Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1418 results about "Porous composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SiCOH dielectric

InactiveUS20070173071A1Improve cohesive strengthReduce brittlenessSemiconductor/solid-state device detailsSolid-state devicesDielectricDevice material

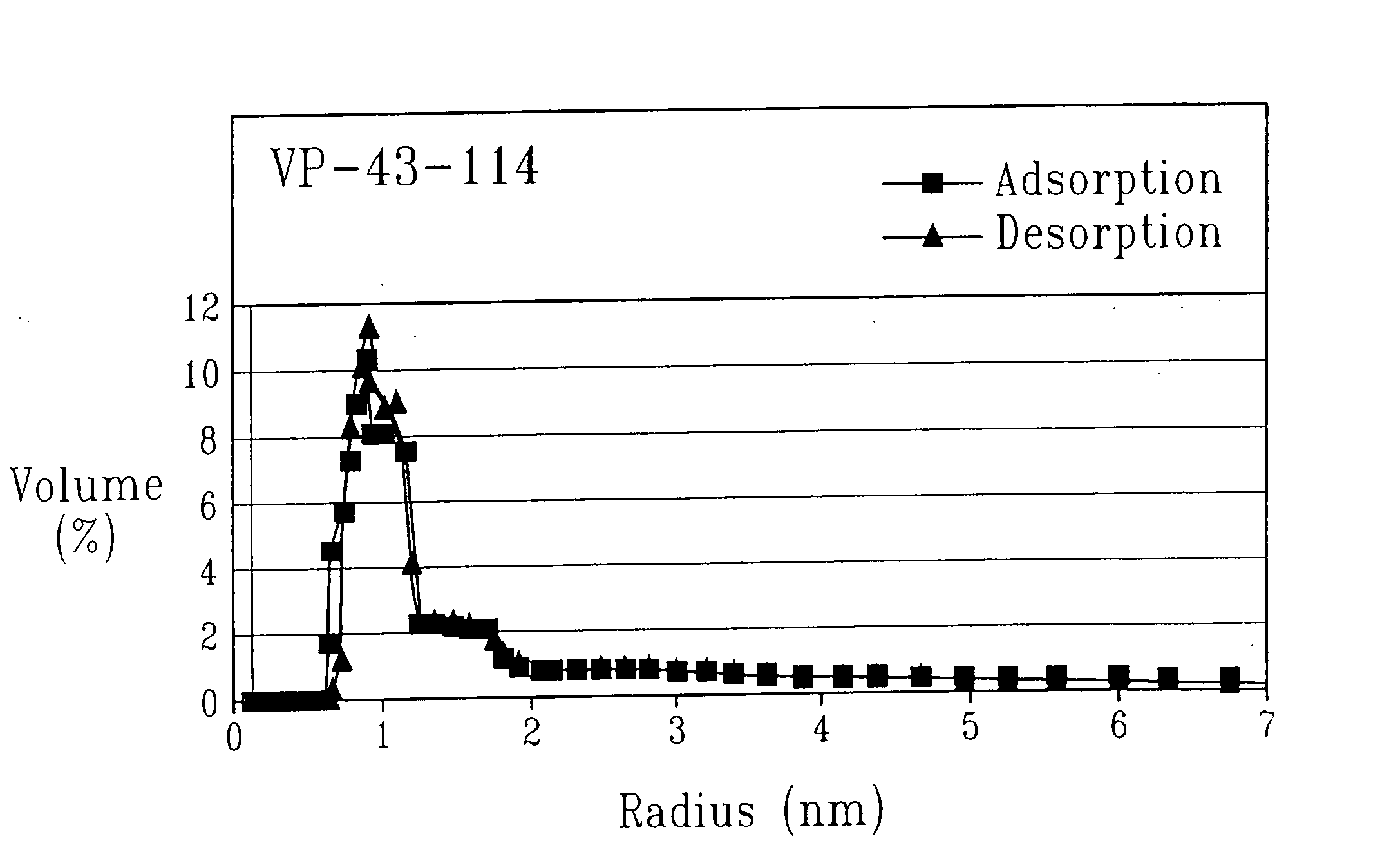

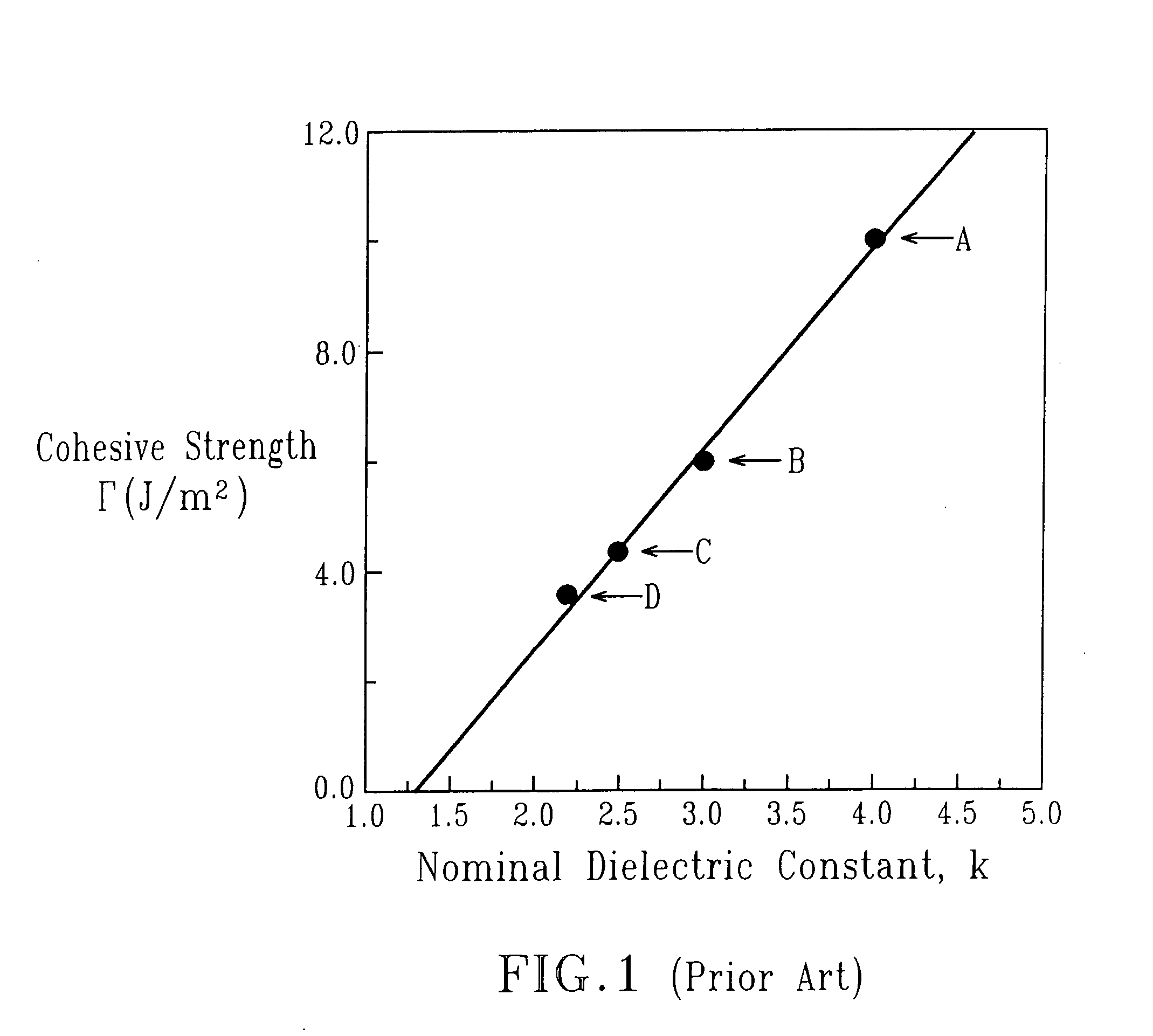

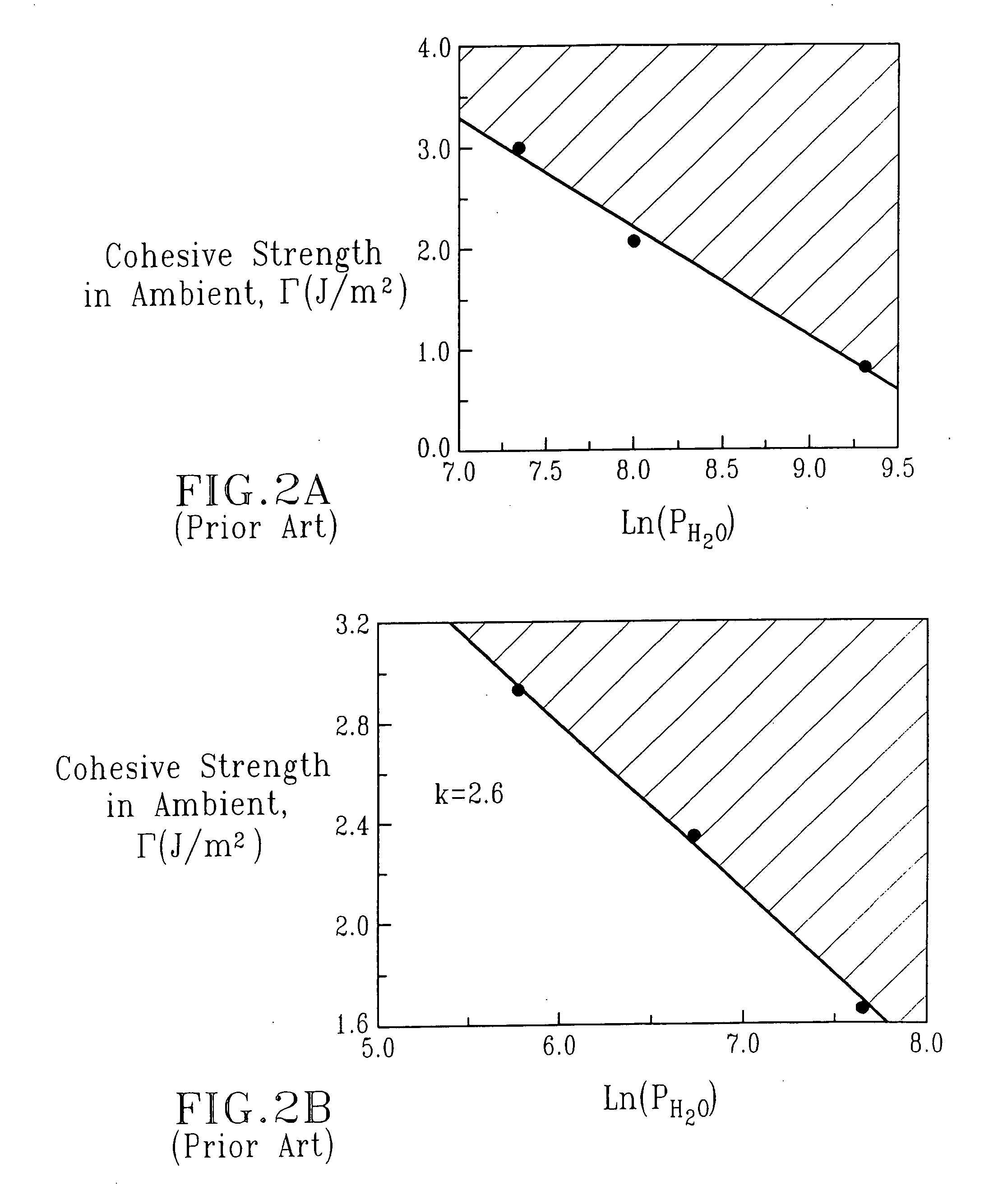

A porous composite material useful in semiconductor device manufacturing, in which the diameter (or characteristic dimension) of the pores and the pore size distribution (PSD) is controlled in a nanoscale manner and which exhibits improved cohesive strength (or equivalently, improved fracture toughness or reduced brittleness), and increased resistance to water degradation of properties such as stress-corrosion cracking, Cu ingress, and other critical properties is provided. The porous composite material is fabricating utilizing at least one bifunctional organic porogen as a precursor compound

Owner:INTEL CORP

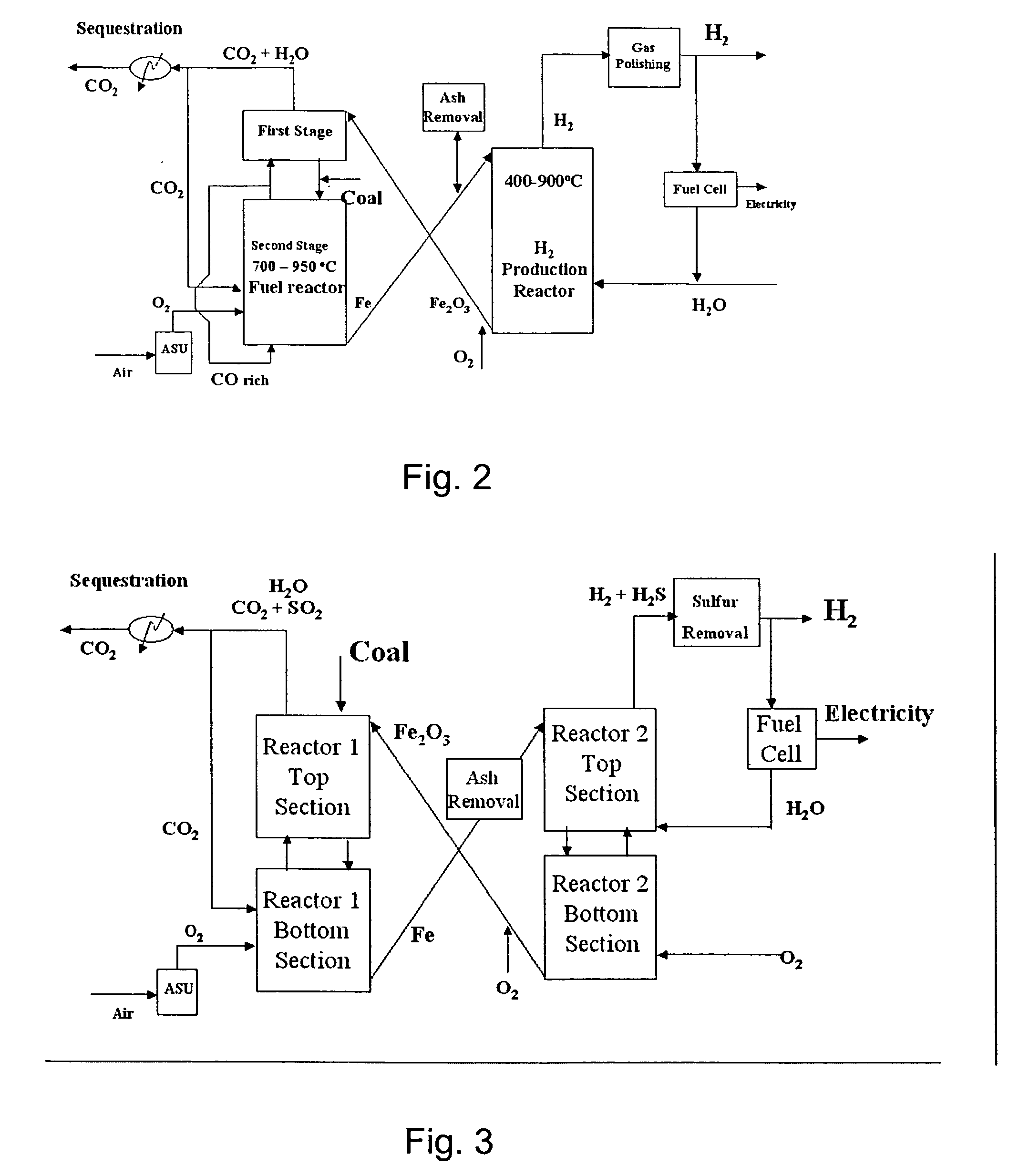

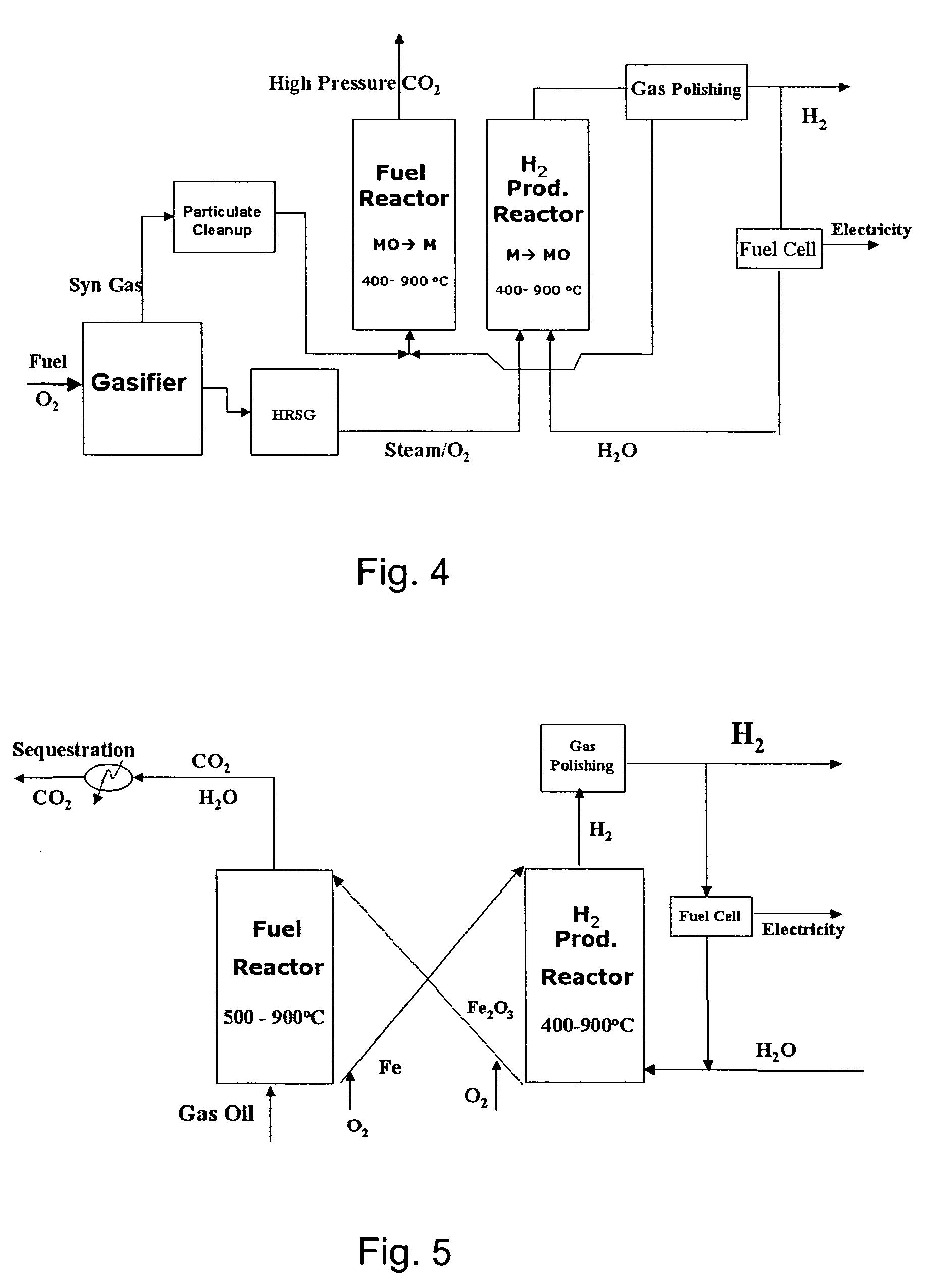

Combustion looping using composite oxygen carriers

ActiveUS20050175533A1Increase surface areaImprove energy conversion efficiencyHydrogen productionIndirect carbon-dioxide mitigationHydrogenCombustion

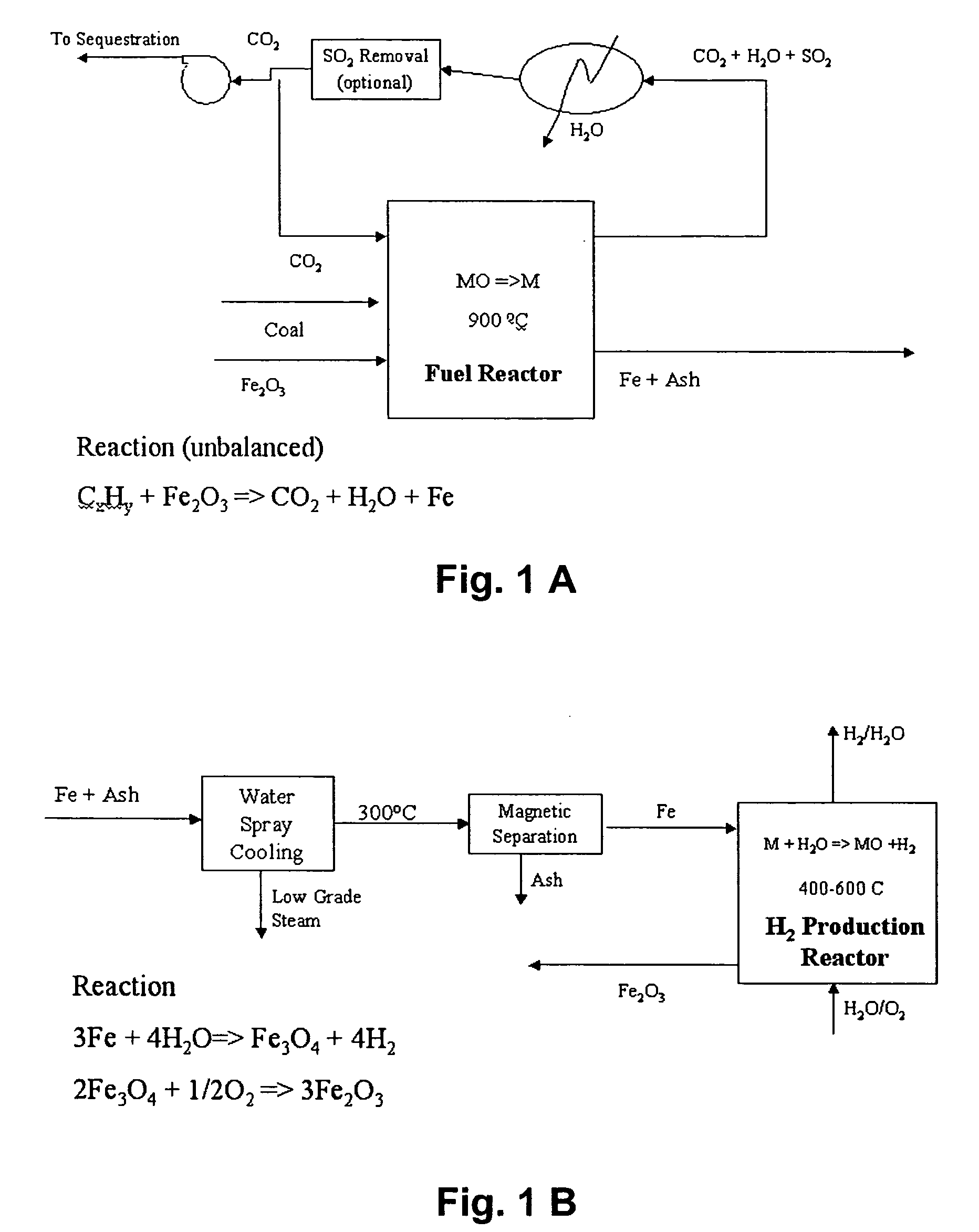

A method for producing hydrogen gas is provided and comprises reducing a metal oxide in a reduction reaction between a carbon-based fuel and a metal oxide to provide a reduced metal or metal oxide having a lower oxidation state, and oxidizing the reduced metal or metal oxide to produce hydrogen and a metal oxide having a higher oxidation state. The metal or metal oxide is provided in the form of a porous composite of a ceramic material containing the metal or metal oxide. The porous composite may comprise either a monolith, pellets, or particles.

