Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1167results about "Upholstery manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

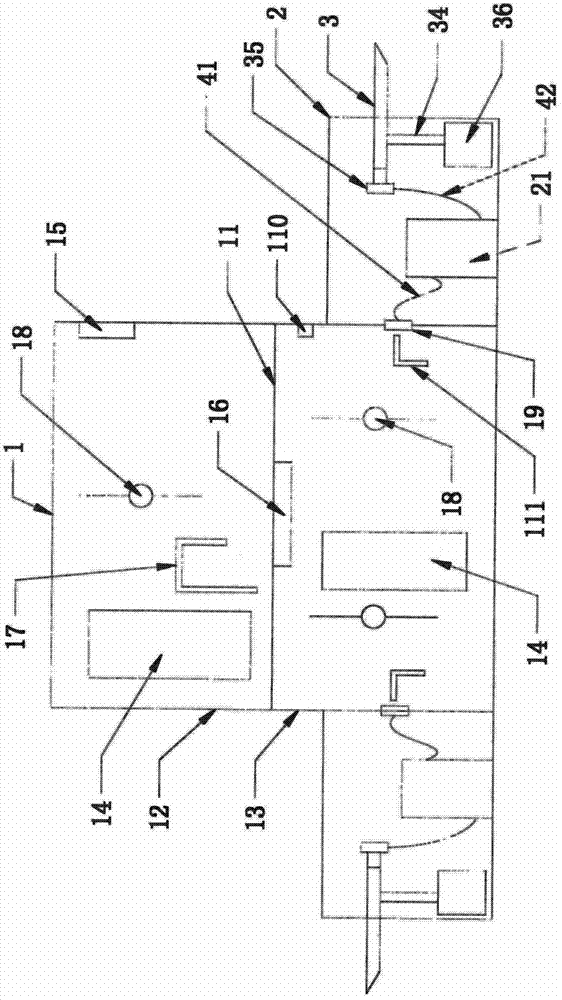

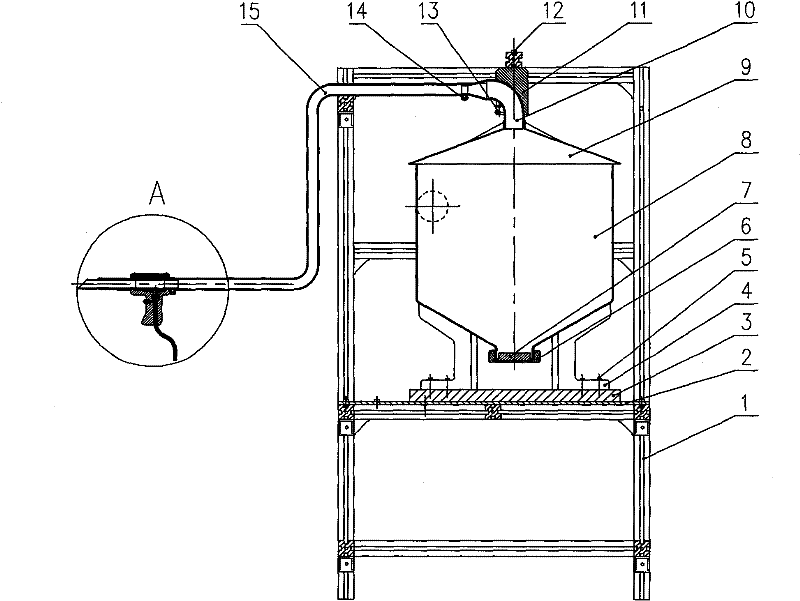

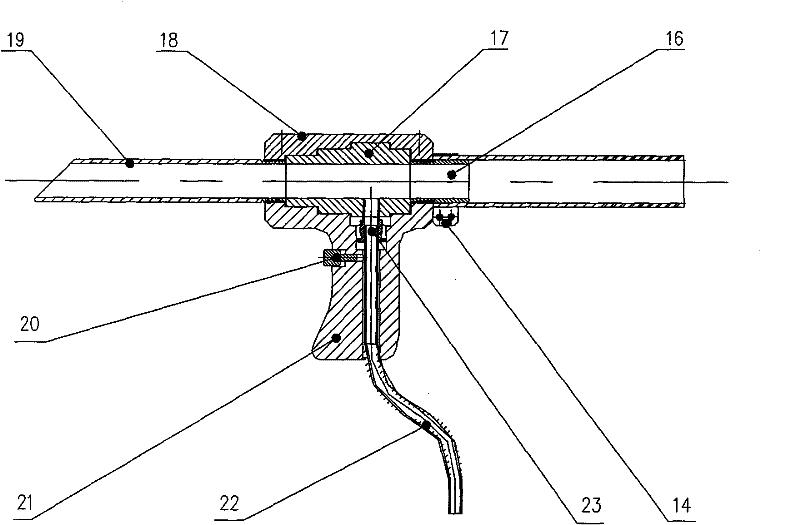

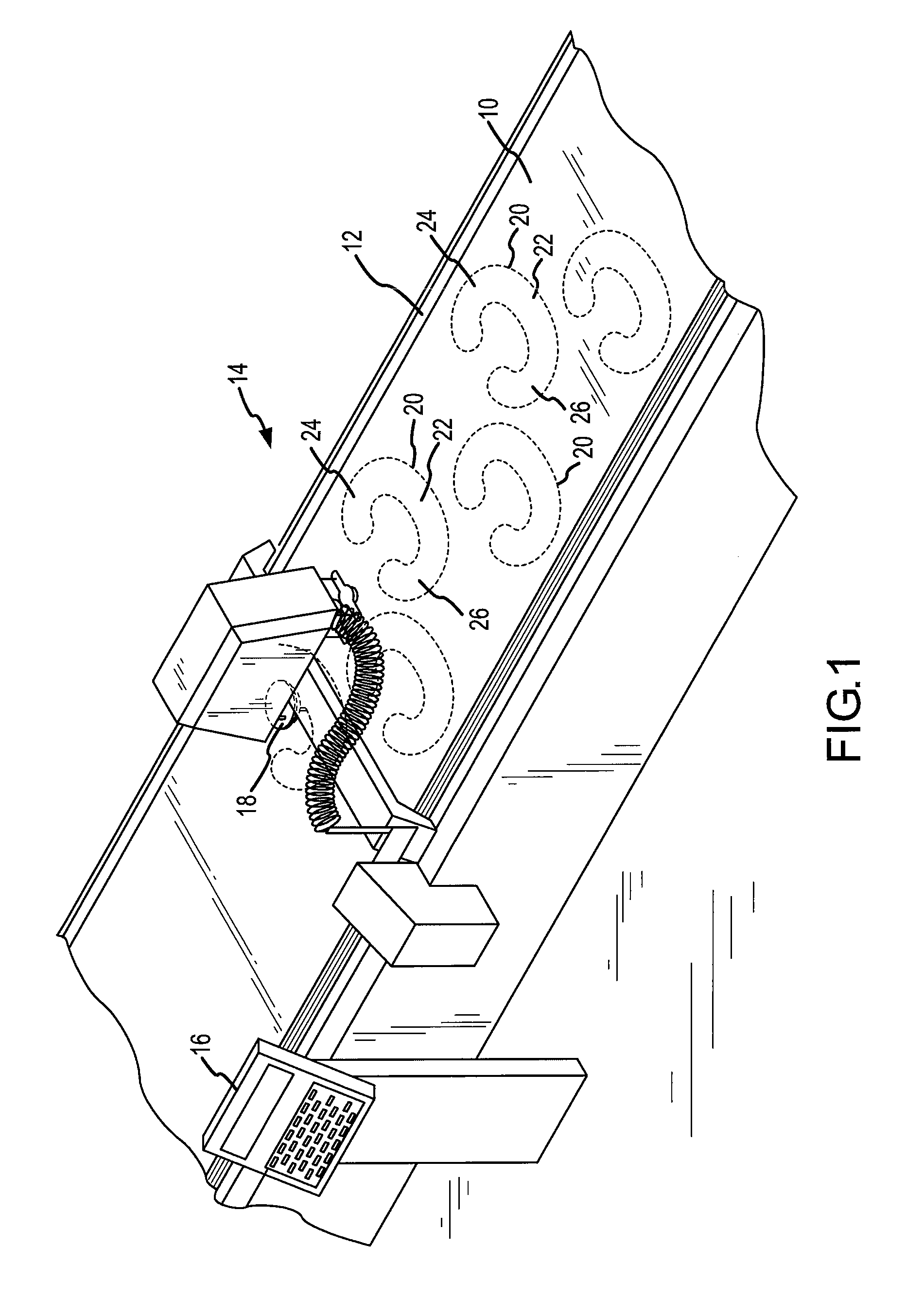

Down filling machine

ActiveCN102808245AStable outputHighly stable suedeUpholstery manufactureOakum treatmentEngineeringUltimate tensile strength

The invention discloses a down filling machine, which comprises a down storage box, weighing cabinets, down filling pipes and a programmable controller, wherein the down storage box is provided with at least two weighing cabinets; at least two weighing boxes are arranged in each weighing cabinet; the total number of the weighing boxes is equal to the total number of down outlets of the down storage box; each weighing cabinet is provided with at least one down filling pipe; the total number of the weighing boxes in each weighing cabinet is dual, and the number of the down filling pipes is a half of the total number of the weighing boxes. According to the down filling machine, the close full-automatic down filling can be carried out, the labor intensity is reduced, the production efficiency is improved, and the production cost is decreased. The down filling machine has the advantages of reasonable design, simple structure, low cost and good practicability. The down storage box of the down filling machine has stable down output, so that the down filling consistence and the down filling precision are ensured; a weighing process of the weighing boxes is independent, precise and effective; the down filling pipes cannot fill the down to airtight cutting pieces; working conditions of the multiple weighing boxes are alternatively changed and one down filling pipe is used for outputting, so that the down filling efficiency is further improved.

Owner:CHANGSHU BEALEAD AUTO MACHINERY

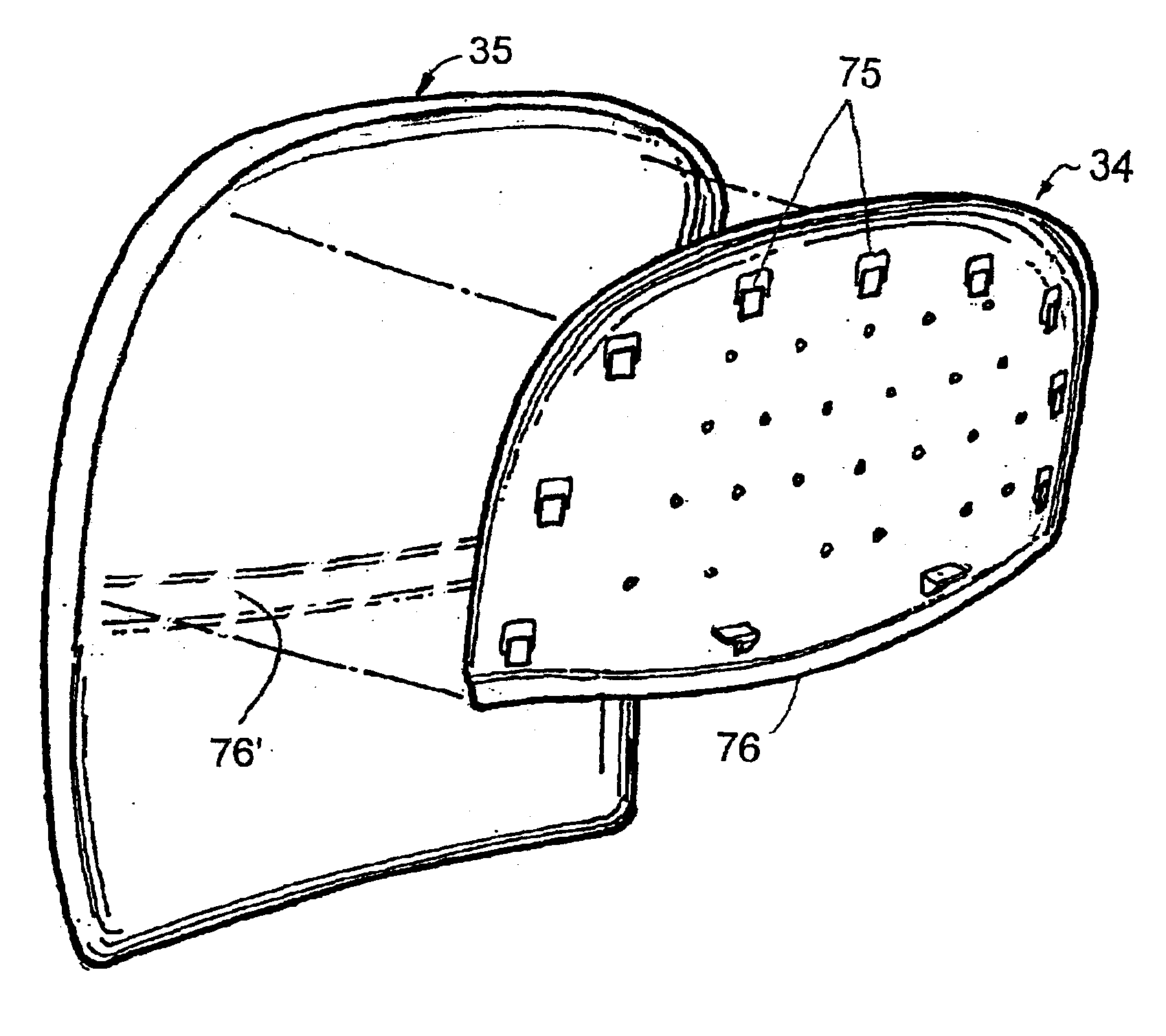

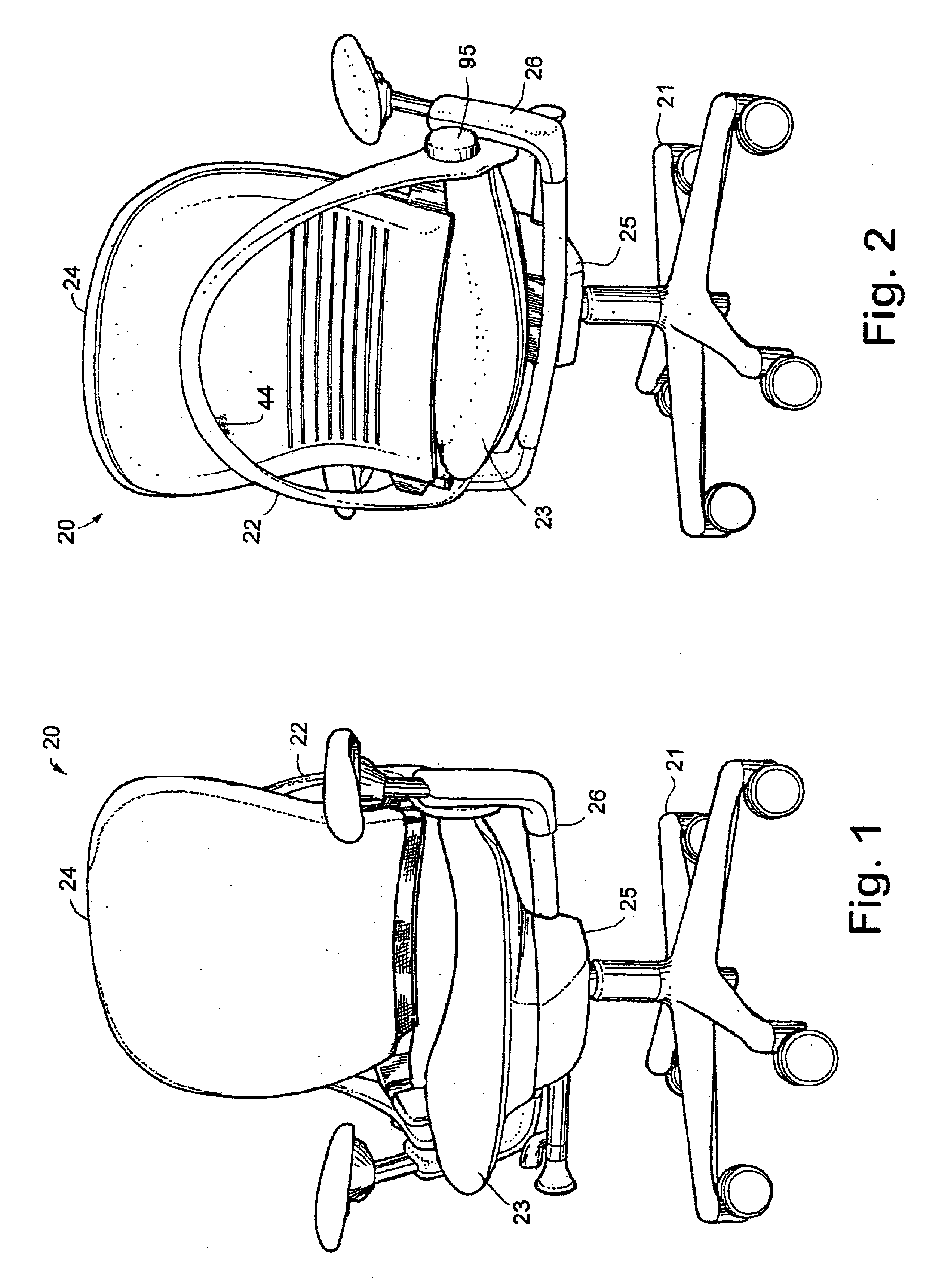

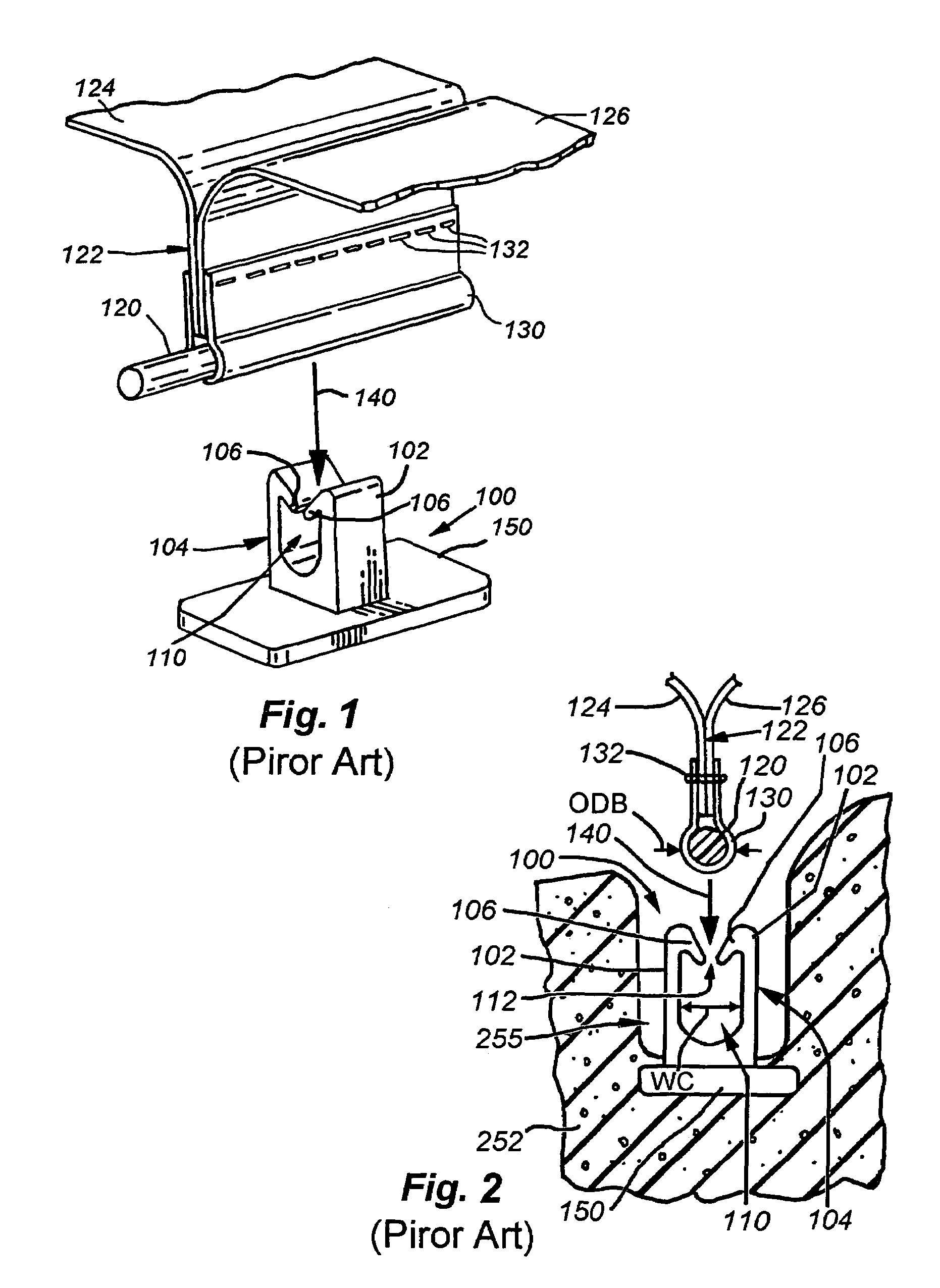

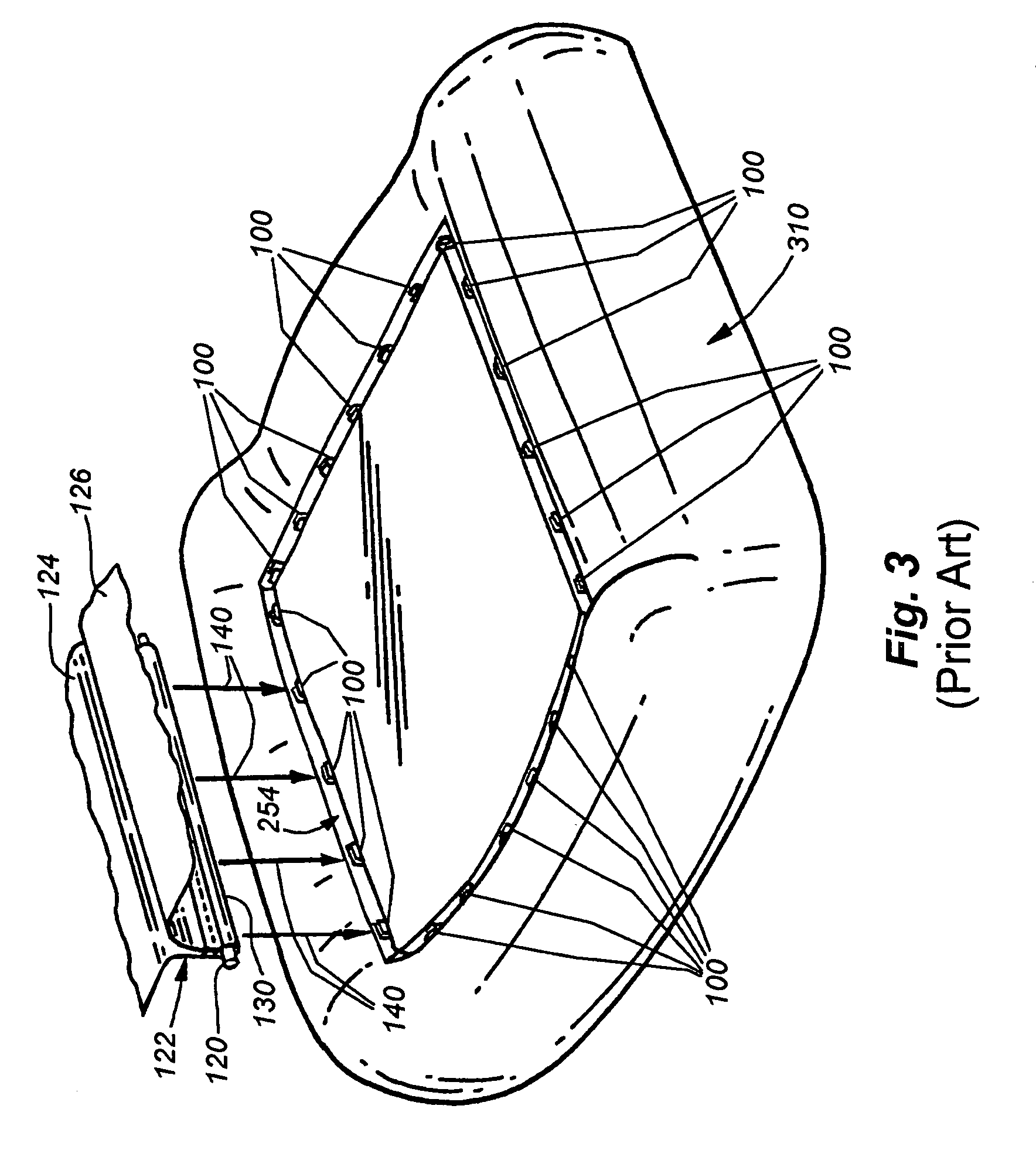

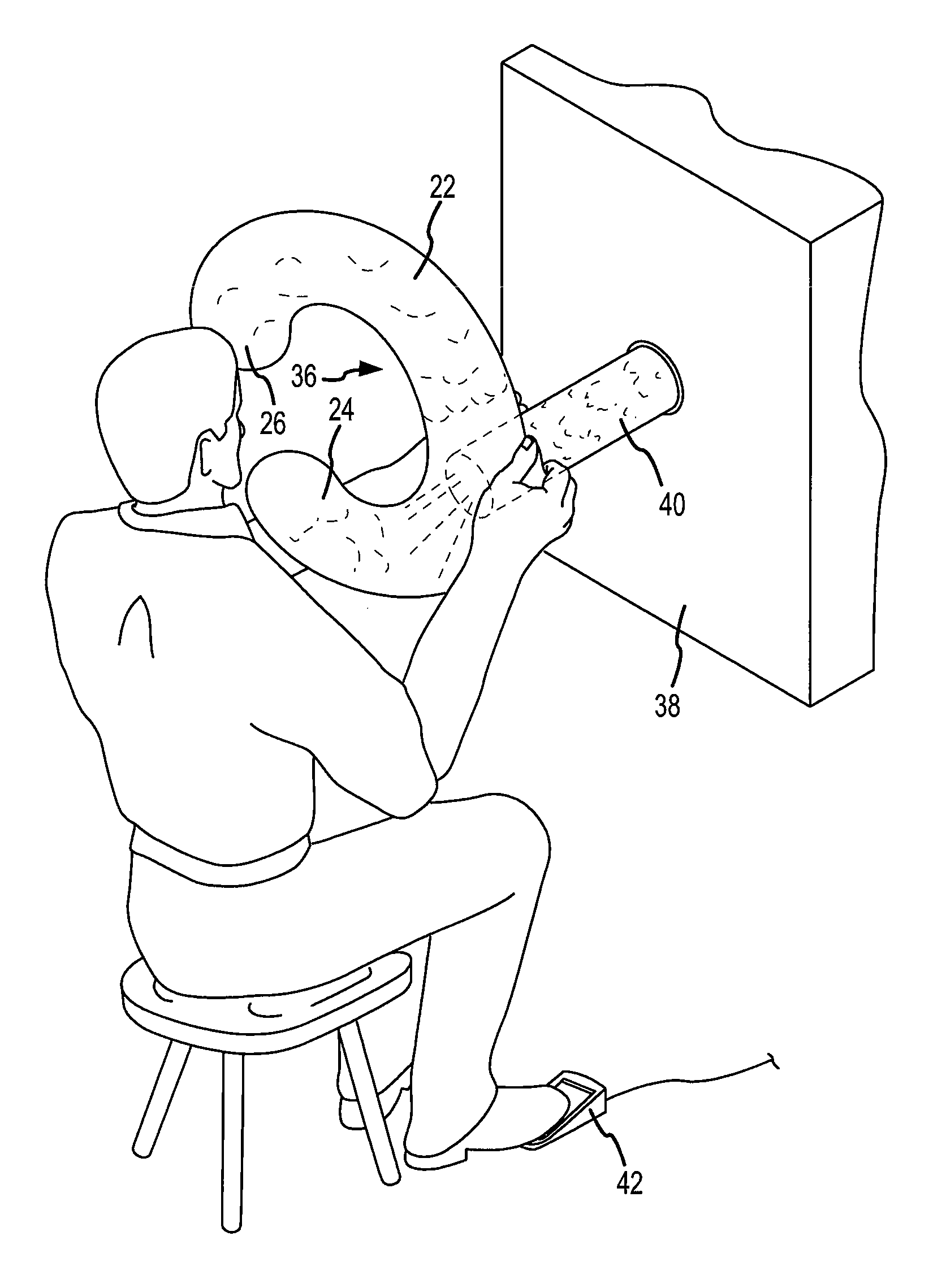

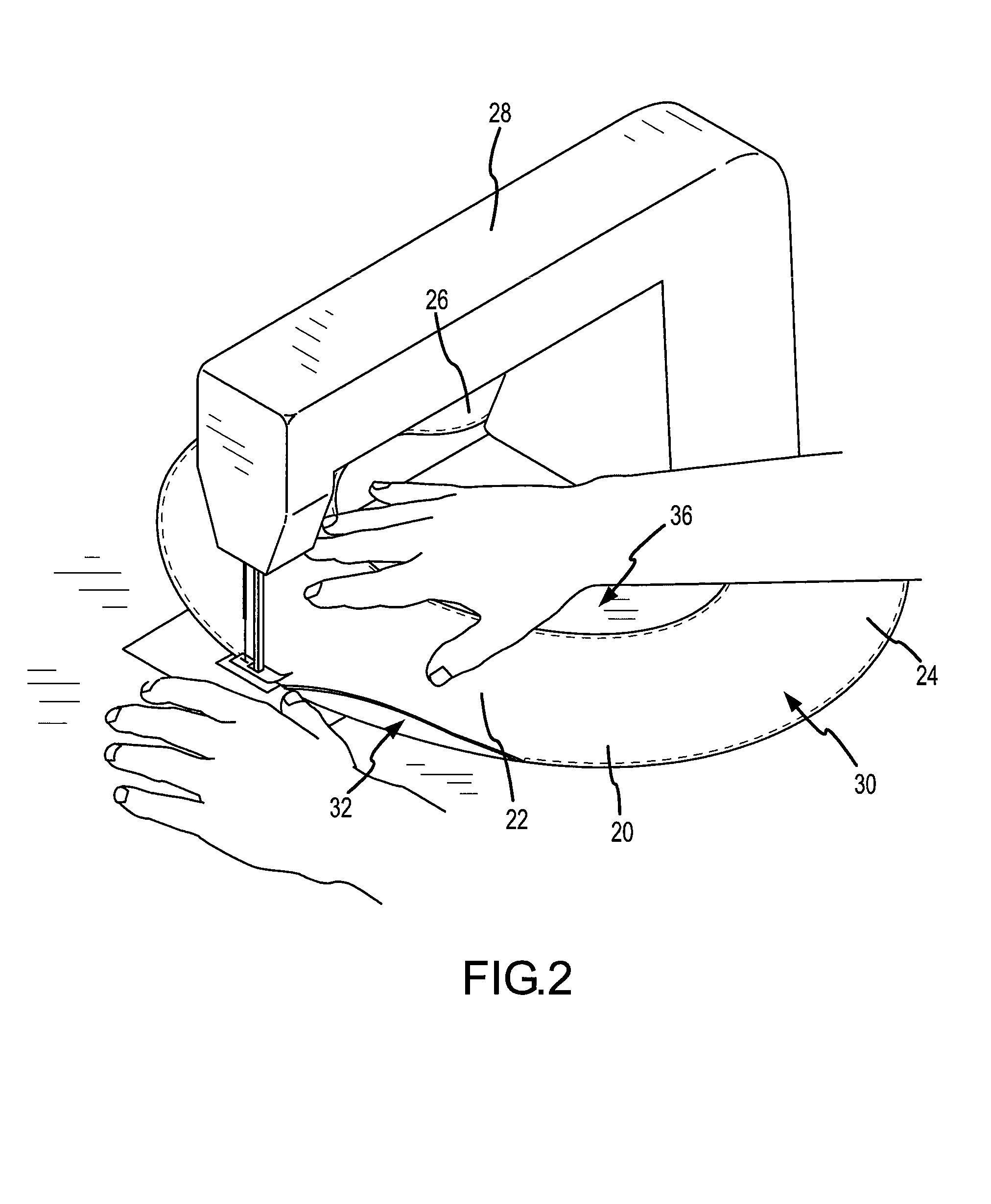

Method of manufacturing cushion construction for seating unit

A method of manufacturing a seating unit, such as a chair, includes manufacturing a cushion made from a non-woven fibrous material, and attaching the cushion to the seating unit for comfortable support. The cushion is made by cutting a blank from non-woven fibrous sheet material, steam-forming the blank into a pre-formed cushion shaped to support a user, and attaching a stiffener panel to the pre-formed cushion to provide a stiffened cushion assembly. The cushion assembly is aesthetically covered and assembled to seating unit. Advantageously, trimmings from the fibrous material can be recycled.

