Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1979 results about "Stamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal, but can also be used on other materials, such as polystyrene. Progressive dies are commonly fed from a coil of steel, coil reel for unwinding of coil to a straightener to level the coil and then into a feeder which advances the material into the press and die at a predetermined feed length. Depending on part complexity, the number of stations in the die can be determined.

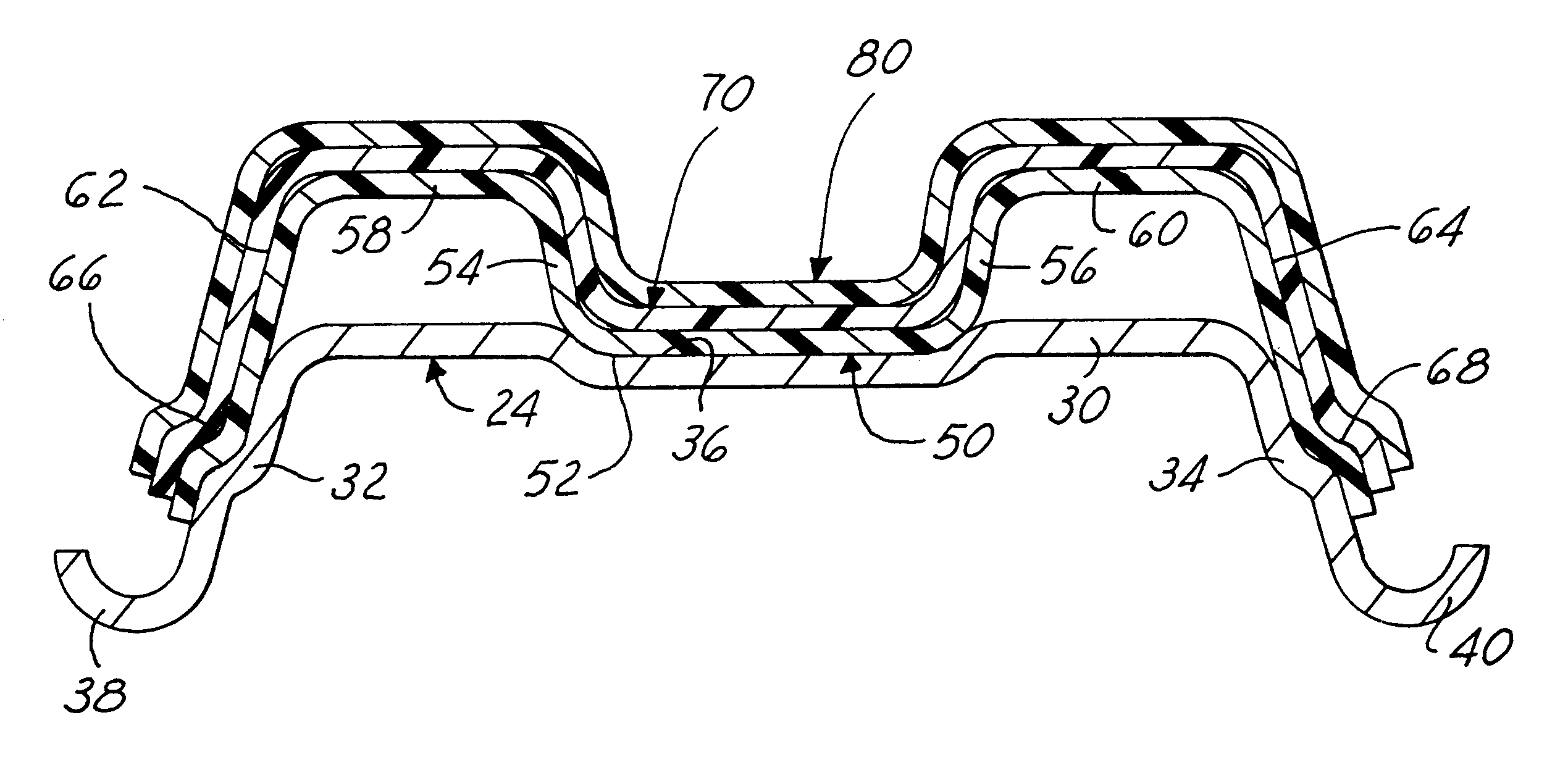

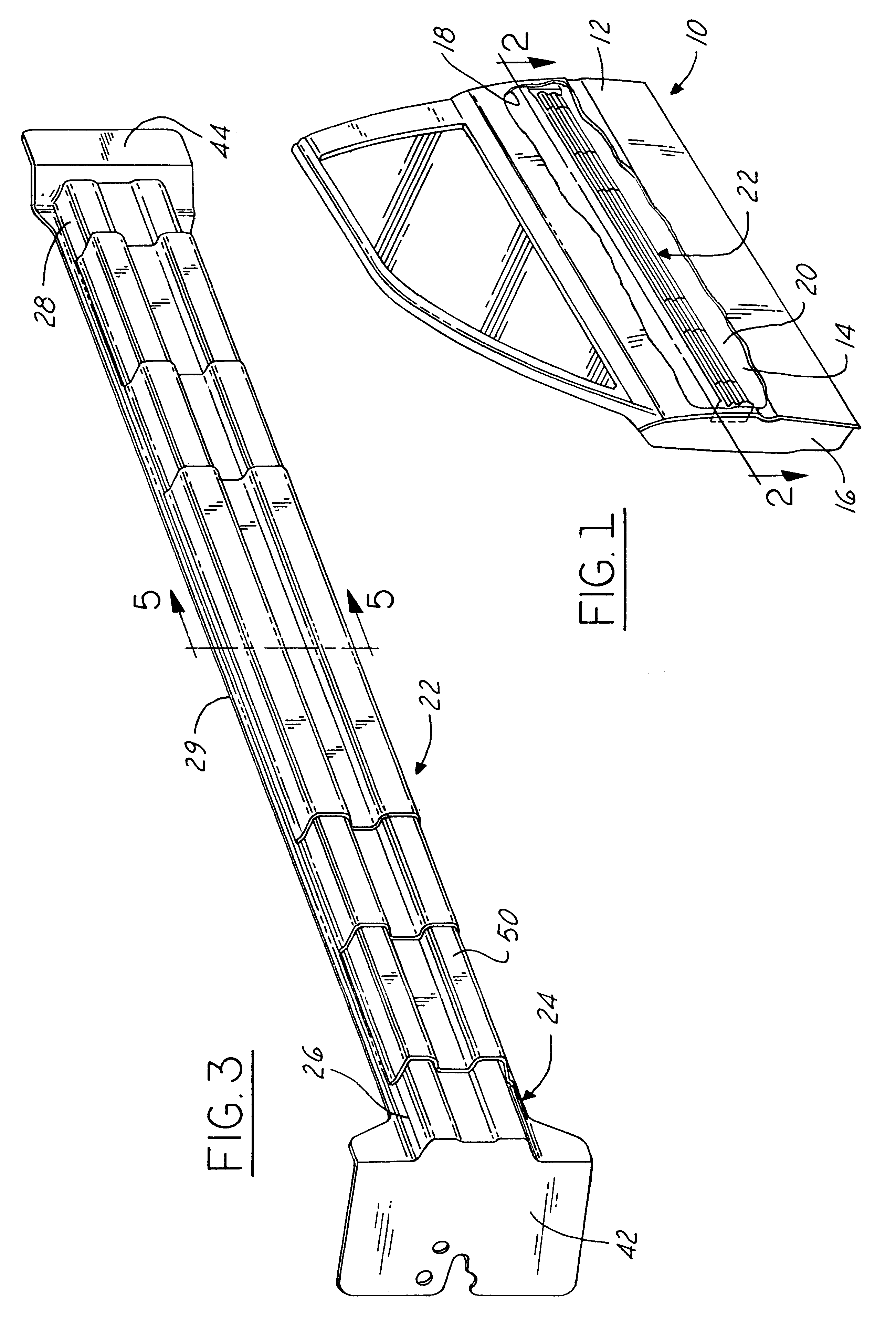

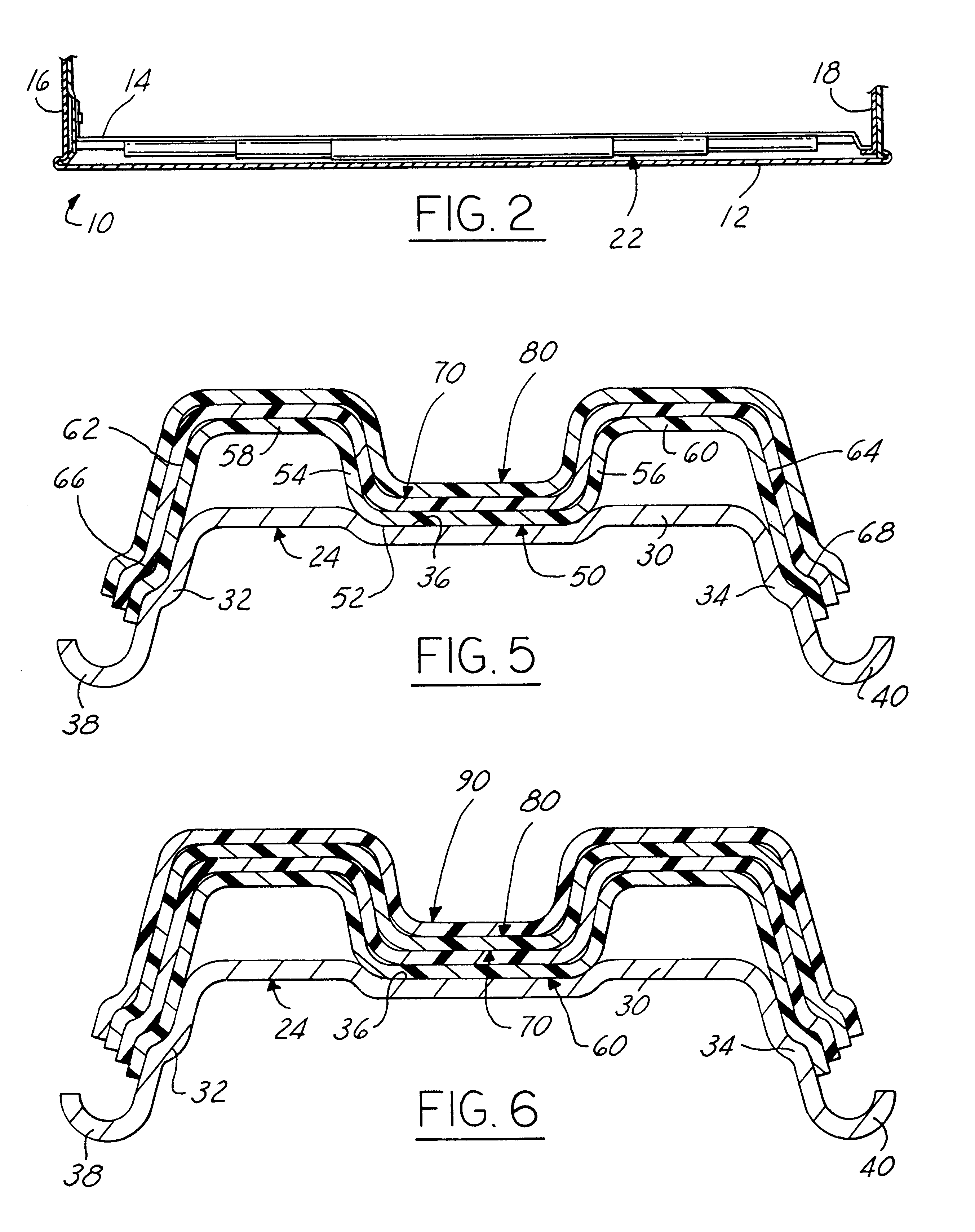

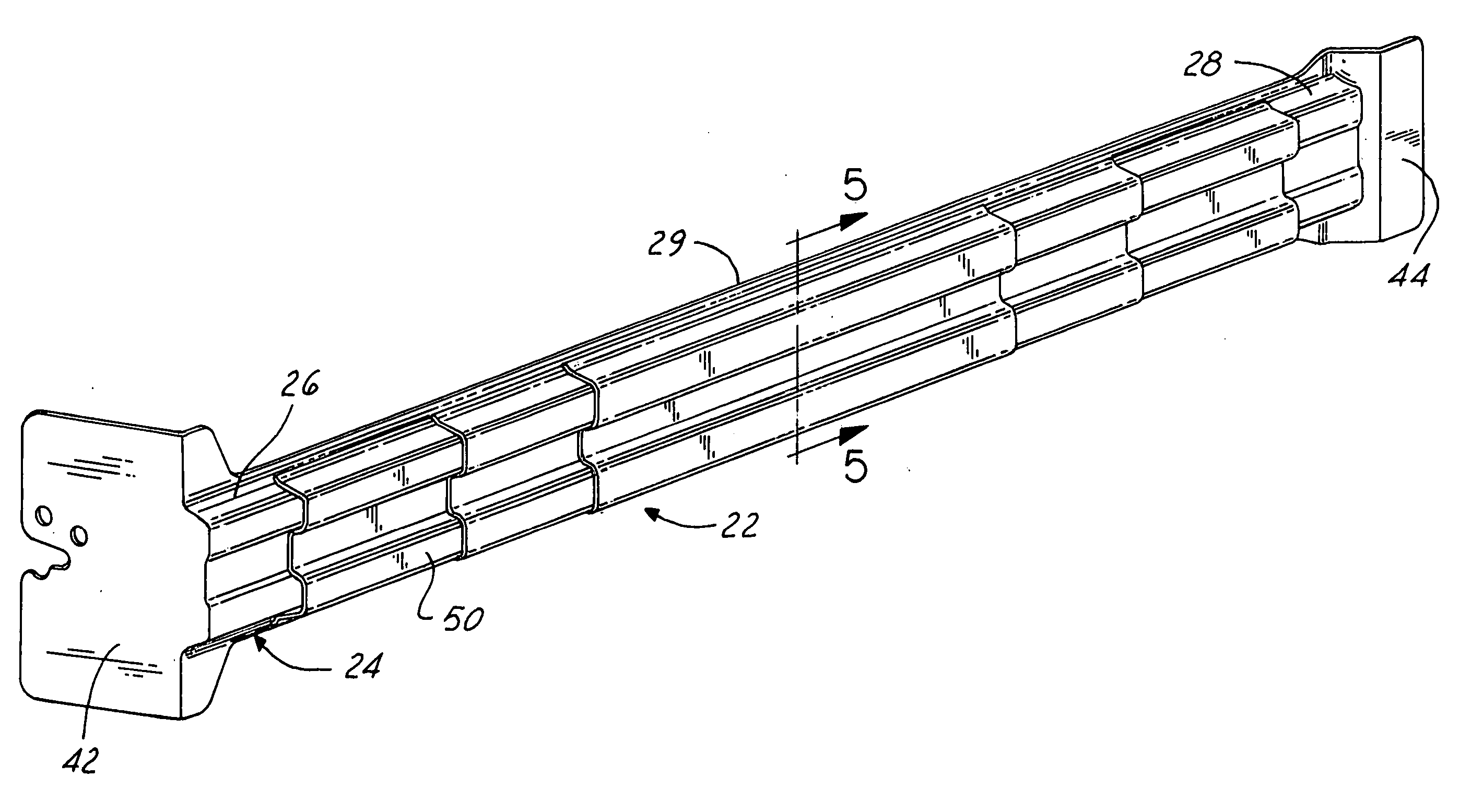

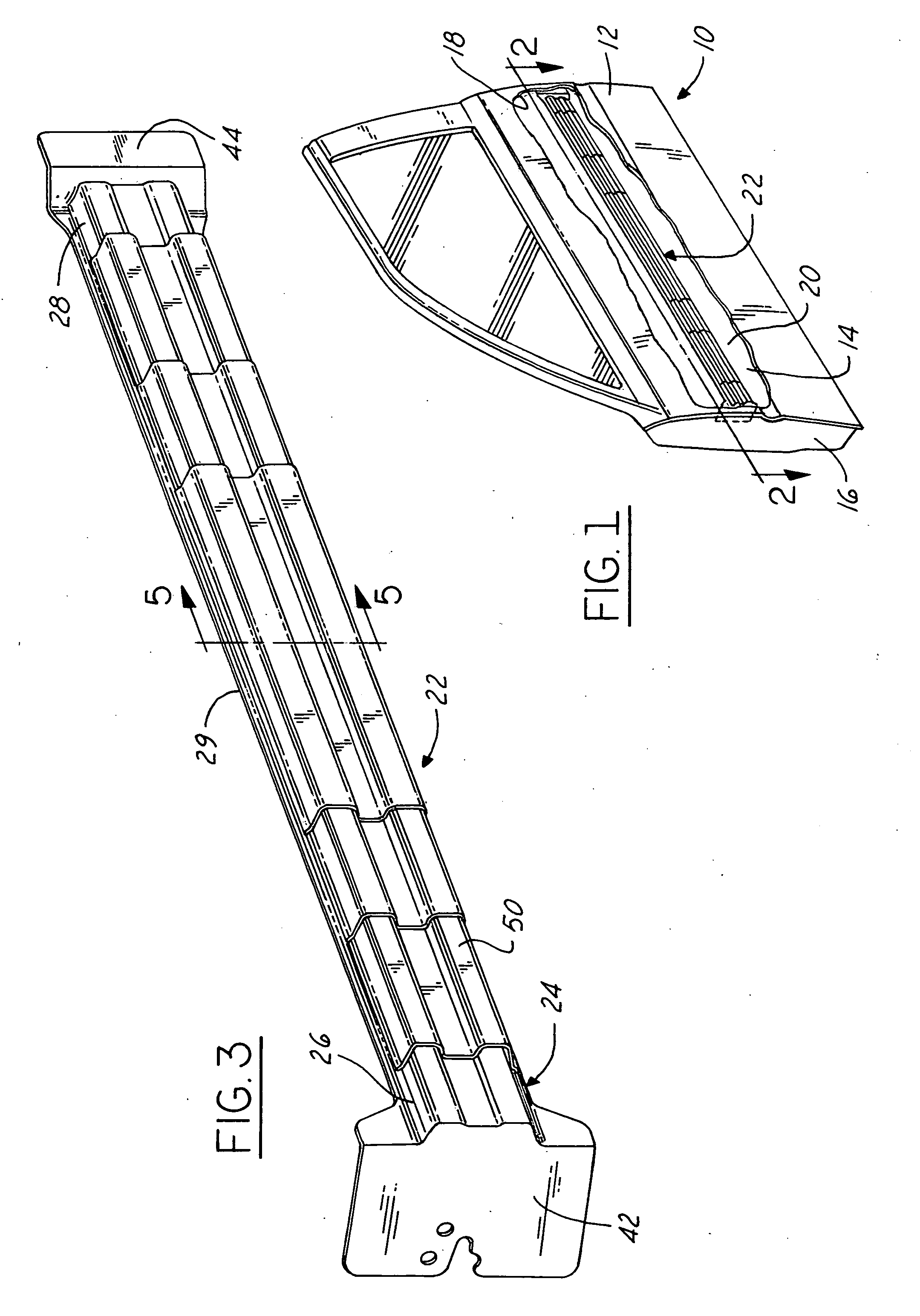

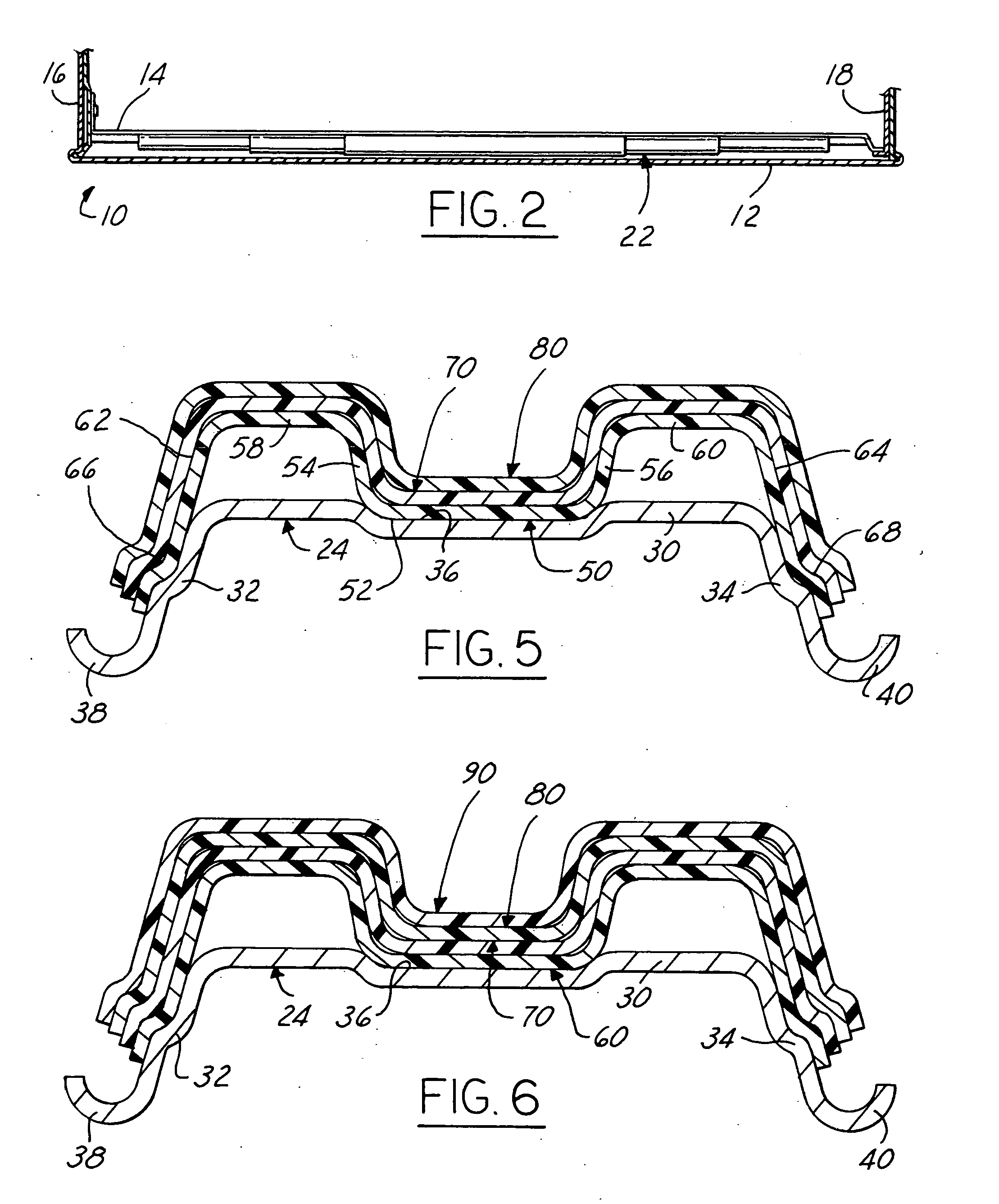

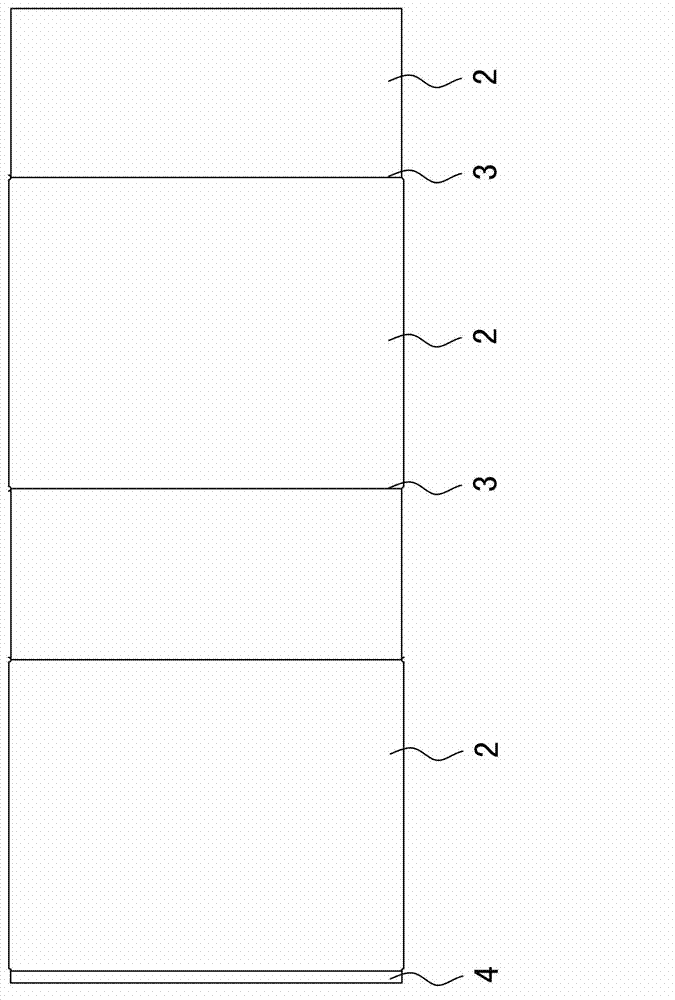

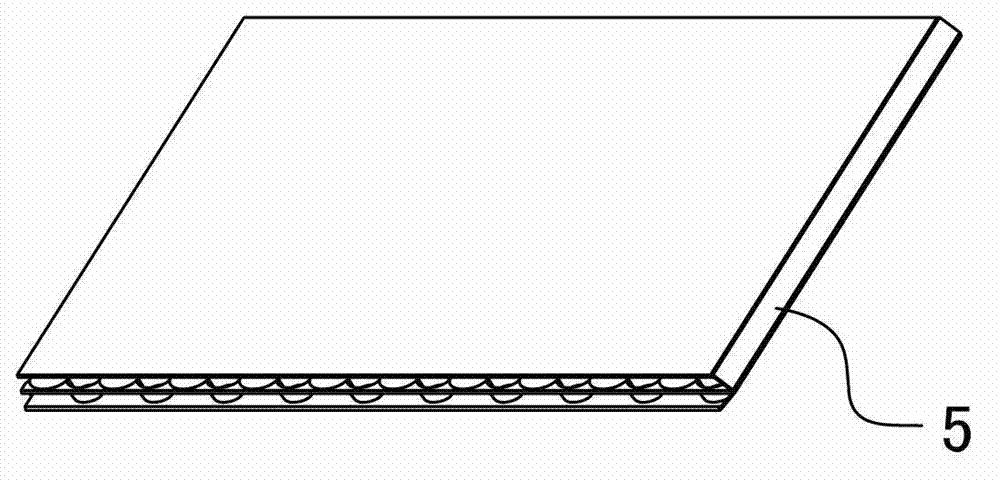

Epoxy bonded laminate door beam

A door intrusion beam is of laminated construction and has a base metal stamping with end flanges, with the base metal stamping being of an inverted generally U-shaped cross section. Slidable and nested on the base metal stamping are a plurality of slidable and stackable elongated plastic elements each having a generally M-shaped configuration. The first plastic element next to the metal stamping and all stackable elongated plastic elements are secured together by layers of adhesives where surfaces contact one another. The plastic elements are of varying length.

