Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

223 results about "Melting rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

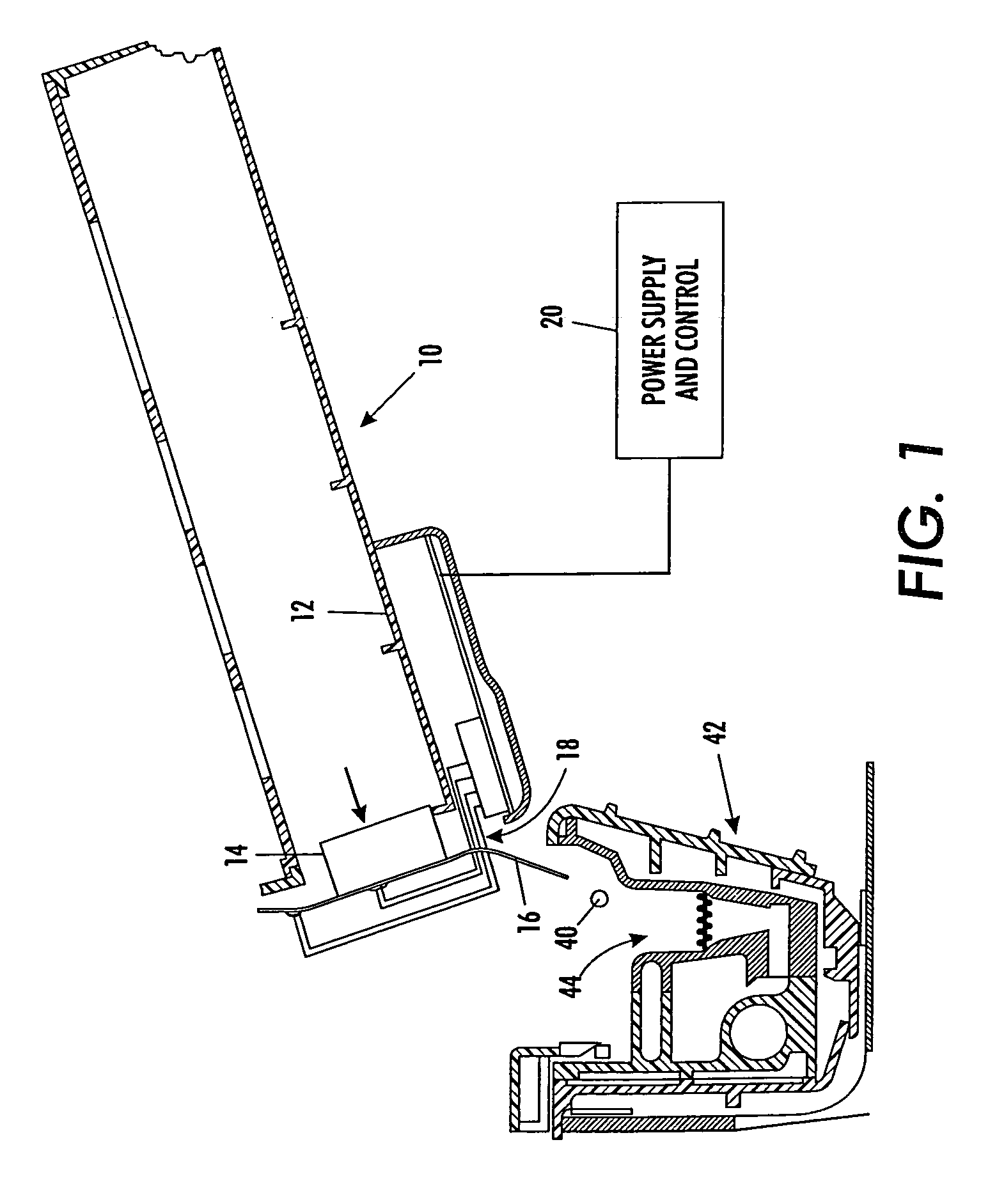

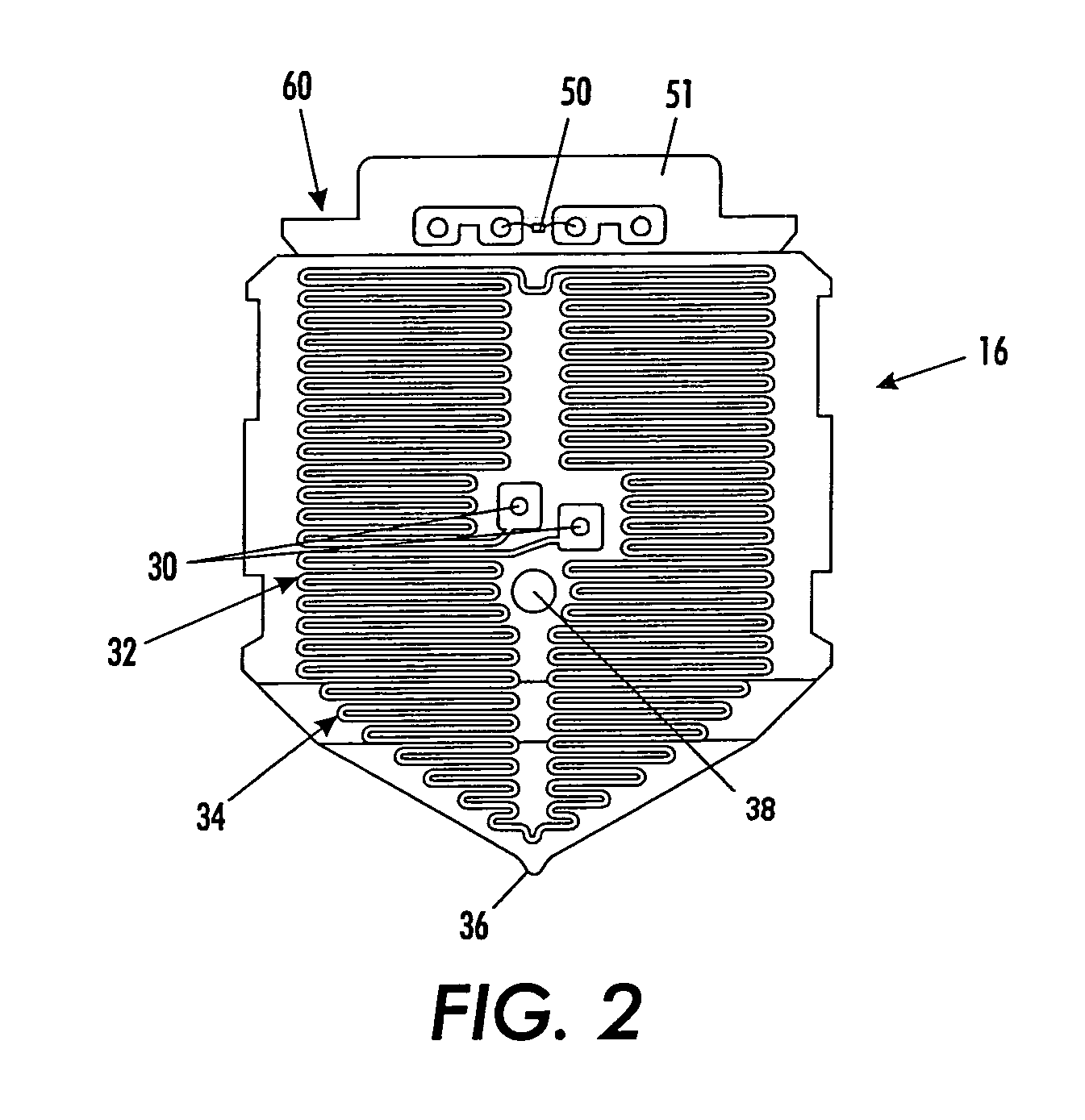

Beverage container with ice compartment

InactiveUS6112537ALighting and heating apparatusClosure with auxillary devicesEngineeringMelting rate

A beverage container having a beverage compartment and an ice compartment separated by a removable seal which, when removed, allows the ice and beverage to mix thereby cooling the beverage. The removable seal prevents premature mixing of the beverage and the ice and allows the container to be stored warm, with water in the ice compartment, indefinitely. Prior to use, the container is placed in a dual-temperature environment that freezes the water in the ice compartment but doesn't freeze the beverage. Freezing of the beverage is prevented by an air gap between the beverage and the ice that acts as a thermal barrier. An ice anchor and an air gap in the ice compartment reduce the melting rate of the ice by suspending the ice within the ice compartment, out of contact with the melt water and surrounded by an insulating layer of air.

