Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

403 results about "Carnallite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

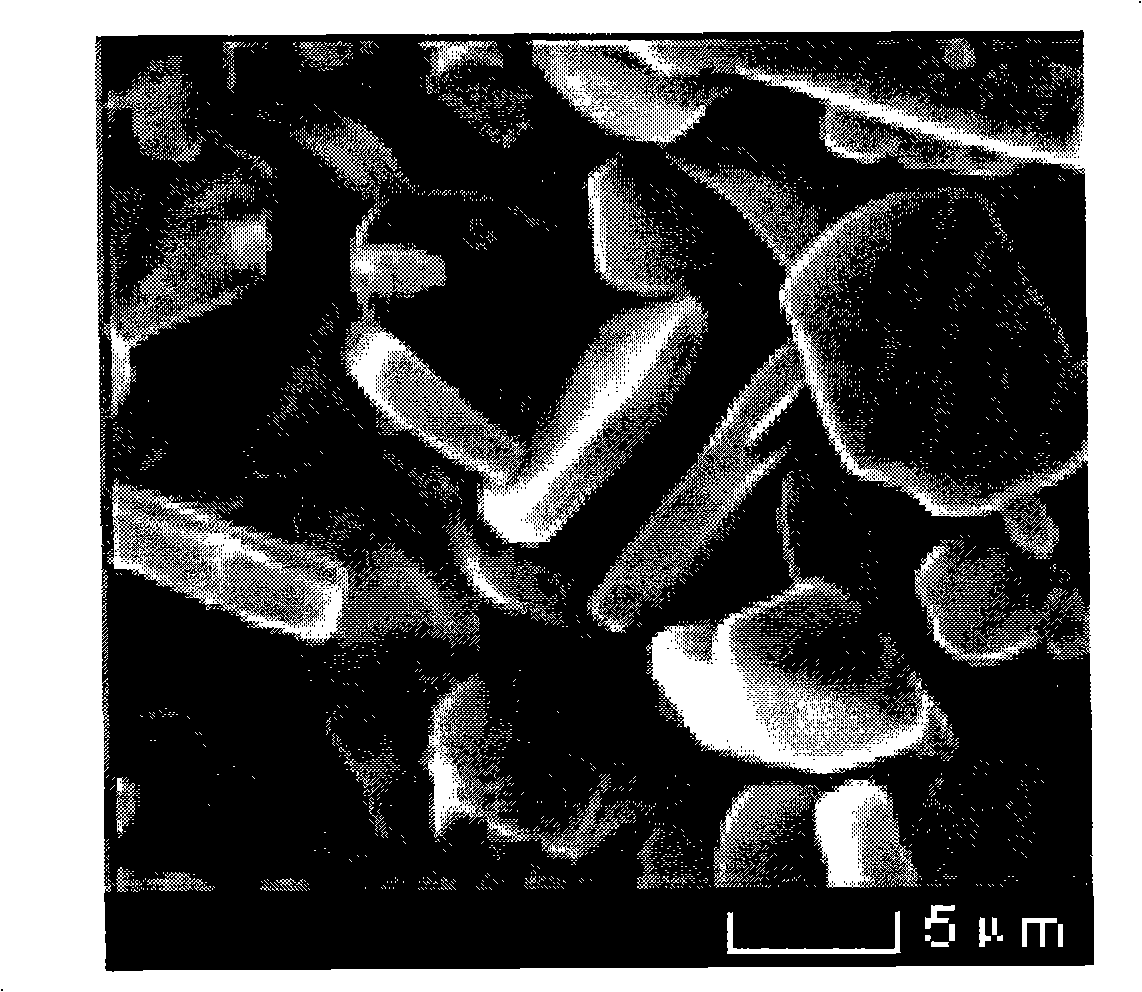

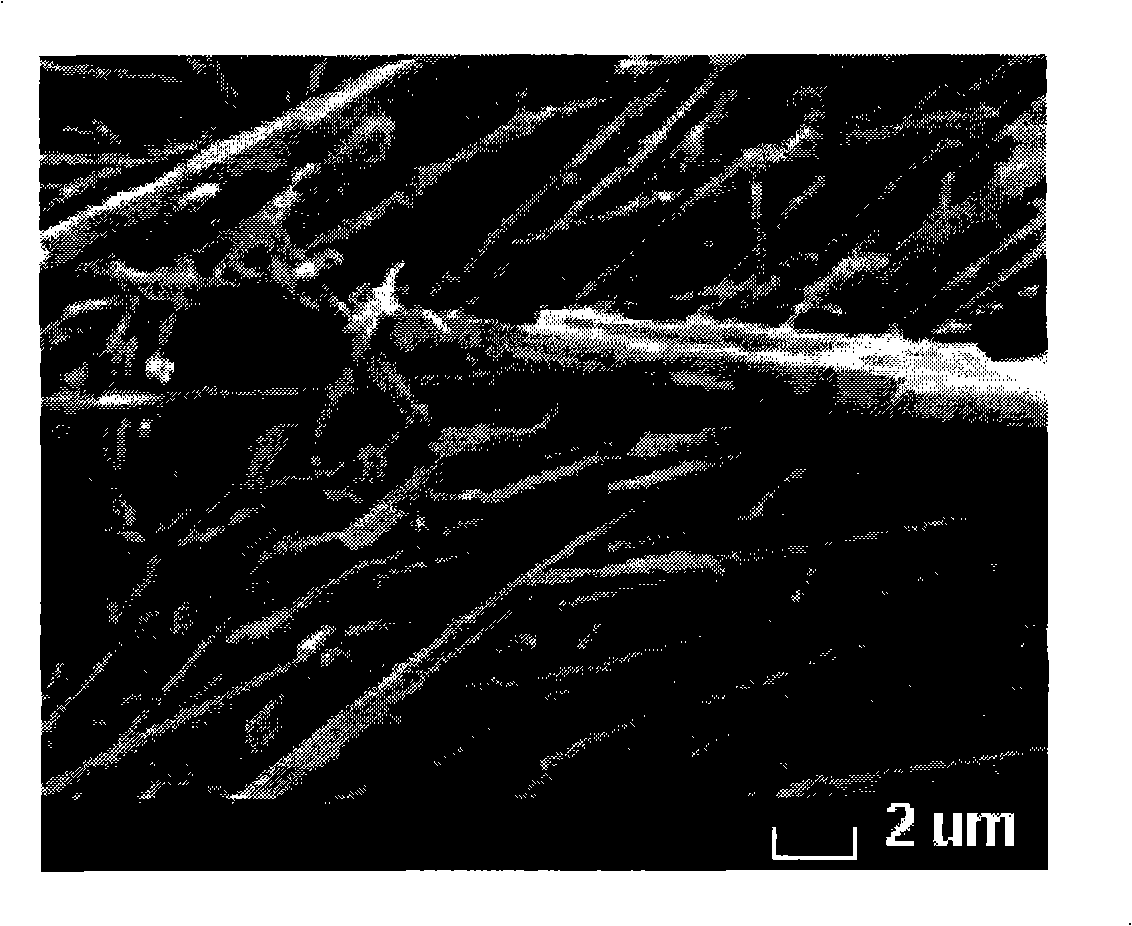

Carnallite (also carnalite) is an evaporite mineral, a hydrated potassium magnesium chloride with formula KMgCl₃·6(H₂O). It is variably colored yellow to white, reddish, and sometimes colorless or blue. It is usually massive to fibrous with rare pseudohexagonal orthorhombic crystals. The mineral is deliquescent (absorbs moisture from the surrounding air) and specimens must be stored in an airtight container.

Recovery of common salt and marine chemicals from brine

InactiveUS6776972B2High purityLow costGeneral water supply conservationSeawater treatmentSaline waterEvaporation

A new process for recovery of common salt, potassium chloride, concentrated magnesium chloride with enriched bromide, and high purity magnesia from brine in an integrated manner, said process comprises preparation of calcium chloride by reaction of hydrochloric acid generated in the process with limestone, desulfatation of brine with calcium chloride, production of sodium chloride of superior quality in solar pans, solar evaporation of bittern thereby producing carnallite and end bittern, processing carnallite through established processes to produce potassium chloride, recovering end bittern containing highly concentrated magnesium chloride and enriched bromide and calcination of a part of the end bittern after solidification to produce high purity magnesia and hydrochloric acid utilizable in the process.

Owner:COUNCIL OF SCI & IND RES

Recovery of common salt and marine chemicals from brine

InactiveUS20030080066A1High purityLow costGeneral water supply conservationSeawater treatmentSaline waterEvaporation

A new process for recovery of common salt, potassium chloride, concentrated magnesium chloride with enriched bromide, and high purity magnesia from brine in an integrated manner, said process comprises preparation of calcium chloride by reaction of hydrochloric acid generated in the process with limestone, desulfatation of brine with calcium chloride, production of sodium chloride of superior quality in solar pans, solar evaporation of bittern thereby producing carnallite and end bittern, processing carnallite through established processes to produce potassium chloride, recovering end bittern containing highly concentrated magnesium chloride and enriched bromide and calcination of a part of the end bittern after solidification to produce high purity magnesia and hydrochloric acid utilizable in the process.

Owner:COUNCIL OF SCI & IND RES

Clean production process of plateau sulfate type boron-lithium salt lake brine

InactiveCN102910652AHigh purityReduce the ratio of magnesium to lithiumChemical industryAlkali metal halide purificationHydration reactionSylvinite

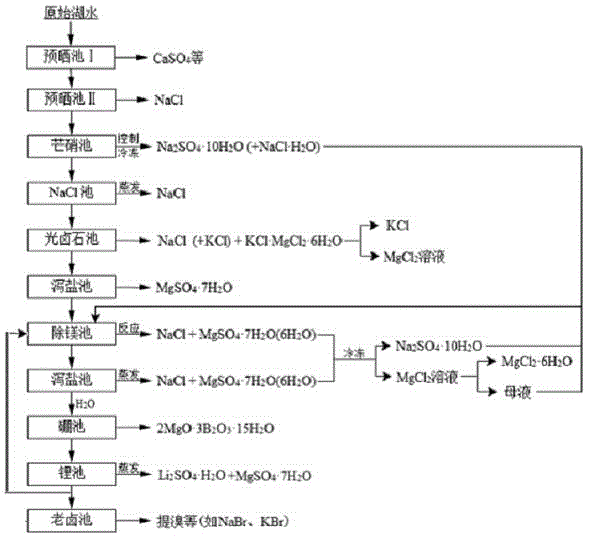

The invention relates to a clean production process of plateau sulfate type boron-lithium salt lake brine. The process comprises the following steps of: (1) arranging a pre-airing pond, a mirabilite pond, a NaCl pond, a carnallite pond, an epsom salt pond I, a magnesium removing pond, an epsom salt pond II, a boron pond, a lithium pond and an old brine pond; (2) controlling the sodium ion concentration in plateau sulfate type boron-lithium salt lake brine, precipitating mirabilite out in winter to obtain brine A, naturally evaporating the brine A, and salting out to obtain brine B; (3) naturally evaporating the brine B, and precipitating sylvine and carnallite out in sequence to obtain brine C; (4) naturally evaporating the brine C, precipitating an epsom salt out, and performing solid-liquid separation to obtain brine D and a solid A; (5) blending the brine D with mirabilite, removing magnesium to obtain brine E, and naturally evaporating brine E to obtain brine F and a solid B; (6) performing a hydration reaction on brine F, naturally evaporating, and precipitating reservoir water / inderite and brine G out; and (7) evaporating brine G or refrigerating for precipitating lithium sulfate, and processing the lithium sulfate into a corresponding product. The process has the advantages of comprehensive utilization of natural energy, saving in energy and environment friendliness.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Cleaning agent for ceramic film and its preparation method

