Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3973 results about "Hydration reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, a hydration reaction is a chemical reaction in which a substance combines with water. In organic chemistry, water is added to an unsaturated substrate, which is usually an alkene or an alkyne. This type of reaction is employed industrially to produce ethanol, isopropanol, and 2-butanol.

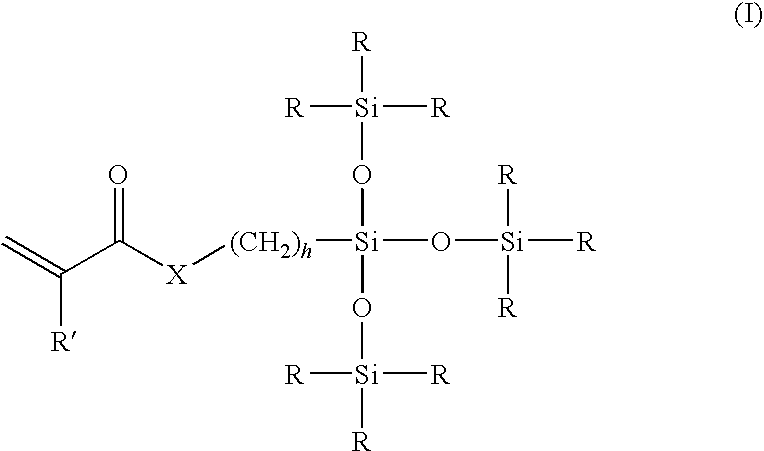

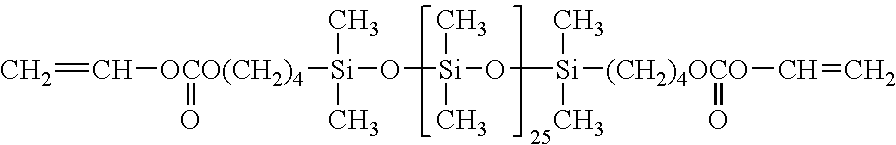

High water content silicone hydrogels

ActiveUS7934830B2Increase moisture contentSuitable oxygen permeability propertyLayered productsThin material handlingHydration reactionHydrophilic monomer

Owner:BAUSCH & LOMB INC

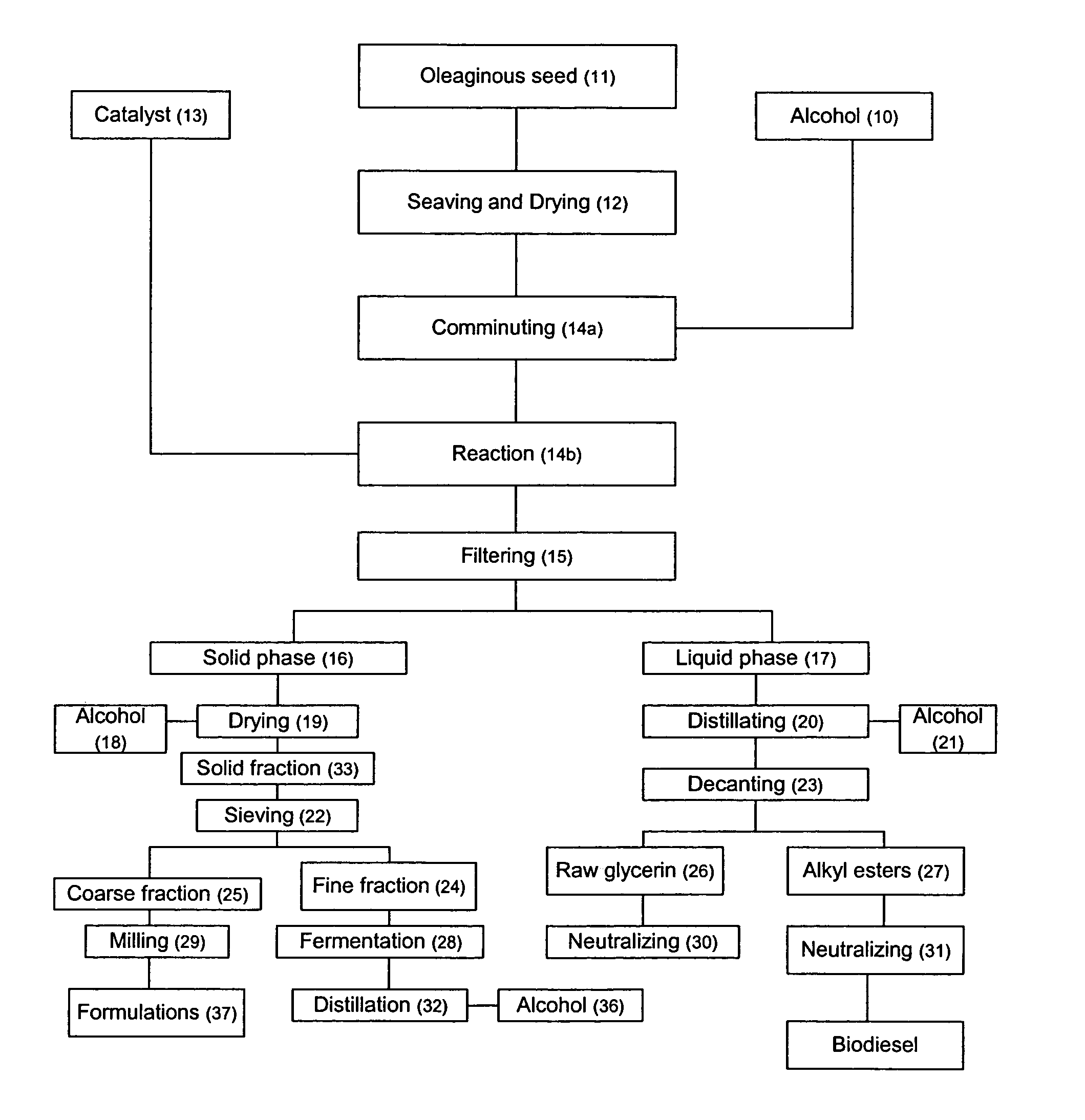

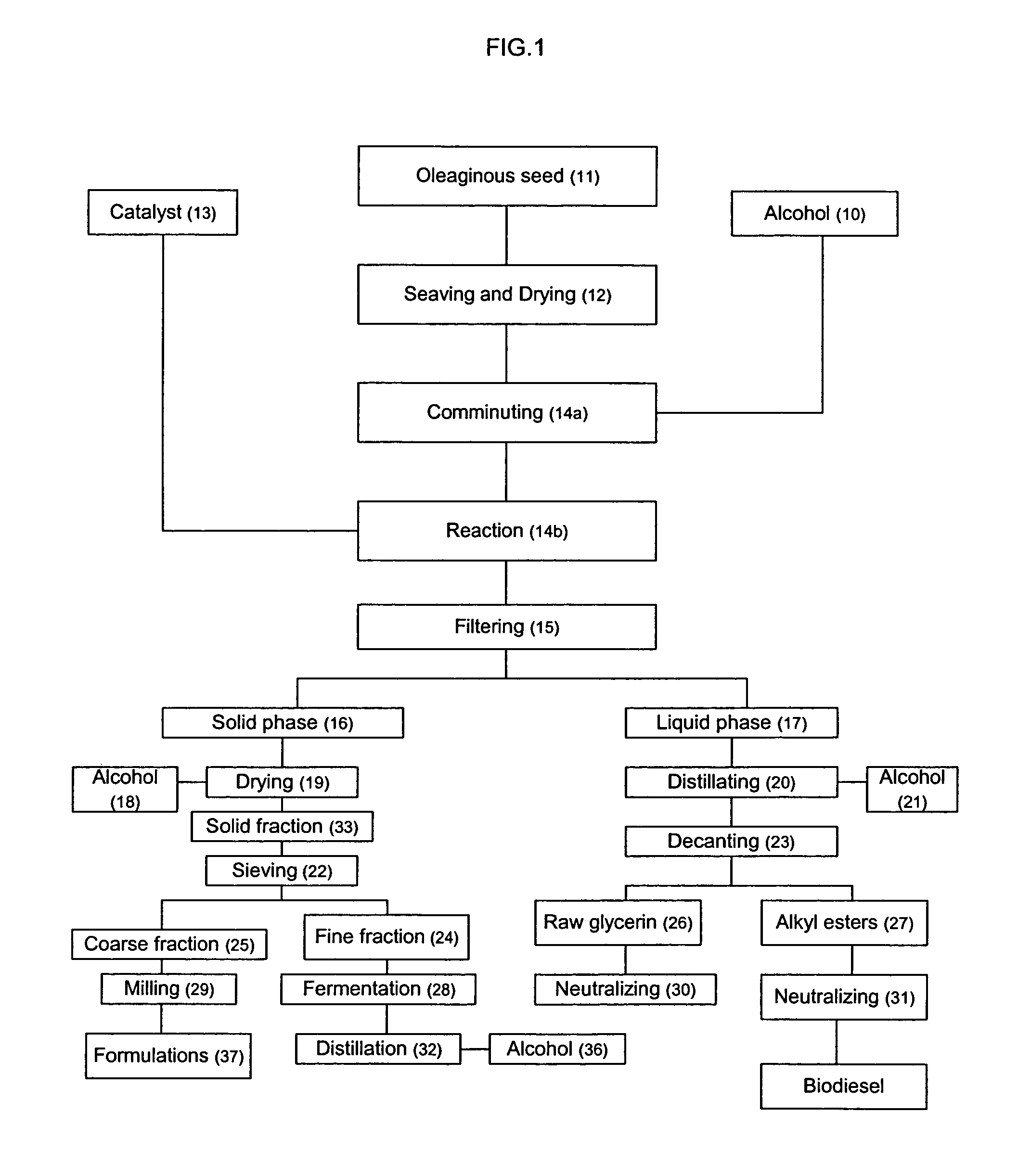

Process for producing biodiesel fuel using triglyceride-rich oleagineous seed directly in a transesterification reaction in the presence of an alkaline alkoxide catalyst

InactiveUS7112229B2Fatty oils/acids recovery from wasteFatty acid esterificationOil and greaseBiodiesel

An integrated process is described for producing biodiesel from oleaginous seeds, preferably castor bean seeds. The inventive process includes a transesterification reaction where the seeds themselves react with anhydrous ethyl alcohol in the presence of an alkaline catalyst. The resulting ethyl esters are then separated by decantation and neutralized and used as fuel for diesel engines, co-solvents for diesel and gasoline mixtures with anhydrous or hydrated ethyl alcohol. The solid fractions may be used as fertilizers, for feeding cattle and as a raw material for producing ethyl alcohol.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Desulfurization waste water zero discharging process and system

ActiveCN104843927ASolve pollutionWaste water treatment from gaseous effluentsMultistage water/sewage treatmentWater useHydration reaction

The invention discloses a desulfurization waste water zero discharging process. The process comprises a chemical dosing softening process and a microfiltration membrane treatment process; after incoming water is subjected to two-stage softening, nanofiltration and reverse osmosis separation are performed; sodium sulfate decahydrate with the purity of more than 99% is separated out by utilizing freezing crystallization; a reverse osmosis concentrated water regeneration sodium ion exchange device is utilized; sodium chloride with the purity of more than 98% is separated out by utilizing evaporative crystallization; solids are comprehensively utilized, and no liquid is discharged outside. The invention further provides a desulfurization waste water zero discharging system. According to the desulfurization waste water zero discharging process and the system, water in desulfurization waste water can be separated to be reutilized as domestic and industrial usable water, and other impurities in the desulfurization waste water are separated in solid form, so that pollutants harmful to the natural environment do not generate, and the problem that the desulfurization waste water pollutes the environment can be completely solved.

Owner:华电水务工程有限公司

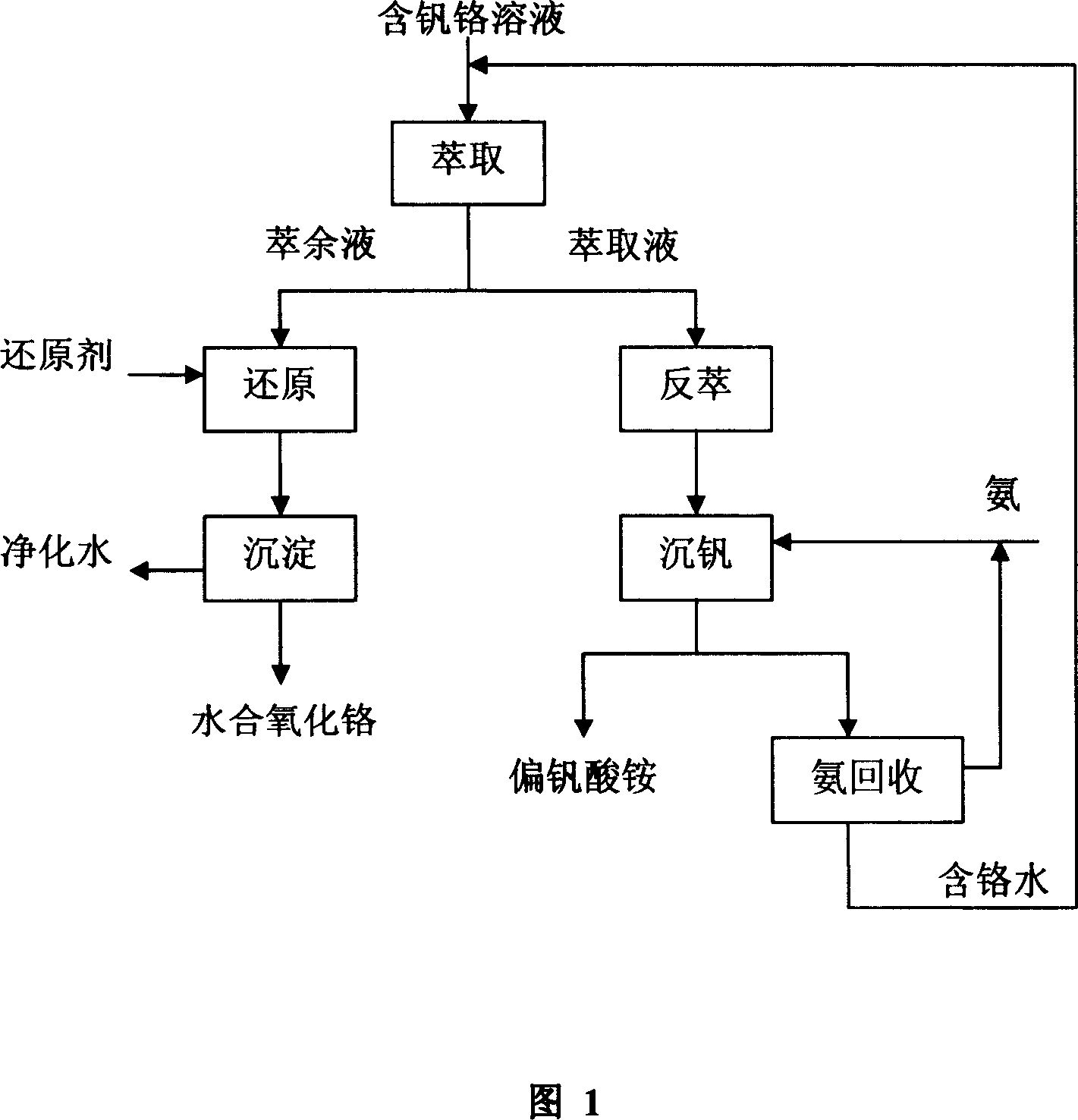

Method for separating and reclaiming vanadium and chromium from solution containing vanadium and chromium

