Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

683 results about "Slump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A slump is a form of mass wasting that occurs when a coherent mass of loosely consolidated materials or rock layers moves a short distance down a slope. Movement is characterized by sliding along a concave-upward or planar surface. Causes of slumping include earthquake shocks, thorough wetting, freezing and thawing, undercutting, and loading of a slope.

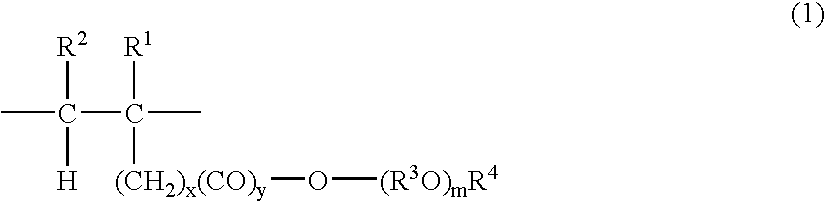

Cement dispersant, method for production thereof, and cement composition using the dispersant

InactiveUS6376581B1Delayed slump lossLowering of unit water contentPolymer sciencePolyethylene glycol

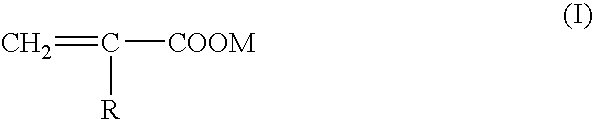

A cement dispersant having excellent ability to prevent slump loss and high water-reducing property which comprises a polycarboxylic acid type polymer having a specific molecular weight distribution, a method for the production thereof, and a cement composition using the dispersant are provided. The cement dispersant comprises as a main component thereof a polycarboxylic acid type polymer (A), having a weight average molecular weight in the range of 10,000 to 500,000 in terms of polyethylene glycol determined by gel permeation chromatography, and having a value determined by subtracting the peak top molecular weight from the weight average molecular weight in the range of 0 to 8,000.

Owner:MBT HLDG

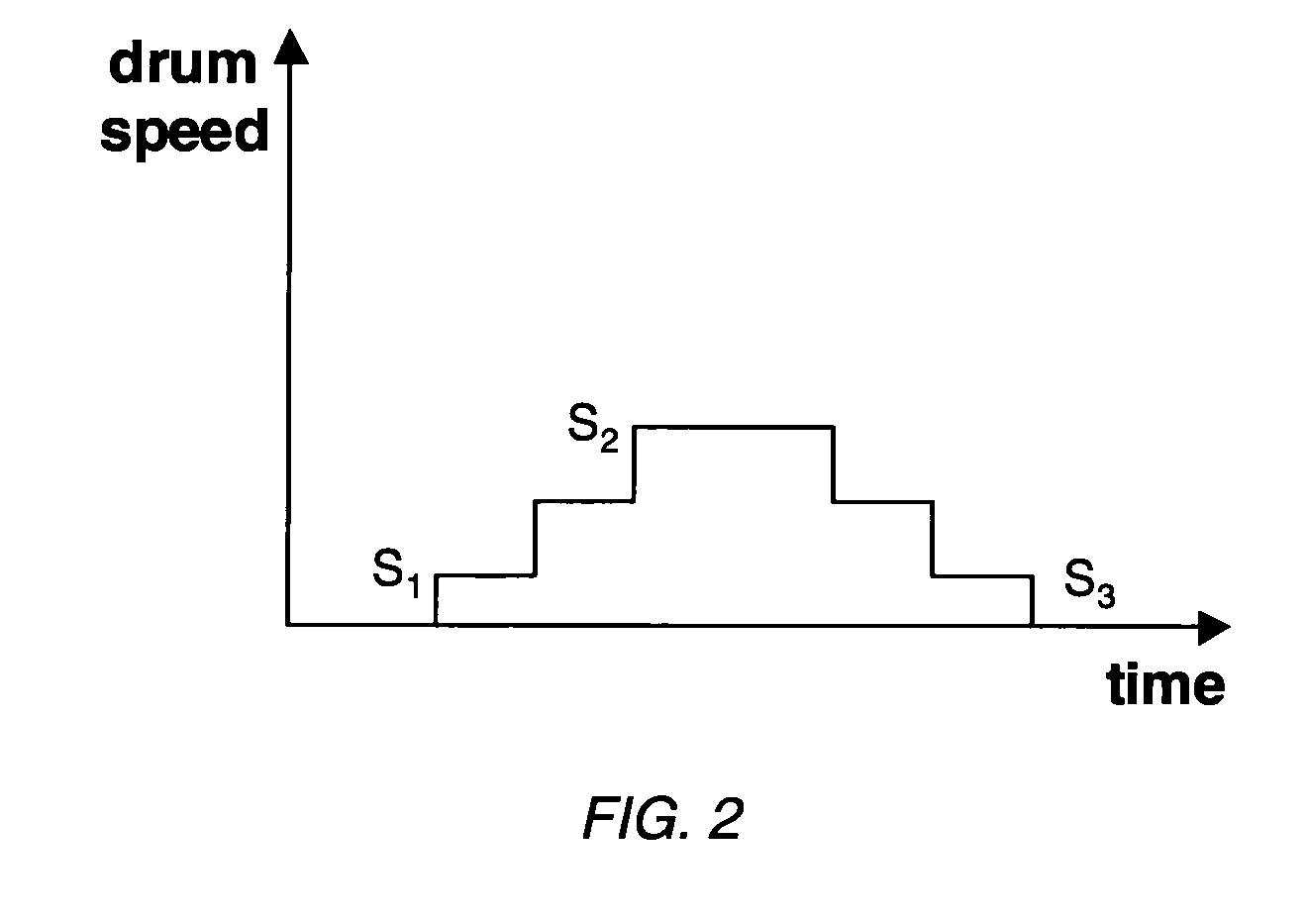

Method For Monitoring Thixotropy In Concrete Mixing Drum

The invention provides ‘thixotropy’ monitoring, by measuring the reversible, time-dependent reduction in viscosity occurring when concrete is subjected to mixing, and employs a mixing drum and conventional slump monitoring equipment as used on ready-mix trucks. In one embodiment, the drum is rotated until concrete is completely mixed; the speed is altered, such as by increasing it to a predetermined level; and the energy required to rotate the drum (ER) is monitored; the maximum (ER-MAX) and minimum (ER-MIN) values are recorded in computer memory; and these values are compared to pre-determined (target) values. Rheology factors (including viscosity, yield stress, and / or thixotropy) can be adjusted accordingly by adding liquid component(s) into the mix. This method, suitable for delivery of highly fluid concrete speed such as SCC, can involve transit and placement rheology targets during monitoring.

