Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2945results about How to "Increase dosage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood-plastic composite material and prepration method thereof

The invention discloses a wood-plastic composite material and a preparation method thereof, and the wood-plastic composite material comprises the following raw materials according to the mixing ratio by parts by weight: 30-80 parts of modified fiber powder; 15-80 parts of plastics; 2-10 parts of phase solvent; 2-10 parts of lubricant; 0-10 parts of stabilizer; 0.2-1.0 part of antioxidant; 5-15 parts of filler; and 2-20 parts of flame retardant. Lignin is utilized for modifying fiber powder, then composition with the plastics is carried out, and a finished-product material is formed by extrusion. The preparation method can solve the problems of the compatibility of wood fibers with the thermoplastic plastics, the surface treatment technology of the raw materials by utilizing the lignin and the like, realize the comprehensive utilization of the lignin and the waste plastics, be capable of replacing wood, increase the additional value of the lignin and solve the utilization problem of the lignin wastes. The manufactured wood-plastic composite material can significantly improve the mechanical performance, the tensile strength, the flexural strength and the impact resistance, and realize the industrial production of high-performance products, such as construction materials.

Owner:BEIJING FORESTRY UNIVERSITY

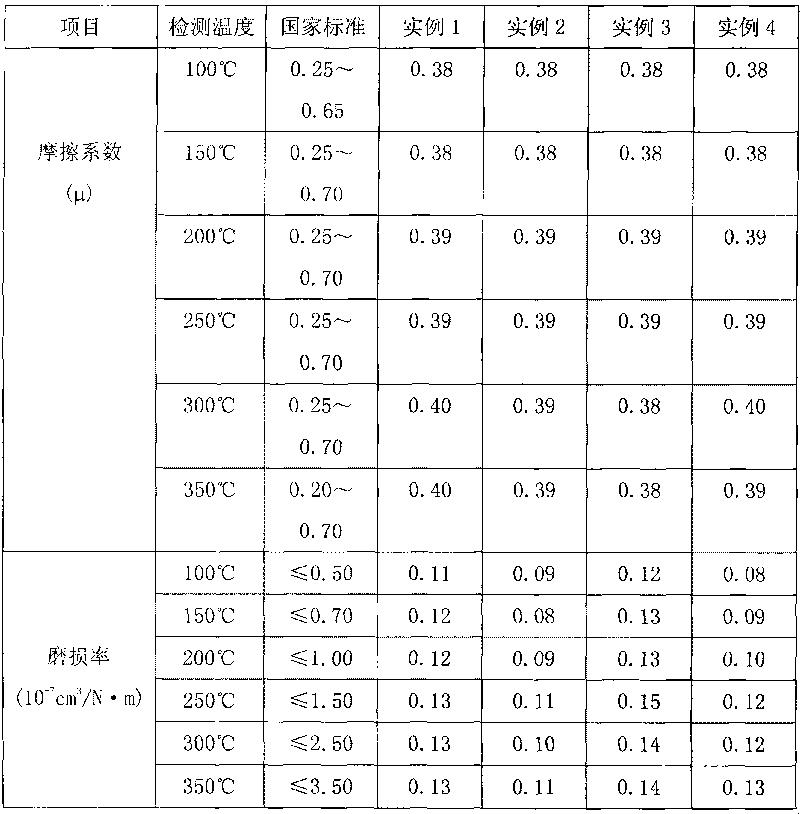

Method for preparing nanoparticle-modified friction material

The invention discloses a method for preparing a nanoparticle-modified friction material, which comprises the following steps: dissolving a resin in a solvent to obtain solution of the resin, uniformly dispersing nanoparticles in the solution of the resin, soaking reinforcing fibers in the solution and adding surfactant to allow the resin, the nanoparticles and the reinforcing fibers to be tightly bonded and uniformly disperse; and mixing the resin-coated nanoparticles and the resin-coated reinforcing fibers with a friction performance regulator and a filler, uniformly stirring the mixture and drying the mixture. In the method, the flowability of the solution of the resin is used to coat the nanoparticles and the reinforcing fibers, so the uniform mixing of the nanoparticles, the fibers and the resin is realized; the bonding strength of the nanoparticles, the fibers and the resin is increased under the action of the surfactant; and the friction performance and the service life of a brake pad can be improved on the basis of reducing the dosages of the nanoparticles, the reinforcing fibers and the resin. The friction material of the invention can be widely used in the preparation of brake pads of motor vehicles, brakes of machine tools and electrodes, clutch liners and the like.

Owner:CHINA JILIANG UNIV

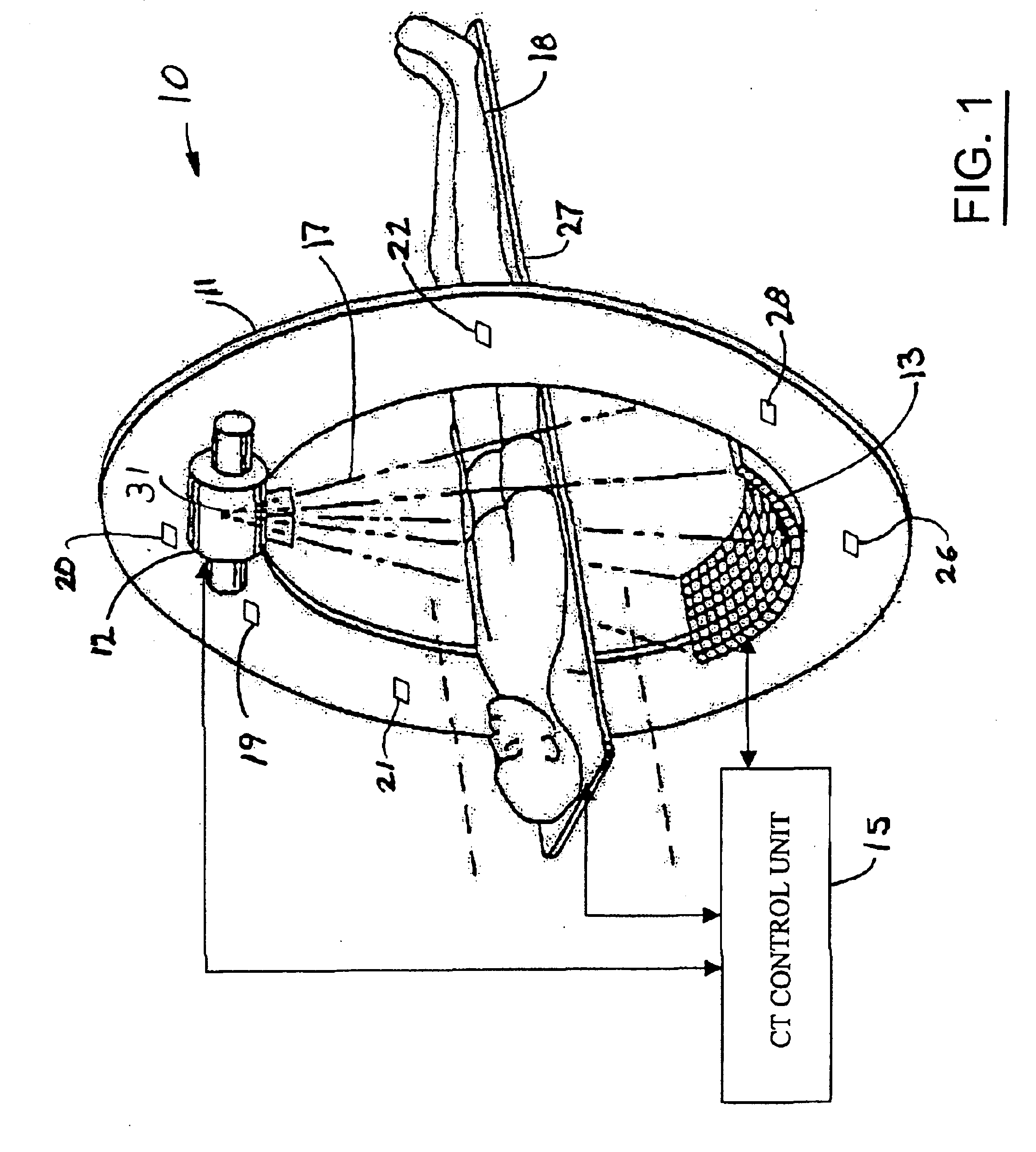

Computed tomography system with integrated scatter detectors

InactiveUS6879657B2Increase in numberIncrease dosageMaterial analysis using wave/particle radiationRadiation/particle handlingPhysicsComputed tomography

An imaging system includes an x-ray source coupled to a gantry. The x-ray source generates an x-ray flux, wherein a portion of the x-ray flux becomes scatter radiation. A scatter detector is also coupled to the gantry to receive the scatter radiation. The scatter detector generates a scatter signal in response to the scatter radiation, and a host computer receives the scatter signal.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

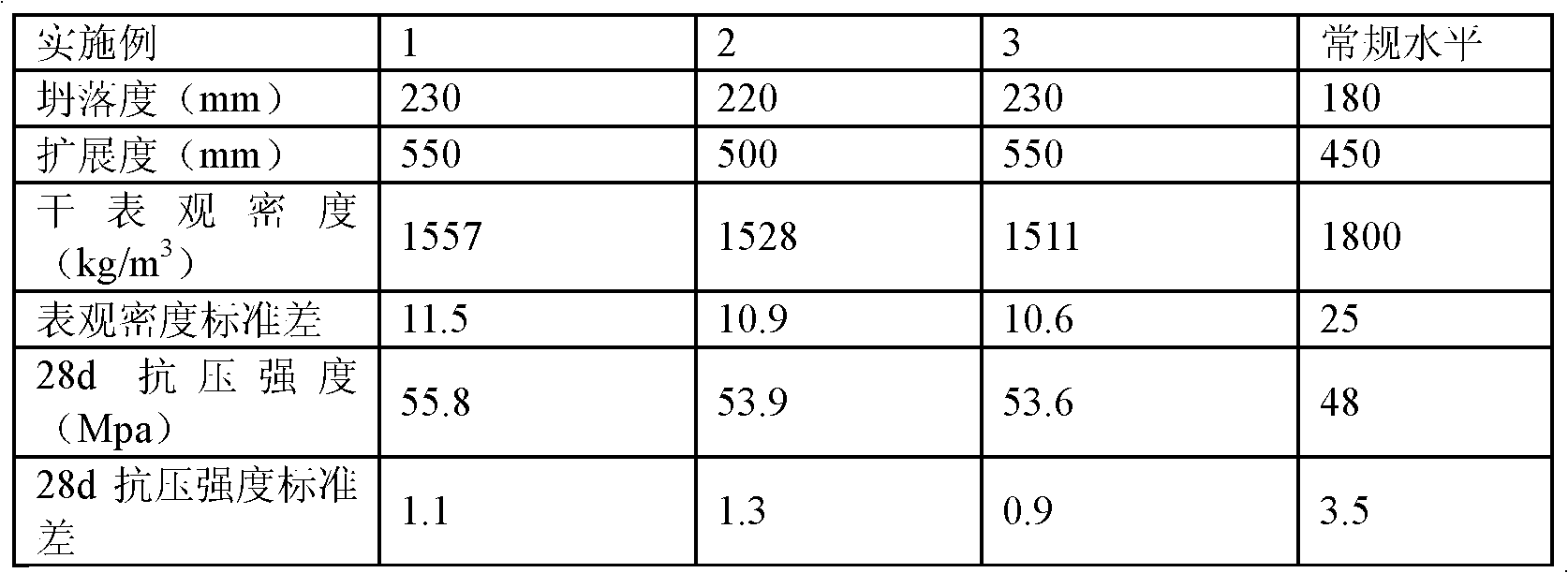

Light high-strength concrete and preparation method thereof

The invention discloses light high-strength concrete, which is prepared from the following raw materials in percentage by weight: 10 to 15 percent of silicate cement, 8 to 12 percent of mineral powder, 6 to 10 percent of coal ash, 2 to 6 percent of wollastonite, 20 to 30 percent of ceramsite,25 to 35 percent of ceramic sand, 0.2 to 0.8 percent of high-performance water reducing agent, 0.05 to 0.3 percent of exciting agent, 0.05 to 0.8 percent of tackifier and 8 to 12 percent of water. The light high-strength concrete has the advantages that compact accumulation is realized by optimizing the grain composition of cementing materials; the mineral powder is subjected to ultrafine grinding, so that the hydrated activity of the mineral powder is improved substantially; and the using quantity of the low-density cementing materials can be increased, and the cohesiveness of slurry is improved by combining the high-performance water reducing agent, the exciting agent and the tackifier, so that the concrete slurry is high in working performance and is not segregable, and the aim of reducing the volume weight of the hardened slurry substantially is fulfilled on the basis of ensuring the mechanical property of the hardened slurry.

