Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2176 results about "Prill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A prill is a small aggregate or globule of a material, most often a dry sphere, formed from a melted liquid. Prilled is a term used in mining and manufacturing to refer to a product that has been pelletized. The pellets are a neater, simpler form for handling, with reduced dust.

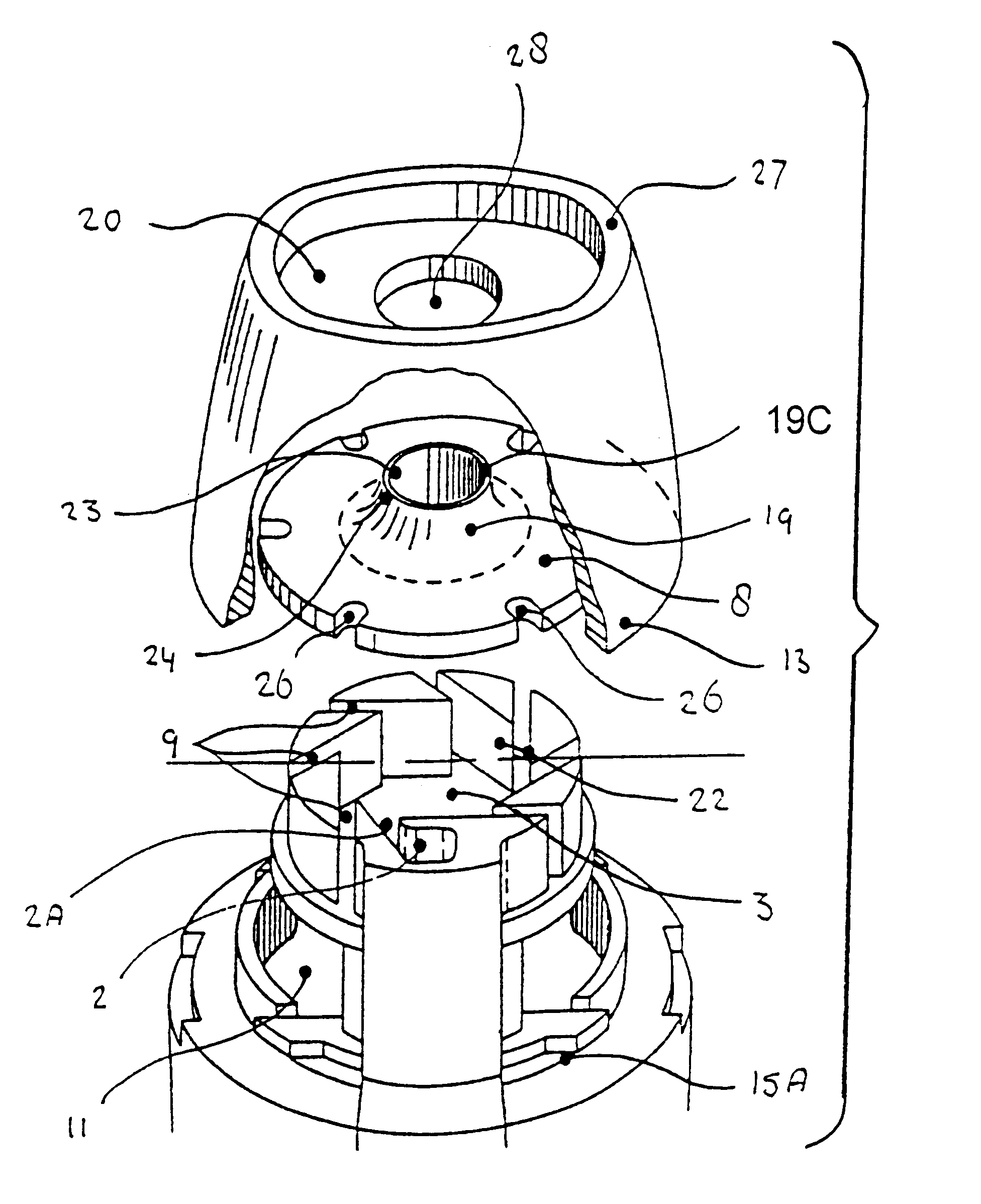

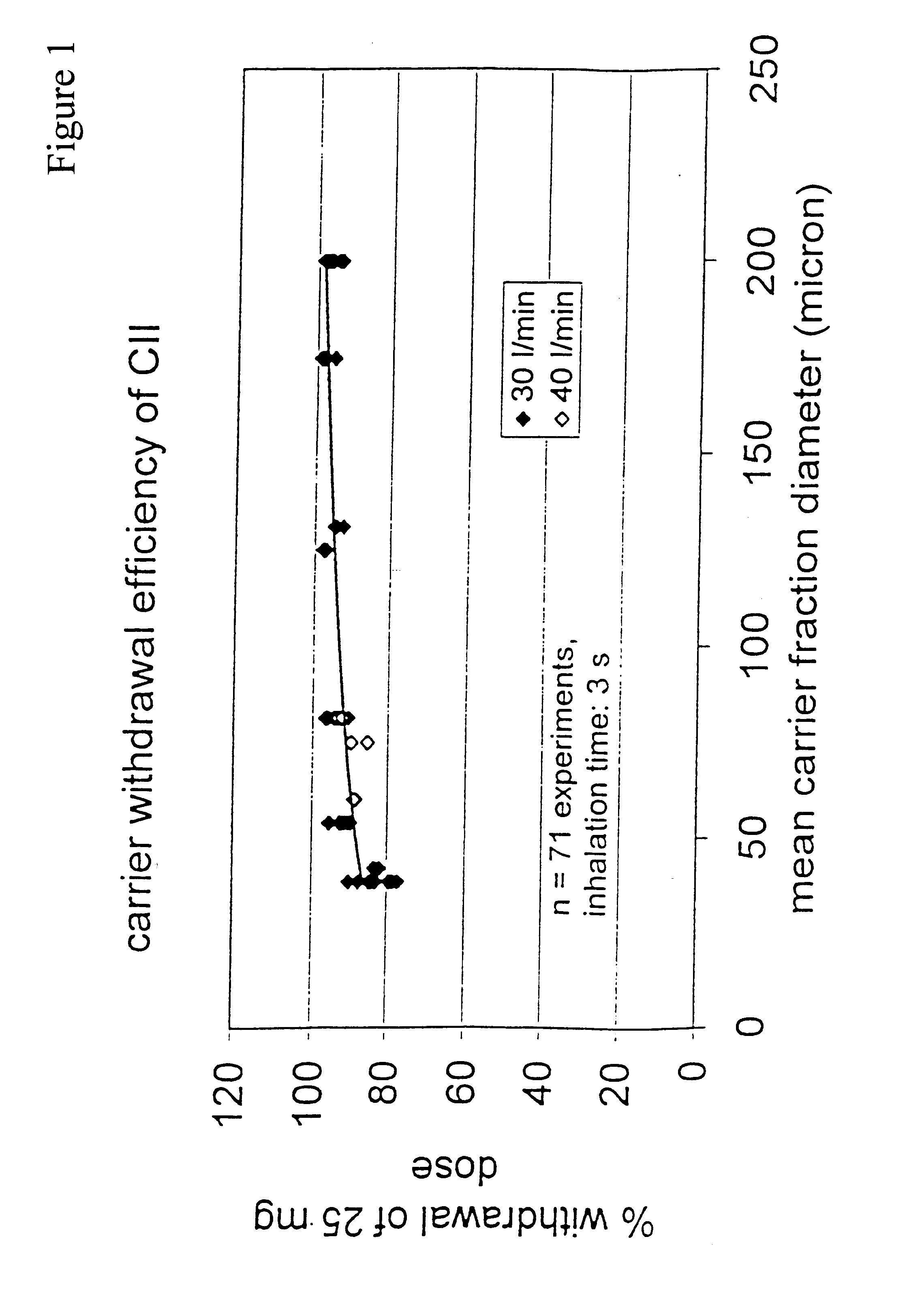

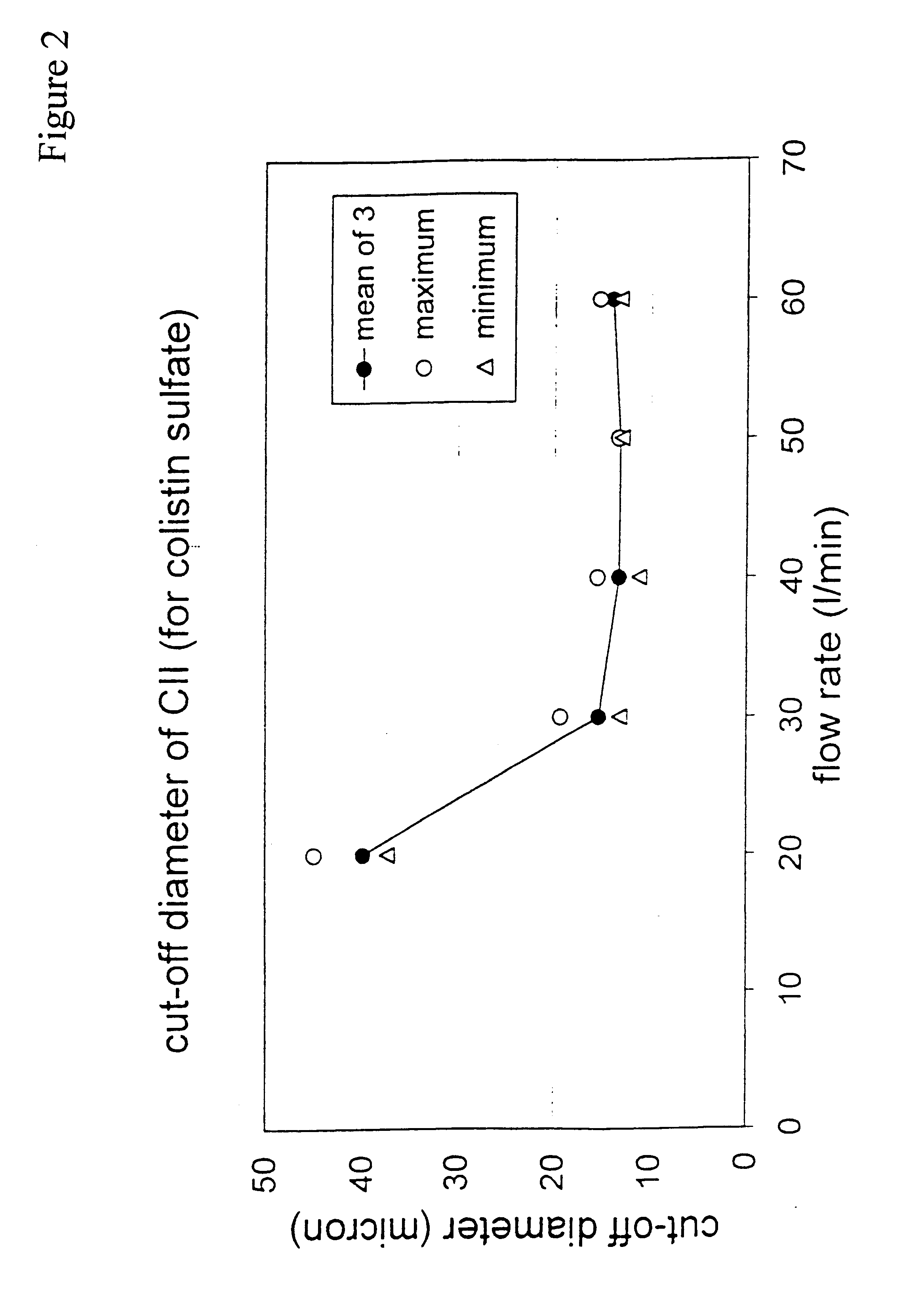

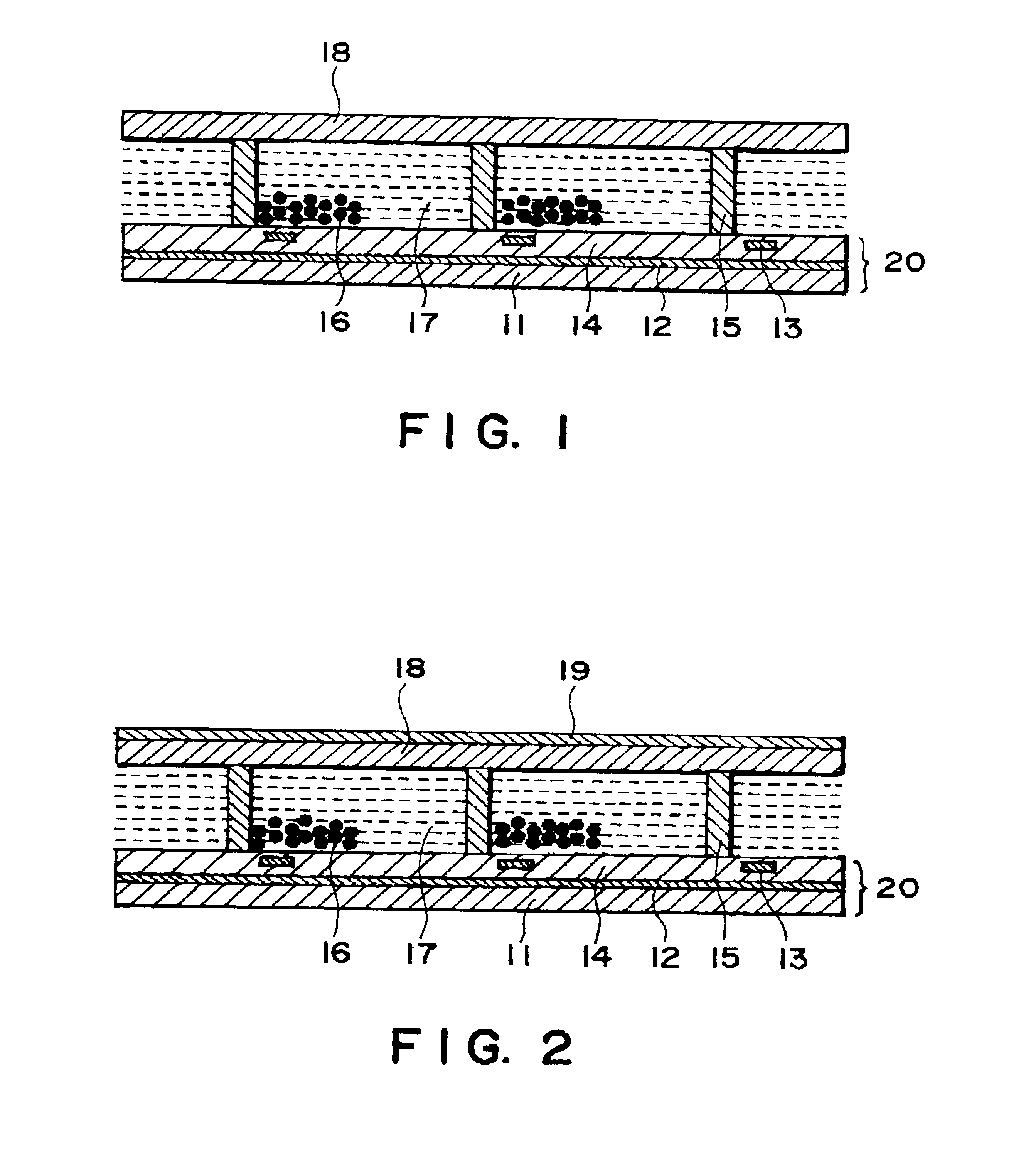

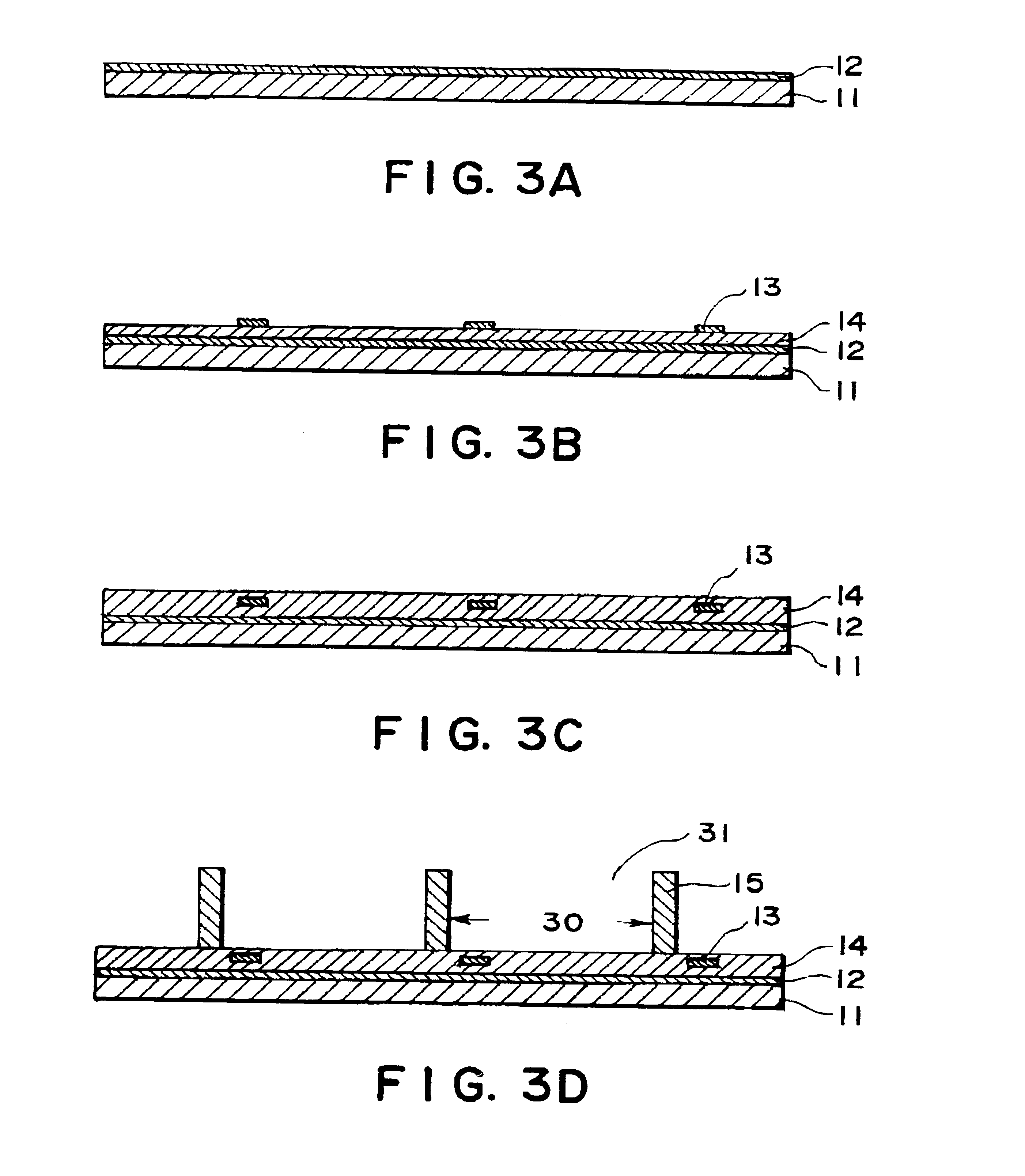

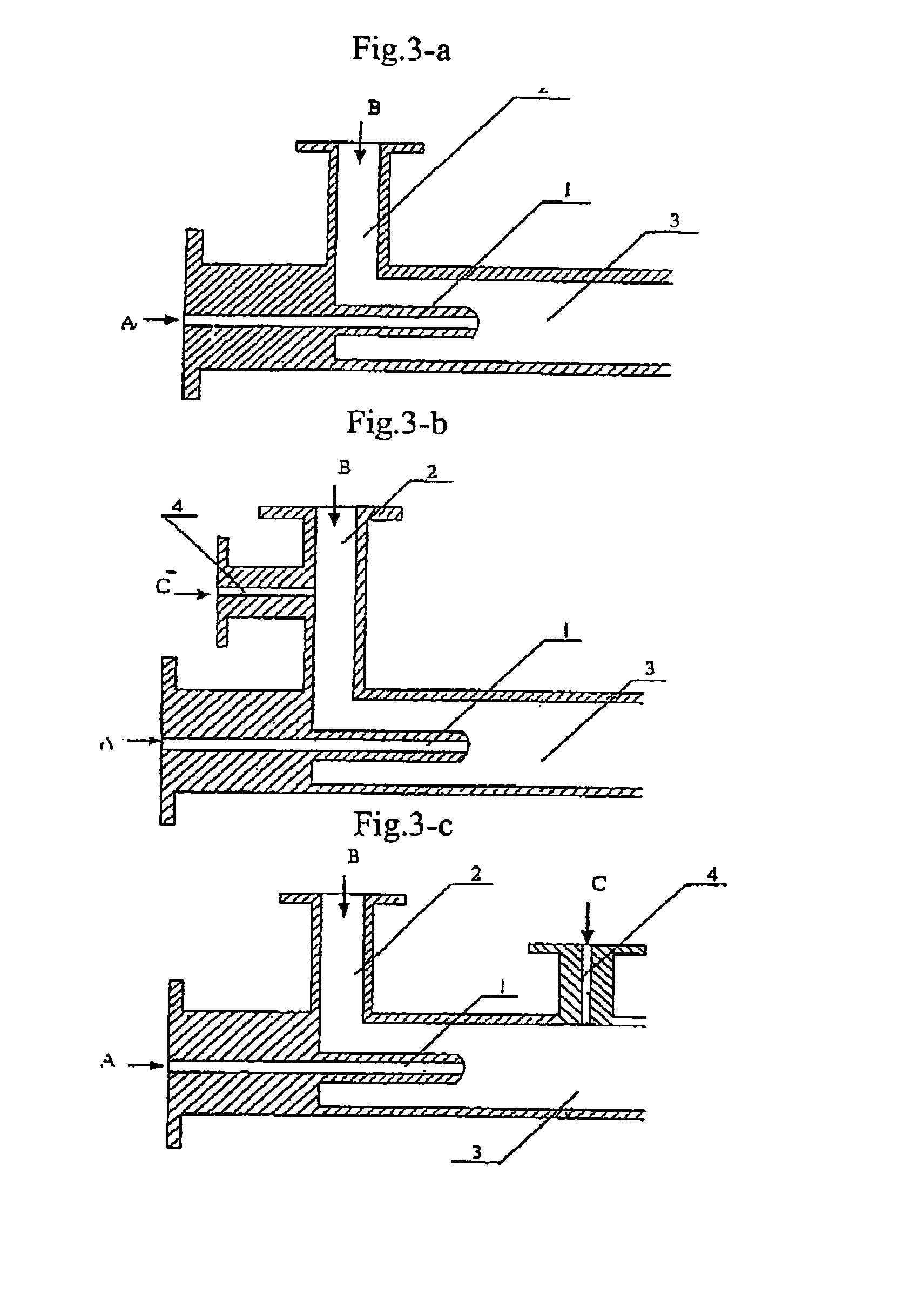

Powder formulation disintegrating system and method for dry powder inhalers

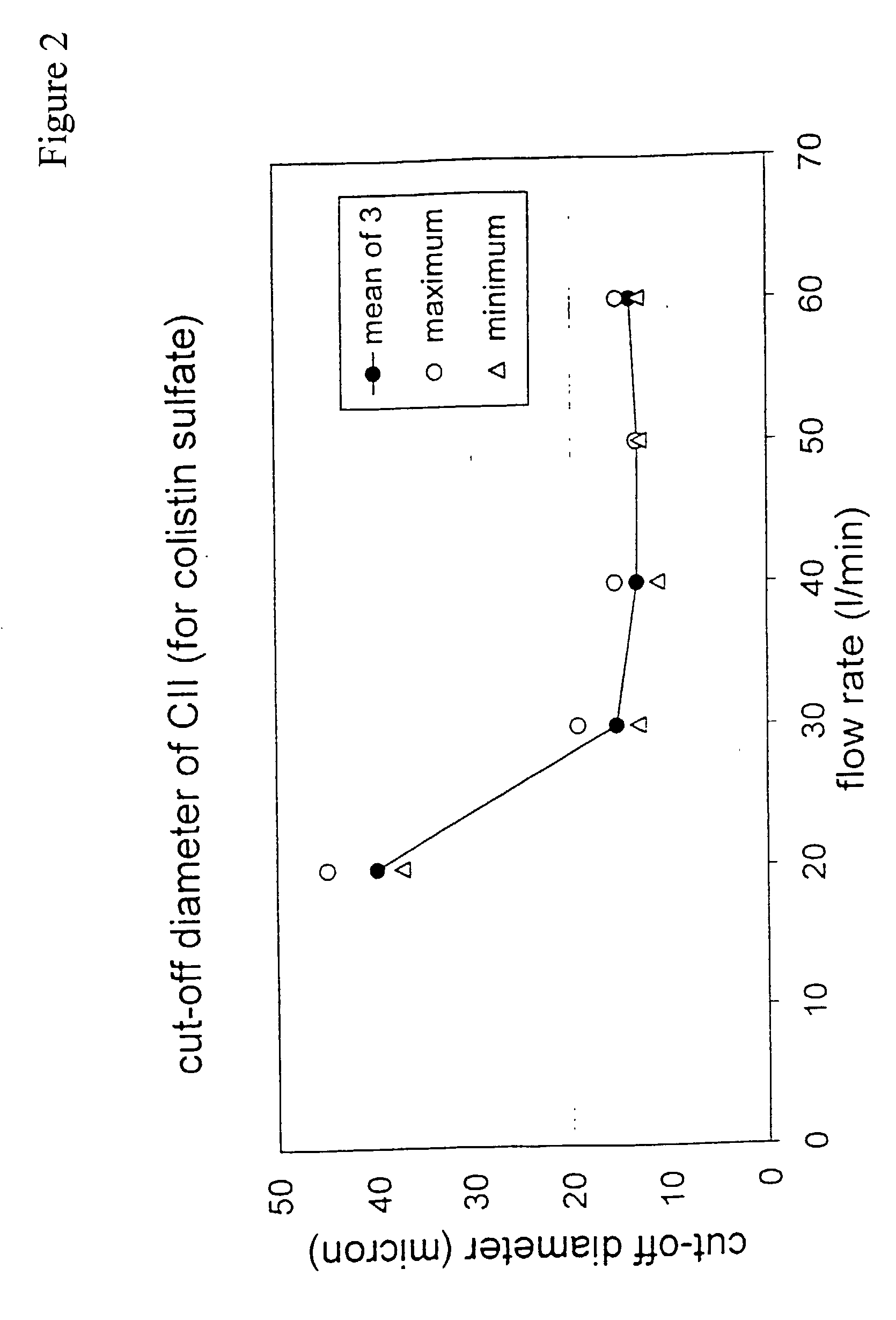

A disperser for dry powders which can be used with different dose systems, dose weights ranging from 2 to 25 mg and different types of powder formulation. In one embodiment, the disperser acts both as a de-agglomeration (disintegration; aerosolization) means and as an air classifier for especially adhesive mixtures. Only fine drug particles are emitted whereas the larger agglomerates and carrier crystals are retained by the disperser. Another embodiment enables time controlled release of carrier crystals in these mixtures. Yet another embodiment has optimized performance with spherical pellets, containing no carrier crystals. Other possible embodiments of the invention make it possible to control the total inhaler resistance and the powder deposition in the upper respiratory tract by means of the addition of a so-called sheath flow of clean air. Modifications also enable carrier retainment in the mouthpiece and elimination of the tangential flow component of the discharge cloud.