Owner:STEELCASE INC

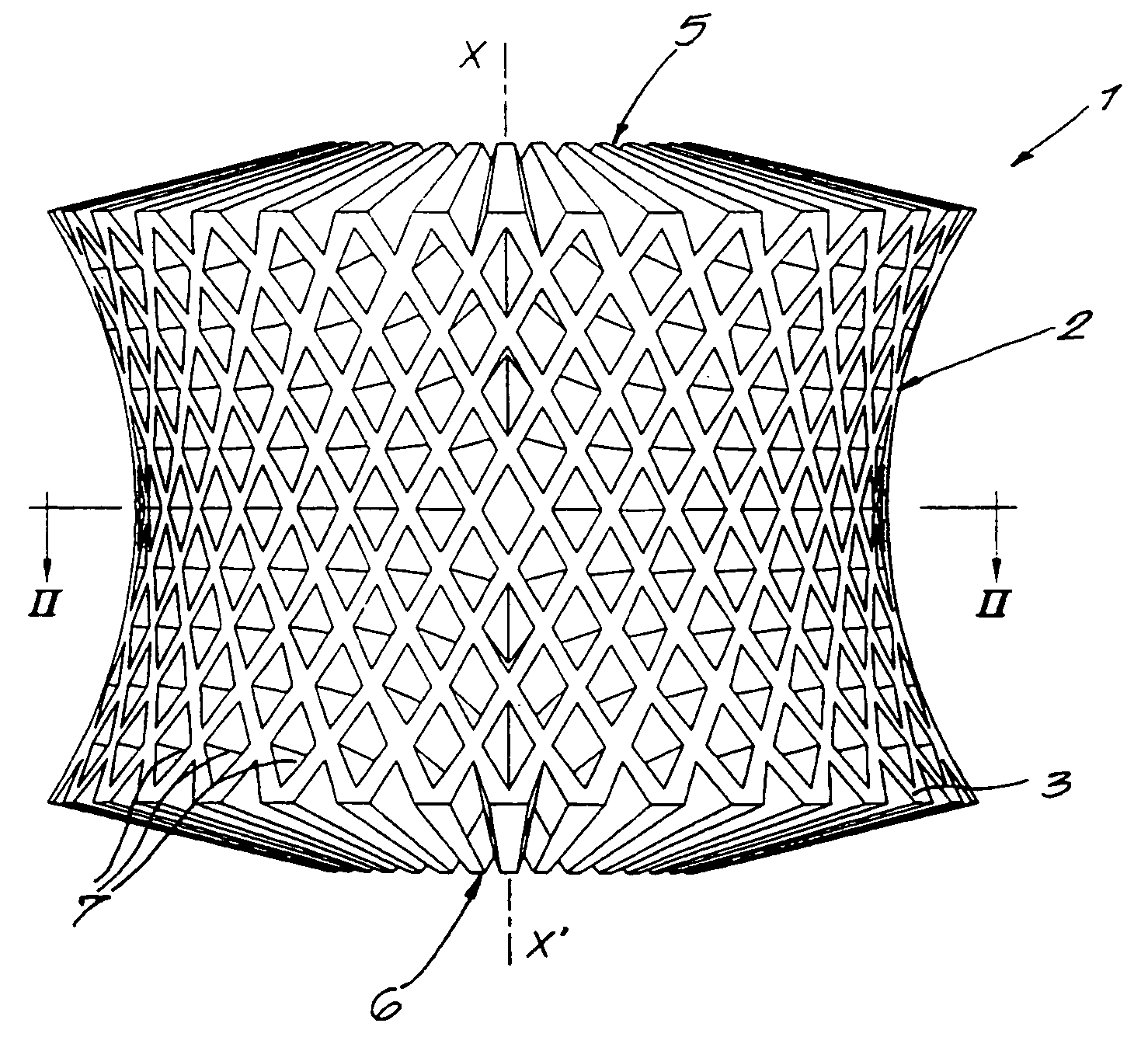

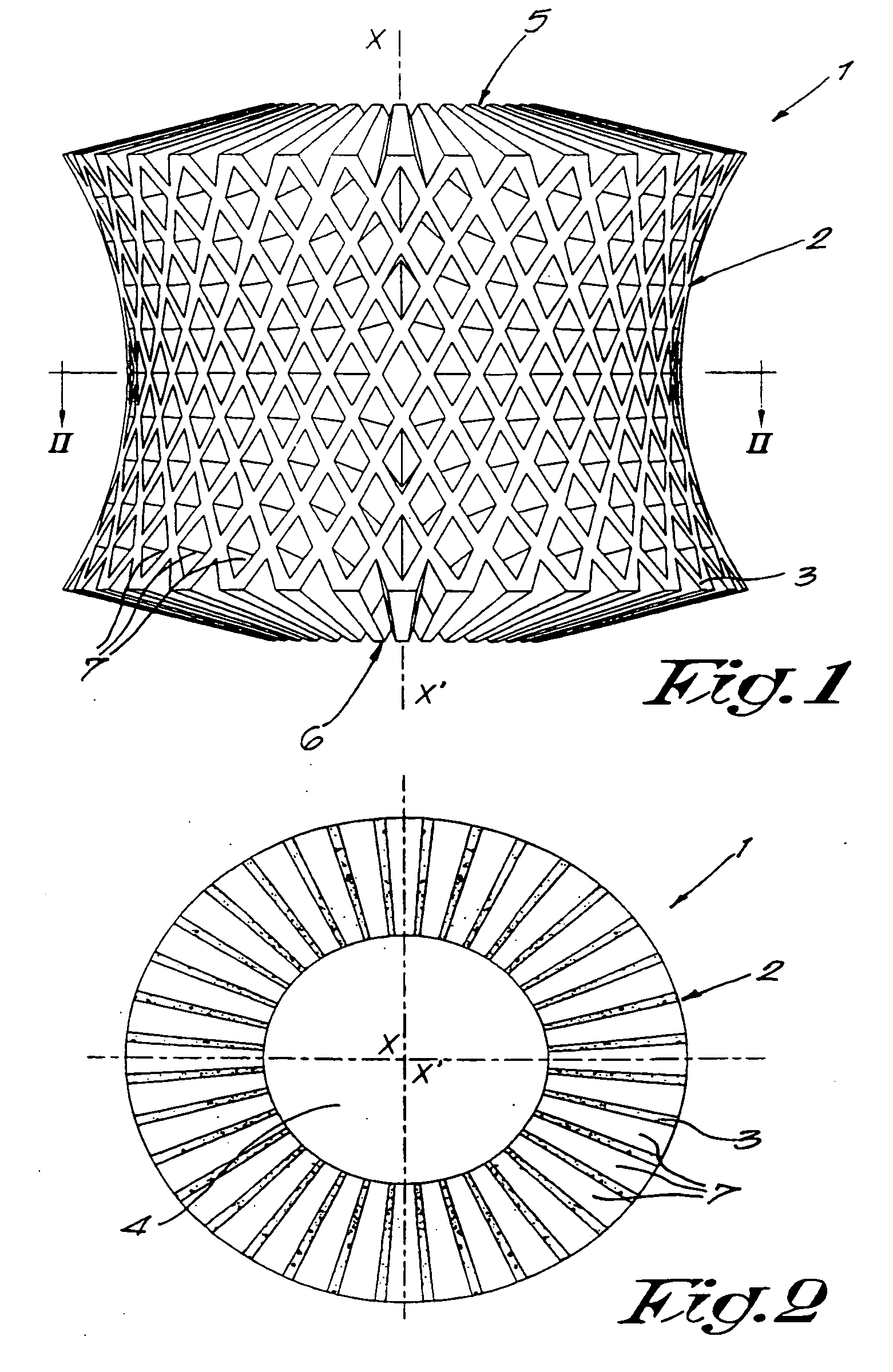

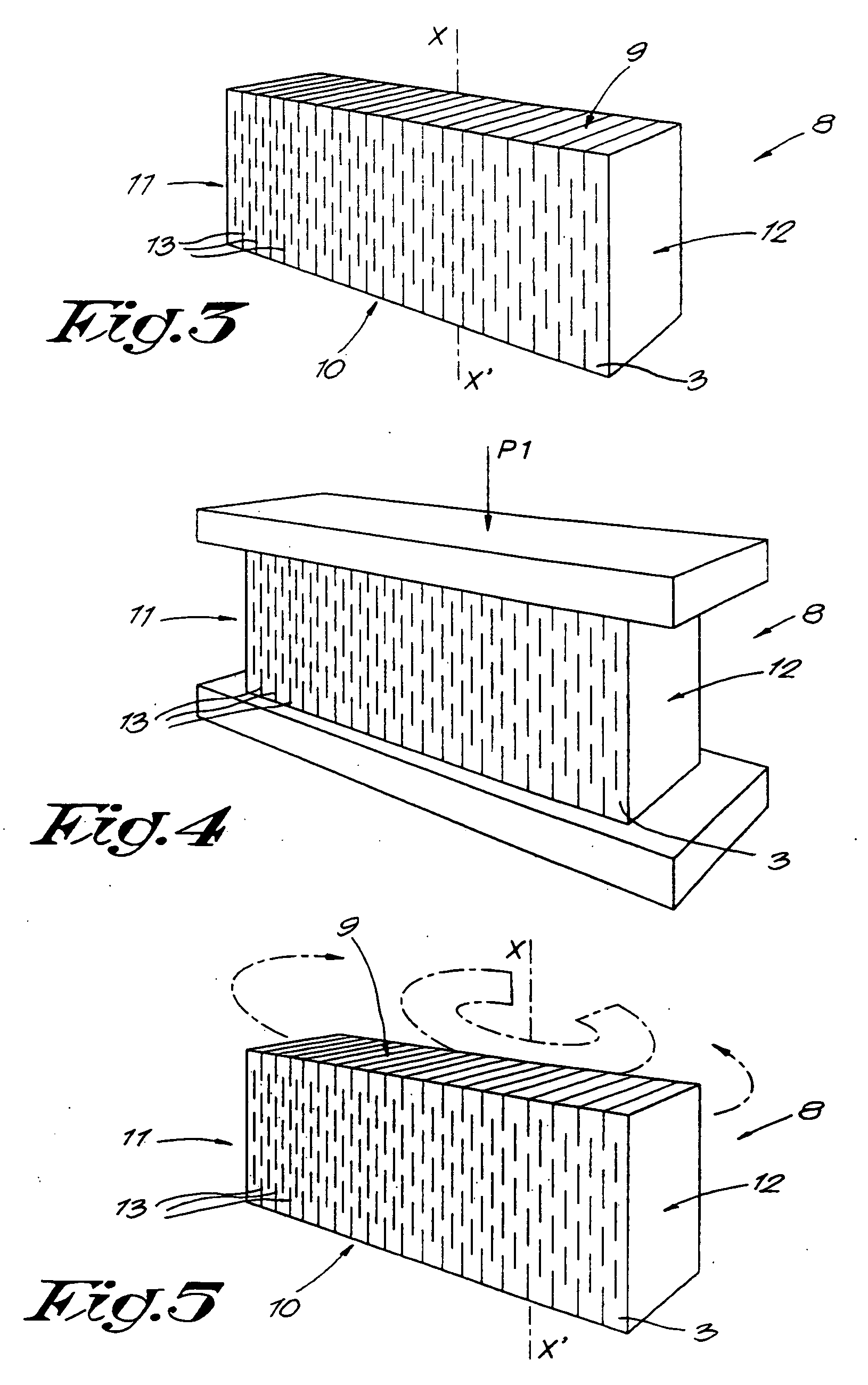

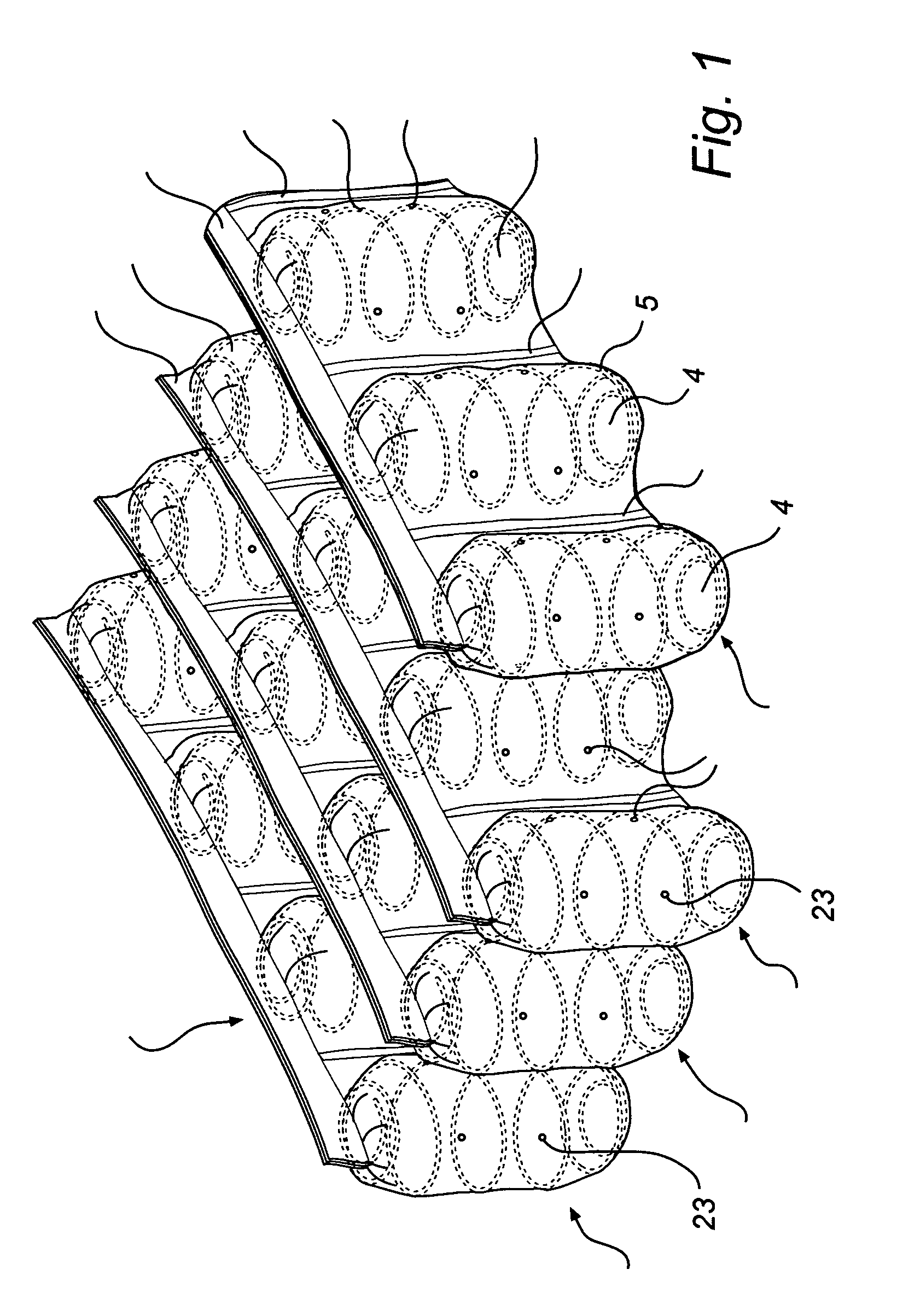

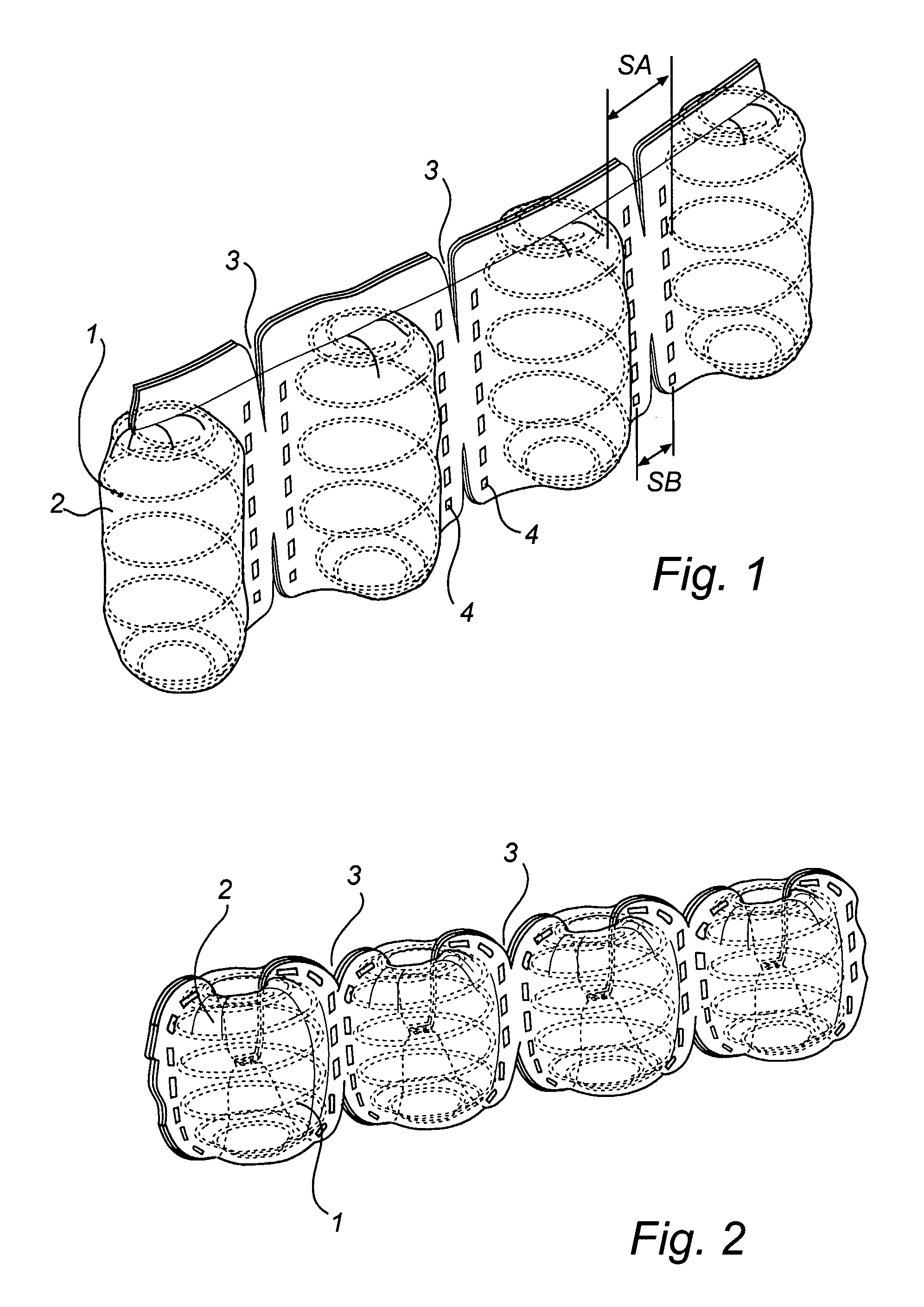

Method for manufacturing a resilient body which can be applied in cushions, mattresses or the like

InactiveUS20050172468A1Improvement of the user's comfortUpholstery manufacturePillowsElastomerEngineering

Method for manufacturing a tubular, resilient body for pillows, mattresses or the like, which method mainly consists in providing slits (13) in a foam layer (2); in cutting a strip (8) out of this foam layer (2); in bending two opposite ends (11-12) of the strip (8) towards each other; and in fixing both these far ends (11-12) in order to form the aimed tubular, resilient body (1), characterised in that the foam layer (2) is made of what is called a viscoelastic foam (3), and in that at least a part of the cells present in the foam (3) are broken open.

Owner:IMHOLD

Seat cushion with adjustable contour and method of adjusting the contour of a seat cushion

Owner:ASPEN SEATING

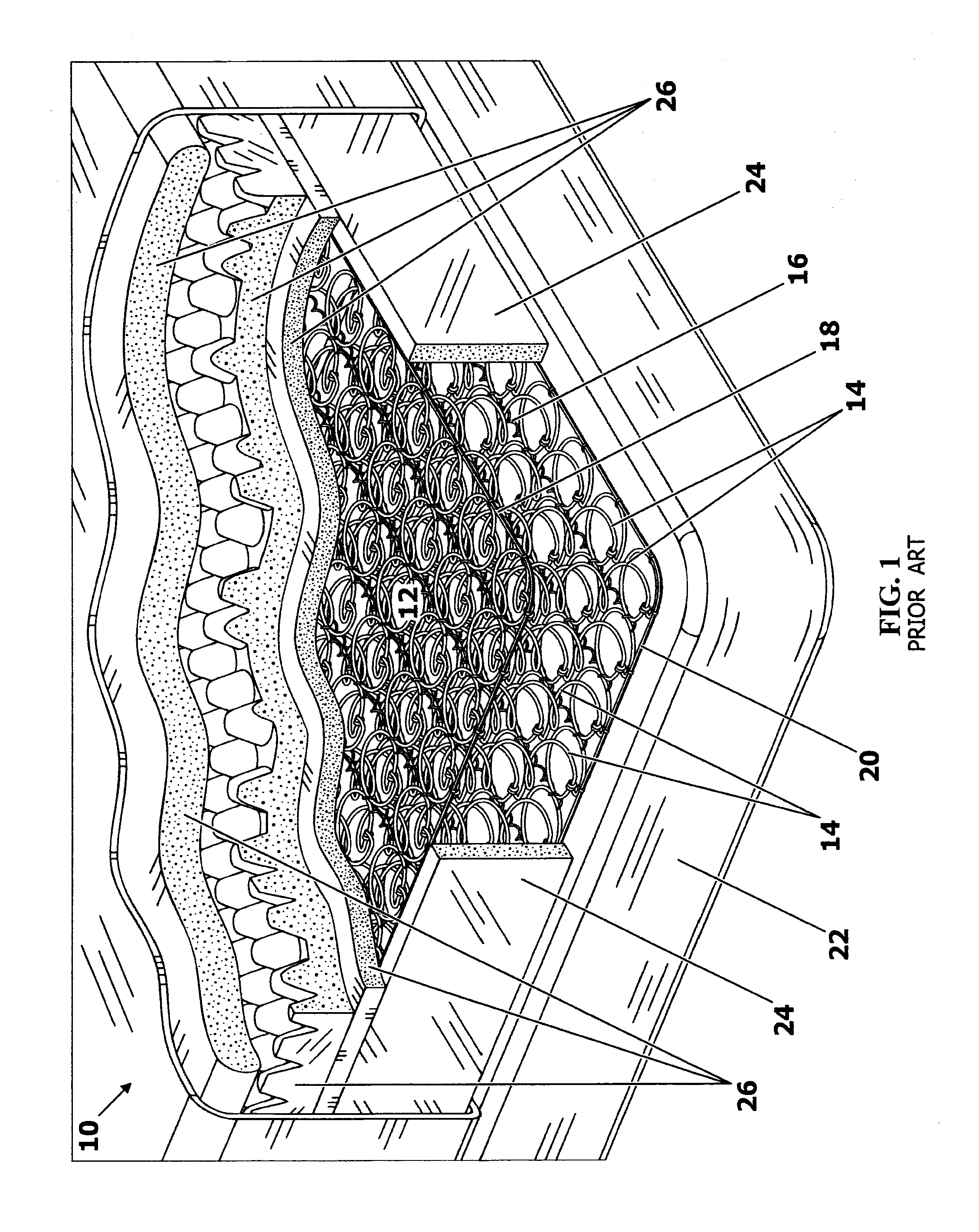

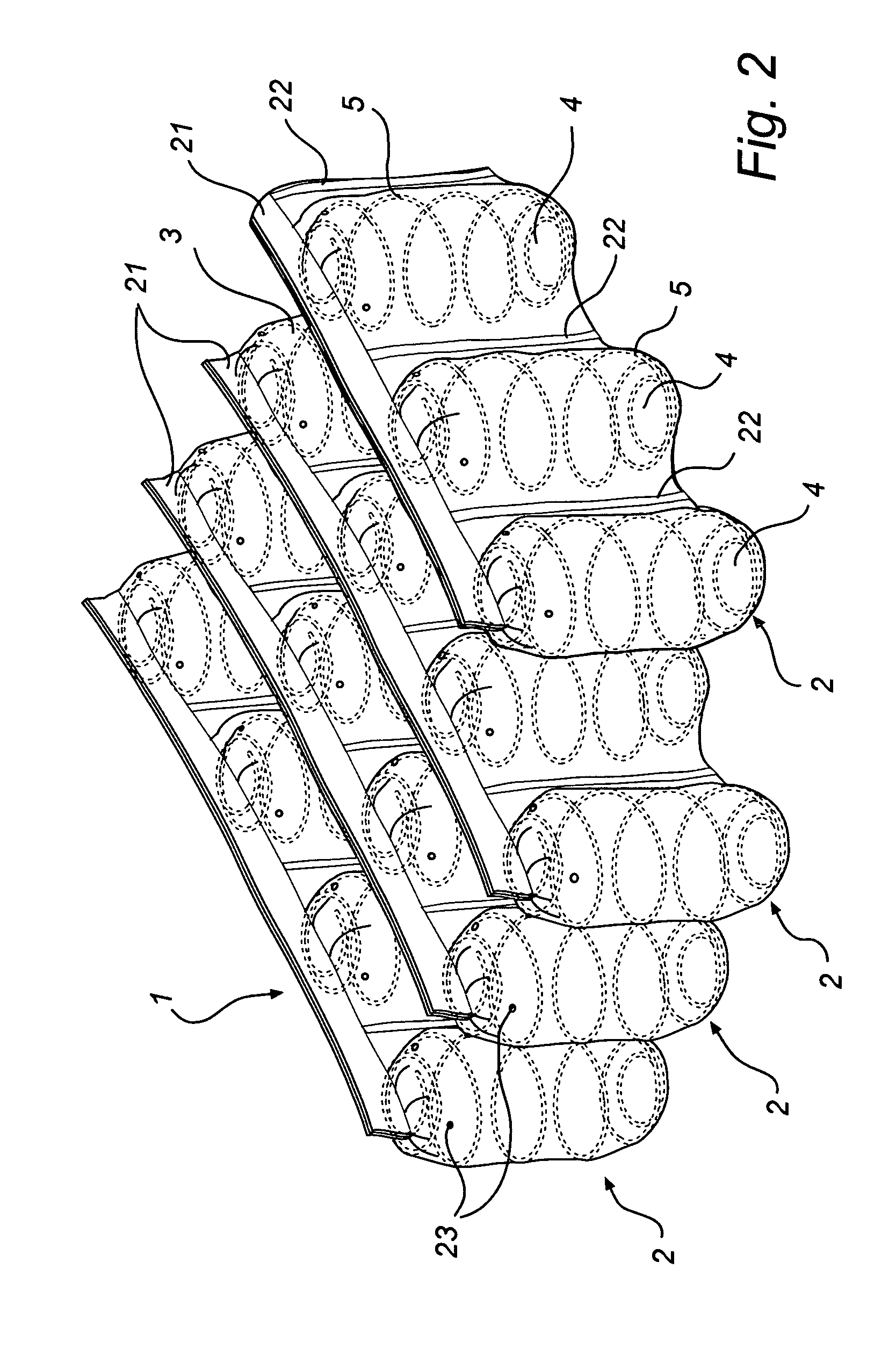

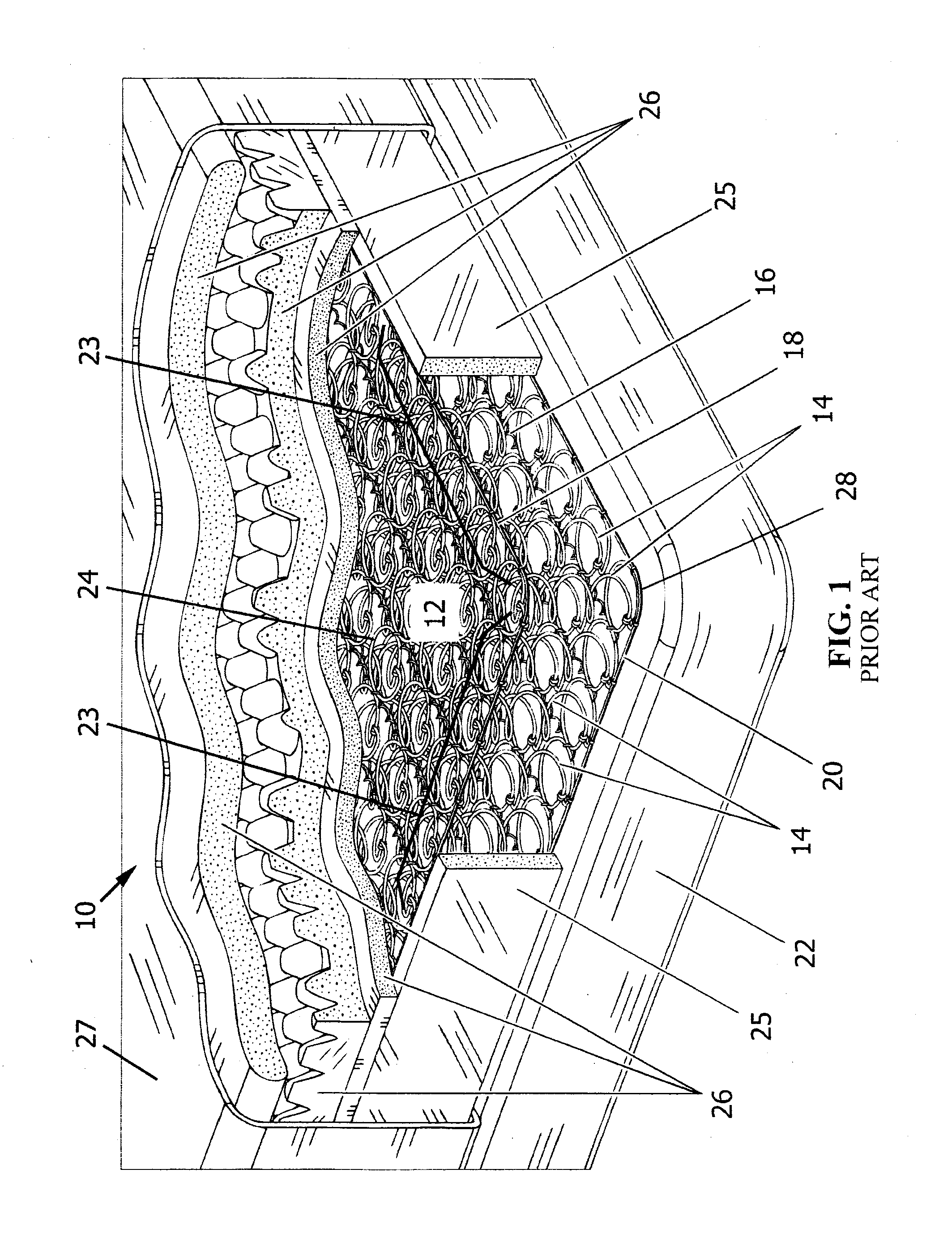

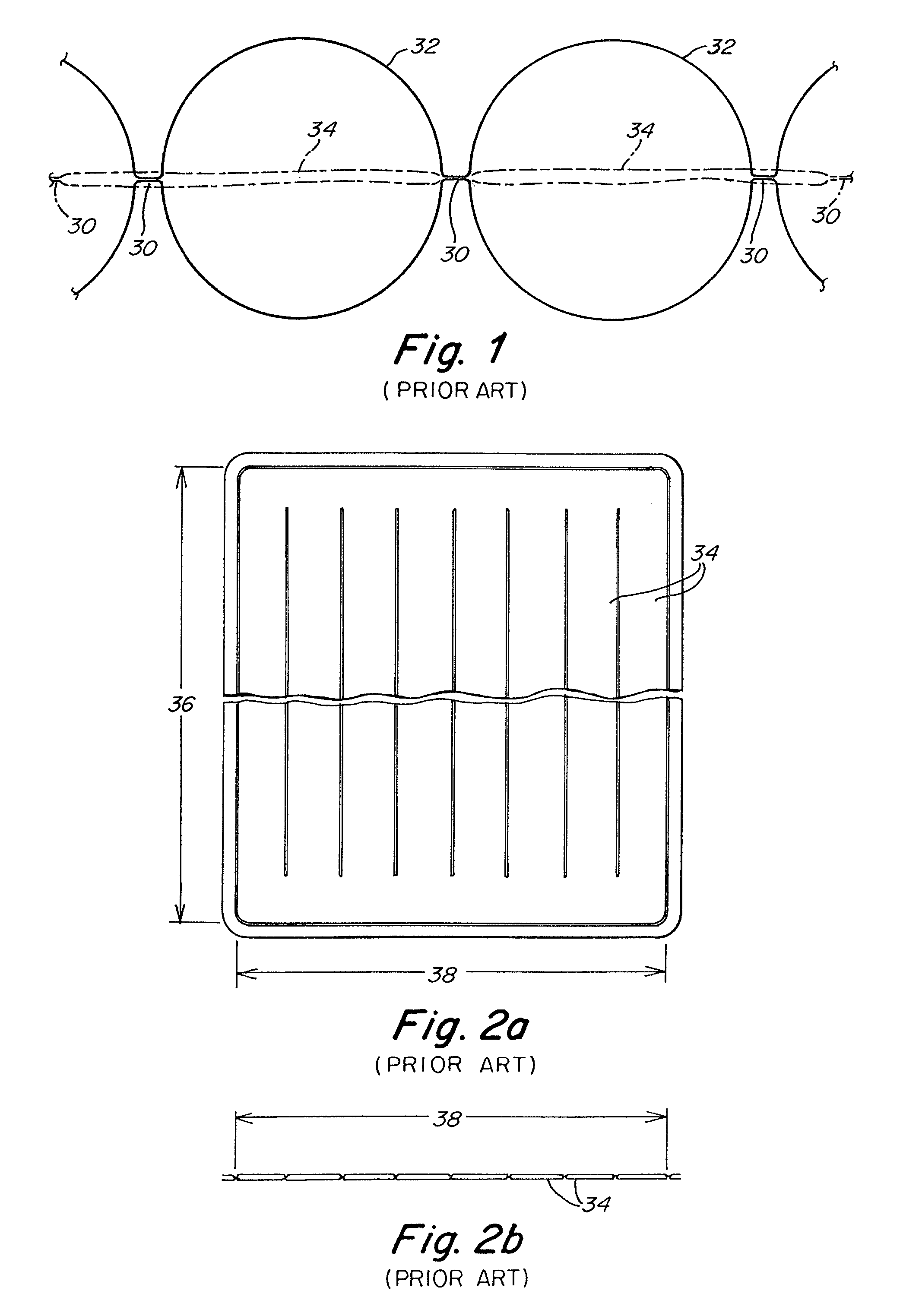

Stepped-edge and side-support members, assemblies, systems, and related methods, particularly for bedding and seating

InactiveUS20100319137A1Low costReduce the amount requiredUpholstery manufactureStuffed mattressesCompression setMechanical engineering

Stepped-edge and side-support members, systems, assemblies, and related methods for an innerspring assembly or other core are disclosed. In one embodiment, an innerspring assembly or core is provided having an interior area of a first height surrounded by one or more exterior, perimeter area(s) of shorter height(s) to provide a stepped-edge innerspring assembly or core. At least a portion of side-support members are placed onto at least a portion of the top surface of the perimeter area to provide edge-support for the innerspring assembly or core. In this manner, a greater portion of the side-support members can be disposed in the sleeping area of the innerspring assembly or core since the underlying perimeter area provides spring support to the side-support members. Further, this support can assist in retention and / or recovery of the shape of the side-support members to further prevent or reduce compression set of the side-support members.

Owner:NOMACO

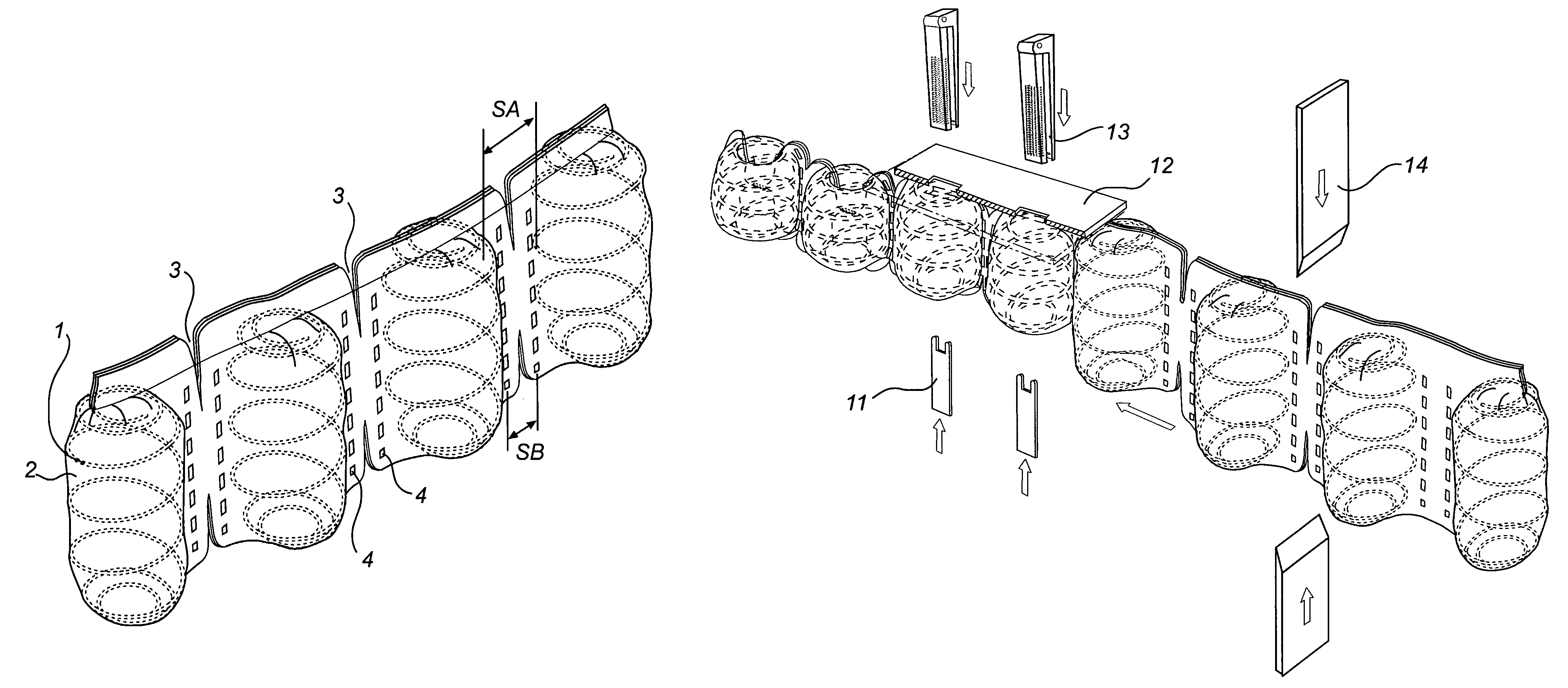

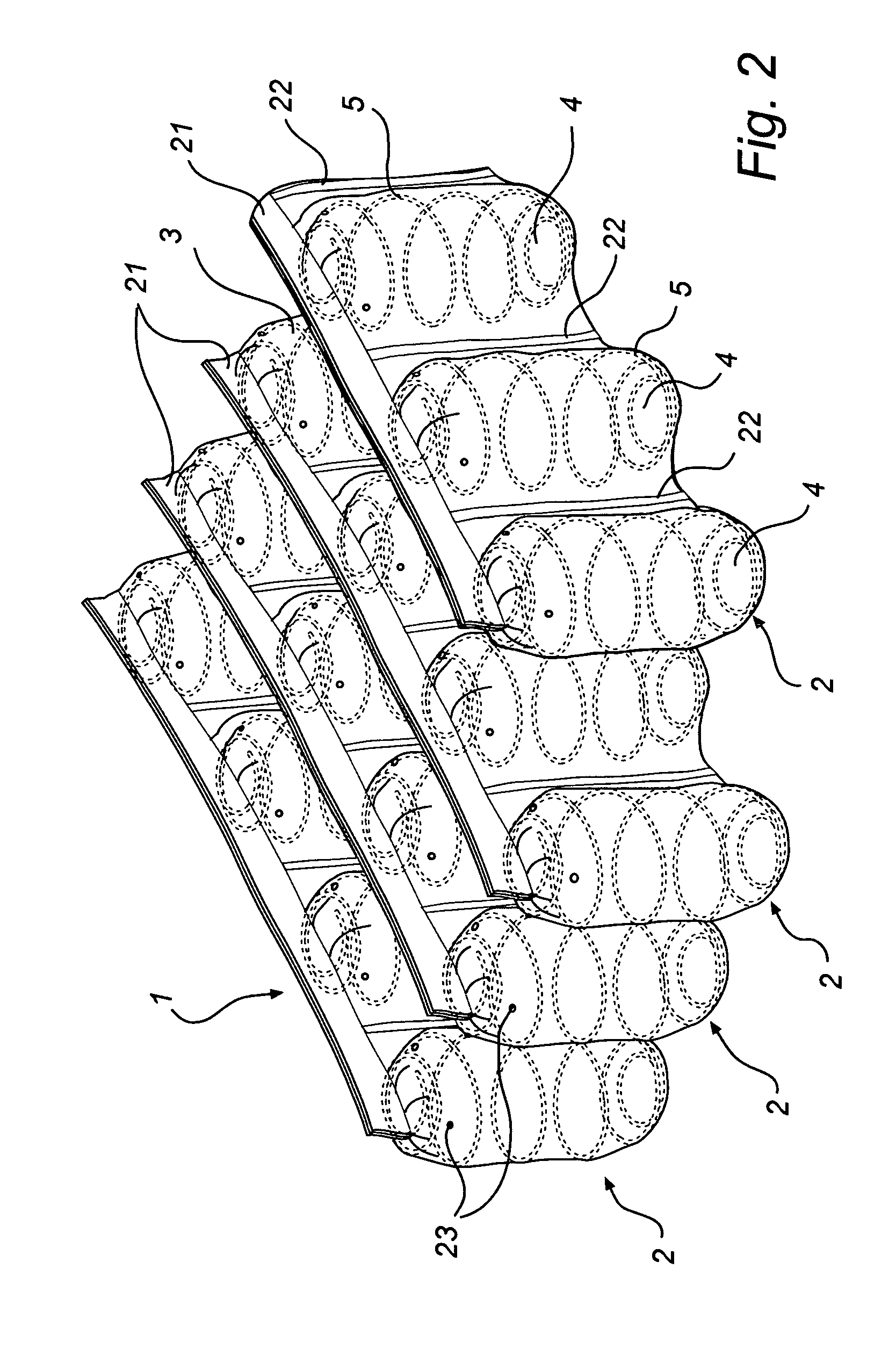

Pocket Spring Mattress

ActiveUS20100212090A1Adequate dampingCool and pleasant to useUpholstery manufactureStuffed mattressesCoil springEngineering

