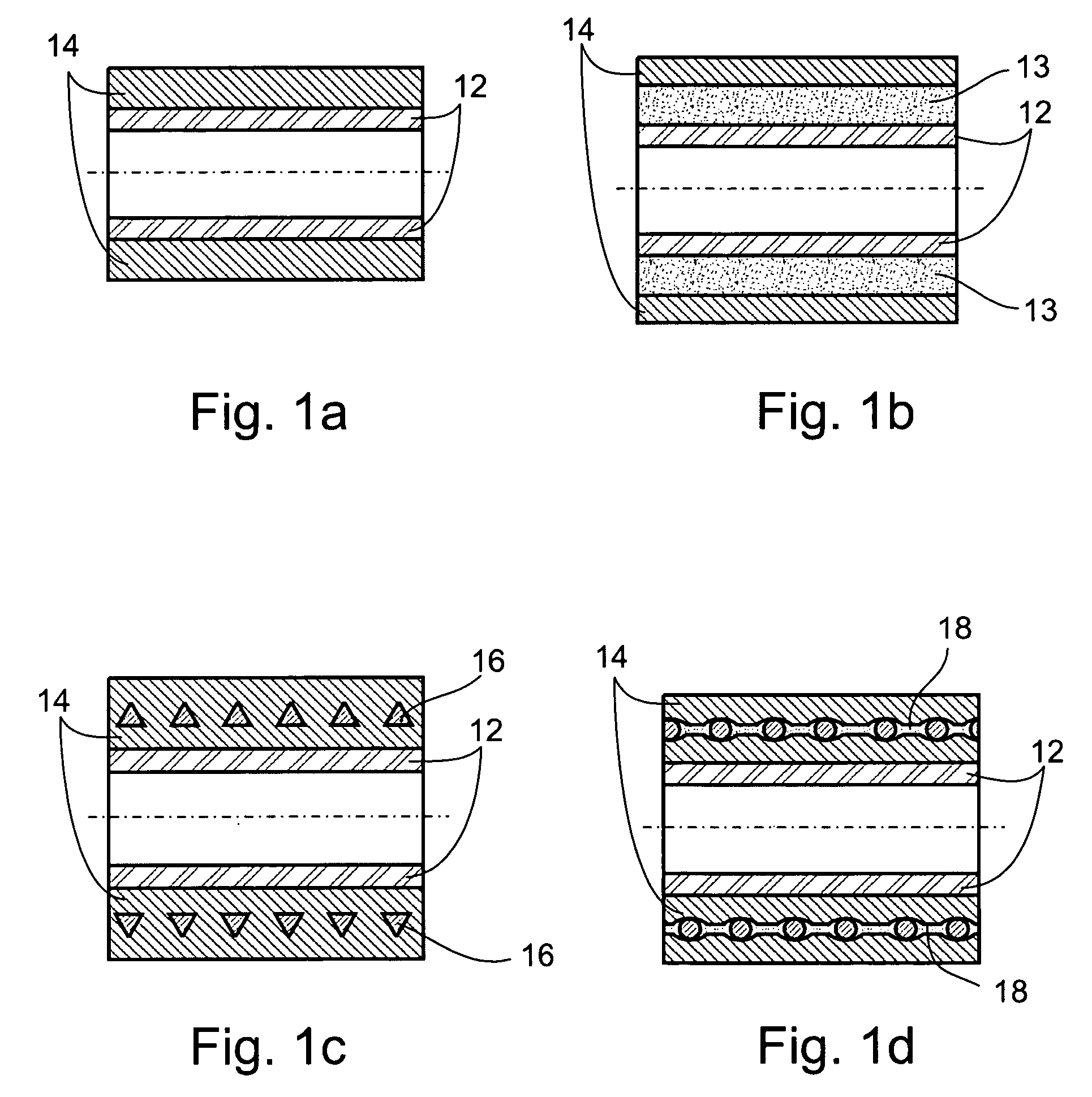

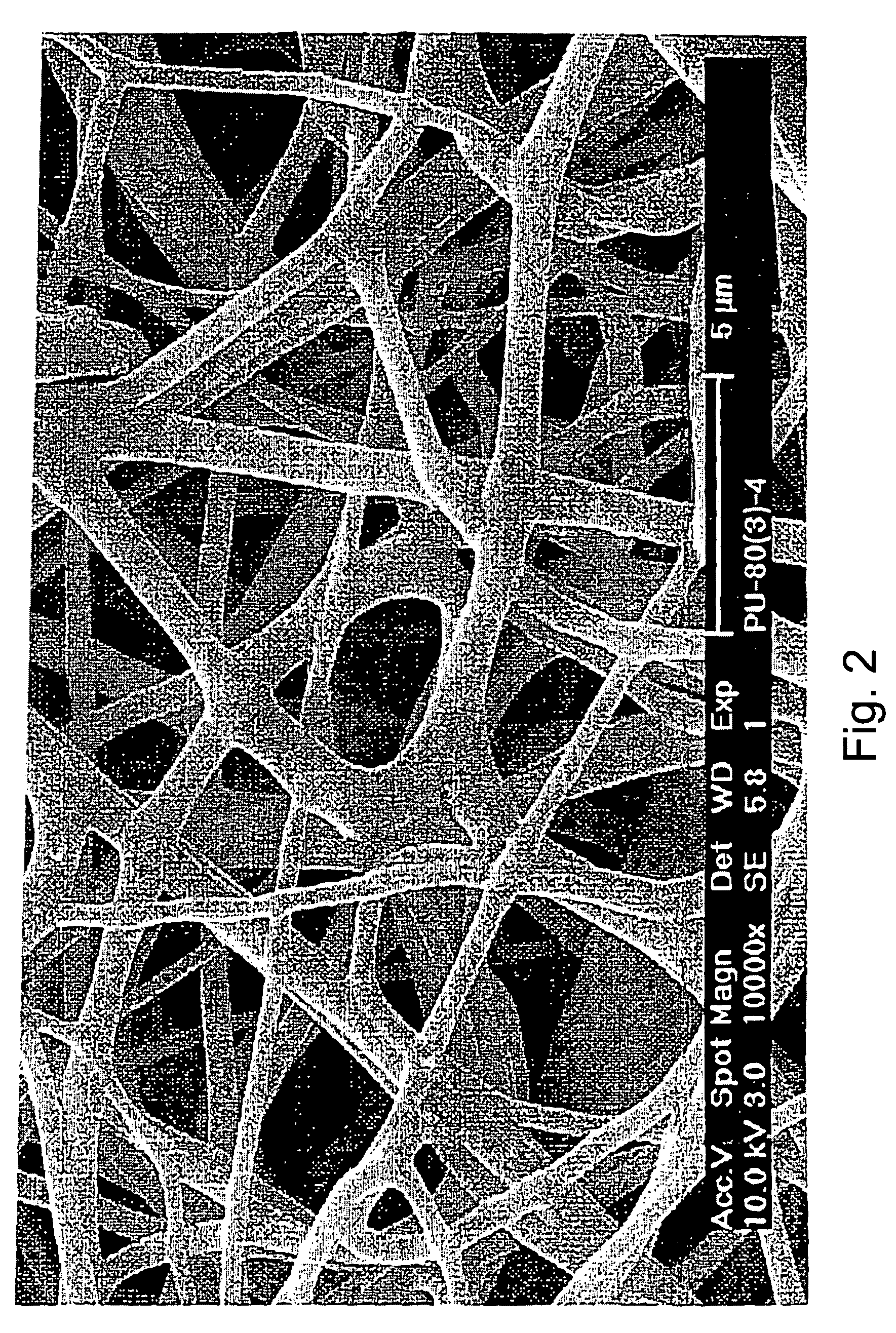

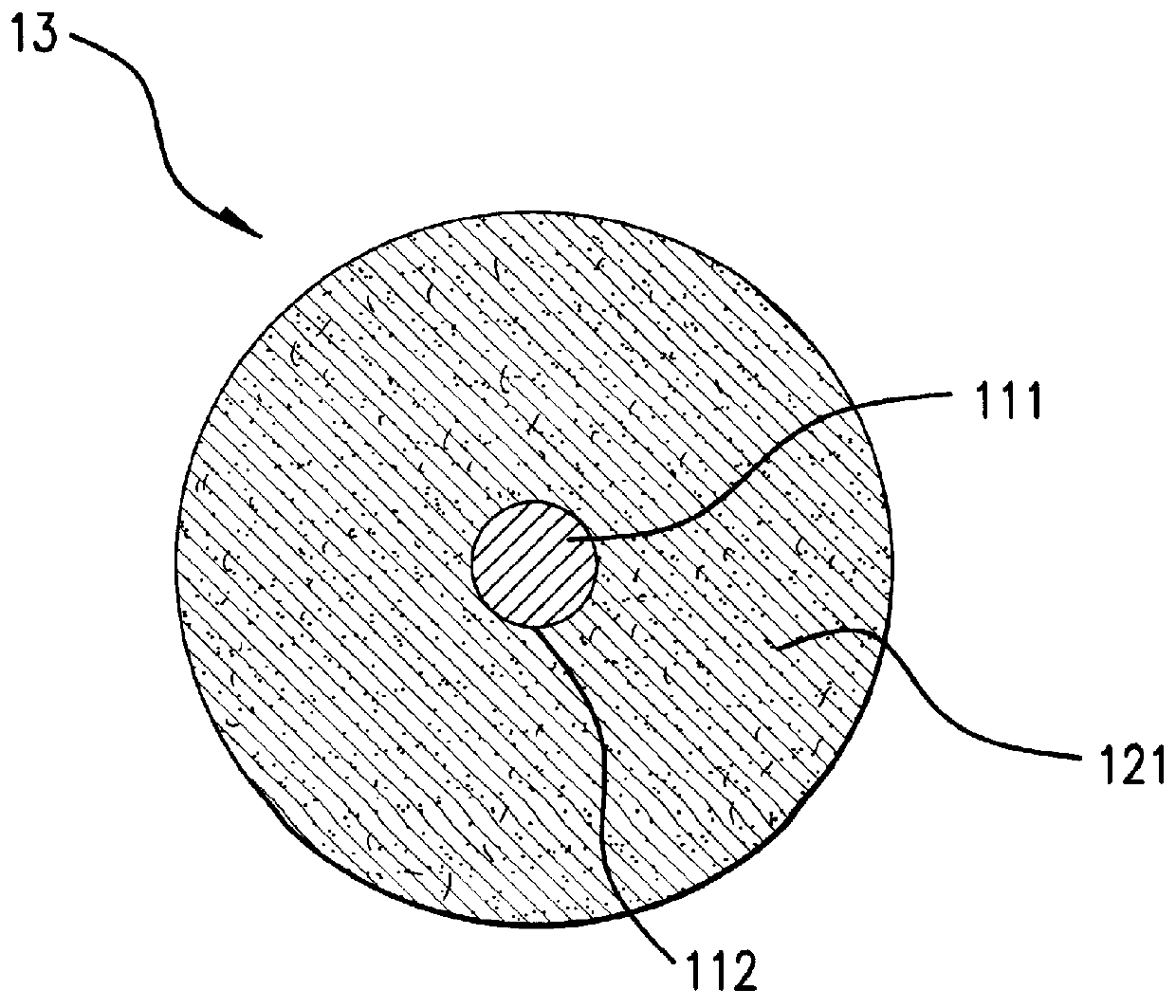

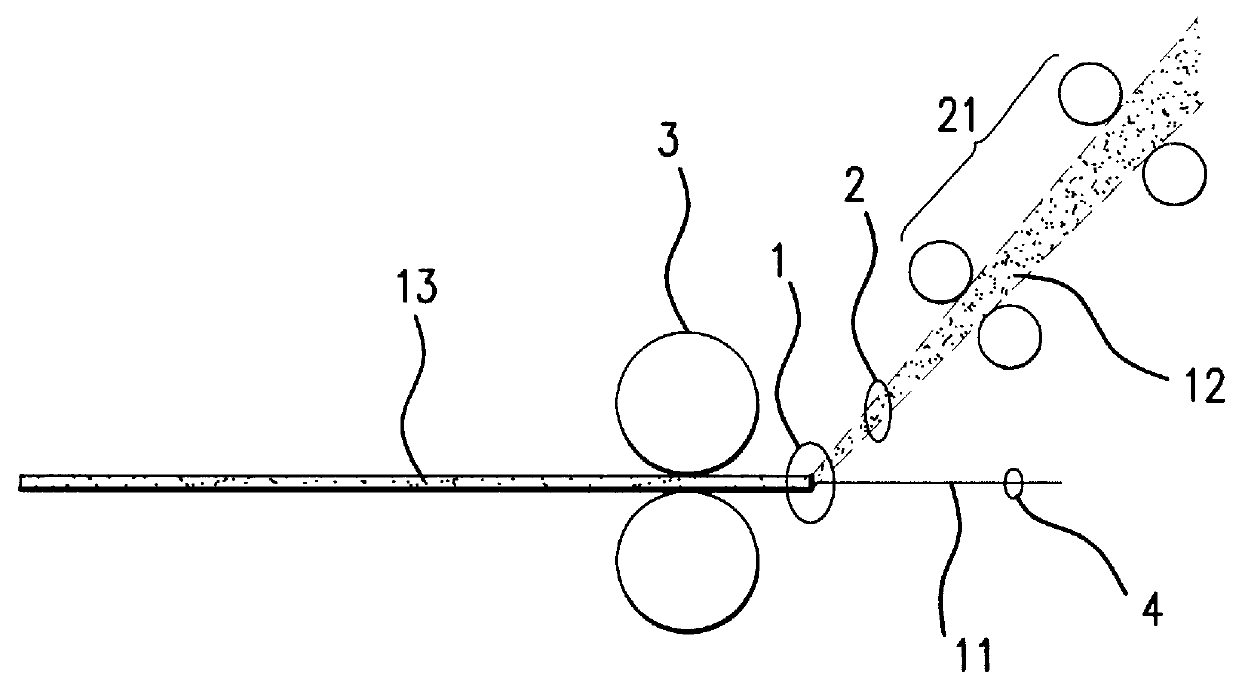

Vascular prosthesis and method for production thereof

A vascular prosthesis comprising a first layer having a predetermined first porosity and a second layer having a predetermined second porosity, wherein the first layer and the second layer are each made of first and second electrospun polymer fibers.

Owner:NICAST LTD

Method for producing an electrically conductive yarn, the electrically conductive yarn and use of the electrically conductive yarn

InactiveUS6032450ACounteracts brittlenessImprove adhesionInorganic material artificial filamentsContinuous wound-up machinesTextile fiberYarn

A method for producing an electrically conductive compound yarn. An electrically conductive monofilament metal thread is spun into a compound yarn together with textile fibers. A compound yarn of this type is particularly suitable for producing woven and knit materials.

