Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

143results about How to "Raise the outlet temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phospholipid-based powders for drug delivery

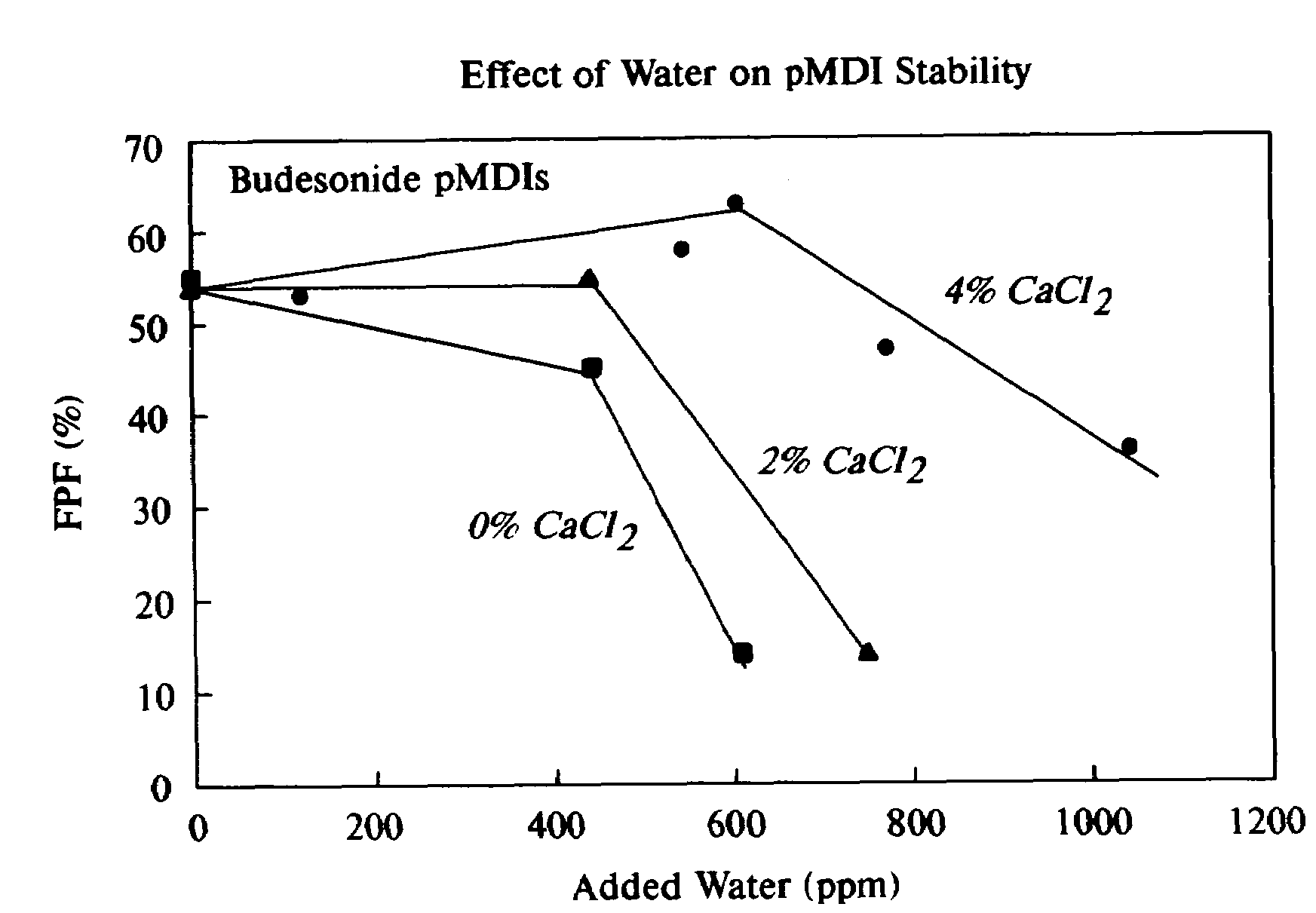

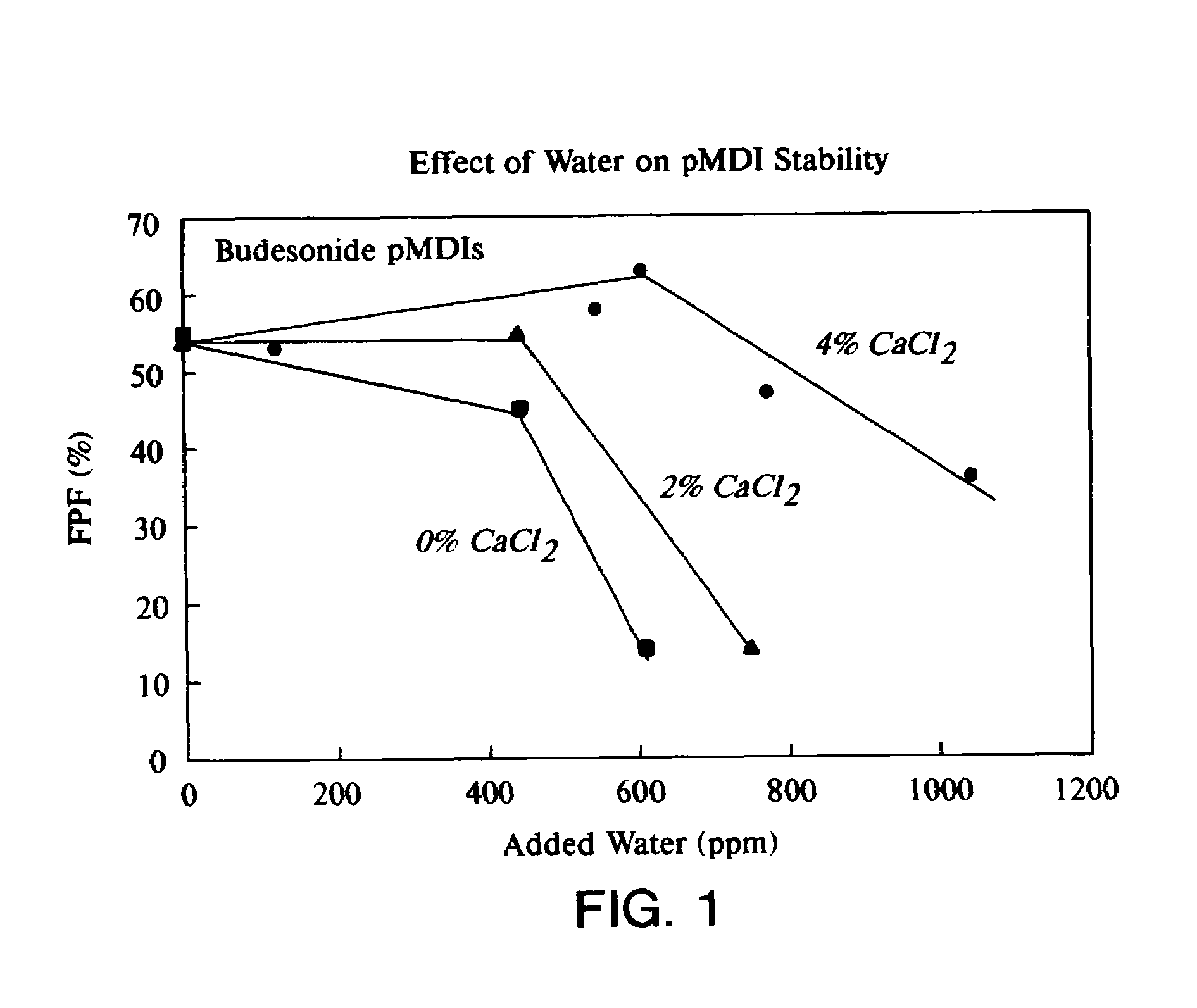

InactiveUS7442388B2Raise the inlet temperatureRaise the outlet temperaturePowder deliveryBiocidePrillMedicine

Phospholipid based powders for drug delivery applications are disclosed. The powders comprise a polyvalent cation in an amount effective to increase the gel-to-liquid crystal transition temperature of the particle compared to particles without the polyvalent cation. The powders are hollow and porous and are preferably administered via inhalation.

Owner:NOVARTIS AG

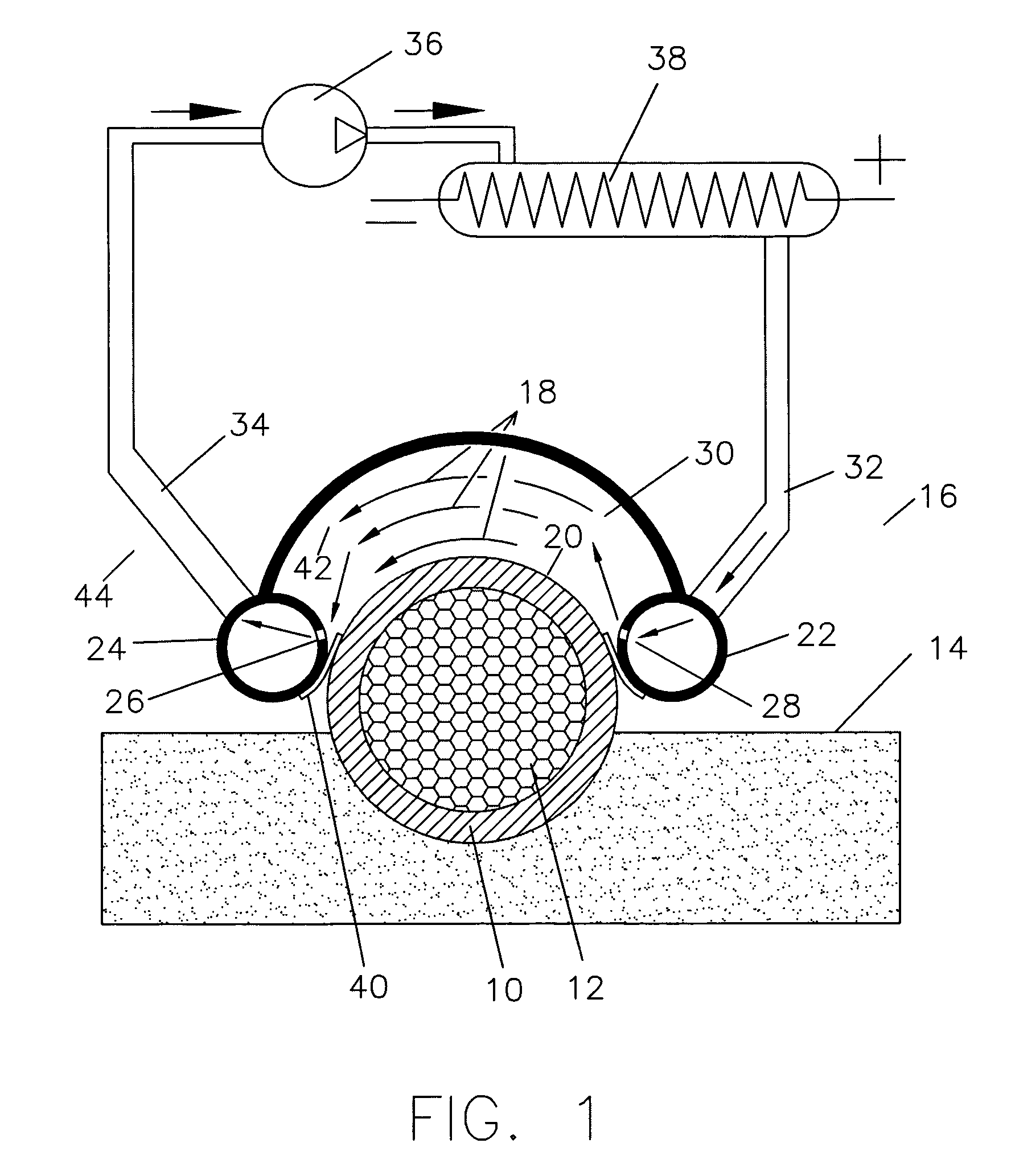

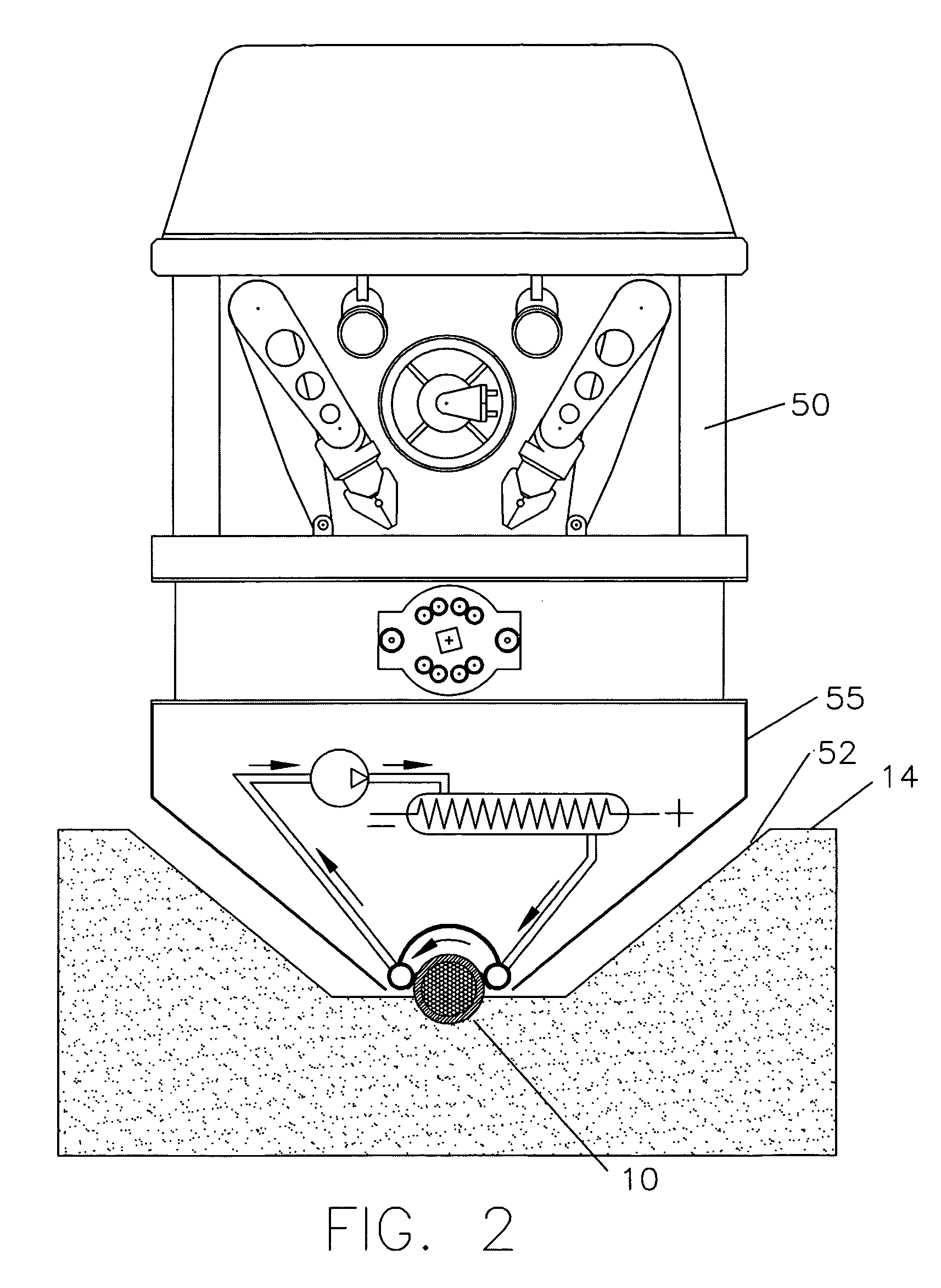

Subea pipeline blockage remediation method

InactiveUS6939082B1Raise the outlet temperatureMinimize disturbanceUnderground chambersPipe heating/coolingOcean bottomMarine engineering

The method of taking a remotely operated vehicle to the ocean floor to land on and move along a subsea pipeline above or below the seafloor and repeatedly circulate seawater which has been heated electrically, mechanically, or chemically across the outer surface of the pipeline to melt hydrates or paraffins which have formed on the inside of the pipeline.

Owner:BAUGH BENTON F

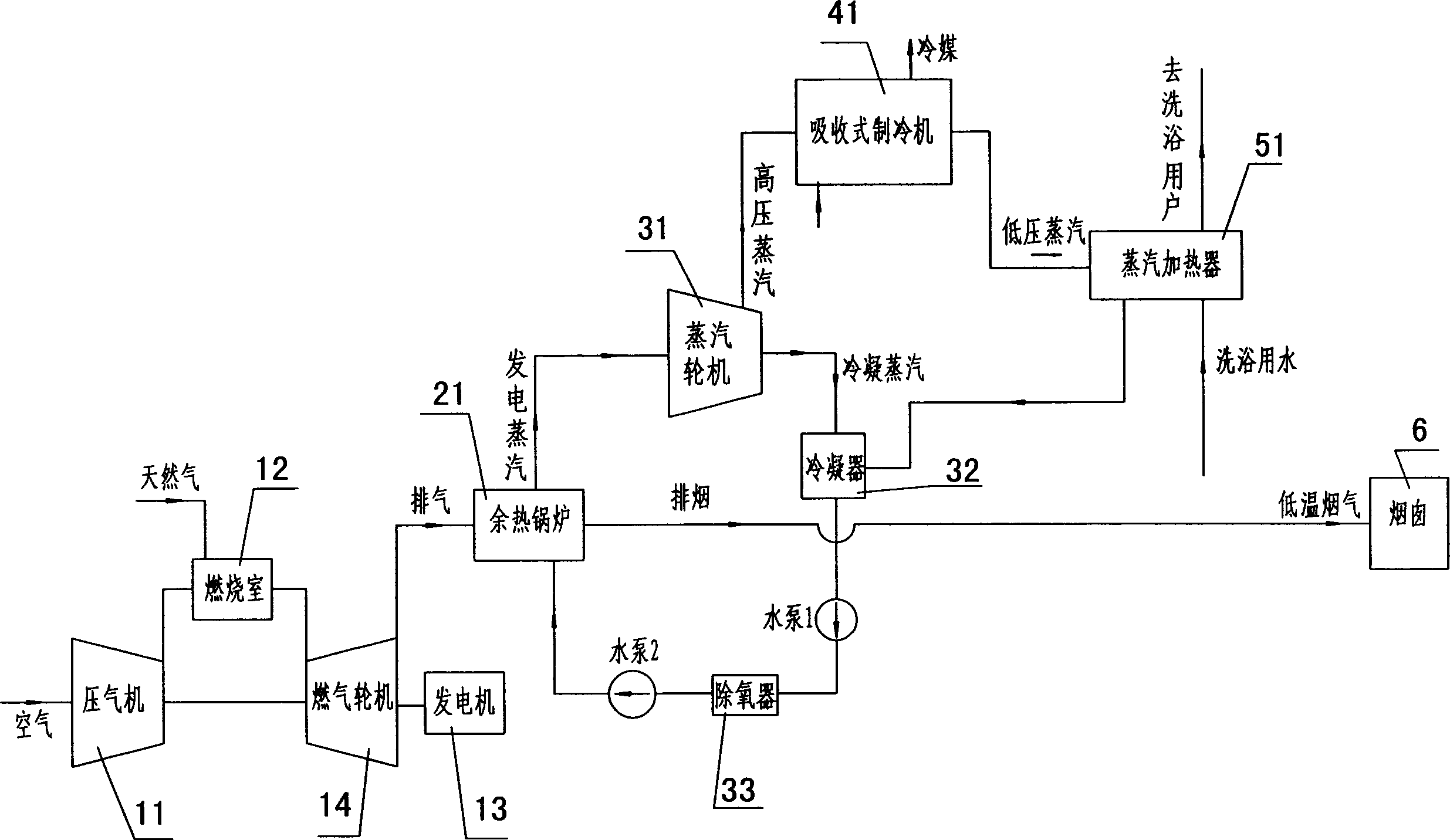

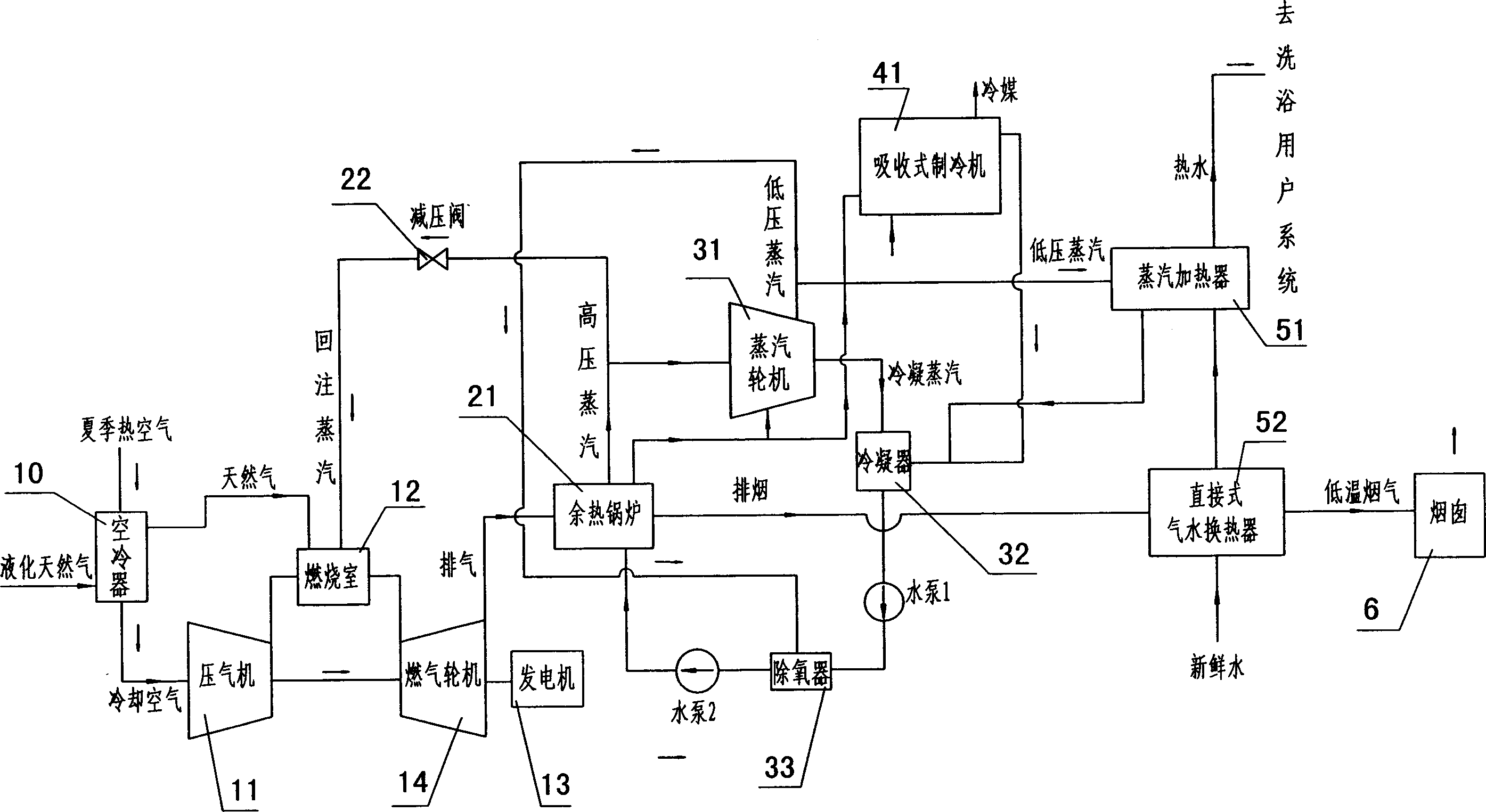

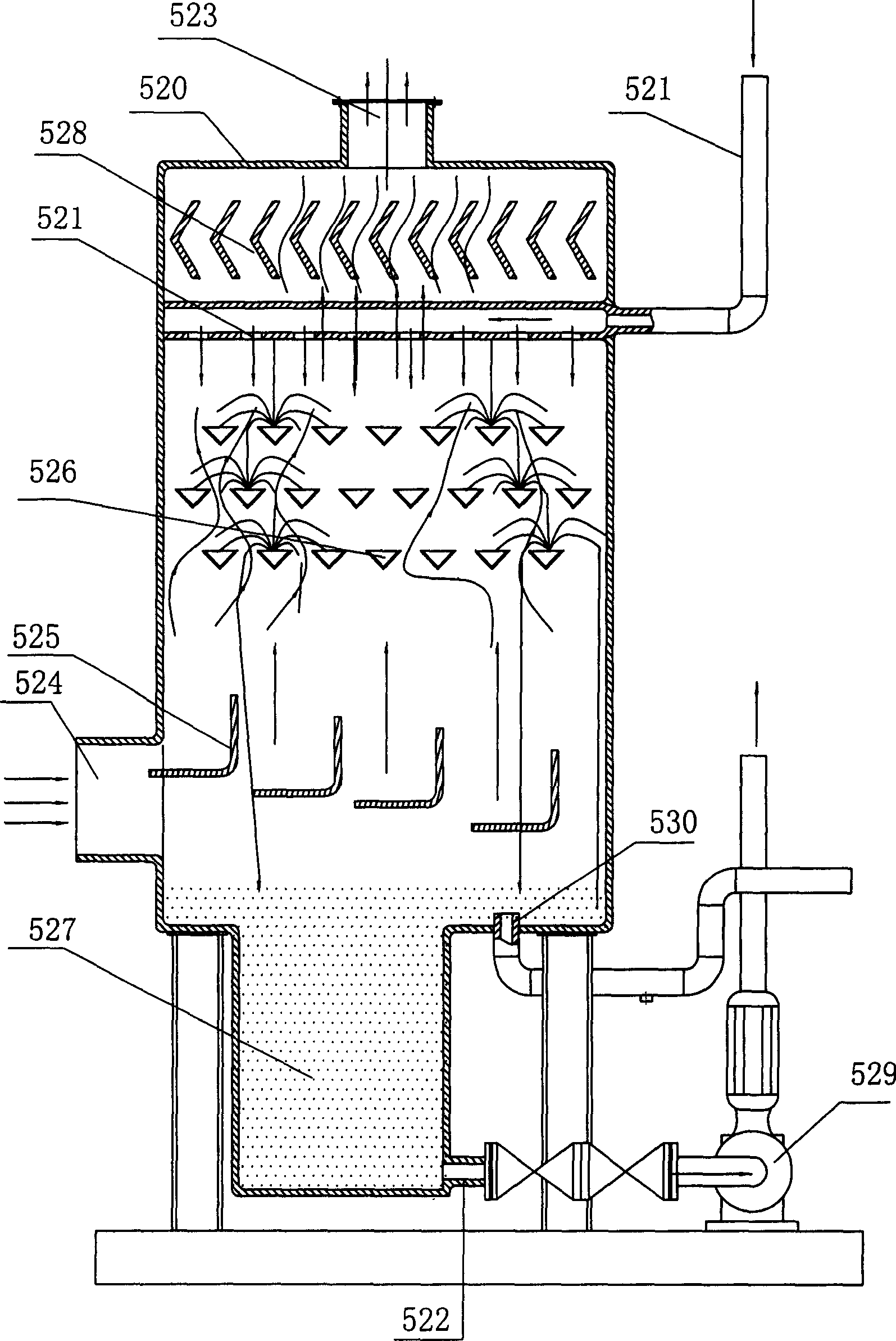

Smoke low-temperature residual heat utilization system with natural gas cooling-heating combined power device and operating method thereof

InactiveCN1807860AIncrease flexibility and economyRaise the outlet temperatureClimate change adaptationGas turbine plantsCombustion chamberHeating efficiency

The invention relates to a smoke low-temperature heat utilization system of natural gas cold-heat electric supply and relative operation method. Said system comprises a fuel gas generator, a waste heat boiler, an adsorption refrigerator, and a heating water supply device. Wherein, the heating water supply device comprises a direct gas-water heat exchanger which contains a gondola water faucet whose water channel forms the smoke channel; the smoke outlet of waste heat boiler is connected to the chimney via the direct gas-water heat exchanger; the water inlet and outlet pipes of direct gas-water heat exchanger are serially connected to the pipe of life hot water or water supply; the gas transmission pipe of waste heat boiler has a branch of the reflux gas pipe connecting the burning of fuel gas generator; and the reflux gas pipe is serially connected with a depressurizing device. The invention has simple heat transmission device, lower cost, improved heat efficiency and improved economic benefits.

