Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about "Rinsing apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

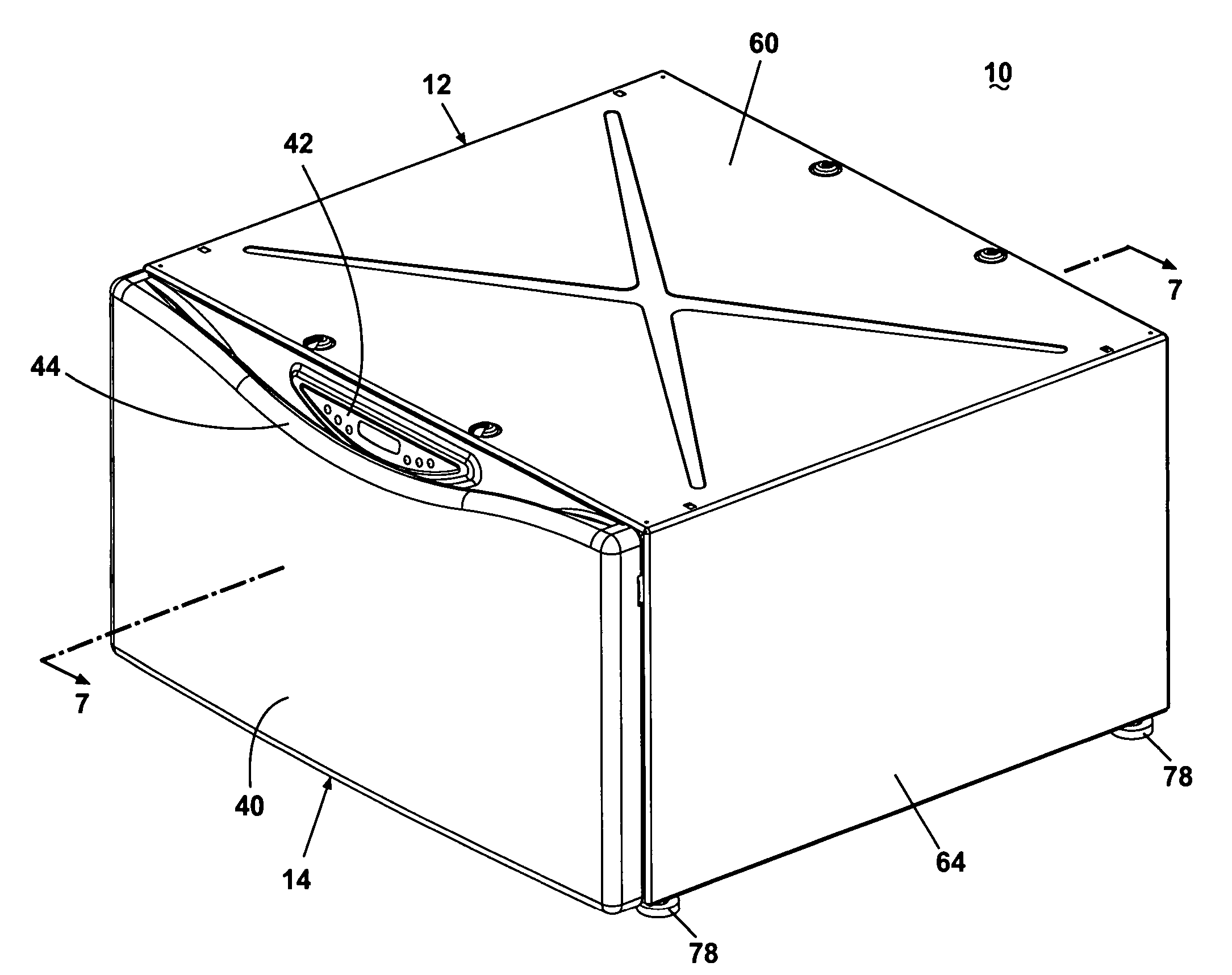

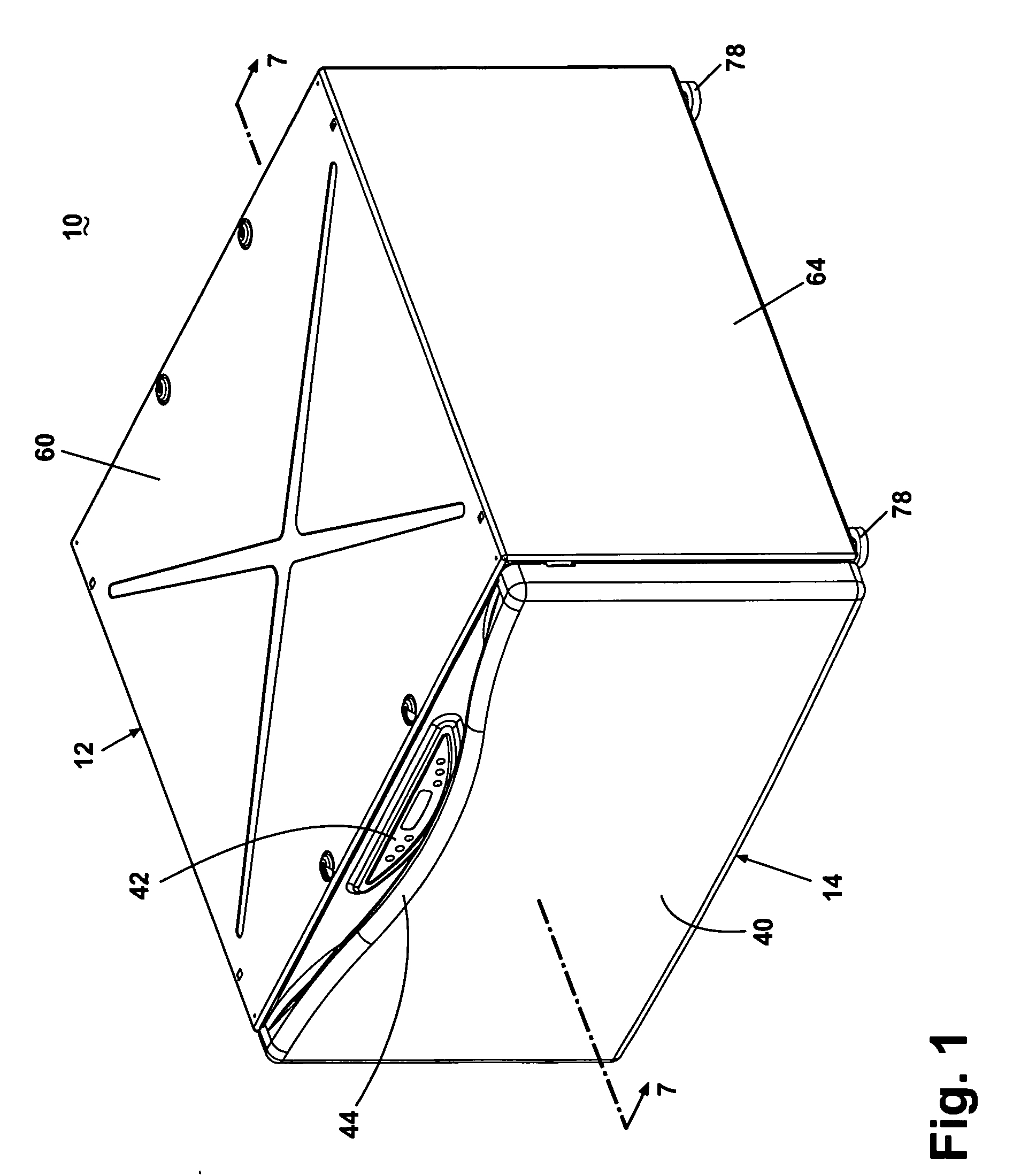

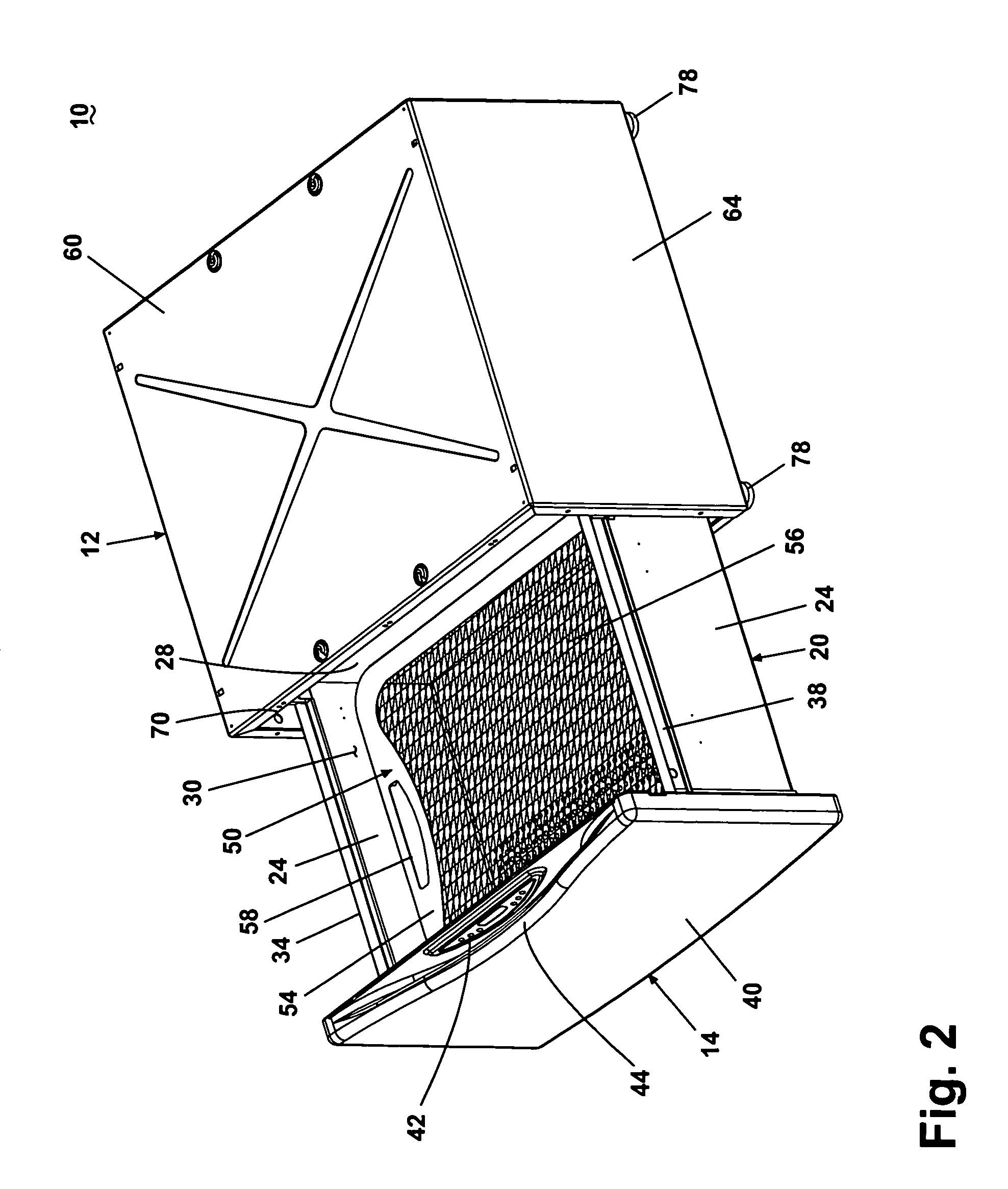

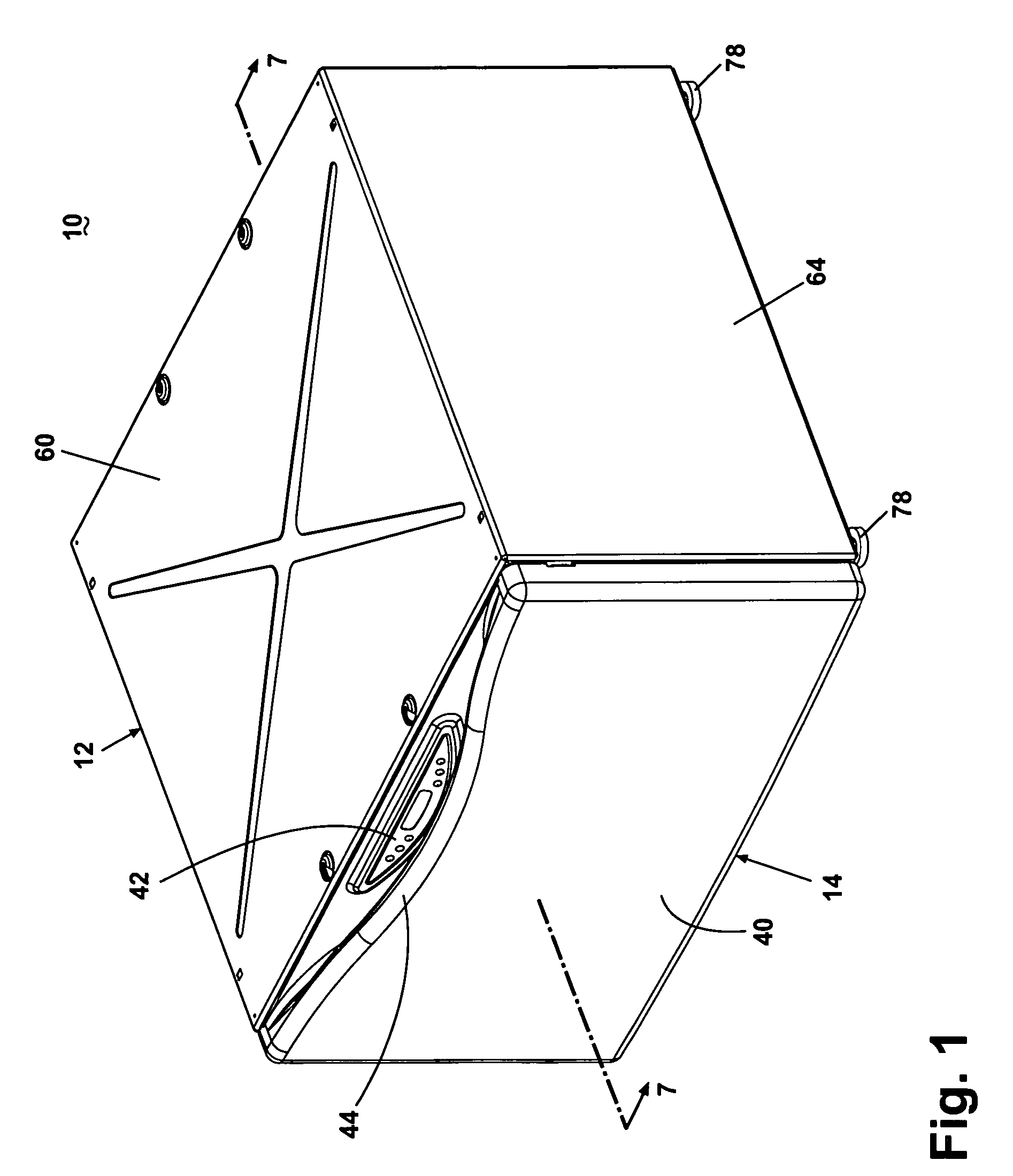

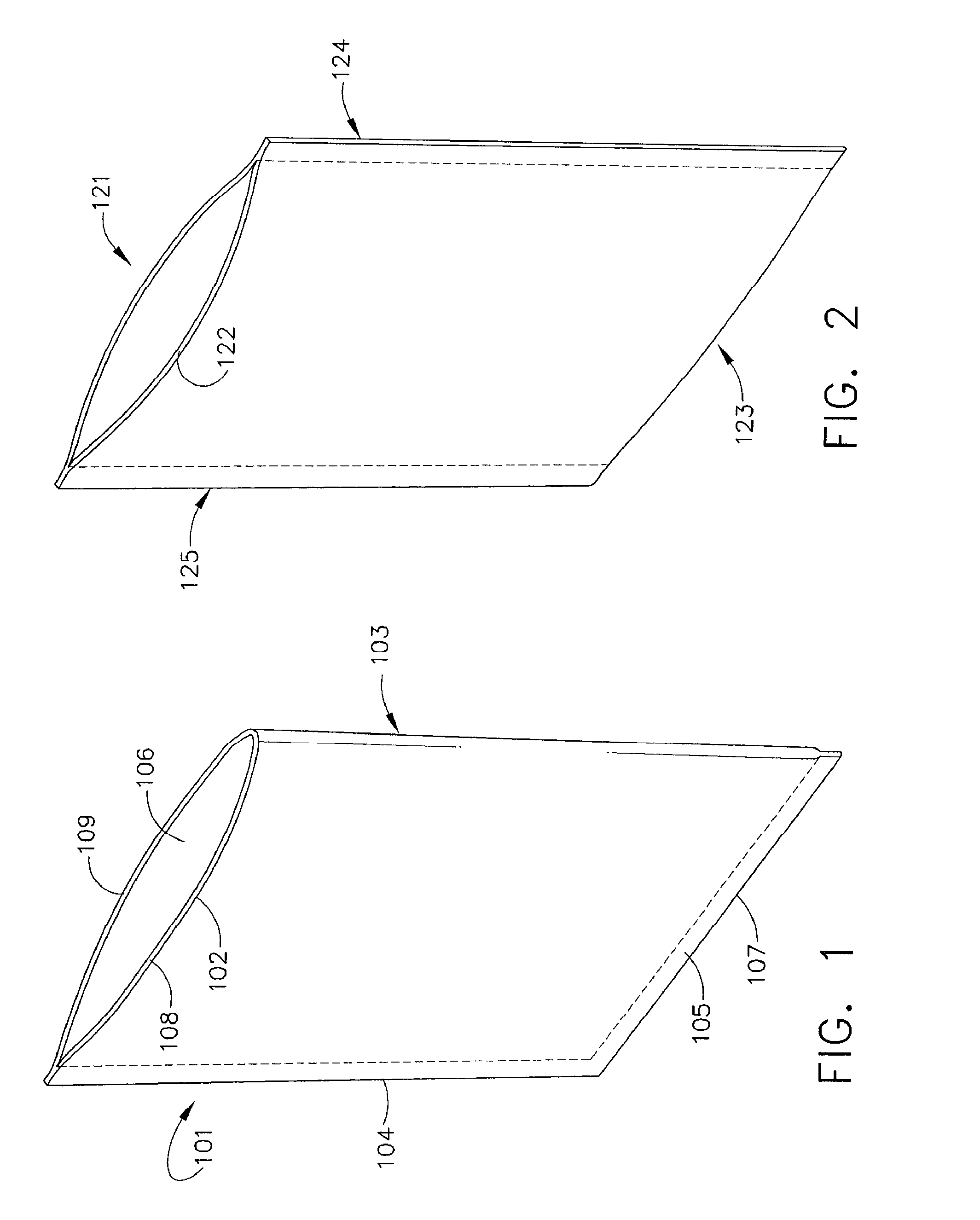

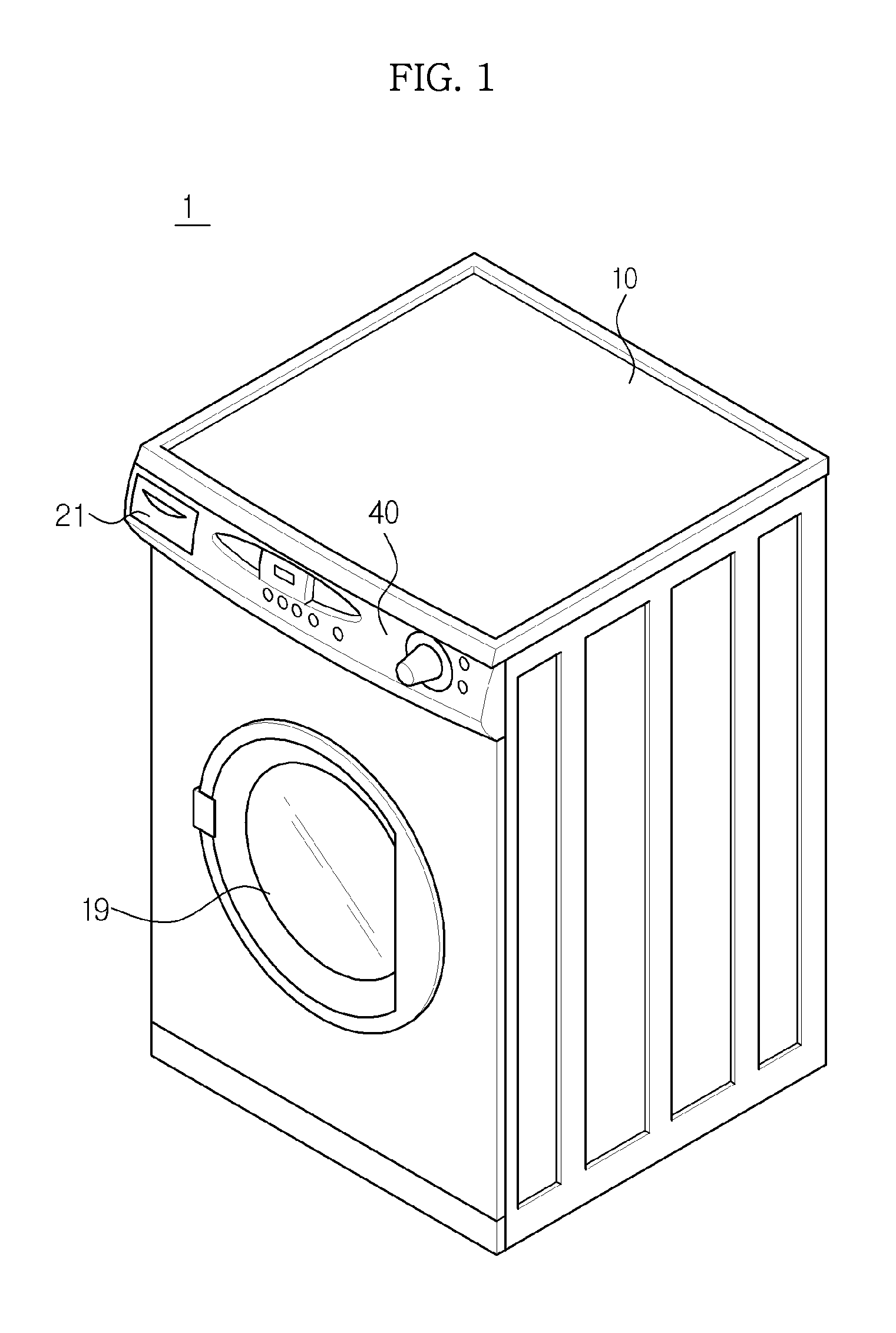

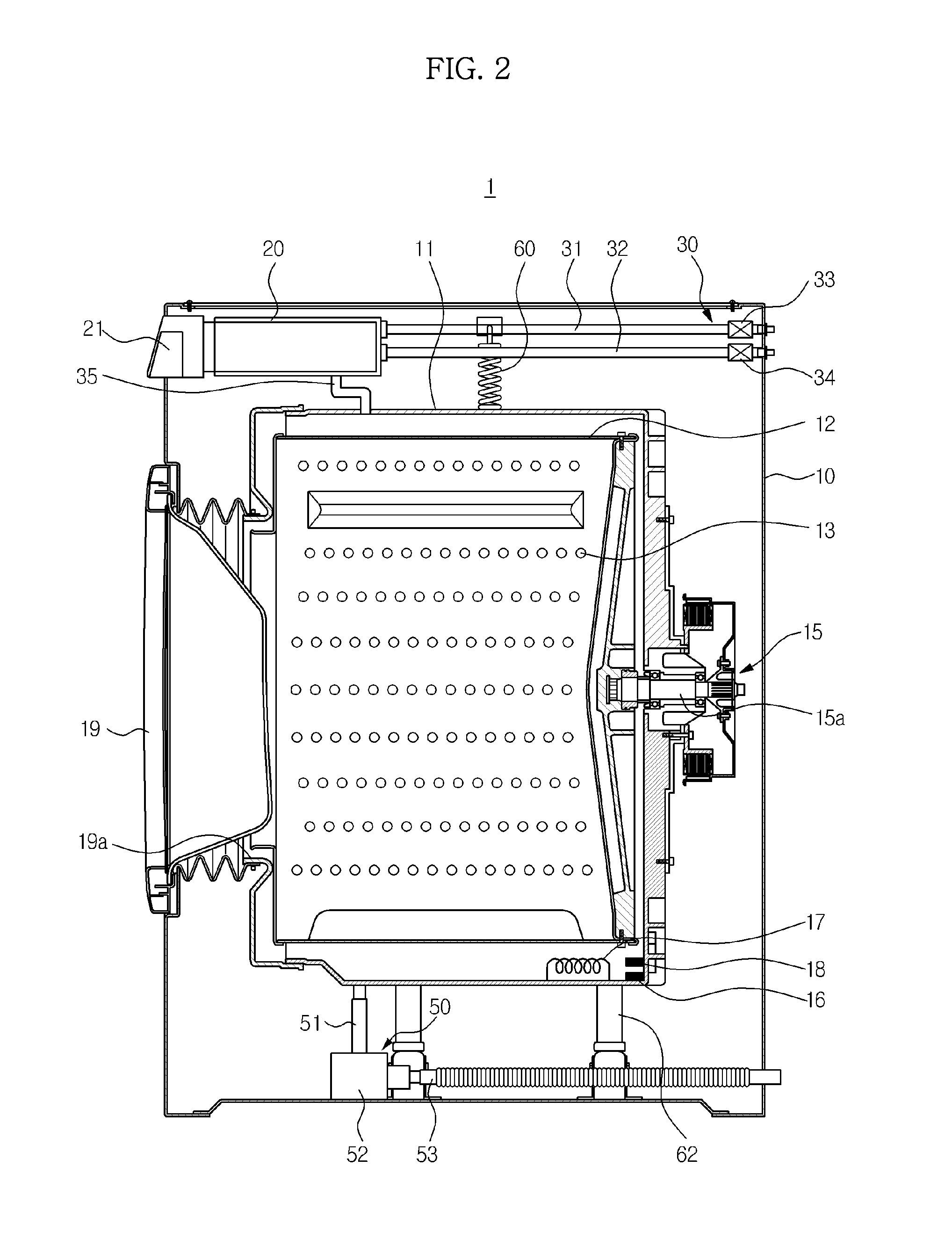

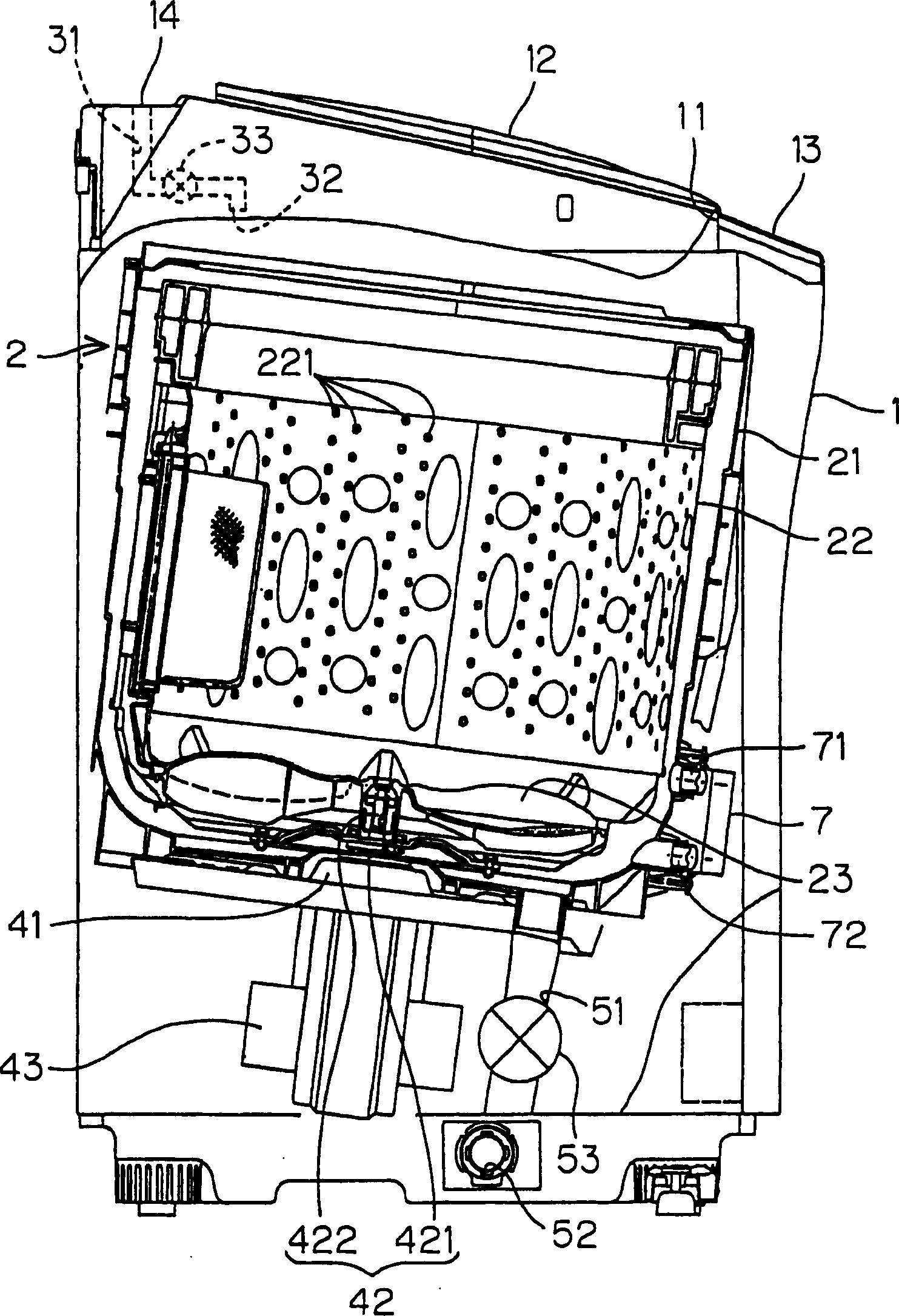

Non-tumble clothes dryer

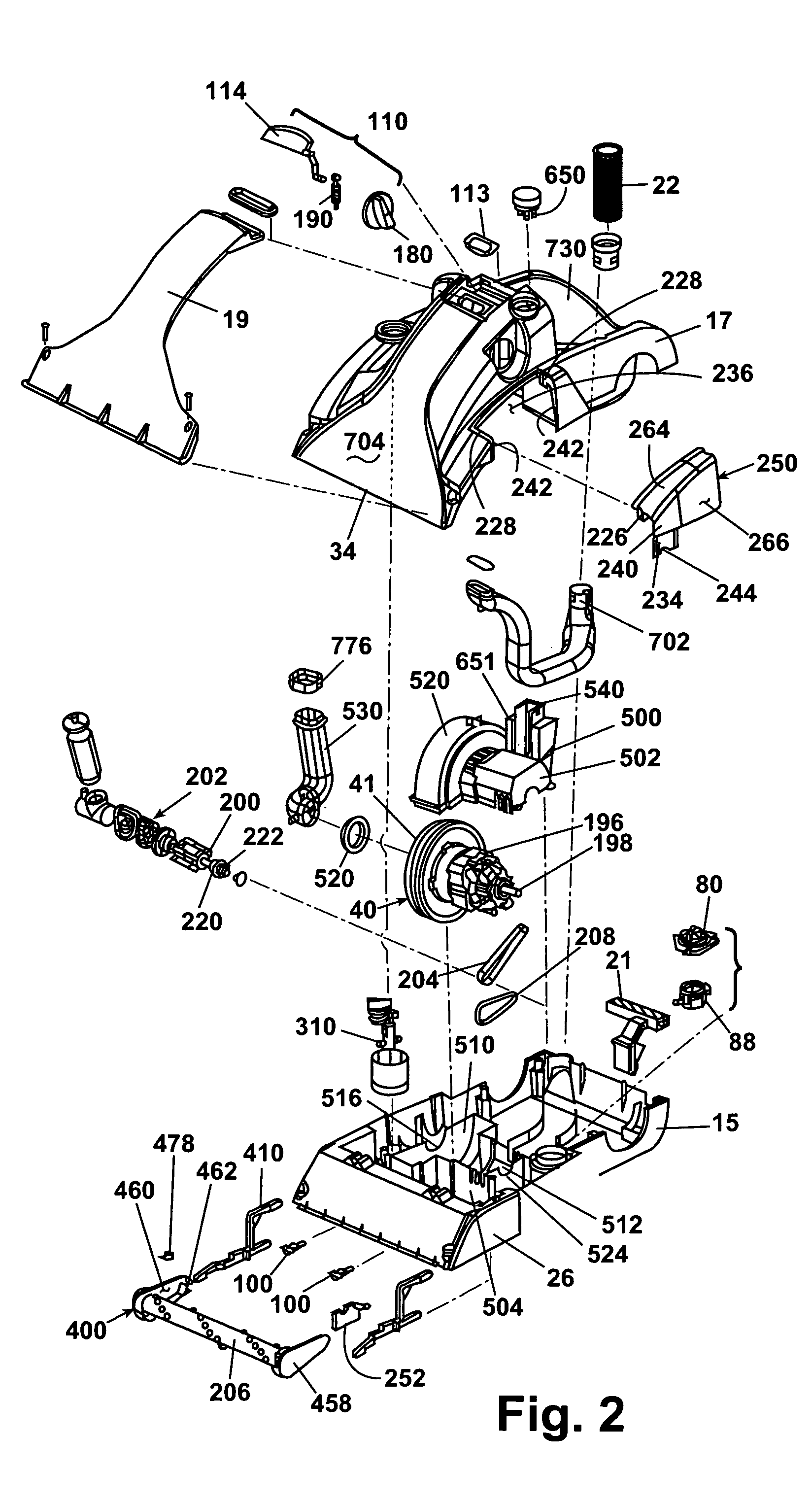

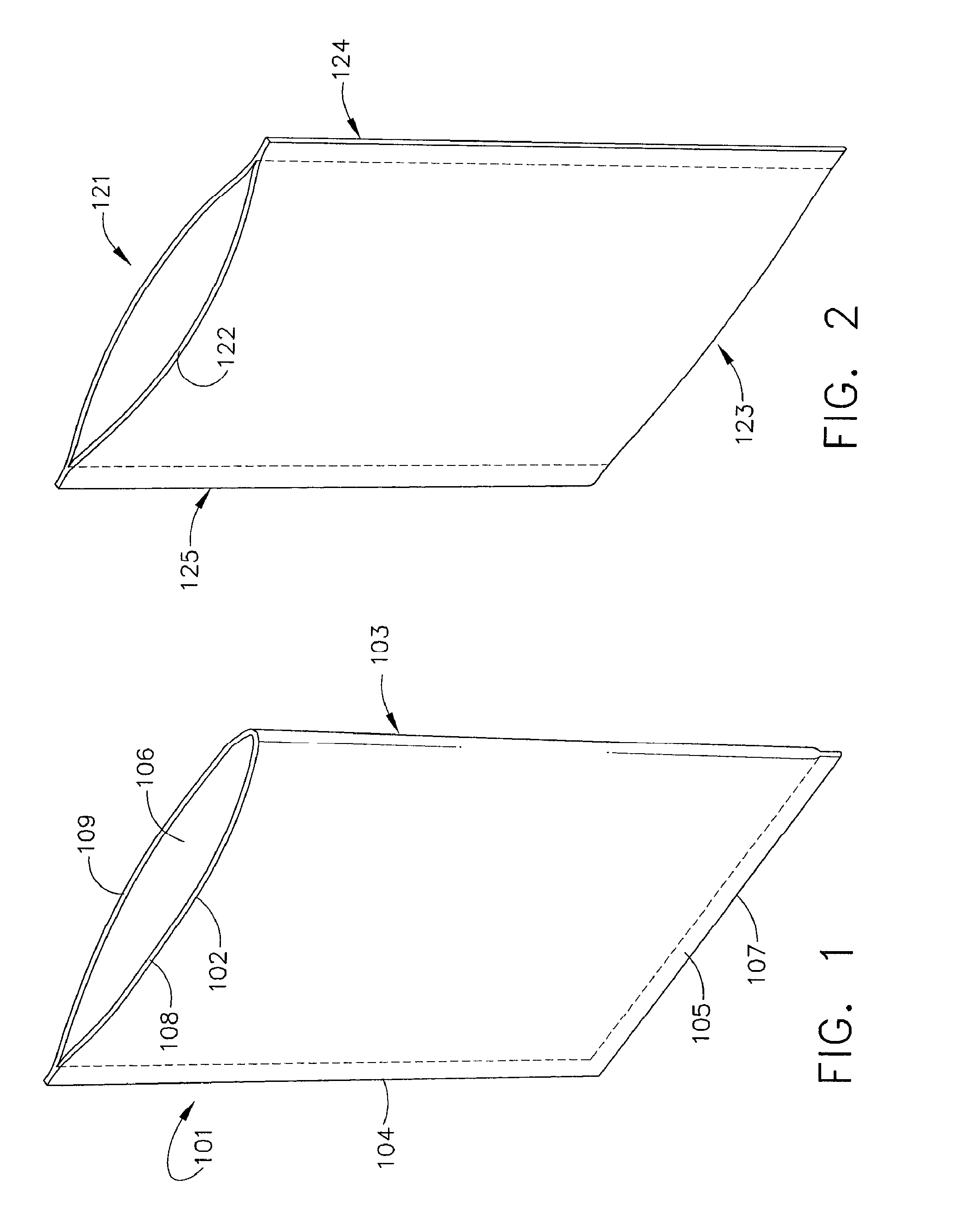

ActiveUS20070151120A1Rinsing apparatusAgriculture tools and machinesMechanical engineeringEngineering

A non-tumble dryer comprises a cabinet and a drawer configured to support an article to be dried and slidably mounted to the cabinet. An air supply system provides air to a drying chamber formed at least partially by one of the cabinet and the drawer for drying the article supported by the drawer. The non-tumble dryer can function as a pedestal whereby the top of the cabinet can be configured to support a laundry appliance in an elevated position. Alternatively, the cabinet can overlie one or more laundry appliances.

