Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

359results about How to "Low apparent density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

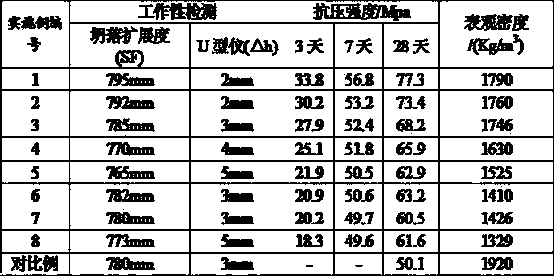

Self-compacting light aggregate concrete and preparation method thereof

InactiveCN103803904ALow densityLow apparent densitySolid waste managementStructural engineeringWater reducer

The invention provides self-compacting light aggregate concrete and a preparation method thereof, and belongs to the technical field of concrete preparation. The self-compacting light aggregate concrete consists of such raw materials as cement, fly ash, silica fume, floating beads, light fine aggregate, light coarse aggregate, a water reducing agent and water. The self-compacting light aggregate concrete provided by the invention has the advantages of being low in appearance density, high in slump expansion degree and capable of avoiding floating of the floating beads; self-compacting light aggregate concrete differing in grade, especially self-compacting light aggregate concrete with strength grade above C60 and appearance density at 1400-1800kg / m<3>, can be prepared through the raw materials.

Owner:北京中联新航建材有限公司

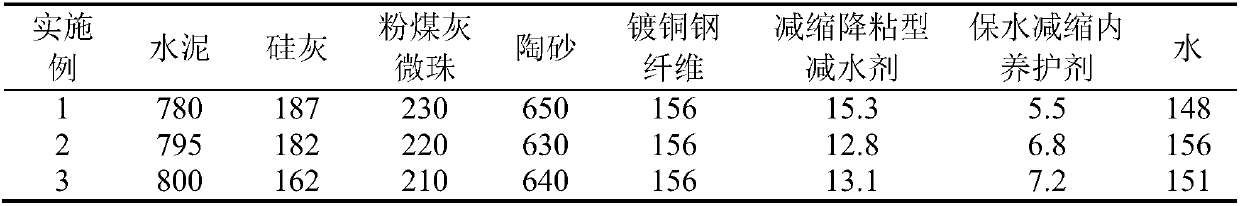

Light low-shrinkage super-high performance concrete and preparation method thereof

The invention discloses light low-shrinkage super-high performance concrete which is prepared from cement, coal ash beads, silica fume, pottery sand, a brass coated steel fiber, shrinkage and viscosity reduction type water reduction agent, a water-retention shrinkage-reduction inner curing agent and water as main raw materials. According to the concrete, the pottery sand is adopted as aggregate, the self weight of the concrete is reduced, and a high-strength and dense 'arch housing' interface area is formed on the surface of the pottery sand by using a pre-mixing process, so that the interfacestrength is improved, and the mechanical properties and the anti-penetrability performance of the concrete are improved; due to the adoption of the shrinkage and viscosity reduction type water reduction agent and the coal ash beads, the working performance and the density of the concrete are improved; due to the adoption of the pre-wetted pottery sand and the developed water-retention shrinkage-reduction inner curing agent, reduction of wetness inside the concrete is retarded, the self-shrinkage and the drying shrinkage of the concrete are reduced, and the volume stability of the concrete isimproved. While the self weight of the concrete is reduced, the light low-shrinkage super-high performance concrete disclosed by the invention is good in working performance, mechanical property, anti-penetrability and durability, and has significant practical application values.

Owner:WUHAN UNIV OF TECH

Plant fiber-reinforced polylactic acid foam material and preparation method thereof

The invention discloses a plant fiber-reinforced polylactic acid foam material, which is prepared from the following components: 20 to 95 percent of polylactic acid, 1 to 60 percent of plant fiber powder, 1 to 5 percent of foaming agent, 1 to 5 percent of nucleating agent, 1 to 5 percent of antioxidant and 1 to 5 percent of bulking agent. The invention also discloses a preparation method for the material. The foam material has the advantages of low apparent density, biodegradability, no environmental pollution, capacity of replacing polyolefin foam materials, wide application in the fields of heat insulation, buffer and packaging, simple preparation process and high production efficiency.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

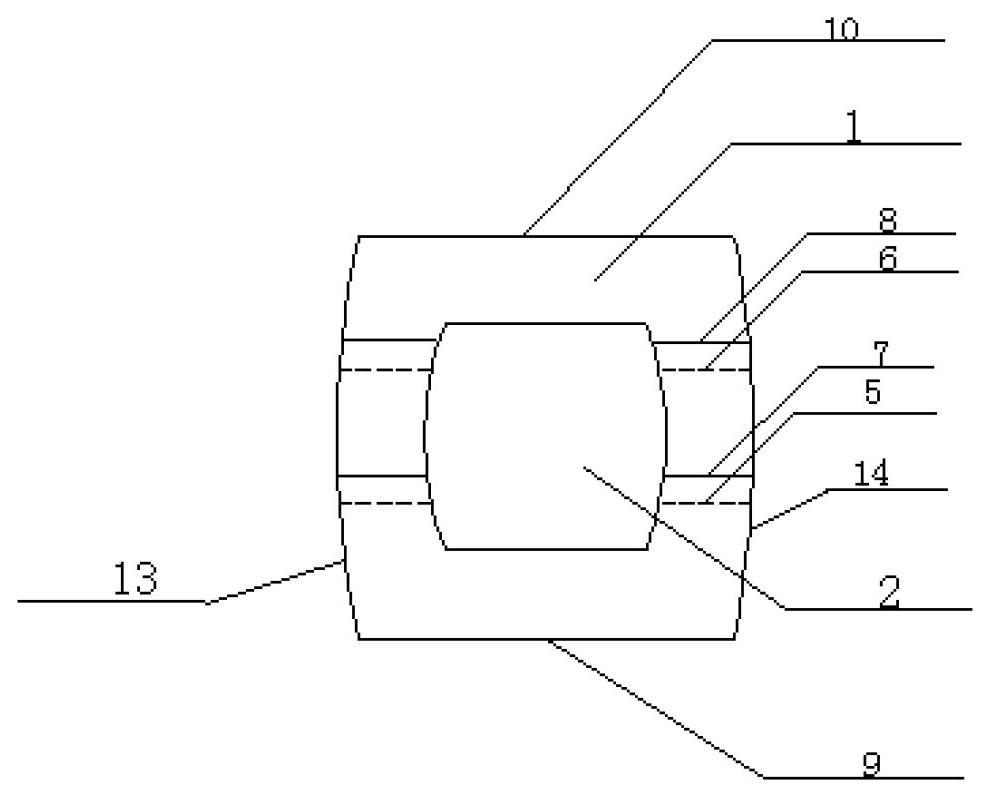

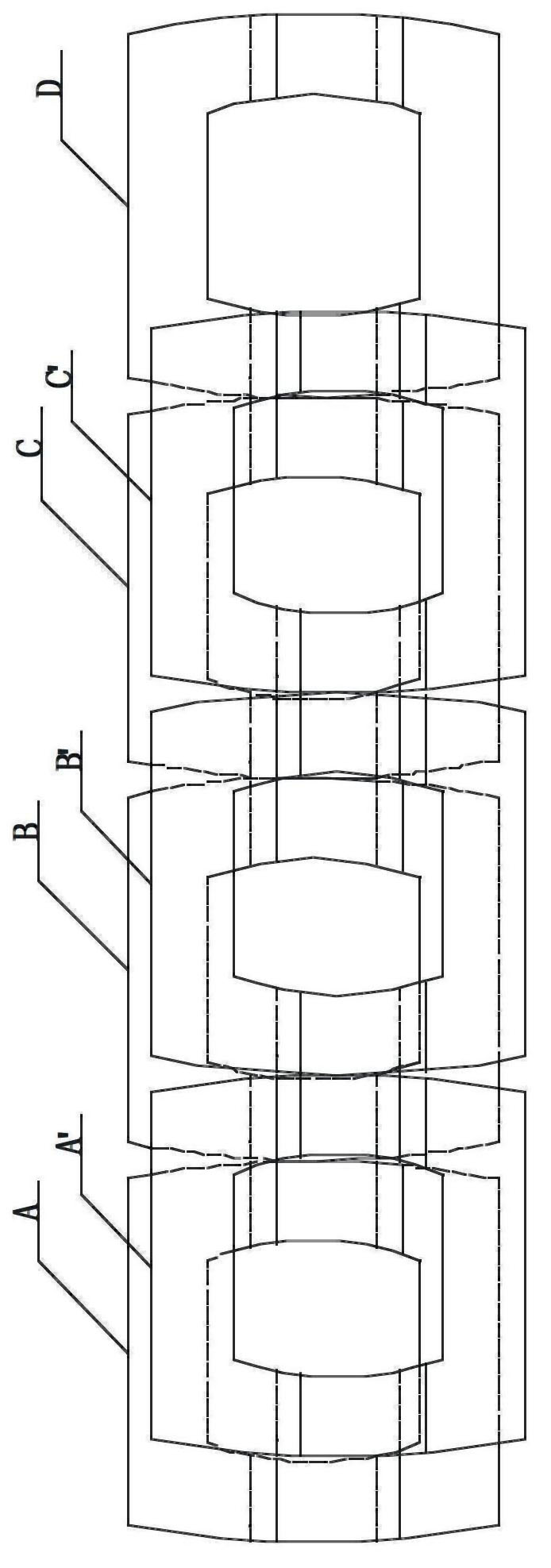

Mutually-embedded ecological building block retaining wall and construction method thereof

InactiveCN102677695AImprove practicalityAdapt to the requirements of inclination changesArtificial islandsCoastlines protectionArchitectural engineeringRetaining wall

The invention provides a mutually-embedded ecological building block retaining wall and a construction method thereof, and belongs to the field of buildings. The mutually-embedded ecological building block retaining wall is formed by two or more than two layers of mutually embedded ecological building blocks which are arranged transversely side by side and stacked upwards; each of the mutually embedded ecological building blocks has a front surface of the building block and a back surface of the building block which are parallel to each other; a hole is formed in the middle part of the building block; a groove is formed on the top part of the building block; the front surface of the groove and the back surface of the groove are respectively parallel to the front surface of the building block and the back surface of the building block; a bump is arranged on the bottom part of the building block; the groove is matched with the bump in size; and the bump of the building block on the upper layer is embedded into the groove of the building block on the lower layer. The construction method comprises the following steps of: placing a building block on a construction foundation to serve as a first layer; placing a building block on the first layer building block to serve as a second layer, wherein the bump on the bottom part of the second layer building block is completely embedded into the groove of the first layer building block; and repeatedly placing the building blocks to a designed height. Grass-like vegetation and vine-like plants can be grown in openings of the building blocks and gaps among the building blocks, so that a good ecological effect is achieved.

Owner:HOHAI UNIV

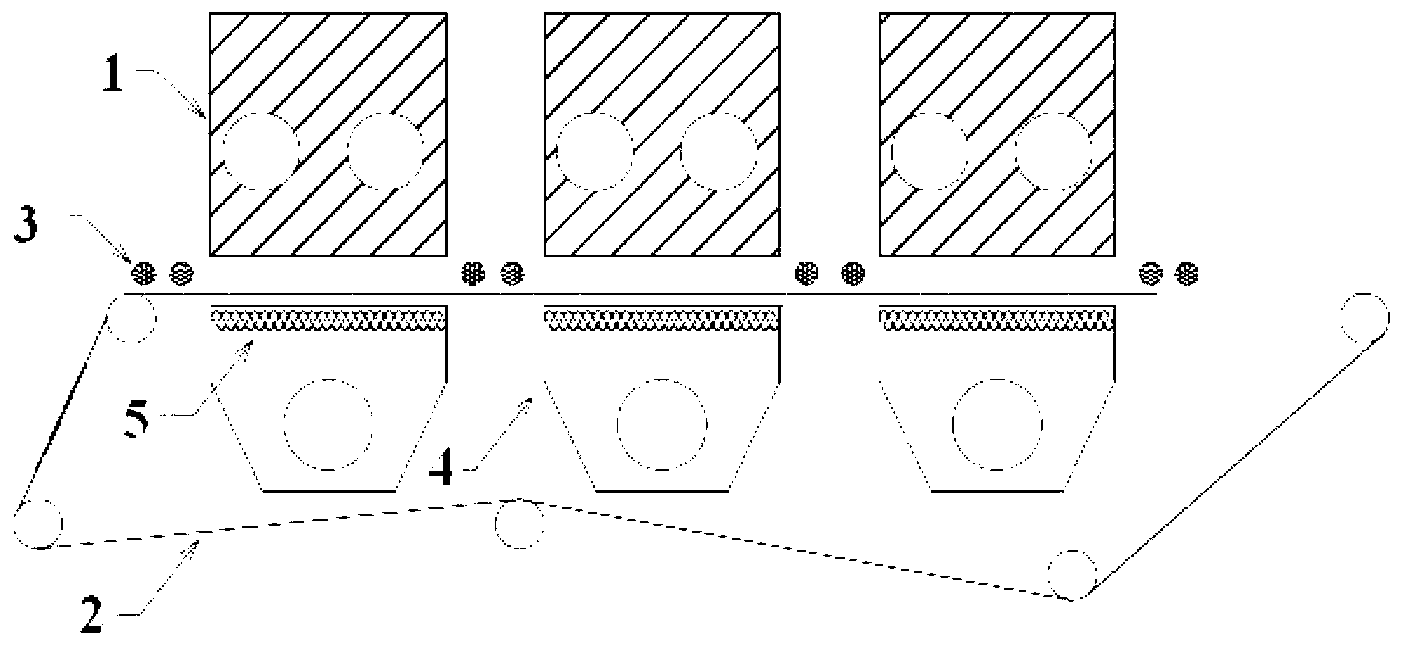

Method for manufacturing tobacco sheet taking substrate as carrier through dry paper making method

A method for manufacturing tobacco sheet taking substrate as a carrier through a dry paper making method comprises the following steps: spraying slurry onto the right side of the substrate through a high pressure spraying method, and meanwhile carrying out negative pressure suction across a wire belt to the reverse side of the substrate; then sending the substrate into an oven and carrying out medium temperature baking and humidity discharging under the condition that the temperature of the substrate is 55 DEG to 70 DEG, and enabling hot air inside the oven to flow directional from the right surface of the substrate to the reverse surface of the substrate to carry out humidity discharging; sequentially, carrying out normal temperature humidity discharging treatment; setting medium temperature baking and humidity discharging time and the normal temperature baking and humidity discharging alternatively; and repeating the steps on the reverse side of the substrate, namely a tobacco sheet is prepared. The substrate is prepared by that scattered material is evenly paved and absorbed onto a formation fabric for dry paper making to form a fiber thin layer under the vacuumpumping of a vacuum air pumping device under the formation fabric, and carrying out antistatic-electricity treatment; and spraying adhesion agent onto a fiber thin layer, under the combination of mist spraying and vacuum take-off on sprayed back surface; and finally carrying out drying.