Owner:ASTRAZENECA AB

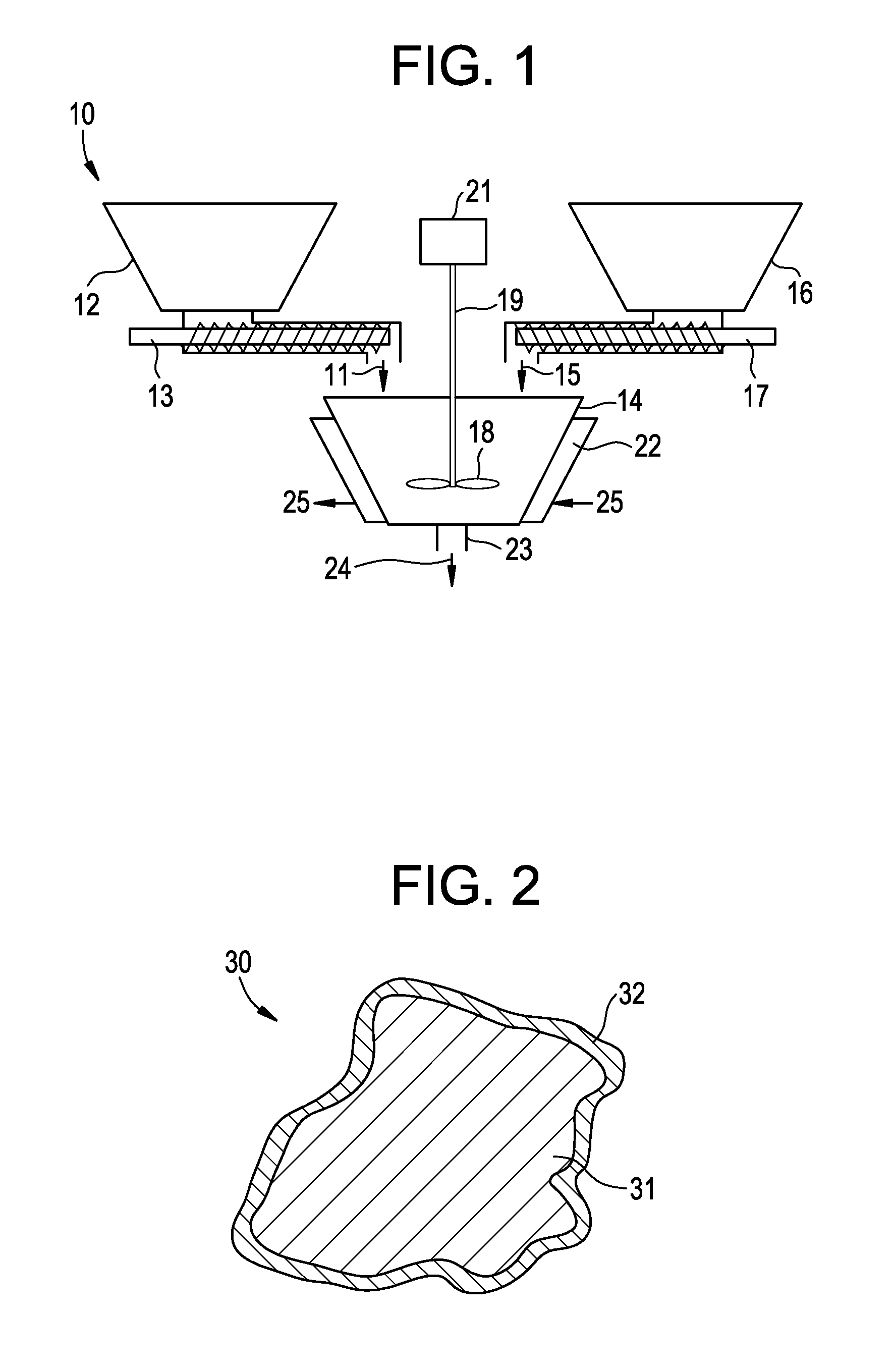

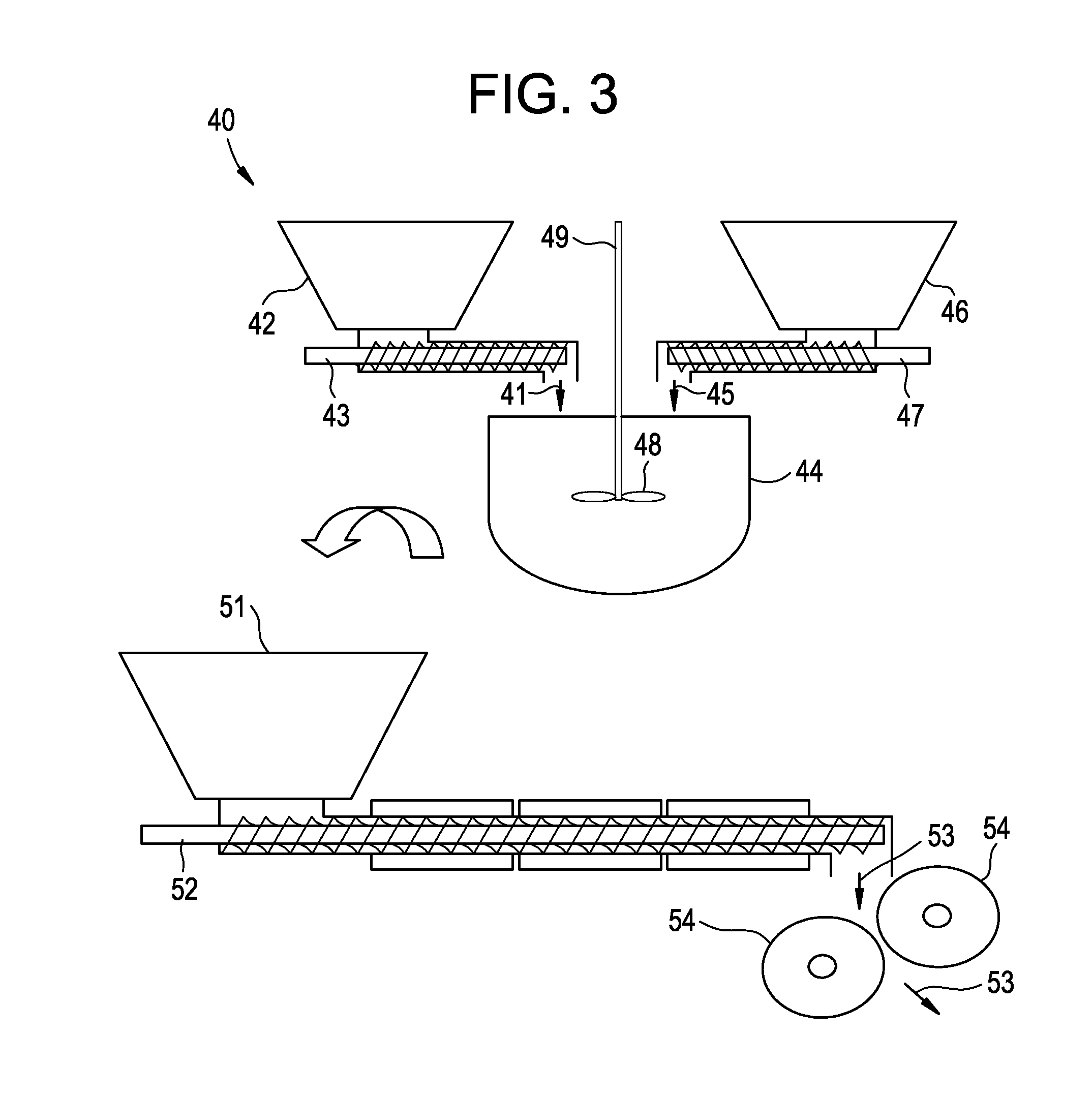

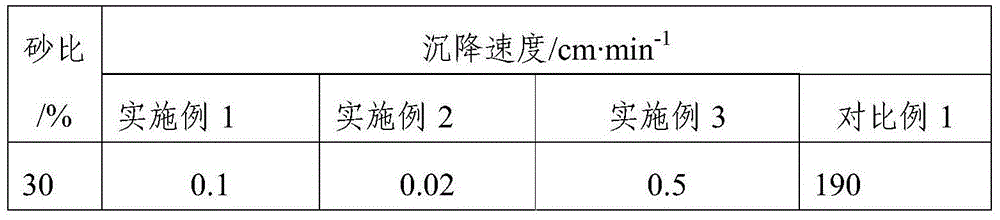

Lightweight proppant and method of making same

InactiveUS20060016598A1Manufactured usingSuitable viscosityFluid removalDrilling compositionPrillHigh intensity

A lightweight, high-strength proppant is disclosed, comprising the formation of finely dispersed ceramic precursors and sintering at low temperatures, causing the formation and retention of mesopores and micropores in pelletized ceramic. A method of manufacturing such a proppant is also disclosed, comprising the steps of manufacturing finely divided ceramic precursors and additives using grinding, milling, and preferably sol-gel processes, and dispersing the finely divided ceramic precursors and additives in a liquid, preferably water. The dispersion has a viscosity profile, which permits the shaping of spheres using conventional pelletizing techniques. Drying of the pellets and sintering at temperatures below 1,400.degrees. C. forms and retains mesopores and micropores in the ceramic. Preferred total pore volumes range from 0.05 to 0.7 cm.sup.3 / g. The pelletized and porous ceramic is useful as lightweight and high-strength proppants.

Owner:URBANEK THOMAS WILHELM

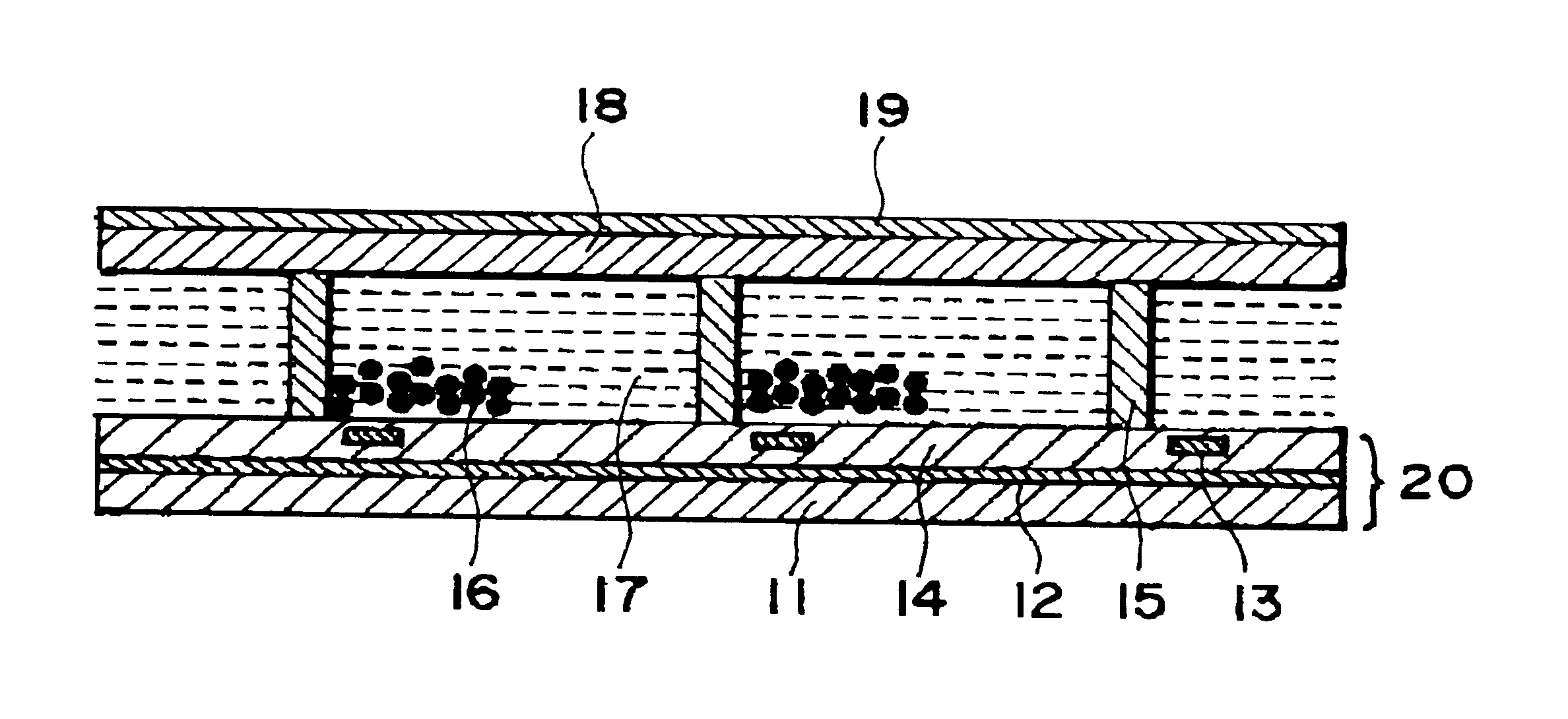

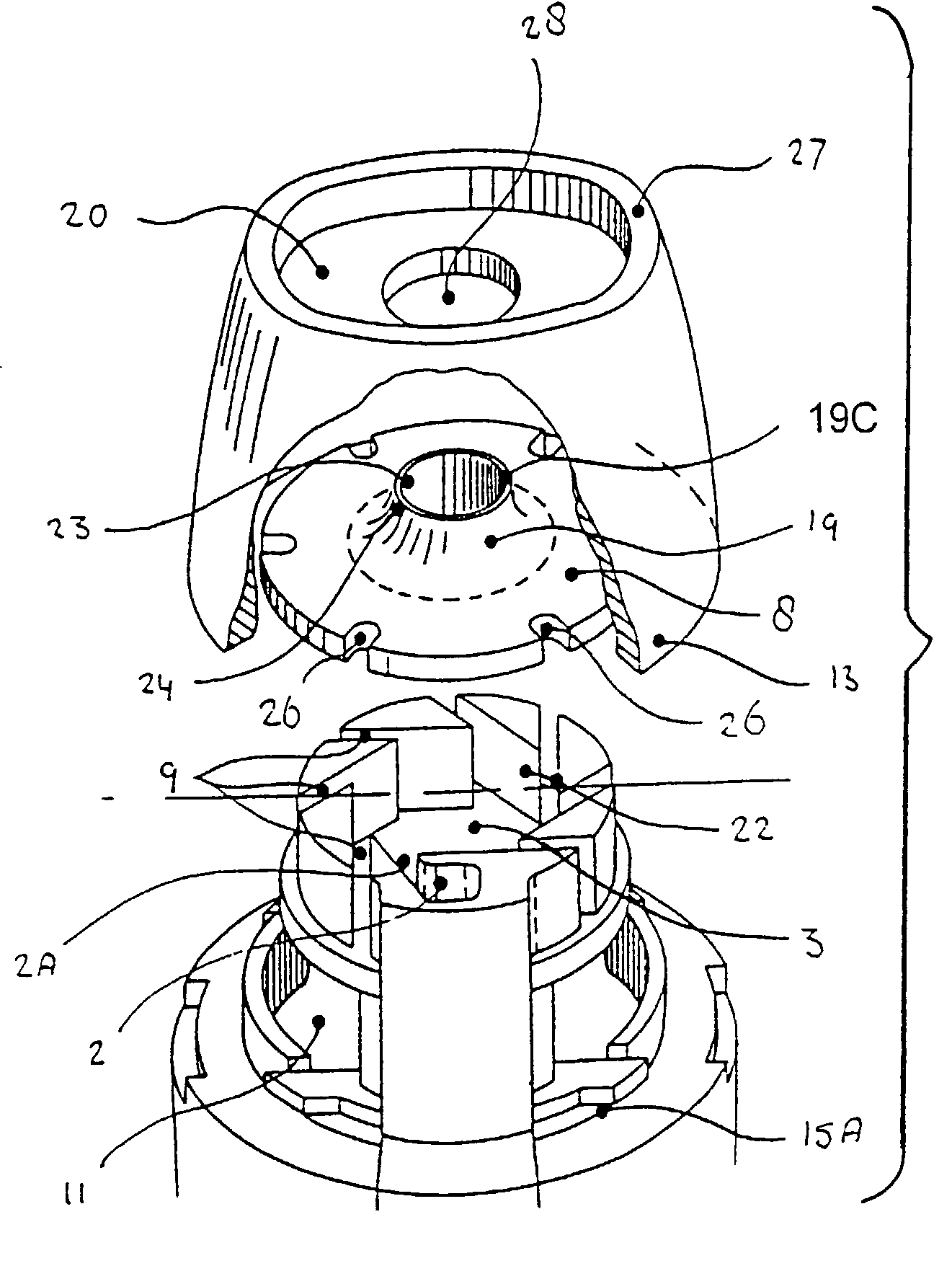

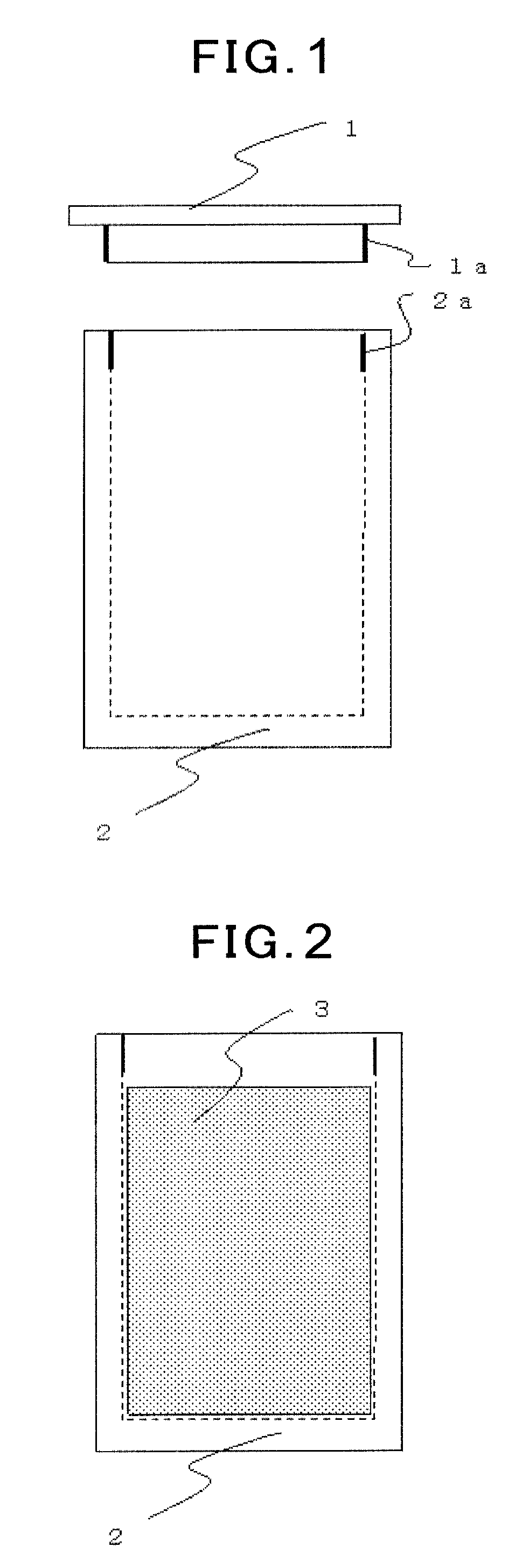

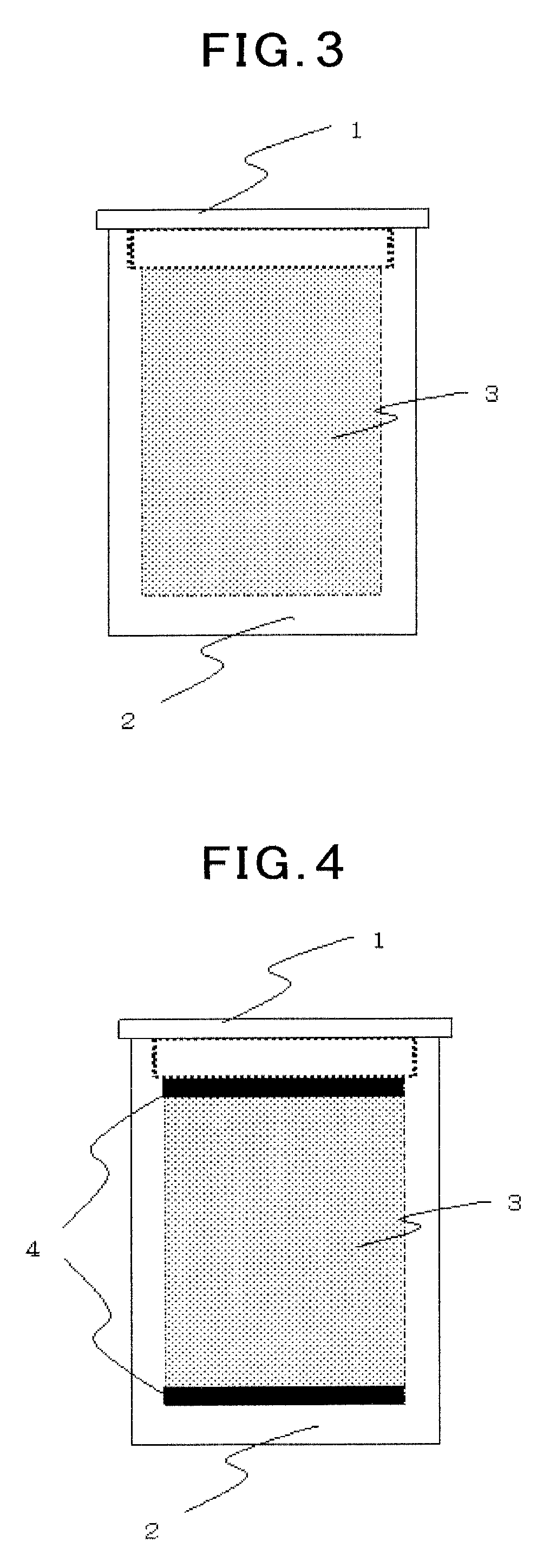

Electrophoretic display device and process for production thereof

A pliable electrophoretic display device having a deformation-resistant memory characteristic is provided by covering a plurality of partitioning walls defining display sections containing a dispersion liquid with electrophoretic particle dispersed therein with an expandable ceiling sheet. Such a ceiling sheet is formed by applying a hardenable precursor liquid, which is immiscible with the dispersion liquid, over the partitioning walls containing the dispersion liquid and hardening the precursor liquid in situ by exposure to light, heat or by drying.

Owner:CANON KK

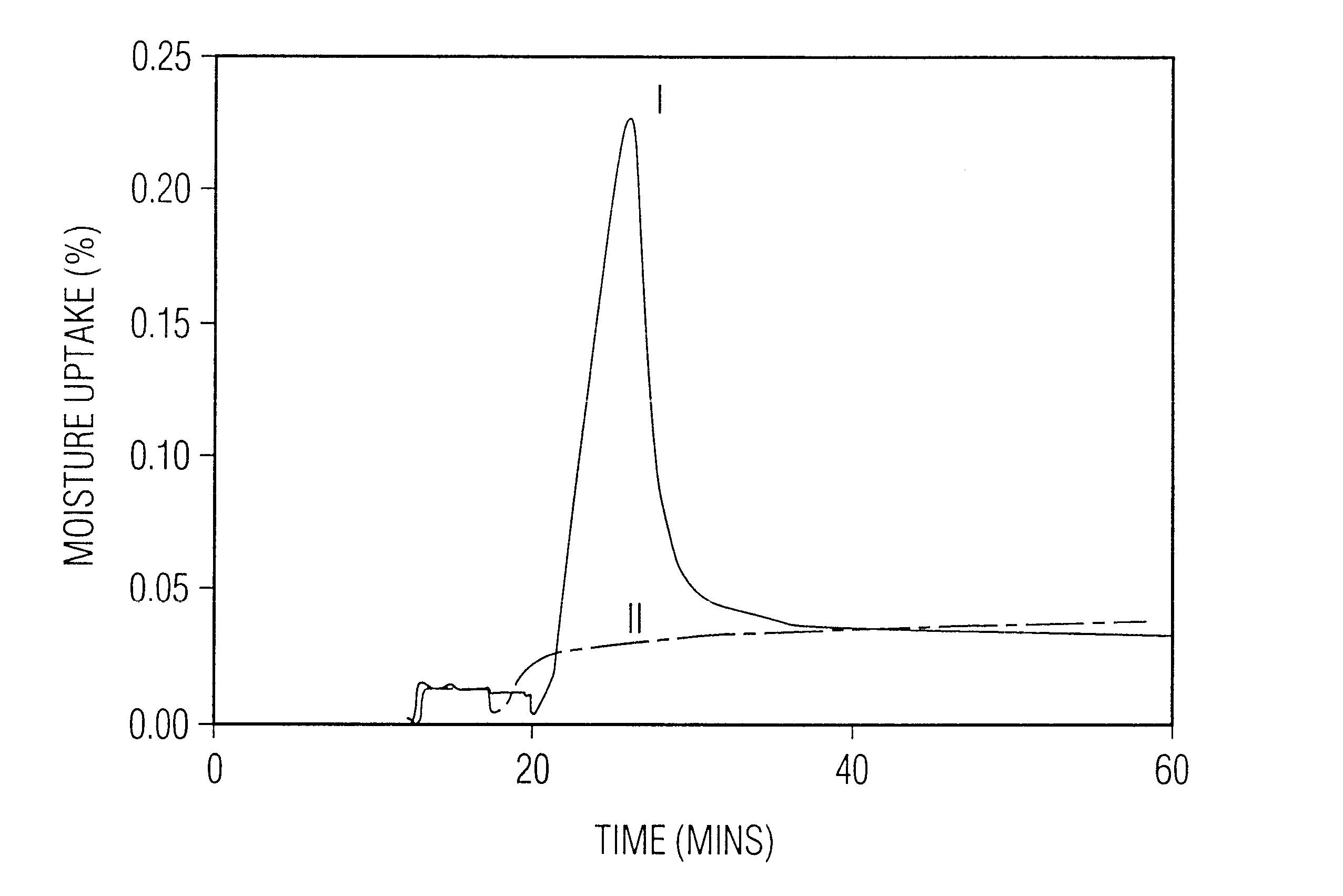

Powder formulation disintegrating system and method for dry powder inhalers

A disperser for dry powders which can be used with different dose systems, dose weights ranging from 2 to 25 mg and different types of powder formulation. In one embodiment, the disperser acts both as a de-agglomeration (disintegration; aerosolization) means and as an air classifier for especially adhesive mixtures. Only fine drug particles are emitted whereas the larger agglomerates and carrier crystals are retained by the disperser. Another embodiment enables time controlled release of carrier crystals in these mixtures. Yet another embodiment has optimized performance with spherical pellets, containing no carrier crystals. Other possible embodiments of the invention make it possible to control the total inhaler resistance and the powder deposition in the upper respiratory tract by means of the addition of a so-called sheath flow of clean air. Modifications also enable carrier retainment in the mouthpiece and elimination of the tangential flow component of the discharge cloud.