Owner:WHIRLPOOL CORP

Non-tumble clothes dryer

A non-tumble dryer comprises a cabinet and a drawer configured to support an article to be dried and slidably mounted to the cabinet. An air supply system provides air to a drying chamber formed at least partially by one of the cabinet and the drawer for drying the article supported by the drawer. The non-tumble dryer can function as a pedestal whereby the top of the cabinet can be configured to support a laundry appliance in an elevated position. Alternatively, the cabinet can overlie one or more laundry appliances.

Owner:WHIRLPOOL CORP

Washing machine rinse cycle method and apparatus

An apparatus and method for operating a washing machine in a rinse cycle is provided for a washing machine including a rotatable basket and a fresh water spraying device. The method comprises rotating the basket at a first rate of rotation, spraying water into the basket while the basket is rotating at the first rate, and rotating the basket at a second rate of rotation, the second rate of rotation greater than the first rate of rotation.

Owner:HAIER US APPLIANCE SOLUTIONS INC

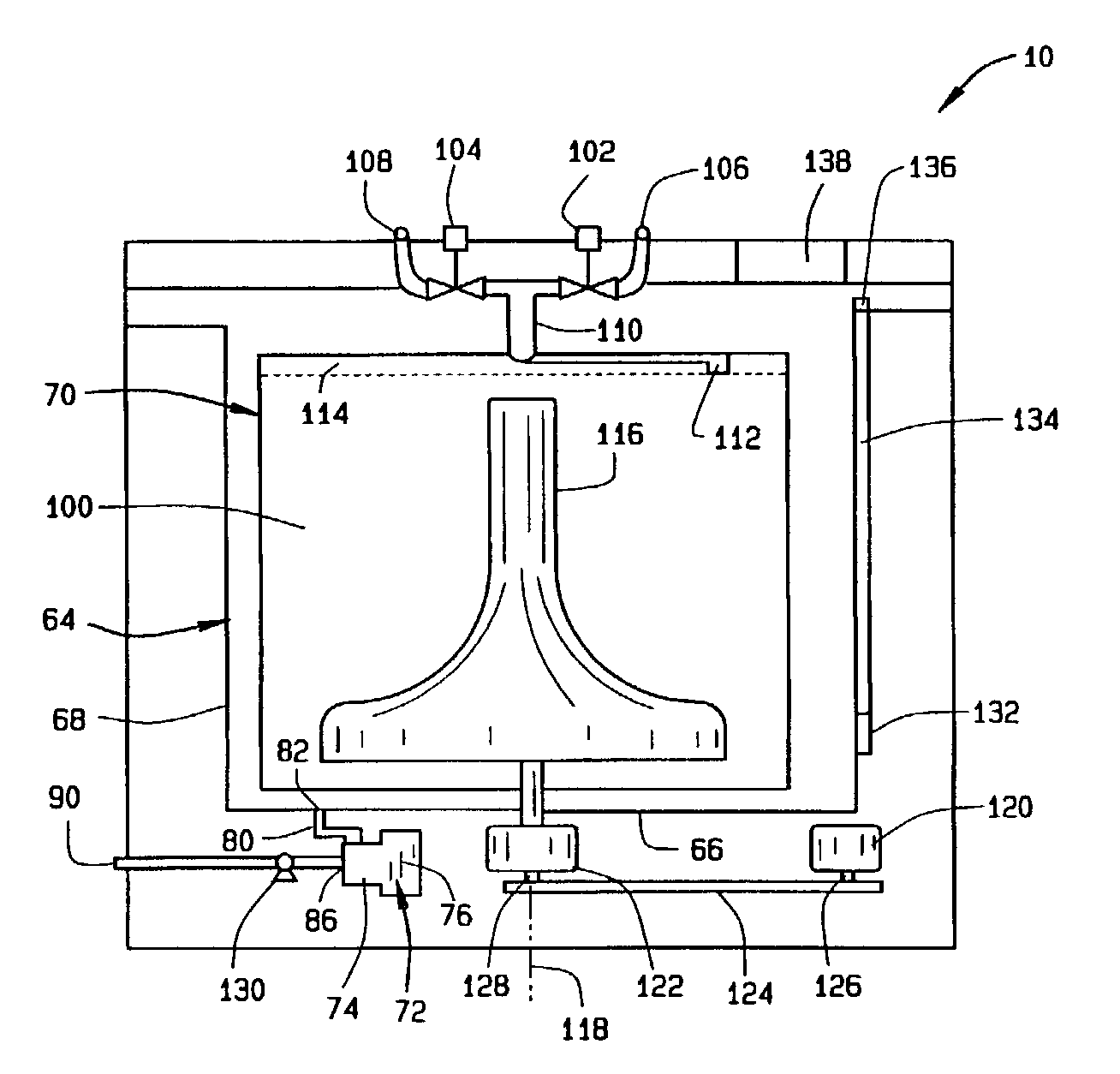

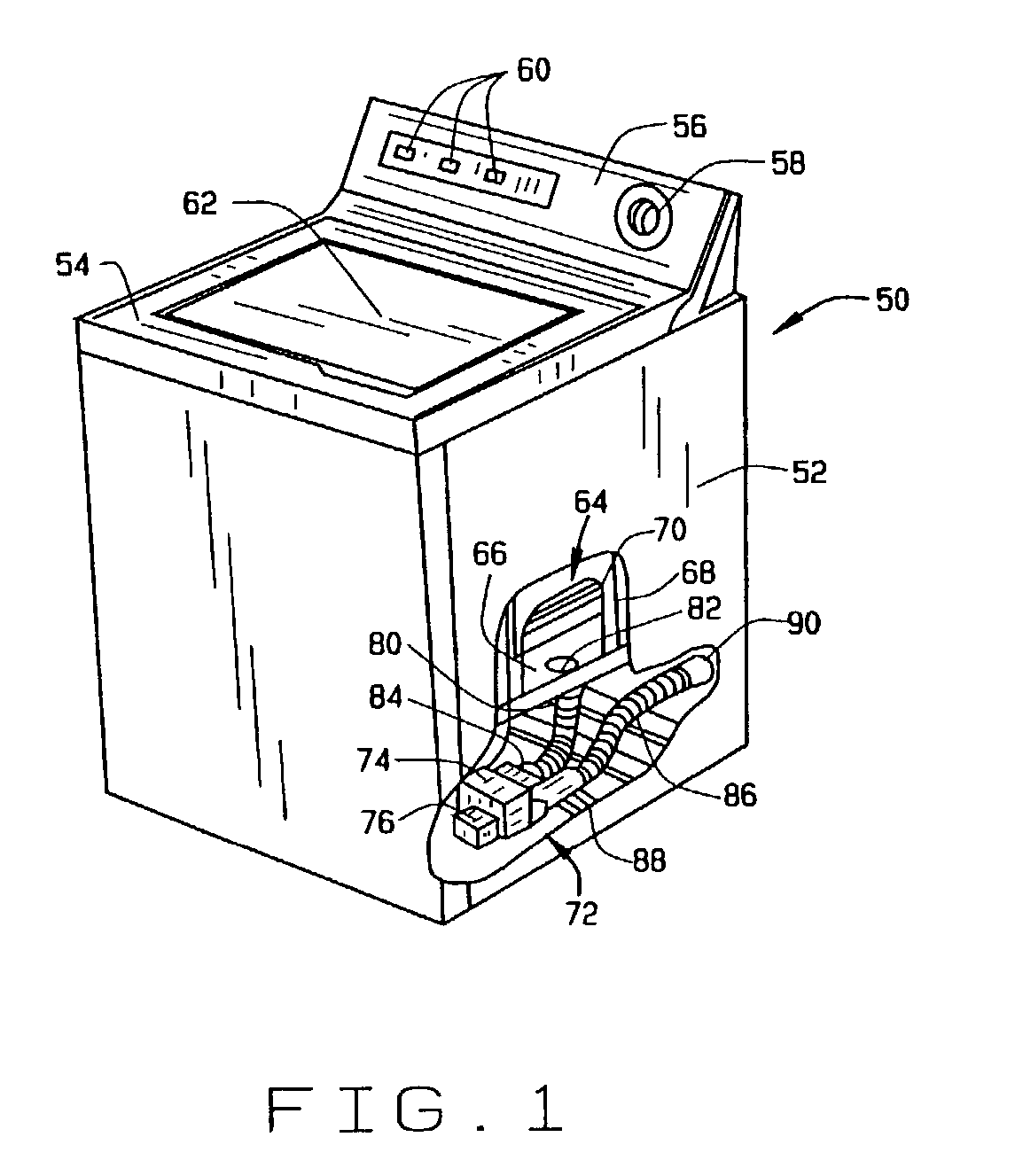

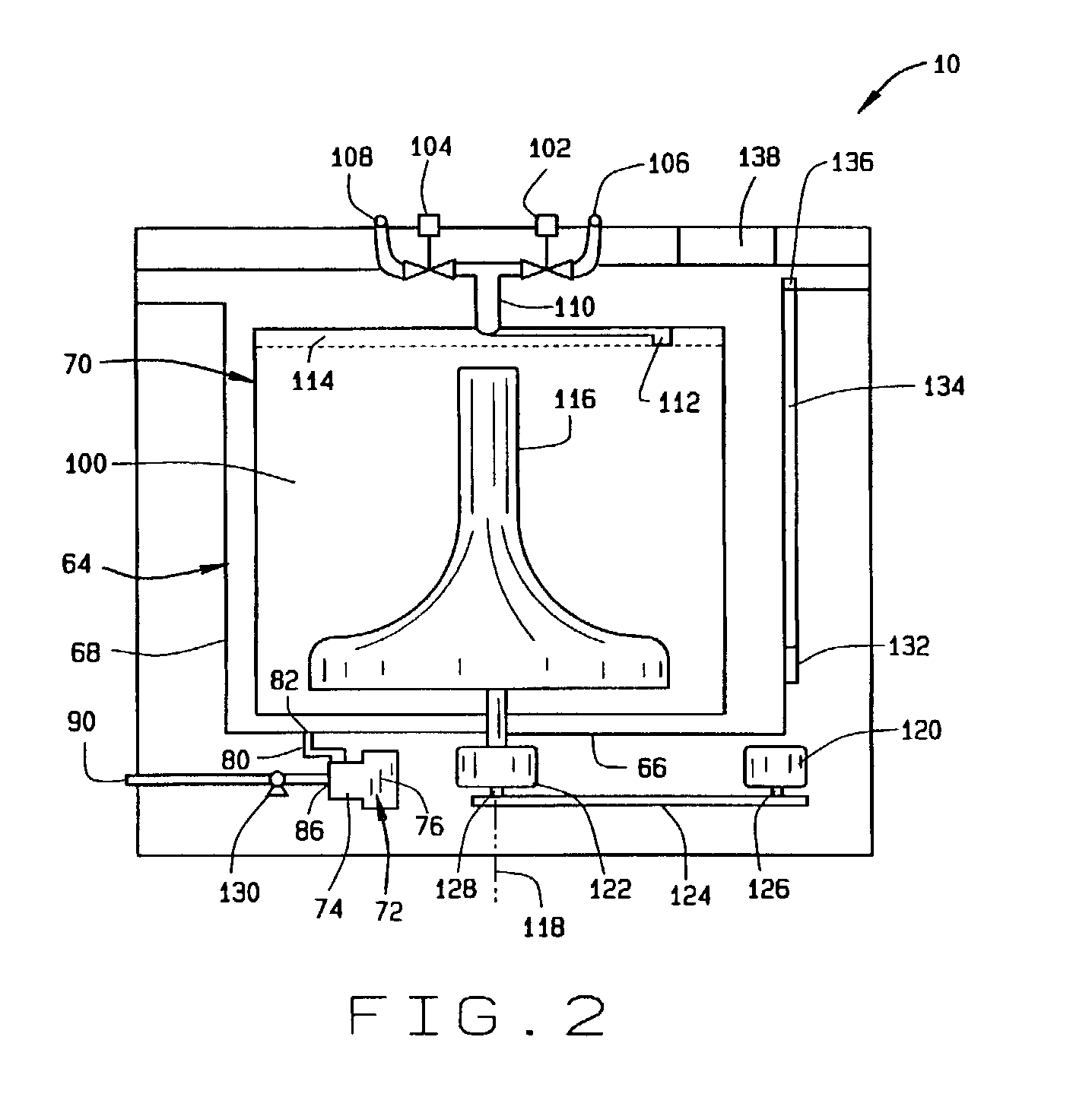

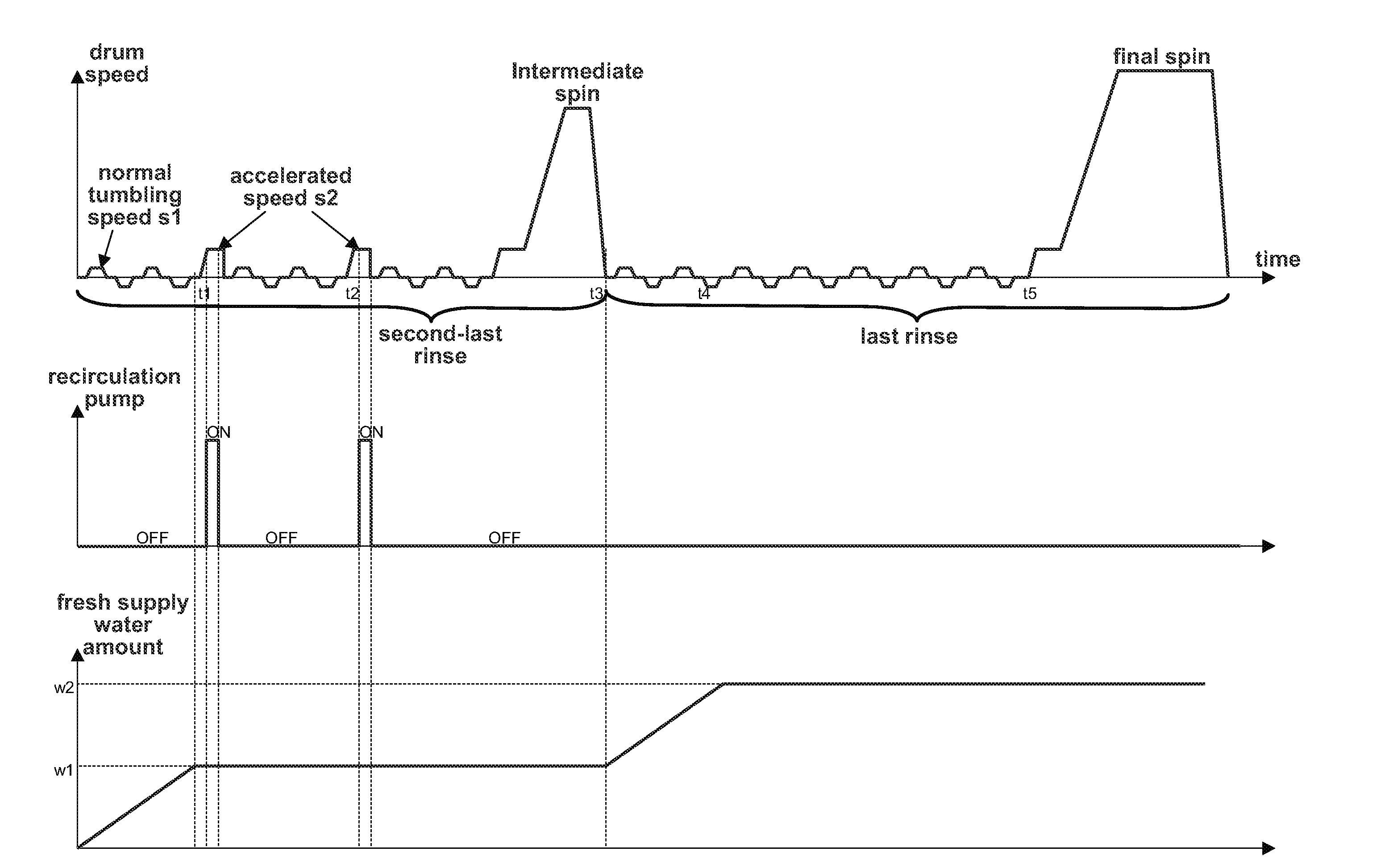

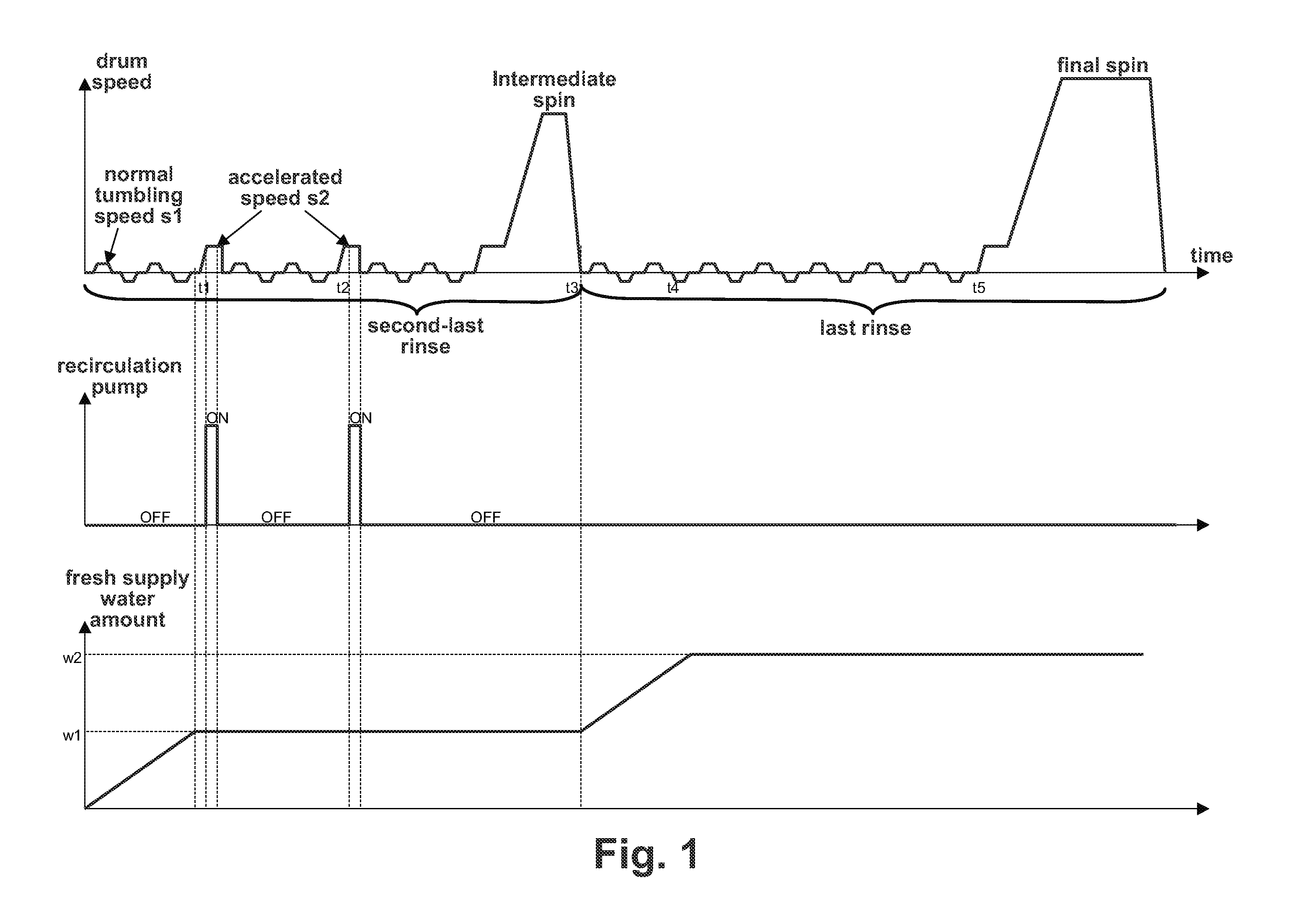

Method for rinsing fabric in a washer and washer adapted to carry out this method

A method of rinsing fabric in a washer having a wash chamber rotatable about a horizontal axis comprises the step of adding water to the wash chamber and spraying the rinse water by recirculating it onto the fabric while spinning the wash chamber at a speed to effect a centrifugal force on the fabric such that the fabric will not tumble within the wash chamber as it spins. The method further comprises at least a last rinsing step in which the rotating speed of the wash chamber is such that the fabric tumbles within the wash chamber and in that the rinsing water is not recirculated and sprayed onto the fabric.

