System and method for gasification melting of household refuse and treatment of household refuse leachate

A technology for landfill leachate and domestic waste, which is applied in the field of domestic waste gasification and melting and its leachate treatment system, can solve the problems of low exhaust gas temperature efficiency, high exhaust gas temperature, insufficient fuel burning rate, etc. The effect of utilization, improving carbon conversion rate, and increasing the calorific value of garbage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

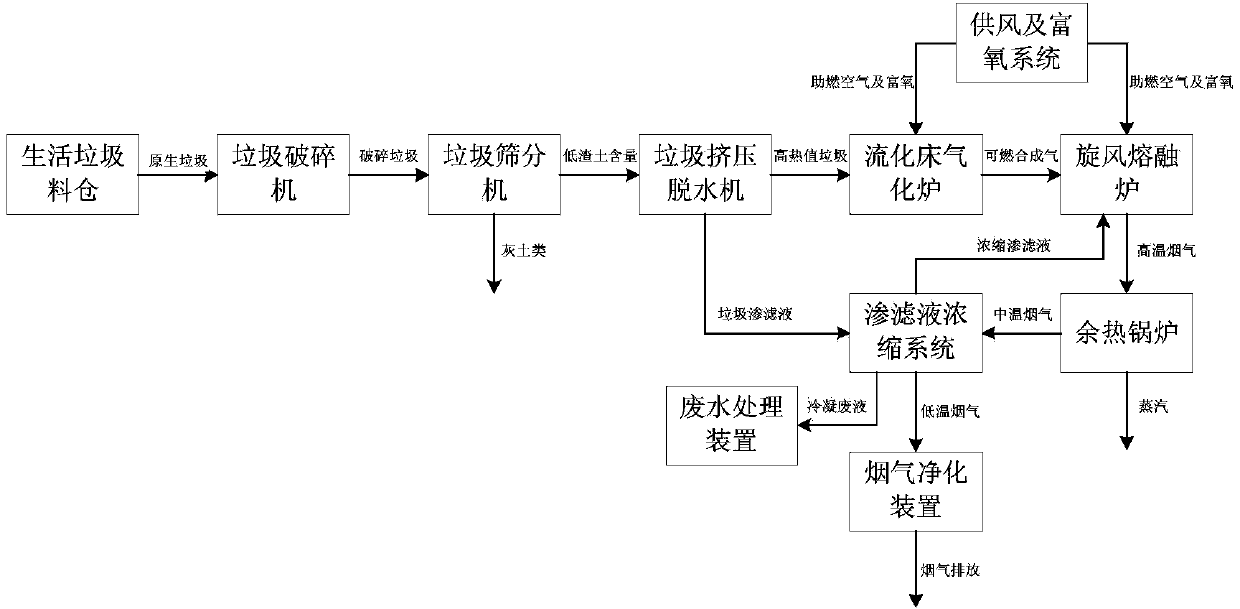

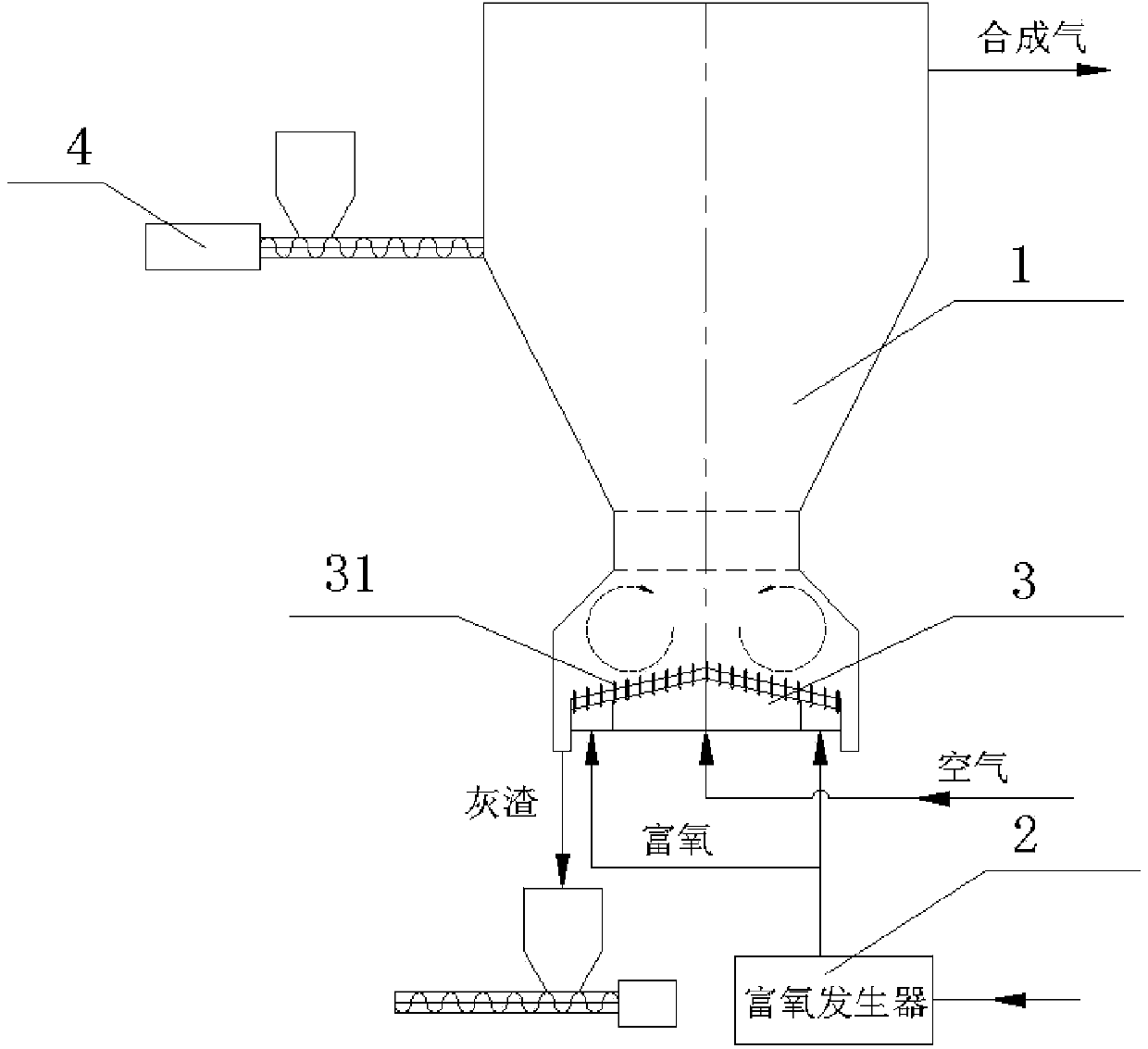

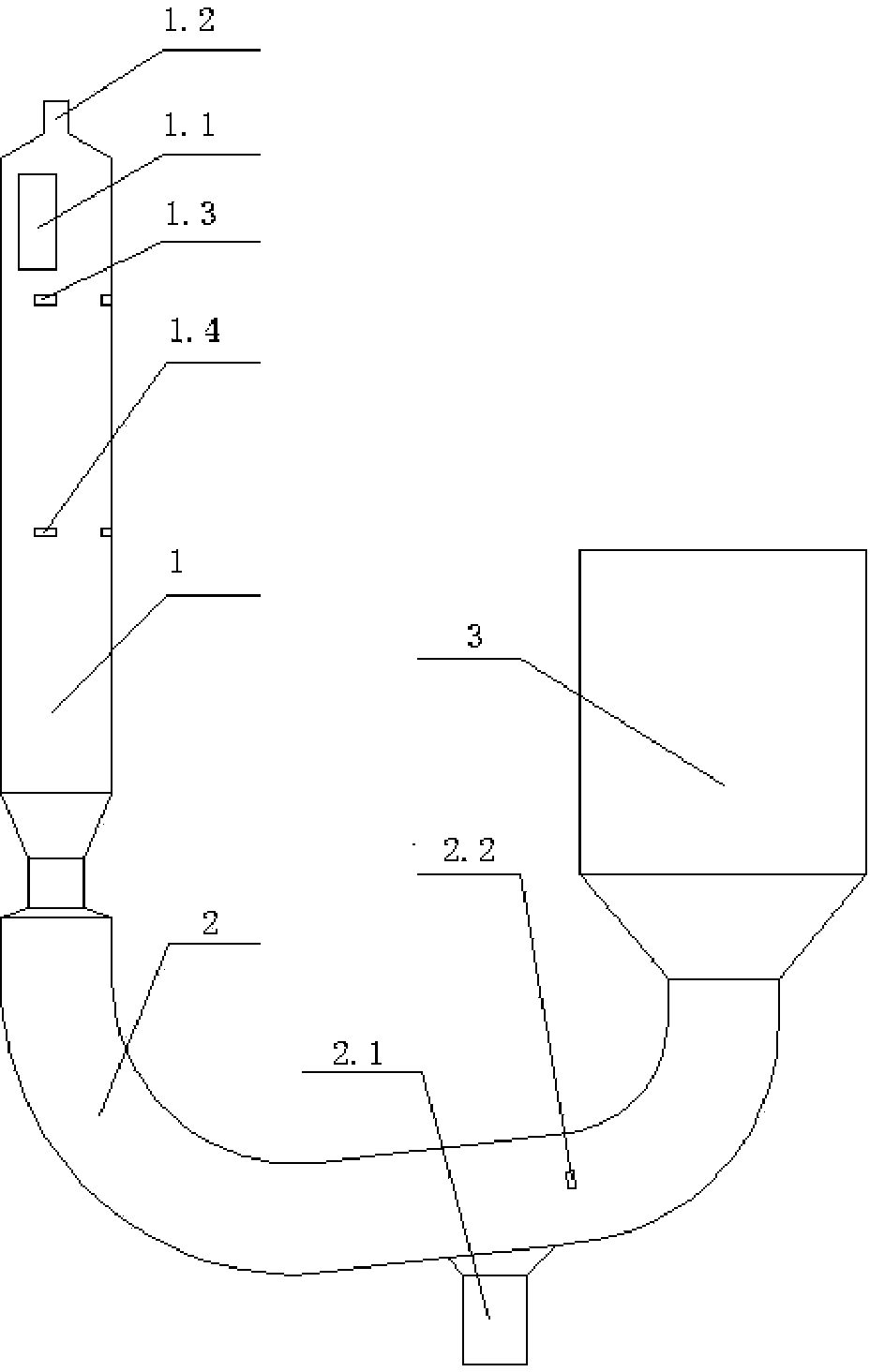

[0039] The present invention will be further described below in conjunction with the accompanying drawings. see Figure 1 to Figure 6 As shown in (b), the present invention is a domestic waste gasification melting and leachate treatment system, including a domestic waste pretreatment system, waste energy recovery system, waste leachate concentration and flue gas treatment system.

[0040] The domestic waste pre-treatment system consists of a domestic waste silo, a domestic waste crusher, a domestic waste screening machine, and a domestic waste extrusion dehydrator. Raw garbage is collected from the clearing station and stored in the domestic garbage silo. After being crushed by the garbage crusher, it enters the garbage screening machine. After the dusty soil waste with a particle size of less than 2mm is removed by screening, it enters the garbage extrusion dehydrator and passes through the extrusion machine. Pressure dehydration reduces the moisture content of garbage, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com