Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

235results about How to "High apparent density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

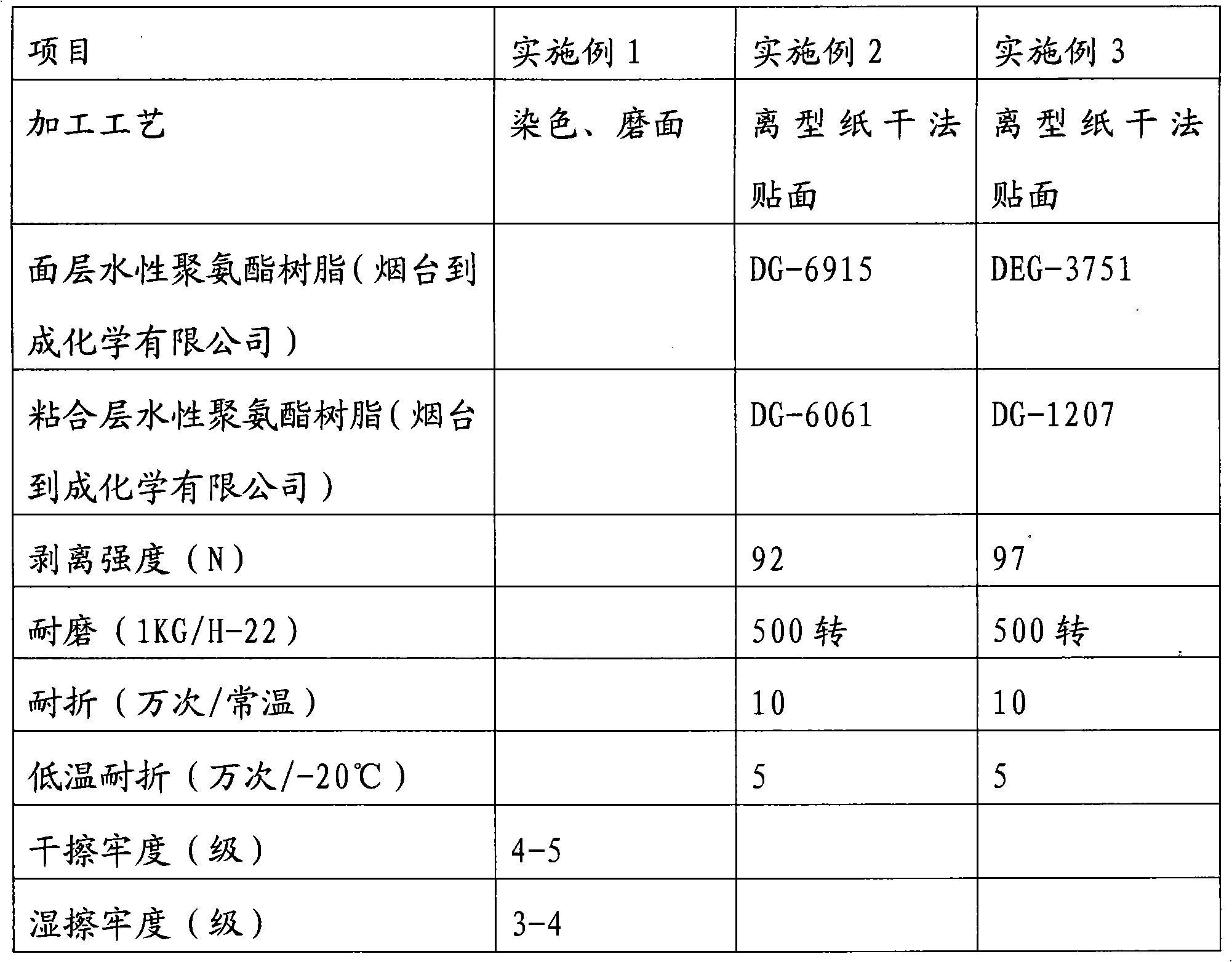

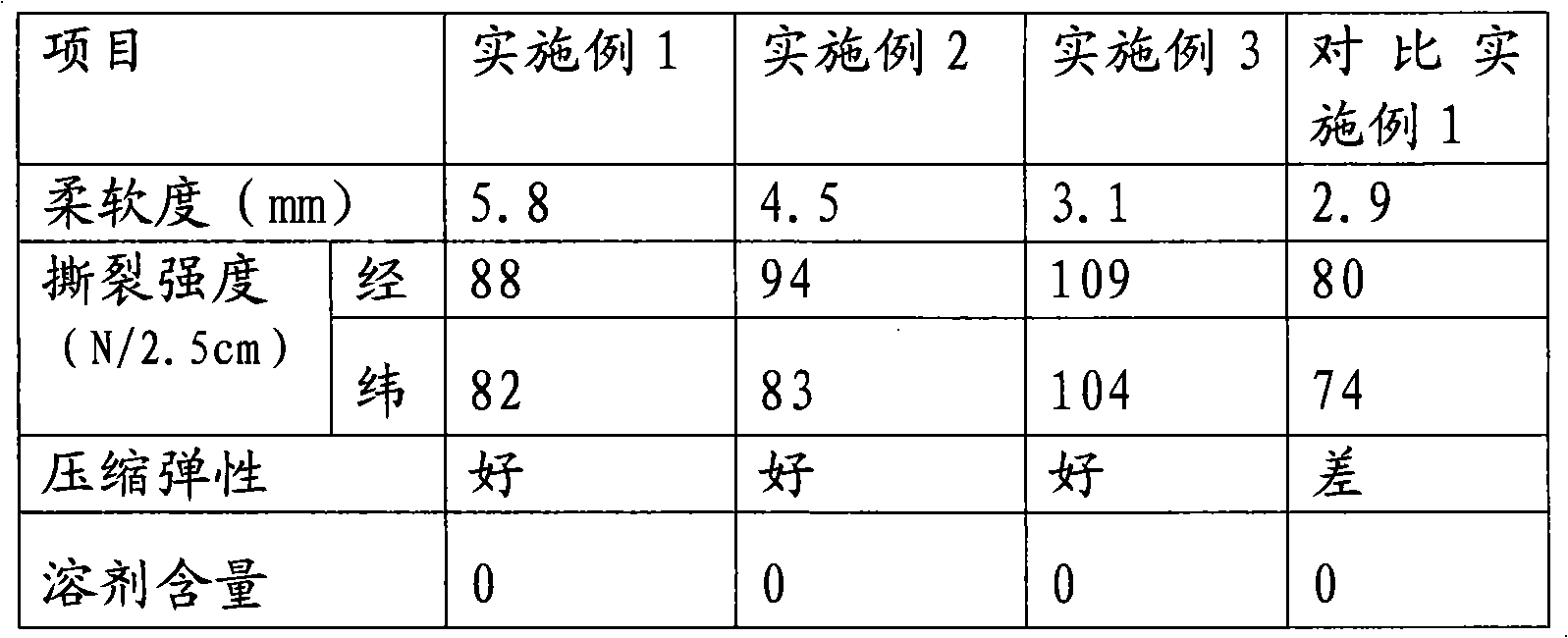

Aqueous polyurethane superfine fiber synthetic leather and preparation method thereof

The invention relates to aqueous polyurethane superfine fiber synthetic leather and a preparation method thereof. The preparation method comprises the following steps of: firstly, adding the following components according to parts by weight, i.e. 2-5 parts of foaming agents, 50-200 parts of water, 2-3 parts of foam stabilizers and 0-3 parts of waterborne colorants, into 100 parts of aqueous anionic polyurethane dipping sizing agents, and stirring the components and the sizing agents uniformly at high speed by using a blender so as to prepare a sizing agent; secondly, dipping non-woven fabricsin the sizing agent, scrapping the surface of the fabrics and keeping partial cells; thirdly, solidifying aqueous polyurethane on the dipped non-woven fabrics through aqueous coagulating liquid so asto form cells; fourthly, carrying out water scrubbing after aqueous polyurethane resin is completely solidified, and drying the aqueous polyurethane resin by an infrared drying oven so as to obtain base cloth; fifthly, treating the dried base cloth through an alkali reducing process; sixthly, treating the base cloth treated through the alkali reducing process through an postprocessing process; and seventhly, preparing the obtained base cloth into the synthetic leather. The aqueous polyurethane superfine fiber synthetic leather is prepared by the method.

Owner:HUADA CHEM GRP CO LTD

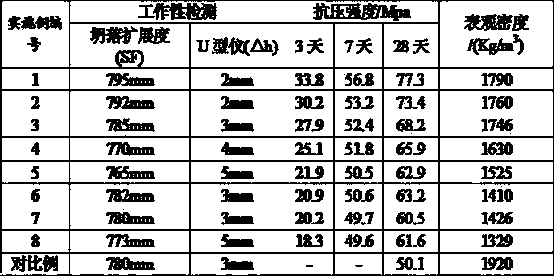

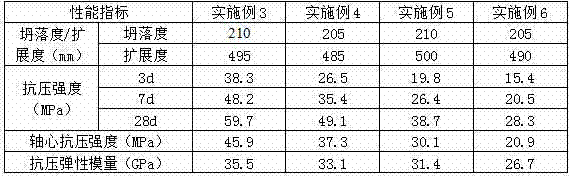

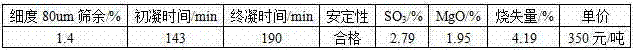

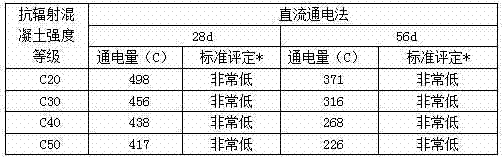

Self-compacting light aggregate concrete and preparation method thereof

InactiveCN103803904ALow densityLow apparent densitySolid waste managementStructural engineeringWater reducer

The invention provides self-compacting light aggregate concrete and a preparation method thereof, and belongs to the technical field of concrete preparation. The self-compacting light aggregate concrete consists of such raw materials as cement, fly ash, silica fume, floating beads, light fine aggregate, light coarse aggregate, a water reducing agent and water. The self-compacting light aggregate concrete provided by the invention has the advantages of being low in appearance density, high in slump expansion degree and capable of avoiding floating of the floating beads; self-compacting light aggregate concrete differing in grade, especially self-compacting light aggregate concrete with strength grade above C60 and appearance density at 1400-1800kg / m<3>, can be prepared through the raw materials.

