Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5928results about "Clothes making applicances" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

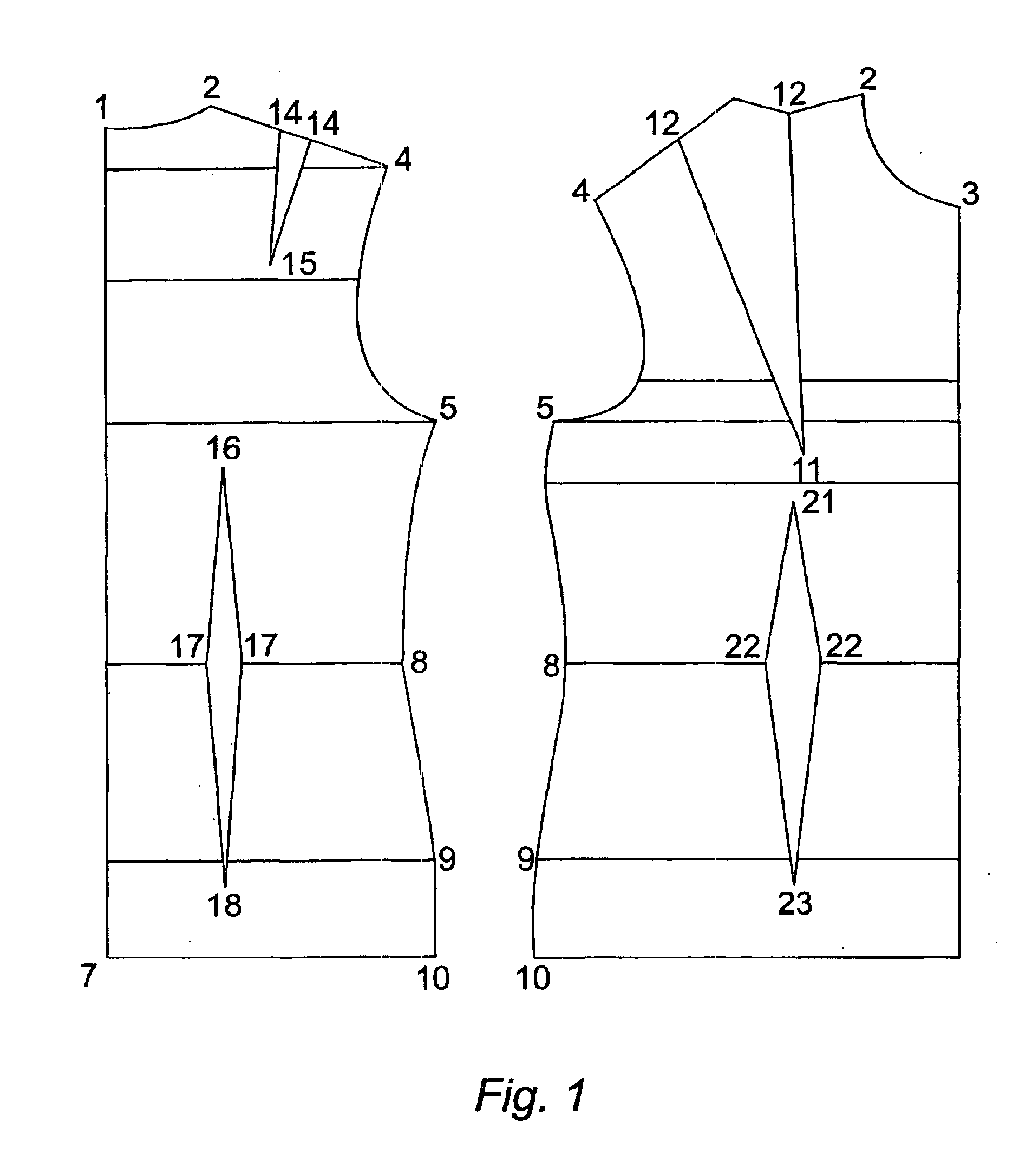

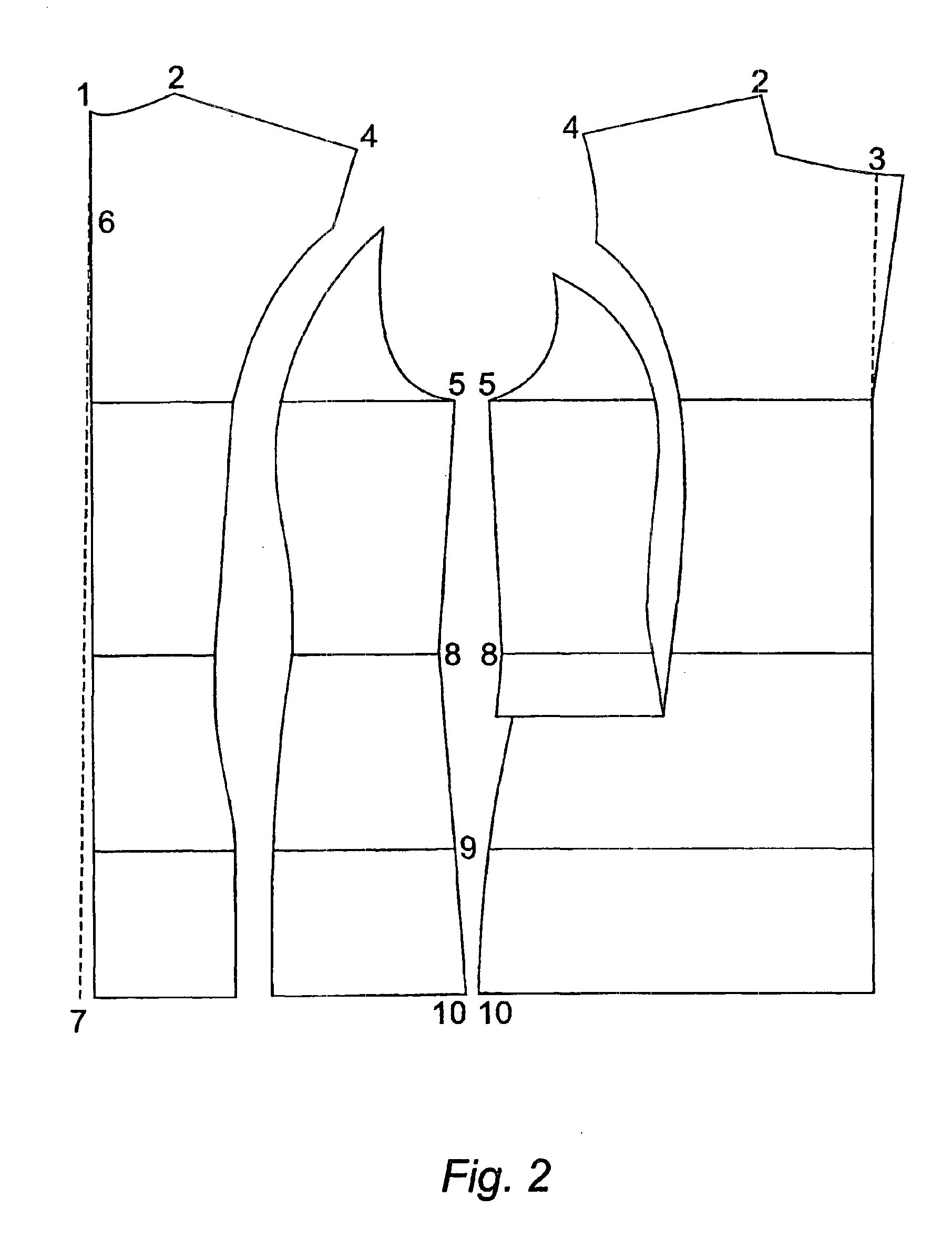

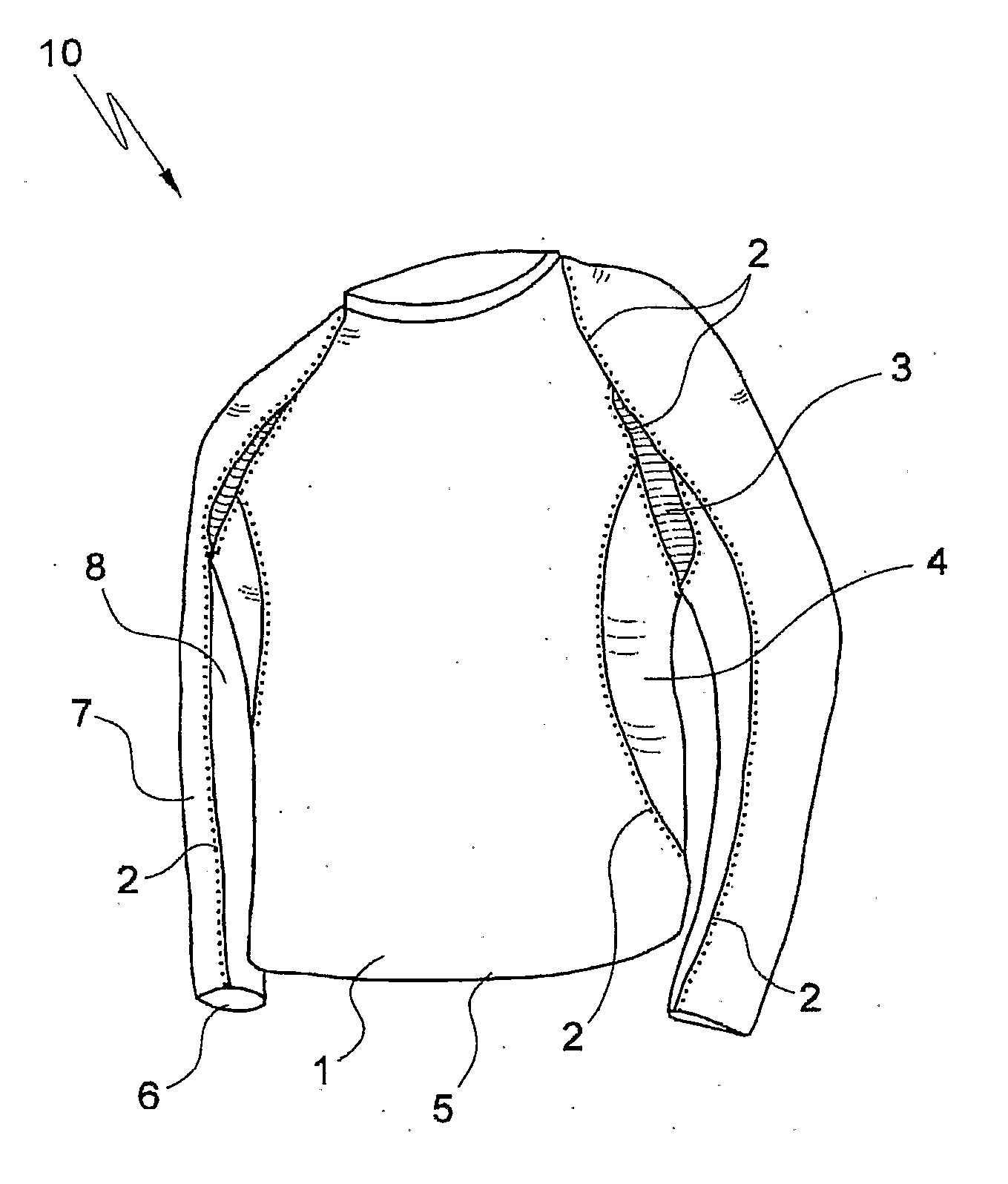

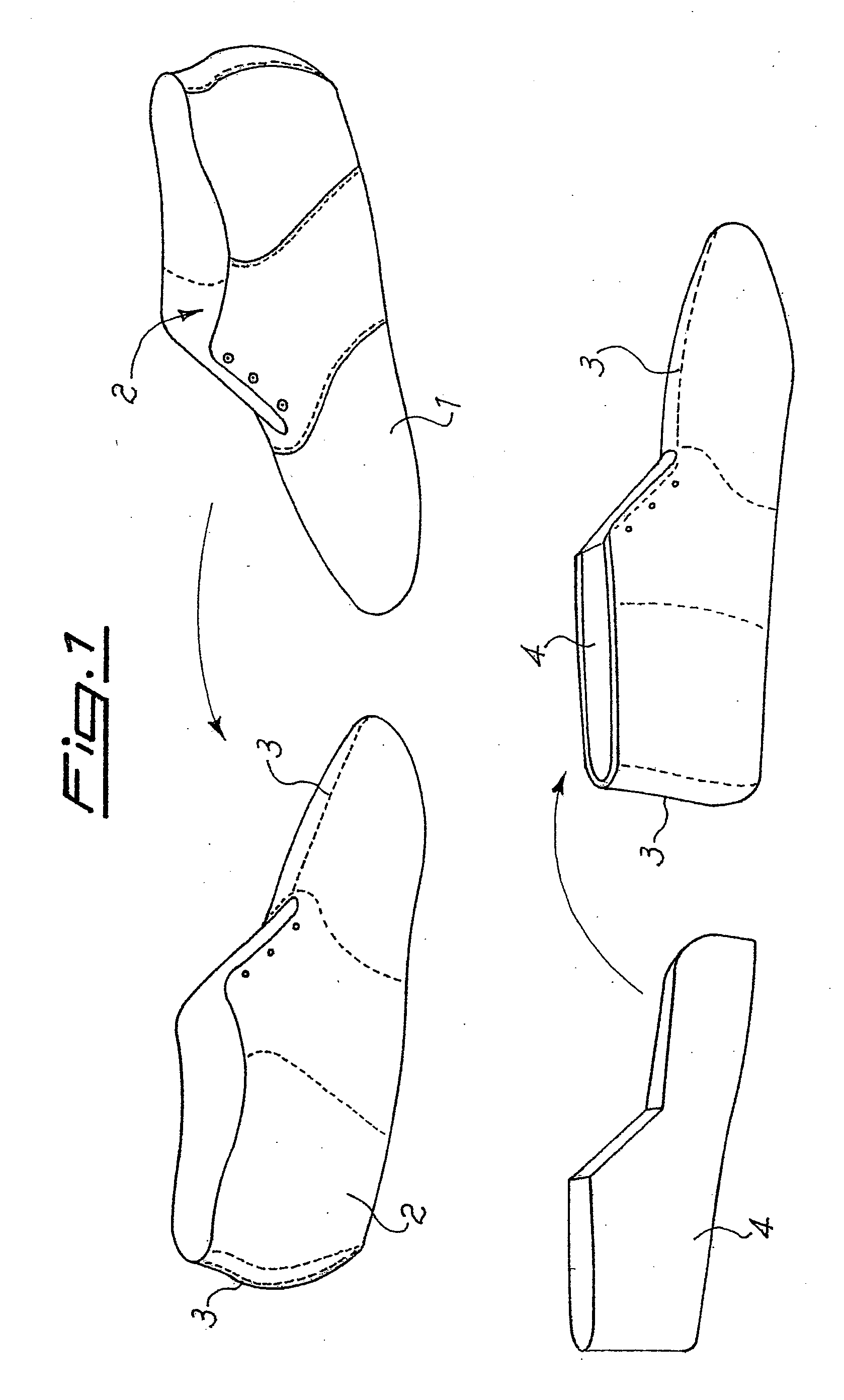

Production and visualisation of garments

InactiveUS20040049309A1Special data processing applicationsClothes making applicancesSoftware engineeringMechanical engineering

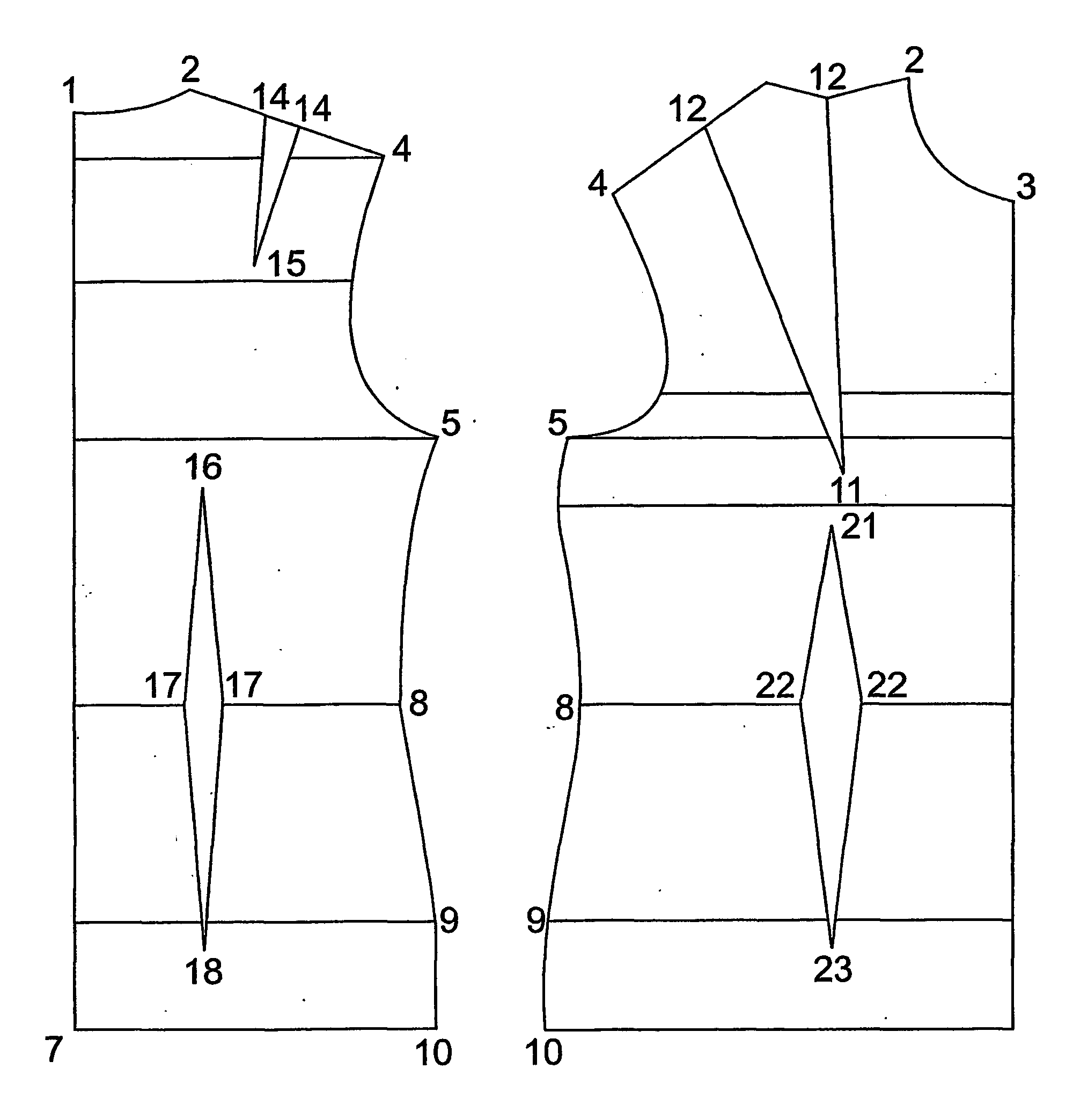

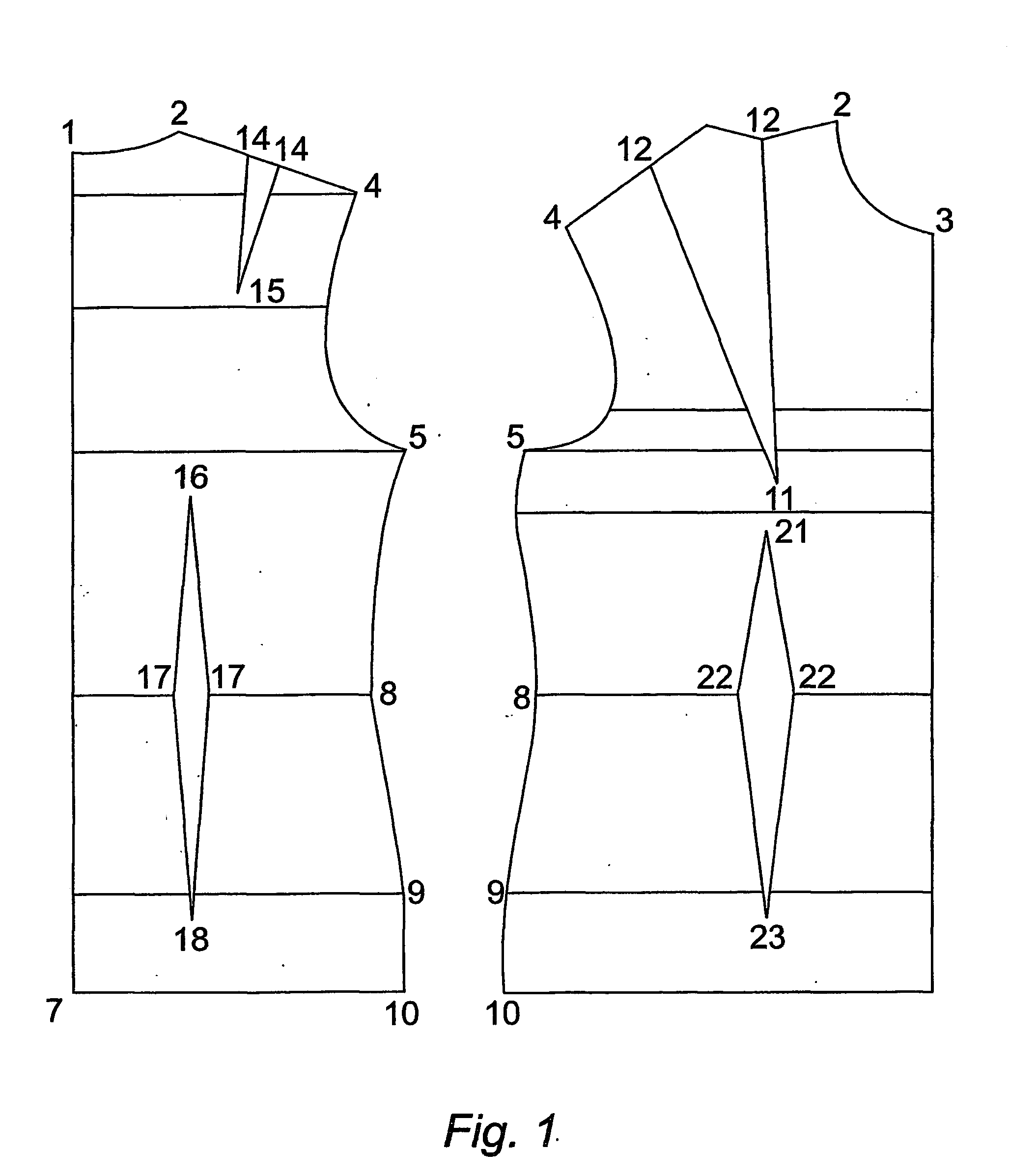

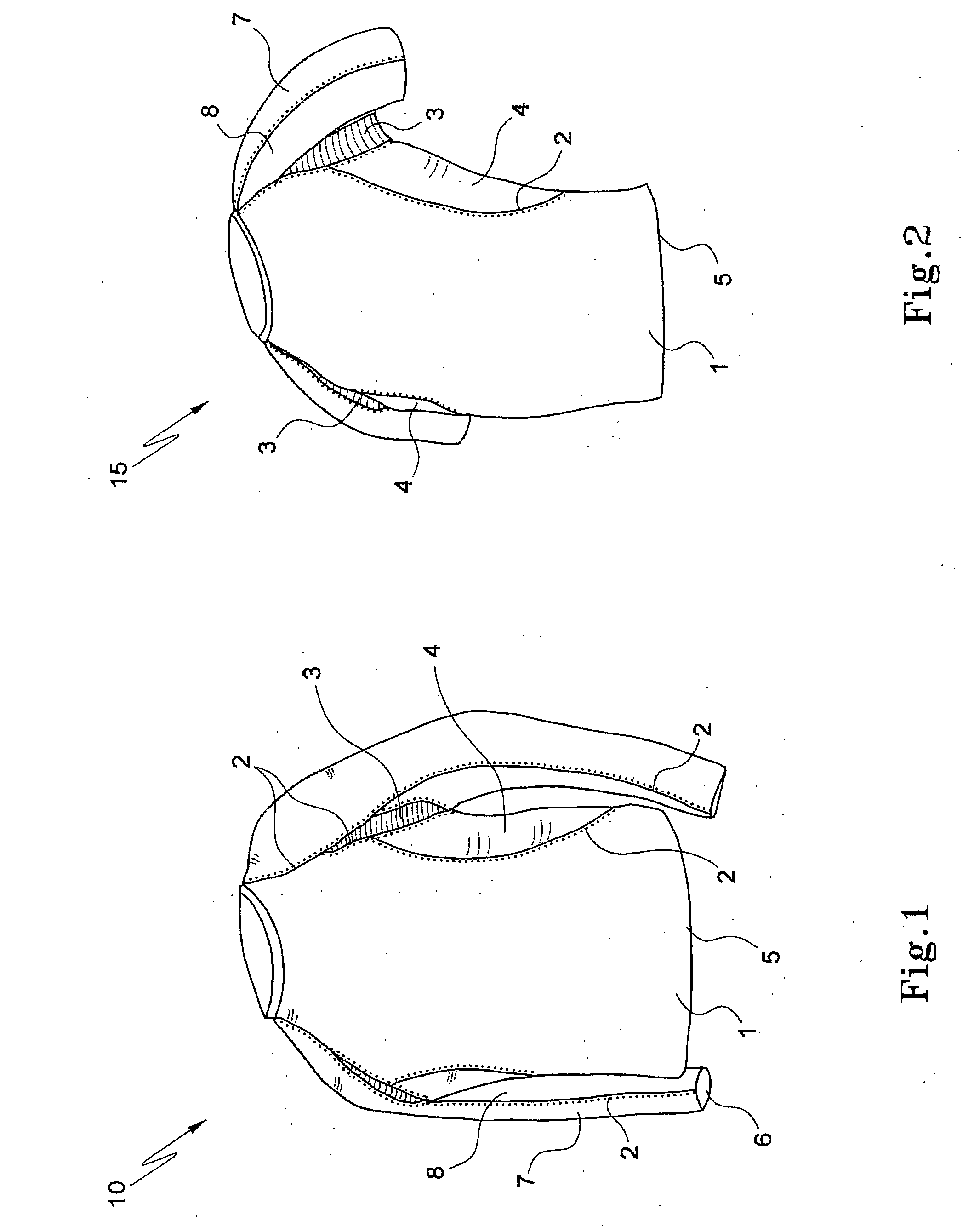

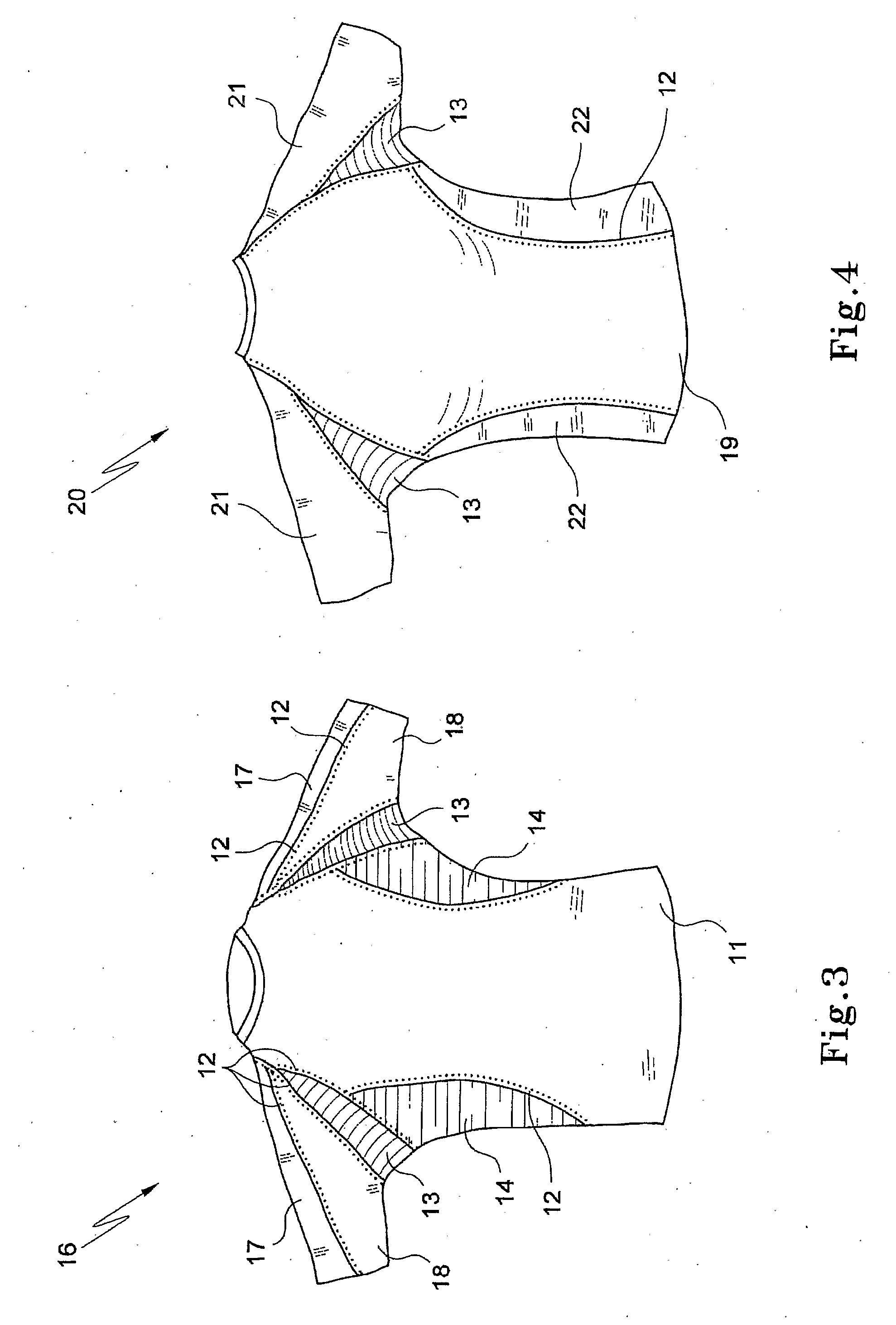

Methods and systems for modelling and modifying garments, providing a basis for integrated "virtual tailoring" systems and processes. The garment models provided relate specific design points of the garment to specific body regions in terms of explicit 3D relationship rules, enabling garments to be modified holistically, by a constrained 3D warp process, to fit different body shapes / sizes, either in order to generate a range of graded sizes or made-to-measure garments, for the purposes of visualization and / or garment production. The methods described further facilitate the generation of 2D pattern pieces by flattening 3D representations of modified garments using a constrained internal energy minimization process, in a manner that ensures that the resulting pattern pieces can be assembled in substantially the same way as those of the base garment. The methods enable the visualisation and / or production of bespoke or graded garments, and garment design modifications, within an integrated virtual tailoring environment.

Owner:VIRTUAL MIRRORS

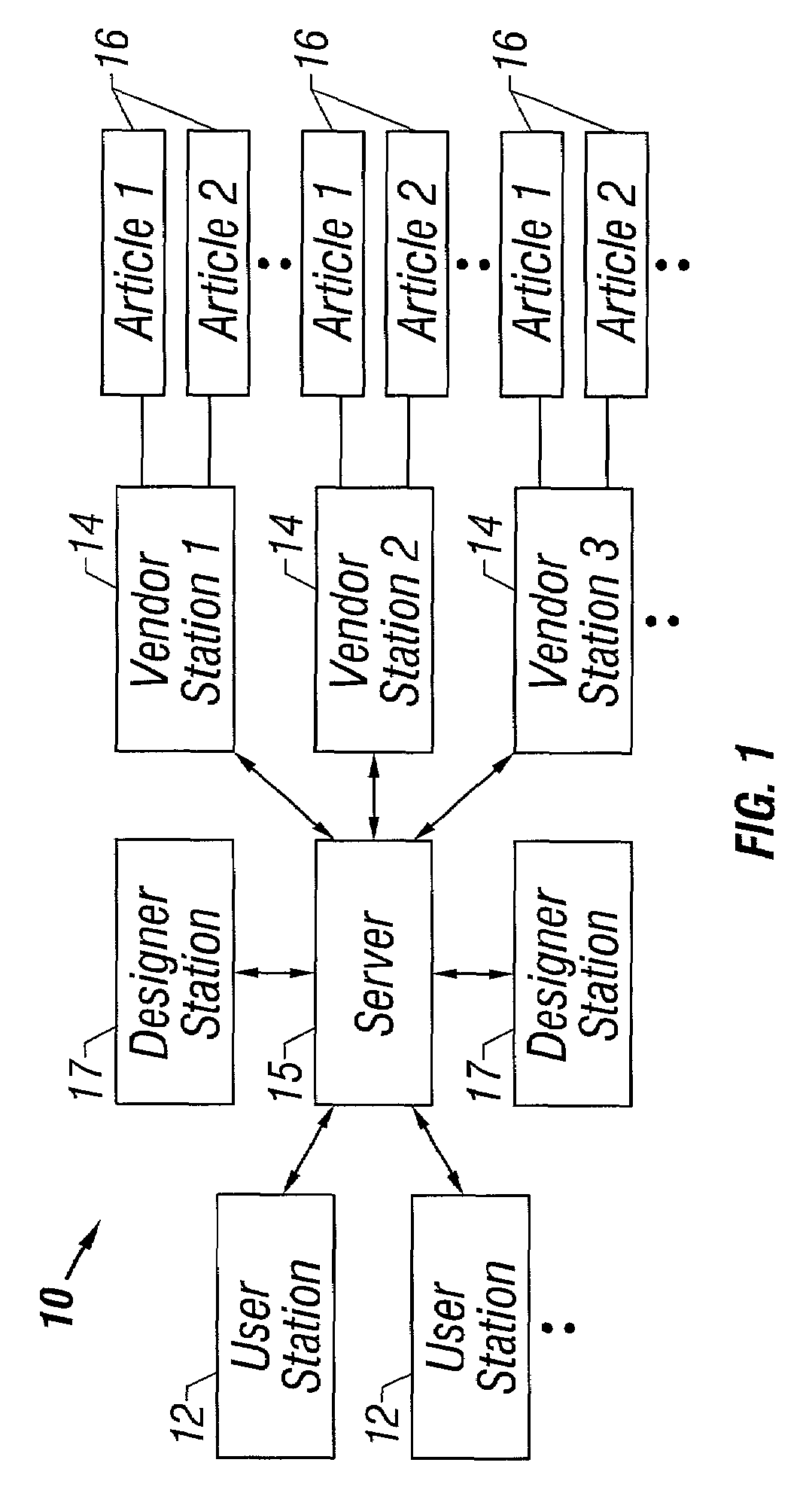

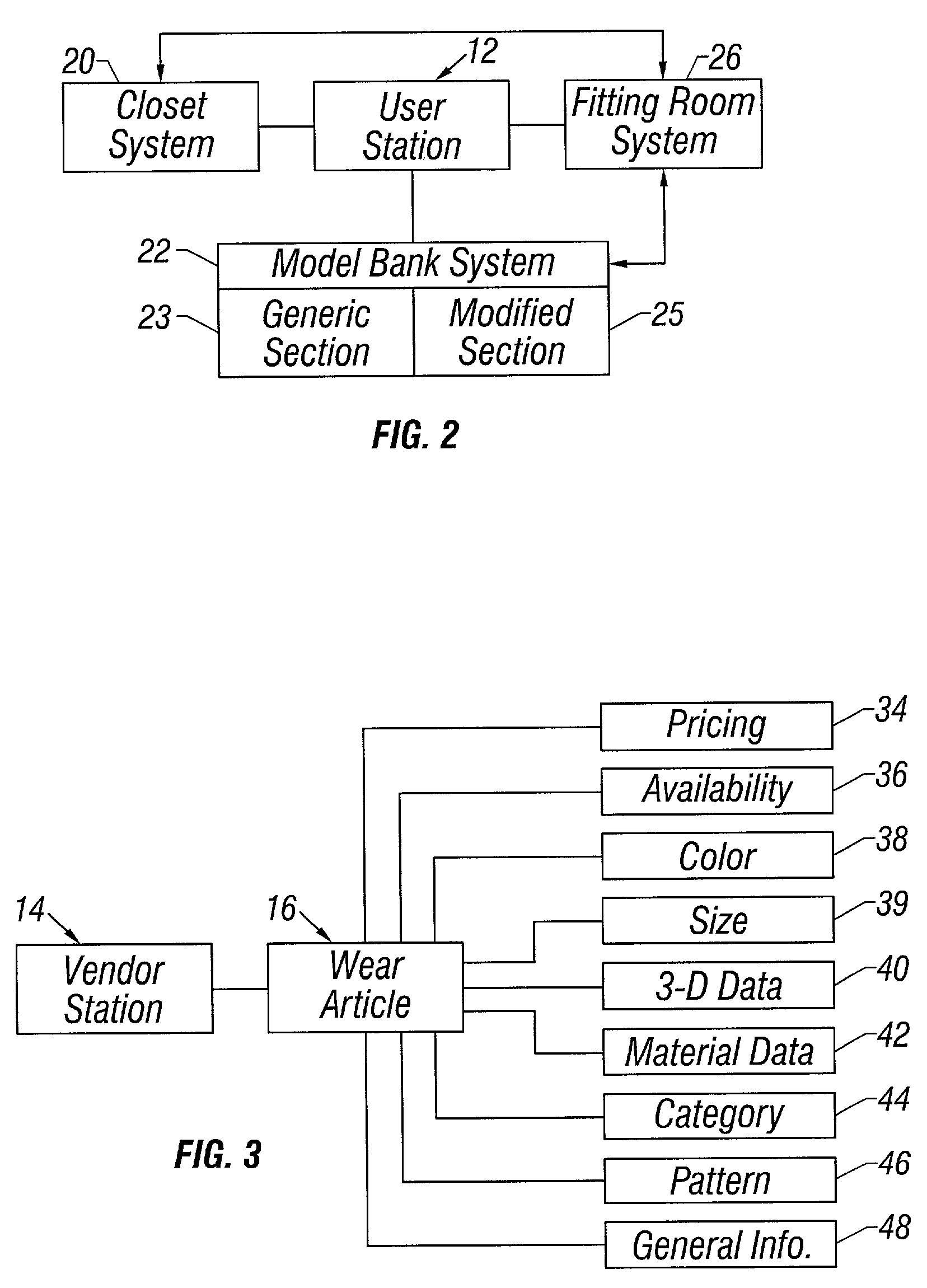

System and method for simulation of virtual wear articles on virtual models

InactiveUS7149665B2Reduce and eliminate needEasy to viewCathode-ray tube indicatorsComputation using non-denominational number representationMaterial typeComputer science