Owner:ASTRAZENECA AB

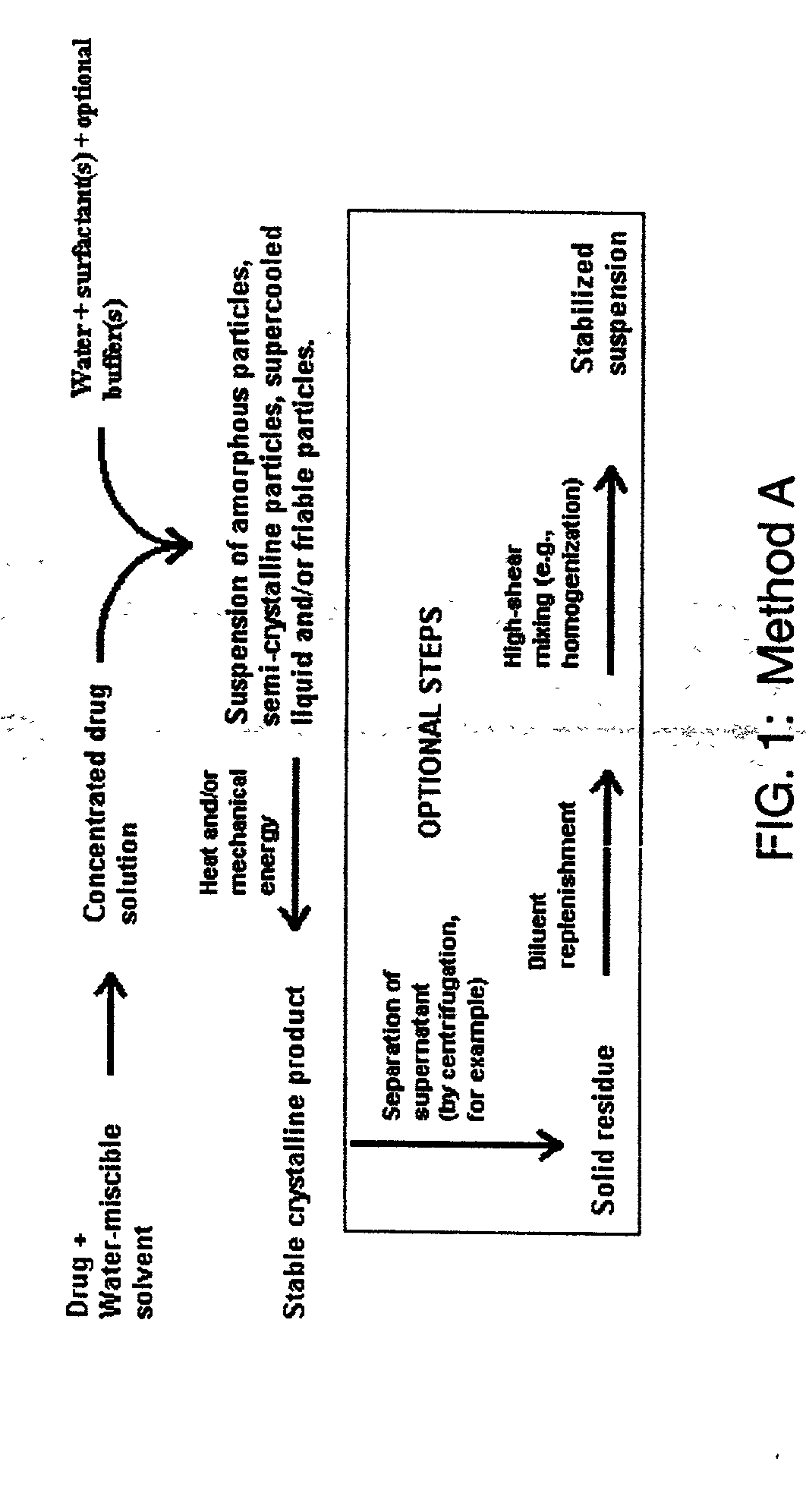

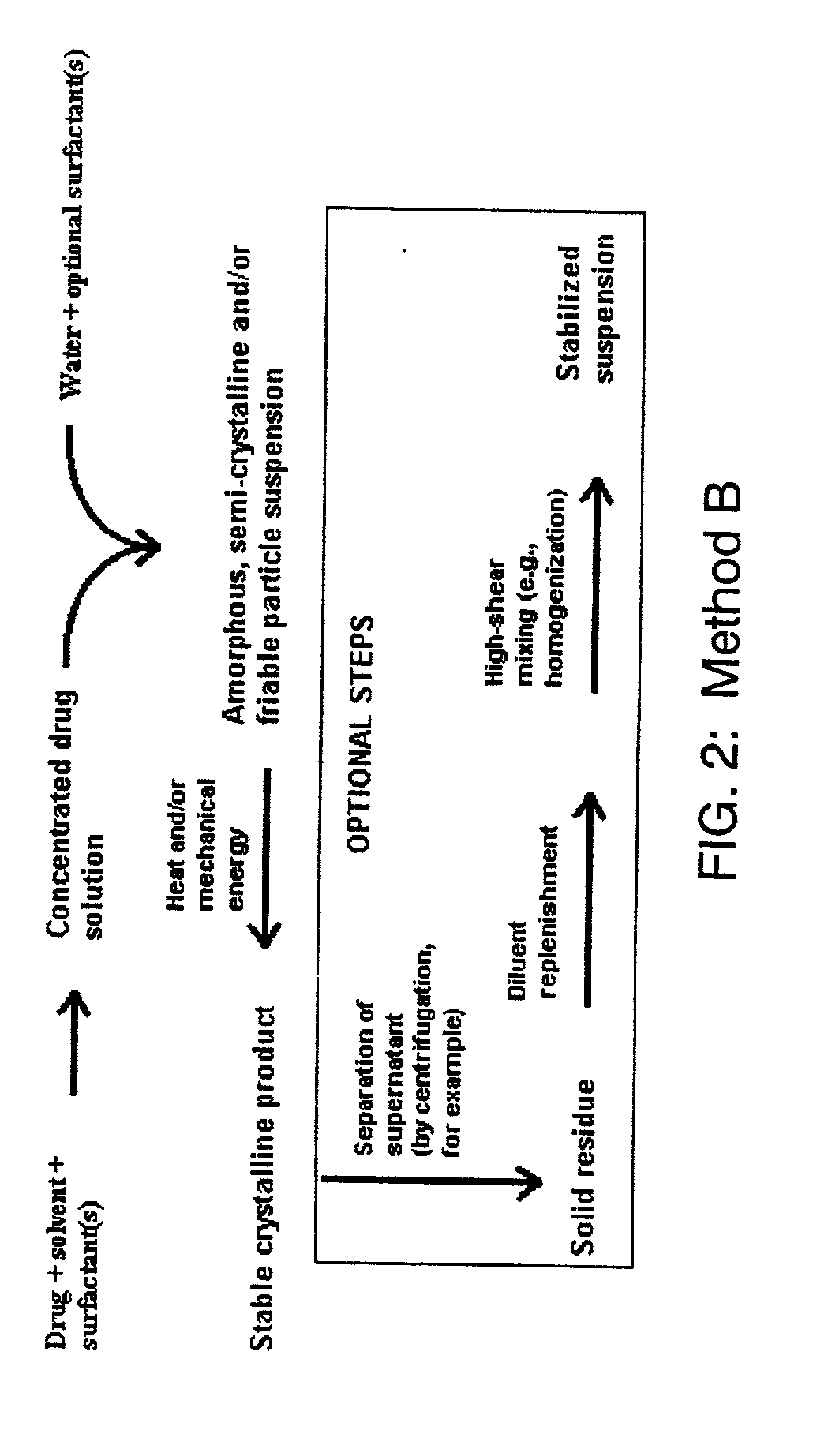

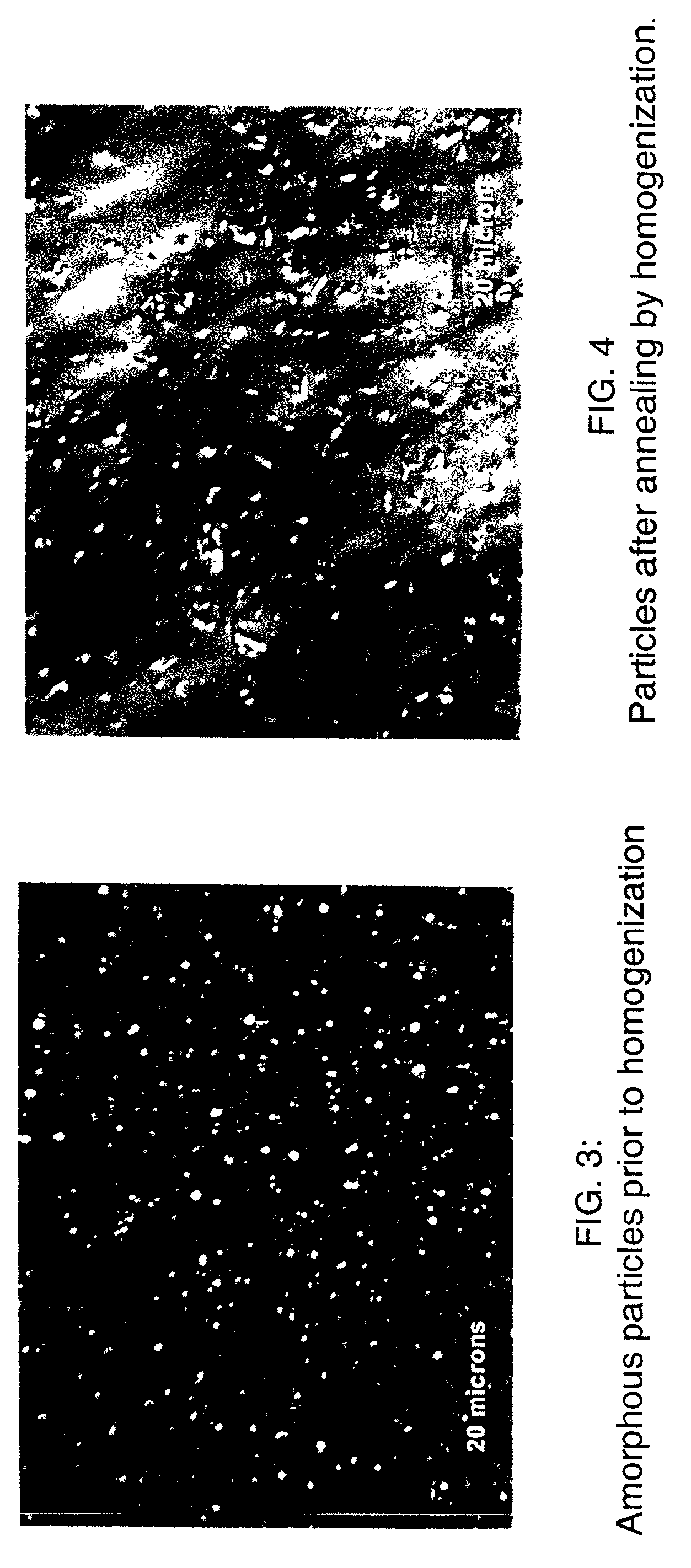

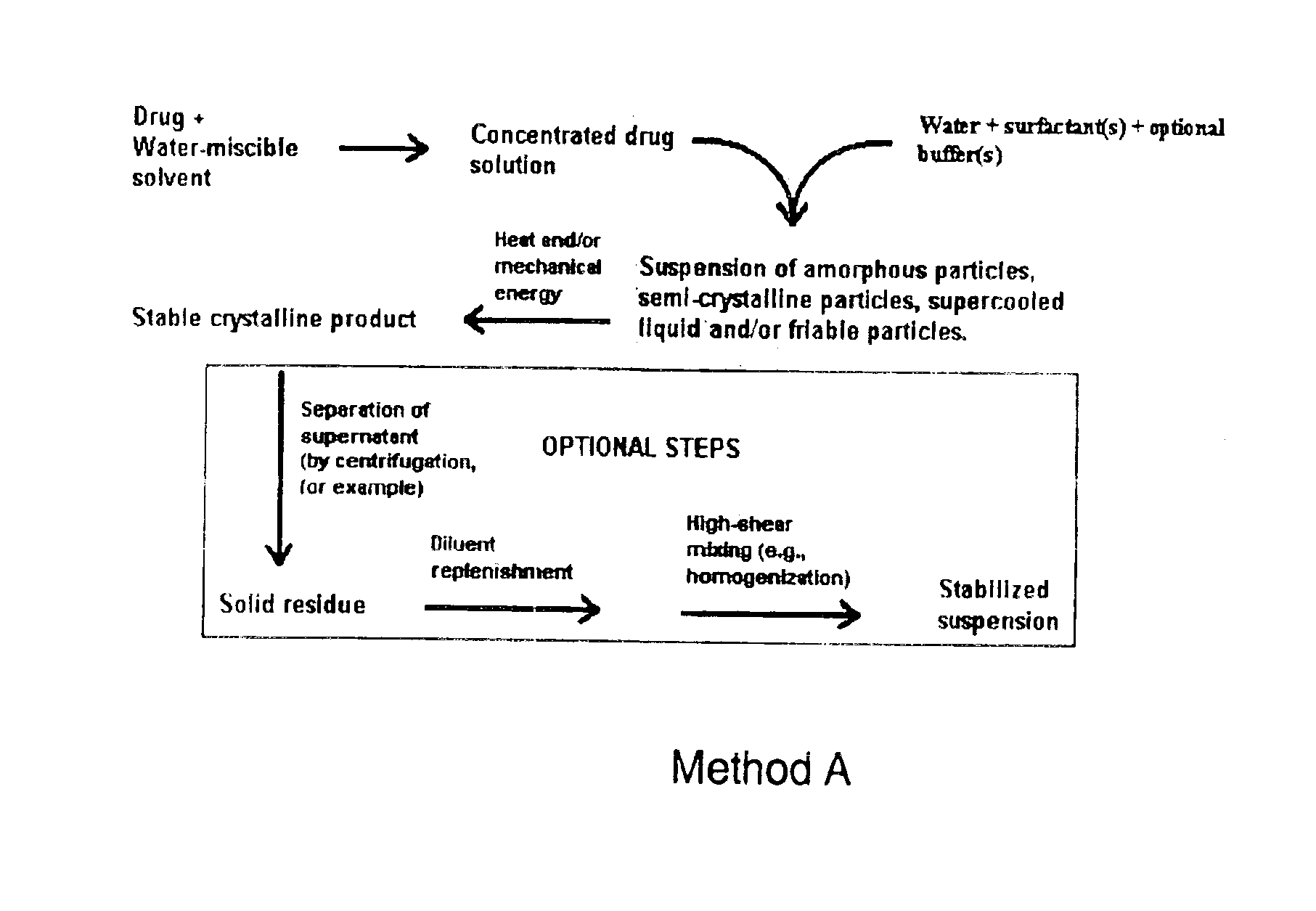

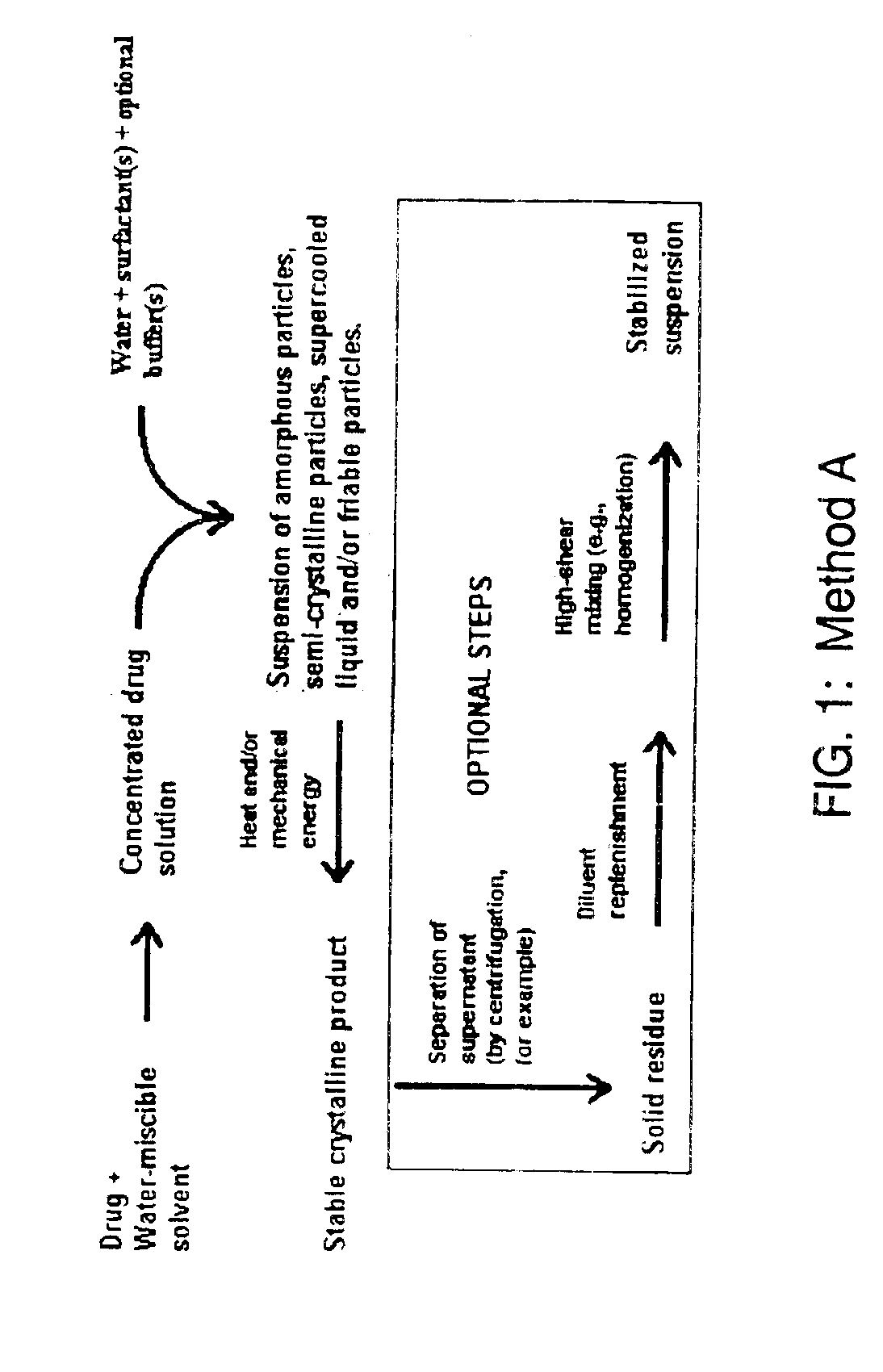

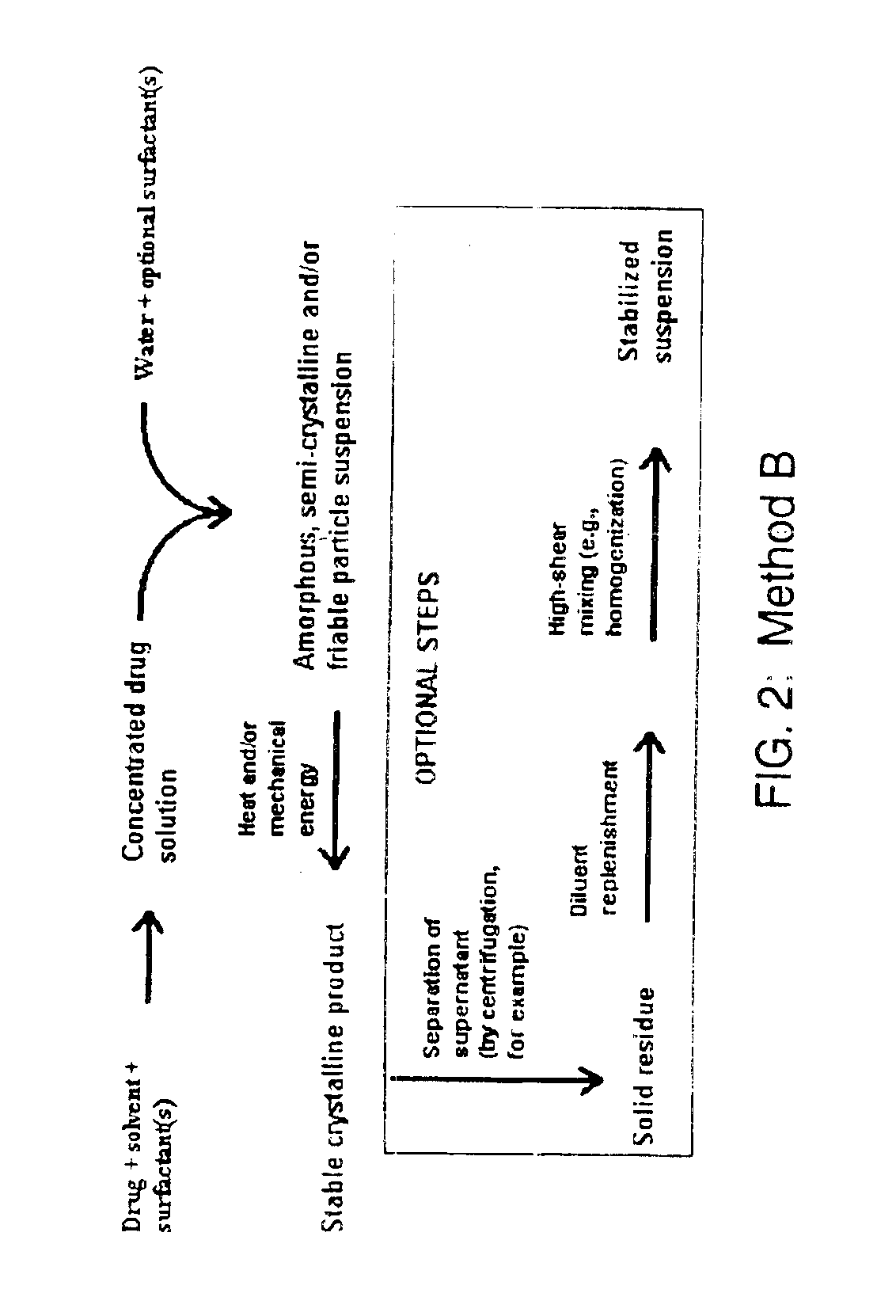

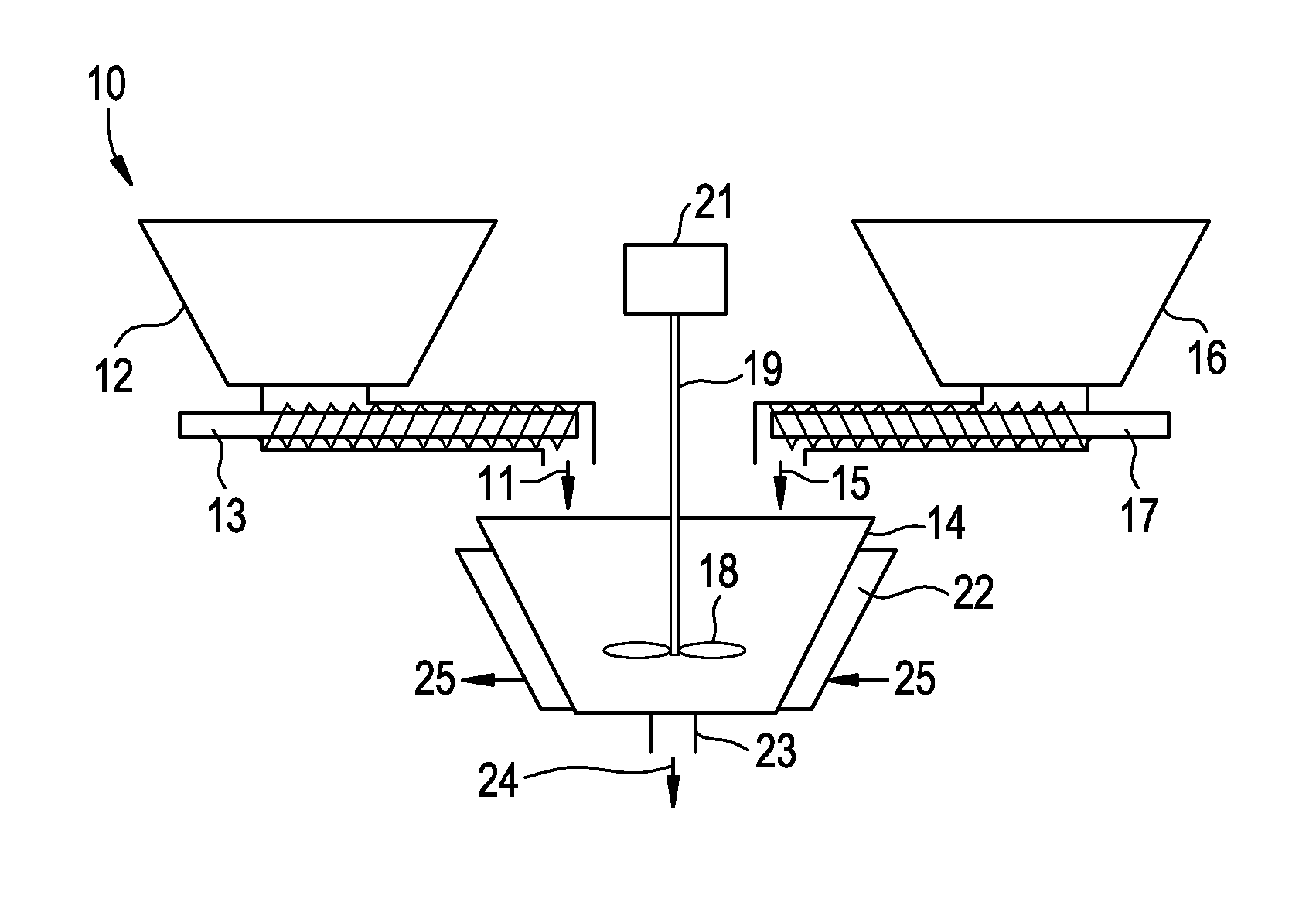

Microprecipitation method for preparing submicron suspensions

InactiveUS20020127278A1Carry-out quickly and efficientlyOrganic active ingredientsPowder deliverySolubilitySimple Organic Compounds

The present invention provides a method for preparing submicron sized particles of an organic compound, the solubility of which is greater in a water-miscible first solvent than in a second solvent which is aqueous, the process including the steps of: (i) dissolving the organic compound in the water-miscible first solvent to form a solution, (ii) mixing the solution with the second solvent to define a pre-suspension; and (iii) adding energy to the pre-suspension to form particles having an average effective particle size of 400 nm to 2 microns.