Owner:WHIRLPOOL CORP

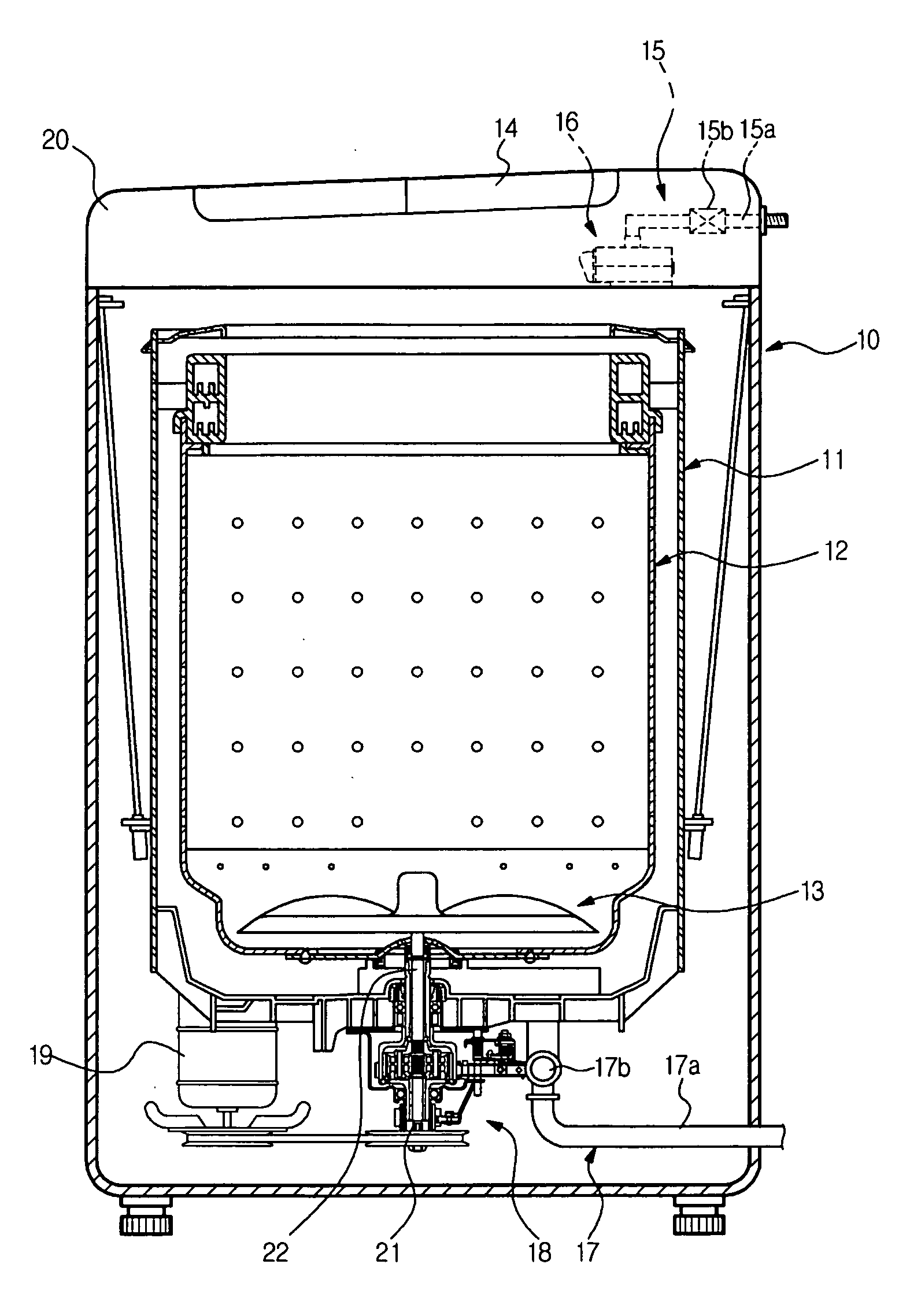

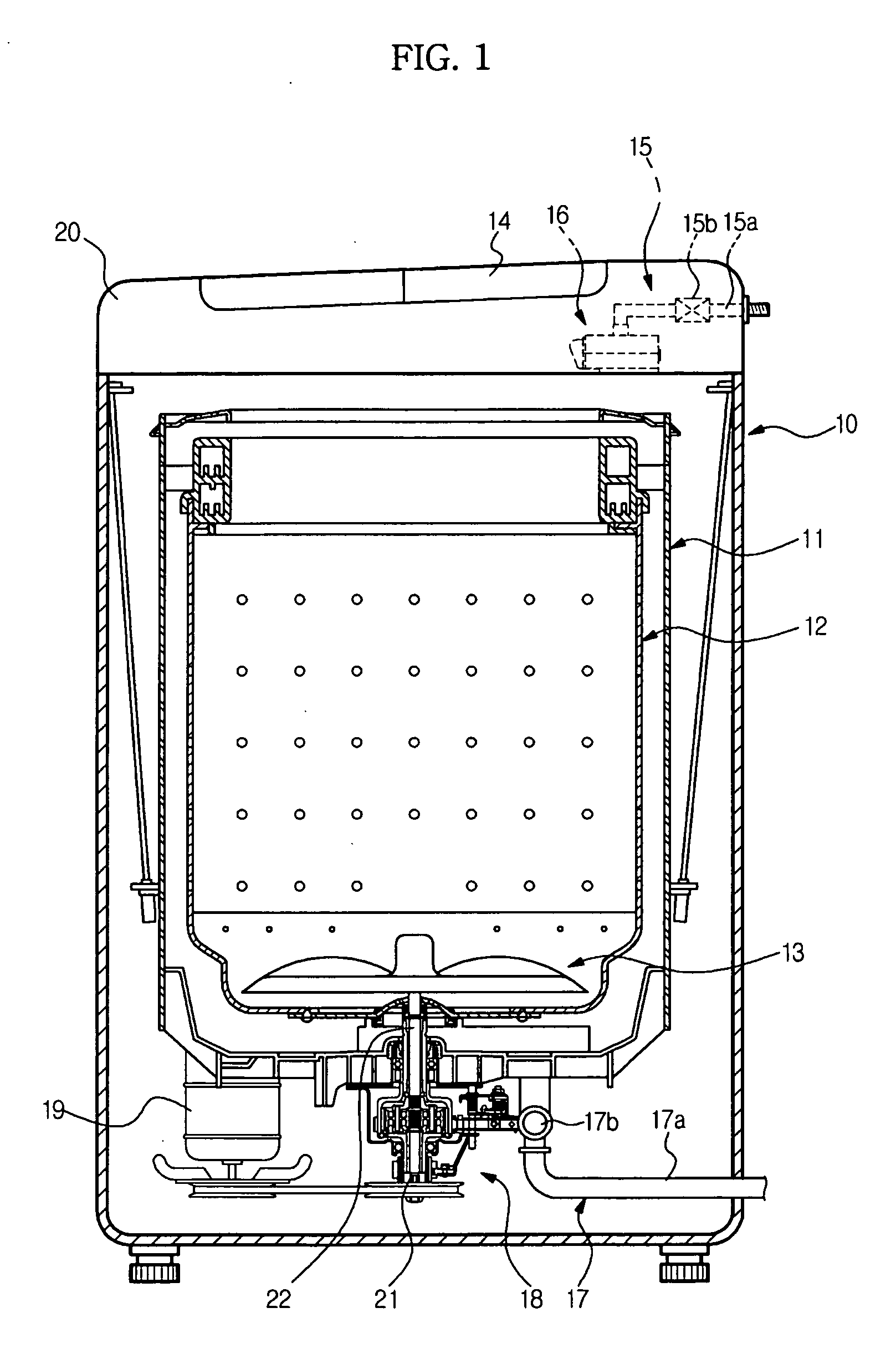

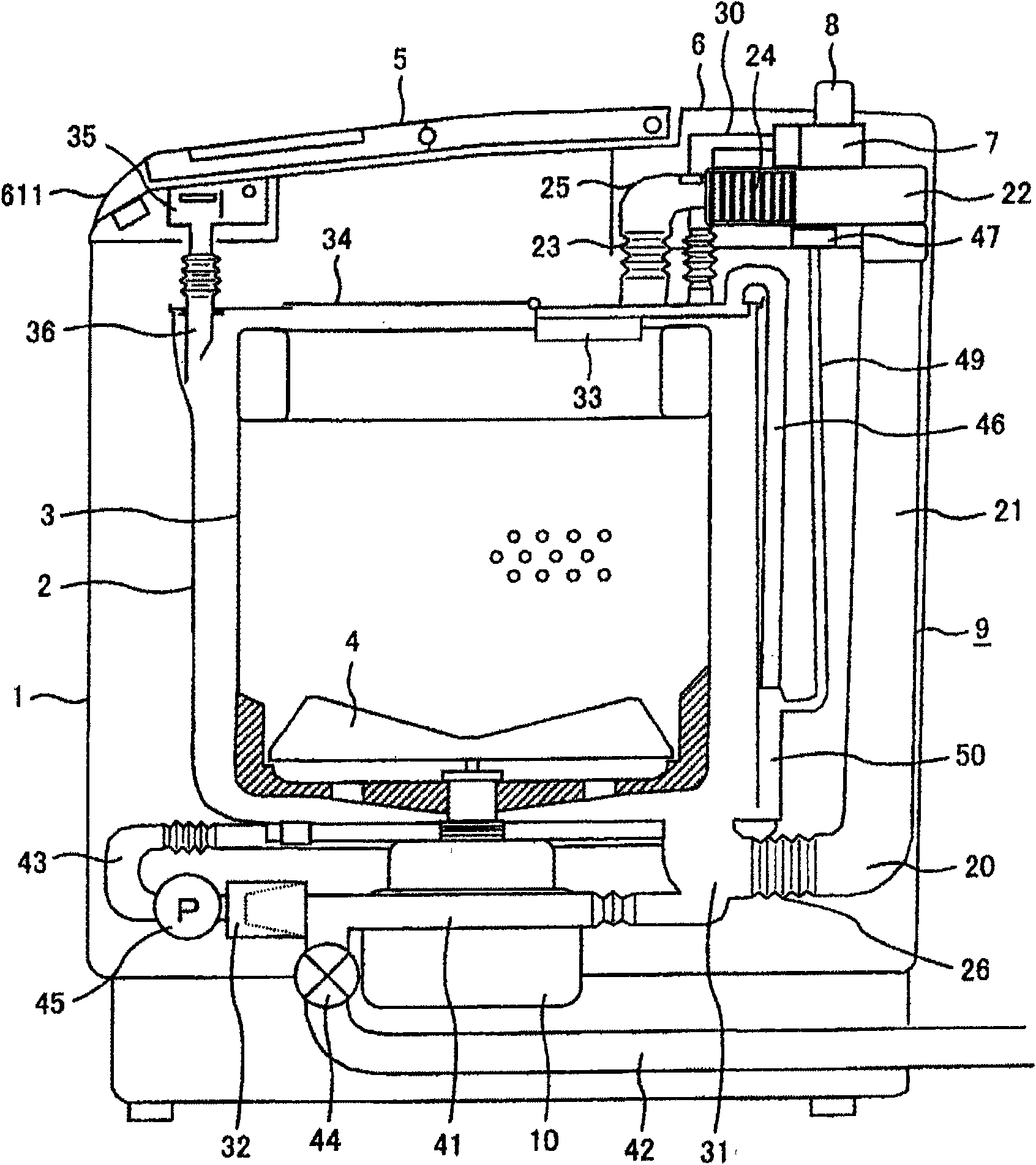

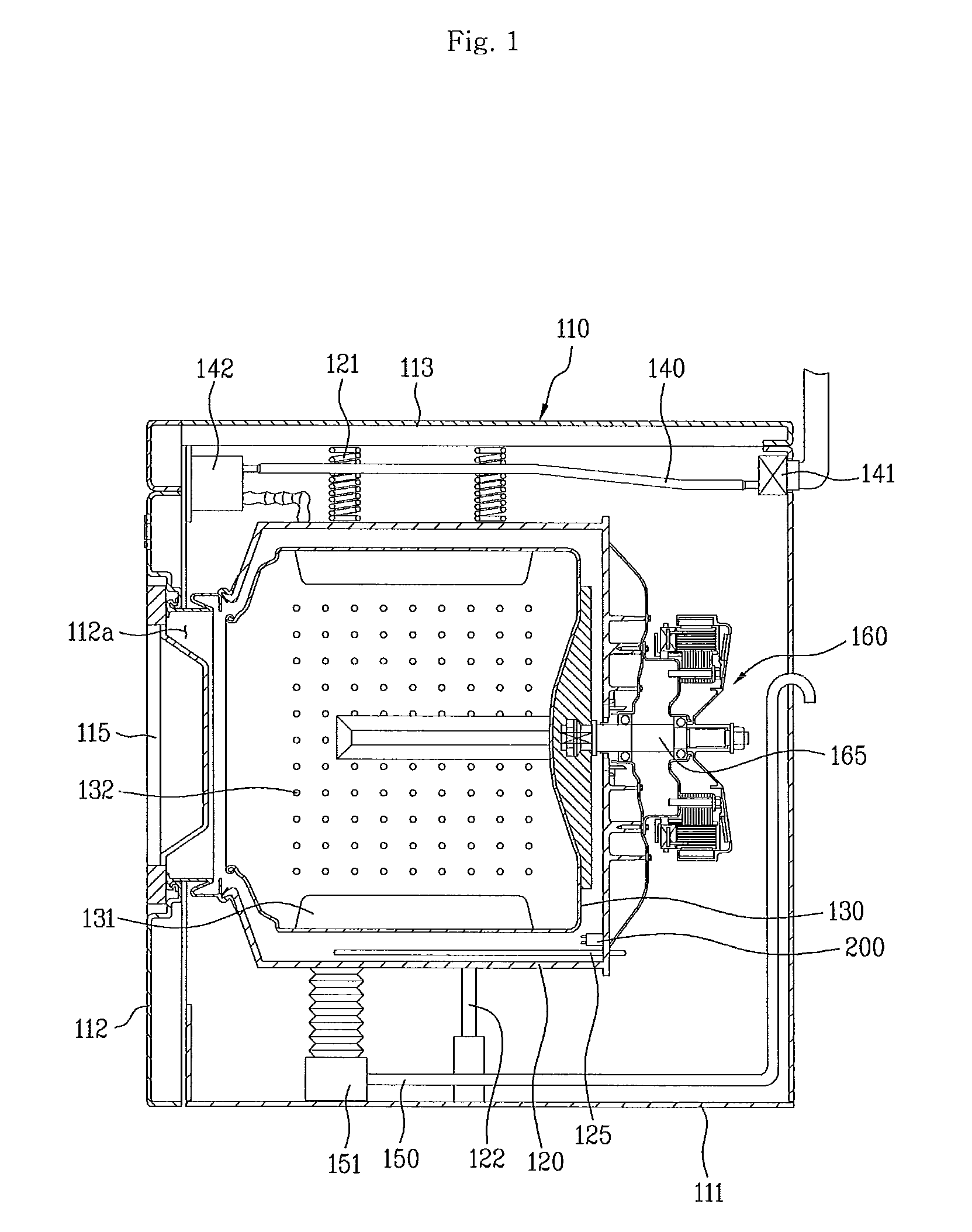

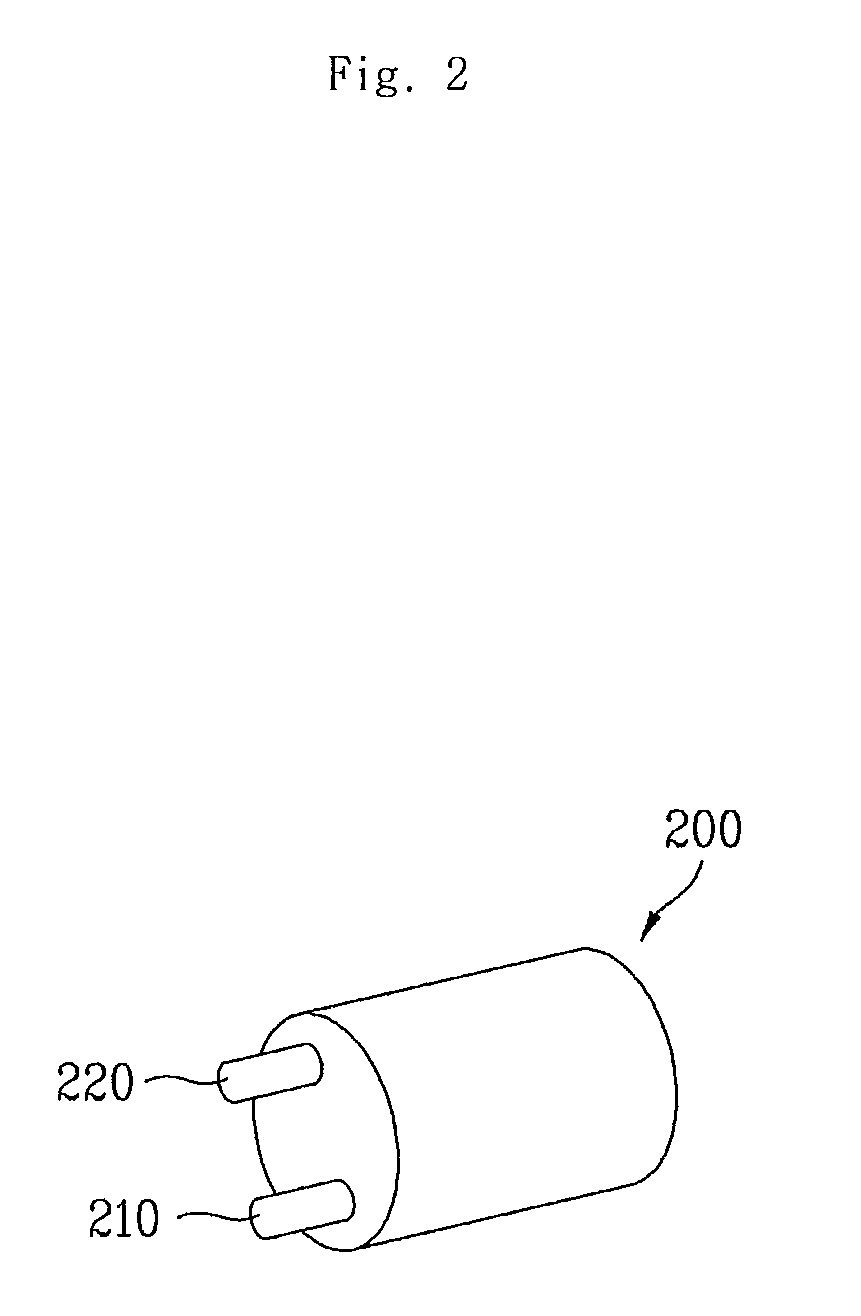

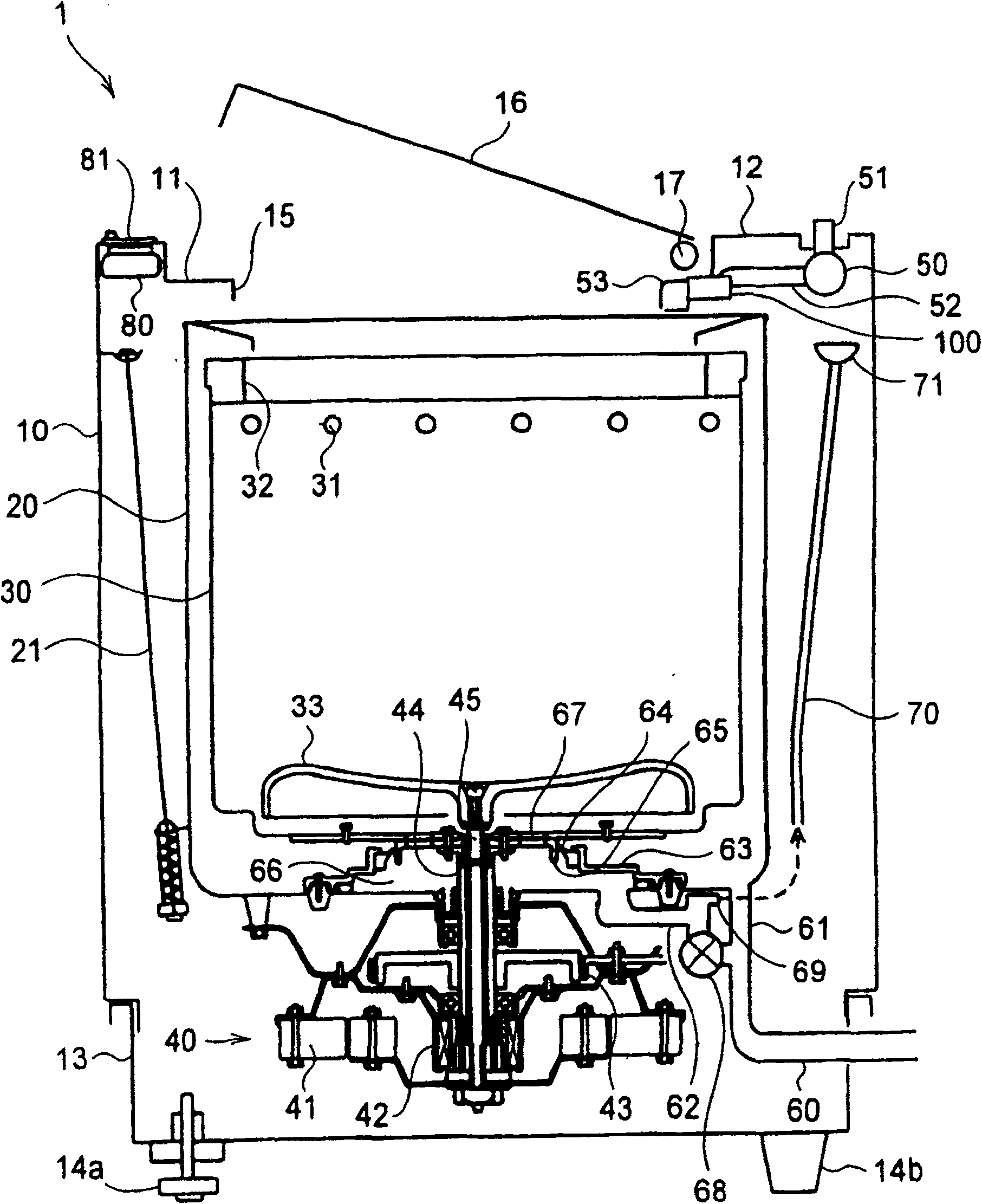

Penetration type washing machine, method for controlling the same, and tub cover for the same

InactiveUS7263864B2Simple structureImprove washing efficiencyRinsing apparatusCapsPulp and paper industryCentrifugal force

Method for controlling a full automatic washing machine, the method comprising a washing cycle, a rinsing cycle, and a dewatering cycle, wherein the washing or the rinsing cycle includes the step of rotating an inner tub at a high speed higher than a preset speed in one direction, thereby making a centrifugal force caused by high speed rotation of the inner tub, to push laundry against a wall of the inner tub, to enforce washing water in the inner tub to penetrate through the laundry at a speed higher than required to make the washing done, and to pump the washing water penetrated through the laundry and discharged into an outer tub upward, to recirculate to the inner tub.

Owner:LG ELECTRONICS INC

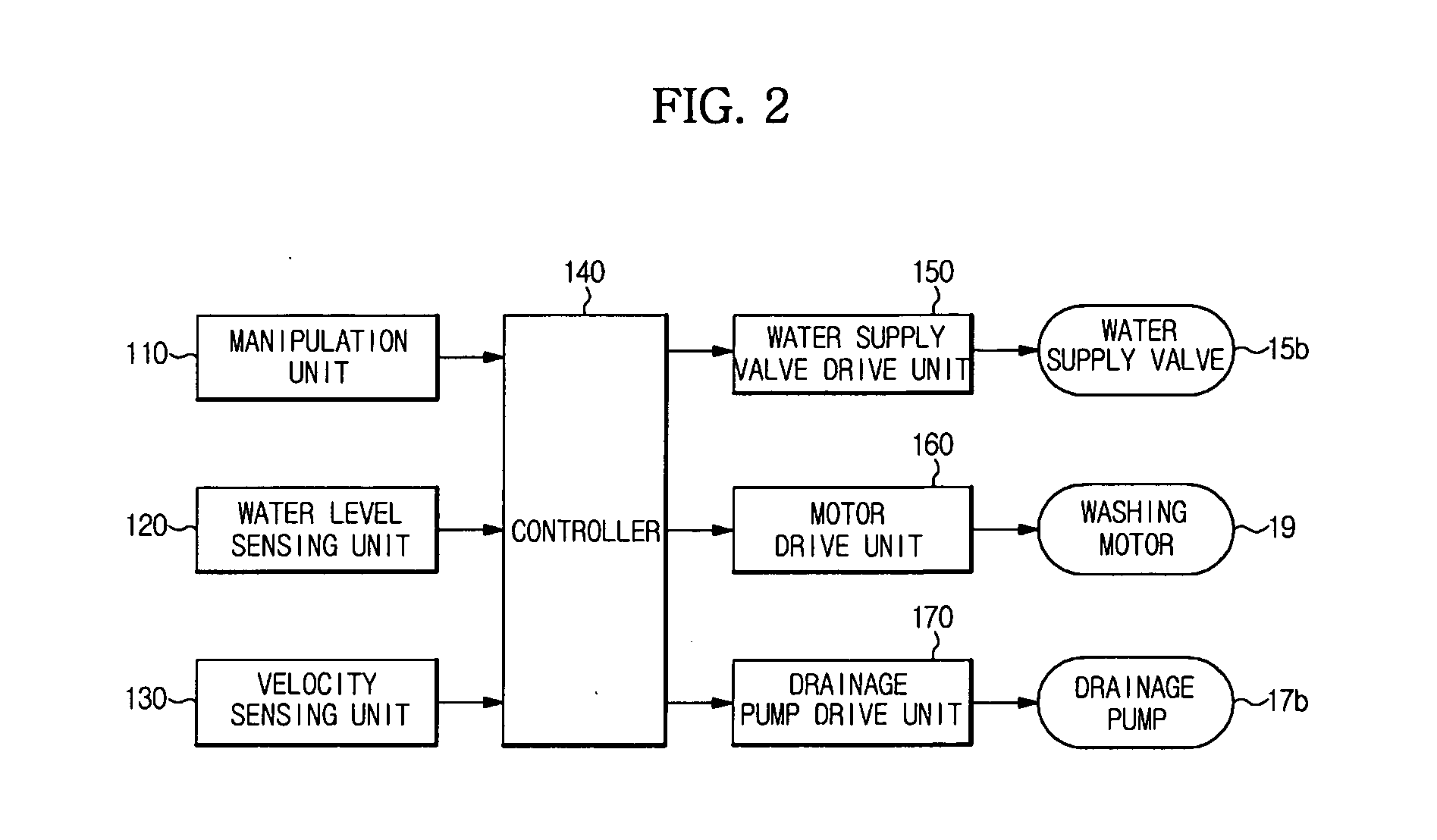

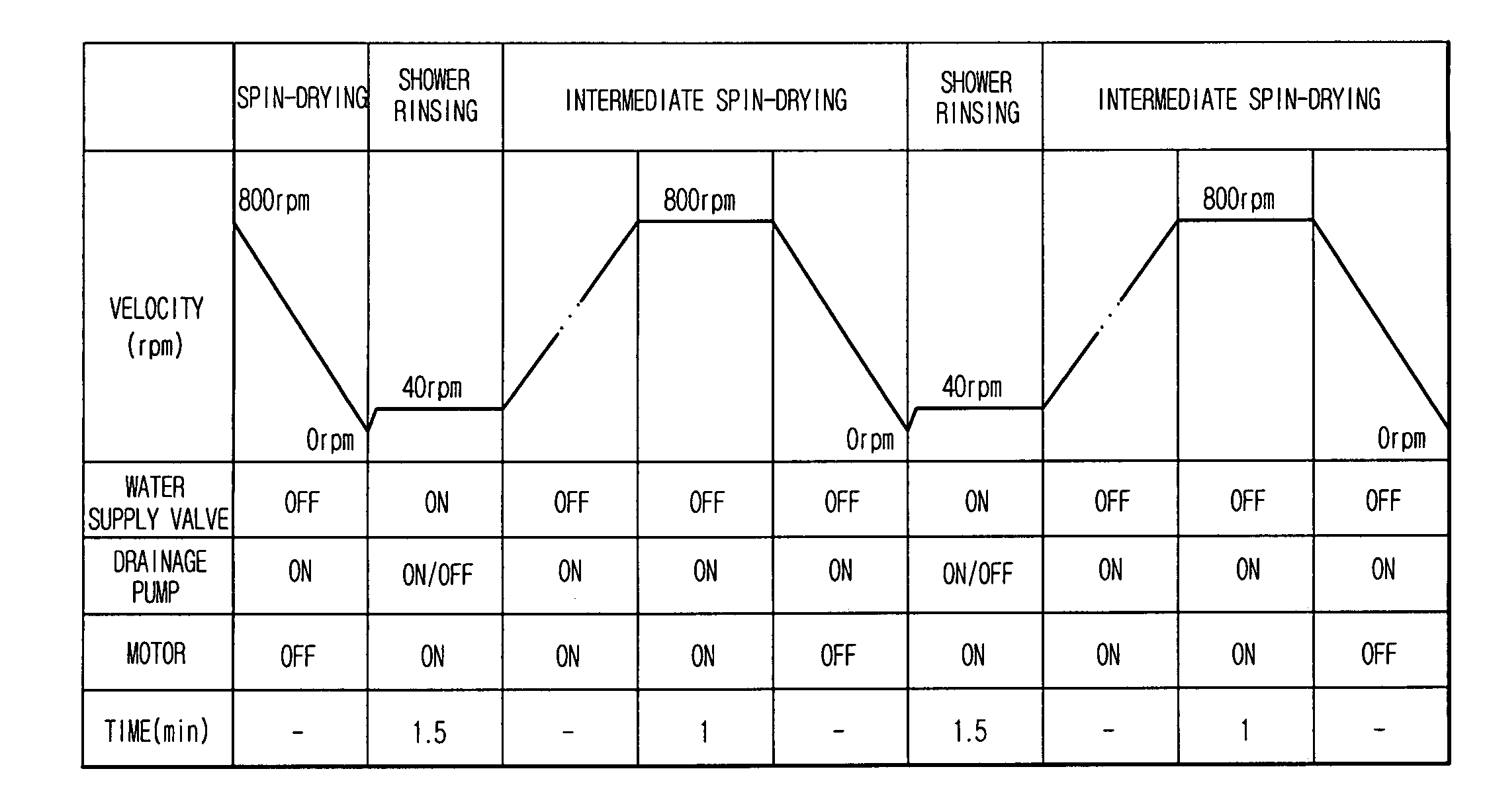

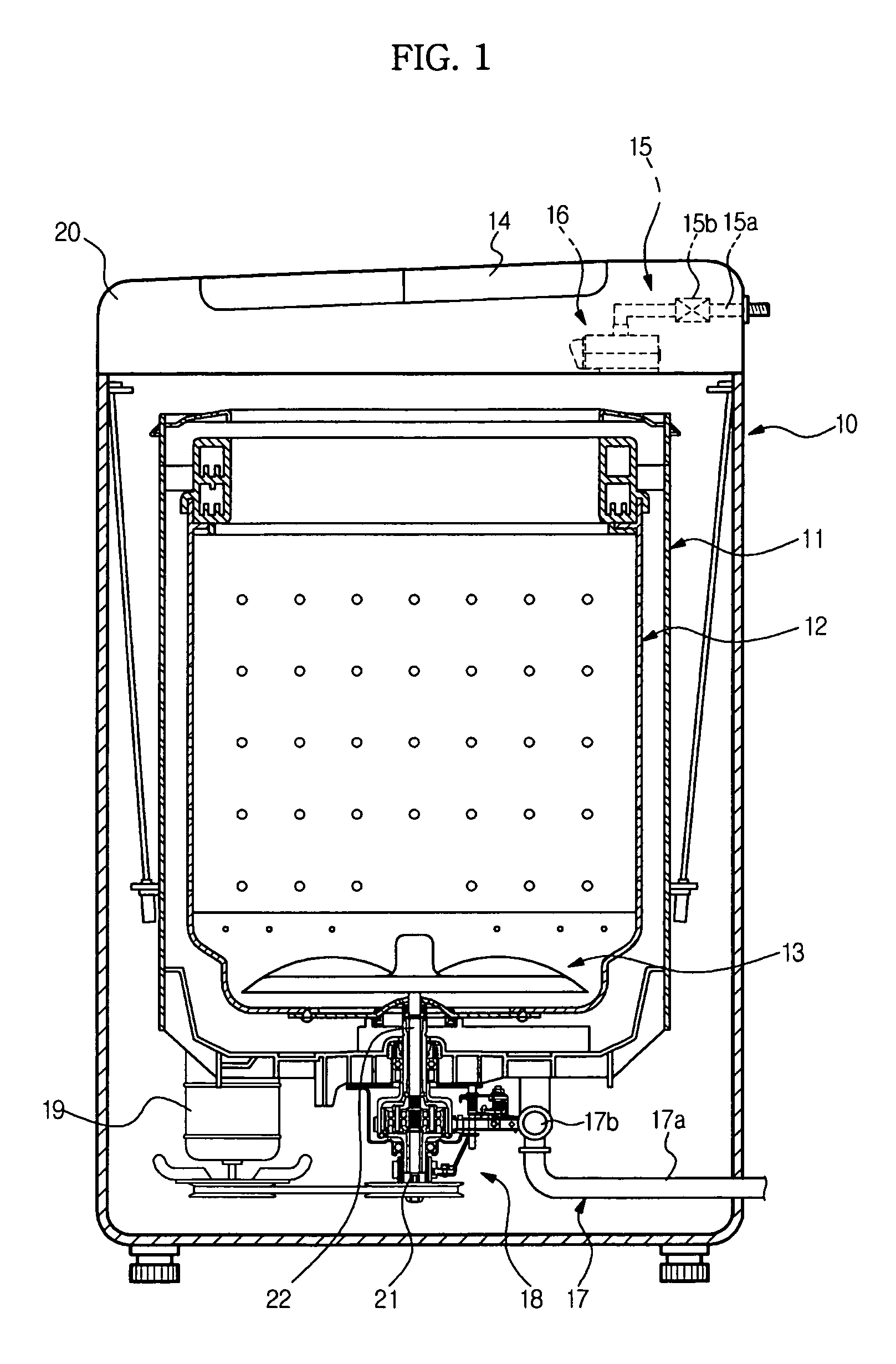

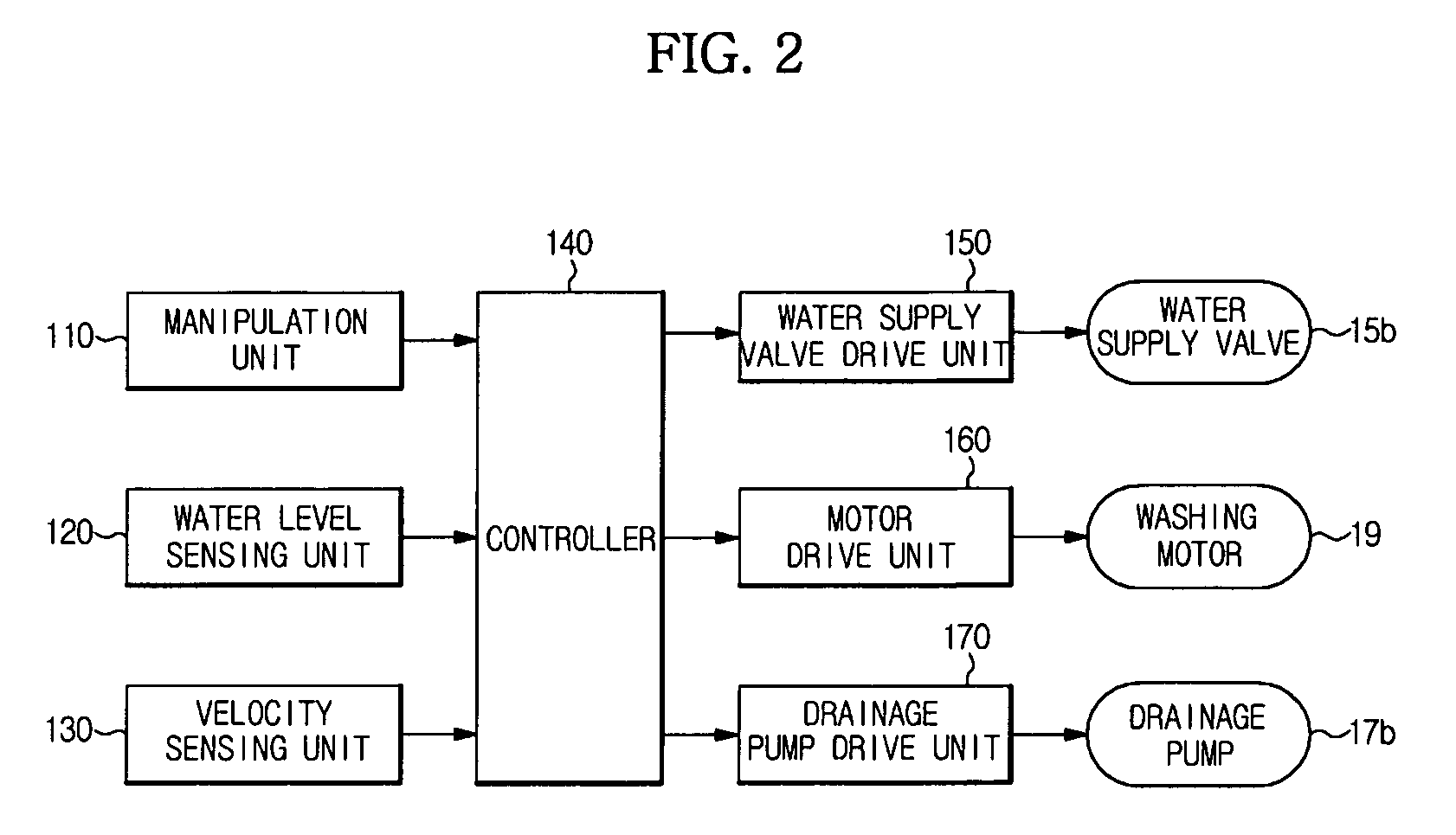

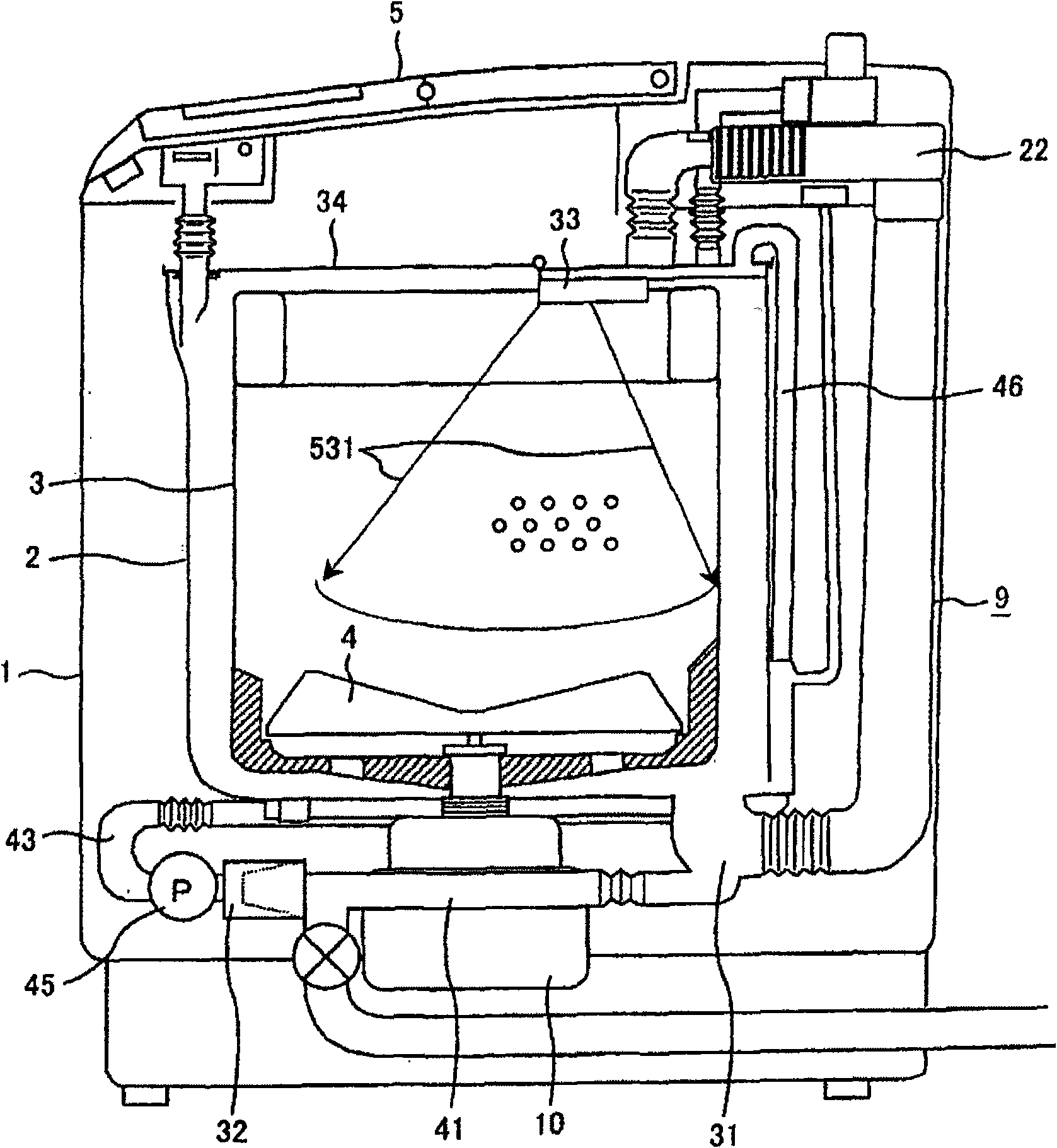

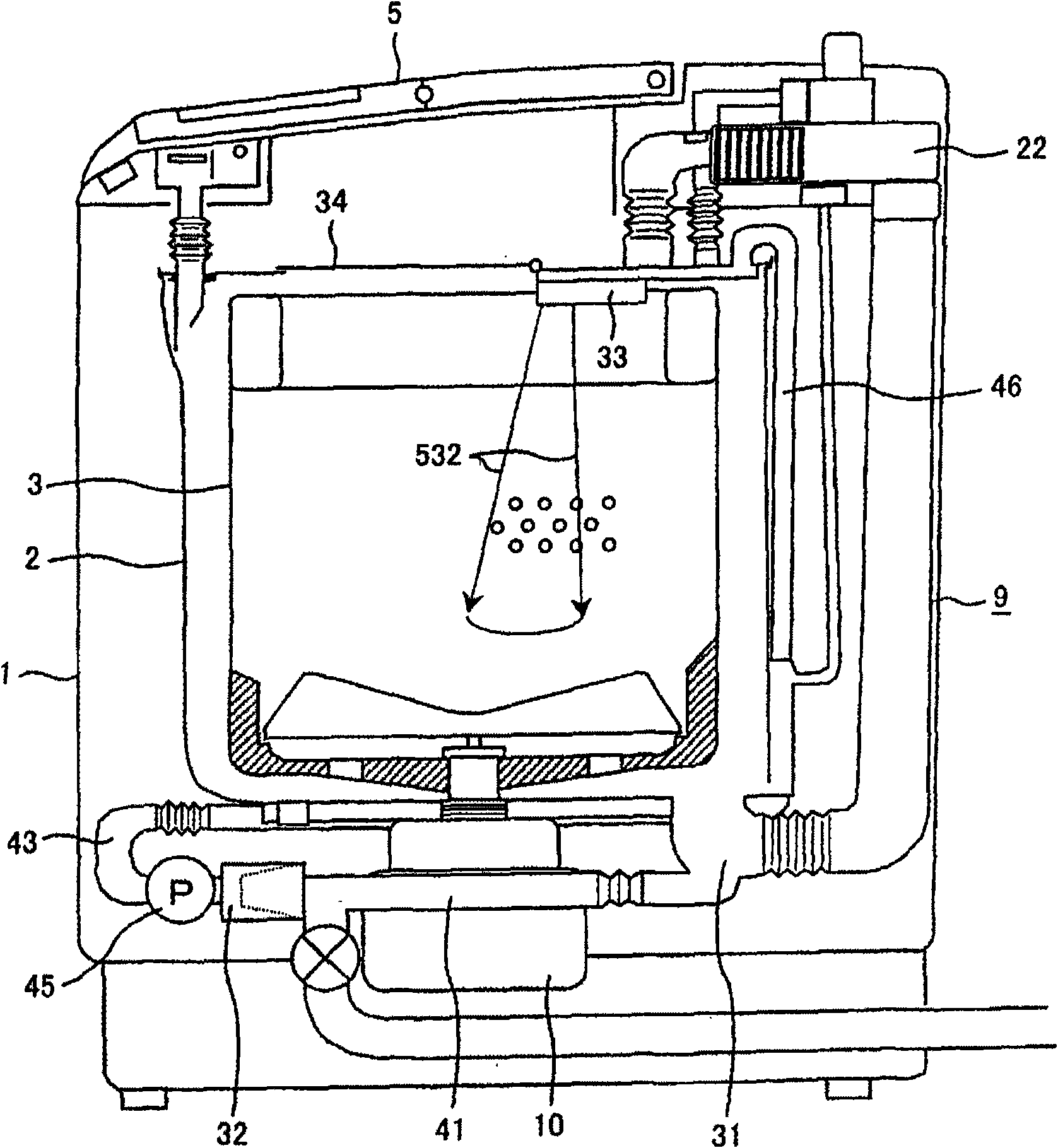

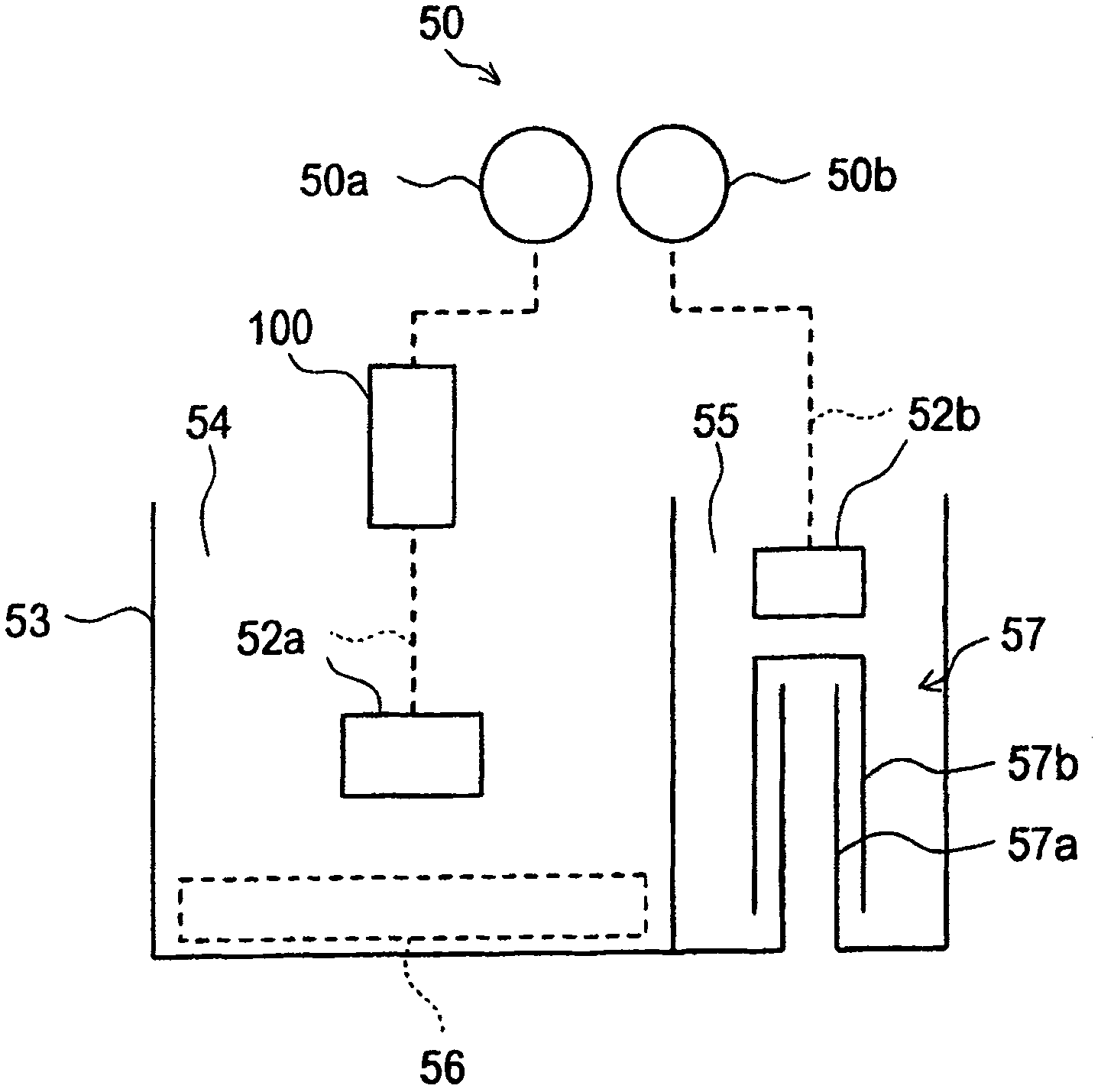

Washing machine performing shower rinsing and method of controlling the same

A method of controlling a washing machine to perform shower rinsing, including repeatedly performing a process to store water supplied to a washing tub in the washing tub and discharge the water from the washing tub while rotating the washing tub during the shower rinsing is described. In a state in which laundry clings to the washing tub by a spin-drying operation, it may be possible to rinse the laundry clinging to the upper part of the washing tub using water supplied to the washing tub rotating at the predetermined velocity, to rinse the laundry clinging to the lower part of the washing tub using the water stored in the washing tub according to the off operation of a drainage unit, and to periodically replace water necessary to rinse the laundry by discharging the used water from the washing tub according to the periodic operation of the drainage unit.

