Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101 results about "Cyclone furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cyclone furnace is a type of coal combustor commonly used in large industrial boilers.

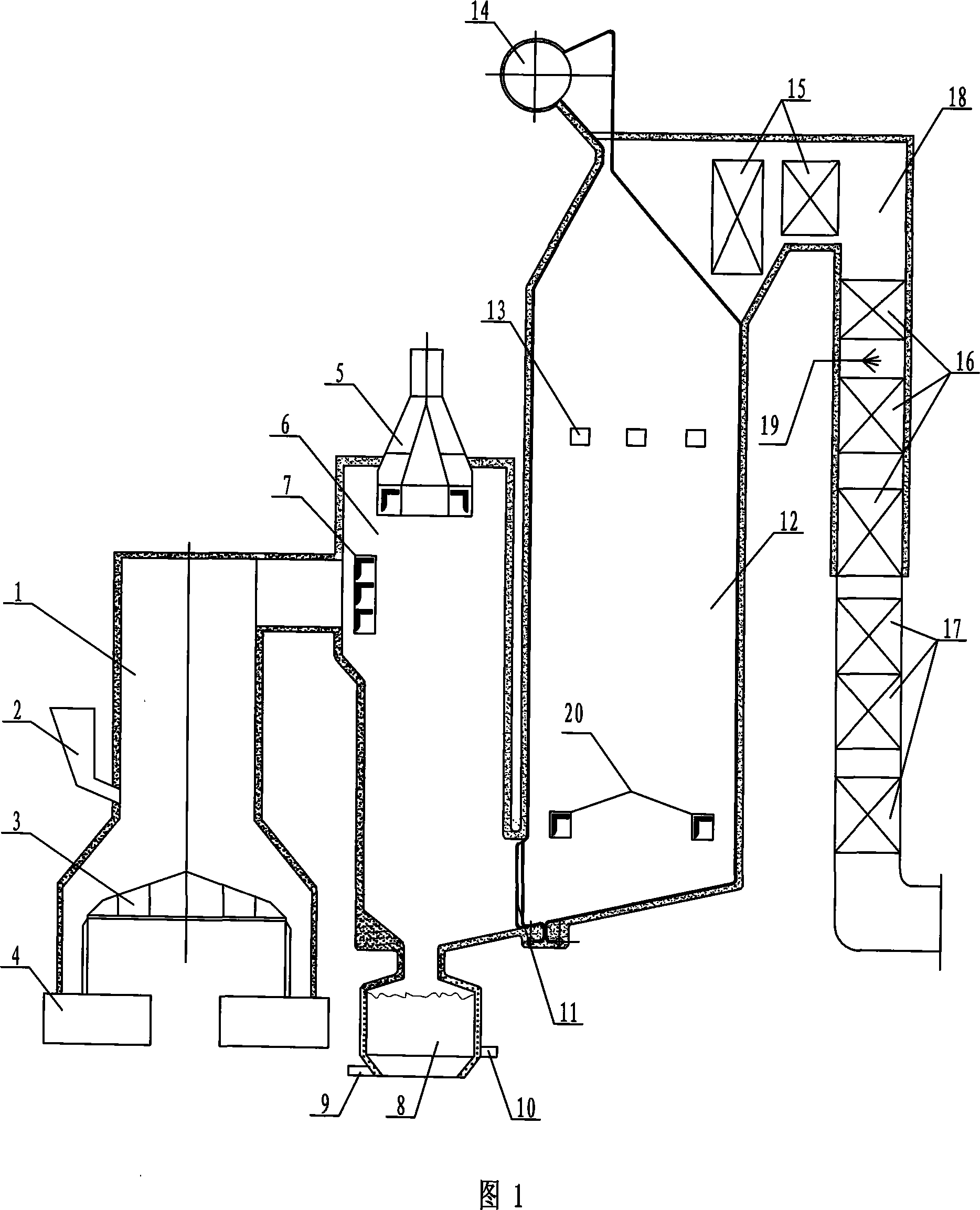

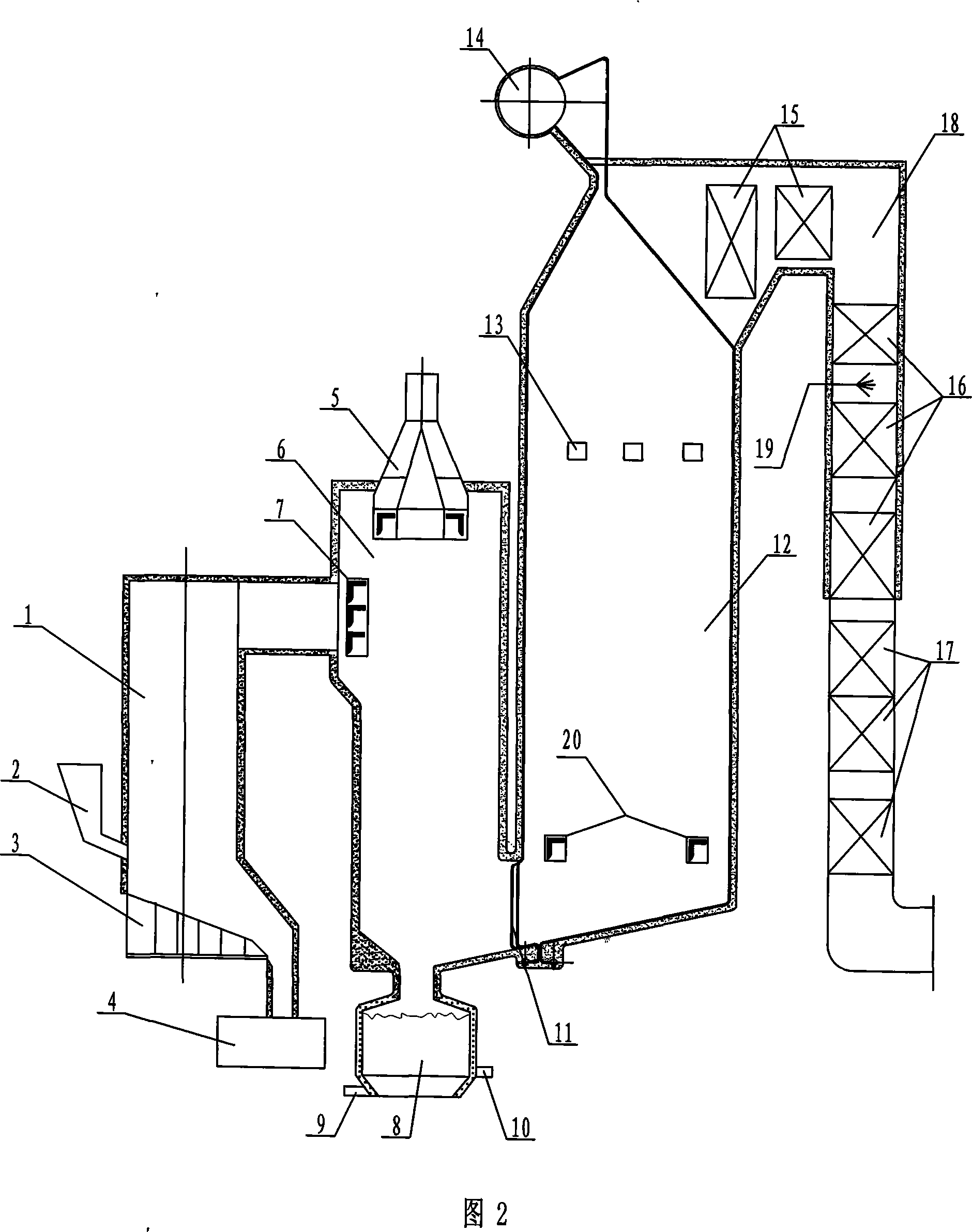

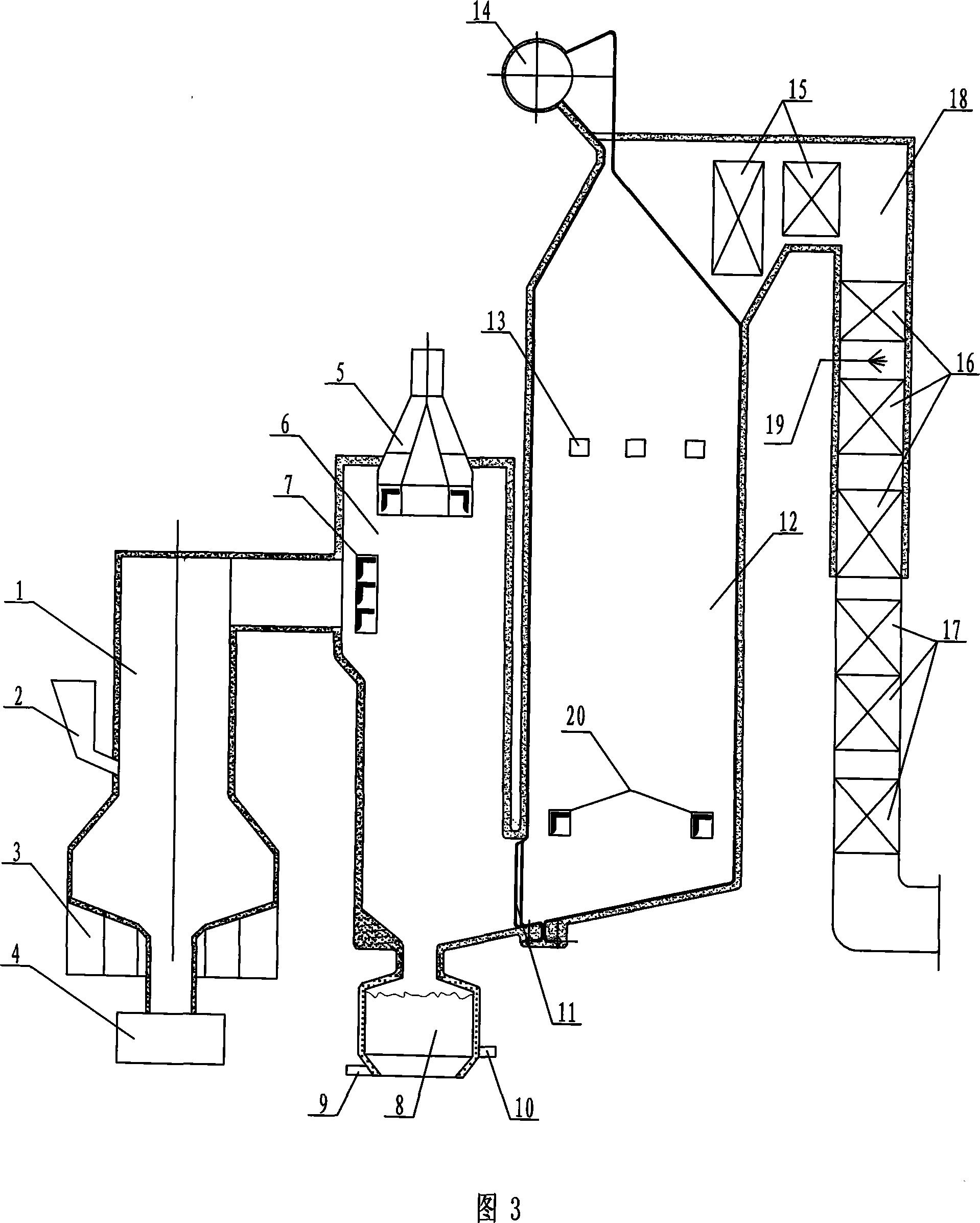

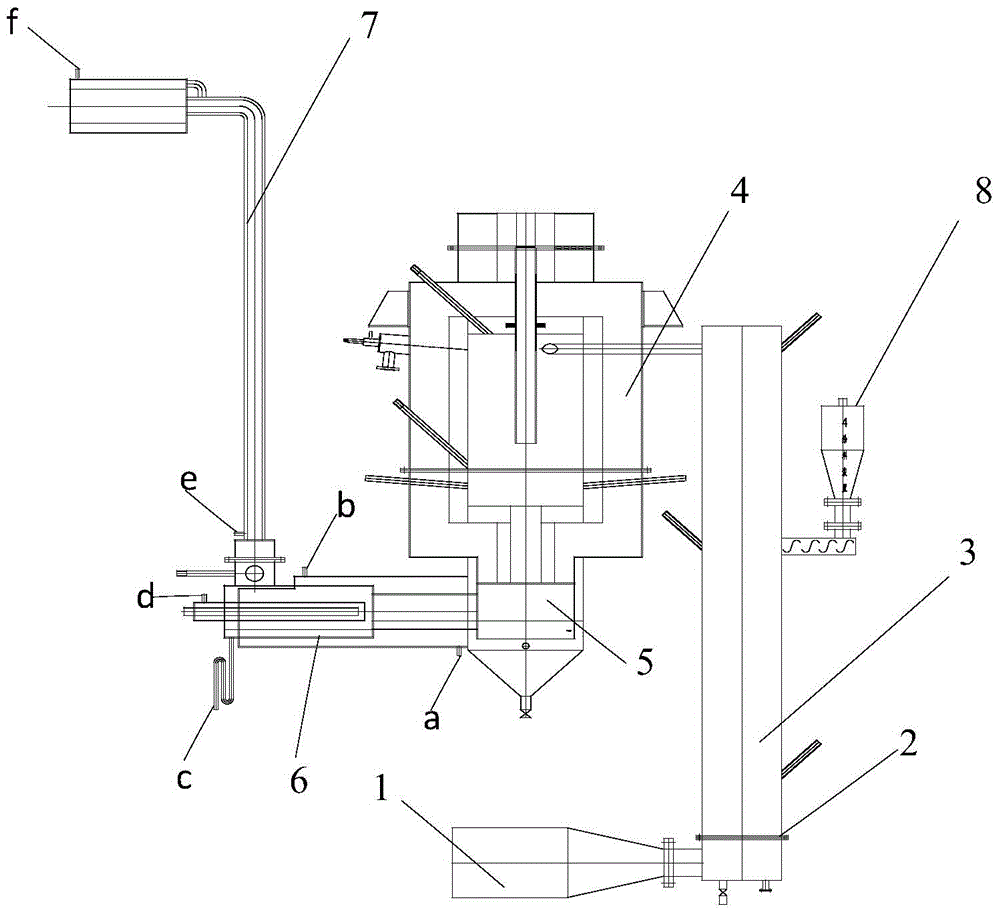

Apparatus and method for gasification of refuse and hyperthermia melt processing of flying ash

ActiveCN101201167AWith waste heat utilizationHigh heat intensity of combustionDamper arrangementIndirect carbon-dioxide mitigationAir preheaterEngineering

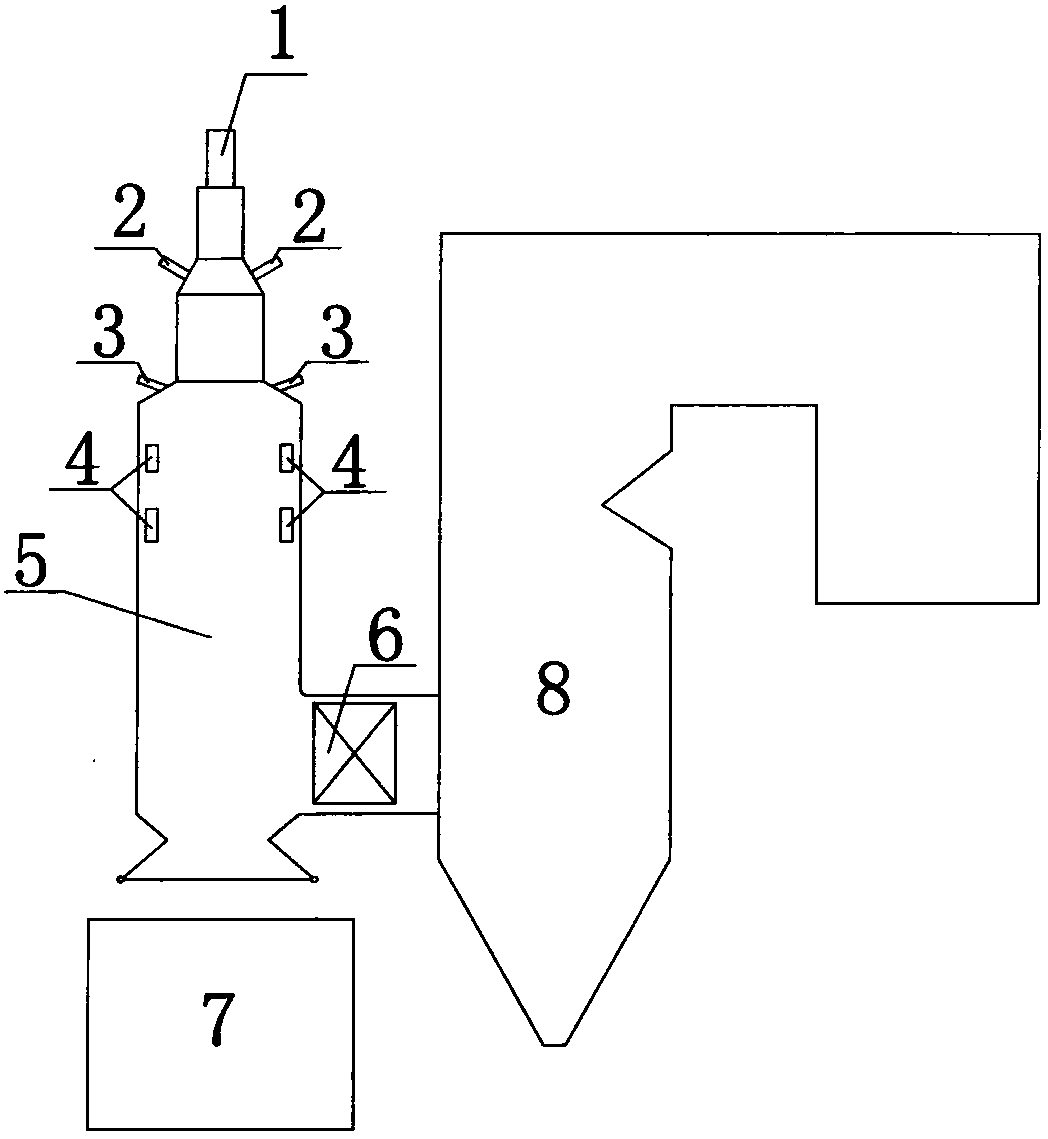

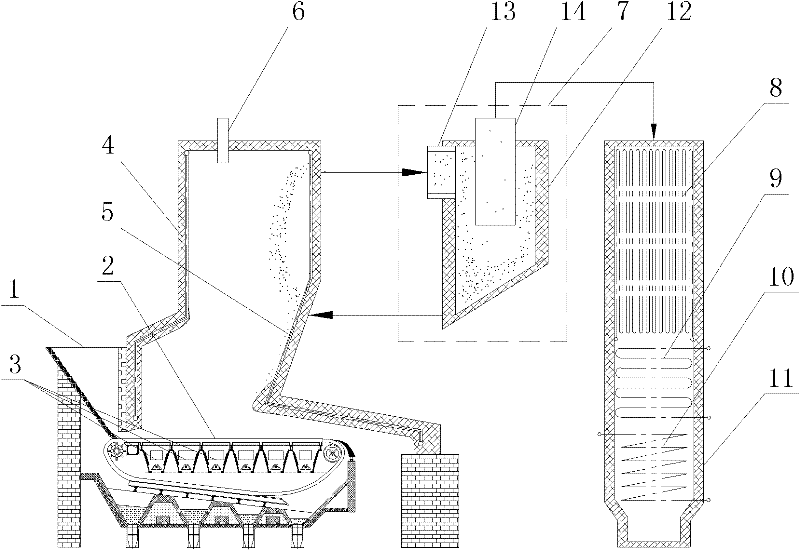

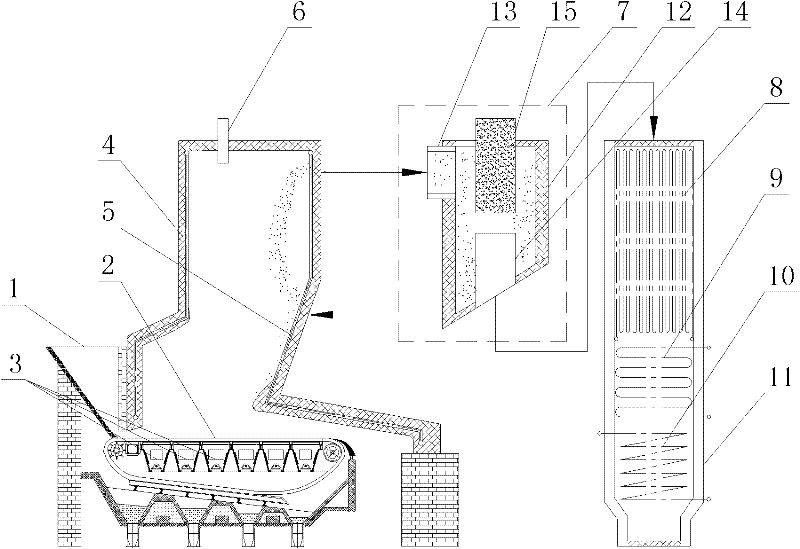

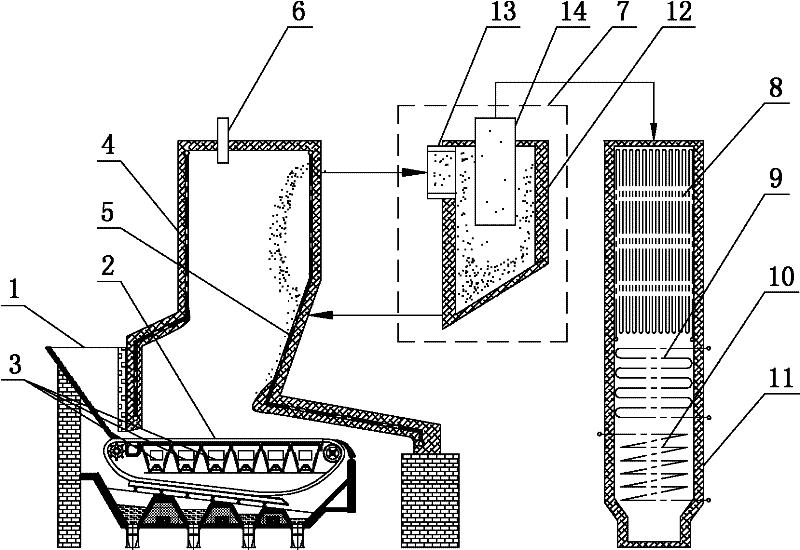

A device and method for garbage gasification and flying ash high temperature melting treatment relates to an integrated technology for garbage gasification and flying ash high temperature melting. The invention aims at solving the problem that the heavy metals and dioxins in the ash collected by a hop-pocket in an incinerator for garbage gasification exceeds the standard limits greatly. The device is formed in the way that a fluidized bed gasifier is communicated with a cyclone furnace; the cyclone furnace is communicated with a burnt chamber and the burnt chamber is communicated with a flue. The method includes that the smoke and gas generated by the gasification of the garbage in the fluidized bed gasifier enters the cyclone furnace and burns with the help of coal powder; the heavy metals in the flying ash are reduced to metals and recycled; the dioxins in the flying ash are decomposed; the exhaust smoke and gas enters a tail gas treatment device after entering the burnt chamber, a superheater, a coal saving device and an air preheater. The invention leads the smoke and gas generated by the gasification and burning of the garbage in the fluidized bed gasifier to enter the cyclone furnace for high temperature melting treatment so as to lead the dioxins in the tail gas collecting ash and in the tail gas to be respectively lower than 50ng-TEQ / kg, 0.1ng-TEQ / m{3}.

