Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1863 results about "Heat processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat processing. Subjecting a substance to higher than normal temperatures to obtain desired properties. Cooking is heat processing in which bacteria in food are killed and flavor, consistency, and texture is enhanced.

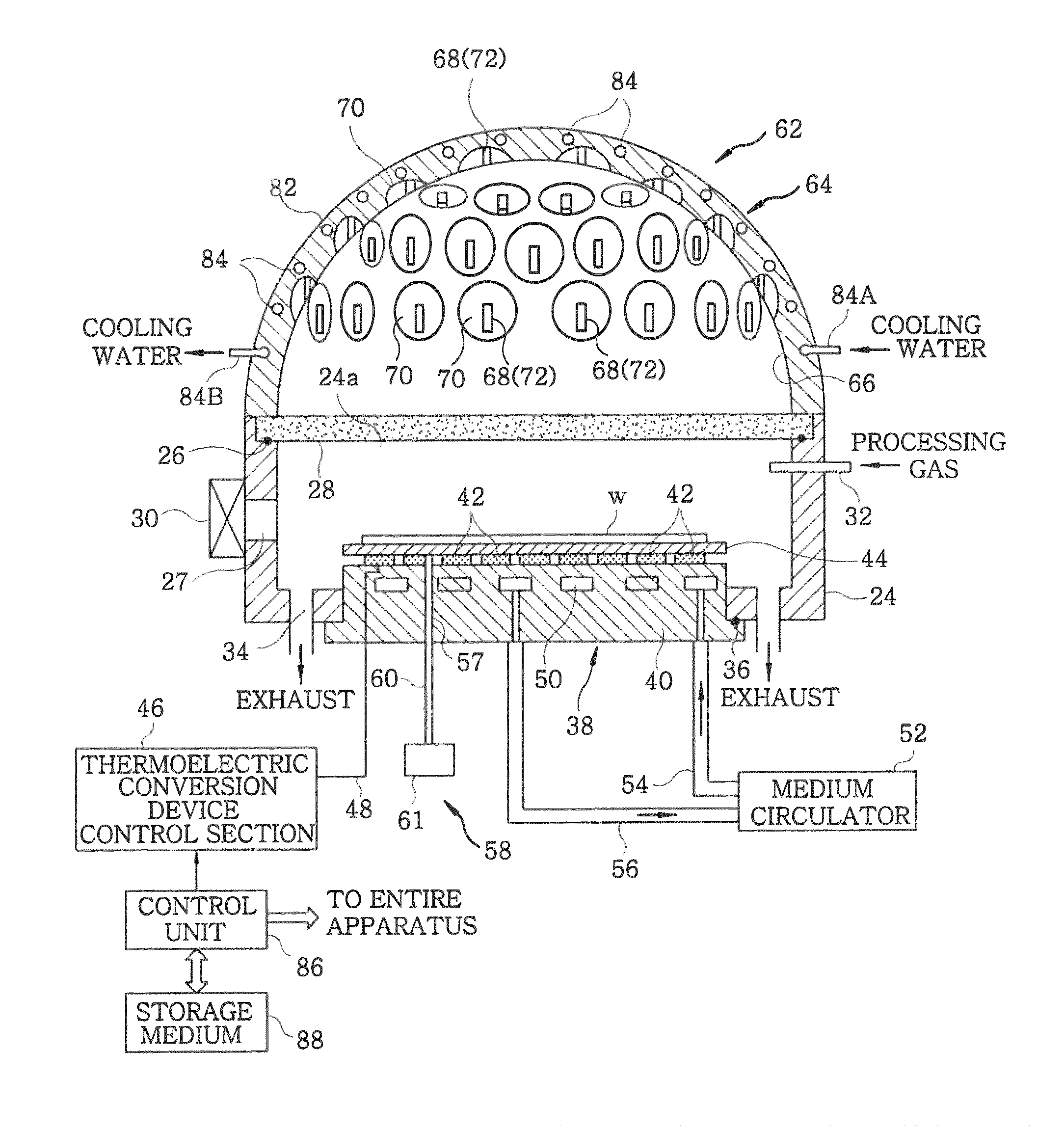

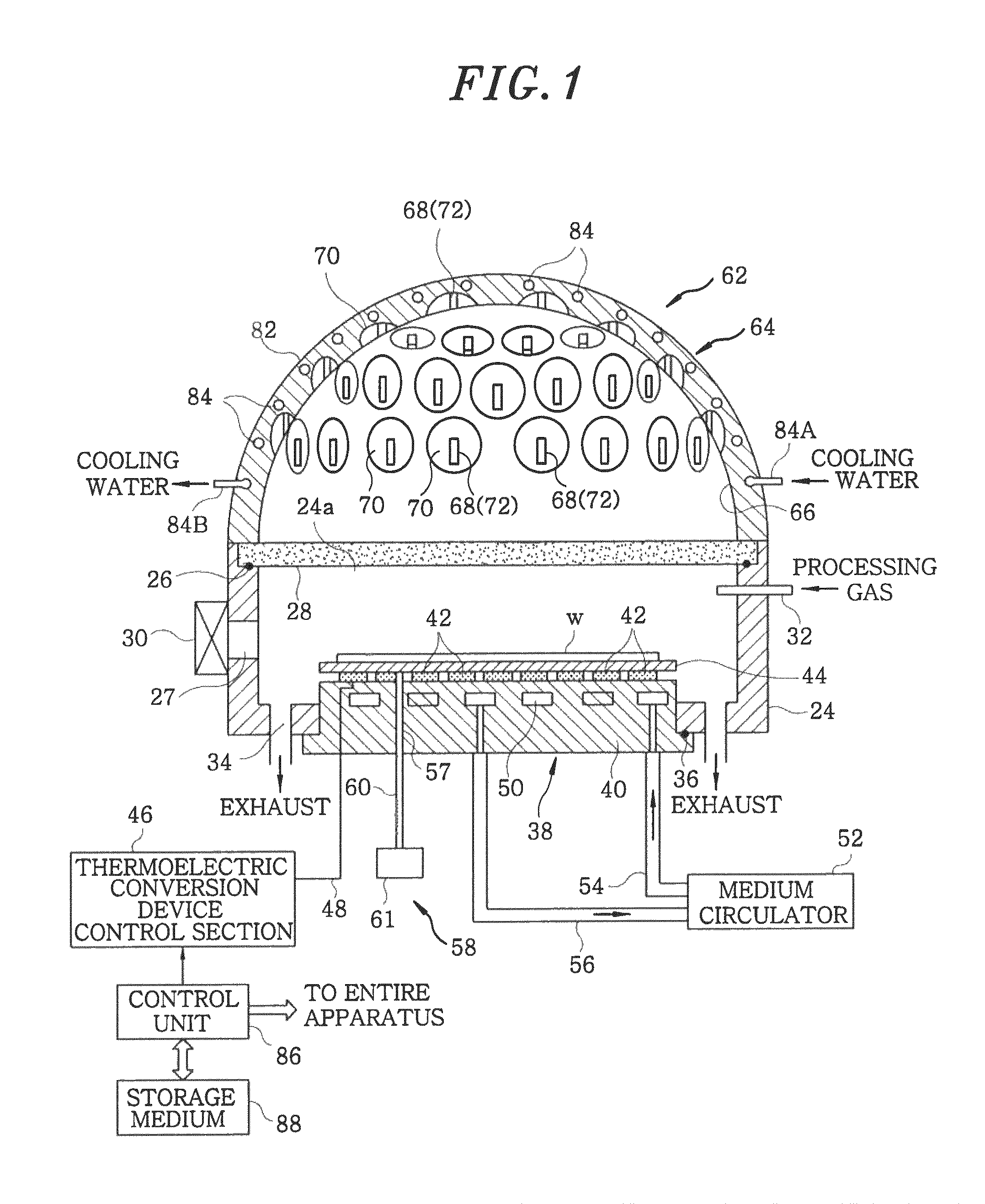

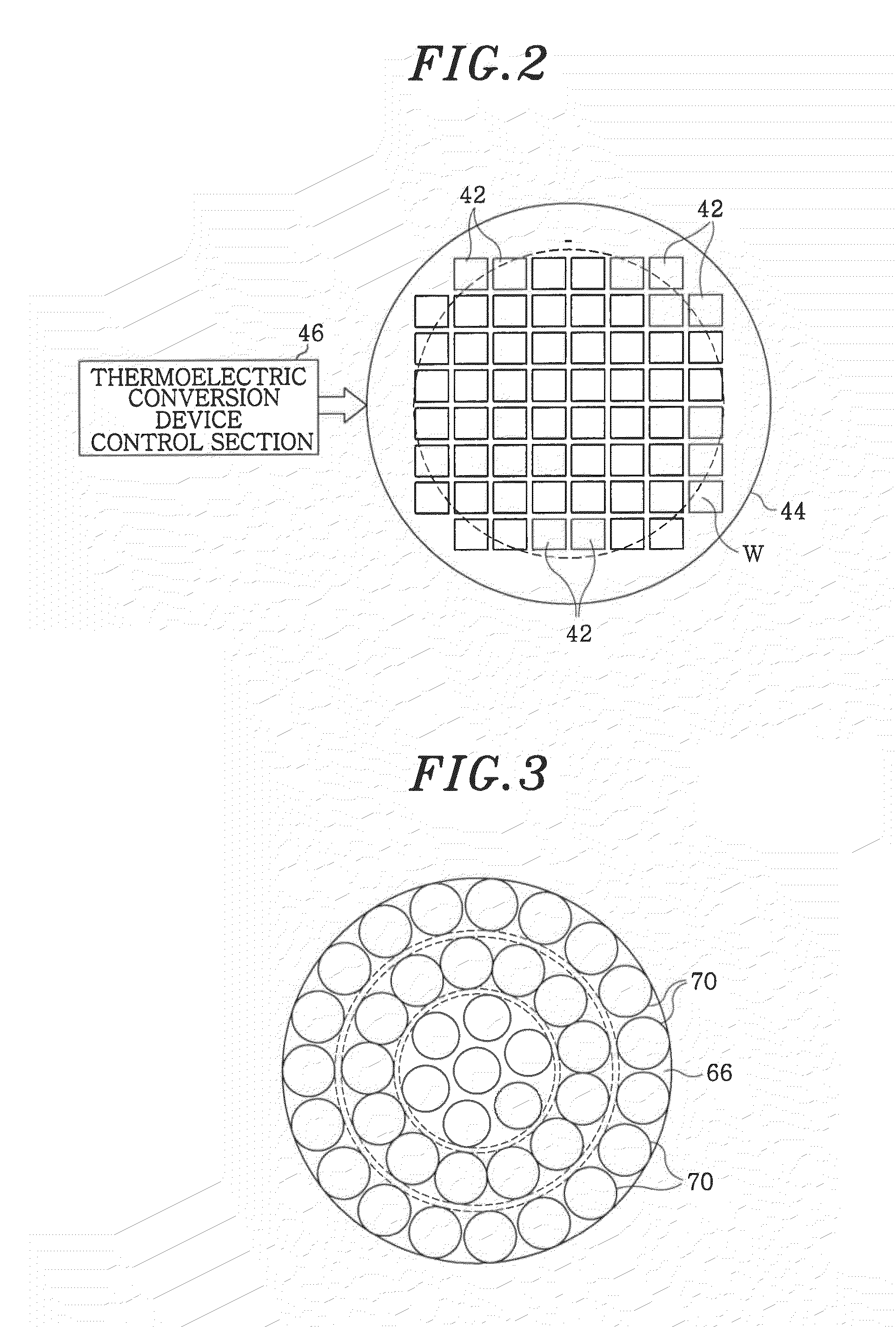

Heating apparatus, heat treatment apparatus, computer program and storage medium

ActiveUS8041197B2Efficient solutionRapidly heating up and coolingDomestic stoves or rangesDrying solid materials with heatLength waveSemiconductor

A heating apparatus for heating a target object W is provided with a plurality of heating light sources, including LED elements for applying heating light having a wavelength within a range from 360 to 520 nm to the object. Thus, a temperature of only the shallow surface of the object, such as a semiconductor wafer, is increased / reduced at a high speed in uniform temperature distribution, irrespective of the film type.

Owner:TOKYO ELECTRON LTD

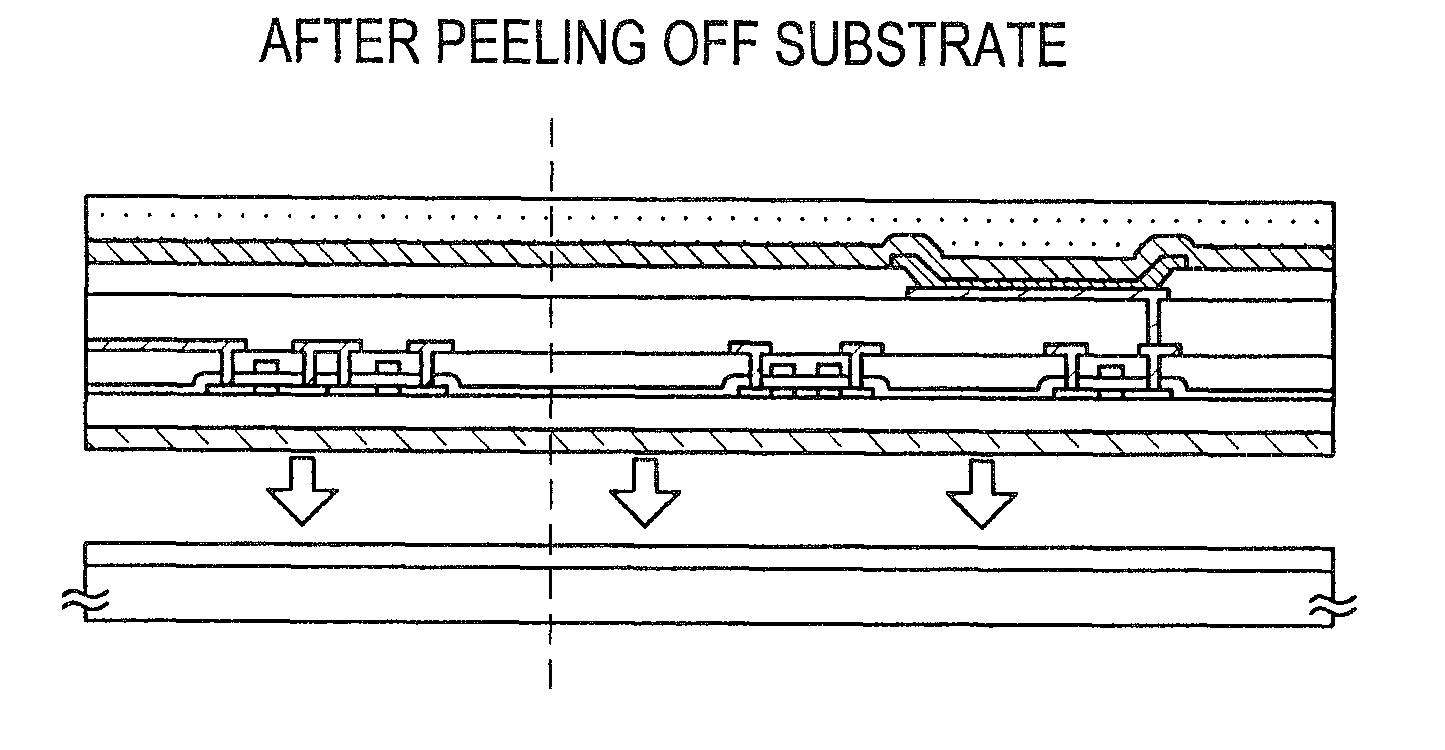

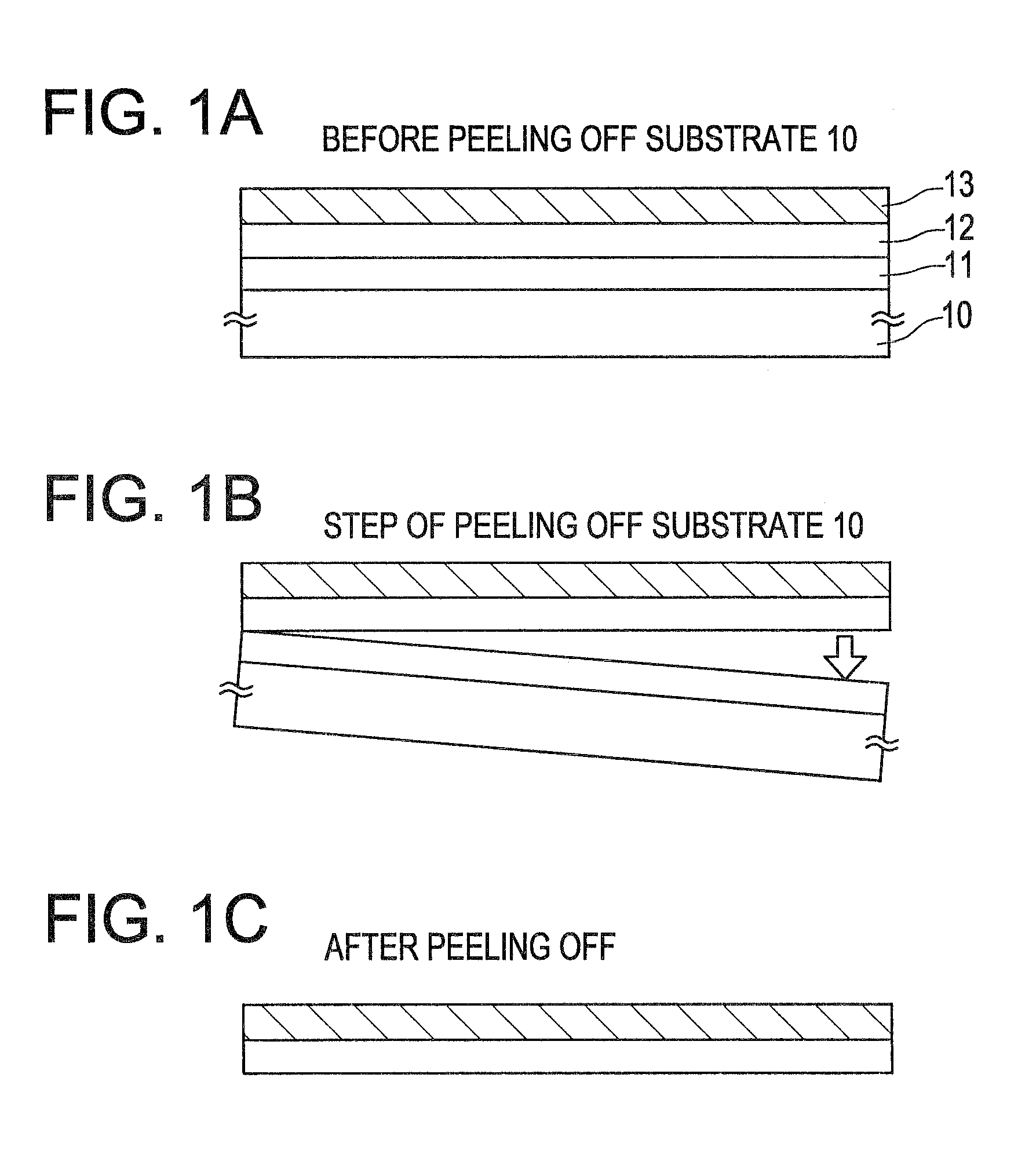

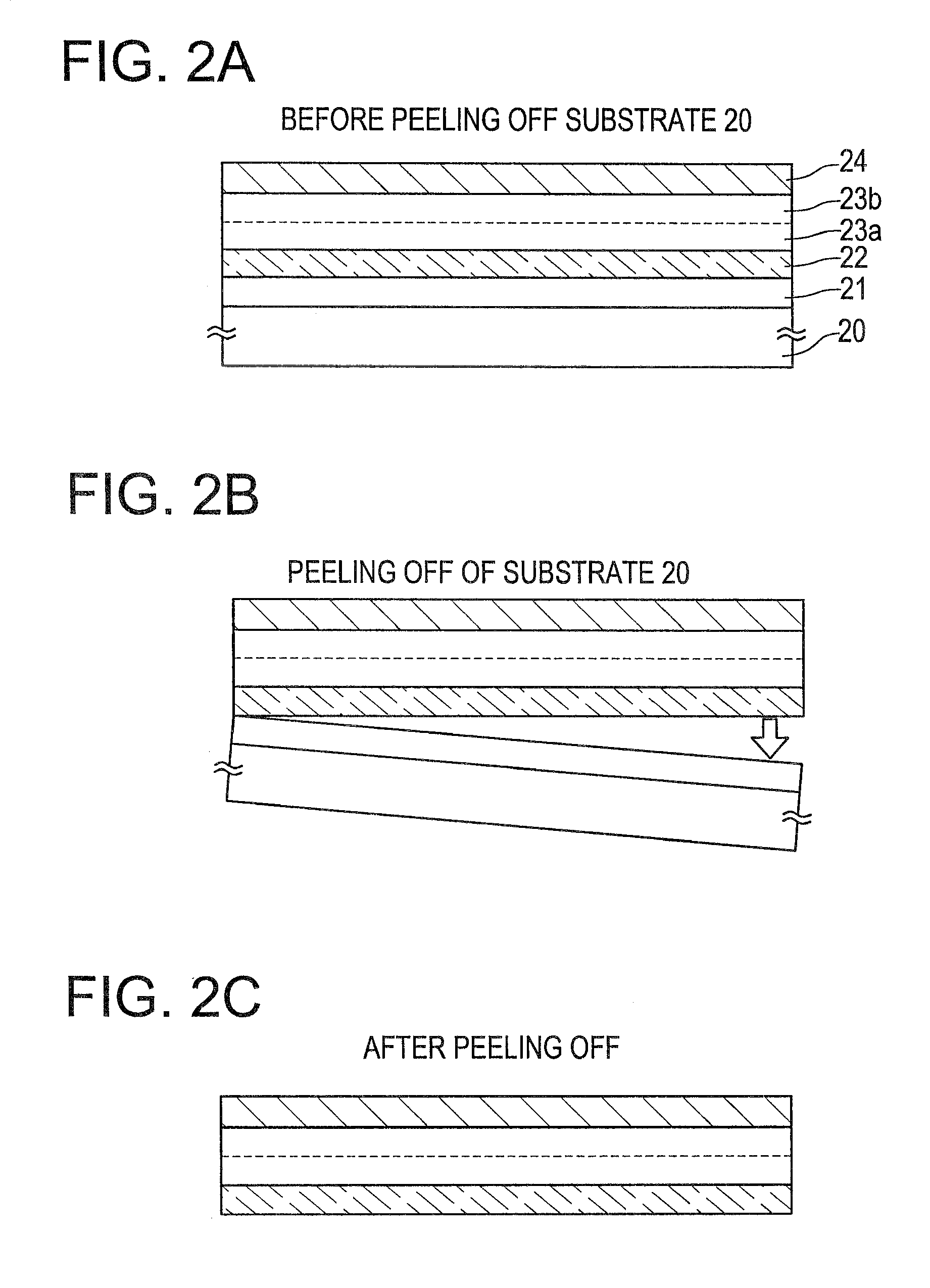

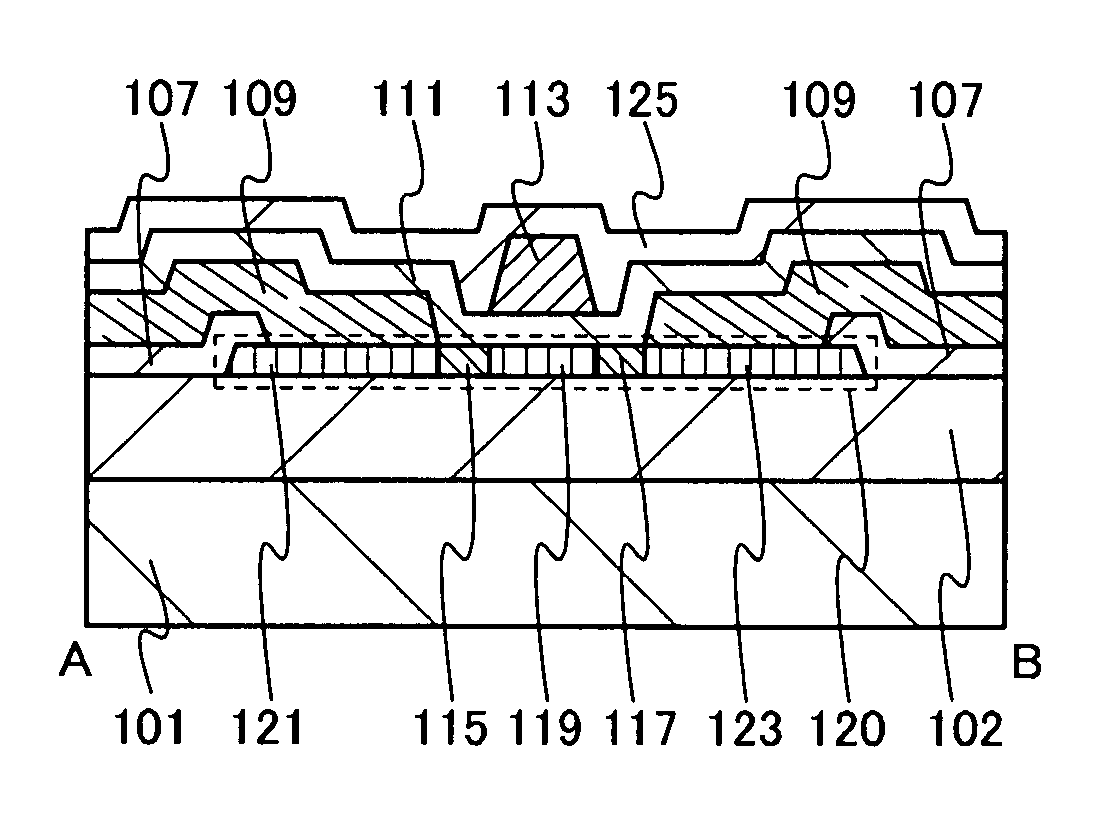

Semiconductor device and peeling off method and method of manufacturing semiconductor device

InactiveUS8367440B2Easily and clearly separatedReduce weightTransistorElectroluminescent light sourcesYield ratioNitride

The present invention provides a peeling off method without giving damage to the peeled off layer, and aims at being capable of peeling off not only a peeled off layer having a small area but also a peeled off layer having a large area over the entire surface at excellent yield ratio. The metal layer or nitride layer 11 is provided on the substrate, and further, the oxide layer 12 being contact with the foregoing metal layer or nitride layer 11 is provided, and furthermore, if the lamination film formation or the heat processing of 500° C. or more in temperature is carried out, it can be easily and clearly separated in the layer or on the interface with the oxide layer 12 by the physical means.