Owner:JIANGSU MINGHE GRP

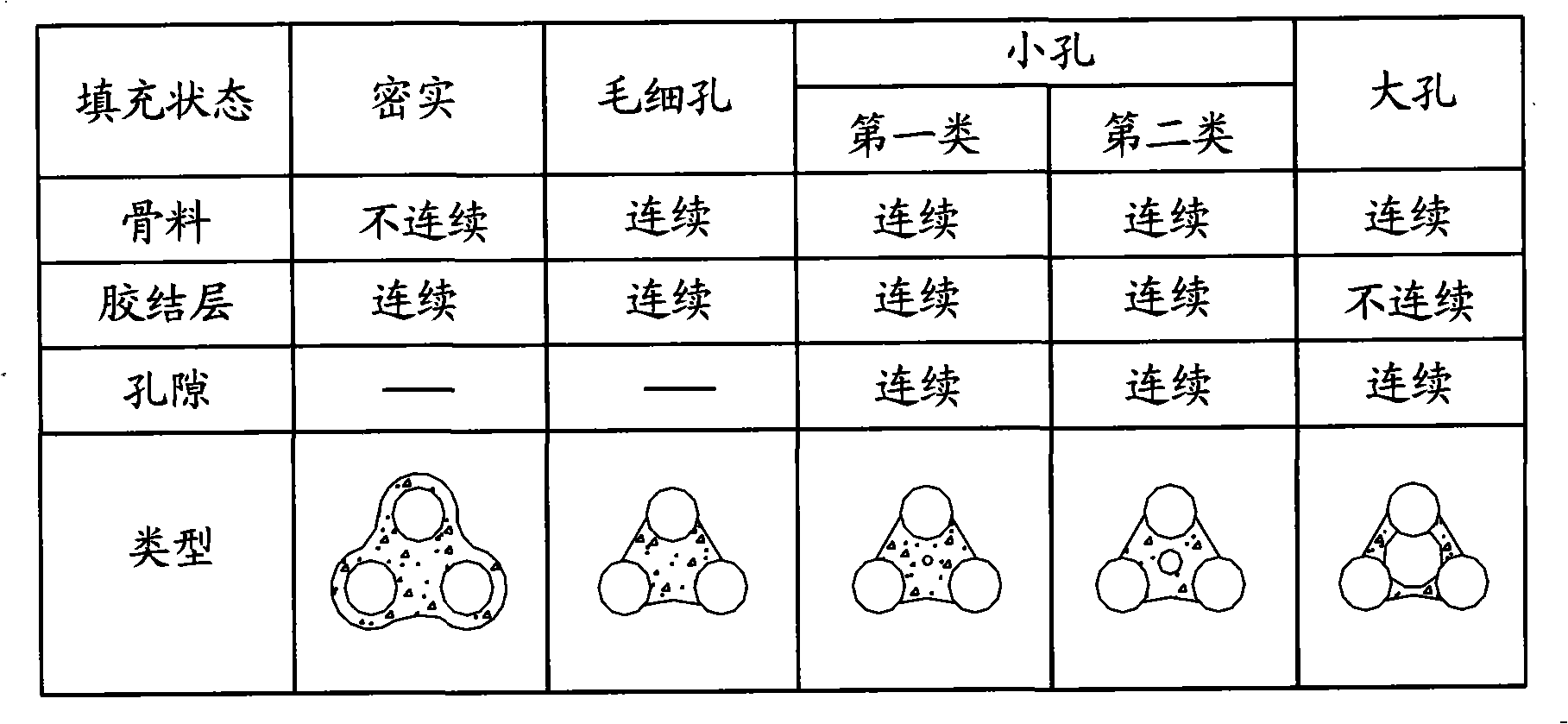

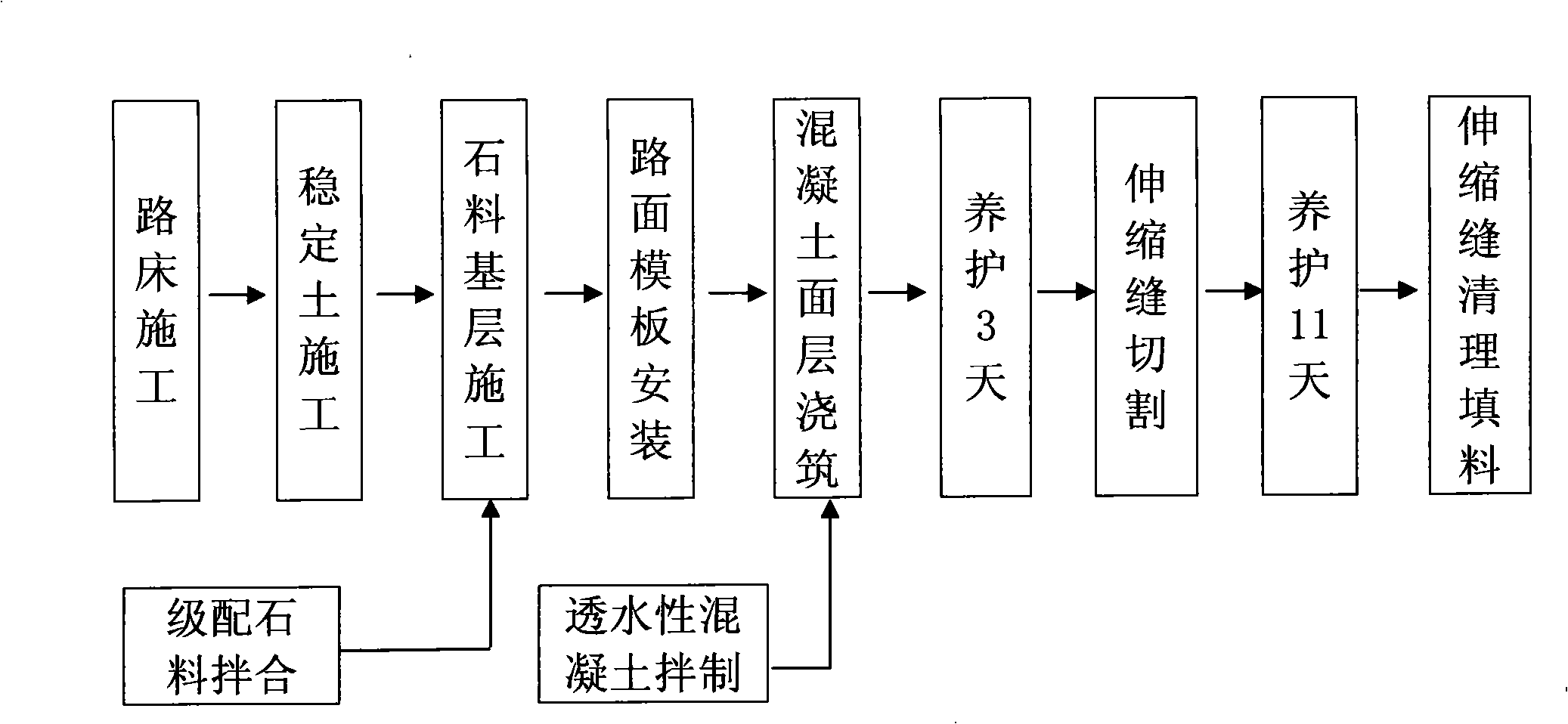

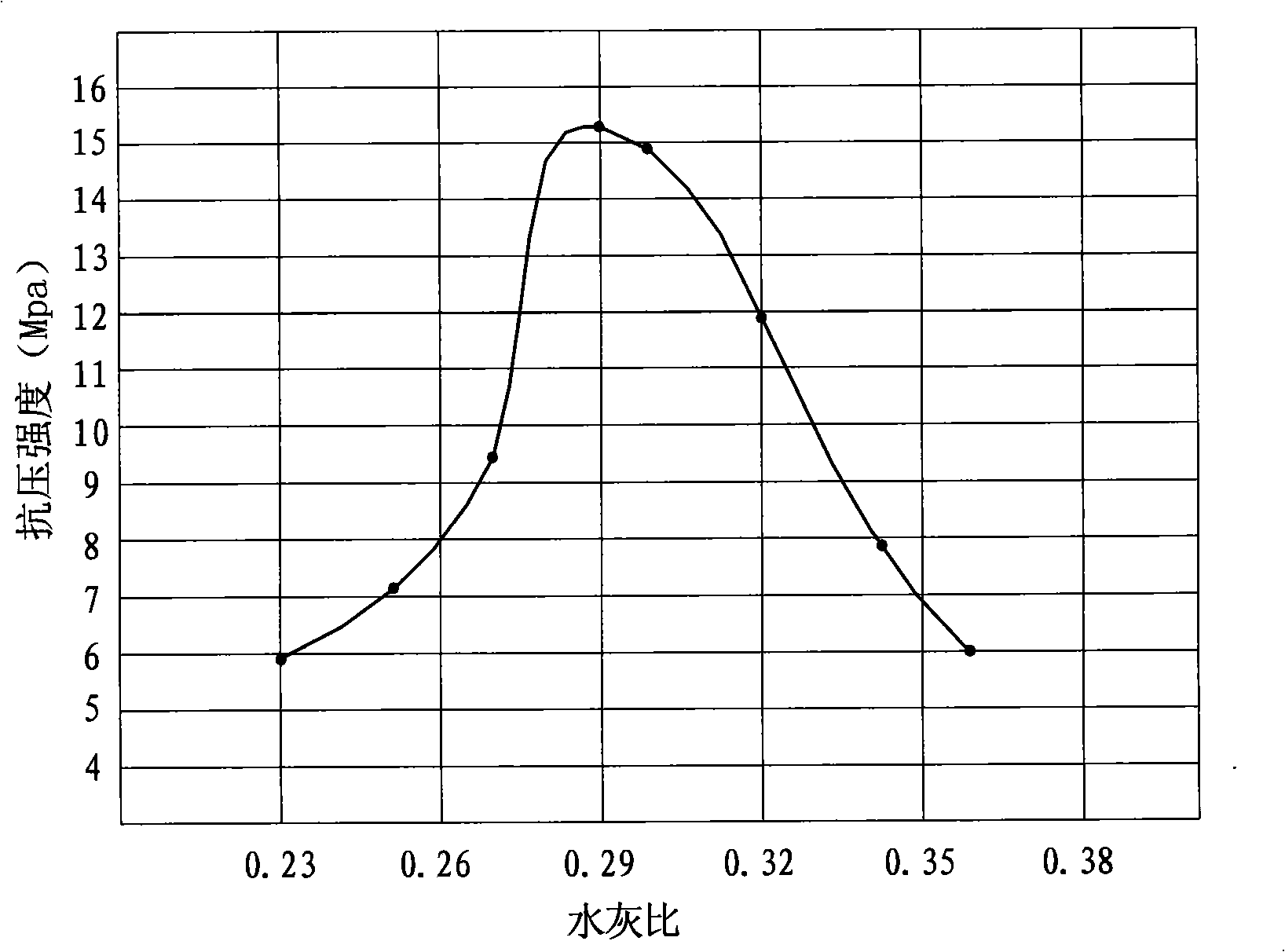

Water permeable concrete and pavement construction method

InactiveCN101293763AHigh strengthGood water permeabilityIn situ pavingsSolid waste managementFlexural strengthRoad surface

The invention discloses permeable concrete and a pavement construction method. The permeable concrete comprises the following components: 1350 to 1800 parts of broken stones, 90 to 150 parts of water, 300 to 350 parts of cement, 10 to 70 parts of mineral powder, 10 to 70 parts of silicon ash and 0.3 to 7 parts of water reducing agent; if necessary, organic intensifying agent can be added. The construction method comprises the following steps: permeable concrete is mixed, poured and cured, an expansion joint is cut, and the filling and the other processes are performed. Concrete pavement prepared by the method has higher strength and water permeability, and the compression strength can reach or exceed 30 MPa; the flexural strength is above 4 MPa; the coefficient of water permeability is more than or equal to 1 mm / s; the requirements for the permeable concrete pavement can be fully satisfied. The permeable concrete is suitable for the construction of permeable concrete pavement, squares and parking lots; by adopting the method, the consumption of cement is small, the construction is simple, and the method is favorable for being popularized.

Owner:HENAN GUOJI CONSTR GRP +1

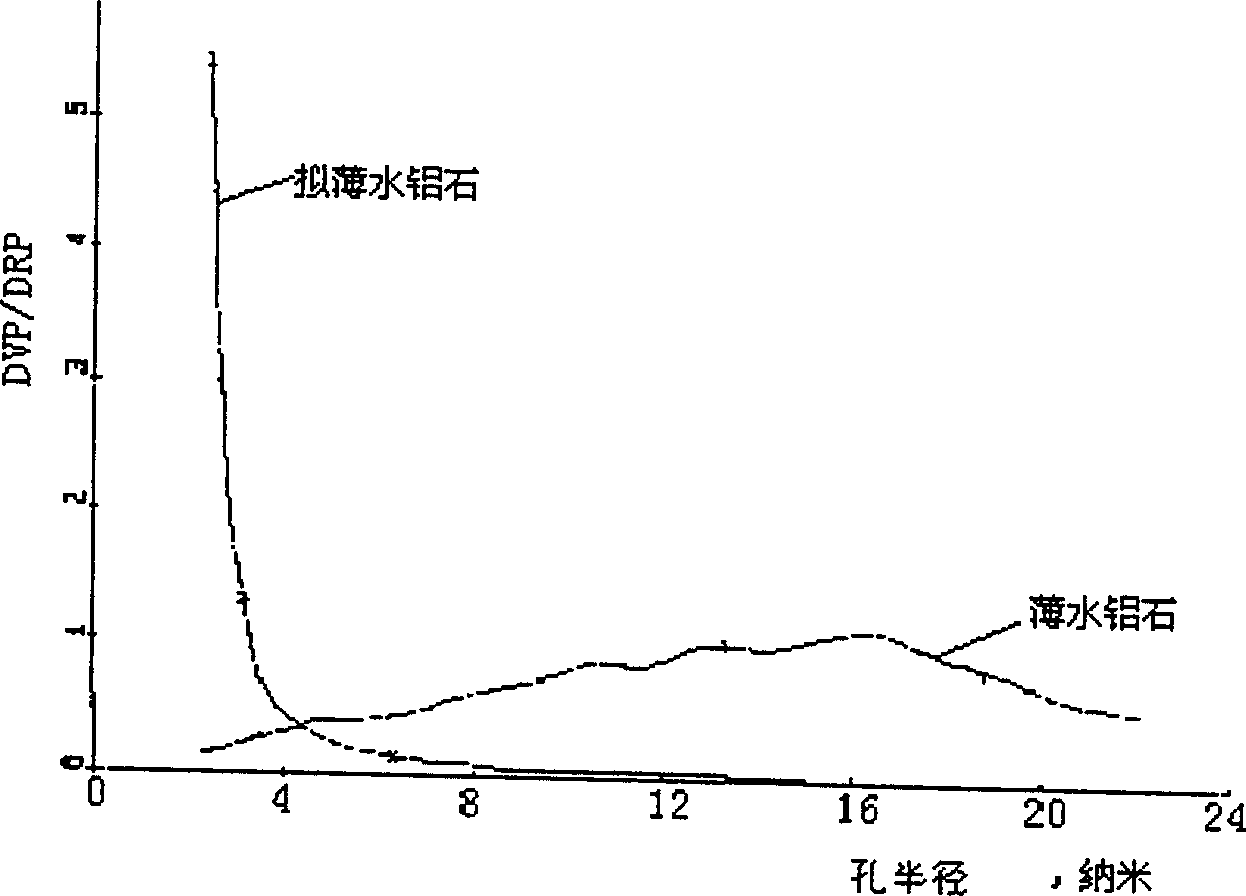

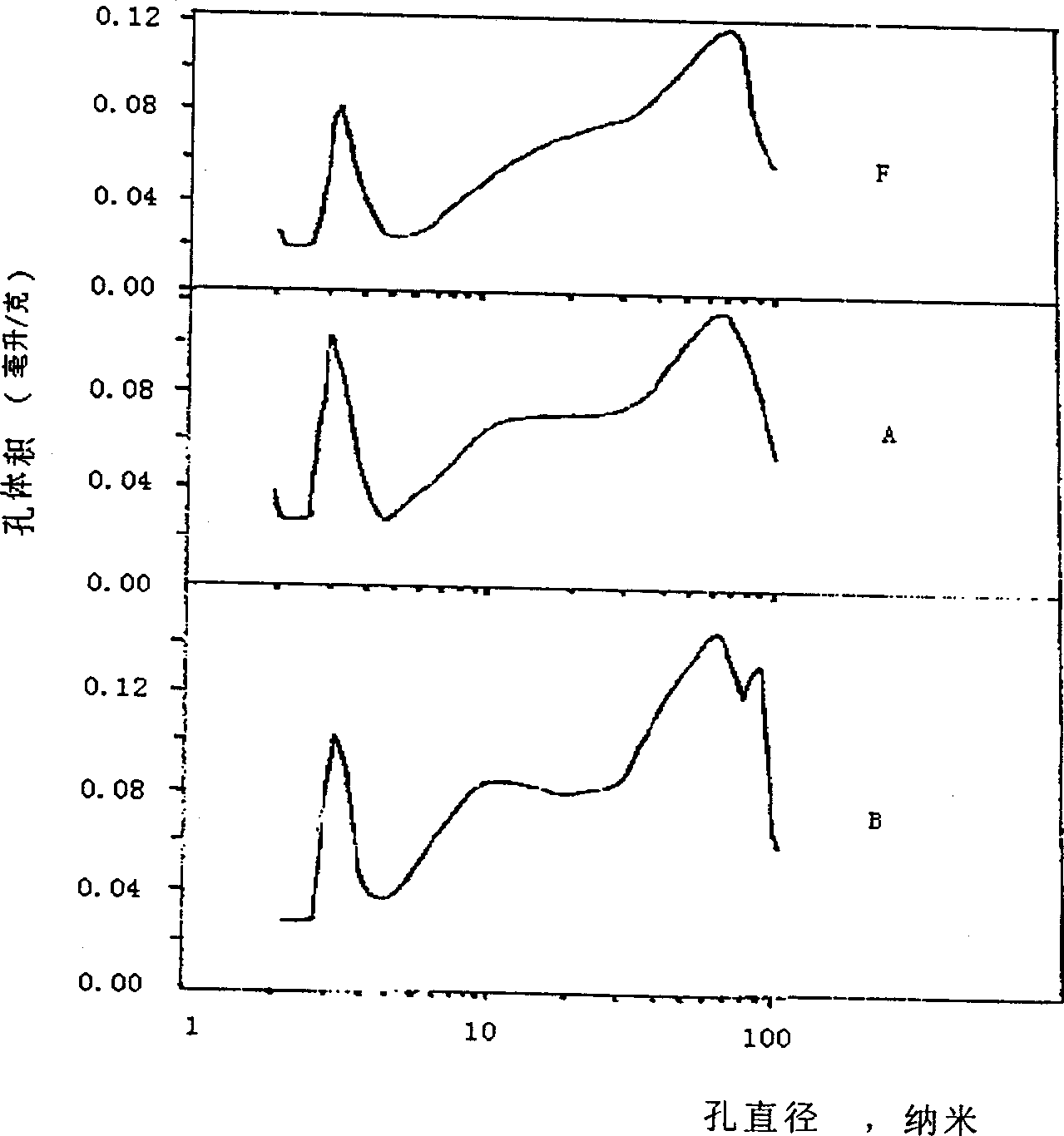

Catalytic cracking catalyst and its prepn

The catalytic cracking catalyst contains medium and large pore alumina with average pore size not smaller than 3 nm 5-60 wt%, zeolite 5-60 wt%, adhesive 5-40 wt% and clay 5-85 wt%. The preparation process includes mixing the said materials, spraying, roasting, washing and drying. Compared with conventional catalyst, the catalyst has strengthened heavy oil converting capacity, obviously improved gasoline and coke selectivity and strengthened heavy metal nickel resistance.