Owner:HARBIN INST OF TECH

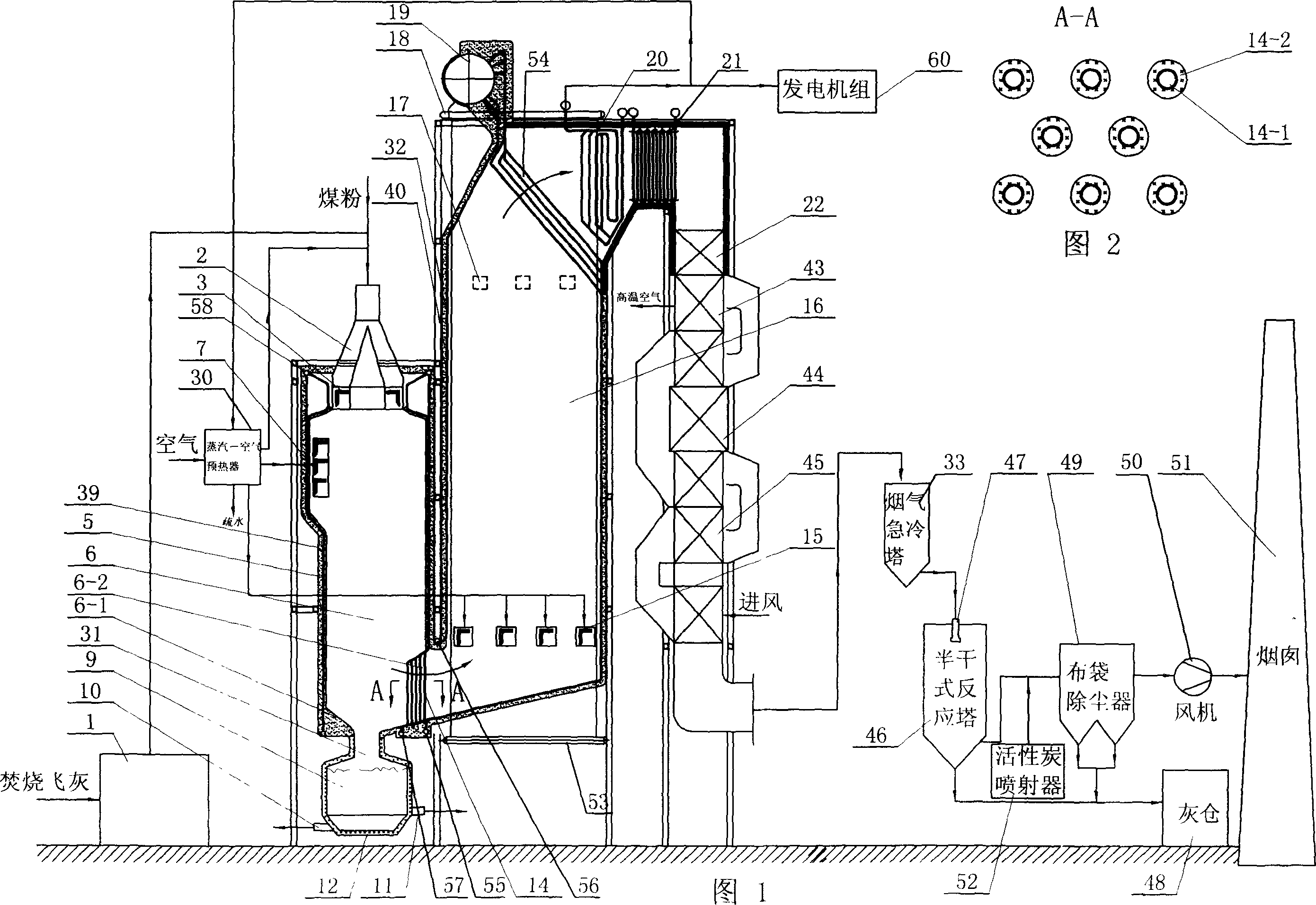

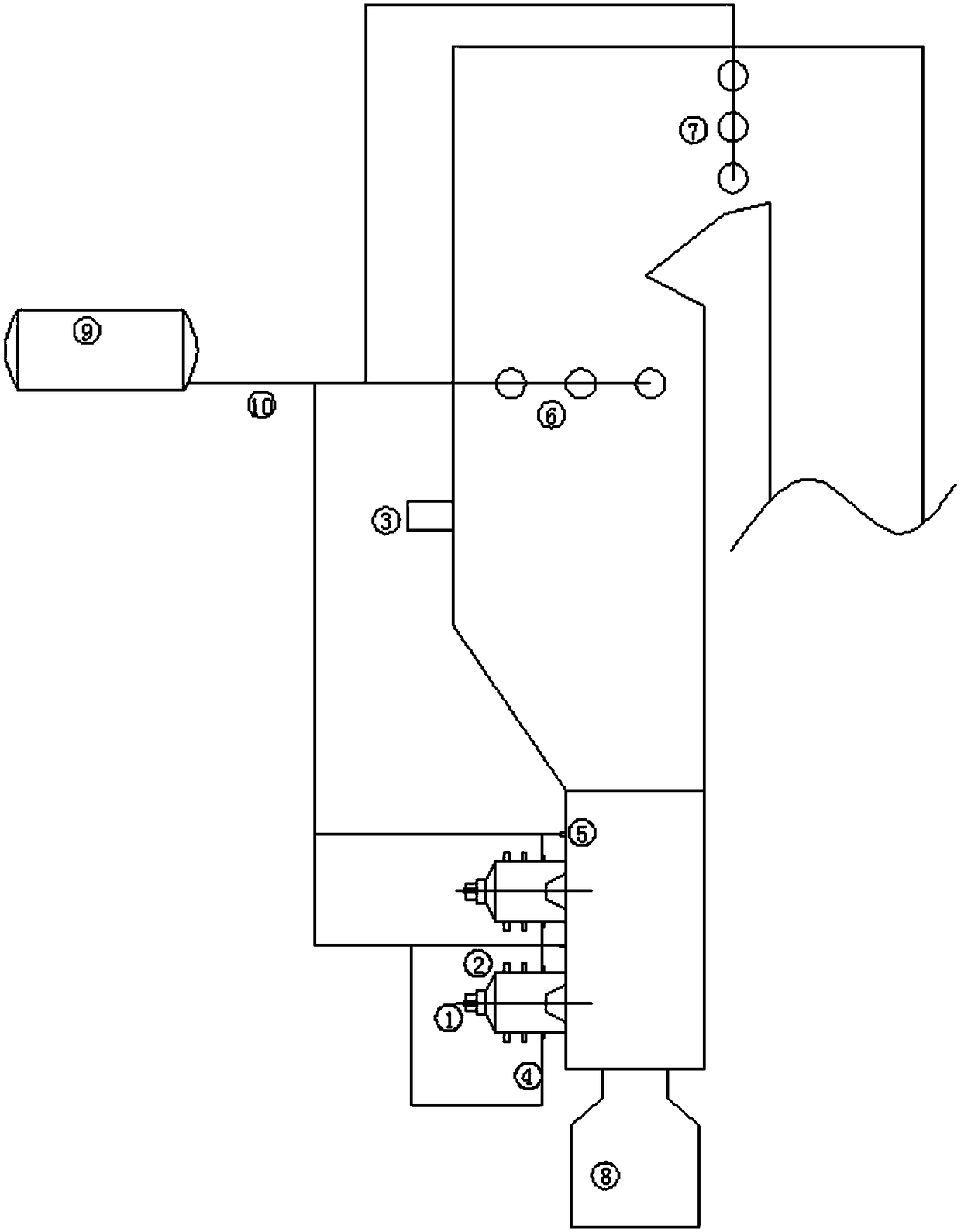

Method of processing refuse burning fly ash through cyclone furnace high temperature melting

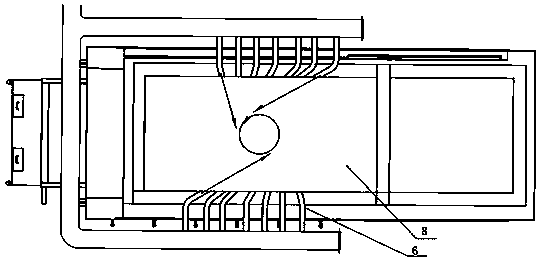

The invention relates to a method for processing fly ash after incineration of domestic waste. The high-temperature melting treatment method of fly ash in a garbage incineration is completed by the following steps: 1. The fly ash produced after garbage incineration is mixed with coal powder at a ratio of 15 to 25: 75-85 mixed in a ratio of 75 to 85 and sent to the cyclone furnace 6 for combustion until high-temperature melting; 2. The combustion in the cyclone furnace 6 is in a reduced state; 3. The heavy metals in the fly ash sink to the bottom of the slag pool 9 and are discharged and recovered , and the slag floating on the liquid metal flows out of the slag pool from the slag recovery outlet 11, and is then rapidly cooled by water as cement raw material or building material recycling. The method can not only recover valuable metals in fly ash, decompose dioxin, recover waste heat to generate electricity, but also recycle molten ash as cement raw material or building material after being quenched with water, and has low operating cost. Or the combustion in the cyclone furnace 6 is in an oxidized state, the air excess coefficient is kept at 1.1 to 1.2, and only the quenched glass body is recovered.

Owner:HARBIN INST OF TECH

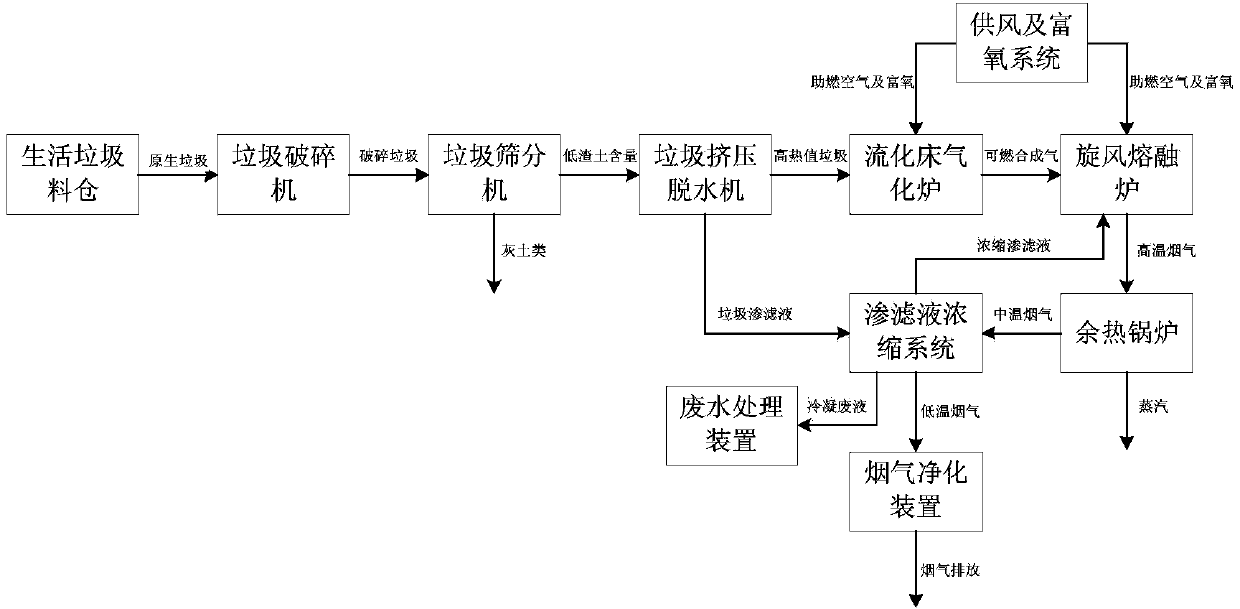

System and method for gasification melting of household refuse and treatment of household refuse leachate

ActiveCN103471105AHigh calorific valueAchieve enrichmentIndirect carbon-dioxide mitigationIncinerator apparatusCrusherTreatment system

The invention provides a system and a method for gasification melting of household refuse and treatment of household refuse leachate. The system comprises a household refuse pretreatment system, a refuse energy recovering system and a refuse leachate concentration and flue gas treatment system, wherein the household refuse pretreatment system comprises a household refuse stock bin, a household refuse crusher, a household refuse sieving machine and a household refuse extrusion dehydrator which are sequentially connected; the refuse energy recovering system comprises a fluidized-bed gasifier, a cyclone melting furnace, a waste heat boiler and an air-supplying and oxygen-enriching system matched with the fluidized-bed gasifier, the cyclone melting furnace and the waste heat boiler; the refuse leachate concentration and flue gas treatment system comprises a leachate concentrating system, a flue gas purifying device and a wastewater treatment device. According to the system, the heat value of the refuge is increased by a pretreatment process; an oxygen-enriching gasifier and a high-temperature cyclone melting furnace technology are used as a recovering system of refuge energy; the refuge leachate is concentrated by using medium-temperature flue gas exhausted by the waste heat boiler; the concentrated leachate is sprayed into the high-temperature cyclone furnace for harmless treatment.

Owner:陕西圣昊朗道科技有限公司

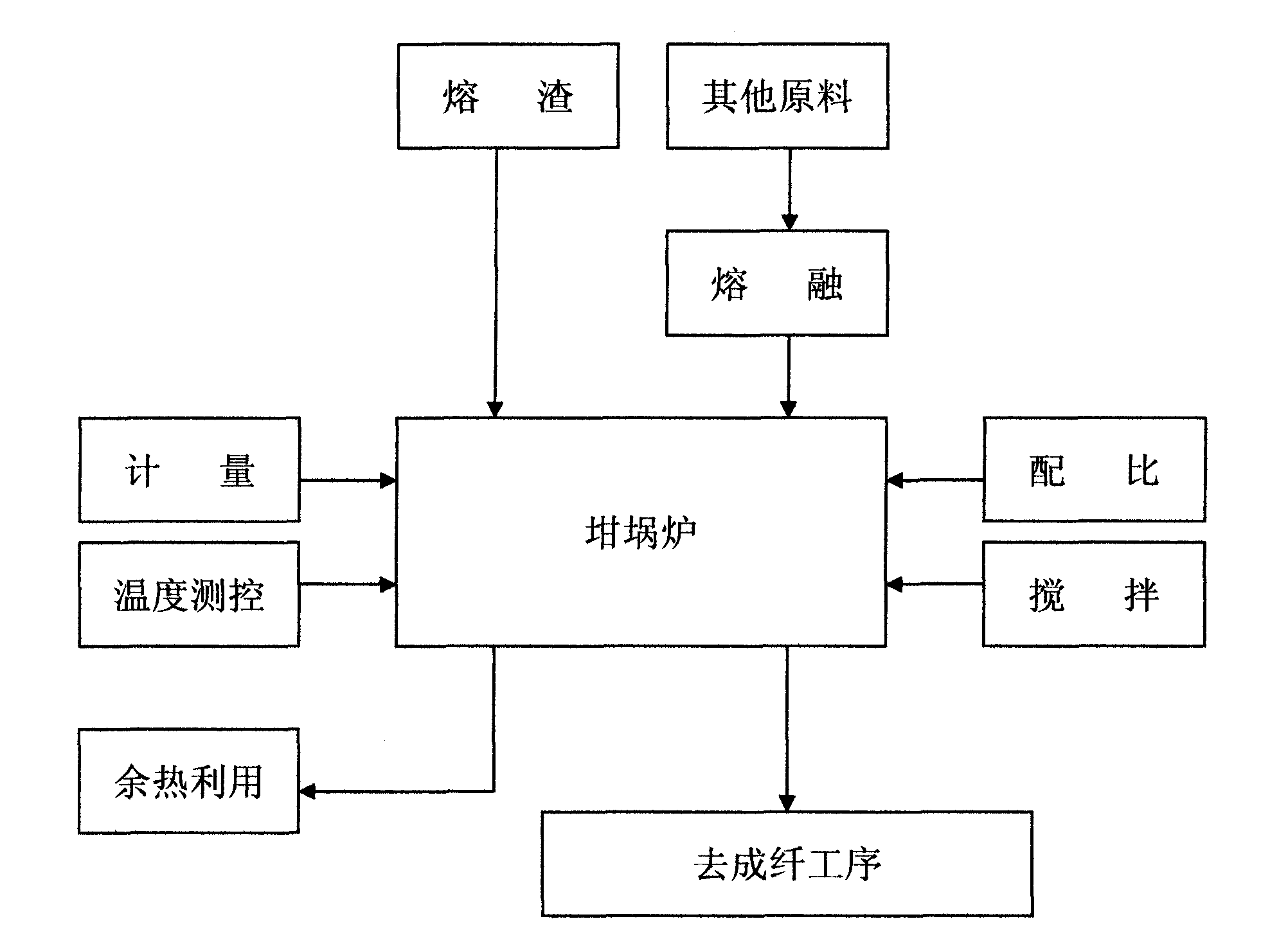

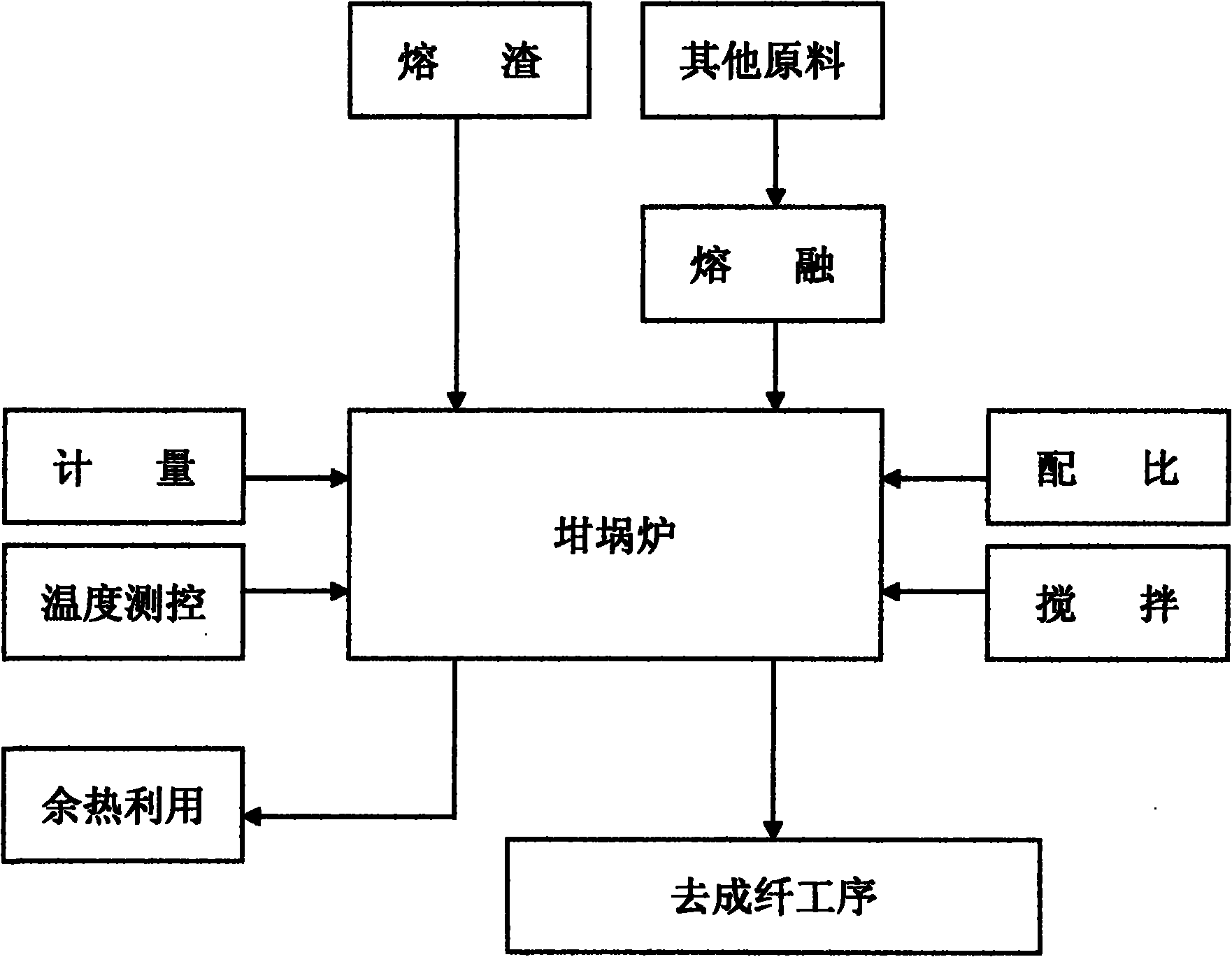

One-stage mineral wool technology high-effectly utilizing industrial furnace smelting slag heat

InactiveCN1418834AObvious fluctuationsSolve the problem of continuous temperature measurementGlass making apparatusQuality levelManganese

The one-step method for producing mineral wool by using industrial furnace molten slag sensible heat includes the following steps: according to the requirement for chemical composition of mineral wool adding proper auxiliary raw material, at the same time, in homogenizing furnace making concurrent heating and regulating its chemical composition temp. and viscosity to make them reach to the requirements of mineral wool molten body, making molten body acidity coefficient be up to 1.1-1.8 (acidity coefficient=SiO2+Al2O3 / CaO+MgO), and the molten body temp. is 1300-1340 deg.C, homogenizing its chemical components, feeding the thermally-refined molten body into high-speed centrifuge and feeding it into fibre-forming procedure of mineral wool so as to obtain the invented product.

Owner:杨铧

Method for extracting germanium from brown coal

The invention provides a process of germanium extraction from brown coal, which is germanium extraction by employing a cyclone furnace. The process includes that the brown coal is added in the cyclone furnace to mix with hot wind which is sent into the cyclone furnace, the brown coal is burned, the CO content inside the cyclone furnace is controlled within the range of 0.5-1%, germanium in the brown coal is reduced and volatilized into flue gas, and flue dust is collected as raw material of the germanium. The process can achieve the purposes that the flour shaped brown coal is fully used to enlarge the productivity of the germanium, the recovery ratio of the germanium is increased, and the excess energy is effectively recovered.