Owner:STJERNFJADRAR

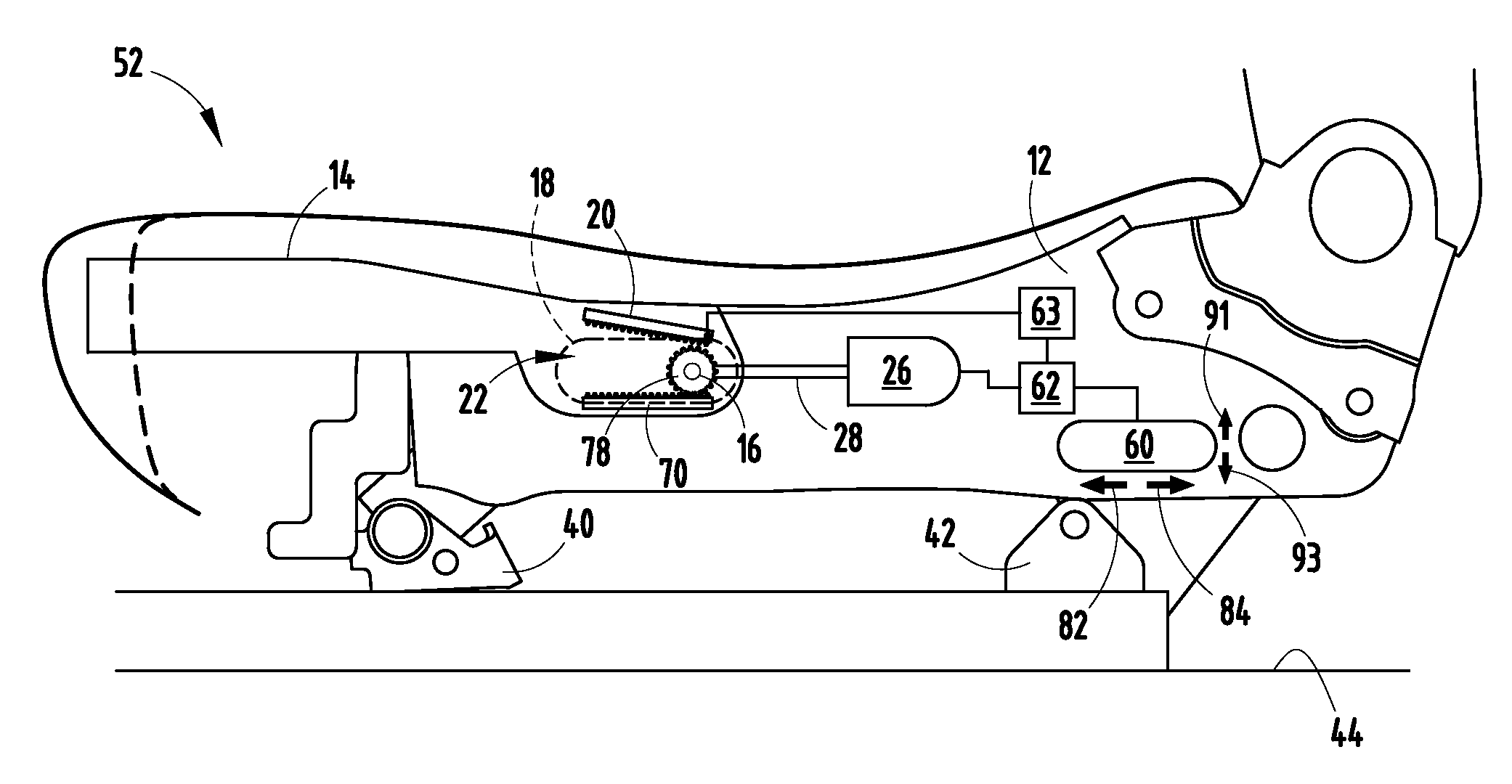

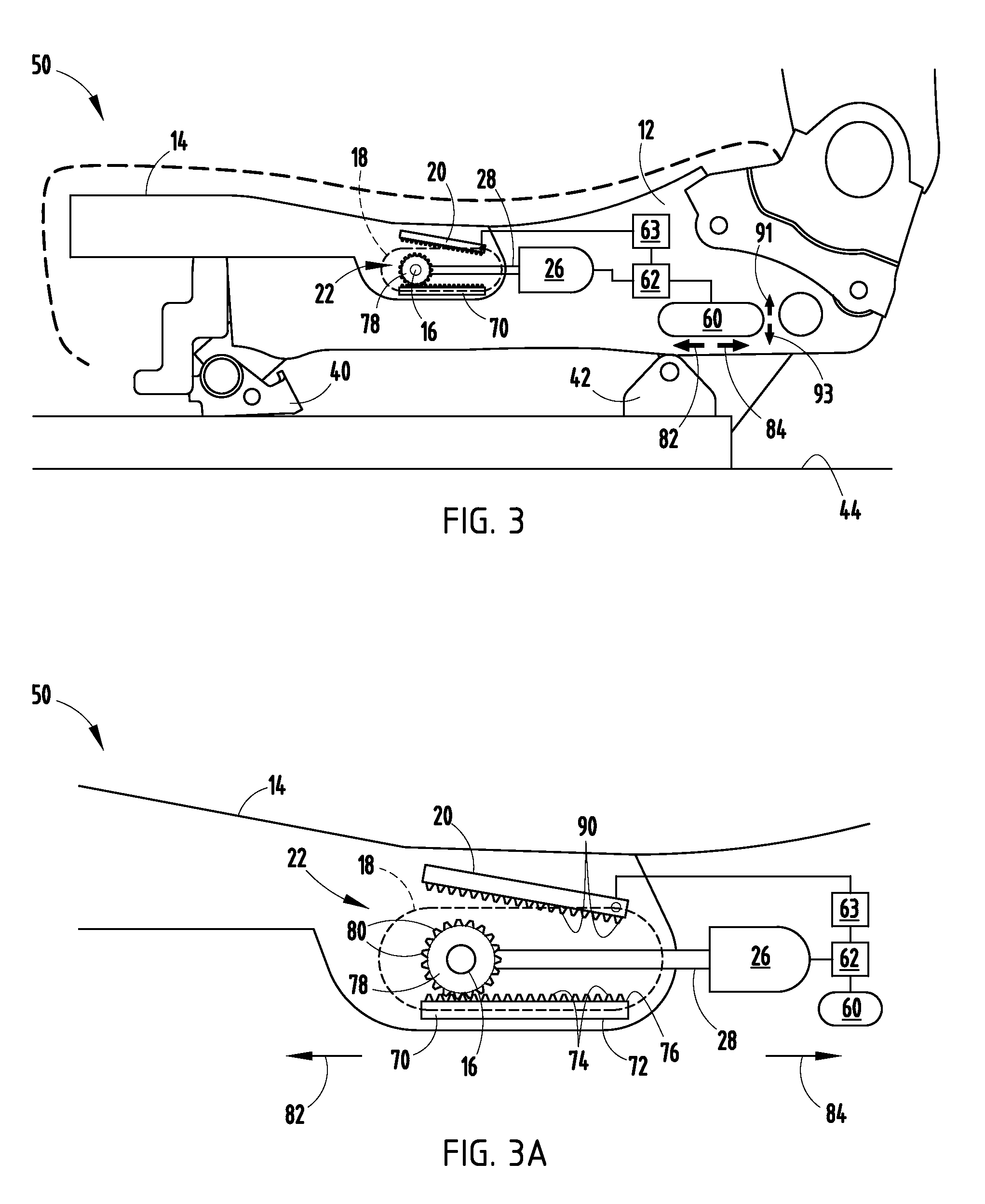

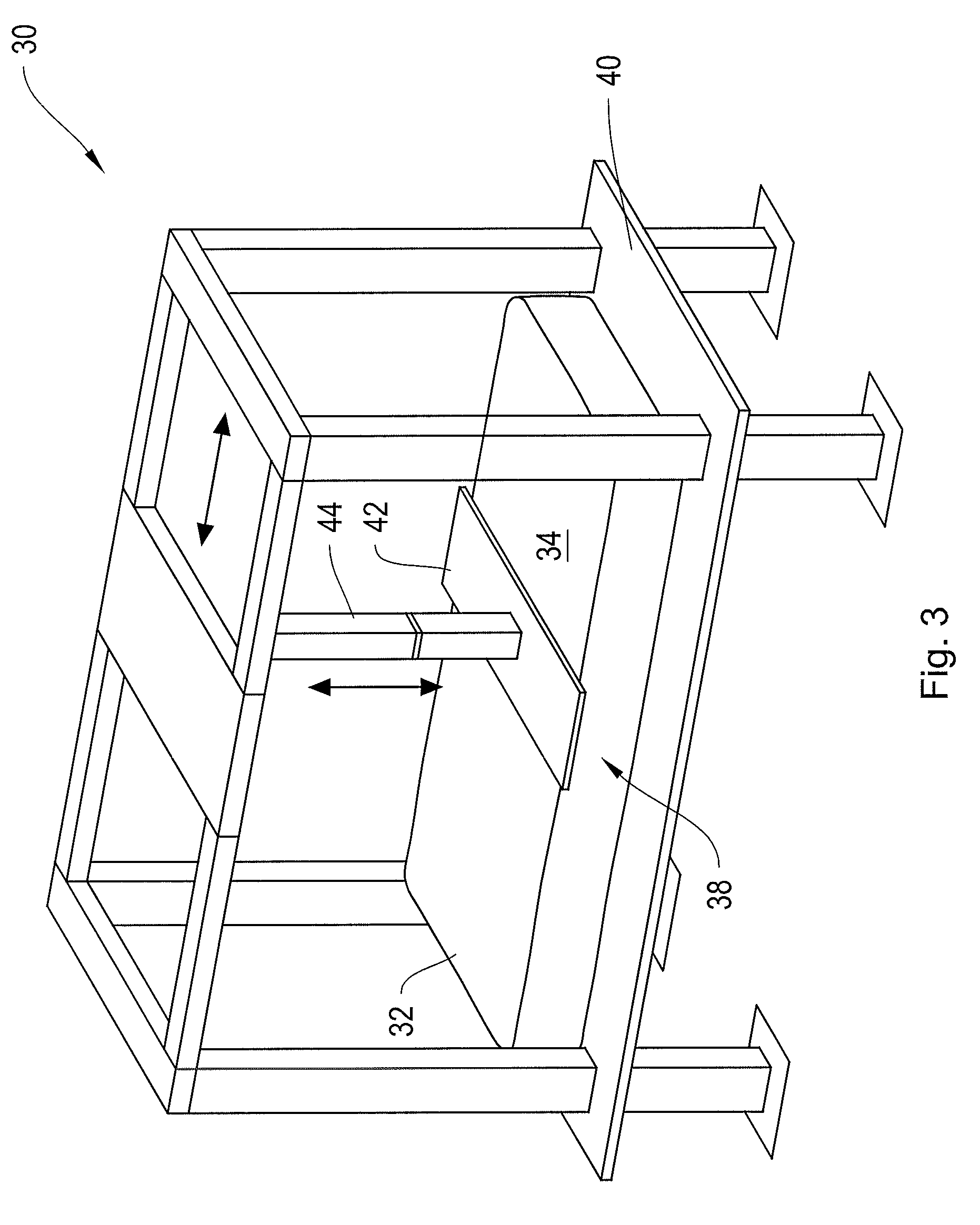

Seat cushion extension mechanism

A seat assembly having a seat base. A seat pan is operably connected to the seat base. A rod extends across the seat base into elongated slots in the seat pan. An engagement member is operable between a first position out of contact with the rod and a second position in contact with the rod. A motor includes a drive shaft operably connected with the rod and adapted to rotate the rod. Rotation of the drive shaft when the engagement member is in the first position causes longitudinal displacement of the seat pan. Rotation of the drive shaft when the engagement member is in the second position causes rotation of the rod and the seat pan.

