Intelligent hanging flow line system and control method of system

An assembly line and intelligent technology, applied in the direction of sewing tools and other directions, can solve the problems of low efficiency, unable to achieve reasonable allocation of resources, etc., to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

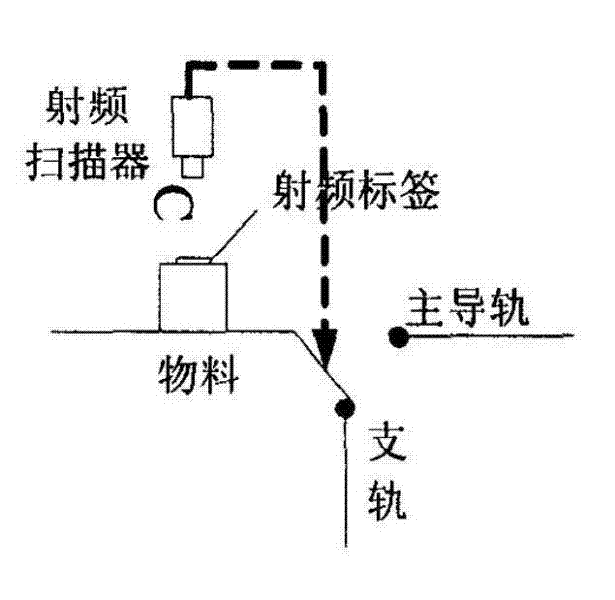

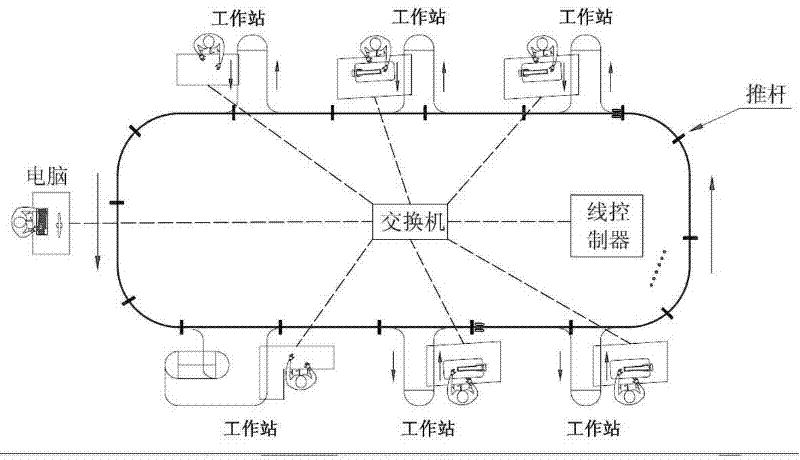

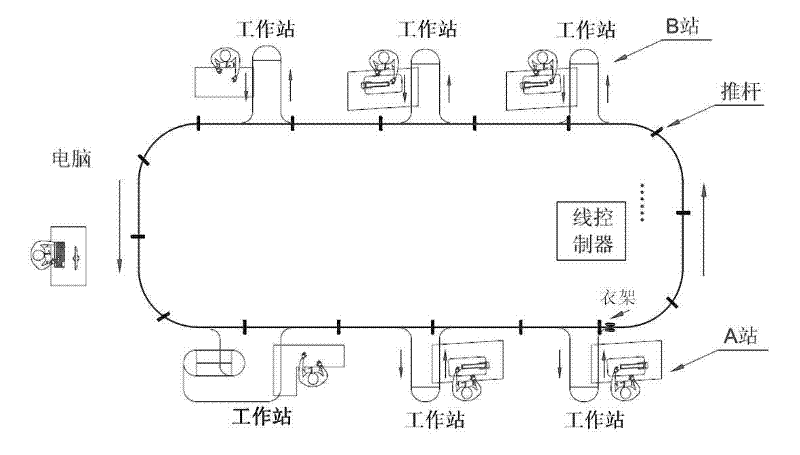

[0021] Such as Figure 2-7 As shown, a kind of intelligent assembly line hanging system, comprises computer, switchboard, line controller, main track 1, several workstations and card reader 6, line controller and each workstation are all connected with switchboard, switchboard is connected with computer, in The main track 1 is provided with a number of push rods 2, the push rods 2 are fixed on the drive chain, and the drive chain is connected to the power mechanism. The main track 1 is not provided with an on-off switch, and is a continuous closed track. One or more line card readers 8 and inductive proximity switches 9 are installed around the main track described above. The line card readers 8 are used to identify the hanger lost, and the inductive proximity switches 9 are used to detect the information of the push rod, and control it through the line. The device transmits the information to the computer; a branch rail 3 is provided at the entrance of the workstation, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com