Owner:BROADBENT JOHN A

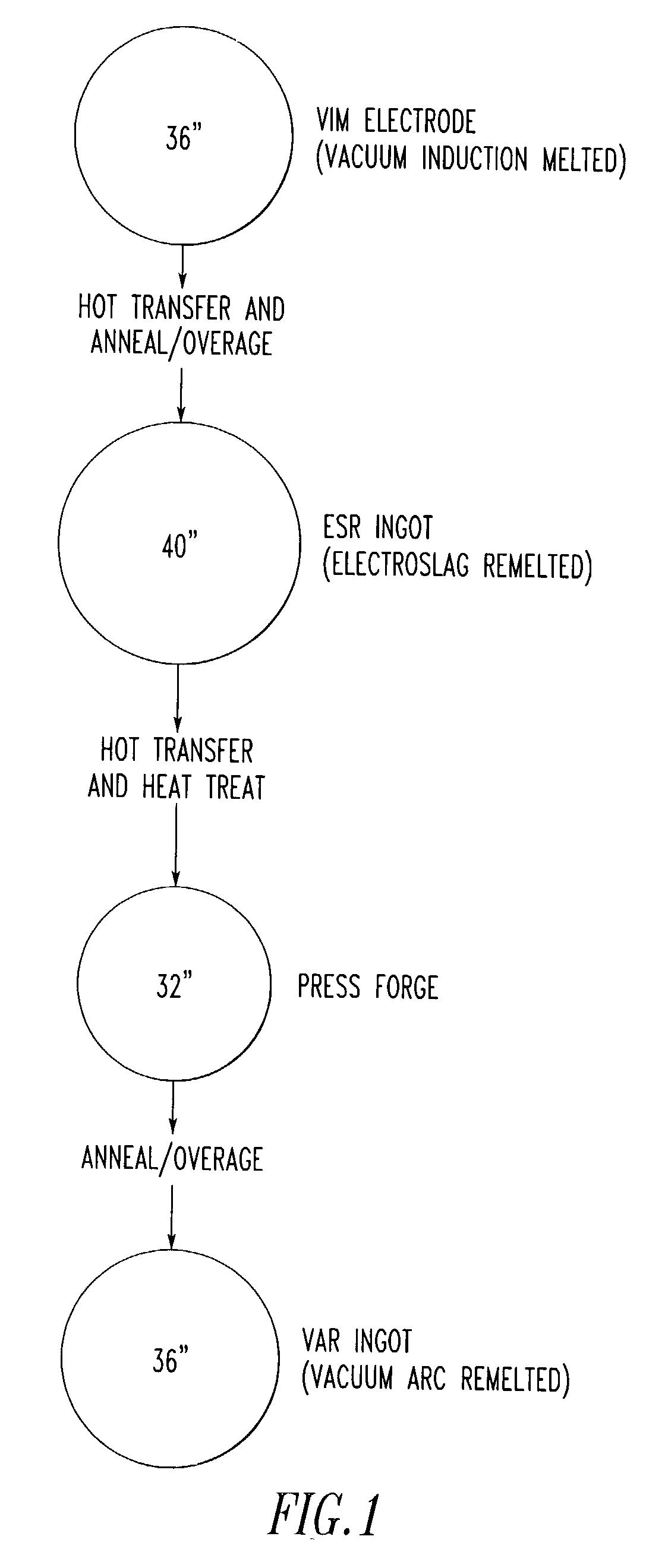

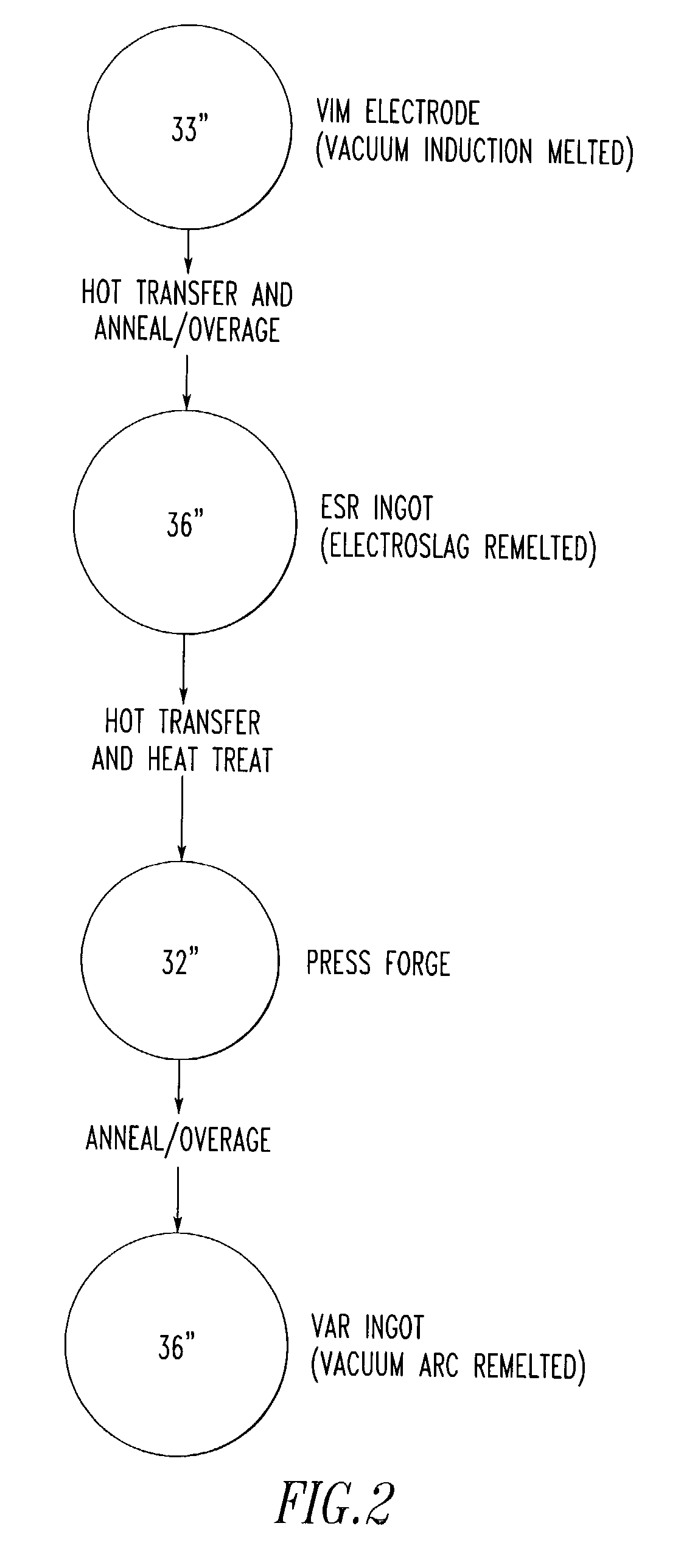

Method for producing large diameter ingots of nickel base alloys

InactiveUS6416564B1Inhibit thermal stressLarge caliberWelding/cutting media/materialsElectric furnaceCasting moldHeating furnace