InactiveCN1837341AReduce concentration polarizationReduce cleaning frequencySemi-permeable membranesSurface-active detergent compositionsCelluloseCleansing Agents

The invention discloses a ceramic film abluent and preparing method, which comprises the following parts: 50-75 percent NaOH, 3-15 percent sodium polyphosphate, 5-15 percent sodium alkyl benzene sulphonate, 2-8 percent diatomite, 1-8 percent liquid glass, 0-5 percent sodium sulfate, 0-20 percent sodium carbonate, 0-5 percent methylol cellulose and 0-5 percent ethylene diamine tetraacetic acid tetrasodium salt. These components are added int the stirring and grinding corrosion-proof reactor sequently, which is stirred and grinded evenly at room temperature at 4-8 h to obtain the product. The invention shortens the system cleaning time and reduces the system consumption, which doesn't damage ceramic film.

Owner:JIANGSU JIUWU HITECH

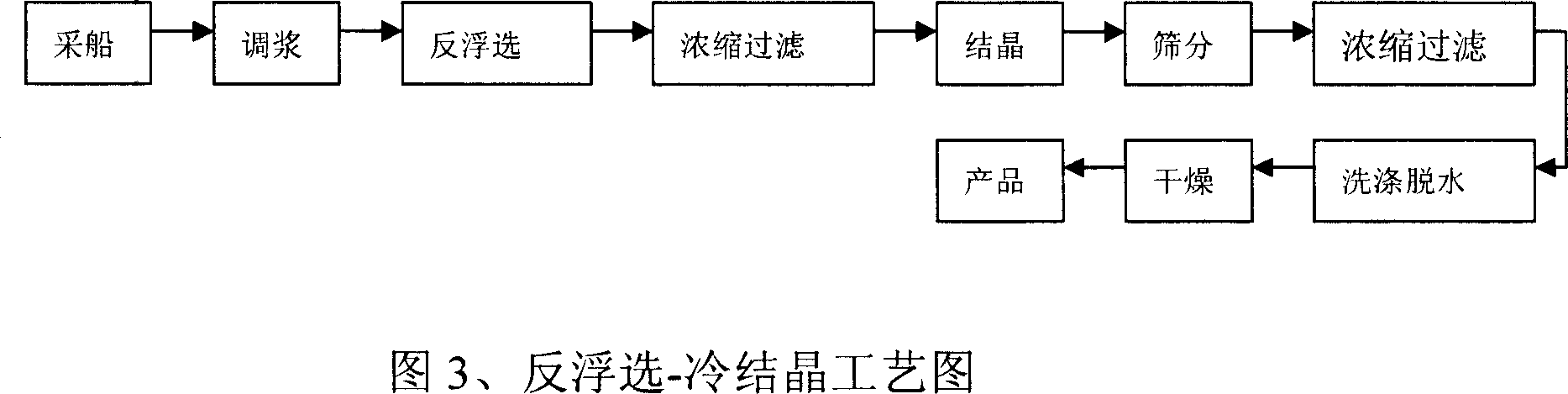

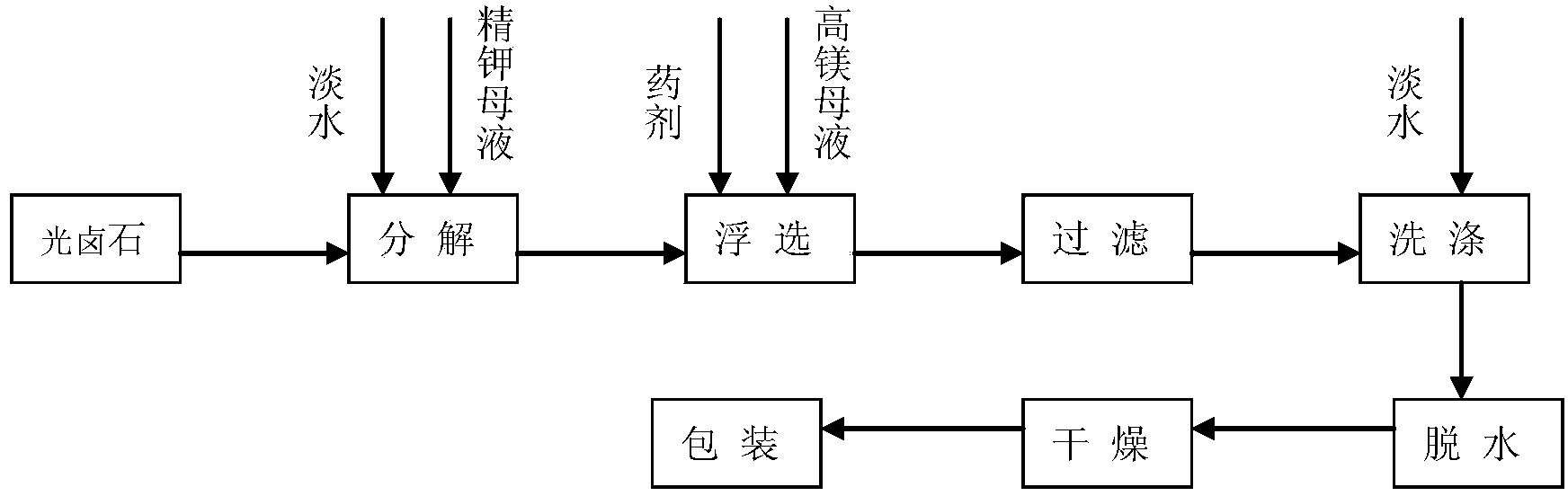

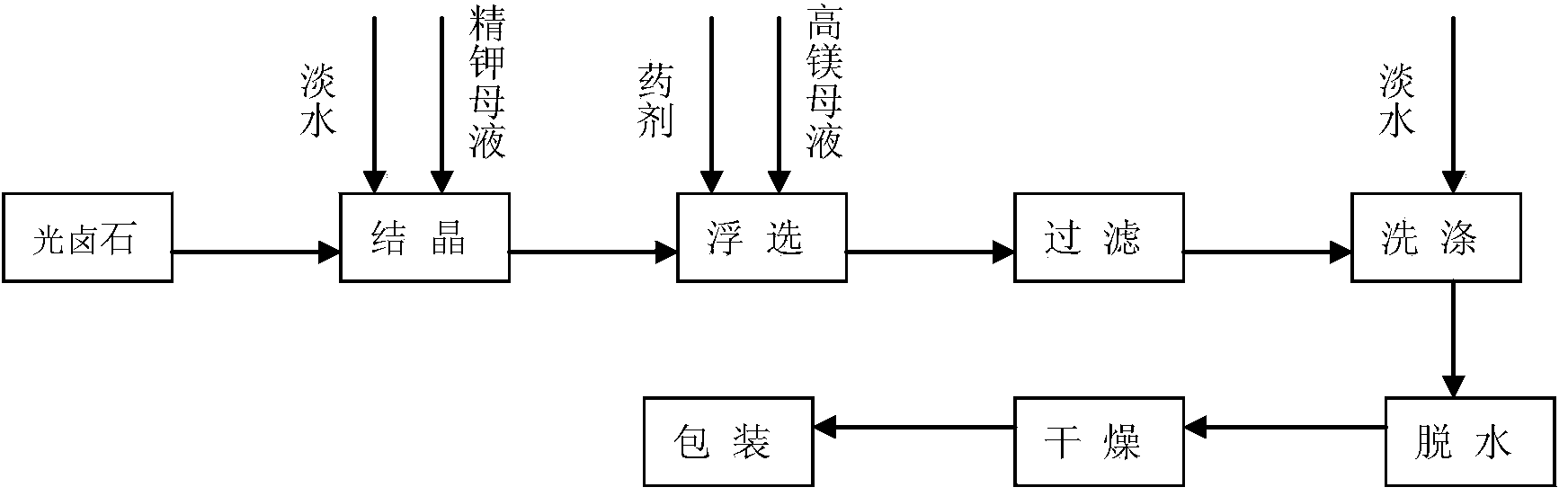

Reverse floatation-cold crystallization process for producing potassium chloride

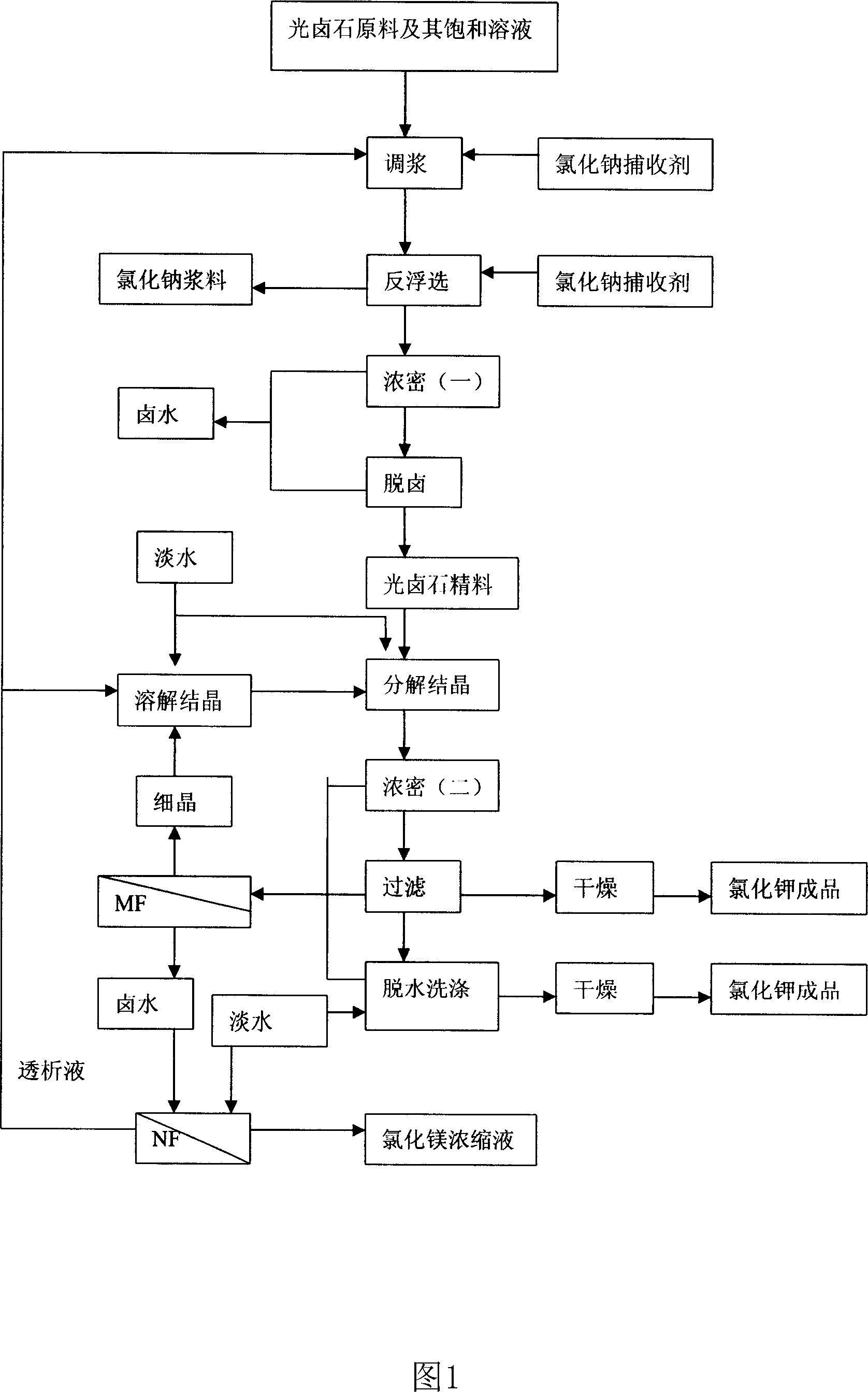

InactiveCN101066769ALarge particlesQuality improvementAlkali metal chloridesAlkali metal halide purificationGranularityFresh water

The reverse floatation and cold crystallization process for producing potassium chloride includes the following four steps: 1. reverse floatation to prepare low sodium carnallite; 2. decomposing low sodium carnallite in fresh water, crystallizing, centrifugally filtering and drying to prepare potassium chloride product; 3. microporous membrane filtering to recover fine potassium chloride crystal, dissolving, returning to potassium chloride crystallizer for secondary crystallization to prepare potassium chloride; and 4. returning the bittern for reuse. The process has potassium chloride yield up to 80 %, great potassium chloride crystal granularity and high product quality, and is suitable for industrial production.

Owner:陈颖

Method for synergistic treatment and harmless cyclic utilization of refuse fly ash by using cement kiln

ActiveCN105478438AIncrease temperatureAvoid foulingSolid waste disposalSnow meltingMembrane distillation

The invention relates to a method for synergistic treatment and harmless cyclic utilization of refuse fly ash by using a cement kiln. The method for synergistic treatment and harmless cyclic utilization of refuse fly ash by using thecement kiln comprises a three-stage washing desalination technology, a technology of removing heavy metals by coagulation and sedimentation, a membrane distillation concentration technology, a technology of removing slight trace carnallite and a triple-effect evaporation crystallization technology, wherein the three-stage washing desalination technology can remove heavy metals and chloride ions in the fly ash, and the fly ash which contains water and dioxin and the fly ash which contains less than 1% of chlorine ions enter the cement kiln and are incinerated at the temperature of above 1400 DEG C to turn into cement raw materials, and the dioxin is split at the temperature of above 800 DEG C; the technology of removing the heavy metals by coagulation and sedimentation can remove multiple metal ions in the fly ash, and precipitates are dried in advance and then enter the cement kiln to be incinerated; the membrane distillation concentration technology can remove the rest of chloride ions in a solution, and generated distilled water can be recycled; the technology of removing the slight trace carnallite can remove the slight trace carnallite, and heat energy can be recycled; and the triple-effect evaporation crystallization technologyevaporates and separates high salt content concentrated liquid to obtain industrial salt which is used for a paper making technology, snow-melting agents and chloro-alkali industries.

Owner:HUZHOU SENNUO MEMBRANE TECH ENG

Process for recovery of sulphate of potash

ActiveUS7041268B2Eliminate needMaximize recoveryChemical industrySulfate preparationPhysical chemistryCarnallite

The present invention is directed to a novel integrated process for the recovery of sulphate of potash (SOP) from sulphate rich bittern. The process requires bittern and lime as raw materials. Kainite type mixed salt is obtained by fractional crystallization of the bittern, and is converted to schoenite which is subsequently reacted with muriate of potash (MOP) for its conversion to SOP. End liquor from kainite to schoenite conversion (SEL) is desulphated and supplemented with MgCl2 using end bittern generated in the process of making carnallite. Decomposed carnallite liquor produced is reacted with hydrated lime for preparing CaCl2 solution and high purity Mg(OH)2 having low boron content. It is shown that the liquid streams containing potash are recycled in the process, and the recovery of potash in the form of SOP is quantitative.

