Porous grapheme/ MnO2 composite film and preparation method and application thereof

A technology of porous graphene and composite film, applied in the manufacture of hybrid/electric double-layer capacitors, electrodes of hybrid capacitors, etc., can solve the problems of increasing the quality and cost of supercapacitors, low effective specific surface area, and reduced effective area, etc. The supercapacitor has good performance, good cycle stability, and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

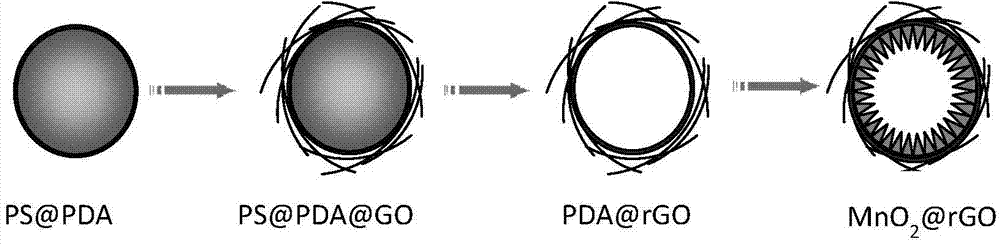

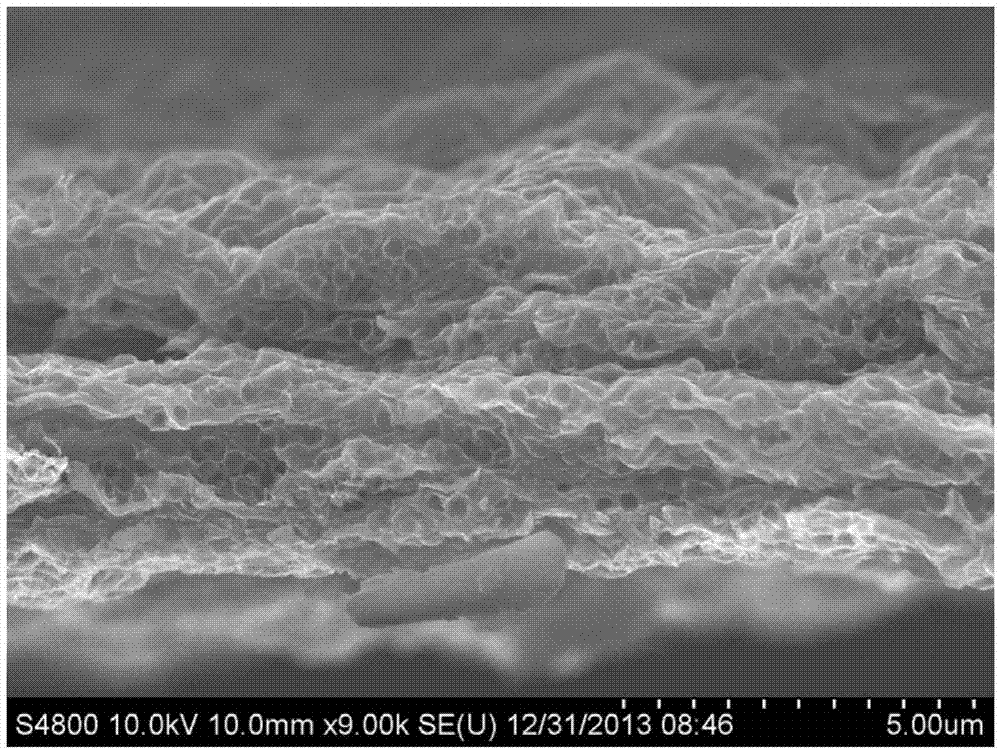

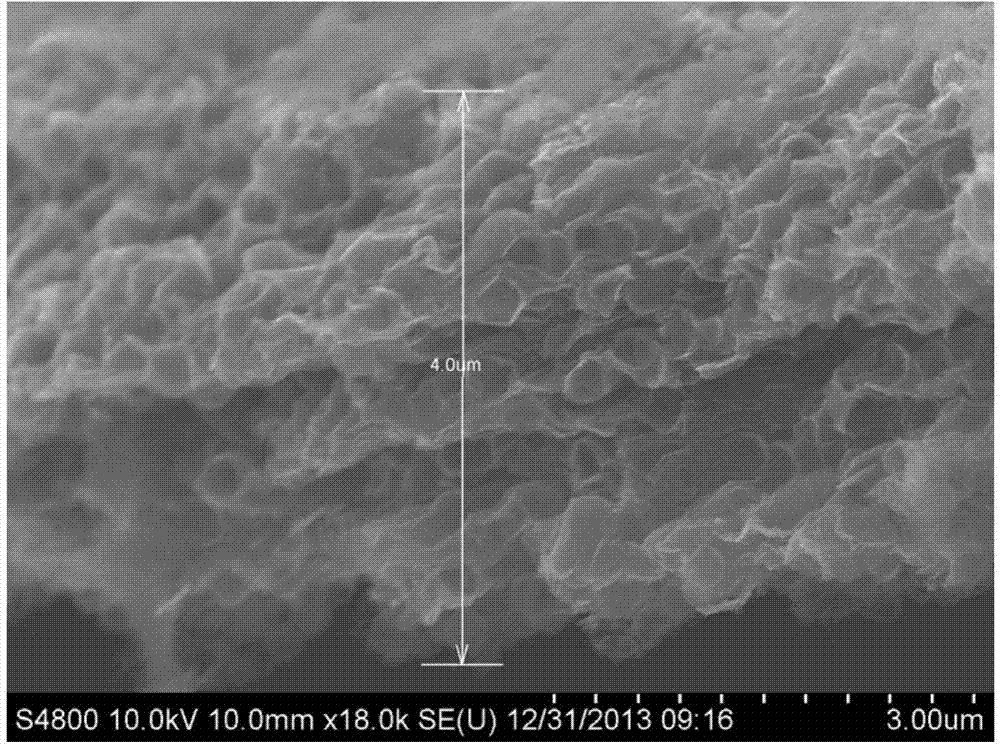

[0044] refer to figure 1 , 100 mg of PS beads with an average diameter of about 300 nm were dispersed in 2 mg / mL of DA in Tris-HCl (pH = 8.5) solution, stirred at room temperature for 15 h, then centrifuged, washed, and dried to obtain PSPDA powder. Disperse the PSPDA powder into a 10mg / mL aqueous solution, take 0.25mL and 10mL graphene solution (1.25mg / mL) and ultrasonically disperse for 40min, then vacuum filter the mixture, dry it naturally and peel off the composite film from the filter membrane Down, get PSPDAGO composite film. The composite film was annealed at 500° C. for 5 h in an Ar atmosphere to remove the template PS pellets to obtain a hollow-structured graphene composite film. Put this film in 10mM potassium permanganate aqueous solution, and conduct a hydrothermal reaction at 180°C for 25min, as figure 2 Porous graphene / MnO shown 2 Composite film. Cut the composite membrane into discs with a diameter of 1 cm, select two pieces of similar mass as electrode ma...

Embodiment 2