Owner:SOUTH CHINA UNIV OF TECH

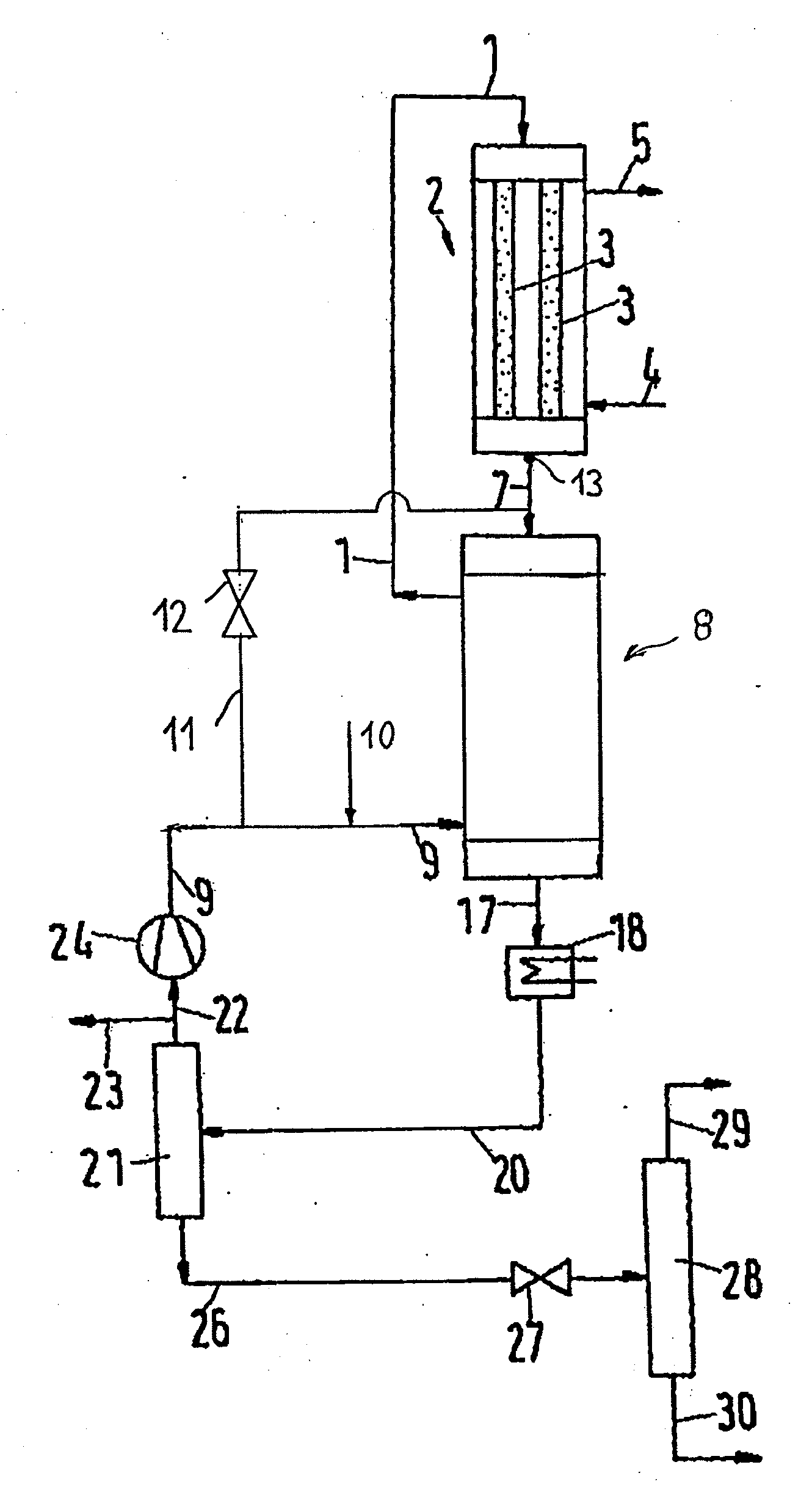

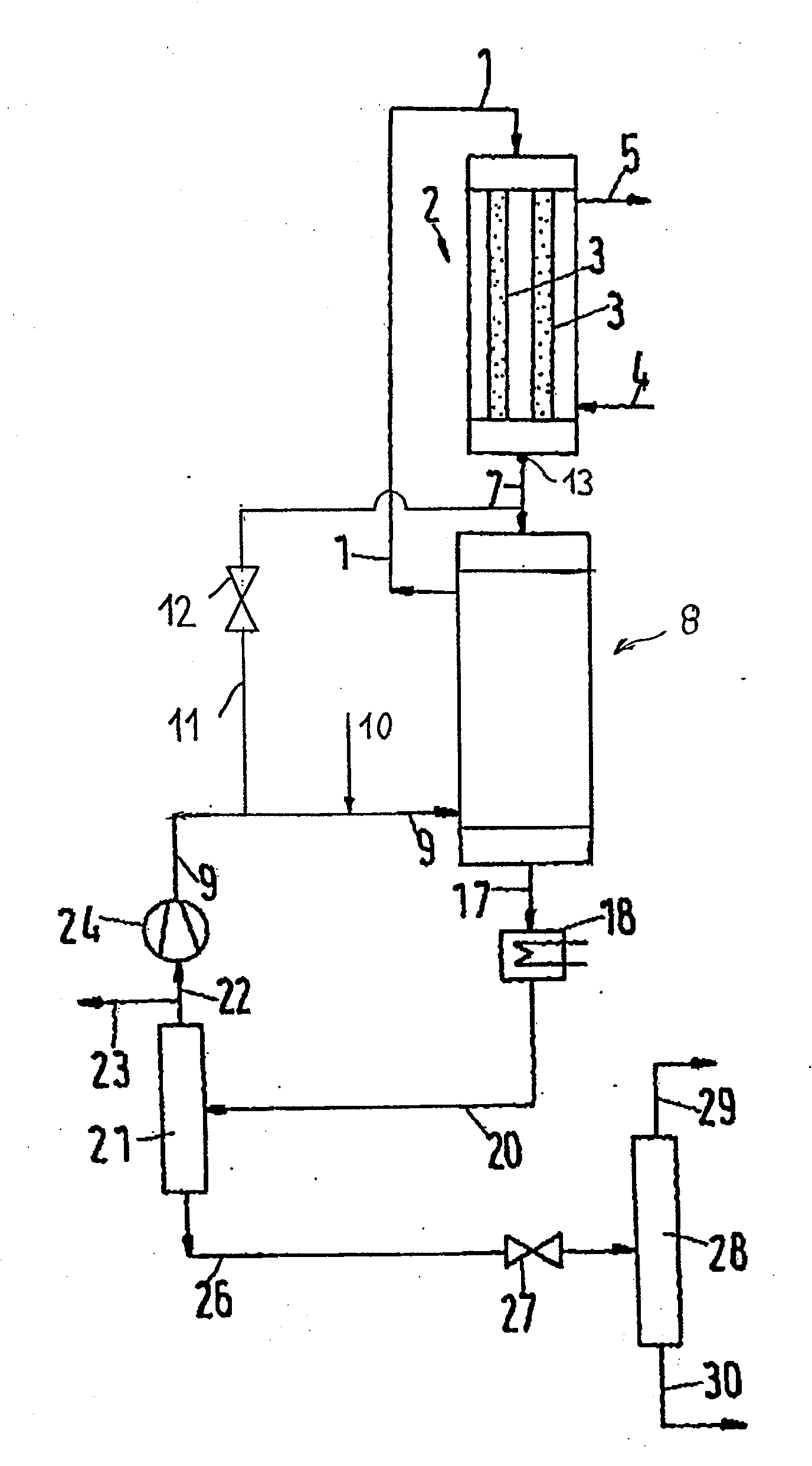

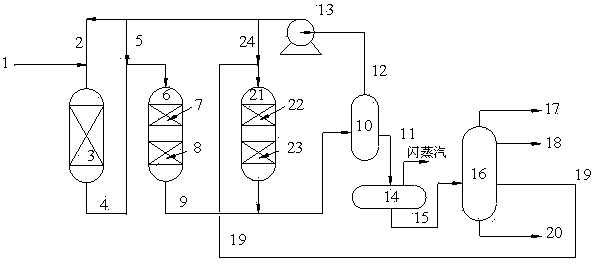

Process and plant for producing methanol

ActiveUS20110065966A1Raise the outlet temperatureHigh yieldOrganic compound preparationOxygen compounds preparation by reductionHydrogenCarbon oxide

In the production of methanol from a synthesis gas containing hydrogen and carbon oxides, the synthesis gas is passed through a first, preferably water-cooled reactor, in which a part of the carbon oxides is catalytically converted to methanol. The obtained mixture containing synthesis gas and methanol vapor is supplied to a second, preferably gas-cooled reactor, in which a further part of the carbon oxides is converted to methanol. Subsequently, methanol is separated from the synthesis gas, and the synthesis gas is recirculated to the first reactor. To achieve a maximum methanol yield even with an aged catalyst, a partial stream of the synthesis gas is guided past the first reactor and introduced directly into the second reactor.

Owner:LURGI

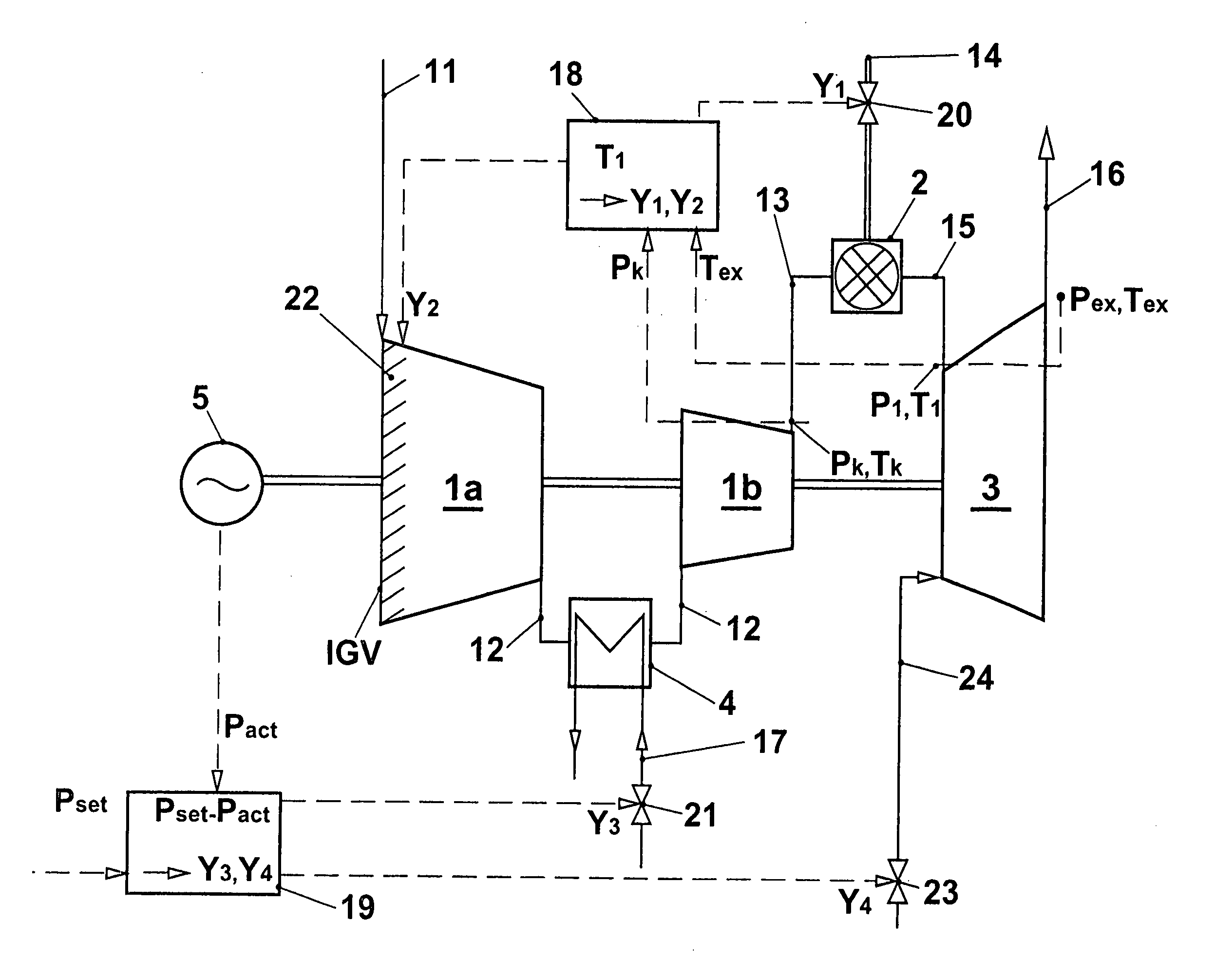

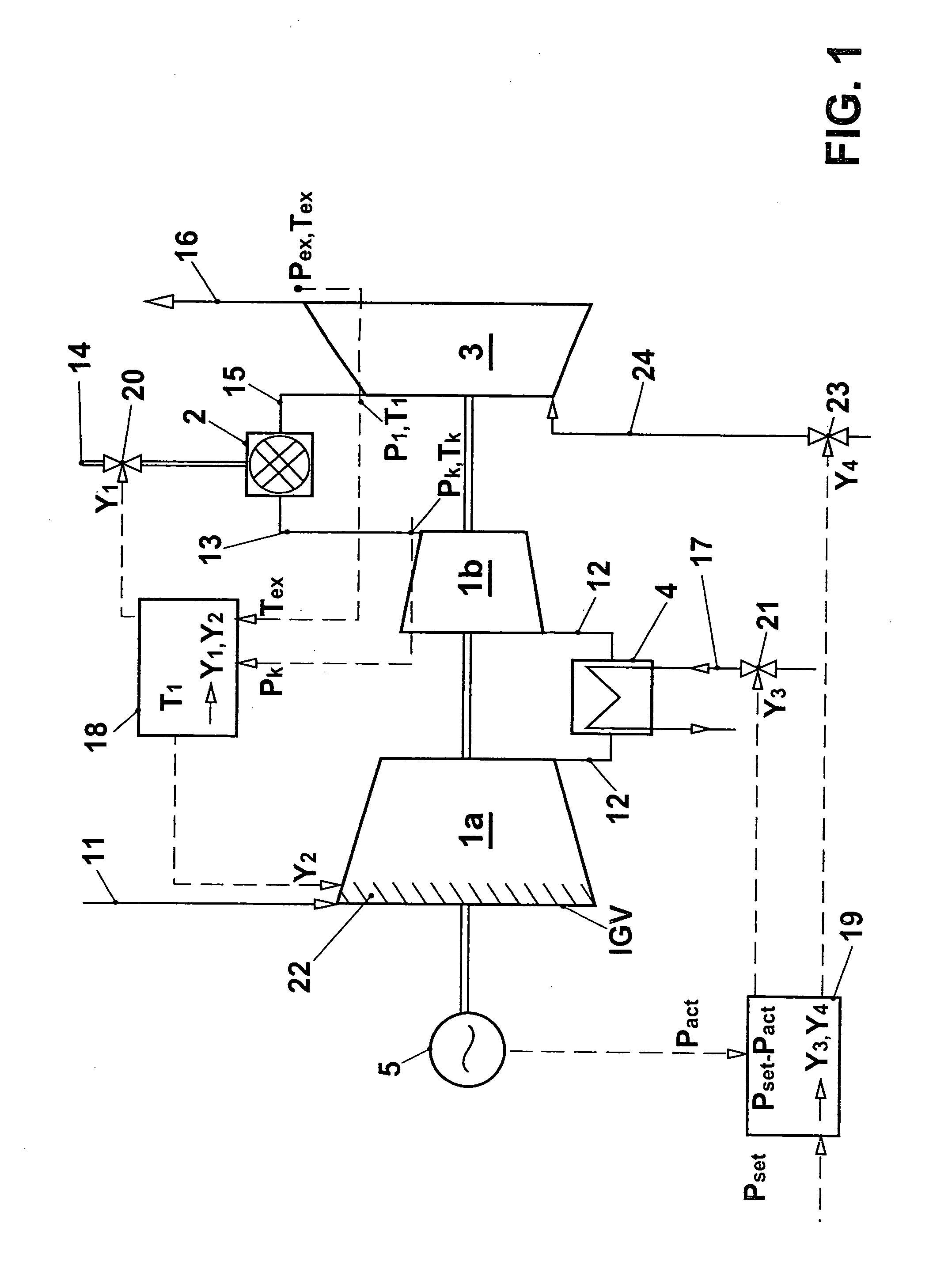

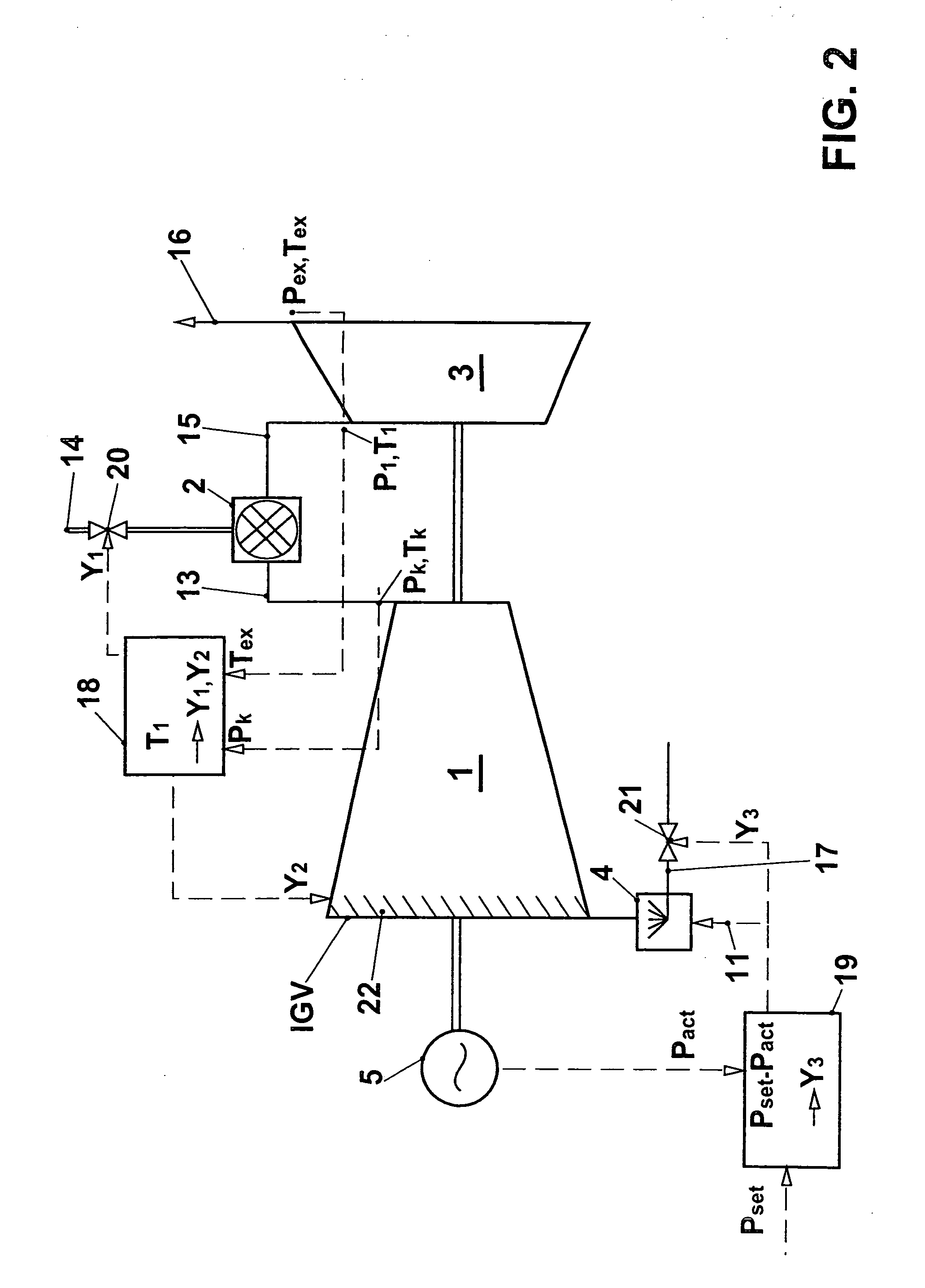

Method for operating a gas turbine group

InactiveUS20050109033A1Increase powerReduces compressor outlet temperatureEngine fuctionsGas turbine plantsCooling powerLimit value

A gas turbine group is provided with at least one cooling apparatus for cooling the working medium before and / or during the compression. The cooling power of the cooling apparatus can be adjusted by suitable means. A controller controls the cooling power of the cooling apparatus as a function of a control deviation in the useful power of the gas turbine group. The cooling controller interacts with other controllers of the gas turbine group in such a way that the gas turbine group is itself always operated at least close to its full load operating state. In this context, it is preferable for the inlet guide vane row of the compressor to be maximally open, and for the hot-gas temperature on entry into the turbines to be controlled so that it is constantly at an upper limit value.

Owner:ANSALDO ENERGIA IP UK LTD

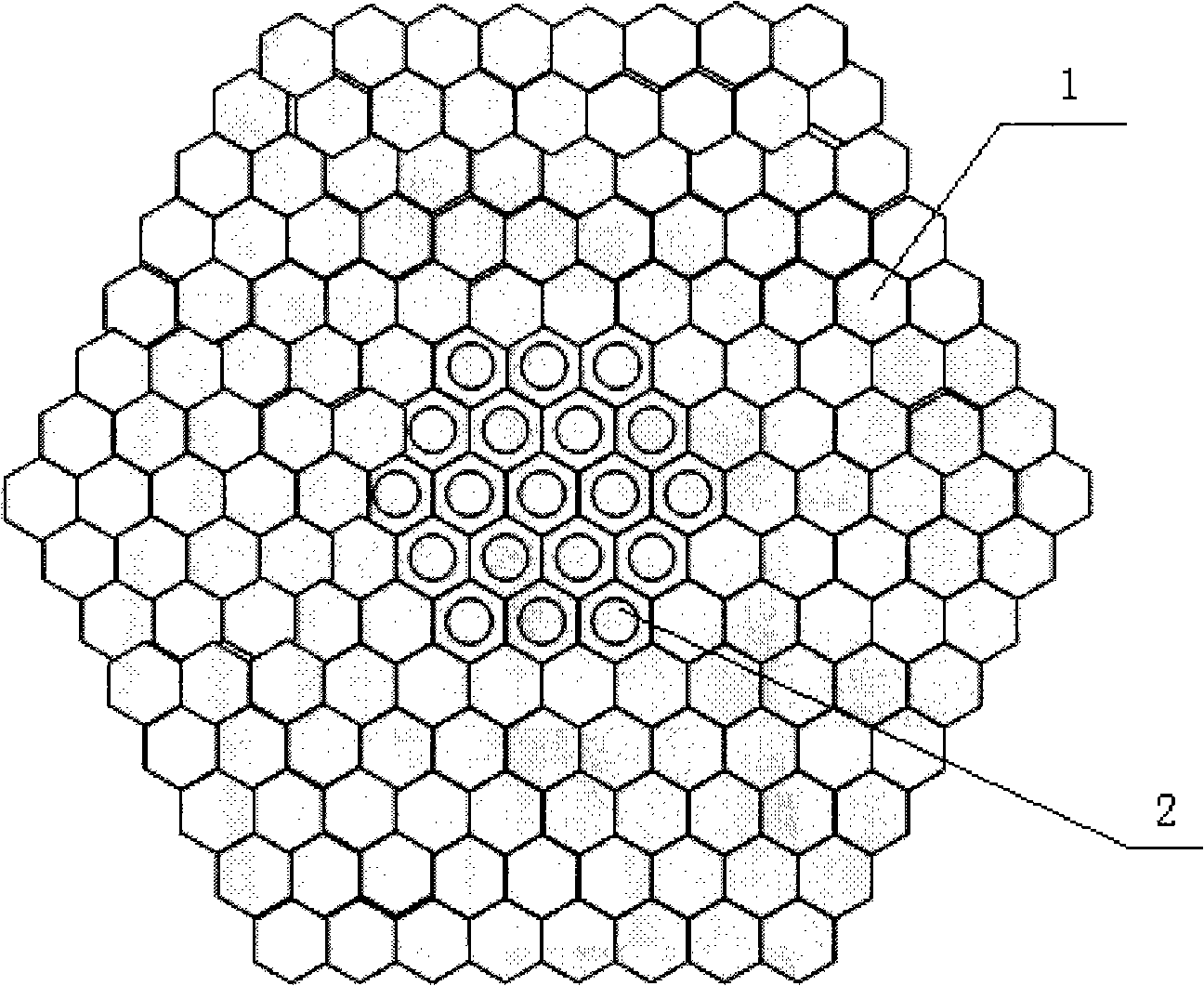

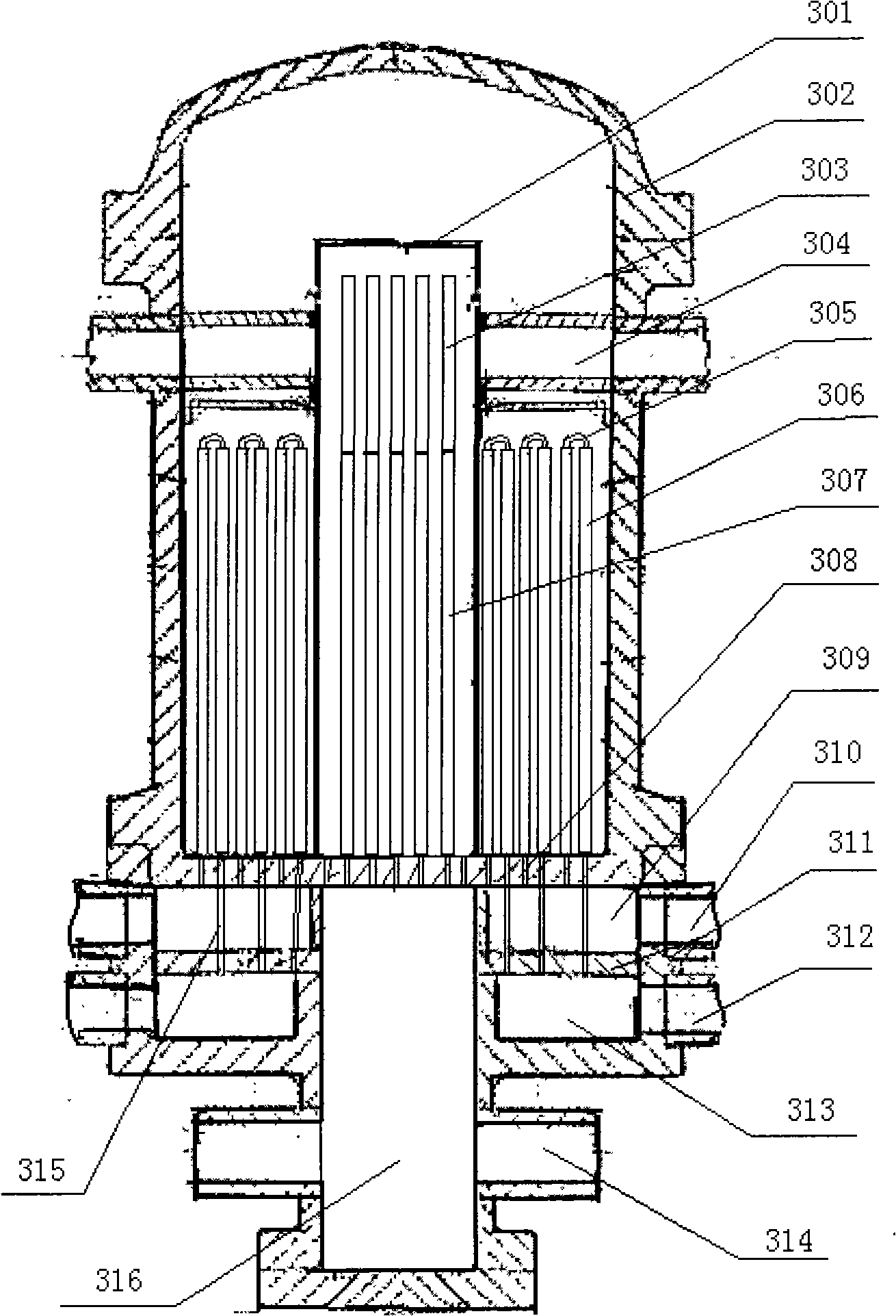

Stack core of water-cooling double-section breeding nuclear reactor as well as nuclear reactor using the same

InactiveCN101299351AIncrease temperatureInclusiveNuclear energy generationShieldingNuclear reactor coreNuclear reactor

The invention belongs to the technical field of the nuclear reactor engineering, particularly to the water-cooling two-region multiplication nuclear reactor core and the nuclear reactor adopting the same, wherein the water-cooling two-region multiplication nuclear reactor core includes a fast neutron energy spectrum area adopting the coating grain sheath fuel assembly and a thermal neutron energy spectrum area adopting the dense rod bundle fuel assembly or the coating grain sheath fuel assembly. The water-cooling two-region multiplication nuclear reactor core of the invention adopts the coating grain sheath fuel assembly, which breaks through the restrain of the stainless steel shell to the outlet scream temperature, realizes the higher coolant outlet temperature, meanwhile the fast neutron core is leaked to the thermal neutron energy spectrum core constituted by the rod bundle fuel assembly dense boom at the subcritical to be multiplied.