Owner:PETROCHINA CO LTD

High-impact polystyrene blend and preparation thereof

InactiveCN101372548AFlame-retardant high-impact polystyrene blend, environmentally friendlyEnvironmentally friendlyAntioxidantMechanical property

The invention relates to a synthetic material, in particular to a halogen-free flame retardant high impact polystyrene blend and a preparation method thereof. The high impact polystyrene blend comprises high impact polystyrene resin with the mass percent of 35-75%, an inorganic flame retardant with the mass percent of 7-45%, an intumescent flame retardant with the mass percent of 5-20%, a flame retardant synergist with the mass percent of 1-5%, a toughening agent with the mass percent of 10-20%, a coupling agent with the mass percent of 0.5-2.0%, a lubricant with the mass percent of 0.5-3.0% and an antioxidant with the mass percent of 0.2-3.0%. The halogen-free flame retardant high impact polystyrene blend is produced by high-speed premixing and extrusion prilling, and has the advantages of environmental protection, flame retardation, low smoke, weather resistance, good thermal stability and mechanical property, easy machine shaping, etc.

Owner:珠海市远康企业有限公司

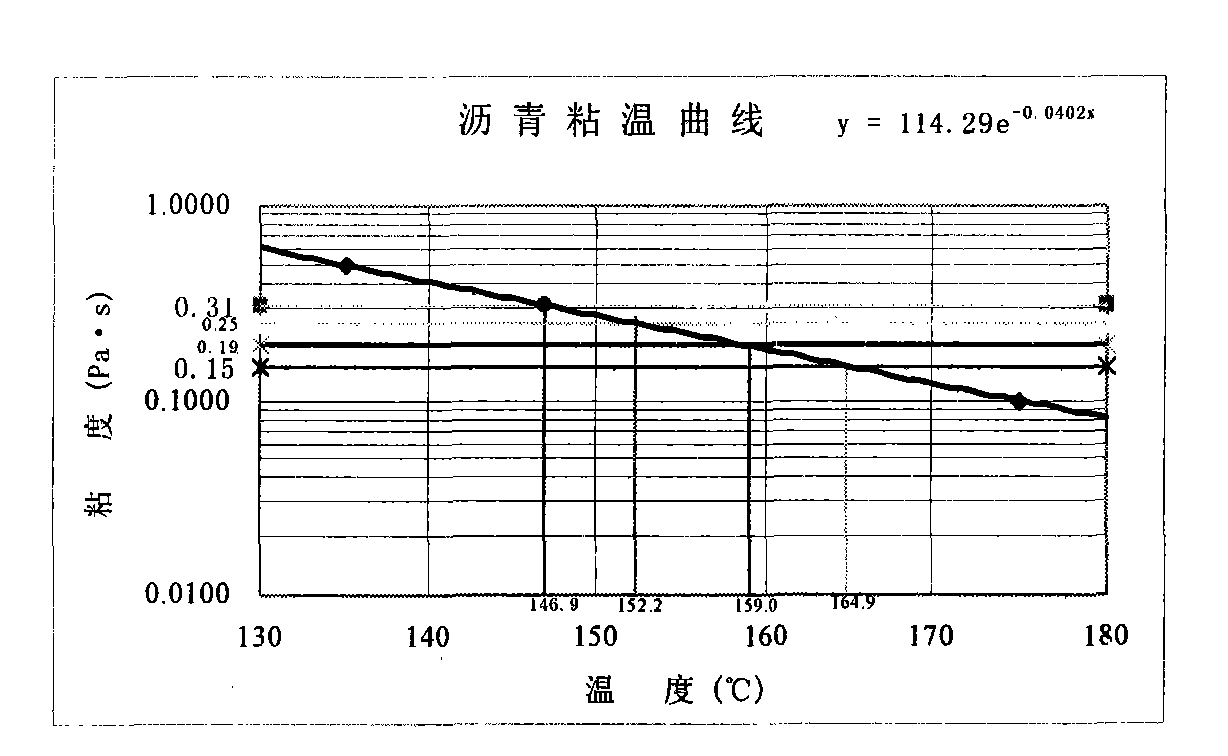

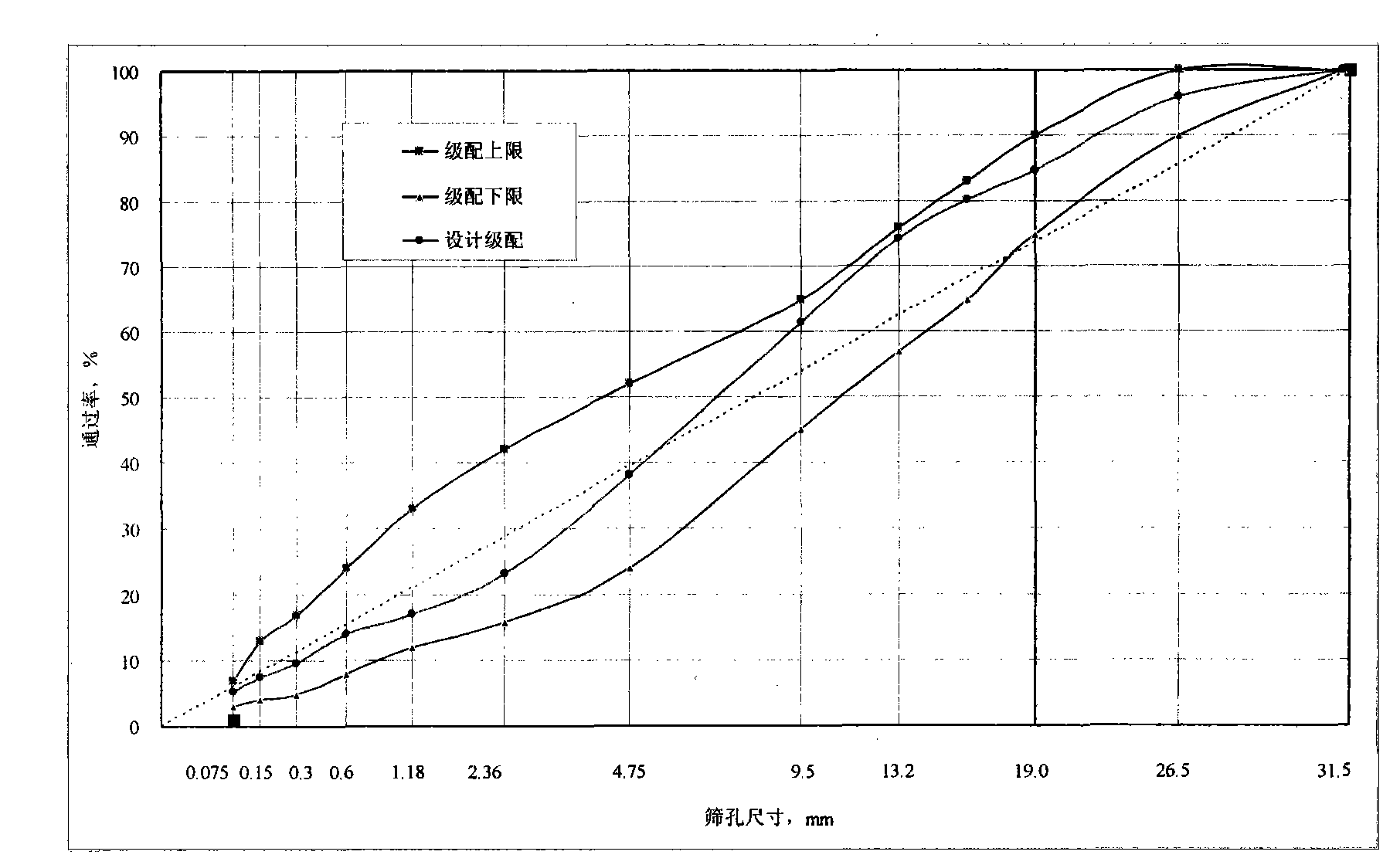

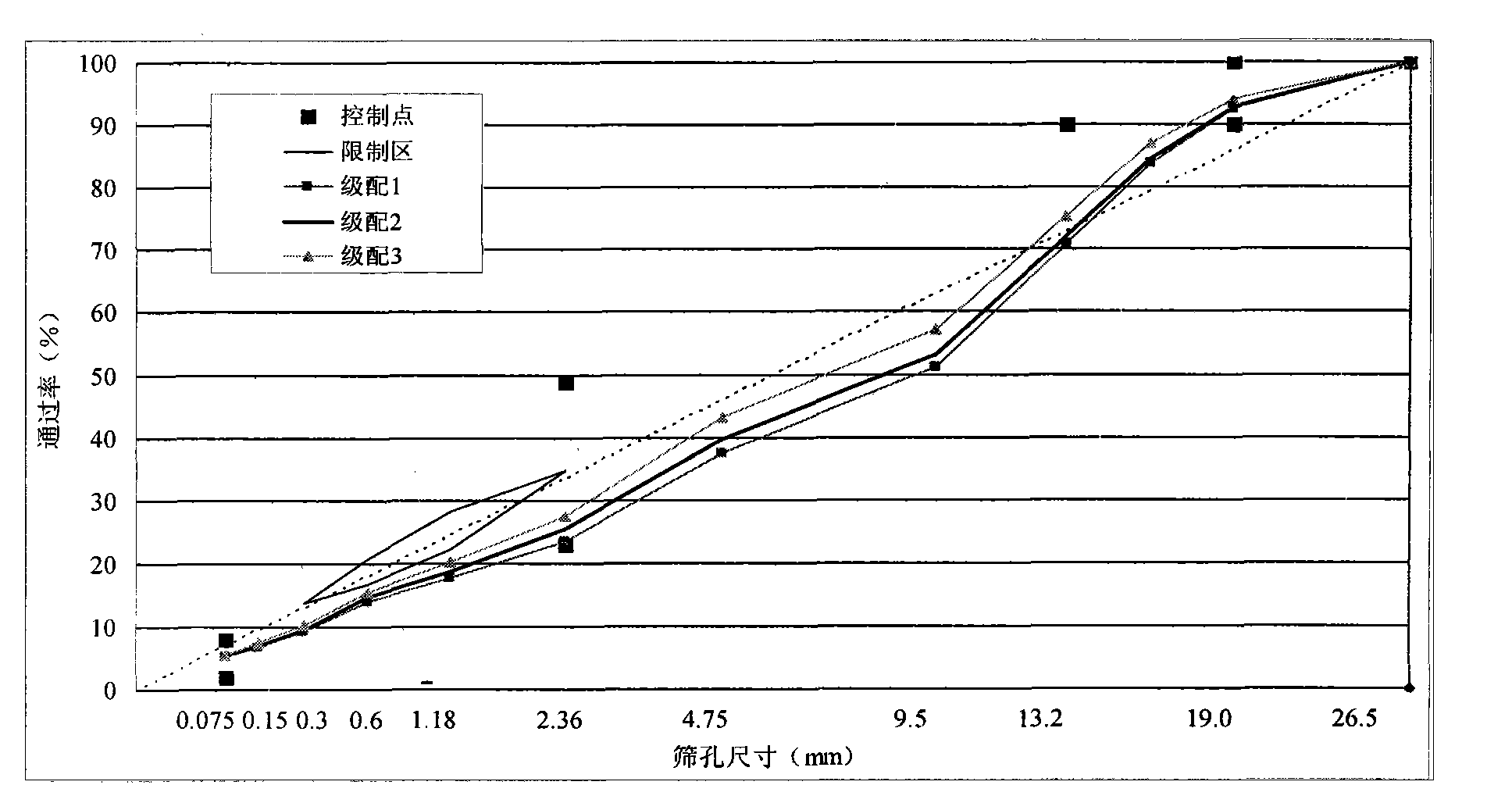

Hot in-plant reclaimed asphalt mixture

ActiveCN101654347AIncrease dosageImprove high temperature performanceSolid waste managementEconomic benefitsRoad surface

The invention relates to a hot in-plant reclaimed asphalt mixture. The mixture includes the following components by mass percent: 30 to 50 percent of milling materials, 44 to 67 percent of newly collected materials, 1.5 to 4 percent of mineral powder, 1.5 to 4 percent of new asphalt, and ARA regenerant which is 0 to 10 percent of the mass of the recycled asphalt contained in the milling materials.The processing method includes the following steps: (1) extraction and analysis of the milling materials; (2) asphalt performance test; (3) regenerant addition; (4) formation of mixture of the recycled asphalt; (5) Marshall test or rotary compacting test; and (6) mixture performance test. The proportion of milling material RAP reaches as high as 50 percent in the engineering application of the hot recycled asphalt mixture, the milling material RAP can be applied to a middle layer, and the proportion is higher than the proportions of other hot recycled mixtures by more than 20 percent. The mixture can be applied to various grades, such as the AC type, SUPERPAVE, and the like, and the RAP proportion can respectively reach 30 percent or even more than 50 percent. When the mixture is used forpaving a road surface, the road performance can respectively meet the requirements on performance of a newly proportioned asphalt mixture, and the high temperature performance is even superior to thenewly proportioned asphalt mixture. Therefore, the invention has obvious economic benefit.

