Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4134results about How to "Wear-resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser-cladding high-entropy alloy powder and preparation method of high-entropy alloy coating

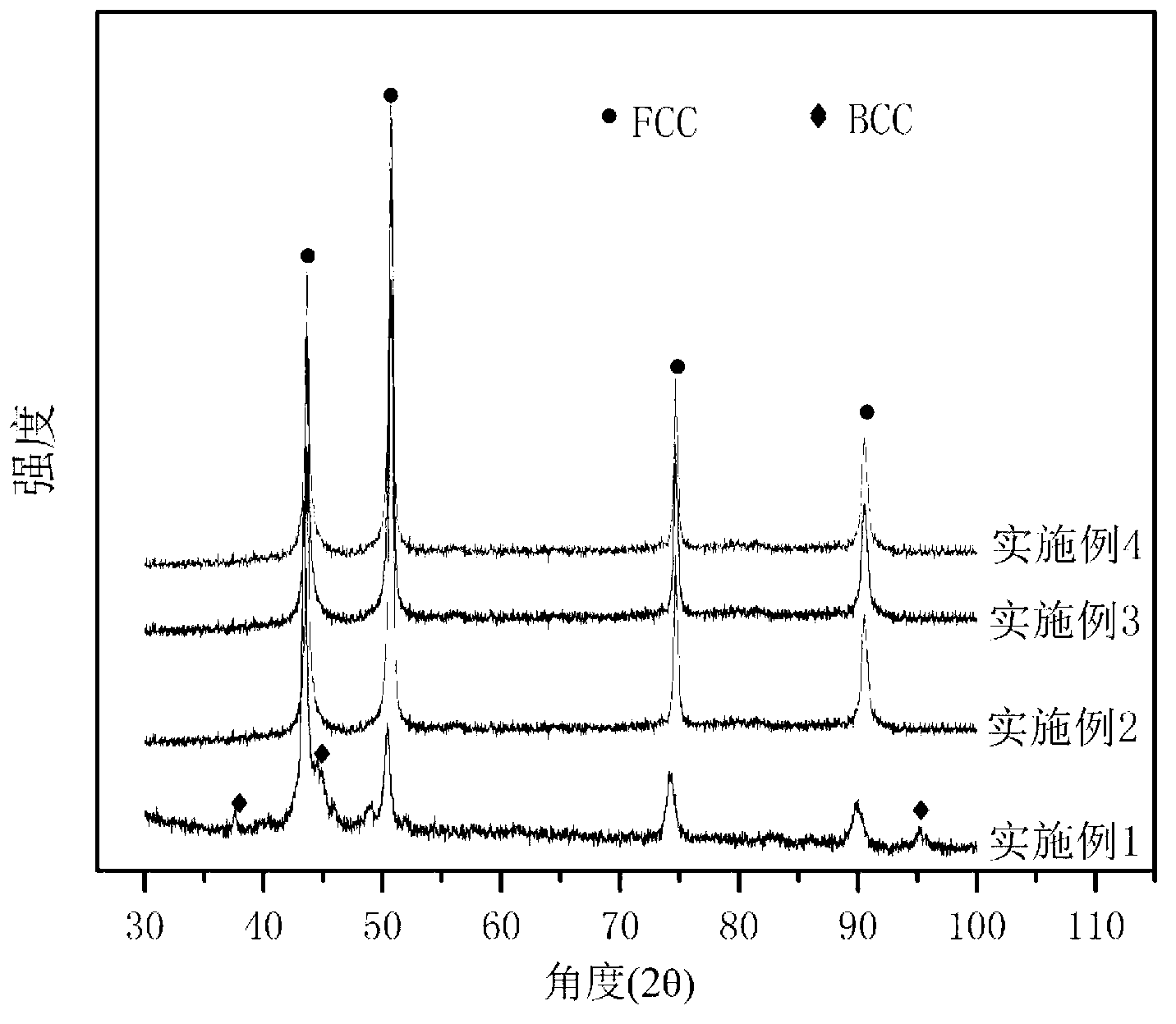

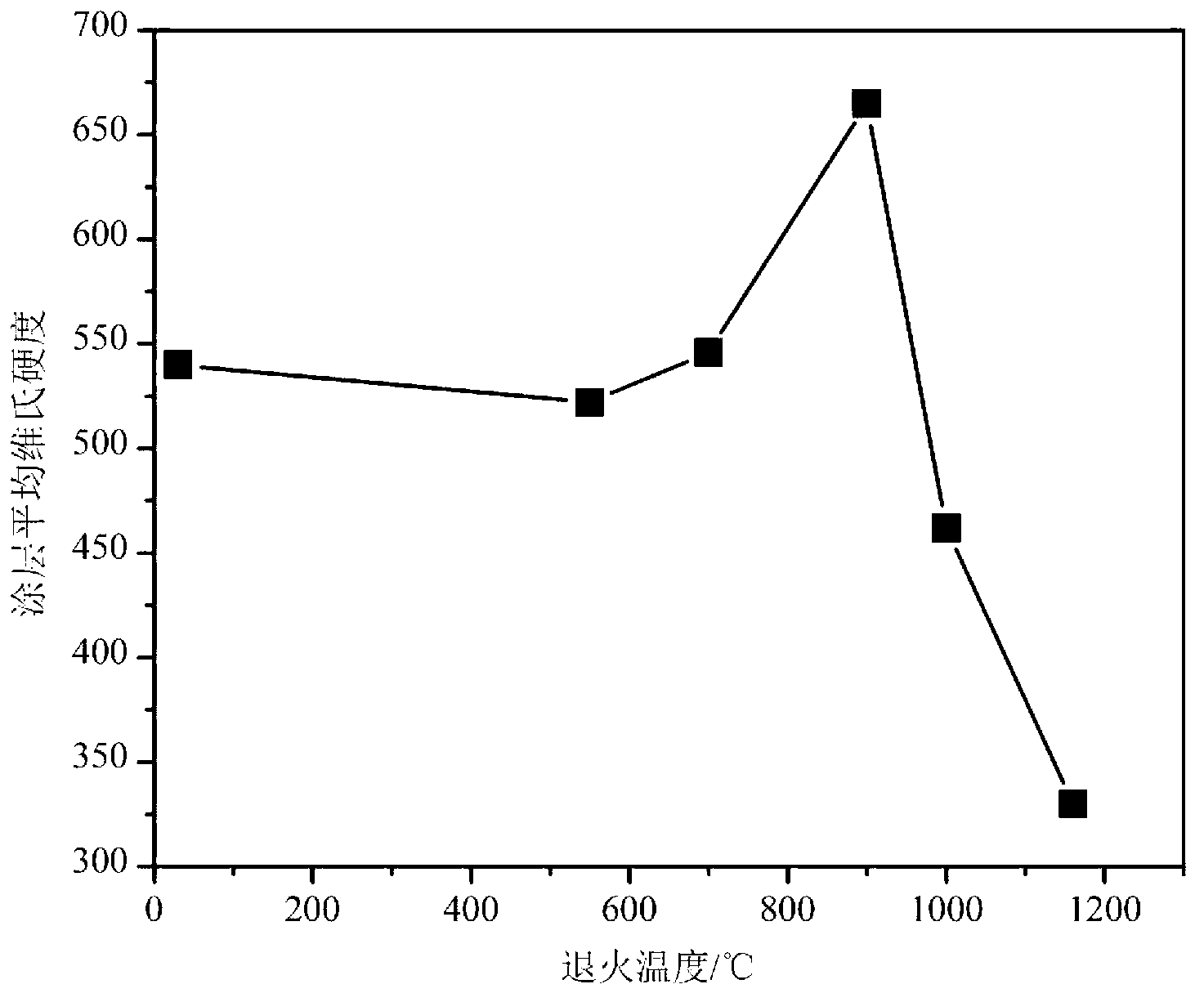

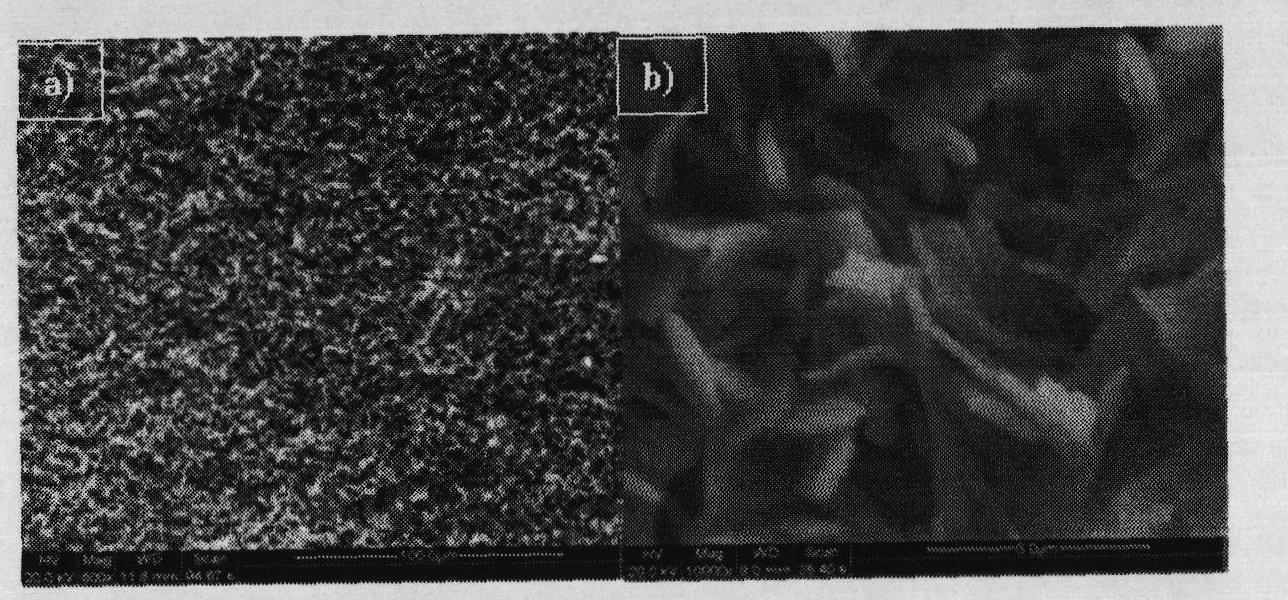

ActiveCN103290404AImprove coating qualityHigh hardnessMetallic material coating processesHigh entropy alloysOperability

The invention discloses laser-cladding high-entropy alloy powder. The laser-cladding high-entropy alloy powder comprises the following elements in percentage by weight: 10%-15% of Fe, 14%-17% of Cr, 22%-25% of Ni, 22%-24% of Co, 22%-24% of Mn, 0%-4% of Si and 0%-4% of B. The invention further discloses a scheme of adding another element Al based on the gradients of the scheme, and a method for preparing a high-entropy alloy coating by using the laser-cladding high-entropy alloy powder. According to the technical scheme, after laser cladding, good coating quality is realized; a phase structure of the coating retains peculiar solid solution structure of high-entropy alloy, and the atomic percent of each main metal element in the cladding coating satisfies nominal category of the high-entropy alloy; the coating has a plurality of excellent performances of high rigidity, high temperature resistance, wear resistance, corrosion resistance and the like; the technical repeatability and operability are both greatly improved, so that the high-entropy alloy is popularized and applied in surface modification of laser materials.

Owner:ZHEJIANG UNIV OF TECH +1

Super-hydrophobic polyurethane/ oxide nano particle hybrid coating material and preparation method thereof

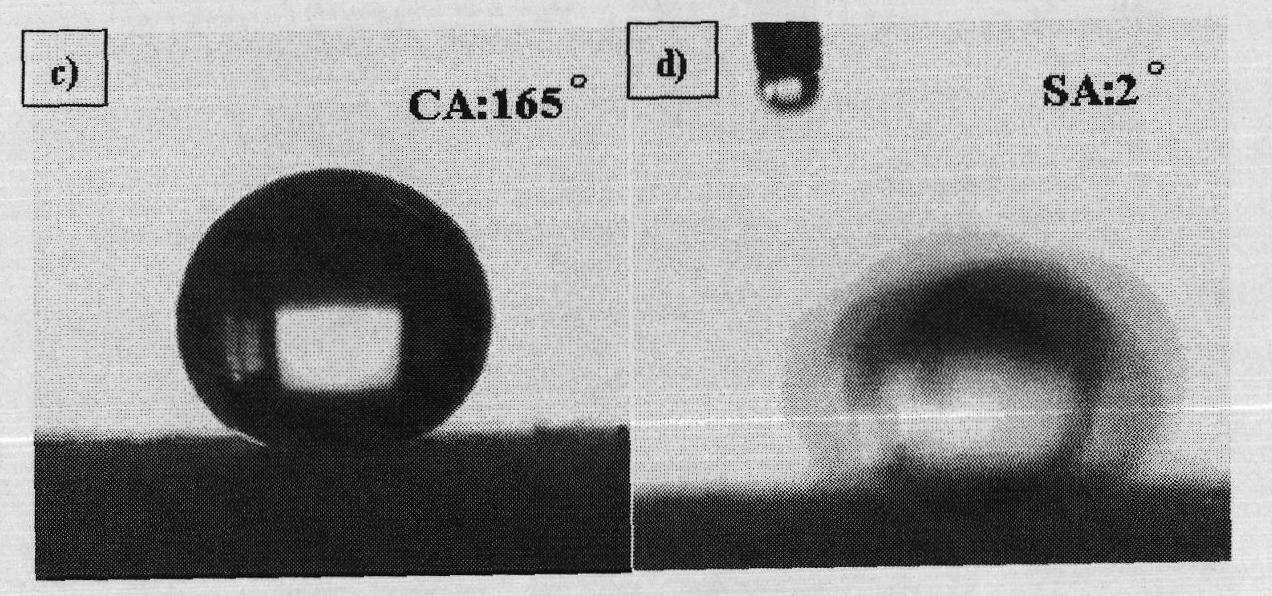

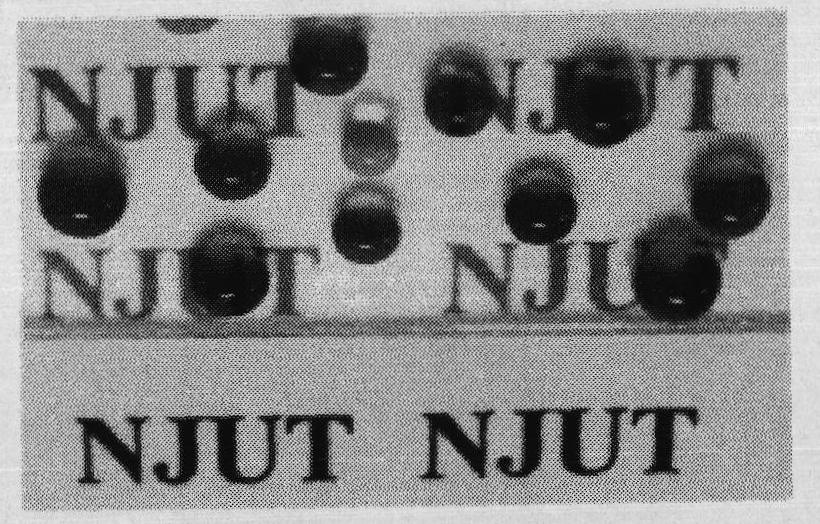

ActiveCN101838496ALow costSimple equipment and preparation processPolyurea/polyurethane coatingsSurface energySelf-assembly

The invention relates to a super-hydrophobic polyurethane / oxide nano particle hybrid coating and a preparation method thereof. The super-hydrophobic coating is prepared by oxide nano particles, silane coupling agent and polyurethane which have wide material source and are easily obtained through a self-assembly method, and has the contact angle of 140-168 degrees and the rolling angle of 1-20 degrees as well as good visible light permeability. The invention solves the problems that the currently prepared transparent super-hydrophobic coating needs extremely low surface energy perfluorinated silane modification, has high production cost and complicated technique, and can not realize large-scale production. The method has simple technique, easily obtained raw material and low cost; and theprepared super-hydrophobic coating can be taken as a dustproof and antifogging protective coating of the surface of solids such as glass and the like, and a waterproof insulating layer used in a micro-electronic device, a sensor and the like.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

Anti-icing and abrasion-resistant coating suitable for blades of wind driven generator

ActiveCN102031057AWith anti-icing effectWear-resistantPolyurea/polyurethane coatingsWind drivenIsocyanate

The invention discloses an anti-icing and abrasion-resistant coating for blades of a wind driven generator. The coating at least comprises two following components of: polyurethane resin and a solid additive with the anti-icing property and 3-15% by mass of the polyurethane resin. For the solid additive, the range of dielectric constant is 1 to 4, the range particle diameter is 0.5 micron to 200 microns, and the range of density is 0.8g / cm<3> to 4g / m<3>. The polyurethane resin consists of an A component and a B component by the reaction, wherein the A component at least comprises aliphatic isocyanate or aliphatic isocyanate derivates or aliphatic isocyanate polymer, and the B component at least comprises hydroxylated acrylic resin or polyester polyol or polyether polyol or polyaspartic ester or micro-molecule polyol chain extender. The invention has the anti-icing property and abrasion resistance at the same time, the adhesion force of the coating and the ice is smaller than 300N, and the abrasion is lower than 50mg; therefore, the invention is suitable for the protective coating materials of the blades of the wind driven generator.

Owner:上海康达新材料科技有限公司

Explosion-proof energy-absorbing polyurea elastic coating and preparation method thereof

InactiveCN104497823AImprove the protective effectHigh strengthAnti-corrosive paintsPolyurea/polyurethane coatingsShock wavePolyol

The invention discloses an explosion-proof energy-absorbing polyurea elastic coating and a preparation method thereof. The explosion-proof energy-absorbing polyurea elastic coating comprises an ingredient A and an ingredient B. The ingredient A comprises, by weight, 40-80 parts of isocyanate, 15-35 parts of polyether polyol, 0-10 parts of a chain extender and 5-15 parts of a diluent. The ingredient B comprises, by weight, 40-80 parts of amine-terminated polyether, 20-40 parts of an amine chain extender, 0-10 parts of a filler and 0-10 parts of an auxiliary agent. The invention discloses the preparation method of the explosion-proof energy-absorbing polyurea elastic coating. A coating layer obtained by spray-coating of the explosion-proof energy-absorbing polyurea elastic coating has ultrahigh strength and good flexibility, can effectively resist explosive shock wave and fragments and is especially suitable for being used as a weapon equipment composite armour and a protective coating of military facility.

