Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

946results about How to "Melting fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

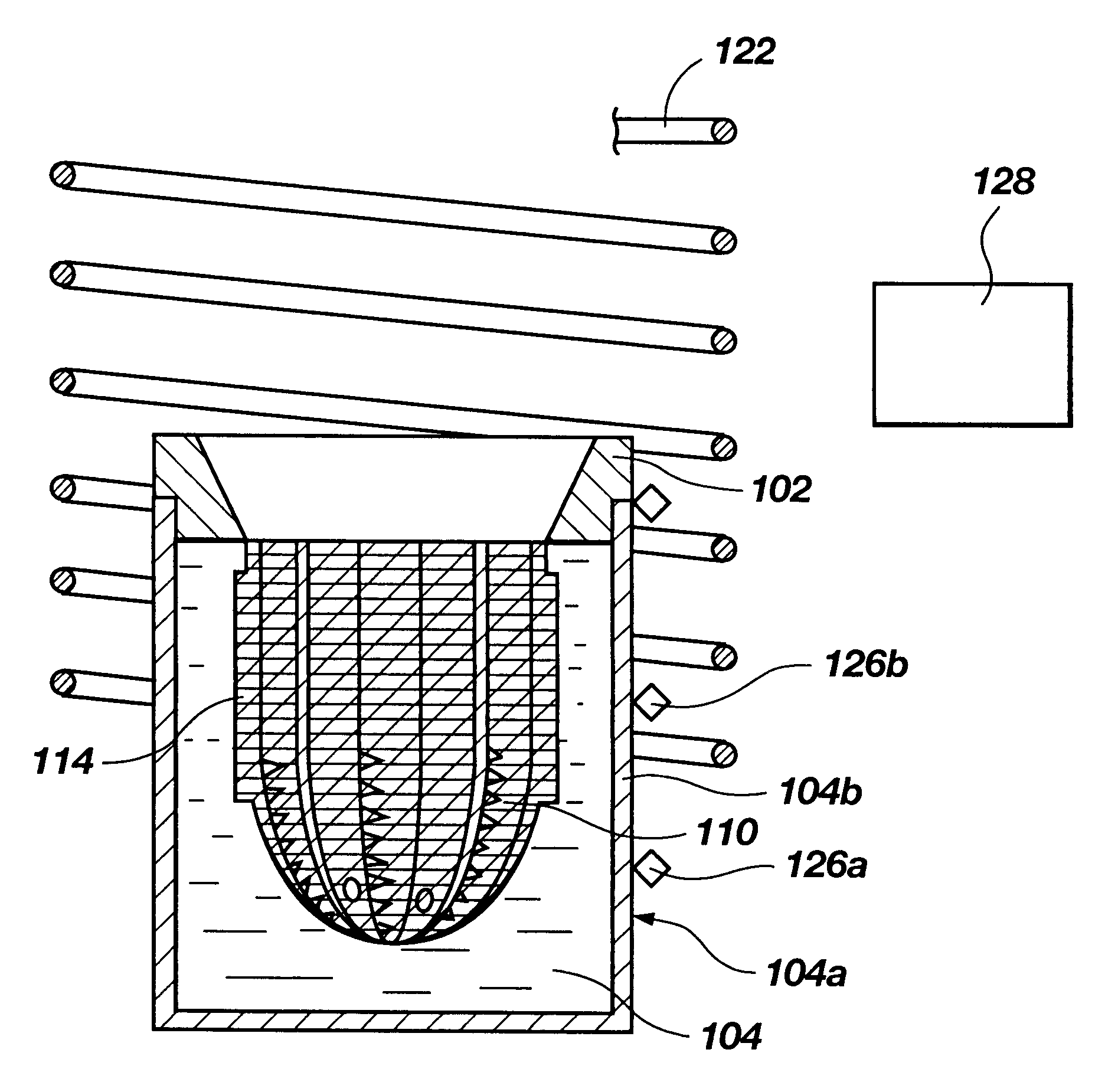

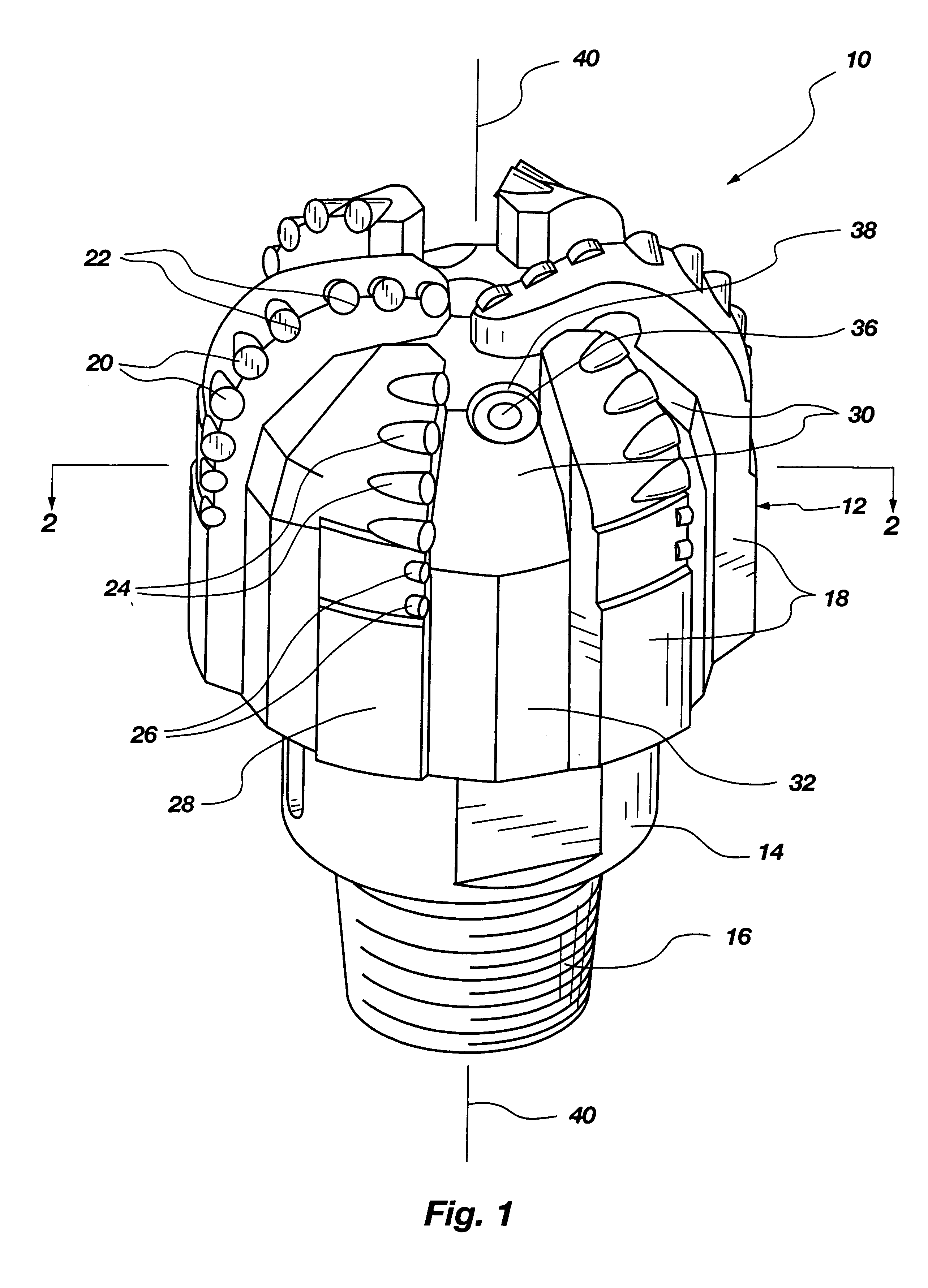

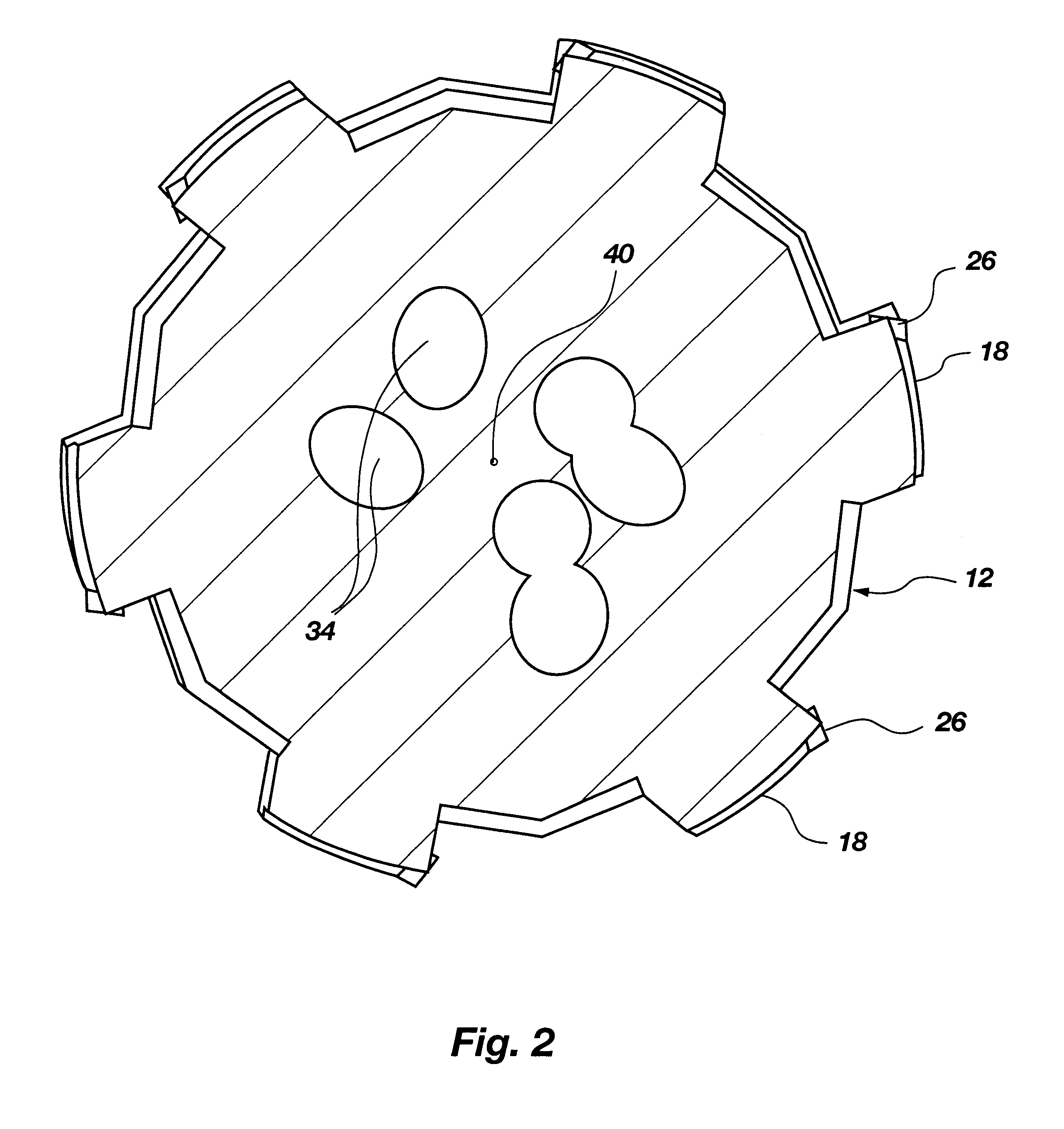

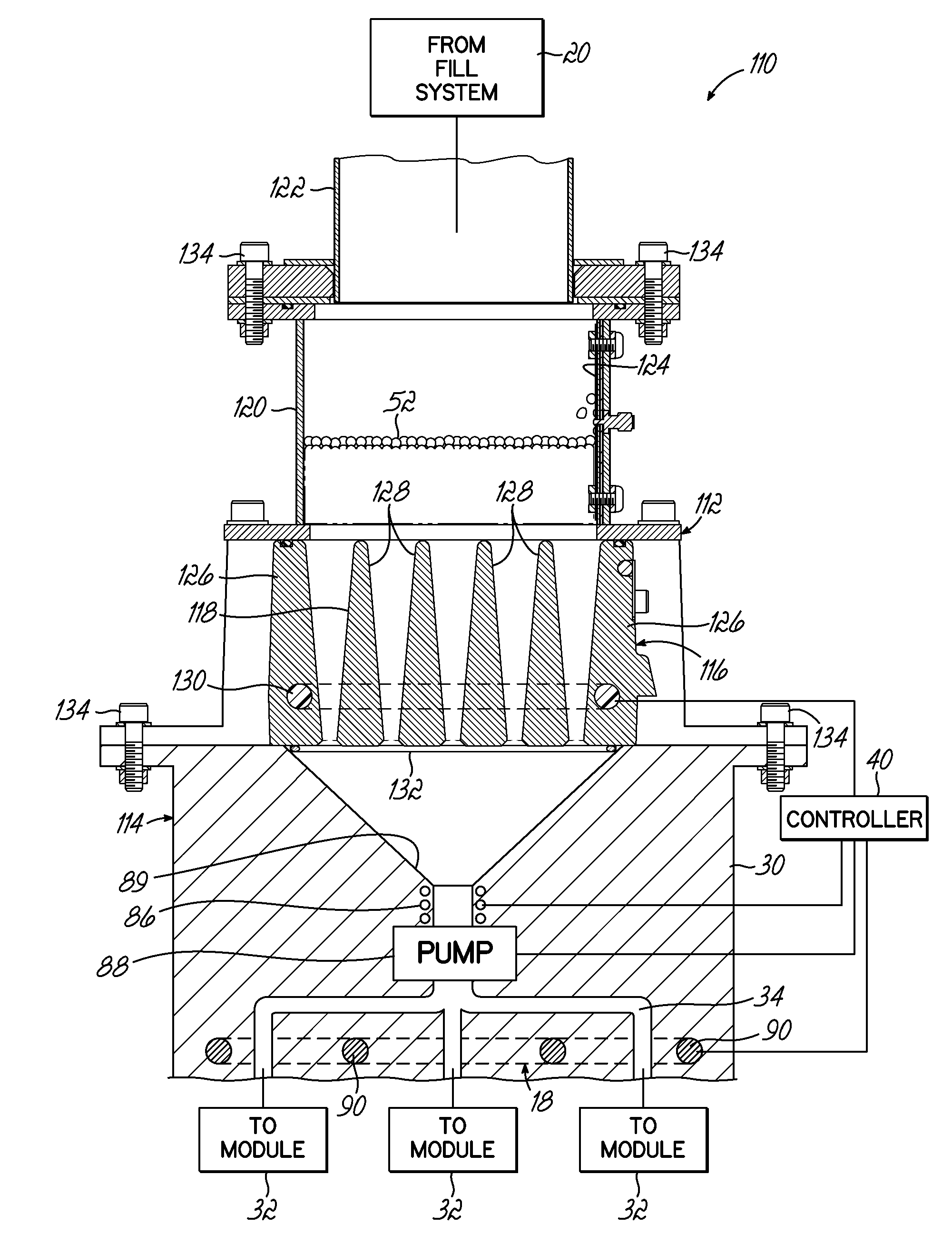

Methods of high temperature infiltration of drill bits and infiltrating binder

A method of manufacturing a bit body, other drilling-related component, or other article of manufacture, including fabricating a particulate-based matrix and infiltrating the particulate-based matrix with a binder that includes cobalt or iron. The binder may be a cobalt alloy or an iron alloy. The particulate-based matrix may be disposed within a non-graphite mold. The particulate-based matrix and binder are placed within an induction coil and an alternating current is applied to the induction coil in order to directly heat the binder, permitting the binder to infiltrate or otherwise bind the particles of the matrix together. The molten binder may then be directionally cooled by forming a cooling zone around an end portion of the bit body and increasing the size of the cooling zone relative to the bit body. The invention also includes a bit body, other drilling-related component, or other article of manufacture which includes a particulate-based matrix that is bound together with a binder that includes iron or cobalt.

Owner:BAKER HUGHES INC

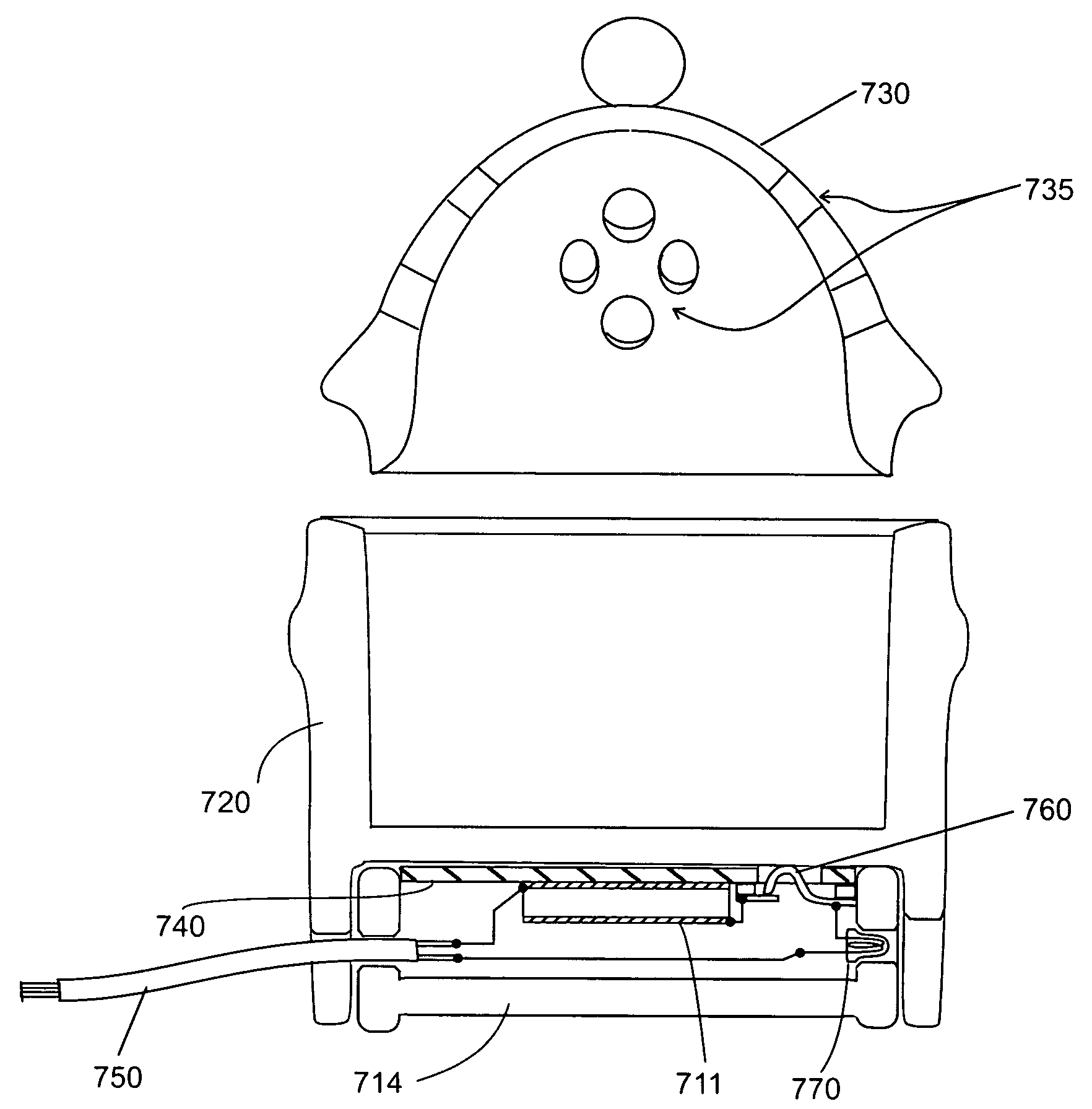

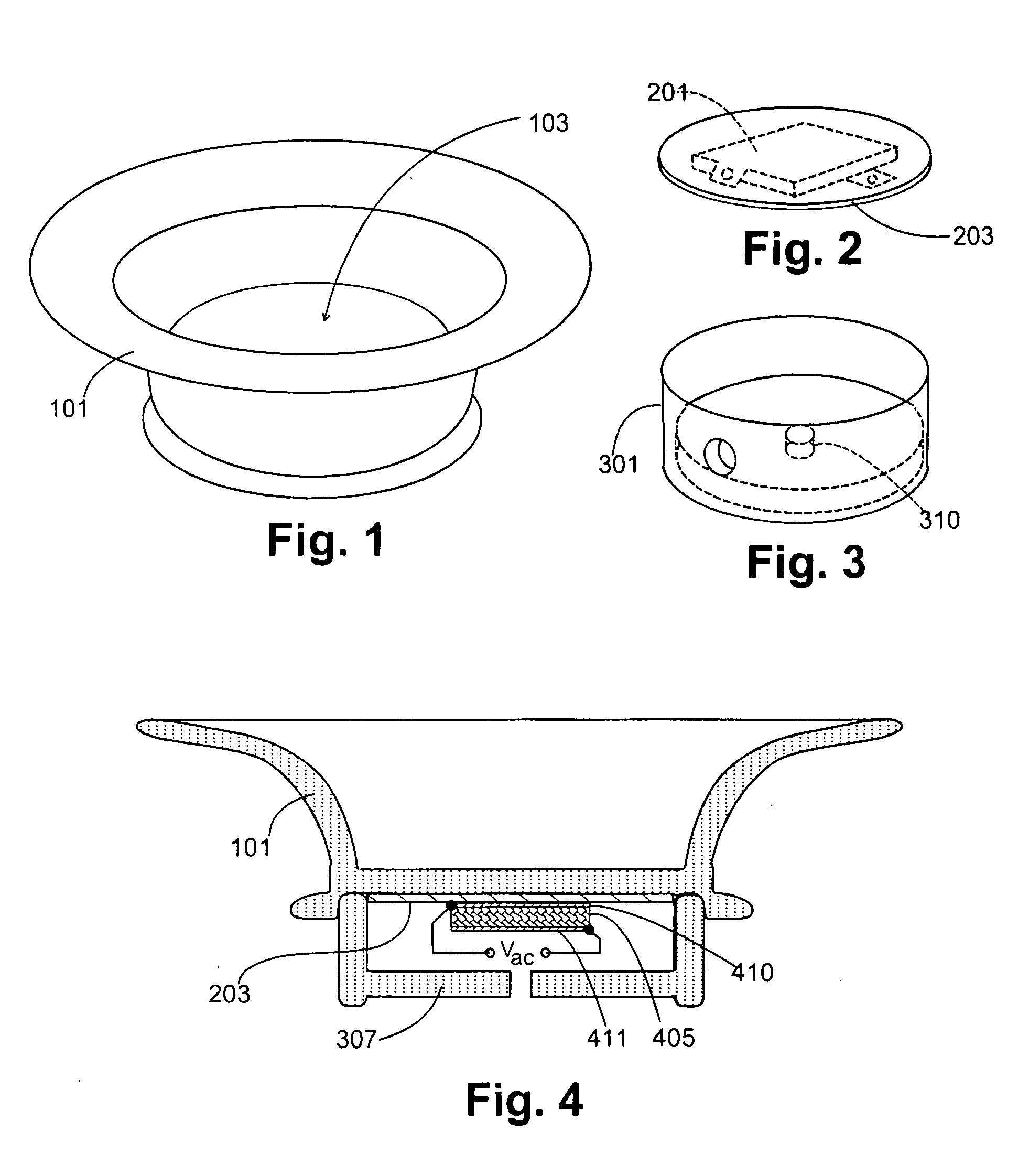

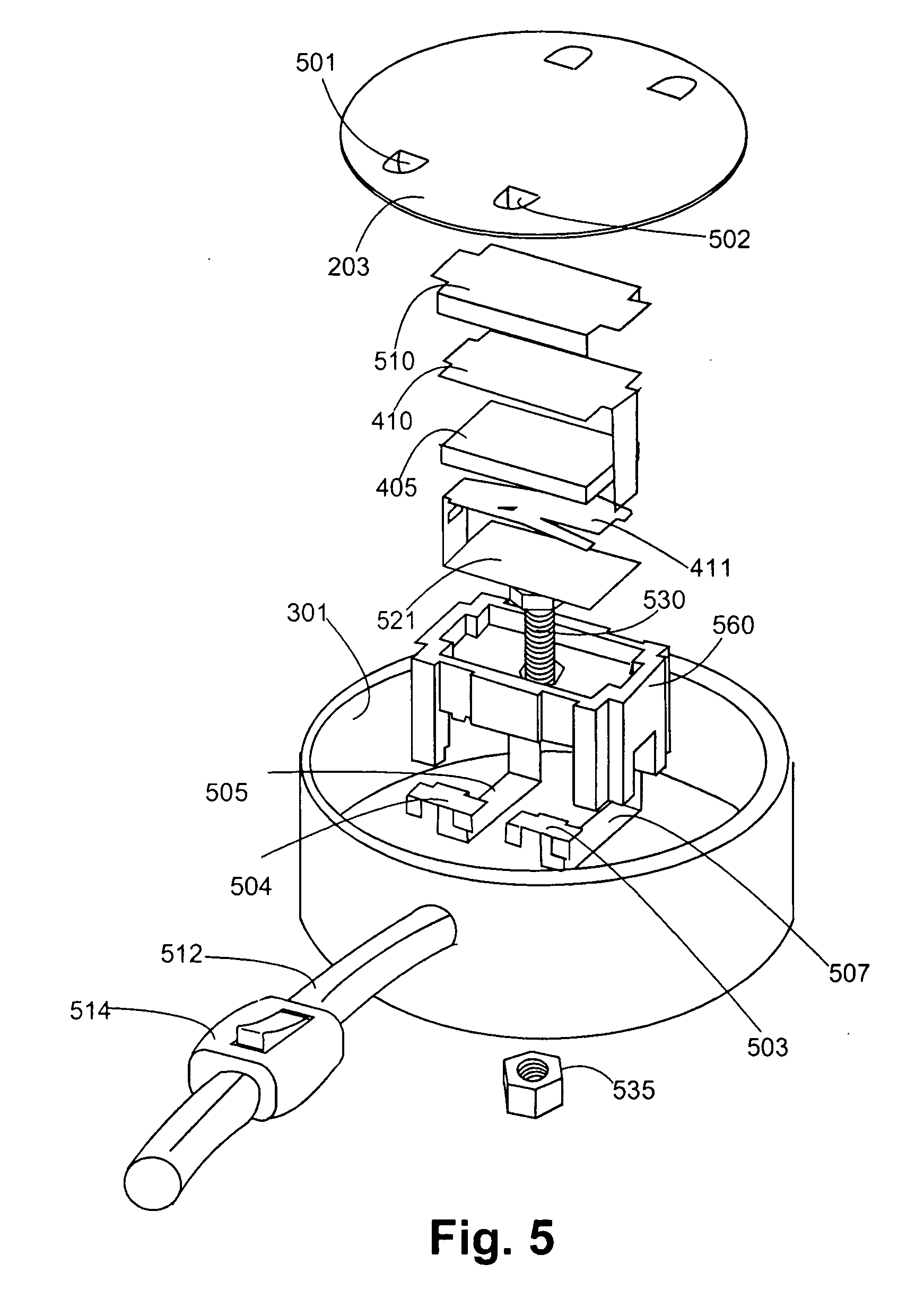

Electrically-operated temperature-regulated scented wax warmer

InactiveUS20050016985A1Efficiently transfer heatImprove thermal conductivityRespiratorsHand ironContact padEngineering

An electrically operated scented wax holder that forms a receptacle for receiving unmelted blocks of wax which are heated to the melting point and thereafter maintained at a safe temperature by a temperature-regulated electrical heating element. The wax receptacle is removable mounted on a base section that houses a positive temperature coefficient (PTC) thermistor which has a transition temperature substantially higher than the melting point of the wax to insure that the wax is rapidly melted, but substantially below the temperature that would constitute a danger to a human who might touch the exterior surface of the warmer, or constitute a fire hazard. The heating element is preferably placed in thermal contact with a contact pad having high thermal conductivity that is in turn placed closely adjacent to the wax receptacle, thereby efficiently transferring heat from the electrically operated temperature regulated heating element to the wax in the receptacle. A switch is positioned to de-energize the heating element whenever the wax receptacle is removed from the base section, and a visible pilot light is illuminated whenever the heating element is energized.