Owner:JIANGSU HUAIAN TRAFFIC SURVEY & DESIGN INST

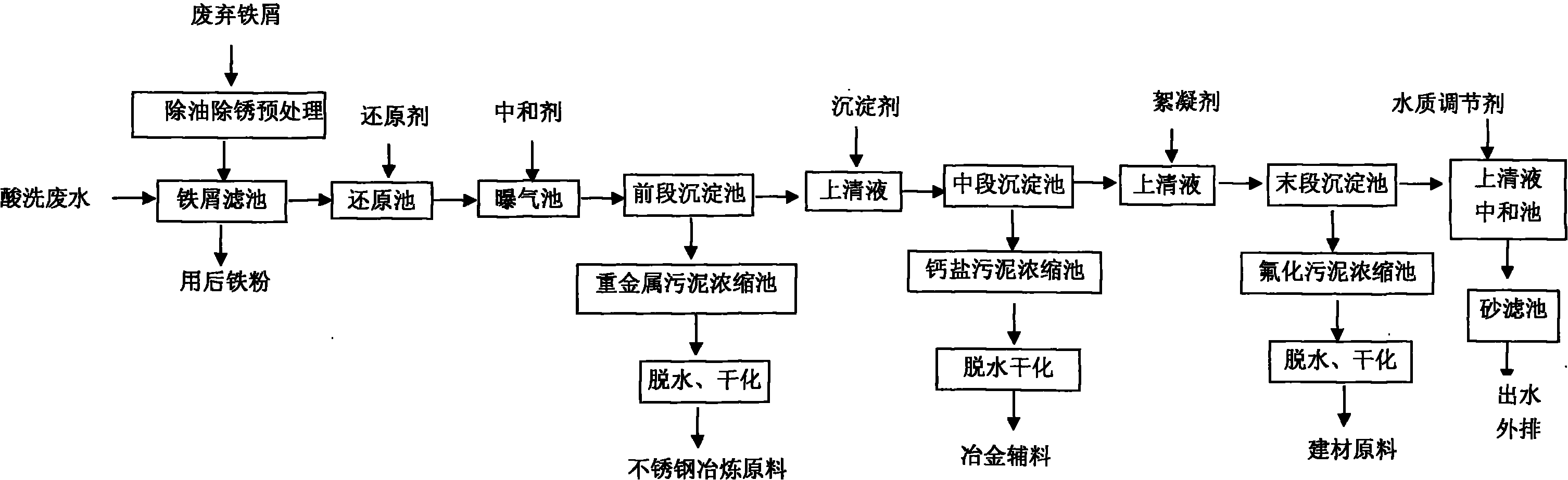

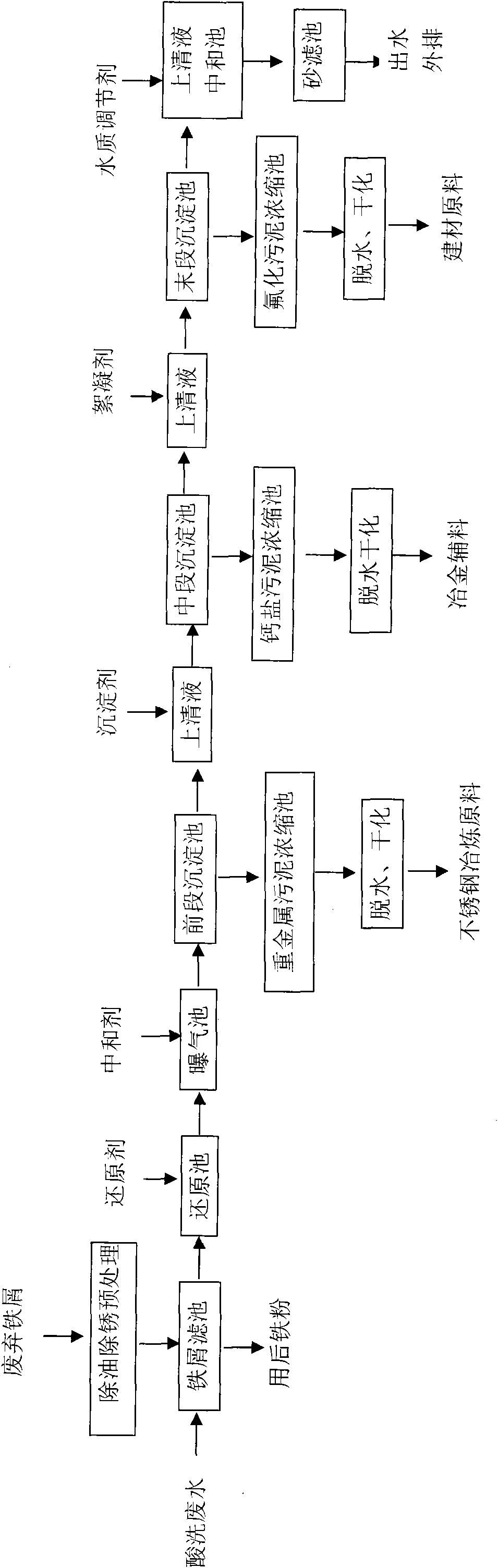

Processing method of stainless steel cold rolling pickling wastewater

ActiveCN101811792AIncrease dosageIncrease productionSludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processScrapHexavalent chromium

The invention relates to a processing method of stainless steel cold rolling pickling wastewater. The pickling wastewater enters a hexavalent chrome secondary reduction pool after the actions of micro-electrolysis and hexavalent chrome preliminary reduction of a scrap iron filtering pool; the reduced wastewater enters a front-segment precipitation tank after neutralization and aeration, heavy metal sludge is concentrated and dehydrated, and the heavy metal sludge and scrap iron after the use of the scrap iron filtering pool are recycled and used as stainless steel smelting raw materials; middle-segment precipitation is carried out after a primary supernatant acts with a precipitant, and dehydrated and dried fluoride sludge is recycled and used as a metallurgical adjuvant material; final-segment precipitation is carried out after a secondary supernatant continues to act with a flocculating agent to obtain calcium salt which can be used as a building material raw material; and after the three segments of precipitation of acidic wastewater, the final third level supernatant reaches a standard and is discharged through water quality regulation and sand filtering. The invention has the advantages of less investment, low wastewater processing cost, convenient maintenance and the like, and not only can effectively utilize discarded scrap iron of a stainless steel enterprise, but also can greatly lower the subsequent wastewater processing cost and the operating load.

Owner:BAOSHAN IRON & STEEL CO LTD

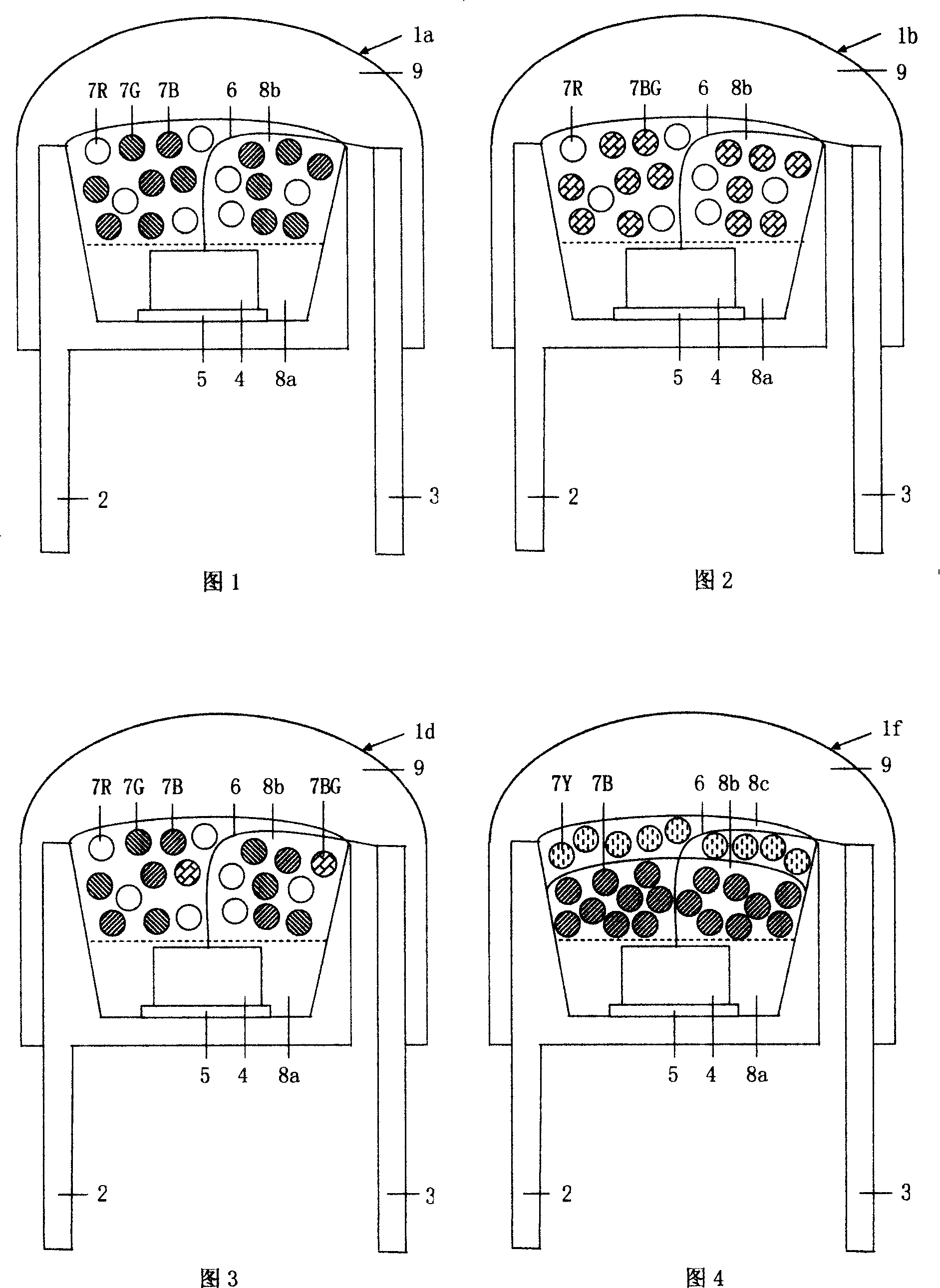

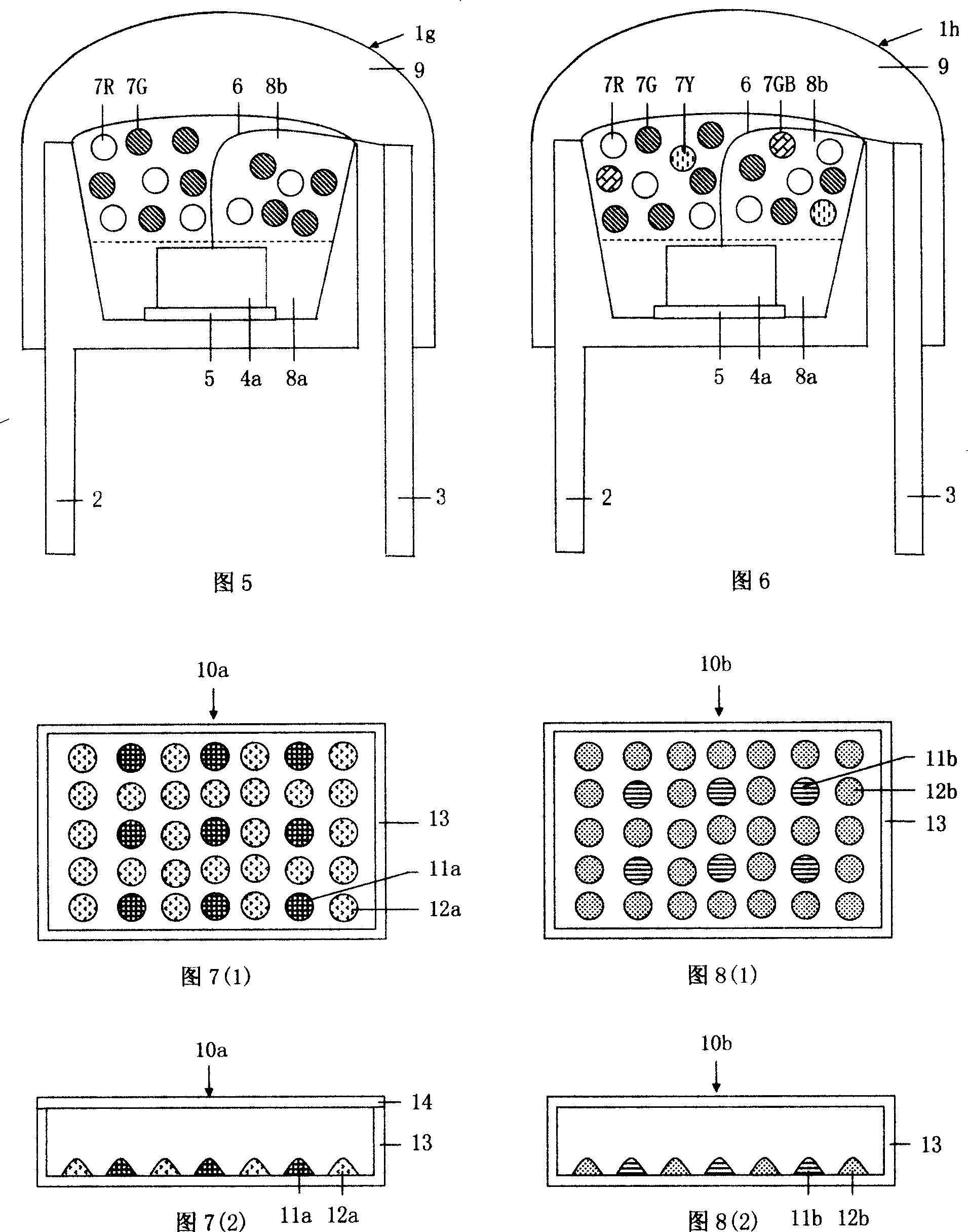

White light LED and lighting apparatus

InactiveCN101118935AImprove luminous efficiencyGood colorLight source combinationsElectric lightingFluorescenceEffect light

The present invention relates to a white light LED which has a high lighting efficiency, a good color displaying capability and has a plurality of afterglow colors or light storing capability. The present invention adopts at least two white light LED which have different peak value wave lengths and launching spectral and adjusts the two weights of the two fluorescences through the white LED to get the white LED lighting device which has a good color displaying capability, a high lighting efficiency, a plurality of afterglow colors and times.

Owner:黎涤萍

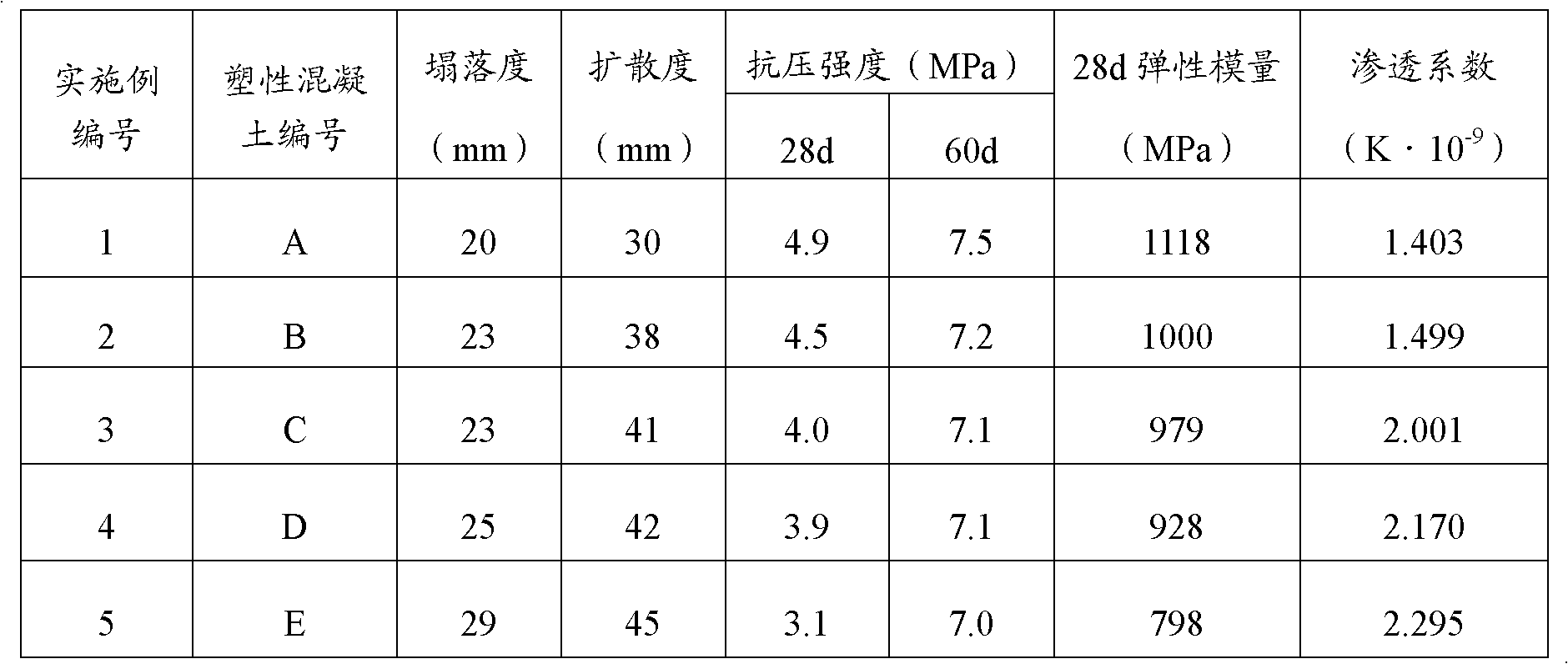

Plastic concrete for cutoff wall

ActiveCN102617073AHigh bonding strengthImprove workabilityPulverised fuel ashParticle-size distribution

The present invention provides a plastic concrete for a cutoff wall, and belongs to the technical field of cutoff concrete engineering. The plastic concrete comprises a cementitious material, an aggregate, a water-reducing agent and water, wherein a ratio of the water to the cementitious material in the plastic concrete is 0.92, the cementitious material comprises, by weight, 15-35 parts of cement, 10 parts of bentonite, 25 parts of clay, and 30-50 parts of fly ash, the aggregates comprises sand and stone, the sand ratio of the aggregate is 47%, per stere of the plastic concrete is added with 1485 kg of the aggregate, the particle size of the stone is 5-20 mm (continuous particle size distribution), and the plastic concrete comprises 0.2 parts by weight of the water-reducing agent. With the plastic concrete prepared by the method of the present invention, the addition amount of the fly ash can be significantly improved, and the use amount of the cement can be reduced, such that the cost of the plastic concrete is significantly reduced; based on the current raw material market price (the cement is 490 yuan / t, the type II fly ash is 160 yuan / t), the cost of per stere of the plastic concrete can be reduced by about 33-56 yuan.