Owner:SEMICON ENERGY LAB CO LTD

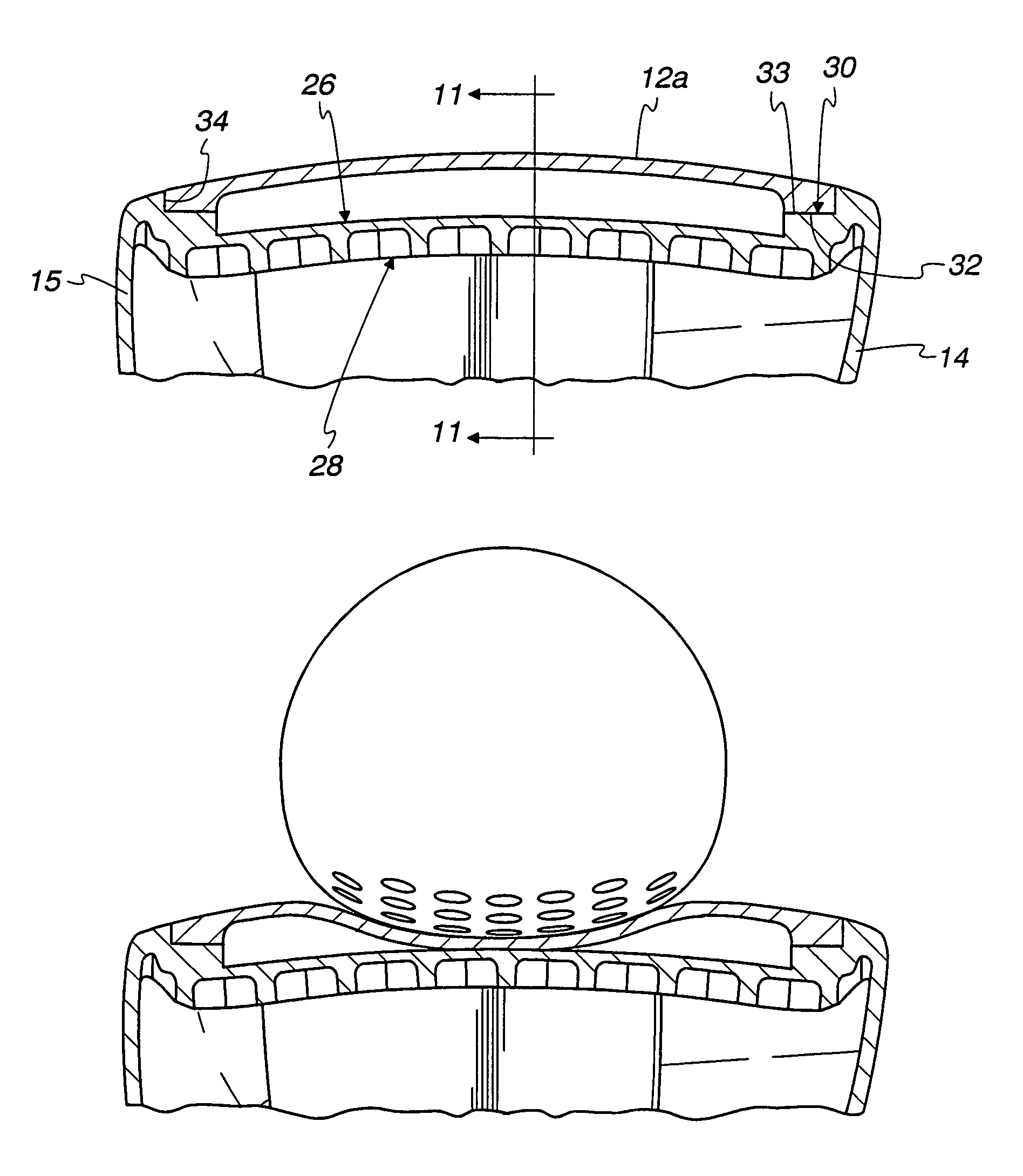

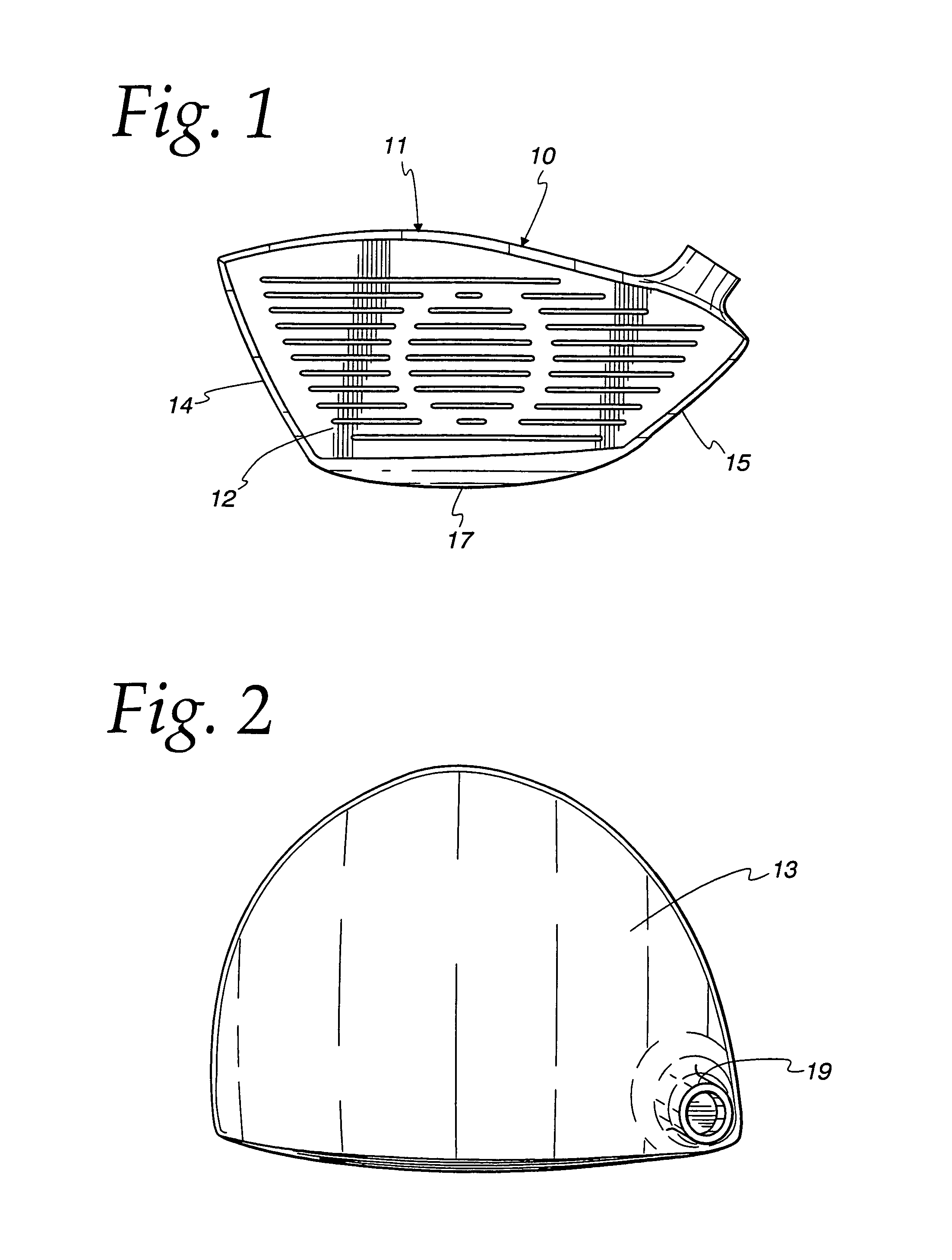

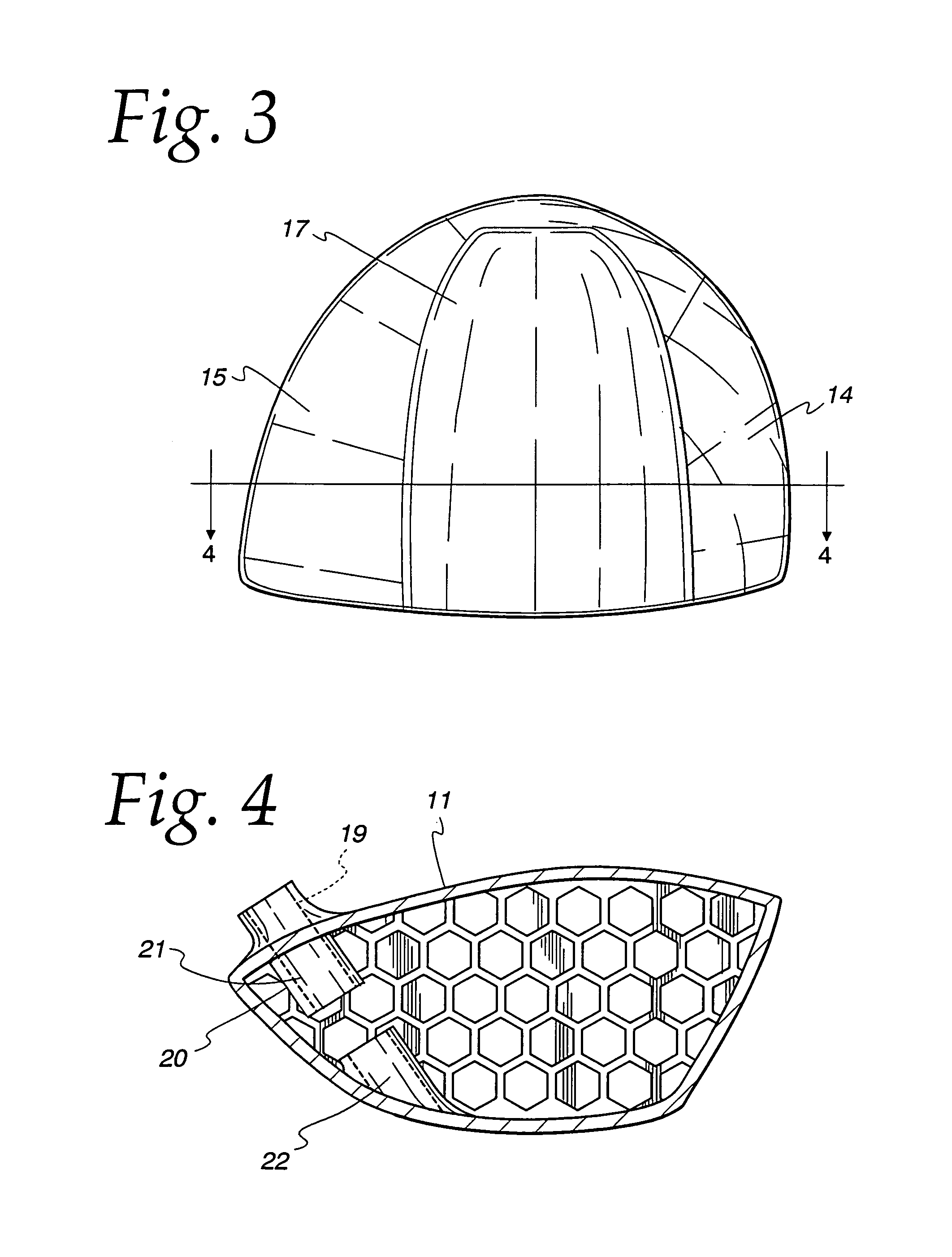

Golf club face flexure control system

InactiveUS6979270B1High modulusImprove energy transferGolf clubsRacket sportsControl systemGolf Ball

An improved line of golf clubs tailored to the golfer. The face wall firstly is designed so that the face wall modulus of elasticity increases from a low modulus for the low swing speed range to progressively higher modula for the higher swing speed ranges. Face modulus can be altered by a variety of techniques including face wall thinning, material selection and heat treatment or a combination thereof. In each of the swing speed range clubs, the face has a first modulus of elasticity determined by the face itself and after the face deflects to a predetermined value, the face modulus is significantly increased by a secondary wall parallel to and closely spaced behind the face wall.

Owner:KARSTEN MFG CORP

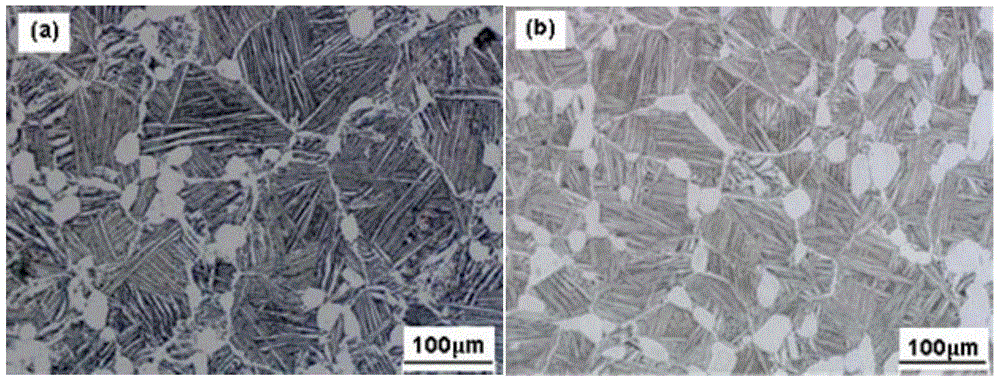

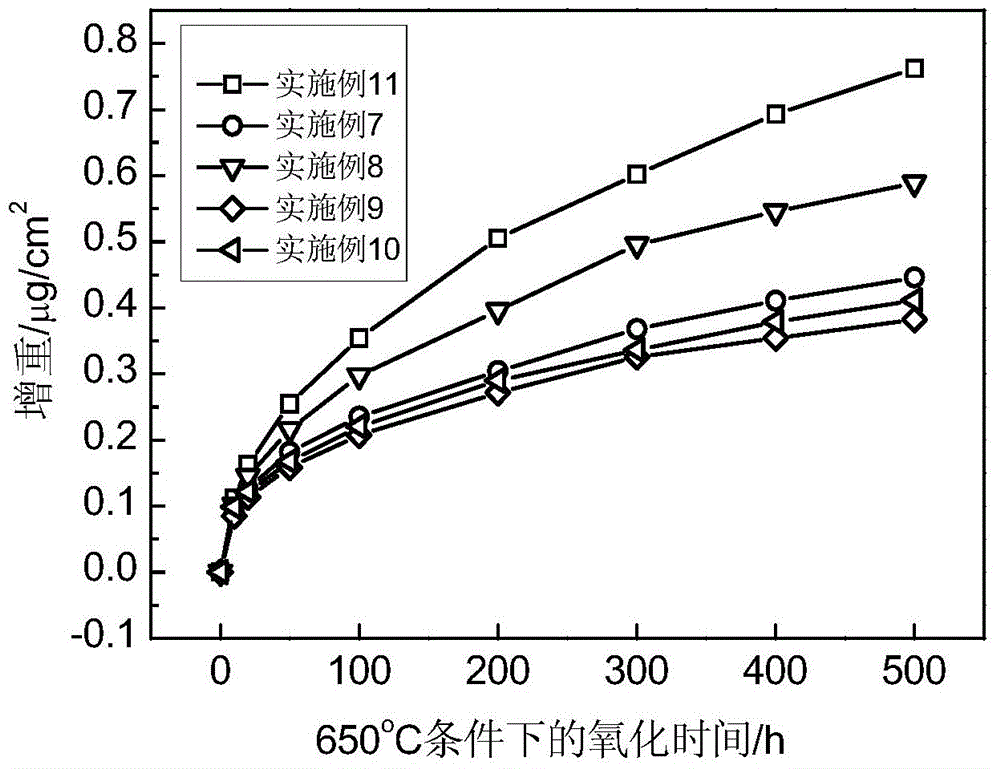

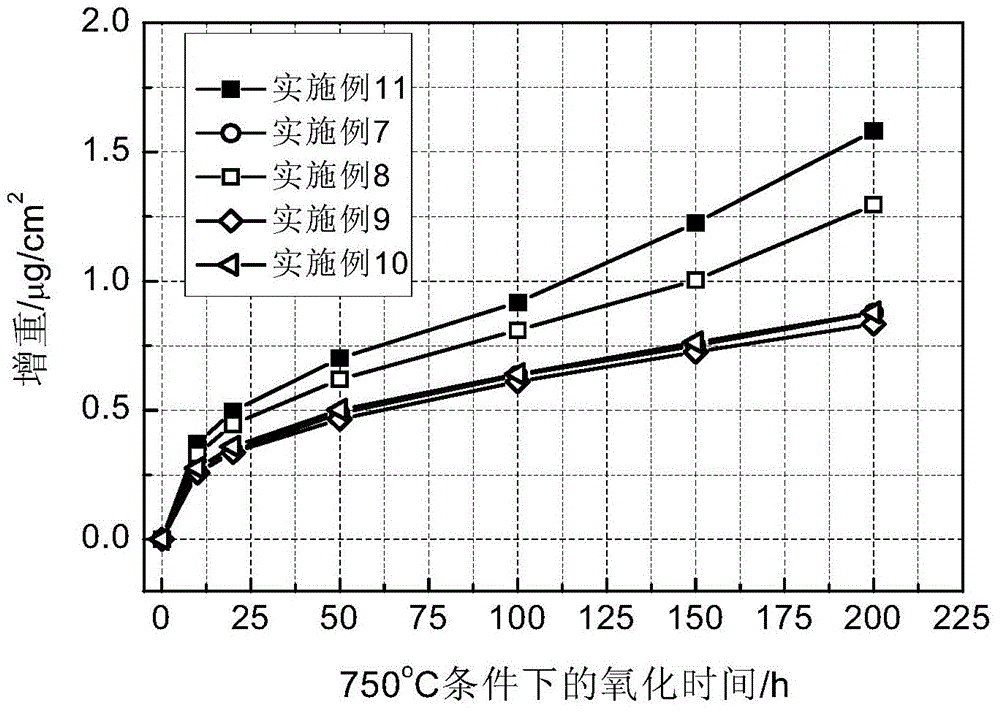

Novel heat-resisting titanium alloy and processing and manufacturing method and application thereof

The invention belongs to the field of titanium-based alloys, and particularly relates to a novel heat-resisting titanium alloy and a processing and manufacturing method and application thereof. The processing and manufacturing method comprises the composition elements of alloy components, smelting, heat processing, heat treatment and the like, wherein the alloy components are as follows (in percentage by weight): 5.4%-6.3% of Al, 3.0%-5.0% of Sn, 2.5%-6.4% of Zr, 0.0%-0.96% of Mo, 0.25%-0.5% of Si, 0.2%-0.5% of Nb, 0.3%-3.4% of Ta, 0.2%-1.6% of W, 0.0%-0.07% of C, less than or equal to 0.17% of O, less than or equal to 0.03% of Fe and the balance of Ti and inevitable impurity elements. The novel heat-resisting titanium alloy disclosed by the invention can obtain different matching of tensile strength, plasticity, permanence, creep strength and heat stability through the combination of different heat processing process and heat treatment processes, can be used for manufacturing parts, namely blades, coil assemblies and the like which are positioned on the high-temperature parts of an advanced aircraft engine, is used for a long time within a range of 600-650 DEG C, can also be used for manufacturing high temperature-resistant structural members, namely aerospace craft skin and the like, is used for a short time at about 700 DEG C and can be used as a material and the like used for high temperature-resistant corrosion-resistant valves of an automobile and a boiler.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

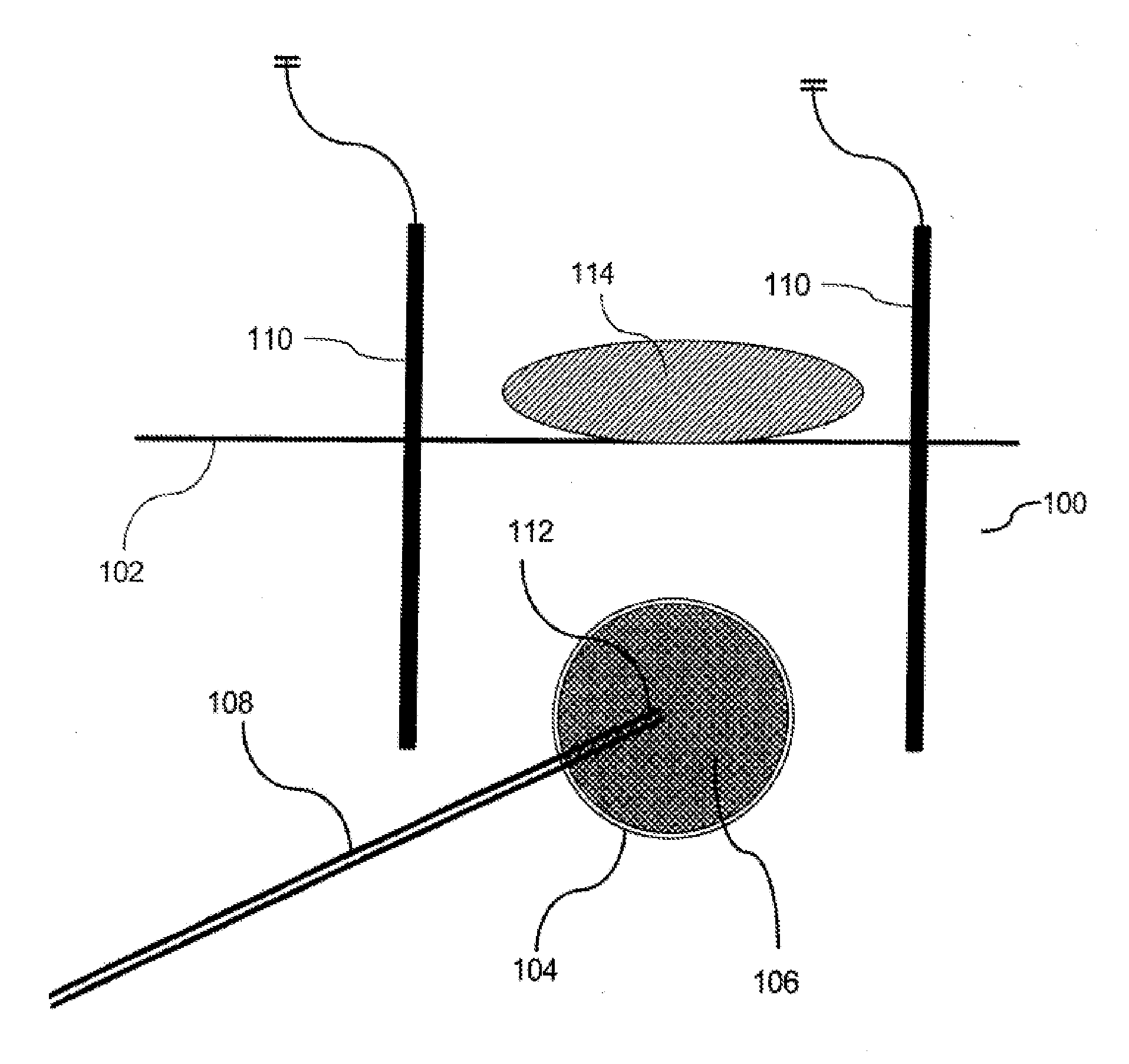

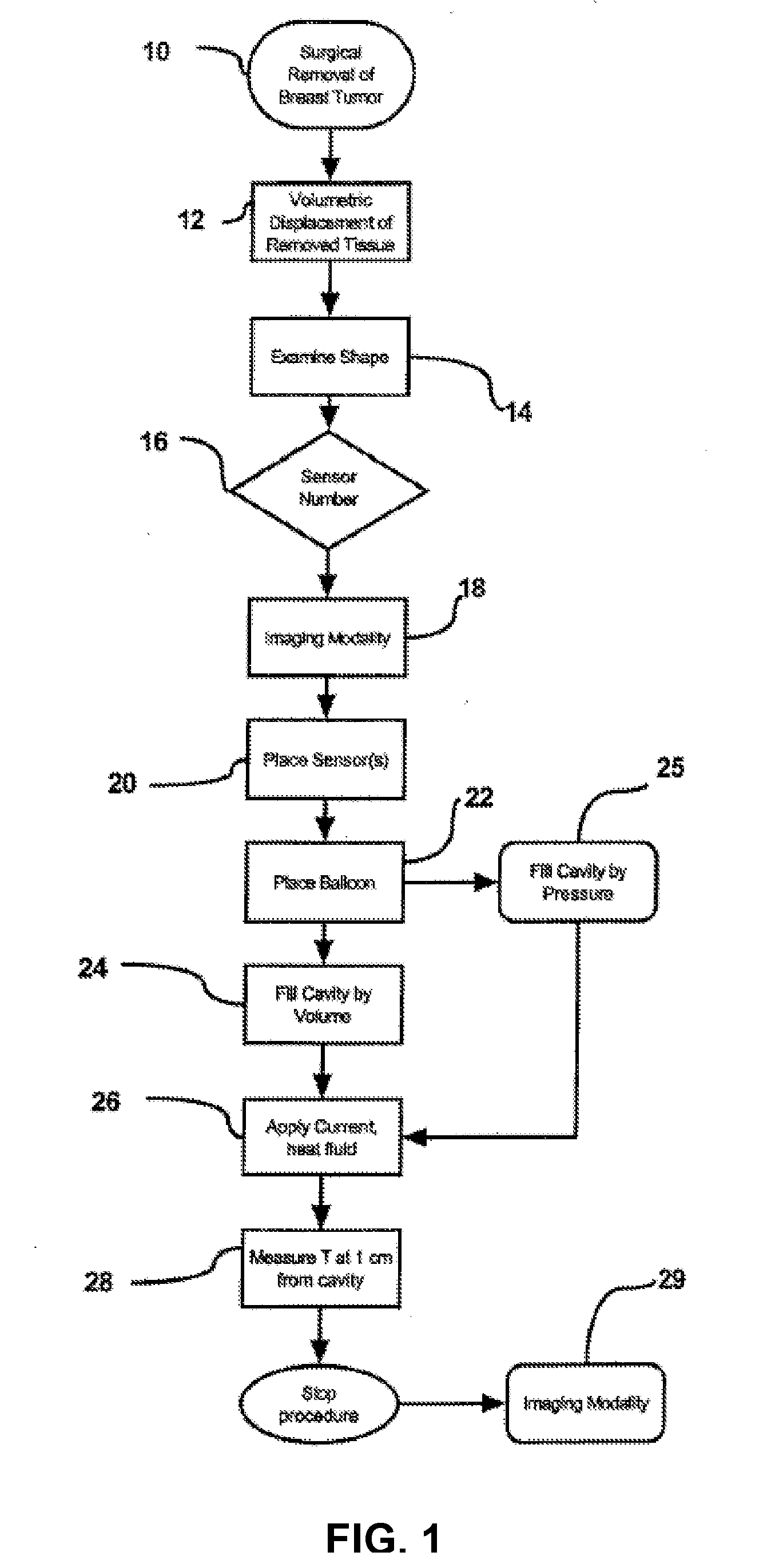

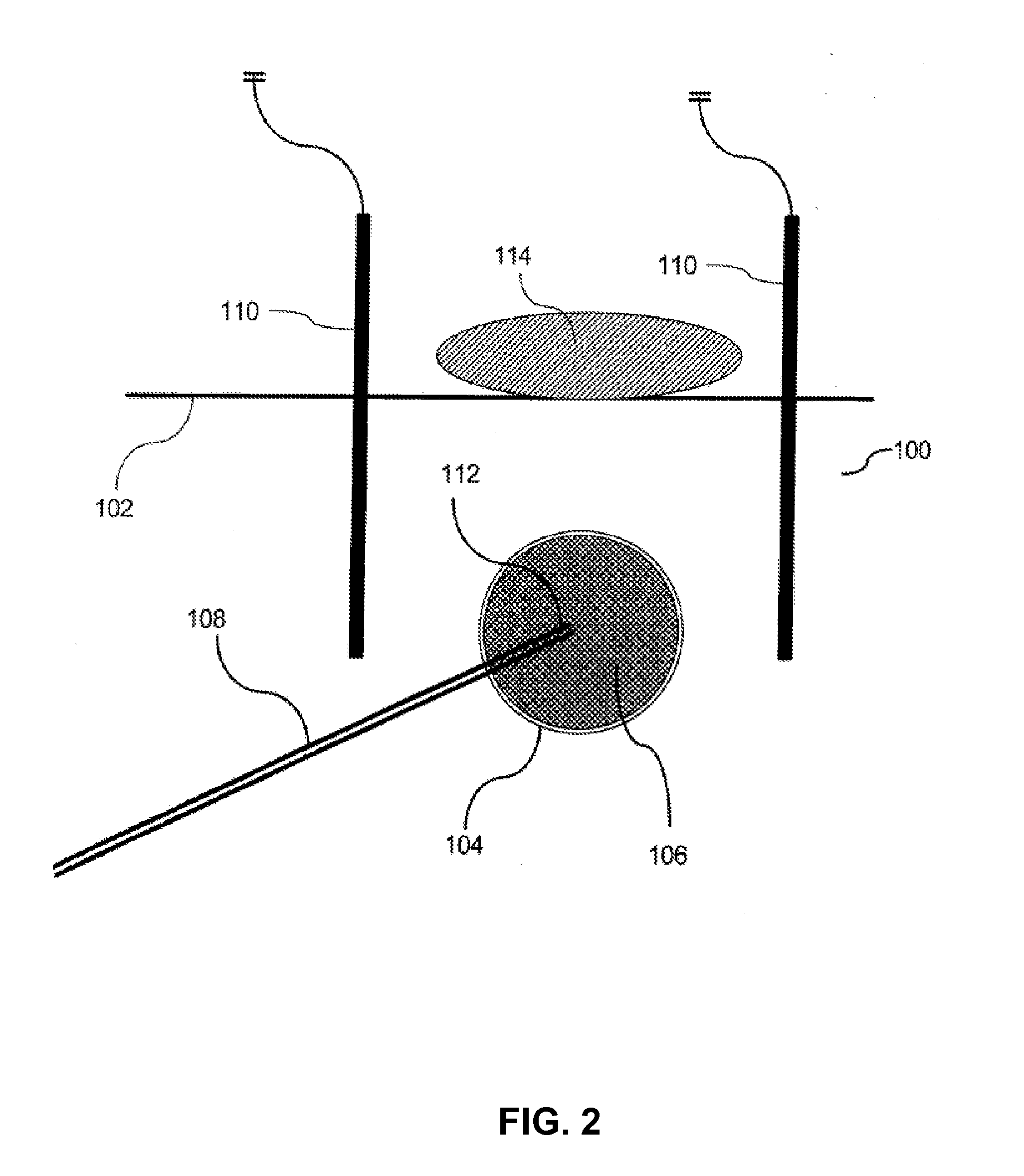

High temperature thermal therapy of breast cancer

A method is described for preventing breast cancer recurrence after surgical removal of a breast cancer mass. Specifically, the method is thermal treatment of breast tissue surrounding a cavity after lumpectomy for breast cancer. Delivery of a heated fluid is through a balloon catheter to the cavity generated after lumpectomy with the goal of ablating the surrounding tissue, including transformed cells that were not removed through surgery. A balloon and controller were designed for this application.