Owner:SPOERRY 1866 AG

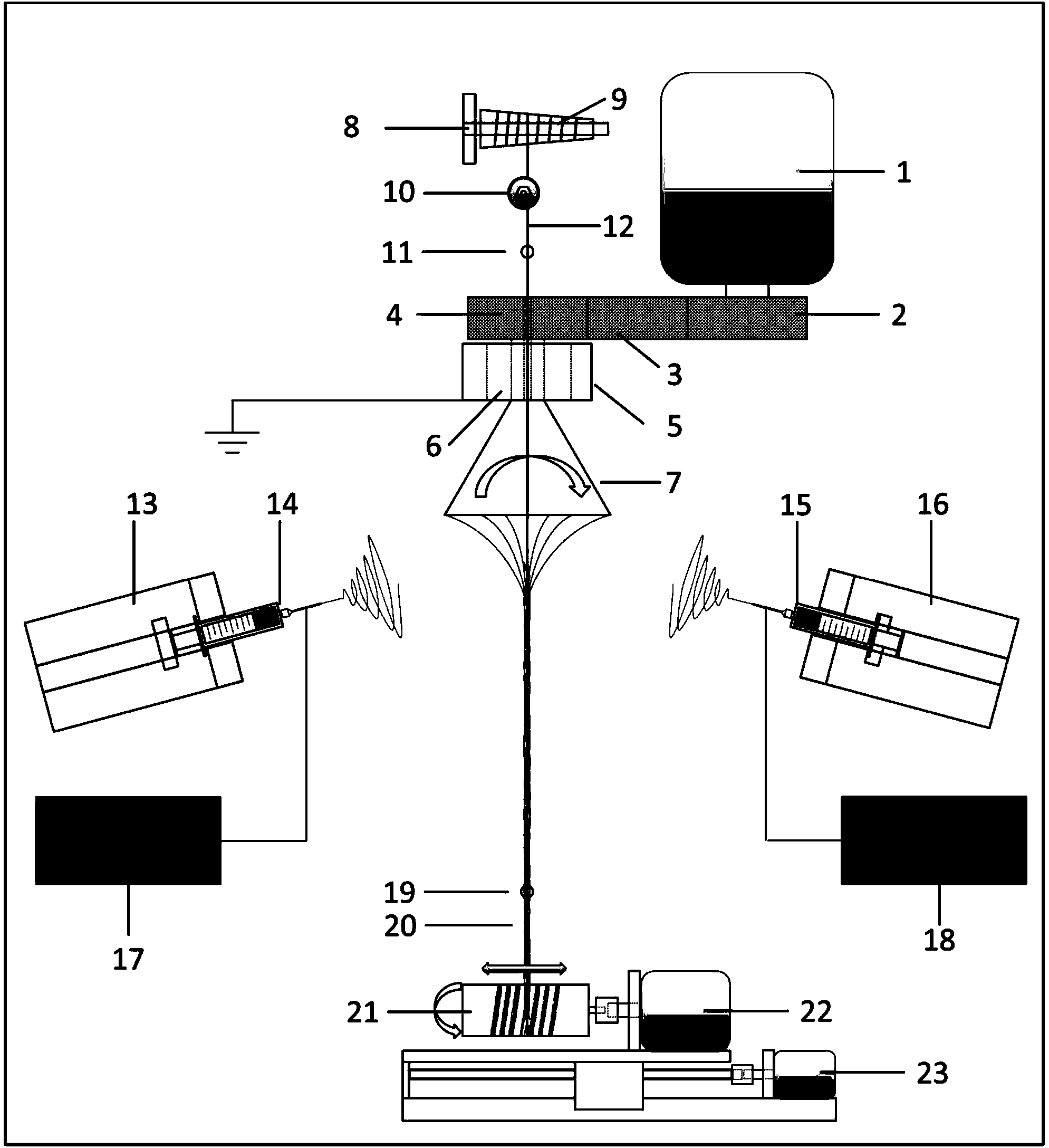

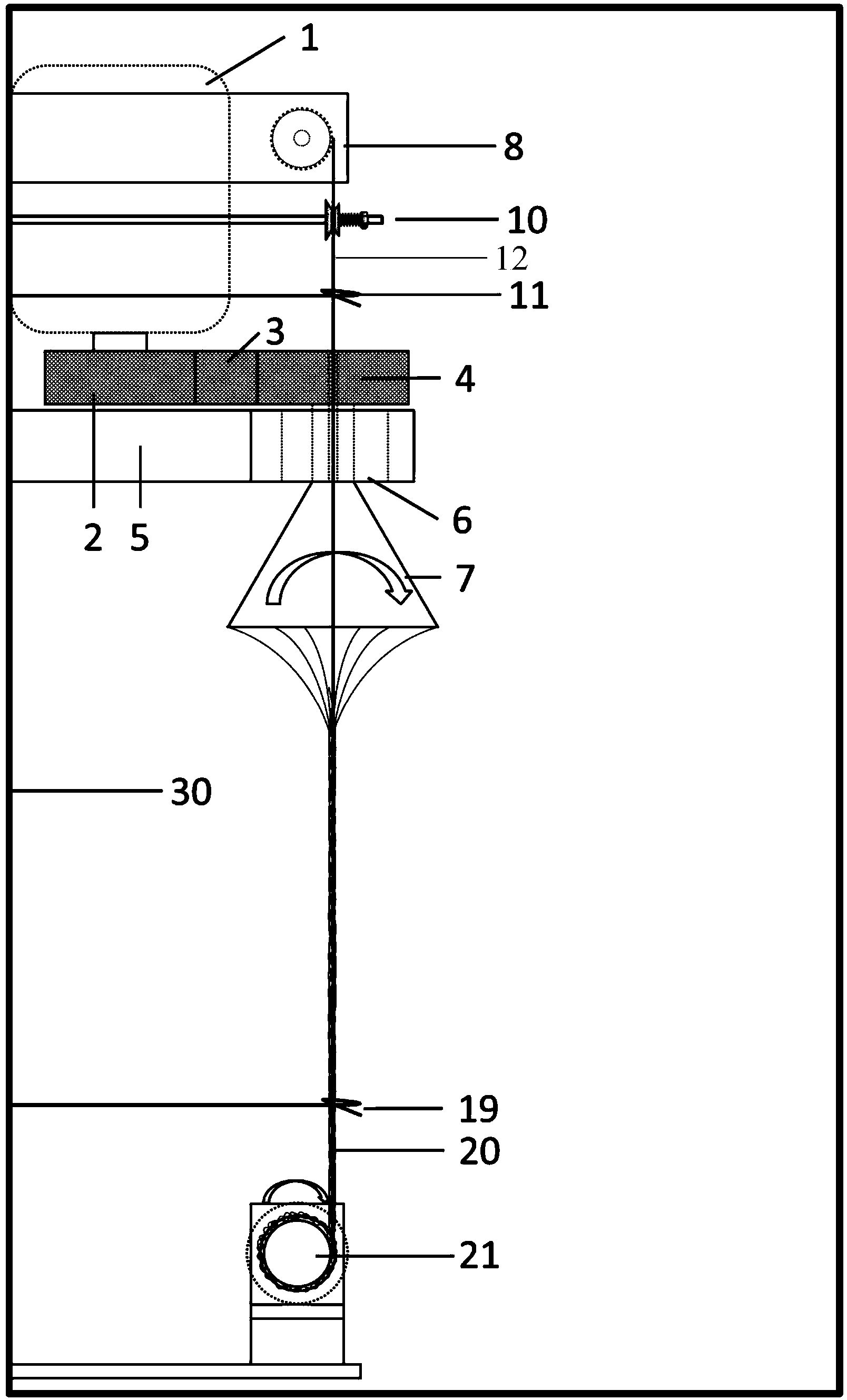

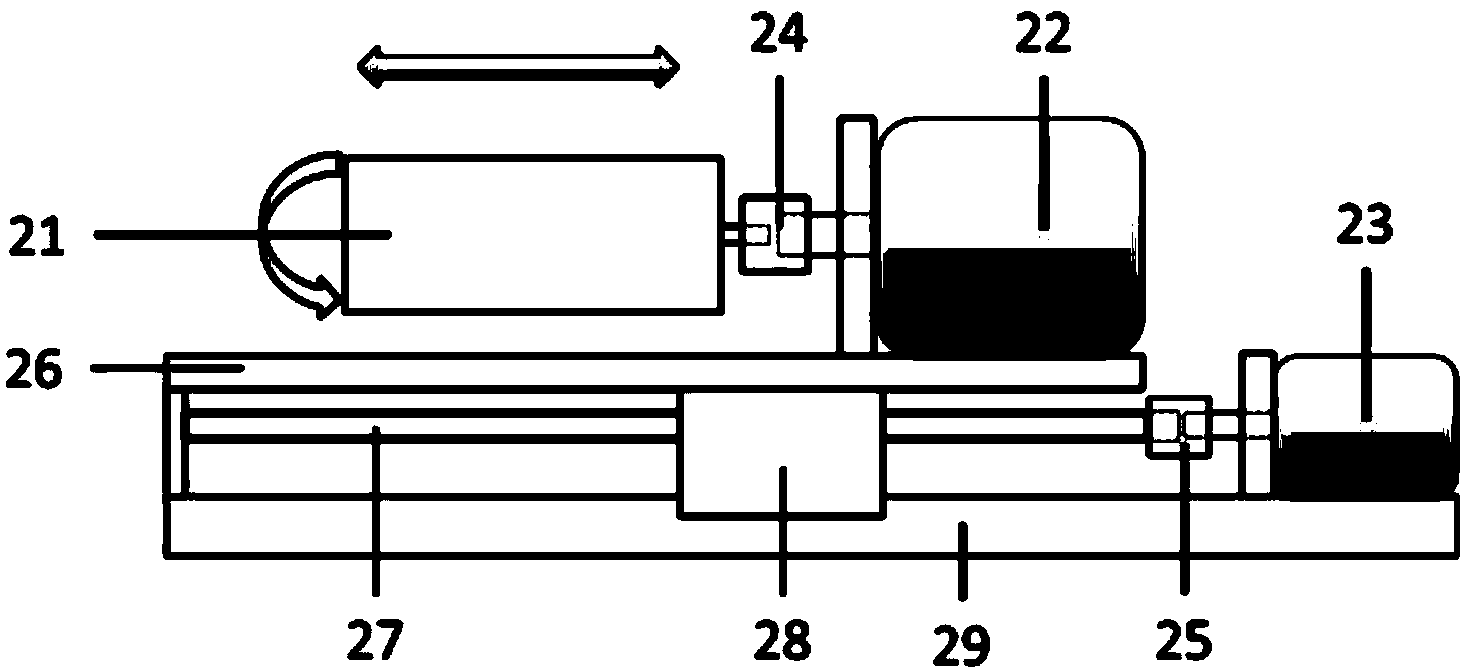

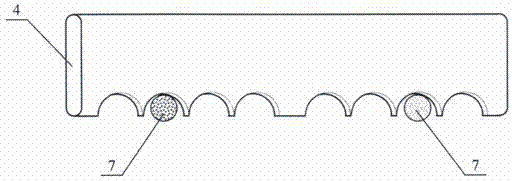

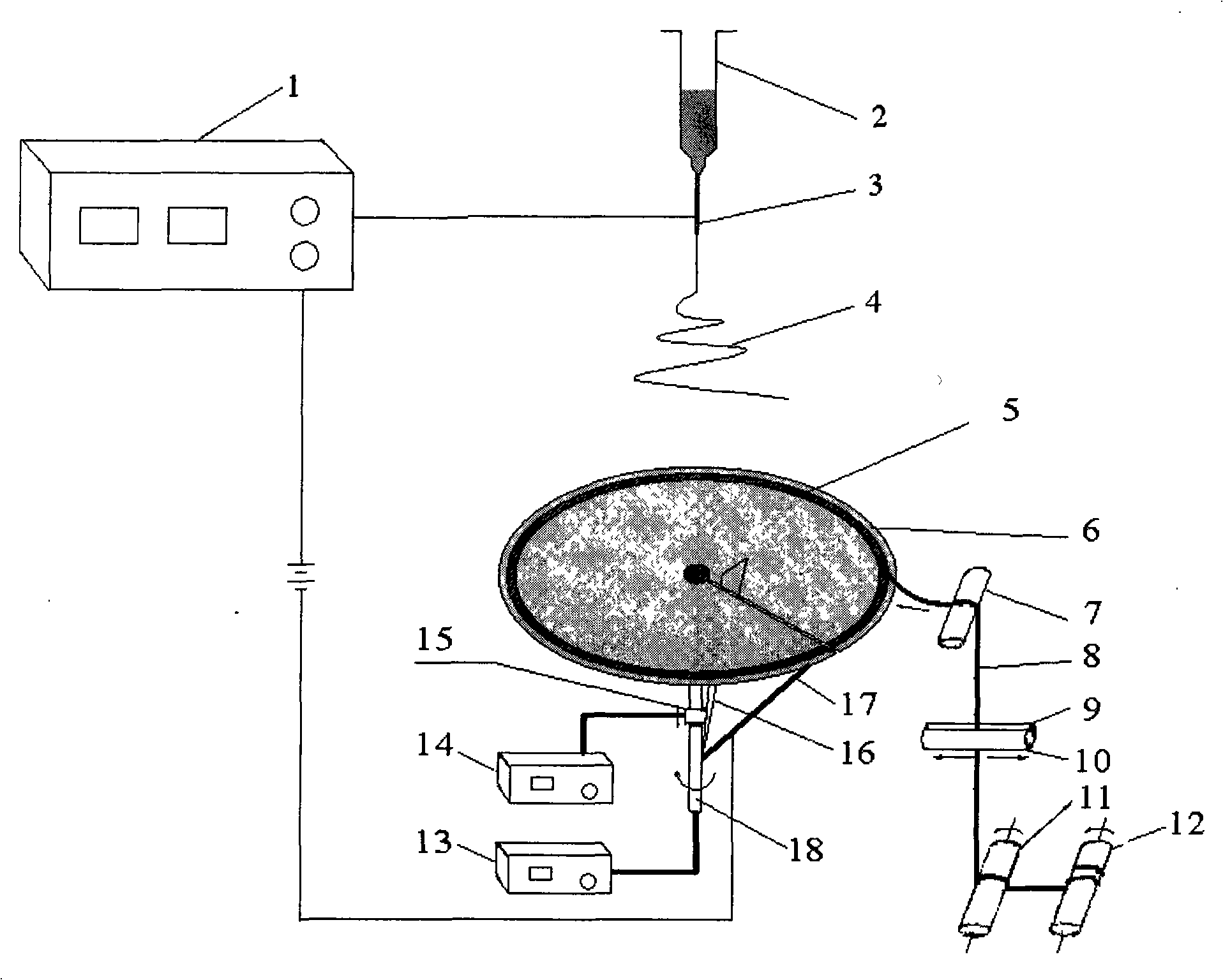

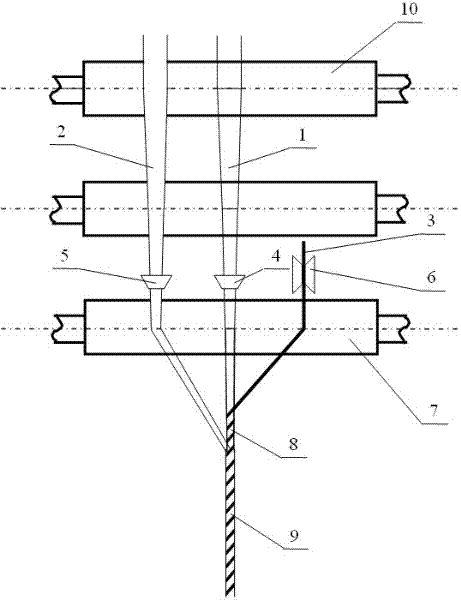

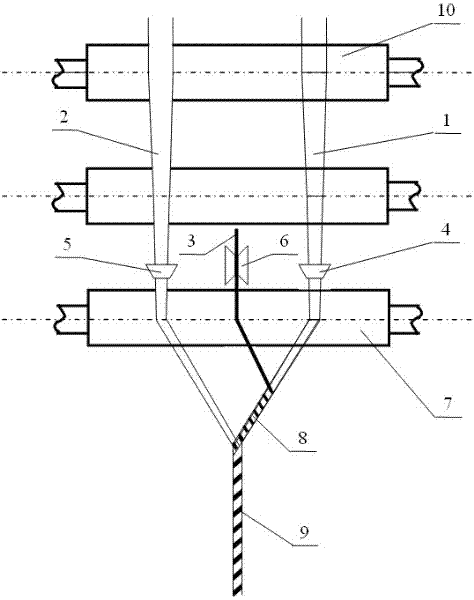

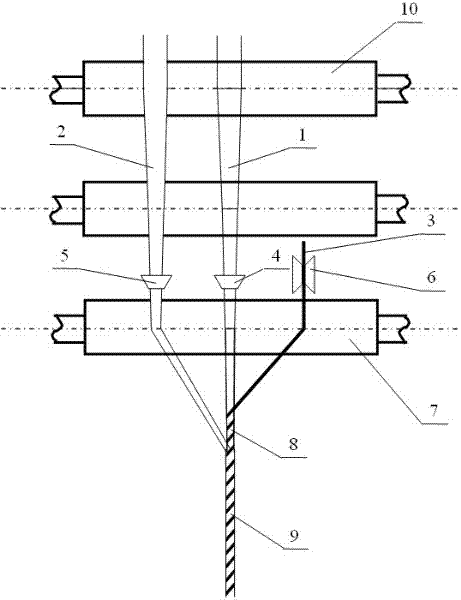

Nano-fiber covering yarn electrostatic spinning device and application thereof

ActiveCN104032423AArrangement structure controllableControllable twistWeft knittingWarp knittingTextile technologyFiber

The invention relates to a nano-fiber covering yarn electrostatic spinning device and application thereof. The nano-fiber covering yarn electrostatic spinning device comprises a twisting device, a backing-off device, a winding device, a double-needle electrostatic spinning device and a control system. The invention also provides a method for preparing electrostatic spinning nano-fiber covering yarns. The method comprises the following steps of performing spinning by using prepared spinning liquor through the double-needle electrostatic spinning device; depositing nano-fibers on a metal funnel and core yarns; uniformly winding the nano-fibers on the core yarns moving at constant speed by rotating the metal funnel; and finally forming the nano-fiber covering yarns of which skin layers are nano-fibers. The invention also provides another method for preparing a nano-fiber fabric. The other method for preparing the nano-fiber fabrics comprises the following steps of using water soluble yarns as core yarns; preparing the nano-fiber covering yarns by using the method; preparing a covering yarn fabric by using a textile technology; and dissolving the core yarns to obtain the nano-fiber fabric. The maneuverability is high; the nano-fiber covering yarn electrostatic spinning device is novel in structure; and the nano-fibers on surfaces of the covering yarns are arranged controllably.

Owner:诺一迈尔(山东)医学科技有限公司

Composite spinning device and spinning method for chemical fiber filament coated rigid fiber filament

The invention provides a composite spinning device and a spinning method for covering rigid fiber filaments with chemical fiber filaments. The composite spinning device comprises a ring spinning frame, and is characterized by also comprising an unreeling roller, a positioning yarn guide, a tension disk and a multi-position yarn guide, wherein the positioning yarn guide is positioned behind a feed jaw of a front roller pair of the ring spinning frame; and the multi-position yarn guide is positioned in front of an output jaw of the front roller pair of the multi-position yarn guide. The rigid fiber filaments which unreeled from a rigid fiber filament drum pass through the unreeling roller and the positioning yarn guide in sequence and then are converged with two bundles of chemical fiber filaments which are unreeled from a chemical fiber filament drum, are fed into the front roller pair through the tension disk and the multi-position yarn guide and are output from the front roller pair at a convergent point; meanwhile, the chemical fiber filaments and the rigid fiber filaments are twisted at the convergent point to form a composite yarn under the action of rotation of a spindle of the ring spinning frame. Through the device and the method, the problems of high brittleness of carbon fibers and high probability of bending and brittle fracture of fibers during back-roll and weaving can be solved.

Owner:DONGHUA UNIV

Core spun yarn and woven stretch fabric

InactiveUS20080318485A1Increase draftContinuous wound-up machinesWoven fabricsPolyethylene terephthalateEthylene

A core spun yarn comprising a bi-component polyester filament and an elastomeric fiber. The polyester filament has a denier from about 20 to about 150 and the elastomeric fiber has a denier from 20 to 140. The polyester filament is about 2 weight percent to about 60 weight percent, based on total weight of the yarn and the elastomeric fiber is from about 1 percent to about 40 percent, based on total weight of the yarn. The elastomeric fiber may have higher draft than the bi-component polyester fiber. The polyester filament comprises poly (trimethylene terephthalate) and at least one polymer selected from the group consisting of poly (ethylene terephthalate) and poly (tetramethylene terephthalate) and said elastomeric fiber is spandex. The yarn may include a sheath of at least one staple fiber. The disclosure also includes a fabric of the bi-component polyester filament and an elastomeric fiber.

Owner:CENT TEXTILES HK

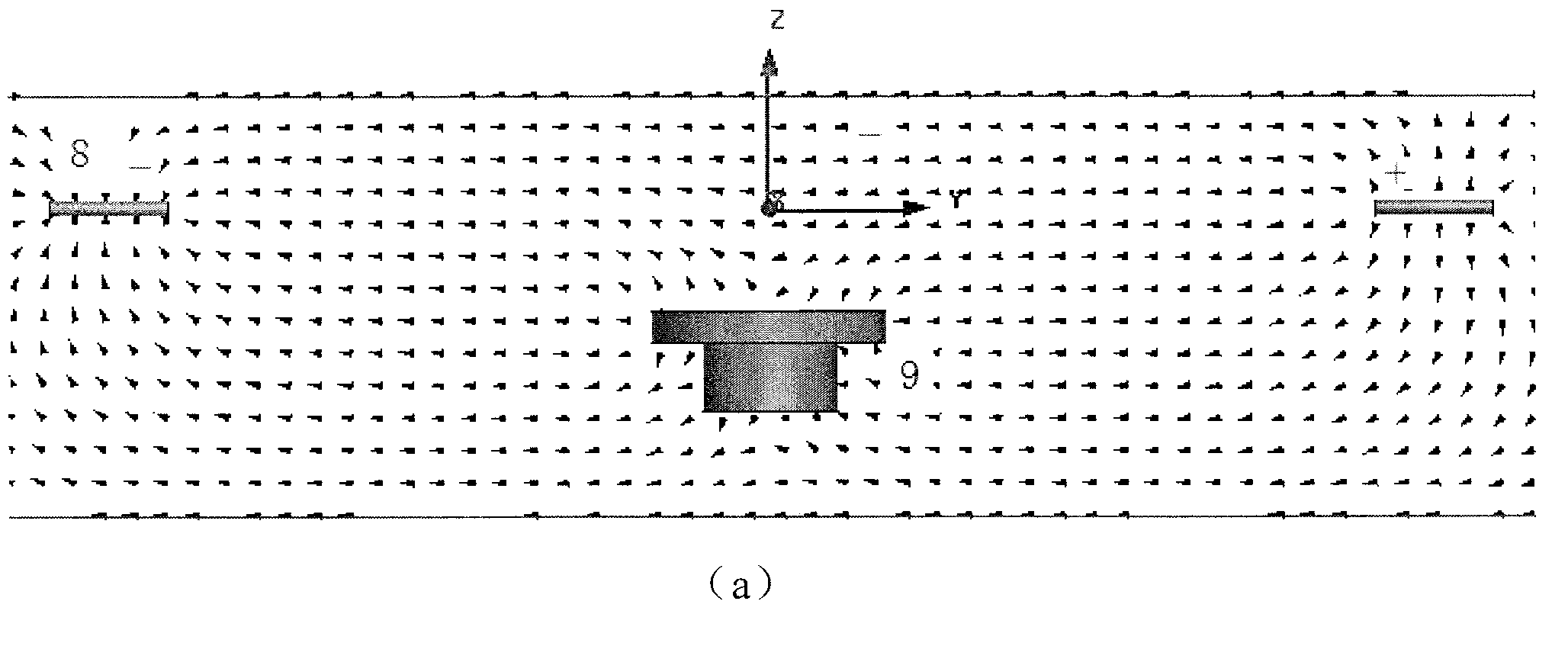

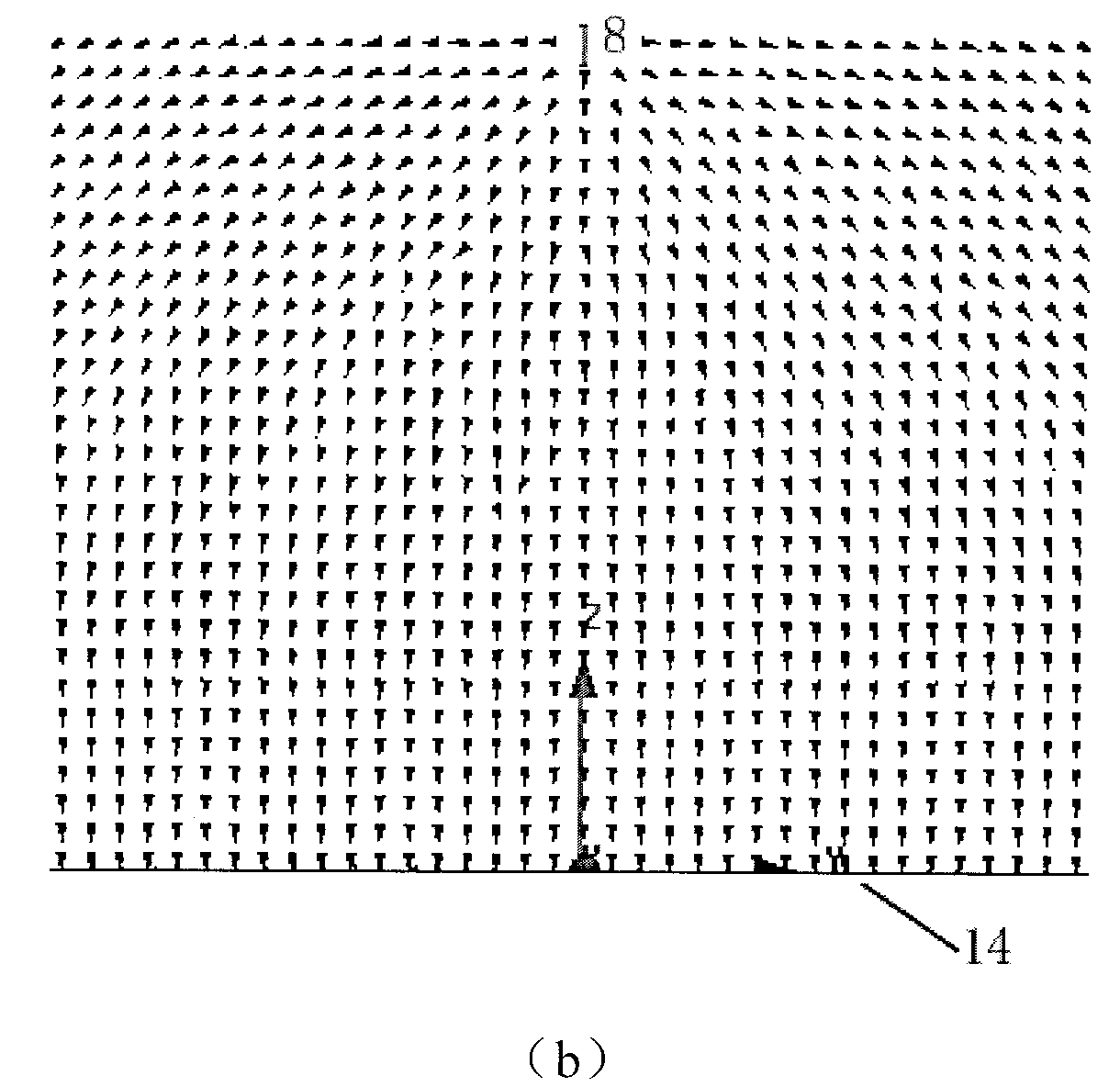

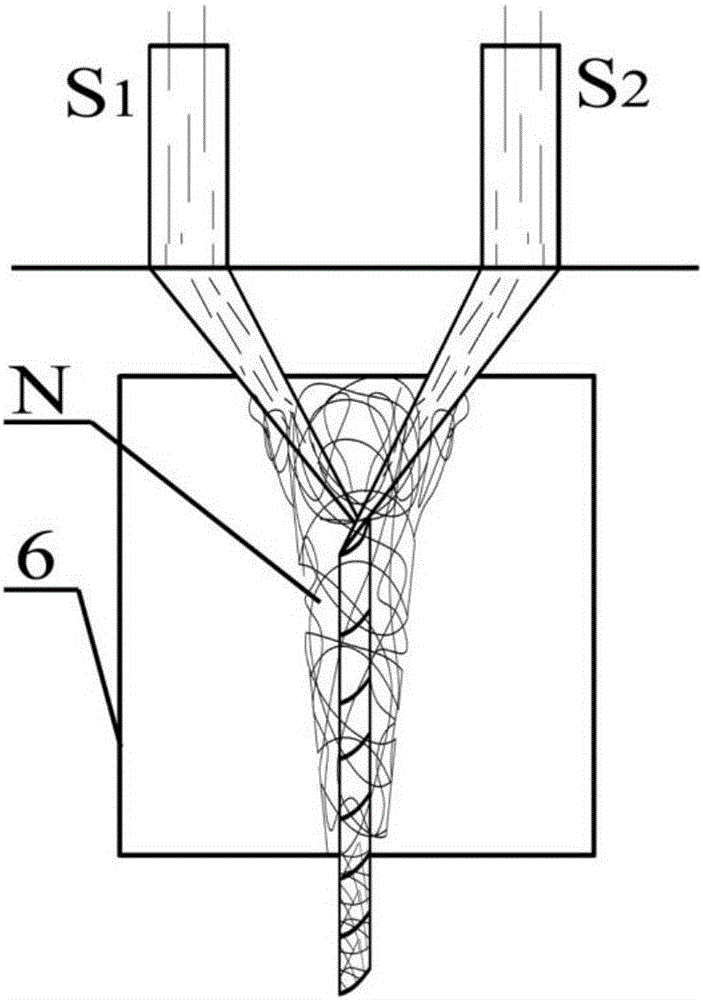

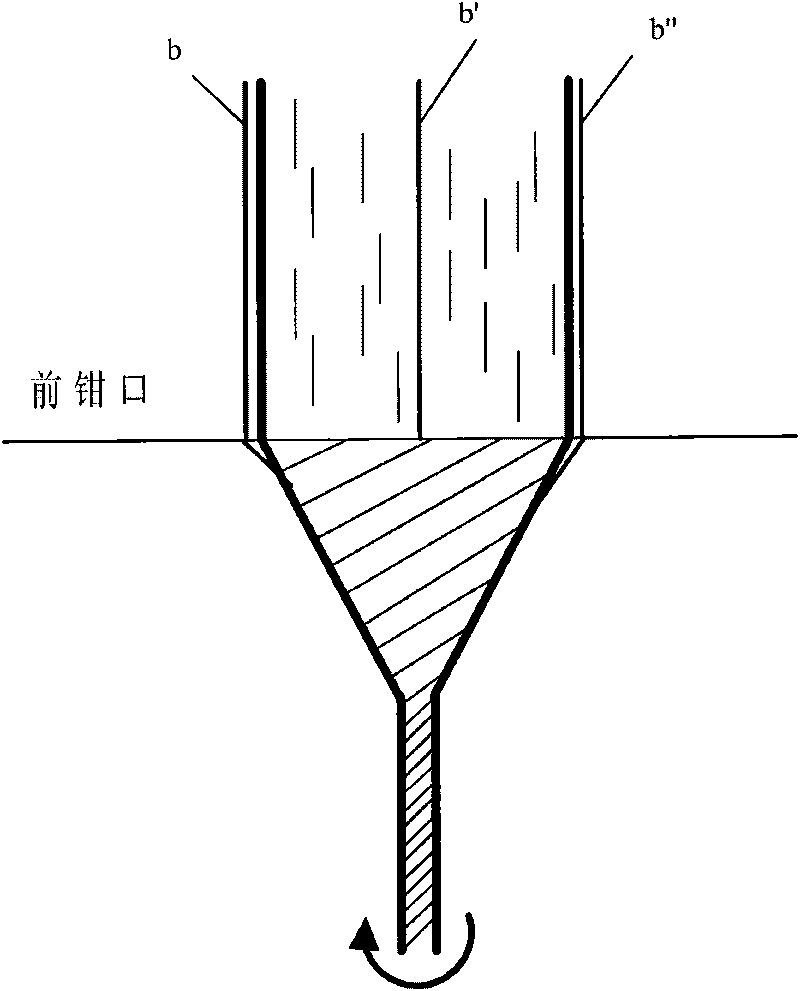

Orientation electro-spinning nanometer fiber spinning method and device thereof

InactiveCN103132194AHigh degree of axial orientationSuppress spinning instabilityDrafting machinesFilament/thread formingBobbinEngineering

The invention discloses an orientation electro-spinning nanometer fiber spinning method and a device thereof. A metal shower nozzle which exerts positive and negative high pressure is adopted to spin two strands of nanometer fibers with opposite charges, an electric field line of a spinning electric field, relative to a common spinning electric field, is straight, stability of spinning is effectively restrained, and the spinning nanometer fibers are straight. Two strands of the fibers surround the yarn tail and form a cone-shaped twisting trigonum on the upper portion of a metal twisting machine, and enable the nanometer fibers to be further oriented and twisted to form yarn through electric field force, tractive force of the yarn and acting force of the metal twisting force. The spinning nanometer fiber yarn is conducted heat shaping through a heat processing device under certain tensile force, degree of orientation of the nanometer fibers along the axial direction of the yarn, breaking force and yarn levelness are further improved, and the yarn after shaped is collected by a winding bobbin. The device can achieve the aim that orientation nanometer fiber yarn can be continuously prepared, is simple in device, convenient to operate, and good in resultant yarn continuity, yarn breaking strength and yarn levelness, and not only can spin pure nanometer fiber yarn, but also can spin nanometer fibers / filament core composite yarn. The orientation nanometer fiber spinning method and the device thereof have important application value in the fields, such as a biomedical field and a sensor field.