Owner:OHIO STATE INNOVATION FOUND

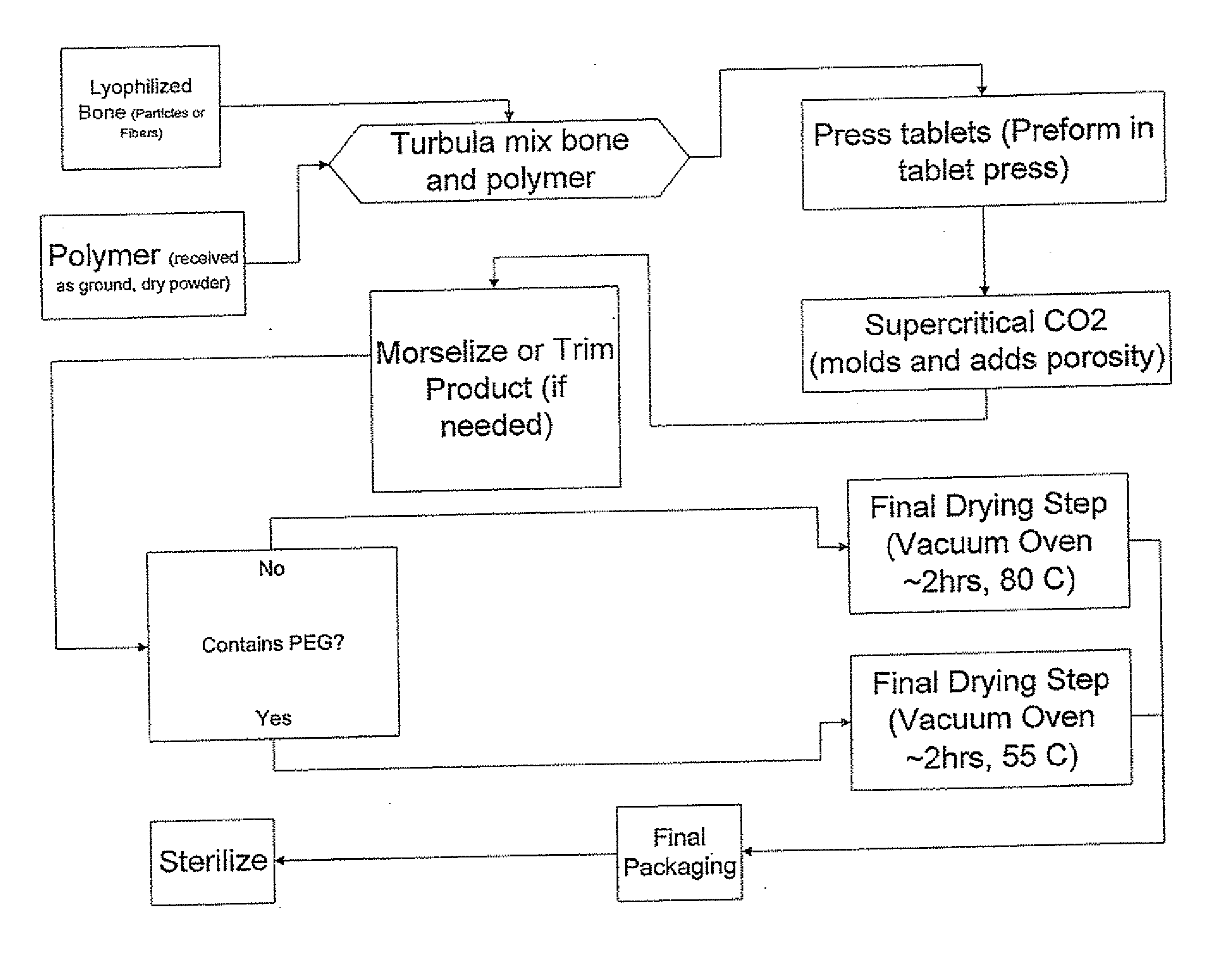

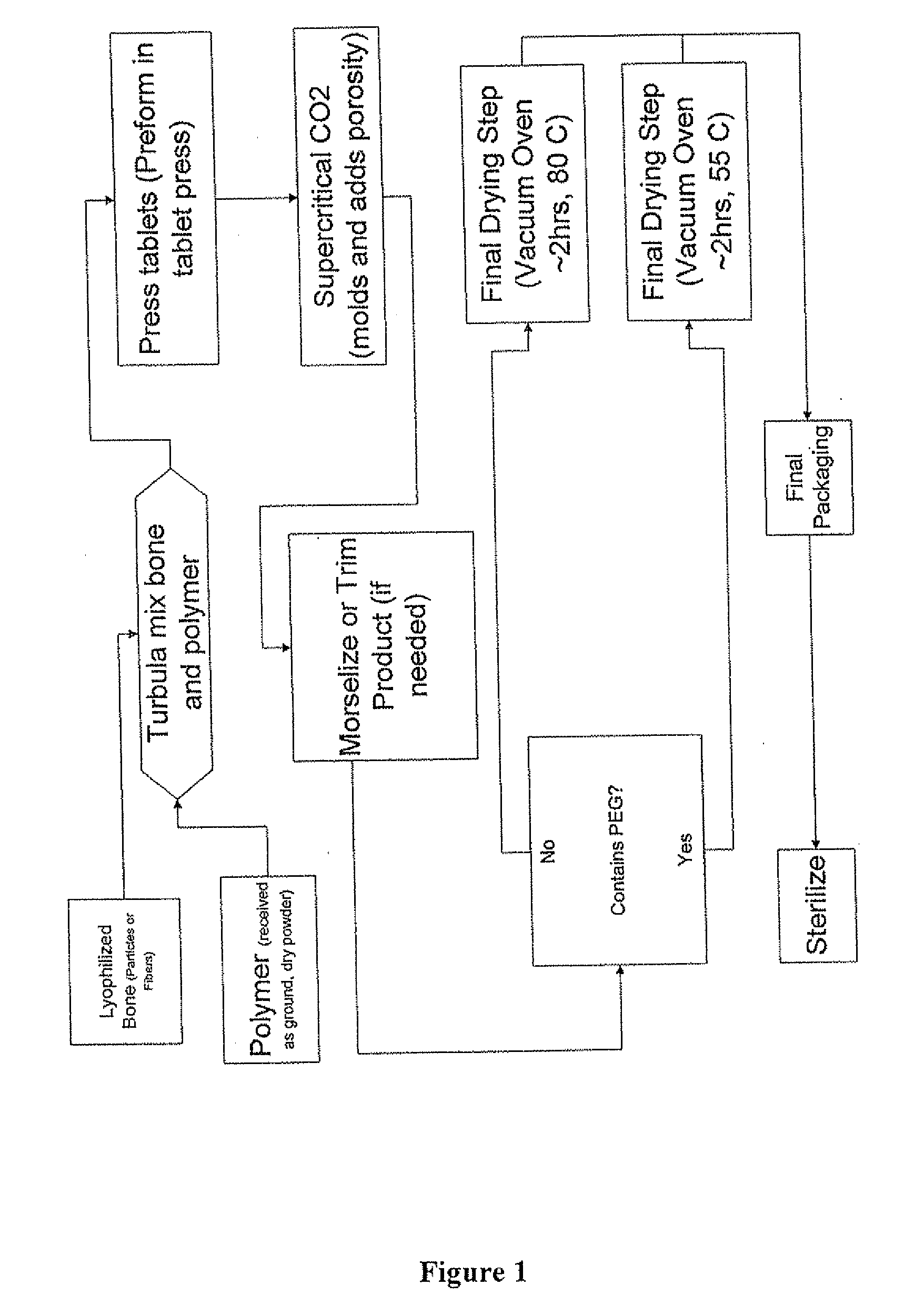

Porous osteoimplant

ActiveUS20080069852A1Accelerate the remodeling processImprove permeabilityBone implantSkeletal disorderBone growthBone defect

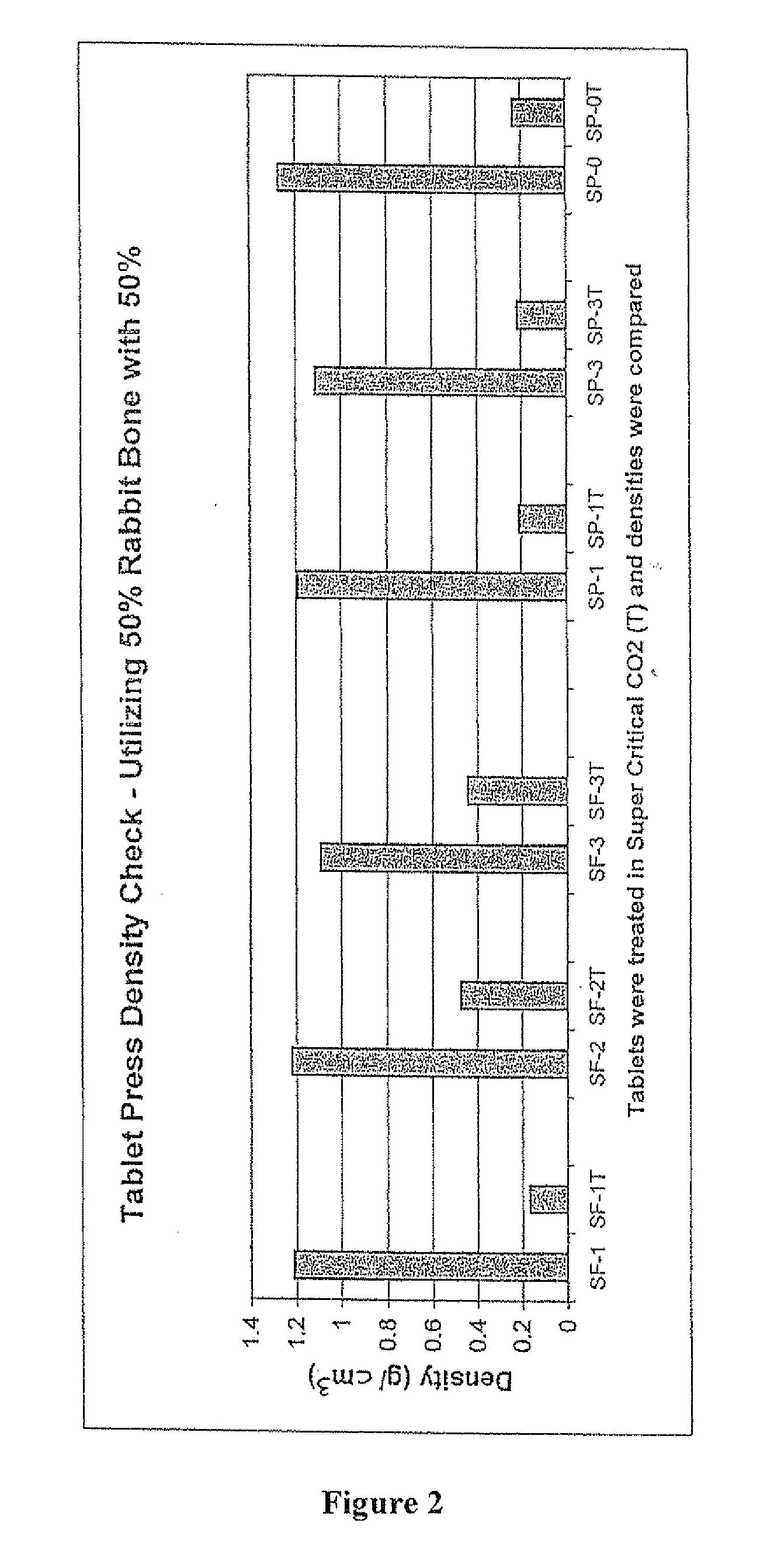

The invention is directed toward porous composites for application to a bone defect site to promote new bone growth. The inventive porous composites comprise a biocompatible polymer and a plurality of particles of bone-derived material, inorganic material, bone substitute material or composite material. In certain embodiments, the porous composites are prepared using a method that includes a supercritical fluid (e.g., supercritical carbon dioxide) treatment. The invention also discloses methods of using these composites as bone void fillers.

Owner:WARSAW ORTHOPEDIC INC

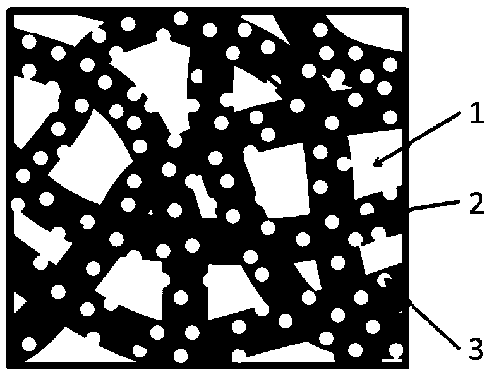

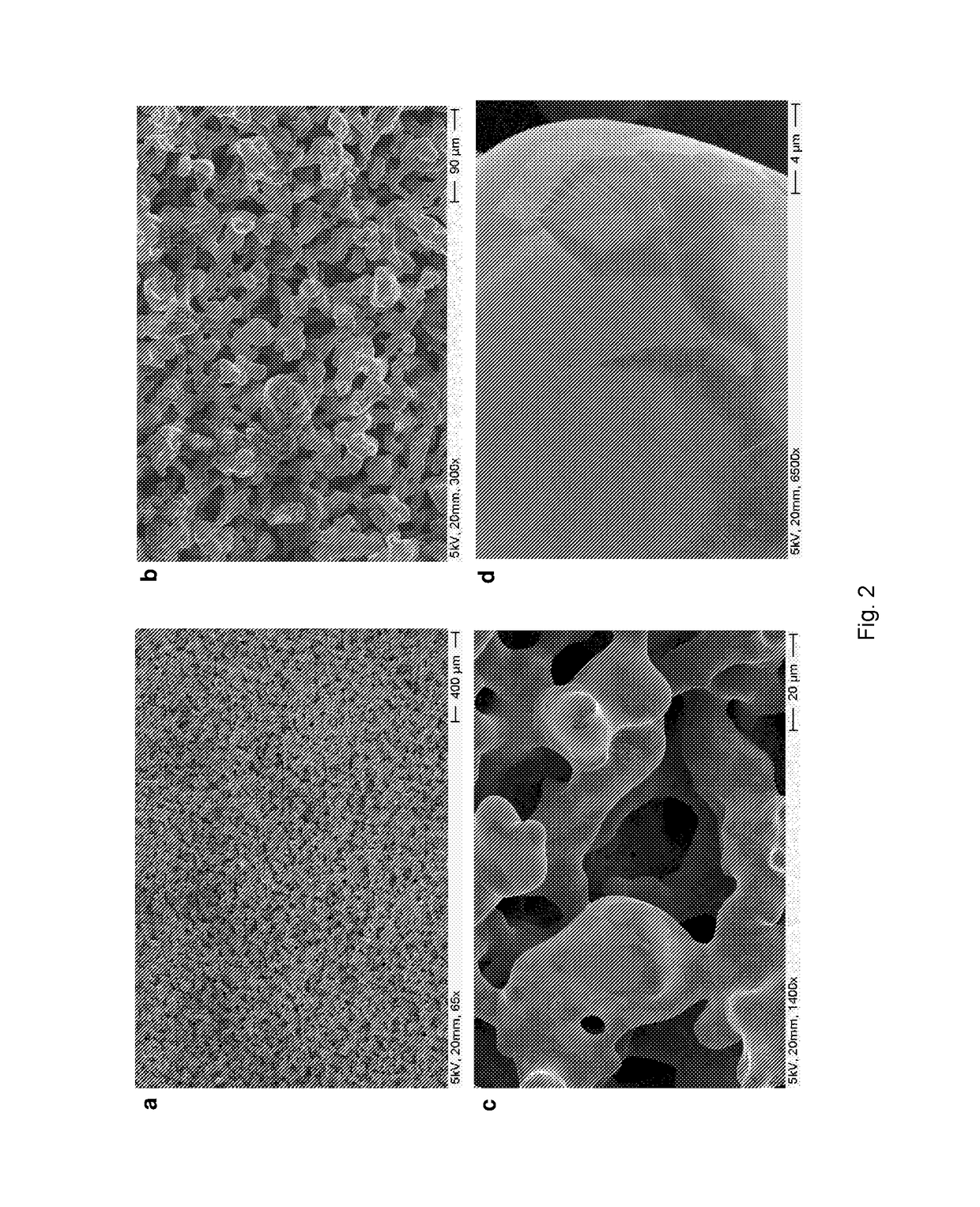

Porous composite materials having micro and meso/macroporosity

InactiveUS20070087934A1Molecular sieve catalystsOrganic compound preparationMaterials scienceInorganic oxide

A composite material comprises: (a) a porous crystalline inorganic oxide material comprising a first framework structure defining a first set of uniformly distributed pores having an average cross-sectional dimension of from 0.3 to less than 2 nanometers and comprising a second framework structure defining a second set of uniformly distributed pores having an average cross-sectional dimension of from 2 to 200 nanometers and (b) a co-catalyst within the second set of pores of the porous crystalline inorganic oxide material (a).