Owner:锡林郭勒通力锗业有限责任公司

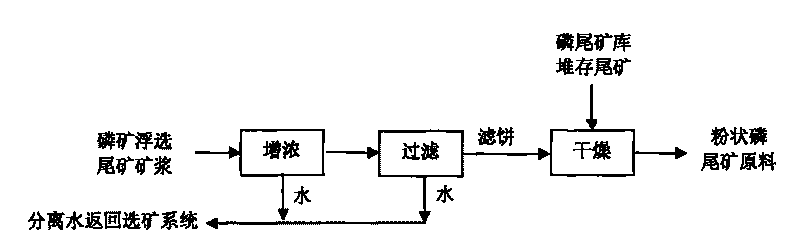

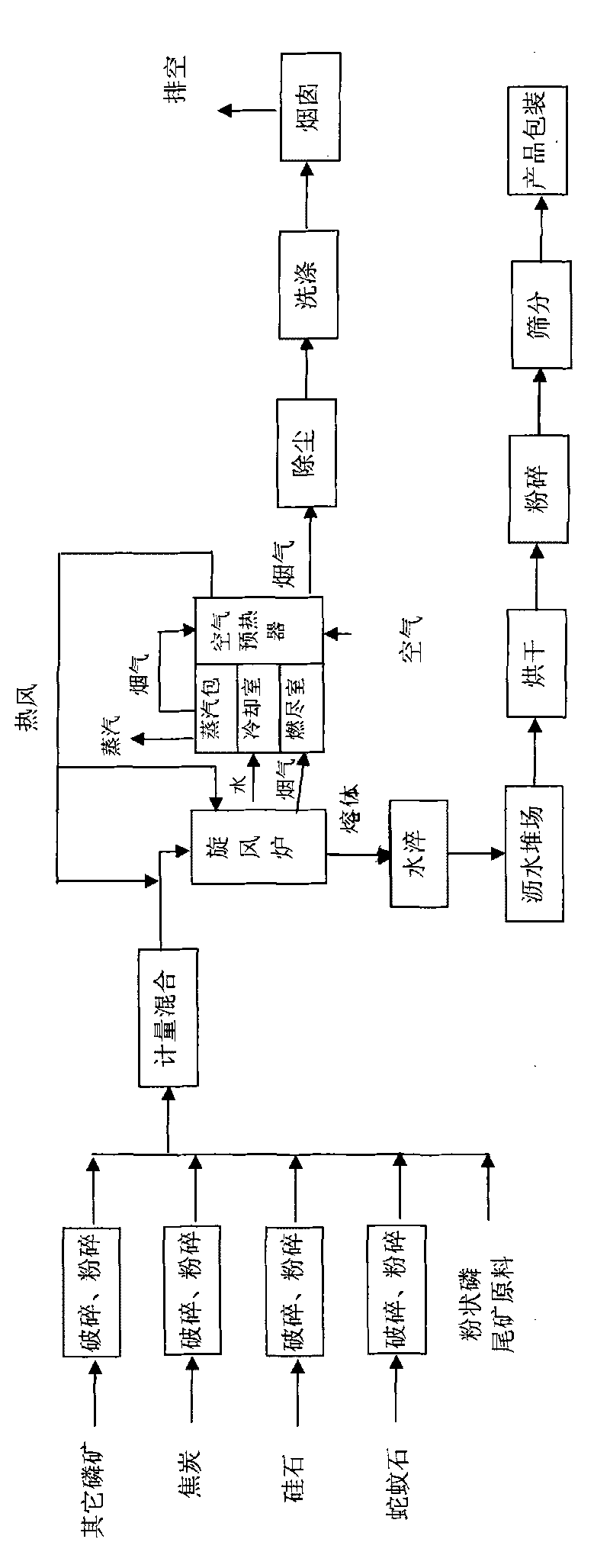

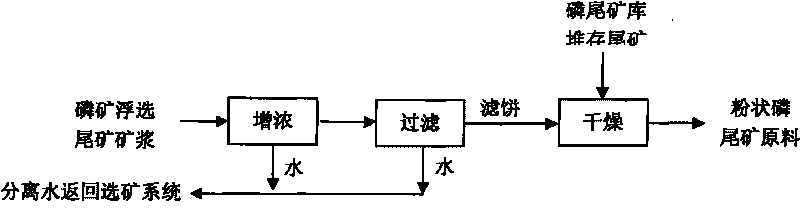

Method for preparing calcium magnesium phosphate fertilizer by using phosphorite floatation tailing as raw material

ActiveCN101747091AReduce manufacturing costPromote the development of circular economyThomas phosphate fertilisersChemical industryPhosphoric acid

The invention relates to a method for preparing calcium magnesium phosphate fertilizer through cyclone furnace process by using phosphorite floatation tailings as raw materials, in particular to a method for preparing calcium magnesium phosphate fertilizer through adopting a cyclone furnace by using phosphorite floatation tailings as main raw materials, belonging to the technical field of phosphate fertilizer chemical industry. The method uses the phosphorite floatation tailings as the main raw materials and adopts the cyclone furnace to prepare calcium magnesium phosphate fertilizer, and comprises the following steps: (1) the phosphorite floatation tailings are used as the raw materials, pulp dry basis contains 8-12 percent of P2O5 by weight percent, tailing filter cakes are obtained through treatment and the tailing filter cakes contain 20-40 percent of water; (2) the tailing filter cakes obtained through the step (1) are dried to tailing power containing water less than 2 percent by using a dryer, and the required grain size of tailing powder is that more than 80 percent of particles can pass through a 100-mesh sieve; (3) other primary phosphorite, coal, serpentine stone and silica to be jointly calcined are metered, mixed, cracked and crushed into joint-calcination mixed powder with fineness that more than 80 percent of particles can pass through the 100-mesh sieve; (4) 100 parts of phosphorite raw material, 190-280 parts of pulverized coal, 0-10 parts of silica and 0-20 parts of serpentine stone powder are added in the cyclone furnace by weight; and (5) the calcined powder raw material obtained through the step (4) is used to prepare calcium magnesium phosphate fertilizer by adopting the cyclone furnace. The invention has the advantages that the source of the raw materials is wide and the cost is low; sulfuric acid and phosphoric acid are not consumed, the product quality is reliable, the use is economic and feasible, and the social benefit is remarkable.

Owner:YUNNAN CHEM RES INST

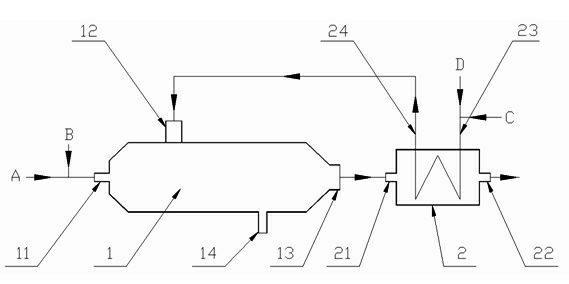

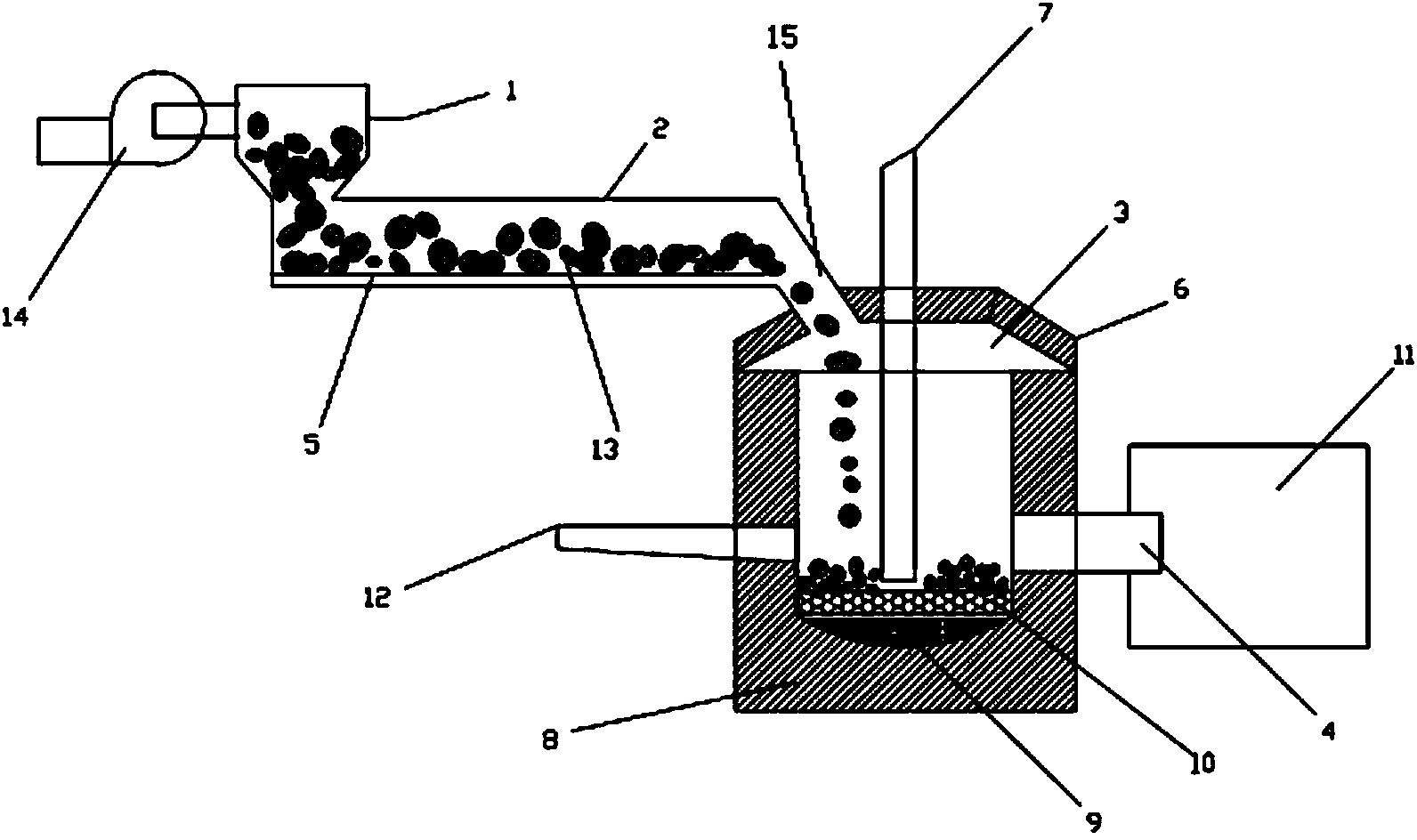

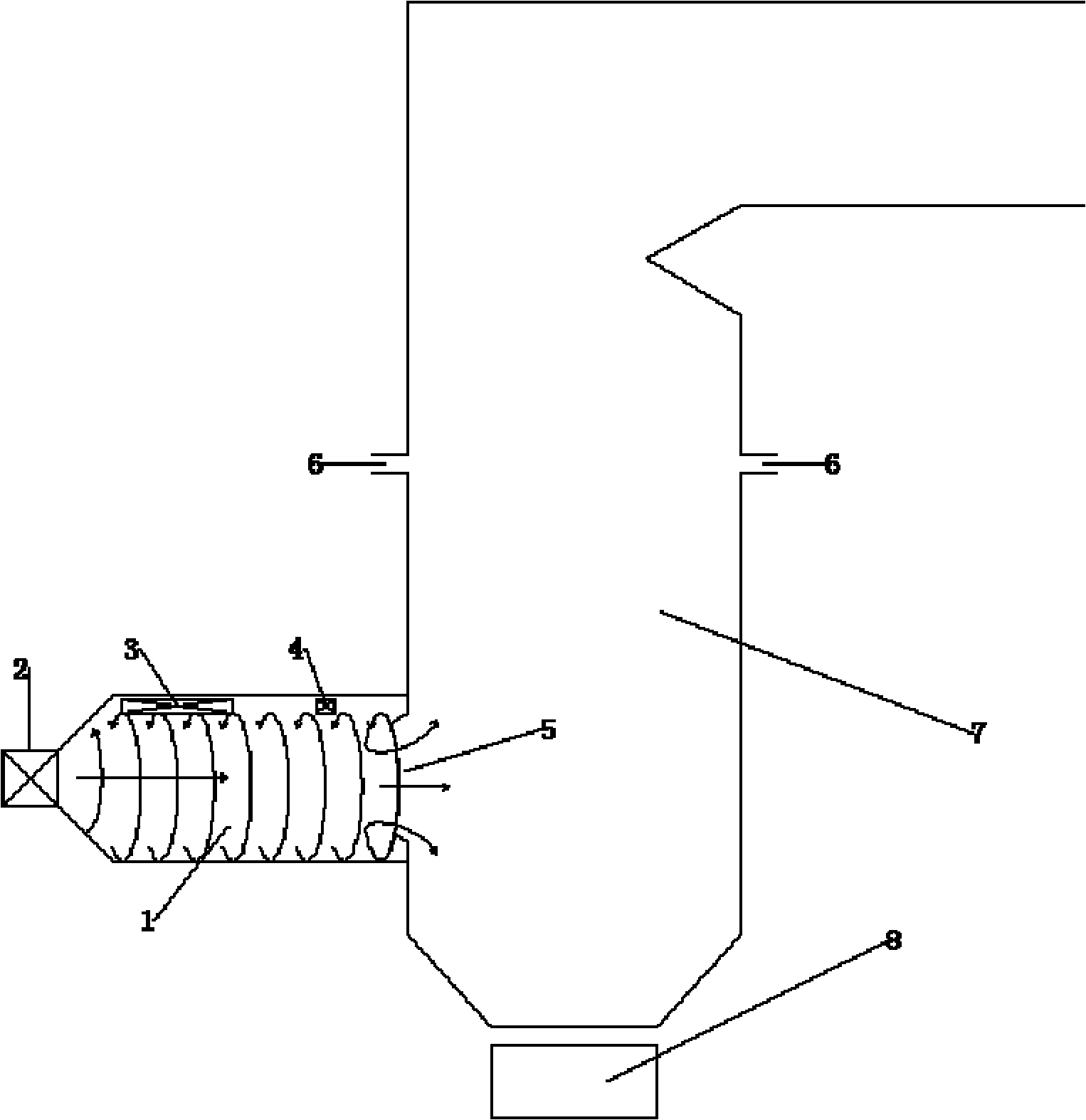

Cyclone melting device and method for fly ash preheating

InactiveCN102620299AImprove leaching rateLow melting slag collection rateIncinerator apparatusThermodynamicsLiquid slag

The invention discloses a cyclone melting device and a cyclone melting method for fly ash preheating, particularly relates to a device and a method for fly ash melting treatment. The device comprises a cyclone furnace and a fly ash preheater, wherein a smoke outlet of the cyclone furnace is connected with a hot smoke inlet of the fly ash preheater, and a working medium outlet of the fly ash preheater is communicated with a secondary air tangential inlet of the cyclone furnace. The method comprises the steps as follows: mixing the primary air with coal powders; spraying into the front end of the cyclone furnace from a primary air inlet of the cyclone furnace; carrying fly ashes into the fly ash preheater through the secondary air for the combustion of the coal powders through adopting the pneumatic transmission technology, enabling high-temperature smoke generated by combustion in the cyclone furnace to enter the fly ash preheater for heating the secondary air and the fly ashes, enabling the fly ashes after heated through the high-temperature smoke to enter the cyclone furnace, quickly heating the fly ashes to reach the fly ash melting temperature, rotating the secondary air in the cyclone furnace at a high speed, throwing the fly ashes to the wall surface of the cyclone surface under the action of a centrifugal force, quickly melting the fly ashes through the high-temperature wall surface, and discharging the molten fly ashes in the form of liquid slags from a liquid deslagging hole at the bottom of the cyclone furnace.

Owner:NANJING XINYE ENERGY TECH

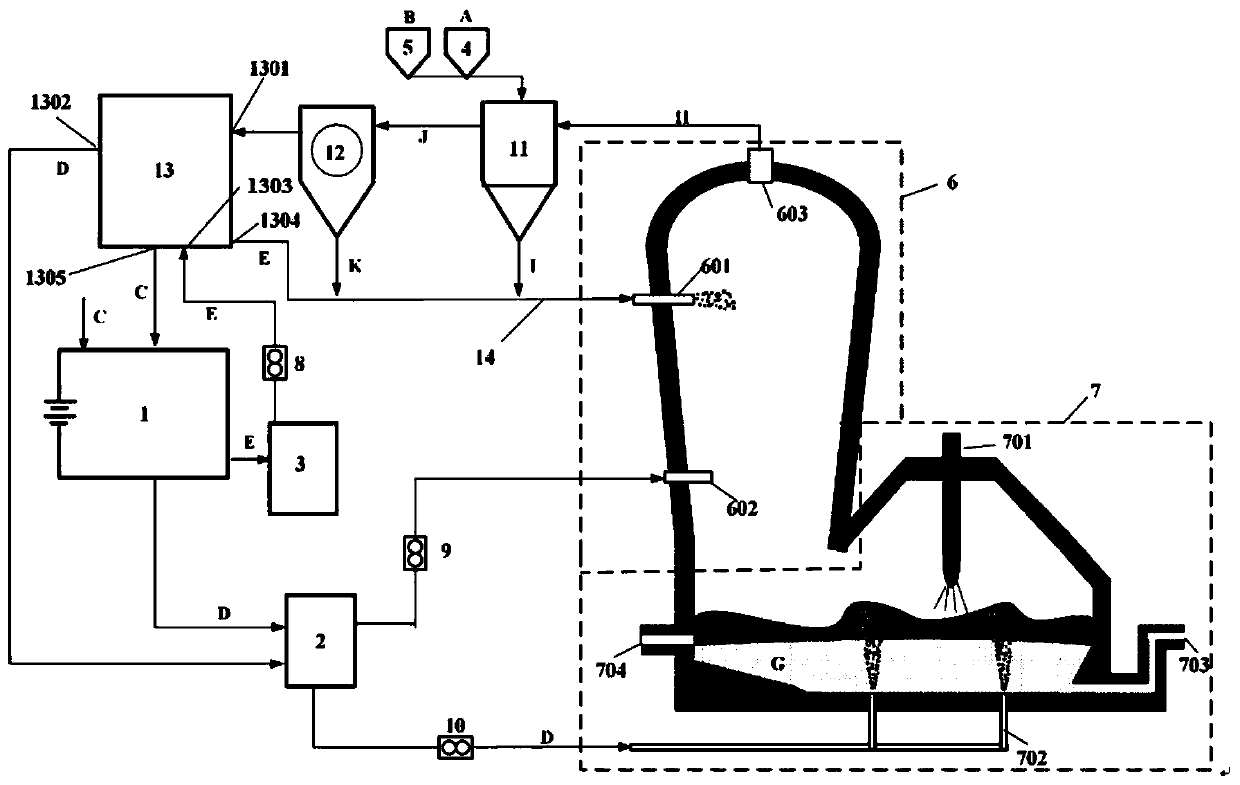

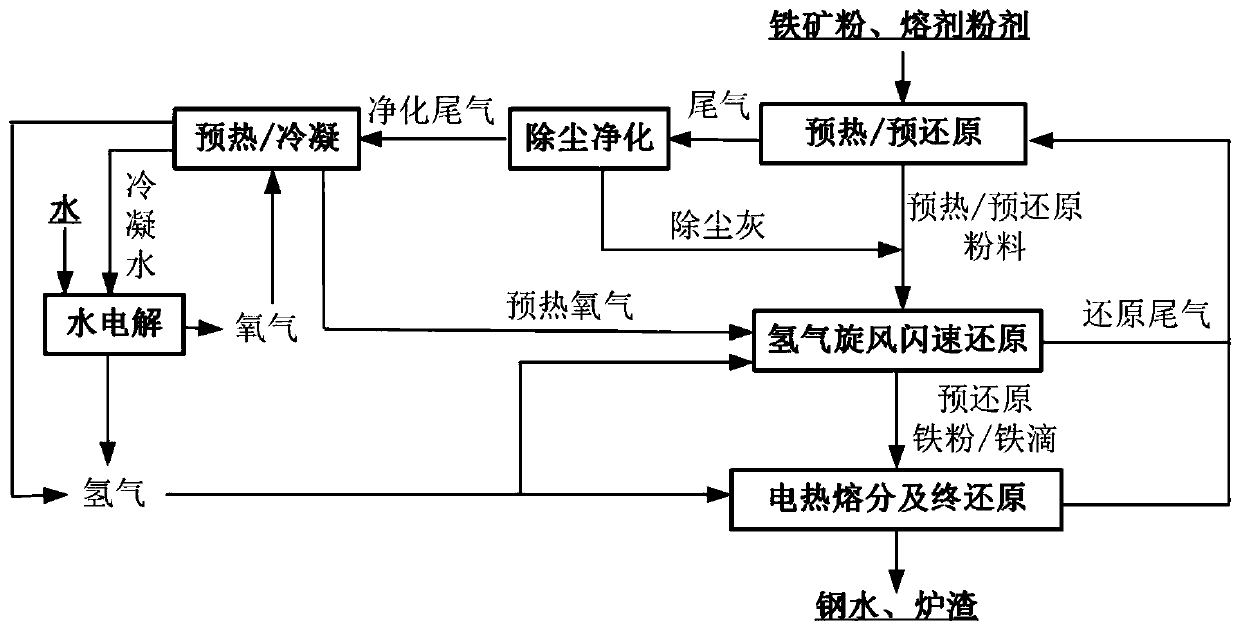

Direct steelmaking system and process for electric energy all-hydrogen flash reduction

ActiveCN110423854AAlleviate shortagesStrong reductionProcess efficiency improvementElectric furnaceSteelmakingElectrolysis

The invention provides a direct steelmaking system and a process for electric energy all-hydrogen flash reduction, the system comprises an electrolysis water hydrogen production device, a cyclone flash reduction furnace, an electric heating melting furnace and a tail gas post-treatment device; the process is as follows: the reducing hydrogen and oxygen are prepared by water electrolysis, the oxygen and the steelmaking powder are sprayed into the cyclone flash reduction furnace, meanwhile, the lower part is blown with hydrogen, and reduction reaction occurs between the two phases of gas and solid at 500-1500 DEG C during the countercurrent movement in the cyclone furnace to obtain the pre-reduced iron powder / iron droplets with metallization ratio greater than 80%, and then the oxygen and the steelmaking powder enter the electric melting furnace to carry out melting separation, the bottom blowing hydrogen is stirred and molten to be reduced, continuous steelmaking is carried out, the tail gas preheating / pre-reduction powder is reduced and molten and subjected to dust removing purification, the purified exhaust gas preheats the oxygen and is condensed and separated, the hydrogen returns to the cyclone flash reduction furnace, and the condensed water returns to the electrolysis water to produce hydrogen; the process completely uses electric energy for smelting without relying on fossil fuel, completely uses hydrogen as a reducing agent, and has no pollutant emission in the process, so the efficient, recycling, and cleaning melting of raw materials are achieved.

Owner:NORTHEASTERN UNIV

Method for preparing inorganic fiber fused mass from blast furnace molten slag

The invention relates to a method for preparing inorganic fiber fused mass from blast furnace fused slag, which utilizes fused slag discharged by a blast furnace or an electric furnace. The method comprises the following steps: introducing the fused slag into accommodating equipment; metering the mass of the fused slag; proportionally adding other fused ingredients, wherein the temperature of other fused ingredients is between 600 and 1700 DEG C; then, mixing other fused ingredients and the fused slag into uniform fused mass through stirring; and measuring and controlling the temperature of the inorganic fused mass so that the chemical composition, the temperature, the viscosity and the like of the fused mass meet the inorganic fiber forming requirement to obtain the inorganic fiber fused mass. The inorganic fiber fused mass prepared by adopting the method of the invention can be used for preparing various kinds of inorganic fiber. The method mainly has the following advantages: (1) various kinds of industrial furnace slag, such as blast furnace fused mineral slag, electric furnace fused phosphorous slag, iron alloy fused slag, cyclone furnace liquid state slag and the like can be utilized; (2) the sensible heat of the industrial furnace slag is fully utilized, a large number of energy sources are saved, and the carbon discharge is greatly reduced; and (3) the technology is reasonable and advanced, various kinds of inorganic fiber can be prepared, and the stability of the product quality can be ensured.

Owner:杨锦耀

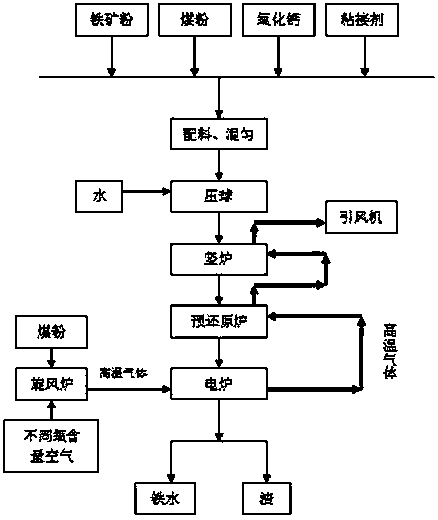

CEO compound smelting reduction ironmaking plant and technology

The invention relates to a CEO compound smelting reduction ironmaking plant and technology. The CEO compound smelting reduction ironmaking plant comprises combination of a vertical furnace, a pre-reduction furnace, an electric furnace, and a cyclone furnace which is arranged on the lateral wall of the electric furnace, wherein an outlet of the vertical furnace is directly connected with an inlet of the pre-reduction furnace; the pre-reduction furnace is connected with the electric furnace through a pipeline; the cyclone furnace is connected with the electric furnace through a pipeline. The technology comprises the following processes: firstly, preparing phi 10-40mm of carbon-containing pellets from iron ore powder, pulverized coal, lime and a binder; drying the carbon-containing pellets by using flue gas of 160-500 DEG C inside the vertical furnace and then feeding the dried carbon-containing pellets to the pre-reduction furnace connected with the vertical furnace; carrying out pre-reduction at the temperature of 300-1450 DEG C of the flue gas discharged from the inside of the electric furnace, and feeding the pre-reduced carbon-containing pellets to the electric furnace; and carrying out reduction and smelting separation at the temperature of 1500-1800 DEG C, wherein the cyclone furnace supplies a high-temperature gas of about 1000-1500 DEG C to the electric furnace by taking coal, air and oxygen as raw materials. The process disclosed by the invention has the characteristics of high energy efficiency, and high recovery rate of iron; kinds of coals and iron ores are used.