Owner:北京中联新航建材有限公司

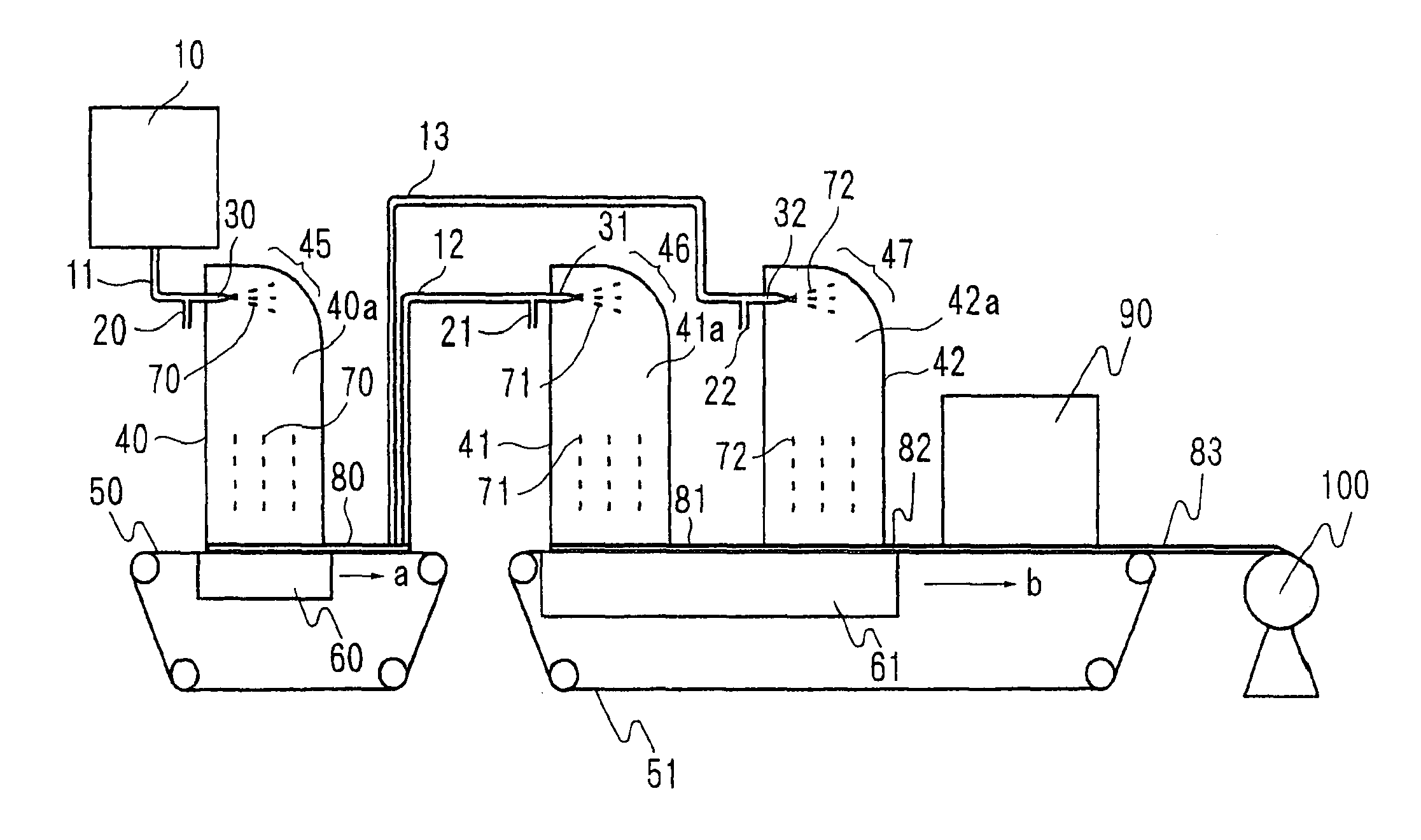

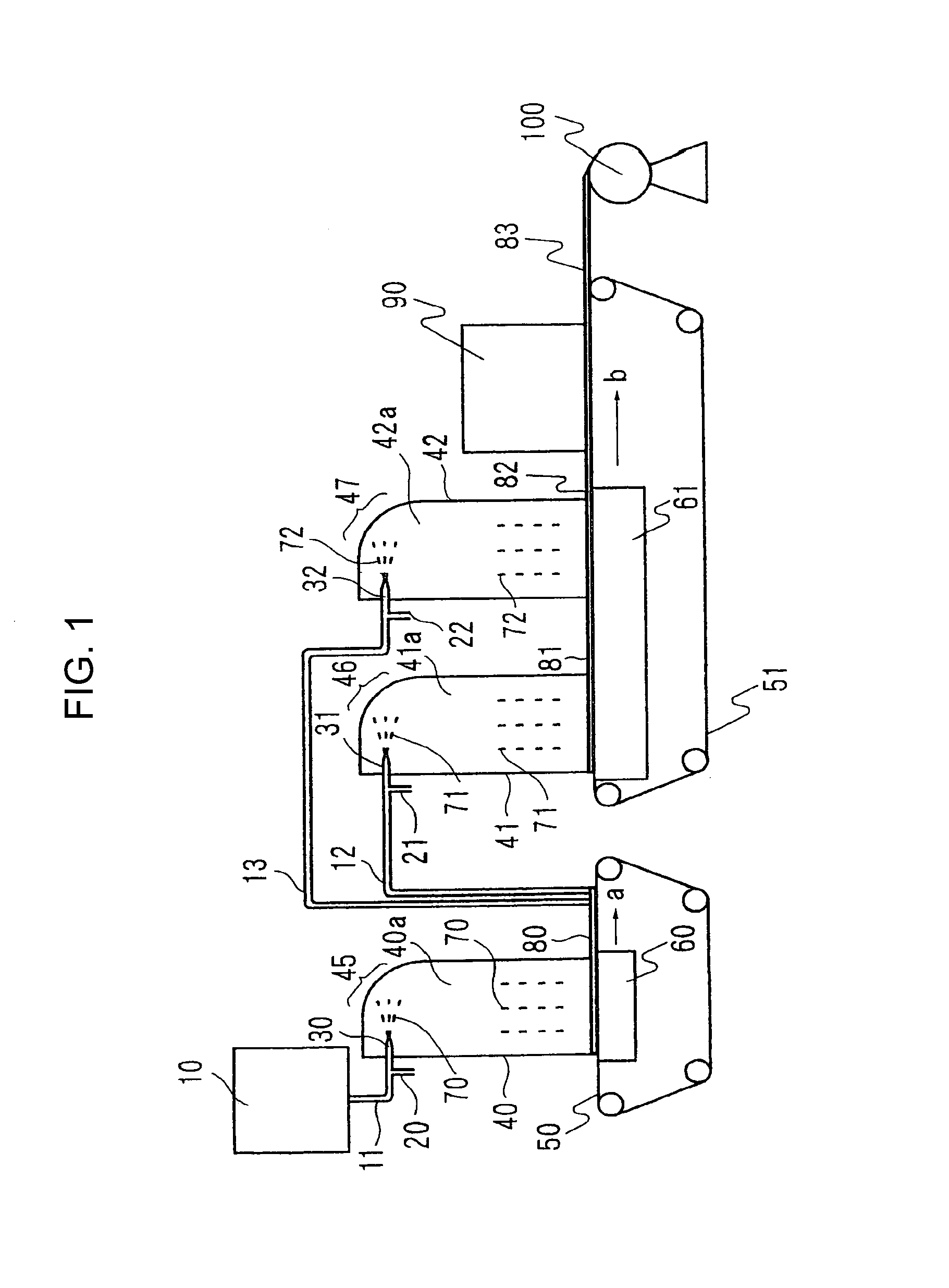

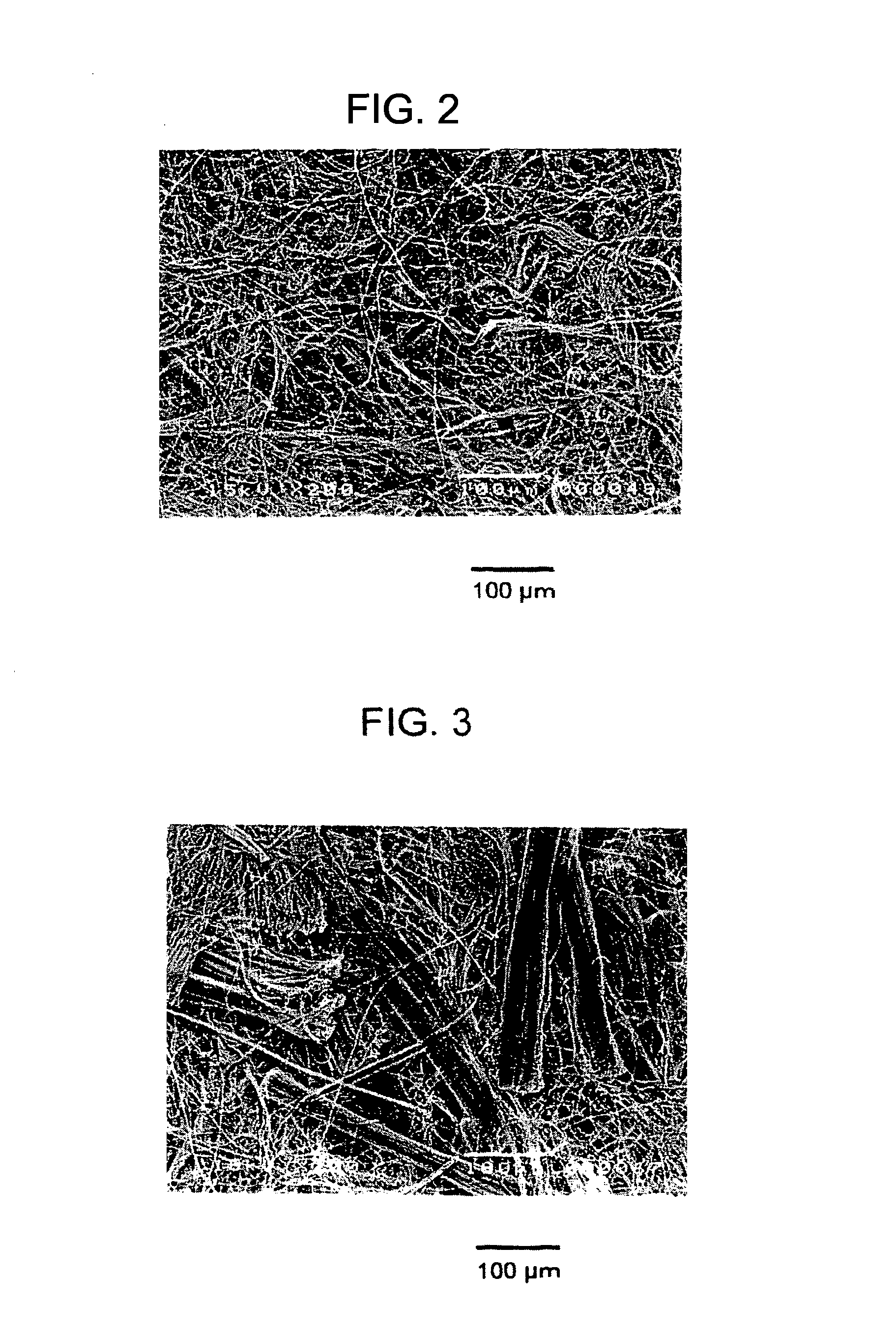

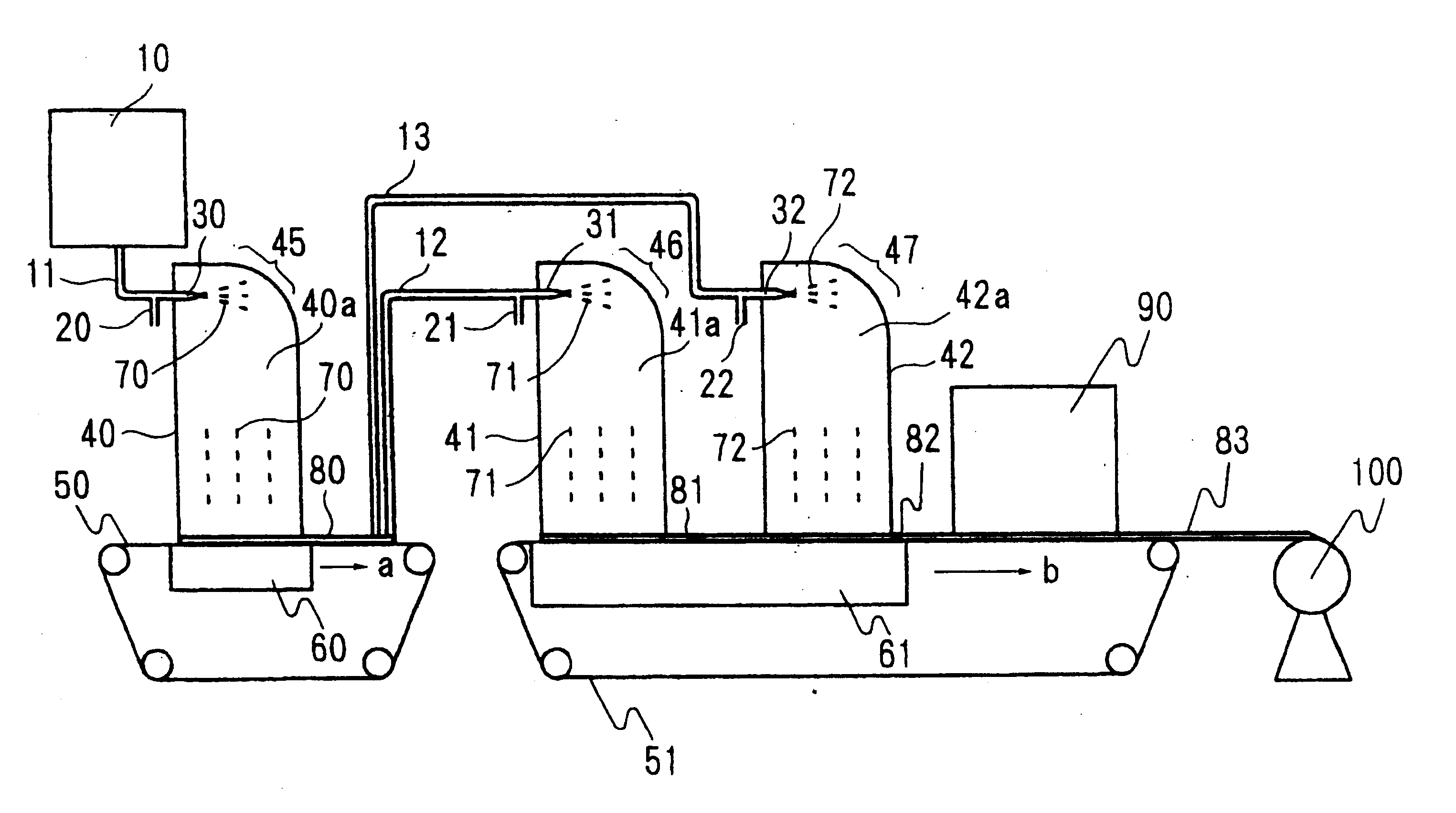

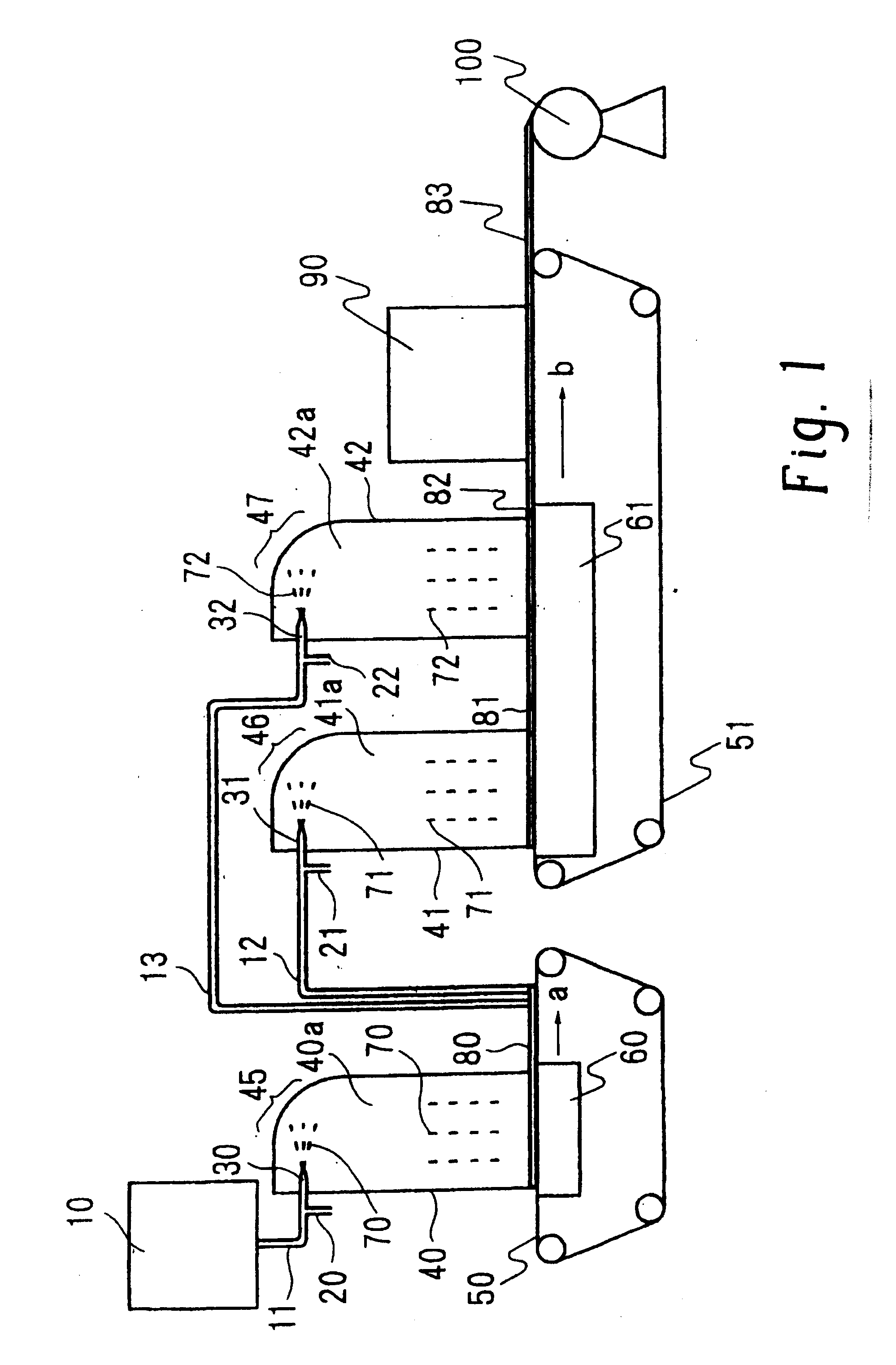

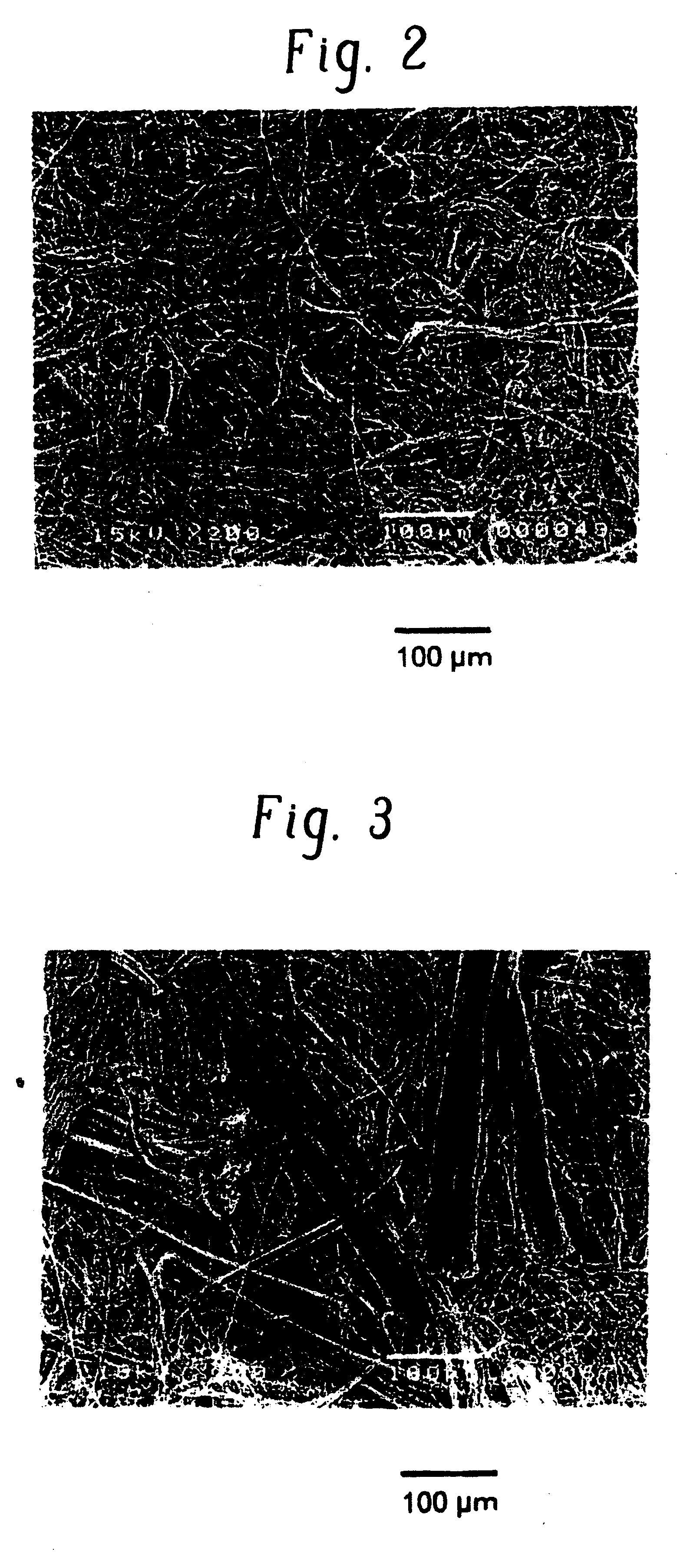

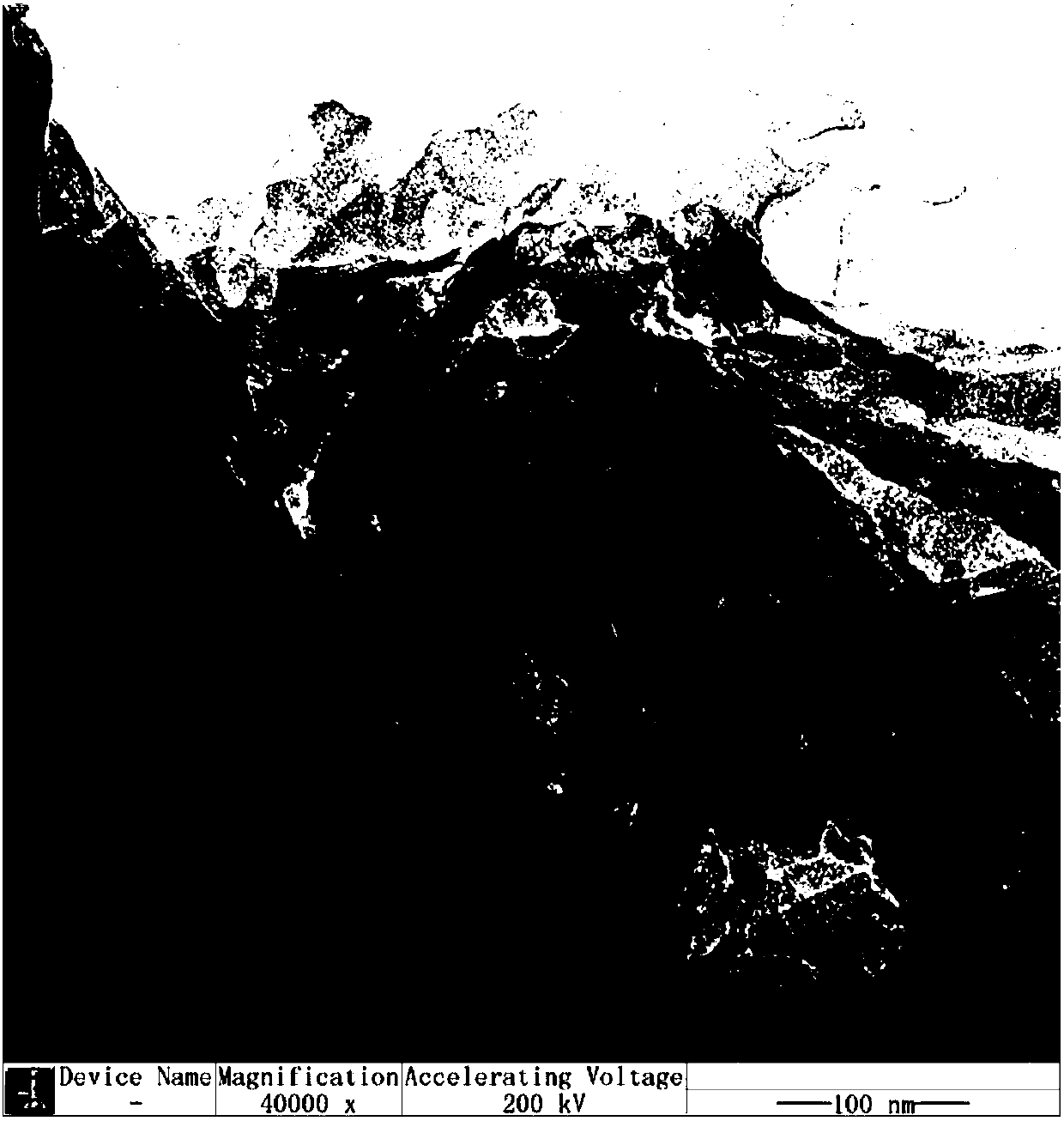

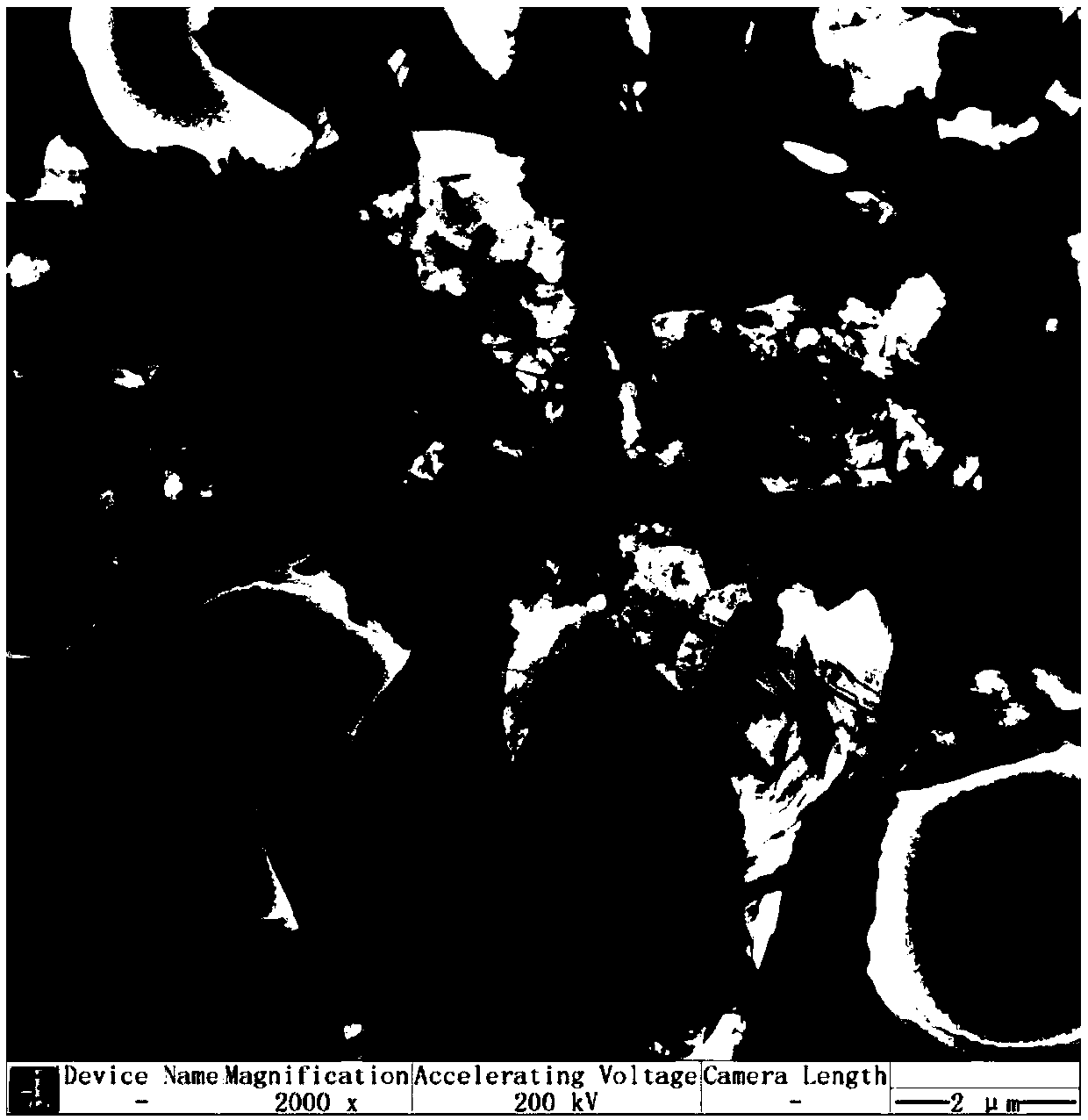

Fine-fibers-dispersed nonwoven fabric, process and apparatus for manufacturing same, and sheet material containing same

InactiveUS7837814B2High apparent densityGood adhesionSynthetic resin layered productsAbrasion apparatusPolymer scienceFiber diameter

Disclosed is a fine-fibers-dispersed nonwoven fabric comprising dispersed fine fibers having a fiber diameter of 4 μm or less and a fiber length of 3 mm or less, wherein an adhesion rate of substances adhered to the nonwoven fabric is 0.5 mass % or less. Further, a process and an apparatus for manufacturing the fine-fibers-dispersed nonwoven fabric, as well as a sheet material comprising the fine-fibers-dispersed nonwoven fabric are also disclosed.

Owner:JAPAN VILENE CO LTD

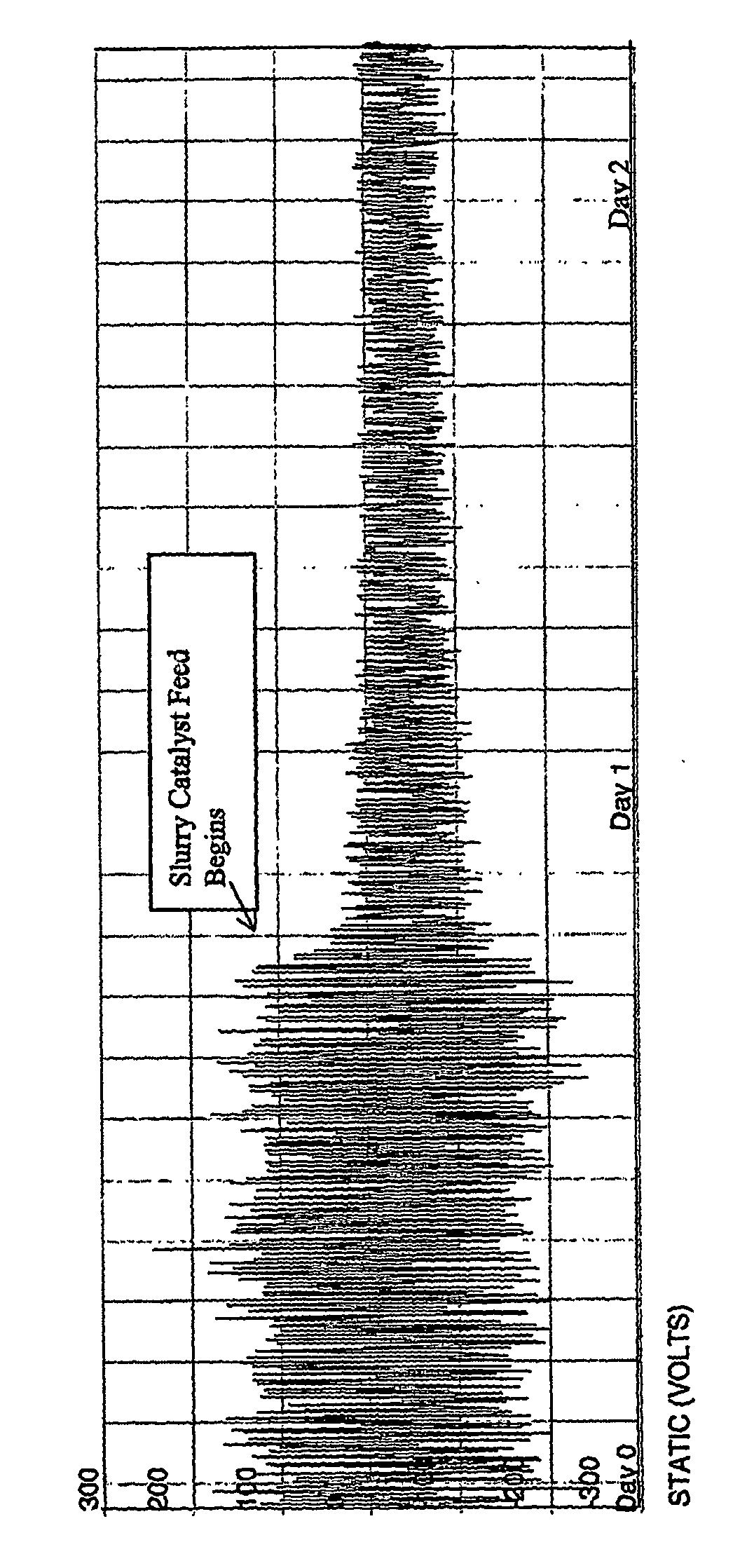

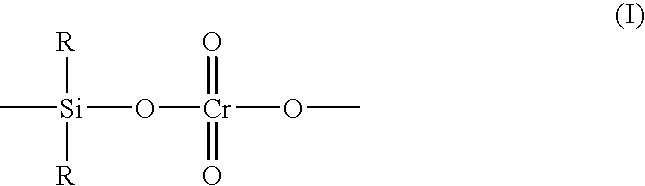

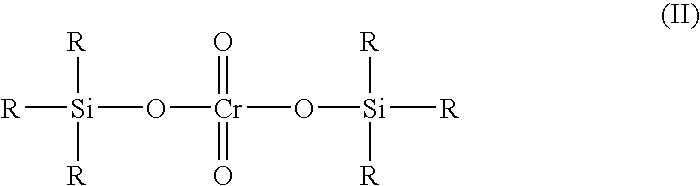