Owner:FORD GLOBAL TECH LLC

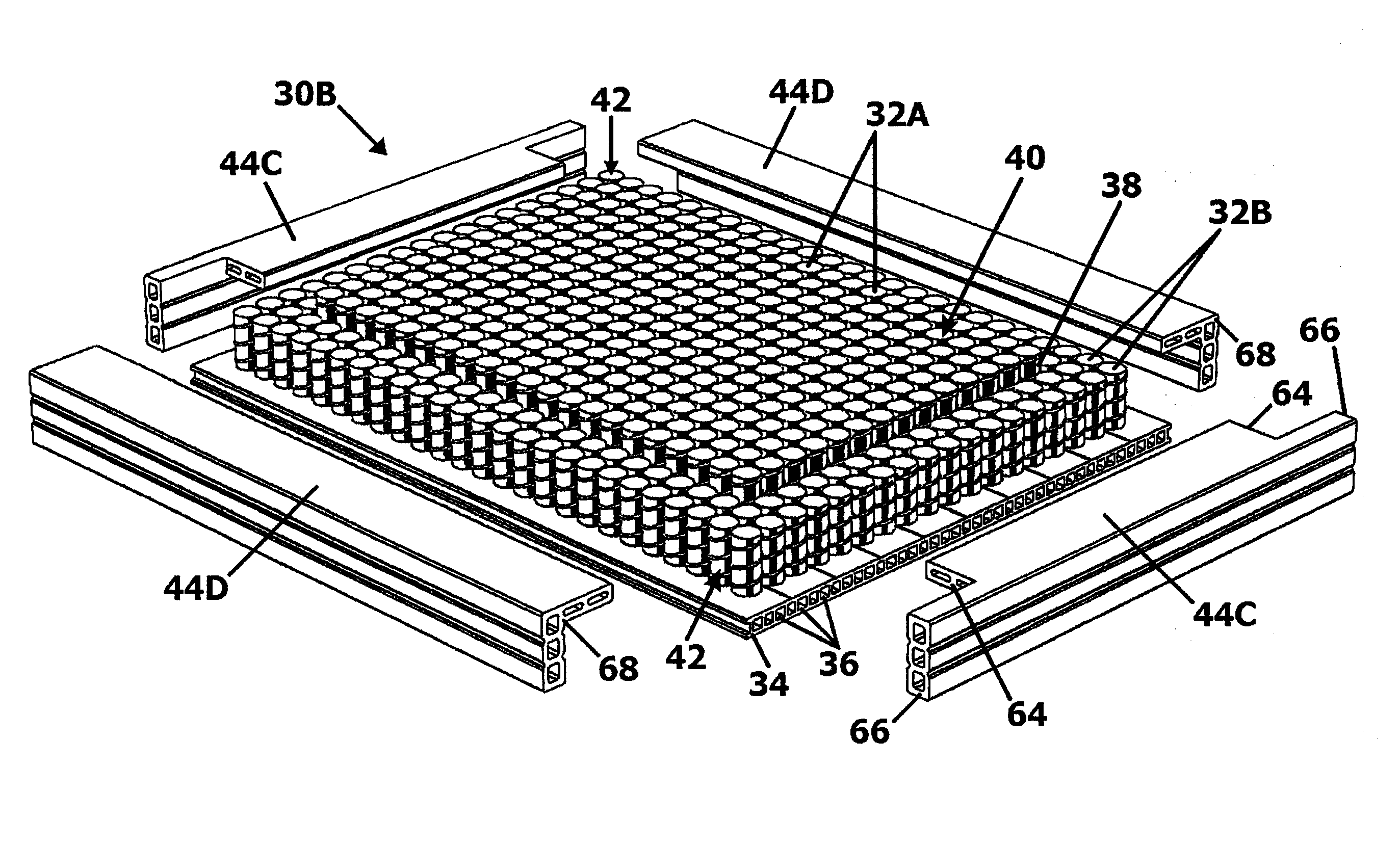

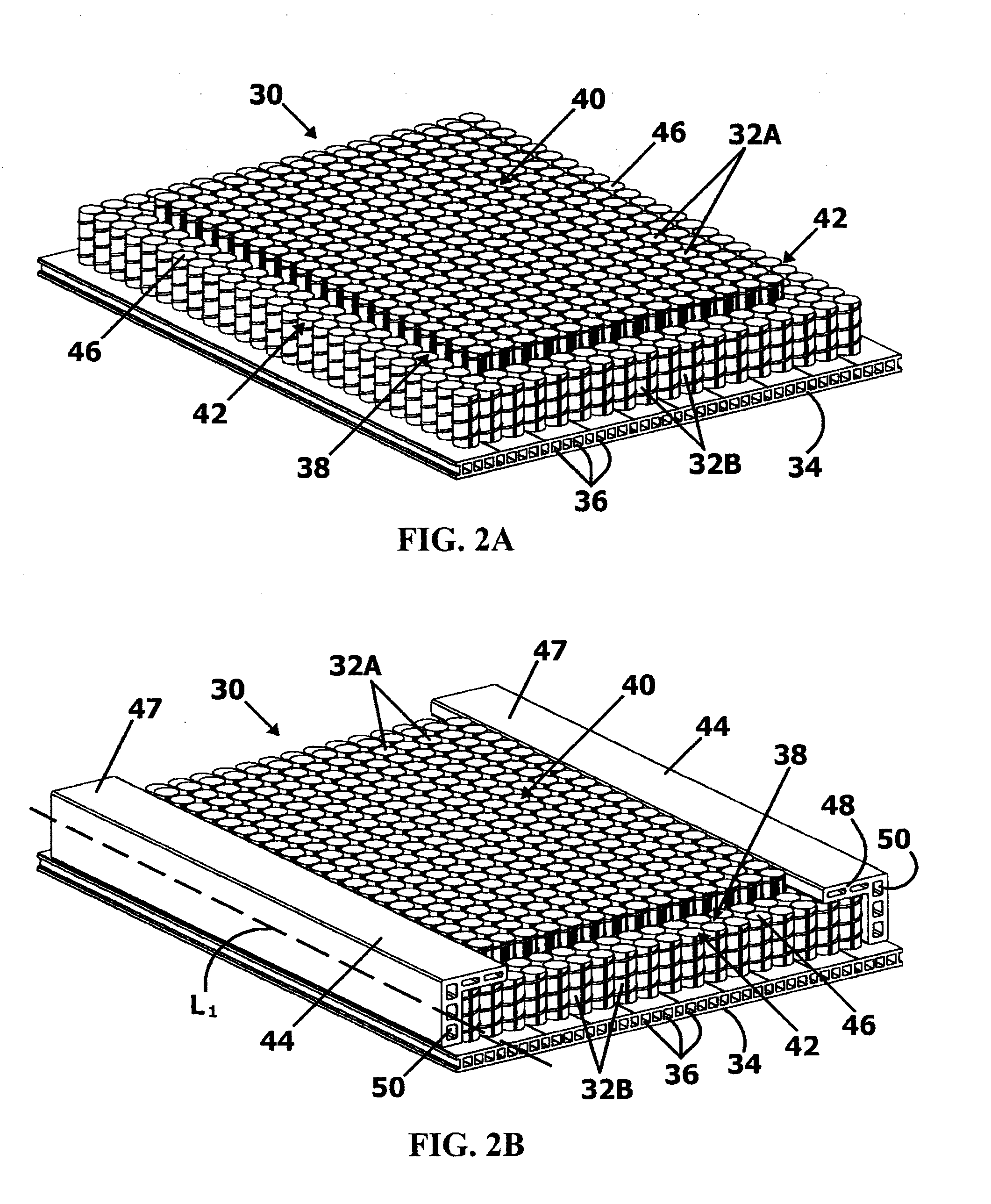

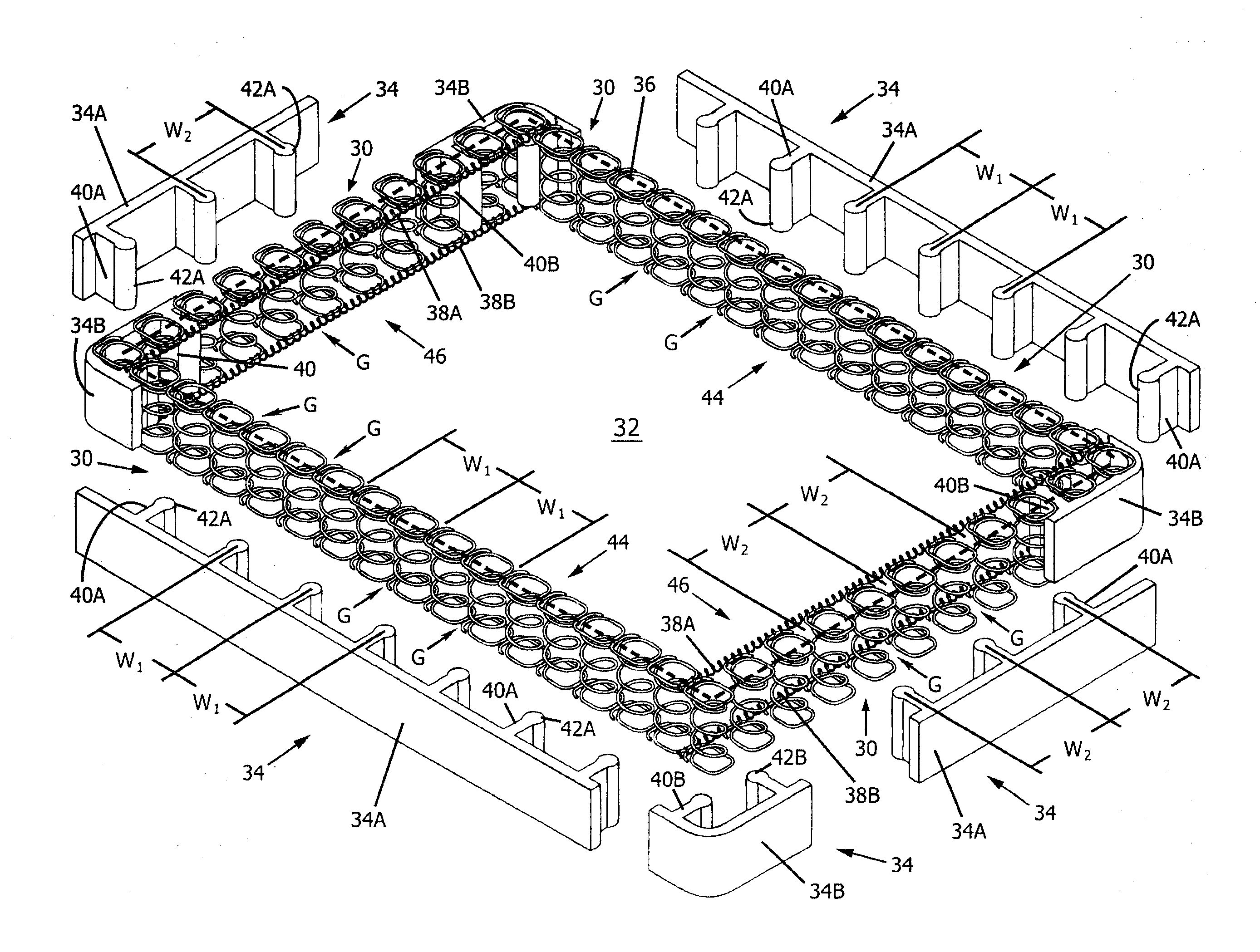

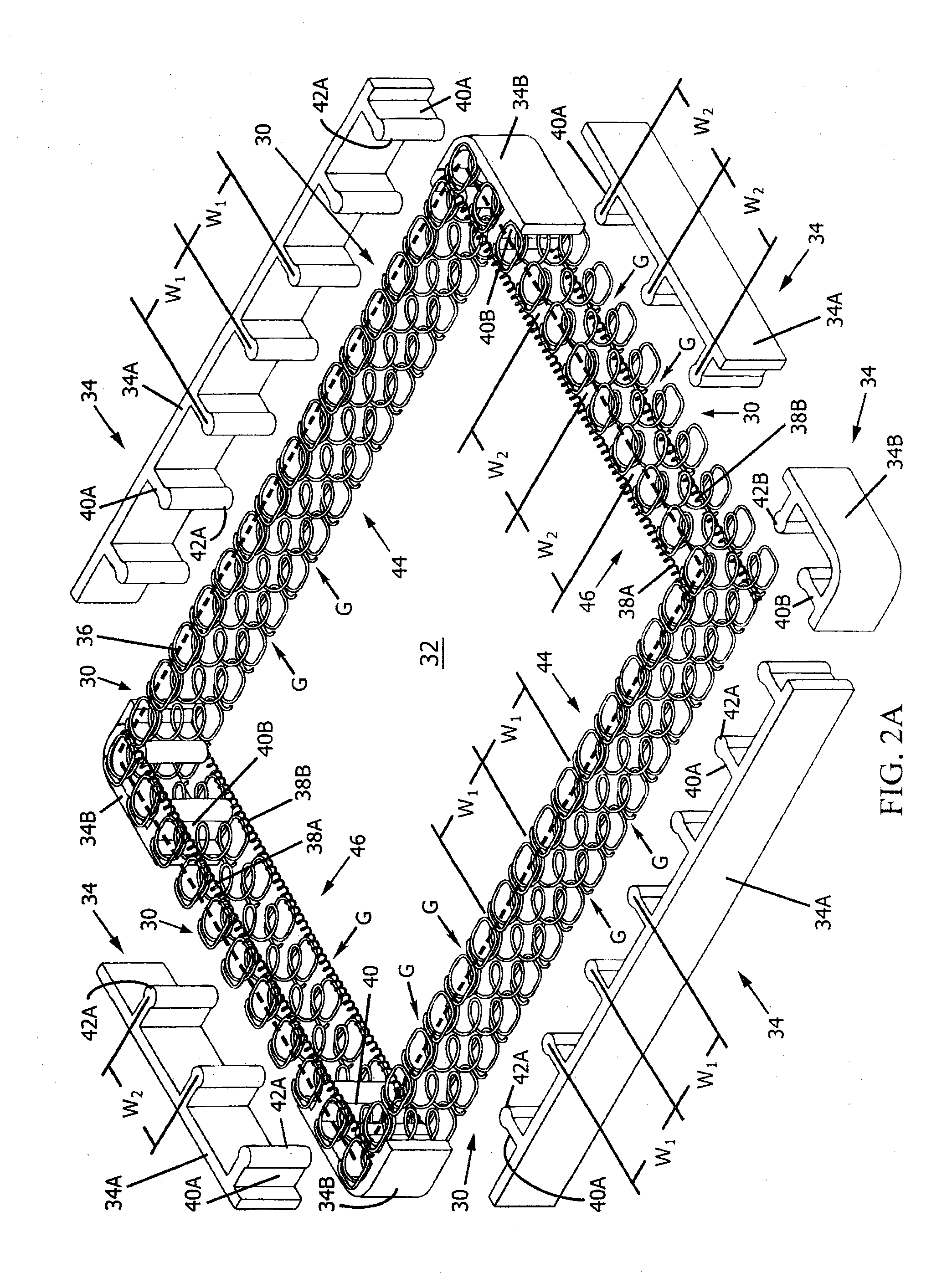

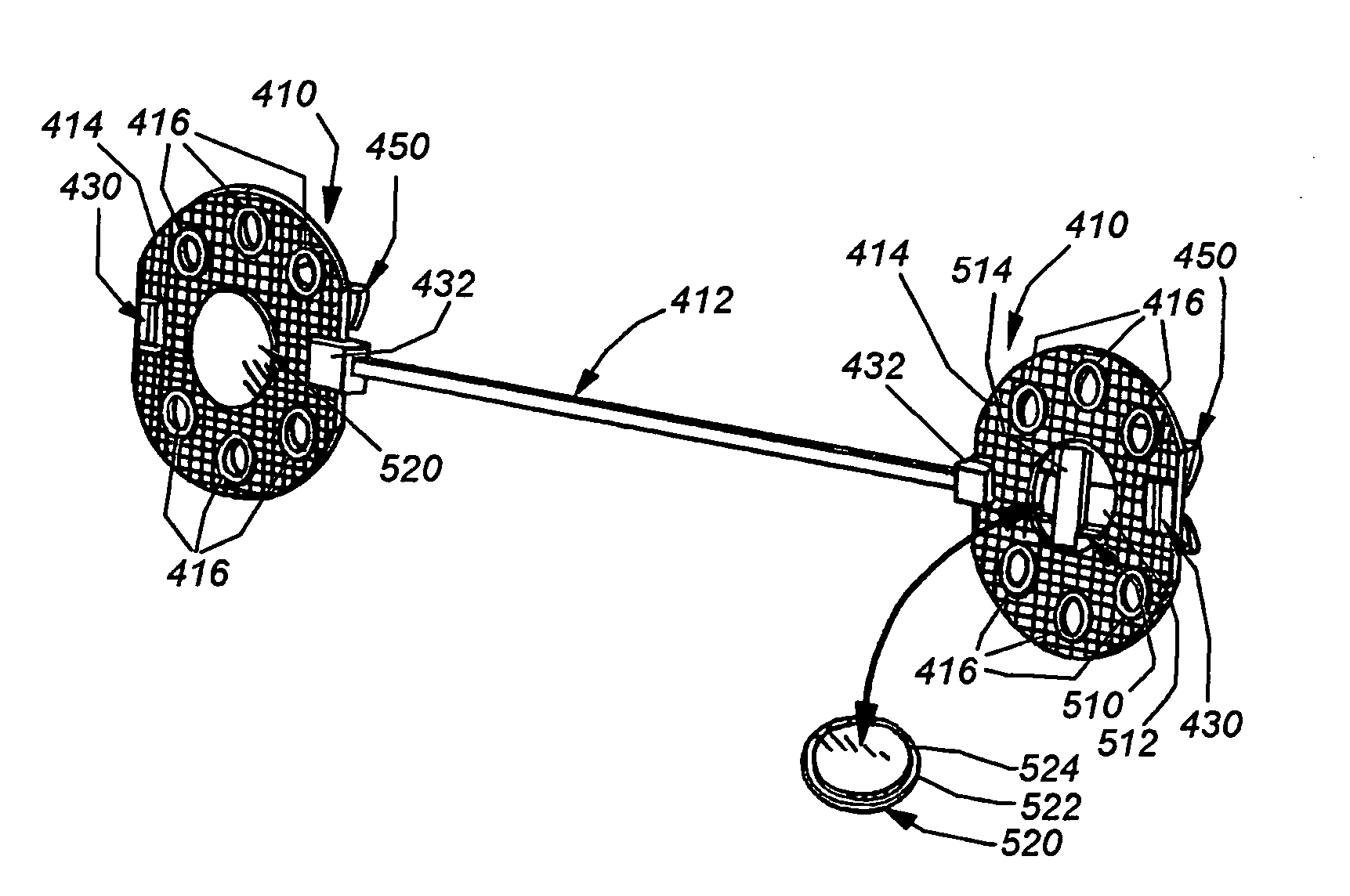

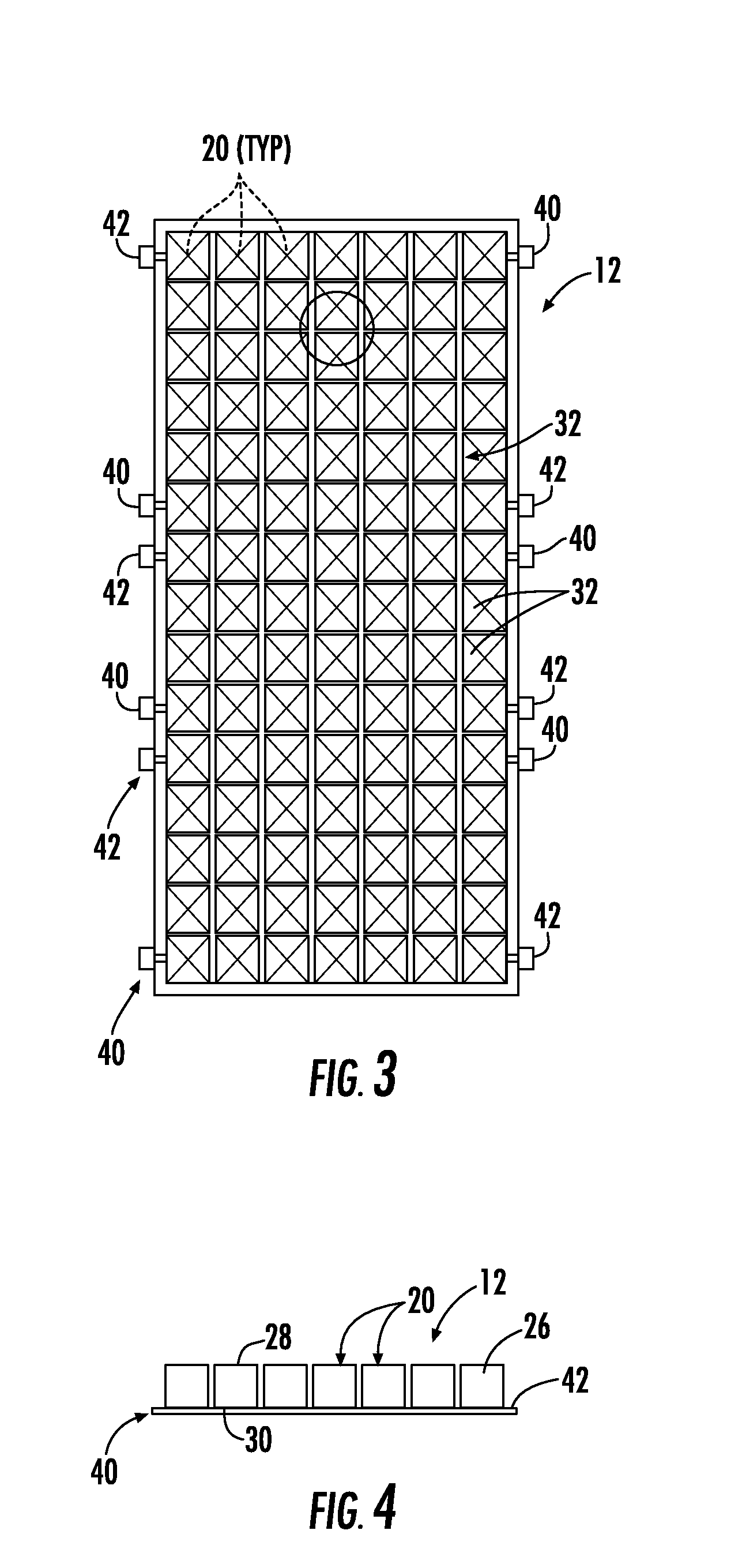

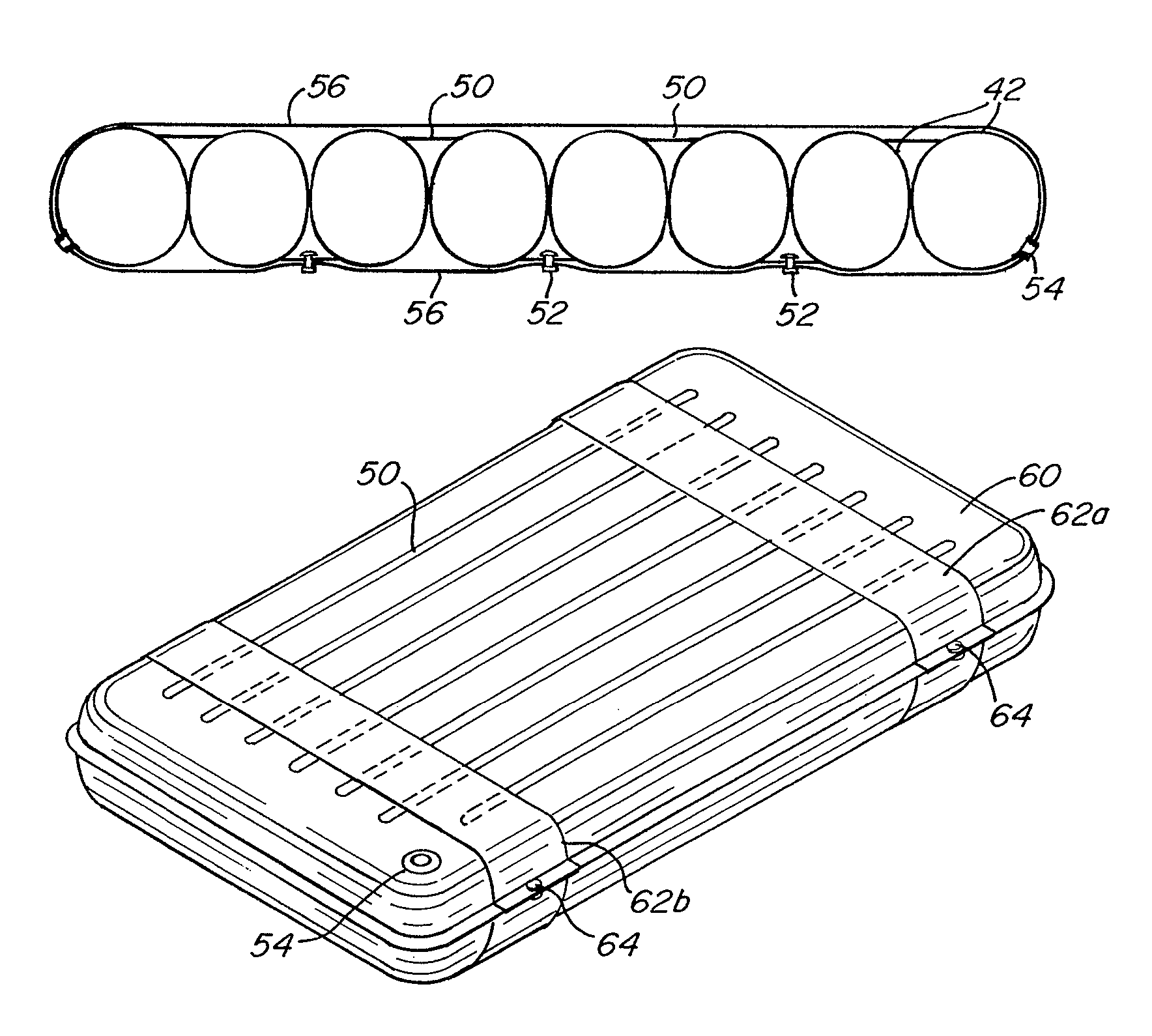

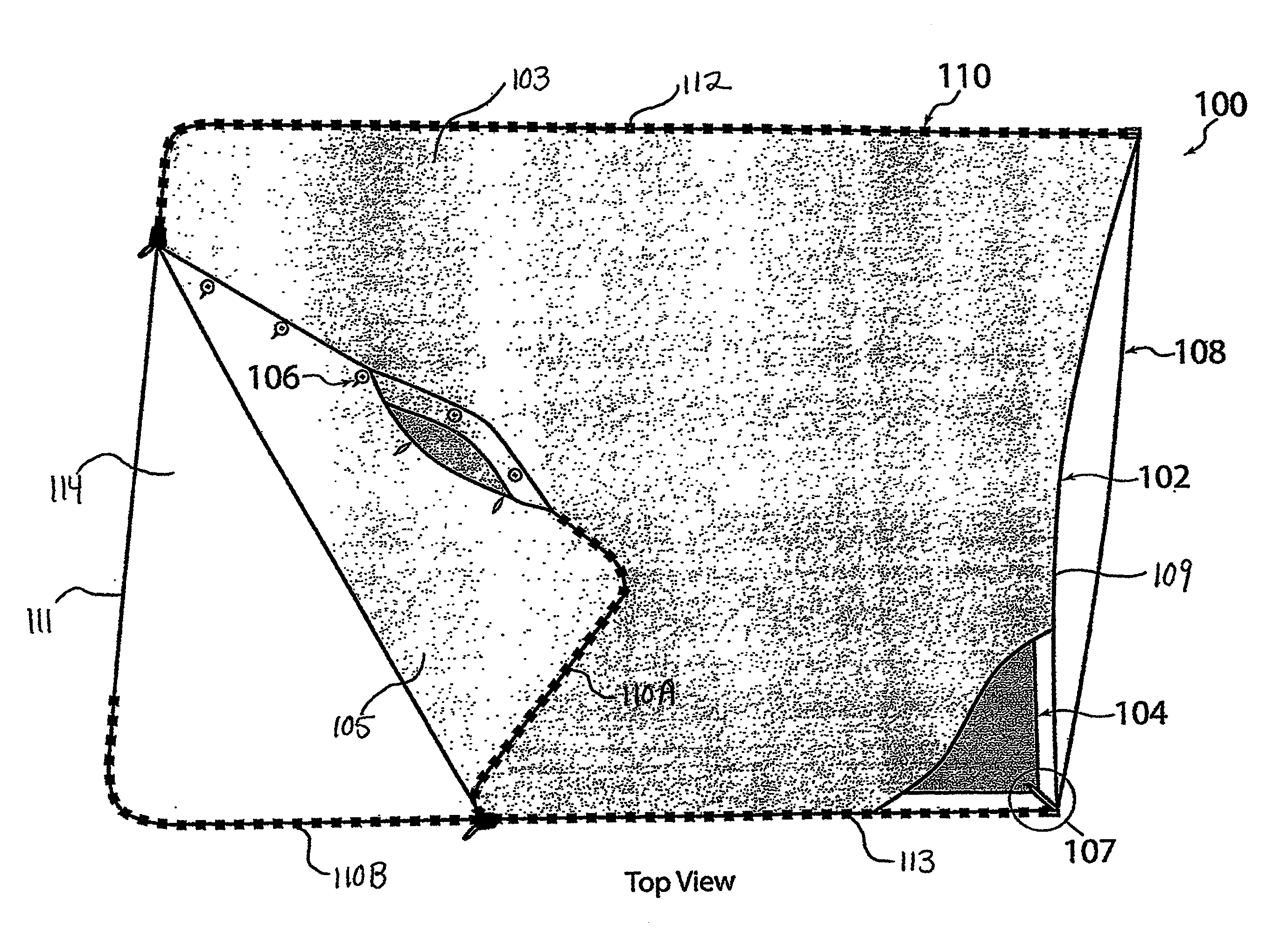

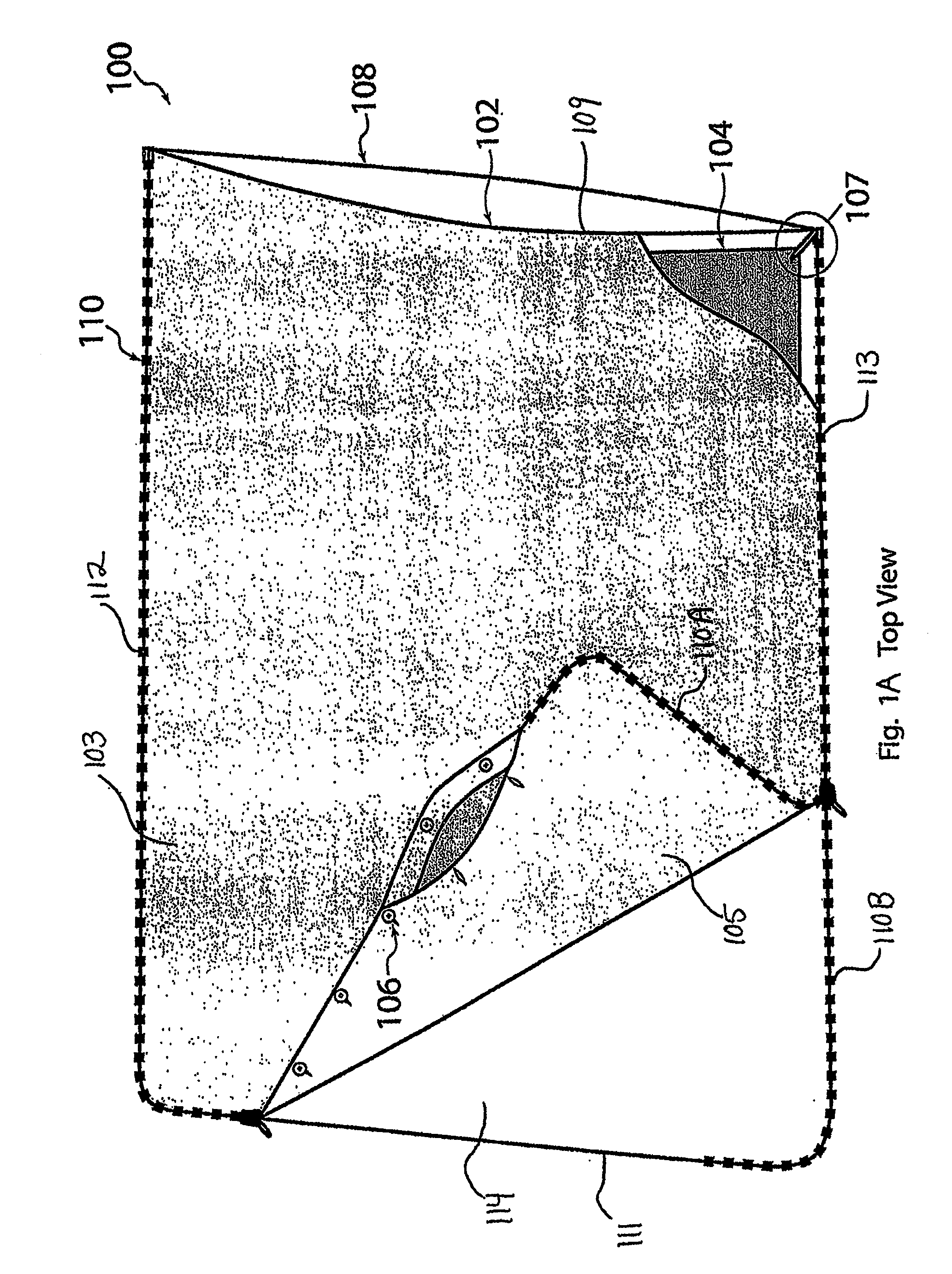

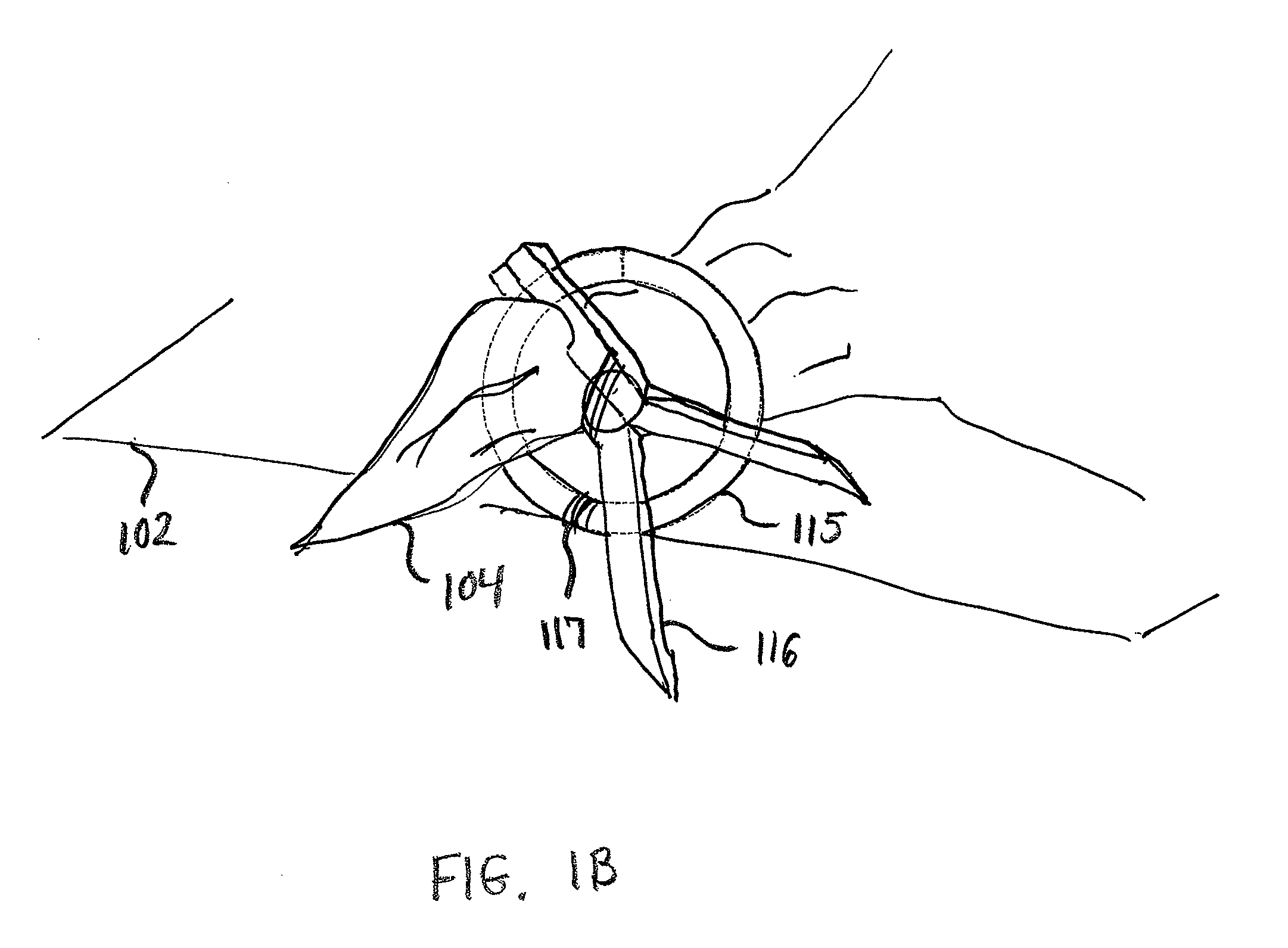

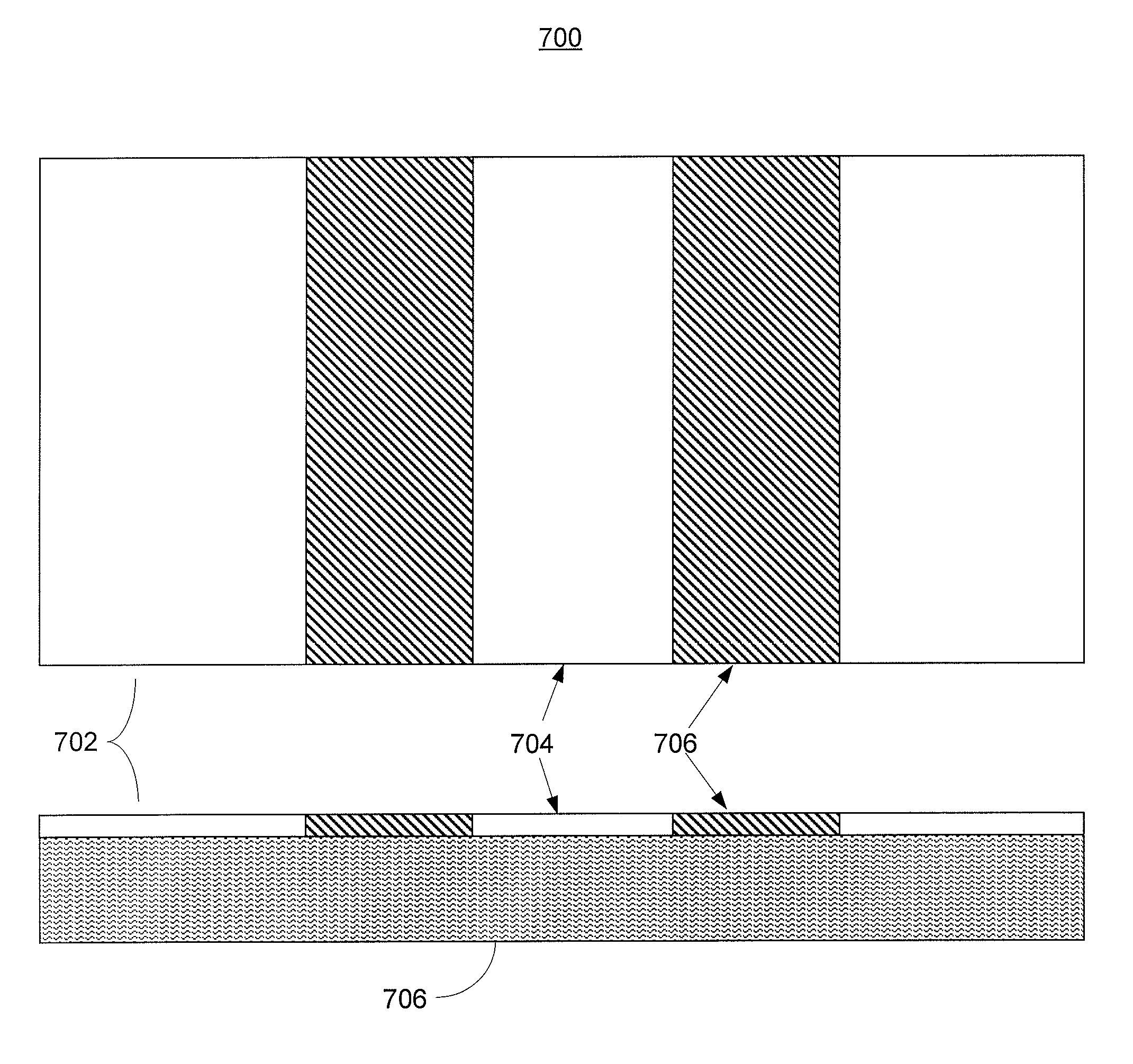

Expandable edge-support members, assemblies, and related methods, suitable for bedding and seating applications and innersprings

Expandable edge-support members, assemblies, and related methods are disclosed. The expandable edge-support members can be used to provide edge support, including side support and corner support. The expandable edge-support members are suitable for bedding and seating applications as examples. The expandable edge-support members are expandable in length. Thus, the expandable edge-support members can be expanded in length as needed to be utilized to provide edge support for an innerspring having variations in perimeter lengths and different types of innersprings having variations in perimeter lengths. Further, the edge-support members may include a plurality of lateral members, which may be configured to be disposed between adjacent perimeter coils of an innerspring to support attachment to the innerspring. Thus, expansion of the expandable edge-support members can also allow the spacings between lateral members to be adjusted, including to fit between adjacent perimeter coils which may have variations in spacings in an innerspring.

Owner:NOMACO

System for attaching trim covers to a flexible substrate

InactiveUS7487575B2Increase elasticityHigh wear-resistanceSnap fastenersUpholstery manufactureEngineeringWear resistance

Owner:SMITH LYLE J

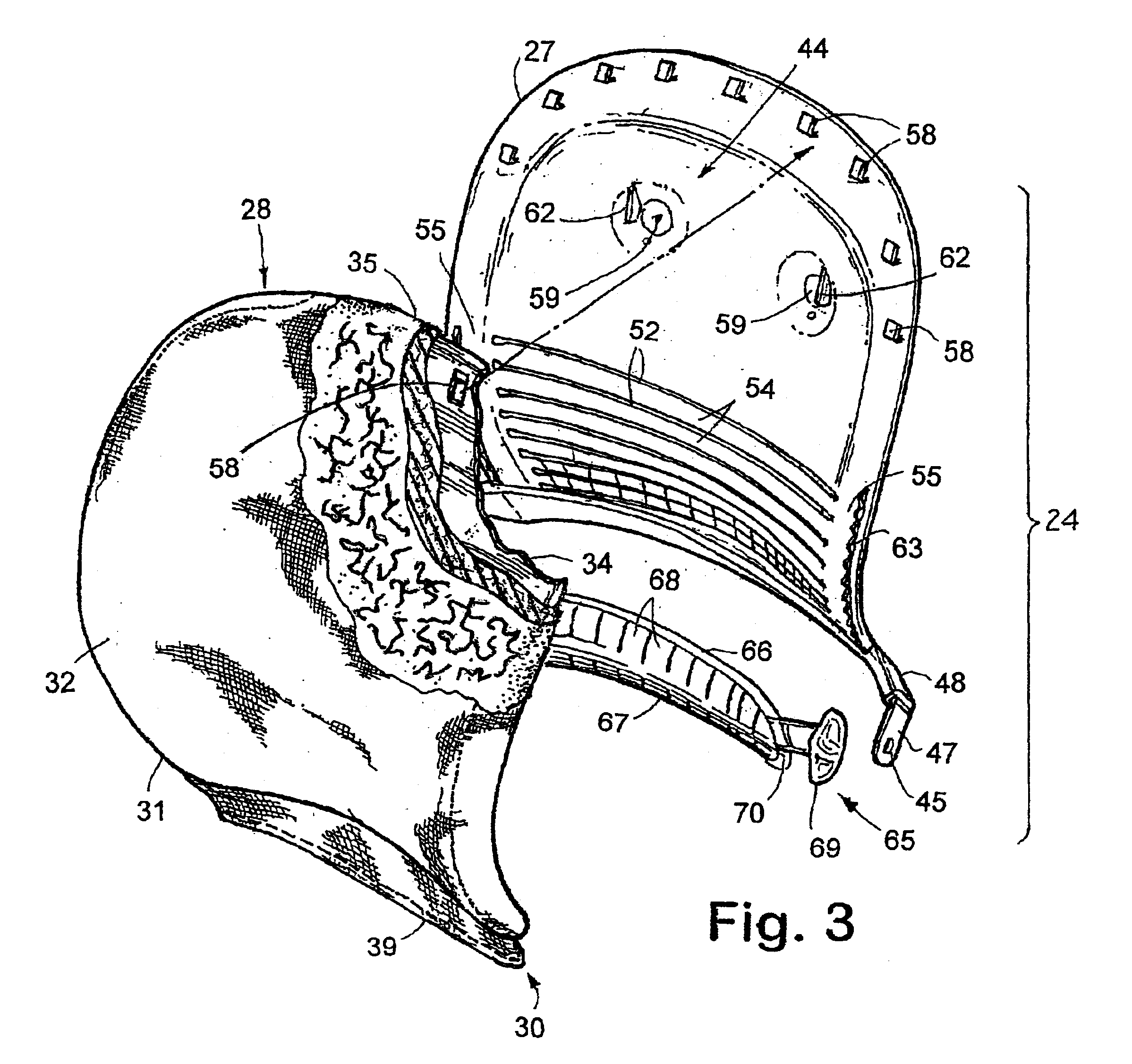

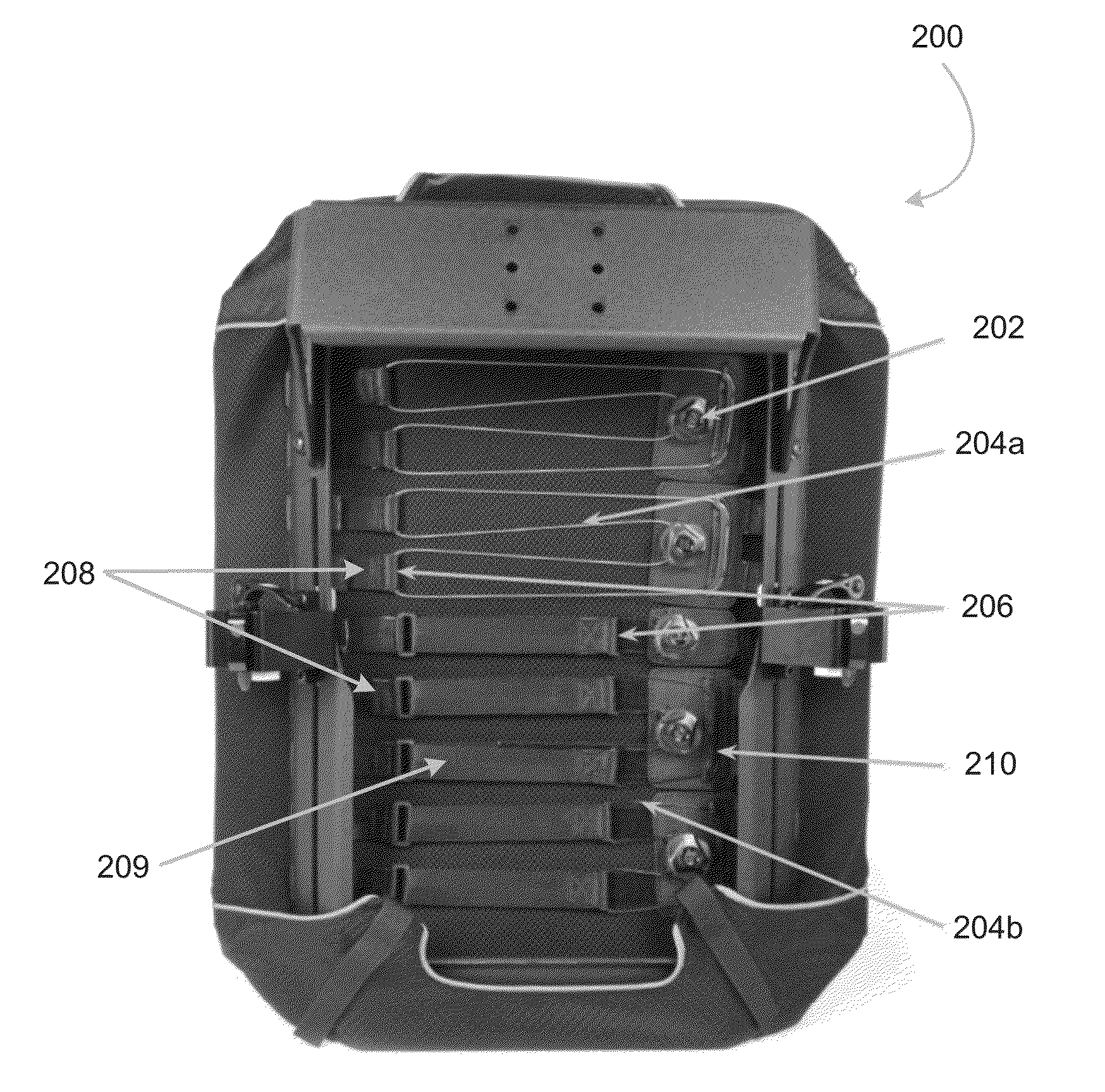

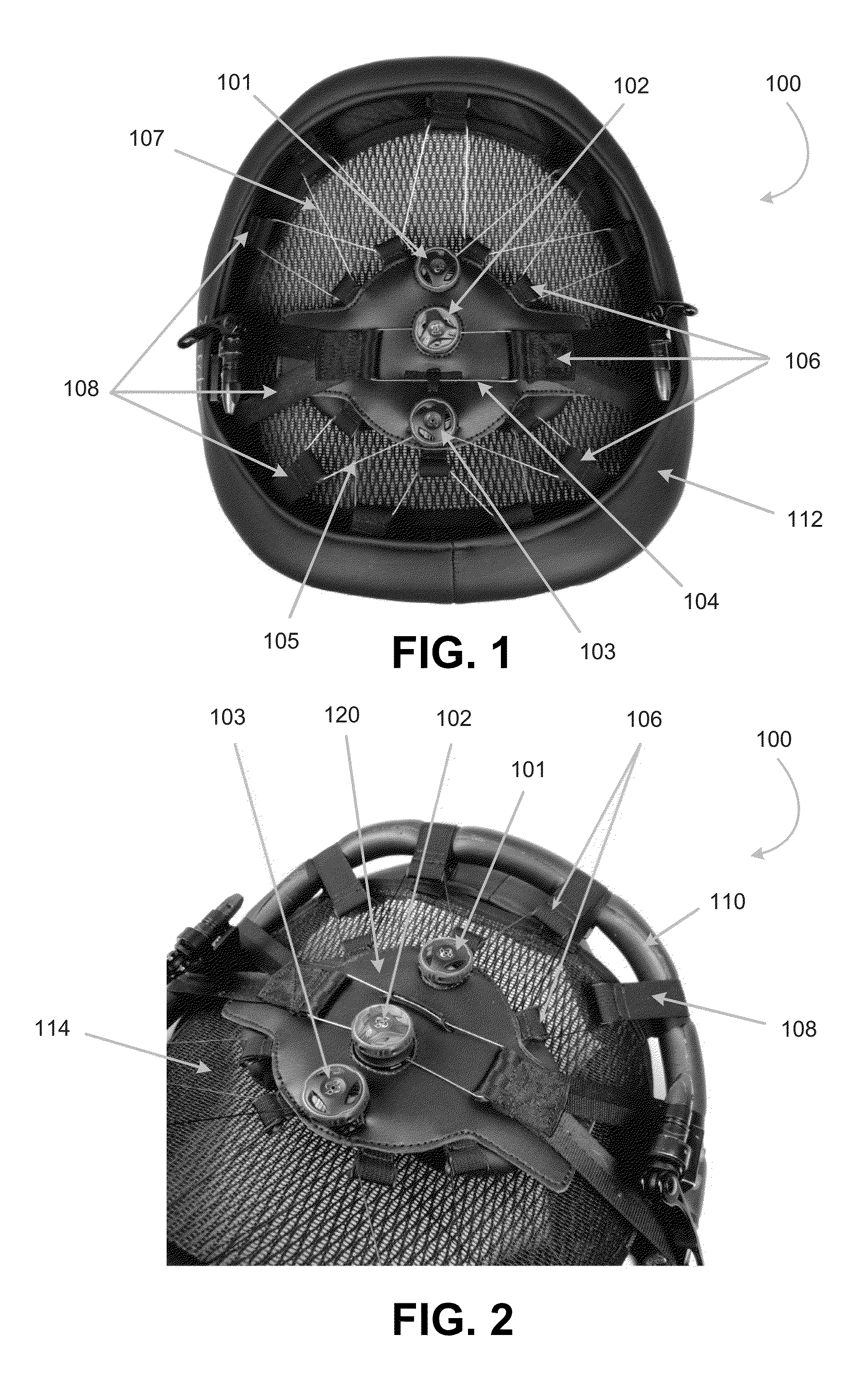

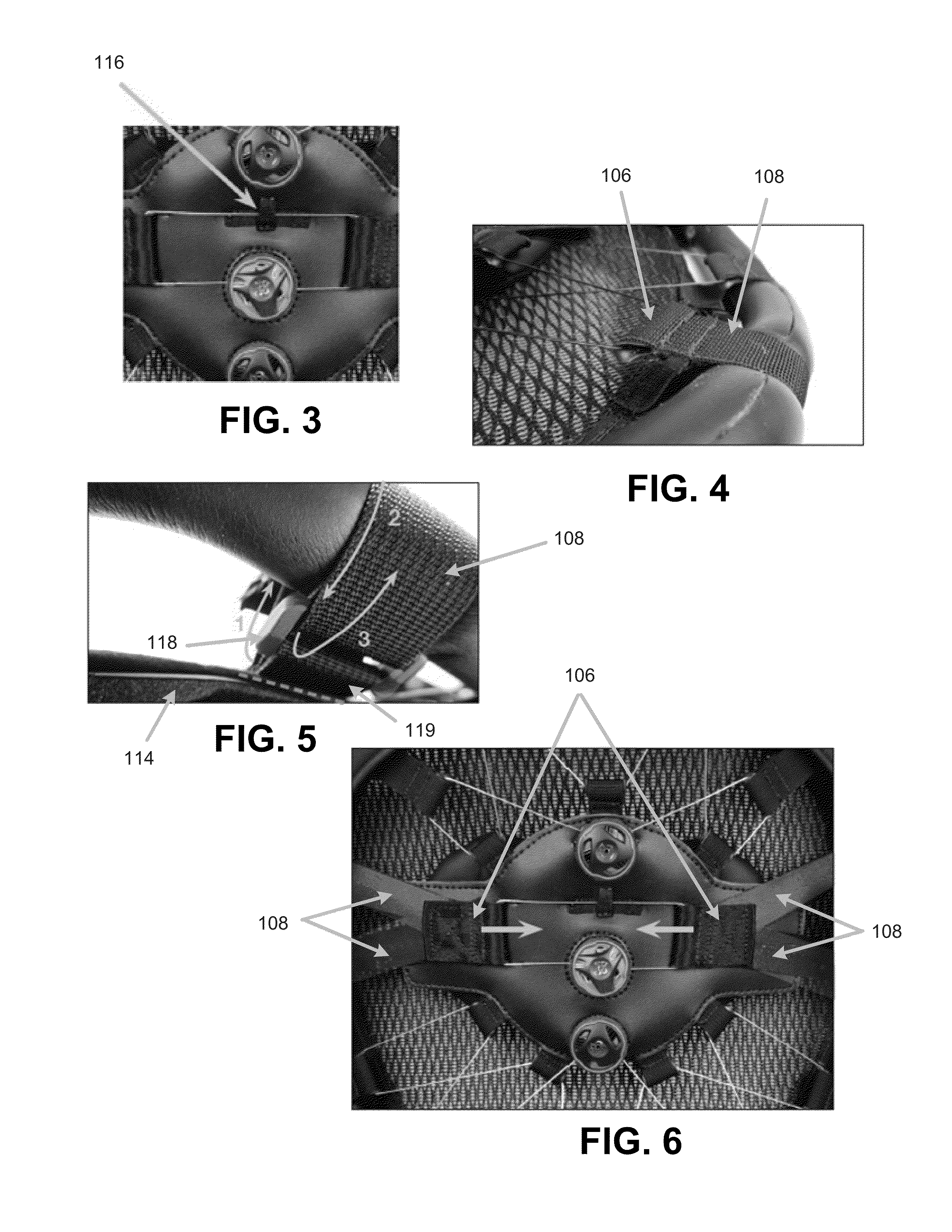

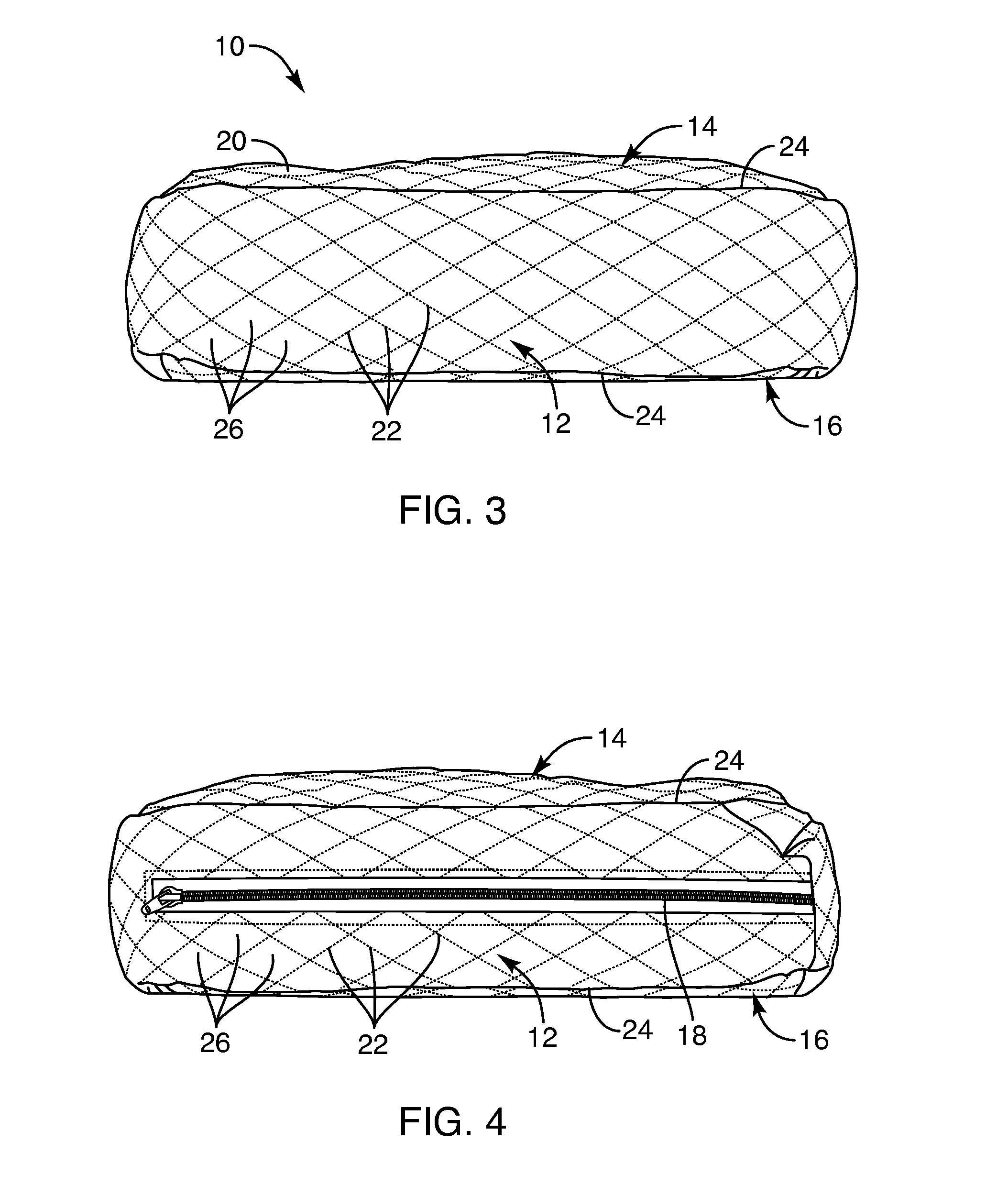

Closure devices for seat cushions

An adjustable seat back includes a frame having a perimeter and a cushioning material that is disposed at least partially within the frame's perimeter. The adjustable seat back also includes a tension member and a plurality of straps that are disposed over the frame with a distal end that is coupled with the cushioning material and a proximal end that is operationally coupled with the tension member. A reel based tightening mechanism is operably coupled with the tension member and configured to tension the tension member and thereby tension the plurality of straps. Tensioning of the plurality of straps effects adjustment of the cushioning material.

Owner:PERMOBIL INC

Patient support

ActiveUS20100146709A1Improve immersionIncreased contact surface areaUpholstery manufactureStuffed mattressesElastomerEngineering

A patient support includes a layer of fluid pressurized bladders, the bladders each having a chamber and an upwardly facing surface for facing and supporting a patient, and a cover over the layer of fluid pressurized bladders. Respective bladders in at least a group of the bladders each have a resilient body in its respective chamber to reform the shape of the respective bladder when a compression load on the respective bladder is removed wherein the pressure in the respective bladders is generally maintained without a powered supply of air. The cover has an upwardly facing patient surface and a bladder layer facing surface, with the patient surface for forming a patient support surface on the support, and the bladder layer facing surface for lying on the upwardly facing surfaces of the bladders.

Owner:STRYKER CORP

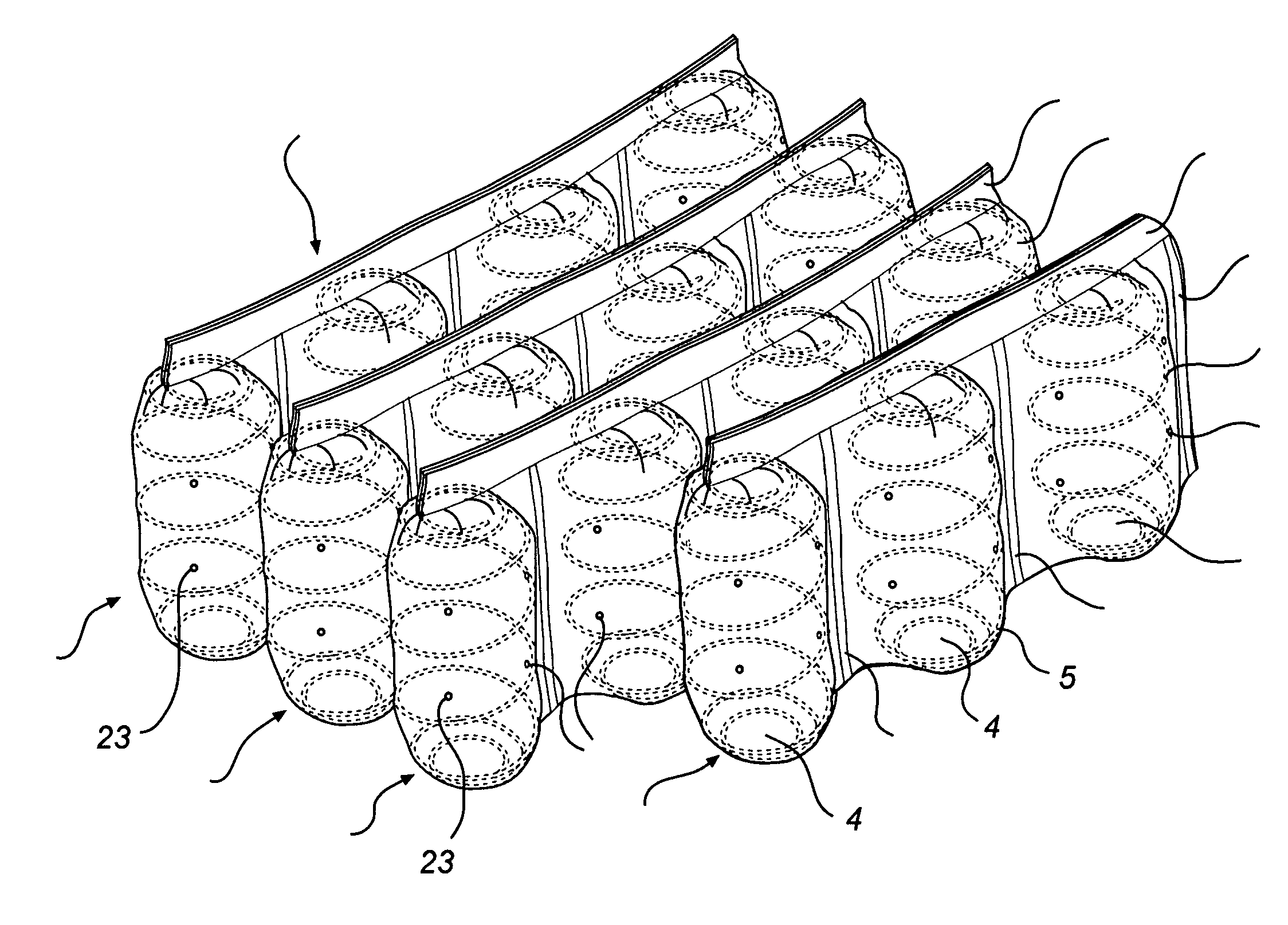

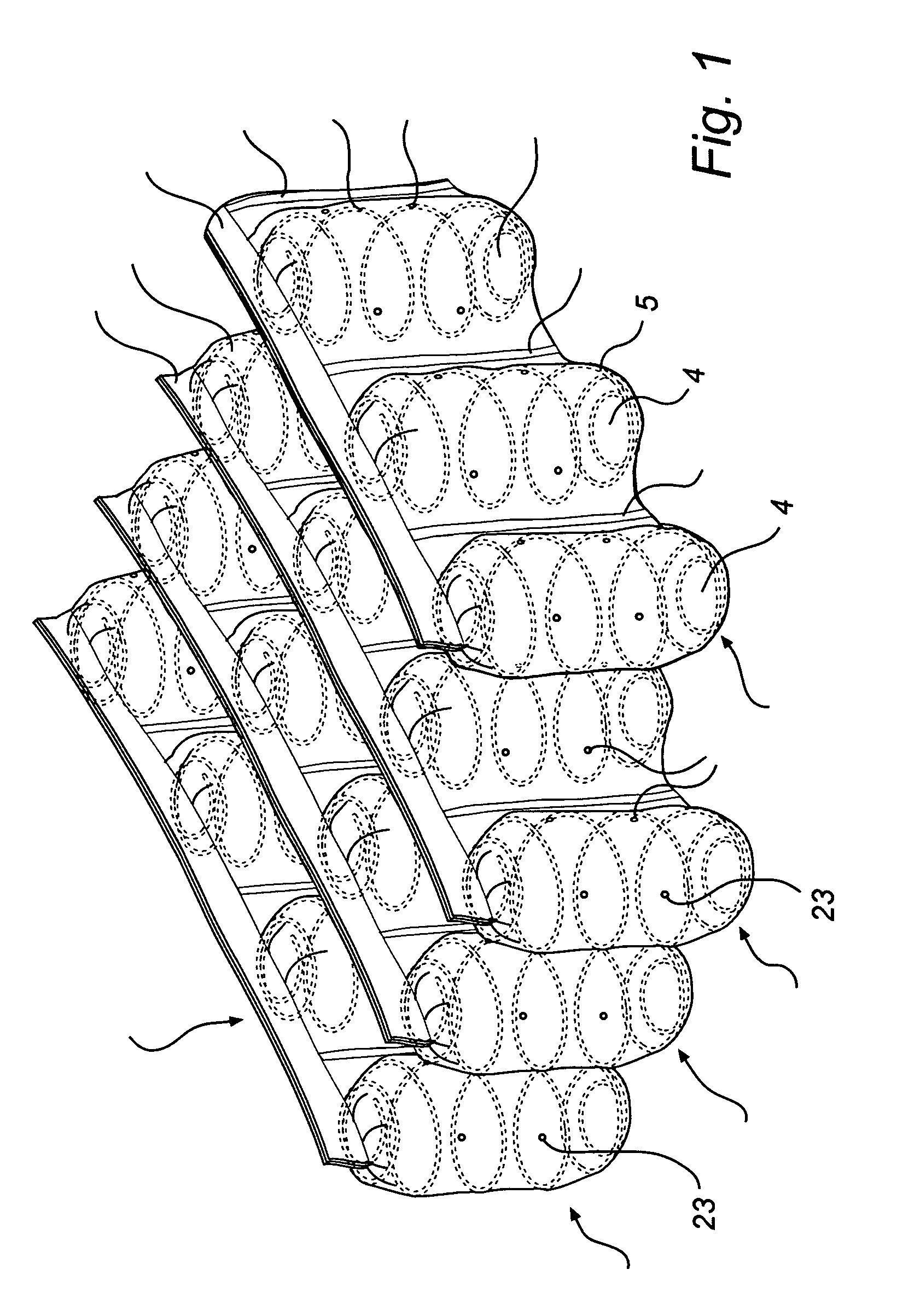

End separated pocketed mattress as well as method and device for manufacturing the same

ActiveUS7748065B2Less actuationIncreasing individual and independent resilienceUpholstery manufactureStuffed mattressesCoil springEngineering