Owner:北京新奥混凝土集团有限公司 +1

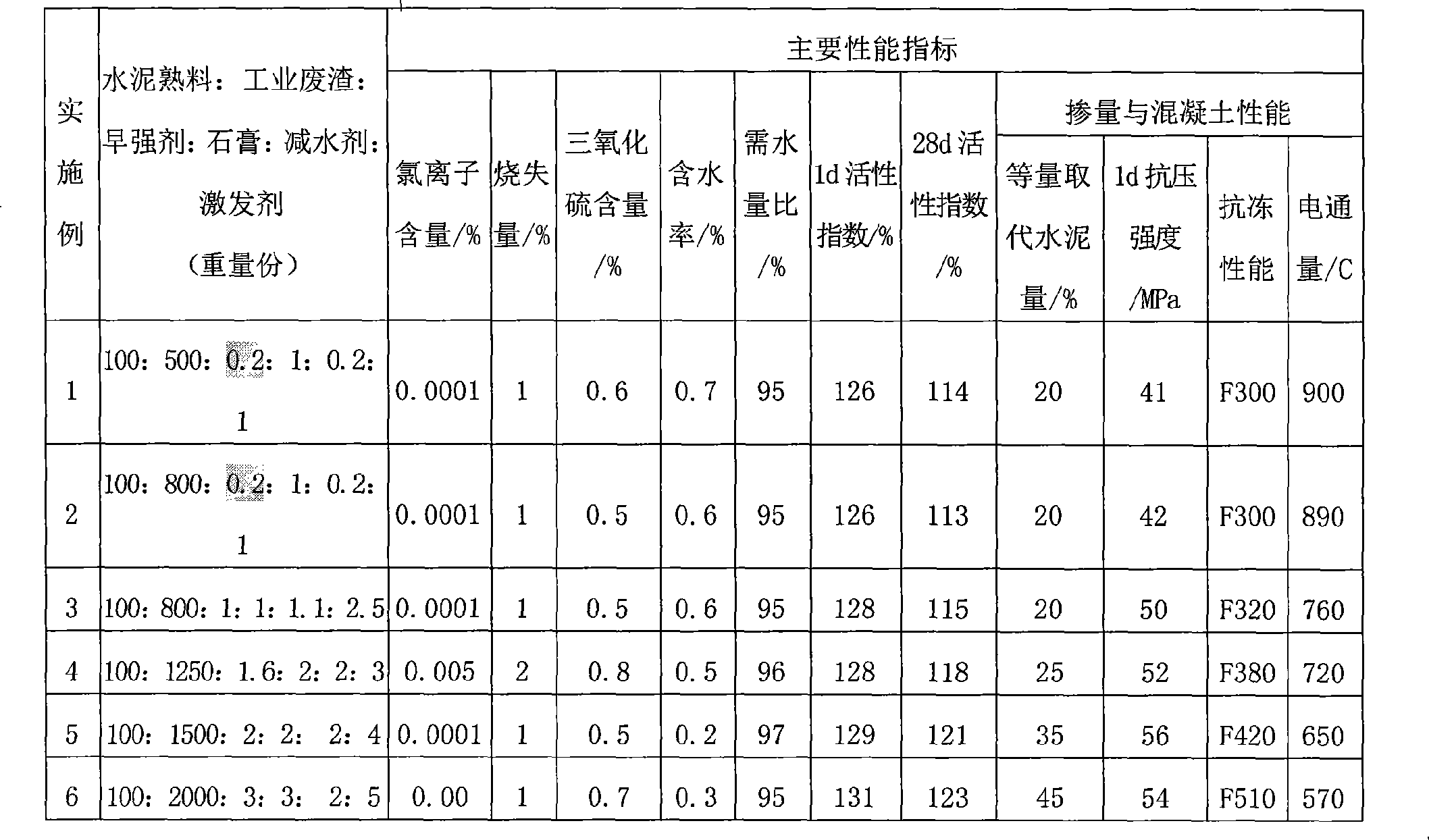

Blending material for high-early-strength concrete

InactiveCN101508557AImprovement of early strength and high strengthReduce dosageSolid waste managementHigh strength concreteCalcium formate

The invention relates to an admixture for high early strength of concrete, characterized in that the admixture is formed by mixing and stirring cement clinkers, industrial residues, early strength agents, plaster, water reducing agents and excitants. The parts by weight of the components are as follows: 100 parts of cement clinkers, 500-2000 parts of industrial residues, 0.2-3 parts of early strength agents, 1-3 parts of plaster, 0.2-2 parts of water reducing agents and 1-5 parts of excitants. The excitant is the mixture of aluminum hydroxide, calcium nitrite and calcium nitrate; wherein, the aluminum hydroxide accounts for 50% of the mixture while the calcium nitrite and the calcium nitrate are in any proportion; the early strength agent is the mixture of trolamine, lithium carbonate and calcium formate, wherein, the trolamine accounts for 50% of the mixture while the lithium carbonate and the calcium formate are in any proportion. The admixture for concrete provided by the invention has high activity index and low content of harmful ions. Adding the admixture can obviously improve the demoulding strength, long-term mechanical property and durability of the concrete.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

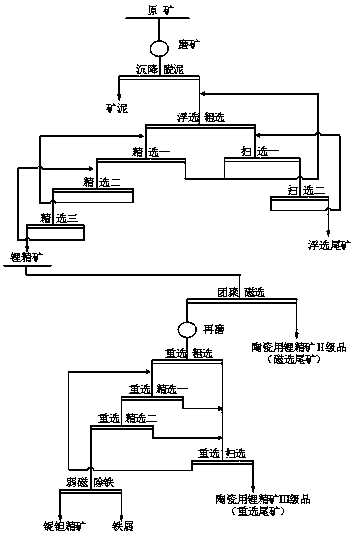

Comprehensive recovery process for lithium-containing polymetallic ore with associated fine-grained niobium-tantalum

InactiveCN103418488ASolve the problems of low recovery rate, single beneficiation products, and poor economic benefitsRaise the gradeFlotationMagnetic separationLithiumNiobium

The invention relates to a comprehensive recovery process for lithium-containing polymetallic ores with associated fine-grained niobium-tantalum. The process comprises the steps of raw ore crude grinding, settlement for desliming, flotation, agglomeration and magnetic separation, gravity separation and the like. The process provided by the invention is particularly applicable to the comprehensive recovery of lithium-containing polymetallic ores which contain a great amount of slime, are located in mining areas at low temperature all through the year, are low in grade of associated niobium-tantalum minerals and are fine in disseminated grain size, the process is advanced, reliable, simple, reasonable and highly targeted, the requirement on raw ore grinding fineness is not high, the regrinding amount is small, the operation cost is low, the comprehensive recovery rate is higher and the industrialization prospect is good.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Liquid agent multielement fertilizer and its production method

InactiveCN1410395AChange physiologyPromote absorptionOrganic fertilisersFertilizer mixturesManganesePlant cell

A multi-element liquid fertilizer contains active components, additive and water. Its active components includes 13 components, such as potassium sulfate, borax, copper sulfate, manganese sulfate, zinc sulfate, etc.. The additives include 9 components, such as disodium hydrogen phosphate, nitric acid, useful bacteria, useful enzyme, etc.. It can improve the activity of plant cells, change physiological mechanism of plant, increase yield, and make plant robust.

Owner:孙国庆 +1

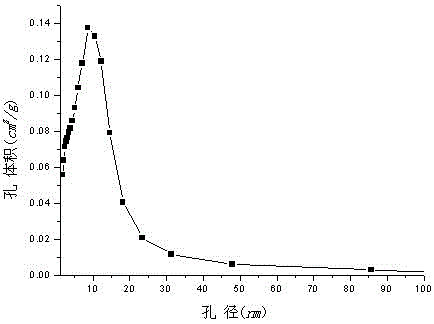

Melamine modified polyvinylalcohol formal foam, preparation and uses thereof

InactiveCN101508747AIncrease dosageImprove mechanical propertiesAbsorbent padsFiltration separationFoaming agentAdjuvant

The invention relates to a melamine modified polyvinyl formal foam material and a preparation method thereof. The foam material is prepared by proportionally mixing and reacting among polyvinyl alcohol, melamine, formaldehyde, an acidic catalyst, a basic catalyst, an emulsifier, a foaming agent, a pore former, an adjuvant and the like. The foam material has the advantages of simple preparation process, adjustable aperture ratio, high mechanical strength and good temperature resistance, and can be widely used as medical sponge, filtering material, sound insulation protection material, wiping and dedusting material and biological carrier material.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

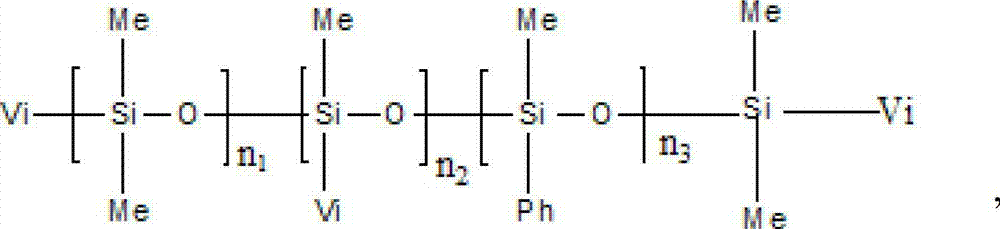

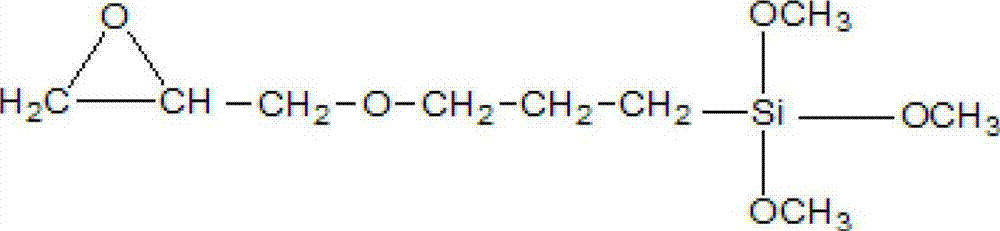

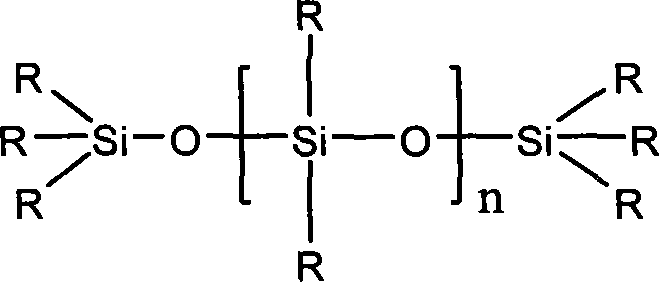

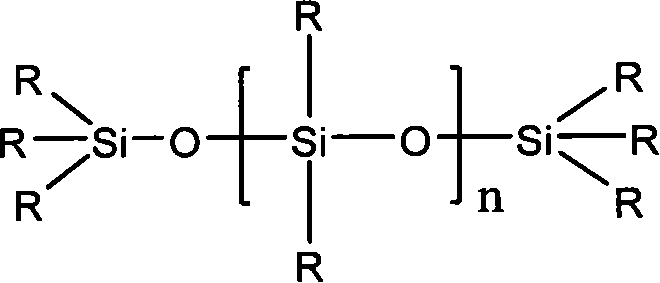

Vulcanization-proof LED (light-emitting diode) packaging silica gel

InactiveCN102965069AStrong adhesionIncrease dosageNon-macromolecular adhesive additivesMacromolecular adhesive additivesVulcanizationAdhesive

The invention relates to an LED (light-emitting diode) packaging silica gel, and in particular relates to a vulcanization-proof LED packaging silica gel, belonging to the technical field of adhesives. The vulcanization-proof LED packaging silica gel comprises a component A and a component B, wherein the weight ratio of the component A to the component B is 1: 1; the component A comprises raw materials based on parts by weight: 50-60 parts of methyl phenyl vinyl silicone oil, 30-60 parts of methyl vinyl MQ resin, 0.1-0.3 part of platinum catalyst and 3-5 parts of bonding agent; and the component B comprises raw materials based on parts by weight: 40-50 parts of methyl phenyl vinyl silicone oil, 30-50 parts of methyl vinyl MQ resin, 5-15 parts of cross-linking agent and 0.1-0.3 part of inhibitor. The vulcanization-proof LED packaging silica gel has excellent adhesive force for silver, phenyl-propanolamine (PPA), glass and the like, and has the light transmittance of more than 98%; and phenyl-containing functional groups and branched chain type vinyl are introduced into the LED packaging silica gel, and the dosage of the vinyl MQ resin is increased, so that the crosslinking density and the curing handness are improved, and therefore, the vulcanization resistance of a packaging adhesive layer can be improved.

Owner:YANTAI DEBANG ADVANCED SILICON MATERIALS

High-performance recovered PET/ABS alloy

The invention discloses a high-performance recycled PET / ABS alloy. The alloy comprises the following components in percentage by weight: 30 to 80 percent of recycled PET, 10 to 50 percent of ABS, 1 to 10 percent of reinforcing agent, 2 to 15 percent of compatilizer, 0.5 to 5 percent of flexibilizer, 0.5 to 3 percent of polyhydroxy chemical coupling agent, and 0.1 to 1 percent of antioxidant. The alloy can improve a recycled PET system by using reasonable matching of additives, effects of the polyhydroxy chemical coupling agent, and excellent physical mechanic properties of an ABS system. Therefore, the recycled PET / ABS alloy has the advantages of high compatibility, high tensile strength, high mobility, good machinability and the like, is particularly suitable for producing complicated components and parts and large plates, has a simple process, is suitable for mass production of medium-sized and small enterprises, and has obvious economic benefit and social benefit.