Owner:UNIV OF SCI & TECH BEIJING

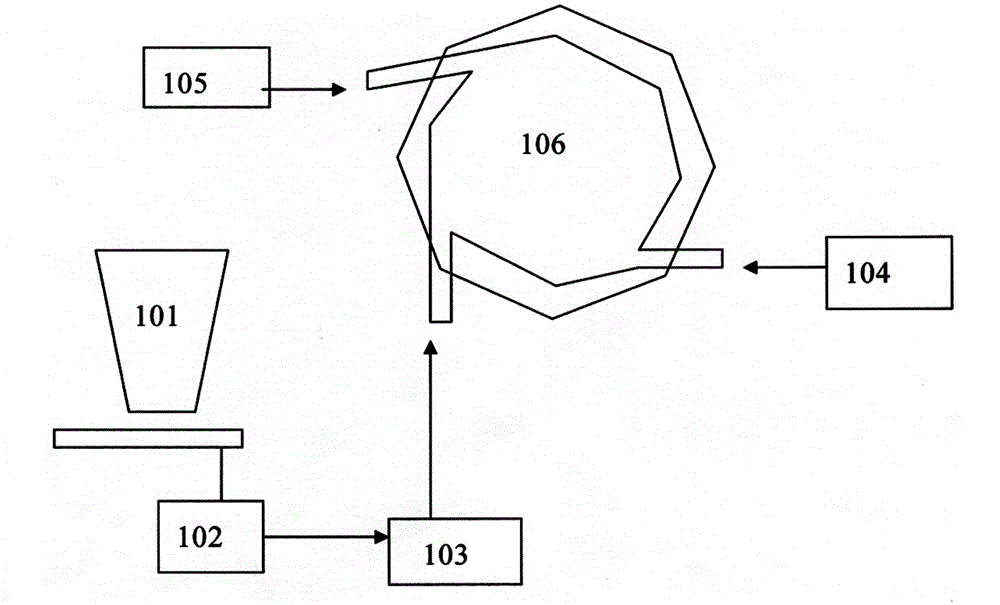

Cyclone burning method and device for reburning fuel in cyclone drum for denitration

InactiveCN102062393AExtended staySolve the problem of high smoke temperatureCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelSocial benefitsLiquid slag

The invention discloses a cyclone reburning method and device for reburning fuel in a cyclone drum for denitration. The device comprises a cyclone drum, a boiler main hearth and a granulating water tank, wherein the cyclone drum and the boiler main hearth are connected seamlessly through a concave outlet of the cyclone drum, overfire air nozzles are distributed at the upper part of the boiler main hearth, and the granulating water tank used for granulating liquid slag is arranged at the bottom of the boiler main hearth. In the invention, since reburning denitration is realized in the cyclone drum, reburnt fuel can stay in a boiler for a longer time; meanwhile, the upper part of the boiler main hearth at the rear part of the boiler has enough space for the distribution of the overfire air nozzles; therefore, the problem that the normal operation of a cyclone furnace boiler is threatened when a conventional reburning technology is adopted is solved very well, and the problems of the reburning technology per se, such as low burn-off rate of reburnt fuel and high smoke temperature of a hearth outlet and the like, can be overcome very well. The method disclosed in the invention not only has high denitration rate, but also uses simple equipment, is convenient and easy to implement, has low cost, is easy in the reformation of a traditional boiler, has remarkable social benefit and can be promoted and applied widely.

Owner:XI AN JIAOTONG UNIV

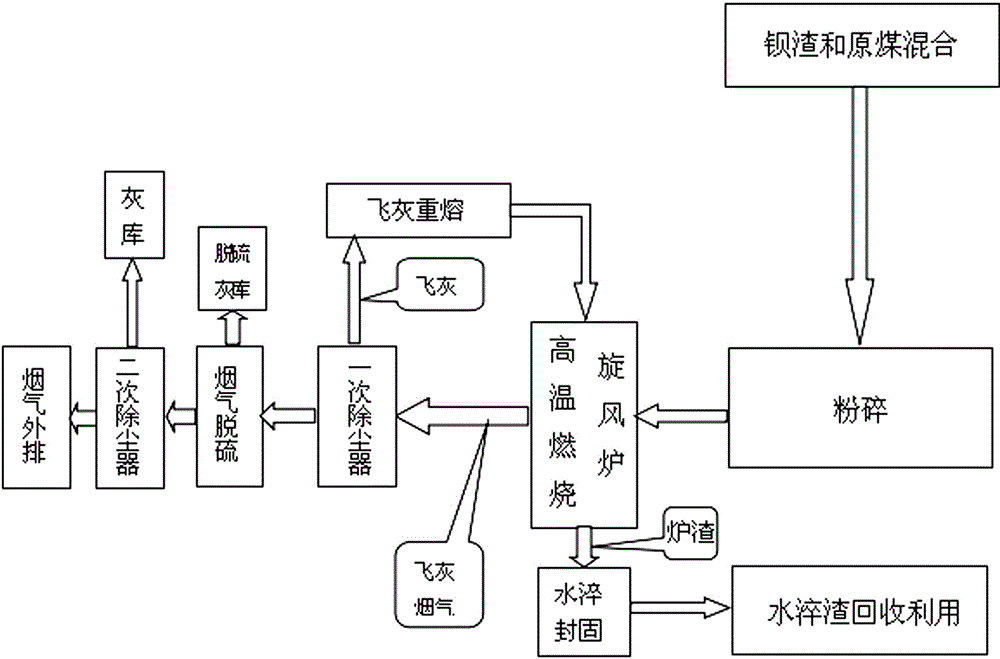

Chromium slag processing method

ActiveCN105039726AEffective detoxificationHigh strengthProcess efficiency improvementCyclone furnaceFly ash

The invention relates to a chromium slag processing method which includes the steps of weighing and blending of ash of a refuse incineration power plant, medical incineration ash and raw coal, incineration and detoxification, fly ash remelting, smoke exhausting, water quenching and sealing, and the like. Poisonous chromium slag is detoxified by reduction at high temperature through a cyclone furnace. By making the best of the characteristic that a reducing area formed in operation with high heat strength, sufficient reducing power and a small air coefficient of excess air of the cyclone furnace reduces hexavalent chromium into trivalent chromium, the process of chromium slag processing is finished on the premise of guaranteeing the heat generation capacity. The chromium slag processing method is thorough in detoxification and free of secondary pollution, the chromium slag is recycled, and both positive benefits and environmental protection are achieved.

Owner:河南景耀热电环保科技有限公司

Barium slag processing system and method

The invention discloses a barium slag processing system and method which are thorough in detoxication, high in processing efficiency and high in resource recycling rate. The barium slag processing system comprises a crusher, a cyclone furnace, a primary dust remover, a secondary dust remover, a sweetener and a water quenching water tank. The barium slag processing method includes the following steps of (1) raw material crushing, (2) high-temperature combustion, (3) smoke processing and fly ash remelting and (4) water quenching and sealing. Barium slag processed through the processing system and method is detoxified thoroughly and has no secondary pollution. Water quenching slag obtained after detoxication can serve as auxiliary materials for producing cement or can be used for paving roads, making construction materials and the like, so that recycling of waste slag is facilitated. Heat generated in the combustion process of the cyclone furnace can be applied to chemical industry production, and both economic and environmental protection benefits are gained.