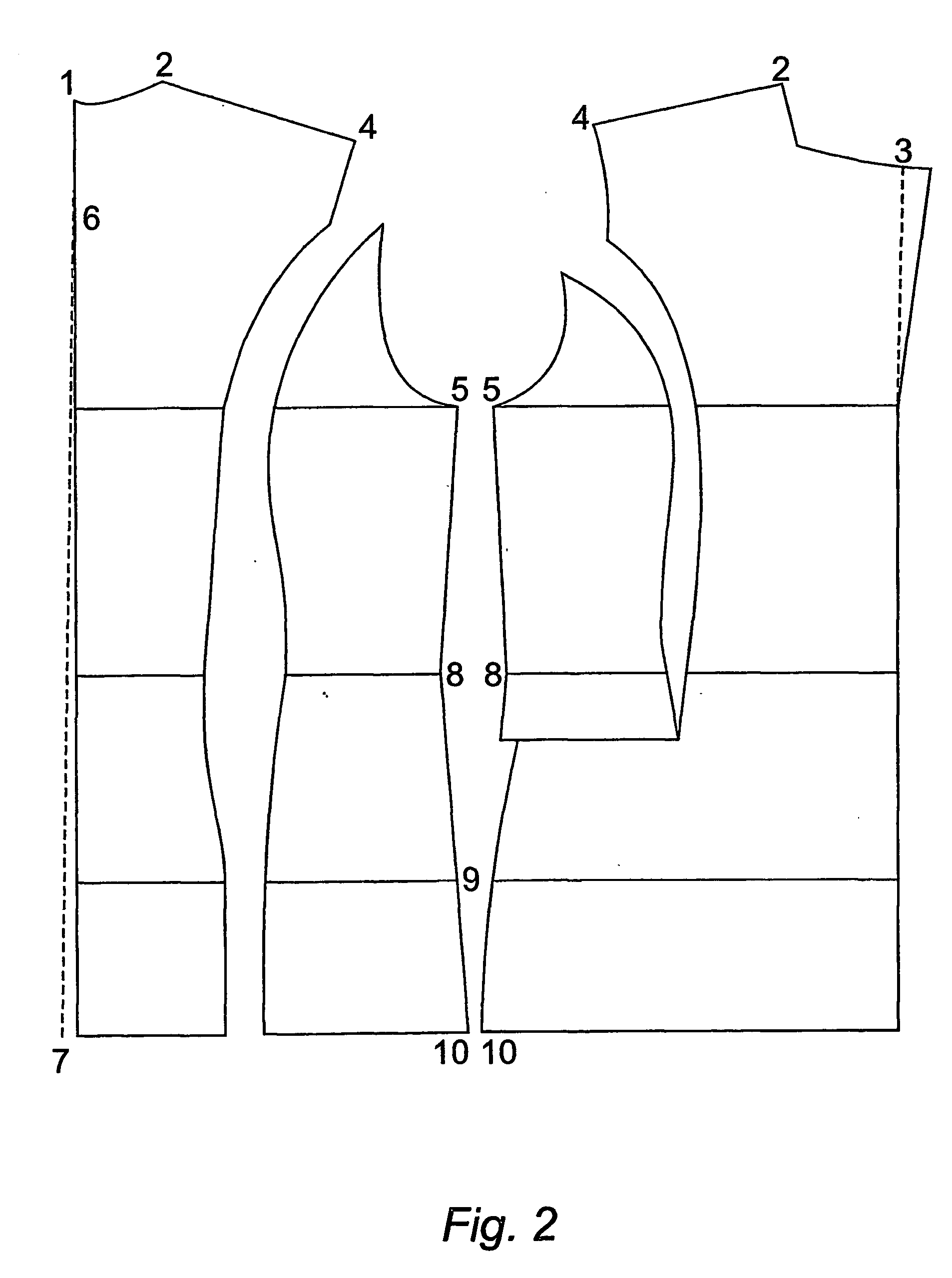

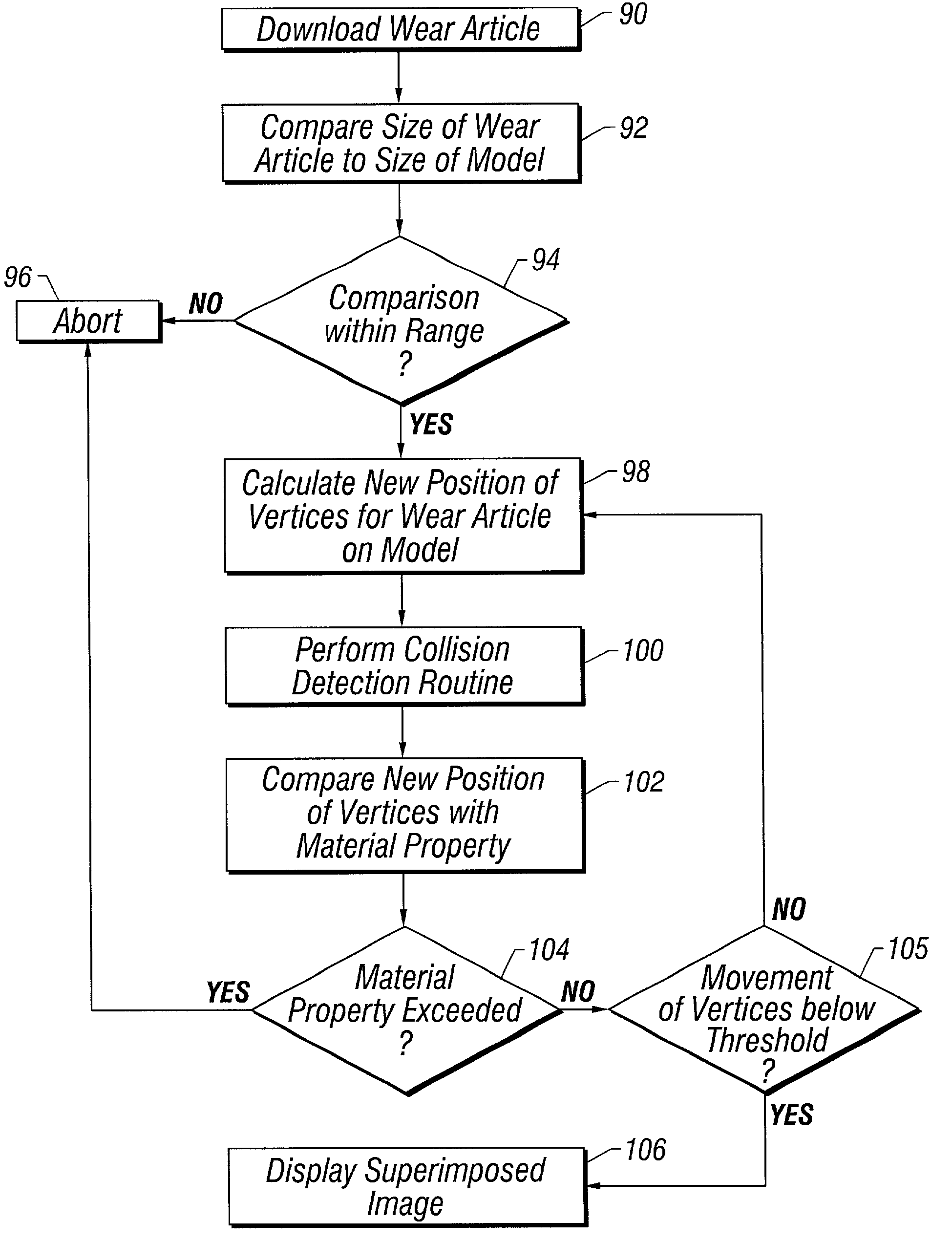

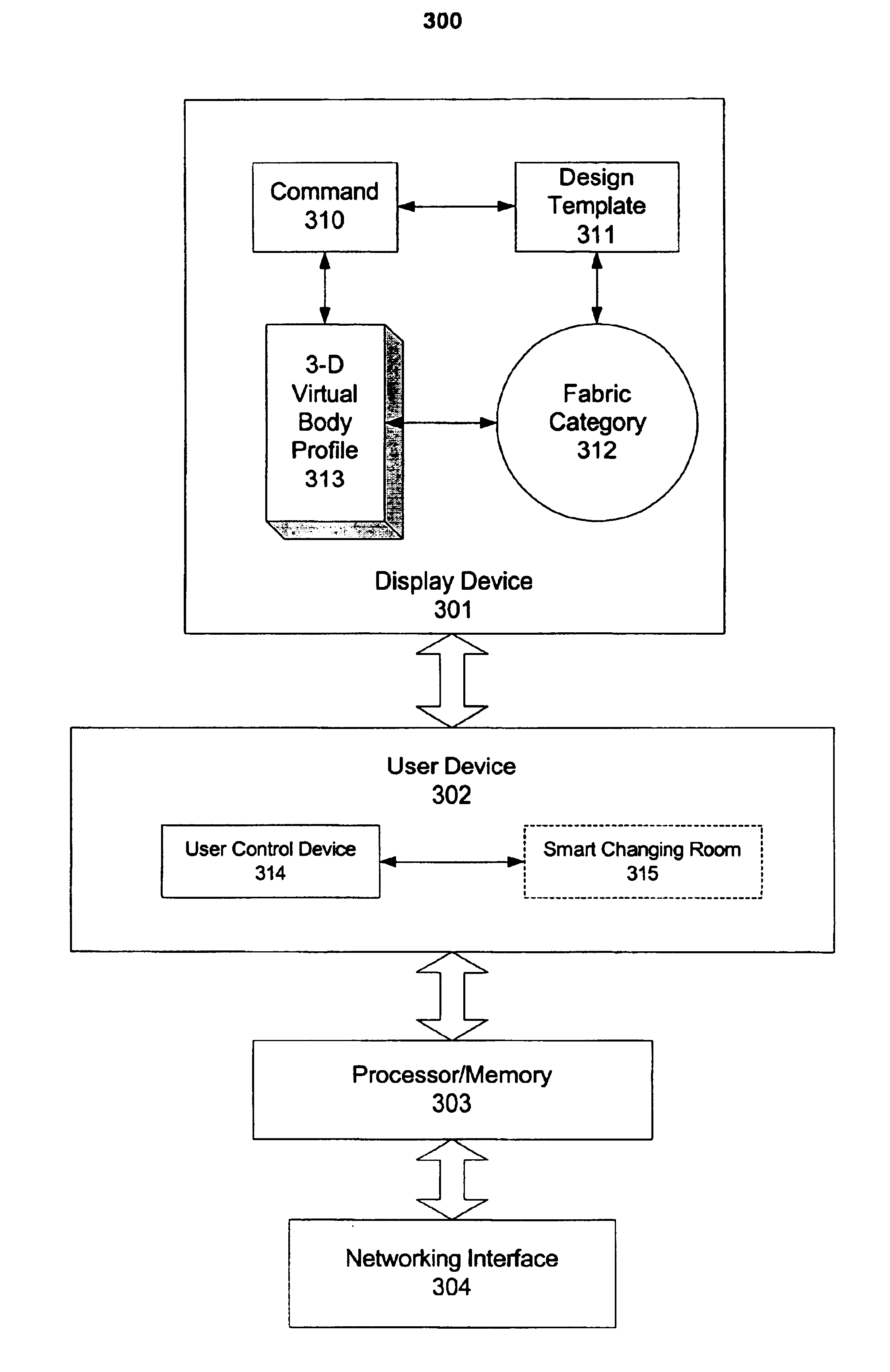

A system and method for designing a wear article for an object comprises providing a virtual three-dimensional model of the object, including first data representing three dimensions of the object. Virtual two-dimensional patterns representing different portions of the wear article are assembled into a virtual three-dimensional wear article. The virtual three-dimensional wear article includes second data representing three dimensions of the wear article. A material type is associated with one or more of the virtual patterns and the virtual three-dimensional wear article. The material type has third data representing at least one physical property of the material type. In order to display the virtual three-dimensional wear article on the virtual three-dimensional model, the first and second data are compared to determine the non-intersection of the virtual three-dimensional wear article with the virtual three-dimensional object. The virtual three-dimensional wear article is then conformed to the virtual three-dimensional model within constraints imposed by the third data. With this arrangement, the system and method enables the virtual wear article to stretch, flex, sag, etc., on the virtual model to better approximate the real-life fit and look of the wear article on an object during design of the wear article.

Owner:BROWZWEAR SOLUTIONS

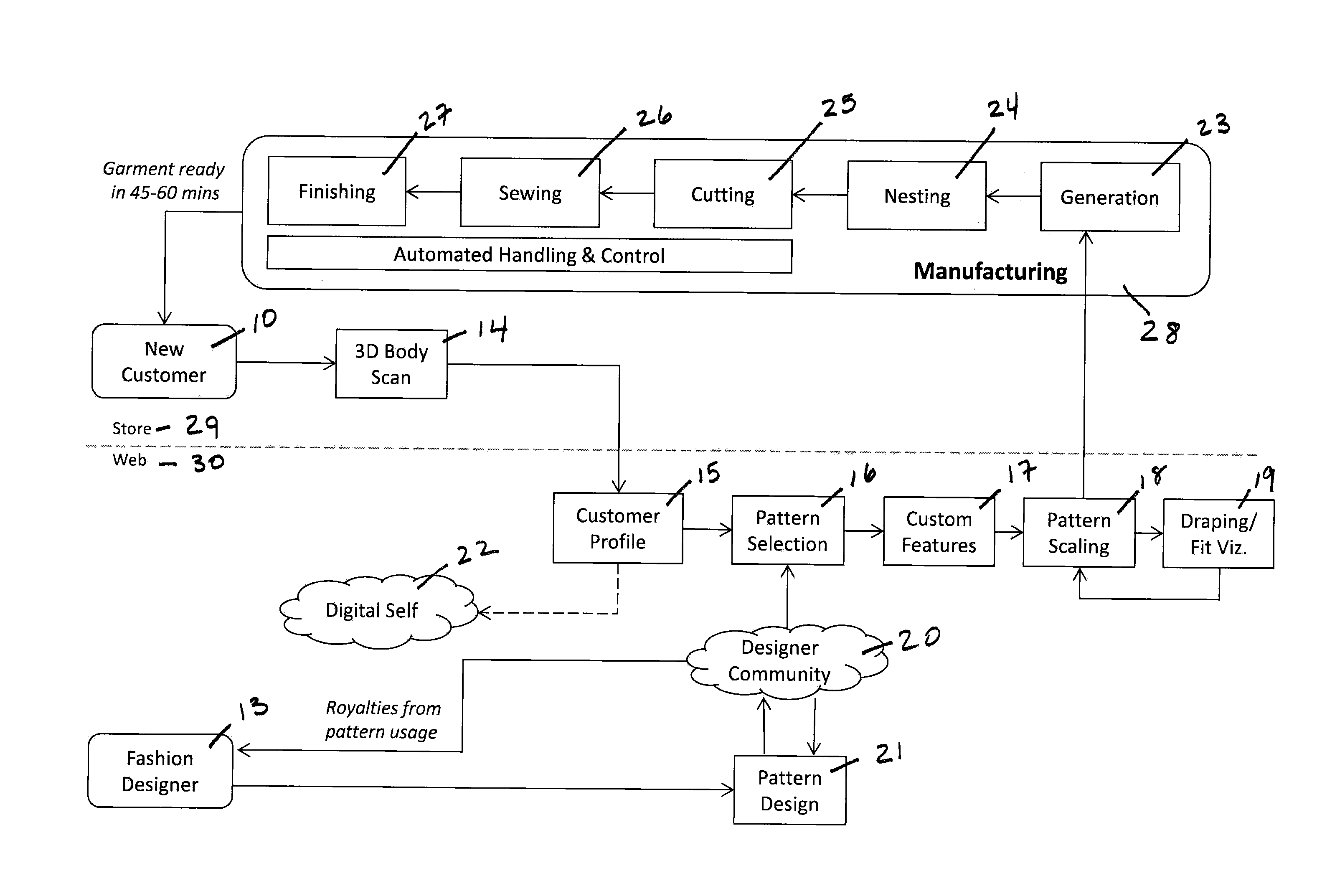

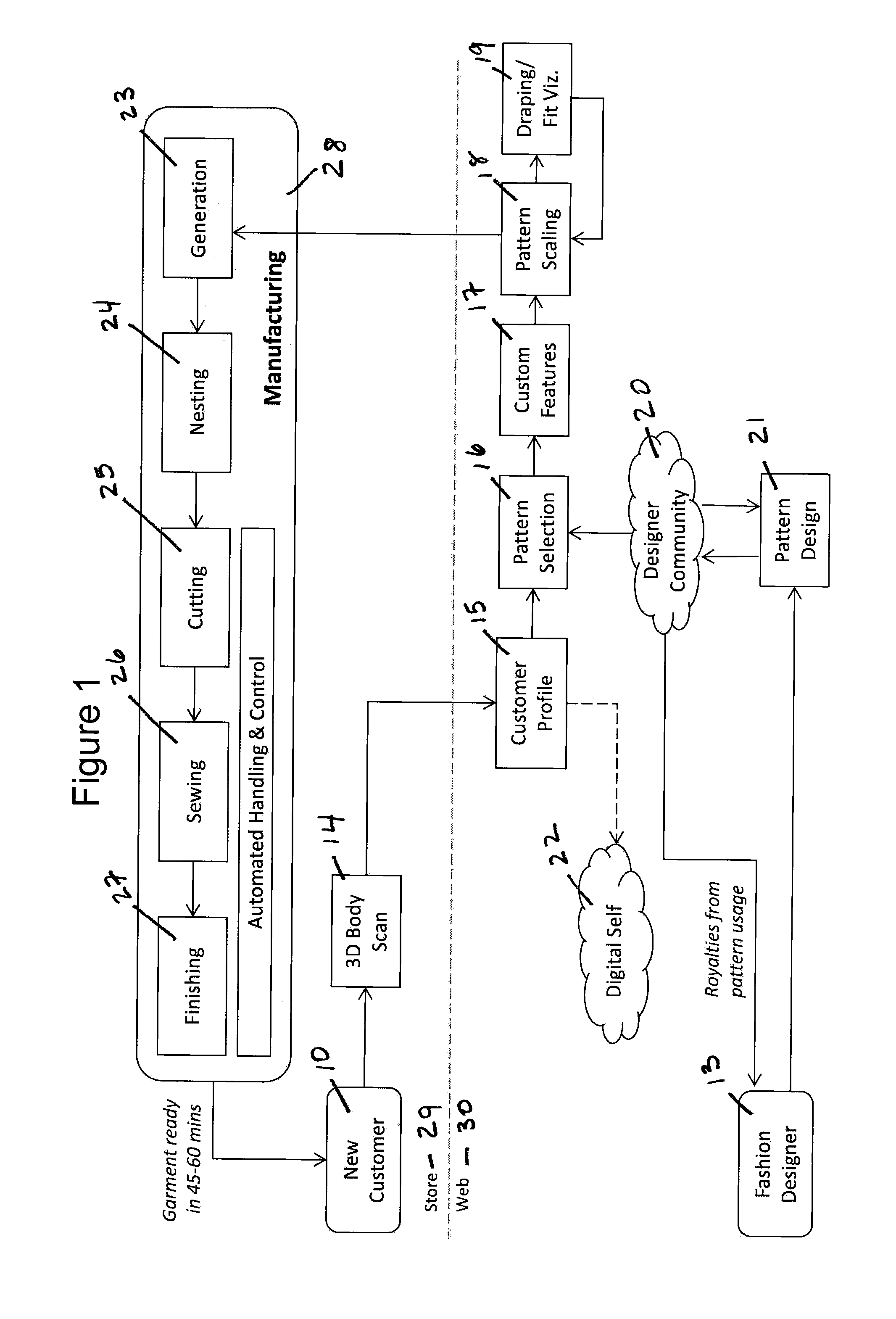

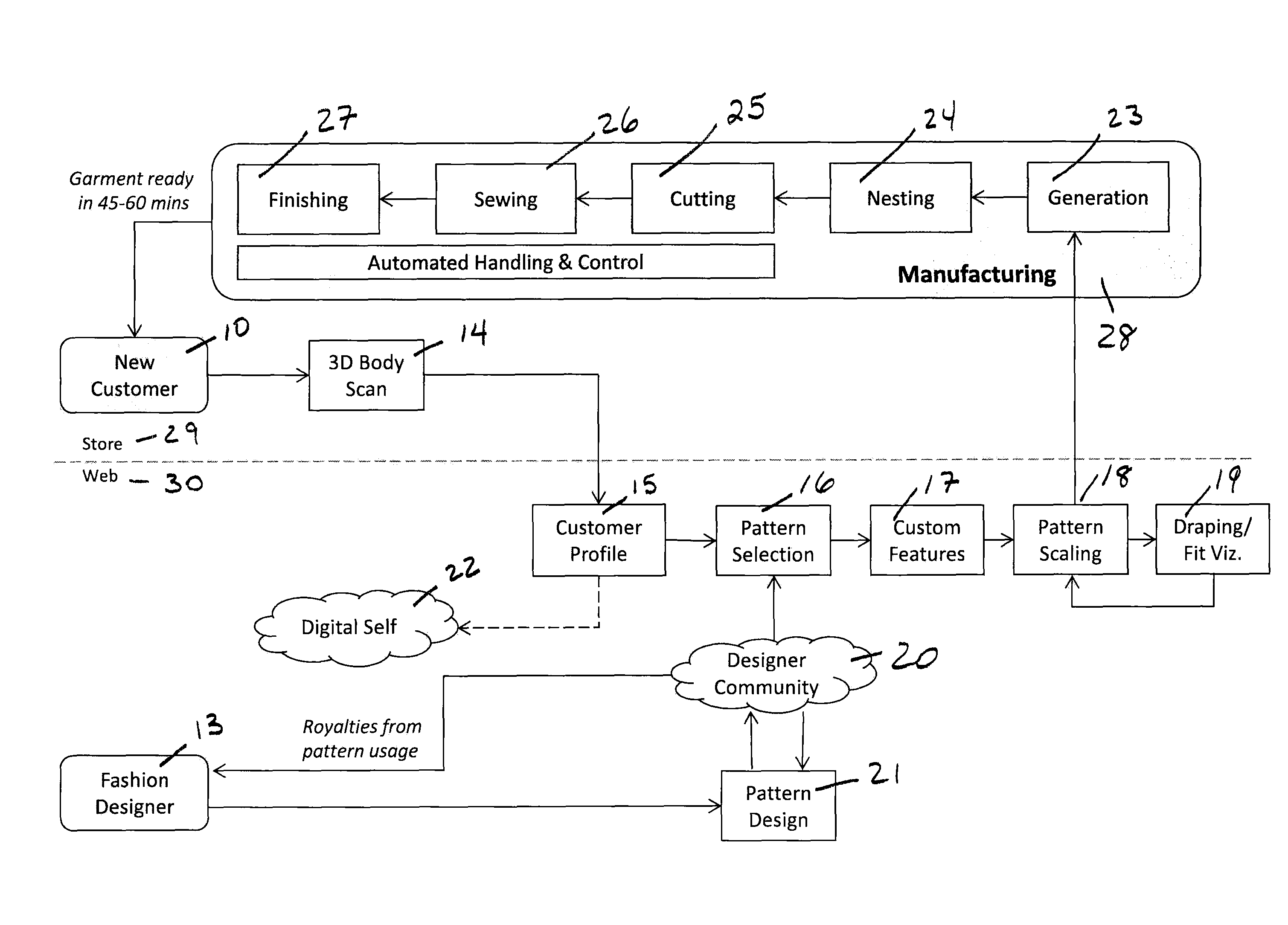

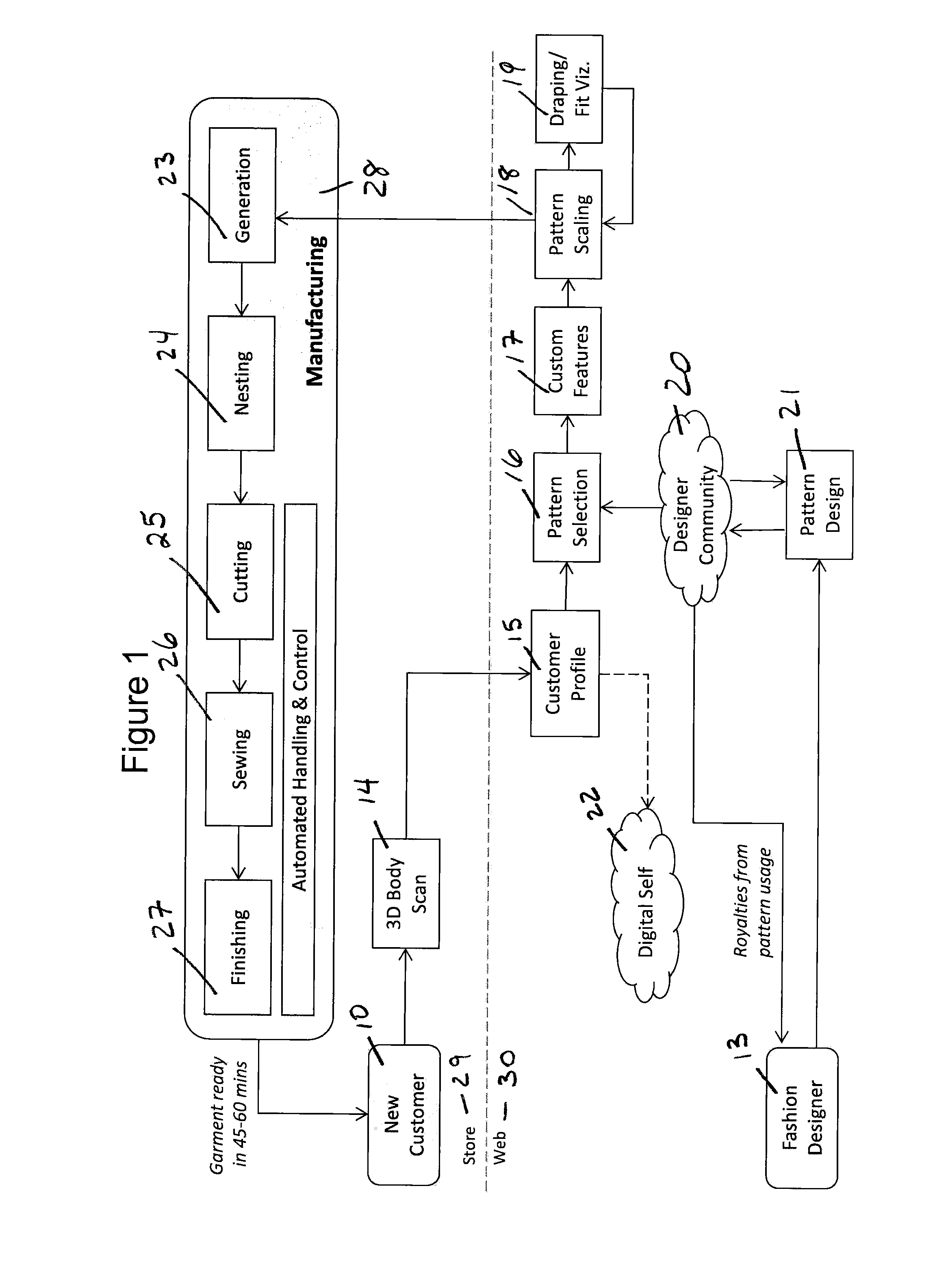

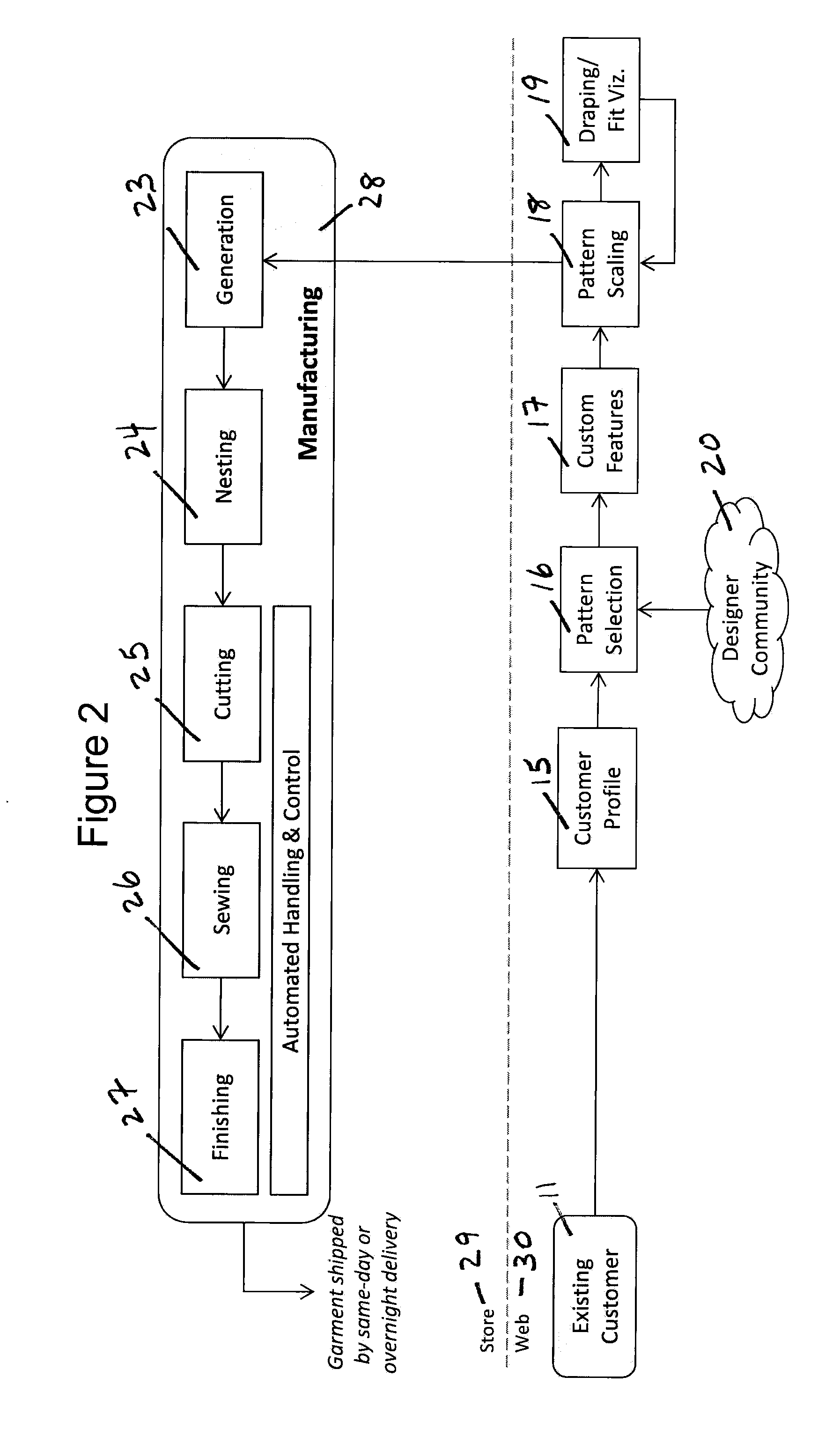

System and Method for Creating Custom-Fit Apparel Designs

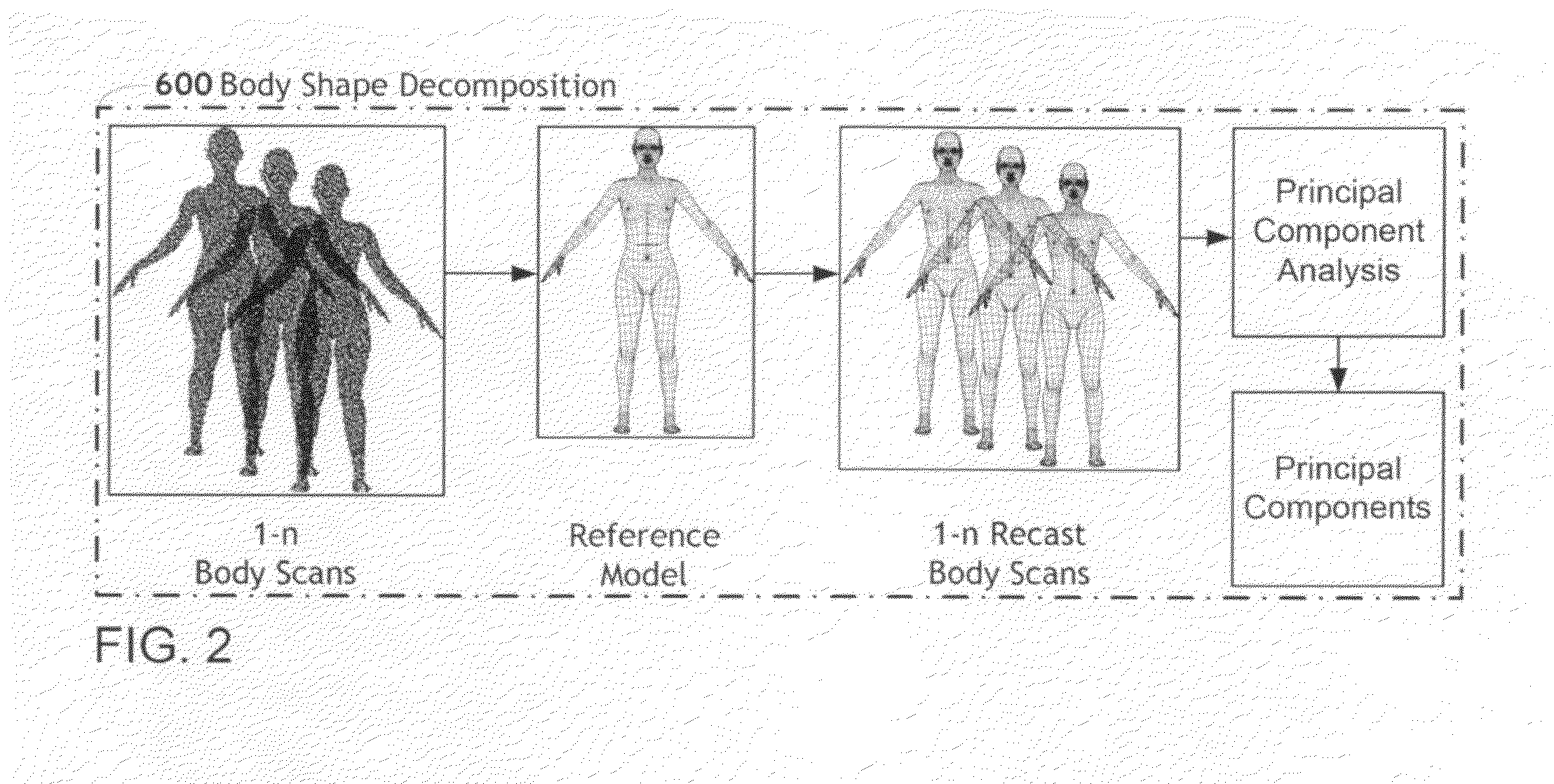

InactiveUS20140277663A1Rapid visualizationShort amount of timeCommerceComputer aided designBody shapePersonalization

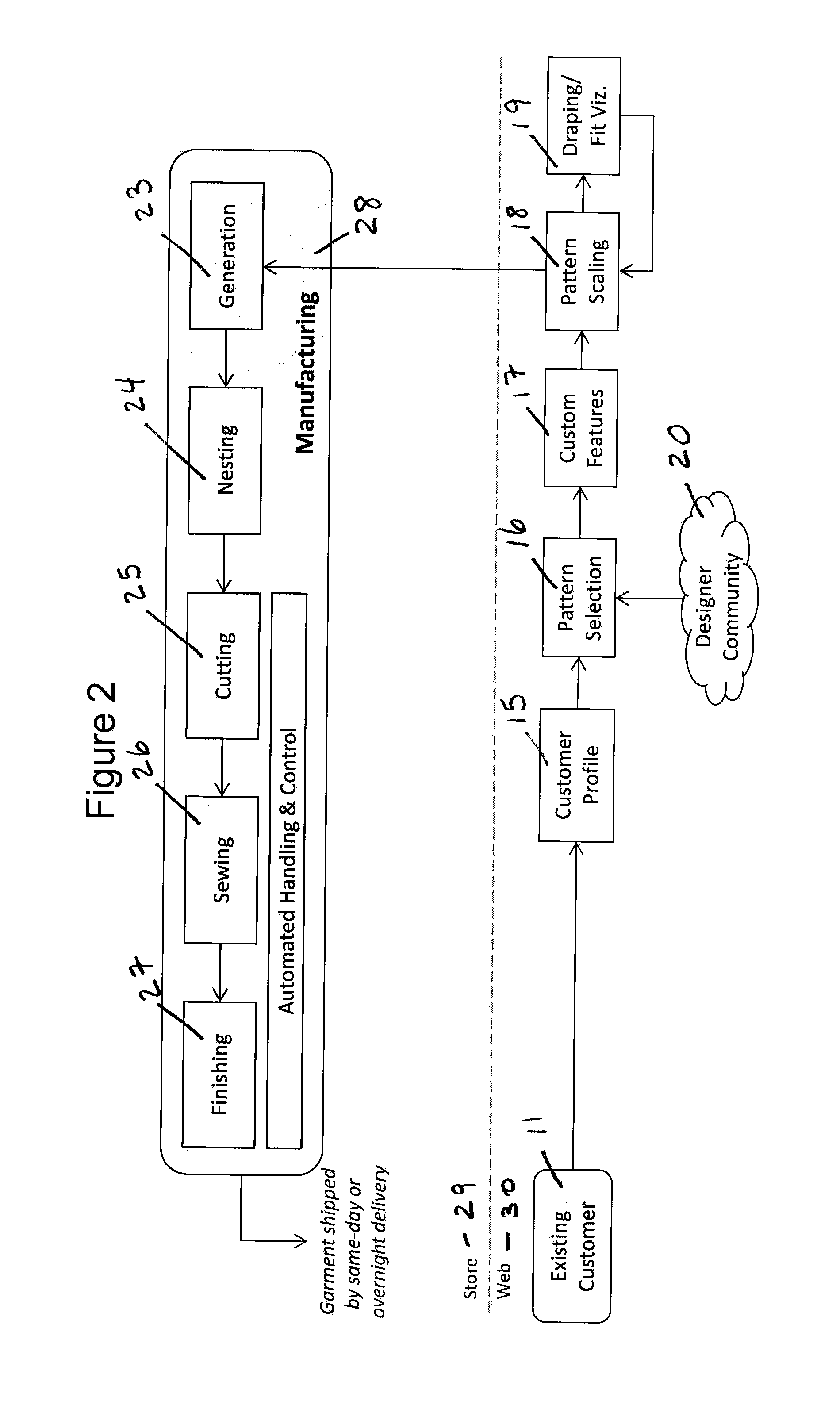

An automated system for the production of a personalized custom-fit garment comprises a scanner for obtaining a three-dimensional model of a customer's body shape; a computer having non-transitory computer algorithms for scaling a digital design to the customer's body shape, customizing the digital pattern with the customer's fit and style preferences, and visualizing the drape and fit of the garment; a database comprising a set of digital design patterns; and an automated garment manufacturing system networked to a central controller. A method for creating a personalized custom-fit garment comprises obtaining three-dimensional body measurements of a customer, having the customer select and customize a particular garment design, and manufacturing the personalized garment using an automated manufacturing process. The system and method can be used to prepare any kind of garments without substantive manual intervention or touch labor.