Owner:ZOHAR TT ACQUISITION LLC

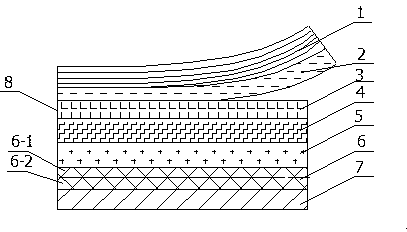

Hot stamping foil applied to overlapping hot stamping on gold stamping layer and preparation method of hot stamping foil

ActiveCN103465668AImprove trimming effectTransfer completelyDuplicating/marking methodsPolyurea/polyurethane coatingsHot stampingCellulose

The invention discloses a hot stamping foil applied to overlapping hot stamping on a gold stamping layer and a preparation method of the hot stamping foil. When overlapping hot stamping is carried out on an existing hot stamping foil, the defects that the transferring is incomplete, the hot stamping is not carried out on some portions due to omission, scumming is caused, powder falls off, and the edge of a hot stamping layer is not clear can happen. The hot stamping foil is composed of a base membrane layer, a release layer, a color coating layer, a vacuum aluminum coated layer and a gumming layer. The gumming layer is prepared by raw materials which comprise, by weight, 1-6 parts of chloroethylene-vinyl acetate resin, 1-10 parts of polyvinyl alcohol, 1-10 parts of acrylic ester, 1-5 parts of nitrocellulose, 1-5 parts of fumed silica, 20-70 parts of ethyl acetate, 10-50 parts of ethyl alcohol and 1-5 parts of propyl acetate. According to the hot stamping foil applied to the overlapping hot stamping on the gold stamping layer, the hot stamping foil has the good stamping performance and the good trimming performance, the overlapping hot stamping layer is complete in transferring, the edge is smooth and free of burrs, the adhesion is firm, the phenomena of dusting, powder falling and the like do not exist, the hot stamping effect is strong in third dimension, and the anti-fake performance is more outstanding.

Owner:云南玉溪东魅包装材料有限公司

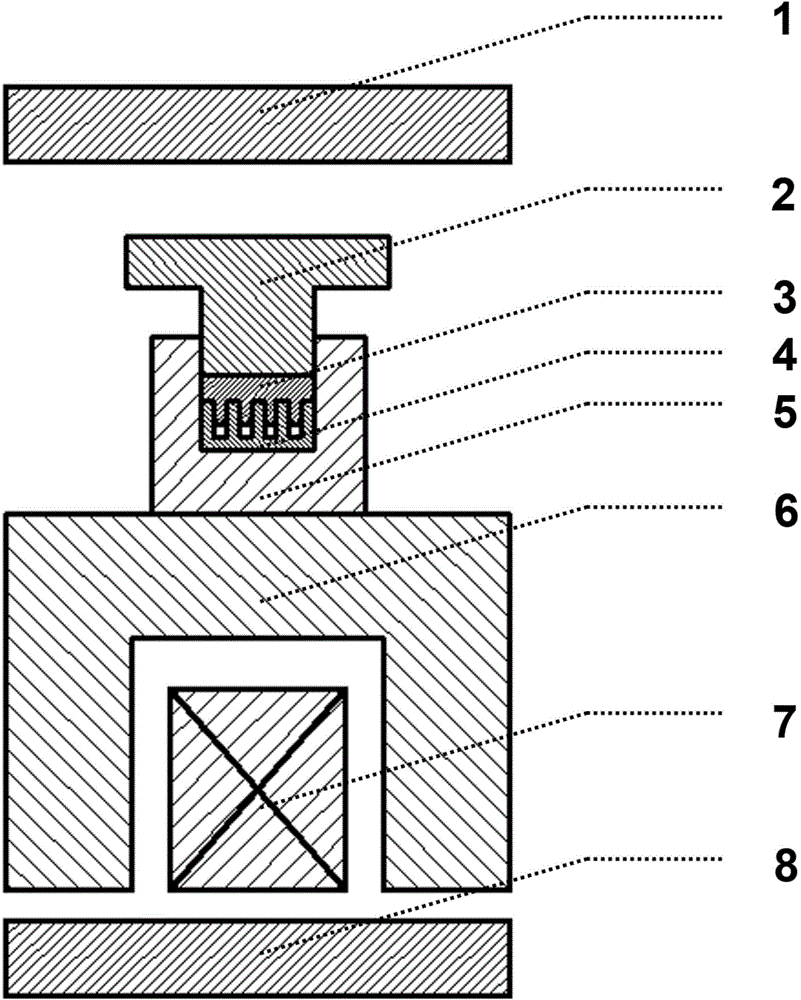

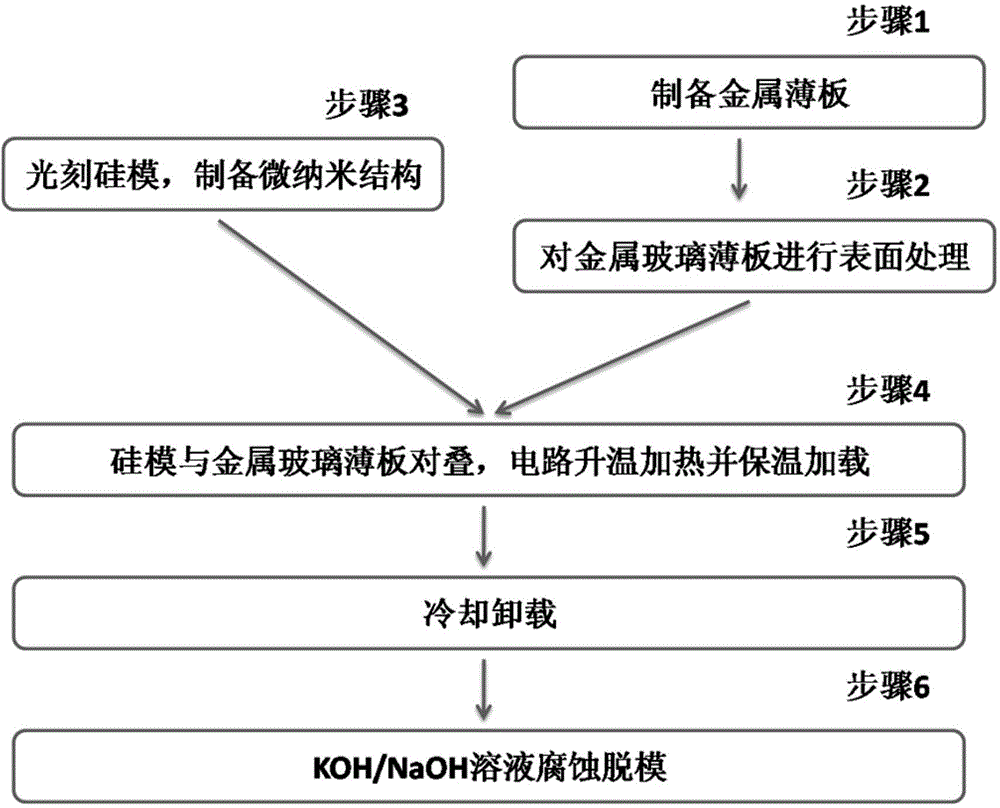

Amorphous alloy micro-nano structure stamping forming mould and preparation and application methods thereof

The invention belongs to the field of materials science and engineering, and particularly relates to an amorphous alloy micro-nano structure stamping forming mould and preparation and application methods thereof. The thermoplastic mould pressing forming method is adopted for processing and preparing the amorphous alloy micro-nano structure stamping forming mould, and a designed micro-nano structure is prepared on an amorphous alloy surface and serves as a metal and polymer micro-nano structure stamping forming mould. According to the invention, the micro-nano structure can be directly and quickly formed on a metal material surface through stamping and can also be prepared on a polymer material surface through the thermoplastic mould pressing method or the quick stamping method. The amorphous alloy micro-nano structure stamping forming mould has the characteristics of high strength, hardness, ductility and abrasion resistance, favorable surface texture, good corrosion resistance and the like. The method for preparing the amorphous alloy micro-nano structure stamping forming mould through thermoplastic mould pressing has the characteristics of high forming precision, convenient preparation, high preparation efficiency and the like.

Owner:TSINGHUA UNIV

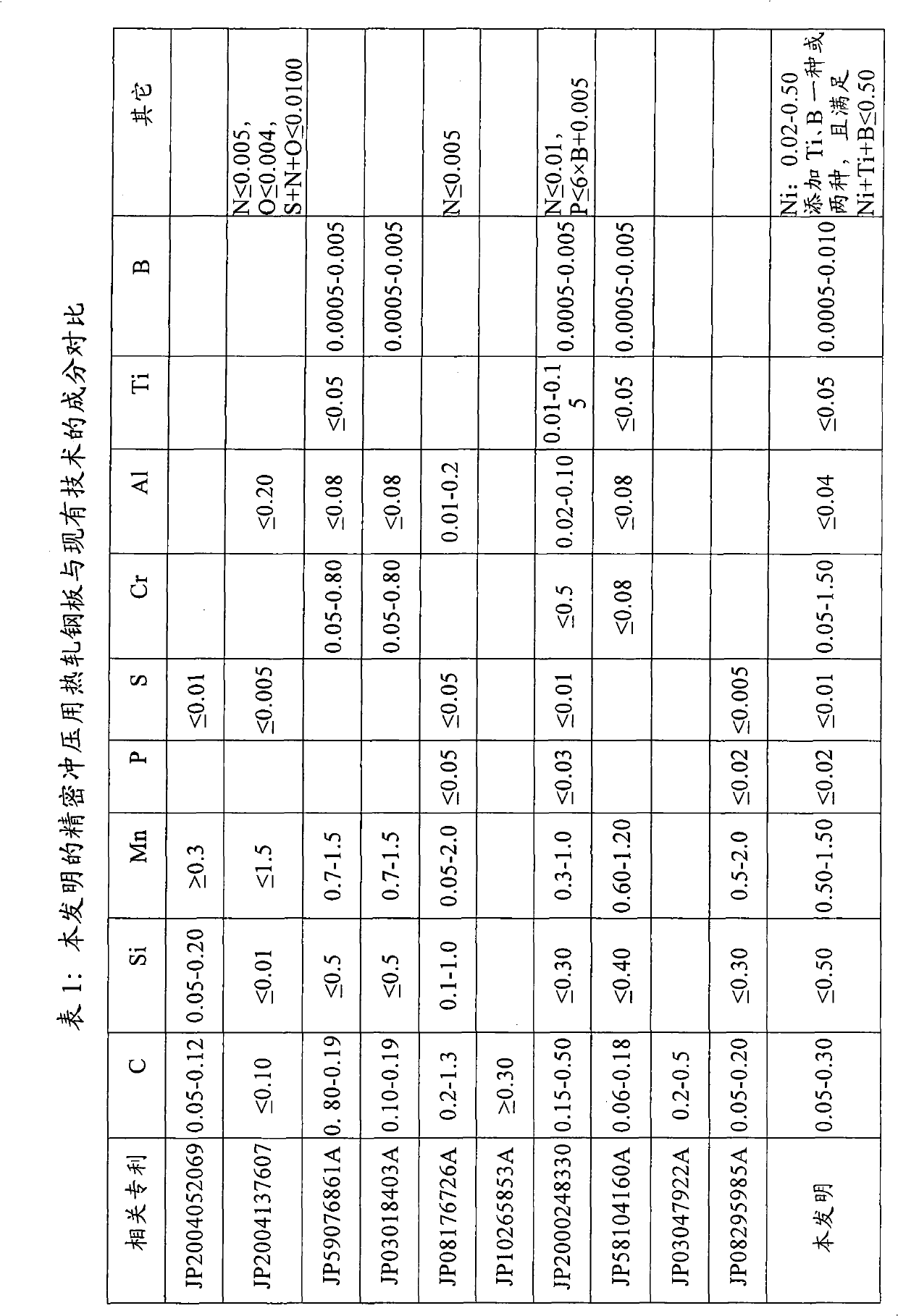

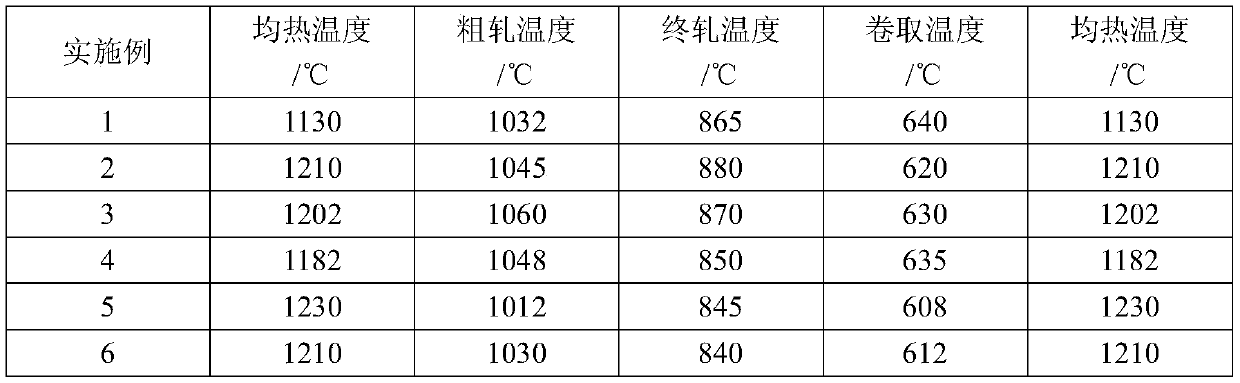

Hot rolled steel plate for precision stamping and manufacturing method thereof

InactiveCN102021493ATemperature control deviceManufacturing convertersChemical compositionSheet steel

The invention provides a hot rolled steel plate for precision stamping, which comprises, by weight, the following chemical constituents: 0.05-0.30% of C, not more than 0.50% of Si, 0.05-1.50% of Mn, not more than 0.02% of P, not more than 0.01% of S, 0.05-1.50% of Cr, not more than 0.04% of Alt, 0.02-0.50% of Ni; the hot rolled steel plate also comprises one or two of Ti and B, wherein the steel plate comprises not more than 0.05% of Ti, 0.0005-0.010% of B, not more than 0.50% of Ni+Ti+B, and the balance of iron and unavoidable impurities. The invention also provides a manufacturing method of the hot rolled steel plate, which comprises the following steps: pre-desulfurization of molten iron; converter smelting; secondary refining; continuous casting; reheating of slabs at a heating temperature of 1100-1250 DEG C; rolling with a termination temperature of finish rolling of 780-950 DEG C; coiling at a coiling temperature of 500-700 DEG C; spheroidizing annealing at a spheroidizing annealing temperature of 700-740 DEG C. The steel plate of the present invention not only is easy to precision stamping, but also has well balanced strength and toughness.

Owner:BAOSHAN IRON & STEEL CO LTD

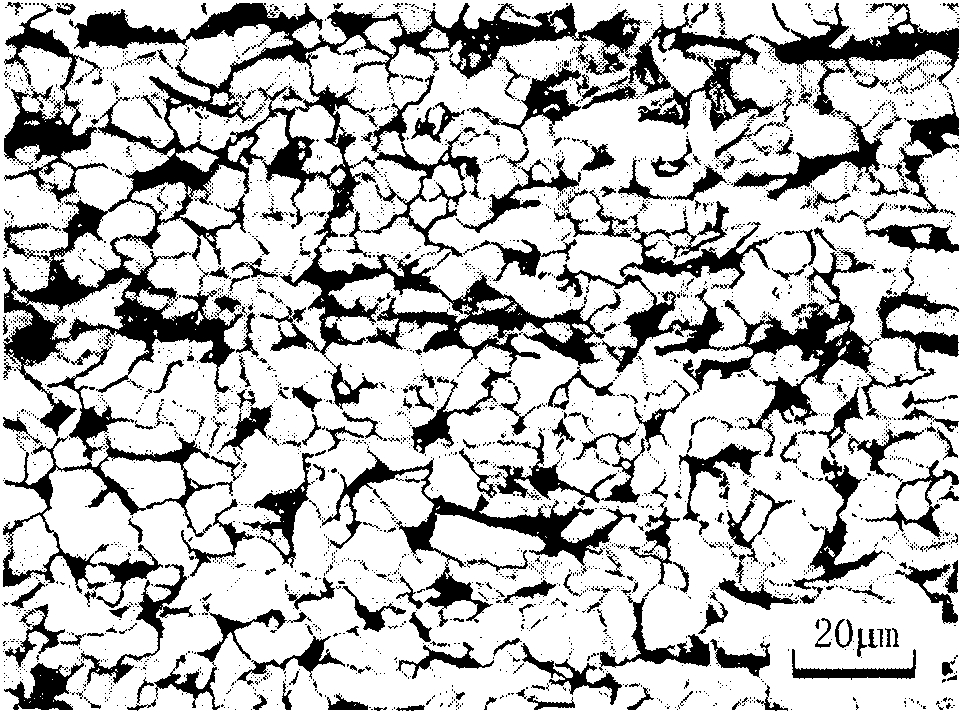

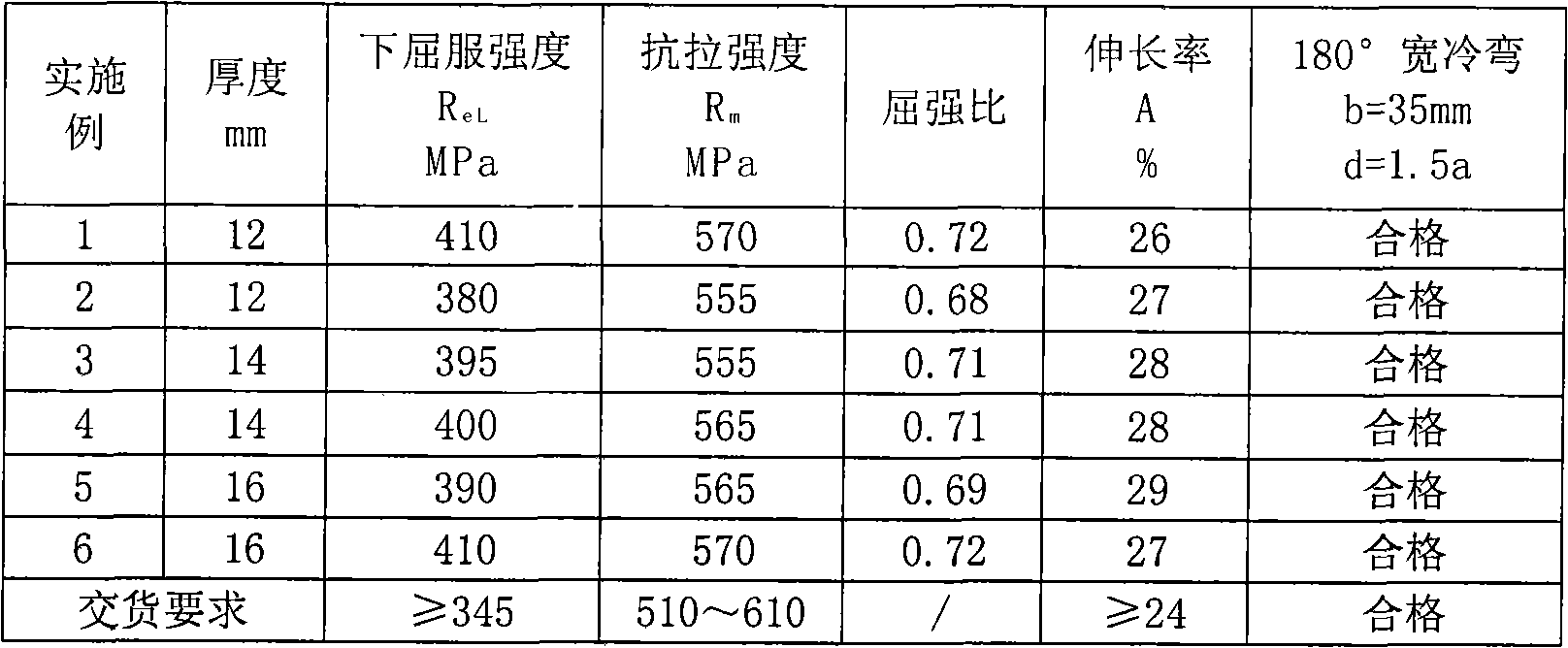

Hot-rolling stamping axle housing steel for automobile with 510Mpa-grade tensile strength and preparation method thereof

InactiveCN101660093AImprove stamping formabilityImprove welding effectTemperature control deviceAxle unitsChemical compositionHigh intensity

The invention relates to hot-rolling stamping axle housing steel for an automobile with 510Mpa-grade tensile strength and a preparation method thereof. The axle housing steel comprises the following chemical components in percentage by weight: 0.12-0.20 percent of C, 0.20-0.60 percent of Si, 1.20-1.60 percent of Mn, less than or equal to 0.030 percent of P, less than or equal to 0.008 percent of S, 0.01-0.06 percent of Als, 0.005-0.030 percent of Ti and the balance of Fe and inevitable impurities. The axle housing steel has high strength, excellent stamping and forming properties and good welding performance, is suitable for hot-rolling forming process and a cold-stamping forming process, and has small rebound during stamping to form and excellent shape keeping performance.