Owner:COUNCIL OF SCI & IND RES

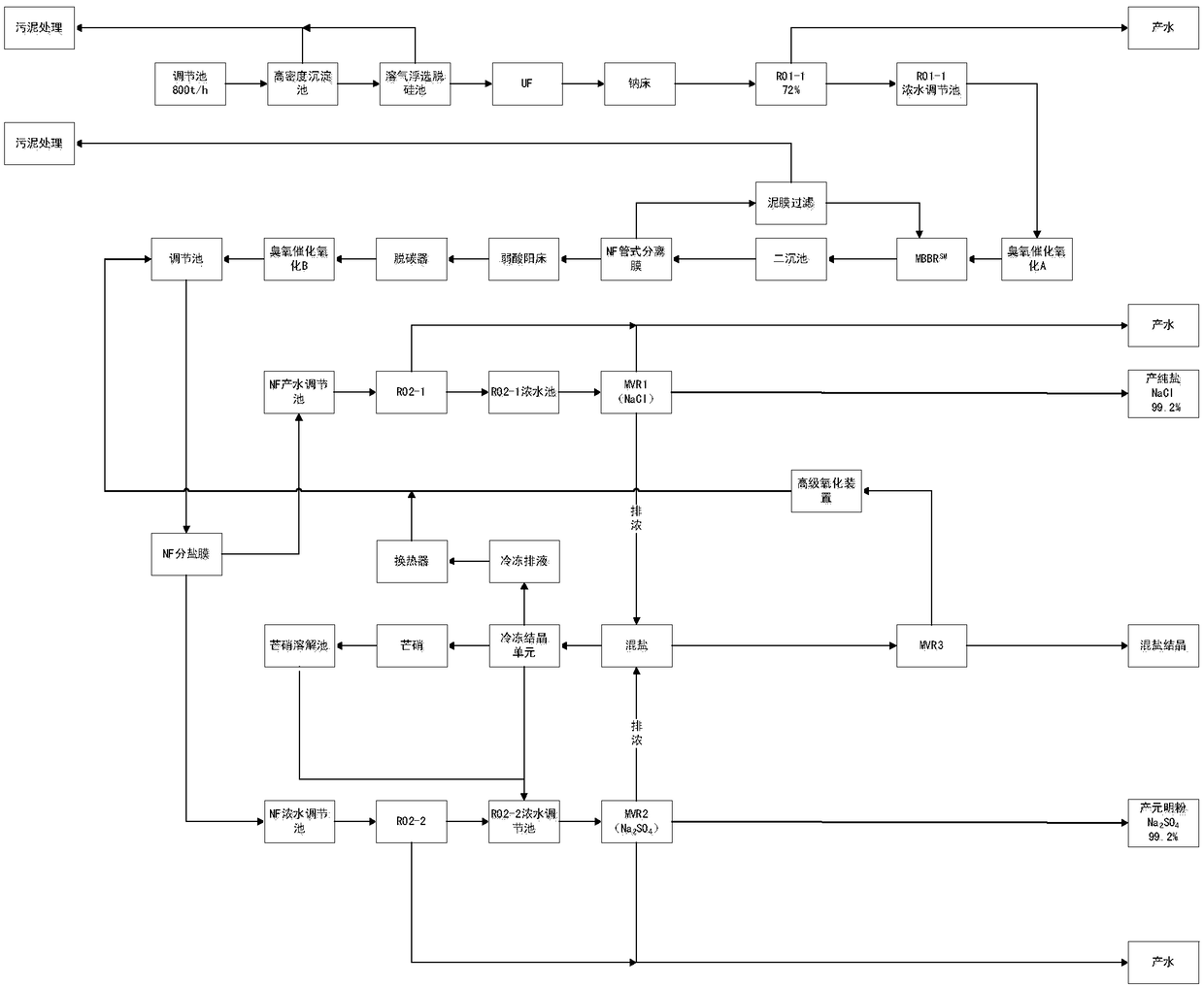

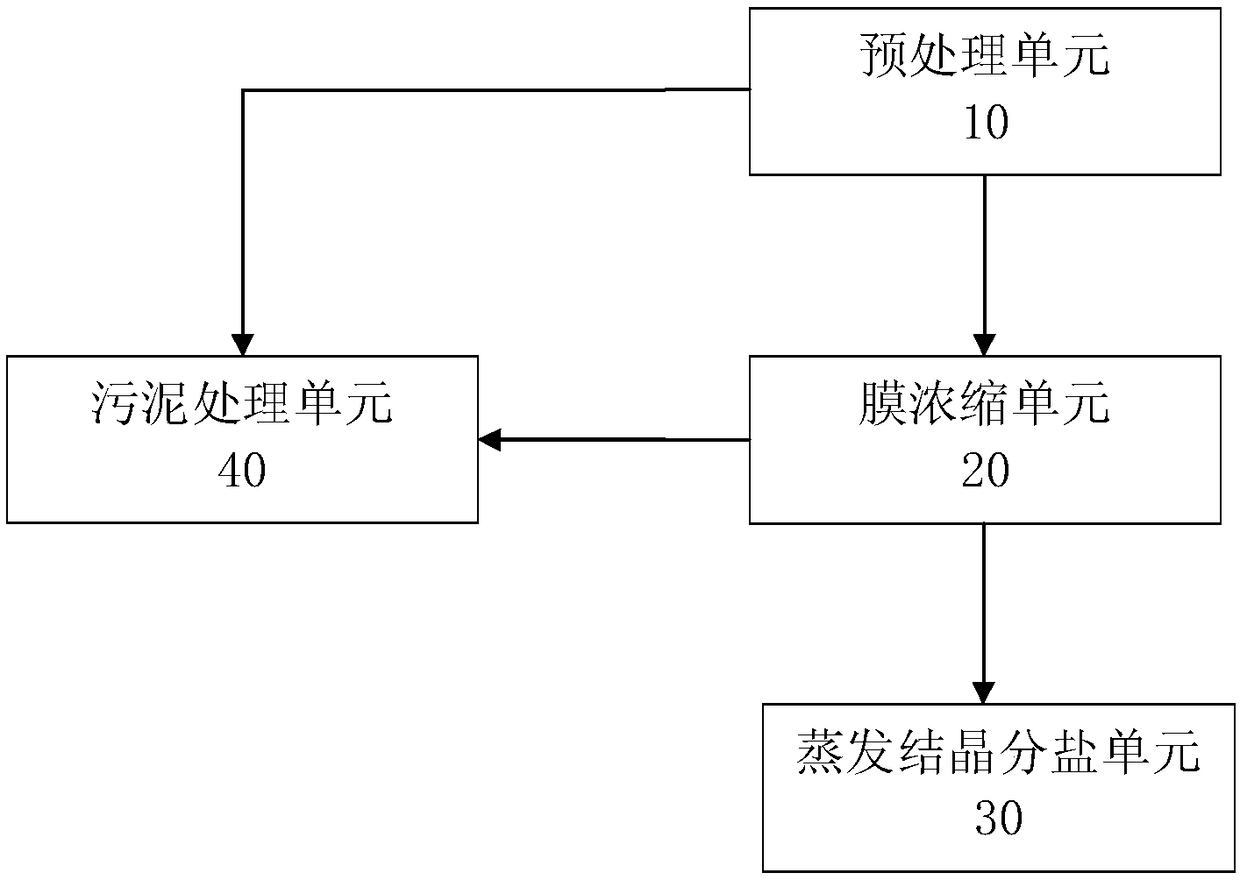

Salinity wastewater zero-discharging method and system

PendingCN108128961AImprove adsorption capacityGuaranteed purityGeneral water supply conservationTreatment involving filtrationDissolved gas flotationFiltration

The invention relates to a salinity wastewater zero-discharging method and system. The method comprises the following steps: further hardness and silicon removal treatment is performed on suspension-removed degummed body by adopting a lime-sodium carbonate softening method and dissolved gas flotation filtration; the hardness is removed deeply through ion exchange; deep treatment is performed by adopting RO concentrated water; COD and NO3- are further reduced by adopting an advanced oxidation and hypersaline microorganism combination technology; an NF membrane salt separation process is adopted; multi-effect Mechanical Vapor Recompression (MVR) is adopted to perform a constant-temperature evaporative crystallization process to concentrate and separate salt; before MVR drained concentrated water is put into catalytic oxidation or an NF membrane, or all is put into carnallite MVR, carnallite is generated; a mother liquor of an MVR device is discharged, and enters a low-temperature refrigeration method to product a large amount of mirabilite to eliminate COD interference; a refrigerating fluid is subjected to advanced oxidization to eliminate COD in a discharged mother liquor outside acrystallization device. A pretreatment technology of the salinity wastewater zero-discharging method is efficient and stable; membrane concentration pretreatment, NF membrane salt pre-separation andreverse osmosis membrane concentration technologies are energy-saving and reliable; total product water and the finished product salt yield are high; the pretreatment technology is an energy-saving technology for reducing the carnallite yield.

Owner:东莞市圆明生物科技有限公司

Cement kiln co-processing system for waste incineration fly ash

ActiveCN105107820ANo secondary pollutionAvoid pollutionSolid waste disposalCement productionFiltrationReverse osmosis

The invention relates to a cement kiln co-processing system for waste incineration fly ash. Washing water generated by a waste incineration fly ash three-stage washing desalination system enters a coagulating sedimentation heavy-metal removal system through a pipeline; a solution with the salt content of 1-2 percent, obtained by the coagulating sedimentation heavy-metal removal system, enters a sodium filtration and reverse osmosis pre-concentration system; and the sodium filtration and reverse osmosis pre-concentration system removes calcium and magnesium ions in washing water and concentrates the solution with the salt content of 1-2 percent into a concentrated liquor with the salt content of 6-8 percent, which is conveyed into a slight trace carnallite removal system for carnallite removal, and finally, a nearly saturated liquid enters an MVR (Mechanical Vapor Recompression) evaporative crystallization system for evaporative crystallization. The cement kiln co-processing system for waste incineration fly ash is a device for cement kiln co-processing of waste incineration fly ash, can dispose a great amount of fly ash, is high in cement output, realizes innocent treatment, and obtains industrial salt through evaporative crystallization, which is used in paper making process, snow-melting agents and the chlor-alkali industry.

Owner:湖州京兰环保科技有限公司

Process for recovery of sulphate of potash

ActiveUS20050220698A1Minimize effluent generationEnhance potash recoveryEnergy inputSulfate preparationDecompositionCarnallite

A novel integrated process for the recovery of sulphate of potash (SOP) from sulphate rich bittern is disclosed. The process requires only bittern and lime as raw materials. Kainite type mixed salt is obtained by fractional crystallization of the bittern, Kainite is converted to schoenite with simultaneous removal of NaCl by processing it with water and end liquor obtained from reaction of schoenite with MOP for its conversion to SOP. The end liquor from kainite to schoenite conversion (SEL) is used for the recovery of MOP. SEL is desulphated and supplemented with MgCl2 using end bittern generated in the process of making carnallite. The carnallite is decomposed to get crude potash which in turn processed to get MOP. The carnallite decomposed liquor produced in the decomposition of carnallite is reacted with hydrated lime for preparing CaCl2 solution and high purity Mg(OH)2 having low boron content, The CaCl2 solution is used for desulphatation of SEL producing high purity gypsum as a byproduct. It is shown that the liquid steams containing potash are recycled in the process, the recovery of potash in the form of SOP is quantitative.