Owner:GCP APPL TECH INC

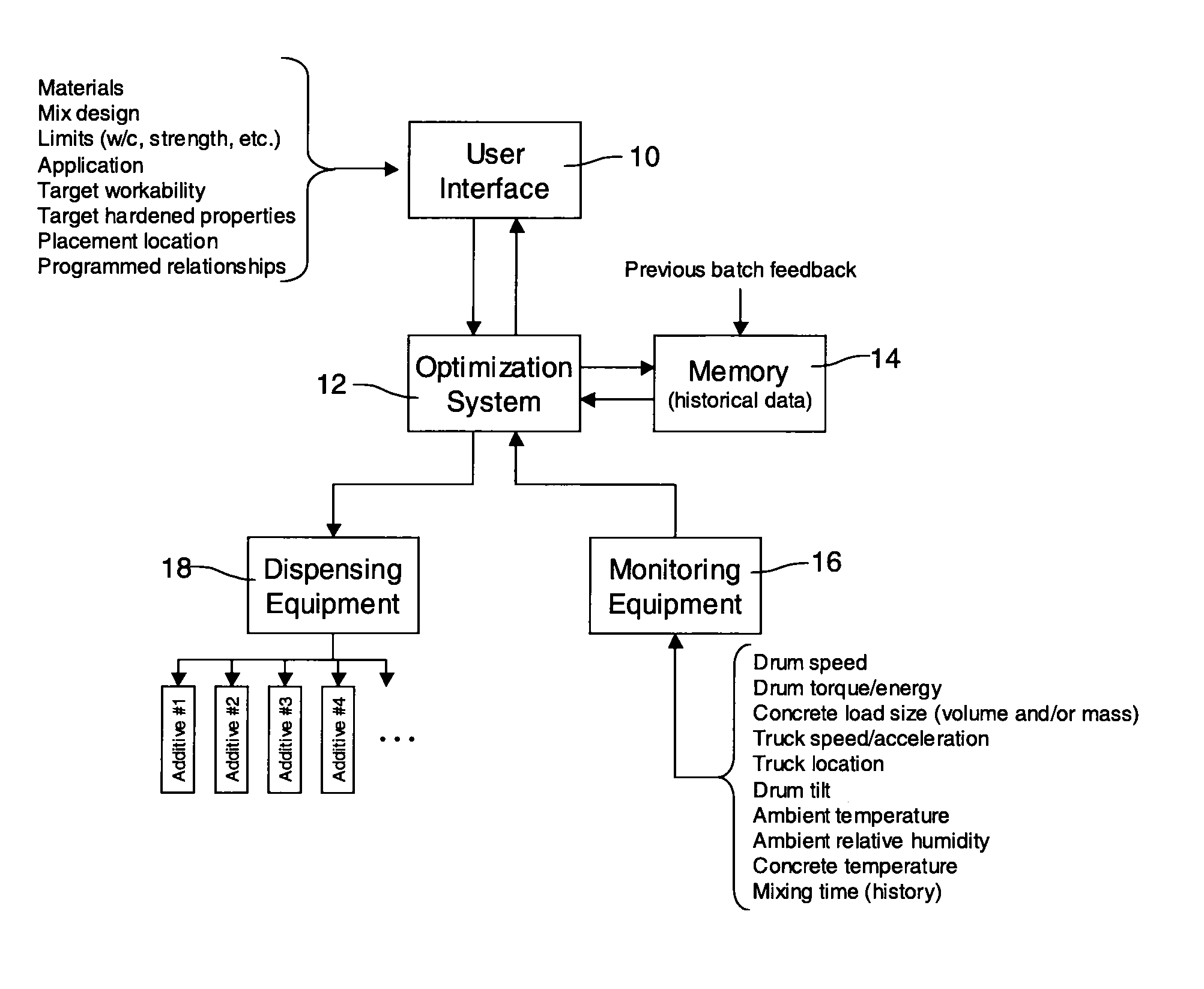

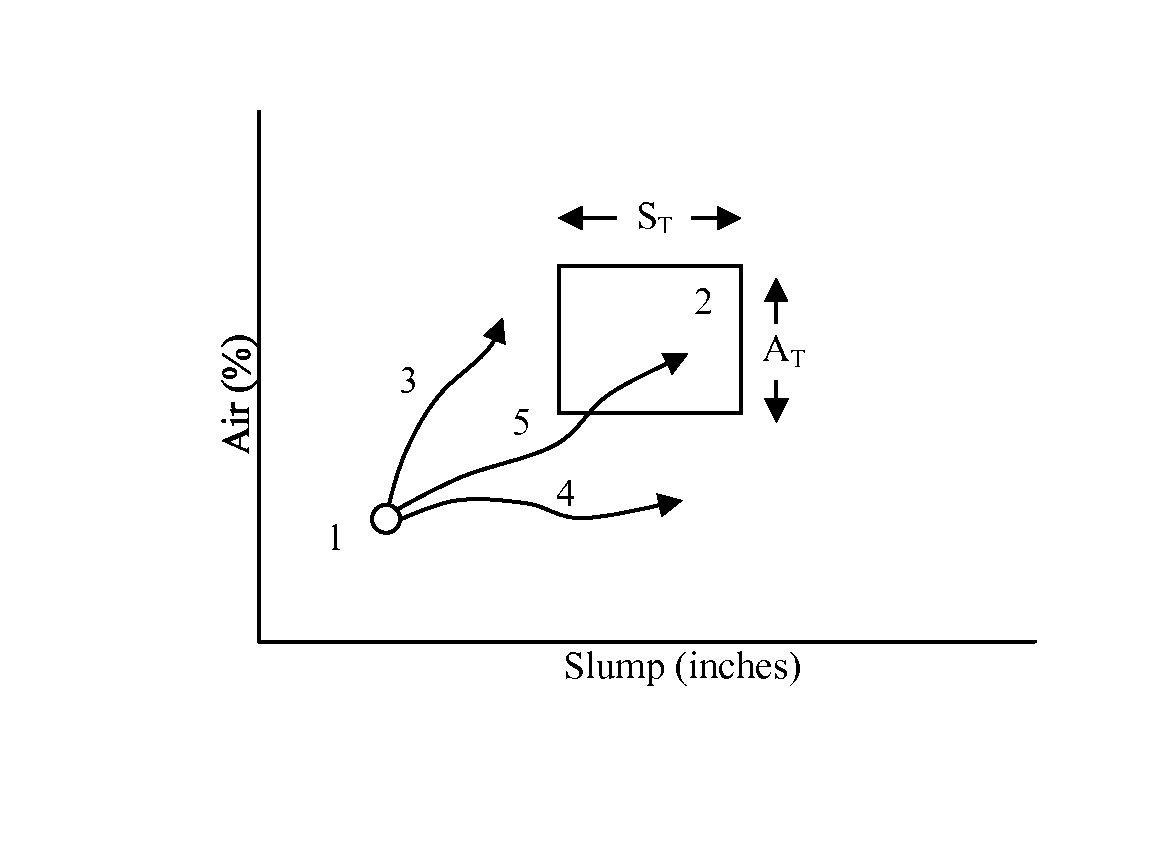

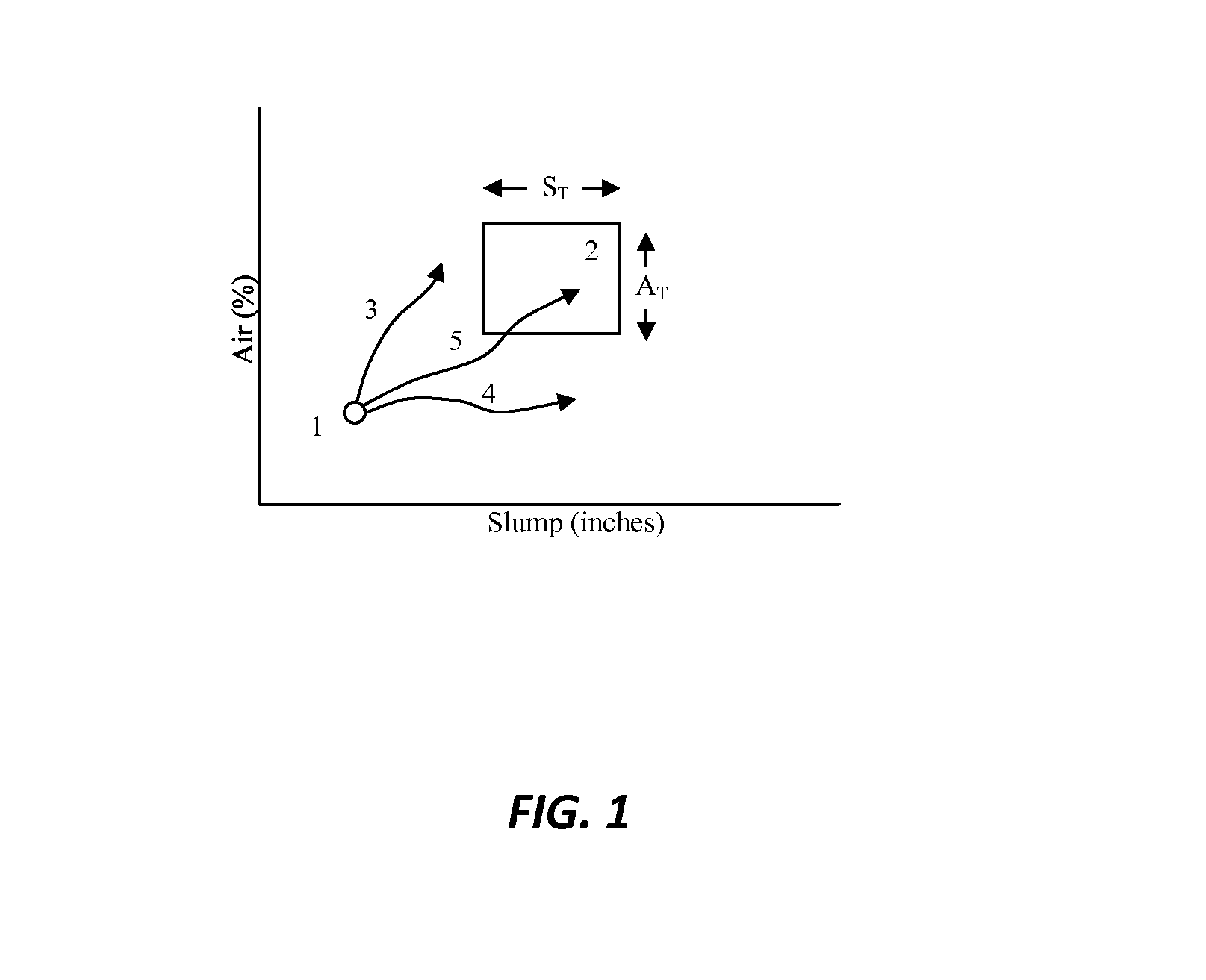

Multivariate management of entrained air and rheology in cementitious mixes

ActiveUS8491717B2Efficiently and accurately updatingHighly inventiveSampled-variable control systemsMixing operation control apparatusHydration reactionBLENDER/MIXER