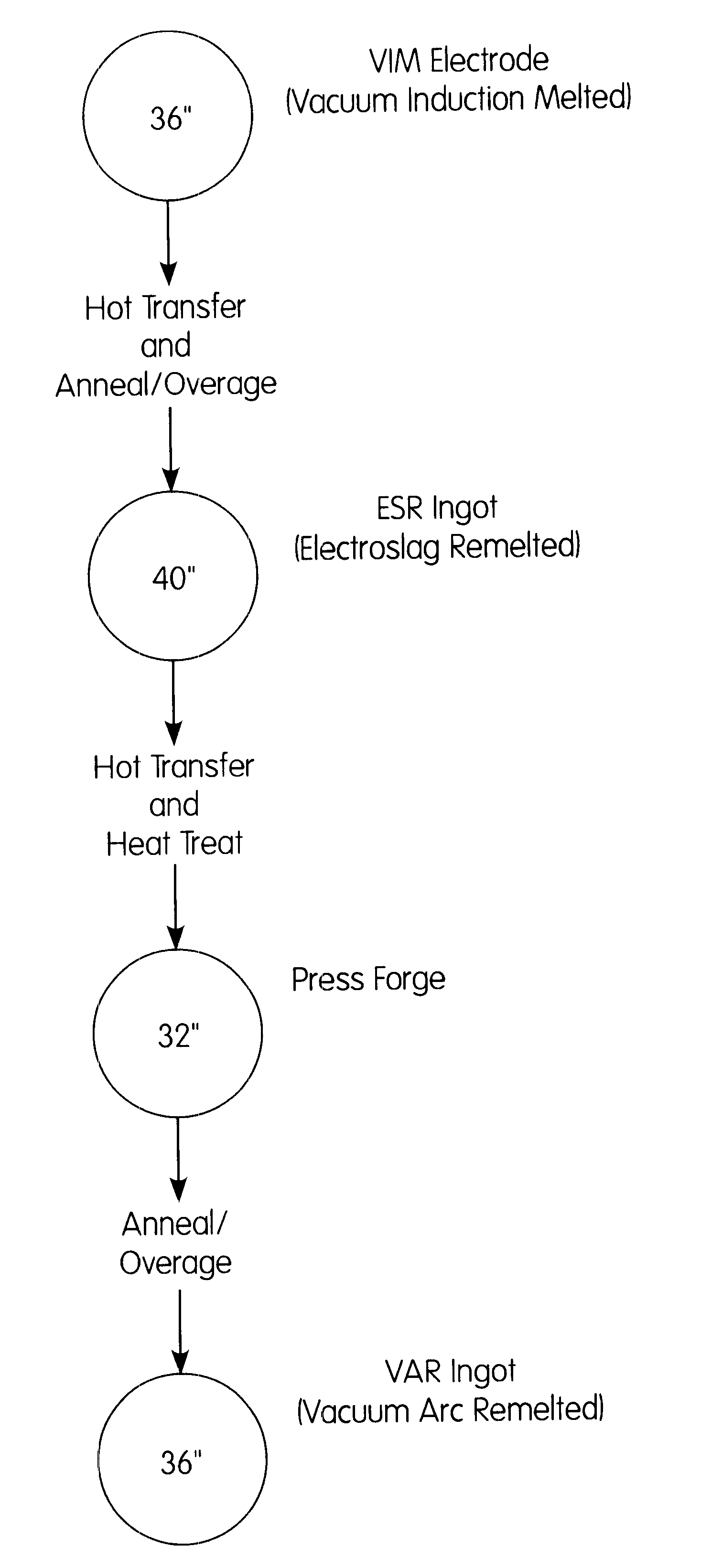

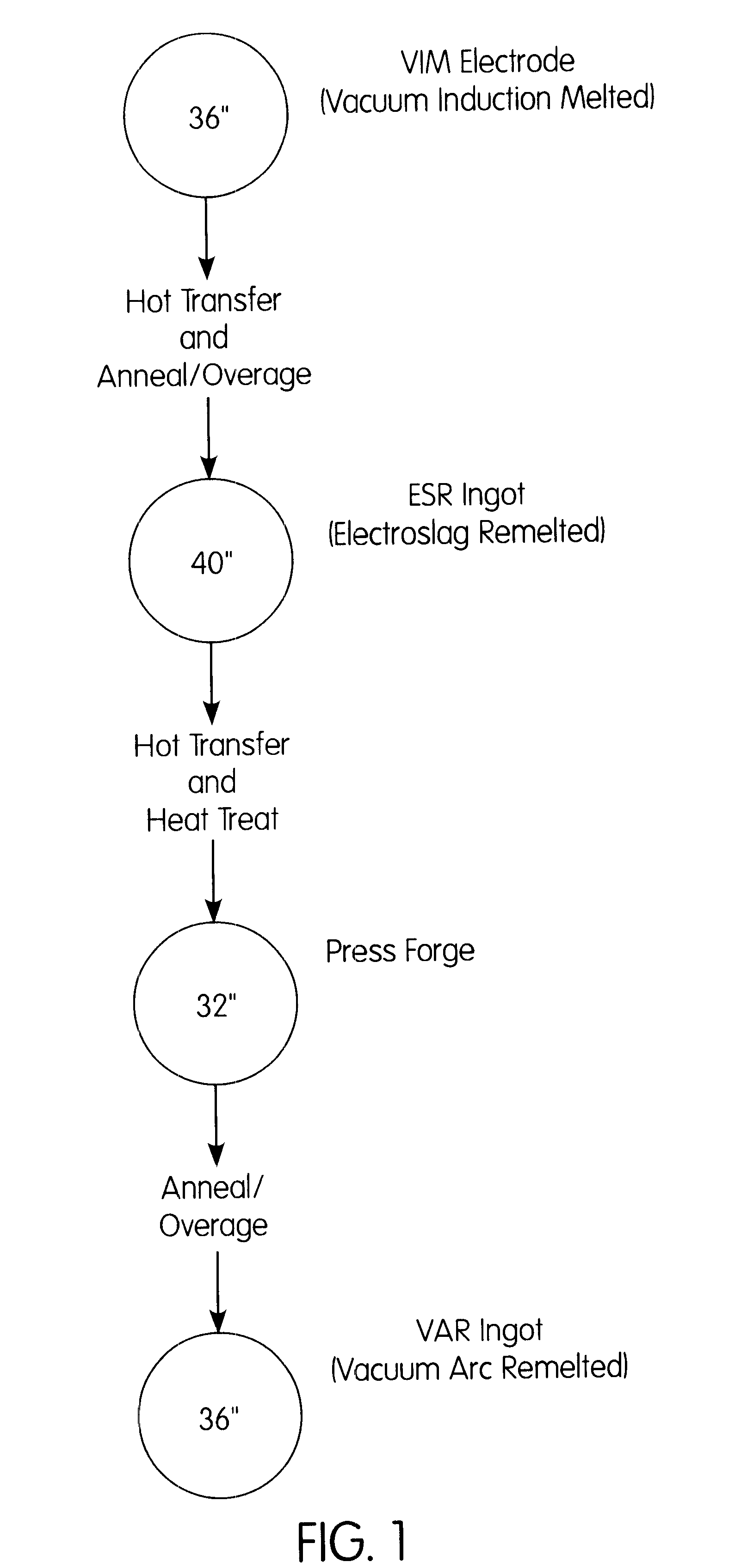

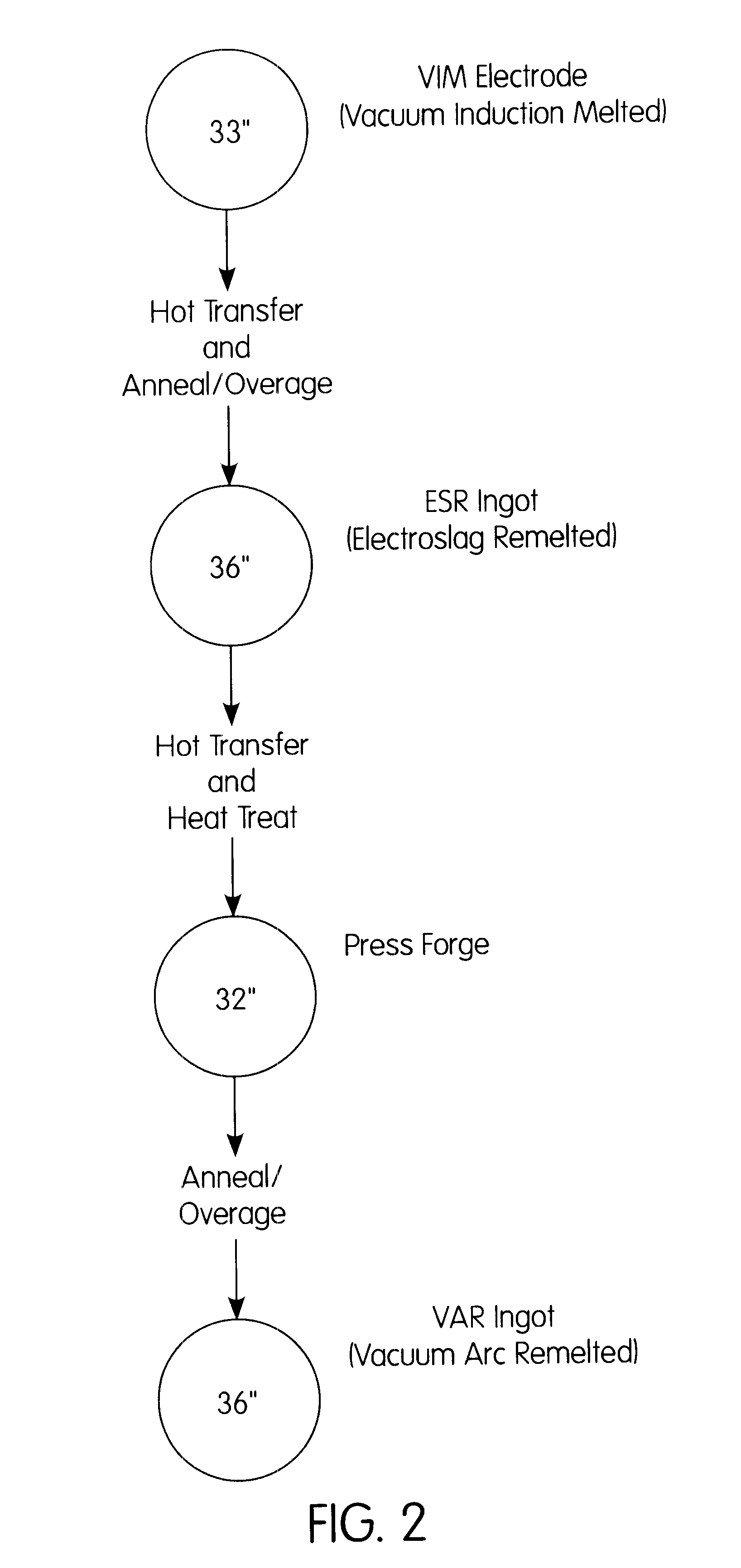

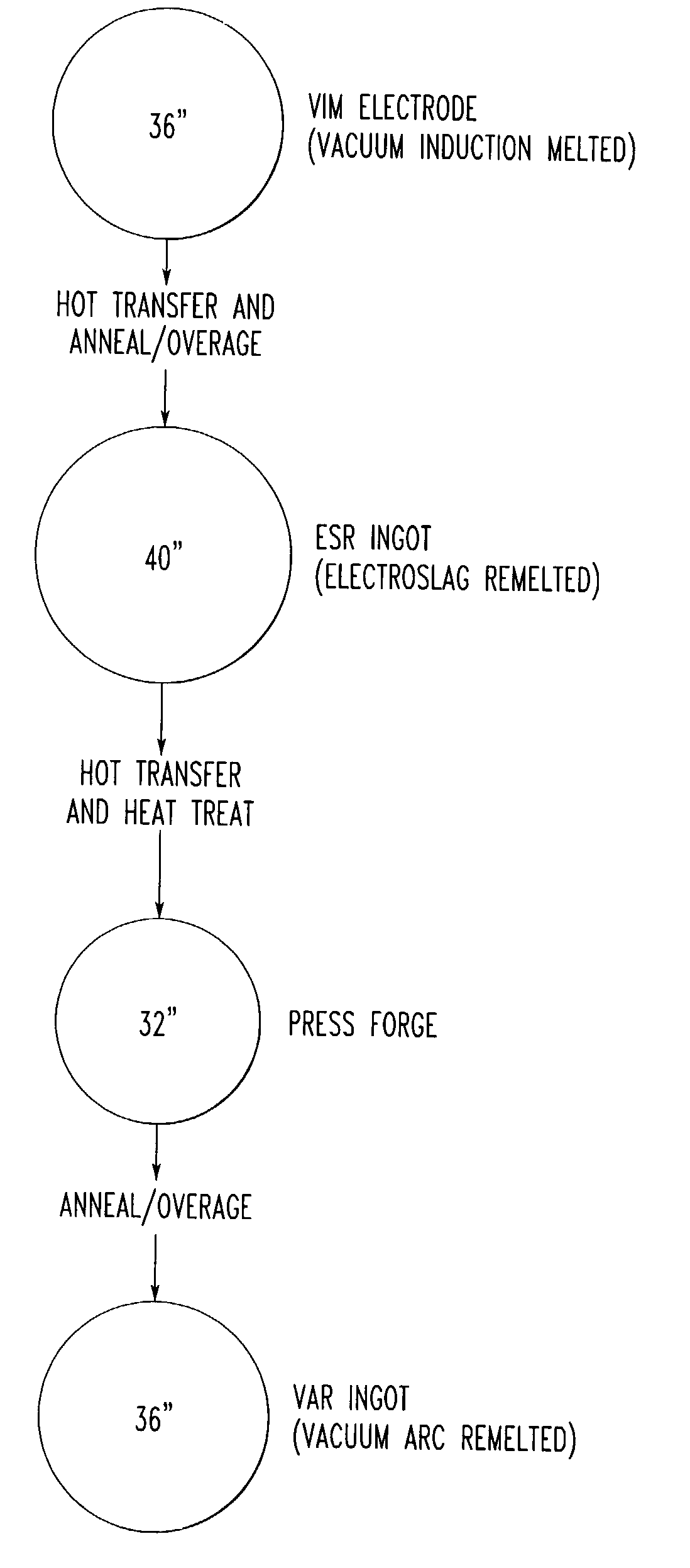

A method of producing a nickel base alloy includes casting the alloy within a casting mold and subsequently annealing and overaging the ingot at at least 1200° F. (649° C.) for at least 10 hours. The ingot is electroslag remeelted at a melt rate of at least 8 lbs / min (3.63 kg / mm.), and the ESR ingot is then transferred to a heating furnace within 4 hours of complete solidification and is subjected to a novel post-ESR heat treatment. A suitable VAR electrode is provided form the ESR ingot, and the electrode is vacuum arc remelted at a melt rate of 8 to 11 lbs / minute (3.63 to 5.00 kg / minute) to provide a VAR ingot. The method allows premium quality VAR ingots having diameters greater than 30 inches (762 mm) to be prepared from Alloy 718 and other nickel base superalloys subject to significant segregation on casting.

Owner:ATI PROPERTIES

Gas-shielded AC arc welding method and machine making use of consumable electrode

An EP output voltage to be outputted during a period of EP polarity is set so that a welding current becomes equal to or lower than a critical current level, and an EN output voltage to be outputted during a period of EN polarity is set at a level lower than the EP output voltage. This makes it possible to substantially equalize a wire melting rate in the period of EN polarity and that in the period of EP polarity with each other. Even at such a short arc length as causing frequent short circuiting, gas-shielded AC arc welding making use of a consumable wire can be still performed stably so that high wire melting rate, shallow penetration, convex weld reinforcement and the like, which are characteristic features of AC welding, can each be set selectively at a desired level or in a desired shape depending on the application.

Owner:HITACHI SEIKO LTD +1

Asphalt modifier compositions with an improved melting rate and modified asphalt prepared using the same

ActiveUS20100273915A1Increase melting rateShorten melting timeBuilding insulationsProduction rateButadiene-styrene rubber

The present invention relates to a pellet type SBS-asphalt master batch modifier composition comprising styrene-butadiene-styrene (SBS) block copolymer and asphalt, and modified asphalt prepared by melting and mixing the pellet type SBS-asphalt master batch modifier composition with asphalt. The modified asphalt prepared thereof has advantages that deterioration of physical properties and thermal oxidation can be prevented while productivity can be improved due to reduced melting time of modifier.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

Large diameter ingots of nickel base alloys

InactiveUS20020170386A1Difficult to extractIncrease the diameterWelding/cutting media/materialsElectric furnaceCasting moldHeating furnace

A method of producing a nickel base alloy includes casting the alloy within a casting mold and subsequently annealing and overaging the ingot at at least 1200° F. (649° C.) for at least 10 hours. The ingot is electroslag remelted at a melt rate of at least 8 lbs / min. (3.63 kg / min.), and the ESR ingot is then transferred to a heating furnace within 4 hours of complete solidification and is subjected to a novel post-ESR heat treatment. A suitable VAR electrode is provided form the ESR ingot, and the electrode is vacuum arc remelted at a melt rate of 8 to 11 lbs / minute (3.63 to 5.00 kg / minute) to provide a VAR ingot. The method allows premium quality VAR ingots having diameters greater than 30 inches (762 mm) to be prepared from Alloy 718 and other nickel base superalloys subject to significant segregation on casting.

Owner:ATI PROPERTIES

Method capable of improving quality of large-section peritectic steel continuous casting billet

The invention discloses a method capable of improving the quality of a large-section peritectic steel continuous casting billet. The method comprises control over the following processing steps that (1) the chemical ingredients of low-alloy peritectic steel are optimized; (2), after VD treatment, a fed calcium line is controlled to perform final deoxidation and inclusion modification treatment, and soft blowing is performed before casting; (3), full package operation is adopted for a tundish, the tonnage is controlled, and low-liquid-level casting is avoided; (4), the superheat degree of the tundish is controlled in the continuous-casting throwing process, and meanwhile the temperature difference of molten steel between two furnaces is controlled; (5), the fed-water temperature of a crystallizer and the temperature difference between fed water and discharged water are controlled, meanwhile, the narrow edge taper of the crystallizer is increased, and the shrinkage quantity of the peritectic steel is compensated; (6), casting powder special for the peritectic steel is selected, wherein the casting powder is high in alkalinity, low in viscosity and high in melting rate; (7), after thecontinuous casting billet is controlled to enter a secondary cooling zone by 12 meters, electromagnetic stirring is applied, and meanwhile the secondary cooling water amount is lowered. The surface quality and the internal quality of the large-section peritectic steel continuous casting billet cast through the method are both improved to a great extent.