Owner:COUNCIL OF SCI & IND RES

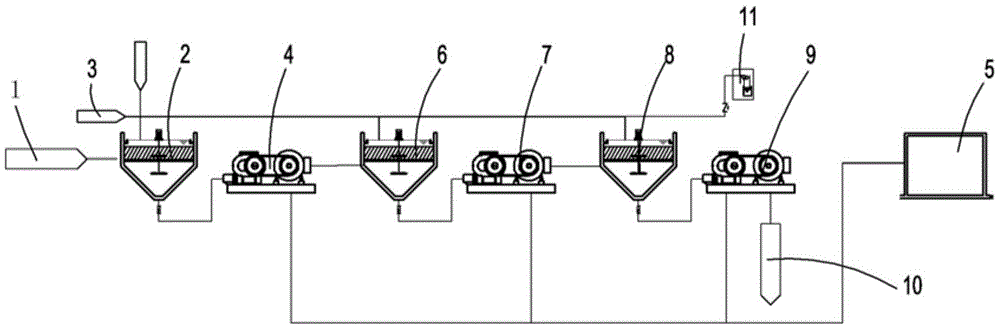

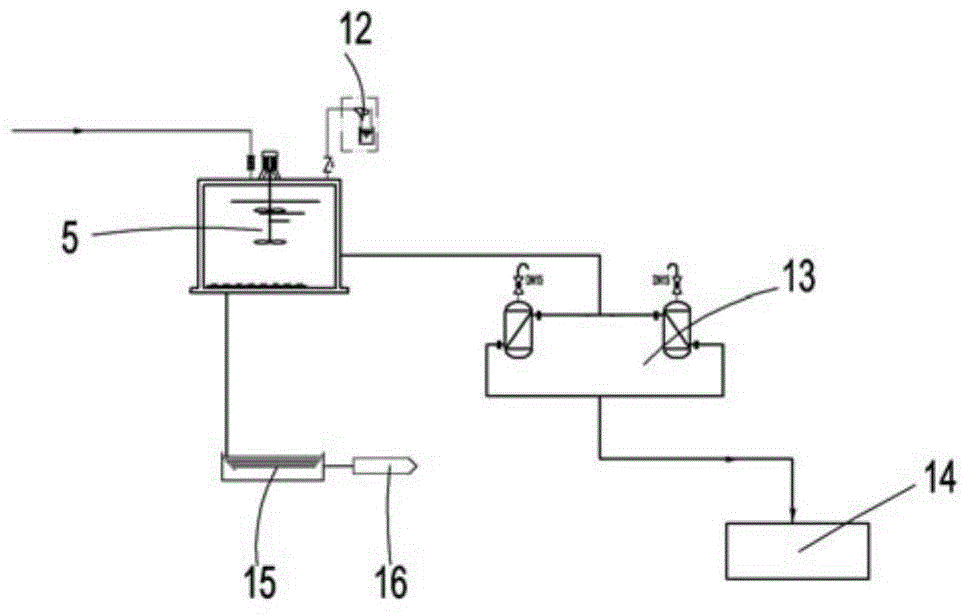

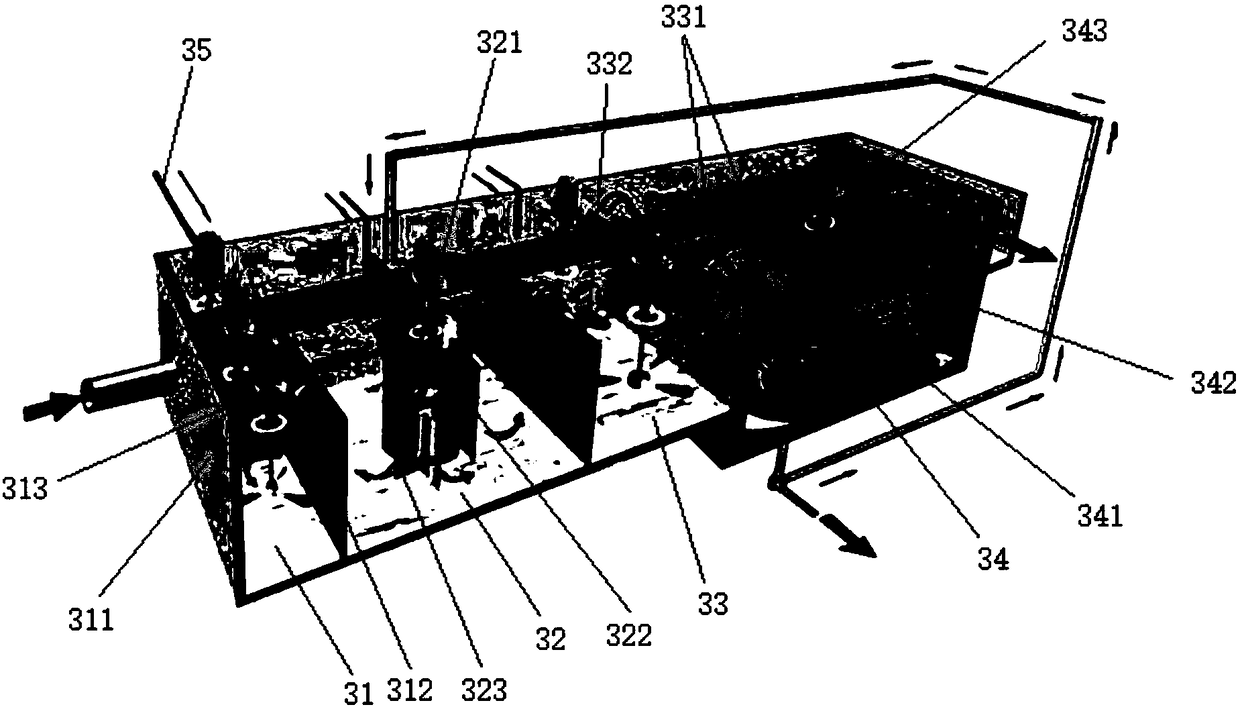

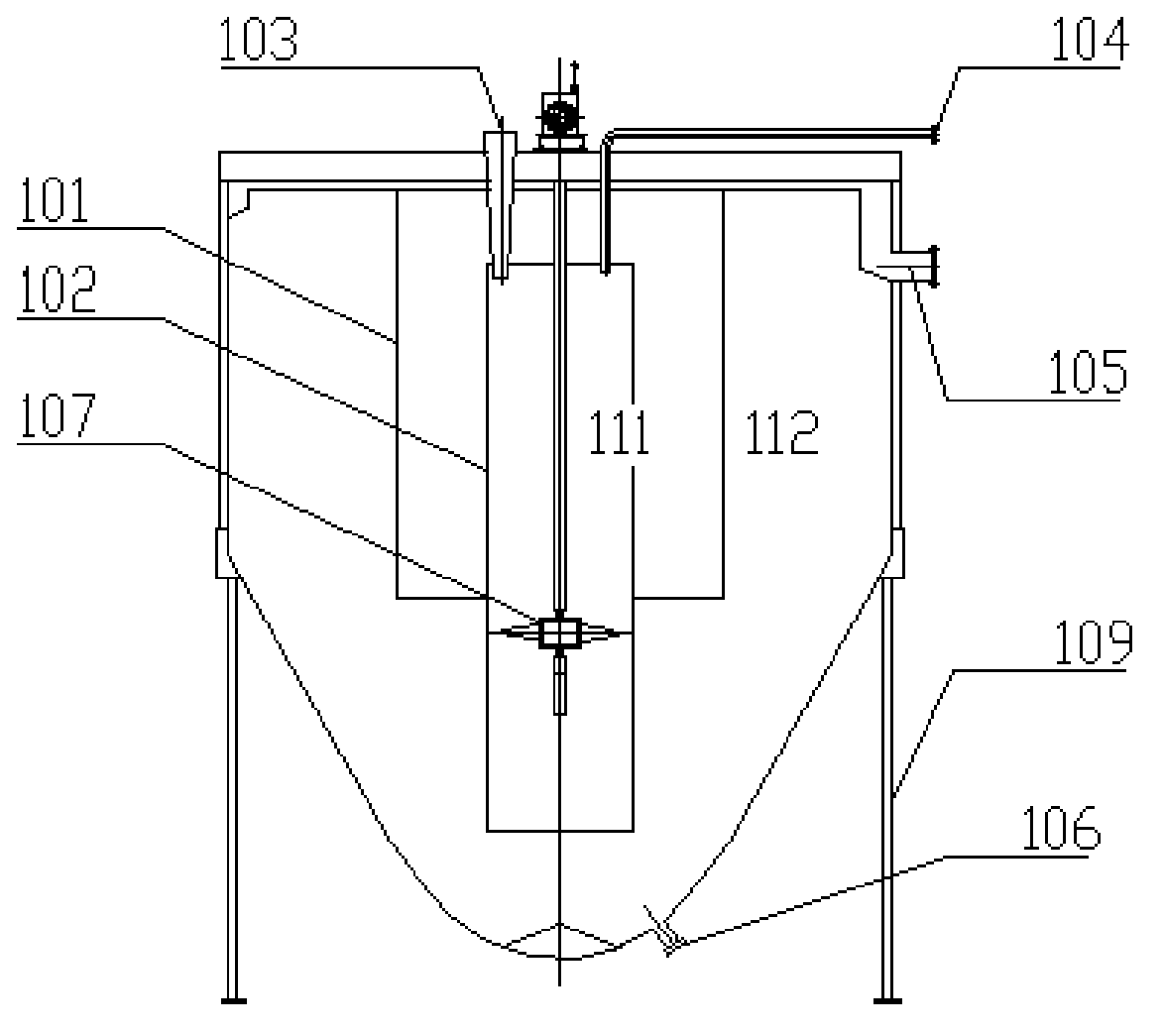

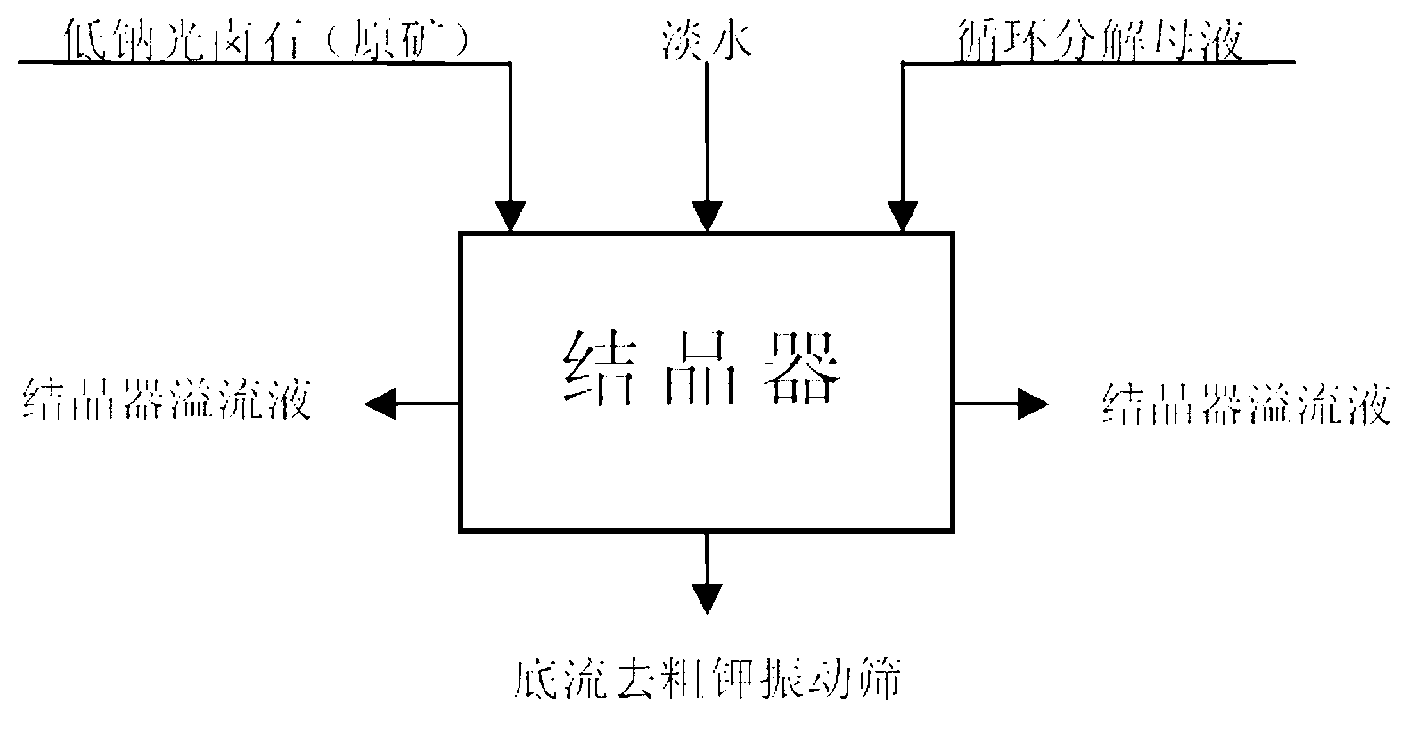

Crystallizer for hydrolyzing carnallite

ActiveCN103073030AIncrease contact areaSolve the problem of overflow from the upper part of the inner cylinder to the bottom of the crystallizer without sufficient mixing and decompositionAlkali metal halide formation shapeDecompositionChloride

The invention relates to a crystallizer for hydrolyzing carnallite. The crystallize comprises an inner cylinder, an outer cylinder, a mother solution distributor, a stirring paddle, a crystallizer cylinder body, a low-sodium carnallite inlet, a mother solution inlet, a decomposition liquid outlet and a product outlet. According to the crystallizer, the remaining time of low-sodium carnallite in a dissolving region can be prolonged, and the problem that low-sodium carnallite is not fully mixed and decomposed and then overflows to the bottom of the crystallizer from the upper part of the inner cylinder in the existing crystallizer is solved; and generated potassium chloride particles can grow above 0.2mm in particle size to ensure that solid potassium chloride is easily dewatered and dried, and washing water and heat energy required by drying are saved.

Owner:ЦИНХАЙ СОЛТ ЛЕЙК ИНДАСТРИ ГРУП КО ЛТД