Owner:CHINA TOBACCO HUNAN INDAL CORP +1

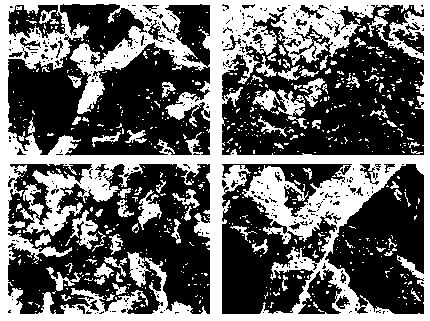

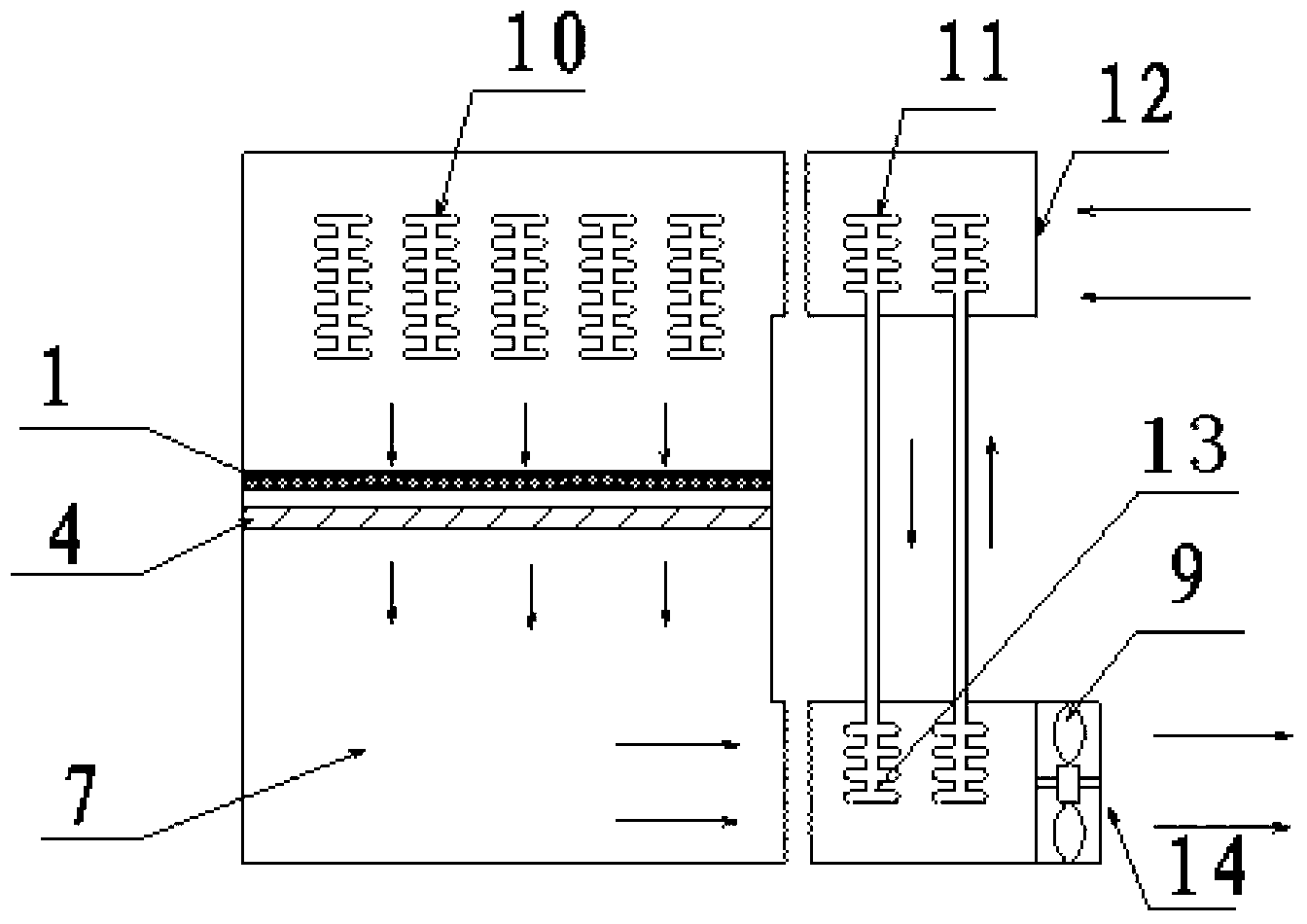

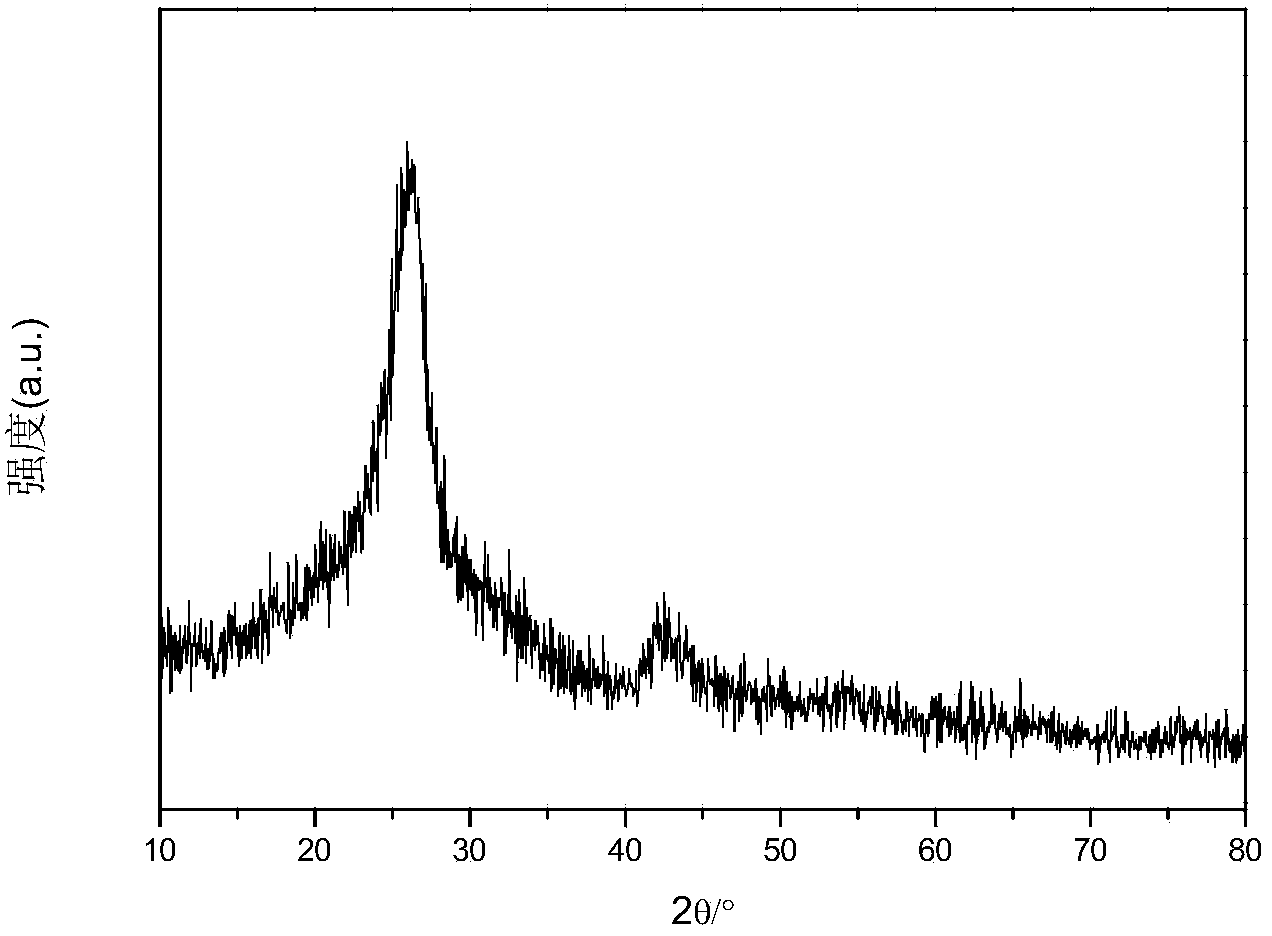

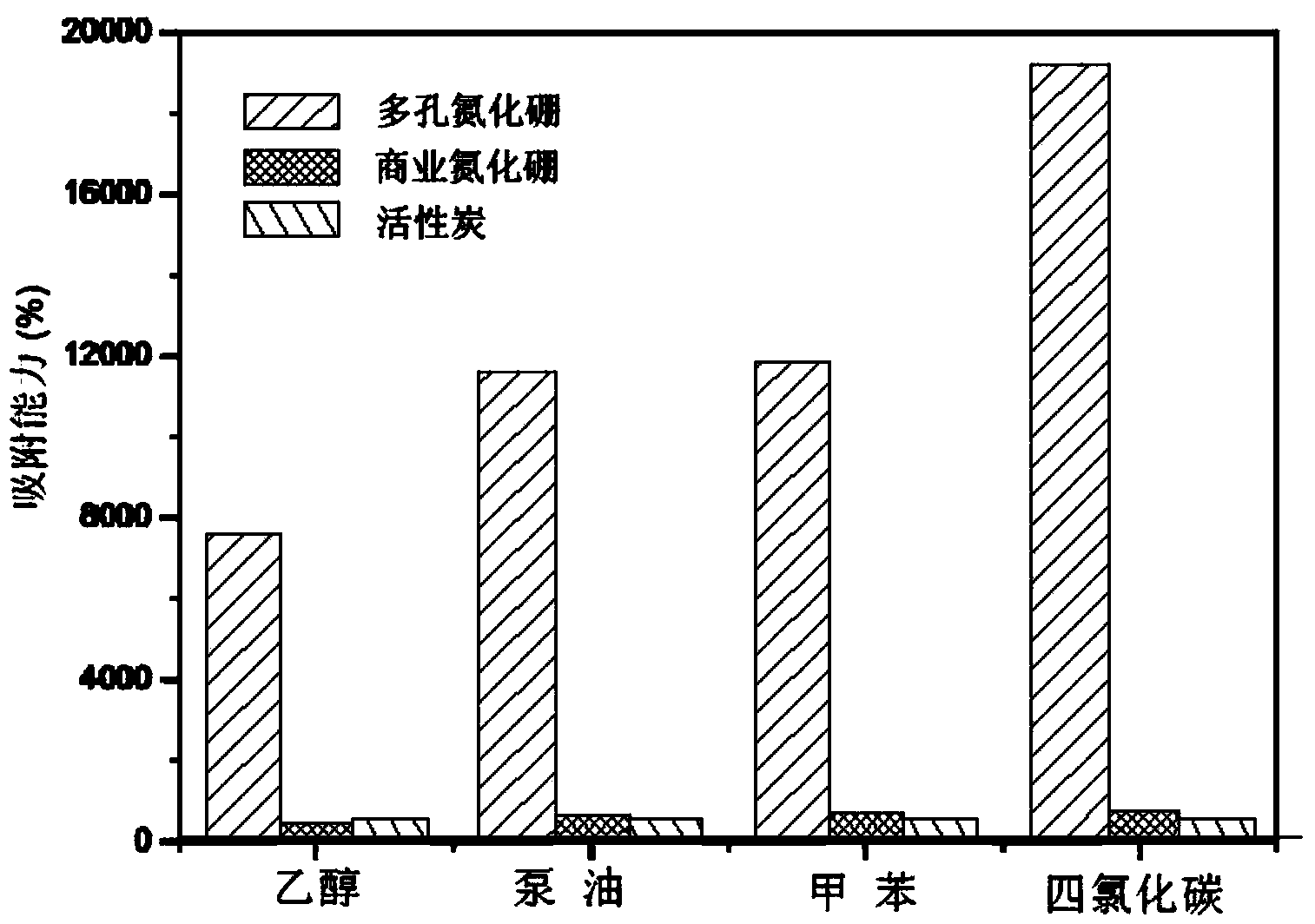

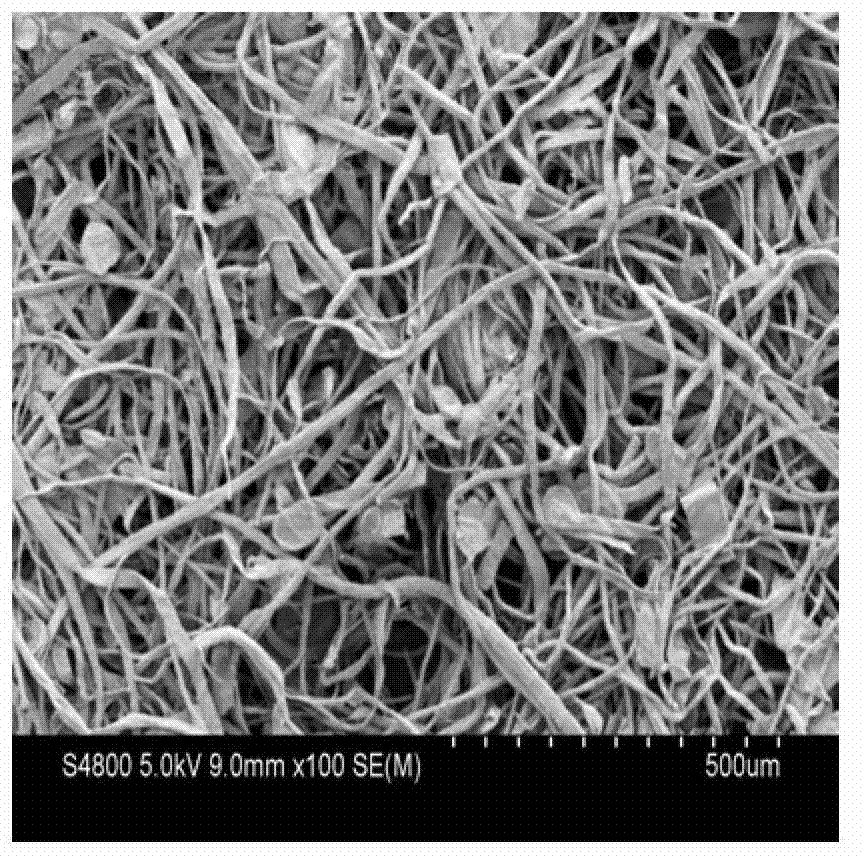

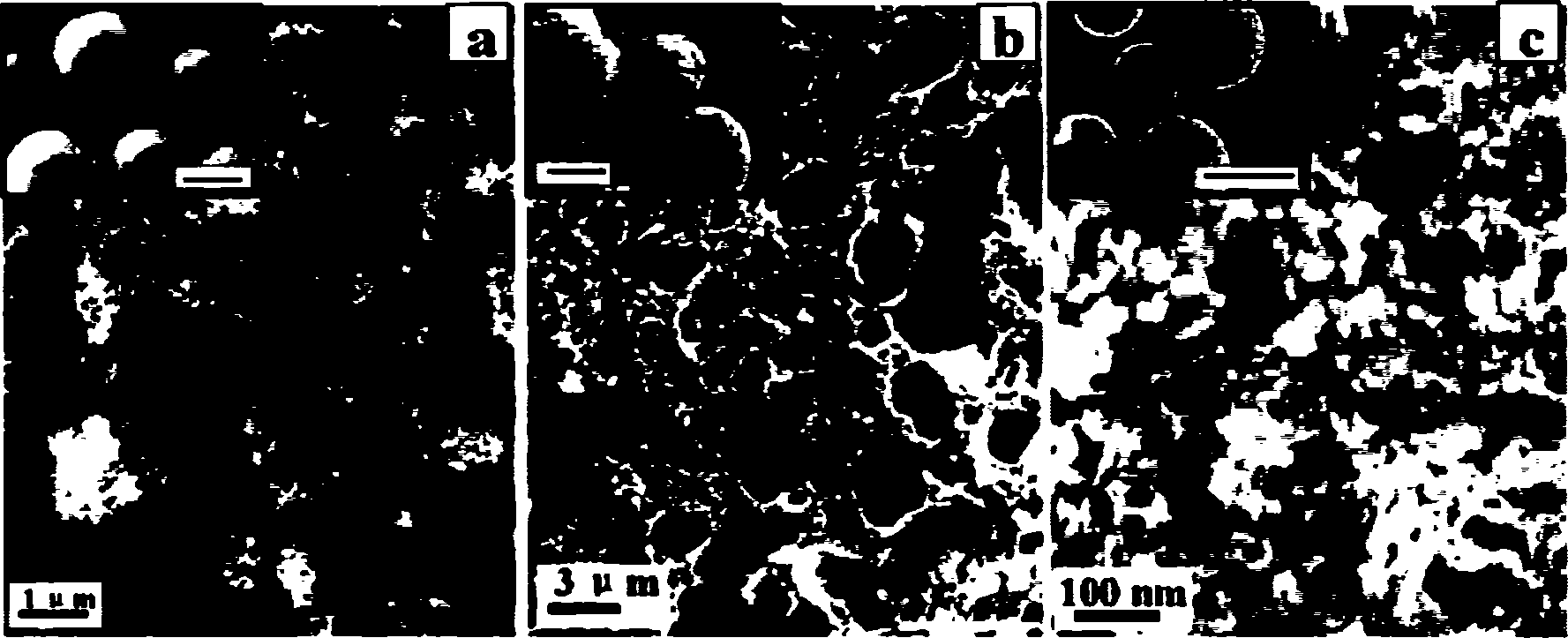

Preparation method of three-dimensional porous hexagonal boron nitride

InactiveCN103964403ALow apparent densityImprove adsorption capacityNitrogen compoundsUreaAmmonia borane

The invention discloses a preparation method of three-dimensional porous hexagonal boron nitride. The preparation method comprises steps as follows: step one, a precursor is placed into a crucible, wherein the precursor comprises a nitrogen source and a boron source, the nitrogen source is one or more of ammonia, urea, sodium azide, pyridine, melamine and ammonia borane, and the boron source is one of boron powder, boron oxide, boric acid, ammonium borate, sodium borohydride, boron carbide and ammonia borane; step two, the crucible is placed in a high-temperature furnace, vacuum pumping is performed to 1-40 Pa, gas is introduced and oxygen is eliminated; step three, the temperature is increased to 900-1,600 DEG C in 10 min-4 h, and a reaction is performed for 0.5-5 h; and the temperature is reduced to the room temperature, and three-dimensional porous hexagonal boron nitride is obtained. The preparation method of three-dimensional porous hexagonal boron nitride is simple in technology, complex raw material pretreatment and follow-up treatment are not needed, the repeatability is good, batch preparation can be achieved, and industrialized application is easy to achieve.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Process for preparing hydrophobic silicon dioxide aerogel using rice husk ash as raw material

A process for preparing the hydrophobic SiO2 aero-gel from rice husk ash includes such steps as burning rice husk to obtain its ash, extracting its hydro-gel in inorganic strong-alkaline aqueous solution, neutralizing by inorganic strong acid, laying aside to generate SiO2 hydro-gel, filter, acid treating, ageing, water washing, displacing the water from the hydro-gel by organic solvent, supercritical drying and modifying surface. Its advantages are high specific surface area and pore volume, and low apparent density.

Owner:TSINGHUA UNIV

Method for manufacturing remanufactured tobacco base sheets with dry paper-making method

The invention discloses a method for manufacturing remanufactured tobacco base sheets with a dry paper-making method. The method comprises the steps as follows: raw materials including cabo and plant fibers are ground and broken into short fibers, and then fed by wind into a forming head box for breaking up; by the aid of the vacuum pumping action of a vacuum evacuating device under a forming net, the broken-up materials are uniformly laid and adsorbed on the forming net for dry paper-making, so that a thin fiber layer is formed; the thin fiber layer is sprayed with an adhesion agent, and a manner combing mist spraying and vacuum drawing of a prayed back surface is adopted; finally the materials are dried and the tobacco base sheets are obtained; an antistatic rope is laid between the forming net and the forming head box and / or between the forming net and an opening of a vacuum box; or / and an antistatic net is arranged between the forming net and the opening of the vacuum box; the adhesion agent comprises chitosan and the like; and the remanufactured tobacco base sheets having higher wet strength stretching-resistant capacity and filling value and good processing performance are prepared with the dry paper-making method successfully for the first time.