Owner:THERMATOME

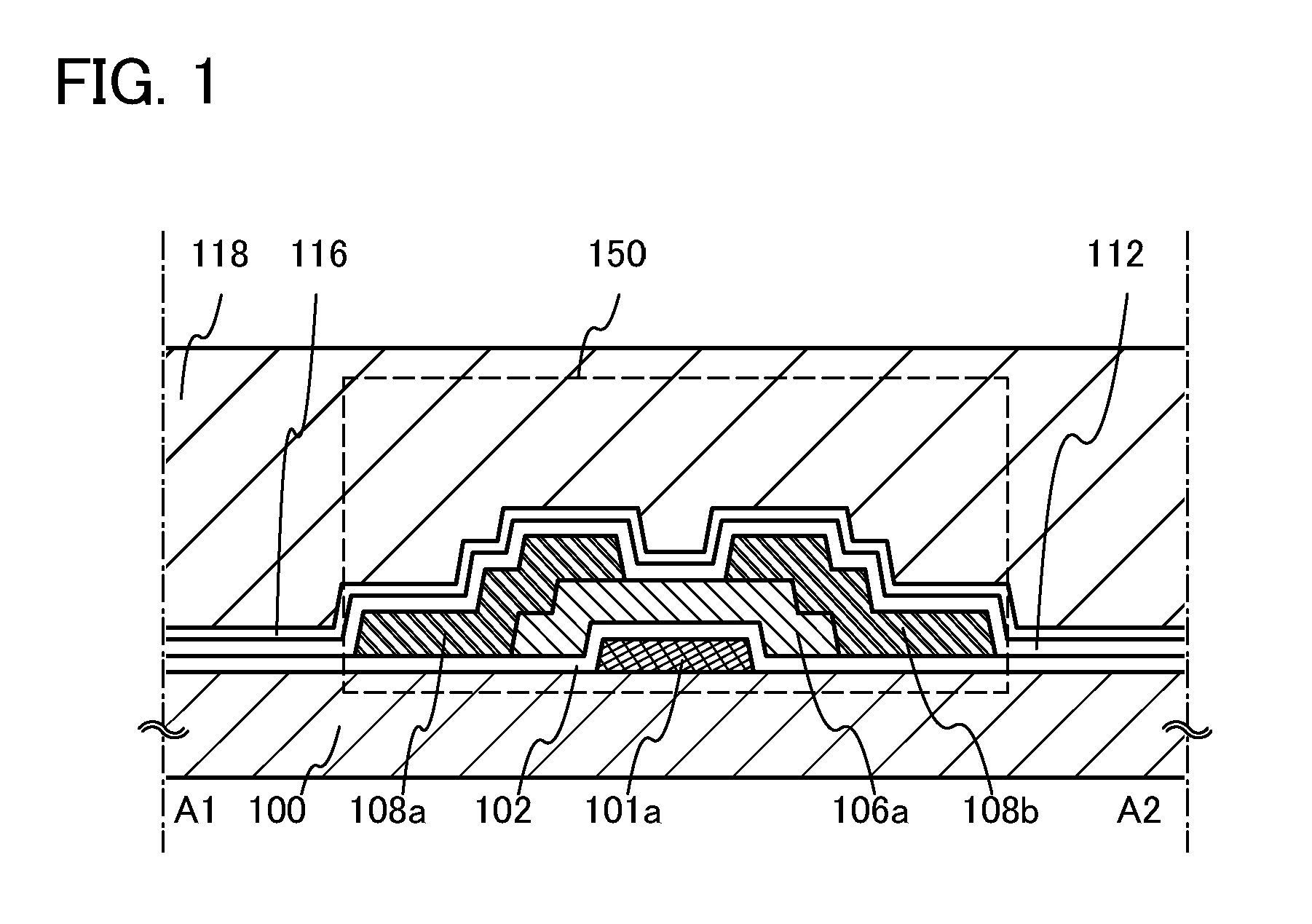

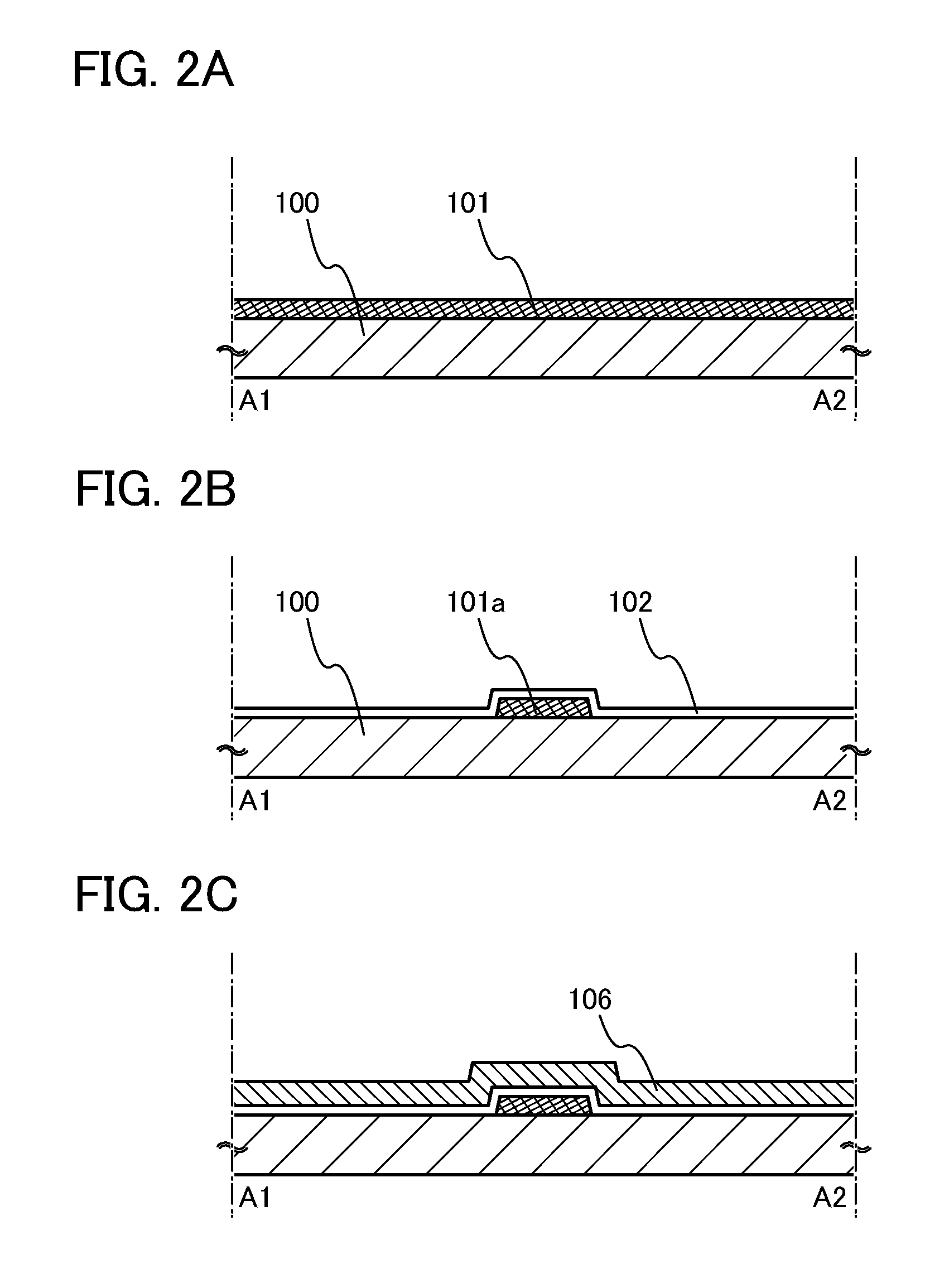

Semiconductor device and manufacturing method thereof

ActiveUS20120175609A1Threshold voltage shiftLeakage currentTransistorElectroluminescent light sourcesHydrogen concentrationSemiconductor

A first oxide insulating film is formed over a substrate. After a first oxide semiconductor film is formed over the first oxide insulating film, heat treatment is performed, so that hydrogen contained in the first oxide semiconductor film is released and part of oxygen contained in the first oxide insulating film is diffused into the first oxide semiconductor film. Thus, a second oxide semiconductor film with reduced hydrogen concentration and reduced oxygen defect is formed. Then, the second oxide semiconductor film is selectively etched to form a third oxide semiconductor film, and a second oxide insulating film is formed. The second oxide insulating film is selectively etched and a protective film covering an end portion of the third oxide semiconductor film is formed. Then, a pair of electrodes, a gate insulating film, and a gate electrode are formed over the third oxide semiconductor film and the protective film.

Owner:SEMICON ENERGY LAB CO LTD

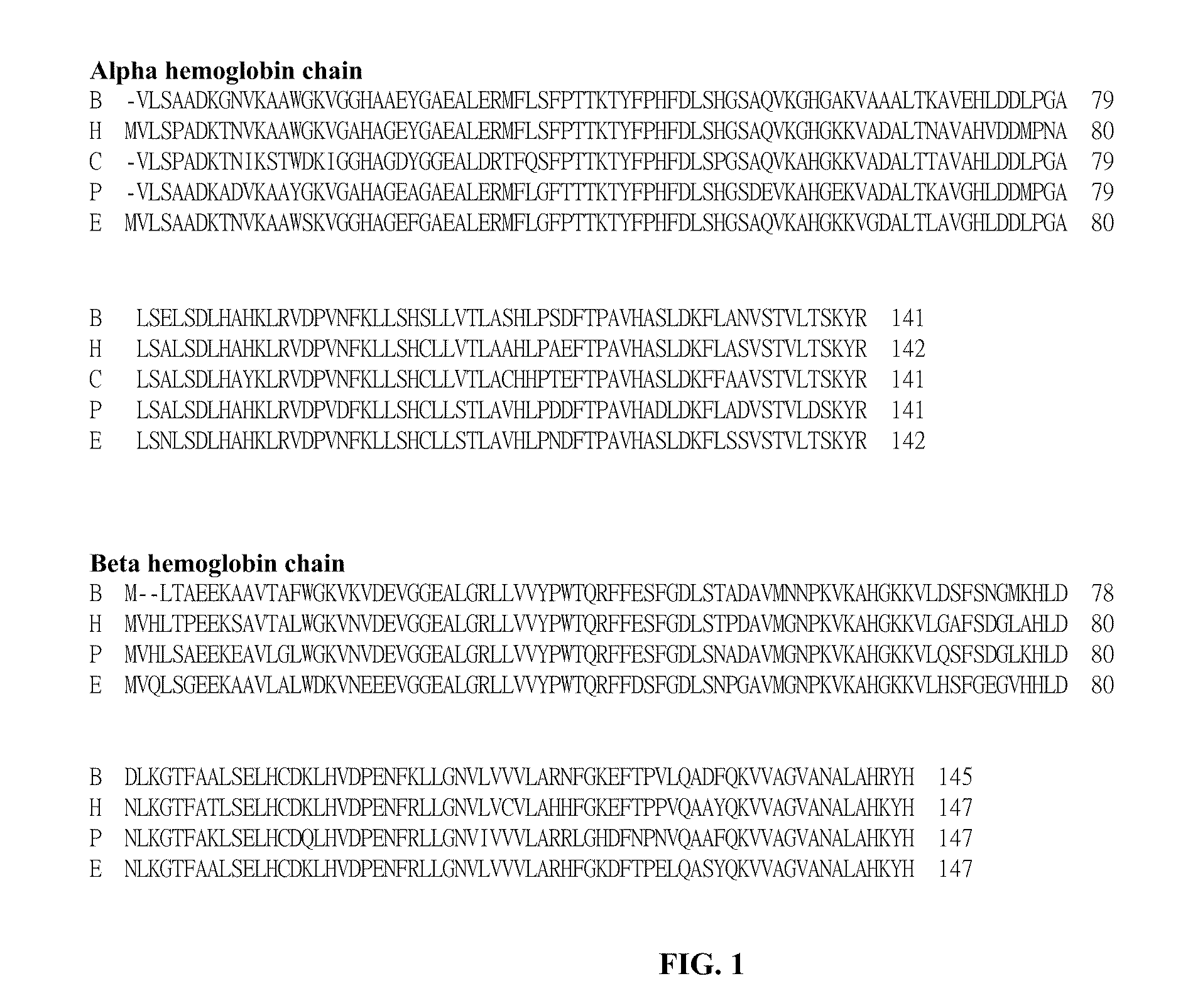

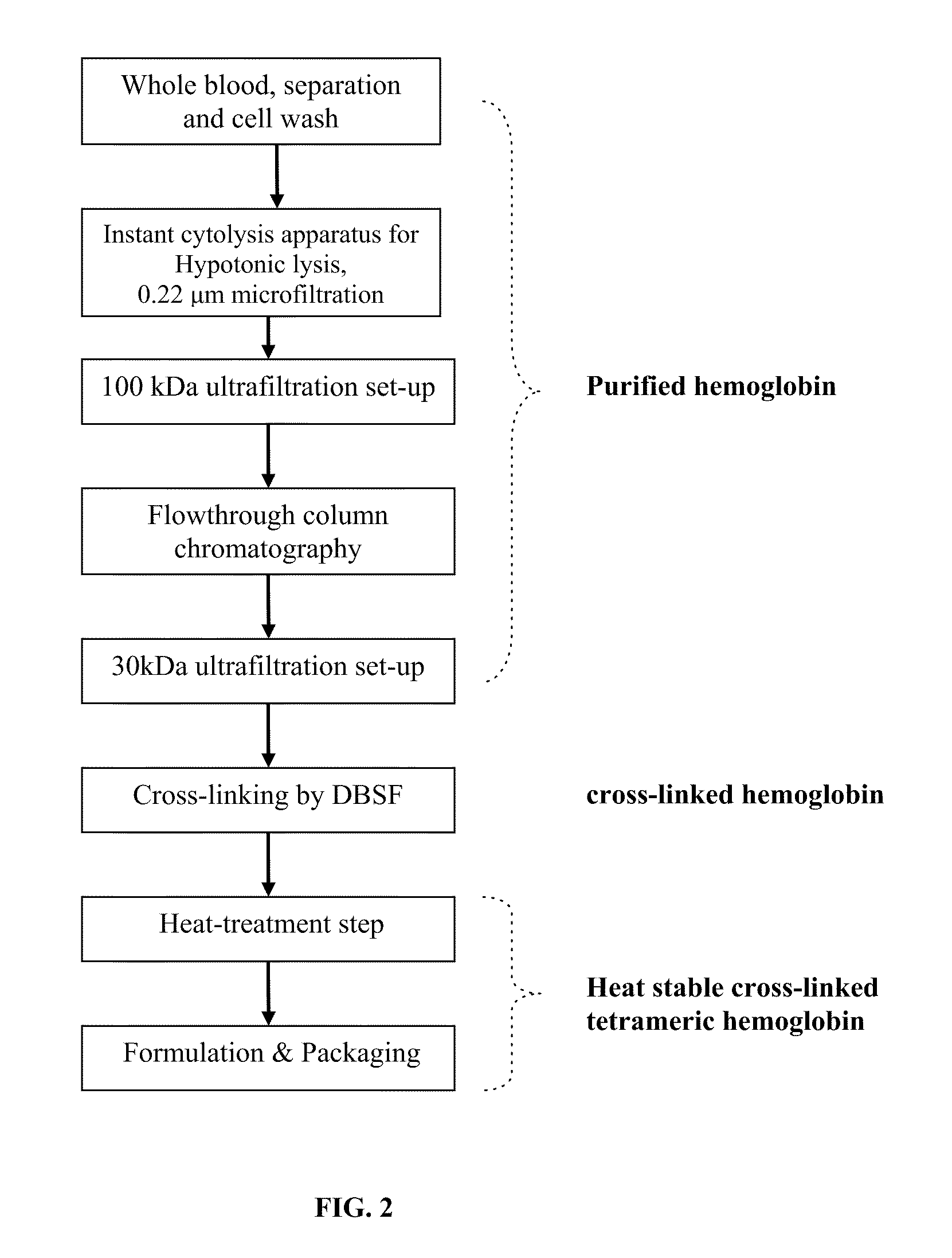

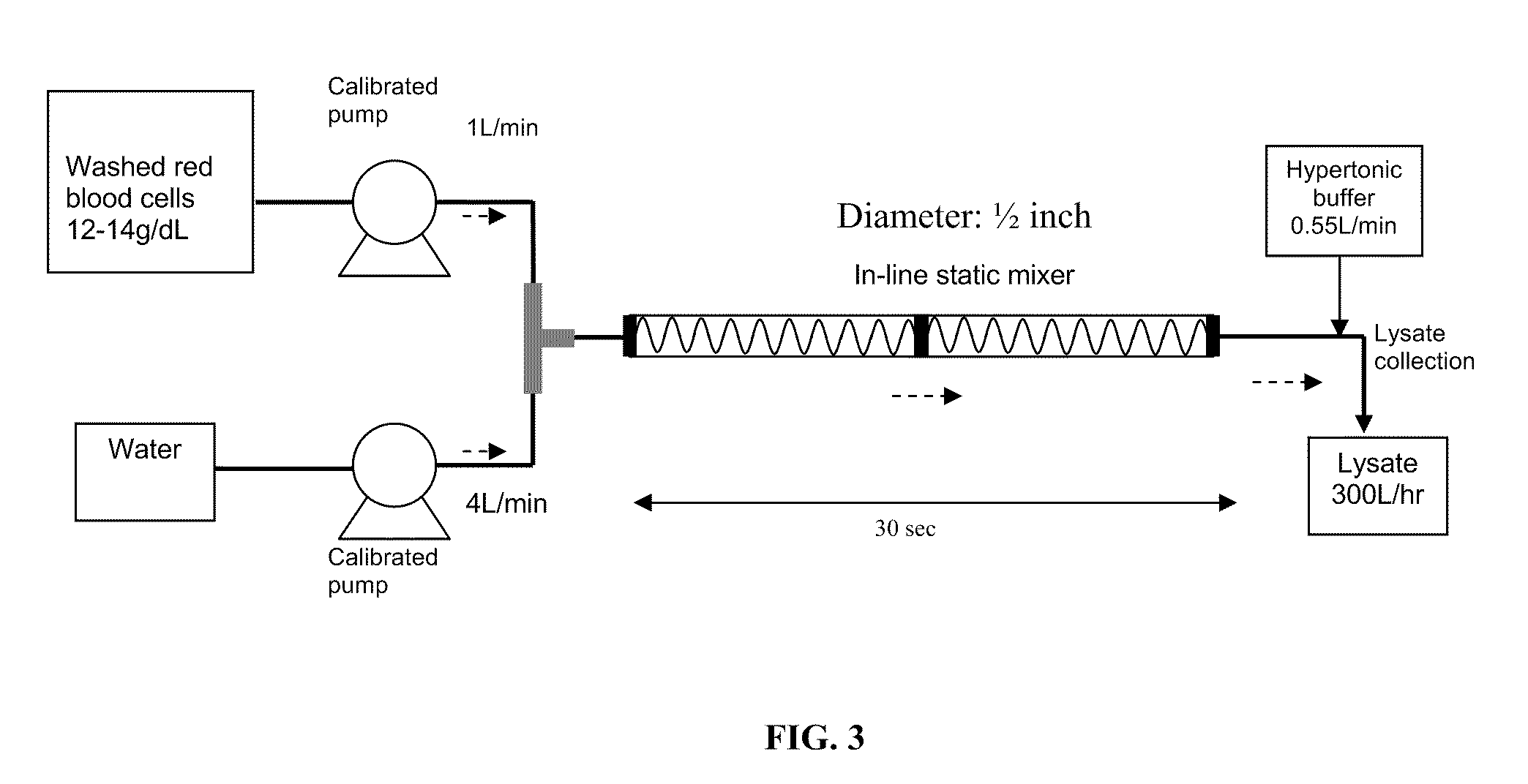

Method for the preparation of a heat stable oxygen carrier-containing pharmaceutical composition

ActiveUS7932356B1Increase oxygenationHigh sensitivityPeptide/protein ingredientsMammal material medical ingredientsArteriolar VasoconstrictionCross-link

A highly purified and heat stable cross-linked nonpolymeric tetrameric hemoglobin suitable for use in mammals without causing renal injury and vasoconstriction is provided. A high temperature and short time (HTST) heat processing step is performed to remove undesired dimeric form of hemoglobin, uncross-linked tetrameric hemoglobin, and plasma protein impurities effectively. Addition of N-acetyl cysteine after heat treatment and optionally before heat treatment maintains a low level of met-hemoglobin. The heat stable cross-linked tetrameric hemoglobin can improve and prolong oxygenation in normal and hypoxic tissue. In another aspect, the product is used in the treatment of various types of cancer such as leukemia, colorectal cancer, lung cancer, breast cancer, liver cancer, nasopharyngeal carcinoma and esophageal cancer. Another application is heart preservation in situations where there is a lack of oxygen supply in vivo, such as in heart transplant or oxygen-deprived heart.

Owner:BILLION KING INT

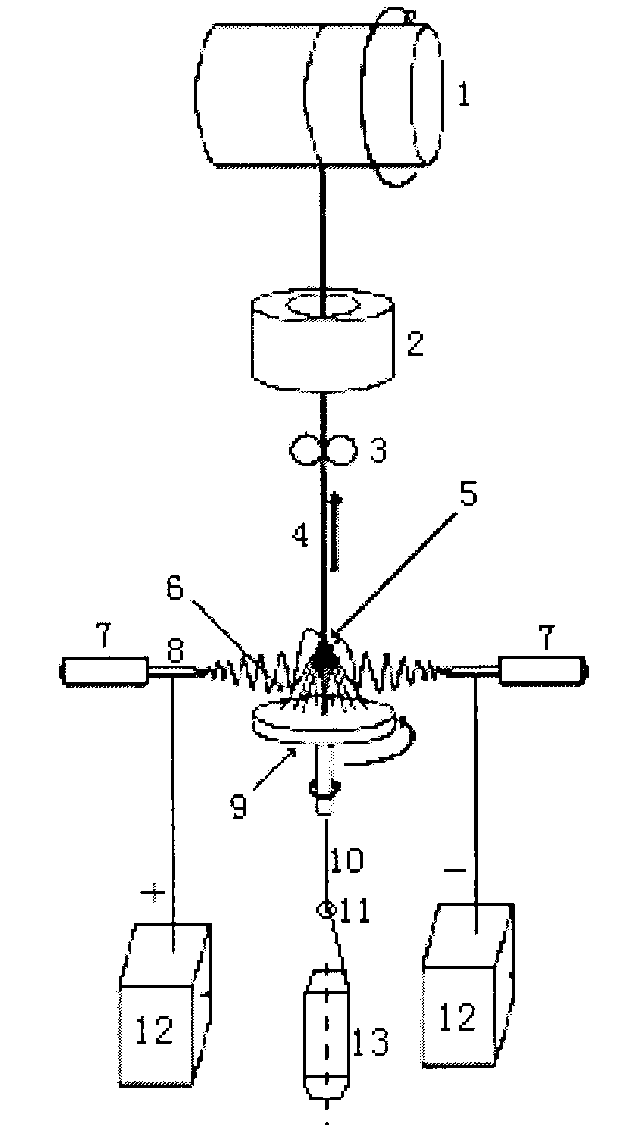

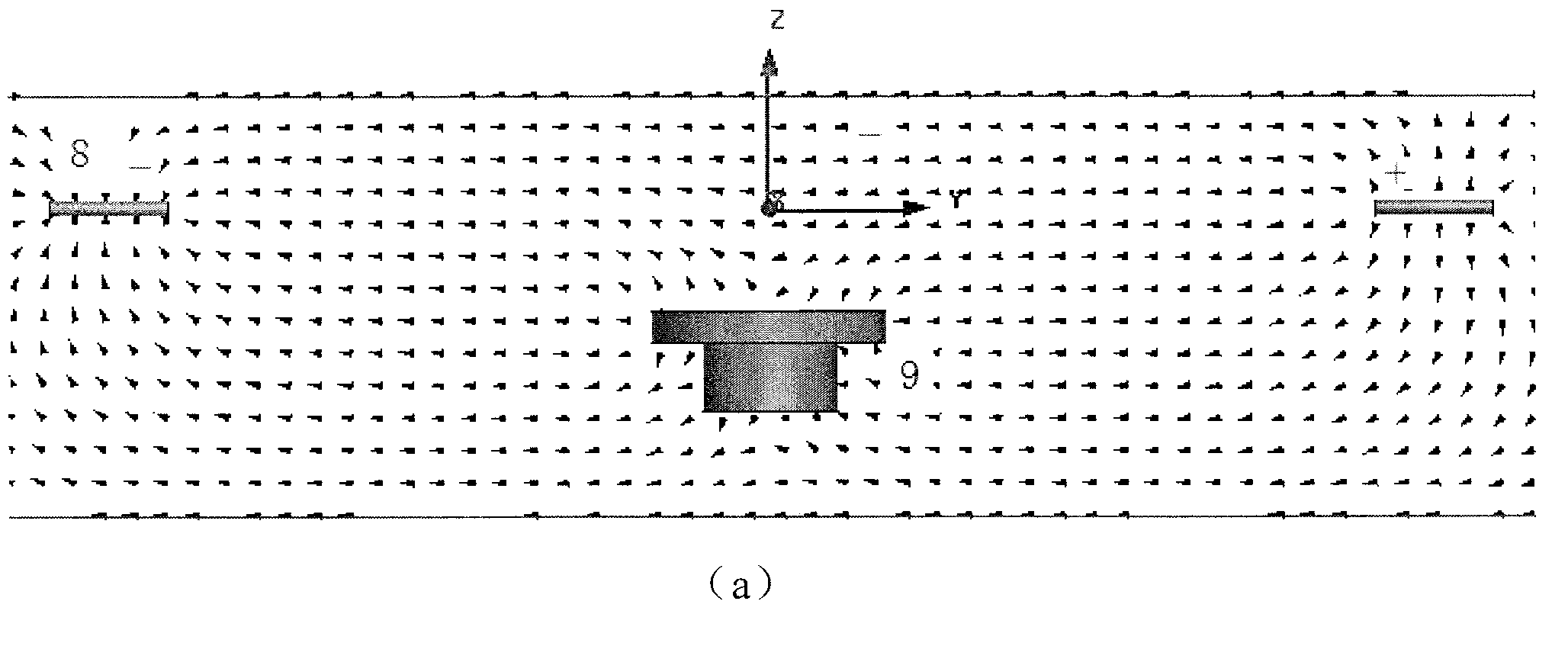

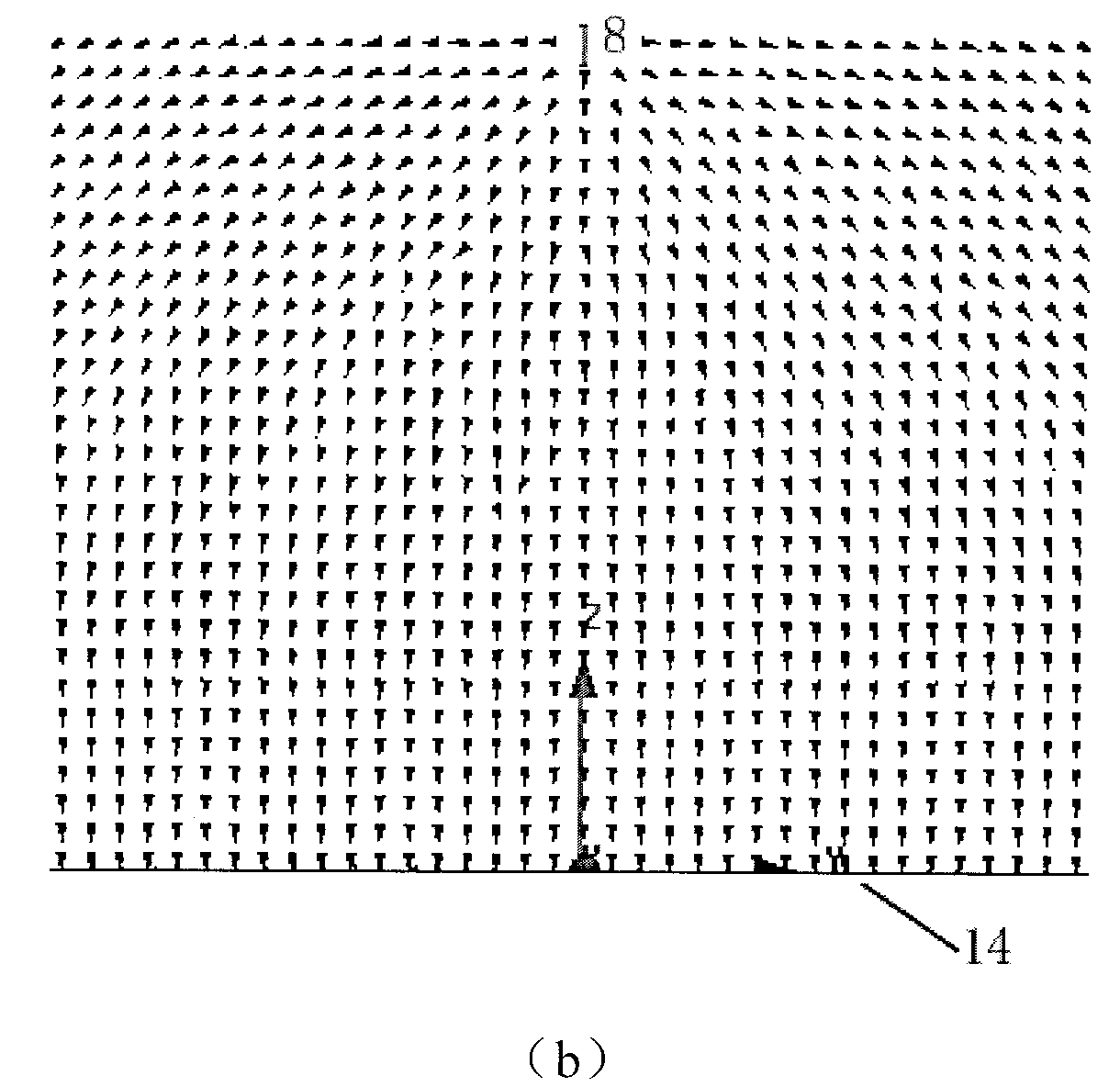

Orientation electro-spinning nanometer fiber spinning method and device thereof

InactiveCN103132194AHigh degree of axial orientationSuppress spinning instabilityDrafting machinesFilament/thread formingBobbinEngineering

The invention discloses an orientation electro-spinning nanometer fiber spinning method and a device thereof. A metal shower nozzle which exerts positive and negative high pressure is adopted to spin two strands of nanometer fibers with opposite charges, an electric field line of a spinning electric field, relative to a common spinning electric field, is straight, stability of spinning is effectively restrained, and the spinning nanometer fibers are straight. Two strands of the fibers surround the yarn tail and form a cone-shaped twisting trigonum on the upper portion of a metal twisting machine, and enable the nanometer fibers to be further oriented and twisted to form yarn through electric field force, tractive force of the yarn and acting force of the metal twisting force. The spinning nanometer fiber yarn is conducted heat shaping through a heat processing device under certain tensile force, degree of orientation of the nanometer fibers along the axial direction of the yarn, breaking force and yarn levelness are further improved, and the yarn after shaped is collected by a winding bobbin. The device can achieve the aim that orientation nanometer fiber yarn can be continuously prepared, is simple in device, convenient to operate, and good in resultant yarn continuity, yarn breaking strength and yarn levelness, and not only can spin pure nanometer fiber yarn, but also can spin nanometer fibers / filament core composite yarn. The orientation nanometer fiber spinning method and the device thereof have important application value in the fields, such as a biomedical field and a sensor field.