Owner:EXXONMOBIL CHEM PAT INC

Medical devices comprising a reticulated composite material

InactiveUS20070003753A1Easy to modifyCost-efficient productionStentsLayered productsReady to useMedical device

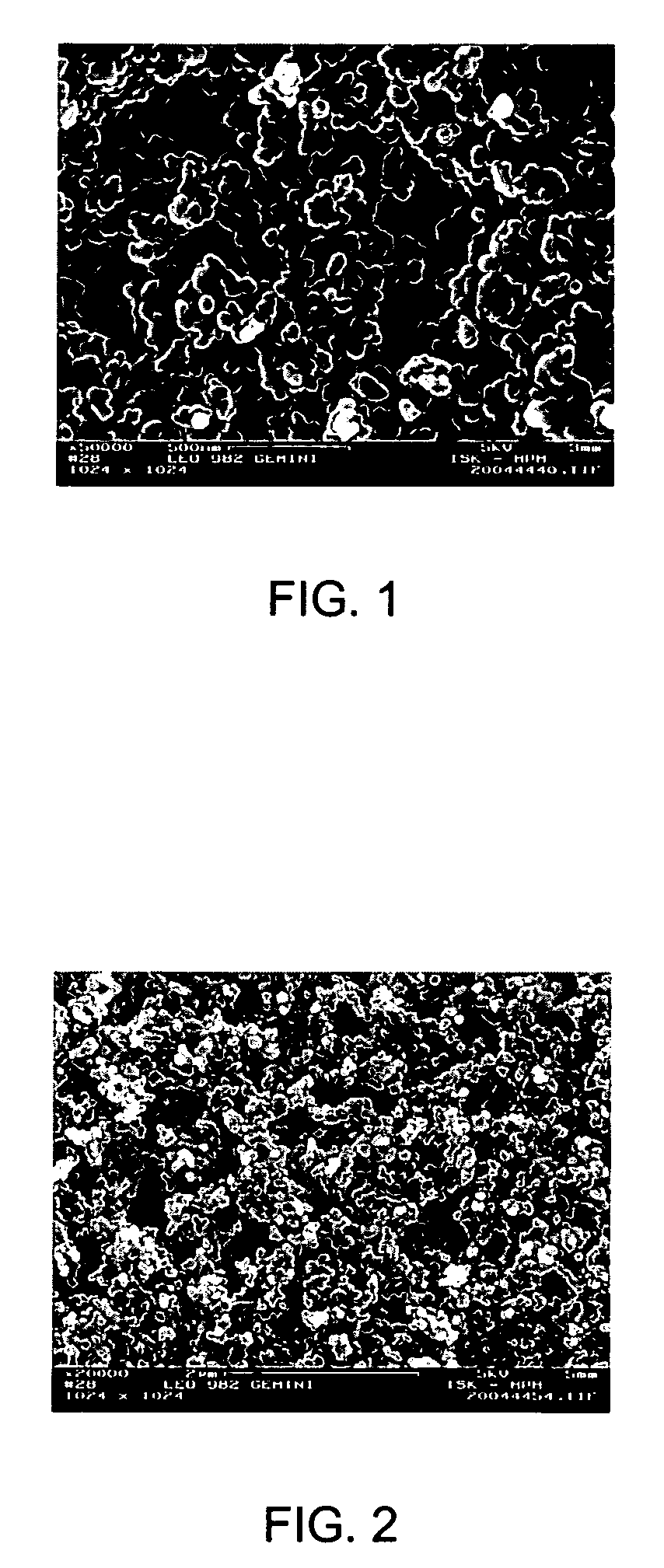

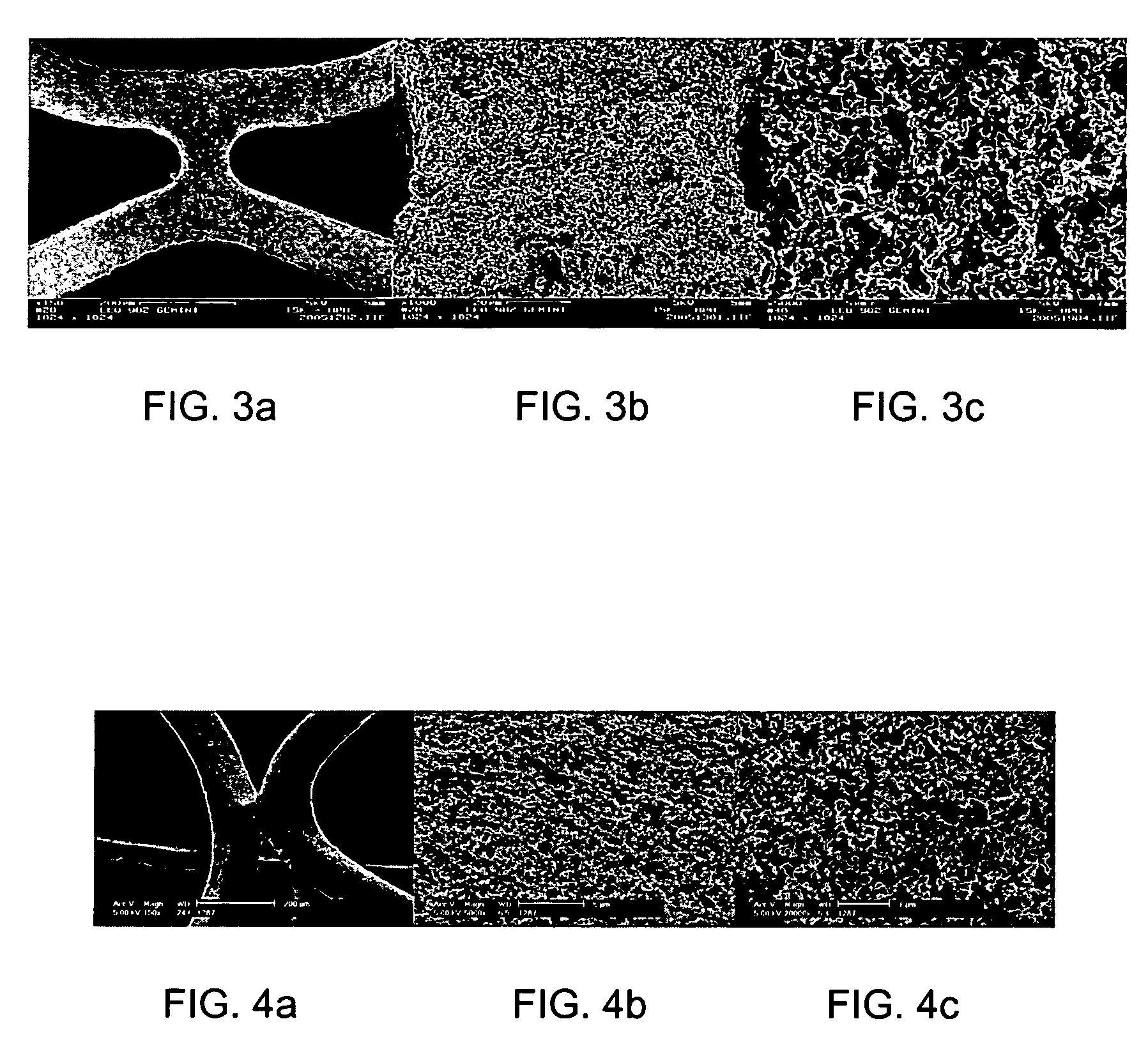

The present invention relates to medical devices, particularly for therapeutic and / or diagnostic purposes, which may coated or at least partially formed using porous reticulated composite materials. Specifically, the present invention relates to medical devices which include a porous composite material, where the composite material can be formed using a process comprising the steps of providing a liquid mixture that includes at least one inorganic and / or organic reticulating agent; and at least one matrix material that is a polymer or combination of polymers; and solidifying the liquid mixture.

Owner:CINVENTION AG

Composite and its use

InactiveUS6248344B1Rapid ossificationQuick upgradeDental implantsNervous disorderMaterials scienceCompound s

A porous composite suitable for filling a recess or a through-passing hole in an implant. The composite includes particles A prepared from a bioactive material and particles B prepared from a non-bioactive material or weakly bioactive material, which is sintratable with the bioactive material, such that particles A and particles B have been sintered together to a porous composite. Particles A and particles B are essentially homogeneous in size. Also disclosed is an implant which contains a core and the composite.