Owner:河南景耀热电环保科技有限公司

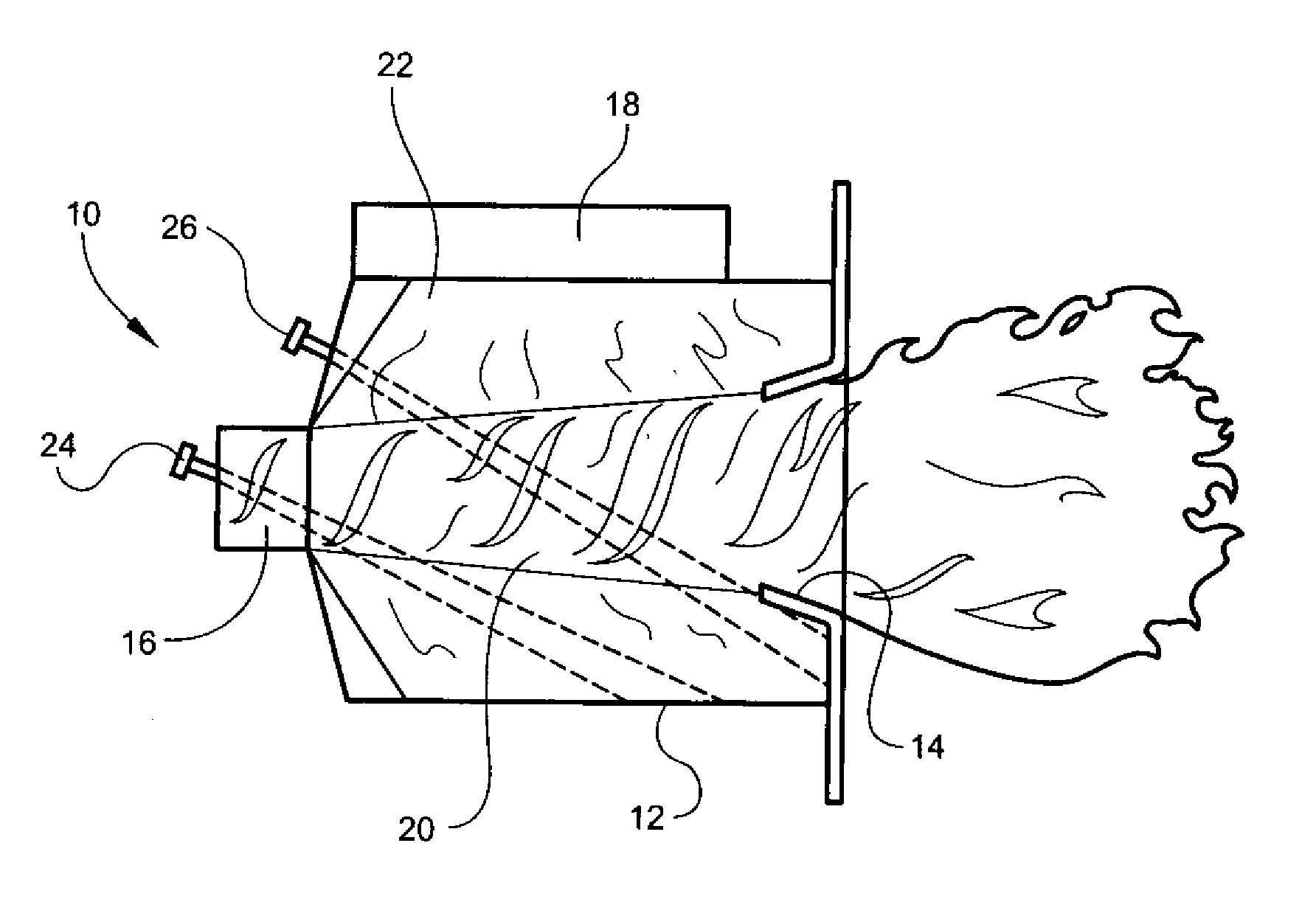

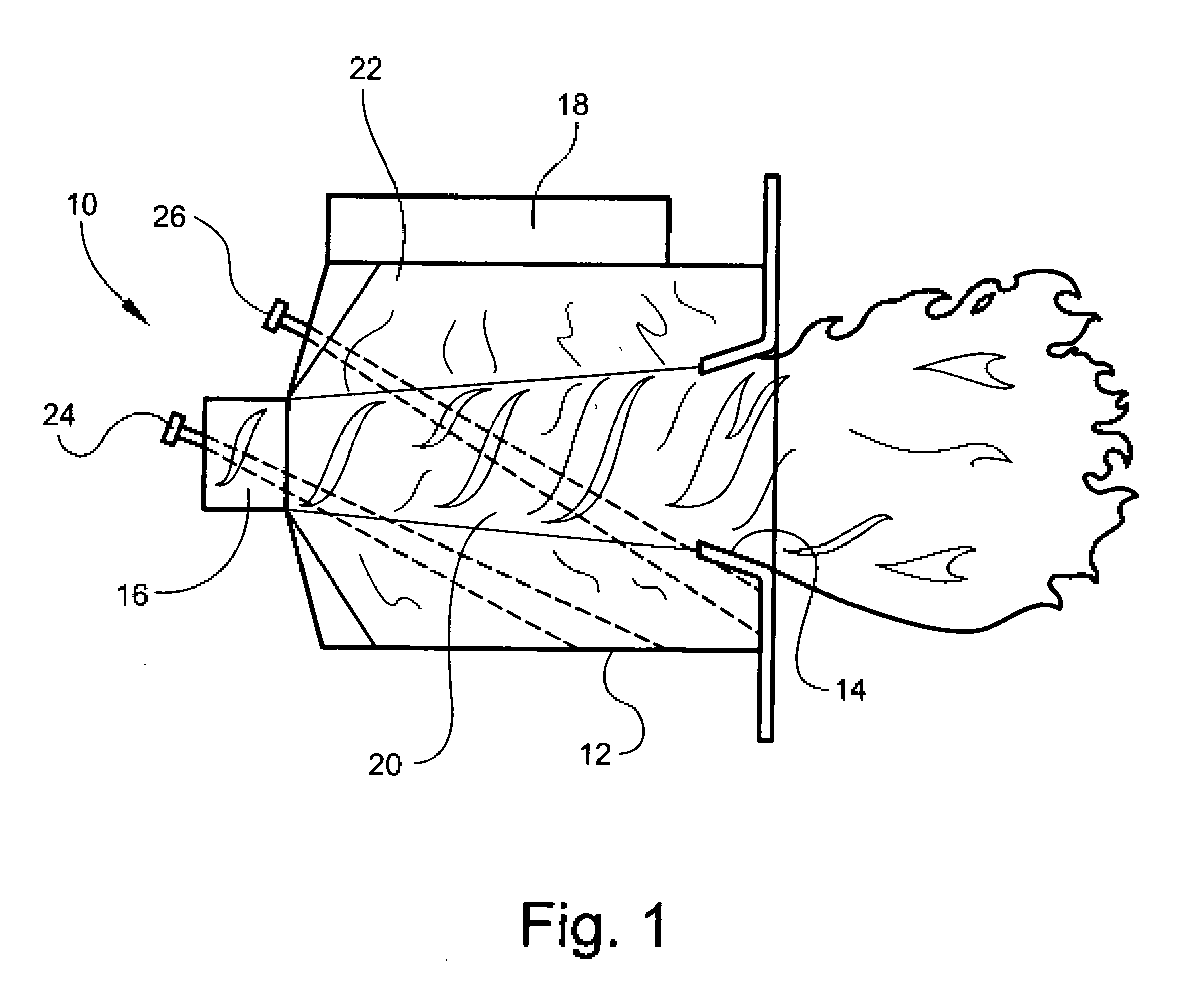

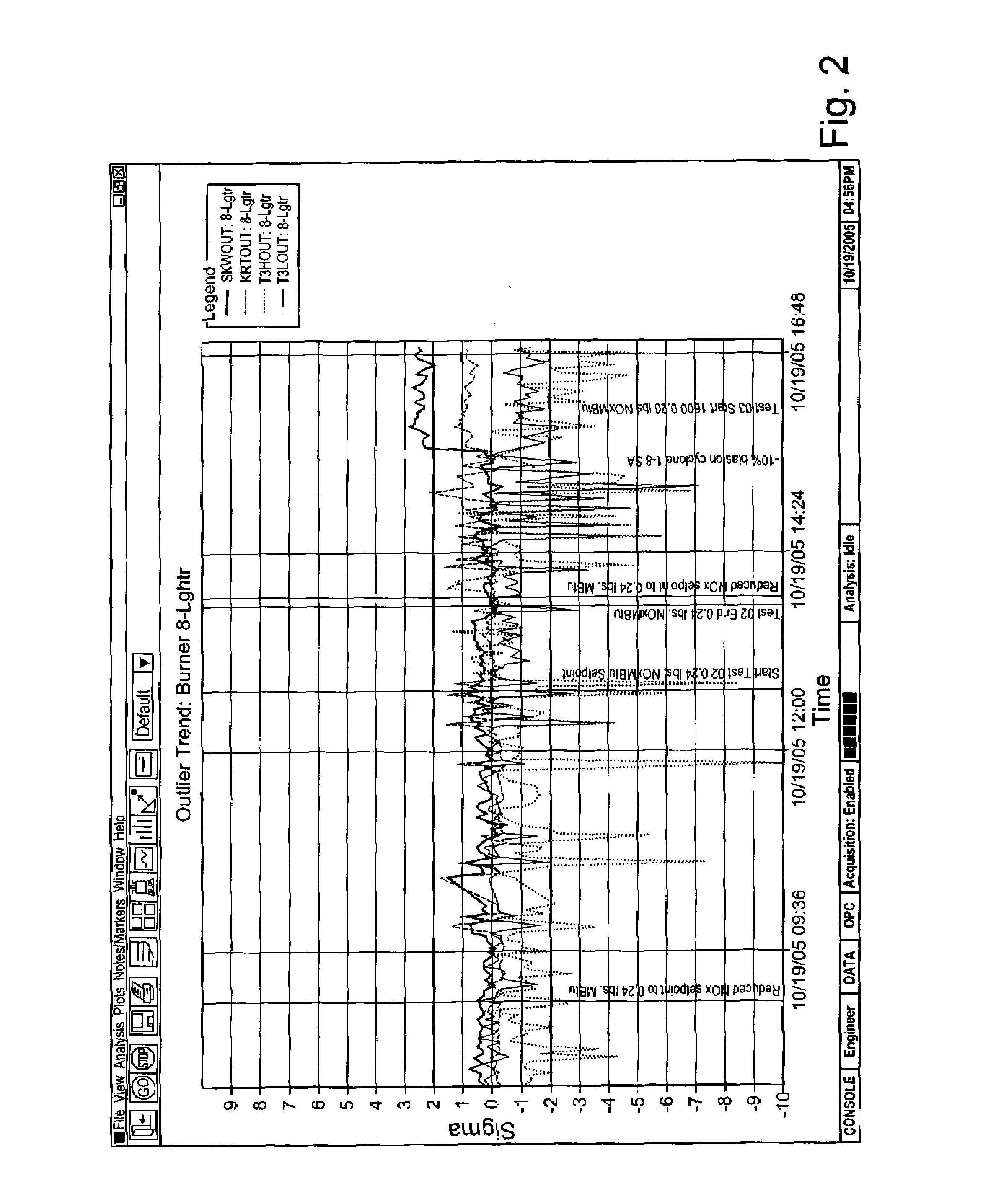

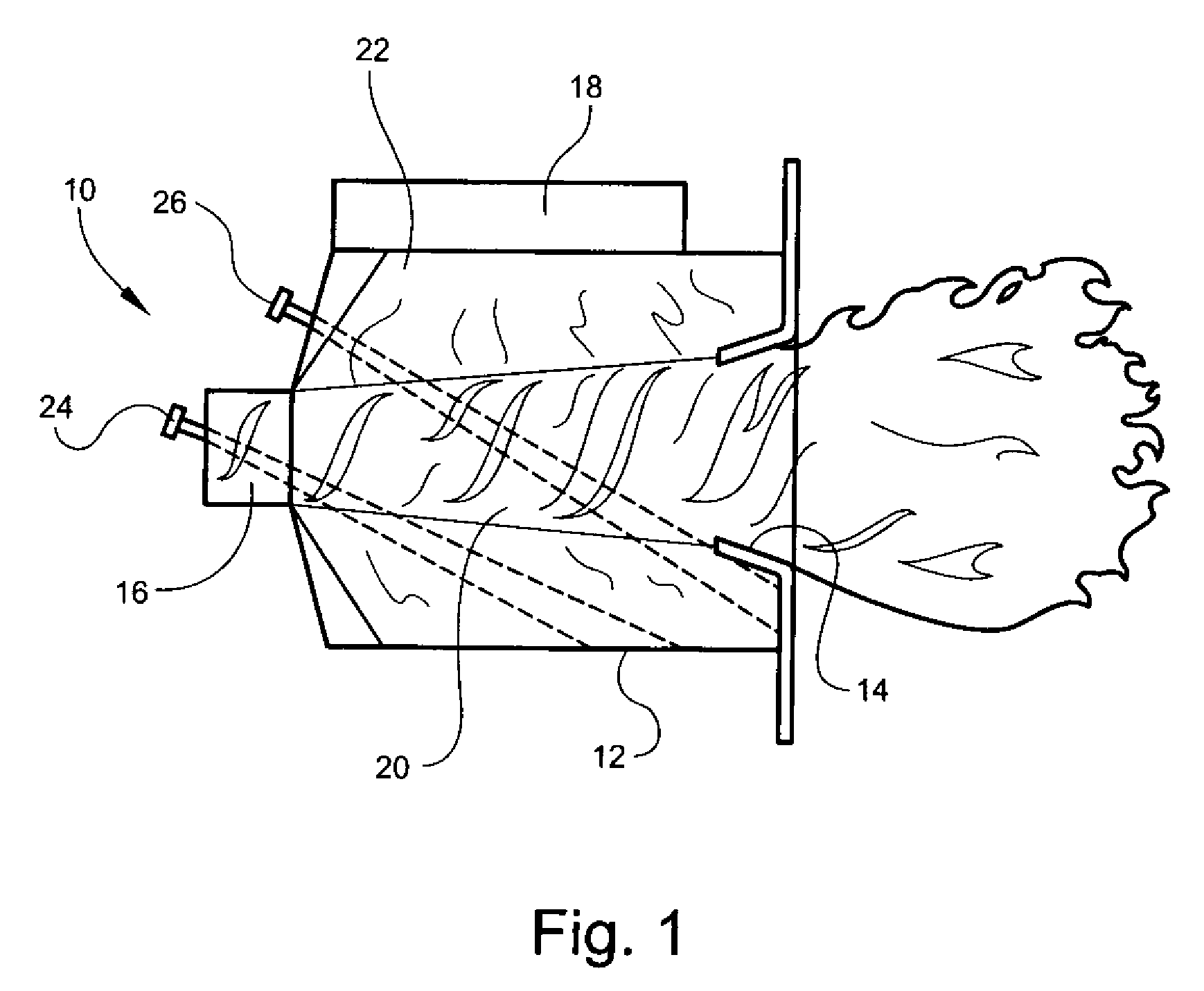

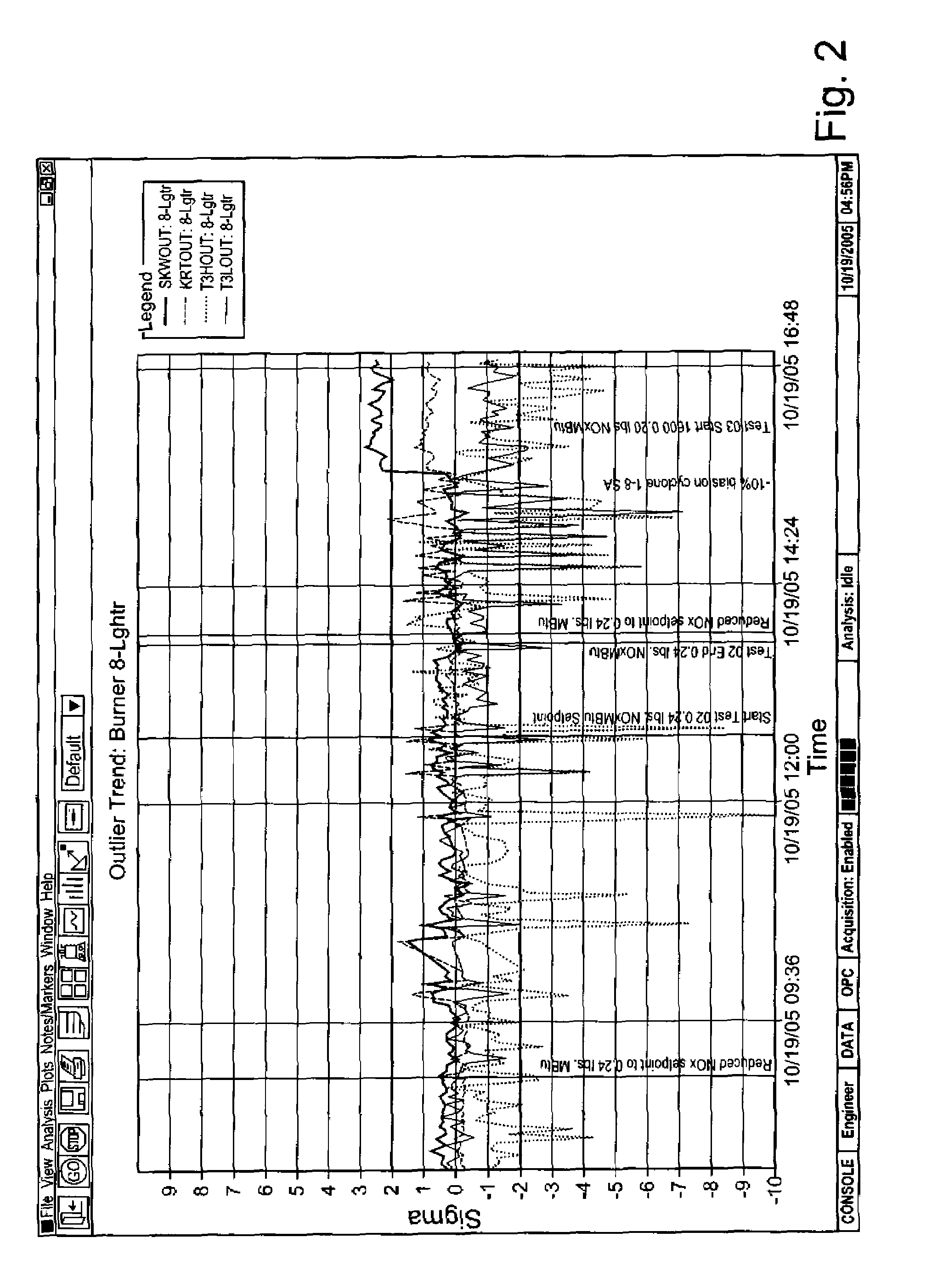

Method for controlling air distribution in a cyclone furnace

ActiveUS20080050684A1Improve performanceAccurate distributionDomestic stoves or rangesTemperatue controlCombustorEngineering

Methods for cyclone boiler flame diagnostics and control, including methods for monitoring the operating state of a cyclone furnace using linear and nonlinear signal analysis techniques, including temporal irreversibility and symbol sequence. Adjustments may be made in the air flow distribution to optimize performance. Signals for the main flame and lighter scanners are relatively independent, thereby allowing for independent control of the primary air flow to the burner and secondary air flow to the barrel.

Owner:ELECTRIC POWER RES INST INC

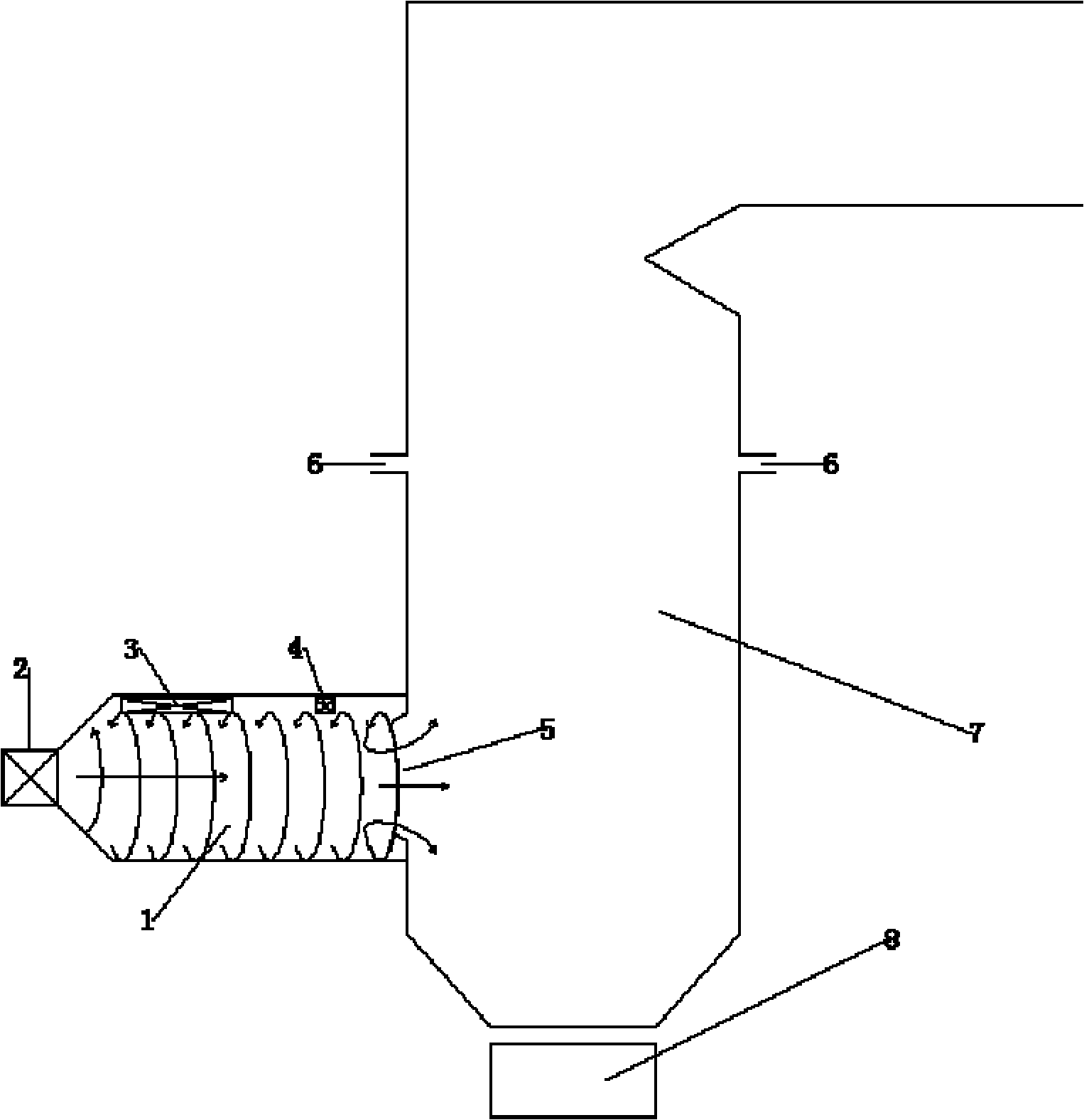

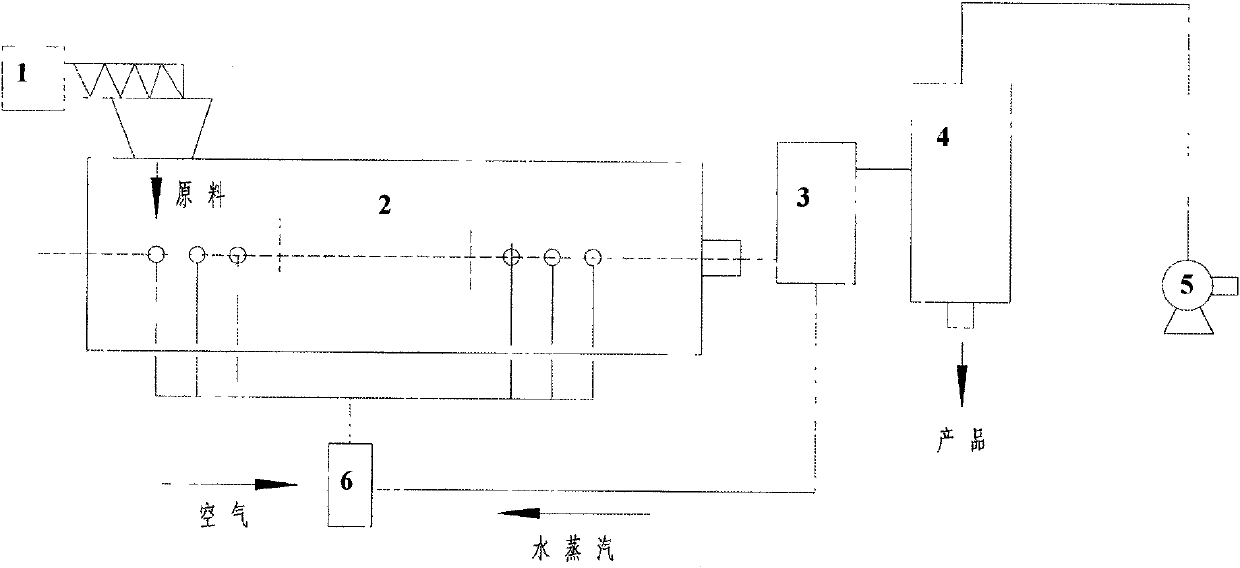

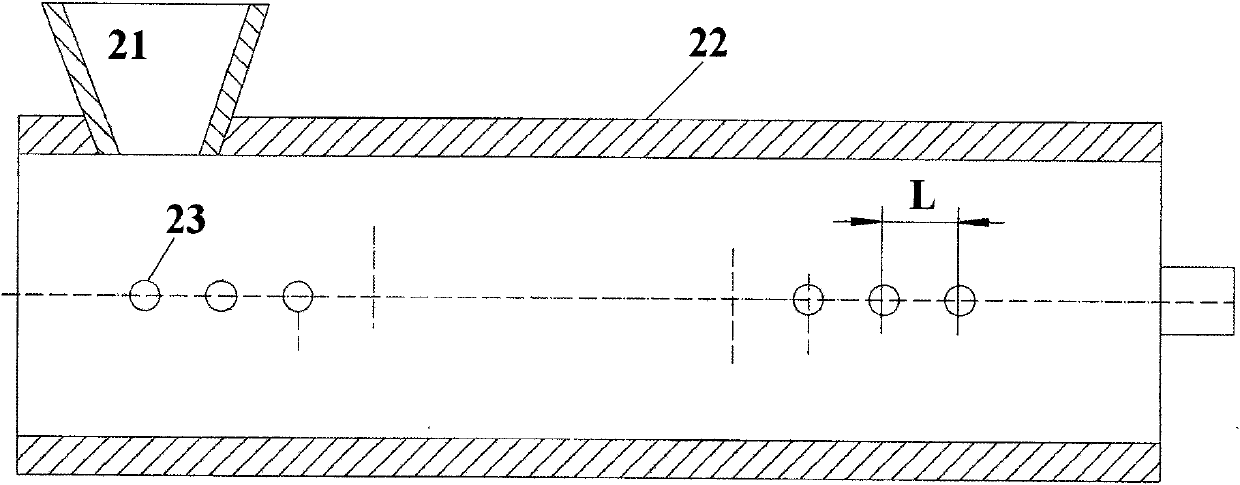

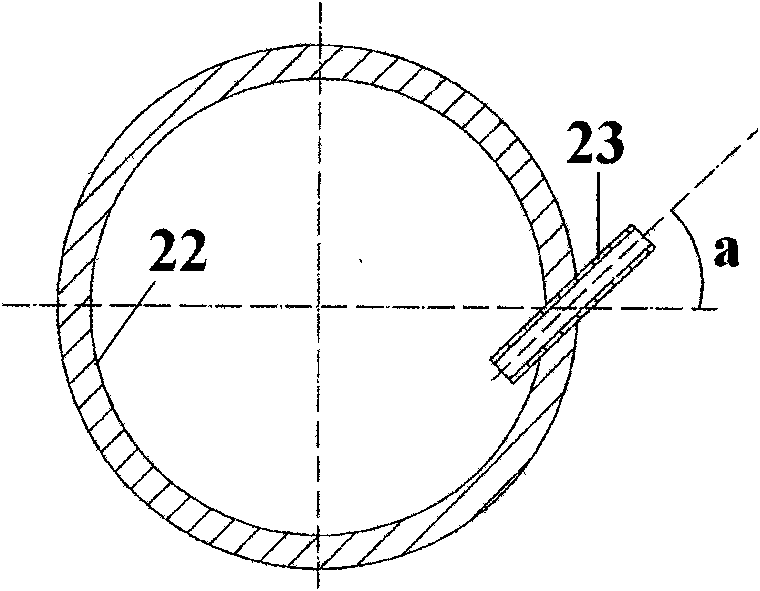

Self-heating continuous powdery biomass activated carbon preparation method and cyclone furnace thereof

InactiveCN101792138AImprove adsorption capacityFully activatedProductsCarbon compoundsComing outWater vapor

The invention discloses a self-heating continuous powdery biomass activated carbon preparation method and a cyclone furnace thereof. The method is as follows: a screw feeder feeds powdery biomass carbonized material into the cyclone furnace with the temperature of 90 DEG C to 1300 DEG C via a feed inlet on the furnace head of the cyclone furnace; under the joint action of the axial draft of a draught fan from the furnace head to the furnace tail and the activating mixed gas obliquely entering via a row of inlet tubes on the furnace wall of the cyclone furnace, the powdery biomass carbonized material is formed into a cyclone in the cyclone furnace, rotationally flows from the furnace head to the furnace tail and carries out activating reaction with the entered activating mixed gas in the process of motion to generate gas, the generated gas continues to burn with oxygen, and the produced heat is used for keeping the internal temperature of the cyclone furnace at 900 DEG C to 1300 DEG C; powdery biomass activated carbon and reaction tail gas coming out of the cyclone furnace enter a waste heat boiler, and the produced steam reenters the cyclone furnace. The 0.15-percent methylene blue absorption of the obtained powdery activated carbon is more than 18ml, and meanwhile, the powdery activated carbon has the A-method caramel decolorization rate of more than 70 percent.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

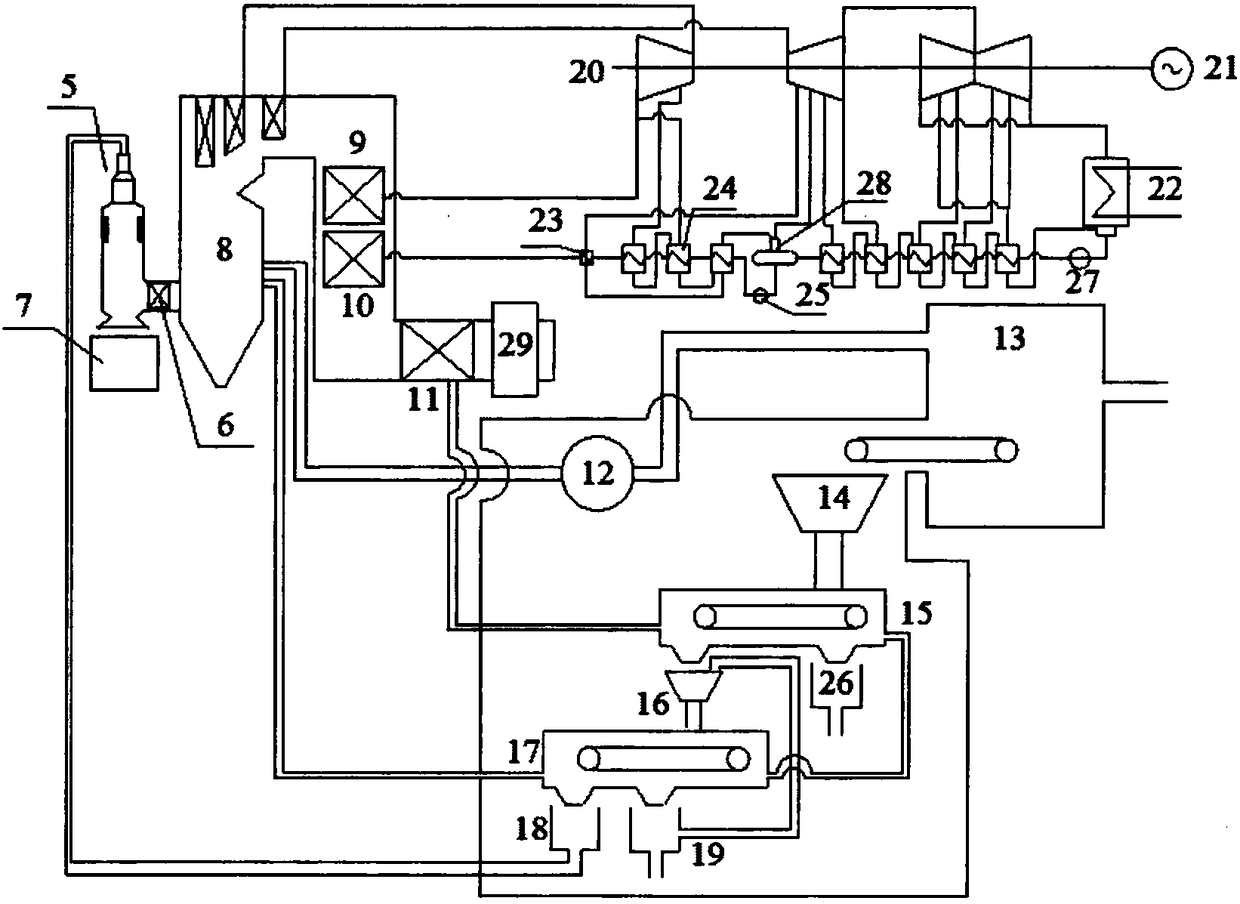

Urban waste cyclone combustion system and coupled coal-fired power plant generating system and method thereof

PendingCN108278617AEasy to handleSmall footprintSteam engine plantsIncinerator apparatusCoal dustWaste treatment

The invention provides an urban waste cyclone combustion system. The urban waste cyclone combustion system comprises a cyclone furnace, wherein a waste fuel inlet is formed in the top of the cyclone furnace, and a hot air inlet, a coal dust primary air inlet and a secondary air inlet are formed in the peripheral wall of the cyclone furnace in sequence from top to bottom; a fume outlet is formed inthe lower part of the cyclone furnace, and the fume outlet is connected with a coal-fired boiler through a flue; and a slag discharge opening is formed in the bottom of the cyclone furnace, and a liquid slag granulating water tank is arranged below the slag discharge opening. The invention further provides an urban waste cyclone combustion method. The invention further provides an urban waste cyclone combustion coupled coal-fired power plant generating system and a method. According to the urban waste cyclone combustion system, the cyclone furnace coupled with the large coal-fired boiler is used as an urban household waste treatment system for the first time, heat of urban household waste is effectively used, and additionally, the waste treatment cost is reduced; ash generated after the urban household waste is burnt can be collected through the burning of the cyclone furnace, so that the ash pollution of the large coal-fired boiler is reduced; and the equipment investment is reduced,and great economic and social benefits are obtained.

Owner:SHANGHAI POWER EQUIP RES INST

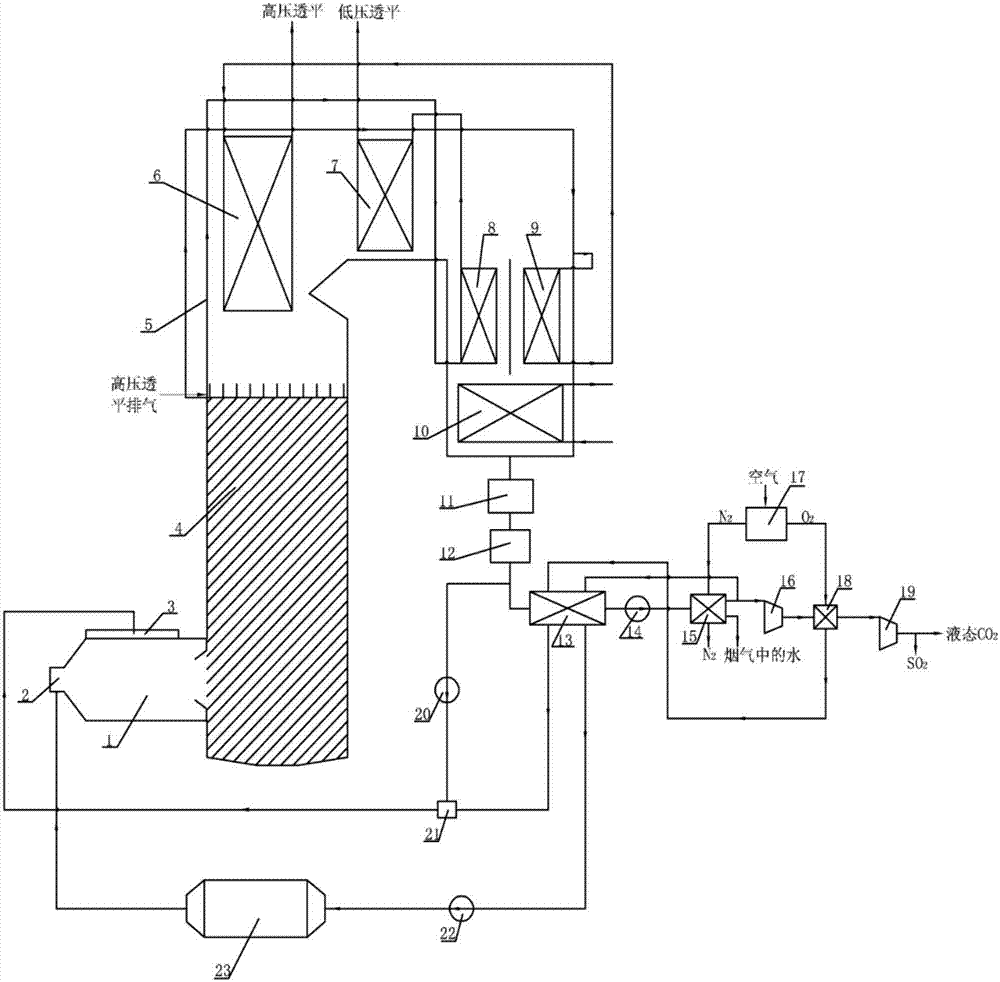

Oxygen-enriched combustion supercritical carbon dioxide cyclone furnace

ActiveCN107191921AImprove cycle efficiencyReduced share of fly ashIndirect carbon-dioxide mitigationCombustion apparatusPower cycleFlue gas

The invention discloses an oxygen-enriched combustion supercritical carbon dioxide cyclone furnace. The cyclone furnace comprises a cyclone furnace body and a tail flue gas comprehensive treatment system. The cyclone furnace body comprises a cyclone tube and a supercritical carbon dioxide boiler. The tail flue gas comprehensive treatment system comprises an SCR denitration device, a dust collector, a gas-gas heat exchanger, a condenser, a first-stage compressor, an air separation device, a cooler, a second-stage compressor, a flue gas mixing device and a pulverizing system. The oxygen-enriched combustion supercritical carbon dioxide cyclone furnace integrates the oxygen-enriched combustion technology and supercritical carbon dioxide power cycle generation organically.