Owner:3D TECH LLC

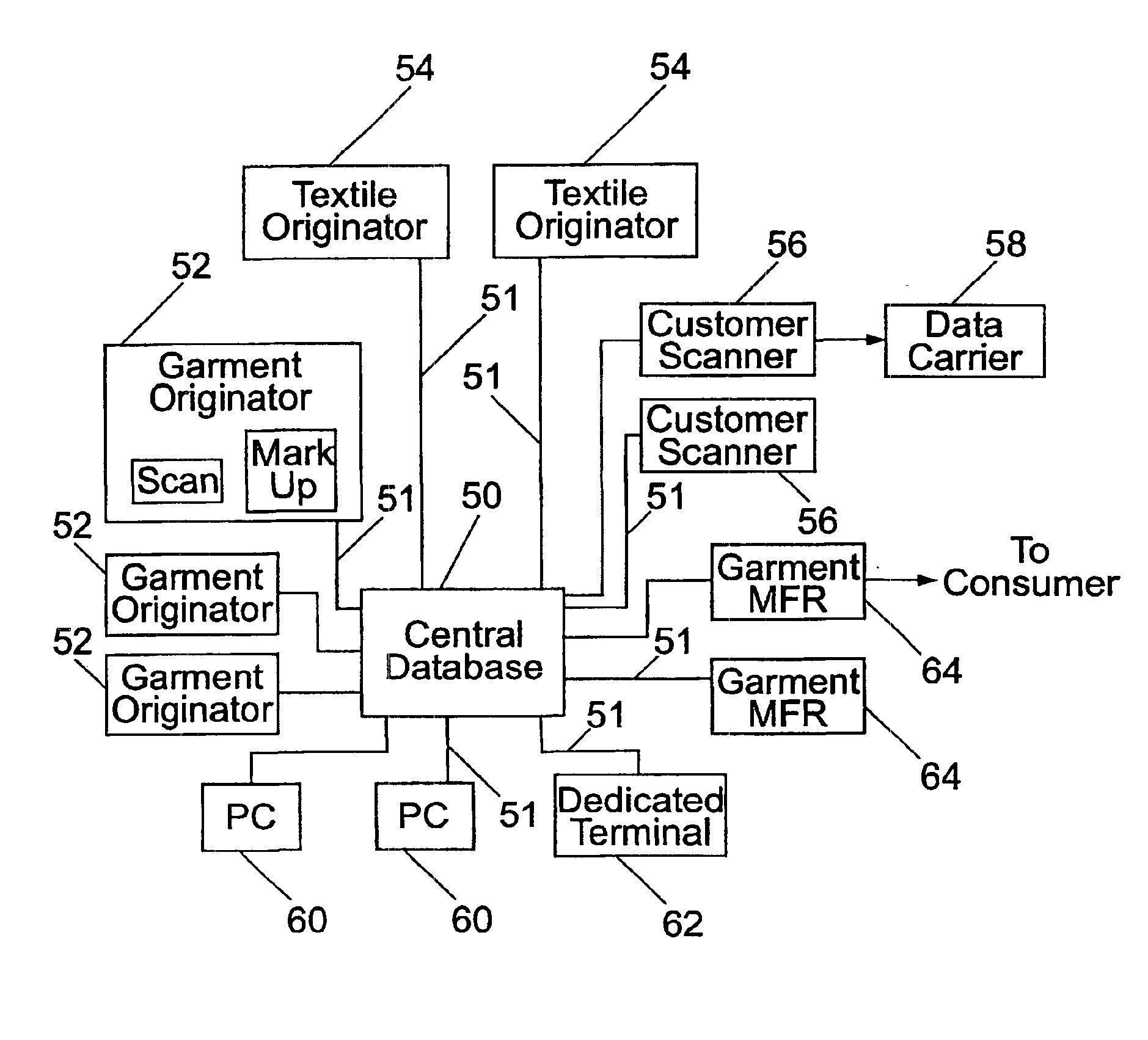

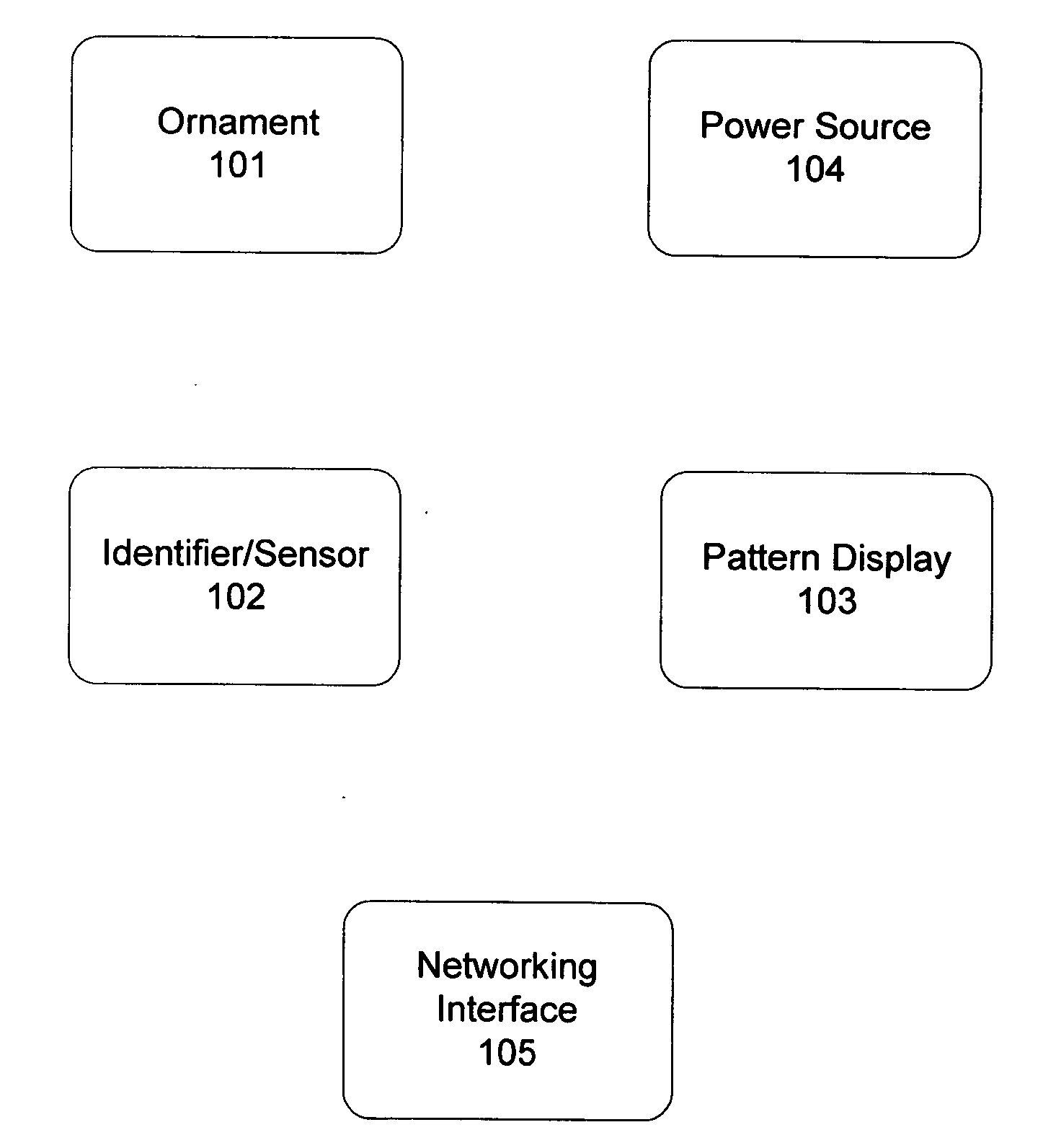

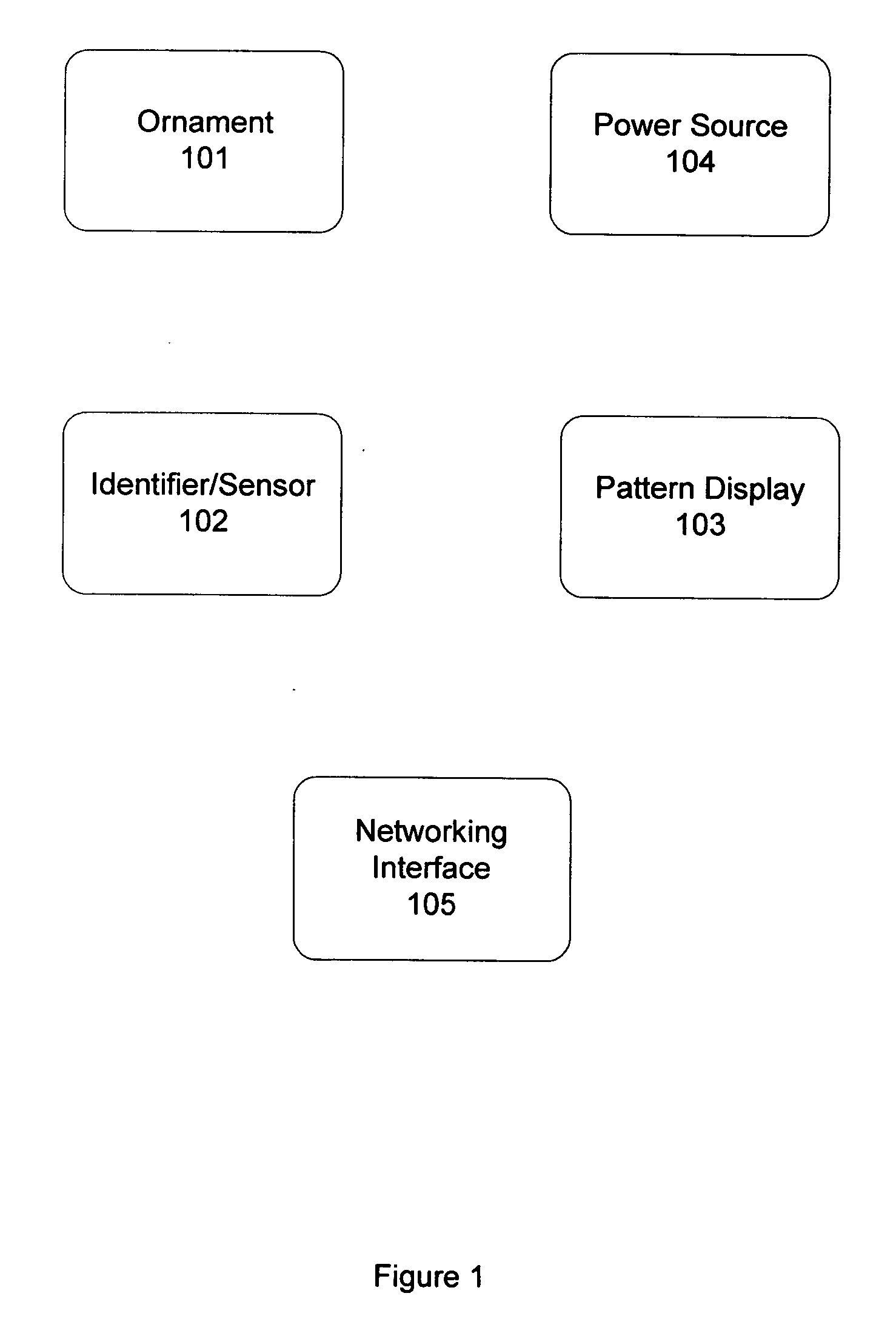

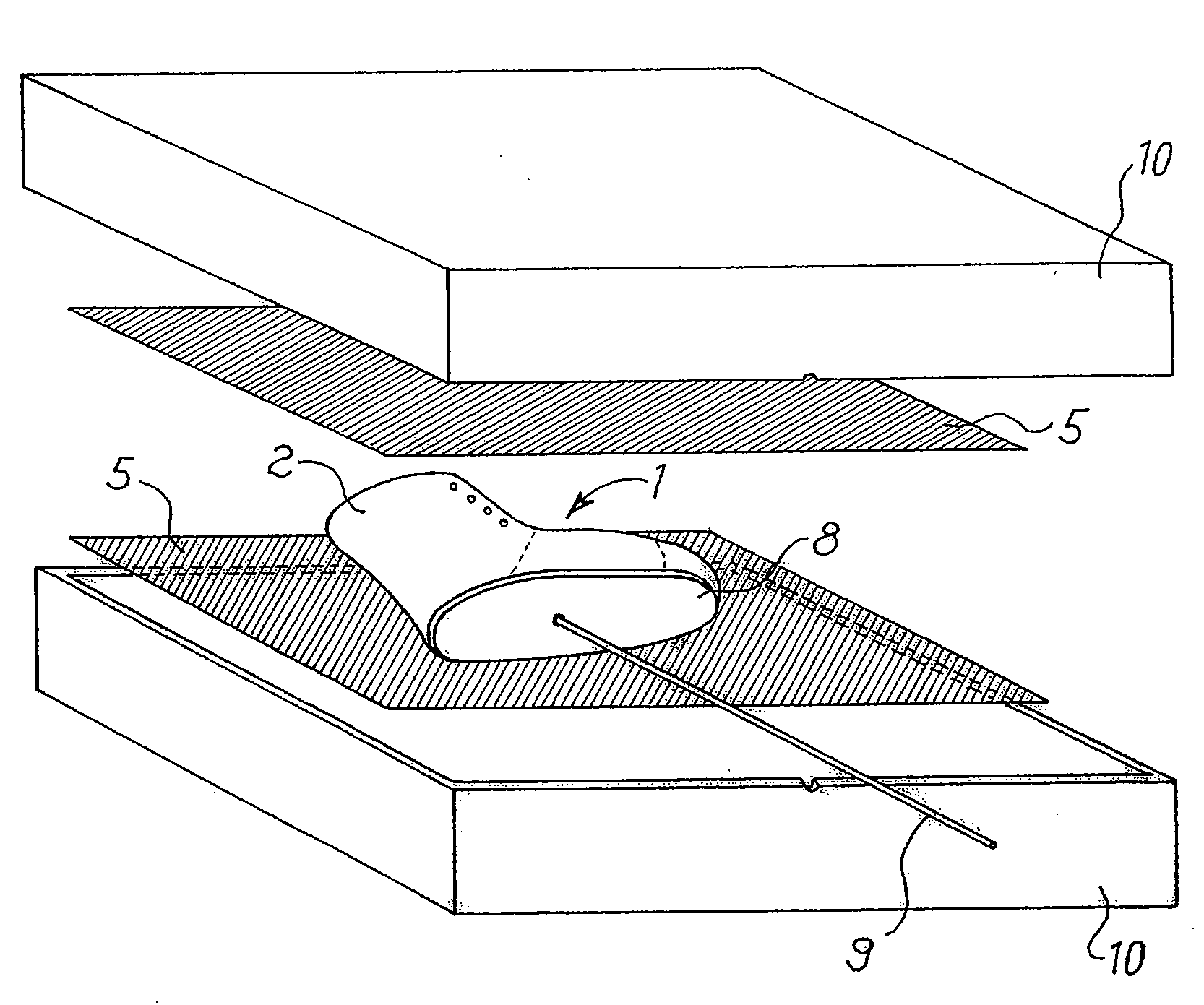

Reconfigurable garment definition and production method

InactiveUS6882897B1Efficient integrationSimple designGarmentsSurgeryLine sensorComputer Aided Design

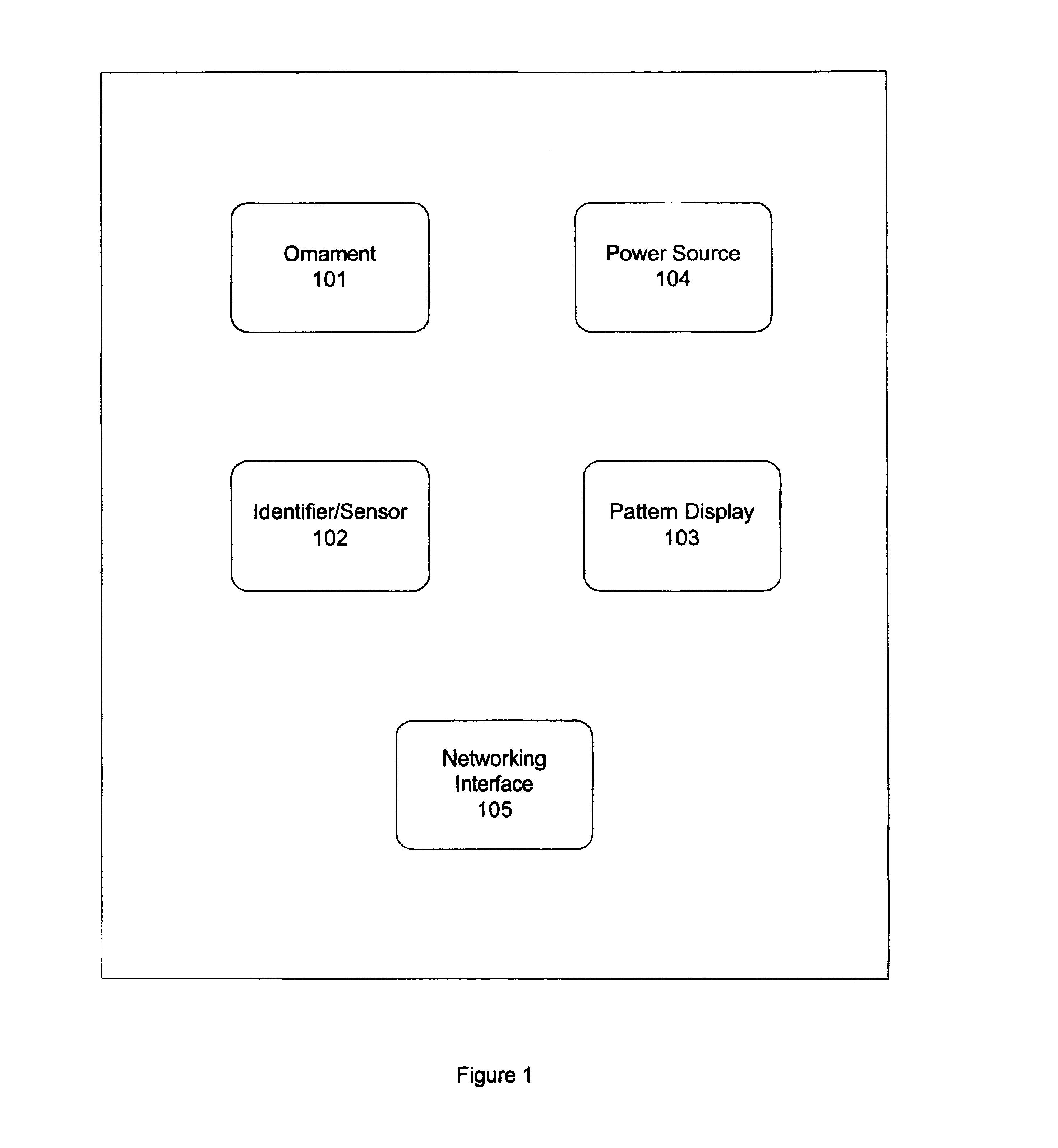

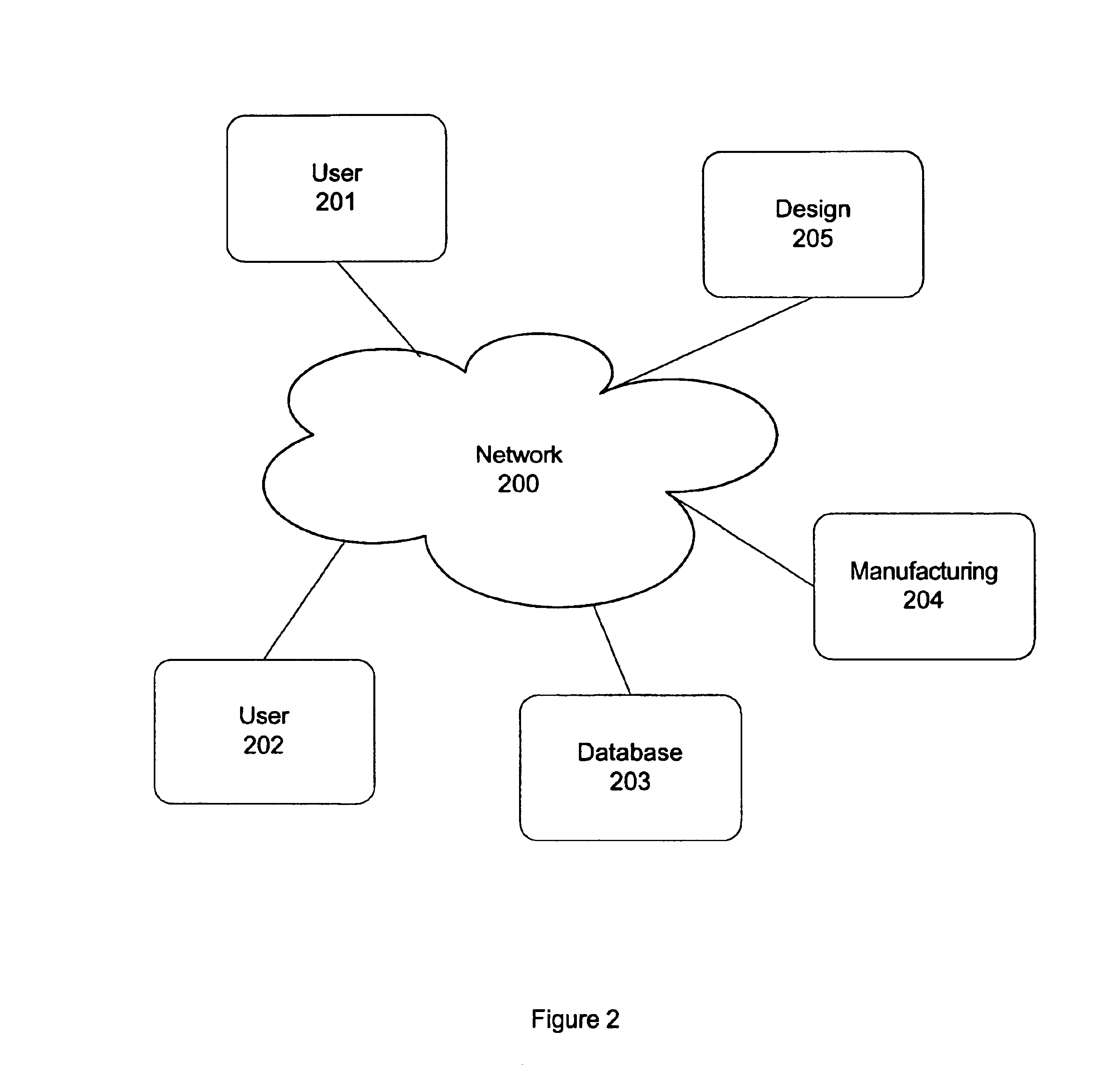

Computer-aided design and manufacture software and hardware automate garment and fashion definition and production. Configurable garment includes ornamental element, pattern display, and personal identifier and wireless sensor electronics.

Owner:FERNANDEZ DENNIS S

Production and visualization of garments

InactiveUS6907310B2Special data processing applicationsClothes making applicancesBody shapeEnergy minimization

Methods and systems for modelling and modifying garments, providing a basis for integrated “virtual tailoring” systems and processes. The garment models provided relate specific design points of the garment to specific body regions in terms of explicit 3D relationship rules, enabling garments to be modified holistically, by a constrained 3D warp process, to fit different body shapes / sizes, either in order to generate a range of graded sizes or made-to-measure garments, for the purposes of visualization and / or garment production. The methods described further facilitate the generation of 2D pattern pieces by flattening 3D representations of modified garments using a constrained internal energy minimization process, in a manner that ensures that the resulting pattern pieces can be assembled in substantially the same way as those of the base garment. The methods enable the visualisation and / or production of bespoke or graded garments, and garment design modifications, within an integrated virtual tailoring environment.

Owner:VIRTUAL MIRRORS

Compression Garments And A Method Of Manufacture

The invention provides a compression garment (50) for clothing a body part, such as a lower torso and the legs. The body part includes a muscle ridge, such as a lateral edge of the gluteus maximus (49). Compression garment (50) has first and second panels of stretchable material joined by a seam (32). At least part of the seam (32) is adapted to correspond to at least part of the muscle ridge, being at the edge of the gluteus maximus (49). The invention also provides a method of manufacturing a compression garment, using an algorithm to calculate size changes to produce desired compression.

Owner:SKINS INTEMATIONAL TRADING AG

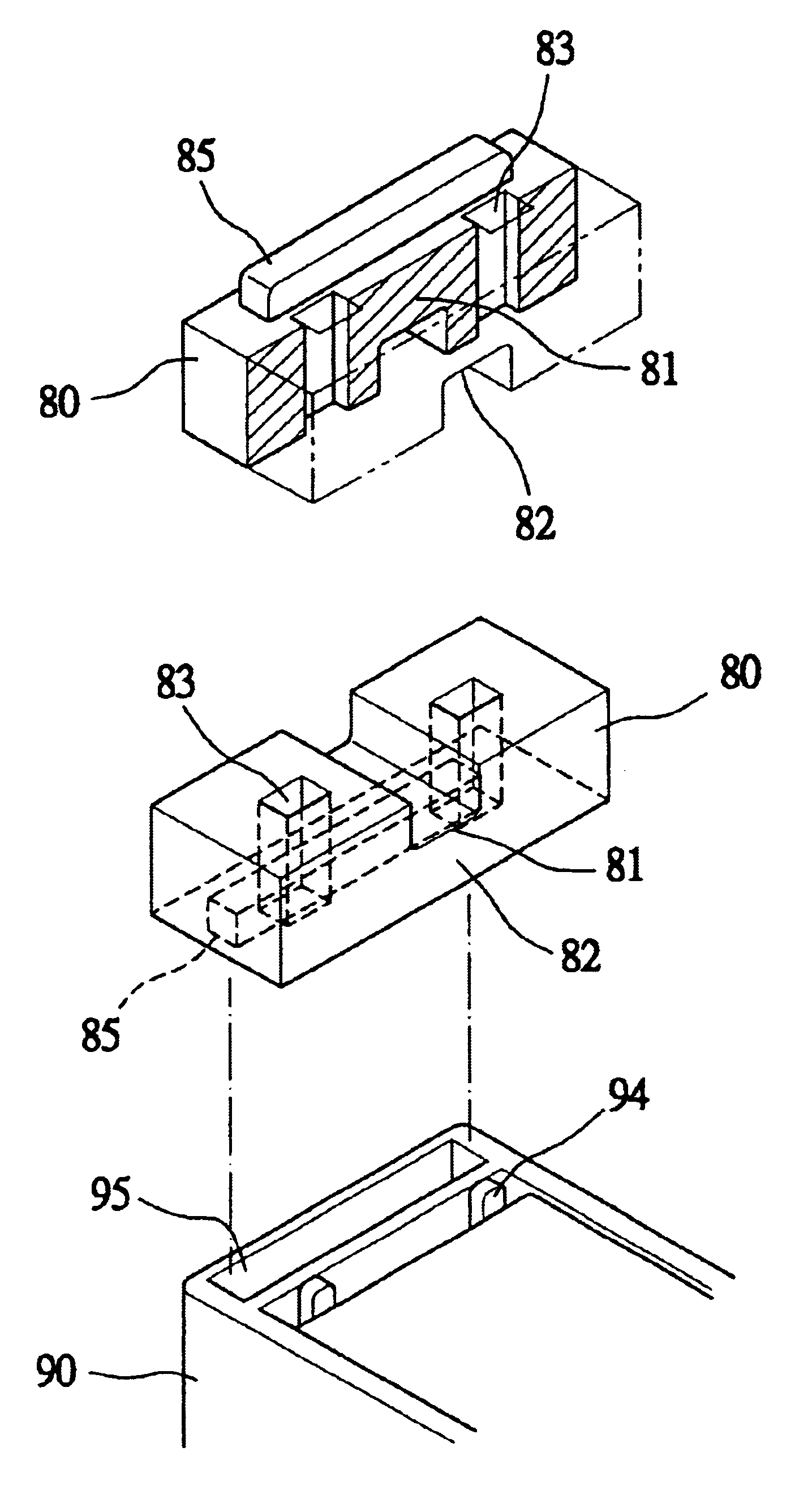

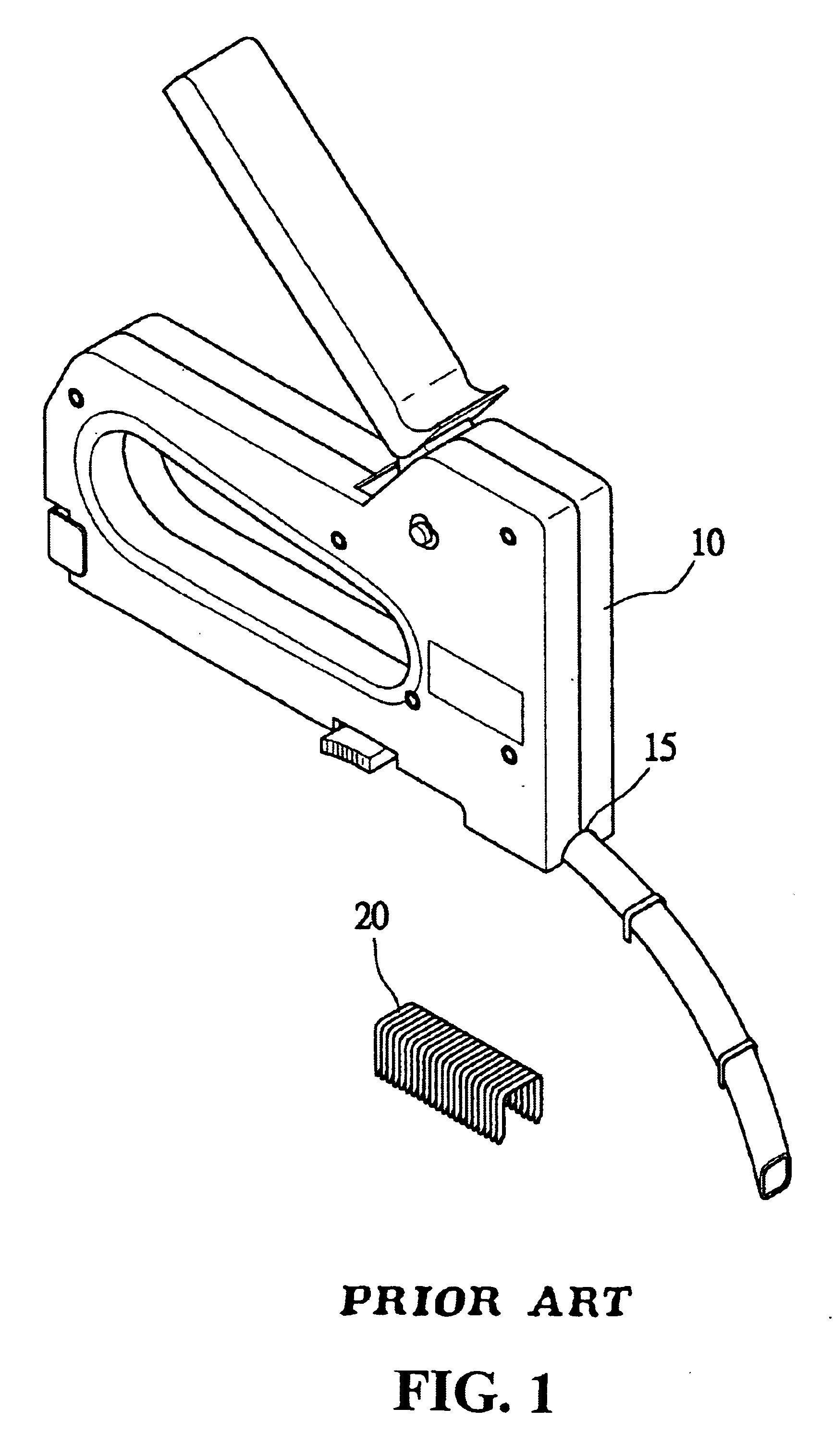

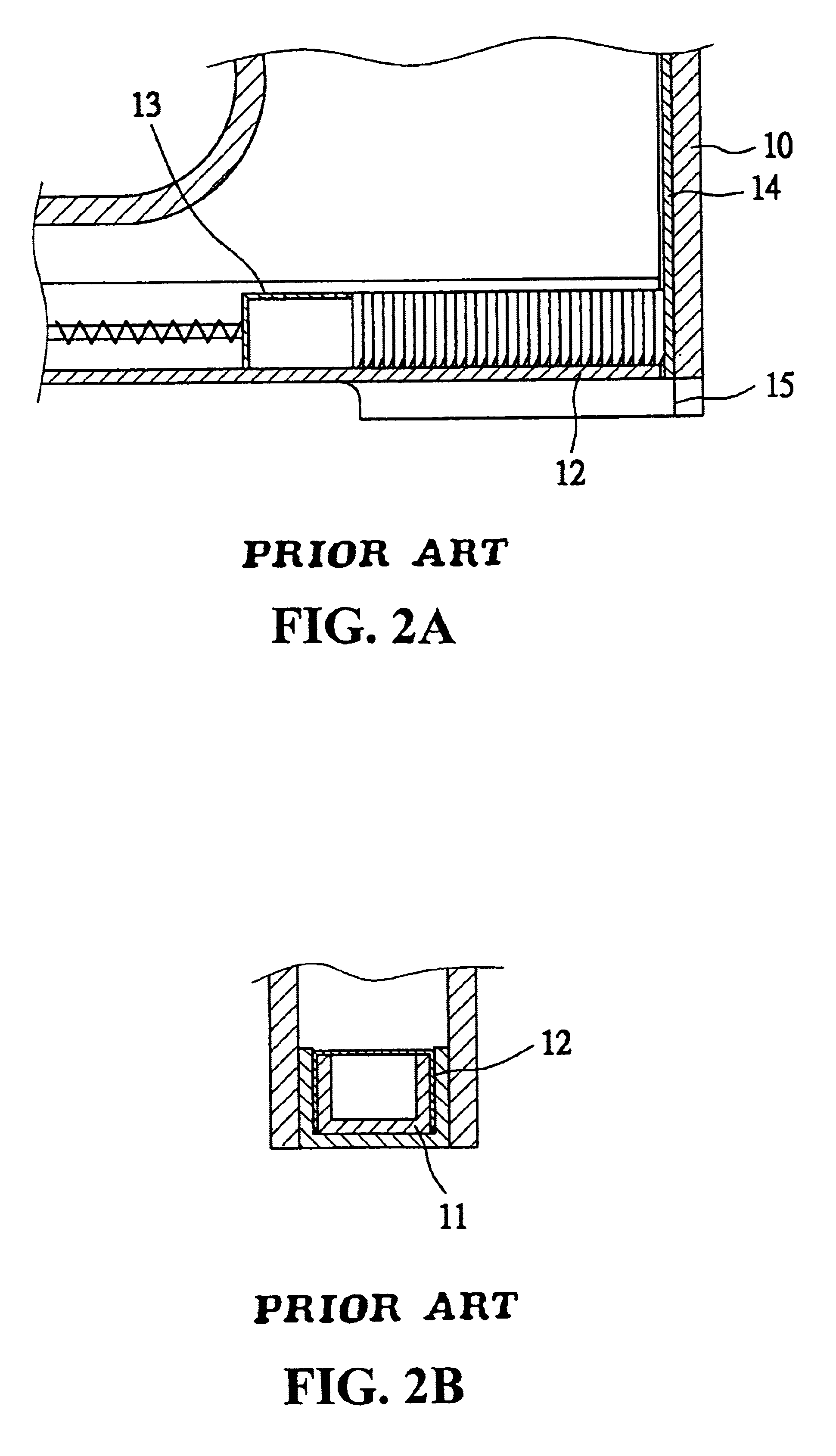

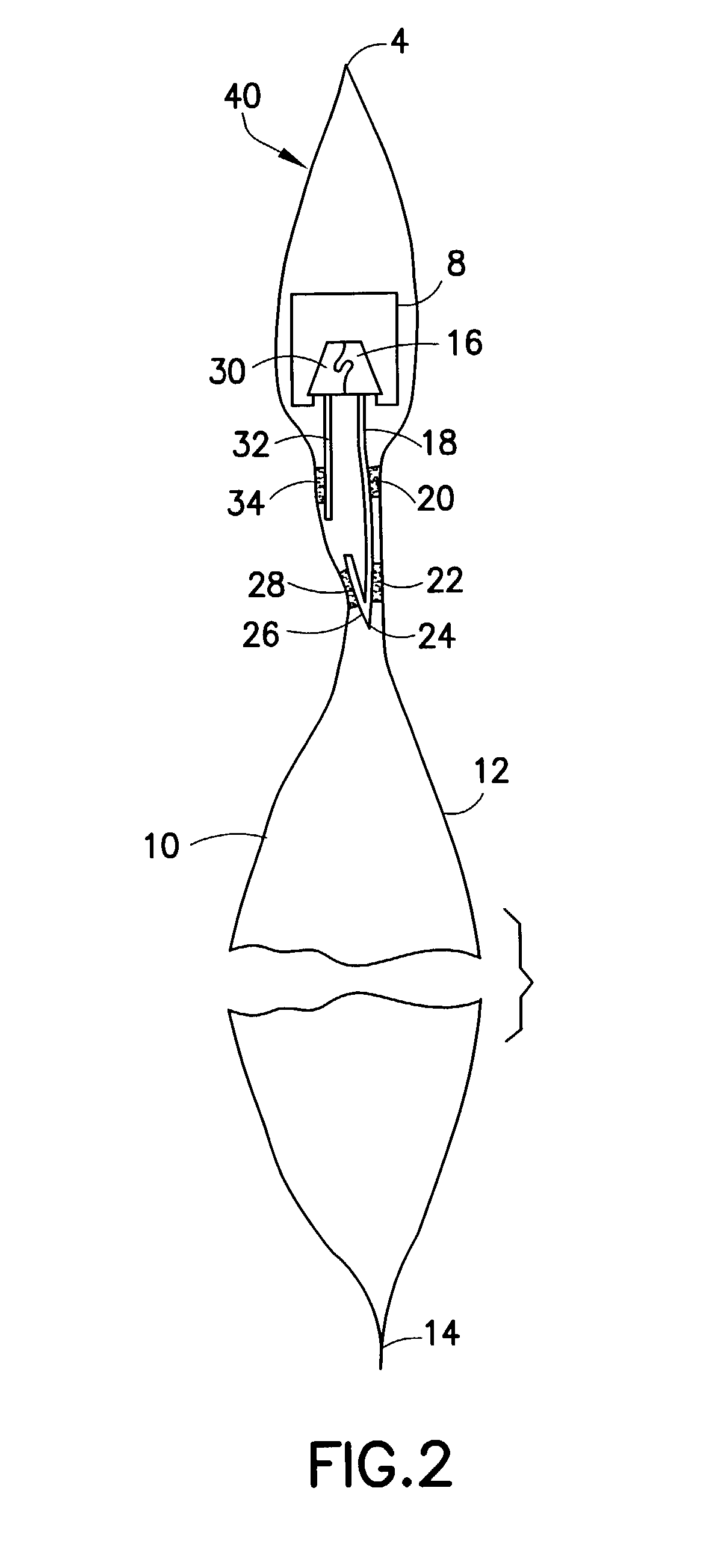

Detachable insulation wire-pressing element of a stapling device

A detachable insulation wire-pressing element of a stapling device is disclosed. The wire-pressing element has a wire-pressing section at the center of the element and the bottom face of the wire-pressing section is provided with a wire slot having an opening facing downward the two sides of the wire-pressing section are respectively provided with a corresponding nailing hole, and the nailing hole is corresponding to a staple-impacting plate of the stapling device, thereby a wire-pressing element is formed. When the front edge of the wire-pressing element is aligned with the front edge of the stapling device the nailing holes are corresponding to the staple-impacting plate of the stapling device, and thereby a staple row utilized in the stapling device and by aligning the wire-pressing element with the front edge of the stapling device, the wire-pressing element can be used to secure insulation wires. The wire-pressing element can be utilized in stapling device for outdoors and indoors.< / PTEXT>