Owner:SHANGHAI ORIENTAL YUHONG WATERPROOF TECH

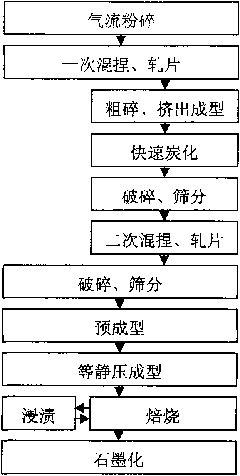

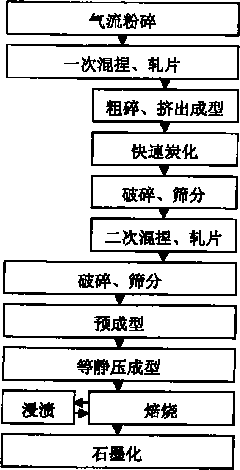

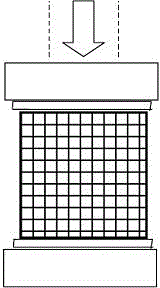

Technical method for producing isostatic pressure graphite

The invention provides a technical method for producing isostatic pressure graphite, which comprises the following steps: using refinery coke or pitch coke as raw materials; crushing raw materials to 5 to 20 mum through airflows; then, carrying out treatment through work procedures such as primary mixing squeezing and sheet milling, extrusion forming, fast carbonization, crushing, sieving, secondary mixing squeezing and sheet milling, crushing, sieving, pre-forming, isostatic pressure forming, calcination, impregnating, graphitization and the like; and obtaining fine particle isostatic pressure isotropical graphite materials. Compared with traditional coarse particle graphite materials, the invention has the characteristics of fine and compact structure, good uniformity, excellent mechanical property, isotropy and the like, and is particularly suitable for the production of large-specification graphite products.

Owner:SICHUAN GUANGHAN SHIDA CARBON +1

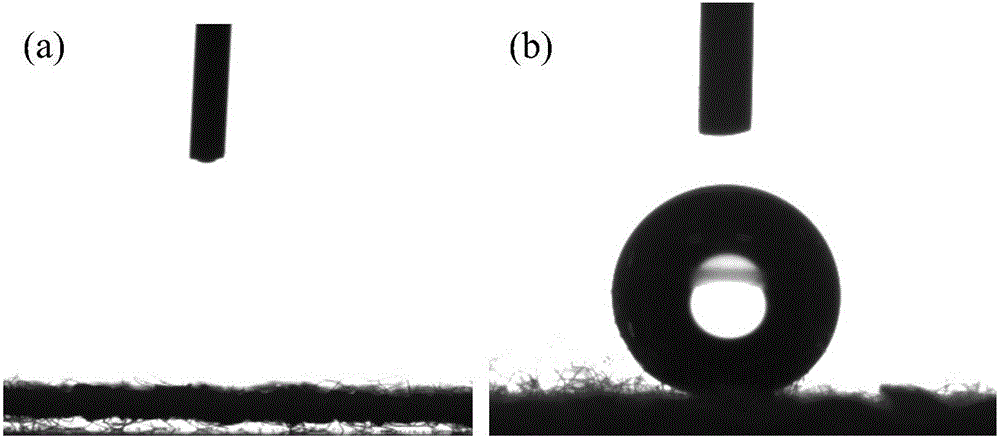

Method for preparing super-hydrophobic textile from thiol-ene click chemistry-modified fiber

InactiveCN105696306AWashableWear-resistantLiquid repellent fibresAbrasion resistant fibresFiberPolyester

The invention relates to a preparation method of a functional textile, and belongs to the field of textile surface grafting modification. The method for preparing a super-hydrophobic textile from a thiol-ene click chemistry-modified fiber is characterized by comprising the steps that alkali liquor steaming treatment is performed on a polyester fiber, then mercaptosilane is fixed to the surface of the polyester fiber, finally a methacrylate monomer is grafted to the surface of the polyester through a thiol-ene click chemistry reaction to reduce the surface tension of the fiber, and then the super-hydrophobic polyester textile is obtained. The contact angle between the polyester textile prepared through the method and water drops is larger than 150 degrees, and the polyester textile is stable to acid, alkali, salt and solvent and capable of resisting friction and washing and has the very good hydrophobic stability.

Owner:SHAANXI UNIV OF SCI & TECH

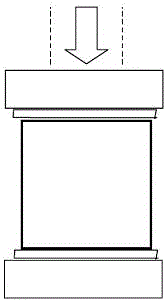

Honeycomb flue gas denitrification catalyst and preparation method thereof

ActiveCN103143396AHigh mechanical strengthWear-resistantOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationCellulosePtru catalyst

The invention relates to a honeycomb flue gas denitrification catalyst and a preparation method thereof, belonging to the technical field of inorganic new materials. The honeycomb flue gas denitrification catalyst is mainly prepared by carrying out extrusion molding and sintering on the following raw materials in parts by weight: 68-92.8 parts of nano TiO2, 3-10 parts of nano SiO2, 2-10 parts of glass fiber, 0.1-0.5 part of extrusion aid, 0.1-0.2 part of carboxymethyl cellulose, 0.1-0.3 part of polyoxyethylene and 0.1-0.2 part of sesbania powder. The preparation method comprises the following steps: (1) weighing the nano TiO2 and nano SiO2 powder, adding the extrusion aid, adding water while stirring to obtain paste, and adding ammonia water to regulate the pH value to 7-11; (2) adding the rest of raw materials, evenly mixing, and extruding with an extruding machine to obtain a honeycomb blank; (3) drying the blank at 30-70 DEG C under the relative humidity of 20-100% for 7-15 days; and (4) calcining the dried blank at 250-300 DEG C for 8-15 hours, calcining at 380-420 DEG C for 5-10 hours, and calcining at 580-620 DEG C for 8-12 hours to obtain the finished product.

Owner:河南康宁特环保科技股份有限公司

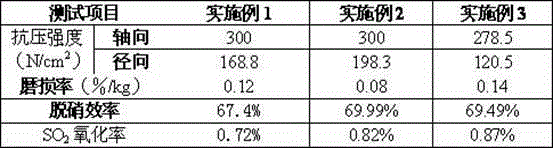

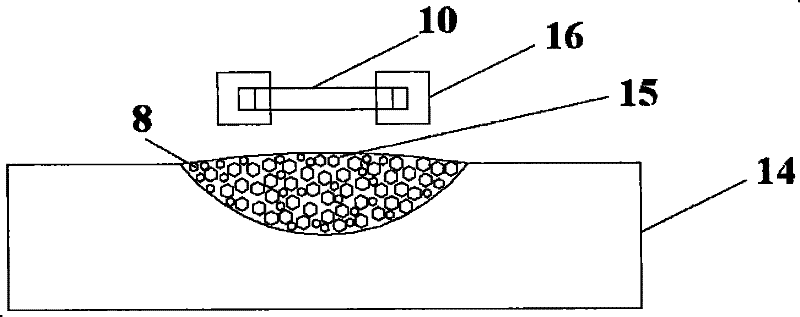

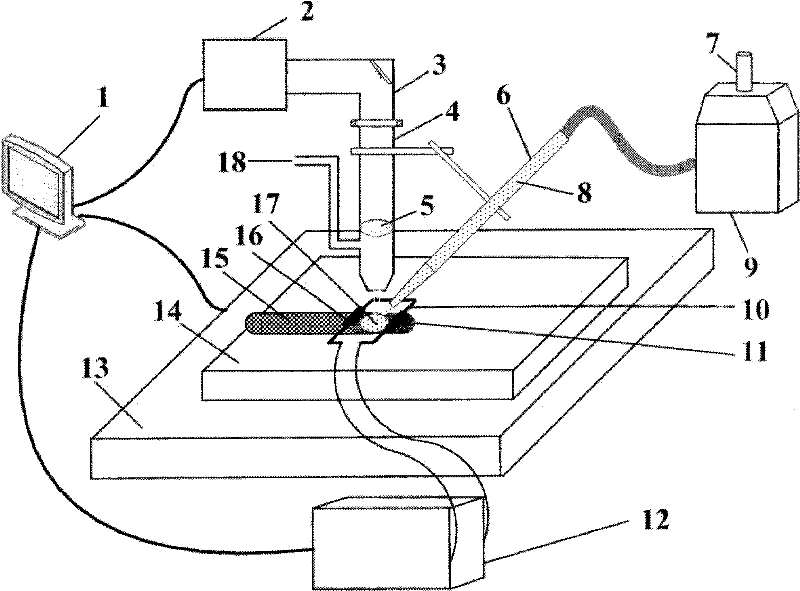

Method for quickly preparing metal ceramic coating through laser induced composite fusioncast

InactiveCN102191495ALarge injection depthHigh volume percentageEfficient propulsion technologiesMetallic material coating processesHardnessMetal

The invention discloses a method for quickly preparing metal ceramic coating through laser induced composite fusioncast. The method comprises the following steps that: (1) a high-melting point and high-hardness ceramic phase is put into a hopper of an automatic powder feeder; (2) the ceramic phase is prevented from being oxidized at a high temperature; (3) a focused laser beam and a powder nozzle of the automatic powder feeder are positioned in an induced heating area to compound a laser heating source and an induced heating source; (4) the moving space is 80 to 20 percent of the diameter of a laser light spot; and (5) the work is finished. The method has the advantages that: the injection depth of the ceramic phase is high in a base material; the volume percent content is high; the chemical components of the metal ceramic coating and the base material are in slow gradient transition; the burning loss of the ceramic phase is low in the process of laser induced composite fusioncast; the obtained metal ceramic coating has a series of excellent properties, such as dense organization, high hardness, high toughness, high wear resistance, no air holes and cracks and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

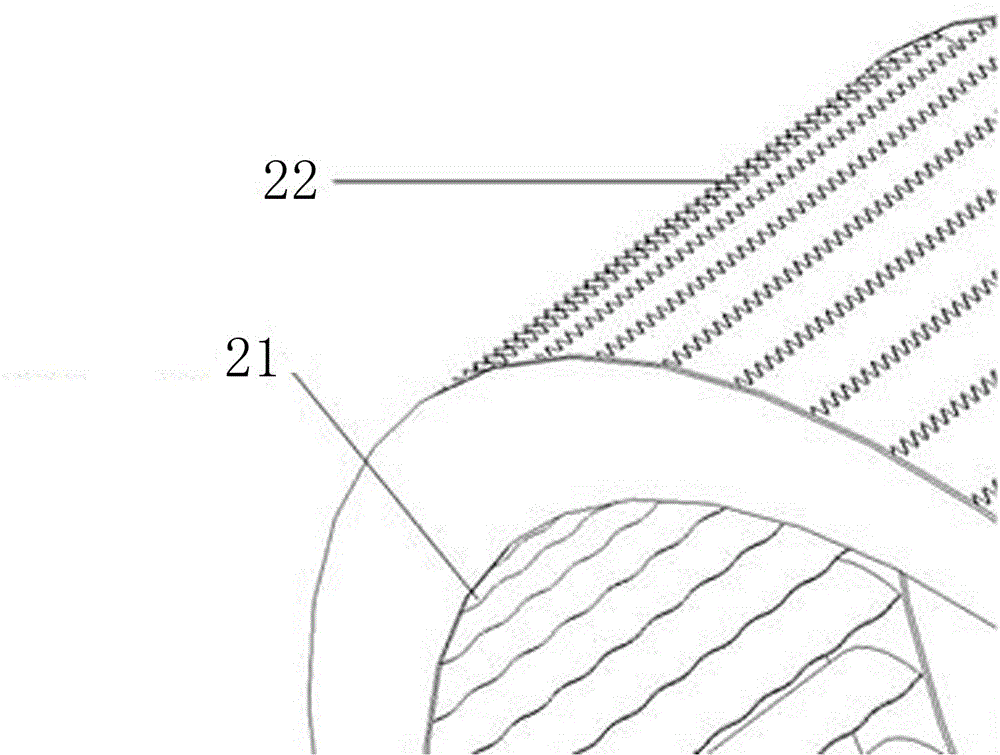

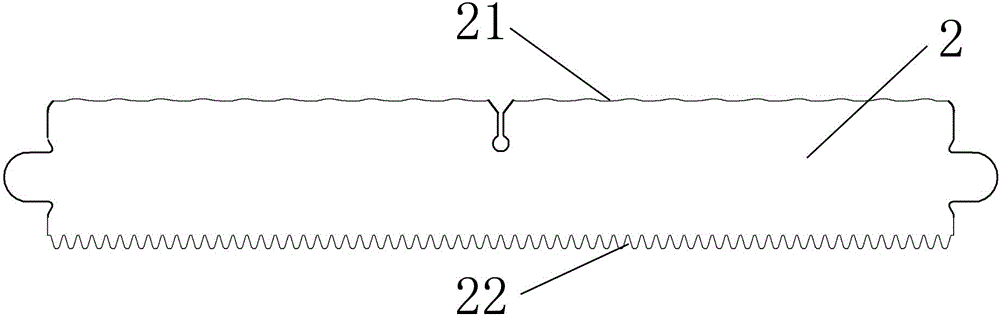

Bionic impeller for exhaust hood

ActiveCN104100570AEasy to processReduce leading edge pressure shockDomestic stoves or rangesPump componentsImpellerEngineering

The invention relates to a bionic impeller for an exhaust hood. The bionic impeller is applied to the exhaust hood and comprises a plurality of groups of annular end surfaces and blades. The corresponding blades are uniformly in bridge connection between each two groups of annular end surfaces. The bionic impeller is characterized in that the blades are bionic blades, the front edges of the bionic blades face a suction side of the exhaust hood and are of wavy structures, and the tail edges of the bionic blades face a blowout side of the exhaust hood and are of sawtooth structures. The bionic impeller has the advantages that pressure impact on the front edges of the blades and vortex-shedding frequencies of the tail edges of the blades can be reduced advantageously, and accordingly pneumatic noise generated when the impeller works can be reduced; extended areas of the blades can be reduced by 13.5% as compared with blades in original shapes, accordingly, the weight of the impeller can be reduced, loads on a motor can be decreased, and the efficiency of a fan can be improved advantageously.

Owner:HANGZHOU DE&E ELECTRICAL CO LTD

High-strength nickel-chromium-silicon-copper alloy material and processing technology thereof

The invention relates to a copper alloy material and a processing technology thereof, in particular to a high-strength nickel-chromium-silicon-copper alloy material and a processing technology thereof. The alloy material has low toxicity and low cost. The alloy material comprises the following components by mass: 2.1-2.9% of Ni, 0.4-0.7% of Cr, 0.3-0.7% of Si, not more than 0.3% of total impurities and the balance of Cu. The processing technology comprises the steps of casting, press processing, high-temperature solution hardening and heat treatment, cold press processing, aging heat treatment and mechanical processing.