Owner:BAXTER INT INC

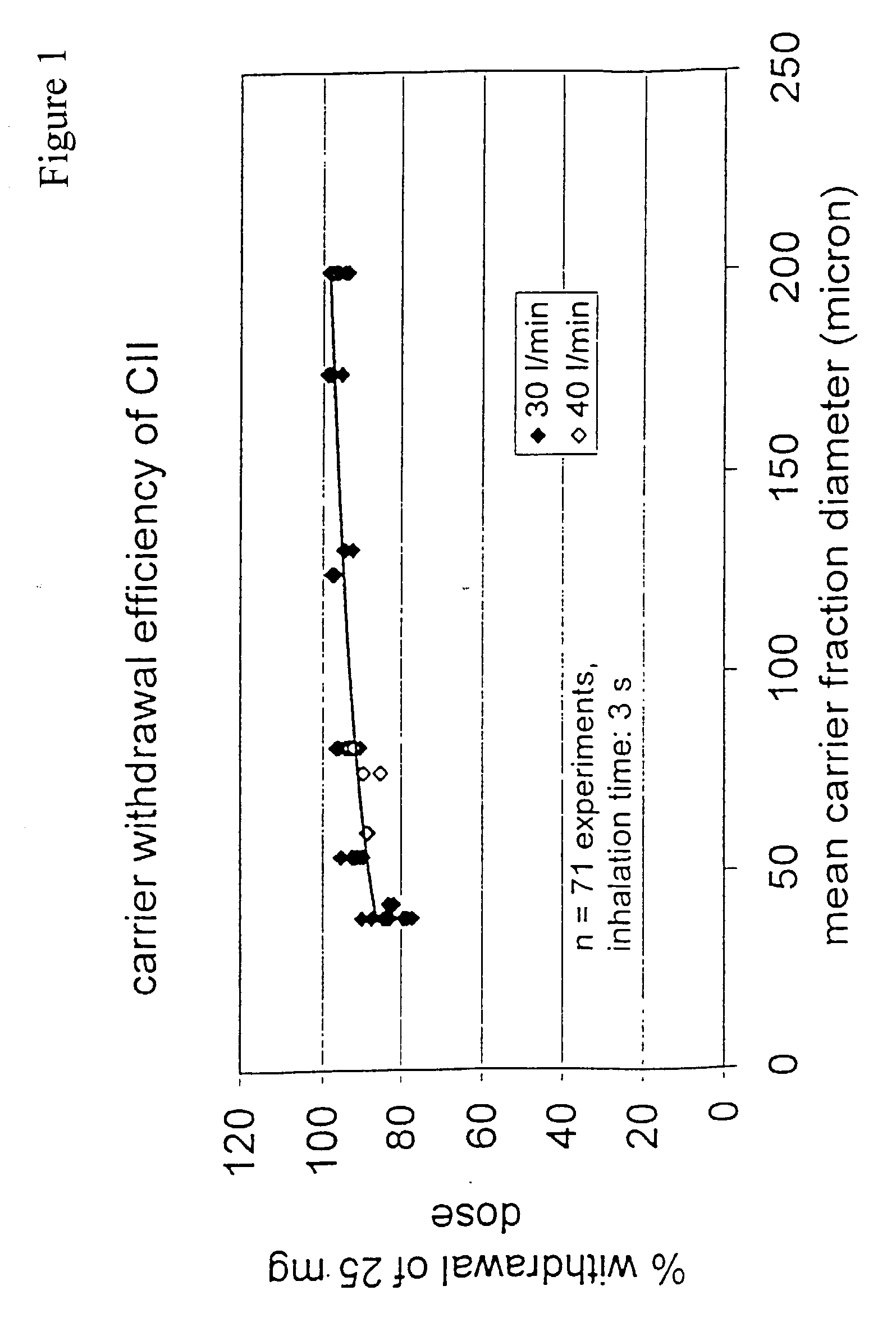

Pharmaceutical formulations for dry powder inhalers in the form of hard-pellets

InactiveUS20030180227A1Reduce intensityEfficient deliveryPowder deliveryDispersion deliveryPrillInhalation

The invention provides a formulation to be administered as dry powder for inhalation suitable for efficacious delivery of active ingredients into the low respiratory tract of patients suffering of pulmonary diseases such as asthma. In particular, the invention provides a formulation to be administered as dry powder for inhalation freely flowable, which can be produced in a simple way, physically and chemically stable and able of delivering either accurate doses and high fine particle fraction of low strength active ingredients by using a high- or medium resistance device.

Owner:CHIESI FARM SPA

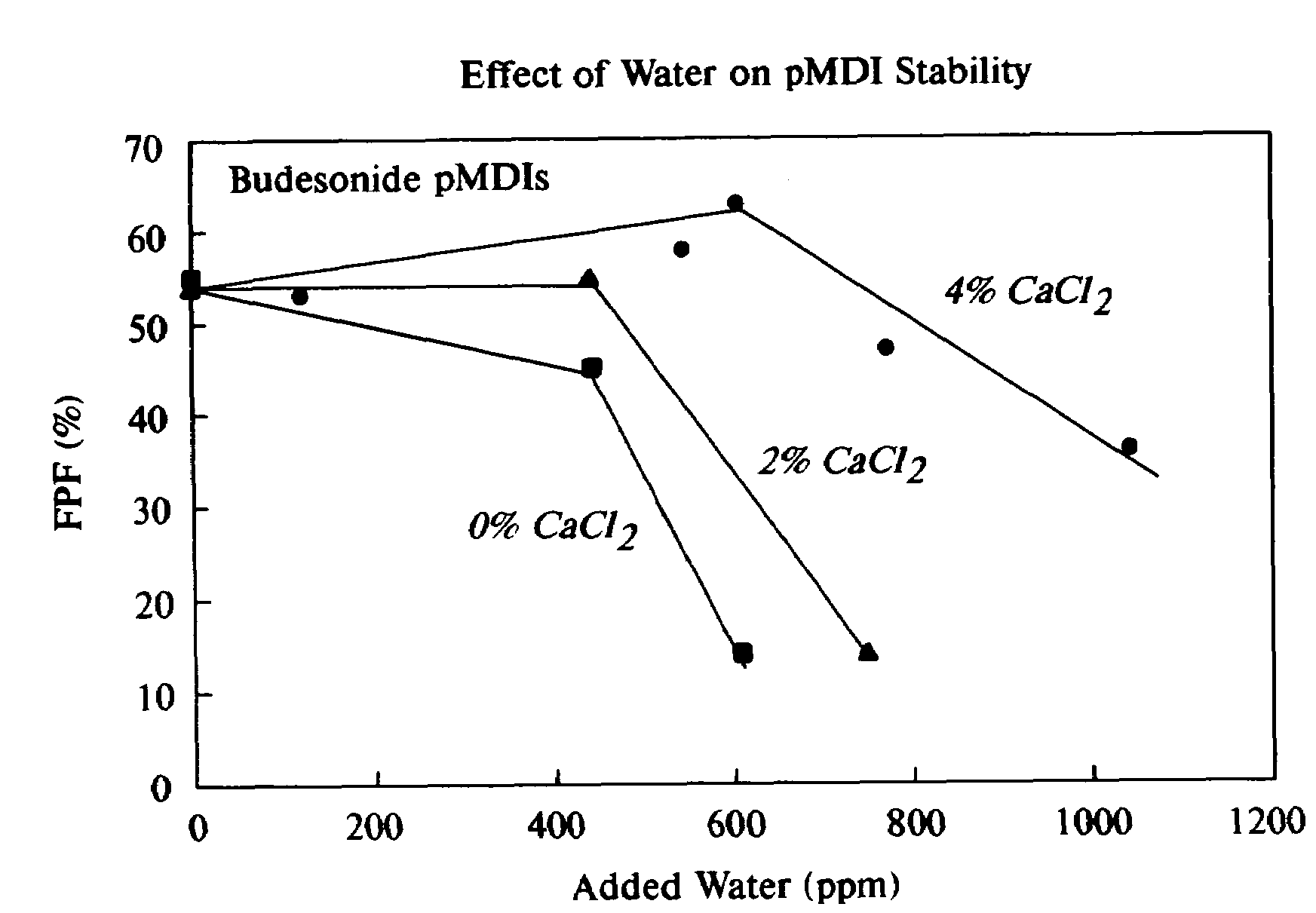

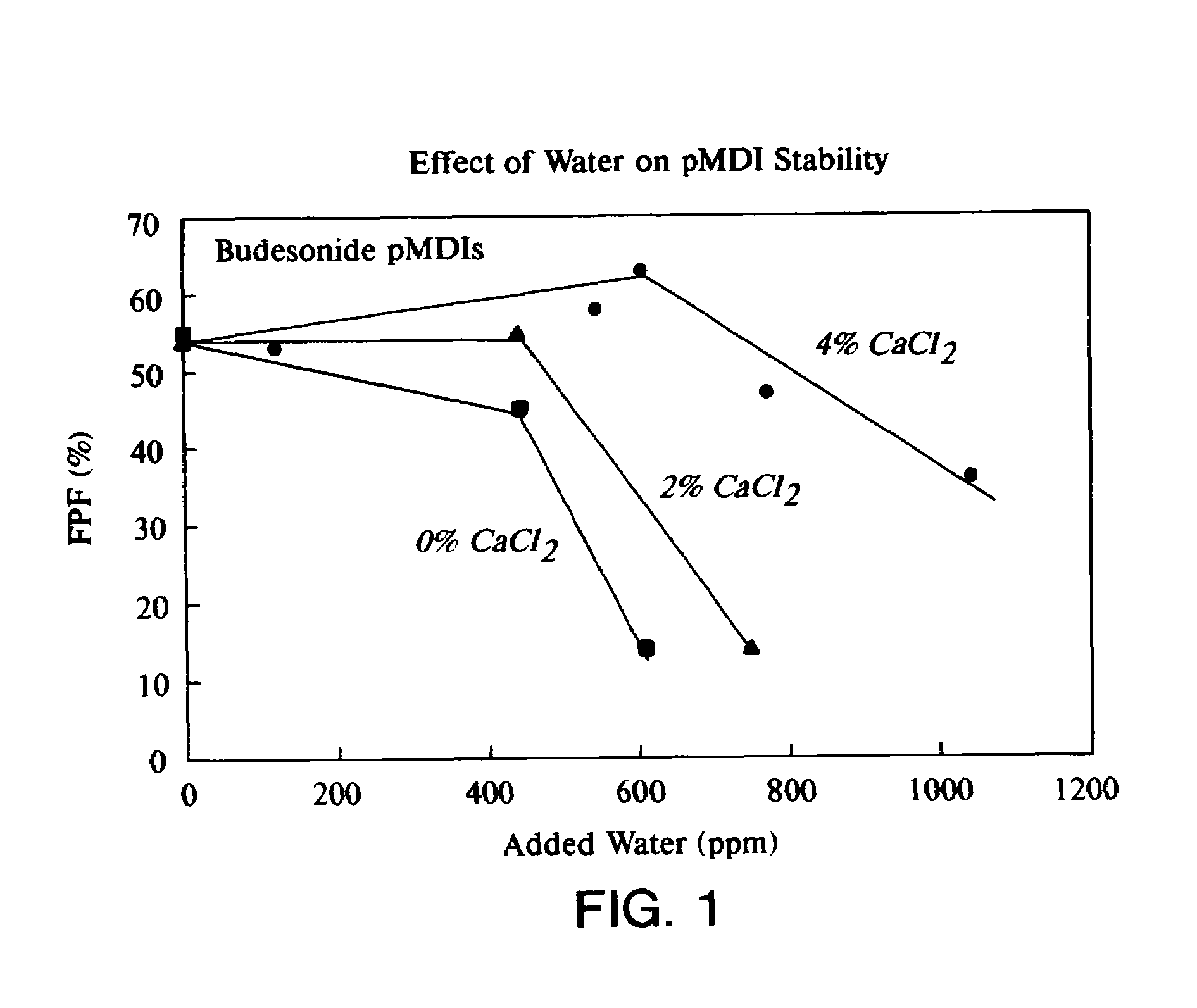

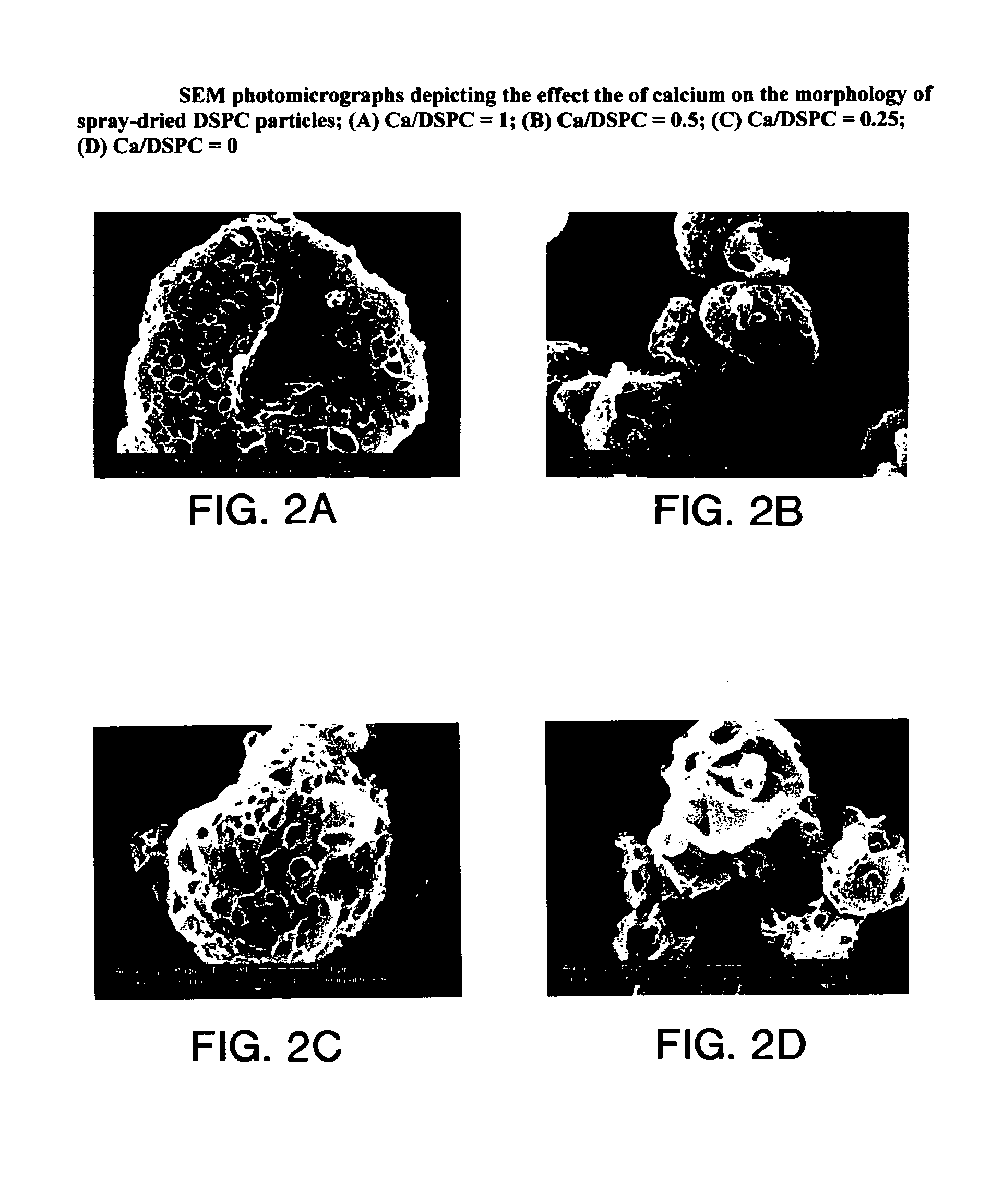

Phospholipid-based powders for drug delivery

InactiveUS7442388B2Raise the inlet temperatureRaise the outlet temperaturePowder deliveryBiocidePrillMedicine

Phospholipid based powders for drug delivery applications are disclosed. The powders comprise a polyvalent cation in an amount effective to increase the gel-to-liquid crystal transition temperature of the particle compared to particles without the polyvalent cation. The powders are hollow and porous and are preferably administered via inhalation.

Owner:NOVARTIS AG

Microprecipitation method for preparing submicron suspensions

InactiveUS6869617B2Carry-out quickly and efficientlyOrganic active ingredientsPowder deliverySolubilitySimple Organic Compounds

The present invention provides a method for preparing submicron sized particles of an organic compound, the solubility of which is greater in a water-miscible first solvent than in a second solvent which is aqueous, the process including the steps of: (i) dissolving the organic compound in the water-miscible first solvent to form a solution, (ii) mixing the solution with the second solvent to define a pre-suspension; and (iii) adding energy to the pre-suspension to form particles having an average effective particle size of 400 nm to 2 microns.

Owner:BAXTER INT INC

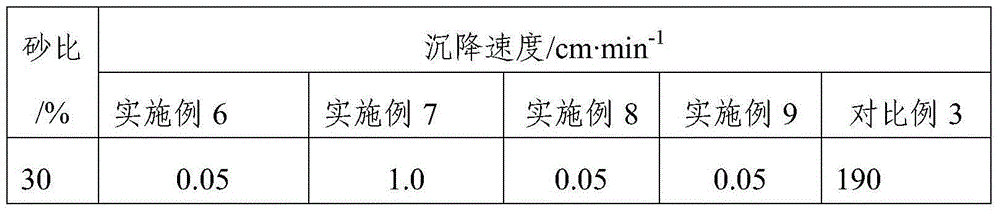

Method for treating and regenerating reuse building waste

ActiveCN101099974AAvoid excessive cement slurry contentAvoid Excessive Water DemandSolid waste managementSolid waste disposalPrillBrick

The present invention discloses building waste treating and reusing process, which includes the following steps: classifying building wastes into waste concrete, waste stone material, waste ceramic, waste sintered brick and waste lime-sand brick; crushing separately into coarse grains and eliminating metal, timber and other impurity; milling into 5 mm below regenerated fine aggregate; sorting 0.15 mm below high quality fine aggregate and milling into regenerated fine powder material of 250-600 sq m / kg specific surface area; and preparing mortar, concrete, asphalt concrete and other building material with the regenerated fine aggregate and the regenerated fine powder.

Owner:SOUTH CHINA UNIV OF TECH

Powder coated proppant and method of making the same

A process for producing a proppant particulate substrate having a coating layer thereon including the step of blending a proppant particulate substrate with a powder coating composition at a temperature sufficient to cause the powder coating composition to coat the proppant particulate substrate with a powder coating; and a proppant particulate substrate coated by such a process.

Owner:DOW GLOBAL TECH LLC

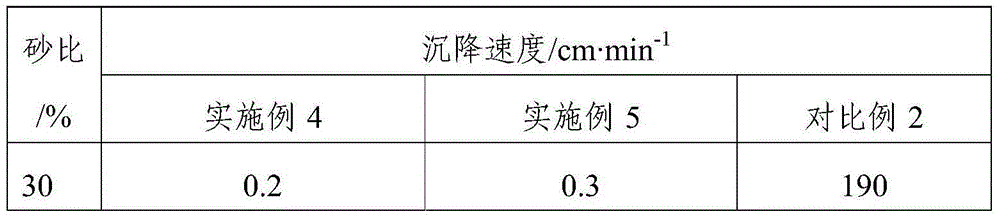

Preparation method of self-suspension proppant for natural hydrofracturing construction

The invention provides a preparation method of a self-suspension proppant for natural hydrofracturing construction, which comprises the following steps: by using 6-200-mesh granules as aggregate, adding an adhesive solution accounting for 10-30 wt% of the aggregate into the aggregate, and adding a water-soluble high polymer material accounting for 0.1-5 wt% of the aggregate; and stirring uniformly, drying and screening. The optimal selection of the raw materials and technological conditions greatly enhances the mechanical properties of the proppant. The obtained proppant has the advantages of small friction resistance and high strength, can be suitable for high-temperature conditions, and can be easily recovered; and the used coating material can not cause environmental pollution.

Owner:BEIJING RECHSAND SCI & TECH GRP

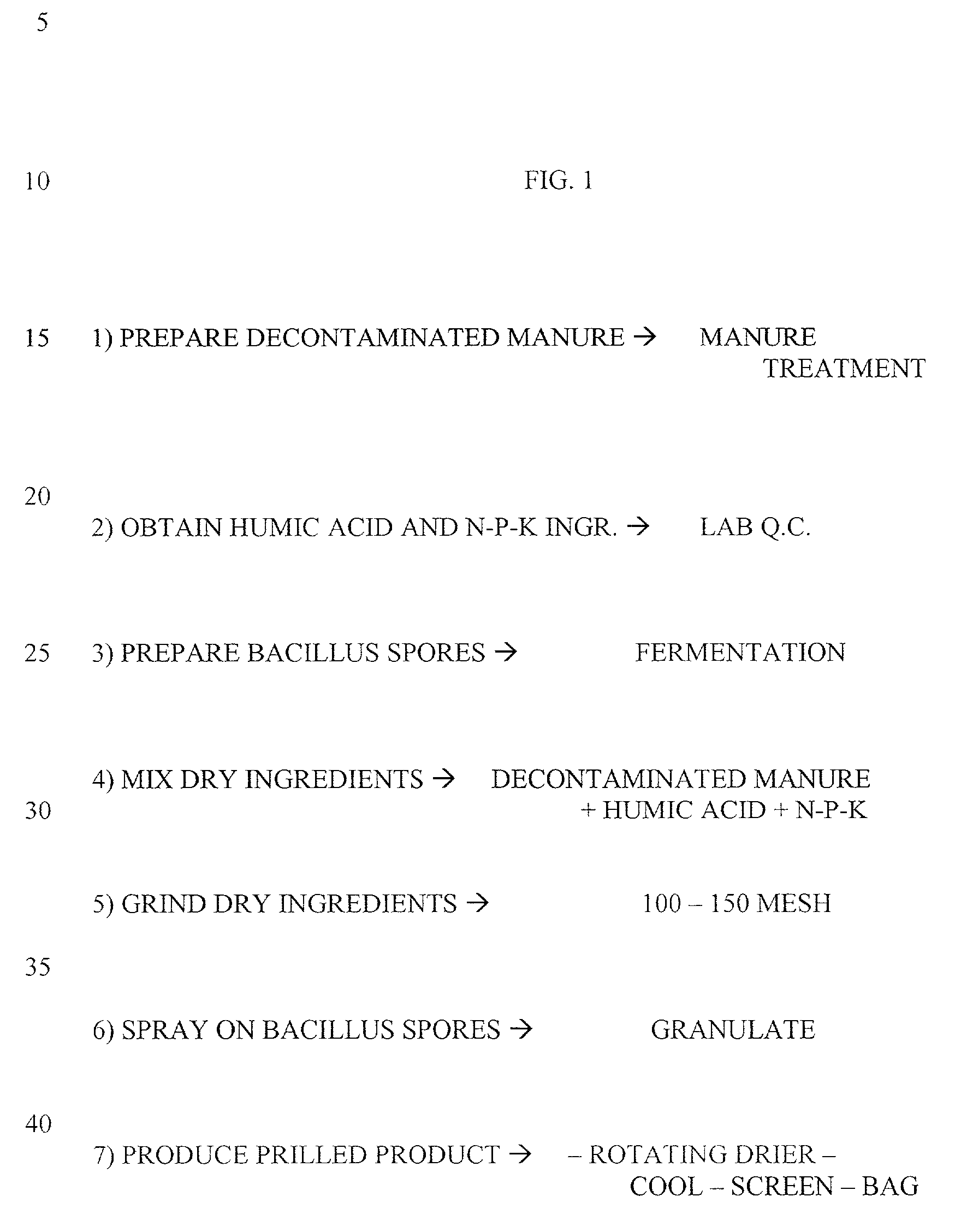

Fertilizer compositions and methods of making and using same

Fertilizer compositions for plant production are described, comprised of decontaminated manure and Bacillus spores, preferably a humic acid derived from lignite and, optionally, one or more of N compounds, P compounds, K compounds, and combinations of two or more of these compounds. Preferred compositions are those wherein the ingredients are blended into an admixture resulting in a granular product. Other preferred compositions are those blended into an admixture resulting in a powdered product. Preferably, the ingredients are formed into hardened prills or pellets. Processes for production and use are also presented.