Owner:STJERNFJADRAR

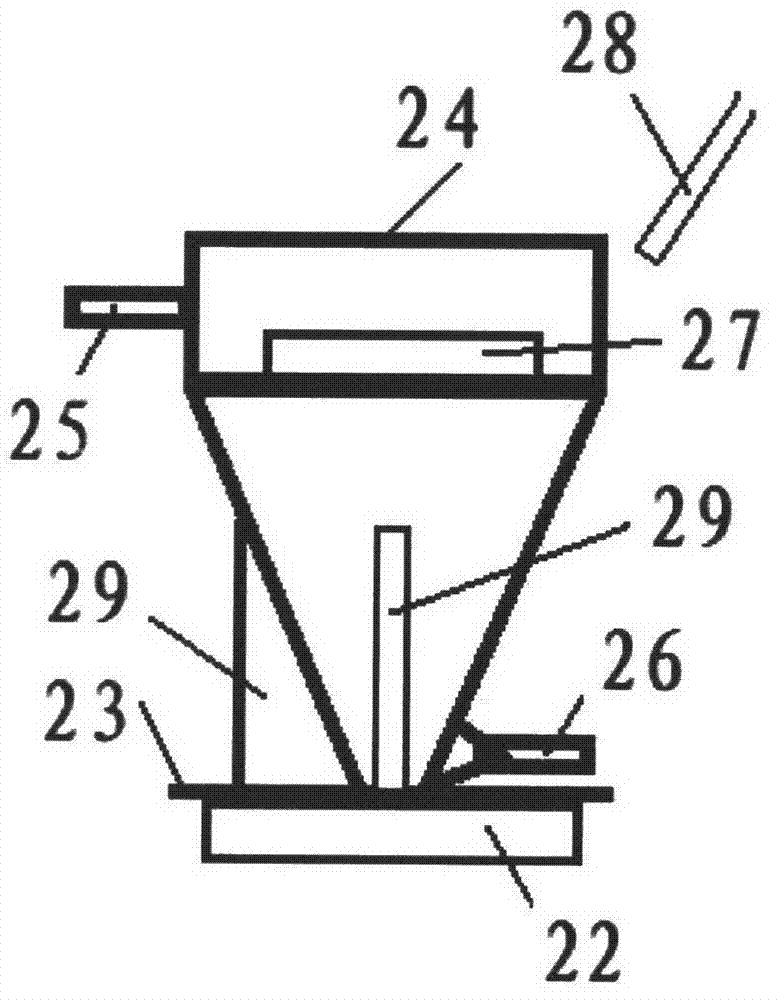

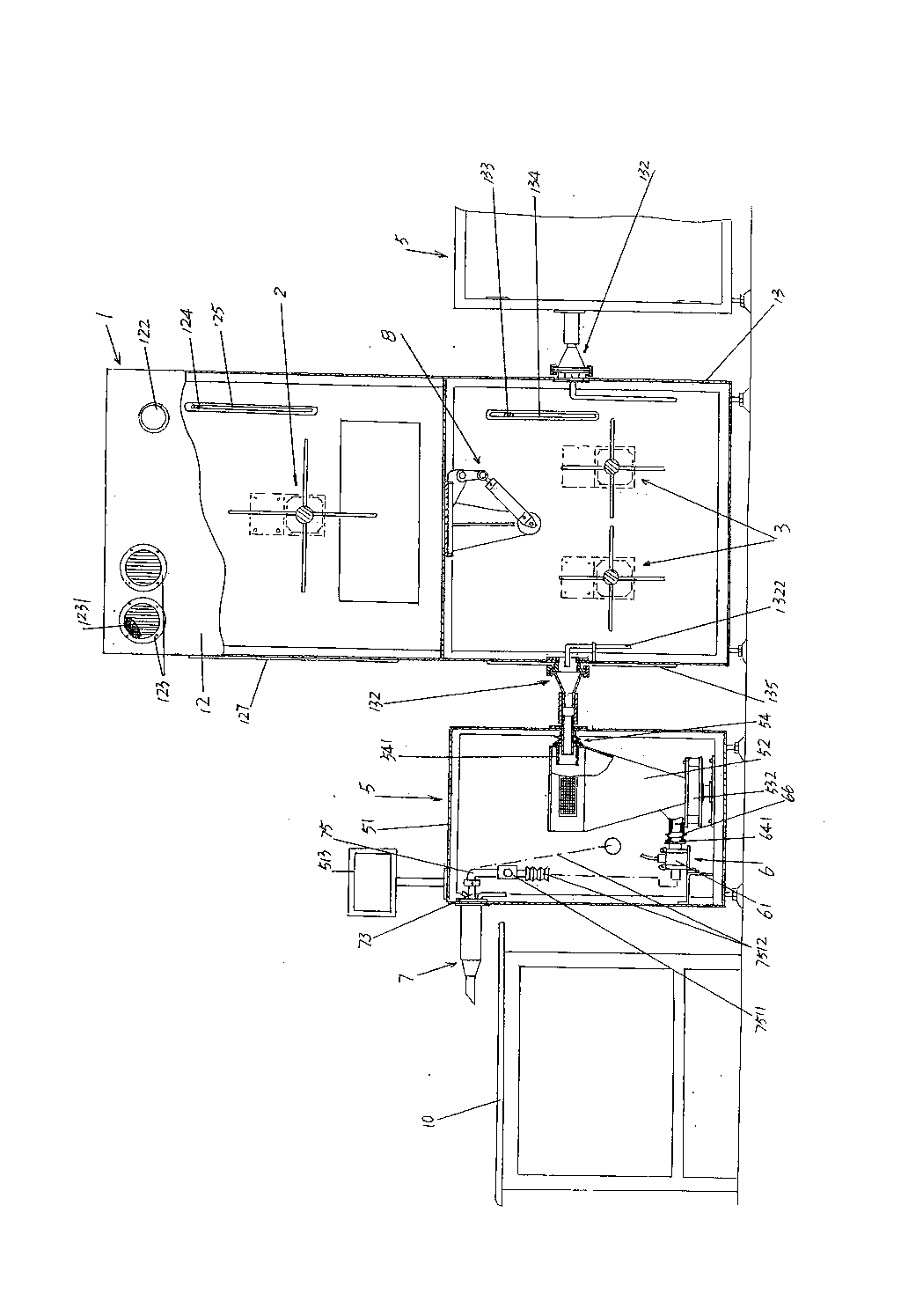

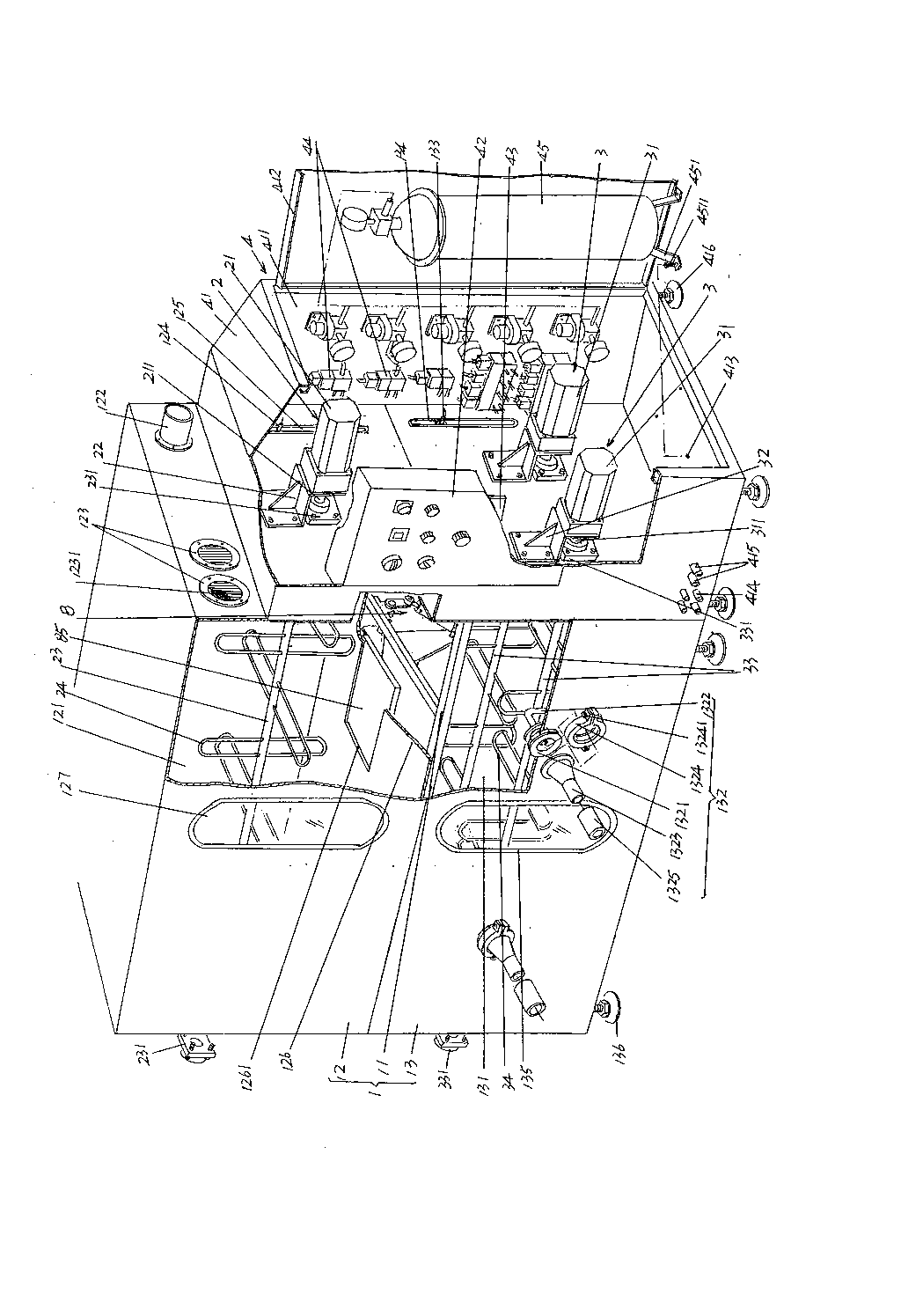

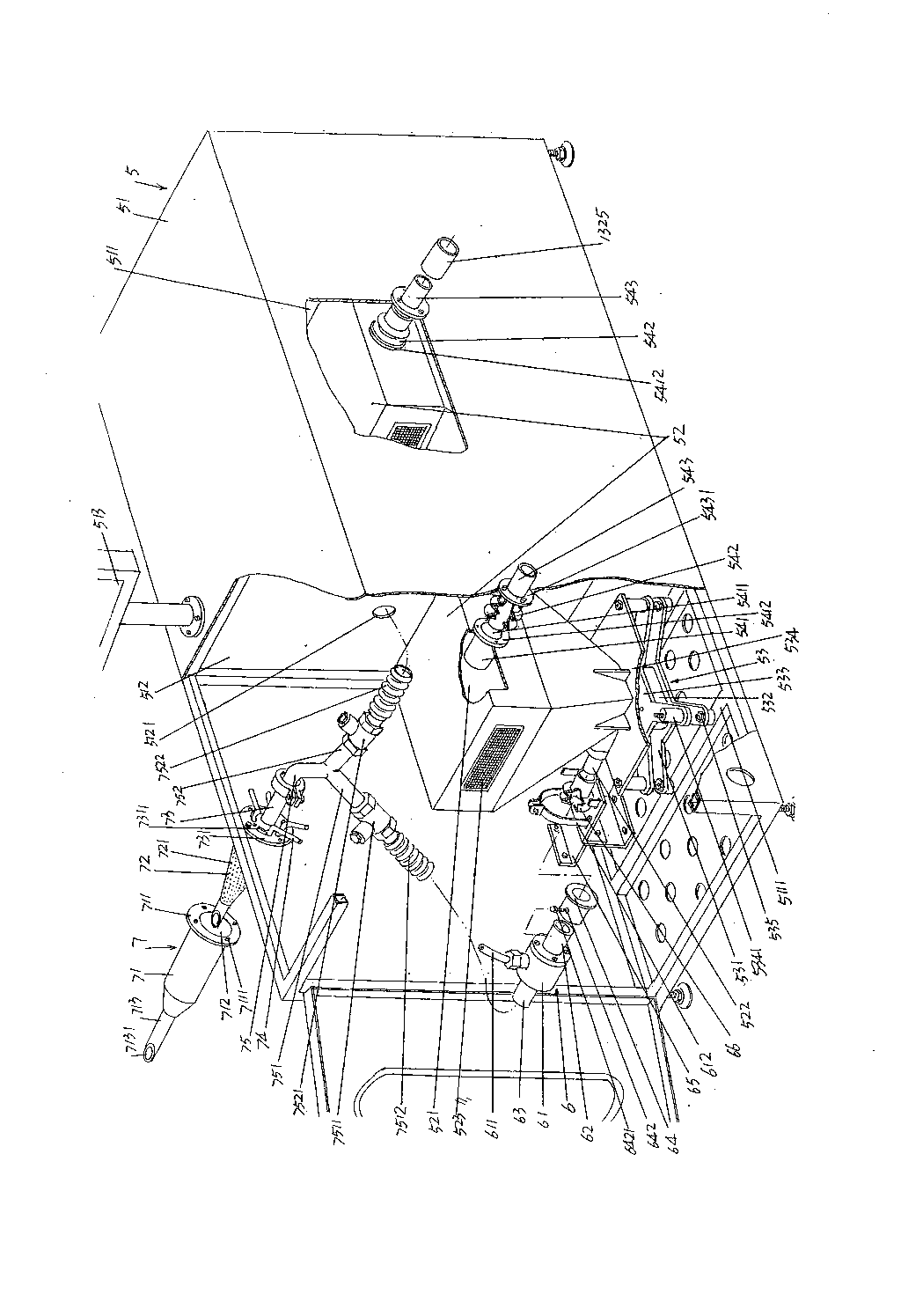

Automatic down filling machine

ActiveCN103101871AReduce escapeNo escapeUpholstery manufactureClothes making applicancesMagnetic valveEngineering

The invention discloses an automatic down filling machine, and belongs to the technical filed of a stowage unit for down and feather filled products. The automatic down filling machine comprises a box body, a first down stirring mechanism, a second down stirring mechanism, an electrical automatic control mechanism, a pair of weighing metering mechanisms, a pair of down output mechanisms, a pair of down filling heads and a box cavity channel start-and-stop mechanism. The box body comprises a box frame, a down storage box and a down delivering box. The first down stirring mechanism is used for stirring down in a down storage box cavity, and the second down stirring mechanism is used for stirring down in a down delivering box cavity. The pair of weighing metering mechanisms is connected with a pair of down leading out connector pipelines on two sides of the down delivering box, the pair of down output mechanisms is connected with the pair of weighing metering mechanisms, the pair of down filling heads is connected with the pair of down output mechanisms in a matched mode, and the box cavity channel start-and-stop mechanism is placed on the box frame. The electrical automatic control mechanism is provided with an electrical box body, a control panel, a programmable controller, a group of magnetic valves and a high-pressure air storage tank. The automatic down filling machine has the advantages of showing rhythmic continuity of down supplying, being capable of providing guarantee for subsequent continuously weighing and down filling, showing good down filling efficiency, reducing operation intensity of workers, eradicating down wasting and showing good automatic control effect.

Owner:苏州比阳特服装设备有限公司

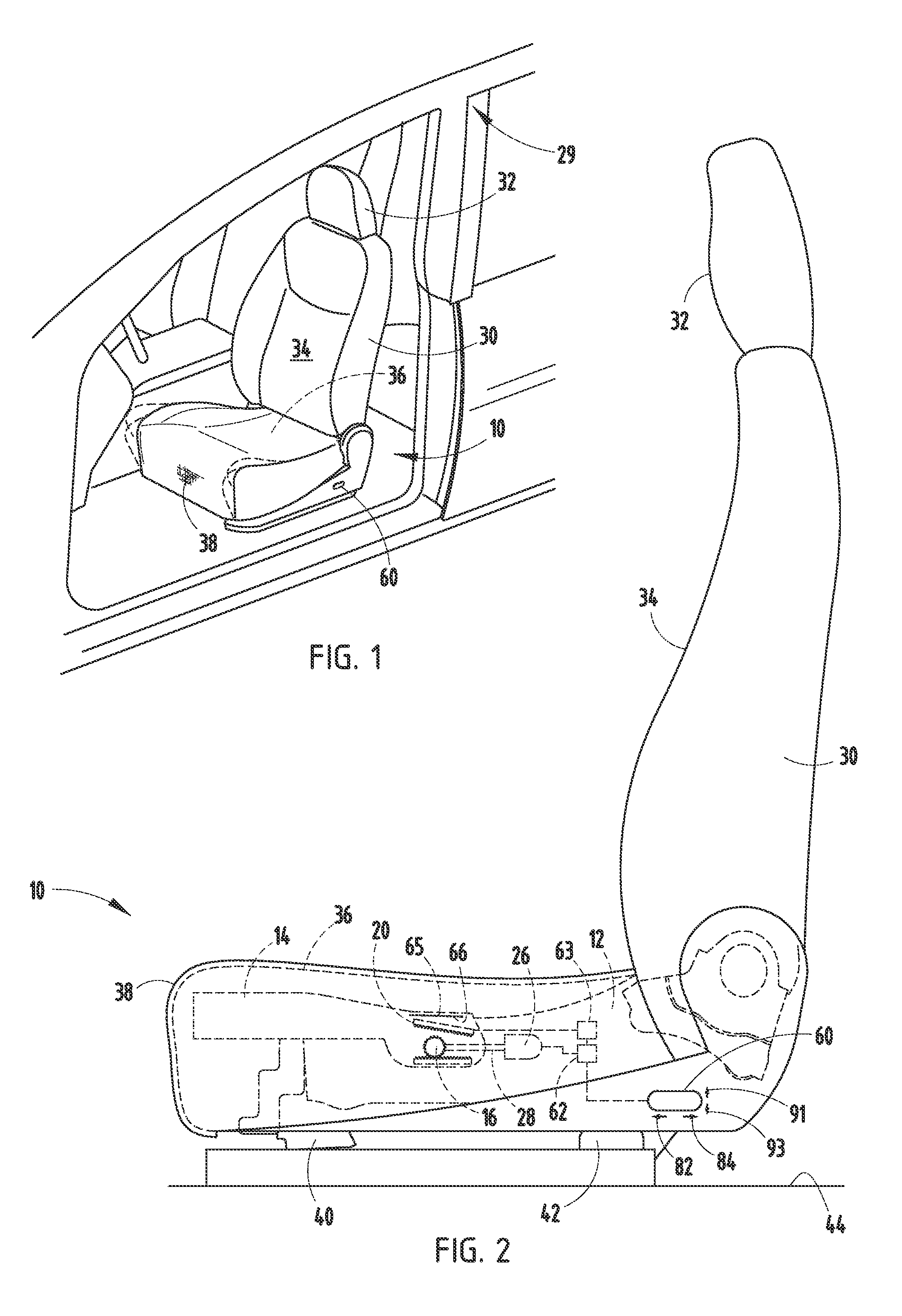

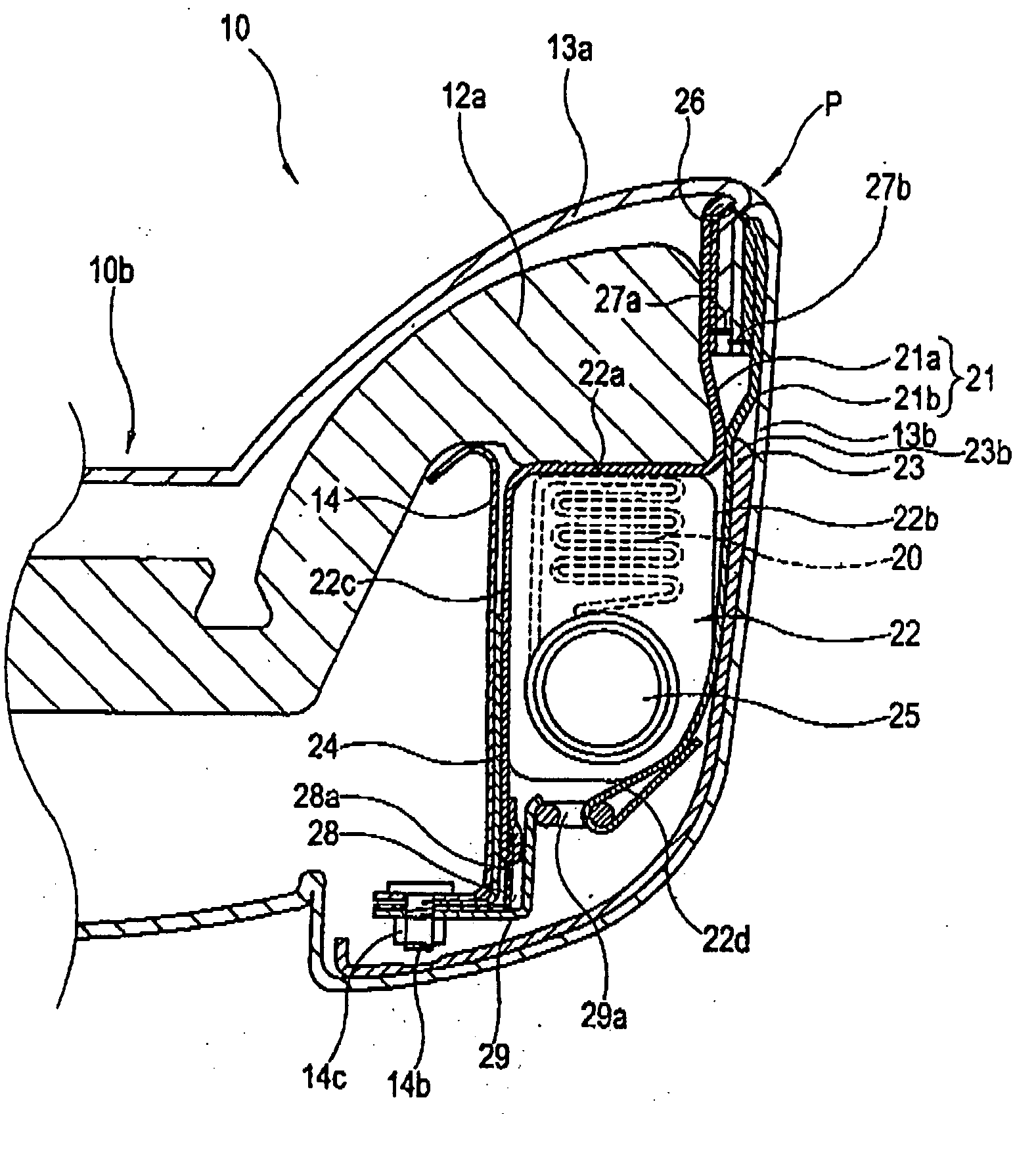

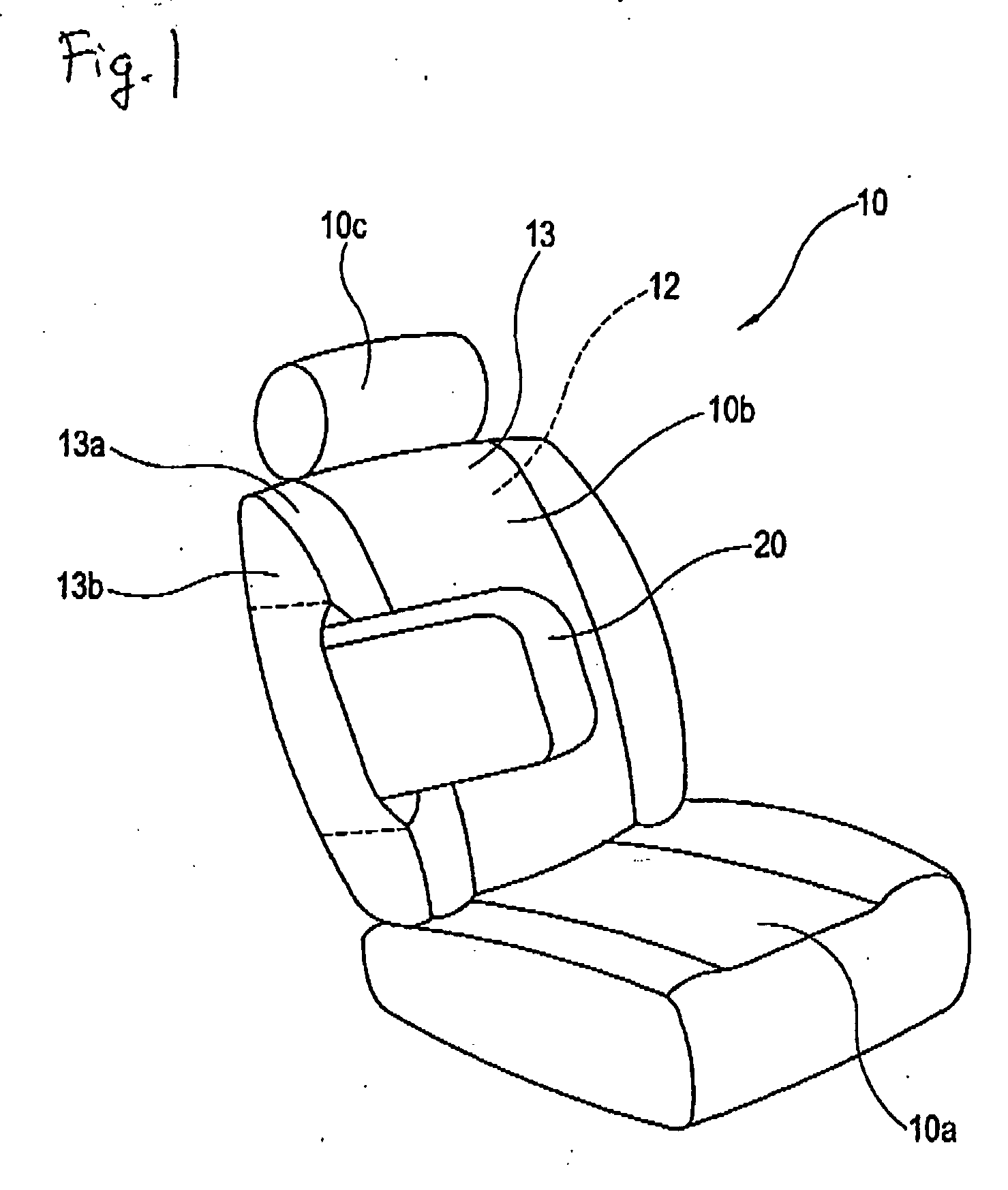

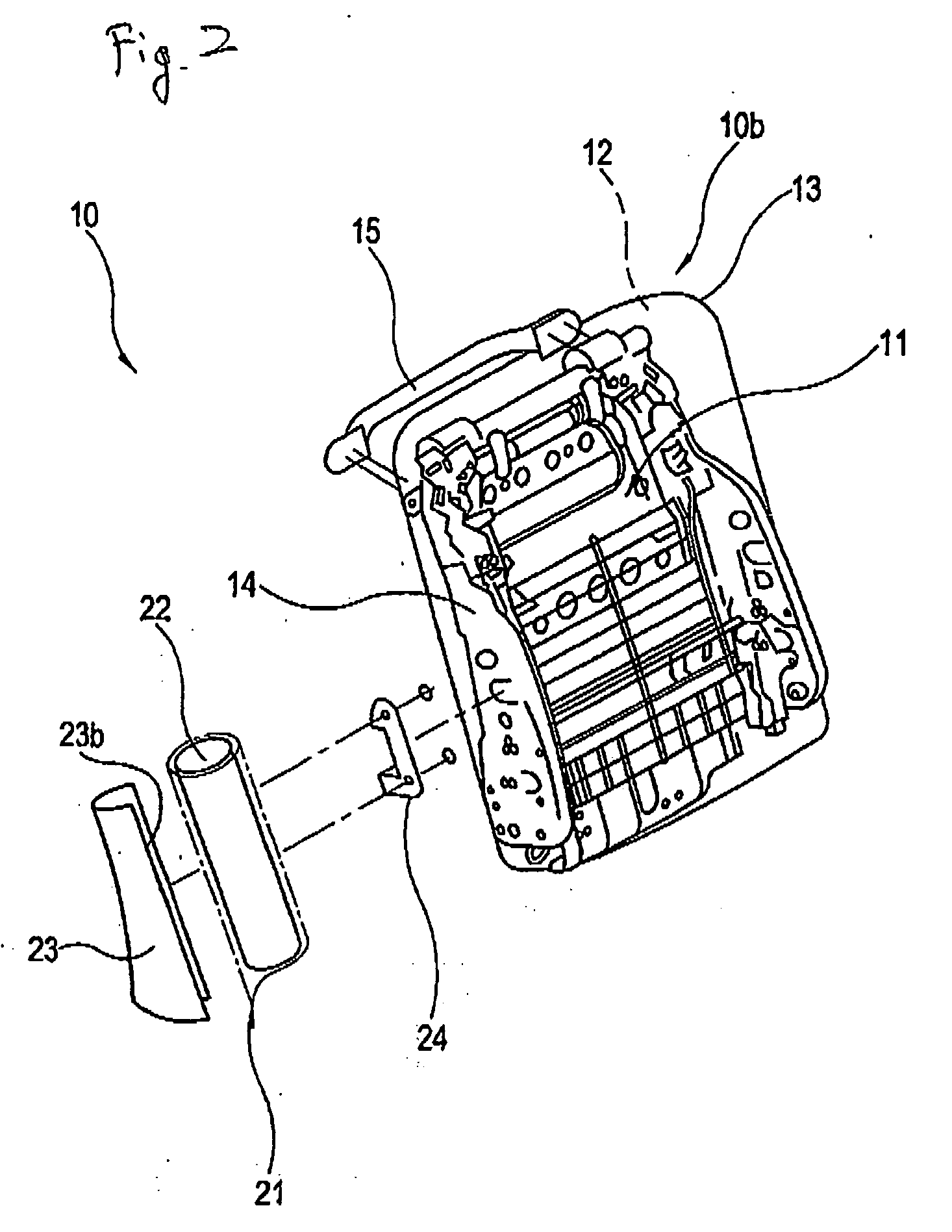

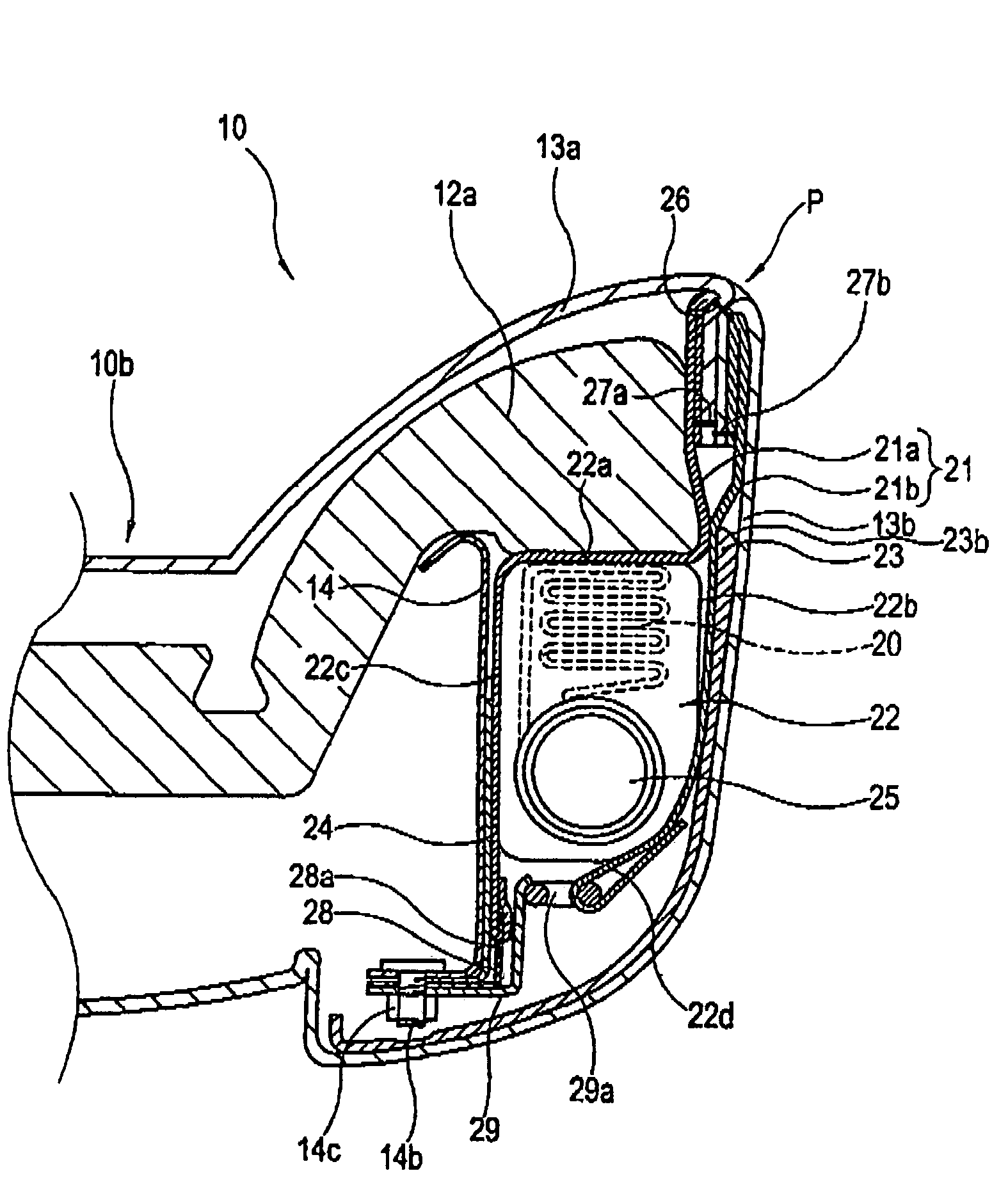

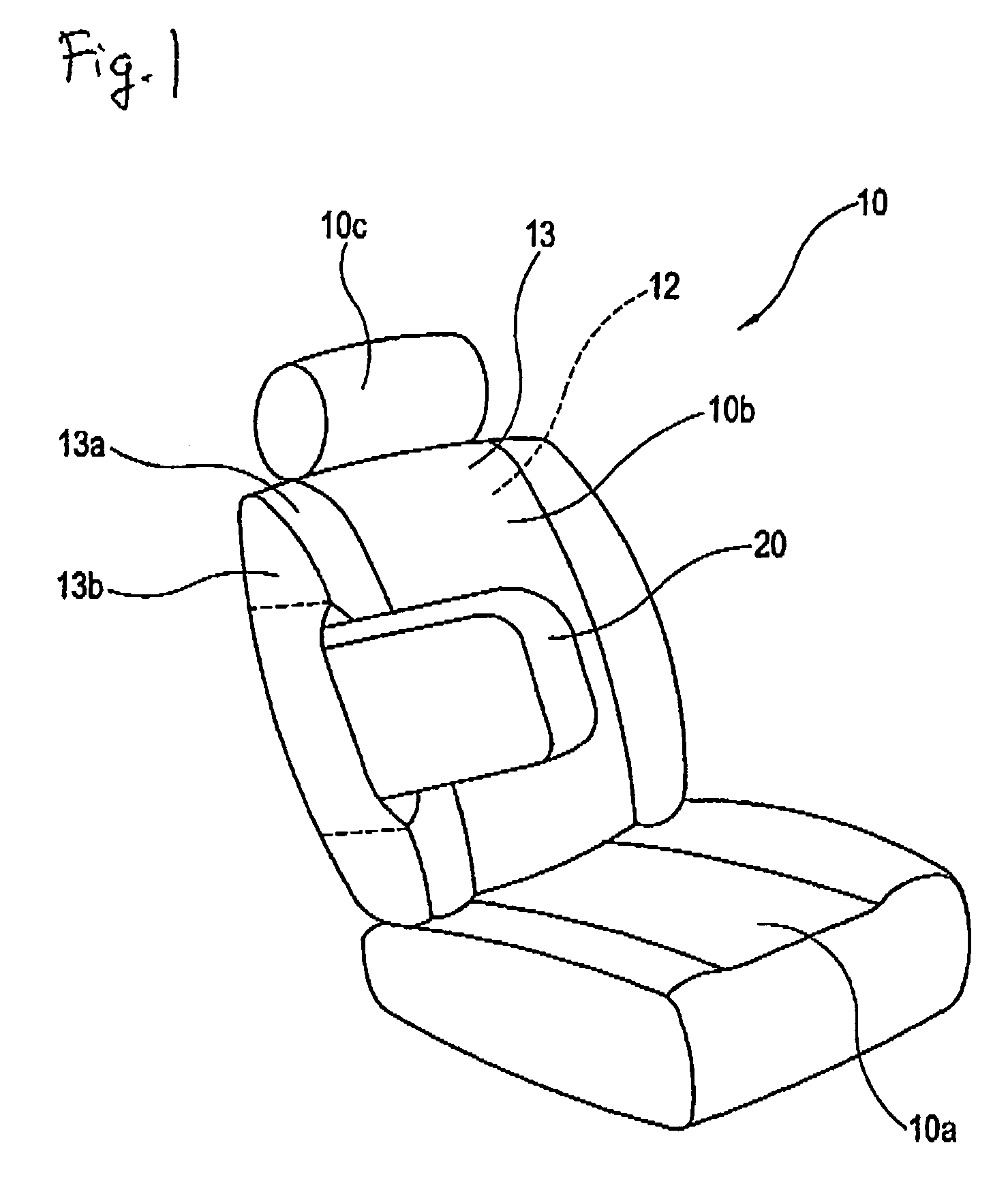

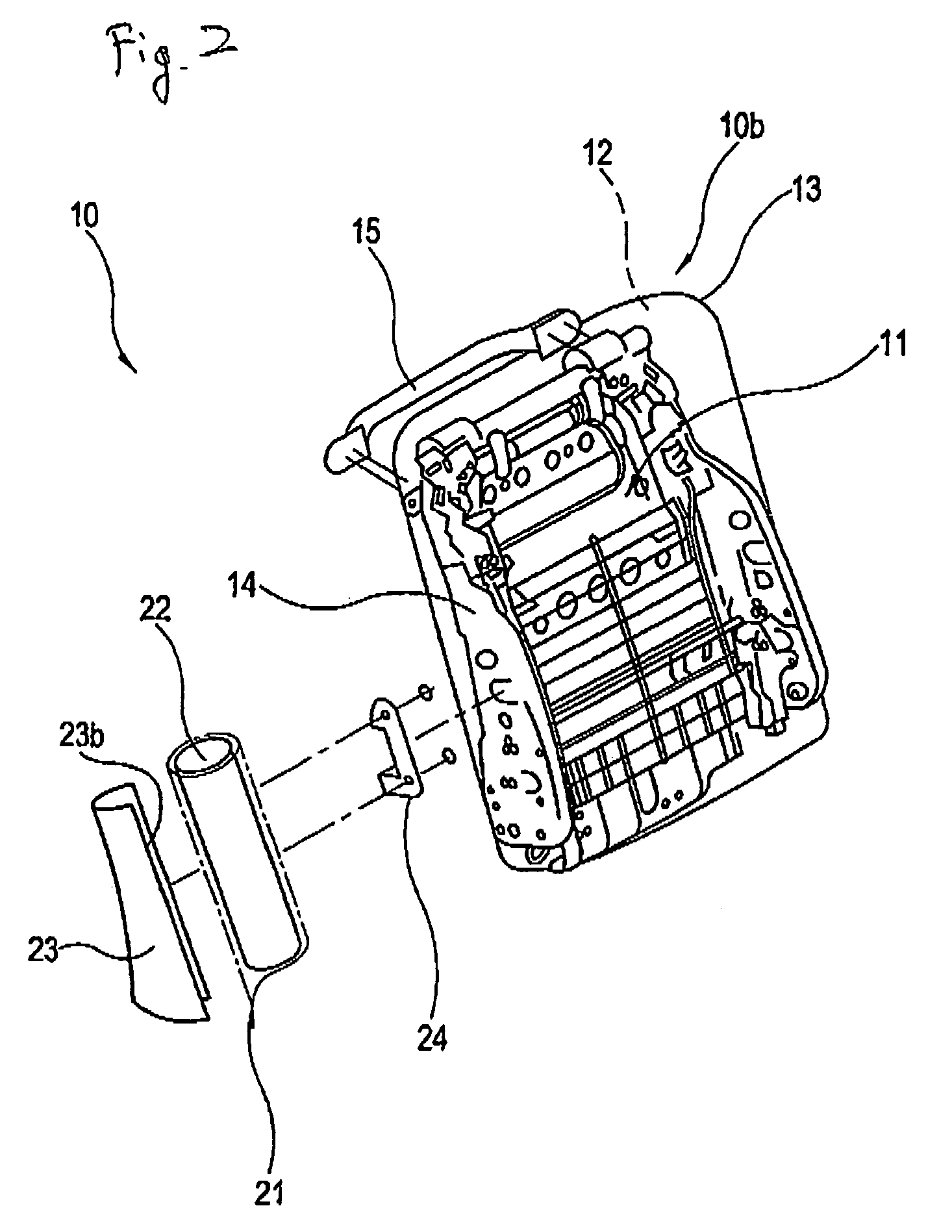

Seat with a side airbag

InactiveUS20060131848A1Improve responseStable expansionUpholstery manufactureVehicle seatsLateral airbagEngineering

A seat 10 with a side airbag has front and side reinforcement fabrics 21a and 21b covering a front and a side of an airbag unit 22, respectively. These reinforcement fabrics are joined to each other so as to be deployed at an inflating position of an airbag 20 by virtue of an inflating force. The front reinforcement fabric 21a and a front skin 13a are joined to each other so as not to be broken at the inflating position P by virtue of the inflating force. A side skin 13b is provided on an outside of a shape retaining member 23 that is provided on an outside of the side reinforcement fabric 21b, and the side reinforcement fabric 21a and the side skin 13b are joined to each other so as not to be broken at the inflating position P by virtue of the inflating force.

Owner:NHK SPRING CO LTD

Configurable inflatable support devices

A configurable, adjustable inflatable device including one or more inflatable bladders and a shape-defining membrane that combines with the inflatable bladders such that an overall shape of the configurable inflatable device is at least partially controlled by the shape-defining membrane, and wherein the overall shape of the configurable inflatable device is substantially different from an inflated shape of inflatable bladders alone. The configurable adjustable inflatable device may include a covering layer that may partially or completely surround the inflatable bladders and may attach to the membrane or the inflatable bladders. The level of inflation of the inflatable bladders may also be controlled, further adding to the adjustability of the inflatable device.