Owner:武钢集团有限公司

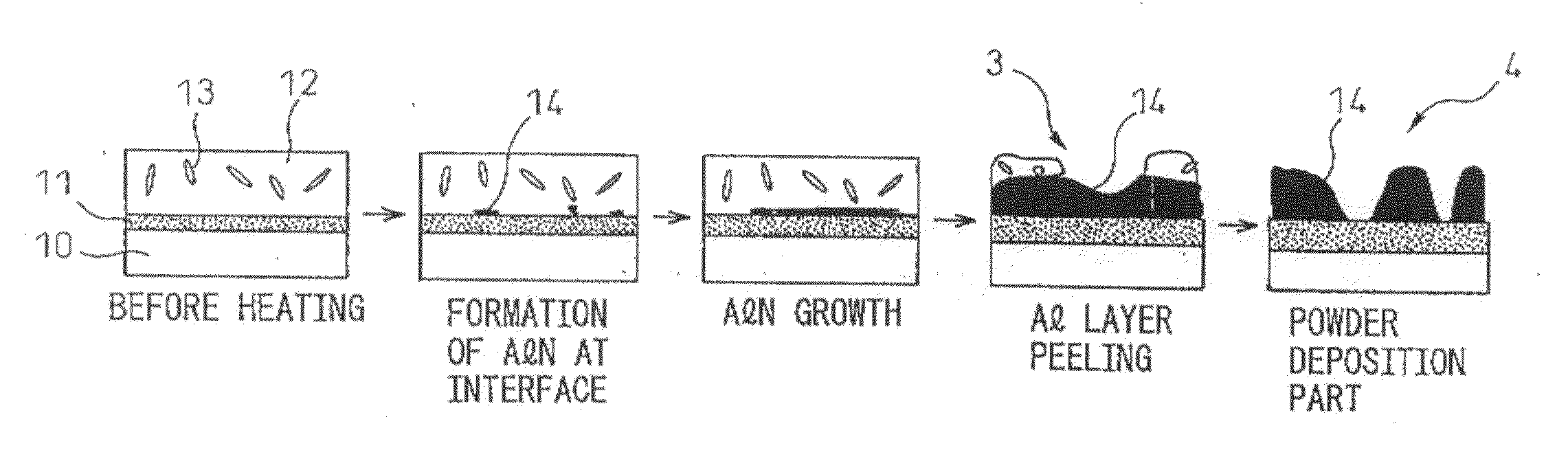

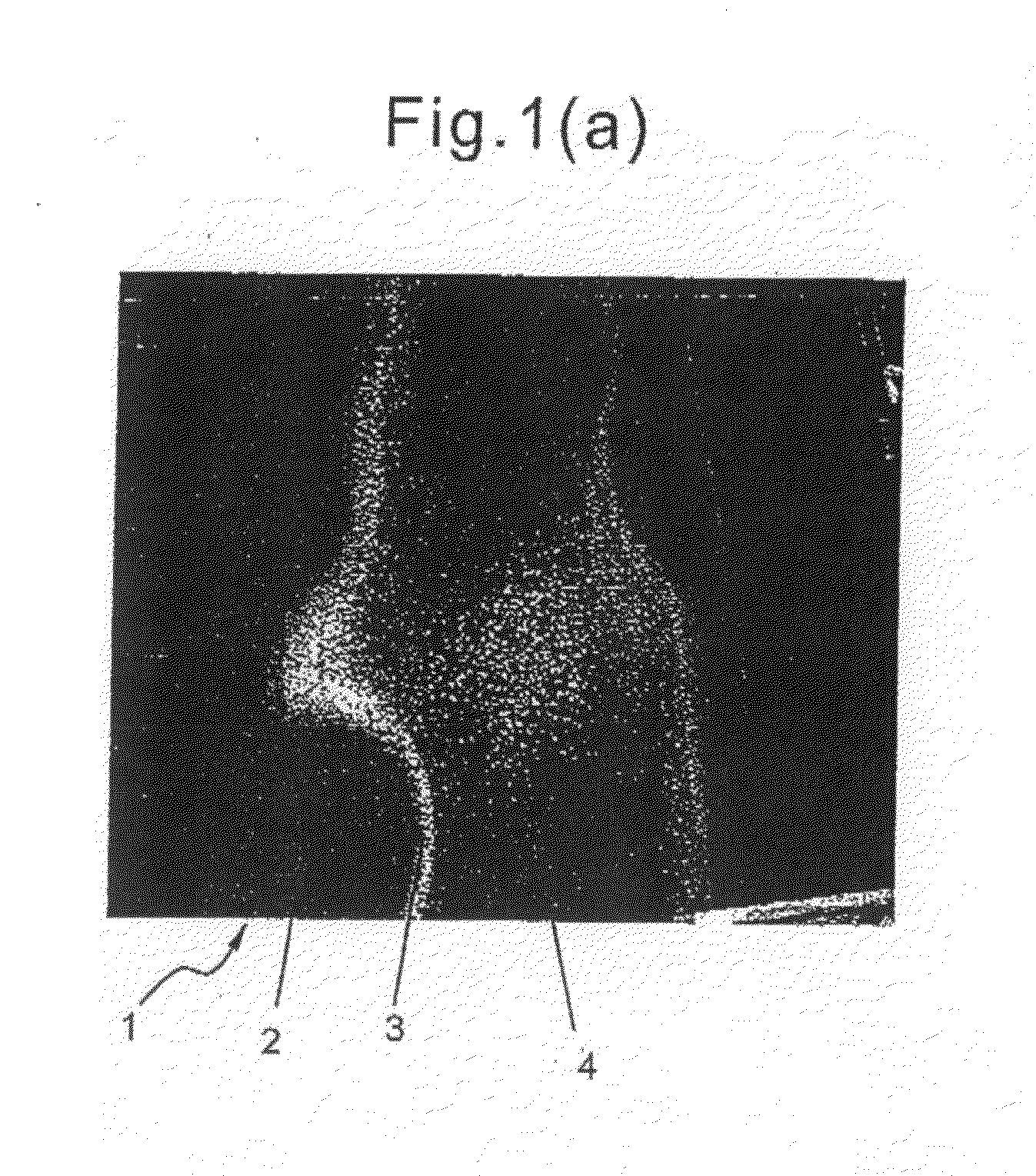

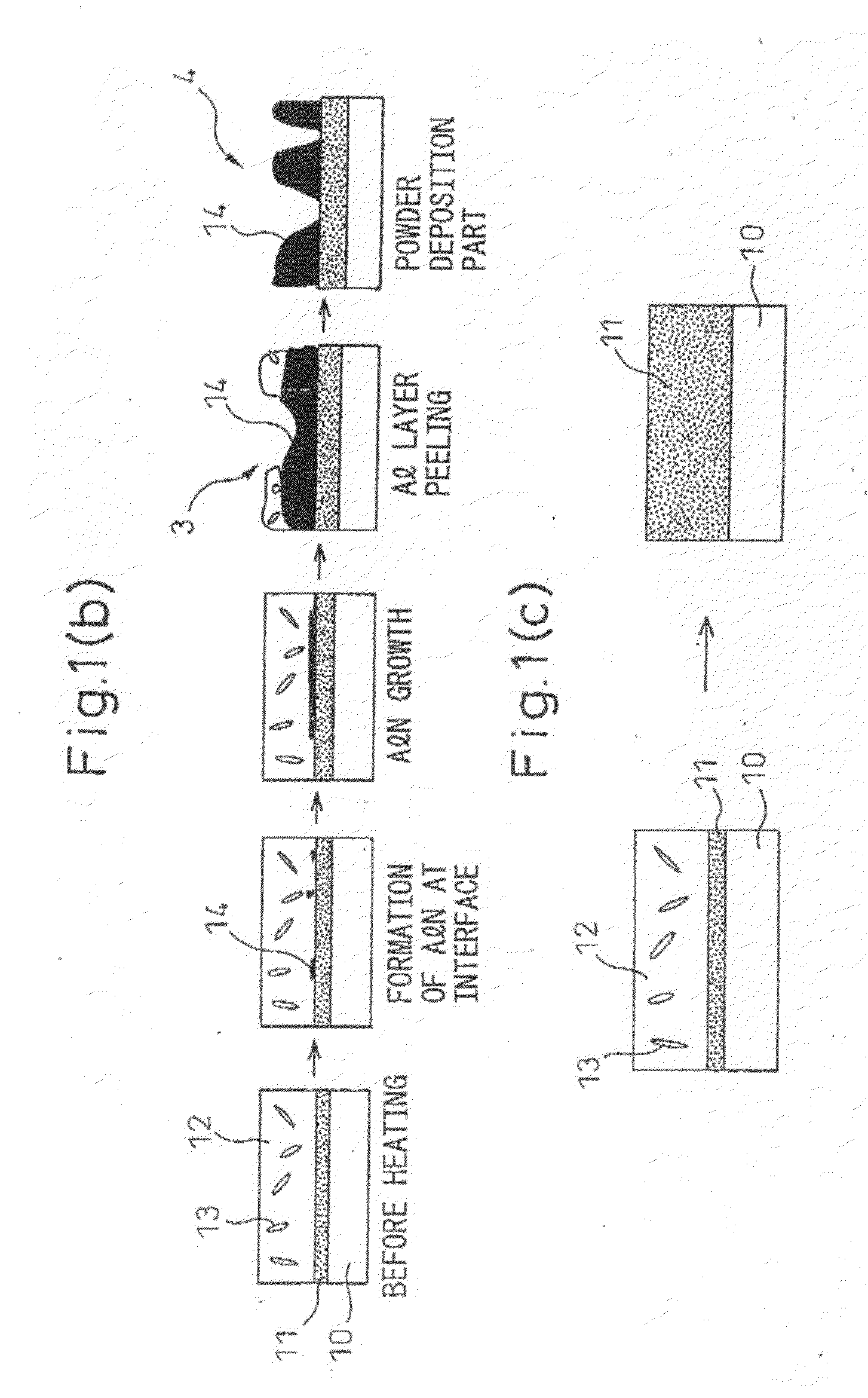

Aluminum plated steel sheet for rapid heating hot-stamping, production method of the same and rapid heating hot-stamping method by using this steel sheet

ActiveUS20110174418A1Eliminate generationReduce riskShaping toolsHot-dipping/immersion processesHot stampingHydrogen

The present invention solves the problem of melting of Al in heating before hot-stamping, which had been a problem in the past in applying hot-stamping to Al-plated steel sheet, and provides Al-plated steel sheet for hot-stamping and a method of hot-stamping using that Al-plated steel sheet to solve the problem of delayed fracture due to residual hydrogen, and, furthermore, a method of a rapid heating hot-stamping using that Al-plated steel sheet.The Al-plated steel sheet of the present invention is produced by annealing the Al-plated steel sheet as coiled in a box-anneal furnace for the time and at the temperature indicated in FIG. 5, and alloying of a plated Al and a steel sheet.Further, a method of rapid heating hot-stamping in the present invention is characterized by cutting out a stamping blank of an Al-plated steel sheet, and heating that blank in heating before hot-stamping by an average temperature with a rising rate of 40° C. / sec or more and a time of exposure to an environment of 700° C. or more of 20 seconds or less, and then hot-stamping it.

Owner:NIPPON STEEL CORP

Cold stamping die for aluminium foil container

InactiveCN101758139AImprove processing efficiencyReduce labor intensityShaping toolsHollow articlesStampingAluminum foil

The present invention discloses a cold stamping die for aluminium foil container, which completes the whole processing through once stamping, mainly comprising an upper die composed of an upper die holder, an upper die cylinder arranged on the upper die holder, an ejector cylinder, an upper pressing side liner plate and a stretching base arranged on the piston rod of the upper die cylinder, an ejecting block arranged on the piston rod of the ejector cylinder and an upper pressing side arranged on the upper pressing side liner plate and a lower die composed of a lower die holder, a lower die cylinder, a support plate and a secondary stretching base arranged on the lower die holder, a secondary stretching male die disposed on the secondary stretching base, a stretching forming male die arranged on the secondary stretching male die, a lower pressing side liner plate arranged on the piston rod of the lower die cylinder, a lower pressing side ring arranged on the lower pressing side liner plate and a lower shearing plate arranged on the support plate. The cold stamping die can complete the whole processing of aluminium foil container and aluminium foil tableware through once stamping, therefore, processing efficiency is improved and labor intensity is lowered.

Owner:江苏新炜实业有限公司

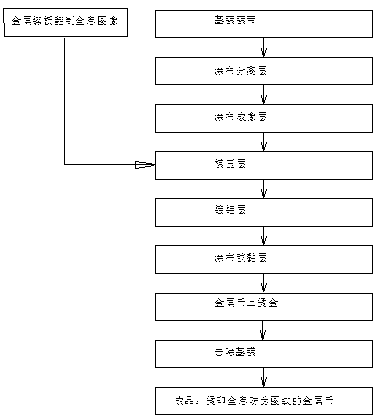

Metallic coin stamped with holographic anti-counterfeiting pattern and manufacturing method thereof

InactiveCN103054284ATo achieve the purpose of printingWear-resistantDuplicating/marking methodsOther printing apparatusStampingEngineering

The invention relates to a laser holographic anti-counterfeiting stamping technology and particularly relates to a metallic coin stamped with a holographic anti-counterfeiting pattern and a manufacturing method thereof and provides the metallic coin which has a laser holographic anti-counterfeiting function and exquisite pattern and is stamped with the holographic anti-counterfeiting pattern and the manufacturing method of the metallic coin. The manufacturing method comprises the following steps of: duplicating a laser holographic image on a metallic nickel plate to form a metal nickel plate for die pressing; coating a release layer, an imaging layer, a die pressing layer, an aluminum plating layer and a dual-layer adhesive layer on a film belt of a base film; positioning, transferring and stamping a laser electrochemical aluminum stamping foil on the metallic coin; heating a stamping head to 80-90DEG C; meanwhile, preheating and improving the temperature of the original metallic coin to 90-100DEG C; and removing the film belt of the base film by the release layer to form the metallic coin with laser holographic pattern. The metallic coin generates a new visual color in the overlapped laser effect and is a novel metal coin anti-counterfeiting type; and in addition, the metallic coin has the advantages of accuracy in positioning, strong three-dimensional sense, abundant layers, simple and quick process, one-time transfer stamping, favorable reproducibility and no pollution.

Owner:HUBEI LHTC ANTI COUNTERFEITING TECH CO LTD

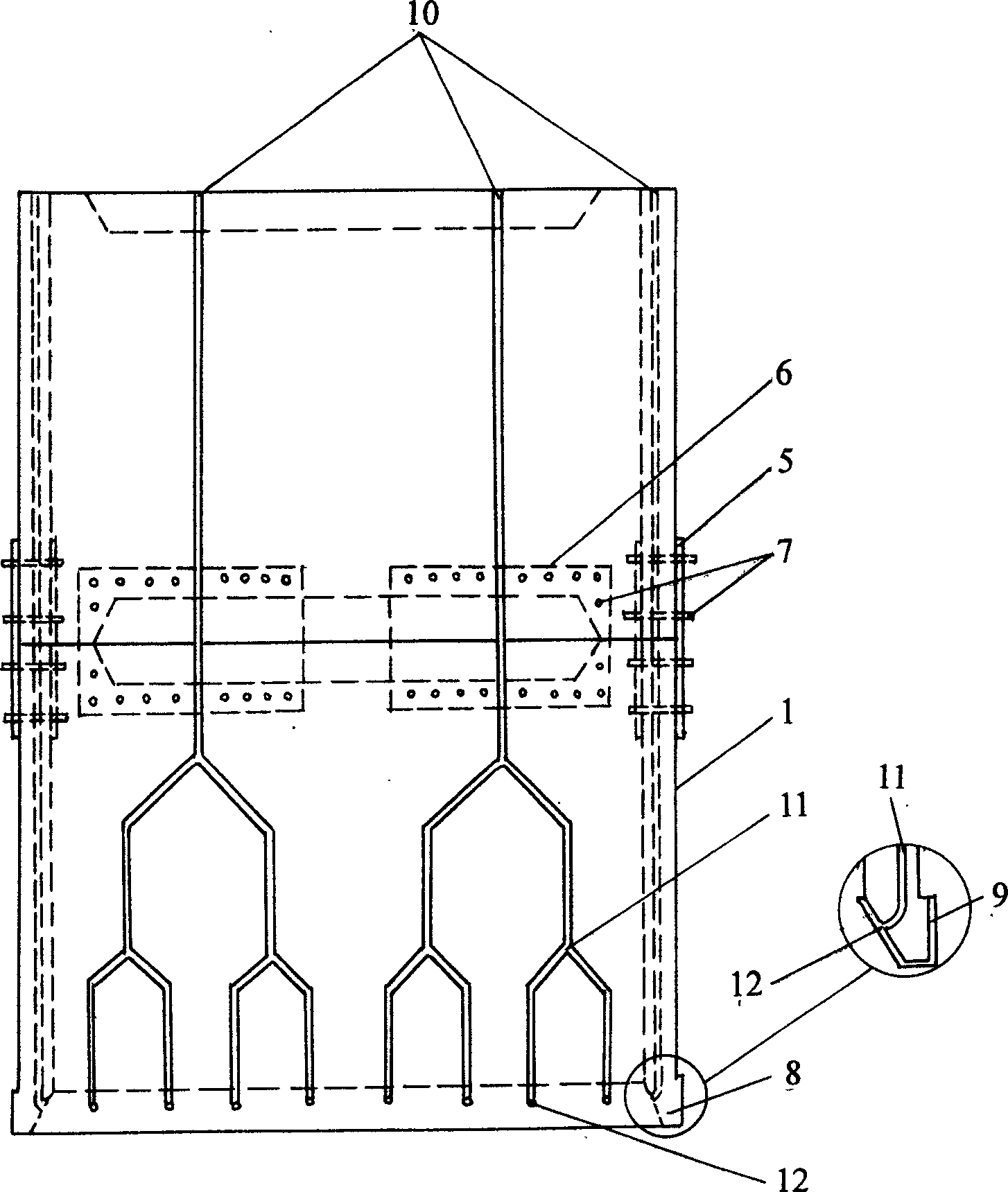

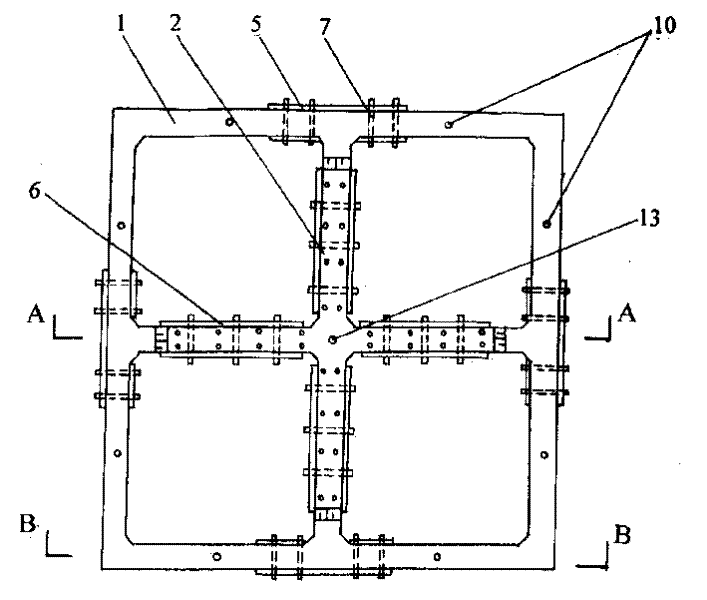

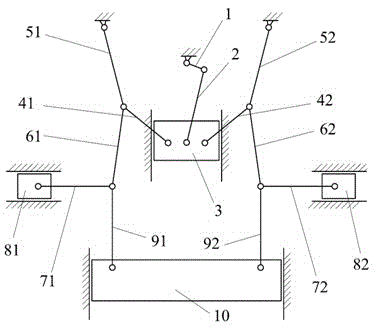

Caisson structure and fast construction method of opencaisson

The caisson structure contains caisson walls to constitute the caisson enclosure separated into several sections, and partition walls and crossbeams inside the caisson enclosure. There are edged feet in the lowest caisson section, steps on the containing partition walls between each two sections, vibrators inside the steps, built-in high pressure water pipe inside the caisson walls, branch pipes, built-in cable tubes communicated with the vibration controller, and clamping steel plates around the upper and the lower caisson enclosures and on two sides of the partitions to integrate the caisson structure. The fast construction method of open caisson includes sectional prefabrication, sectional installation and sectional stamping until reaching the designed height, and has fast construction speed and low cost.

Owner:王民寿

Automatic stamping equipment for accountancy

ActiveCN111086334AImprove work efficiencyEasy to operateStampingArticle separationStampingElectric machinery

The invention relates to stamping equipment, in particular to automatic stamping equipment for accountancy. The purpose that the automatic stamping equipment for the accountancy can always conduct conveying stamping on files, does not need to be operated by people, and is convenient to operate and high in working efficiency is achieved. The automatic stamping equipment for the accountancy comprises a rack, a machine body is installed on one side of the rack, a containing box is slidably arranged on one side of the machine body, springs are connected to the inner side of the containing box, a friction plate is slidably arranged in the containing box, one side of the friction plate is fixedly connected with the tail ends of the springs, and a collecting box is installed on the side, far awayfrom the containing box, of the interior of the machine body. According to the automatic stamping equipment for the accountancy, the files are put into the containing box to make contact with a pickup roller, a motor is started to reversely rotate, then the pickup roller can drive the files to move to a conveyer belt, the conveyer belt rotates forwards to drive the files to move rightwards, a clamping sleeve drives a stamp to stamp the files, therefore, the working efficiency is high, operation is convenient, and manual operation is not needed.

Owner:陈曦

Method for manufacturing radio frequency tags with hot and cold stamping technology

ActiveCN102339402AWide range of useFast hot stampingAntenna supports/mountingsRadiating elements structural formsHot stampingInsulation layer

The invention discloses a manufacturing method of radio frequency tags, and the radio frequency tags are manufactured with a hot and cold stamping technology; the process method has the steps that: polyvinyl chloride (PVC), polypropylene (PP), polyethylene terephthalate (PET), paper, plastics and the like are adopted as base materials, and electro-metal stamping foils are stamped on the base materials by a stamping machine through a hot stamping or cold stamping technology, then waste is discharged from other parts of the metal foils, and antenna patterns are obtained; and if coil antennas are to be manufactured, insulation layers need to be paved on coils, the electro-metal stamping foils are stamped on the insulation layers and are connected with the ends of the antennas to form bridges, i.e. radio frequency antennas. Finally, chips are reversely pasted on the antenna bridges, coated and packaged, and radio frequency tags are obtained. A traditional radio frequency tag process has the disadvantages of too high cost, complicated process, long production time, certain pollution to the environment and the like, and the method for manufacturing radio frequency tags with the hot and cold stamping technology can effectively reduce the radio frequency tag manufacturing cost, simplify the complicated process, and meet the market demand for the low-cost radio frequency tags.

Owner:哈尔滨大东方新材料科技股份有限公司

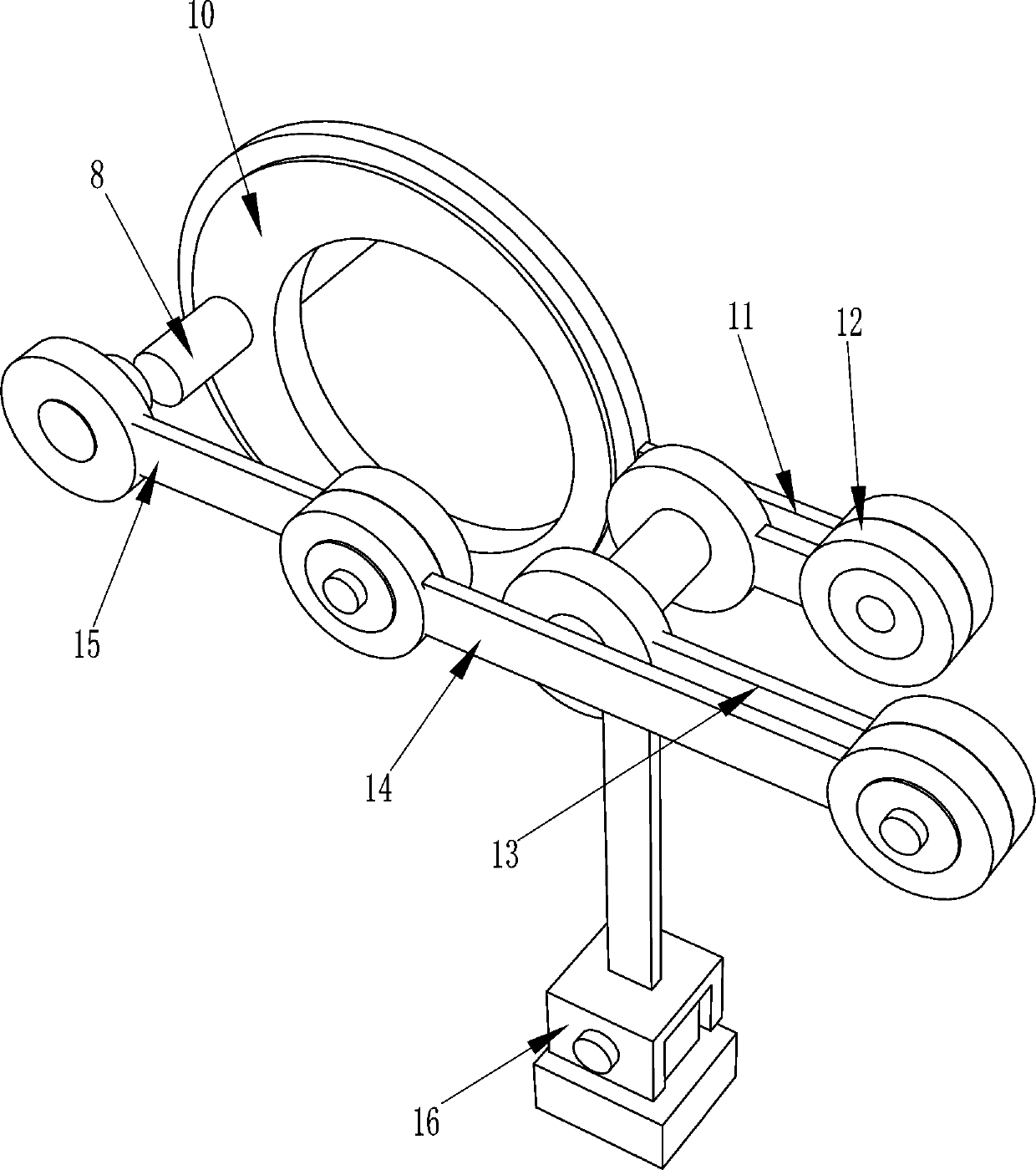

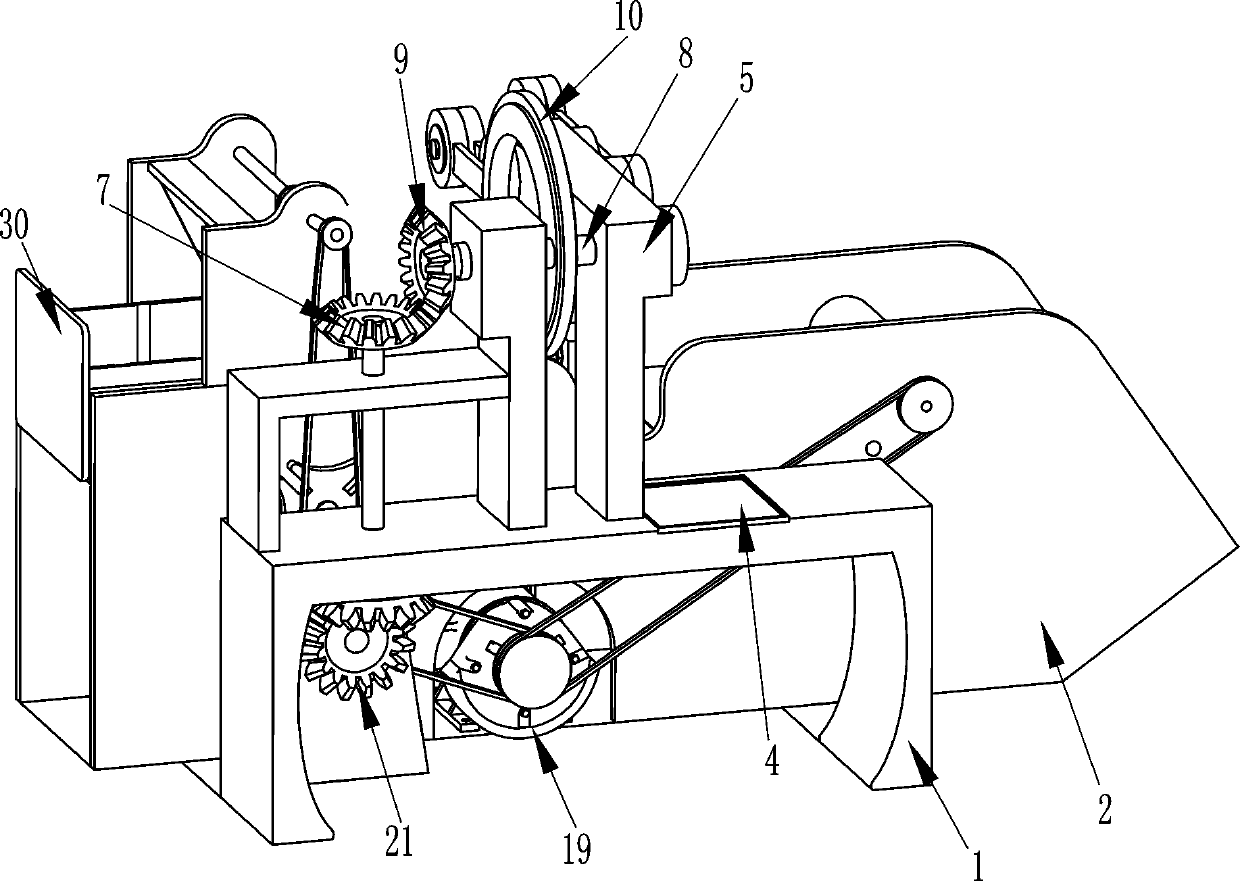

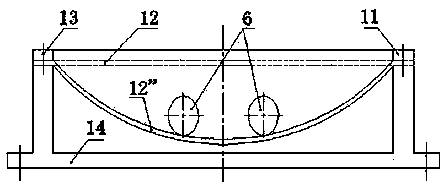

Large diameter-thick ratio and vertical distance ratio seal head rotary percussion forming device and rotary percussion method thereof