Owner:杨恩龙 +1

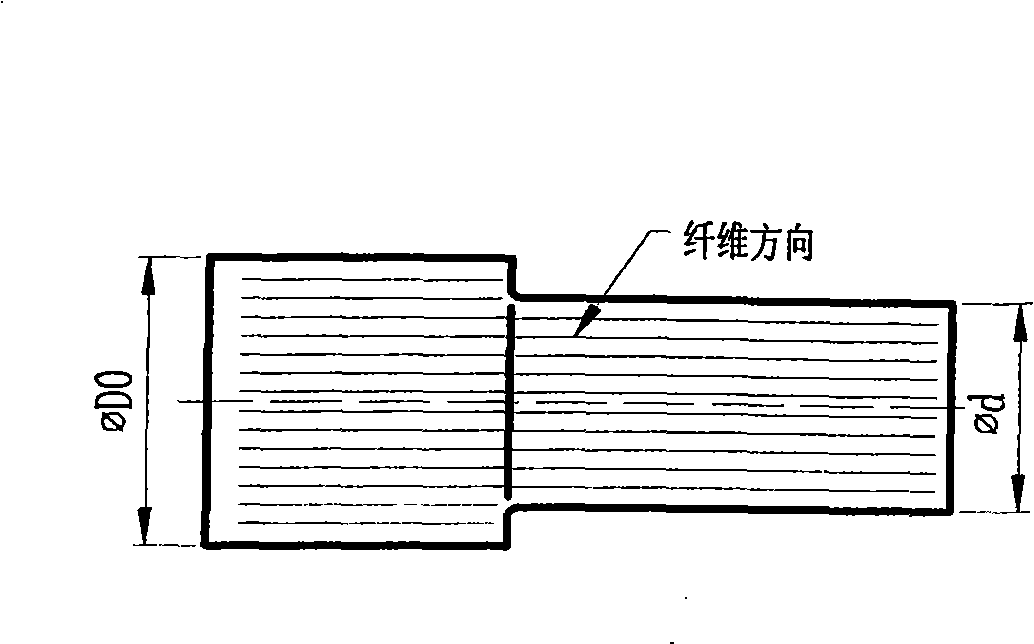

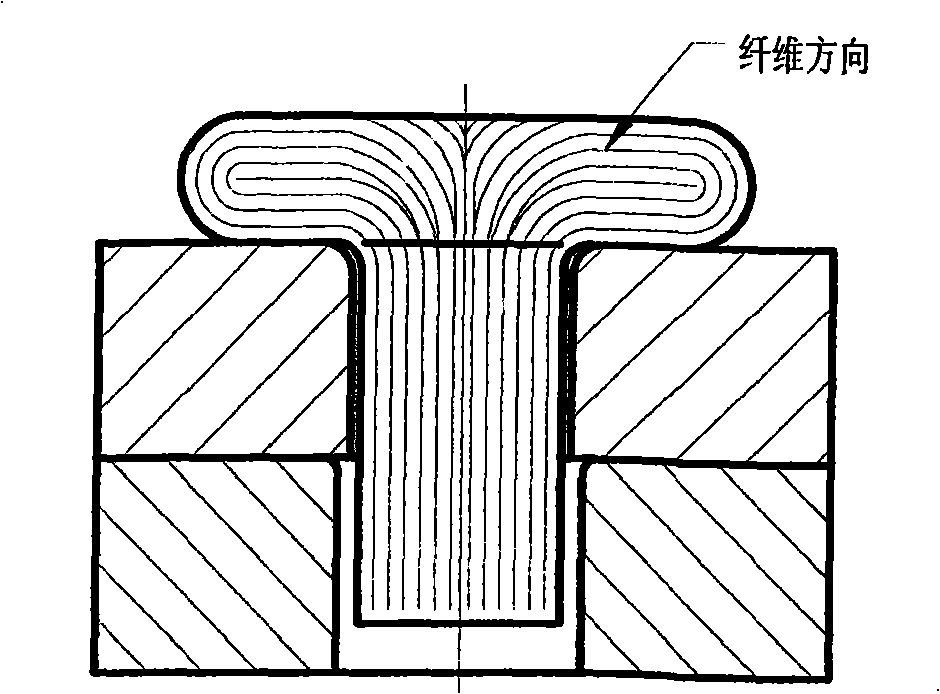

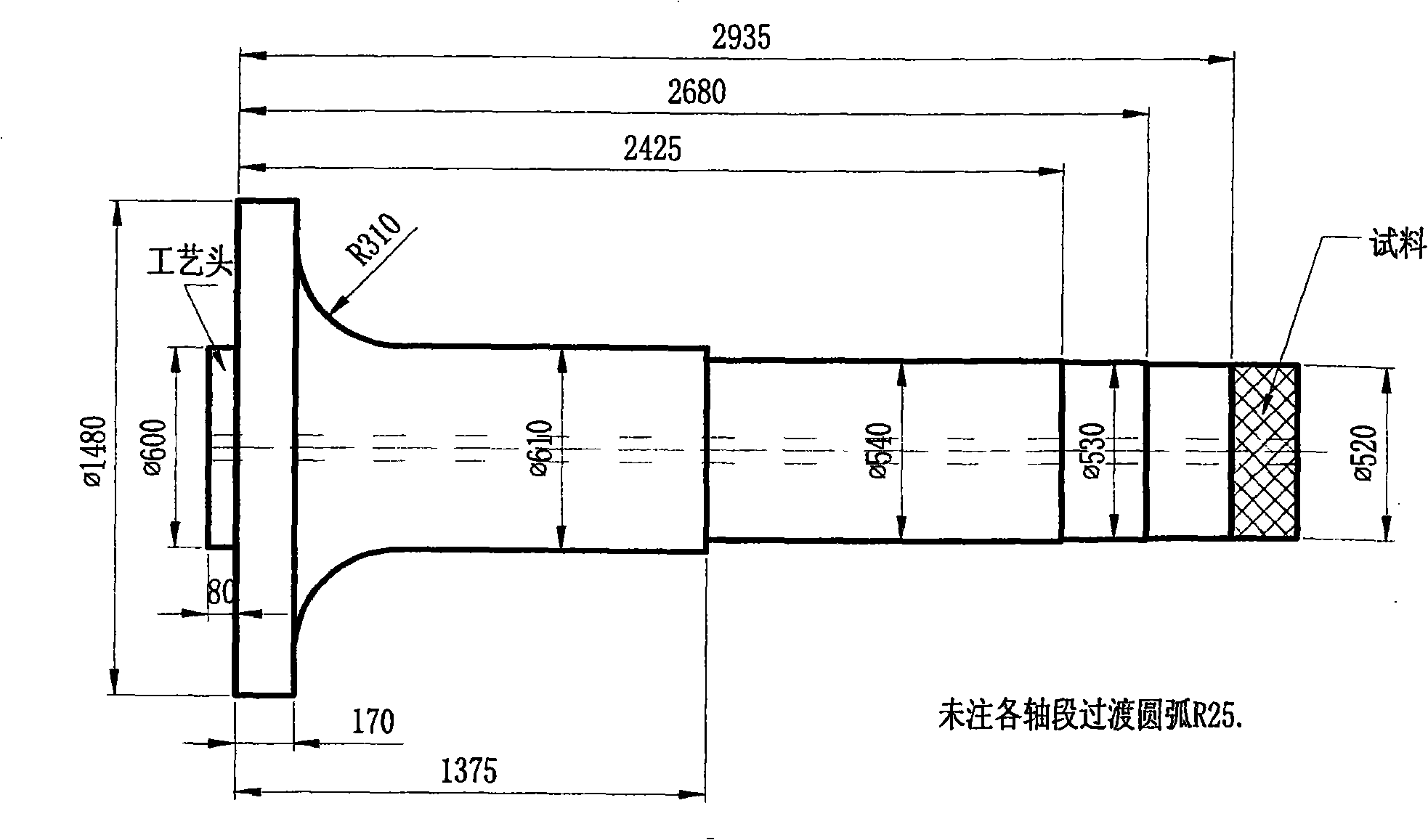

Method for producing wind-electricity principal axis with gathering stock full fibre upset forging

InactiveCN101314202ASolve the strength problemSolve process problemsShaftsFurnace typesElectricityIngot

The invention relates to a method for producing a wind-power mainshaft by local continuous upsetting and all-fibre upset forging. The method comprises the following: step one, the heating of steel ingot; step two, forging; step three, first heat processing; step four, rough machining and ultrasonic inspection; step five, quenching and tempering and heat processing; step six, fine machining, wherein, during the step two, the forging comprises that: (1) a first fire, during which, a steel ingot is subject to upset forging at a forging temperature of between 1250 and 900 DEG C; firstly, the bottom of the steel ingot is sawed off, and the steel ingot is subject to capping and upset forging; (2) a second fire, during which, the steel ingot is stretched towards various directions, marked and subject to intermediate billet cogging; after a pole part is molded, scrap on a T end is chopped and removed; after the forging is finished, the steel ingot returns to a heating furnace for being reheated; (3) a third fire, during which, the steel ingot is subject to local continuous upsetting and all-fibre upset forging; (4) a fourth fire, during which, the steel ingot is subject to rolling and leveling; the pole part is stretched; the disc edge of a hub end on the head part of an intermediate billet material after the local continuous upsetting and all-fibre upset forging is subject to rolling operation; after the rolling, the intermediate billet material is inserted into a leaking disc component again; the end face of the disc is pressed and leveled; after the shaping of the disc end is completed, a manipulator clamps the disc and stretches the pole part of the intermediate billet material to a dimension of a forgeable piece; thus, the mainshaft forging is completed. The method can improve the fatigue resisting strength of a wind-power mainshaft forging piece.

Owner:JIANGYIN ZENKUNG FORGING CO LTD

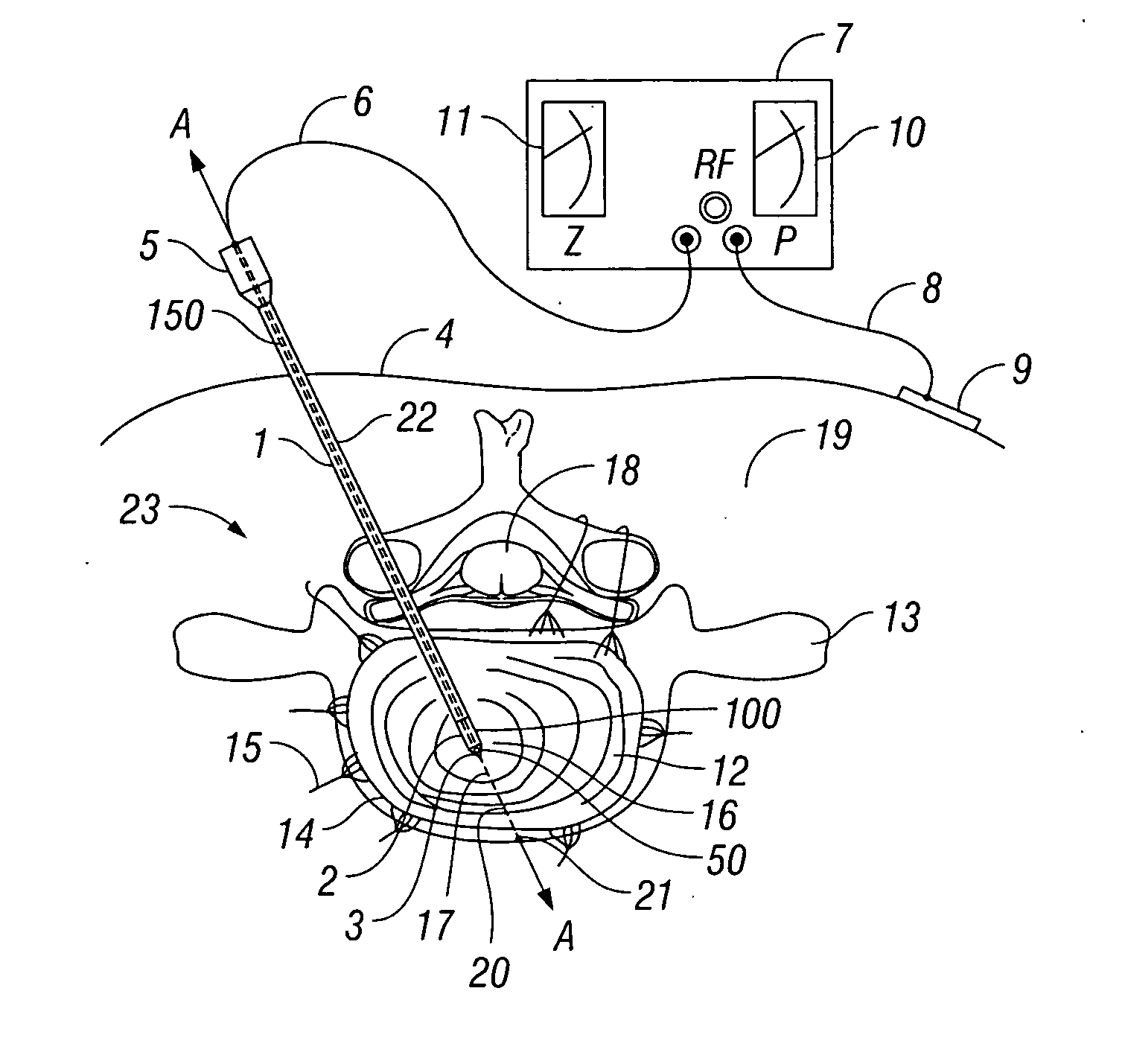

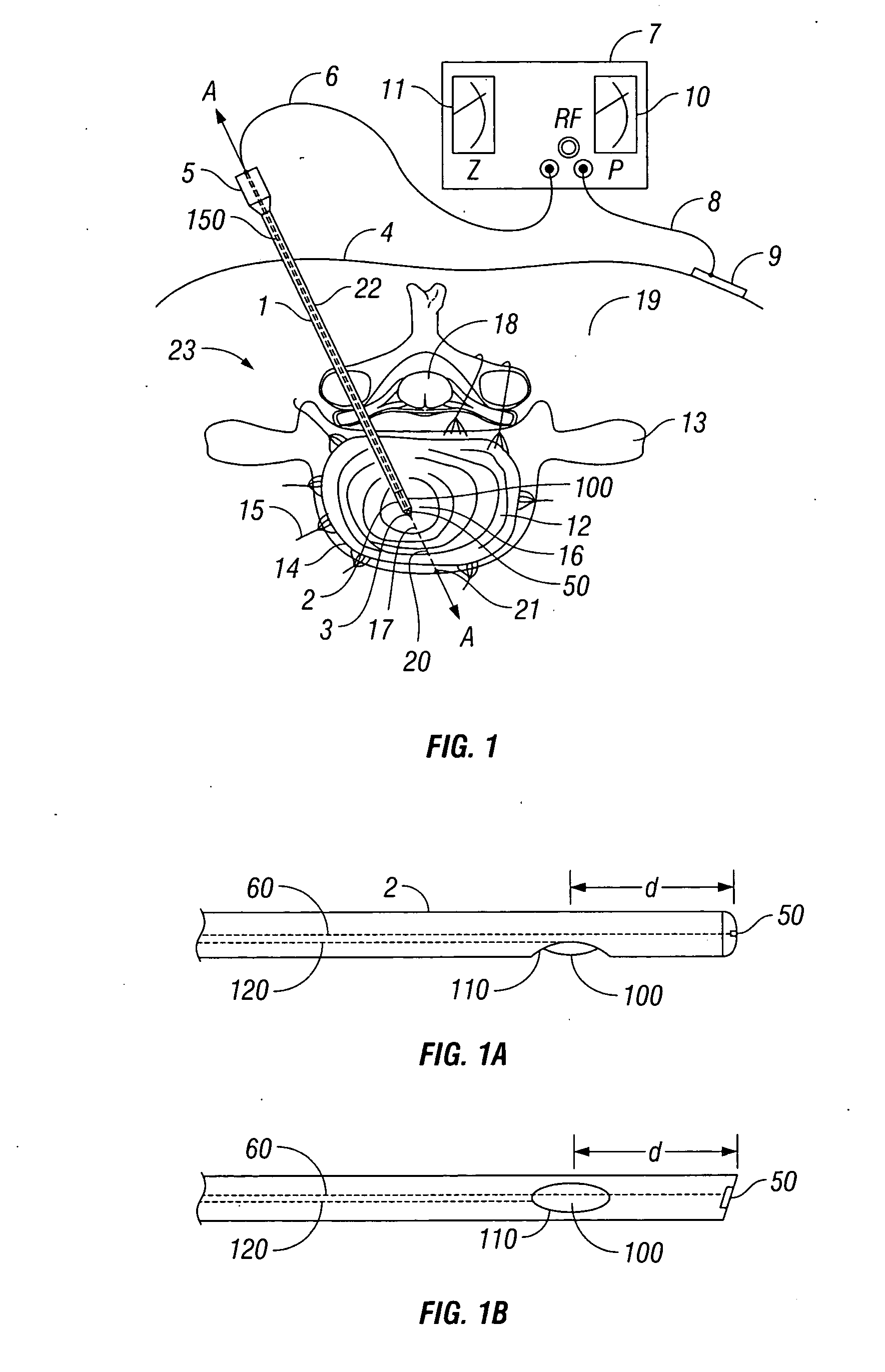

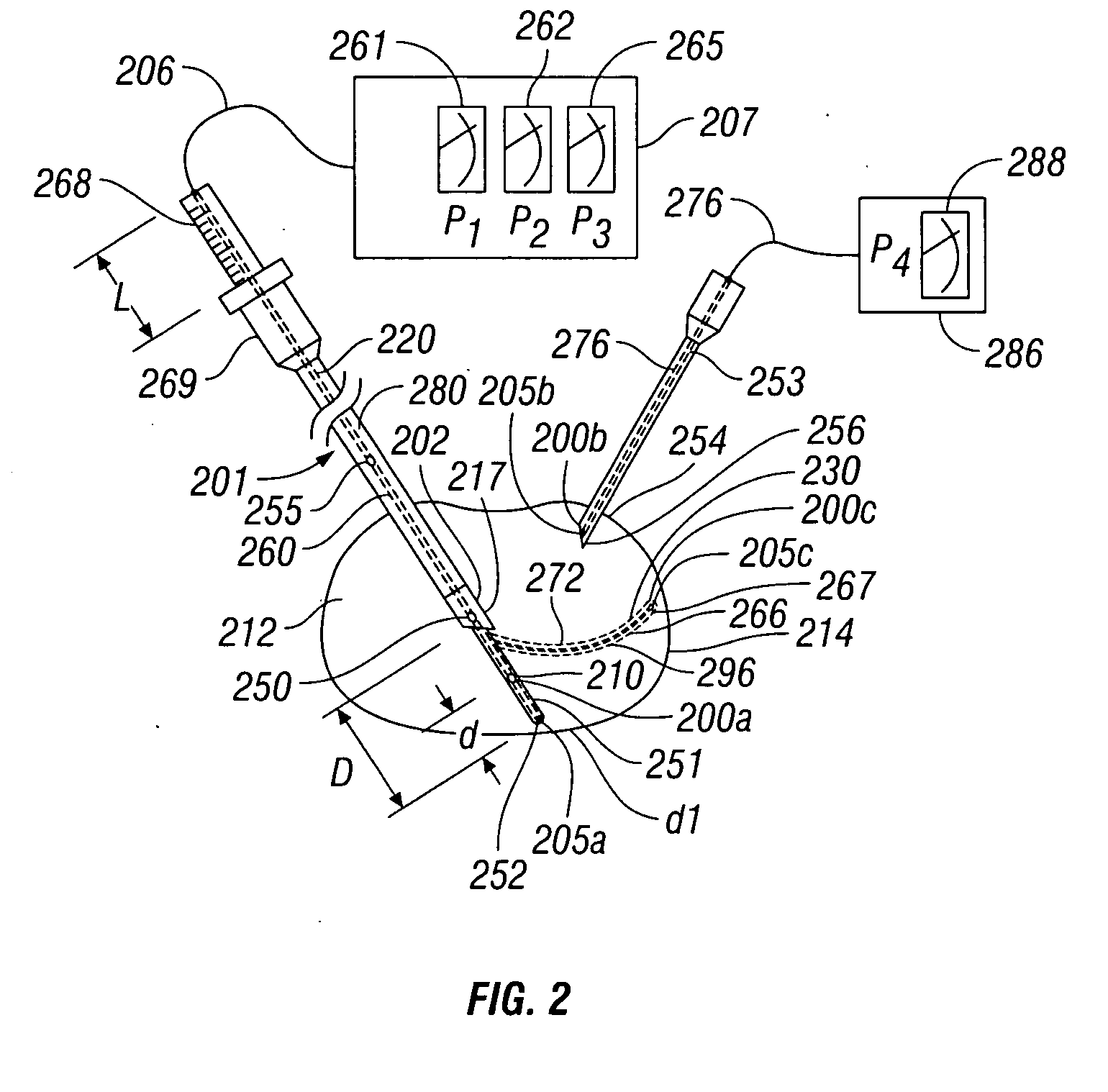

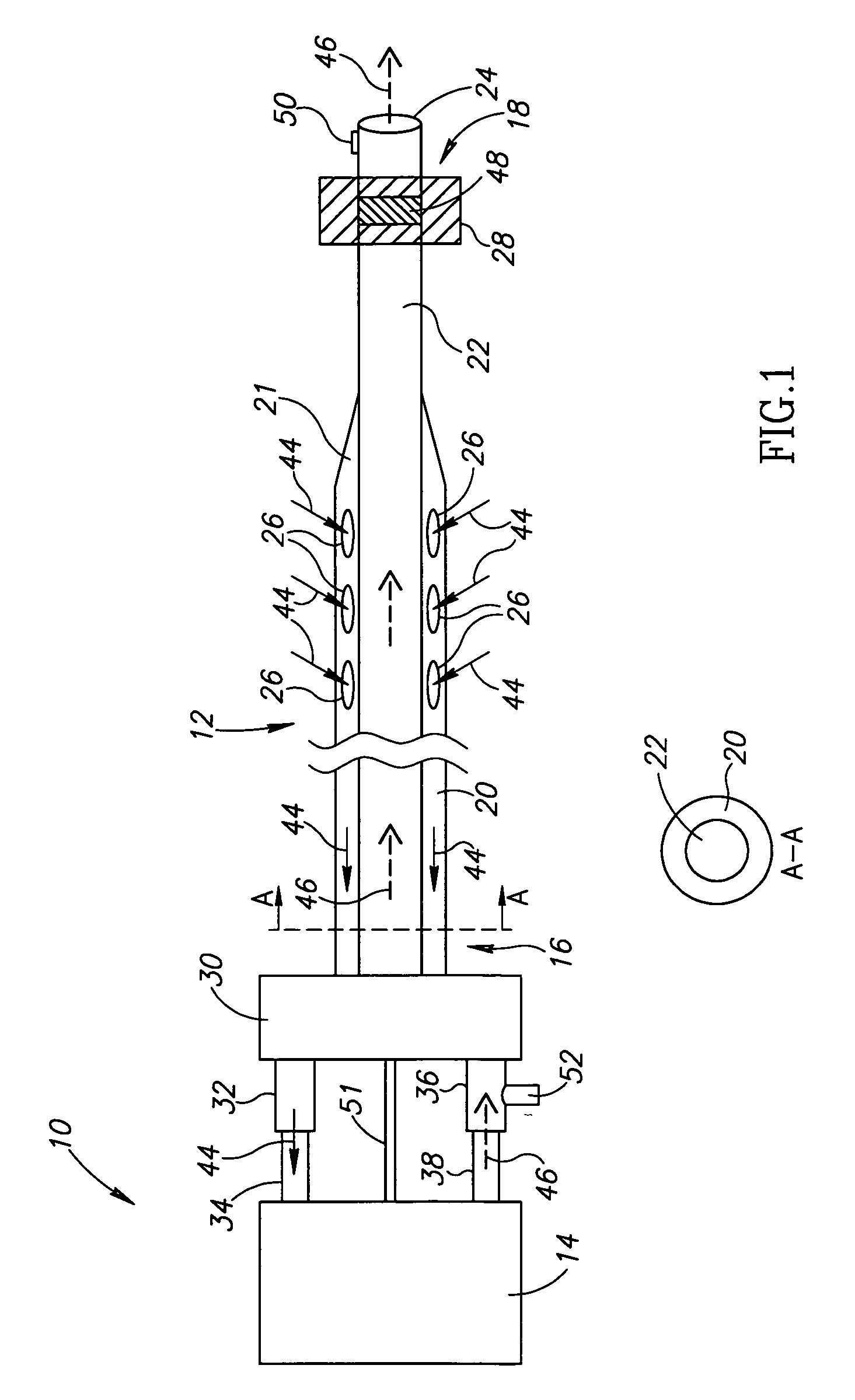

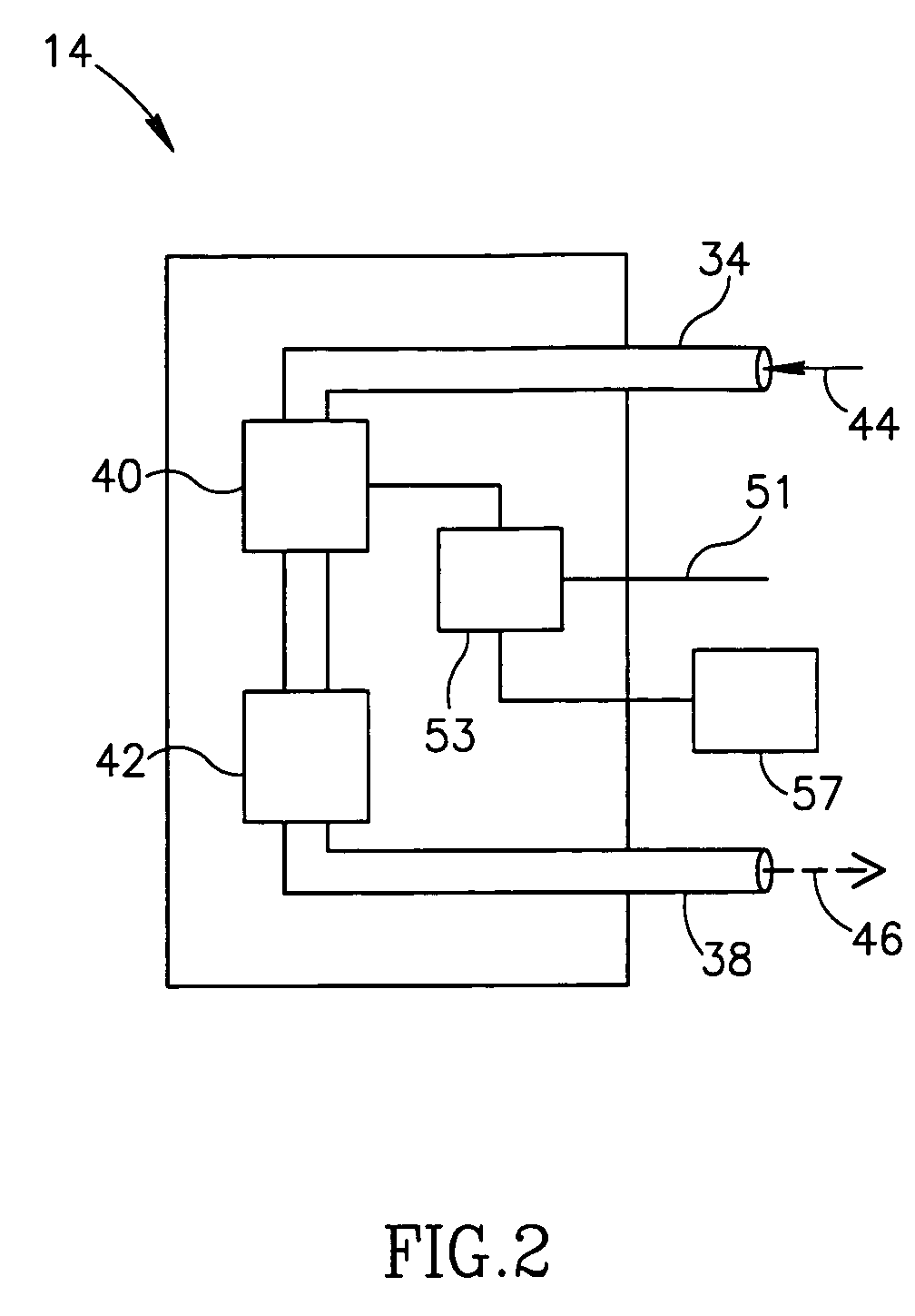

Method and apparatus for monitoring disc pressure during heat treatment of an intervertebral disc

InactiveUS20060224223A1Relieving patient pain associated with the discElectrotherapyDiagnosticsIntervertebral diskForce sensor

A probe system and method for treating an intervertebral disc of a patient are disclose. A probe has a cannula having an open end defined at a distal end and adapted to couple to a power source. A stylet fits into the cannula so that a distal end of the stylet occludes the open end at the distal end of the cannula. The probe system also includes a pressure monitoring apparatus coupled to the stylet, with the stylet including a pressure sensor in proximity to the distal end of the stylet. The pressure sensor communicates with the pressure monitoring apparatus to measure the pressure of the intervertebral disc. The power source delivers power to the distal end of the cannula, causing heating of the disc when the distal end of the cannula is disposed within the disc, thereby relieving patient pain associated with the disc.