Owner:HUANENG POWER INTERNATIONAL +1

Recycling system for waste cathode block from electrolytic aluminum and recycling method

ActiveCN103851632ARealize recycling of resourcesAchieve high purity recoveryDispersed particle separationIncinerator apparatusThermal energyCyclone furnace

The invention discloses a recycling system for a waste cathode block from electrolytic aluminum and a recycling method. The invention aims to solve the technical problems of low recycling rate of the present waste cathode block, serious energy waste and high recycling cost. The recycling system comprises a high-temperature cyclone furnace and a dry purifying device, wherein the high-temperature cyclone furnace comprises a furnace body, a burner and a heat exchanger. The recycling method comprises the following steps: crushing the waste cathode block from electrolytic aluminum into powder; adding combustion improvers and burning the powder by the high-temperature cyclone furnace; preheating the secondary inlet air of the high-temperature cyclone furnace by the smoke generated by burning through the heat exchanger and purifying through the dry purifying device. The high-purity recycling of the electrolyte in the waste cathode block can be realized by the recycling system provided by the invention; the heat energy generated by powder combustion can be fully utilized; the production energy consumption is reduced; the waste of energy resource is avoided; the recycling method is simple in operation, energy-saving and environment-friendly; the recycling of the waste cathode block can be realized according to the recycling method.

Owner:ZHENGZHOU JINGWEI TECH & IND

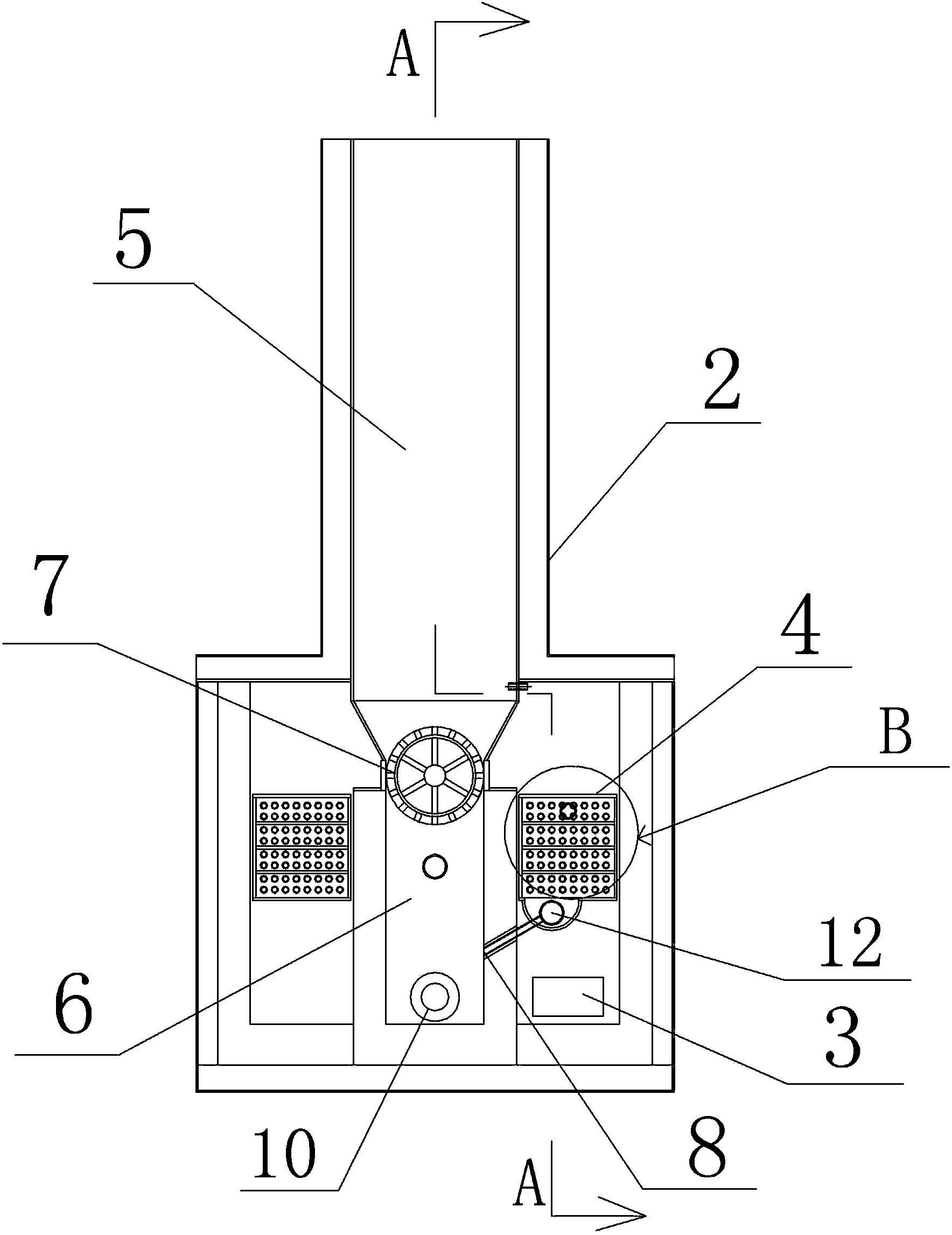

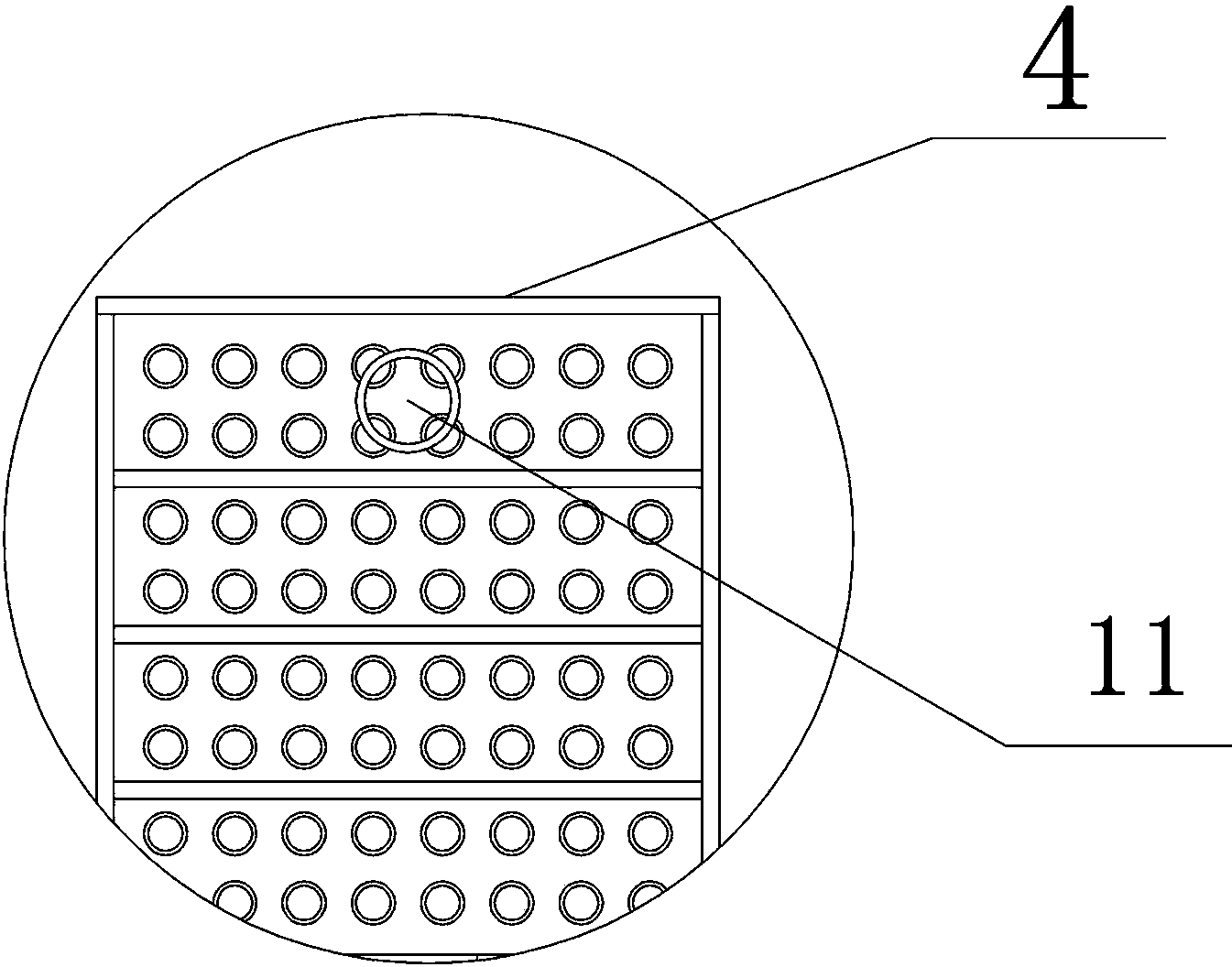

Combined cyclone boiler combustion device and device for flying ash fusion

InactiveCN102425797AStable combustionIncrease temperatureIncinerator apparatusThermodynamicsCombustion chamber

The invention discloses a combined cyclone boiler combustion device and method for flying ash fusion. The device is composed of a horizontal cyclone combustion chamber, a vertical cyclone combustion chamber and a water channel, wherein the outlet of the horizontal cyclone combustion chamber is connected with the inlet of the vertical cyclone combustion chamber; after pulverized coal conveying air is mixed with pulverized coal, the mixture is injected into the horizontal cyclone combustion chamber from the boiler head of the horizontal cyclone combustion chamber; after primary air is mixed with the flying ash, the mixture tangentially enters the horizontal cyclone combustion chamber from the lower reaches of the fuel inlet, so that the temperature of the front end of the horizontal cyclone combustion chamber can not be lowered, and the front-end area of the horizontal cyclone combustion chamber can be kept at high temperature, which is favorable for the pulverized coal to stably catch fire and burn; secondary air tangentially enters the vertical cyclone combustion chamber; and the rotation direction of the secondary air is same with the rotation direction of the primary wind. According to the device and the method, flying ashes of different particle diameters can be guaranteed to fully fuse, and the integral fusion collection efficiency of the flying ash can be improved.

Owner:SOUTHEAST UNIV

Method for controlling air distribution in a cyclone furnace

ActiveUS7484955B2Improve performanceAccurate distributionDomestic stoves or rangesTemperatue controlCombustorEngineering