Owner:SAMSUNG ELECTRONICS CO LTD

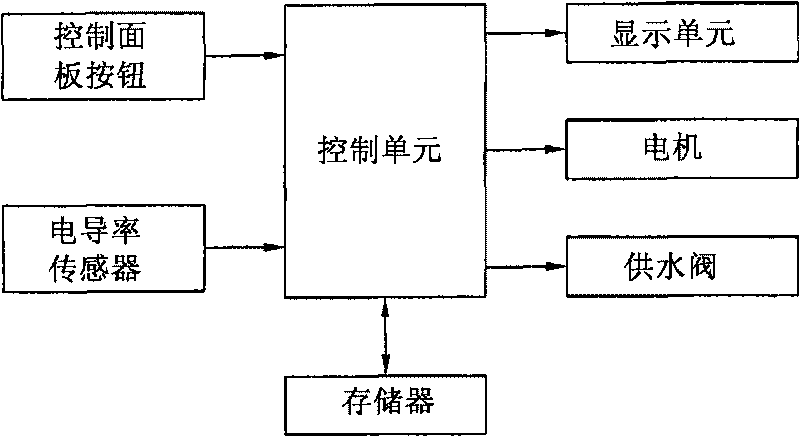

Control methid of washing machine

The present invention relates to a method for controlling a washing machine, in which functioning of a safe rinsing is shown to a user visibly for improving user's reliability. The method, having a detergent amount calculating step for calculating a remained detergent amount at the time of finishing a washing course or a starting of a rinsing course by means of a conductivity sensor, and a determining step for determining whether an additional rinsing is performed or not according to the remained detergent amount calculated thus, the method includes a user informing step for informing a change of the rinsing pattern to the user if the rinsing pattern which is a parameter that gives influence to the rinsing course with reference to the remained detergent amount calculated in the detergent amount calculating step.

Owner:LG ELECTRONICS INC

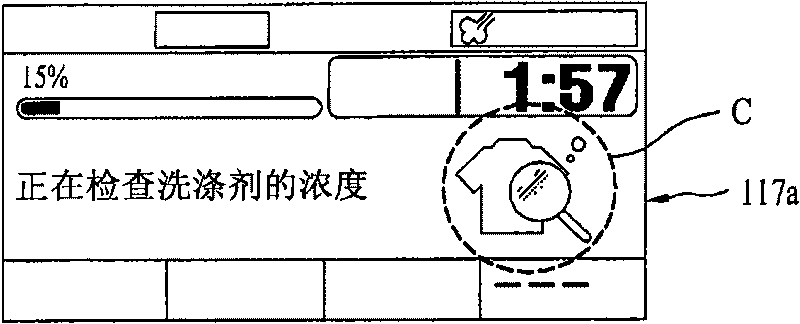

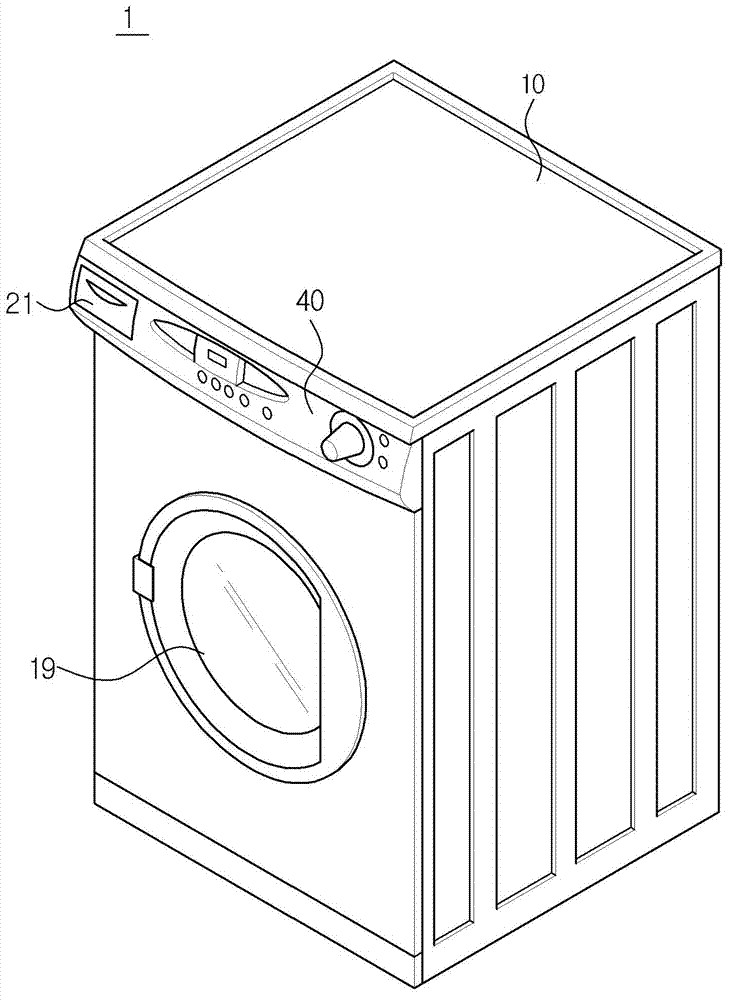

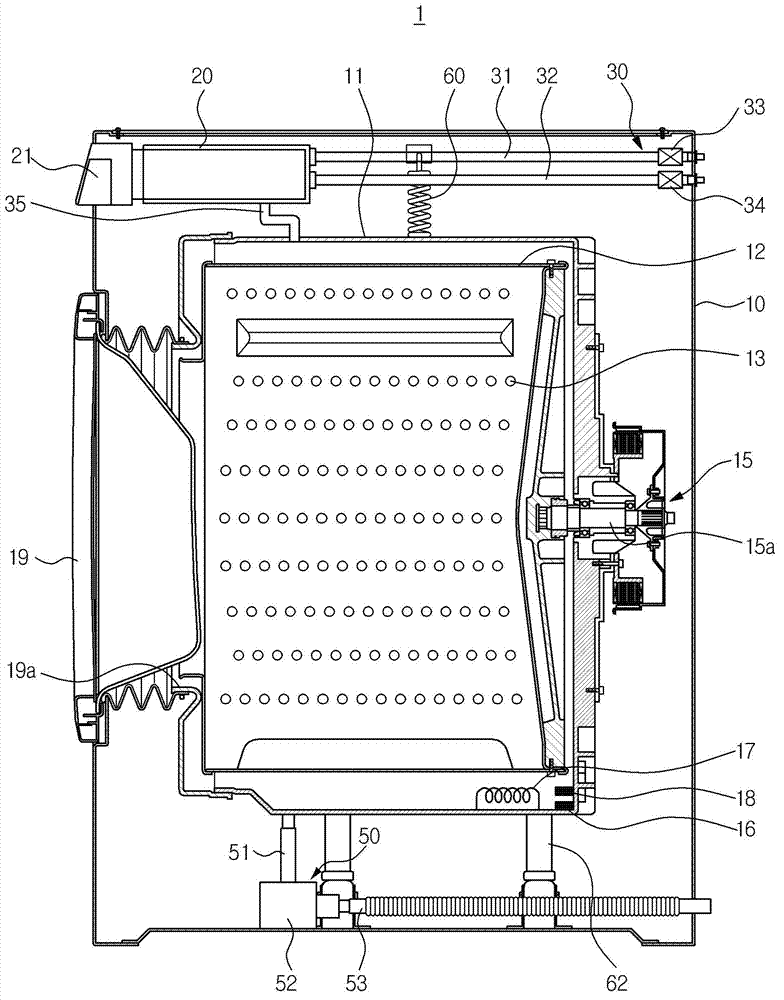

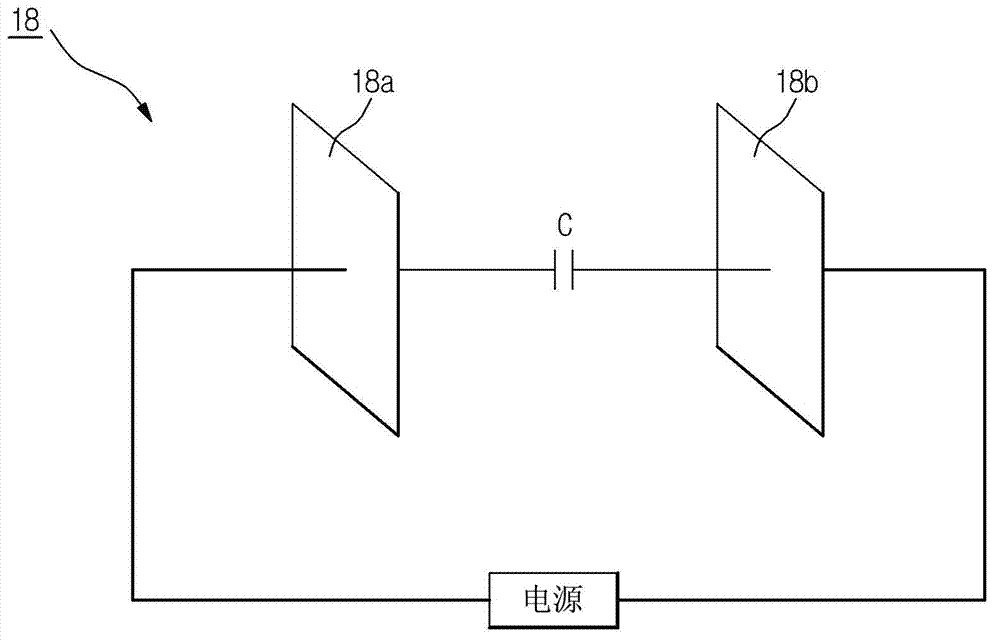

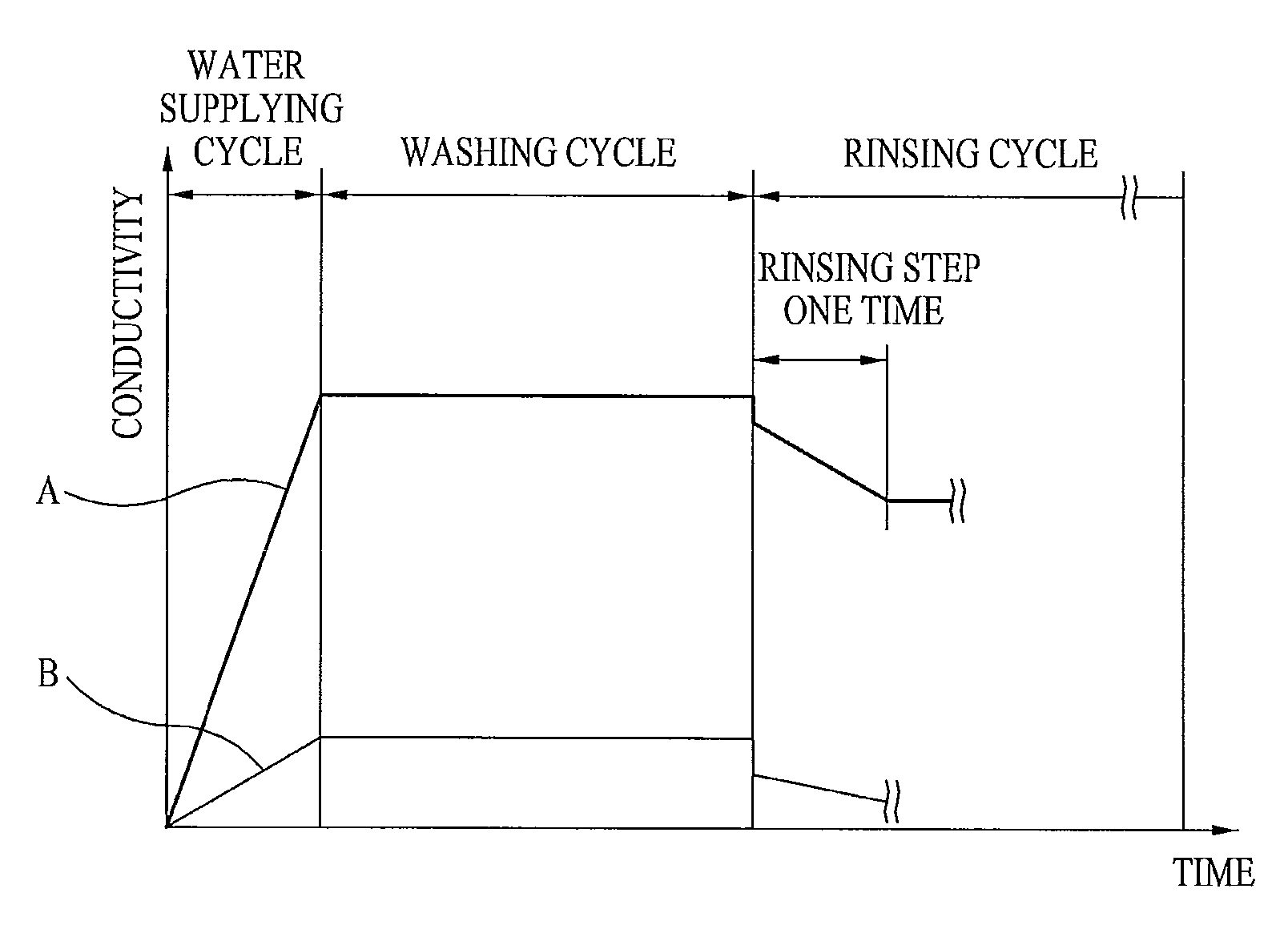

Washing machine with conductivity sensor and method of controlling rinsing cycle

InactiveCN103161051AExtension of timeMinimize timeRinsing apparatusOther washing machinesRinse waterEnvironmental engineering

A washing machine capable of optimizing the rinsing time and the amount of rinsing water by using a conductivity sensor (18), and a method of controlling a rinsing cycle thereof. When the amount of detergent remaining in the rinsing water is determined to be small according to the measured conductivity, the amount of rinsing water and the rinsing time are minimized, that is, the rinsing water is alternately supplied in stages of times, the conductivity of the rinsing water is measured at the stop of the supply of rinsing water, and if the measured conductivity is below a reference value, the rinsing cycle is stopped and enters to a final-spin dry cycle, so that the water and energy is saved and the rinsing is achieved with the optimum algorithm when laundry having a little contamination and a small amount of detergent is input.

Owner:SAMSUNG ELECTRONICS CO LTD

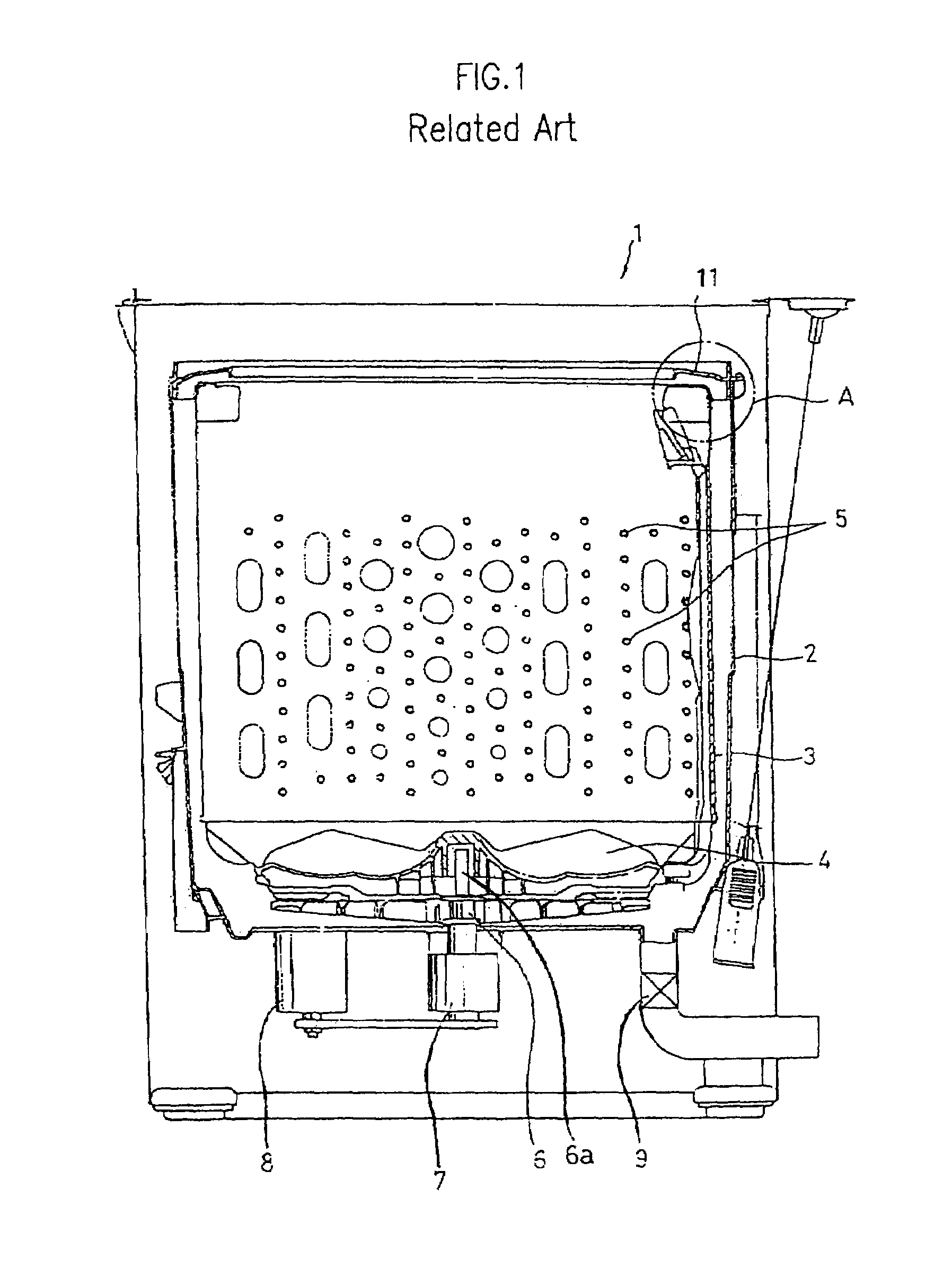

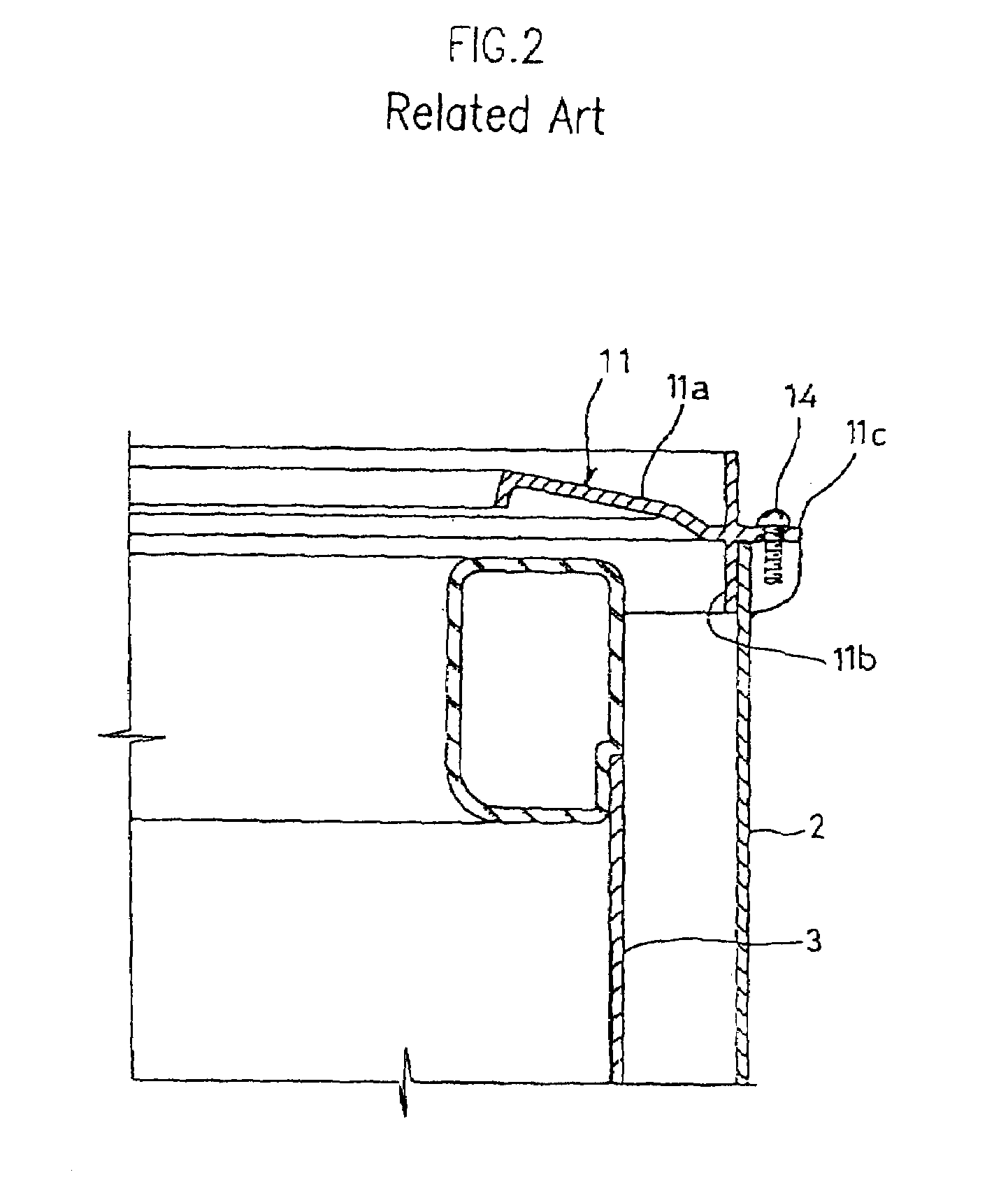

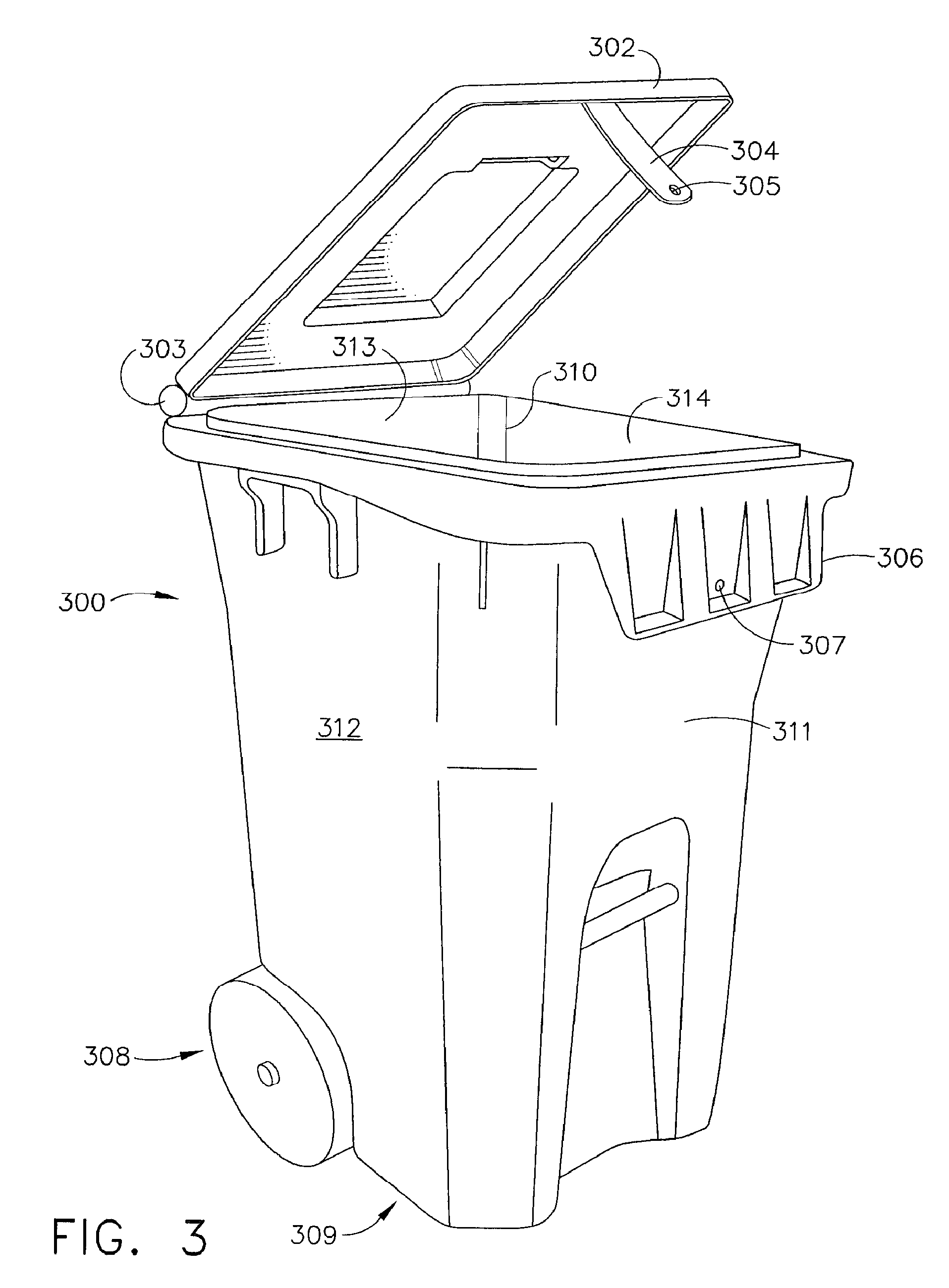

Water supply assembly of washing machine

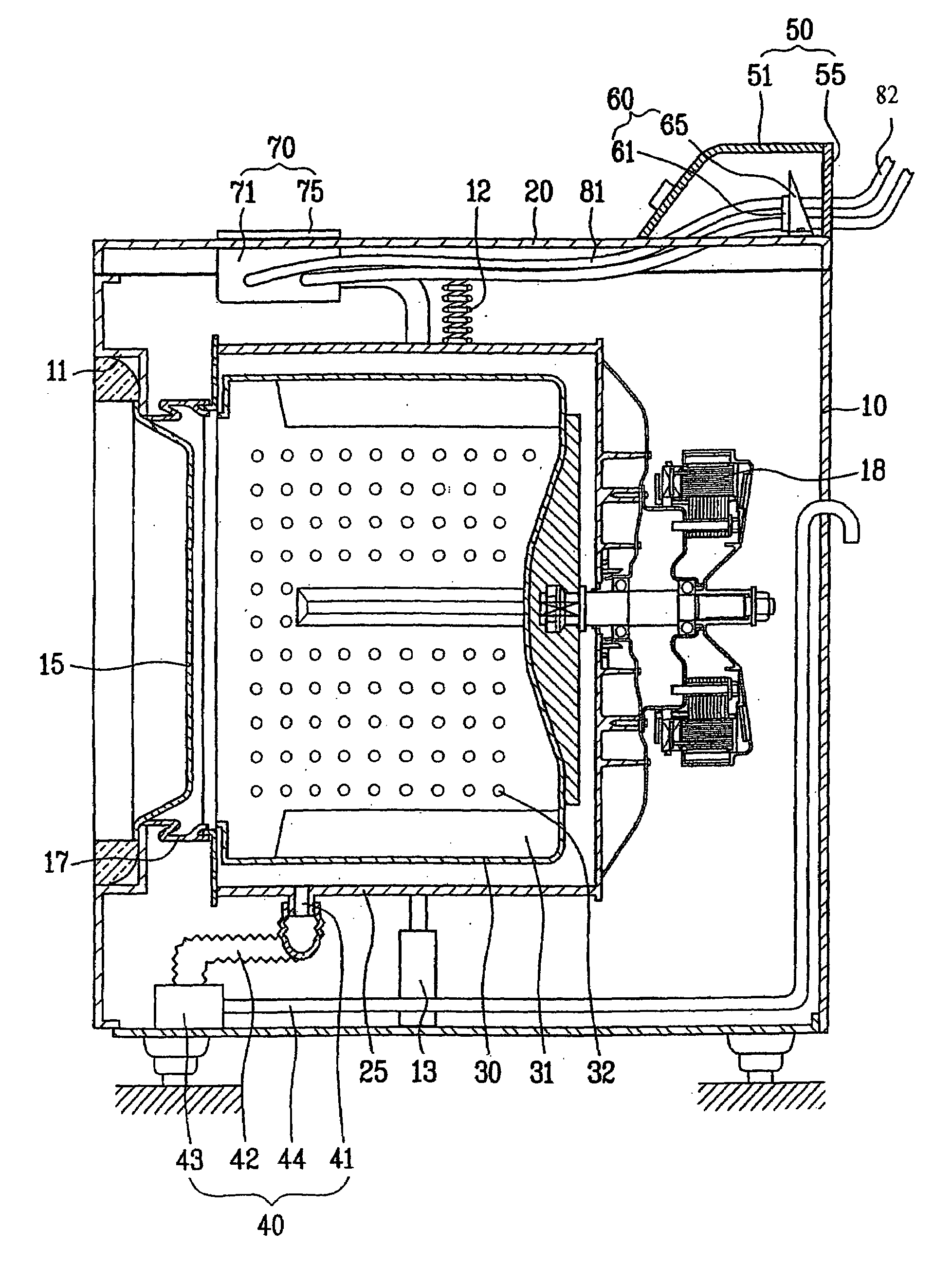

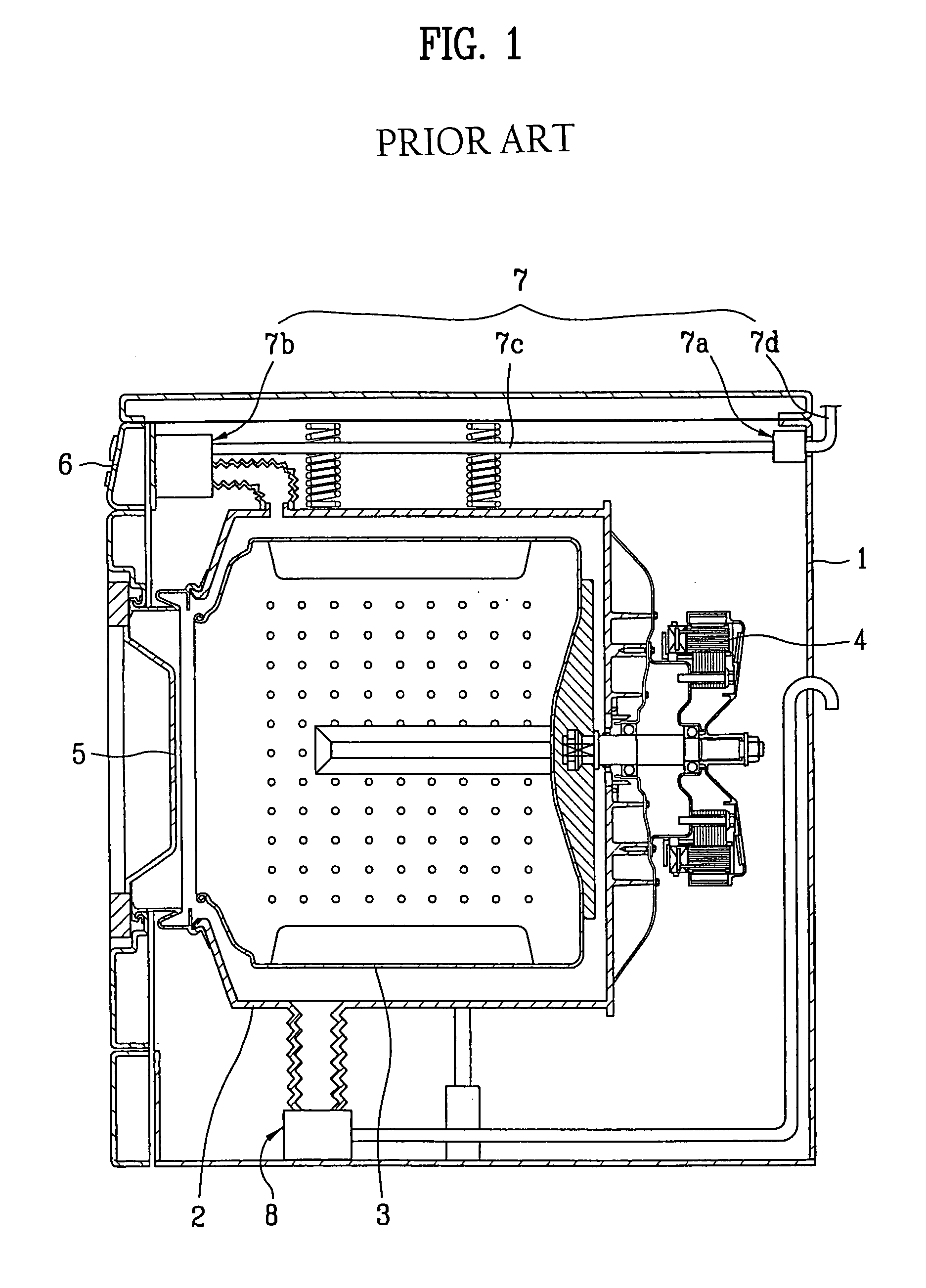

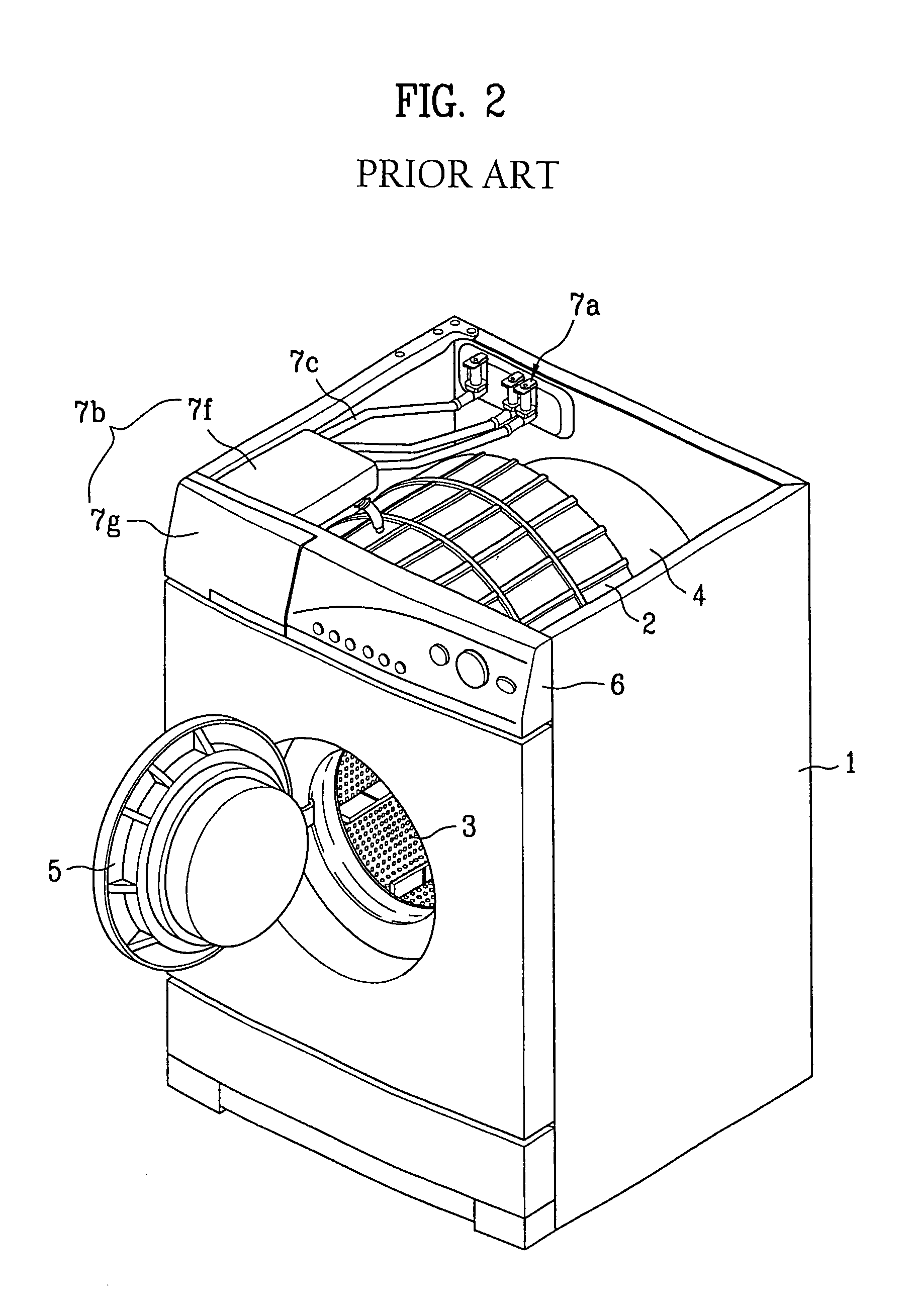

InactiveUS7293436B2Avoid breakingEasy to installRinsing apparatusHand rubbing apparatusWater flowEngineering

An improved water supply assembly for a washing machine is provided which prevents breakage of a water supply hose due to freezing. The water supply assembly includes a detergent box assembly provided in a cabinet so as to communicate with a tub of the washing machine, and a water supply valve assembly connected to the detergent box assembly by a hose so as to control a flow of water into the washing machine. By positioning the water supply valve assembly higher than the detergent box, the hose extending therebetween is oriented at a downward slant, thus causing any excess water remaining in the hose after the flow of water into the washing machine has been cut off to naturally drain into the detergent box assembly.