Owner:SHENYANG XINGGONG COPPER IND

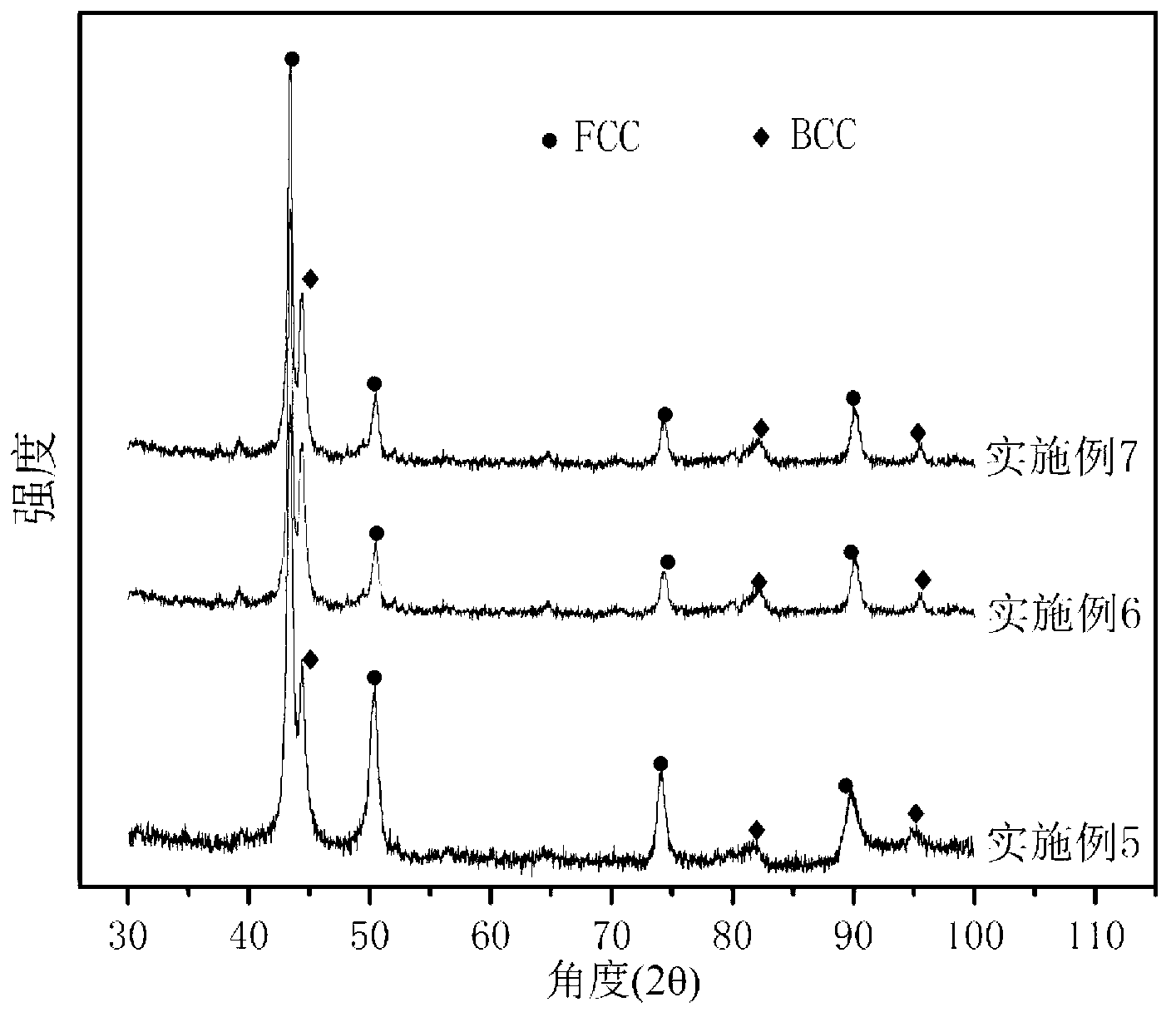

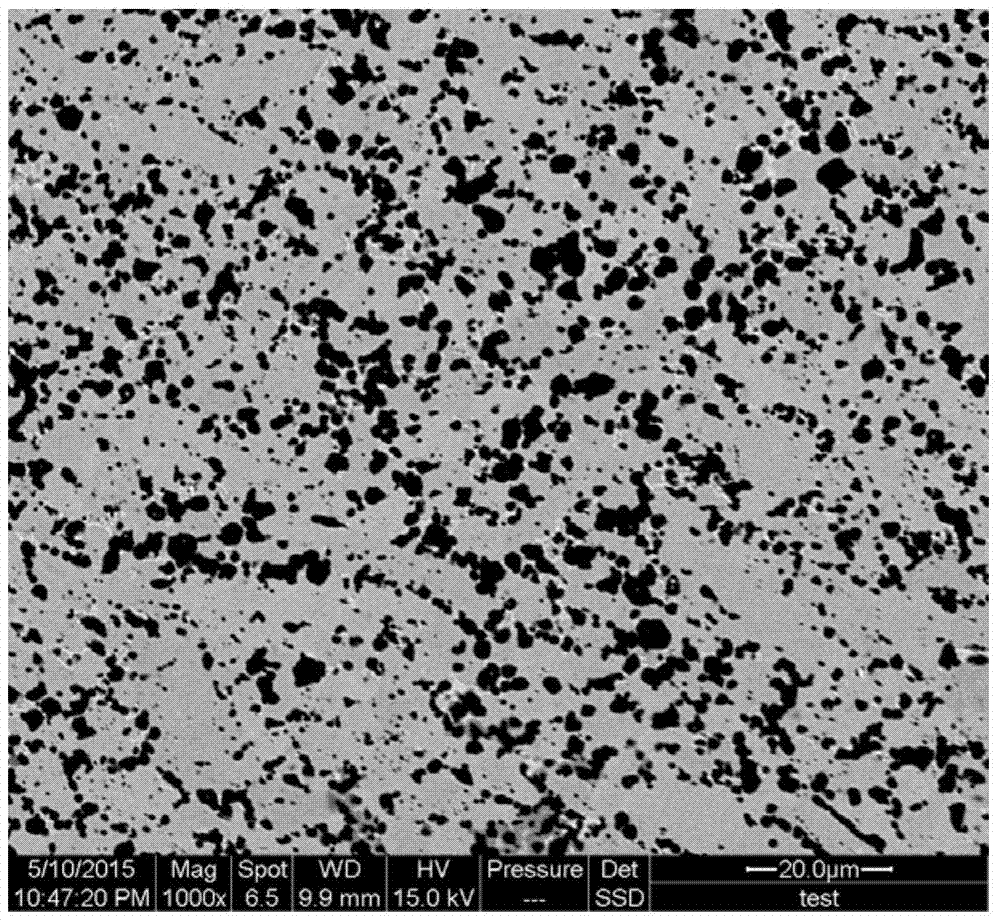

High-entropy alloy powder for 3D (three-dimensional) printing and method for preparing high-entropy alloy coating by using high-entropy alloy powder

ActiveCN104841930AImprove performanceScientifically optimize the ratioIncreasing energy efficiencySelective laser sinteringHigh entropy alloys

The invention provides high-entropy alloy powder for 3D (three-dimensional) printing and a method for preparing a high-entropy alloy coating by using the high-entropy alloy powder, and belongs to the technical field of coating preparation. By the high-entropy alloy powder, the wear resistance of the existing powder materials for 3D printing is improved. The high-entropy alloy powder is prepared by using the following ingredients in atomic percentage by weight: 16%-25% of Ni, 16%-25% of Co, 16%-25% of Cr, 16%-25% of Ti and 16%-25% of V. The preparation method comprises the following steps of (1) performing ball-mill mixing on raw materials to obtain mixed powder; (2) grinding and cleaning a matrix; and (3) placing the mixed powder in a powder feeder of 3D printing equipment and sintering the mixed powder on the surface of the matrix to form the high-entropy alloy coating by using selective laser. The NiCoCrTiV coating is prepared by selective laser sintering and has the advantages of high hardness, wear resistance, corrosion resistance and the like. The high-entropy alloy powder for 3D printing and the method for preparing the high-entropy alloy coating by using the high-entropy alloy powder can be widely used in the field of 3D printing.

Owner:HARBIN ENG UNIV

Graphene conductive coating material, preparation method therefor and application of graphene conductive coating material

ActiveCN105778740AUniform and stable dispersionEasy to prepareAnti-corrosive paintsPolyurea/polyurethane coatingsChemical reactionMetallic materials

The invention discloses a graphene conductive composite coating material. The graphene conductive composite coating material contains macromolecular film-forming resin, graphene and a graphene dispersant; and the graphene dispersant contains an aniline oligomer or a derivative thereof or soluble polyaniline which can be combined with the graphene through PI-PI interaction so as to enable the graphene to be uniformly and stably dispersed in the macromolecular film-forming resin or a mixture of the macromolecular film-forming resin and water and / or an organic solvent. The invention also discloses a preparation method for the coating material. According to the coating material disclosed by the invention, the graphene can be uniformly and stably dispersed in a coating material matrix, so that the application of the coating material in the aspects of conductive macromolecular coatings and the like can be greatly promoted; the preparation process is simple, does not need complex chemical reactions and is easy to control, and the coatings made from the coating material have good bonding capability on surfaces of macromolecular materials, metallic materials, textile materials and ceramic materials; and meanwhile, the coating material also has the characteristics of radiation resistance, electrostatic resistance, corrosion prevention, wave absorbing, wear resistance and the like, thereby being broad in application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

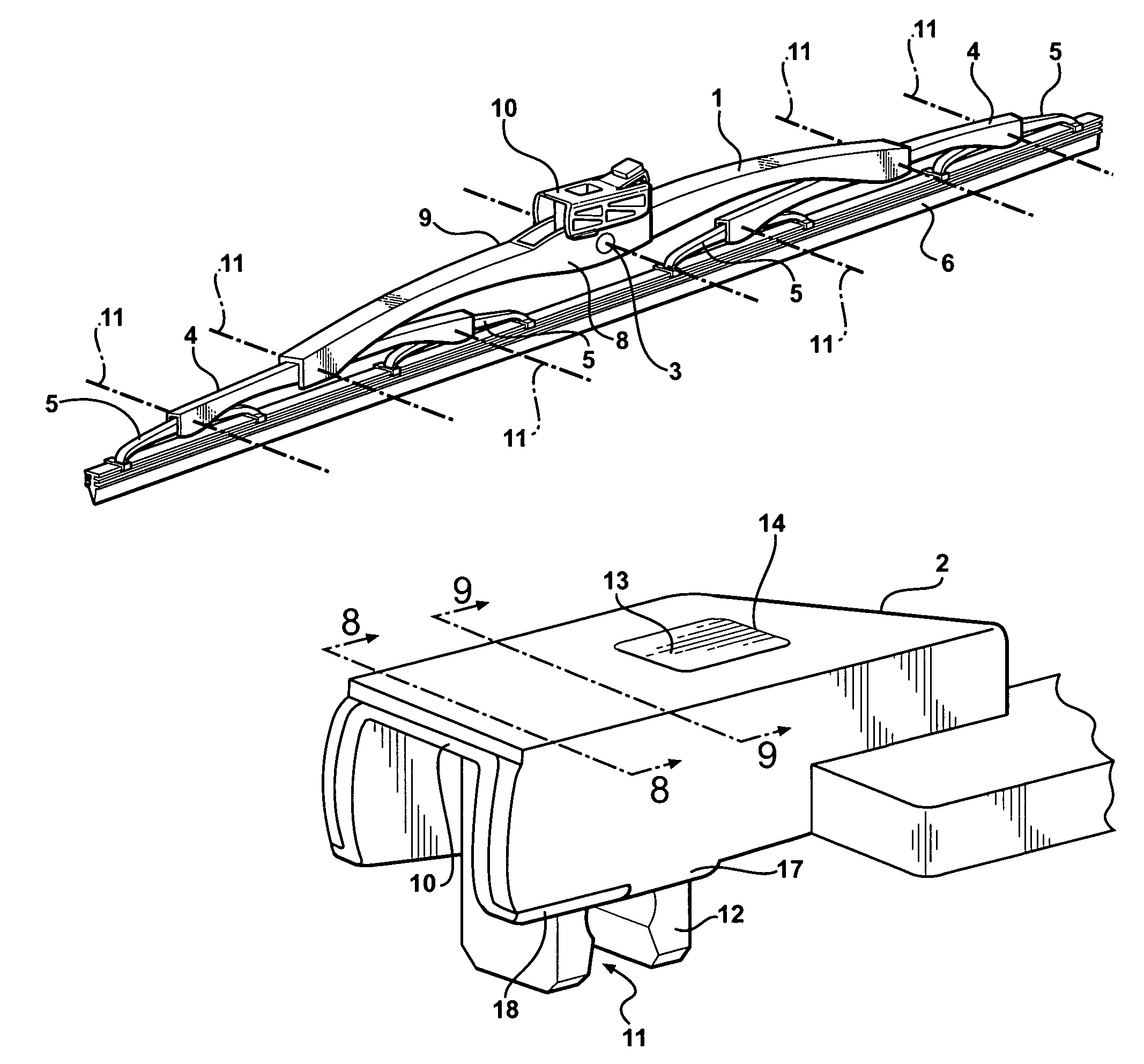

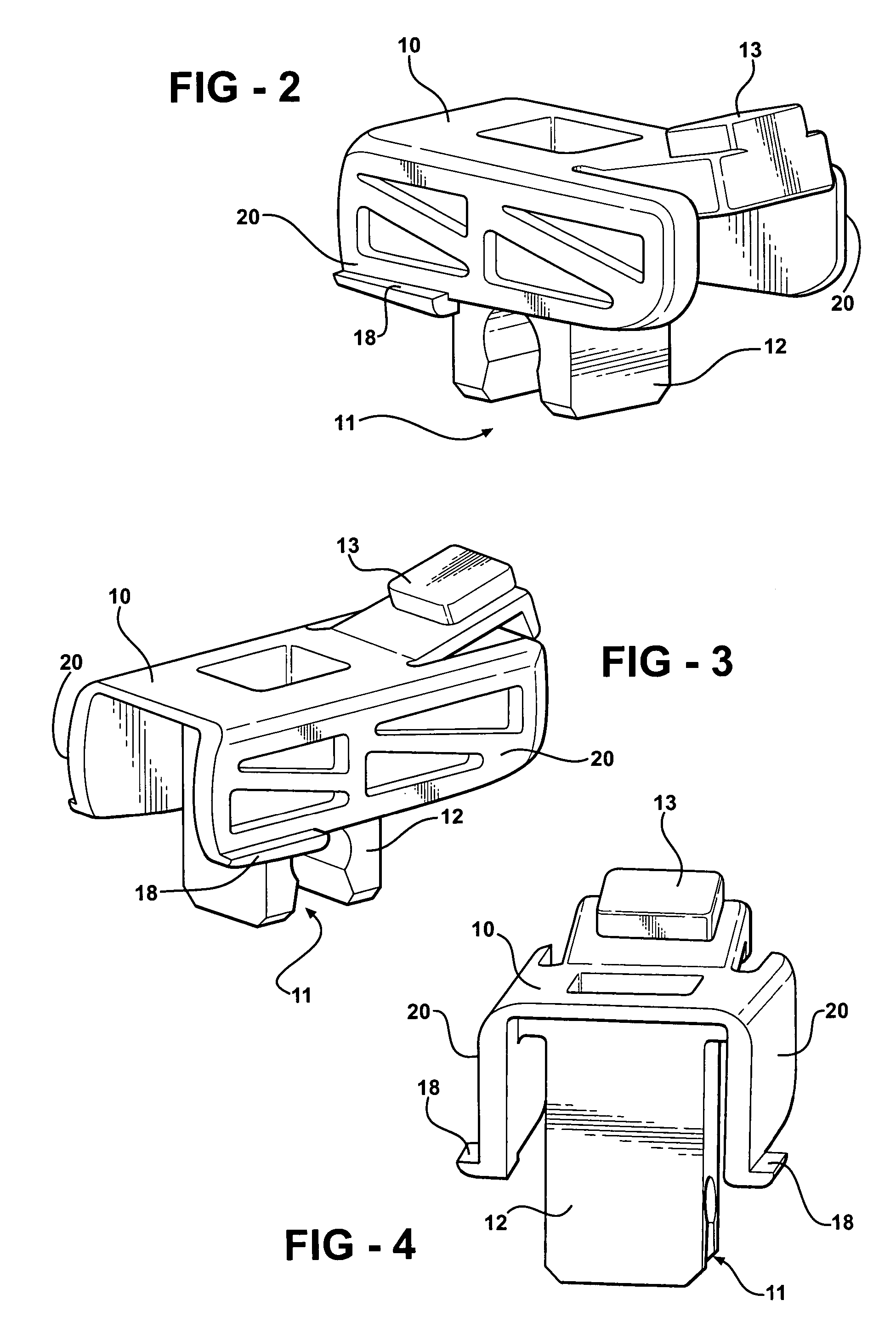

Windscreen wiper device

ActiveUS7398577B2Simple wayEasy to operateWindow cleanersVehicle cleaningTransverse axisInterconnection

A windscreen wiper device comprising at least one yoke which is attached to a carrier in such a manner as to be capable of pivotating movement about a first pivot axis, wherein both said carrier and said yoke have a substantially U-shaped cross-section at the location of their interconnection, said windscreen wiper device further comprising a oscillating arm pivotally connected to said carrier about a second pivot axis near one end, wherein said carrier is provided, at the location of said second pivot axis, with a transverse shaft, with the special feature that said oscillating arm and said carrier are interconnected with the interposition of a joint part, wherein said joint part comprises at least one resilient tongue engaging in a correspondingly shaped hole provided in said oscillating arm.

Owner:TRICO BELGIUM SA

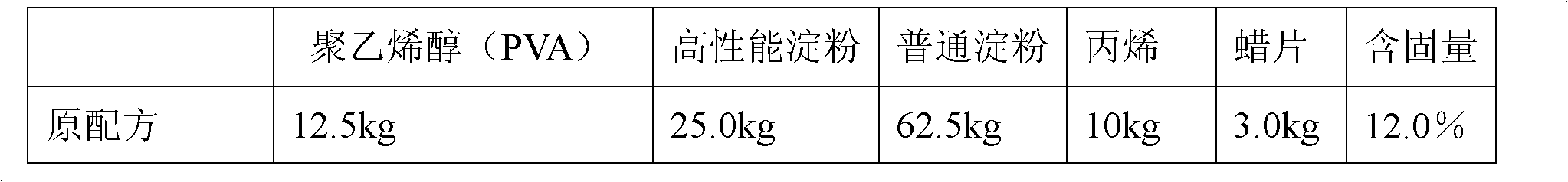

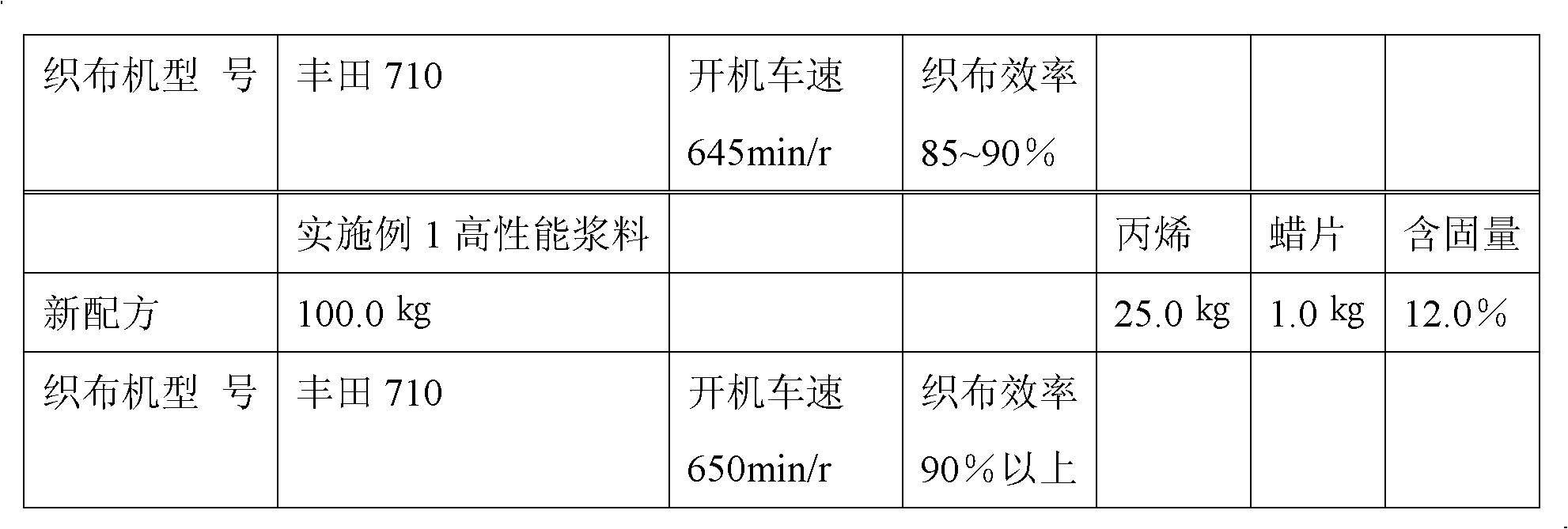

Multi-component high-performance sizing agent

The invention discloses a multi-component high-performance sizing agent. The sizing agent is prepared from various raw materials by a mixing reaction, wherein the raw materials comprise corn starch, phosphate, tween, persulfate, and at least one of phosphorus oxychloride and epoxy chloropropane. The sizing agent has the characteristics that the adhesion force is high, the film-forming ability is high, a serous film is coriaceous, the elasticity is high, the bending resistance (fatigue resistance) is improved by 3 to 4 times compared with a common modified starch sizing agent, and the abrasion resistance and the ageing resistance are high. The serous liquid is not frozen, caked or layered at normal temperature, and has high liquidity and stable viscosity. The sizing agent has no polyvinyl alcohol; when the sizing agent is sized on spinning cotton yarns; for the variety with general tightness, the polyvinyl alcohol does not need to be used for less than 50 yarns; or no or less polyvinyl alcohol is used for sizing on polyester cotton or over 50 cotton yarns; the yarns are easy to desize; the serous liquid waste water is easy to treat; the environment pollution is low; and the production process has zero pollution emissions.