Owner:WUYANG IRON & STEEL

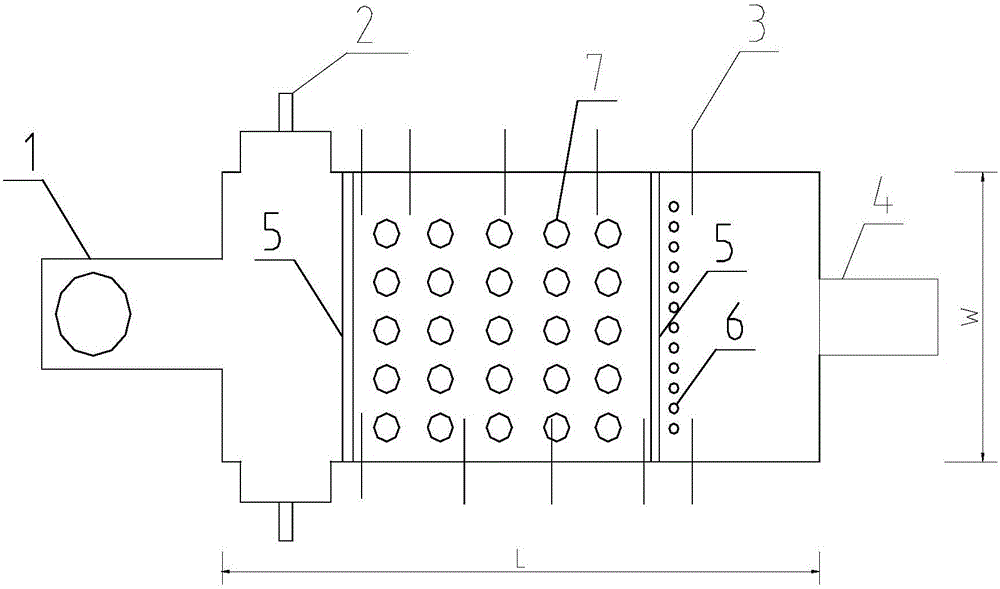

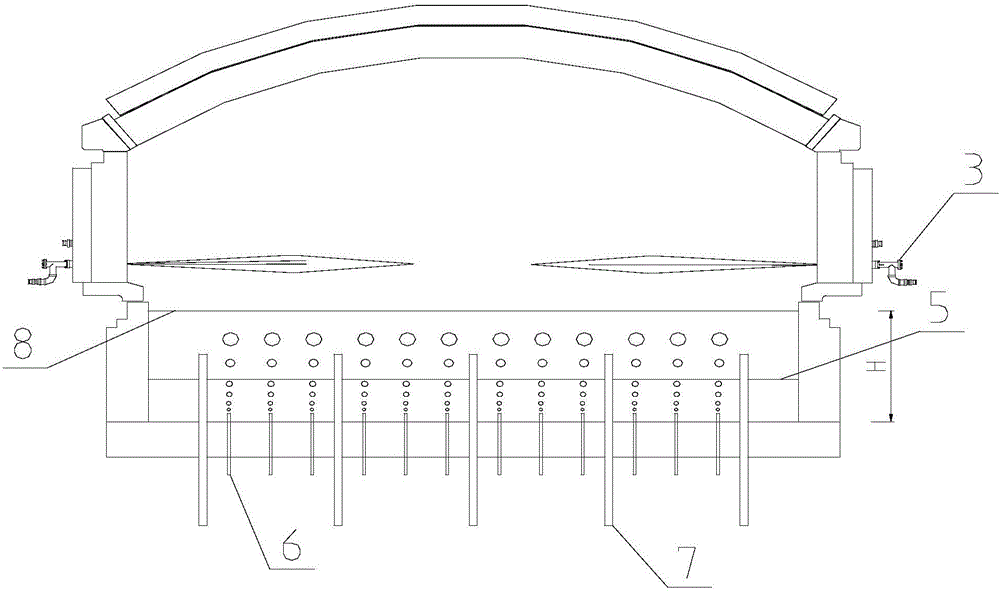

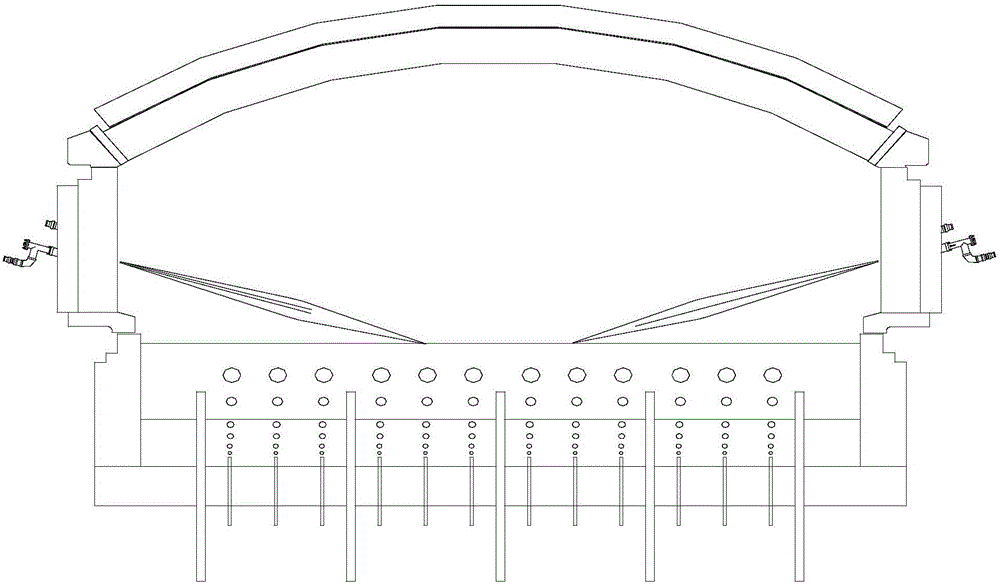

Glass tank furnace with high melting rate

ActiveCN105776819AHigh aspect ratioReduce lossTank furnacesGlass furnace apparatusHeat lossesEngineering

The invention discloses a glass tank furnace with high melting rate. The ratio of the length of the glass tank furnace to the width of the glass tank furnace is 2.3-2.8. The glass tank furnace has the advantages that the area of the tank furnace is reduced and the length-width ratio of the tank furnace is optimized so as to reduce heat loss; reasonable liquid glass tank depth is designed to improve the bottom temperature of the tank furnace and guarantee the quality of liquid glass; a pure-oxygen burner and an auxiliary capacitor provides sufficient energy to increase the melting ability and heating efficiency of the tank furnace, and the energy consumption and the discharge amount of carbon dioxide are lowered greatly; furnace ridges at the bottom of the tank furnace increase the outlet temperature of the liquid glass, lower energy consumption, lower the furnace bottom temperature of an electrode area, prolong the service life of the furnace bottom and guarantee the increasing of auxiliary electric energy proportion; bubbling at the bottom of the tank furnace increases the return strength of the liquid glass and increases the melting ability and the quality of the liquid glass; to sum up, the melting rate of the tank furnace can be increased effectively, and the energy consumption can be lowered.

Owner:JUSHI GRP CO

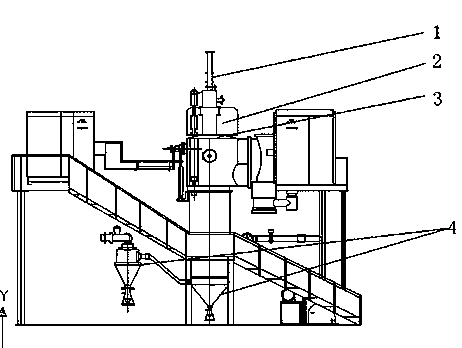

Process and equipment used for preparing high-purity spherical titanium and titanium alloy powder material

The invention discloses a process and equipment used for preparing a high-purity spherical titanium and titanium alloy powder material. The equipment comprises an electrode vertical conveying device 1, a vacuum induction melting device 2, a gas atomizer 3 and an atomizing tower 4, and is characterized in that the vertical displacement and the rotating speed of titanium and titanium alloy electrode bars entering a vacuum induction melting furnace are precisely controlled by the electrode vertical conveying device; the titanium and the titanium alloy electrode bars are molten into liquid in the induction furnace under a non-crucible contact state; the melting rate of the titanium and titanium alloy electrode bars can be adjusted through controlling the displacement speed of the titanium and titanium alloy electrode bars entering the melting furnace and the heating temperature in the induction furnace; when the metal liquid passes through a gas confluence focus of the high-pressure inert gas atomizer, a titanium and titanium alloy liquid phase flow is crushed into a superfine fogdrop state; under the effect of surface tension, liquid drops settle, cool and form the spherical superfine powder material in the atomizing tower and are separated and collected by a filter; the titanium and titanium alloy powder materials with different granularities and size distribution can be obtained through controlling atomizing gas pressure and flow. By using the process and the equipment, high-purity spherical magnesium, aluminum, nickel, chromium, tungsten, molybdenum and corresponding alloy powder and ceramic powder can be prepared.