ActiveCN104275378AImprove the shortcomings of easy wrinkling and instabilityInhibition of deformation and instabilityRotary stageStamping

The invention relates to a large diameter-thick ratio and vertical distance ratio seal head rotary percussion forming device and a rotary percussion method thereof. The forming device comprises a machine tool gantry formed by stand columns and a top beam, a base, a cross beam, double rotary wheel carriers, a rotating platform, a cylinder-shaped mould, a ring-shaped pressure plate fixture, and the like, wherein the rotating platform is arranged on the base of a machine tool; the cylinder-shaped mould is arranged on the rotating platform; a workpiece to be processed is closely clamped on the cylinder-shaped mould, so that the workpiece and the mould can synchronously rotate along with the rotating platform; the two rotary wheel carriers are respectively arranged at the left side and right side of the cross beam, and each rotary wheel carrier is provided with a rotating wheel as a spinning tool; the vertical-direction feed and the horizontal-direction feed of the rotating wheel are realized by a stepping motor and a screw rod. The double-rotating wheel structure is adopted, so that the stress stability of the workpiece can be improved in the spinning forming process, and the influence of vibration to the machining process can be reduced. According to the spinning method, double rotating wheels are respectively used for feeding and extruding the workpiece so as to form the workpiece along the symmetrical arc shapes from the left side and right side of the periphery of the workpiece to the center. The device is simple, the stamping of a drum roller is avoided, is stable in forming process, and is capable of avoiding the phenomenon of instability in the forming process of a large diameter-thick ratio and vertical distance ratio seal head, thus realizing the whole precision shaping of the large diameter-thick ratio and vertical distance ratio seal head.

Owner:长沙超旋机械科技有限责任公司

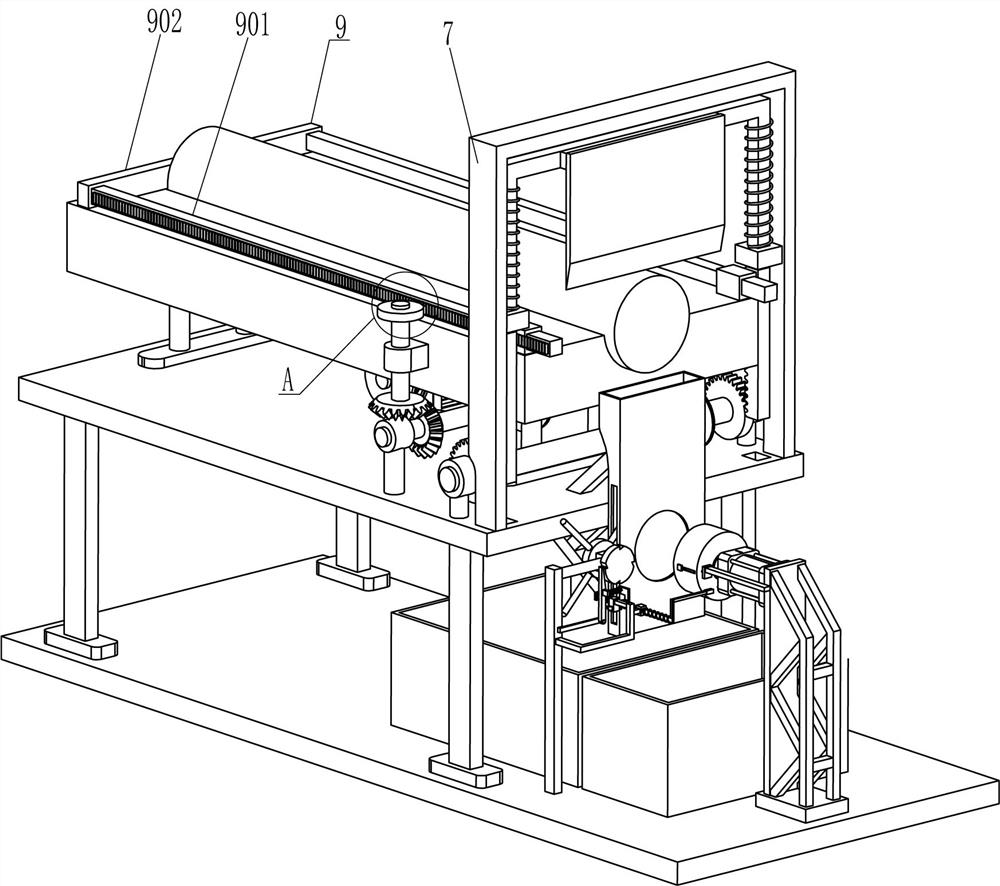

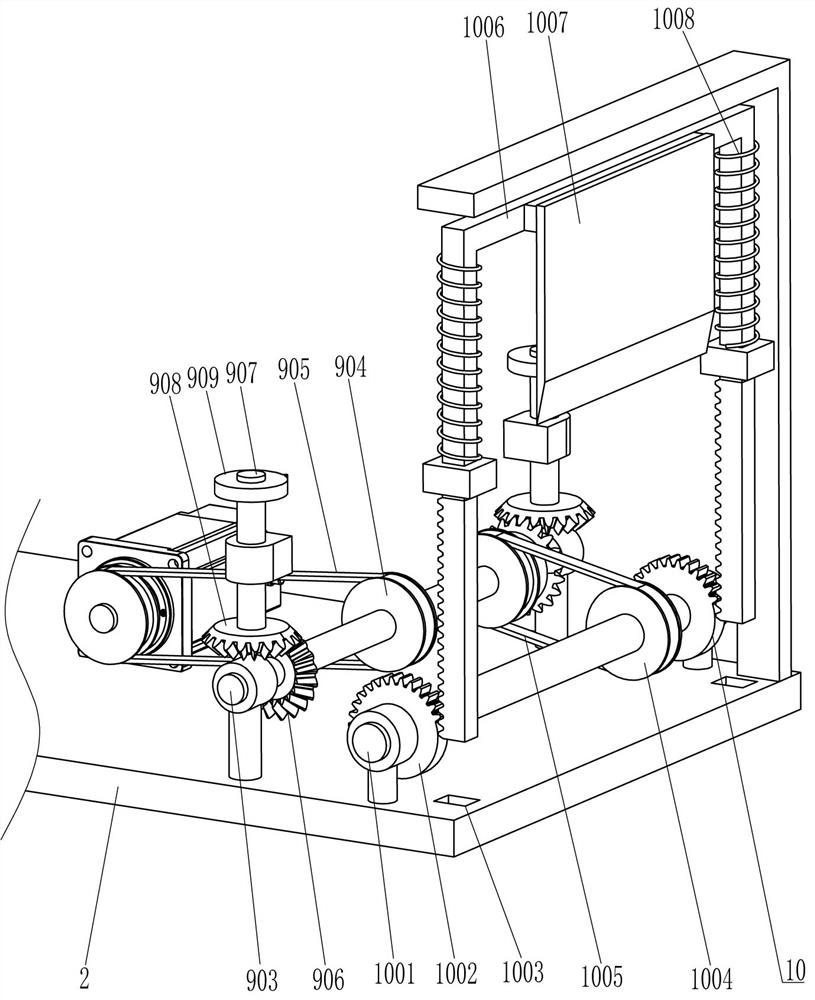

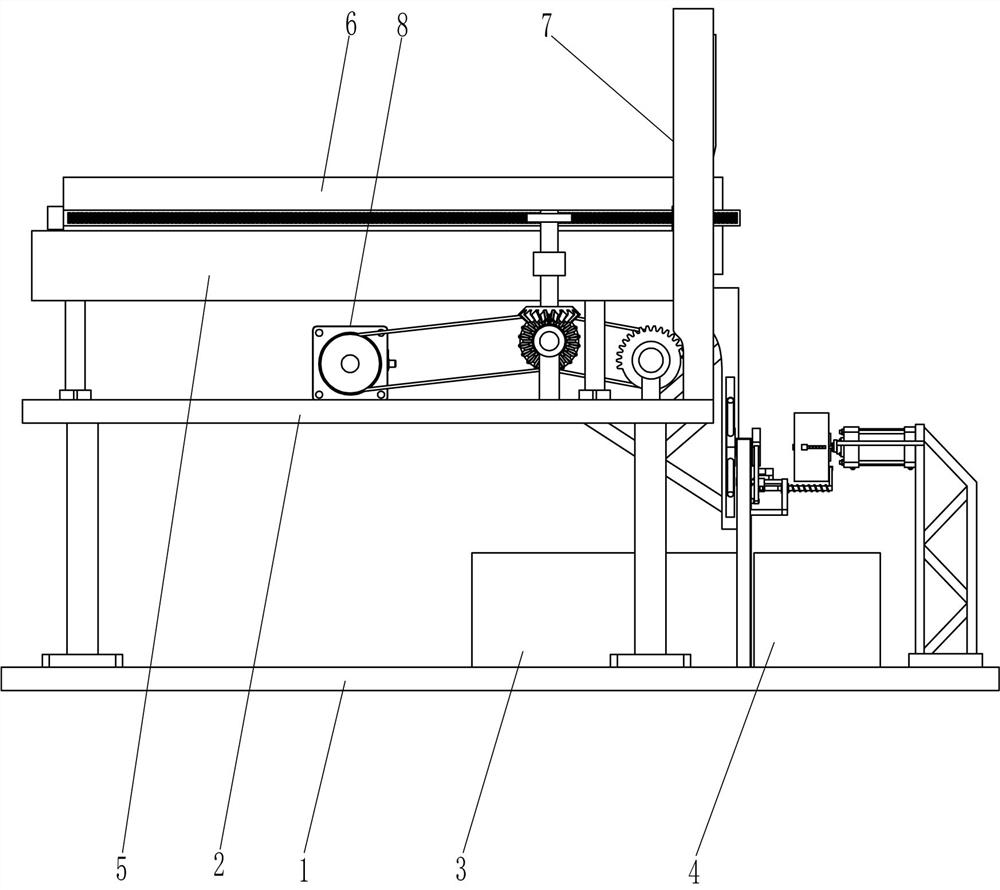

Graphite rod slicing and graphite gasket processing equipment

ActiveCN111823412AGuaranteed thicknessImprove work efficiencyWorking accessoriesStone-like material working toolsStampingEngineering

The invention relates to the field of graphite sheet processing, in particular to graphite rod slicing and graphite gasket processing equipment. The graphite rod slicing and graphite gasket processingequipment is high in working efficiency, can control the thickness of graphite sheets, and avoids defective products. According to the technical scheme, the graphite rod slicing and graphite gasket processing equipment comprises a bottom plate and a first collecting frame, wherein an objective table is bolted on the bottom plate; and the first collecting frame and a second collecting frame are placed on the bottom plate. According to the graphite rod slicing and graphite gasket processing equipment, a graphite rod can be cut through a cutting assembly, a stamping assembly can stamp the cut graphite sheets, so that cutting and stamping are carried out at the same time, and therefore the working efficiency can be improved; and the graphite rod is conveyed by a machine instead of manual work, so that the thickness of the graphite sheets can be effectively guaranteed.

Owner:内蒙古骅扬高新材料科技有限公司

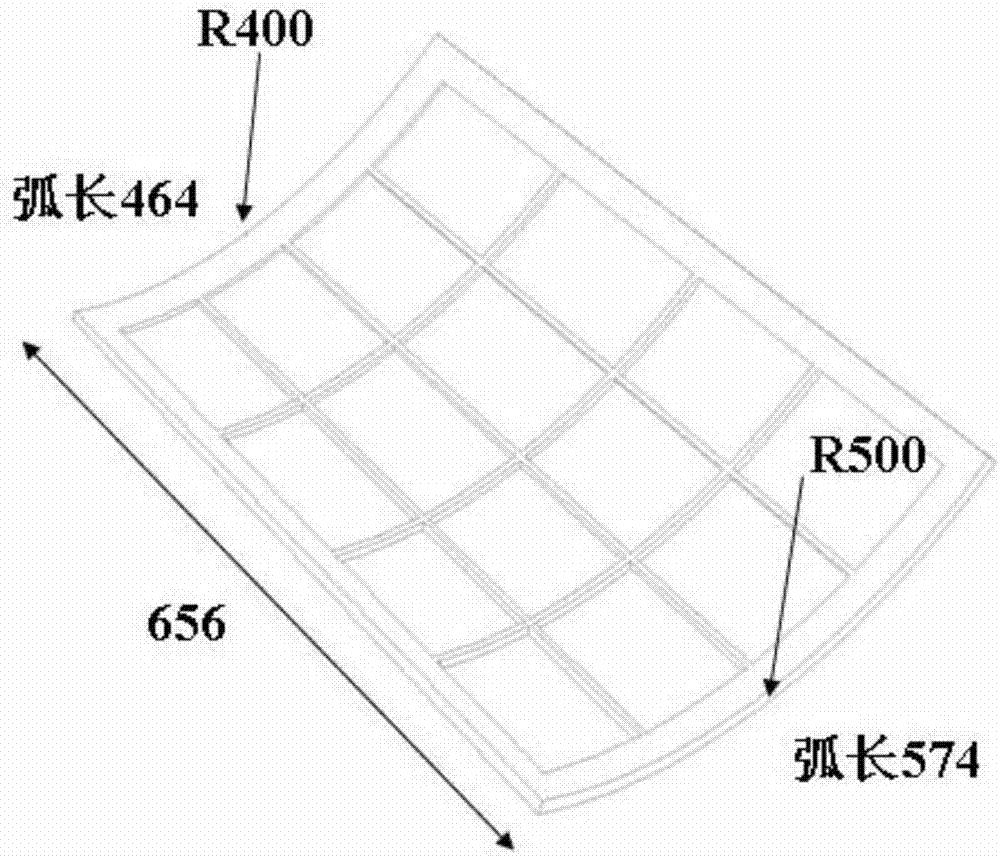

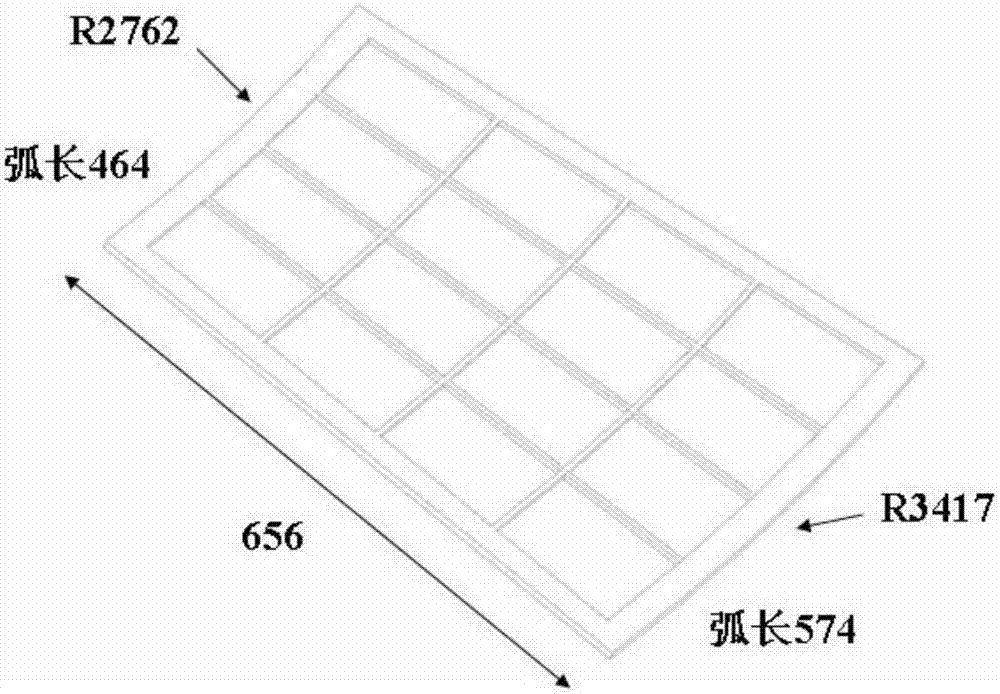

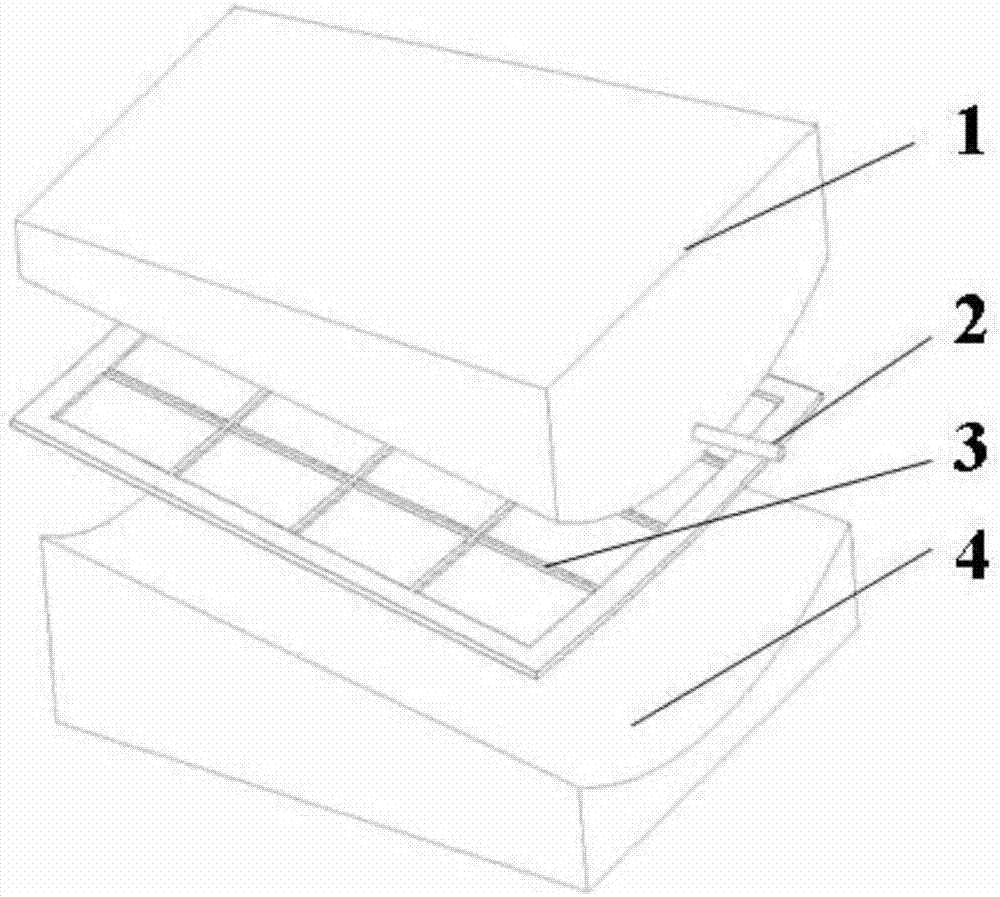

Hot-pressing forming method for aluminum-alloy curved reinforcing rib plate

The invention discloses a hot-pressing forming method for an aluminum-alloy curved reinforcing rib plate. The method comprises the steps of 1, carrying out plane unfolding on the aluminum-alloy curved reinforcing rib plate; 2, preparing corresponding reinforcing ribs on the plate according to the positions of the reinforcing ribs in the plane unfolding diagram; 3, designing and processing a hot-pressing forming die of the aluminum-alloy curved reinforcing rib plate; 4, performing hot-pressing forming on the aluminum-alloy curved reinforcing rib plate; and 5, performing air inflation correction on the aluminum-alloy curved reinforcing rib plate. According to the method, the aluminum-alloy curved reinforcing rib plate is formed by adopting hot-pressing formation and air inflation correction combined technologies, the problem that the size precision and the profile precision of the parts are difficult to control in the conventional cold stamping or machining process is solved, the surface quality of the parts is improved, and the overweight problem in the casting process is avoided; firstly, hot-pressing forming is adopted so that resilience, wrinkling, cracking and other defects in the cold forming process can be effectively avoided; and then air inflation correction is adopted so that the size precision, the profile precision and the surface quality requirements of the parts can be guaranteed.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