Owner:张育曼 +1

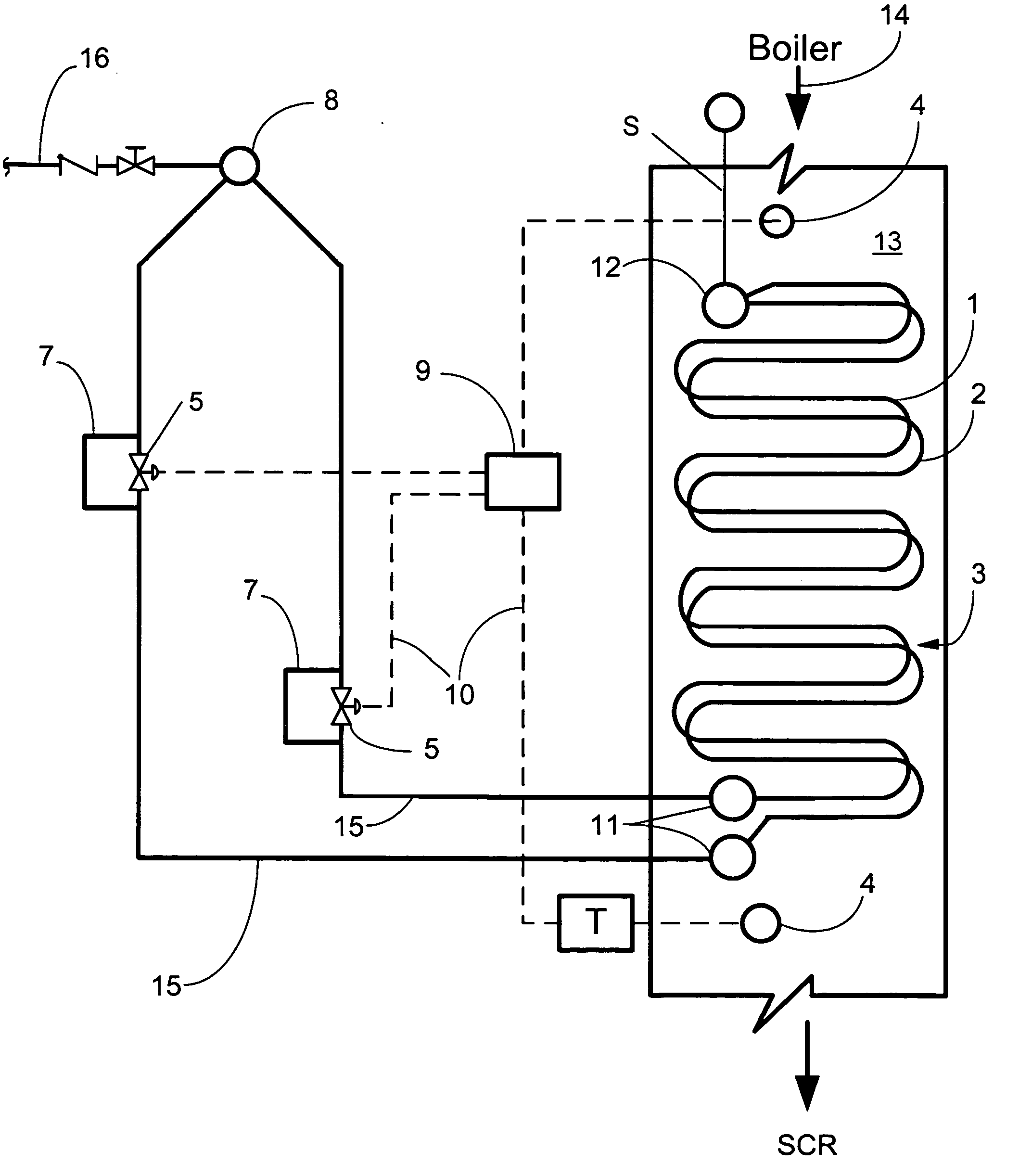

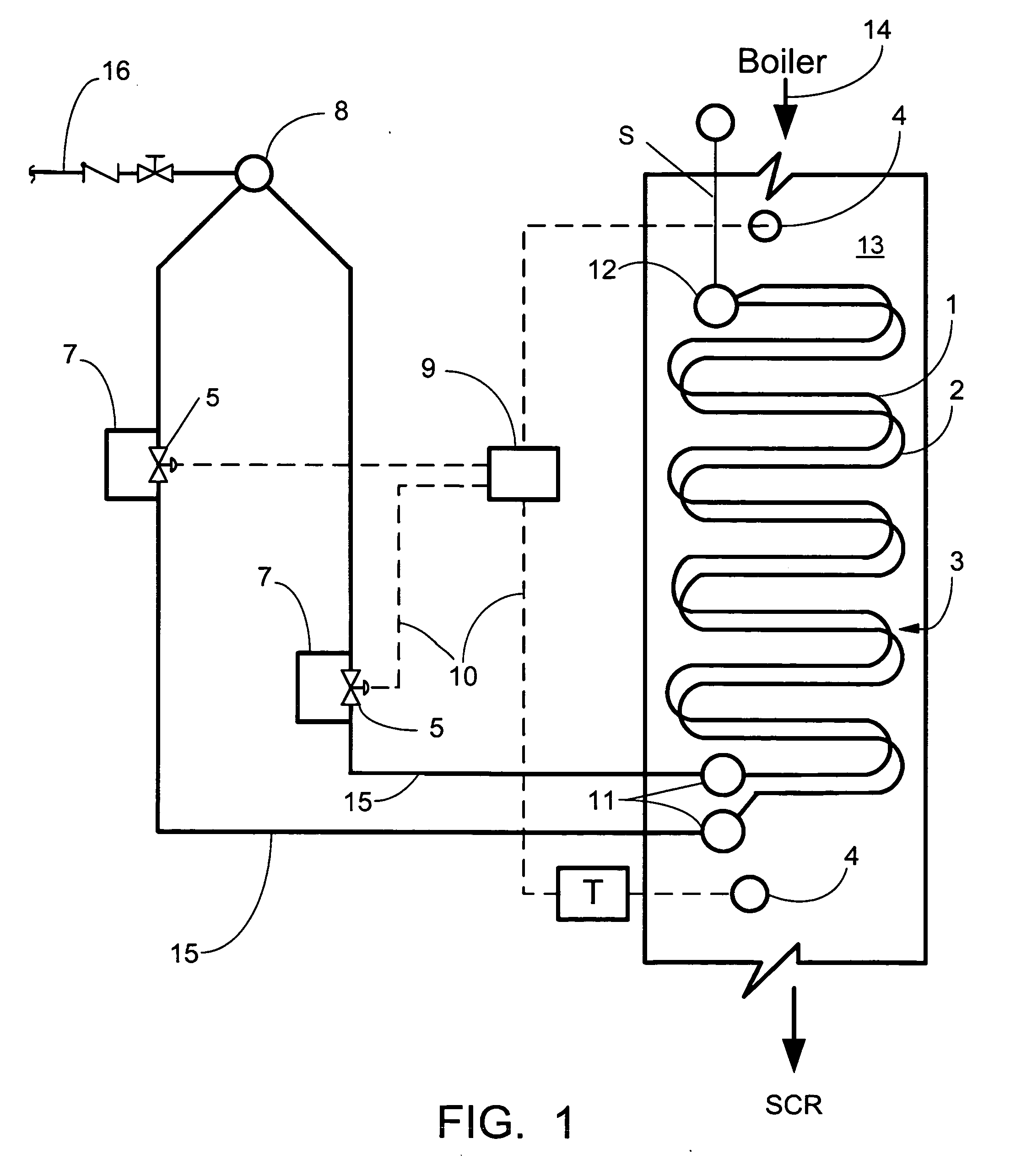

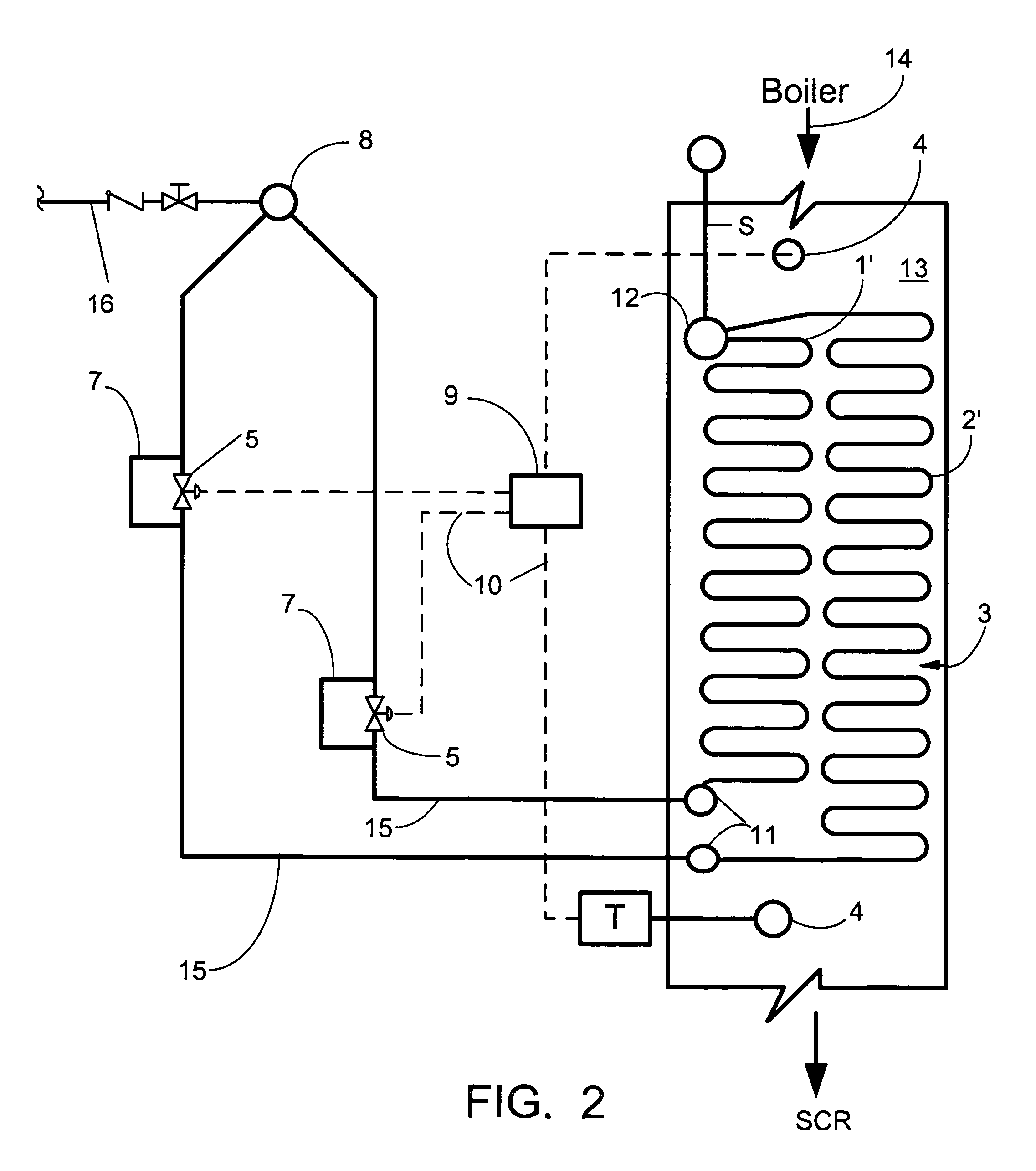

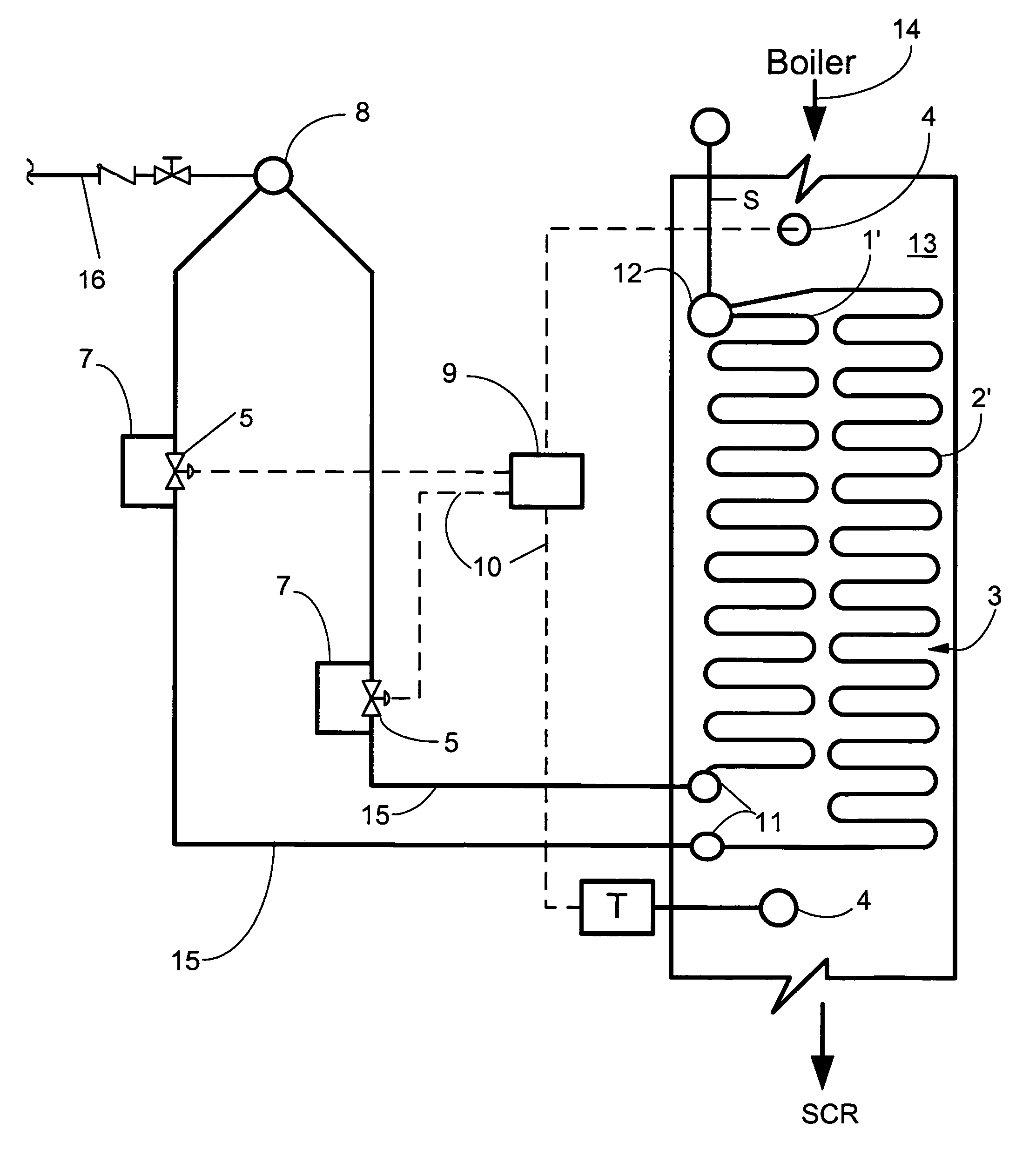

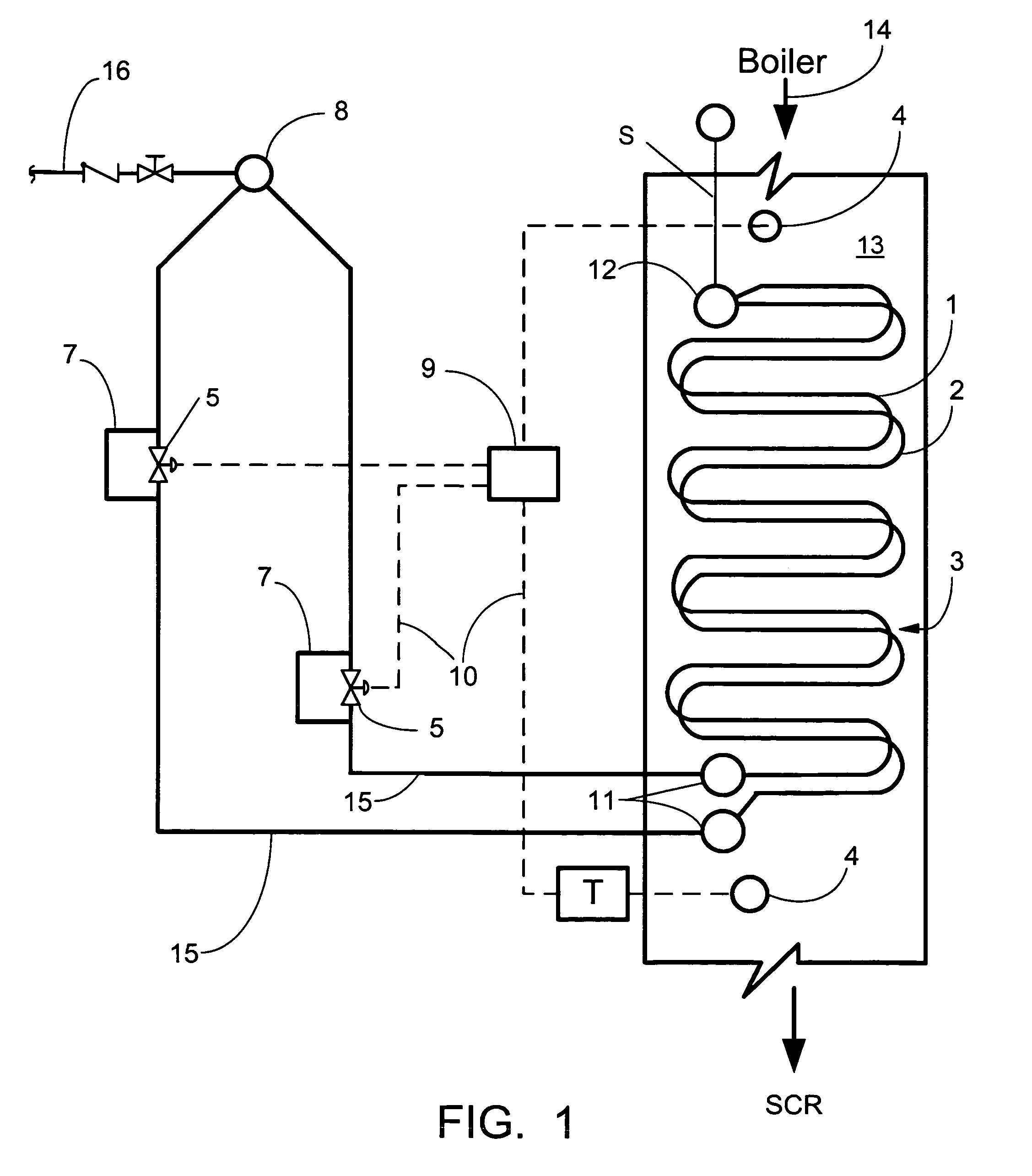

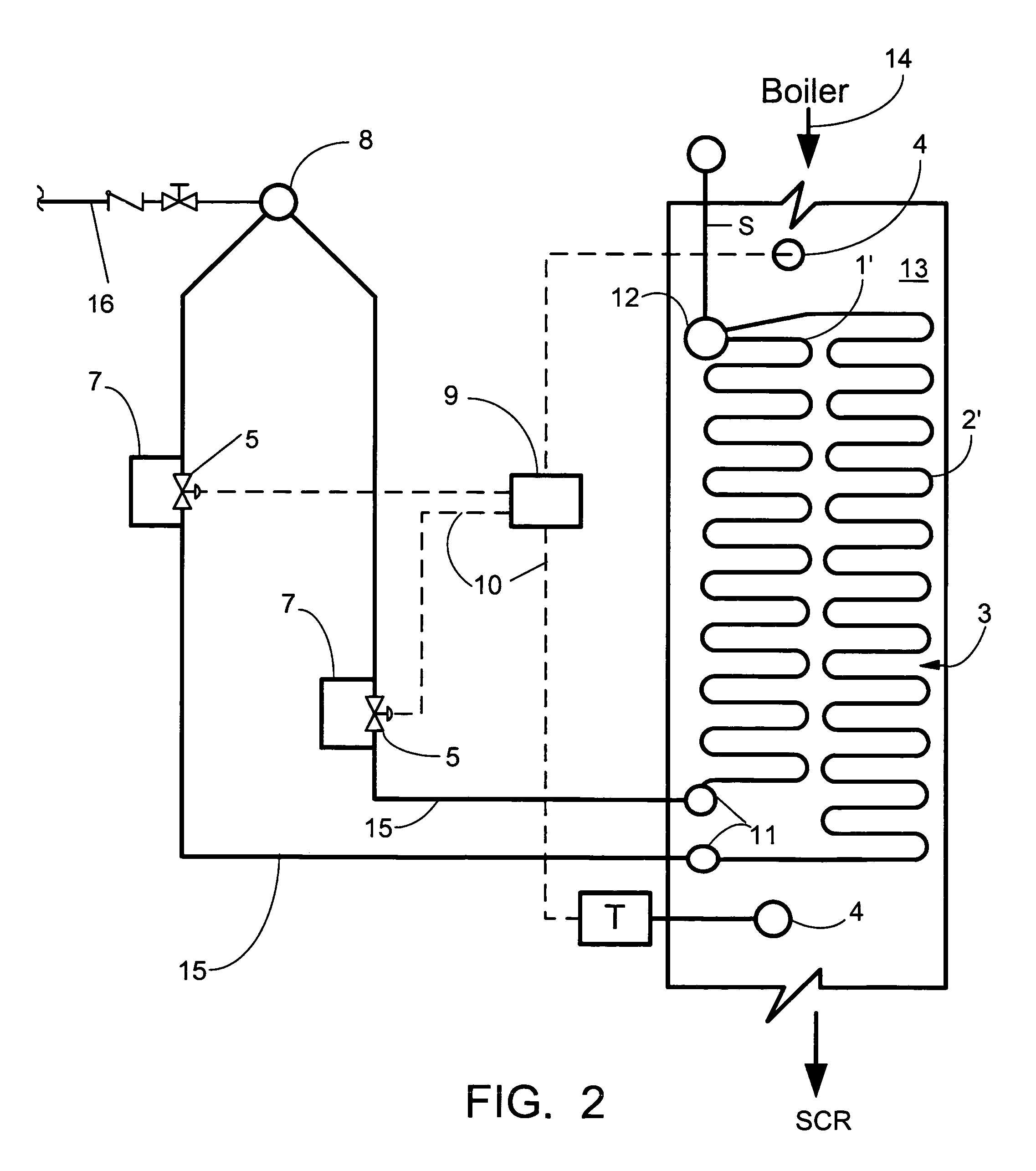

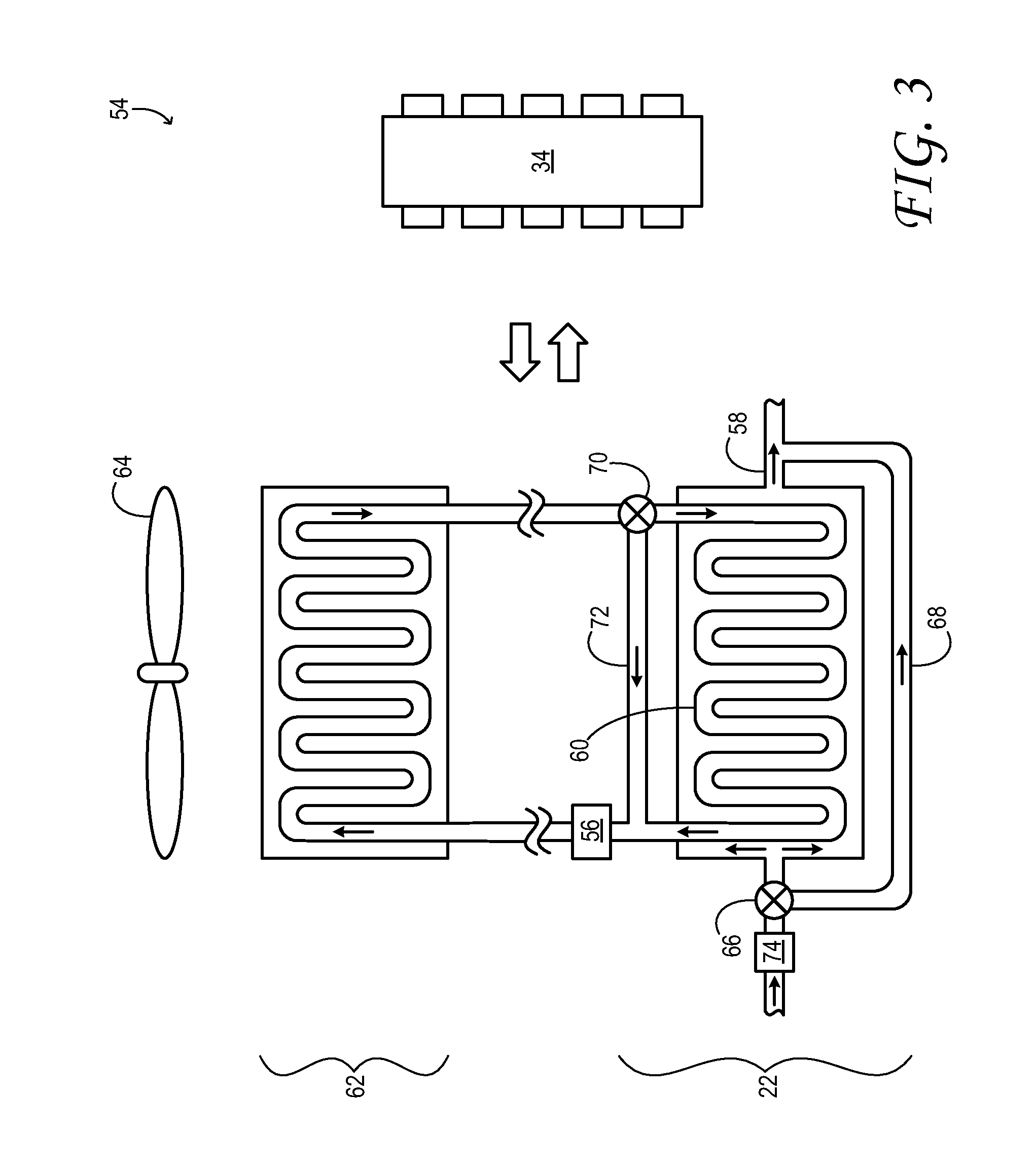

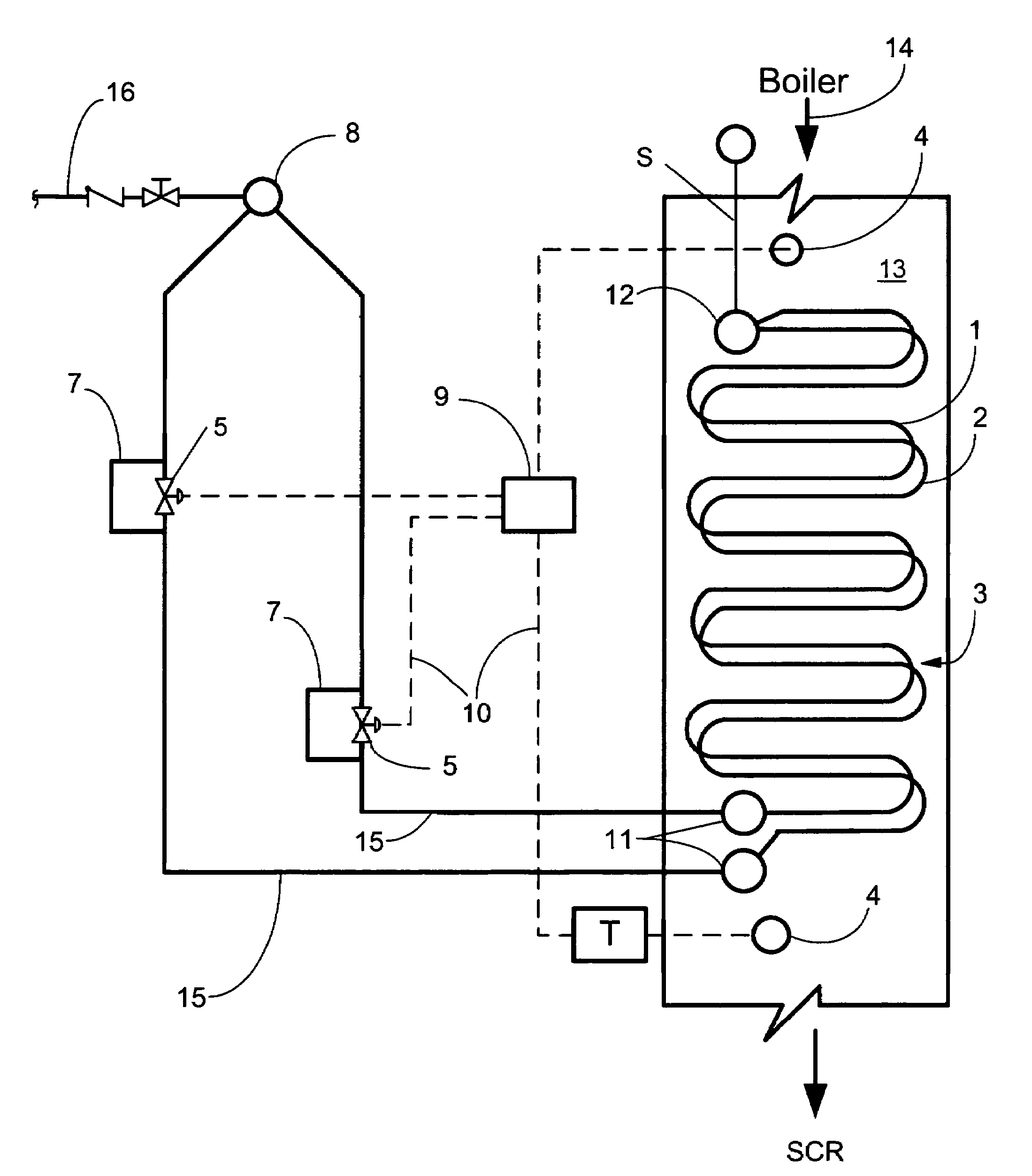

Multiple pass economizer and method for SCR temperature control

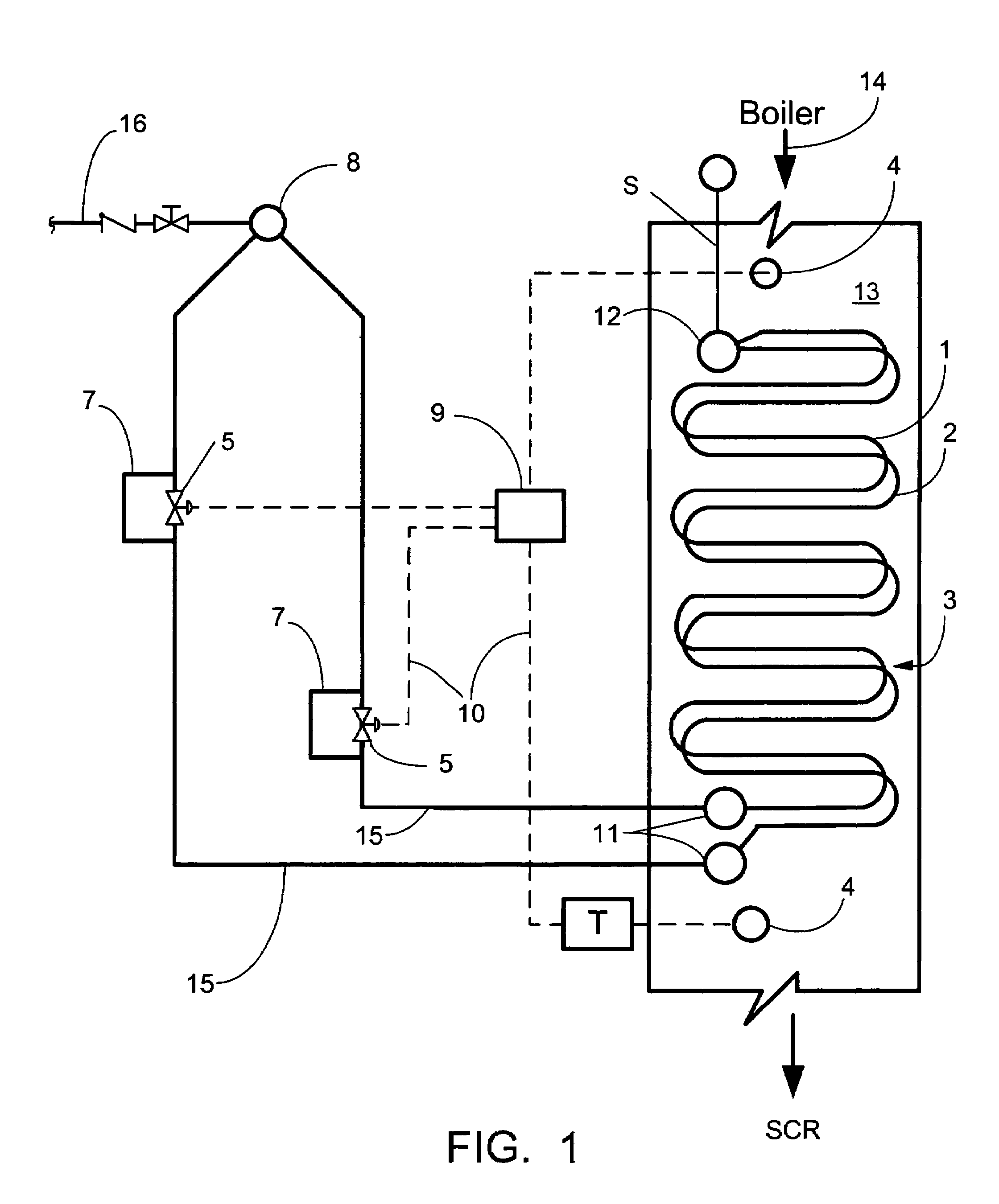

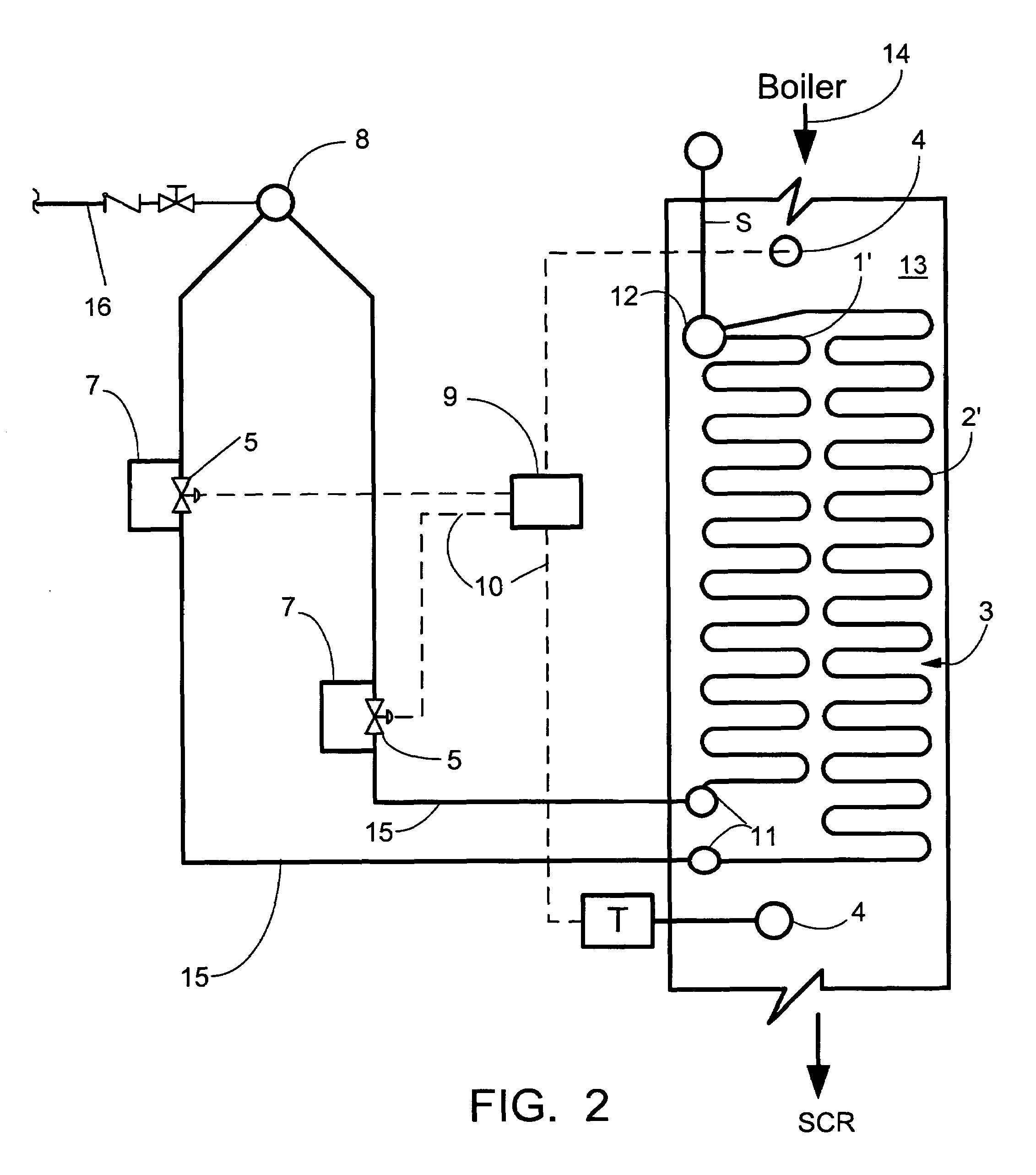

InactiveUS20070261647A1Raise outlet temperatureReduce water flowWater circulationFuel injection apparatusFlueProduct gas

A gas temperature control system for maintaining a desired economizer outlet gas temperature across a range of boiler loads comprises a plurality of tubular configurations having surfaces that are in contact with the flue gas. Each tubular configuration, preferably, comprises a plurality of serpentine or stringer tubes arranged horizontally or vertically back and forth within the economizer, and each tubular configuration having a separate feedwater inlet. Heat transfer from the flue gas is accomplished by controlling the feedwater flow rates through the tubular configurations. In a temperature control system having two tubular configurations, the overall heat transfer capacity of the economizer may be reduced to maintain the desired economizer outlet gas temperature during low boiler loads by reducing feedwater flow through one tubular configuration and by overflowing the other tubular configuration, such that total flow of feedwater through the economizer is maintained substantially constant. Feedwater flow rate entering the economizer may be used to engage / disengage the economizer water internal proportion or bias system. Once engaged, the measured feedwater flow to the economizer is used to generate a proportioned or biased flow rate demand signal. The demand signal is then compared to the measured underflow proportioned or biased flow rate. If there is a difference between the demand signal flow rate and the measured flow rate, control valve(s) modulating the proportioned or biased flow is / are adjusted.

Owner:THE BABCOCK & WILCOX CO

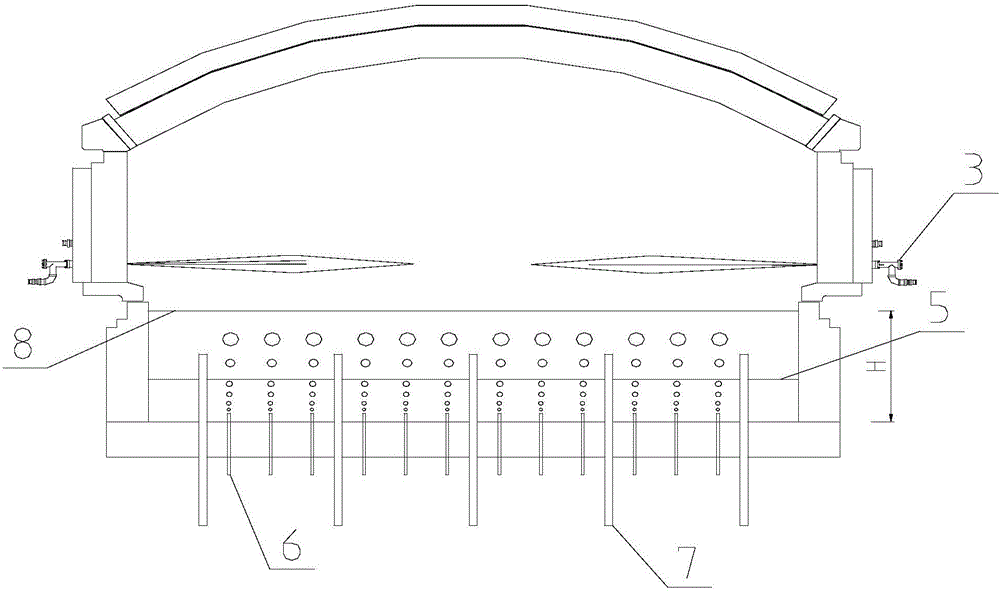

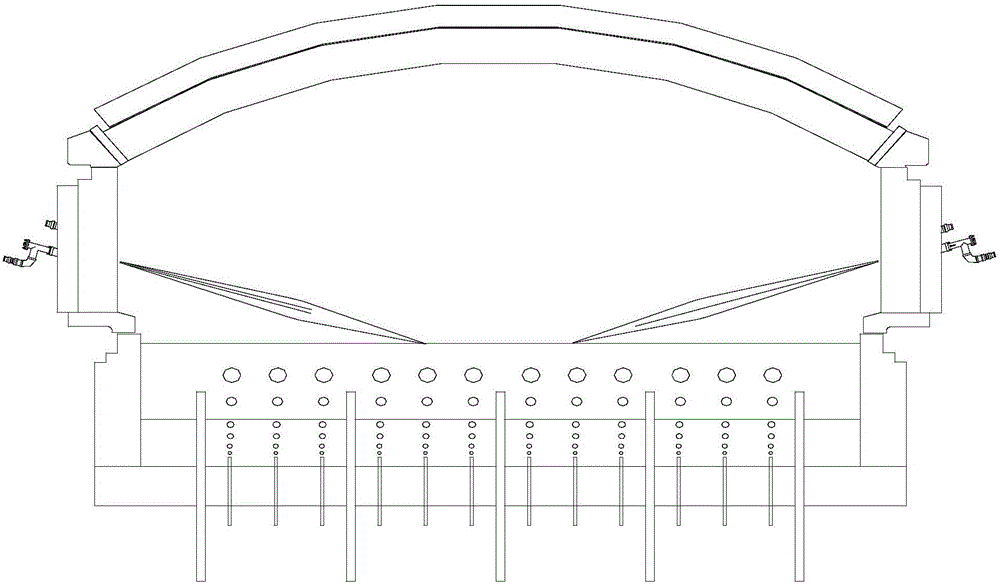

Glass tank furnace with high melting rate

ActiveCN105776819AHigh aspect ratioReduce lossTank furnacesGlass furnace apparatusHeat lossesEngineering