Owner:MICROBES

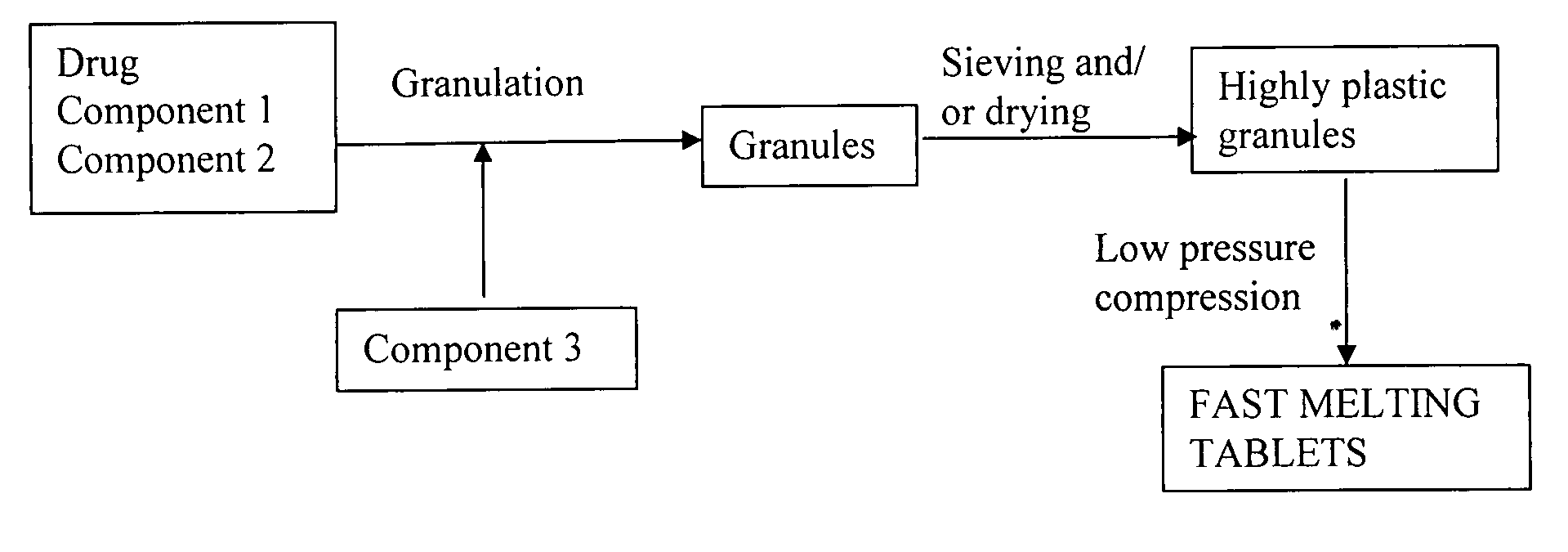

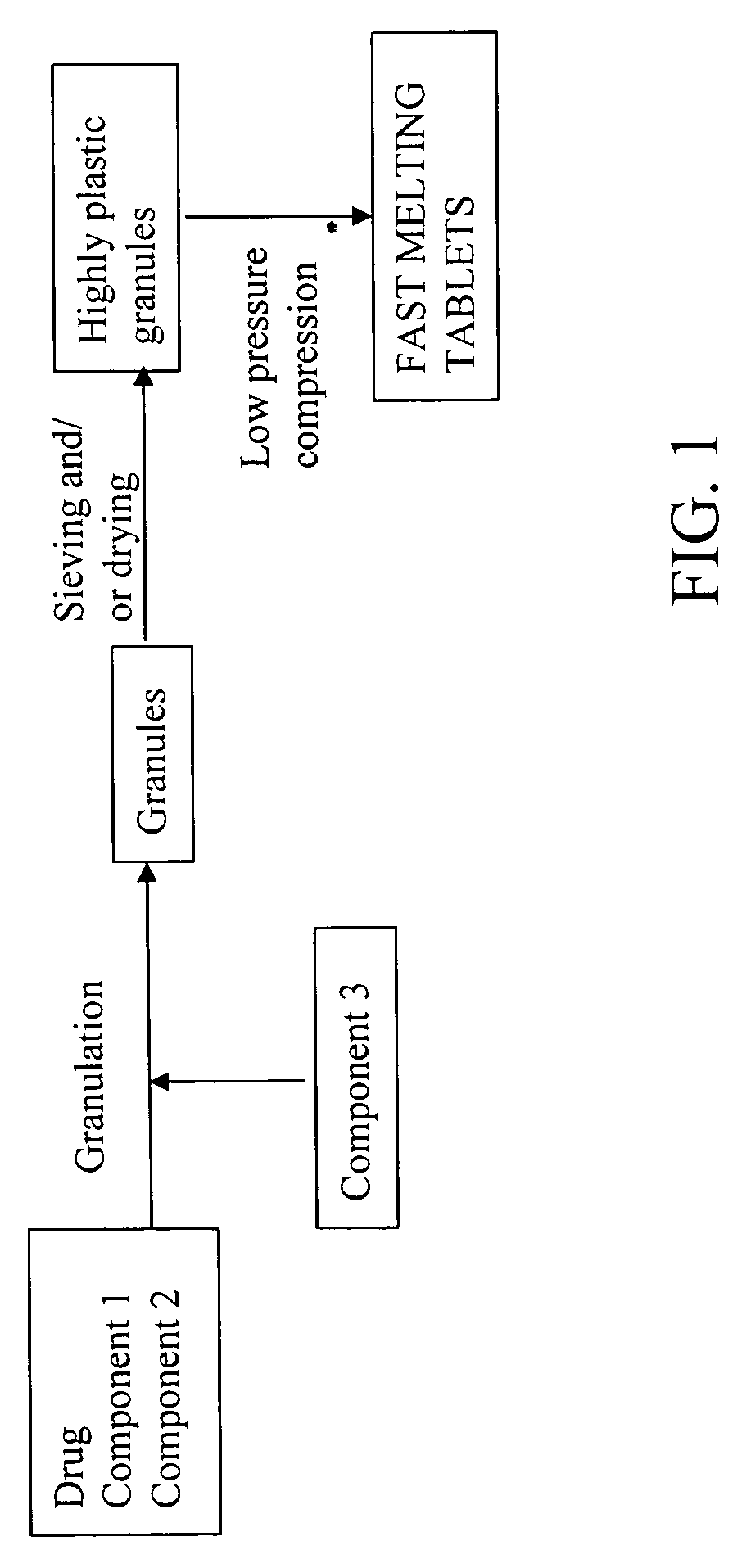

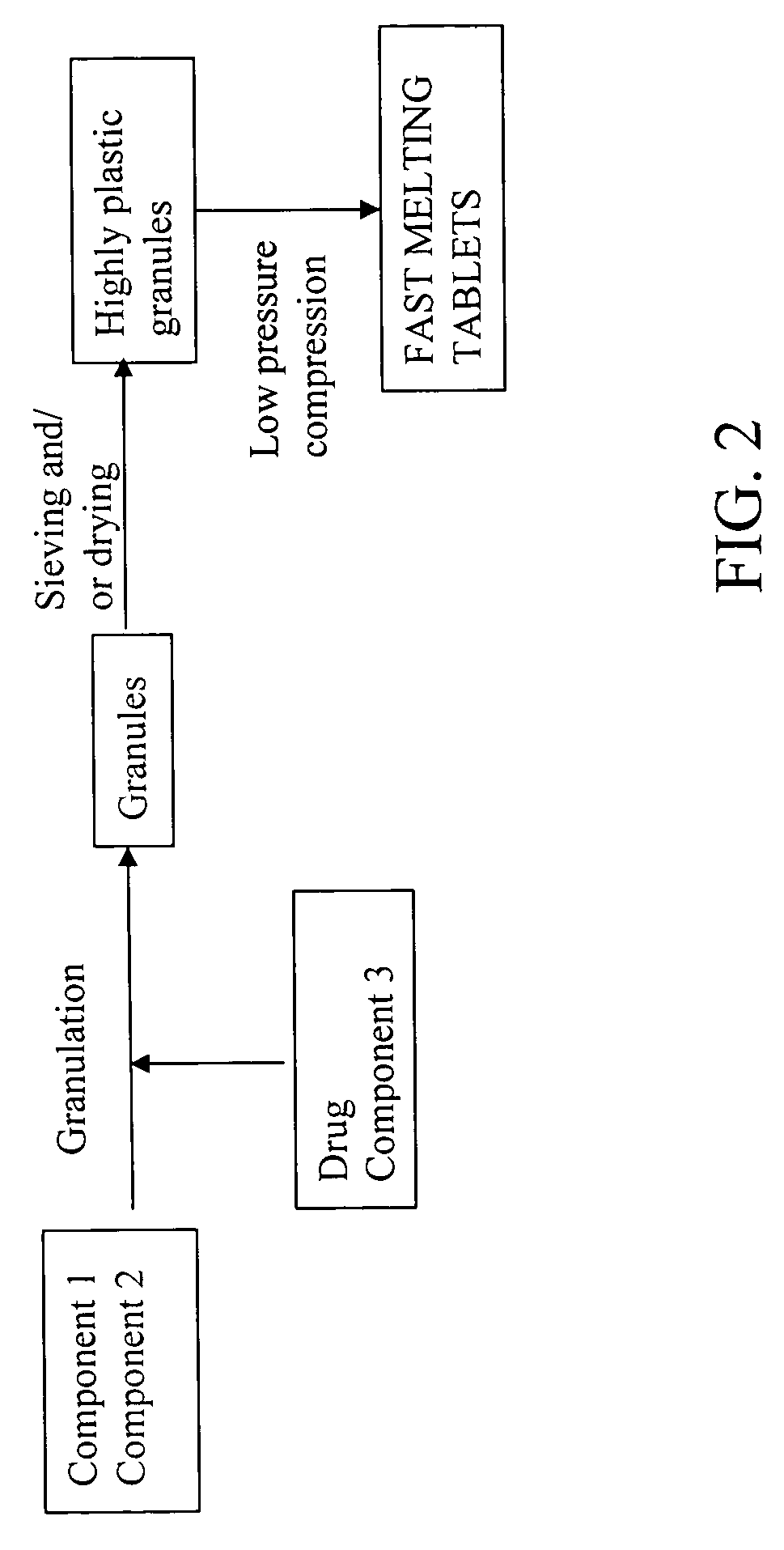

Highly plastic granules for making fast melting tablets

A fast-melting pharmaceutical tablet comprises a porous, plastic substance, a water penetration enhancer and a binder. One or more drugs can be incorporated into the formulation at different stages of the process so as to afford a pharmaceutically active tablet. Methods of making the pharmaceutical tablet entail combining the porous, plastic material, the water penetration enhancing agent, and the binder so as to form highly plastic granules, which are compressed into tablets. The resulting tablets dissolve rapidly in the mouth and have good hardness with low brittleness. The tablets are particularly valuable to those who have difficulty swallowing conventional pills.

Owner:AKINA INC

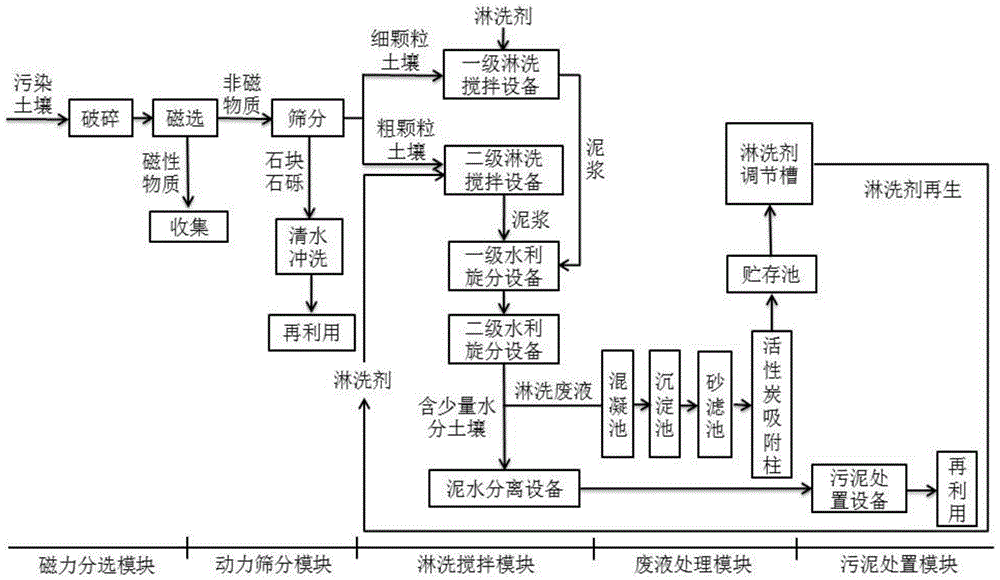

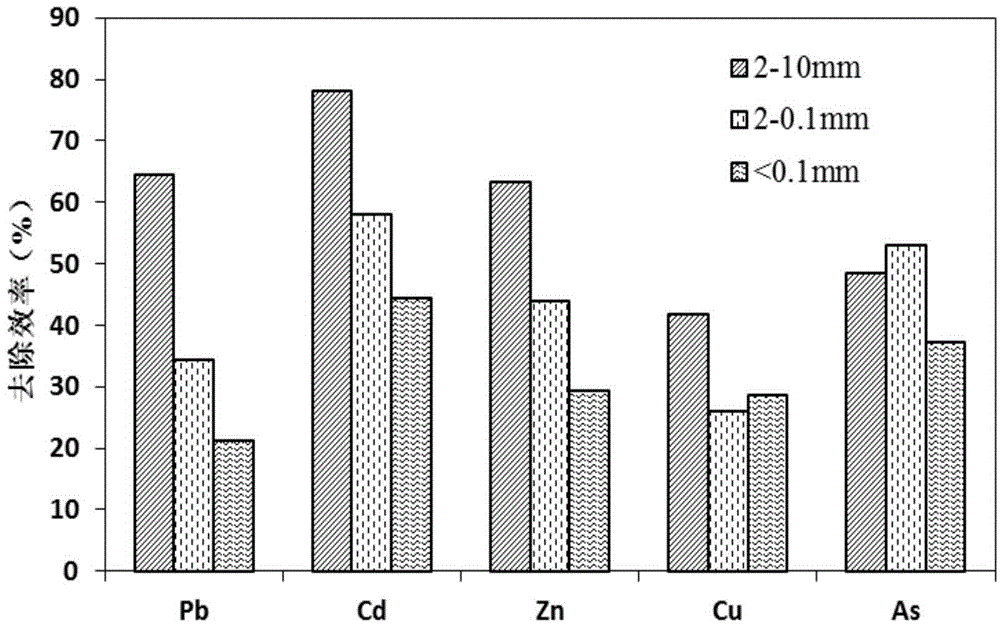

Ectopic classification leaching repair complete process of arsenic and heavy metal contaminated soil

ActiveCN104889149ASolve the regeneration problemSolve the recycling problemContaminated soil reclamationCyclonePrill

The invention discloses an ectopic classification leaching repair complete process of arsenic and heavy metal contaminated soil. The repair process comprises the following steps: the contaminated soil is magnetically separated to extract and recover target metals; a nonmagnetic component is divided into three grades by a vibrating screen after being primarily crushed; stones and boulders are flushed by clear water to directly serve as building materials; thick and fine soil particles obtained through screening respectively enter second-grade leaching mixing equipment for washing; the solid-liquid separation is performed for mud generated by washing through a two-stage hydraulic cyclone device; leaching waste liquid is purified and regenerated for recycling; sludge is added with such repair materials as curing / stabilizing agents for safety treatment after being dehydrated; and after the treatment, the soil particles can be backfilled, or can serve as roadbeds, building materials and the like. Based on the characteristic of large difference of arsenic and heavy metal contents in soils with different particle sizes, the soil leaching treatment according to the particle size is performed, so that the process has such advantages as low repair cost, high treatment efficiency and saving of energy consumption, provides a new method for soil heavy metal pollution abatement, and is broad in application prospect.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS +1

Inhaleable spray dried 4-helix bundle protein powders having minimized aggregation

The present invention provides highly dispersible spray-dried powder compositions, and in particular, inhaleable dry powder compositions for aerosolized delivery to the lungs. The powders of the invention are produced by spray drying a 4 α-helix bundle protein under conditions which both (i) protect the protein from aggregation and (ii) provide particles suitable for inhalation (i.e., demonstrating superior aerosol performance).

Owner:NOVARTIS FARMA

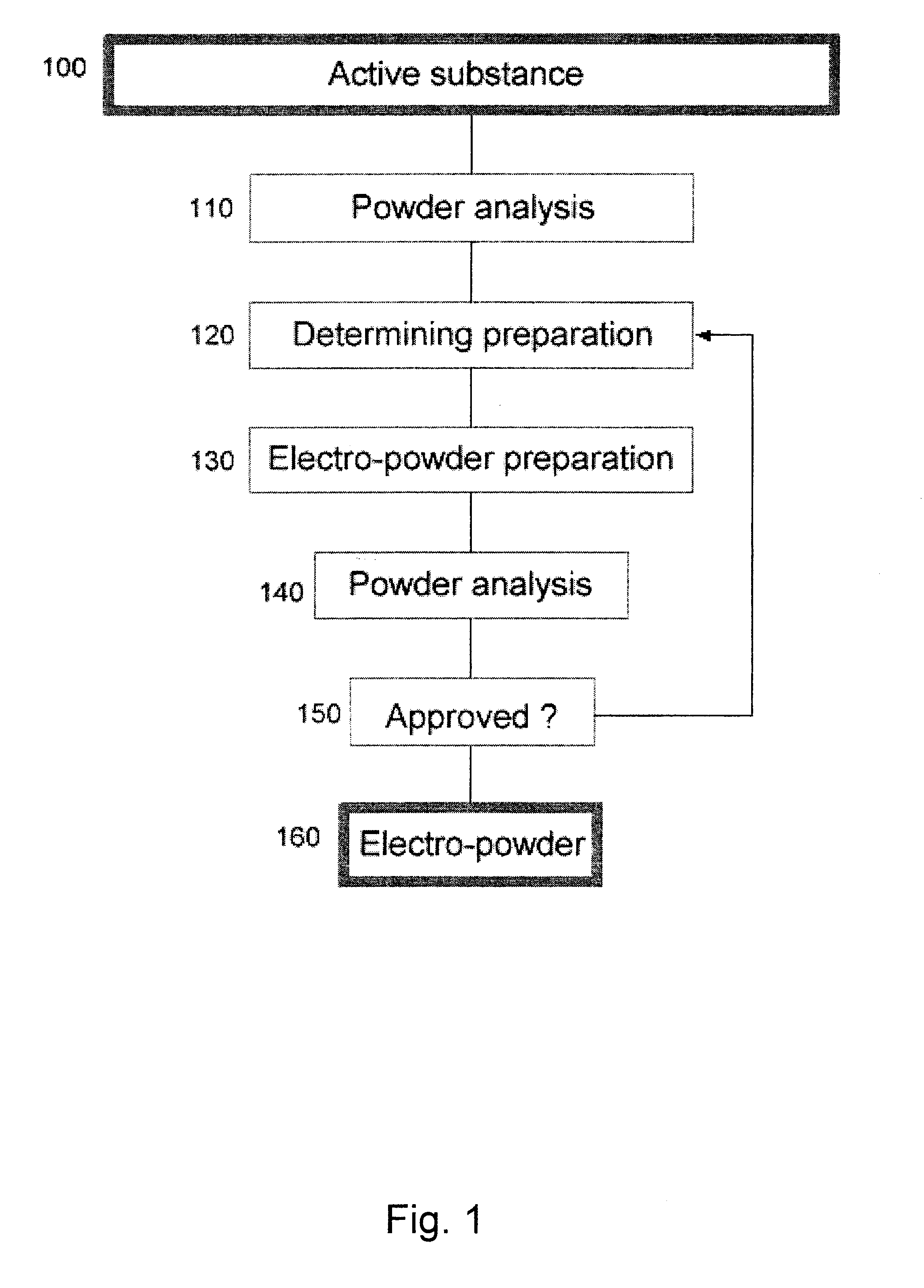

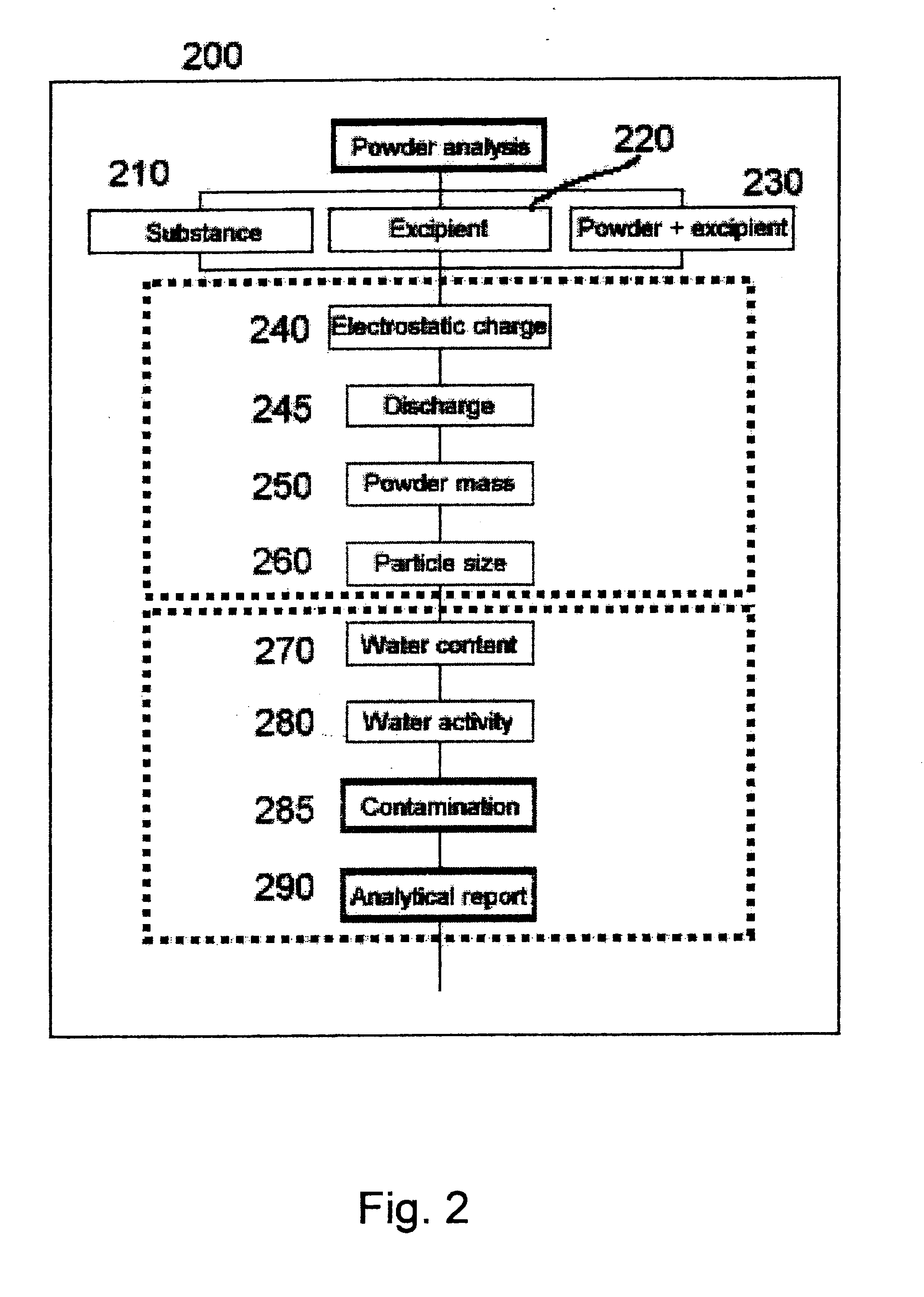

Electro-powder

A method and a process are disclosed for preparation of medical electro-powders. The electro-powder results from preparations of chemical and biological substances to form electro-powders suitable for electrostatic charging and dosing for functionality in a dry powder inhaler device. The electro-powder resulting from the method and process forms an active powder substance or a dry powder medical formulation with a fine particle fraction representing of the order 50% or more of the content having a size ranging between 0.5-5 mum and provides electrostatic properties with an absolute specific charge per mass after charging of the order 0.1x10<-6 >to 25x10<-6 >C / g and presenting a charge decay rate constant Q50>0.1 sec with a tap density of less than 0.8 g / ml and a water activity aw of less than 0.5. In the processing the active substance is a generally pharmaceutical active chemical or biological substance, for instance a polyeptide or any other corresponding substance selected alone or mixed or blended together with one or more excipients being a compound to improve electrostatic properties of the medical dry powder substance or dry powder medical formulation. Further the electro-powder may even be formed as a micro-encapsulation by coating micronized powder with the excipient in such a way that the active substance is capsulated, whereby the powder electrostatic properties mainly comes from the excipient.

Owner:MEDERIO AG

Accessory ingredient pre-dispersed masterbatch used for refining sizing material and preparation method thereof

The invention discloses an accessory ingredient pre-dispersed masterbatch and a preparation technology thereof. Powdery or granular accessory ingredient is dispersed into a rubber matrix to form a new evenly-mixed flaky accessory ingredient form which has small possibility of flying. The preparation technology has the beneficial effect that the accessory ingredient is pre-dispersed in the rubber matrix. Compared with the traditional powder or granules, the accessory ingredient pre-dispersed masterbatch is characterized in that the flaky masterbatch does not have flying and scattering loss in the using process to guarantee the accuracy of the formula and improve the quality and the stability of the sizing material; because the accessory ingredient is subjected to the pre-dispersed mixing process, the accessory ingredient masterbatch can be quickly and easily dispersed into the sizing material in the using process, and the dispersibility of the accessory ingredient as well as the uniformity and the production efficiency of the sizing material are improved; the flaky accessory ingredient pre-dispersed masterbatch is more suitable for automatically or semi-automatically weighing, the automation degree of the whole production system is improved, and the production efficiency is improved.