Owner:CHANGSHA WEITE METALLURGY ENG TECH

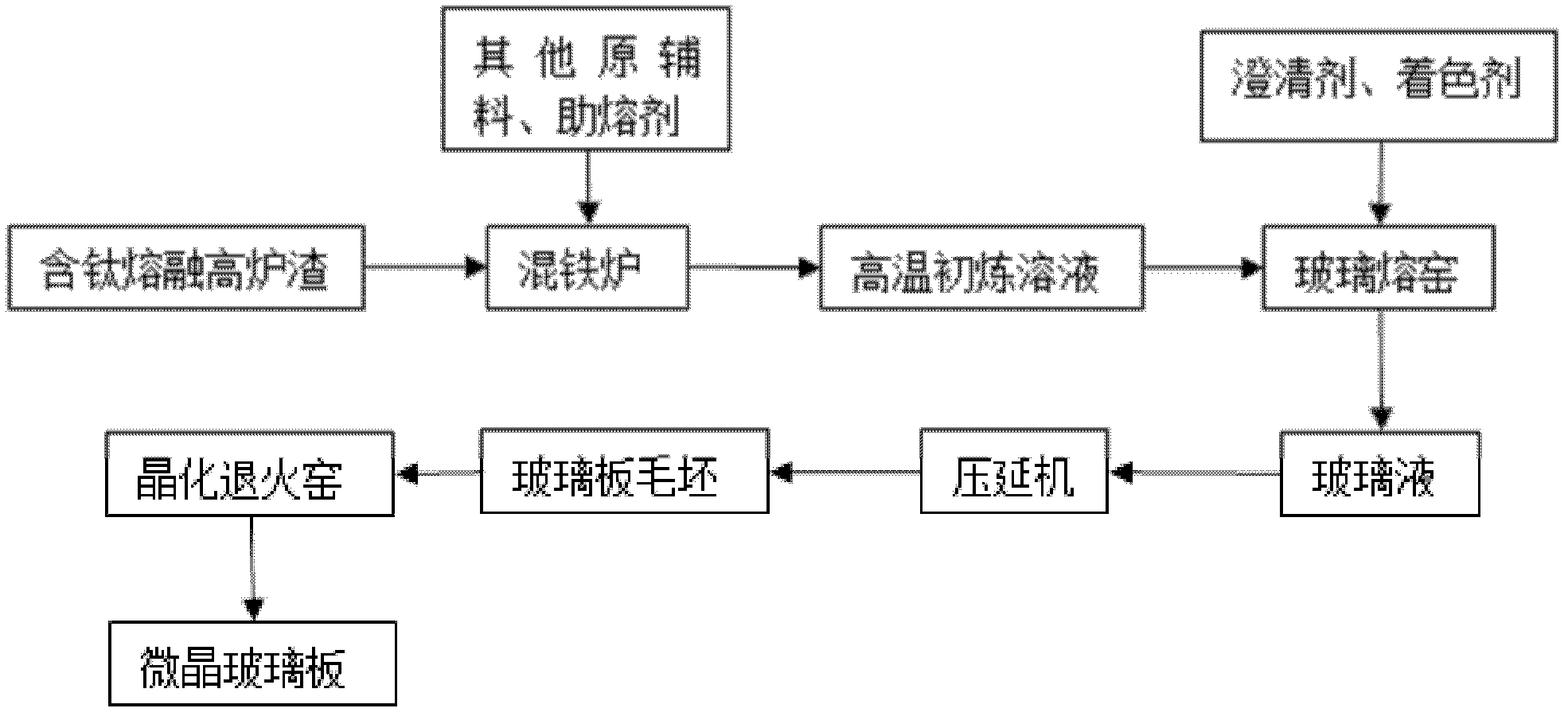

Method for manufacturing glass ceramic by titanium-containing melting blast furnace slag

The invention discloses a method for manufacturing glass ceramic by titanium-containing melting blast furnace slag. The method comprises the following steps of: directly feeding titanium-containing high-temperature melting blast furnace slag flowed out of a blast furnace into a metal mixer, mixing the slag with other auxiliary raw materials and a fluxing agent, feeding high-temperature initial-refining solution into a glass melting furnace and also adding a clarifying agent and a coloring agent, refining in the glass melting furnace to form the smelted glass with uniform elements, uniform temperature and good flowability, feeding the smelted glass into a calendar to form red and hot glass blanks by pressing, and feeding the pressed glass blanks into a crystallization annealing kiln to carry out thermal treatment to manufacture the glass ceramic which takes diopside as a main crystalline phase. Compared with the prior art, the method for manufacturing the glass ceramic by the titanium-containing melting blast furnace slag has the advantages that the blast furnace slag with high titanium content is taken as the raw material for preparing the glass ceramic, thus the effectively utilization rate of the blast furnace slag with the high titanium content is improved, the discharge of the blast furnace slag with the high titanium content is further reduced, and the recovery of an industrial solid waste resource is also realized when the environment is improved.

Owner:达州市海蓝冶金设备制造有限公司

Control method and system for metal arc welding

ActiveUS7705270B2Quality improvementIncrease deposition rateArc welding apparatusCarbon Dioxide / HeliumShielding gas

A method of controlling an arc welding system during a welding process is disclosed. The welding process has a plurality of welding cycles in which a consumable electrode is advanced towards a workpiece. The method includes dynamically regulating a rate of advancement and instantaneous melt rate of the electrode during each welding cycle in response to predetermined events occurring during the welding process. The melt rate may be coordinated with the rate of advancement of the electrode to provide a wide range of stable deposition rates with a shielding gas such as CO2. An arc welding system for carrying out the method is also disclosed.

Owner:UNIV OF WOLLONGONG

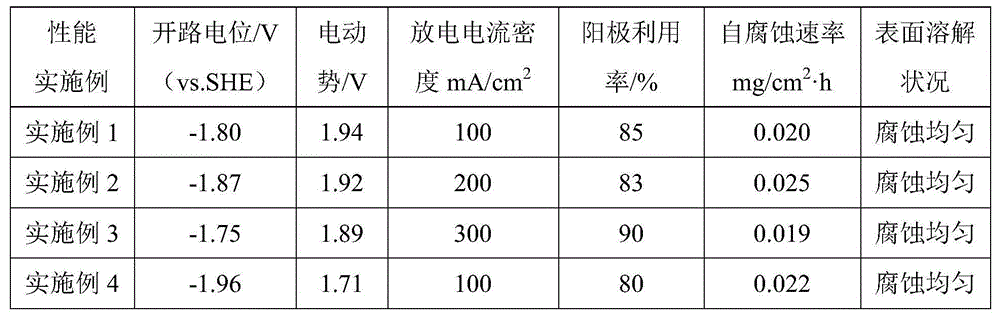

Rare earth-containing amorphous/nanocrystal aluminum anode composite material, preparation method and aluminum air battery

InactiveCN104372206AImprove electrochemical performanceAbundant resourcesFuel and primary cellsCell electrodesRare-earth elementDissolution

The present invention discloses a rare earth-containing amorphous / nanocrystal aluminum anode composite material, a preparation method and an aluminum air battery, and belongs to the techncial field of air batteries. The aluminum anode composite material comprises, by weight, 0.5-5% of Mg, 0.02-2% of Sn, 0.02-2% of Ga, 0.1-5% of La or Ce, and the balance of Al. According to the present invention, aluminum with the purity of more than or equal to 99.8% is adopted as the base, the trae amounts of Mg, Sn, Ga and the rare earth element La or Ce are added so as to reduce the self-corrosion rate and improve the electrochemical property and the surface dissolution uniformity of the alloy, especially the trae amount of the rare earth element is added to the aluminum alloy, and the addition of the rare earth element to the aluminum has effects of oxygen removing, hydrogen removing, desulfuration, melting rate accelerating, metal burning loss reducing, change of species distribution and refinement modification of iron and other harmful impurities, and the like so as to slow down the self-corrosion of the aluminum alloy, such that the anode utilization rate is improved.

Owner:HENAN UNIV OF SCI & TECH

Ultrahigh-alkalinity crystallizer mould flux special for high-pulling-rate peritectic steel

The invention discloses an ultrahigh-alkalinity crystallizer mould flux special for high-pulling-rate peritectic steel. 38%-42% of CaO, 25%-29% of SiO2 and 7%-10% of F- are adopted to improve the crystallization capacity of the mould flux, reduce stress concentration and improve lubrication; 2%-5% of MgO and 2%-5% of Al2O3 are adopted to improve the fluidity of a flux film and reduce cracks; an excellent heat transfer coordination and heat transfer control effect is achieved by adopting the mould flux with the alkalinity ranging from 1.35 to 1.52, 25%-29% of SiO2, 2%-5% of Al2O3 and 2%-5% of MgO; the effects of effectively controlling the melting rate to guarantee melt flux feeding and preventing subsurface blowholes can be achieved with the carbon proportioning range of 4%-7%. Raw materials for preparing the ultrahigh-alkalinity crystallizer mould flux can be easily obtained, the flux consumption ranges from 0.32 kg per ton of steel to 0.38 kg per ton of steel, and cost of per ton of steel is low; on-spot practical application indicates that the mould flux can be well spread in a crystallizer and be evenly and stably melt and is high in casting percent of pass.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

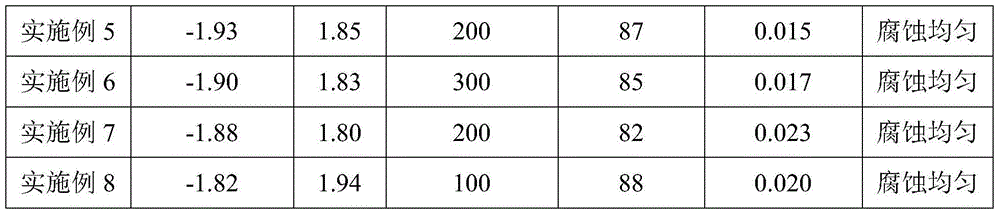

Gas metal arc welding method and system

InactiveCN102873435AIncrease the conductive areaLower resistanceArc welding apparatusWelding power supplyPeak value

The invention discloses a gas metal arc welding method and a gas metal arc welding system, and belongs to the field of gas metal arc welding control. Constant wire feed is adopted, the wire feed rate ranges from 1.5 to 18m / min, a welding source outputs pulse current, and the average value of the pulse current is preset according to the wire feed rate before welding and is kept unchanged in the welding process; the arc voltage Ug is given before welding, a feedback value Uf of the arc voltage is sampled in real time in the welding process, and delta I is equal to the absolute value of k(Uf-Ug), wherein delta I is regulation current, and k is a proportionality coefficient and ranges from 10 to 100; when the feedback value Uf of the arc voltage increases, delta I is subtracted from the peak value Ip of the pulse current, and the basic value current Ib is added to delta I to keep the arc voltage stable; and when the feedback value Uf of the arc voltage decreases, the adjusting process is reversed. By the high frequency pulse current, the average value and the effective value of the current are obviously different, so that on the premise that the heat input of a base metal the heating of a solder wire is not changed basically, the heating of a solder wire is changed, the melting rate of the solder wire is adjusted and the arc length is adjusted.

Owner:BEIJING UNIV OF TECH

Copper alloy electroslag remelting process

Copper alloy electroslag remelting process belongs to field of copper alloy production technology. Electroslag remelting chooses slag system whose melting point is lower 100-200degC than copper alloy, slag is thorough dry before remelting; electroslag remelting can take place under the protection of dry nitrogen gas. In the process of electroslag remelting add metal aluminium, metal RE, zirconium iron, carbon powder, calcium carbide, or magnesium alloy as deoxidizer continuously or interruptedly, add remelting metal 0.3-1.5Kg in one ton. In the process of electroslag remelting take out of ingot to produce electroslag ingot, by blowing or spraying take the second cooling. If it do not take the second cooling,electroslag remelting melting rate(Kg / h)=(1.0-1.5)*crystallizer diameter(mm). If it take the second cooling, electroslag remelting melting rate(Kg / h)=(1.5-3.0)*crystallizer diameter(mm). The designing height of taking out of ingot crystallizer is 1.2-2.0 times as crystallizer diameter, taper is 0.2-2%. The copper alloy has good hot workability produced by this invention.

Owner:ZHONGYUAN SPECIAL STEEL

Induction and electrical arc composite heat source stud welding method

ActiveCN101468419AConvenient for preheating before weldingAutomate operationArc welding apparatusEngineeringStud welding

The invention discloses a method for welding a stud with composite heat resources of induction and electrical arc. The method comprises: an induction heating power supply is adopted to heat a position to be welded, and the induction heating power supply stops working when reaching the preset time and temperature; an electric arc stud welding machine starts working, the end head of the stud carries out striking arc and arcing on the position to be welded, and the stud is sent to a melting pool, cooled and solidified after the melting pool is formed; and an induction coil carries out heat treatment on a joint after welding. The method can weld a board with a thick and large size and realize metallurgical bonding of the stud and a steel board base body. The welding process can realize automatic operation with high efficiency. The joint strength can reach more than 100 percent of the stud strength, and the inner melting rate of the joint is 100 percent. A ceramal sleeve is adopted to protect and obtain the welding joint without inclusions or oxidation. The method can be used for welding a steel board and a steel stud, or an aluminum alloy board and an aluminum alloy stud, or a copper alloy and a copper alloy stud and so on.

