Acetylene hydrocarbon selective hydrogenation method

A technology for selective hydrogenation and alkynes, applied in chemical instruments and methods, purification/separation of hydrocarbons, hydrogenation hydrocarbon production, etc., can solve the problems of small liquid space velocity and high product circulation ratio, and increase the effective contact area , high hydrogenation stability, and the effect of avoiding adverse factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

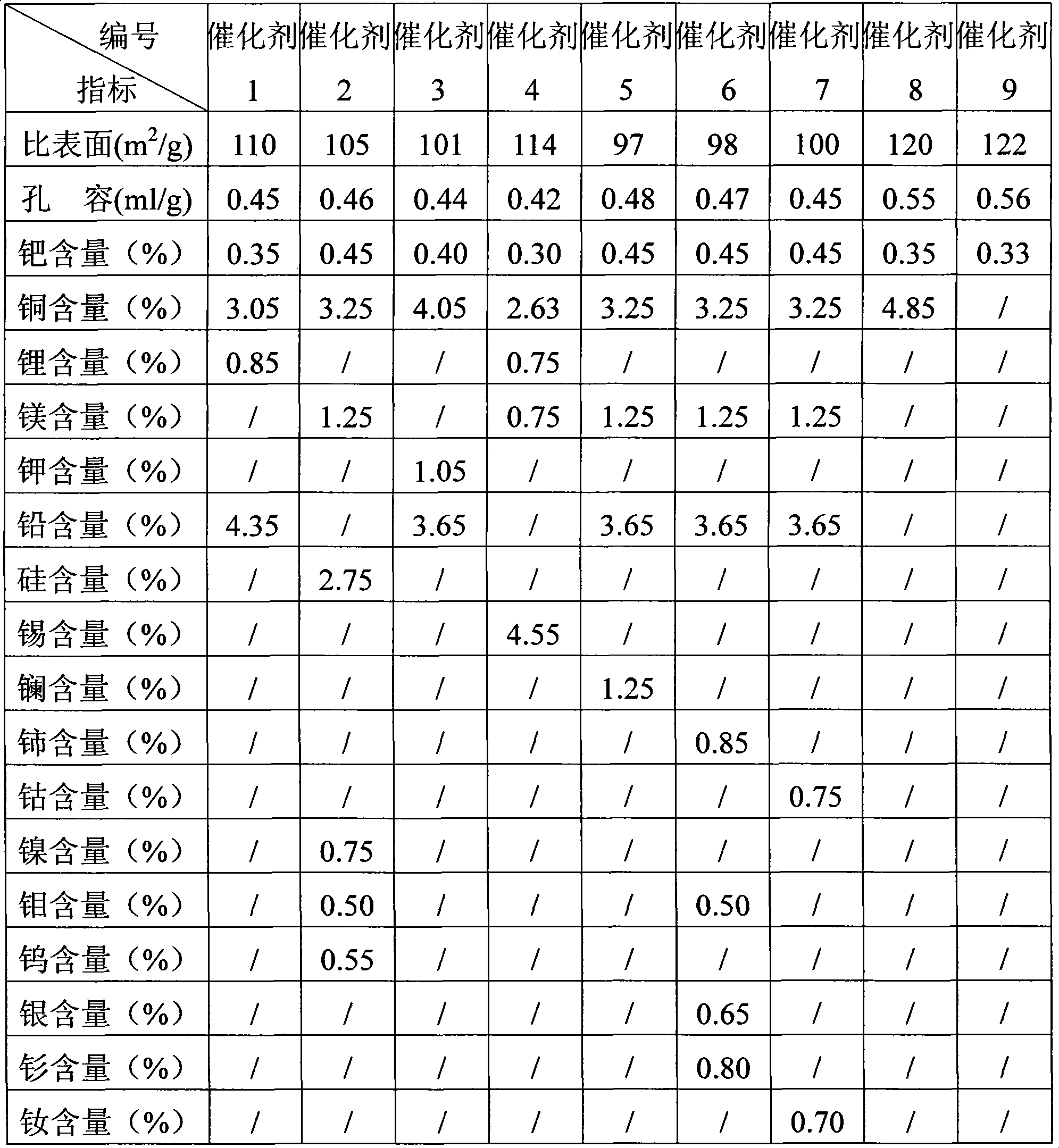

[0017] Preparation of Catalysts 1-7

[0018] Take Al 2 o 3 The carrier is calcined at 450-600°C for 8 hours, and then the alkali metal and / or alkaline-earth metal nitrate solution is prepared according to the acidity required by the catalyst, and the carrier is immersed in the solution, dried at 80-200°C for 2-6 hours, and then dried at 500-200°C Roast at 1100°C for 3 to 8 hours to obtain the carrier of the present invention; then prepare a palladium chloride or palladium nitrate solution according to the Pd content