Owner:HAAS RODNEY +1

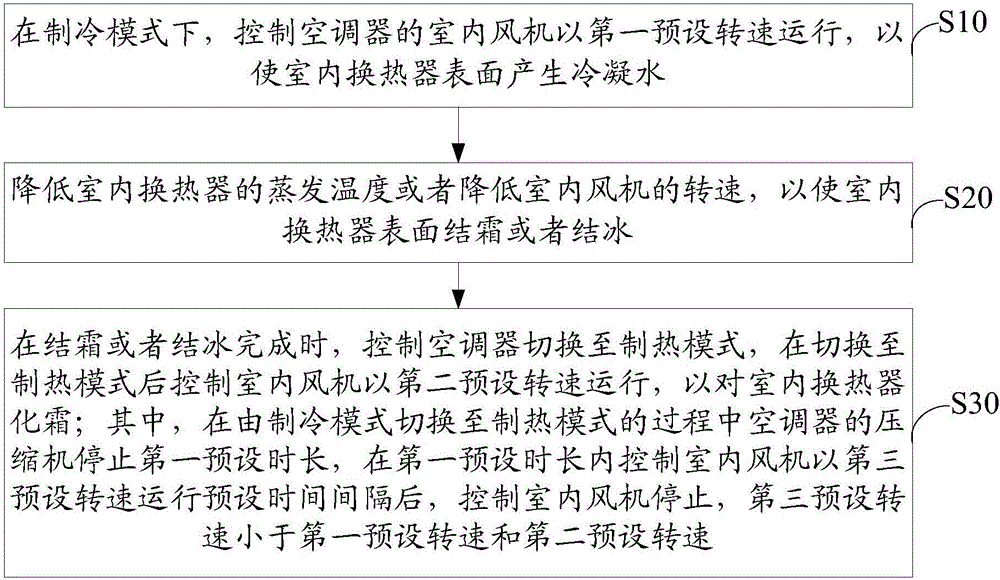

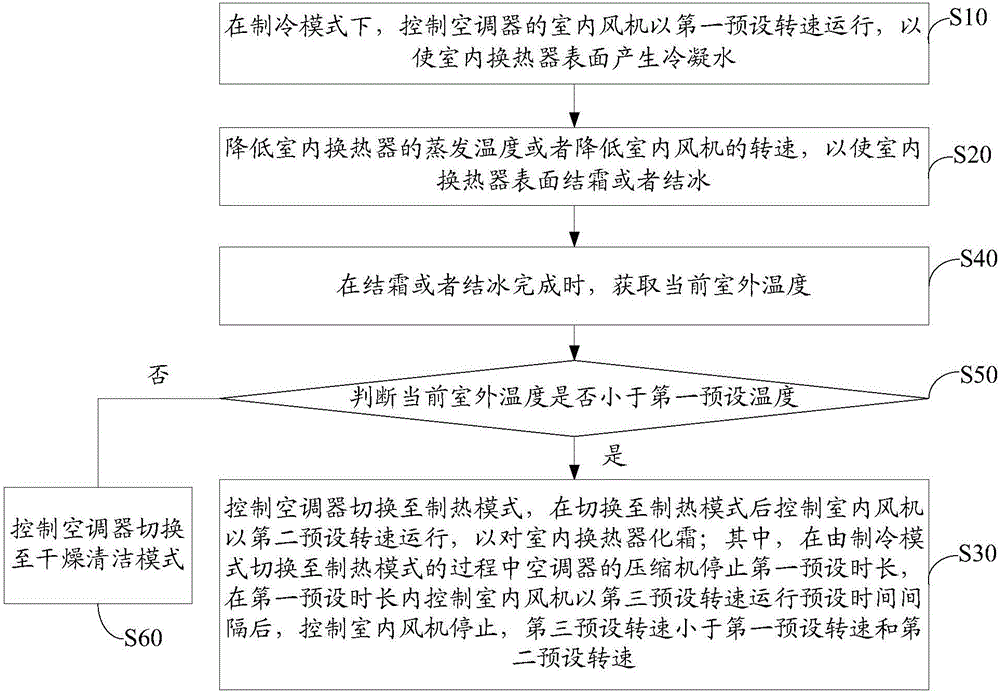

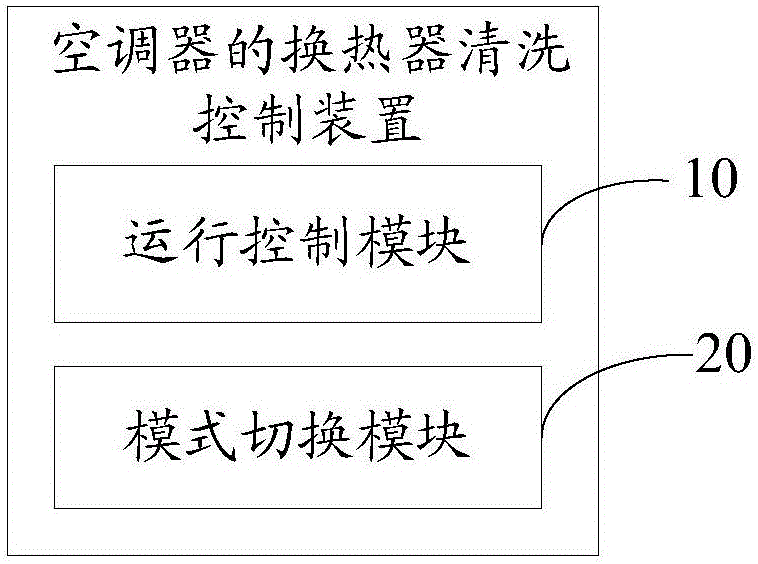

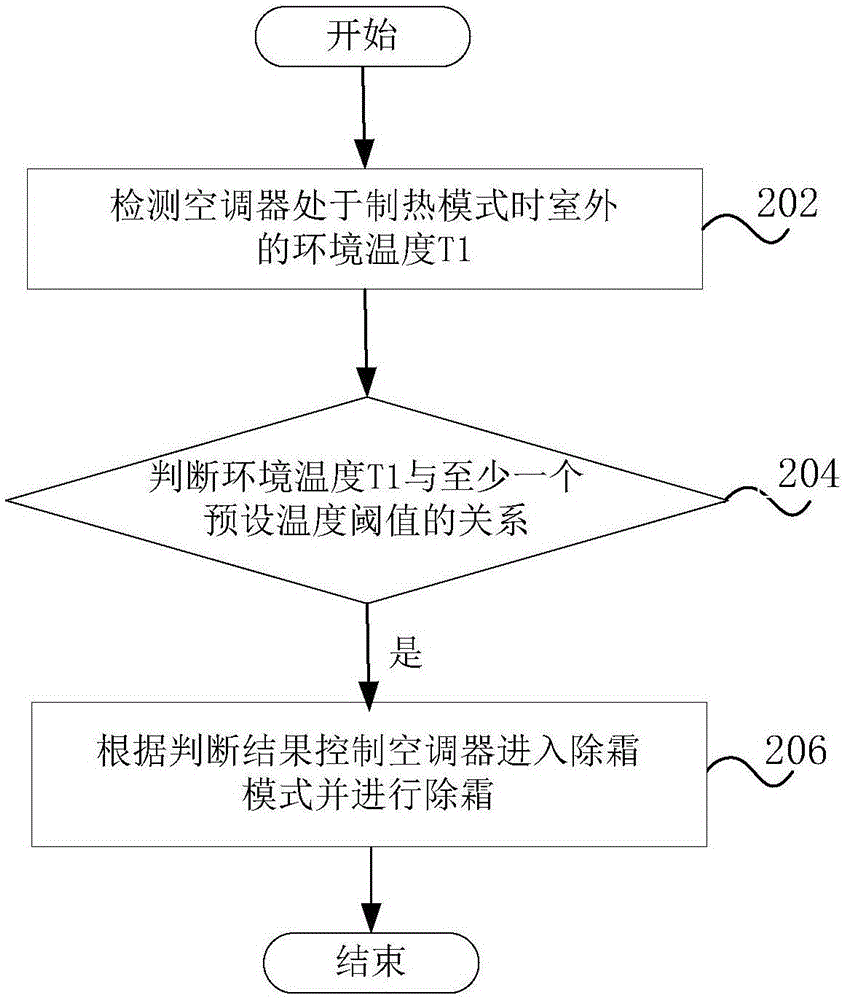

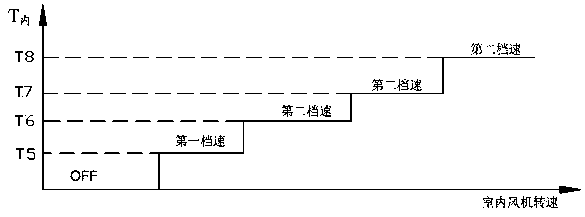

Cleaning control method and device for heat exchanger of air conditioner

InactiveCN106545975AEasy to cleanRealize automatic cleaningMechanical apparatusSpace heating and ventilation safety systemsEngineeringMicro heat exchanger

The invention discloses a cleaning control method for a heat exchanger of an air conditioner. The cleaning control method comprises the following steps that under a refrigerating mode, an indoor draught fan is controlled to run at a first preset rotating speed so as to enable the surface of the indoor heat exchanger to generate condensate water; the evaporating temperature of the indoor heat exchanger or the rotating speed of the indoor draught fan is reduced so as to enable the surface of the indoor heat exchanger to frost or freeze; and the air conditioner is controlled to switch to a heating mode, and the indoor draught fan is controlled to run at a second preset rotating speed, so that the indoor heat exchanger is subjected to defrosting. In the process that the refrigerating mode is switched to the heating mode, a compressor of the air conditioner stops first preset duration; after the indoor draught fan is controlled to run at a third preset rotating speed for preset time intervals within the first preset duration, the indoor draught fan is controlled to stop; and the third preset rotating speed is smaller than the first preset rotating speed and the second preset rotating speed. The invention also discloses a cleaning control device for the heat exchanger of the air conditioner. According to the cleaning control method and device for the heat exchanger of the air conditioner, automatic cleaning for the indoor heat exchanger is achieved, so that cleaning of the air conditioner is very convenient.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP +1

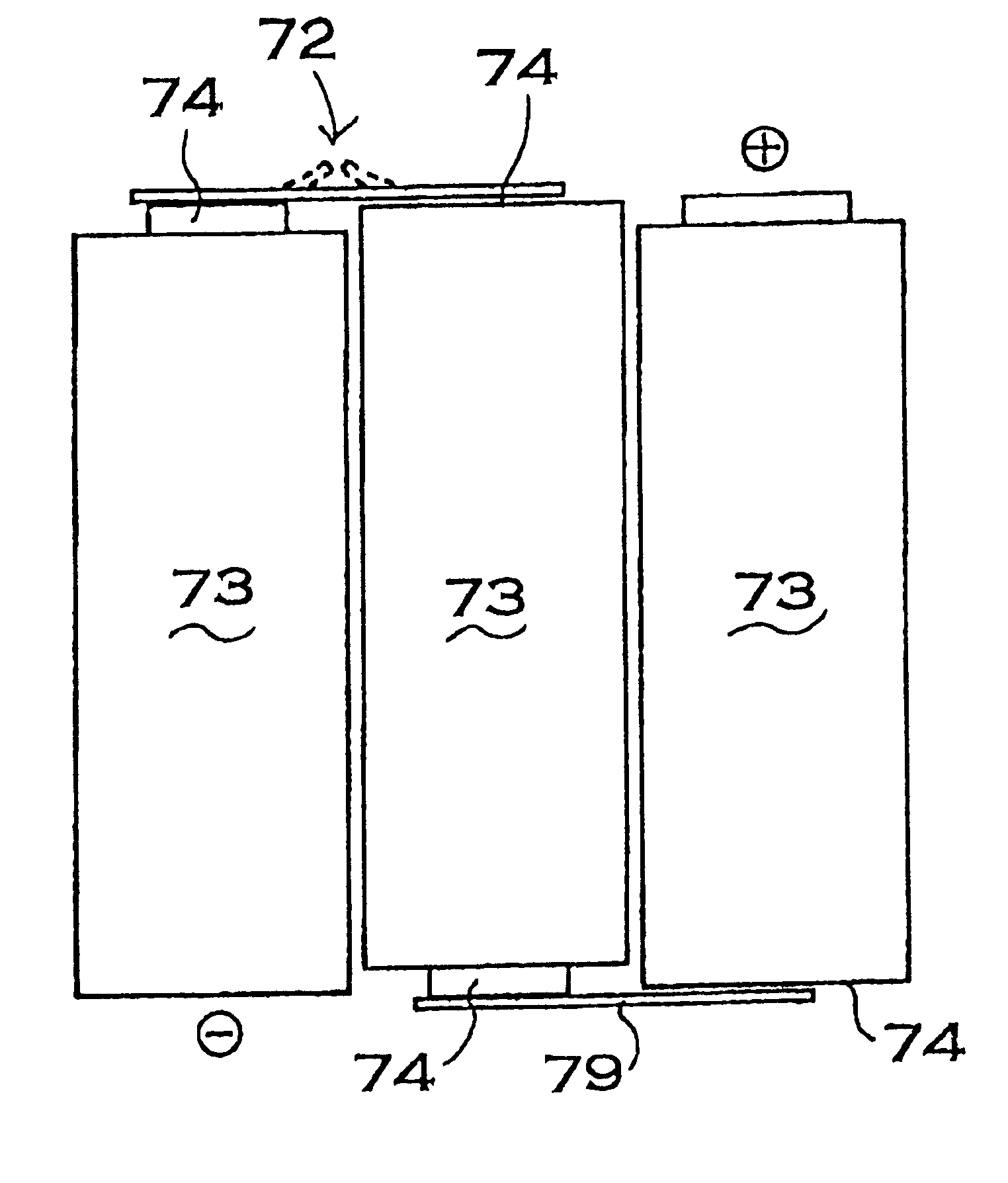

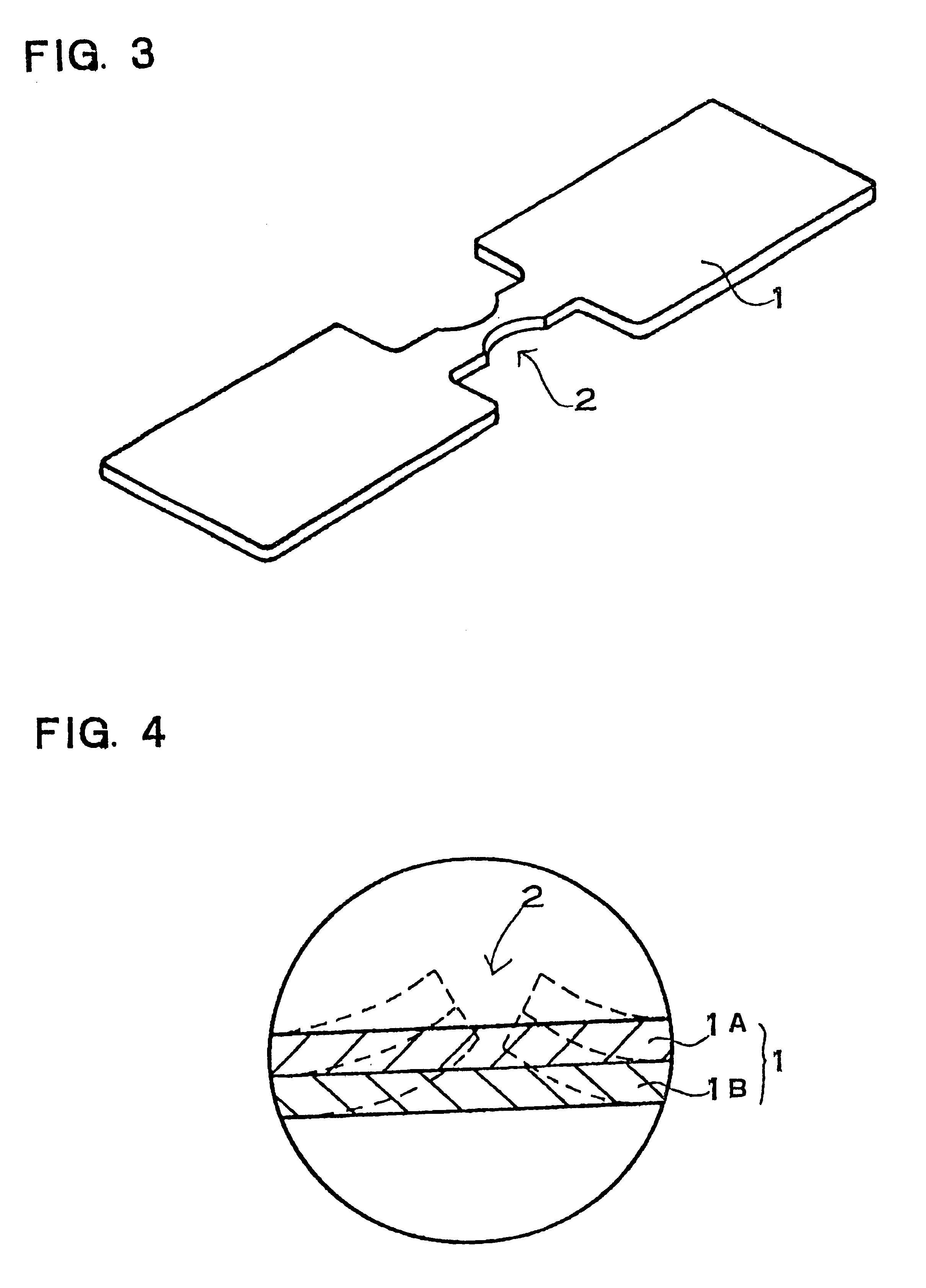

Fuse and battery pack containing the fuse

InactiveUS6377432B1Surely interrupt currentEasy to usePrimary cell maintainance/servicingEmergency protective arrangements for automatic disconnectionOvercurrentEngineering

A fuse is melted and cut off when an overcurrent flows through the fuse. The fuse has a different thermal expansion coefficient metal laminate obtained by laminating a plurality of different thermal expansion coefficient metal plates. When the fuse is melted and cut off by heat of the overcurrent, a mechanical deforming force is applied to a melting portion of the fuse. The mechanical force is caused by the difference between thermal expansion coefficients of the different thermal expansion coefficient metal plates.

Owner:SANYO ELECTRIC CO LTD

Fiber reinforced thermolplastic plastic preparation method

The invention provides a fiber reinforced thermolplastic plastic preparation method, which is obtained by mixing thermoplastic resin, fortifying fiber and auxiliary substance with exhaust type single screw-spindle extrusion machine, and extruding them, the extrusion temperature being 190-350 deg. C, the screw-spindle rotate speed being 20-120 r / min.