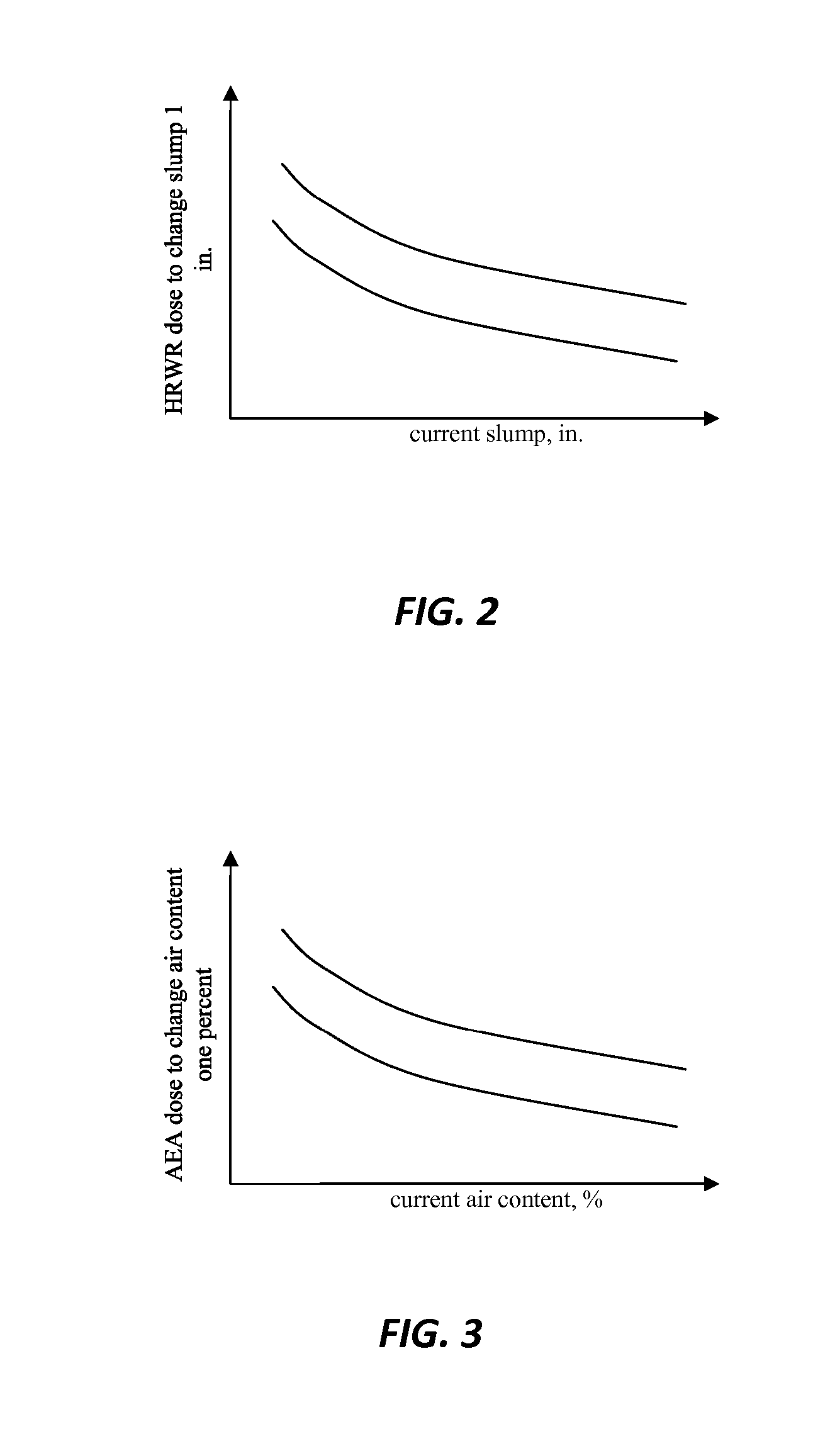

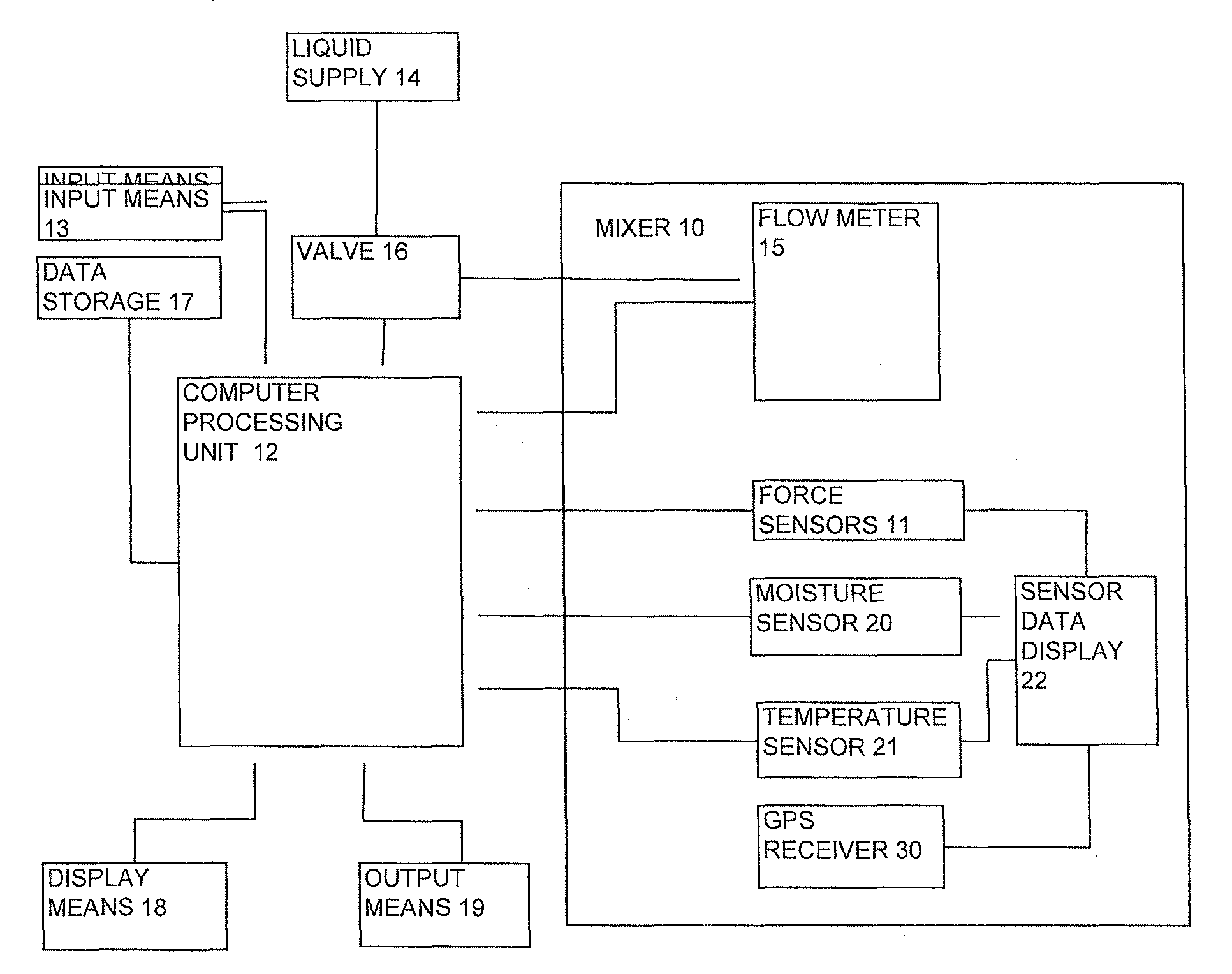

The invention relates to a method and system for monitoring and adjusting both air content and rheology (e.g., slump, slump flow) properties of a hydratable concrete mix contained within a concrete mixer. The system simultaneously tracks dosage of both rheology-modifying admixture (e.g., polycarboxylate polymer cement dispersant) and air control agent or “ACA” (e.g., air entraining agent) by reference to at least four nominal dose response (“NDR”) curves or profiles, which at least four NDR profiles are based on the respective behaviors of each of the ACA and rheology-modifying agent on air content and rheology.

Owner:VERIFI INC

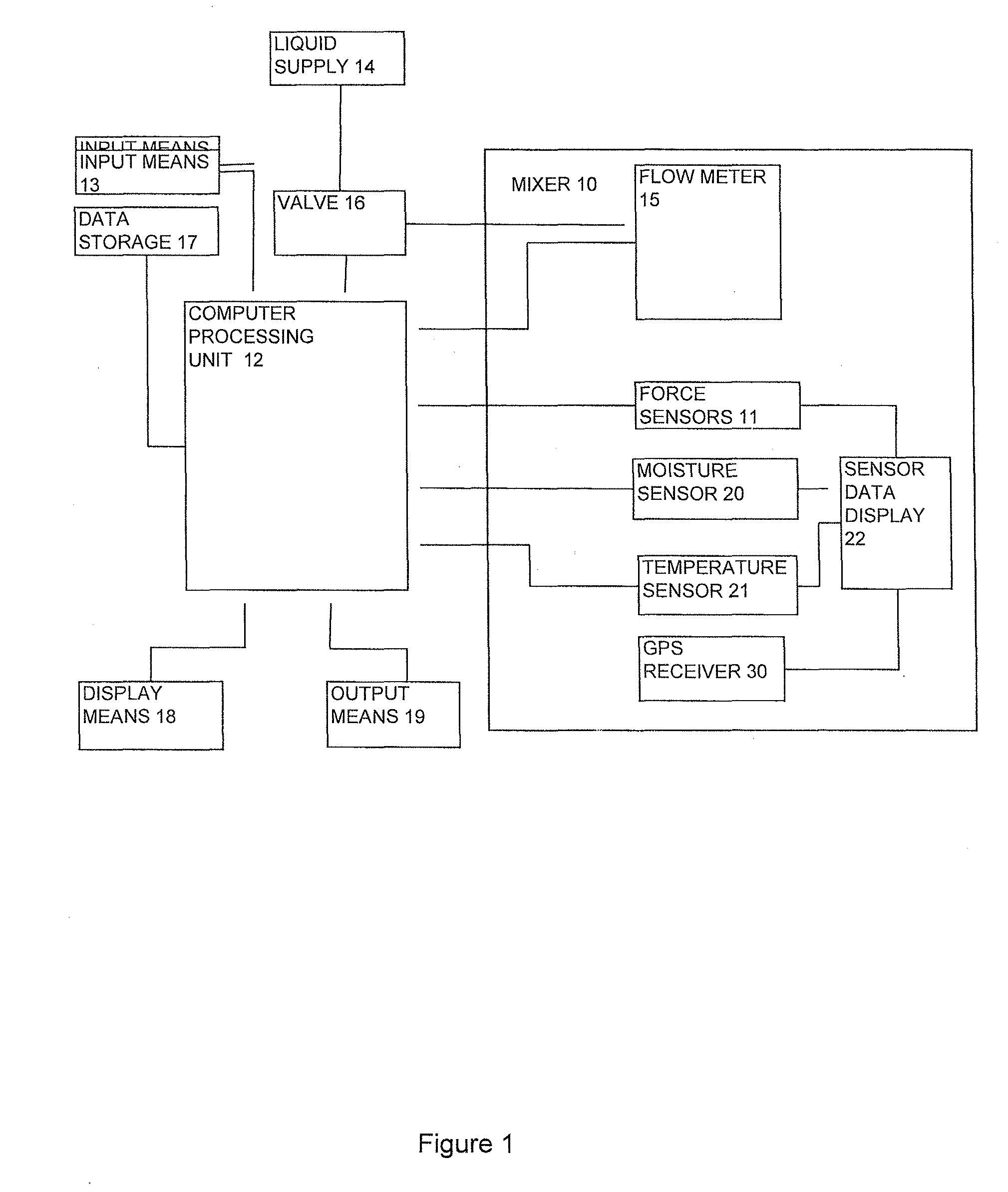

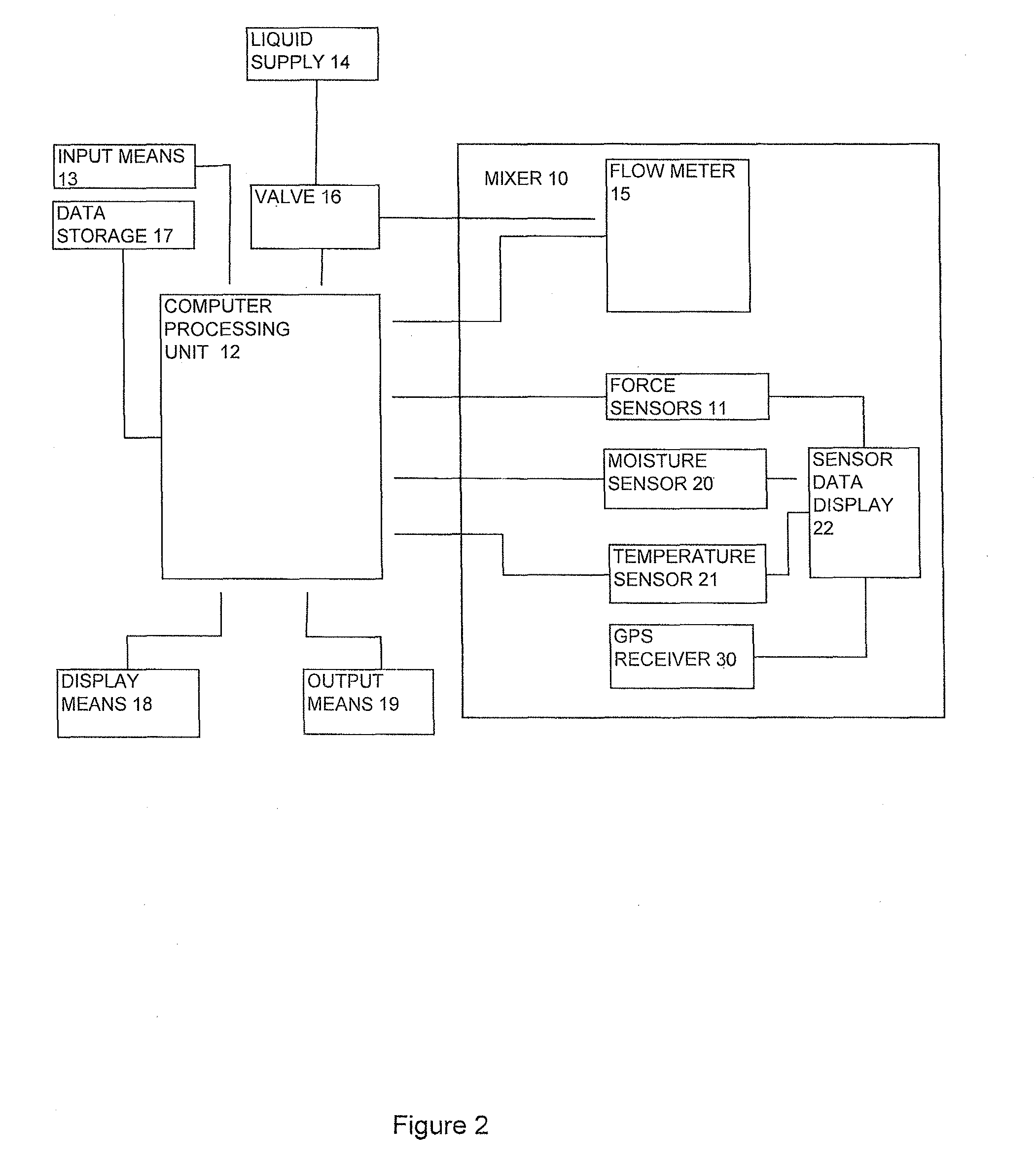

Concrete slump measurement and control system

ActiveUS20110077778A1Preventing loss through unauthorized poursSampled-variable control systemsRotating receptacle mixersControl systemEngineering

An apparatus and method to measure and control the slump of concrete by monitoring sensor within the interior surface of a concrete mixer and a liquid flow meter. Data is analyzed by a computer processing unit to determine the slump of the concrete, liquid needed the quantity of concrete within the mixer, the amount of concrete poured, and the starting and ending time of the pour.

Owner:GCP APPL TECH INC

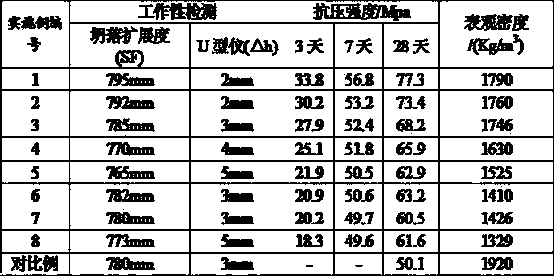

Self-compacting light aggregate concrete and preparation method thereof

InactiveCN103803904ALow densityLow apparent densitySolid waste managementStructural engineeringWater reducer

The invention provides self-compacting light aggregate concrete and a preparation method thereof, and belongs to the technical field of concrete preparation. The self-compacting light aggregate concrete consists of such raw materials as cement, fly ash, silica fume, floating beads, light fine aggregate, light coarse aggregate, a water reducing agent and water. The self-compacting light aggregate concrete provided by the invention has the advantages of being low in appearance density, high in slump expansion degree and capable of avoiding floating of the floating beads; self-compacting light aggregate concrete differing in grade, especially self-compacting light aggregate concrete with strength grade above C60 and appearance density at 1400-1800kg / m<3>, can be prepared through the raw materials.