Owner:CHEN TUNG I

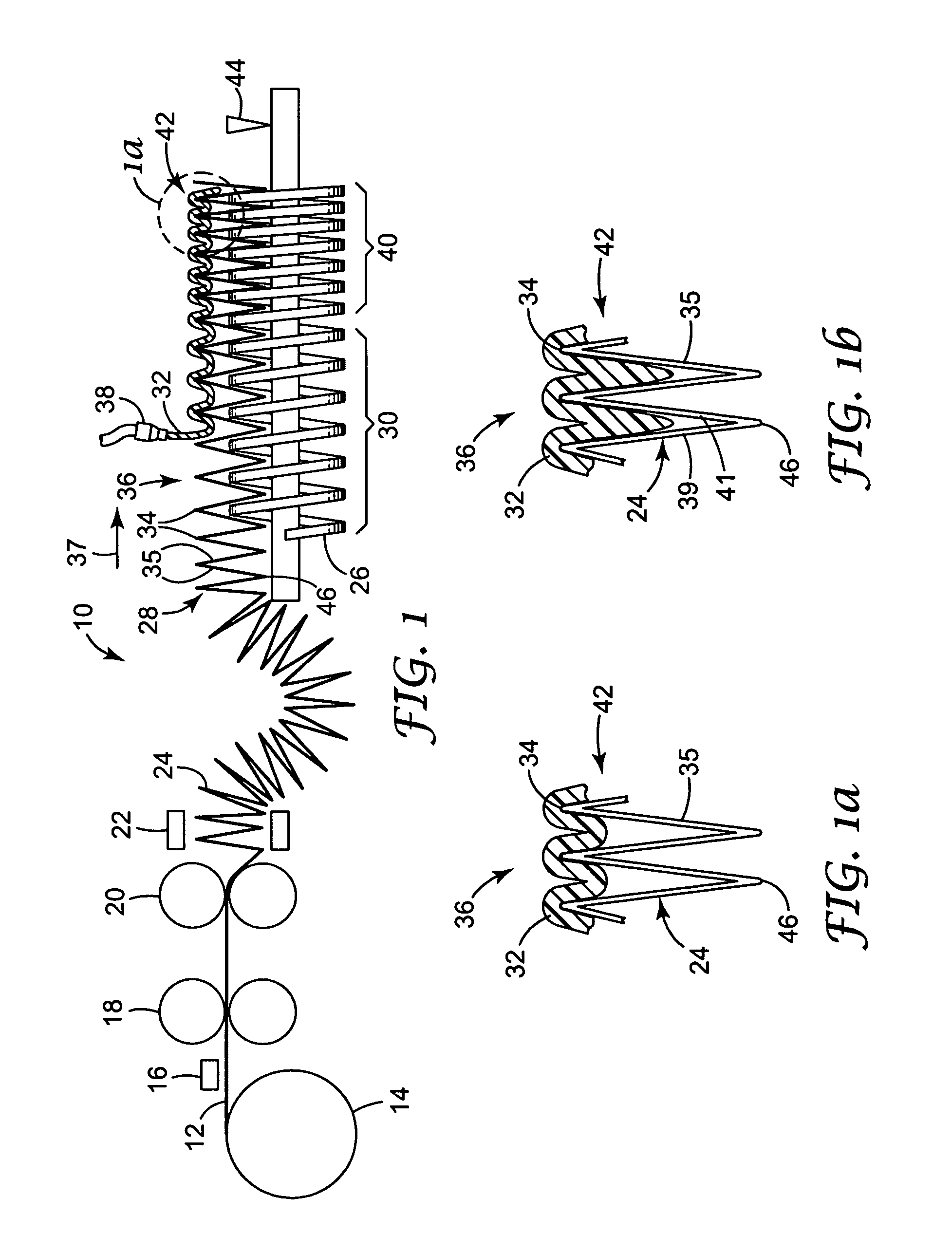

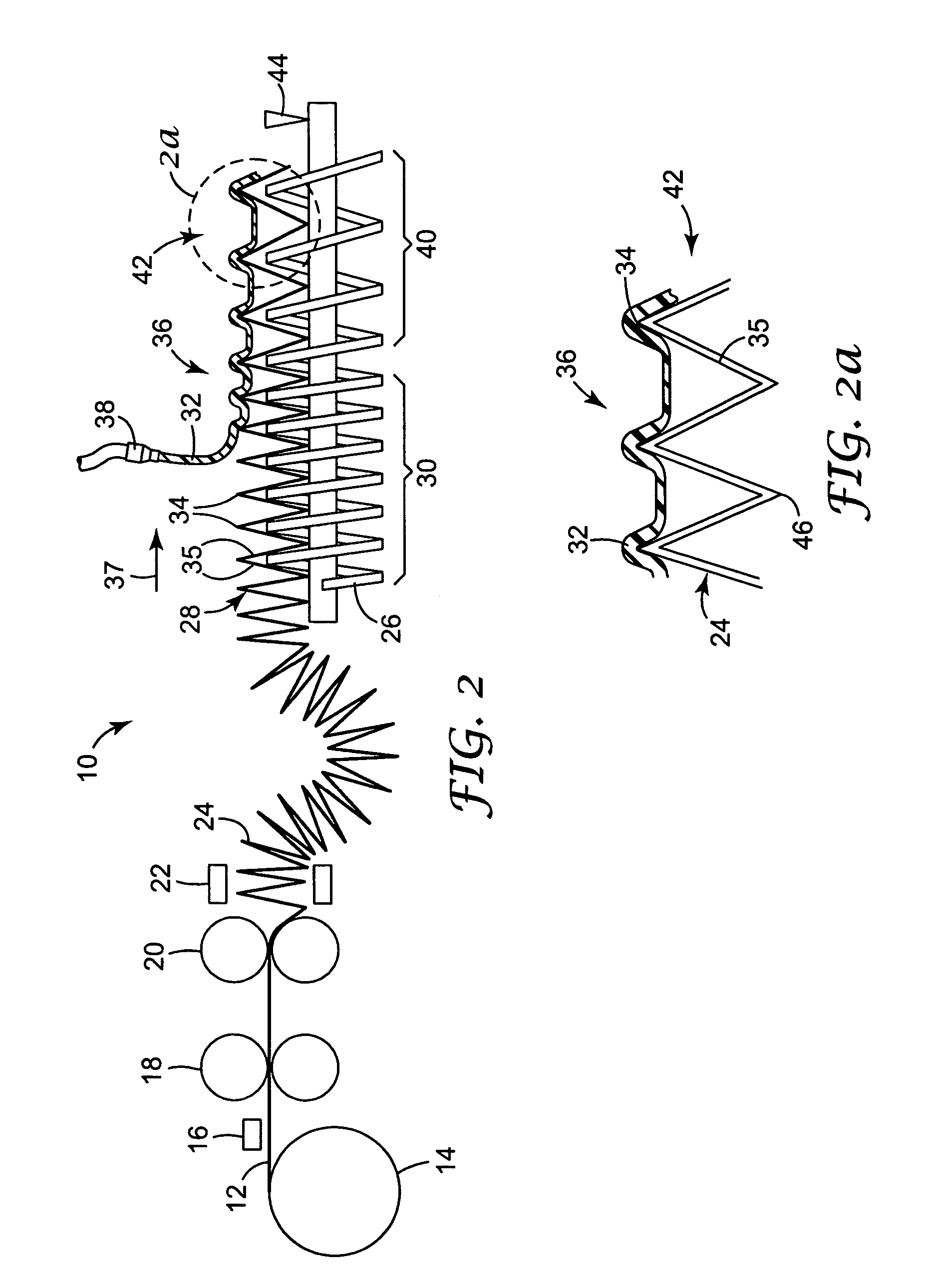

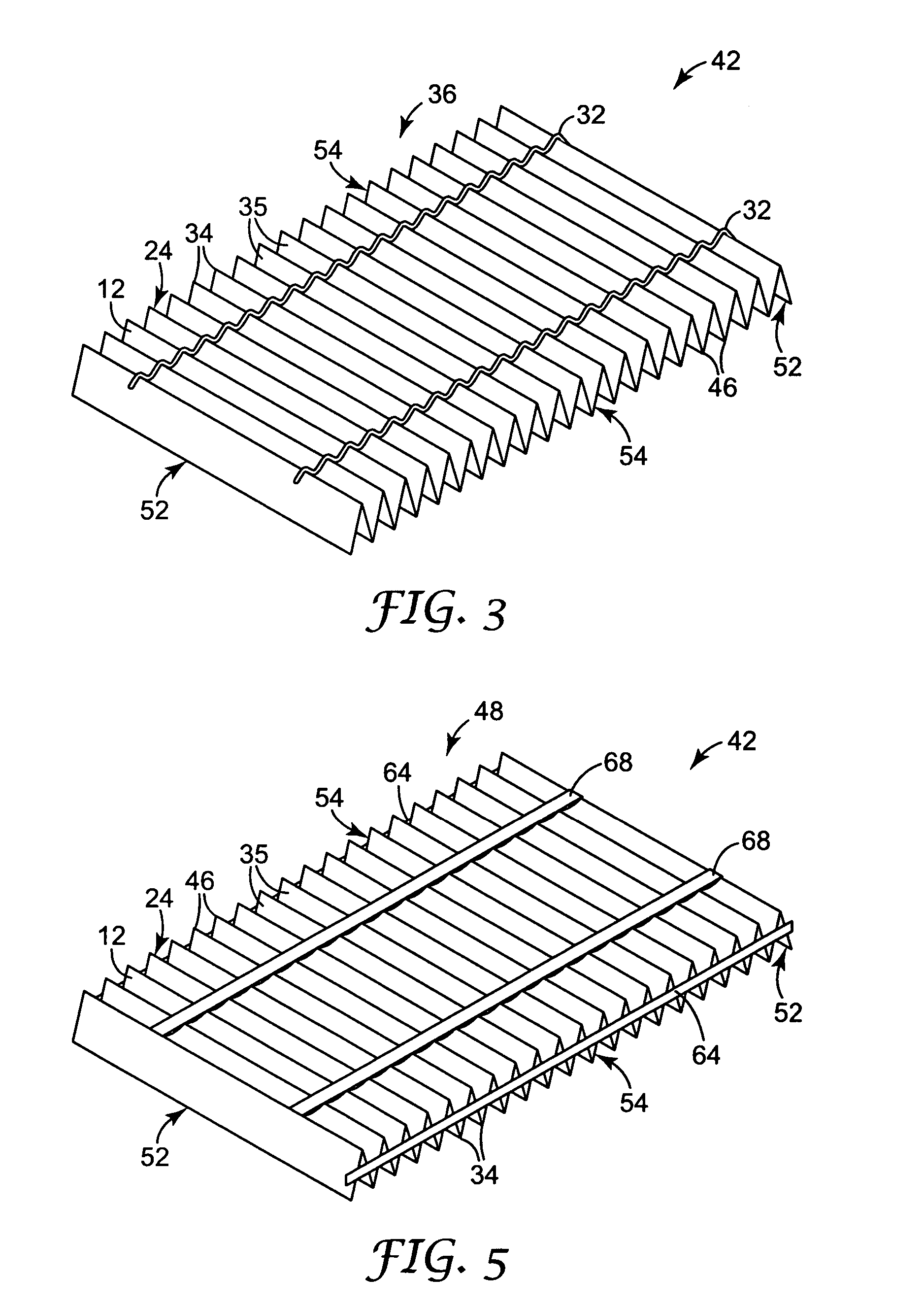

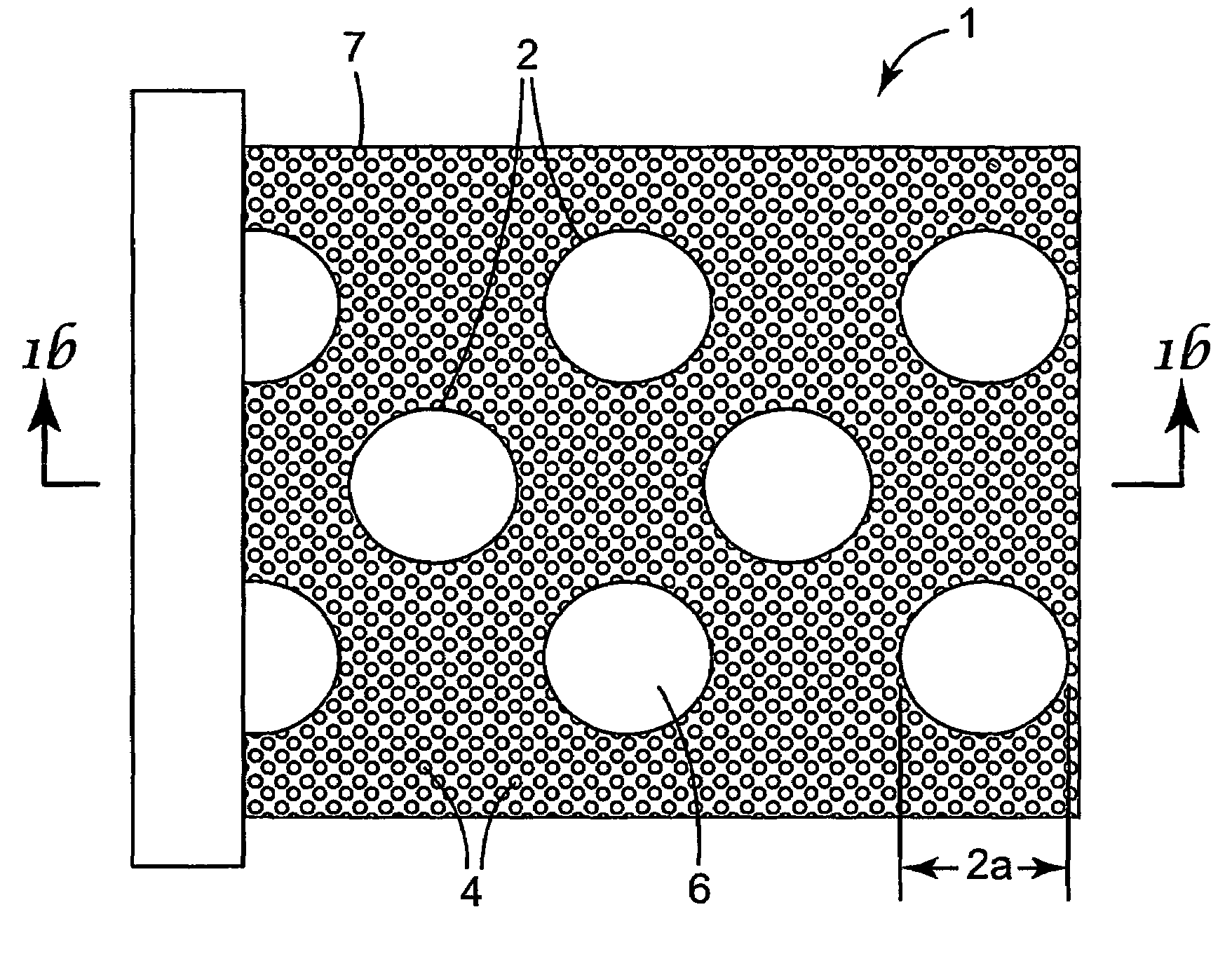

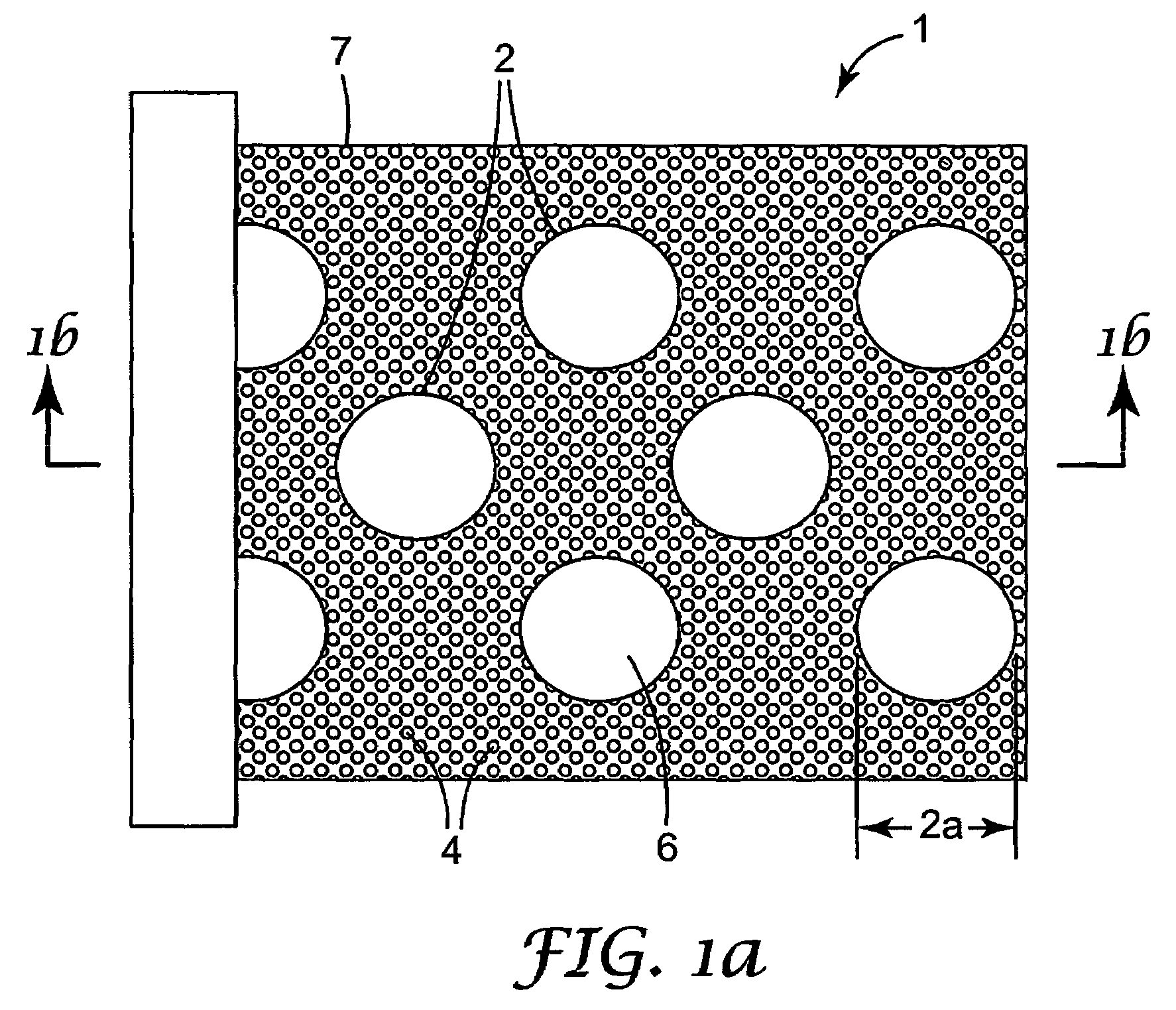

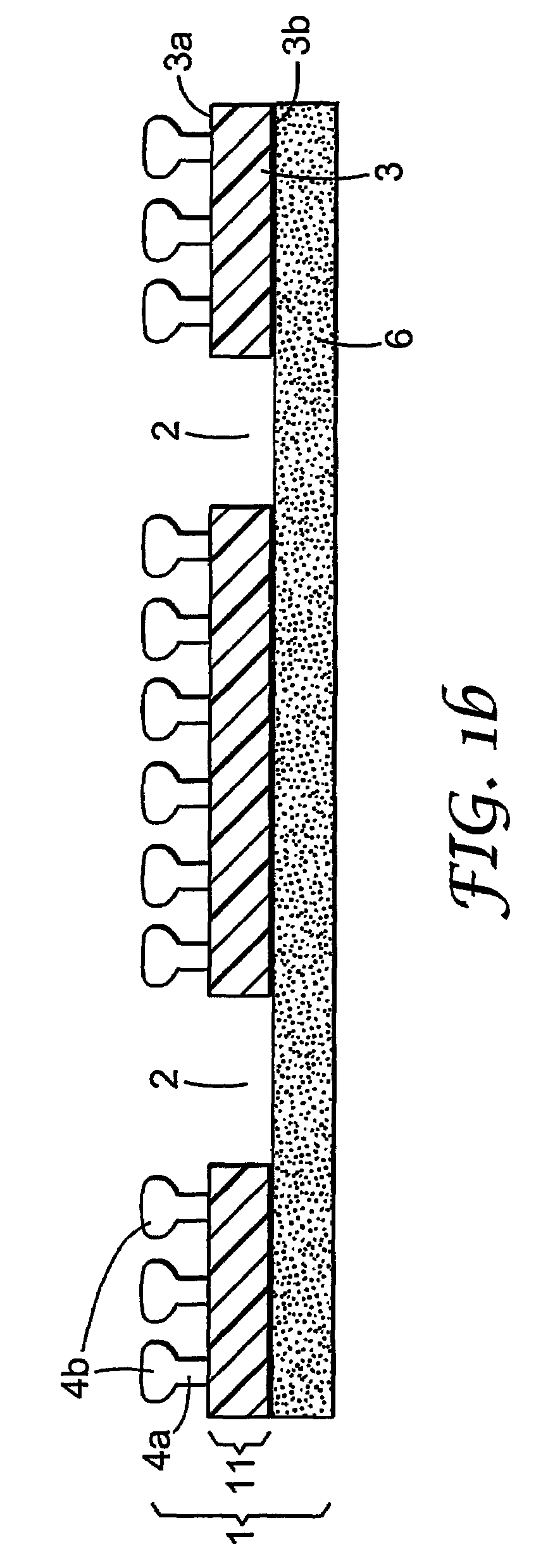

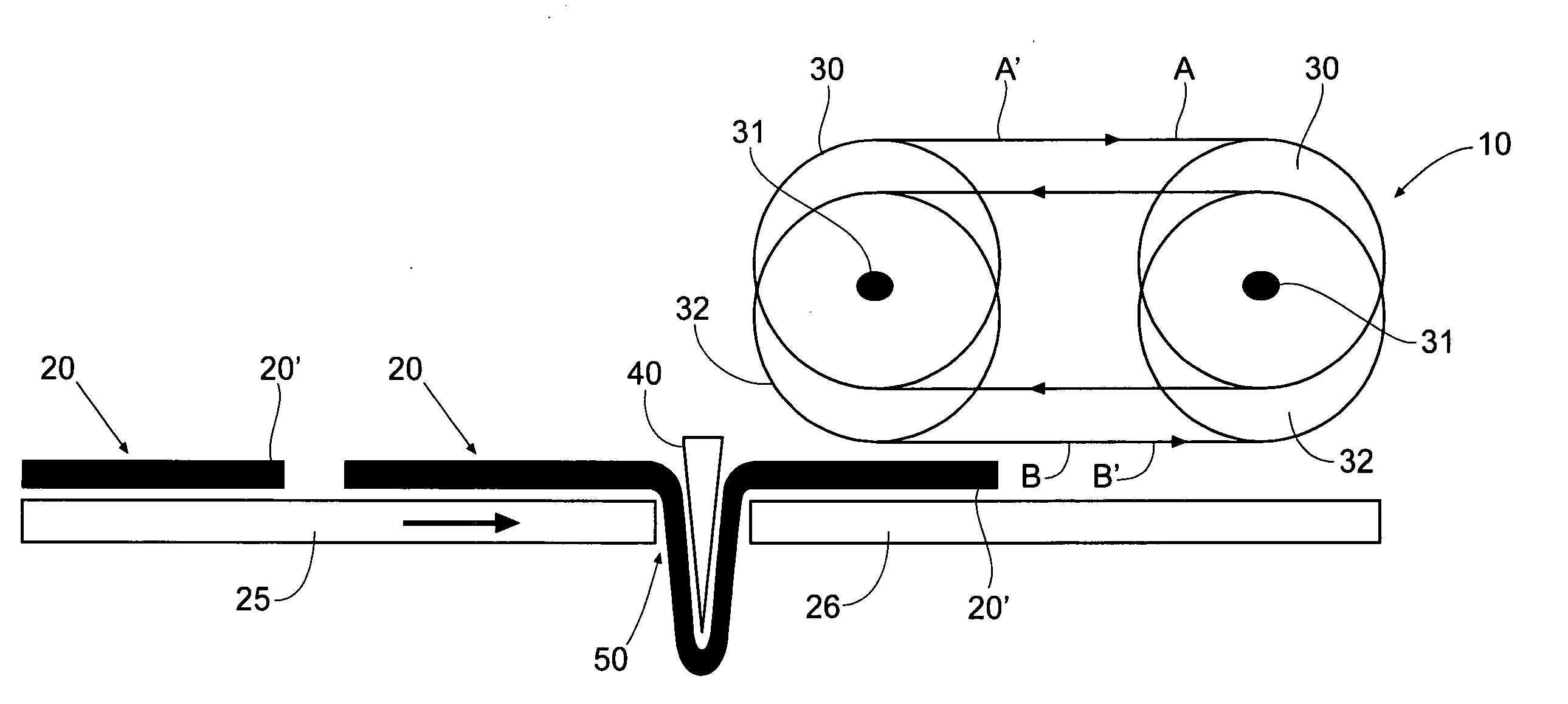

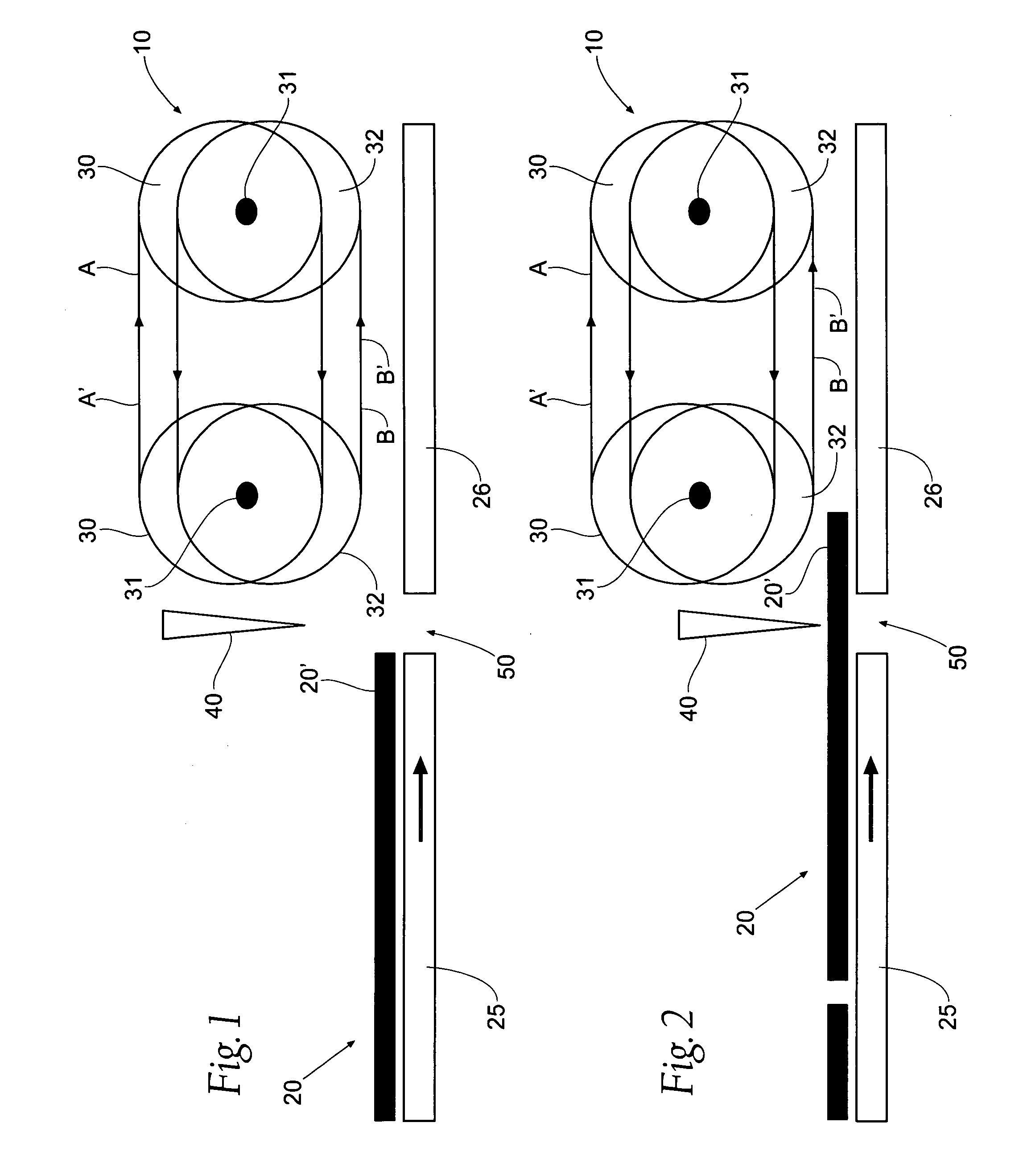

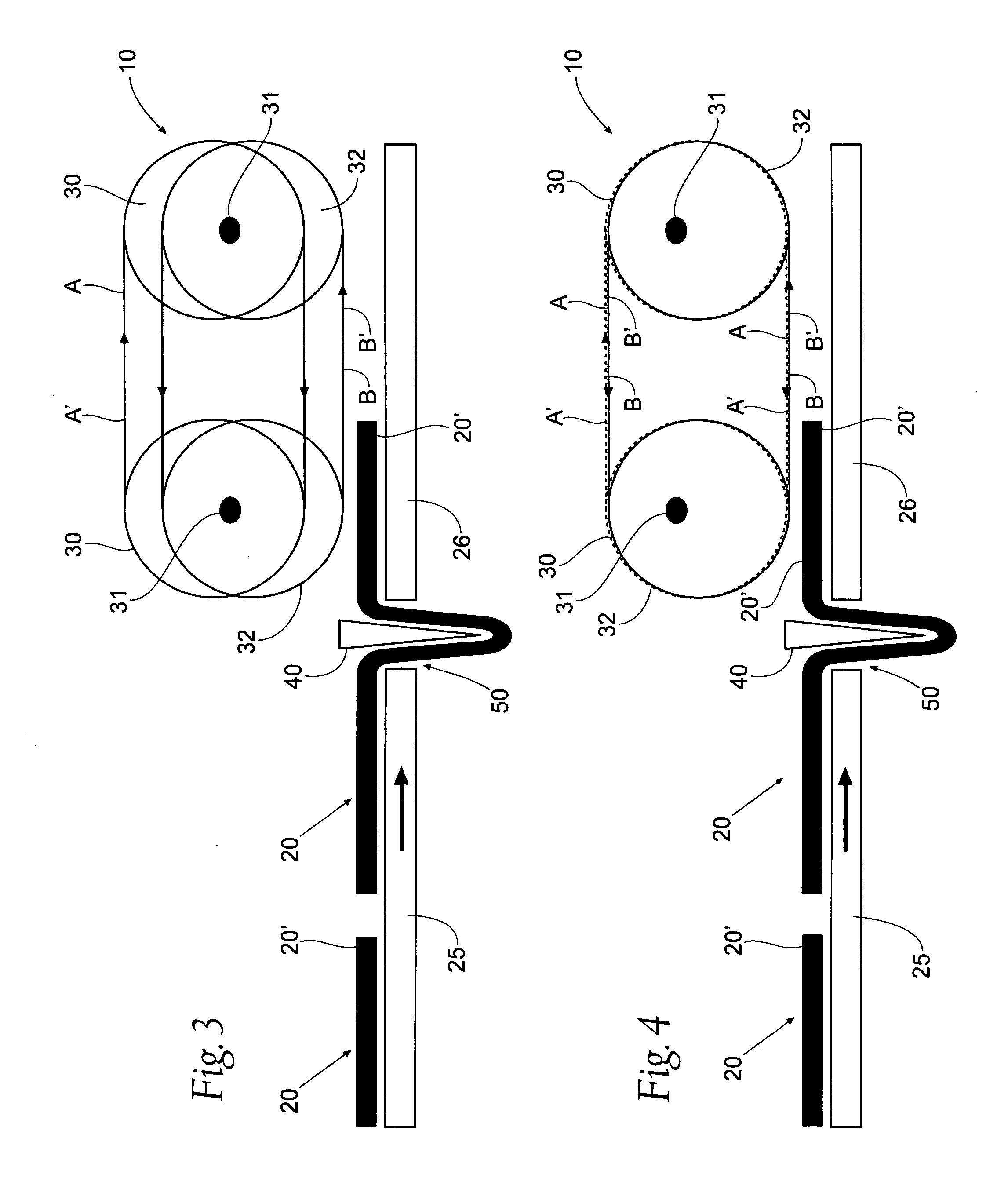

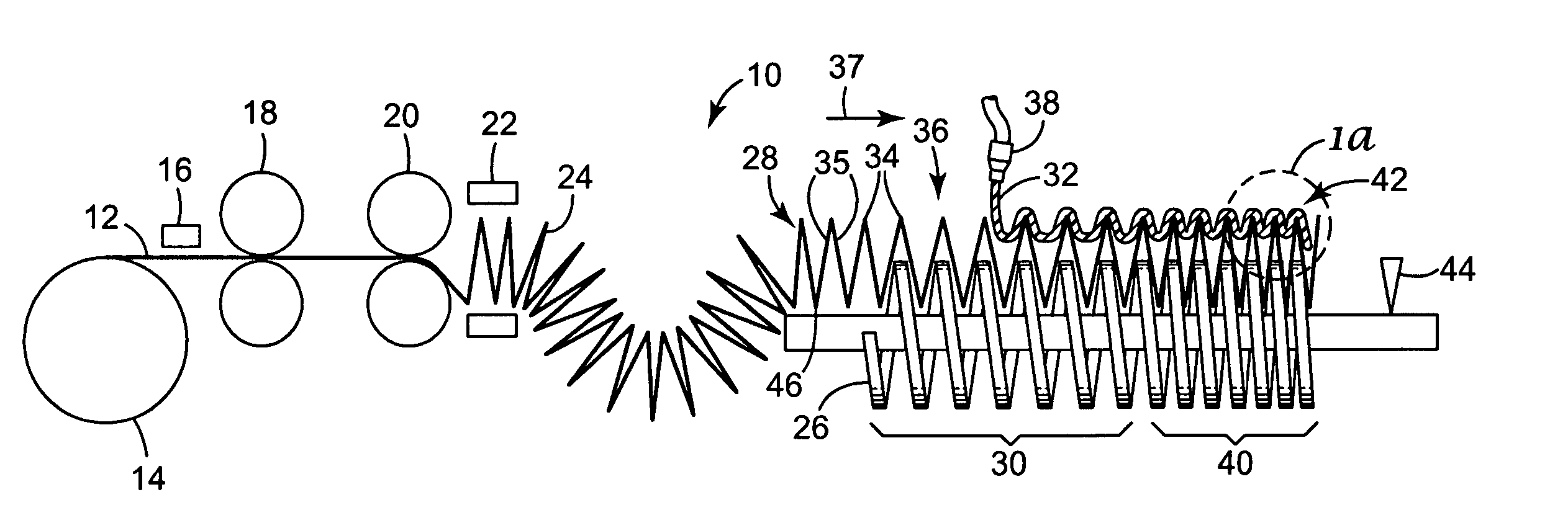

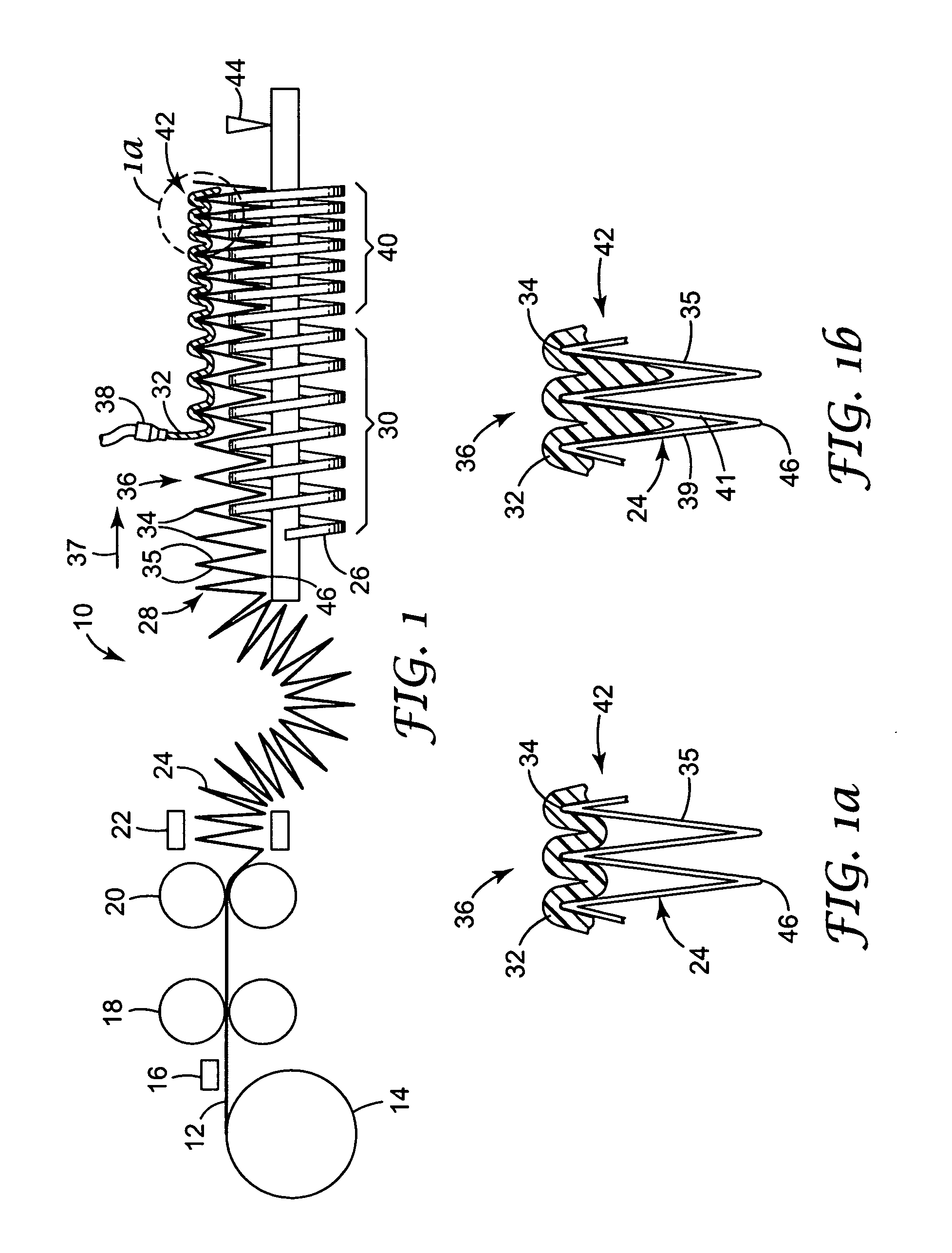

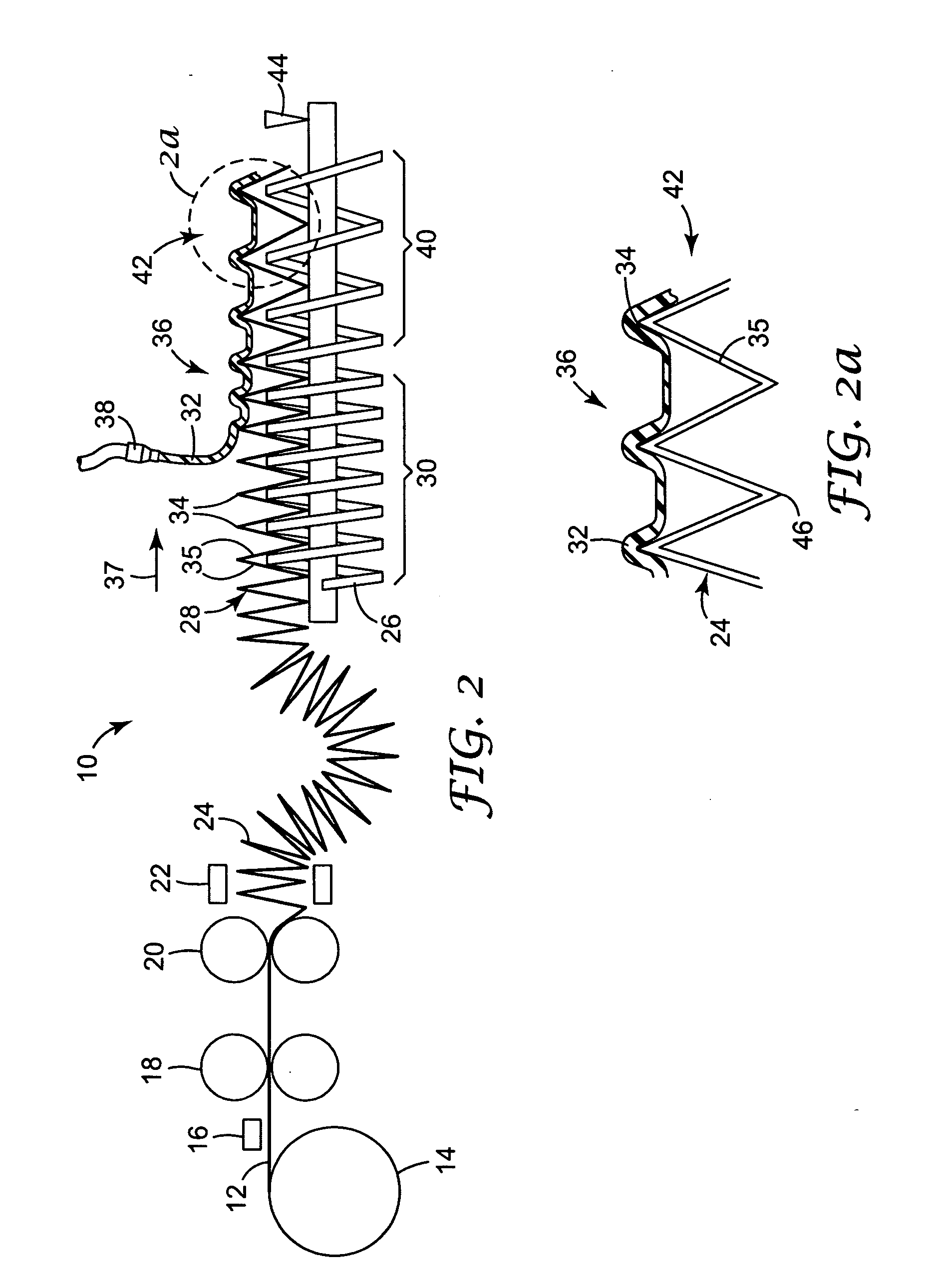

Method of forming self-supporting pleated filter media

The method of forming pleated filter media includes providing a generally planar web of filter material, folding the web to form a pleated web having a plurality of fold lines, arranging the plurality of pleats in a first spaced configuration defined by a first distance between adjacent pleat tips, applying a continuous strand of adhesive to the web, and adjusting the arrangement of the plurality of pleats into a second spaced configuration defined by a second distance between adjacent pleat tips. The web has a front face and a rear face. Each fold line is intermediate oppositely sloping first and second wall surfaces. The plurality of fold lines form a plurality of pleats having a first plurality of pleat tips and a second plurality of pleat valleys. The second distance is different from the first distance.