Owner:安善兴

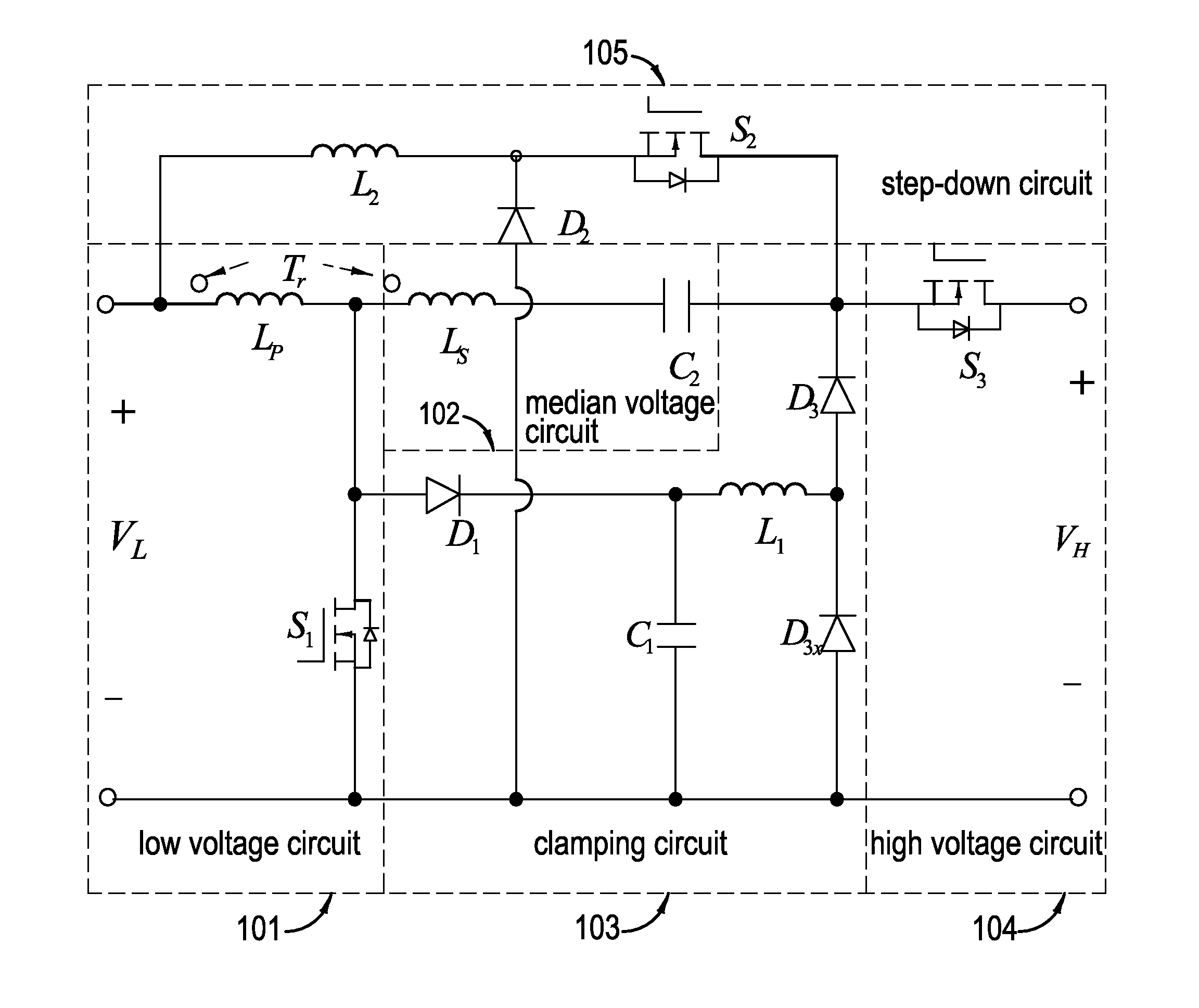

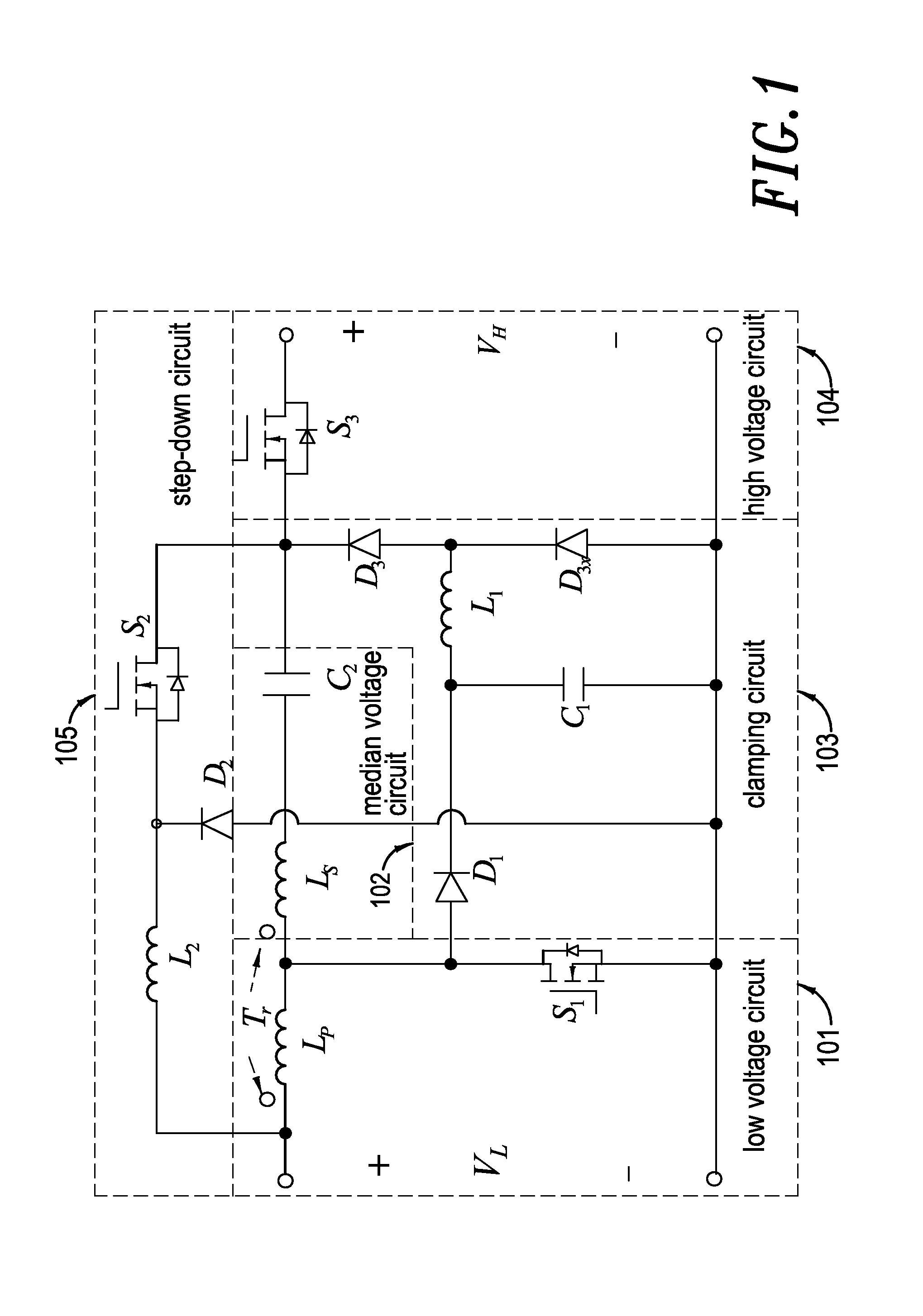

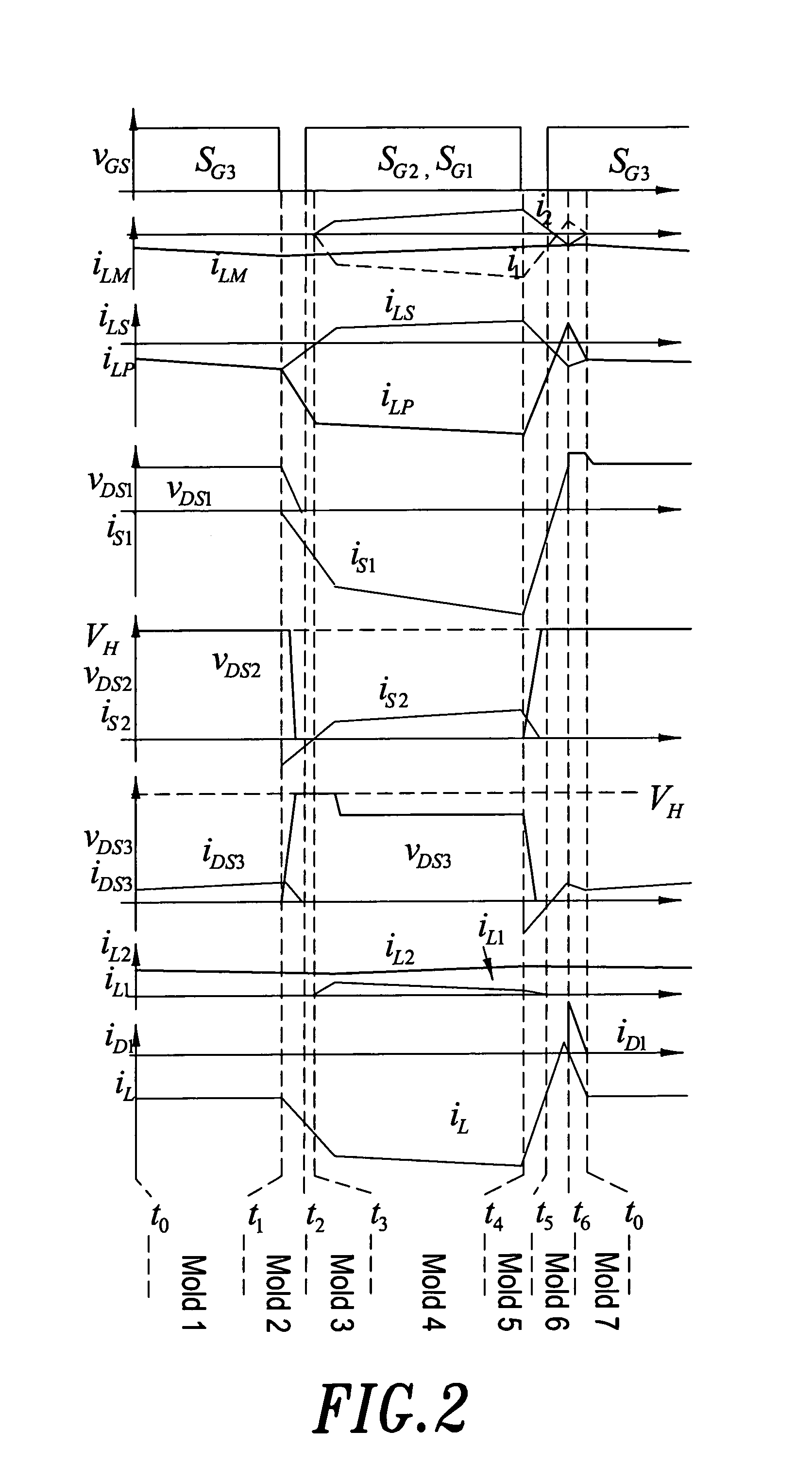

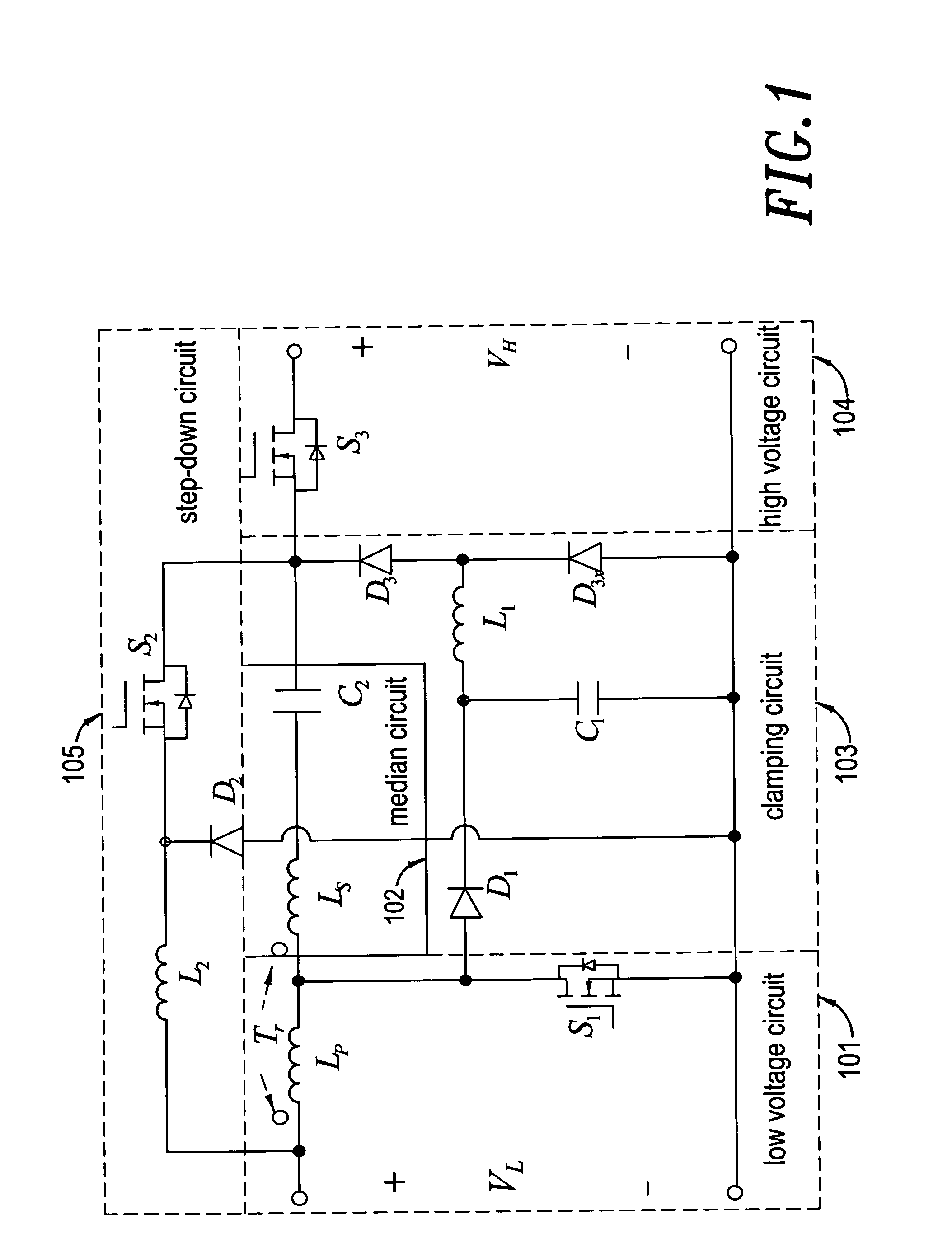

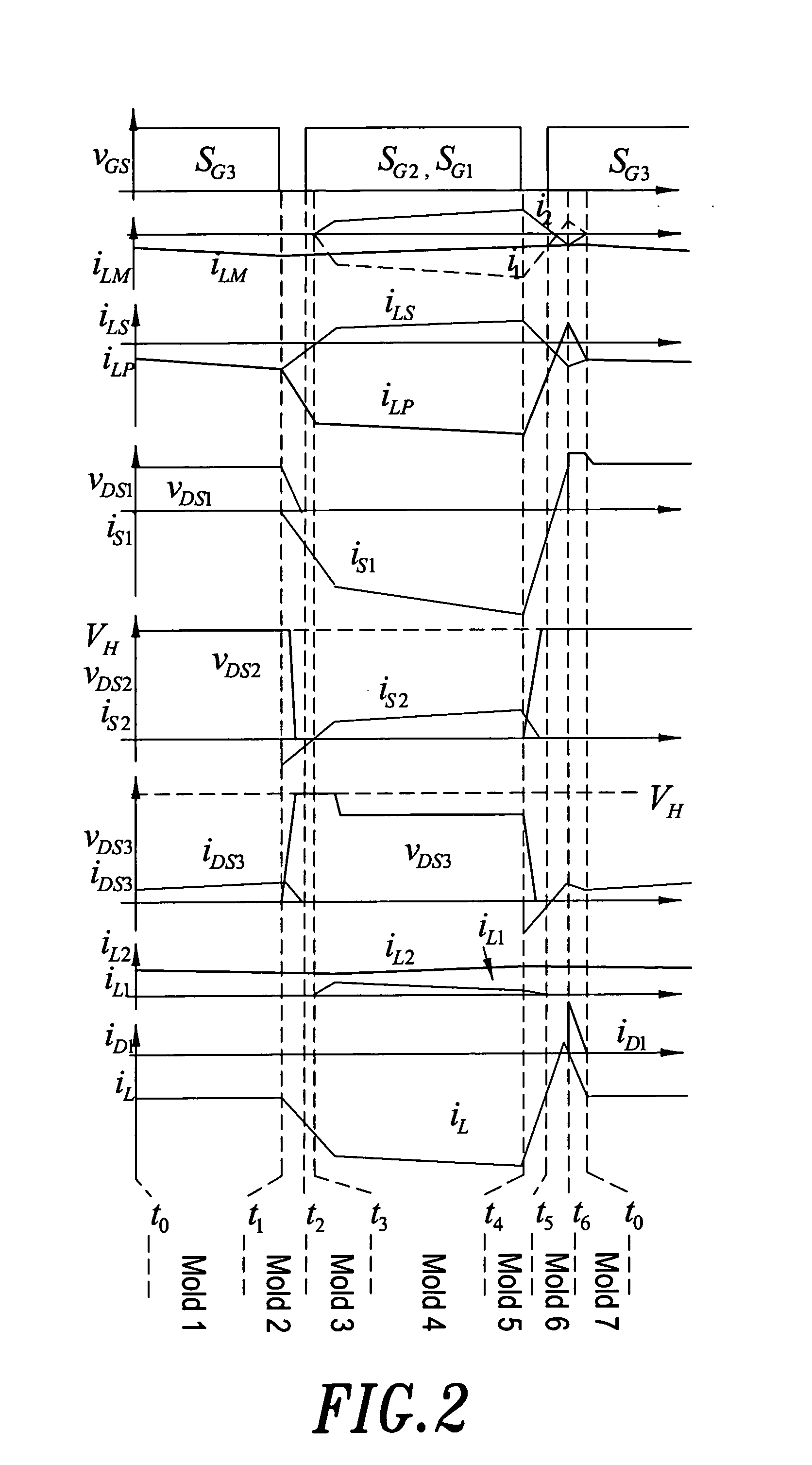

High-efficiency high-voltage difference ratio bi-directional converter

InactiveUS7382113B2Reduce conduction lossReduce voltageDc network circuit arrangementsAc-dc conversionTransformerLow voltage

The aim of this invention focuses on the development of a high-efficiency bidirectional converter for power sources with great voltage diversity. In traditional bidirectional converters, the circuit topology with transformer form is the common usual. Moreover, the soft-switching techniques including zero-voltage-switching (ZVS) or zero-current-switching (ZCS) are usually used for alleviating the corresponding switching losses. However, there are four and upward power semiconductor switches in these circuit schemes. By this way, it will result in the increase of production cost, and the degeneration of conversion efficiency. The coupled-inductor bidirectional scheme in the proposed converter only adopts three power semiconductor switches to accomplish the objective of bidirectional current control. Under the situation of non-isolation circuit topology, it still possesses the protection of electric safety for operators. Due to the characteristics of high step-up and step-down ratio, the battery module with low voltage could be injected into a high-voltage dc bus for the later utilization, e.g., high-voltage load, front-end of inverter. Since the techniques of voltage clamping, synchronous rectification and soft switching are manipulated in this circuit topology, and the corresponding device specifications are adequately performed, it can achieve the goal of high-efficiency bidirectional power conversion for power sources with great voltage diversity.

Owner:YUAN ZE UNIV

High-efficiency high-voltage difference ratio bi-directional converter

InactiveUS20070216390A1Reduce conduction lossReduce voltageDc network circuit arrangementsAc-dc conversionLow voltageTransformer

The aim of this invention focuses on the development of a high-efficiency bidirectional converter for power sources with great voltage diversity. In traditional bidirectional converters, the circuit topology with transformer form is the common usual. Moreover, the soft-switching techniques including zero-voltage-switching (ZVS) or zero-current-switching (ZCS) are usually used for alleviating the corresponding switching losses. However, there are four and upward power semiconductor switches in these circuit schemes. By this way, it will result in the increase of production cost, and the degeneration of conversion efficiency. The coupled-inductor bidirectional scheme in the proposed converter only adopts three power semiconductor switches to accomplish the objective of bidirectional current control. Under the situation of non-isolation circuit topology, it still possesses the protection of electric safety for operators. Due to the characteristics of high step-up and step-down ratio, the battery module with low voltage could be injected into a high-voltage dc bus for the later utilization, e.g., high-voltage load, front-end of inverter. Since the techniques of voltage clamping, synchronous rectification and soft switching are manipulated in this circuit topology, and the corresponding device specifications are adequately performed, it can achieve the goal of high-efficiency bidirectional power conversion for power sources with great voltage diversity.

Owner:YUAN ZE UNIV

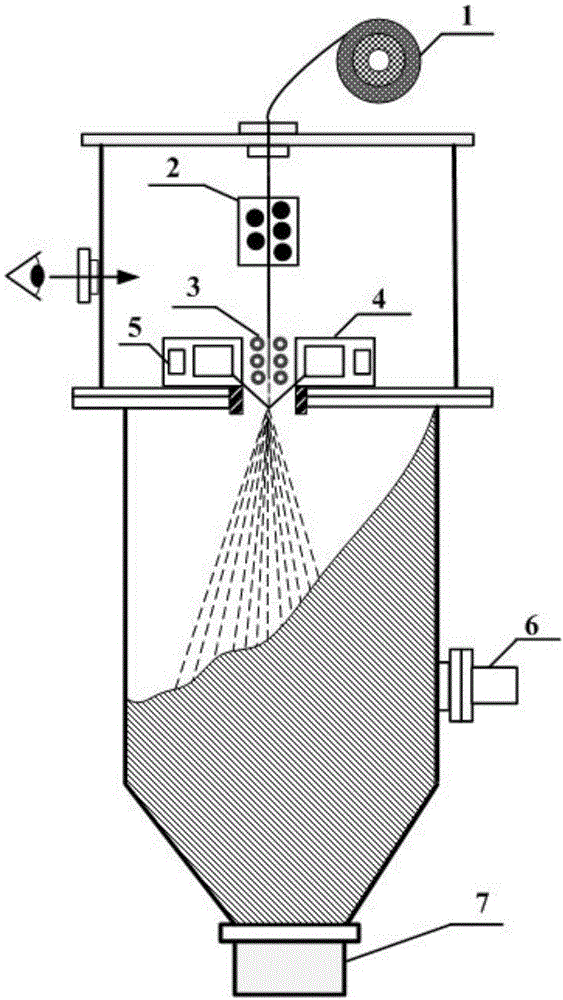

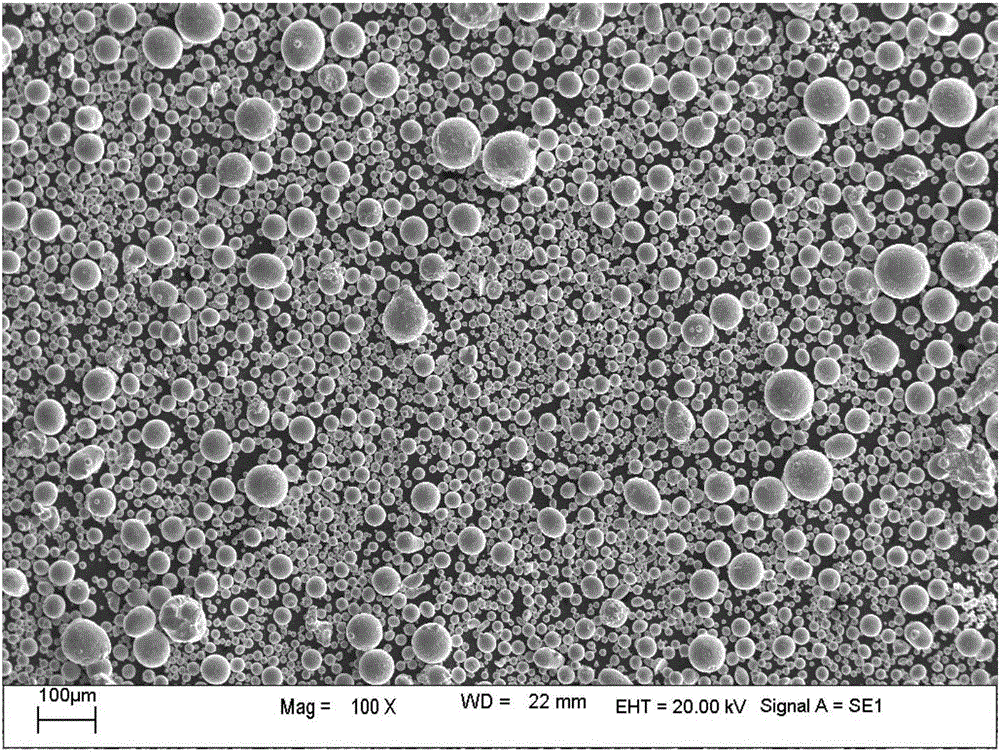

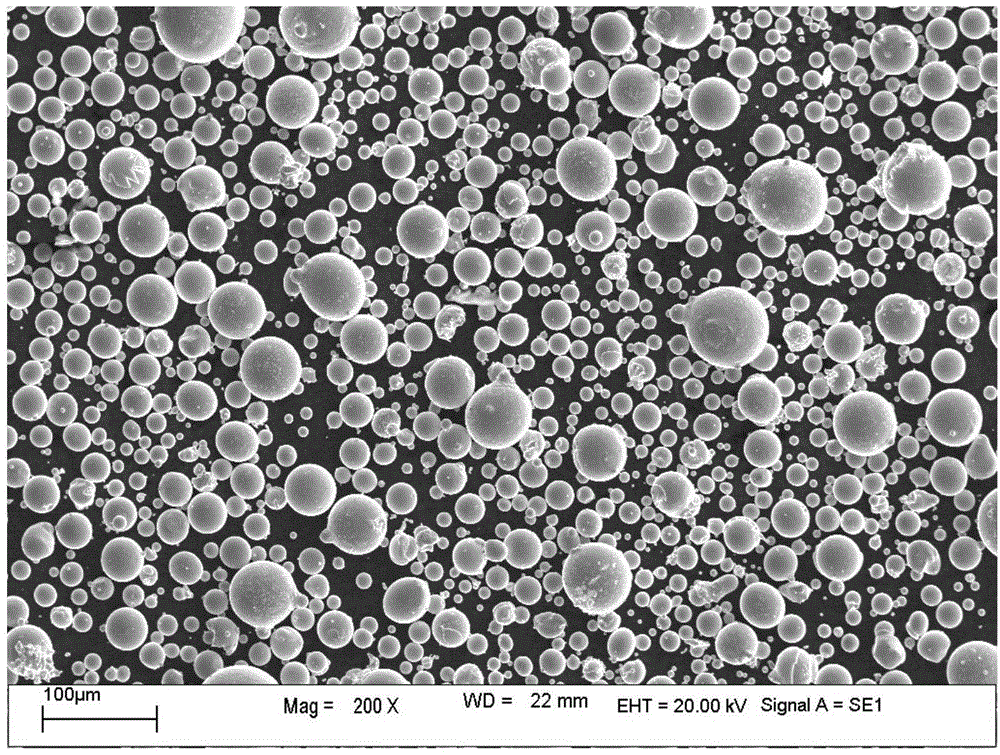

Manufacturing method of micro spherical titanium and titanium alloy powder

ActiveCN104475743AFast purification smeltingControlled purification smeltingSpherical shapedTitanium alloy

The invention relates to a manufacturing method of micro spherical titanium and titanium alloy powder, and belongs to the technical field of metal and alloy powder manufacturing. The manufacturing method comprises the steps that a titanium and titanium alloy wire or bar is manufactured by using sponge titanium in the national standard TA1 grade as a raw material; forvacuum treatment is conducted on a powder manufacturing device, and then the powder manufacturing device is filled with inert protective gas; the raw material wire or bar is fed into a smelting chamber through a continuous feeding mechanism and a straightener, the raw material is heated and smelted through a high-frequency induction coil, and the alloy raw material is molten to form stable liquid flow or drip flow; supersonic atomizing nozzles in atomizers are opened, and breakage, dispersion and forced cooling powder manufacturing are conducted on the molten liquid flow or the drip flow; powder is obtained through a powder collector, and is screened through an ultrasonic vibrating screen to obtain the micro spherical titanium and titanium alloy powder. The micro spherical titanium and titanium alloy powder manufactured through the manufacturing method is small in particle size, high in degree of sphericity, good in liquidity and low in impurity content, and has smooth surfaces.