Owner:COVIDIEN AG

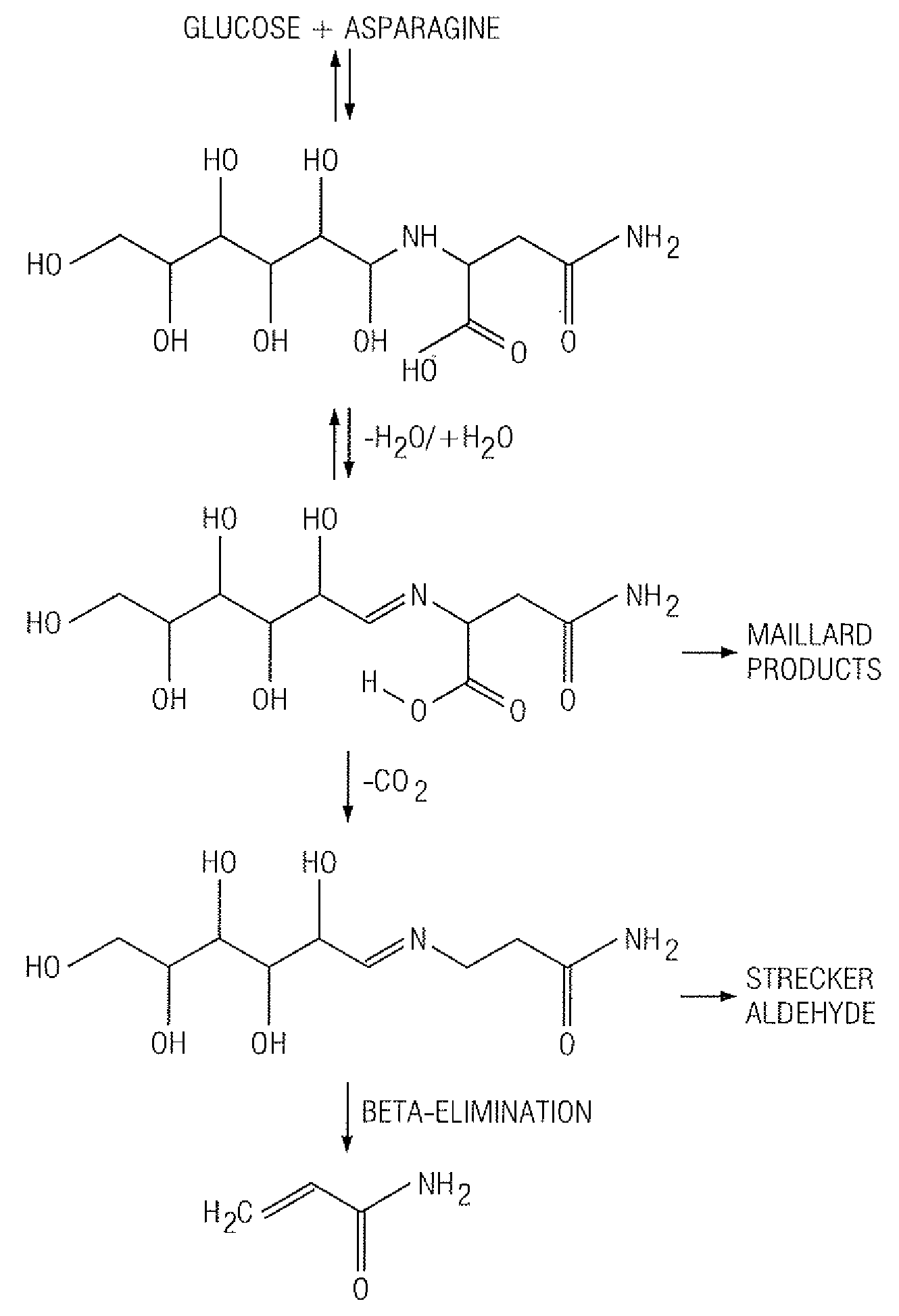

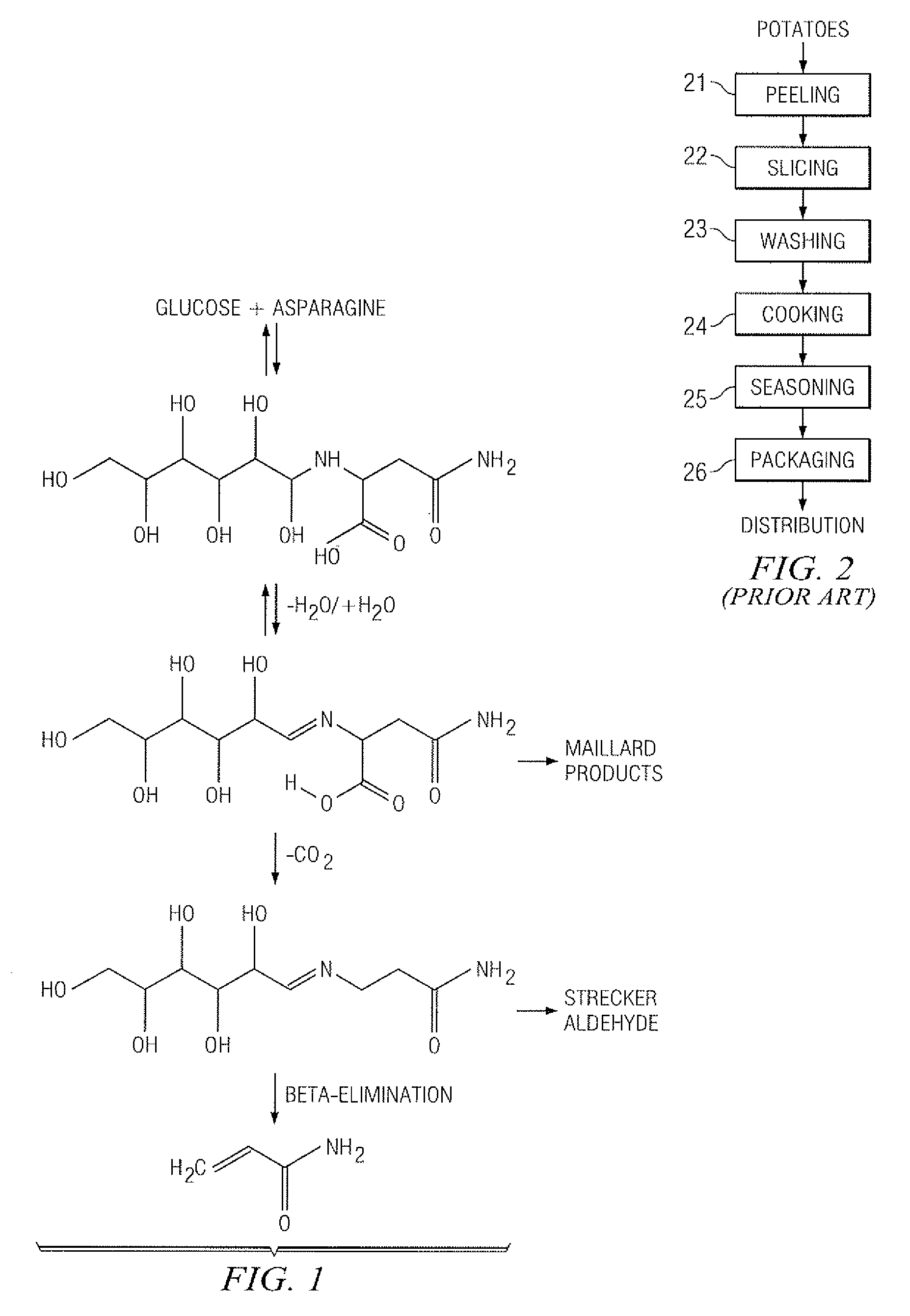

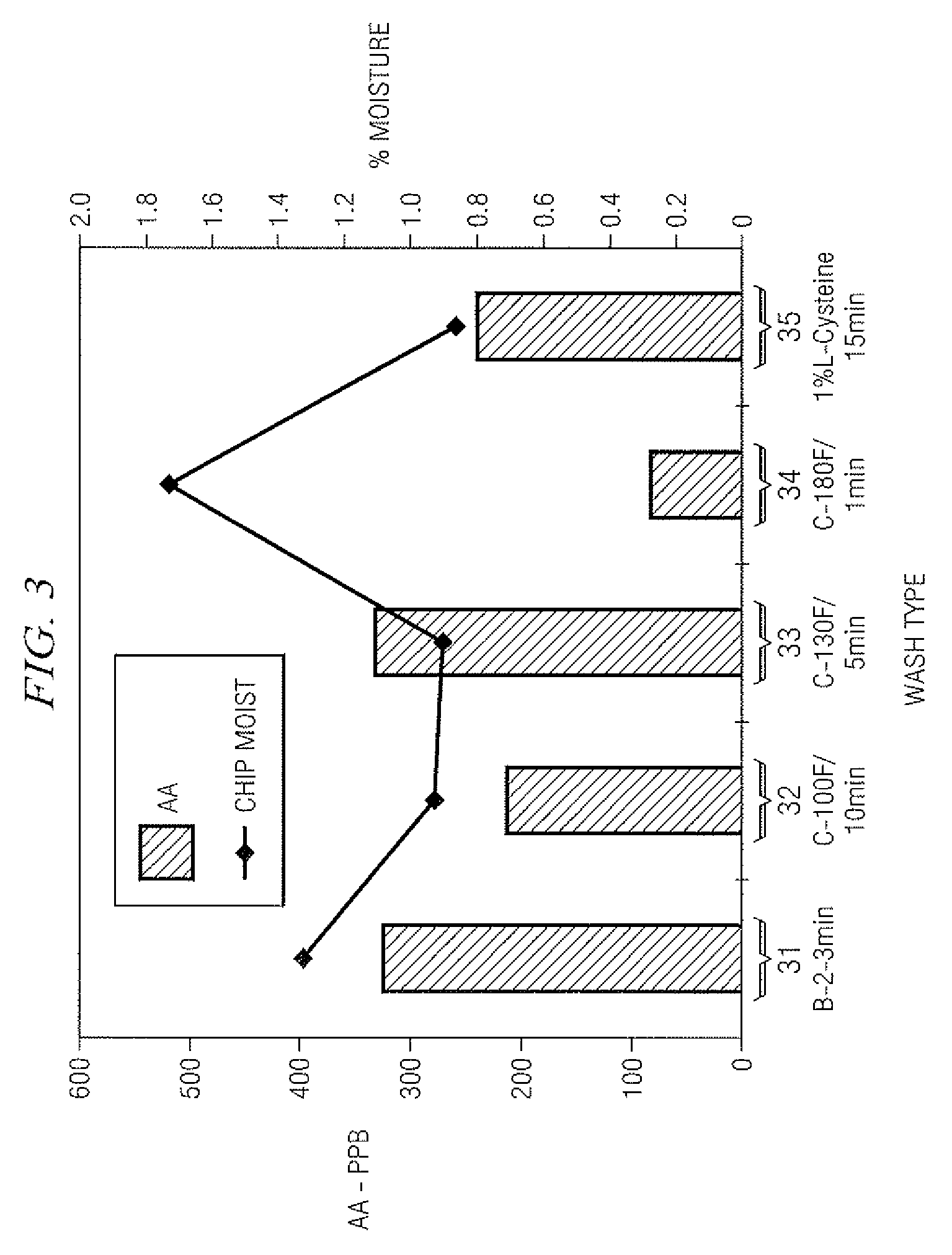

Method for Reducing Acrylamide Formation in Thermally Processed Foods

InactiveUS20070141227A1Reduce the amount requiredFood preparationHops treatmentIngested foodAsn - Asparagine

A method for reducing the amount of asparagine, a pre-cursor of acrylamide, in food products that are thermally processed. This invention permits the production of foods having significantly reduced levels of acrylamide. The method relies on contacting a potato feed such as potato slices containing asparagine, an acrylamide pre-cursor, with a leaching solution to extract asparagine out of the potato feed. Thermally processing the leached potatoes will result in a potato product having a lower level of acrylamide than a non-leached, thermally processed potato product.

Owner:FRITO LAY NORTH AMERICA INC

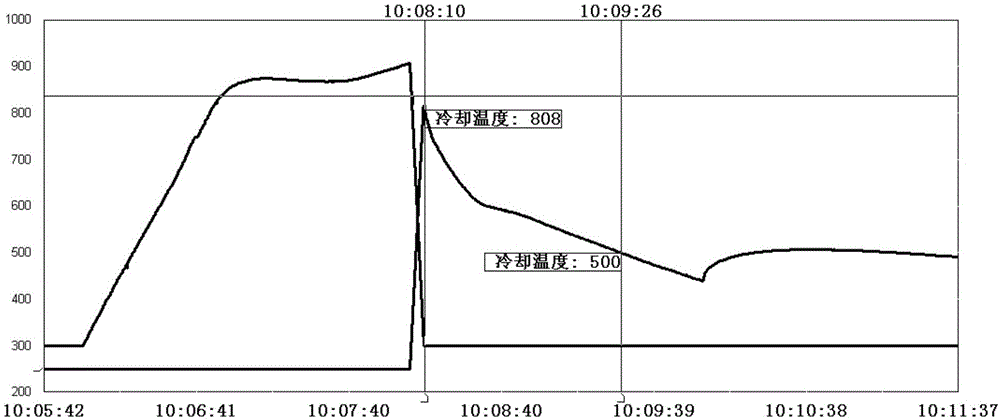

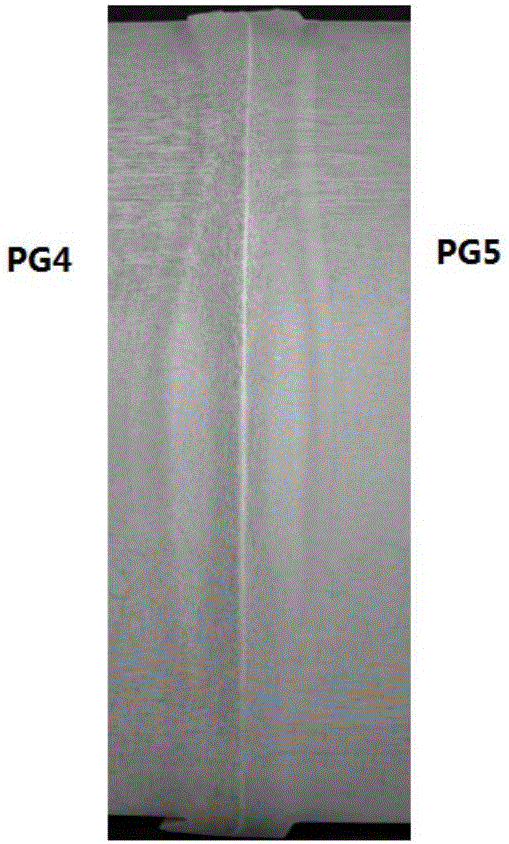

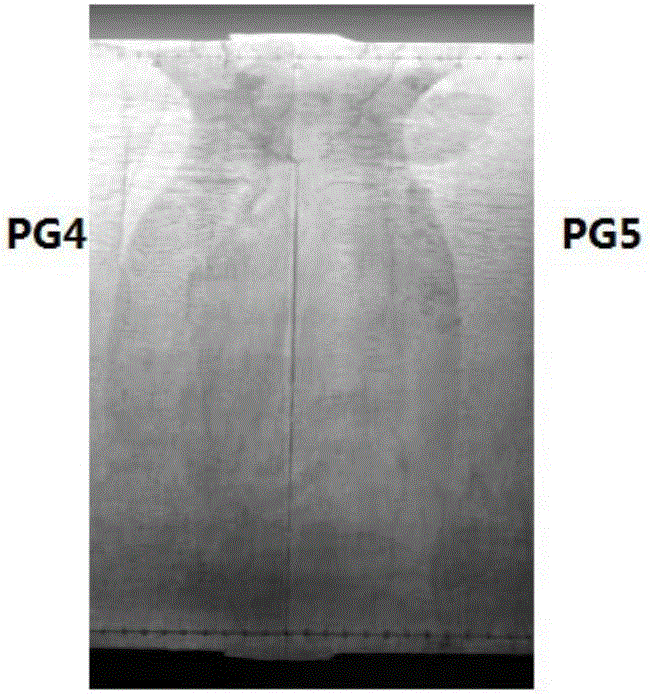

Method for post-weld heat processing of rail welded joint

ActiveCN106544933AGood toughness matchReduce internal defectsFurnace typesRailway track constructionEngineeringTread

The invention relates to the field of rail welding and discloses a method for post-weld heat processing of a rail welded joint. The method comprises the steps that first cooling is conducted to the to-be-cooled rail welded joint obtained through welding till the temperature is lower than 400 DEG C; then, the rail welded joint obtained after the first cooling is heated to a temperature between 860 DEG C and 930 DEG C; and second cooling is then conducted to the rail welded joint till a tread face temperature of the joint is between 410 DEG C and 450 DEG C, wherein the rail welded joint is a welded joint of a 75kg / m hypereutectoid steel rail and a pearlite steel rail. The method disclosed by the invention is used for the post-weld heat processing of the welded joint of the hypereutectoid steel rail and the PG4 heat-processing steel rail; and the heterogeneous rail joint has fewer internal defects and stable welding quality, and can satisfy requirements for passing tests such as a fatigue test, a stretching and impact test and a static bending test.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