Owner:杨恩龙 +1

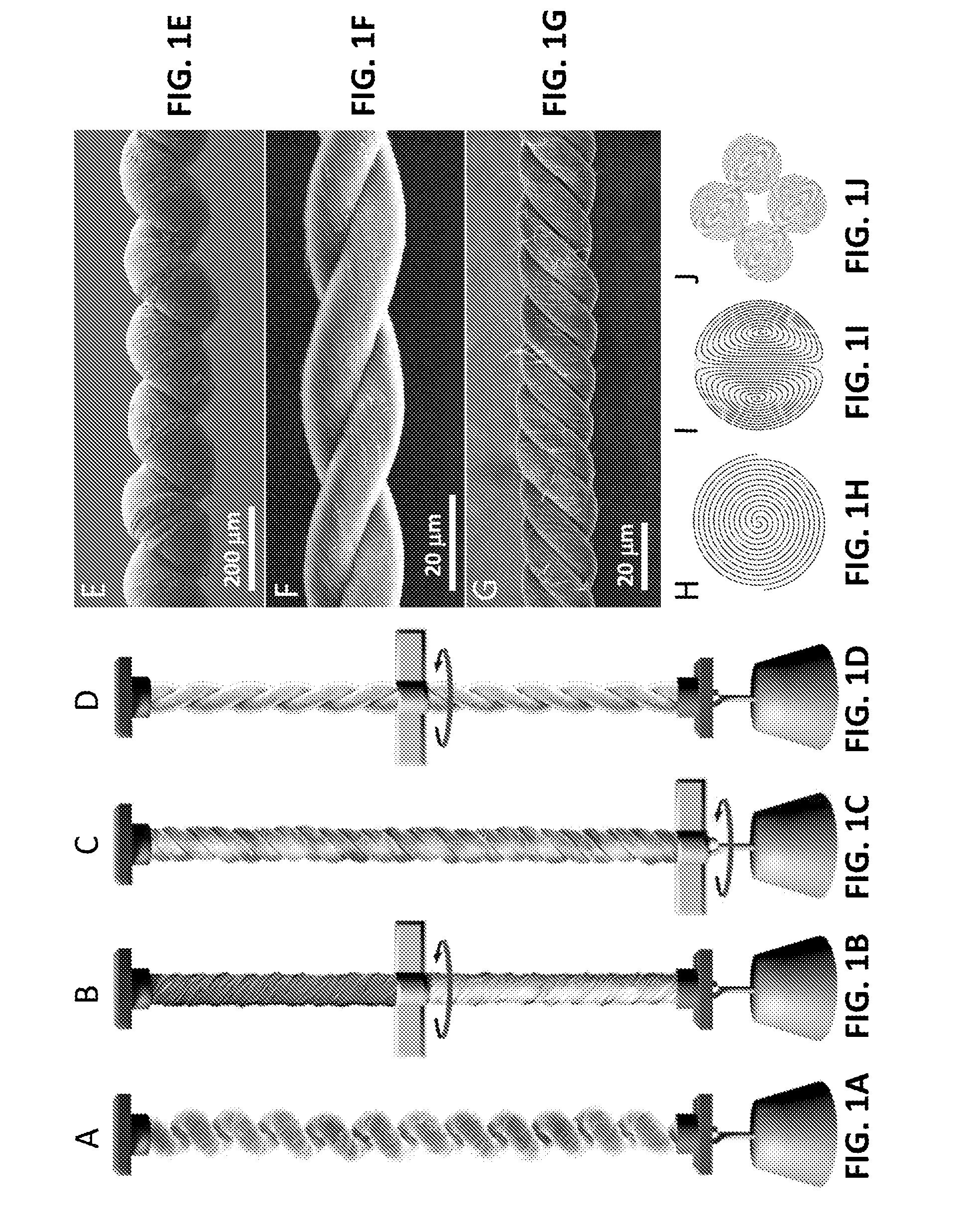

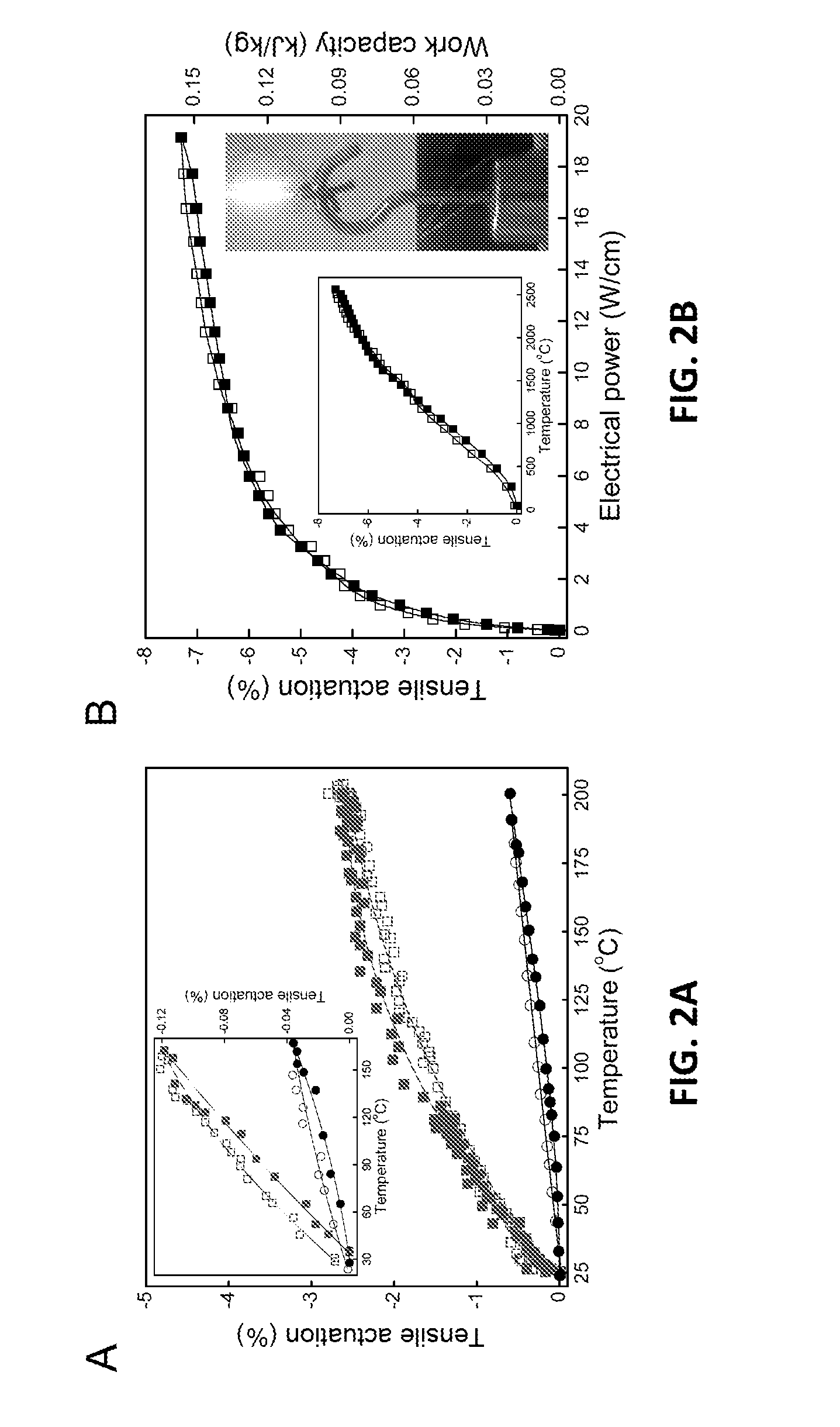

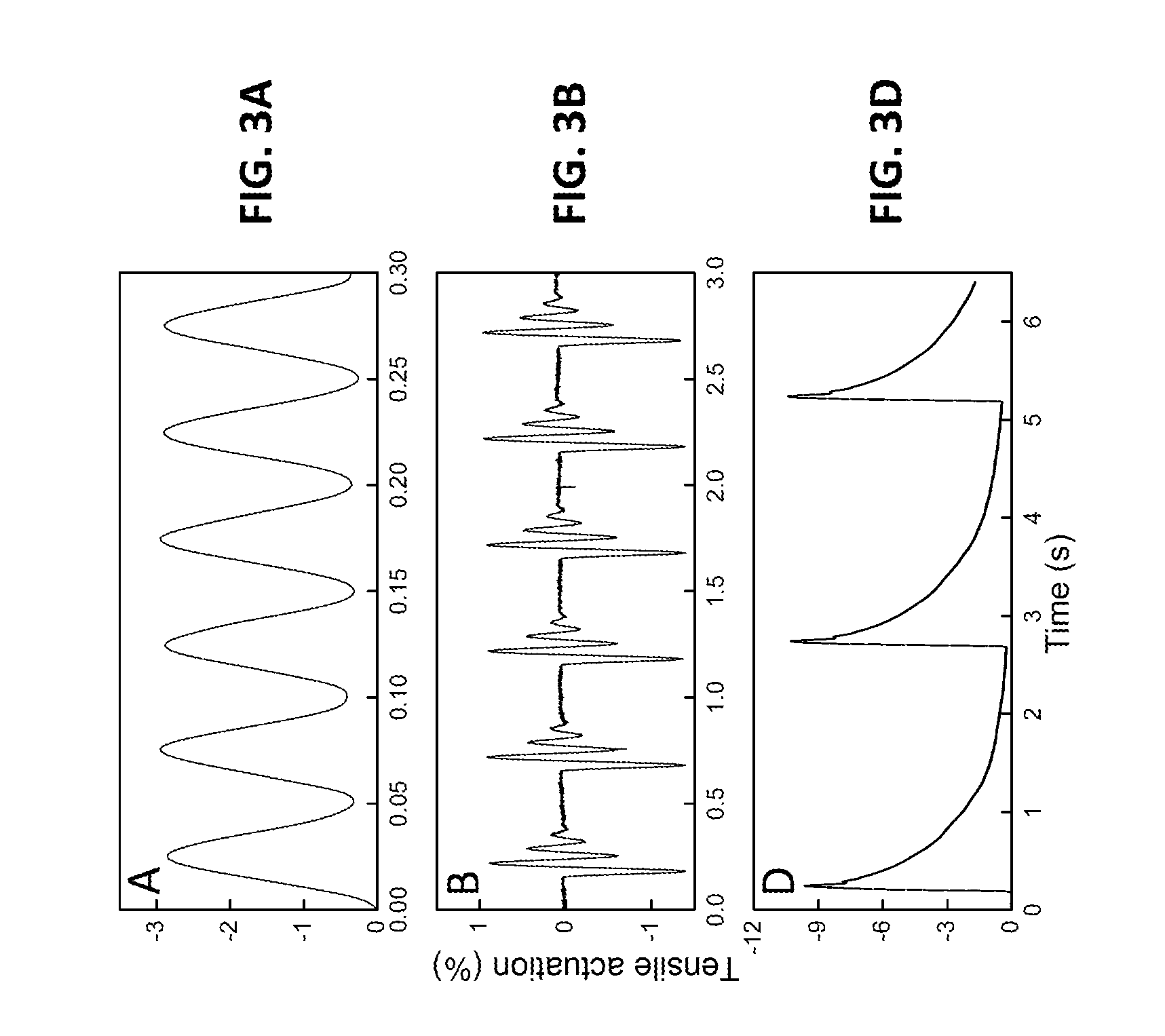

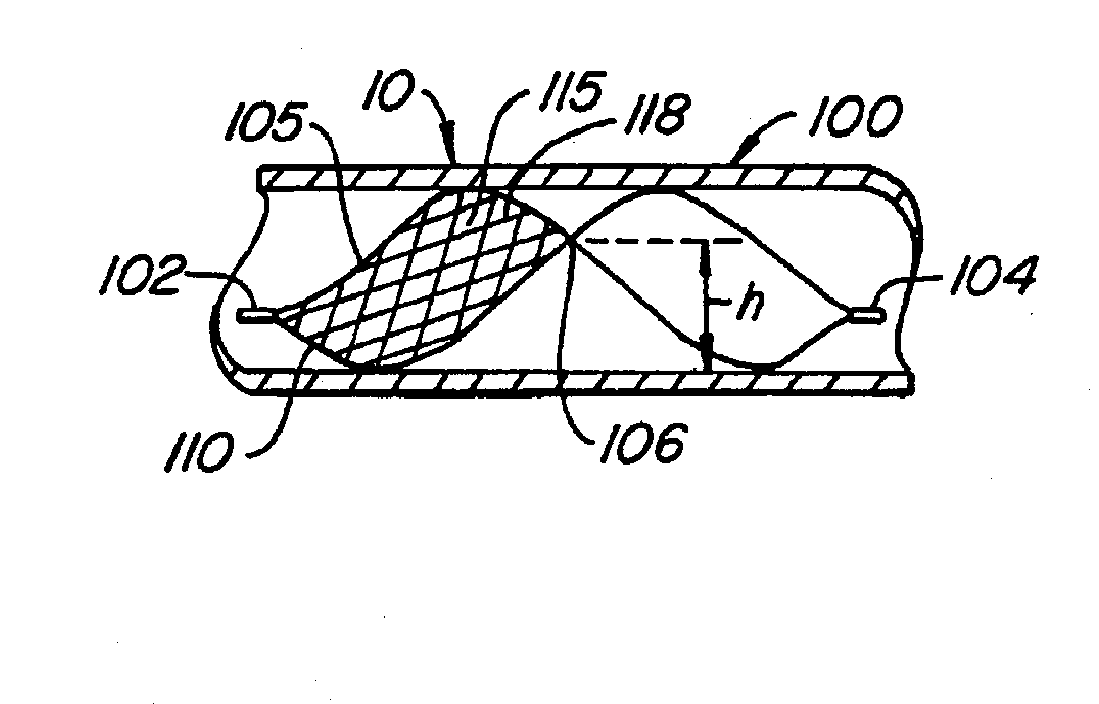

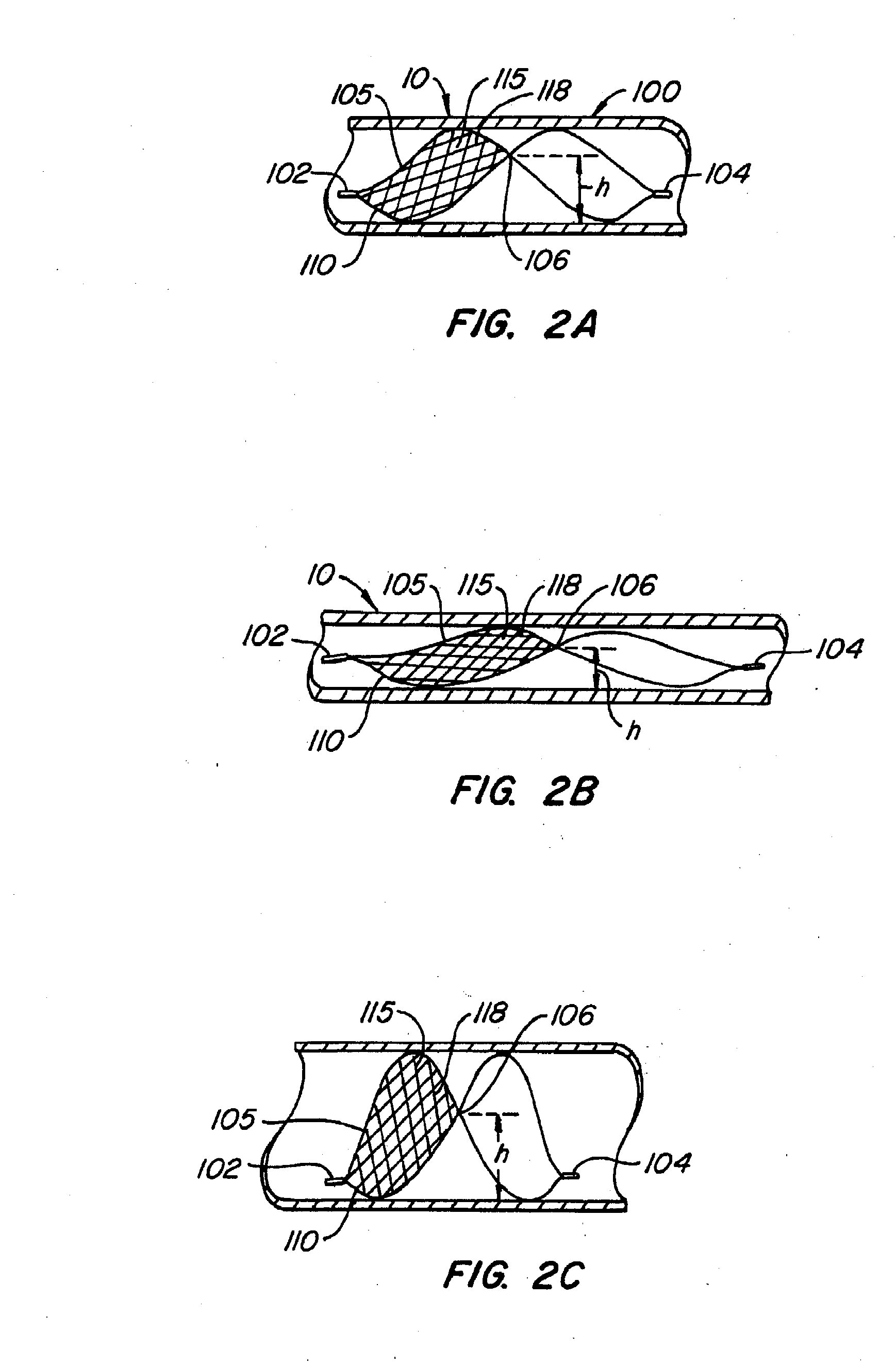

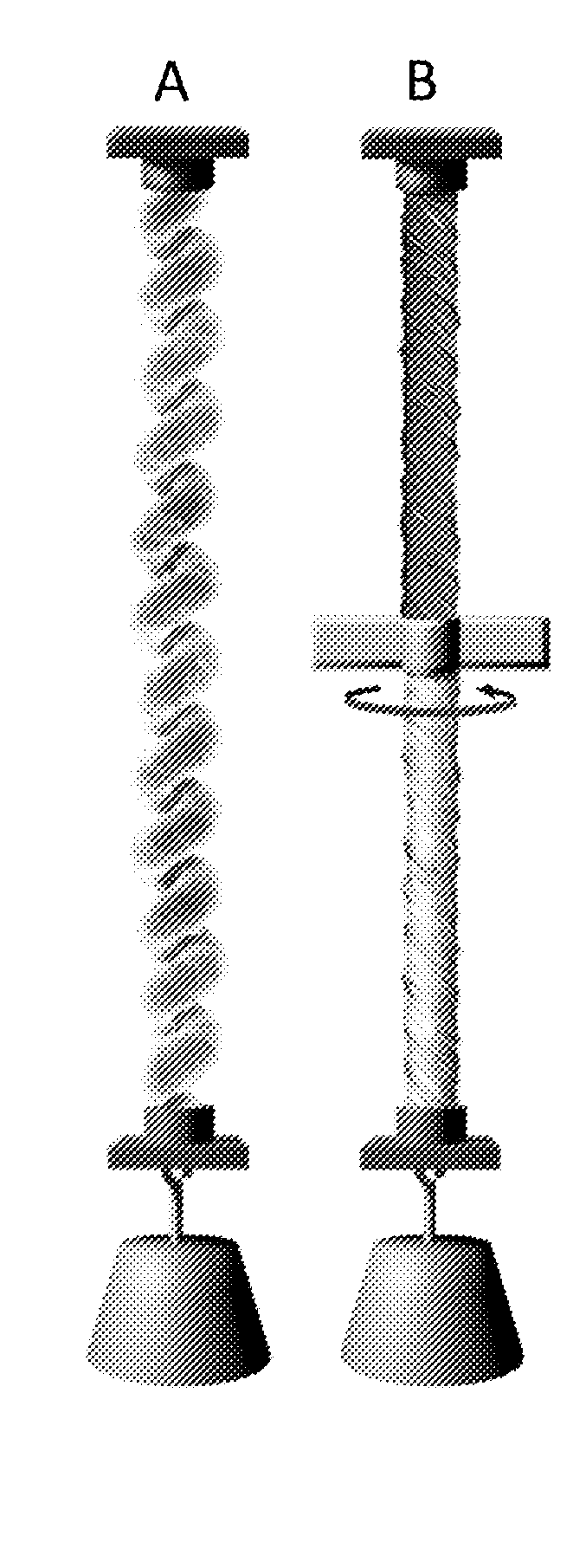

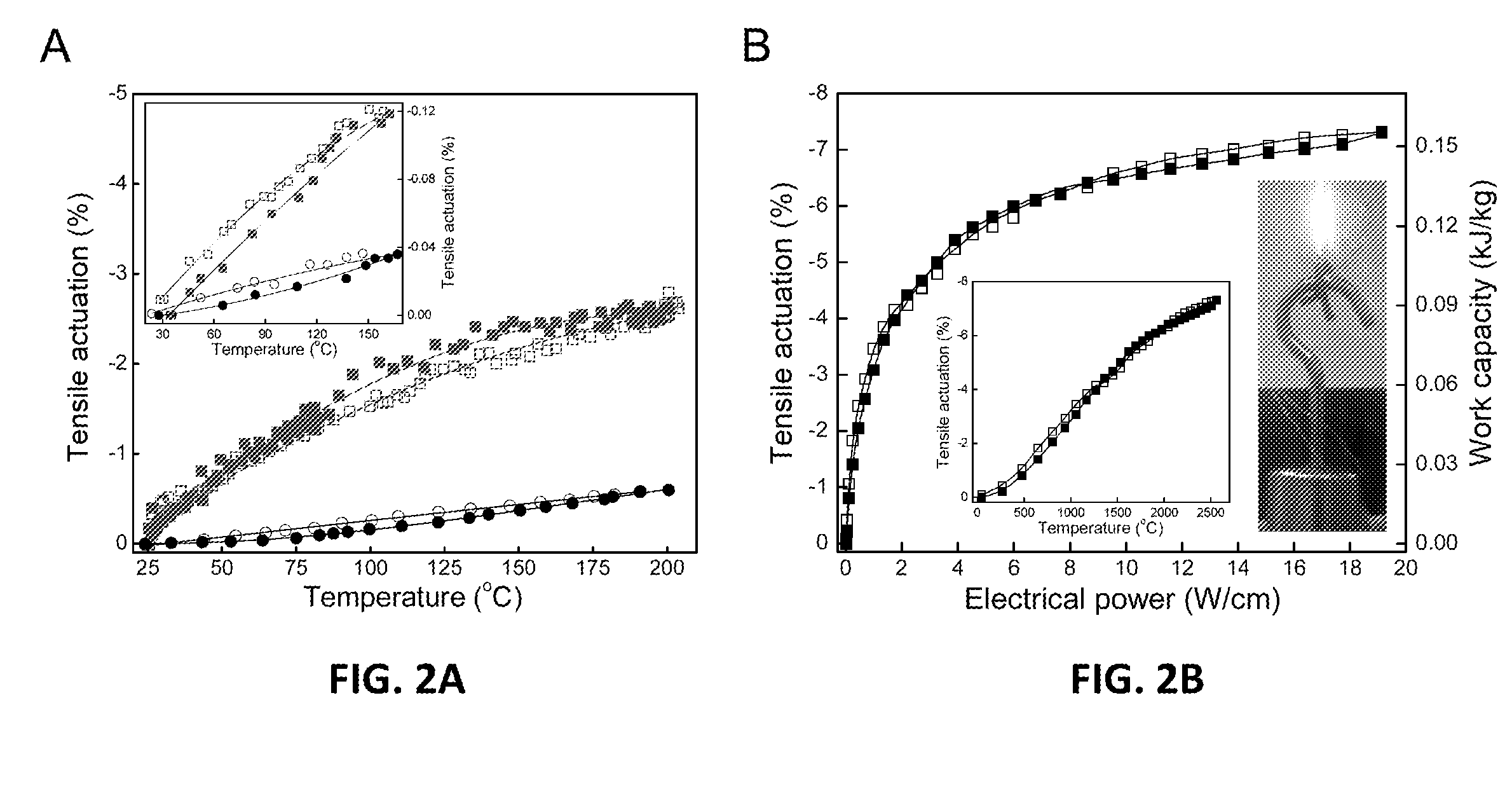

Coiled and non-coiled twisted nanofiber yarn torsional and tensile actuators

Actuators (artificial muscles) comprising twist-spun nanofiber yarn or twist-inserted polymer fibers generate torsional and / or tensile actuation when powered electrically, photonically, chemically, thermally, by absorption, or by other means. These artificial muscles utilize non-coiled or coiled yarns and can be either neat or comprising a guest. Devices comprising these artificial muscles are also described.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Electrostatic spinning nano-fibre yarn system and preparation of nano-fiber yarn

InactiveCN101302673ASimple processing methodMonocomponent polyethers artificial filamentFilament/thread formingCircular discFiber

The invention discloses a static spinning nano-fiber yarn system and a preparation method for the nano-fiber yarn. The invention comprises a rotation axis which is provided with a disc grooved along the radius, a sliding block and a cutter groove, wherein, the upper surface of the disc is provided with an annular copper film which has a radial notch corresponding to the groove of the disc; the upper part of the disc is provided with a syringe, the outlet of which is provided with a metal syringe needle connected with the positive pole of a direct-current high voltage generator. One end of the cutter groove goes through the disc groove to contact with both sides of the radial notch of the copper film and be connected with the negative pole of the direct-current high voltage generator; a cutter with one free end is arranged in the cutter groove, wherein, the free end extends above the disc through the disc groove and moves along the groove. The sliding block slides axially along the rotation axis. Furthermore, the outer side of the disc is provided with a silk guide roller, a twister, a winding roller and a lead recovery roller. The spinning solution is made into nano-fiber yarn by the system. The yarn prepared by the invention has relatively higher strength, thus being prospective to provide the static spinning fiber products with a wider application field.