Owner:VIVOXID

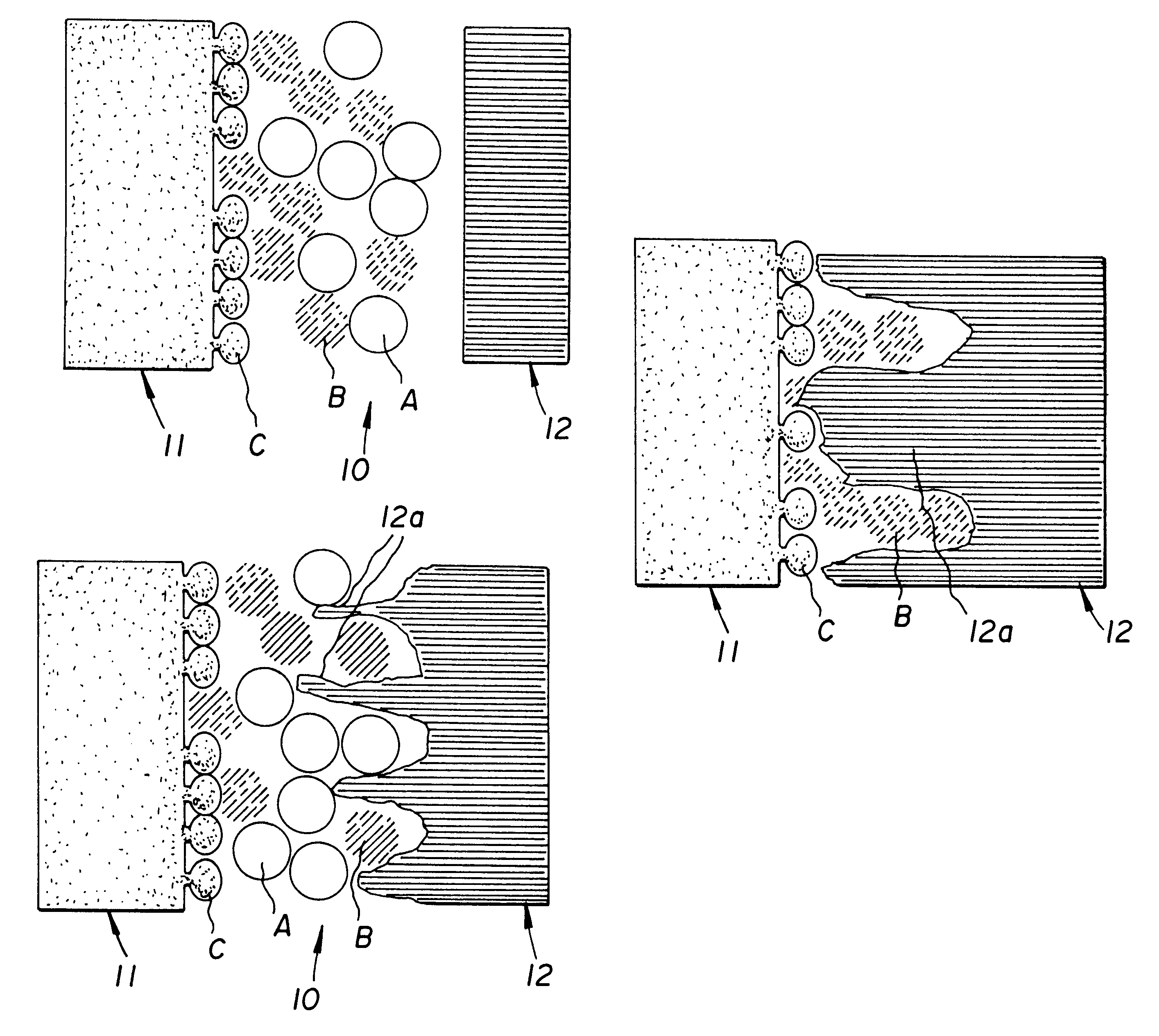

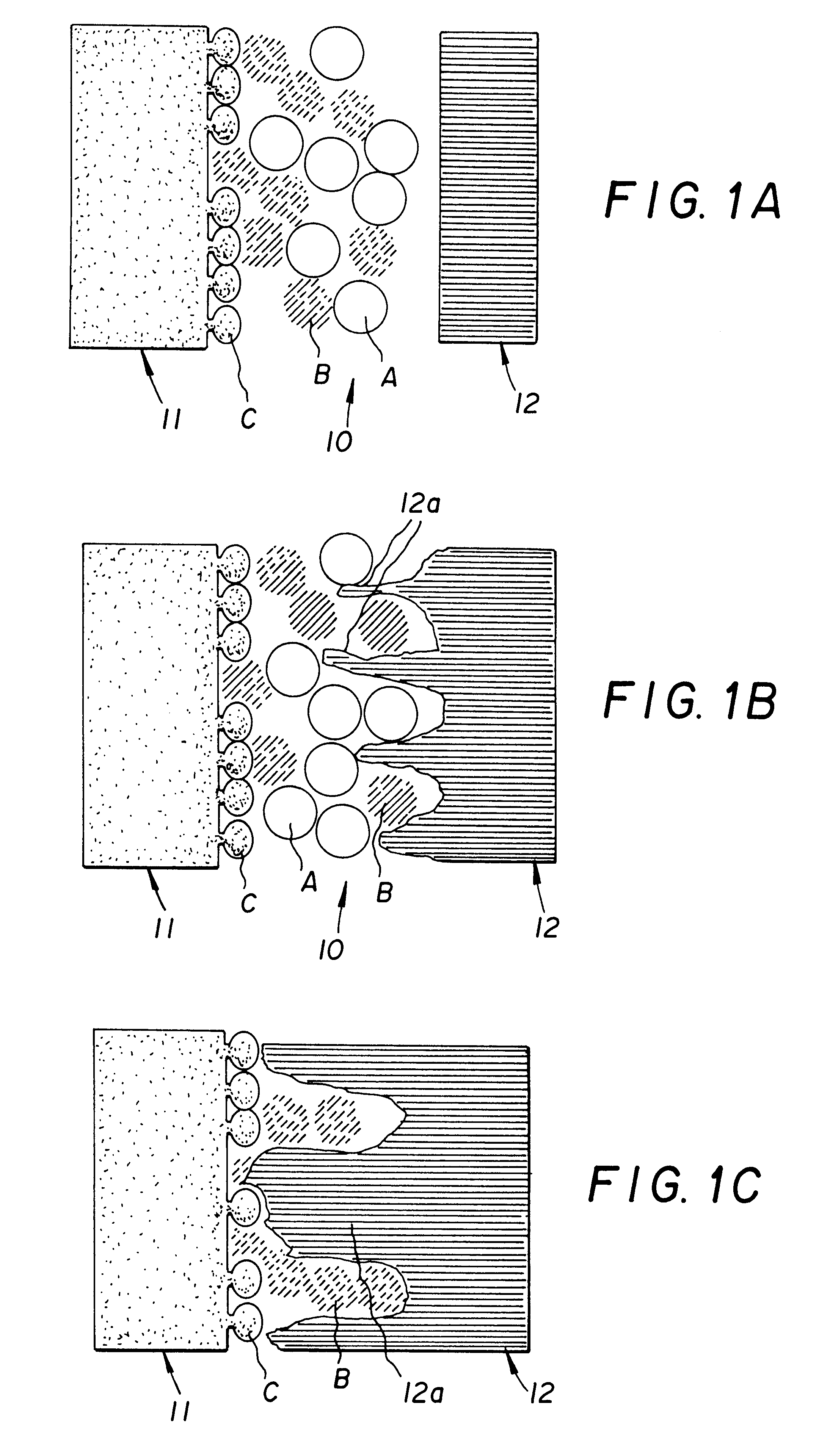

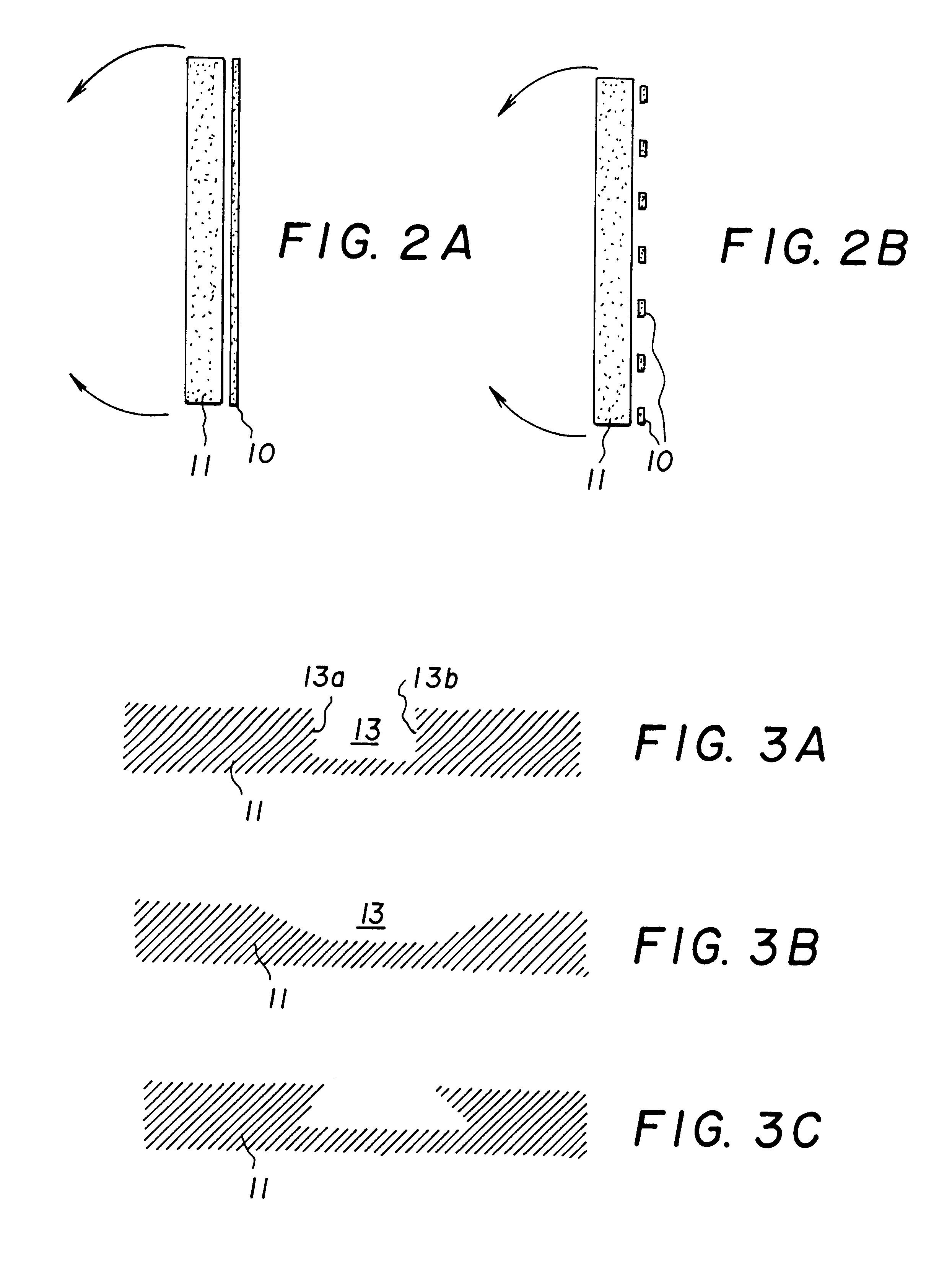

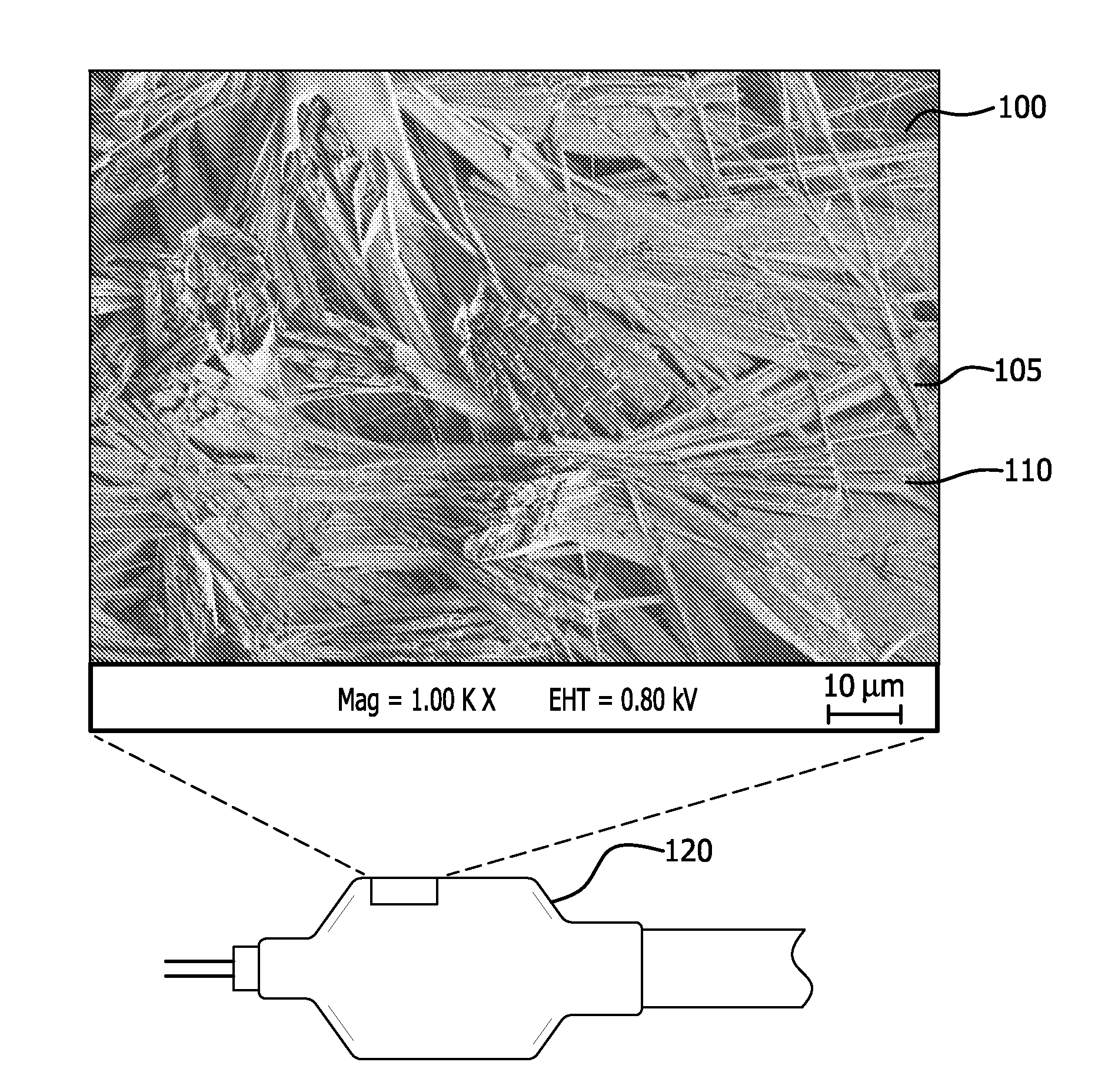

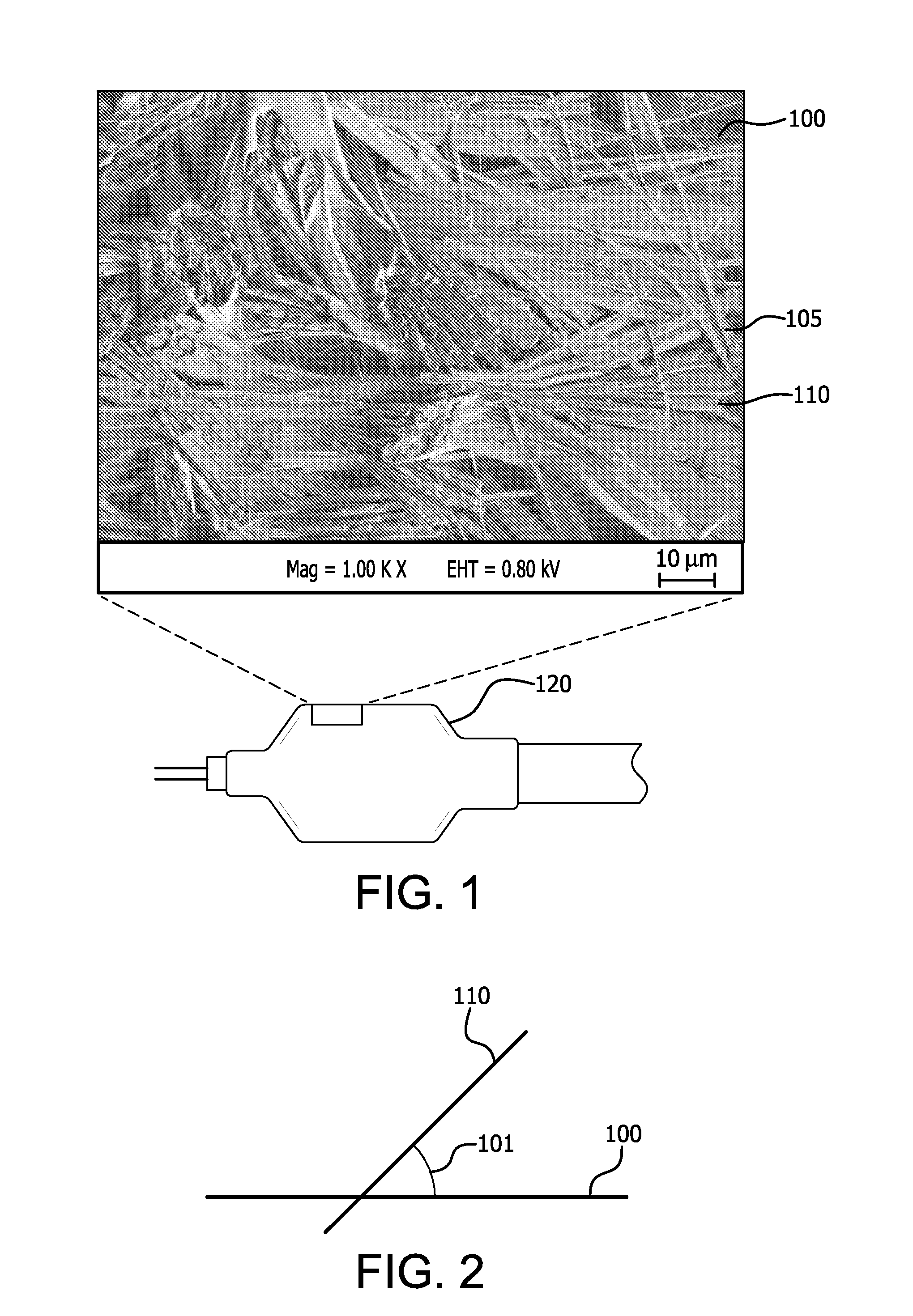

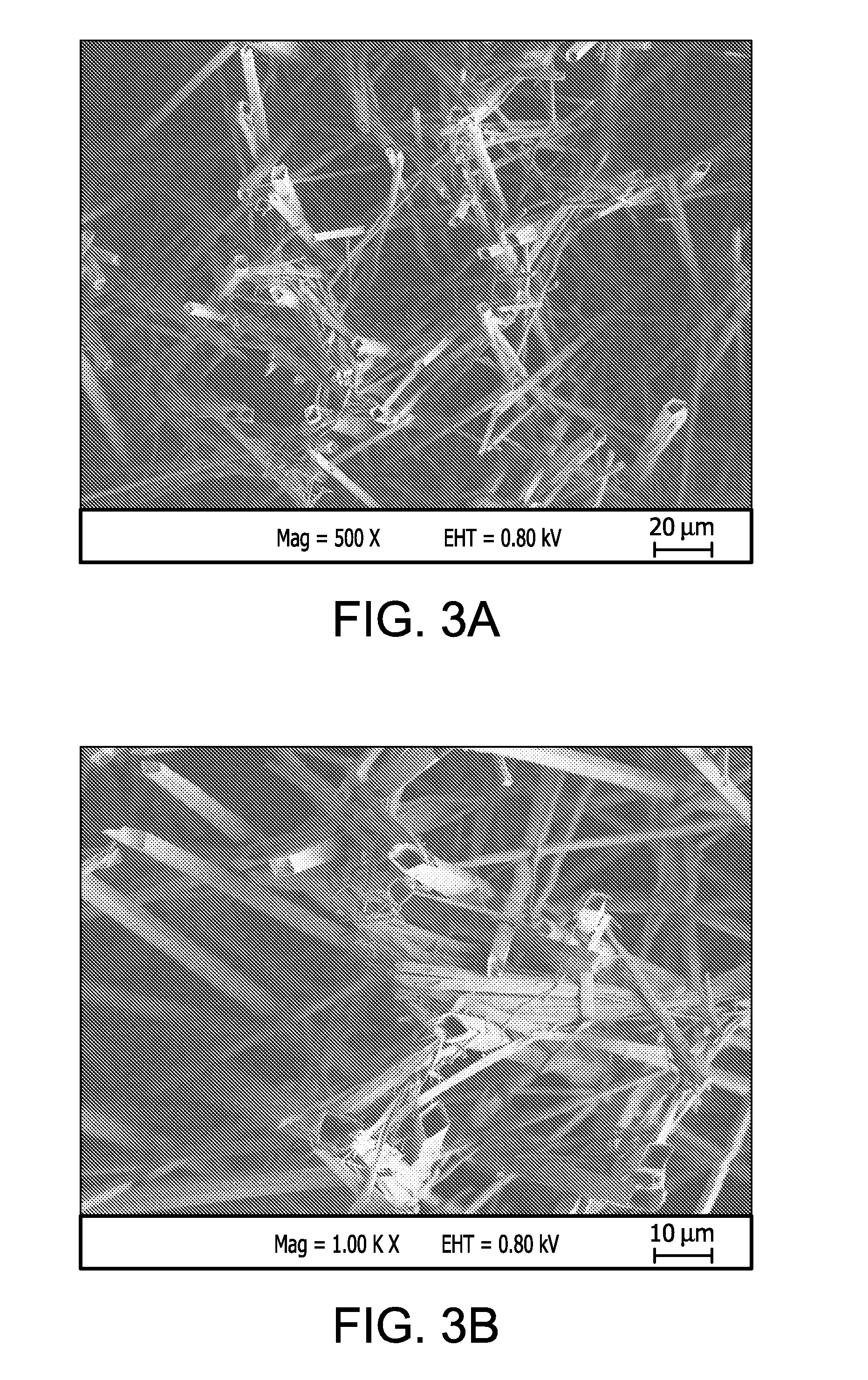

Porous composites with high-aspect ratio crystals

ActiveUS20140271775A1Easy to attachHigh aspect ratioOrganic active ingredientsBiocideVascular diseaseMedicine

The present disclosure is directed toward composite materials comprising high aspect ratio habits of drug crystals which can be partially or fully extending into a substrate, and additionally, can be projecting from a substrate at an angle of about 20° to about 90°. The present disclosure is directed toward medical devices, such as medical balloons, comprising said composite and methods of using and making the same. The described composite can be used for the local treatment of vascular disease. The present disclosure is also directed toward paclitaxel crystals with a hollow acicular habit.

Owner:WL GORE & ASSOC INC

Process for production of porous reticulated composite materials

InactiveUS20070003749A1Easy to modifyCost-efficient productionLayered productsSurgeryMaterials sciencePolymeric matrix

The present invention relates to porous reticulated composite materials and processes for the production thereof. For example, a process for the production of porous composite materials can be provided in which a mixture capable of flowing comprising at least one inorganic and / or organic reticulating agent and at least one polymeric matrix material is provided, and the liquid mixture is caused to be solidified.

Owner:CINVENTION AG

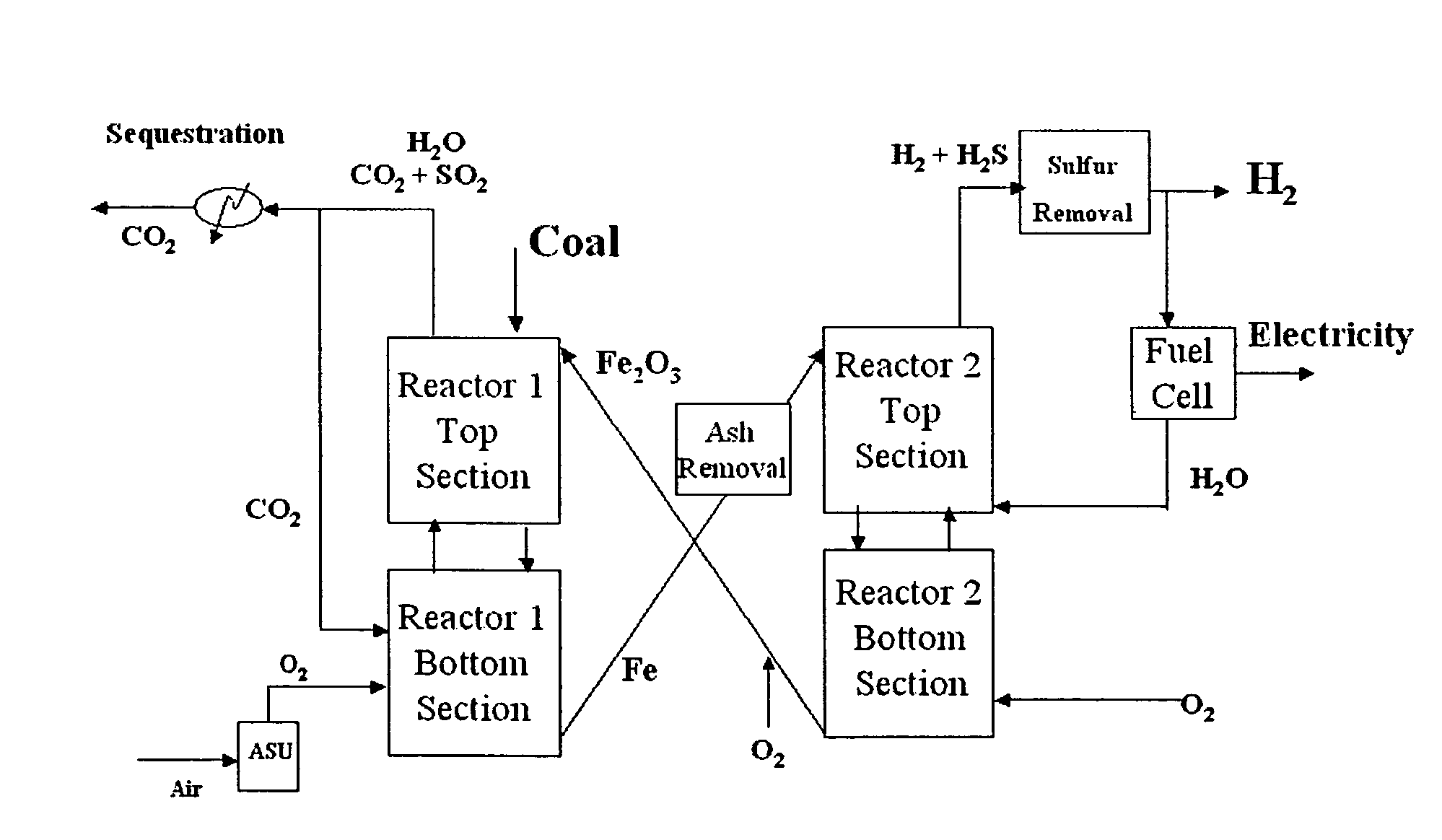

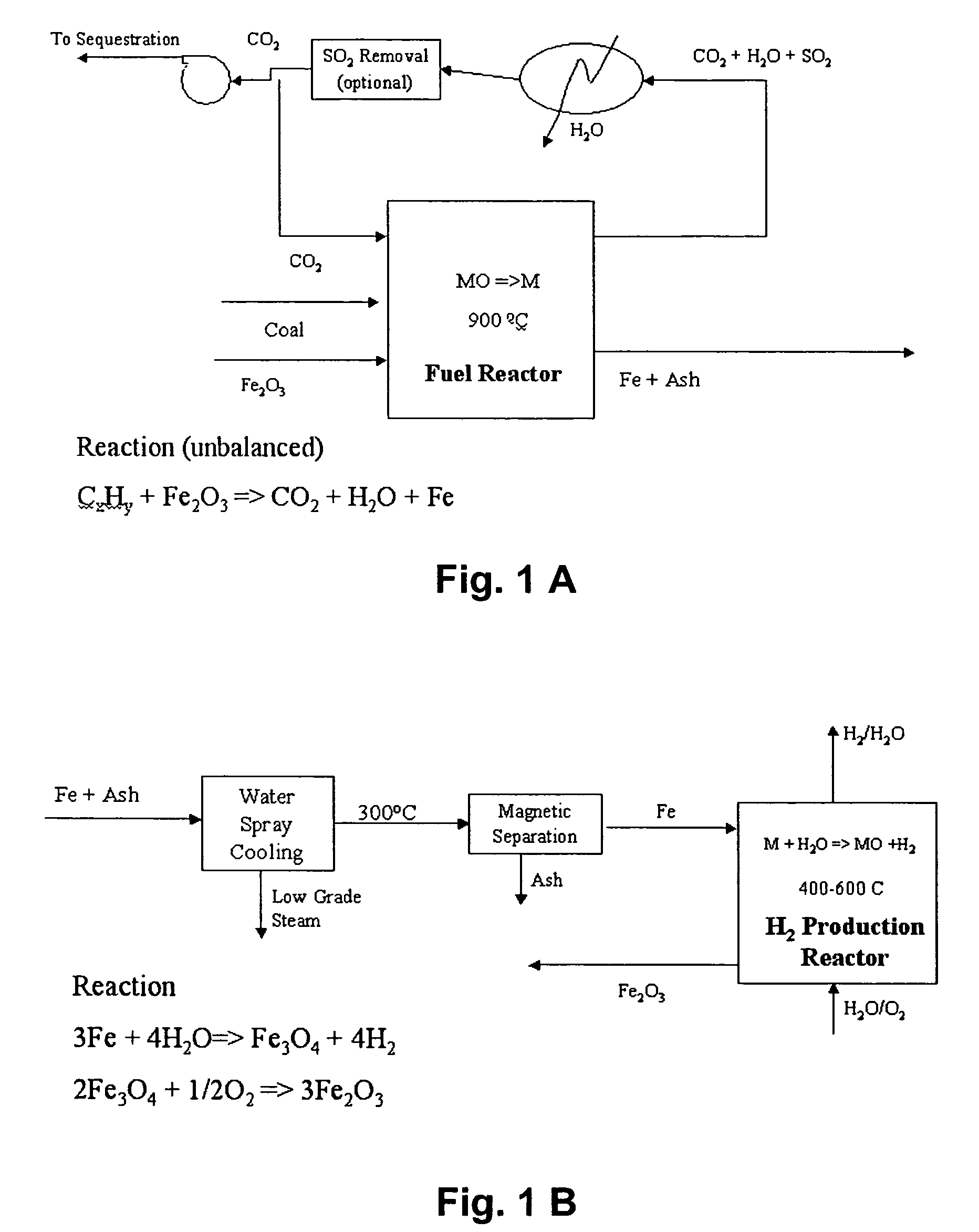

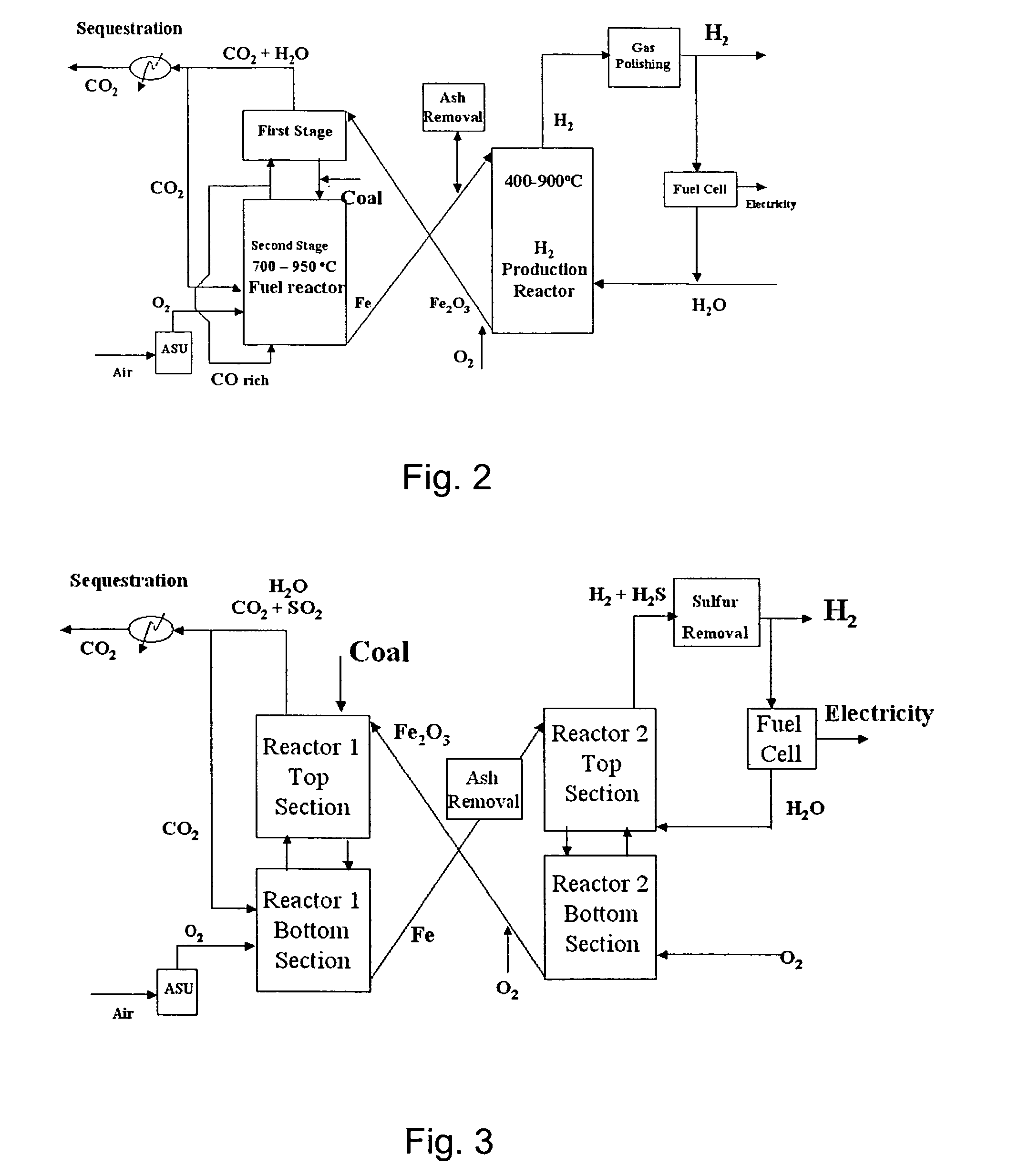

Combustion looping using composite oxygen carriers

ActiveUS7767191B2Increase surface areaImprove energy conversion efficiencyHydrogen productionIndirect carbon-dioxide mitigationHydrogenCombustion

A method for producing hydrogen gas is provided and comprises reducing a metal oxide in a reduction reaction between a carbon-based fuel and a metal oxide to provide a reduced metal or metal oxide having a lower oxidation state, and oxidizing the reduced metal or metal oxide to produce hydrogen and a metal oxide having a higher oxidation state. The metal or metal oxide is provided in the form of a porous composite of a ceramic material containing the metal or metal oxide. The porous composite may comprise either a monolith, pellets, or particles.