required by the catalyst, adjust the pH value of the solution to 1.0 to 3.0 with sodium carbonate or sodium bicarbonate, and impregnate the alkali Metal and / or alkaline earth metal carrier, remove the residual liquid after 10-30 minutes, wash with distilled water, then age, dry, and roast to obtain the catalyst precursor; finally prepare copper and IVA elements or cobalt, nickel, One or more soluble salt solutions of molybdenum, tungsten, lanthanum, silver, ceriu...

Embodiment 1

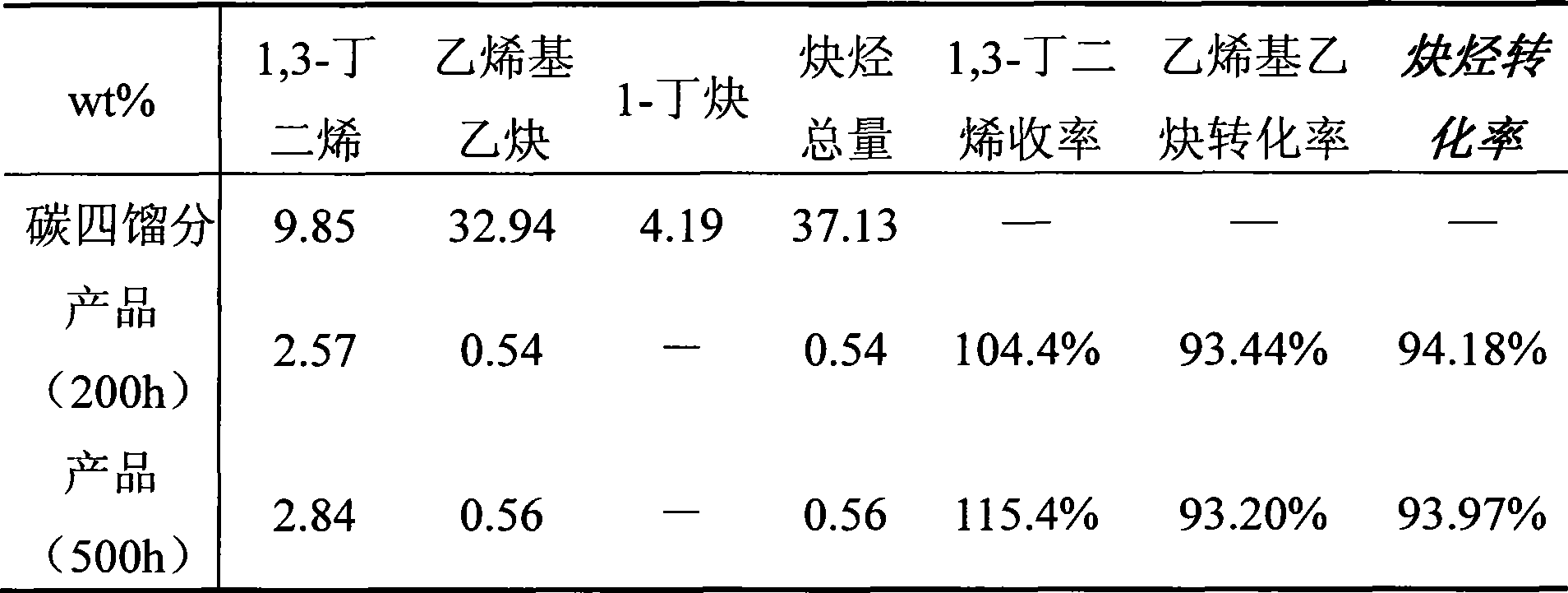

[0027] The raw materials are C4 fraction and raffinate C4 fraction rich in alkynes, and the weight ratio of C4 fraction and raffinate C4 fraction is 1:3. The hydrogenation reactor uses catalyst 1, the catalyst carrier is alumina, the hydrogenation reactor adopts a single-stage isothermal fixed bed, the reaction temperature is 45°C, the reaction pressure is 1.5MPa, and the liquid space velocity is 13.4h -1 , the molar ratio of hydrogen to alkyne is 2.0, Table 2 is the composition of materials before and after the reaction.