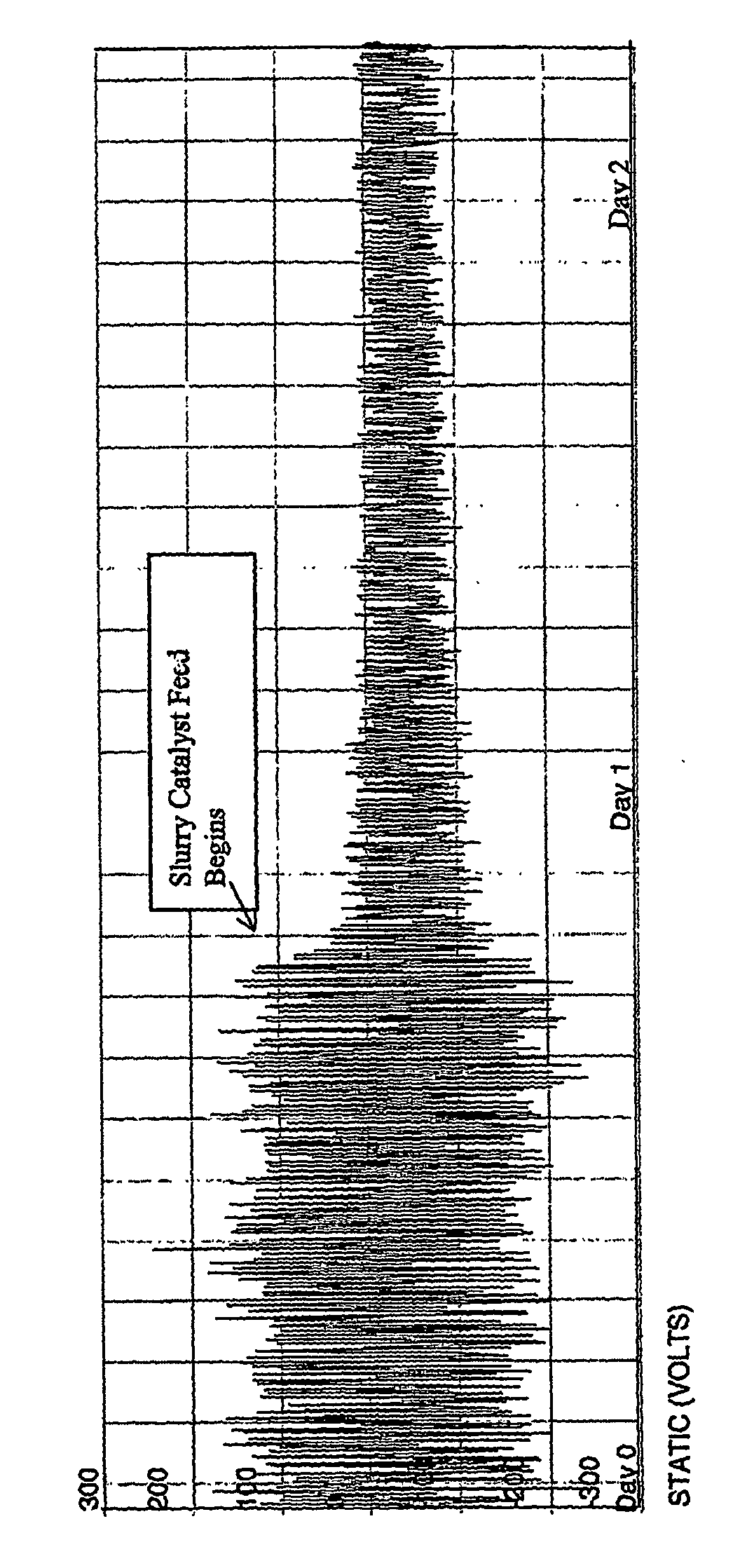

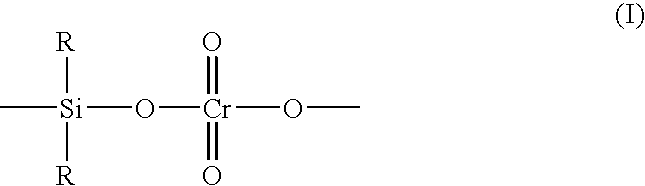

Chromium-based catalysts in mineral oil for production of polyethylene

A process for polymerizing polyethylene with chromium-based catalysts wherein one or more supported chromium-based catalysts is mixed with mineral oil to form a slurry and the slurry is then introduced into a polymerization reactor, especially a gas-phase polymerization reactor.

Owner:UNIVATION TECH LLC

Fine-fibers-dispersed nonwoven fabric, process and apparatus for manufacturing same, and sheet material containing same

InactiveUS20060081330A1Maintain good propertiesSmall pressure lossSynthetic resin layered productsAbrasion apparatusPolymer scienceFiber diameter

Disclosed is a fine-fibers-dispersed nonwoven fabric comprising dispersed fine fibers having a fiber diameter of 4 μm or less and a fiber length of 3 mm or less, wherein an adhesion rate of substances adhered to the nonwoven fabric is 0.5 mass % or less. Further, a process and an apparatus for manufacturing the fine-fibers-dispersed nonwoven fabric, as well as a sheet material comprising the fine-fibers-dispersed nonwoven fabric are also disclosed.