ActiveCN101121962ALow costSimple processProcess efficiency improvementHydration reactionDistillation

This invention relates to an entirely new technology of completely recovering chromium and vanadium from vanadium-chromium miscible liquid. The main procedures include: first a primary-secondary compound amine extracting agent contacts the vanadium-chromium miscible liquid by means of countercurrent contact and extract, so as to extract most of vanadium and a small amount of chromium into a organic phase while most of chromium stays into a aqueous phase; and a reduction reaction is conducted with pH of acid adjustable faffinate (aqueous phase) and a certain amount of a reducing agent; the sodium hydroxide is used for adjusting pH value of the solution and filter, and finally the product is hydrous chromium oxide; at that time, the lye is used as a stripping agent; the vanadium is stripped from the vanadium-rich organic phase into water in the manner of countercurrent contact; and the vanadium is separated from the solution witthe method of ammonium precipitation and in the form of ammonium metavanadate; and finally the supernatant clear solution of the one is processed with deposited vanadium with a high-efficient distillation technology, and the strong aqua ammonia is left in the tower top and deamidization solution is left in the tower bottom until the extraction process is reached. The invention uses the primary-secondary compound amine as the extracting agent, extracts and separates vanadium and chromium selectively at a low temperature. The invention not only has a simple process flow, but also is low-cost, quite applicable in large-scale industrial production. In addition, the invention also provides high-purity ammonium metavanadate and 16 percentage strong aqua ammonia, and makes sure the vanadium and chromium can be completely recovered through re-use of the solution.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

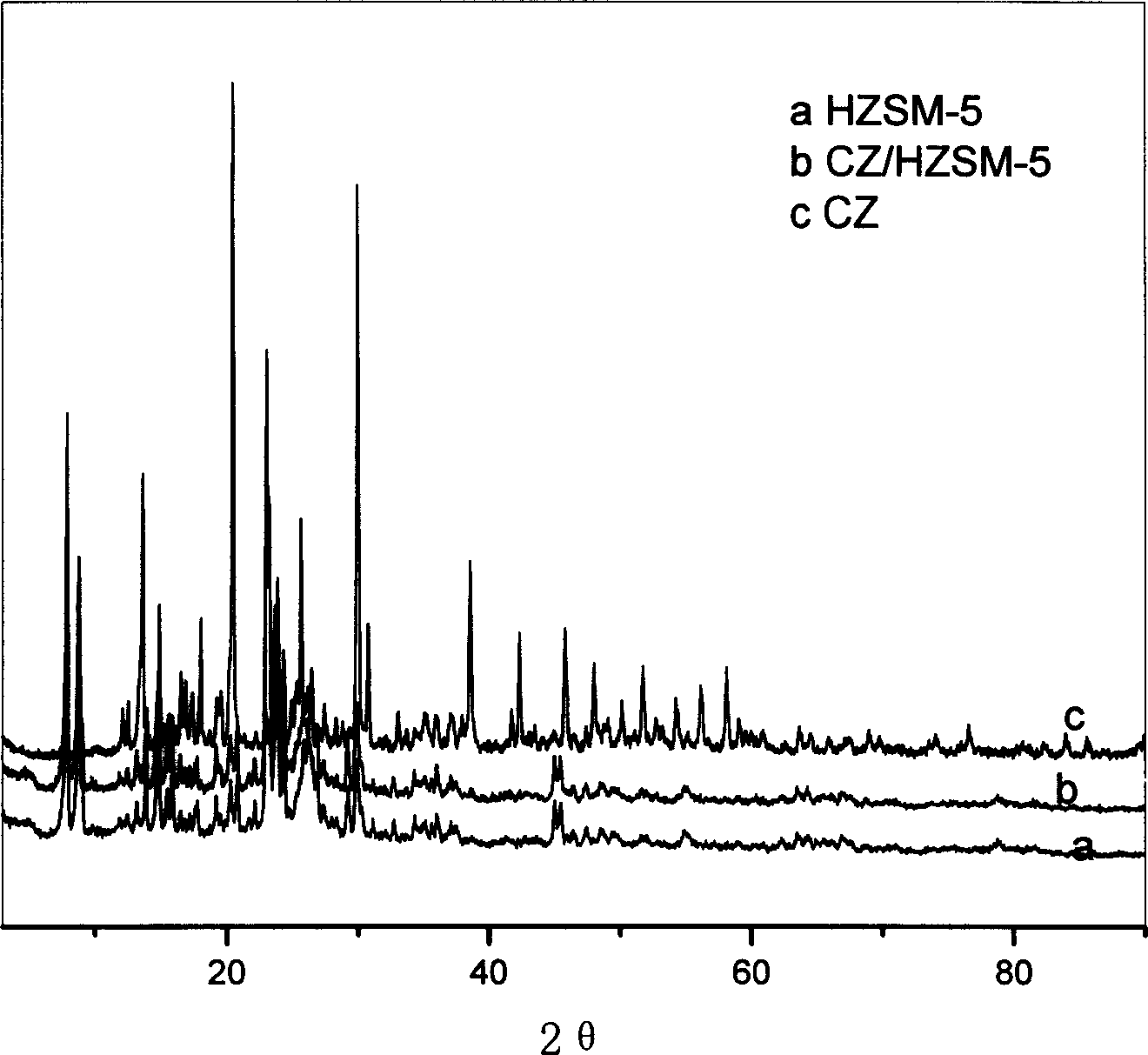

Preparation for hydrophobic solid acid catalyst

InactiveCN1613559AAcidicHydrophobicMolecular sieve catalystsCatalyst activation/preparationHydration reactionAlkyl transfer

A hydrophobic solid, acid catalyst for the acid catalyzing reaction, such as esterifying reaction, alkylation reaction and hydration reaction, is prepared by attaching the inorganic metal salt to the high-hydrophobicity carrier. Its advantages are high catalyst activity and selectivity, high stability, and high hydrophobicity.

Owner:BEIJING UNIV OF CHEM TECH

Metal catalysts

InactiveUS6747180B2Low bulk densityHigh activityOrganic compound preparationCatalyst activation/preparationHydration reactionAlkyl transfer

Owner:DEGUSSA AG +1

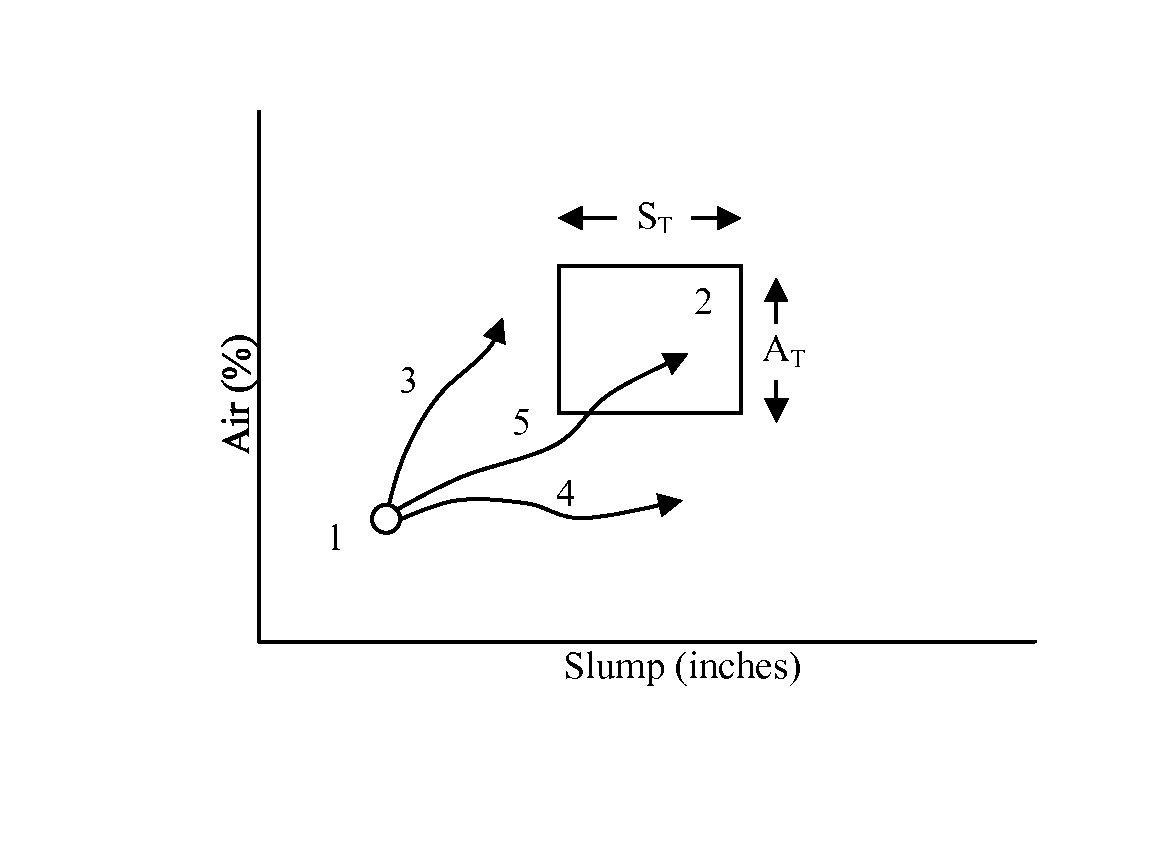

Multivariate management of entrained air and rheology in cementitious mixes

ActiveUS8491717B2Efficiently and accurately updatingHighly inventiveSampled-variable control systemsMixing operation control apparatusHydration reactionBLENDER/MIXER

The invention relates to a method and system for monitoring and adjusting both air content and rheology (e.g., slump, slump flow) properties of a hydratable concrete mix contained within a concrete mixer. The system simultaneously tracks dosage of both rheology-modifying admixture (e.g., polycarboxylate polymer cement dispersant) and air control agent or “ACA” (e.g., air entraining agent) by reference to at least four nominal dose response (“NDR”) curves or profiles, which at least four NDR profiles are based on the respective behaviors of each of the ACA and rheology-modifying agent on air content and rheology.

Owner:VERIFI INC

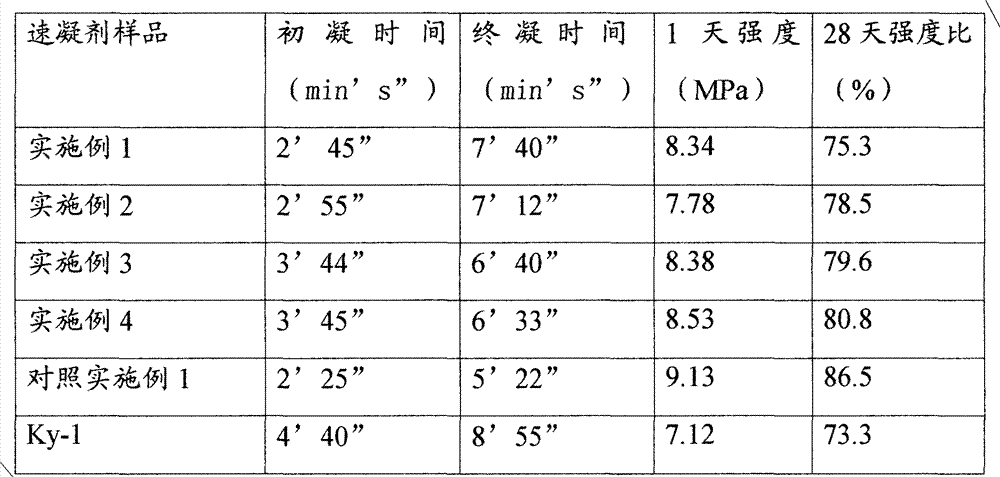

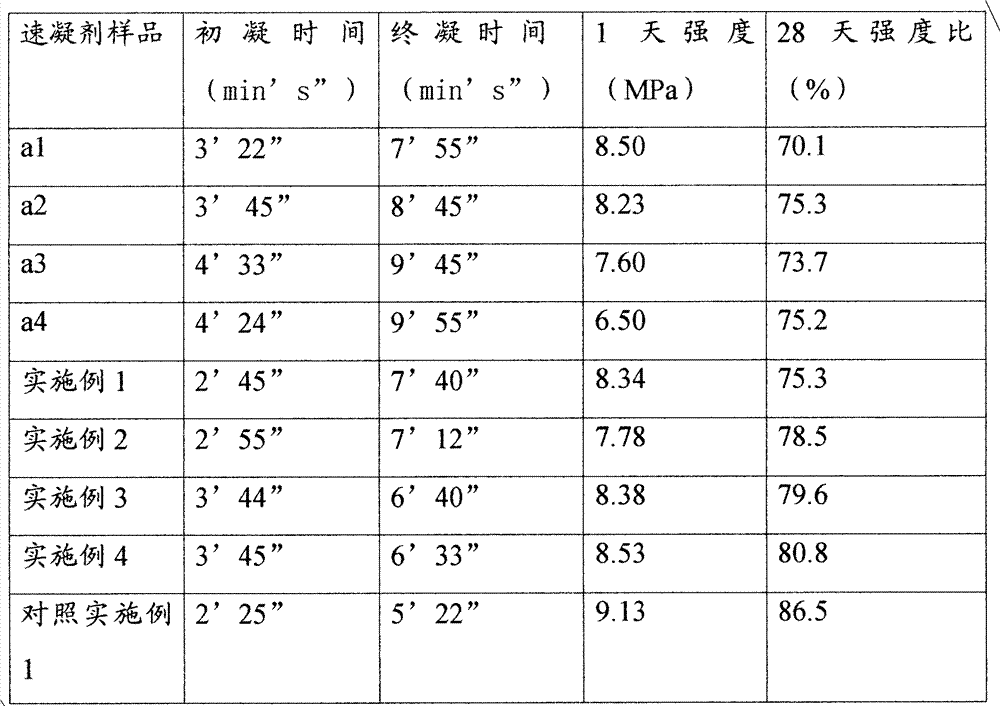

Liquid alkali-free chloride-free accelerating agent as well as methods for preparing and using same

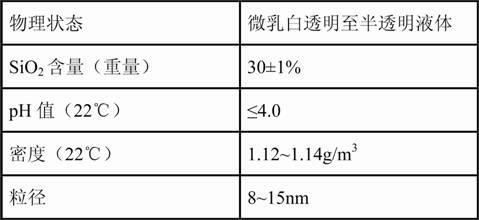

The invention discloses a liquid alkali-free chloride-free accelerating agent and methods for preparing and using the same. Raw materials for preparing the accelerating agent include one or a plurality of the following components of aluminum sulfate, magnesium sulfate, hydramine, an early strength agent, a synergist and water. The aluminum sulfate is the purchasable industrial-grade aluminum sulfate hydrate Al2(SO4)3.18H2O and has the solid content of 51%-52%. The magnesium sulfate is MgSO4.7H2O with the solid content of 48%-49%. The hydramine is one or a plurality of mono ethanol amine, diethanolamine, triethanolamine or isopropoxide. The early strength agent is one or a plurality of calcium sulfate, calcium formate or calcium nitrite. The synergist is magnesium fluosilicate and / or magnesium fluoride. The liquid alkali-free chloride-free accelerating agent provided by the invention has the characteristics of good adaptability, low price, low mixing amount, good performance, good stability and the like; and moreover, the liquid alkali-free chloride-free accelerating agent is added into the concrete to be used as sprayed concrete, has the characteristics of low resilience, small dust pollution and the like and can satisfy the requirements of the 'JC477-2005 sprayed concrete accelerating agent' standard.