Owner:CHINA TOBACCO HUNAN INDAL CORP +1

Cast-in-situ straw/ash magnesium oxychloride cement wall and construction method

InactiveCN101818531AAvoid ignitionImprove flame retardant performanceSolid waste managementWallsSocial benefitsAdhesion process

The invention discloses a cast-in-situ straw / ash magnesium oxychloride cement wall and a construction method. The straw / ash magnesium oxychloride cement wall is obtained by processing straw, ash, light burned magnesia, magnesium chloride and the like and performing in-situ casting under the action of a modifier. The straw / ash magnesium oxychloride cement wall comprises the following raw materials in percentage by mass: 45 and 60 percent of magnesium oxide, 25 to 40 percent of solution of magnesium chloride, 2 to 20 percent of straw, 5 to 15 percent of ash and 0.5 to 2 percent of modifier. When the wall is cast in situ, the magnesium oxide, the solution of magnesium chloride, the straw, the ash and the modifier are mixed and stirred, and water is added into the mixture according to the water absorption of the straw to perform one-time forming through in-situ casting after the mixture is stirred uniformly. The wall is characterized in that the doping volume of the straw can be changed according to design requirements, and the straw can be used as inner and outer partition plates; the binding power is strong, so the adhesion process of the cast-in-situ wall materials and the conventional wall materials is avoided; due to the addition of the straw, the volume weight of products is reduced and the heat-insulating and heat-shielding performance of the products is improved; and a large amount of waste material ash, straw and the like is utilized to relieve the environmental burden effectively and reduce the cost, so the wall has great economic and social benefits.

Owner:SOUTHEAST UNIV

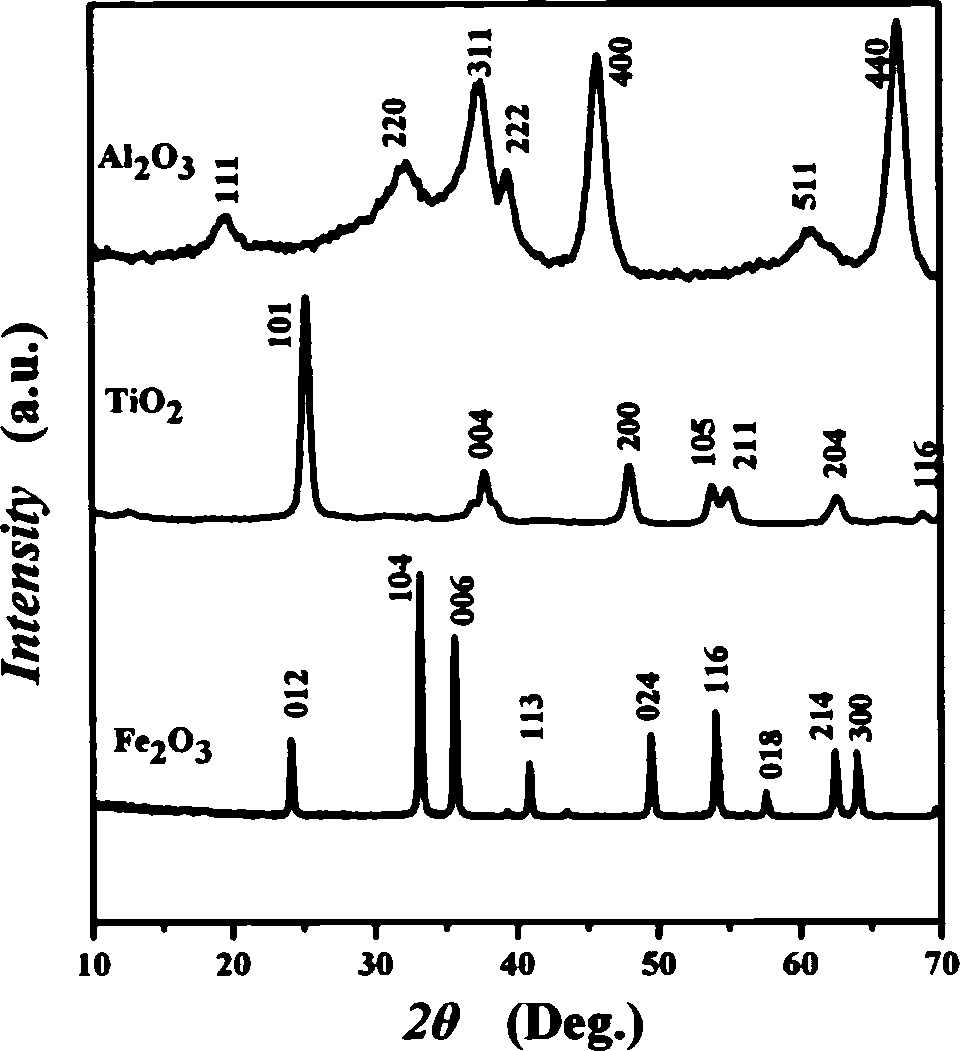

General method for preparing spherical porous metal oxide

InactiveCN1884047ALarge specific surface areaHigh porosityCatalyst carriersOxide/hydroxide preparationIon-exchange resinTitanium oxide

The invention discloses a universal method and utility of porous metal oxide and preparing method of organic spherical grain in the porous inorganic spherical grain preparing technological domain, which is characterized by the following: adopting ionic exchanging resin as mould; sedimenting complex compound or coordinate through acting metal salt and mould through alkali; drying; sintering to remove organic mould and carbon; synthesizing series of metal oxide ball with multi-size structure of iron scale, aluminium oxide, titanium oxide and cobalt oxide. The invention possesses high specific surface area, multi-size hole diameter, which displays important utility in the catalytic, adsorbing and spectrum domains.