Owner:有研增材技术有限公司

Completely fused paper soap and its making process

InactiveCN1357613AImprove solubilityImprove decontamination abilityDetergent materialsPhenolFatty alcohol

The component of the paper soap include carboxymethyl cellulose sodium, fatty alcohol polyioxymethyl ethyleneethere sodium sulfate, sodium dodecyl benzene sulfonate, lauryl sodium sulfate, cocinin diethanolamide, nonly phenol polyoxyethyleneether, glycerine, quaternary ammonium salt and citric acid. Its preparation includes preparing carboxymethyl cellulose sodium mother liquor, adding the mixed solution of other components to prepare solution through stirring, spraying the prepared solution of PVC plate and drying in a sealed room and moisture extract at 35-40 deg.c to form film.

Owner:成都洁利康实业发展有限公司

Powder injection molding feedstock preparing method and powder injection molding method

Disclosed are a powder injection molding feedstock preparing method and a powder injection molding method. The powder injection molding feedstock preparing method includes: stirring and heating 80% to 94%, preferably 85% to 94%, by percent, of forming powder in an internal mixer, adding 6% to 20%, preferably 6% to 15%, by percent, of binder component when the forming powder is heated to 180 DEG C to 200 DEG C, and continuing stirring for 60min to 120min according to the mixing temperature 175 DEG C to 195 DEG C, preferably at the mixer speed 10rpm to 30rpm, thus obtaining evenly mixed feedstock. The powder injection molding method includes performing injection molding and degreasing sintering with the feedstock. The powder injection molding feedstock preparing method and the powder injection molding method have the advantages that degreasing efficiency is high, the process is simple and easy to control, blank quality is good and the methods are sanitary and environment friendly.

Owner:DONGGUAN HUAJING POWDER METALLURGY

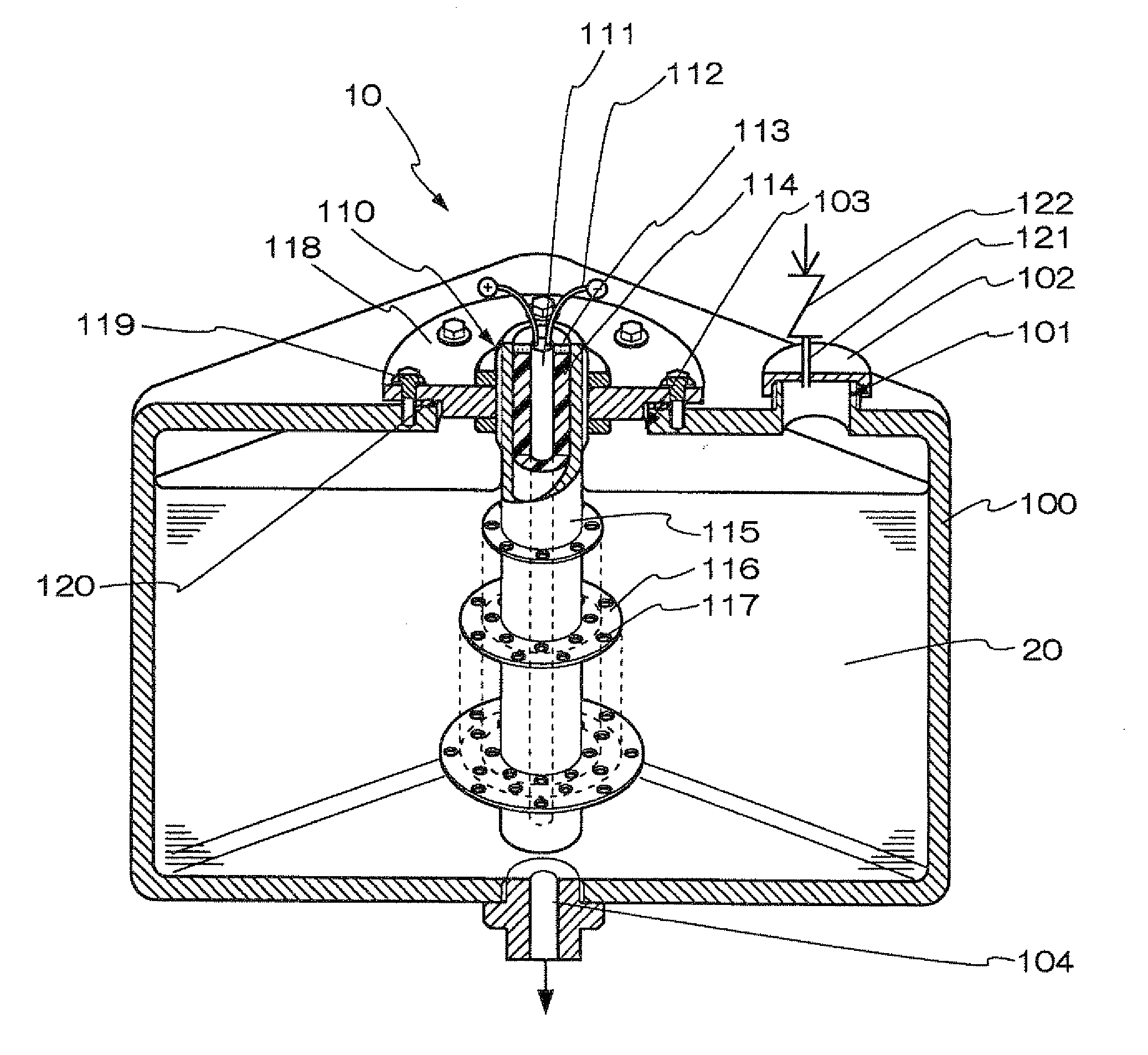

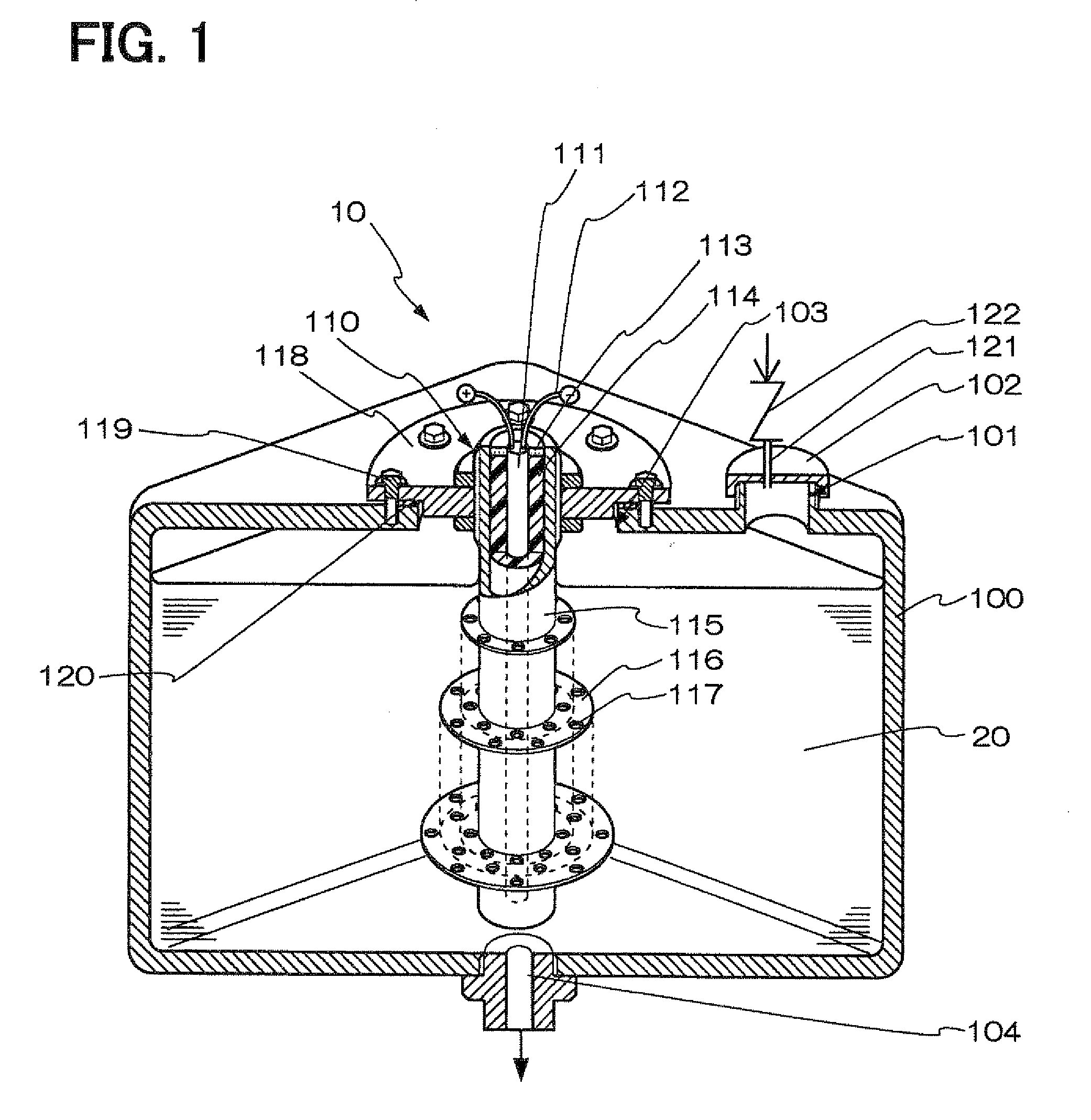

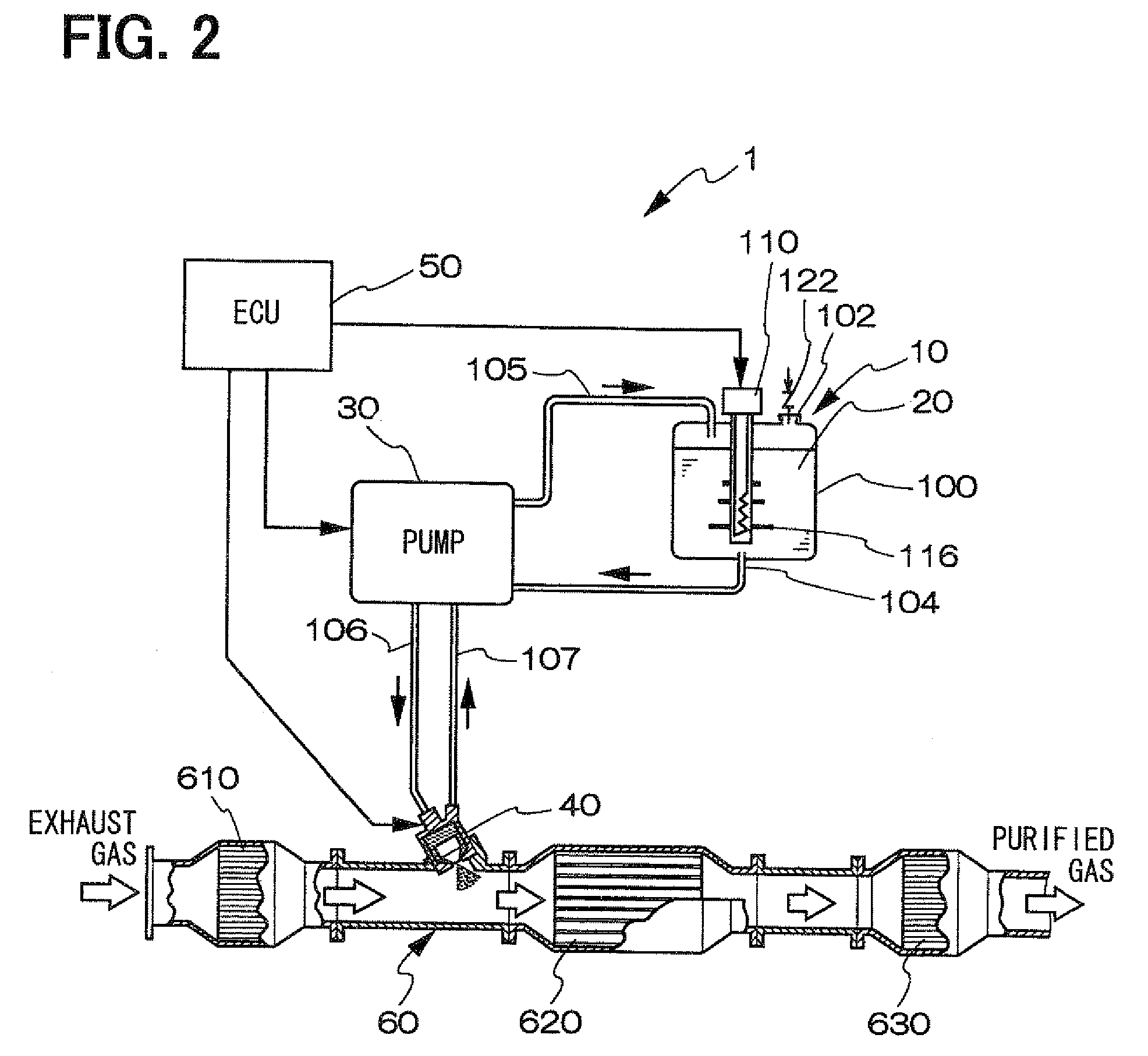

Fluid heating device and exhaust gas purifying apparatus

InactiveUS20080256937A1High thermal efficiencySimple structureInternal combustion piston enginesExhaust apparatusElectricityExhaust fumes

A fluid heating device includes a heating part and a plurality of heat transfer sections. The heating part is disposed in a fluid stored in a container and is elongated in an axial direction for heating the fluid between a lower portion and an upper portion of the container by being supplied with electricity. The heat transfer sections arranged along the axial direction of the heating part. Each of the heat transfer sections has a plate shape extending from the heating part to a radial outside of the heating part approximately perpendicularly to the axial direction of the heating part.

Owner:DENSO CORP

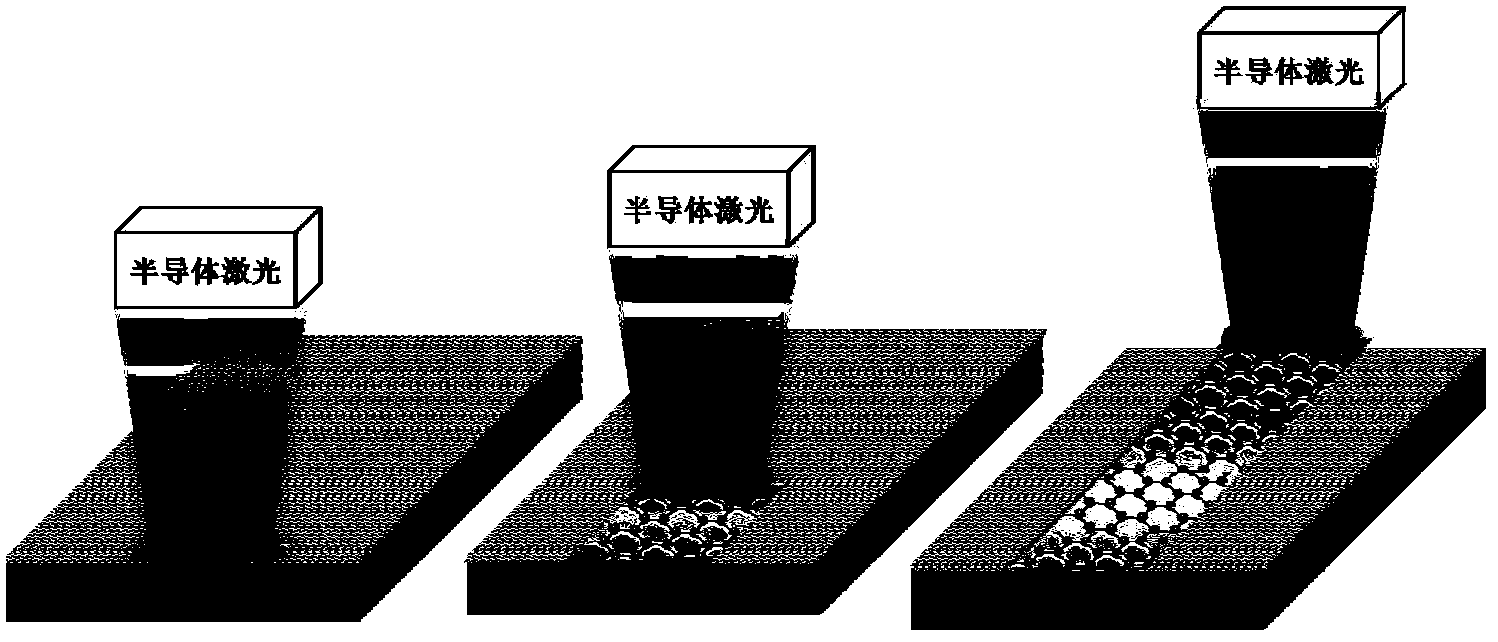

Laser preparation method for large-area patterned graphene

The invention discloses a laser preparation method for large-area patterned graphene. The preparation method comprises the following steps: (1) a solid carbon source is dispersed in an organic solvent to obtain a dispersion liquid, and the surface of a metal substrate is coated with the dispersion liquid in a spinning manner to obtain a uniform carbon coating; (2) under the condition of the protection of inert gas, a high power density laser beam is adopted to irradiate the carbon coating, and carbon atoms in the solid carbon source and metal atoms in the metal substrate are formed into a solid solution under function of irradiation; the high power density laser beam is moved away or the irradiation operation is stopped, when the metal substrate is cooled, the oversaturated solid solution is formed, and the carbon atoms are separated out of the oversaturated solid solution and formed on the surface of the substrate to form graphene. The invention provides a novel method which is convenient, fast, low in cost and high in efficiency and prepares the large-area patterned graphene. The product obtained through the method can be applied to the following fields: next generation microcomputers, flat-panel displays, super-capacitors, transparent conductive electrodes, sensors, solar batteries, micro-nano electronic devices, photoelectronic devices, self-spinning quantum devices, novel compound materials and so on.