Owner:CHAFFEE ROBERT B

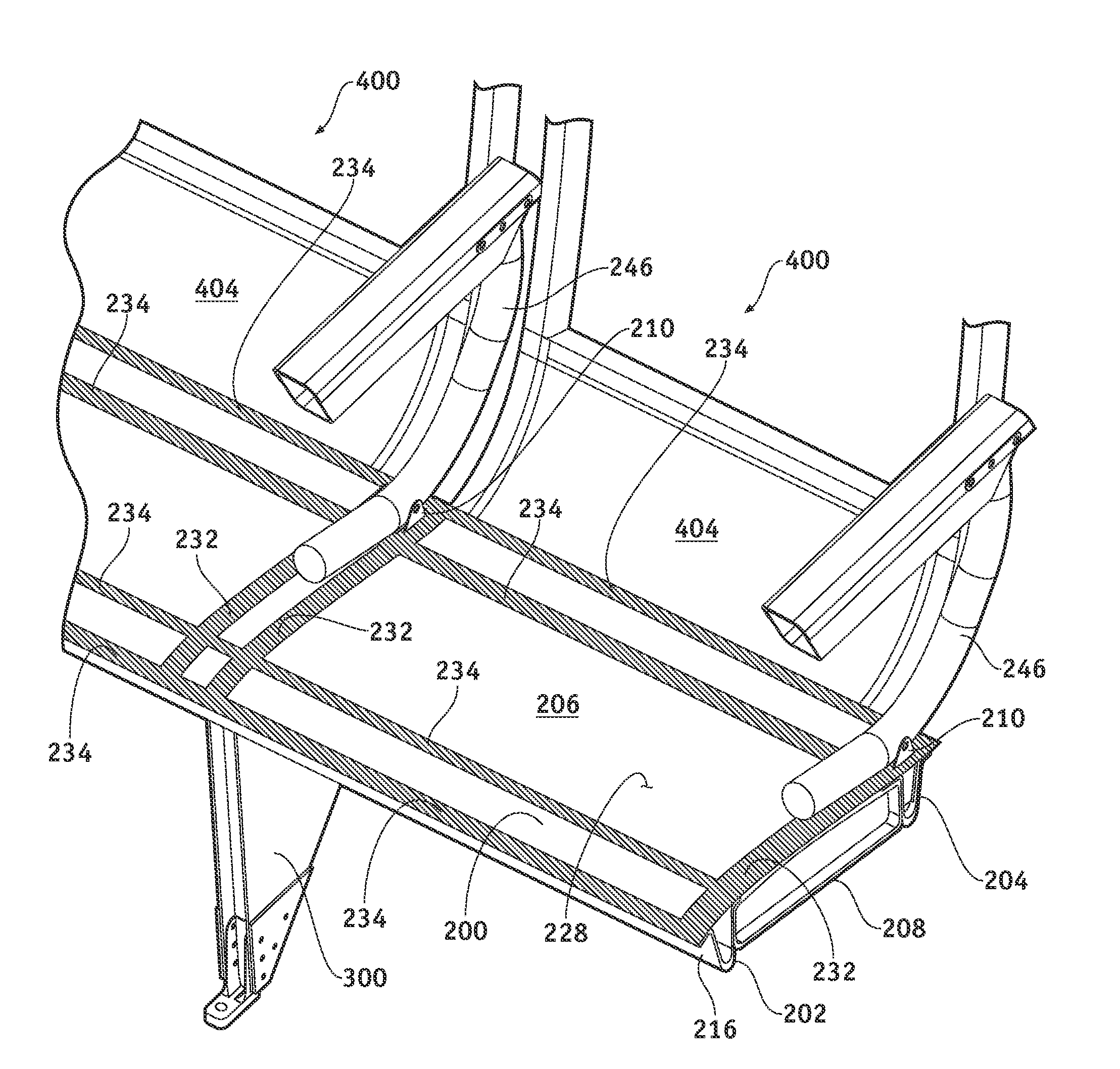

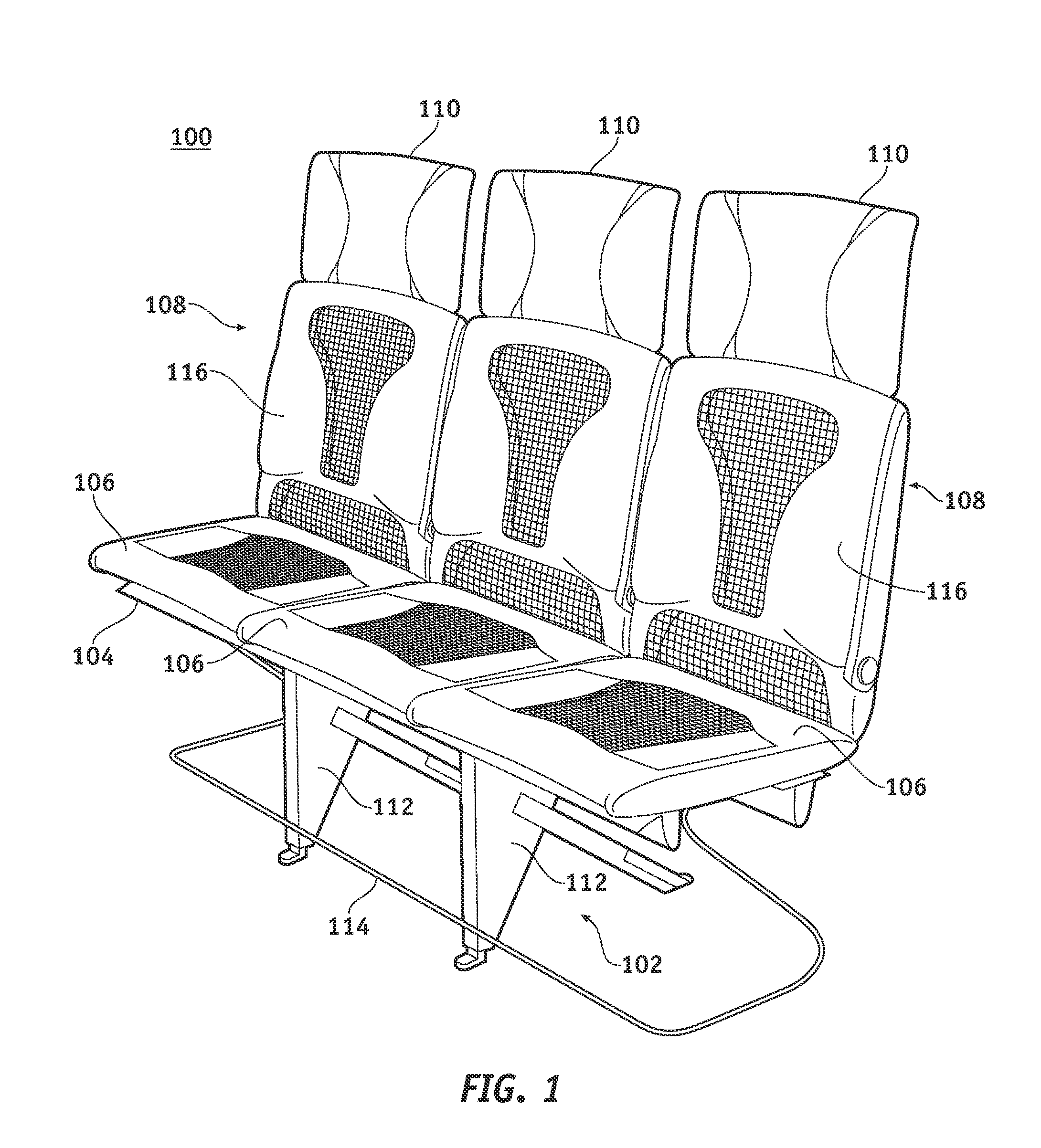

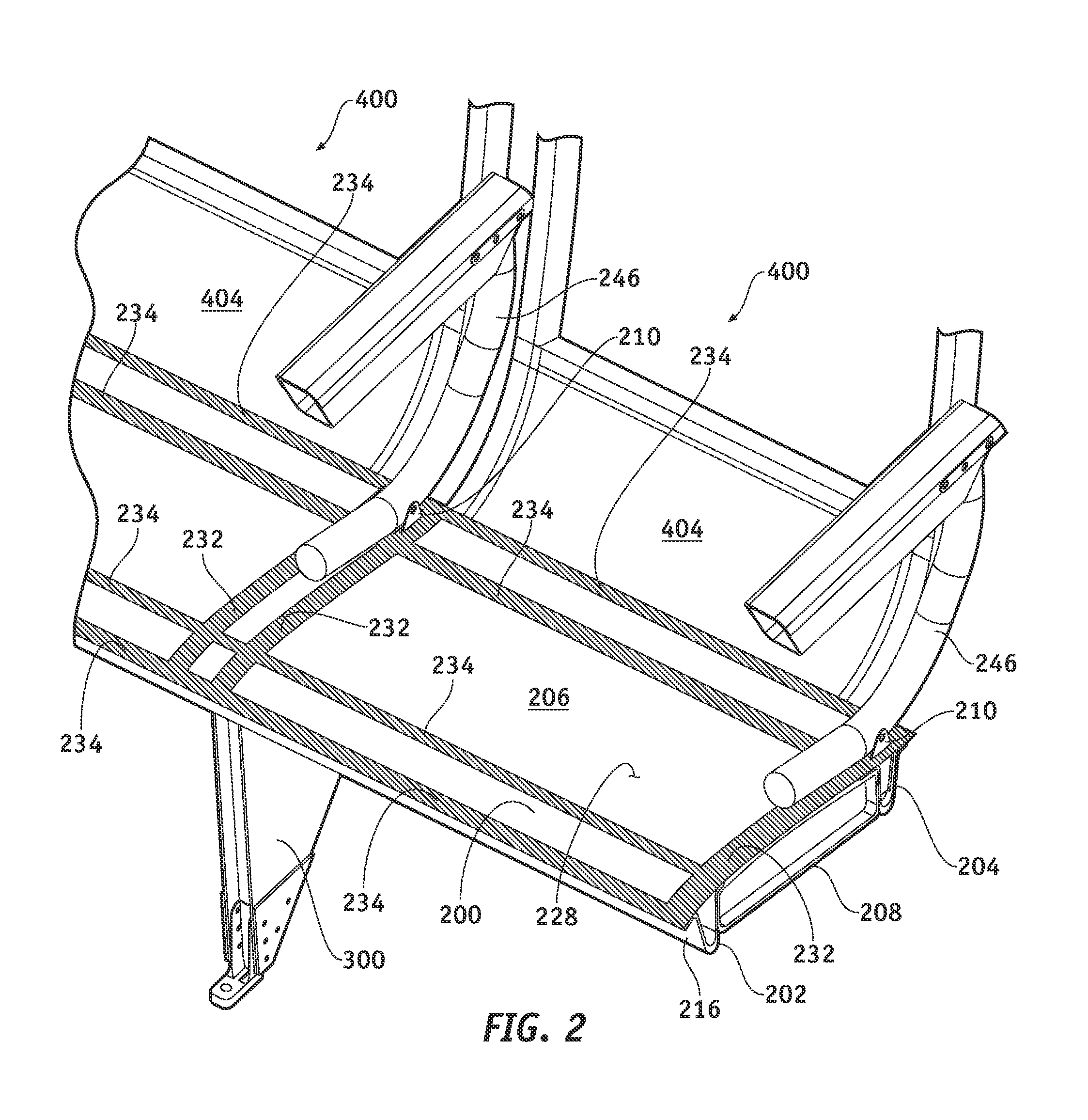

Composite seat pan structure for a lightweight aircraft seat assembly

InactiveUS7716797B2Reduce weightSmall sizeUpholstery manufactureSeating arrangementsManufacturing technologyBack structure

An aircraft passenger seat configured in accordance with an embodiment of the invention utilizes composite materials to achieve significant weight savings relative to conventional seat designs. The seat includes one or more lightweight composite support legs, a lightweight composite seat pan, and a lightweight composite seat back structure. The support legs are coupled to the seat pan, which is in turn coupled to the seat back structure. The support legs utilize composite frame elements that are formed as continuous compression molded composite extrusions. The seat pan includes composite fore and aft cross beams that are also formed as continuous compression molded composite extrusions. The aft cross beam includes a rear flange that serves as a flexible “hinge” for the seat back structure. The seat can leverage producible and relatively inexpensive composite manufacturing techniques such that the seat can be economically produced for use as an economy class seat.

Owner:THE BOEING CO

Automatic quantitative down-filling machine

InactiveCN101779837BImprove down filling efficiencyRealize quantitative weighingUpholstery manufactureClothes making applicancesAutomatic controlSolenoid valve

Owner:CHINA JILIANG UNIV

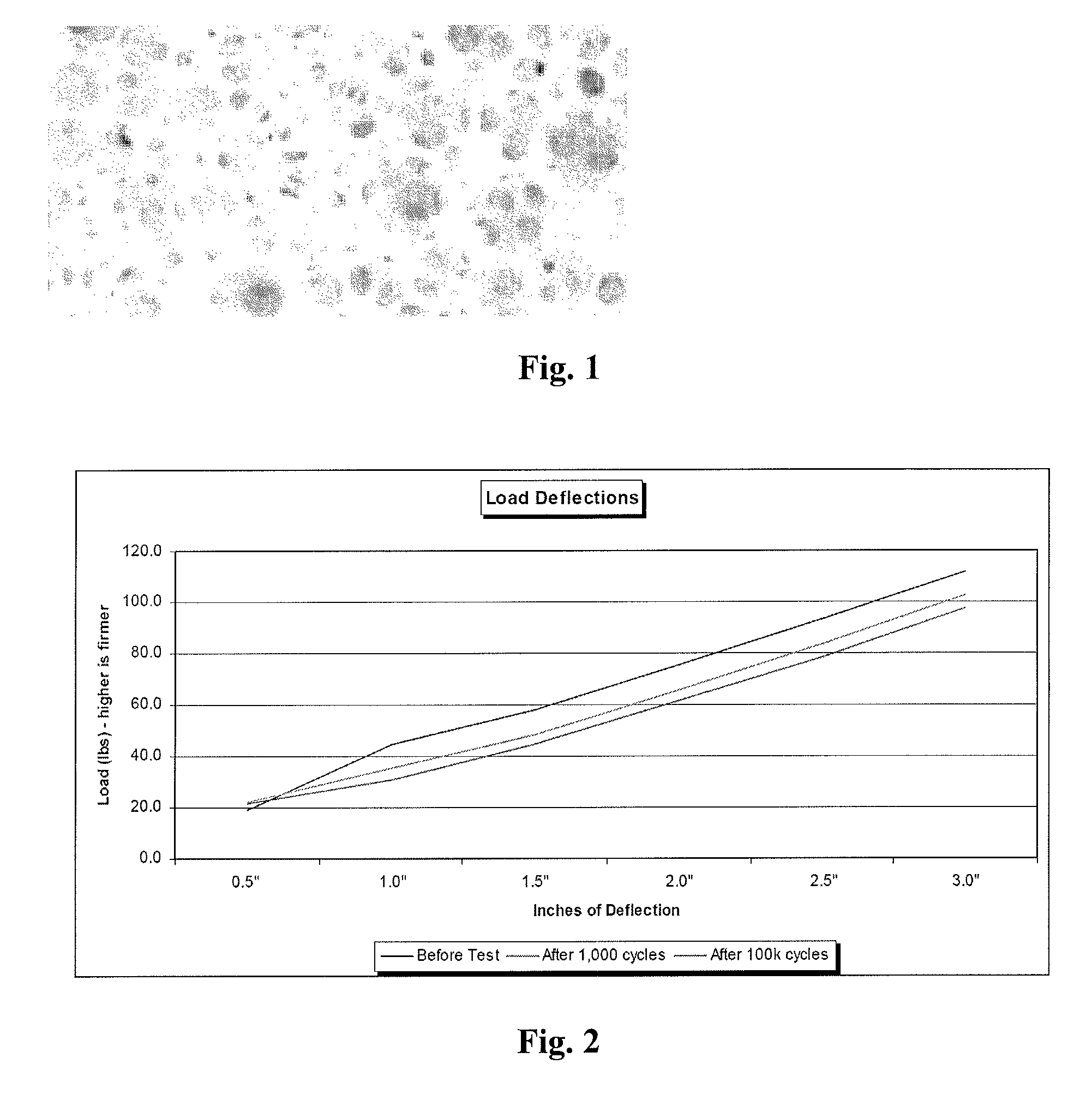

Method for manufacturing support pillows

In one embodiment, a method for making a pillow comprises cutting at least one piece of fabric to form a pair of skins that each comprise a midsection and two arm sections. The two skins are sewn together near their outer edges except for a portion of the mid section to form a shell defining and interior and having a middle region with an opening into the interior and two opposing arms extending from the middle region to form a well region. A fill material is blown into the interior of the shell until the pillow has a firmness defined by an IFD of at least about 20 Newtons with 25% deflection, and the opening in the middle region is closed.

Owner:THE BOPPY CO LLC

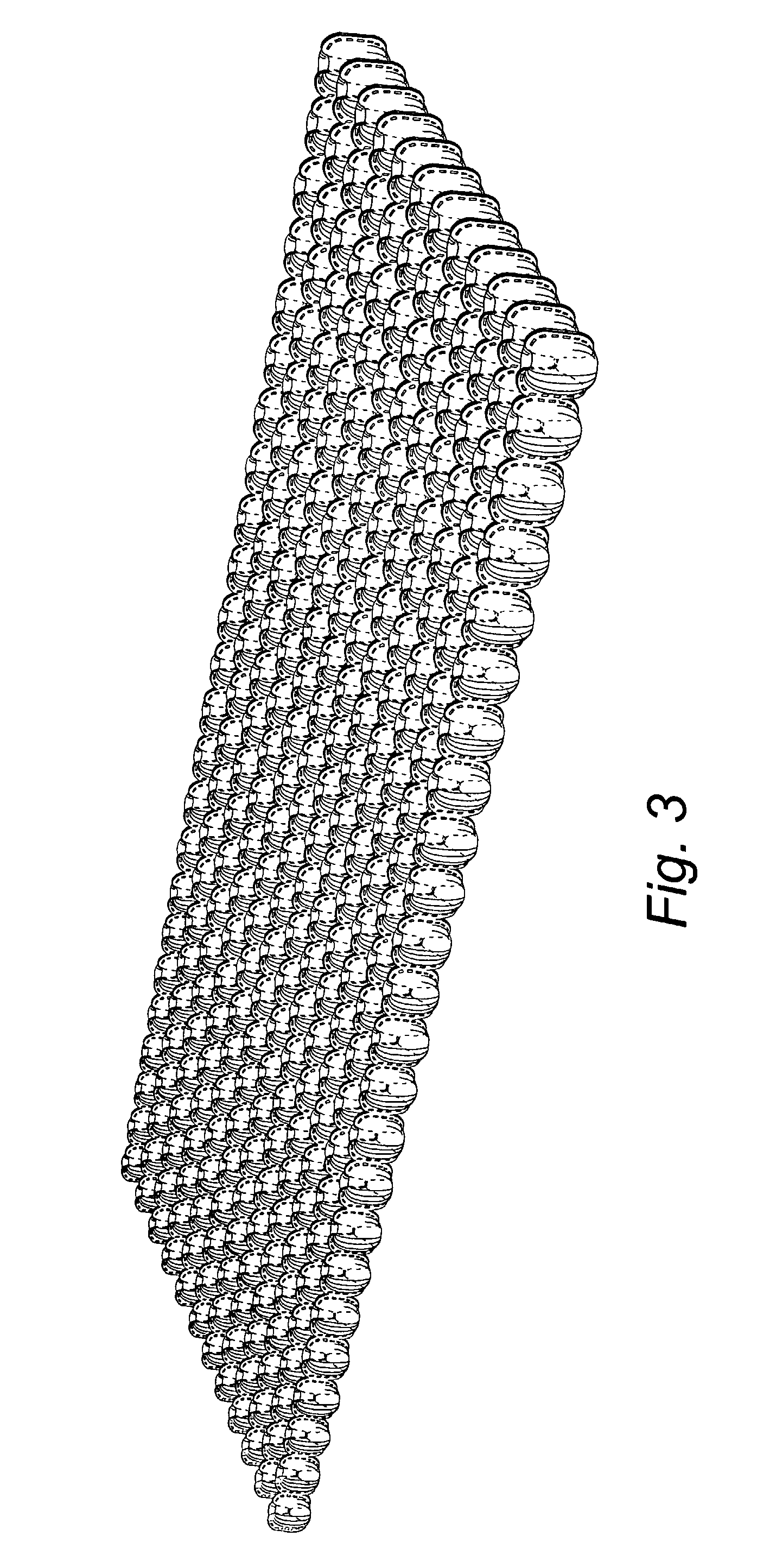

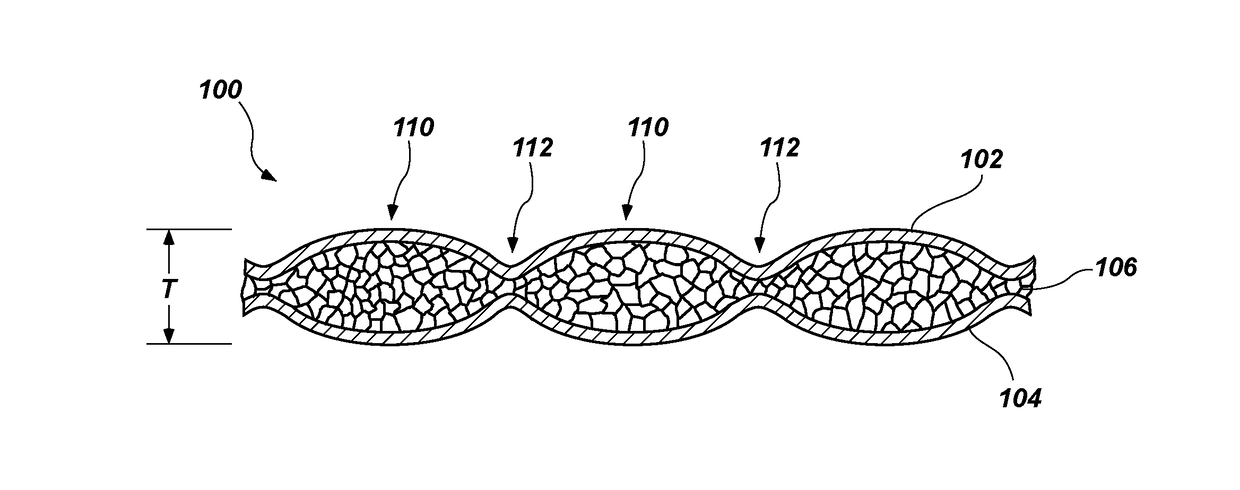

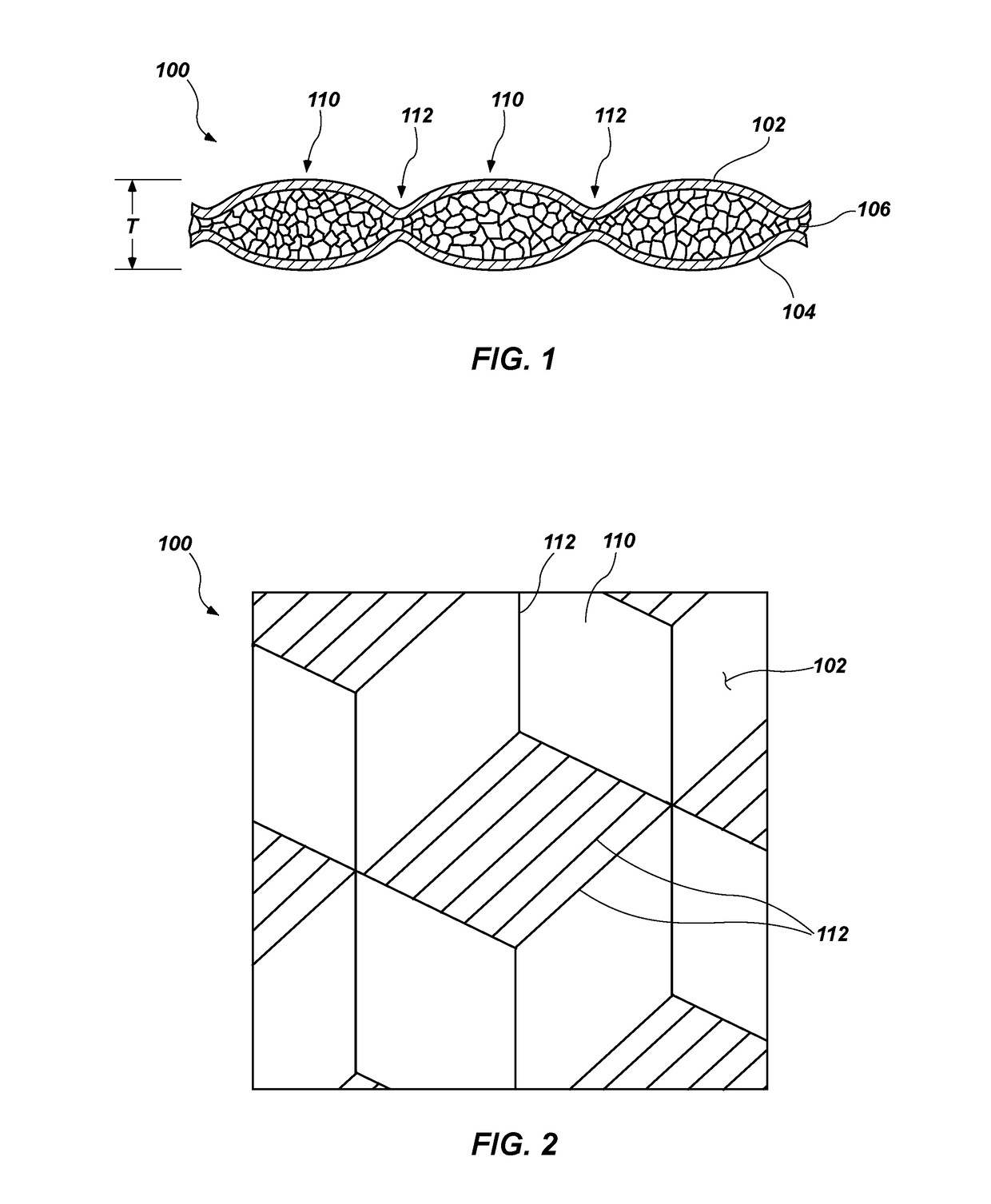

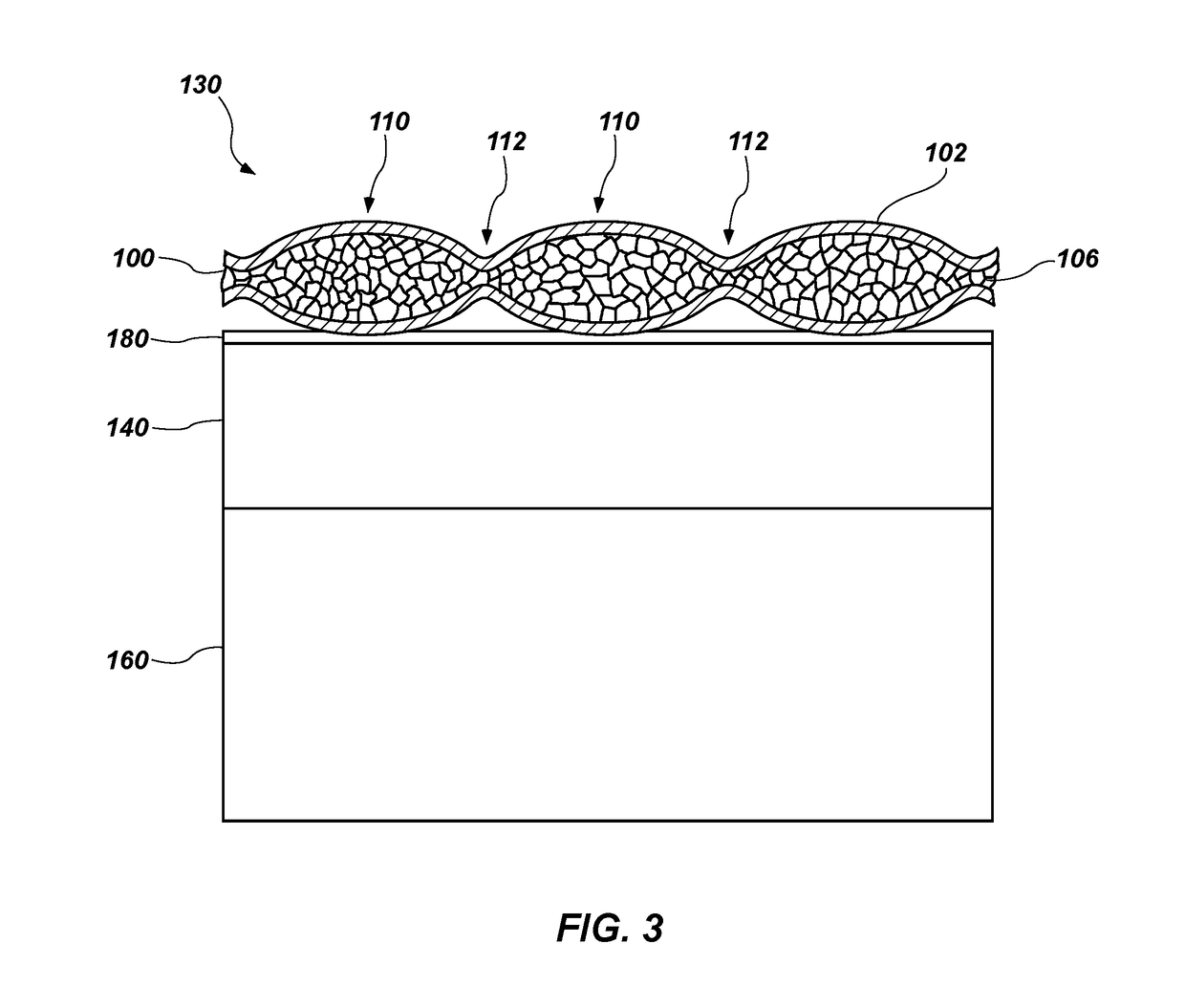

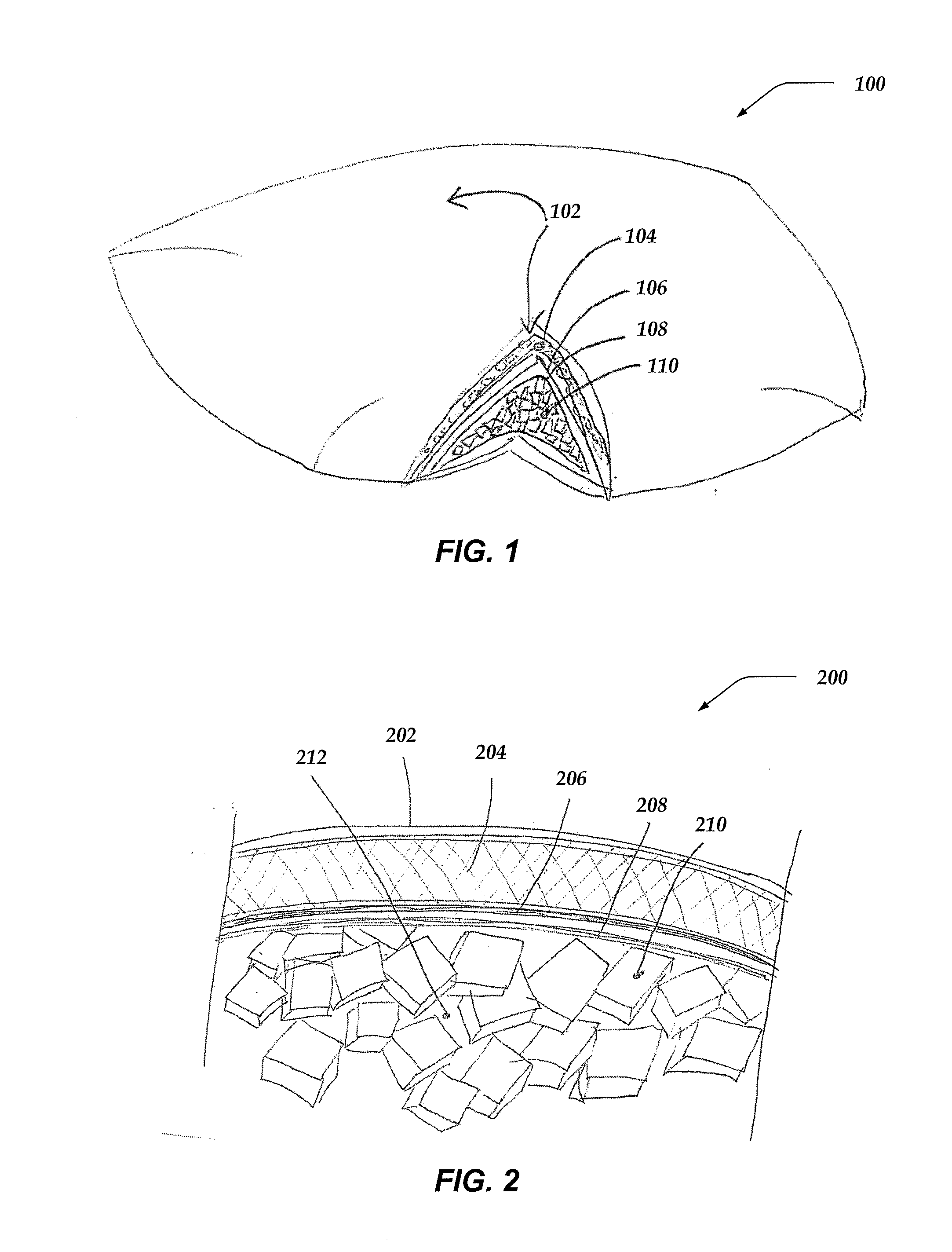

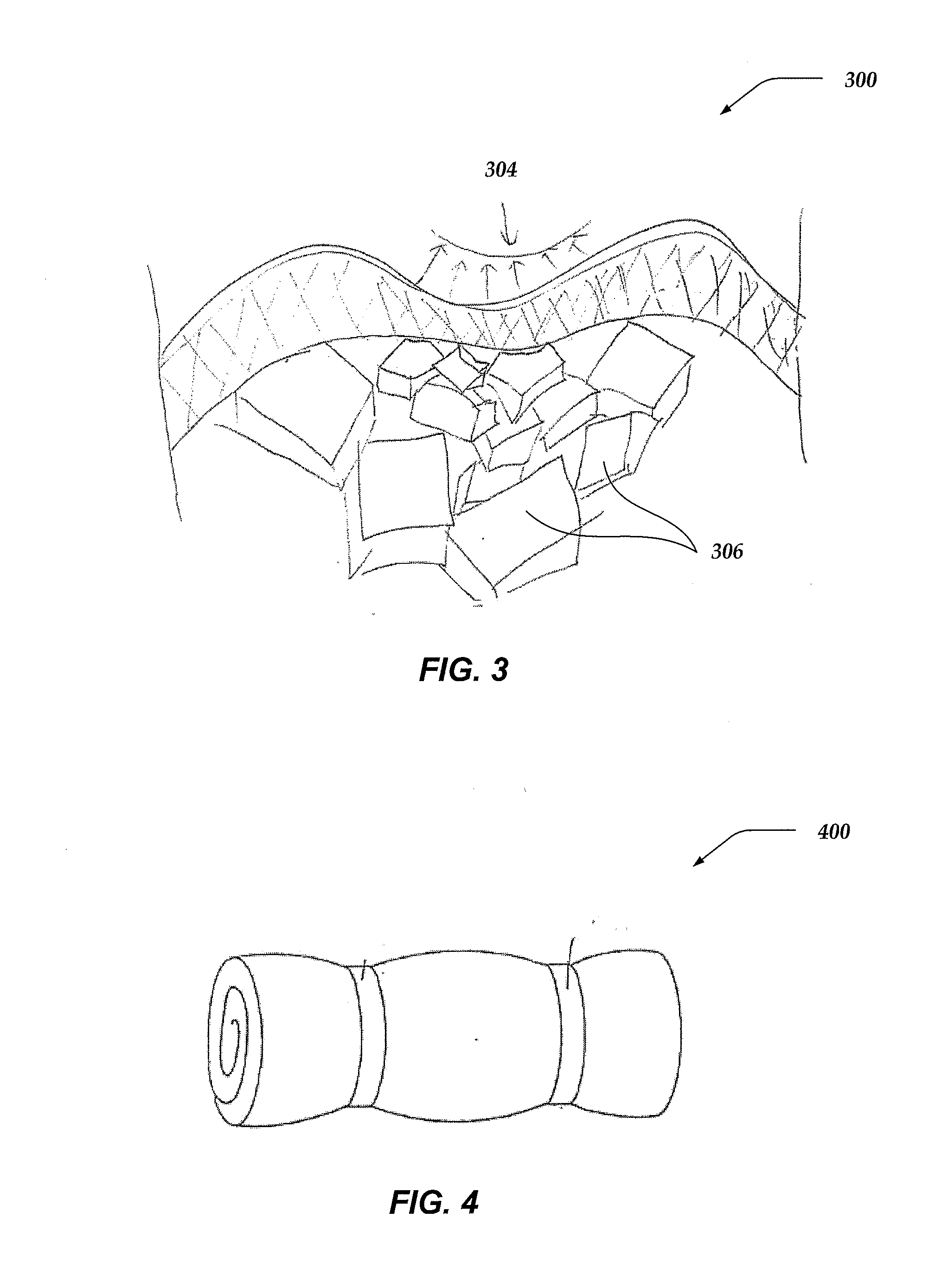

Mattresses and mattress toppers including knitted fabric, and related methods

A mattress or mattress topper includes a cushioning element having an elastomeric material forming intersecting buckling walls that define hollow columns, and a knitted fabric disposed over the cushioning element and configured to move independently of the buckling walls. The elastomeric material includes an elastomeric polymer and a plasticizer. The knitted fabric includes a first layer of stretchable material; a second layer of stretchable material; and a layer of stretchable fill material between the first layer of stretchable material and the second layer of stretchable material. The first layer of stretchable material is knitted together with the second layer of stretchable material as a unitary sheet of fabric including the layer of stretchable fill material. A method of forming a mattress or mattress topper includes disposing a knitted fabric over a cushioning element comprising intersecting buckling walls and configuring the knitted fabric to move independently of the buckling walls.

Owner:PURPLE INNOVATION LLC

Integrated bedding cover system and method

ActiveUS20100107339A1Easily and securely aligningUpholstery manufactureBlanketFilling materialsCovering system

The embodiments described herein generally relate to a system and method for joining a detachable fabric sheet to a cover through the use of one or more corresponding fastening or temporary joining mechanisms located on the cover and fabric sheet. In an embodiment, the cover includes one or more mechanisms to align and / or secure a filling material to the cover, as well as one or more fastening or temporary joining mechanisms for attaching the detachable fabric sheet to the cover. Methods and systems are provided for detachably joining the fabric sheet to the cover, for creating a multi-layer unit of a cover and detachable sheets, as well as for aligning and securing the filler to the cover. A method is also provided for manufacturing the integrated bedding cover system.