Porous ceramic-loaded catalyst used for biomass catalytic liquefaction, and preparation method thereof

ActiveCN104844264ASolve the strength problemSolve the problem of easy wear and tearCeramicwareHeat carrierCarnallite

The invention discloses a porous ceramic-loaded catalyst used for biomass catalytic liquefaction, and belongs to the technical field of porous functional ceramic. A natural inorganic catalyst is taken as an active ingredient of the porous ceramic-loaded catalyst, is subjected to smashing, grinding, and screening, and is mixed with a ceramic aggregate, a pore forming agent, and a binder at a mass ratio of 30-40:40-50:5-10:10-15; an obtained mixture is processed so as to obtain a porous ceramic body material; the porous ceramic body material is subjected to drying, sintering, and activation so as to obtain the porous ceramic-loaded catalyst; wherein the active ingredient is one or a combination of a plurality of ingredients selected from dolomite, limestone, diatomite, kaoline, olivine, cordierite, montmorillonite, hydrotalcite, carnallite, beryl, celestite, and gypsum at random, and dolomite and montmorillonite preferably. The porous ceramic prepared via above steps can be taken as a catalyst of biomass pyrolysis liquidation processes and a reactor internal heat carrier at the same time, possesses activity on biomass pyrolysis processes, is capable of increasing bio oil yield, improving bio oil quality, and reducing biomass pyrolysis reaction conditions.