Owner:3M INNOVATIVE PROPERTIES CO

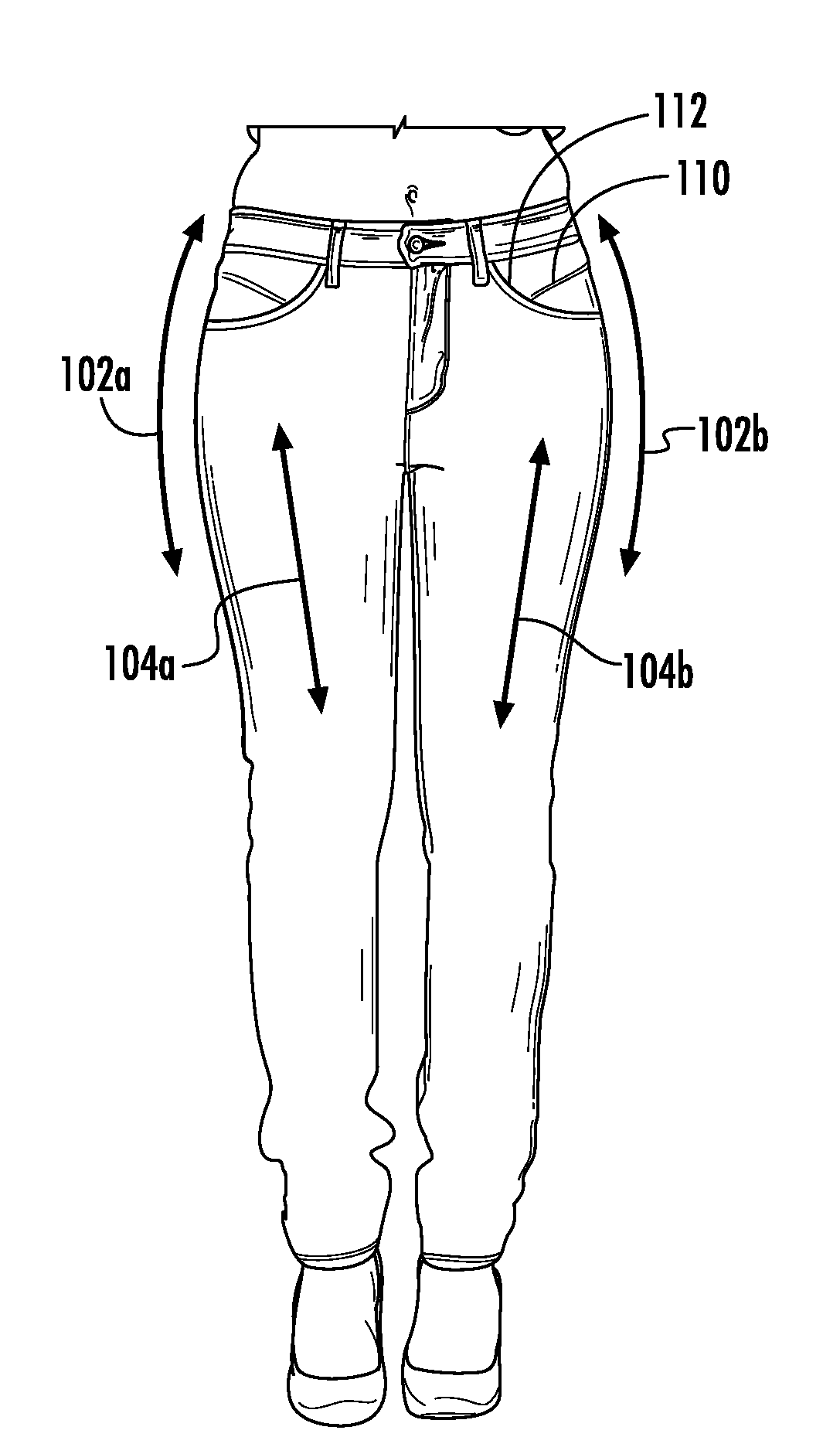

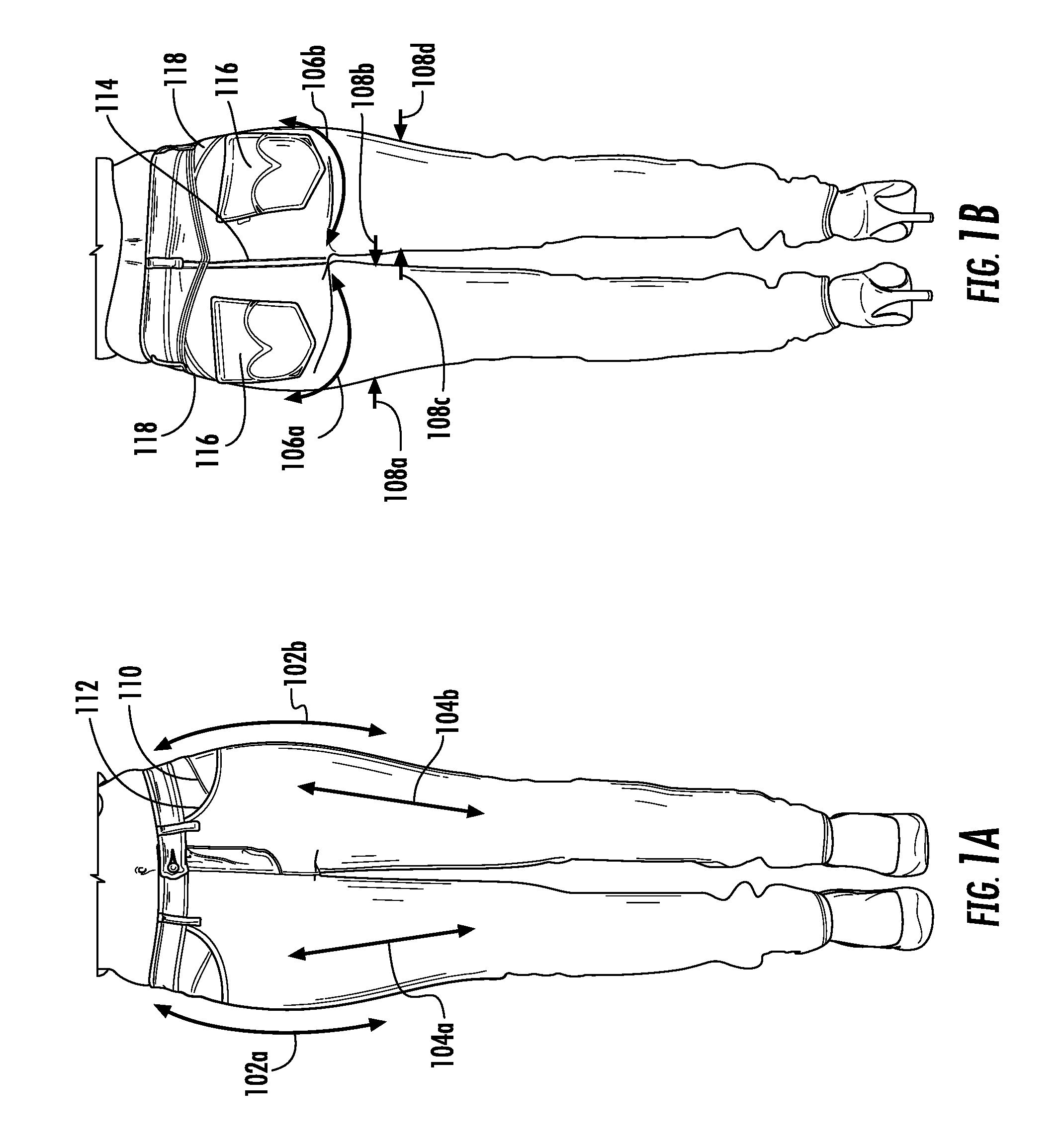

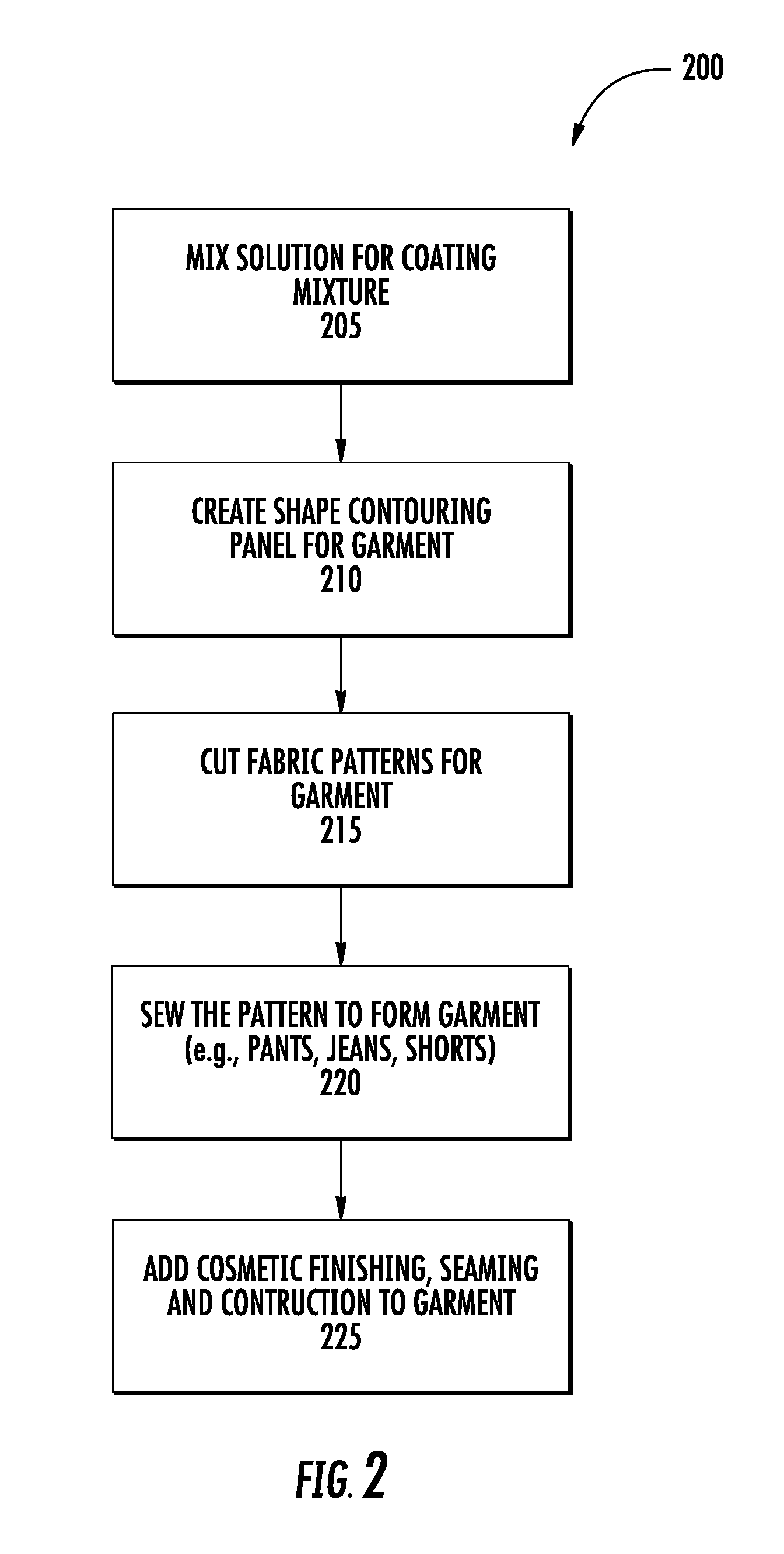

Shaped Fit Sizing System with Body Shaping

InactiveUS20140165265A1Reduce stretchIncrease elasticityGarment special featuresTrousersBody shapeEngineering

Jeans are fitted based on the concept of shape, not size. There are at least three shape categories for different levels of curviness. With shape category information, the consumer can more easily find and fit a pair of form-fitting jeans. These jeans can also include a body shaping panel on an inside surface of a material of the pants to help actively shape the body. The body shaping panel enhances the body's natural curves while de-emphasizing the body's flaws, so the consumer can feel confident and attractive in their jeans.

Owner:LEVI STRAUSS & CO

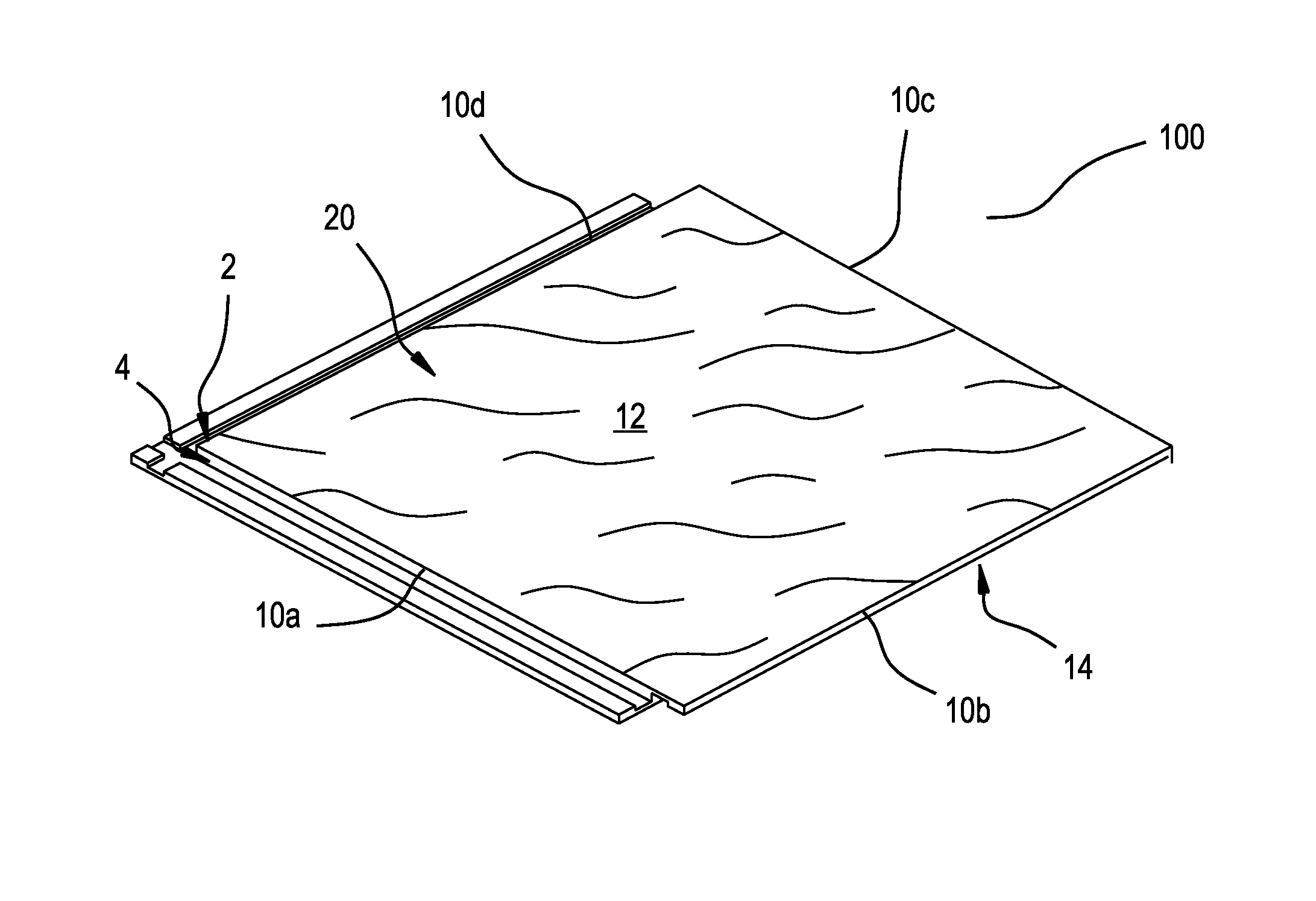

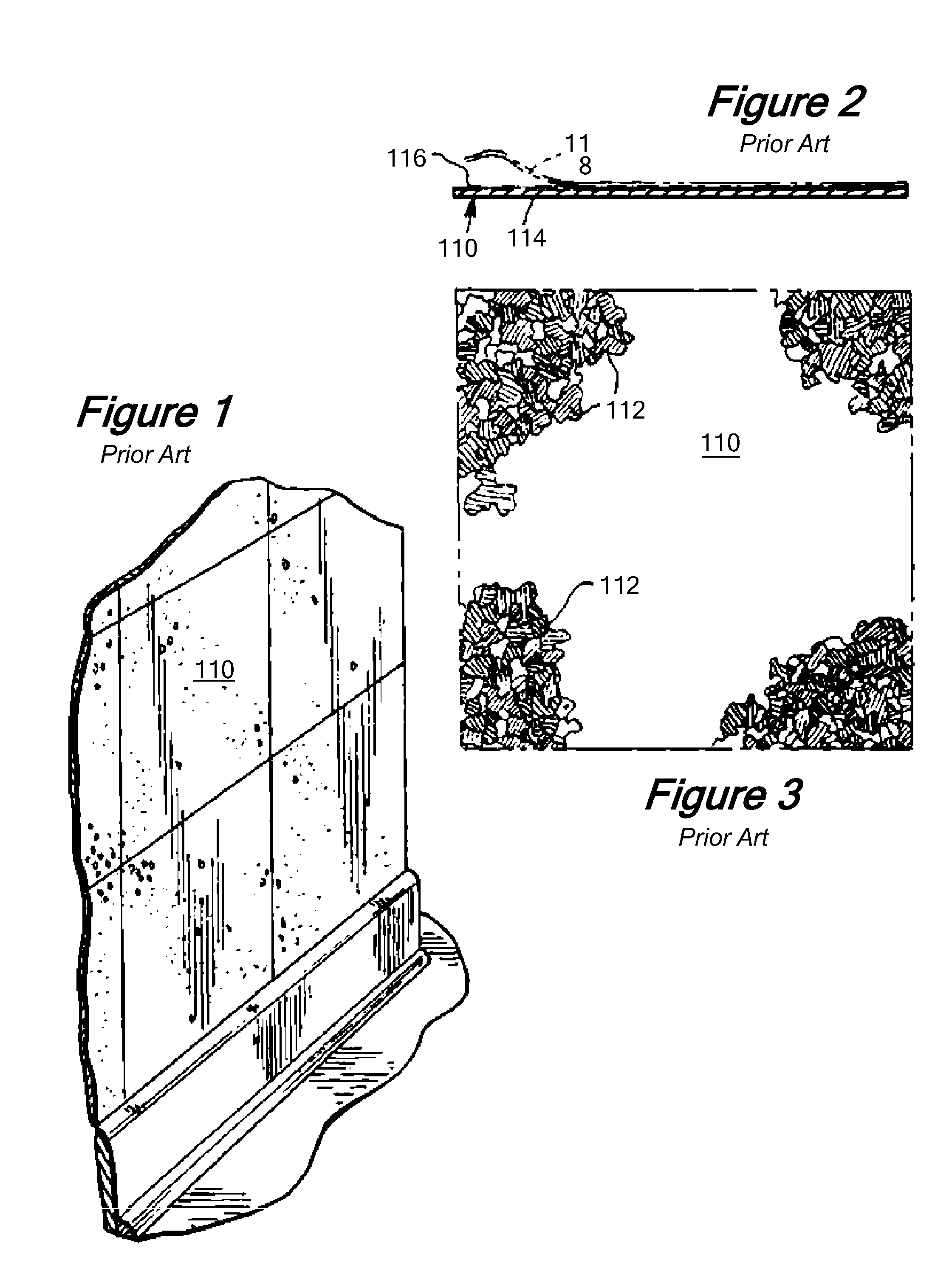

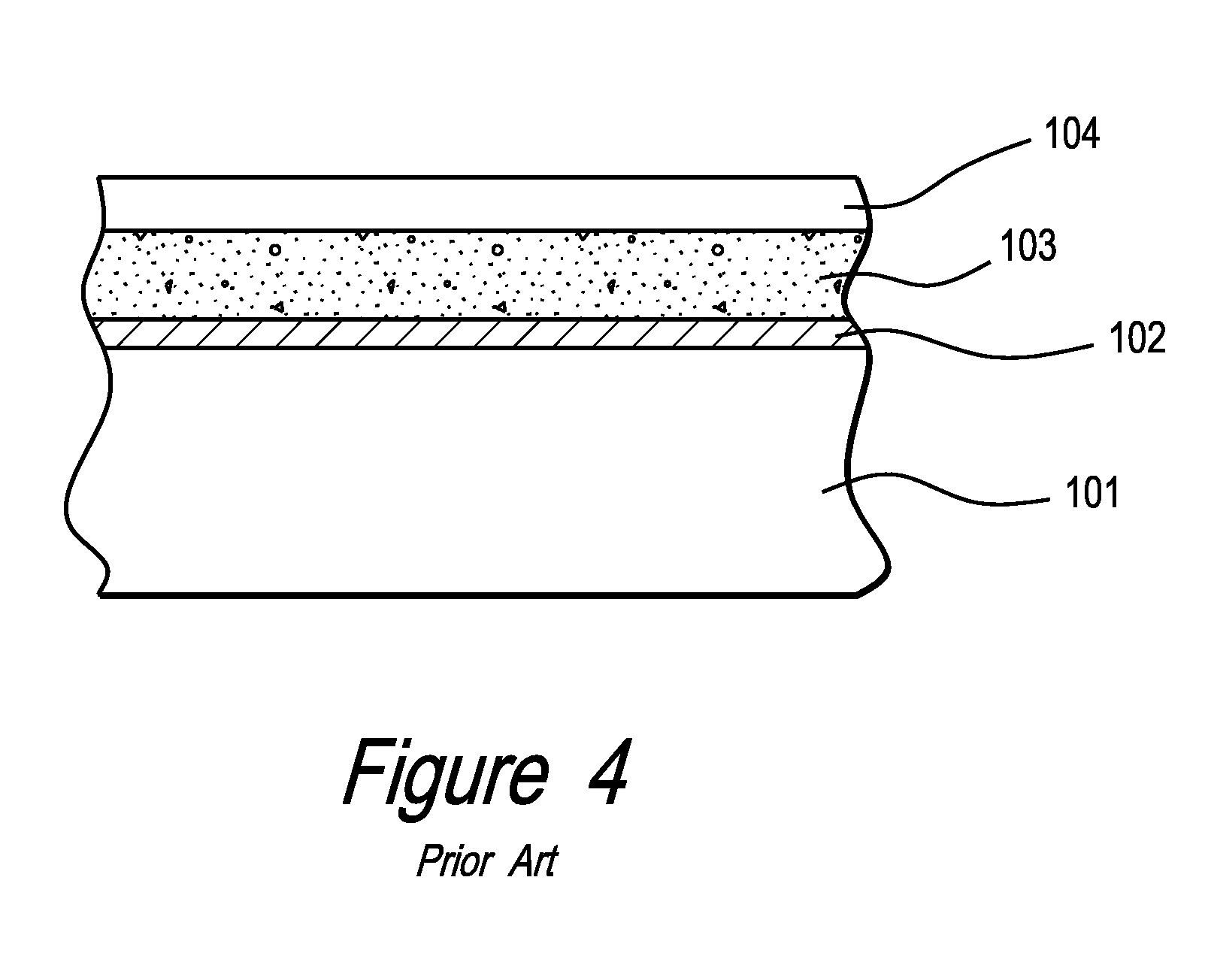

Floor Panel Containing A Polymer And Cork

ActiveUS20100319282A1Improve material performanceSlide fastenersBaby linensPolyvinyl chlorideEngineering

A vinyl floor panel for a flooring system prepared from a blend of a polymer and cork granules. The floor panel includes top and bottom surfaces with a first layer between both surfaces. A printed pattern is located on the top surface. The first layer is prepared from a blend of a polymer polyvinyl chloride and cork granules, where the cork granules are evenly distributed with the polyvinyl chloride throughout the length, width, and thickness of the first layer.

Owner:NOVALIS HLDG

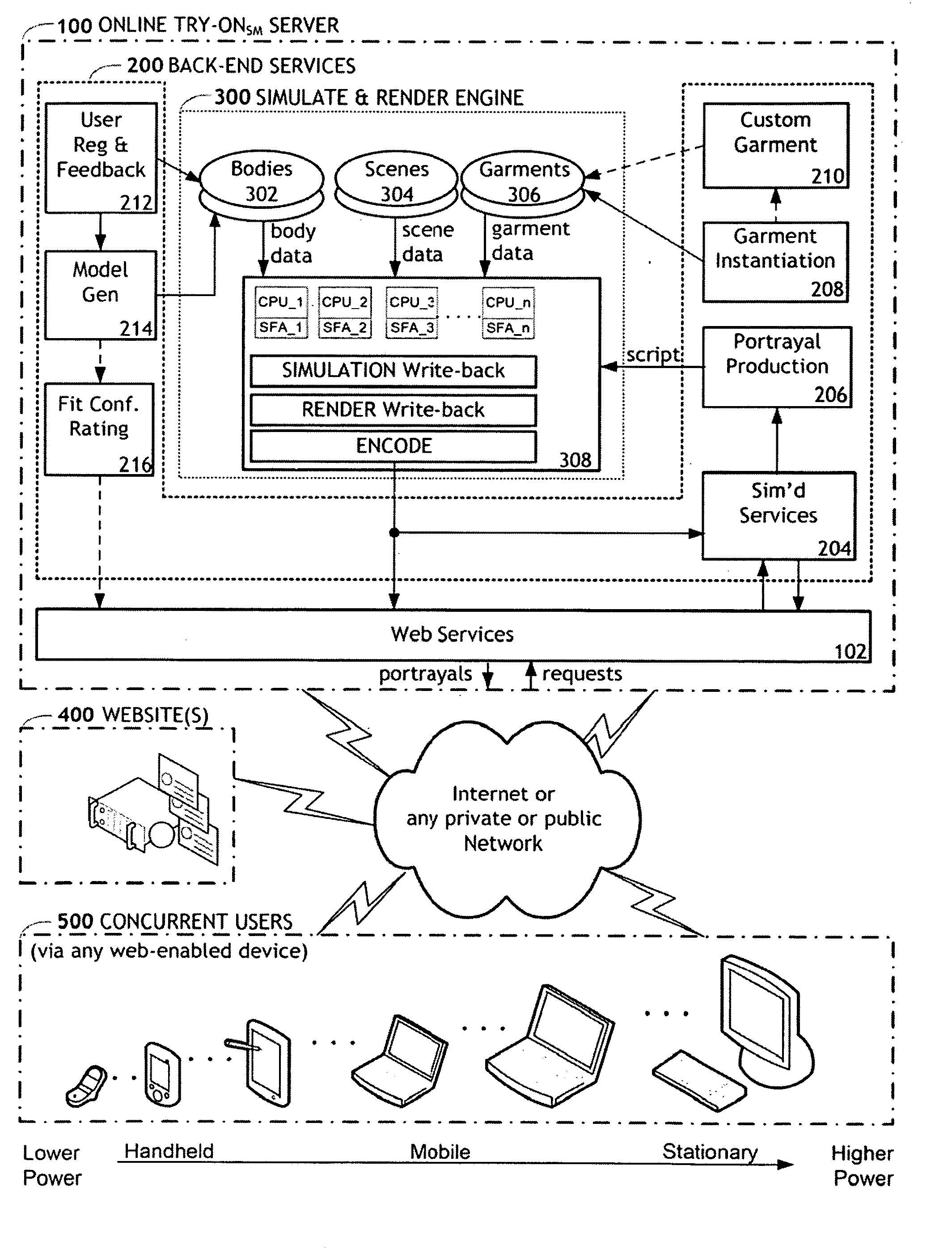

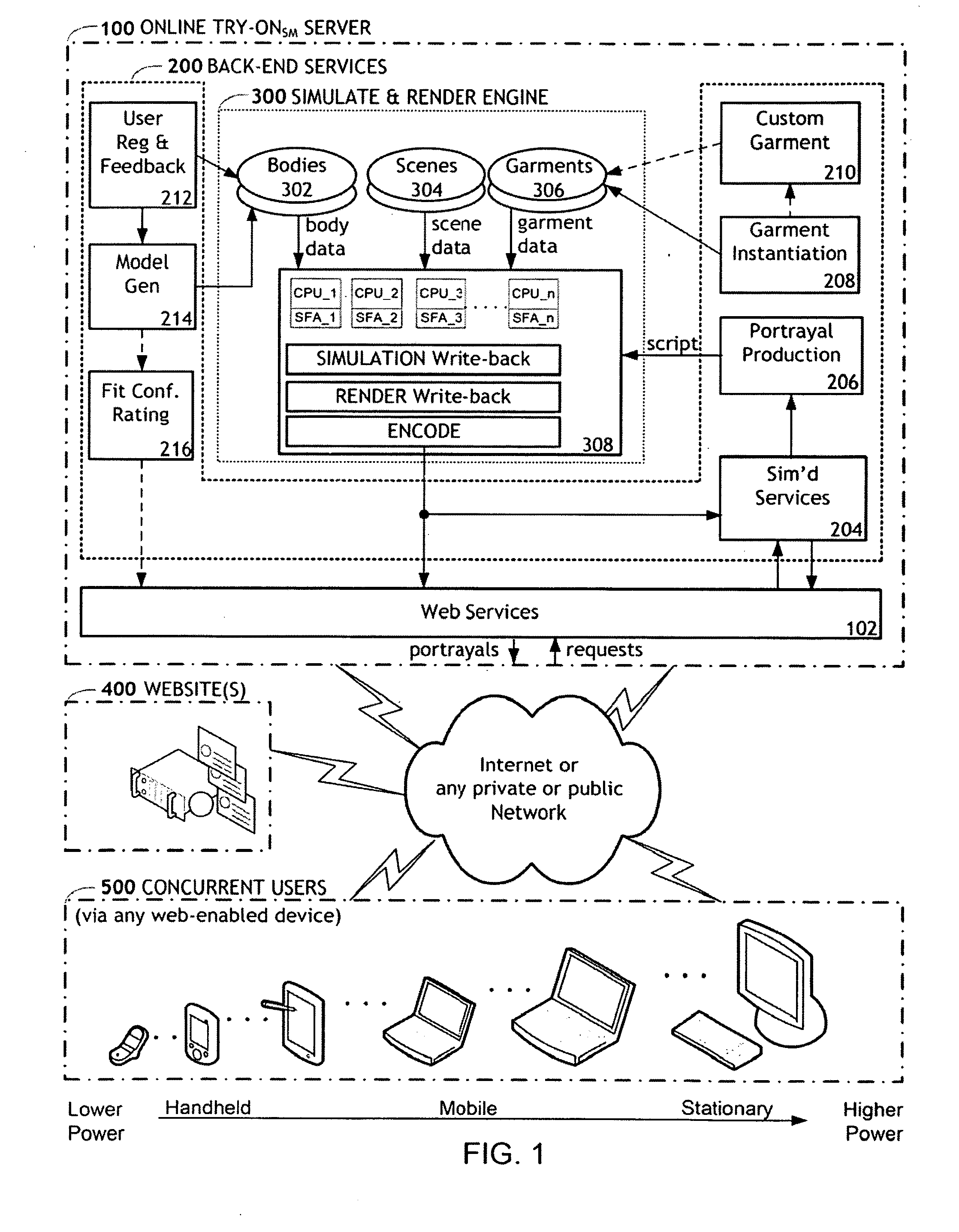

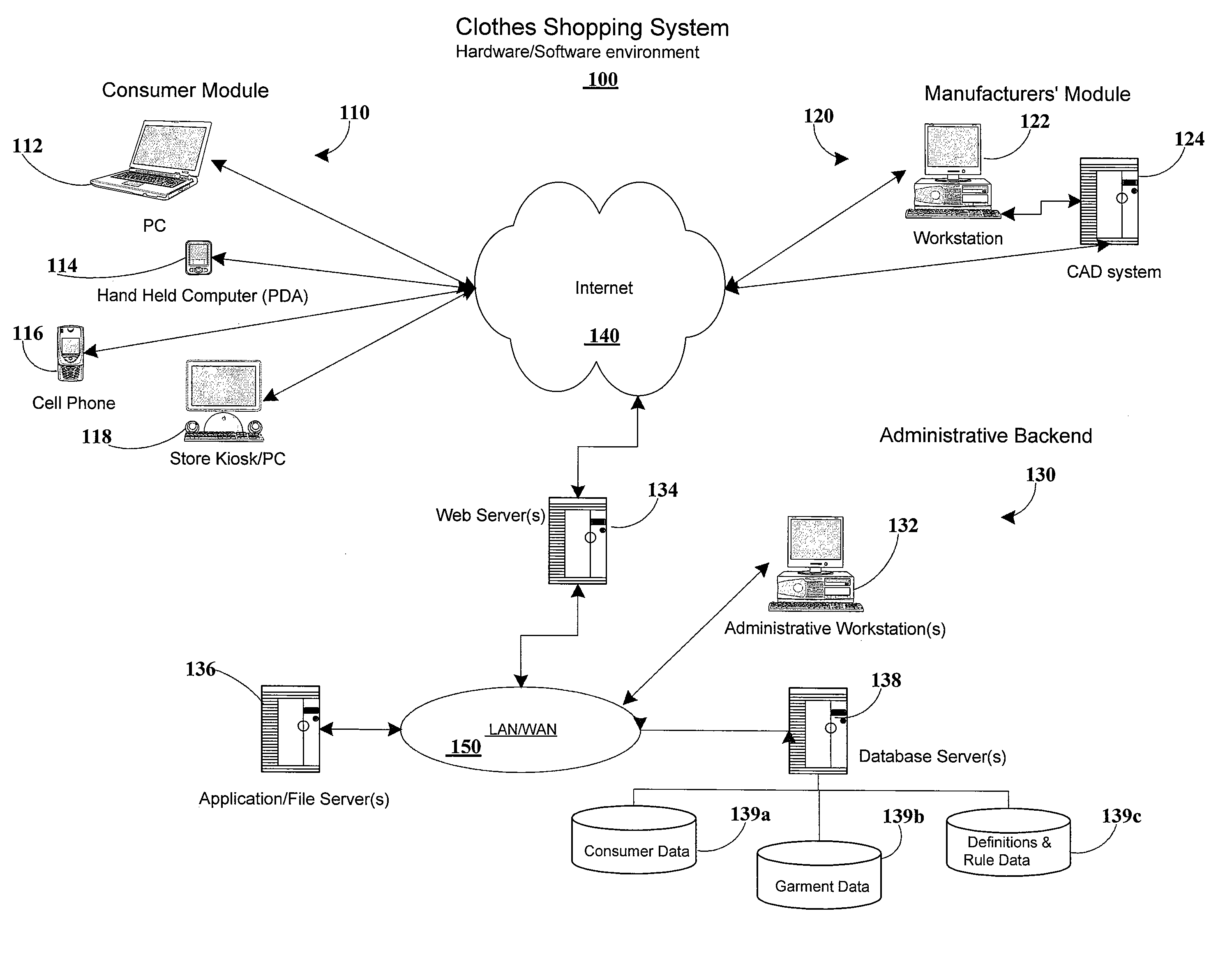

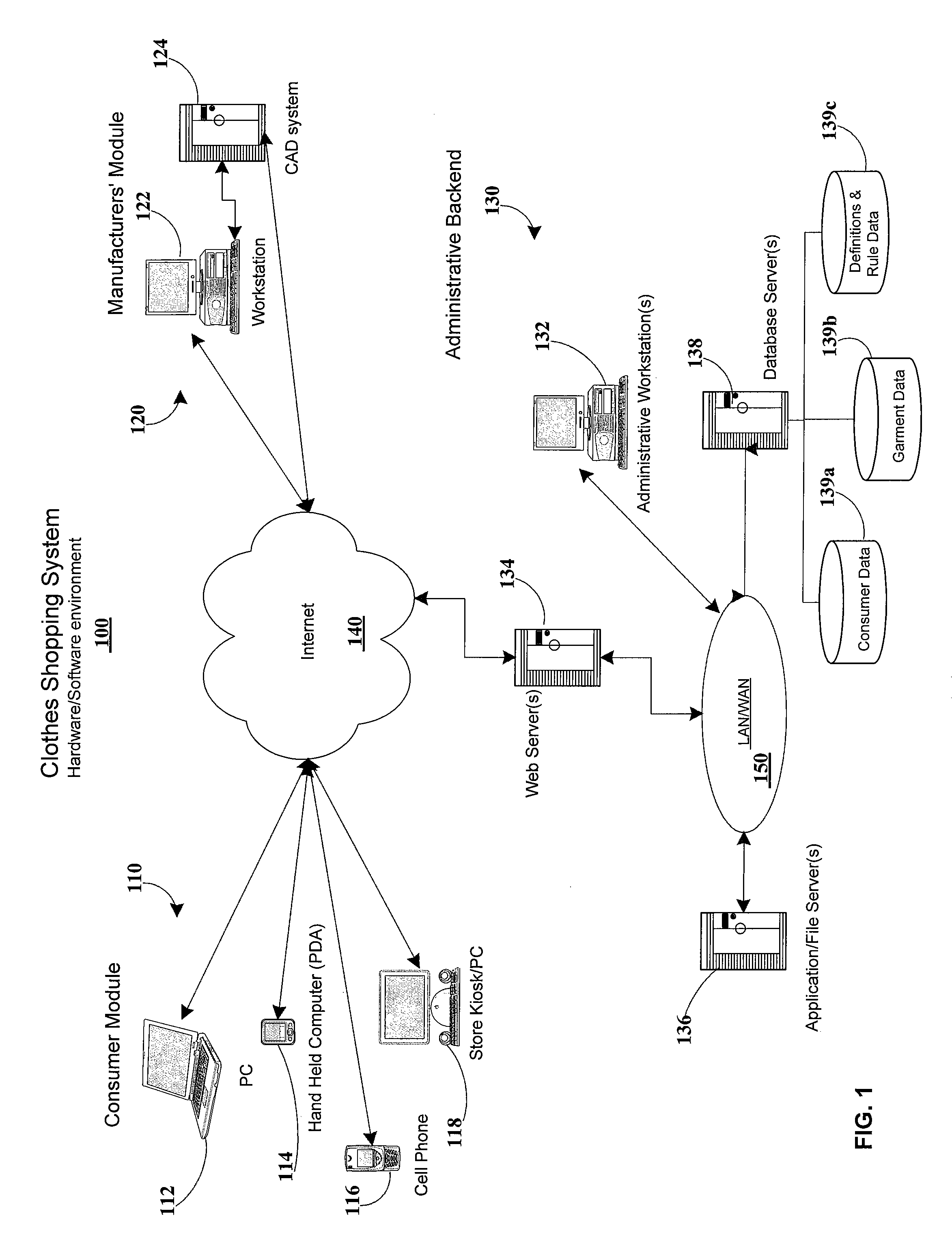

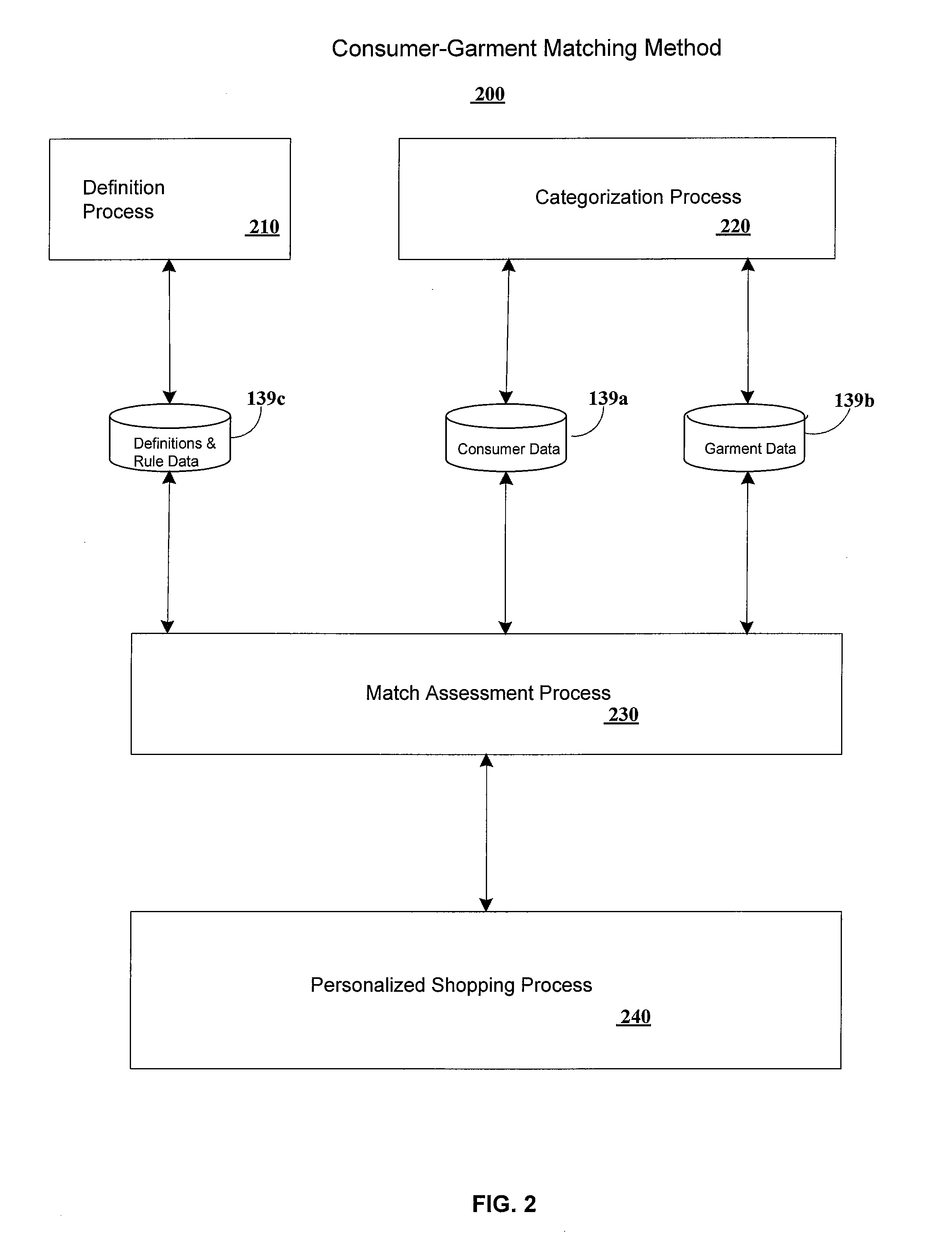

Garment fit portrayal system and method

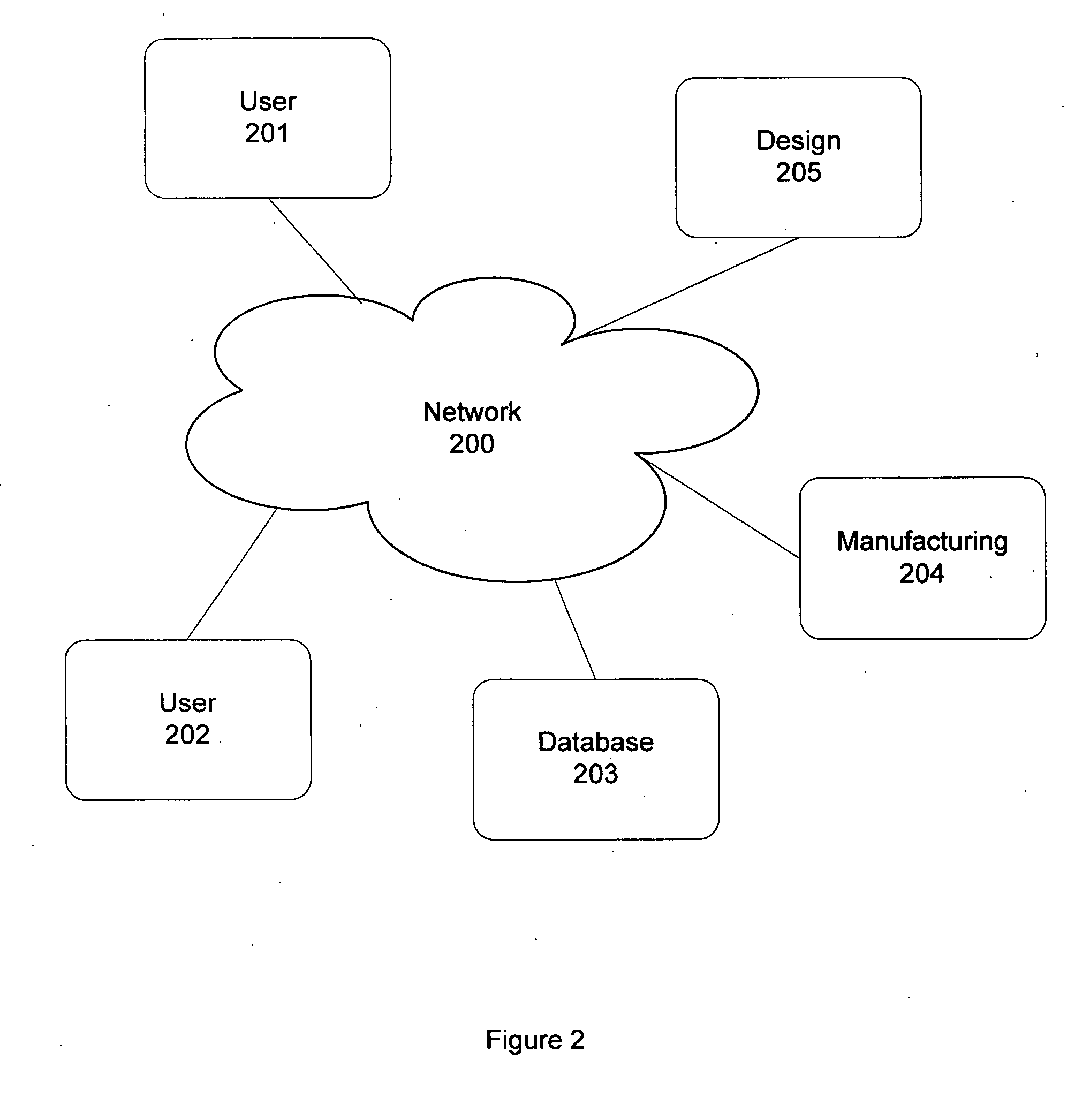

ActiveUS20100306082A1Cathode-ray tube indicatorsImage data processing detailsWeb serviceThe Internet

