Granular heating non-combustible tobacco matrix and preparation method thereof

A heat-not-burn, granular technology, applied in the direction of tobacco, tobacco preparation, tobacco processing, etc., to achieve the effect of increasing the specific surface area, reducing harmful components, and meeting the requirements of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

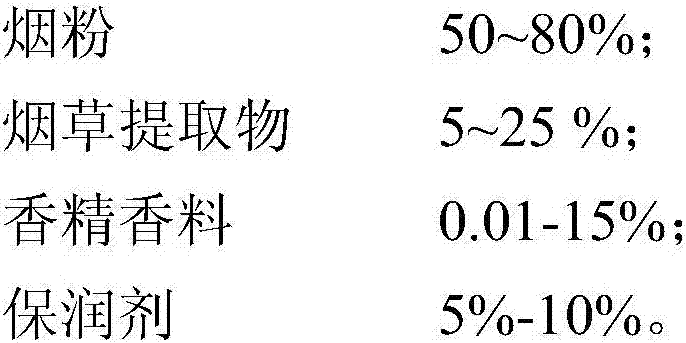

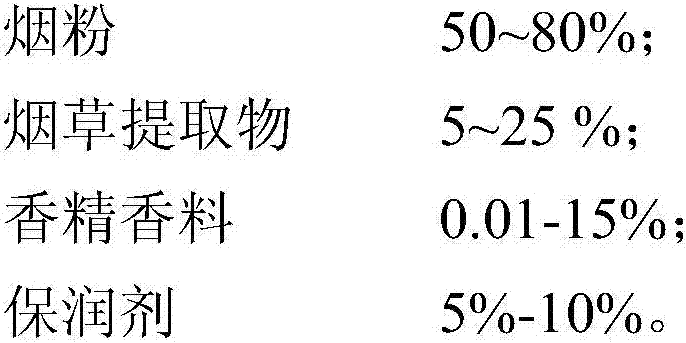

Method used

Image

Examples

Embodiment 1

[0040] (1) Take 60g of tobacco powder, 35g of flavor and fragrance and tobacco extract and mix together, then add 5g of propylene glycol glycerol, 30g of ethanol, and mix well to prepare soft material;

[0041] (2) The soft material is granulated through a 10-mesh sieve by the extrusion method, and the wet granules are dried in a blast dryer at 40~50℃ for 3 hours, aired to room temperature, and placed in a 20-mesh medicine sieve for granulation. The diameter is 0.83mm granular matrix.

[0042] (3) Fill the particle matrix directly into the heat-not-burn cartridge. The cartridge is cylindrical with a length of 30mm and a bottom diameter of 8-10mm. After the particles are filled, the test draw resistance is 883pa. The sensory evaluation results in good smoke uniformity. , The amount of aroma is moderate, the fragrance of smoke is more transparent, and the amount of smoke is sufficient.

Embodiment 2

[0044] (1) Take 60g of tobacco powder, 35g of flavor and fragrance and tobacco extract and mix together, then add 5g of propylene glycol glycerol, 30g of ethanol, and mix well to prepare soft material;

[0045] (2) The soft material is granulated through a 10-mesh sieve by the extrusion method, and the wet granules are dried in a blast dryer at 40~50℃ for 3h, aired to room temperature, and placed in a 24-mesh medicine sieve for granulation. The diameter is 0.70mm granular matrix.

[0046] (3) Fill the particle matrix directly into the heat-not-burn cartridge. The cartridge is cylindrical with a length of 30mm and a bottom diameter of 8-10mm. After the particles are filled, the test draw resistance is 961pa, and the sensory evaluation results in good smoke uniformity. , The amount of aroma is moderate, the fragrance of smoke is more transparent, and the amount of smoke is sufficient.

Embodiment 3

[0048] (1) Take 60g of tobacco powder, 35g of flavors and fragrances and tobacco extract and mix together, then add 10g of propylene glycol glycerol, 30g of ethanol, and mix well to prepare soft material;

[0049] (2) The soft material is granulated through a 10-mesh sieve by the extrusion method, and the wet granules are dried in a blast dryer at 40~50℃ for 3h, aired to room temperature, and placed in a 24-mesh medicine sieve for granulation. The diameter is 0.70mm granular matrix.

[0050] (3) Fill the particle matrix directly into the heat-not-burn cartridge. The cartridge is cylindrical, 30mm long, and has a bottom diameter of 8-10mm. After the particles are filled, the test suction resistance is 981pa. The sensory evaluation results in good smoke uniformity. , The amount of fragrance is moderate, the fragrance of smoke is more transparent, and the amount of smoke is sufficient.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com