Owner:NIPPON BAIRIIN

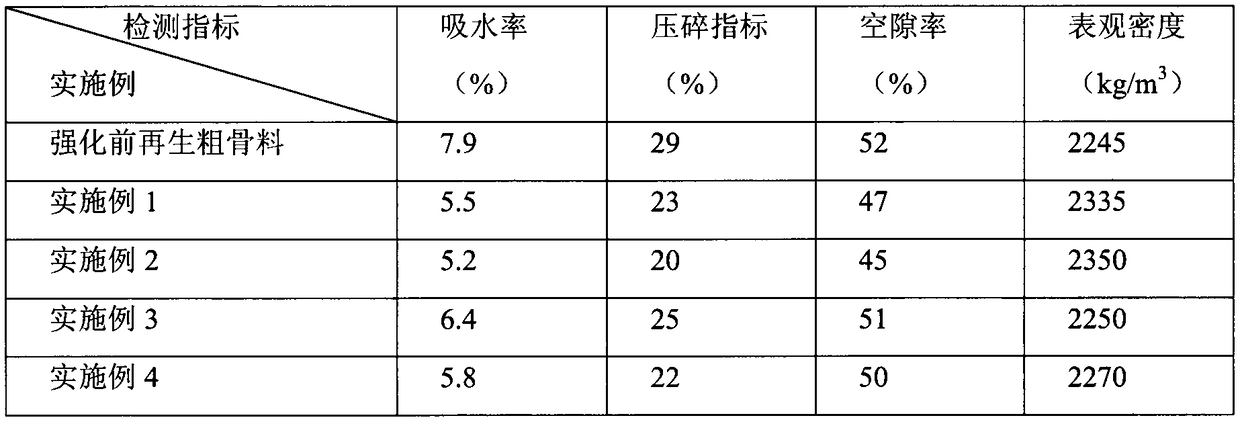

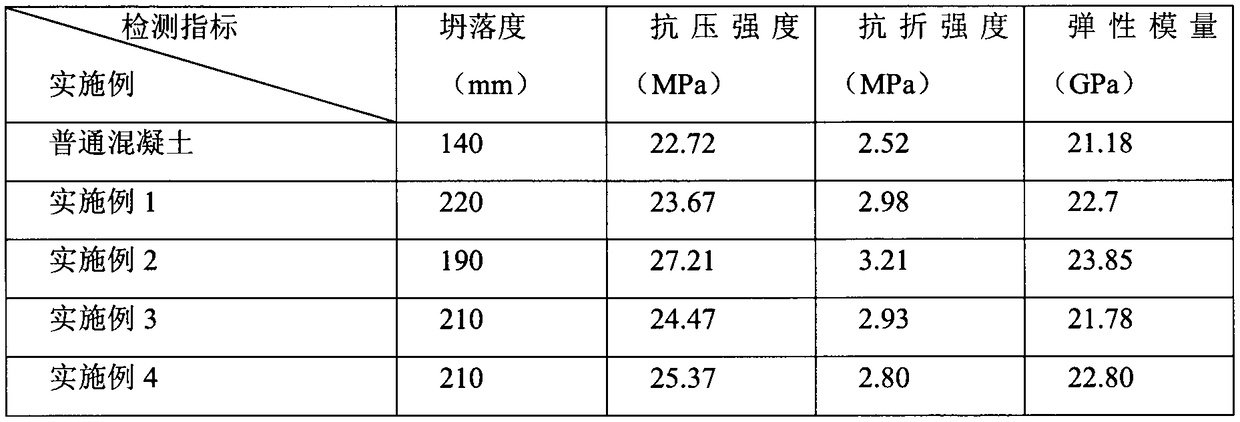

Recycled concrete and preparation method thereof

InactiveCN111039624AReduce porosityCompact structureSolid waste managementEpoxyCompressive resistance

The invention relates to recycled concrete and a preparation method thereof, and belongs to the technical field of concrete. The recycled concrete comprises (by weight): 150-280 parts of cement, 90-130 parts of water, 800-950 parts of modified recycled coarse aggregate, 400-530 parts of fine aggregate, 40-85 parts of fly ash, 80-100 parts of mineral powder, 50-140 parts of zeolite powder, 30-60 parts of epoxy resin, 4-10 parts of a water reducing agent and 2-6 parts of an air entraining agent. The preparation method of the modified recycled coarse aggregate comprises the following steps: S1, crushing and screening waste concrete to obtain recycled coarse aggregate; S2, soaking the recycled coarse aggregate obtained in the step S1 in an acetic acid solution with the mass concentration of 2-7%, and airing; S3, stirring 80-110 parts of polyvinyl alcohol, 60-110 parts of silica fume, 40-80 parts of sodium silicate and 800-1,000 parts of water to obtain a modified liquid; and S4, soaking the recycled coarse aggregate obtained in the step S2 in the modified liquid obtained in the step S3, taking out the soaked recycled coarse aggregate, and baking the recycled coarse aggregate to obtainthe modified recycled coarse aggregate. The recycled concrete provided by the invention has a good compressive strength effect.

Owner:泸州临港思源混凝土有限公司

Preparation method of fine globular tungsten powder

The invention relates to a powder material preparation method, in particular to a method for preparing fine spherical tungsten powder. Plasma parameters are adjusted by building a stable argon plasma, thereby heating tungsten powder material and acquiring the fine spherical tungsten powder through the separation after cooling and solidification, and the obtained tungsten powder has better fluidity, higher density, purity and particle cleanliness of surface, and lower powder particle porosity compared with the tungsten original powder; and the method has advantages of changing shapes of tungsten powder particles, high sphericity, increasing the apparent density of powder, improving the tungsten powder fluidity and physical characteristics of the tungsten powder, and reducing costs.

Owner:SOUTHWESTERN INST OF PHYSICS

Barite anti-radiation pump concrete

The invention discloses barite anti-radiation pump concrete. The concrete comprises the following components: cement, water, barite powder, barite sand, barite, synergist and admixture according to a ratio of [340-450]:[110-170]:[75-150]:[1000-1400]:[1800-2000]:[2-4]:[7-19]. According to selection of raw materials and design of the ratio, the anti-radiation concrete which is high in density and high in liquidity and can be used for pumping is obtained.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

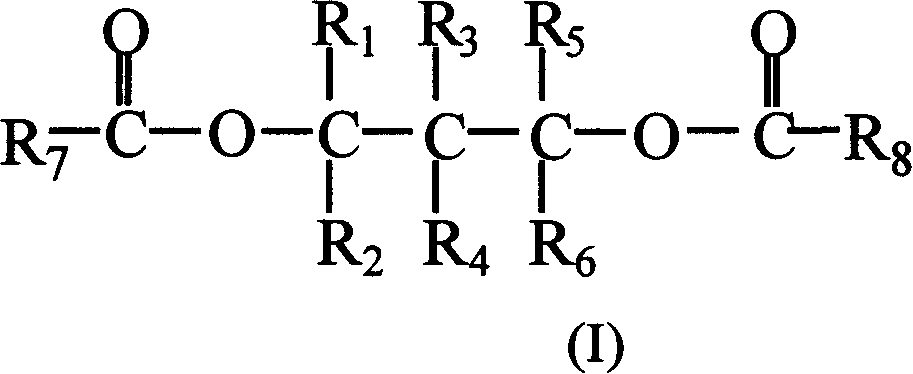

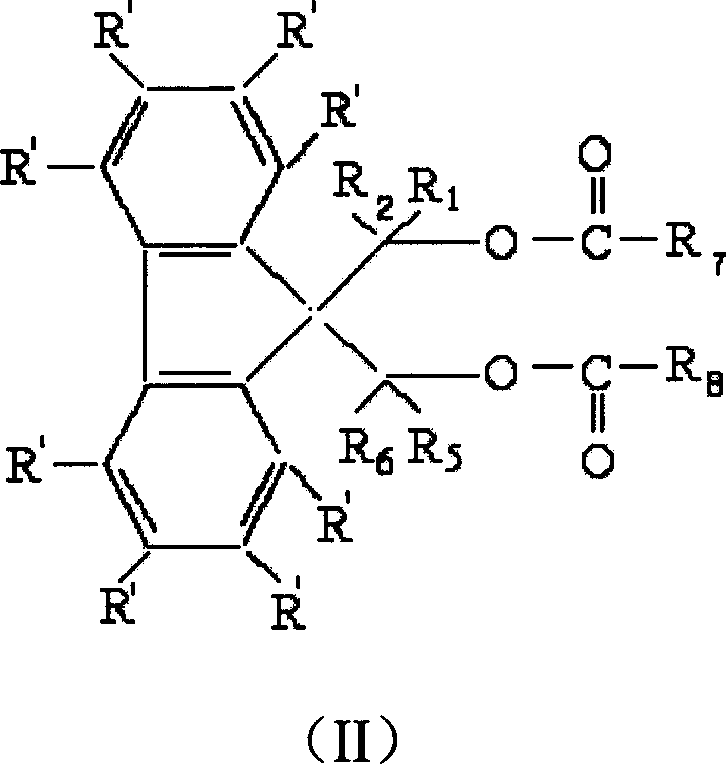

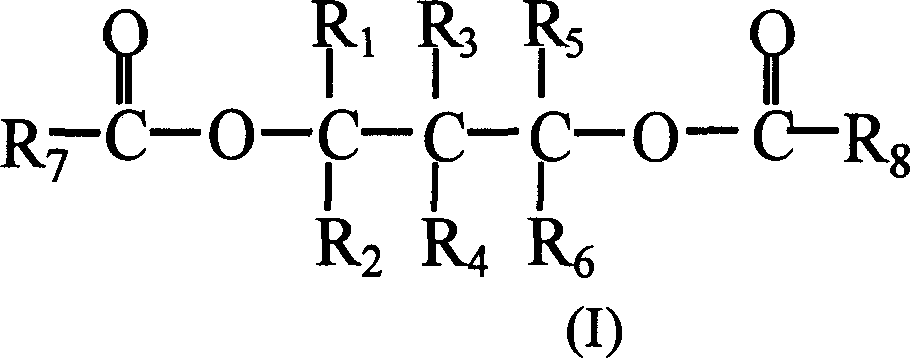

Catalyst compsns. for olefin polymerization and catalyst thereof

This invention relates to a catalyst component for alkene polymerization and its catalyst, and magnesium chloride-silica gel composite gel is adopted for this component. By introducing diol ester compounds which have a common formula (I) in the preparation of the catalyst component, the catalytic activity can be promoted. When the catalyst component in this invention is used in propylene polymerization, the obtained polymer has higher apparent density, narrower particle size distribution, high isotacticity, wide molecular weight distribution and outstanding comprehensive properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ardealite-based high-strength light building blocks prepared from ardealite and production process thereof

The invention relates to an ardealite-based high-strength light building block prepared from ardealite and a production process thereof. The ardealite-based high-strength light building block is prepared from the following raw material components by weight percent: 50-70% of dry basis of alpha high-strength gypsum, 3-10% of cement, 10-20% of coal ash, 10-20% of glass beads and 0.1-0.4% of air entraining agent. The raw materials are mixed together evenly in a water-material ratio from 0.4 to 0.6 and stirred into slurry; then the slurry is moulded to form the ardealite-based high-strength light building block. The ardealite-based high-strength light building block produced through the production process provided by the invention is found by detection that the apparent density of the solid building block is not higher than 1000 kg / m<3>, the strength grade is above MU10, the softening coefficient is not lower than 0.6 and the utilization rate of the solid waste is more than 70%.

Owner:WUHAN UNIV OF TECH

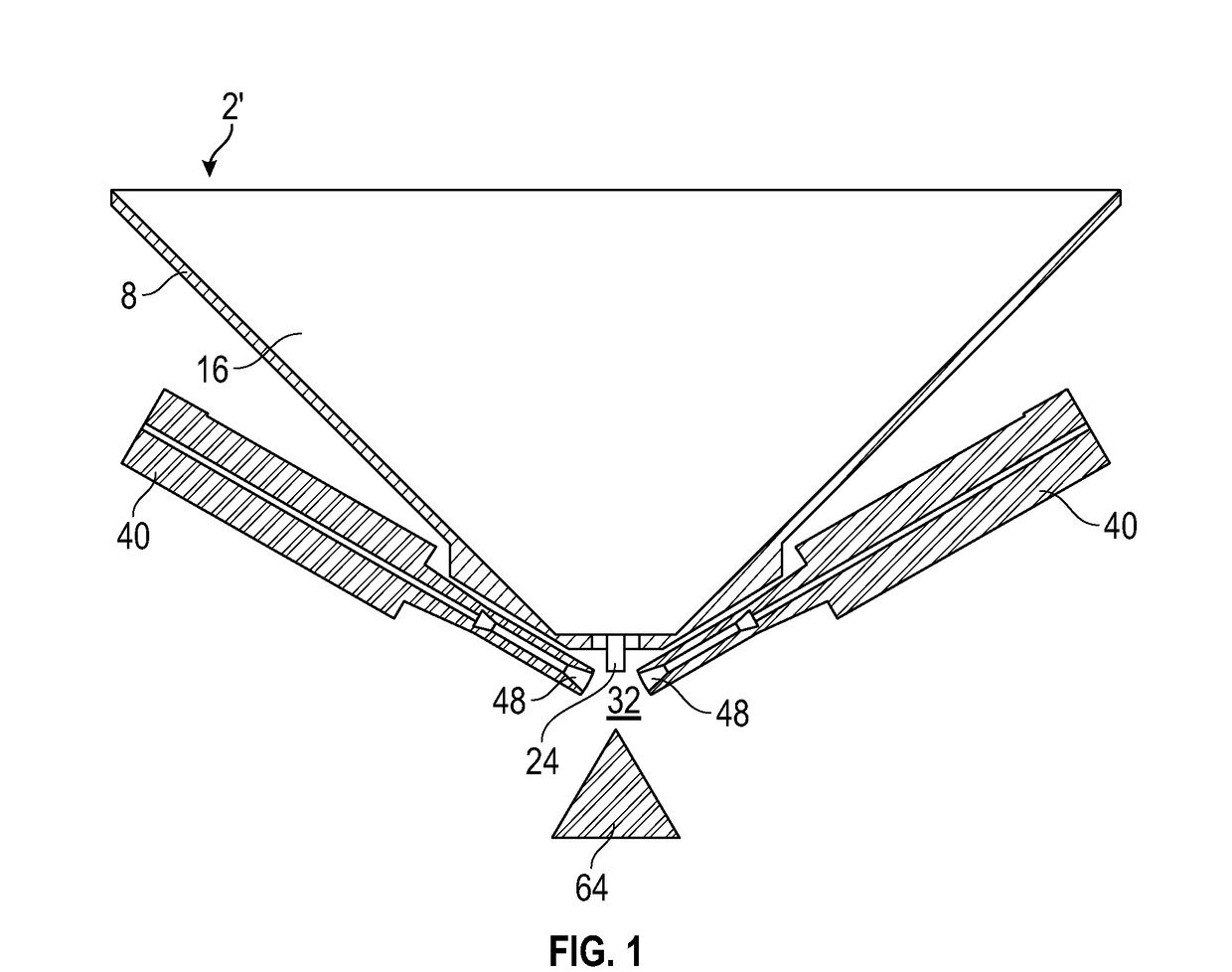

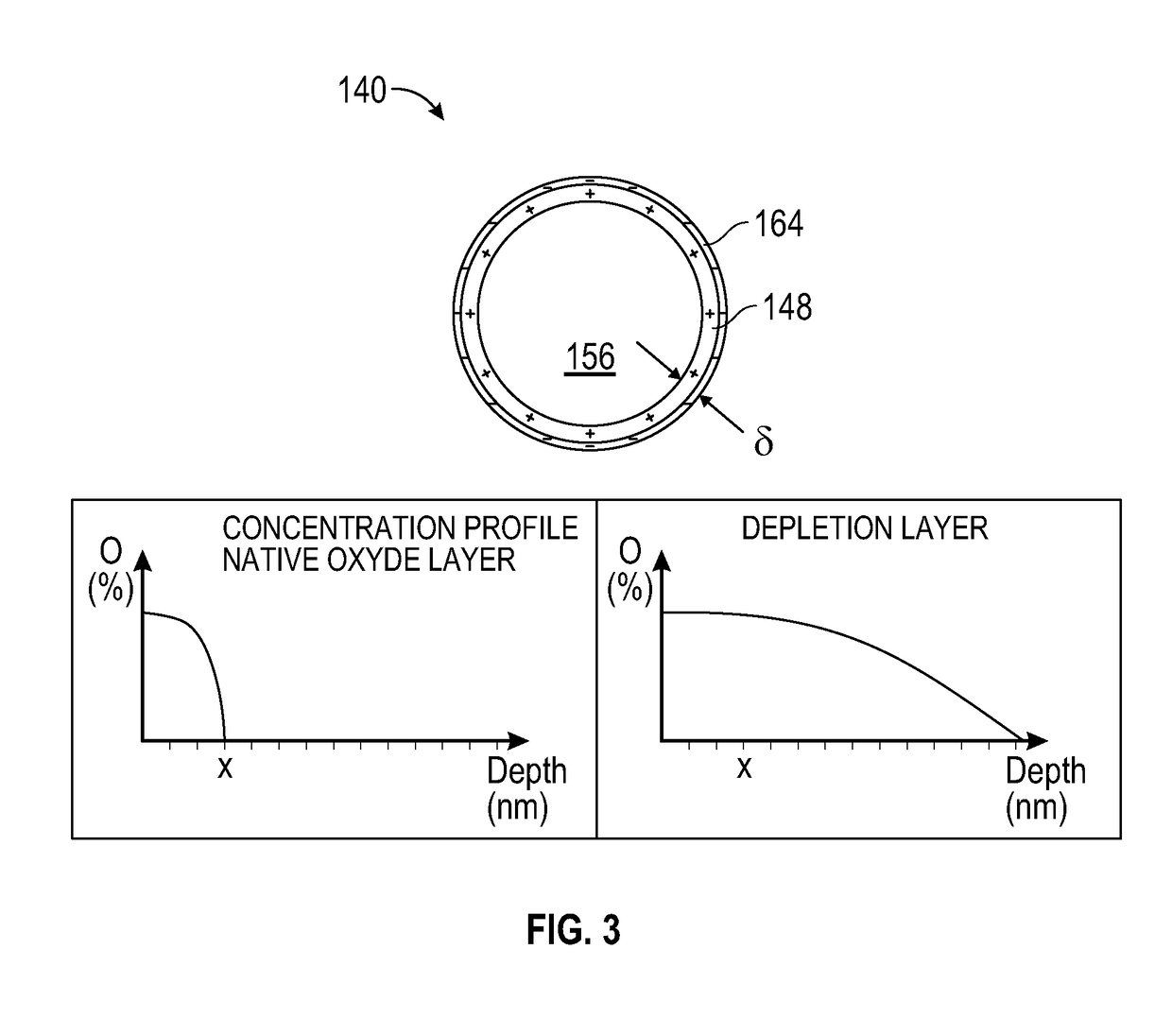

Metal powder atomization manufacturing processes

PendingUS20190001416A1Improve liquidityEasy to useTransportation and packagingMetal-working apparatusMetal powder

There are provided reactive metal powder atomization manufacturing processes. For example, such processes include providing a heated metal source and contact the heated metal source with at least one additive gas while carrying out the atomization process. Such processes provide raw reactive metal powder having improved flowability. The at least one additive gas can be mixed together with an atomization gas to obtain an atomization mixture, and the heated metal source can be contacted with the atomization mixture while carrying out the atomization process. Reactive metal powder spheroidization manufacturing processes are also provided.