Owner:TSINGHUA UNIV

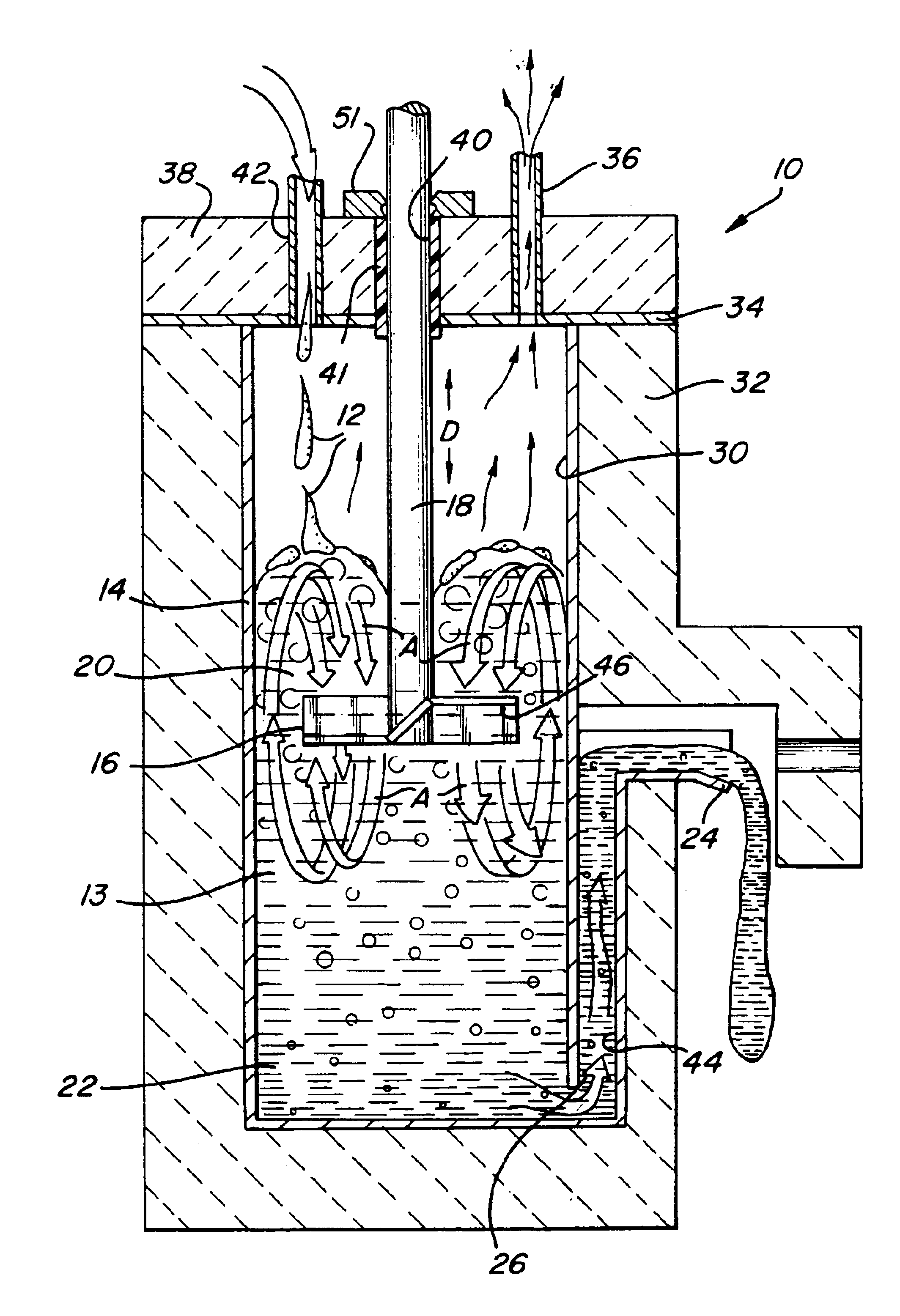

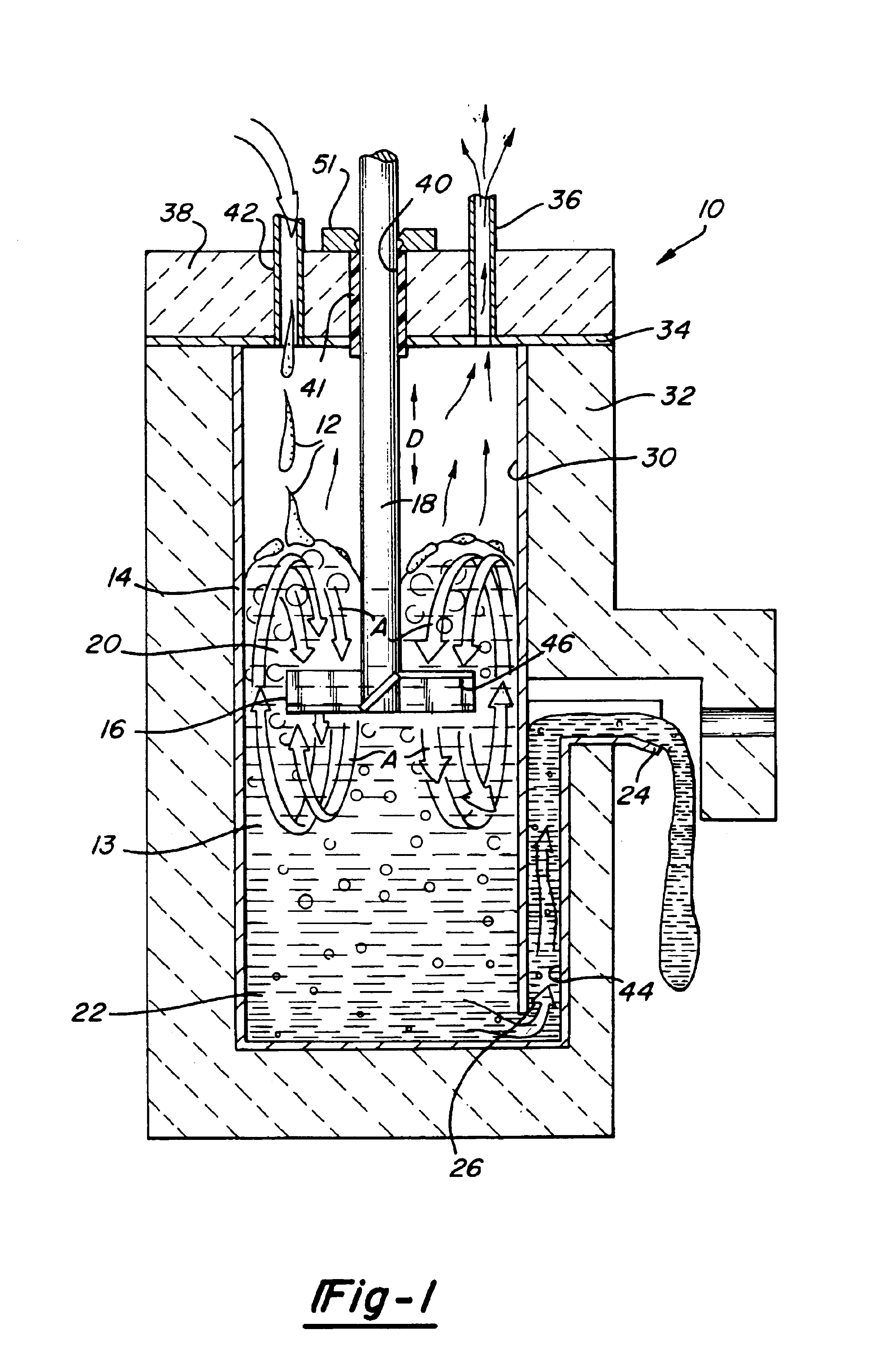

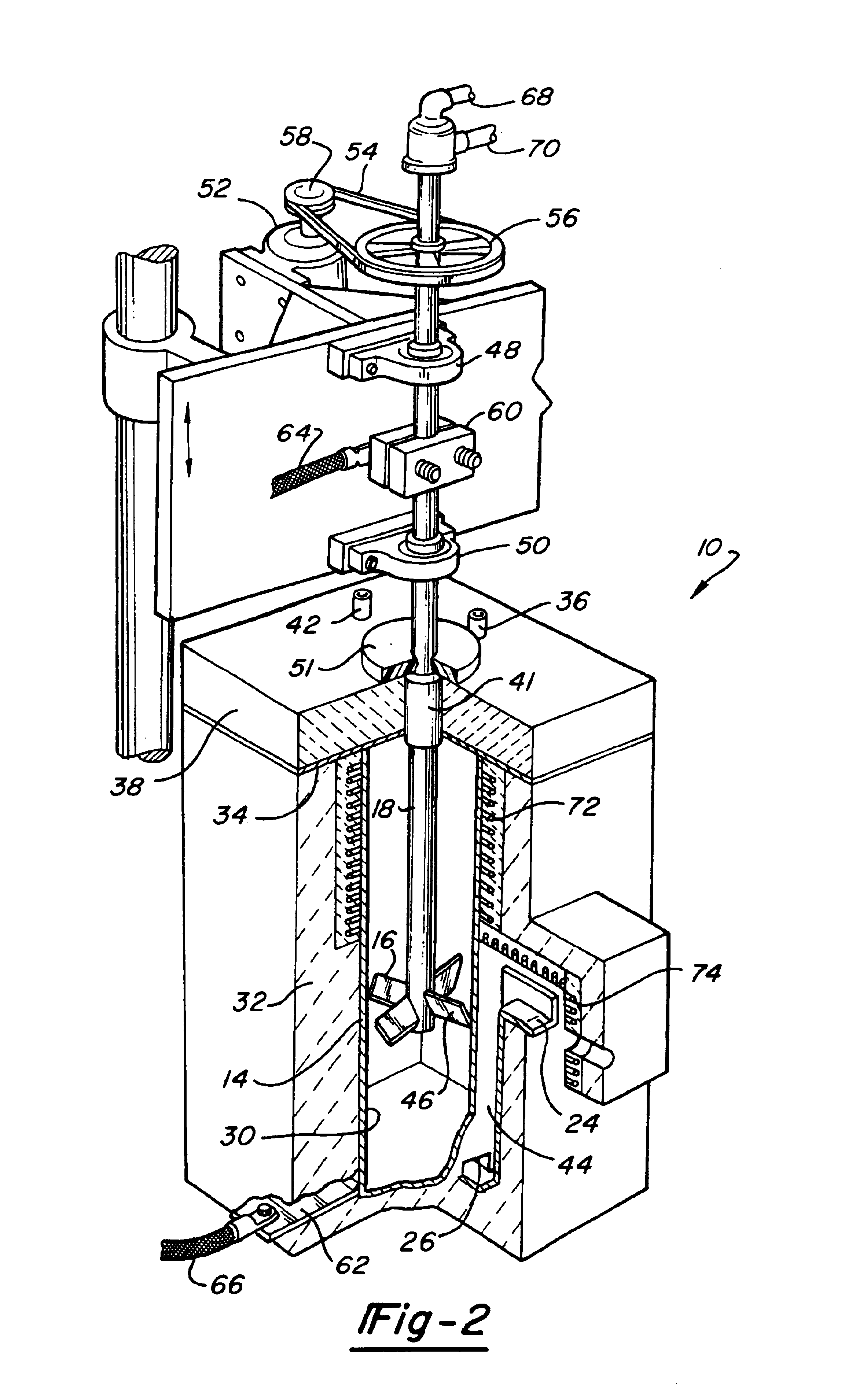

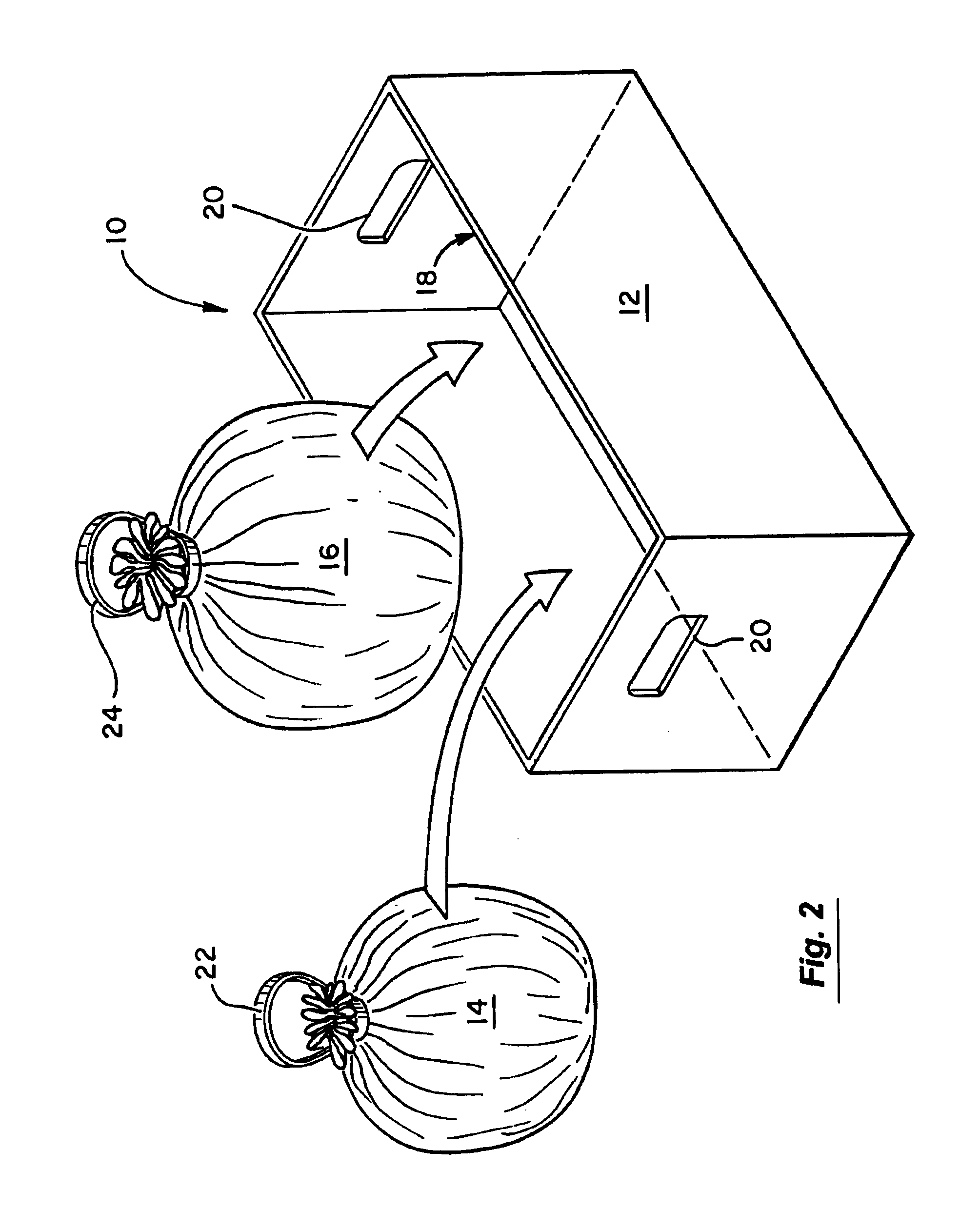

Method and apparatus for waste vitrification

A waste vitrification apparatus (10) having rotatable mixer impeller (16) functioning as a shaft electrode (60) and metallic vessel (14) functioning as a vessel electrode (62). A stream (12) of waste material and vitrifiable material are mixed and melted in the vessel (14) for vitrification. The waste vitrification method converts a feed stream (12) by mixing the feed stream into a glass melt (13) and melting glass batch of the feed stream (12) to form a foamy mass. The stream is dispersed by the impeller (16) to form a foam which is then densified in a settling zone (22), recovered through a spout (24) and solidified in storage containers. Means are provided to adjust the location of the mixing impeller (16) in the vessel (14) to change the depth of the settling zone (22). The impeller (16) is mounted on a drive shaft (18) having a recirculating coolant flow.

Owner:STIR MELTER

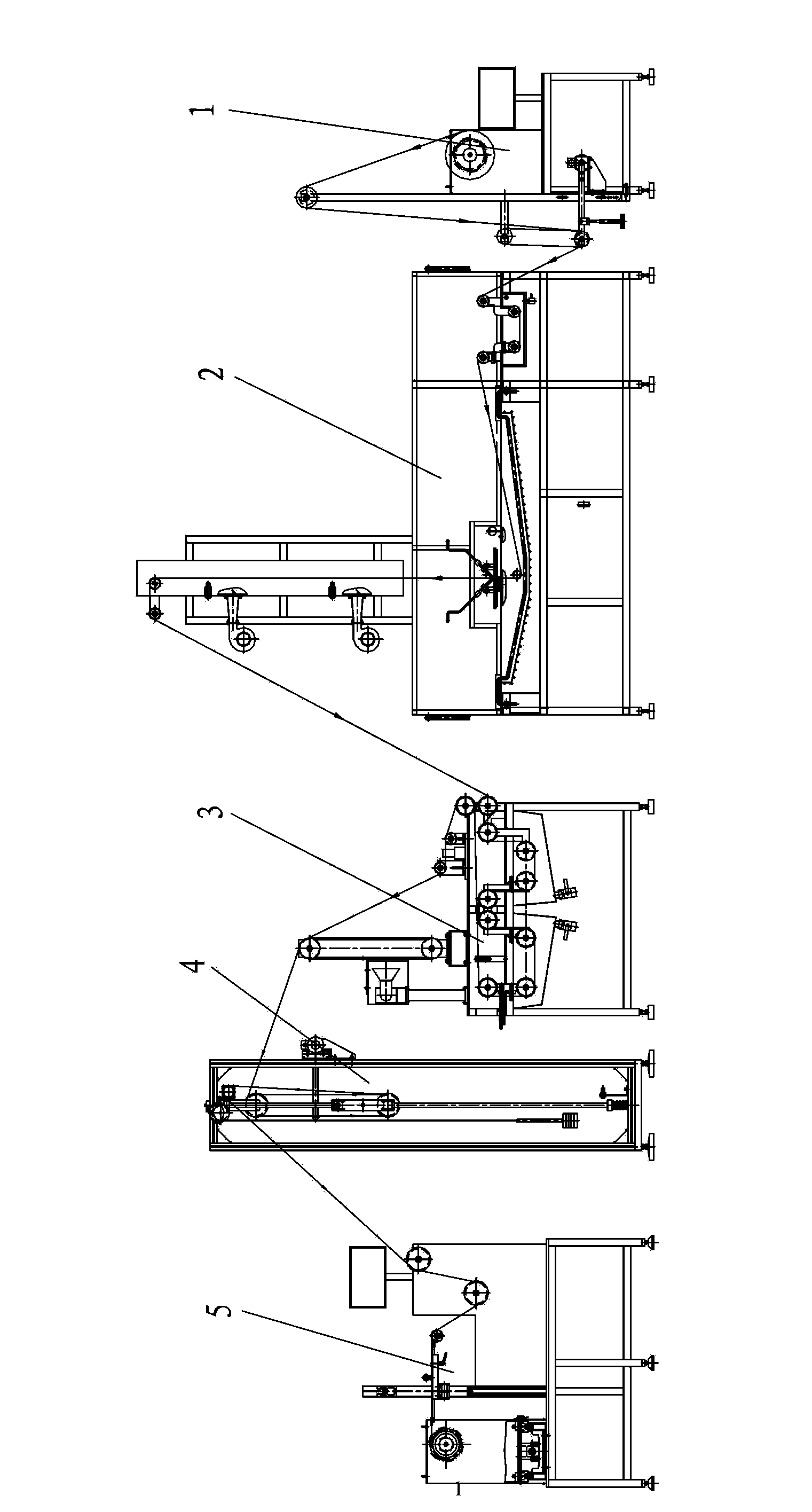

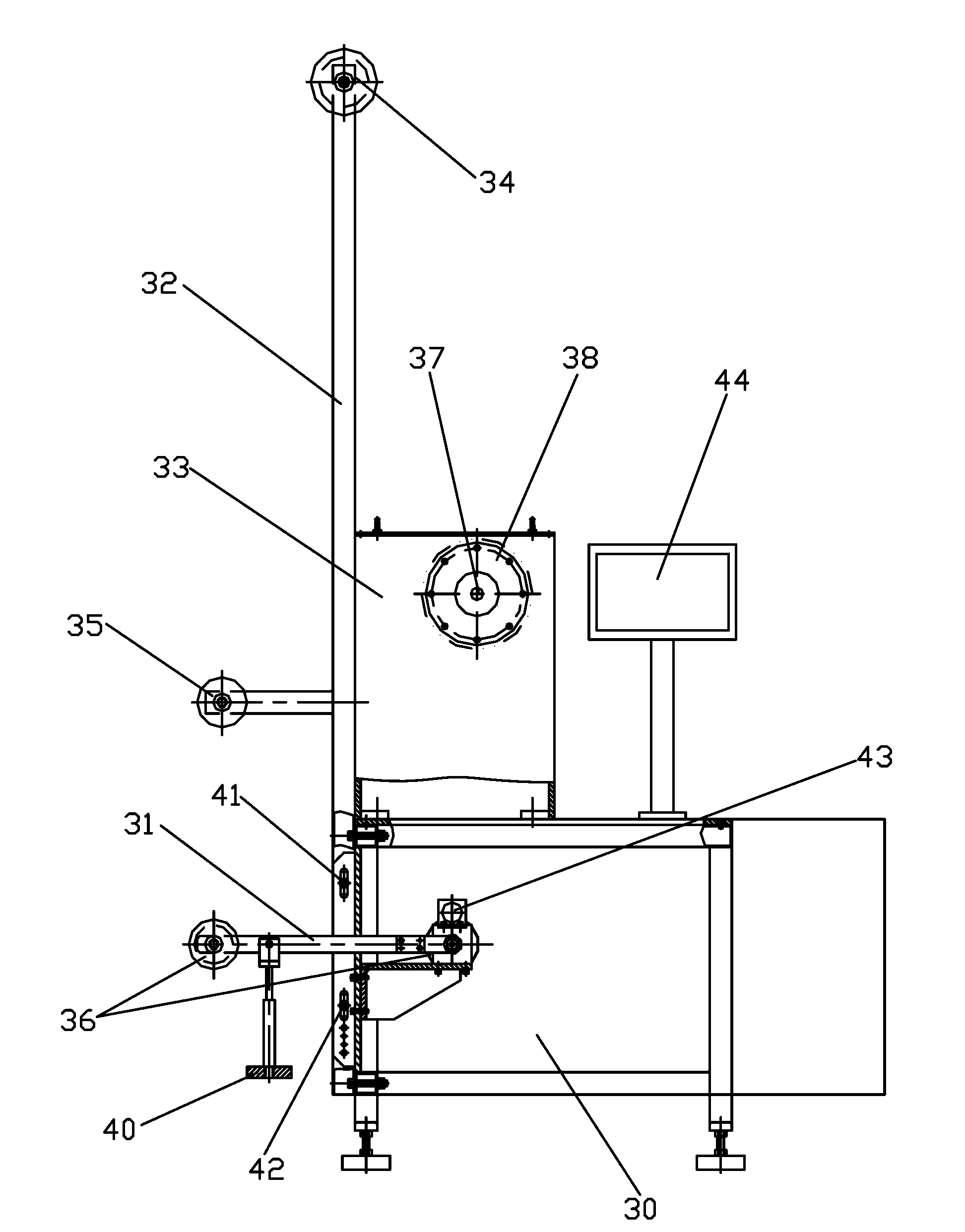

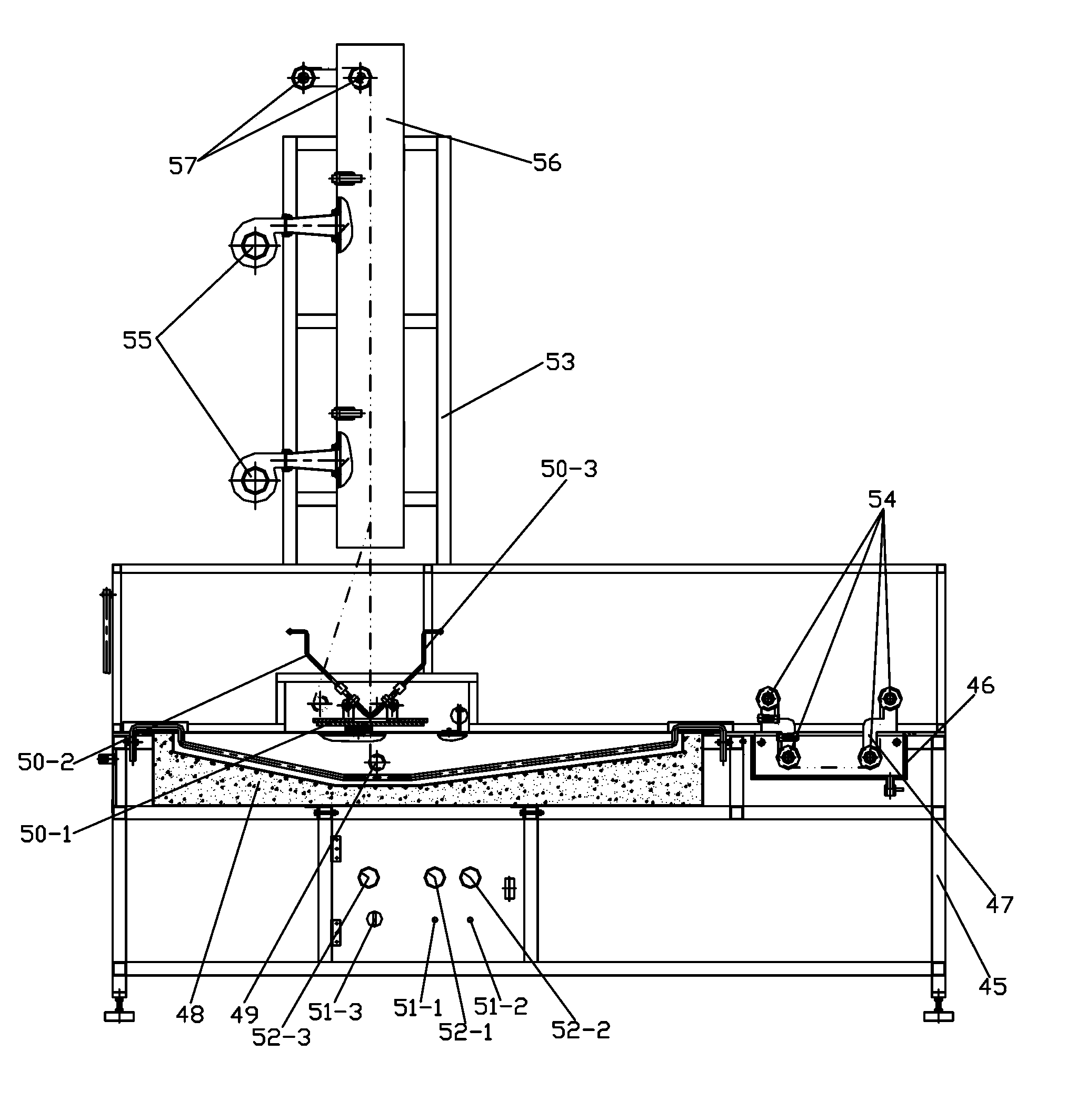

High speed automatic tin-plating machine

InactiveCN103834891ACompact structureNovel and reasonable designHot-dipping/immersion processesControl systemTin plating

The invention discloses a high speed automatic tin-plating machine which comprises an unreeling mechanism, a tin-plating mechanism, a driving and cleaning mechanism, a storage mechanism, a reeling mechanism and a control system sequentially arranged, wherein the unreeling mechanism comprises an unreeling frame, a paying off swing rod, an unreeling transitional wheel, an unreeling belt wheel, a tension adjusting wheel and an unreeling motor; the tin-plating mechanism comprises a tin-plating frame, an acidifying box, an acidifying transitional wheel frame, a solder machine, a pinch roller, a wind knife assembly and an air flue frame; the driving and cleaning mechanism comprises a cleaning frame, a cleaning agent groove, a cleaning transitional wheel bracket, a thickness measuring assembly and a traction assembly; the storage mechanism comprises a storage frame, a fixed wire storage wheel set, a mobile wire storage wheel set and a tension detection mechanism; the reeling mechanism comprises a reeling frame, a reeling guide rail bracket, a vertical wiring device and a horizontal wiring device. The high speed automatic tin-plating machine disclosed by the invention is novel and reasonable in design, ensures the quality and efficient production of tin-plating welding strips, is high in working reliability, better realizes continuous, efficient, high-quality and low-cost tin plating, and is convenient to popularize and use.

Owner:THE NORTHWEST MACHINE

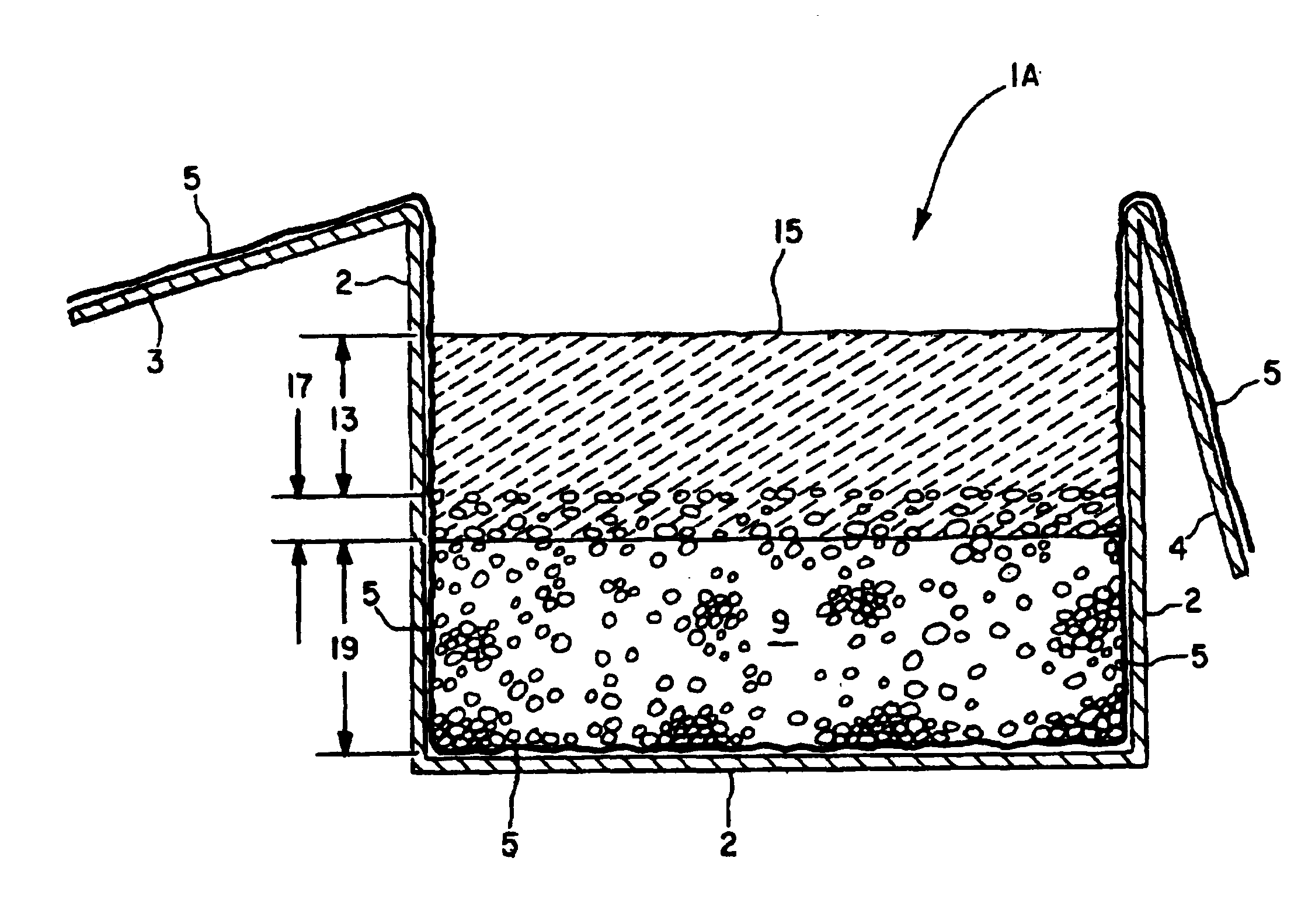

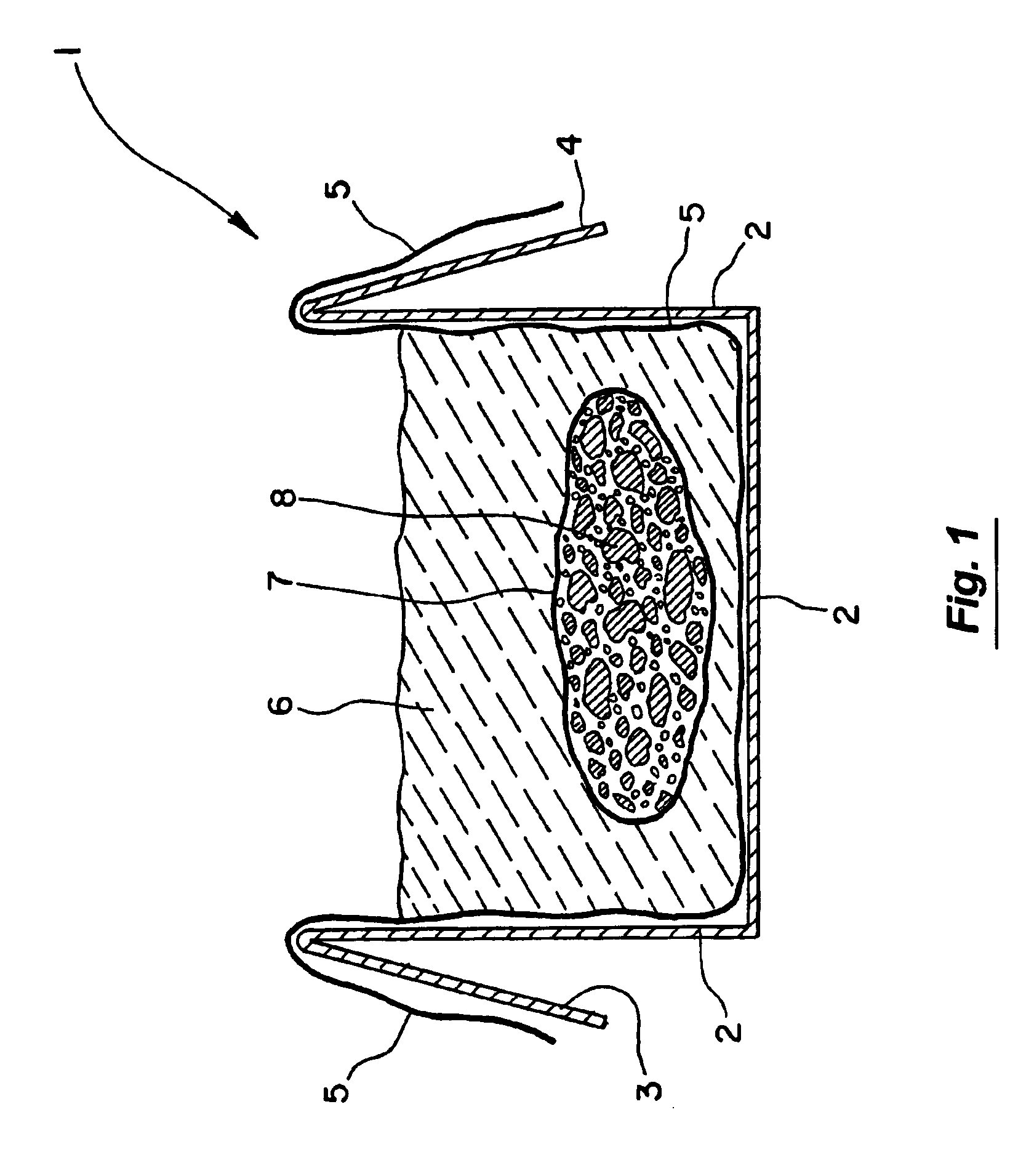

Binder/aggregate/container systems

InactiveUS6966723B2Melting fastLess overall consumptionIn situ pavingsLayered productsEngineeringConstruction aggregate