Owner:OHIO STATE INNOVATION FOUND

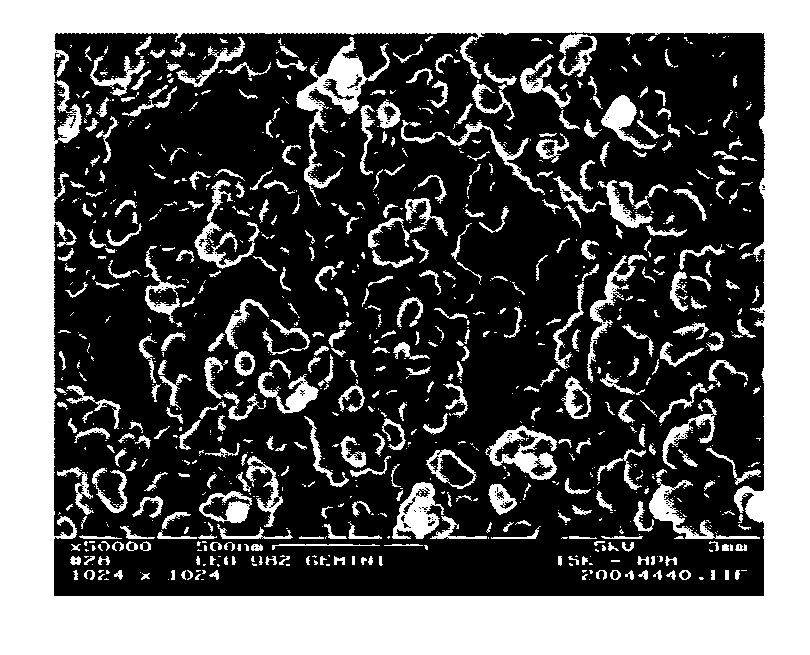

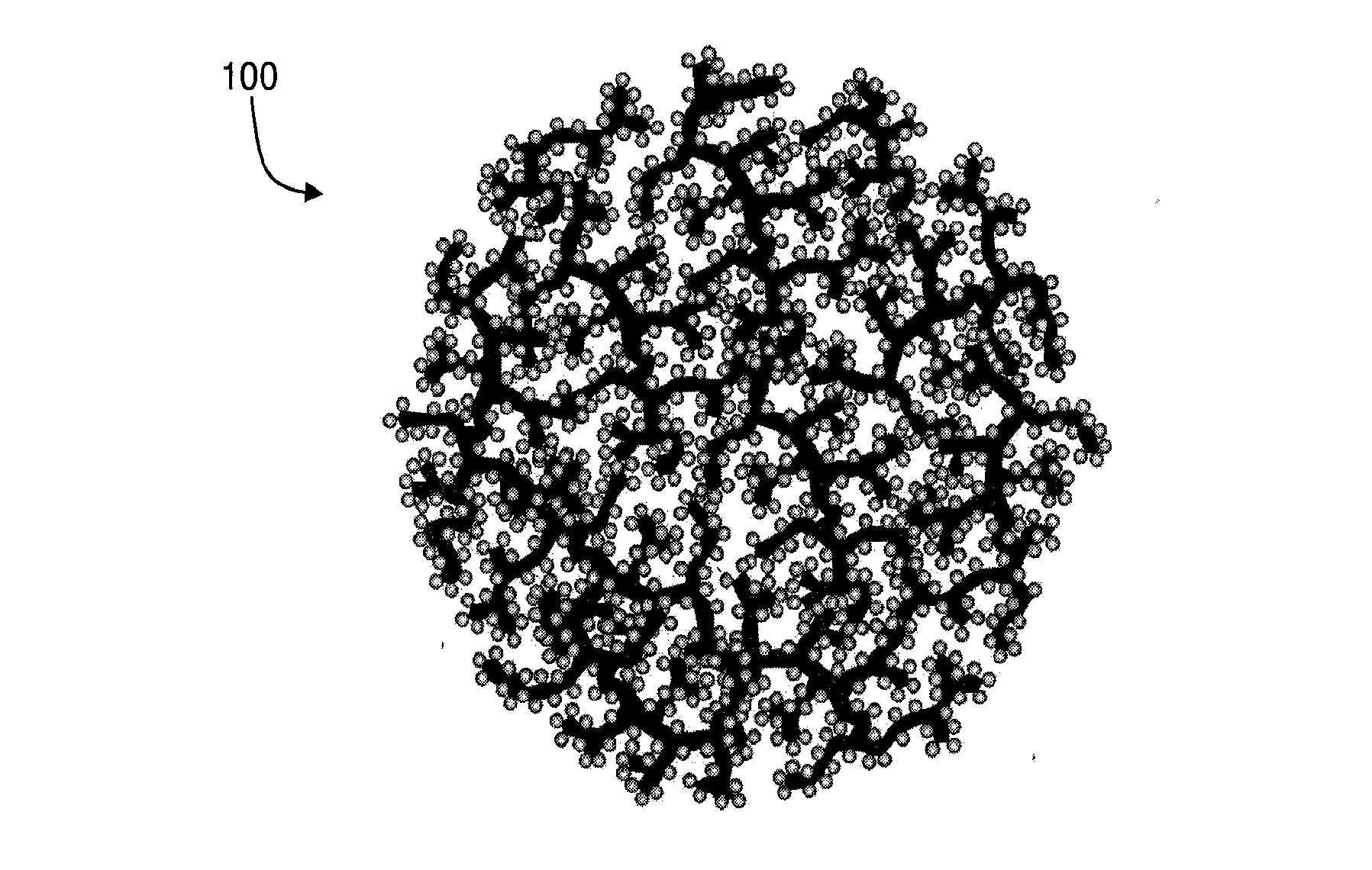

Electrodes, lithium-ion batteries, and methods of making and using same

ActiveUS20120321959A1Facilitate communicationMaterial nanotechnologyConductive materialNanoparticleLithium-ion battery

Described herein are improved composite anodes and lithium-ion batteries made therefrom. Further described are methods of making and using the improved anodes and batteries. In general, the anodes include a porous composite having a plurality of agglomerated nanocomposites. At least one of the plurality of agglomerated nanocomposites is formed from a dendritic particle, which is a three-dimensional, randomly-ordered assembly of nanoparticles of an electrically conducting material and a plurality of discrete non-porous nanoparticles of a non-carbon Group 4A element or mixture thereof disposed on a surface of the dendritic particle. At least one nanocomposite of the plurality of agglomerated nanocomposites has at least a portion of its dendritic particle in electrical communication with at least a portion of a dendritic particle of an adjacent nanocomposite in the plurality of agglomerated nanocomposites.

Owner:GEORGIA TECH RES CORP +1

Process for production of porous reticulated composite materials

Owner:CINVENTION AG

Plant polysaccharide cigarette filter tip and preparation method thereof

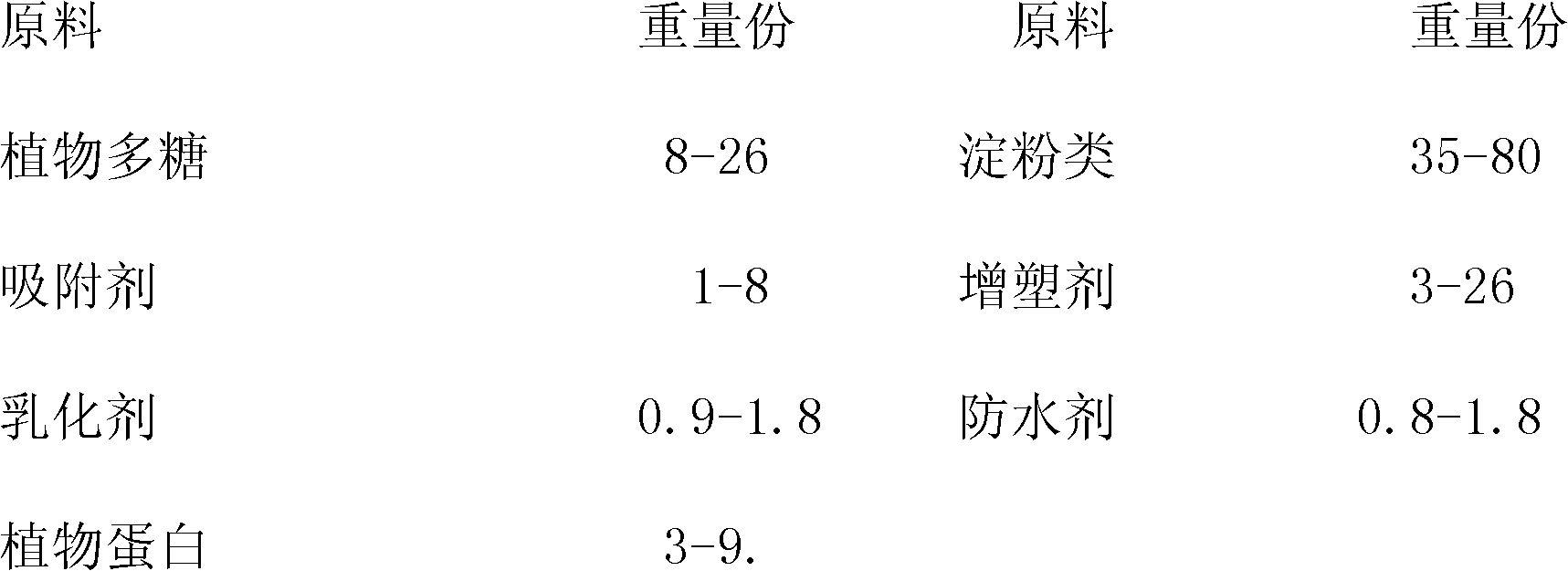

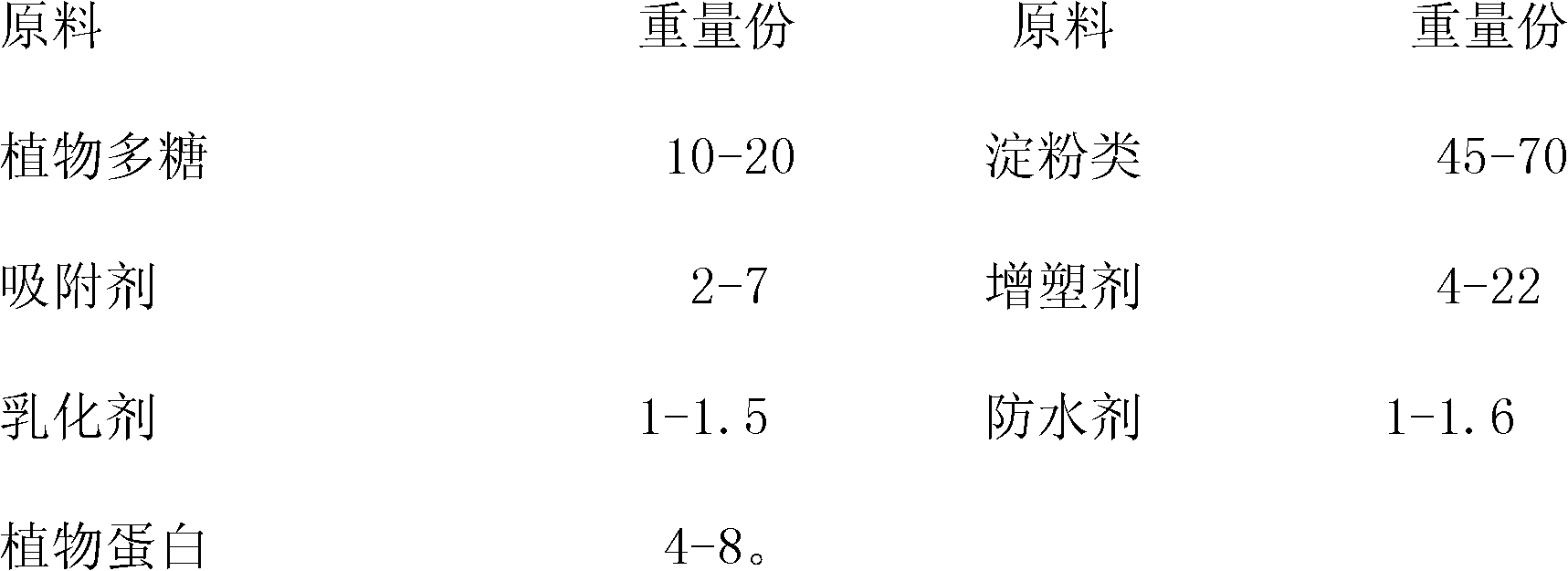

The invention discloses a plant polysaccharide cigarette filter tip and a preparation method thereof. Plant polysaccharide, starch, adsorbent, plasticizer, emulsifier, waterproofing agent and plant protein are blended according to a certain proportion, so that the filter tip is prepared. The preparation method includes the following steps: (a) the starch, water and the plasticizer are blended and stirred, so that modified starch solution is obtained; (b) the plant polysaccharide and the modified starch solution are blended; (c) under certain conditions, the emulsifier, the waterproofing agent and the adsorbent are added into the mixture of the plant polysaccharide and the modified starch solution, and after stirring, the mixture is injected into a long cylindrical mold made of anti-freezing, heat-proofing material and molded; (d) the semifinished product is placed into a freezing environment and frozen, i.e. prefreezing; (e) the semifinished product in step d is placed into a freeze dryer and freeze-dried; (f) the porous composite body is taken out of the mold and deburred, and thereby a filter tip stick is obtained. Material resources are rich, the cost is low, and the three wastes cannot be produced. The performance is good, the filter tip can reduce the nicotine content by 40.2 to 84.1 percent, the tar by 26 to 72.1 percent and the nicotinamide by 20 to 39.2 percent, and after use, waste can be biodegraded.

Owner:WUHAN LICHENG BIOTECH +1

Composite filter membrane with multidimensional pore structure and preparation method thereof

ActiveCN103894077APotential for industrial production application promotionEffective filteringSemi-permeable membranesFiberElectrospinning

The invention provides a composite filter membrane with a multidimensional pore structure and a preparation method thereof. The composite filter membrane comprises nonwoven base cloth and a porous composite nanofiber layer, wherein the nonwoven base cloth and the porous composite nanofiber layer are composited in a manner of hot rolling, and the porous composite nanofiber layer is prepared from a polymer and an additive. The preparation method comprises the following steps: adding the additive into a spinning solution solvent, carrying out ultrasonic treatment to achieve homodisperse, then adding the polymer, and stirring at room temperature until the solution is clear and transparent. A multiple-nozzle electrostatic spinning device is used for electrostatic spinning, and the obtained porous composite nanofibers are directly deposited on the surface of the nonwoven cloth and are composited through a subsequent hot rolling device. The composite filter membrane combines the advantages of common filter materials and nanofiber filter materials, has a good filtering effect, a simple production process and low production cost and is easy to realize large scale production.

Owner:JIANGNAN UNIV

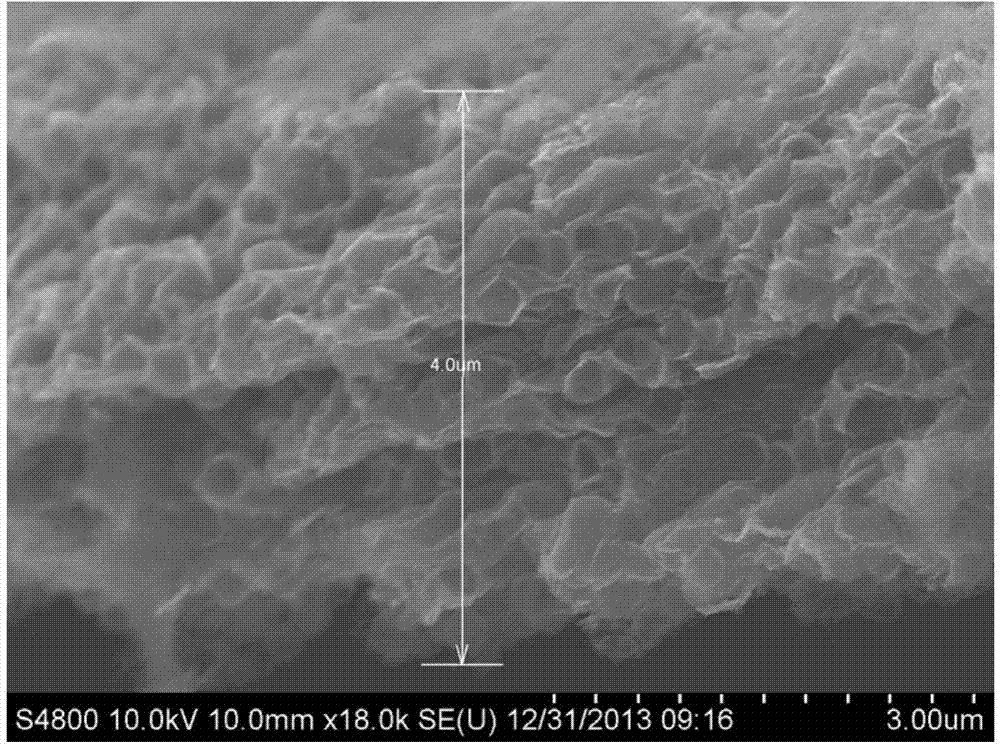

Porous composite diaphragm for lithium ion secondary battery and preparation method thereof

The invention discloses a porous composite diaphragm for a lithium ion secondary battery and a preparation method thereof. The porous composite diaphragm comprises a polyethylene microporous membrane; and single surface or two surfaces of the polyethylene microporous membrane is / are covered with a heat-resistant coating layer containing heat-resistant resin and inorganic non-conductive insulated particles. Due to use of the composite diaphragm, the mechanical performance, the aperture and the porosity of a base layer can be controlled, the thickness, the aperture and the porosity of the coating layer can be similarly controlled. The diaphragm has the advantages of low hole-closing temperature, high diaphragm-breaking temperature and less heat shrinkage; and the diaphragm used for the lithium ion secondary battery has excellent safety performance.

Owner:FOSHAN JINHUI HIGH TECH OPTOELECTRONICS MATERIAL

Medical devices comprising a reticulated composite material

Owner:CINVENTION AG

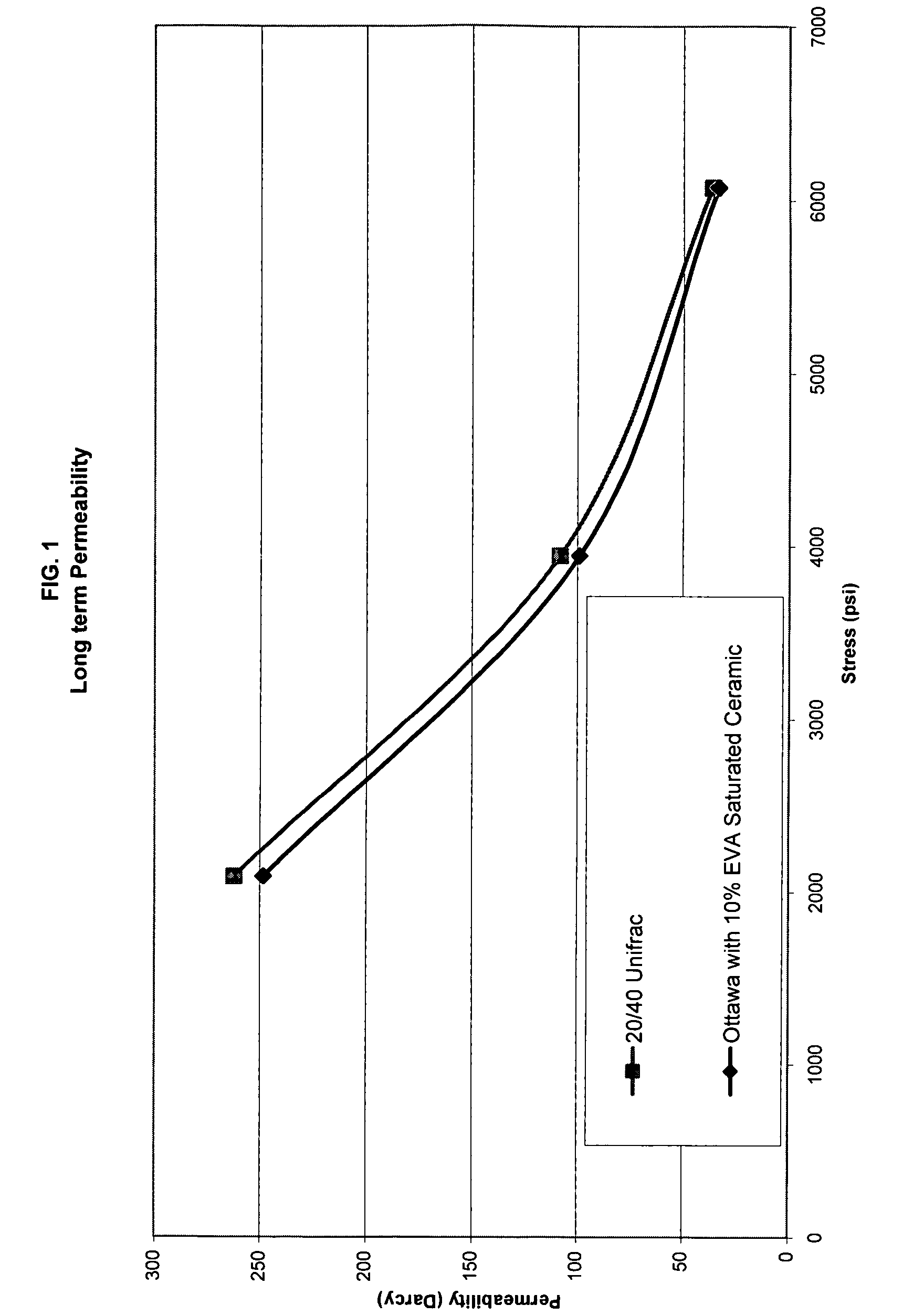

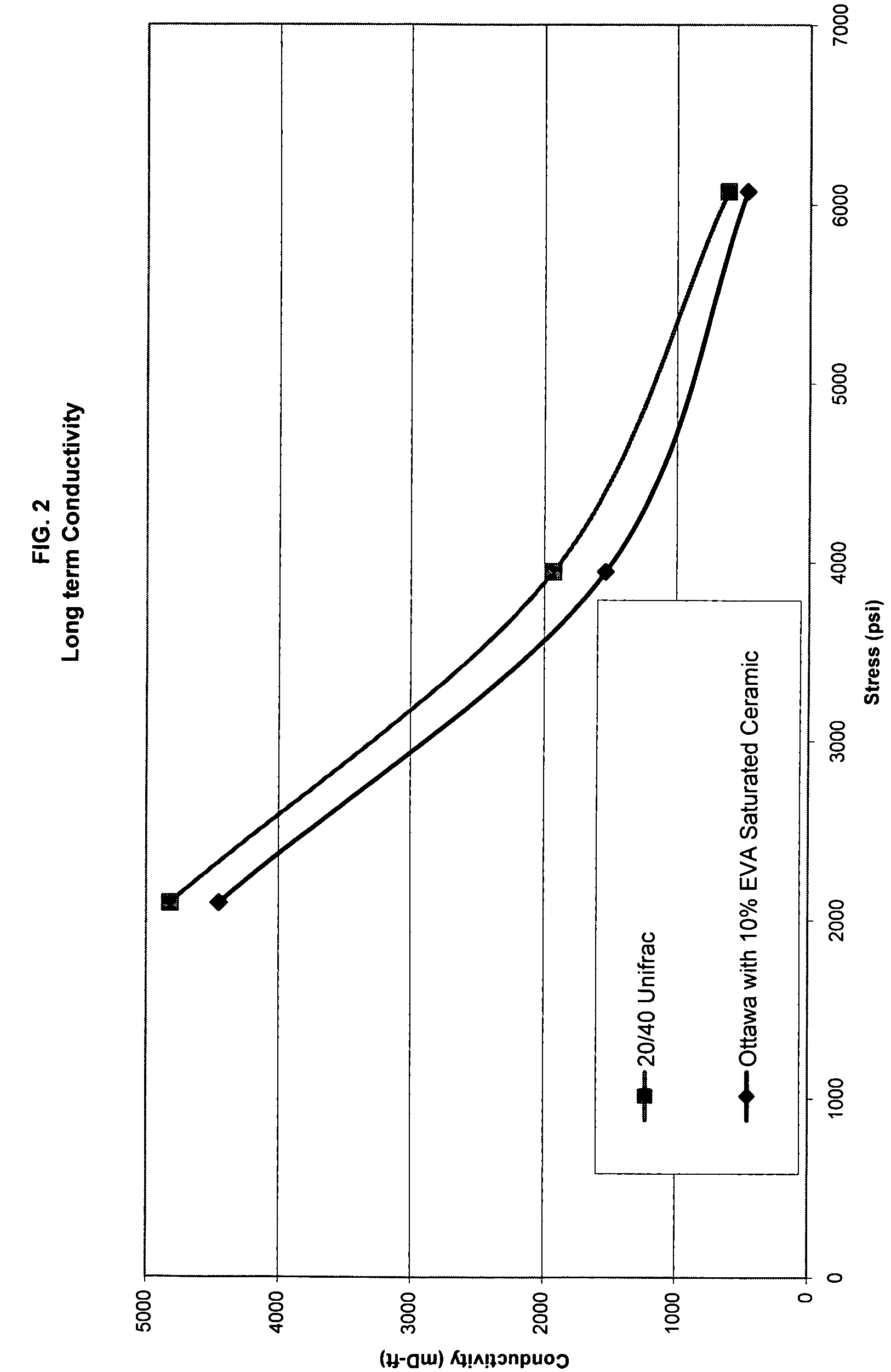

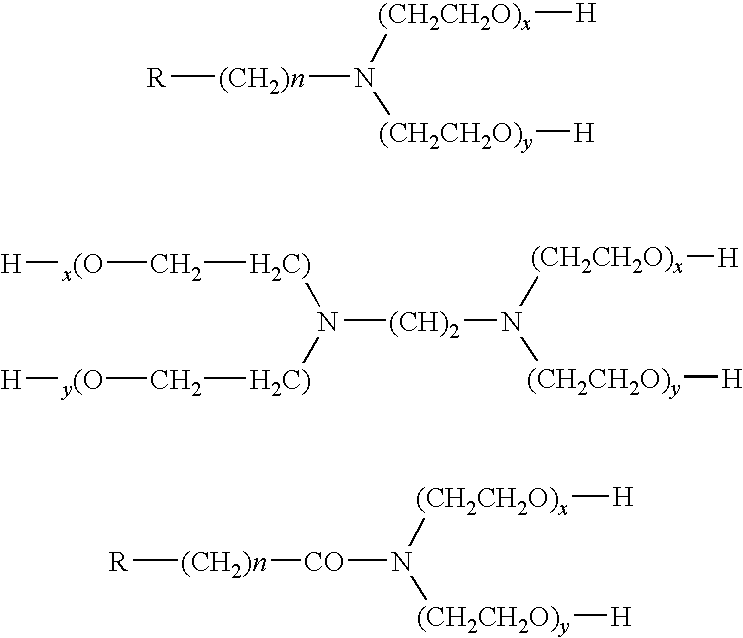

Porous composites containing hydrocarbon-soluble well treatment agents and methods for using the same