Owner:NANJING UNIV OF SCI & TECH

Oil composition for reducing generation of polar compounds of frying oil

ActiveCN104171029AExtended service lifeSuppress or reduce harmful substancesEdible oils/fatsChemical compositionTriglyceride

The invention provides an oil composition for reducing the generation of polar compounds of frying oil. Triglyceride comprises 48-65wt% of SUS type triglyceride, 5-10wt% of SSU type triglyceride, 0.5-15wt% of SSS type triglyceride, 15-31wt% of SU2 type triglyceride and 0-10wt% of U3 type triglyceride, and saturated fatty acids in the oil composition account for 42-58% weight of the weight of total fatty acids; and the SUS type triglyceride with the unsaturated fatty acids being oleic acid accounts for 70-90% of the weight of all the SUS type triglyceride. The oil composition obtained in the invention has the characteristics of slow color change, few generated polar compounds, and fast fusing speed as frying oil.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

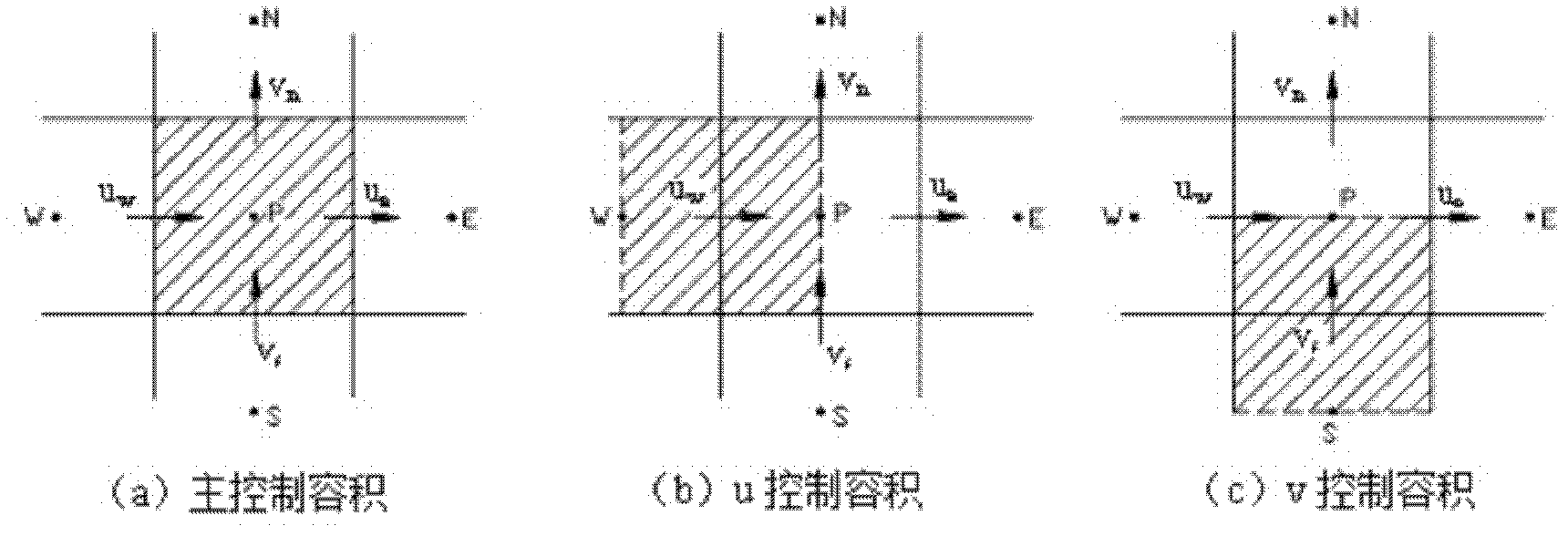

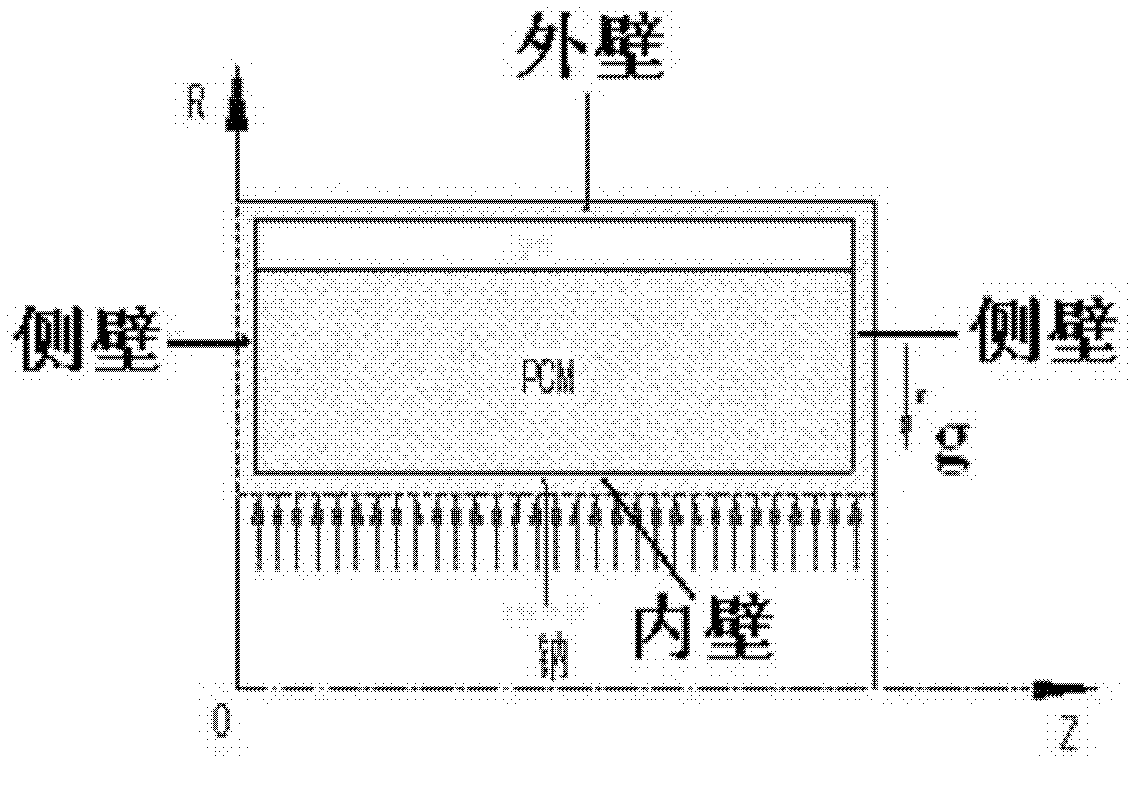

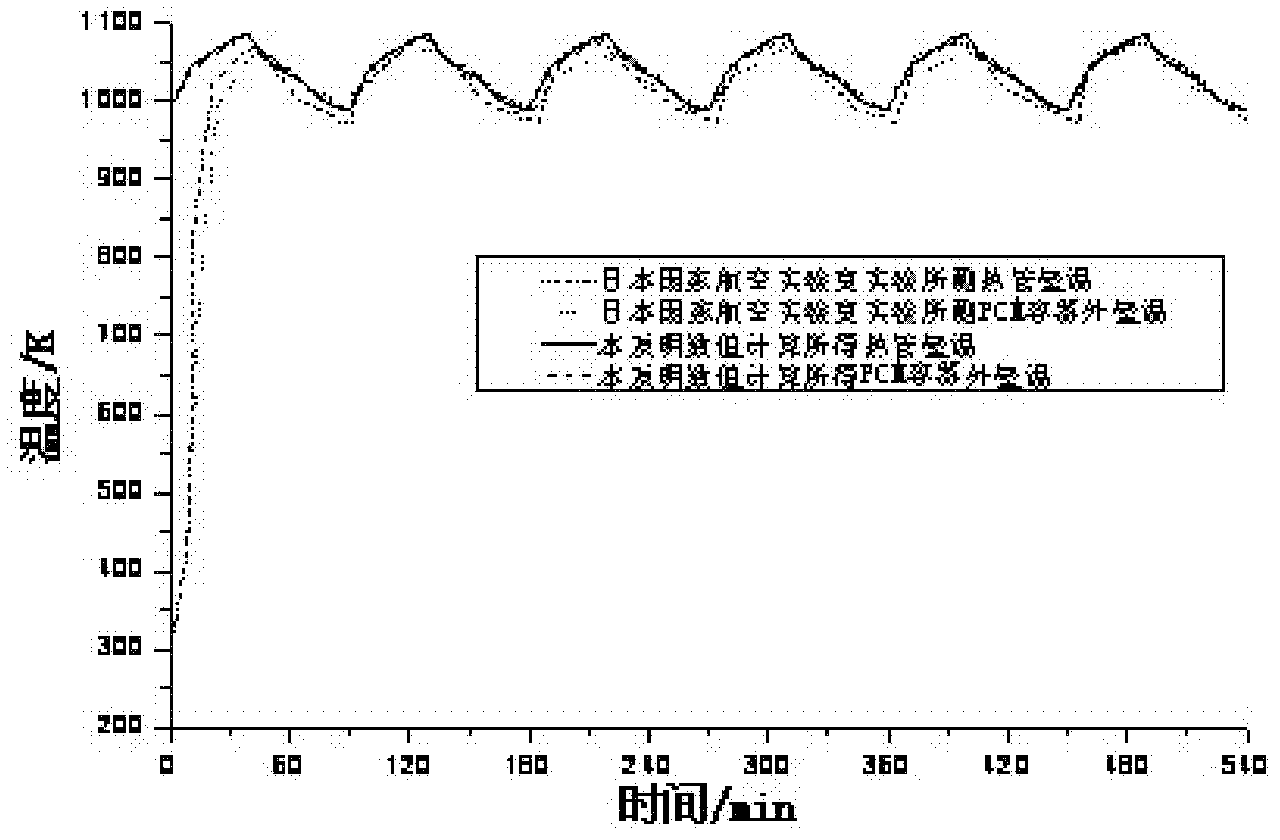

Numerical simulation method for solid/liquid phase change in high-temperature heat storage container in gravity condition

The invention provides a numerical simulation method for solid / liquid phase change in a high-temperature heat storage container in a gravity condition. Numerical calculation is carried out for the complicated problem of phase change heat transfer while natural convection, cavitation and radiation conditions are simultaneously considered, technicians can acquire change of melting rate of solid / liquid phase change materials in the high-temperature heat storage container in a field and distribution of a flow field, a temperature field and liquid phase by the aid of a computer, and accordingly important references for optimizing the design of heat storage containers, suppressing cavitation, improving heat storage efficiency and reducing 'hot spots' and 'hot release'. By the aid of the numerical simulation method, the complicated problem of melting / solidification inside the high-temperature heat storage container in the gravity condition is simply and efficiently solved by the aid of a calculation program based on an enthalpy method, a finite control volume method and SIMPLE algorithm, and the numerical simulation method has important practical values.