Owner:北京中联新航建材有限公司

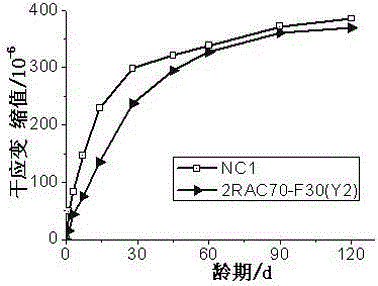

Low-drying shrinkage high-performance recycled concrete

InactiveCN104591656ASmall drying shrinkageImprove volume stabilityResource recoveryArchitectural engineering

The invention discloses low-drying shrinkage high-performance recycled concrete satisfying pumping requirements, and belongs to the technical field of civil engineering concrete. Every cubic meter of the high-performance recycled concrete comprises 400-500 kg of binding material, 950-1150 kg of coarse aggregate, 660-715 kg of fine aggregate, 160-180 kg of water and 4-9 kg 0f superplasticizer, wherein the coarse aggregate is a recycled coarse aggregate or a mixture of the recycled coarse aggregate and natural coarse aggregate; the fine aggregate is a natural fine aggregate or a mixture of the natural fine aggregate and a recycled fine aggregate and prepared by a process of stone enveloped with cement. The strength grade of the obtained high-performance recycled concrete is C30-C50 and the slump is 180-210 mm; the dry shrinkage of the recycled concrete can be effectively improved to ensure that the dry shrinkage value is reduced by more than 25% relative to the common recycled concrete and lower than the common concrete with same proportion. The low-drying shrinkage high-performance recycled concrete has a significant theoretical value and social meaning for the reasonable and wide application of recycled concrete and the resource recovery of construction waste.

Owner:FUJIAN JIANGXIA UNIV

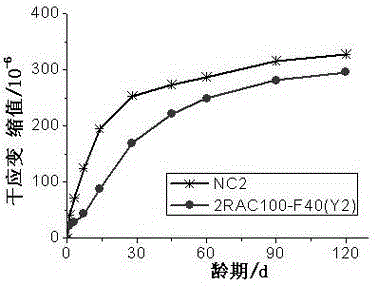

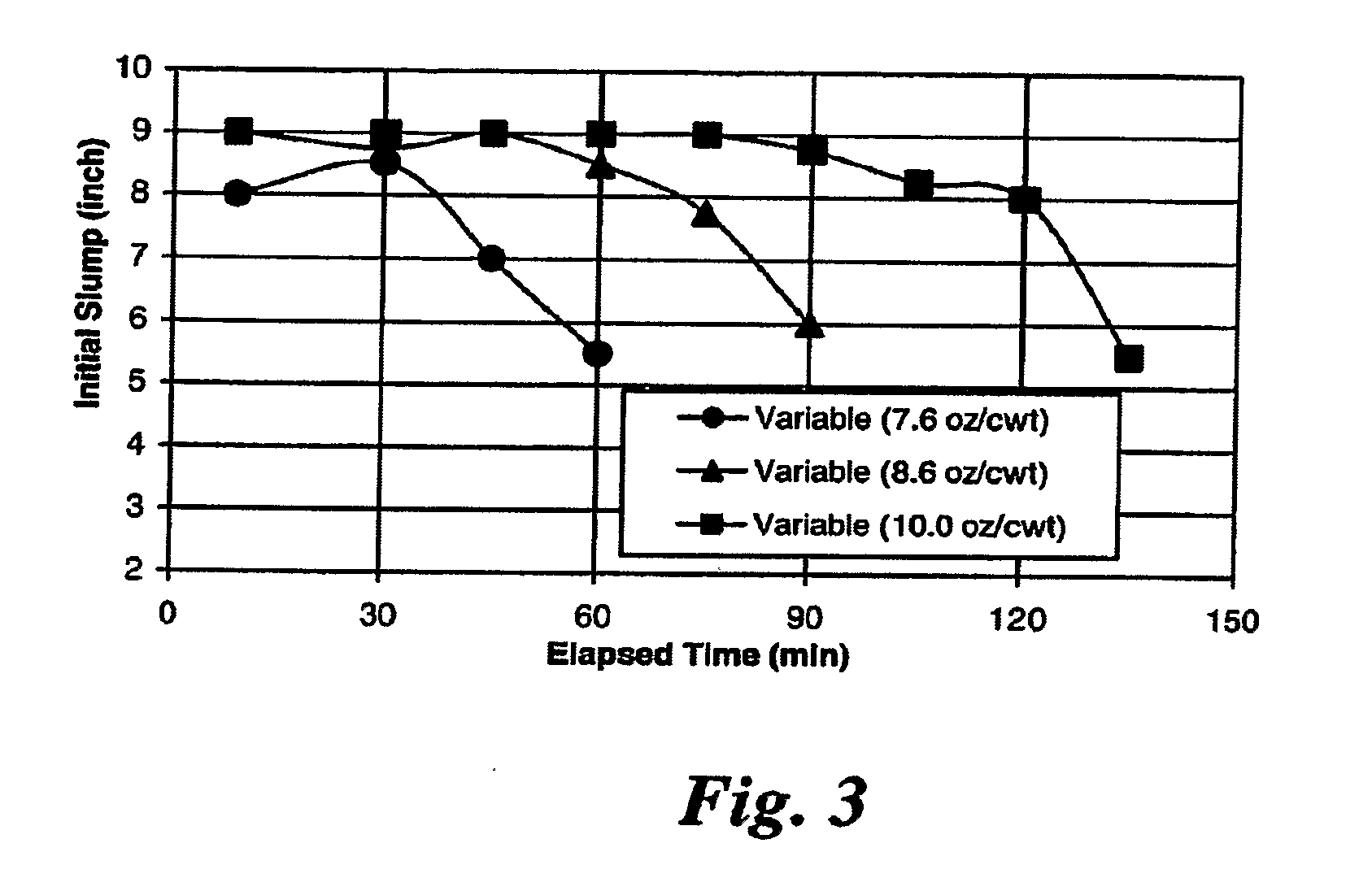

Slump Retention in Cementitious Compositions

The present invention relates to dispersants such as superplasticizers for hydratable cementitious compositions, and more particularly to methods for achieving variable degrees of longer slump life in concrete and mortar without loss of stability. This is achieved by using two admixture systems. The first admixture composition has multi-components for achieving initial-slump-enhancement, later-slump-retention, and limiting initial slump. The second admixture composition has the later-slump-enhancing component. Alternatively, conventional water reducers or superplasticizers can be employed initially, followed by the later-slump-enhancing admixture composition.

Owner:GCP APPL TECH INC

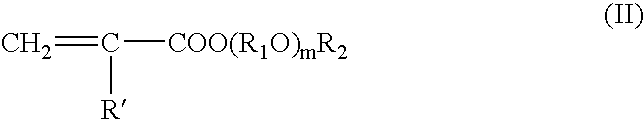

Cement dispersant and concrete composition containing the dispersant

A cement dispersant (especially a dispersant for concretes with ultrahigh performance) comprising as a main component a water-soluble amphoteric copolymer obtained by copolymerizing (A) a polyamide-polyamine of an alkylene oxide adduct thereof with (B) (meth)acrylic acid or an alkali metal, ammonium, or alkanolamine salt thereof and (C) a polyalkylene glycol ester of (meth)acrylic acid in an A / B / C ratio of (10-40) / (10-40) / (50-80) (wt. %); and a concrete composition (especially an ultral high-performance concrete) containing the dispersant. The dispersant satisfies all of a water-reducing effect, slump flow retention, strength development, etc.

Owner:TOHO CHEM IND

Polycarboxylate superplasticizer for machine-made sand concrete

The invention discloses a polycarboxylate superplasticizer for machine-made sand concrete. The polycarboxylate superplasticizer comprises a polycarboxylic acid copolymer, a mud-resistant component, a crack-resistant component, an air entraining agent, an antifoaming agent and a retarder. The polycarboxylate superplasticizer is low in mixing amount, and enables the machine-made sand concrete, in particular the machine-made sand concrete containing high amount of mud and powder to achieve excellent initial working performance, long-term slump holding capability, keep the surface of the hardened concrete from cracking, and improve the durability of the machine-made sand concrete.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

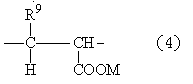

Poly carboxylic acid series compound water reducing agent used for hydraulic self-compacting concrete and preparation method and application

The present invention discloses a poly carboxylic acid series compound water reducing agent used for hydraulic self-compacting concrete and a preparation method and application, the poly carboxylic acid series compound water reducing agent comprises the following components by weight: 50 % to 80% of a water-reducing component; 5% to 40% of a slump retaining component; 1% to 10% of a thickening component; 1% to 20% of a retarding component; and 0.1% to 2% of an air entraining component. The poly carboxylic acid series compound water reducing agent improves the workability, fluidity, segregation resistance and slump retaining properties of the self-compacting concrete.

Owner:CHINA BUILDING MATERIALS ACAD

Self-compacted concrete of resisting erosion of sulfate and its preparing method

The invention relates to a sulfate corrosion-resistant self-compacted concrete and the preparing method, adopting fly ash, slag and siliceous dust and cement as concrete cementitous material and adding in water reducer and thickening agent to prepare a high-fluidity self-compacted concrete. And the components in the concrete which are corroded by sulfate are remarkably reduced so as to reduce possibility of corrosion to the concrete. And the concrete has high fluidity, slump above 25 cm, extensibility above 60 cm, and blocking ratio above 0.8; and the corrosion test of above 9 months with 10% sodium sulfate solution shows that compressive ratio is above 0.8 and the surface is complete. And the preparing method is simple, and has low cost and wide application.

Owner:TONGJI UNIV

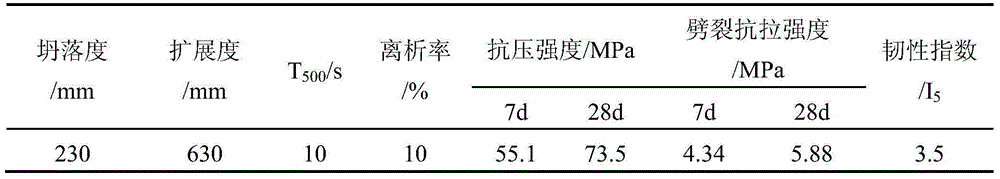

Low shrinkage anti-cracking C60 grade self-compacting bridge tower concrete based on internal curing, shrinkage compensating and toughening, and preparation method thereof

The present invention discloses a low shrinkage anti-cracking C60 grade self-compacting bridge tower concrete based on internal curing, shrinkage compensating and toughening, wherein the low shrinkage anti-cracking C60 grade self-compacting bridge tower concrete is prepared from the following raw materials: cement, fly ash, mine powder, an expander, an AN-ICA internal curing agent, crushed stone, river sand, polyacrylonitrile fibers, micro-scale modified degreasing cotton cellulose, a cement slurry microstructure regulation agent, water and an ultra-dispersed water-reducing and shrinkage-reducing superplastic admixture. According to the present invention, the initial slump is more than or equal to 230 mm, the expansion degree is more than or equal to 630 mm, the 28 d compressive strength is more than or equal to 70 MPa, the 28 d splitting tensile strength is more than or equal to 5.8 MPa, the toughness index I5 is more than or equal to 3.0, the 28 d self-shrinkage is less than 100*10<-6>, the 28 d dry shrinkage rate is less than 150*10<-6>, the carbonization grade achieves T-IV, the anti-cracking grade achieves L-V, the product has characteristics of excellent mechanical property, excellent cracking resistance and excellent durability, and the difficult problems of high cement and cementing material material consumption, large shrinkage and easy cracking of the bridge tower concrete at the current stage can be solved.

Owner:WUHAN UNIV OF TECH +2

Lightweight concrete compositions

A lightweight ready-mix concrete composition that contains 8-20 volume percent cement, 11-50 volume percent sand, 10-31 volume percent prepuff particles, 9-40 volume percent coarse aggregate, and 10-22 volume percent water, where the sum of components used does not exceed 100 volume percent. The prepuff particles have an average particle diameter of from 0.2 mm to 8 mm, a bulk density of from 0.02 g / cc to 0.64 g / cc, an aspect ratio of from 1 to 3. The slump value of the composition measured according to ASTM C 143 is from 2 to 8 inches. After the lightweight ready-mix concrete composition is set for 28 days, it has a compressive strength of at least 1400 psi as tested according to ASTM C39.