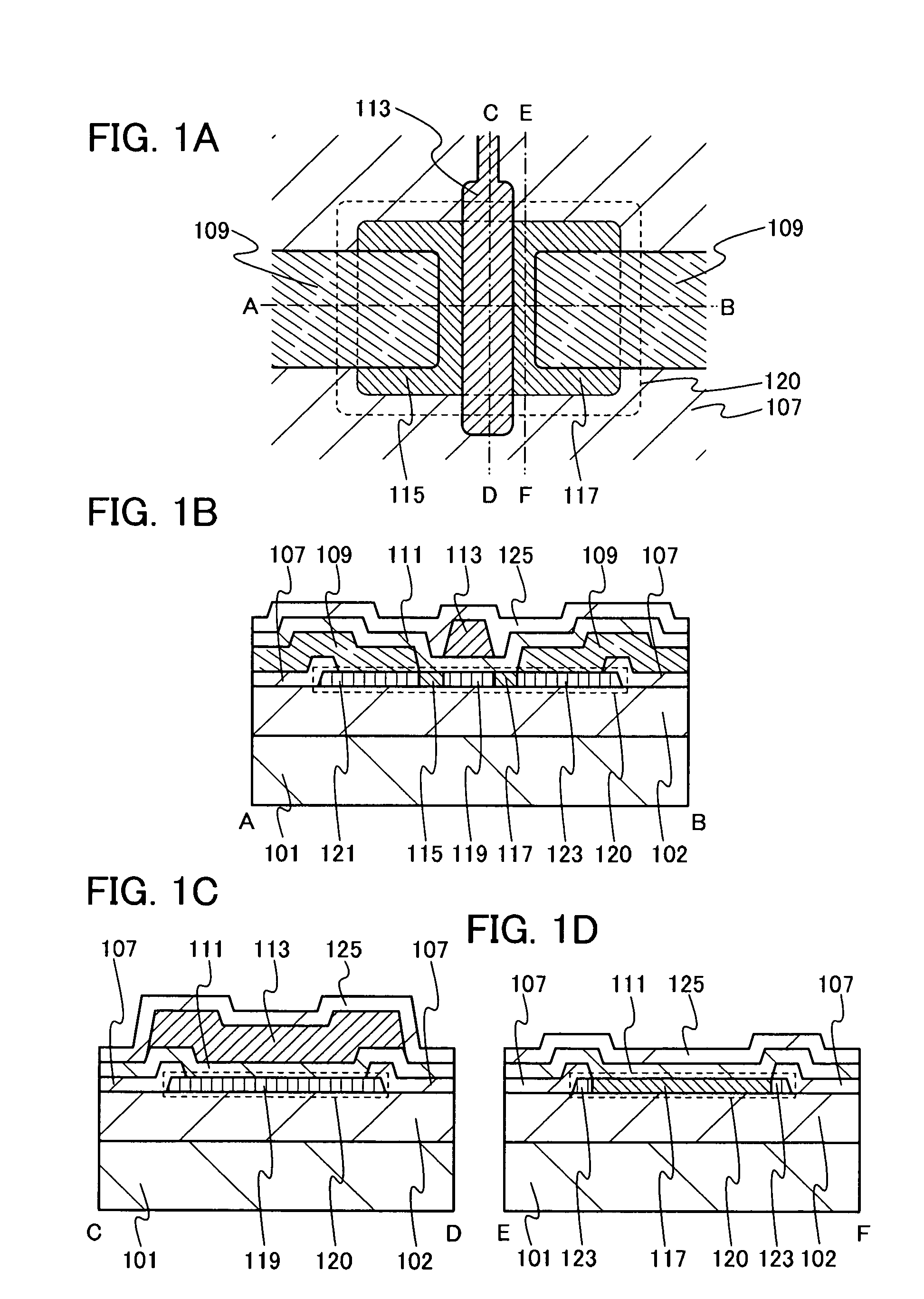

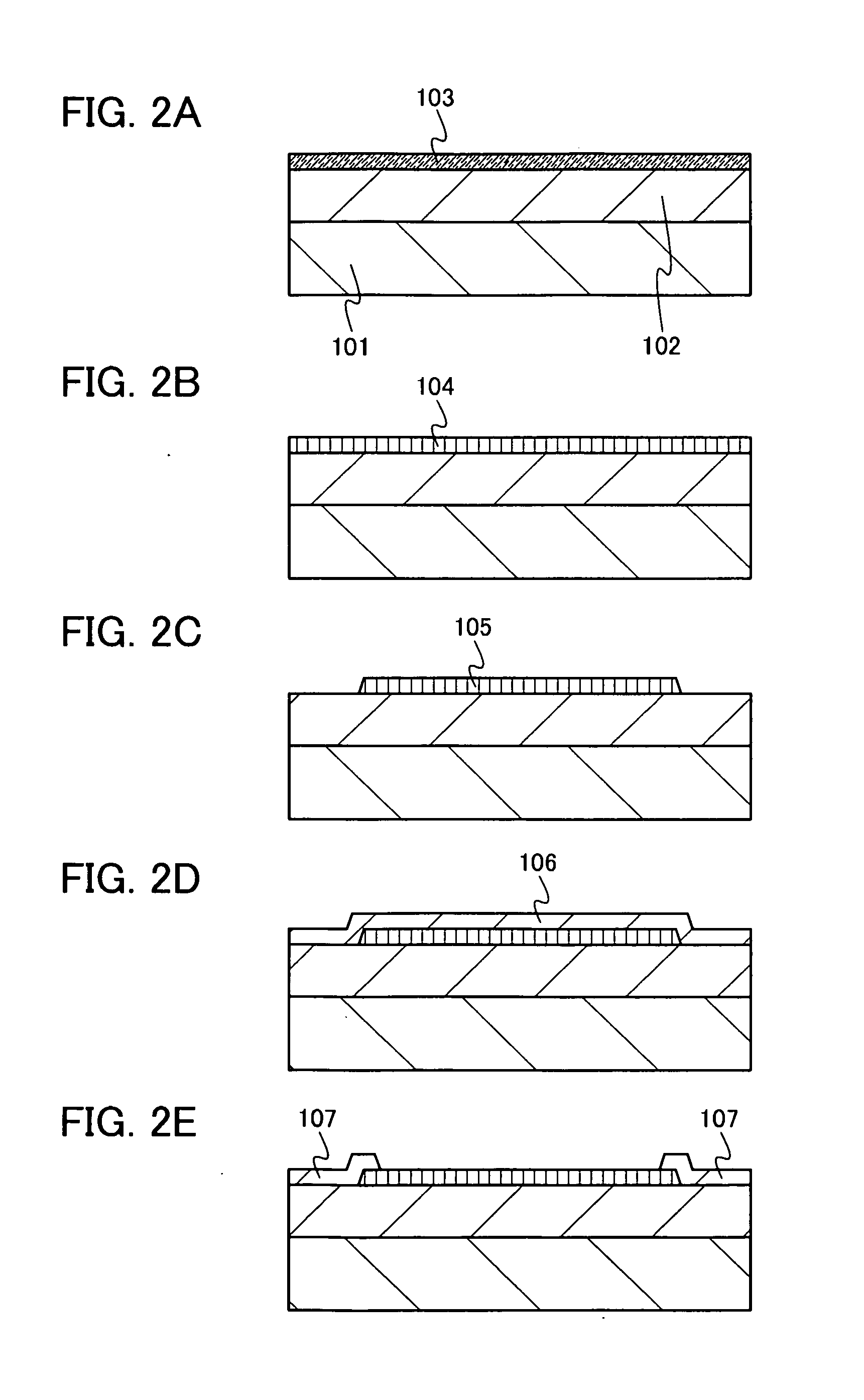

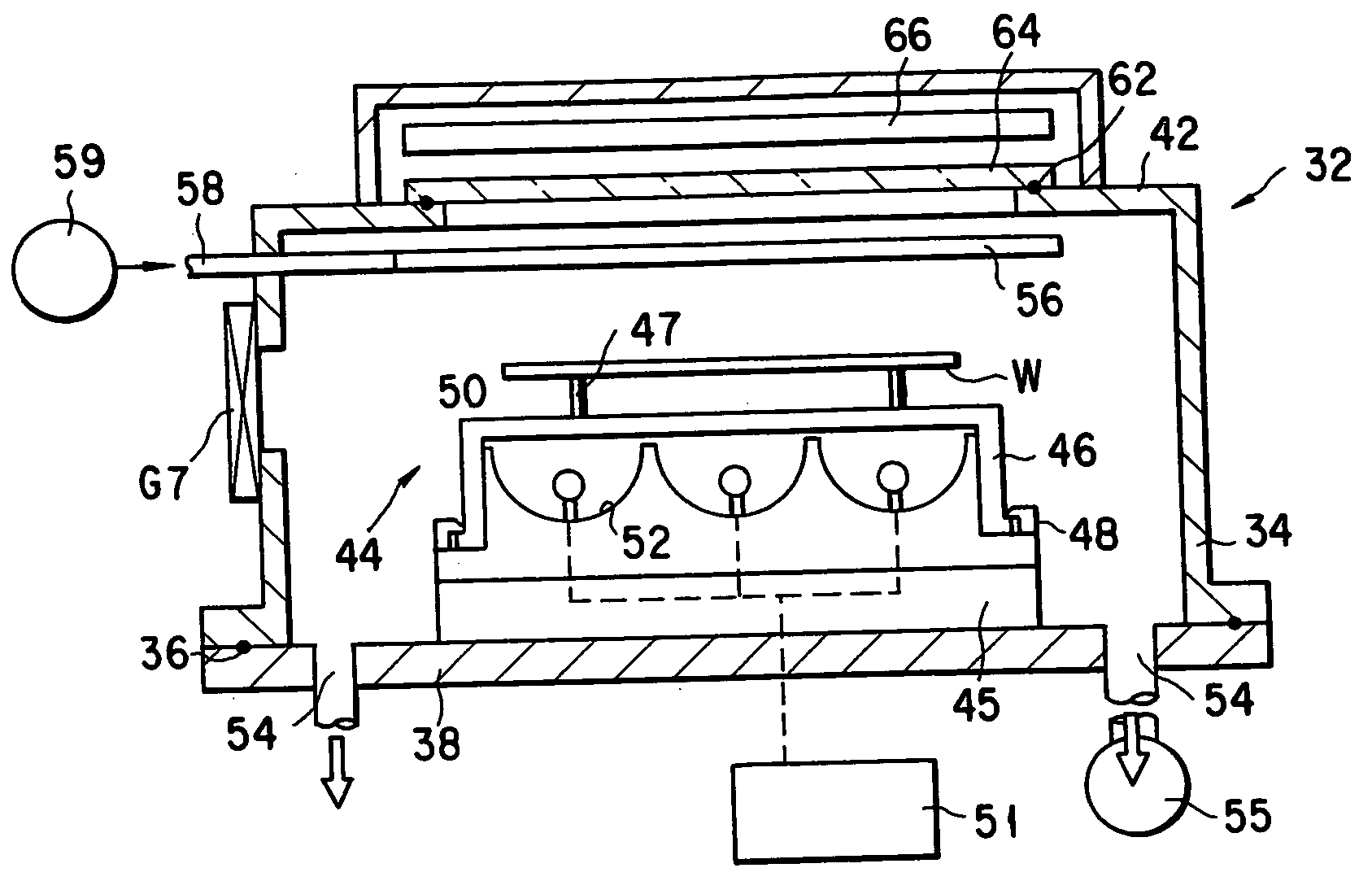

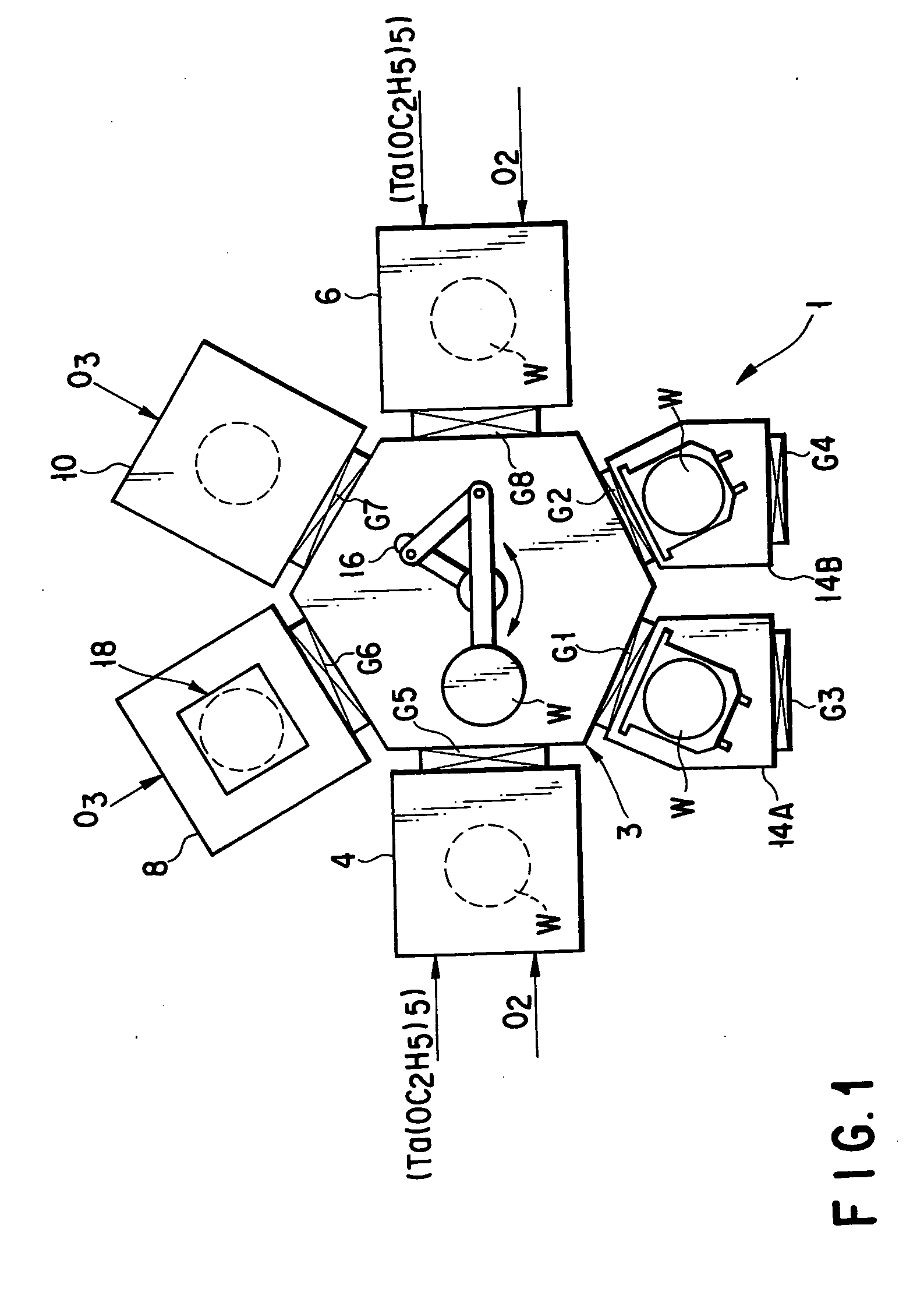

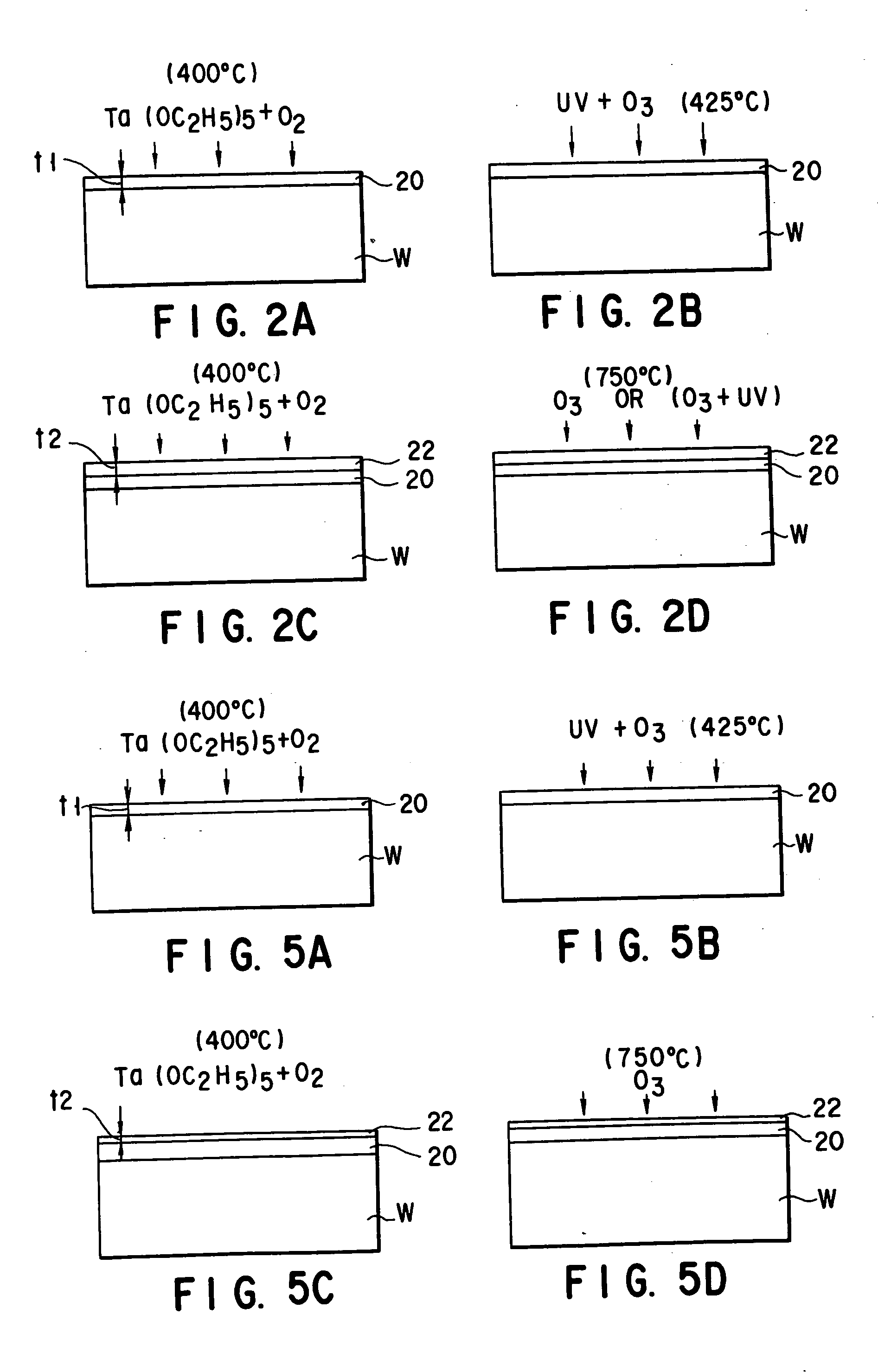

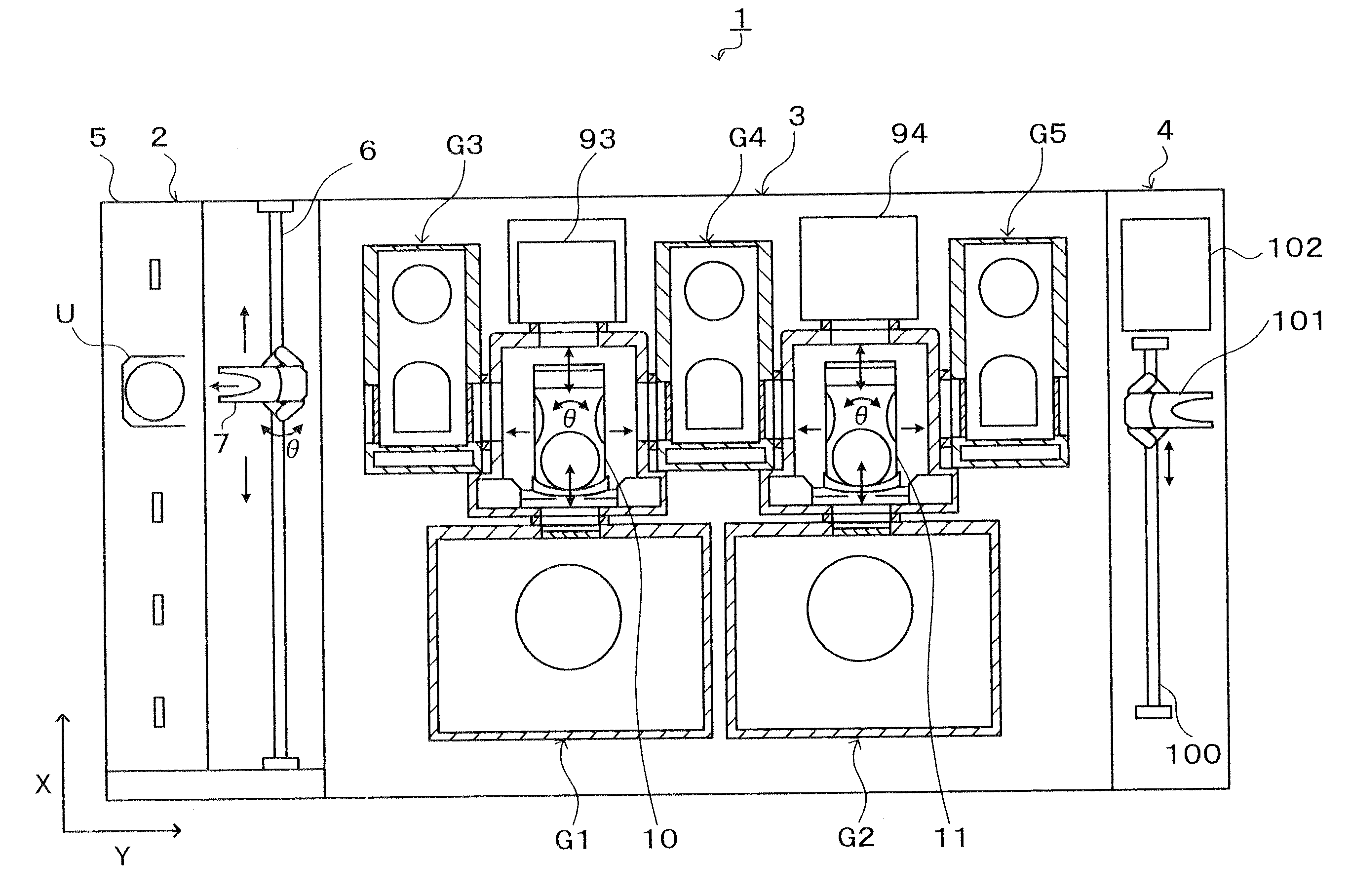

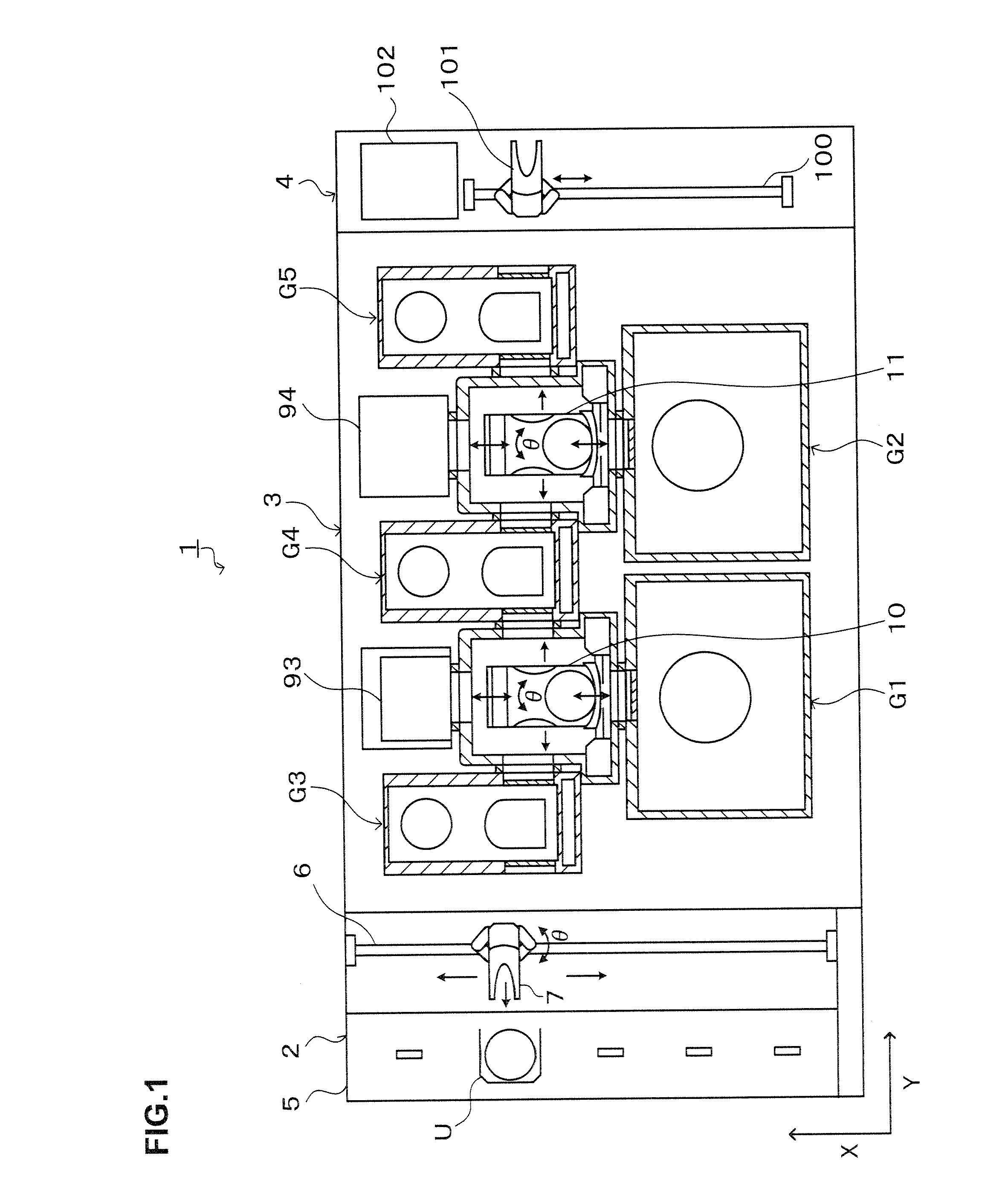

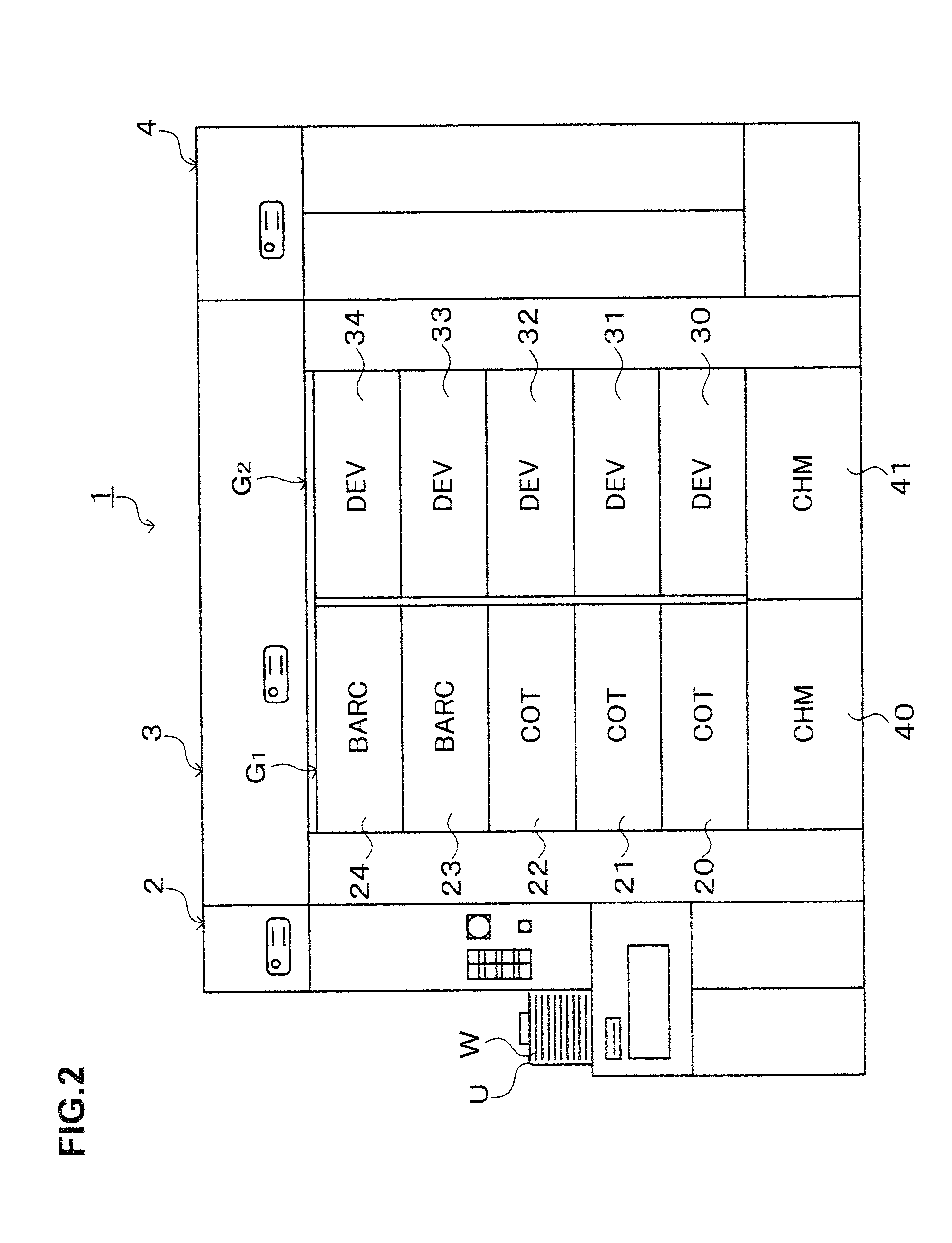

Single-substrate-heat-processing apparatus for performing reformation and crystallization

InactiveUS20050016687A1Improve throughputLow costSemiconductor/solid-state device manufacturingCapacitorsMetallurgySemiconductor

An insulating film consisting of first and second tantalum oxide layers is formed on a semiconductor wafer. First, an amorphous first layer is formed by CVD, and a reforming process for removing organic impurities contained in the first layer is carried out. Then, an amorphous second layer is formed by CVD on the first layer. Then, a reforming process for removing organic impurities contained in the second layer is carried out by supplying a process gas containing ozone into a process chamber while heating the wafer to a temperature lower than a crystallizing temperature over a certain period. Further, within the same process chamber, the wafer is successively heated to a second temperature higher than the crystallizing temperature, followed by cooling the wafer to a temperature lower than the crystallizing temperature so as to crystallize the first and second layers simultaneously.

Owner:TOKYO ELECTRON LTD

6063 aluminium alloy with high strength and elongation coefficient an dproduction thereof

The invention opened a high strength and high extensibility 6063 Al alloy which contain the Cu, Mn, chrome, Fe, Zn, Ti, Al. The process is: a, founding: adding the material to the furnace melting stir ring and skimming coving refining skimming and refining thermal retardation casting ingot. b extruding and heat processing: isotroping air cooling, heating extruding quenching cutting cooling stretching straightening aging treatment product. The process has improved the mechanics of the alloy, also the elongation percentage (60%) and the intensity (40%). The tensile strength has been improved to 280-300 MPa, the elongation percentage is improved to 13%. So it satisfy the windows and the curtain wall's need.

Owner:CENT SOUTH UNIV +1

High temperature water heat processing method for timber

ActiveCN1876343AImprove water absorptionSmall water absorptionWood treatment detailsWood dampingMetallurgyIncrease size

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

Functional soy peptide fermented milk and preparation method thereof

InactiveCN101642221AHigh dissolution rateExtended shelf lifeCheese manufactureFood preparationSlurrySoya bean

The invention provides functional soy peptide fermented milk and a preparation method thereof and relates to a manufacturing method of fermented dairy products in the field of food processing. The method is carried out according to the following steps: (1) the preparation of fermented base stock; (2) the preparation of mother cultures; (3) synchronous enzymolysis and fermentation; (4) blending and homogenizing; (5) ultrahigh pressure sterilization and filling; by adopting the steps, a finished product is obtained. The method adopts protease and lactic acid bacteria synchronous-enzymolysis fermentation technology, and ultrasonic waves are adopted to process slurry-residue mixture which is ground, so as to increase the dissolving-out rate of the protein and prepare acidity soy-bean milk by ultrahigh pressure and non-heat processing. The product taste is coordinated without enzymolysis odour; the enzymolysis fermentation time can shorten to 2-4h, and the production cost is low. The ultrahigh pressure processing can remarkably improve the product taste; the method can keep and produce new functional peptide, the lactic acid bacteria is inhibited to ferment continuously, and a certain micro-organism viable counts are kept; the shelf life of the acidity soy-bean milk is prolonged, so as to prevent the acid milk from being whey-separated owning to continuous increasing of acidity; inaddition, the product can be stored and marketed at normal temperature.

Owner:JIANGSU UNIV

System and methods for selective thermal treatment

Systems and methods for selective cooling of a target site include a catheter having a supply lumen and a delivery lumen, with inlet and exit ports. Blood is withdrawn from the supply lumen and cooled or heated in a control unit. The treated blood is sent to the targeted area via delivery lumen. The supply lumen can act as an insulator for the delivery lumen.

Owner:THERMOPEUTIX

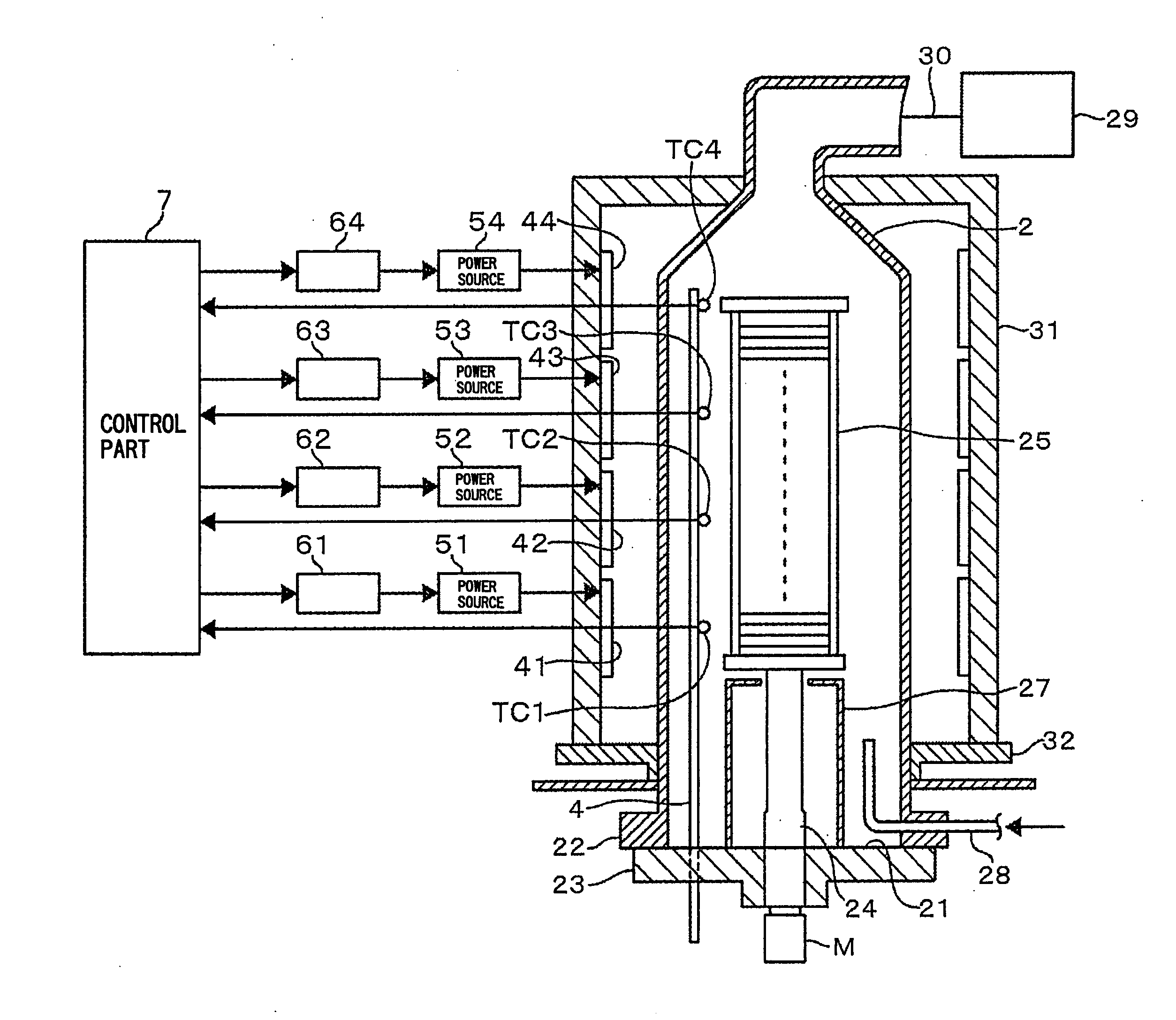

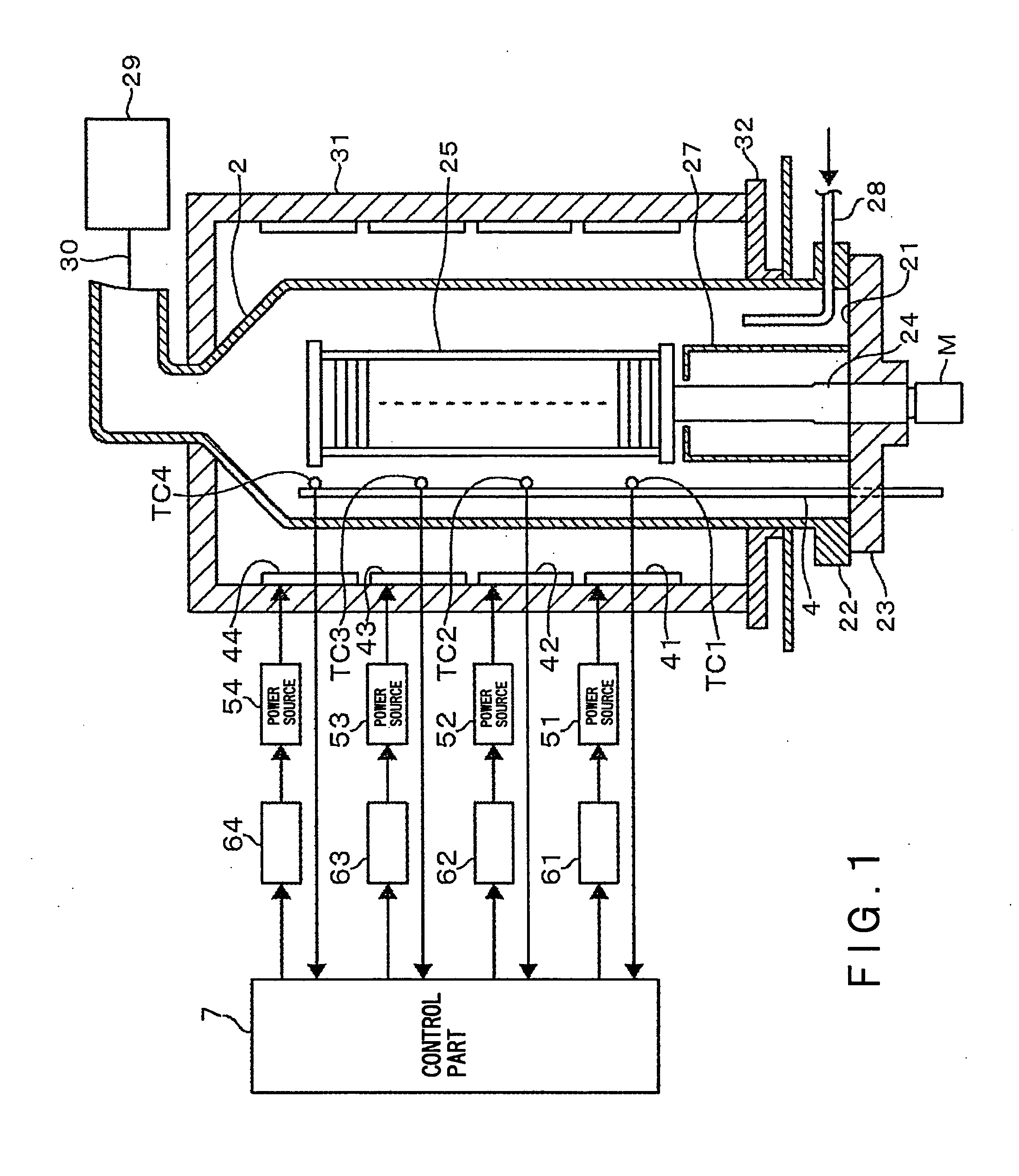

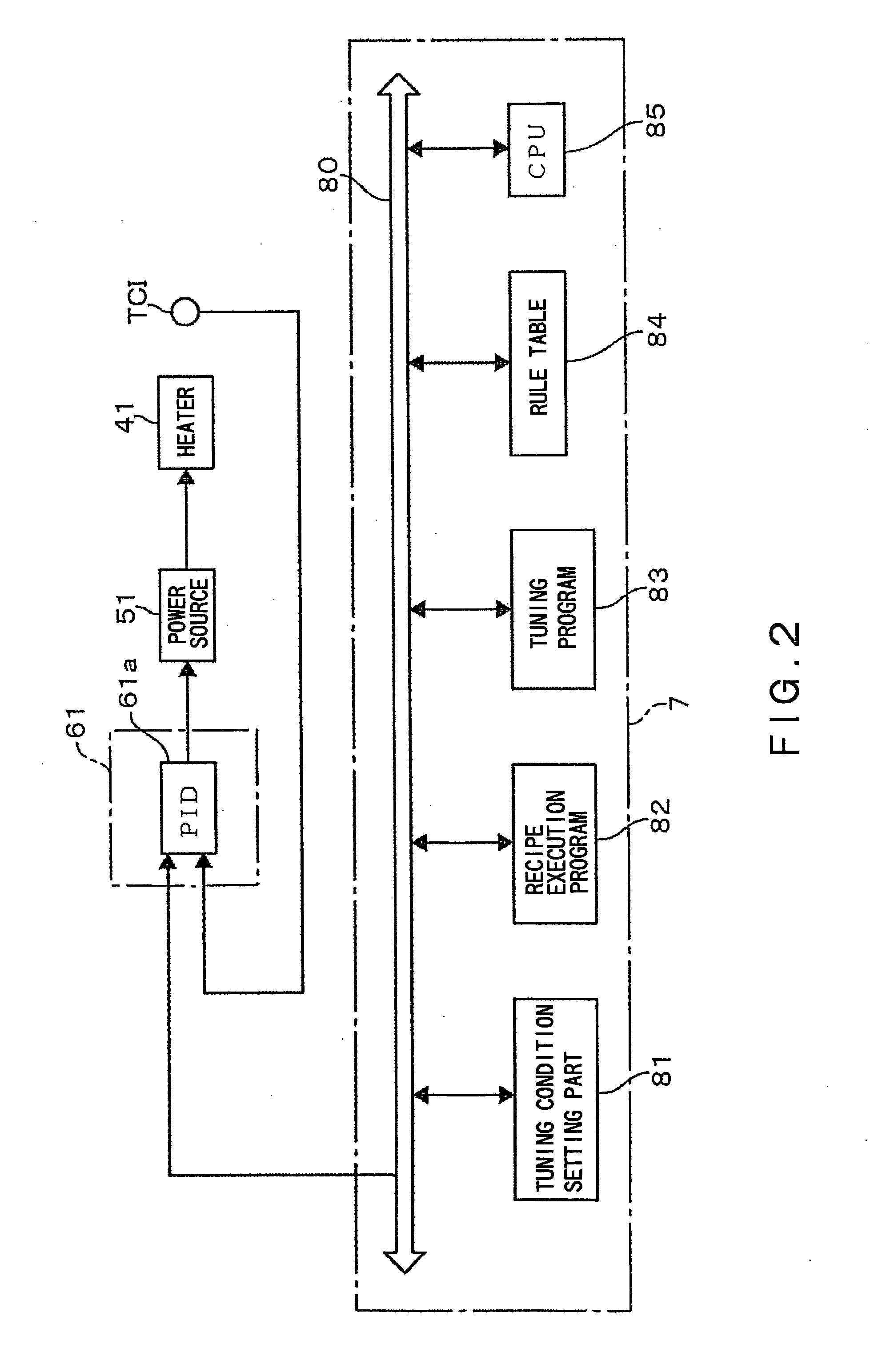

Heat processing apparatus, method of automatically tuning control constants, and storage medium

ActiveUS20080255683A1Reliable and easy mannerSemiconductor/solid-state device testing/measurementTemperatue controlTemperature curveProcess region

A heat processing apparatus comprises: a reaction vessel; a heating unit disposed in the reaction vessel and configured to heat the processing region; a temperature detection part configured to detect a temperature of the processing region; and a control part configured to control the heating unit by a PID control. The control part includes: a rule table that is prepared such that predicted change amounts of a temperature property item when a temperature of the processing region is increased up to a target value, and change ratios of PID constants are correspondingly related to each other; a performance unit configured to repeatedly perform: a step of obtaining a temperature profile based on a temperature detected value of the temperature detection part and calculating a difference between an actually measured value and a target value of the temperature property item based on the temperature profile; and a step of, when the difference is over an allowable range and larger than a prescribed value, referring to the rule table and changing the PID constants to reset new PID constants by a change ratio corresponding to an predicted change amount of the temperature property item relative to the difference; until the difference can fall within the allowable range. The control part also includes an updating unit configured to update, when there is a difference between an actually measured change amount of the temperature property item with reference to the rule table and an predicted change amount of the temperature property item that has been predicted in the preceding cycle, the corresponding relationship between the PID constants and the predicted change amounts of the temperature property item described in the rule table, based on the actually measured change amount.