Owner:XI'AN POLYTECHNIC UNIVERSITY

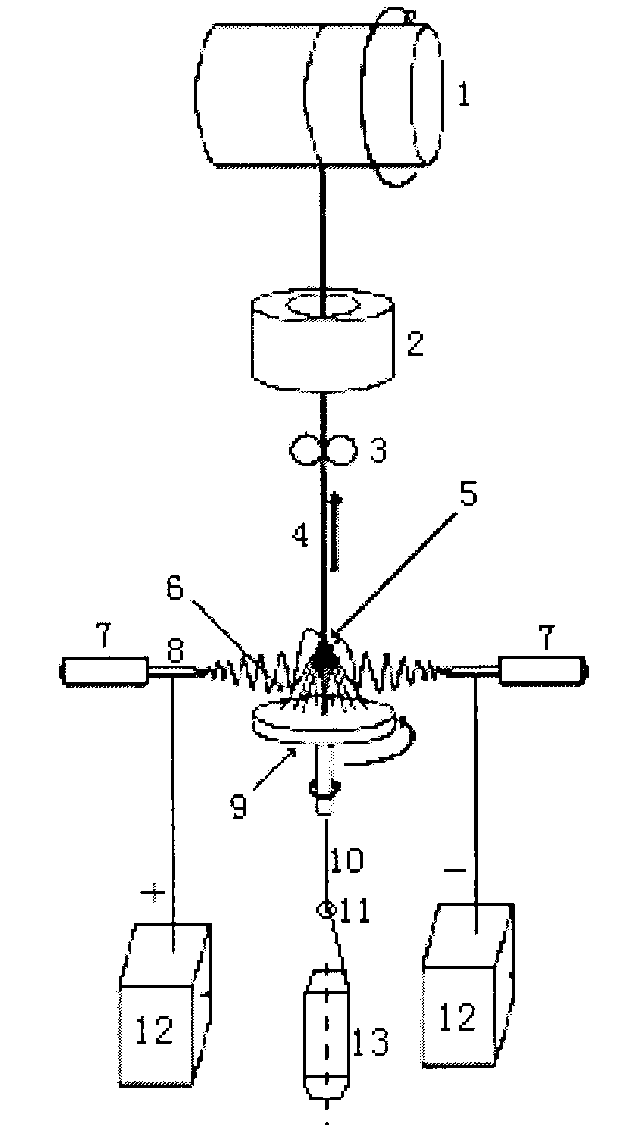

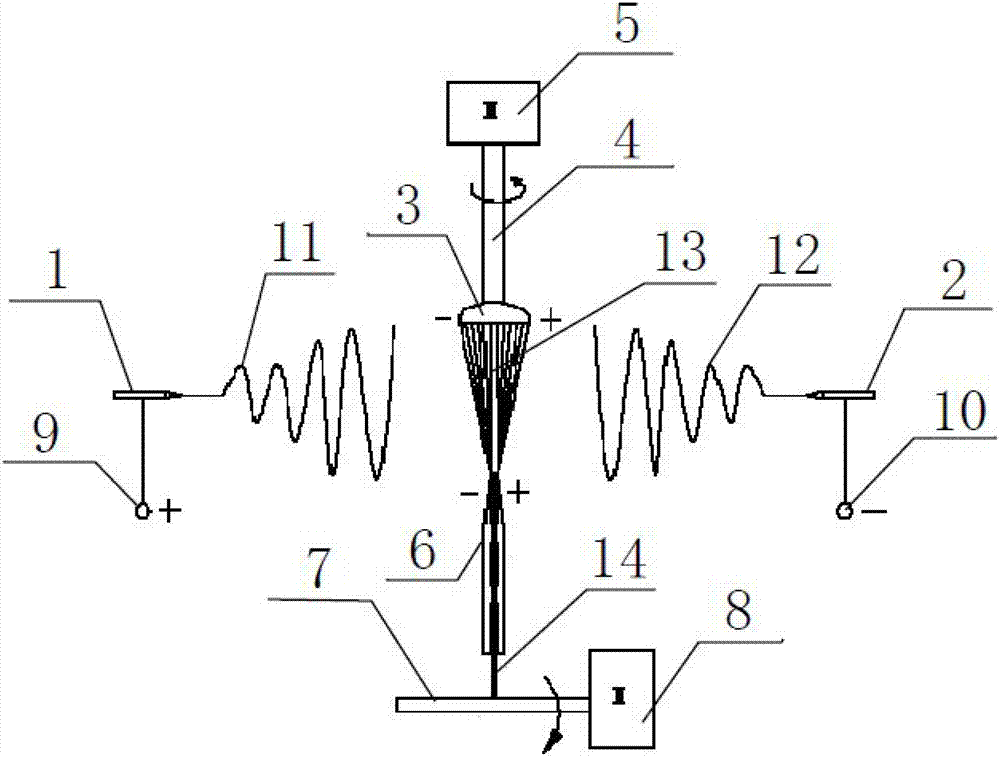

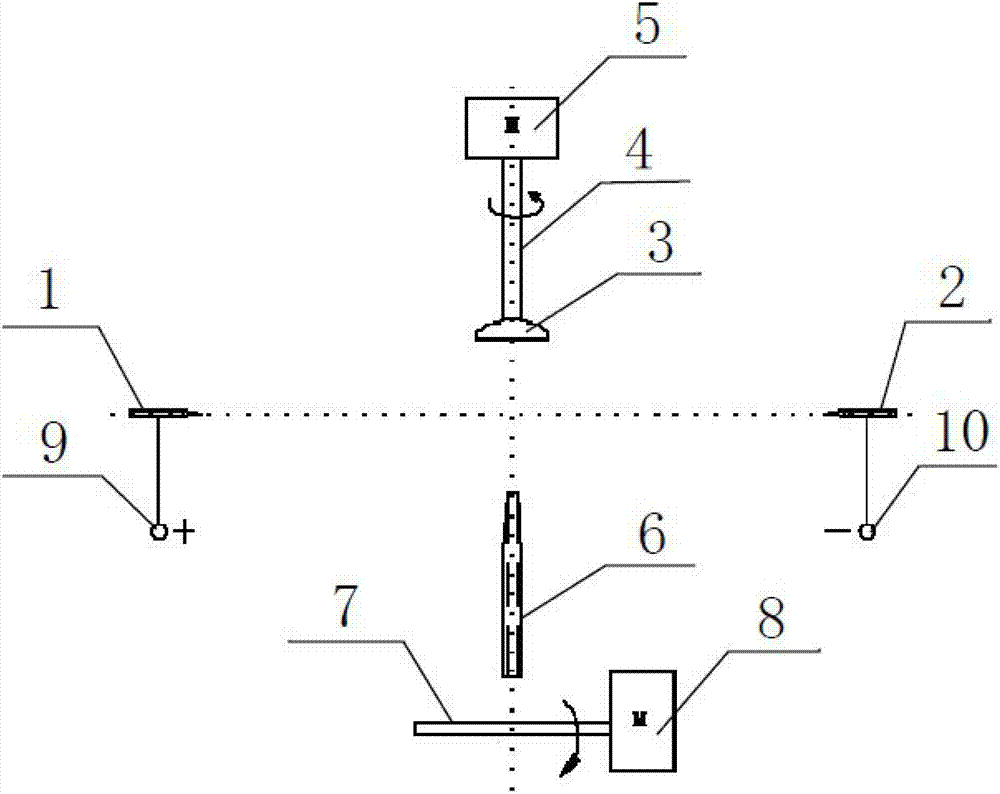

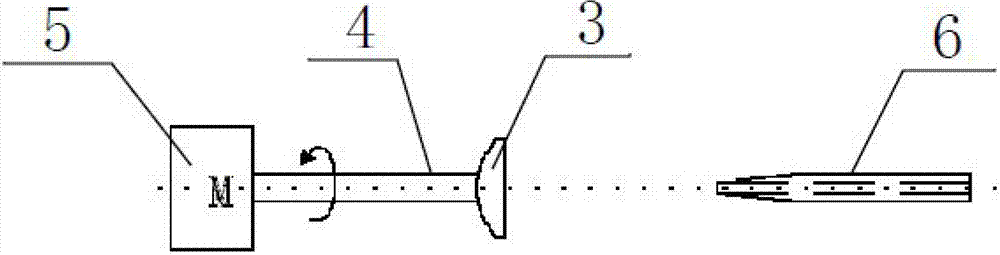

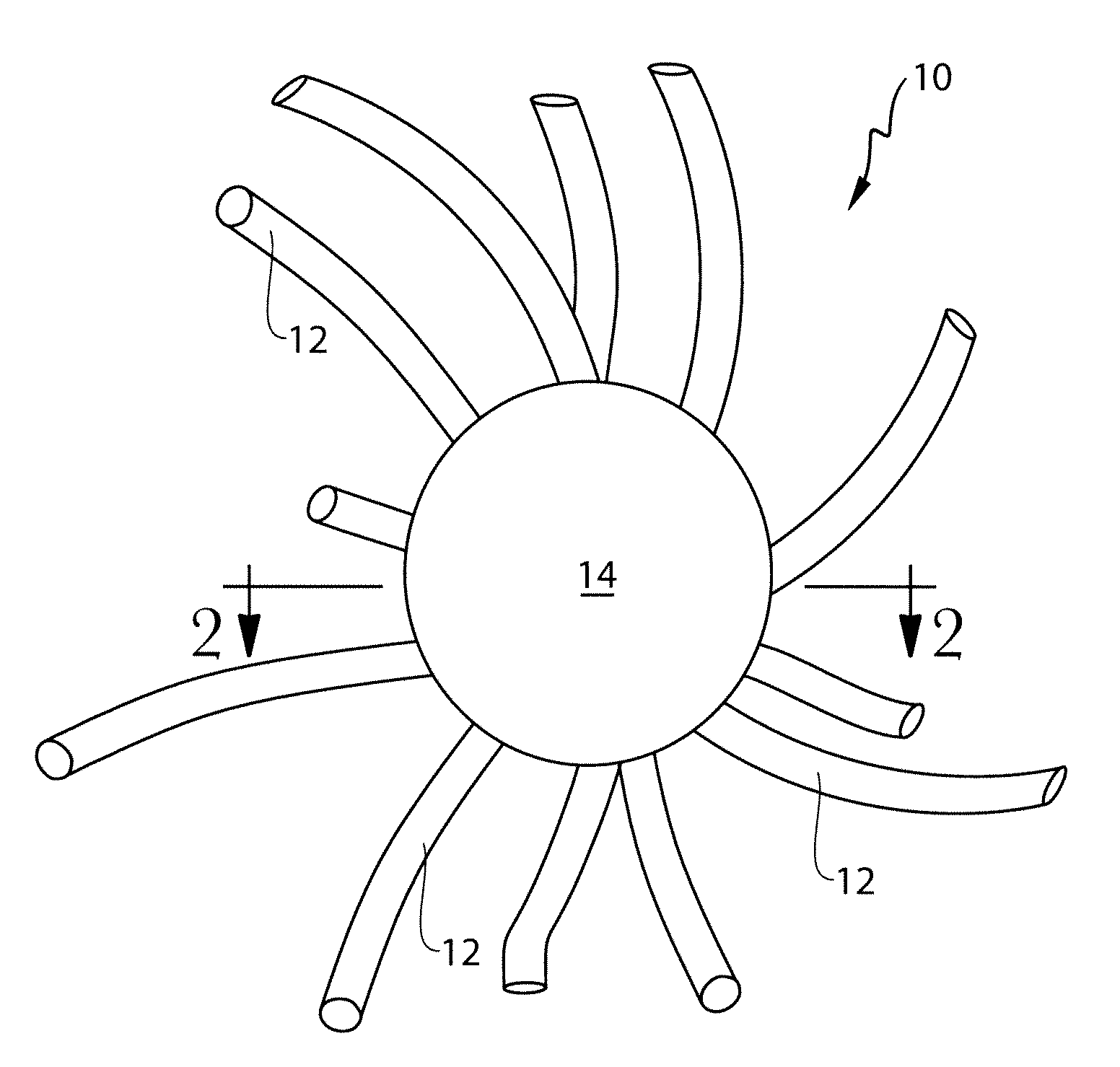

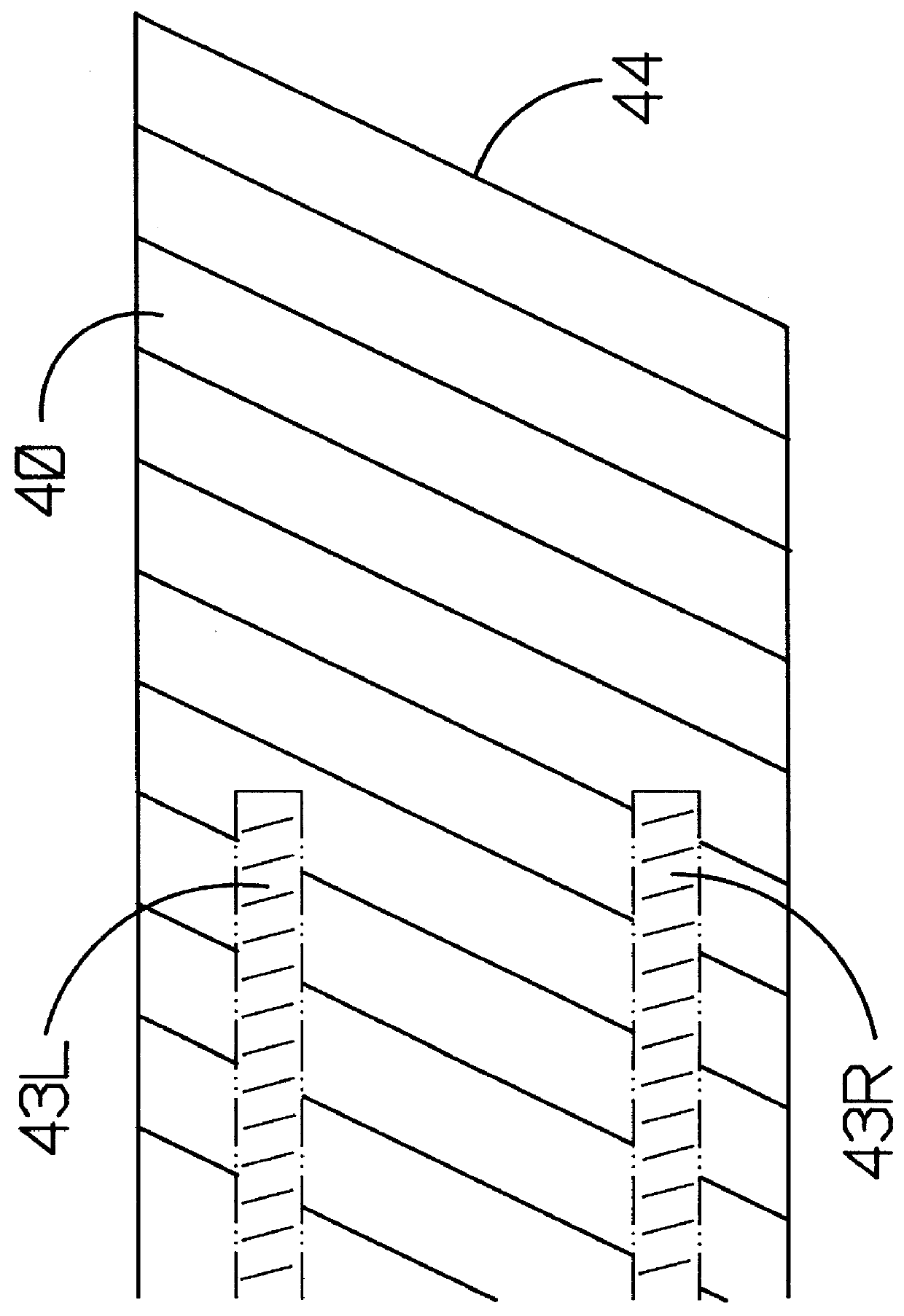

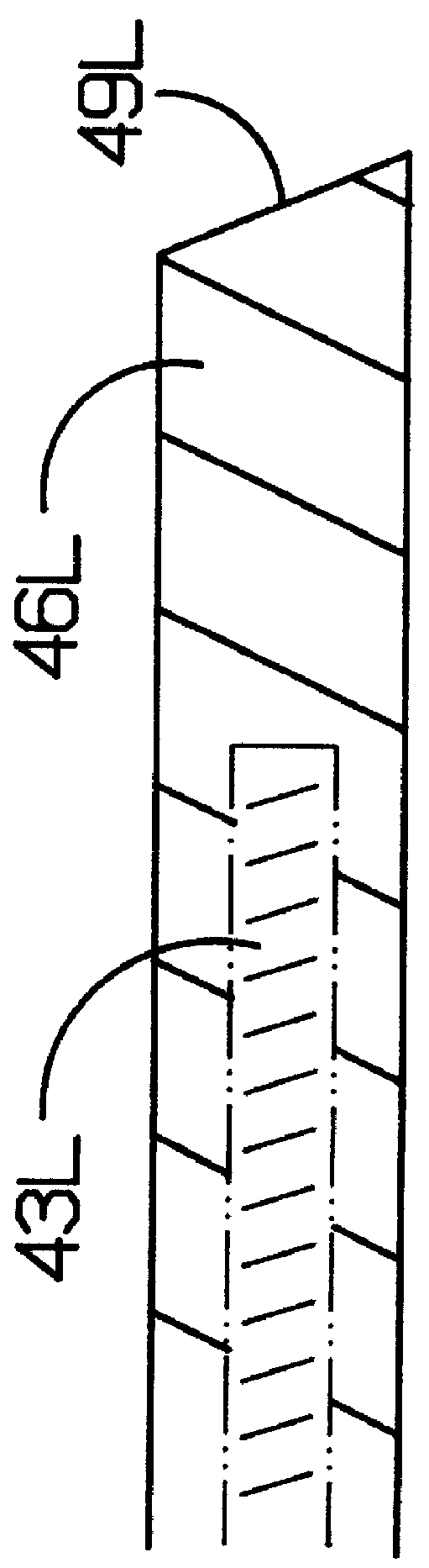

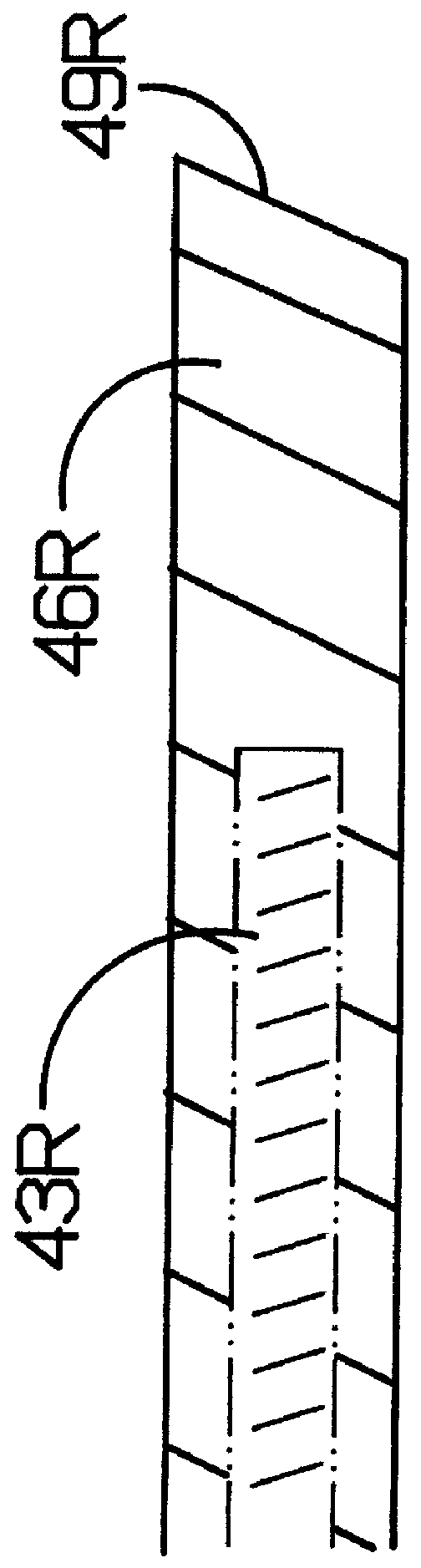

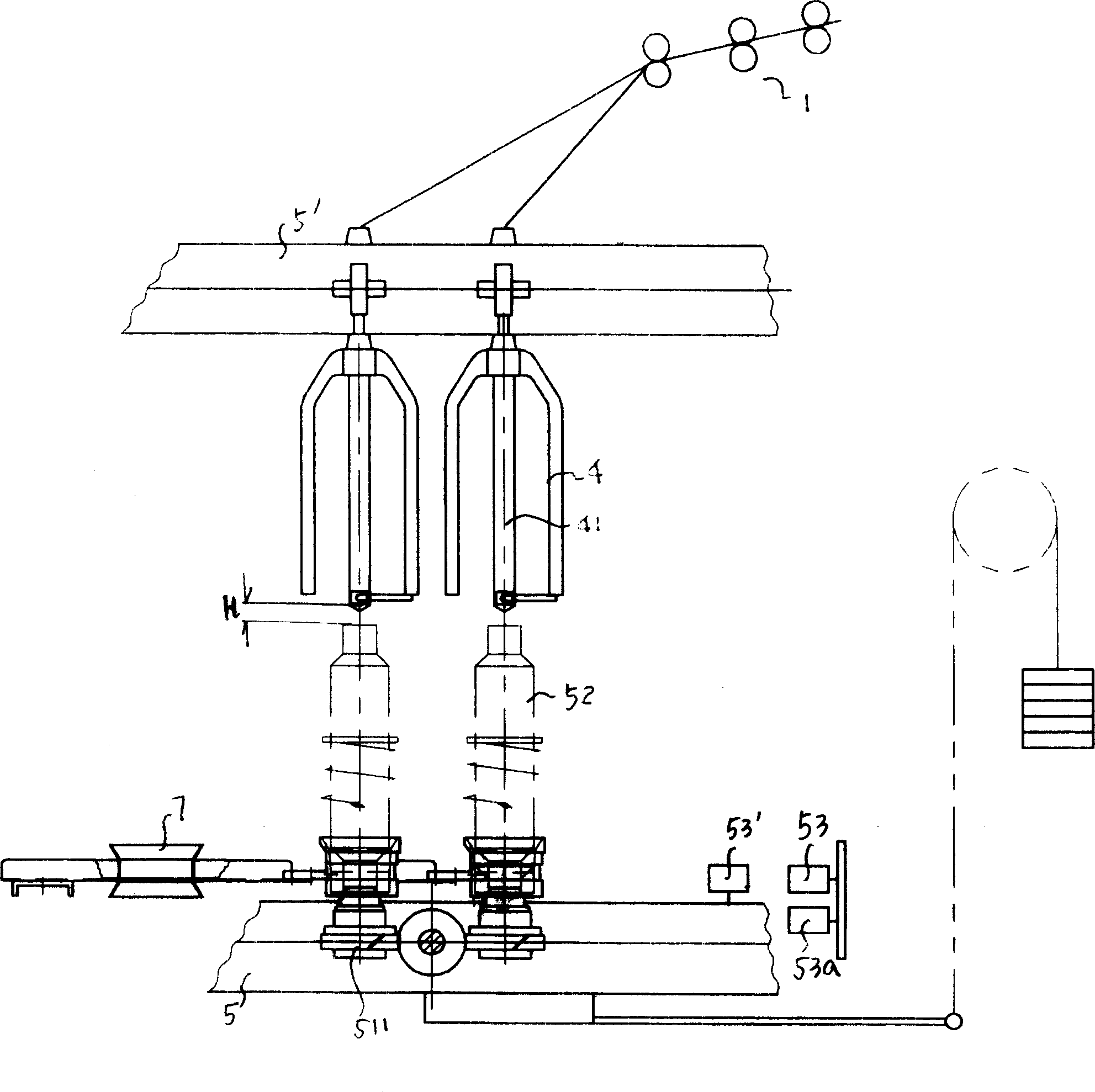

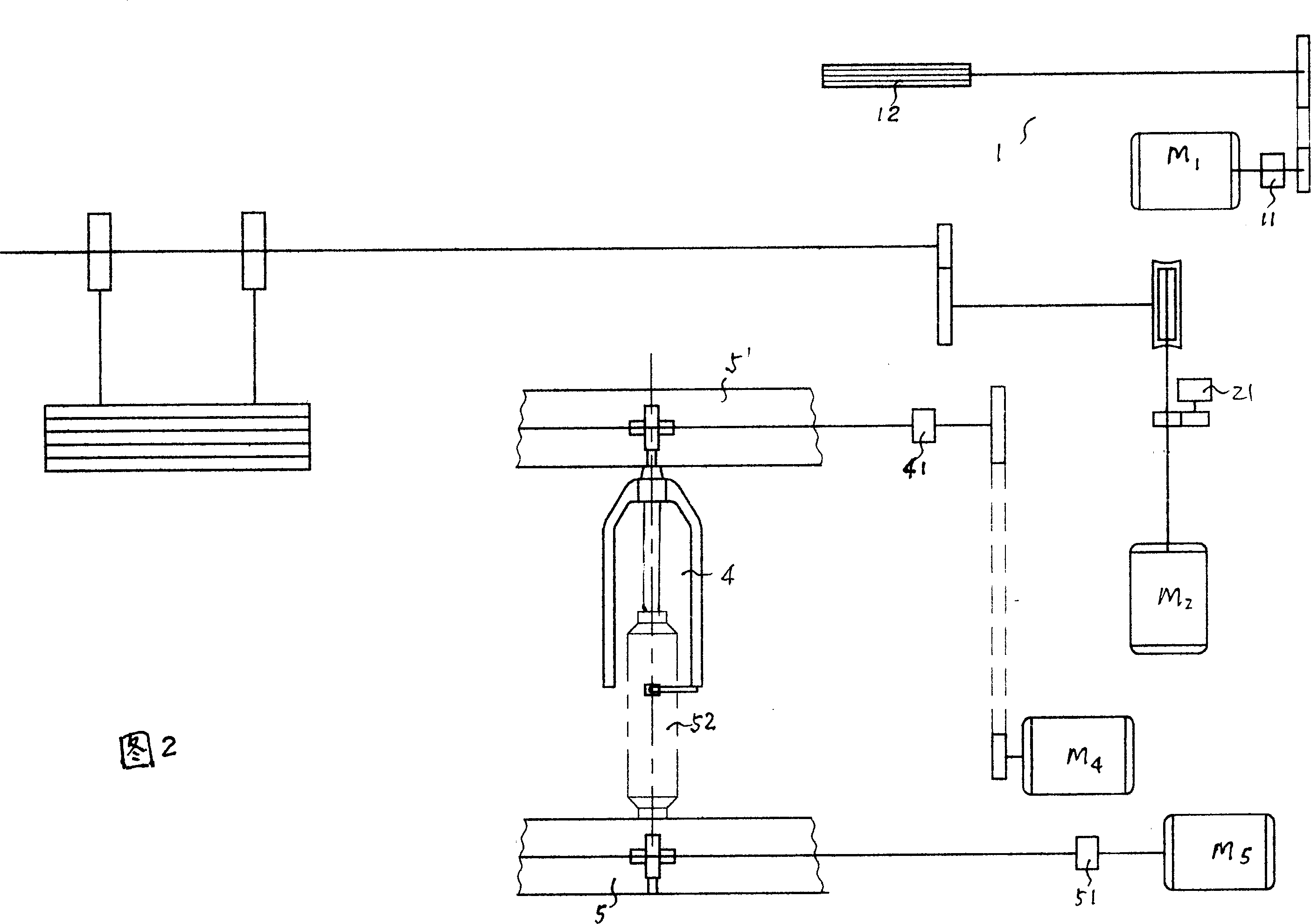

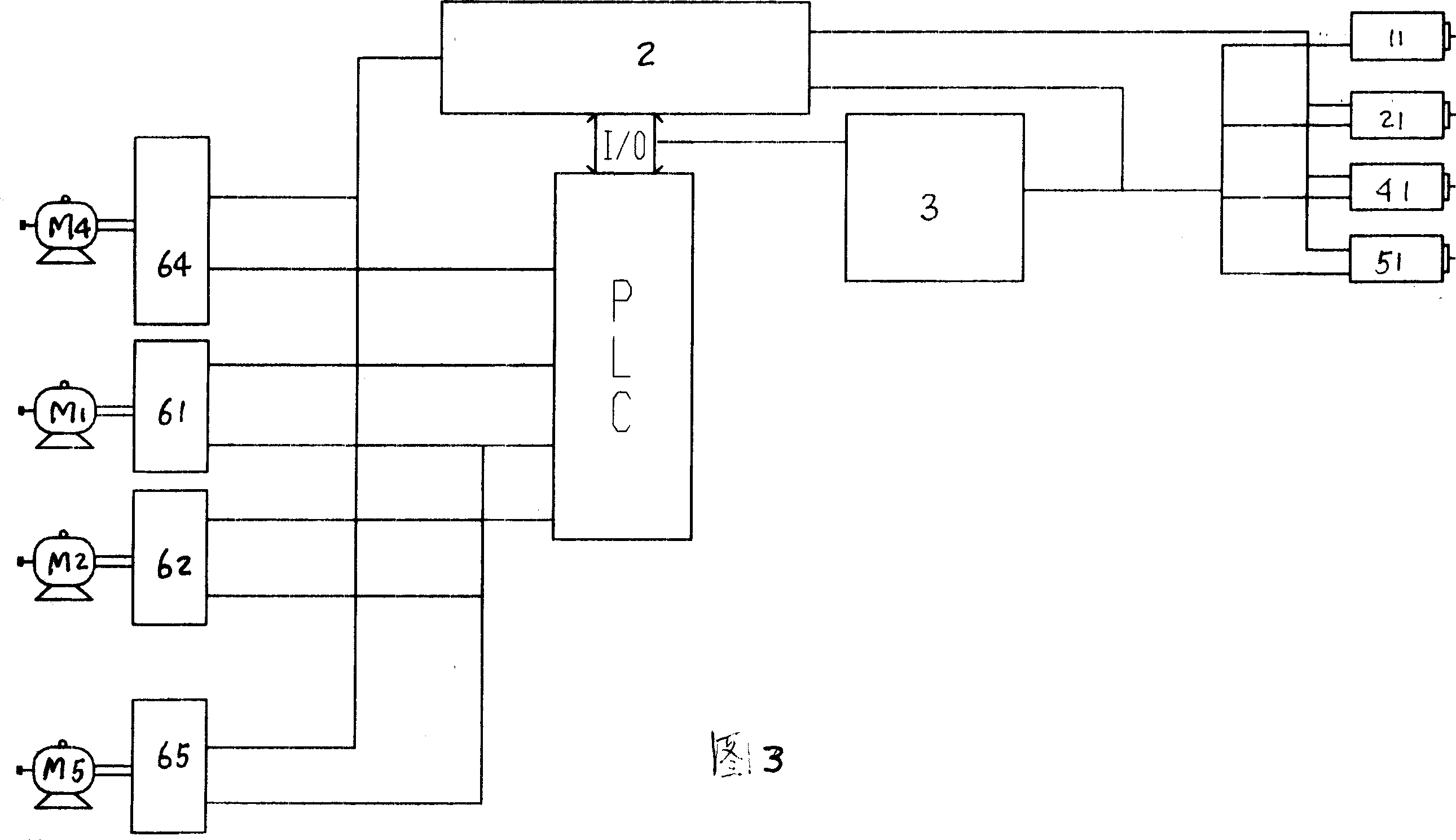

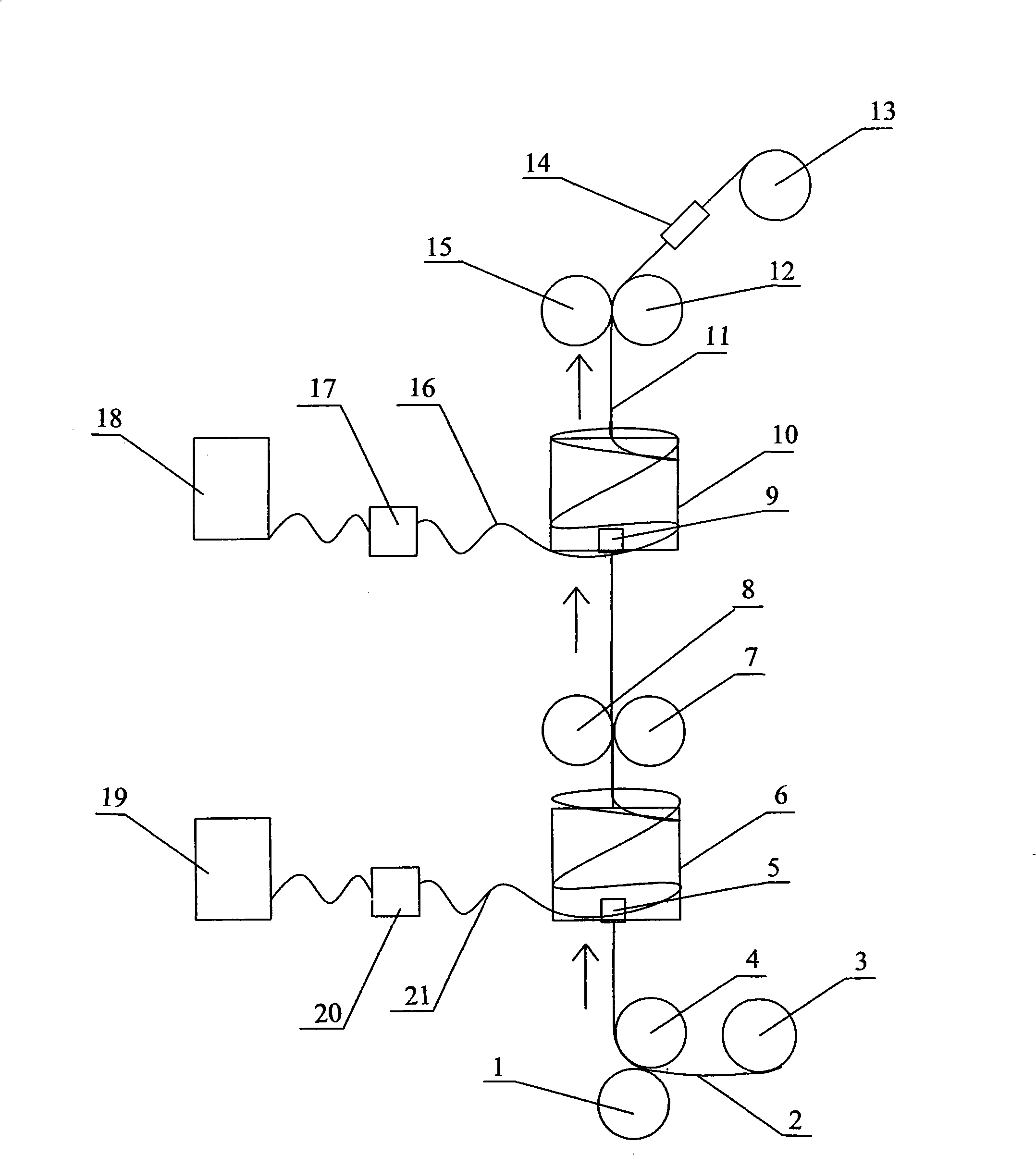

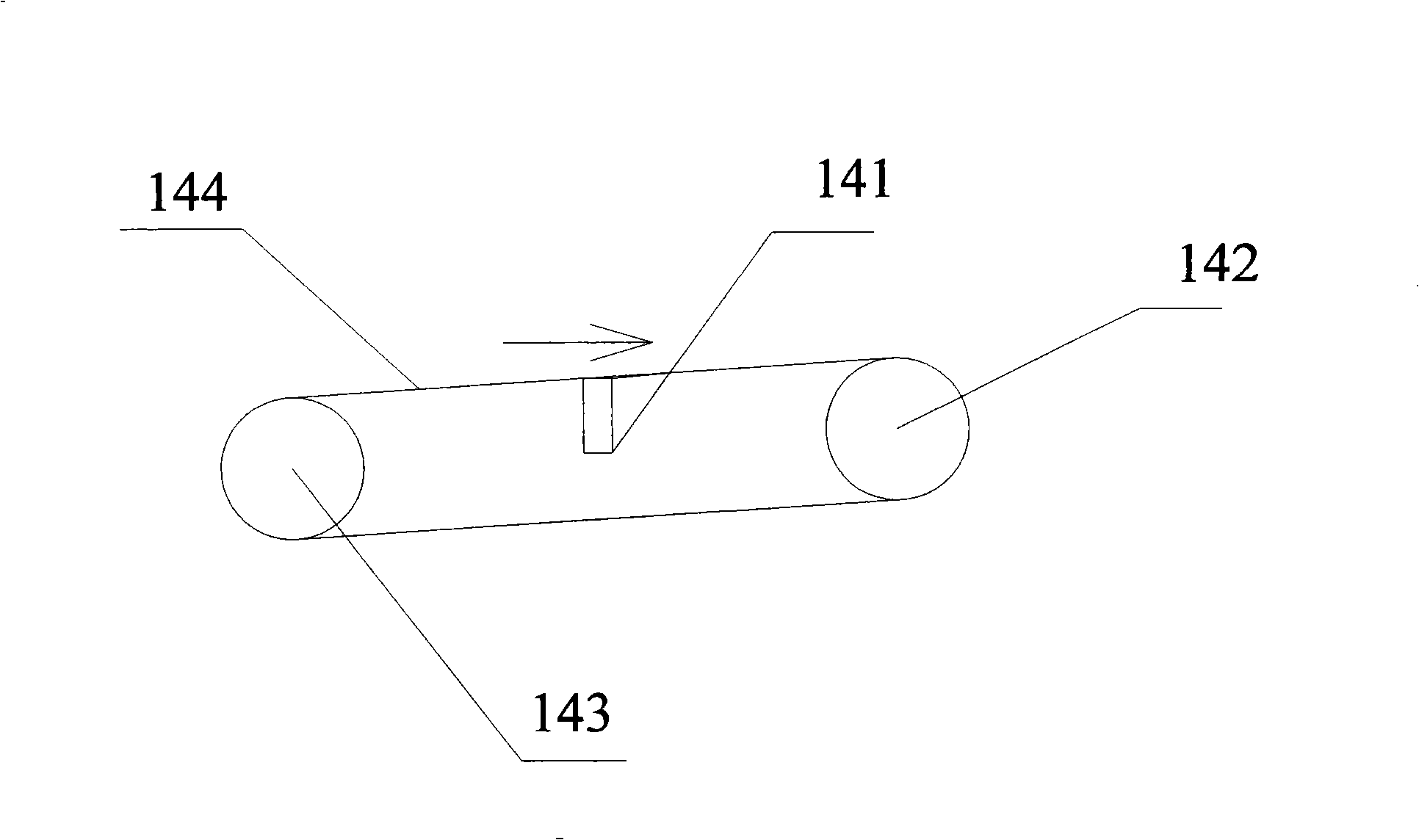

Continuous preparation device and method for orientated electrostatic spinning nanofiber yarn

ActiveCN103088478AGood orientationIncrease productionFilament/thread formingContinuous wound-up machinesFiberYarn

The invention relates to a continuous preparation device and a method for orientated electrostatic spinning nanofiber yarn. The device comprises a metal round target and a yarn guide rod. The center of the metal round target is connected with one end of an insulating rod, the insulating rod is driven by a motor I to rotate, a metal top end of the front portion of the yarn guide rod is aligned with the center of the metal round target, the yarn guide rod is perpendicular to a bobbin, the bobbin is driven by a motor II to rotate, the metal round target, the insulating rod, the motor I and the yarn guide rod are arranged on the same center straight line, a spinning jet I and a spinning jet II which are symmetrical with each other are arranged on the left side and the right side of the metal round target and the yarn guide rod, the spinning jet I is connected with a high voltage static positive terminal, and the spinning jet II is connected with a high voltage static negative terminal. By means of the continuous preparation device and the method for the orientated electrostatic spinning nanofiber yarn, continuous production of the nanofiber yarn is achieved, the yield of electrostatic spinning is increased, and both the degree of orientation and the yield of the nanofiber yarn are high.

Owner:DONGHUA UNIV

Filaments comprising an ingestible active agent nonwoven webs and methods for making same

ActiveUS20120027838A1Monocomponent protein artificial filamentOrganic active ingredientsFiberActive agent

Filaments containing a filament-forming material and an additive, such as an ingestible active agent, nonwoven webs, and methods for making such filaments are provided.