Owner:北京冶建特种材料有限公司 +1

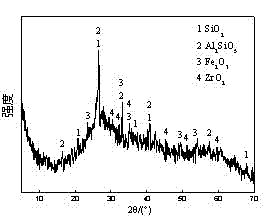

Reproducible phosphorus-uptake ceramsite and preparation method thereof

InactiveCN102515830AStrong phosphorus removal capacityAdaptableOther chemical processesCeramic materials productionHydration reactionWastewater

The invention discloses a reproducible phosphorus-uptake ceramsite and a preparation method thereof. The technical scheme provided by the invention comprises the following steps of: respectively drying 70-85 wt% of fly ash, 10-16 wt% of pore-forming agent and 5-14 wt% of clay powder and uniformly mixing the raw materials; after balling the mixture, baking at a temperature in a range of 950-1100 DEG C for 30-50 min to obtain a baked porous ceramsite; sequentially immersing the baked porous ceramsite with HCl, washing with water and drying; and loading zirconium oxide hydrate to obtain the phosphorus-uptake ceramsite. The phosphorus-uptake ceramsite prepared by the invention can be directly added into or filled as a filtering column to remove phosphorus in the water and the adsorbed phosphorus-uptake ceramsite can be desorbed by a NaOH solution to be reproduced; the saturated adsorption capacity to the phosphorus is 10-11 mg / g and the adaptability to the change of the phosphorus concentration in the water is good; after the treatment, the solid-liquid separation is easy to realize and the water quality of the discharged water is better. The reproducible phosphorus-uptake ceramsite provided by the invention has the advantages of strong phosphorus-uptake capability, easiness of realizing the solid-liquid separation, good cyclic usability and higher cost performance, so that the reproducible phosphorus-uptake ceramsite is applicable to phosphorous removal of various types of wastewater and surface water.

Owner:WUHAN UNIV OF SCI & TECH

Metal catalysts

InactiveUS6573213B1Low bulk densityHigh activityOrganic compound preparationCatalyst activation/preparationHydration reactionAlkyl transfer

Metal catalysts comprising hollow forms or spheres are made of metal alloy and optionally activated. The metal catalysts can be used for the hydrogenation, dehydrogenation, isomerization reductive alkylation, reductive amination, and / or hydration reaction of organic compounds.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

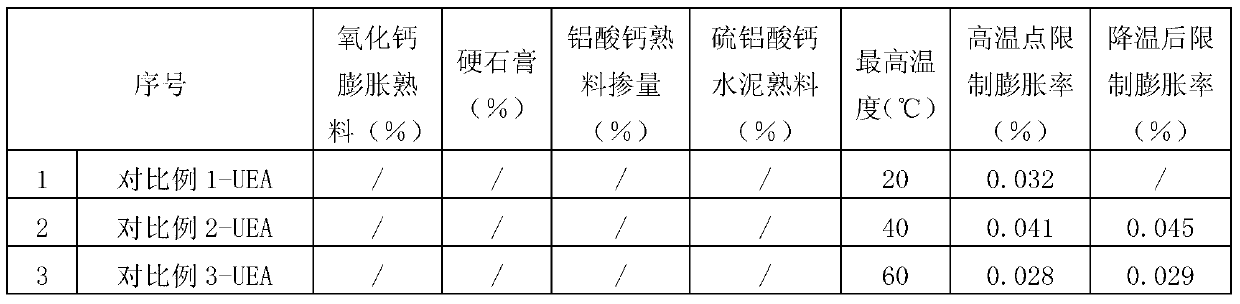

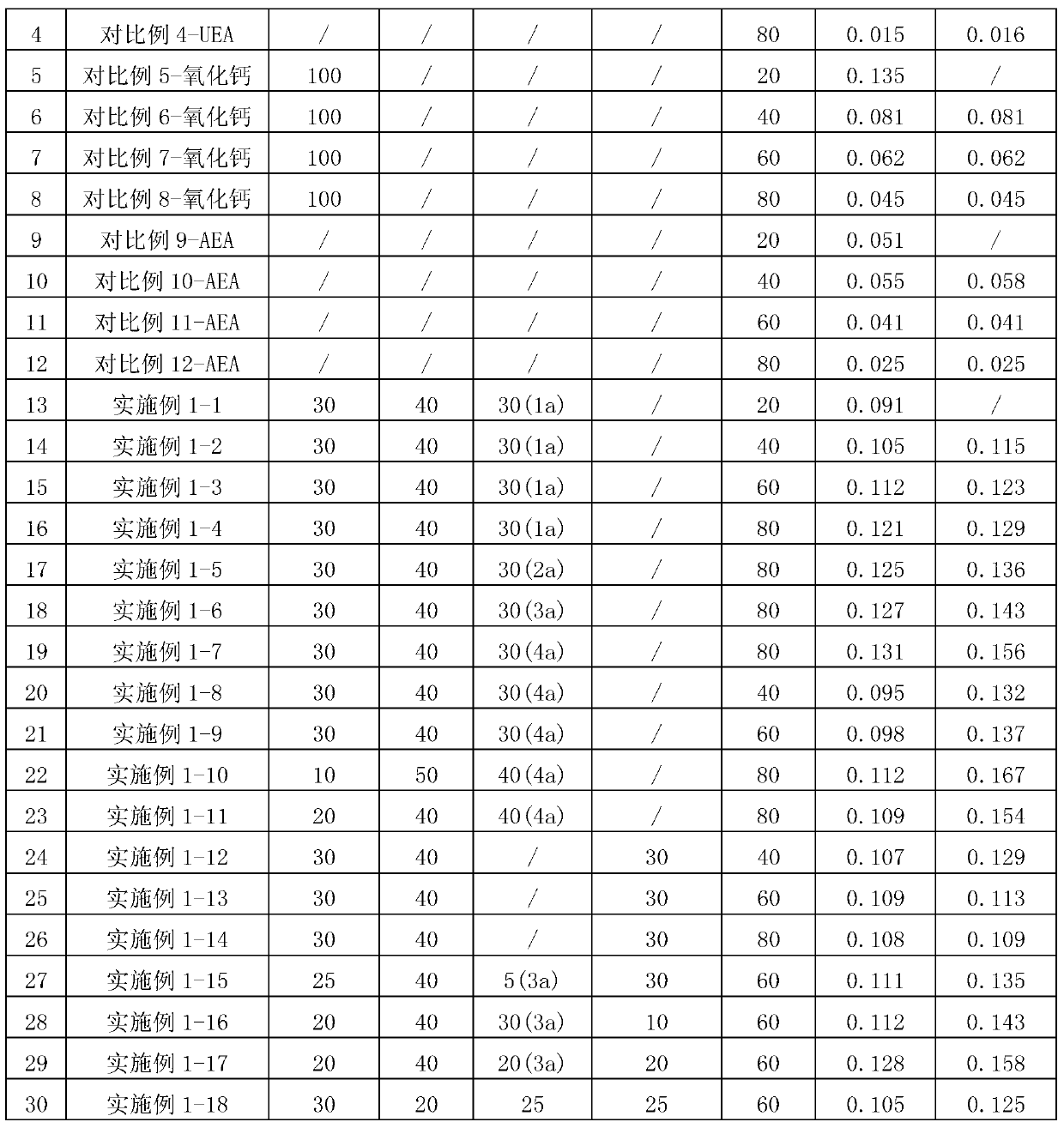

Hydration heat inhibited concrete expanding material as well as preparation method and applications thereof

The invention discloses a hydration heat inhibited concrete expanding material as well as a preparation method and applications thereof. The hydration heat inhibited concrete expanding material is implemented by complexly using first two or three of an expanding agent, a hydration heat inhibitor and an inner curing agent. The hydration heat inhibited concrete expanding material disclosed by the invention fully plays the superimposed effect of the three types of materials, so that the dry shrinkage resistance and cold shrinkage resistance of concrete can be maximized. Experiments prove that concrete with the hydration heat inhibited concrete expanding material disclosed by the invention produces a large expansion in the temperature-fall period, thereby considerably improving the temperature shrinkage (caused by hydration heat) resistance of the concrete; the temperature rise of concrete can be effectively reduced; high relative humidity can be kept in the concrete for a long time, thereby providing a good hydration reaction environment for the expanding agent, and reducing dry shrinkage.

Owner:CHINA BUILDING MATERIALS ACAD

Colored aluminum pigment with high color depth and preparation method thereof

InactiveCN101445675AGood acid and alkali resistanceColorfulInorganic pigment treatmentMetallic aluminumKetone solvents

The invention relates to a colored aluminum pigment with high color depth and a preparation method thereof. The colored aluminum pigment is obtained by depositing a layer of silicon dioxide on a flaky metallic aluminum sheet substrate and then depositing one or more layers of metal oxide on the surface of the silicon dioxide, and the colored aluminum pigment exists in the form of dry powder. The preparation method comprises the following steps: a. stirring to disperse commercially available aluminum pigment slurry in alcohol, alcohol ether or a ketone solvent; b. regulating the temperature to 30-80 DEG C, respectively adding tetraethoxysilane and aqueous solution to the dispersed aluminum pigment slurry with the mol ratio of the tetraethylorthosilicate to the water ranging from 1:0.5 to 1:20, adding a catalyst such as ethylenediamine solution or aqueous ammonia, and obtaining aqueous aluminum pigment slurry by vacuum filtration and washing after the reaction; and c. cladding the aqueous aluminum pigment slurry obtained in the step b with the hydrated metal oxide on the powdered aluminum surface in a liquid phase. The preparation method help prepare the colored aluminum pigment with diversified colors and high color depth without reducing brightness of the original aluminum pigment slurry.

Owner:WENZHOU YOUNGBIO CHEM

Multiple element composite metal oxidate arsenic removal settling agent and use method thereof

The invention belongs to the material field for removing the arsenic in water by settlement, more particularly relates to polyelement composite metal oxide arsenic removal settlement agent and an application method thereof based on iron oxide, manganese oxide, and aluminum oxide. The invention uses an ectopic preparation method or situ preparation method for preparing and obtaining polyelement composite metal oxide arsenic removal settlement agent which comprises hydrated iron oxide, hydroxyl-hydrated ferric hydroxide, hydrated aluminum oxide, hydroxyl-hydrated alumina, hydrated manganese oxide and the like. The polyelement composite metal oxide arsenic removal settlement agent can be used for removing the arsenic pollutants in water bodies such as lakes, reservoirs, rivers, groundwater, drinking water, industrial waste water, and the like; in addition, the settlement agent can also be used for removing the heavy metals such as copper, chromium, cadmium, lead, and the like, and the pollutants such as iron, manganese, phosphates, and the like in water by settlement.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

High performance water-based mud system

InactiveUS20050187113A1Premature consumptionEffectively stopFluid removalFlushingWater basedPolystyrene

A drilling fluid or mud additive having several components, including leonardite (humic acid); potassium acetate; partially hydrolyzed polyacrylamide (PHPA); polyanionic cellulose polymer (PAC); sulfonated asphalt; sulfoalkylated tannin; polystyrene maleic anhydride copolymer; micronized cellulose fiber; and calcium carbonate. These components are preferably premixed in a dry formulation as a powder or as pellets, and shipped to the site in bags or bulk tanks. This offers substantial advantages over the prior art in that the drilling mud of the present invention may be formed simply by adding the dry mix to a predetermined amount of water, and is thus much easier to make than the prior art wet mix drilling fluids, which typically require precise ratios of several different powders and liquids to be mixed together. Hydration buffers help keep the powder or pellets dry and flowable.

Owner:HAYES JAMES R

Nano solid-liquid phase change energy storage composite material

InactiveCN101982518AHigh energy storage densityGood heat transfer performanceHeat-exchange elementsIndustrial wasteCorrosion

The invention relates to a nano solid-liquid phase change energy storage composite material, belonging to a phase change energy storage technology. The composite material comprises the following components in parts by weight: 88 to 98 parts of hydrated salt, 1 to 7 parts of a nano material and 1 to 5 parts of thickener. With regard to the nano solid-liquid phase change energy storage composite material, the hydrated salt is taken as a main body for phase change energy storage, thus having higher energy storage density and good heat transfer performance; the nano material is taken as nucleating agent, thereby reducing and even eliminating the degree of supercooling of the hydrated salt and having stable property and corrosion resistance; and a proper amount of the thickener is added to increase the viscosity of liquid hydrated salt, thereby preventing the phase separation of the hydrated salt and simultaneously strengthening the suspension stability of the nano material. The nano solid-liquid phase change energy storage composite material of the invention can be widely applied to the fields of solar thermal utilization, industrial waste heat recovery, air conditioning energy storage and the like.