Owner:江苏中国科学院能源动力研究中心 +1

Double-phase stainless steel smelting technology

The invention belongs to the technical field of steel smelting, and relates to a double-phase stainless steel smelting technology. According to the technology, a carbon steel material head, a stainless steel material head, stainless steel cuttings and high carbon ferro-chrome are adopted to serve as raw materials, high-chromium high-carbon molten steel is smelted through an intermediate frequency furnace, and relatively-high-cost low-carbon or micro-carbon chromium iron is not required to be adopted for smelting; after the temperature is proper, the molten steel is transferred into an AOD furnace from a steel ladle; smelting devices like the AOD furnace is adopted for conducting oxygen blowing, decarbonization and molten steel refining, and nitrogen is blown to the steel for increasing nitrogen to the steel; the cost generated by adopting nitralloy for nitrogen adding is reduced, and after the components are qualified, the steel is cast into an electrode blank; when electric slag is remelted, argon or dry air is adopted for protection, and the suction amount of a furnace hearth is further reduced; and the voltage and the current are adjusted to control the melting rate. The double-phase stainless steel smelting technology is also suitable for other applicable fields.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

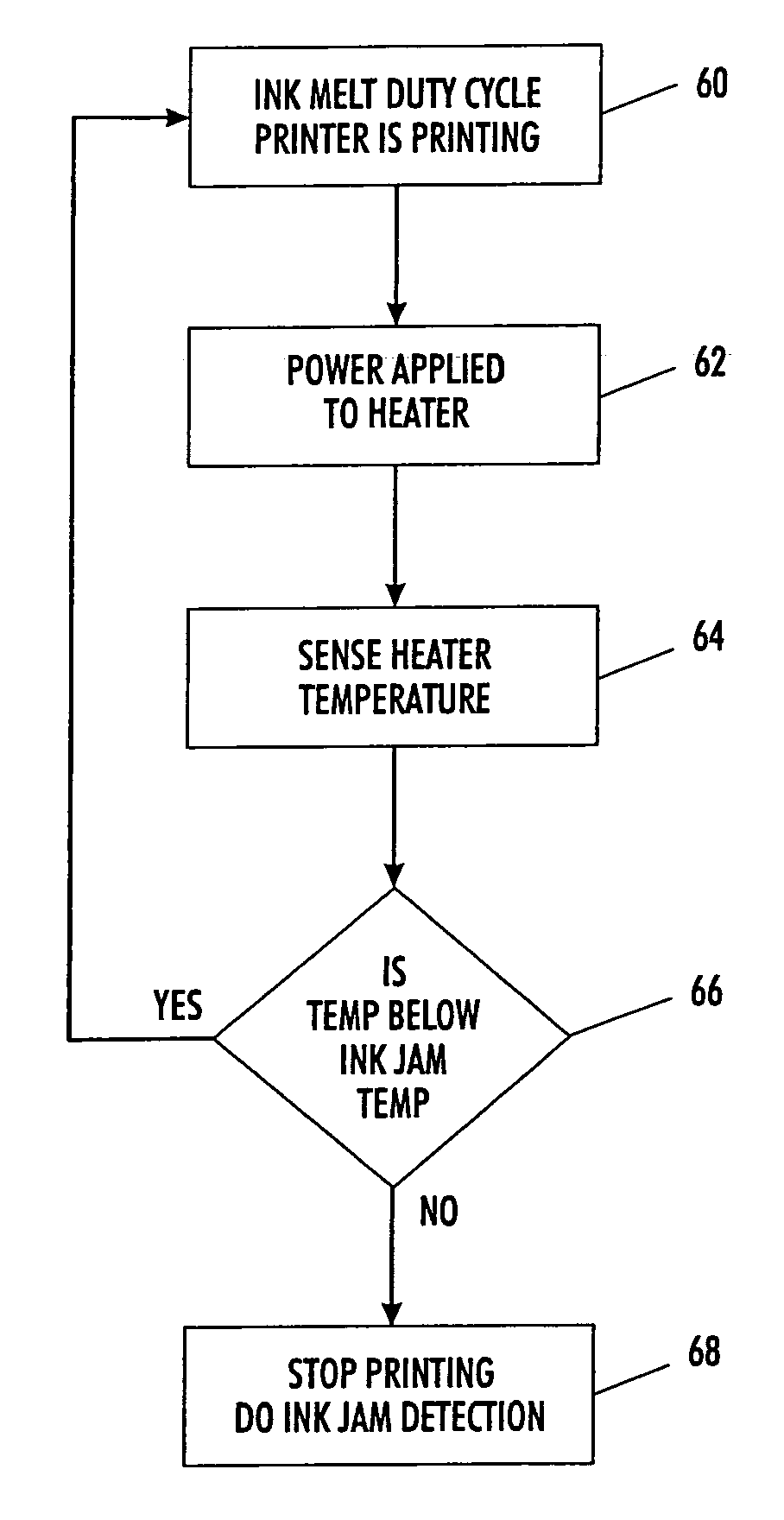

Real time detection of ink stick jams in phasing printing systems

InactiveUS7147313B2Avoid damageAvoid starvationMeasurement apparatus componentsOther printing apparatusControl systemEngineering

A method and system for detecting an ink stick jam in a solid liquid ink phasing delivery system for supplying ink to a printer. The phasing system includes a heater plate disposed to engage a solid ink stick and heat an engaging portion of the ink stick to a liquid phase. A temperature sensing device associated with the heater plate detects the temperature thereof. A control system selectively supplies power to the heater plate. The method comprises supplying a predetermined amount of power through the control system to the heater plate intended to achieve the desired melt rate of the ink stick during a phase change from solid to liquid. The desired melt rate is associated with the predetermined desired temperature of the heater plate. The temperature of the heater plate is sensed with the sensing device during the supply of power thereto. When a sensed temperature of the heater plate varies from the predetermined desired temperature by a selected amount, the supply power is interrupted, whereby heater damage and printer ink starvation can be avoided.

Owner:XEROX CORP

High-desalting-rate seawater desalination method and device based on liquefied natural gas cold energy

ActiveCN104891593AHigh desalination rateReduce engineering costsGeneral water supply conservationSeawater treatmentLiquid stateEngineering

The invention discloses a high-desalting-rate seawater desalination method based on liquefied natural gas cold energy, which comprises the following steps: sufficiently carrying out indirect heat exchange on liquefied natural gas and a gas-state secondary coolant, and sufficiently carrying out indirect heat exchange on the obtained liquid-state secondary coolant and seawater to obtain ice and concentrated seawater; (2) taking the ice obtained in the step (1), standing under atmospheric pressure until the melting rate of ice is 10-50%, recovering the liquid, and taking the residual ice for later use; (3) crushing the residual ice obtained in the step (2) to obtain ice crystal granules, centrifuging, recovering the liquid, and taking the ice crystal granules for later use; and (4) completely melting the ice crystal granules obtained in the step (3). The invention also discloses a seawater desalination plant based on liquefied natural gas cold energy. The method utilizes the cold energy released in the liquefied natural gas gasification process, comprehensively utilizes the freeze desalting, gravity desalting and centrifuging desalting techniques, has the advantages of simple steps, energy saving and environment friendliness, and enhances the seawater desalting rate on the basis of freeze desalting.

Owner:CHINA PETROLEUM & CHEM CORP +1

Adaptive power control of ink melt heaters for uniform ink melt rate

InactiveUS7182448B2Measurement apparatus componentsOther printing apparatusEngineeringAir temperature

A method and system for selectively controlling supplied power to an ink melt heater for maintaining a desired ink melt rate despite a varying ambient parameter affecting an actual melt rate. A predetermined amount of power is supplied to the ink melt heater intended to cause the desired ink melt rate. The ambient parameter is detected by the ink melt heater. A determination is made if the detected ambient parameter will cause a variance in the actual ink melt rate from the desired ink melt rate. If a variance is so determined, the supplied power is adjusted from the predetermined amount to an adjusted amount for realizing desired ink melt rate. The ambient parameter preferably comprises sensing a factor representative of at least one of local environmental air temperature to the printing system or adjacent ink temperature to the heat plate.

Owner:XEROX CORP

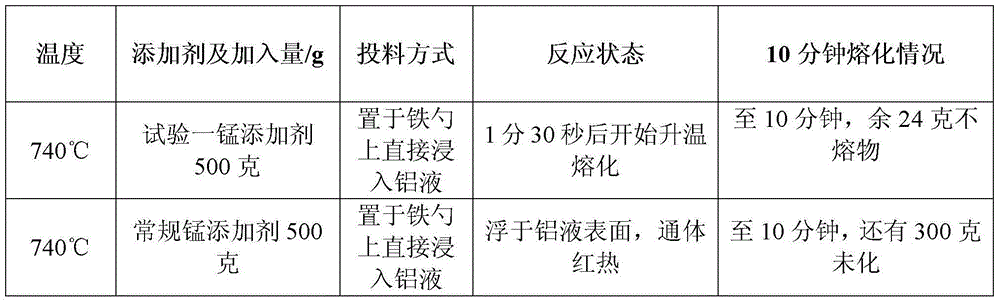

Manganese additive for casting aluminum magnesium alloy and preparation method of manganese additive

The invention discloses a manganese additive for casting aluminum magnesium alloy and a preparation method of the manganese additive, relates to an additive for casting aluminum magnesium alloy and a preparation method of the additive, and aims at solving the problems that a conventional manganese additive is low in melting rate or infusible, low in casting yield, high in smelting temperature, long in smelting time and high in energy consumption under the existing environment with high content of magnesium. The manganese additive disclosed by the invention is prepared from manganese powder and a fluxing agent. The method disclosed by the invention comprises the following steps: mixing the manganese powder with the fluxing agent, and pressing into a cake at the pressure intensity of 7-8MPa, so as to obtain the manganese additive. The manganese additive is low in melting temperature, high in melting rate and high in casting yield, and can be completely molten at 740 DEG C; the melting rate is over 50% greater than that of the conventional manganese additive; the additive which is fed to molten aluminum magnesium alloy over 740 DEG C can be rapidly molten and can be absorbed by molten aluminum within 8-10 minutes; and the casting yield of a manganese element within 20 minutes can be up to over 90%.

Owner:哈尔滨东盛金材科技(集团)股份有限公司

Emulsion antiwax remover

The invention relates to an emulsion antiwax remover, which comprises polyethylene polyamine ethylene oxide ethylene oxide polyoxyethylene ether, fatty acid methyl ester ethoxylate sodium sulfonate and water, belonging to a paraffin inhibitor. The emulsion antiwax remover comprises the following compounds in percentage by weight: 40-50% of C5-C9 splitting fraction, 5-8% of polyethylene polyamine ethylene oxide epoxypropane polyoxyethylene ether, 7.5-11% of fatty acid methyl ester ethoxylate sodium sulfonate, 1.5-3.5% of sorbitan mo-nooleate, 0.5-1% of tributyl phosphate and 25.5-44.5% of water. The emulsion antiwax remover provided by the invention has the beneficial effects that the wax melting rate is larger than 125g / min.m<2>, and the paraffin controlling rate is larger than 50%; 2, the emulsion antiwax remover has no possibility of burning and exploding during use; the proportion is larger than 0.90, can be added into a crude oil well with high water content through a sleeve, can fall into the bottom hole easily, and can play roles in removing and controlling paraffin; the paraffin removing and controlling agent does not have corrosivity and has small corrosivity on oil extraction equipment.