Owner:SOUTH CHINA NORMAL UNIVERSITY

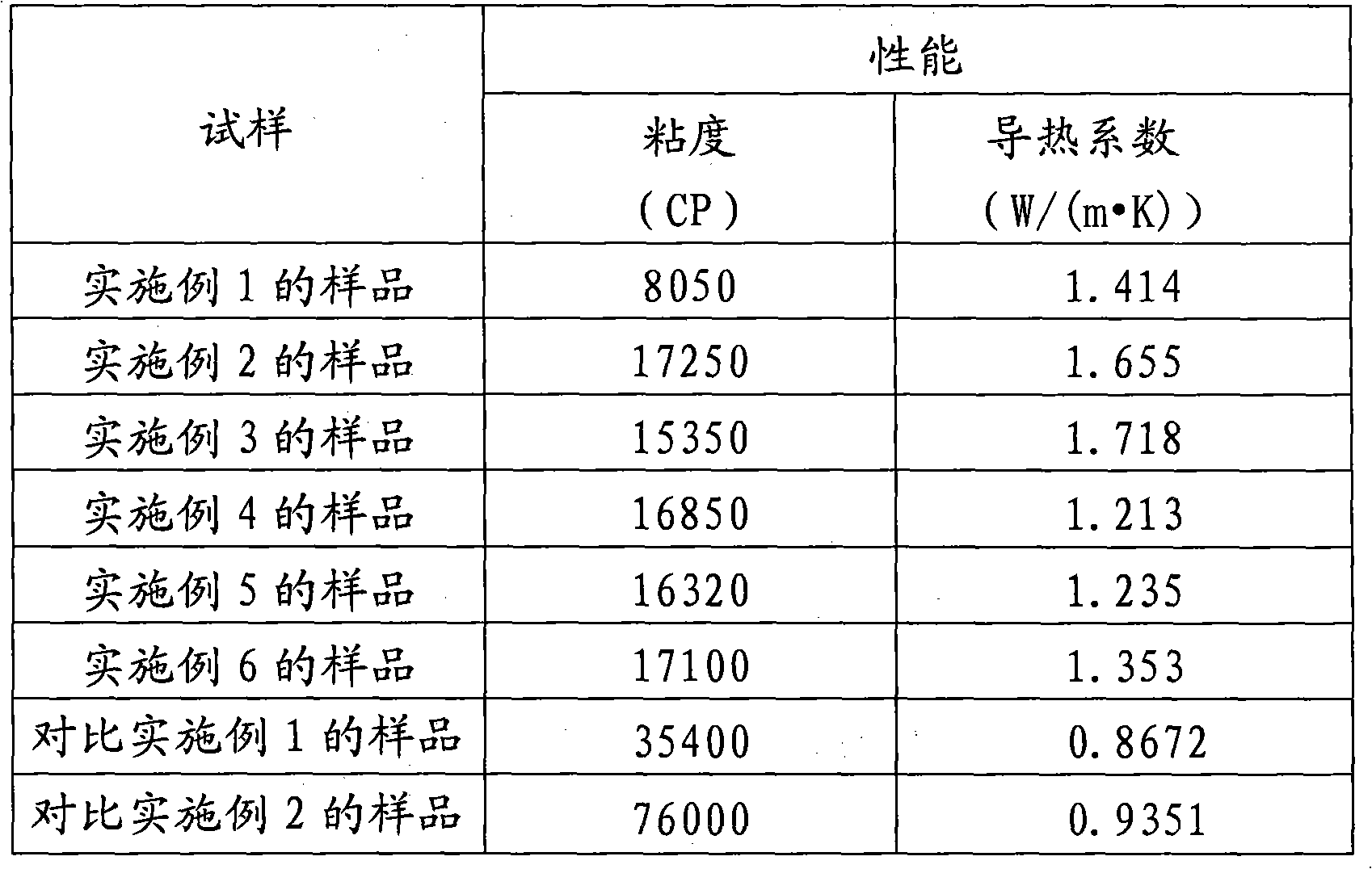

High heat conduction organosilicon filling and sealing gum

InactiveCN101054507AImprove mechanical propertiesGood electrical propertiesOther chemical processesAdhesivesHeat conductingCohesive strength

The invention discloses an organic silicon potting adhesive with a high heat conduction capacity. The curing time of the additive type organic silicon potting adhesive with a high heat conduction capacity can be controlled by the temperature and the amount of the catalyst. The condensate has good mechanical and electrical properties, especially outstanding cohesive strength, high and low temperature resistance and radiation resistance. The inventive heat-conducting organic silicon potting adhesive includes component A and B: said component A is mixed by following parts by weight: 100 shares of organic silica-base adhesive, 10-80 shares of heat-conducting filling, 3-20 shares of reinforced-filling, 1-10 shares of catalyst; said component A is mixed by following parts by weight: 100 shares of organic silica-base adhesive, 10-80 shares of heat-conducting filling, and 1-10 shares curing agent.

Owner:NANJING UNIV OF TECH

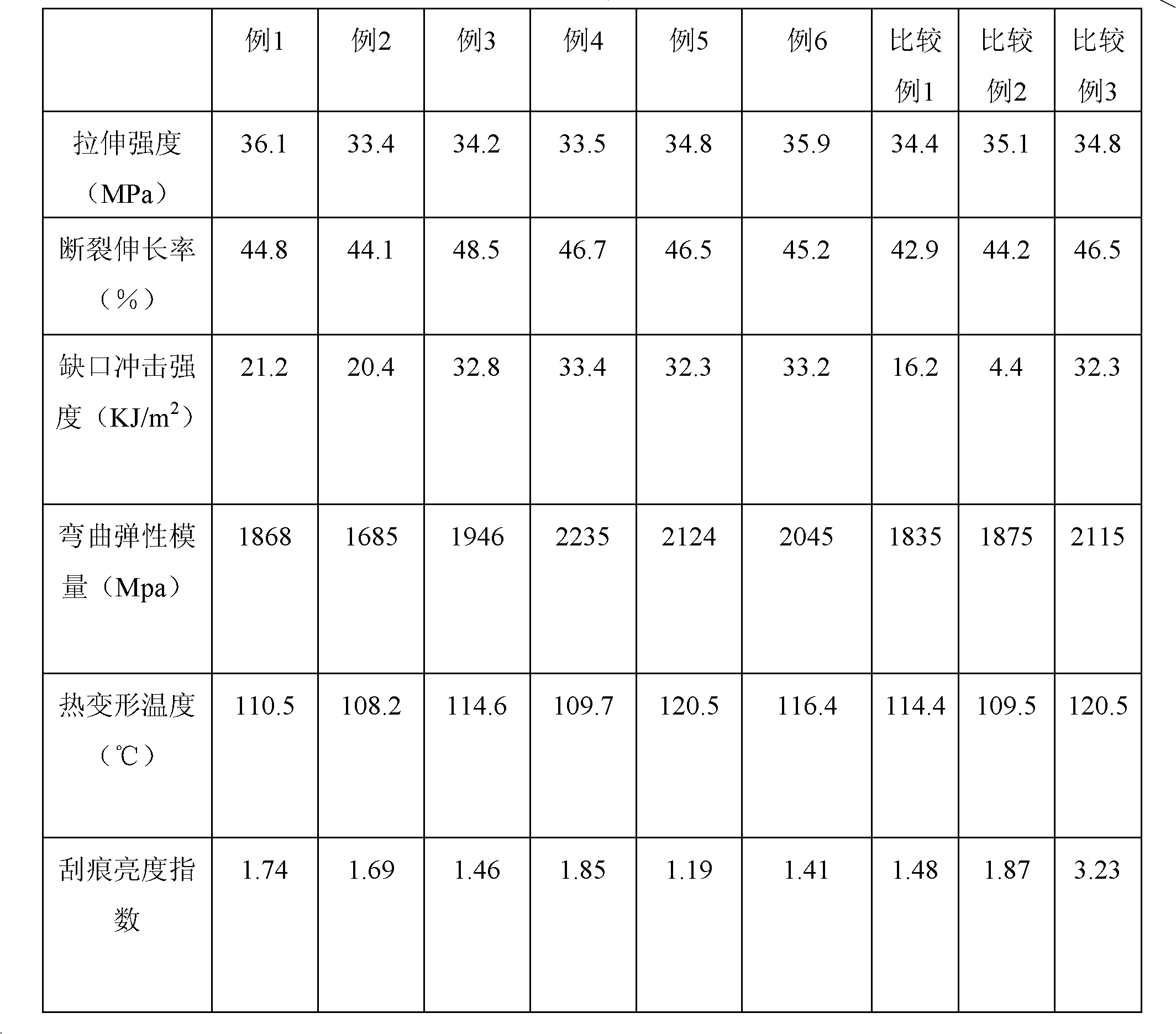

Modified polypropylene material as well as preparation method and application thereof

InactiveCN102464830AImprove rigidityNo lack of resilienceLinear low-density polyethyleneAging resistance

The invention belongs to the technical field of high molecule modification and processing and relates to a modified polypropylene material as well as a preparation method and application thereof. The material provided by the invention comprises the following components in parts by weight: 40-50 parts of bulk polypropylene, 20-35 parts of co-polypropylene, 15-24 parts of toughening agent, 0-15 parts of linear low-density polyethylene, 8-15 parts of filler retention aid, 6-12 parts of compatilizer, 0-8 parts of scratch-resistant smoothing agent, 0.5-1 part of lubricating agent, 3.5-5 parts of composite antioxidant and 1.5-3 parts of coupling agent. Compared with the prior art, the modified polypropylene material provided by the invention has the advantages of good rigidity, ductility, improvement on impact strength, heat resistance, ageing resistance, scratch resistance and excellent processing performance. The material provided by the invention can be widely applied to various interior trim parts of automobiles.

Owner:华砻树脂股份有限公司 +1

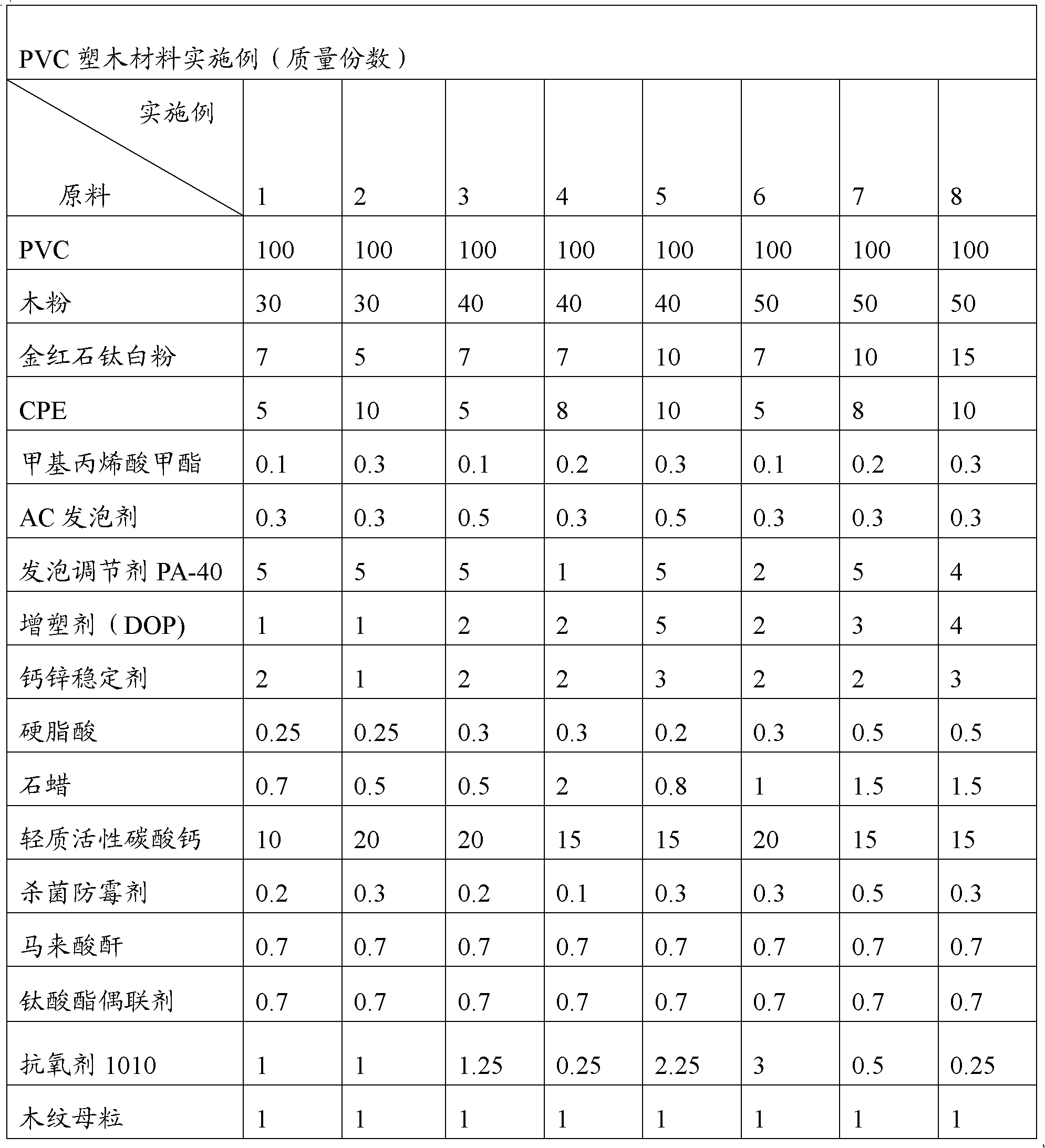

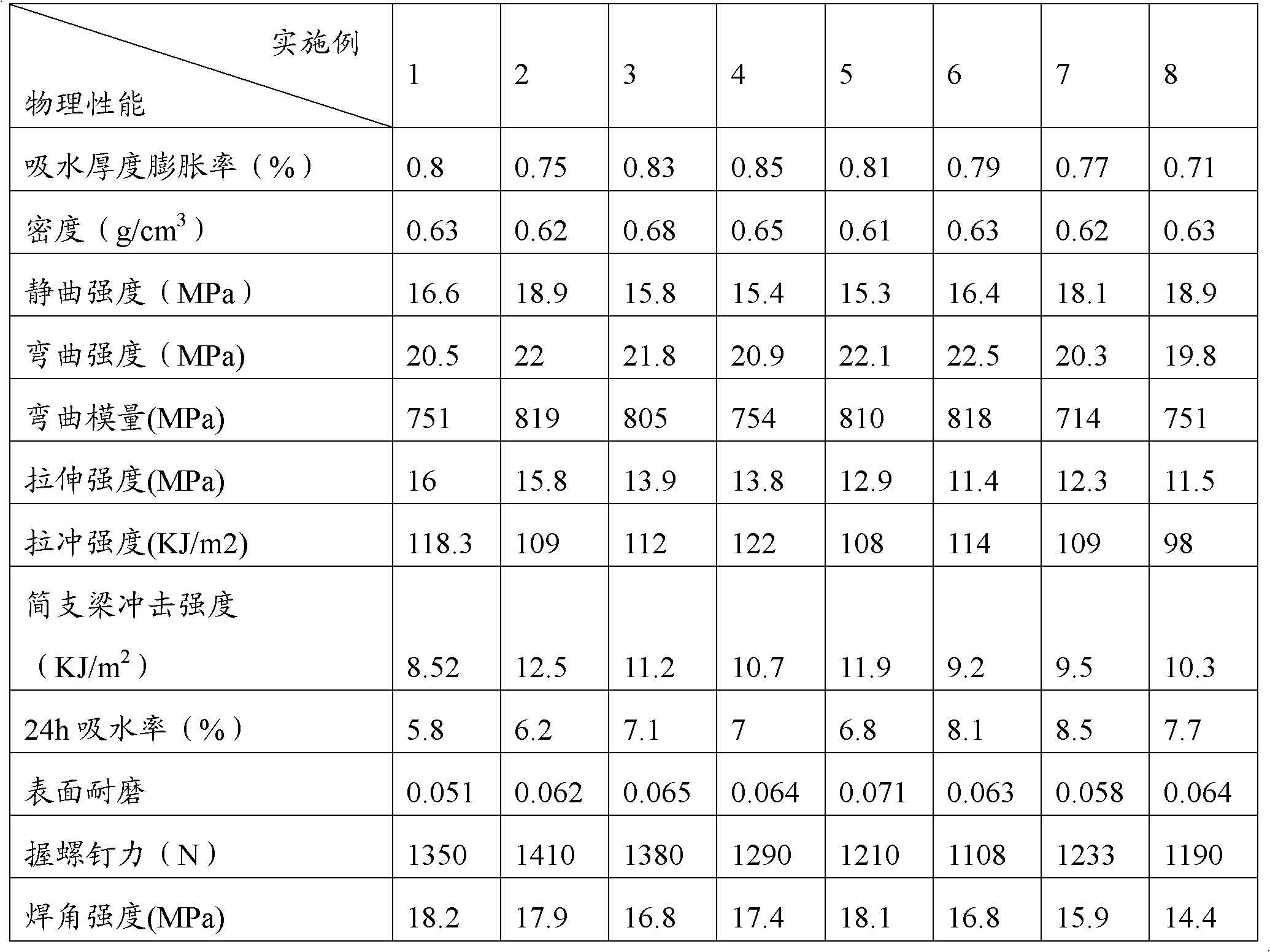

PVC plastic-wood material

The invention relates to a PVC plastic-wood material which has large wood powder consumption, high strength and smooth appearance. The PVC plastic-wood material comprises the following components in parts by mass:100 parts of PVC, 30-50 parts of wood powder, 5-10 parts of chlorinated polyethylene, 0.1-0.3 part of methyl methacrylate, 0.3-0.5 part of AC foaming agent, 1-5 parts of plasticizer, 1-5 parts of foaming adjusting agent, 1-3 parts of calcium-zinc stabilizing agent, 0.2-0.5 part of octadecanoic acid, 0.5-2 parts of ceresin wax, 10-20 parts of light activated calcium carbonate, titanate coupling agent, maleic anhydride and 1-3 parts of antioxygen, wherein the mass ratio of the titanate coupling agent to the wood powder is 1:100-8:100, and the mass ratio of the maleic anhydride to the wood powder is 1:100-8:100. By adopting the proportion of the materials in the invention, the wood powder doping amount can be effectively improved, and the obtained PVC plastic-wood material has high strength and smooth appearance.