Composites containing a hydrocarbon-soluble well treatment agent may be supplied to a well using a porous particulate. Such well treatment agents may for example inhibit the formation of paraffins, salts, gas hydrates, asphaltenes and / or other deleterious processes such as emulsification (both water-in-oil and oil-in-water). Further, other well treatment agents include foaming agents, oxygen scavengers, biocides and surfactants as well as other agents wherein slow release into the production well is desired.

Owner:BAKER HUGHES INC

Porous composites containing hydrocarbon-soluble well treatment agents and methods for using the same

Composites containing a hydrocarbon-soluble well treatment agent may be supplied to a well using a porous particulate. Such well treatment agents may for example inhibit the formation of paraffins, salts, gas hydrates, asphaltenes and / or other deleterious processes such as emulsification (both water-in-oil and oil-in-water). Further, other well treatment agents include foaming agents, oxygen scavengers, biocides and surfactants as well as other agents wherein slow release into the production well is desired.

Owner:BAKER HUGHES INC

Porous composite metal oxide and method of producing the same

InactiveUS20060043651A1Increased durabilityArea highMaterial nanotechnologyOther chemical processesMetalPorous composite

A method of producing a porous composite metal oxide comprising the steps of: dispersing first metal oxide powder, which is an aggregate of primary particles each with a diameter of not larger than 50 nm, in a dispersion medium by use of microbeads each with a diameter of not larger than 150 μm, thus obtaining first metal oxide particles, which are 1 nm to 50 nm in average particle diameter, and not less than 80% by mass of which are not larger than 75 nm in diameter; dispersing and mixing up, in a dispersion medium, the first metal oxide particles and second metal oxide powder, which is an aggregate of primary particles each with a diameter of not larger than 50 nm, and which is not larger than 200 nm in average particle diameter, thus obtaining a homogeneously-dispersed solution in which the first metal oxide particles and second metal oxide particles are homogeneously dispersed; and drying the homogeneously-dispersed solution, thus obtaining a porous composite metal oxide.

Owner:TOYOTA CENT RES & DEV LAB INC

Porous composite containing calcium phosphate and process for producing the same

ActiveUS20060292350A1Small apertureImprove thermal conductivityImpression capsSynthetic resin layered productsLinking collagenCalcium biphosphate

A porous composite comprising a porous layer containing a calcium phosphate ceramic, and a dense layer formed on part of the porous layer and having a smaller average pore size than that of the porous layer. The porous composite can be produced by (1) introducing a slurry containing a calcium phosphate ceramic / collagen composite and collagen into a molding die having a high thermal conductivity, (2) rapidly freezing and drying the slurry in the molding die, to form a porous body comprising a porous layer and a dense layer formed on the porous layer, (3) cross-linking collagen in the porous body, and (4) removing the dense layer except for a portion thereof on a surface coming into contact with a soft tissue when implanted in a human body, so that the porous layer is exposed.