The invention discloses a glass tank furnace with high melting rate. The ratio of the length of the glass tank furnace to the width of the glass tank furnace is 2.3-2.8. The glass tank furnace has the advantages that the area of the tank furnace is reduced and the length-width ratio of the tank furnace is optimized so as to reduce heat loss; reasonable liquid glass tank depth is designed to improve the bottom temperature of the tank furnace and guarantee the quality of liquid glass; a pure-oxygen burner and an auxiliary capacitor provides sufficient energy to increase the melting ability and heating efficiency of the tank furnace, and the energy consumption and the discharge amount of carbon dioxide are lowered greatly; furnace ridges at the bottom of the tank furnace increase the outlet temperature of the liquid glass, lower energy consumption, lower the furnace bottom temperature of an electrode area, prolong the service life of the furnace bottom and guarantee the increasing of auxiliary electric energy proportion; bubbling at the bottom of the tank furnace increases the return strength of the liquid glass and increases the melting ability and the quality of the liquid glass; to sum up, the melting rate of the tank furnace can be increased effectively, and the energy consumption can be lowered.

Owner:JUSHI GRP CO

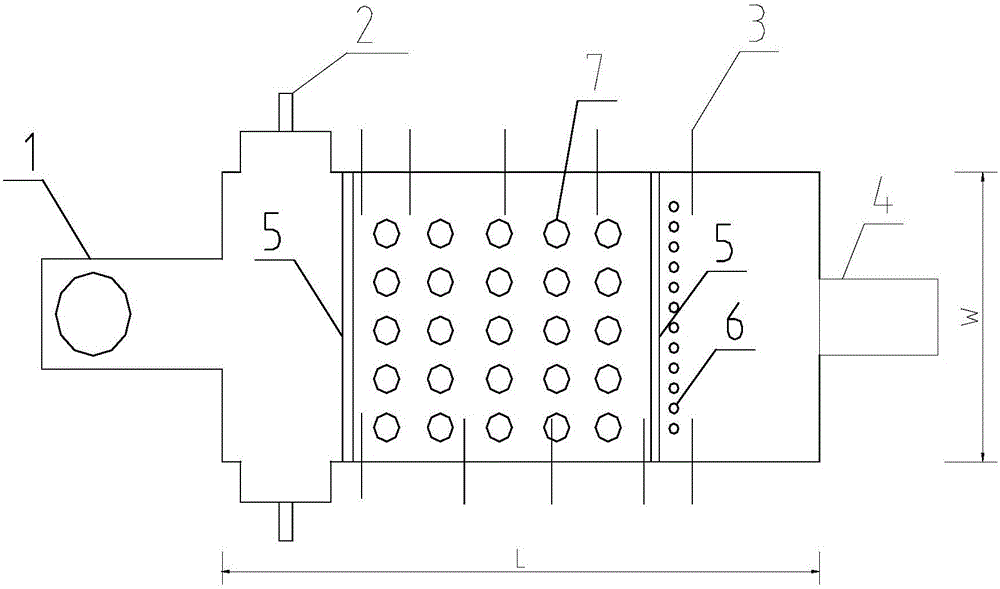

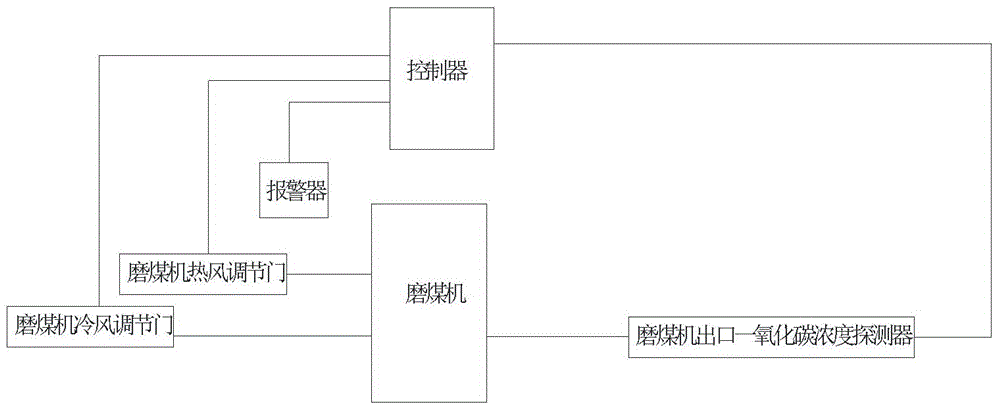

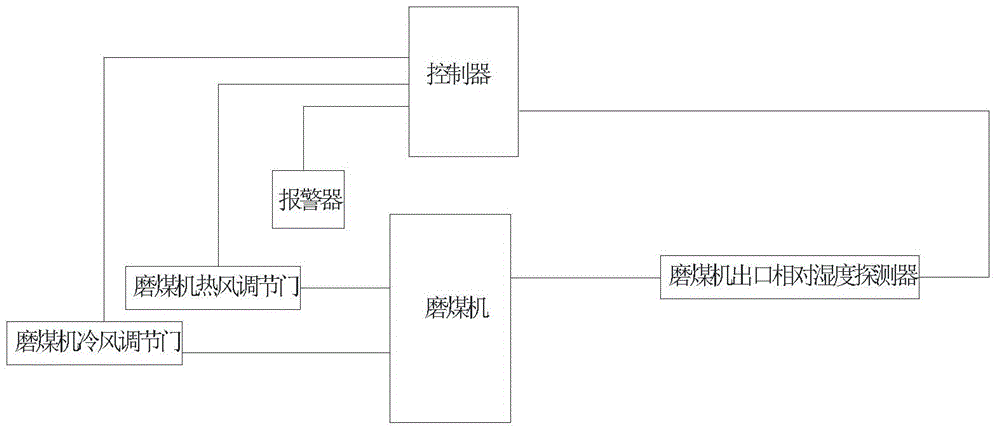

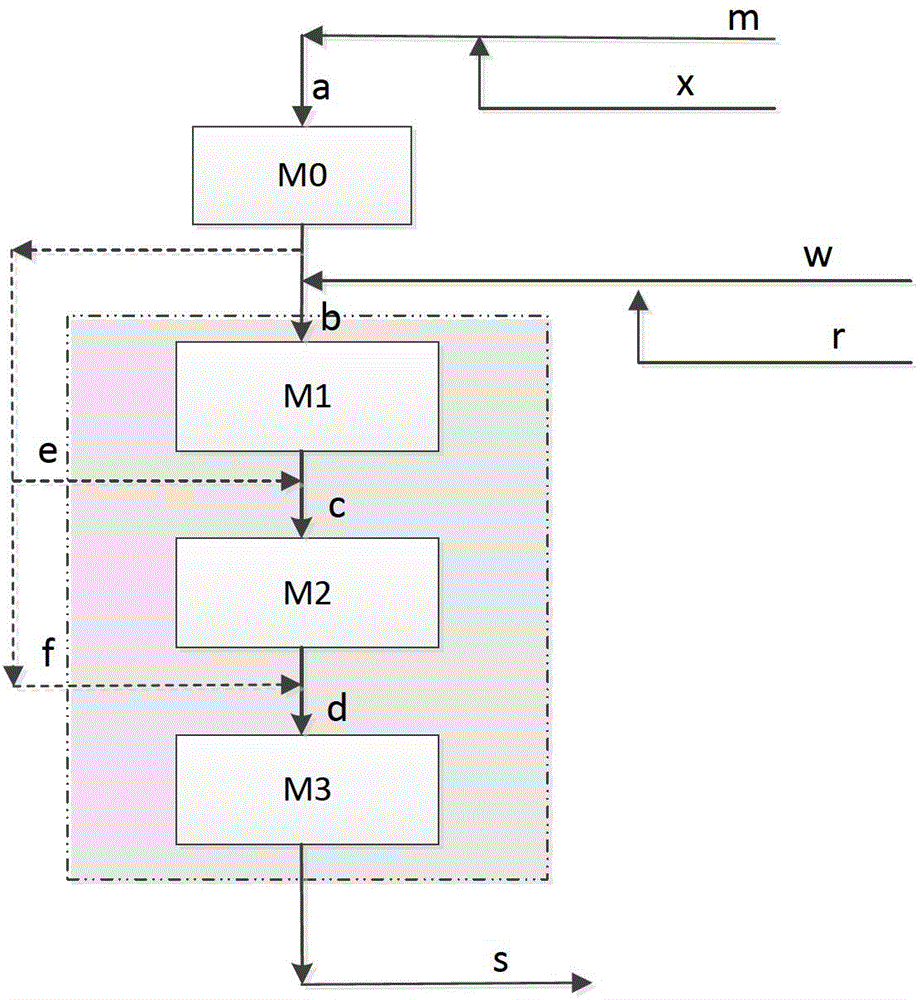

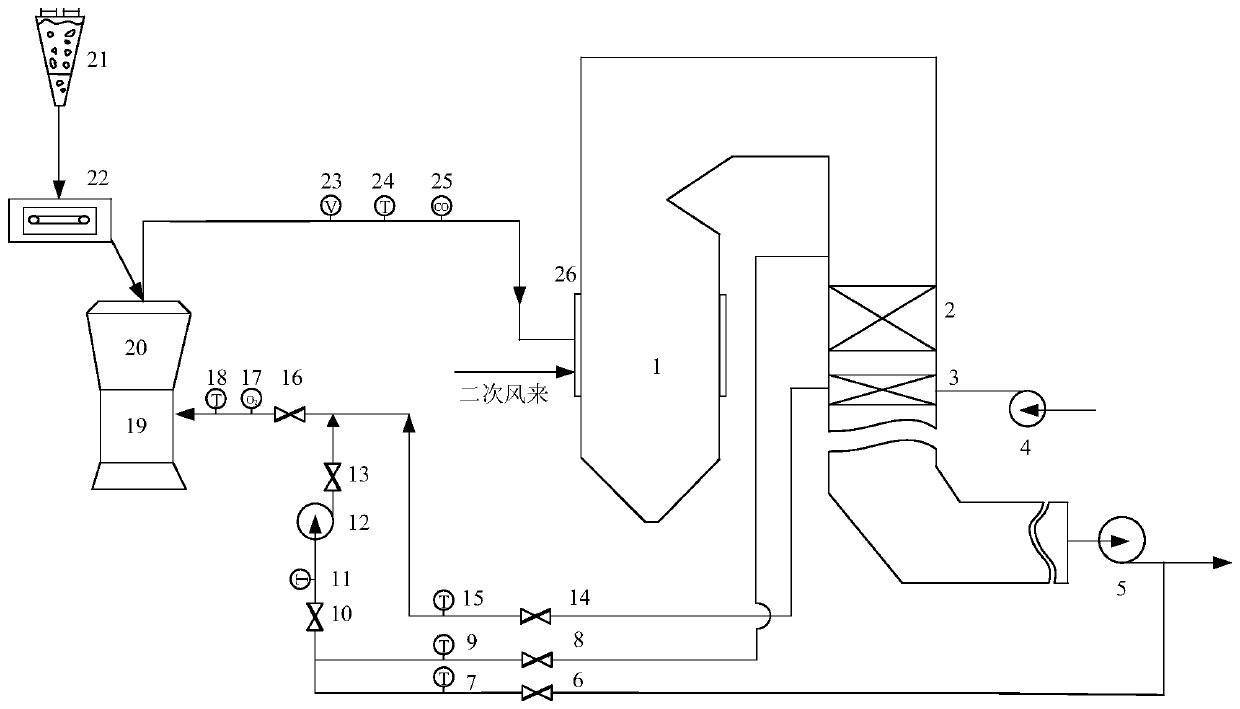

Control system and control method for outlet temperature of novel coal mill

ActiveCN104801416ARaise the outlet temperatureIncrease the level of automationGrain treatmentsLump/pulverulent fuel preparationTemperature controlCombustion

The invention discloses a control system and control method for outlet temperature of a novel coal mill. The control system comprises a controller, a coal mill outlet temperature detector and a coal mill hot air damper, wherein the coal mill outlet temperature detector is mutually connected with the controller; the controller is connected to the coal mill hot air damper. Compared with an existing control method, the control method disclosed by the invention can overcome the defects existing in an existing coal mill outlet temperature control method that a coal mill outlet temperature upper limit value is only set aiming at specific coal, the frequent change of the quality of coal supplied by the coal mill cannot be adapted, and a coal mill outlet temperature running value is low. According to the control system and the control method disclosed by the invention, the automatic level of coal mill operation can be improved, the outlet temperature of the coal mill is effectively improved, the power consumption generated during coal milling of the coal mill is reduced, and the carbon content of a product after pulverized coal combustion can be reduced.