Owner:NOVA CHEM (INT) SA

Building anti-freezing accelerator

The invention discloses a antifreeze early strength admixture used in construction using concrete that includes anhydrous calcium chloride, fly ash, inositol hexaphosphate, triethanolmine, sodium benzoate, azimidobenzene, and adding monoethanolamine to adjust the pH value to 9-9.5. The advantages of the invention are that: low cost, easy to gain raw material, no toxin, and no pollution to environment; improving the compressive strength and anti-leaking, anti-charring, antifreeze ability; shortening time limit for a project; ensuring intension and saving cement content.

Owner:北京中通润泽科技有限公司 +1

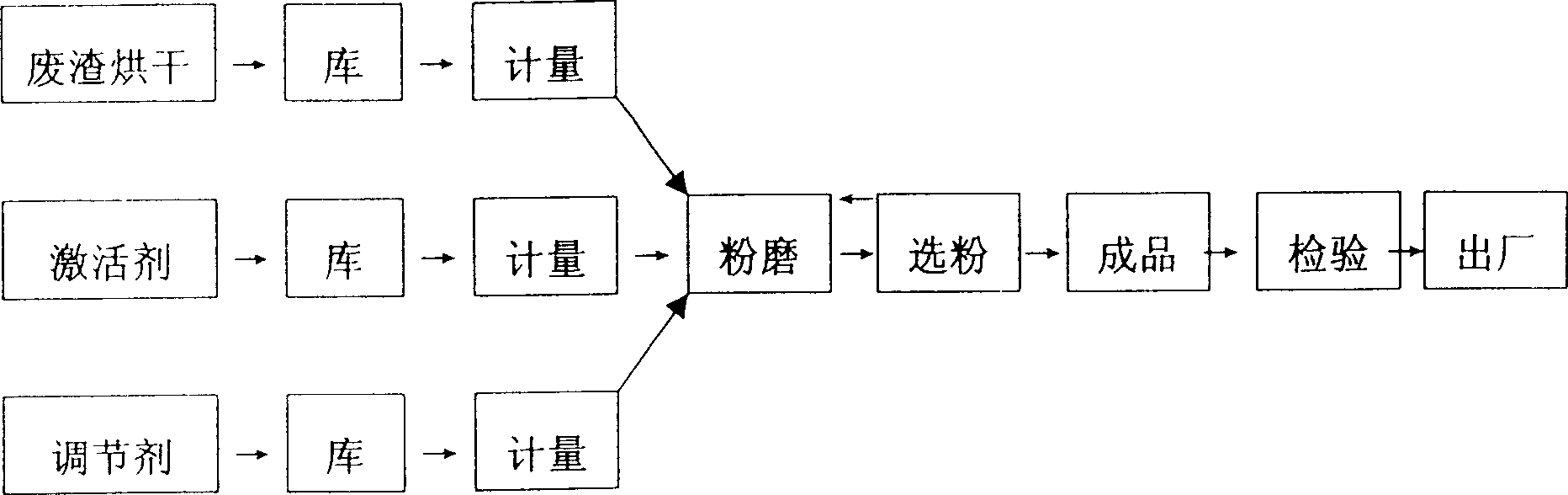

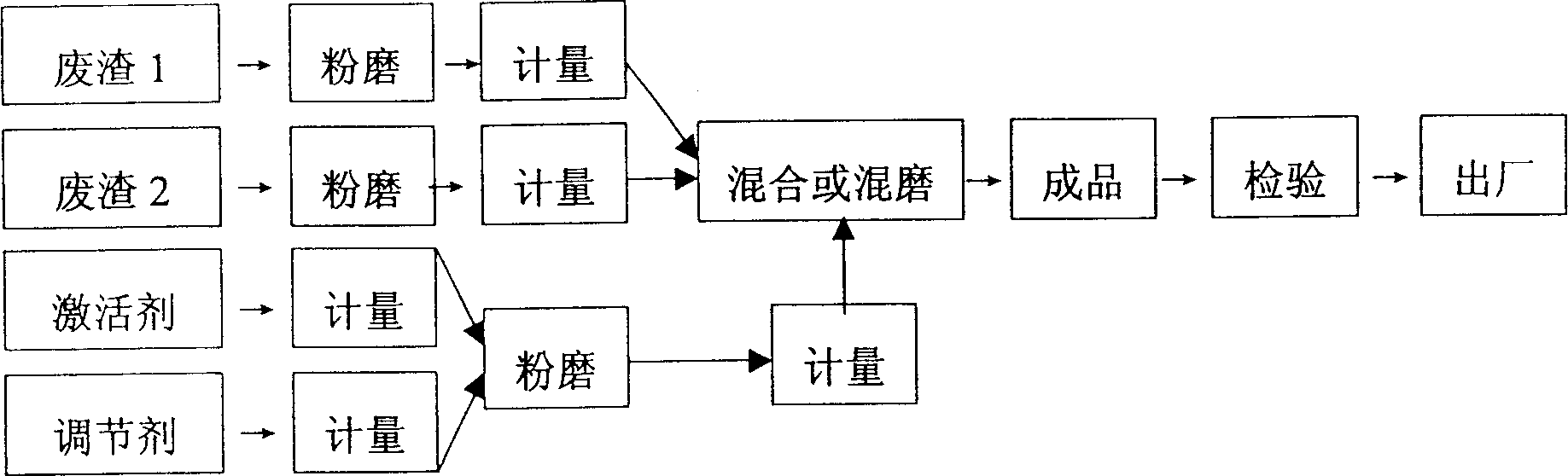

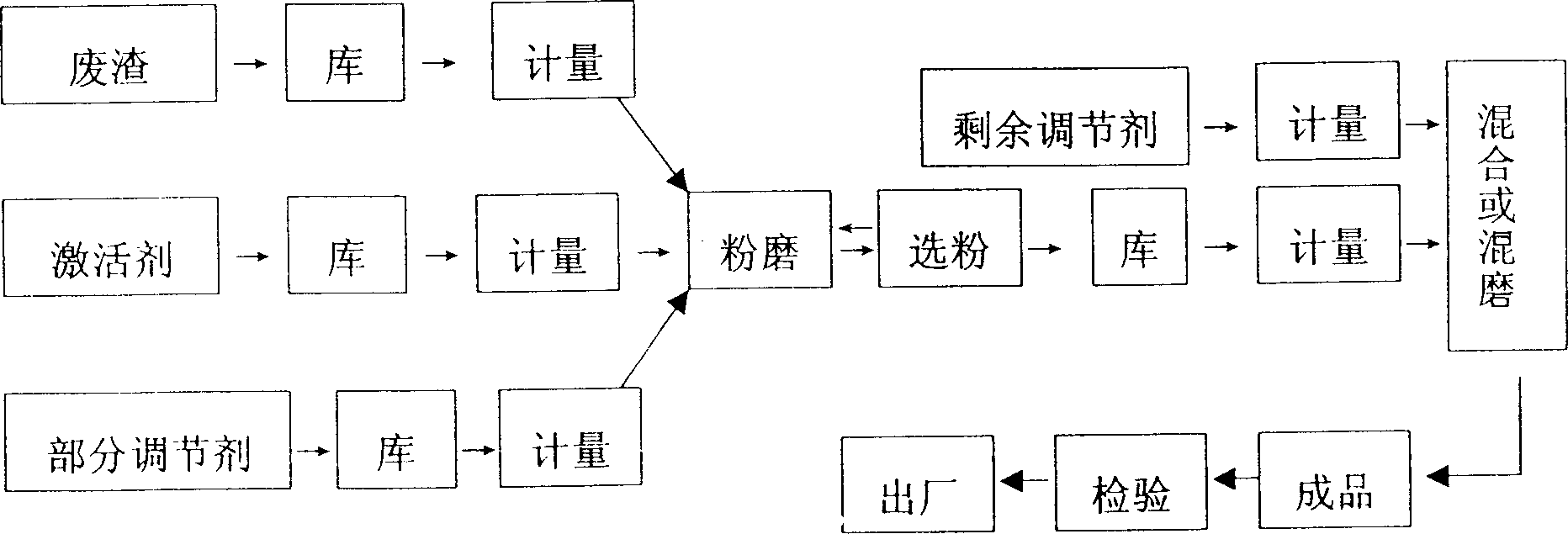

High-performance cement and concrete and their production

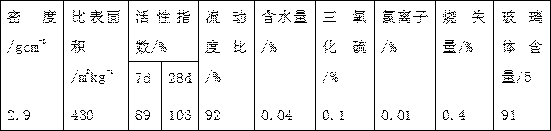

InactiveCN1896024AImprove compactnessImprove liquidityCement productionMaterials scienceHeating energy

High-performance cement, concrete and its production are disclosed. The cement consists of industrial fag end, activator, functional regulator and performance regulator, and Bosi specific surface is 300-550m2 / kg. Its advantages include excellent fluidity and endurance, less loss and hydrated heat energy, better density and strength.

Owner:张卫党

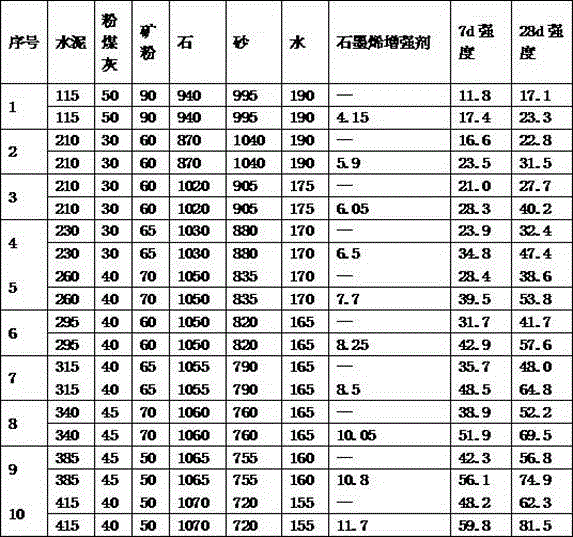

Graphene oxide concrete

ActiveCN105541210ACompact structureHigh strengthSolid waste managementPyrrolidinonesPhysical chemistry

The invention relates to graphene oxide concrete, which is prepared from the following components: 115 to 415 parts of cement, 30 to 50 parts of coal ash, 50 to 90 parts of mineral powder, 940 to 1070 parts of stone, 720 to 1040 parts of sand, 155 to 190 parts of water and 4.15 to 11.70 parts of graphene fortifier, wherein the graphene fortifier is prepared from 10 to 14 percent of water reducing component, 12 to 18 percent of slump retaining component, 3.2 to 3.6 percent of sodium gluconate, 8 to 12 percent of graphene oxide, 0.4 to 0.6 percent of stabilizer polyvinylpyrrolidone and 51 to 66 percent of deionized water. According to the graphene oxide concrete disclosed by the invention, a technical defect that strength loss is caused by a cement matrix flaw due to the fact that dispersity of graphene oxide concrete is low in the prior art is solved; a microstructure of a cement hydration product can be effectively regulated and controlled, therefore strength, permeability resistance and durability of the concrete are increased, and the strength of the graphene oxide concrete is increased by 30 percent to 46 percent in comparison with concrete with an equal ratio.