Owner:UNIV OF SCI & TECH OF CHINA

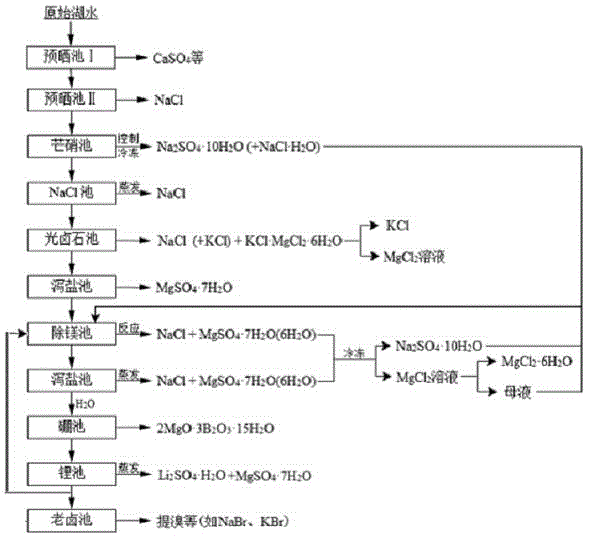

Clean production process of plateau sulfate type boron-lithium salt lake brine

InactiveCN102910652AHigh purityReduce the ratio of magnesium to lithiumChemical industryAlkali metal halide purificationHydration reactionSylvinite

The invention relates to a clean production process of plateau sulfate type boron-lithium salt lake brine. The process comprises the following steps of: (1) arranging a pre-airing pond, a mirabilite pond, a NaCl pond, a carnallite pond, an epsom salt pond I, a magnesium removing pond, an epsom salt pond II, a boron pond, a lithium pond and an old brine pond; (2) controlling the sodium ion concentration in plateau sulfate type boron-lithium salt lake brine, precipitating mirabilite out in winter to obtain brine A, naturally evaporating the brine A, and salting out to obtain brine B; (3) naturally evaporating the brine B, and precipitating sylvine and carnallite out in sequence to obtain brine C; (4) naturally evaporating the brine C, precipitating an epsom salt out, and performing solid-liquid separation to obtain brine D and a solid A; (5) blending the brine D with mirabilite, removing magnesium to obtain brine E, and naturally evaporating brine E to obtain brine F and a solid B; (6) performing a hydration reaction on brine F, naturally evaporating, and precipitating reservoir water / inderite and brine G out; and (7) evaporating brine G or refrigerating for precipitating lithium sulfate, and processing the lithium sulfate into a corresponding product. The process has the advantages of comprehensive utilization of natural energy, saving in energy and environment friendliness.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

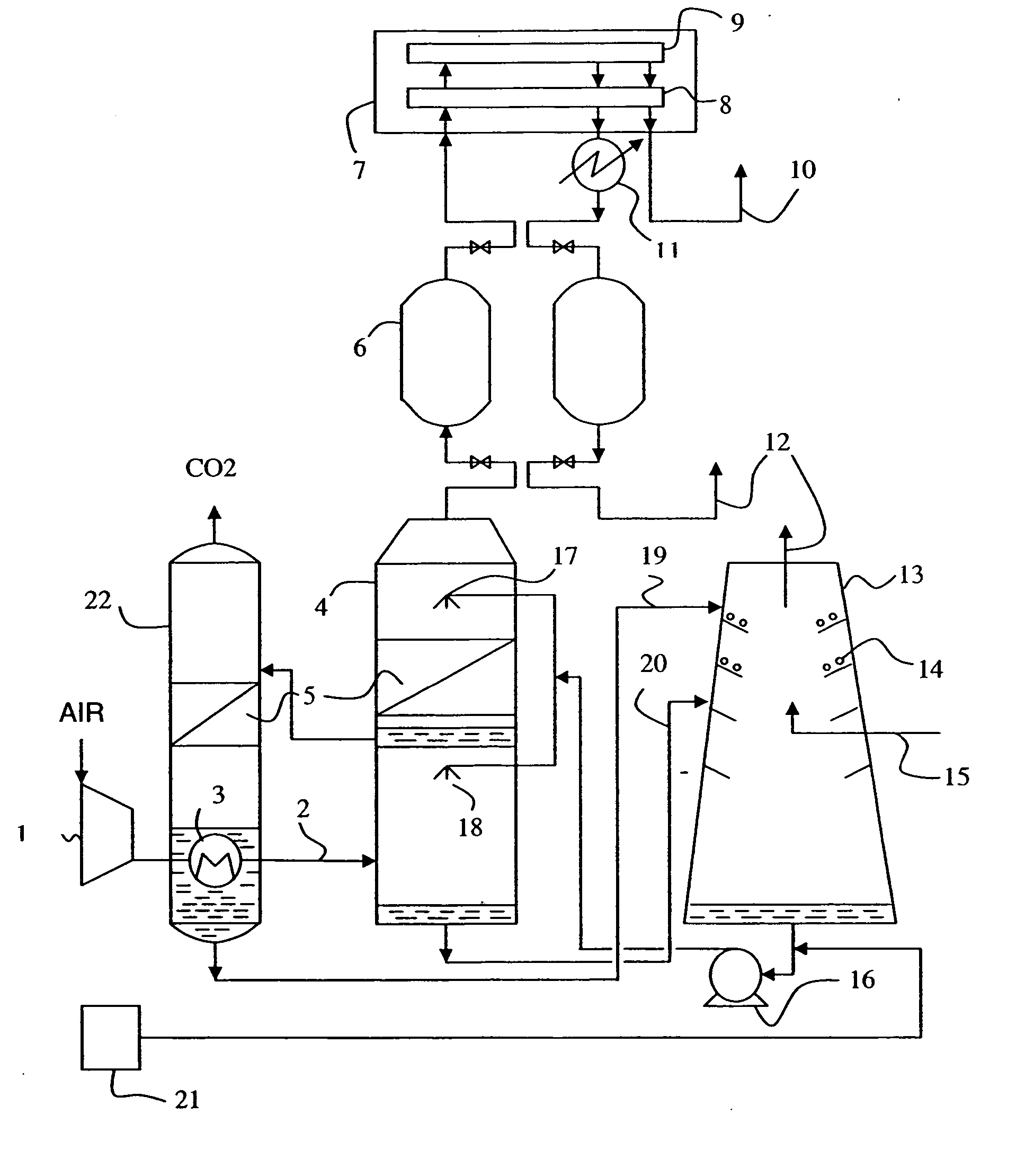

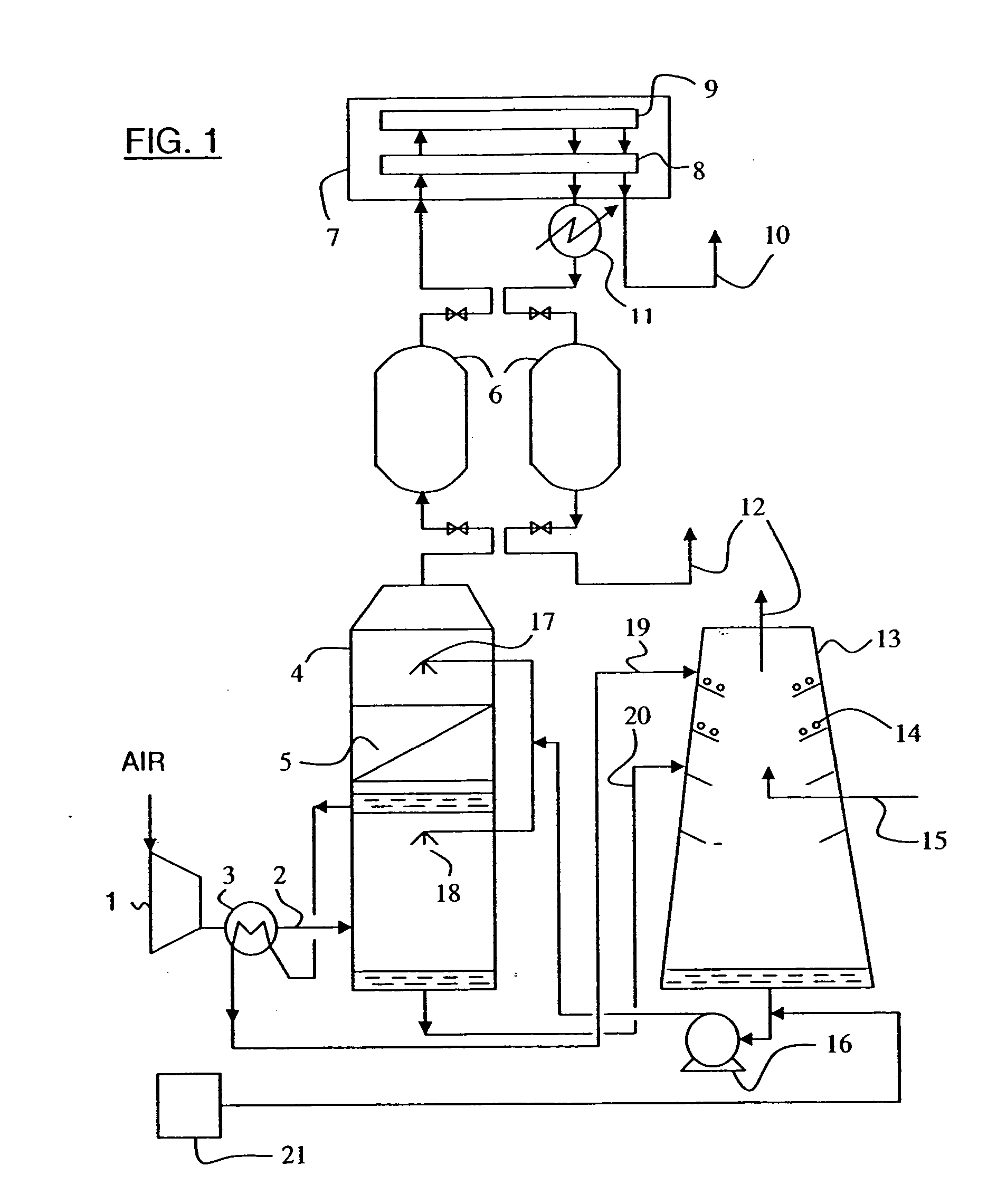

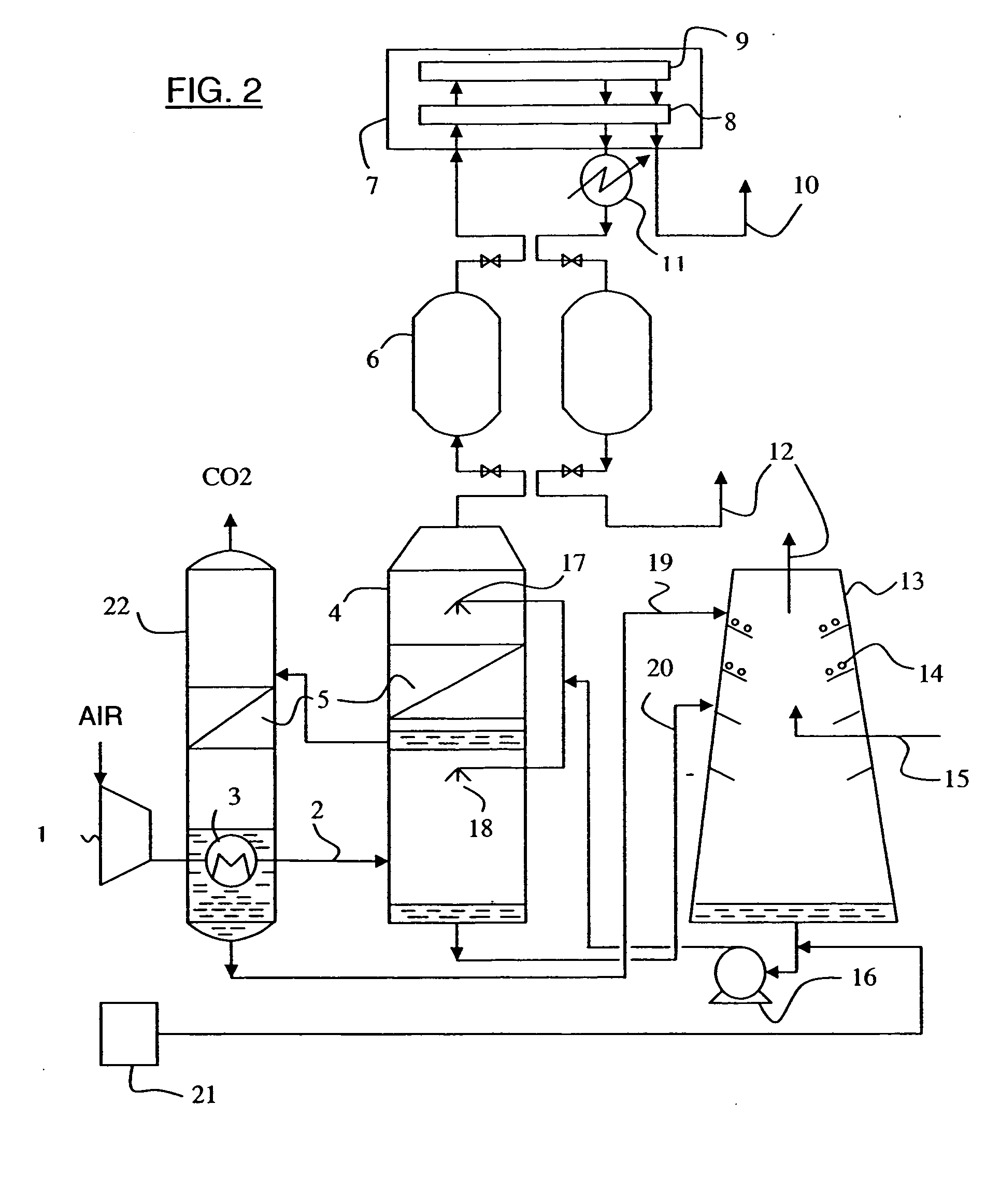

Process and installation for the fractionation of air into specific gases

InactiveUS20060213224A1Improve conversion performanceSolidificationLiquefactionHydration reactionCooling tower