Owner:YIXING JUNDA SLURRY TECH

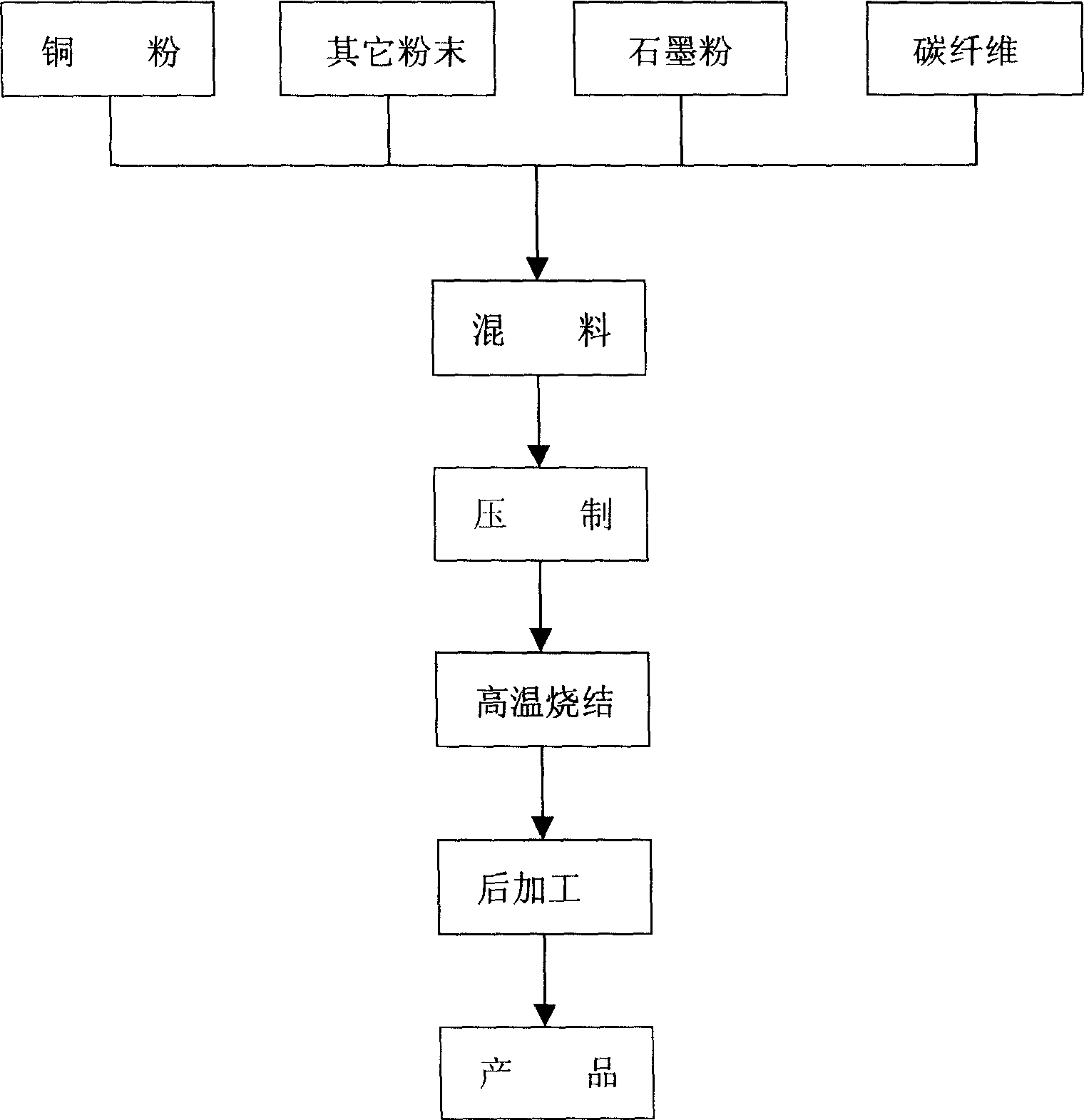

Leadless copper base high temperature self lubricating composite material

InactiveCN1718795AImprove toughnessImprove heat resistanceChemical vapor deposition coatingChemical compositionGraphite

A high-temp self-lubricating non-Pb Cu-base composition has a chemical formula: Ni+C+Sn+Zn+MX+Fe+Cu, where MX is chosen from BN, Si3N4, SiC, Al2O3, TiN, TiC and Cr3 C2 and C is graphite and carbon fibres. It has anti-oxidizing, anti-corrosion and high-temp anti-wear characteristics.

Owner:合肥波林新材料股份有限公司

Sewing-free hot melt adhesive TPU-PU leather and preparation method thereof

ActiveCN103437195AExcellent physical and chemical propertiesHigh bonding strengthPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterPolymer science

The invention provides a piece of novel sewing-free hot melt adhesive TPU-PU leather, and a preparation method thereof. The TPU-PU leather comprises release paper, a hot melt adhesive film, a TPU film and a dry-type PU film, wherein the release paper comprises a paper bottom layer, an adhesive layer, a plastic layer, a transition layer, and a release layer; a hot melt adhesive raw material is composed of polyester polyol, diisocyanate, polyether polyol, and a plurality of additives; a TPU raw material is composed of polymer polybasic alcohol, 1,4-cyclohexane-diisocyanate, a chain extender and a plurality of functional additives; a PU raw material is composed of polyester dibasic alcohol, straight chain diol, isocyanate, TDI trimer, dimethyl formamide, butanone, black sand, and a plurality of functional addictives. Through the adoption of the preparation method, innovations are conducted on the raw material components of the release paper, the hot melt adhesive, the TPU film and the PU film; the manufactured sewing-free TPU-PU leather has the technical advantages of firmness in adhesion, durability, environment-friendly materials, no invisible harm to a human body, and the like.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

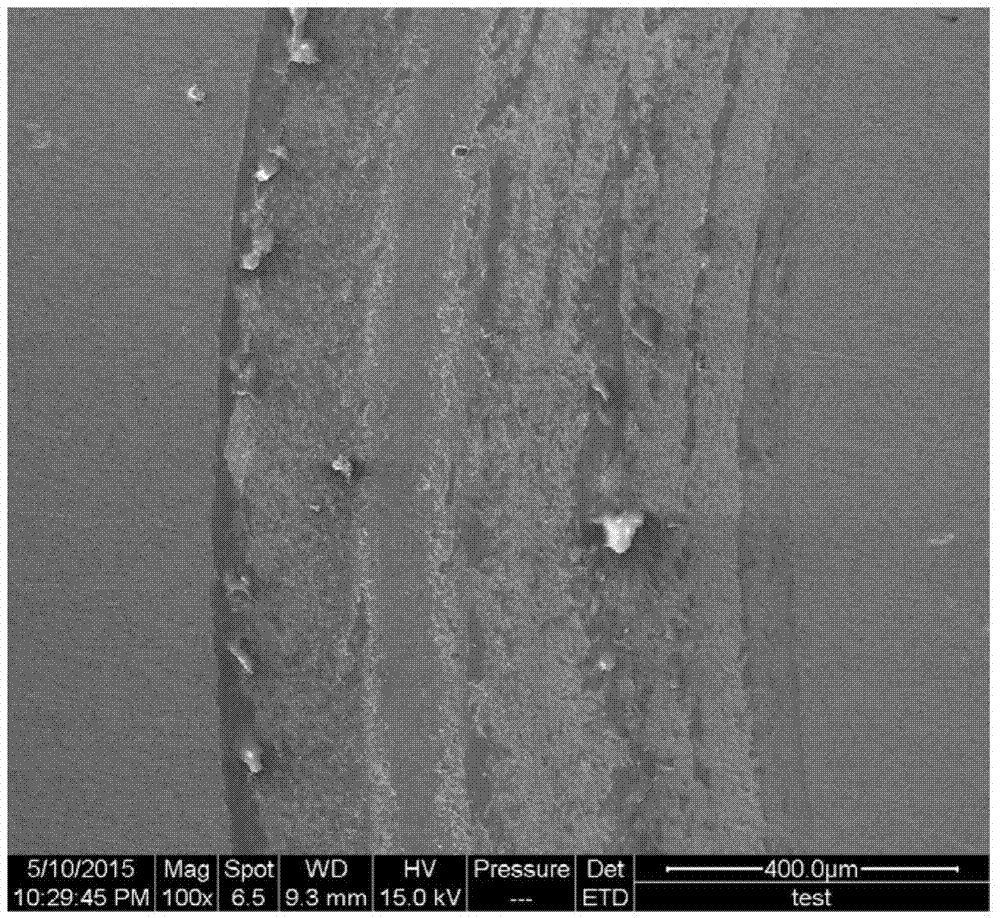

Method for preparing silver metallized organic fiber and textile

This is a argent metallization producing method of organic fibre and fabric, which belongs to vacuum membrane plating and electroplating technologic field and mainly solves the problems of quality and producing batches of silver-gilt organic and fabric. Through physical vapour phase deposition technology, it firstly arranges smoothly and rolls up tidily the organic fibre bundle and fabric; lay them in the vacuum room, plate silver by magnetic controlling and sputtering, and monolayer or multilayer continuously plate membrane; then plate mulriple argent membrane according to different using demands. The binding force of the metallic argentic ion and organ fibre of the present invention is strong, it has no pollution, low costs and can be continuously produced. The products are applied in such industry as electronics, war industry communication, medical treatment, special type of spinning and so on. For instance, electric shielded products, military used shielded tent, special type of spinning antibacterial materials and civil health care spinning products.

Owner:夏芝林

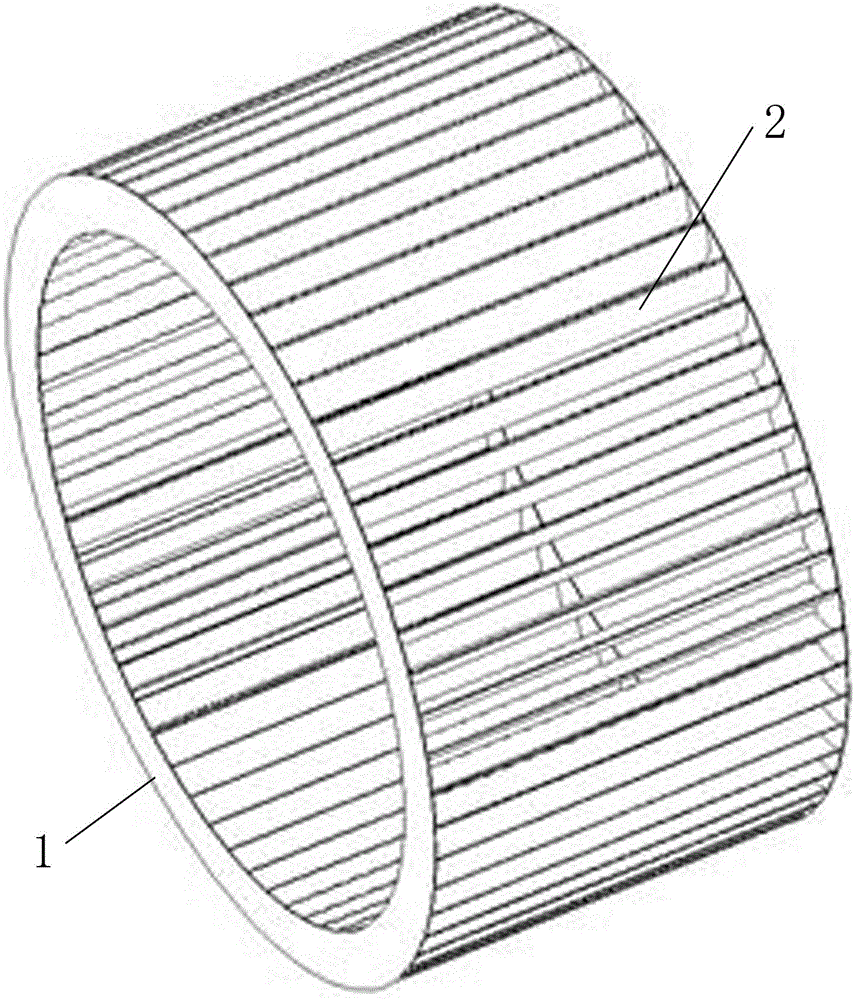

Powder metallurgy production method of internal helical gear

The invention relates to a powder metallurgy production method of an internal helical gear. The powder metallurgy production method comprises the following steps: 1) preparing metal powder raw materials in proportion; 2) putting the prepared metal powder raw materials into a mould of a powder extrusion moulding machine for moulding by rotary extrusion to form a mould green compact; 3) putting the mould green compact into a high temperature mesh belt furnace for sintering treatment; and 4) putting a sintered product into a carburizing furnace for carburizing treatment. The powder metallurgy production method helps produce the internal helical gear with easy production and operation, less cost, high production efficiency, high material utilization rate and high product accuracy.