Owner:SHANDONG UNIV OF TECH

Rubbish-fly-ash and cement-kiln cooperation treatment method

ActiveCN105080936ANo secondary pollutionAvoid pollutionSolid waste disposalThree levelReverse osmosis

The invention relates to a rubbish-fly-ash and cement-kiln cooperation treatment method. The treatment method sequentially includes the technological steps of three-level washing desalting, and dioxin microorganism removing; heavy metal micellar-enhanced removing; nanofiltration; reverse osmosis pre-concentrating; slight-trace-carnallite removing; and MVR evaporative crystallization. Heavy metal and chloride ions in fly ash can be removed through the three-level washing desalting and dioxin microorganism removing technological step, and fly ash produced during dioxin microorganism erosion can be used as building materials. Heavy metal, most calcium and most magnesium in the fly ash can be removed through the heavy metal micellar-enhanced removing technological step, and precipitate is pre-dried to enter a cement kiln to be incinerated. The calcium and the magnesium left in washing water are removed through the nanofiltration technological step. The washing water can be concentrated to 6% to 8% through the reverse osmosis pre-concentrating technological step, and produced water can be used for washing. A slight trace of carnallite is removed through the slight-trace-carnallite removing technological step. Concentrated liquor is evaporated and separated to obtain industrial salt through the MVR evaporative crystallization technological step.

Owner:浙江京兰环保科技有限公司

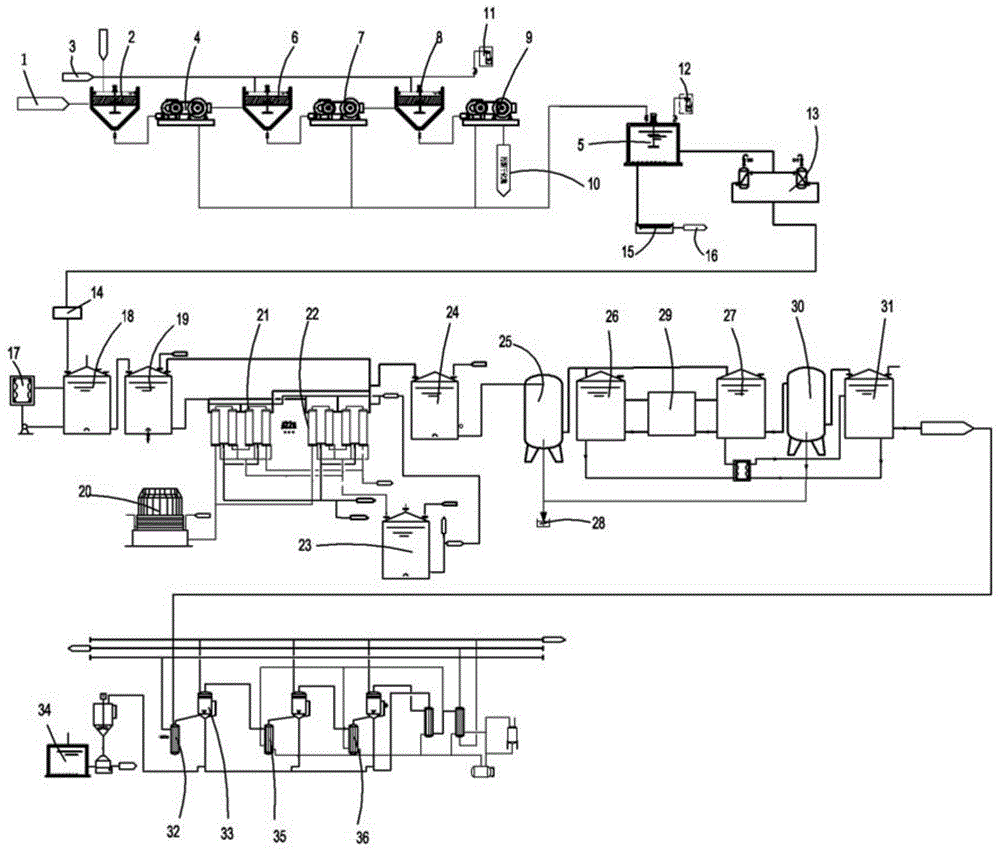

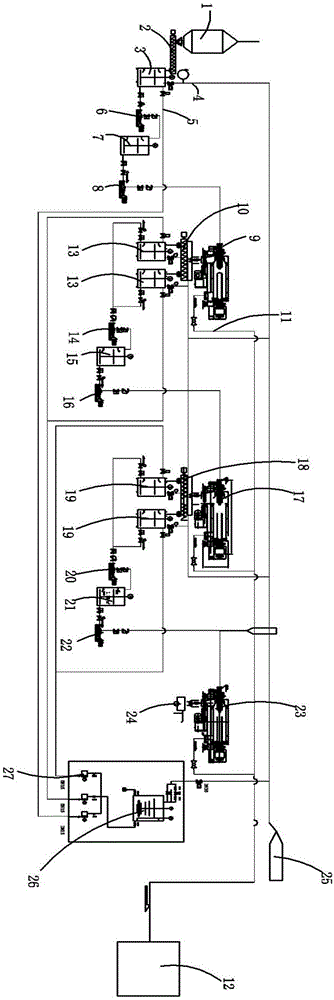

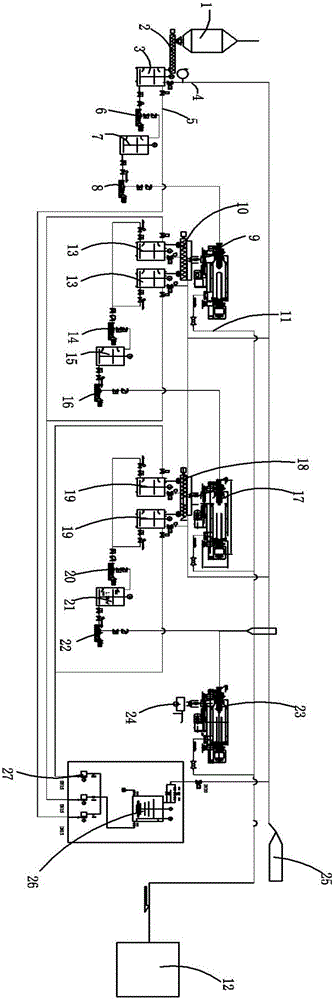

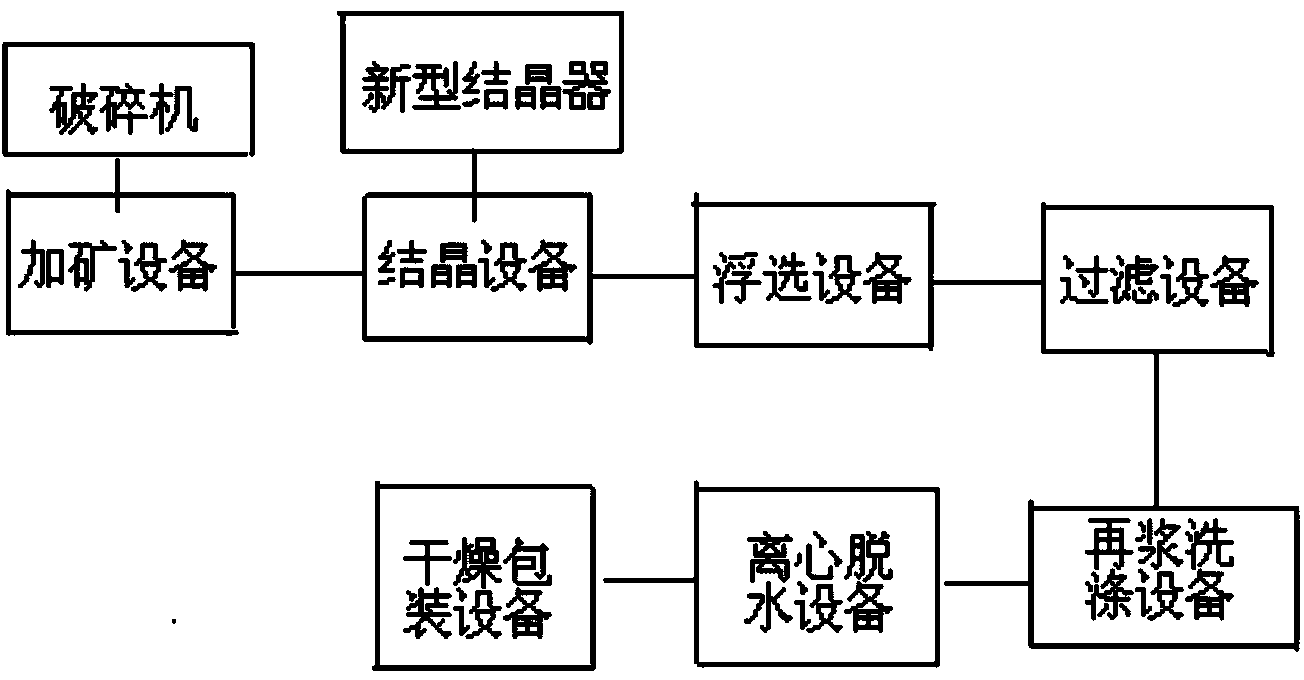

Novel system and method for producing potassium chloride by utilizing carnallite

ActiveCN104058428AHigh recovery rateRealize learning from each otherAlkali metal chloridesDecompositionFiltration

The invention discloses a novel system and method for producing potassium chloride by utilizing carnallite. The novel system for producing the potassium chloride by utilizing the carnallite comprises ore adding equipment, crystallization equipment, floatation equipment, filtration equipment, repulping and washing equipment, centrifuging and dehydrating equipment and drying and packaging equipment which are sequentially connected; a crushing machine is added on the ore adding equipment, so that a crystallization system can conveniently decompose crystals; meanwhile, in the crystallization equipment, a novel crystallizer invented by the company (described in the specification) is used for replacing carnallite decomposition equipment in the conventional cold decomposition-direct floatation technology. The novel system and method for producing the potassium chloride by utilizing the carnallite have the advantages that production technological conditions of the conventional direct floatation technology are improved, the recovery rate of potassium chloride is increased to 60%, a potassium chloride product with the purity of 90% is eliminated, the purity of the potassium chloride product is increased to 93-95%, product granularity is increased, and energy consumption is reduced.

Owner:QINGHAI SALT LAKE IND

Simultaneous recovery of potassium chloride and KCL enriched edible salt

The present invention relates to recovery of industrial grade potassium chloride and low sodium edible salt from bittern as part of an integrated process. The process comprises, mixing low sulphate concentrated feed bittern (a by-product of salt industry) of density 31.5 to 32.5° Be (sp.gr. 1.277-1.289) with high density end bittern of density 36.5 to 37.5° Be′ (sp.gr. 1.336-1.35), thereby producing low sodium carnallite, from which industrial grade potassium chloride is produced. The resultant bittern is evaporated in forced evaporation system, thereby producing crude carnallite, from which low sodium salt that would be beneficial to persons suffering from hypertension is produced. When sulphate-rich bittern is used, such bittern is desulphated with CaCl2 that is generated from carnallite decomposed liquor through reaction with lime, and wherein low B2O3-containing Mg(OH)2 is a by-product. The entire content of potassium in feed bittern is recovered in the process of the invention.