Owner:CO2 SOLUTION

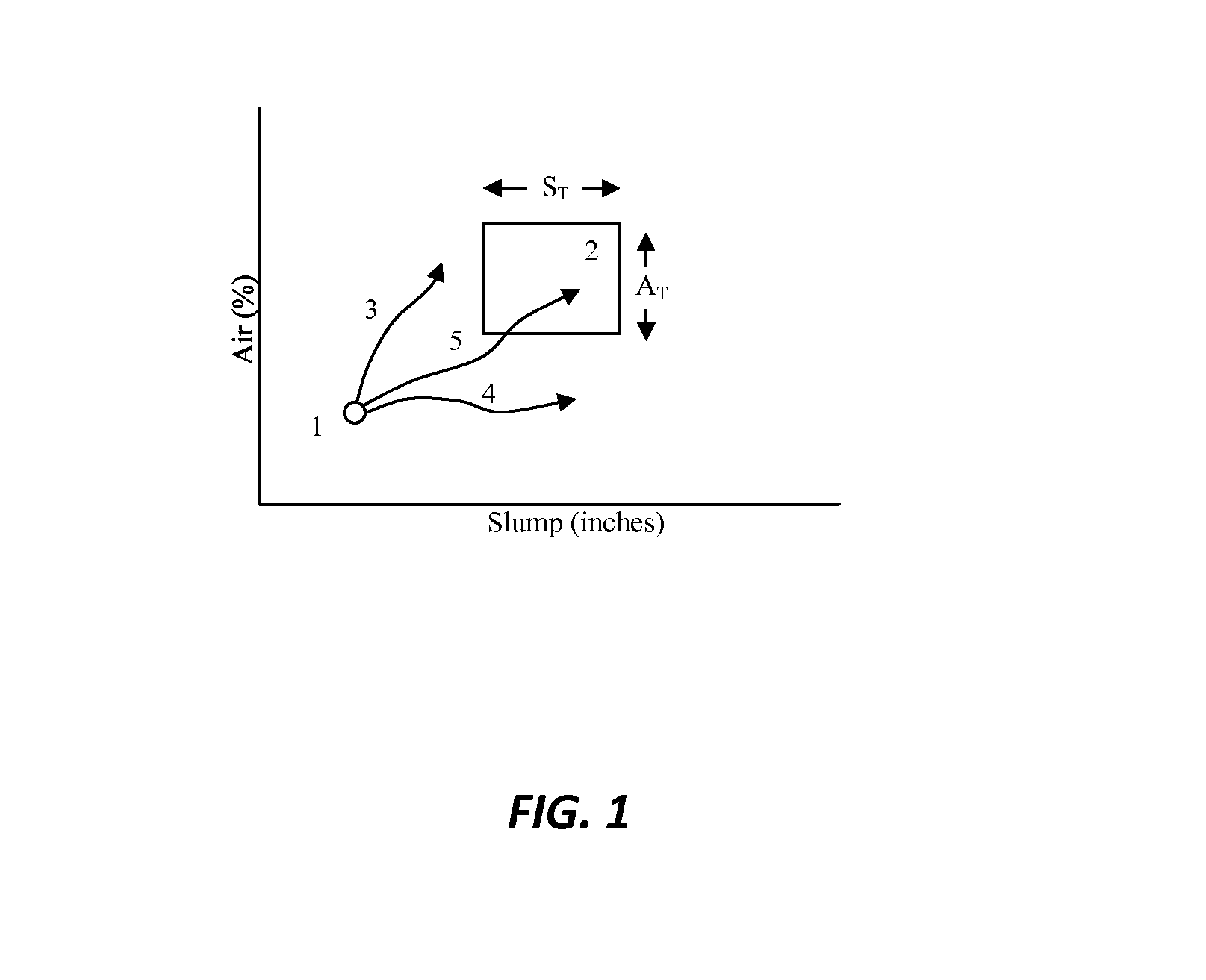

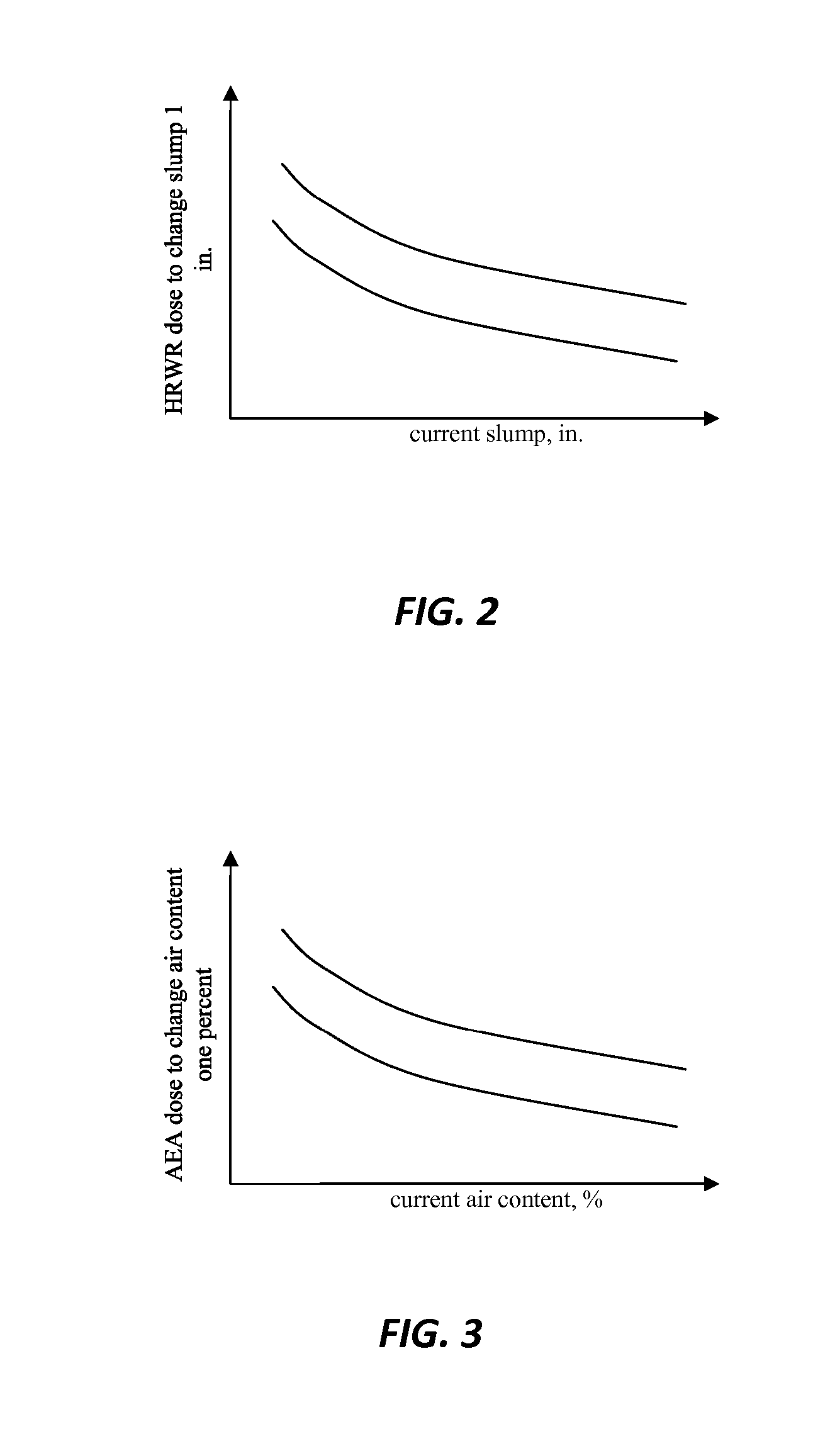

Method For Adjusting Concrete Rheology Based Upon Nominal Dose-Response Profile

ActiveUS20110320040A1Increase complexityIncreased complexitySampled-variable control systemsControlling ratio of multiple fluid flowsEngineeringRheology