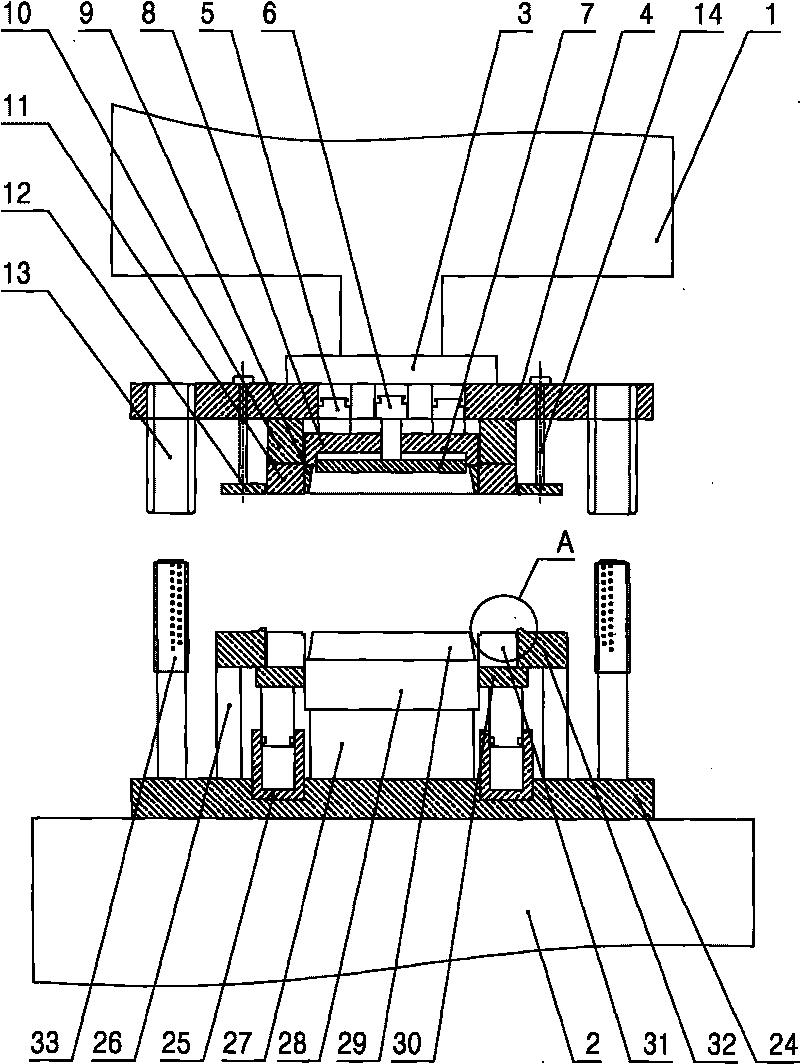

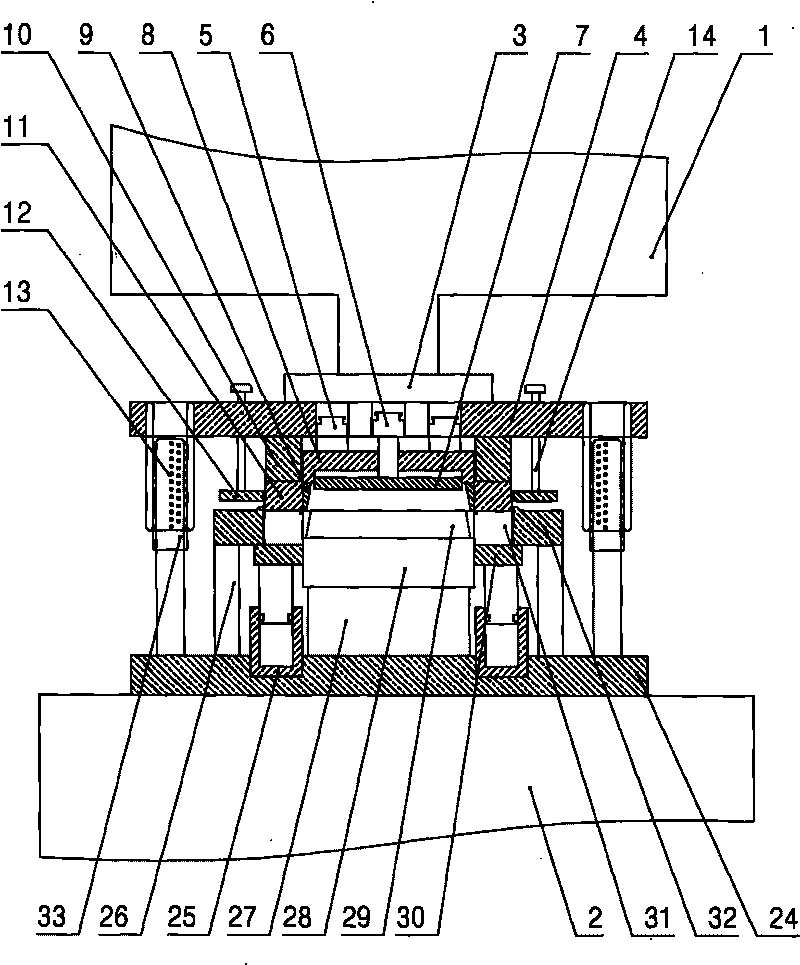

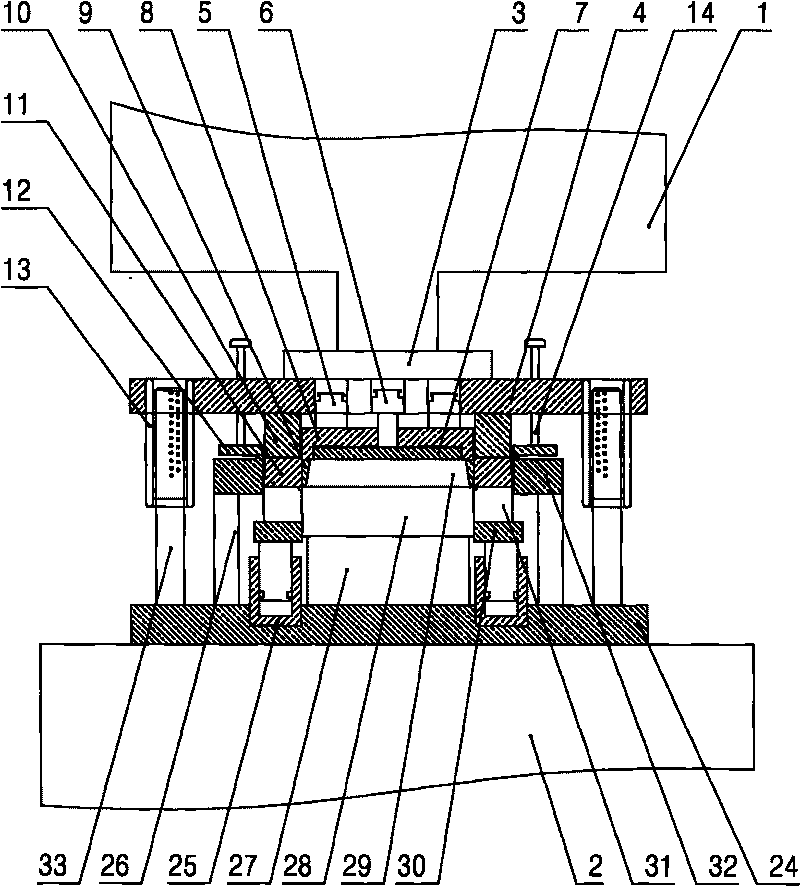

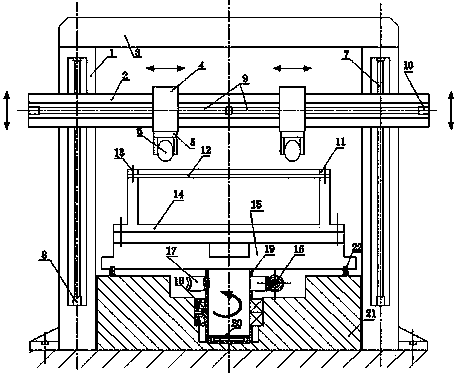

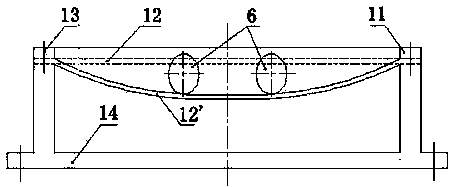

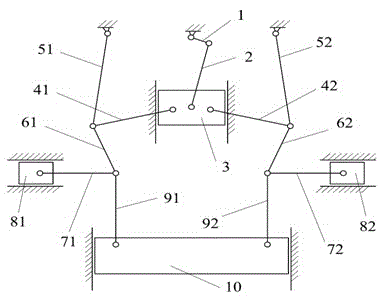

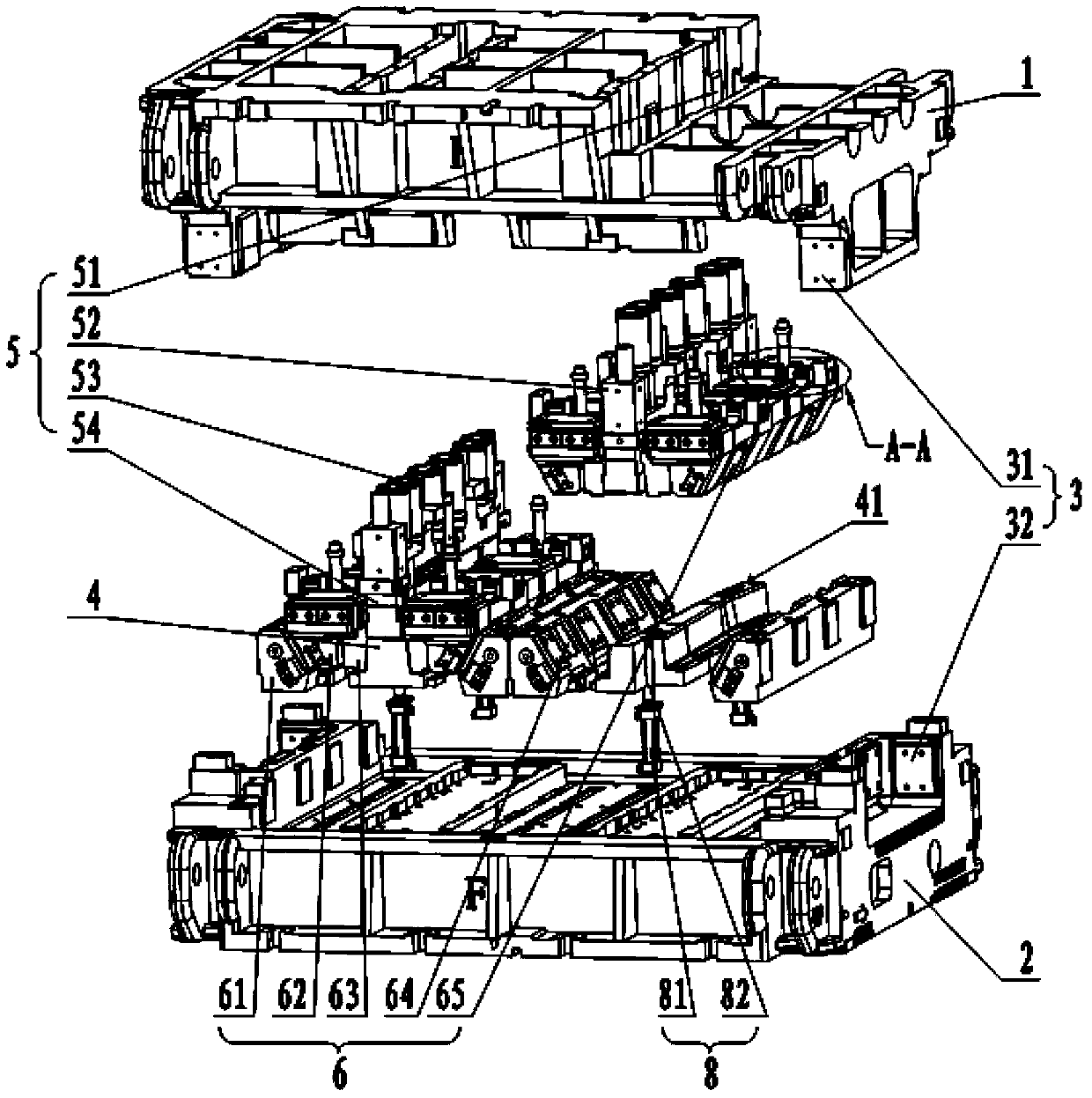

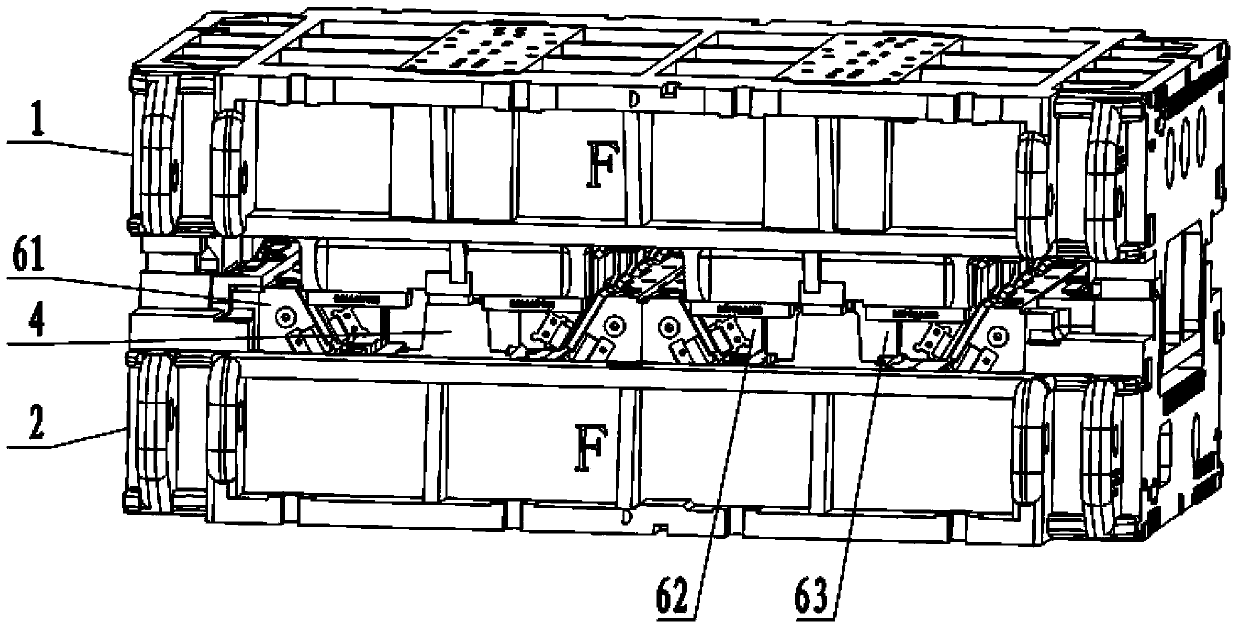

High-speed precise numerical-control stamping machine mechanismstructure capable of realizing dynamic lower dead point precision compensation

The invention discloses a high-speed precise numerical-control stamping machine mechanismstructure capable of realizing dynamic lower dead point precision compensation. The high-speed precise numerical-control stamping machine mechanismstructure consists of a slider-crank mechanism, two push rods, two multi-rod mechanisms, two lower connecting rods and a stamping slider, wherein the slider-crank mechanism is arranged on a stamping machine body along the vertical direction, the vertical-movement stamping slider is arranged right belowunder the slider-crank mechanism, the two push rods, the two multi-rod mechanisms and the two lower connecting rods are respectively and symmetrically arranged at the two sides of the slider-crank mechanism, the slider-crank mechanism and the two multi-rod mechanisms are connected together by the two push rods, and the stamping slider and the two multi-rod mechanisms are connected together by the two lower connecting rods. According to the high-speed precise numerical-control stamping machine mechanismstructure capable of realizing the dynamic lower dead point precision compensation, the influence on horizontal-movement sliders, subjected to dynamic precision adjustment, caused by a stamping machining impact load is little, thereby being beneficial to the improvement of compensation precision and the prolongation of the service life of an adjustment system.

Owner:NANJING UNIV OF SCI & TECH

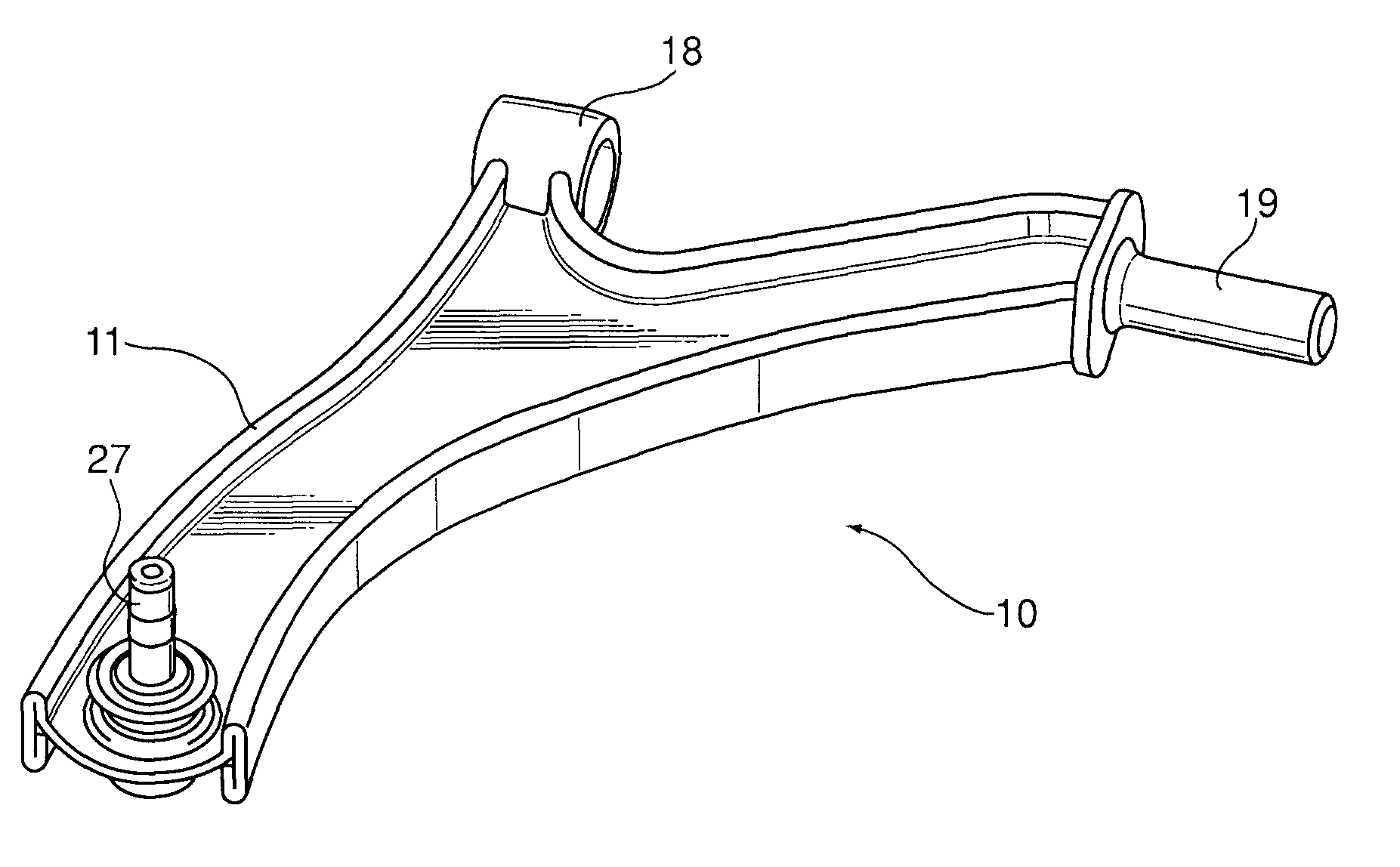

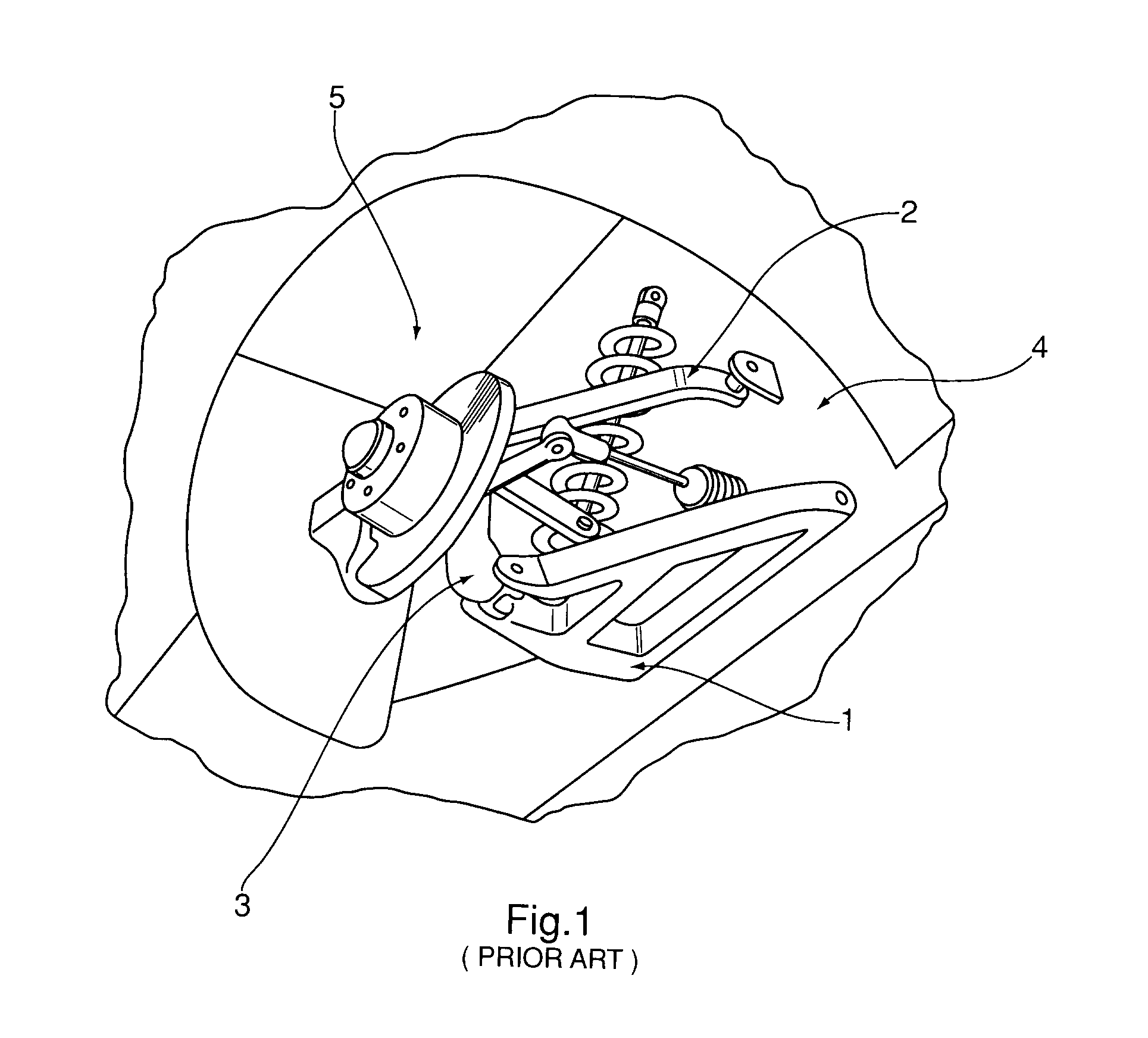

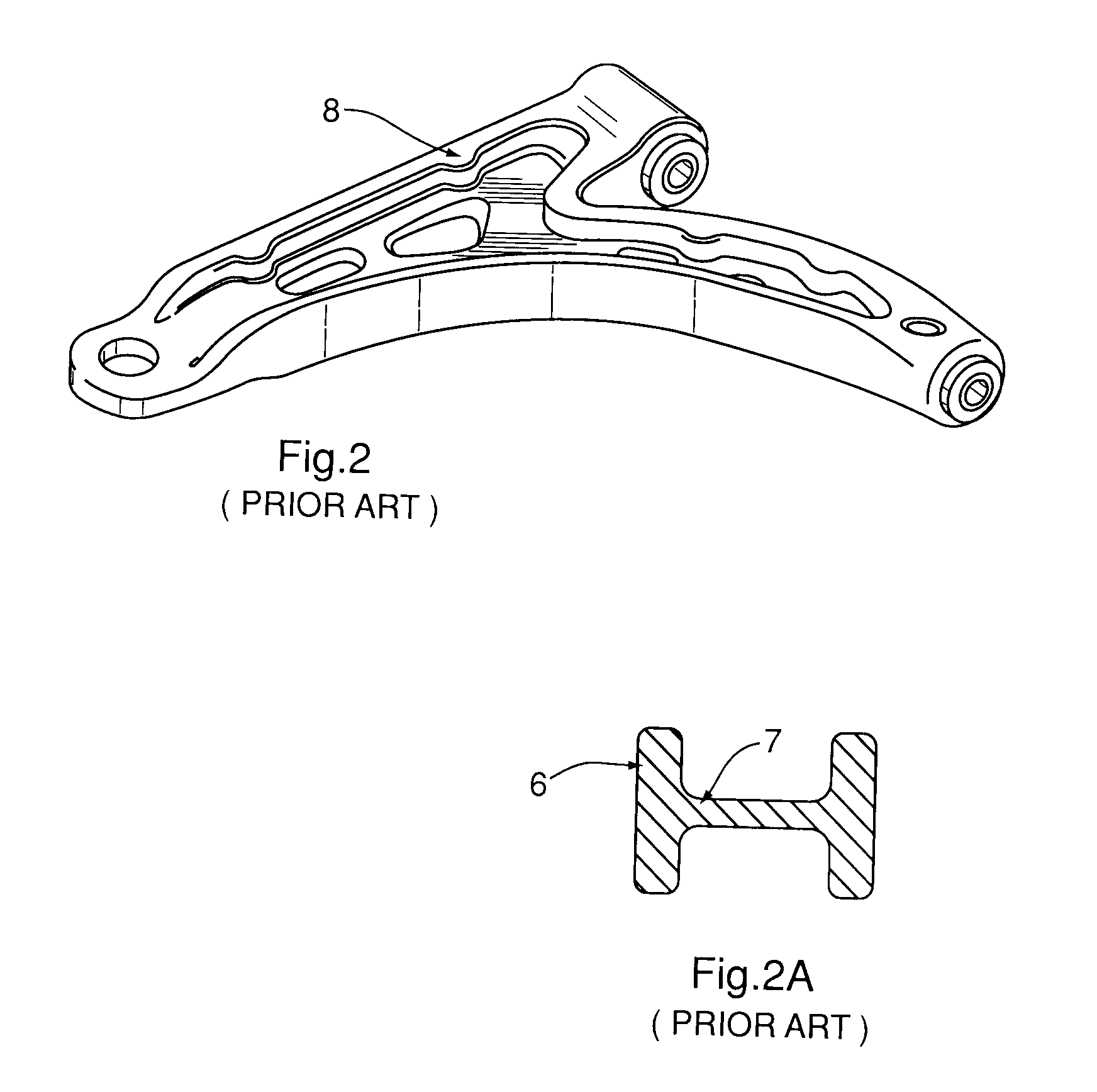

Structural i-beam automotive suspension arm

ActiveUS20100264615A1High inherent stiffness and strengthReduce quality problemsResilient suspensionsPivoted suspension armsControl armI-joist

A structural element comprising a vehicle suspension control arm is constructed from a complex, single piece, sheet metal stamped component formed from a material of uniform thickness. The stamping is configured with the correct plan view shape and formed into an I-beam cross-section comprising a central web portion and two flange portions. The central web portion is configured as a single material thickness and the flange portions comprise upstanding and downstanding closed sections with a continuous double returned segment. The open ends of the sheet metal terminate at or near the central web portion and are welded to the web portion, and in an alternative embodiment also to the continuous double returned segment, to create a favorable structural I-beam section with flange portions twice the thickness of the web portion.