Owner:LG ELECTRONICS INC

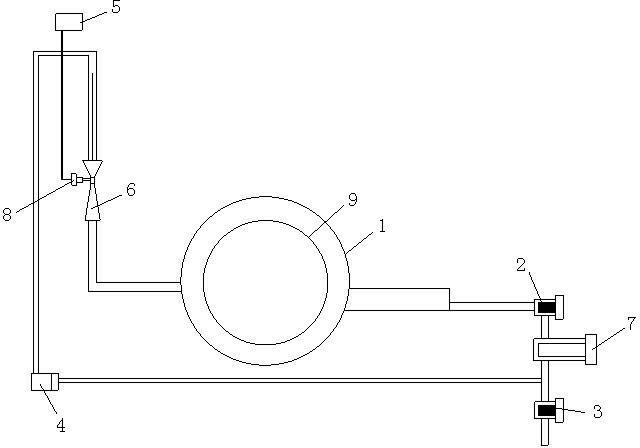

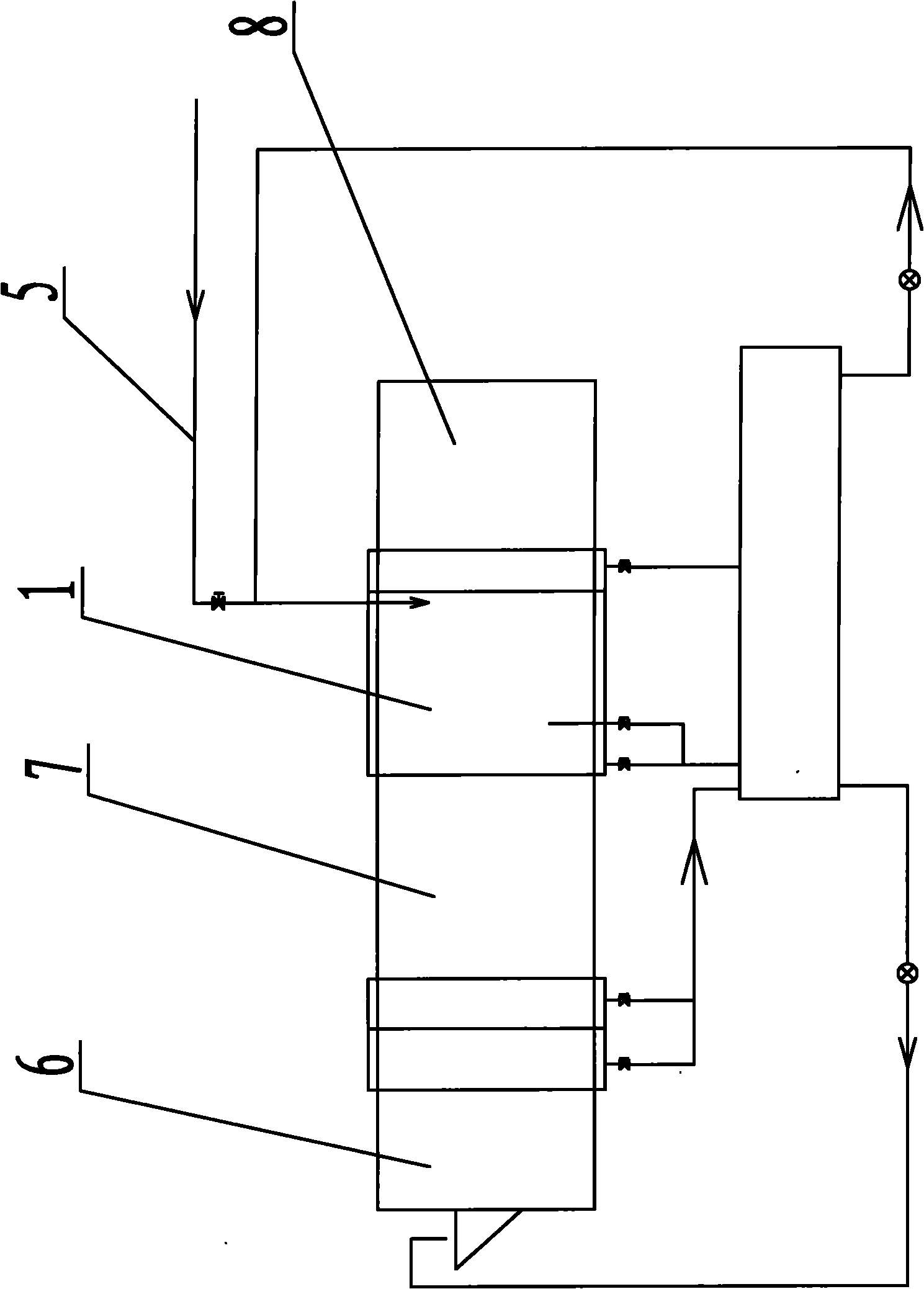

Ozone water washing and rinsing system of washing machine

InactiveCN102425064AAvoid yellowingAvoid residueRinsing apparatusOther washing machinesLaundry washing machineWater flow

The invention relates to an ozone water washing and rinsing system for a washing machine. The ozone water washing and rinsing system comprises an inner barrel and an outer barrel, and the outer barrel is provided with a water inlet and a water outlet; and a first drainage valve and a second drainage valve are arranged at the water outlet in sequence. The system further comprises a water circulating pump and an ozone generator, wherein the inlet of the water circulating pump is connected with a pipeline between the first drainage valve and the second drainage valve, the outlet of the water circulating pump 4 is connected with the water inlet of the outer barrel through a Venturi valve, and the ozone generator is connected with the Venturi valve. According to the technical scheme, the water circulating pump runs to pump water into the Venturi valve from the outer barrel, water slows down to form negative pressure after passing through the Venturi, so that ozone generated by the ozone generator is sucked in the Venturi valve and mixed with the water to form ozone water; and then, the ozone water enters the inner barrel from the outer barrel and is used for washing clothes to remove sebum from the clothes, therefore, the yellowing phenomenon of the clothes because of sebum can be avoided; meanwhile, washing powder can be prevented from remaining on dewatered clothes.

Owner:WHIRLPOOL CHINA

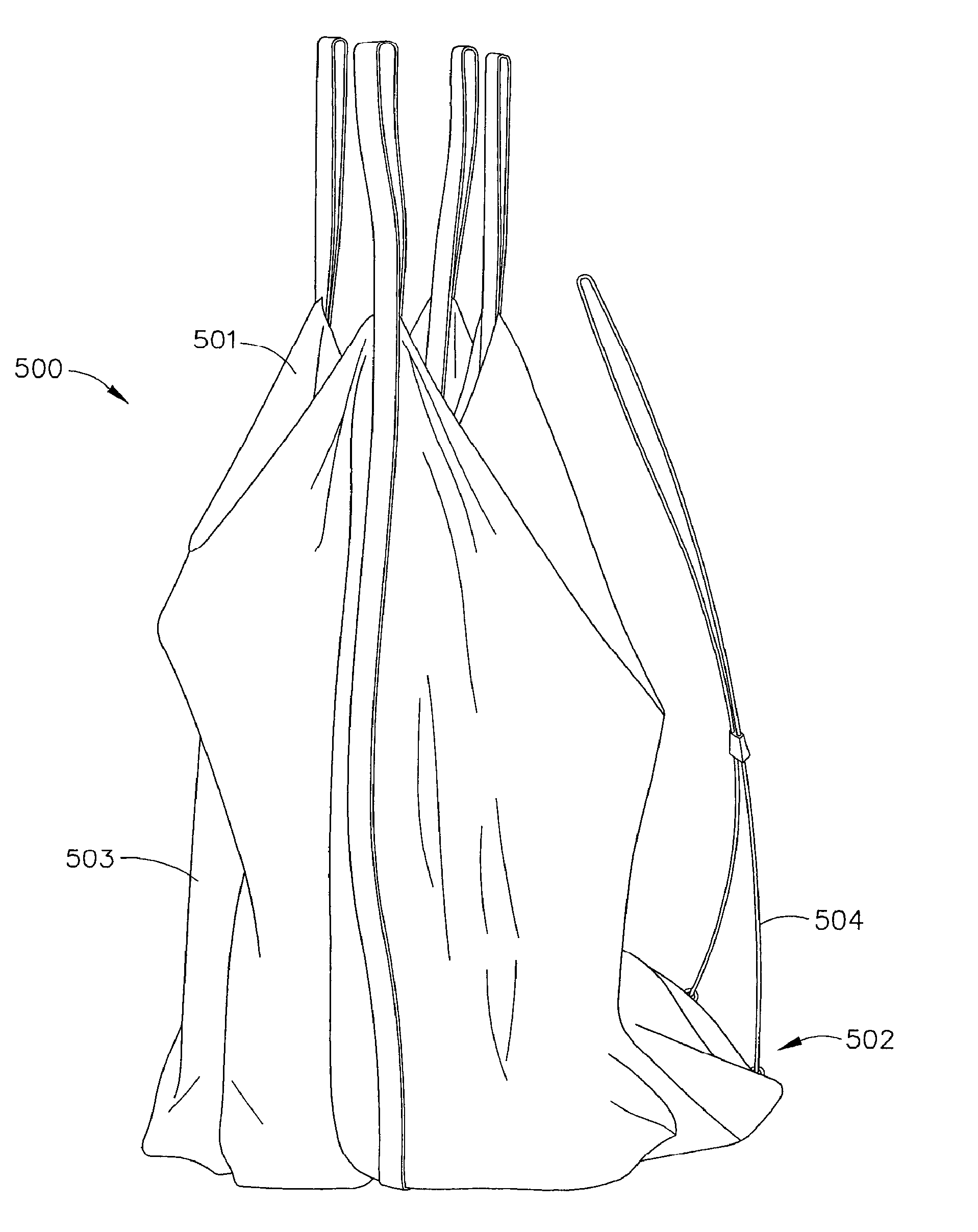

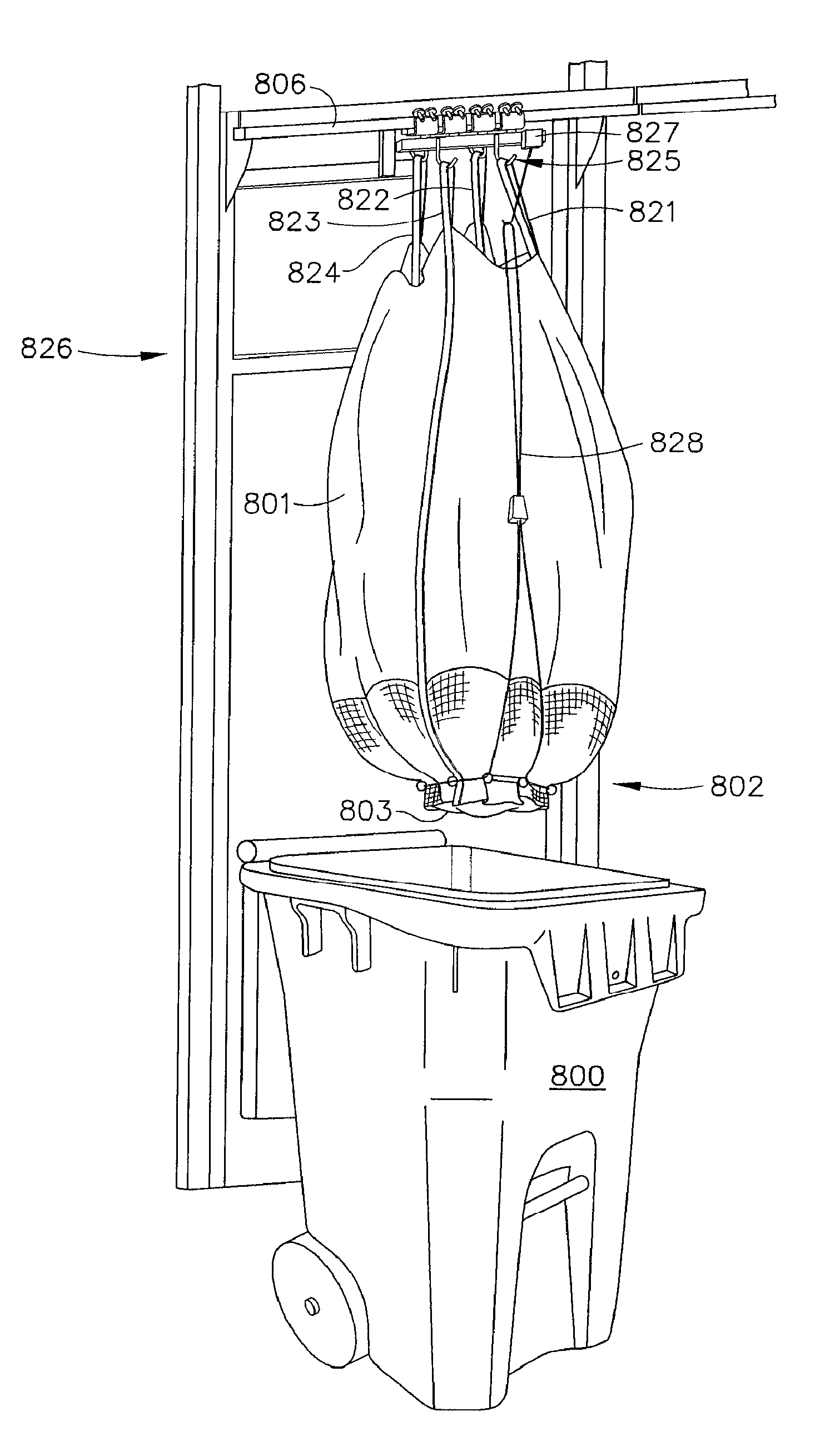

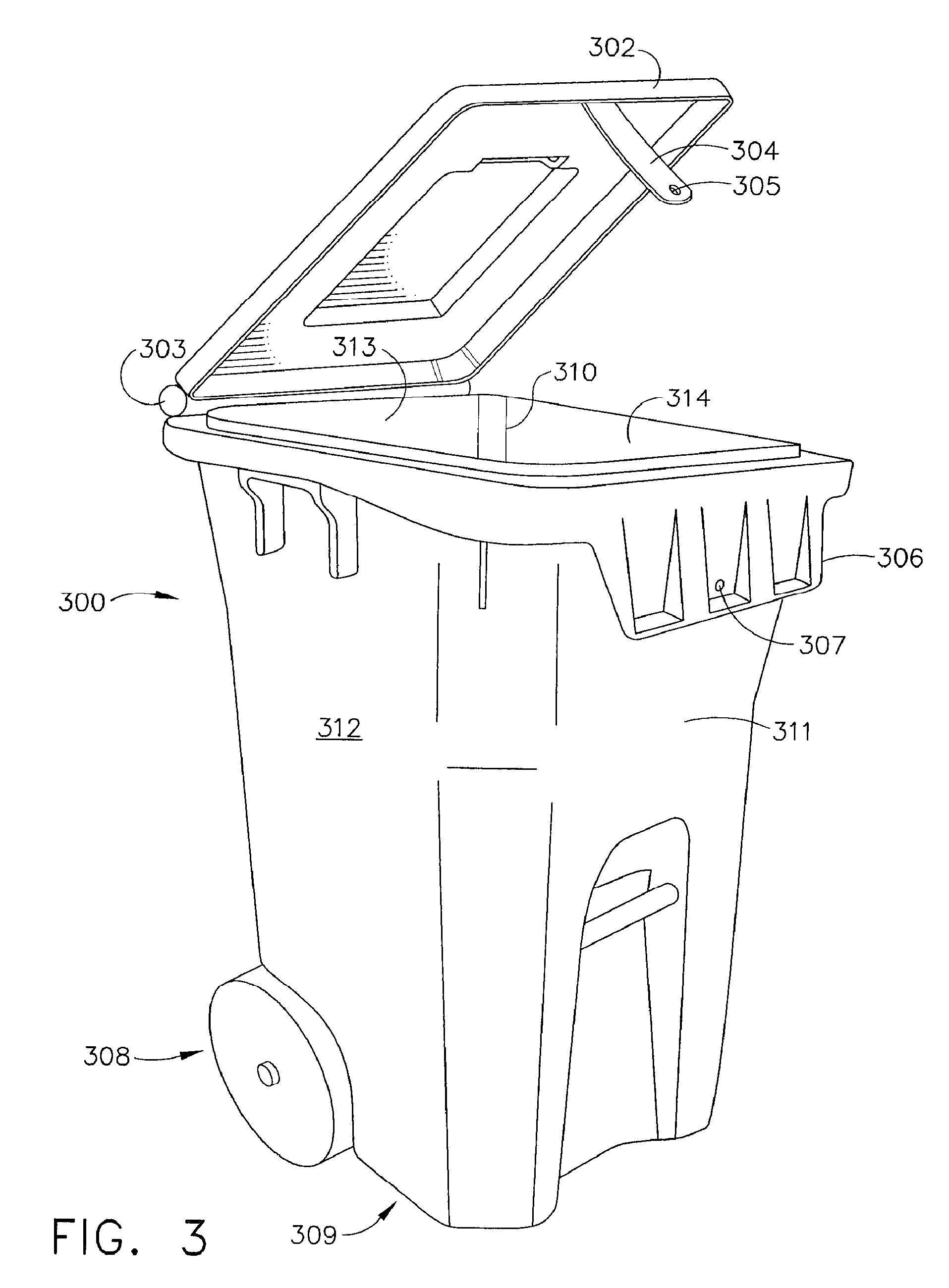

Method of collecting, transporting and cleaning soiled textiles

A method of collecting soiled textiles to be cleaned, comprising the steps of providing a container having an open end, a closed end, and sides extending therebetween, providing a sling having an open end, a second end, and sides extending therebetween disposed in and supported by said container, providing a water soluble bag having an open end, a closed end, and sides extending therebetween and made of a plastic film having a thickness of at least 1.3 mils, wherein said bag dissolves in water at a temperature of 165° F. in less than about 250 seconds, does not dissolve in water at a temperature of 85° F. in 7 days, being capable of containing at least 175 lbs. of soiled textiles, and having a capacity of at least 50 gallons, wherein said bag is disposed in and supported by said sling, and wherein soiled textiles deposited in said container are contained in said bag.

Owner:CINTAS CORP SERVICES INC

Control method of laundry machine

A control method of a laundry machine comprising a water supply, washing and rinsing cycle, the control method includes first determination step performed prior to the rinsing cycle and determining a kind of detergent, second determination step performed during a first rinsing course of the rinsing cycle and determining an amount of remained detergent in a rinsing water, and condition determination step of at least one following rinsing course based on the kind and amount of the remained detergent.

Owner:LG ELECTRONICS INC

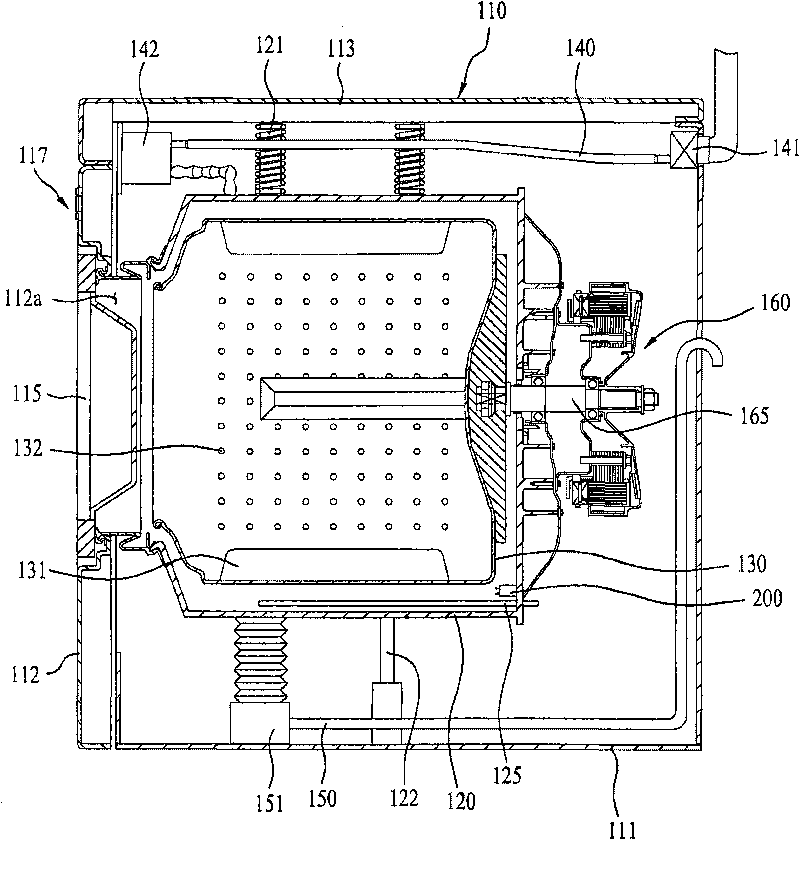

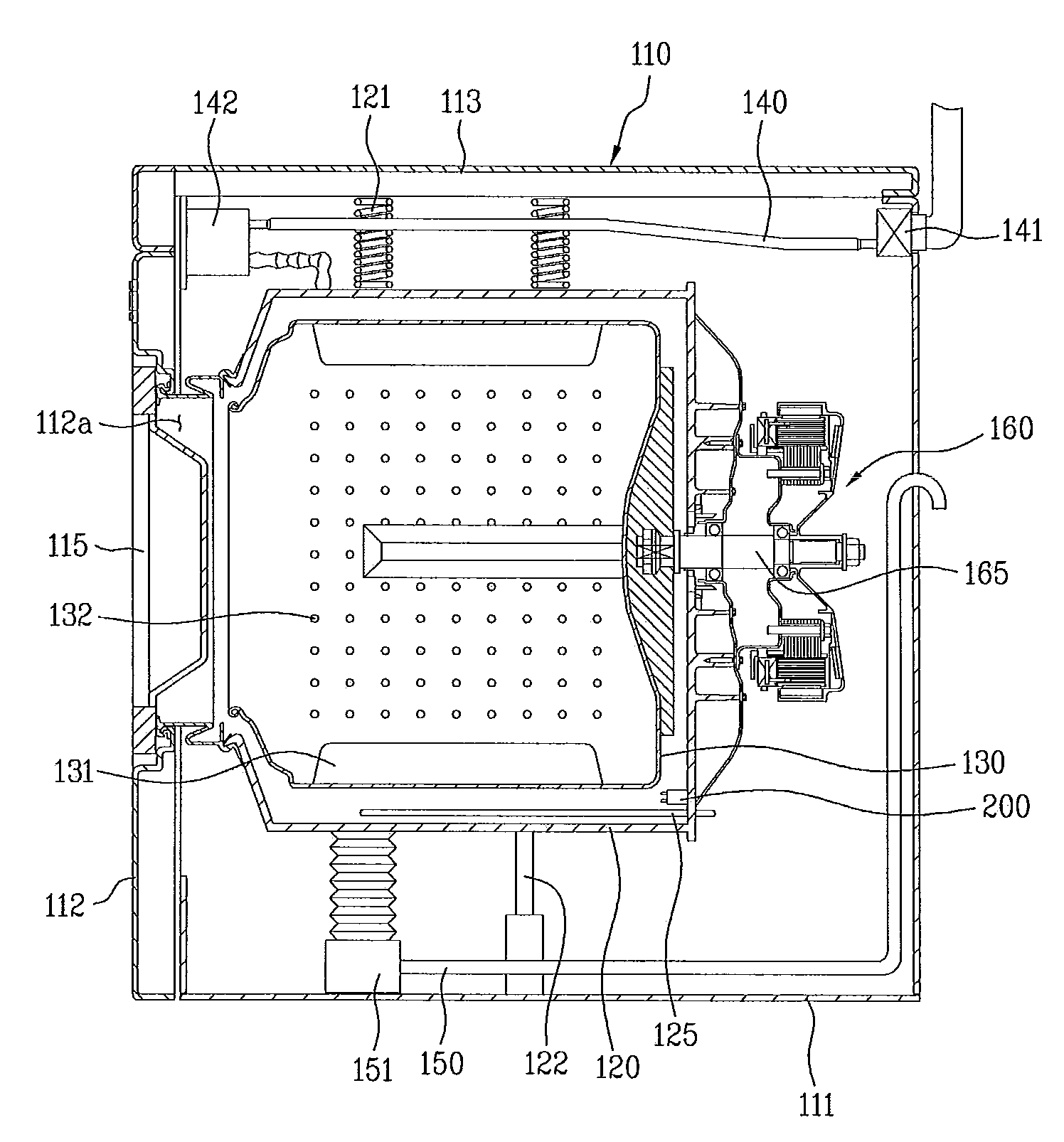

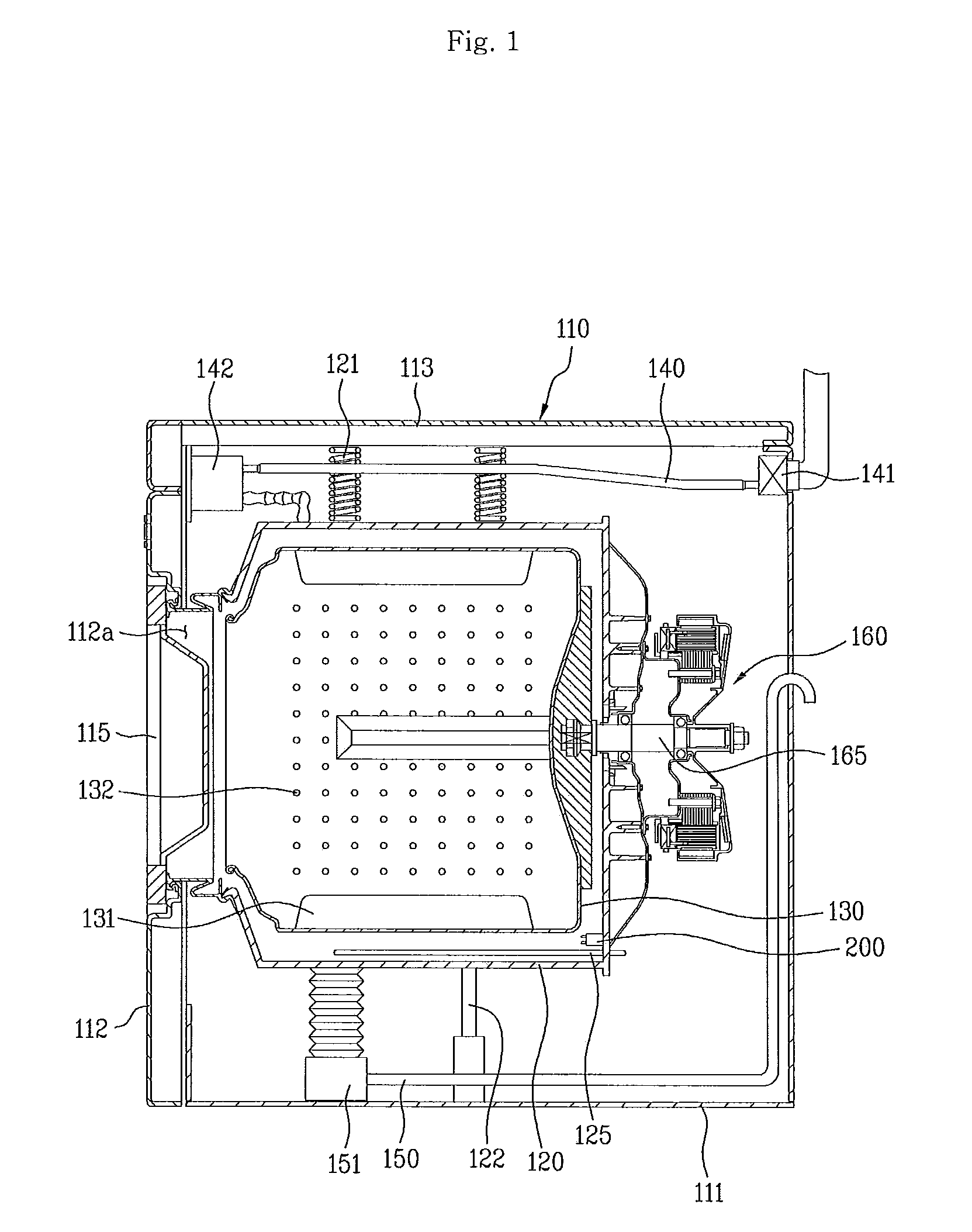

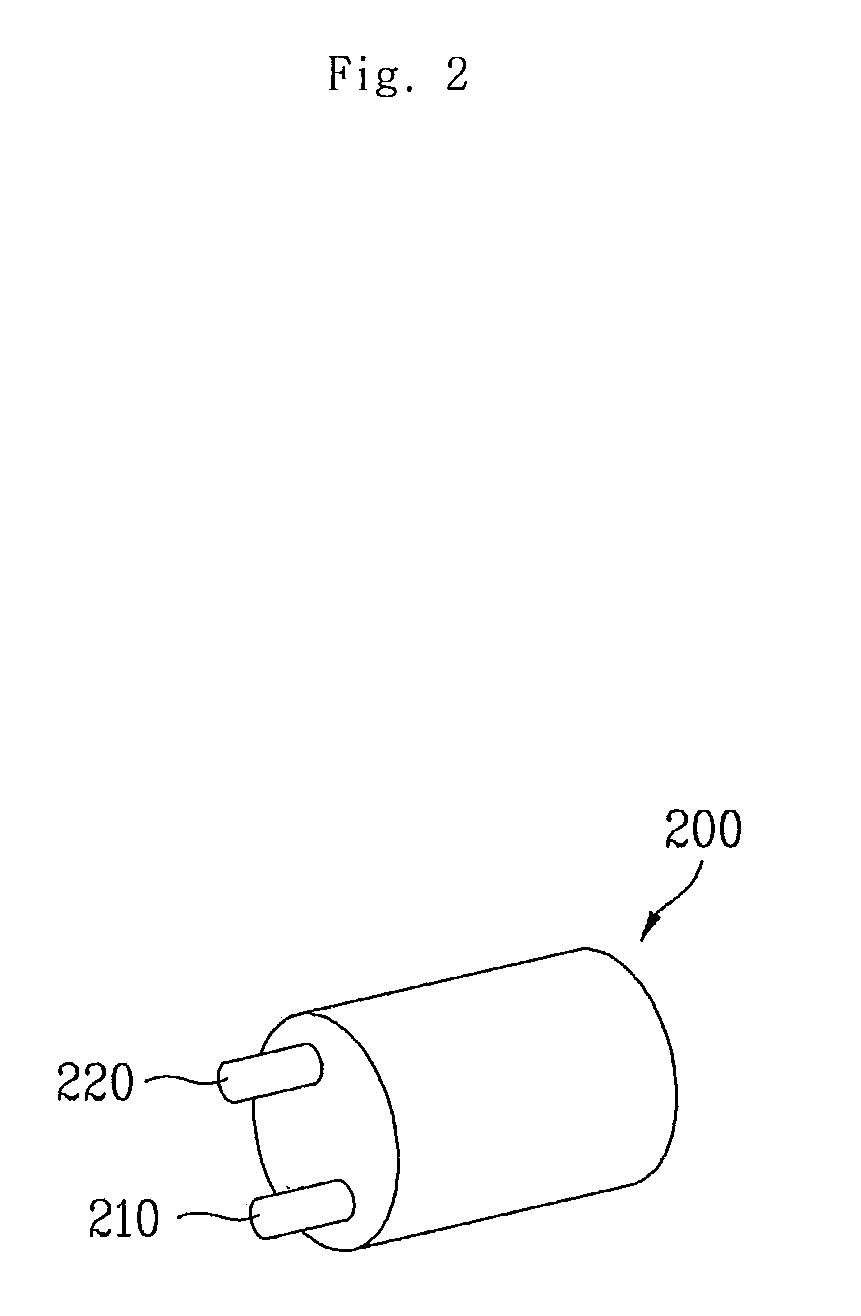

Washing machine and method of controlling rinsing cycle

InactiveUS20130145563A1A large amountSave energyRinsing apparatusOther washing machinesRinse waterSpins

A washing machine capable of optimizing the rinsing time and the amount of rinsing water by using a conductivity sensor, and a method of controlling a rinsing cycle thereof. When the amount of detergent remaining in the rinsing water is determined to be small according to the measured conductivity, the amount of rinsing water and the rinsing time are minimized, that is, the rinsing water is alternately supplied in stages of times, the conductivity of the rinsing water is measured at the stop of the supply of rinsing water, and if the measured conductivity is below a reference value, the rinsing cycle is stopped and enters to a final-spin dry cycle, so that the water and energy is saved and the rinsing is achieved with the optimum algorithm when laundry having a little contamination and a small amount of detergent is input.