Owner:ELECTRIC POWER RES INST INC

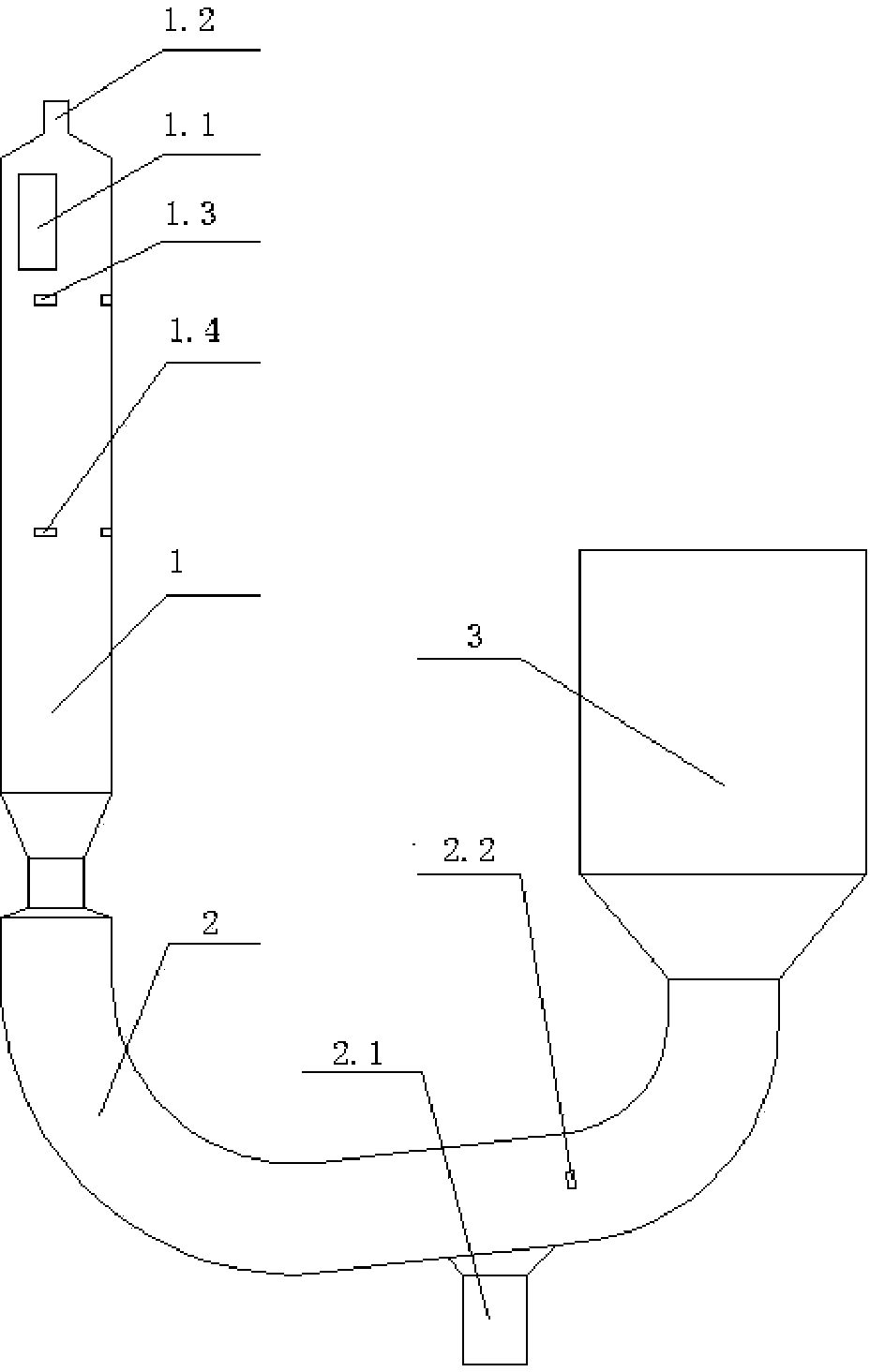

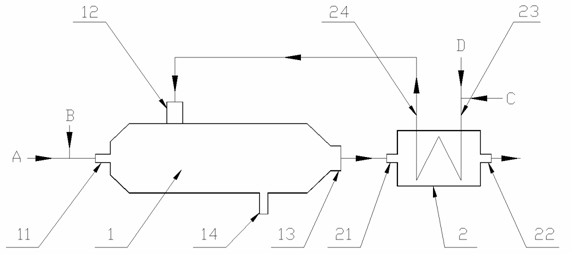

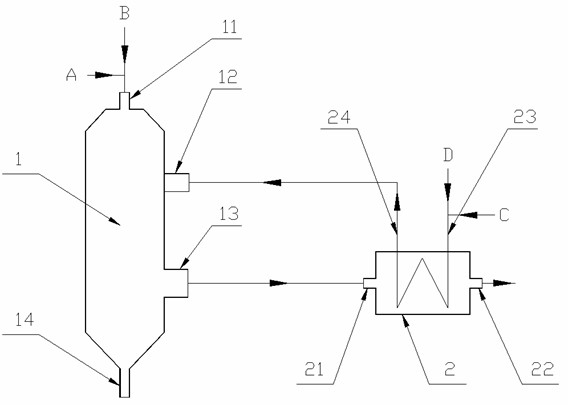

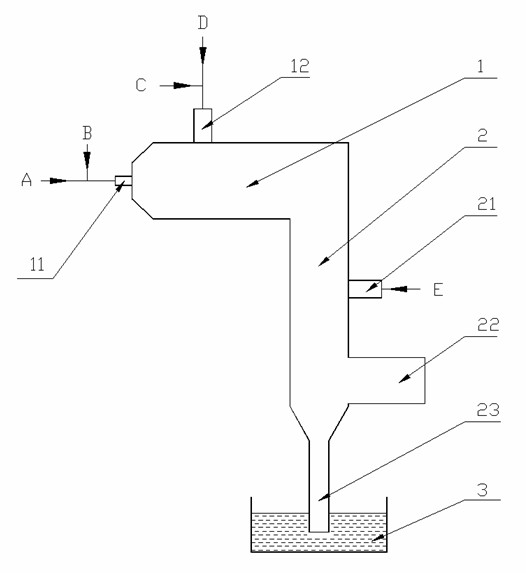

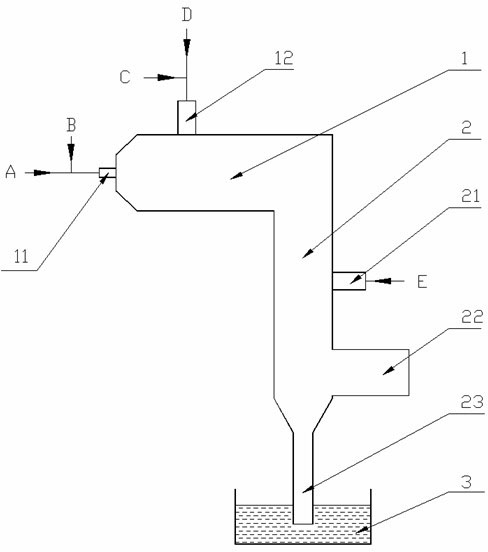

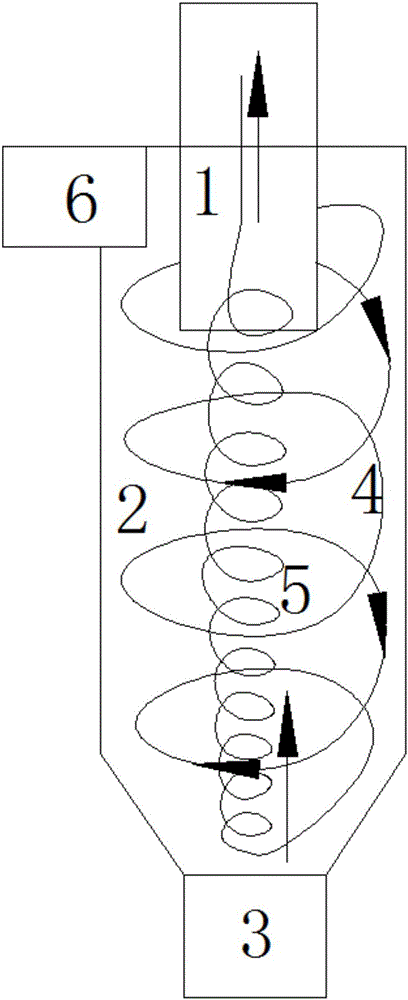

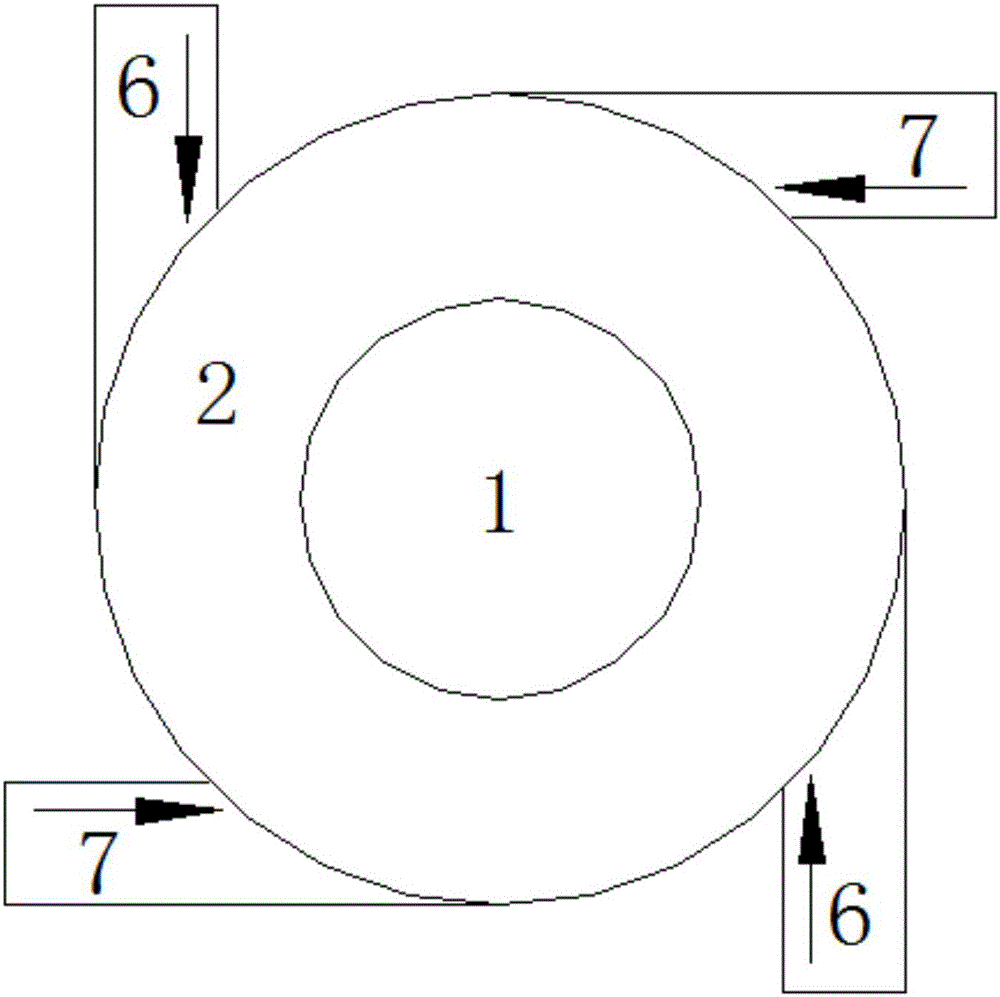

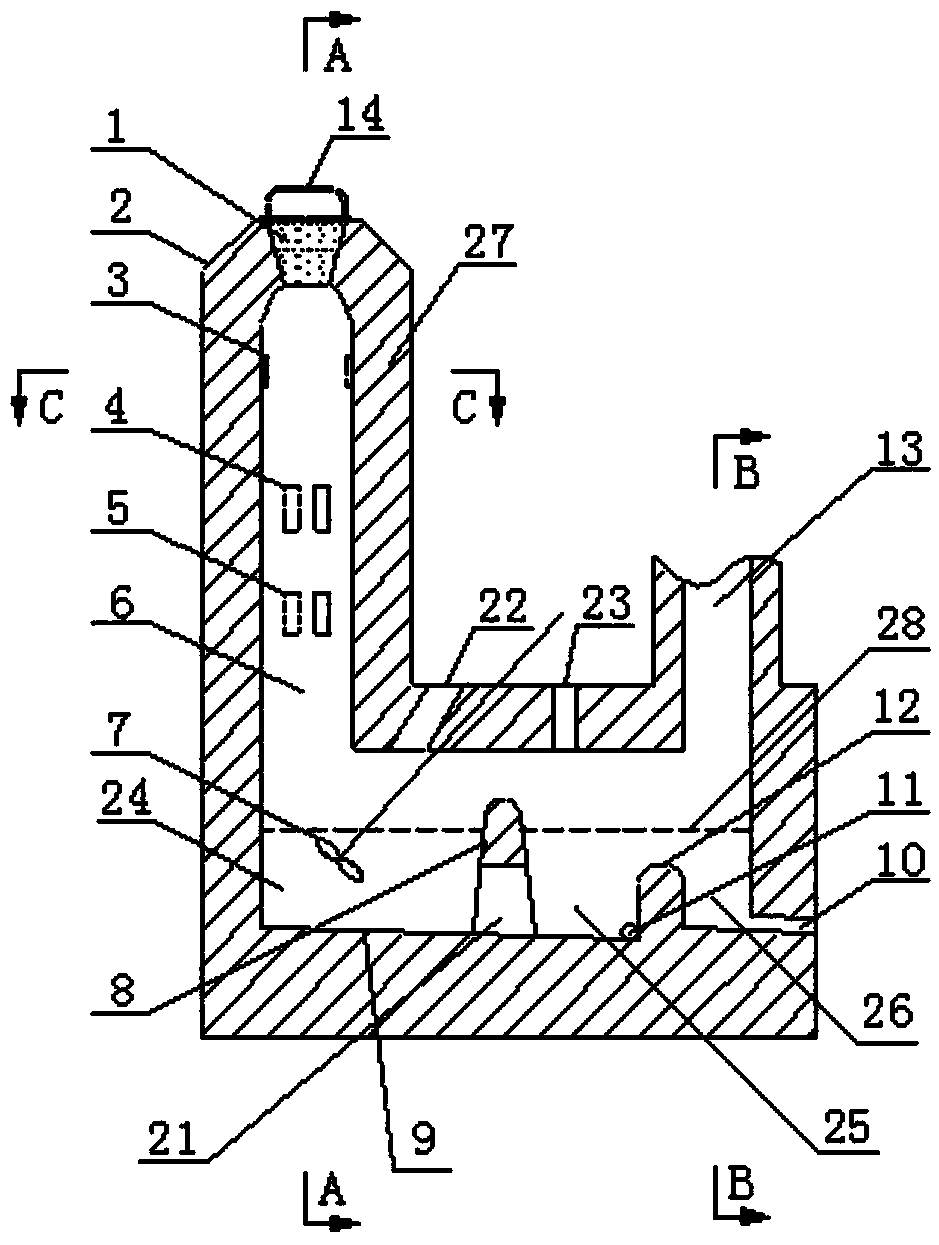

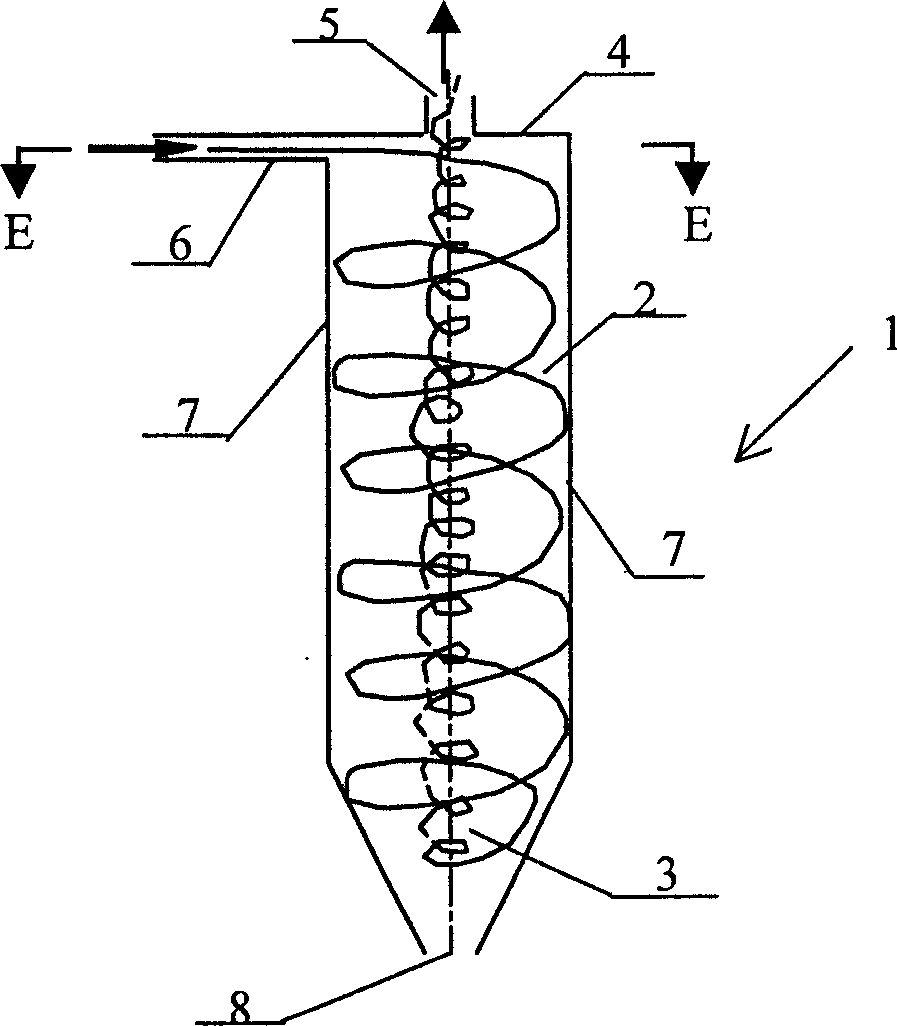

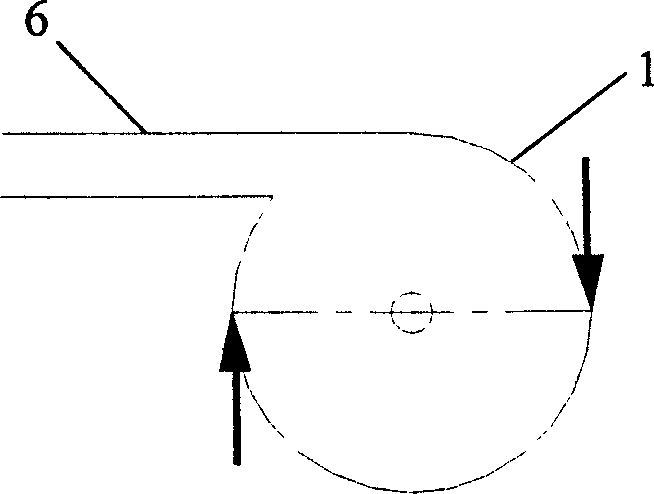

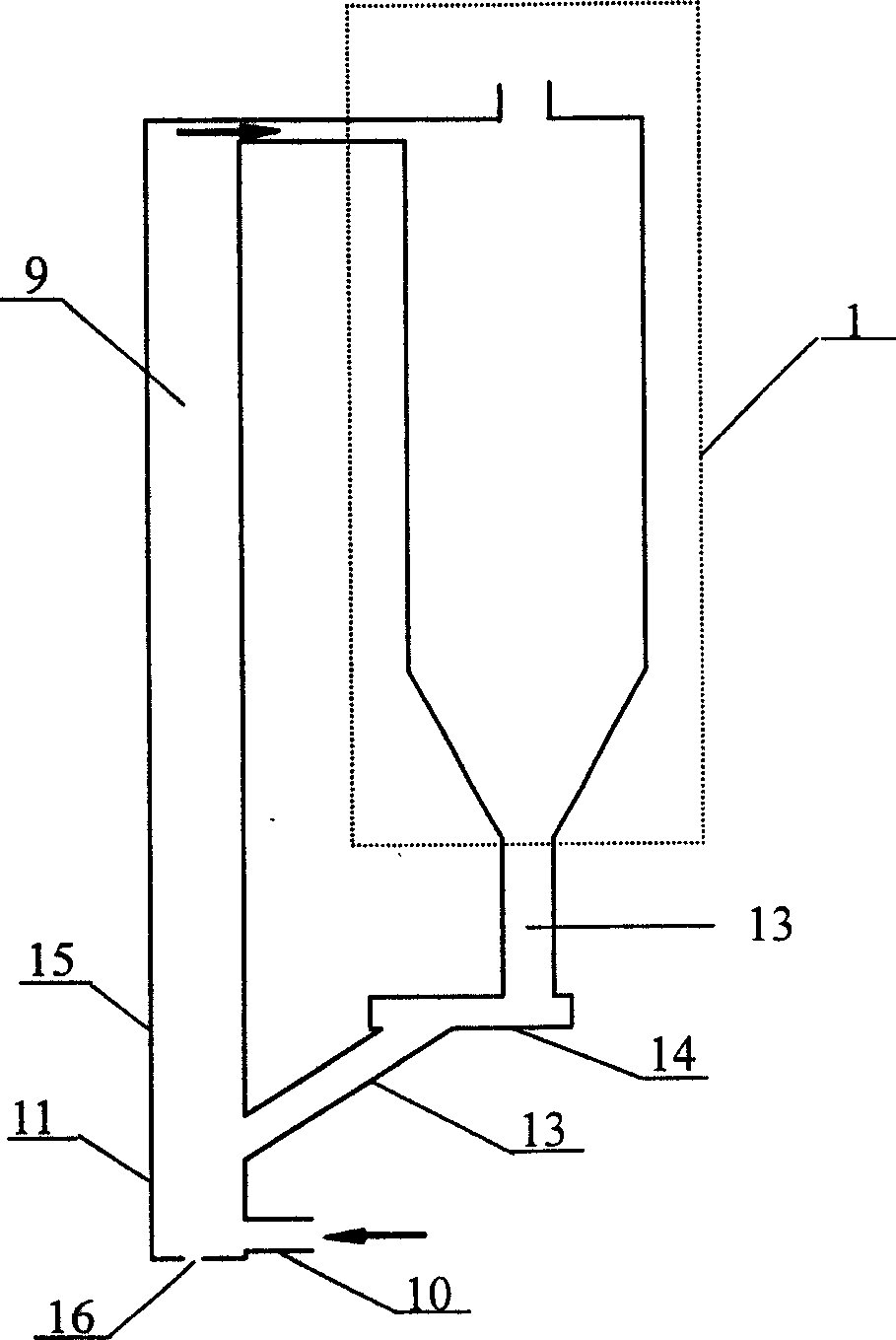

Cyclone furnace and method for improving slag captured rate of cyclone furnace

InactiveCN105114943AHigh slag collection rateCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelLiquid slagFlue gas

The invention relates to a cyclone furnace and a method for improving the slag captured rate of the cyclone furnace. The cyclone furnace comprises a cyclone furnace cyclone cylinder (2) and a central cylinder (1) additionally arranged inside the cyclone furnace cyclone cylinder (2). The method for improving the slag captured rate of the cyclone furnace comprises the steps that the cyclone furnace is adopted, after fuels are combusted in the cyclone furnace cyclone cylinder, and generated high-temperature flue gas carrying liquid slags rotates along the inner wall of the cyclone furnace cyclone cylinder and flows from top to bottom; the liquid slags are discharged through a solidified slag pool; the high-temperature flue gas returns into the cyclone furnace cyclone cylinder when flowing to the lower portion of the cyclone furnace cyclone cylinder, then flow from bottom top top from the central position of the cyclone furnace cyclone cylinder and is exhausted from the interior of the central cylinder. By adopting the cyclone furnace, the flow track of slag films can be changed, and the slag captured rate of the cyclone furnace can be improved substantially.