Owner:扬州保来得科技实业有限公司

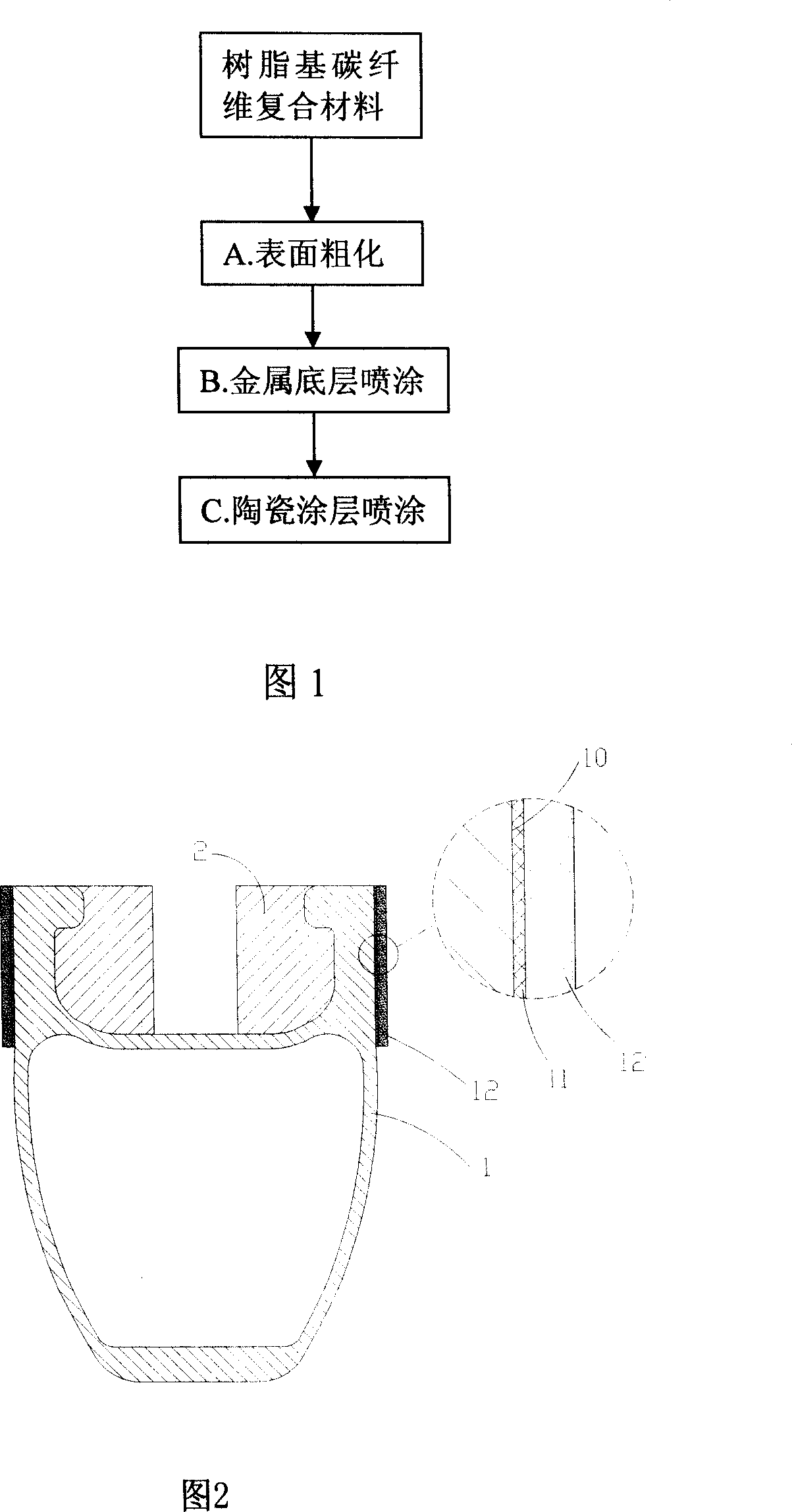

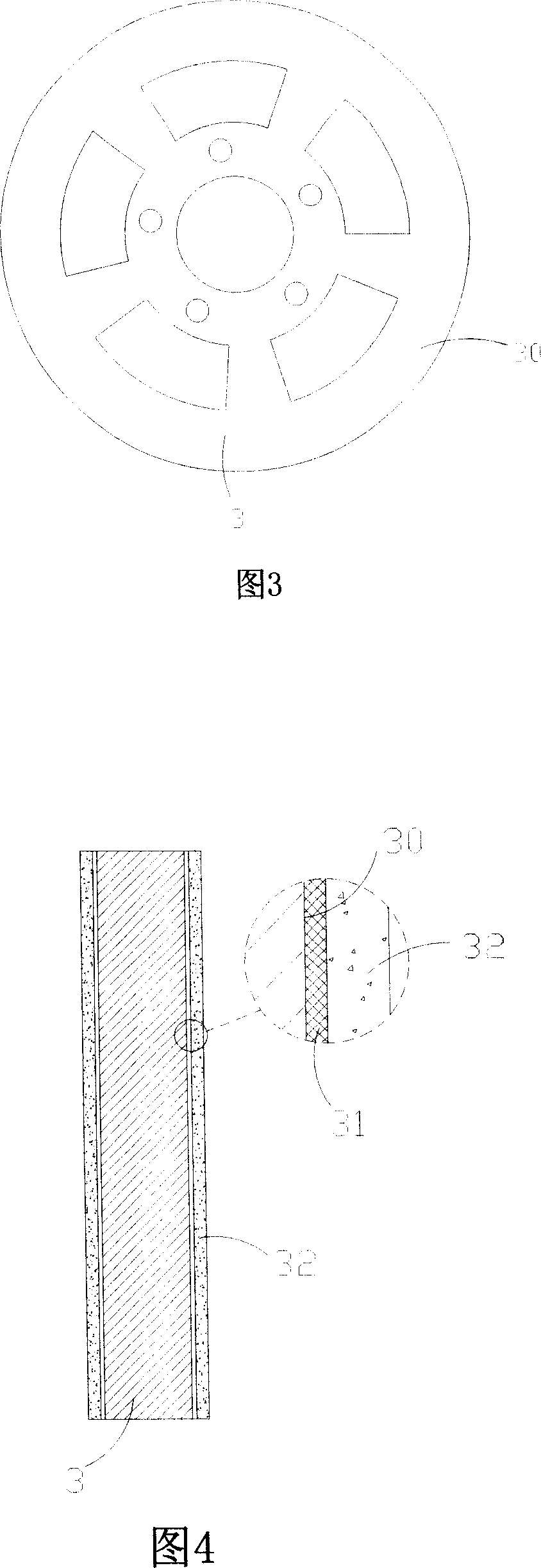

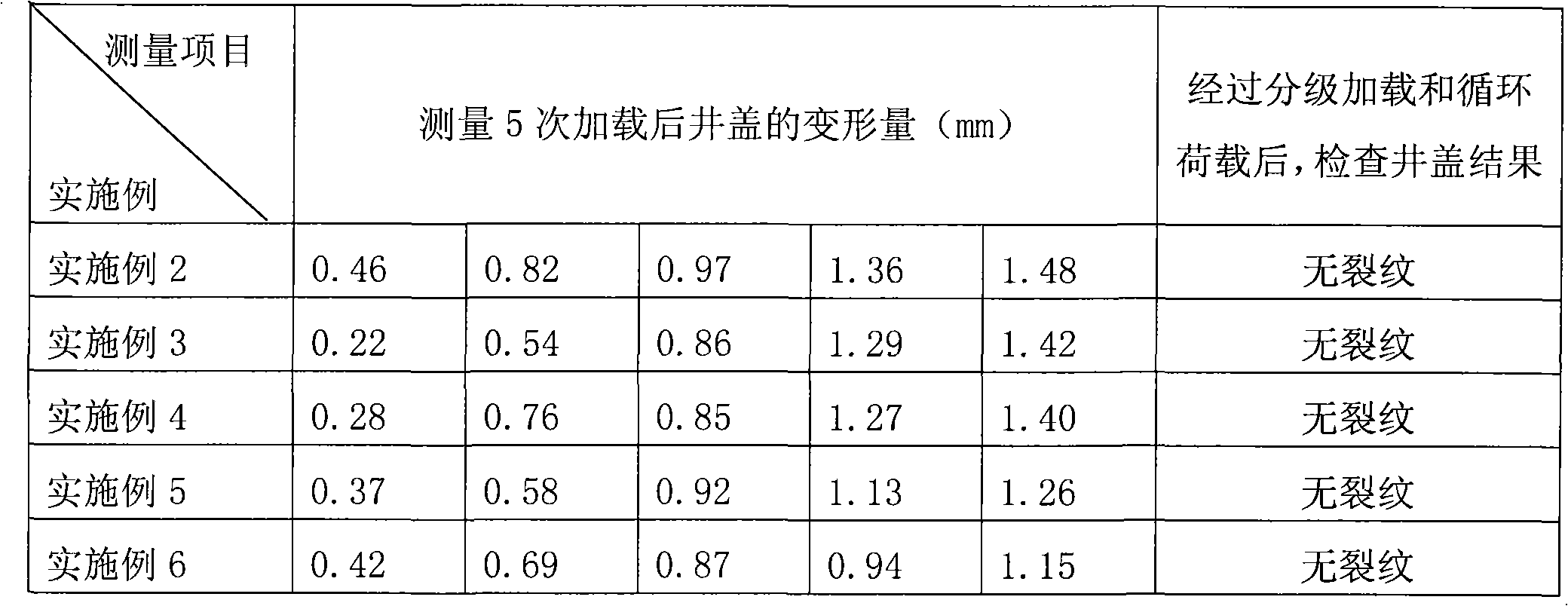

Process of spraying ceramic on epoxy resin base carbon fiber composite material article surface

InactiveCN101016614AHigh temperature resistantWear-resistantMolten spray coatingEpoxyCeramic coating

The invention discloses a craft to spray ceramic on the surface of epoxide resin group carbon fiber composite material product, which comprises the following steps: A, proceeding roughening treatment for the surface of epoxide resin group carbon fiber composite material product; B, spraying metallic substratum on the roughening surface; C, spraying ceramic powder on the surface of metallic substratum; forming ceramic coating. This invention can increase the safe property and durability of the product, which can make epoxide resin group carbon fiber composite material possess wide application area.

Owner:陈锦松 +1

Nanocomposite road marking coating material

InactiveCN104263198AWith sterilizationWear-resistantAntifouling/underwater paintsLuminescent paintsEpoxyNano structuring

The invention discloses a nanocomposite road marking coating material. The nanocomposite road marking coating material comprises the following ingredients in parts by weight: 20-30 parts of glass powder, 6-10 parts of aluminum oxide powder, 50-80 parts of filler, 30-40 parts of epoxy resin, 15-20 parts of aqueous epoxy modified acrylate, 15-20 parts of glass micro-beads, 10-20 parts of chitin, 15-20 parts of chitosan, 20-40 parts of nano titanium white, 15-20 parts of nano zinc oxide, 10-15 parts of nano-silica, 2-4 parts of 25wt% ammonia water, 30-40 parts of acrylic emulsion and 15-20 parts of nano rare-earth self-luminous material. The invention further discloses a preparation method of the nano coating material. The nanocomposite road marking coating material disclosed by the invention is high in drying speed and long in service life, is wear-resistant and anti-fouling and has a bacterium resisting effect, and nano-materials or nano-structured ingredients are introduced into an organic coating material, so that organic and inorganic matched compositing or hybridization is realized. The advantages of organic polymers and inorganic-structured ingredients are integrated, so that the properties of the coating material are obviously improved.

Owner:句容亿格纳米材料厂

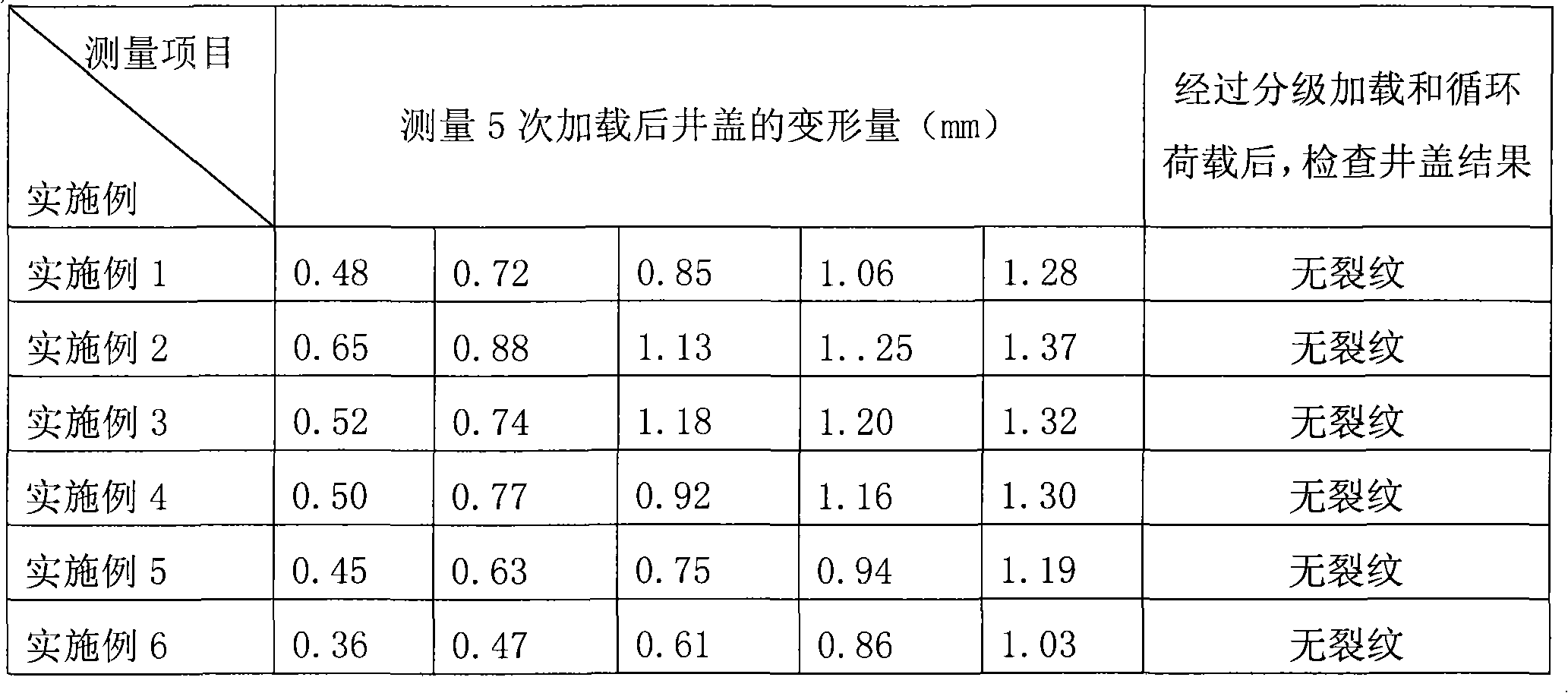

High-strength polyester composite well cover as well as formula and preparation method thereof

InactiveCN101871219AImprove carrying capacityImpact resistantArtificial islandsUnderwater structuresEnvironmental resistanceAlkali free

The invention discloses a formula of a high-strength polyester composite well cover, which comprises the following raw materials in parts by weight: 21-22 parts of unsaturated polyester resin, 8-9 parts of low shrink additive, 40-50 parts of heavy calcium carbonate, 1-1.5 parts of zinc stearate, 0.2-0.8 part of active magnesia, 0.12-0.28 part of curing agent, 0.2-0.8 part of carbon black, 10-20 parts of alkali-free glass fiber roving and 10-20 parts of glass fiber woven roving. A production method of the well cover of the invention comprises the following steps of: firstly preparing resin paste, preparing sheets by utilizing the resin paste, and then, forming the sheets by die pressing. The well cover of the invention has the characteristics of strong carrying capacity, shock resistance, ageing resistance, wear resistance, corrosion resistance, novel and attractive appearance, simple structure, environmental protection and the like, and basically solves the problem of well cover pilfering.

Owner:北京泛亚电通工贸有限责任公司

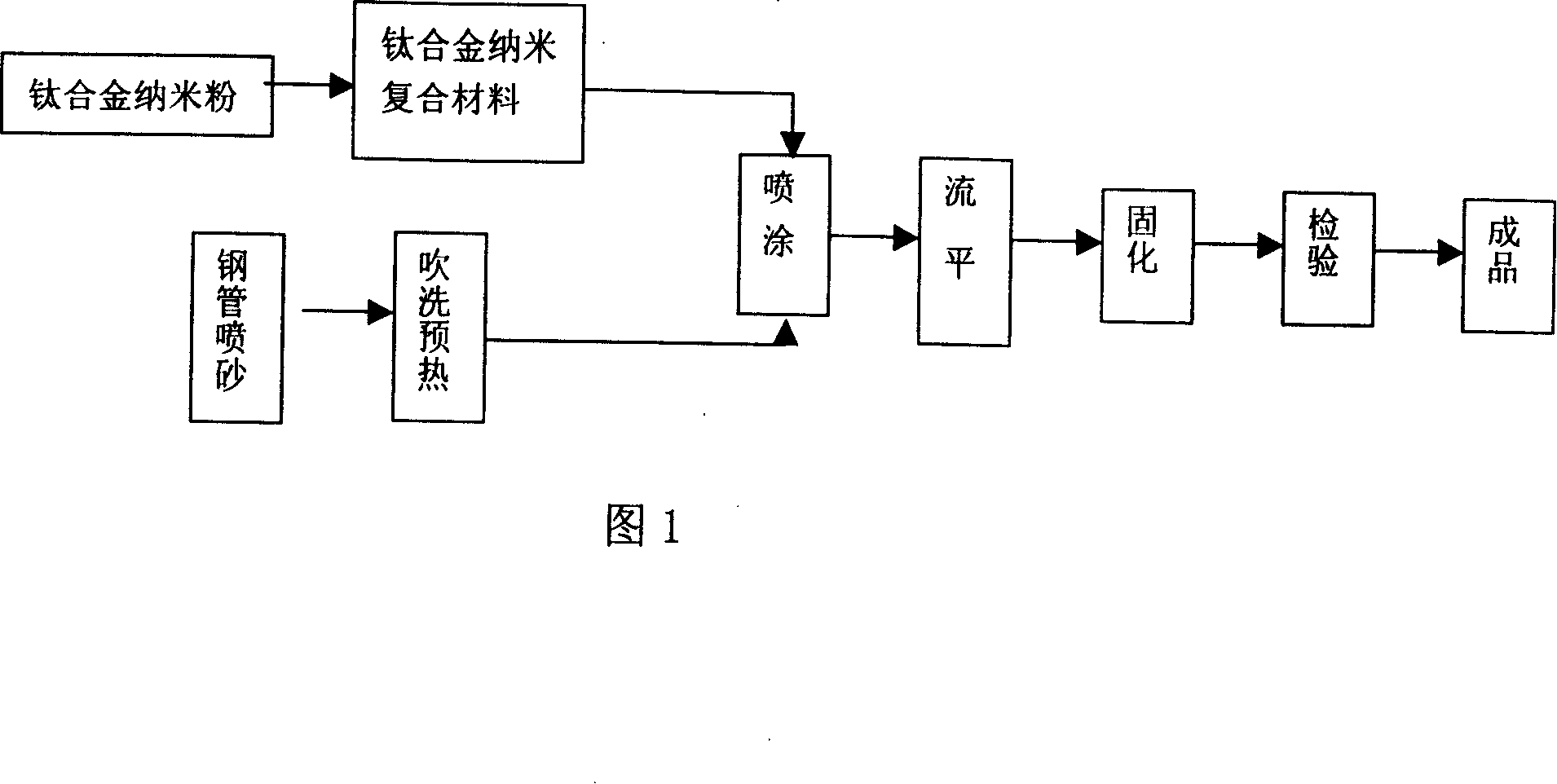

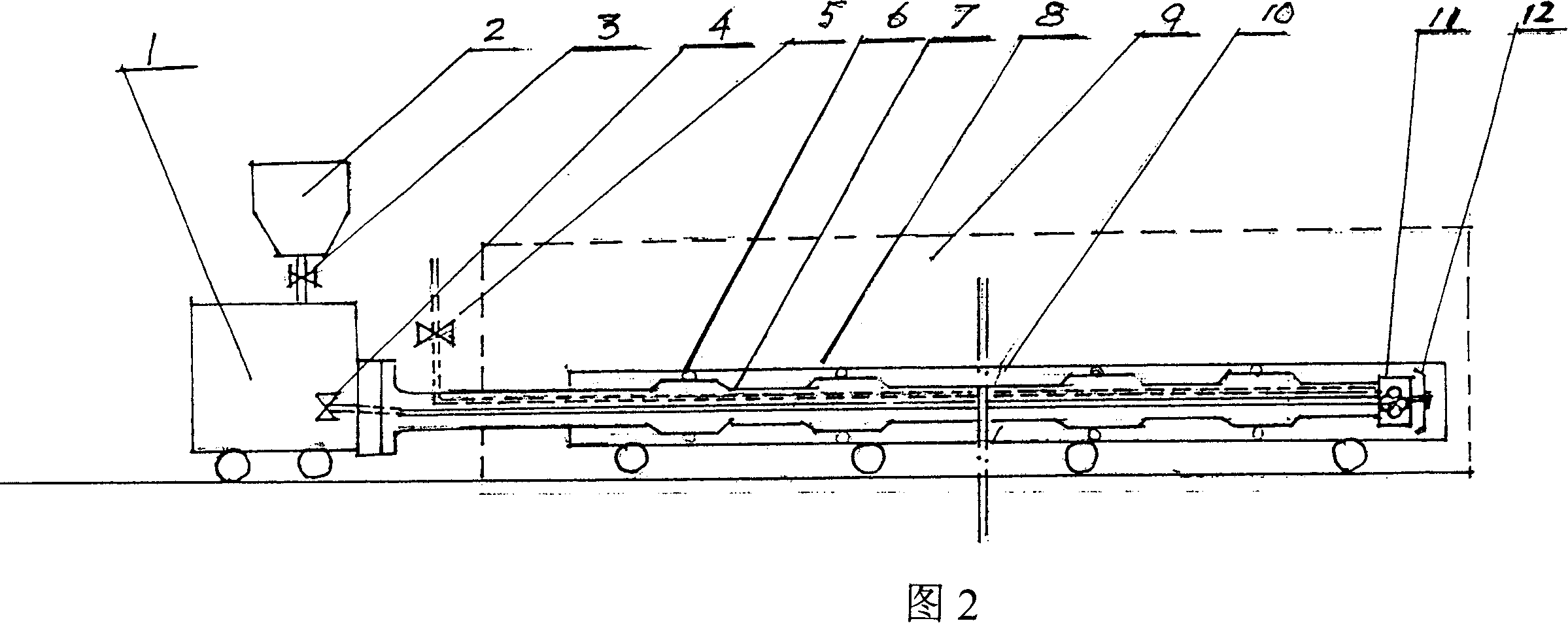

Production technology of steel tube with high-elasticity heat-resistant anti-corrosion abrasion-proof nano composite material coating

