Method for preparing catalytic cracking catalyst

A catalytic cracking and catalyst technology, applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of high catalyst compensation rate and high catalyst operation cost, and achieve improved wear performance, excellent catalytic performance and anti-wear performance , the effect of reducing the volume load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1( comparative Embodiment

[0044] Example 1 (comparative example): preparation of a slurry with a solids content of 35%:

[0045] (1) Add 4.15 kilograms of USY molecular sieves (loss on ignition is 7.6%) produced by China Qingdao Shida Excellent Catalyst Co., Ltd. to 17.94 kilograms of distilled water, and use a saw blade mixer to stir at 200 rpm;

[0046] (2) Add 5 kilograms of aluminum chloride solution (loss on ignition is 74.54%) produced by China Qingdao Shida Excellent Catalyst Co., Ltd.;

[0047] (3) 1.97 kg of alumina (loss on ignition: 2.5%) produced by Shandong Aluminum Corporation of China was added.

[0048] (4) Then 7.40 kg of kaolin (loss on ignition 22.14%) produced by China Kaolin Company in Suzhou City, Jiangsu Province, China was added.

[0049] The resulting mixture contained 30 wt.% molecular sieve of type USY, 10 wt.% binder, 15 wt.% alumina and 45 wt.% kaolin. The slurry is ground by a ball mill. The spray drying equipment produced by Changzhou Qunli Drying Equipment Co., Ltd., ...

example 2

[0052] Example 2 (invention): A slurry with a solids content of 44.3 wt.% was prepared by the following steps:

[0053] (1) Weigh out 2347 grams of distilled water;

[0054] (2) While adding 3005 grams of concentrated aluminum chloride solution (loss on ignition: 76.04%) provided by China Qingdao Shida Excellence Technology Co., Ltd., stir at a speed of 500 rpm with a stirring device. The slurry has a pH of 2.6 at 29°C;

[0055] (3) In the state of stirring, add 2105 grams to the slurry in step (2) and be the LISY-2Y type molecular sieve that the loss on ignition of 14.5wt.% is produced by China Qingdao Shida Excellence Technology Co., Ltd., thus The resulting slurry has a pH of 3.1 at 31°C;

[0056] (4) Under stirring, 2343 grams of kaolin with a loss on ignition of 22.14% produced by China Kaolin Company in Suzhou City, Jiangsu Province, China was added, and the resulting slurry had a pH value of 3.1 at 30 degrees Celsius.

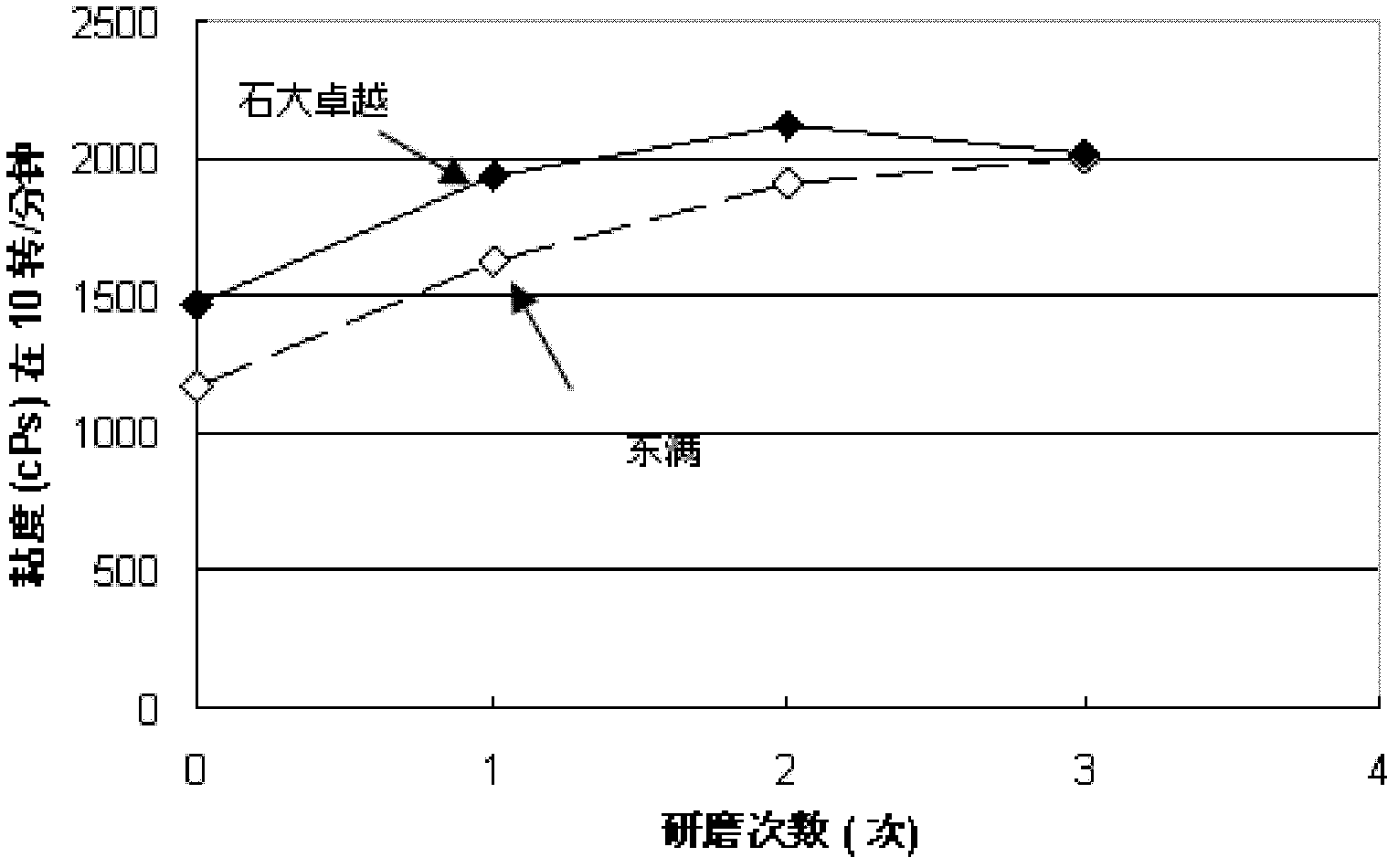

[0057] The slurry was stirred at 6000 rpm for 1...

