Method for thermal spraying of composite bottom layer of aluminum pan of electromagnetic oven

A technology of induction cooker and thermal spraying, which is applied in the direction of coating, metal material coating process, heating fuel, etc., and can solve the problem that the electromagnetic induction heating layer cannot be formed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

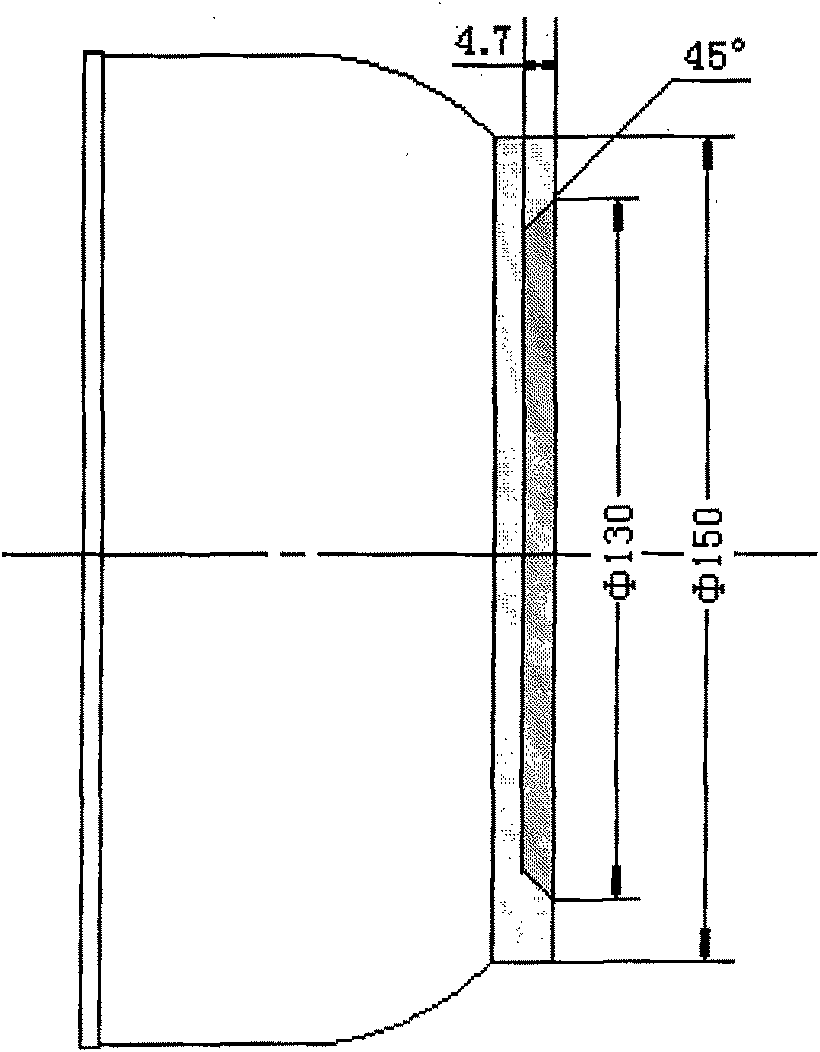

[0068] Embodiment one: the spraying of the single-layer composite bottom (430 stainless steel) coating of induction cooker aluminum pan

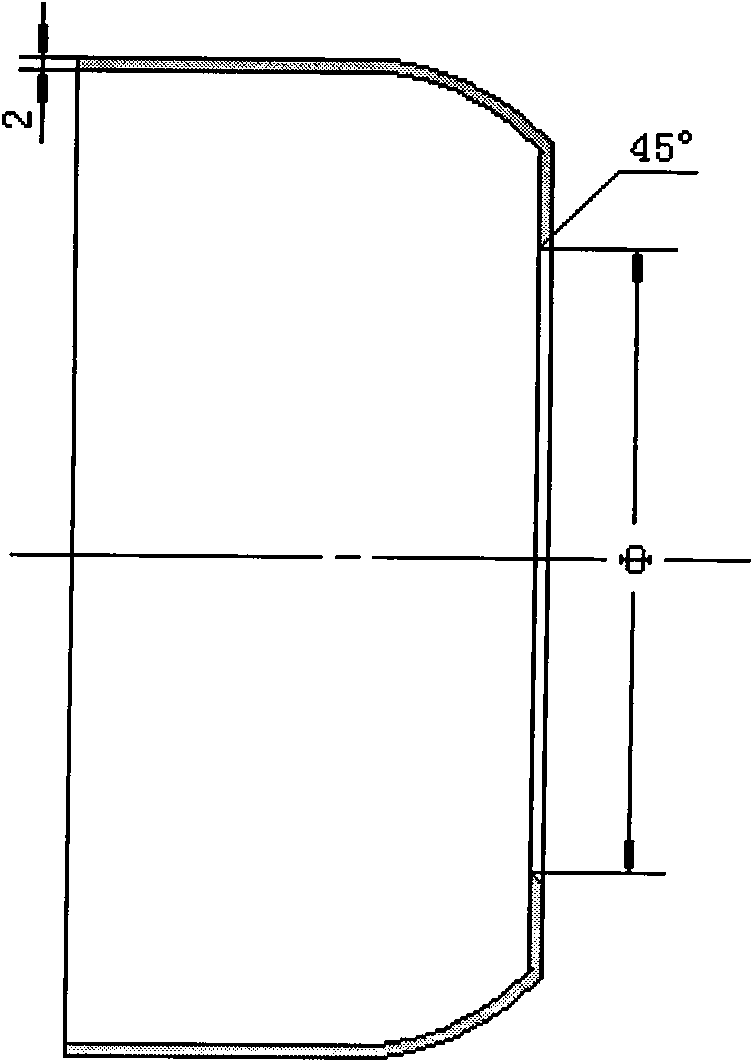

[0069] 1. Conditions: the shape of the pot is attached Figure 5 , The diameter of the bottom of the pot is 150mm, the diameter of the pot mouth is 210mm, the height of the pot is 50mm, the material is aluminum alloy, and the pot body is a thin-walled and thick-bottomed structure. Spraying the composite layer on the bottom of the pot is used in the induction cooker, and it is a low-to-medium-grade pot.