Owner:SICHUAN CARBON WORLD TECH CO LTD

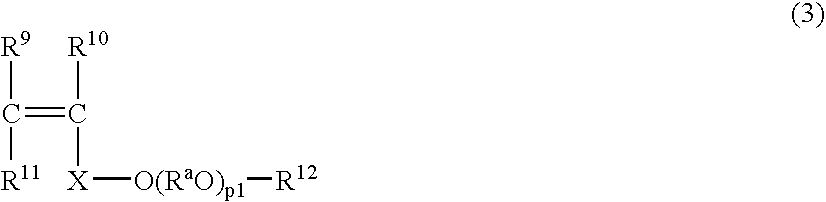

Cement admixture

ActiveUS20070142505A1Simple working processReduce the amount requiredAntifouling/underwater paintsInksSites treatmentSide chain

A cement admixture object of the present invention can make slump-retaining ability excellent to retain fluidity and, at the same time, can realize a viscosity of cement compositions so that work becomes easy at a field handling them, can make the state of a cement composition better. The present invention relates to a cement admixture which comprises a polycarboxylic acid copolymer having a polyalkylene glycol side chain, said polycarboxylic acid copolymer being constituted of two or more species of copolymers with different acid values, and at least one of said two or more species of copolymers with different acid values having an oxyalkylene group containing 3 or more carbon atoms.

Owner:NIPPON SHOKUBAI CO LTD

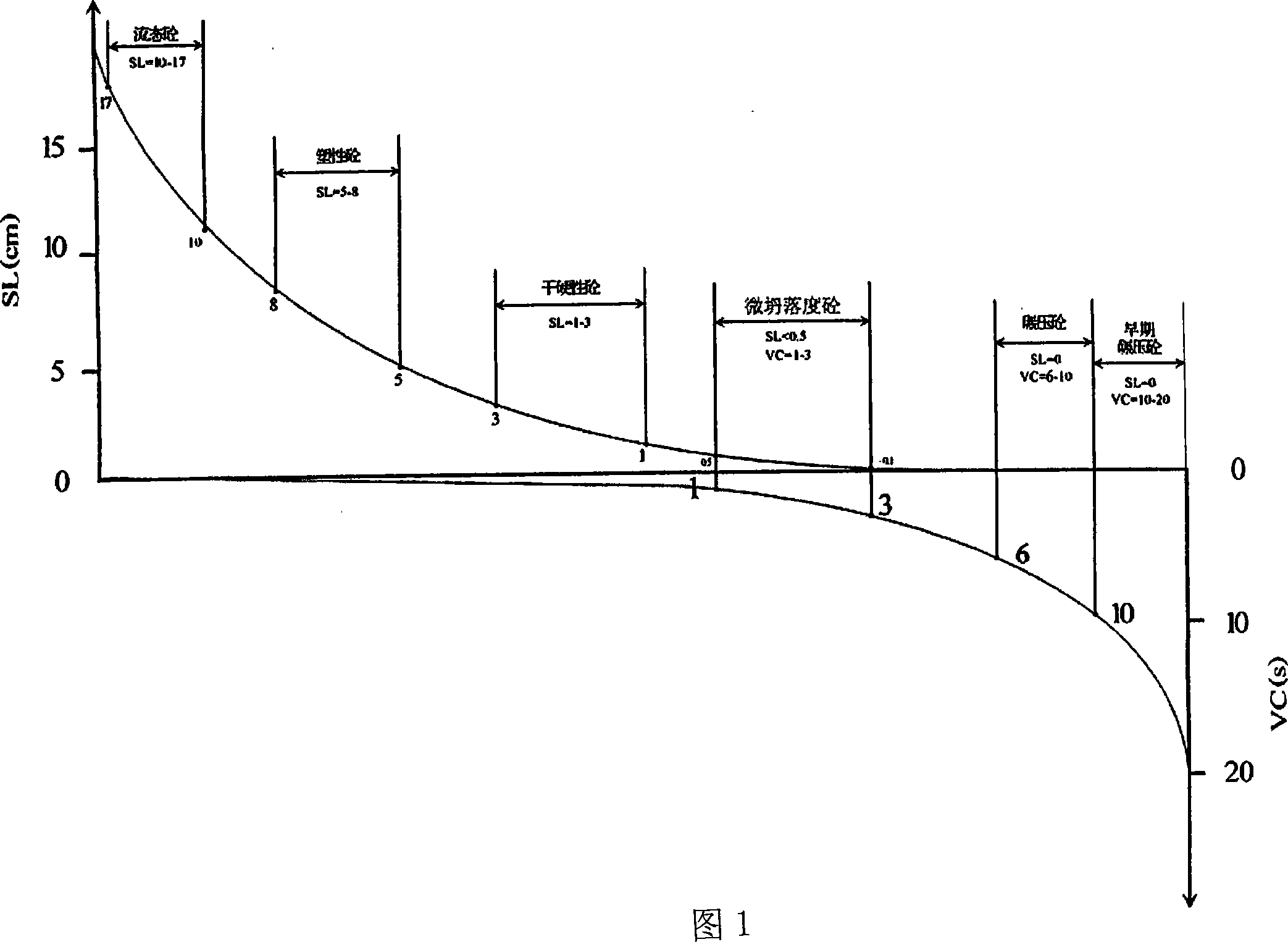

Micro-slump concrete for roller compacted concrete dam and construction method thereof

ActiveCN101058495AMechanics are excellentIncreased durabilitySolid waste managementCeramic shaping apparatusRoller-compacted concreteSuperplasticizer

The invention discloses a micro-collapse concrete of rolled concrete dam and constructing method, which comprises the following parts: cement, coal ash, rough aggregate, fine aggregate, slow setting high-effective dehydragent, air-entrainer and water, wherein the slump of allocated concrete is less than 0. 5cm with consistency value VC at 1-3s; the allocation of the micro-collapse concrete is similar to internal rolling concrete of dam through adding some gelling material slightly, which saves cost with high quality obviously.

Owner:CHINA WATER RESOURCES BEIFANG INVESTIGATION DESIGN & RES

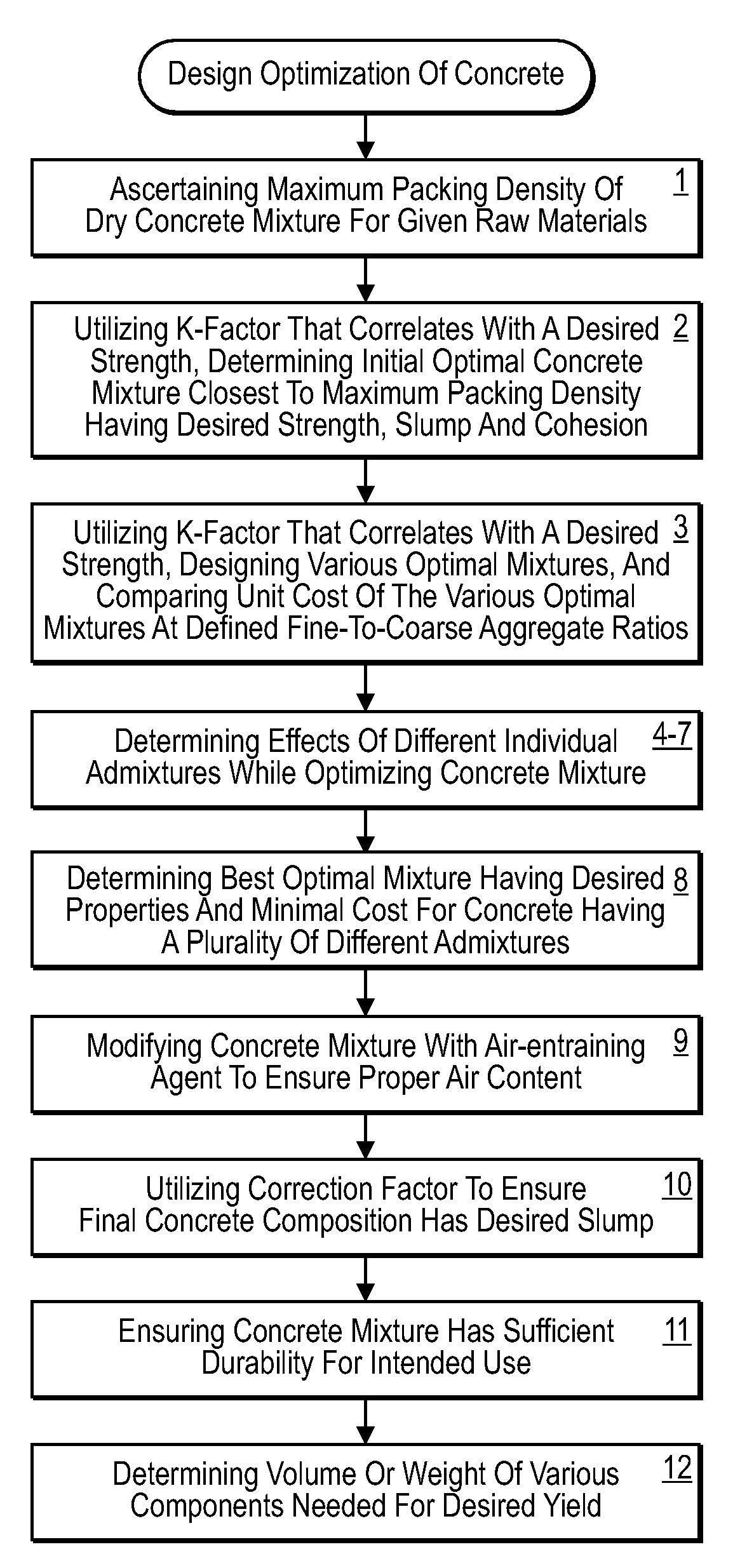

Methods and systems for manufacturing optimized concrete

InactiveUS20080009976A1Accurate predictionEfficient identificationGeometric CADSampled-variable control systemsEngineeringMultiple case