Owner:NANKAI UNIV

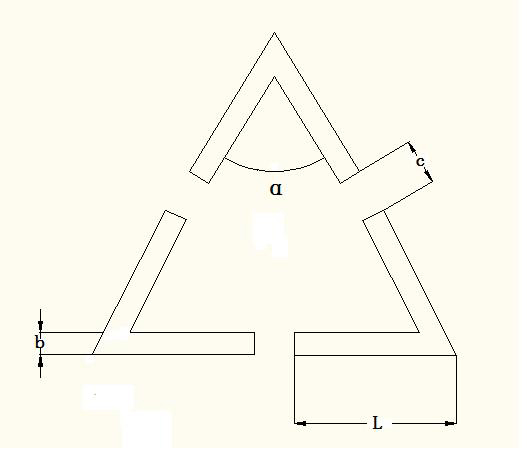

Flexible and heterogeneous nylon-6 fiber and preparation method thereof

ActiveCN102409419AStable structureLow apparent densityHollow filament manufactureFilament/thread formingSOCKSNylon 6

The invention relates to the technical field of functional and differentiated fiber production, and aims to provide flexible and heterogeneous nylon-6 fiber and a preparation method thereof. The flexible and heterogeneous nylon-6 fiber is formed by V-shaped jet micropore spinning and a melting spinning method by using fiber-level nylon-6 chips as substrates; the internal part of the section of the flexible and heterogeneous nylon-6 fiber is hollow, and the periphery of the section is triangular; and the relative radial profile degree of the cross section of the flexible and heterogeneous nylon-6 fiber is 20 to 30 percent, and the relative section profile degree is 35 to 55 percent, and hollowness of the flexible and heterogeneous nylon-6 fiber is 10 to 30 percent. The fiber has good mechanical properties, and high elasticity, hygroscopicity and heat retention, and can be widely used for the fields of underwear, socks, clothing and the like.

Owner:YIWU HUADING NYLON

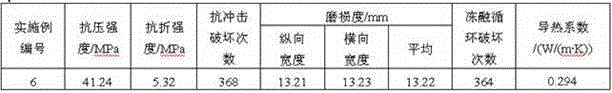

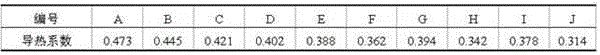

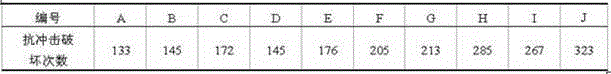

High-strength lightweight aggregate concrete and preparation process thereof

PendingCN110218051ALow apparent densityHigh strengthCeramicwareApparent densityUltimate tensile strength

The invention discloses a high-strength lightweight aggregate concrete and a preparation process thereof. The concrete is prepared from the following raw materials in parts by weight: 411 to 417 partsby weight of cement, 75 to 88 parts by weight of mineral admixture, 50 to 60 parts by weight of floating beads, 550 to 680 parts by weight of coarse aggregate, 615 to 627 parts by weight of fine aggregate, 11.5 to 12.3 parts by weight of additive and 171 to 180 parts by weight of water. It has the advantages of high strength, low apparent density and low thermal conductivity. In addition, the preparation method comprises the following steps: firstly, the coarse aggregate is mixed with 50% of water, then cement, mineral admixture, floating beads and fine aggregate are added and uniformly mixed, finally, the remaining 50% of water and the additive are added and uniformly stirred to obtain concrete. The preparation method of the invention has the advantages of simple process, easy implementation, safety and high efficiency.

Owner:成都精准混凝土有限公司

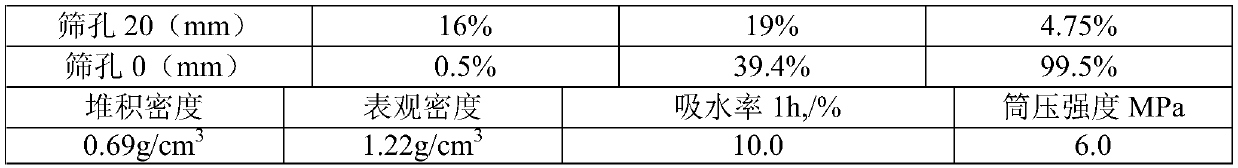

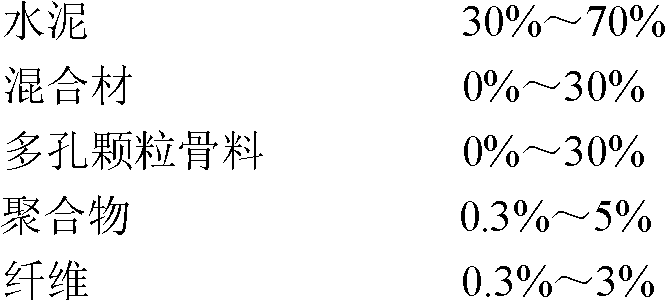

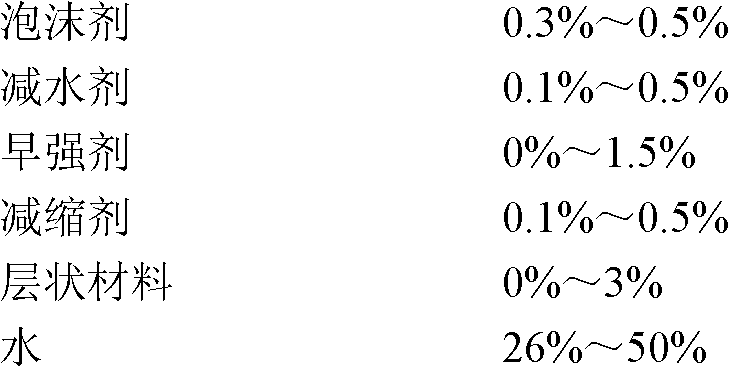

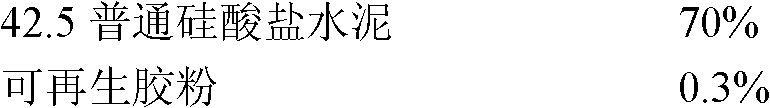

Ultra-low apparent density and high-performance foam concrete material and its preparation method

InactiveCN102424556ALow apparent densityLow thermal conductivityCeramicwareFoam concreteShrinkage cracking

The invention relates to an ultra-low apparent density and high-performance foam concrete material and its preparation method. The material comprises the following components by mass: 30%-70% of cement, 0%-30% of an admixture, 0%-30% of a porous particle aggregate, 0.3%-5% of a polymer, 0.3%-3% of a fiber, 0.3%-0.5% of a foaming agent, 0.1%-0.5% of a water reducing agent, 0%-1.5% of an early strength agent, 0.1%-0.5% of a shrinkage reducing agent, 0%-3% of a layered material, and 26%-50% of water. Compared with ordinary foam concrete, the material prepared in the invention has the technical advantages of ultra-low apparent density, small coefficient of heat conductivity, and no dry shrinkage cracking, etc. And compared with current foam polyphenyl boards for exterior wall external thermalinsulation, the material of the invention has the advantage of non-combustion.

Owner:TONGJI UNIV

Production method of ultralow density high-tenacity high-elasticity melamine foams

The invention discloses a production method of ultralow density high-tenacity high-elasticity melamine foams, which comprises the following steps: using melamine formaldehyde resin or modified melamine formaldehyde resin as a base material, and adding an emulsifier, a foaming agent, a curing agent and molecules with an enhanced Marangoni effect; and after uniform emulsification, heating in a microwave oven, curing for a while, and molding. During the microwave foaming process, the addition of the molecules with an enhanced Marangoni effect not only can reduce the use amount of the foaming agent to a large extent, but also can regulate the aperture and the length-diameter ratio of edges of the foams in a large range, so as to greatly improve the various properties of melamine foams.

Owner:QILU UNIV OF TECH

Sintered light-weight environment-friendly brick produced from electroplating sludge and manufacture method thereof

The invention relates to a sintered light-weight environment-friendly brick produced from electroplating sludge and a manufacture method thereof. The sintered light-weight environment-friendly brick is characterized by being prepared by adopting electroplating sludge, base waste sludge, furnace slag, refuse ash, calcium oxide, calcium sulfate, sodium carbonate, boric acid, ferrous sulfate, magnesium sulfate, Li macromolecular heavy metal trapping agent and water are adopted as raw materials; and the manufacture method comprises the following steps of: mixing and stirring the raw materials in a biaxial mixer to be in a moisture state; extruding into rectangular bars by a vacuum sludge extruder; cutting and forming by a blank cutter; manufacturing light-weight environment-friendly brick blanks of electroplating sludge under the pressure of 20-30 MPa; and conveying the formed and naturally dried light-weight environment-friendly brick blanks into a tunnel kiln to roast and manufacture light-weight environment-friendly brick products. Air laying bricks and pavement bricks in different specifications can also be manufactured by the raw materials of the invention, and the product has the advantages and the effects of light weight, great strength, zero pollution, low cost and good benefits.

Owner:清远绿由环保科技有限公司

Preparation method of porous hydrophobic oleophylic sponge

The invention provides a preparation method of a porous hydrophobic oleophylic sponge. The method comprises the steps: taking polymer foams, placing in a heating furnace, under the protection of inert gas, heating up to 150-1000 DEG C, calcining for 0.2-10 h, and thus obtaining the porous hydrophobic oleophylic sponge. The porous hydrophobic oleophylic sponge obtained by the method adsorbs oil, does not adsorb water, can adsorb the oil or organic matters which are hundreds of times heavier than the sponge, and has good toughness; and after the oil or organic matters are adsorbed, the adsorbed oil or organic matters can be removed through extrusion, distillation, burning and other methods, and thus the porous hydrophobic oleophylic sponge can be used repeatedly. The preparation method is simple, needs no complicated chemical reactions or material preparation processes, and has the advantages of convenient operation, good repeatability and easily industrialized implementation. The porous oil-adsorption sponge has the characteristics of large specific surface area, low density, good flexibility, hydrophobic oleophylic performance and the like, can be used for oil-water separation, and has good application prospects in the fields of wastewater treatment, adsorption of leaking crude oil or organic matters and the like.