Owner:MULTIMATIC INC

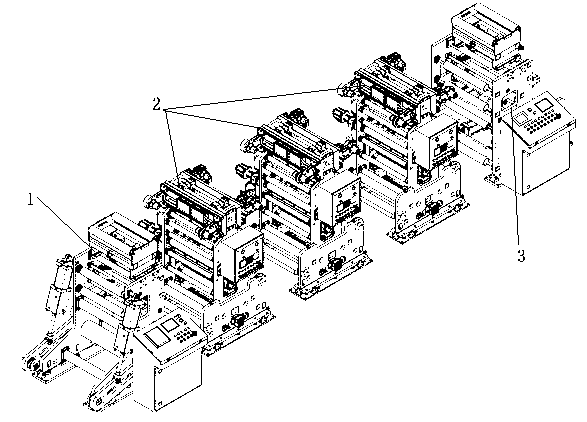

Modular wide hot stamping machine

The invention aims at providing a modular wide hot stamping machine and belongs to the field of printing equipment. According to the hot stamping machine, modular design is adopted, mechanical devices corresponding to different technologies are designed and integrated to be different modules with independent functions; a tipping paper unwinding unit and a tipping paper traction unit are integrated into an unwinding module; a film winding unit, a film unwinding unit, a film traction unit, an automatic registration unit and a gold stamping unit are integrated into a gold stamping module; and a tipping paper winding unit serves as a winding module. The units can be increased or decreased as required to change the existing combination mode in a technology application, mono-color or multicolor gold stamping can be switched quickly on the same gold stamping device, requirements for diversification, scientification, standardization, large scale and short product refresh cycles in the modern gold stamping industry are satisfied, the machine structure is exquisite and compact, accurate technique indicators and energy-saving and consumption-reducing indicators are achieved, and control performances and product quality are streamlined.

Owner:YUNNAN YUXI TIPPING PAPER FACTORY

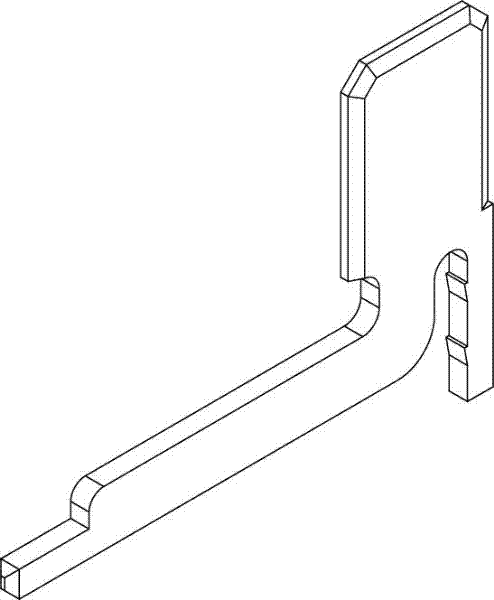

Epoxy bonded laminate door beam

A door intrusion beam is of laminated construction and has a base metal stamping with end flanges, with the base metal stamping being of an inverted generally U-shaped cross section. Slidable and nested on the base metal stamping are a plurality of slidable and stackable elongated plastic elements each having a generally M-shaped configuration. The first plastic element next to the metal stamping and all stackable elongated plastic elements are secured together by layers of adhesives where surfaces contact one another. The plastic elements are of varying length.

Owner:ZOHAR TT ACQUISITION LLC

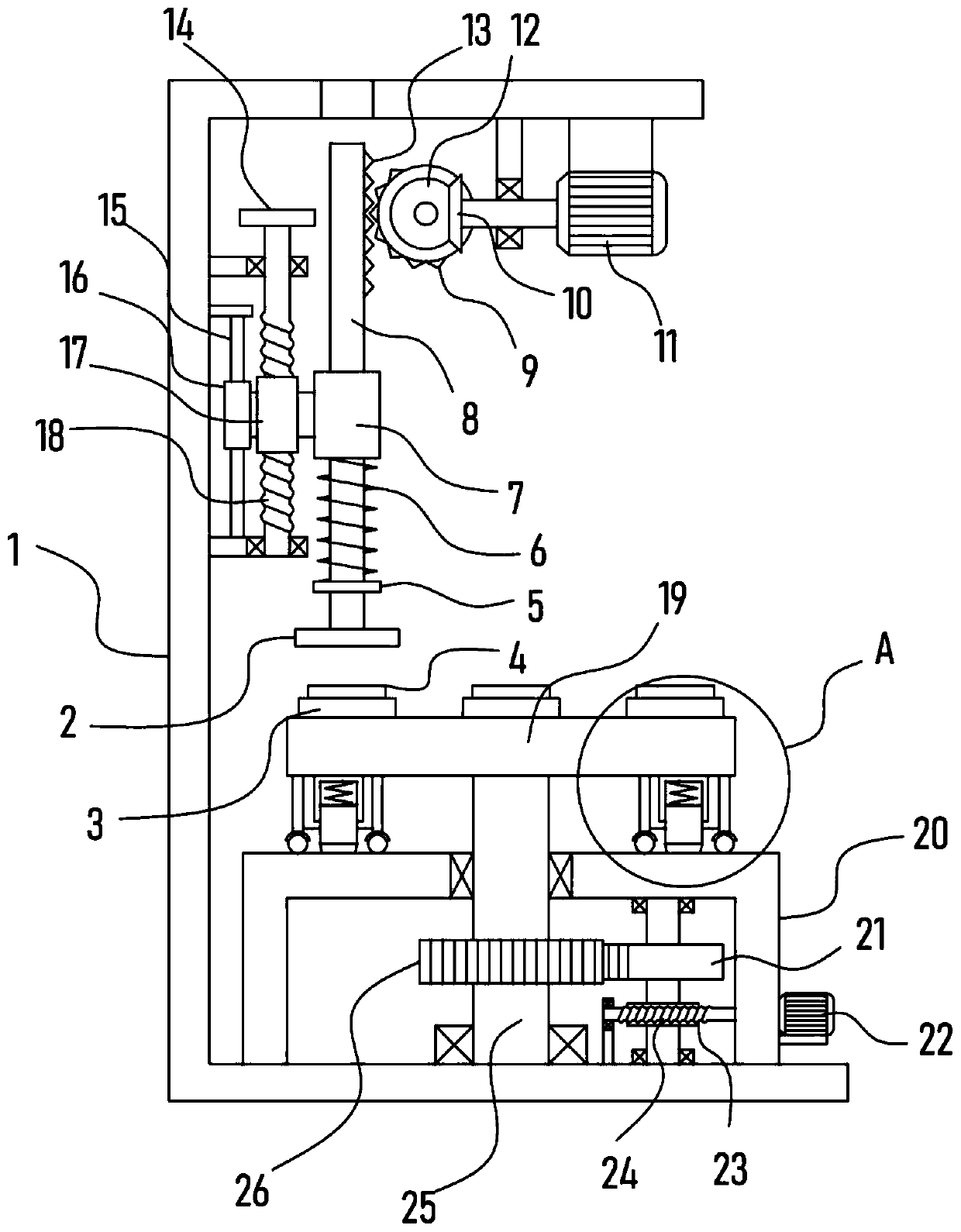

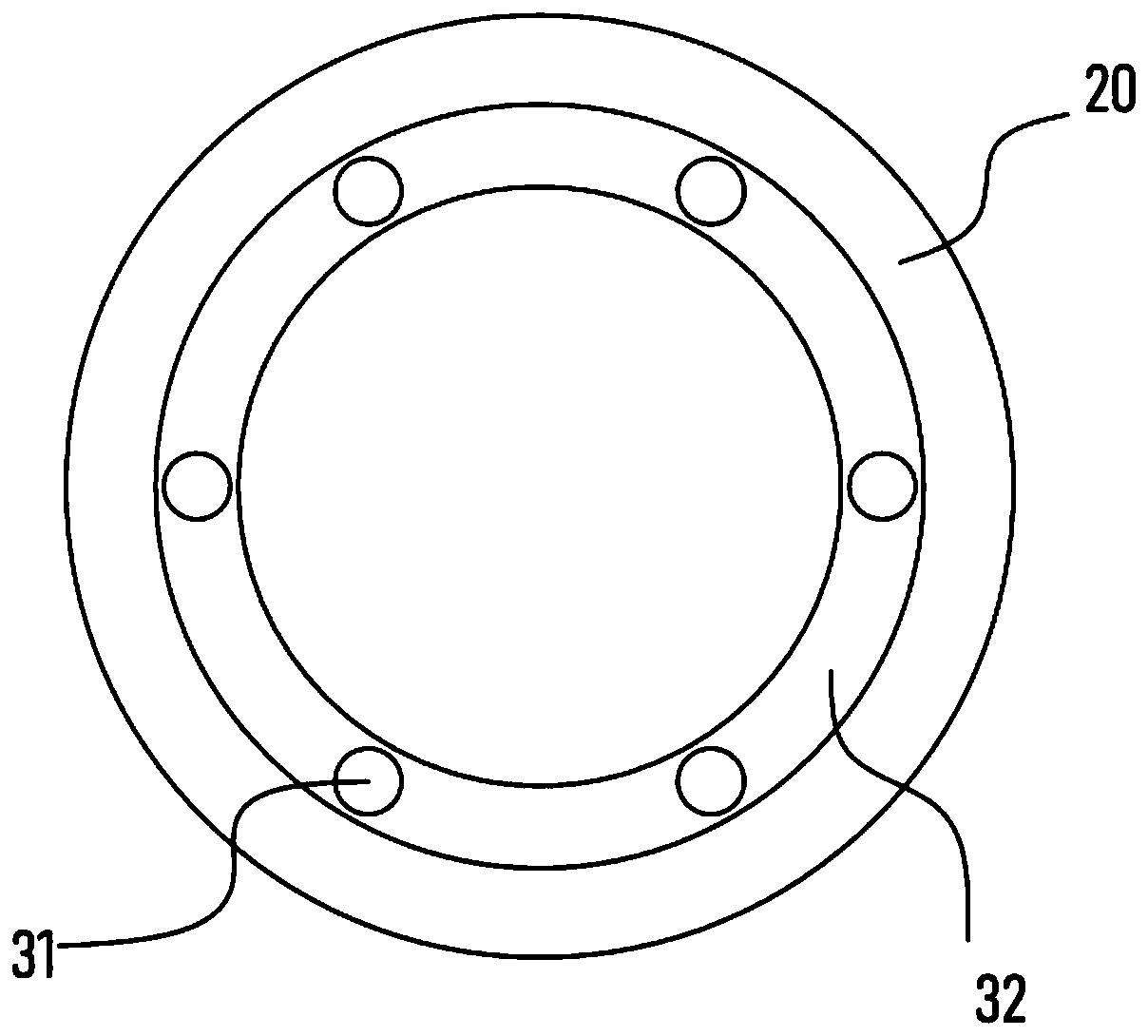

Shell stamping device for machining motor

InactiveCN111496052AImprove stamping efficiencyMetal-working feeding devicesPositioning devicesStampingElectric machinery

The invention discloses a shell stamping device for machining a motor, and relates to the technical field of motor machining. The shell stamping device comprises a supporting frame, an elastic positioning mechanism is arranged between a rotary disc and a fixed frame, a motor I is fixed to the supporting frame, the motor I is in driving connection with a vertical lifting mechanism, upper dies intermittently corresponding to lower dies are connected to the vertical lifting mechanism, and an adjusting mechanism is arranged on the supporting frame. According to the shell stamping device for machining the motor, the vertical lifting mechanism can drive a stamping rod to vertically rise and fall with the upper dies, and the stamping operation of the upper dies on motor shells of the lower dies is realized through elastic force of a spring ring; the adjusting mechanism can adjust the impact force that is the initial length of the spring ring, and sufficient stamping of the motor shells is convenient to realize; and the rotary disc can realize marching type rotation under the driving of a rotation mechanism, so that the motor shells of the multiple lower dies are subjected to stamping operation one by one, and the stamping efficiency of the motor shells is greatly improved.

Owner:黄国普

High-elongation automobile axle housing steel for cold stamping, and production method thereof

The invention provides high-elongation automobile axle housing steel for cold stamping, and a production method thereof. The automobile axle housing steel comprises the following components in percentage by weight: 0.14%-0.17% of C, 0.020%-0.080% of Si, 1.25%-1.65% of Mn, 0.010%-0.065% of Al, 0.025%-0.065% of V, 0.15%-0.25% of Cr, not greater than 0.020% of P, not greater than 0.006% of S, and thebalance Fe and inevitable impurities. The production method comprises the steps of smelting, continuous casting, heating, rolling, cooling and coiling. The steel has high elongation under the tensilestrength of 470MPa, and the elongation A is not less than 40%; and integral forming of stamping can be realized by applying the steel plate, no welding is achieved, and the cost is saved.

Owner:ANGANG STEEL CO LTD

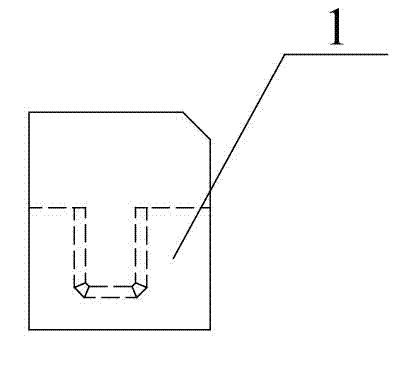

Chamfering die

The invention discloses a chamfering die and relates to a cold stamping die. The chamfering die is designed for solving the problems the step-by-step thinning stamping is mostly adopted for generating chamfer angels against the current various terminal products during the production process, the manual operation is time-consuming and a chamfering machine can easily produce phenomena of scratches and burrs on the surfaces of the products. The chamfering die comprises a male die and a female die which are matched, and the male die and the female die have a chamfering upper die and a chamfering lower die which correspond to the shape of chamfer angle parts of the products. The chamfering die is particularly suitable for die-pressing production of metal parts with chamfer angles at the end parts.

Owner:SUZHOU RISING CREATION PRECISION TOOLS

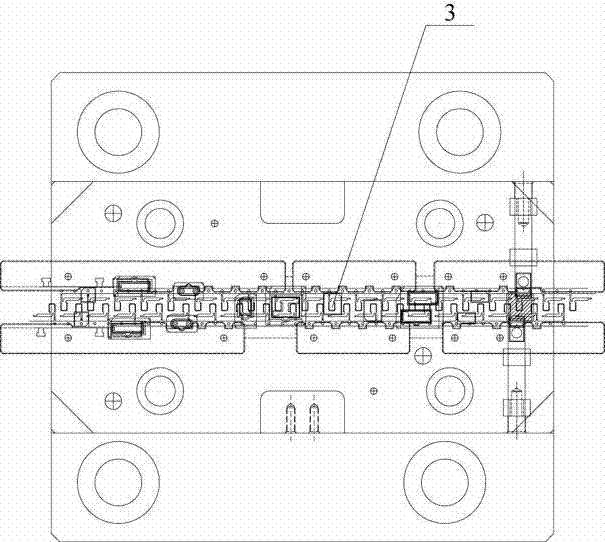

Novel automobile beam forming process and stamping die structure

InactiveCN104209406AReduce wrinklesControlled reboundShaping toolsVehicle componentsStampingEngineering

The invention provides a novel automobile beam forming process and a stamping die structure. The stamping die structure comprises a material pressing core, a material pressing mechanism and a forming and side shaping mechanism. When the stamping die structure works, a workpiece is placed on the material pressing core, the material pressing mechanism makes contact with the workpiece firstly and then presses and fixes the workpiece, and then the forming and side shaping mechanism begins to make contact with the workpiece and works. The forming process includes a blanking procedure, a forming and side shaping procedure and a hole stamping and edge trimming procedure, wherein in the forming and side shaping procedure, wrinkling, cracking, unstability and surface quality of the workpiece are debugged, all profiles are shaped, and resilience of the side wall of the workpiece is controlled; in the hole stamping and edge trimming procedure, hole stamping and edge trimming are carried out on the workpiece. According to the stamping die structure, wrinkles of parts are reduced, resilience of the parts is effectively controlled, beam forming parts do not excessively rely on production equipment any longer, and the production mode that two workpieces can be produced through one die is achieved. By means of the process, an automobile beam can be formed through the three procedures, and production efficiency is improved. The process and the stamping die structure are suitable for production of the automobile beam parts.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Automatic stamping method

InactiveCN102815106AImprove clarityAvoid paper jamsOther printing apparatusStampingStampingComputer printing

The invention discloses an automatic stamp method, comprising the steps of: firstly outputting paper by a printer at the speed of V, and feeding the paper into the paper feeding channel of a stamping machine; then synchronously driving the paper to continue move forwards by a drive mechanism in the paper feeding channel at the speed of V; when the paper is at the position to be stamped, and the position is matched with the position of the stamping mechanism of the stamping machine, stopping the drive mechanism to stop conveying the paper, so that the stamping mechanism can be contacted with the paper, and then stamping; after delaying a segment of time, ending stamping; when the stamping mechanism leaves the paper, restarting the drive mechanism; if stamping is needed on the next position on the same paper, feeding the paper to move forwards by the drive machine at a faster speed of V1, and then stamping at the next position to be stamped; and if the stamping of the same paper ends, feeding the paper to move forwards by the drive mechanism at the speed of V unit the paper is output outside the stamping machine.

Owner:苏州合亚信息技术有限公司

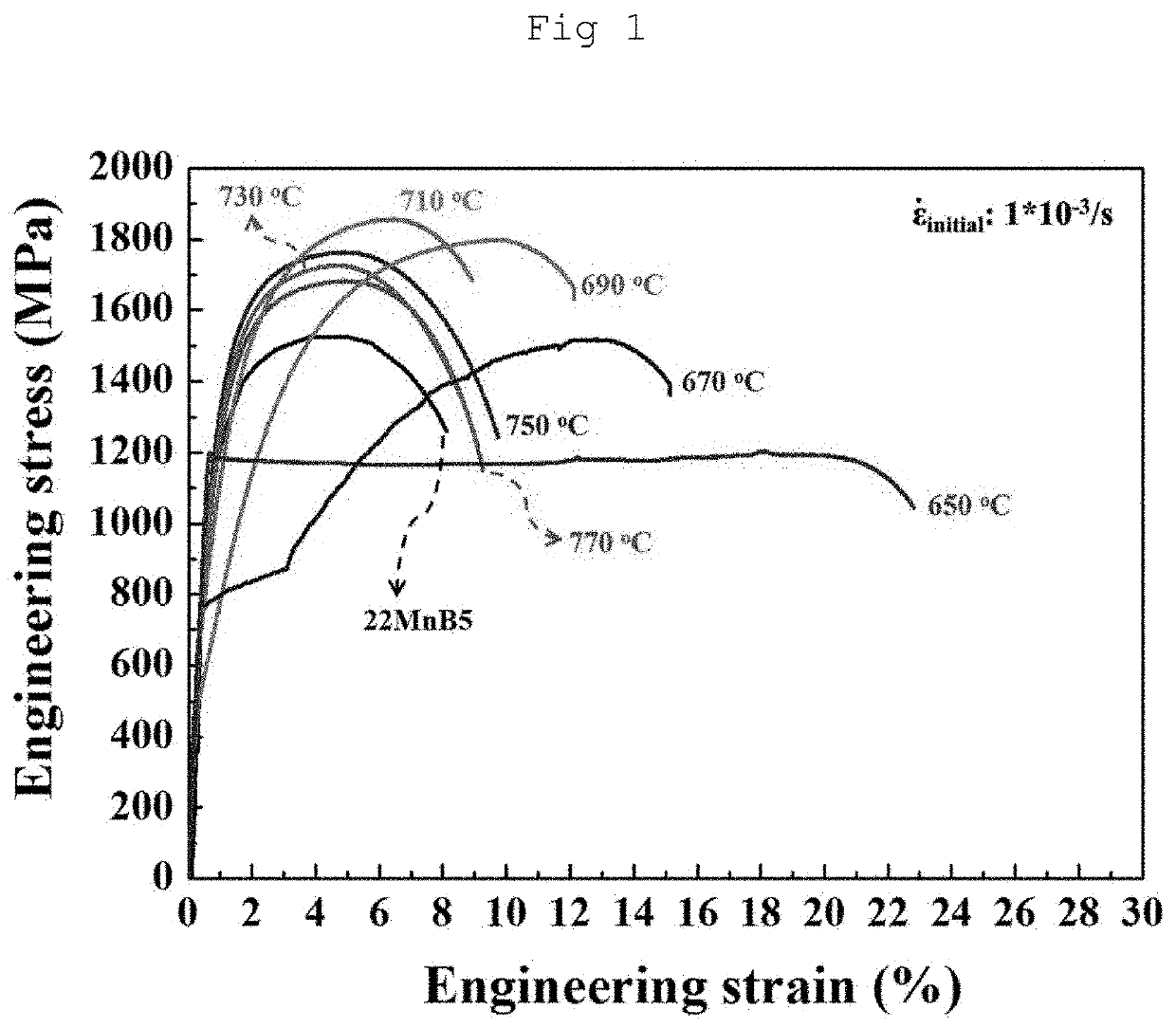

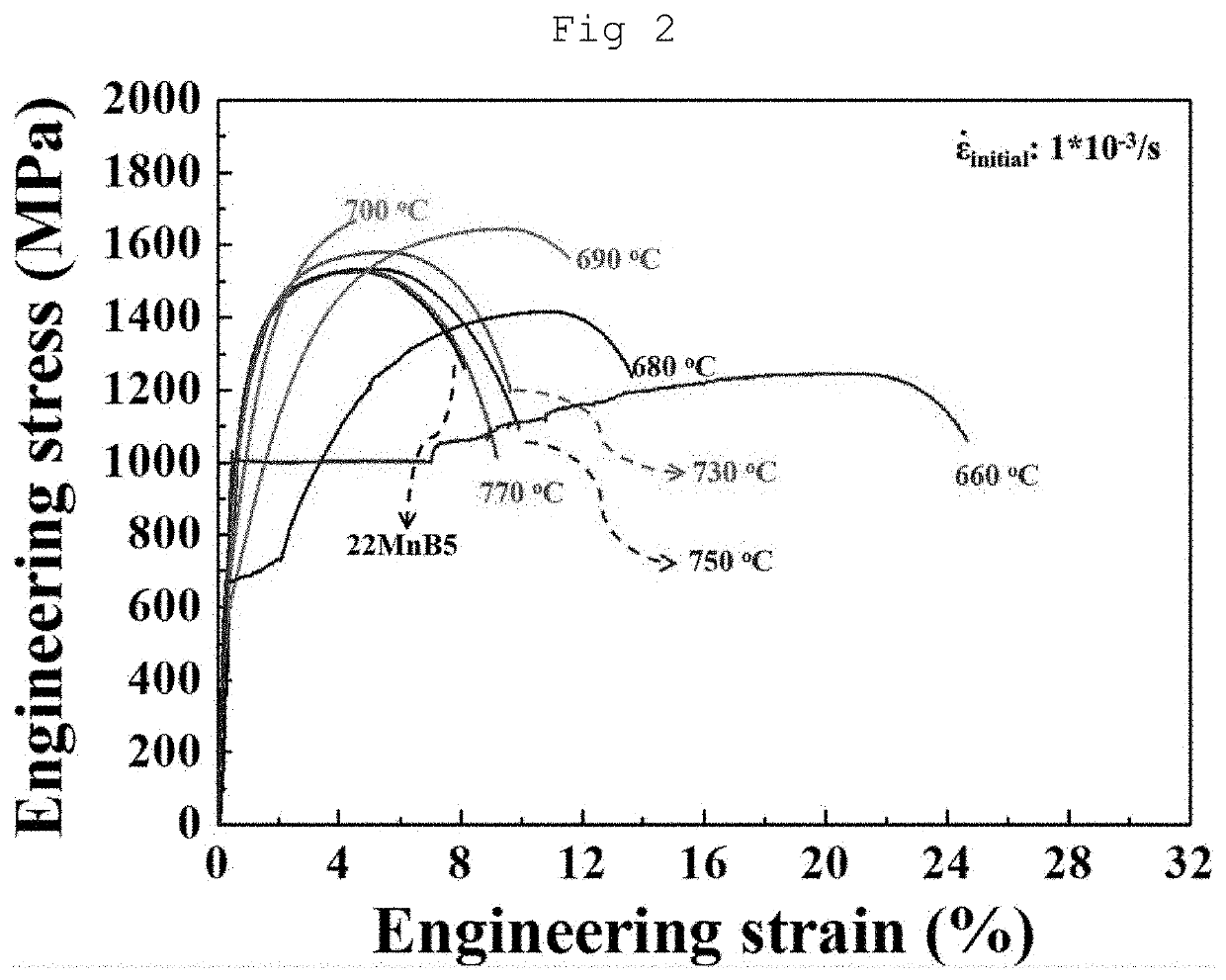

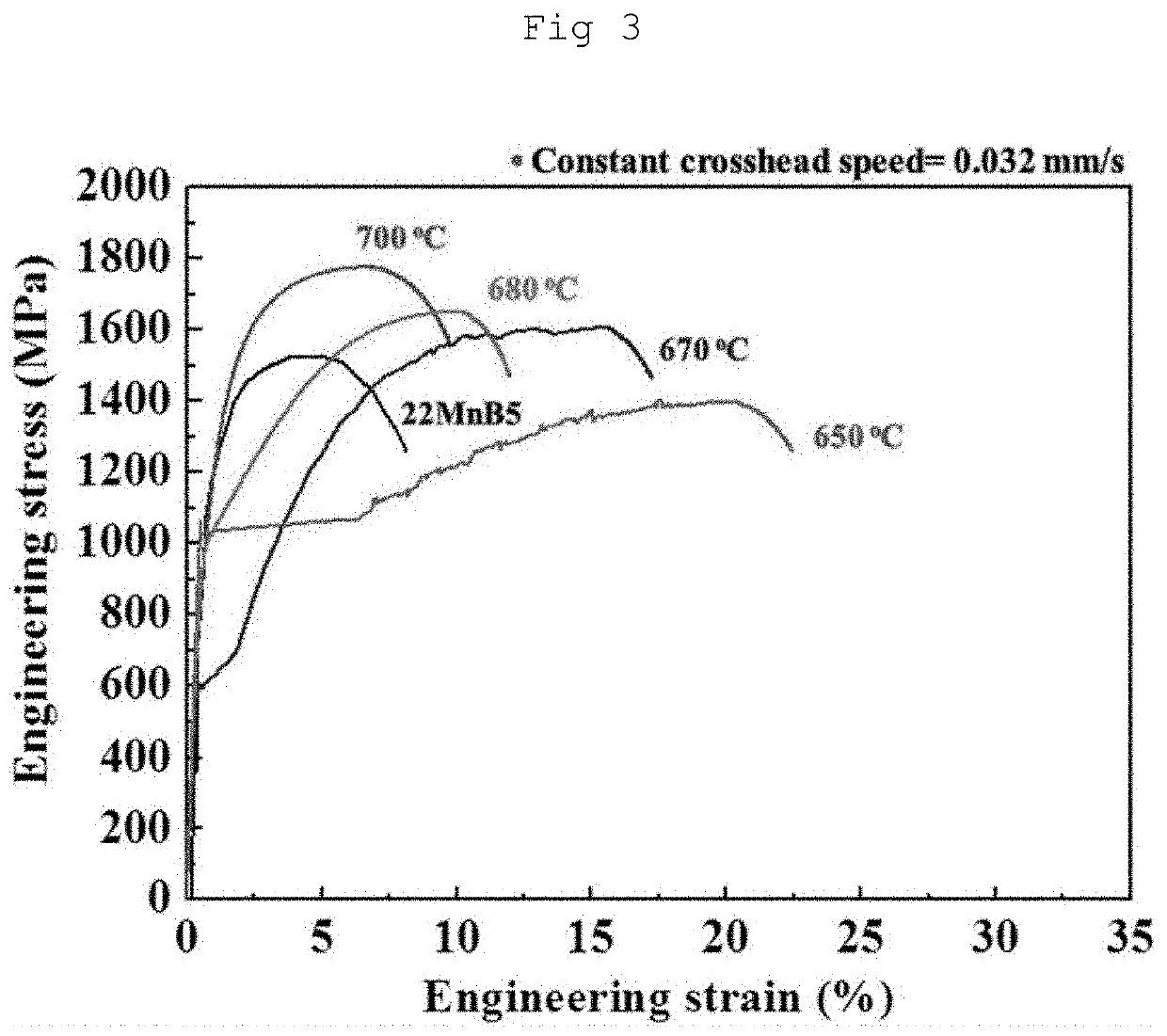

High-strength medium manganese steel for warm stamping and method for manufacturing same