Owner:特拓(青岛)轮胎技术有限公司

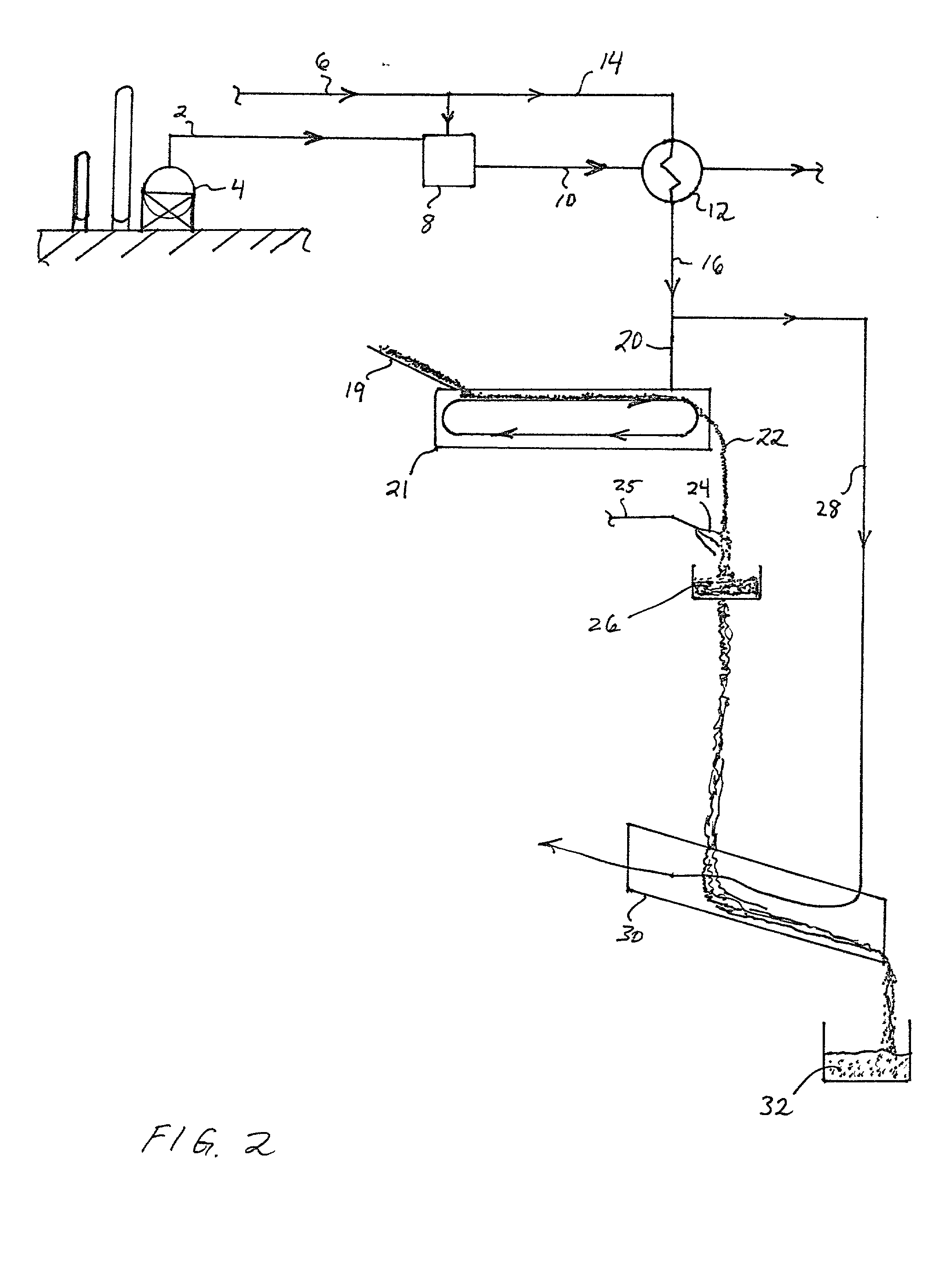

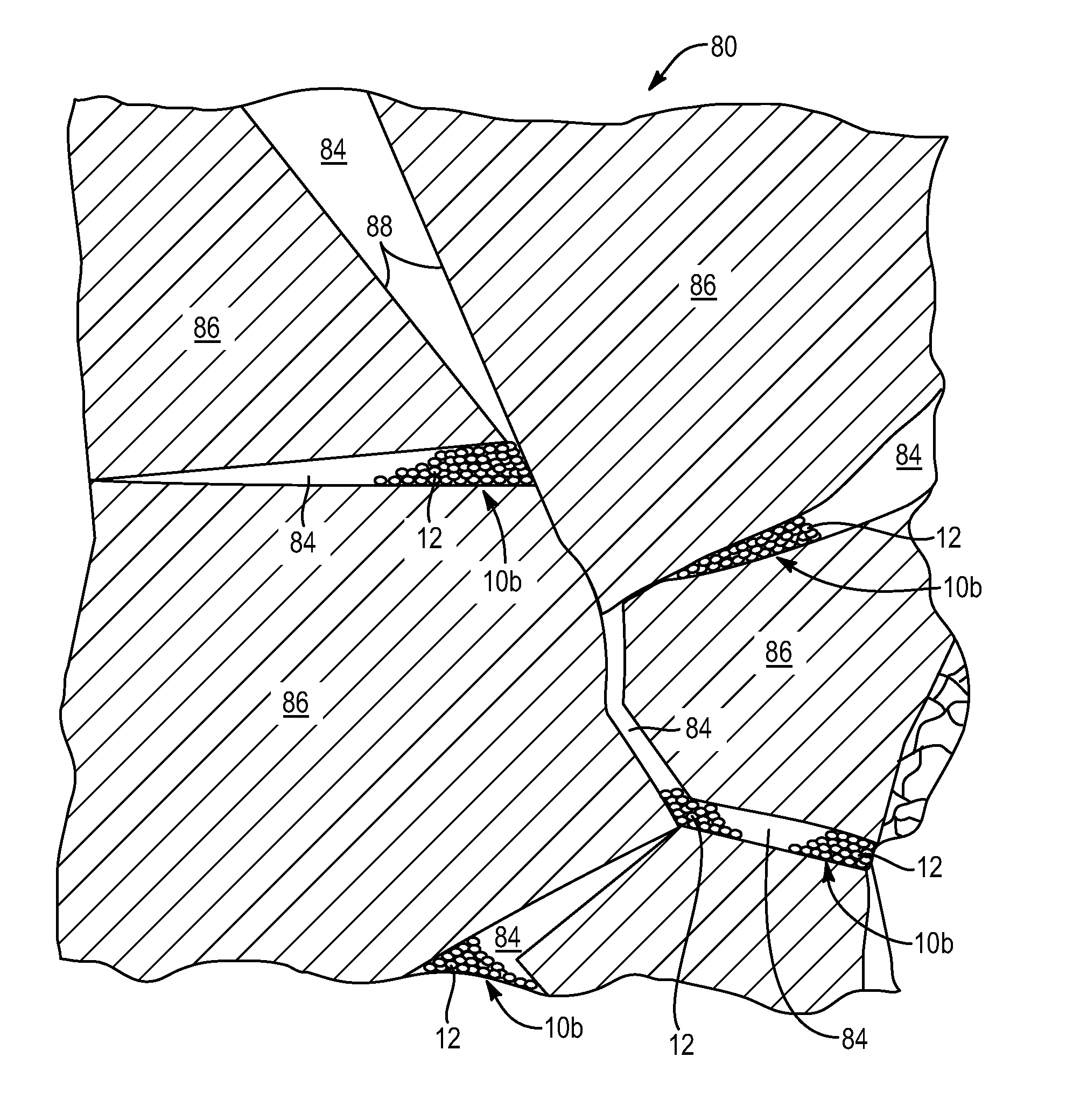

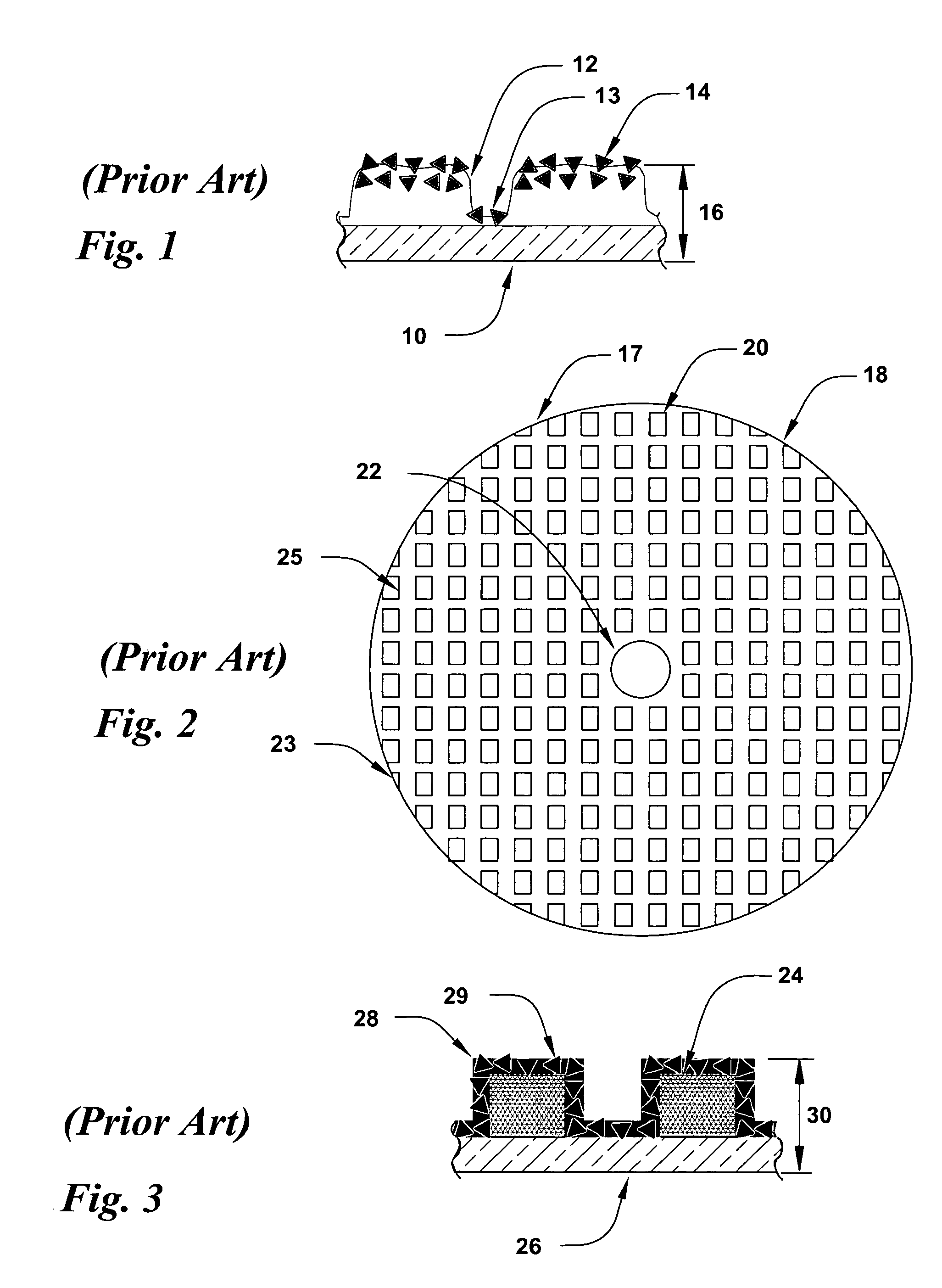

Hydraulic fracture composition and method

A method for improving hydraulic fracturing creates coated proppants containing one or more chemical constituents bonded to a substrate and introduced into the fracturing fluid itself. The substrate that eventually acts as a proppant may be sand, ceramic, resin coated sand, and other materials. Typically, the materials that are coated as powders adhered to the substrate may include friction reducers, biosides, oxygen scavengers, clay stabilizers, scale inhibitors, gelling agents, or the like. By adhering solid materials to a substrate 12 by a binder 14, a single, solid, granular material may be maintained onsite, requiring reduced footprint, reduced mixing and may introduce almost instantaneously into a fracturing flow stream all the necessary chemical constituents, which will eventually become mixed. The result is reduced time, energy, manpower, equipment, and space at the sight, while reducing the environmental impact of transportation, spills, hydrocarbon use, and the like.

Owner:AQUASMART ENTERPRISES +1

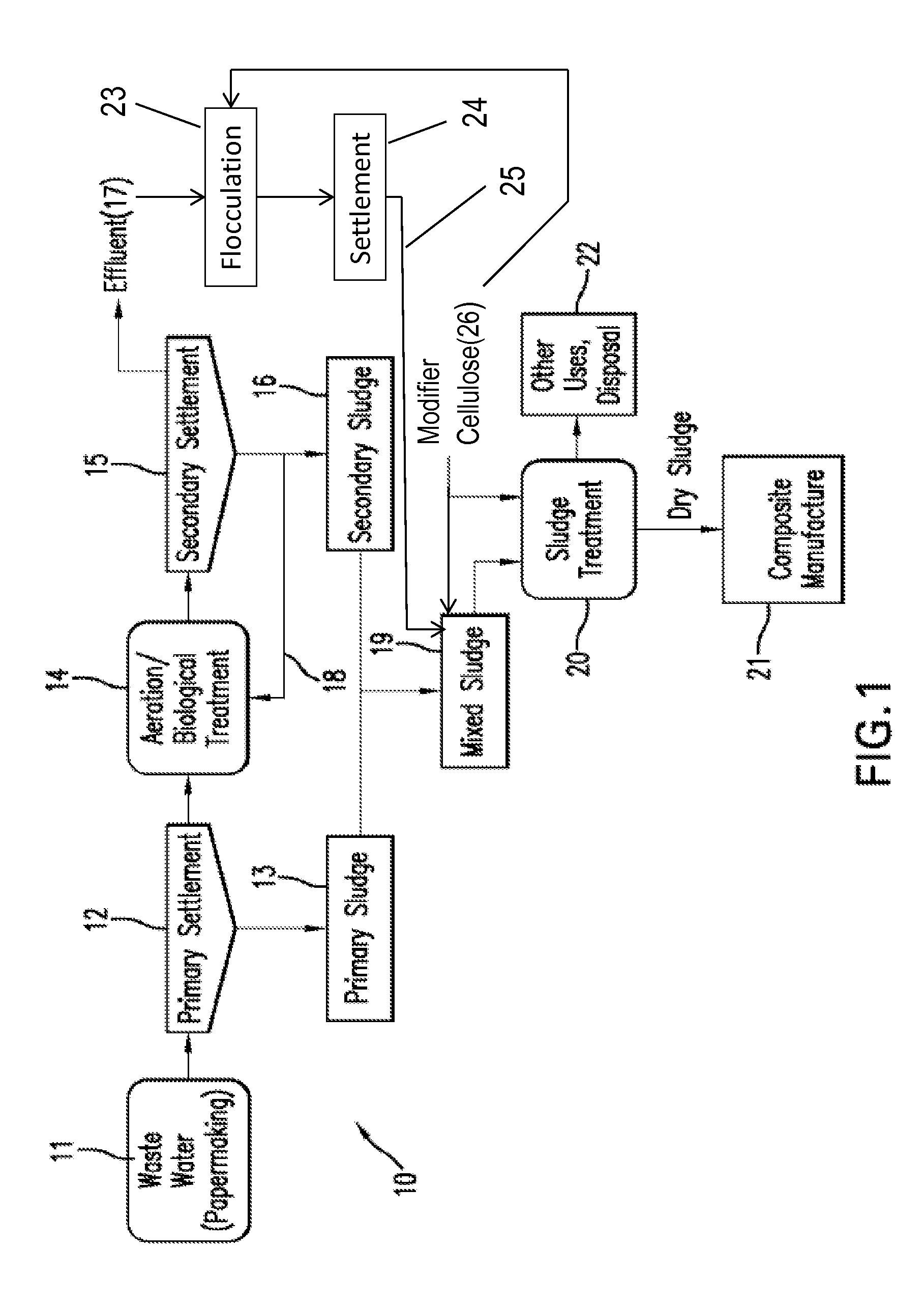

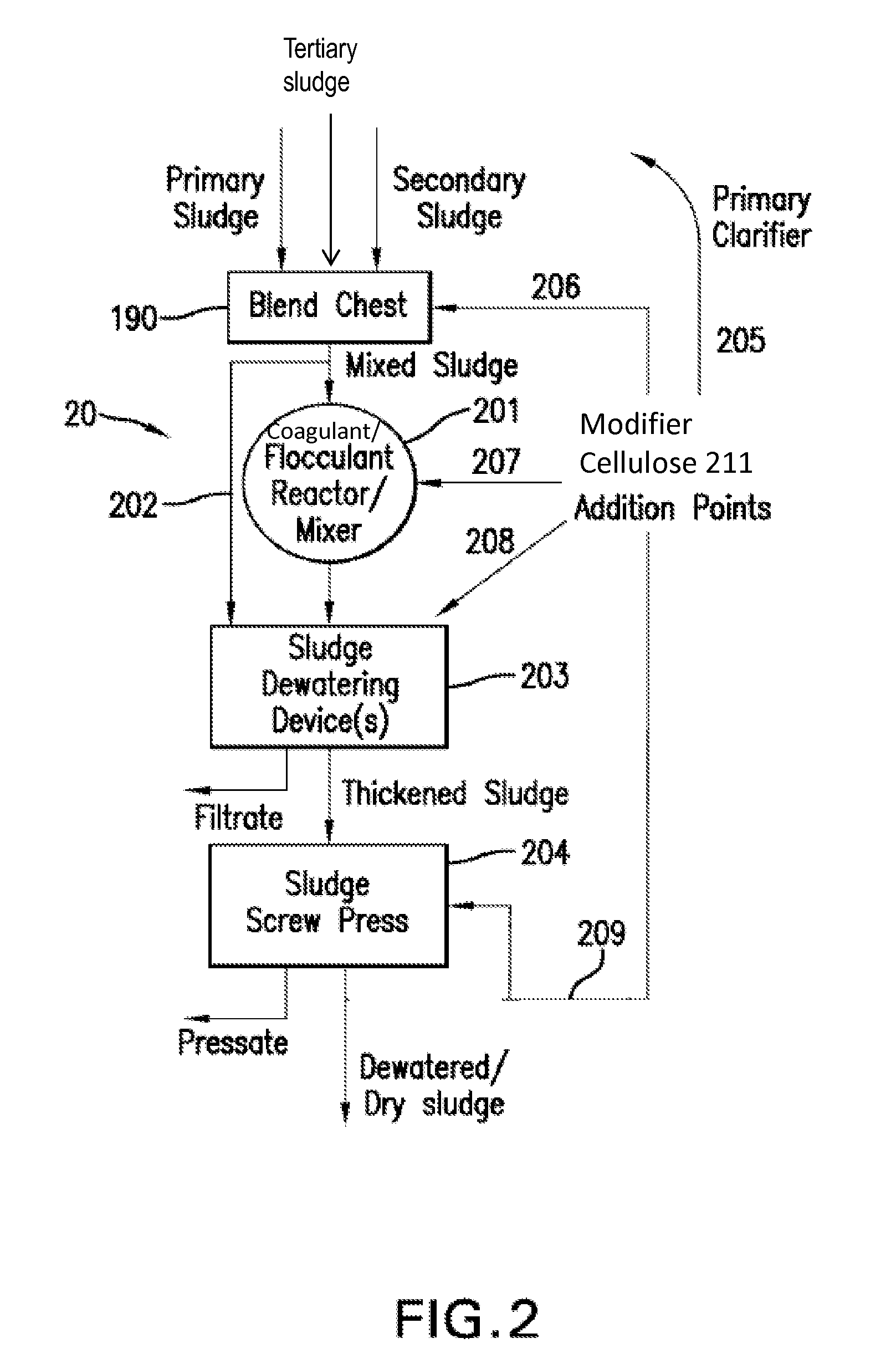

Use Of Celluloses In Sludge Dewatering, And Sludge Products Thereof

InactiveUS20150197439A1Accelerates the dehydration processNon-macromolecular adhesive additivesInksParticulatesPrill

Methods to improve dewatering in industrial and municipal sludges are described. One method involves admixing sludge from a papermaking process and modified cellulose to provide modified sludge with the modified cellulose present in an effective amount to improve dewatering in the treated sludge, such as in allowing use of reduced amounts of coagulant and / or reducing dewatering times, increased dewatered volumes, and reduced sludge product moisture contents, and the like. The dewatered sludge may be formed into a dried particulate, and may be used as filler or other component of concrete, rubber, asphalt, plastics, resin-wood composite products, and other composite products.

Owner:BUCKMAN LAB INT INC

Granular heating non-combustible tobacco matrix and preparation method thereof

ActiveCN107307466ALarge specific surface areaQuick releaseTobacco preparationTobacco treatmentPrillFlue gas

The invention discloses a granular heating non-combustible tobacco matrix and a preparation method thereof. The preparation method comprises the following steps that firstly, tobacco raw materials are ground and sieved to obtain tobacco powder with particle size of 60-200 mesh; secondly, the tobacco powder, tobacco extracts and a humectant are evenly mixed, and then ethanol is added to prepare a soft material suitable for granulation; thirdly, the soft material is granulated through an extrusion method by means of a screen, wet granules are dried and aired to room temperature, and the granules are placed into a medicine sieve for size stabilization so as to obtain granular matrixes with different particle sizes. According to the method, the tobacco powder raw materials are prepared into porous particles with different particle sizes through a certain technology, so that the specific surface area of the raw materials is increased, and the suction resistance can be regulated during suction through pores of the matrixes and pores between the matrix particles; flue gas can be rapidly released in a heating state, and the uniformity of the flue gas can be improved.

Owner:CHINA TOBACCO ZHEJIANG IND

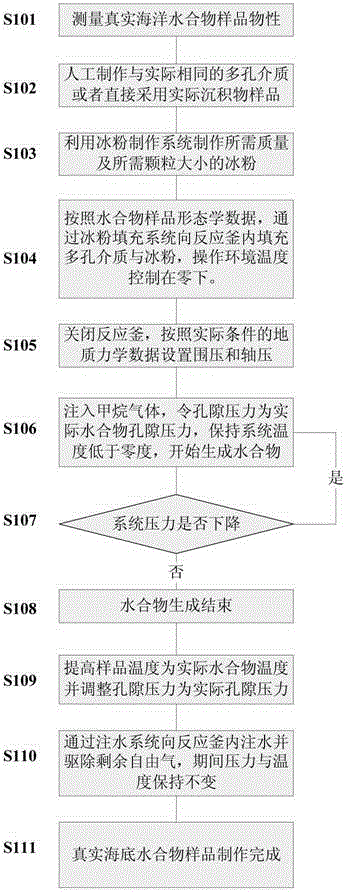

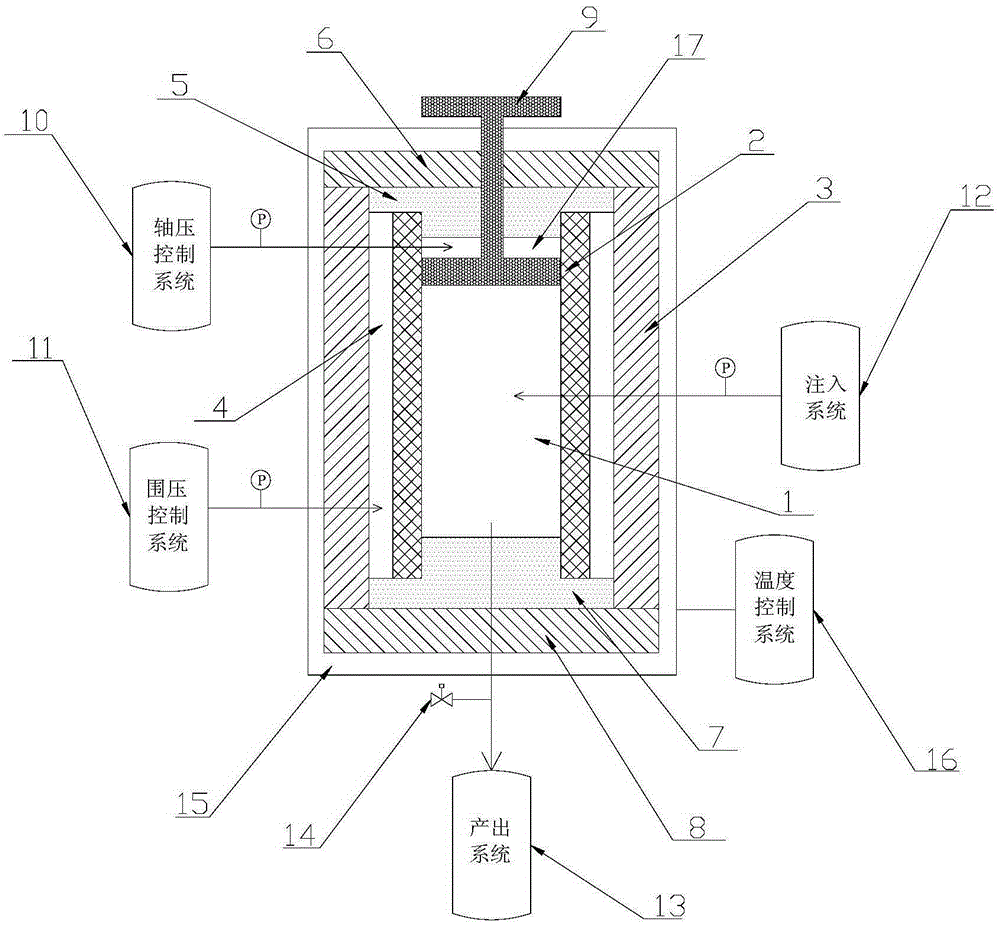

Experiment device and method for synthesizing marine natural gas hydrate sample

ActiveCN105259003AEconomic gainEfficiently obtainedPreparing sample for investigationOcean bottomPrill

The invention discloses an experiment device for synthesizing a marine natural gas hydrate sample. The device comprises a reaction kettle, an axial compression piston, a kettle outer jacket, an injection system, an axial compression control system, a confining pressure control system and an output system. The invention further discloses an experiment method adopting the experiment device for synthesizing the marine natural gas hydrate sample. The method comprises the steps that firstly, ice powder particles are manufactured, then, the ice powder particles and dried porous medium particles are mixed and placed into the high-pressure reaction kettle in the subzero low-temperature environment so as to simulate seabed geomechanical properties, then, methane is injected to generate a hydrate, ice is directly converted into the hydrate, and finally free gas inside the reaction kettle is removed through the liquid injection system. According to the experiment device and method, true marine natural gas hydrate samples which are hard to obtain on various geological conditions and various occurrence form conditions can be economically, efficiently and accurately obtained, the research on the hydrate is closer to the reality, and the experiment basis is provided for research of natural gas hydrate exploitation.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