Owner:THE PROCTER & GAMBLE COMPANY

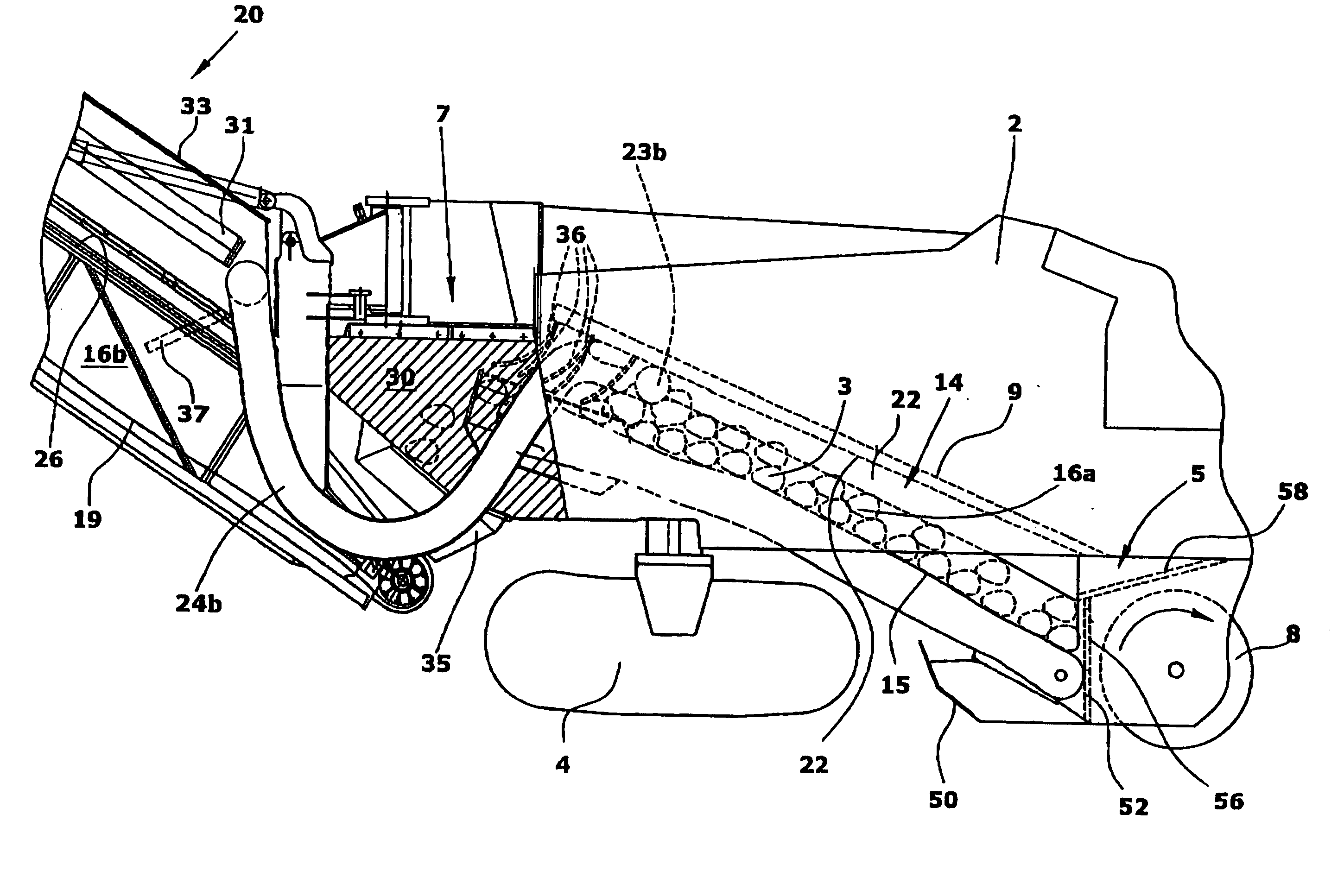

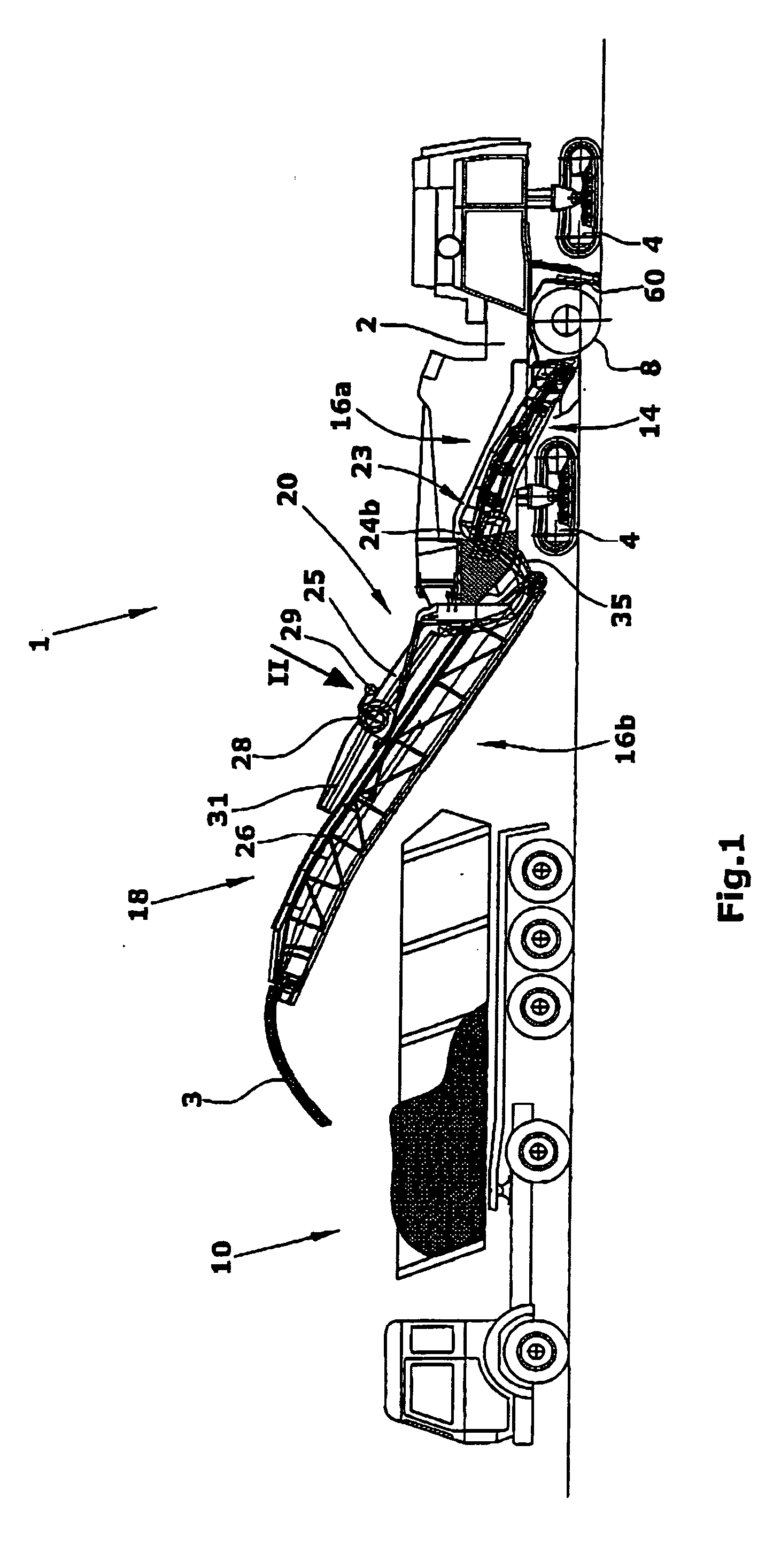

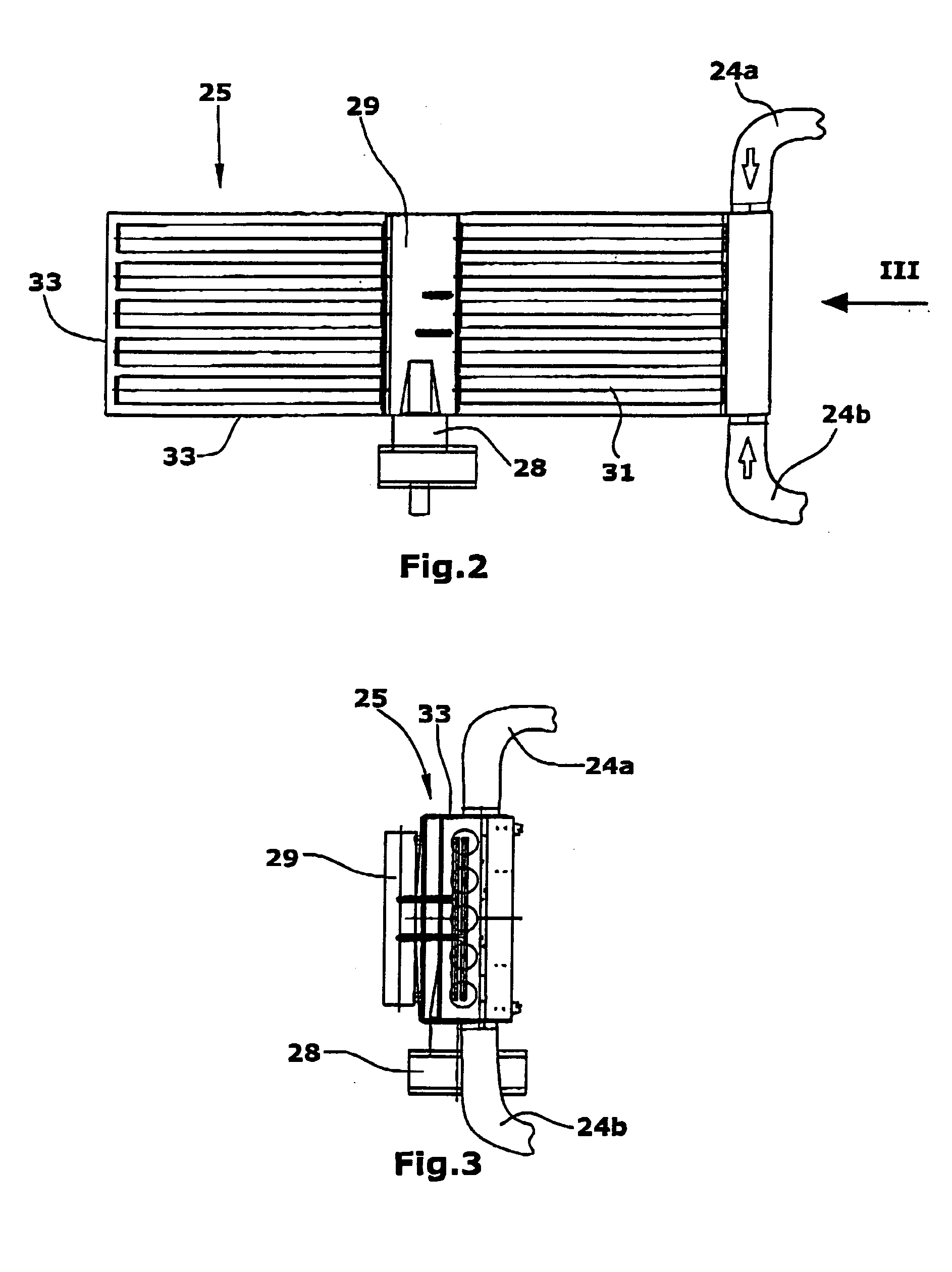

Milling machine as well as method for working ground surfaces

ActiveUS20050179309A1Inhibit currentEasy to useCombination devicesSlitting machinesEngineeringContaminated air

At a milling machine to work ground surfaces, with a machine frame, a milling drum supported at the machine frame, at least one transport device arranged at the machine frame which accepts the milled material from the milling drum, as well as with a suction device for the air polluted with dusts and vapors, whereby the milled material on the at least one transport device is enclosed by a channel, the suction device is connected to a rear channel section of the channel in the direction of the material transport and sucks off the air polluted during milling at the milling drum and in the rear channel section essentially in the direction of the material transport, it is provided that the suction device consists of a suction ventilator, a separator device for solids and a suction channel which is connected to the rear channel section, that the suction ventilator is arranged downstream of the separator device, and that the suction device disposes of the separated solids onto the transport device in a forward channel section in the direction of the material transport or into a collecting device, and the suction ventilator blows off the cleaned air into the environment.

Owner:WIRTGEN GMBH

Composite, break-resistant sewing thread and method

InactiveUS6405519B1Improve fracture resistanceReduce tensionDrafting machinesContinuous wound-up machinesFiberYarn

A composite, break-resistant sewing thread having a core of continuous multi-filament, non-stretch high-tenacity synthetic yarn and a cover of drafted staple fibers air-jet twisted around and covering the core for protecting the core from heat and friction during a sewing operation. The yarn is plied.

Owner:BURKE MILLS

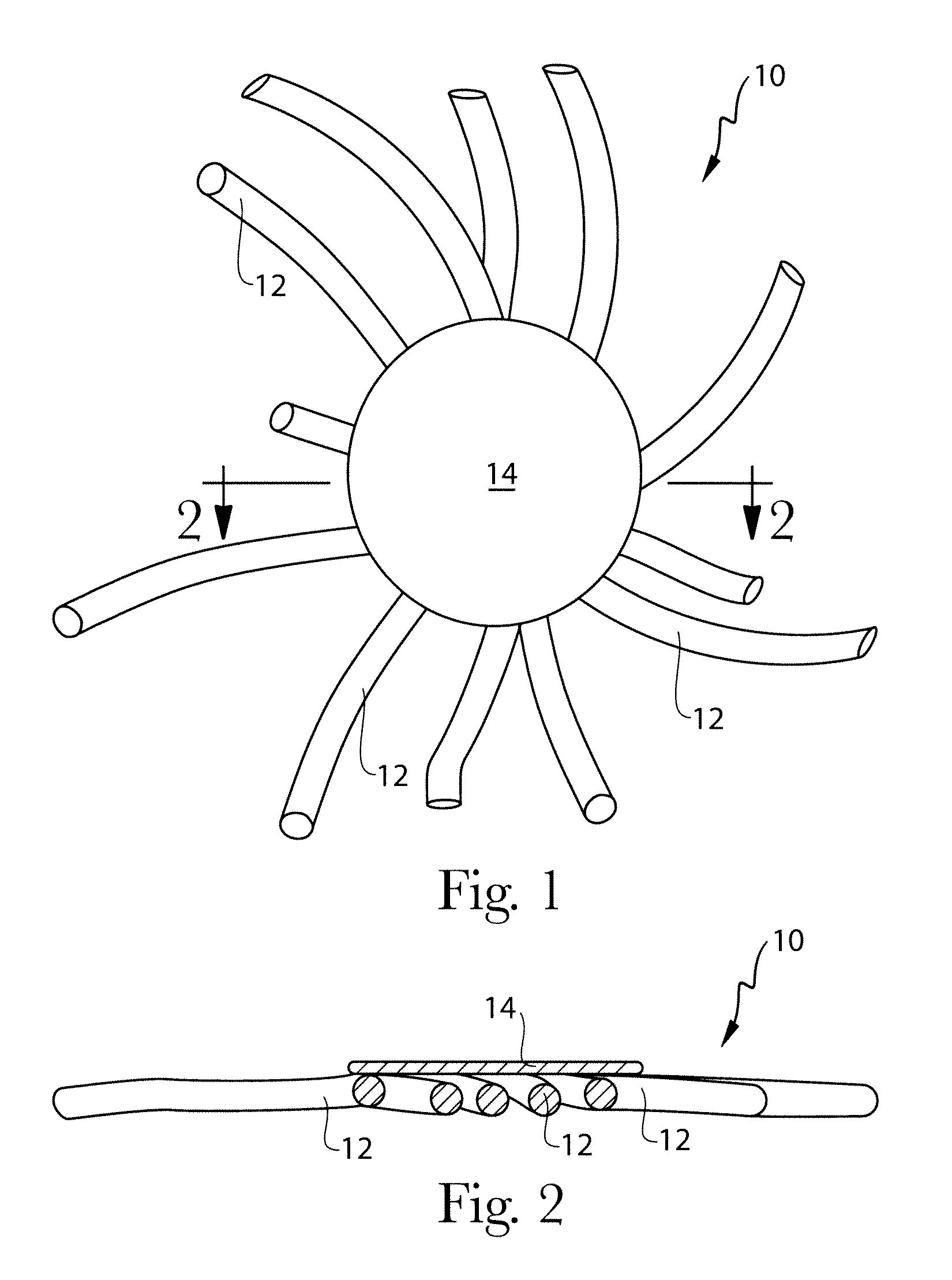

Spiral shaped filter

Owner:CRUX BIOMEDICAL

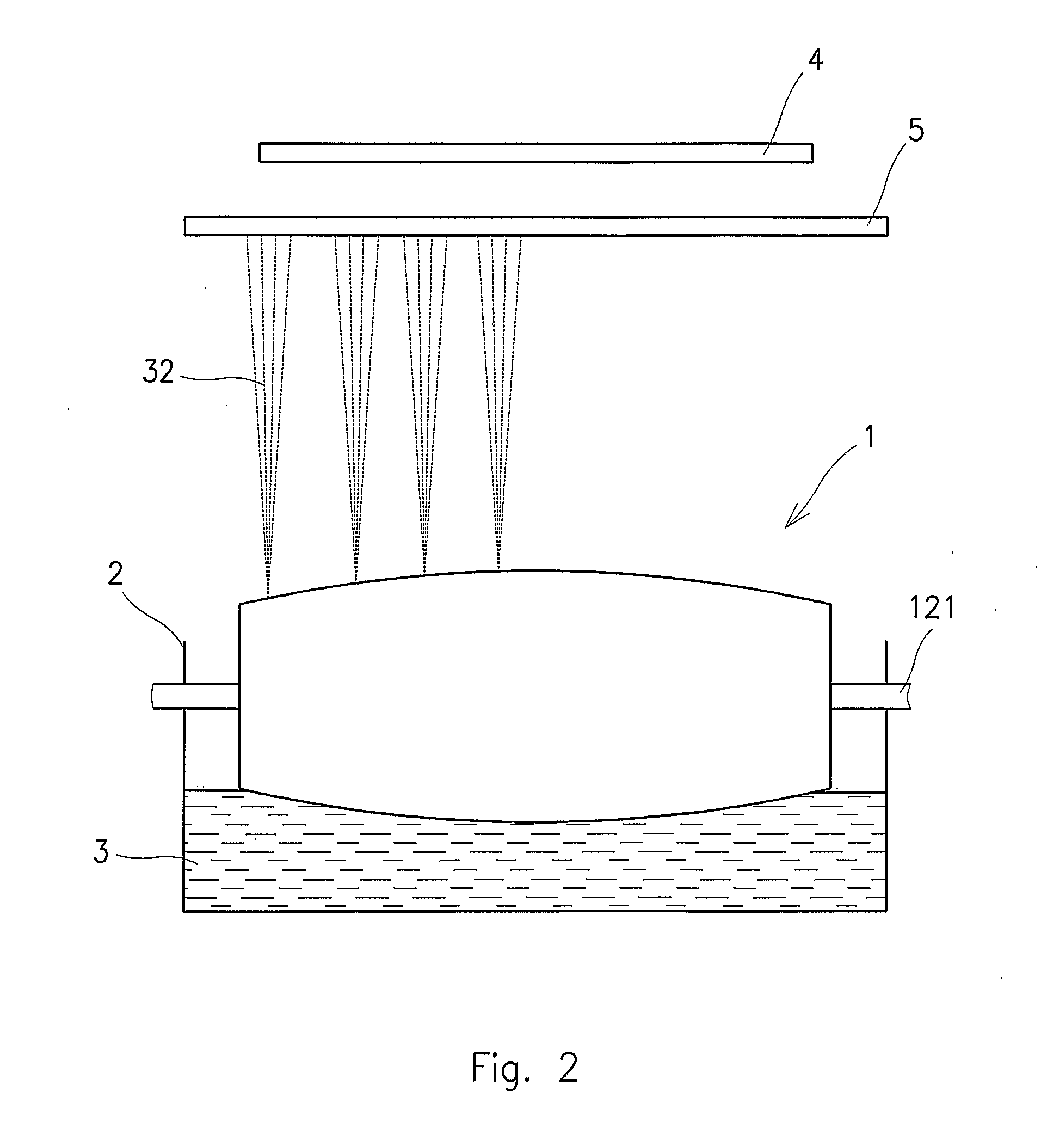

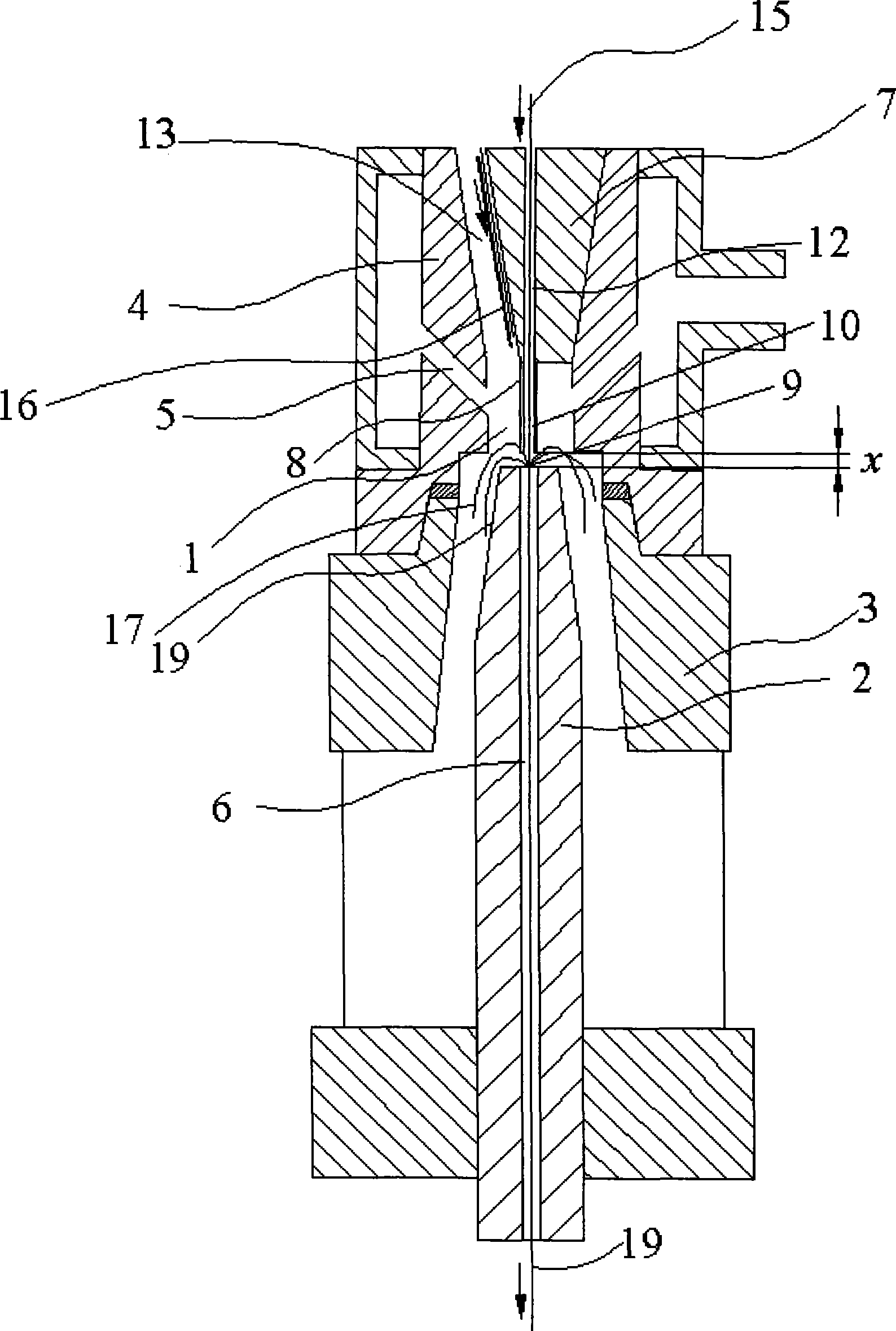

Method and Device for Production of Nanofibres From the Polymeric Solution Through Electrostatic Spinning

Production method of nanofibres from the polymeric solution through electrostatic spinning in electric field created by a difference of potentials between the collecting electrode (4) and pivoted spinning electrode (1) of an oblong shape touching by a part of its circuit the polymeric solution (3), while by rotation of the spinning electrode (1) the polymeric solution (3), at least by a portion of its surface, is carried out into the electric field in which on the surface of the collecting electrode (4) the nanofibres are created which are carried to the collecting electrode (4) and deposited on the surface of a basic material (5) guided between the spinning electrode (1) and the collecting electrode (4) in vicinity of the collecting electrode (4). The polymeric solution (3), on surface of the spinning electrode (1) in a place of intersection of surface of the spinning electrode (1) with the plane interlaid by the axis of the spinning electrode (1) and being perpendicular to the plane of the base material (5), along the whole length of the spinning electrode (1), is subject to the electric field of a maximum and equal intensity, through which a high and even spinning effect is achieved along the whole length of the spinning electrode (1). The invention also relates to the device for production of nanofibres from polymeric solution through electrostatic spinning.