ActiveUS20200354822A1High strengthIncrease heatFurnace typesHeat treatment furnacesHot stampingStamping

The present invention relates to high-strength medium manganese steel for warm stamping, which contains 3-10 wt % of manganese (Mn), 0.05-0.3 wt % of carbon (C), and 0.1-1.0 wt % of silicon (Si) as components thereof, with the balance being iron (Fe) and unavoidably contained impurities. The present invention performs heat treatment at the low austenitizing temperature of medium manganese steel, and thus has the effect of reducing the high thermal energy consumption of the prior art hot stamping process. Furthermore, the present invention does not require an additional temperature process, and can obtain high strength by only slow cooling such as air cooling outside a mold without performing cooling at high rate inside the mold, and thus has the effects of simplifying a process and improving manufacturing efficiency.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

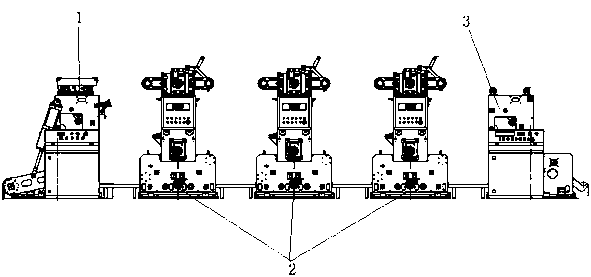

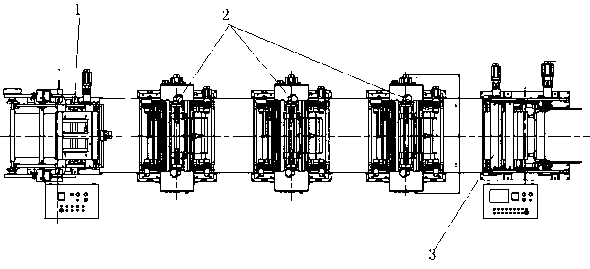

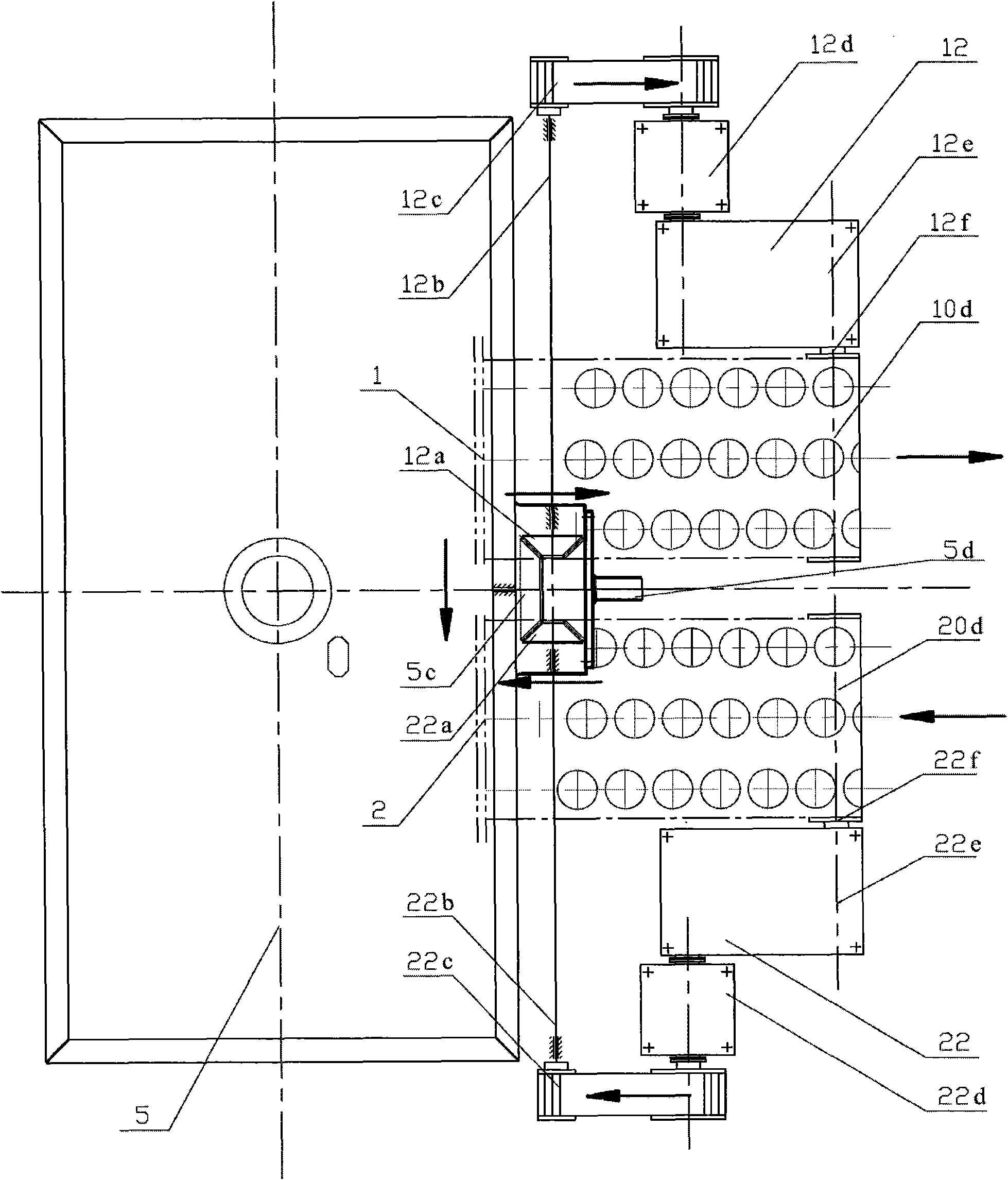

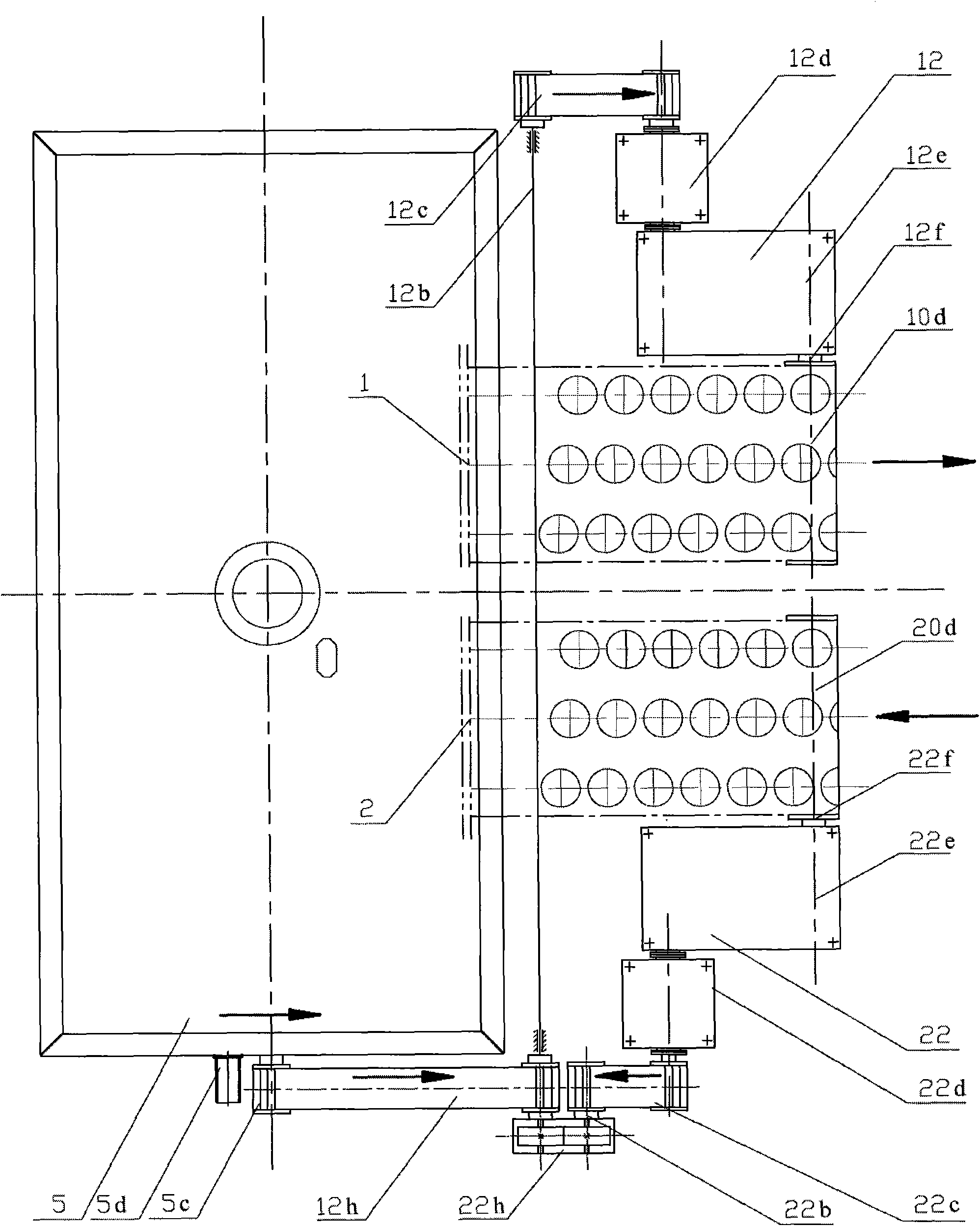

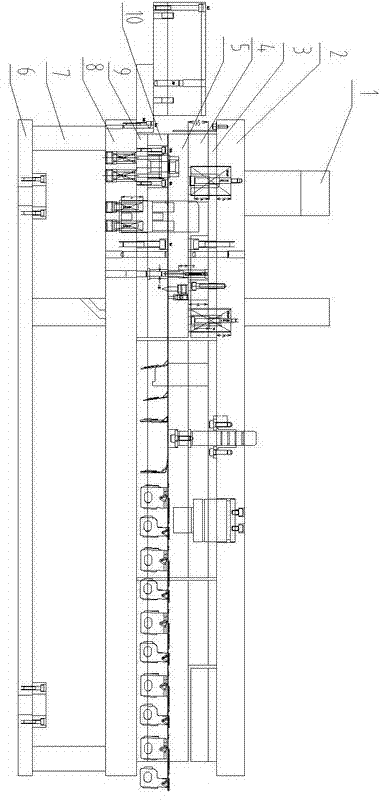

Multi-channel easy-open lid automatic stamping engineering design scheme and production line

InactiveCN101623728ASolve the problem of stamping eccentric loadBreak through the bottleneck limitHollow articlesProduction linePunch press

The invention relates to a multi-channel easy-open lid automatic stamping engineering design scheme and a production line, particularly suitable for constructing a metal easy-open lid automatic stamping production line with 4 channels, 6 channels, 8 channels, 10 channels or more even channels. An easy-open lid stamping channel group A (1) and a channel group B (2) in opposite progressive directions are arranged in parallel on a high-speed punch; the same numbers of forming channels are respectively arranged on the channel group A (1) and the channel group B (2), and the progressive directions of all the forming channels on either channel group are the same. The invention solves the eccentric load problem of easy-open lid stamping, constructs the automatic stamping production line with 6 channels, 8 channels, 10 channels or more even channels on the high-speed punch, decreases the investment cost and manifolds the yield and the quality stability of the single stamping line, wherein the yield of the production line with 6 channels is larger than 3600 pieces / min, the yield of the production line with 8 channels is larger than 4800 pieces / min, and the yield of the production line with 10 channels is larger than 6000 pieces / min.

Owner:温庆普

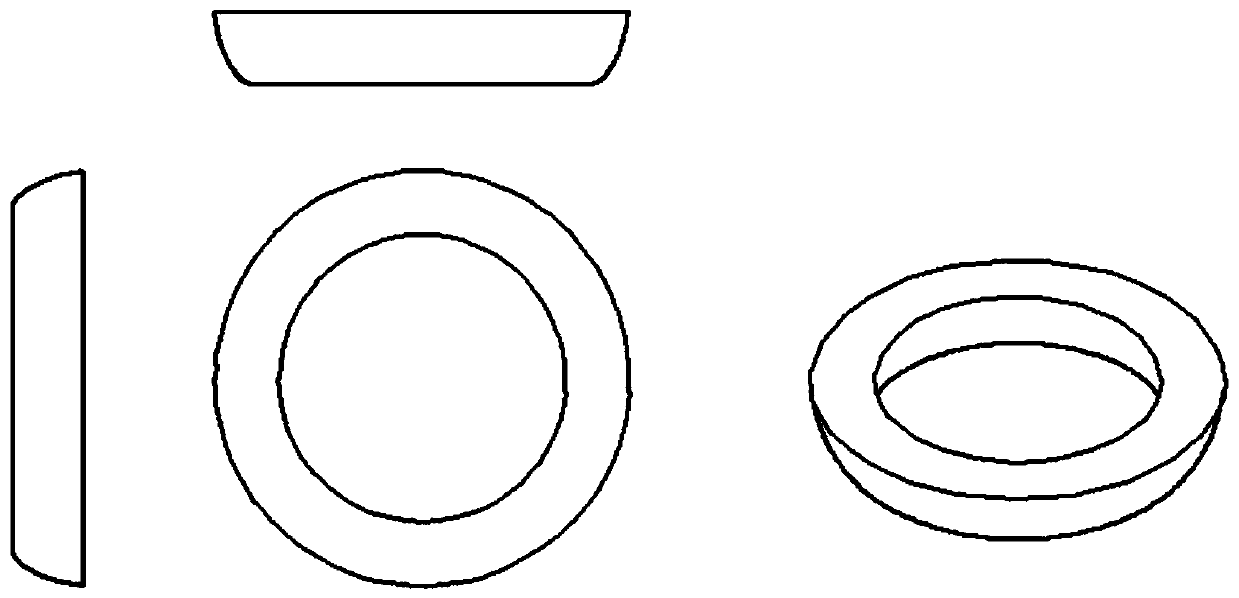

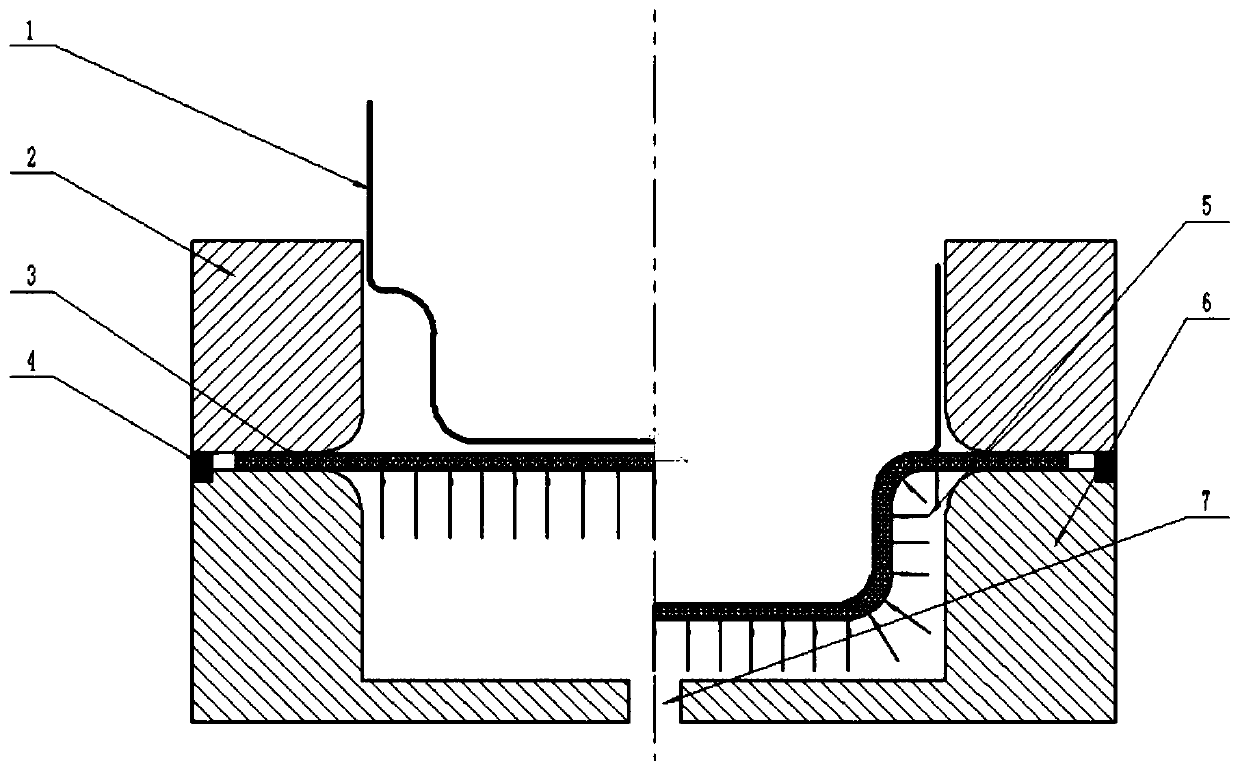

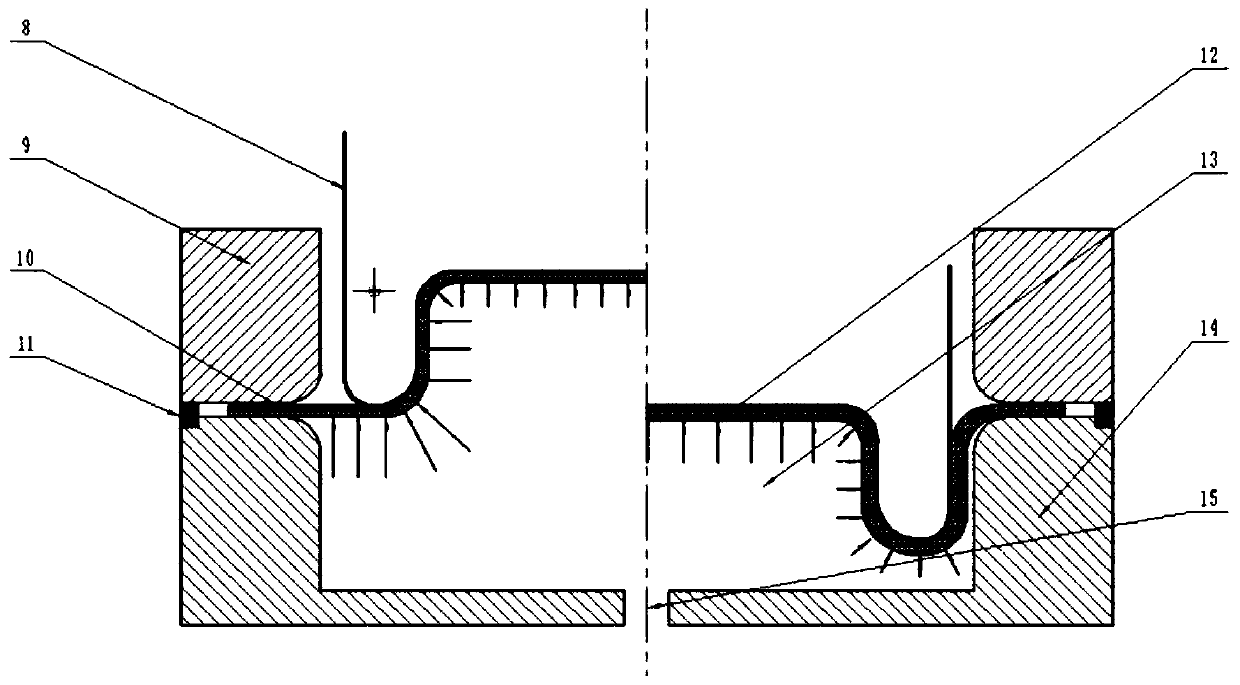

Integral liquid-filling forming method for large annular lip part

The invention provides an integral liquid-filling forming method for a large annular lip part, belongs to the technical field of aviation aerospace sheet metal forming, and can solve the problem thatlarge annular lip parts are difficult to integrally form. The method comprises the steps of design and manufacturing of a transition forming die and a final forming die, selection and debugging of technological parameters, post-processing and the like. According to the method, a novel technology of multi-step liquid-filling forming is carried out on the basis of guaranteeing integral forming of the lip parts; and the integral forming of the lip parts is realized through a two-sequence liquid filling forming process and a one-sequence shaping process. The method has the advantages of being highin forming limit, high in size precision, good in surface quality, low in cost and the like, and can effectively reduce the problems of uneven deformation, thinning or serious wrinkling in local areas, difficult elimination of resilience and the like in a traditional stamping mode, so that the local defects of the lip are reduced and the advantages are remarkable. Meanwhile, the technology can bepopularized to other parts with similar characteristics, and has good development potential.