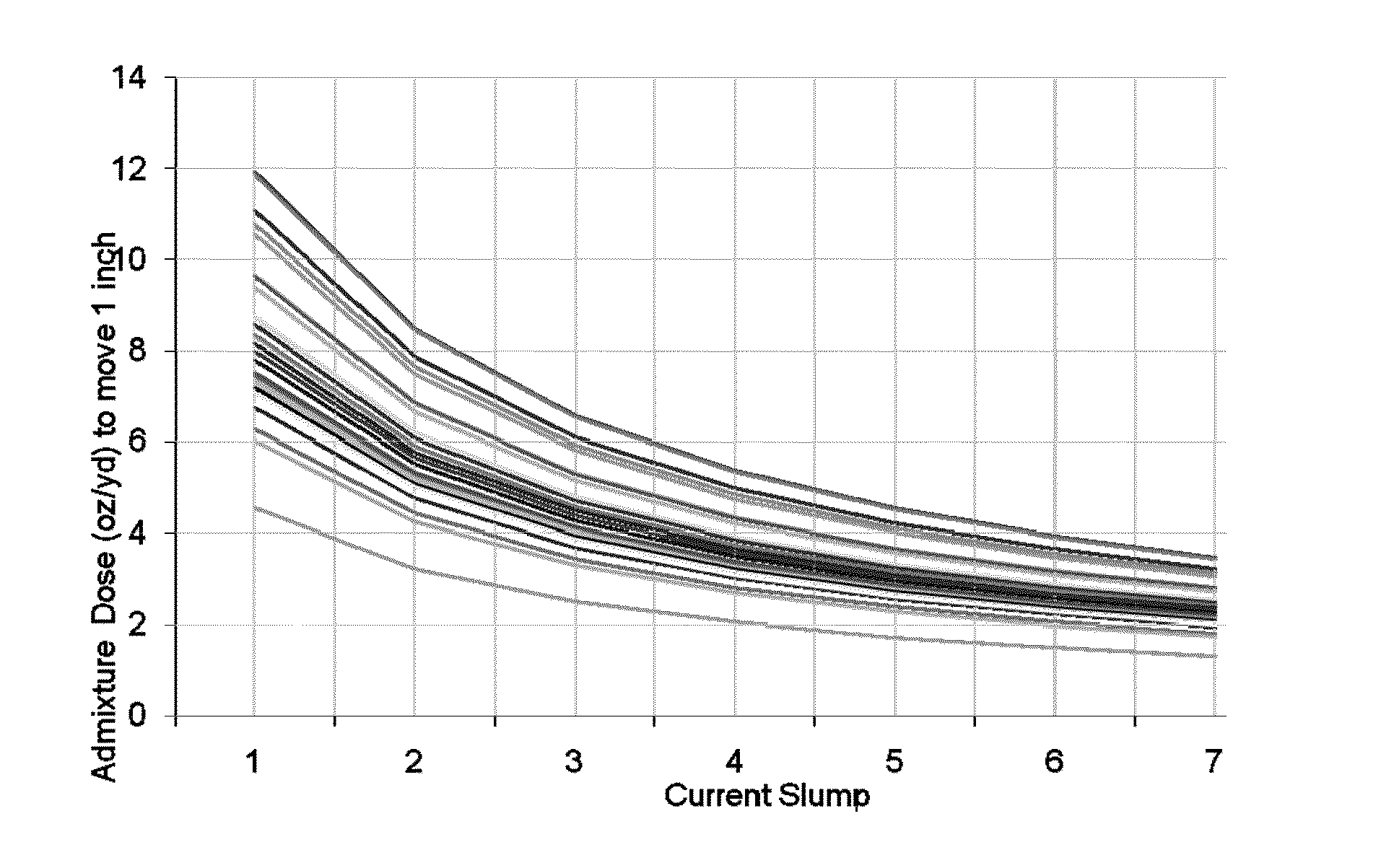

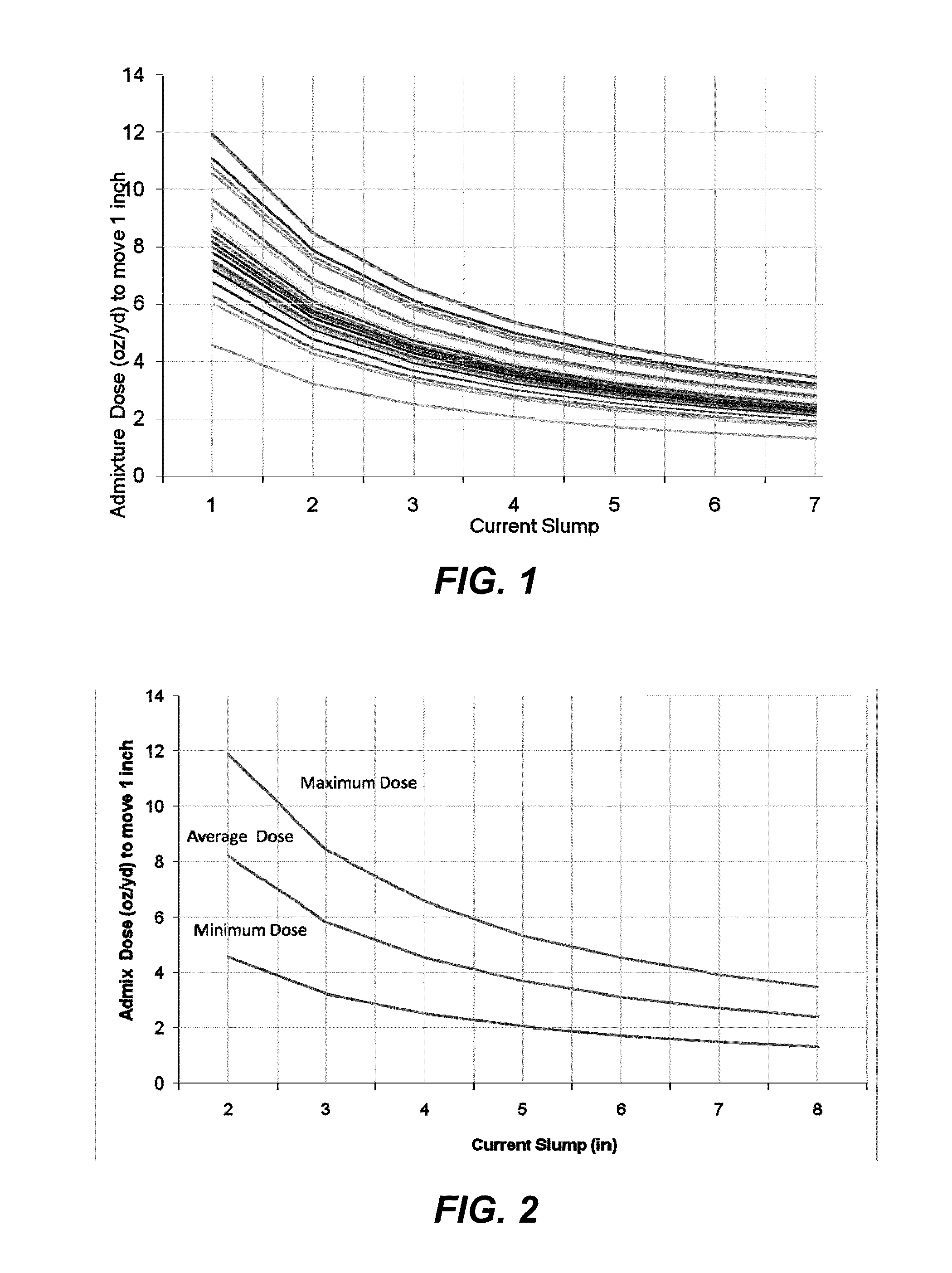

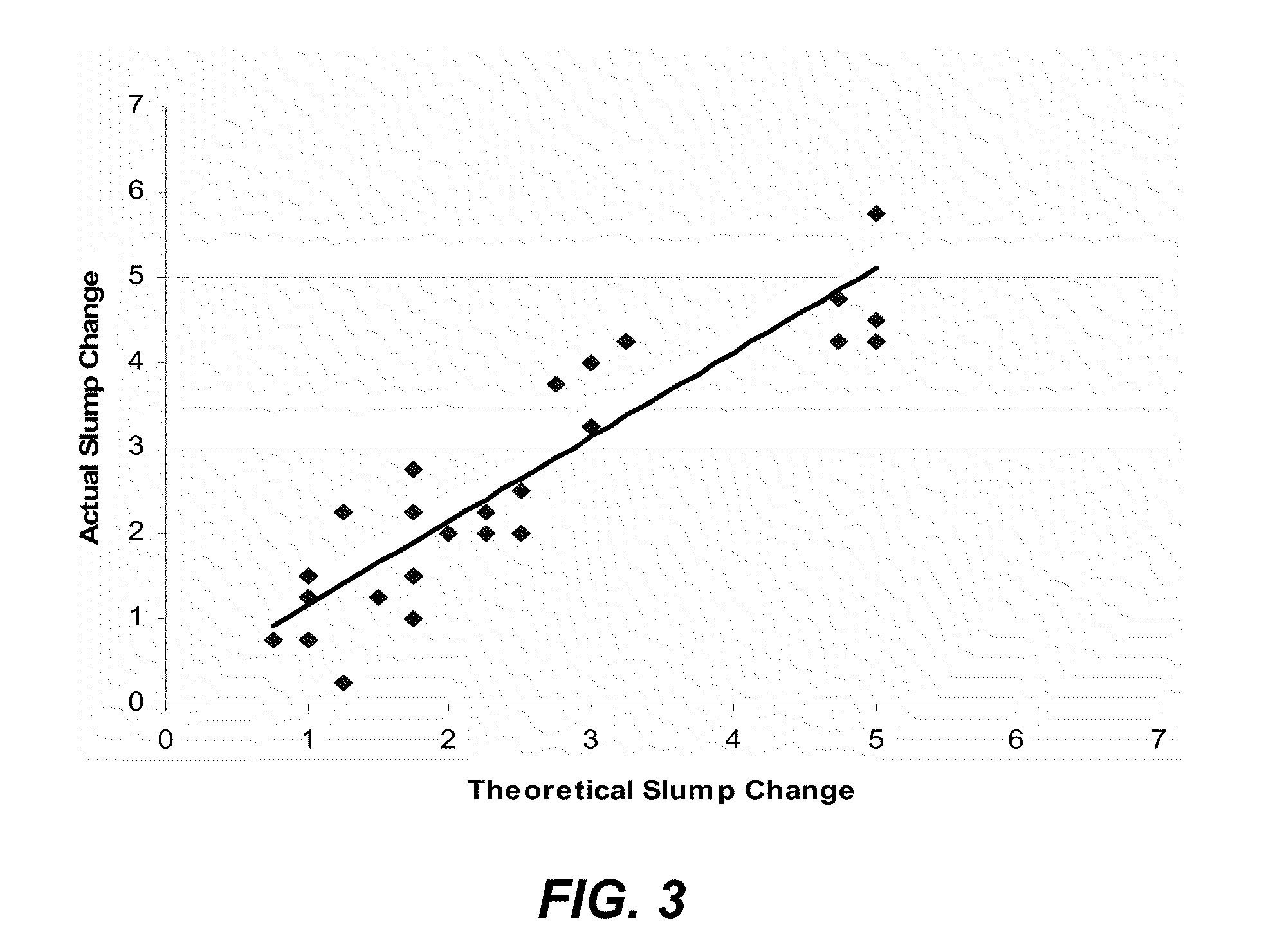

The invention relates to a method for adjusting concrete rheology requiring only that load size and target rheology value be selected initially rather than requiring inputs into and consultation of a lookup table of parameters such as water and hydration levels, mix components, temperature, humidity, aggregate components, and others. Dosage of particular rheology-modifying agent or combination of rheology-modifying agents is calculated based on a percentage of a nominal dose calculated with reference to a nominal dose response (“NDR”) curve or profile. The NDR profile is based on a correlation between a rheology value (e.g., slump, slump flow, yield stress) and the rheology-modifying agent(s) dose required to change rheology value by one unit (e.g., slump change from 2 to 3 inches) such that exemplary methods can employ corrective dosing based on the NDR and the measured deviation by the system.

Owner:VERIFI

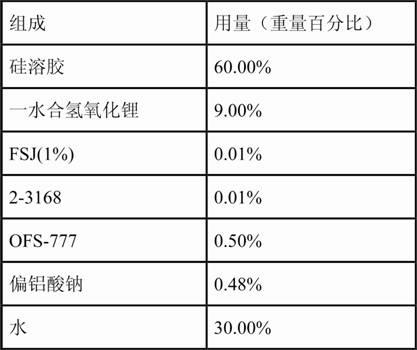

Lithium-based concrete sealing solidifying agent

The invention discloses a lithium-based concrete sealing solidifying agent. The lithium-based concrete sealing solidifying agent comprises the following components in percentage by weight: 50.0-90.0 percent of lithium silicate sol, 0.01-1.0 percent of wetting and dispersing agent, 0.01-1.0 percent of defoaming agent, 0.01-1.0 percent of permeability-resistant agent, 0.0-10.0 percent of stabilizing agent, 0.0-1.0 percent of accelerating agent and the balance of water. The lithium-based concrete sealing solidifying agent can produce C-S-H gel through the effective permeability and the hydration reaction with dissociative calcium ions in concrete to seal capillary pores in the concrete, so that the permeability resistance, the wear resistance, the hardness and other performance of the concrete can be improved.

Owner:SHANGHAI SUNRISE CHEMISTRY CO LTD

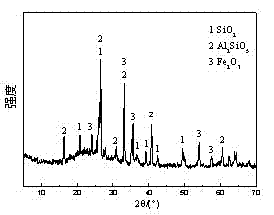

Curing agent and curing method for heavy metals in fly ash from mswi (municipal solid waste incineration)

InactiveCN106377867ARealize harmless treatmentStrong Stabilizing TetheringChemical protectionHydration reactionResource utilization

The invention provides a curing agent and a curing method for heavy metals in fly ash from mswi (municipal solid waste incineration). The curing agent comprises an aluminum-rich high-silicon material and an alkaline exciting agent, wherein the mass of the aluminum-rich high-silicon material is 15% to 25% of the mass of the fly ash from mswi; the mass of the alkaline exciting agent is 3% to 5% of the mass of the fly ash from mswi. The curing agent adopts industrial waste residues, and raw materials are cheap and easy to obtain; according to the curing method, lots of calcium oxide, chloride and sulfide existing in the fly ash from mswi have a hydration reaction with the aluminum-rich high-silicon material to generate a C-S-H (calcium silicate hydrate), Friedel (calcium chloroaluminate) phase and Aft (ettringite) phase system; during the formation process of the mineral system, a solid solution is formed through ion exchange, a new phase is formed through coprecipitation, and a relatively strong stable constraint effect can be played on heavy metals through physical adsorption and coating, so that wastes can be treated by using wastes, and harmless treatment of the fly ash from mswi and resource utilization of the industrial waste residues are realized.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Dental Treatment Compositions and Conformable Dental Treatment Trays Using the Same

ActiveUS20090087393A1Easy to optimizeHigh peroxide concentrationCosmetic preparationsHair cosmeticsHydration reactionDecomposition

The present invention is a formable dental treatment tray utilizing poly(2-ethyl-2-oxazoline) and a gelatinous active. Blending of the active is accomplished by mixing the Poly(2-ethyl-2-oxazoline) with an active ingredient, such as a peroxide like hydrogen peroxide, carbamide peroxide, sodium perborate, or sodium percarbonate, usually also with water or an appropriate organic solvent. Peroxide concentrations in these new gels can reach a 30% concentration of hydrogen peroxide while maintaining a shelf life of six months at room temperature without developing peroxide decomposition. The gels are applied to an appropriate backing and dried to a gelatinous state. In use, the active is hydrated and regains adhesiveness. Then the tray is pressed and formed around a user's dental arch to form the customizable tray. Multiple active ingredients may be used, with or without peroxide, for accomplishing desired treatment regimens.