Owner:CRAFCO

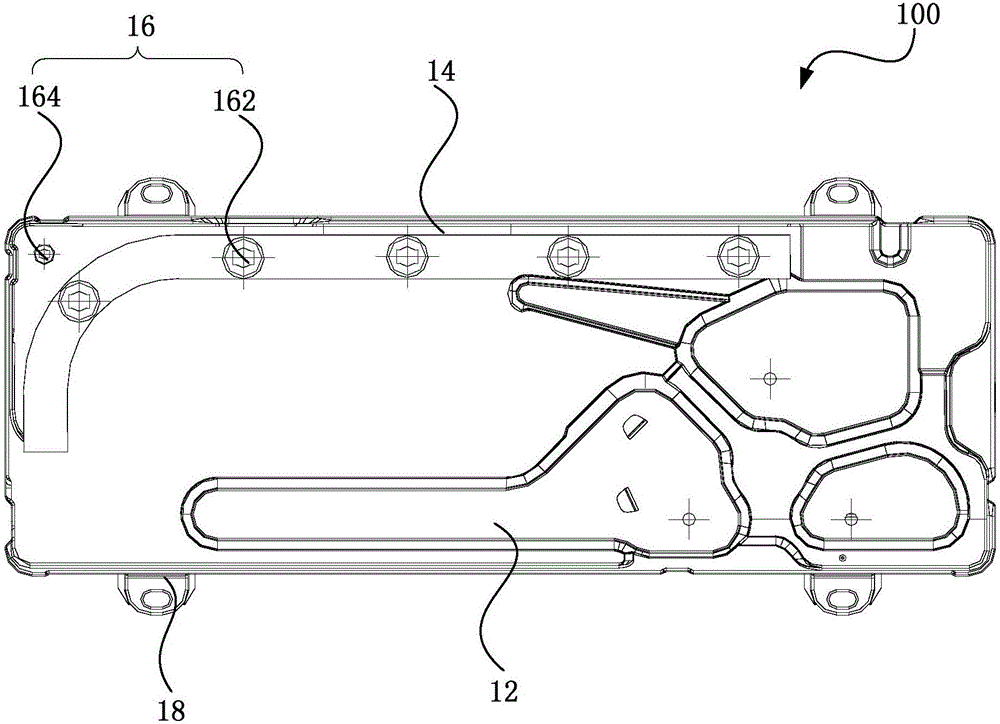

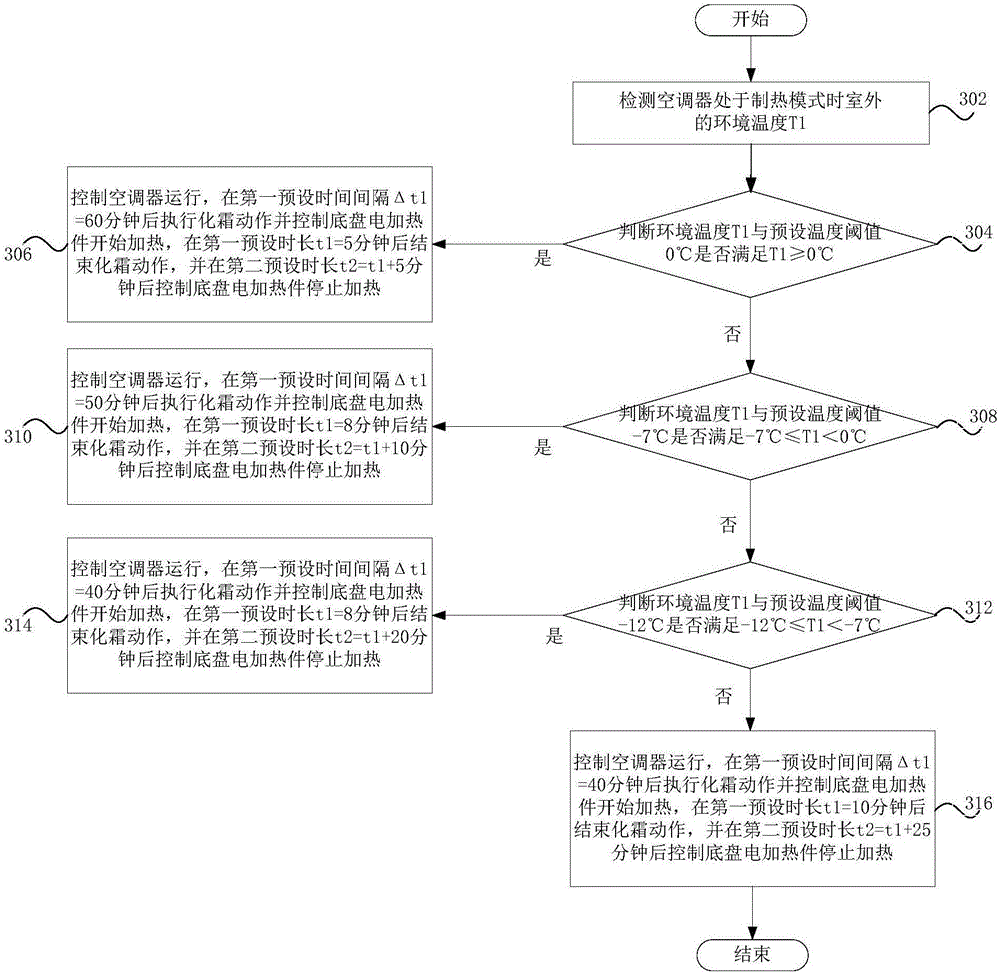

Base plate structure, air conditioner and defrosting control method for air conditioner

PendingCN106352443AHigh speedImprove defrosting efficiencyMechanical apparatusSpace heating and ventilation safety systemsFrostEngineering

The invention provides a base plate structure for an outdoor unit of an air conditioner, the outdoor unit of the air conditioner, the air conditioner and a defrosting control method for the air conditioner. The base plate structure for the outdoor unit of the air conditioner comprises an outdoor unit base plate, a base plate electric heating element and a drainage part, wherein a compressor fixing support is arranged on the outdoor unit base plate, and a condenser is installed on the outdoor unit base plate; the base plate electric heating element is arranged at the bottom of the condenser and located above the outdoor unit base plate; and the drainage part is arranged on the outdoor unit base plate and comprises at least one main drainage port, and the main drainage port is located below the base plate electric heating element. By adopting the base plate structure, when the air conditioner is heated for defrosting at a lower outdoor temperature, frost on the condenser and the outdoor unit base plate can be quickly and thoroughly thawed, and the thawed water quickly and smoothly flows out of the main drainage port, so the frost is thawed cleanly and thoroughly, the temperature of an indoor air port is improved, a good heating effect is guaranteed, and the market competitiveness of the product is improved.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP +1

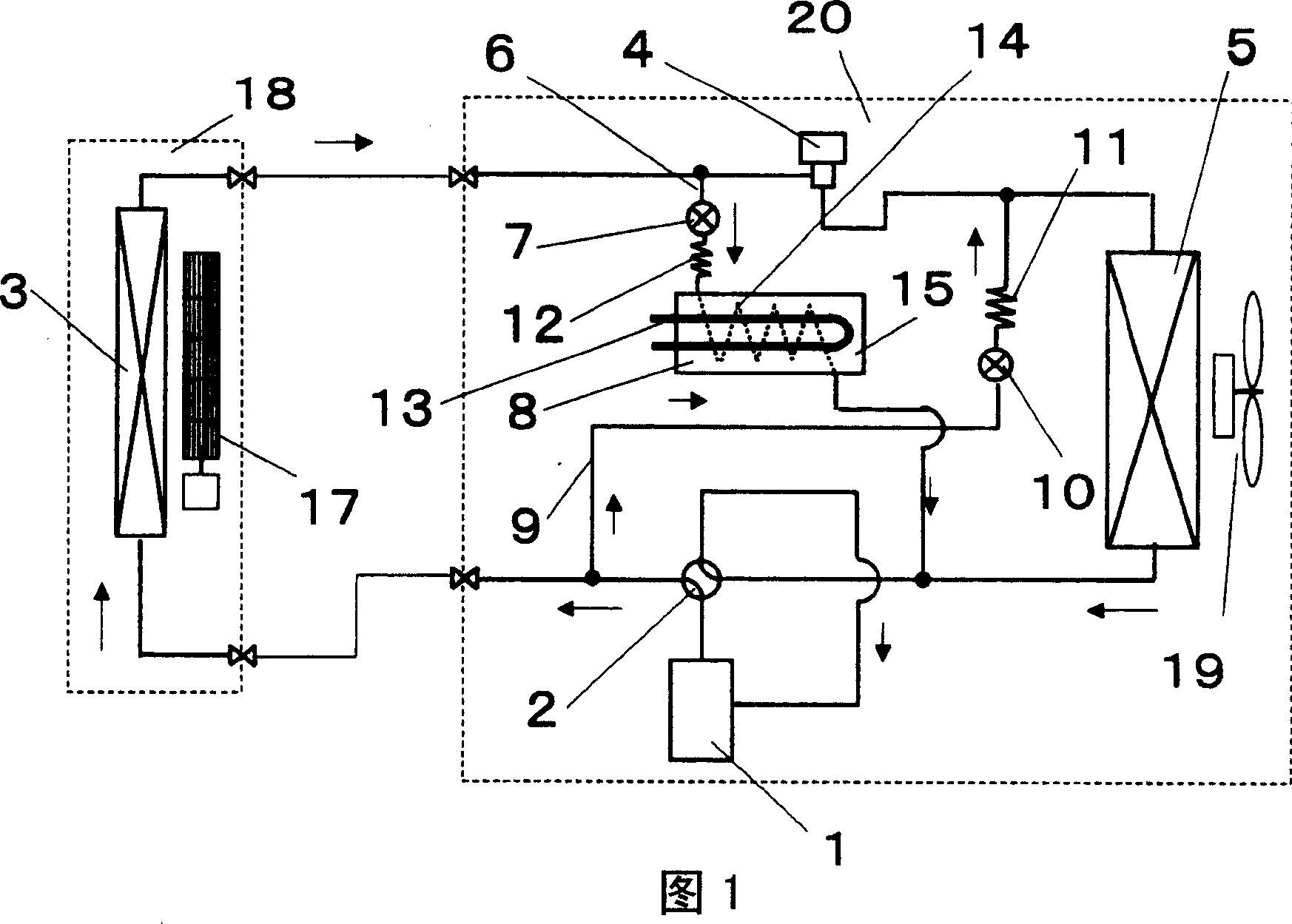

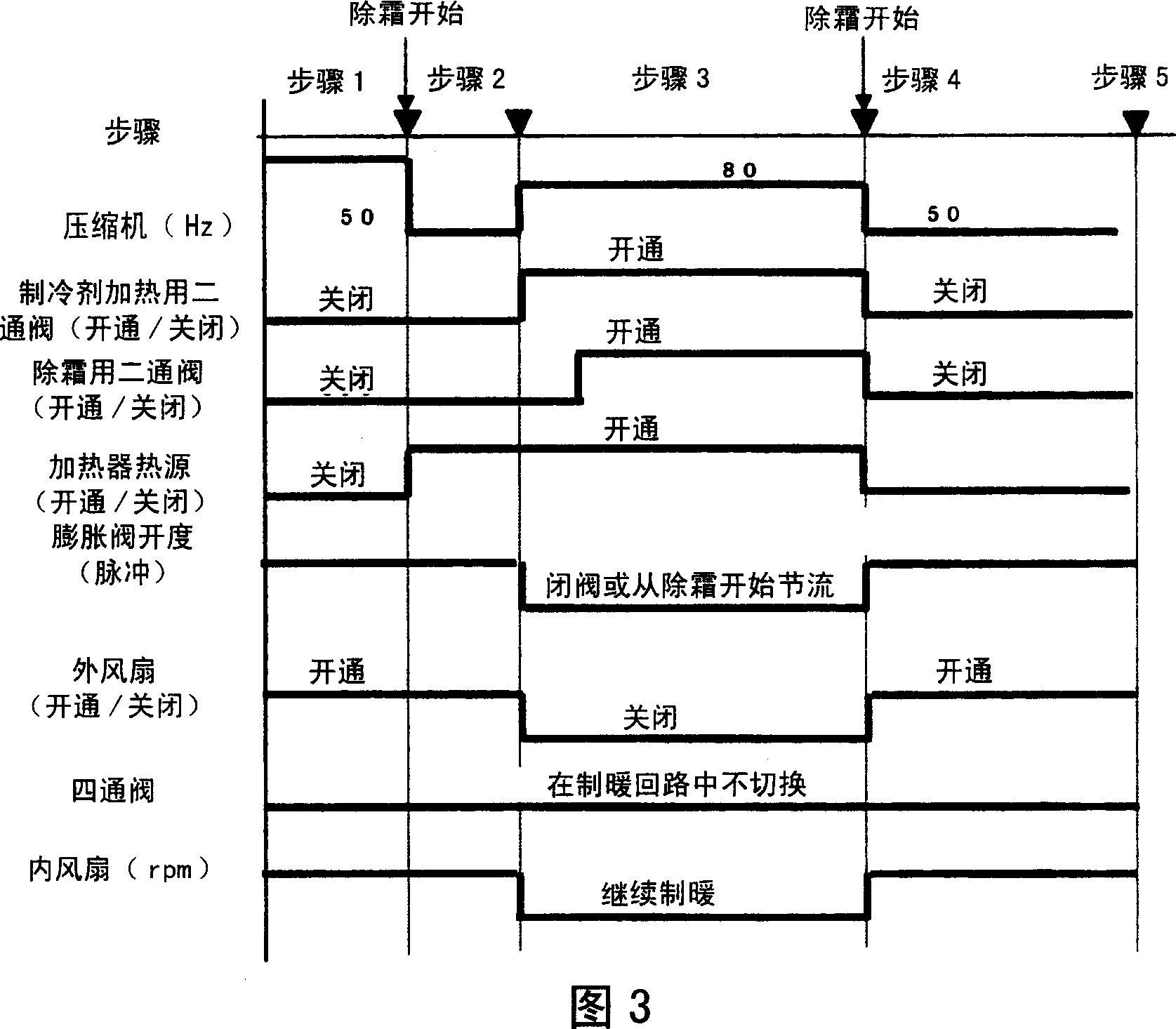

Air conditioner

InactiveCN1932417AImprove reliabilityShorten defrost timeCorrosion preventionCompression machines with reversible cycleEngineeringHeat pump and refrigeration cycle

To provide an air conditioner carrying out defrosting operation while continuing heating operation. This air conditioner comprises a first bypass circuit connecting the suction side of a compressor between an indoor heat exchanger and a decompressor of a heat pump type refrigeration cycle, the first bypass circuit including a two-way valve and a refrigerant heater; and a second bypass circuit connecting a part between a four-way valve connected to the refrigeration cycle and the indoor heat exchanger to a part between the decompressor and an outdoor heat exchanger, the second bypass circuit is provided with two-way valve. When defrosting the outdoor heat exchanger is performed, the two-way valve of the first bypass circuit and the two-way valve of the second bypass circuit are opened to guide current to the refrigerant heater for heat storage prior to the defrosting operation, and the defrosting operation is performed while continuing heating.

Owner:PANASONIC CORP

Method for preparing air inlet edge surface wear-resistant anti-corrosion alloy coating of tail stage blade of steam turbine

InactiveCN102453896AMelting fastFreeze fastMetallic material coating processesNumerical controlEdge surface

The invention relates to a method for preparing an air inlet edge surface wear-resistant anti-corrosion alloy coating of a tail stage blade of a steam turbine. The method is characterized by comprising the following steps that: 1) the air inlet edge surface of the tail stage blade of the steam turbine is pre-treated; 2) alloy powder is selected, and an automatic powder conveyor is regulated; 3) light beams are regulated; 4) the wear-resistant anti-corrosion coating laser cladding is carried out, a DL-HL-T5000 type CO2 laser is adopted, a work table is a SIMENS numerical control laser processing machine, a synchronous powder conveyor is adopted for conveying the alloy powder into a laser molten pool, high-power focus laser beams and an automatic powder conveying head are fed in the specified direction of the air inlet edge surface of the blade, and uniform and compact laser cladding layers are formed on the blade surface through processing; and 5) flaw detection is carried out after the cladding. According to the method, the laser cladding is adopted for uniformly cladding the alloy powder with the wear-resistant anti-corrosion performance onto the blade of the steam turbine, the uniform and compact metallurgical combining coatings are formed, the anti-corrosion performance reaches the stainless steel level, the cladding layer and a substrate form firm metallurgical combination, and the peeling is not easy to occur.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

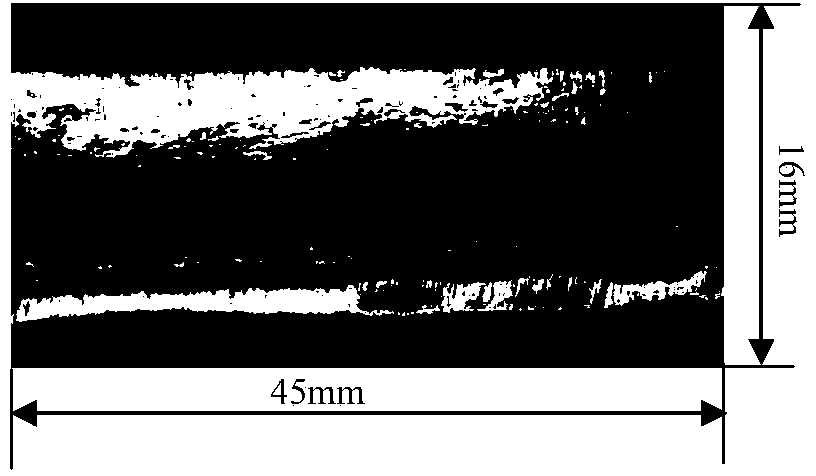

Process for performing laser cladding on alloy coating with characteristics of wear resistance and heat resistance by hot rolling of seamless steel pipe

ActiveCN104250801AGood compatibilityMelting fastMetallic material coating processesHardnessHigh-speed steel

The invention relates to a process for performing laser cladding on an alloy coating with characteristics of wear resistance and heat resistance by hot rolling of a seamless steel pipe, which is characterized by comprising the following steps: removing oil and rust on the surface of a transport roller under room temperature, washing by alcohol; preparing the alloy powder, mixing superhard high speed steel powder alloy powder and carbide powder according to proportion of 4:1; selecting a 3.5*1mm focusing mirror, adjusting defocusing amount to make a focused laser spot as an elliptical shape, employing a synchronization powder feeding apparatus for automatically seeding the alloy powder into a laser molten pool, focusing laser beam with high power, feeding by an automatic powder feeding head along the axial direction of the transport roller of the seamless steel pipe, setting rotating speed for rotation, forming an uniform and compact laser cladding layer on the surface of the transport roller; performing hot rolling on the transport roller of the seamless steel pipe, and then performing heat treatment; and grinding and processing a laser cladding hard alloy coating to the required size. The cladding layer hardness of the formed uniform and compact wear-resistant anti-corrosion cladding layer can reach more than HRC 65, and the service life is increased by more than 8 times.