Owner:TOKYO ELECTRON LTD

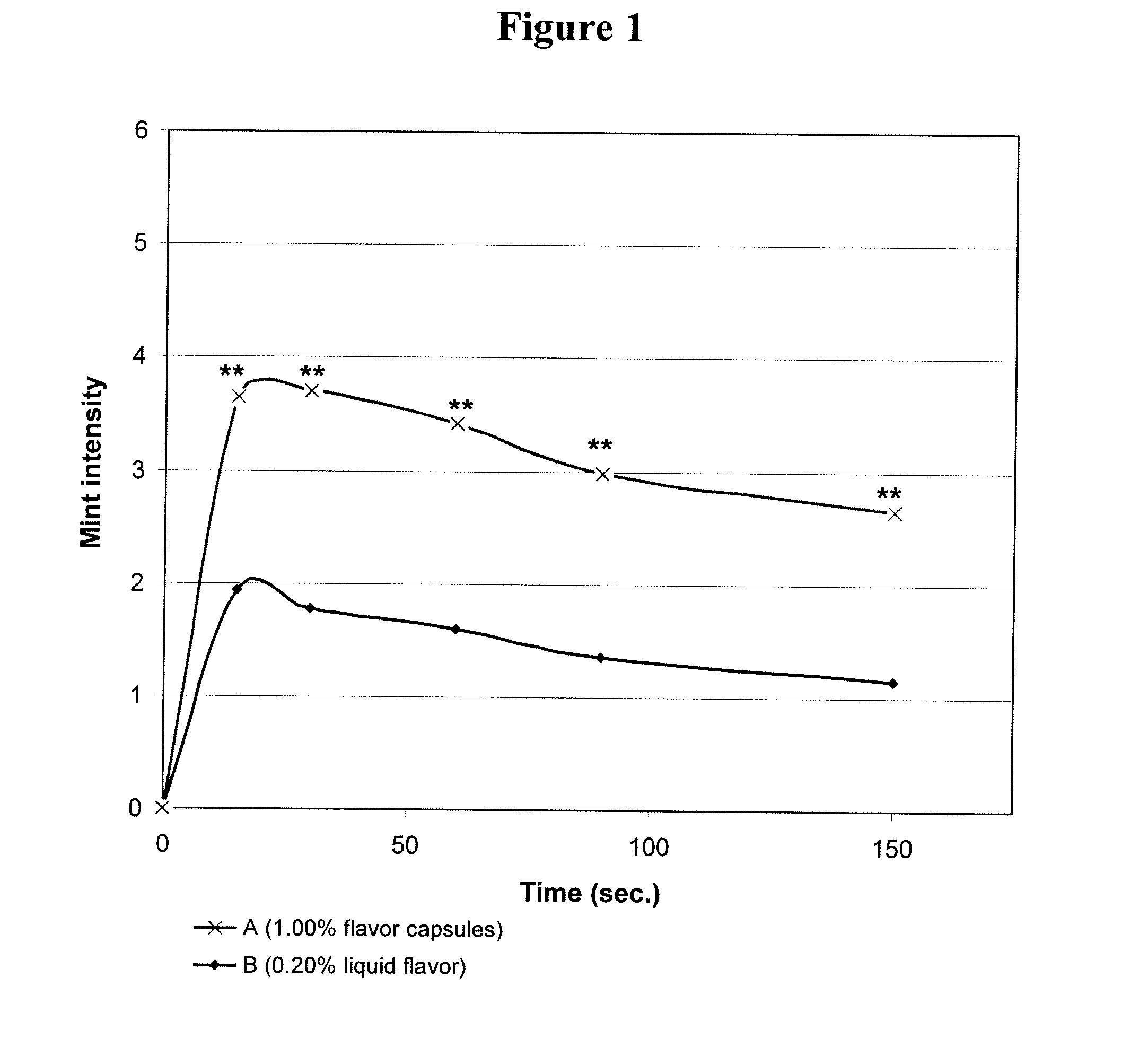

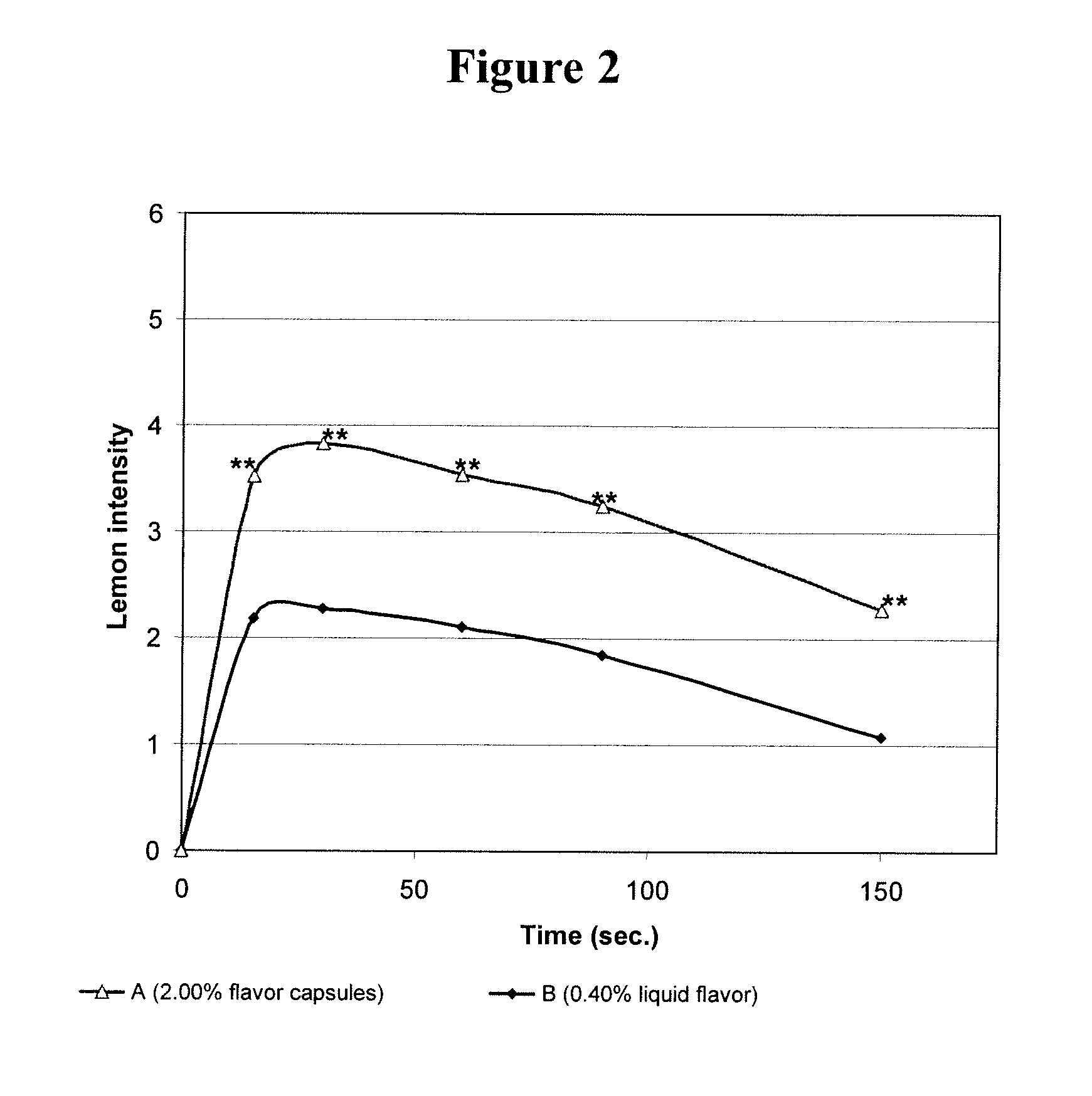

Heated food product with coating of encapsulated flavors

InactiveUS20070269553A1Improve performanceLess Flavor LossYeast food ingredientsChewing gumFlavouring agentEvaporation

The present invention relates to a method for preparing a flavored food product, and to a method for reducing loss of flavors in a flavored product due to heat treatments. Loss of flavors by evaporation at high temperatures could be prevented by applying coating solutions in which water and encapsulated flavors have been mixed at 0.5% to 30 wt. % of capsules based on micro-organisms, a matrix component and encapsulated flavors. The coating solution was applied in high temperature coating processes or processes including heat treatment following the coating step and resulted in surprising retention of flavors in the coated food product.

Owner:FIRMENICH SA

Preparation method and application of magnesium oxide-rice husk biological carbon composite material

ActiveCN106669603AReduced bioavailabilityImprove the phenomenon of low pollution adsorption effectOther chemical processesContaminated soil reclamationCarbon compositesMixed materials

The invention belongs to the technical field of water and soil pollution restoration, and discloses a magnesium oxide-rice husk biological carbon composite material as well as a preparation method and application of the magnesium oxide-rice husk biological carbon composite material. The preparation method comprises the following steps: cleaning rice husks, drying the rice husks under a temperature of 80 to 90 DEG C for 10 to 16 hours, carrying out smashing and screening, heating to a temperature of 300 to 400 DEG C under a condition of feeding nitrogen and isolating oxygen at the rate of 3 to 8 DEG C per minute, carrying out thermal cracking for 2 to 4 hours, naturally cooling to a room temperature, cleaning the smashed rice husks, and drying the smashed rice husks to constant weight, so as to obtain rice husk biological carbon; adding the rice husk biological carbon into a magnesium oxide suspension with the mass percentage of 0.6 to 3 percent to obtain a mixed material; carrying out uniform stirring and mixing and then ultrasonic reaction for 1 to 2 hours, putting the mixed material under a condition of 85 to 105 DEG C for 20 to 24 hours, and carrying out thermal treatment at 300 to 400 DEG C for 20 to 60 minutes under a condition of feeding N2 to obtain the magnesium oxide-rice husk biological carbon composite material. The composite material can be applied to adsorbing and removing cadmium from cadmium polluted wastewater or cadmium polluted soil.

Owner:GUANGDONG UNIV OF TECH

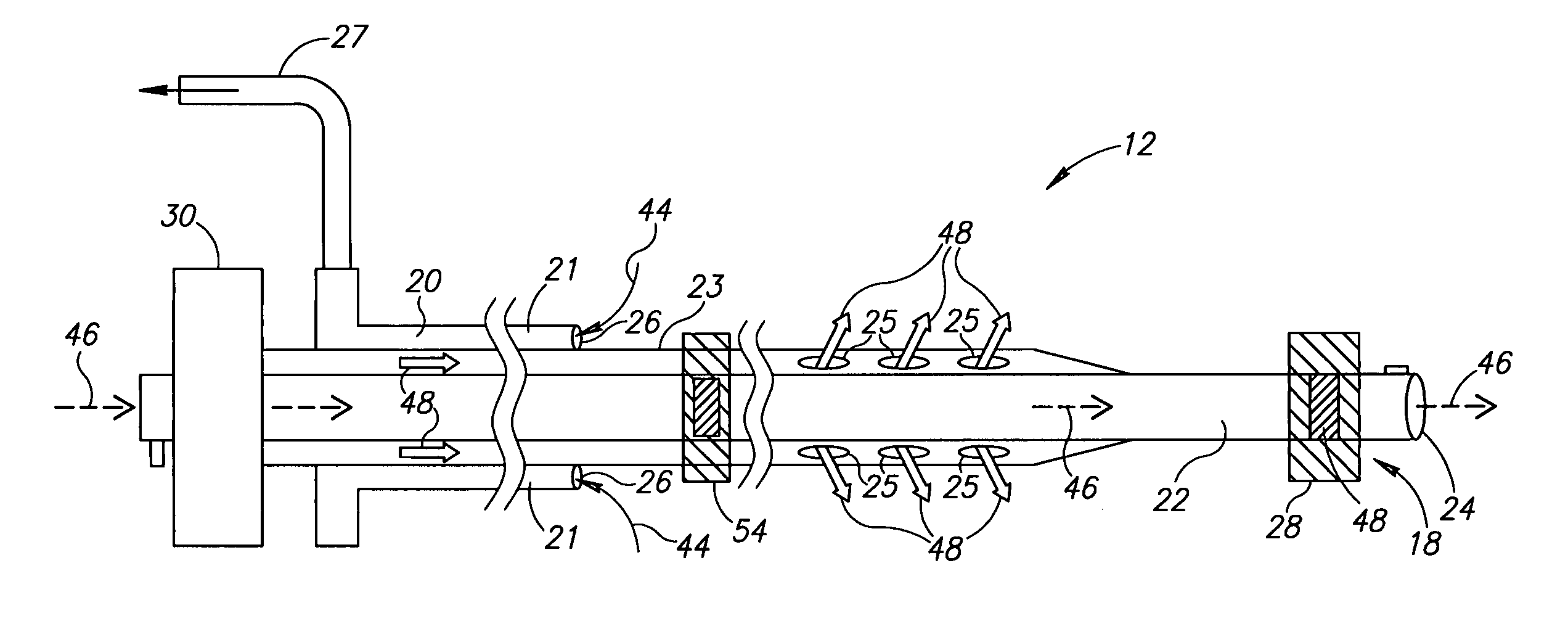

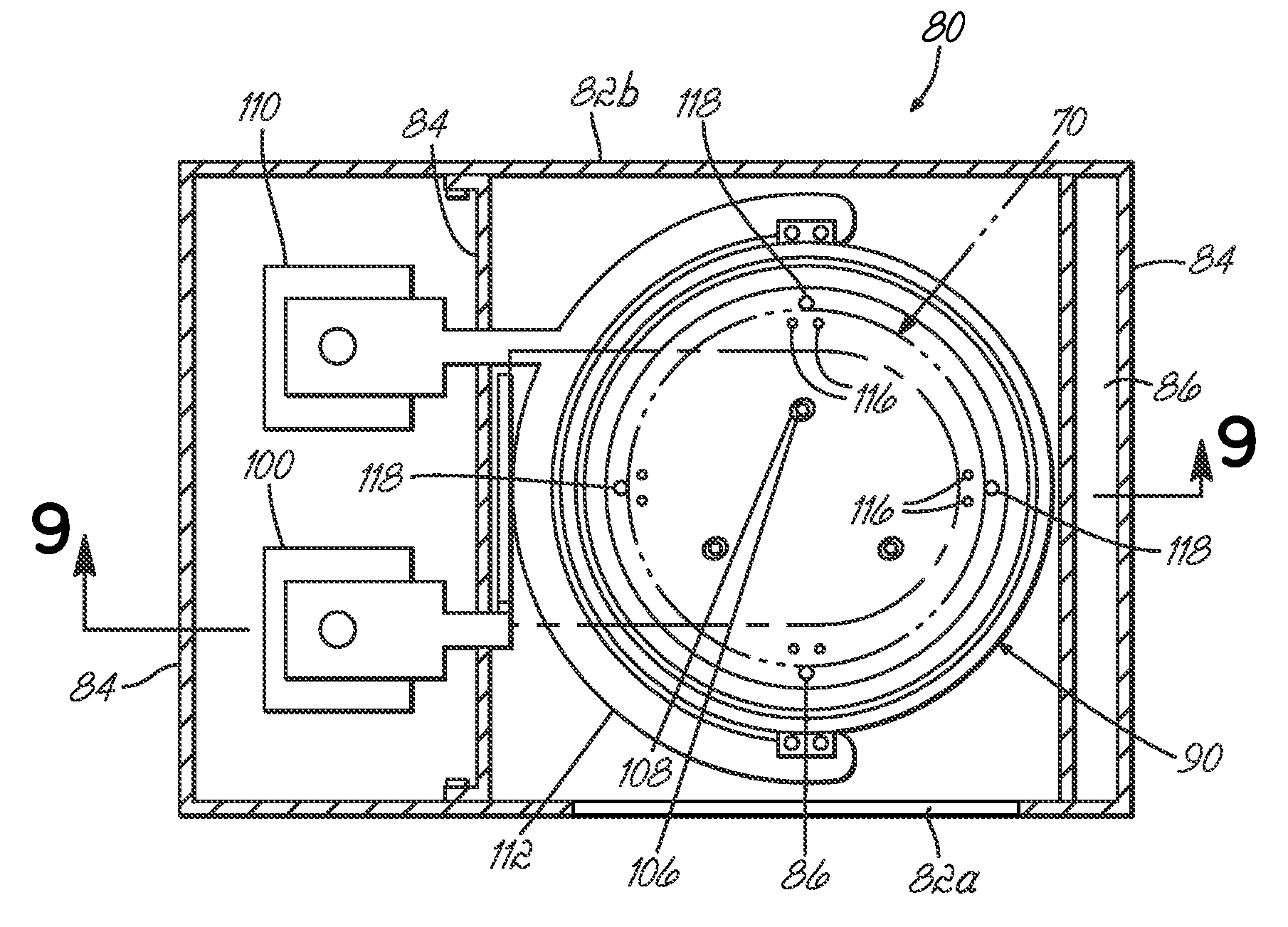

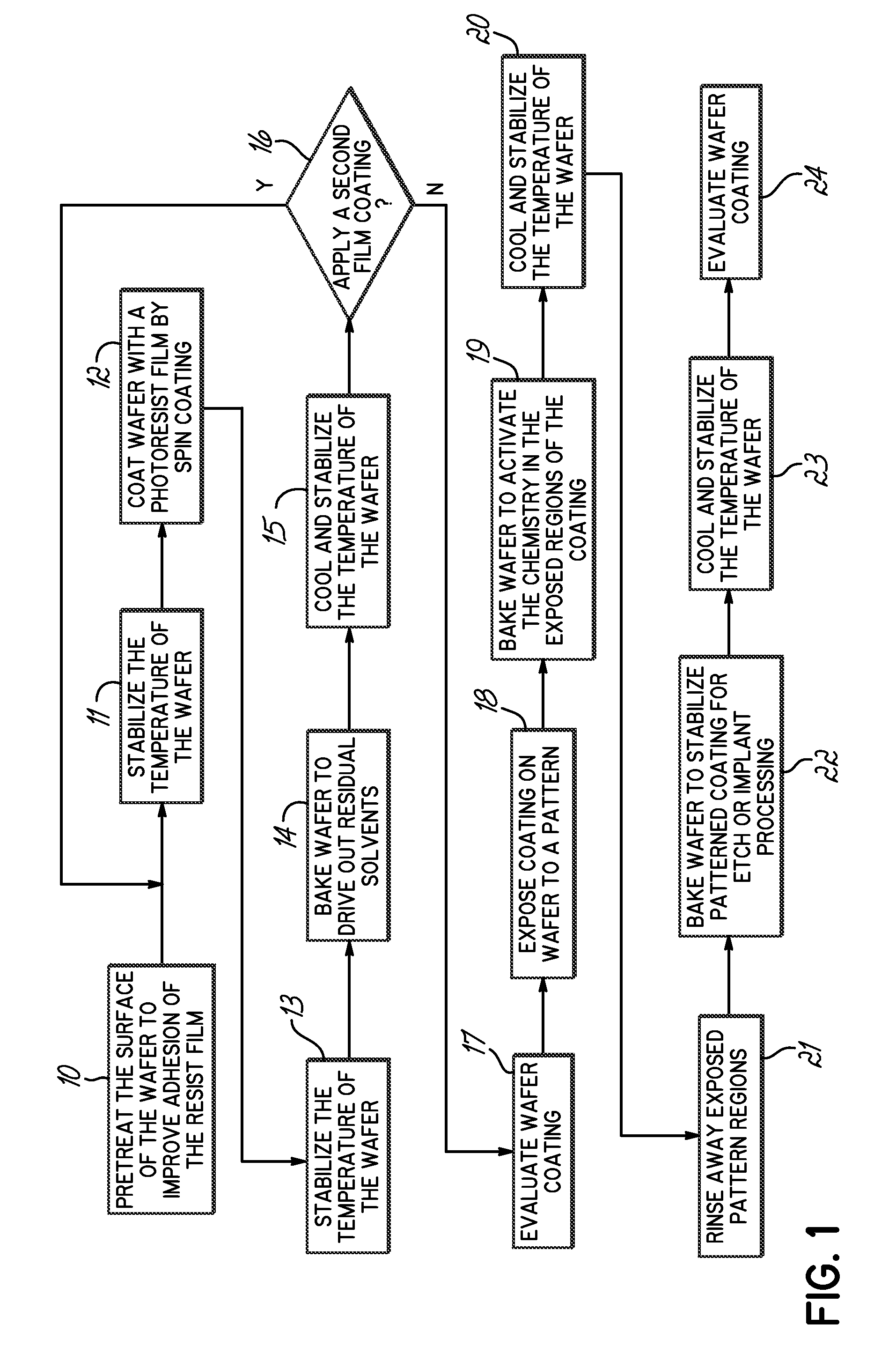

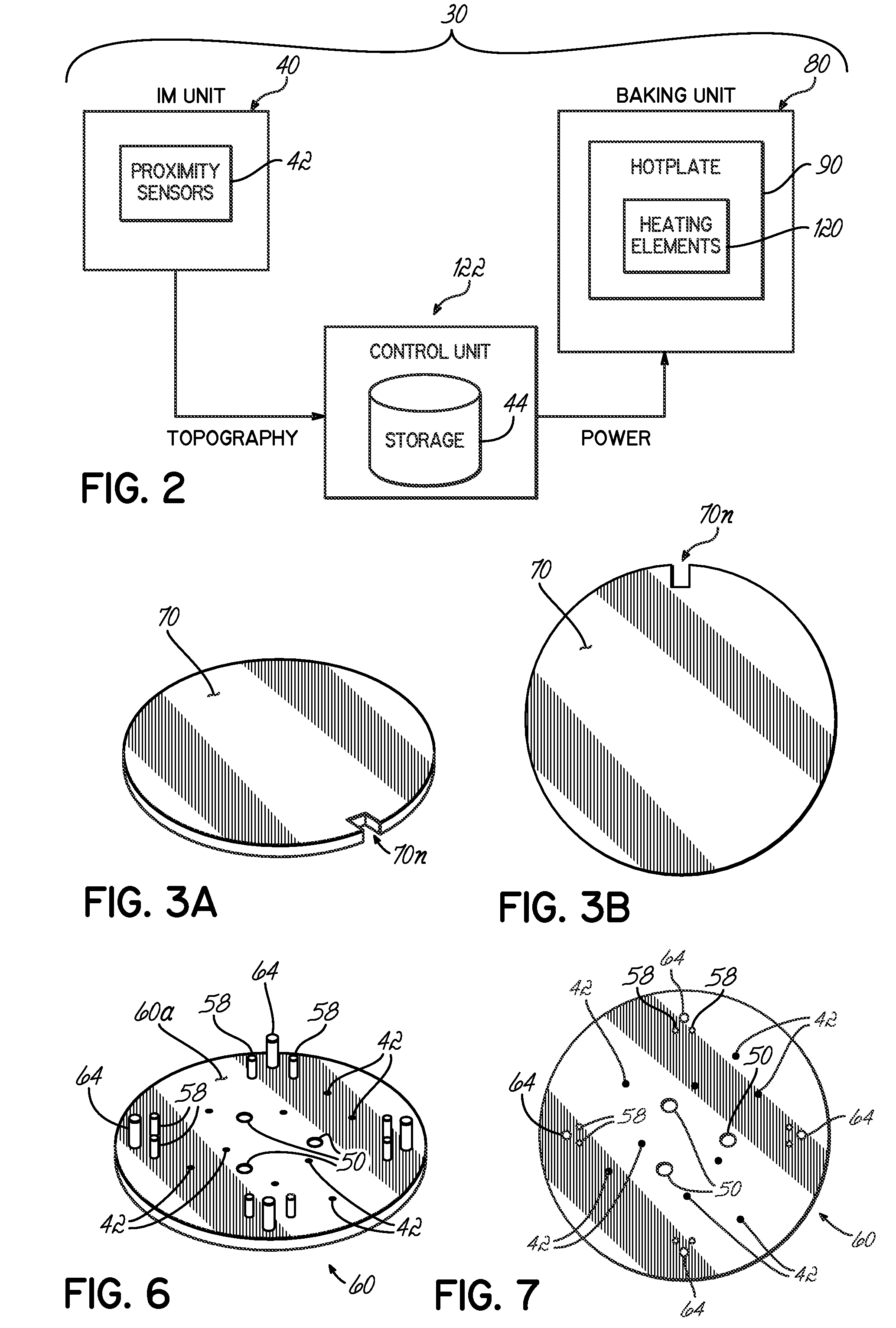

Apparatus and method for predictive temperature correction during thermal processing

InactiveUS20080241778A1No loss in productionIncrease speedCharge supportsSemiconductor/solid-state device manufacturingEngineeringHeat processing

A thermal processing apparatus and method with predictive temperature correction. Distances are measured from a backside of the wafer relative to a reference plane. Heat is transferred to the backside of the substrate in relation to the measured distances. This allows a baking unit to uniformly heat the substrate to compensate for irregularities or warpage.