Owner:AP&C ADVANCED POWDERS & COATINGS

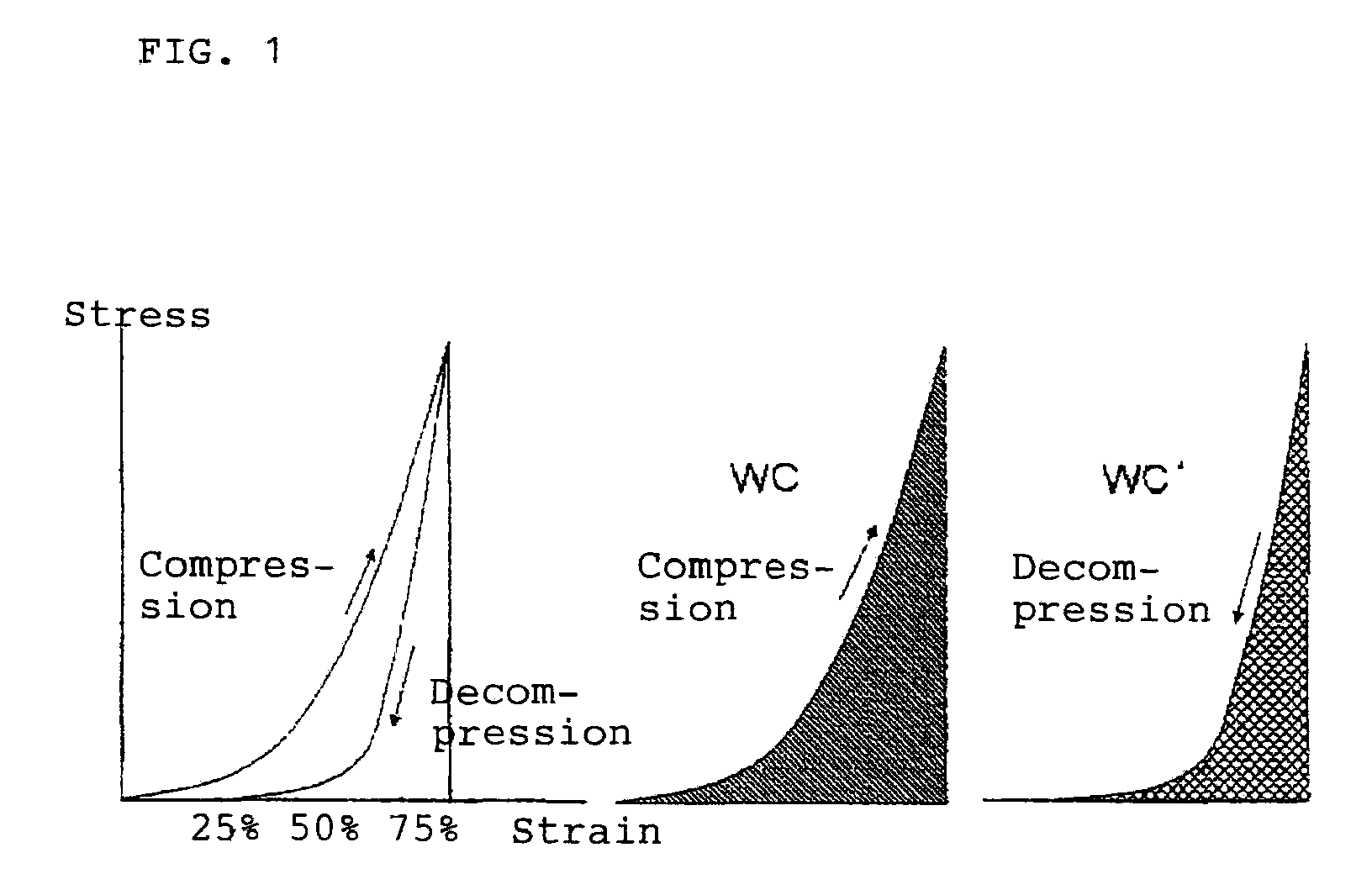

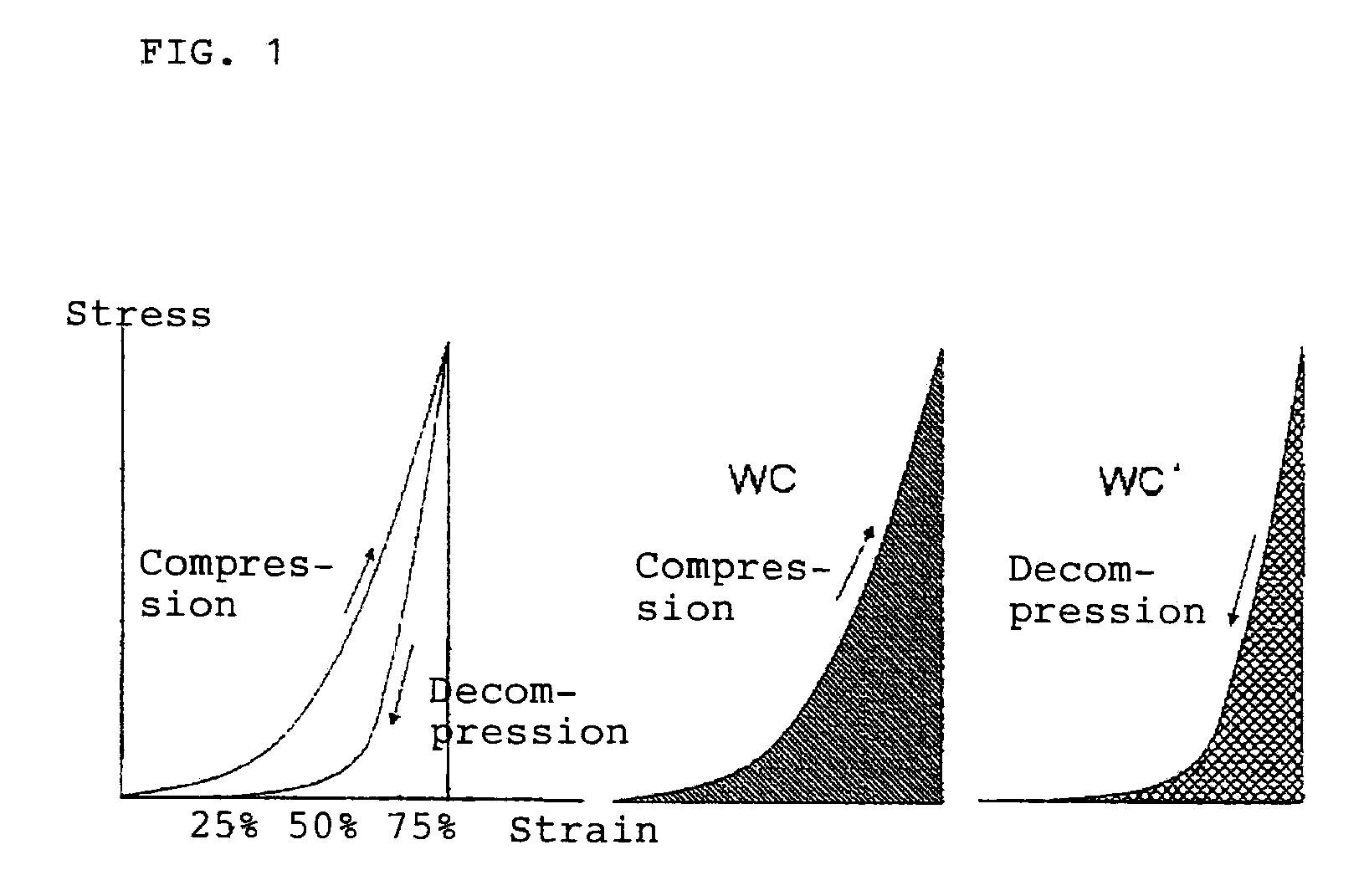

Elastic network structure

ActiveUS7892991B2Little restriction in handling and usageGood chemical resistanceWoven fabricsNon-woven fabricsLow-density polyethyleneCushioning

Provided is an elastic network structure having durability and cushioning properties suitable for furniture, bedding such as a bed, seats for vehicles, seats for shipping, etc., the network structure being lightweight and having excellent chemical resistance, excellent light resistance, soft repellency, and excellent cushioning characteristics in a low temperature environment. The elastic network structure comprises a three-dimensional random loop bonded structure obtained by forming random loops with curling treatment of a continuous linear structure having not less than 300 decitex, and by making each loop mutually contact in a molten state to weld the majority of contacted part, the continuous linear structure mainly including a low density polyethylene resin with a specific gravity of not more than 0.94 g / cm3.

Owner:TOYOBO MC CORP

Method for manufacturing high-density vanadium-nitrogen alloy

The invention provides a method for producing vanadium-nitrogen alloy. In the method, powdered vanadium oxide or ammonium metavanadate, carbon powder, bonding agents and density increasing agents are evenly mixed and are subjected to briquetting and forming; the mixture is continuously added in an external-heat type rotary kiln under the atmosphere of nitrogen gas and preheated up to the temperature of below 1,000 DEG C under the protection of the nitrogen gas, and at a discharge port, preheated massive products which are cooled down to the room temperature under the protection of nitrogen gas are collected; and the massive products are put in an improved soft magnetism nitrogen atmosphere kiln and heated up to the temperature of between 1,000 and 1,500 DEG C so as to make materials carry out the carbonization reaction and the nitriding reaction, and the vanadium-nitrogen alloy products are obtained after discharge. In the vanadium-nitrogen alloy obtained, the V content is between 78 and 83 percent, the N content is between16 and 21 percent, the C content is less than or equal to 6 percent max, the contents of silicon, phosphor and aluminum are less than 0.01 percent, and the apparent density is more than 4.4g / cm<3>. The apparent density can be adjusted according to the requirements of a customer, and the maximum apparent density is 5.0 g / cm<3>. The method is characterized in that under the condition of not changing prior production processes, the apparent density of the vanadium-nitrogen alloy is improved by adding the density increasing agents, and the adsorption rate of molten steel in the vanadium-nitrogen alloy is more than 98 percent.

Owner:云南昆钢冶金新材料股份有限公司

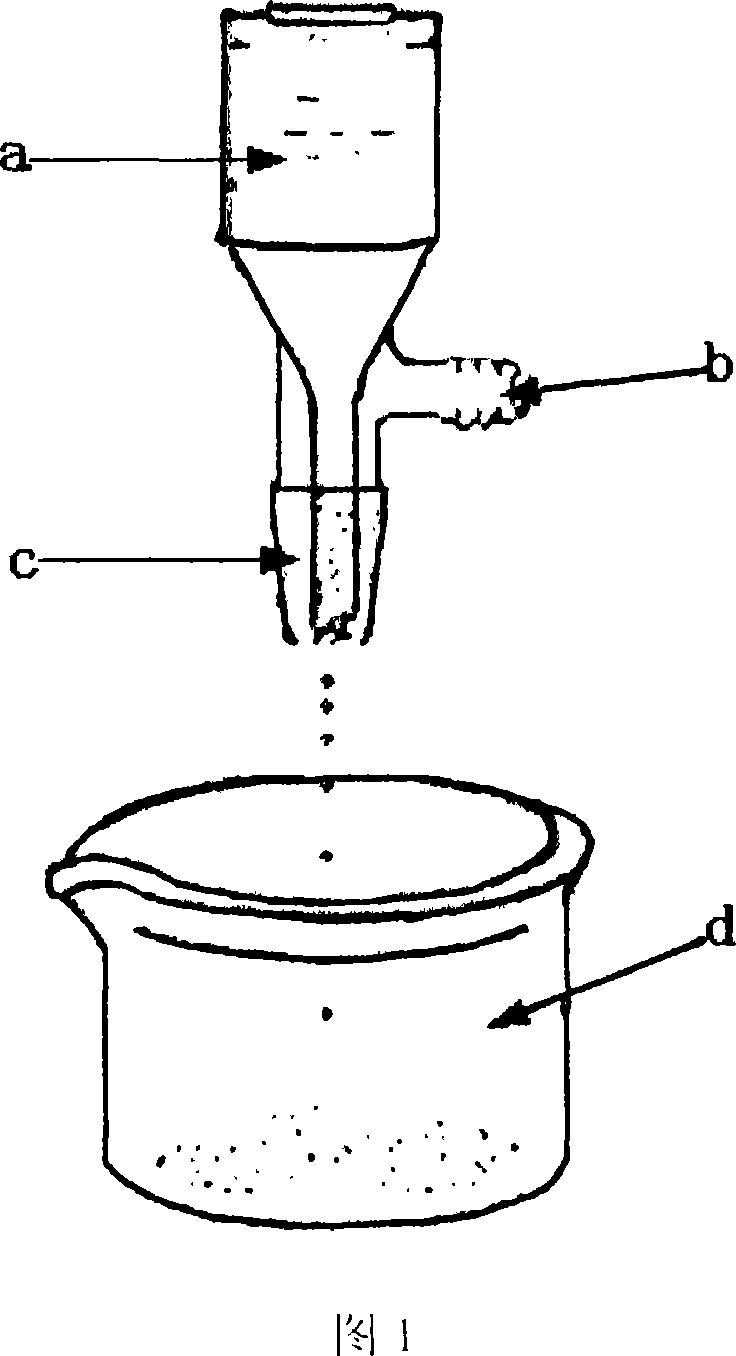

Freeze forming prepn process of ternary lithium ceramic microphere

The freeze forming preparation process of ternary lithium ceramic microsphere includes the following steps: mixing the material for ternary lithium ceramic microsphere, high molecular adhesive and solvent, mixing in a ball mill to form suspension slurry and defoaming; dropping the slurry into cooling medium to form microsphere in a microsphere forming unit, and low temperature vacuum drying in a freezing drier to form ceramic microsphere precursor; roasting, calcining and sintering; and programmed heat treatment to obtain ternary lithium ceramic microsphere. The ternary lithium ceramic microsphere has high sphericity, controllable size, high size dispersivity, high apparent density, high phase purity, high strength and other features.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Chromium-based catalysts in mineral oil for production of polyethylene

A process for polymerizing polyethylene with chromium-based catalysts wherein one or more supported chromium-based catalysts is mixed with mineral oil to form a slurry and the slurry is then introduced into a polymerization reactor, especially a gas-phase polymerization reactor.

Owner:UNIVATION TECH LLC

Metal powder composition

ActiveUS8992659B2High green strengthEnsure durabilityTransportation and packagingMetal-working apparatusPolyolefinOligomer

A metal powder composition including: an iron or iron-based powder composition, and a lubricating combination including a substance A, a substance B, and a substance C; wherein: substance A is a polyolefin, substance B is chosen from a group of saturated and unsaturated fatty acid amides, saturated and unsaturated fatty acid bisamides, saturated fatty alcohols and fatty acid glycerols, and substance C is an amide oligomer having a molecular weight between 500 g / mol and 30 000 g / mol; and wherein the amounts of respective substances A, B and C in weight percent of the iron or iron-based powder composition are: 0.05≦A+B<0.4 wt %, C≧0.3 wt %, A+B+C≦2.0 wt %, and the relation between substances A and B is: B / A>0.5. Also, a method of producing a metal powder composition and a method for producing a green component.

Owner:HOGANAS AB

Method for producing high-degree of polymerization polyvinyl chloride resin by using suspension method

The invention discloses a method for producing high-degree of polymerization polyvinyl chloride resin by using a suspension method, which comprises the following steps of: step 1, charging by adopting a constant-temperate water feeding technology, a whole-process airtight feeding technology and a DCS (Distributed Control System) automatic control technology; step 2, producing the high-degree of polymerization polyvinyl chloride resin by adopting a low-temperature method; and step 3, obtaining the high-degree of polymerization polyvinyl chloride resin with a degree of polymerization of 1700-3000. With the adoption of the method for producing the high-degree of polymerization polyvinyl chloride resin by using the suspension method, the high-degree of polymerization polyvinyl chloride resin with a degree of polymerization of 1700-3000 can be produced in a 70 m<3> polymerization kettle system, has the advantages of low energy consumption, large batch production and stable quality and can be produced in the whole year.

Owner:HANGZHOU ELECTROCHEM GROUP

Size and method for treating recycled coarse aggregates

InactiveCN102757208AReduce crush indexLow water absorptionSolid waste managementPorosityHydration reaction

The invention relates to size and a method for treating recycled coarse aggregates, and belongs to the field of concrete recycled aggregates treating agents and concrete recycled aggregates treating. In order to solve the technical defects that the strength of the recycled coarse aggregates is low due to high water absorption and large porosity, the invention provides the size and the method for treating the recycled coarse aggregates. The size for treating the recycled coarse aggregates comprises sulphoaluminate cement, admixtures and water. The sulphoaluminate cement of the size permeates into the recycled coarse aggregates, so that the microcracks generated in recycled coarse aggregates crushing are filled to a certain degree; meanwhile, through the use of the dilution and nucleation effects of the admixtures and Ca(OH)2 enriched in old mortar of the recycled coarse aggregates consumed in secondary hydration reaction, the mortar structures of the recycled coarse aggregates are improved, so that the strength of the waste concrete recycled coarse aggregates is improved. After the size and the method are adopted, the crush indexes of the recycled coarse aggregates are remarkably reduced and meet the requirement regulated Pebble and crushed stone for construction GB / T14685-2011.