Owner:YANTAI LONGYUAN POWER TECH

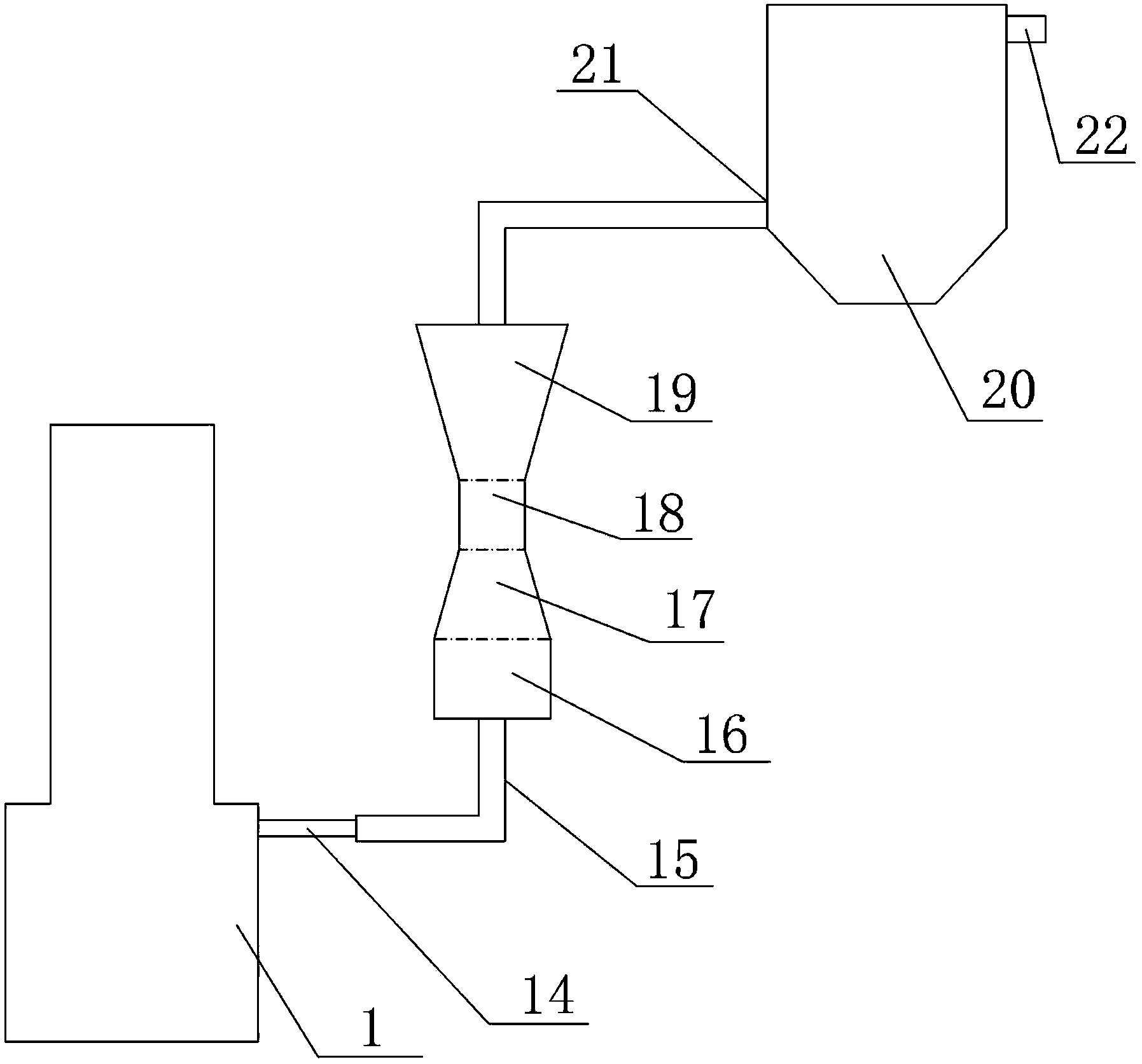

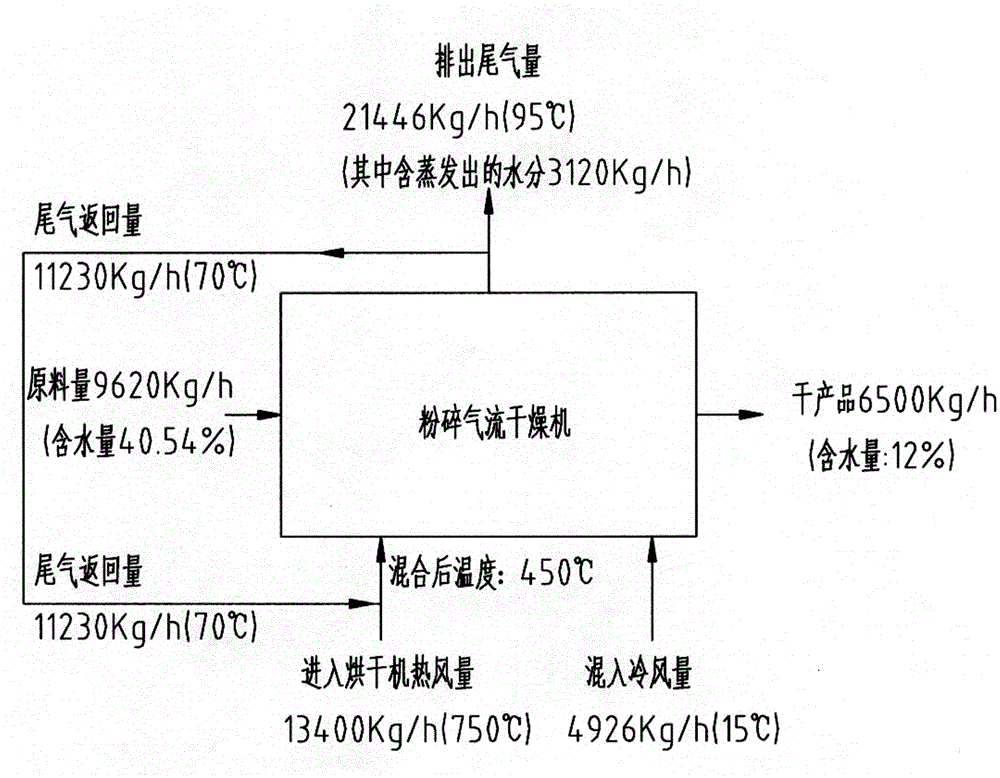

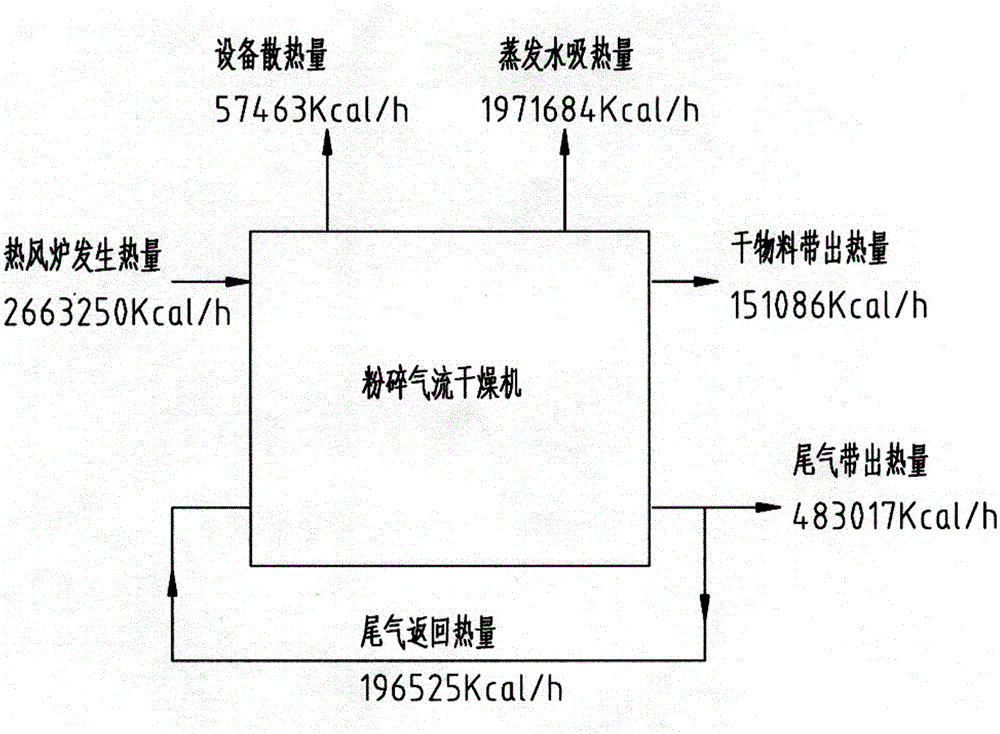

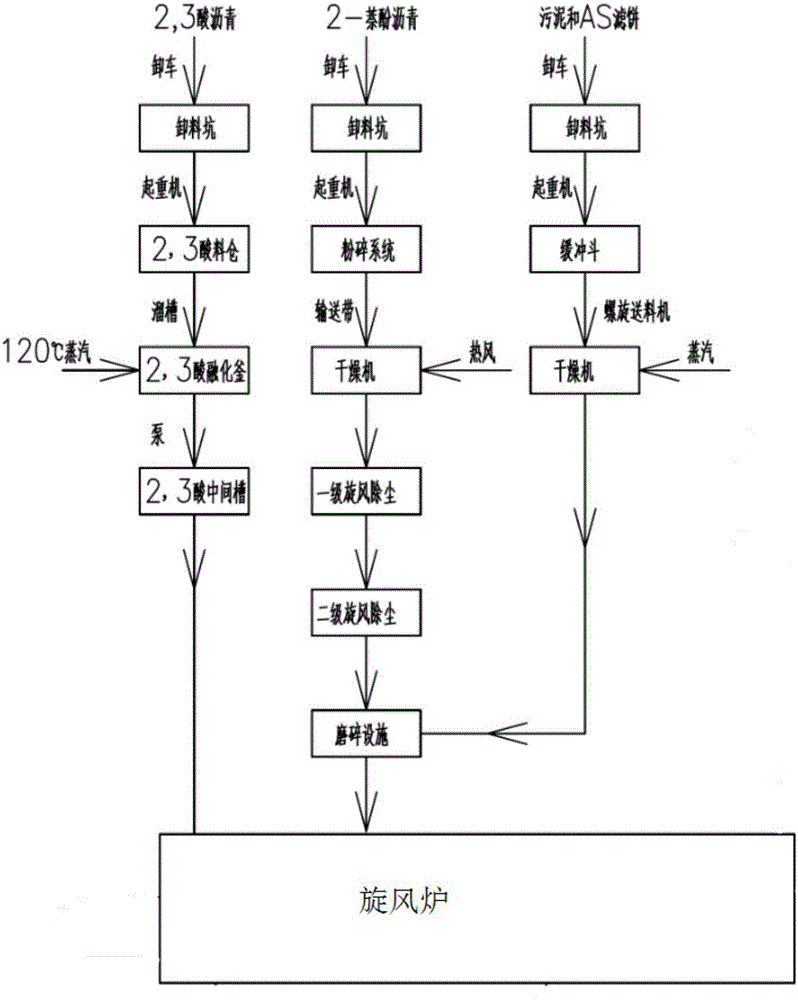

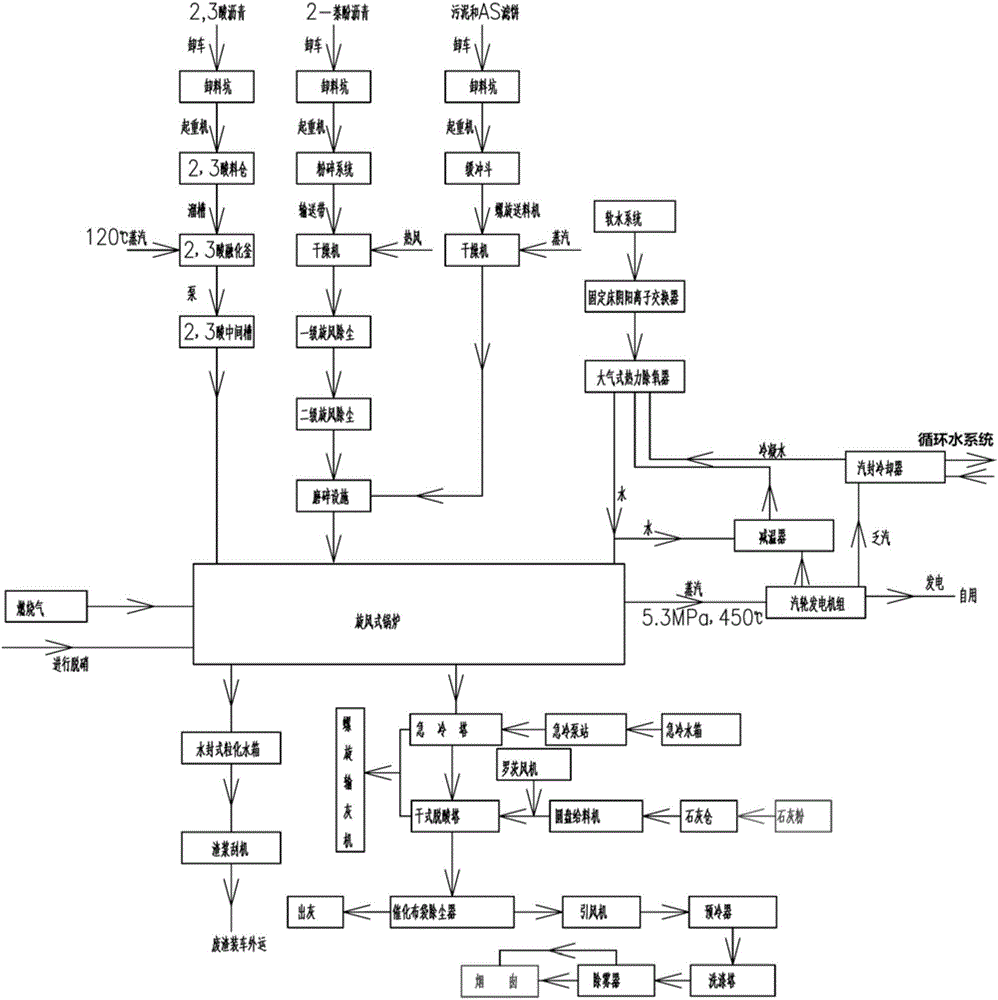

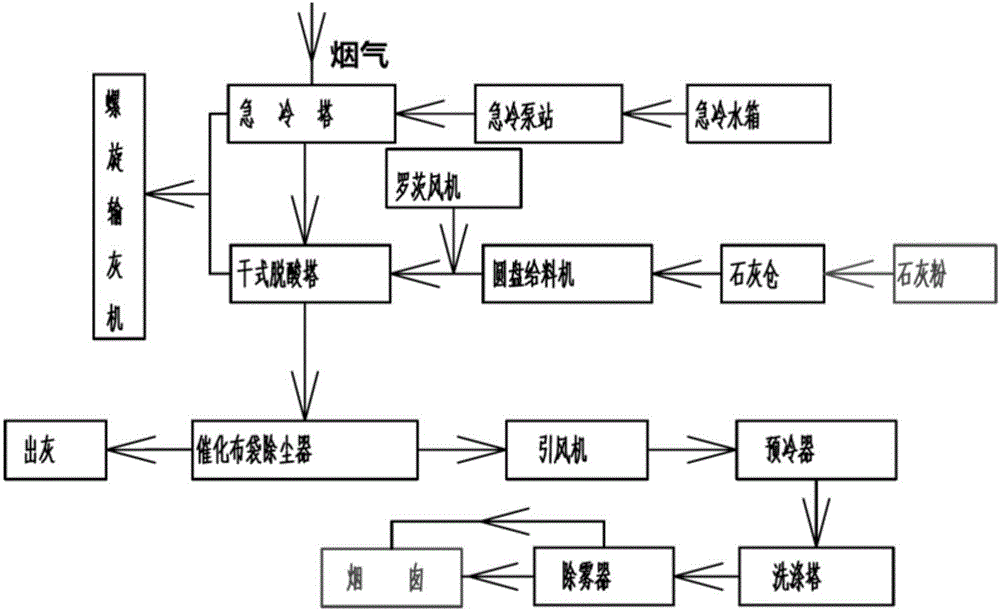

Brown coal drying technology and system

ActiveCN105135822AImprove controllabilityIncrease productionDrying solid materials with heatDrying gas arrangementsBrown coalBaghouse

The invention discloses a brown coal drying technology and system. When brown coal containing germanium is processed at present and smoke containing germanium is recycled, due to the fact that brown coal has the characteristics of being high in water content and volatile component, the requirement for production cannot be completely met through a raw material steam drying system. According to the novel brown coal drying system technology, high-temperature smoke generated in a cyclone combustion furnace and brown coal with the water content of about 40% are rapidly mixed, crushed and dried in a crushing airflow drying machine, powdery brown coal with the water content of 10-12% after water removing is brought out through airflow, and the powdery brown coal is used for a cyclone furnace after being collected by a plurality of sets of cyclone dust collectors and a plurality of sets of bag-type dust collectors. The controllability of the system is high. Due to the fact that fuel of the cyclone combustion furnace is supplied through the dried powdery brown coal in the system, the smoke containing germanium is enriched in the dried brown coal for next germanium extraction, and the yield is increased.

Owner:锡林郭勒通力锗业有限责任公司 +1

Cyclone furnace denitration system and method

PendingCN109058979AEmission reductionImprove economyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorHearth

Owner:CHINA HUANENG GRP CO LTD +1

An ultra-low temperature exhaust gas energy-saving boiler

InactiveCN102297439AImprove running stabilityCause corrosiveLighting and heating apparatusSorbentEngineering

An ultra-low temperature smoke-exhausting energy-saving boiler relates to an energy-saving boiler capable of reducing pollution discharge. The invention aims to solve the problems of low fuel utilization efficiency caused by high dust concentration and high carbon content of fly ash in exhaust gas of existing coal-fired industrial boilers, and wear and tear of heat exchange equipment such as convection tube bundles and economizers at the tail of the boiler. The upper end of the furnace body communicates with the upper end of the vertical flue through the cyclone dust collector, the bottom end of the cyclone dust collector communicates with the furnace body, and a desulfurizer spout is opened on the upper end surface of the furnace body. The invention realizes the recycling of the desulfurizer in the effective area of high-temperature sulfur fixation, greatly reduces the SO3 content in the flue gas while improving the SO2 removal efficiency, and improves the energy efficiency of the boiler by more than 10%; the unburned carbon particles are sent back for reburning The carbon content of the fly ash can be reduced to less than 2%, and at the same time, it can improve energy efficiency and reduce equipment wear. The energy-saving boiler of the invention can be used not only for newly-built boilers, but also for technical transformation of existing boilers.

Owner:HARBIN INST OF TECH

Method for gas-phase vanadium extraction by utilizing combustion of stone coals in cyclone furnace

The invention provides a method for gas-phase vanadium extraction by utilizing combustion of stone coals in cyclone furnace. After stone coals are crushed, fuels are added, and ground to powder, and the additive fuels weigh 5%-15% of the stone coal raw material. The powder and air with an oxygen content of 21%-30% are sent to a cyclone furnace, gas-state vanadium pentoxide is generated and discharged along with furnace gas, formed ash slag adheres to a cylinder wall and forms liquid-state ash membranes, which are discharged through a kettle opening. Furnace gas is mixed with cool air, cooled, dedusted by cyclones and enriched in an electrostatic fabric filter. The enrichment objects are soaked by an alkali solution to obtain a vanadium-containing soaking solution. The dust in the furnace gas is sent to a secondary spray tower, and the gas-state vanadium pentoxide is dissolved in a vanadium-containing spray solution. Sulfuric acid or hydrochloric acid are added to the two vanadium-containing solutions, and vanadium pentoxide crude products are precipitated through acid neutralization. The temperature in the furnace is high, and low-valence-state vanadium can be oxidized and gasified fully. The cyclone furnace has high slag-capturing rate, and the burden of dedusting devices is light. The powder in the furnace is thrown onto slag membranes, the resistance time is long, and the continuity and sufficiency of combustion can be maintained.

Owner:SHENWU TECH GRP CO LTD

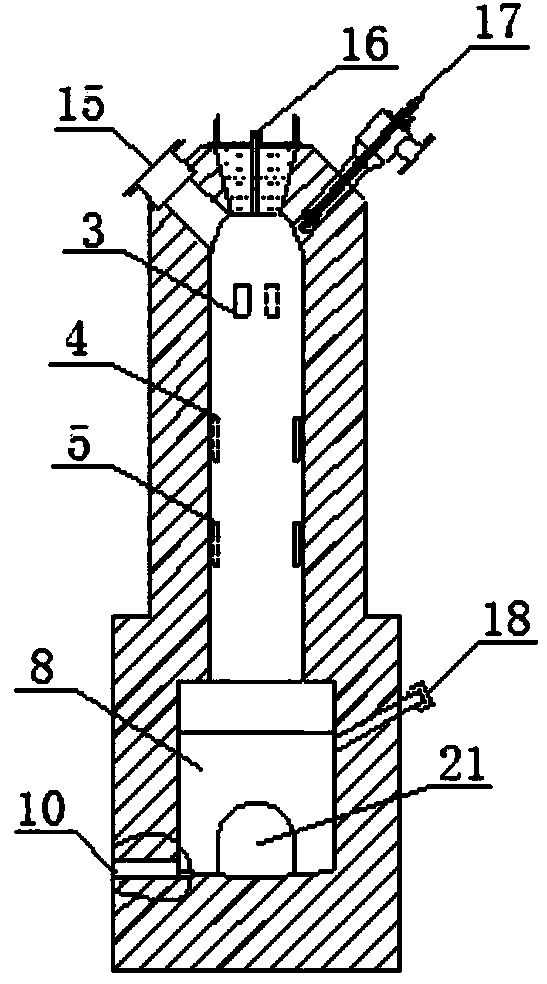

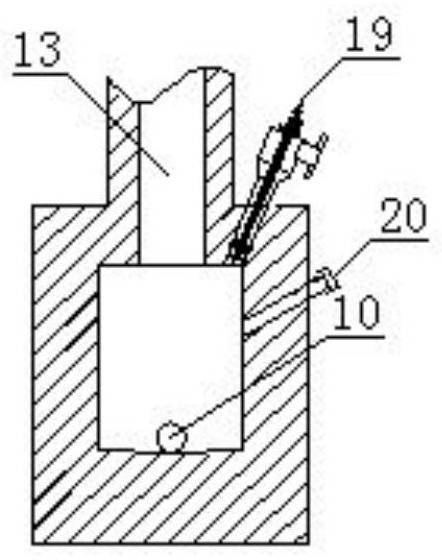

Thermal-state slag online modification device

ActiveCN103834752AReduce conventional processingSmall footprintRecycling and recovery technologiesProcess efficiency improvementThermal stateCyclone furnace

The invention relates to the fields of sensible-heat utilization of metallurgical high-temperature slag and efficient comprehensive utilization of resources, and provides a thermal-state slag online modification device. Through the device, high-quality modified slag can be prepared by use of the sensible heat of slag. The device comprises a top plug, a modification furnace body, a primary wind gap, a secondary wind gap, a third wind gap, a cyclone hearth, a stirring paddle, a partition wall, a slope pool bottom, a slag discharge hole, an iron liquid discharge hole, a scrap iron separation wall, a flue, a handle, a pressure relief hole, a combustion observation hole, an ignition burner, a modification chamber observation hole, a concurrent heating burner, a slag discharge chamber observation hole, a liquid flow hole, a charging hole, a sampling hole, a modification chamber, a scrap iron separation chamber, a slag discharge chamber and a cyclone furnace body. The high-quality modified slag after the treatment by the device can be directly applied to the fields such as building materials and industries; the metal iron can be recycled from the iron-containing slag. The device is simple to operate, low in operation cost and wide in application range, and has relatively good application prospect and economic value.

Owner:京津冀钢铁联盟(迁安)协同创新研究院有限公司

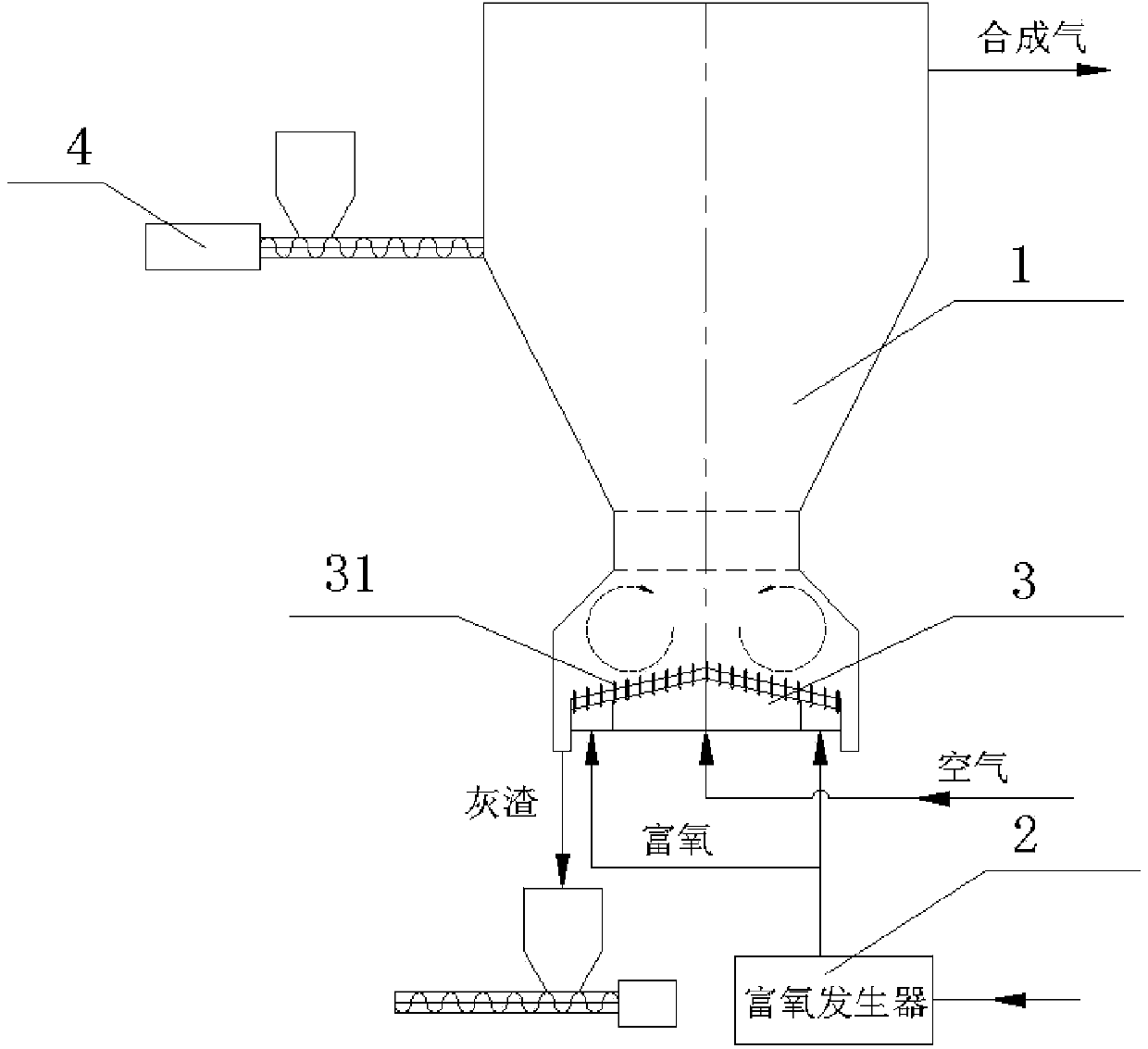

Response operator for gasifying solid fuels

InactiveCN1519298AImprove responseExtended reaction timeCombustible gas productionInlet channelSludge

A gasifying reactor of solid fuel (coal, sludge, or solid waste) has a cyclone furnace consisting of a cylindrical upper part with a top cover having a central gas discharge tube, and a conic lower part with an ash dischaging opening on its bottom. Said cyclone furnace has a solid inlet channel and a gas supplementing channel, which are spiral in same direction relative to the side wall of cyclone furnace.

Owner:中科清能燃气技术(北京)有限公司

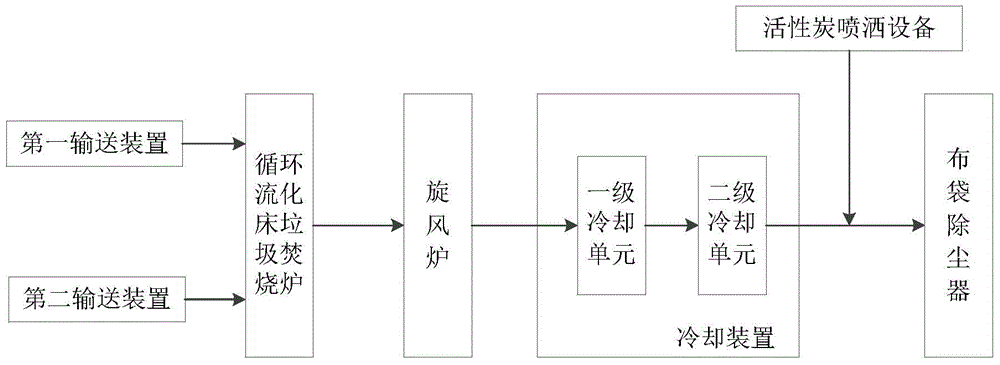

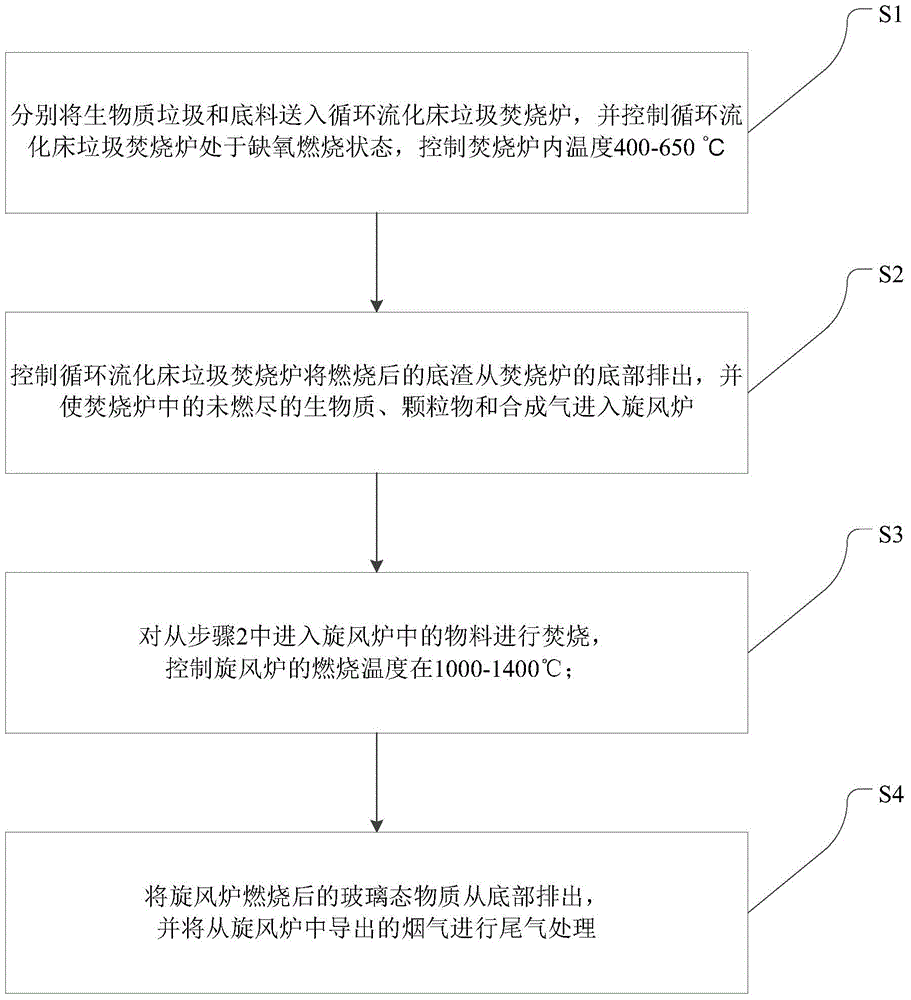

Biomass garbage combustion system and method

InactiveCN104949131ASolve slaggingSolve dust accumulationEmission preventionIncinerator apparatusCombustion systemHigh probability

The invention provides a biomass garbage combustion system and method. The garbage combustion system comprises a first conveying device, a second conveying device, a circulating fluidized bed garbage incinerator and a cyclone furnace, wherein the first conveying device and the second conveying device are communicated with a feeding port of the circulating fluidized bed garbage incinerator respectively; the circulating fluidized bed garbage incinerator is used for combusting biomass garbage primarily and is provided with a bottom slag discharging port and a smoke outlet, the bottom slag discharging port is used for discharging bottom slag after combustion in the circulating fluidized bed garbage incinerator, and the smoke outlet is communicated with the cyclone furnace and used for guiding unburnt biomass and fly ash in the circulating fluidized bed garbage incinerator into the cyclone furnace for combustion; the cyclone furnace is used for combusting materials entering the cyclone furnace secondarily, so that the biomass and the fly ash are molten into glass materials and discharged from the bottom, and produced smoke is guided out for follow-up treatment. The biomass garbage combustion system and method can effectively solve the problems of high probability of coking and ash accumulation, lower incineration temperature and the like caused by high content of alkali metal in the biomass.

Owner:BEIJING CHINA SCI GENERAL ENERGY & ENVIRONMENT CO LTD

Solid waste incineration cyclone furnace and incineration process for liquid slag of solid waste incineration cyclone furnace

InactiveCN106524178AReasonable structureRealization of slaggingIncinerator apparatusCombustion chamberLiquid slag

The invention discloses a solid waste incineration cyclone furnace and an incineration process for liquid slag of the solid waste incineration cyclone furnace. A pre-chamber is arranged at the top end of a secondary combustion chamber and the top end of a cyclone; the top of the pre-chamber is connected with a spray burner; the spray burner is connected with solid waste conveying equipment; the secondary combustion chamber is connected at one side of the cyclone; a gas exhaust opening of the secondary combustion chamber is connected with a waste heat utilization and tail gas treatment device; a slag outlet of the secondary combustion chamber is connected with the bottom of the cyclone through an inclined conveying device; a slag bar is arranged on the bottom of the cyclone; and a kettle opening used for collecting flowing slag is formed in the slag bar. A liquid slag-discharge incineration process for the solid waste incineration cyclone furnace can incinerate multiple industrial wastes such as solid waste, thick asphalt waste and waste gas, realizes liquid discharge, and can realize waste heat utilization.

Owner:山东济宁阳光环保动力工程设计院有限公司 +3

Formaldehyde waste gas treatment system

InactiveCN107726339ATake advantage ofImprove combustion efficiencyIncinerator apparatusChemical reactionEngineering

The invention discloses a formaldehyde waste gas treatment system. The formaldehyde produced during the chemical reaction of rubber making in a reaction kettle is connected to a fan through a pipeline, and the outlet of the fan is connected to a secondary fan through a pipeline. The air outlet of the secondary fan is It is connected with the pipeline leading to the boiler, and the pipeline protruding into the furnace is welded with sub-pipes. The number of the sub-pipes is at least six, and the sub-pipes are inserted into the furnace at a certain angle. The angle to which each sub-pipe is arranged is based on the cyclone that can be formed when inserted into the furnace. When preparing urea-formaldehyde resin adhesive, formaldehyde and urea are mixed in a certain molar ratio in a reactor, and react in the reactor to form a urea-formaldehyde resin. In this technical solution, after the rubber-making chemical reaction is carried out in the reactor, the formaldehyde waste gas produced is led to the boiler through the pipeline, and is fully burned in the furnace to generate water and carbon dioxide, thereby improving the combustion efficiency and fully utilizing the waste gas.

Owner:河南鑫饰板业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com