[0070] 2. Coating design: According to the use conditions of the spraying object, the coating adopts a single-layer structure, and the coating material is 430 stainless steel wire with Ф1.6mm, which has the characteristics of good magnetic conductivity, corrosion resistance and wear resistance. The coating thickness after processing is 4.5mm, considering the processing allowance, the coating thickness after spraying is ≥4.8mm. The structur...

Embodiment 2

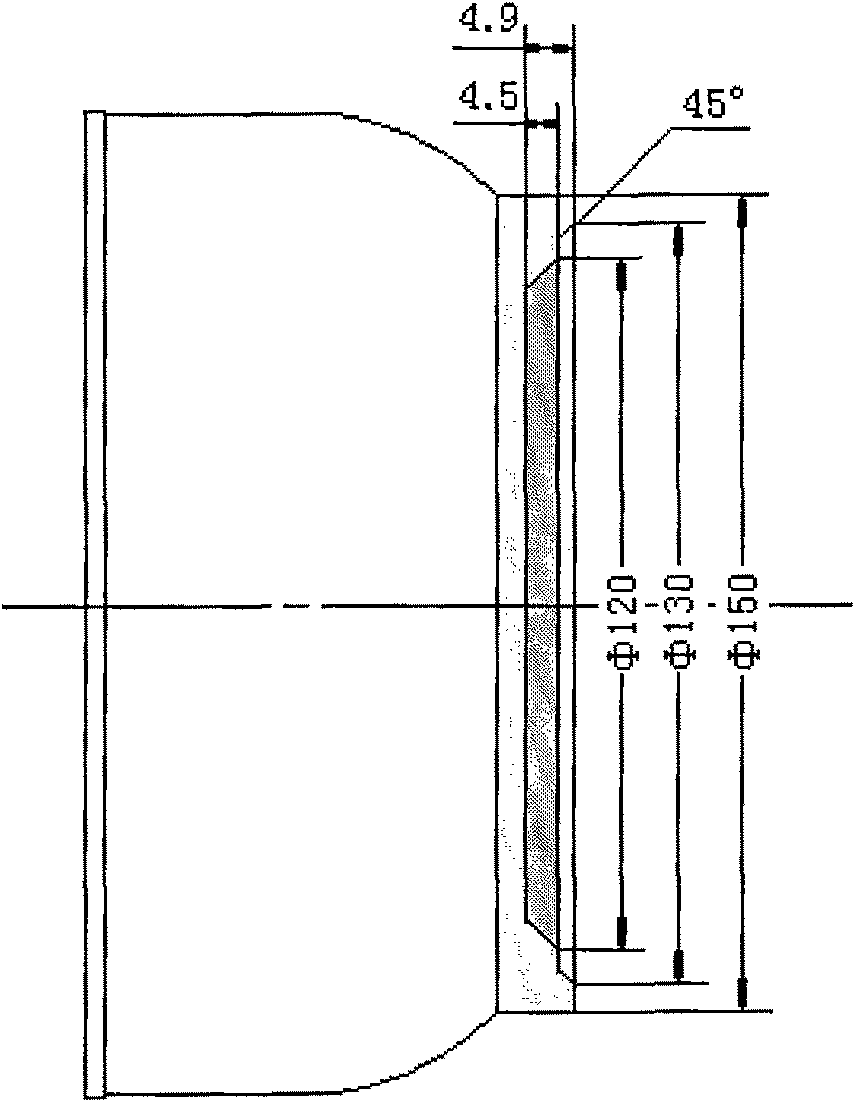

[0073] Embodiment two: the spraying of the double-layer composite bottom (iron+brass) coating of induction cooker aluminum pan

[0074] 1. Conditions: the shape of the pot is attached Figure 5 , The diameter of the bottom of the pot is 150mm, the diameter of the pot mouth is 210mm, the height of the pot is 50mm, the material is aluminum alloy, and the pot body is a thin-walled and thick-bottomed structure. Spraying the composite layer on the bottom of the pot is used for induction cooker, and it is a high-end and high-end pot.

[0075]2. Coating design: According to the use conditions of the spraying object, the coating adopts a double-layer structure, the inner layer is a magnetically conductive coating, and the outer layer is a functional coating. The magnetically conductive material is made of Ф1.6mm iron wire, which has good magnetic conductivity. , high bonding strength and low price; the functional material is brass wire with Ф1.6mm, which has the characteristics of go...

Embodiment 3

[0079] Embodiment three: the spraying of the double-layer composite bottom (iron+aluminum) coating of induction cooker aluminum pan

[0080] 1. Conditions: the shape of the pot is attached Figure 5 , The diameter of the bottom of the pot is 150mm, the diameter of the pot mouth is 210mm, the height of the pot is 50mm, the material is aluminum alloy, and the pot body is a thin-walled and thick-bottomed structure. Spraying the composite layer on the bottom of the pot is used for induction cooker, and it is a high-end and high-end pot.

[0081] 2. Coating design: According to the use conditions of the spraying object, the coating adopts a double-layer structure, the inner layer is a magnetically conductive coating, and the outer layer is a functional coating. The magnetically conductive material is made of Ф1.6mm iron wire, which has good magnetic conductivity. , high bonding strength and low price; the functional material is made of Ф1.6mm aluminum alloy wire, which has the cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com