Owner:NAT INST FOR MATERIALS SCI +1

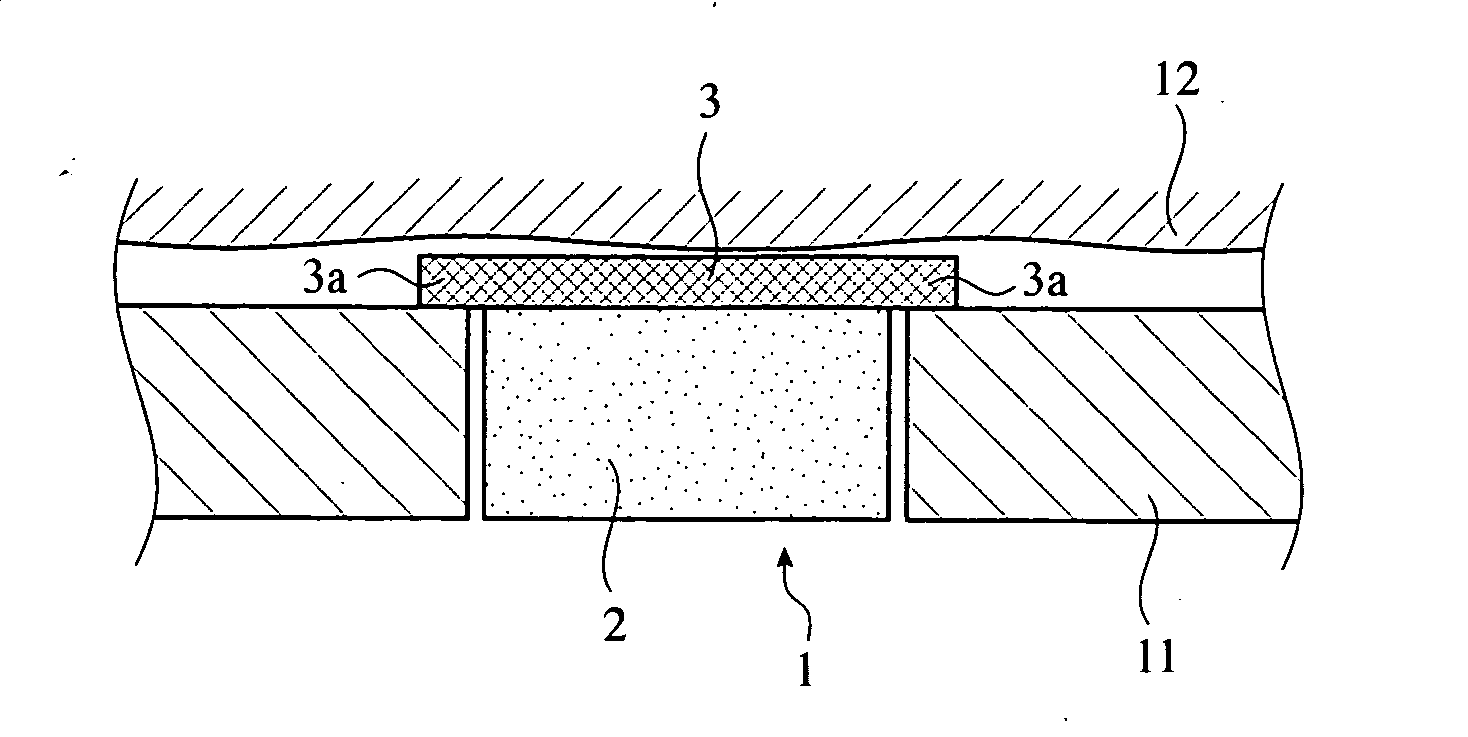

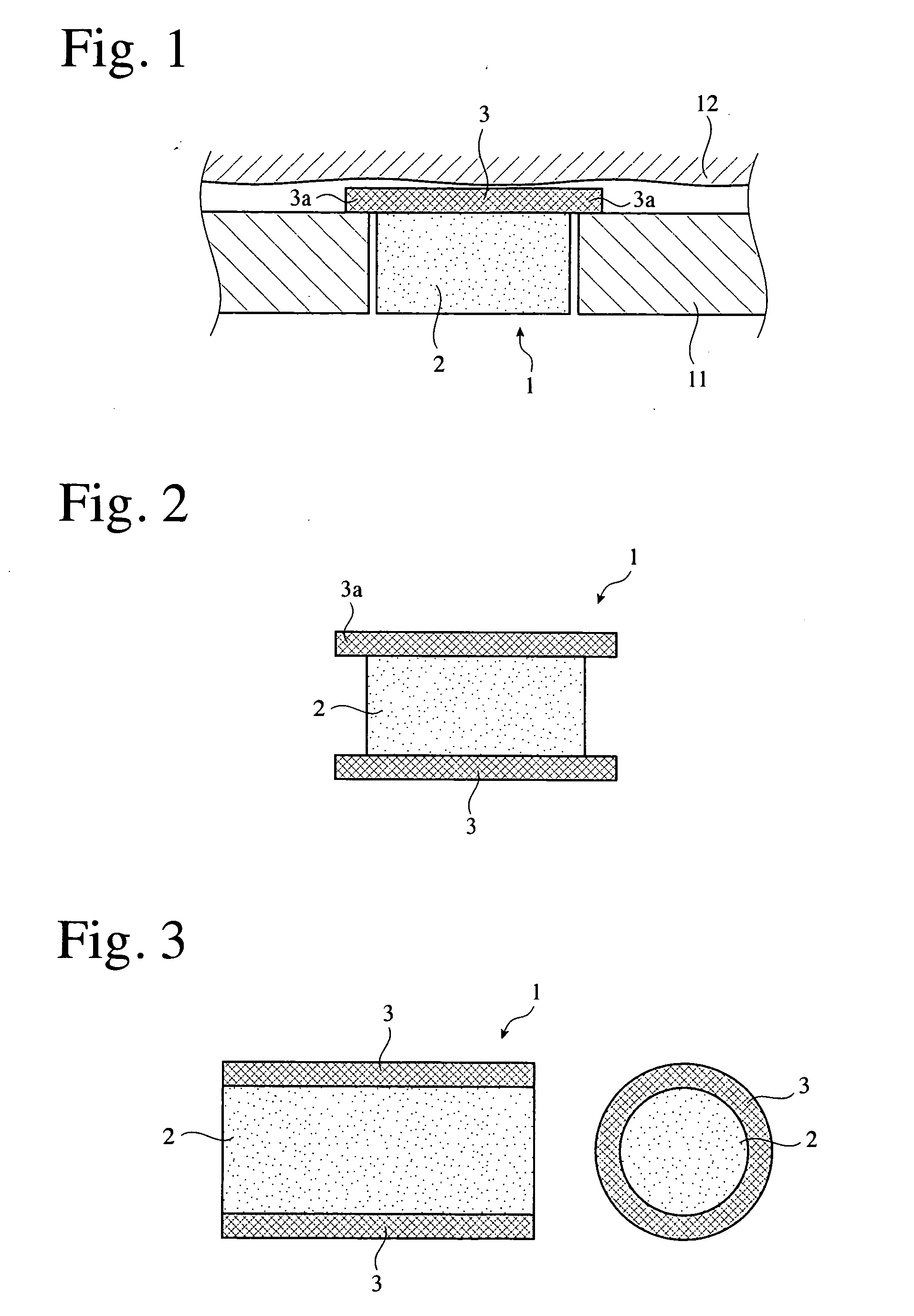

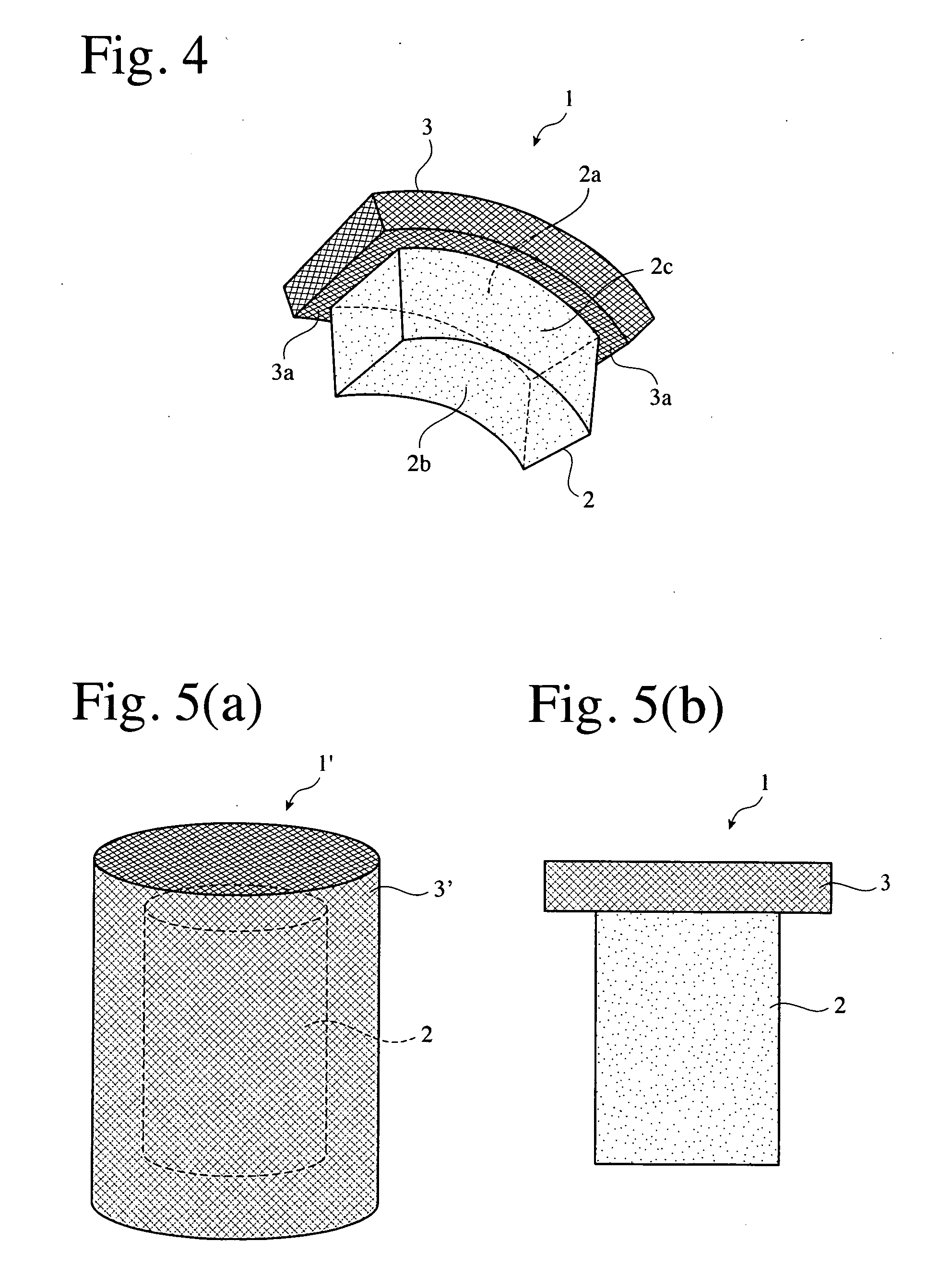

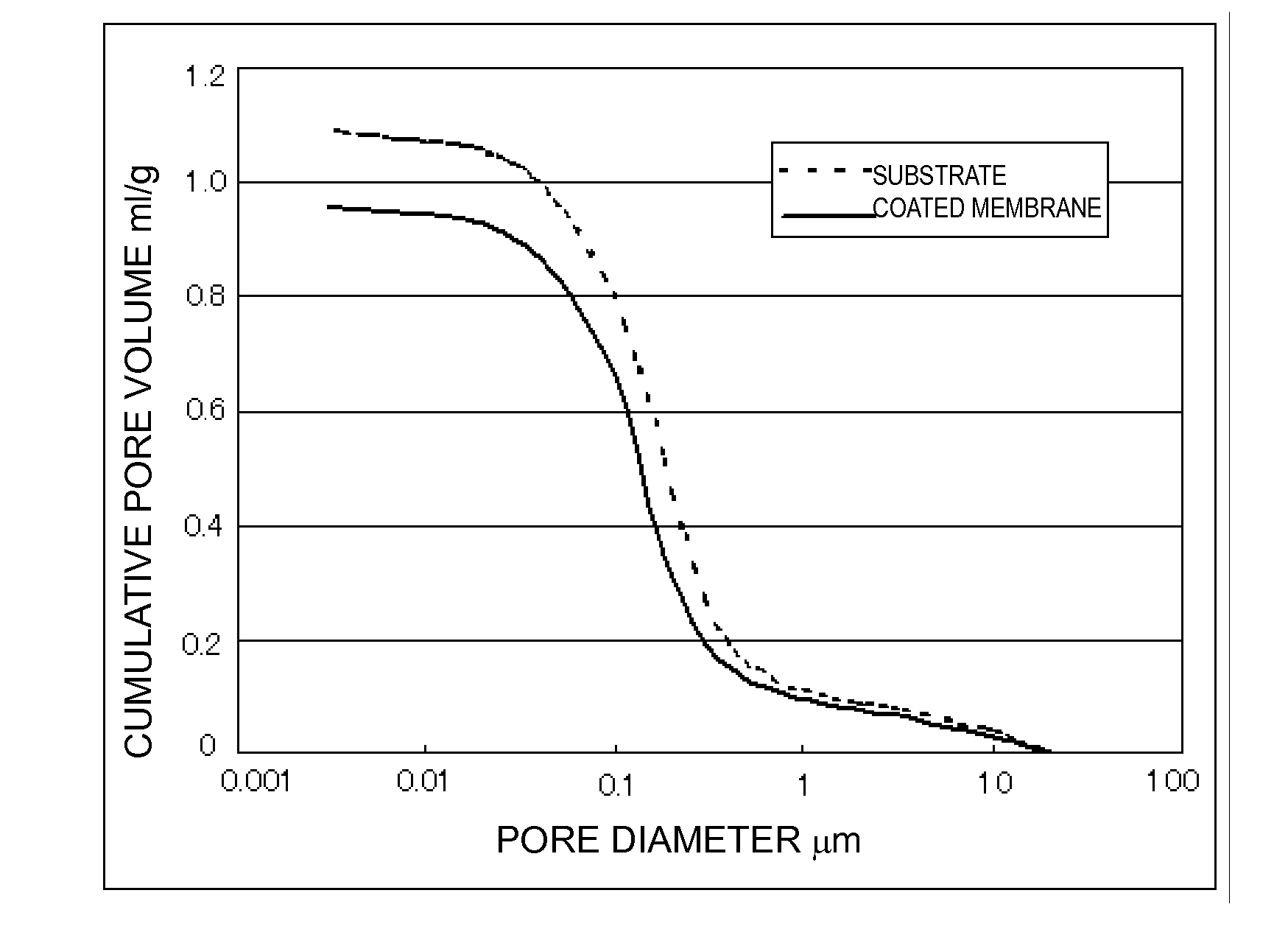

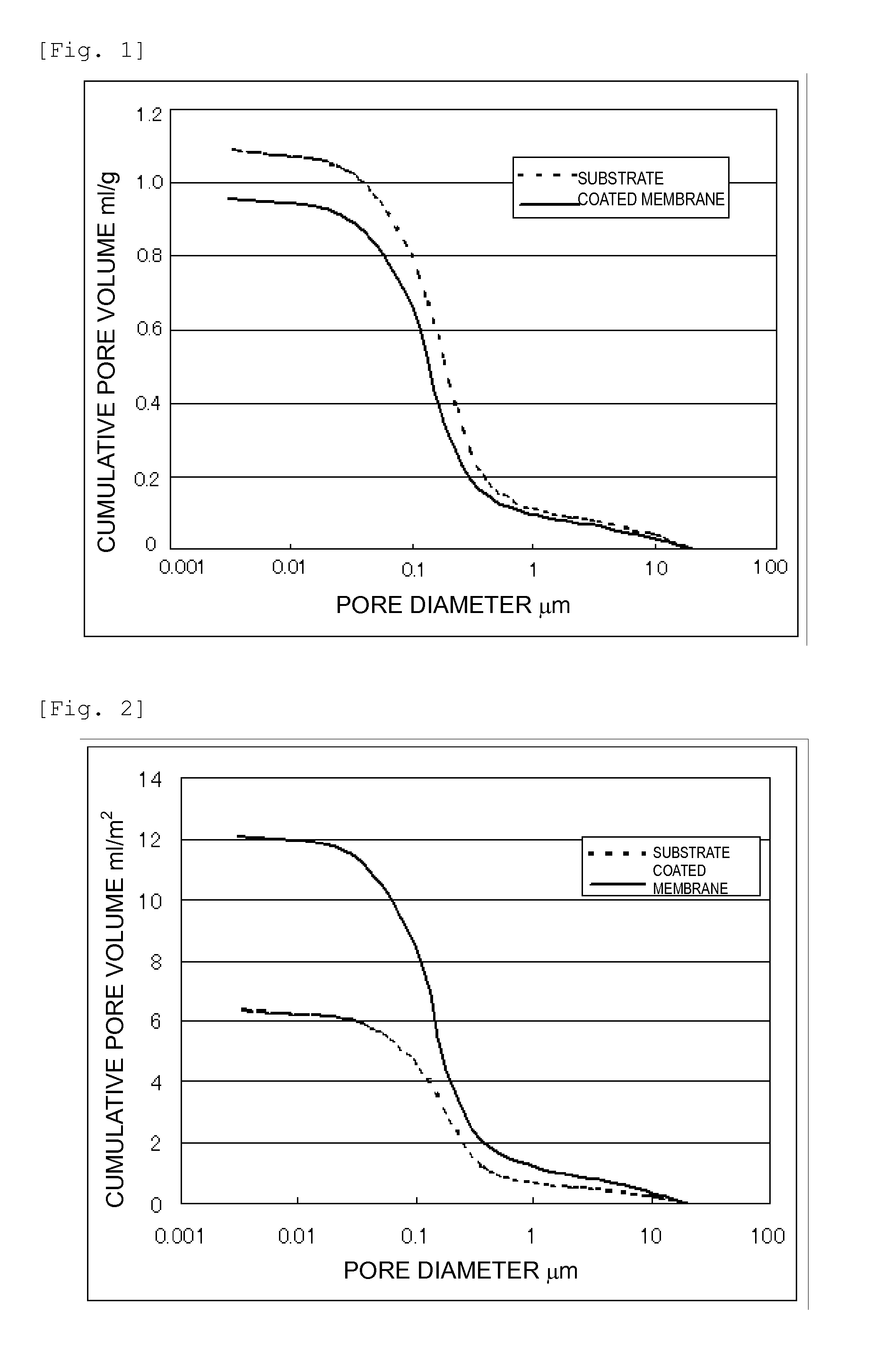

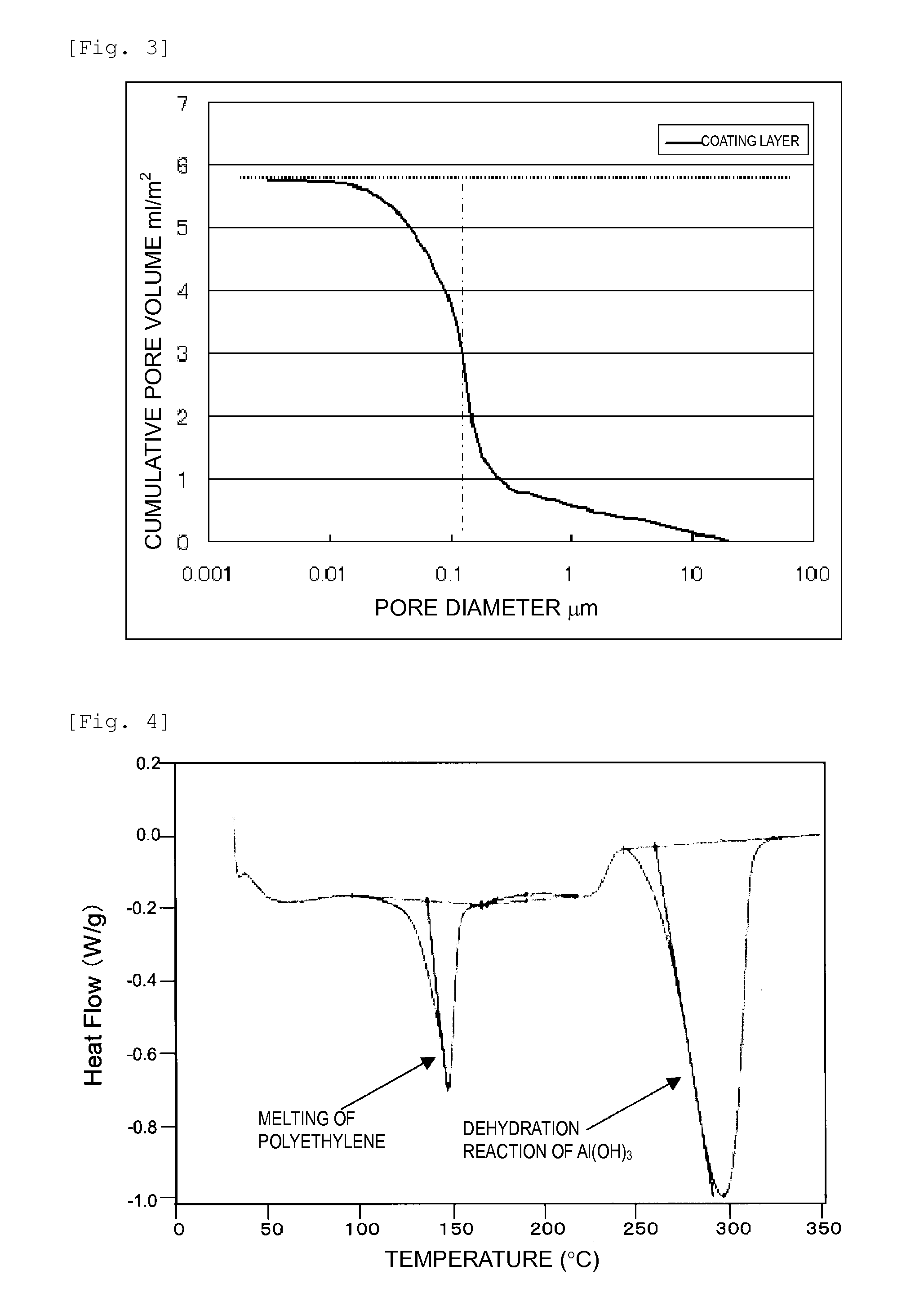

Separator for nonaqueous secondary battery

ActiveUS20110143185A1Improve heat resistanceImprove securitySecondary cellsCell component detailsFiberPolyolefin

An object of the present invention is to provide a separator for a nonaqueous secondary battery having excellent heat resistance and excellent ion permeation as well as shut-down properties. The first invention is a separator for a nonaqueous secondary battery, comprising a porous composite membrane which includes a substrate comprising a polyolefin microporous membrane and a heat-resistant porous layer comprising a heat-resistant resin, the heat-resistant porous layer being formed on at least one surface of the substrate, wherein the separator is characterized in that the sheet resistance (A) of the substrate, the Gurley value (B) of the substrate, the sheet resistance (C) of the porous composite membrane, and the Gurley value (D) of the porous composite membrane satisfy a specific relationship. The second invention is characterized in that the heat-resistant porous layer has an average pore size of 0.1 to 0.2 μm as measured by mercury intrusion porosimetry. The third invention is characterized in that the heat-resistant resin fibrils have an average fibril diameter of 10 to 80 nm, and the pores in the heat-resistant porous layer have an average pore size of 50 to 250 nm.

Owner:TEIJIN LTD

Method for manufacturing fully dense metal sheets and layered composites from reactive alloy powders

InactiveUS20040096350A1Improve mechanical propertiesReduce residual porosityIncreasing energy efficiencyWelding/cutting media/materialsTi 6al 4vVolumetric Mass Density

The method is suitable for the manufacture of flat or shaped titanium aluminide articles and layered metal matrix composites such as lightweight plates and sheets for aircraft and automotive applications, thin cross-section vanes and blades, composite electrodes, heat-sinking lightweight electronic substrates, bulletproof structures for vests, partition walls and doors, as well as for sporting goods such as helmets, golf clubs, sole plates, crown plates, etc. The method includes the following steps: (a) forming a porous preform of the reactive powder alloy or a porous multi-layer composite preform consisting of reactive powder metals and alloys by consolidation using at least one method selected from low-temperature loose sintering in vacuum, high-temperature loose sintering in vacuum, low-pressure sintering in an inert gas, cold pressing, direct powder rolling, isostatic or die pressing, and other means of room temperature and warm temperature consolidation, and / or combination thereof, to provide the density not less than 25% from the theoretical density of said reactive alloy; (b) hot consolidating by hot pressing said preform, hot rolling, hot isostatic pressing, or hot extrusion to obtain the density of 98-100% from the theoretical density of said reactive alloy; (c) additional sintering and / or annealing at the temperature being at least 900° C. to decrease the residual porosity, control the microstructure, and improve the mechanical properties, especially ductility and / or plasticity of the resulting metal sheets or layered composites. The hot pressing is carried out at the temperature ranging 950-1700° C., preferably at 1250-1450° C., and at pressure ranging 50-350 kg / cm<2>. The HIP is carried out at the temperature ranging 1250-1350° C. and at pressure ranging 15000-40000 psi. The layered composite preform is manufactured by individual loose sintering, one layer of the composite at a time, and assembling them in the desired order. The composite consists of layers of titanium and / or titanium hydride, Ti-6Al-4V alloy, alpha-titanium aluminide alloy, beta-titanium aluminide alloy, and gamma-titanium aluminide alloy in any combinations.

Owner:ADVANCED MATERIALS PRODS

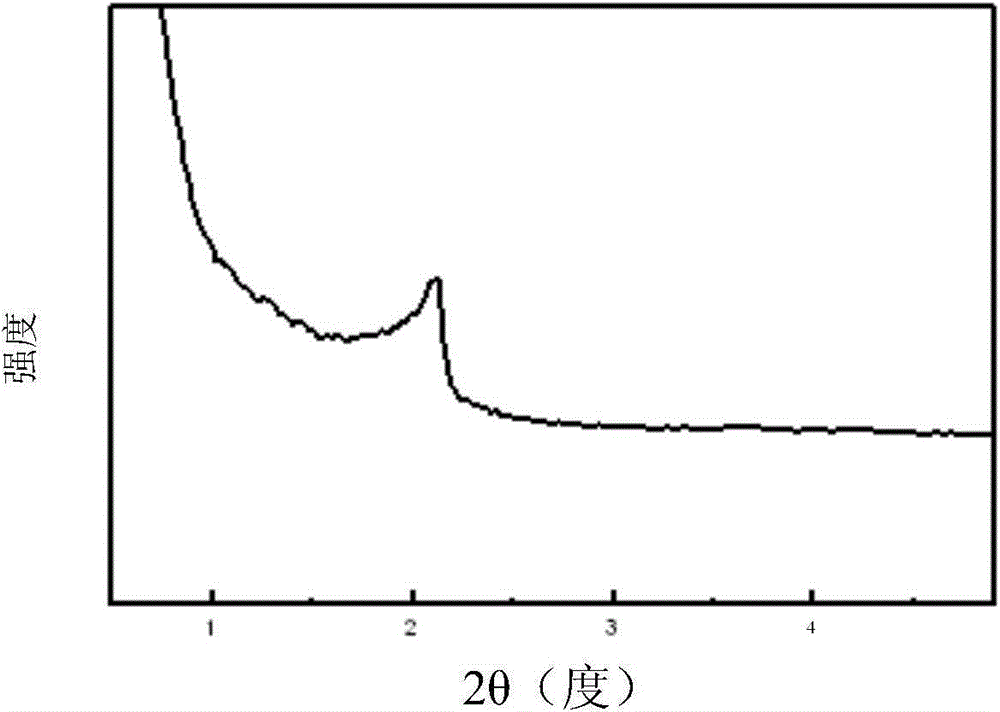

Meso-porous composite material, preparation method thereof, catalyst ingredient preparation method, and polyethylene preparation method

ActiveCN105175586AHigh catalytic activityOrdered mesoporous structureBulk chemical productionMolecular sieveTitanium

The invention discloses a meso-porous composite material, a preparation method thereof, a catalyst ingredient preparation method, and a polyethylene preparation method. The meso-porous composite material comprises a molecular sieve material with a hexagonal tunnel structure and silica gel, the meso-porous composite material is spherical, the pore volume of the meso-porous composite material is 0.5-1.8mL / g, the specific surface area is 200-650m<2> / g, the average particle size is 20-60[mu]m, the apertures are distributed in a double peak manner, two peaks respectively correspond to a first most probable aperture and a second most probable aperture, the first most probable aperture is 1-3nm, and the second most probable aperture is 10-30nm. The meso-porous composite material still keeps an ordered meso-structure after loading. Active components Mg and Ti are loaded on the composite material to prepare a catalyst ingredient, and the catalyst ingredient makes a catalyst keep high catalytic activity in ethylene polymerization and allows polyethylene particle powder to be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for Al2O3 hollow sphere/aluminum porous composite material

ActiveCN103614586AImprove mechanical propertiesAdjustable sizeMold removalAluminum matrix composites

The invention provides a preparation method for an Al2O3 hollow sphere / aluminum porous composite material, relates to a preparation method for an aluminum-based porous composite material, which solves the problems that the strength of a traditional foam aluminum material is low, the process conditions are harsh and the cost is high in an existing preparation method. The preparation method 1 comprises the following steps: step 1. filling an Al2O3 hollow sphere; step 2. pre-heating; step 3. pouring; step 4. pressurizing and immersing; and step 5. maintaining pressure, cooling and carrying out de-molding to obtain the Al2O3 hollow sphere / aluminum porous composite material. The preparation method 2 comprises the following steps: step 1. mixing the Al2O3 hollow spheres with different grain diameters and filling; step 2. pre-heating; step 3. pouring; step 4. pressurizing and immersing; and step 5. maintaining pressure, cooling and de-molding to obtain the Al2O3 hollow sphere / aluminum porous composite material. The Al2O3 hollow sphere / aluminum porous composite material is prepared by immersing aluminum or aluminum alloy into a gap between Al2O3 hollow ball prefabricated blocks; porous structure characterizes of the Al2O3 hollow spheres are maintained and a strengthening mechanism of the aluminum-based composite material is introduced, so that the mechanical properties of materials are improved. According to the preparation method, the operation is convenient, the cost is low, the process is simple, and the production cost is reduced.

Owner:HARBIN INST OF TECH

Preparation method of crop straw fiber ecological composite material

ActiveCN102085680AImprove mechanical propertiesGood heat insulationWood treatment detailsDomestic articlesCelluloseMass ratio

The invention relates to a preparation method of a crop straw fiber ecological composite material, which is characterized by comprising the following steps of: mechanical separation: mechanically separating crop straws into short straws to improve the accessibility of alkali treatment to the crop straws; alkali treatment: carrying out alkali treatment on the short straws in a sodium hydroxide solution with mass percent of 3-6 percent, wherein the mass ratio of the sodium hydroxide solution to the short straws is (30-50):1; carrying out alkali treatment, washing and acid neutralizing and then drying for 2-10h at a temperature of 60-80 DEG C to obtain straw fibers; with the straw fibers as an enhancement phase and a polylactic acid material as a substrate, thermally pressing to obtain a composite material; and keeping pressure, naturally cooling or water-cooling the obtained composite material at normal temperature to obtain a porous composite material plate. The straw fiber extracted in the invention has the advantages of high cellulose content, good fineness, good mechanical property of the composite material and more and small gaps inside straw fibers inside the composite material, and excellent heat insulation and sound isolation performances.

Owner:万华禾香生态科技股份有限公司

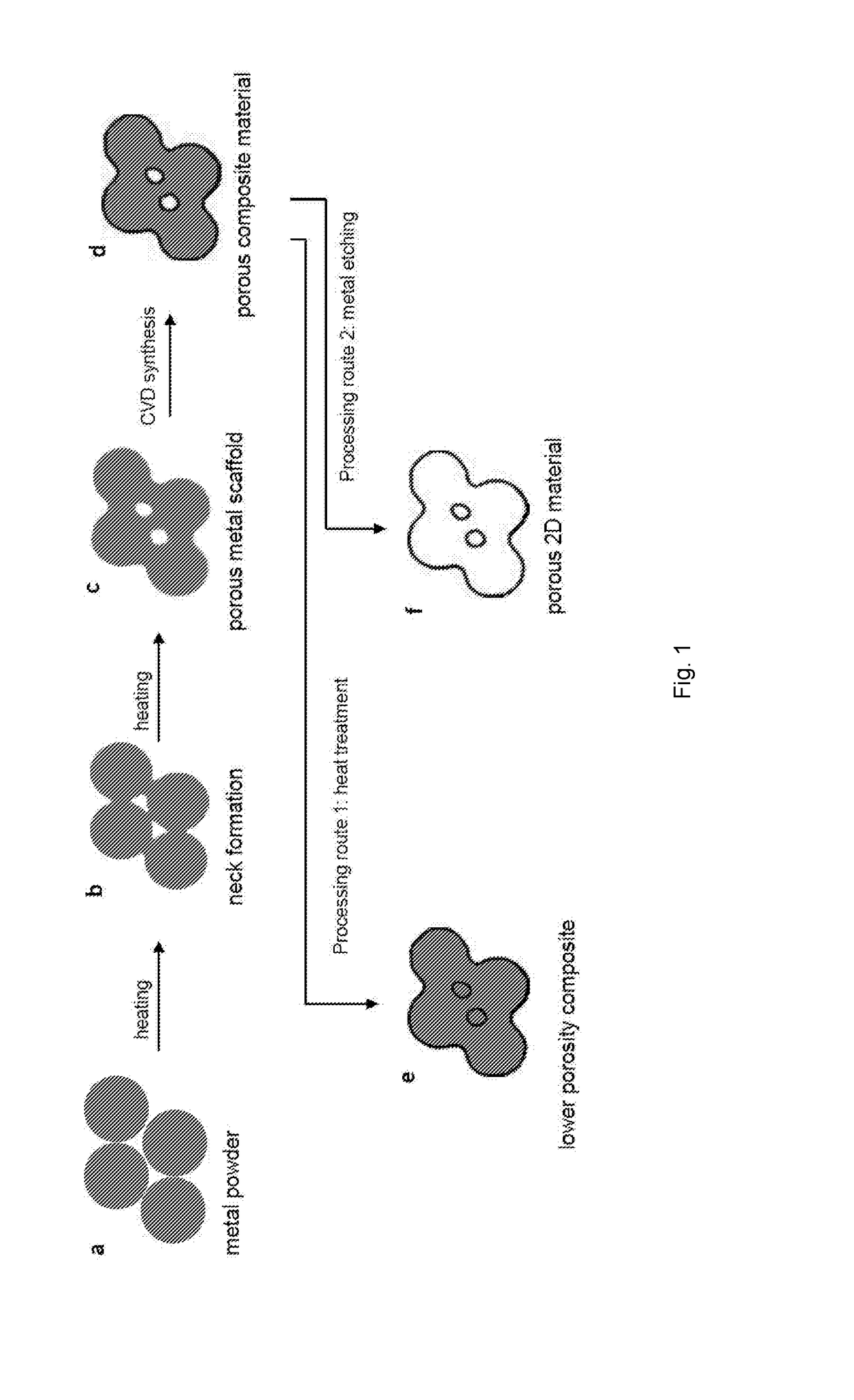

Porous materials comprising two-dimensional nanomaterials

ActiveUS20170216923A1Low costImprove scalabilityNitrogen compoundsElectrode thermal treatmentCompound (substance)Metal particle

According to the present invention, there are provided processes for preparing a porous composite material comprising a metal and a two-dimensional nanomaterial. In one aspect, the processes comprise the steps of: providing a powder comprising metal particles; heating the powder such that the metal particles fuse to form a porous scaffold; and forming a two-dimensional nanomaterial on a surface of the porous scaffold by chemical vapour deposition (CVD). Also provided are materials obtainable by the present processes, and products comprising said materials.

Owner:OXFORD UNIV INNOVATION LTD

Synthesis and Application of MOFs/natural Polymers Composite Beads Adsorbents

ActiveUS20180339284A1Reduce the amount requiredOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsSorbentNanoparticle

The present invention discloses the Synthesis and application of MOFs / natural polymers composite beads adsorbents. To overcome the drawback of MOFs, in an embodiment, both novel MOFs / sodium alginate (MOFs / SA) and MOFs / chitosan (MOFs / CS) composite beads were prepared and characterized. Each composite beads include one or more of MIL-101 (Cr), MIL-100 (Cr), MIL-53 (Al), MIL-100 (Al), NH2-MIL-101 (Al), UIO-66, ZIF-8, ZIF-68, ZIF-67, and ZIF-9-67 nanoparticles. Adsorption of anionic contaminants onto the two composite beads was investigated and compared with pristine sodium alginate beads (SA) and chitosan beads (CS). The novel MOFs / SA beads all exhibit much higher adsorption capacity than SA beads; the novel MOFs / CS beads all exhibit much higher adsorption capacity than CS beads, which indicates that MOFs played a key role in the adsorption of anionic contaminants. The porous composite beads disclosed herein and related methods and devices may be used in adsorption technologies.