Owner:SOUTHEAST UNIV

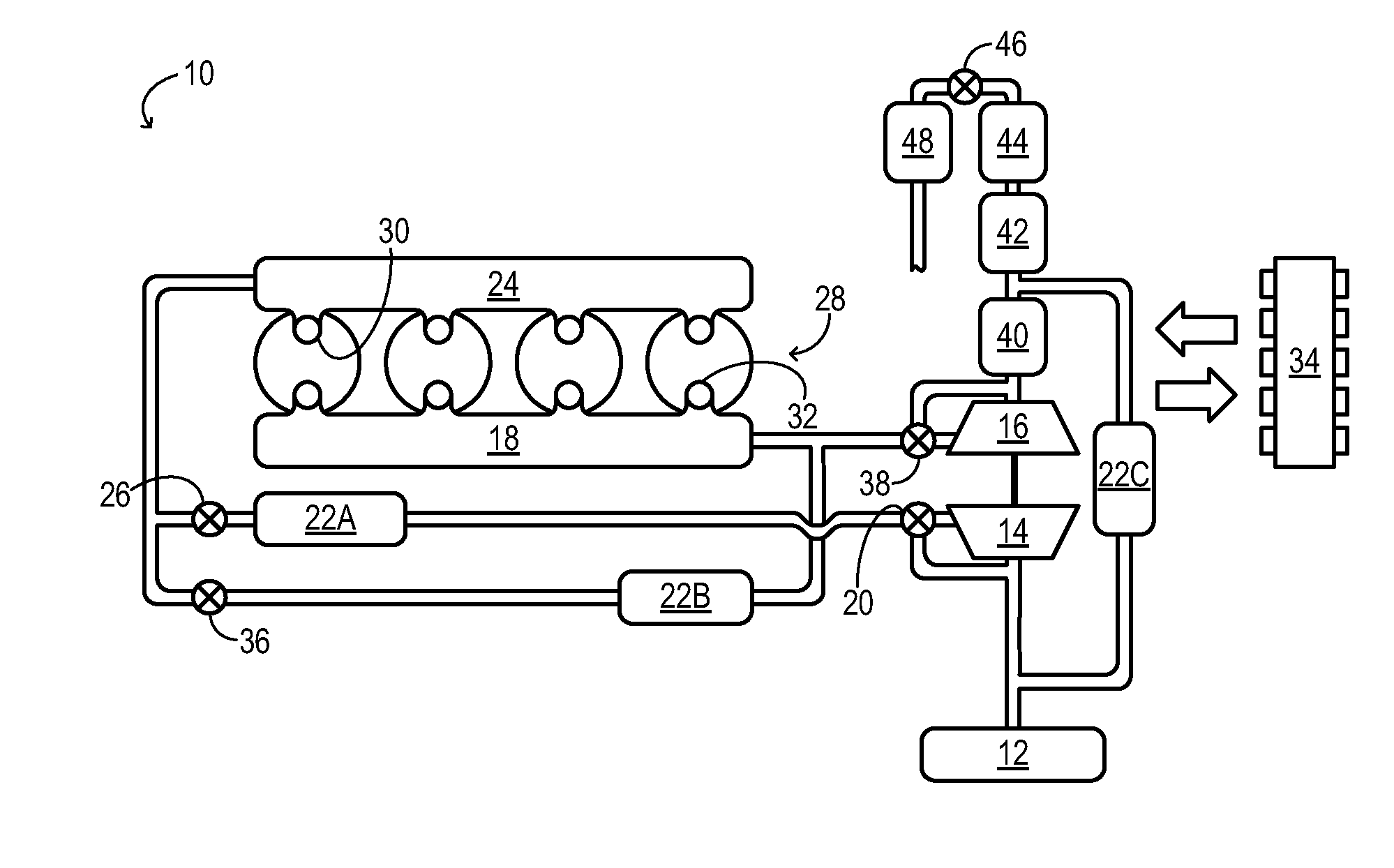

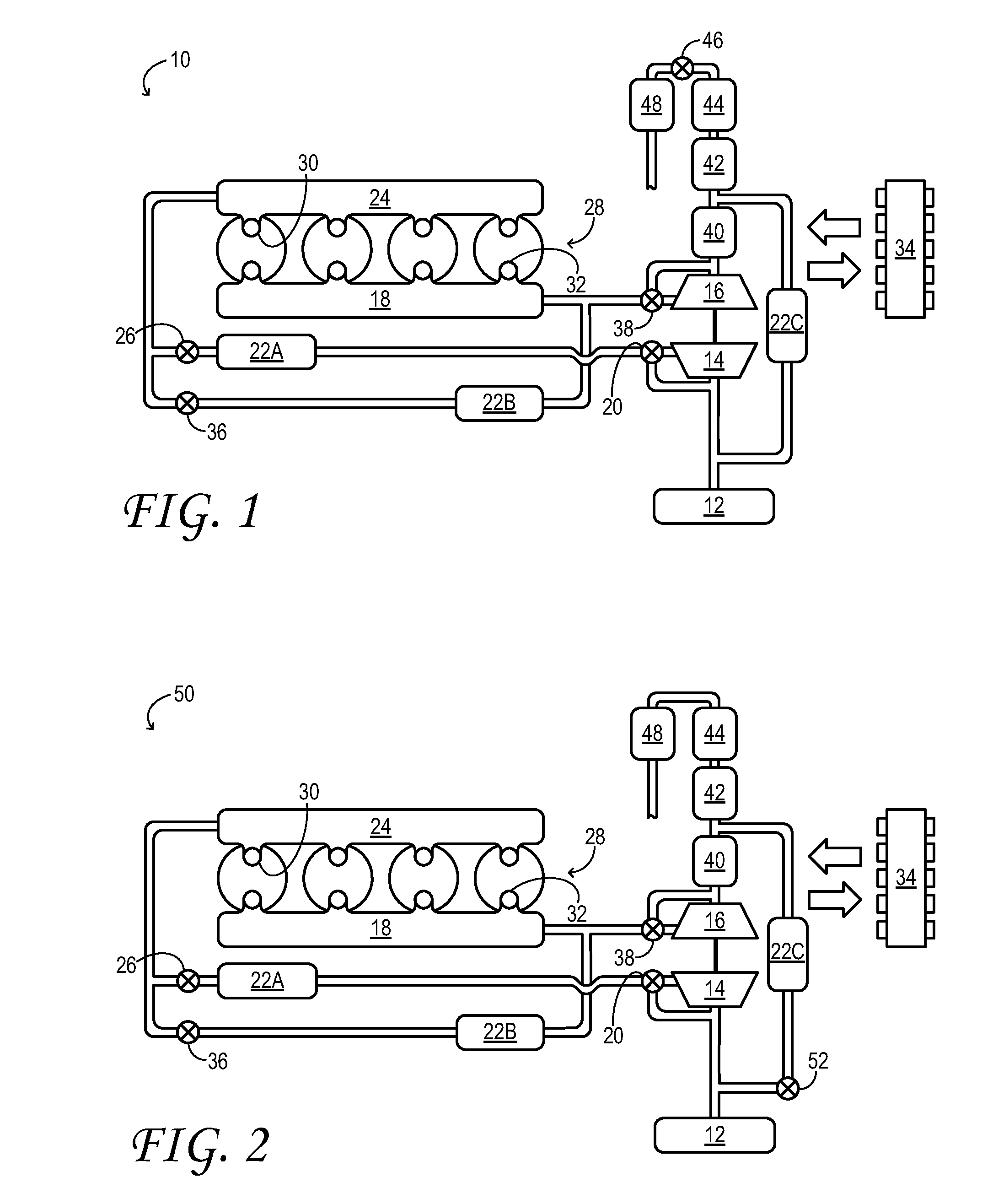

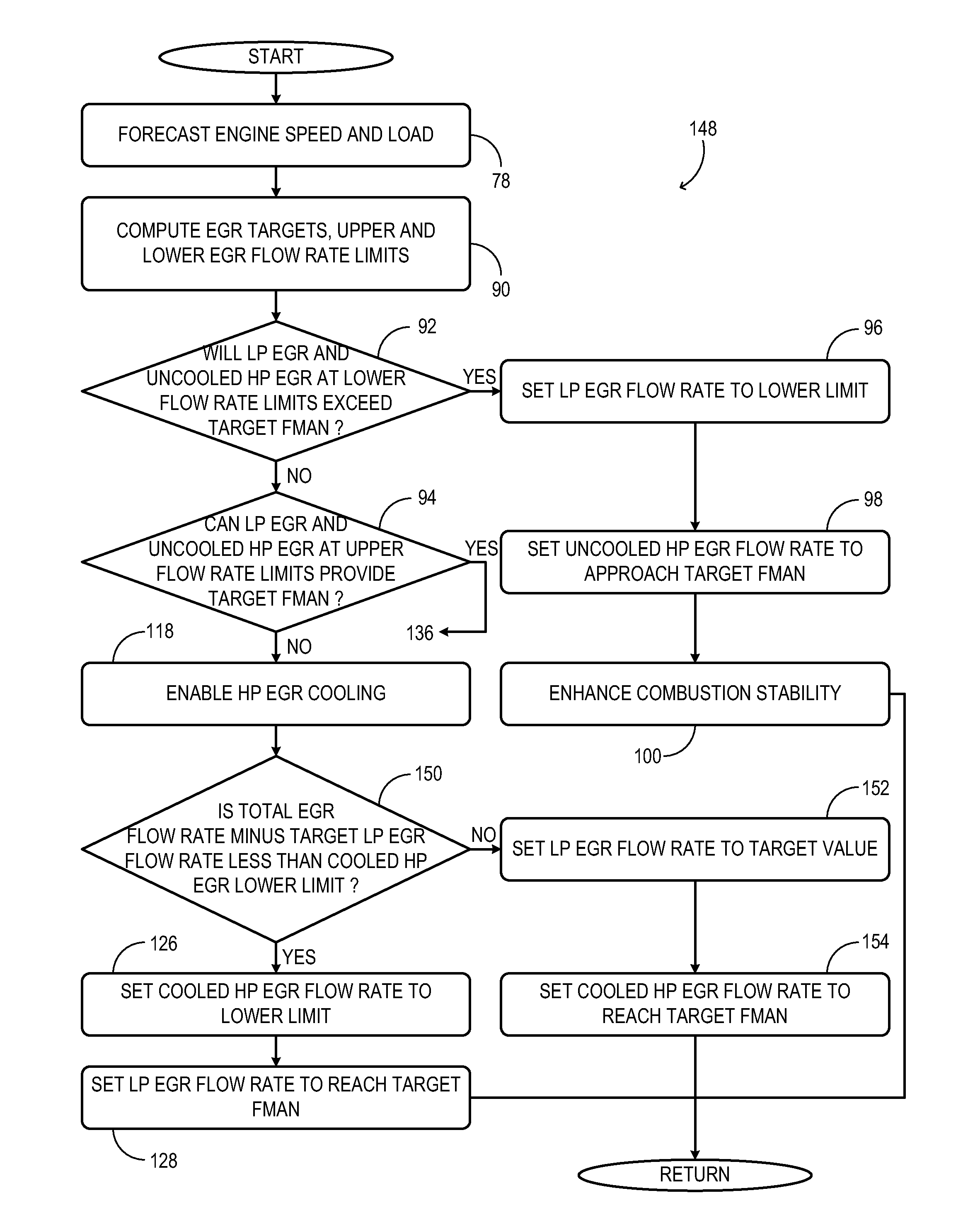

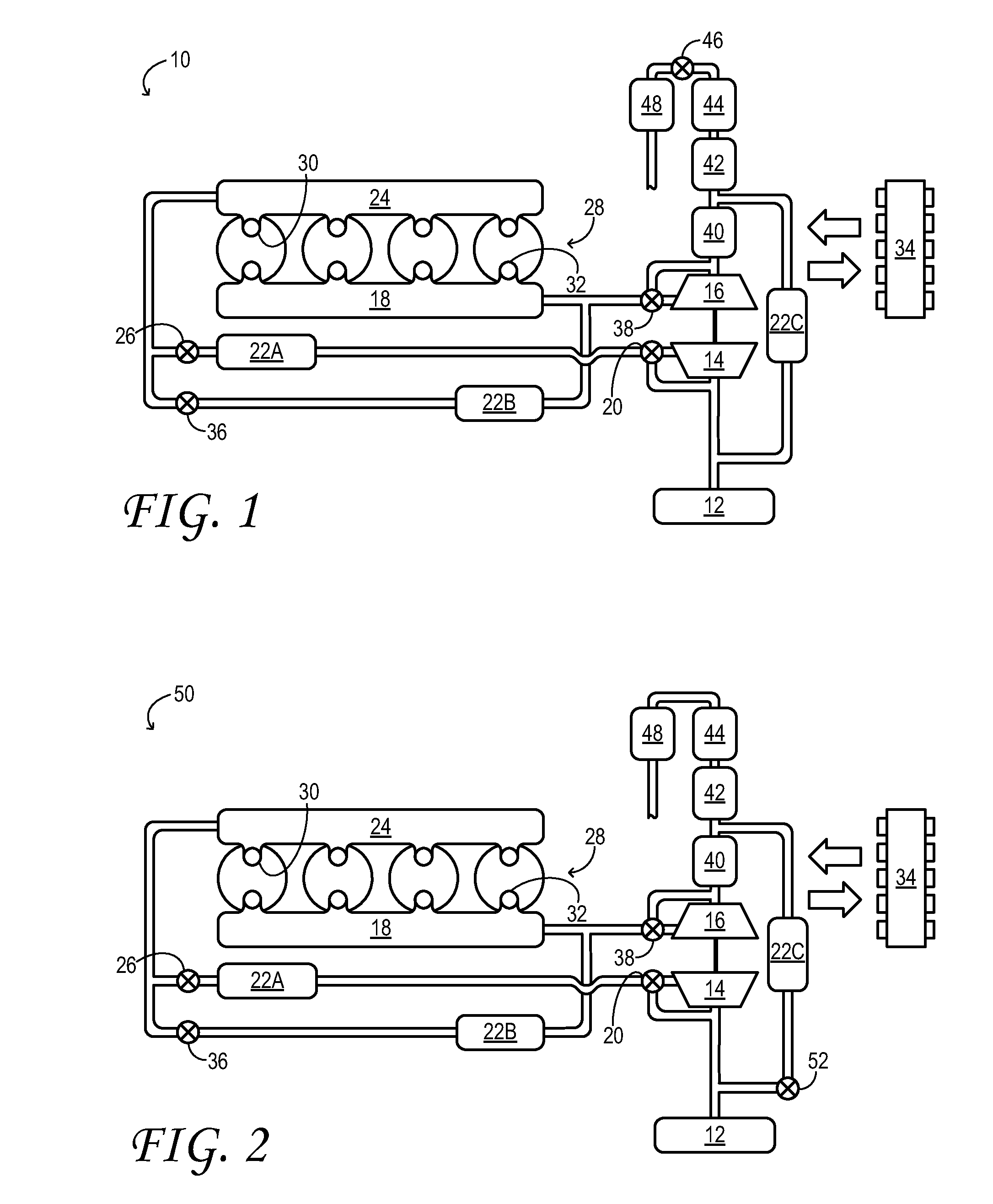

Coordination of HP and LP EGR

ActiveUS20110162626A1Low oxygenImprove fuel economyElectrical controlNon-fuel substance addition to fuelEngineeringStreamflow

A method for charging an intake manifold of an engine comprises adjusting an LP EGR flow rate and an uncooled HP EGR flow rate within first limits to maintain a target dilution level in the intake manifold at steady-state. The method further comprises adjusting the LP EGR and uncooled HP EGR rates within second limits, different from the first, to maintain the target dilution level in the intake manifold during transient conditions.

Owner:FORD GLOBAL TECH LLC

Multiple pass economizer and method for SCR temperature control

InactiveUS7637233B2Raise the outlet temperatureReduce water flowWater circulationFuel injection apparatusTemperature controlFlue gas

A control system for maintaining a desired heat exchanger outlet flue gas temperature across a range of boiler loads. The heat exchanger includes a plurality of tubular configurations in heat exchange contact with the flue gas with each tubular configuration having a separate feedwater inlet. Flue gas temperature control is achieved by modulating the feedwater flow rates through the tubular configurations. In a system having two tubular configurations, the overall heat transfer capacity of the heat exchanger may be reduced to maintain the desired heat exchanger outlet flue gas temperature by reducing feedwater flow through one tubular configuration and overflowing the other, while maintaining the total flow of feedwater through the heat exchanger substantially constant.

Owner:THE BABCOCK & WILCOX CO

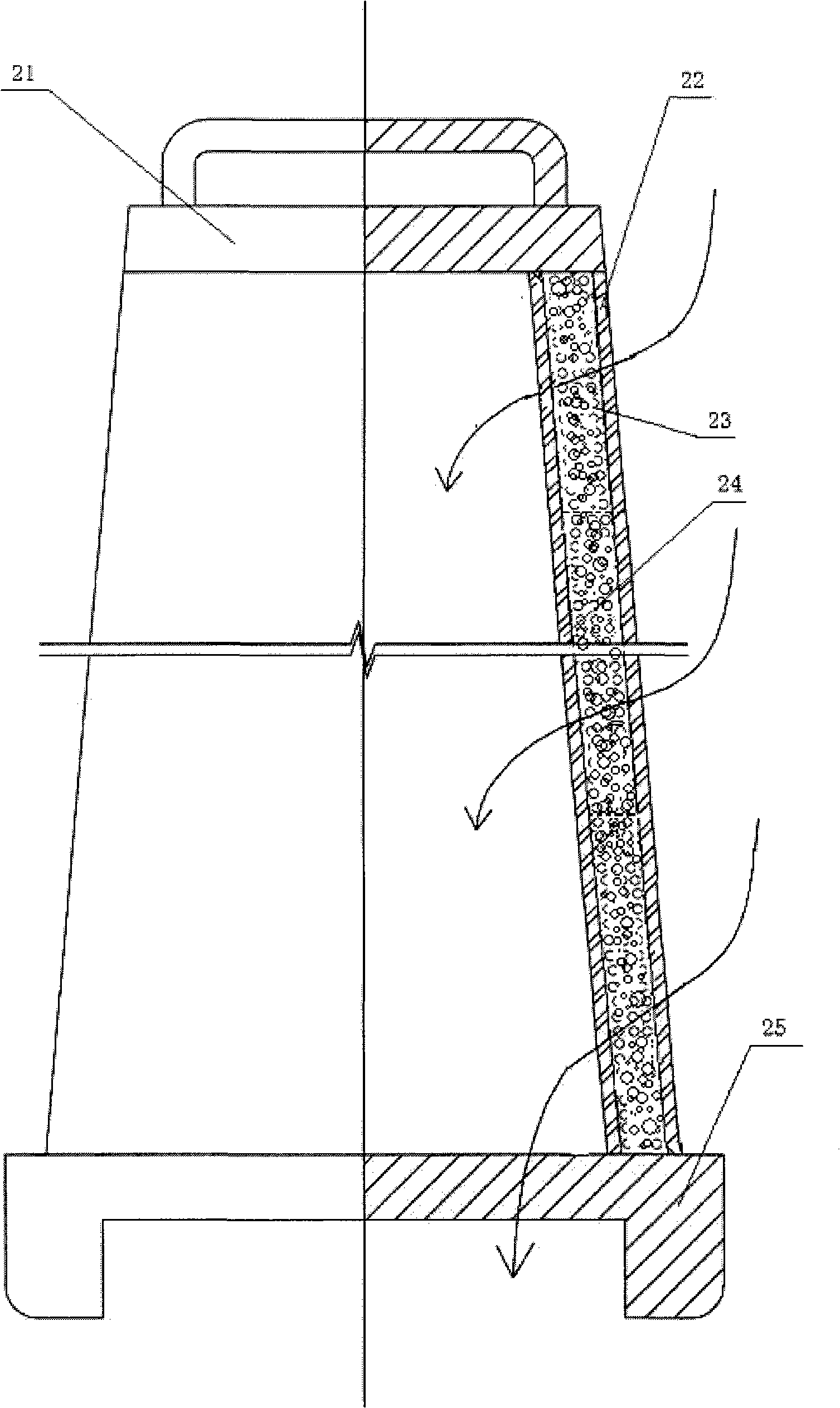

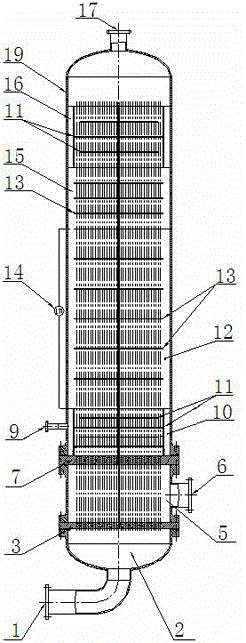

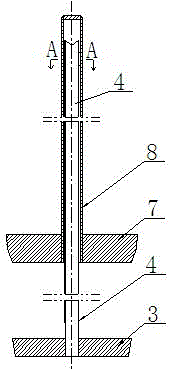

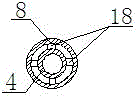

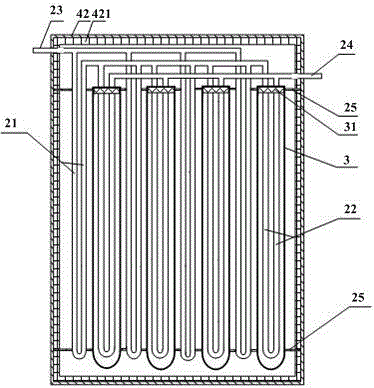

Straight-flow steam generator

InactiveCN102721031ARaise the outlet temperatureReasonable designSteam generation using hot heat carriersForced-flow steam boilerEngineeringHigh heat

The invention discloses a straight-flow steam generator which comprises a shell and a plurality of heat exchange tubes. The shell is sequentially divided into an oil inlet chamber, an oil outlet chamber, a preheating chamber, an evaporating chamber, a dehumidifying chamber and an overheating chamber from bottom to top, a heat transfer oil inlet is arranged on the oil inlet chamber, an inner tube plate is arranged between the oil inlet chamber and the oil outlet chamber, a heat transfer oil outlet is arranged on the oil outlet chamber, an outer tube plate is arranged between the oil outlet chamber and the preheating chamber, a feed-water inlet is arranged on the preheating chamber, a steam outlet is arranged on the overheating chamber, each heat exchange tube comprises an inner tube and an outer tube, the bottom end of each inner tube extends into the oil inlet chamber and is fixed onto the inner tube plate, the top end of each inner tube extends to the upper portion of the corresponding outer tube, the bottom end of each outer tube extends to the oil outlet chamber and is fixed onto the outer tube plate, the top end of each outer tube is provided with a closed structure and extends to the overheating chamber, and each inner tube and the corresponding outer tube form an interlayer structure. The straight-flow steam generator effectively solves the problem of poor heat expansion, and has the advantages of stability, reliability, safety, high heat exchange efficiency and the like.

Owner:DONGFANG TURBINE CO LTD

Hydrocracking method of high-yield high-quality chemical raw material

ActiveCN103773452AGood choiceFang QiangaoTreatment with hydrotreatment processesMolecular sievePetroleum naphtha

The invention discloses a hydrocracking method of a high-yield high-quality chemical raw material. According to the hydrocracking method comprises following steps: raw oil and hydrogen are subjected to hydrofinishing and are delivered through a first cracking reaction zone successively, and middle fraction oil is obtained via separation, and is delivered to a second cracking reaction zone for cracking; the first cracking reaction zone comprises two cracking catalysts, an upper zone is filled with a catalyst I, and a lower zone is filled with a catalyst II; the catalyst I comprises 30 to 70% of modified Y molecular sieve; the catalyst II comprises 15 to 50% of modified Y molecular sieve; and the content of the modified Y molecular sieve in the catalyst I is 10 to 30% higher than that in the catalyst II. Acid center of the catalyst I matches hydrogenation center, and the catalyst I possesses excellent heavy naphtha selectivity; and the catalyst II possesses excellent aromatic hydrocarbon transformative capacity, and is capable of transforming aromatic hydrocarbons in heavier components into smaller molecules so as to distribute in heavy petroleum fractions. The two catalysts are combined, so that demands of the high-yield high-quality chemical raw material are satisfied.