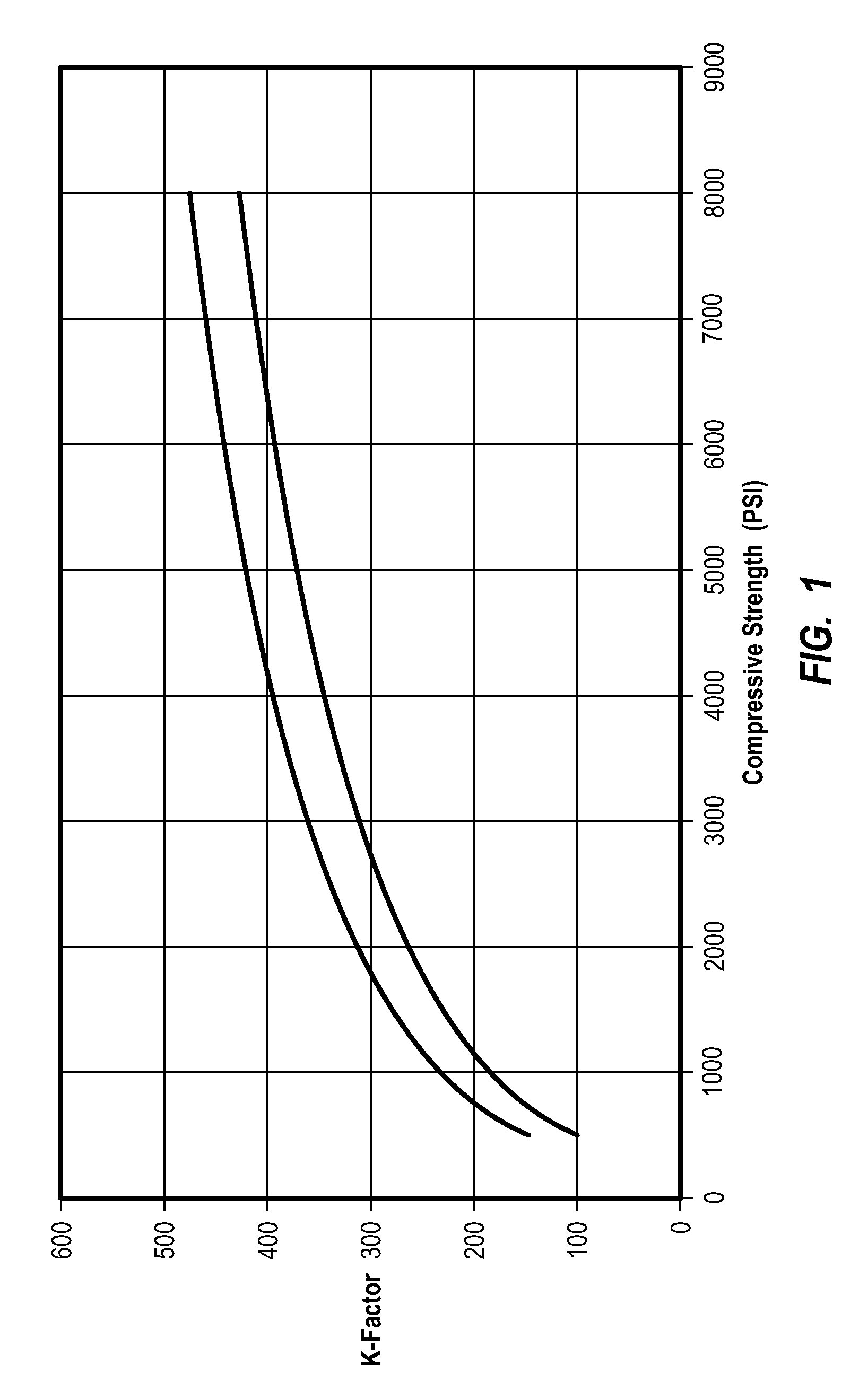

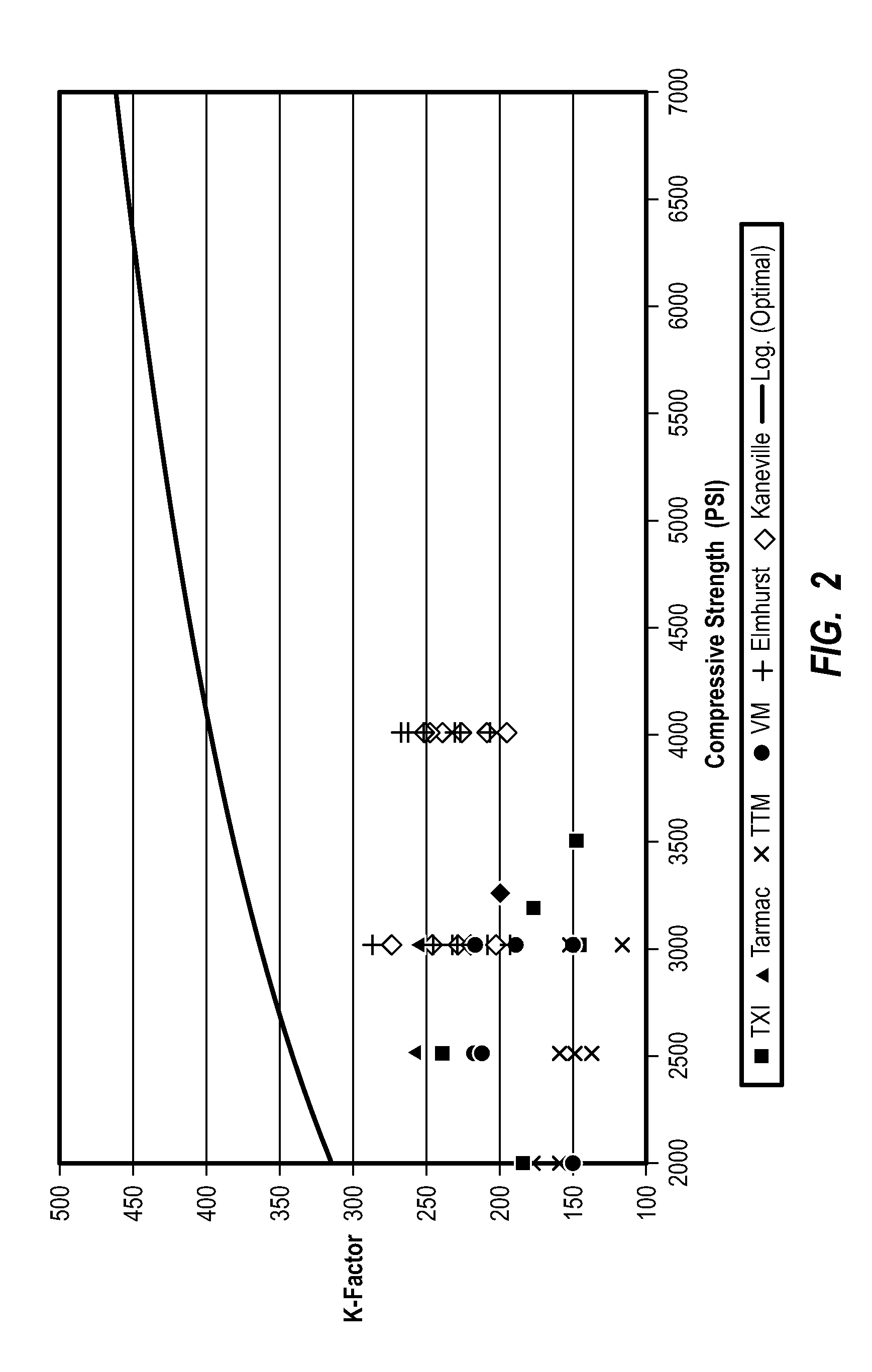

Design optimization methods can be used to design concrete mixtures having optimized properties, including desired strength and slump at minimal cost. The design optimization methods use a computer-implemented process that is able to design and virtually “test” millions of hypothetical concrete compositions using mathematical algorithms that interrelate a number of variables that affect strength, slump, cost and other desired features. The design optimization procedure utilizes a constant K (or K factor) within Feret's strength equation that varies (e.g., logarithmically) with concrete strength for any given set of raw material inputs and processing equipment. That means that the binding efficiency or effectiveness of hydraulic cement increases with increasing concentration so long as the concrete remains optimized. The knowledge of how the K factor varies with binding efficiency and strength is a powerful tool that can be applied in multiple circumstances. A concrete manufacturing process may include accurately measuring the raw materials to minimize variation between predicted and actual strength, as well as carefully controlling water content throughout the manufacturing and delivery process.

Owner:ICRETE LLC

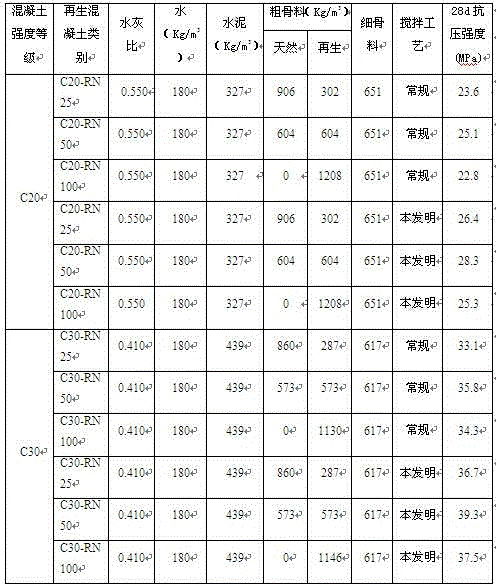

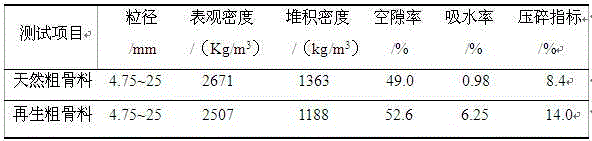

Method for reinforcing recycled aggregate concrete by changing stirring technology

InactiveCN103819152AHigh strengthEnhanced interfacial transition zoneSolid waste managementCompressive resistanceProcess engineering

The invention discloses a method for reinforcing recycled aggregate concrete by changing a stirring technology, and belongs to the field of building materials. The method comprises the following steps that (1) solid waste is crushed via a jaw crusher, and then sieved and assembled into a recycled coarse aggregate meeting a 4.75-25mm continuous grading requirement; and (2) cement and water with 50% of the total water consumption are mixed and stirred for 30-60s; the recycled coarse aggregate is added and stirred for 30-60s; natural coarse and fine aggregates are added and stirred for 30-60s; the residual 50% of water is added and stirred for 30-60s; the slump of a discharged material is measured; and a test block is prepared. Compared with conventional stirring, the stirring technology adopted by the method can wrap and form low-water-cement-ratio cement mortar on the surface of the recycled coarse aggregate, exerts repair and reinforcing effects on a weak area on the surface of the recycled coarse aggregate, and reinforces interface transition areas among the recycled coarse aggregate, the natural aggregates and the cement mortar, so that the compressive strength of the recycled concrete is improved.

Owner:LIAONING TECHNICAL UNIVERSITY

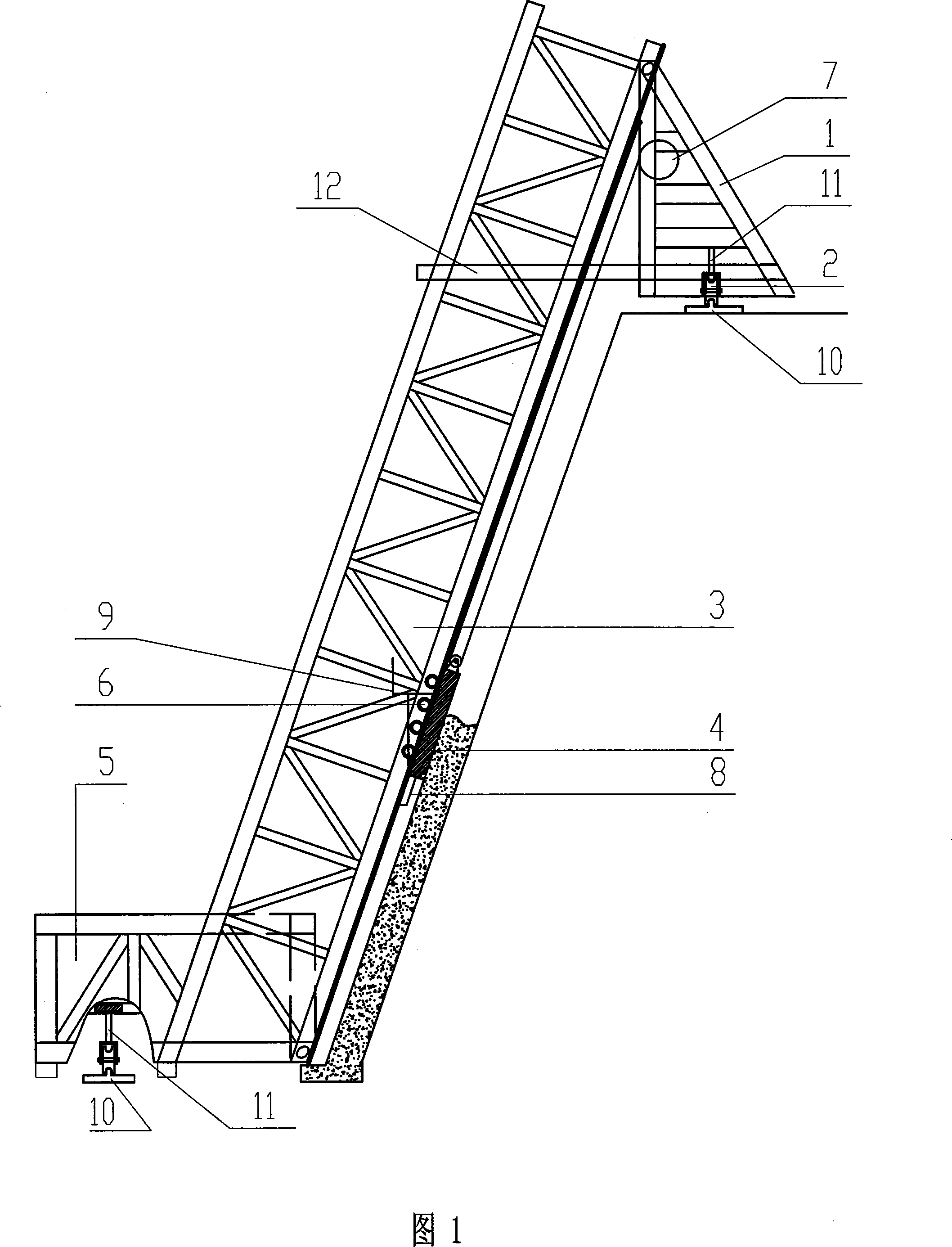

Sliding form parallel translation concrete lining machine as well as construction method thereof

InactiveCN101250877AImprove stabilityEasy to move up and downFoundation engineeringSloping shouldersOrbit

The invention discloses a sliding formwork parallel moving concrete lining machine and a construction method, a machinery of the invention comprises a walking mechanism, a trimming lifting device, a tamping device and a stretch main frame, wherein the main frame is hinged with a top frame and a bottom frame, the top frame is arranged on the upper portion of the main frame, the bottom frame is arranged on the lower portion of the main frame, a sliding orbit on the main frame is engaged with a sliding template, the sliding template is driven by a winding mechanism which is arranged on the top portion of the sliding template. The construction method using the invention comprises the processes of machinery installment and location, elevation adjustment, emptying, tamping, sliding template lifting and pressing surface and the like, which is construction by course, segmentation jolting and a segmentation pressing surface from upper to lower until a slope top and a slope shoulder. After an active section is completed, the lining of next working position is integrally moved. The width of the work surface of the invention is above 2m, the slope length is 3-30m, the slope degree is 1 / 0.1-1 / 1.99, the collapsed slump is smaller than 8, the inner portion of a concrete surface is tight, the surface is even and smooth, staggered platform and pockmark do not exist, the project progress is rapid, and the efficacy is 3-12 times of the sliding template.