Owner:BEIJING DALU TIANRUI LASER ENG TECHCO

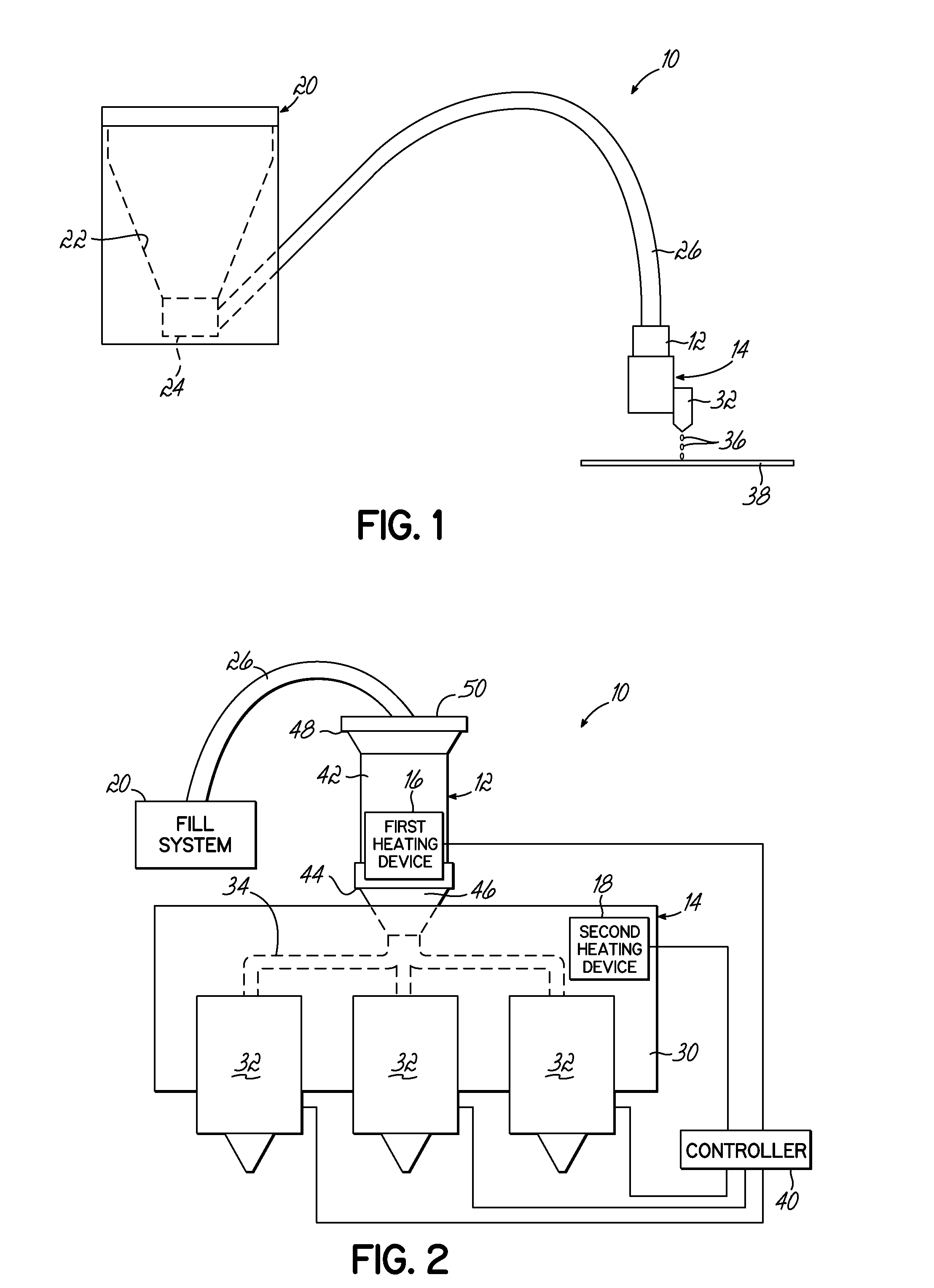

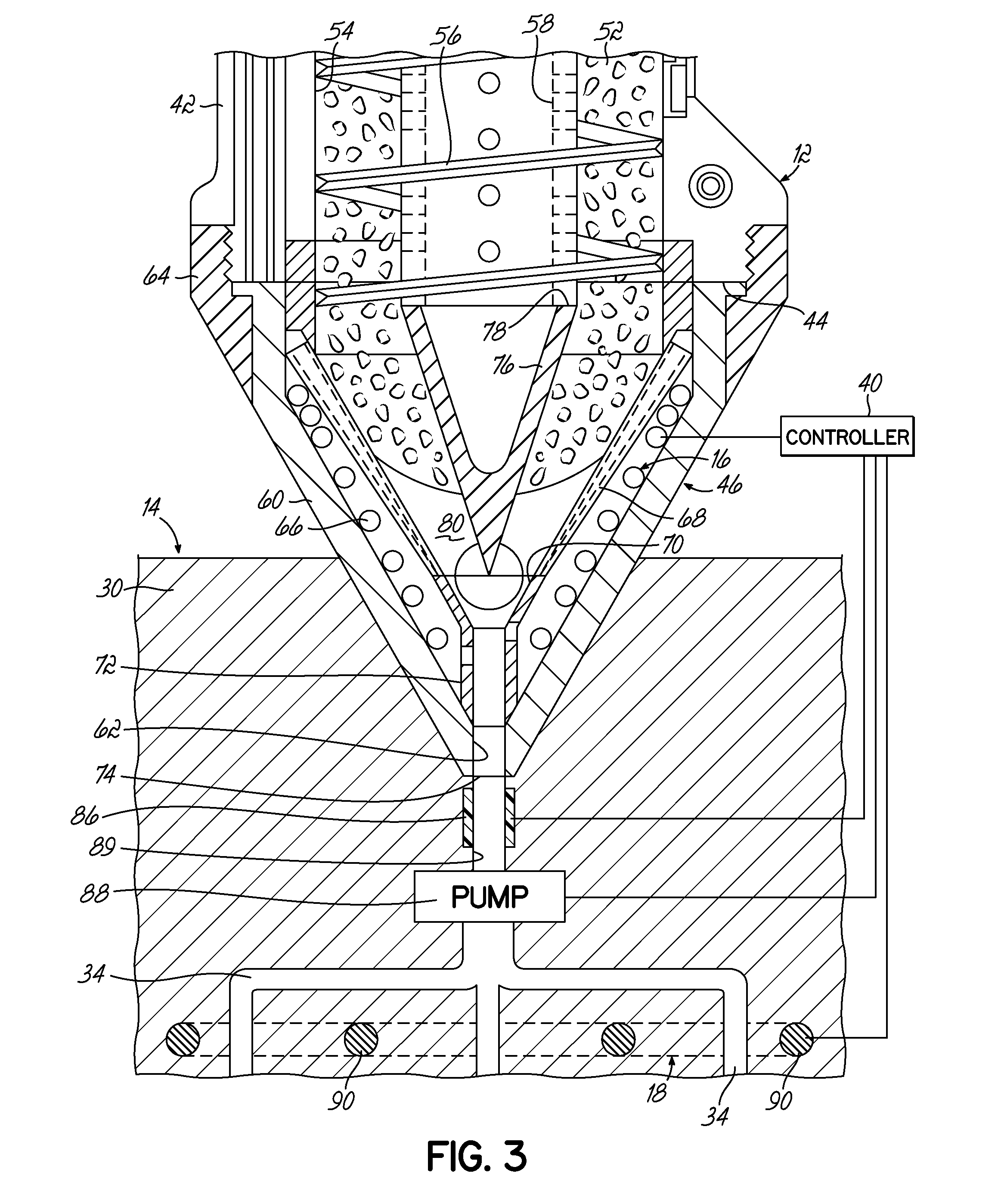

Adhesive dispensing system and method with melt on demand at point of dispensing

ActiveUS20140117049A1Rapidly melts the adhesiveAvoid problemsLiquid surface applicatorsLiquid transferring devicesAdhesiveLiquid state

An adhesive dispensing system and method are configured to melt adhesive on demand and maintain the adhesive in a liquid state between dispensing cycles. The dispensing system includes a dispensing applicator with a manifold passage, a receiving device including a receiving chamber for holding a small amount of solid adhesive at the dispensing applicator and a first heating device for melting the adhesive on demand, and a second heating device at the manifold to maintain the temperature of the melted adhesive before dispensing. The receiving device is positioned adjacent to or partially nested within a manifold of the dispensing applicator such that the melted adhesive is delivered directly into the dispensing applicator. The second heating device applies heat energy to maintain the adhesive in the manifold passage as a liquid.

Owner:NORDSON CORP

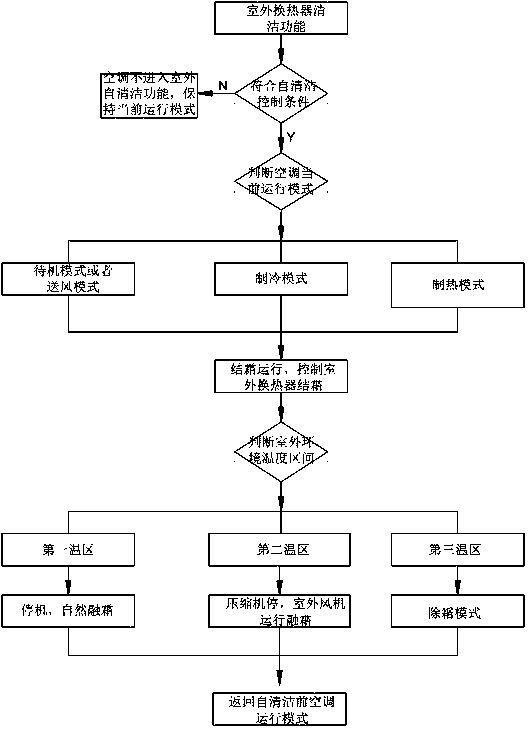

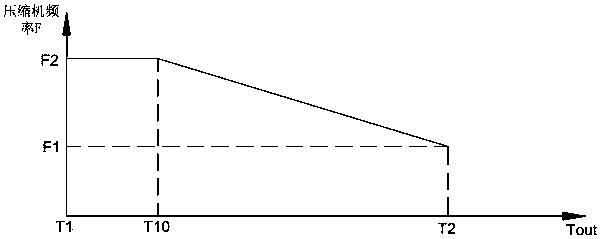

Self-cleaning control method of outdoor heat exchanger of variable-frequency air conditioner and air conditioner

InactiveCN109114745AFast knotMelting fastMechanical apparatusSpace heating and ventilation safety systemsFrostEngineering

The invention discloses a self-cleaning control method of an outdoor heat exchanger of a variable-frequency air conditioner and the air conditioner. The method comprises the following steps that (1),the current outdoor environment temperature T-out is detected, moreover, whether the current outdoor environment temperature meets the condition of entering the self-cleaning control of the outdoor heat exchanger or not is judged, if yes, the step (2) is executed, otherwise, the self-cleaning control of the outdoor heat exchanger is not executed; (2), the outdoor heat exchanger is controlled for frosting; (3), frost formed by the outdoor heat exchanger is melted, and self-cleaning control is completed. According to the self-cleaning control method of the outdoor heat exchanger of the variable-frequency air conditioner, a large amount of low-density frost is formed quickly in a short time through the outdoor heat exchanger, then the frost is quickly melted, and then dust attached to the outdoor heat exchanger is washed away.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

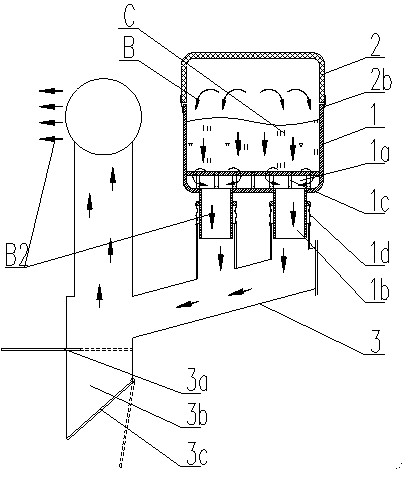

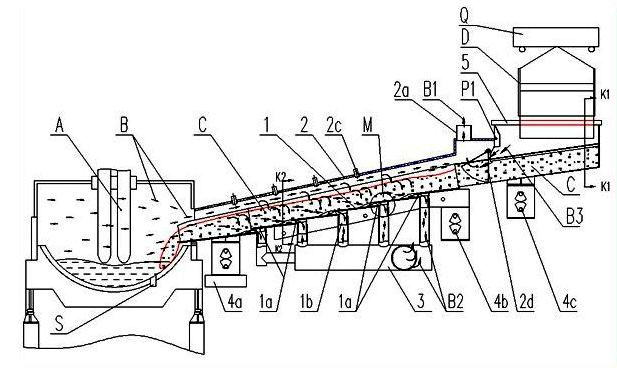

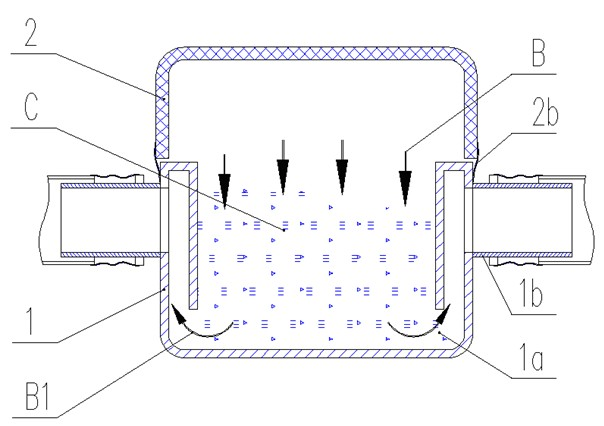

Scrap steel pre-heating conveyor with short process

InactiveCN101907401AExtend your lifeReduce wearCharge manipulationPreheating chargesNew energyEngineering

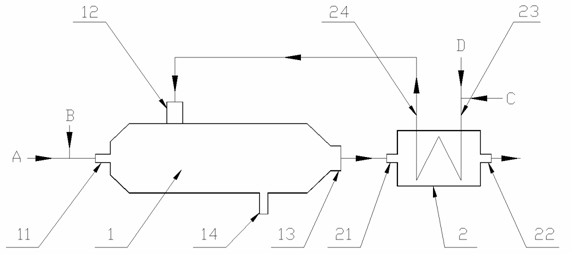

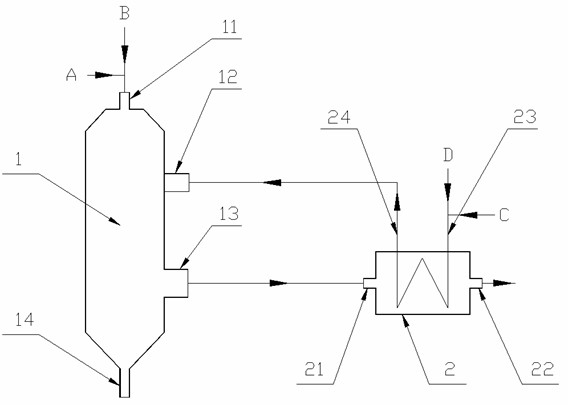

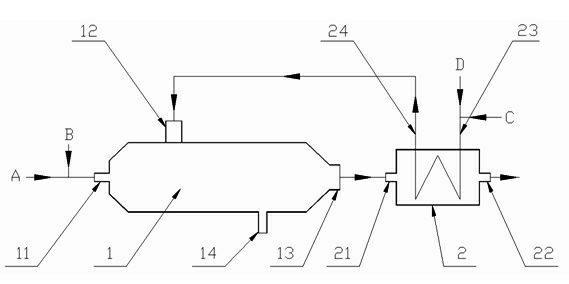

The invention discloses a scrap steel pre-heating conveyor with a short process, comprising a conveying trough (1) which is provided with a fume guiding hood (2) and is inclined relative to the horizontal plane. The lower end of the conveying trough (1) extends into an electric furnace (A) via an opening on the sidewall of the electric furnace (A); a bottom-opened long distributing trough (D) is arranged above the other end of the conveying trough (1), is arranged above a material receiving section of the conveying trough (1) by a swing device (Q), and is arranged in the downward projection of the material receiving section of the conveying trough (1) longitudinally; and scrap steels (C) are longitudinally arranged at the bottom of the material receiving section of the conveying trough (1) in a strip shape, and then the conveying trough (1) conveys the scrap steels (C) into the electric furnace (A). The scrap steel pre-heating conveyor with a short process is short, has high heat exchange efficiency, low operation rate of a crane, small abrasion, less maintenance, energy conservation, environment protection and reduces investment and operation cost, thus the invention is a new energy-saving and environment-friendly technology with promotional value in smelting technique, such as electric furnaces and the like.

Owner:CISDI ENG CO LTD

Total-converting steelmaking method of electric furnace

ActiveCN102534112AReduce noise and radiation pollutionReduce smelting costProcess efficiency improvementElectric furnaceDeoxidizationScrap

The invention discloses a total-converting steelmaking method of an electric furnace. The method achieves the purposes of energy saving and consumption reducing through the working procedures containing adjustment for ratio of raw materials and strict control for the converting process. The method specifically comprises the following steps of: controlling the proportion of molten iron to be 71-79 percent; adding steel scraps through a furnace mouth for one time, and adding the molten iron through an iron exchanging mouth for two times; preheating, warming and decarburizing the steel scraps and molten steel in a furnace through a nozzle of an oxygen-burning system 3 installed on a furnace wall; during converting, regulating a corresponding gear according to demands, meanwhile converting with a furnace door oxygen gun, and making the converting efficiency to be maximized; adding slag making materials such as lime into the electric furnace to make slag; and when the molten steel achieves the temperature and components needed by steel grades, carrying out ladle deoxidization for steel tapping. Compared with the general steelmaking method of the electric furnace, the total-converting steelmaking method of the electric furnace has the advantages that electrode heating is cancelled, the consumptions of the electric energy, electrode and steel scrap are greatly reduced, the smelting cost per ton of steel is greatly reduced, the pollution is decreased, meanwhile the contents of harmful elements in the steel are reduced, and the product quality is increased.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Low-melting-point resin material for three-dimensional printer and manufacturing method of low-melting-point resin material

ActiveCN104693637AProne to cloggingLarge specific surface areaAdditive manufacturing apparatusAcrylic resinFumed silica

The invention provides a low-melting-point resin material for a three-dimensional printer. The material comprises the following components in percentage by weight: 30-60% of styrene-acrylic resin, 10-50% of first polyester resin, 0-10% of second polyester resin, 1-15% of additives, 0.5-6% of wax, and 0.1-2% of fumed silica, wherein the glass transition temperature Tg of the styrene-acrylic resin is 55-65 DEG C and the softening point temperature T1 / 2 is 120-130 DEG C; the glass transition temperature Tg of the first polyester resin is 43-48 DEG C and the softening point temperature T1 / 2 is 80-85 DEG C; the glass transition temperature Tg of the second polyester resin is 45-65 DEG C and the softening point temperature T1 / 2 is 80-110 DEG C. By adopting the scheme, the glass transition temperature Tg of the low-melting-point resin material for the three-dimensional printer is 48-65 DEG C and the softening point temperature T1 / 2 is 85-110 DEG C. Therefore, the melting temperature of an FDM three-dimensional printer material is remarkably reduced, and the scald risk of an operator is correspondingly reduced while the energy consumption is reduced.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Cyclone melting device and method for fly ash preheating

InactiveCN102620299AImprove leaching rateLow melting slag collection rateIncinerator apparatusThermodynamicsLiquid slag

The invention discloses a cyclone melting device and a cyclone melting method for fly ash preheating, particularly relates to a device and a method for fly ash melting treatment. The device comprises a cyclone furnace and a fly ash preheater, wherein a smoke outlet of the cyclone furnace is connected with a hot smoke inlet of the fly ash preheater, and a working medium outlet of the fly ash preheater is communicated with a secondary air tangential inlet of the cyclone furnace. The method comprises the steps as follows: mixing the primary air with coal powders; spraying into the front end of the cyclone furnace from a primary air inlet of the cyclone furnace; carrying fly ashes into the fly ash preheater through the secondary air for the combustion of the coal powders through adopting the pneumatic transmission technology, enabling high-temperature smoke generated by combustion in the cyclone furnace to enter the fly ash preheater for heating the secondary air and the fly ashes, enabling the fly ashes after heated through the high-temperature smoke to enter the cyclone furnace, quickly heating the fly ashes to reach the fly ash melting temperature, rotating the secondary air in the cyclone furnace at a high speed, throwing the fly ashes to the wall surface of the cyclone surface under the action of a centrifugal force, quickly melting the fly ashes through the high-temperature wall surface, and discharging the molten fly ashes in the form of liquid slags from a liquid deslagging hole at the bottom of the cyclone furnace.

Owner:NANJING XINYE ENERGY TECH

Antenna radiation body made of low-melting-point metal or metal alloy, and manufacturing method

InactiveCN102570024AGood chemical resistanceReduce the impactRadiating elements structural formsMetal alloyInjection moulding

The invention relates to the field of wireless communication technology, in particular to an antenna radiation body made of low-melting-point metal or metal alloy, and a manufacturing method therefor. The manufacturing method for the antenna radiation body made of low-melting-point metal or metal alloy comprises the following steps: (1), a plastic bracket is formed through injection moulding, and a plurality of grooves are formed on the plastic bracket; and (2), molten low-melting-point metal or metal alloy is injected into the grooves of the plastic bracket, and after solidification, the antenna radiation body is made. Compared with the prior art, the manufacture method for the antenna radiation body made of low-melting-point metal or metal alloy material has the advantages that deformation and melting to the plastic bracket can not be caused, and a thinner antenna radiation body can be manufactured; and meanwhile, the electric conductivity is excellent, and the performance of the antenna is improved.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