An on-line garment fit portrayal system configured to operate on a specialized server linked over the internet or any network using standard web services to at least one web-enabled player device capable of common image format display is described. The system comprises a server-side garment model storage capability containing one or more garments, with parameters for each garment chosen from the groupings that include a garment piece parts list, piece spatial properties, piece mechanical parameters, piece optical parameters, and assembly information; a server-side modeler mechanism configured for generating a three-dimensional model of a subject's body from individual body data, the model being represented by body data stored in a body model storage capability; a server-side simulator mechanism operatively coupled with the garment model storage capability and the body model storage capability for simulating a three-dimensional form fit of a garment represented in the garment model storage capability onto a body represented in the body model storage capability, the simulator mechanism producing a portrayal subject model; and a server-side rendering mechanism operatively coupled with the simulator mechanism for portraying a perspective view on any web-enabled device's display screen of the portrayal subject model representing a three-dimensional form fit of the garment on the subject's body.

Owner:EMBODEE PR LLC

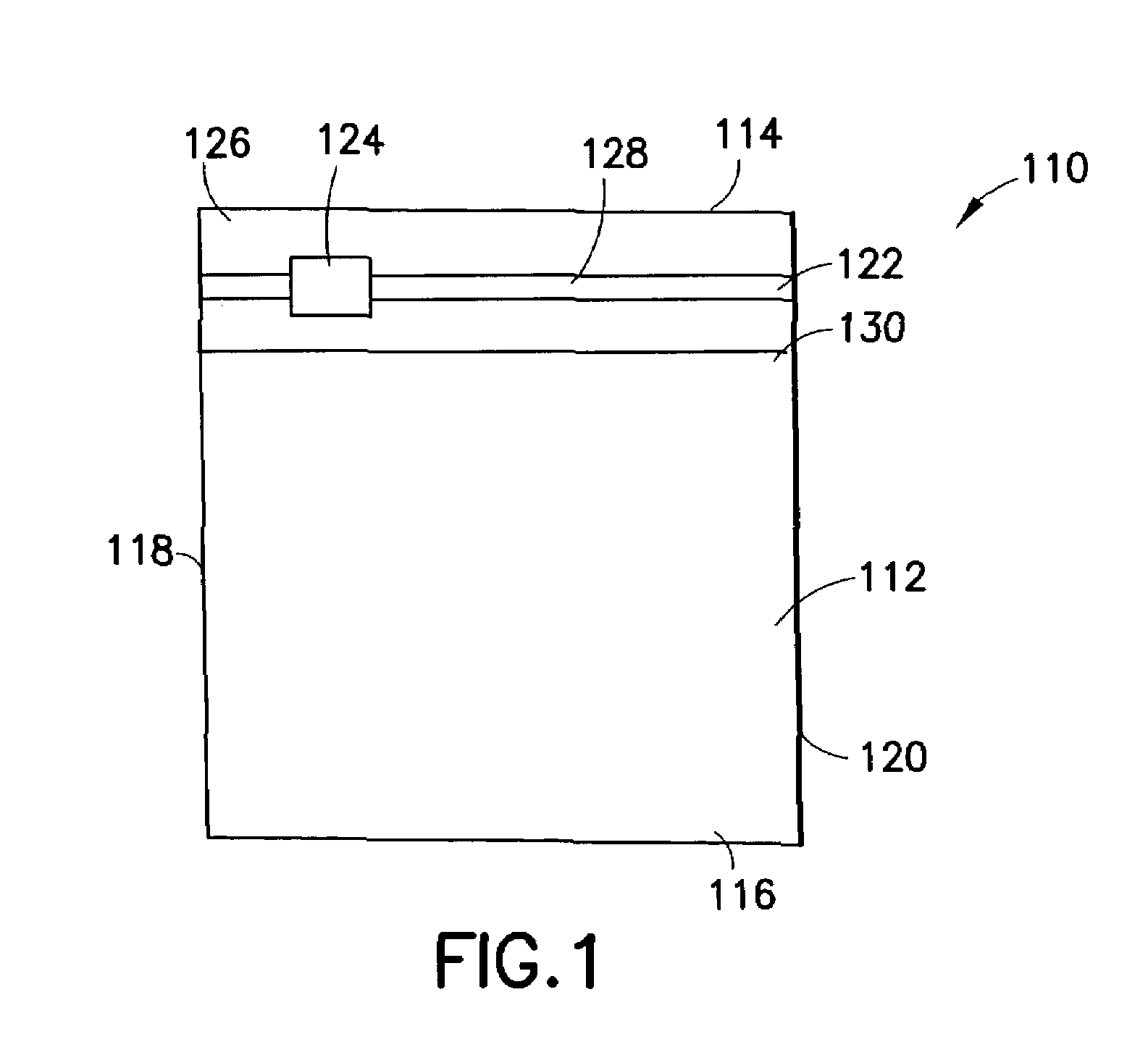

Fastening film system and assembly comprising a fastening film system and a substrate

Owner:3M INNOVATIVE PROPERTIES CO

Method and apparatus for guiding and sealing split-flange zipper tape to bag making film

A method and an apparatus for sealing a split-flange zipper tape in a center fold of a web of bag making film without sealing or tacking the two sides of the split zipper web together.

Owner:ILLINOIS TOOL WORKS INC

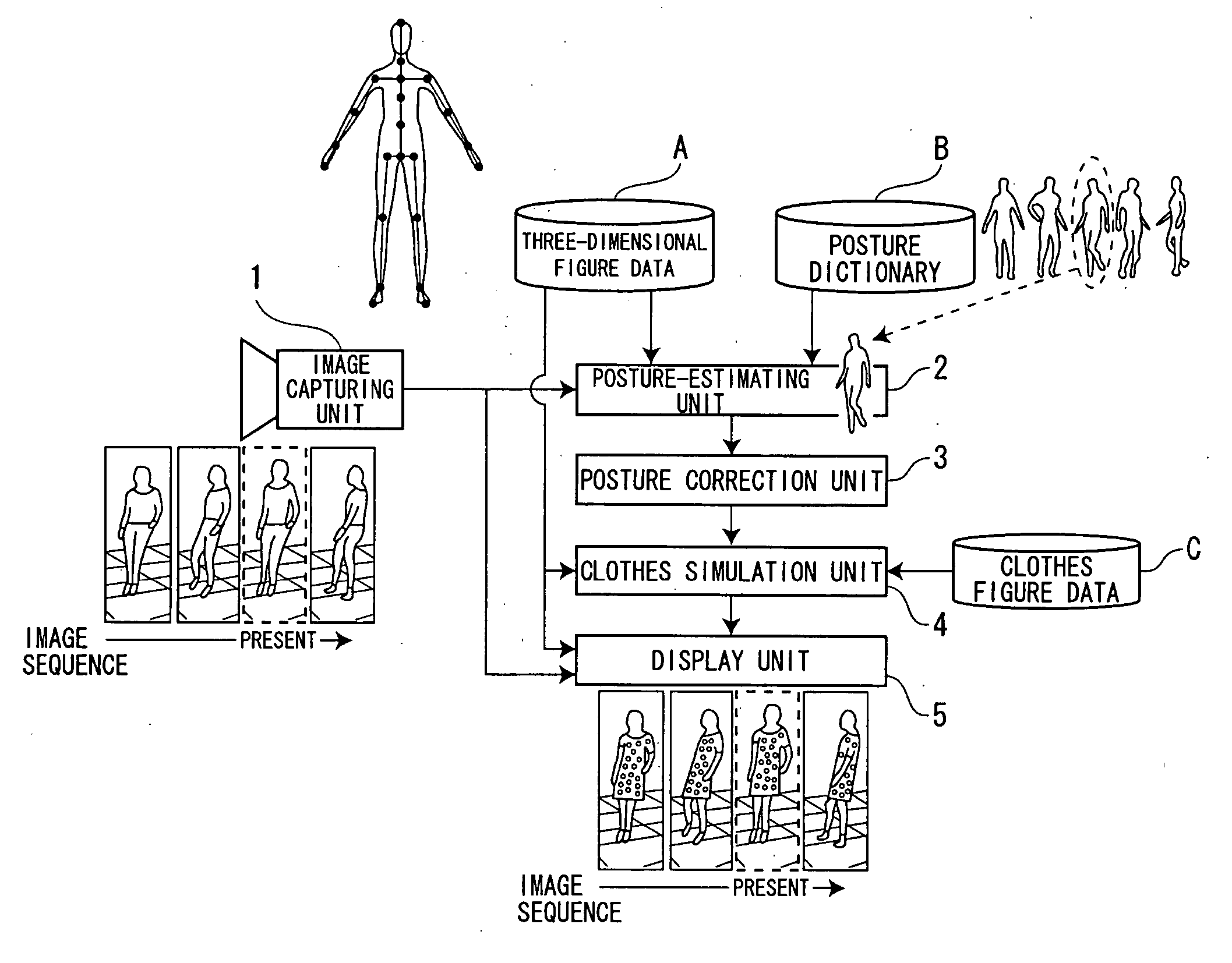

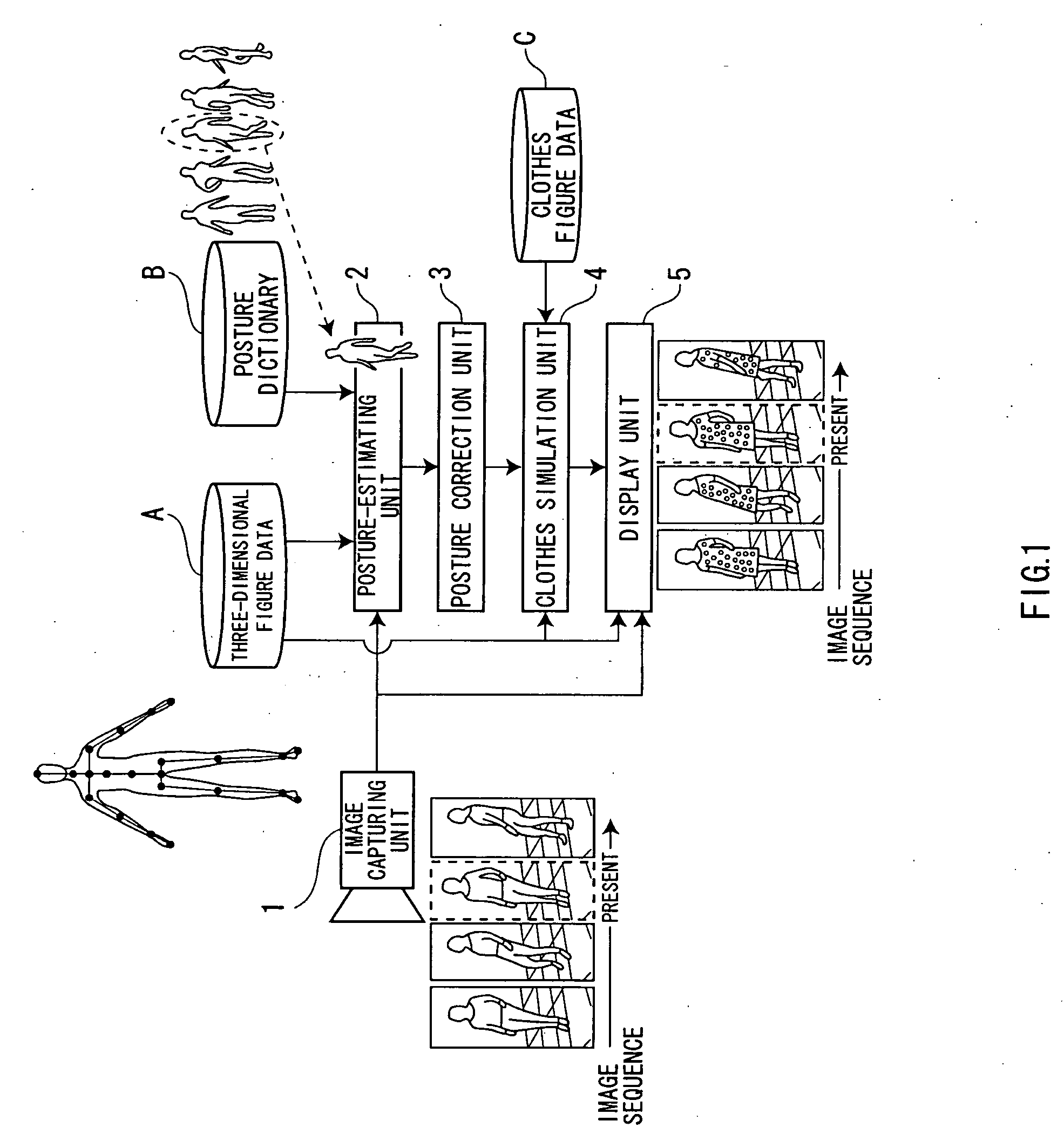

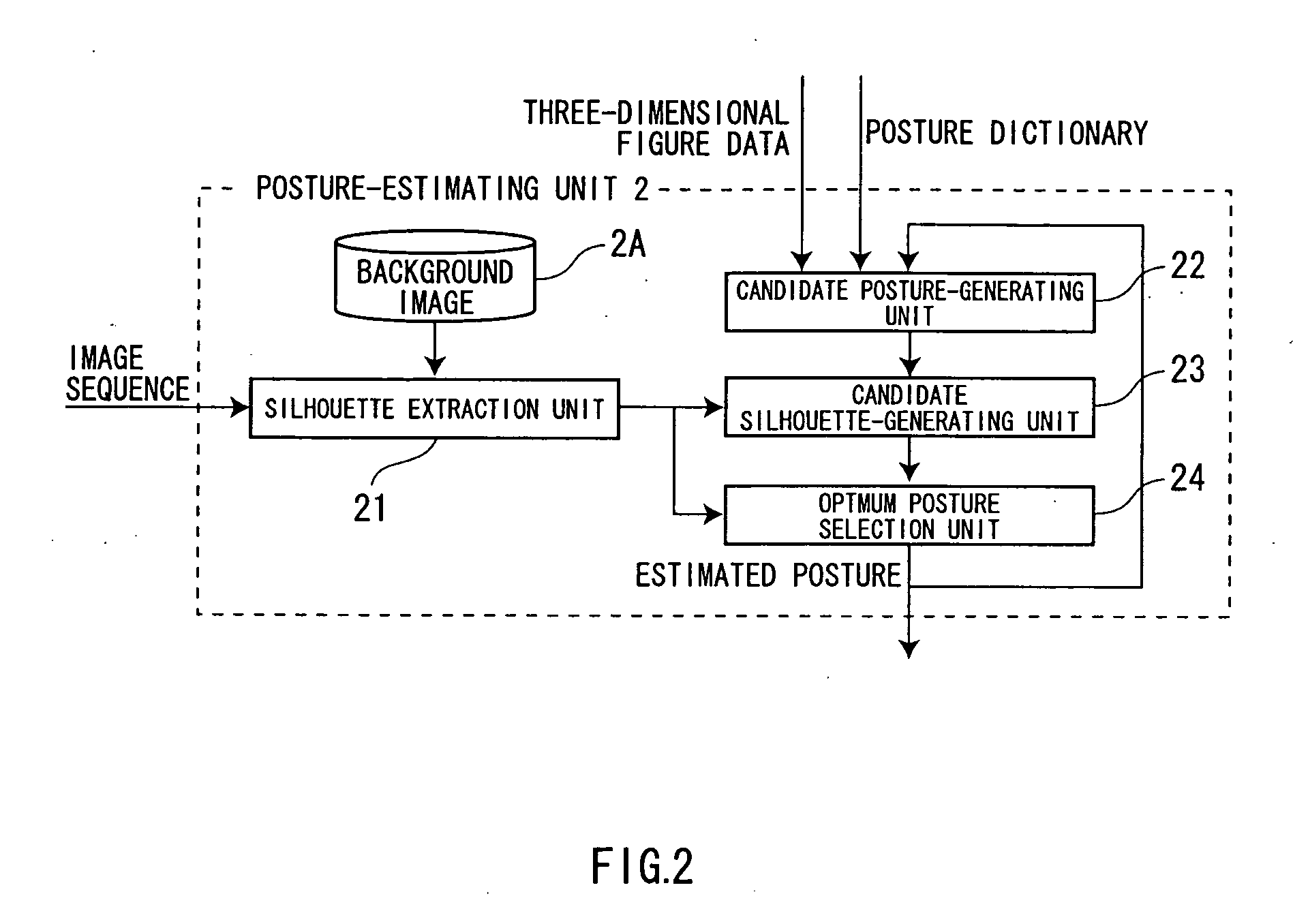

Virtual clothing modeling apparatus and method

Trying on the clothes is simulated by processing an image sequence by using a posture dictionary, and a three-dimensional figure, obtained in advance, of a person who wishes to try on clothing. The process includes estimating the posture of the person, and simulating the motions of the clothes, in agreement with estimated time series posture data. A virtual modeling apparatus comprises an imaging device configured to take an image sequence, a posture-estimator which estimates the posture of a person in the image sequence from the three-dimensional figure data of the person and from data for various postures, a posture corrector which generates smooth and natural posture time series data from the time series of estimated postures, a clothes simulator which calculates the motions of the clothing being modeled, and a display device which displays images of the person as if they were actually wearing the clothing.

Owner:TOSHIBA DIGITAL SOLUTIONS CORP

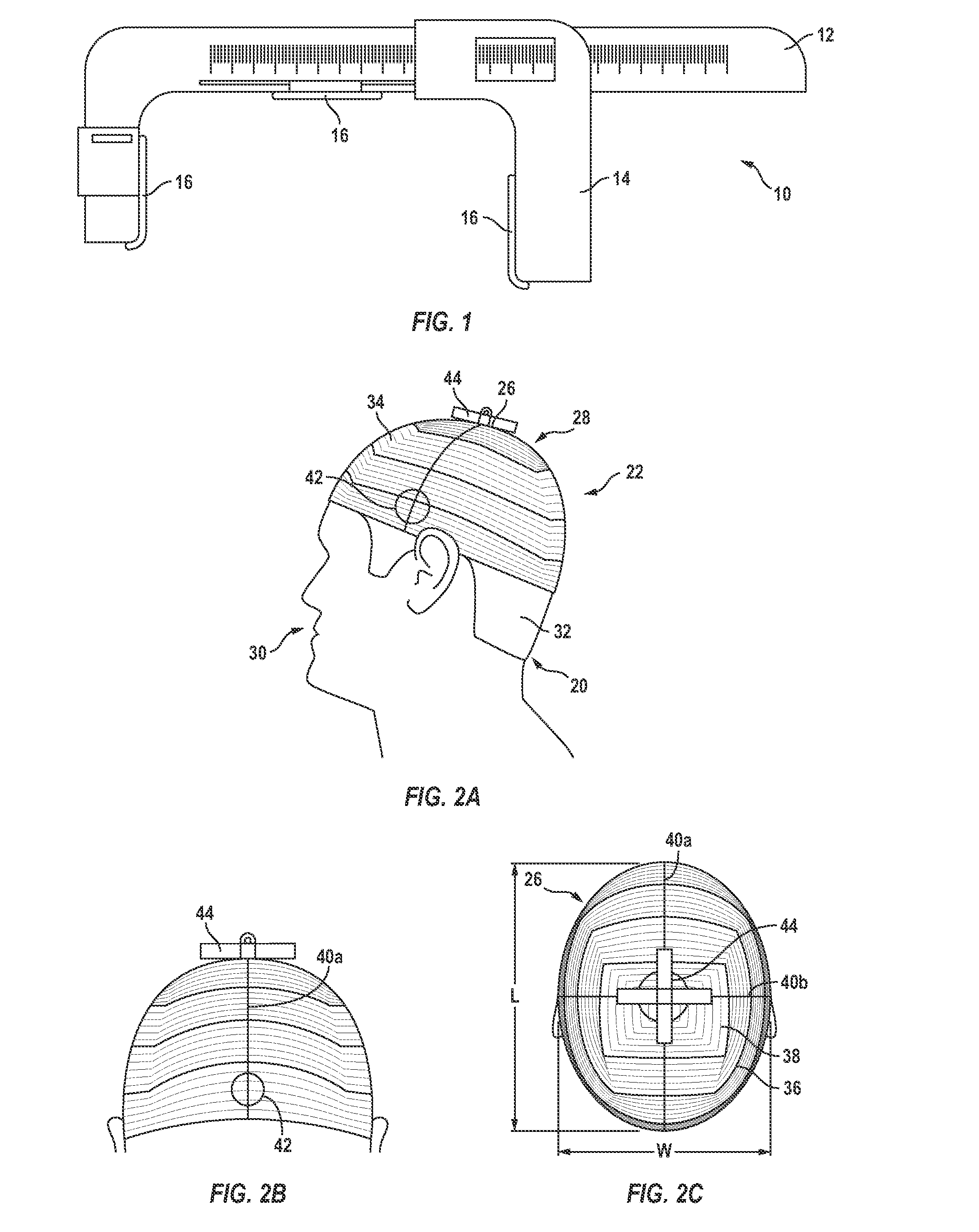

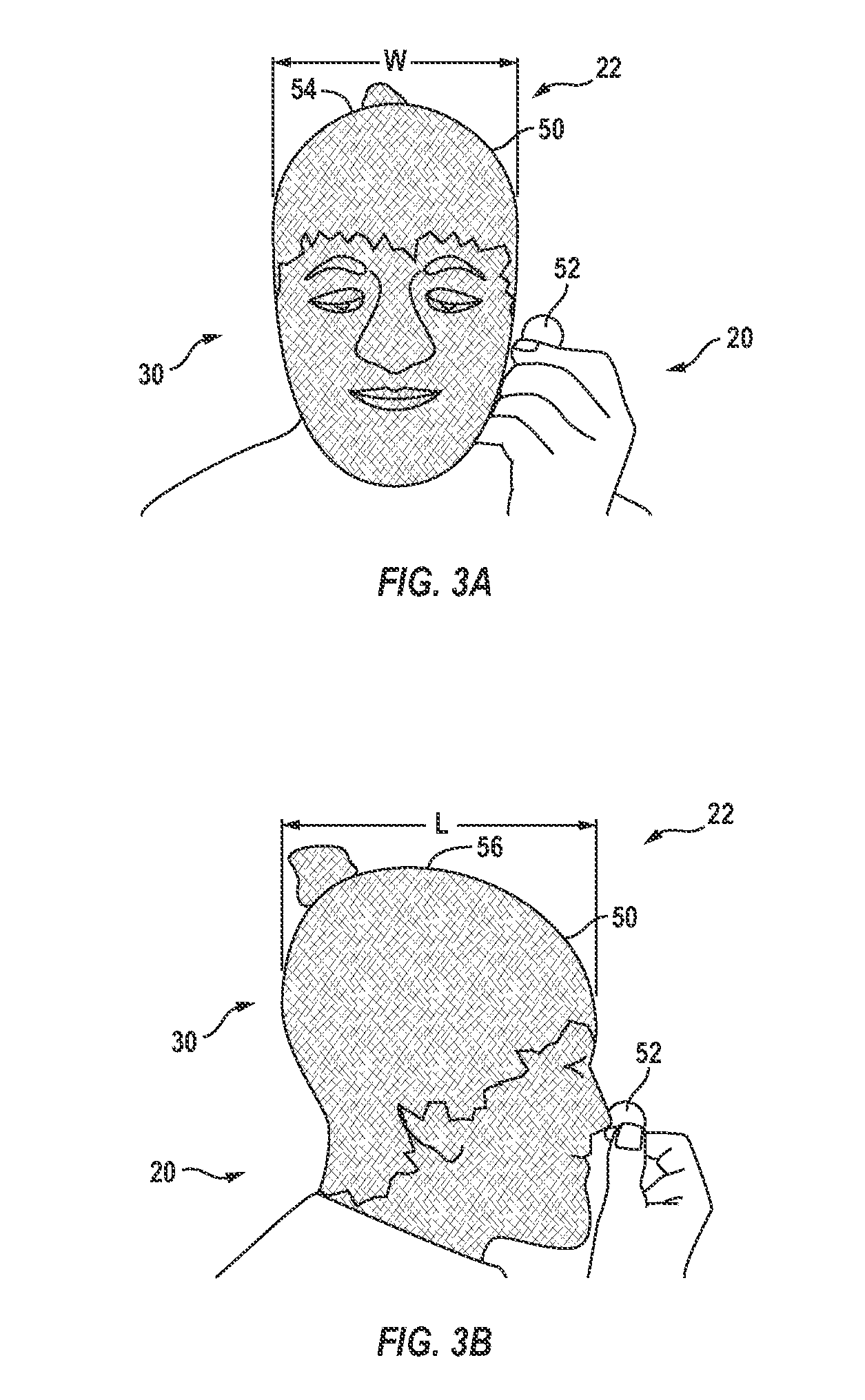

System and method for custom forming a protective helmet for a customer's head

ActiveUS20140201889A1Easy to viewProgramme controlAdditive manufacturing apparatusHead shapeTopography

A custom-fitted helmet and a method of making the same can comprise, at a first location, obtaining head data for a customer's head comprising a length, a width, and at least one head contour. With at least one processor, generating a computerized three-dimensional (3D) headform matching the customer's head length, width, and head contour from the head data. The 3D headform can be compared to a helmet safety standard. At a second location different from the first location, a custom-fitted helmet based on the 3D headform can be formed, wherein the custom-fitted helmet satisfies the safety standard and comprises an inner surface comprising a topography that conforms to the length, width, and at least one contour of the customer's head. The first location can be a home or a store. Obtaining the head data from photographic images of a deformable interface member disposed on the customer's head.

Owner:BELL SPORTS INC

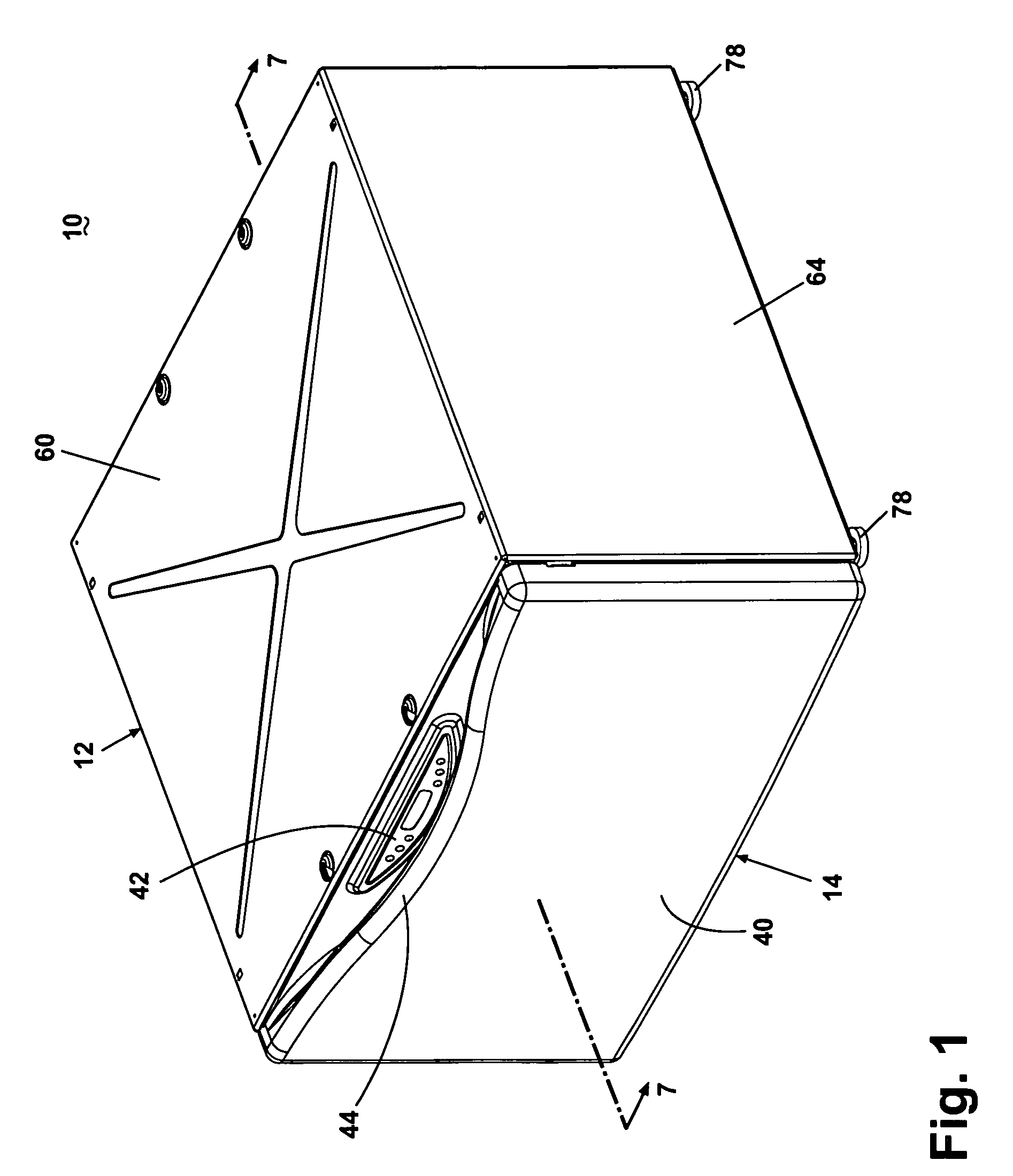

Non-tumble clothes dryer

A non-tumble dryer comprises a cabinet and a drawer configured to support an article to be dried and slidably mounted to the cabinet. An air supply system provides air to a drying chamber formed at least partially by one of the cabinet and the drawer for drying the article supported by the drawer. The non-tumble dryer can function as a pedestal whereby the top of the cabinet can be configured to support a laundry appliance in an elevated position. Alternatively, the cabinet can overlie one or more laundry appliances.