Owner:UNIV OF JINAN

Method for preparing catalytic cracking catalyst

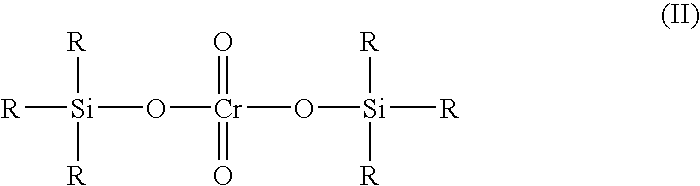

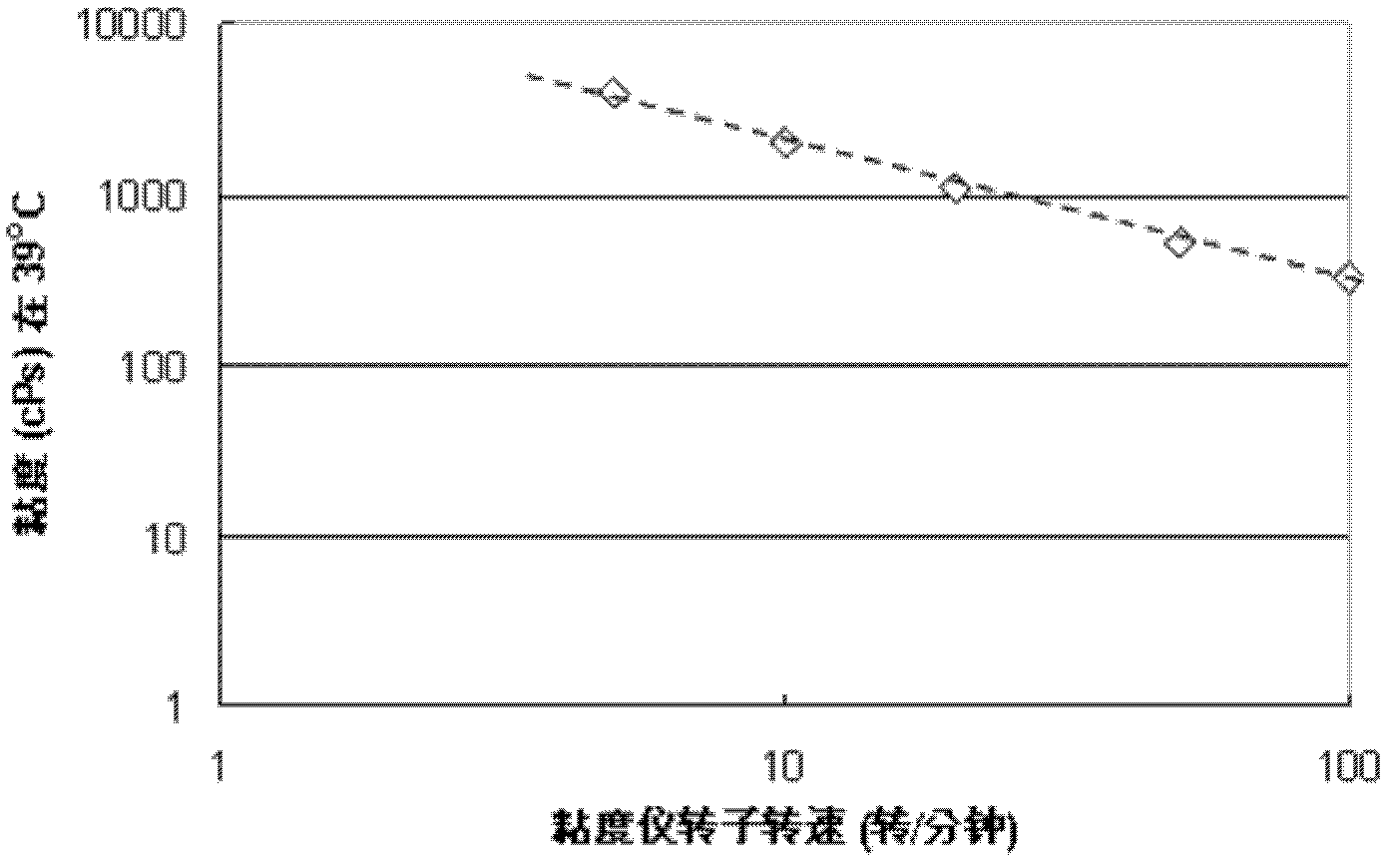

InactiveCN102319582AHigh apparent densityReduce volume loadCatalytic crackingMolecular sieve catalystsApparent densitySlurry

The invention relates to a method for preparing a catalytic cracking catalyst, which comprises the following steps: (1) weighting zeolite, a binder precursor, a substrate precursor and a pulpable intermediate; (2) forming a solid-liquid slurry containing the zeolite, the binder precursor, the substrate and the pulpable intermediate; (3) stirring and / or grinding the slurry, performing a uniform mixing and uniformization to the above components to realize the refinement of particle size; (4) converting catalyst slurry into molded particles, and converting the molded catalyst particles into a catalyst finished product by drying or calcinating. The solid content in the catalyst formula is 30%-65%, the addition of the solid content enables a great addition to the apparent density of the catalyst, the addition of the catalyst bulk density enables a close association with the enhancement of the wearing performance, accordingly, the addition of the catalyst bulk density is capable of reducing the volume load of the catalyst or filling more catalyst in a given volume of a reactor.

Owner:常云峰 +1

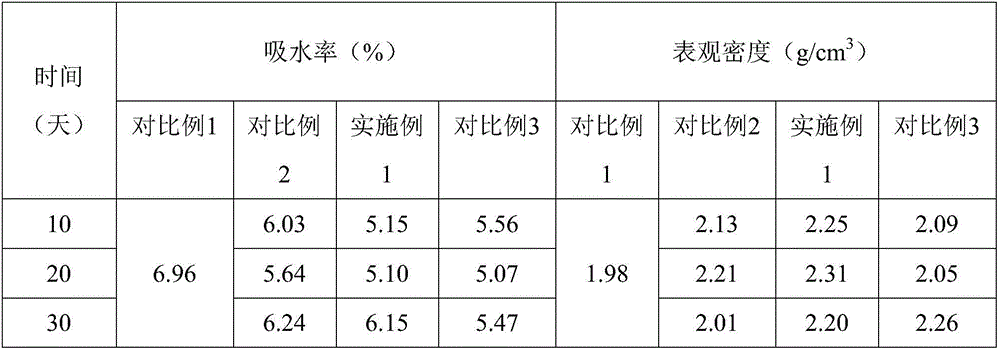

Method for improving quality of waste concrete recycled aggregate by using sodium carbonate solution

ActiveCN106746828AResolve disposal issuesHigh apparent densitySolid waste managementApparent densityNational standard

The invention discloses a method for improving the quality of a waste concrete recycled aggregate by using a sodium carbonate solution. The waste concrete recycled aggregate of which the particle size grade is 5-20mm is soaked in a Na2CO3 solution of which the mass concentration is 4-8%, and the soaking repair time is 15-25 days. The method provided by the invention has the following beneficial effect: the water absorption rate of the recycled aggregate is reduced, the apparent density is increased, the quality of the recycled aggregate is greatly improved, the recycled concrete coarse aggregate repaired by the sodium carbonate solution can be used for preparing new concrete when the water absorption rate and the apparent density of reach a III-grade standard of the recycled concrete coarse aggregate of a national standard GB / T25177-2010, and the problem of waste concrete construction waste disposal is solved.

Owner:SHANDONG JIANZHU UNIV

Elastic Network Structure

ActiveUS20080146763A1Little restriction in handling and usageGood chemical resistanceWoven fabricsNon-woven fabricsElastic networkLow-density polyethylene

Provided is an elastic network structure having durability and cushioning properties suitable for furniture, bedding such as a bed, seats for vehicles, seats for shipping, etc., the network structure being lightweight and having excellent chemical resistance, excellent light resistance, soft repellency, and excellent cushioning characteristics in a low temperature environment. The elastic network structure comprises a three-dimensional random loop bonded structure obtained by forming random loops with curling treatment of a continuous linear structure having not less than 300 decitex, and by making each loop mutually contact in a molten state to weld the majority of contacted part, the continuous linear structure mainly including a low density polyethylene resin with a specific gravity of not more than 0.94 g / cm3.

Owner:TOYOBO MC CORP

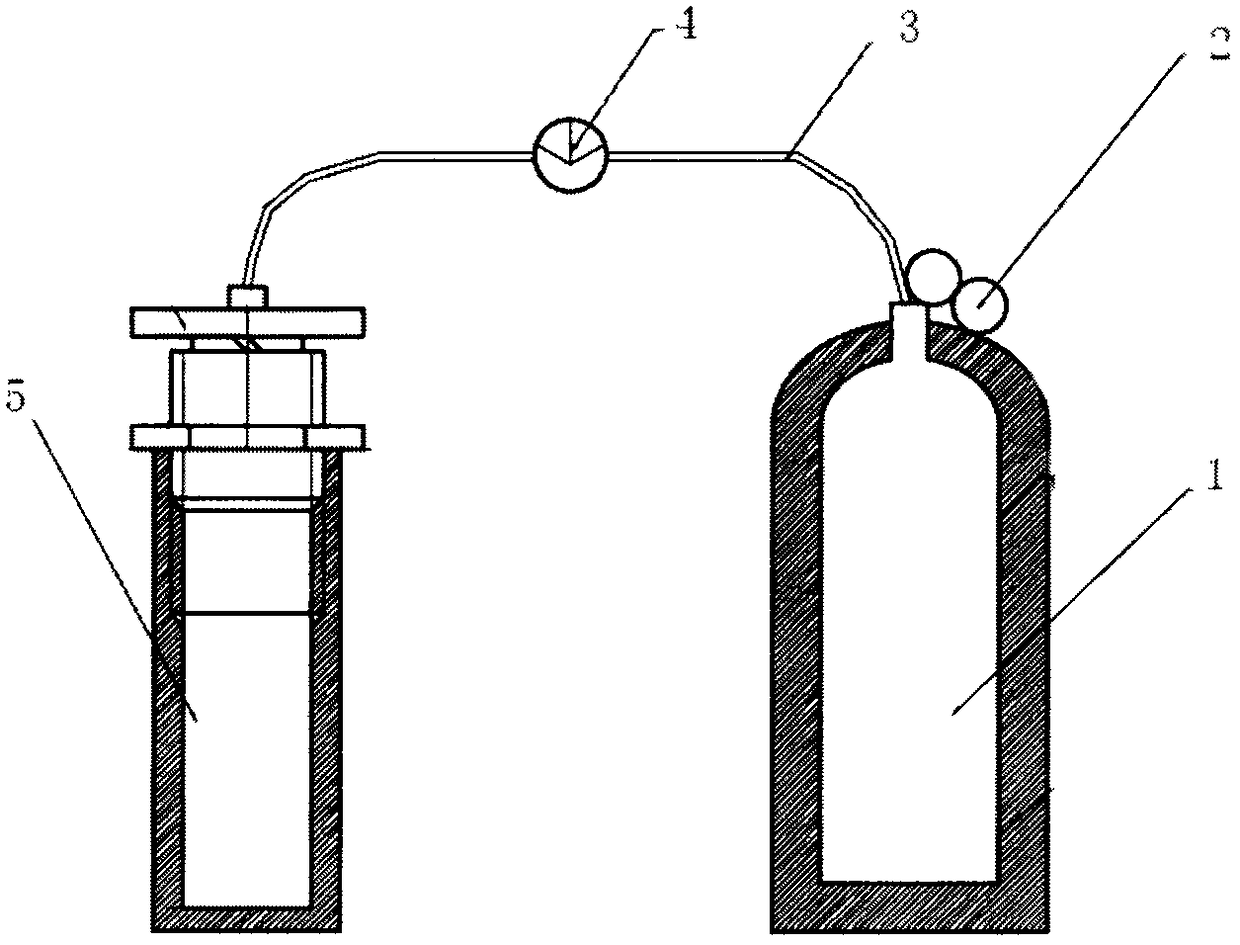

Method for strengthening recycled concrete coarse aggregate by using CO2

InactiveCN108726910AEfficient use ofImprove the strengthening effectSolid waste managementVoid ratioNano sio2

The invention discloses a method for strengthening recycled concrete coarse aggregate by using CO2. The method comprises the following steps: (1) manually primary breaking waste concrete, secondary breaking the waste concrete by adopting a jaw-type breaking machine, screening to obtain recycled coarse aggregate for standby use; (2) sprinkling prepared nano SiO2 slurry onto the recycled coarse aggregate prepared in step (1), spreading, and air drying for standby use; (3) strengthening the recycled coarse aggregate prepared in step (2) in a self-made carbonization apparatus to obtain high-quality recycled concrete aggregate; and (4) completely substituting natural aggregate by using the recycled coarse aggregate strengthened by CO2 in step (3), and preparing recycled concrete. Compared withthe unprocessed recycled coarse aggregate, the water absorption rate of the recycled concrete coarse aggregate strengthened by CO2 is decreased by 18.98 to 34.17 percent, the breaking index is decreased by 13.79 to 31.03 percent, the void ratio is decreased by 3.85 to 13.47 percent, and the appearant density is increased by 1.13 to 4.55 percent.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

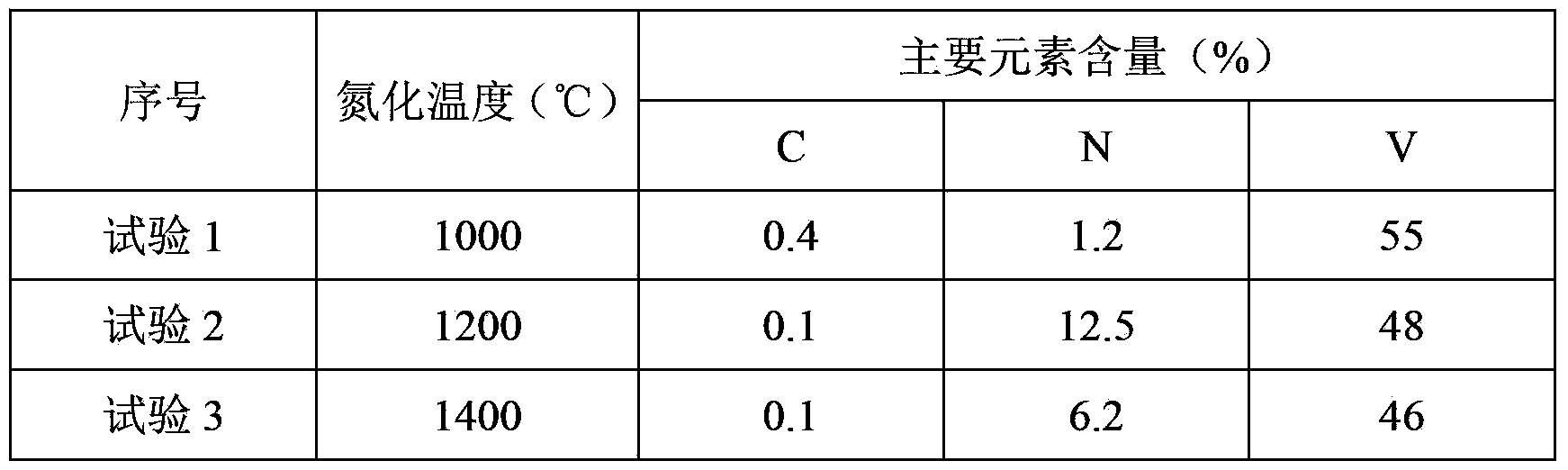

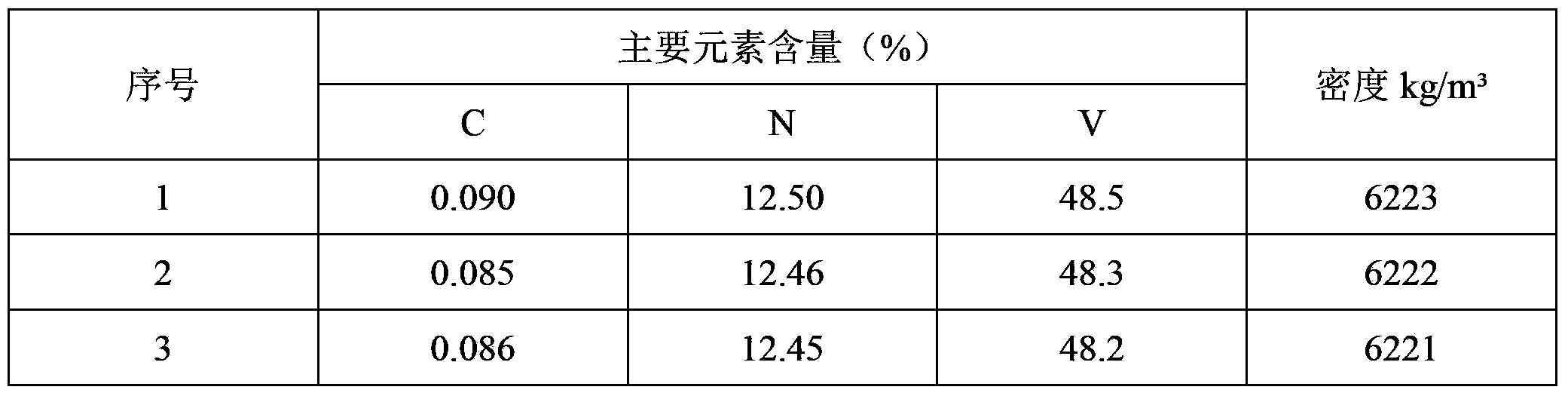

Vanadium nitrogen alloy preparing method

The invention relates to a vanadium nitrogen alloy preparing method. Powdered vanadium oxide, or ammonium metavanadate or ammonium polyvanadate and carbonaceous powder are uniformly mixed and stirredaccording to the requirement of a raw material formula. After undergoing dry powder extrusion and ball formation on a dry powder balling machine, the mixture is put into a vacuum intermediate-frequency heating reacting furnace. When the furnace is vacuumized to 270 Pa and the temperature in the furnace is raised to 900 DEG C, nitrogen gas is introduced. Under the protection of the nitrogen gas, the following preparation processes are carried out: when the temperature in the furnace is gradually raised to 1000-1400 DEG C and the vacuum degree in the furnace is kept at 400 Pa, carbonization andnitrogenization reactions are carried out; when the temperature in the furnace is raised to 1500-1600 DEG C and the pressure in the furnace is kept at 0.05 MPa, further heating is conducted to improvethe apparent density of a billet; and finally the billet is cooled in a storage cabin inside the furnace to obtain a temperature lower than 100 DEG C, thereby obtaining the vanadium nitrogen alloy product, wherein V is 78-81%, N is 16-19%, C is 2-3%, si. P. L is less than or equal to 0.05%, and the apparent density is 6.3-6.8 g / cm<3>. The method is characterized in that the billet preparation eliminates the use of binder, instead, the dry powder balling machine is used for extrusion and ball formation; and the apparent density of the vanadium nitrogen alloy is great.