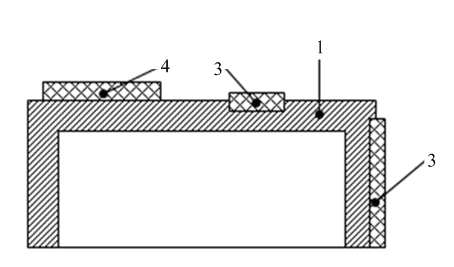

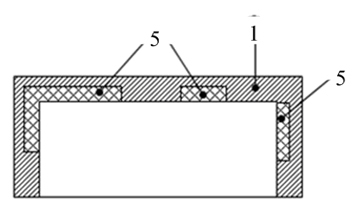

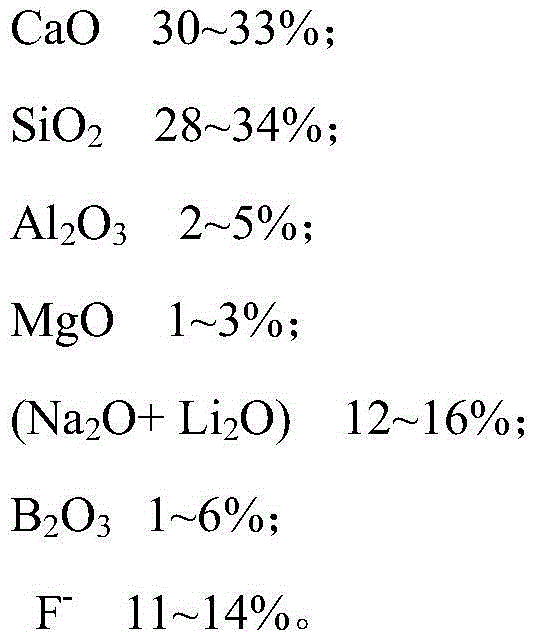

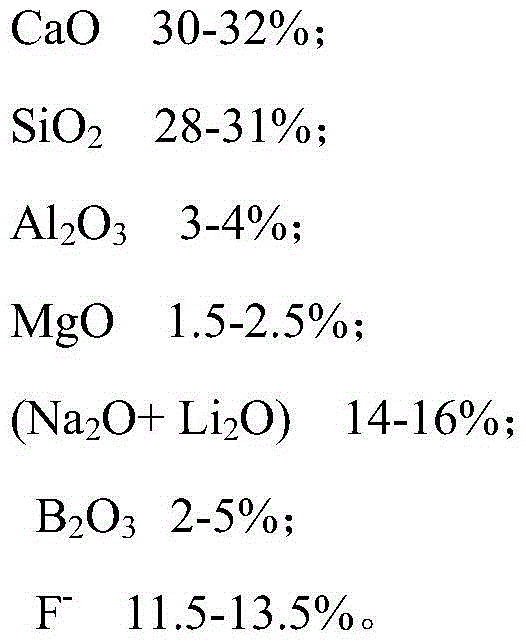

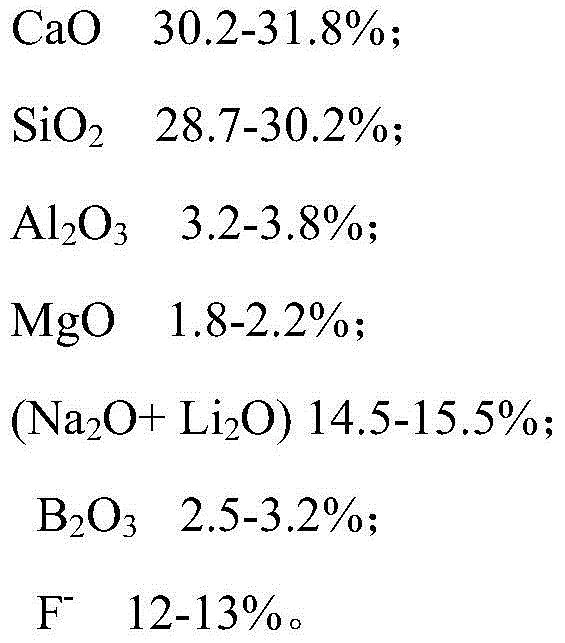

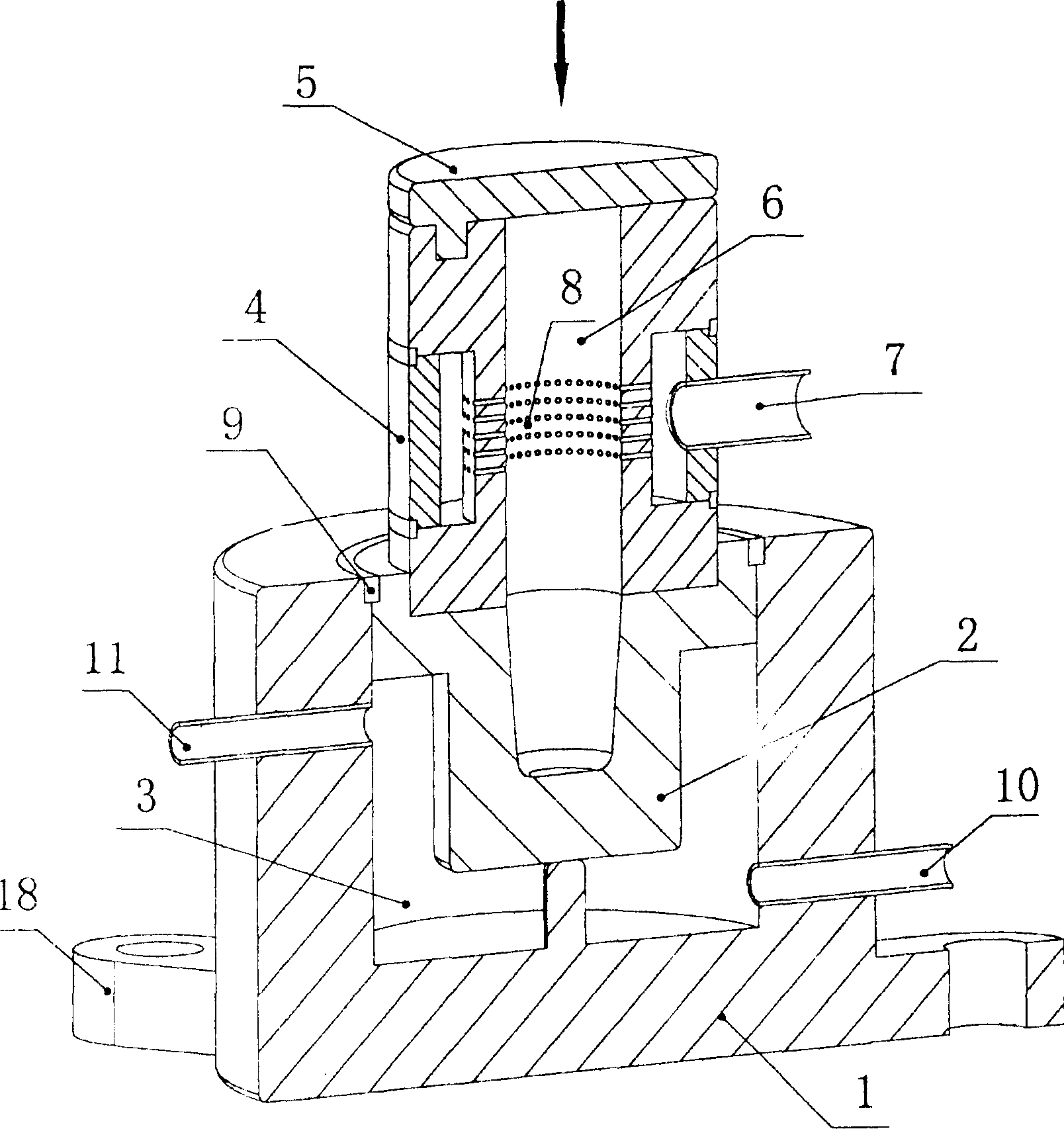

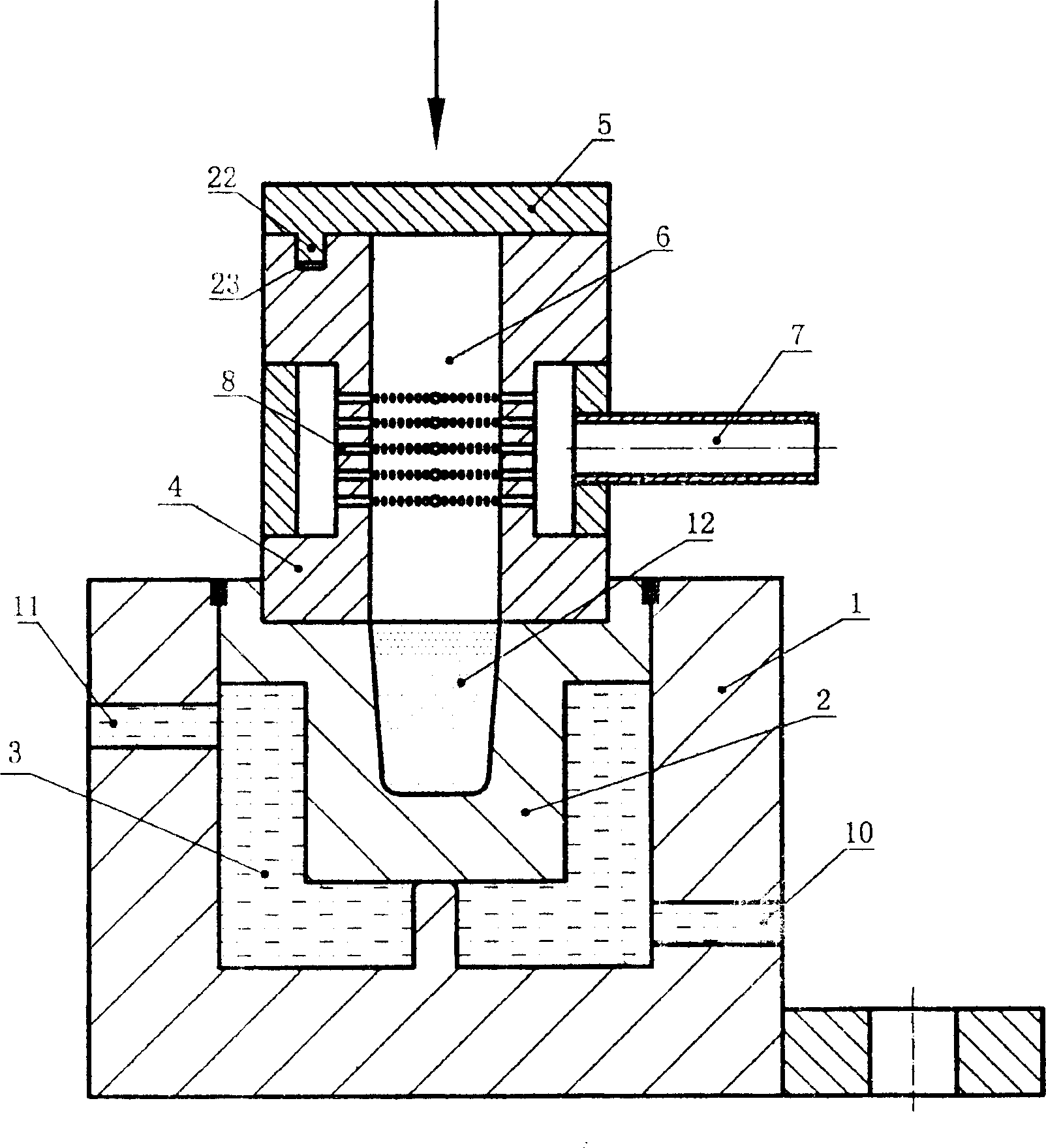

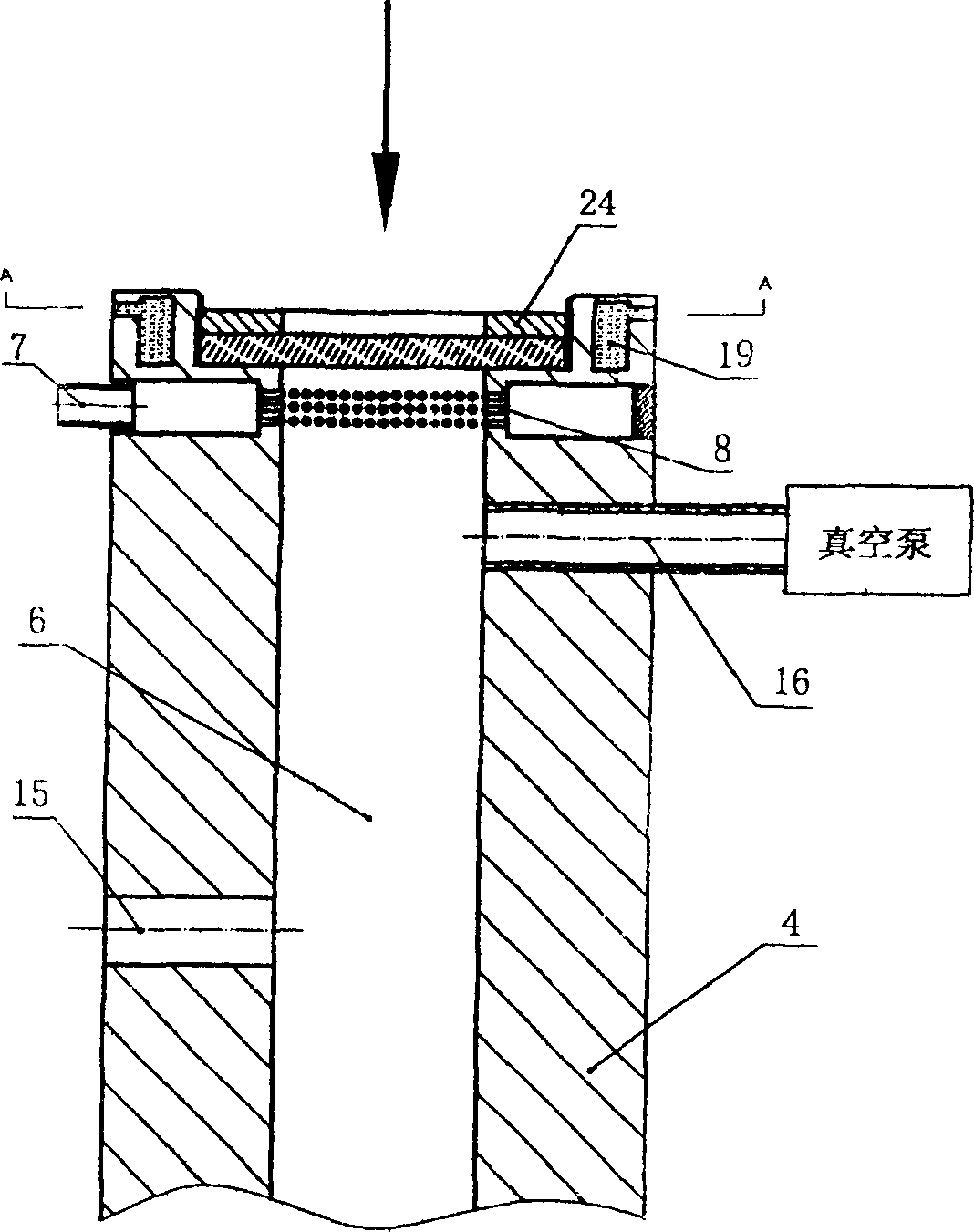

Novel casting powder and application thereof

The invention relates to novel casting powder and application thereof, and belongs to the technical field of steel continuous casting powder. The casting powder comprises the following components according to mass percentage, 30-33% of CaO, 28-34% of SiO2, 2-5% of Al2O3, 1-3% of MgO, 12-16% of (Na2O+Li2O), 1-6% of B2O3, and 11-14% of F-. The casting powder has the characteristics of low melting point (950 to 1,050 DEG C), low viscosity (the viscosity is 0.06 to 0.10Pa.s at the temperature of 1,300 DEG C), high crystallization temperature (1,215 to 1,302 DEG C) and the like. The casting power designed by the invention is suitable for the continuous casting of high-carbon chromium-containing steel of which the mass percentage of C is 1.3-1.8% and the mass percentage of Cr is 10-15%. When the casting powder is applied to the continuous casting production of a high-carbon chromium-containing steel slab, Cr2O3 and other impurities with a high melting point in a crystallizer can be effectively absorbed, the infiltration capability of the casting powder is improved, and the slow cooling of a meniscus is implemented, so that the objectives of increasing the lubricating of a casting blank, controlling the heat transferring at the meniscus, reducing the cracking and inclusion of the casting blank and improving the quality of the casting blank are achieved.

Owner:CENT SOUTH UNIV

Laser smelting furnace with water cooled copper mould and method for smelting ingot

Owner:BEIHANG UNIV

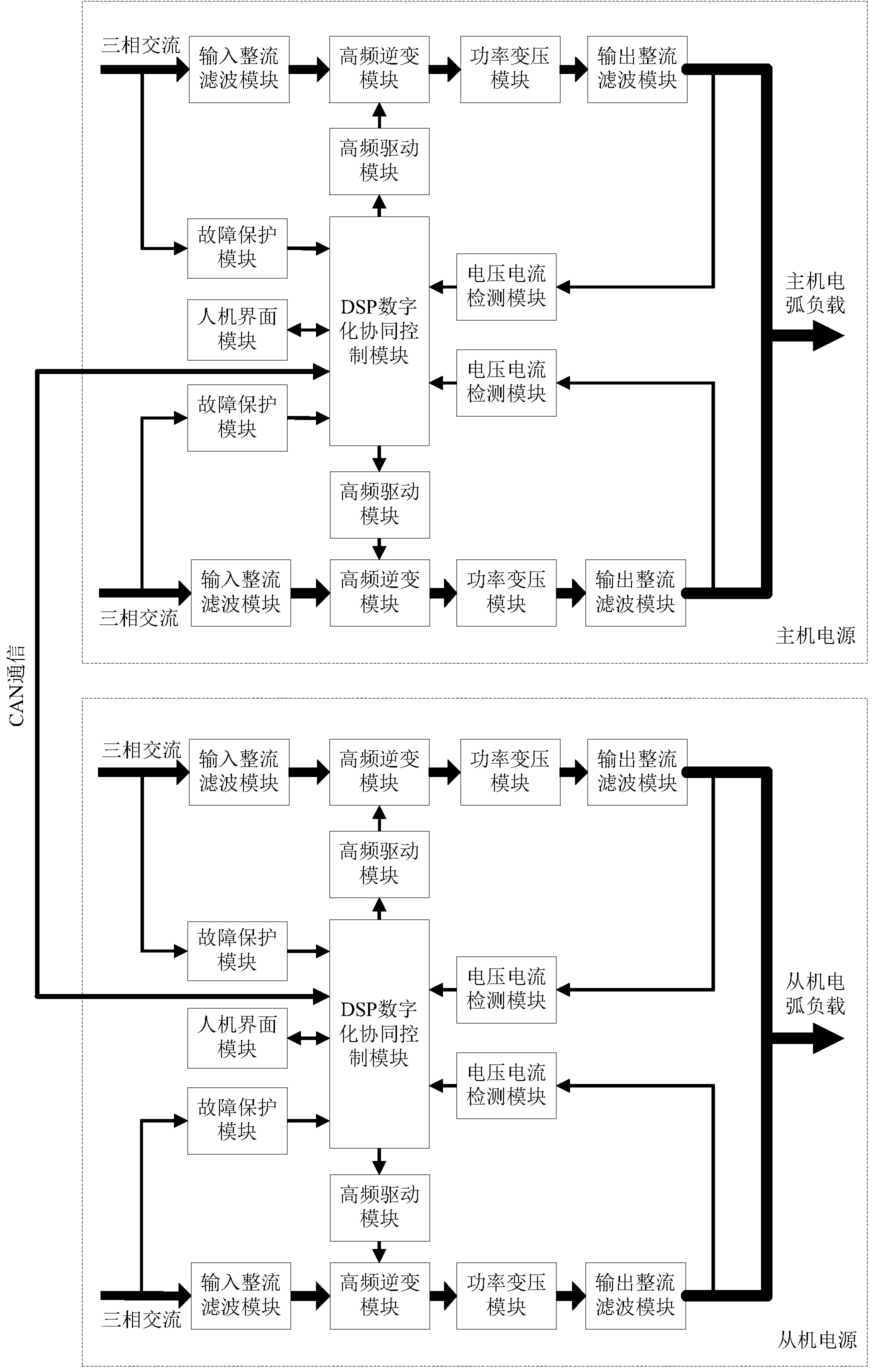

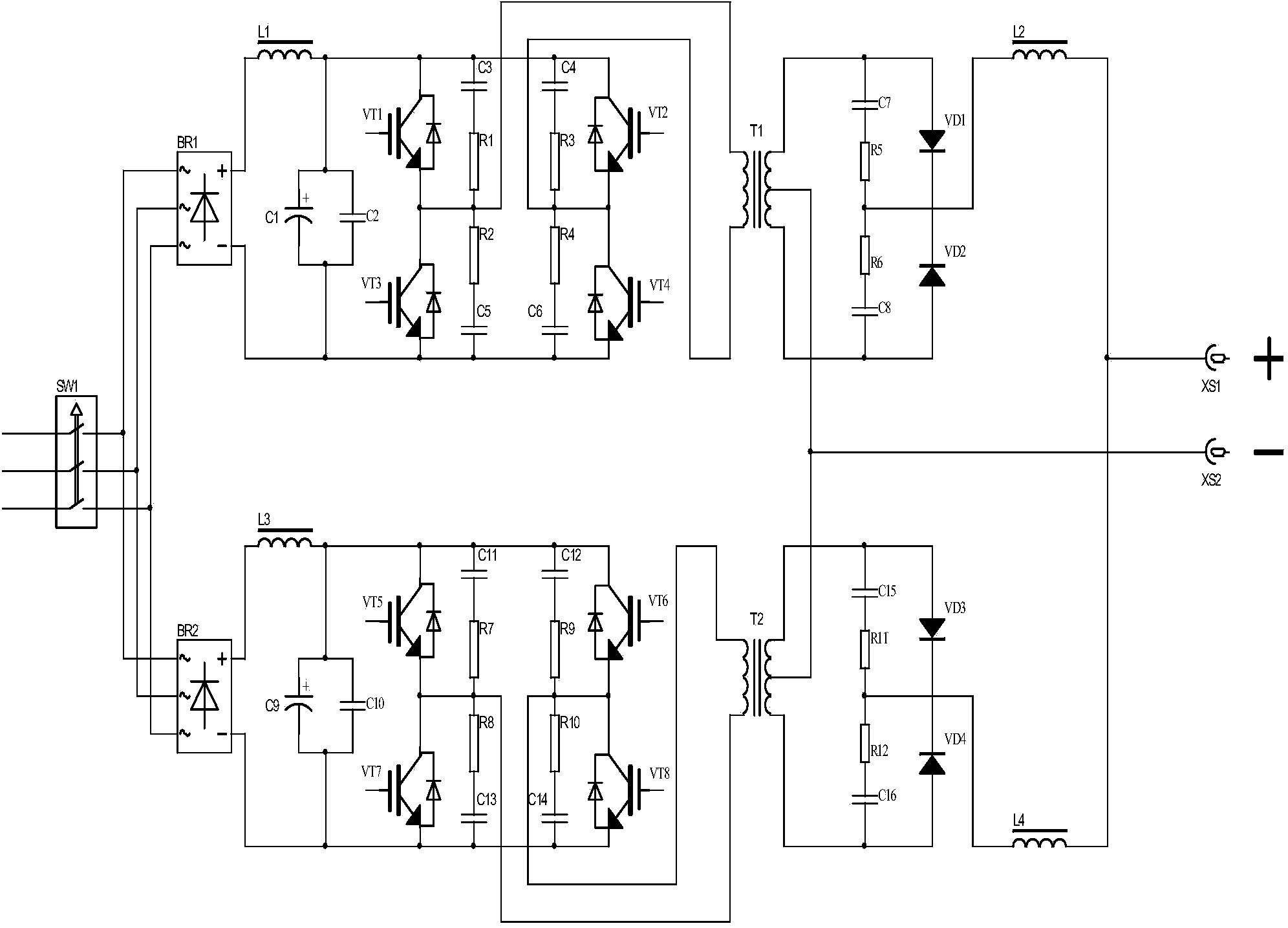

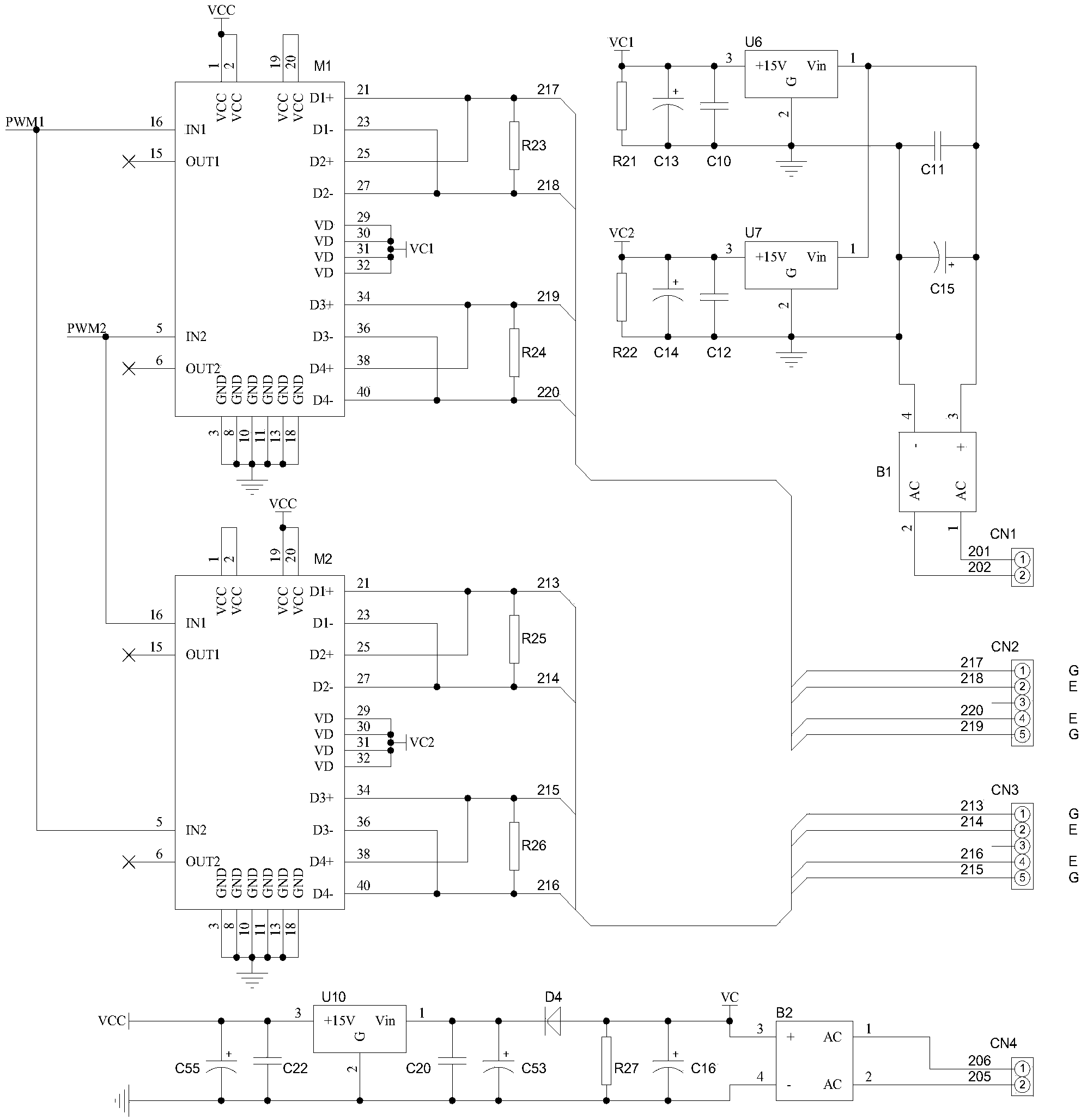

High-power two-wire pulse MIG inverter power supply system and digital cooperative control method thereof

InactiveCN103480945ALarge output currentThe output current is consistentArc welding apparatusHuman–machine interfaceFull bridge

The invention discloses a high-power two-wire pulse MIG inverter power supply system and a digital cooperative control method thereof. The system comprises a host power supply and a slave power supply which are connected through a CAN bus, each of the host power supply and a slave power supply comprises a main circuit and a control circuit, each main circuit is formed by parallel connection of two or more full bridge inverters and comprises an input rectifying and filtering module, a high frequency inverting module, a power transformation module and an output rectifying and filtering module, each input rectifying and filtering module is connected with a three-phase alternating current input power grid, each output rectifying and filtering module is connected with an electric arc load, and each control circuit comprises a voltage and current detection module, a fault protection module, a DSP digital cooperative control module, a human-machine interface module and a high frequency driving module. The output power, the welding speed and the fusion covering efficiency of welding wires are doubly improved by adopting the main circuits formed by parallel connection of the full bridge inverters and in combination with the DSP digital cooperative control technology.

Owner:SOUTH CHINA UNIV OF TECH

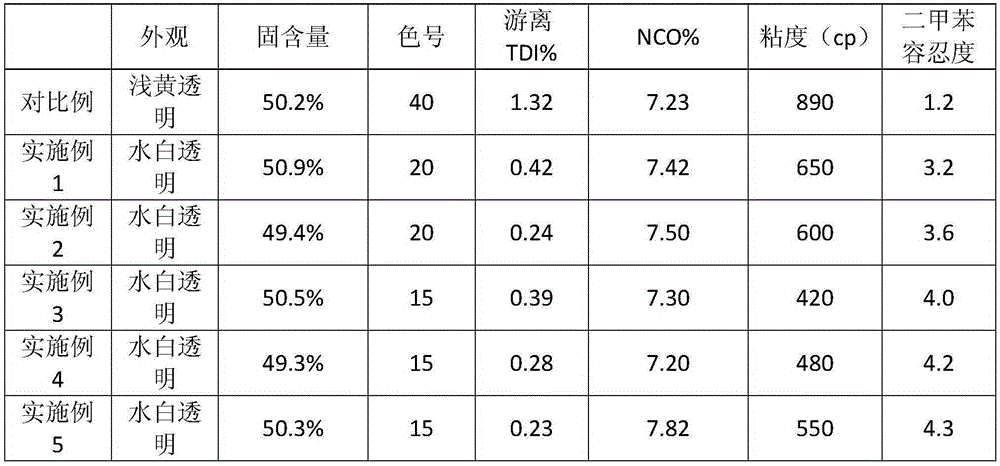

Low-free high-compatibility toluene diisocyanate trimer curing agent and preparation method thereof

ActiveCN105315433AFacilitated DiffusionReduce contentPolyurea/polyurethane coatingsToluene diisocyanateAntioxidant

The invention discloses a low-free high-compatibility toluene diisocyanate trimer curing agent and a preparation method thereof. The preparation method comprises the following steps: under nitrogen protection, putting a toluene diisocyanate monomer, a solvent and an antioxidant into a reaction vessel; controlling the reaction temperature to be 10-50 DEG C at an earlier stage; adding a catalyst in batches when NCO% is 12-14wt% and 10-11wt% and reaction is started; when NCO is 9.3-10wt%, adding the residual catalyst and controlling the temperature to be 50-100 DEG C; when NCO% is 8.0-9.3wt%, adding a polymerization inhibitor, reacting for 0.5-1 h, adding a component A, reacting for 2-4 h, adding a component B, reacting for 1-2 h, stopping reaction, cooling to room temperature and discharging materials so as to obtain the toluene diisocyanate trimer curing agent with free TDI less than 0.5%, xylene tolerance larger than 3, light color, quick drying and stable performance finally.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com