Owner:SAMSUNG ELECTRONICS CO LTD

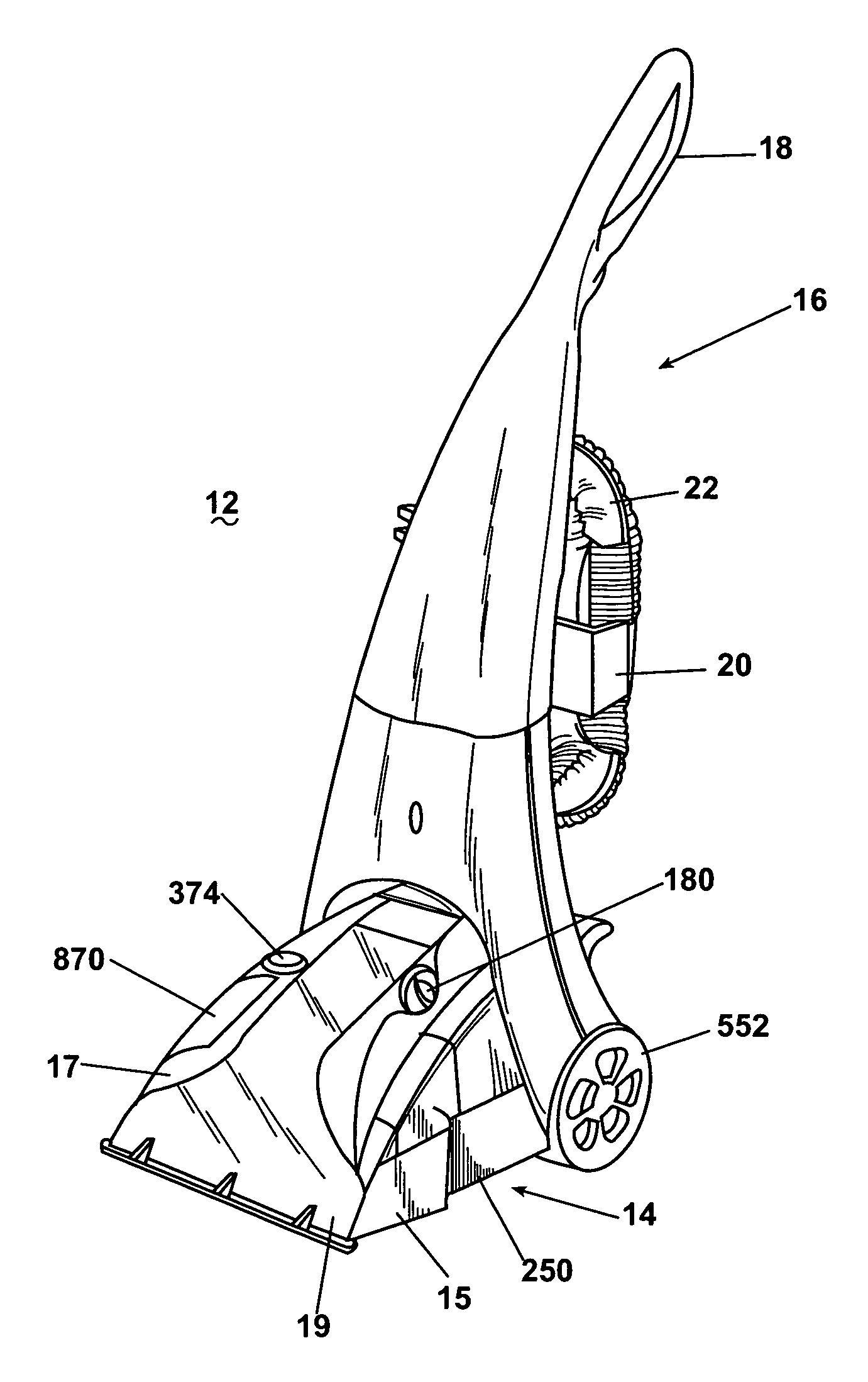

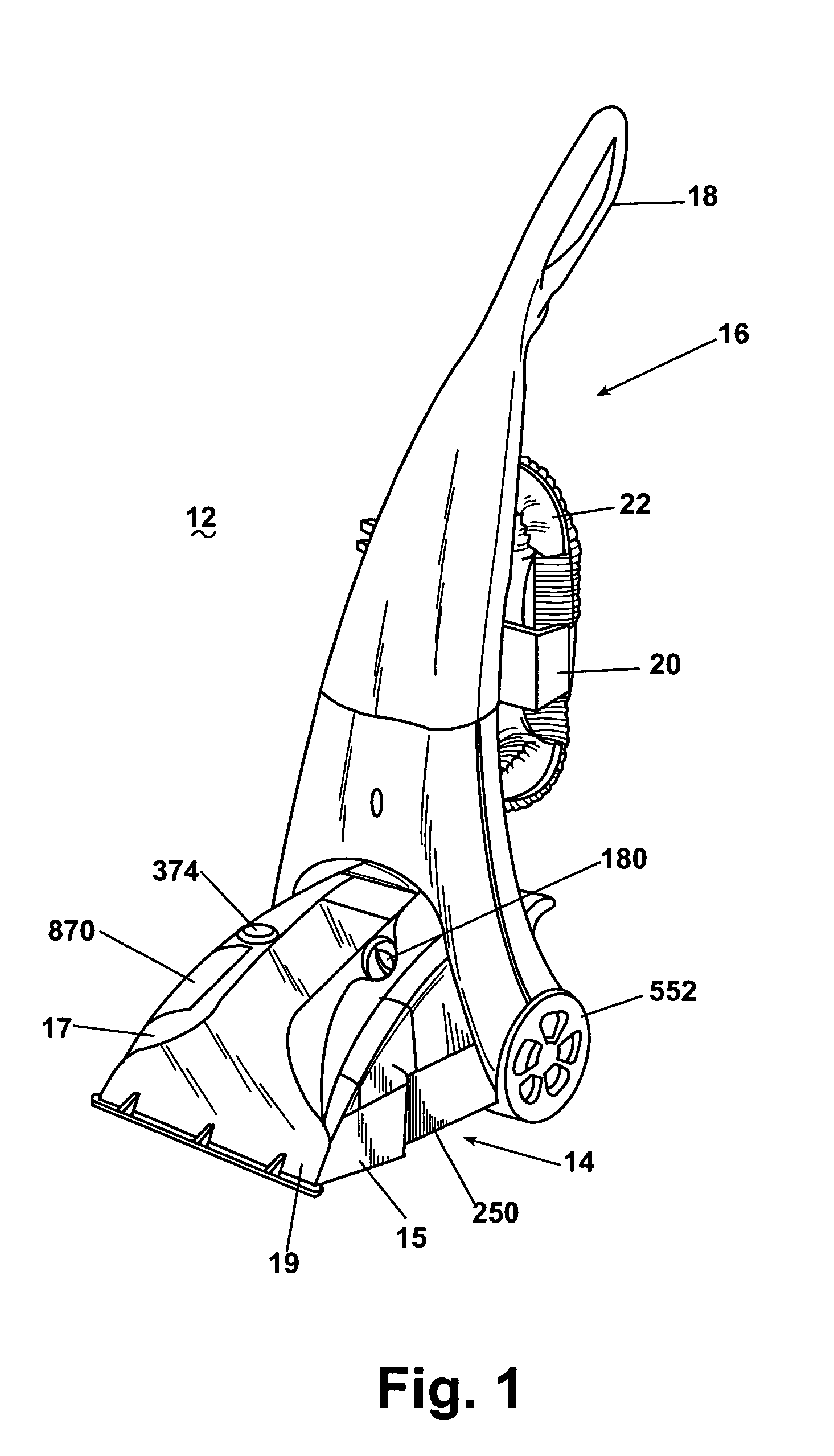

Extraction cleaning with oxidizing agent

ActiveUS7862623B1Rinsing apparatusTransportation and packagingSurface cleaningBiomedical engineering

A portable surface cleaning apparatus comprises a base module for movement along the surface; an upright handle pivotally attached to the base module; a fluid dispensing system including at least one fluid supply tank mounted to the handle or the base module, a dispensing nozzle mounted to the base module for applying a cleaning fluid to an upholstery or carpet surface to be cleaned, and a heater for heating the fluid to be applied to the surface to be cleaned to a temperature less than boiling; a fluid recovery tank mounted to the handle or the base module for holding recovered fluid; a suction nozzle associated with the base module; a working air conduit extending between the recovery tank and the suction nozzle; and a vacuum source and fluid communication with the recovery tank for generating a flow of working air from the suction nozzle through the working air conduit and through the recovery tank to thereby recovering fluid from the surface to be cleaned through the suction nozzle and working air conduit and into the recovery tank. A method for cleaning an upholstery or carpet surface in which a fluid cleaning solution is contained in a tank and dispensed on the surface through a nozzle and the cleaning solution is recovered from the surface with suction and deposited into a recovery tank includes, according to the invention, the steps of admixing an oxidizing agent with the cleaning solution, and heating the admixture prior to the step of dispensing the cleaning solution onto the surface to be cleaned.

Owner:BISSELL INC

Method of collecting, transporting and cleaning soiled textiles

A method of collecting soiled textiles to be cleaned, comprising the steps of providing a container having an open end, a closed end, and sides extending therebetween, providing a sling having an open end, a second end, and sides extending therebetween disposed in and supported by said container, providing a water soluble bag having an open end, a closed end, and sides extending therebetween and made of a plastic film having a thickness of at least 1.3 mils, wherein said bag dissolves in water at a temperature of 165° F. in less than about 250 seconds, does not dissolve in water at a temperature of 85° F. in 7 days, being capable of containing at least 175 lbs. of soiled textiles, and having a capacity of at least 50 gallons, wherein said bag is disposed in and supported by said sling, and wherein soiled textiles deposited in said container are contained in said bag.

Owner:CINTAS CORP SERVICES INC

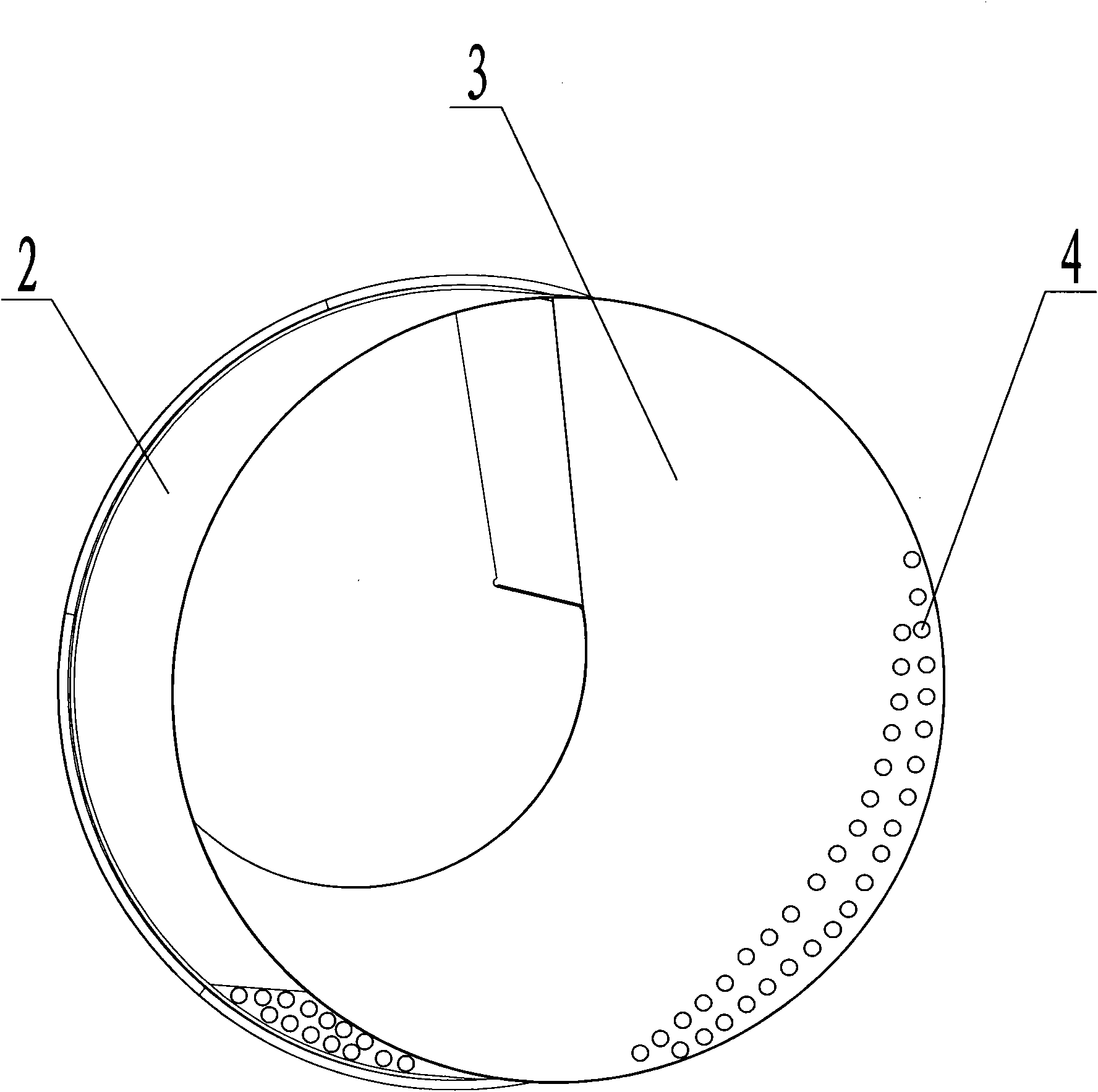

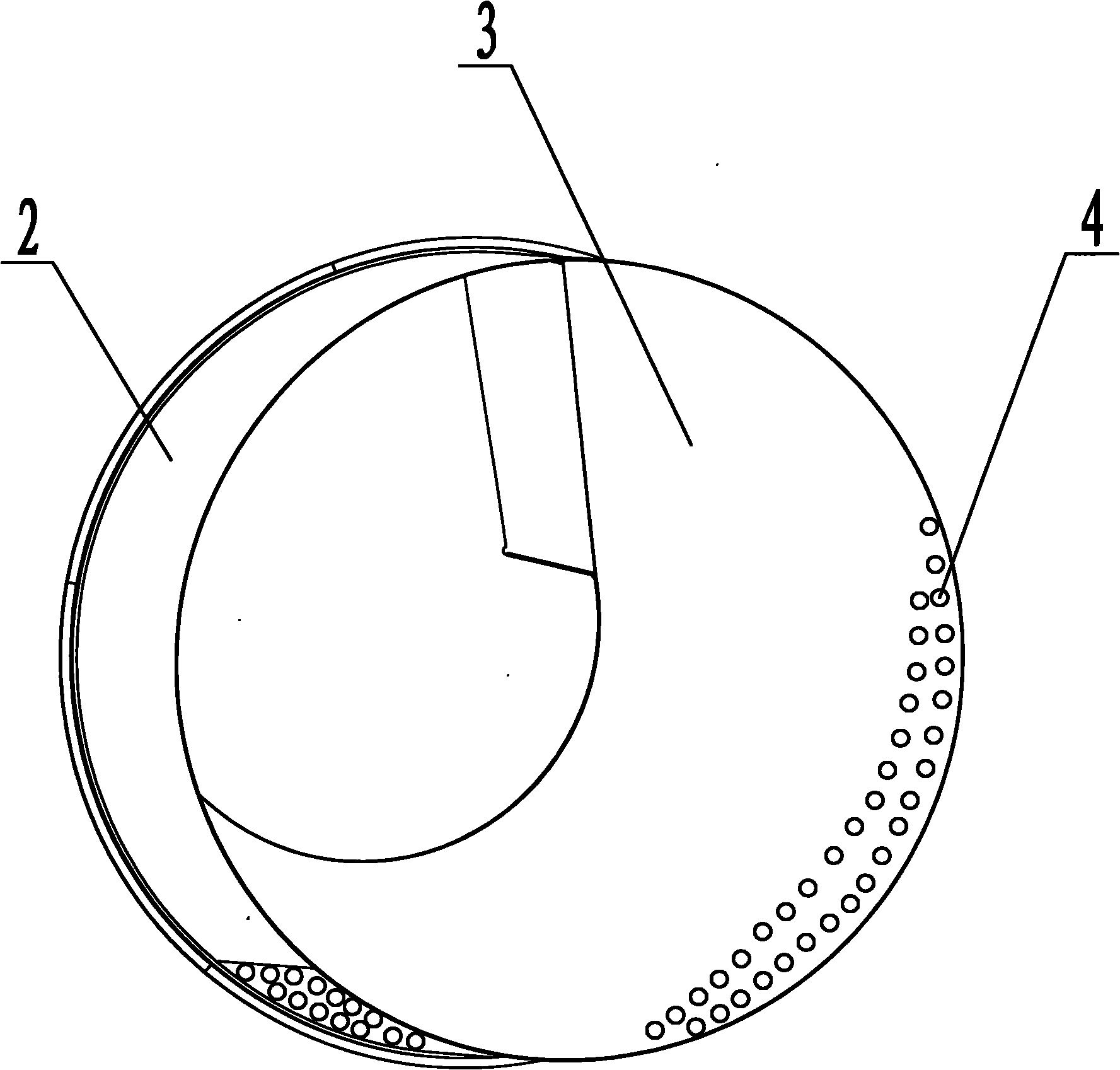

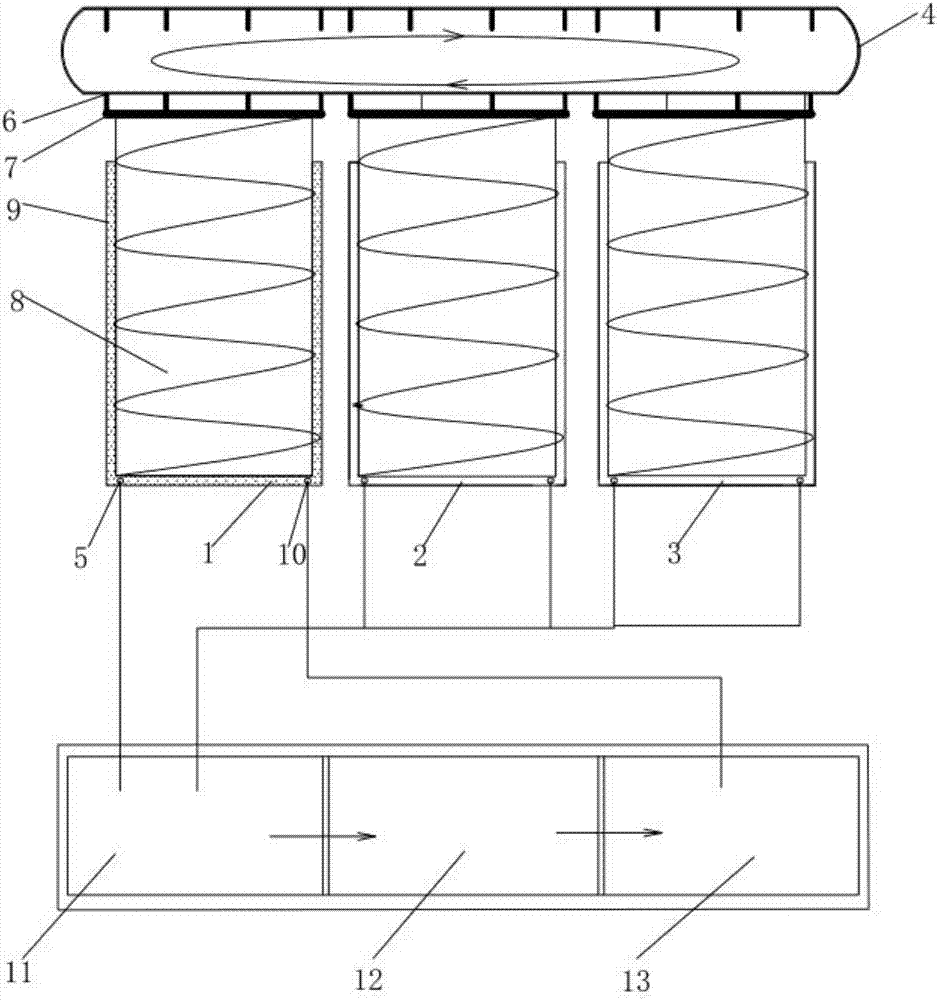

Countercurrent rinsing device in tunnel type washer

ActiveCN101812798AReasonable useSave washing waterRinsing apparatusTextiles and paperWaste managementPiping

The invention discloses a countercurrent rinsing device in a tunnel type washer, which can save a large amount of washing water. The countercurrent rinsing device comprises a rising area, wherein a plurality of rinsing-area drums are arranged in the rising area, a baffle plate is arranged between the adjacent rinsing-area drums, permeable holes are uniformly in the baffle plates, the setting heights of the permeable holes in the adjacent partitions are arranged in an ascending order, the permeable holes in the partition at the back end of the rising area are the highest, a water inlet pipe is arranged above the rinsing area, and water forward orderly flows through the permeable holes from the back end of the rinsing area to carry out the countercurrent rinsing on washings in the rinsing-area drums. The countercurrent rinsing device in a tunnel type washer can realize the countercurrent rinsing of clothes to be washed in the rinsing process, reasonably utilize and save the washing water, and reduces the washing cost.

Owner:JIANGSU SEA LION MASCH GRP CO LTD

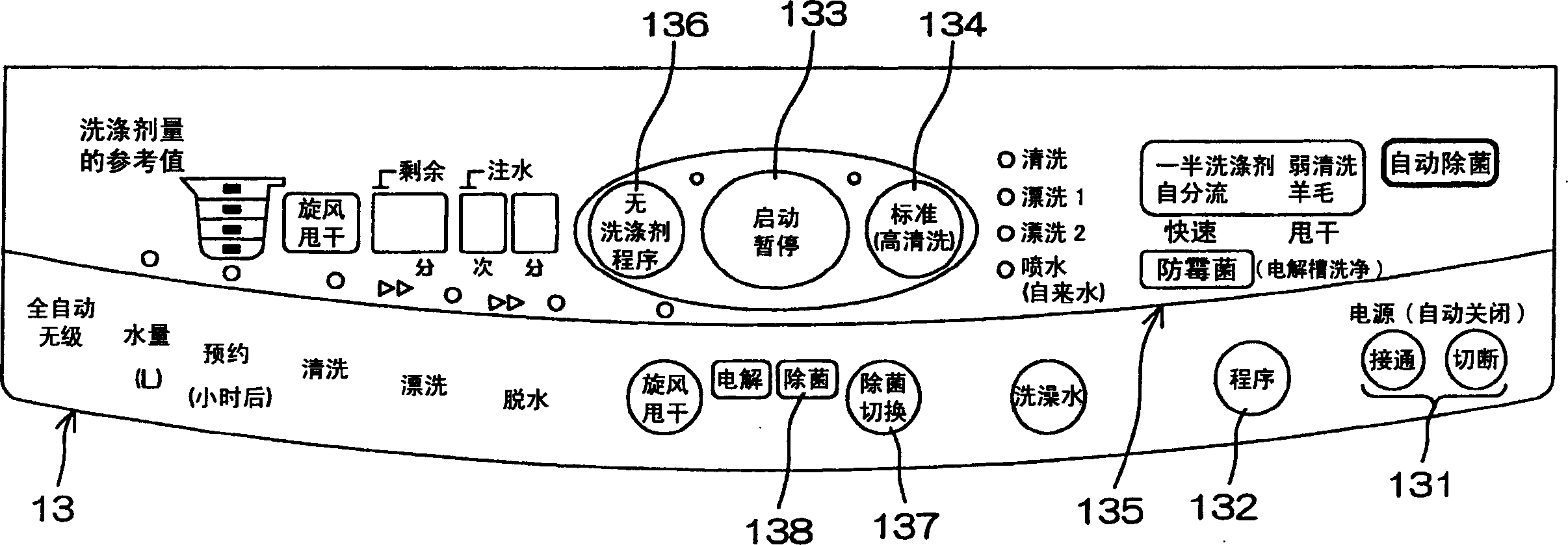

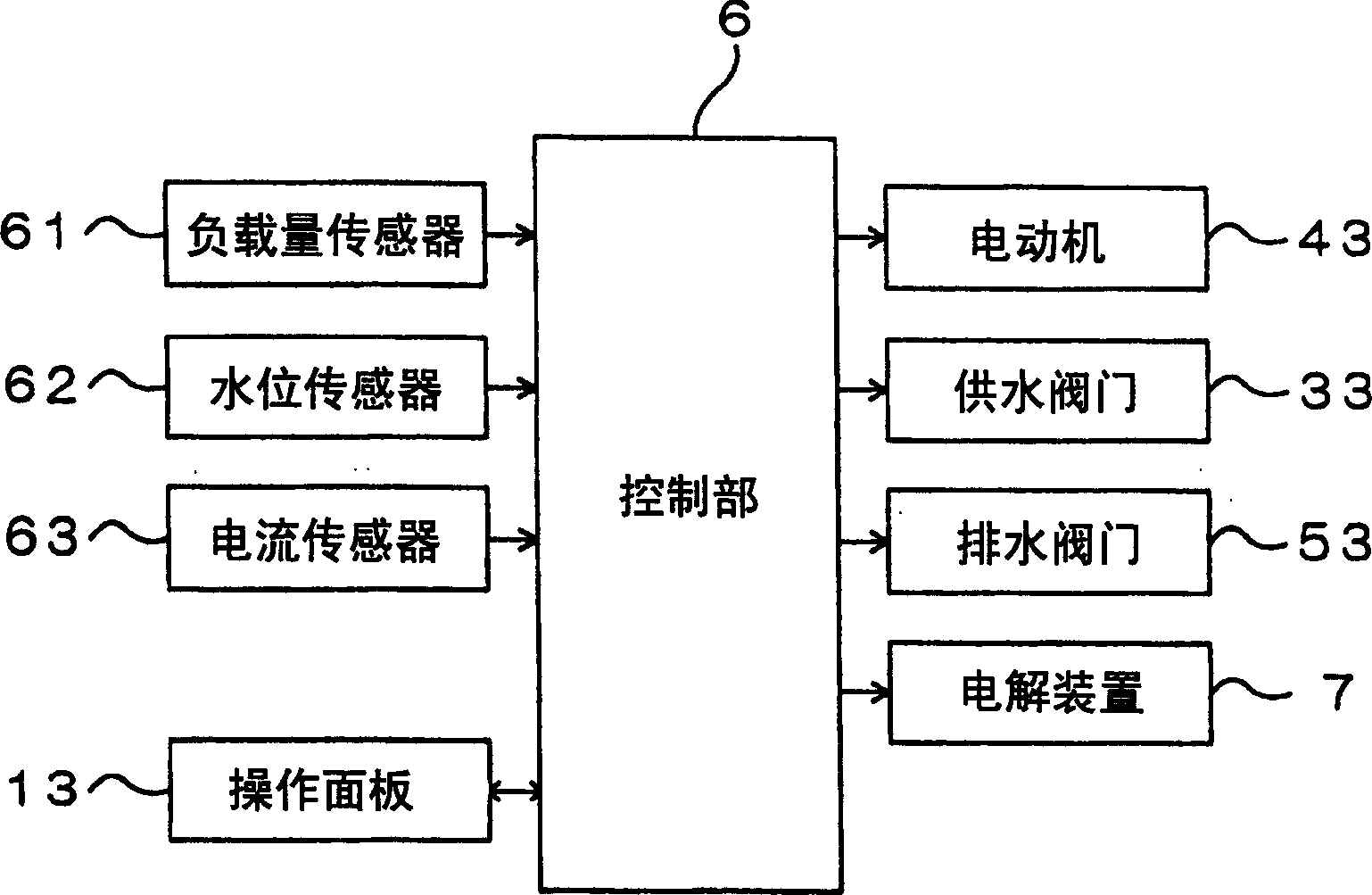

Washer

InactiveCN1576440AOdor suppressionRinsing apparatusWater/sewage treatment by electrochemical methodsElectrolysisEngineering

The invention prevents a reduction in sterilizing function by electrolytic water at the time of electrolytic rinsing.When an electrolytic rinsing (Step 15) is carried out, at the time of a spin-rinsing A2 (Step 13) prior to the electrolysis rinsing, water-supplying is performed longer than in the normal spin-rinsing A1, provided with the normal water-supply time plus an additional 20 seconds, for example. Therefore, the detergent component left in the laundry is more diluted than that in the normal spin-rinsing A1, to be fully eliminated.