Owner:CHINA PETROLEUM & CHEM CORP +1

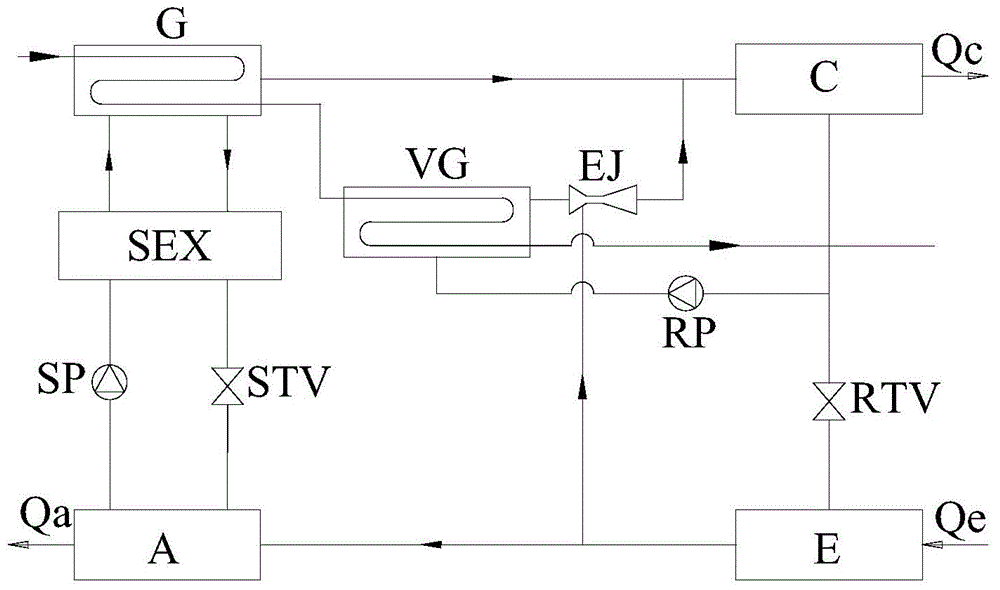

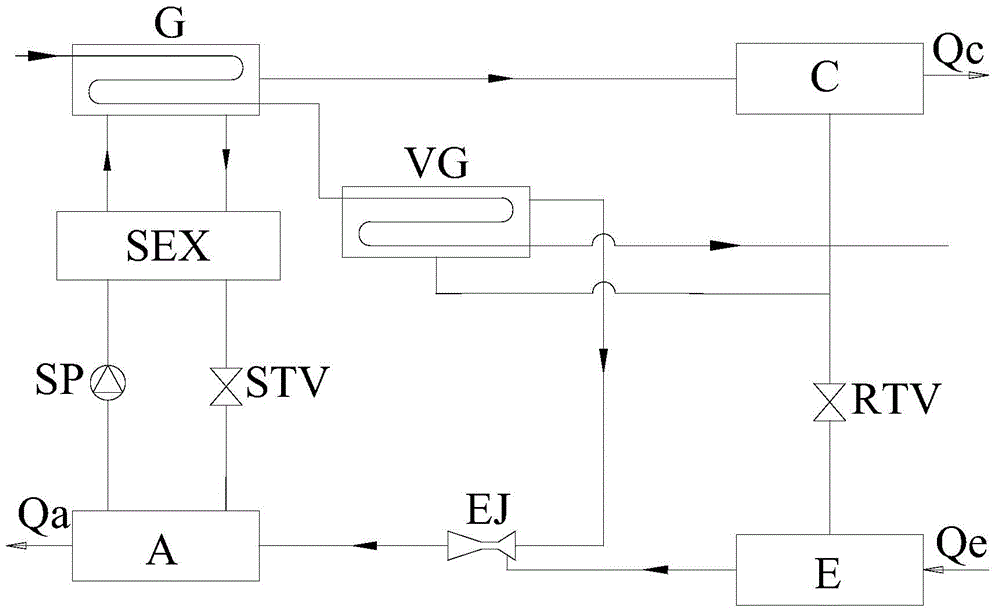

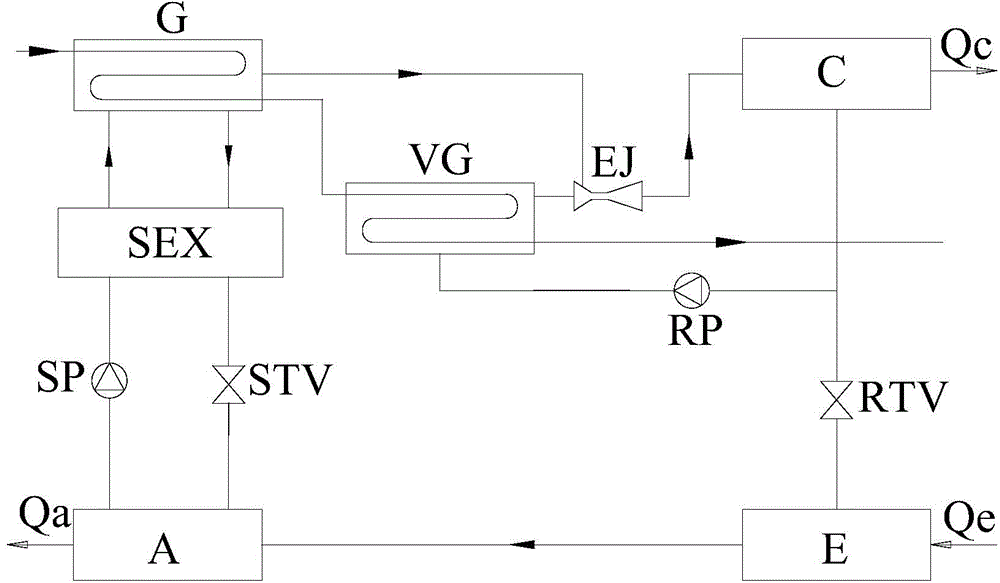

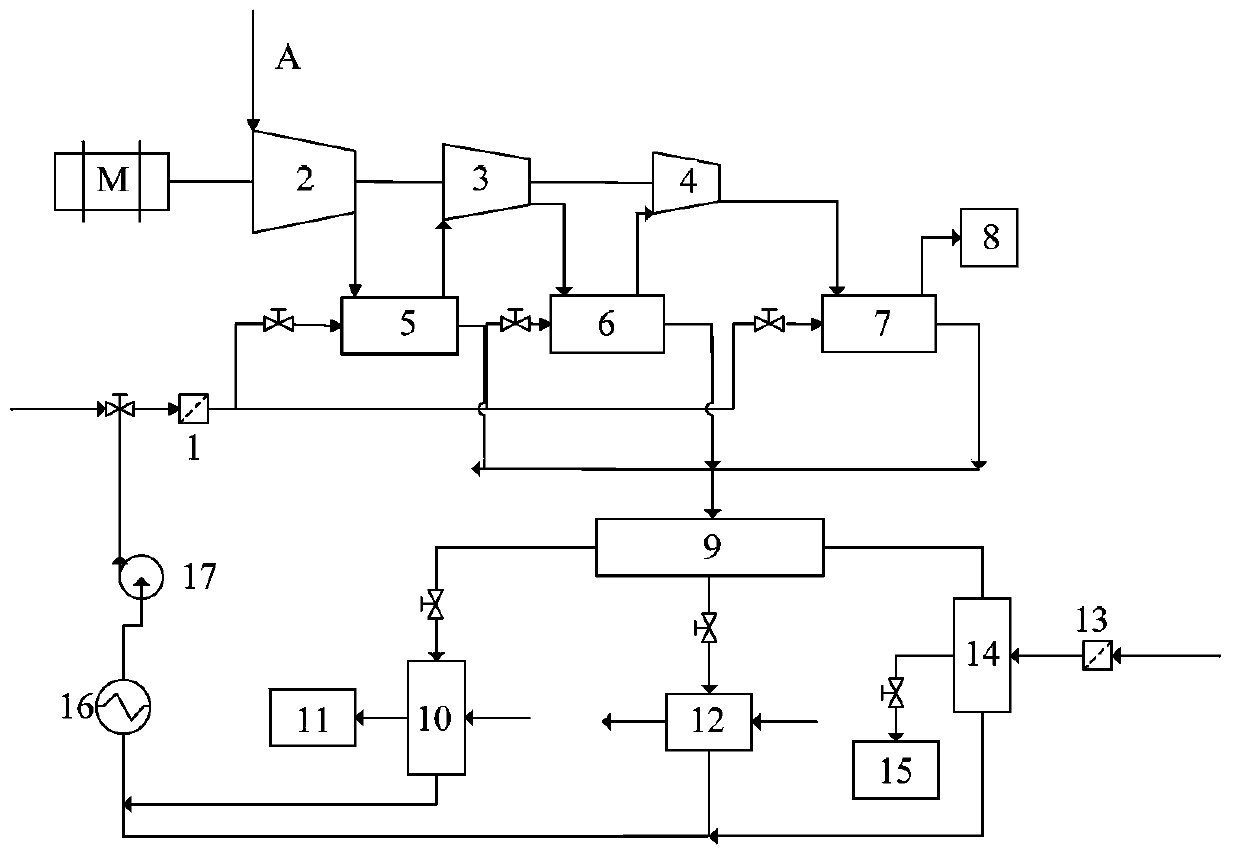

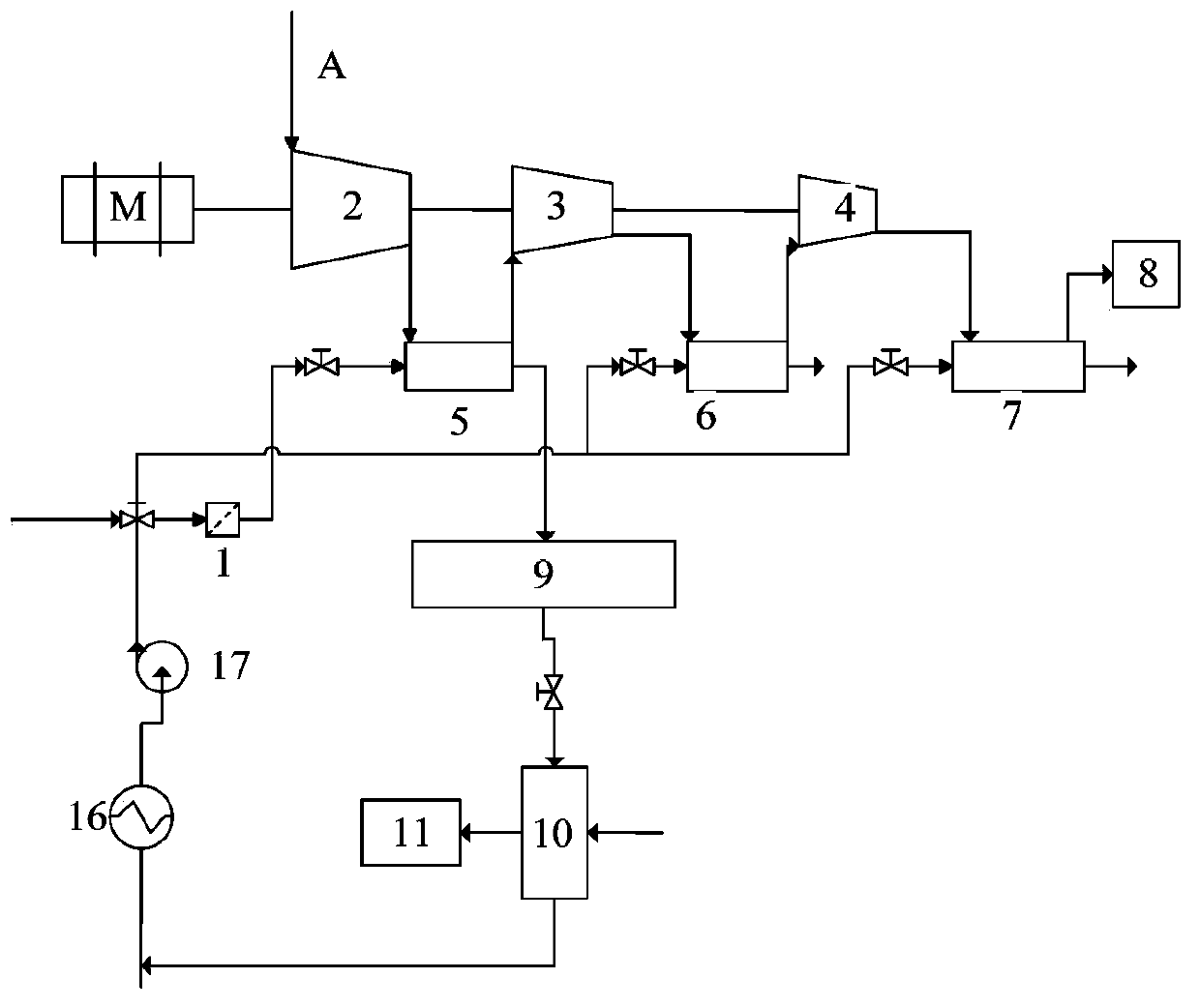

Ejection-absorbing hybrid refrigerating and heat pump unit and operating method thereof

InactiveCN104676958ALower outlet temperatureRaise the outlet temperatureHeat pumpsSteam generation plantsSteam pressureEngineering

The invention belongs to the technical field of refrigerating and heat pumps and particularly relates to an ejection-absorbing hybrid refrigerating and heat pump unit and an operating method thereof. The unit comprises generators, a condenser, an evaporator, an absorber, a solution heat exchanger, a solution pump, a solution throttle valve, a coolant throttle valve, a steam generator and a gas ejector. By providing one or multiple steam generators, outlet temperature of a high-level drive heat source of the unit can be decreased, utilization efficiency of heat and hierarchy of coolant steam pressure are increased, and the gas ejector can be conveniently set according to different pressure level; high-temperature high-pressure steam generated by the steam generator allow coolant steam to be ejected from outlets of the generators to the condenser, thereby decreasing the high-level heat source temperature of the generators; the coolant steam from an outlet of the evaporator can also be ejected to the absorber so as to enhance absorbing pressure of the absorber and reduce the size of the absorber; the coolant steam from the outlet of the evaporator can also be ejected to the condenser to increase refrigerating and heating quantity of the unit and improve comprehensive thermal performance of the unit.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

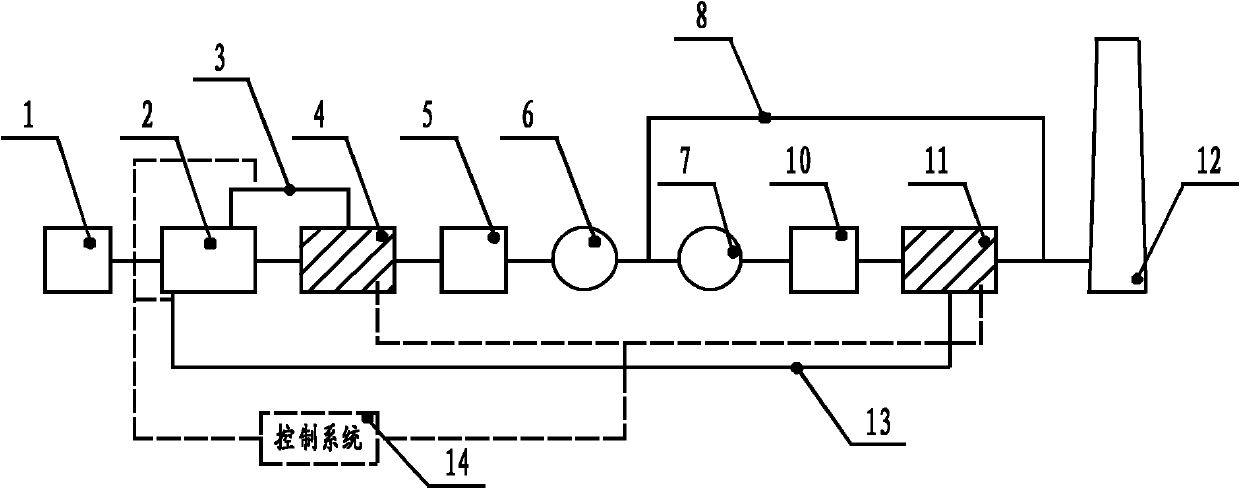

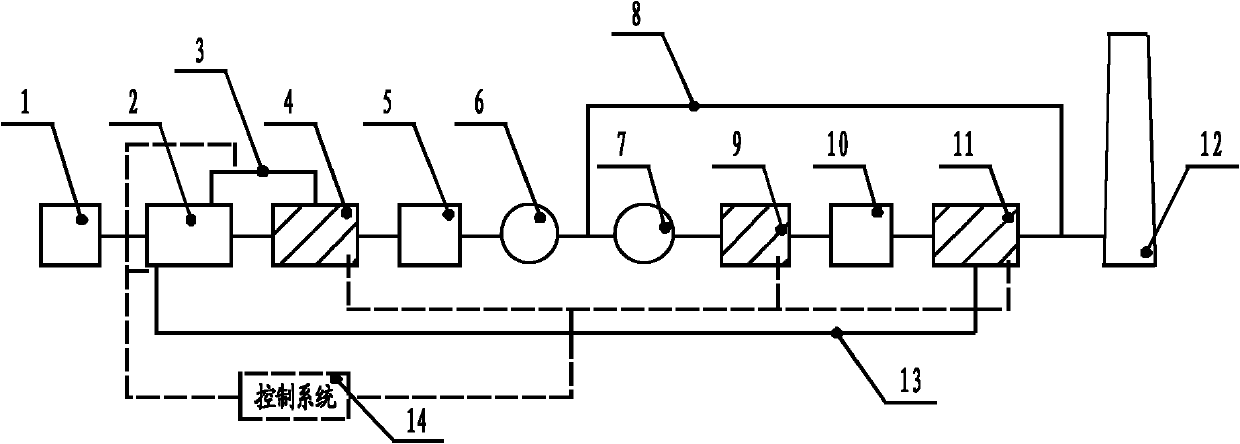

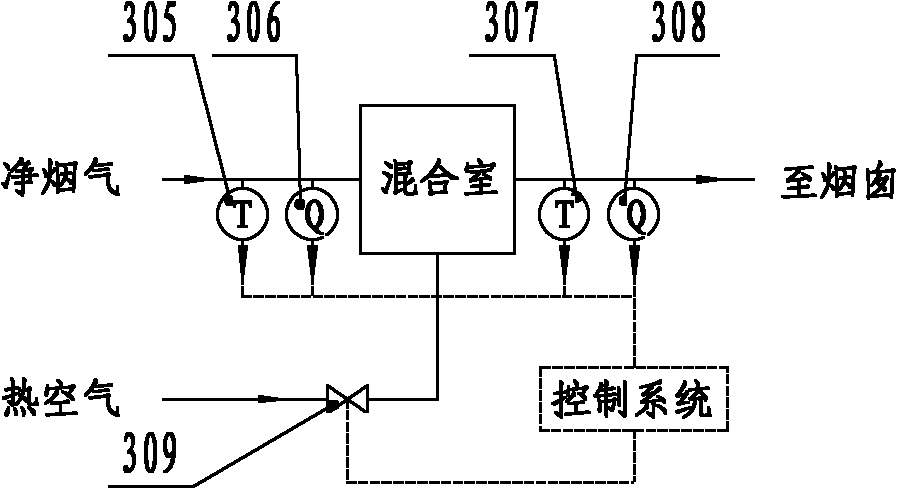

Energy and water saving desulphuration integrated system for power plant

InactiveCN101995028ARaise the outlet temperatureLow costCombustion processIndirect carbon-dioxide mitigationAir preheaterGas heater

The invention discloses an energy and water saving desulphuration integrated system for a power plant in the technical field of heat transmission. The system comprises an I-level phase change heat exchanger, a mixing chamber and a control system, wherein the I-level phase change heat exchanger is arranged on the back of an air preheater arranged on a gas duct at the tail end of a boiler and then is connected with the mixing chamber through a pipeline, the mixing chamber is connected with the air outlet of the air preheater of a boiler system through a pipeline, and the I-level phase change heat exchanger and the mixing chamber are all connected with the control system through connecting wires; or an II-level phase change heat exchanger is arranged between the desulfurization fan and desulfurizing tower of the boiler system. In the invention, the phase change heat exchanger absorbs the energy of raw gas to heat clean air, and the heated clean air is mixed with the low-temperature clean gas after being further heated to a higher temperature by the air preheater, the gas outlet temperature of a chimney is increased, thus the problems of low temperature corrosion of the existing clean gas heater and invalid integral device caused by low temperature corrosion are avoided radically, the low temperature exhaust heat of the raw gas is used fully, the thermal efficiency of the integral electric generating system is improved, and meanwhile, the water resource is saved greatly.

Owner:杨本洛

Low energy consumption propylene production technology

InactiveCN103333040ARaise the outlet temperatureTemperature controlHydrocarbon from oxygen organic compoundsEthylene productionAlkaneWater saving

The invention discloses a low energy consumption propylene production technology, which comprises the following steps of (1) after mixing raw material methyl alcohol and diluent gas, carrying out etherification reaction, after mixing the primary product and the stream of the diluent gas with steam water and refined hydrocarbon and heat exchanging, preparing olefin so as to obtain a secondary product; (2) separating the secondary product so as to obtain propylene, ethylene, C1-C3 alkane, C4-C6 components comprising olefin and alkane, C7 and heavy components comprising arene; and (3) taking the vaporized purified water obtained through separation as part of the steam water and circulating to step (1), taking the products of ethylene, C1-C2 alkane, C4-C6 as the refined hydrocarbon, and returning to an OTP (one time programmable) reactor for preparing olefin continuously. According to the preparation method, the problem that high propylene yield needs a large amount of steam water and the problem of selectivity in the MTP (methanol to propylene) technology are solved, and the purposes of water saving and energy saving are finally realized through comprehensive regulation of diluent gas, refined hydrocarbon and catalyst carbon deposit quantity.

Owner:ZHEJIANG UNIV

Coordination of HP and LP EGR

ActiveUS8042527B2Low oxygenImprove fuel economyElectrical controlInternal combustion piston enginesEngineeringInlet manifold

A method for charging an intake manifold of an engine comprises adjusting an LP EGR flow rate and an uncooled HP EGR flow rate within first limits to maintain a target dilution level in the intake manifold at steady-state. The method further comprises adjusting the LP EGR and uncooled HP EGR rates within second limits, different from the first, to maintain the target dilution level in the intake manifold during transient conditions.

Owner:FORD GLOBAL TECH LLC

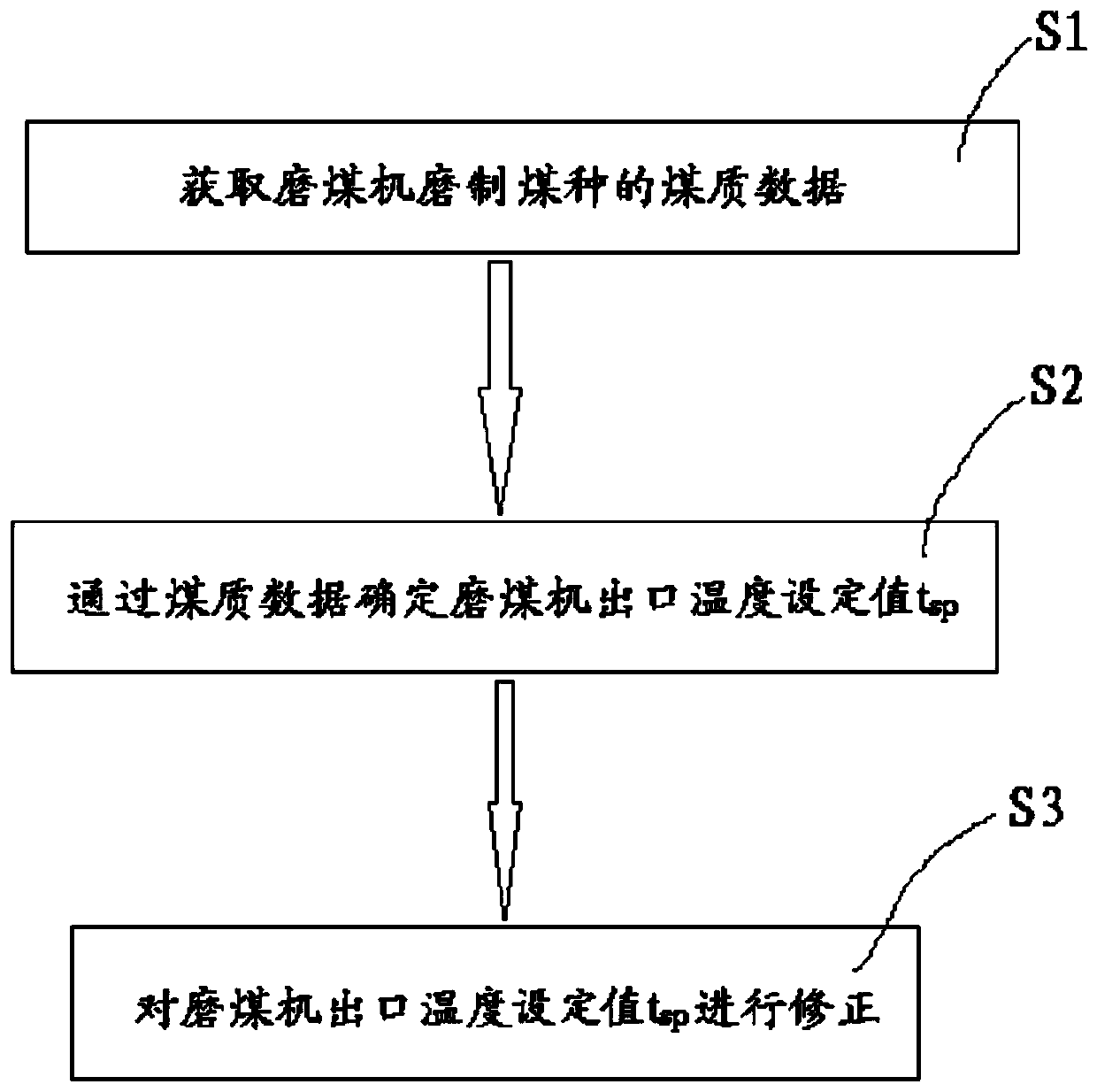

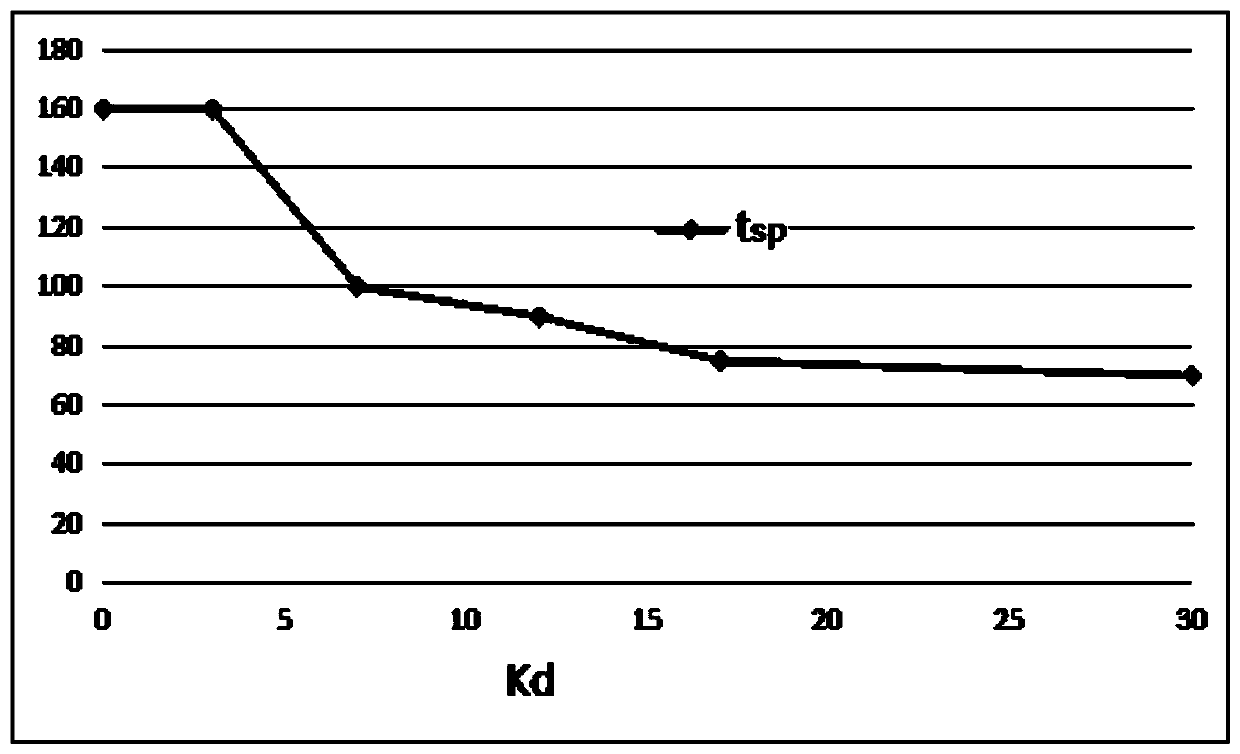

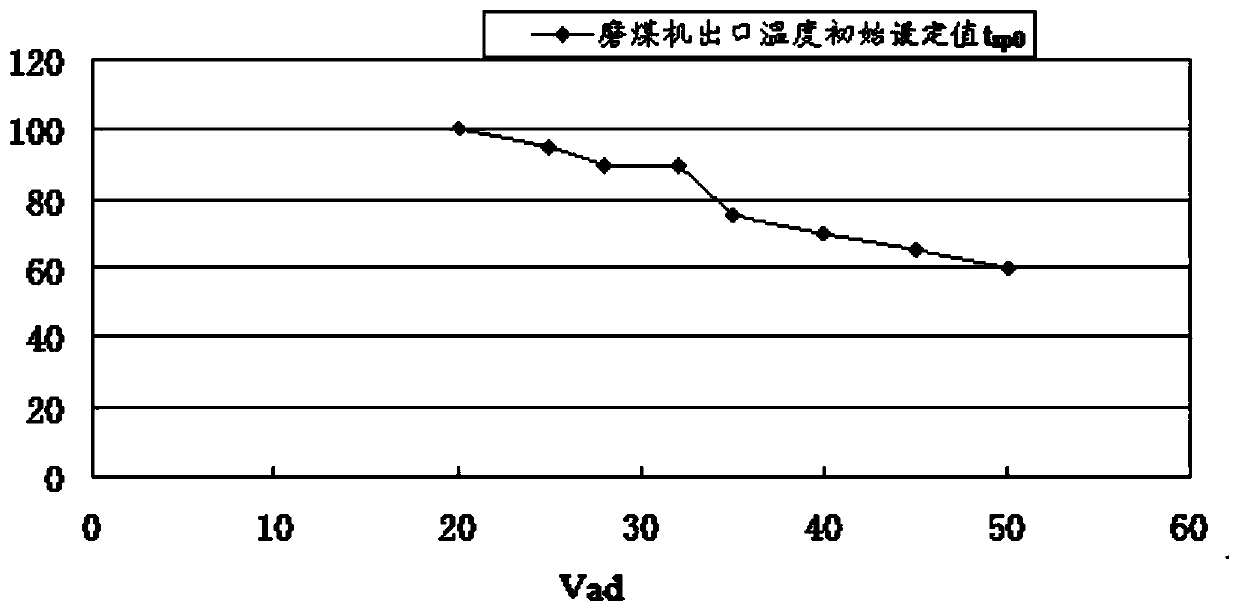

Boiler unit and coal mill outlet temperature control method and system thereof

ActiveCN110124842ARaise the outlet temperatureIncrease temperatureGrain treatmentsTemperature controlControl system

The invention discloses a coal mill outlet temperature control method. The method comprises the following steps of acquiring coal quality data of a ground coal type of a coal mill; determining a coalmill outlet temperature set value tsp through the coal quality data; and correcting the coal mill outlet temperature set value tsp. The invention further discloses a coal mill outlet temperature control system and a boiler unit comprising the coal mill outlet temperature control method and system. According to the coal mill outlet temperature control method, the coal mill outlet temperature set value is given by acquiring the coal quality data of the ground coal type of the coal mill on line, and the stability and the safe operation requirement of the coal mill outlet temperature are comprehensively considered, so that the operation safety of the coal mill is improved, the difference of the level and the operation habit among different operators is avoided, the outlet temperature of the coal mill can be effectively improved, and accordingly the operation economy of the boiler unit is improved.