[0028] Table 2 Composition of materials before and after reaction

[0029]

Embodiment 2

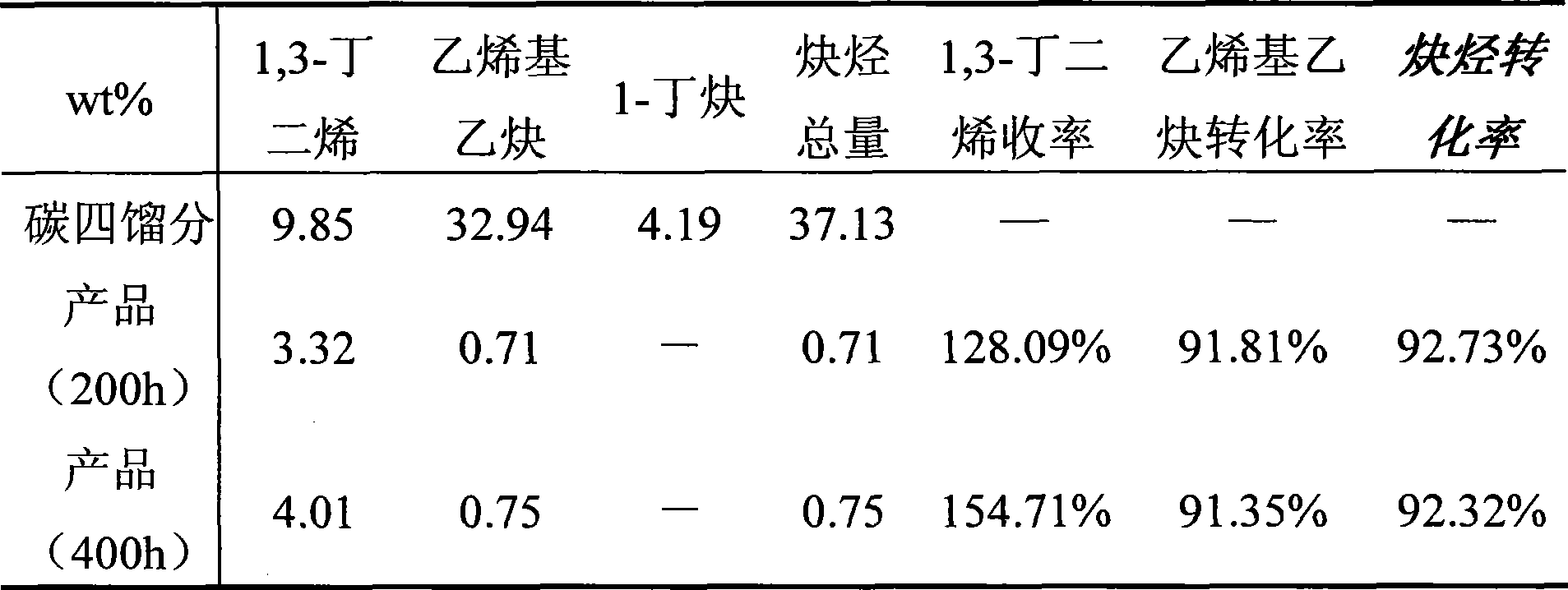

[0031] The raw material is C4 cut and raffinate C4 cut rich in alkyne, the weight ratio of C4 cut and raffinate C4 cut rich in alkyne is 1:2.8, and hydrogenation reactor adopts catalyst 2, and catalyst carrier is Alumina, the hydrogenation reactor adopts a single-stage isothermal fixed bed, the reaction temperature is 50°C, the reaction pressure is 2.0MPa, and the liquid space velocity is 15.0h -1 , the molar ratio of hydrogen to alkyne is 1.50, Table 3 is the composition of materials before and after the reaction.

[0032] Table 3 Composition of materials before and after reaction

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com