Owner:COUNCIL OF SCI & IND RES

Method of producing high-purity anhydrous lithium chloride

InactiveCN101172624AEfficient separationEfficient purificationAlkali metal chloridesLithium chlorideSolvent

The invention belongs to the chemical field of inorganic salts, in particular to a preparation method of high-purity anhydrous lithium chloride; wherein, sodium hydroxide and barium chloride are added into the high-potassium sodium brine containing lithium chloride which is used as a raw material; the mixture is stirred and filtered to eliminate a great amount of Mg 2 <+> and SO 4 <2->; and the micro Mg 2 <+> and the SO 4 <2-> can be eliminated by adding sodium carbonate into the mixture, and then is filtered to get a refined mother liquid. The refined mother liquid can be evaporated and filtered to eliminate potassium chloride and sodium chloride; and high-potassium mixed salt containing 60 to 95 percent of lithium chloride can be achieved by spraying and drying the refined mother liquid. After adding low-carbon organic solvent, the high-potassium mixed salt is stirred to extract lithium chloride and filtered to eliminate potassium sodium salt. High-purity anhydrous lithium chloride with the purity of over 99.5 percent can be achieved by depressurizing and distilling the mother liquid. The invention is applicable to the extraction art of the lithium chloride used in all present low-magnesium salt lakes containing lithium, and the extraction process of the lithium chloride from the mother liquid achieved after pressing solid lithium ore. The invention not only has the advantages of simple process and low cost, but also is easy to be operated and used in industrialization and has no three-waste pollution.

Owner:青海中信国安科技发展有限公司

Process for producing potassium chloride by using carnallite

The invention relates to a process for producing potassium chloride by using carnallite. The process comprises the steps: S1. flotation: subjecting the carnallite to flotation treatment, so as to prepare low-sodium carnallite; S2. crystallization: adding isometric plain water into a first-section crystallizer and a second-section crystallizer, adding 55% to 75% of the low-sodium carnallite into the first-section crystallizer, adding 25% to 45% of the low-sodium carnallite into the second-section crystallizer, conveying underflow slurry formed in the first-section crystallizer into the second-section crystallizer for continuous decomposed crystallization, and carrying out decomposition in the second-section crystallizer, so as to form coarse-potassium slurry; S3. aftertreatment: subjectingthe coarse-potassium slurry to subsequent treatment, thereby preparing the product potassium chloride. According to the process for producing the potassium chloride by using the carnallite, provided by the invention, the low-sodium carnallite subjected to flotation is subjected to crystallizing treatment by connecting two sections of crystallizers in series, so that the complete decomposition of the low-sodium carnallite in a crystallization process is guaranteed, the content of potassium chloride in overflow liquor during crystallization is fundamentally lowered, and thus, the yield of the potassium chloride is increased to 75% or more.

Owner:ЦИНХАЙ СОЛТ ЛЕЙК ИНДАСТРИ ГРУП КО ЛТД

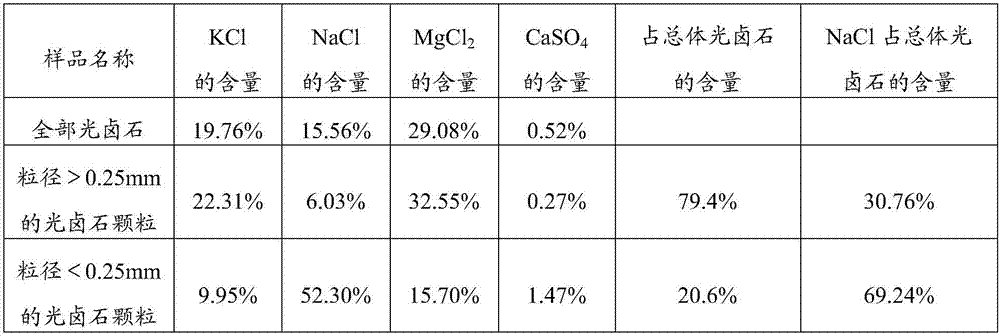

Technology for producing potassium chloride from carnallite

The invention discloses a technology for producing potassium chloride from carnallite. The technology comprises the following steps: determining a critical particle diameter of particles with the mostaverage content of the potassium chloride and selecting a standard screen mesh for sieving carnallite particles; sieving the carnallite particles into a primary oversize material and a primary undersize material by utilizing the standard screen mesh; adding a water amount for completely dissolving magnesium chloride into the primary oversize material to obtain a primary dissolving solution and primary mixed slurry; sieving the primary mixed slurry into a secondary oversize material and a secondary undersize material by utilizing the standard screen mesh; carrying out reverse flotation to obtain low-sodium carnallite and tail salt foam; adding the water amount for completely dissolving the magnesium chloride into the low-sodium carnallite to obtain a secondary dissolving solution and secondary mixed slurry; carrying out solid-liquid separation on the secondary undersize material and the secondary mixed slurry to obtain a crude potassium product; washing an obtained potassium chloride crude product to obtain a qualified potassium chloride finished product. The technology disclosed by the invention has the advantages of simplicity in operation, less investment, low energy consumptionand high yield and the quality of the prepared potassium chloride finished product is good.

Owner:ЦИНХАЙ СОЛТ ЛЕЙК ИНДАСТРИ ГРУП КО ЛТД

Method for producing potassium chloride, sodium chloride and magnesium sheet from bittern extracted from carnallite mine

ActiveCN102491373AReduce consumptionReduce dosageMagnesium chloridesAlkali metal chloridesSolubilityEvaporation

The invention discloses a method for producing potassium chloride, sodium chloride and a magnesium sheet from bittern extracted from a carnallite mine. The method provided by the invention comprises the following steps of 1, decomposing carnallite, 2, carrying out evaporation concentration, 3, separating carnallite, 4, preparing a mining injection agent, 5, carrying out heating dissolution and crystallization to obtain potassium chloride, 6, carrying out salt-leaching and drying to obtain sodium chloride, and 7, carrying out magnesium sheet processing. The method provided by the invention has the advantages that the hot mining injection agent is utilized for ore dissolution and thus a yield of sodium chloride and magnesium chloride is greatly reduced in production of per unit amount of potassium chloride because the solubility of potassium chloride is far greater than the solubility of sodium chloride and the solubility of magnesium chloride; a waste salt discharge amount of a follow-up process is reduced; a backfill amount is reduced obviously; a cost is reduced; comprehensive utilization of potassium and magnesium resources of carnallite is realized; and the economic benefits are high.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN +1

Modified calcium adsorbent for purifying incinerated smoke and preparation process thereof

InactiveCN1623648ALarge Bore SizeIncreased final conversion rateOther chemical processesDispersed particle separationCarnalliteIncineration

An modified Ca-base adsorbent for cleaning the fume of garbage incinerator by removing the acidic gas, heavy metal, dioxin, etc from it is prepared from industrial light calcium carbonate (CaCO3) and Na salt as modifier through proportionally immersing the powder of light calcium carbonate in the solution of Na salt, heating while stirring, and calcining.

Owner:TSINGHUA UNIV

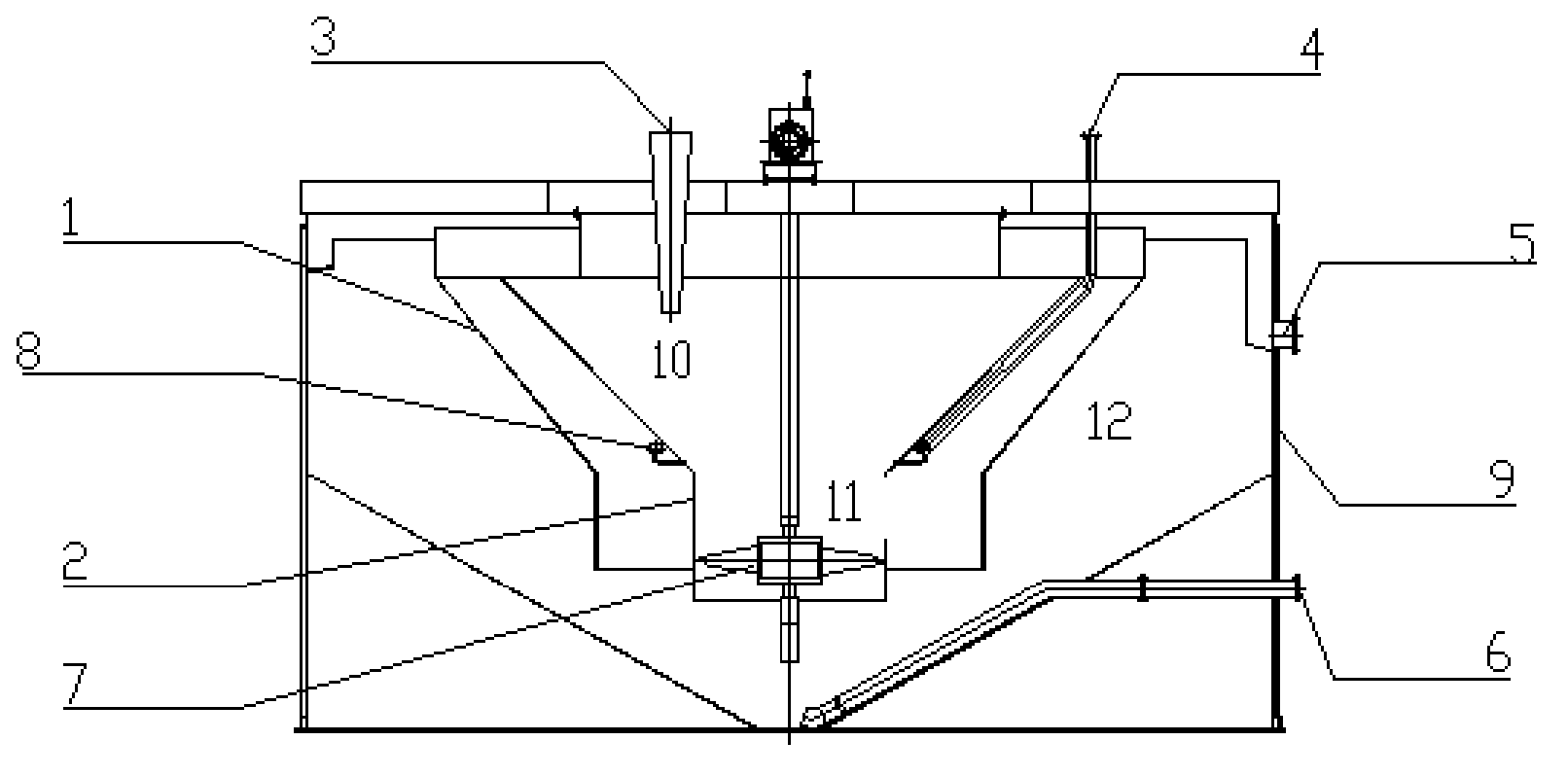

Production process of preparing high-quality potassium chloride from carnallite

ActiveCN106185994AImprove qualityImprove market competitivenessAlkali metal chloridesDecompositionClosed loop