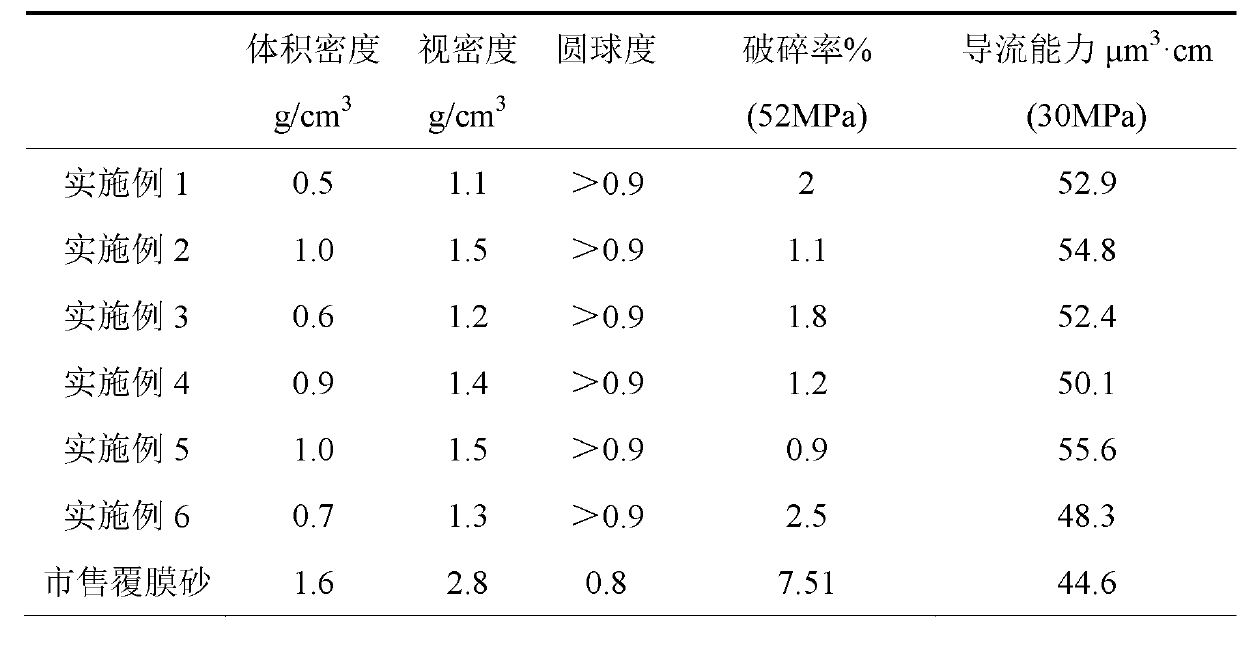

Clean-water-carrying petroleum proppant for petroleum production of low-permeability petroleum reservoir and preparation method thereof

The invention provides a clean-water-carrying petroleum proppant for petroleum production of a low-permeability petroleum reservoir. The proppant is prepared through coating macromolecular polymer particles with the particle sizes of 3-100 meshes by using macromolecular resin, wherein the macromolecular polymer particles are white polymer balls formed through polymerizing olefin monomers or polymer microspheres formed through compounding after a silane coupling agent modified mineral material is added; and the proppant has the volume density of 0.5-1.0 g / cm<3> and the apparent density of 1.1-1.5 g / cm<3>. The invention simultaneously provides a preparation method of the petroleum proppant. The clean-water-carrying petroleum proppant prepared by adopting the preparation method can greatly reduce the viscosity of sand carrying liquid, reduce the damage to strata and pumps and even realize clean fracturing. Through the low-density proppant, the entire construction cost can be reduced, and the phenomenon of proppant discharging or crack emptying is difficult to occur.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Formulation for spray-drying large porous particles

InactiveUS7279182B2Reduce and eliminate needEasy to preparePowder deliveryBiocidePrillVolumetric Mass Density

Particles having a tap density less than about 0.4 g / cm3 are formed by spray drying from a colloidal solution including a carboxylic acid or salt thereof, a phospholipid, a divalent salt and a solvent such as an aqueous-organic solvent. The colloidal solution can also include a therapeutic, prophylactic or diagnostic agent. Preferred carboxylic acids include at least two carboxyl groups. Preferred phospholipids include phosphatidylcholines, phosphatidylethanolamines, phosphatidylglycerols, phophstidylserines, phosphatidylinositols and combinations thereof. The particles are suitable for pulmonary delivery.

Owner:CIVITAS THERAPEUTICS

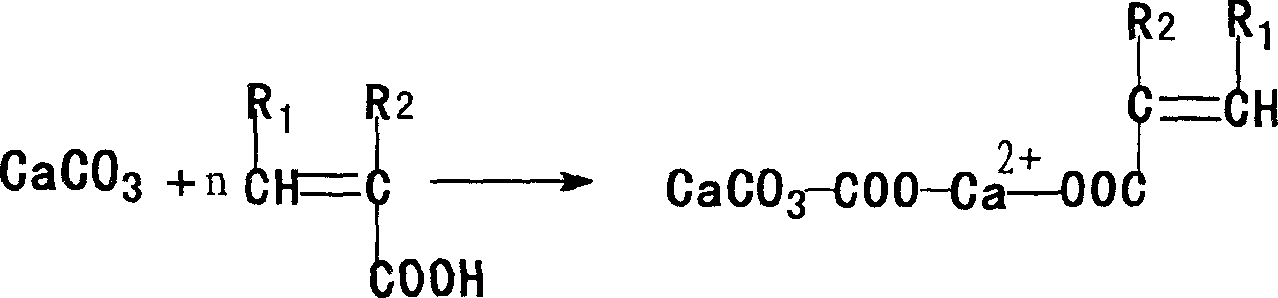

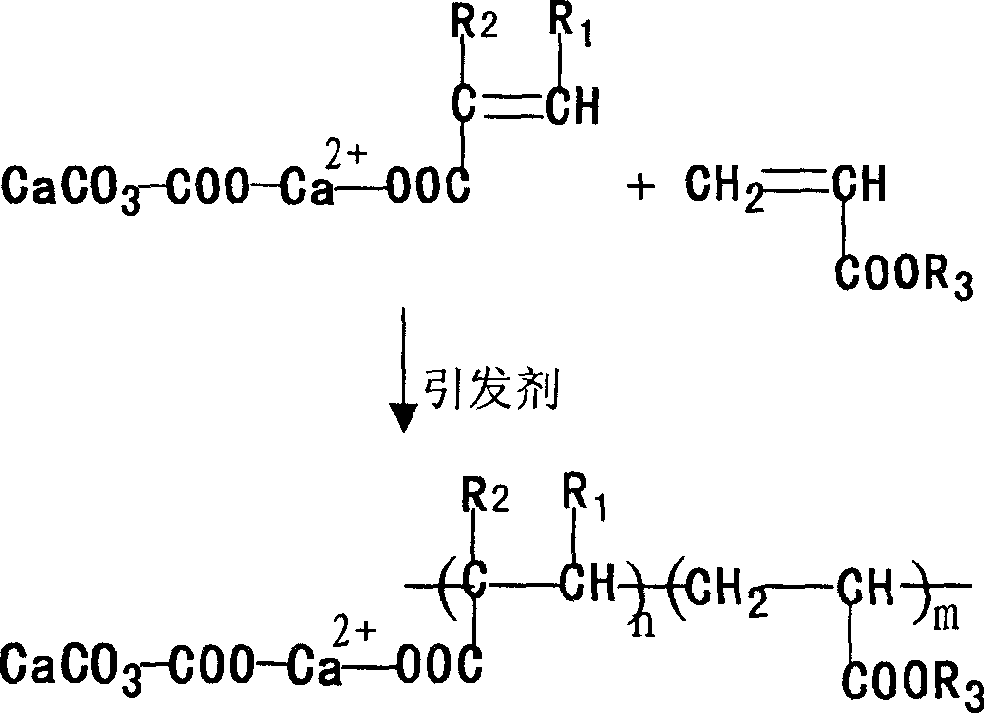

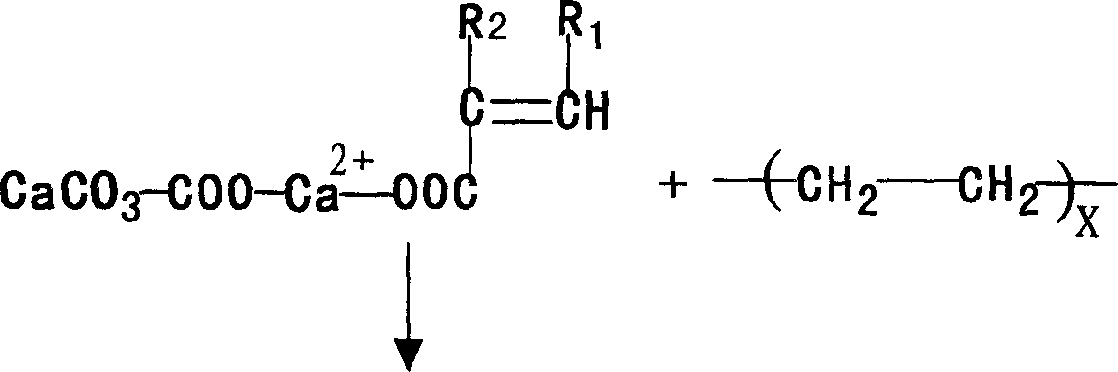

Materials dedicated for antibacterial and permeable polyolefin film and preparation method thereof

The invention relates to a process for preparing polyolefin antibacterial permeability membrane, which consists of mixing 10-30 contents of nanocalcium carbonate and 10-65 contents of heavy calcium carbonate first, adding 0.1-10 contents of unsaturated acid monomer, 0.1-20 contents of long fatty chain monomer, 0.001-5 contents of initiating agent, 0.1-10 contents of polyethersulphonate and 0.1-20 contents of macromolecular coupling agent and 5-80 contents of polyolefin resin, first preparing predisperse masterbatch of mixed calcium carbonate in the twin-screw extruder, afterwards, mixing 20-80 contents of predisperse masterbatch of mixed calcium carbonate, 0.1-5 contents of hole leveler, 0.1-0.5 contents of anti-oxidant, 2-20 contents of compound antibacterial mother particle and 20-70 contents of polyolefin resin in high-speed mixer, squeezing the prill by twin-screw extruder, drying and vacuum-packing, obtaining the special material of antibacterial permeability membrane. The invention is characterized in that the interactive condition between the polyolefin and calcium carbonate is strong, the filling material is readily dispersed in the polymeric matrix, the special material of permeability membrane can not only form film using doctor-blading process, but also can form film using blowing process, the pore diameter of the said permeability membrane is uniform, and its antibacterial behavior is excellent.

Owner:合诚技术股份有限公司

Novel material capable of imitating multiple ornamental sculpture stone materials and manufacturing process of novel material

ActiveCN104478390AGuaranteed dockingGuaranteed aestheticsNatural patternsOrnamental structuresPrillPlasticizer

The invention discloses a novel material capable of imitating multiple ornamental sculpture stone materials. The novel material is prepared from a coagulation material and natural stone sand in percentage by weight, wherein the coagulation materials comprises the following raw materials in percentage by weight: sulfate aluminum cement clinker, white stone, calcium carbonate powder, high-class talcum powder, a super plasticizer, color powder and a thickening time control agent; the natural stone sand comprises the following raw materials in percentage by weight: pure white sand with the grain fineness of 1-2 mm, pure white sand with the grain fineness of 0.2-0.5 mm and colored sand with the grain fineness of 1-2 mm; the colored sand comprises one or two or more of pure red sand, pure pulp sand, pure blue sand and sand of other colors. The raw materials are finely grinded and compounded to obtain a coagulation material which is white in color, short in coagulation time and high in strength, various stone surface effects are achieved when various natural stone sands are compounded, the novel material can be produced in batch, and compared with a manner that sculptures are directly carved on stone materials, the novel material is much excellent in working efficiency, good in consistency of sculpture products, good in pattern abutting of finished products and low in production cost.

Owner:广州新尚艺术股份有限公司

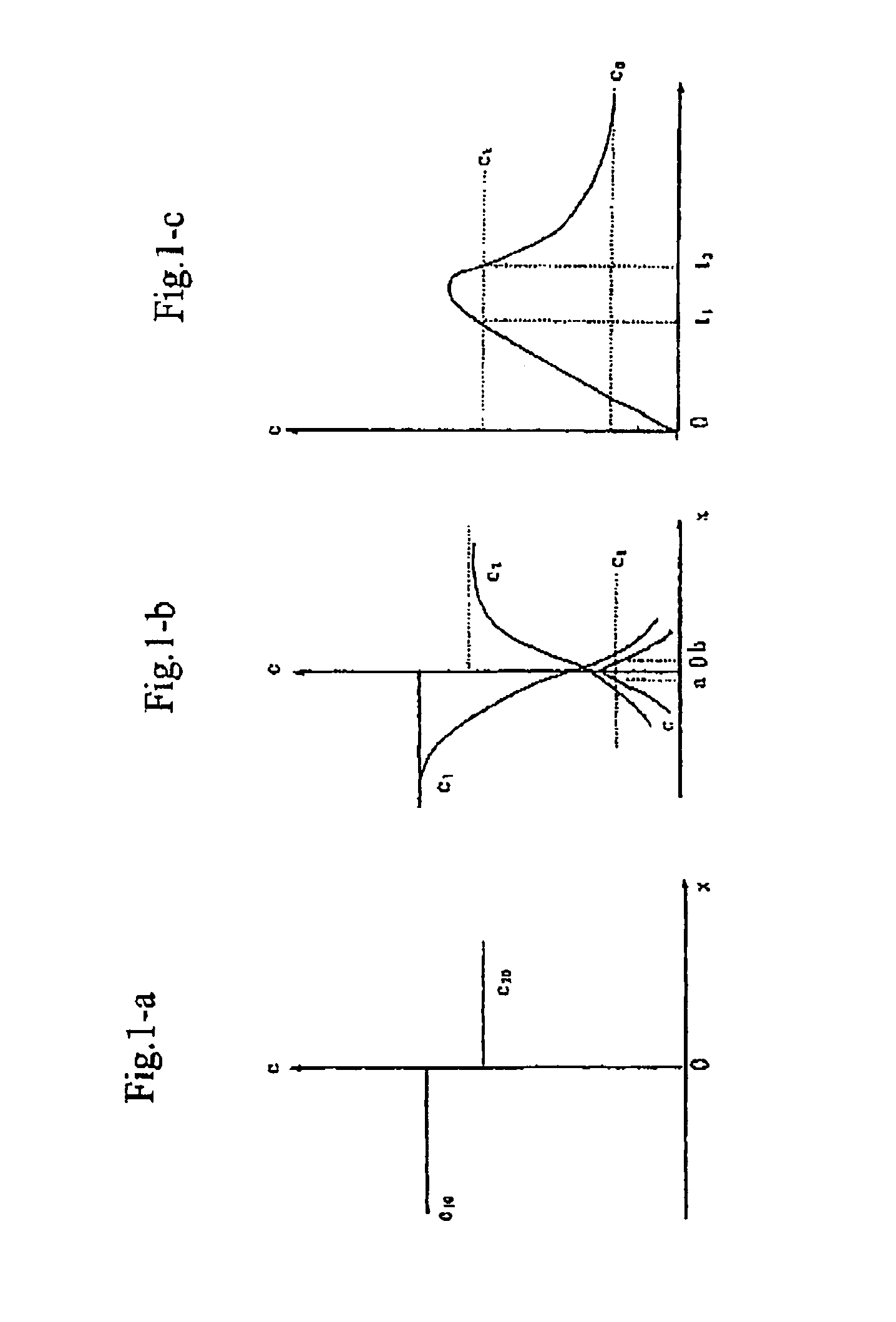

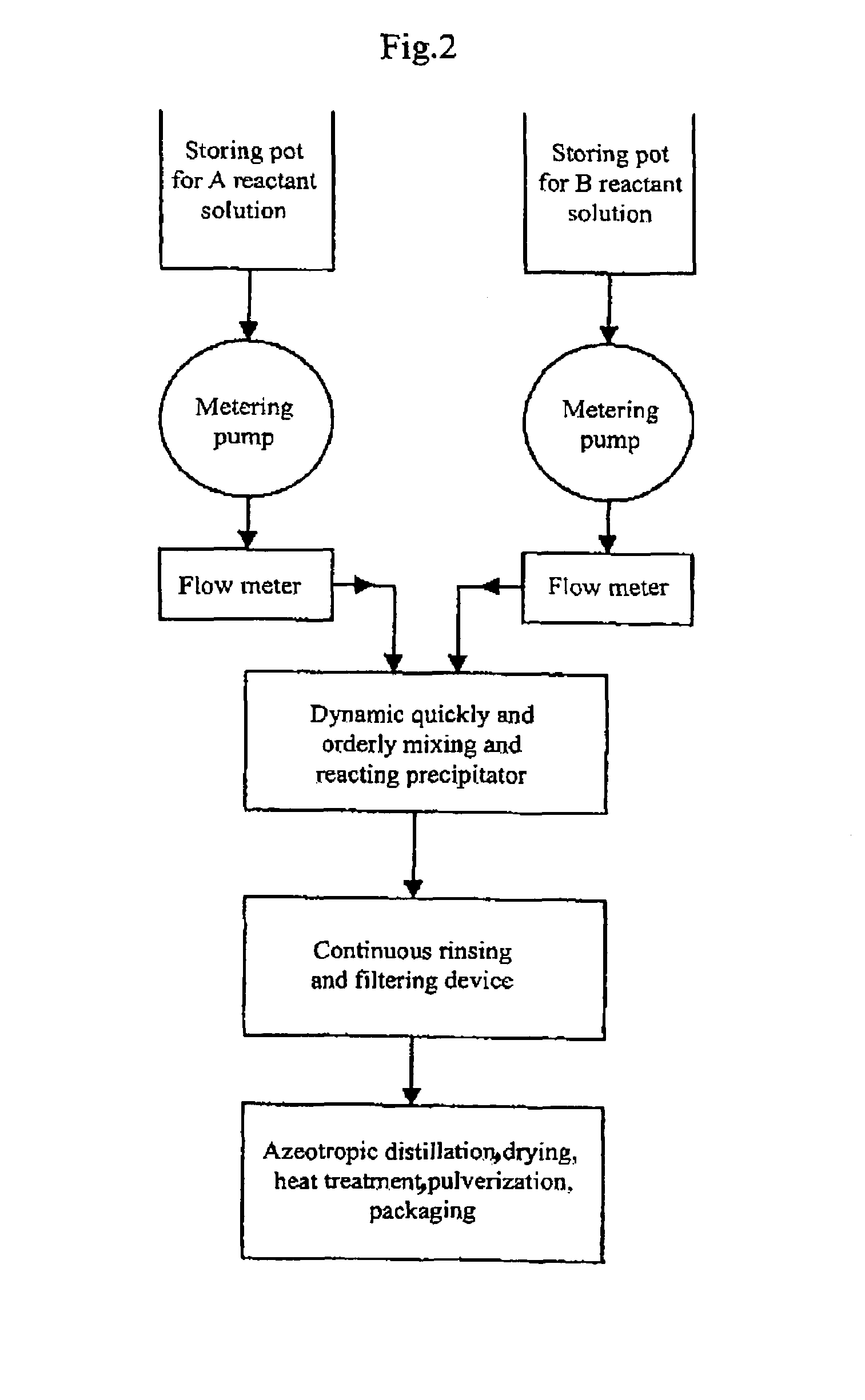

Process for producing nano-powders and powders of nano-particle loose aggregate

InactiveUS7238331B2Speed up the processSimple structureCalcium/strontium/barium carbonatesMaterial nanotechnologyPrillNanoparticle

The present invention discloses a process for producing nano-powders and powders of nano-particle loose aggregate, which includes: (a) providing at least two reactant solutions A and B capable of rapidly reacting to form deposits; (b) supplying the at least two reactant solutions A and B at least at the reaction temperature into a mixing and reaction precipitator respectively, in which mixing reaction and precipitation are continuously carried out in sequence, the mixing and reaction precipitator being selected from at least one of a tubular ejection mixing reactor, a tubular static mixing reactor and an atomization mixing reactor; and (c) treating the deposit-containing slurry continuously discharged from the mixing reaction precipitator.