Owner:ELMARCO SRO

Homeowner's method of snow removal with a motor vehicle

This method provides various high-power-ratio snow removal devices which clear paths narrower than the motor vehicles. We use small, light, low-priced, yet also safe, durable devices to clear the narrow swaths. High power ratios result from applying motor vehicle horsepower to small snow removal devices similar to those found on lawn tractors. Such devices may comprise moldboard plows (FIGS. 3, 9, 10, 11, 15, 16), snow throwers (FIGS. 7 and 13), or combinations of both types (FIG. 12 and 17). Quick-connect and quick-release fittings (FIGS. 3A, 3B, 6, 8, 9A, 9B, 14) position each device for temporary propulsion by a vehicle. The connectors allow quick conversion of the family car to a plowing machine, and when plowing is done, quick re-conversion. A moldboard plow of about half the car's width (FIG. 3) is our preferred embodiment. The mini-moldboard (FIG. 10) is least expensive. Deepest snow can be handled by our tall, narrow moldboard (FIG. 15). We protect homeowners, their cars and their plows from injury when plows strike hidden objects. Protection devices comprise safety springs (60) and pivots (63, 67 and 69) of FIG. 3B, the tension-release mechanism mentioned but not detailed in FIG. 15, annor shields (396, 398) of FIG. 16 and various others mentioned or provided for in our drawings but not detailed. We prefer cars' chassis tie-down ears (72) in FIG. 3A, as connector points for our plow or thrower arms. For cars lacking such ears, we propose add-on ears. For example, tie-down ear (126) in FIG. 6.

Owner:NUGENT GORDON W

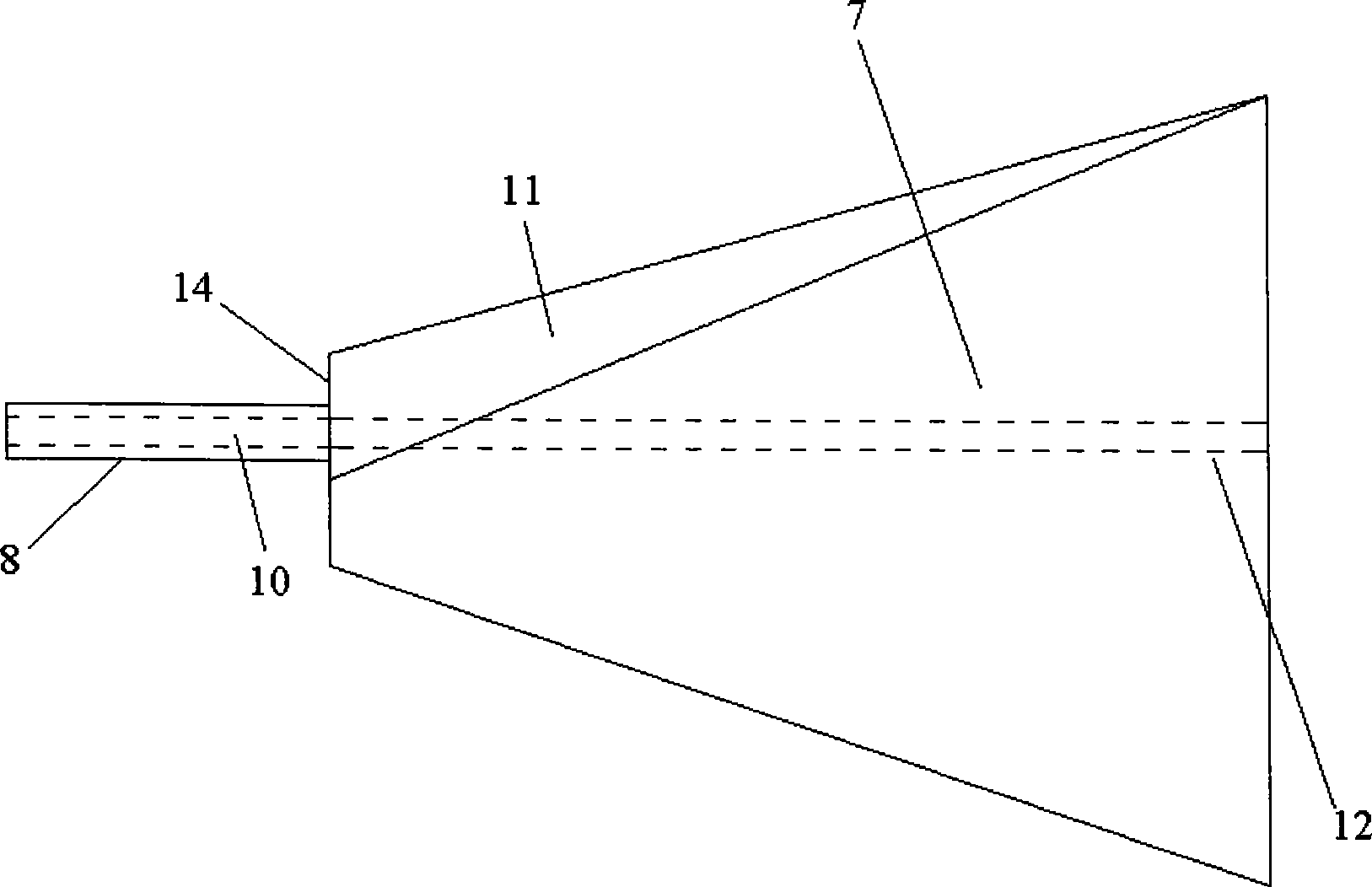

Air injection air vortex spinning apparatus capable of producing composite yarn

InactiveCN101368305AEvenly wrappedContinuous wound-up machinesOpen-end spinning machinesYarnFiber bundle

The invention provides an air-jet vortex spinning device which can be used to produce core-spun yarn. The air-jet vortex spinning device comprises a vortex chamber, a spindle-like doffing tube, a vortex tube connected with a fixing bracket, and an air jet orifice arranged inside the vortex tube. The air-jet vortex spinning device is characterized in that a truncated cone shaped or cylindrical fiber and core yarn guiding assembly is arranged at the entrance of the vortex tube. The air-jet vortex spinning device has the advantages that the air-jet vortex spinning device is capable of enabling the short fiber bundles to evenly wrap and twine the core yarn, and the core-spun yarn produced by the device is even in quality. The air-jet vortex spinning device ensures that the core yarn is totally wrapped by short fiber bundles, thus improving wear resistance of the core-spun yarn.

Owner:DONGHUA UNIV

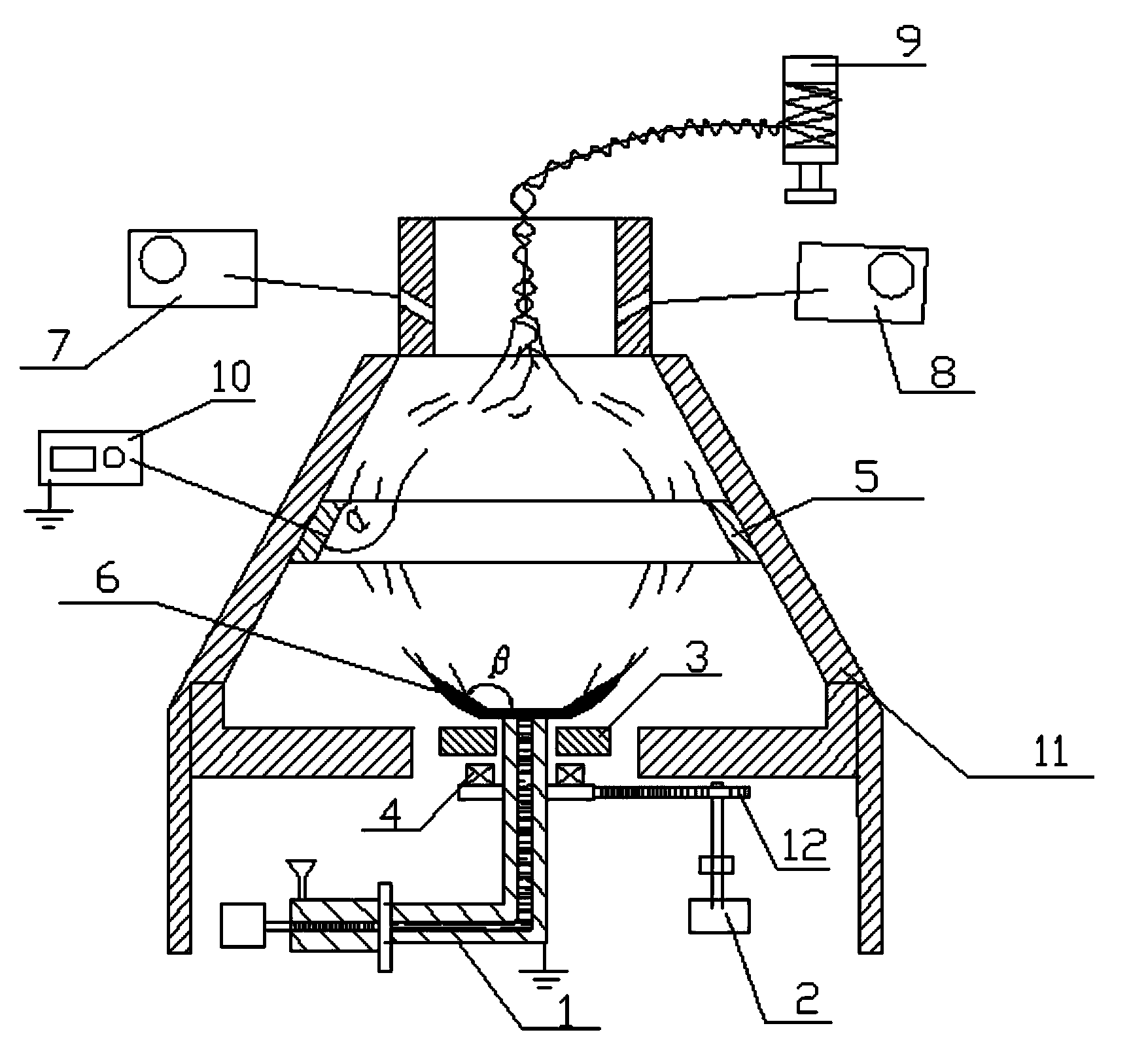

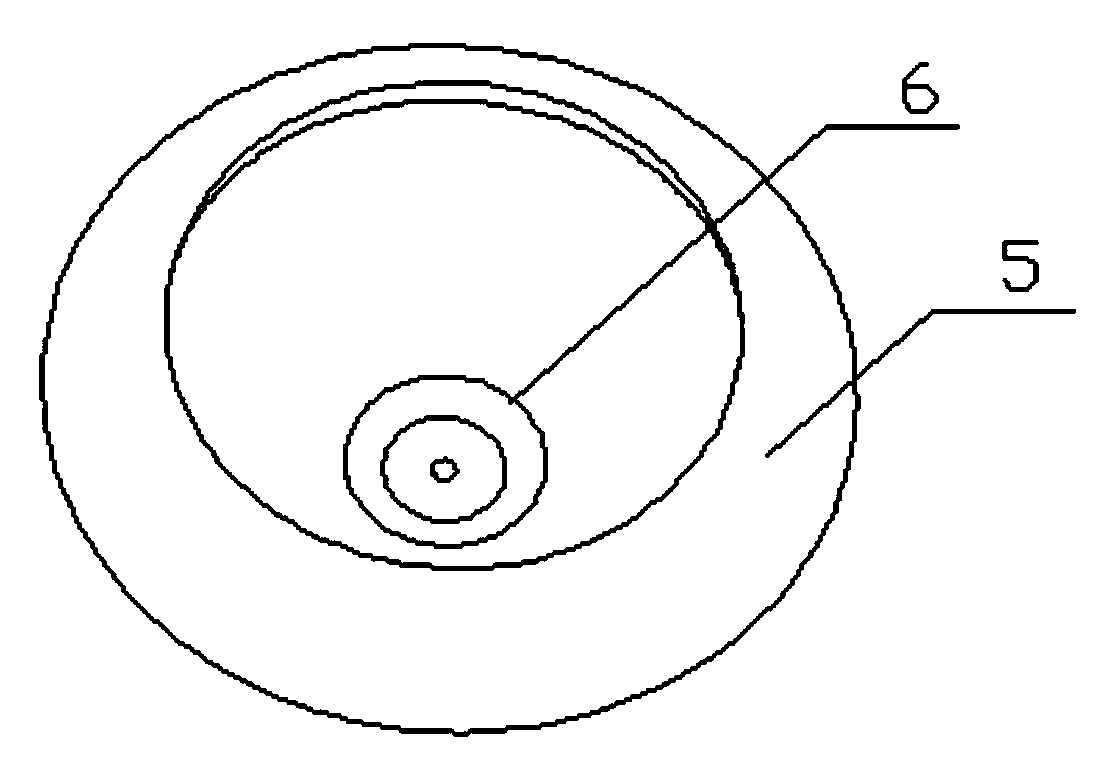

High-speed preparation device and process of centrifugal electrostatic spinning nanometer twisted yarns

ActiveCN103409861AAchieving Orientation ControllabilityIncrease elasticityFilament/thread formingContinuous wound-up machinesFiberYarn

The invention discloses a high-speed preparation device of centrifugal electrostatic spinning nanometer twisted yarns. The high-speed preparation device mainly comprises a feed extrusion device, a motor, an electromagnetic heating coil, a bearing, a conical ring perforated electrode, a centrifugal rotating umbrella-type spray head, an air compressor, a cyclone vacuum generator, a roller receiving device, a high-voltage electrostatic generator, a synchronous toothed belt and a rack, wherein the motor drives the centrifugal rotating umbrella-type spray head to rotate at high speed; the electromagnetic heating coil is in non-contact connection with the centrifugal rotating umbrella-type spray head and is heated through radiation; the feed extrusion device is used for supplying feed to the centrifugal rotating umbrella-type spray head through a hole in the center of the centrifugal rotating umbrella-type spray head; the conical ring perforated electrode is fixed at the middle position of the center of the rack. The high-speed preparation device is combined with an electrostatic spinning technology and a centrifugal spinning technology; a rotating airflow is formed in a chamber by the combined use of the air compressor and the cyclone vacuum generator to guide fiber to form twisted yarns, so that the orientation controllability of nanofiber is achieved; conditions are created for industrial application of the nanofiber in the specific industries, such as water treatment.

Owner:BEIJING UNIV OF CHEM TECH

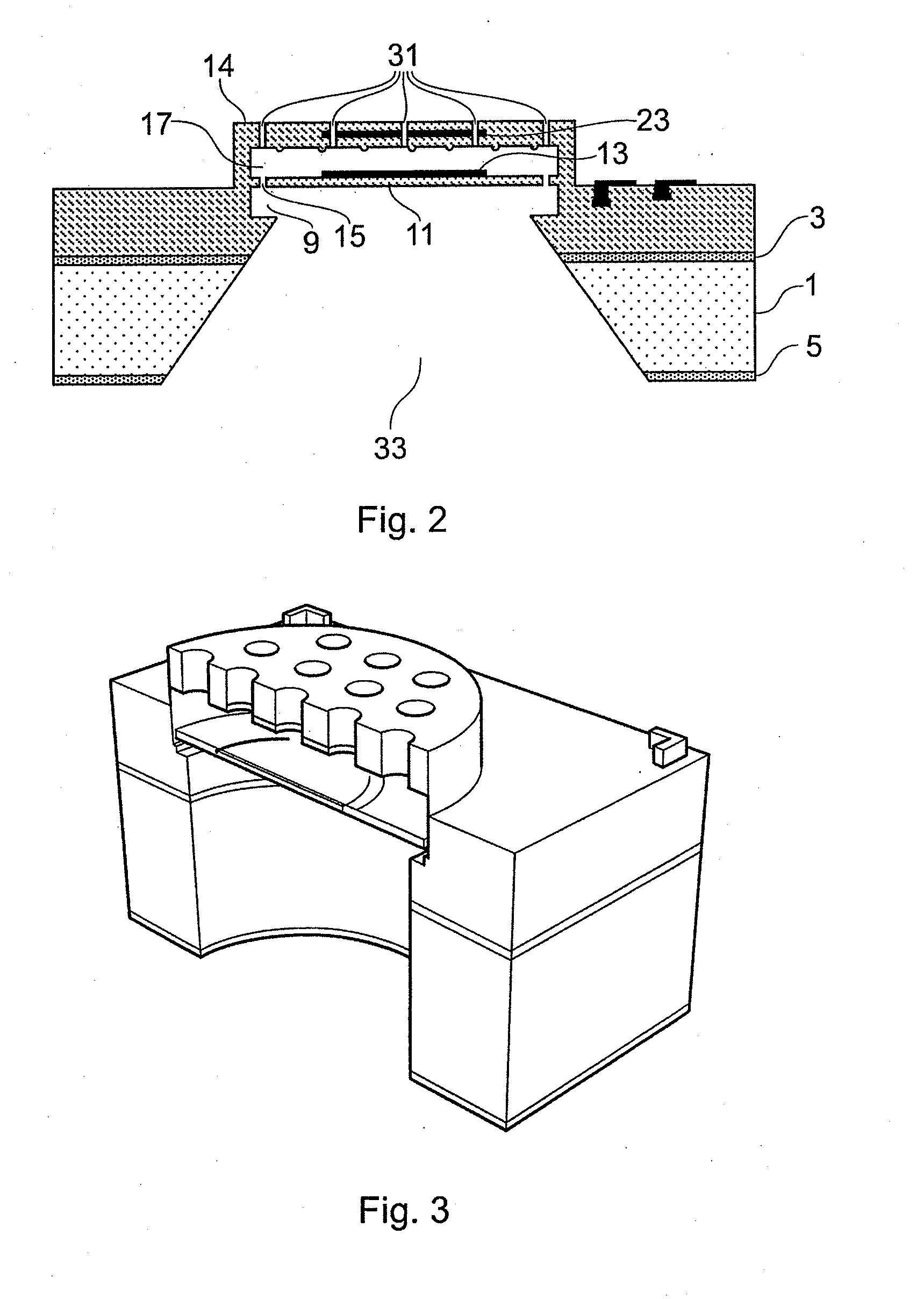

MEMS process and device

A MEMS device, for example a capacitive microphone, comprises a flexible membrane 11 that is free to move in response to pressure differences generated by sound waves. A first electrode 13 is mechanically coupled to the flexible membrane 11, and together form a first capacitive plate of the capacitive microphone device. A second electrode 23 is mechanically coupled to a generally rigid structural layer or back-plate 14, which together form a second capacitive plate of the capacitive microphone device. The capacitive microphone is formed on a substrate 1, for example a silicon wafer. A back-volume 33 is provided below the membrane 11, and is formed using a “back-etch” through the substrate 1. A first cavity 9 is located directly below the membrane 11, and is formed using a first sacrificial layer during the fabrication process. Interposed between the first and second electrodes 13 and 23 is a second cavity 17, which is formed using a second sacrificial layer during the fabrication process. A plurality of bleed holes 15 connect the first cavity 9 and the second cavity 17. Acoustic holes 31 are arranged in the back-plate 14 so as to allow free movement of air molecules, such that the sound waves can enter the second cavity 17. The first and second cavities 9 and 17 in association with the back-volume 33 allow the membrane 11 to move in response to the sound waves entering via the acoustic holes 31 in the back-plate 14. The provision of first and second sacrificial layers has the advantage of protecting the membrane during manufacture, and disassociating the back etch process from the definition of the membrane. The bleed holes 15 aid with the removal of the first and second sacrificial layers. The bleed holes 15 also contribute to the operating characteristics of the microphone.

Owner:CIRRUS LOGIC INC

Coiled and non-coiled twisted polymer fiber torsional and tensile actuators

Actuators (artificial muscles) comprising twist-spun nanofiber yarn or twist-inserted polymer fibers generate torsional and / or tensile actuation when powered electrically, photonically, chemically, thermally, by absorption, or by other means. These artificial muscles utilize non-coiled or coiled yarns and can be either neat or comprising a guest. Devices comprising these artificial muscles are also described.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

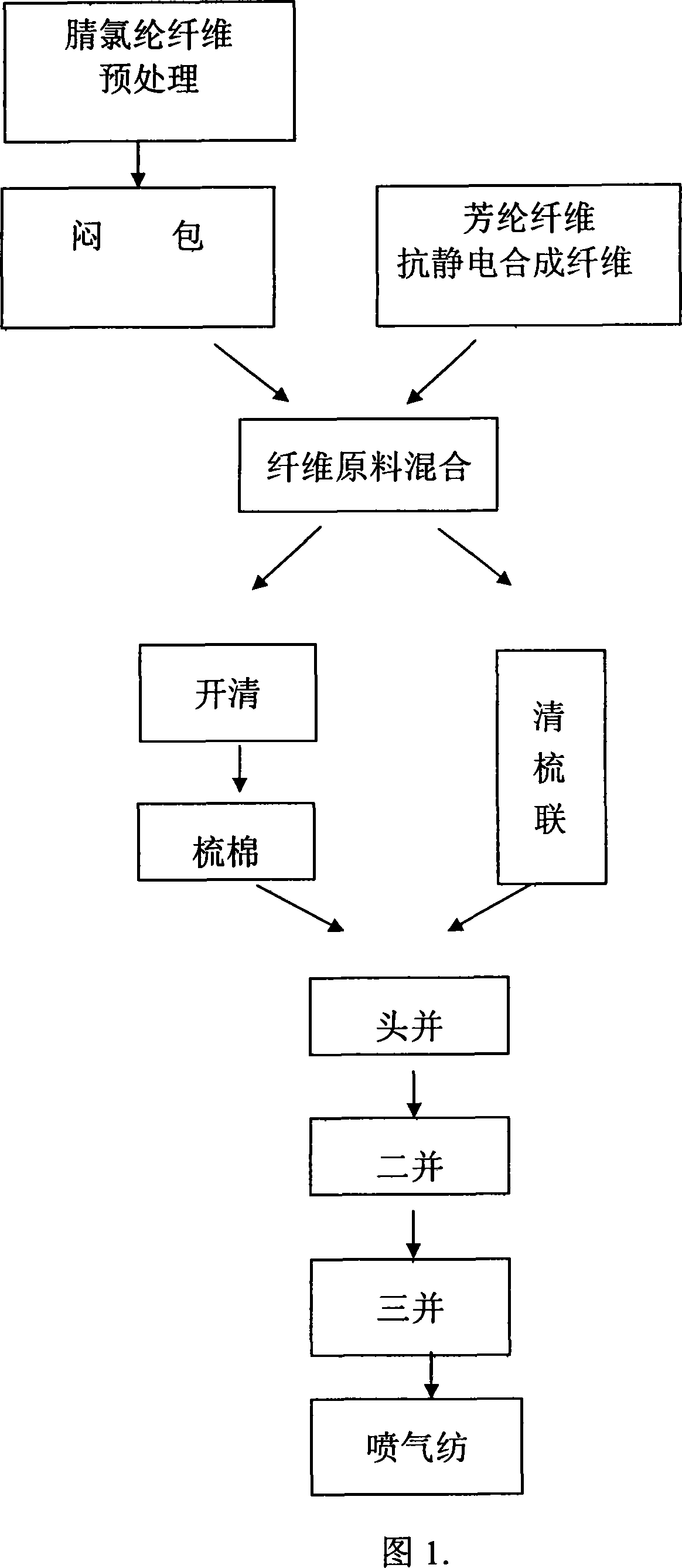

Aromid fiber blend yarn and processing method thereof

InactiveCN101067254AOvercome the defect of prone to static electricityReduce accidental elongationFibre treatmentContinuous wound-up machinesYarnAntistatic agent

The present invention is one kind of blended aramid yarn and its production process. The blended aramid yarn consists of aramid fiber 10-60 wt%, polyacrylic-polyvinyl chloride fiber 30-80 wt% and antistatic synthetic fiber 1-10 wt%, and has fiber length of 38 mm or 51 mm and spinning count of 10 s-50 s. It is produced through mixing material, producing card sliver, drawing and jet spinning. The production process includes spraying the polyacrylic-polyvinyl chloride fiber with antistatic agent, two card sliver producing modes, etc. The blended aramid yarn has excellent wear resisting property, excellent fireproof performance and high electrically insulating performance, and the fabric produced with the blended aramid yarn may be used in special suits for use in high temperature, electric welding and high voltage environment, and used in making fireproof decoration.