InactiveCN101108377AExtended service lifeExtend your lifePretreated surfacesAnti-corrosive paintsAbrasive blastingHeat resistance

A steel tube with a high stretch, heat resistance, anti-corrosion, anti-abrasion Nami compound material coating layer production technique is provided, which comprises: use emery to proceed spraying seed on the inner and outer surface of the steel tube to remove the iron dust erosion product of the inner and outer wall of the steel tube; use compressed air to blow off the floating sand and dust which passes through the inner surface of the steel tube, then preheat in a preheat furnace to remove water and moist on the inner wall of the tube; proceed titanium alloy compound material spray finishing to the inner surface of the steel tube after preheating to form a coating layer; make the steel tube after spray finishing rotate with the tube axle and the coating layer level evenly and the surface of the tube is smooth and neat; then make the coating layer solid completely to get finished steel tube; the titanium alloy compound material is composed of several kinds titanium alloy Nami powder as active addition agent, optimized resin and addition agent, the steel tube with the coating layer can be used as oil well flow string or water inlet to meet the requirements under the working condition of 2000m to 5000m deep well, which has long service life and be used for saving a large amount of steel material and reducing production cost.

Owner:中油新星纳米工程技术有限公司

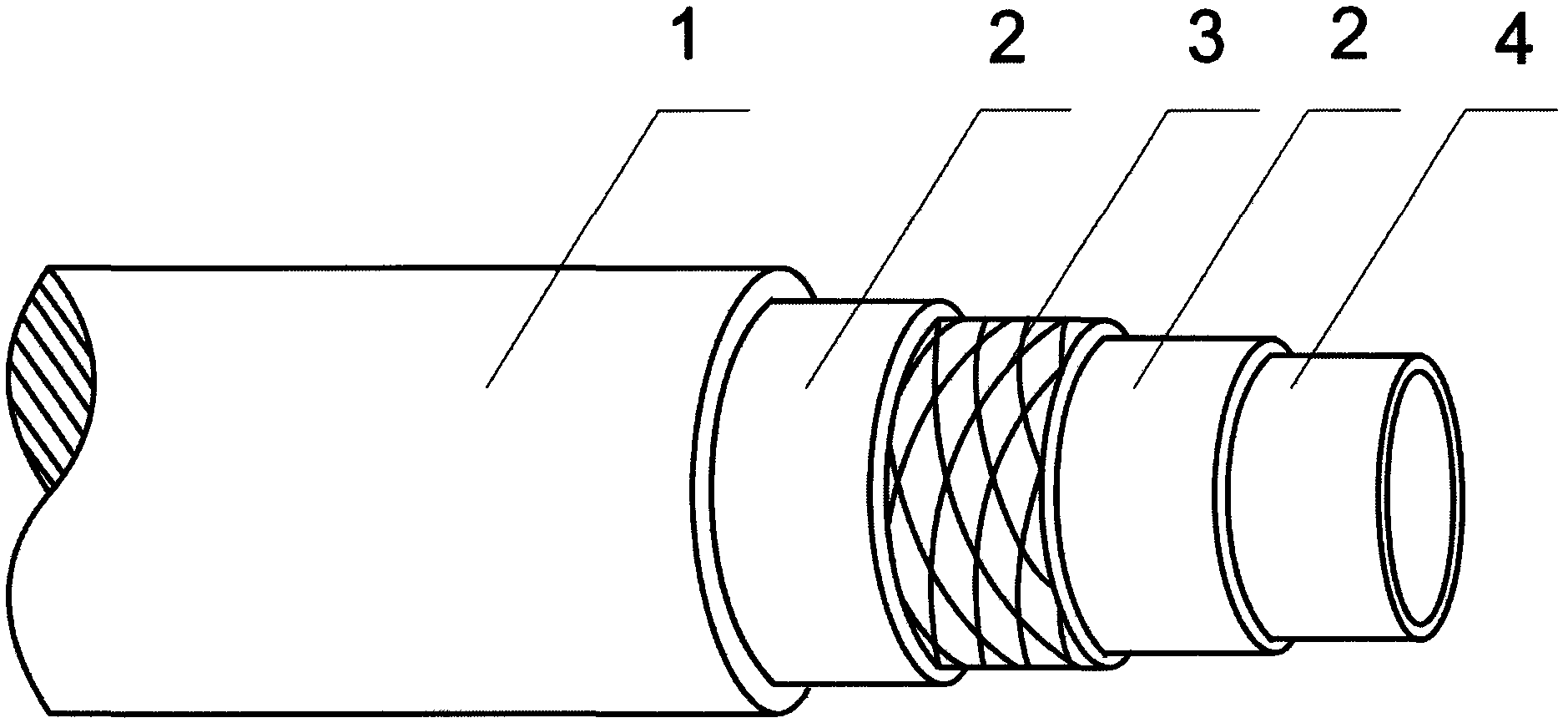

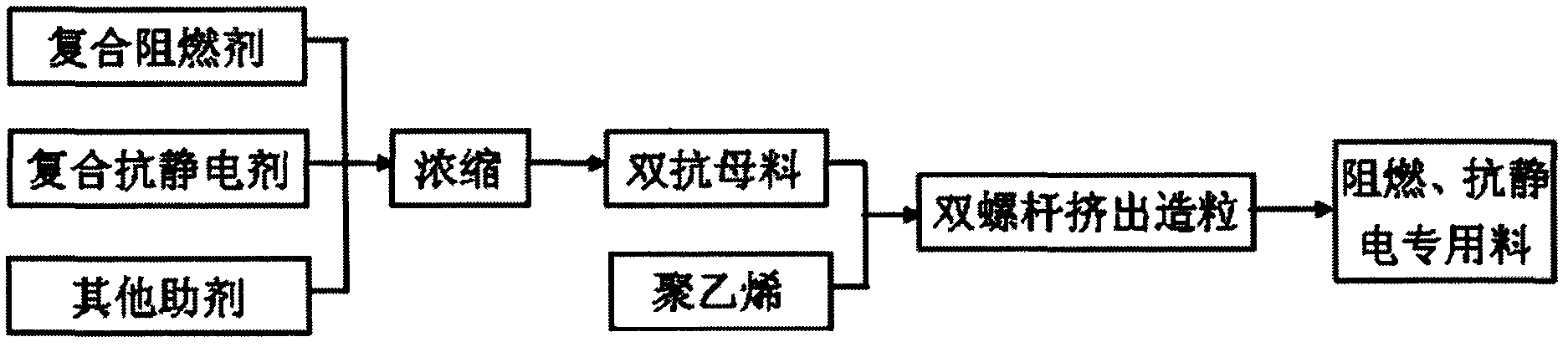

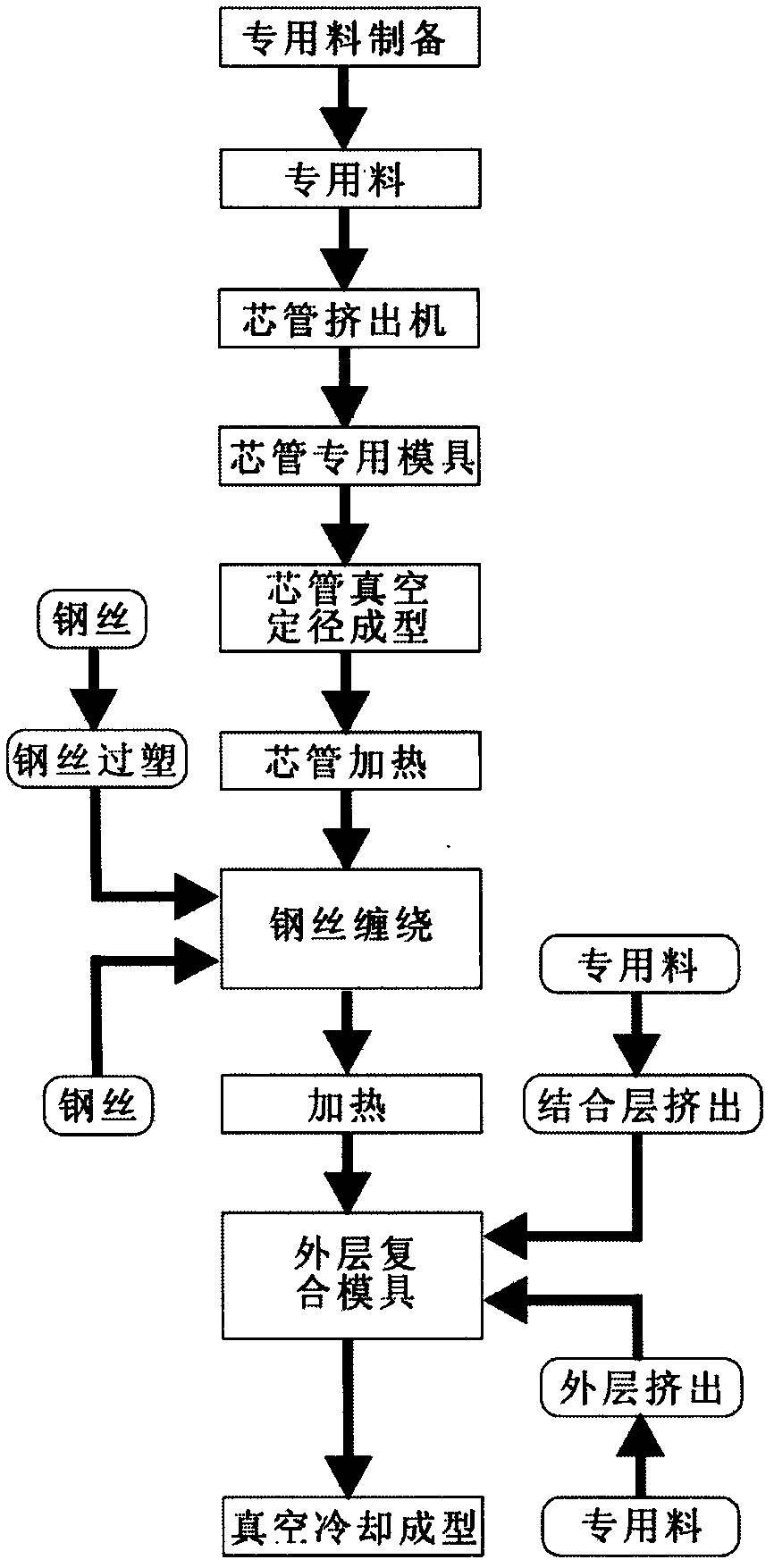

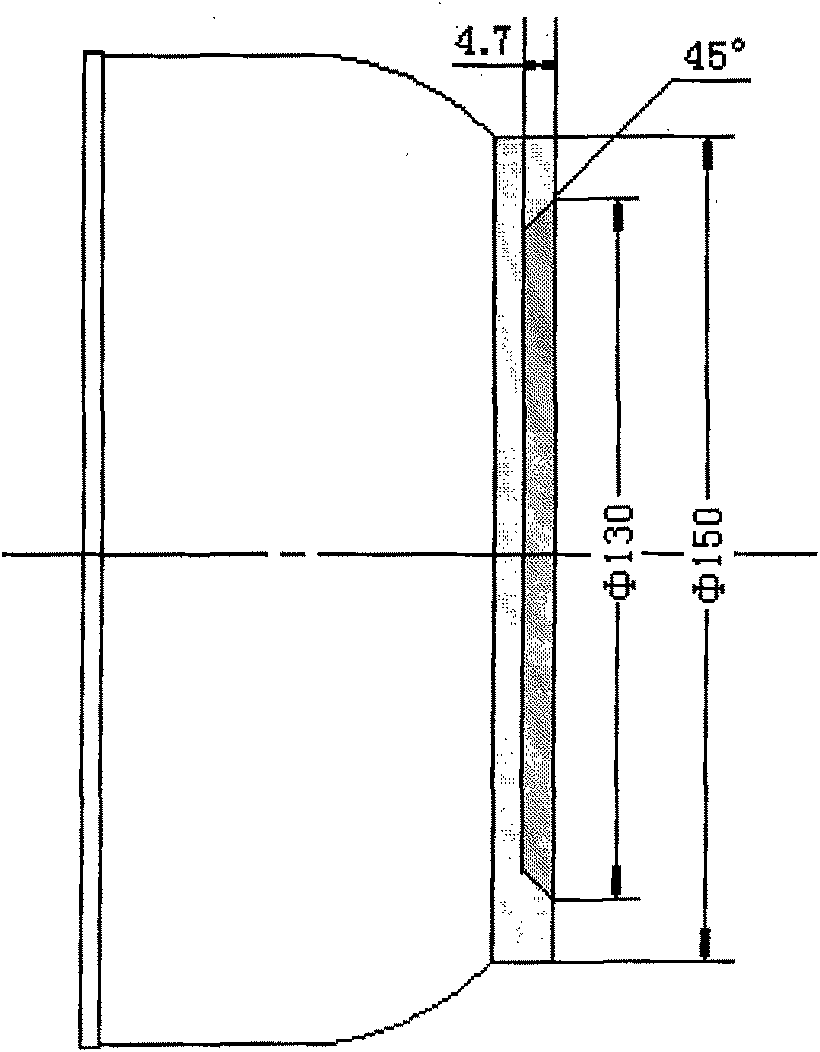

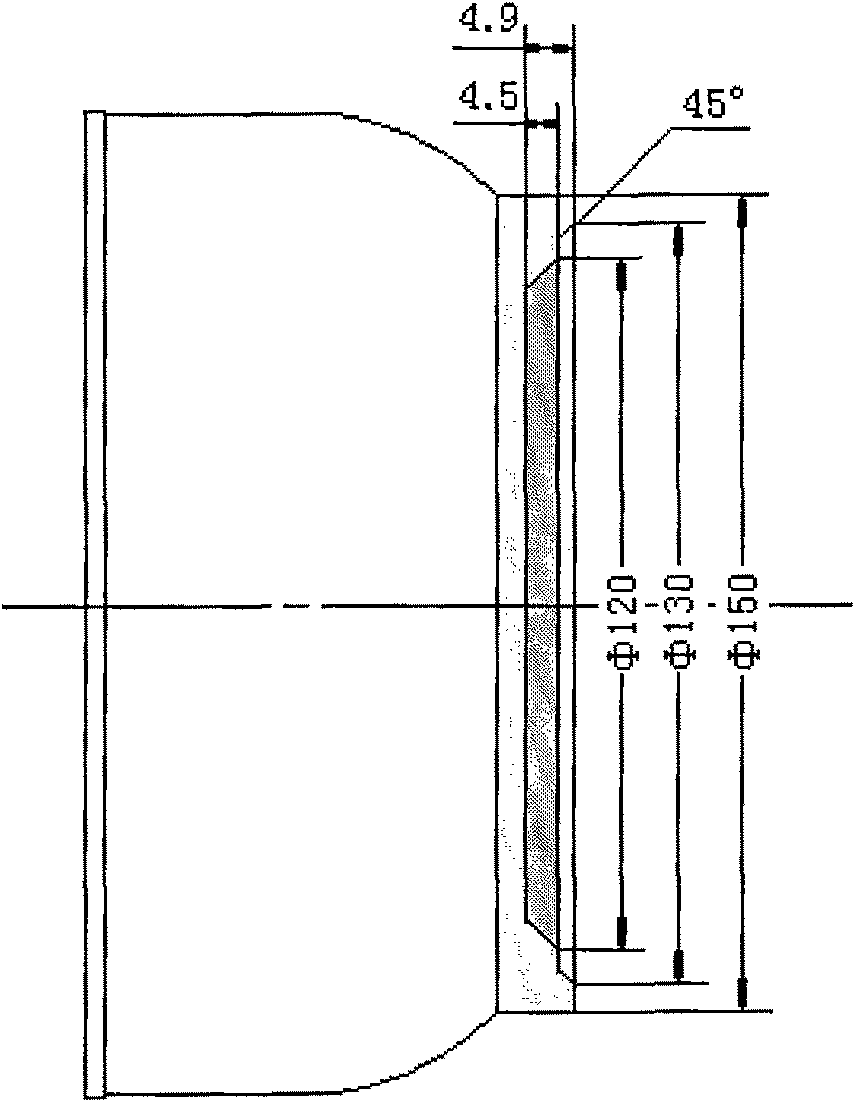

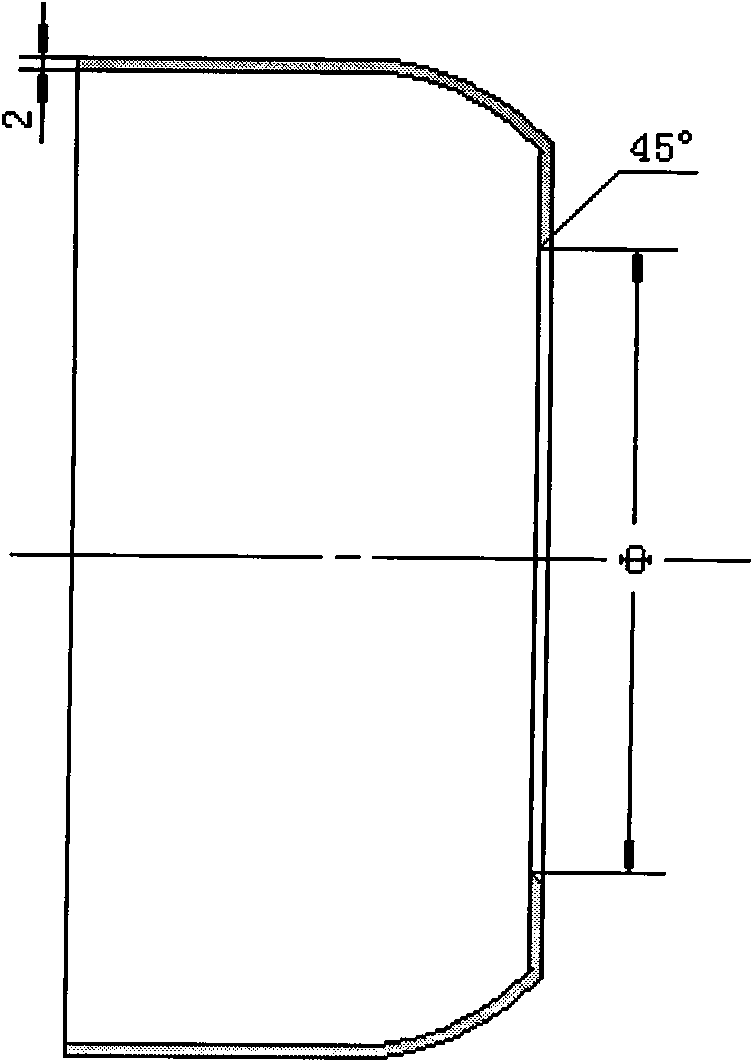

Flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining and manufacturing method thereof

InactiveCN102359668AGuaranteed reliabilityGuaranteed uniformityRigid pipesPipe protection against damage/wearFire retardantCoal

The invention relates to a flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining and a manufacturing method thereof. The method is characterized in that the polyethylene composite pipe is obtained by the manufacturing processes of subjecting dedicated composite modified polyethylene plastics to flame retarding and antistatic treatment in two steps, compositing the treated plastics with a high-strength steel mesh skeleton and a hot melt adhesive bond for several times, and heating and vacuuming the composite for several times. At least two layers of high-strength steel wires are wound to be reticulate in an oblique crossing manner, arranged between the outer wall of the inner layer and the inner wall of the outer layer as a skeleton, and tightly combined with the pipe body of the inner and outer layers into an integral whole by means of a hot melt adhesive, thus forming a composite pipe for underground coal mines, which is flame-retardant and antistatic and has relatively high mechanical strength and pressure resistance, long service life and other excellent properties. As the pipes are connected through welding by electric melting pipe fittings, the flame retardant and antistatic steel mesh skeleton polyethylene composite pipe for mining has high overall properties and convenience in laying, is applicable to the coal mine industry with strict property requirements in all aspects, and is also applicable to water supply and drainage, fire protection and gas delivery in the municipality and construction.

Owner:GUANGDONG EAST PIPES

Method for applying metal wire-imitated coating film on surface of engineering plastics

ActiveCN102166565AAnti-corrosionWear-resistantCoatingsSpecial surfacesWater savingEngineering plastic