Owner:CAO GROUP

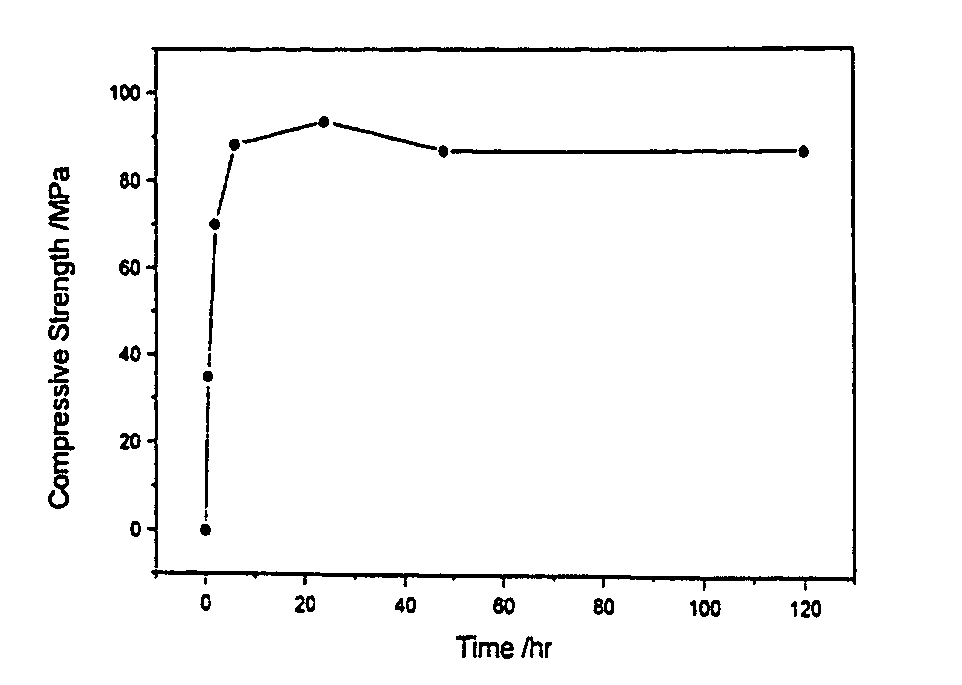

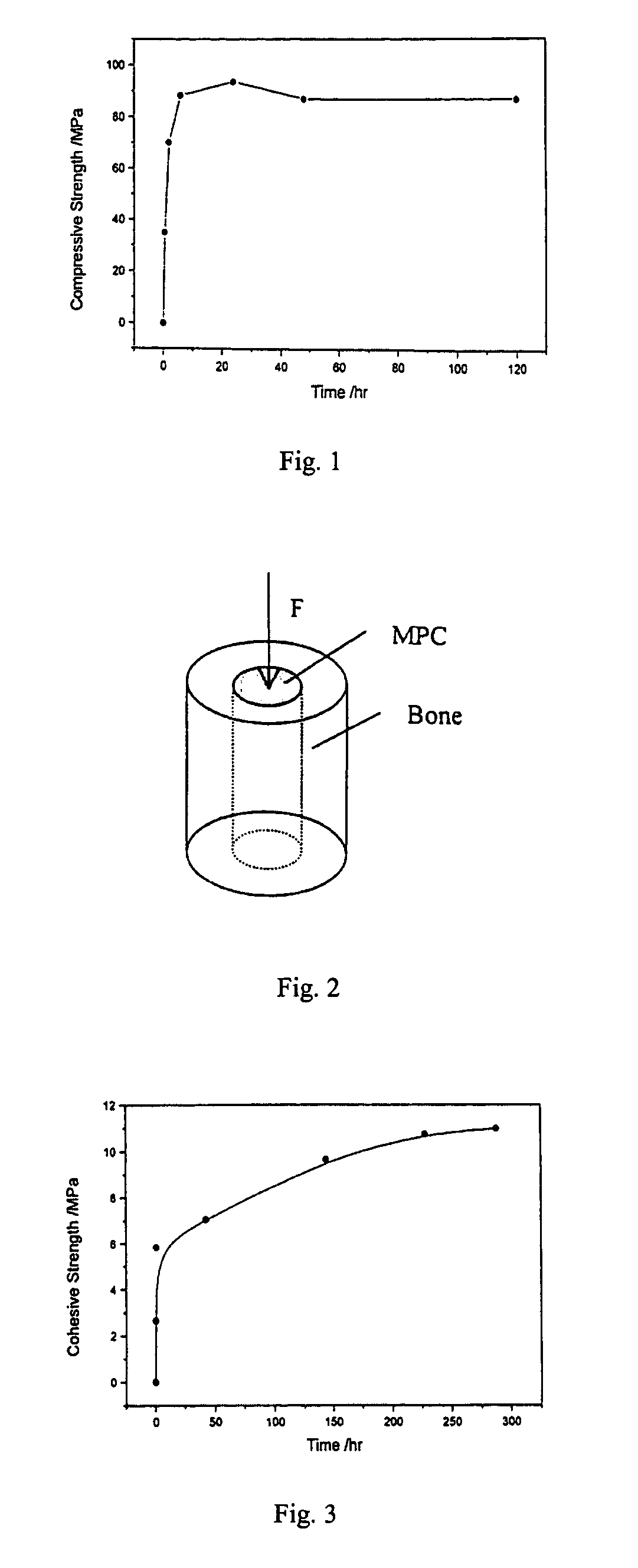

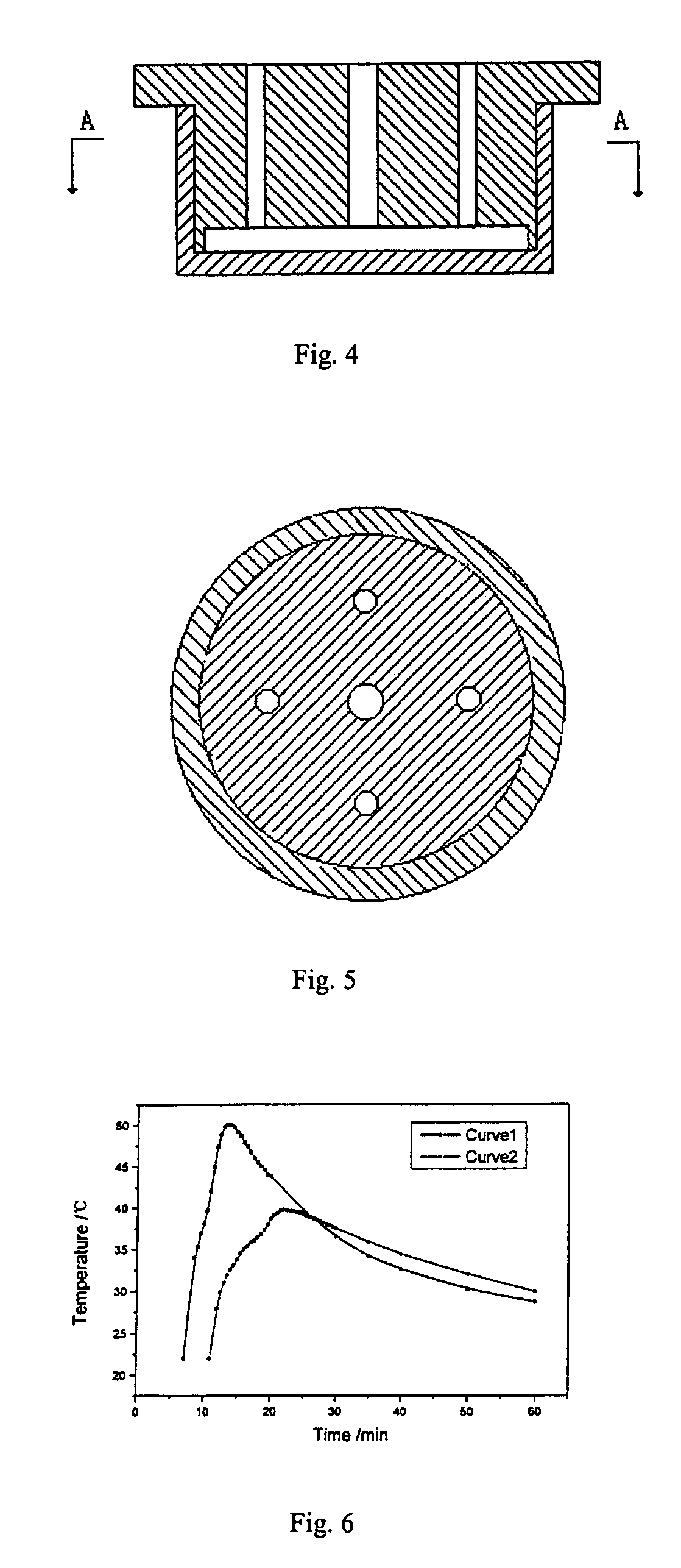

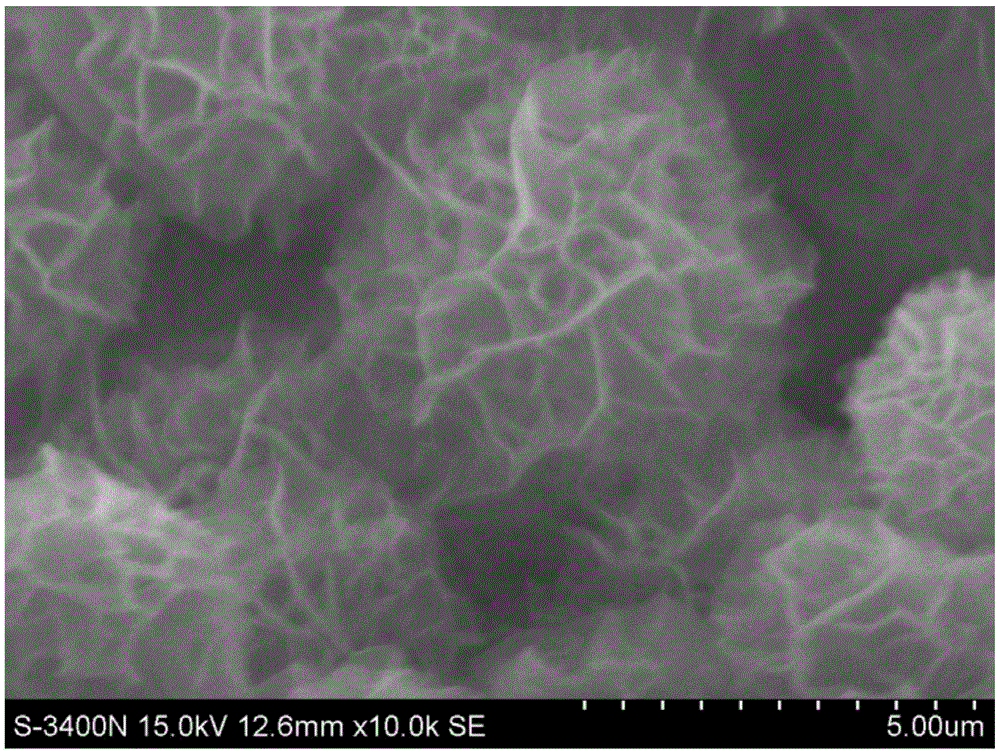

Inorganic bone adhesion agent and its use in human hard tissue repair

InactiveUS7094286B2High strengthGood biocompatibilityBiocideSurgical adhesivesHydration reactionMagnesium phosphate

The present invention discloses an inorganic bone adhesive and its use in human hard tissue repairs. The inorganic bone adhesive comprises basic compound, phosphate, calcium phosphate bone cement and retarder with the characteristics of rapid hydration rate and high early strength. Inorganic Bone adhesive can be widely used in the artificial joints fixation, screw fixation as well as comminuted fracture fixation. It is a kind of safe and effective adhesive material and beneficial for the fast postoperative recovery. The final hydration reaction products contains the composition of magnesium phosphate, bio-mineral containing ammonium and apatite-like materials, which has excellent biocompatibility and can be gradually absorbed by surrounding tissues after being implanted in vivo, which benefits the in-growth of the new bone.

Owner:EAST CHINA UNIV OF SCI & TECH

Ni-Mn layered double hydroxide@nickel foam@carbon three-dimensional hierarchically-structured electrode material and preparation method thereof

InactiveCN105655152AGood flexibilityLow reaction temperatureHybrid capacitor electrodesCell electrodesReaction temperatureCarbonization

The invention discloses a Ni-Mn layered double hydroxide@nickel foam@carbon three-dimensional hierarchically-structured electrode material and a preparation method thereof. The preparation method comprises the following steps: firstly carrying out one-step hydrothermal treatment by respectively taking nickel chloride hexahydrate, anhydrous manganese chloride and nickel foam as a nickel source, a manganese source and a substrate, so as to obtain Ni-Mn LDH@NF; and coating Ni-Mn LDH@NF by virtue of glucose or graphene as a carbon source, and carrying out hydrothermal treatment, so as to obtain Ni-Mn LDH@NF@C. According to the preparation method, by virtue of a stepwise hydrothermal-drying method, the preparation process and the required equipment are simple, raw material sources are rich, the reaction temperature is relatively low, the high temperature carbonization is not needed, and the large-scale production is easy to realize; and the Ni-Mn LDH@NF@C composite material is good in thermal stability, high in crystalline degree, large in specific surface area and strong in shape controllability and is one of ideal energy source materials.

Owner:SHANGHAI INST OF TECH

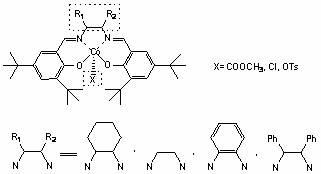

Solid catalyst for hydration of epoxy compound to prepare diol and its application

InactiveCN102688776AEfficient catalytic hydration reactionLow water ratioOrganic-compounds/hydrides/coordination-complexes catalystsChemical recyclingHydration reactionEpoxy

The invention particularly relates to a solid catalyst formed by assembling a racemic Co (salen) metal complex in a nano-reactor and used for the hydration reaction of an epoxy compound to prepare diol. The expression formula of the catalyst is: Co (salen) n / R, wherein R is a nano-reactor with a cage-type pore structure and Co (salen) is a racemic metal complex. A general molecular formula is shown as the following. And n represents the mass percent content of Co in the solid catalyst and ranges from 0. 1% to 1%. The catalyst can be used for a reaction of efficient catalysis of the hydration of an epoxy compound to prepare diol. The catalyst of the invention is characterized by simple preparation method, good reproducibility and easy recycling, thus being able to be used for industrial production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