Owner:湖南汉瑞新材料科技有限公司

Method for preparing hybrid fiber modified light water-permeable and durable recycled concrete

InactiveCN109095823AImprove impermeabilityInhibit drying shrinkageSolid waste managementCeramicwareGlass fiberSlurry

The invention discloses a method for preparing hybrid fiber modified light water-permeable and durable recycled concrete. First a mineral miscellaneous material, a cementing material and a modified regenerated coarse aggregate are evenly mixed, water is poured for stirring to obtain cement paste, a ternary hybrid fiber and water are evenly mixed and then poured into the cement paste for stirring,and an efficient naphthalene water reducer is added; after uniform mixing, foams well made by a foaming device are added, and full and uniform mixing is performed to obtain concrete slurry; the well prepared concrete slurry is poured into a die and lightly and evenly vibrated, the surface of a poured sample is covered with a preservative film, demolding is performed after standing, and curing is performed. A glass fiber, a polypropylene fiber and a steel fiber are mixed into the ternary hybrid fiber, the recycled concrete is modified, the compressive strength can be obviously improved, the steel fiber in the hybrid fiber belongs to high elastic modulus fibers, so that the elasticity modulus of the recycled concrete after the doping of the hybrid fiber is increased, and the doping of the hybrid fiber can obviously improve the vibration resistance of the recycled concrete and enhance ductility and energy dissipation performance of the recycled concrete.

Owner:枞阳县天筑新型建筑材料有限公司

Geopolymer-based concrete for block energy-storage tower, and preparation method thereof

ActiveCN110642582AHigh strengthIncreased durabilityCement productionSocial benefitsWeather resistance

The invention discloses a geopolymer-based concrete for a block energy-storage tower, and a preparation method thereof. The invention aims to solve the problem that the technical requirements of highstrength, durability, high impact resistance, high weather resistance, high apparent density, self-compacting pouring, high volume stability, low energy consumption and low-carbon preparation of concrete blocks of the energy-storage tower cannot be met in the prior art. The geopolymer-based concrete is prepared from an ultrafine powder cementing material, a liquid excitant, a solid excitant, heavyaggregates, a water reducer, a retarder, water and steel fibers. The preparation method comprises the following steps: taking the raw materials; mixing and stirring the ultrafine powder cementing material, the solid excitant, the retarder and the steel fibers; adding the heavy aggregates, and performing stirring; adding the liquid excitant, the water reducer and water, and performing stirring; and molding the obtained mixture by a layered loading and layered vibrating process, and maintaining the molded mixture at normal temperature for 28 d. The preparation method utilizes a large amount ofsolid wastes, has energy-saving and environmentally-friendly properties, is suitable for preparing the concrete blocks of the energy-storage tower, and has good economic and social benefits.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

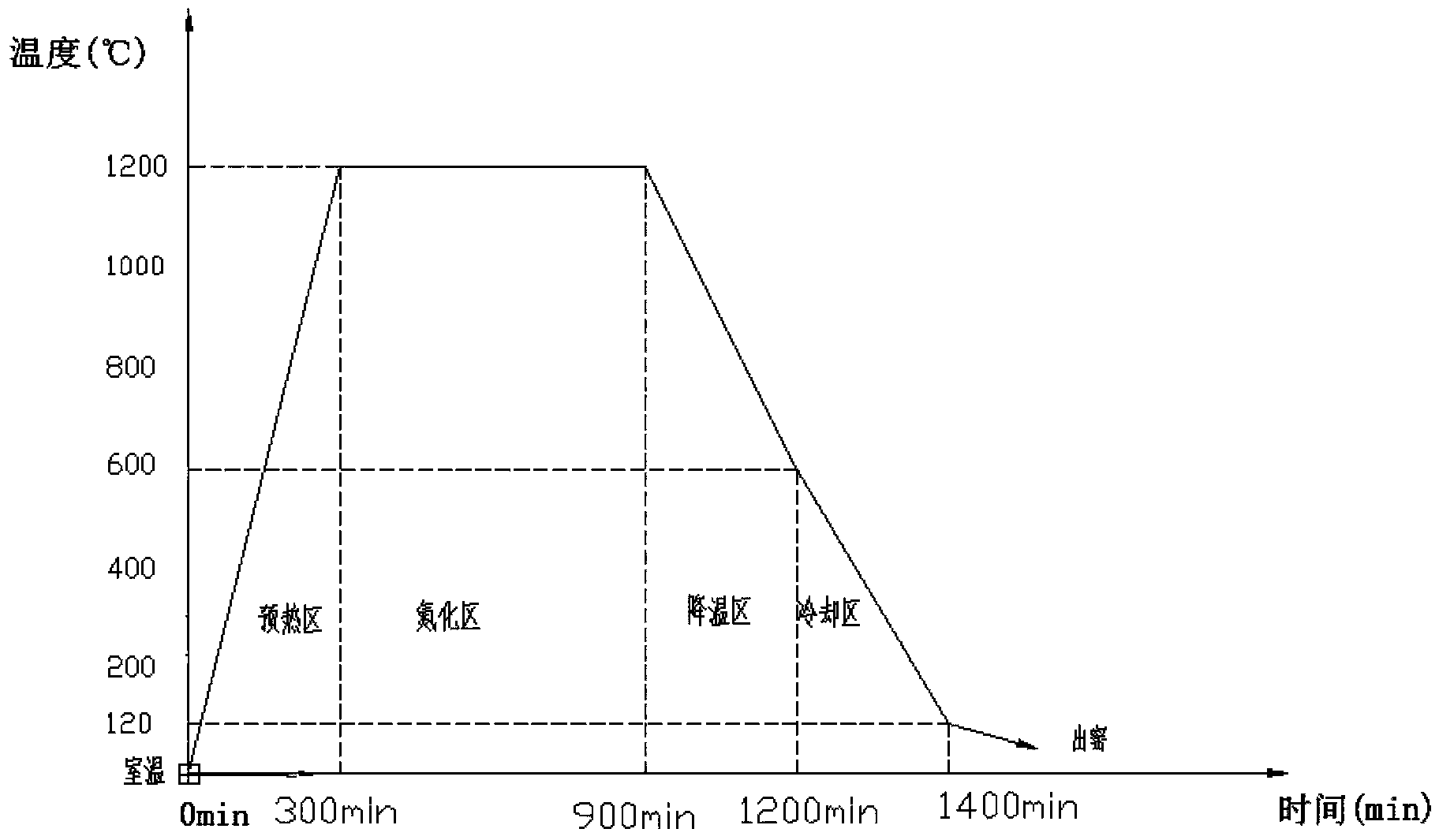

Preparation technology of nitrided ferrovanadium

The invention discloses a preparation technology of nitrided ferrovanadium. According to the preparation technology, a pushed slab kiln is filled with nitrogen for protection, and the oxygen content inside and the oxygen content outside a sealed chamber of the pushed slab kiln are kept the same by washing with nitrogen; and then ferrovanadium with a granularity of 5 to 20mm is delivered into the sealed chamber continuously for nitridation so as to obtain the nitrided ferrovanadium, wherein input pressure of nitrogen is 0.2 to 0.4MPa, the pushed slab kiln is divided into a preheating zone with a temperature of 550 to 650 DEG C, a nitridation zone with a temperature of 1150 to 1250 DEG C, a temperature reducing zone with a temperature of 550 to 650 DEG C and a cooling zone with a temperature of 70 to 170 DEG C, and the raw material is processed for 300min, 600min, 300min and 200min in the four zones respectively. The nitride ferrovanadium prepared by the preparation technology is low in carbon content; apparent density reaches 6000 to 6300kg / m<3>, and is beneficial for addition in steel smelting process; and the input pressure of nitrogen is just 0.2 to 0.4MPa, and the preparation technology is realized under normal pressure.