The invention provides a method for applying a metal wire-imitated coating film on the surface of engineering plastics, and relates to a surface treatment method of the engineering plastics. The method for applying the metal wire-imitated coating film on the surface of engineering plastics can improve the function and the quality of a plastic metalized product, can simplify the technology, can reduce the production cost, and is water-saving and environment-friendly without needing any water liquid in the whole technological process. The method comprises the steps of adding dye into plastic master batch, and coloring; cleaning and activating a plastic blank in a drying way; spraying a color coat onto the plastic blank; performing the wire drawing to a work piece so as to obtain the surface with wire drawing veins; cleaning and activating the work piece in a drying way; and spraying finishing paint to the work piece with the wire drawing veins so as to apply the metal wire-imitated coating film on the surface of the engineering plastics.

Owner:XIAMEN RUNNER IND CORP

Rapid-hardening early-strengthening wearable concrete material for road repair and its preparation method

ActiveCN1699243AHave fast hardening and early strength requirementsSmall shrinkageSolid waste managementSlagMetakaolin

The invention provides a rapid-hardening early-strengthening wearable concrete material for road repair and its preparation, wherein the material mainly comprises the following ingredients, steel slag powdered ore 40-80kg / m3, metakaolin 320-560kg / m3, alkaline exciting agent solution 200-300kg / m3, steel slag fine aggregates 630-1800kg / m3, steel fiber 62-156kg / m3, and polypropylene fiber 1kg / m3.

Owner:WUHAN MUNICIPAL CONSTR GROUP

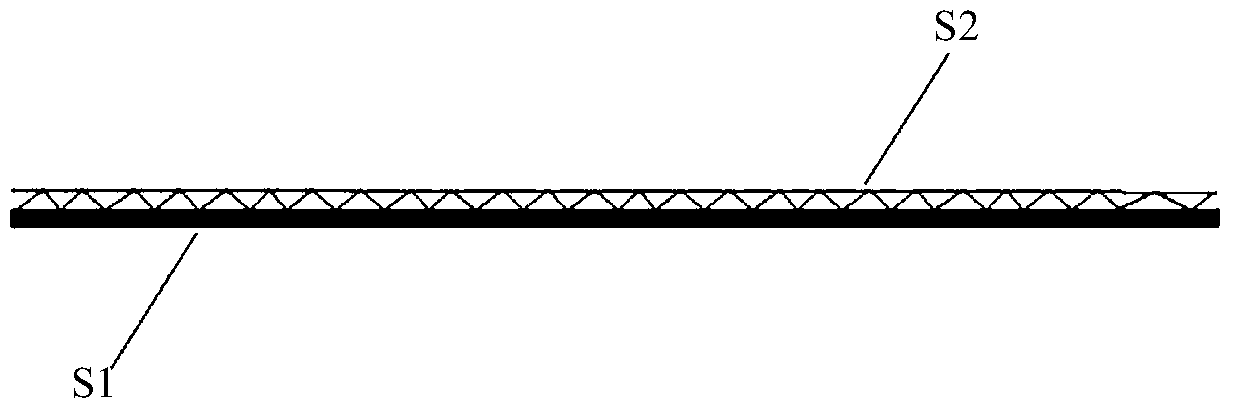

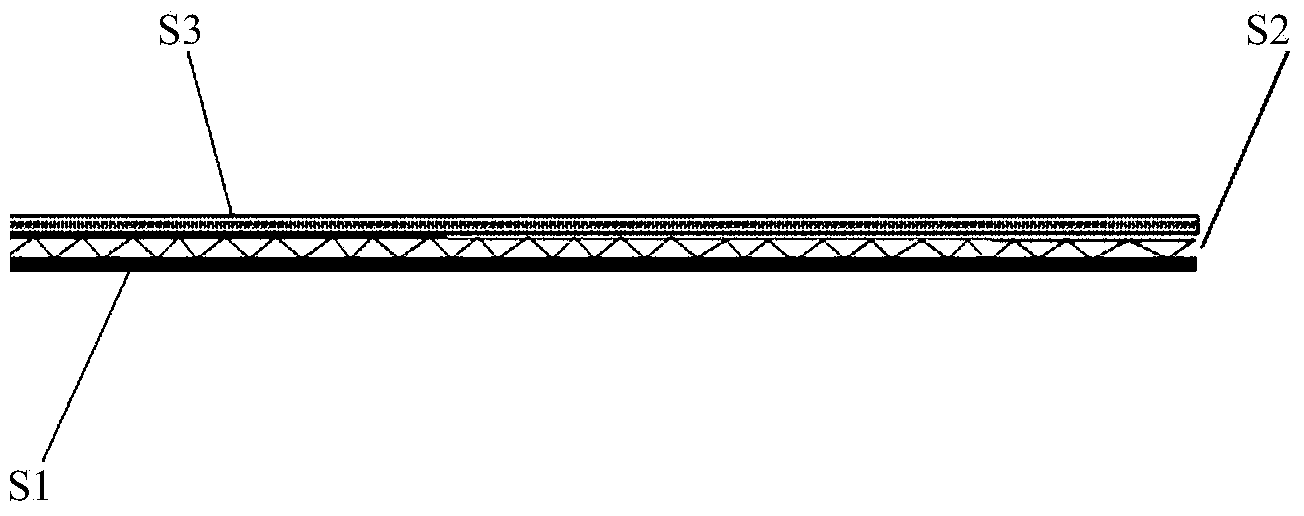

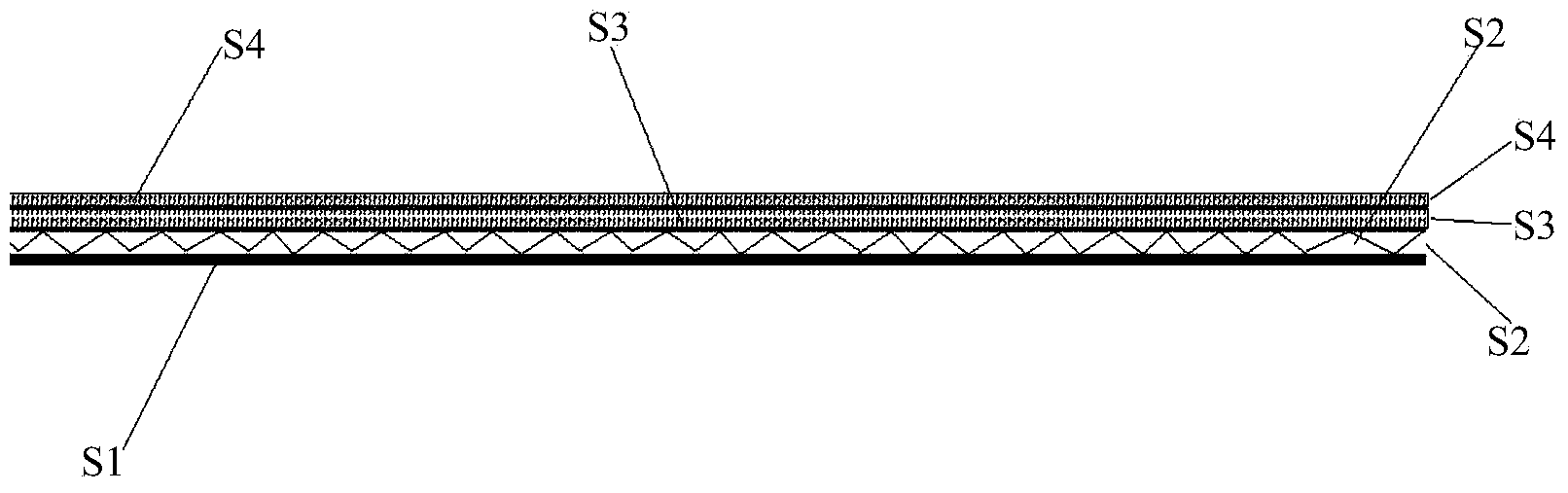

Method for thermal spraying of composite bottom layer of aluminum pan of electromagnetic oven

InactiveCN101880850AWide range of choicesImprove product qualityCooking-vessel materialsDomestic stoves or rangesThermal sprayingThermal printing

The invention discloses a method for thermal spraying of a composite bottom layer of an aluminum pan of an electromagnetic oven, which is used in the manufacturing industry of food cookers and is as shown by a drawing appended to the abstract. A magnetic composite layer with a certain thickness is formed by using an automatic spraying method, designing the joint of a coating and the pan bottom into a concave mosaic structure and spraying a magnetic material (pure iron, iron alloy or 430 stainless steel) to the bottom of the aluminum pan so as to meet the operating requirements of the electromagnetic oven. According to the requirements of a product, one or more material (copper, stainless steel, aluminum, nickel, chromium or ceramic) coatings with different thicknesses or functions can be sprayed to realize aesthetic property, practicability and functionality of the electromagnetic oven pan to ensure that the pans for the electromagnetic oven become various middle-grade and high-grade series products.

Owner:慈溪光华金属复合材料有限公司

Flame retardant polyurethane composite material and preparation method thereof

The invention relates to a flame retardant polyurethane composite material and a preparation method thereof. The traditional flame retardant polyurethane foamed material has a poor use effect. The flame retardant polyurethane composite material provided by the invention is a mixed system comprising 70-99wt% of flame retardant polyurethane and 1-30% of blending type fire retardant, wherein the blending type fire retardant is one or more than one of ammonium polyphosphate, melamine, melamine cyanurate acid, polysiloxane, graphine, a carbon nano tube and kaolin, the fire retardant polyurethane is a random copolymer consisting of a polycarbonate unit, a polyether and an isocyanate unit. The preparation method of the flame retardant polyurethane composite material comprises the following steps of: firstly, preparing fire retardant polyalcohol; then, mixing the fire retardant polyalcohol and the blending type fire retardant into a mixed system; and then adding polyisocyanates into the mixed system and reacting to finally obtain the flame retardant polyurethane composite material. The flame retardant polyurethane composite material prepared by using the preparation method disclosed by the invention has the advantages of excellent fire retardance, low-fogging performance and low-gas-releasing performance.