Owner:TOKYO ELECTRON LTD

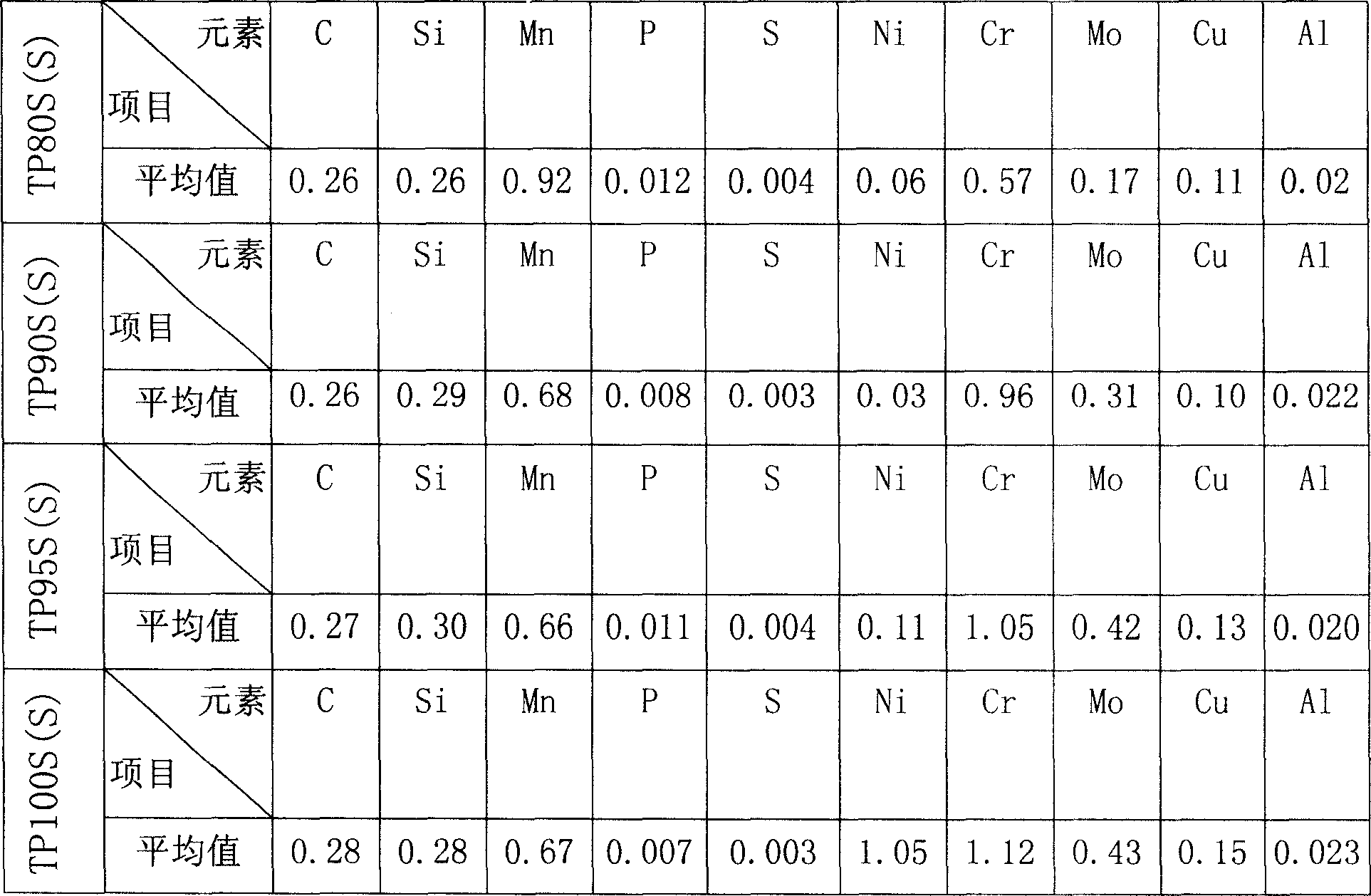

Petroleum steel tube capable of anti hydrogen sulfide stress corrosion and its manufacturing method

ActiveCN1948538AExcellent physical and chemical propertiesEasy to useDrilling rodsFurnace typesElectric arc furnaceArc melting

The invention offers oil steel pipes which can resist stress corrosion by hydrogen sulfide. Weight proportion of their compound is: C 0.25-0.32%,Si 0.10-0.40%,Mn 0.60-1.20%, P<=0.020%,S<=0.010%,Ni<=0.25%,Cr 0.55-1.20%,Mo 0.10- 0.50%,Cu<=0.30%,Al 0.010-0.040% and the allowances are Fe. Scrap steel and spongy iron or melted iron is taken as melting materials. After arc melting, external refinement and vacuum deaeration, they are cast continuously to get round billiets. Then, they are hot rolled to seamless steel pipes and finally to bushing and oil pipes by heat processing of quench and temper. The steel pipes have good physicochemical property and their indexes all reach or exceed API standard. Threshold value of resisting stress corrosion by hydrogen sulfide reaches 90%SMYS, which precedes the standard request and can be extensively applied in oil-gas field with hydrogen sulfide.

Owner:TIANJIN PIPE GROUP CORP

High-strength low-temperature-resisting spheroidal graphite cast iron and preparing method thereof

The invention relates to the field of spheroidal graphite cast iron, in particular to high-strength low-temperature-resisting spheroidal graphite cast iron and a preparing method thereof. The spheroidal graphite cast iron comprises, by mass percent, 3.2% to 3.5% of carbon, 2.1% to 2.3% of silicon, 0.4% to 0.5% of manganese, 0.4% to 0.6% of copper, 0.2% to 0.4% of nickel, 0.2% to 0.4% of molybdenum, 0.04% to 0.06% of magnesium, 0.05% to 0.08% of chromium, 0.005% to 0.008% of titanium, 0.002% to 0.003% of vanadium, not larger than 0.04% of phosphorus, not larger than 0.02% of sulphur and the balance iron. The preparing method of the high-strength low-temperature-resisting spheroidal graphite cast iron comprises following steps: firstly, raw materials are smelted; secondly, spheroidizing treatment and inoculation are carried out; and thirdly, heat treatment is carried out. Through reasonable arrangement of all element components, the tensile strength of the spheroidal graphite cast iron is improved, a proper nucleating agent is prepared, internal inoculation matched with inoculation in a ladle is adopted, the inoculation effect is reinforced, meanwhile, during heat treatment, the heating temperature, the heat preservation time, the cooling rate and the manner are reasonably arranged, the strength and low temperature resistance of the iron are effectively improved, the spheroidal graphite cast iron is high in strength and excellent in low temperature resistance, and the preparing method is simple and efficient.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

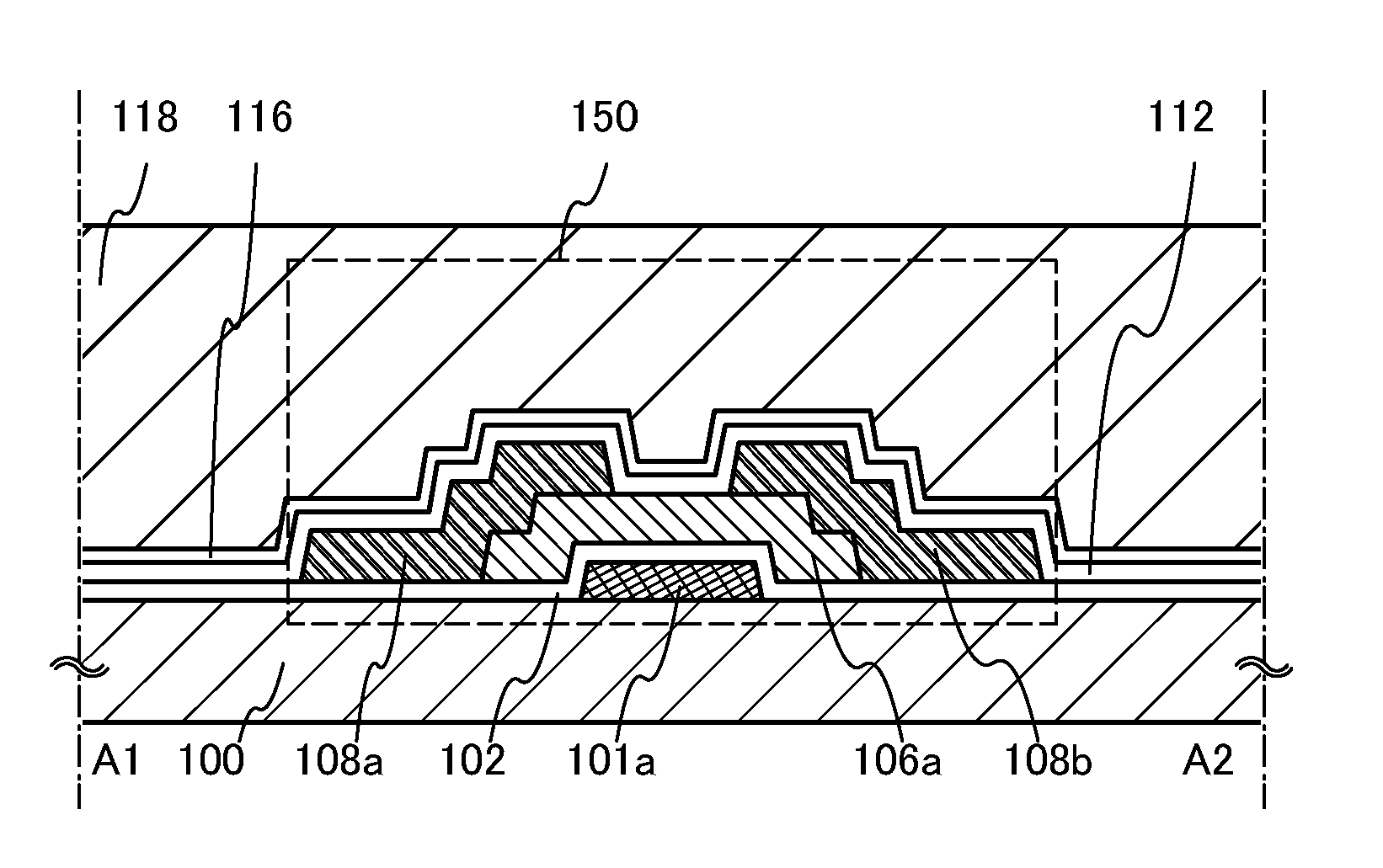

Semiconductor device and manufacturing method thereof

ActiveUS20110133179A1Increase currentOn-off ratio can be increasedElectroluminescent light sourcesSolid-state devicesHydrogenEngineering

A manufacturing method of a semiconductor device, which includes the steps of forming a gate electrode layer over a substrate having an insulating surface, forming a gate insulating layer over the gate electrode layer, forming an oxide semiconductor layer over the gate insulating layer, forming a source electrode layer and a drain electrode layer over the oxide semiconductor layer, forming an insulating layer including oxygen over the oxide semiconductor layer, the source electrode layer, and the drain electrode layer, and after formation of an insulating layer including hydrogen over the insulating layer including oxygen, performing heat treatment so that hydrogen in the insulating layer including hydrogen is supplied to at least the oxide semiconductor layer.

Owner:SEMICON ENERGY LAB CO LTD

Comminution and densification of biomass particles

A method is disclosed for reducing the mechanical strength of solid biomass material, in particular ligno-cellulosic biomass. The method comprises heating the solid biomass material to a temperature in the range of 105° C. to 200° C. The heat treatment, which is referred to as “toasting”, significantly reduces the mechanical energy required for reducing the particle size of the solid biomass material.The method is particularly suitable as a pretreatment step to a conversion reaction of the solid biomass material.

Owner:MARD INC

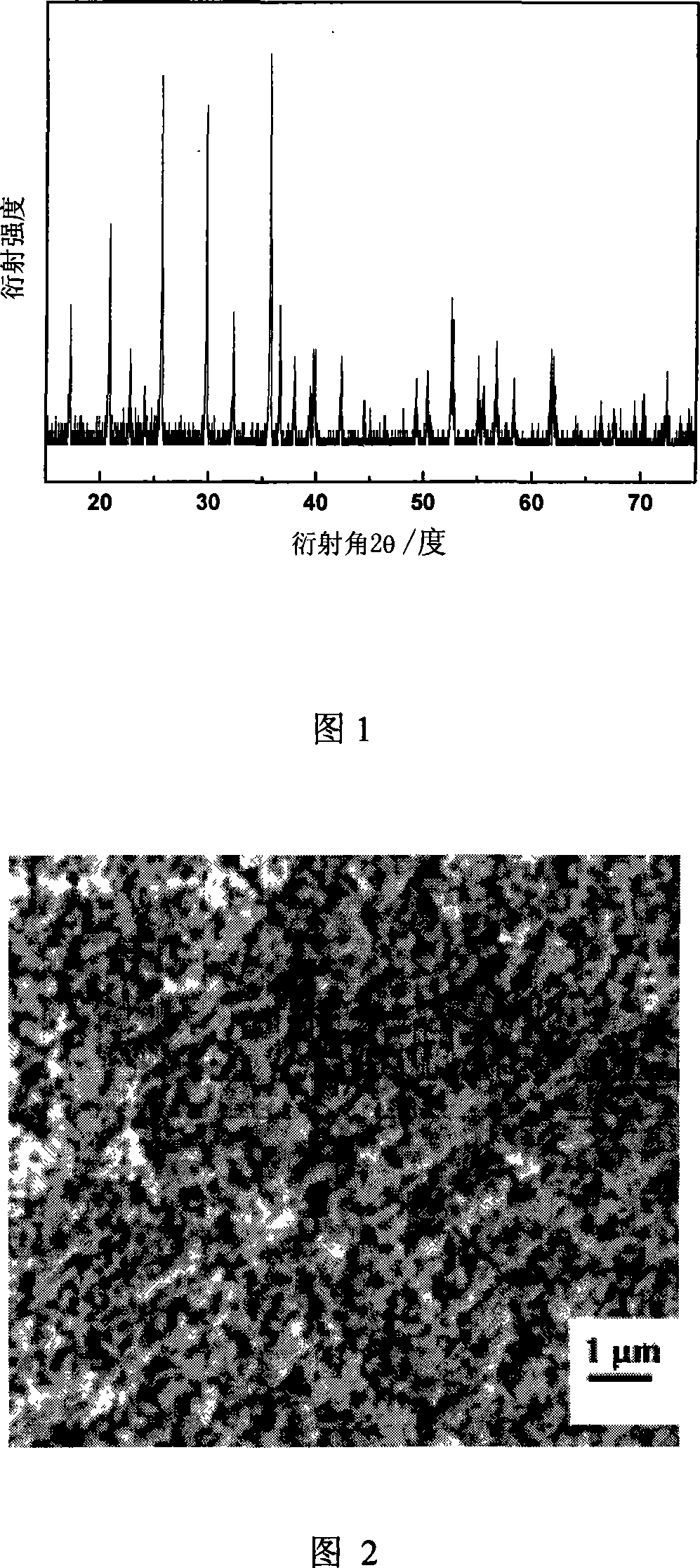

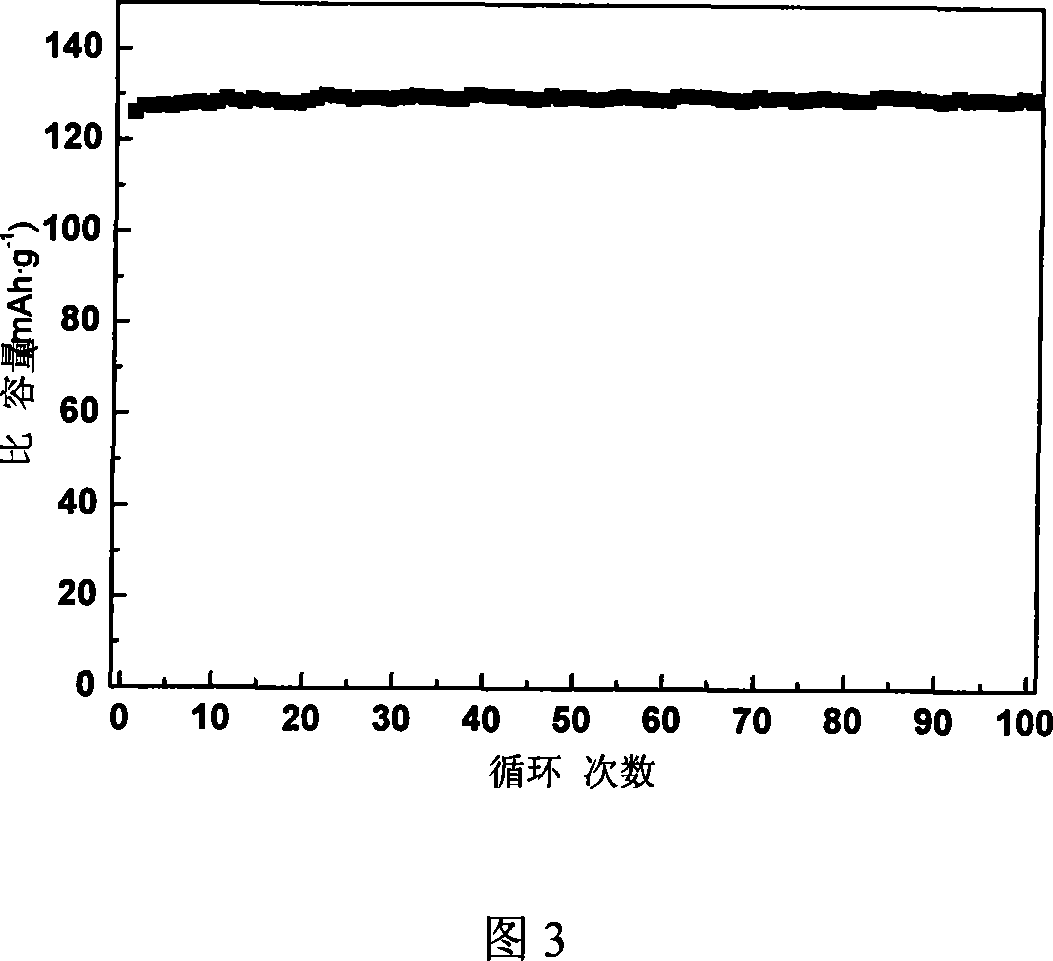

Method for preparing lithium iron phosphate as lithium ion cell positive-pole material

ActiveCN101070148AImprove interface performanceExcellent lithium ion conductivityElectrode manufacturing processesPhosphorus compoundsLithium iron phosphatePhosphate

It is a kind of preparation method of lithium iron phosphate which is an anode material of lithium ion battery, it adopts two-step technics: firstly, mix the following material such as iron, lithium and phosphate evenly and compound lithium iron phosphate of better crystal degree at lower temperature; then mix up lithium iron phosphate and composite conductive agent (inorganic conductive matter and precursor which is a carbon-contained conductive agent) sufficiently, it can get anode material of lithium ion battery which has a good electrochemistry capability through heat processing for short time at higher temperature, and the material has a good crystal performance and a strong interface function with conductive agent which makes material's conductivity of lithium ion and electron high, and it is suitable for charge / discharge of large rate. This technique's material is cheap chemical product, the composed techniques is simple, it is easy for large-scale production, the method to add conductive agent of electron is unique, electrochemistry capability of the products is of good performance.

Owner:WUXI KAITIANXING PHOTOELECTRIC MATERIAL

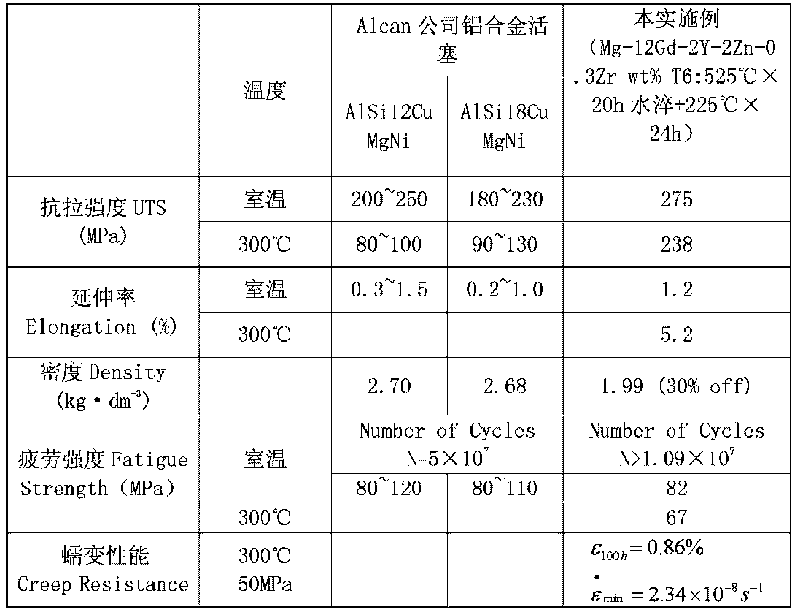

Low-pressure casting preparation method of heat resistant rare earth-magnesium alloy engine pistons

ActiveCN101693971AFine grainImprove creep resistanceMachines/enginesPistonsManufacturing technologyPressure casting

A low-pressure casting preparation method of heat resistant rare earth-magnesium alloy engine pistons in the field of the automobile manufacturing technology comprises preparing master alloy Mg-Y, Mg-Gd, Mg-Zr, industrial pure magnesium and industrial pure zinc, smelting alloy, obtaining magnesium alloy fused mass, squeezing and casting the magnesium alloy fused mass, obtaining the primary blank of a magnesium alloy piston, and obtaining a heat resistant tare earth-magnesium alloy engine piston through orderly carrying out the solid solution treatment, the cold treatment and the aging treatment. The method can prepare pistons with excellent high-temperature strength, fatigue strength and creep resistance performance through applying 0.2-0.8 atm pressure and selecting proper heat resistant rare earth-magnesium alloy, selecting proper low-pressure casting technical parameter and adjusting corresponding heat processing technology.

Owner:SHANGHAI JIAO TONG UNIV

Temperature control method of heat processing plate, computer storage medium, and temperature control apparatus of heat processing plate

ActiveUS20070272680A1Uniform line widthIncrease spacingDrying solid materials with heatSemiconductor/solid-state device manufacturingTemperature controlEngineering

In the present invention, temperature drop amounts of heating plate regions when the substrate is mounted on a heating plate are detected to detect a warped state of the substrate. From the temperature drop amounts of the heating plate regions, correction values for set temperatures of the heating plate regions are calculated. The calculation of the correction values for the set temperatures of the heating plate regions is performed by estimating steady temperatures within the substrate to be heat-processed on the heating plate from the temperature drop amounts of the heating plate regions using a correlation obtained in advance. From the estimated steady temperatures within the substrate and the temperature drop amounts of the heating regions, the correction values for the set temperatures of the heating plate regions are calculated. Based on the correction values for the set temperatures, the set temperatures of the heating plate regions are changed.

Owner:TOKYO ELECTRON LTD

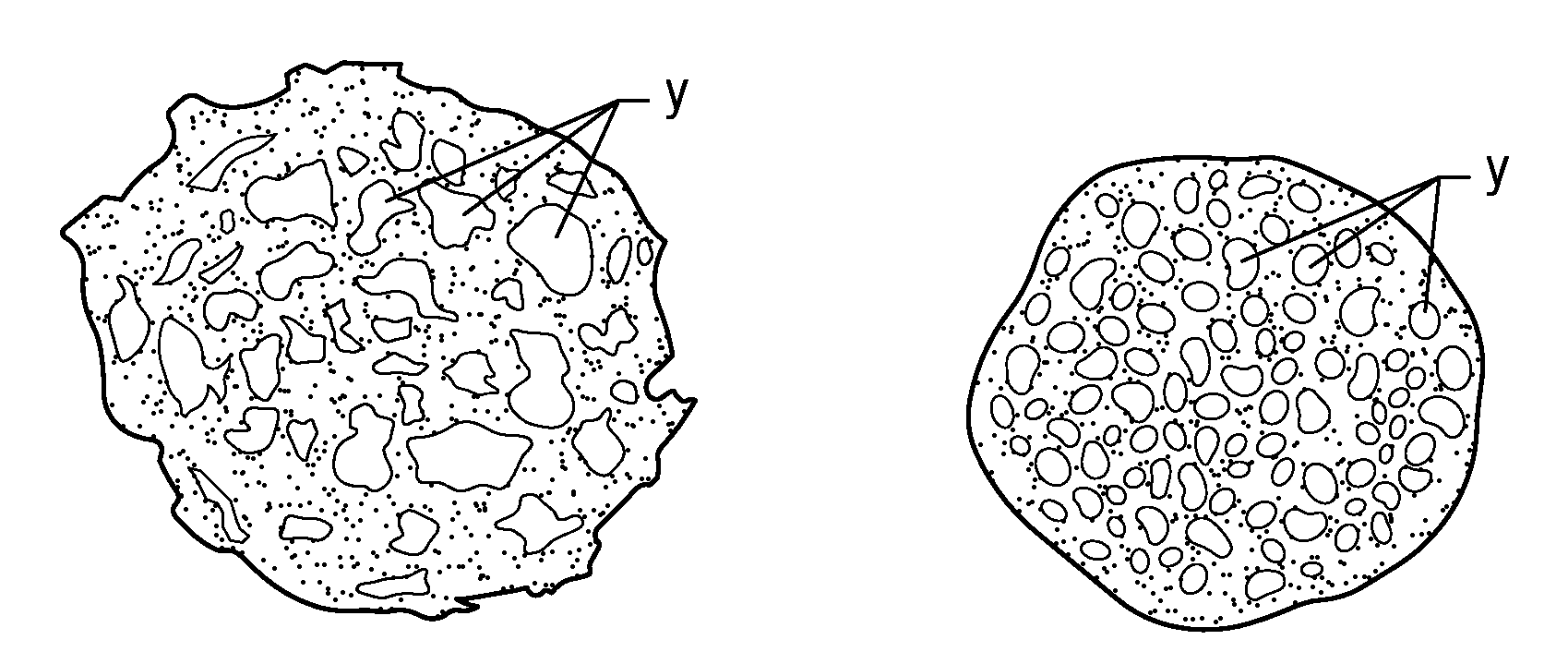

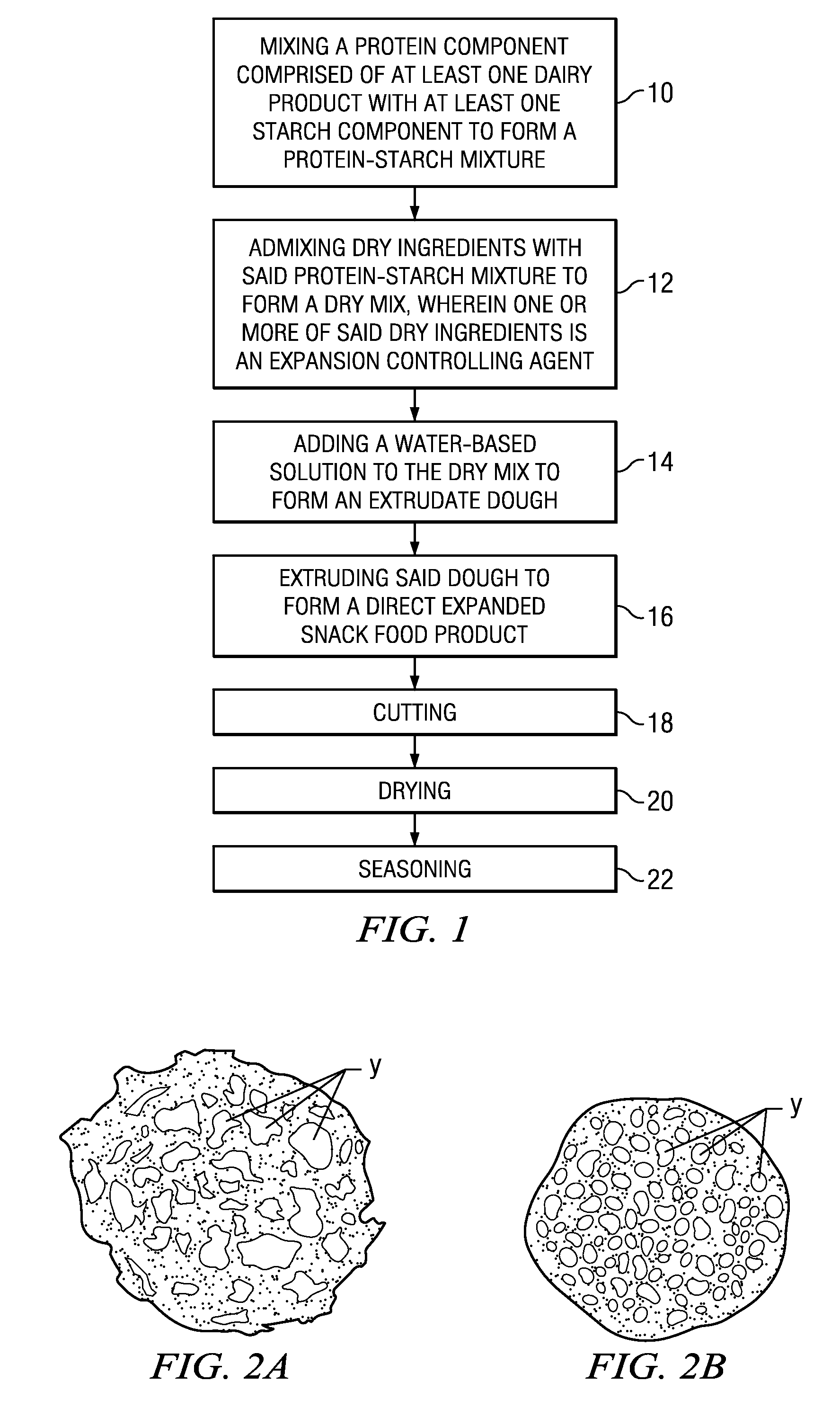

Protein Ingredient Selection and Manipulation for the Manufacture of Snack Foods

InactiveUS20120064209A1Increase expansionImprove textureMilk preservationPre-baking dough treatmentWhey proteinAdditive ingredient

Methods for the incorporation of dairy proteins into extruded snack products to provide a good source of protein are presented. In a first aspect, direct expanded, puffed products are obtained by selecting at least one filtered protein derived from milk and controlling unwanted reactions with one or more expansion controlling agents. Through the addition of expansion controlling agents such as a calcium carbonate, the thermally-treated, dairy protein-containing dough surprisingly results in a crunchier puffed snack food product. In a second aspect, the present invention provides for the manipulation of whey protein by ensuring the protein is denatured prior to combining with additional dry ingredients to form a sheetable whey-based dough suitable for cold extrusion-type processes.

Owner:FRITO LAY NORTH AMERICA INC

C-C-SiC-ZrC ceramic matrix composite and preparation method thereof

InactiveCN103722823AAvoid destructionPromote infiltrationCeramic layered productsGas phaseBoron containing

The invention discloses a C-C-SiC-ZrC ceramic matrix composite and a preparation method thereof. The C-C-SiC-ZrC ceramic matrix composite comprises C fiber, a C matrix, an SiC matrix and a ZrC matrix, and is characterized in that the SiC matrix exists between a C / C framework and the ZrC matrix. The preparation method comprises the steps as follows: the C fiber is woven or laminated to form an enhancement structure, pyrolytic carbon is deposited with a chemical vapor infiltration method, then the synthesized C / C framework is subjected to high-temperature graphitization, an SiC densified composite is introduced through liquid-phase infiltration and pyrolysis of polycarbosilane, boron-containing phenolic resin is soaked, C is formed through pyrolysis, metal Zr is infiltrated with an infiltration method, and high-temperature heat treatment is performed to obtain the C-C-SiC-ZrC ceramic matrix composite. The C-C-SiC-ZrC ceramic matrix composite has excellent performance including high strength, superhigh temperature resistance, antioxidation, thermal shock resistance and the like.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com