Owner:GUANGDONG POWER GRID CO LTD +3

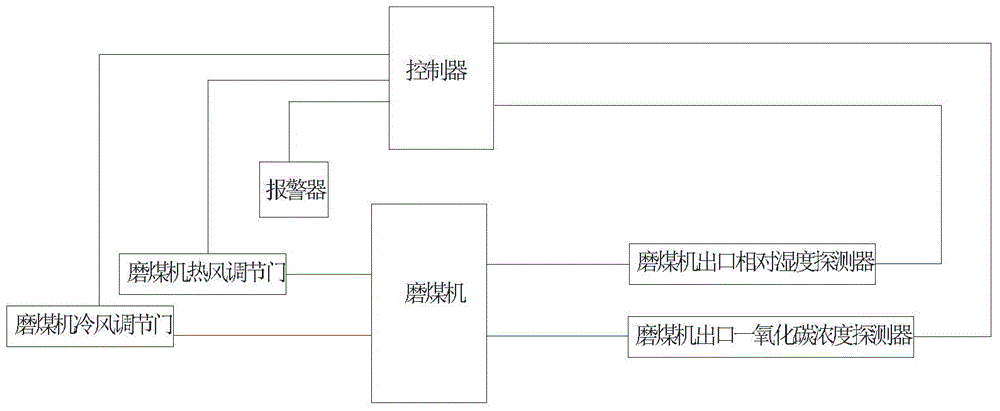

Coal mill outlet temperature control method and system based on flue gas inerting

PendingCN111520737AImprove explosion-proof performanceRealize free adjustmentDrying gas arrangementsDamper arrangementBoiler efficiencyAir volume

The invention discloses a coal mill outlet temperature control method and system based on flue gas inerting. Starting from the mechanism of detonation of a coal pulverizing system, the oxygen contentof the coal pulverizing system is reduced through the tail smoke of a boiler, the coal pulverizing system is inerting, and the anti-explosion capacity is improved. The concentration of combustible gasCO separated out through pyrolysis in the coal mill outlet pulverized coal heating process and the coal mill outlet air speed are monitored, a strategy is provided for adjusting the oxygen content, the air temperature and the air volume of inert media of the coal pulverizing system, and the temperature level of a coal mill outlet in an actual running process is determined. Compared with a traditional coal pulverizing system and method that the coal mill outlet temperature is determined according to an empirical formula, and a large amount of cold air needs to be doped, the remarkable coal type adaptation advantage and the safety guarantee advantage are achieved, the comprehensive output of the coal pulverizing system can be effectively improved, the coal pulverizing power consumption is reduced, and the boiler efficiency is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

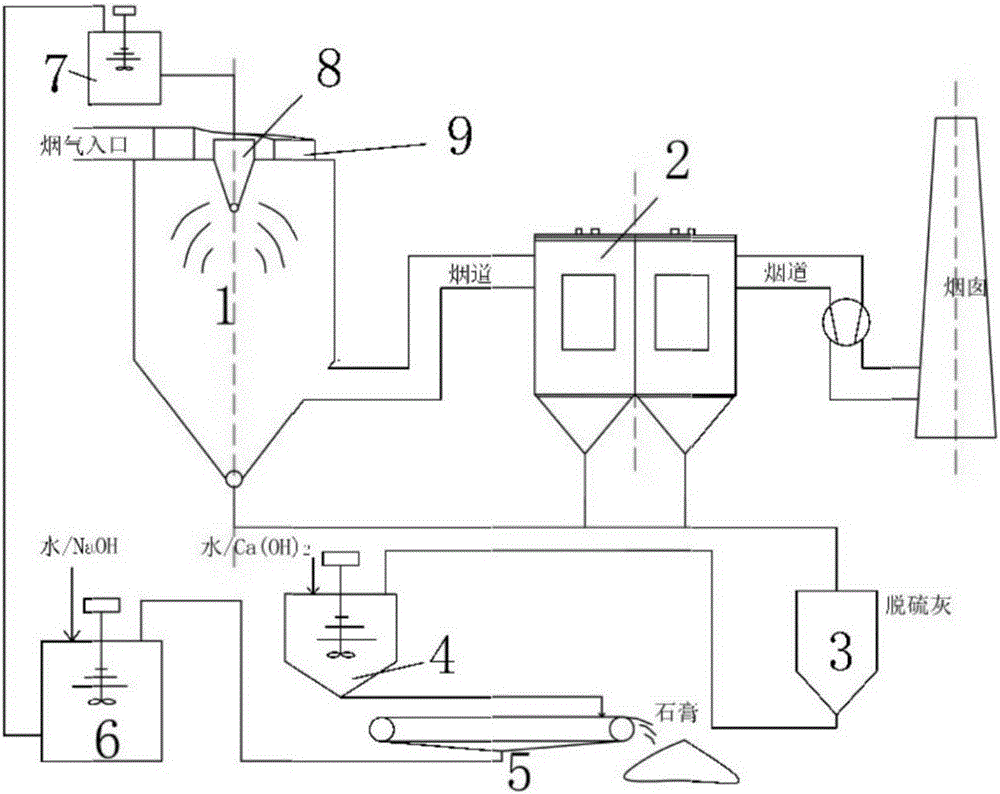

Coke oven flue gas desulfurization technology and system

InactiveCN105944536AImprove desulfurization effectIncrease reaction rateGas treatmentDispersed particle separationFlue gasCoke oven

The invention discloses a coke oven flue gas desulfurization technology and system and mainly aims to reduce temperature drop of flue gas in a desulfurization process so as to meet the hot standby requirement of a chimney. According to the coke oven flue gas desulfurization technology and system, a sodium-alkali solution is taken as a desulfurizing agent, the atomized sodium-alkali solution is subjected to a reaction with SO2 in flue gas, and sulfite is generated, dried with the flue gas and recovered by a dust collector; the recovered desulfurized dust is regenerated by the aid of a Ca(OH)2 solution, desulfurized gypsum and a sodium-alkali regenerated solution are obtained, and the sodium-alkali regenerated solution returns to a desulfurization system for circulating desulfurization. With the adoption of the coke oven flue gas desulfurization technology and system, investment and operation cost of coke oven flue gas desulfurization can be remarkably reduced, the outlet flue gas temperature of desulfurization equipment is increased, the hot standby requirement of the chimney can be met without reheating, and meanwhile, the problems of scaling, difficulty in sodium-alkali regeneration and the like of a wet double-alkali method are solved.

Owner:HUATIAN ENG & TECH CORP MCC +1

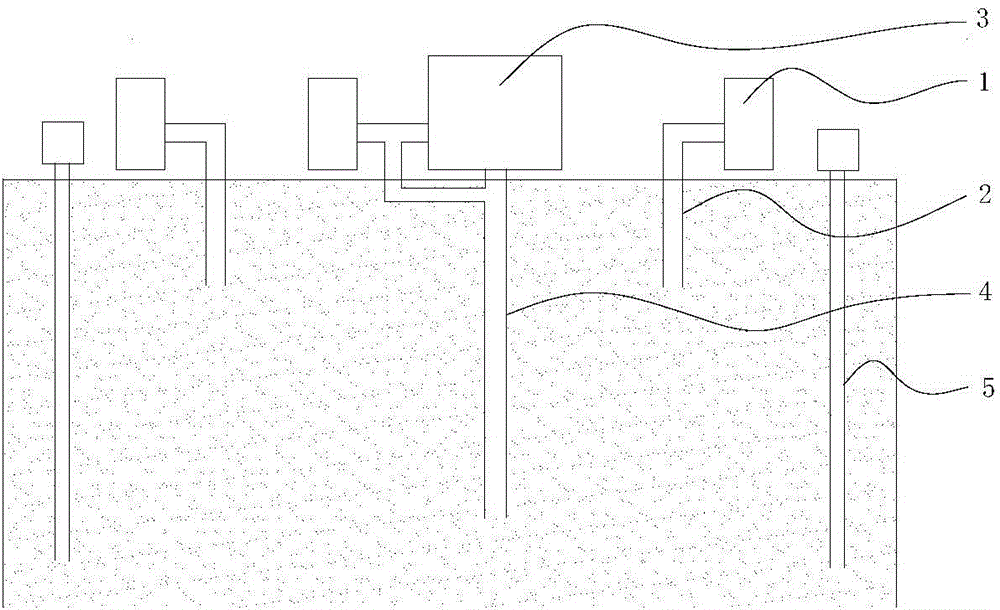

Method and system for contaminant removal by injecting high-temperature dry gas into soil

InactiveCN104815840AIncrease relative volatilityReduce adsorptionContaminated soil reclamationThermal energyCatalytic pyrolysis

The invention discloses a method for contaminant removal by injecting high-temperature dry gas into soil. The method includes the following step: (1), preparing the high-temperature mixed dry gas by a high-temperature mixed gas injector; (2), injecting the high-temperature mixed dry gas prepared in the step (1) into a dry gas injection well deep in contaminated soil; (3), adjusting the temperature of the high-temperature mixed dry gas injected into the dry gas injection well and retention time of the high-temperature mixed dry gas in the dry gas injection well to enable heat energy to be diffused in soil layers to perform mixed-gas soaking; (4), after mixed-gas soaking is finished, refining gaseous contaminants subjected to catalytic pyrolysis to the ground by a contaminated gas refining well, recycling the gaseous contaminants by a contaminated gas recycling device, and pumping contaminants carried in condensate water generated after injection of the high-temperature mixed dry gas to the ground by a pumping well for treatment. The method has the advantages that the temperature of the injected high-temperature dry gas is high and volatile and nonvolatile organic matter and heavy metal contaminants in the contaminated soil can be removed.

Owner:TAICANG BAINUO NANO TECH CO LTD

Multiple pass economizer and method for SCR temperature control

InactiveUS7578265B2Raise the outlet temperatureReduce water flowWater circulationFuel injection apparatusTemperature controlControl system

A gas temperature control system for maintaining a desired economizer outlet gas temperature across a range of boiler loads comprises a plurality of tubular configurations having surfaces that are in contact with the flue gas. Each tubular configuration, preferably, comprises a plurality of serpentine or stringer tubes arranged horizontally or vertically back and forth within the economizer, and each tubular configuration having a separate feedwater inlet. Heat transfer from the flue gas is accomplished by controlling the feedwater flow rates through the tubular configurations. In a temperature control system having two tubular configurations, the overall heat transfer capacity of the economizer may be reduced to maintain the desired economizer outlet gas temperature during low boiler loads by reducing feedwater flow through one tubular configuration and by overflowing the other tubular configuration, such that total flow of feedwater through the economizer is maintained substantially constant.

Owner:THE BABCOCK & WILCOX CO

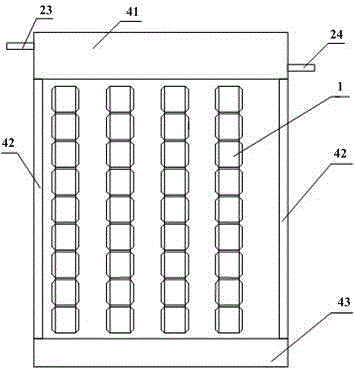

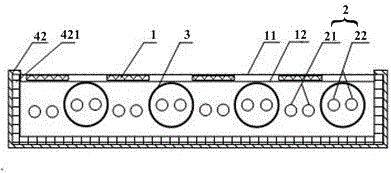

Novel photovoltaic photo-thermal integrated assembly

InactiveCN105356846AImprove photoelectric conversion efficiencyRaise the outlet temperaturePhotovoltaicsPhotovoltaic energy generationEngineeringRadiation

The invention discloses a novel photovoltaic photo-thermal integrated assembly comprising photovoltaic cells, a U-shaped heat exchange tube assembly, and vacuum glass tubes. Photovoltaic cells arranged at multiple rows are arranged at intervals. The U-shaped heat exchange tube assembly that is provided with a heat absorption medium inlet and a heat absorption medium outlet and is arranged below the photovoltaic cells contains a plurality of U-shaped heat exchange tubes that are connected in parallel and or in series. Multiple vacuum glass tubes are arranged below the photovoltaic cells and each glass tube is located between the gap between each two adjacent rows of photovoltaic cells; and the U-shaped heat exchange tube arranged below the gap between each two adjacent rows of photovoltaic cells is arranged in the vacuum glass tube. According to the novel photovoltaic photo-thermal integrated assembly, the solar radiation energy is absorbed by the photovoltaic cells and the vacuum glass tubes arranged in the gaps of the photovoltaic cells simultaneously, thereby improving the solar utilization rate.

Owner:SHANGHAI INST OF TECH

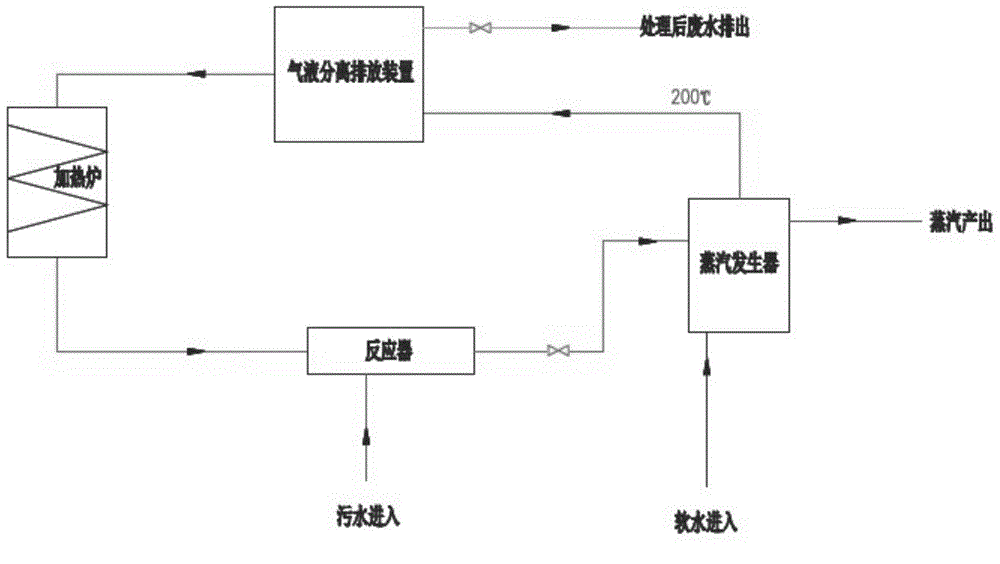

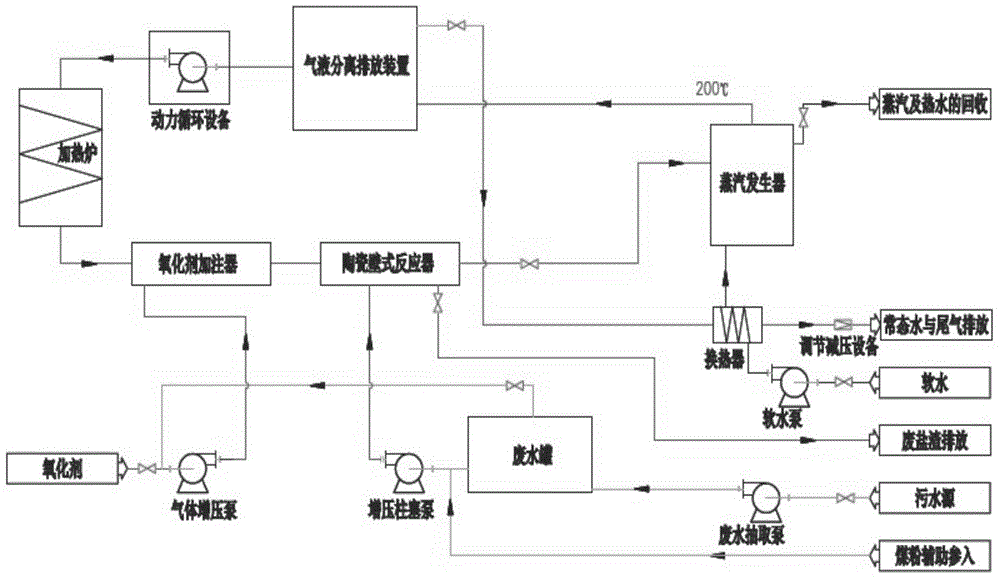

Process for waste oxidation treatment and steam co-production by using supercritical circulating water

ActiveCN103553202AReduce excess spaceShorten the timeSteam generation using hot heat carriersWater/sewage treatment by oxidationInorganic saltsChemical oxygen demand

The invention provides a process for waste oxidation treatment and steam co-production by using supercritical circulating water. A treatment system is a circulating treatment system. The process comprises the steps of filling circulating water into a supercritical circulating water oxidation treatment system, heating the circulating water in a heating device, driving the circulating water to circularly operate in the system, and controlling the temperature to be raised to 395-450 DEG C and the pressure to be higher than 22.1Mpa; inputting sewage and an oxidizing agent to a reactor, and enabling the sewage and the oxidizing agent to react in a supercritical state; enabling the water after reacting to enter a steam generator for heat recovery, and outputting steam; carrying out gas-liquid separation on the water subjected to heat exchange through the steam generator, and discharging inorganic salt gas and a part of water; inputting the other part of water after gas-liquid separation as the circulating water to the heating device. In the process, the sewage is up to the supercritical state through being mixed with the circulating water, a sewage preheating device in traditional sewage treatment is omitted, and the sewage with a high-concentration COD (Chemical Oxygen Demand) value can be directly treated.

Owner:NANJING TECH UNIV

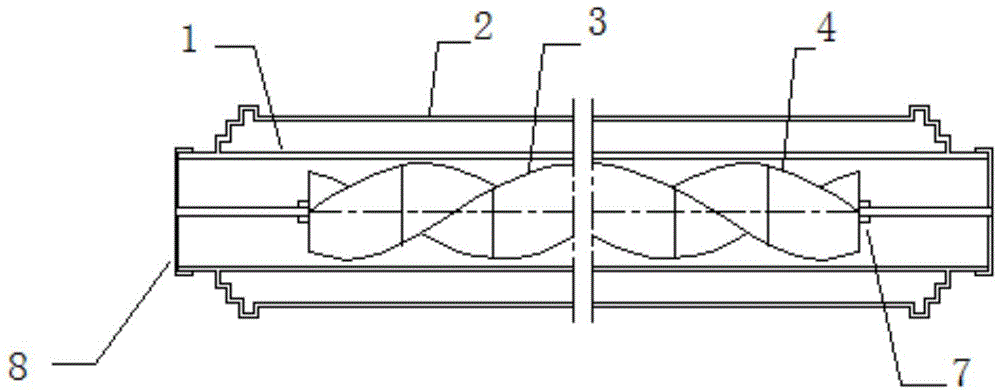

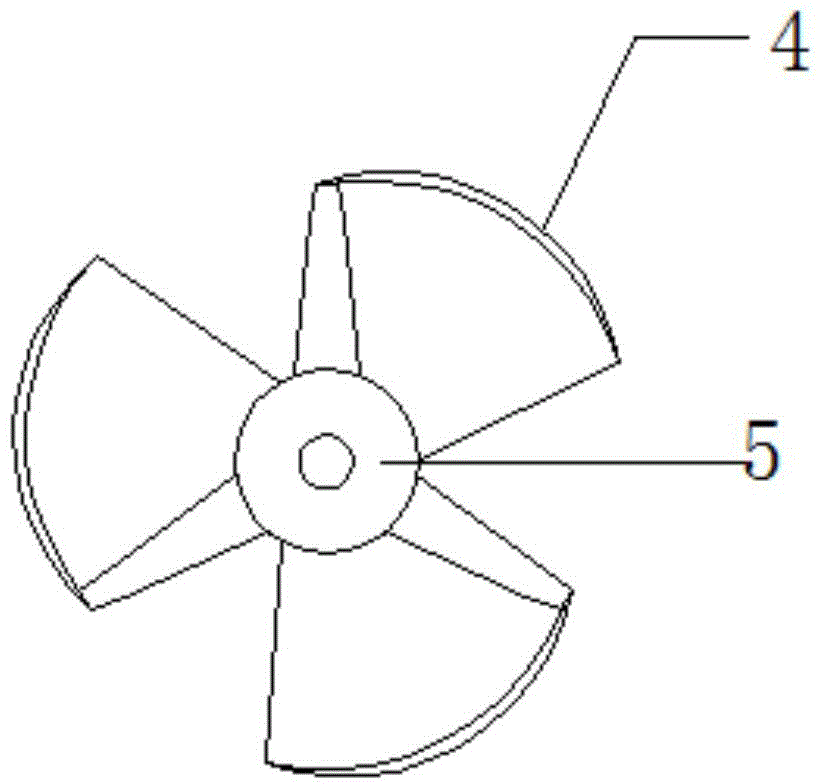

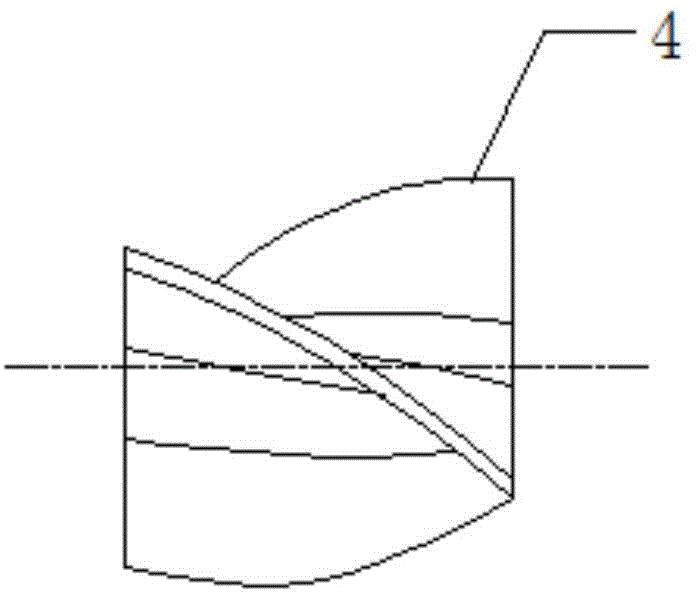

Evacuated collector tube device internally provided with rotors

InactiveCN103557615AEnhanced convective heat transferPrevent scalingSolar heat devicesSolar thermal energy generationHeat transmissionAlloy

The invention relates to an evacuated collector tube device internally provided with rotors, and belongs to the technical field of solar energy application. The device comprises an evacuated collector tube inner tube, an evacuated collector tube outer tube, rotors, a rotating shaft, fixing parts and supporting parts, wherein the rotors are fixed on the rotating shaft through the fixing parts; the rotating shaft is fixed inside the evacuated collector tube inner tube through the supporting parts; the supporting parts and the evacuated collector tube inner tube are connected and fixed through clamping grooves; a heat conduction fluid impacts blades to drive the blades to rotate, so as to form a vortex flow in the tube for reinforcing heat transmission and scale prevention; the rotating shaft is hollow, so that the weight of the device is reduced; the rotors, the rotating shaft, the fixing parts and the supporting parts are made of alloy or high-temperature resistant macromolecular material. Under the turbulence action of the rotors, a boundary layer is broken, the convection heat transfer between the evacuated collector tube inner tube and the heat conduction fluid is reinforced, the outlet temperature of the heat conduction fluid is increased, scaling in the tube is prevented, and the flowing resistance is small.