Owner:秦瑞青

Machine-made sand regulator and preparation method thereof

InactiveCN110655346AImprove work performanceGuaranteed durability requirementsProcess engineeringCarboxylic acid

The embodiment of the invention provides a machine-made sand regulator and a preparation method thereof. The machine-made sand regulator comprises a polycarboxylate water reducing agent, a glue reducing agent, an early strength agent, an air entraining agent, a polyether type defoaming agent, a compact repairing agent, a viscosity thixotropic agent and water; the machine-made sand regulator is suitable for machine-made sand with different gradations; the durability requirement of the concrete can be ensured while good working performance of the concrete can be controlled. According to the machine-made sand regulator, various detection indexes of the newly mixed concrete can be obviously superior to those of a common admixture in the market at present, the slump of the concrete is as high as 200 mm, the volume weight reaches 2438 kg / m<3>, meanwhile, the workability is good, the 28-day strength reaches 66.8 MPa, and the strength increment is increased by more than 30% compared with thatof the common admixture.

Owner:HUNAN ZHONGYAN BUILDING MATERIAL TECH CO LTD

Preparation method of high-activity red mud-based concrete admixture

The invention relates to a preparation method of a high-activity red mud-based concrete admixture, belonging to a preparation method of a composite activated mineral admixture. The preparation method comprises the steps of: by taking red mud as main raw materials and industrial waste slag of carbide slag, desulfurization gypsum and the like as auxiliary materials, performing heating power activation through the self combustion heat of unburned coal gangue to obtain the high-activity red mud-based concrete admixture, wherein in the process of blending concrete materials, 20% by weight of the red mud composite replaces PO52.5, or PO42.5, or PC32.5 portland cement, under the condition of keeping other blending materials, the cost of per cubic meter concrete blended can be saved greatly, the strength of the blended concrete in each age is equal to or higher than that of the compared concrete, and the newly blended concrete has the characteristics of being good in peaceability, small in slump loss, low in hydration heat, good in later strength transitivity, sulfate corrosion-resistant, strong in chemical corrosion resistance, and good in durability, having no adverse influence on the property of the concrete, and the like.

Owner:CHINA UNIV OF MINING & TECH

Composite antifreezing agent and antifreezing pumping agent

The invention provides a composite antifreezing agent and an antifreezing pumping agent. The composite antifreezing agent is a mixture prepared from a salt component and an organic solvent component, wherein the salt component is a mixture of calcium nitrate, calcium formate and sodium thiosulfate; the organic solvent component is alcohol. The invention further discloses the antifreezing pumping agent with the antifreezing agent. The composite antifreezing agent is a liquid antifreezing agent compounded from organic and inorganic early strength components and antifreezing components, and is good in antifreezing effect, and moreover the later strength of concrete constructed in winter can be effectively improved. The antifreezing pumping agent with the antifreezing agent is good in antifreezing effect, good in adaptability with cement, low in slump time loss of concrete and good in antifreezing effect, and the anti-pressure strength of the composite antifreezing agent is far greater than the standard requirements under the condition of the provided temperature of minus 10 DEG C. The composite antifreezing agent is applicable to concrete pumping construction in northern areas in winter, can be applicable to commercial premixed pumping concrete, and can be also applied to on-site mixed pumping concrete.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

Slow-release microcapsule concrete admixture and preparation method thereof

The invention discloses a preparation method of a slow-release microcapsule concrete admixture. The method comprises the following processes: stirring and dispersing a porous carrier into a concrete admixture solution; fully soaking, centrifuging and filtering, and drying to obtain the slow-release microcapsule concrete admixture. When the porous carrier is fully soaked in the concrete admixture solution, one part of concrete admixture molecules enter the pores of the porous carrier and the other part of concrete admixture molecules are adsorbed on the surface of the carrier particle; the two parts of concrete admixture molecules are reserved in the porous carrier after being filtered an dried, so as to form the slow-release microcapsule concrete admixture. In addition, the invention also discloses a slow-release microcapsule concrete admixture. The concrete admixture can keep the flowing property of the concrete mixture, so that the slump of the concrete mixture is not lost within 5 hours, concrete segregation and bleeding are reduced, and the compactness, the strength and the durability of the concrete are improved.

Owner:珠海市振业混凝土有限公司 +1

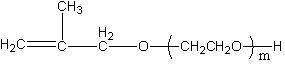

Polycarboxylate water reducing agent with high water reducing rate and low slump loss as well as preparation method thereof

The invention relates to a polycarboxylate water reducing agent with high water reducing rate and low slump loss as well as a preparation method of the polycarboxylate water reducing agent. The polycarboxylate water reducing agent is prepared by copolymerizing 58-92% of monomer A, 3-16% of maleic anhydride, 2-22% of methacrylic acid citrate and 2-15% of monomer D. The polycarboxylate water reducing agent can endow cement with higher dispersity and lower slump loss under lower accretion, has better cement adaptability, and can effectively inhibit slump loss of concrete and remarkably enhance concrete strength. The invention further discloses the preparation method of the water reducing agent. The preparation method has the advantages of simplicity and convenience, easiness in operation, short production cycle, no pollution in a production process and the like.

Owner:江苏超力建材科技有限公司

Air entrained concrete

The invention provides an air entrained concrete and relates to a concrete. The air entrained concrete provided by the invention comprises cement, a fine aggregate, a coarse aggregate, an additive and water, wherein the additive accounts for 2-3 wt% of the cement. The air entrained concrete provided by the invention can be used in paving to improve performances such as strength and impermeability, so as to greatly improve the durability of the pavement, greatly reduce the cost of repair and maintenance, and ensure the traffic capacity and comfort of the road. The main technical parameters of the air entrained concrete are as follows: 1) design flexural strength of the air entrained concrete: >=5.0Mpa; 2) gas content of the air entrained concrete: 5.5 + / - 0.5%; 3) water-cement ratio (W / C) of the air-entrained concrete: <=0.40; 4) slump of the air entrained concrete mixture: 25-50mm; 5) flexural elastic modulus of the air entrained concrete: >=30000Mpa; and 6) antifreeze grade of the concrete: >=F300.

Owner:HEILONGJIANG PROV INST OF COMM

Recycled concrete with high slump loss resistance and preparation method thereof

The invention discloses recycled concrete with high slump loss resistance and a preparation method thereof. The invention belongs to the field of building materials, the key points of the technical scheme comprise that the raw materials comprise 180-220 parts by weight of cement, 380-490 parts of a modified recycled coarse aggregate, 400-500 parts of gravels, 680-820 parts of natural sand, 90-130parts of fly ash, 65-98 parts of mineral powder, 156-185 parts of water, 4.2-5.8 parts of a polycarboxylate superplasticizer and 3.5-6.4 parts of a slump retaining enhancer. A treatment method of themodified recycled coarse aggregate comprises the steps: a crushed coarse aggregate is placed in a sodium silicate solution with the concentration of 3%-7% to be soaked for 4 h-9 h, then the recycled coarse aggregate is added into a mixed solution of a polyvinyl alcohol solution with the concentration of 8%-12% and a silane emulsion with the concentration of 4%-10% to be continuously soaked for 8 h-12 h, and the effect of improving the slump loss resistance of the recycled concrete is achieved.

Owner:深圳市恒星建材有限公司

Sulfamate as high performance reducing water agent for building and preparing proces thereof

The invention relates to a building sulfamate high-performance water reducer and its preparing method, synthesized of benzene solfonic acid, sodium hydroxide, phenol, formaldehyde and water, and the product mainly contains the groups: -CN, benzene ring, -SO3, etc, and the average molecular weight is 4000-9500. It can make the water reduction ratio of concrete up to above 25%, improve the fluidity of concrete by a large margin, makes the loss rate of concrete slump in 2 hours less than 10%, enhances the strength by a large margin, and improves the durability of concrete. It has better adaptability to various cements. It is applied to the constructions (structures) of premixed concrete commodity, high-strength high-performance concrete, reinforced concrete, etc.

Owner:TONGJI UNIV

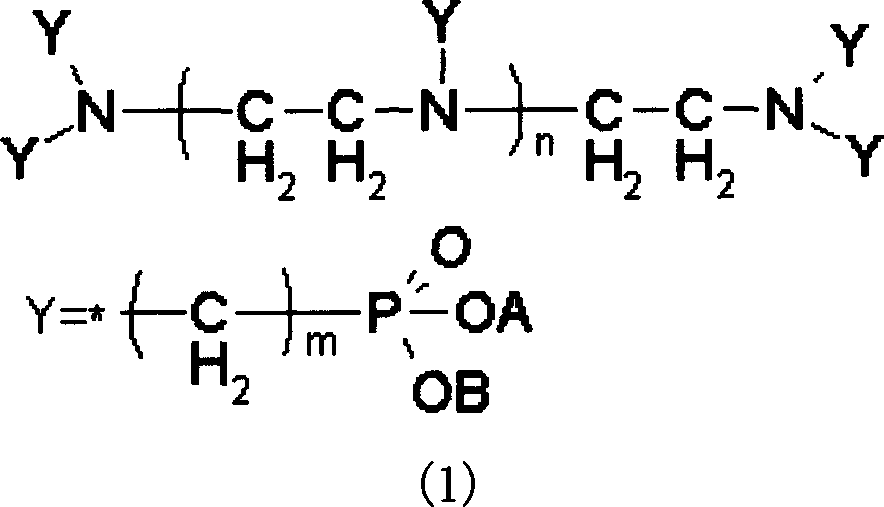

Super-slowly coagulant adaptive to variaty concrete water reducers and prepn. thereof

This invention relates to the field of concrete super-retarding reagents that are compatible with all kinds of concrete water reducers. The super-retarding reagent in this invention has a mass-fraction composition as follows: 6~35% ethylene polyamine alkyl phosphonic acid or its salt, 5~15% phosphonobutane tricarboxylic acid and 50~90% water. The super-retarding reagent is compatible with different kinds of water reducers and cement, and can greatly reduce the loss of concrete mixture slump. The super-retarding reagent performs extraordinary retarding activities, and concrete solidification time can be adjusted to 3~150 hours by modulating product composition and dosage according to actual engineering demand.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com