Owner:WHIRLPOOL CORP

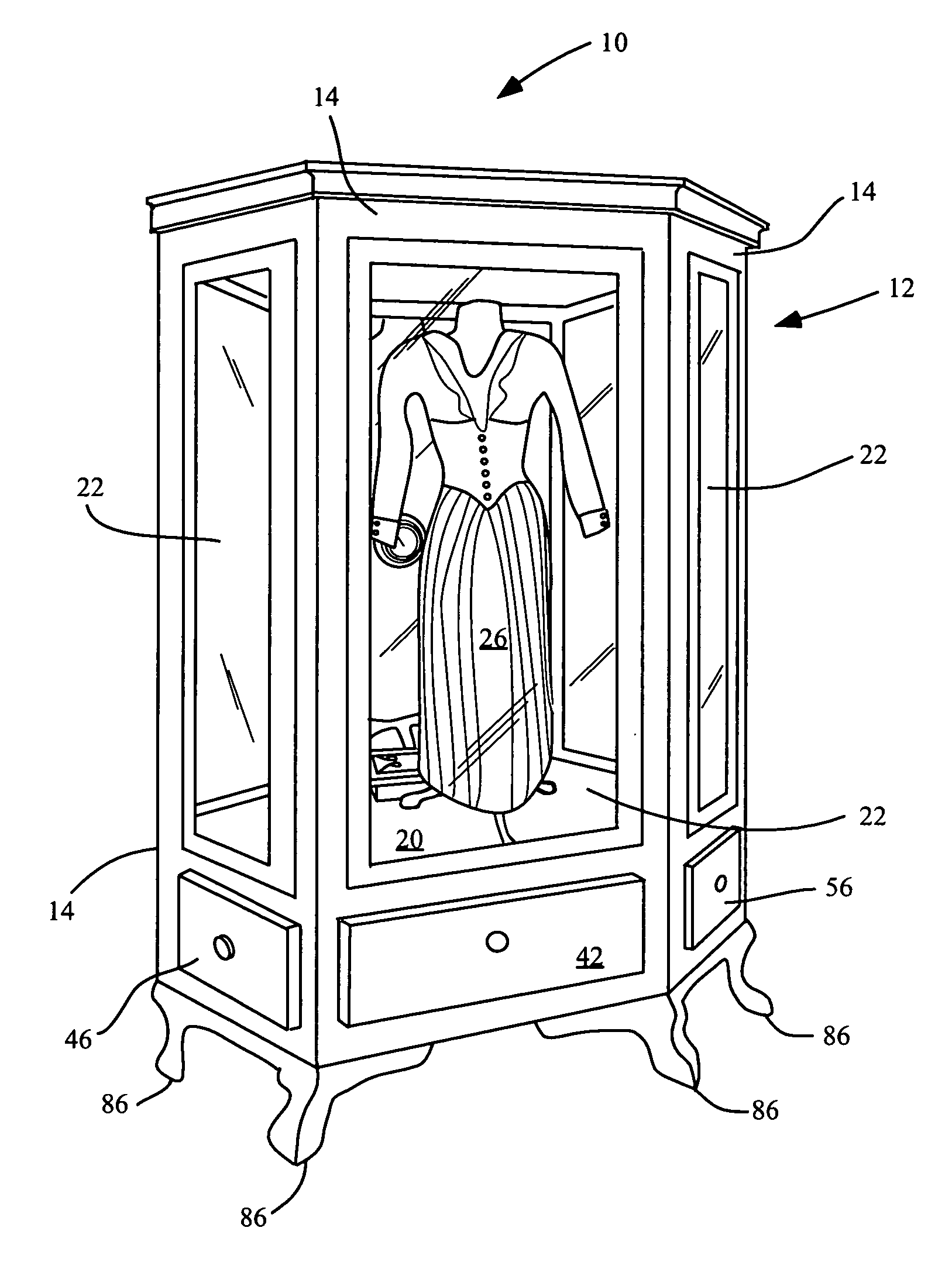

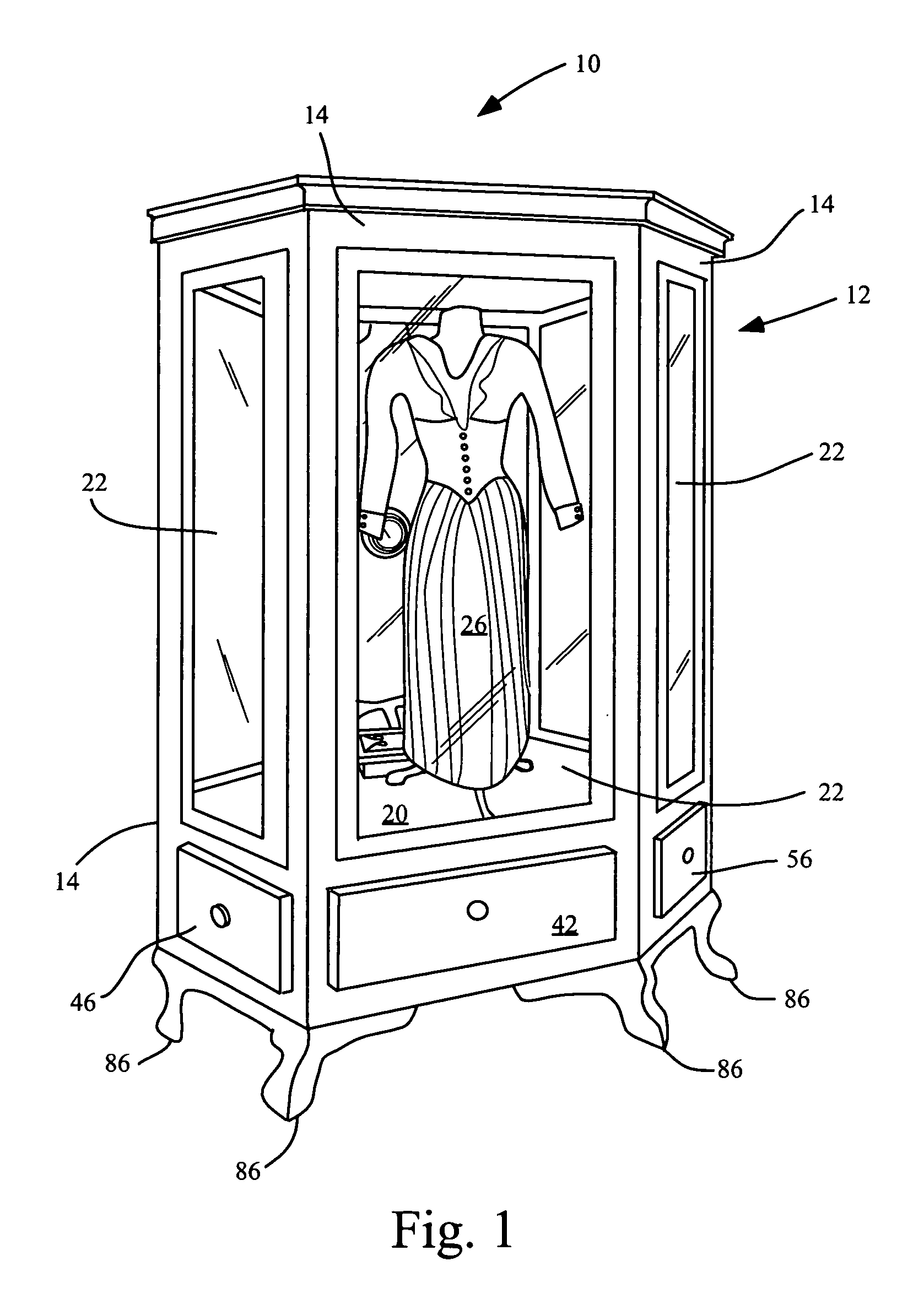

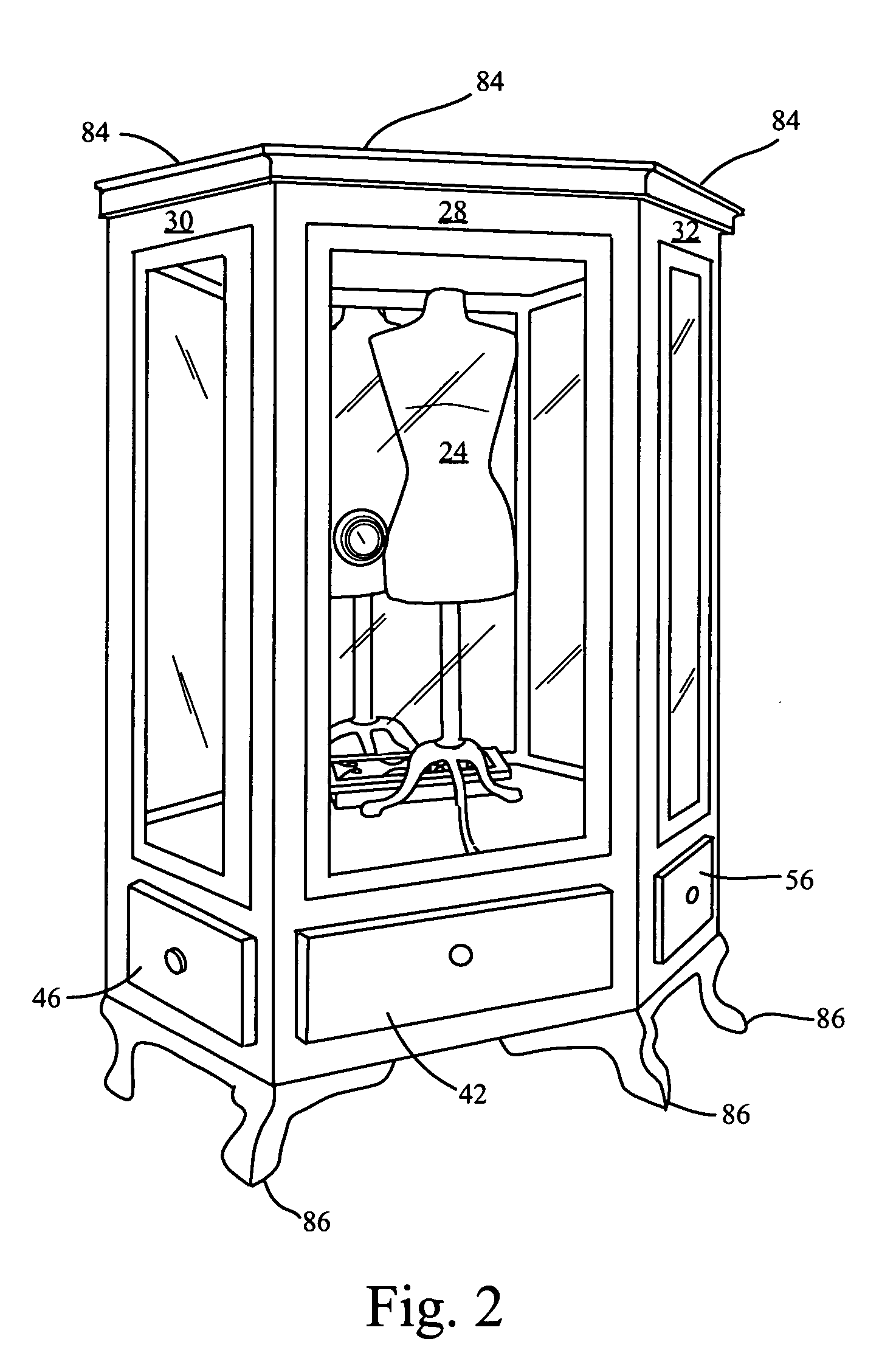

Display case

A display case provides a mechanism for displaying a clothing article in an attractive setting while simultaneously protecting the clothing article. The display case comprises an enclosure comprising a plurality of panels, including an panel which opens to provide access to the interior of the display case. The display case further comprises a dress form disposed within the interior of the display case. Some of the panels comprise glass sections allowing a viewer to observe the clothing article within the enclosing frame. The display case further comprises an enclosing top and bottom. The display case comprises a floor upon which the dress form may be disposed, wherein a cavity is defined by the space between the enclosing bottom and the floor. The display case further comprises humidity control means which may be located within the cavity. One embodiment of the display case may comprise back panels wherein the back panels have mirrored surfaces on the interior side to reflect the back and sides of the clothing article. One embodiment of the display case may be shaped hexagonally.

Owner:BARNETT MICHAEL J +1

Method and apparatus for reversing direction of an article

InactiveUS20050233881A1Little strengthHigh decelerationMechanical working/deformationFunction indicatorsIndustrial engineering

Owner:CURT G JOA

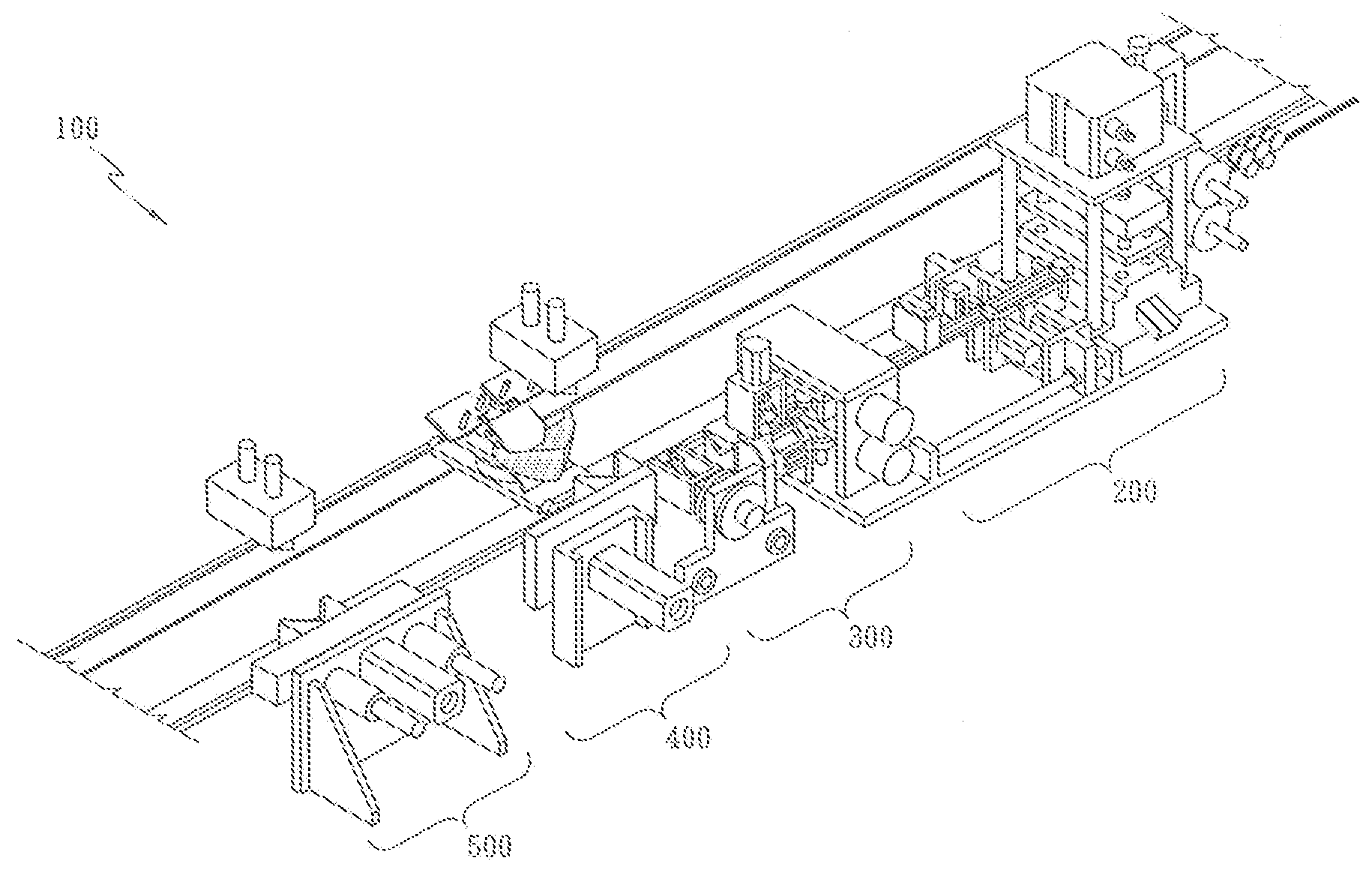

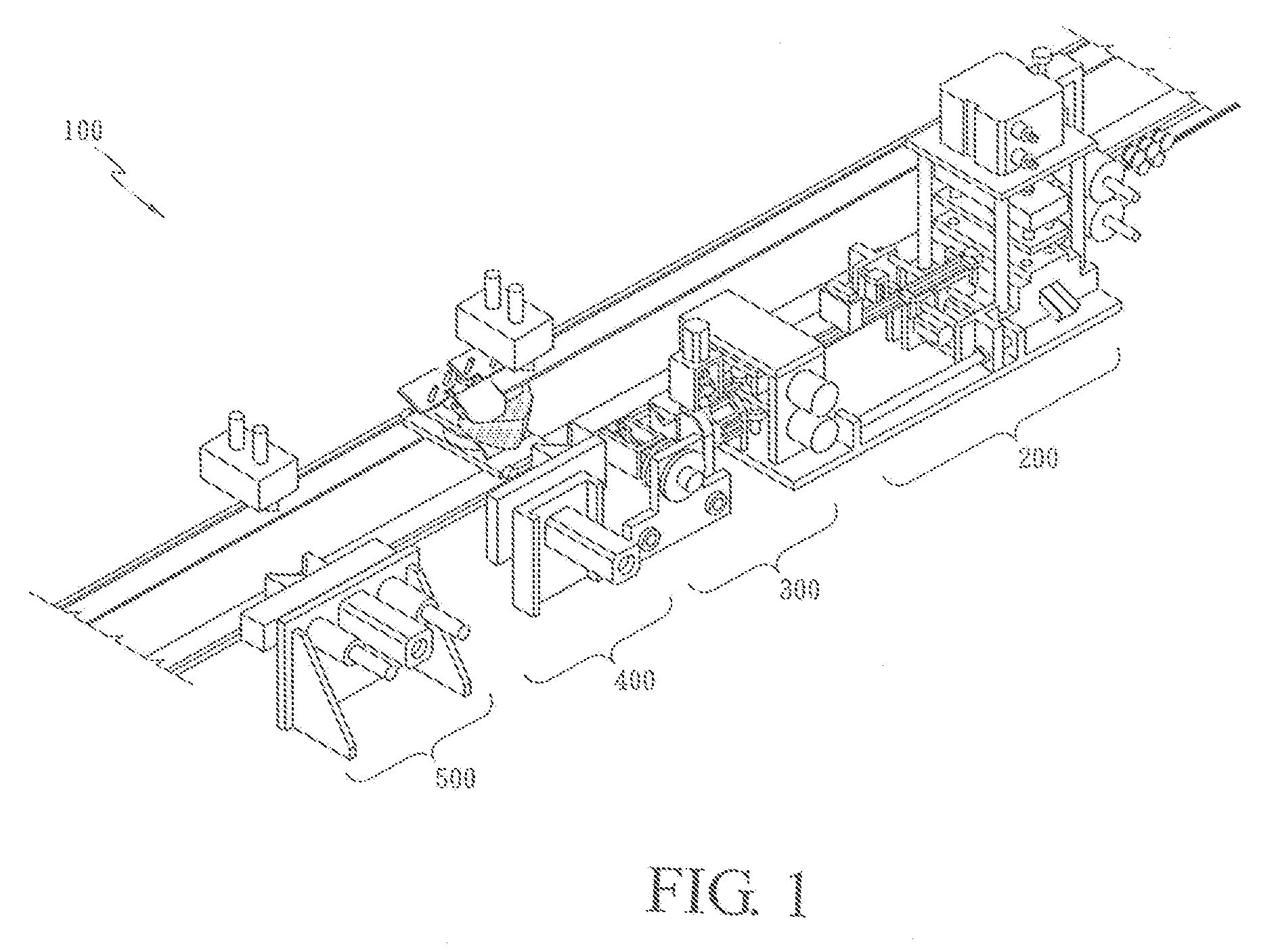

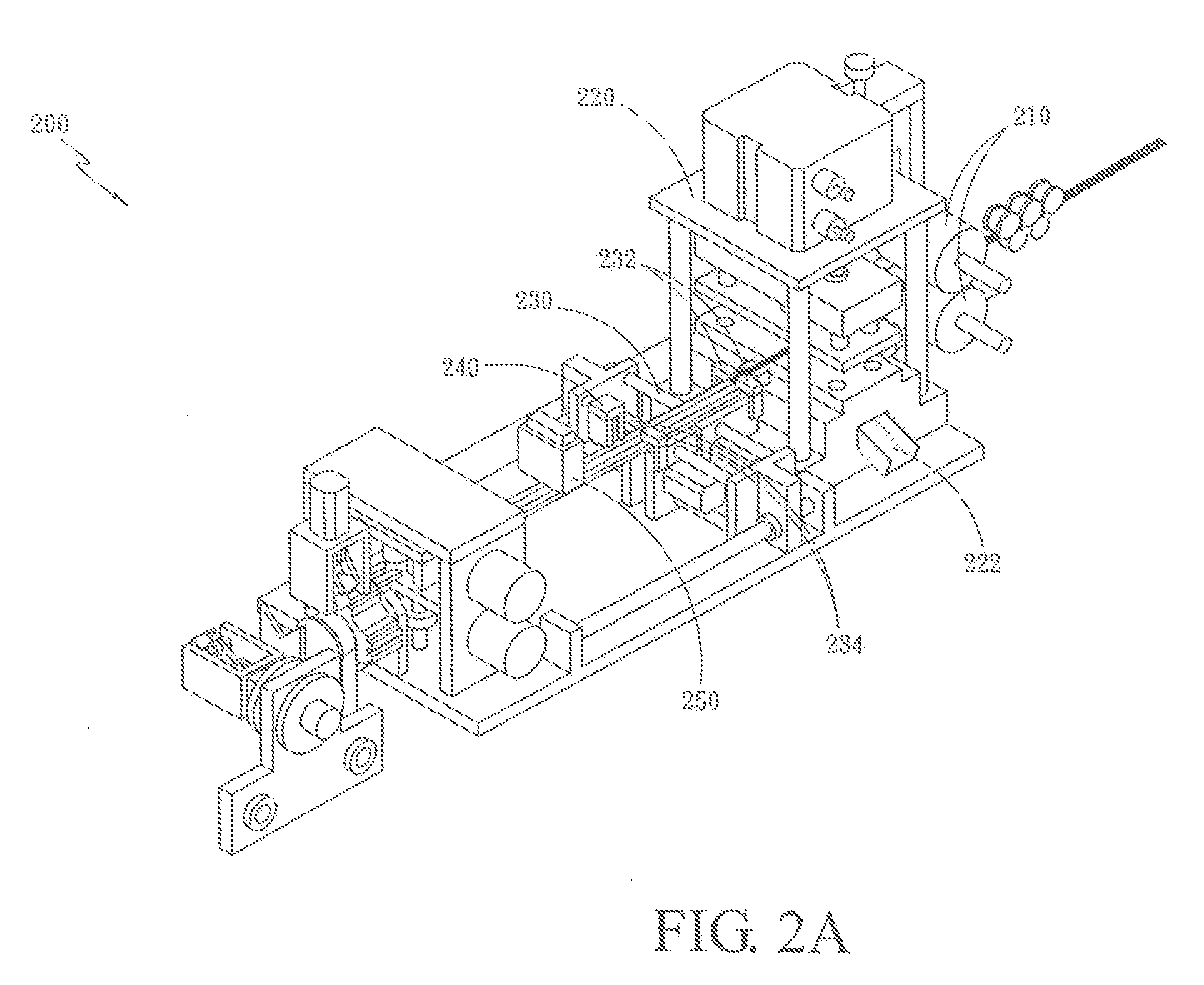

System and Method for Automated Manufacturing of Custom Apparel

A centralized command and control network system for the automated manufacture of a personalized custom-fit garment comprises a centralized control system; automated programmable manufacturing equipment configured for assembling and stitching the personalized custom-fit garment from a digital pattern; and automated programmable material handling equipment configured for transporting the personalized custom-fit garment or its components through each step of the manufacturing equipment. After the customer has had his or her body scanned, and selected and personalized a garment design, the inventive manufacturing system will then manufacture the garment upon receipt of the order in an automated manner without requiring further substantive manual intervention or touch labor. The resultant personalized custom-fit garment is based on the customer's three-dimensional body shape and style and fit preferences. The system can be used to prepare any kind of garments.

Owner:3D TECH LLC

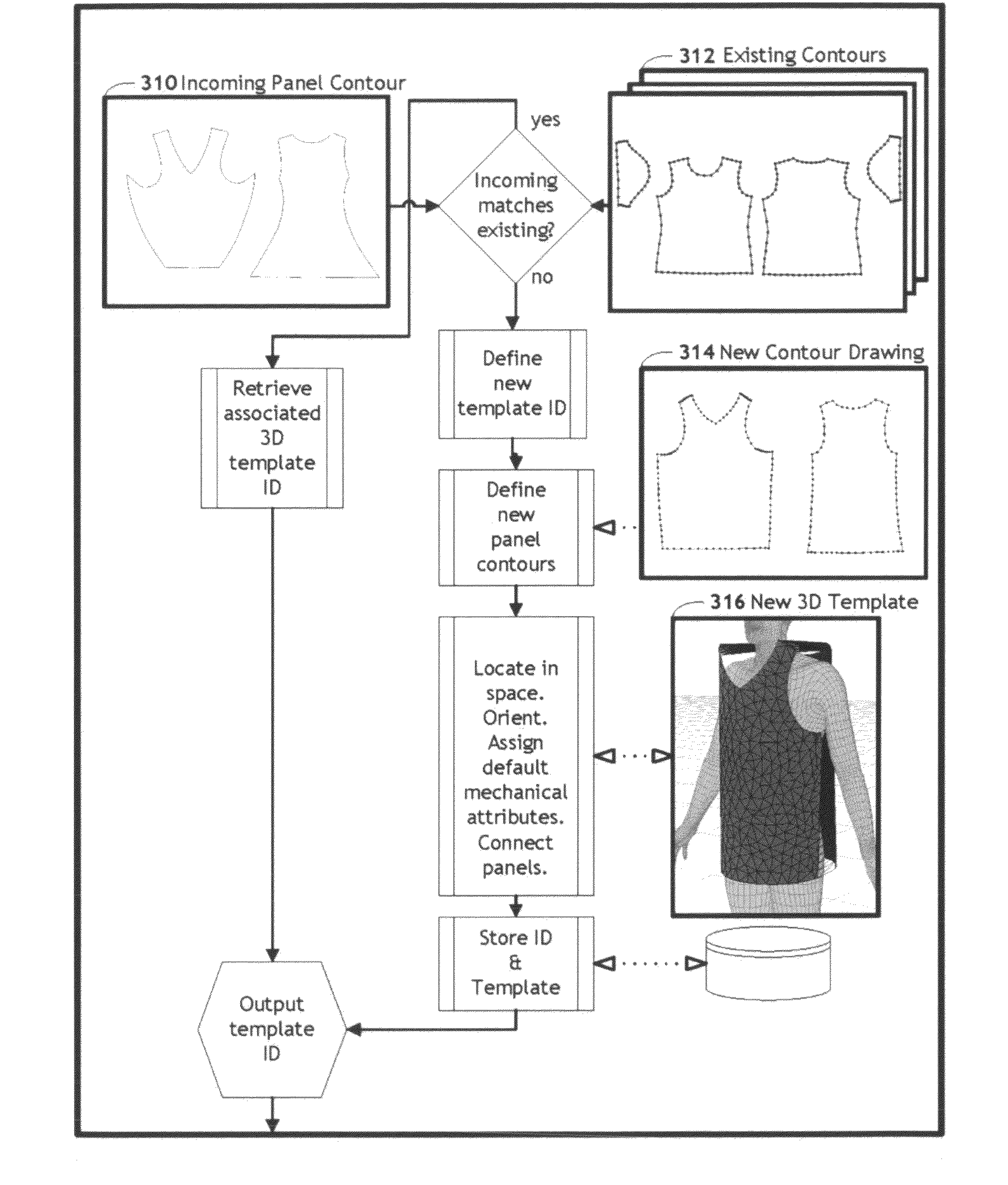

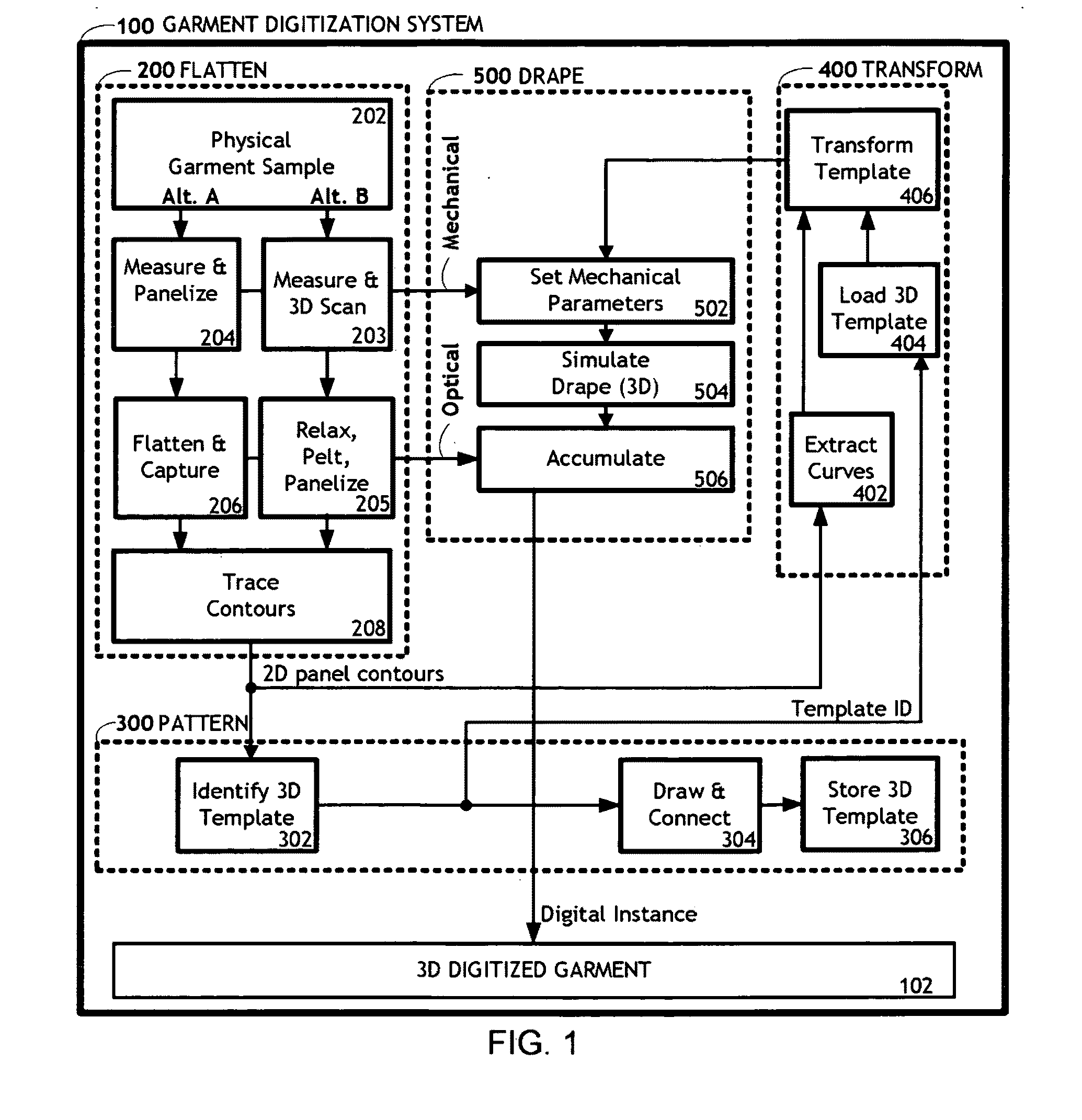

Garment digitization system and method

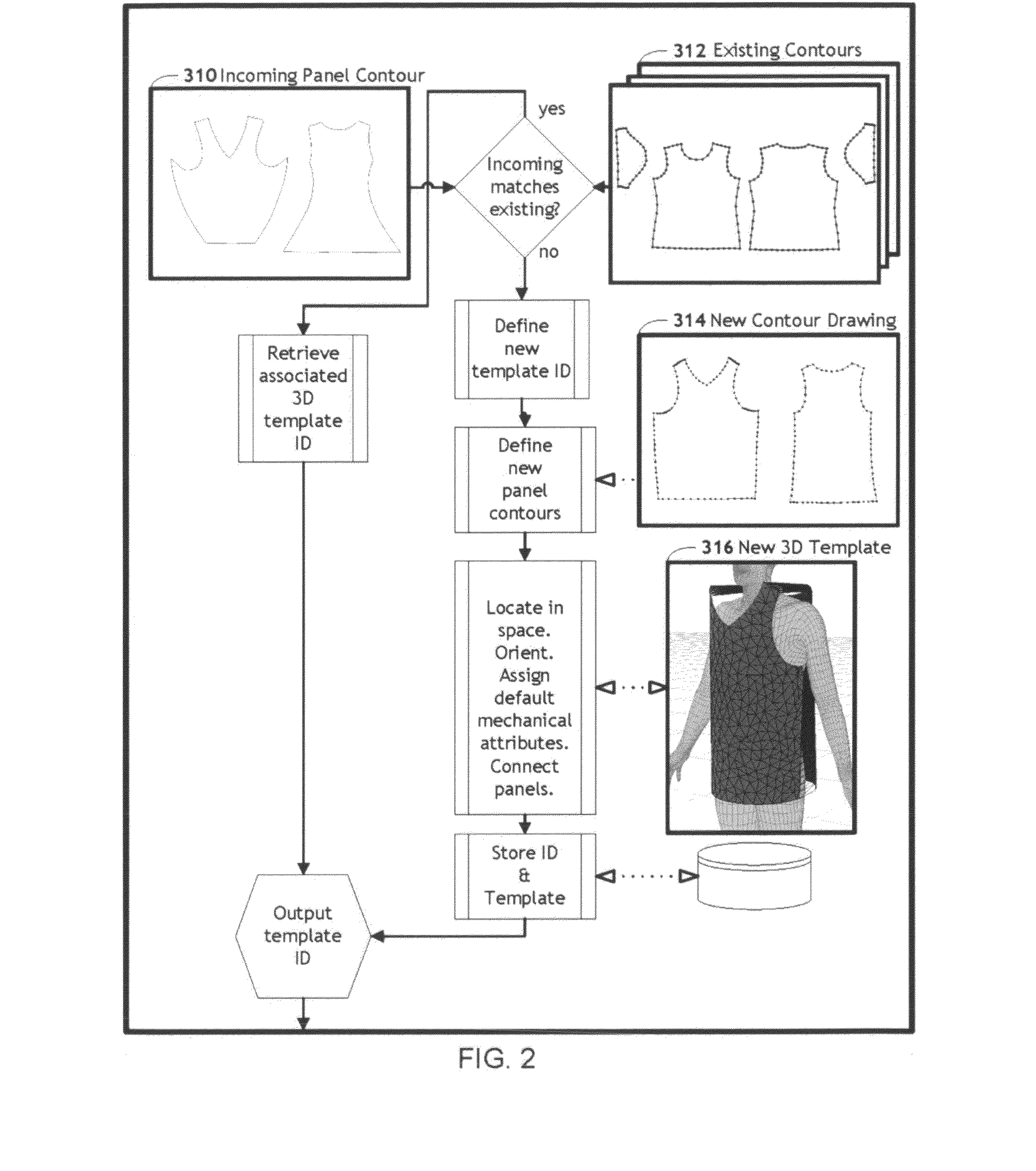

ActiveUS20100305909A1Improve realismImprove utilizationCommerceSpecial data processing applicationsEngineeringDigitization

A garment digitization system configured to determine physical attributes for any given garment including dimensional and spatial properties, mechanical attributes, optical attributes, and assembly information; a mechanism configured to take those properties and attributes and generating a digital three-dimensional model thereof; a mechanism to make such digital three-dimensional garment models available to others; and a mechanism operatively coupled with a local or remote display providing views of said digital garment.

Owner:EMBODEE PR LLC

Computer system for rule-based clothing matching and filtering considering fit rules and fashion rules

InactiveUS20070198120A1Increase probabilityBuying/selling/leasing transactionsSpecial data processing applicationsData miningComputer generation

Owner:MIPSO

Method of forming self-supporting pleated filter media

The method of forming pleated filter media includes providing a generally planar web of filter material, folding the web to form a pleated web having a plurality of fold lines, arranging the plurality of pleats in a first spaced configuration defined by a first distance between adjacent pleat tips, applying a continuous strand of adhesive to the web, and adjusting the arrangement of the plurality of pleats into a second spaced configuration defined by a second distance between adjacent pleat tips. The web has a front face and a rear face. Each fold line is intermediate oppositely sloping first and second wall surfaces. The plurality of fold lines form a plurality of pleats having a first plurality of pleat tips and a second plurality of pleat valleys. The second distance is different from the first distance.

Owner:3M INNOVATIVE PROPERTIES CO

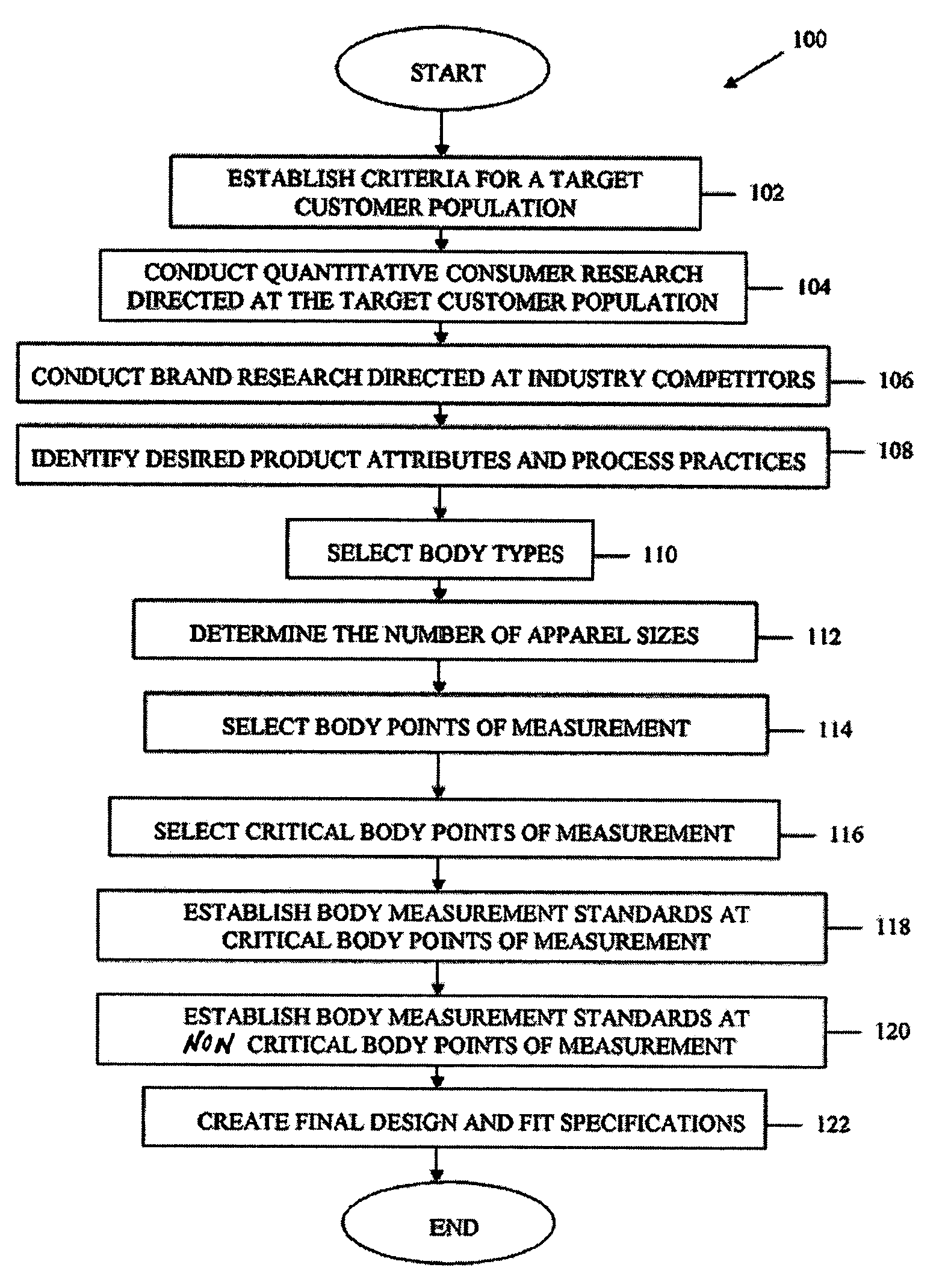

Systems and methods for improved apparel fit

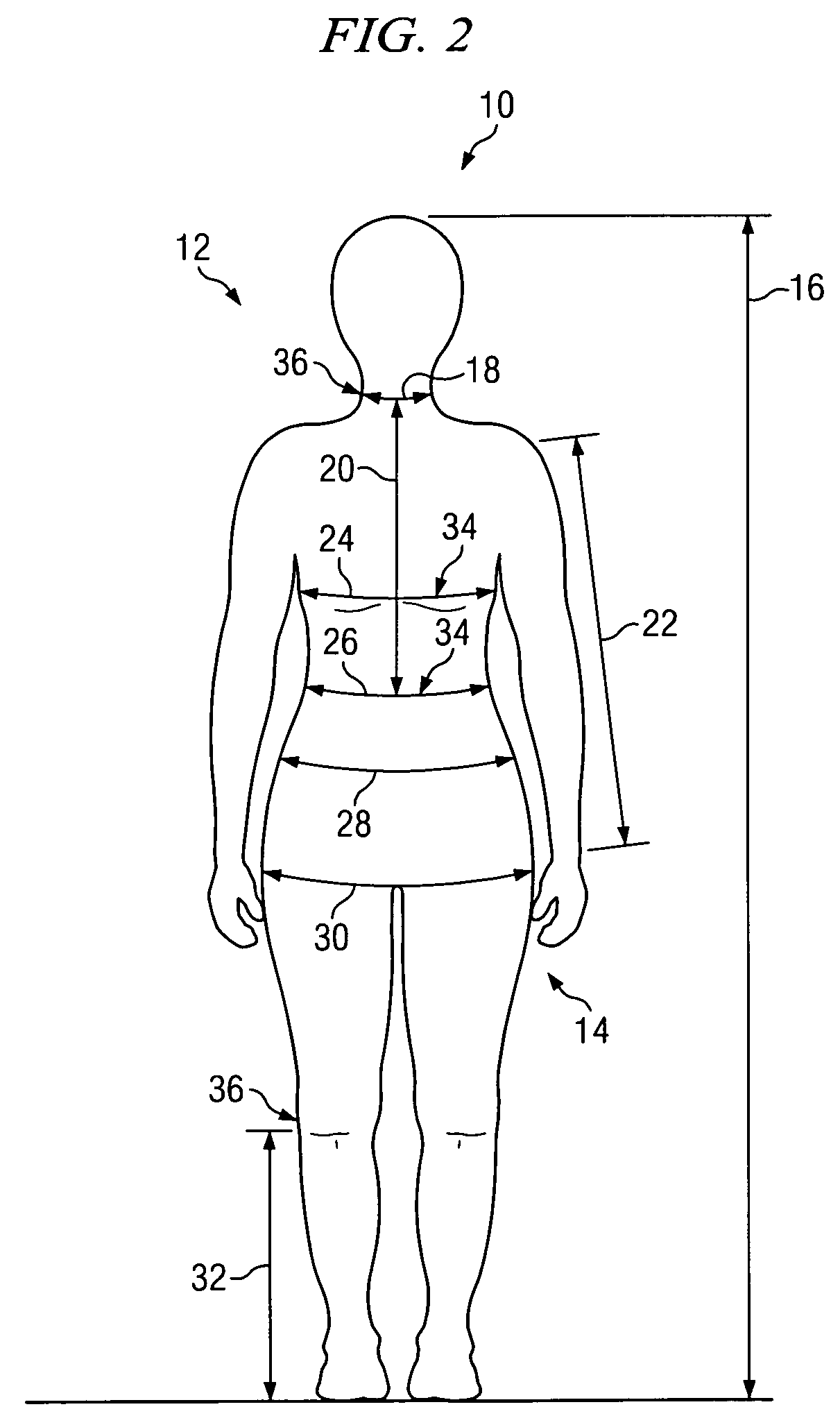

ActiveUS7092782B2Accurate methodIncreasing retail inventoryBuying/selling/leasing transactionsSpecial data processing applicationsEngineeringType selection

Systems and methods for providing garments with improved and customized fits to one or more target consumer groups fit are described in the present invention. One method provides for a garment fit to a target consumer group comprising the steps of determining common body types for the target consumer group, establishing customized body measurement standards for each body type, selecting at least one real fit model for each body type, creating a sample garment in a range of sizes using grading rules, checking each sample garment on a fit model selected for each size and body type, preparing a block for each sample garment size and body type, and using the block to provide a garment fit for a target consumer group. Additional aspects are also disclosed.