Owner:JIANGSU UNIV

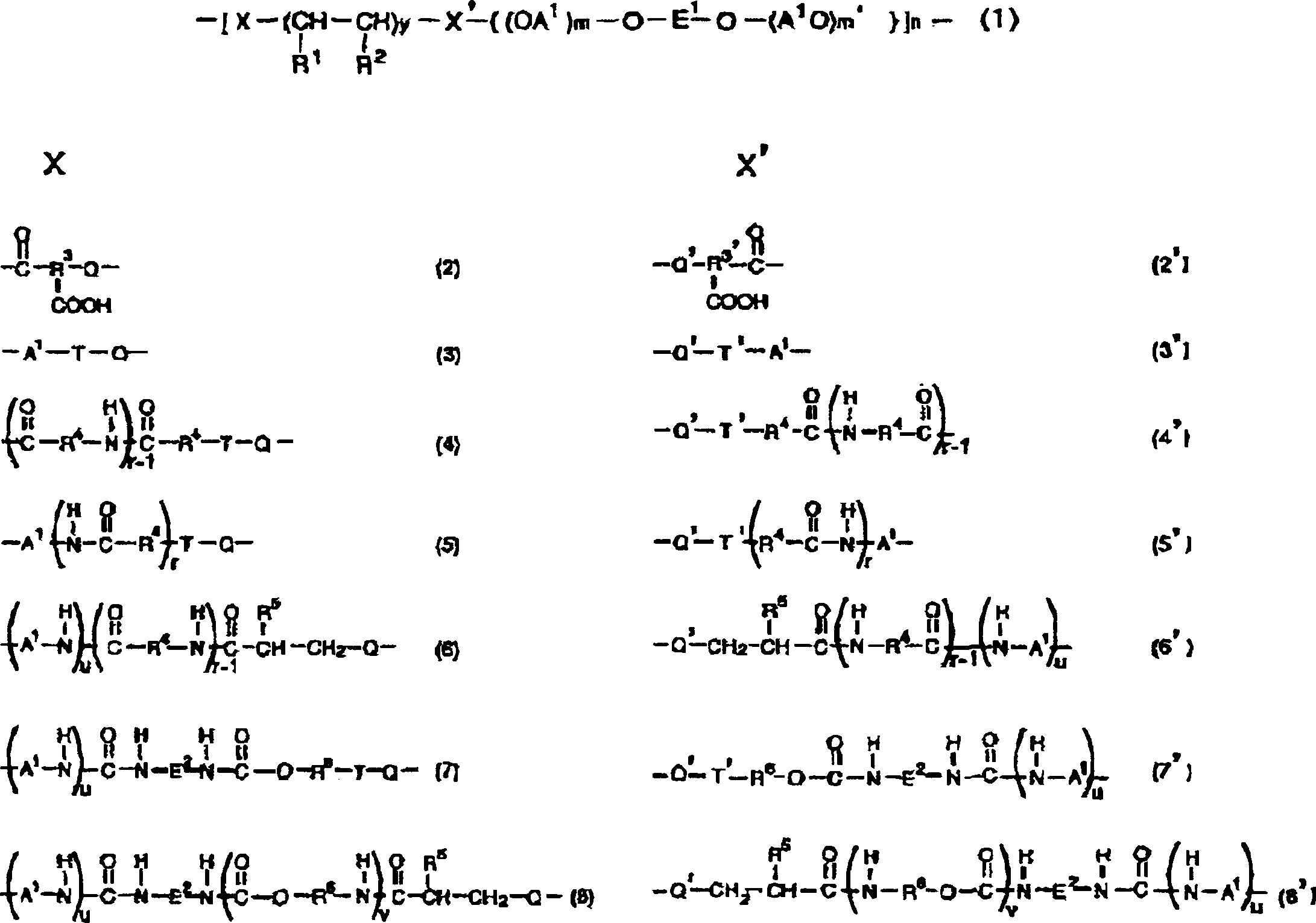

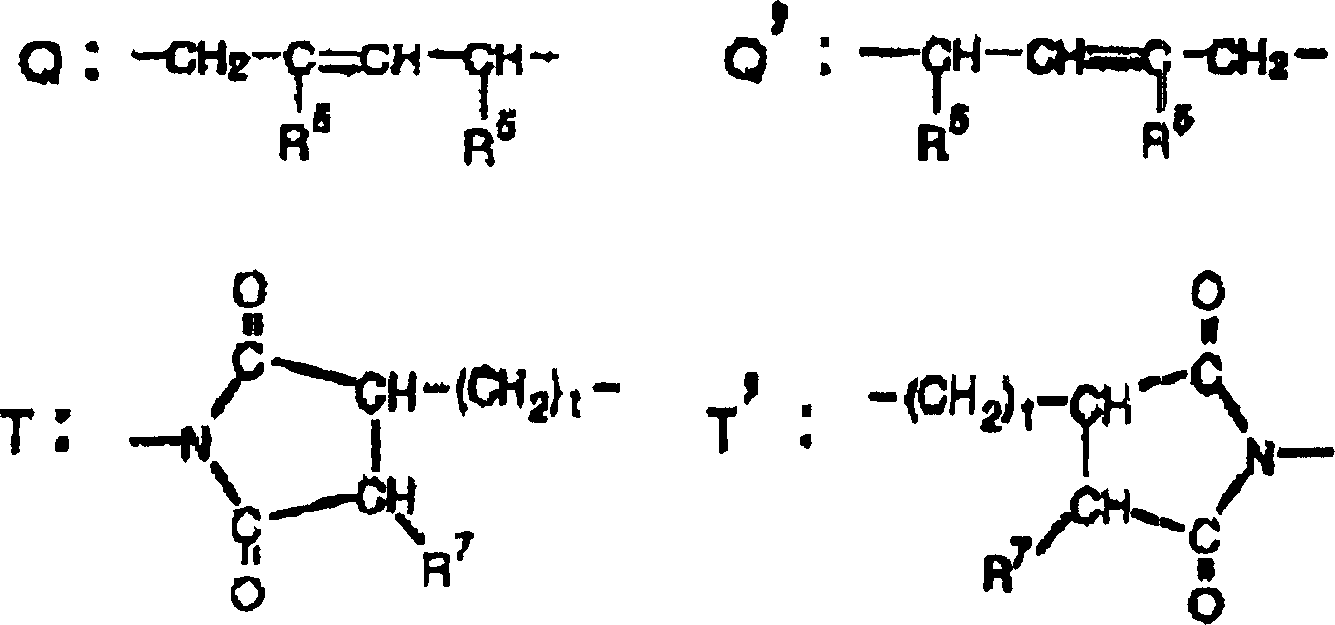

Polyolefin resin foam and manufacturing method thereof

The present invention provides a manufacturing method of a polyolefin resin foamed body which, when used as a packaging material, has least possibility of contaminating the surface of a contacting material, which excels in appearance and which shows antistatic characteristics uniform over the entire surface, and provides the polyolefin resin foamed body. The present invention comprises a specific mount of a polymer type antistatic agent whose apparent density may be 15 to 65 g / L, whose specific surface inherent resistance rate is 1 X 108 to 1 X 1013 (ohm), and whose average foamed body diameter meets a specific relationship.

Owner:JSP CORP

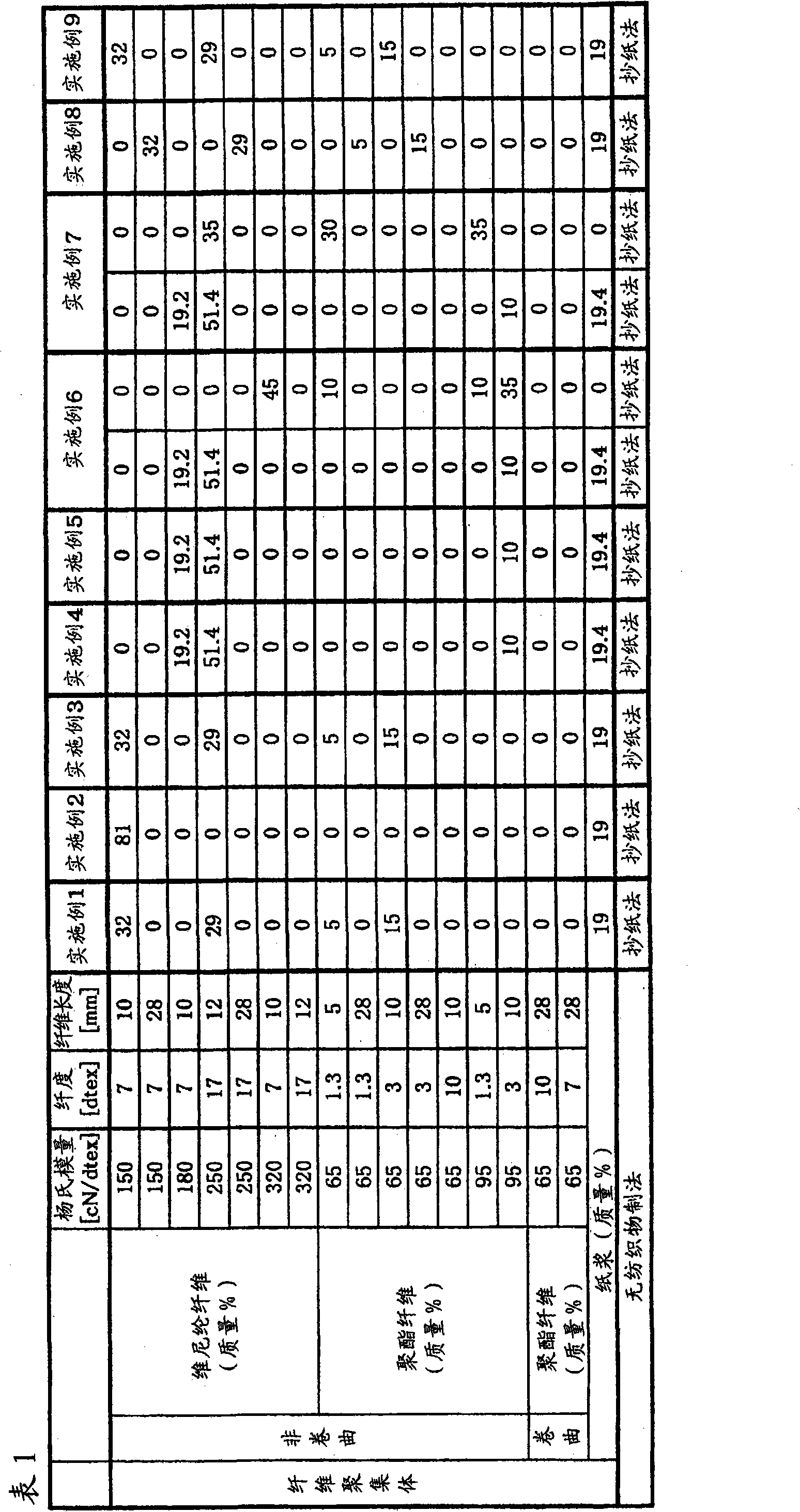

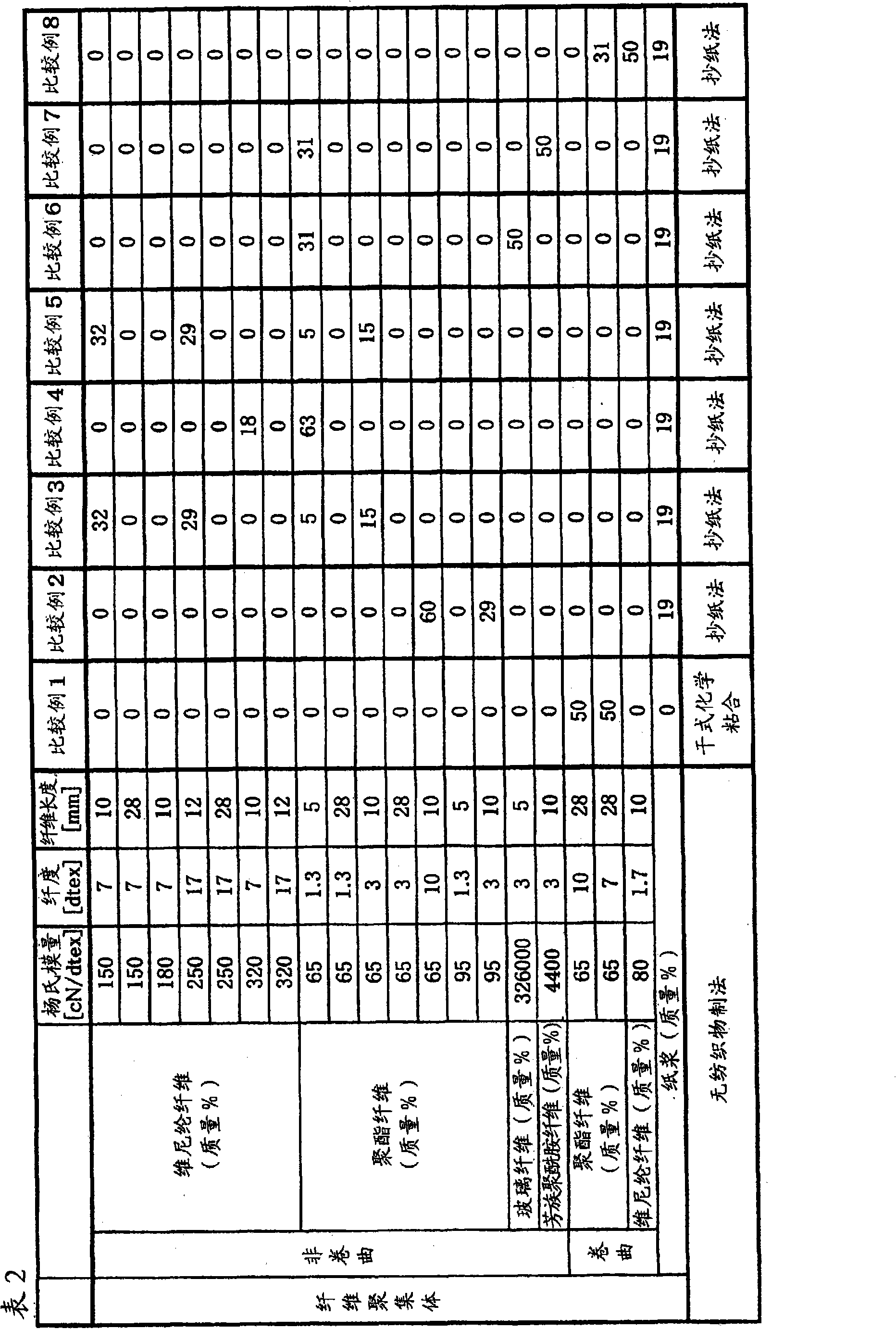

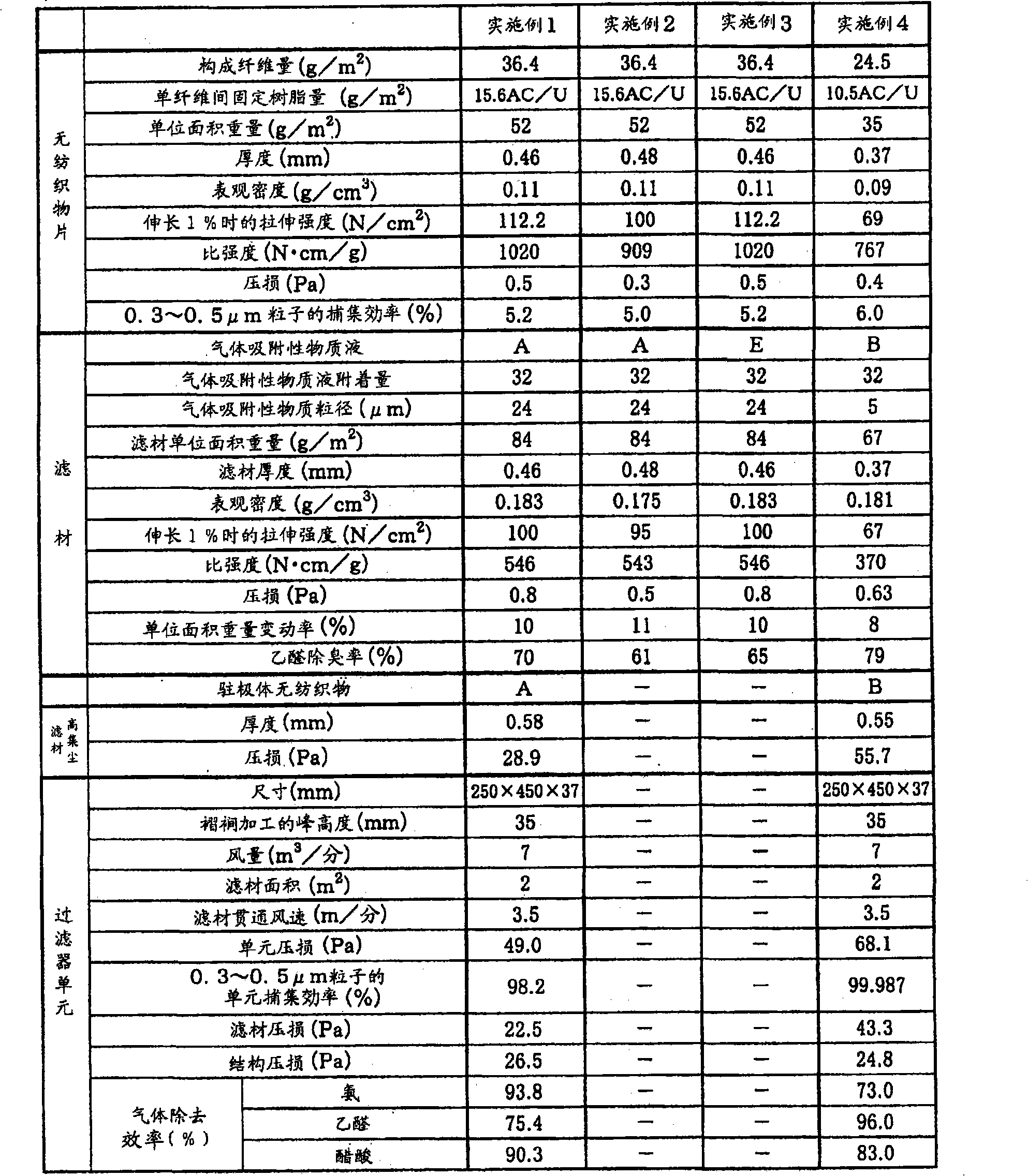

Filter element and filter unit

ActiveCN101808709AHigh strengthLow apparent densityDispersed particle filtrationOther chemical processesAir volumeYoung's modulus