Owner:JIANGSU ZHONGKE JINLONG CHEM

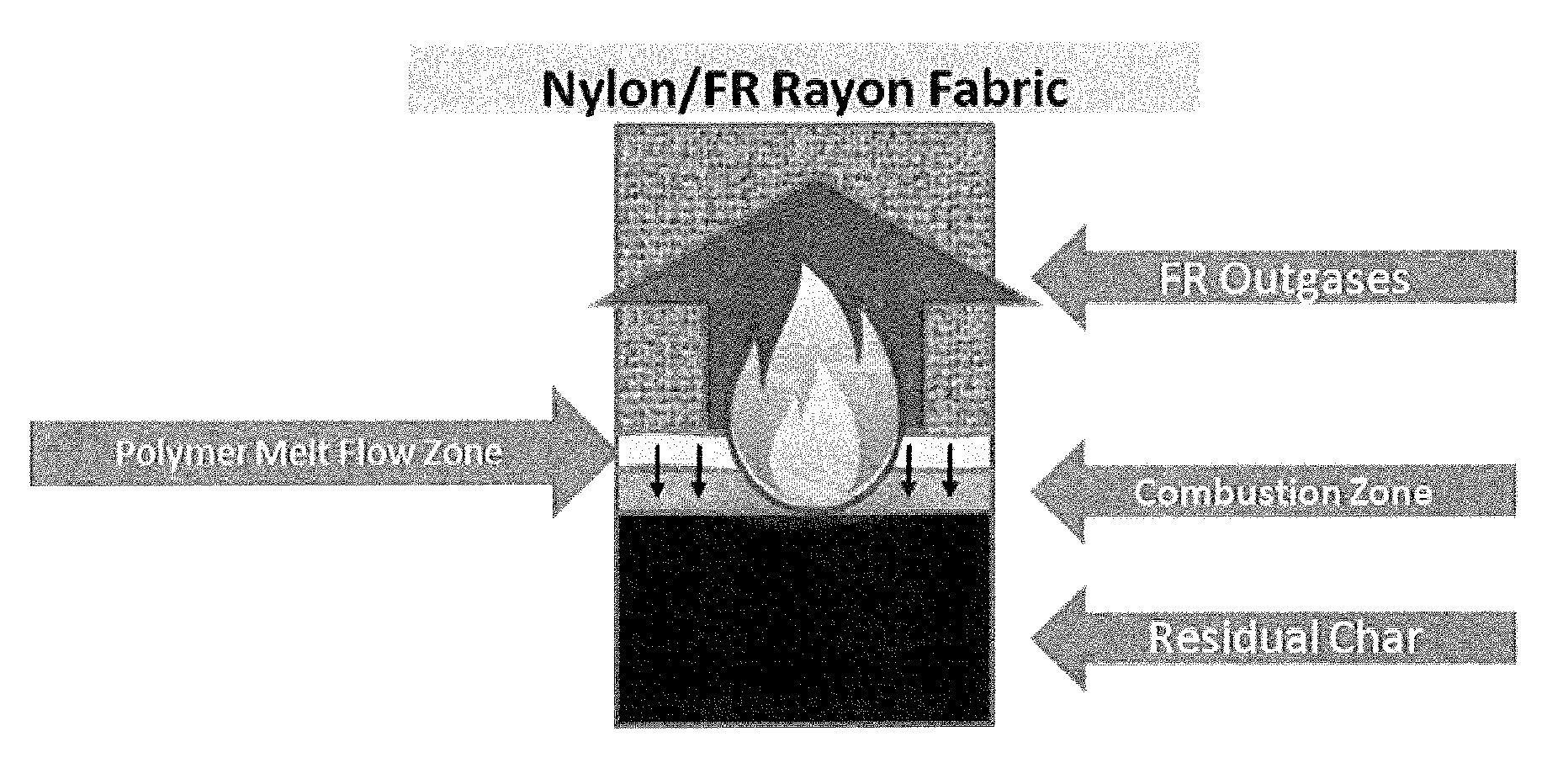

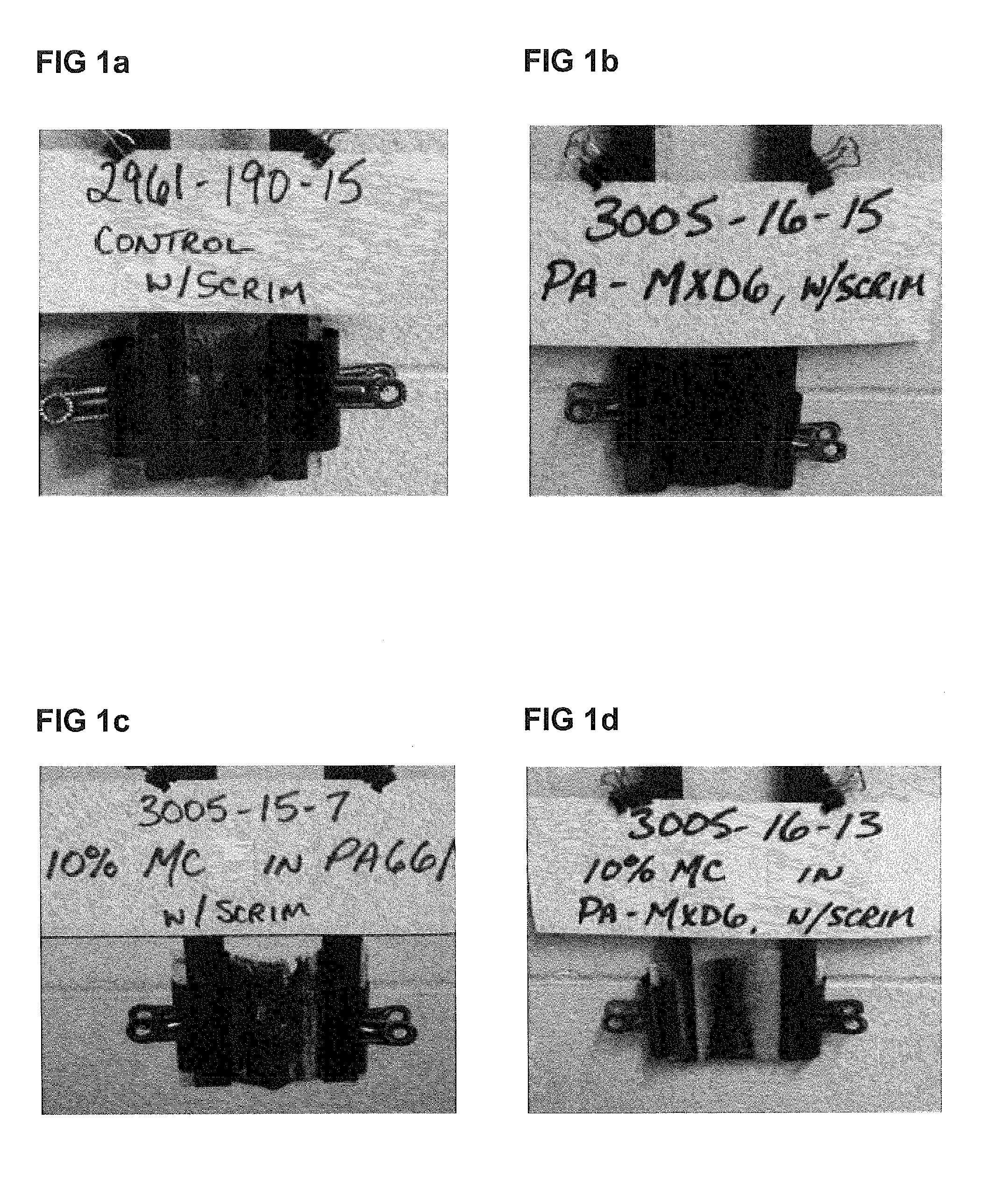

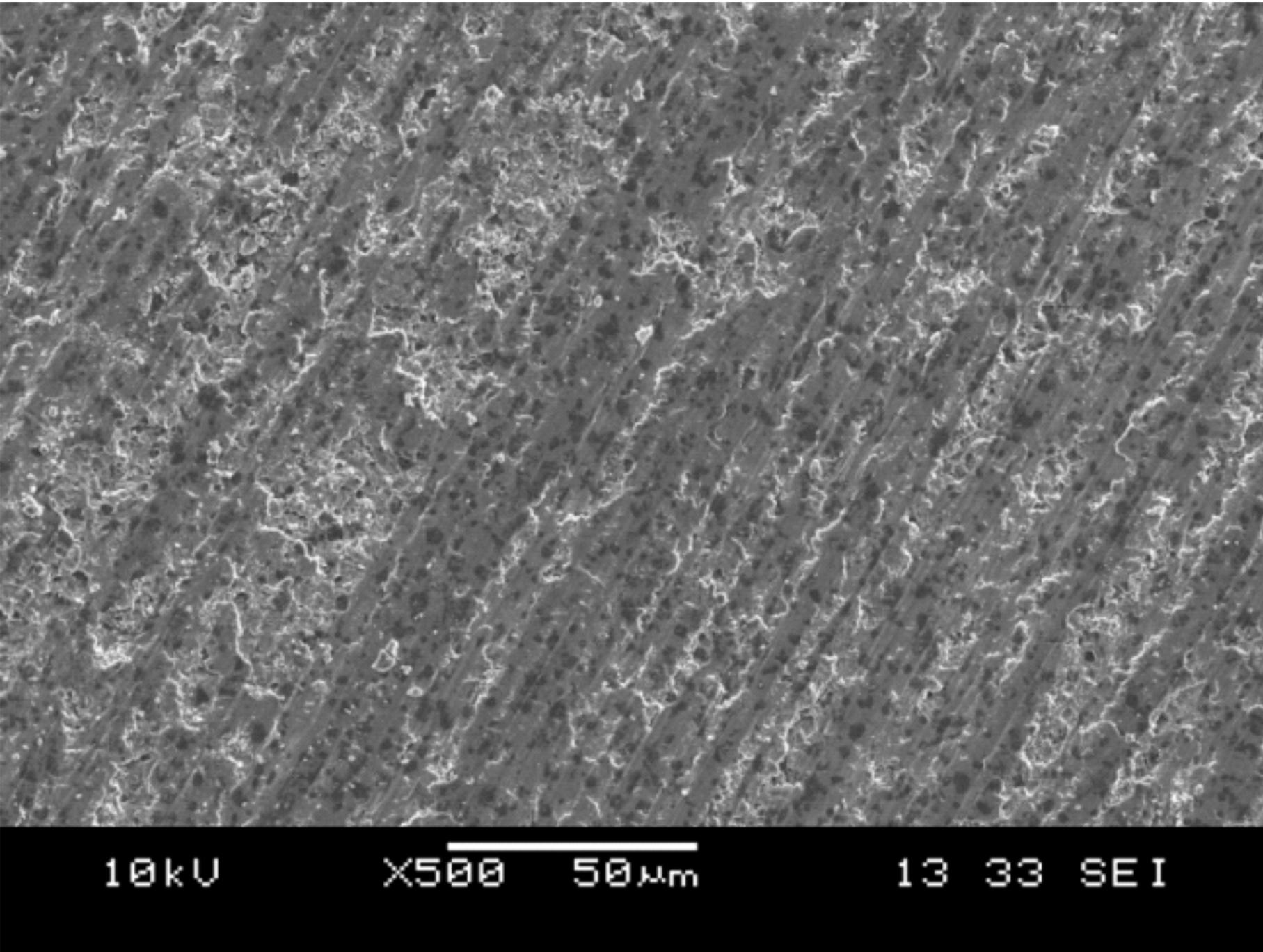

Flame retardant fibers, yarns, and fabrics made therefrom

ActiveUS20130244527A1Eliminate the effects ofImprove flame retardant performanceFlame-proof filament manufactureHeat resistant fibresFiberYarn

Disclosed are technical fibers and yarns made with partially aromatic polyamides and non-halogenated flame retardant additives. Fabrics made from such fibers and yarns demonstrate superior flame retardancy over traditional flame retardant nylon 6,6 fabrics. Further, the disclosed fibers and yarns, when blended with other flame retardant fibers, do not demonstrate the dangerous “scaffolding effect” common with flame retardant nylon 6,6 blended fabrics.

Owner:INV PERFORMANCE MATERIALS LLC

Super intensified abrasion-proof pouring material

The invention discloses a hyper-high strong abrasion-proof casting material, which comprises the following parts: corundum, carborundum, pulverized corundum, bauxite powder, silicon oxide powder, pure calcium aluminate cement and additive, wherein the adding quantity of each component is forced to homogenize, which couples metal and non-metal material in the constructing course.

Owner:ANHUI RUITAI NEW MATERIALS TECH

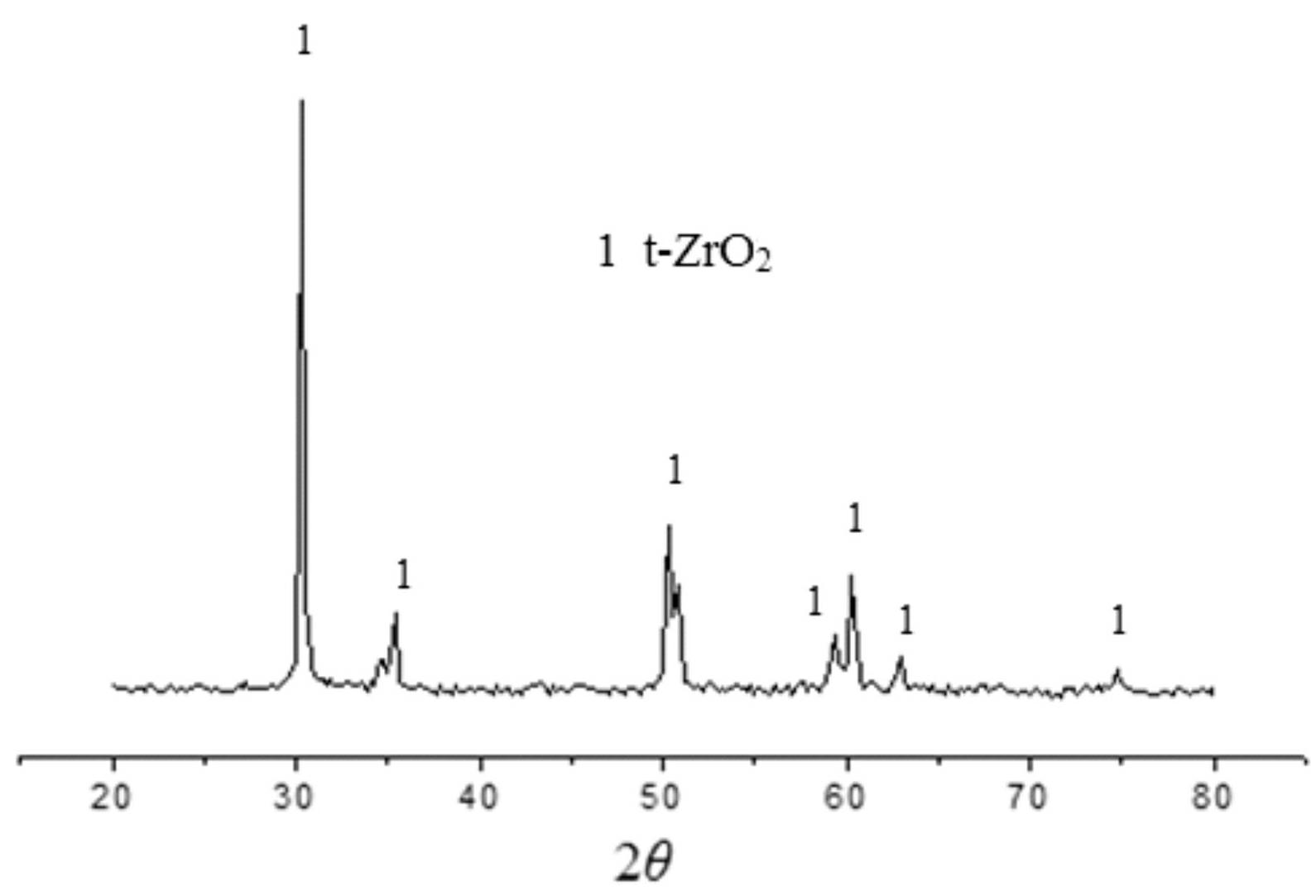

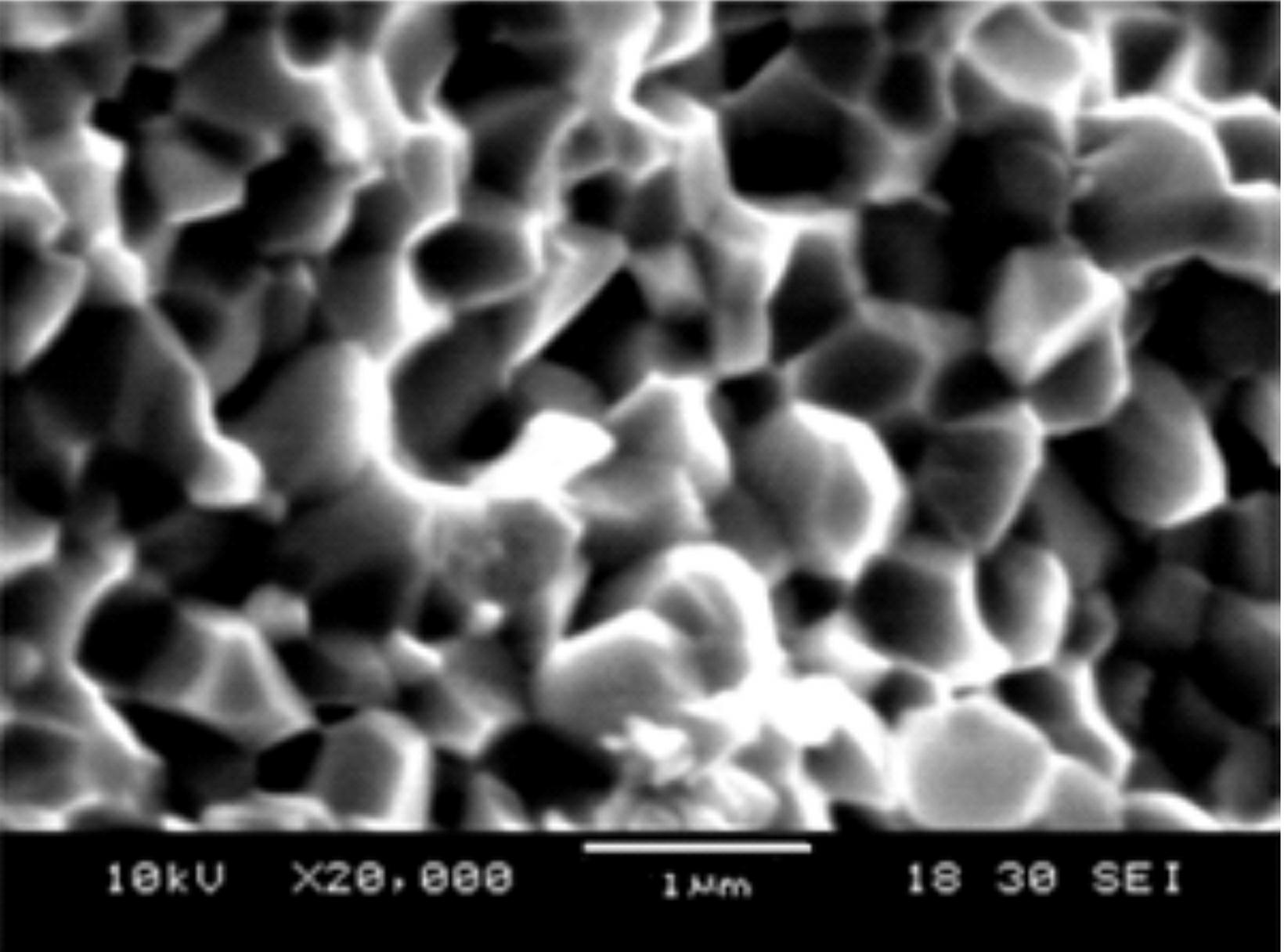

Zirconia ceramic cylinder liner material and preparation method thereof

InactiveCN102320830AWell mixedOvercome the disadvantage of uneven mixingComposite ceramicZirconia ceramic

The invention discloses a zirconia ceramic cylinder liner material and a preparation method thereof, and the material comprises the following components: 60-80 wt% of ZrO2, 20-30 wt% of Al2O3, 3.2-4.3 wt% of Y2O3, 3-4.2 wt% of TiO2, and 1.5-2.1 wt% of La2O3. The method prepares the ZrO2 ceramic cylinder liner material by using Al(NO3)3, ZrOCl2.8H2O, Y(NO3)3, TiCl4, LaCl3 as raw materials, using C6H12N4 as a precipitant, and by a coprecipitation method. Uniform mixing of each component at molecular level is effectively realized. The disadvantage of poor uniformity of the mixing of each component in the material due to routine ball milling mixing technology is overcome; the prepared zirconia ceramic powder has the characteristics of uniform dispersion, homogeneous particle size, and good fluidity; low-temperature sintering is realized; the ZrO2 composite ceramic material green body prepared by the method has bending strength of 980-1200 MPa, fracture toughness of 8.3-10 MPa.m1 / 2, vickers hardness of 2 GPa-14 GPa after calcination at 1330-1380 DEG C; the process is simple, and is applicable to large-scale production.

Owner:SHANTOU UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com