Owner:南京皇家聚锋建筑材料有限公司

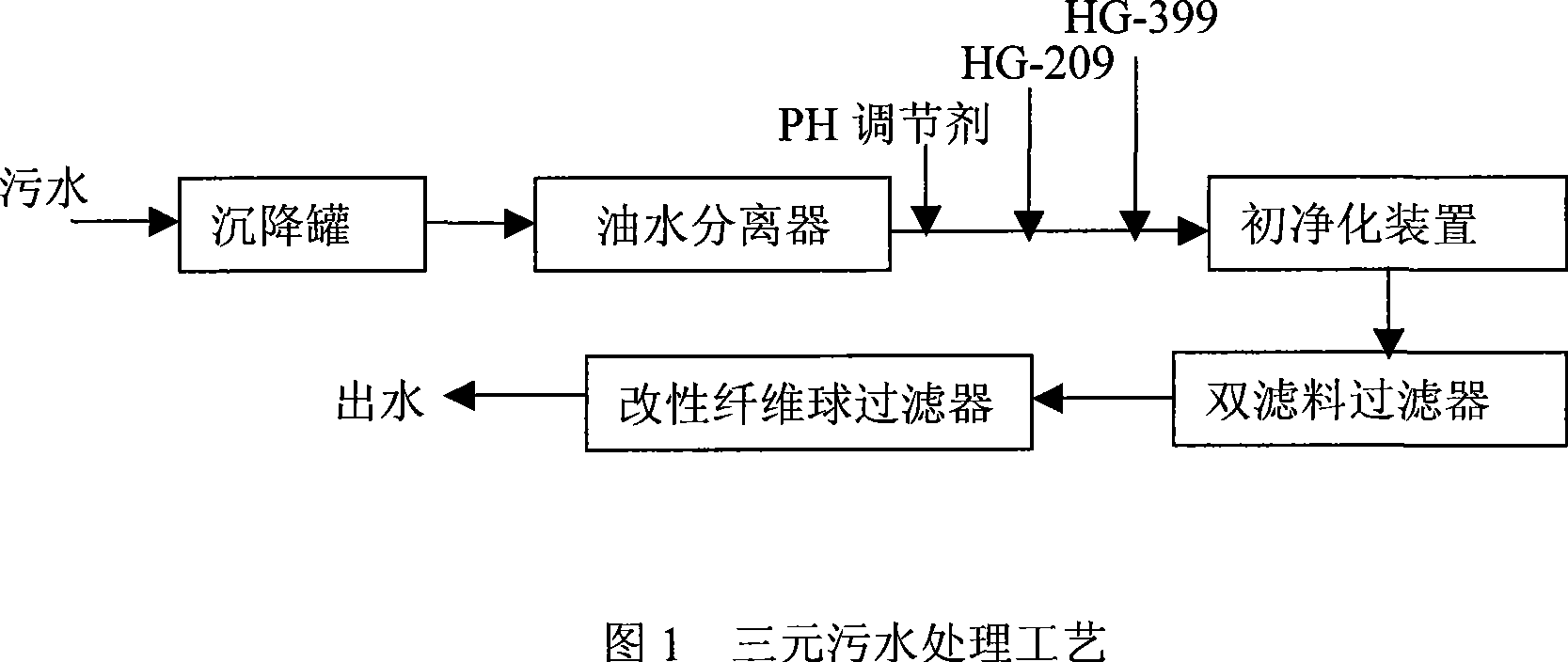

Process of treating oil-bearing sewage for ternary combination flooding in oil field

ActiveCN101066818AFar-reachingIncrease dosageMultistage water/sewage treatmentWater/sewage treatment by neutralisationFiberWater quality

The present invention discloses process of treating oil-bearing sewage for ternary combination flooding in oil field. The process includes the following steps: 1. gravitational settling of the sewage; 2. combined cyclonic and air floating treatment for oil-water separation; 3. regulating pH value of sewage and adding inorganic flocculant and organic flocculant; 4. further settling; and 5. filtering in a double filter material filter and a modified fiber ball filter. The process can treat sewage to reach the requirement for using as recirculated polymer flooding water with oil content not more than 30 mg / 1, suspended matter content not more than 30 mg / 1 and granularity midvalue not greater than 5 micron.

Owner:大庆德美特尔能源科技有限公司

Low-viscosity and high-heat conduction epoxy resin electronic potting adhesive

InactiveCN101974302AImprove thermal conductivityRapid heat buildupNon-macromolecular adhesive additivesOther chemical processesEpoxyAdhesive

The invention relates to a low-viscosity and high-heat conduction epoxy resin electronic potting adhesive which is formed by mixing a component A with an amine curing agent according to the weight ratio of 100:5-12, wherein the component A comprises the following raw materials in weight ratio: 70-85 parts of spherical alumina powder, 10-20 parts of epoxy resin, 2-4 parts of active thinner, 2.5-5 parts of toughening agent and 0.1-0.5 parts of coupling agent. The invention has the advantages that the spherical alumina of the potting adhesive has higher filling amount compared with non-spherical alumina, the viscosity is less affected, the fluidity is favorable and the construction is convenient; the potting adhesive has good dispersibility and is difficult to sedimentate; a condensate has high heat conductivity and can quickly dissipate accumulated heat of heating parts and components; a high-filling filler can reduce a thermal expansion coefficient and a volumetric shrinkage rate and is very suitable for potting parts and components; and the price is cheaper compared with boron nitride and aluminum nitride, and the cost is low.

Owner:YANTAI DARBOND TECH

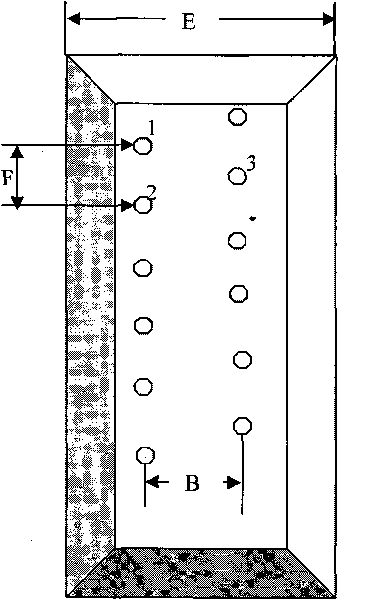

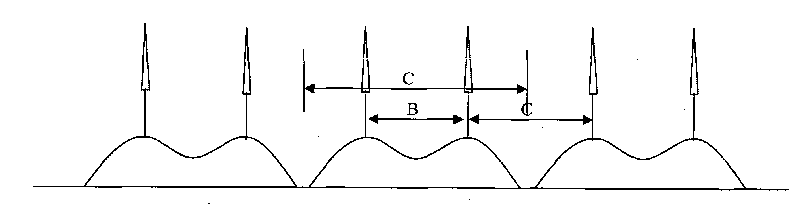

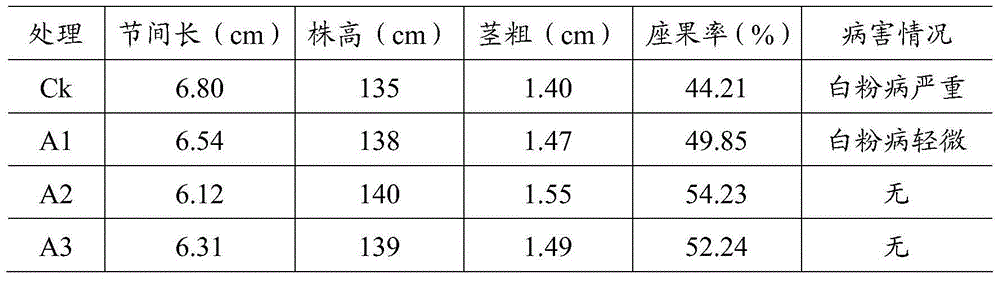

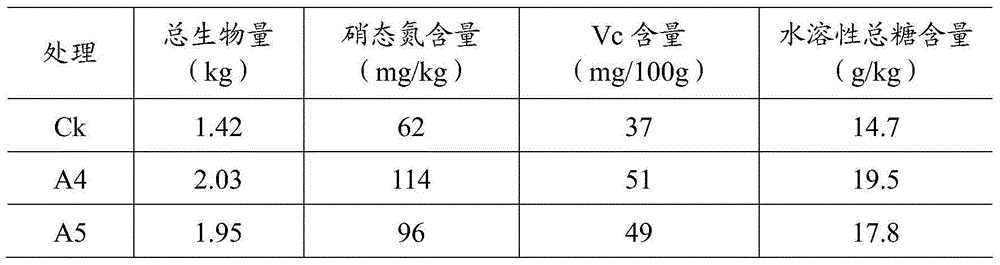

Culturing method of one-ridge double-row flue-cured tobacco dislocation

InactiveCN101699954AGuaranteed housekeepingGuaranteed incomeHorticultureSoil-working methodsOrganic fertilizerDislocation

The invention discloses a culturing method of one-ridge double-row flue-cured tobacco dislocation, comprising the following steps: (1) selecting tobacco field and preparing soil; (2) ridging; (3) applying base fertilizer; (4) transplanting; and (5) uncovering film, ridging and loading. The method has the following advantages that: (1) on the premise that the use amount of fertilizer for soil in unit area is not changed, the fertilizer use amount of single plant in flue-cured tobacco field is reduced, and the use amount of field organic fertilizer, especially oil cake fertilizer is increased to lead the field tobacco plant to present the growth of middle-plant tobacco, thus obviously improving the tobacco leaf quality; (2) compared with the conventional single ridge, the one-ridge double-row tobacco reduces the labor capability of ridging by about one third, the ridging height is obvious lower than the conventional height, thus reducing ridging labor intensity of tobacco growers; and (3) the one-ridge double-row flue-cured tobacco increases flue-cured tobacco planting density, and meanwhile, a dislocated equal plant distance planting method improves utilization rate of tobacco field to the utmost, ensures the housework operation of tobacco growers, and the row space of the ridge just satisfies growth space of tobacco plants in the field, thus ensuring the income of the tobacco growers.

Owner:GUIZHOU TOBACCO SCI INST

High-strength low-temperature-resisting spheroidal graphite cast iron and preparing method thereof

The invention relates to the field of spheroidal graphite cast iron, in particular to high-strength low-temperature-resisting spheroidal graphite cast iron and a preparing method thereof. The spheroidal graphite cast iron comprises, by mass percent, 3.2% to 3.5% of carbon, 2.1% to 2.3% of silicon, 0.4% to 0.5% of manganese, 0.4% to 0.6% of copper, 0.2% to 0.4% of nickel, 0.2% to 0.4% of molybdenum, 0.04% to 0.06% of magnesium, 0.05% to 0.08% of chromium, 0.005% to 0.008% of titanium, 0.002% to 0.003% of vanadium, not larger than 0.04% of phosphorus, not larger than 0.02% of sulphur and the balance iron. The preparing method of the high-strength low-temperature-resisting spheroidal graphite cast iron comprises following steps: firstly, raw materials are smelted; secondly, spheroidizing treatment and inoculation are carried out; and thirdly, heat treatment is carried out. Through reasonable arrangement of all element components, the tensile strength of the spheroidal graphite cast iron is improved, a proper nucleating agent is prepared, internal inoculation matched with inoculation in a ladle is adopted, the inoculation effect is reinforced, meanwhile, during heat treatment, the heating temperature, the heat preservation time, the cooling rate and the manner are reasonably arranged, the strength and low temperature resistance of the iron are effectively improved, the spheroidal graphite cast iron is high in strength and excellent in low temperature resistance, and the preparing method is simple and efficient.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

Rapid preparation method for aerogel material

ActiveCN105536655AShort manufacturing cycleIncrease dosageAluminium compoundsSilicaSupercritical dryingState of art

The invention discloses a rapid preparation method for an aerogel material. The preparation method is a combination of a sol-gel method and a supercritical drying process. According to the invention, wet gel is formed through the sol-gel method at first and is directly put into a container for sealing without ageing; then the sealed container is put into a supercritical drying device and a supercritical medium solvent is added; and the supercritical drying process is carried out so as to prepare the aerogel material. Compared with the prior art, the preparation method provided by the invention has the following advantages: the ageing procedure in general aerogel preparation is eliminated, so the preparation period for the aerogel material is greatly shortened; and the wet gel does not need to soak in the medium solvent, so the consumption of the medium solvent in preparation is reduced. The aerogel prepared by using the method has an intact skeleton structure and a non-shrink volume.

Owner:YANTAI ZHONGKE RES INST OF ADVANCED MATERIALS & GREEN CHEM ENG

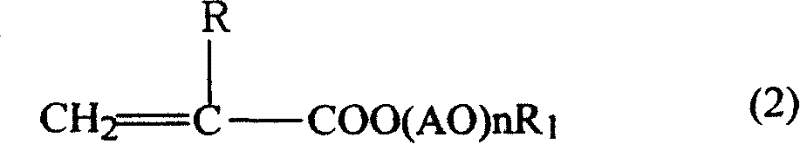

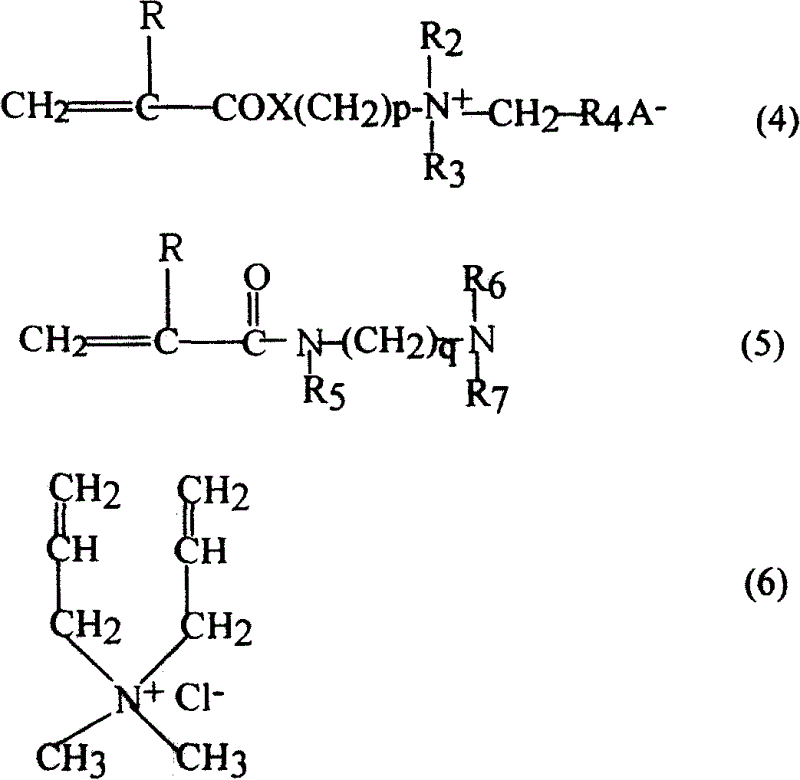

Amphoteric carboxylic acid comb grafted copolymer as concrete super-plasticizing agent

The amphoteric carboxylic acid comb grafted copolymer as concrete super-plasticizing agent is prepared through the following steps: 1) free radical copolymerizing reaction of four kinds of monomers in certain proportion in water soluble medium; 2) crosslinking reaction through introducing crosslinking agent after the polymerization. The present invention proposes that the amphoteric ionic polymer can raise the saturated added amount of concrete super-plasticizing agent, and introduces amphoteric ion concept into the molecular design of concrete admixture. The concrete super-plasticizing agent of the present invention has high water reducing rate, can eliminate the environmental pollution caused by concrete water reducing agent and reduce the added amount while ensuring the outstanding dispersivity and slump maintaining capacity.