Owner:山东济钢泰航合金有限公司

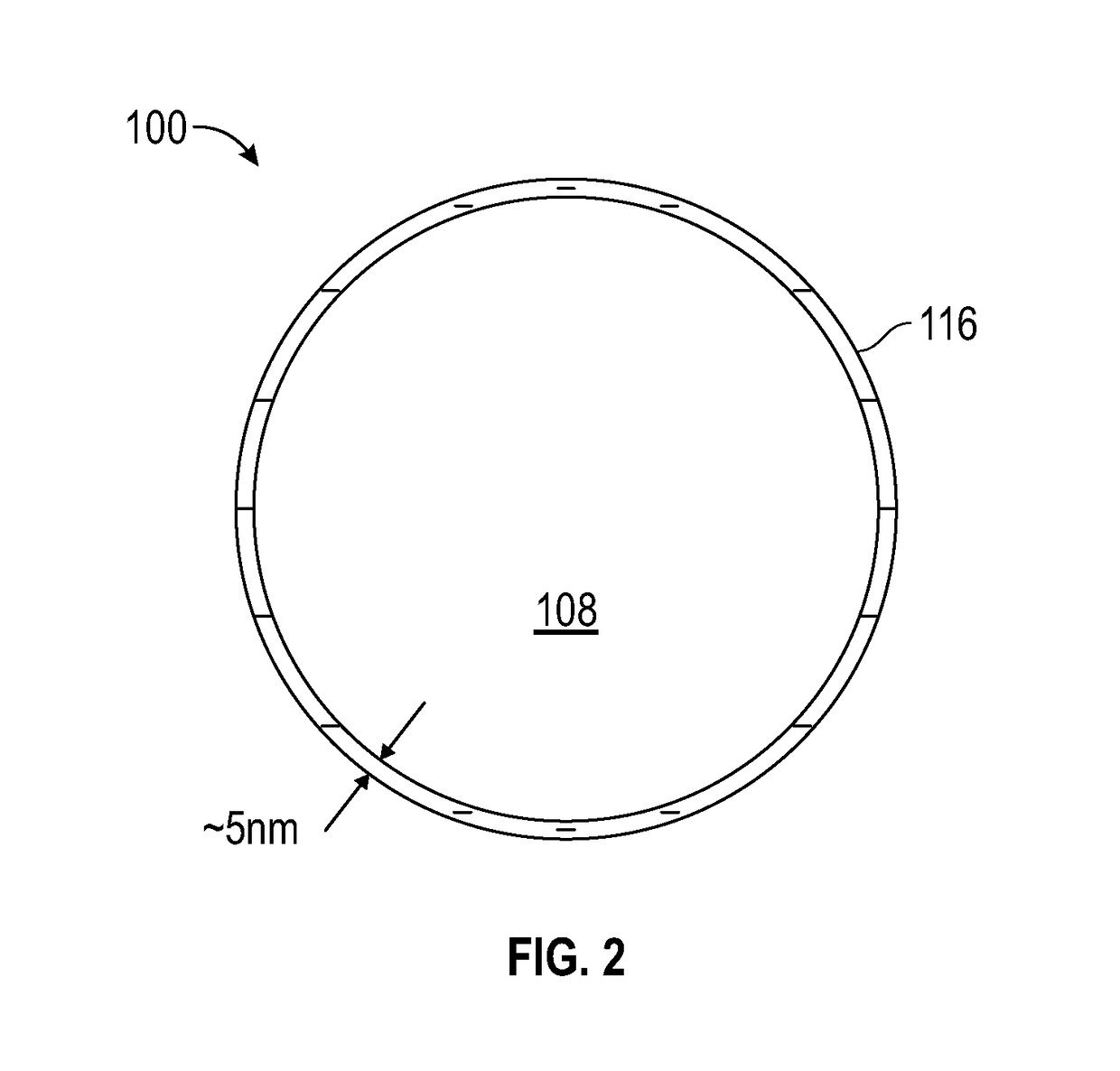

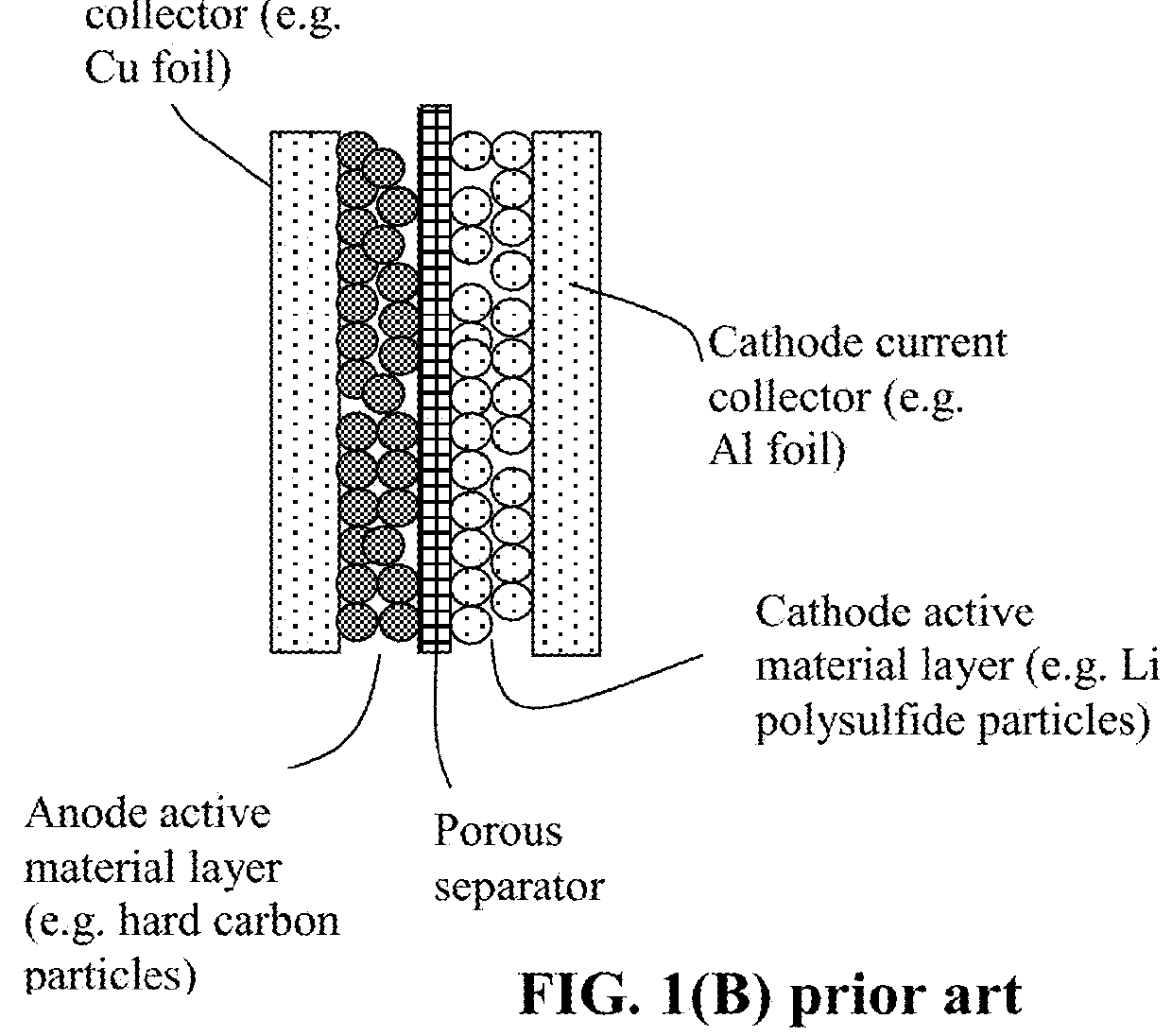

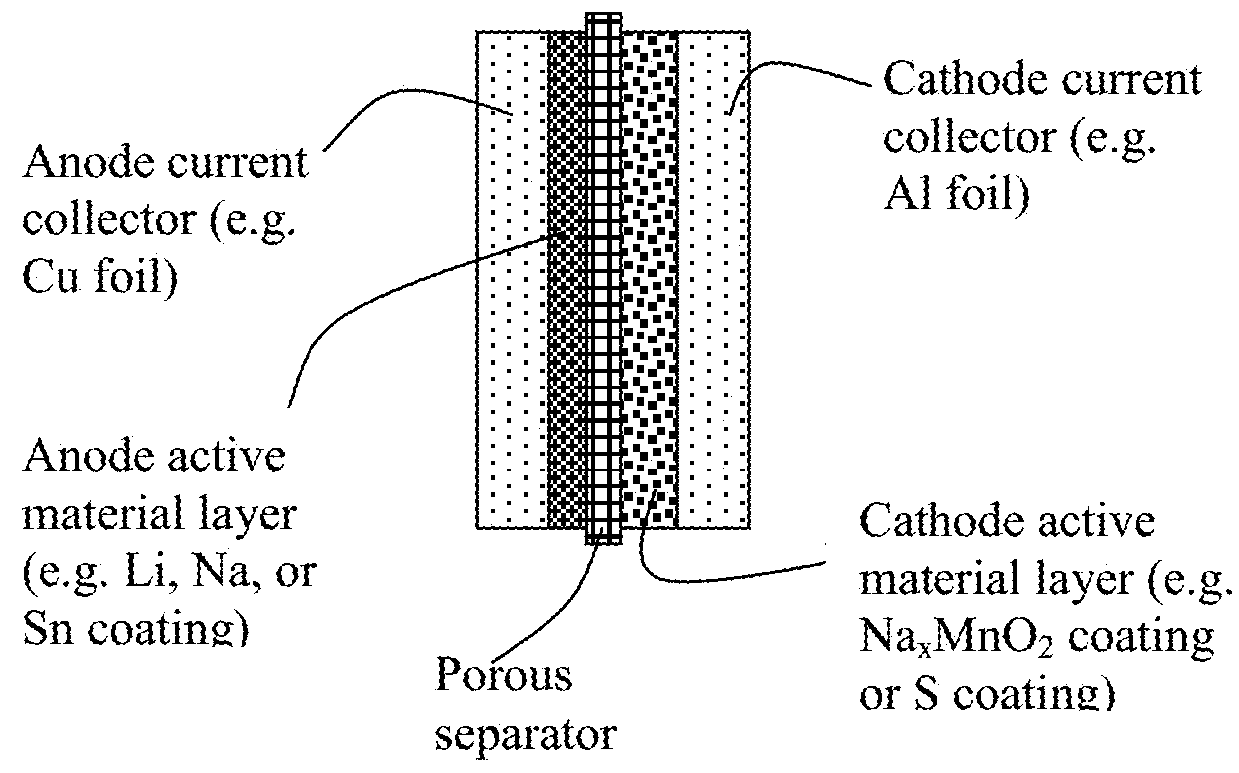

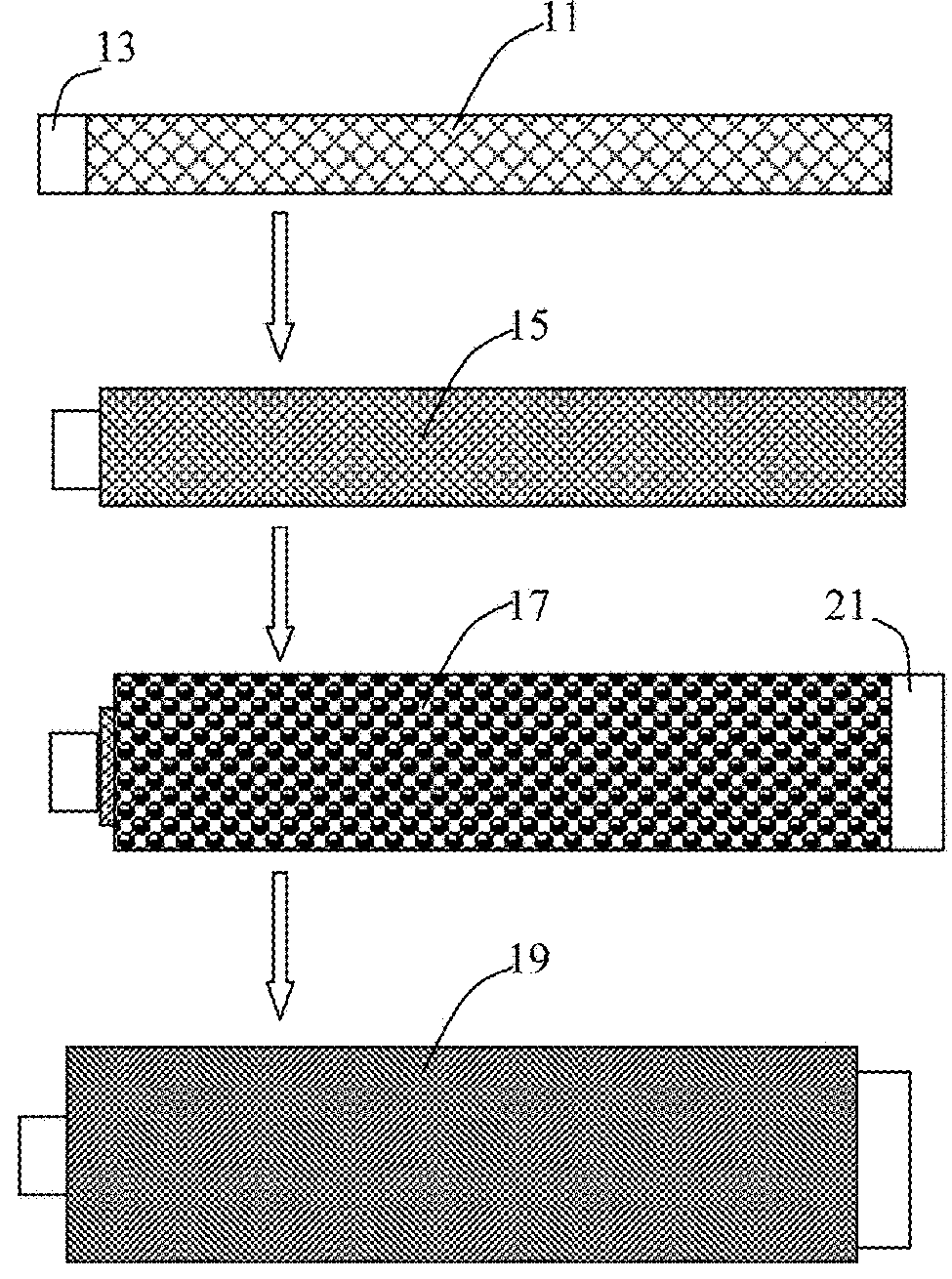

Flexible and Shape-Conformal Cable-Shape Alkali Metal-Sulfur Batteries

ActiveUS20180183024A1High electrode thicknessDecreasing electronFinal product manufactureCylindrical casing cells/batteryPorous layerMetallic sulfide

Provided is a cable-shaped alkali metal-sulfur battery comprising: (a) a first electrode comprising an electrically conductive porous rod and a first mixture of a first electrode active material and a first electrolyte residing in pores of the porous rod; (b) a porous separator wrapping around the first electrode; (c) a second electrode comprising an electrically conductive porous layer wrapping around or encasing the separator, wherein the porous layer contains a second mixture of a second electrode active material and a second electrolyte residing in pores of the porous layer; and (d) a protective sheath encasing the second electrode; wherein one electrode is a cathode containing sulfur, a sulfur-carbon compound, sulfur-polymer composite, or metal sulfide.

Owner:GLOBAL GRAPHENE GRP INC

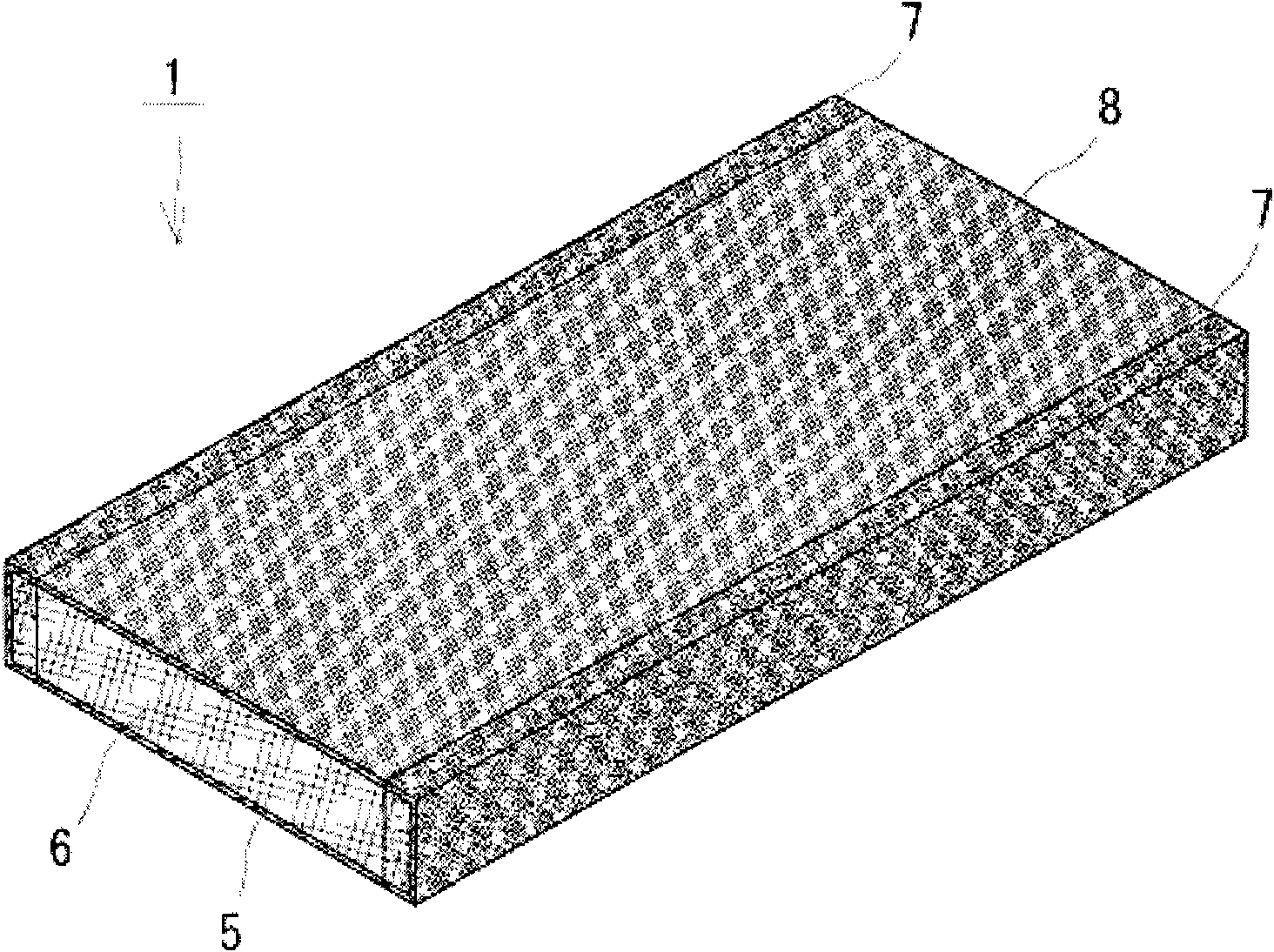

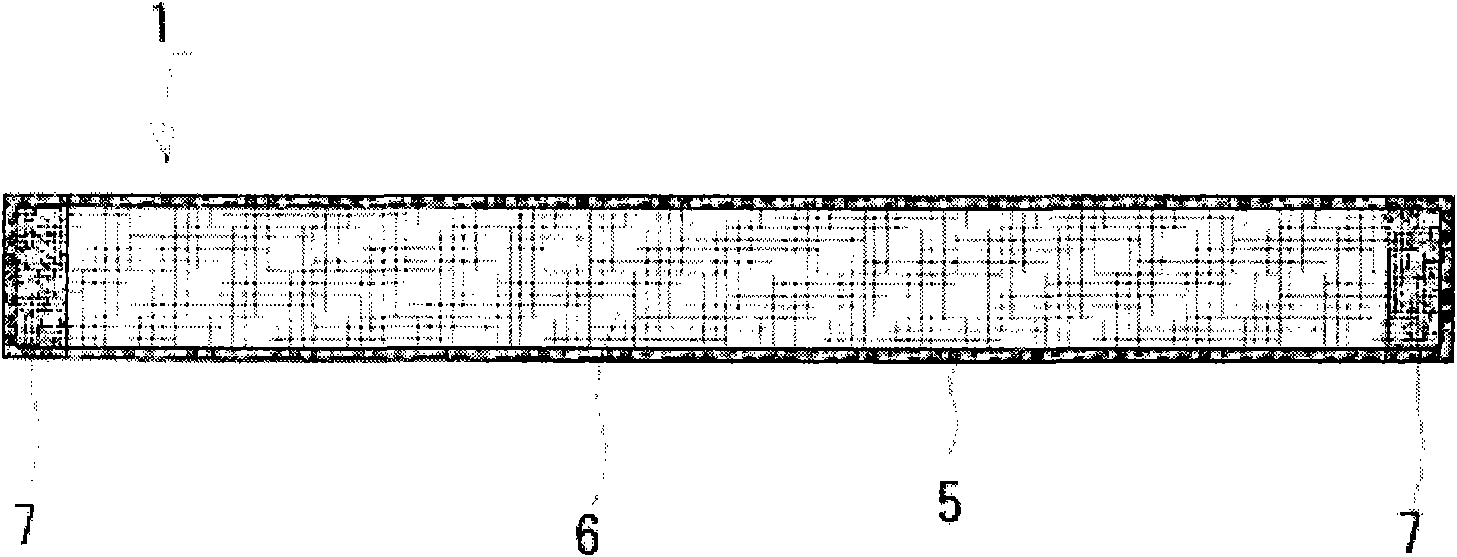

Damp-proof mattress and manufacture method thereof

InactiveCN101874691AGood for healthBeneficial antibacterial effectUpholstery manufactureStuffed mattressesApparent densityEngineering

The invention provides a good mattress capable of preventing dewing and dispensing, characterized in that: the thermal plasticity resin as the raw material or the main raw material melts to be extruded into lines and a large amount of lines are wounded out of order and welded into annular aggregates of the lines and the aggregates are formed into the plate-like shape and then cooled and solidified, therefore a three-dimensional net structure is formed. The left, right relatively-long side-surfaces have side-surface firmness parts with high apparent density.

Owner:C ENG CO LTD

Preparation method of oxidized graphene/sodium lignin sulfonate modified polyurethane rigid foam material

The invention discloses a preparation method of an oxidized graphene / sodium lignin sulfonate modified polyurethane foam material, relates to the preparation method of materials, and aims to solve theproblems of poor compatibility between graphene and a polyurethane monomer and poor dispersity of oxidized graphene in a polyurethane foam material. A method I comprises the following steps: liquidifying a sodium lignin sulfonate solvent; 2, modifying the oxidized graphene; 3, preparing a polyhydroxy component; 4, preparing an isocyanate component for foaming; 5, foaming. A method II comprises thefollowing steps: 1, liquidifying the sodium lignin sulfonate solvent; 2, modifying the oxidized graphene; 3, preparing the polyhydroxy component; 4, foaming. According to the preparation method disclosed by the invention, MDI (Diphenylmethane Diisocyanate) / sodium lignin sulfonate can be utilized for modifying the oxidized graphene, the modified oxidized graphene can be uniformly and stably dispersed in a base material, the modified oxidized graphene and connected sodium lignin sulfonate molecules or MDI are used as a whole, and the problem of compatibility of an inorganic additive-oxidized graphene in a polymer matrix is solved.

Owner:NORTHEAST FORESTRY UNIVERSITY

Preparation method of silicon dioxide for low-specific-surface-area high-density thickening type toothpaste

ActiveCN111484025AAddress manufacturing costsReduce contentCosmetic preparationsToilet preparationsToothpasteSodium silicate

The invention belongs to the technical field of silicon dioxide, and particularly relates to a preparation method of silicon dioxide for low-specific-surface-area high-density thickening type toothpaste. The silicon dioxide for the low-specific-surface-area high-density thickening type toothpaste is prepared by the following steps: taking a sodium sulfate solution with the mass concentration of 10-12% as a mother solution, dripping a sodium silicate solution with the molar concentration of 1.25-1.5 mol / L and a sulfuric acid solution with the molar concentration of 6-7mol / L at the same time, and carrying out a reaction at a segmented temperature and a segmented pH value. When the silicon dioxide for the thickening type toothpaste prepared by the preparation method provided by the inventionis applied to the preparation process of the toothpaste, the time can be shortened, the dust can be reduced, the cost can be saved in the transportation process, and the cleaning effect of the toothpaste cannot be reduced when the silicon dioxide is compounded with the friction type silicon dioxide in the toothpaste body.

Owner:GUANGZHOU FEIXUE MATERIAL TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com