Owner:HAIER GRP CORP +1

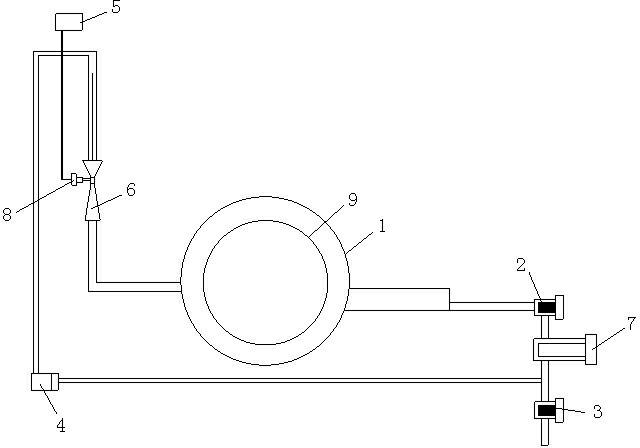

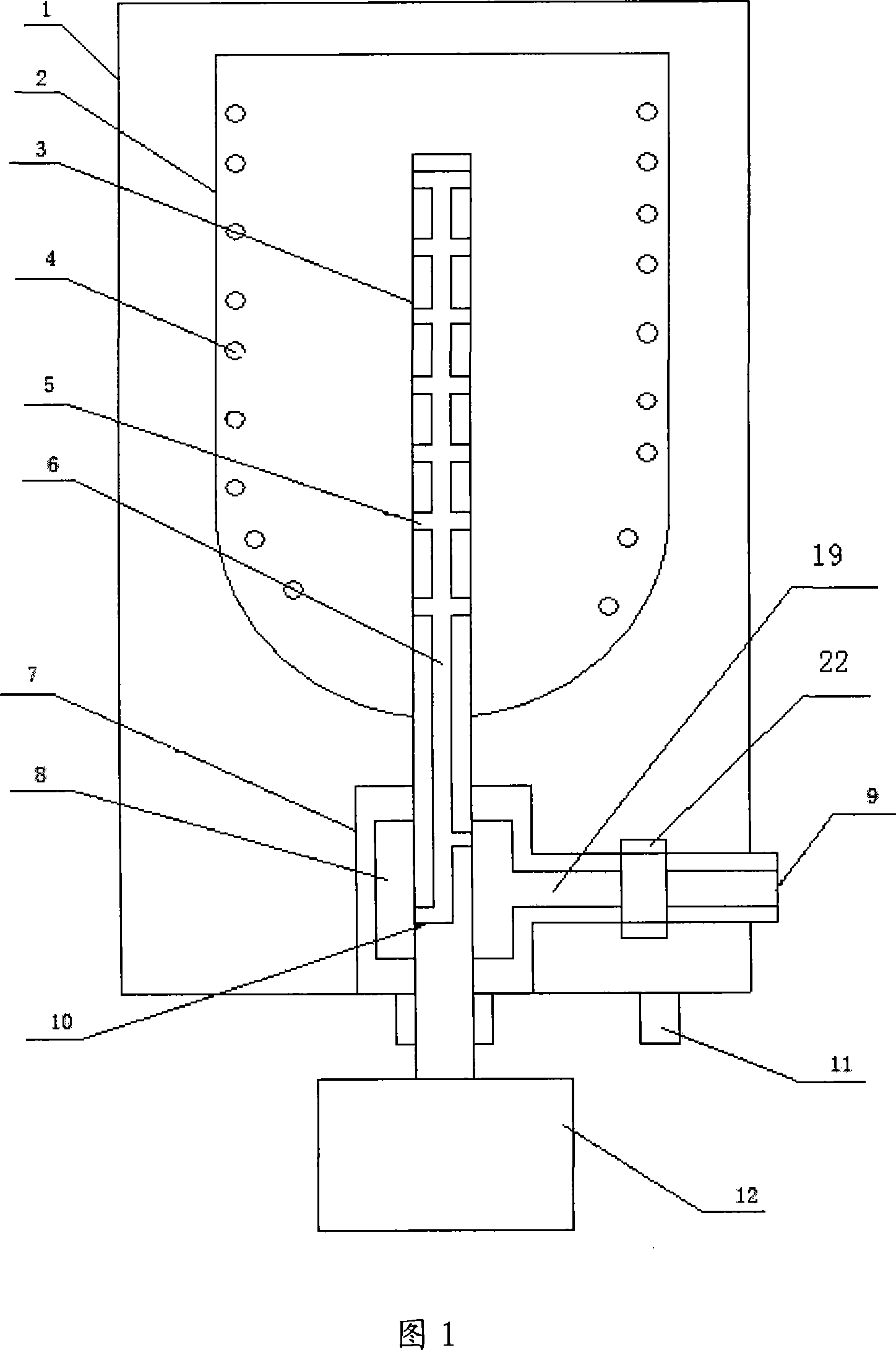

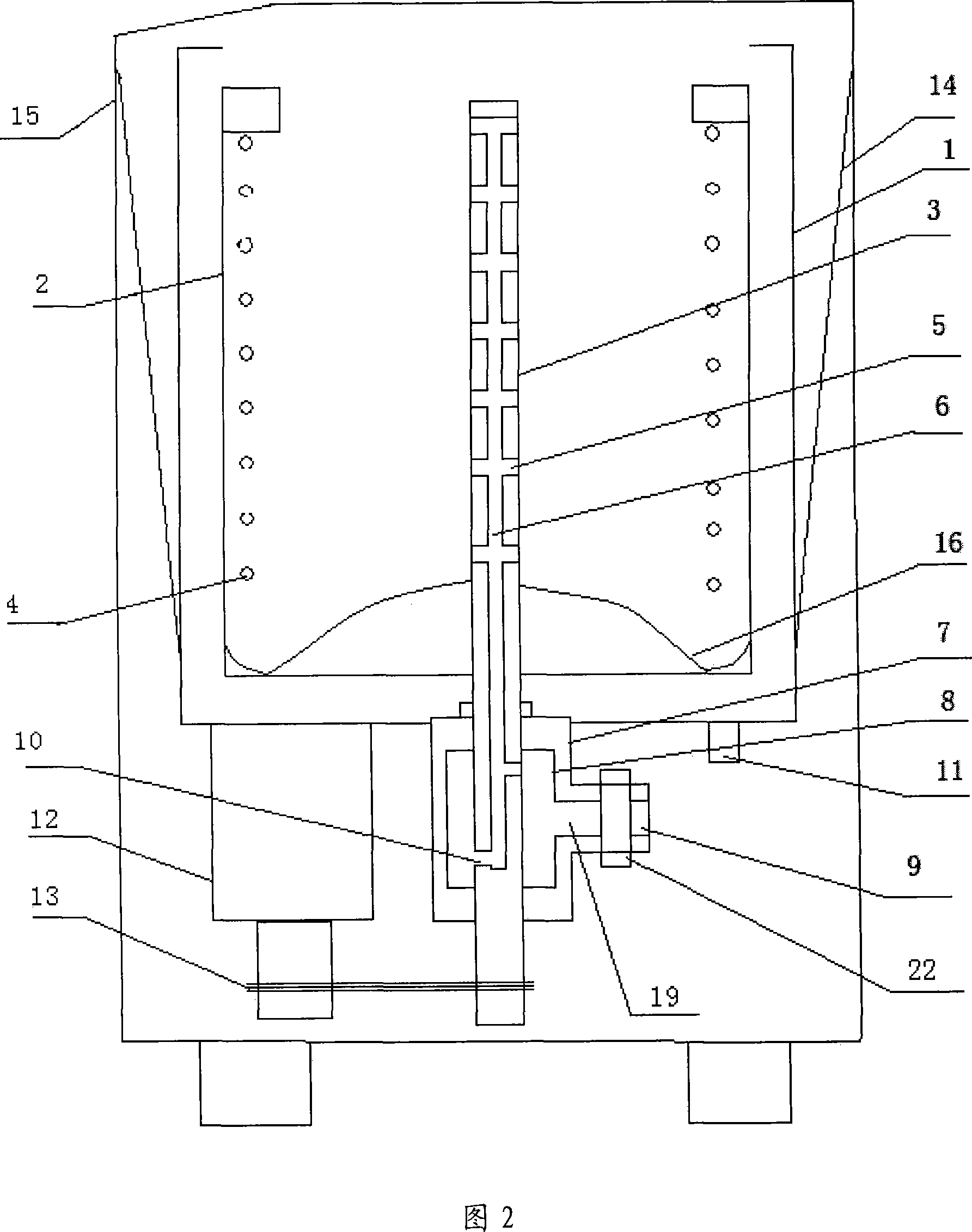

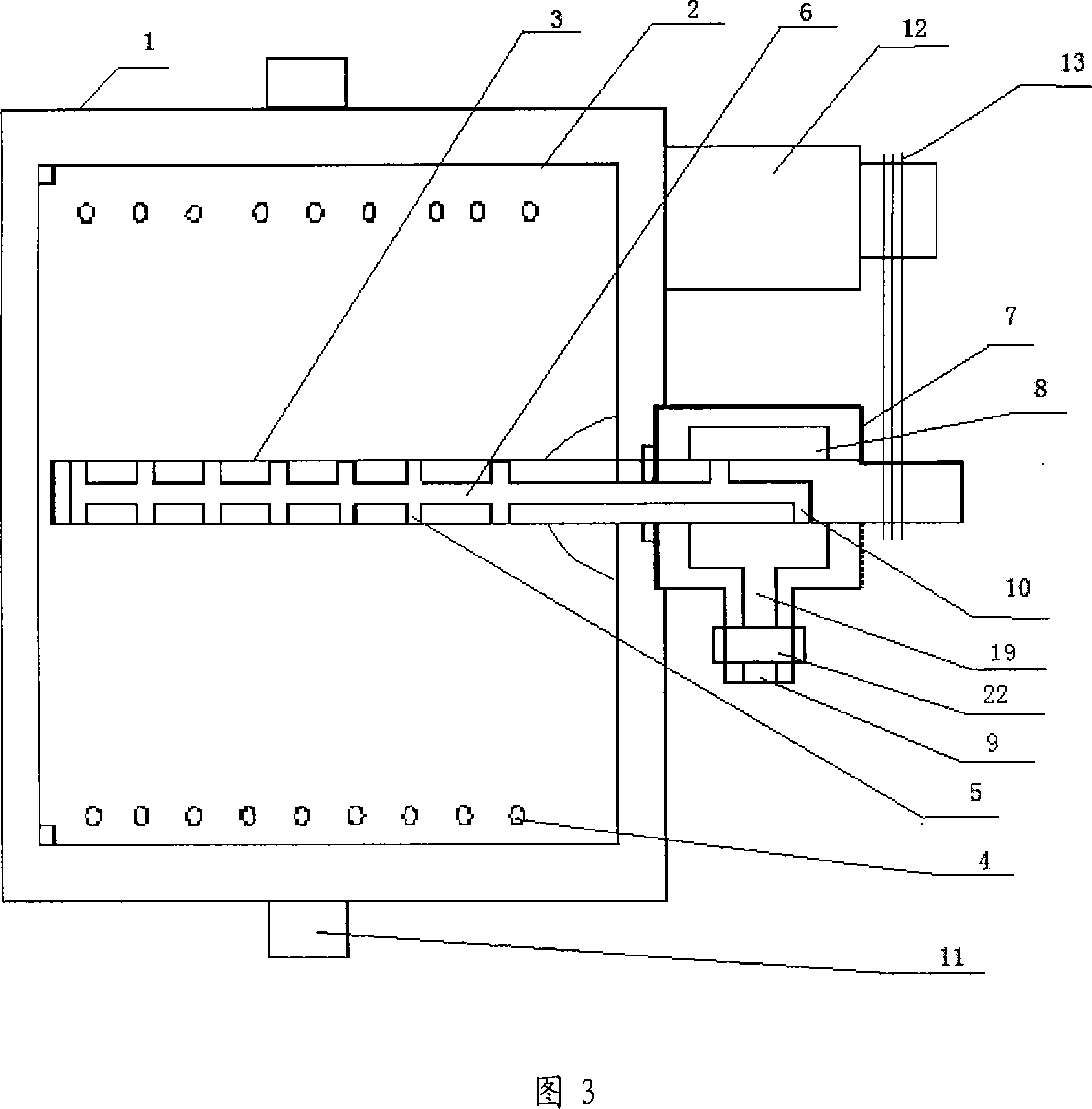

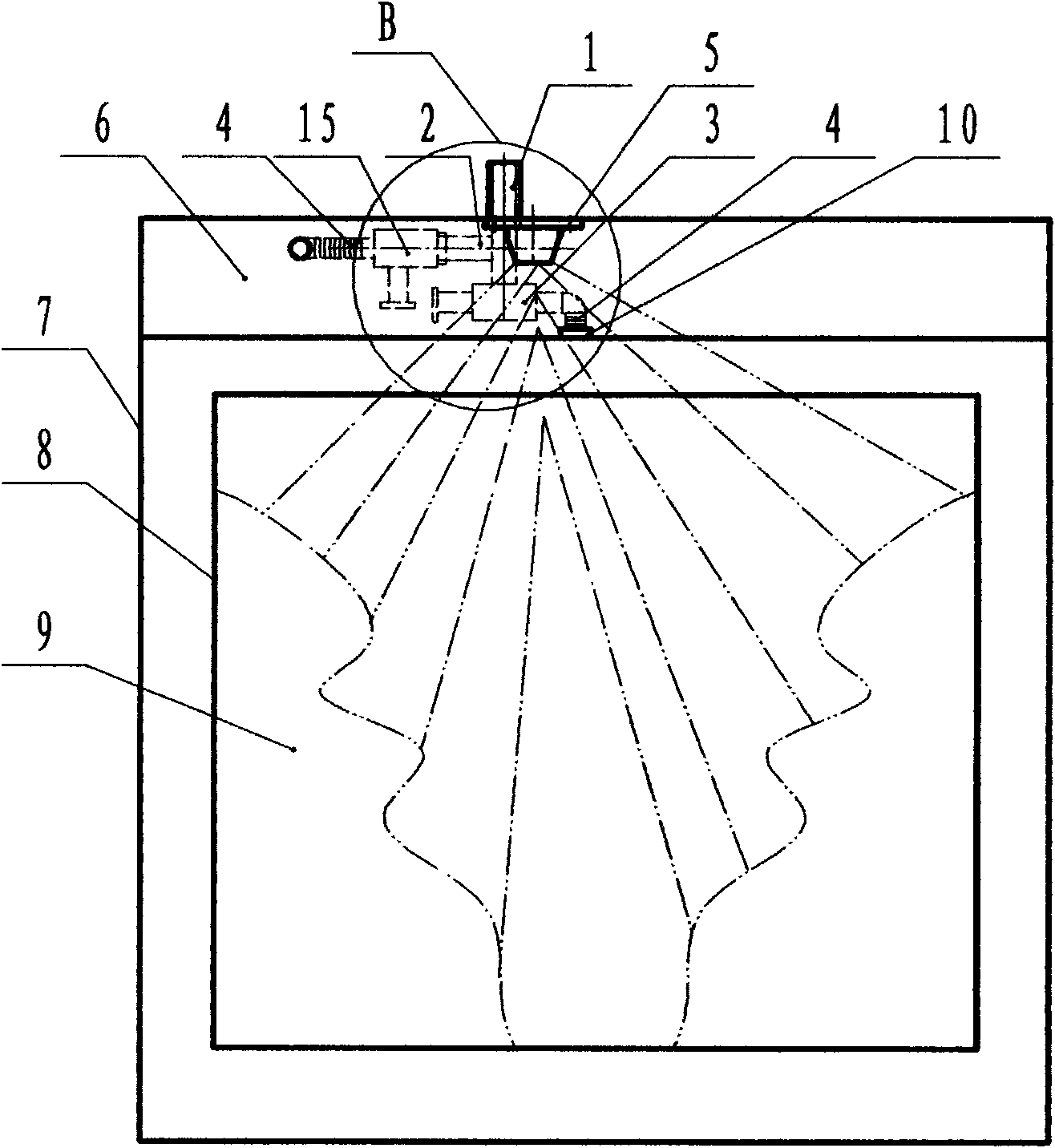

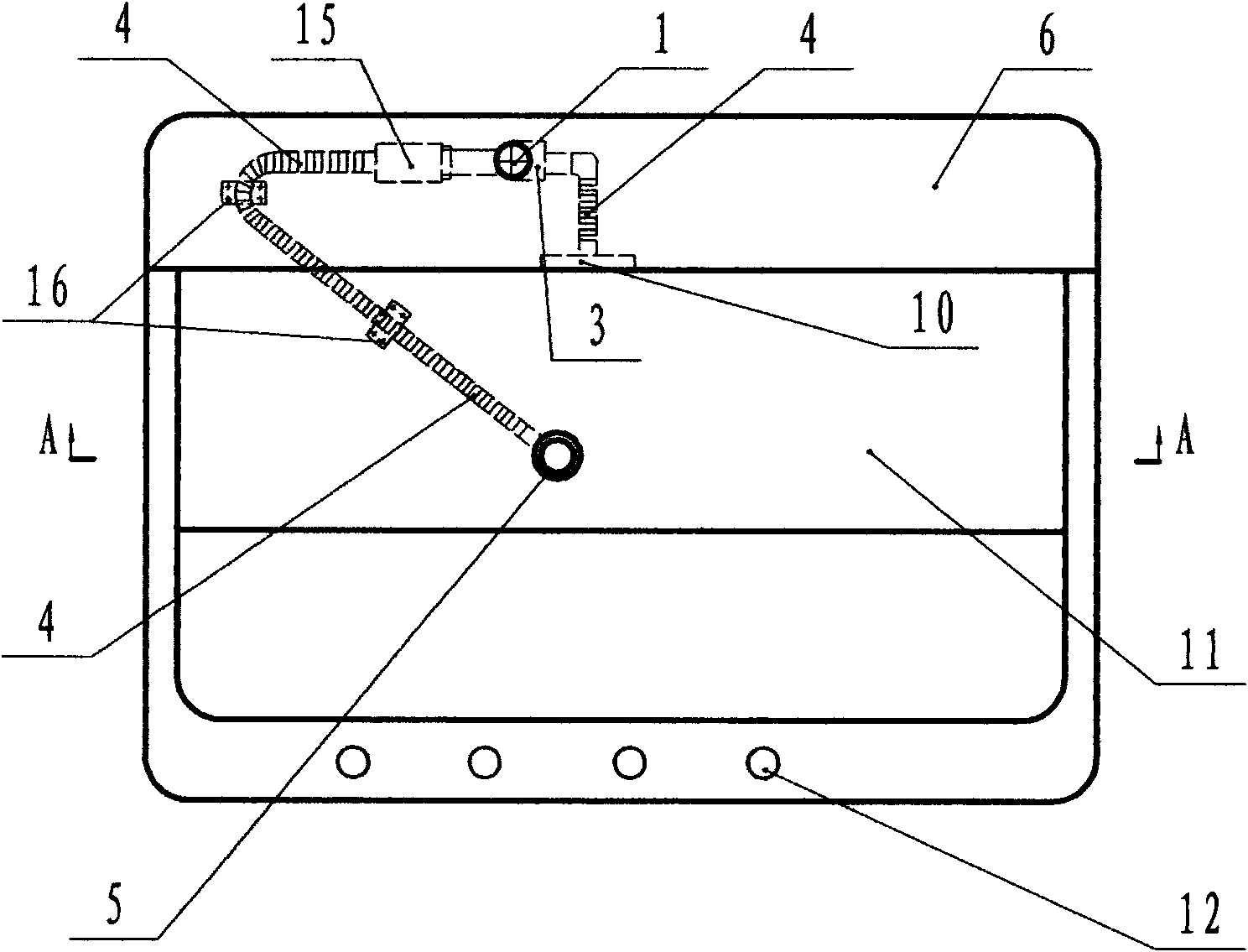

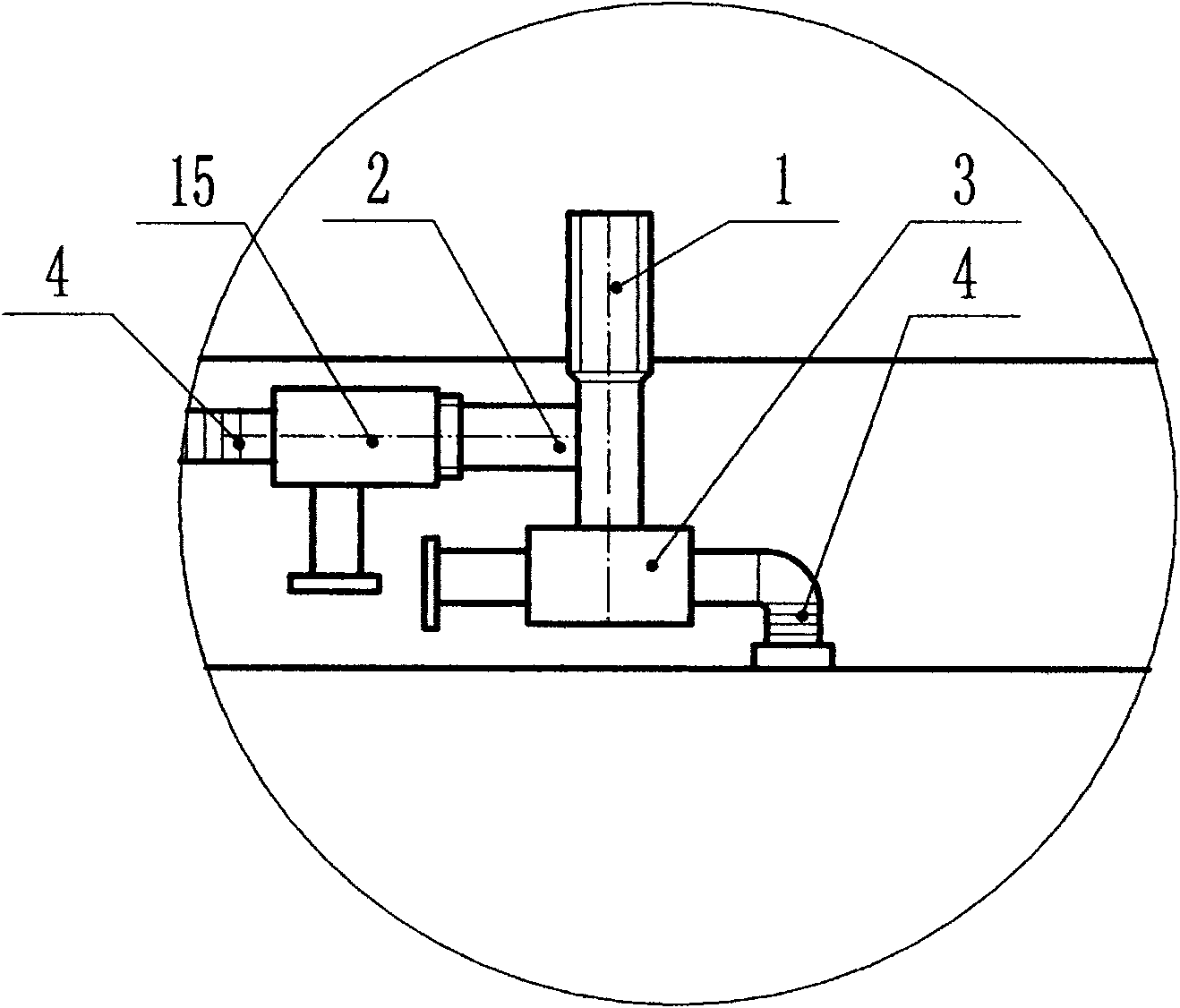

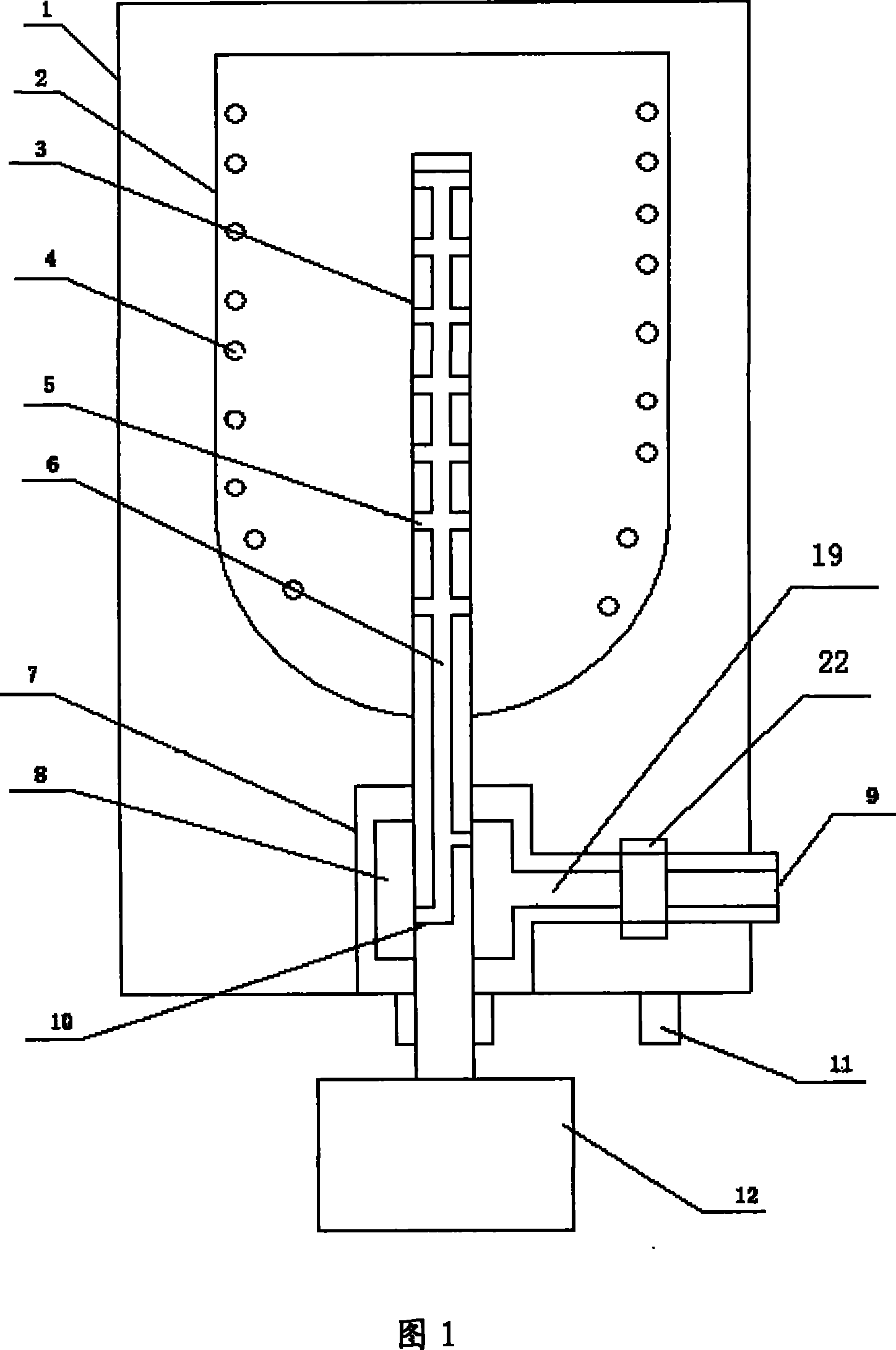

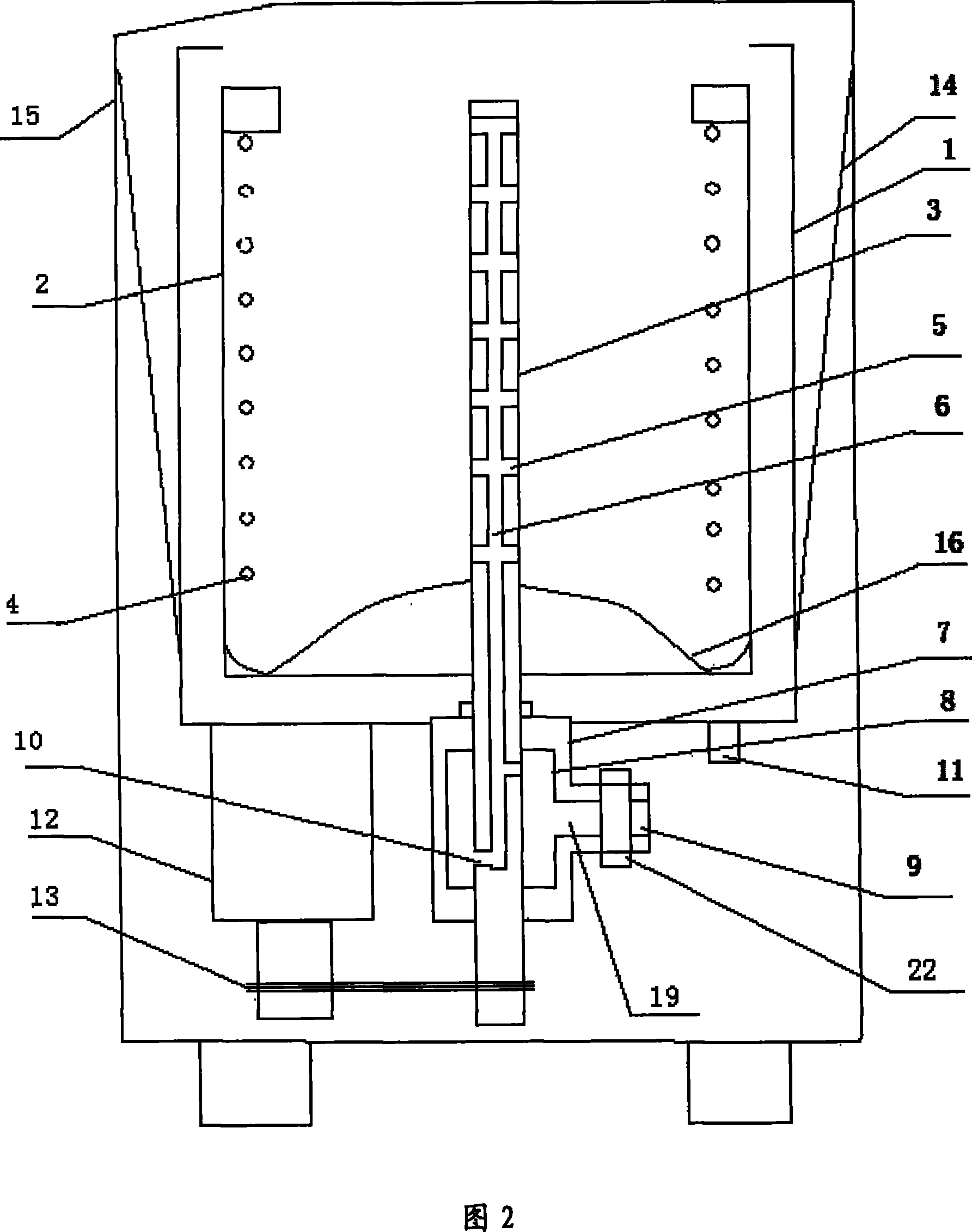

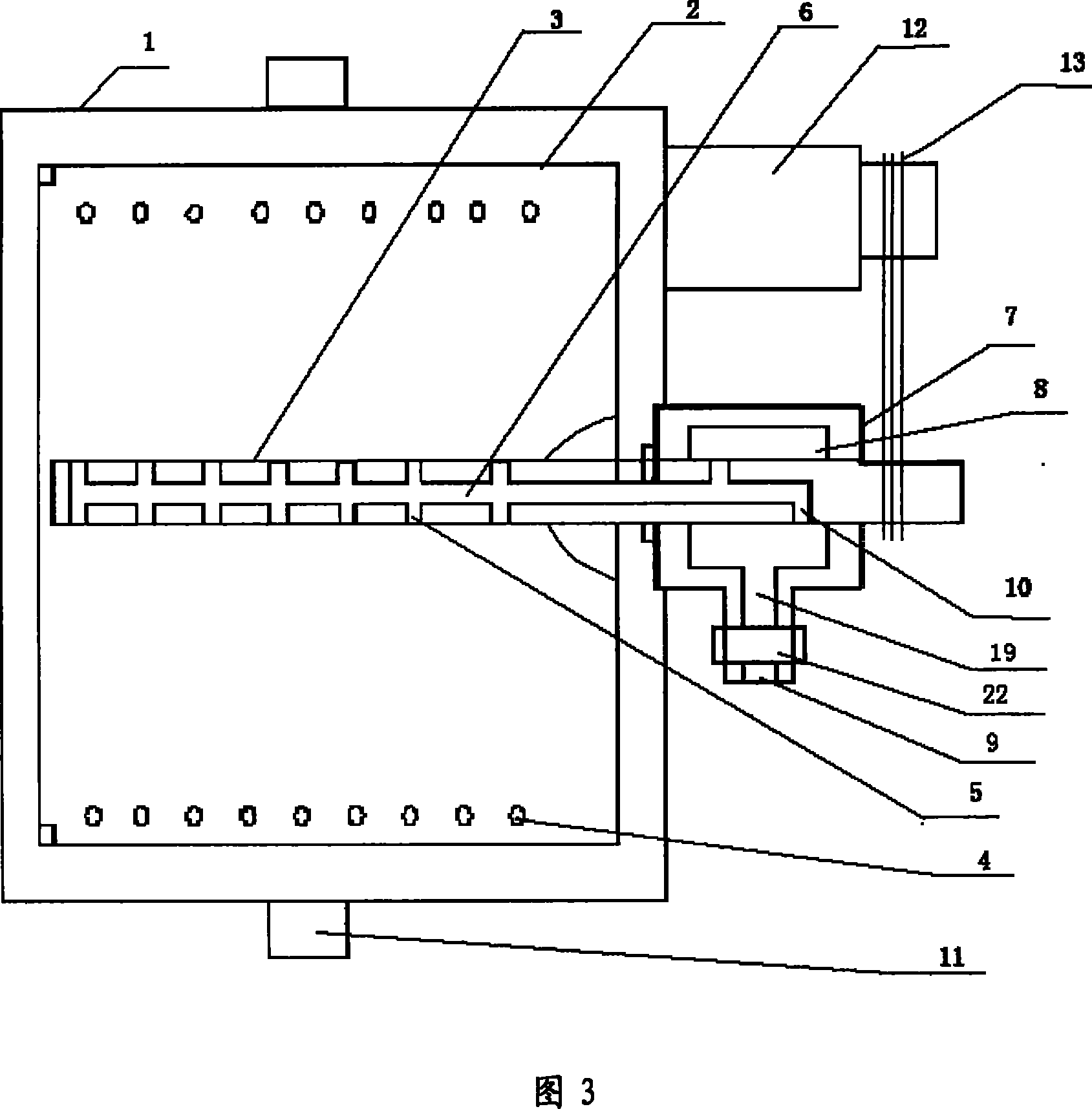

Central pipe throwing-rinsing washing method and washing machine manufactured by the same

InactiveCN101158105AFair priceEmission reductionRinsing apparatusOther washing machinesElectricityEngineering

The invention relates to the household appliance field, which is definitely a washing machine, in particular to a washing machine realized by a drying and rinsing technology of a novel central tube. The washing machine comprises a box body, an outer tank, an inner tank, an electric engine, a belt and a drive mechanism, and further comprises the central tube that is arranged in the center of a dehydration tank and is in the same direction with an axes of the dehydration tank and a water injection channel, wherein, a water outlet is arranged on the central tube. The washing machine provided by the invention makes use of the drying and rinsing technology and centrifugal force to accomplish twice rinsing or third rinsing which is the most water-consuming link of the washing machine, thereby saving a great deal of water, relatively reducing the electricity consumption and saving the time, moreover, the price of the washing machine is moderate and is capable of adapting to various washing machines, thus being easy to be widely used, and the discharge of sewage is reduced by reducing water consumption.

Owner:孙召华

Washing machine performing shower rinsing and method of controlling the same

A method of controlling a washing machine to perform shower rinsing, including repeatedly performing a process to store water supplied to a washing tub in the washing tub and discharge the water from the washing tub while rotating the washing tub during the shower rinsing is described. In a state in which laundry clings to the washing tub by a spin-drying operation, it may be possible to rinse the laundry clinging to the upper part of the washing tub using water supplied to the washing tub rotating at the predetermined velocity, to rinse the laundry clinging to the lower part of the washing tub using the water stored in the washing tub according to the off operation of a drainage unit, and to periodically replace water necessary to rinse the laundry by discharging the used water from the washing tub according to the periodic operation of the drainage unit.

Owner:SAMSUNG ELECTRONICS CO LTD

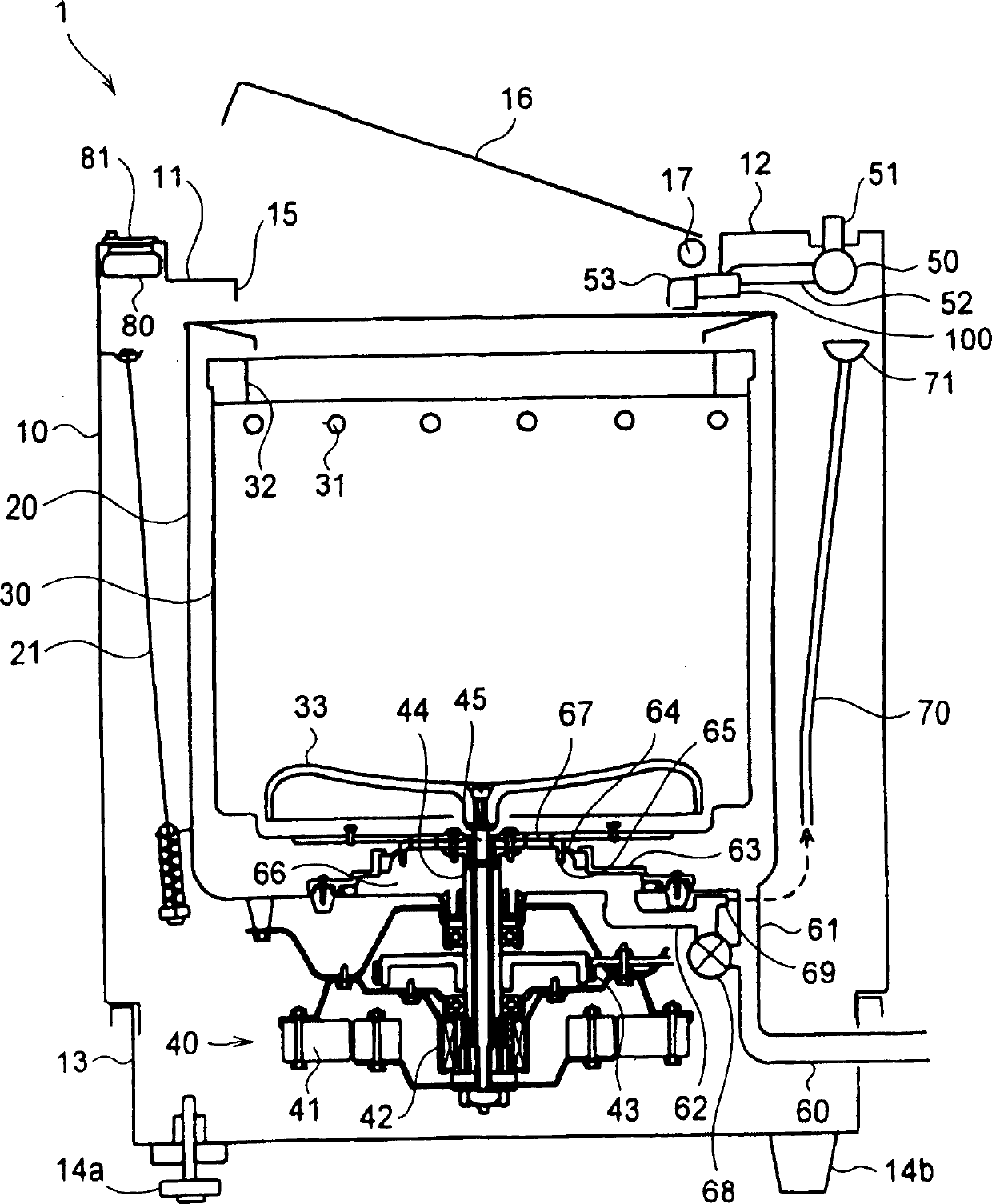

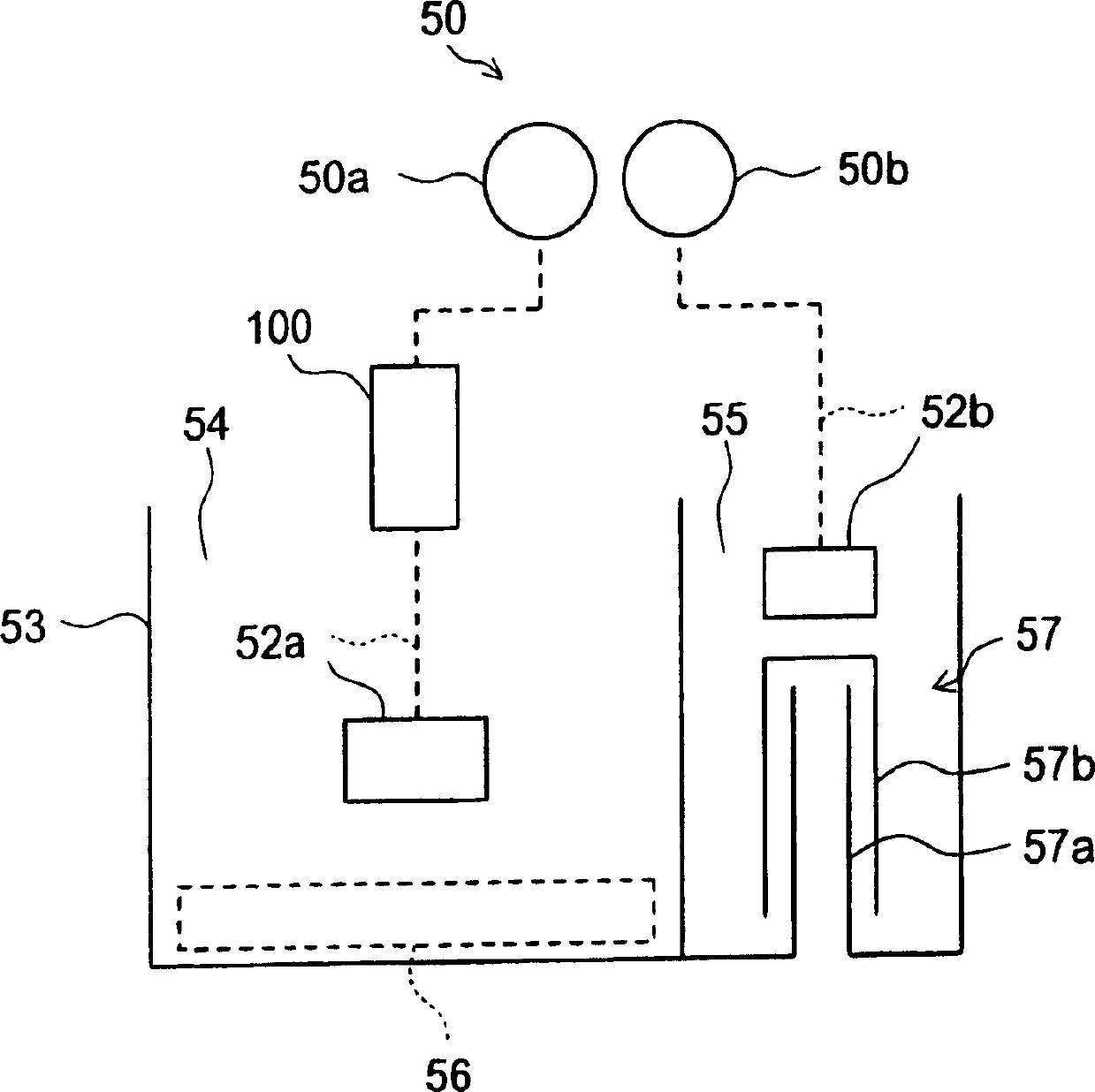

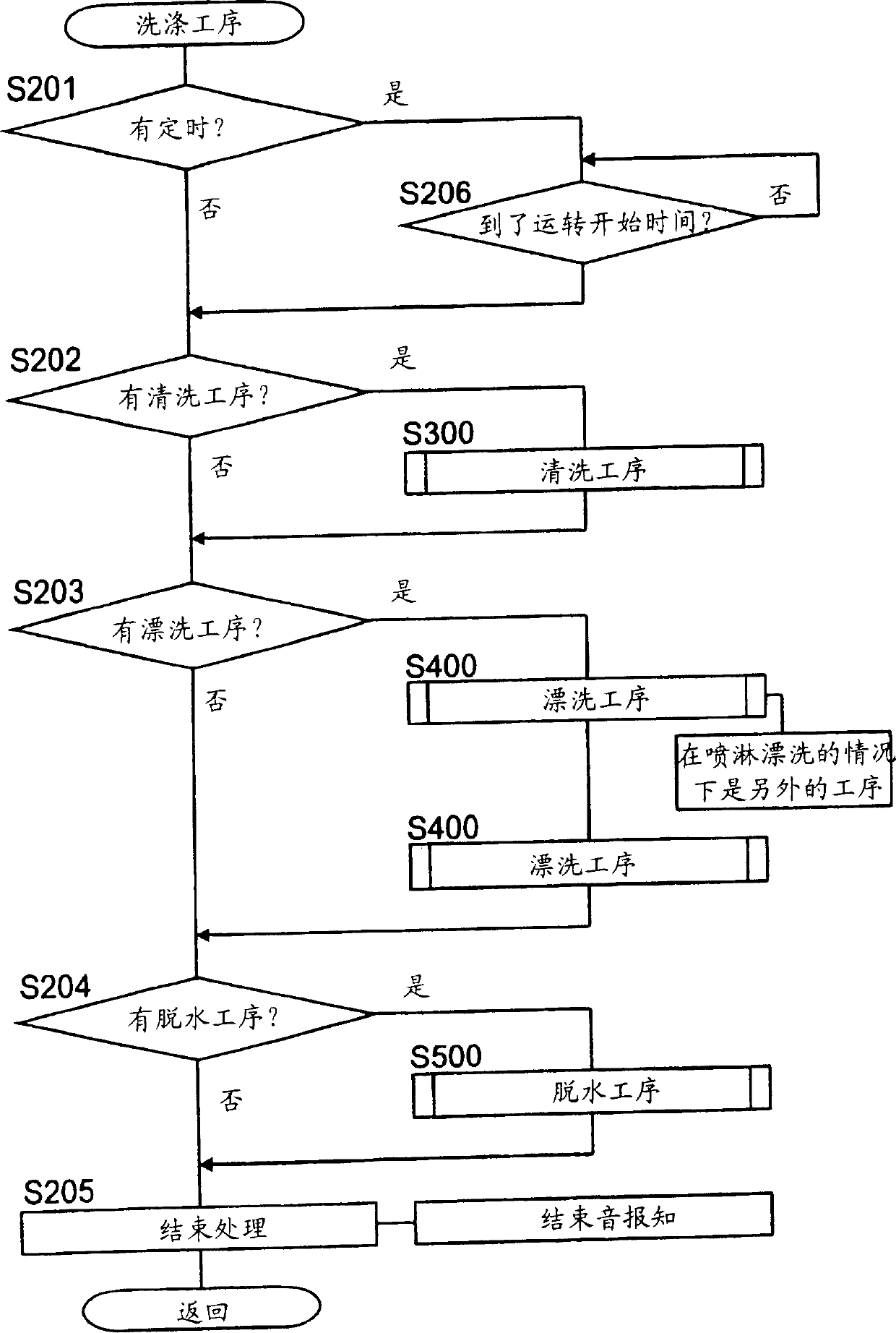

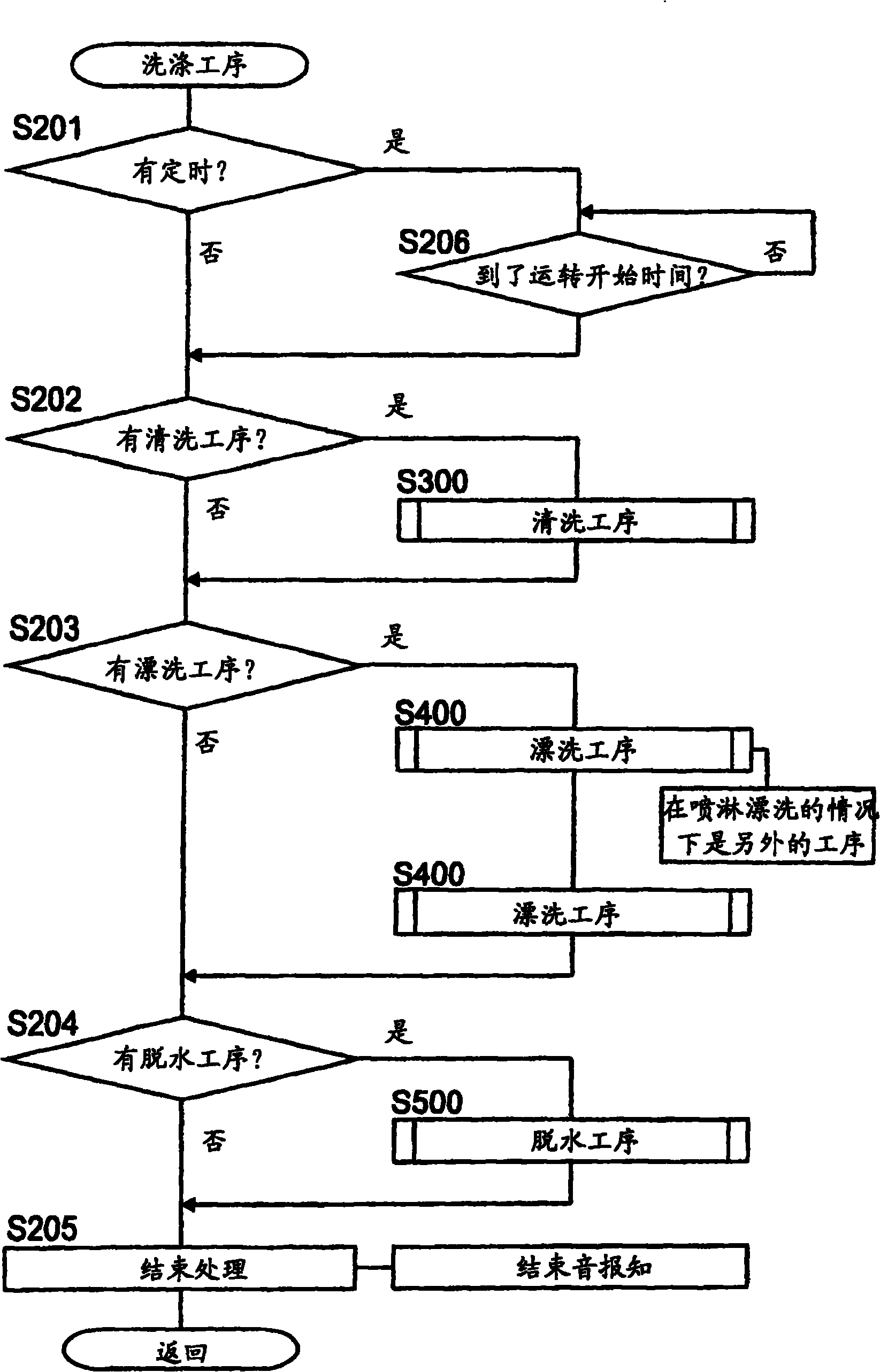

Washing machine and scrubbing-and-drying unit

The object of the invention is to provide a washing machine and a scrubbing-and-drying unit, when operation program is different from preset operation program, wrong operation is not regarded. The invention comprises an external barrel for storing scouring water or washings; an internal barrel for keeping washings and rotatably arranging in the external barrel; a main control circuit; a plurality of operation switches for inputting washing operation information; a display part for displaying the washing operation information; a buzzer for reporting errors contained in the washing operation information; and a sound switch contained in a plurality of operation switches for informing by sound. Information of a voice mechanism comprises change reasons when the information is changed into the operations different from the preset operations preset in the operation program, operated by the sound switch in washing operation program.