Owner:UNIV OF SCI & TECH LIAONING

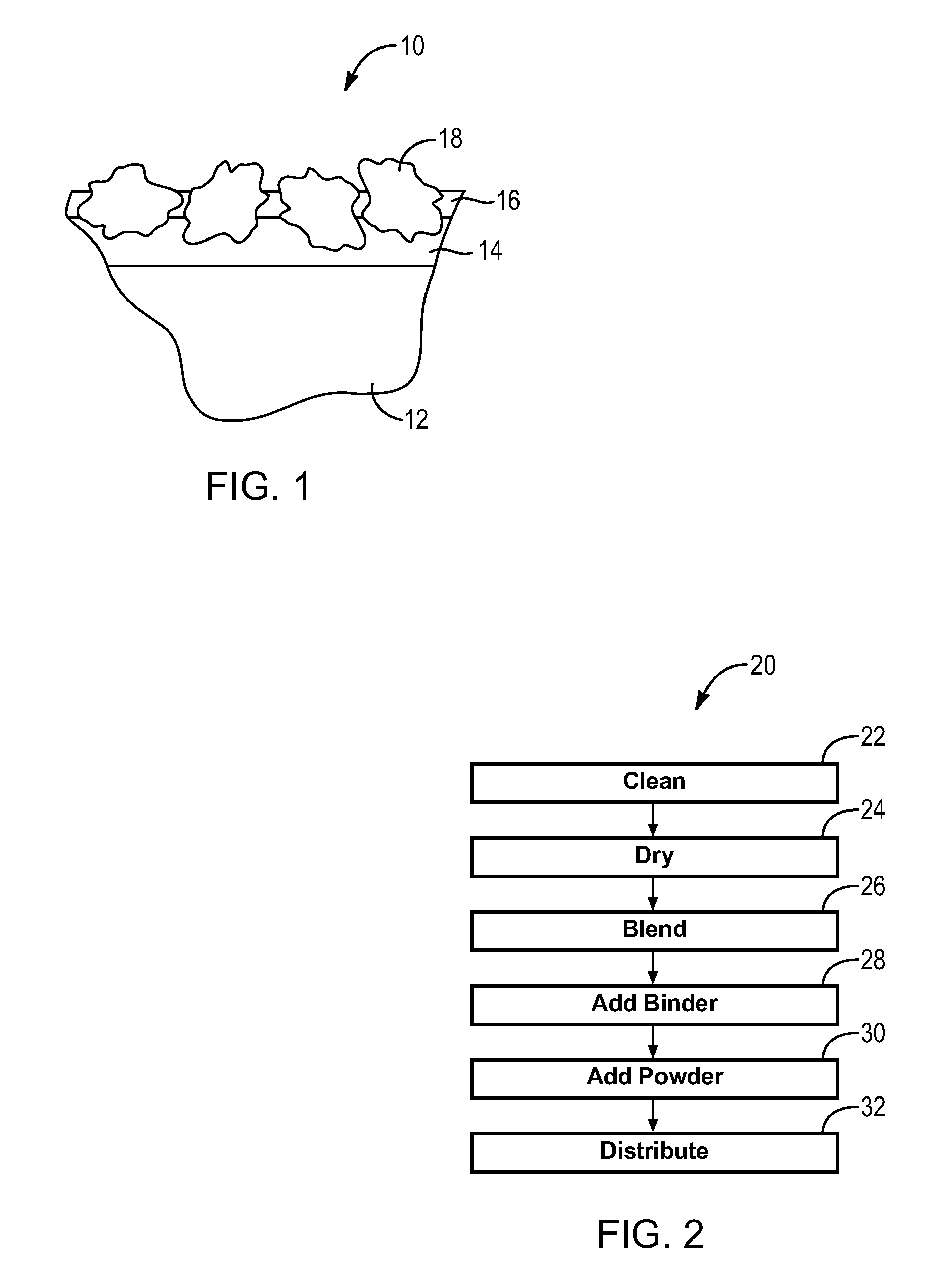

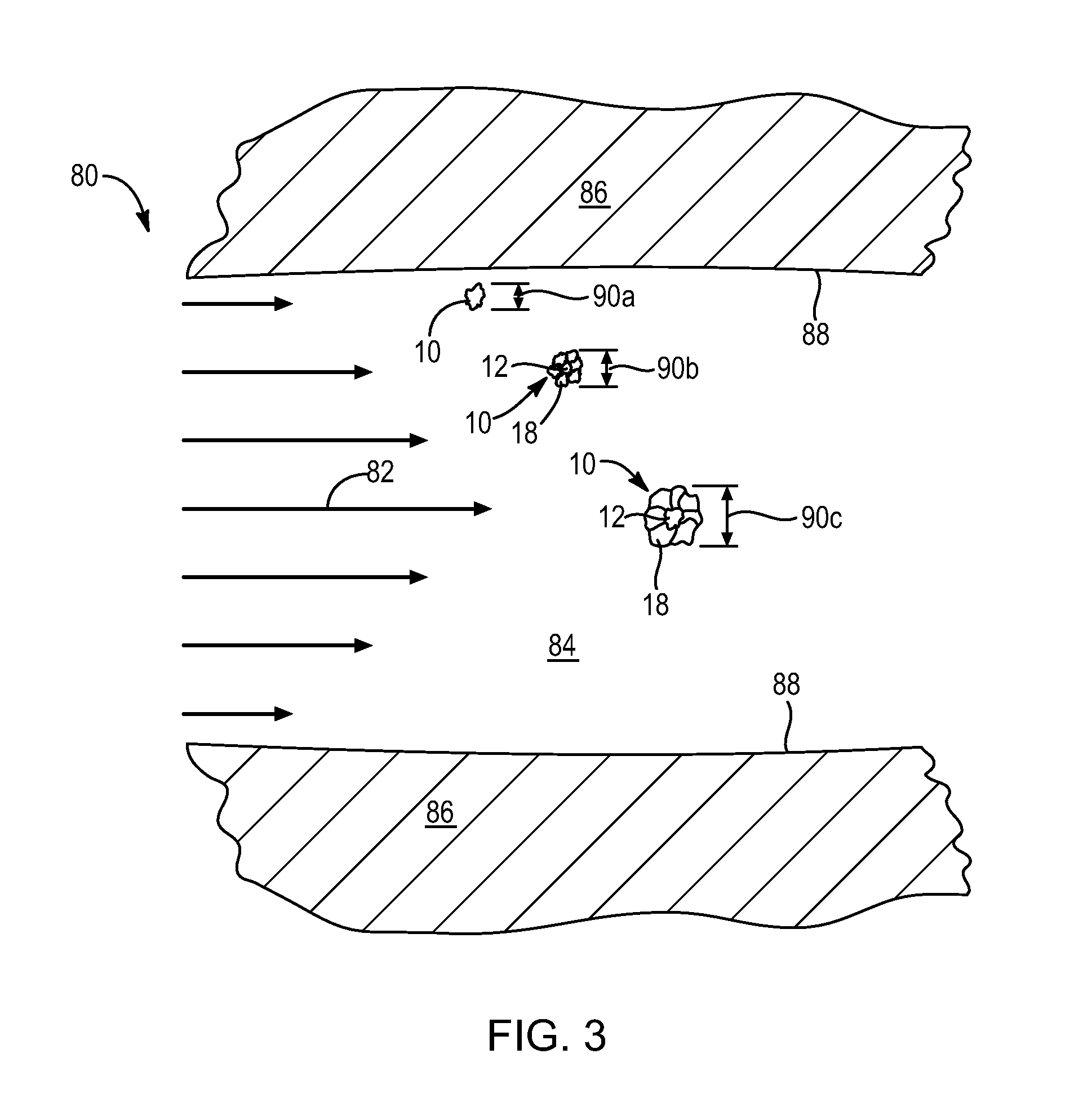

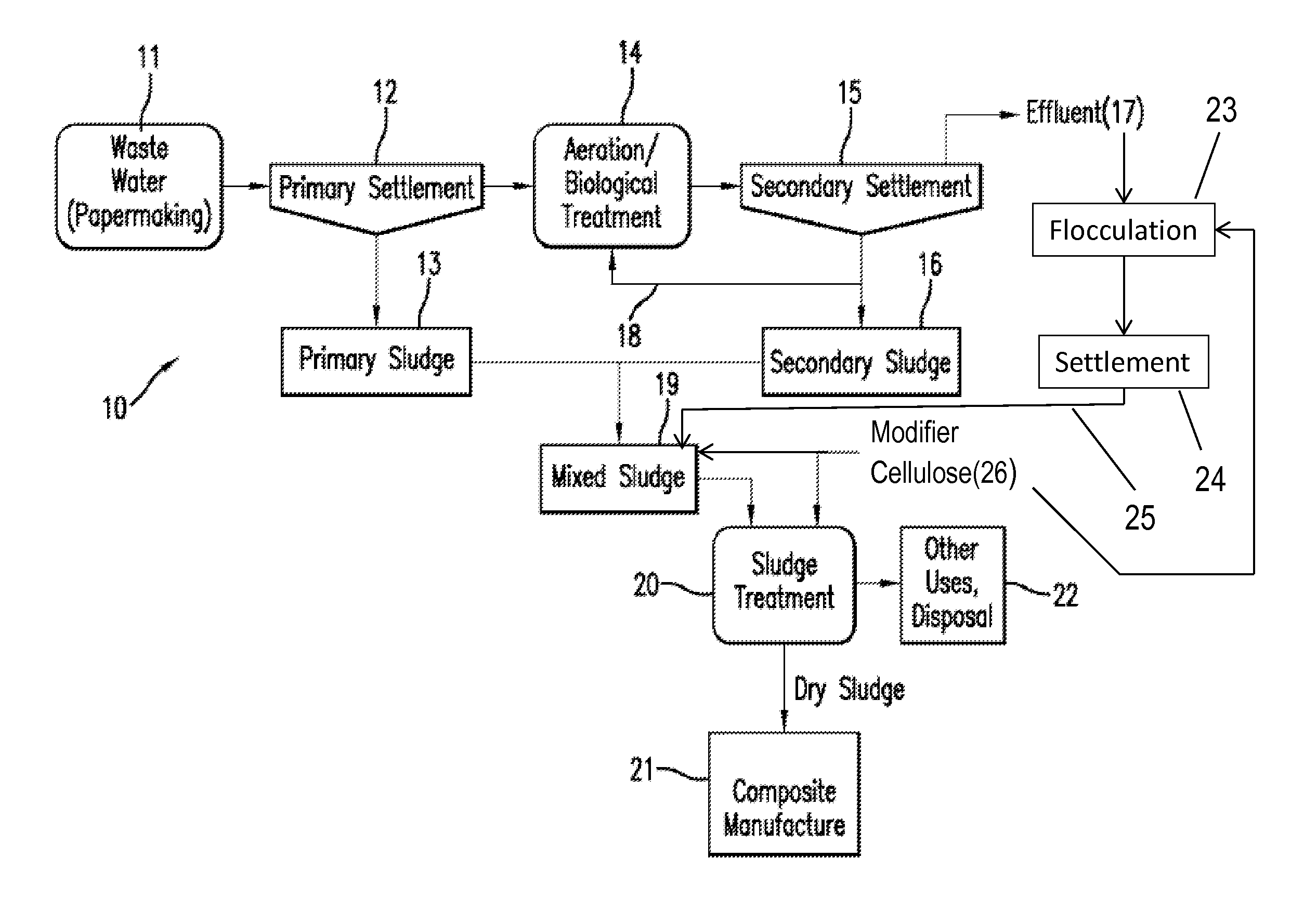

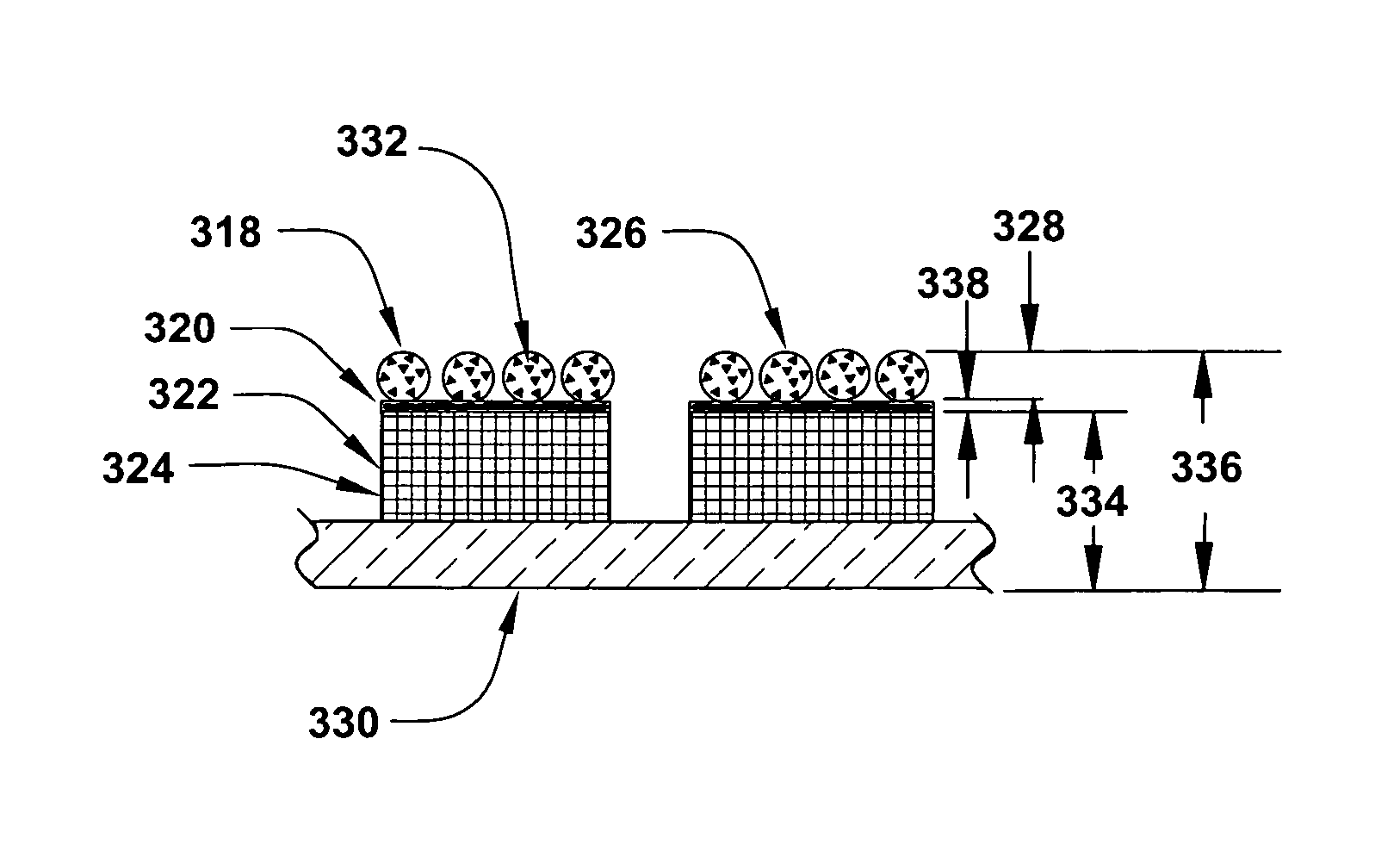

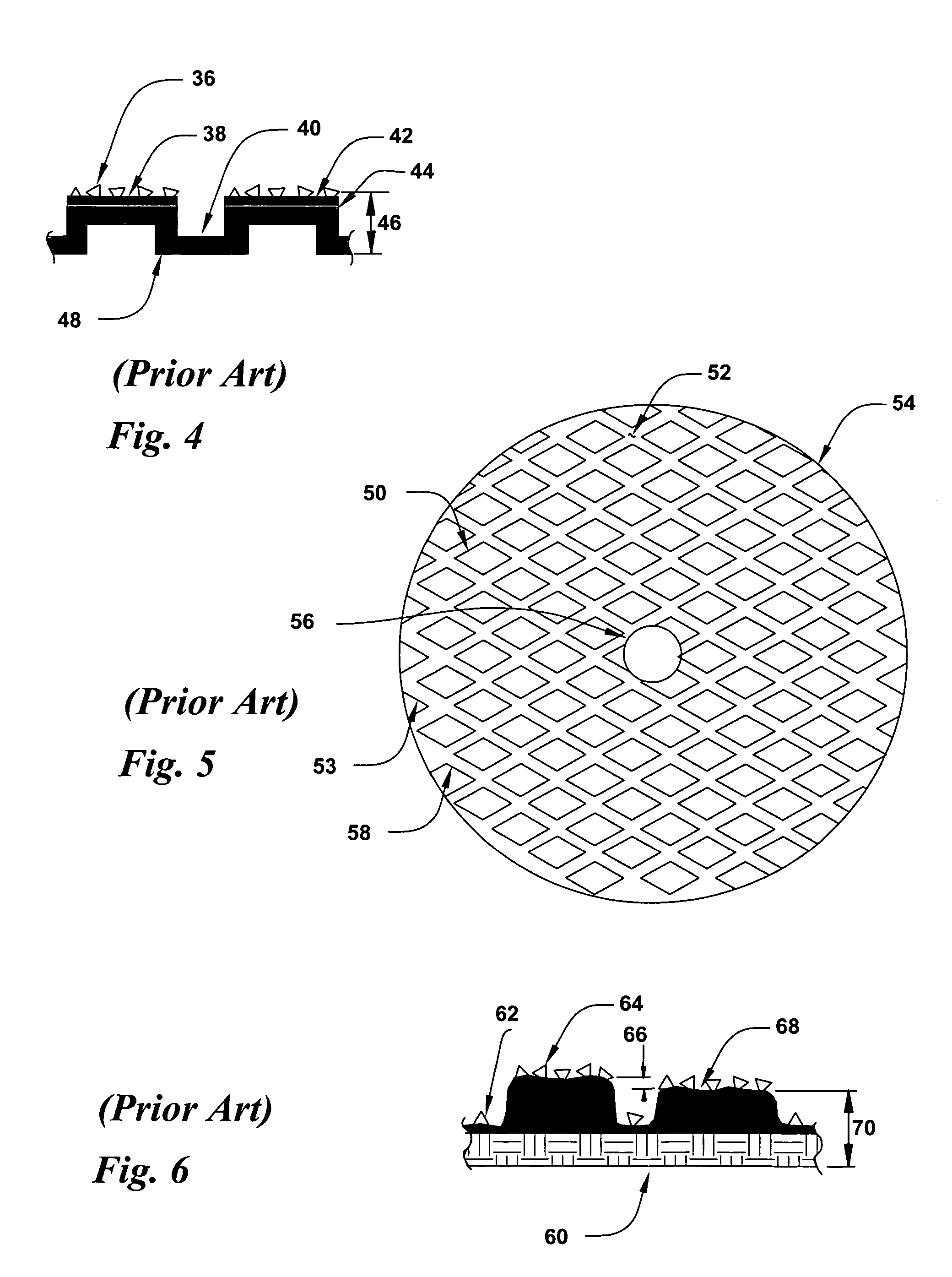

Method of forming a flexible abrasive sheet article

InactiveUS8545583B2Simple processReduce investmentPigmenting treatmentOther chemical processesWater basedPrill

Flexible abrasive sheet articles having precision thickness flat-topped raised island structures that are coated with a monolayer of equal sized abrasive agglomerate are described. Methods of producing high quality equal-sized spherical shaped composite abrasive agglomerate beads containing small diamond abrasive particles are described. Beads are produced by level-filling fine mesh screens or perforated sheets with a water based metal oxide slurry containing abrasive particles and then using a fluid jet to eject the abrasive slurry lumps from the individual screen cells into a dehydrating environment. Surface tension forces form the ejected liquid lumps into spheres that are solidified and then heated in a furnace to form ceramic beads. These porous ceramic abrasive beads can be bonded directly onto the flat planar surface of a flexible backing material or they can be bonded onto raised island surfaces to form rectangular or disk abrasive sheet articles. Abrasive articles having equal sized abrasive beads are particularly suited for lapping and raised island articles are suited for high speed lapping. Non-abrasive equal-sized beads can also be formed using this simple bead manufacturing process, which requires only a very low capital investment.

Owner:DUESCHER WAYNE O

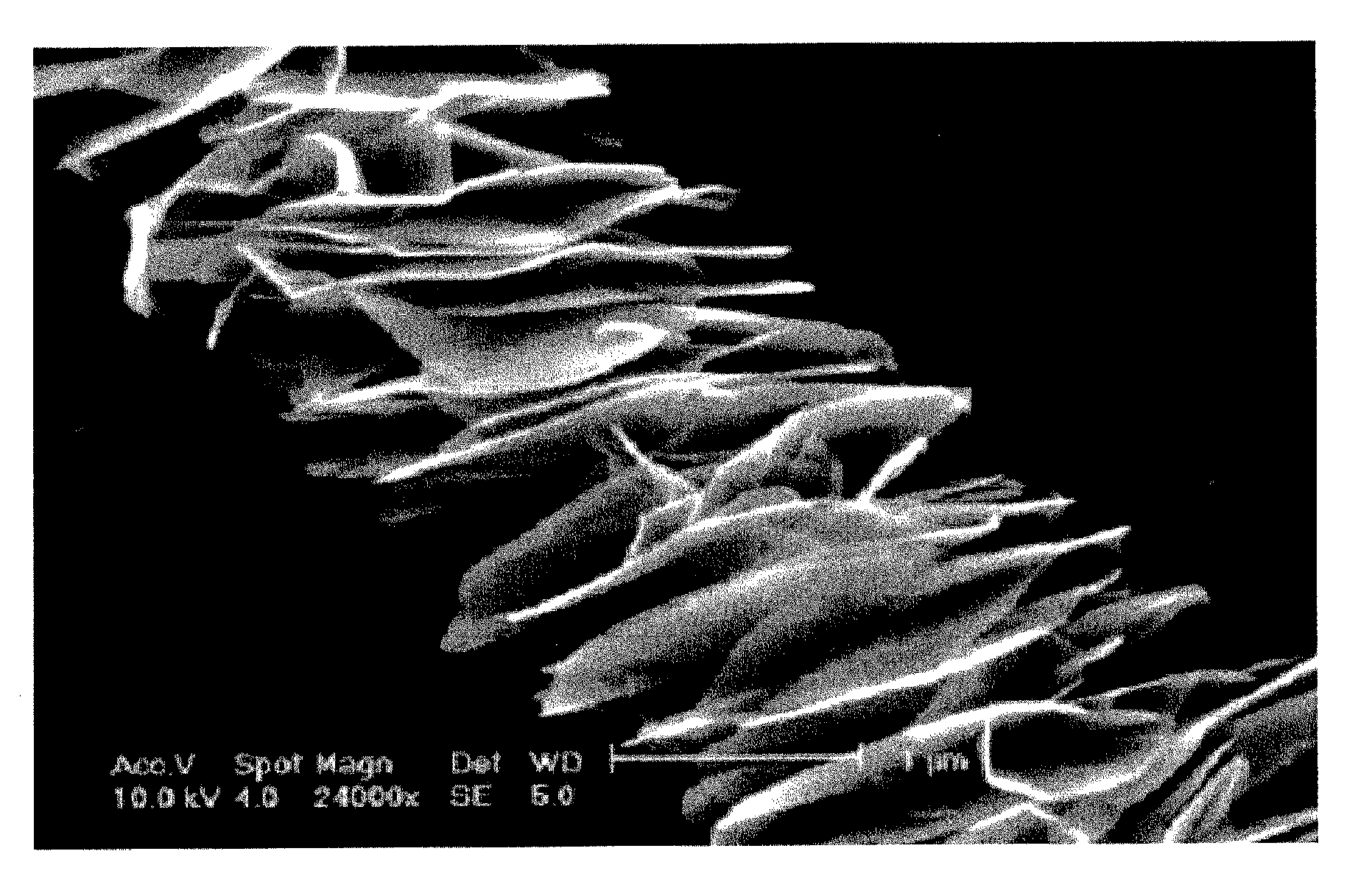

Carbon material and method for producing same

ActiveUS20120315482A1High crystallinityShorten the time periodFrom gel stateMaterial nanotechnologyPrillLithium-ion battery

There are provided a cluster of thin sheet graphite crystals or the like which is useful as an electrode material for lithium ion batteries, hybrid capacitors and the like, and a method for efficiently producing the same at high productivity. The method is one for producing a cluster of thin sheet graphite crystals composed of aggregates in such a state that thin sheet graphite crystals extend from the inside toward the outside, comprising charging a powdery and / or particulate material of an organic compound pre-baked to an extent of containing remaining hydrogen in a graphite vessel, and subjecting the powdery and / or particulate material together with the vessel to hot isostatic pressing treatment (HIP treatment) using a compressed gas atmosphere under the predetermined conditions.

Owner:INCUBATION ALLIANCE

Technology for granulating powder

ActiveCN102107127ASimple processLow equipment requirementsGranulation with special binding agentsPrillAdhesive

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

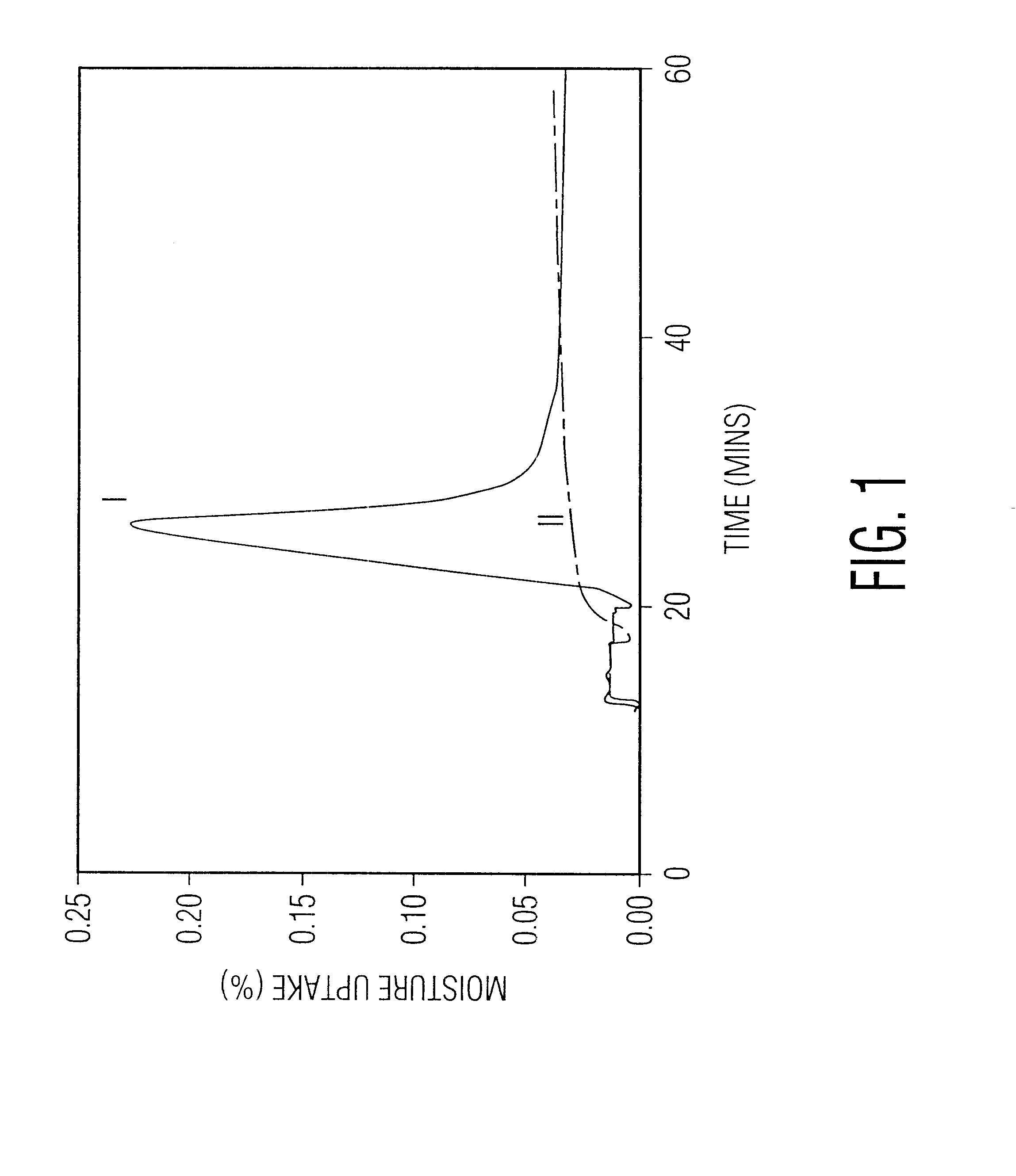

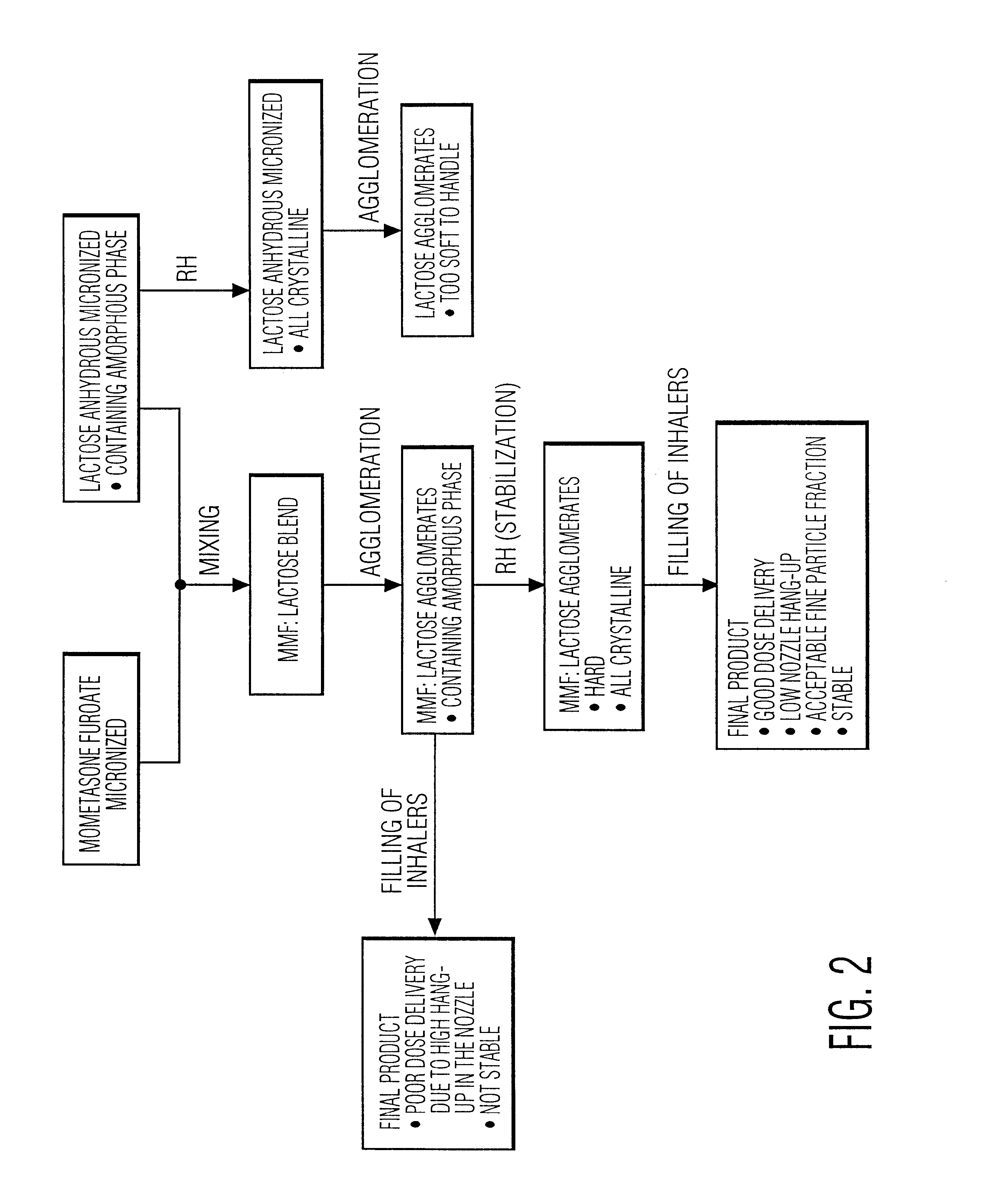

Preparation of powder agglomerates

The invention relates to a method of producing an agglomerate of drug and solid binder. The process involves producing individual agglomerate particles and then converting the convertible amorphous content of same, following agglomeration, by the application of, for example, moisture. Agglomerates capable of conversion as well as the finished agglomerates and oral and nasal dosing systems including same are also contemplated. The process produces agglomerates which are rugged but which will produce an acceptable fine particle fraction during dosing.

Owner:MERCK SHARP & DOHME CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com