example 3

[0062] Example 3: (Invention) A slurry with 44.6 wt.% solids content was prepared by the following steps:

[0063] (1) Weigh out 2493 grams of distilled water;

[0064] (2) In the state of stirring, add 2858 grams of concentrated aluminum chloride solution (loss on ignition: 74.81%) produced by Shanghai Dongman Chemical Co., Ltd. to 2493 grams of distilled water and mix well. The resulting slurry had a pH of 3.1 at 30°C.

[0065] (3) Add 2105 grams of LISY-2Y molecular sieve produced by China Qingdao Shida Excellence Technology Co., Ltd. to the above slurry. At 31°C, the zeolite was easily disintegrated and dispersed into a slurry with a pH of 3.3.

[0066] (4) Add 2543 grams of kaolin produced by China Kaolin Company in Suzhou, China. The slurry after high shear treatment and before media milling was referred to as water slurry SL-3. Its viscosity and pH measurements are listed in Table 2.

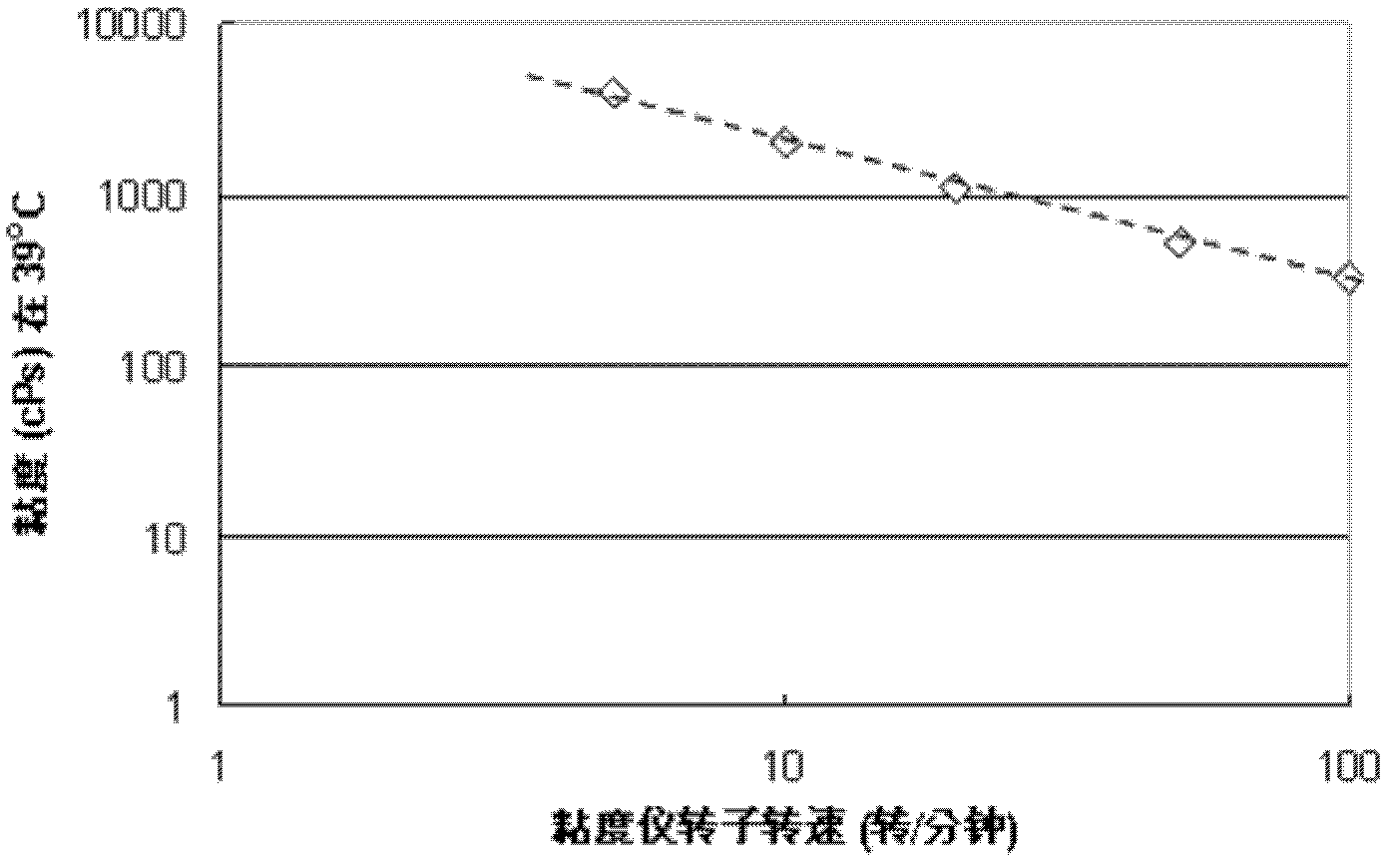

[0067] Same as in Example 2, the viscosity of the slurry was measured using a Br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com