A production process of preparing high-quality potassium chloride from carnallite includes the steps of 1) crushing carnallite ore; 2) adding the crushed carnallite ore to a decomposition crystallizer filled with saturated mother liquid; 3) adding fresh water or a washing mother liquid obtained in subsequent processes into the decomposition crystallizer; 4) stirring the slurry so that a quasi-closed loop circulation flowing status that the ore slurry flows from bottom to top in a flow guide cylinder and flows from top to bottom in an annular chamber being adjacent to the external side of the flow guide cylinder is formed, and during the flowing process, the carnallite is decomposed and the potassium chloride is crystallized; and 5) sieving a bottom flow in the decomposition crystallizer, wherein the oversize substance serves as tailings while the undersize substance is filtered then; and 6) feeding a filtrate to the next process to perform evaporation crystallization to recycle the KCl, and washing, filtering and drying a filter cake. The production process is simple, is low in mechanical loss and energy consumption, is low in production cost, is free of any chemical reagents and is environment-friendly. The potassium chloride product has good quality and large granularity.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

Simultaneous recovery of potassium chloride and KCL enriched edible salt

The present invention relates to recovery of industrial grade potassium chloride and low sodium edible salt from bittern as part of an integrated process. The process comprises, mixing low sulphate concentrated feed bittern (a by-product of salt industry) of density 31.5 to 32.5° Be (sp.gr. 1.277–1.289) with high density end bittern of density 36.5 to 37.5° Be′ (sp.gr. 1.336–1.35), thereby producing low sodium carnallite, from which industrial grade potassium chloride is produced. The resultant bittern is evaporated in forced evaporation system, thereby producing crude carnallite, from which low sodium salt that would be beneficial to persons suffering from hypertension is produced. When sulphate-rich bittern is used, such bittern is desulphated with CaCl2 that is generated from carnallite decomposed liquor through reaction with lime, and wherein low B2O3-containing Mg(OH)2 is a by-product. The entire content of potassium in feed bittern is recovered in the process of the invention.

Owner:COUNCIL OF SCI & IND RES

Method for coproducing sodium chloride, magnesium sulfate and potassium chloride

InactiveCN101591030AHigh extraction rateLong cycleMagnesium sulfatesMultistage water/sewage treatmentDecompositionEvaporation

The invention relates to a method for coproducing sodium chloride, magnesium sulfate and potassium chloride. The method for coproducing the sodium chloride, magnesium sulfate and potassium chloride is characterized in that raw material brine is subjected to processes of primary evaporation, cooling and secondary evaporation to gradually extract and separate the sodium chloride and the magnesium sulfate and prepare carnallite; and the carnallite is performed hydrolytic decomposition, and the potassium chloride is produced after washing and dehydration. The method has the advantages of realizing coproduction of three products, namely the sodium chloride, the magnesium sulfate and the potassium chloride. The extraction yield of the sodium chloride is above 85 percent; the extraction yield of the magnesium sulfate is increased to be between 56.95 and 62 percent; the extraction yield of the potassium chloride is improved by over 7 percentage; the quality of the carnallite is improved; and the content of the potassium chloride is between 19 and 23 percent, which provides good-quality raw materials for the next process.

Owner:天津长芦汉沽盐场有限责任公司

Treatment of waste water in vanadium pentaoxide production and its full circulation technology

InactiveCN100999354ASolve pollutionEfficient use ofWater/sewage treatmentVanadium oxidesSaline waterHigh density

This invention provides a pollution process of vanadic anhydride production waste water and its entire circulation technique. Use end water of resin adsorbing extracting vanadium segment as soaking vanadium water of leaching segment, use ammonium salt immersing vanadium waste water that is added sodium chloride as vanadium salt stripping water of stripping segment, directly cyclically utilize in certain time; add iron sulfide mine powder and sodium sulfide into end water, add calcarea and sodium sulfide into immersing vanadium waste water, mix, stand still, precipitate, cyclically utilize clean liquid; eliminate high density natrium salt into saline water tank of salting producing ball segment, which is used as saline water of salting producing ball segment. This technique solves pollution problems of end water and immersing vanadium waste water in vanadic anhydride production. It also can utilize waste water natrium salt.

Owner:刘强国 +1

Method for recovering potassium chloride from abandon mine of salt lake

This invention discloses a method for recovering KCl from waste ore of salt lake. The method comprises: utilizing waste ore of salt lake as the raw material, dissolving in solvent, removing the solid phase, adjusting Mg content, clarifying the precipitate, and solarizing to obtain high-purity carnallite. The method expands the exploitation range of potassium ore, and extends the service life of salt lake.

Owner:陈天强 +1

Method for preparing potassium sulfate from brine with low sulfur-potassium ratio

The invention discloses a method for preparing potassium sulfate from brine with a low sulfur-potassium ratio. The method includes steps of (1), evaporating the raw brine to obtain potassium-mixed salt mine; (2), sun-curing carnallite; (3), feeding the carnallite to a potassium chloride workshop, and carrying out crushing, decomposing, flotation and dehalogenation on the carnallite to obtain potassium chloride concentrate; (4), feeding the potassium-mixed salt mine to a picromerite workshop, crushing the potassium-mixed salt mine, mixing the potassium-mixed salt mine and tailings with one another in water after the tailings obtained at the step (3) are subjected to dehalogenation, and carrying out grinding, transformation, flotation, separation and washing to obtain picromerite concentrate; (5), mixing the picromerite concentrate and the potassium chloride concentrate with each other in water to obtain mixtures and transforming the mixtures to obtain potassium sulfate products. The method has the advantages that technical routes of existing processes for producing potassium sulfate from salt lakes are improved, accordingly, shortcomings of methods for producing the potassium sulfur from brine with a low sulfur-potassium ratio in the prior art can be overcome, and the reasonable and feasible method which includes simple processes and short procedures and is low in cost and free of pollution can be provided for producing the potassium sulfate from the brine with the low sulfur-potassium ratio from salt lakes.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

Process for producing soft potassium magnesium vanadium

ActiveCN1724374AHigh yieldIncrease profitMagnesium sulfatesConverting sensor outputSulfateCarnallite

A process for preparing soft KMgV from the mixed K salt generated by sunning the sulfate-type bittern includes such steps as breaking, sieving, stage-one converting, mechanical separation of sodium chloride, stage-two converting, and drying. Its advantages are high output rate and high purity of product.

Owner:青海中信国安锂业发展有限公司

Process for the formulation of potassium chloride from a carnallite source

A process for formulating high purity potassium chloride from a carnallite source. The process takes advantage of solubility differences and saturation levels in a multiple salt system generated upon dissolution of carnallite. In the system, the sodium chloride is kept in solution and the magnesium chloride present in the system is controlled to be in a concentration range of between 12% and 25% by weight. This avoids co-precipitation of sodium chloride with the potassium chloride during crystallization and therefore prevents the sodium chloride from contaminating the potassium chloride. The result is high grade potassium chloride.

Owner:KARNALYTE RESOURCES

Method for preparing low-sodium carnallite, sodium chloride and magnesium chloride from refined magnesium slag

InactiveCN102424916AReduce pollutionAvoid pollutionProcess efficiency improvementPhysical chemistryCarnallite

The invention relates to a chemical extraction method, in particular to a method for preparing low-sodium carnallite, sodium chloride and magnesium chloride from refined magnesium slag. The method comprises the following steps of: crushing; screening; dissolving; filtering; adjusting the molar ratio of K<+> to Mg<2+> in the filtrate; evaporating, concentrating, settling, filtering and drying the filtrate to obtain a sodium chloride crystal; cooling and crystallizing the filtrate after the sodium chloride is separated to obtain low-sodium carnallite and brine; putting the filter residue into a reaction kettle; adding a full amount of hydrochloric acid for full reaction according to the contents of magnesium oxides and alkaline matters in the filter residue; after reacting, filtering, and cooling, dehydrating and drying the filtrate to obtain anhydrous magnesium chloride; adding a full amount of hydrochloric acid for full reaction according to the contents of magnesium oxides and alkaline matters in the filter residue; and after reacting, filtering, and cooling, dehydrating and drying the filtrate to obtain anhydrous magnesium chloride. The method provided by the invention has the characteristics of reasonable process route, environmental friendliness and the like and can realize cyclic and efficient utilization of the three wastes as well as cyclic utilization of water, and the utilization ratio can reach 85%.

Owner:SHIZUSN KAIRUI MAGNESIUM CHEM

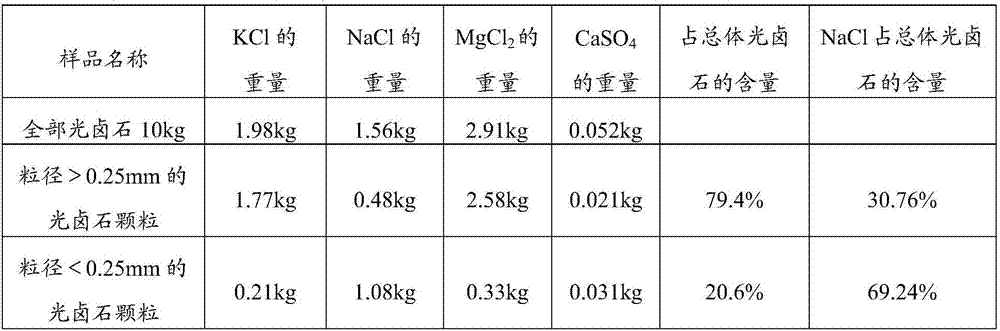

Method for preparing kalium-magnesium titanate by carnallite

The invention discloses a method for preparing potassium magnesium titanate, which includes using carnallite, titanium-containing and potassium-containing compounds as the material, mixing evenly; sintering at 800-1100 DEG C for 30 min-12 h, pulverizing, water washing, filtering, and heat-treating to obtain potassium magnesium titanate. The natural carnallite is used as the material to reduce the material cost of potassium magnesium titanate. Whiskers or lamellas of different purpose can be obtained by adjusting the material proportion. The preparation method simplifies the technological process and improves the production efficiency and is more suitable for large-scale production.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com