Owner:QINGDAO UNIV OF SCI & TECH

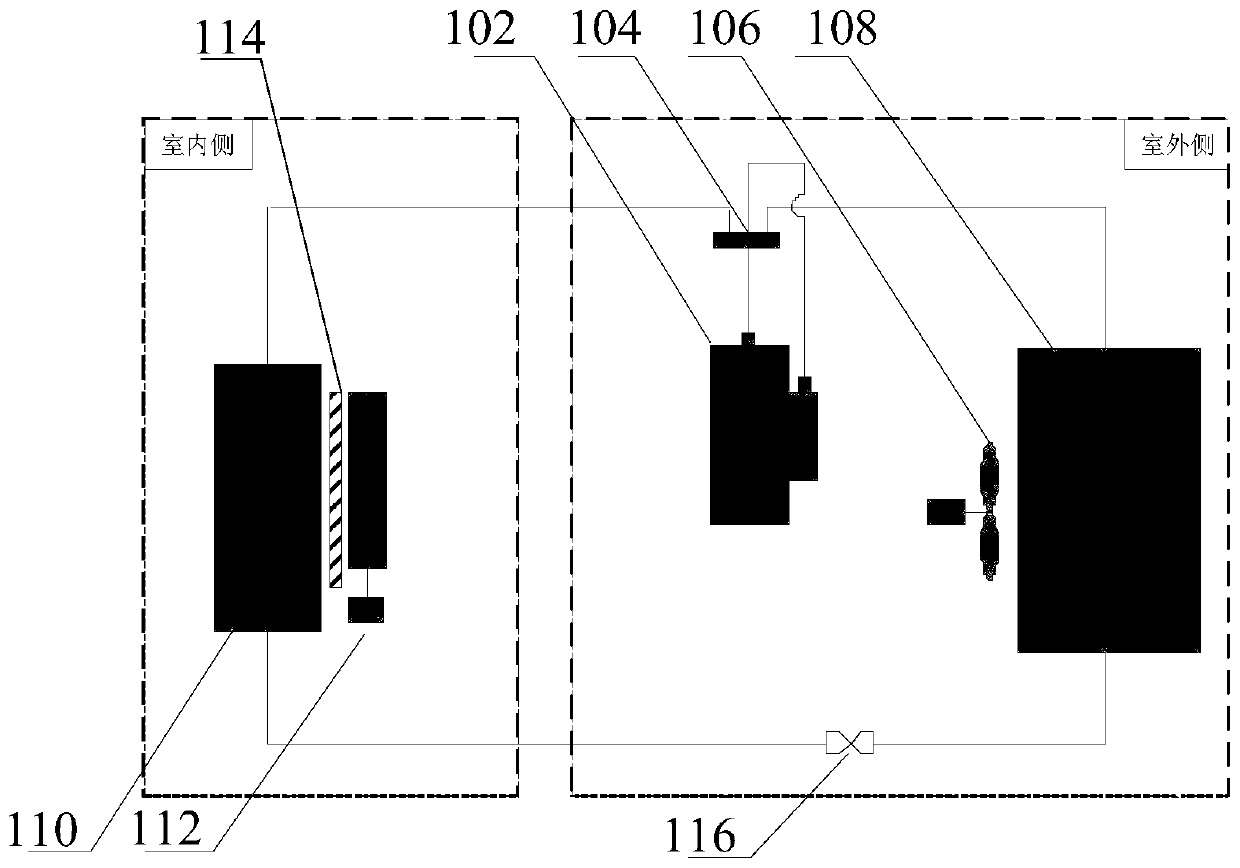

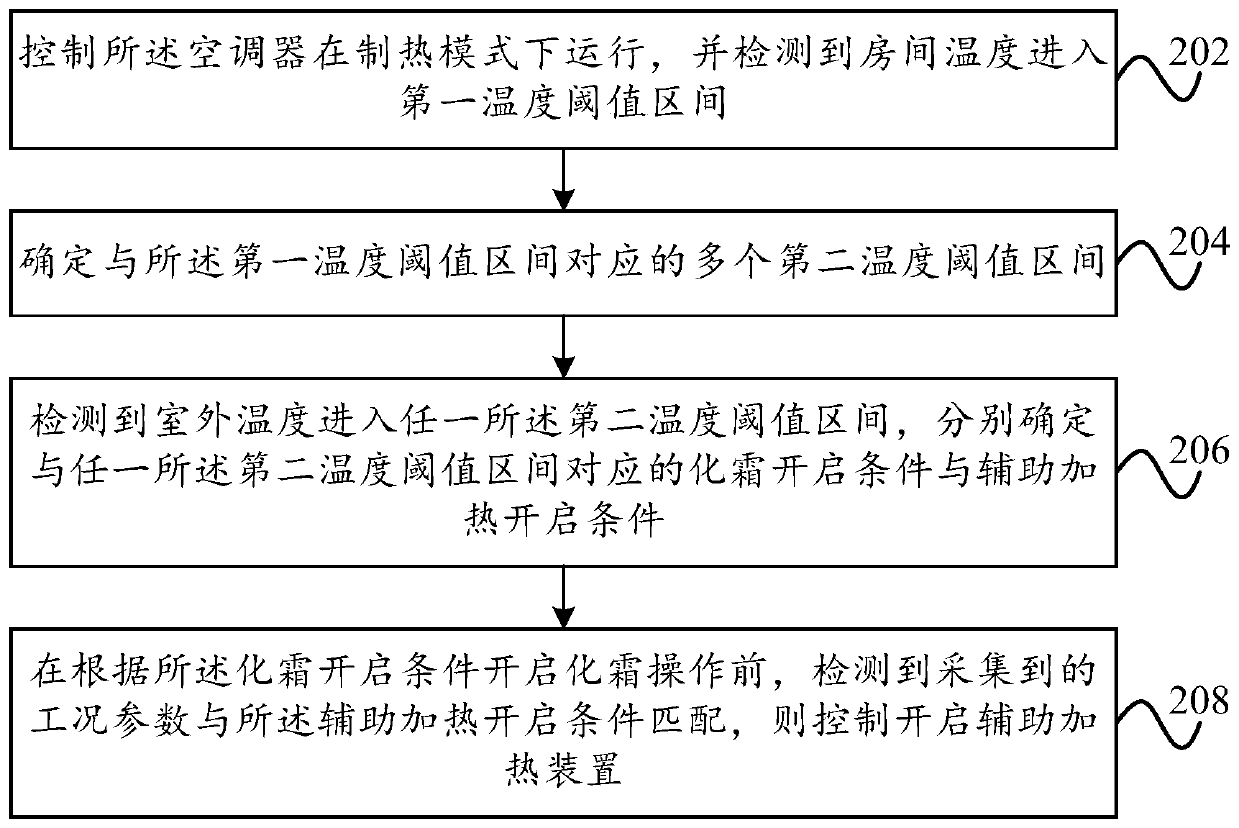

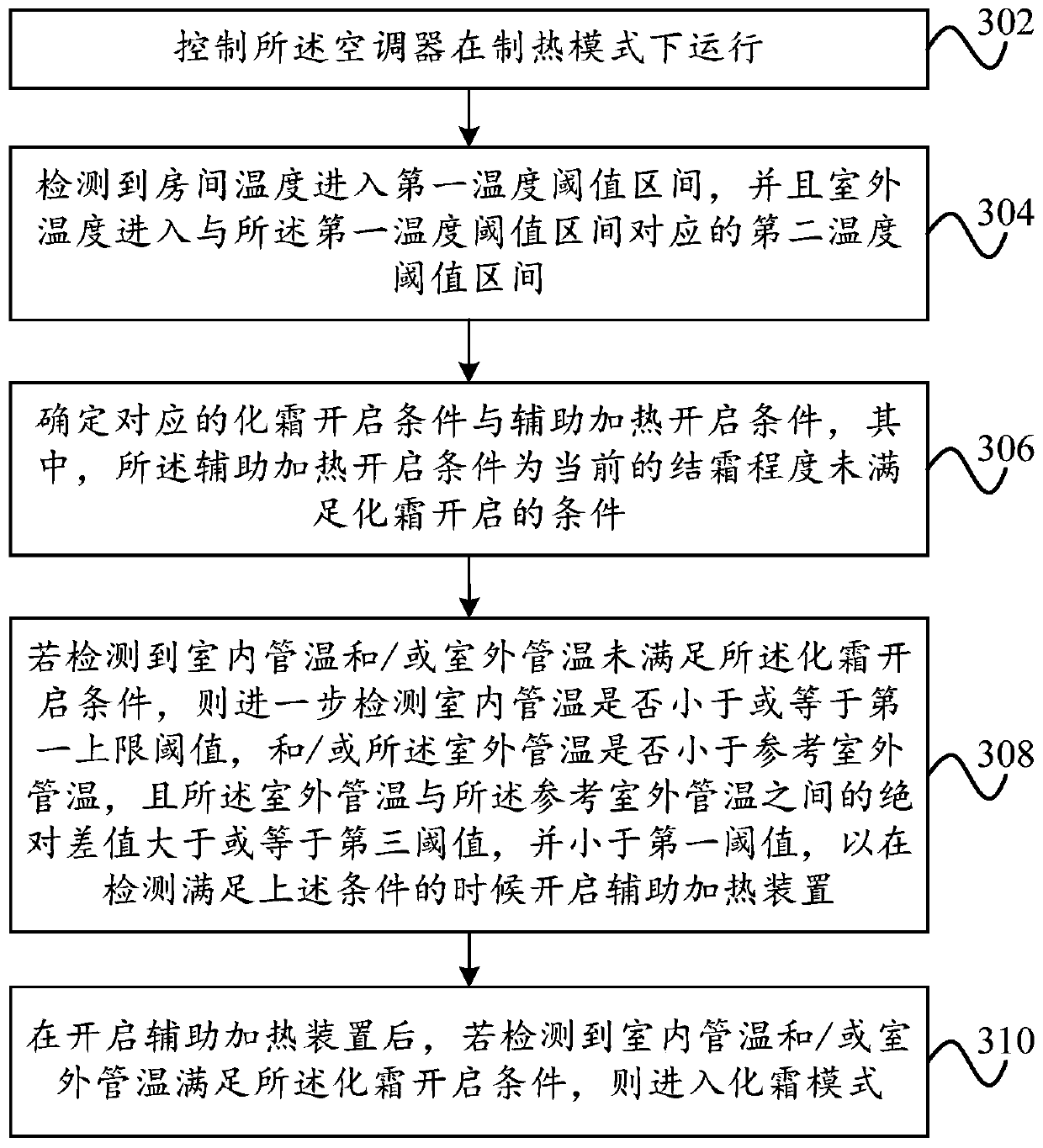

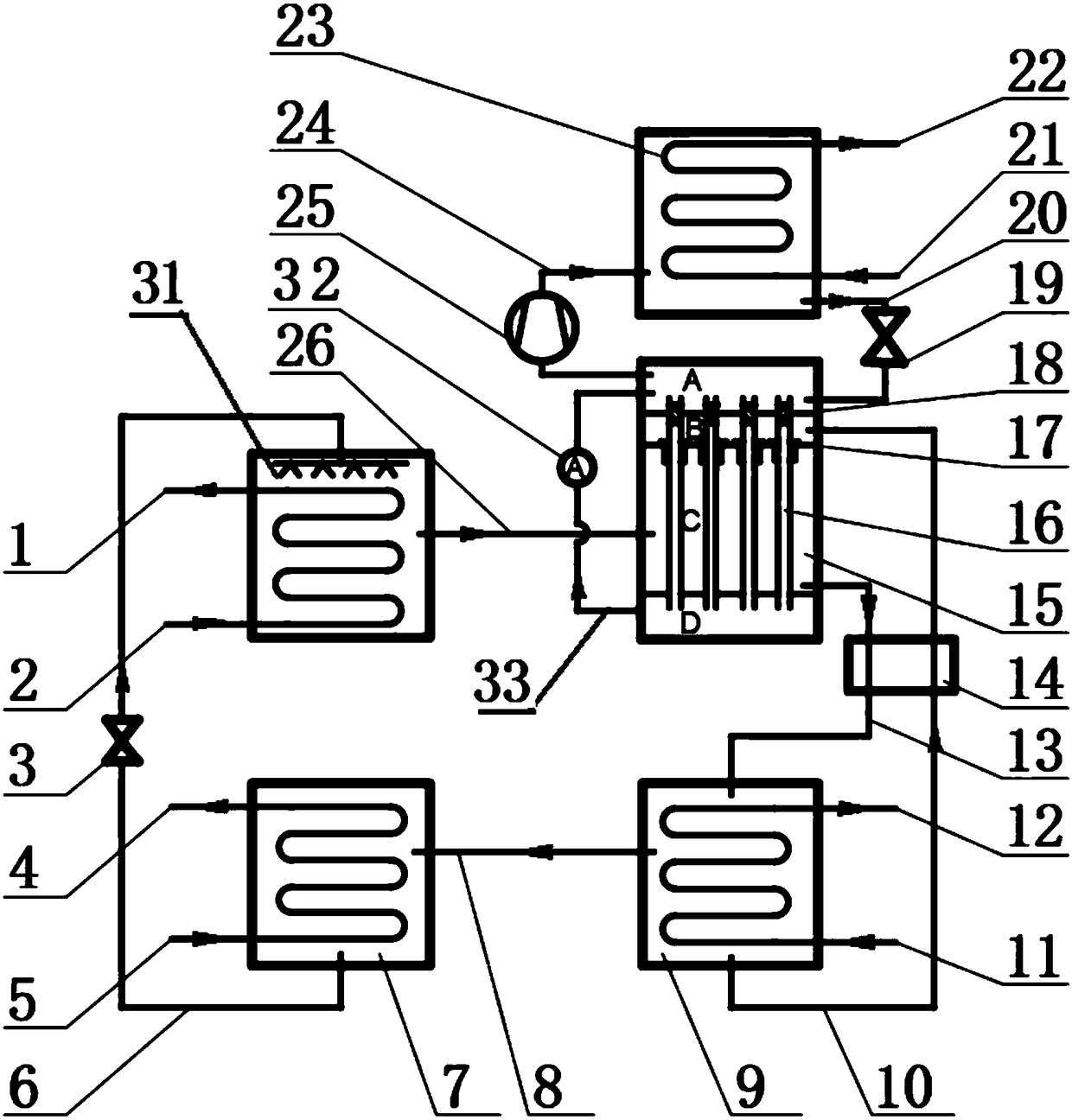

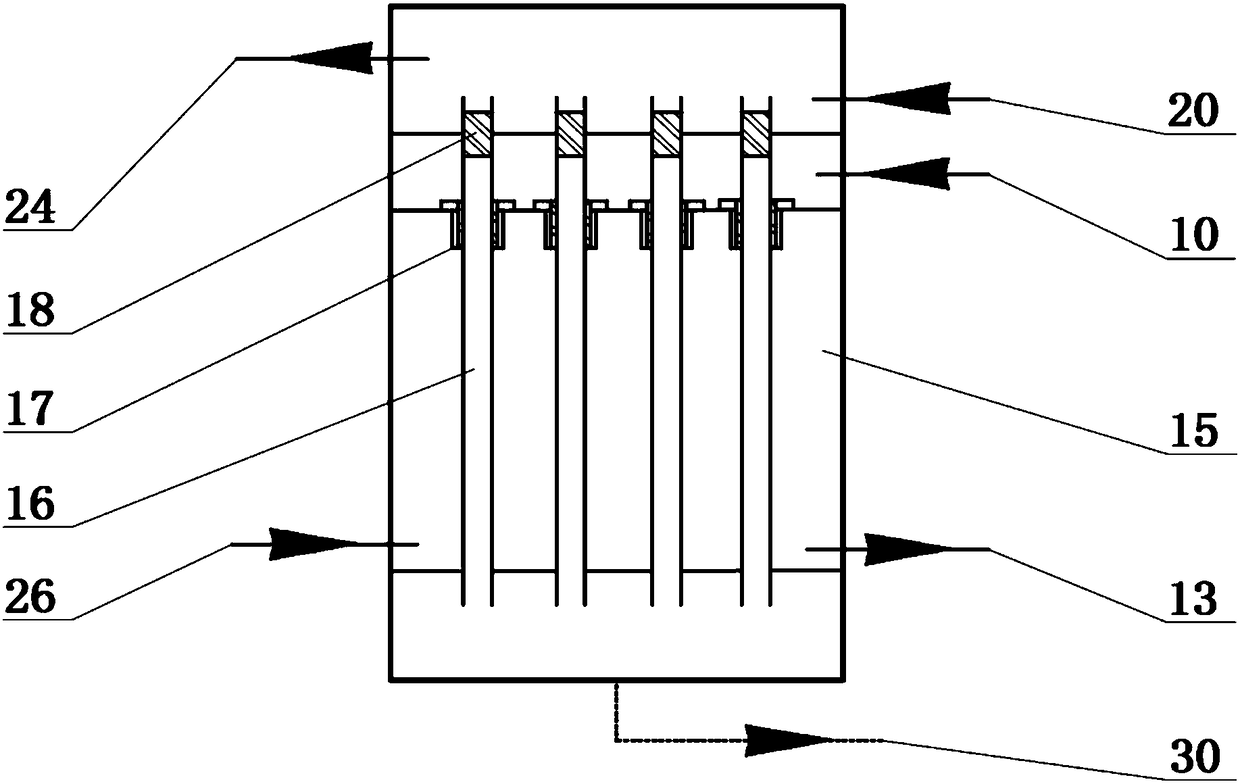

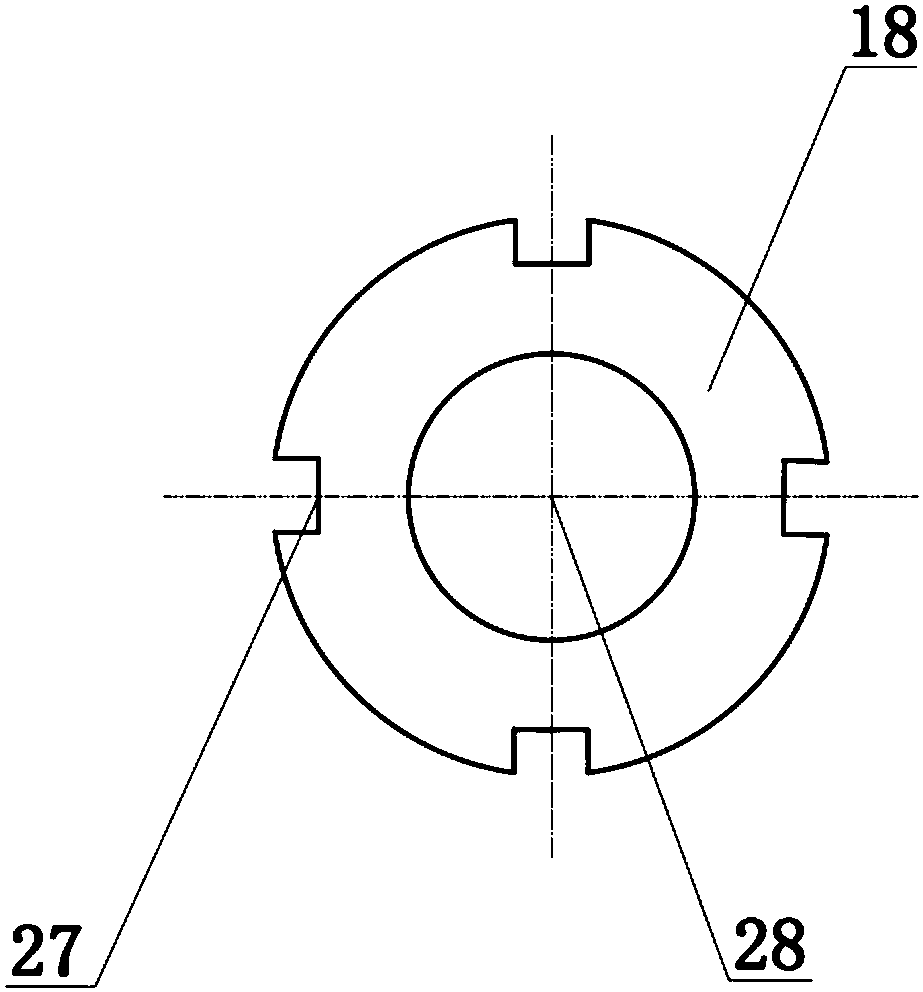

Operation control method, operation control device, air conditioner and computer readable storage medium

ActiveCN110173824AHigh outputImprove temperature rise performanceMechanical apparatusCorrosion preventionOutdoor temperatureEngineering

The invention provides an operation control method, an operation control device, an air conditioner and a computer readable storage medium. The operation control method comprises the following steps:controlling the air conditioner to operate in a heating mode and determining that the room temperature is in a first temperature threshold value interval; determining a plurality of second temperaturethreshold value intervals corresponding to the first temperature threshold value interval; when determining that the outdoor temperature enters any one second temperature threshold value interval, separately determining a defrosting starting condition and an auxiliary heating starting condition corresponding to any one second temperature threshold value interval; and behind starting the defrosting operation according to the defrosting starting condition, if the collected working condition parameter is matched with the auxiliary heating starting condition, controlling to start an auxiliary heating device. By adopting the technical scheme, by starting the auxiliary heating device before executing the defrosting operation, reduction of heating effect of the air conditioner as a result of frosting can be compensated, so that the heating effect before starting the defrosting operation is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Combined heat exchanger unit with electric heat pump and absorption heat pump

PendingCN108592444AReduce irreversible lossReduce heat transfer temperature differenceHeat pumpsEnergy efficient heating/coolingLower gradeLow graded

The invention provides a combined heat exchanger unit with an electric heat pump and an absorption heat pump. The heat exchanger unit comprises an electric heat pump condenser, a bilateral phase change heat exchanger, an absorption heat pump generator, an absorption heat pump condenser, an absorption heat pump evaporator and a pipeline and can be widely applied to various low-grade waste heat recovery occasions. The heat exchanger unit adopts the combined structure of the absorber of the absorption heat pump and an electric heat pump evaporator and can greatly raise the outlet temperature of aheated medium. Compared with the technology only adopting the absorption heat pump, the heat exchanger unit releases the maximum outlet temperature limit caused by the heat pump process and a workingmedium. Compared with the technology only adopting the electric heat pump, the heat exchanger unit greatly reduces powder consumption and significantly reduces the operating cost of equipment. The novel unit has a certain application prospect in the field of energy conservation and environmental protection.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Production technique of propylene

InactiveCN102924214AReduce the intensity of carbon depositionExtend your lifeHydrocarbon from oxygen organic compoundsEthylene productionReaction zoneCarbon deposit

The invention discloses a production technique of propylene, which comprises the following steps: (1) heating the raw material methanol, introducing the methanol into an etherification reaction zone to carry out etherification reaction, and flowing through a primary carbon deposit catalyst to react, thereby obtaining a primary reaction product stream; (2) mixing the primary reaction product stream and a diluter for heat exchange, and introducing into an OTP (one tube purification) to contact a regenerated catalyst so as to carry out OTP reaction, thereby obtaining a secondary reaction product stream containing rich propylene; and (3) after carrying out heat exchange on the secondary reaction product, sending into a separation zone, dehydrating, removing oxides, and separating to obtain the propylene. The carbon deposit quantity of the catalysts used in the etherification reaction zone and OTP reaction zone can be regulated to effectively control the reaction of the etherification reaction zone and the OTP reaction zone, thereby achieving the goals of high propylene selectivity, high yield and energy saving.

Owner:ZHEJIANG UNIV

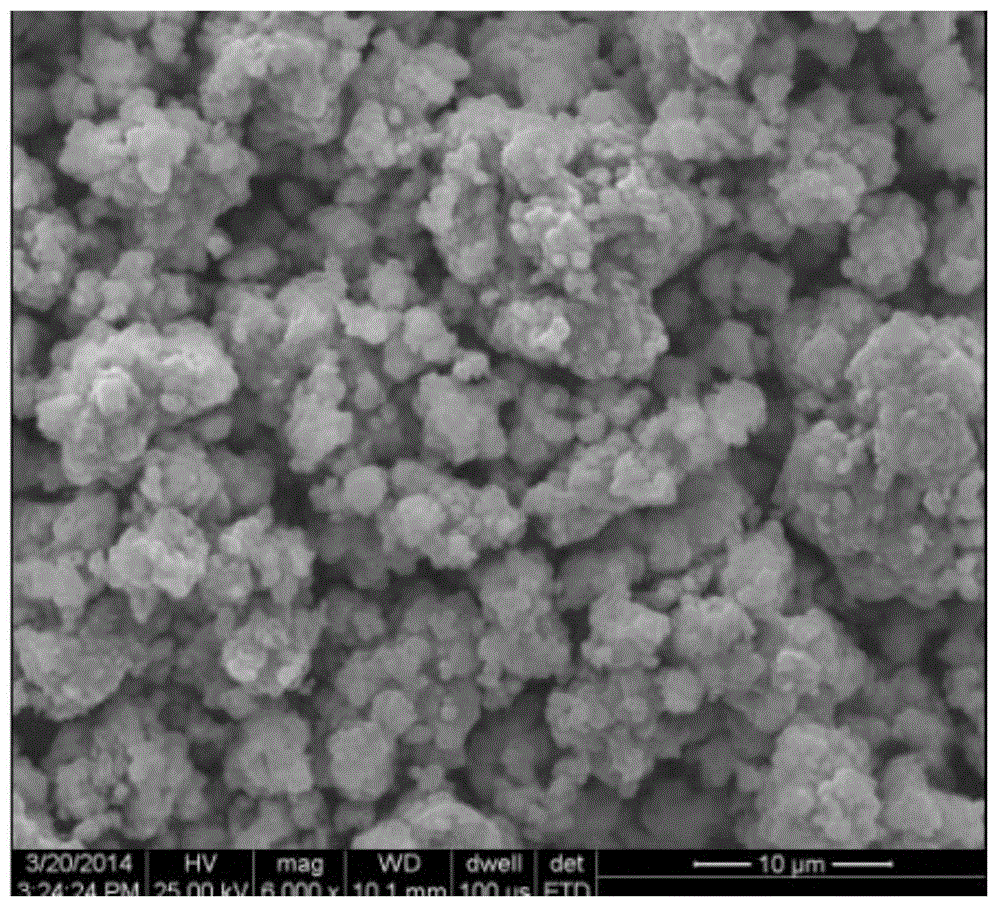

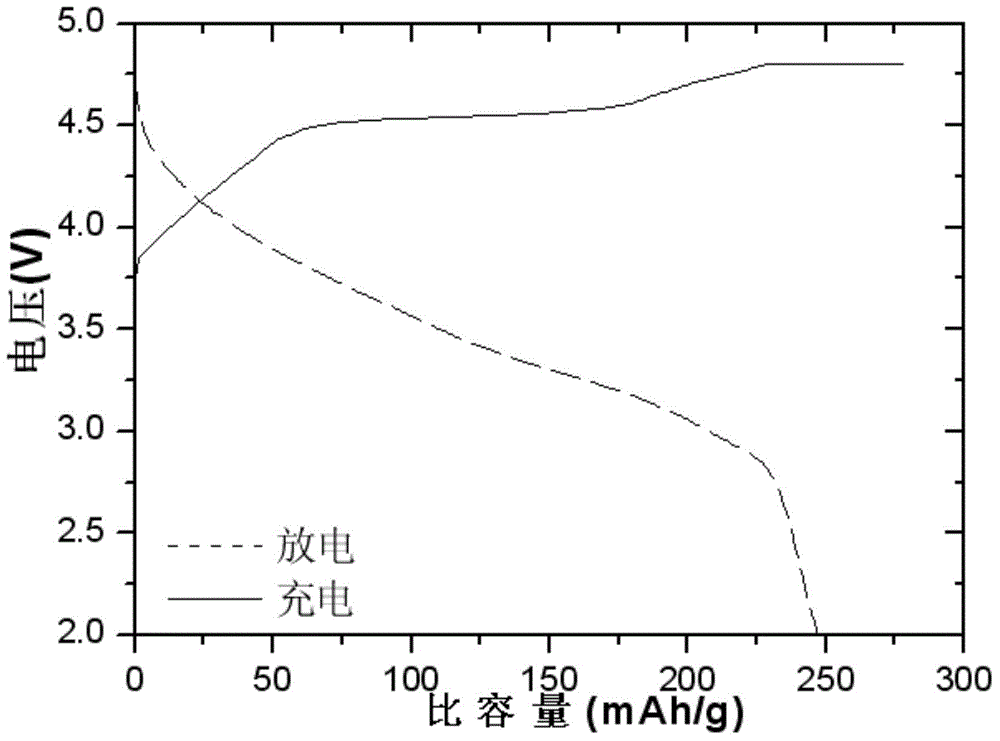

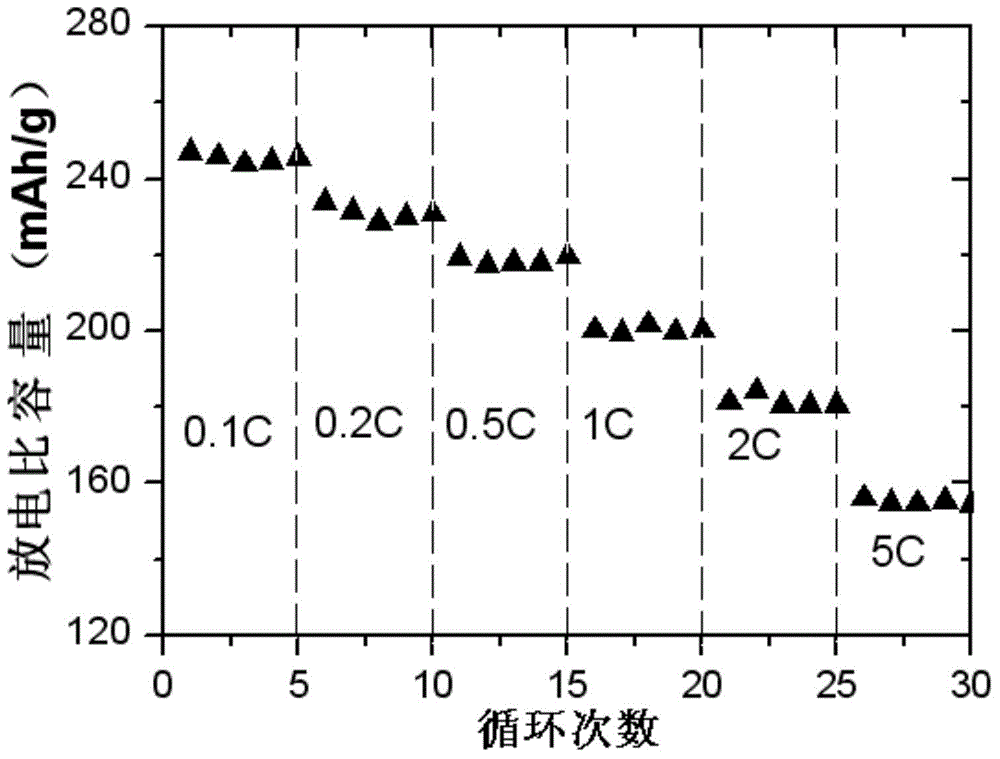

Lithium ion battery cathode material rich in lithium and manganese and preparation method thereof

ActiveCN104810519AImproved magnification performanceSmall particle sizeCell electrodesSecondary cellsMicrometerPhysical chemistry

The invention discloses a lithium ion battery cathode material rich in lithium and manganese and a preparation method thereof, and belongs to the technical field of preparation of the lithium ion battery cathode material. The chemical formula of the cathode material rich in lithium and manganese, provided by the invention is xLi2MnO3. (1-x)LiNi(0.5-a / 2)Mn(0.5-a / 2)FeaO2, wherein the x is not smaller than 0.1 and not greater than 0.9 and the a is not smaller than 0.002 and not greater than 0.008. When the accumulative particle size distribution percentage of the cathode material rich in lithium and manganese reaches 50%, the corresponding particle size is 0.1-0.8 micrometer. The particle size of the cathode material rich in lithium and manganese, provided by the invention is submicron level. Comparatively fine particle size facilitates that the cathode material rich in lithium and manganese is in full contact with electrolyte, can shorten the diffusion path of Li+, and results in the good rate performance of the lithium ion battery using the cathode material rich in lithium and manganese, provided by the invention as the positive active material, wherein the specific discharge capacity of the lithium ion battery at the rate of 5C keeps over 150 mAh / g.

Owner:CHERY AUTOMOBILE CO LTD

Distributed energy resource comprehensive utilization system and method used for natural gas station

ActiveCN103423591ASignificant comprehensive benefitsTake advantage ofOther heat production devicesPipeline systemsRecuperatorProcess engineering

The invention discloses a distributed energy resource comprehensive utilization system and method used for a natural gas station. The system comprises a natural gas compressor set, a heat exchanger, a water processor, a hot water storage tank, a secondary heat exchanger, a water feeding cooling device, a circulating water pump, a connecting pipeline, an adjusting valve and other main devices. A large amount of heat energy can be generated in the compressing process, fed water of the heat exchanger is processed to be soft water through the water processor, after temperature raising, the water enters the hot water storage tank, and heat exchanging is performed on the soft water and return water, used for heat supplying, of the secondary heat exchanger for the heat supplying. The redundant part further can drive a water boiling device to provide living drinking boiling water or living hot water through the secondary heat exchanger, the compressor cooling water after secondary heat exchanging enters the water feeding cooling device again so that the water can be cooled to a normal temperature, and water feeding conditions of cooling water is achieved. The system uses indirect cooling heat energy for heating the cold water in the compressing process, the secondary heat exchanging is performed on the water with raised temperature, so that comprehensive utilization of the energy is achieved, the energy utilization rate of the system is improved, and energy cost is reduced.

Owner:中科九朗(北京)能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com