Owner:HITACHI APPLIANCES INC

Intelligent washing and air-drying ironing-free all-in-one machine

PendingCN107447428AImprove work efficiencyRinsing apparatusOther washing machinesTransmission beltProcess engineering

The invention discloses an intelligent washing and air-drying ironing-free all-in-one machine which comprises a friction scrubbing pressure washing tank, an overhead-sprinkler up-down flushing tank, an overhead hot air natural blow-drying frame and an intelligent electric rotary lifting support. A transmission belt is mounted on the intelligent electric rotary lifting support, so that the intelligent electric rotary lifting support becomes a liftable transmission belt type structure, the friction scrubbing pressure washing tank, the overhead-sprinkler up-down flushing tank and the overhead hot air natural blow-drying frame are sequentially arranged right below the intelligent electric rotary lifting support along a rotating direction of the same, and multiple cloth clamping frames are equidistantly arranged on the transmission belt. The intelligent washing and air-drying ironing-free all-in-one machine has the advantages that middle repeated links of mounting, demounting, airing, hanging, ironing and finishing are omitted by closely connecting the four parts, so that working efficiency is improved greatly, and water after washing can be reutilized after being filtered.

Owner:佛山市绎铭纺织有限公司

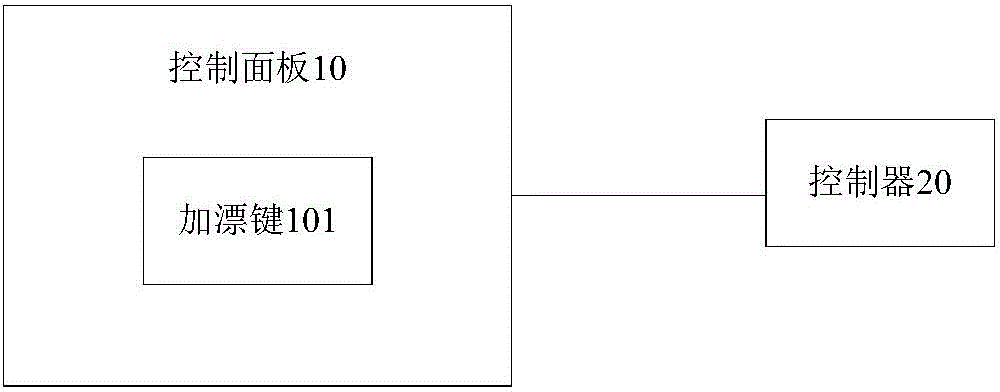

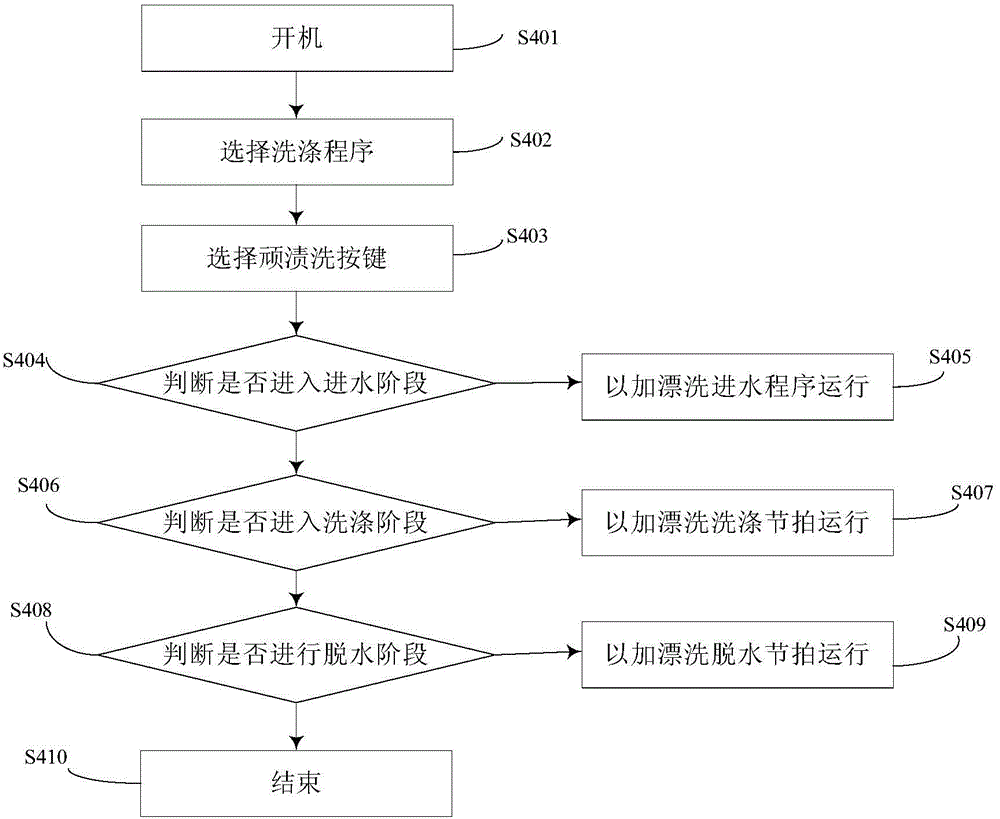

Washing machine and control method thereof

InactiveCN104894804AIncrease the number of rinsesRinse cleanRinsing apparatusControl devices for washing apparatusEngineeringEmbedded system

The invention provides a washing machine and a control method thereof. The washing machine comprises a control panel and a controller connected to the control panel. The control panel is provided with different types of normal procedures and a rinsing plus key, wherein the rinsing plus key and any one of the different types of normal procedures are executed in an associated manner. When the rinsing plus key is further pressed after any one of the different types of normal procedures is selected, the controller increases the number of times of rinsing on the basis of the selected normal procedure, so that clothes can be rinsed more cleanly.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Control method of laundry machine

A control method of a laundry machine comprising a water supply, washing and rinsing cycle, the control method includes first determination step performed prior to the rinsing cycle and determining a kind of detergent, second determination step performed during a first rinsing course of the rinsing cycle and determining an amount of remained detergent in a rinsing water, and condition determination step of at least one following rinsing course based on the kind and amount of the remained detergent.

Owner:LG ELECTRONICS INC

Washing machine

The washing machine of the present invention is provided with a water tank and a washing tank inside, and water is supplied to the washing tank through a water supply port. The water feed has a detergent chamber and a conditioner chamber inside. The main feedwater valve of the feedwater valve is connected to the detergent chamber, and the auxiliary feedwater valve is connected to the finisher chamber. An ion dissolution and desorption unit is arranged between the main water supply valve and the water supply port. The ion eluting and desorbing unit dissolves and elutes the ions of the metal constituting the electrodes by applying a voltage between the electrodes. In the rinsing process, after opening the main water supply valve and injecting metal ions as the first finishing substance into the rinse water, after a predetermined time elapses, the auxiliary water supply valve is opened, and the finishing agent as the second conditioning substance is injected into the rinse water. .

Owner:SHARP KK

Clothes rinsing device of washing machine

InactiveCN102653910AReduce running timeReduce loadRinsing apparatusOther washing machinesLaundry washing machineRinse water

The invention relates to a clothes rinsing device of a washing machine. The device is characterized in that a water inlet pipe is communicated with the water inlet ends of a water inlet electromagnetic valve and a rinsing water inlet electromagnetic valve through a three-way pipe at the same time; one end of a hose is arranged at the water outlet end of the rinsing water inlet electromagnetic valve; the other end of the hose penetrates through a hole in the front of an electrical appliance control box and is communicated with the water inlet end of a spray head; and the spray head is fixed on a cover plate above or in front of a washing tub. By adopting the clothes rinsing device of the washing machine to rinse clothes, water is saved in the rinsing process of the clothes washing of a full-automatic washing machine, and the rinsing time is shortened; and meanwhile, the electromotor operation time and the load of the washing machine are reduced or relieved, thus the power consumption is saved. In the device, a rinsing method that dirty water is carried away by using clean water is adopted, and practice indicates that the rinsed clothes are cleaner than those rinsed by the existing washing machine, water is saved, power and time are saved, thus the device deserves popularization and application.

Owner:尤金龙

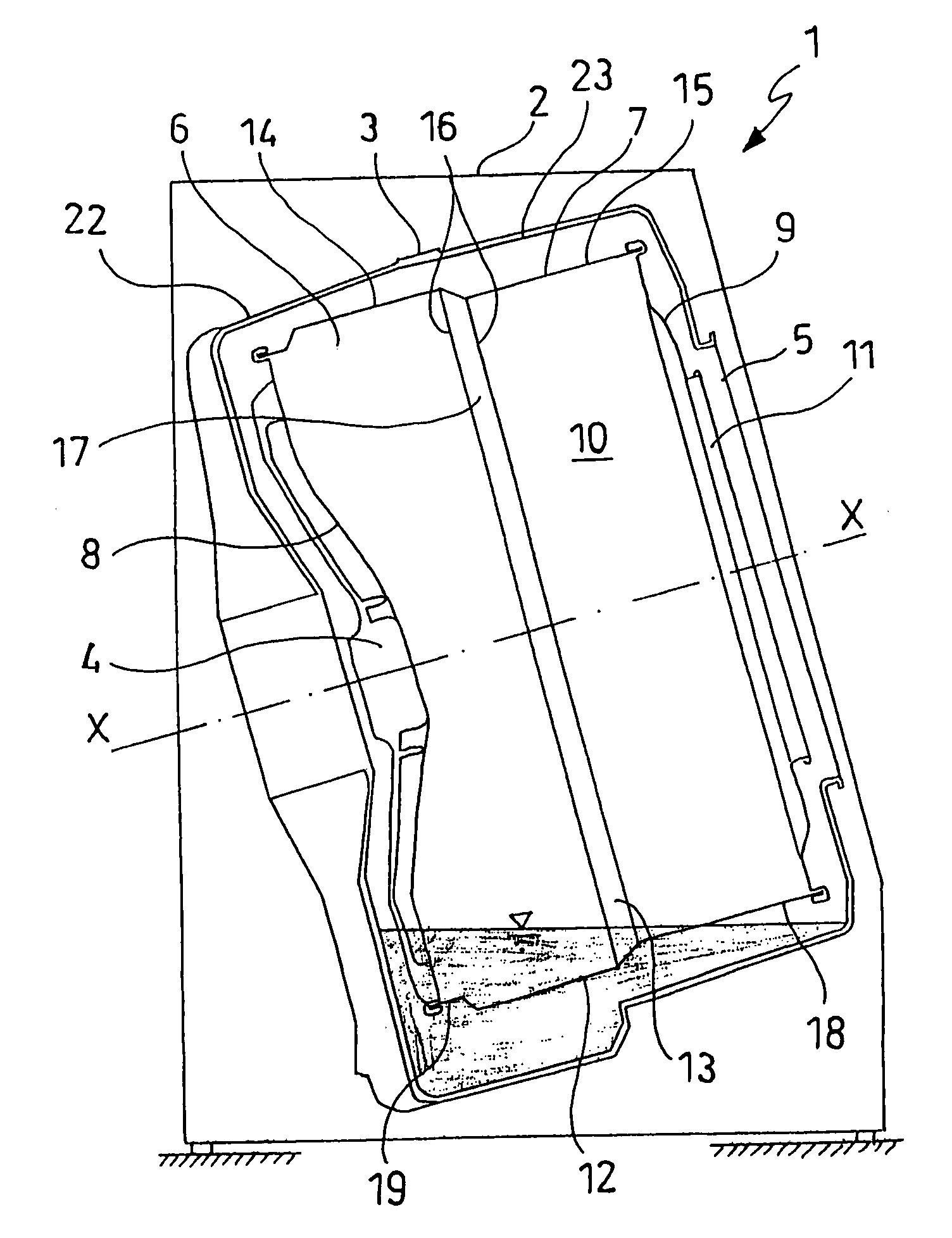

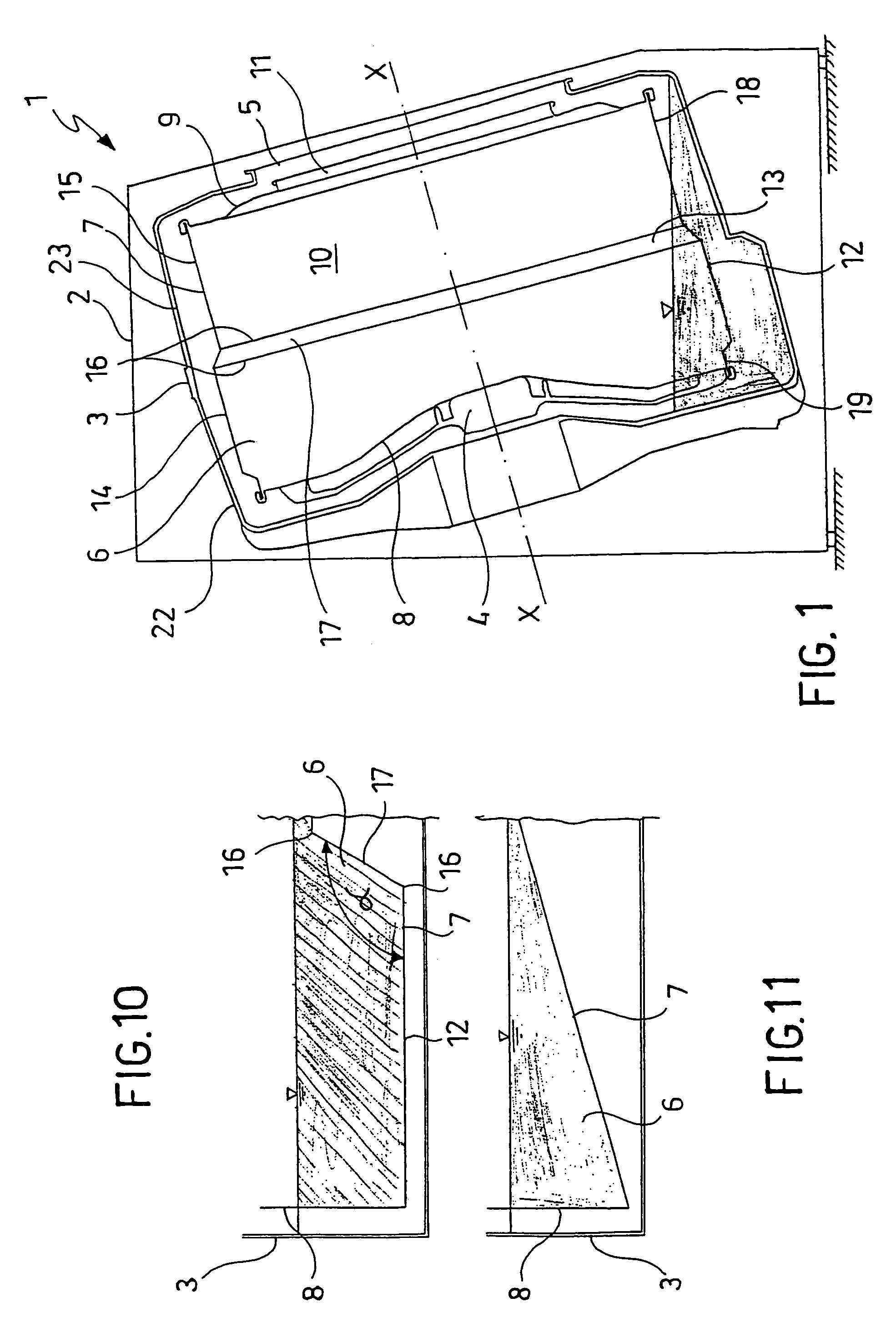

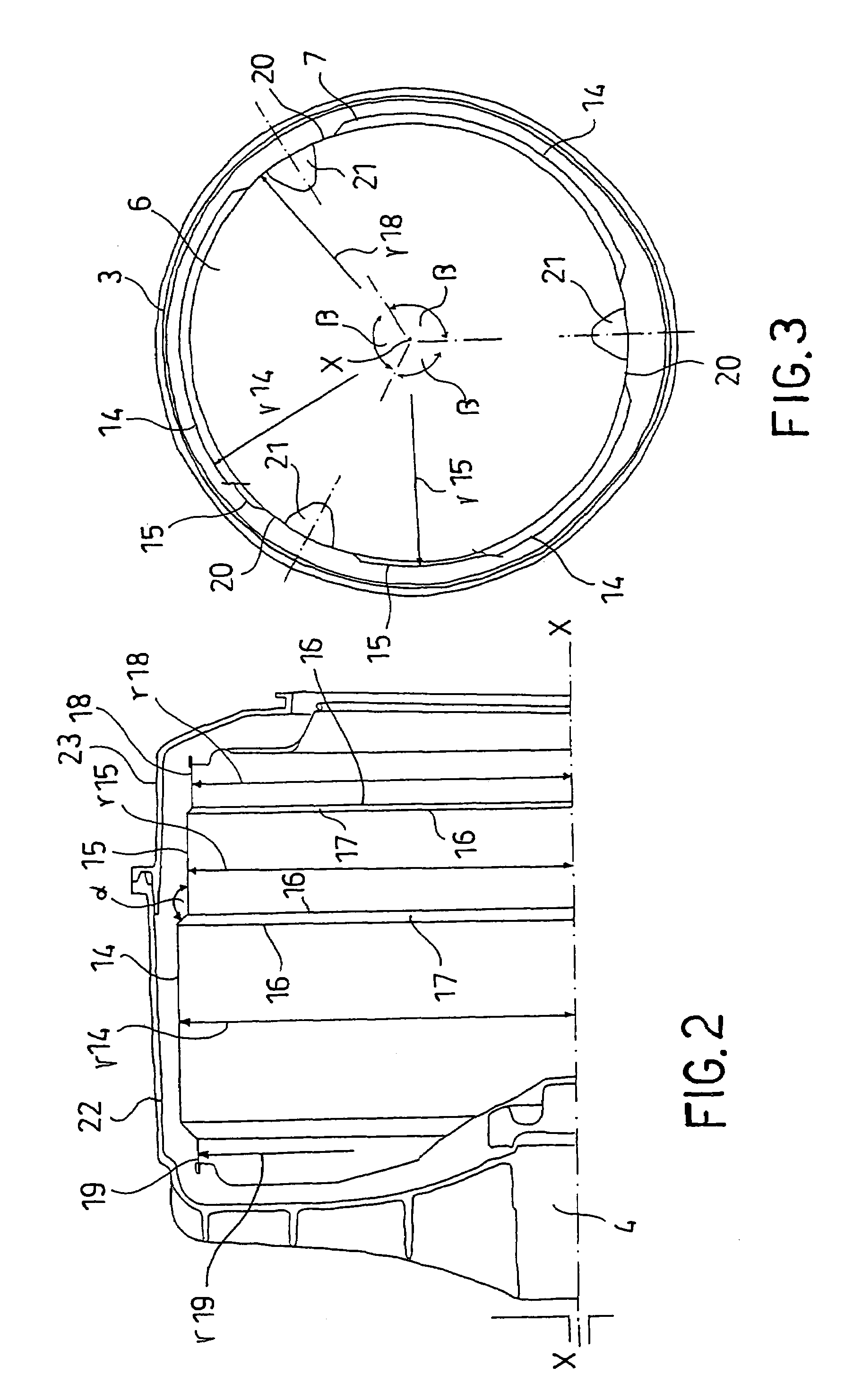

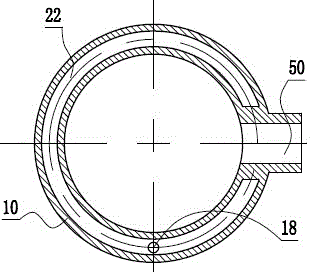

Basket for washing machine, washer-drier, drier, and the like

A basket (6) for loading the laundry in a washing machine, washer-drier, drier and the like comprises a innerly hollow body with a longitudinal axis (X) being the basket (6) rotation axis, wherein said body has at least one shaped length (12) the radial distance (r, r14, r15) thereof from the longitudinal axis (X) is increased towards the rear wall (8) such that the barycentre of the inner volume (10) being defined by the hollow body is displaced towards the rear wall (8), wherein in the shaped length (12) there are formed one or more steps (13) extending along a circumpherential direction to the longitudinal axis (X) each providing an increase in the radial distance (r, r14, r15) of the shaped length (12) from the longitudinal axis (X) and wherein the step defines at least two portions (14, 15) having different radial distances (r, r14, r15) from the longitudinal axis (X).

Owner:CANDY

Central pipe throwing-rinsing washing method and washing machine manufactured by the same

InactiveCN101158105BFair priceEmission reductionRinsing apparatusOther washing machinesElectricityLaundry washing machine

Owner:孙召华

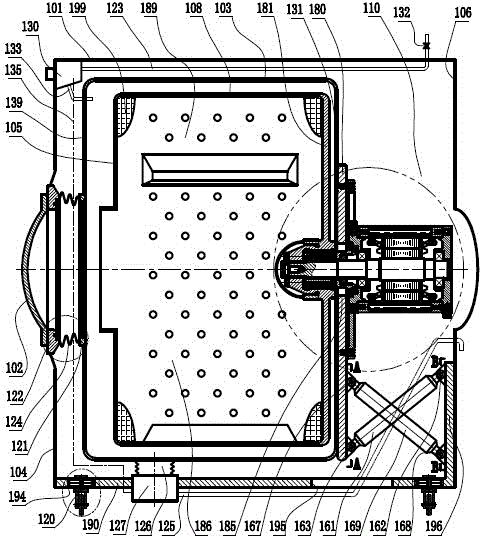

Union piston oscillation damping rinsing equipment of molybdenum alloy cage type motor

ActiveCN104963175ASmall sizeExtended service lifeRinsing apparatusOther washing machinesElectric machineEngineering

The invention relates to a washing machine, and discloses union piston oscillation damping rinsing equipment of a molybdenum alloy cage type motor. The union piston oscillation damping rinsing equipment of the molybdenum alloy cage type motor comprises an outer shell, a drum door, a water containing bucket, a rolling drum body, an upright plate, a base plate, a squirrel-cage type water-cooled motor component, an outer water supply pipe and a drainage outer pipe. A drainage control line is further extracted out of an adjusting operating box. The drainage control line is communicated with a drainage control valve. An upper opening of the drainage control valve is provided with a drainage corrugated pipe connecting to the bottom of the water containing bucket. The drainage outer pipe is extracted out of the drainage control valve. The bottom edges all around the outer shell are fixed to the periphery of the base plate. Four base plate wheel holes are formed in the base plate. A set of dual spring oscillation damping components are arranged on each base plate wheel hole. According to the squirrel-cage type water-cooled motor component, communication pieces are arranged between the motor outer shell and a front cover plate and between the motor outer shell and the rear end cover, so that sealing of a cooling water channel does not much depend on clinging to end faces, therefore flatness demand of the inner-side end face of the end cover and the end face of an engine base is lowered, and the processing difficulty and the motor assembling quality demand are lowered.

Owner:山东融智产业引导基金有限公司

Washing machine

A washer of the invention has a water tub and a washing tub inside, and feeds water to the washing tub through a water feed mouth. The water feed mouth has a detergent chamber and a treatment agent chamber inside. To the detergent chamber connects a main water feed valve of a water feed valve, and to the treatment agent chamber connects a sub water feed valve of the water feed valve. Between the main water feed valve and the water feed mouth is disposed an ion elution unit. The ion elution unit, by applying a voltage between electrodes, elutes ions of the metal of which the electrodes are formed. In a rinsing process, the main water feed valve is opened and the metal ions are added as a first treatment substance to rinsing water. A predetermined period of time thereafter, the sub water feed valve is opened and the treatment agent is added as a second treatment substance to the rinsing water.

Owner:SHARP KK

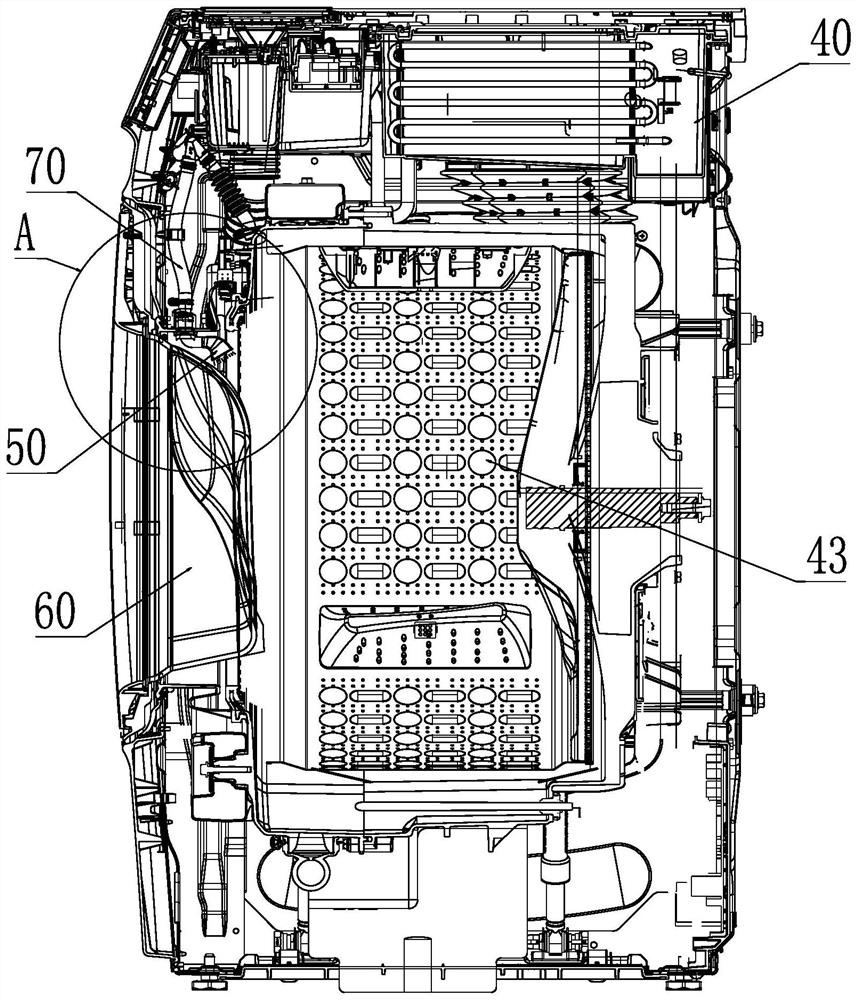

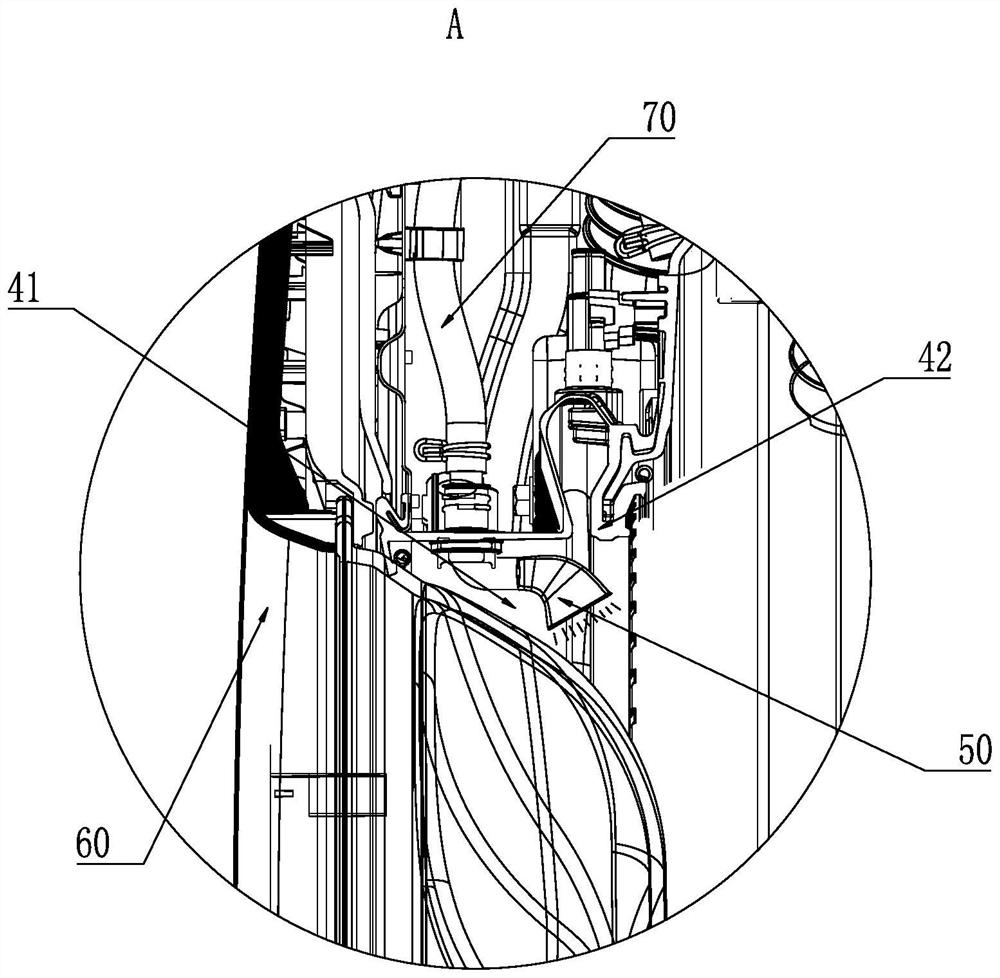

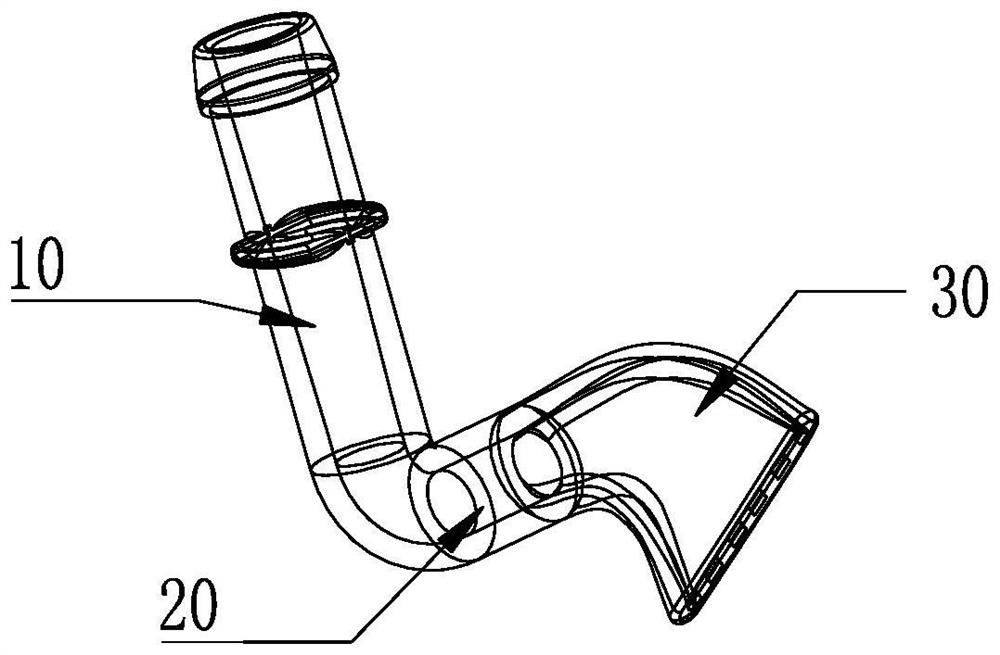

Spray head of washing machine and washing machine

InactiveCN114197141ASimple structureSimple internal pipeline structureRinsing apparatusOther washing machinesLaundry washing machineMechanical engineering

The invention provides a spraying head of a washing machine and the washing machine. The spray header for the washing machine comprises a connecting pipe section and a spray head, wherein the connecting pipe section is used for being connected with a water supply pipeline; a middle pipe section; the two ends of the middle pipe section are connected with the connecting pipe section and the contraction pipe section correspondingly, the contraction pipe section is gradually expanded in the first direction in the direction away from the middle pipe section and gradually contracted in the second direction, and the first direction and the second direction are perpendicular to each other. The problems that in the prior art, a washing machine is long in rinsing time and prone to damaging clothes are solved.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com