Owner:SHANGHAI YUFENG SCI & TECH +1

Multi-layer yarn structure and method for making the same

A multi-layer yarn structure and a method for making the same are provided. The multi-layer yarn structure includes a core layer, a layer of noncircular fibers, and an outer layer. The core layer has a plurality of hydrophobic fibers. The noncircular fibers surround the core layer to form a middle layer. The outer layer surrounds the middle layer and has a plurality of hydrophilic fibers. The method spins different fibers into multi-layer yarn for making textile with a soft, smooth, and thick feel. By utilizing inherent characteristics of the multi-layer yarn structure, the textile may regulate moisture released from the human body and keep the body dry and comfort.

Owner:RUENTEX INDS

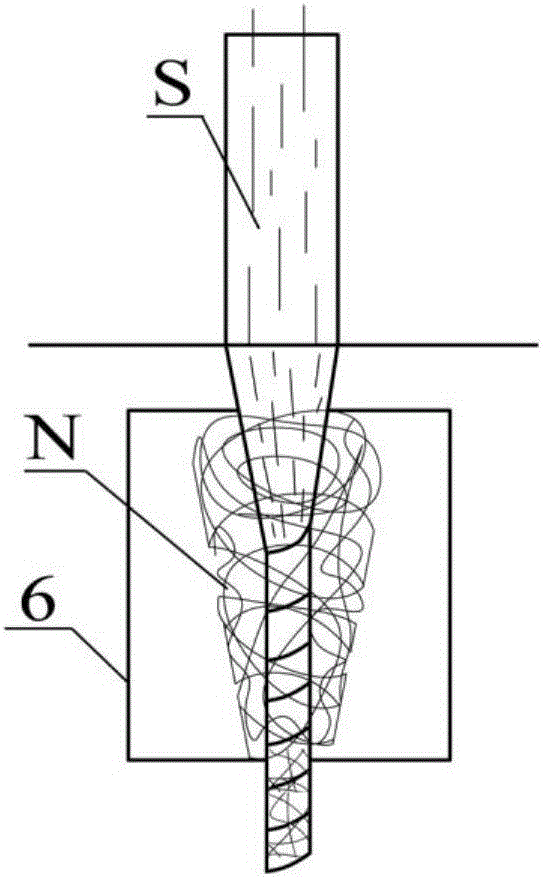

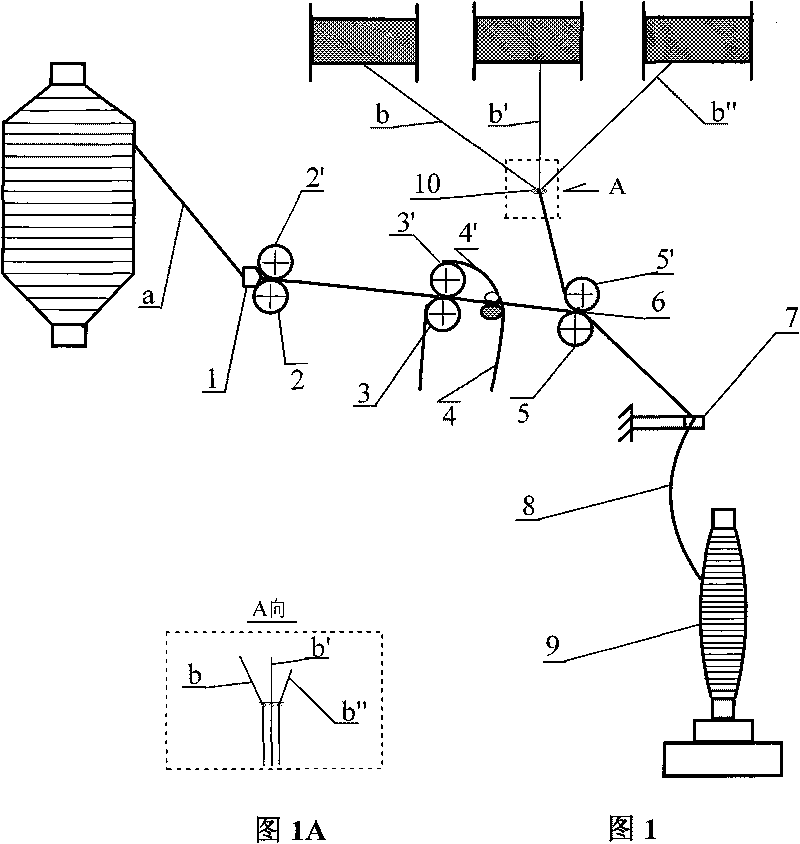

Nano electrostatic spinning and staple fiber ring spinning integrated yarn forming method

The invention relates to a nano electrostatic spinning and staple fiber ring spinning integrated yarn forming method, and belongs to the technical field of textile processing. The method comprises the following steps: arranging an electrostatic spinning apparatus between each yarn guide hook of a ring spinning frame and a front roller jaw formed by a front roller corresponding to the yarn guide hook and a front rubber roll, enabling a receiving surface of the electrostatic spinning apparatus to stay on a same plane with a public tangential surface of a front leather roll and the front roller at the front roller jaw, forming an electrostatic spinning area between an electrostatic spray head and a receiving surface of a receiving plate, and combining and twisting a nano fiber net spun out from the electrostatic spray head and staple fiber strands passing by the receiving surface of the receiving plate. According to the method, the electrostatic spinning and a conventional ring spinning are reasonably integrated, so that the high-speed successful production of nano fiber yarns is guaranteed, the naon fiber net effectively captures exposed fibers and improves the winding tightness, and the yarn forming structure and performance quality of the nano fiber wrapped blended yarns can be greatly improved. Equipment involved in the method is universal, and the operation and the use are convenient.

Owner:WUHAN TEXTILE UNIV

High ratio blended spinning technique for ultrashort low-density fibre based on cotton spinning device

InactiveCN101148797ARaise the ratioReasonable workmanshipFibre cleaning and opening machine combinationsCarding machinesYarnPolymer science

The present invention discloses the process of producing blended cheese yarn with high content of ultra short low density fiber in cotton spinning apparatus. A punching with high homogeneity and great cohesion is first produced through mixing ultra short low density fiber and other fiber in an opening and picking step much loosening and less beating; and then produced into cheese through the steps of combing, drawing, roving, spinning and coning. The blended cheese yarn consists of ultra short low density fiber 51-95 wt%, natural fiber 5-49 wt% and chemical fiber 5-49 wt%. The blended cheese yarn with high content of ultra short low density fiber is light, soft, lofty and high in strength, and its produced fabric has high color fastness.

Owner:DONGHUA UNIV +1

Method and device for automatic spinning repiece

InactiveCN1488798AOptimize structural configurationReduce twistPiercing arrangementsContinuous wound-up machinesYarnLow speed

The present invention relates to an automatic spinning new end forming method and its equipment. The roving machine utilizes the coder positioned at the drafting portion position to detect the full-yarn length when the bobbin can be fulled, and makes the roving machine spin to a certain length in low speed, after the roving is spun to a certain length, makes the roving machine operate in low speed, at the moment makes the spindle rail stop lifting movement and makes the yarn be in said height position, winds 2-3 turns of halching and makes the spindle rail be quickly lowered to form large thread pitch wind so as to make the roving do not take-off in its transportation process; changes the speed ratio of flywer and roller so as to reduce roving twist, and obtain undertwisted roving, and when the ultralowering of spindle rail is made to place, the yarn is stretch-broken to produce fuzzy fibre whose length can be suitable for secondary automatic spinning new end formation.

Owner:TIANJIN HONGDA TEXTILE MACHINERY

Three-axis-system composite spinning device and spinning method for tow-apt-to-fall staple

The invention provides a three-axis-system composite spinning device and a spinning method for tow-apt-to-fall staple. The three-axis-system composite spinning method is characterized in that the method comprises the steps of: feeding roving silvers containing the tow-apt-to-fall staple and cotton roving silvers into the back roller of a ring spinning machine, and conducting drafting to form a tow-apt-to-fall staple strand and a cotton strand which stretch straight in parallel; after the tow-apt-to-fall staple strand and the cotton strand are respectively positioned by using a tow-apt-to-fall staple strand positioner and a cotton strand positioner, feeding the tow-apt-to-fall staple strand and the cotton strand into the jaw of a front roller and directly feeding filament adjustable tension pulley into the jaw of the front roller; and after the tow-apt-to-fall staple strand, the cotton strand and the filament are output from the jaw of the front roller, twisting the tow-apt-to-fall staple strand and the filament at a first converging point outside the jaw of the front roller to form a structural section, and twisting the structural section and the cotton strand at a second converging point to form a three-axis-system composite yarn. The device and the method provided by the invention has the advantages that not only can the content of the tow-apt-to-fall staples in the spun composite yarn be improved, but also the situations of fiber damage and tow falling can be effectively avoided.

Owner:DONGHUA UNIV

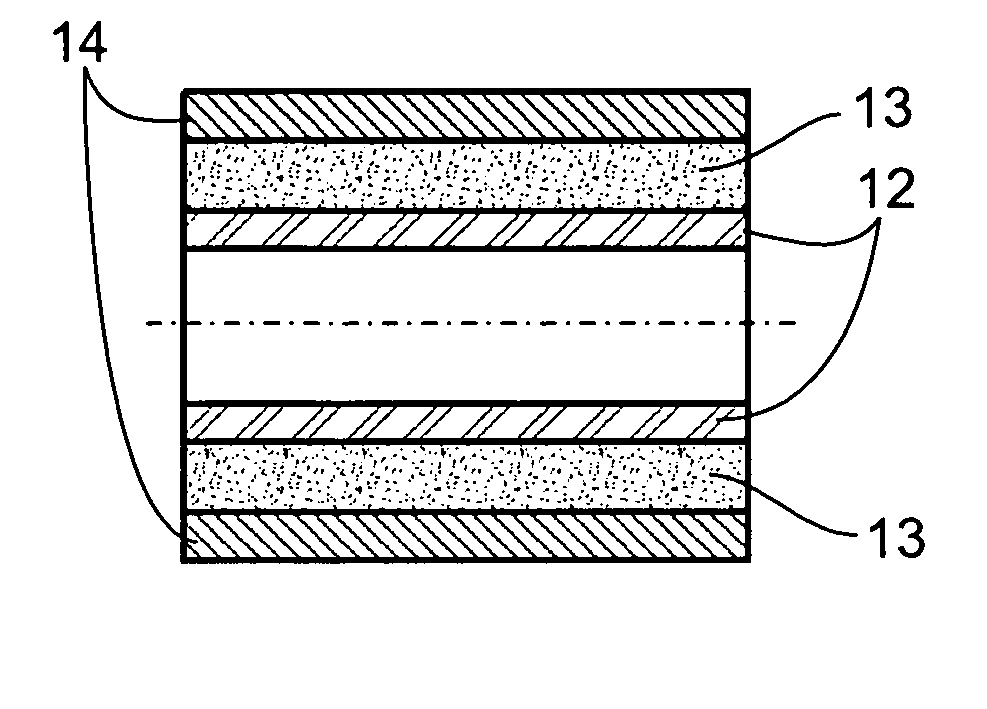

Dissimilar materials double-layer superpacket center thread and manufacturing method thereof

InactiveCN101328637AGuaranteed wrapping tensionFeel comfortableContinuous wound-up machinesYarnYarnFiber

The invention discloses an abnormal material dual-layer composite clad yarn, which comprises an upper fiber-wrapped clad material layer, a lower fiber-wrapped clad material layer and a clad yarn layer which is positioned in the middle, wherein, the clad yarn layer adopts chemical fiber filament clad yarns and fiber-wrapped clad materials with different materials to be compositely processed into a dual-layer composite clad yarn. The invention also discloses a method for manufacturing the dual-layer composite clad yarn. The dual-layer composite clad yarn has the characteristics of comfortable hand feeling, large strength and toughness of chemical fiber filaments of the sandwich layer, burliness and durability, and high performance and use value.

Owner:鲁建国

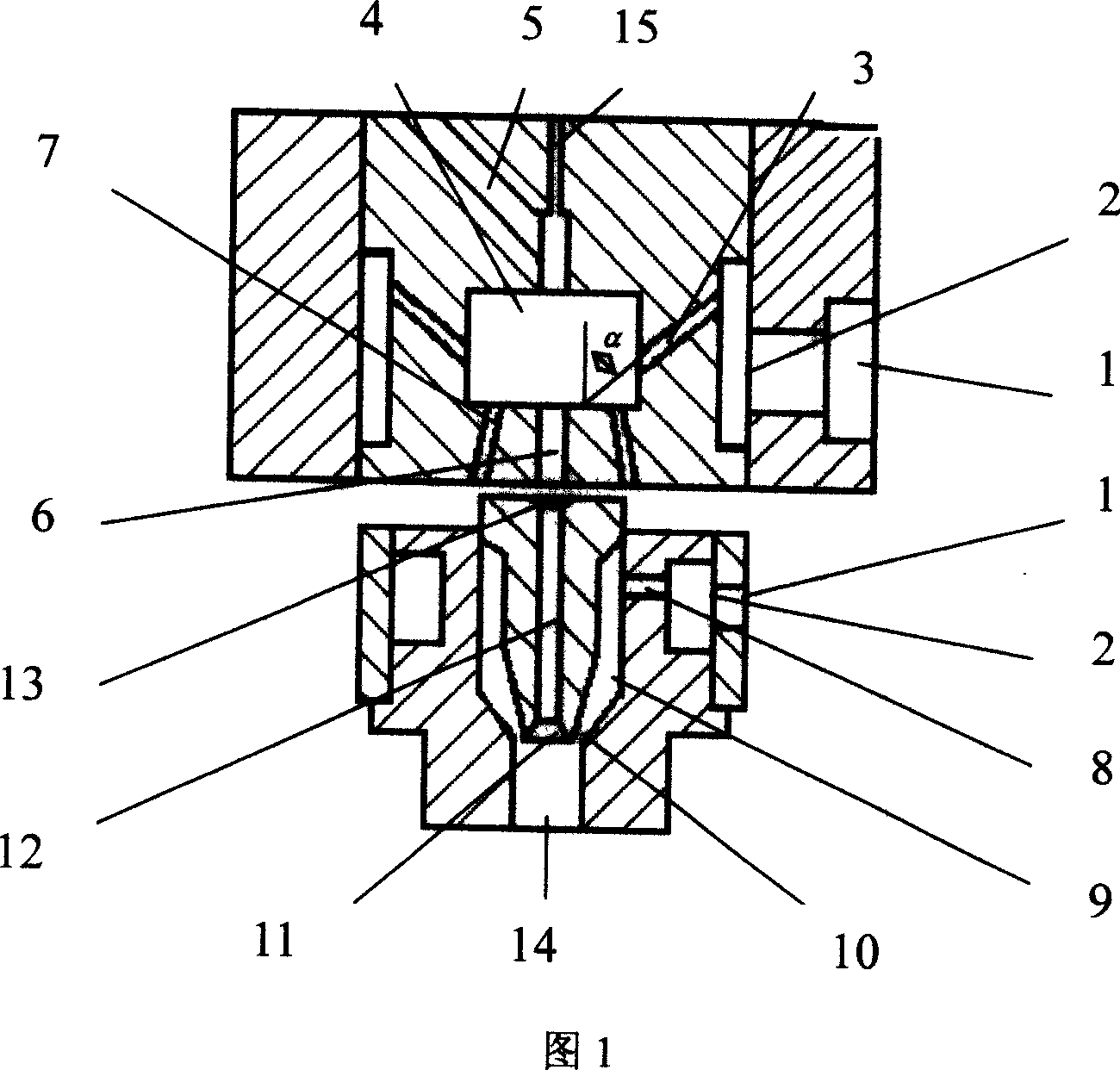

Processing apparatus for jet vortex spinning core spun yard

The invention discloses a machining device for spun core yarn with jet swirl, comprising upper and lower twisters, which is composed of air inlet port 1, fiber inlet port 5, discharging port 7, yarn port 14 and inlet port for synthetic filament 15. Upper and lower twisters contain a matched swirl twisting part, in which eddy current field is formed. Short fibers and synthetic filaments enter into the swirl twisting part from the fiber inlet port 5 and the inlet port for synthetic filament 15 respectively. In the eddy current field fiber strands are twisted into core yarns with twist. The upper twister is combined with the lower twister by the outlet port of strand 6 and the inlet port of strand 13. The whole is installed on the rack between the drafting area and the winding area on the spinning machine. The device improves the manufacturing efficiency obviously and accomplishes the drafting to synthetic filaments.

Owner:DONGHUA UNIV

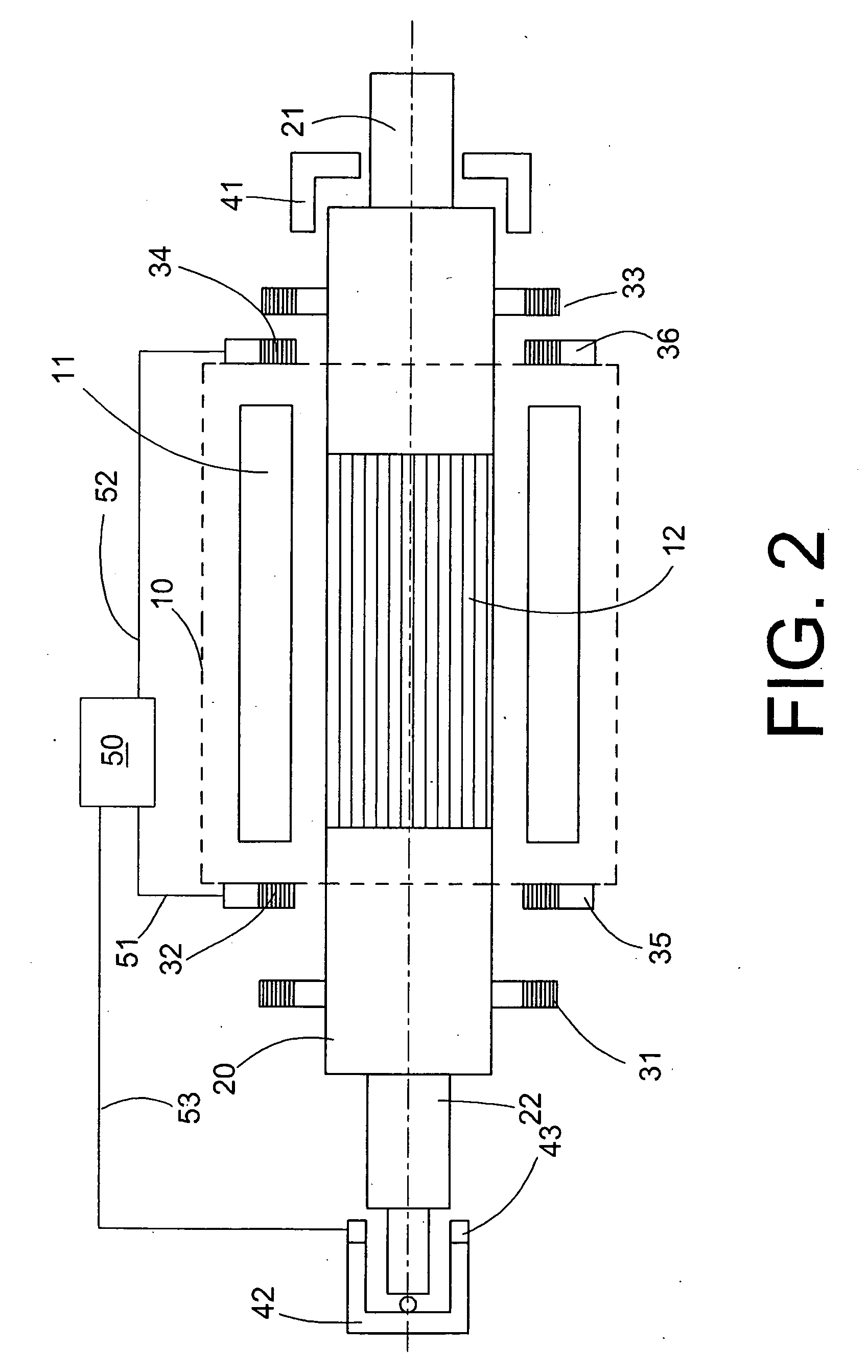

Method and device for starting an electric machine with a magnetically mounted rotor

ActiveUS20080315812A1Operational safety is enhancedAC motor controlTextile treatmentElectric machineEngineering

A method and a device with a control apparatus (50) for starting an electric machine (10) with a rotor (20), particularly the spinning cup of an open-end spinning machine, magnetically mounted by a bearing having permanent magnets (31, 32, 33, 34). An actuator system controls the position in the axial direction (35, 36) and two limitation bearings (41, 42), determine the axial end positions of the rotor. The actuator system brings about a lifting from the first axial end position, and a system variable during such lifting is compared with a reference value, and the rotor (20) is moved into the second end position, and the actuator system brings about a lifting from the second axial end position, and a system variable on lifting from the second end position is compared with a reference value.

Owner:SAURER SPINNING SOLUTIONS GMBH & CO KG

Preparation method of yarn with long and short fiber compound structure

InactiveCN101736469AEasy to transformEasy to operateDrafting machinesContinuous wound-up machinesBobbinCompound structure

The invention discloses a preparation method of a yarn with a long and short fiber compound structure, belonging to the technical field of textile processing. The preparation method comprises the following steps of: feeding short fiber rove fiber strands unwound from a rove tube into a drafting zone through a yarn-guiding horn for drafting on a drafting mechanism of a ring spinning frame; feeding at least three filaments into a front jaw from the rear end of a front roller at an interval of 0.1-3mm; jointing the filaments and the rove fiber strands at the jaw part; outputting and feeding drafted rove fiber strands and the filaments from the front jaw into a twisting triangular zone; twisting the rove fiber strands and the filaments into the yarn and winding the yarn on a spun yarn bobbin; and forming compound yarns with different structures according to the space among the filaments and the different relative positions of the rove fiber strands. The invention can prepare yarns with a unique internal space structure and an external surface structure on the ring spinning frame, enhances the strength, the wear resistance and the bend resistance of the yarns, has favorable conformality of textures and can achieve the effect of wearing after washing. The invention realizes the preparation of the yarns with special structures and special functions on the traditional spinning equipment.

Owner:SOUTHWEST UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com