Self-compacting light aggregate concrete and preparation method thereof

A lightweight aggregate concrete and self-compacting technology, applied in the field of concrete, can solve the problems of poor homogeneity and low floating bead density of the self-compacting lightweight aggregate mixture, and achieve the reduction of apparent density and low apparent density. , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

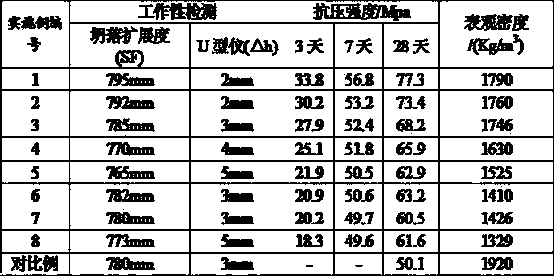

Embodiment 1

[0036] The self-compacting lightweight aggregate concrete described in this example is composed of the following raw materials: P·O 52.5 cement 480kg, apparent density 2000 kg / m 3 The fly ash is 90kg, the apparent density is 2000kg / m 3 , The bulk density is 200kg / m 3 80kg of silica fume, the particle size is 0.01~0.2mm, and the bulk density is 300 kg / m 3 The floating beads are 180kg, and the bulk density is 800 / m 3 The pottery sand is 360kg, and the bulk density is 600kg / m 3 440kg of gravel-type shale ceramsite with cylinder compressive strength of 2.5MPa, 25kg of water reducing agent, and 150kg of water.

Embodiment 2

[0038] P·O 52.5 cement 470kg, apparent density is 2017 kg / m 3 60kg of fly ash, the apparent density is 2107kg / m 3 , The bulk density is 326kg / m 3 70kg of silica fume, the particle size is 0.01~0.2mm, and the bulk density is 312 kg / m 3 The floating beads are 180kg, and the bulk density is 812kg / m 3 The pottery sand is 360kg, and the bulk density is 683kg / m 3 440kg of gravel-type shale ceramsite with cylinder compressive strength of 3.6MPa, 23kg of water reducing agent, and 160kg of water.

Embodiment 3

[0040] P·O 52.5 cement 450kg, apparent density is 2078kg / m 3 70kg of fly ash, the apparent density is 2231kg / m 3 , The bulk density is 243kg / m 3 80kg of silica fume, the particle size is 0.01~0.2mm, and the bulk density is 324 kg / m 3 The floating beads are 200kg, and the bulk density is 827kg / m 3 The pottery sand is 330kg, and the bulk density is 732kg / m 3 4. 450kg of gravel-type shale ceramsite with cylinder compressive strength of 4.3MPa, 26kg of water reducing agent, and 140kg of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com