A thin deodorizing filter element that can be minipleated; accordingly, a filter element resulting from integration of the deodorizing filter element with a dust collection filter element that can be regenerated by washing; and a dust collecting / deodorizing filter unit ensuring low pressure loss that can process a large air volume. A highly rigid nonwoven fabric sheet is produced from a noncrimped monofilament of specified Young's modulus and specified fineness, and a gas adsorptive substance is fixed thereonto.

Owner:TORAY IND INC

Recycled concrete brick and preparation method thereof

ActiveCN102964093ALow densityLow apparent densitySolid waste managementCeramic shaping apparatusSolventConstruction aggregate

The invention discloses a recycled concrete brick and a preparation method thereof. Every cubic meter of the recycled concrete bricks is prepared from the following raw materials in parts by weight: 365-385 parts of cement, 710-750 parts of sand, 669-709 parts of gravel, 446-486 parts of recycled aggregate, 120-140 parts of water and 1.8-2.2 parts of solvent-type water reducing agent when the substitution rate of the recycled aggregate is 35-45%; or 375-395 parts of cement, 720-760 parts of sand, 436-476 parts of gravel, 679-719 parts of recycled aggregate, 125-145 parts of water and 1.7-2.0 parts of solvent-type water reducing agent when the substitution rate of the recycled aggregate is 55-65%. The method for preparing the recycled concrete brick comprises the following steps: preparing the recycled aggregate, premixing the raw materials, mixing at high speed, carrying out vibration demolding, and curing. The invention has the advantages of high compression strength, high folding strength, favorable use functions, flexible assembly mode, high construction waste utilization ratio, high substitution rate of recycled aggregate, and low production cost, and thus, has favorable popularization prospects.

Owner:SHENYANG LIGONG UNIV

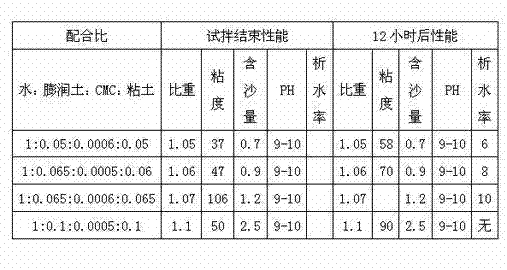

Construction slurry for rotary pile drilling

InactiveCN102226077ARich and stableEnrich and perfect mechanicsDrilling compositionSlurry wallSodium Bentonite

The invention discloses a type of construction slurry for rotary pile drilling. The slurry is a type of compound slurry comprising water, bentonite, hydroxypropyl methyl cellulose solution, clay and soda ash. The construction slurry provided by the present invention can be widely applied in fields of well drilling, rotary pile drilling, and underground diaphragm wall. During a preparing process, the slurry can be mixed quickly and well. The slurry also has advantages of high efficiency, low pollution, low energy consumption and low cost.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HIGHWAY ENG

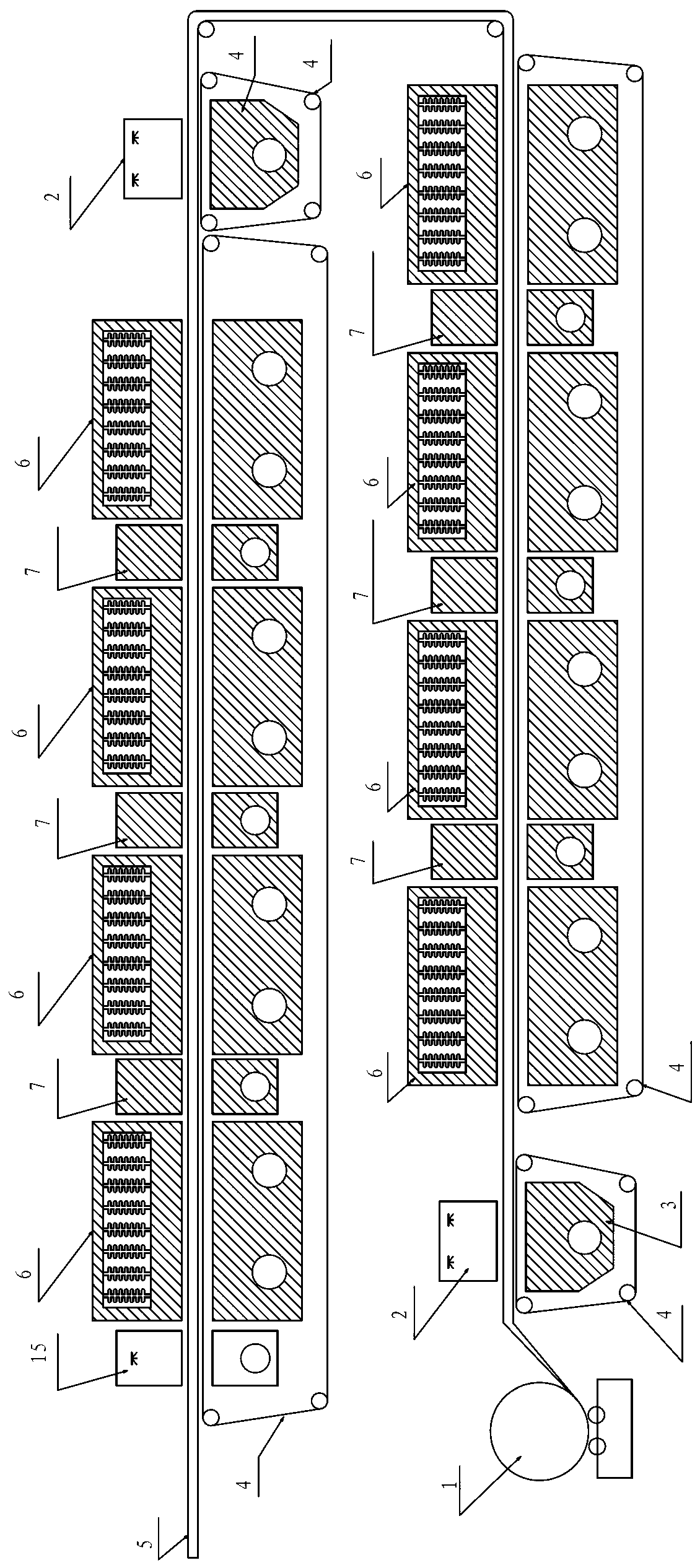

Method for manufacturing reconstituted tobacco substrate by using dry method of paper making

ActiveCN103222676AMake a qualitative leapNo significant emissionsTobacco preparationFiberCarrying capacity

A method for manufacturing a reconstituted tobacco substrate by using a dry method of paper making comprises the following steps: after tobacco stems, plant fiber materials become short fibers by crushing and fiber dissolving, the short fibers are conveyed to forming head boxes to be broken up by wind, and the broken-up materials are evenly laid and adsorbed on a forming net of the dry method of paper making by the vacuumizing effect of an air suction device below the forming net to form a fiber film; an adhesive is added into the fiber film in a spraying manner, wherein a manner combining spraying through mist spray with vacuum suction on the back face of the spraying is adopted; and finally the reconstituted tobacco substrate with a dimensional lattice structure is obtained by oven-drying. Antistatic ropes are laid between the upper part of the forming net and the forming head boxes or between the forming net and openings of vacuum boxes, and / or antistatic nets are laid between the forming net and the openings of the vacuum boxes. According to the invention, dry method of paper making is firstly used successfully to manufacture the reconstituted tobacco substrate which has better wet strength, a stronger tensile capacity, a high load-carrying capacity, a high filling value and an excellent processing capability.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Reinforced cement foaming board and preparation method thereof

InactiveCN103172327AGuaranteed carbonization indexStrength does not shrinkCeramic shaping apparatusCeramicwareFiberPolymer science

The invention relates to a reinforced cement foaming board and a preparation method thereof. The reinforced cement foaming board comprises the following components in percentage by weight: 27.00-35.50% of water, 28.0-61.0% of Portland cement, 0-32.70% of coal ash at grade I or a mixture of coal ash and recycled filler, 0-2.00% of wollastonite powder, 0.10-0.30% of fiber, 0.37-0.65% of ammonium stearate, 1.00-2.00% of a mixture of 10 parts of calcium sulphate and 1 part of calcium formate, 0.10-0.20% of naphthalenesulfonate formaldehyde condensation compound, 0.90-1.20% of hydrogen peroxide and reinforcement net. The reinforced cement foaming board provided by the invention has the advantages of low apparent density, low heat conductivity coefficient, good noise reduction effect, high strength, no crack and shock resistance.

Owner:上海中驰建筑工程有限公司

Process for preparing hydrophobic silicon dioxide aerogel using rice husk ash as raw material

InactiveCN1317188CReduce manufacturing costImprove hydrophobicitySilicaSupercritical dryingStrong acids

A process for preparing the hydrophobic SiO2 aero-gel from rice husk ash includes such steps as burning rice husk to obtain its ash, extracting its hydro-gel in inorganic strong-alkaline aqueous solution, neutralizing by inorganic strong acid, laying aside to generate SiO2 hydro-gel, filter, acid treating, ageing, water washing, displacing the water from the hydro-gel by organic solvent, supercritical drying and modifying surface. Its advantages are high specific surface area and pore volume, and low apparent density.

Owner:TSINGHUA UNIV

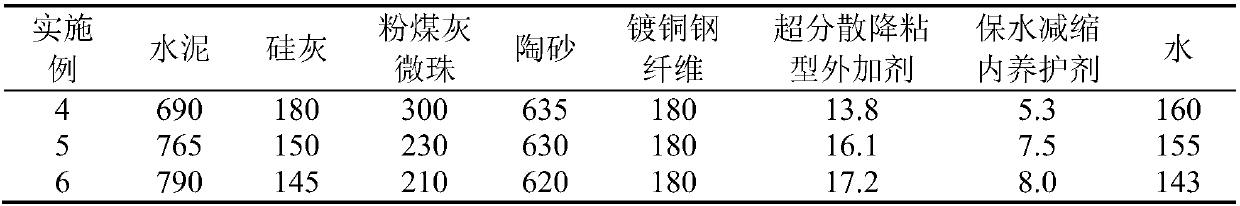

Waste rubber powder mixed model steel fiber reinforced lightweight aggregate concrete and preparation method thereof

InactiveCN104926239APromote resource utilizationImprove performanceSolid waste managementFiberWaste rubber

The invention relates to concrete and a preparation method, in particular to Waste rubber powder mixed model steel fiber reinforced lightweight aggregate concrete and preparation method thereof. The concrete per cubic meter is made of raw materials comprising, by weight, 14%-25% of cement, 0.1%-0.6% of model steel fibers, 0.03%-1.75% of rubber powder, 22%-45% of fine sand, 27%-50% of fly ash ceramsite, 6%-12.9% of net water content and 0%-0.03% of water reducing agents. The old rubber powder and the model steel fibers are mixed into the lightweight aggregate concrete, so that performance advantages of two kinds of materials can be given to full play, on the other hand, the old rubber powder is added in the model steel fiber reinforced lightweight aggregate concrete, vibration energy can be more effectively absorbed, impact performance and bend toughness of the lightweight aggregate concrete can be enhanced remarkably, and meanwhile, frost resistance, corrosion resistance and abrasion resistance of the model steel fiber reinforced lightweight aggregate concrete can be improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