Owner:PEEKOO BEDDING CONCEPTS LLC

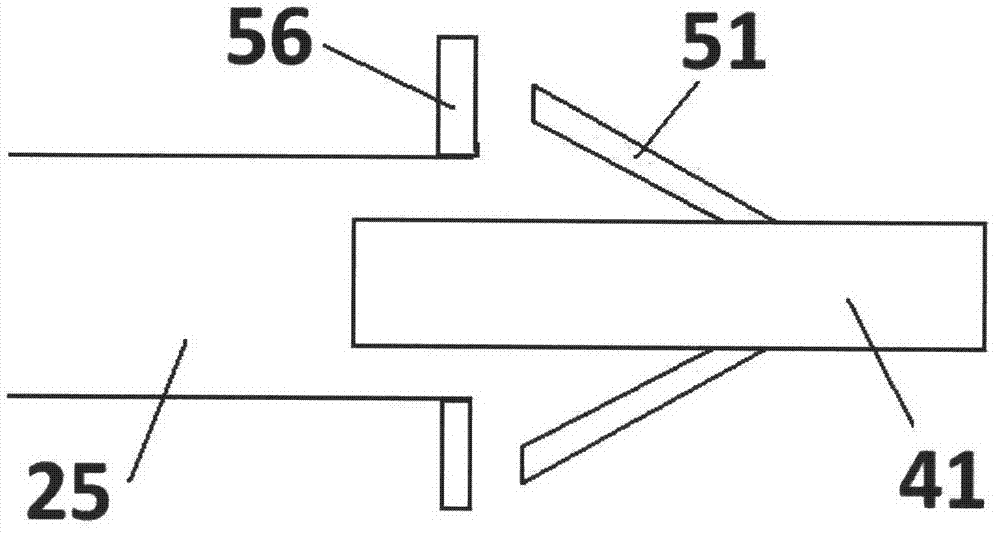

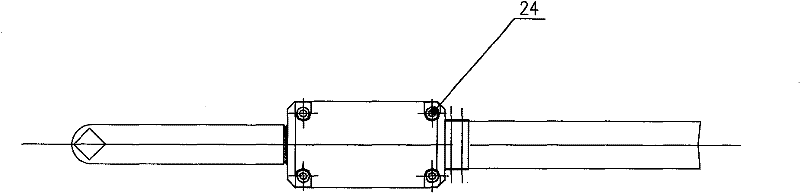

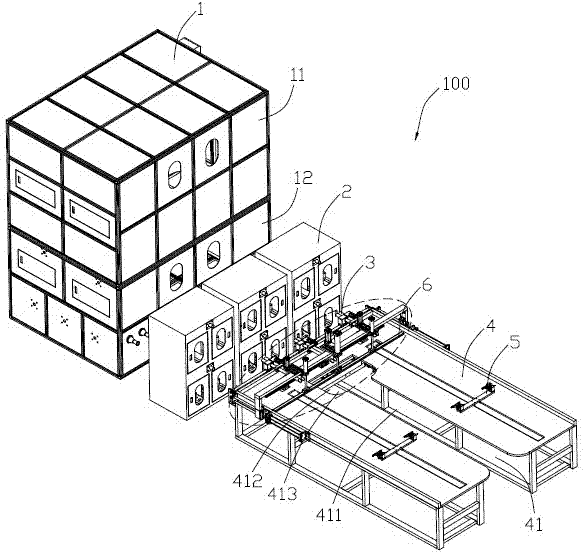

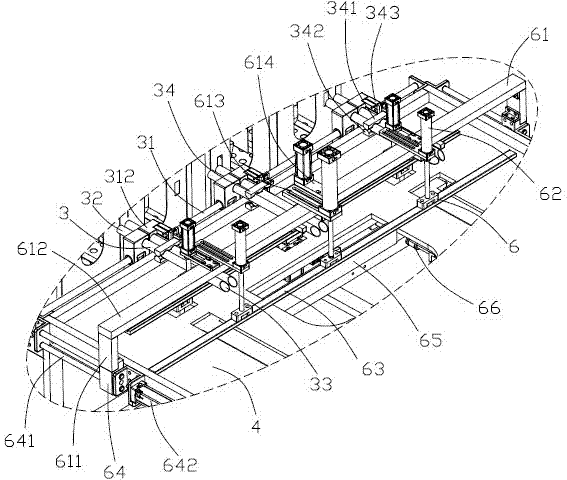

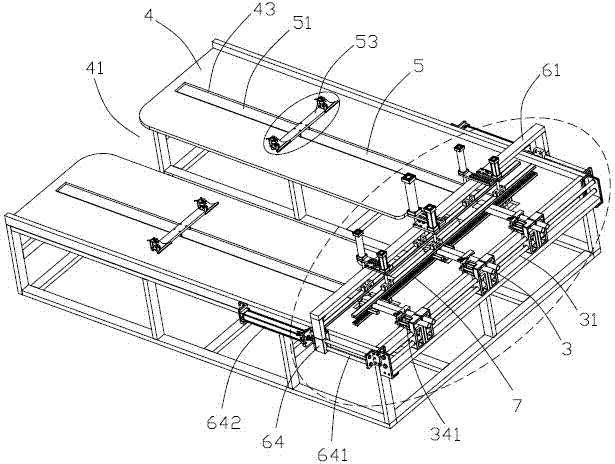

Automatic down filling machine and down filling method thereof

ActiveCN103613062AAutomatic adjustment of filling positionSave human effortUpholstery manufactureClothes making applicancesEngineering

The invention provides an automatic down filling machine and a down filling method thereof. The automatic down filling machine comprises down filling tubes, down filling tables and moving mechanisms, wherein the moving mechanisms drive an object to be filled to move in the direction away from the down filling tubes. The moving mechanisms and the down filling tubes are oppositely arranged. The down filling method comprises the steps: (1) providing the object to be filled; (2) enabling the down filling tubes of the automatic down filling machine to be sleeved with the object to be filled, wherein the head of the object to be filled is fixed to the down filling tubes, and down filling openings of the down filling tubes stretch into the tail of the object to be filled; (3) starting the down filling machine, and conducting down filling on the object to be filled; (4) after the object is filled with a certain amount of down, driving the portion, filled with the down, of the object to be filled to move a certain distance by the moving mechanisms, so that the down filling openings move a certain distance relative to the object to be filled in the direction towards the head of the object to be filled; (5) conducting quantified down filling; (6) after the down filling is completed, repeating the step 4 and the step 5 until the certain distance is formed between the head of the object to be filled and the portions, moving into the object to be filled, of the down filling openings, and resetting the mechanisms of the down filling machine after the down filling is completed.

Owner:CHANGSHU BEALEAD AUTO MACHINERY

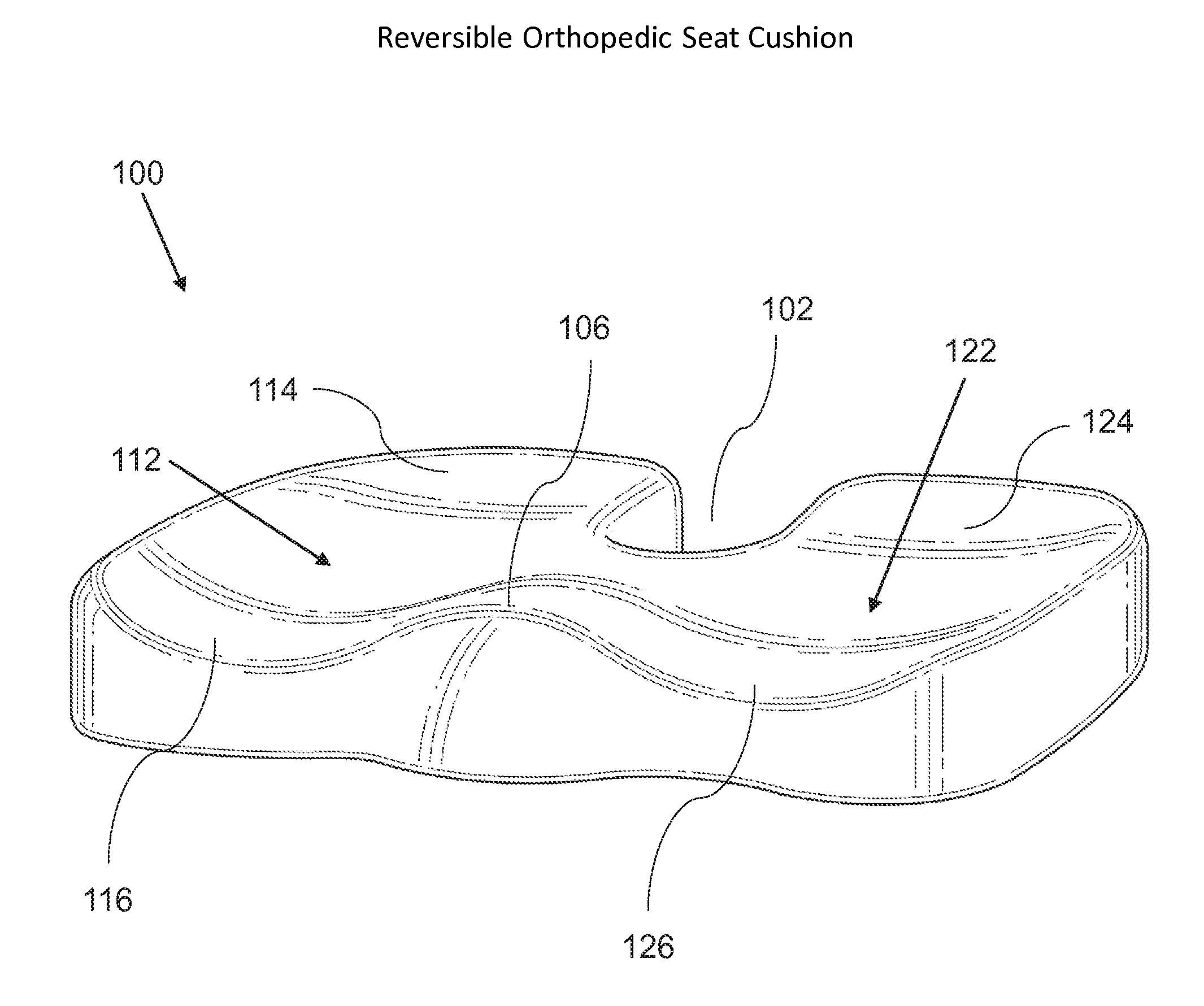

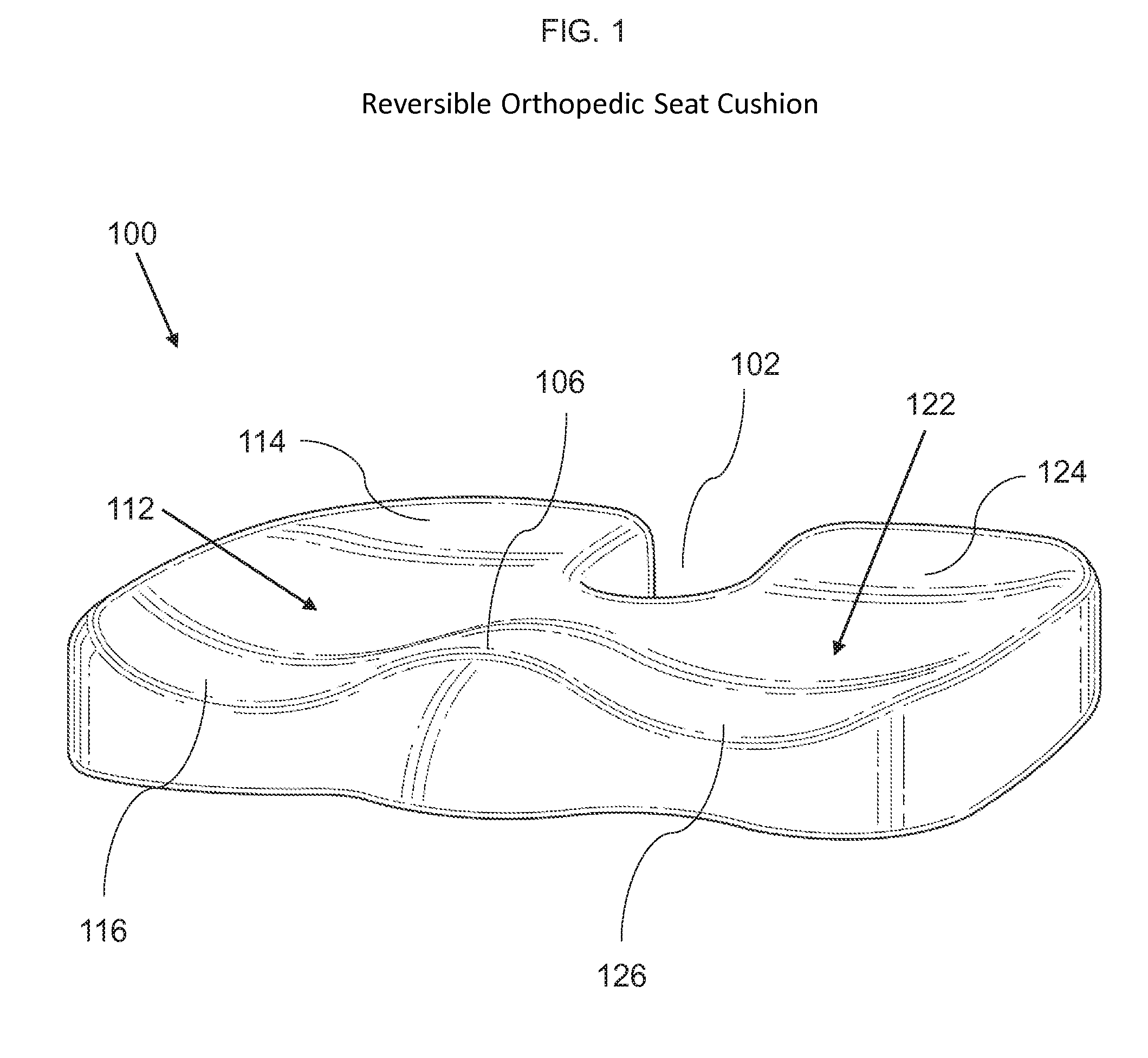

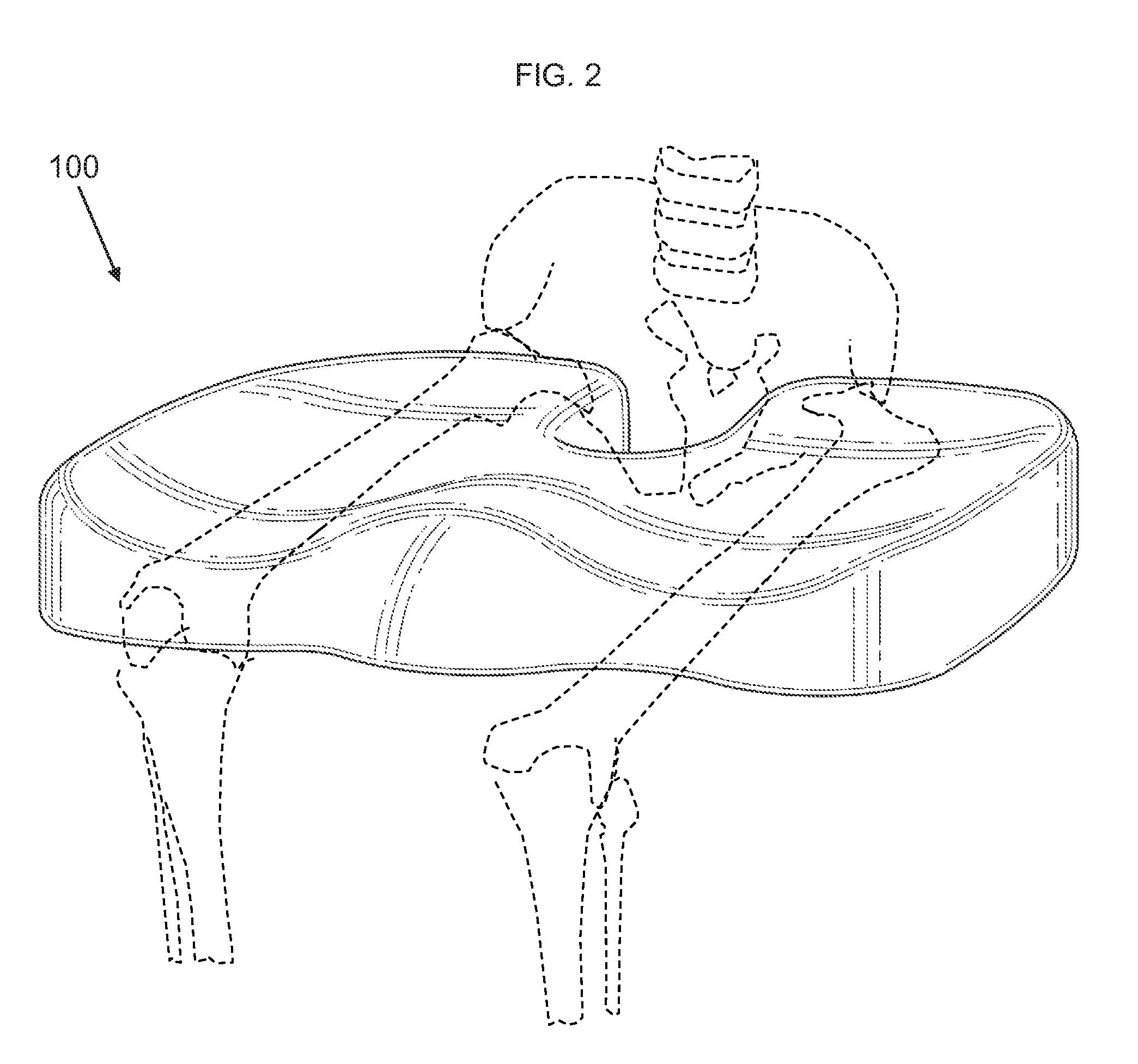

Reversible orthopedic seat cushion

A reversible orthopedic seat cushion can include a right leg support channel, a left leg support channel, a rear cutout, and a front contoured protuberance, which can allow a person sitting in the cushion to experience reduced pressure on the persons coccyx, while having support and guidance to the position of the legs. The seat cushion can also be used in a reversed position. The features of the cushion may promote a healthy sitting posture, and proper spine alignment, and may reduce or prevent back pain. Also disclosed is a method for configuring a support contour of a cushion.