Owner:DAQING HUAYING CHEM IND

Laser three-dimensional fast forming and manufacturing method based on micro arc powder carrying

ActiveCN105834428AIncrease energy densityLow heat inputAdditive manufacturing apparatusIncreasing energy efficiencyArc stabilityOptoelectronics

The invention discloses a laser three-dimensional fast forming and manufacturing method based on micro arc powder carrying. By means of the method, flow carrying and synchronous powder sending of powder are achieved by means of a micro-beam plasma arc, and main energy needed for forming a metal structure is provided by means of a pulse laser heat source. The powder sending precision of powder materials is improved by means of the good arc stability and stiffness of the micro-beam plasma arc; and by means of the characteristic that the energy function of the micro-beam plasma arc is concentrated is utilized, so that the melting rate and the deposition rate of the powder are increased, and the heat absorbing rate of the powder materials and a forming area on the energy of the laser heat source is increased. The main arc current of the micro-beam plasma arc in the method is 30 A-50 A, the pulse peak power of a pulse laser beam is 4 kW-10 kW, and three-dimensional fast forming and manufacturing of metal materials and the structure are achieved by adjusting the relative position relation between the laser beam and the powder carrying flow of the micro-beam plasma arc, the beam spot coinciding ratio and the output energy of the micro-beam plasma arc and the laser beam. The laser three-dimensional fast forming and manufacturing method has the beneficial effects of being high in forming efficiency, high in precision, little in deformation, high in technical adaptability and the like.

Owner:CHONGQING UNIV OF TECH

Refining slag for ultra-pure steel and preparation method thereof

The invention relates the refining slag and preparing method for super clean steel, comprising the following characters: CaOí¦93%, SiO2íœ2%, TiO2íœ100ppm, Al2O3í¦99.5%, TiO2íœ 50ppm. The refining slag comprises the following: CaO45-59%wt, Al2O340-50%wt, SiO21-5%wt, TiO2íœ50ppm, N íœ200ppm, (B+Pb)íœ100ppm, (S+P)íœ200ppm. In the refining slag the impurity and harmful elements content are low, meeting the requirement of super clean steel. That adding the petroleum coke air-captive and barium carbonate research agent reduces the fusion point of super clean steel, accelerates the melting rate, and improves the sulfur-phosphorous specific capacity. The percents of pass of bearing steel and car steel are above 98%, and the international SKF percent of pass of bearing steel is over 90%.

Owner:JIANGSU JIANAI HIGH TEMPERATURE MATERIAL

A method for adding alloying elements to molten aluminum and an alloying element adding bag

The invention discloses a method for adding alloy elements in the melting and casting process of the aluminum industry and an alloy element adding bag used for adding alloy elements. The method is as follows: the alloy element powder to be added is packed into an aluminum foil bag, and vacuum-packed, and the alloy element added bag is dropped into the aluminum liquid. The structure of the alloying element addition bag is that the aluminum foil bag is used to contain the alloying element powder required for the aluminum alloy production, and the inside of the bag is vacuumed. The invention can significantly increase the melting speed of alloy elements, improve production efficiency and reduce production cost.

Owner:SHENZHEN FORAL TECH

Preparation process of high alloy hot work die steel

ActiveCN106636861AExtended service lifeReduce distributionProcess efficiency improvementRetention timeTwo temperature

The invention discloses a preparation process of high alloy hot work die steel and belongs to the technical field of metallurgy. A certain gap still exists between existing domestic high alloy hot work die steel and materials manufactured by foreign manufactures in the aspects of molten steel purity, constituent uniformity, structural fineness and dimensional accuracy. According to the preparation process, in the electroslag-remelting smelting process, the diameter of a crystallizer serves as a key parameter, and the mean melting rate of the smelting process is set through the diameter of the crystallizer; by raising the heating temperature of a steel ingot and prolonging retention time of a high-temperature section, nonuniformity of constituents of the steel ingot is remarkably reduced; an operation mode including three times of upsetting and three times of drawing-out is adopted for forging; according to a calculation method of the upsetting ratio, the ratio of heights, obtained before and after upsetting is conducted, of the steel ingot is adopted, operation can be easy and convenient to conduct, and the upsetting purpose and effect can be easy to achieve; the heat treatment temperature of quenching conducted after forging is completed is raised, and more alloying elements can be dissolved into austenite on the basis that a certain amount of carbide is reserved; and annealing is conducted through two temperature sections, and a spheroidized structure can be uniformly refined.

Owner:建龙北满特殊钢有限责任公司

Control method of aluminum content of heavy rail steel

InactiveCN102864275AReduce the amount addedHigh aluminum contentManufacturing convertersSlagSilicon alloy

The invention provides a control method of aluminum content of heavy rail steel. Carbon content of tapping steel of a converter is controlled, and an carburetant is added in a tapping process; manganese and silicon ingredient adjustment is carried out by using manganese-silicon alloy, and deoxidier-2-3.5kg / ton of steel is added; active lime and bauxite are added in an LF (ladle furnace), an iron sheet ball is added in slag after top slag is completely melted; manganese alloy content fine tuning is carried out by using the manganese-silicon alloy, and the carbon content is adjusted to be 0.68-0.75wt%; and temperature is raised to 1570-1585 DEG C, a liquid steel tank is moved into a vacuum degassing (VD) furnace from the LF to conduct vacuum treatment, pouring is carried out on a continuous casting machine, and a tundish water feeding port is closed to conduct argon blowing in a pouring process. With the adoption of the control method, adding quantity of high price alloy can be substantially reduced, the aluminum content in steel in the LF is prevented from increasing and mass production is achieved under a condition that the aluminum content in the steel is lower than 0.004%; and average aluminum content can achieve lower than 0.0026%, and a melting rate of the heavy rail steel is 0.033%.

Owner:ANGANG STEEL CO LTD

On-line hot preparation method of glass batch

InactiveCN101913752AImprove thermal conductivityIncrease the reaction areaCharging furnaceGlass productionAdhesiveRefractory

The invention discloses an on-line hot preparation method of a glass batch. The method comprises the following steps of: adding a proper quantity of adhesives to a traditional glass batch and pressing the mixture into a block material; preheating to decompose the molded block material in a firing kiln to form a sintered block consisting of silicate and silicon dioxide, immediately pulverizing the block into granules in the hot state; conveying and uniformly scattering the granules into a filling pocket; and pushing into a glass kiln for melting. The on-line hot preparation method of the glass batch can greatly improve the heat conductivity coefficient of the batch, improve the melting rate of the glass kiln, increase the glass capacity and achieve the purpose of saving energy. The compacted glass batch block reduces flying dust in the glass kiln, prolongs the service life of refractory materials, prevents the blockage of a regenerative chamber, purifies the operating environment, reduces the flying loss of the batch and stabilizes the glass component. The method ensures that the melting rate can be improved by 20-30 percent. Compared with a traditional method, the method ensures that the fuel consumed for producing the same quantity of glass can be saved by 10-20 percent.

Owner:杭州蓝星新材料技术有限公司

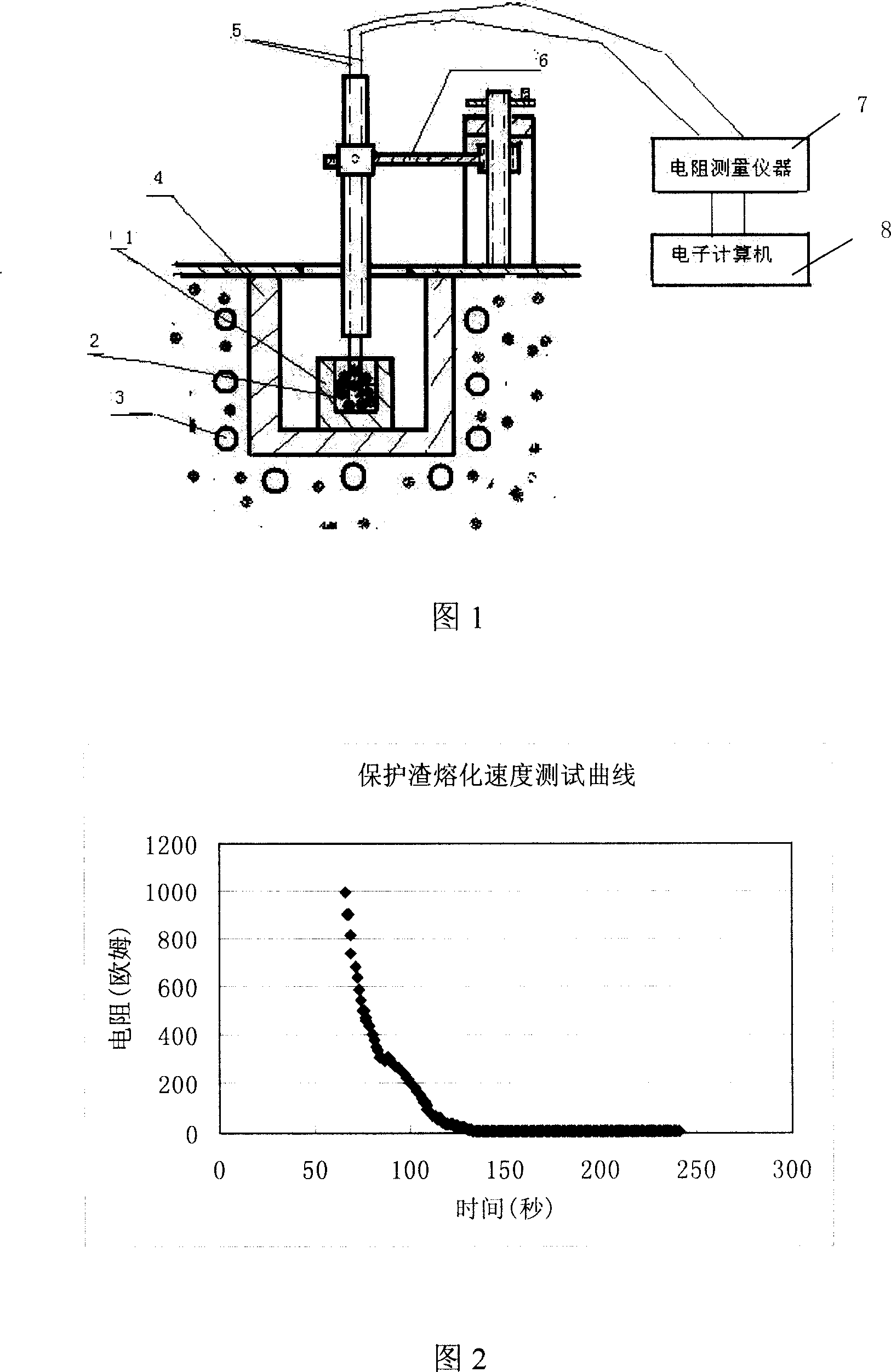

Method and device for mensurating speed of melting protecting slag

InactiveCN101004399AEasy to operateSimple structureMaterial testing goodsMaterial resistanceSlagElectrical resistance survey

A method for determining a melting speed of protective slag includes obtaining time from electrode being inserted into insulator to holding resistance value of protective slag to be constant by measuring resistance value in melting course of protective slag then using obtained time as melting speed of protective slag. The device used for realizing said method is also disclosed.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com