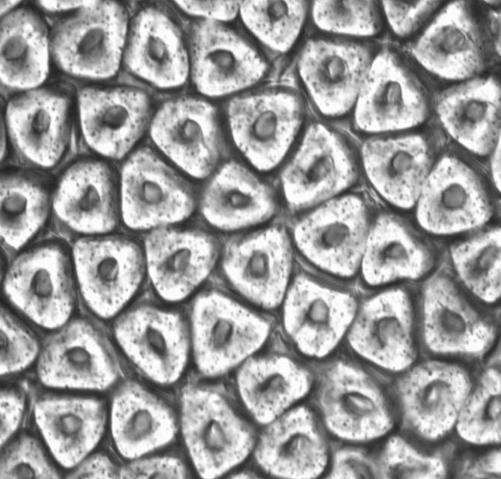

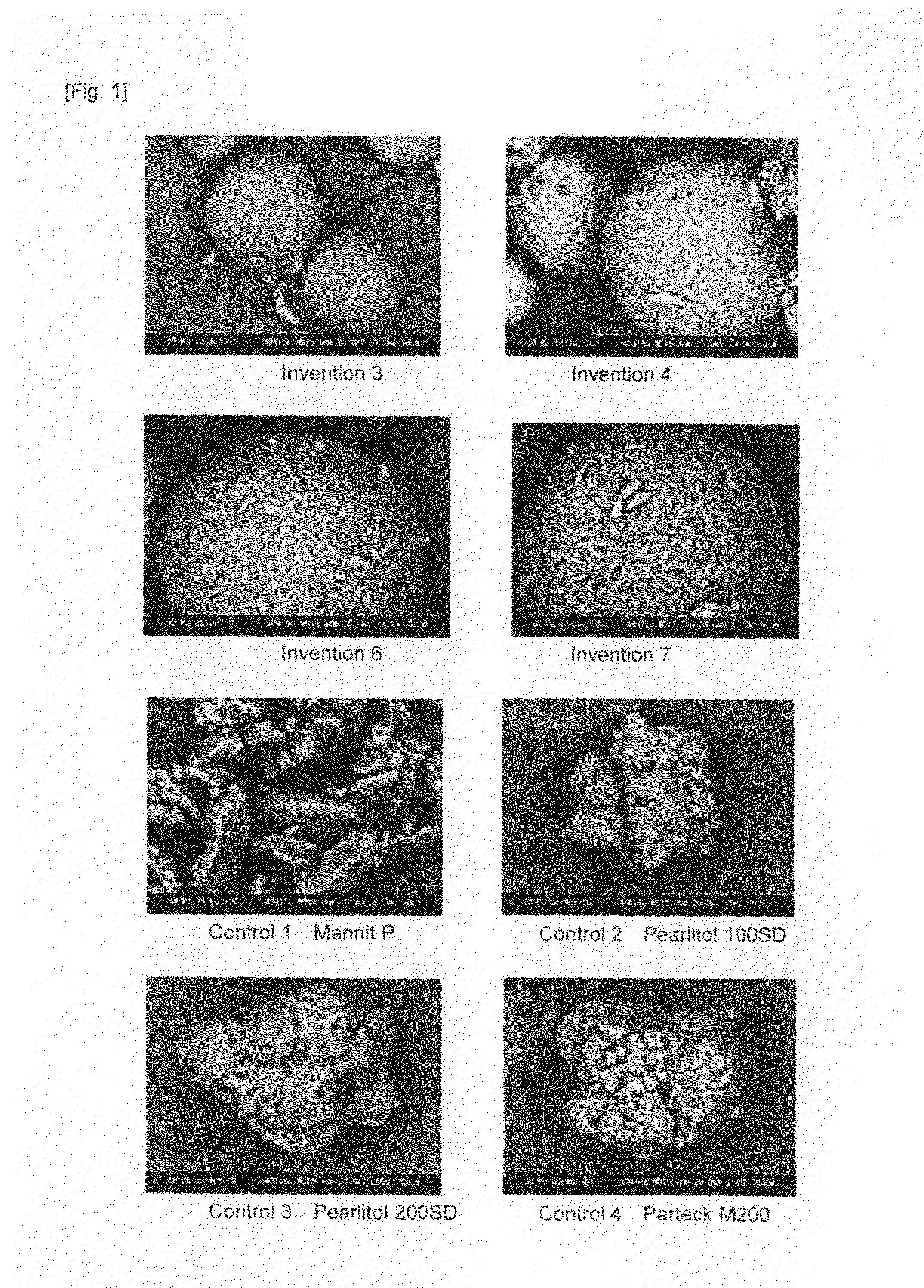

Spherical particle of crystalline mannitol

InactiveUS20100167052A1Improve liquidityHigh oil absorptionPowder deliverySynthetic resin layered productsMANNITOL/SORBITOLHardness

[Summary][Problems] To provide extremely-spherical-three-dimensional-shaped particles of crystalline mannitol containing large hollows and gaps inside.[Solution] Spherical particles of crystalline mannitol made by spray drying, extremely spherical (having an aspect ratio of 1.0 to 1.2), high oil absorption rates according to test method A, wherein powder has a mean particle diameter of 15 to 165 μm, a loose bulk density of 0.35 to 0.60 and an angle of repose of 30 to 50 degrees, and has a hardness of 7 to 20 kgf, when directly compressed.

Owner:MITSUBISHI SHOJI FOODTECH CO LTD

Straw/ash magnesium-oxy-chloride cement hollow slat or hollow building block and preparation method thereof

InactiveCN101817670AReduce energy consumptionSave energySolid waste managementMixing operation control apparatusFiberResource saving

The invention discloses a straw / ash magnesium-oxy-chloride cement hollow slat or hollow building block and a preparation method thereof. The preparation method comprises the steps of: firstly, adding a modifying agent into an MgCl2 solution prepared by a normal bittern's slice to be stirred uniformly, wherein the mass ratio of MgO to MgCl2 is 5:1-6:1, the ash accounts for 10-30 percent by mass of the MgO and the modifying agent accounts for 0.5-2 percent of MgO; secondly, mixing and stirring with uniformly stirred MgO powder and ash to obtain a magnesium-oxy-chloride cement gelled material; thirdly, adding straw fibers into the magnesium-oxy-chloride cement gelled material according to the proportion that the straw fibers account for 10-40 percent of the total volume of the straw fibers and the magnesium-oxy-chloride cement gelled material, uniformly stirring by adding water until the fluidity of a mixture reaches 110-140 mm according to the straw water absorption, and die-filling, vibrating and molding or reducing the water to binder ratio and then pressurizing and molding to obtain the straw / ash magnesium-oxy-chloride cement hollow slat or hollow building block after slurry shows better fluidity. The invention has good watertightness, high strength, good temperature and heat insulating effect, resource saving and environment load reduction.

Owner:SOUTHEAST UNIV

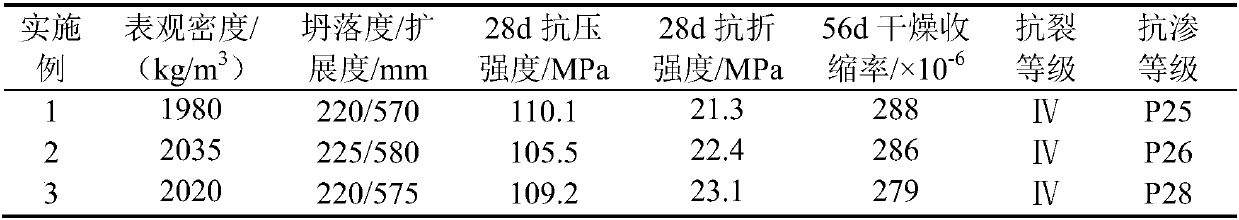

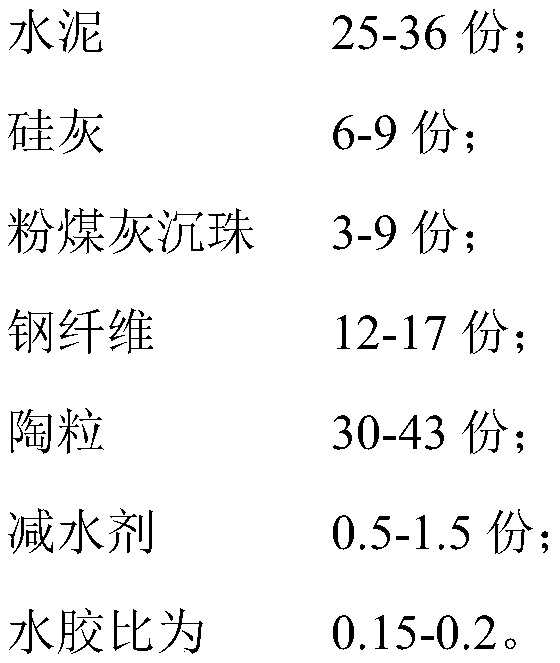

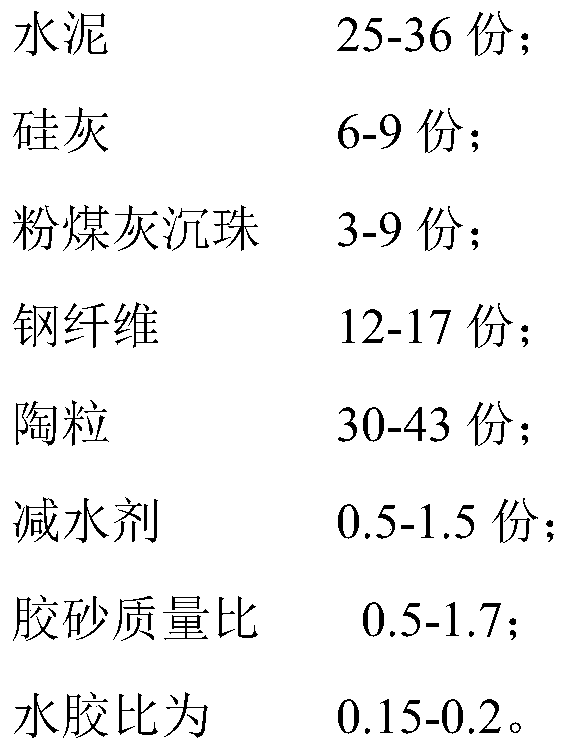

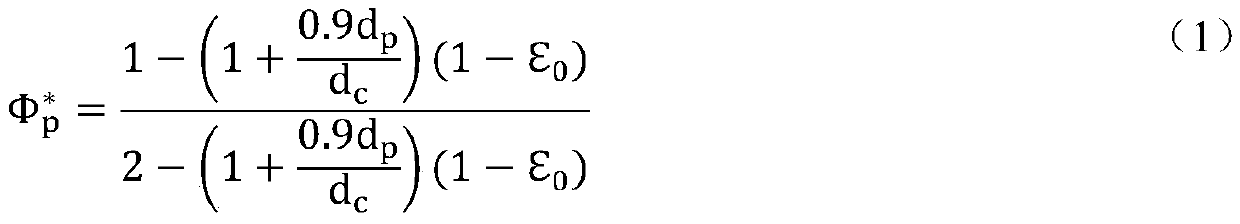

Autoclaving-free light ultra-high-performance concrete and preparation method thereof

The invention belongs to the technical field of building materials, and particularly relates to an autoclaving-free light ultra-high-performance concrete and a preparation method thereof. The ultra-high-performance concrete without high-temperature steam curing or autoclaved curing has the advantages of excellent working performance, low density, ultra-high strength, good volume stability and thelike, the durability of a concrete structure is improved, the problems of large size and dead weight and difficulty in transportation and hoisting of a prefabricated assembly bridge member in currenturban traffic construction can be solved, and the concrete has important practical application values. The preparation method and a construction technology are simple and easy in operation and have practical popularization values. Optimal gradation of the maximum compactness and ceramsites of a cement-silica fume-coal ash ternary system is achieved by the aid of a maximum stacking density theory,cement serves as a base material, silica fume serves as a densification component, coal ash serves as a modifier, the strength of the concrete is effectively improved by steel fibers, and micro-crackextension is delayed.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

EPS foam article and production technology thereof

The invention discloses an EPS foam article which comprises an EPS raw material and a foaming agent; and the mass of the foaming agent is 4.5-7.2% of that of the EPS raw material. The invention further discloses a production technology of the EPS foam article. The production technology comprises the following steps of S1, stock preparation, S2, heating, S3, pre-foaming, S4, curing, S5, moulding, S6, cooling, S7, drying and S8, aftertreatment. The EPS foam article is low in apparent density and high in flexural strength, is of a closed cell structure internally provided with a large number of fine air bubbles and is long in service life. The production technology of the EPS foam article is stable and simple in technological process; the cooling is carried out through a cooling system, so that manual operation is reduced, the cooling effect is good, and the drying time is shortened; cooled water is subjected to settlement by a settling pool, so that pipe clogging is avoided; and the water is softened by water treatment equipment, so that a mould of a forming machine is effectively protected, the service life of the mould is prolonged, the maintenance cost is reduced, and the rate offinished EPS foam is raised.

Owner:南通市金马包装材料有限公司

Rubber modified solidified soil, and preparing and construction method

InactiveCN101323516AImprove toughnessImproved resistance to shrinkage crackingSolid waste managementRubber materialApparent density

A rubber modified solidifying soil comprises the following components by weight percentage: 1 to 20 percent of rubber material, 3 to 35 percent of gelled material, 40 to 95 percent of soil and 0 to 5 percent of water. The rubber modified solidifying soil is formed by mixing soil, gelled material and rubber material with water and stirring and solidifying the mixture. The preparation and construction method comprises the steps as follows: (1) the water content of the engineering soil is measured; (2) the optimal water content of soil is defined; (3) the water content is adjusted; (4) the adopted gelled material is mixed evenly; (5) the soil with the adjusted water content by the step (3) which reaches the optimal or approaches the optimal is mixed with the gelled material and rubber material according to the designed weight percentage of the components, and then water is added into the mixture and then the obtained mixture is stirred evenly, and then the mixture is paved and rolled for shaping; after shaped, water is scattered on the obtained soil for maintaining. The solidifying soil of the invention has higher toughness, anti-shrinking and anti-crack capability and fatigue resistant capability, the apparent density is reduced and simultaneously, the waste rubber is utilized again; the economic and environmental benefits are better and the application field is wide.