[0051] refer to figure 1 , 100 mg of PS beads with an average diameter of about 300 nm were dispersed in 2 mg / mL of DA in Tris-HCl (pH = 8.5) solution, stirred at room temperature for 10 h, then centrifuged, washed, and dried to obtain PSPDA powder. Disperse the PSPDA powder into a 10mg / mL aqueous solution, take 0.25mL and 10mL graphene solution (1.25mg / mL) and ultrasonically disperse for 40min, then vacuum filter the mixture, dry it naturally and peel off the composite film from the filter membrane Down, get PSPDAGO composite film. The composite film was annealed at 500° C. for 5 h in an Ar atmosphere to remove the template PS pellets to obtain a hollow-structured graphene composite film. Put the film in 10mM potassium permanganate aqueous solution, and conduct a hydrothermal reaction at 180°C for 25min.

[0052] The specific capacitance of the material is calculated by constant current charge and discharge to be 75.2F / g (the current is 0.1A / g, and the electrochemical windo...

Embodiment 3

[0054] Disperse 100 mg of PS beads with an average diameter of about 300 nm in 0.5 M glucose solution, stir and react at room temperature for 24 hours, then centrifuge, wash, and dry to obtain polydextrose-coated PS powder. Disperse the above powder into a 10mg / ml aqueous solution, take 1mL of this solution and 10mL graphene solution (1.25mg / mL) and ultrasonically disperse for 40min, then vacuum filter the mixture, dry it naturally and remove the composite film from the filter membrane Peel it off to get the PSPGLGO composite film. The composite film was annealed at 500° C. for 5 h in an Ar atmosphere to remove the template PS pellets to obtain a hollow-structured graphene composite film. Put this film in 5mM potassium permanganate aqueous solution for hydrothermal reaction for 20min. Cut the composite membrane into discs with a diameter of 1 cm, select two pieces of similar mass as electrode materials, glass fiber membrane as a diaphragm, 1M Na 2 SO 4 The aqueous solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com