Owner:NANJING HUACHUANG INST OF ENVIRONMENTAL TECH CO LTD

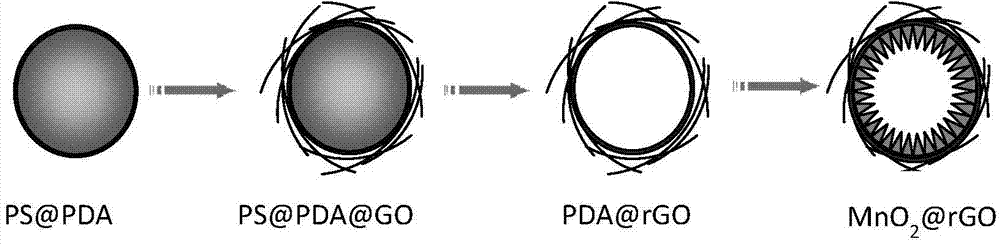

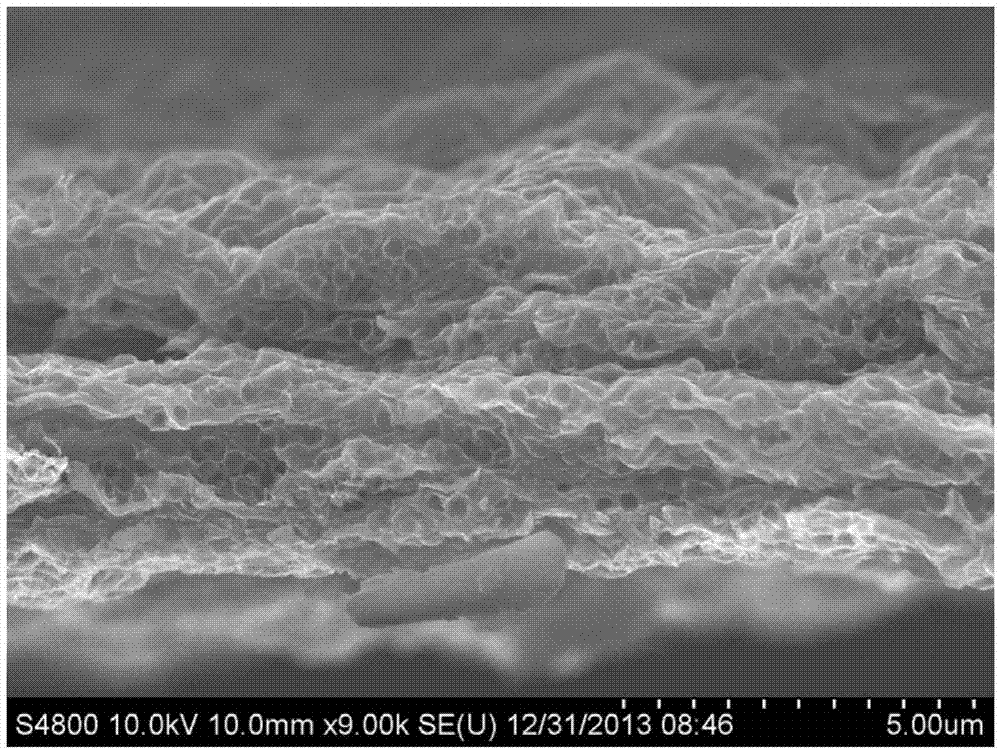

Porous grapheme/ MnO2 composite film and preparation method and application thereof

ActiveCN103903879AIncrease contact areaImprove mechanical propertiesHybrid capacitor electrodesHybrid/EDL manufactureCapacitancePorous graphene

The invention relates to a porous grapheme / MnO2 composite film and a preparation method and application thereof. The preparation method comprises the following steps of (1), providing a ball-shaped formwork and coating the surface of the ball-shaped formwork with a polymer layer; (2) providing graphene oxide solution, evenly mixing a small formwork ball coated with the polymer layer obtained in the step (1) with the graphene oxide solution, performing vacuum filtration, and stripping the composite film from a filter membrane after drying; (3) performing high temperature annealing on the composite film obtained in the step (2) to obtain a film of a porous structure; (4) putting the film obtained in the step (3) into potassium permanganate solution to perform hydrothermal reaction to obtain the porous grapheme / MnO2 composite film. No any binder or conductive agent is needed to be added to the porous composite film prepared by the method, and the porous composite film is good mechanical property and super capacitive performance, has the advantages of being good in high-rate charge and discharge performance, long in circle life and the like, and can be applied to preparing super-capacitors and improve performance of super-capacitors greatly.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

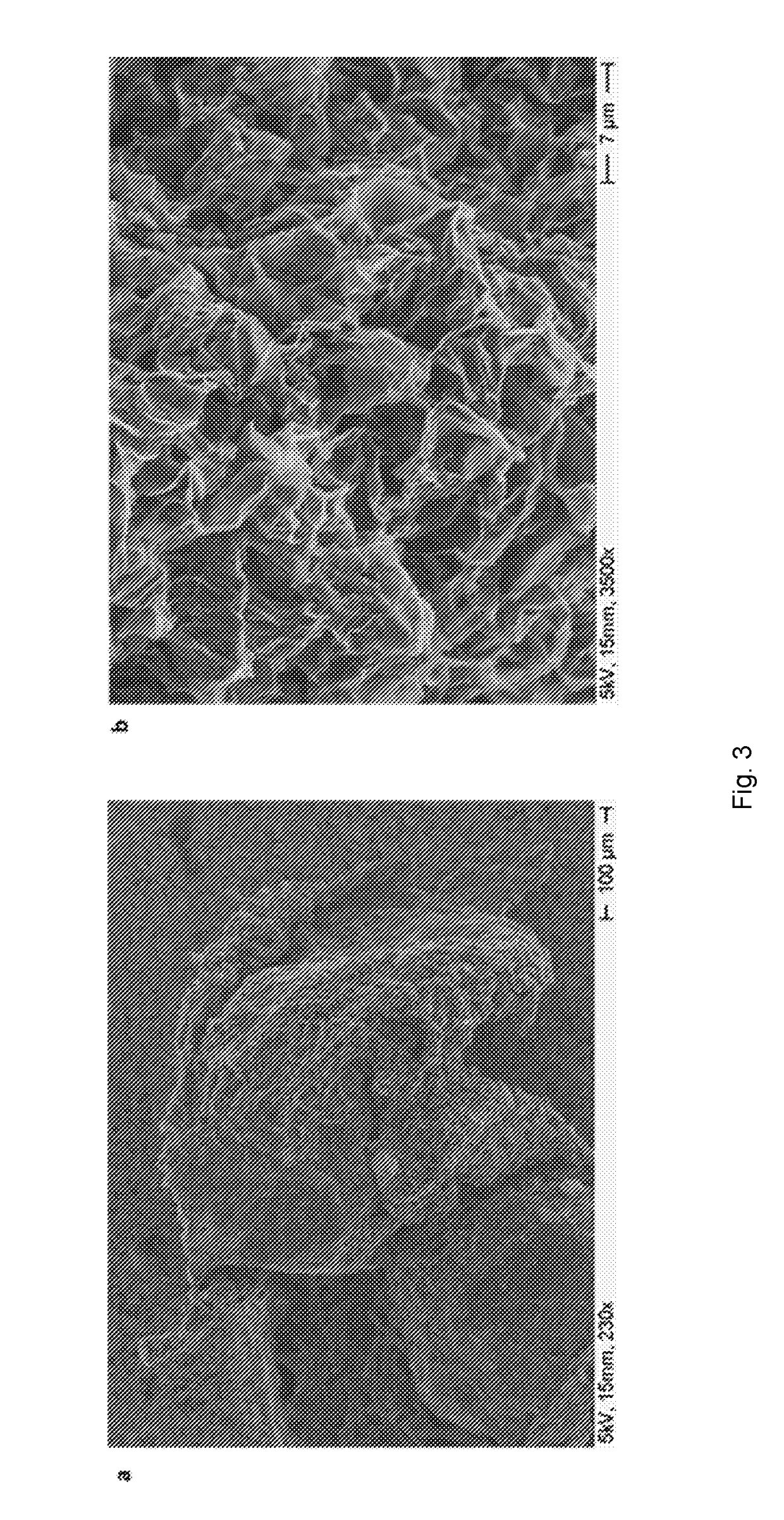

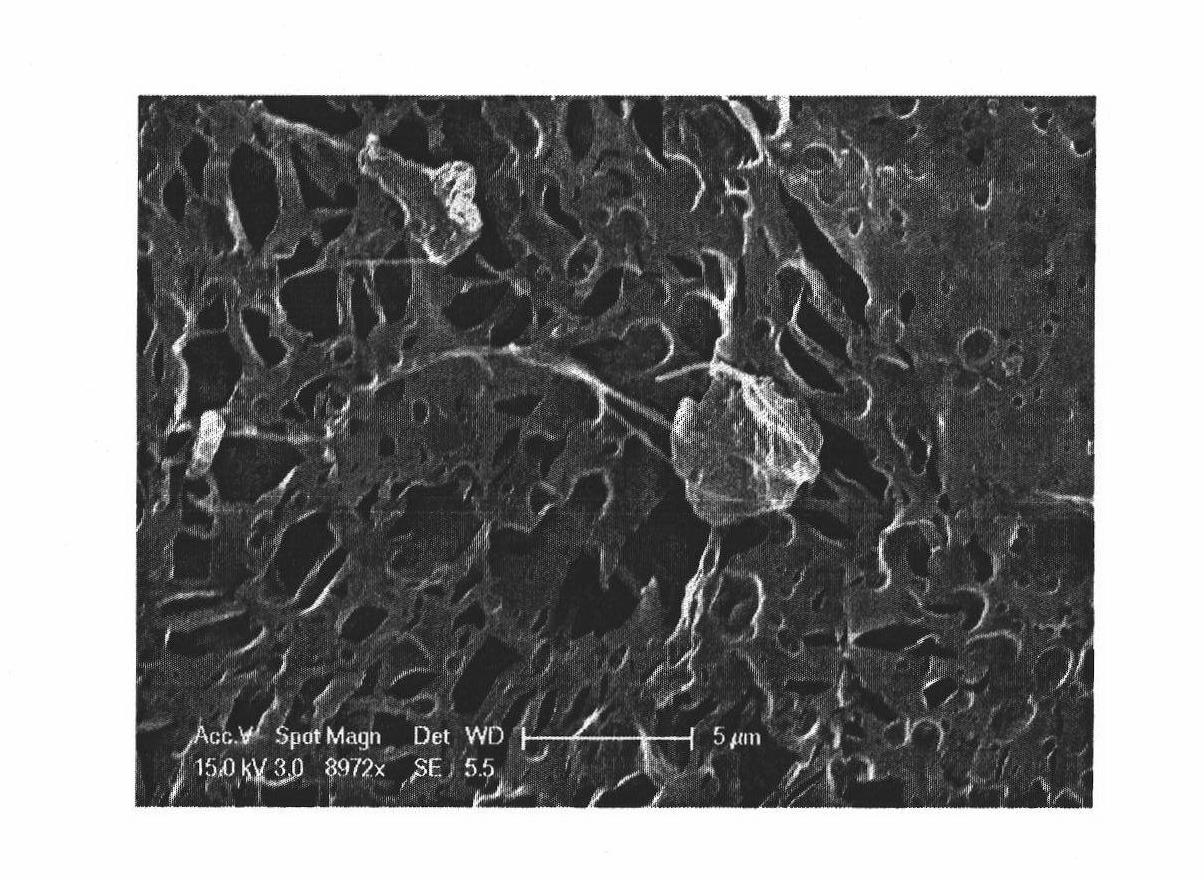

Carbon nanotube-MXene composite three-dimensional porous carbon material and preparation method thereof

ActiveCN109671576AExpand migration spaceHigh yieldMaterial nanotechnologyHybrid capacitor electrodesFreeze-dryingPorous carbon

The invention discloses a preparation method of a carbon nanotube-MXene composite three-dimensional porous carbon material. According to the preparation method of the material, based on the hydrophilic property of the MXene material, the MXene material is dispersed in a carbon nanotube stabilizing solution, and then is added into a PVA water solution to form a uniformly dispersed stable system. The three-dimensional porous composite carbon material is obtained through freeze drying and carbonization. According to the preparation method, a carbon nanotube can be inserted into a two-dimensionallayer structure of MXene, so that sheet agglomeration is prevented. The specific surface area is increased, and the ion migration space is enlarged. The improvement of the unit capacity and the cycling stability is facilitated. The problem that an MXene material and a graphene material are not easy to disperse uniformly is solved. The mesoporous and macroporous composite three-dimensional porous carbon material is prepared. The preparation method is simple, green, environment-friendly, low in cost, high in yield and easy for industrial production.

Owner:四川翔丰华新能源材料有限公司 +1

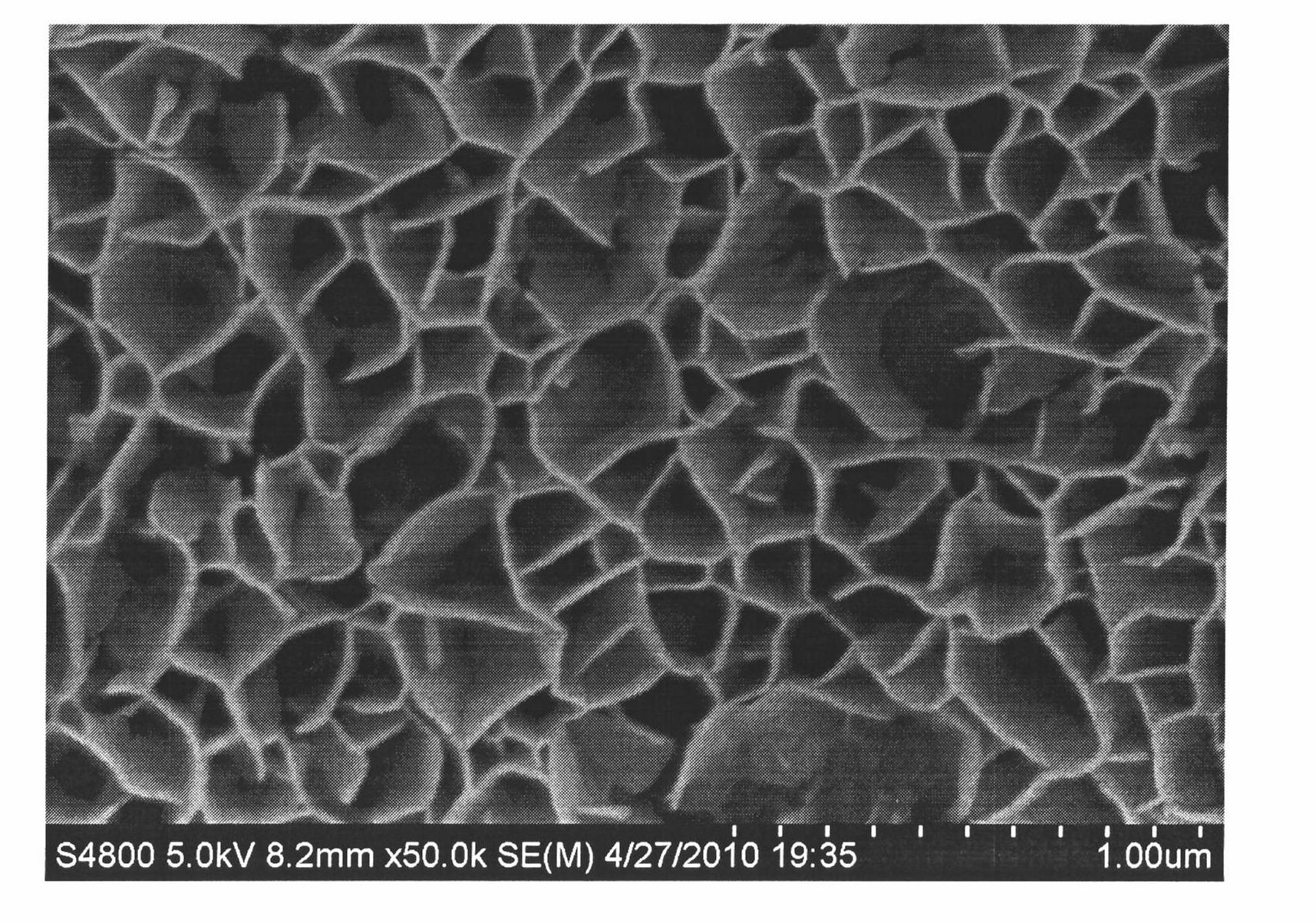

Film for graphene/porous nickel oxide composite super capacitor and preparation method thereof

InactiveCN102013330AIncrease contact areaShorten the diffusion distanceCapacitor electrodesCapacitanceElectron

The invention discloses a film for a graphene / porous nickel oxide composite super capacitor. The invention is characterized in that the film is of a disordered nano porous structure, the aperture range is 10 to 350nm, the thickness of the film is 1 to 5 mu m, and the weight ratio of graphene to nickel oxide is (0.5:100) to (2:100). The method for preparing the film comprises the following steps: dissolving graphite oxide sheets and magnesium nitrate into an isopropanol solution so as to form a positively-charged graphite oxide sheet sol, then carrying out electrophoretic deposition on the obtained sol so as to obtain a graphene film; and through taking the graphene film as a deposition carrier, preparing a three-dimensional porous film for the graphene / porous nickel oxide composite super capacitor by using a chemical bath film-coating method. The porous composite thin film prepared by the method has the advantages of good mechanical capacity and super-capacitance property, high-discharge specific capacitance, high-ratio charge-discharge properties, high cycle life and the like, and has wide application prospects in the fields such as electric automobiles, communication, consumer electronics, signal control and the like.

Owner:ZHEJIANG UNIV

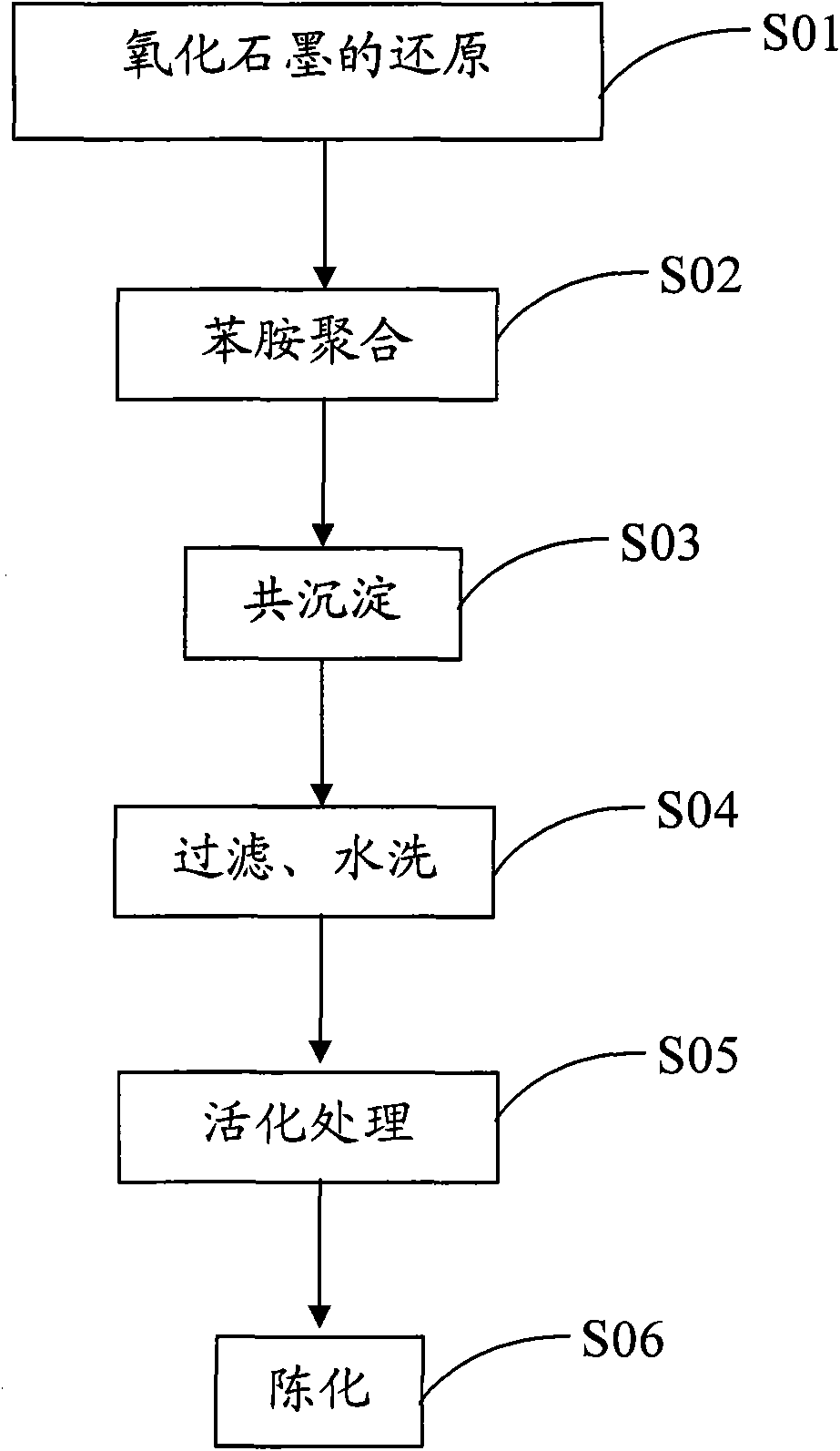

Graphene-polyaniline composite material and preparation method thereof

ActiveCN102115598ALarge specific surface areaGreatly improve conductivityPolyaniline compositeCvd graphene

The invention provides a graphene-polyaniline composite material which comprises the following components in percentage by mass: 0.01-99.99% of graphene and 0.01-99.99% of polyaniline. The graphene and the polyaniline are doped to form a composite structure, and the composite structure has a micro or nano porous structure. The invention also provides a preparation method of the graphene-polyaniline composite material. In the graphene-polyaniline composite material, the graphene and the polyaniline are doped to form a porous composite structure, and such a micro or nano porous structure greatly increases the specific area of the composite material. Due to high conductivity and large specific area, the composite material has high specific capacity when being used as an electrode material. The preparation technique is simple and reliable, can effectively lower the technical cost, and has wide application prospects.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com