Owner:BEIHANG UNIV

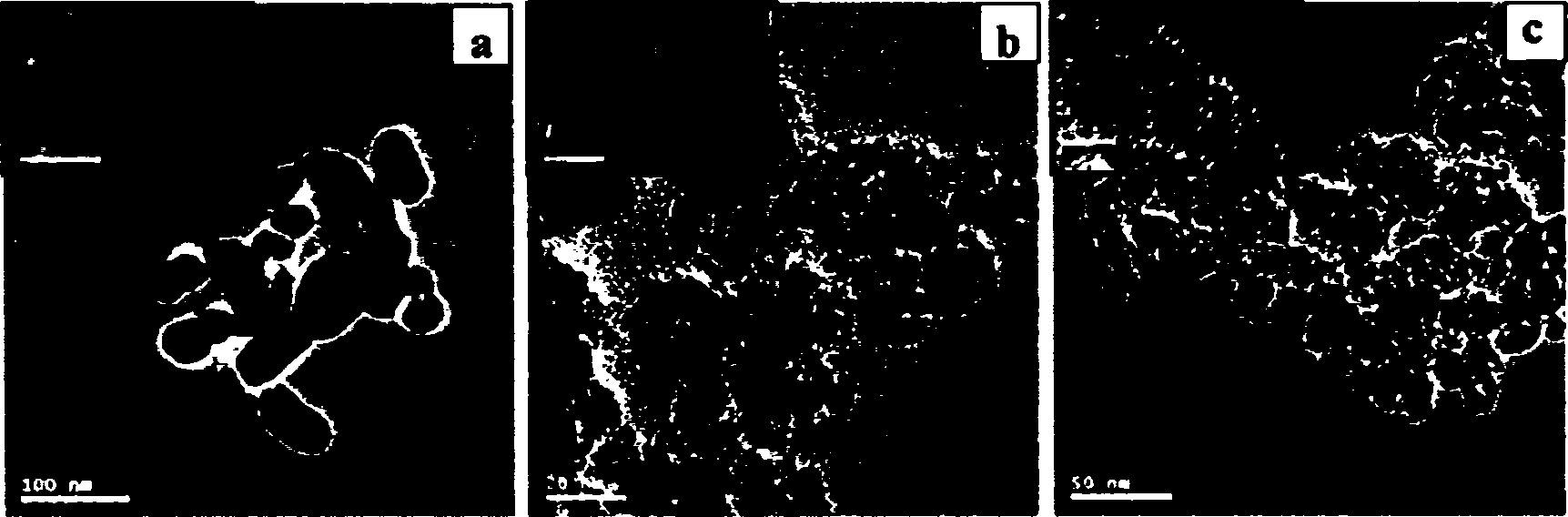

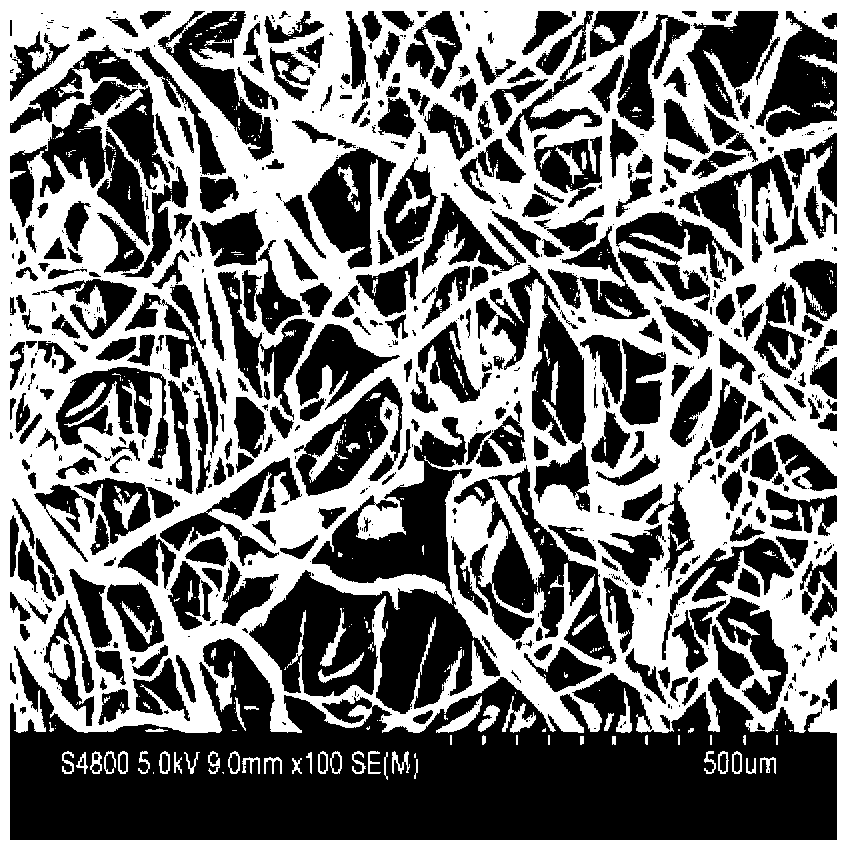

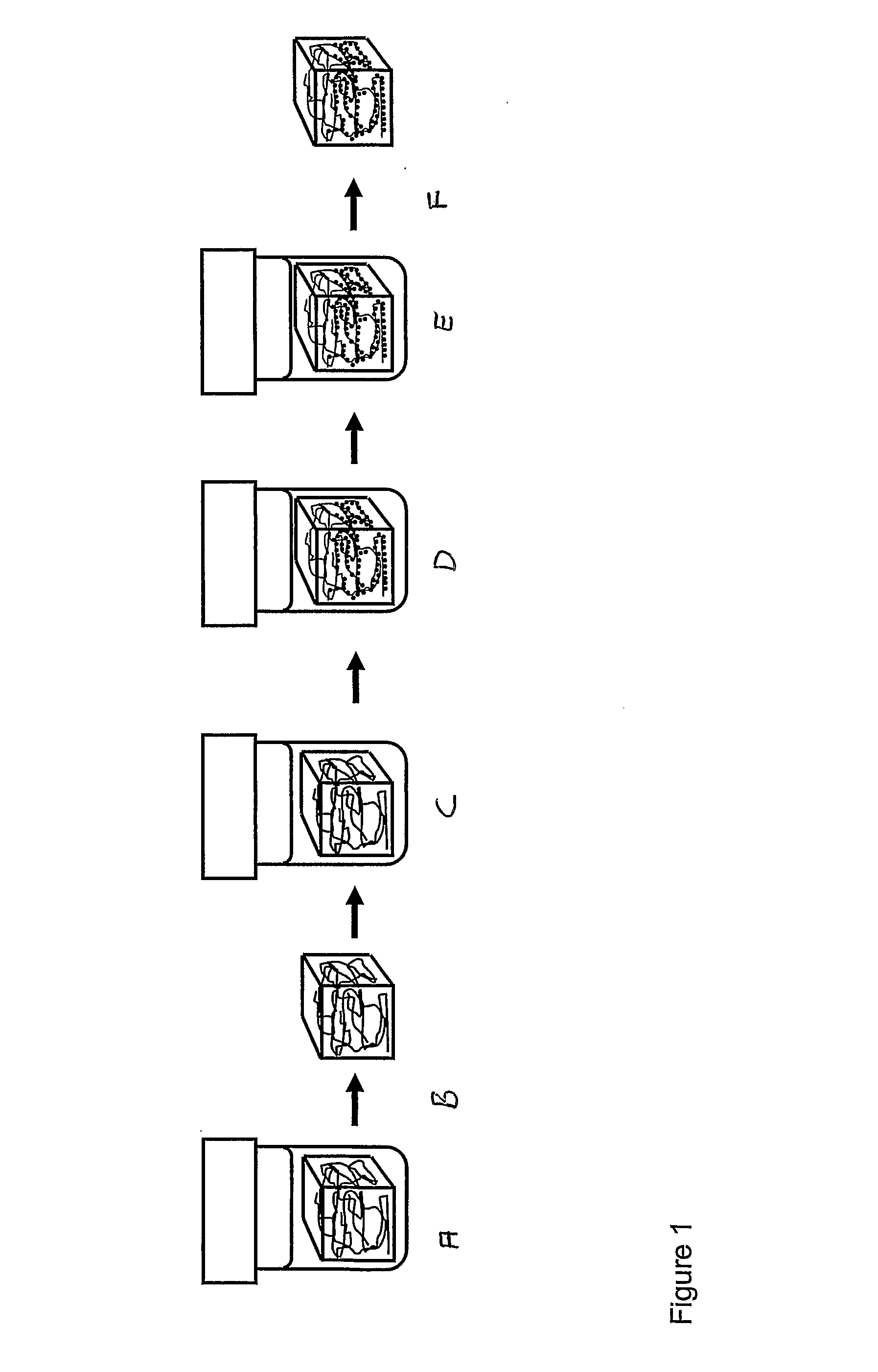

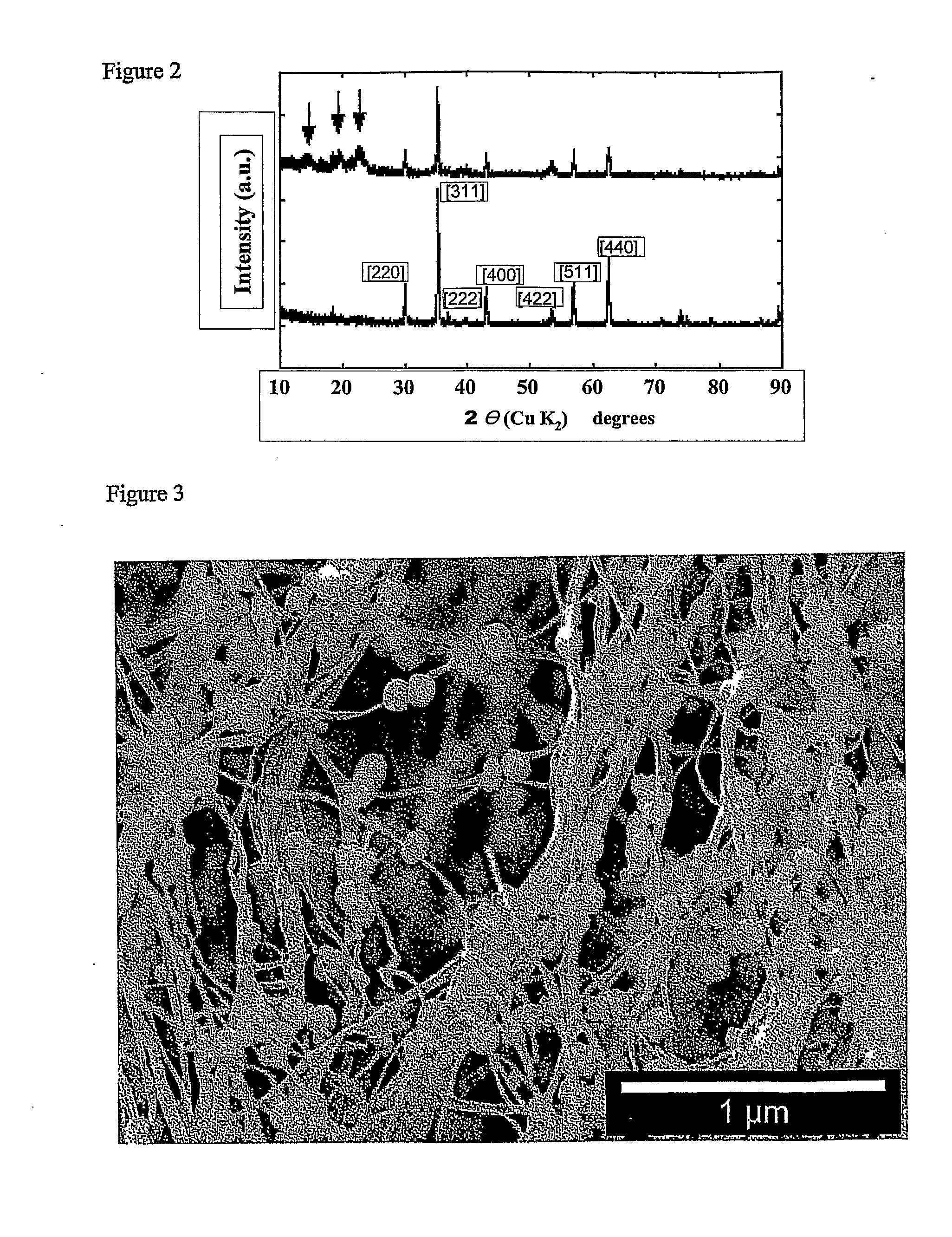

Magnetic nanoparticle cellulose material

InactiveUS20100203313A1Low apparent densityEqually distributedMaterial nanotechnologyNanomagnetismMagnetite NanoparticlesNanometre

The present invention relates to ferromagnetic materials based on nano-sized bacterial cellulose templates. More specifically, the present invention provides an agglomerate free magnetic nanoparticle cellulose material and a method of forming such magnetic nanoparticle cellulose material. Further, the magnetic nonoparticles are physically attached on the cellulose material and evenly distribute.

Owner:CELLUTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com