Owner:JIANGSU SOBUTE NEW MATERIALS

Method for preparing polyurethane/rubber interpenetrating network type water-swellable rubber

The invention belongs to the technical field of sealing materials and relates to a method for preparing polyurethane / rubber interpenetrating network type water-swellable rubber. The method comprises the following steps: firstly, mixing rubber and super-absorbent resin for 10 to 40 minutes in an open mill; further adding solid softener, colorant, anti-ager and promoter to the open mill, and mixing for 10 to 40 minutes; then, adding zinc oxide, reinforcing agent and plasticizer to the open mill, and mixing for 10 to 50 minutes; further adding vulcanizer to the open mill, and mixing to obtain a mixture A; evenly mixing polyethylene glycol and MDI (methyl-di-p-phenylene isocyanate) by equal molar weight to obtain a mixture B; blending the mixture A and the mixture B in the open mill to obtain a product; and finally, vulcanizing the product in a mold on a plate vulcanization machine with the temperature and pressure being respectively controlled at 150 to 160 DEG C and at 10MPa to 15MPa, to obtain the interpenetrating network type water-swellable rubber. The method of the invention has the advantages of simple preparation process, high product expansion ratio, high ion resistance and controllable water absorption rate and mechanical properties.

Owner:QINGDAO UNIV OF SCI & TECH +1

Green totally degradable warming material and producing method thereof

InactiveCN101509175AHigh strengthImprove stabilityHollow filament manufactureFilament/thread formingCardingKapok fiber

A green completely-degradable warm-keeping material and a production method thereof are disclosed, the weight percent of components thereof are: 40-60 parts of kapok fiber, 10-40 parts of polylactic bi-component fiber and 15-40 parts of polylactic hollow fiber; the material is formed by pre-needling at first and then the procedures of hot-melt shaping, cooling, winding, etc. after a fluffy three-dimensional netlike structure fiber net is formed by cotton plucking, cotton mixing, weighting, opening, mechanical carding and disordering. The inventive warm-keeping material employs the completely-degradable raw materials and has no pollution in the entire production process, the product has multiple functions of excellent strength, fluffiness, warm keeping, bacteriostasis and the like, which belongs to green environmentally-friendly products.

Owner:JIAXING UNIV

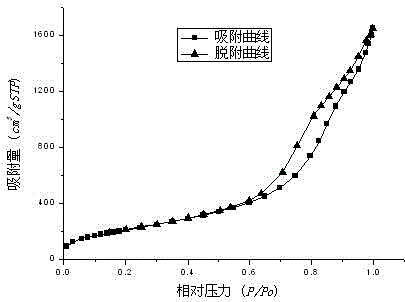

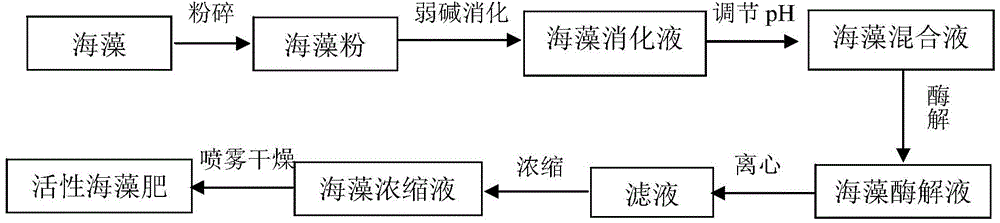

Active seaweed fertilizer and production method thereof

The invention relates to an active seaweed fertilizer and a production method thereof. The preparation method comprises the steps of digestion, enzymolysis, post-treatment and the like. The production method is characterized in that the digestion of weak base is performed before complex enzymes are added, so that large damages on active substances in seaweeds can not be caused, and the preliminary extraction of the seaweeds can be facilitated, so that the dosage of the complex enzymes can be reduced. The seaweed fertilizer product is rich in alginic acid, gibberellin, zeatin and the other active substances, can effectively promote the growth and development of plants and improve the plant yield, and meanwhile greatly keeps the natural adverse resistance ingredient glycine betaine, phenol compounds and the like in the seaweeds, so that the improvement of the stress resistance of the plants can be facilitated.

Owner:领先生物农业股份有限公司

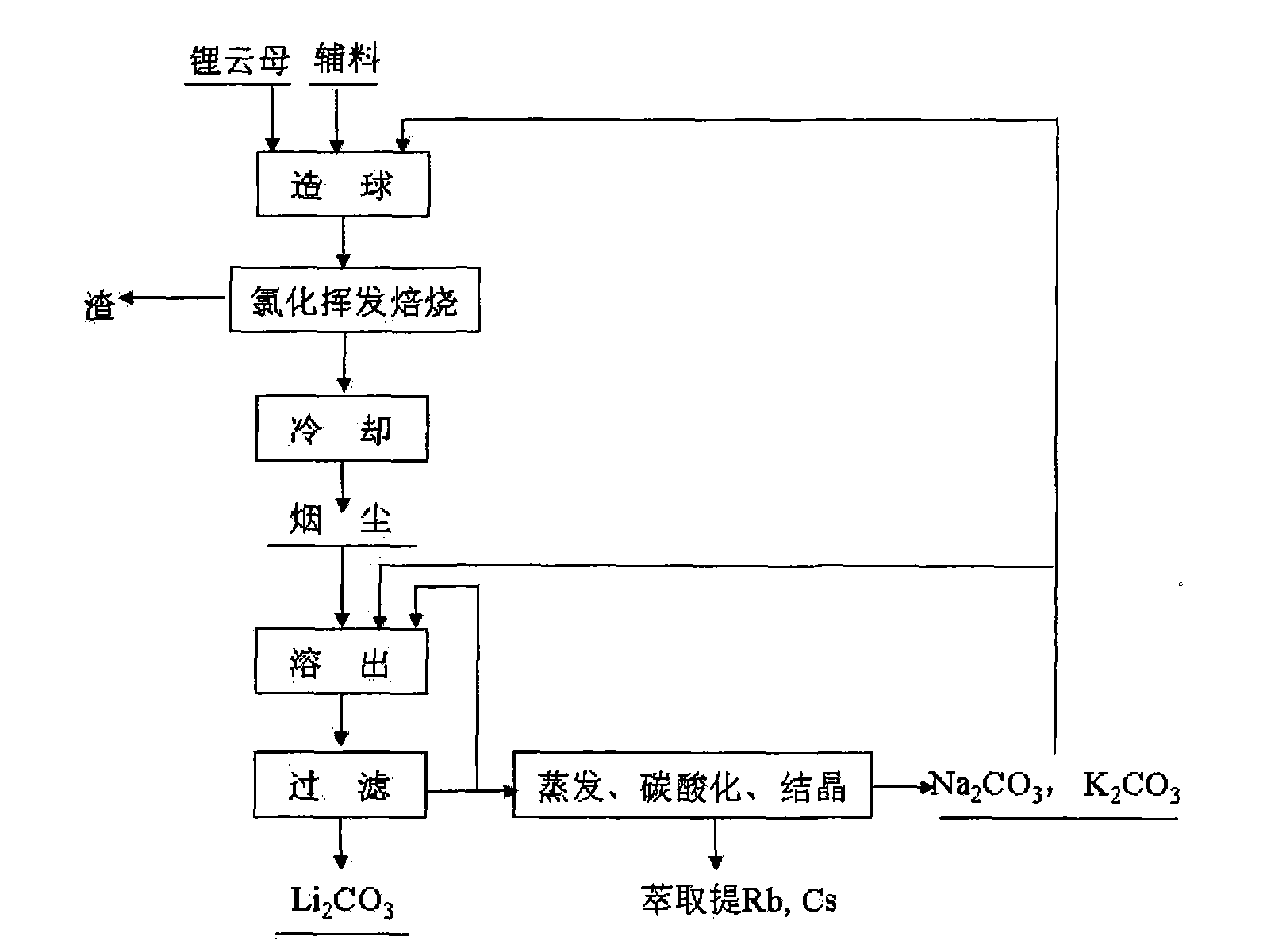

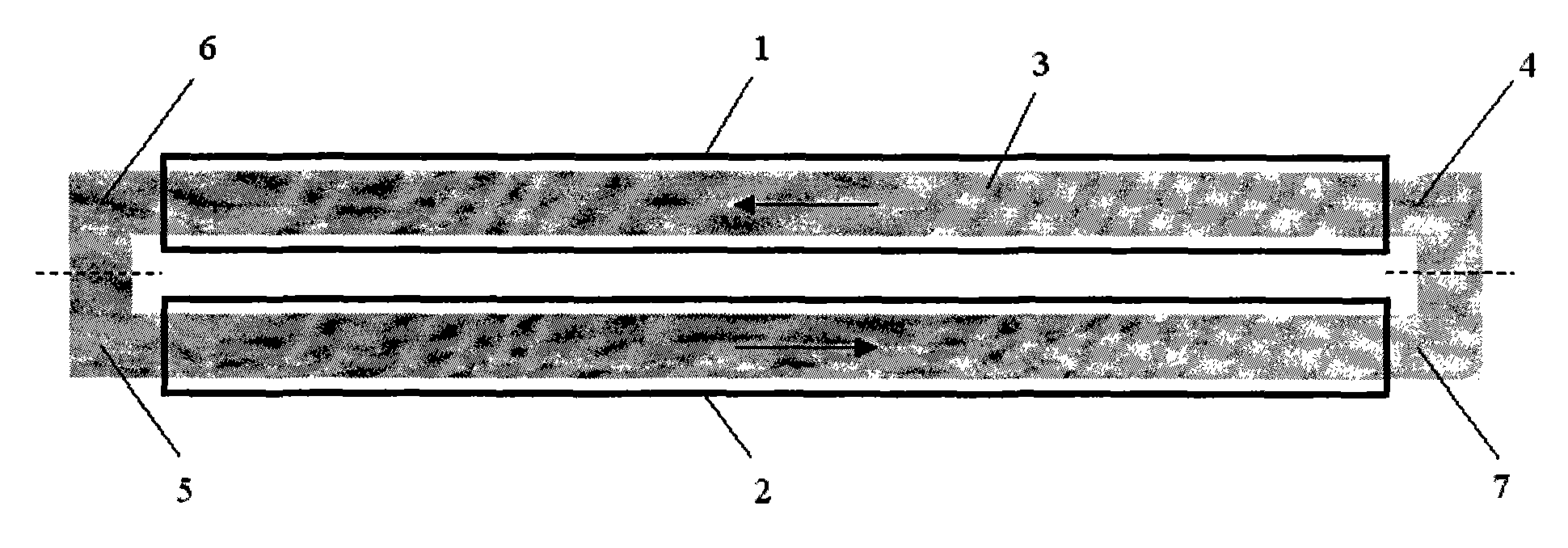

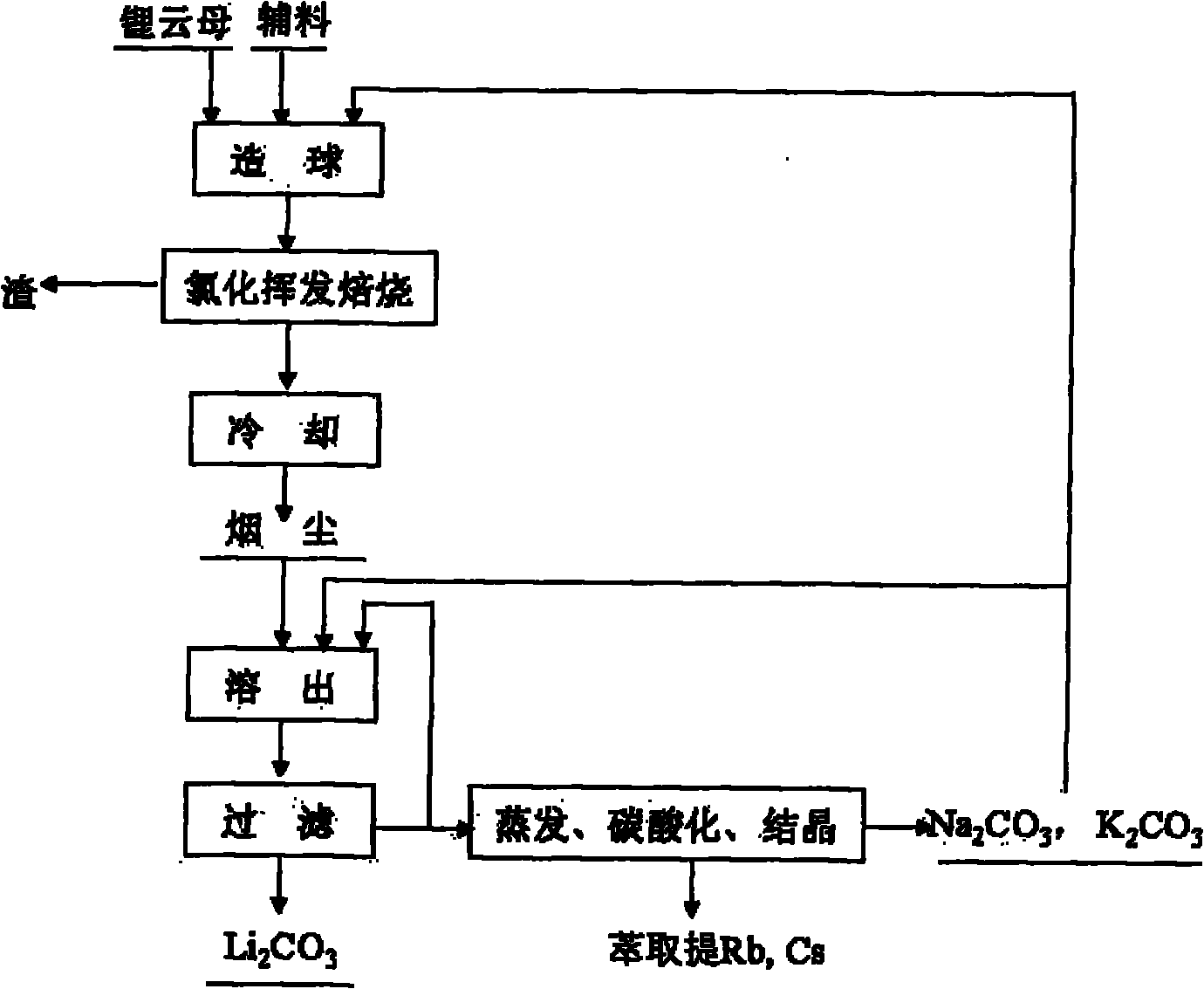

Method and device for extracting lithium from lapidolite by chloridizing roasting method

The invention discloses a method and a device for extracting lithium, which is used for preparing lithium carbonate, from a lapidolite ore by a chloridizing roasting method. The method comprises the following steps of: firstly, mixing the lapidolite ore, calcium chloride and sodium hydroxide with a compound bonding agent for pellet fabrication; secondly, performing chloridizing roasting in a square-frame shaped track type roasting furnace; thirdly, leaching out soot dust by using solution containing sodium carbonate and potassium carbonate to ensure that potassium, sodium, rubidium and cesium enter the solution and convert the lithium into lithium carbonate; fourthly, filtering the mixture to obtain a lithium carbonate solid, and circularly using the filtrated mother liquor to leach out the soot dust; fifthly, when an alkali metal salt is close to be saturated, indirectly heating the filtrated mother liquor by using the residual heat of the gas in the roasting furnace to evaporate part of water; sixthly, passing CO2 into the filtrated mother liquor to perform carbonation; and seventhly, performing cooling crystallization to separate out a mixed salt of the sodium carbonate and the potassium carbonate, returning part of the mixed salt which is used as an auxiliary material mixed and roasted with lapidolite for cyclic utilization, using another part of the mixed salt as a carbonate reagent needed in dissolution, and using the rest part of the mixed salt as byproducts of the sodium carbonate and the potassium carbonate. The method has the advantages of high lithium recovery rate, good material comprehensive utilization, large equipment productivity, high production efficiency, small water consumption in the process and less wastewater discharge.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com