Owner:ADVANTAGE PLATFORM SERVICES INC

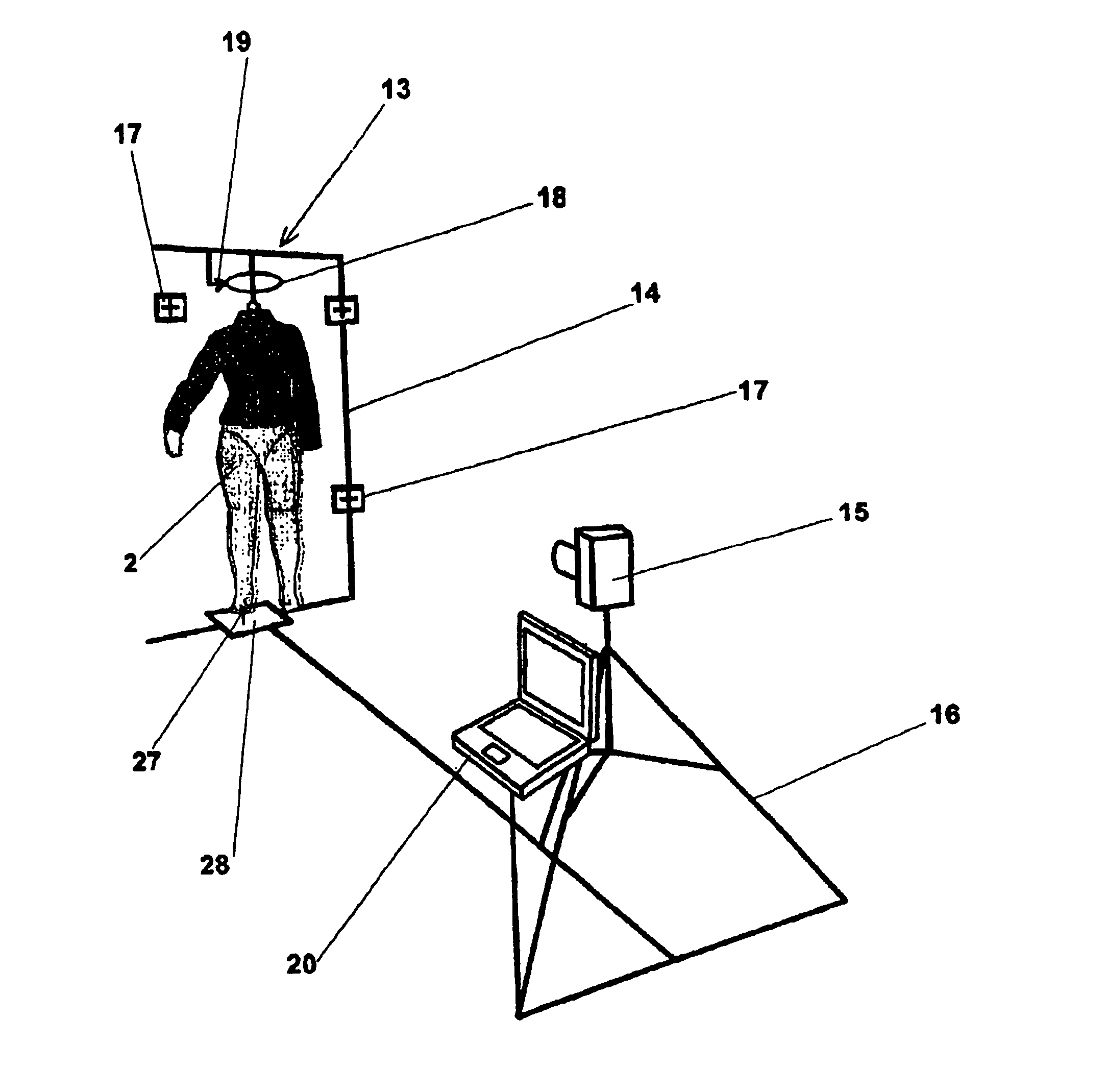

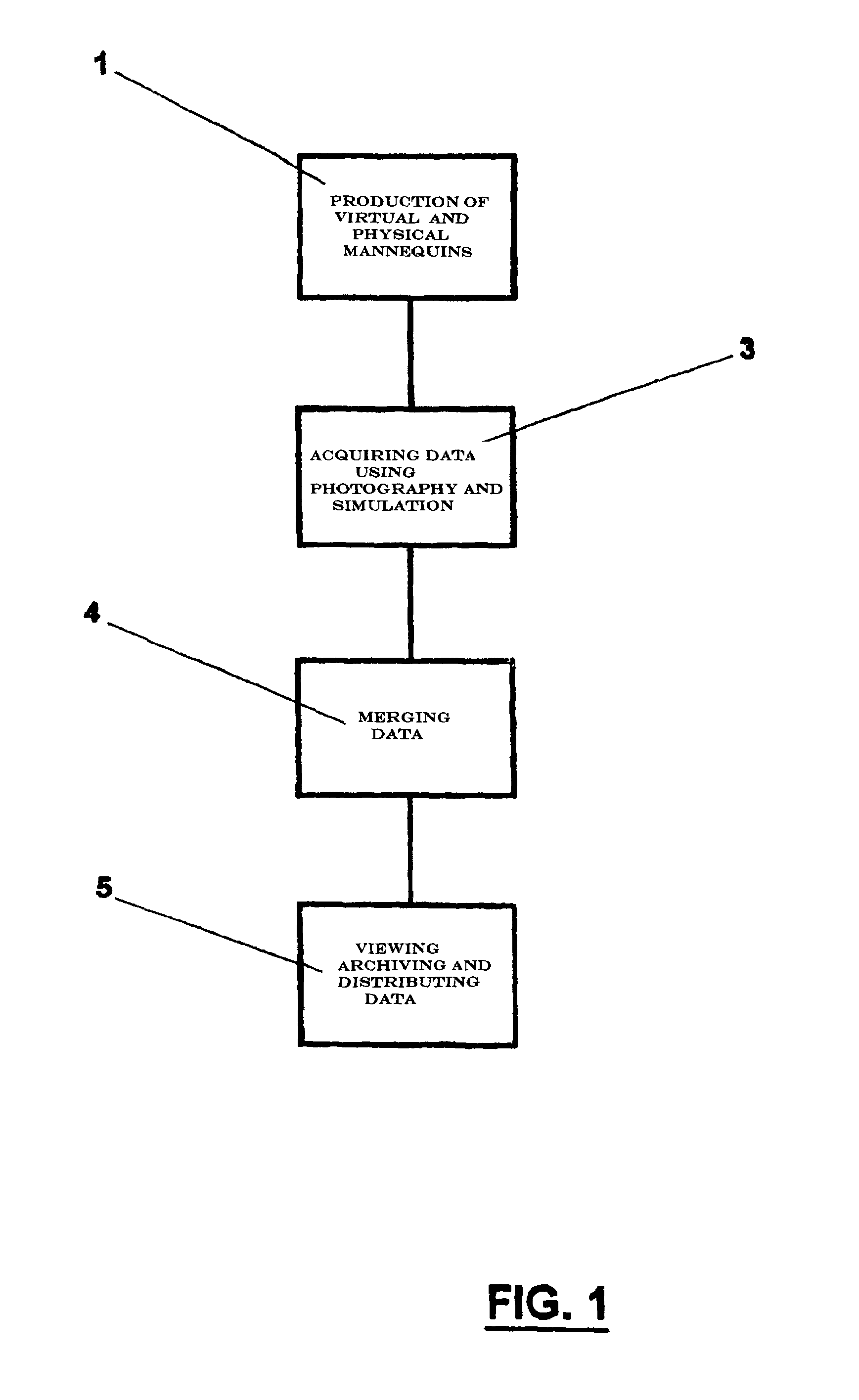

Method and device for viewing, archiving and transmitting a garment model over a computer network

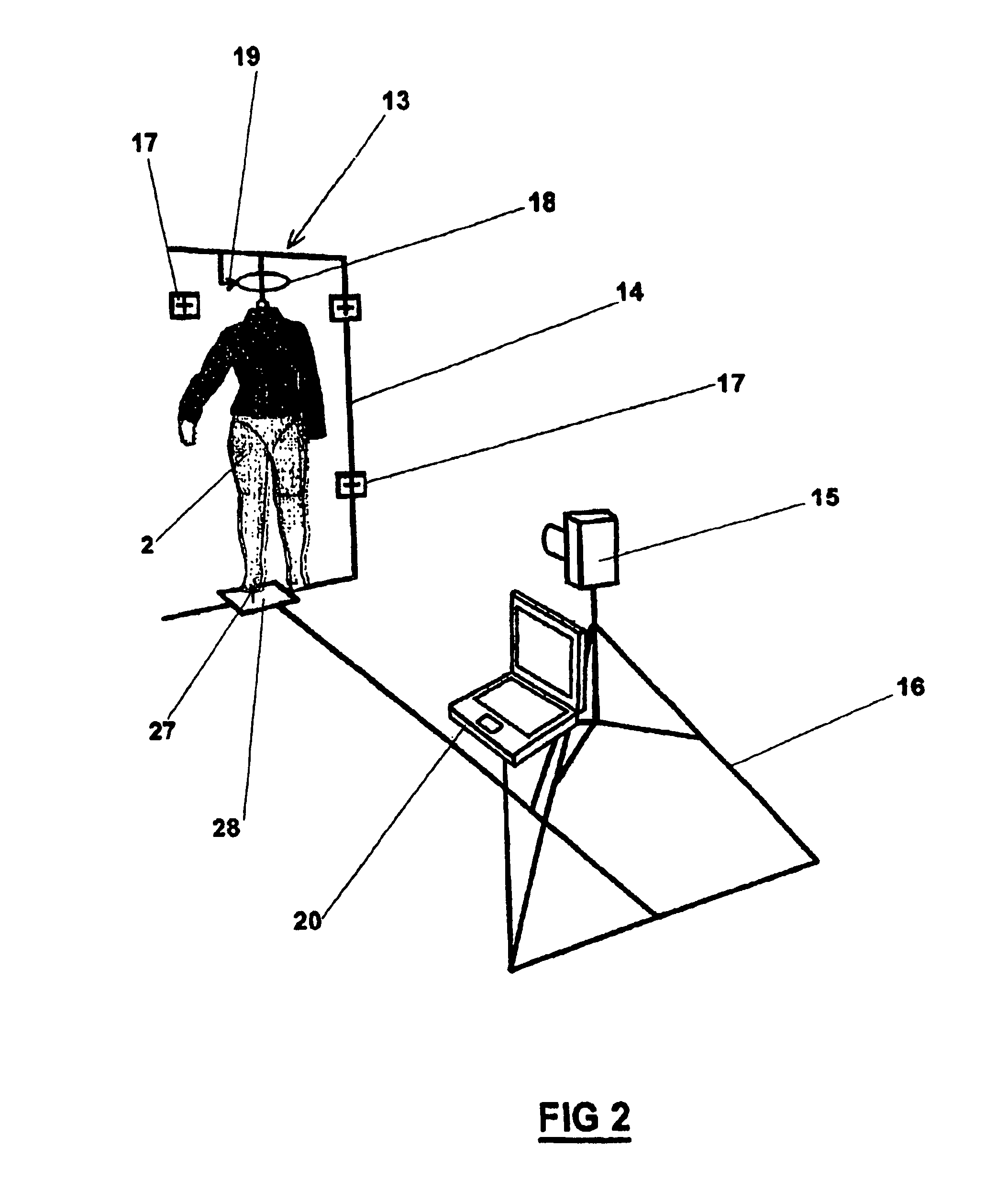

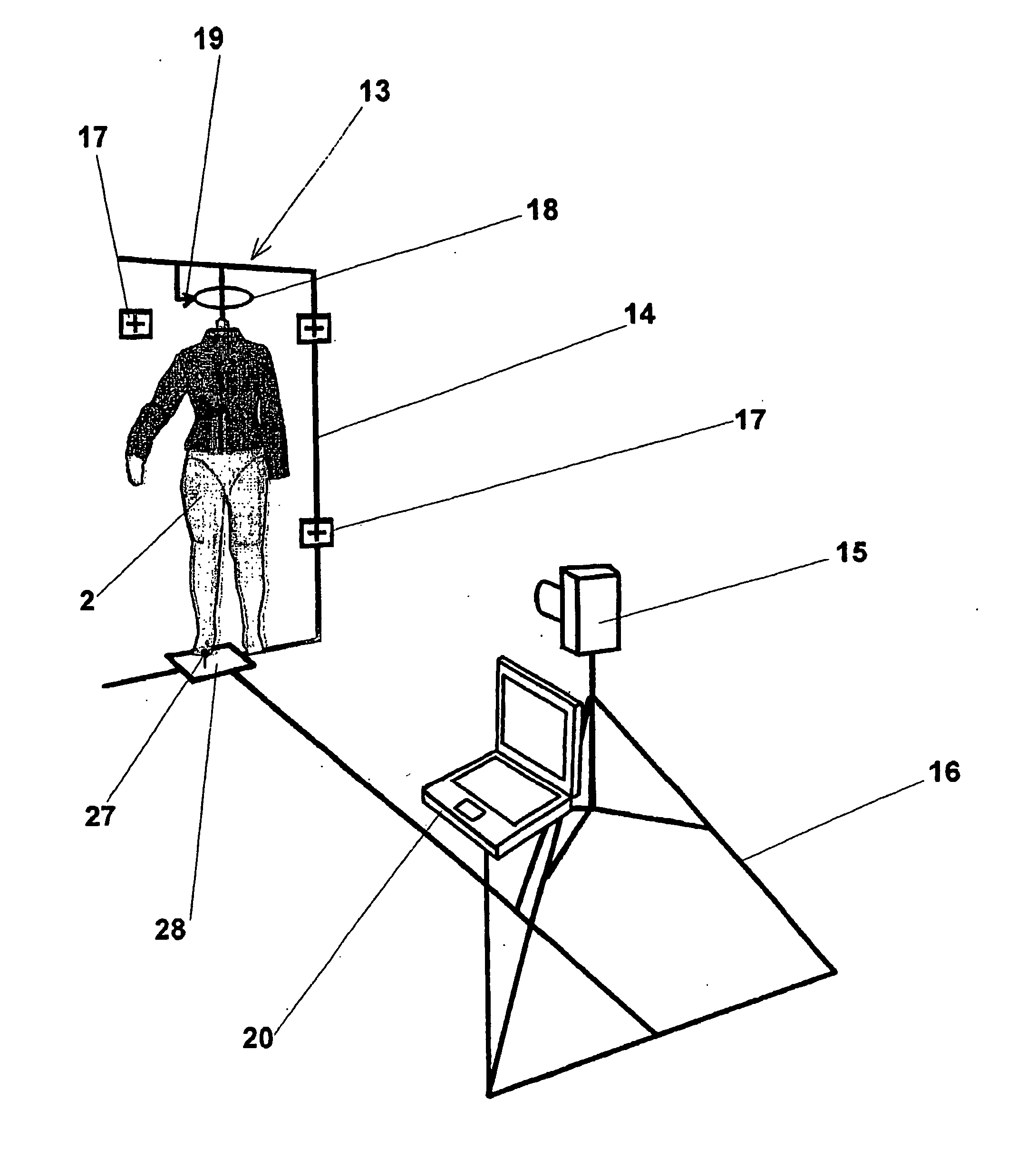

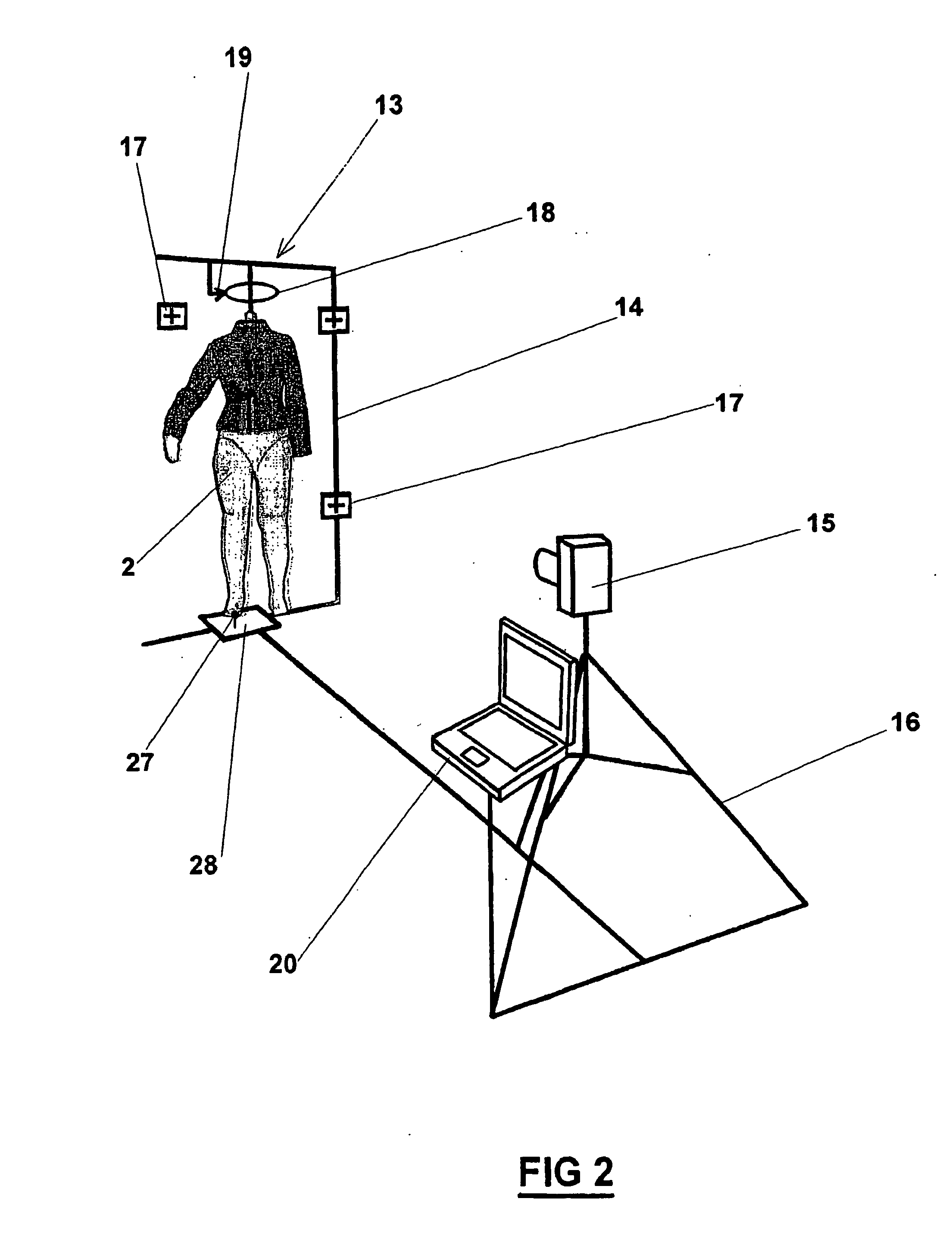

InactiveUS7039486B2Efficient communicationPrecise positioningMeasurement devicesSurgeryDigital imageReference line

A method and device for viewing, archiving and transmitting a garment model over a computer network. The method comprises photographing a physical mannequin from several different directions, the mannequin being a copy of a virtual human model which is representative of the target consumer. The virtual mannequin viewing layers and the garment model are generated from digital images of the naked or clothed mannequin which is suspended from the photography stand. A laser beam is used to determine the exact position of the mannequin. Subsequently, crop marks and recorded reference lines can be used to merge the viewing layers and the model precisely. The data are archived in a base and transmitted over an intranet, an extranet or the Internet for the purpose of remote viewing. The method and device are particularly suitable for the design, manufacture and inspection of clothing samples in the clothing industry.

Owner:WANG KENNETH KUK KEI

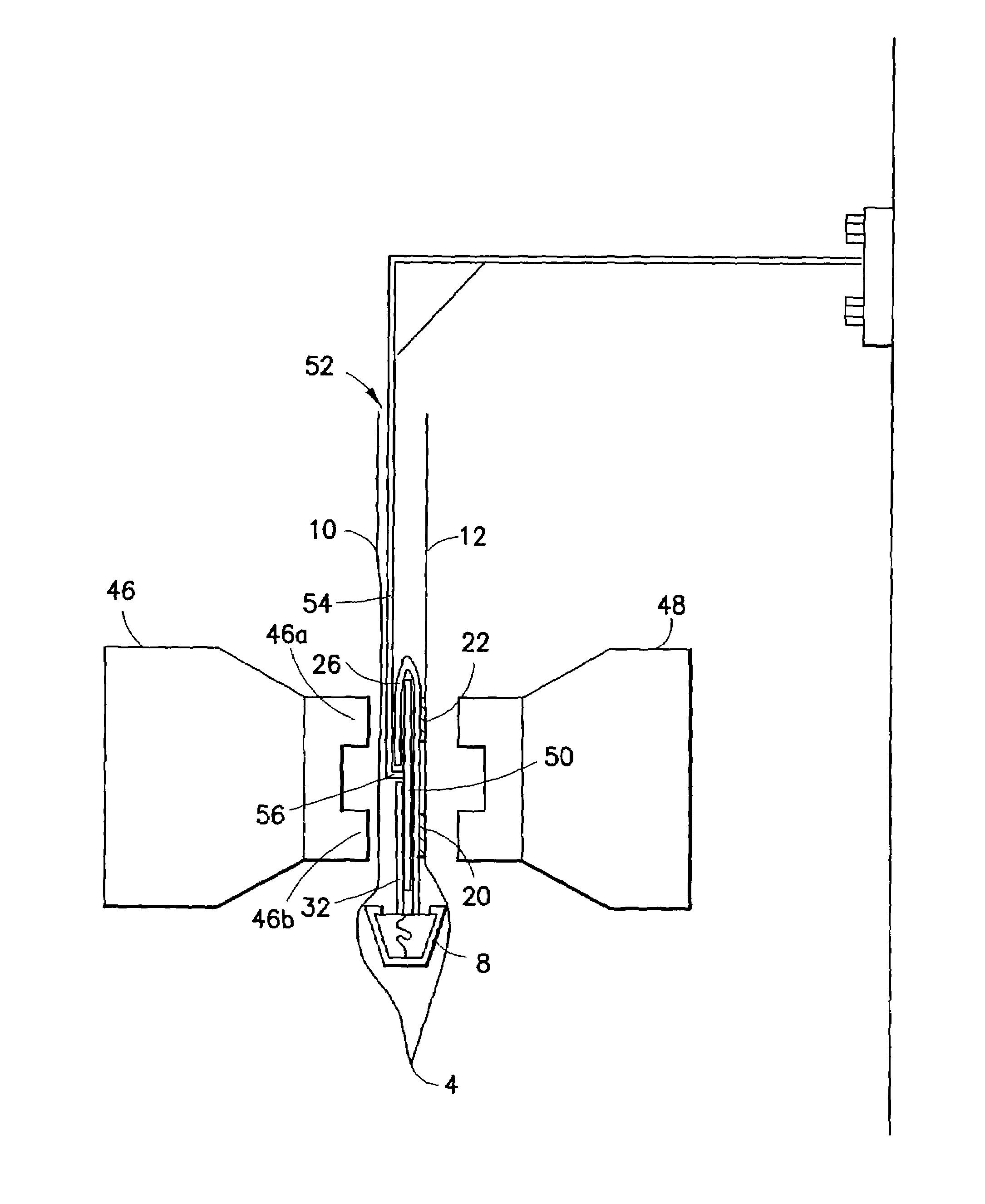

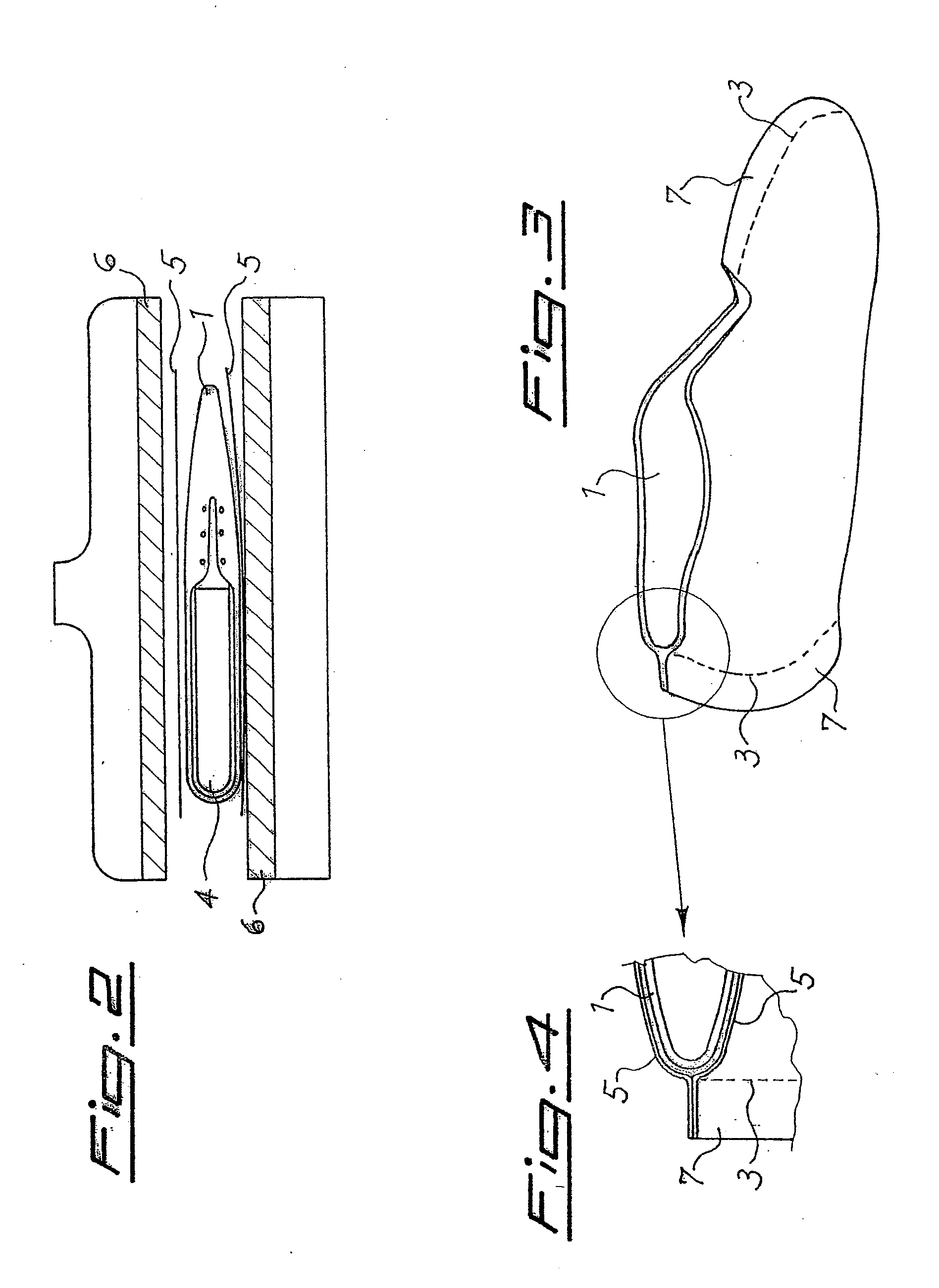

Automatic nose strip bonding apparatus for face mask

InactiveUS20080251210A1Improve manufacturing speedImprove product qualityLiquid surface applicatorsLamination ancillary operationsNoseSecondary bonding

An automatic nose strip bonding apparatus for a face mask is disclosed, including a nose strip providing mechanism, a nose strip turnover mechanism, and a press-to-bond device. The nose strip providing mechanism drives a nose strip forward and carries out stamping operation on the nose strip, and applies a bonding agent to the nose strip. The nose strip turnover mechanism serves to turn over the nose strip that has already been applied with the bonding agent to allow the surface of the nose strip on which the bonding agent is applied to face a face mask. The press-to-bond device includes a first bonding device and a second bonding device to attach the nose strip to the face mask and to carry out a secondary bonding operation, respectively, to ensure firm bonding of the nose strip to the face mask.

Owner:CHEN HUNG HO

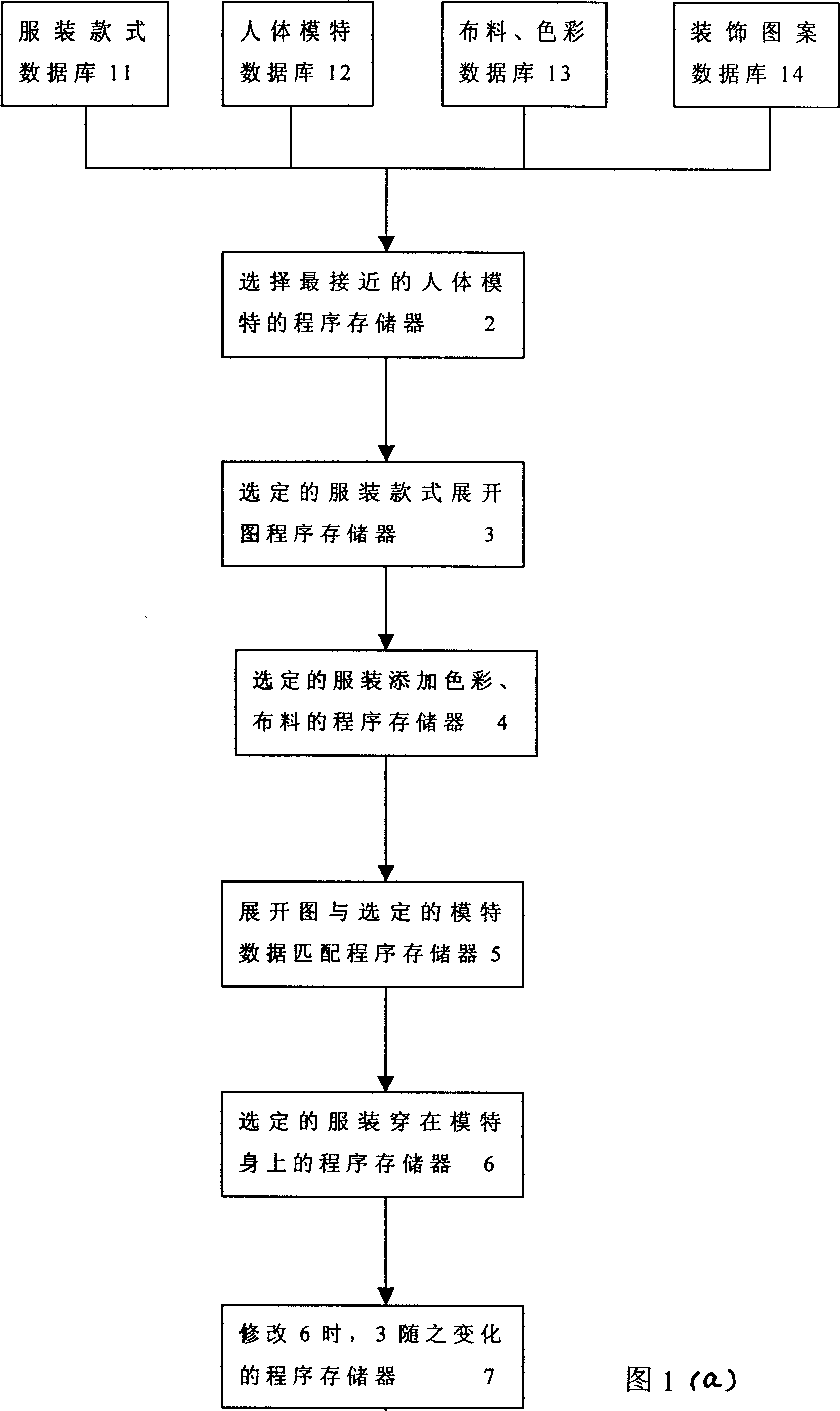

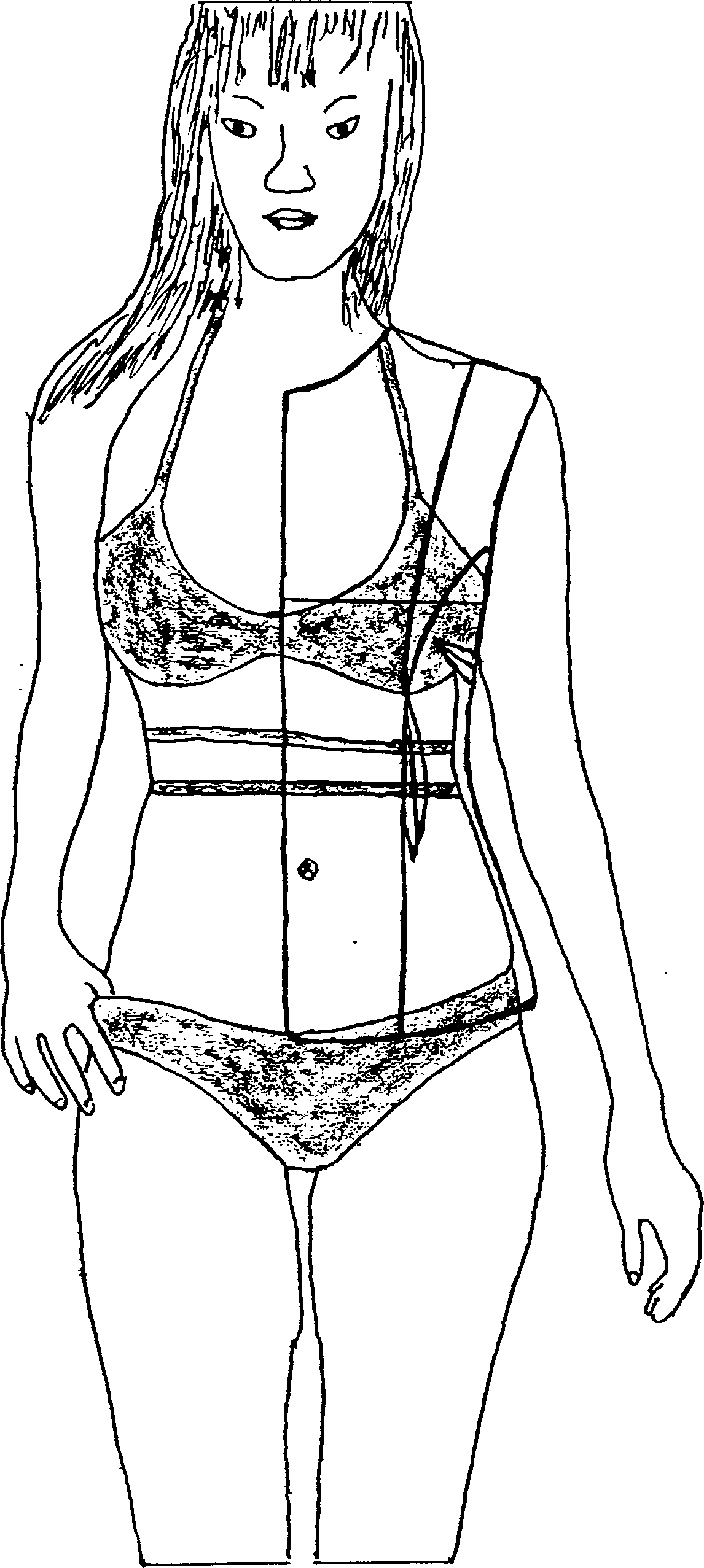

Three-dimensional garment designing and cutting method

InactiveCN1779687ASimple designSpeed upSpecial data processing applicationsClothes making applicancesGraphicsEngineering

A 3D designing method of garment includes setting up databank of 3D dress form data, garment fashion databank, databank of cloth and color as well as decoration, garment developed drawing databank and databank of test dressing drawing; storing said data into storage; collecting body data of client and inputting it in computer; selecting suitable fashion and sewing amount from said databank then putting on garment on model to form original drawing of 3D garment; selecting color, cloth and decoration for garment to form test dressing result drawing and developed drawing of 3D garment.

Owner:叶武月

Reconfigurable garment definition and production method

Computer-aided design and manufacture software and hardware automate garment and fashion definition and production. Configurable garment includes ornamental element, pattern display, and personal identifier and wireless sensor electronics.

Owner:FERNANDEZ DENNIS S

Semimanufactured Waterproofed Products, Particularly Shoes, Clothing Items and Accessories

InactiveUS20080127426A1Improve adhesionPhysical treatmentInsolesWork in processBiomedical engineering

Owner:OUTDRY TECH

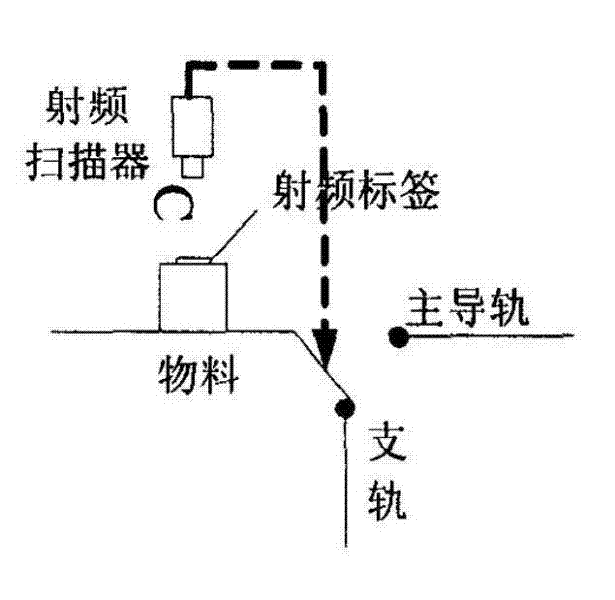

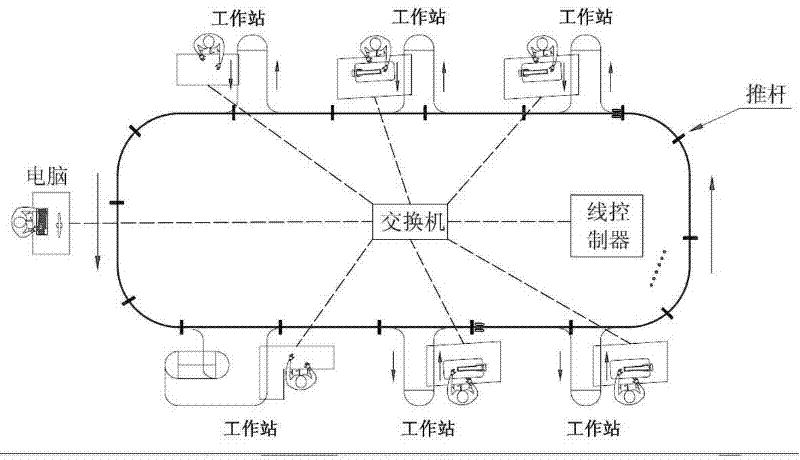

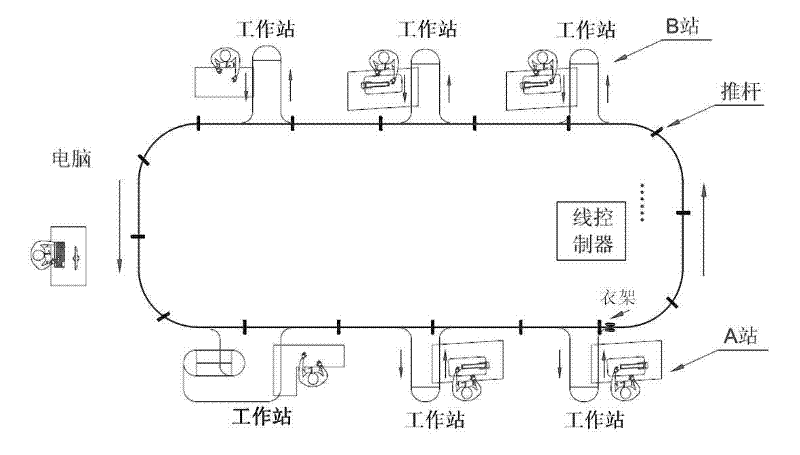

Intelligent hanging flow line system and control method of system

The invention relates to an intelligent hanging flow line system. A card reader of the system for reading clothes rack information is arranged at a station outlet of a work station, the work station access of a clothes rack is realized by adopting a support rail and ramp guide mode, a main rail cannot fracture during the station access of the clothes rack, in addition, the station access of the clothes rack is not controlled by the card reader and is comprehensively and integrally ranged by a system computer, a station controller realizes the automatic judgment and control, the effect of the flow line is exerted to the maximum degree, and the production efficiency is greatly improved.

Owner:JIANGSU RUIYING MACHINERY

Method and device for viewing, archiving and transmitting a garment model over a computer network

InactiveUS20050154487A1Efficient communicationPrecise positioningMeasurement devicesSurgeryComputer graphics (images)Engineering

A method and device for viewing, archiving and transmitting a garment model over a computer network. The method comprises photographing a physical mannequin from several different directions, the mannequin being a copy of a virtual human model which is representative of the target consumer. The virtual mannequin viewing layers and the garment model are generated from digital images of the naked or clothed mannequin which is suspended from the photography stand. A laser beam is used to determine the exact position of the mannequin. Subsequently, crop marks and recorded reference lines can be used to merge the viewing layers and the model precisely. The data are archived in a base and transmitted over an intranet, an extranet or the Internet for the purpose of remote viewing. The method and device are particularly suitable for the design, manufacture and inspection of clothing samples in the clothing industry.

Owner:WANG KENNETH KUK KEI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com