Owner:BEIHANG UNIV

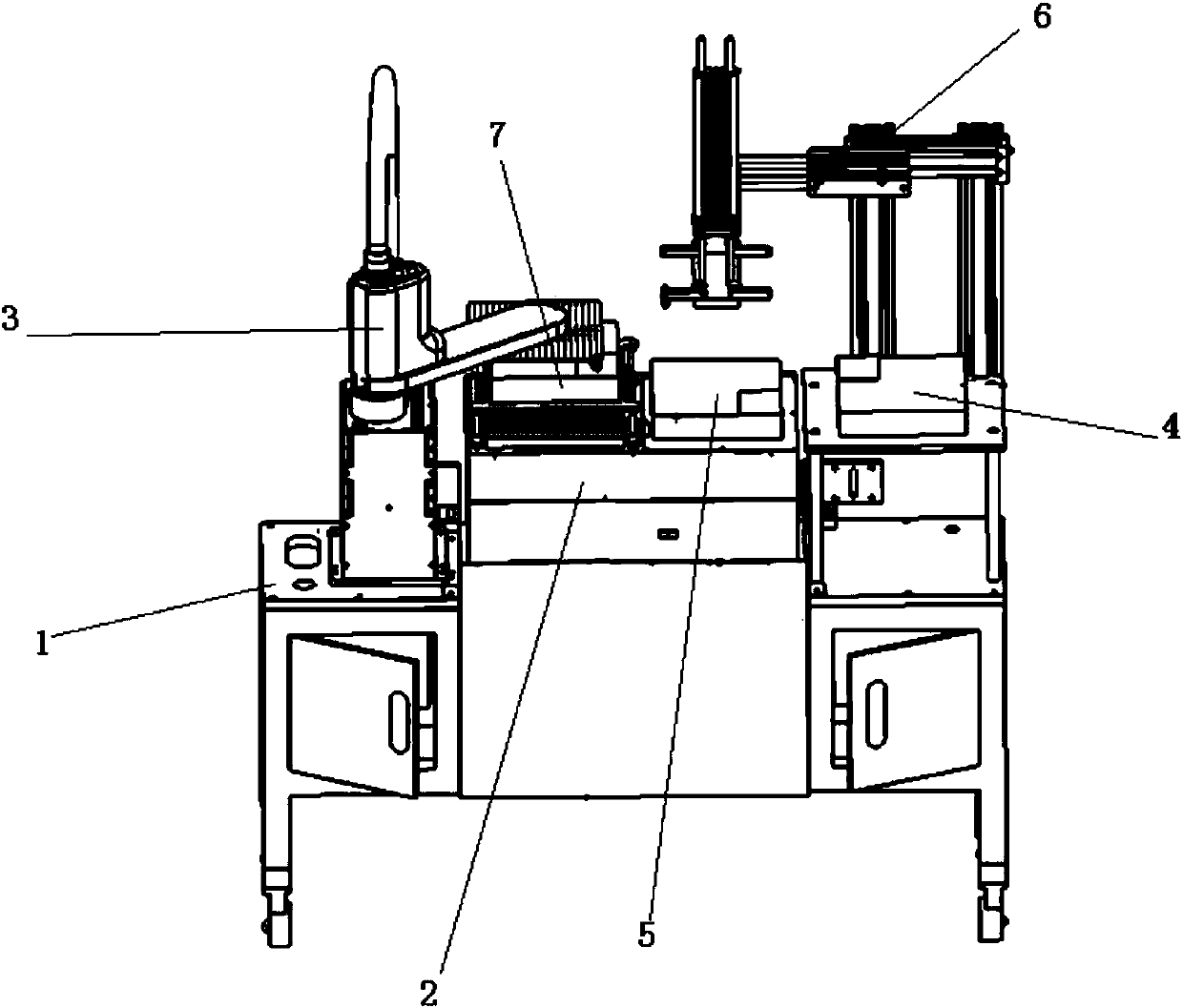

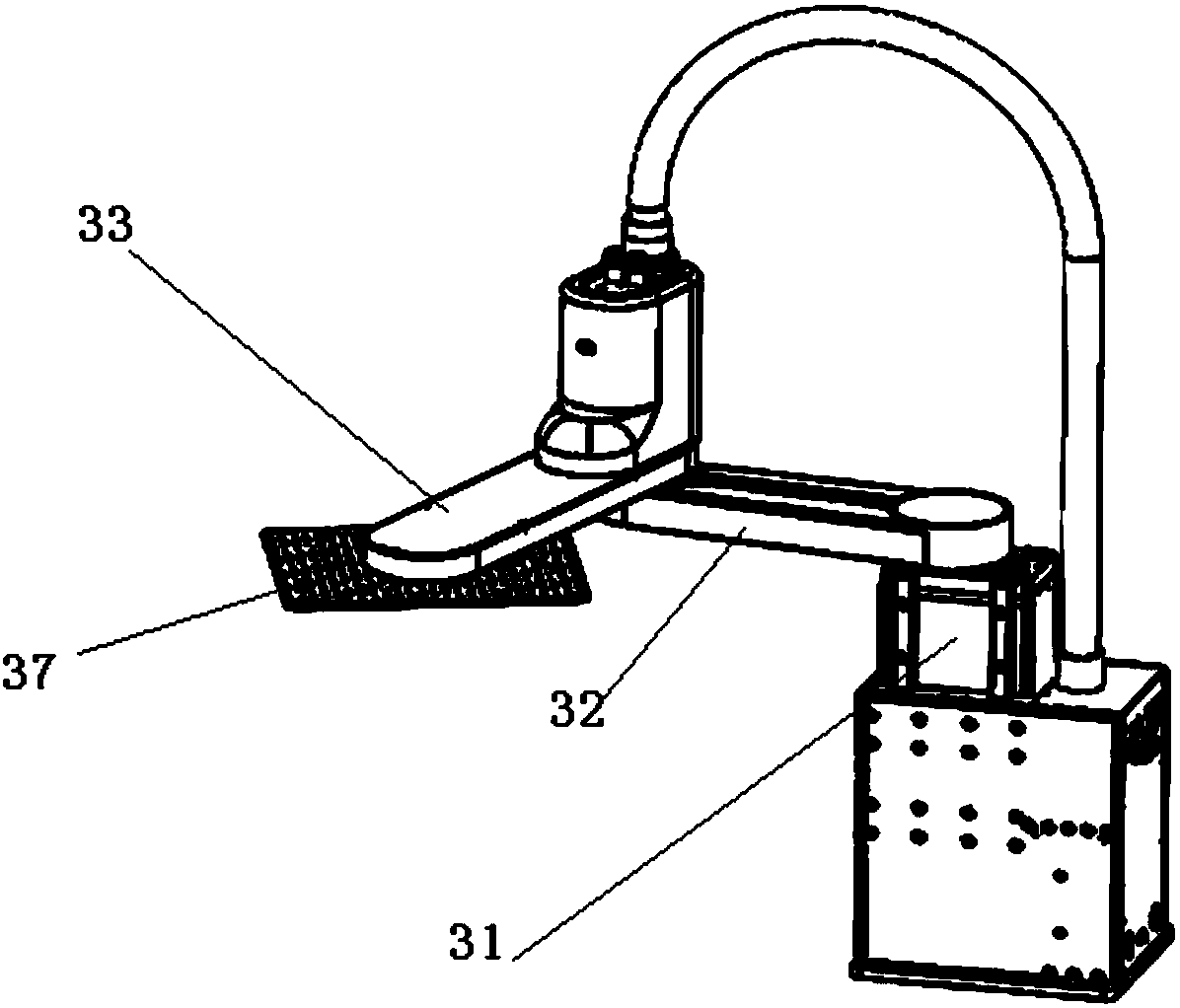

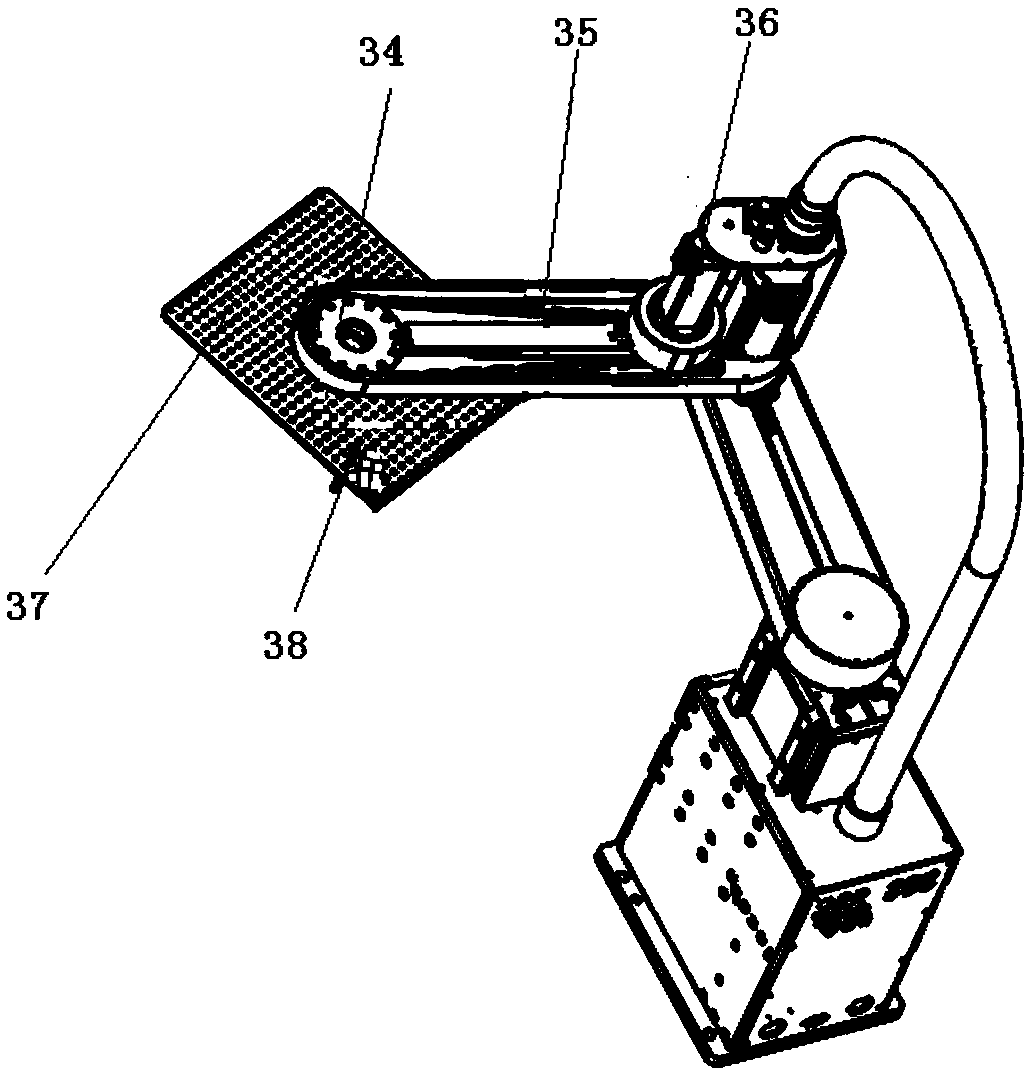

Single-arm robot stamping and carrying apparatus

ActiveCN107801307AGuaranteed positioning accuracyPerfect protection functionProgramme-controlled manipulatorLaminating printed circuit boardsStampingEngineering

The invention discloses a single-arm robot stamping and carrying apparatus. The single-arm robot stamping and carrying apparatus comprise a machine table; a linear lifting platform is arranged in themiddle part of the machine table; a liftable robot carrying apparatus is arranged at one end, positioned on the linear lifting platform, of the machine table; an isolation paper placement plate and anisolation paper carrying apparatus for carrying isolation paper to a finished product placement plate one by one are arranged at the other end, positioned on the linear lifting platform, of the machine table; the finished product placement plate is positioned on the linear lifting platform; and the linear lifting platform is also provided with a supplied material plate structure with a compensating and lifting function. The single-arm robot stamping and carrying apparatus is mainly specific to flexible FPC board stamping and carrying. The apparatus is a four-axis robot with a liftable base; the Z axis of the robot is positioned on the base, so that the robot can walk in the narrow space of upper and lower modules of a punch conveniently; a suction cup is arranged at the tail end of the robot, and a product protection function is added at the suction cup adsorption position; the suction cup is rotatable, so that a secondary stamping function of the symmetrical products can be realizedconveniently; and the four-axis robot with the liftable base is mainly used for material carrying.

Owner:东莞市本润机器人科技股份有限公司

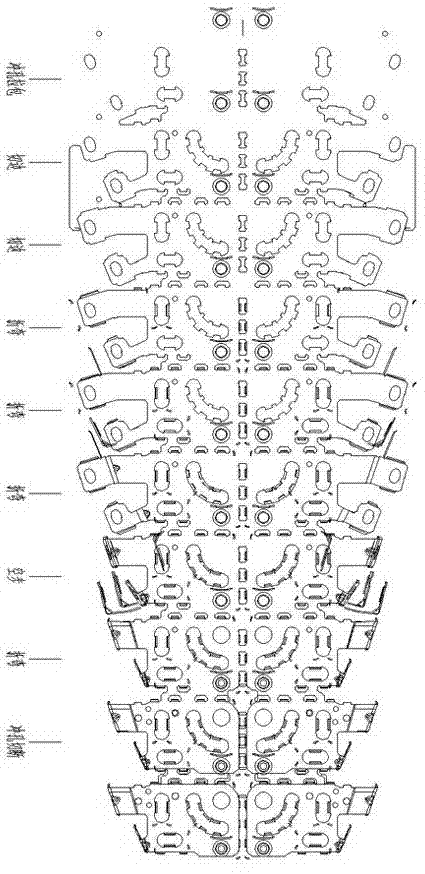

Automobile handrail reinforced left-and-right support continuous die

The invention discloses an automobile handrail reinforced left-and-right support continuous die which comprises a continuous die upper die base and a continuous die lower die base which are used for manufacturing corresponding structures of automobile back row backrest left side plates. The automobile handrail reinforced left-and-right support continuous die is characterized in that a first punching pull pack station, a second edge cutting station, a third edge cutting station, a fourth bending station, a fifth bending station, a sixth bending station, a seventh empty step station, an eighth bending station and a ninth punching cutting station are successively arranged between the continuous die upper die base and the continuous die lower die base, and a conveying device used for conveying a workpiece between the stations is arranged between the continuous die upper die base and the continuous die lower die base. The continuous die provided by the invention is simple in structure, and capable of performing multiple-station continuous stamping.

Owner:ZHEJIANG YAHU AUTO PARTS

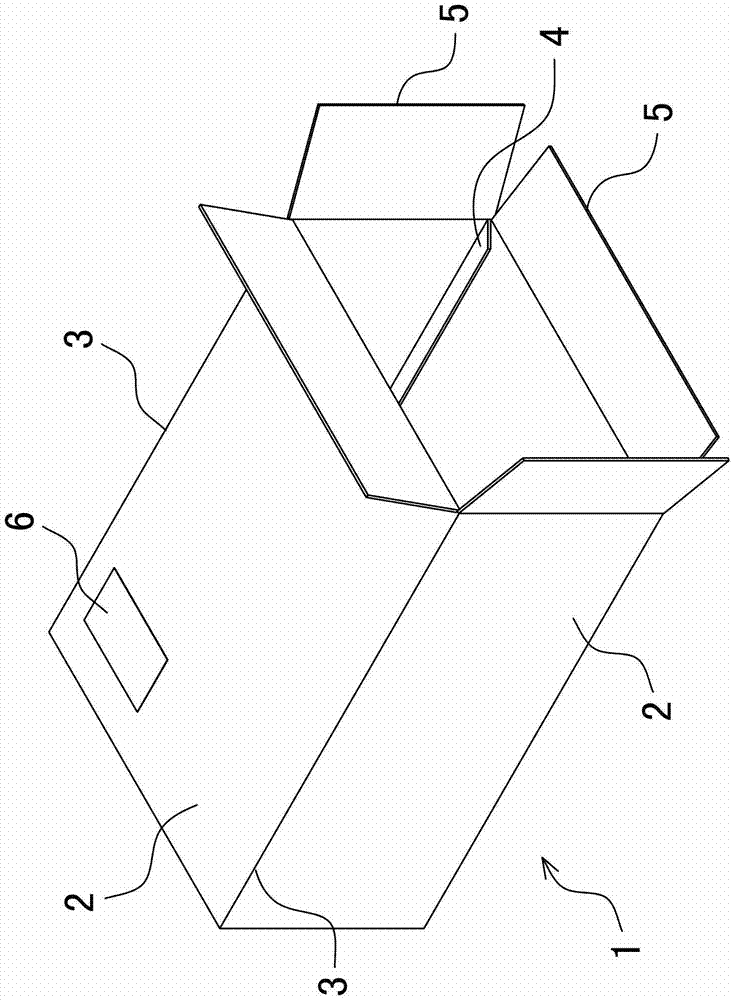

Novel cigarette carton-packaging box and production process thereof

ActiveCN103029882ASolve many deficienciesImprove processing efficiencyRigid containersHollow articlesCartonEngineering

The invention relates to a novel cigarette carton-packaging box and a production process thereof. The cigarette carton-packaging box comprises a box body, which is composed of four side panels. The cigarette carton-packaging box is characterized in that: a planar plate is folded to form the box body, so that the box body has three folds, and the four side panels are defined by the three folds; the two sides of the planar plate, which can be fixedly connected to form the box body, are provided with raised weldable parts, and the weldable parts are welded to fix the head and tail side panels of the box body, so that the whole box body is formed; the non-connected edges on the planar plate are closed and thereby have closed structures; and the production process includes five steps, i.e. cutting, edge stamping, line stamping, folding and welding. The invention solves a lot of defects existing in edge cutting under the open state of a packaging box in the past, and has the advantages of high machining efficiency, low cost, high yield and the like.

Owner:苏州中集良才科技有限公司

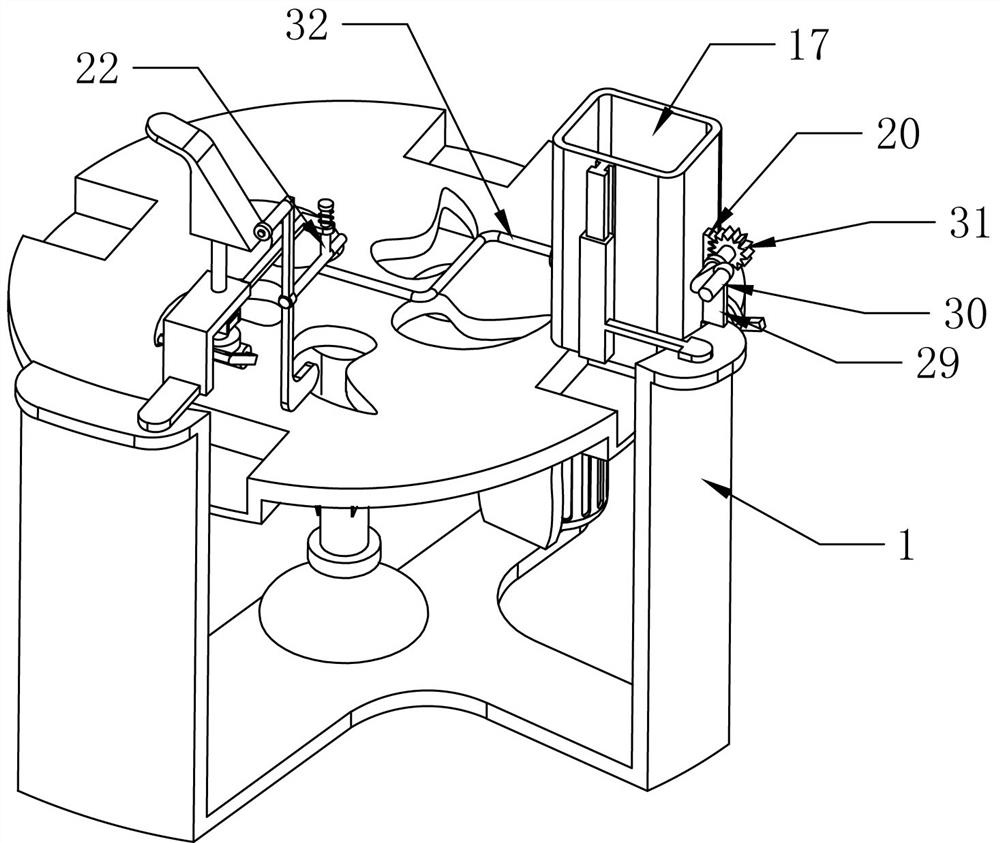

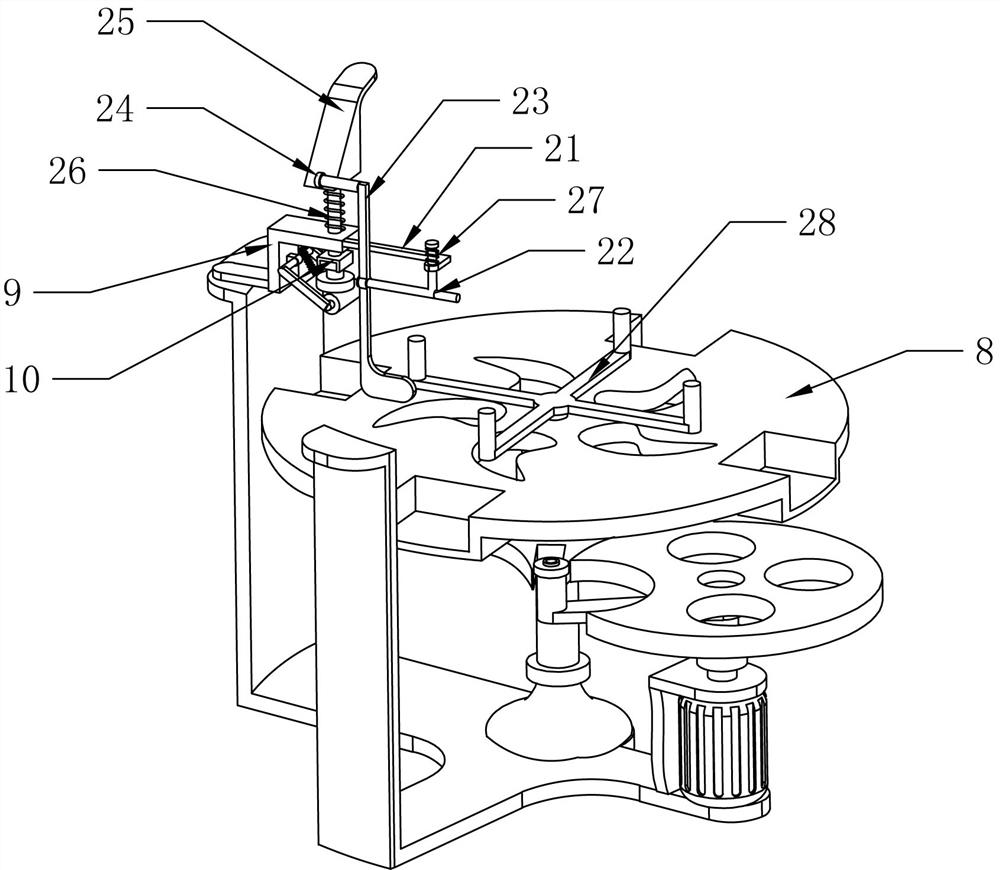

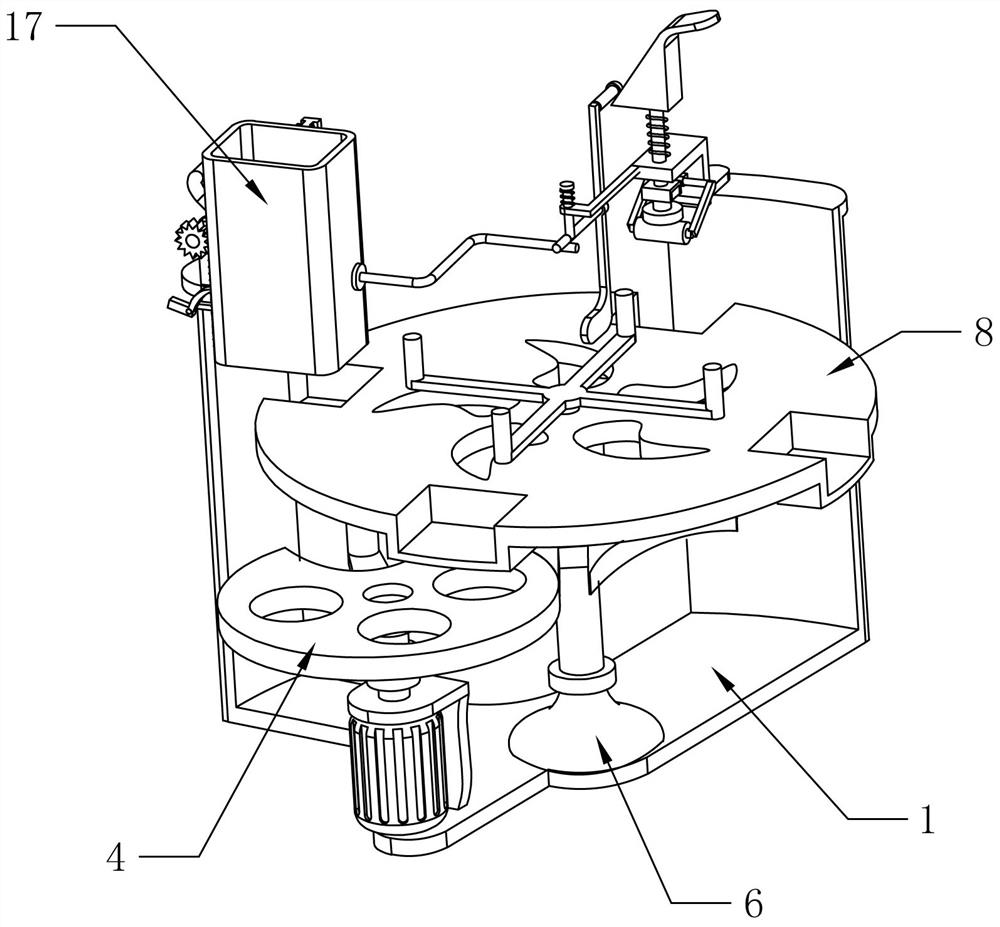

Rotary type multi-specification medicine box stamping device

The invention relates to a stamping device, in particular to a rotary type multi-specification medicine box stamping device. The technical problem to be solved by the invention is to provide a small-size rotary multi-specification medicine box stamping device capable of stamping in batches. In order to achieve the technical purpose, the rotary type multi-specification medicine box stamping devicecomprises a rack, a rotary disc mechanism, a stamping mechanism and a discharging mechanism, the rack is provided with two integrated right-angle L shapes including the L1 shape and the L2 shape, therotary disc mechanism is arranged on the rack, the stamping mechanism is arranged on the rack, located at the top end of the L1 shape and used for stamping the medicine box, and the discharging mechanism is arranged on the rack, located at the top end of the L2 shape and used for containing the medicine box. According to the device, full-automatic stamping work can be carried out, the medicine boxes are placed in a containing box, the full-automatic stamping function can be achieved by starting a motor, manual next-step operation is not needed, simpleness and convenience are achieved, batch stamping can be achieved, and manpower is saved.

Owner:郑泽林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com