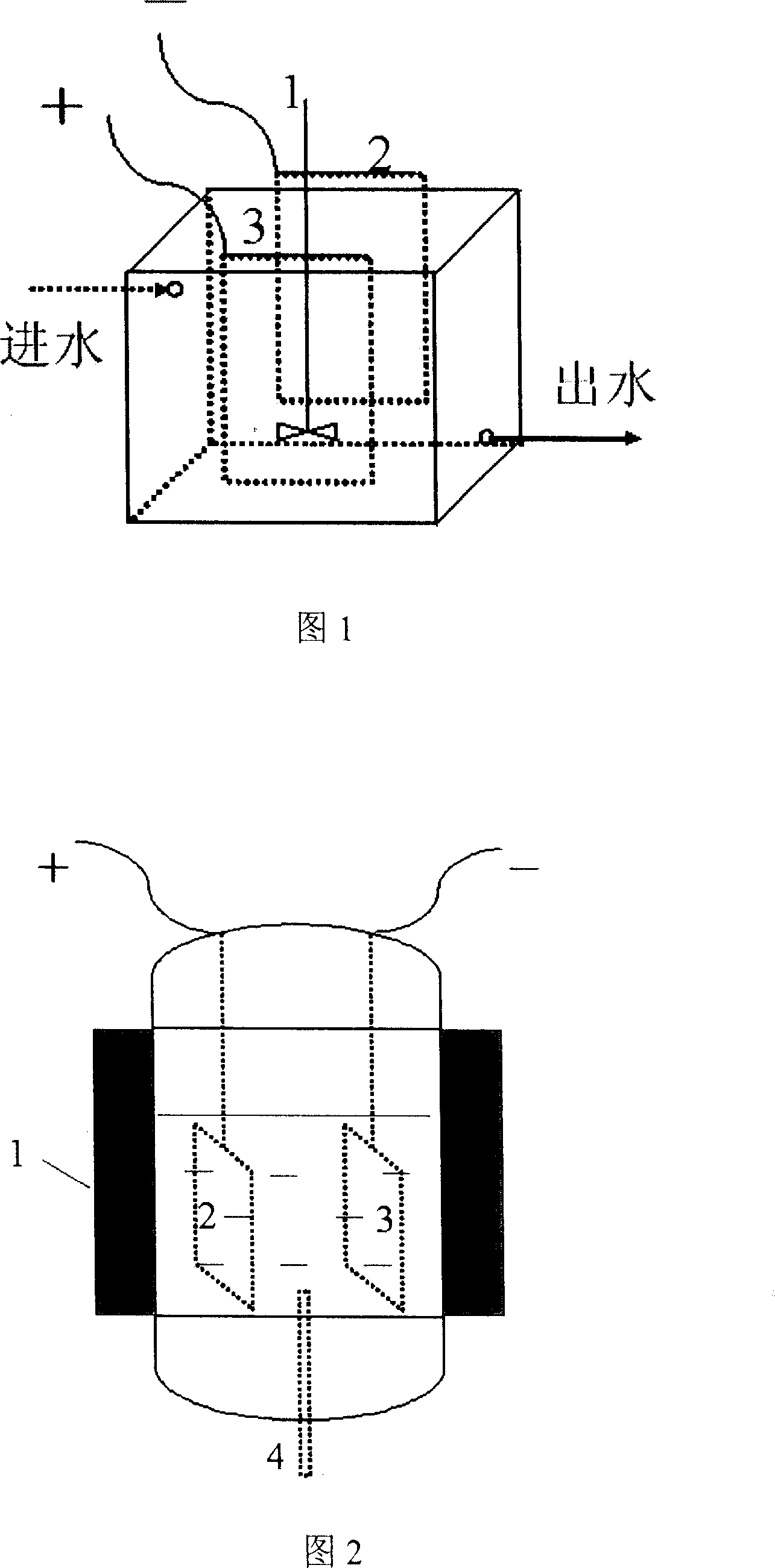

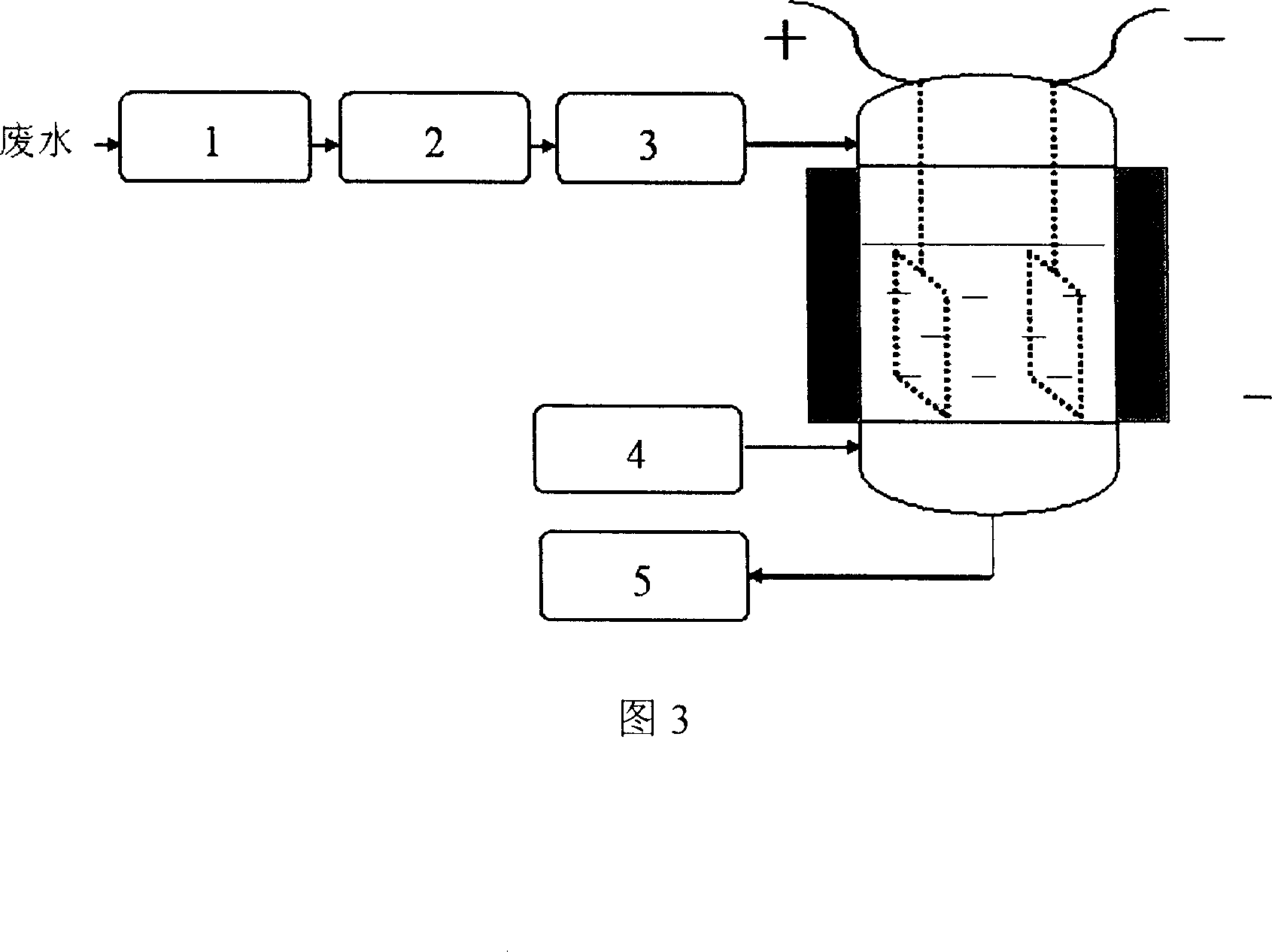

Process of treating refractory organic effluent with free radical and electrically catalyzed reactor therewith

InactiveCN101020590AImprove processing efficiencyEfficient use ofWater contaminantsWater/sewage treatment by electrochemical methodsHigh concentrationDecomposition

The present invention is process of treating refractory organic effluent with free radical and the electrically catalyzed reactor therewith. The present invention features that in an electrochemically hydrating proton reaction kettle and in the presence of initiator, free hydroxyl radical, superoxide anion free radical, free nitrogen radical, active free oxygen radical, etc are generated circularly and reacted in an electrically catalyzing high pressure reaction kettle with various kinds of refractory organic compounds for efficient decomposition. The present invention has high organic waste water degrading rate and low cost, and is suitable for high concentration organic waste water treatment in papermaking, petrochemical and other industry.

Owner:BEIJING GUOLIYUAN POLYMER SCI & TECH R & D CENT

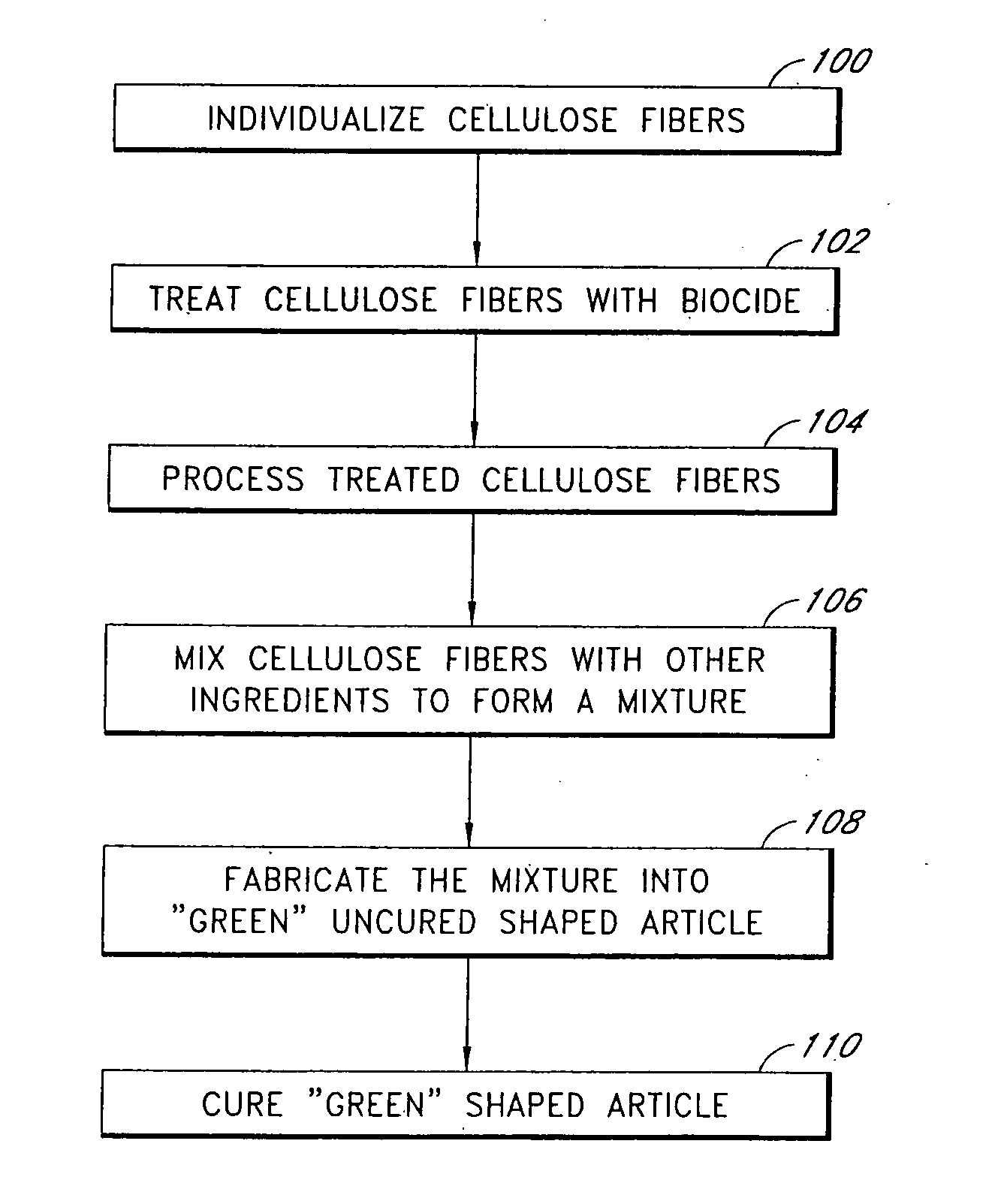

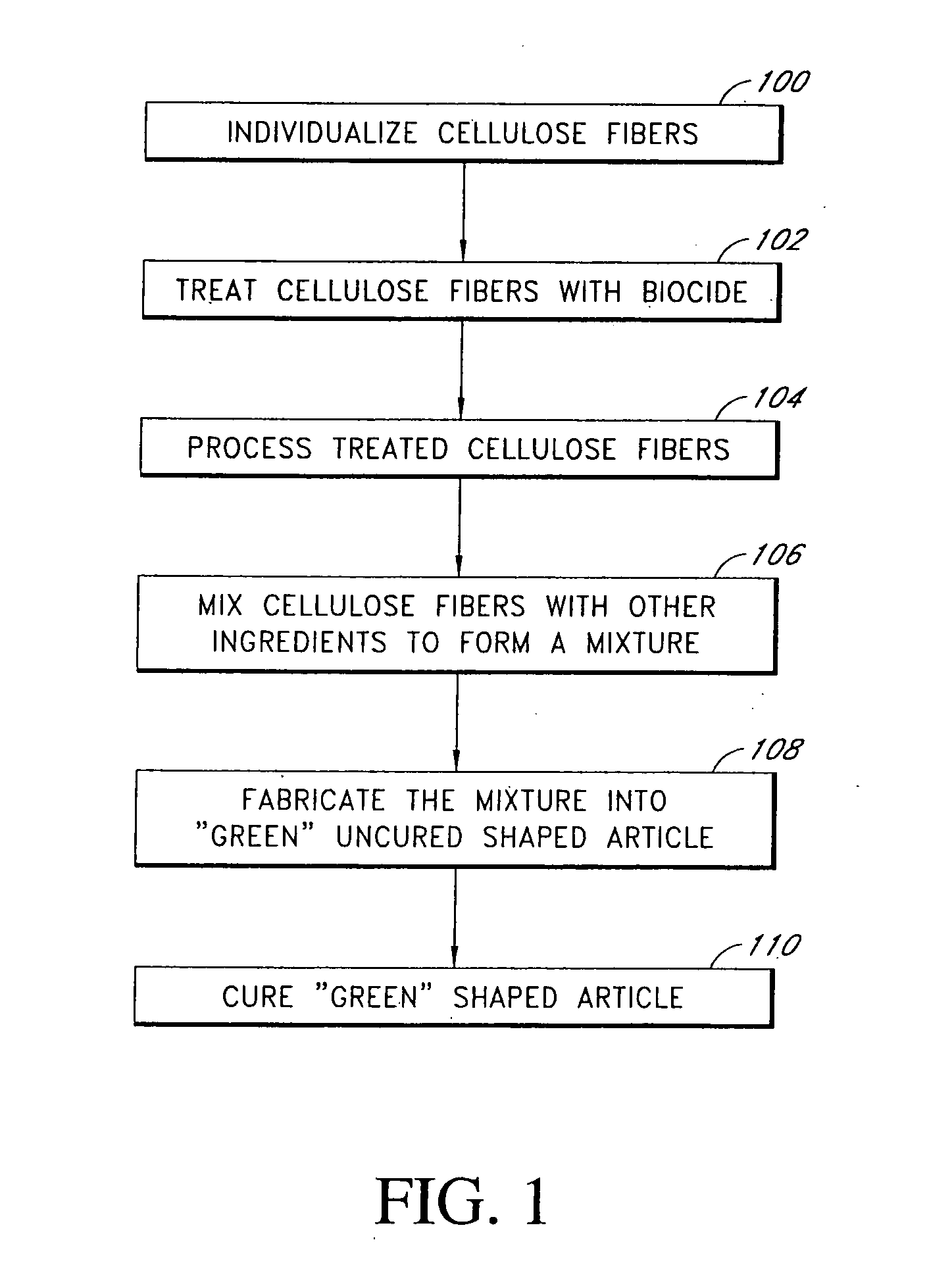

Fiber cement composite material using biocide treated durable cellulose fibers

InactiveUS20050016423A1Increased durabilityImproves rot resistanceFireproof paintsAntifouling/underwater paintsBiotechnologyHydration reaction

A fiber cement composite material providing improved rot resistance and durability, the composite material incorporating biocide treated fibrous pulps to resist microorganism attacks. The biocide treated fibers have biocides attached to inner and outer surfaces of individualized fibers to protect the fibers from fungi, bacteria, mold and algae attacks. The biocides selected have strong affinity to cellulose and do not interfere with cement hydration reactions. This invention also discloses the formulation, the method of manufacturing and the final fiber cement products using the biocide treated fibers.

Owner:JAMES HARDIE TECH LTD +1

Concrete mixtures having aqueous foam admixtures

InactiveUS20070056481A1Avoid interactionInhibition of hydrationSolid waste managementCeramicwareHydration reactionPolymer science

Flowable concrete mixtures have an aqueous foam admixture mixed therein to give the concrete mixture desired strength, flowability, and density. The concrete mixtures include a hydration stabilizer to stabilize the aqueous foam. The hydration stabilizer inhibits the reaction between the hydraulic cement and the water in the aqueous foam. The aqueous foam can be further stabilized using a fluorochemical surfactant. Preferred fluorochemical surfactants comprise an oligomer having at least one hydrophilic nonionic monomer and at least one hydrophilic anionic monomer.

Owner:WELKER CHARLES D

Carbon loaded type noble metal catalyst and preparation method thereof

ActiveCN101450308AHigh activityHigh selectivityCarboxylic preparation by ozone oxidationMetal/metal-oxides/metal-hydroxide catalystsPotassium borohydrideReduction treatment

The invention relates to a carbon loaded noble metal catalyst, which is characterized in that the catalyst consists of a carrier and palladium and ruthenium which are loaded on the carrier, wherein the carrier is powdery fruit shell active carbon and is between 85 and 99.7 percent by weight; the palladium is between 0.2 and 10 percent by weight; and the ruthenium is between 0.1 and 10 percent by weight. The catalyst is obtained by performing acid treatment, ash removal and oxidation treatment on the carrier, namely the active carbon for removing surface reduction functional groups first, using a solution of the palladium and the ruthenium to perform soakage treatment, and using one or more among hydrogen, potassium borohydride or hydrazine hydrate to perform reduction treatment. The catalyst has high activity and selectivity and good stability in hydrogenation reaction of organic compounds containing carbonyl.

Owner:CHINA PETROLEUM & CHEM CORP +1

Packaging shape-stabilizing method of inorganic hydrated salt phase-change heat storage material

InactiveCN104371658AImprove thermal conductivitySimple structureHeat-exchange elementsMolten stateHydration reaction

The invention provides a packaging shape-stabilizing method of an inorganic hydrated salt phase-change heat storage material, which comprises the following steps: (1) adding a nucleator and deionized water into the inorganic hydrated salt phase-change material, and heating until the inorganic hydrated salt phase-change material achieves the molten state; (2) adding a porous propping material into the molten-state inorganic hydrated salt phase-change material, and stirring sufficiently and uniformly; (3) putting the molten-state mixture obtained in the step (2) in a vacuum environment to enhance the adsorptivity of the porous propping material for the inorganic hydrated salt phase-change material; and (4) moving the molten-state mixture out of the vacuum environment, and immediately putting the molten-state mixture into a low-temperature environment suitable for crystallization to perform recrystallization. The composite shape-stabilized phase-change material obtained by the method has the advantages of stable structure, high latent heat, no toxicity, simple preparation process, short time consumption and low cost.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com