Owner:AYLIO INT INC

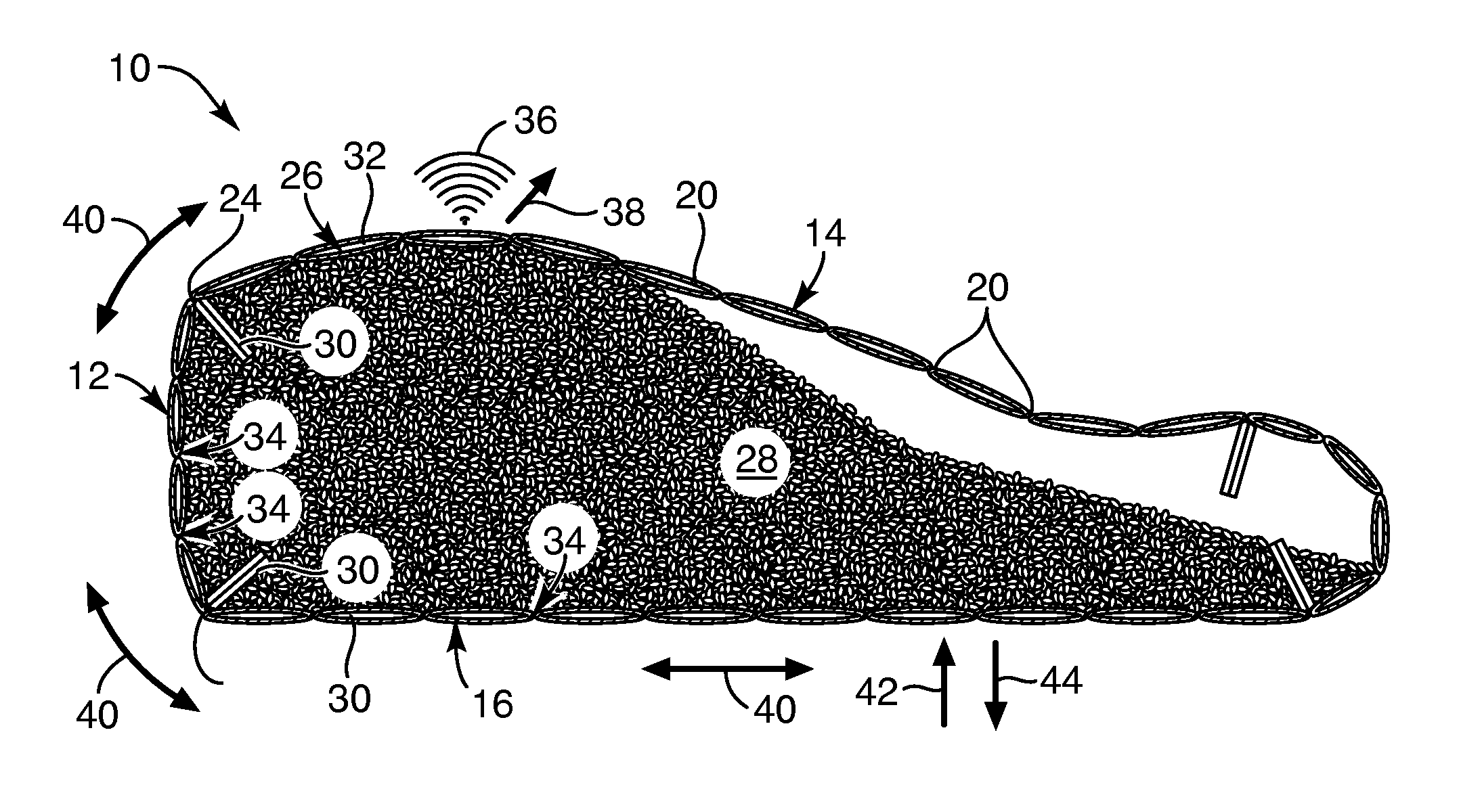

Cpap pillow apparatus and method

Owner:RANDALL BRET

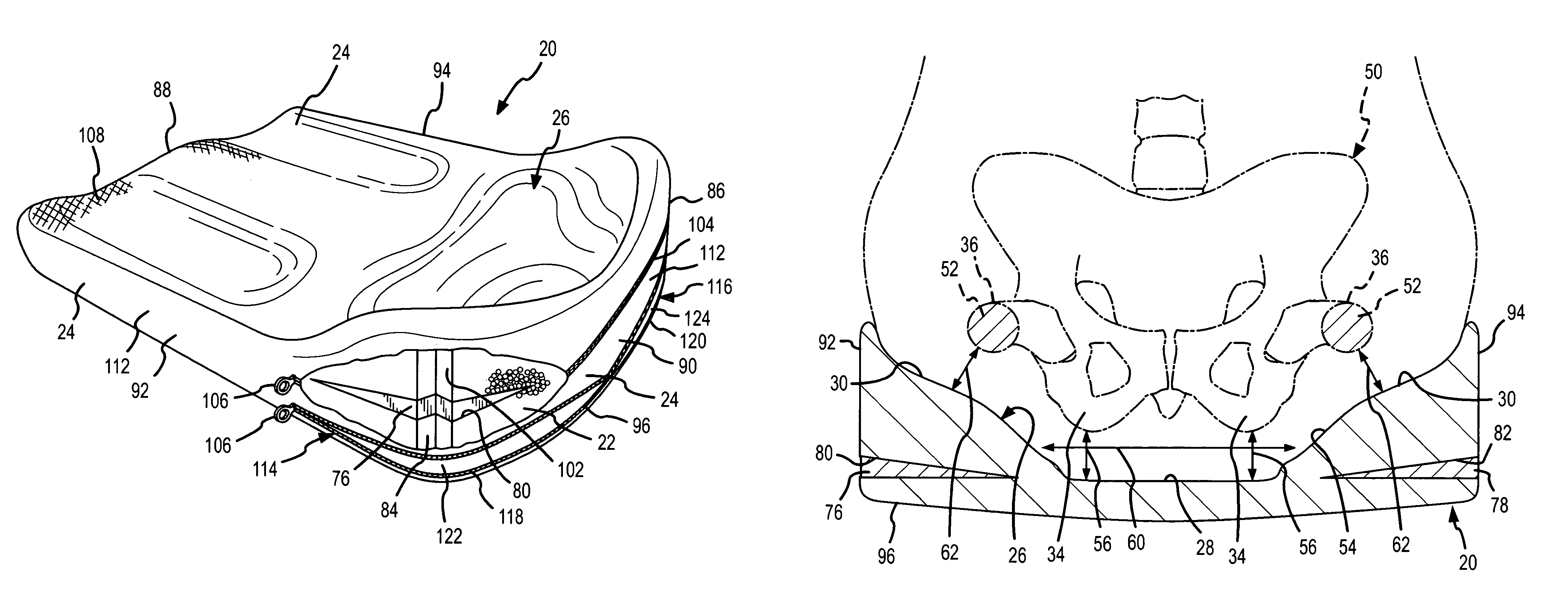

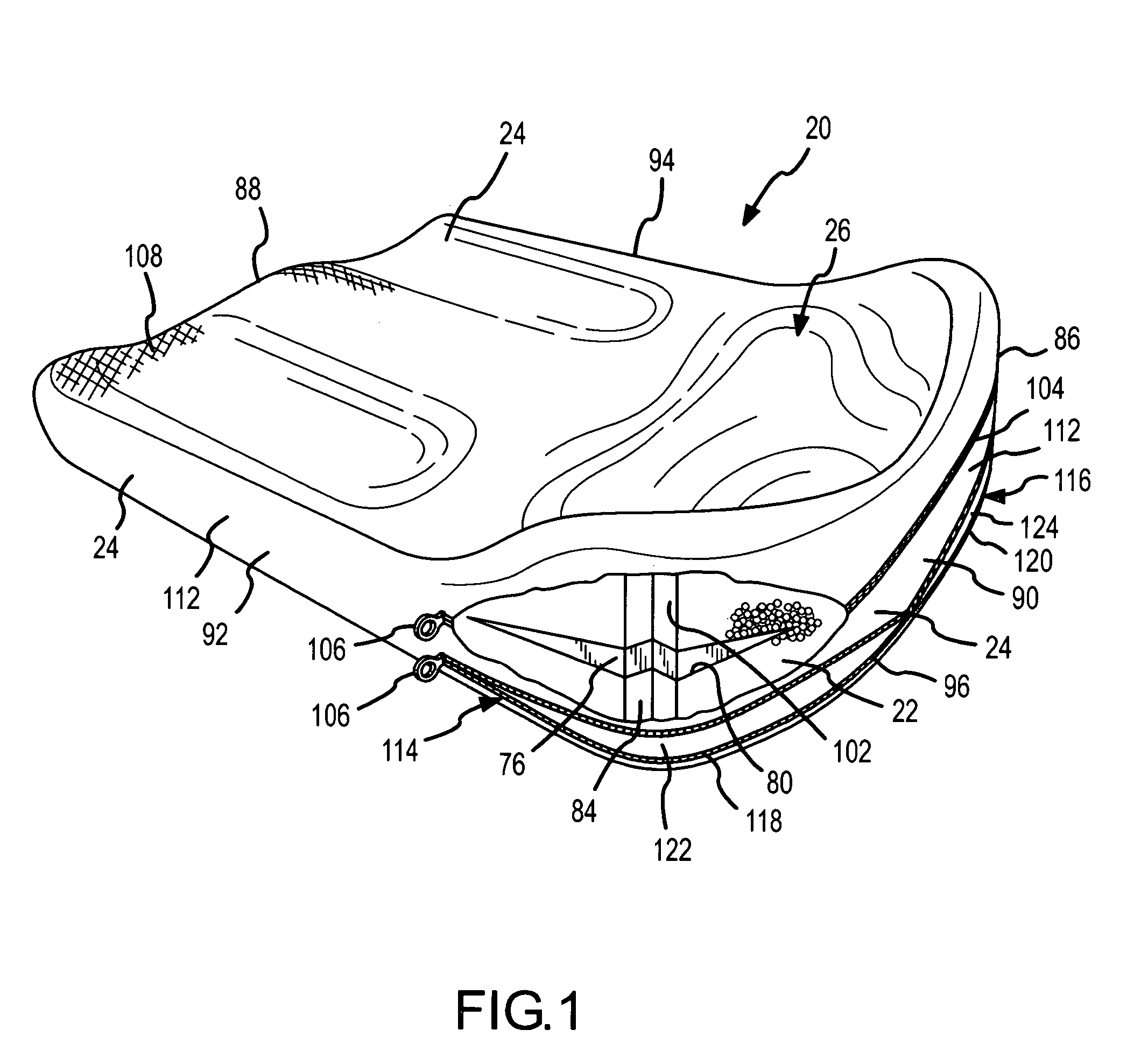

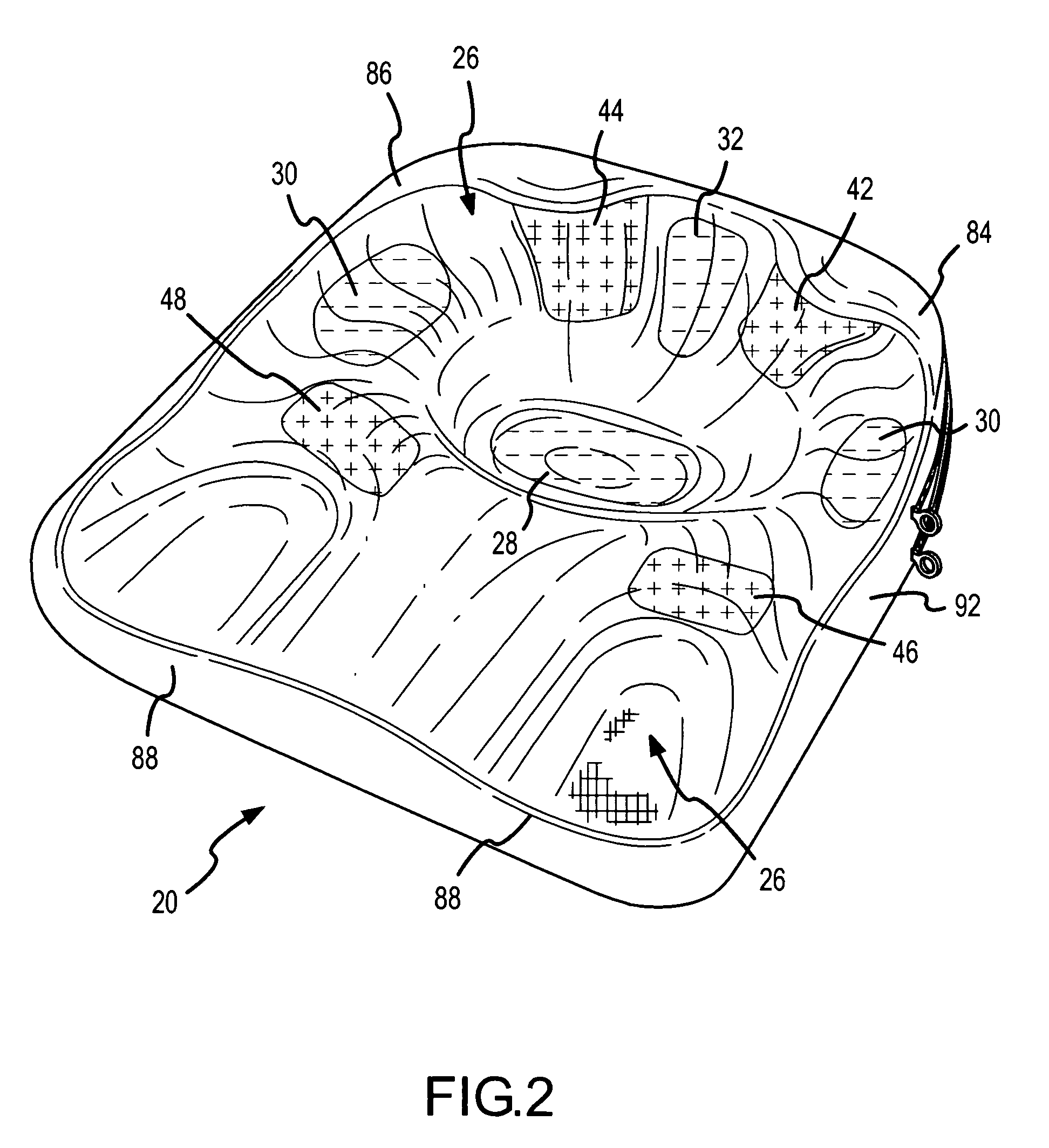

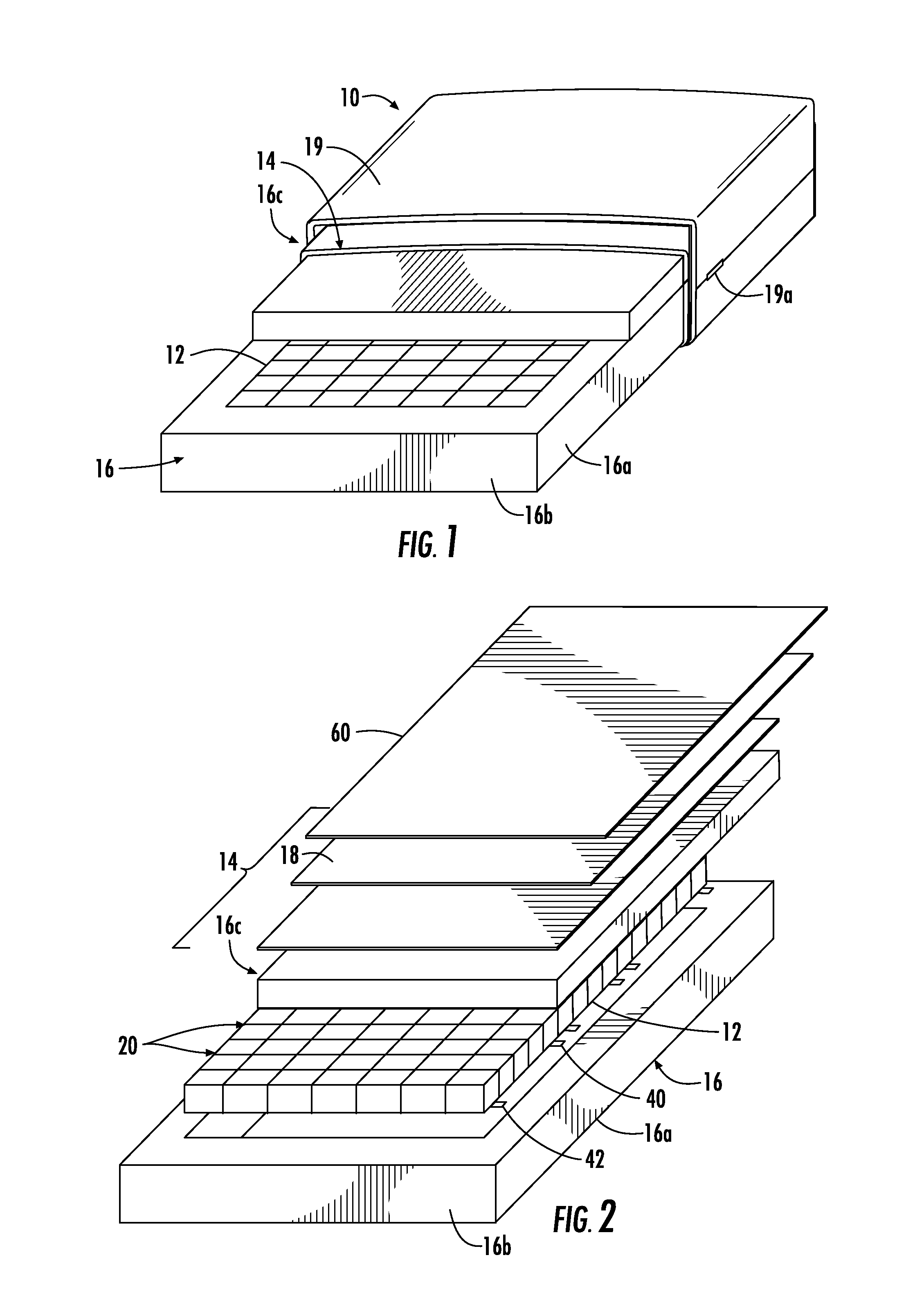

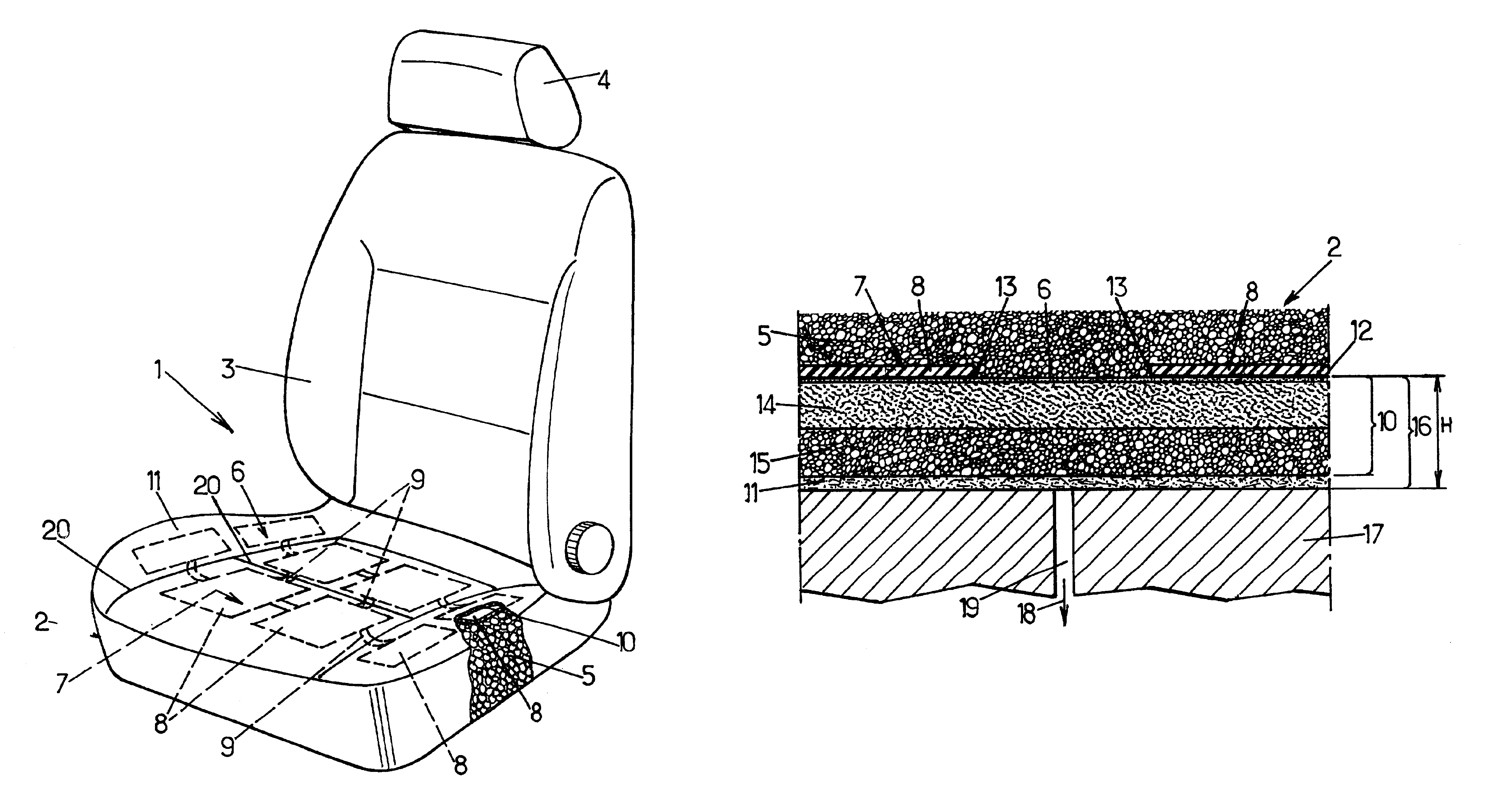

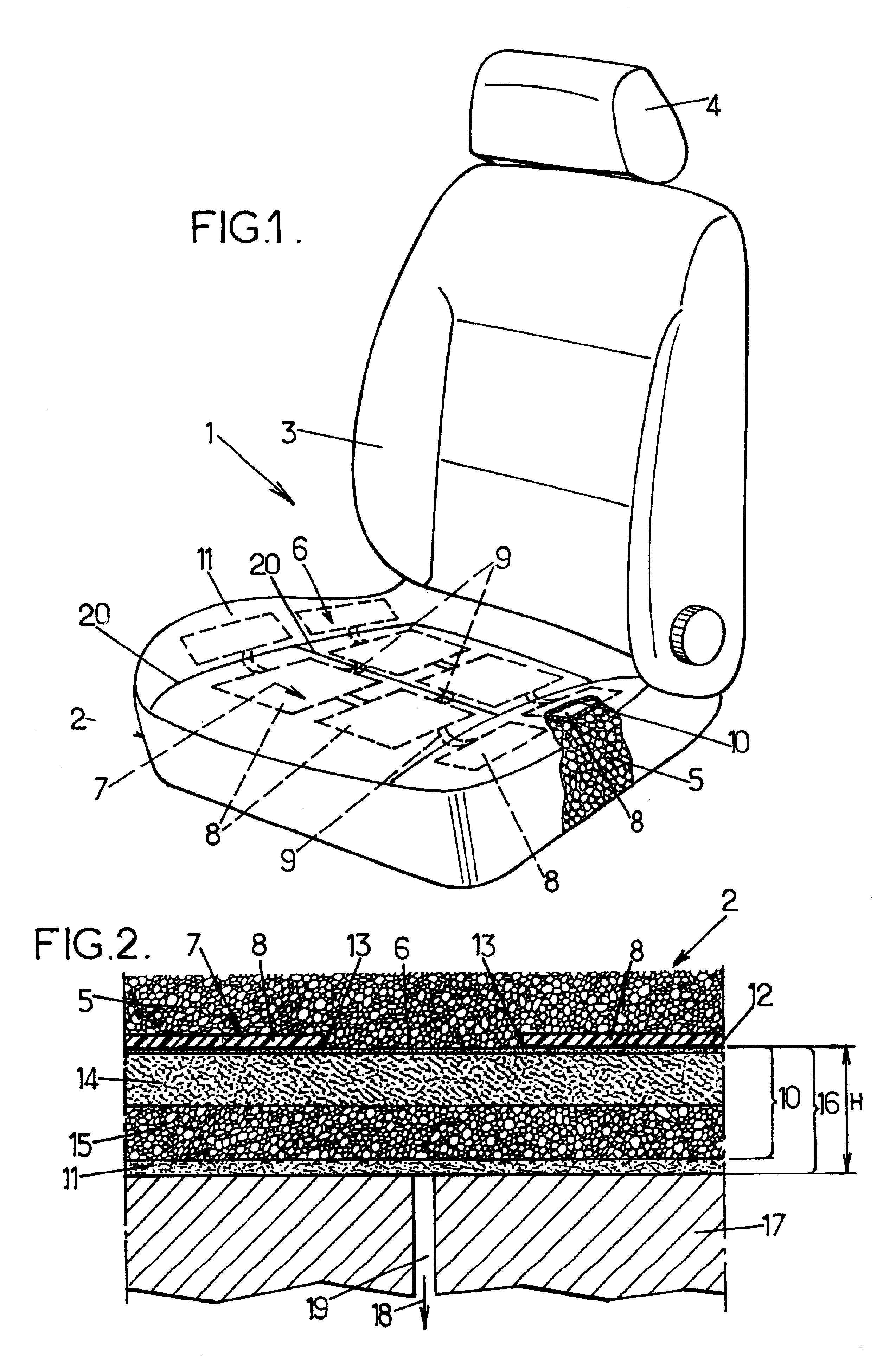

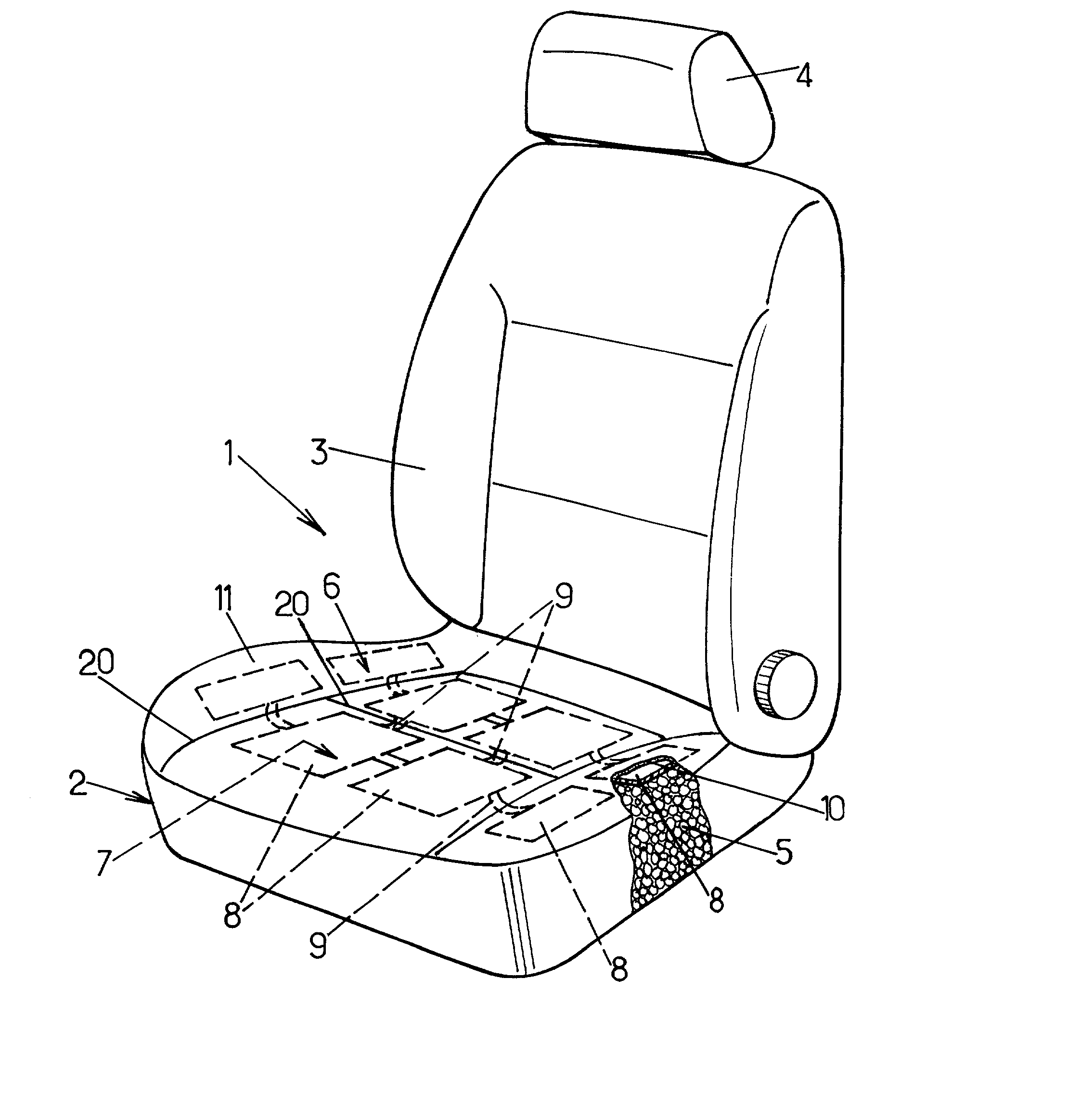

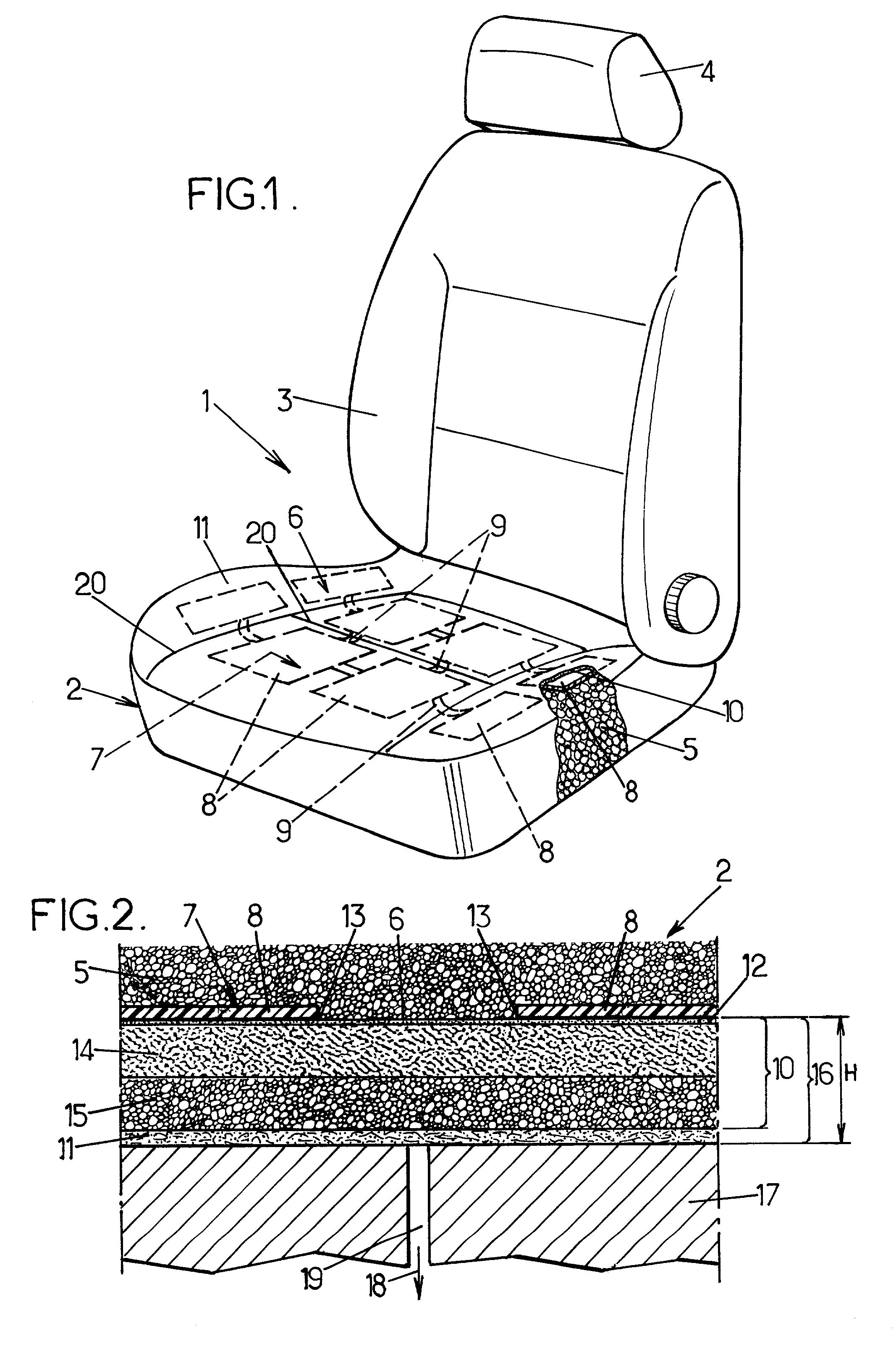

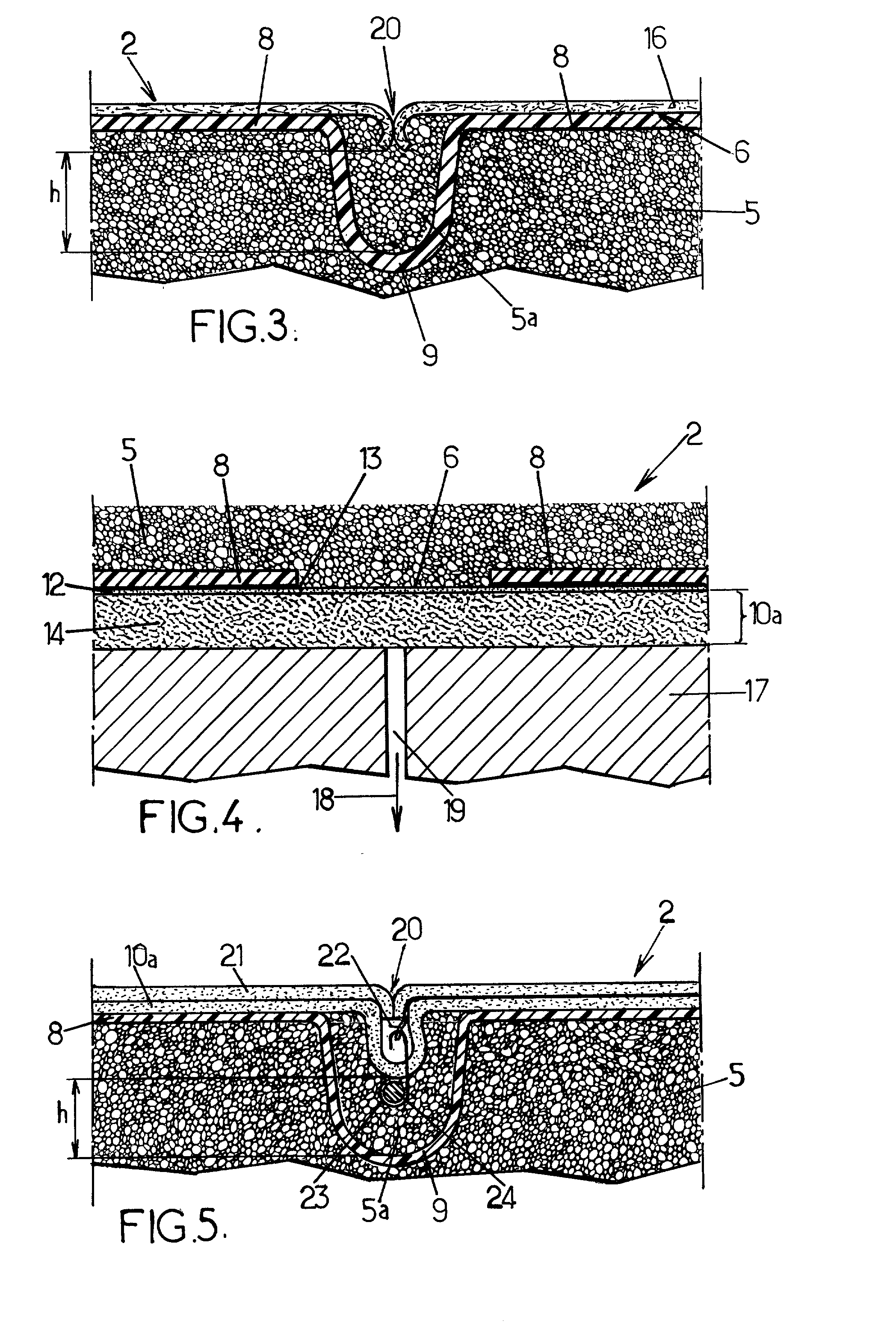

Padded element for a vehicle, and a method of manufacturing it

InactiveUS6733072B2Mitigate such drawbackImprove comfortUpholstery manufactureSeat heating/ventillating devicesPressure differenceBiomedical engineering

A padded element for a vehicle, the element comprising padding of flexible synthetic foam which supports a flexible member and which presents a support face for coming to bear against a user, said support face being covered by:a film suitable for providing a barrier against the synthetic foam before it polymerized;a first compressible flexible layer covering the film on its side opposite side to the padding and presenting permeability to air of less than 200 l.m<-2>.s<-1 >under a pressure difference of 100 Pa, and presenting a load-bearing capacity of 5 kPa;a second flexible layer presenting a load-bearing capacity of 12 kPa; anda flexible outer decorative covering.

Owner:FAURECIA

Pocket spring mattress

ActiveUS8011046B2Adequate damping of the airflowAdequate dampingUpholstery manufactureStuffed mattressesCoil springEngineering

Owner:STJERNFJADRAR

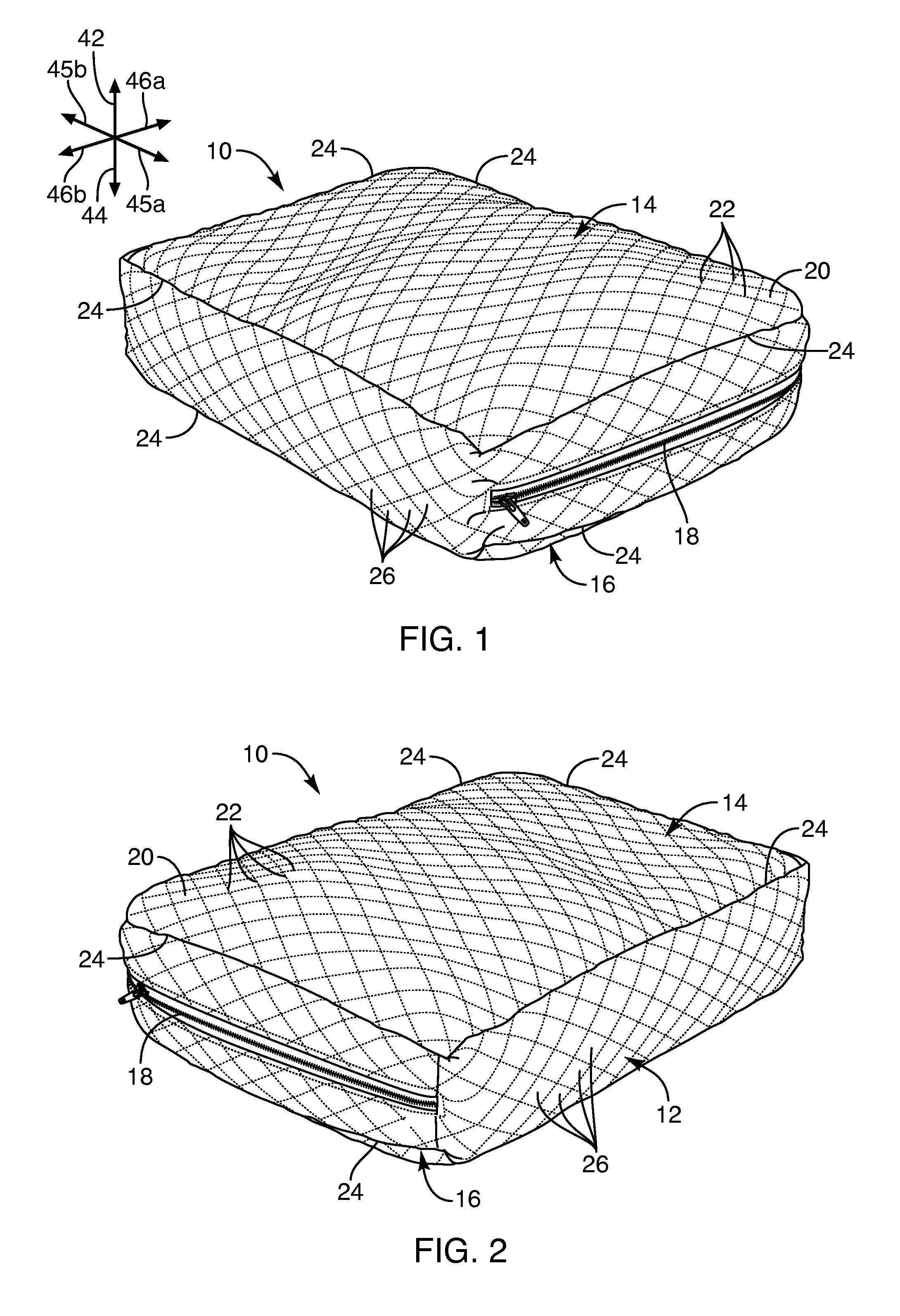

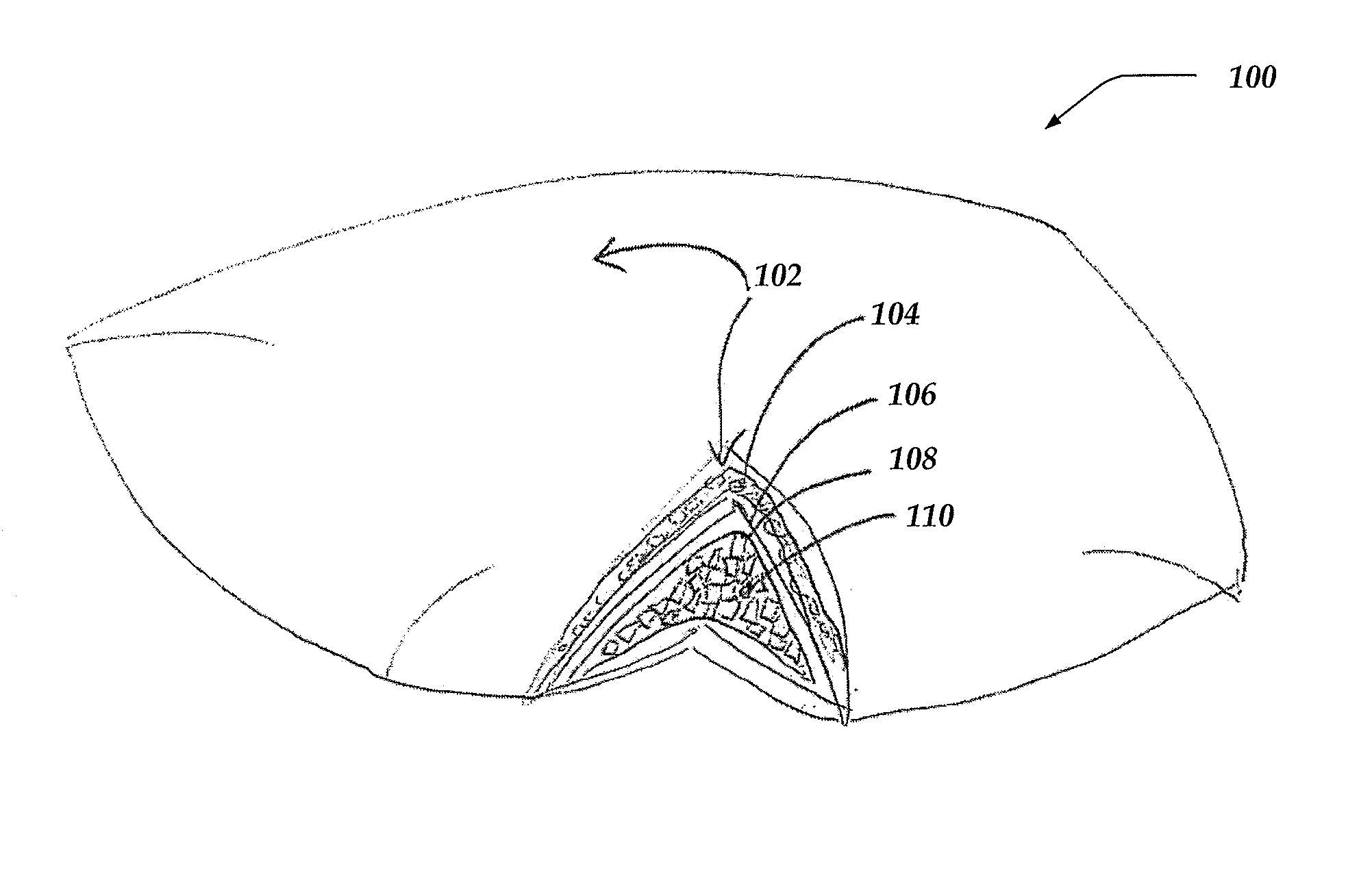

Washable pillow with multiple cases

Embodiments are directed towards a pillow with a removable core that includes a plurality of cut foam pieces of various or similar shapes / sizes. The pillow may include an outer shell case and an inner shell case (i.e., the removable core). The outer shell case may be made of a plurality of layers, including a backing layer positioned between an external layer and an internal layer. The backing layer may comprise a foam material. And the internal layer and the inner shell case may comprise an open mesh material. The inner shell case may be removably inserted into the outer shell case. A plurality of foam pieces may be disposed inside the inner shell case.

Owner:ROCHLIN SCOTT KARL

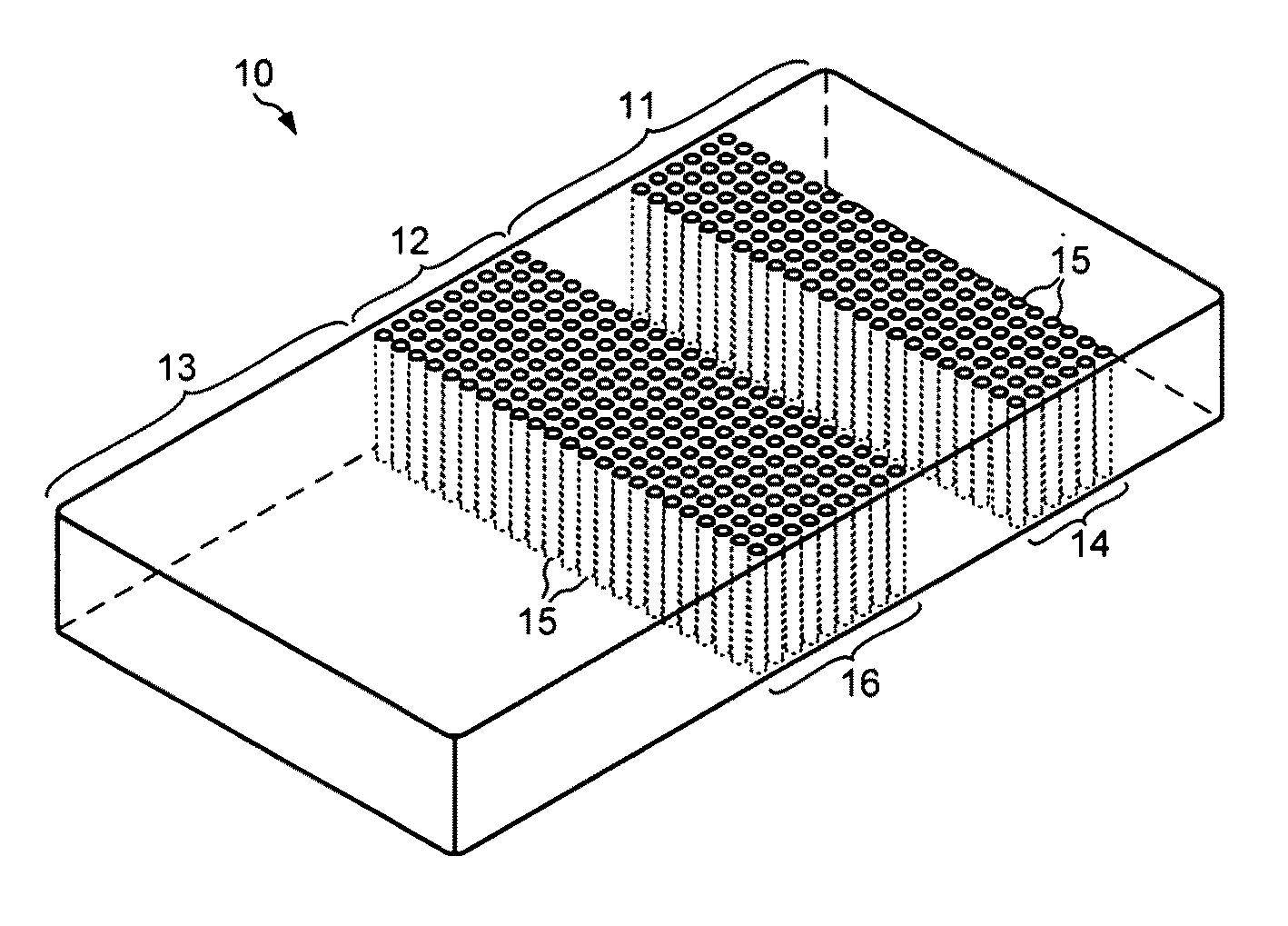

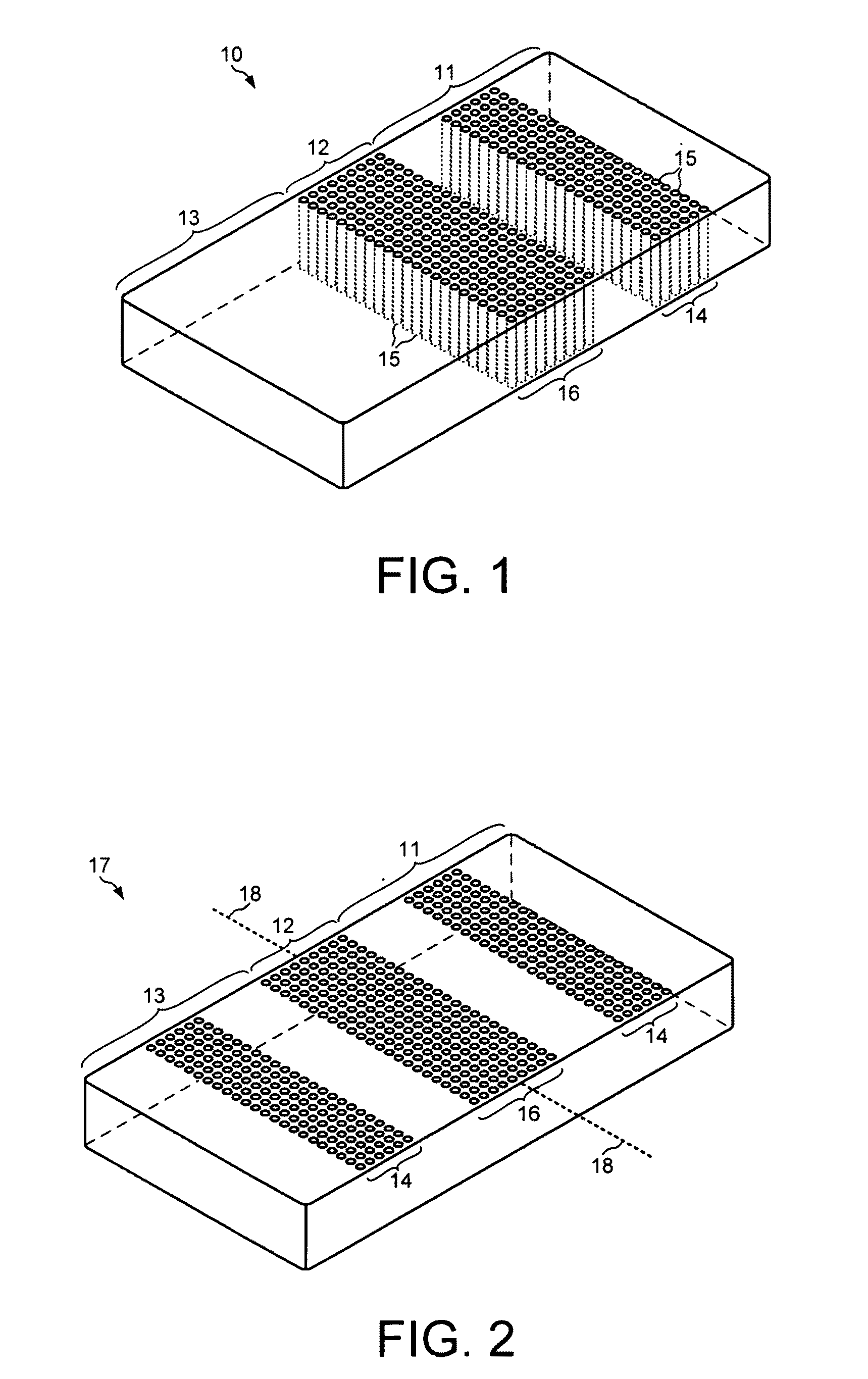

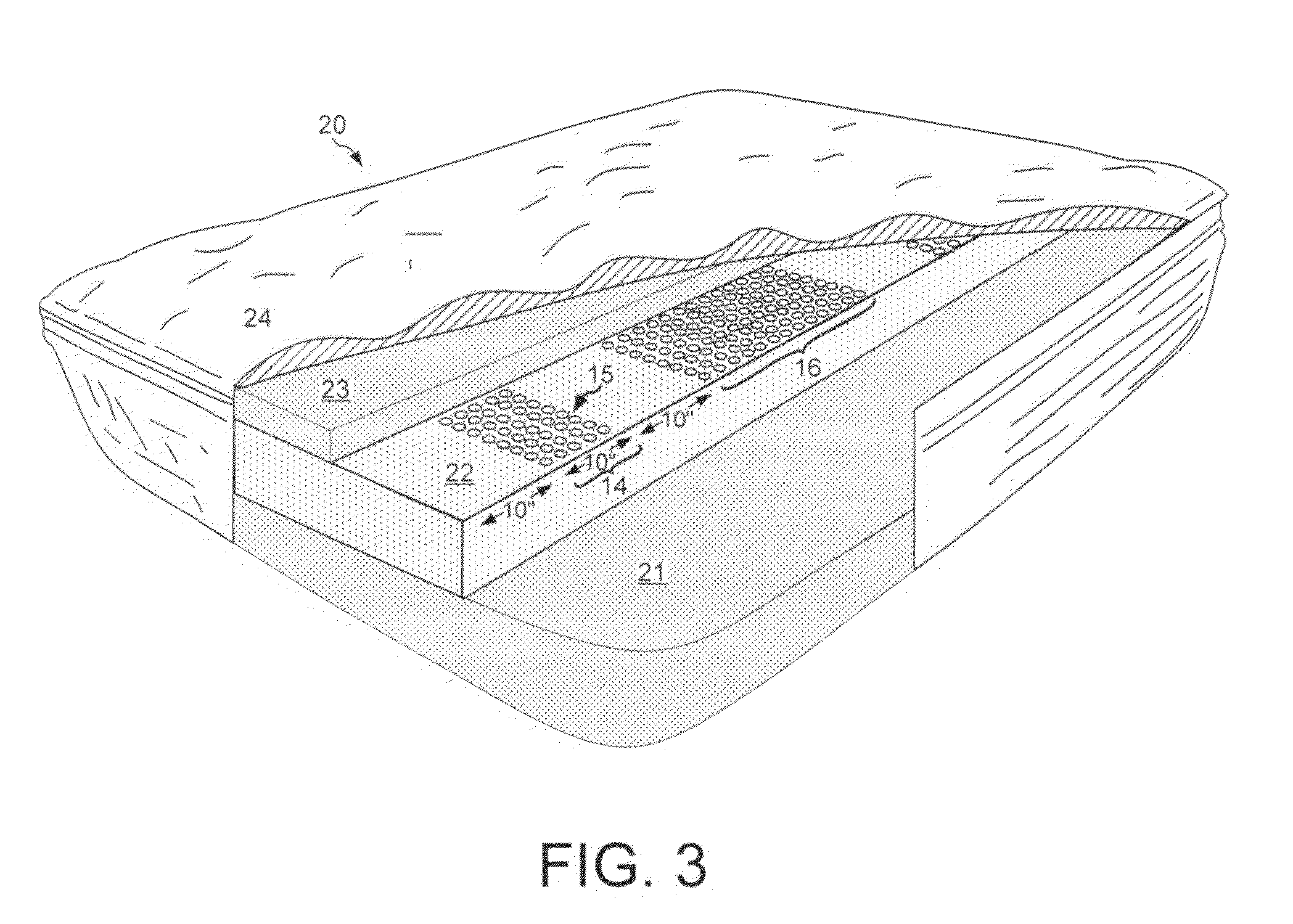

Symmetrical pressure relief foam mattress

ActiveUS20100223734A1Improve comfortGreat degree of deformationUpholstery manufactureStuffed mattressesLateral regionEngineering

A symmetrical pressure relief foam mattress includes an upper foam layer placed on a zoned foam layer. A plurality of cylindrical holes are distributed throughout each of a first, a second and a third lateral region of the zoned foam layer. The first lateral region is less than twelve inches wide and has a middle that is within eighteen inches of the top of the zoned foam layer. The third lateral region is also less than twelve inches wide and has a middle that is within eighteen inches of the bottom of the zoned foam layer. The second lateral region has a middle disposed at the center axis of the zoned foam layer. The middle of both the first and third lateral regions is about fifteen inches from the edge of the mattress regardless of which end the consumer chooses to use as the head of the mattress.

Owner:ZINUS

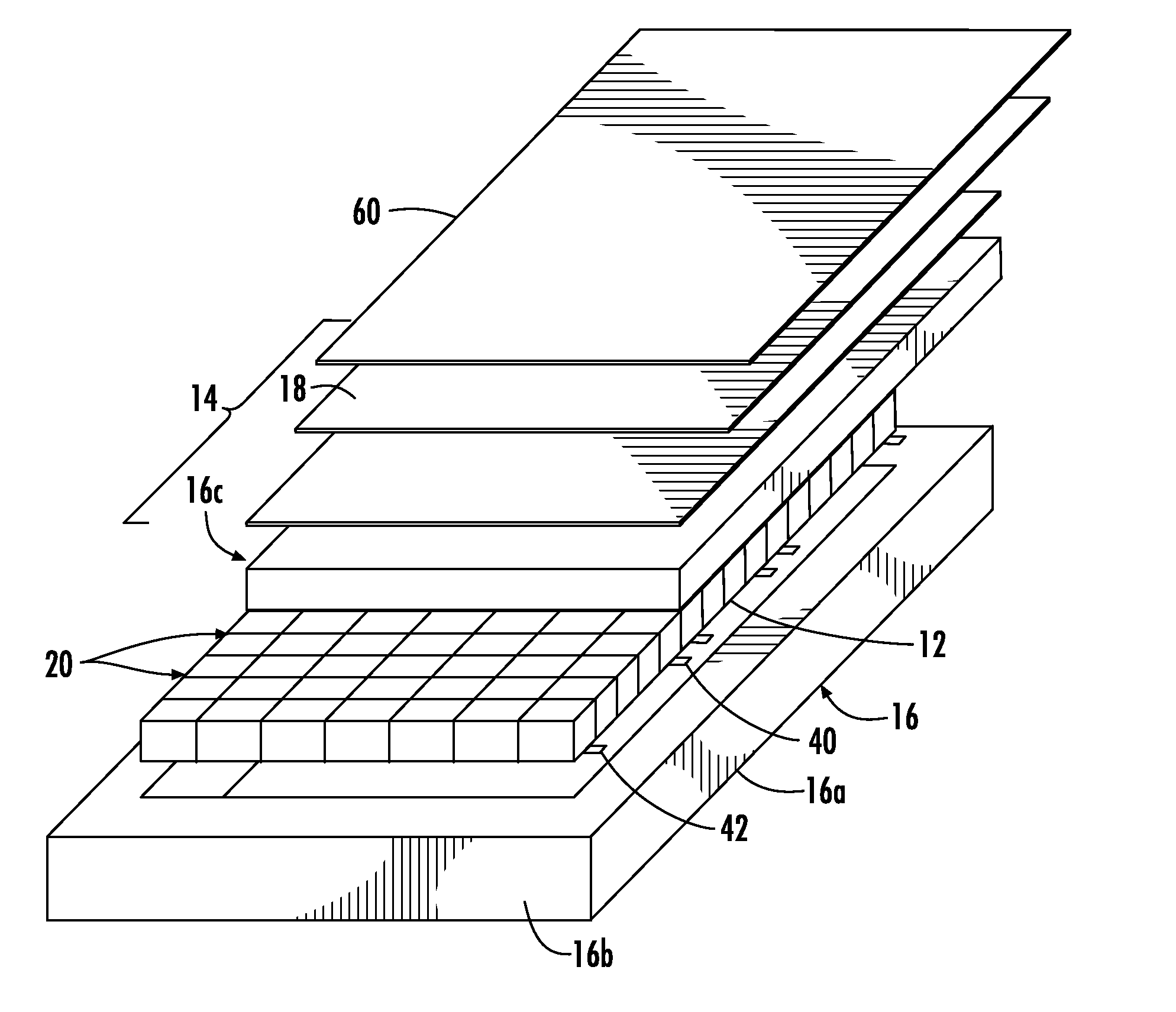

Padded element for a vehicle, and a method of manufacturing it

InactiveUS20020067064A1Mitigate such drawbackUpholstery manufactureStuffed mattressesThin membraneSupport surface

A padded element for a vehicle, the element comprising padding of flexible synthetic foam which supports a flexible member and which presents a support face for coming to bear against a user, said support face being covered by: a film suitable for providing a barrier against the synthetic foam before it polymerized; a first compressible flexible layer covering the film on its side opposite side to the padding and presenting permeability to air of less than 200 l.m-2.s-1 under a pressure difference of 100 Pa, and presenting a load-bearing capacity of 5 kPa; a second flexible layer presenting a load-bearing capacity of 12 kPa; and a flexible outer decorative covering.

Owner:FAURECIA

Seat with a side airbag

InactiveUS7341275B2Improve responseImprove protectionUpholstery manufactureVehicle seatsLateral airbagStructural engineering

Owner:NHK SPRING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com