Cyclone furnace denitration system and method

A cyclone furnace and denitration technology, which is applied in the combustion method, the combustion of lump fuel and powder fuel, and emission prevention, etc., can solve the problems of SCR catalyst poisoning, reduction of cyclone furnace emissions, and high cyclone furnace emissions, so as to ensure stable operation. , Ensure treatment efficiency and treatment effect, and reduce NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

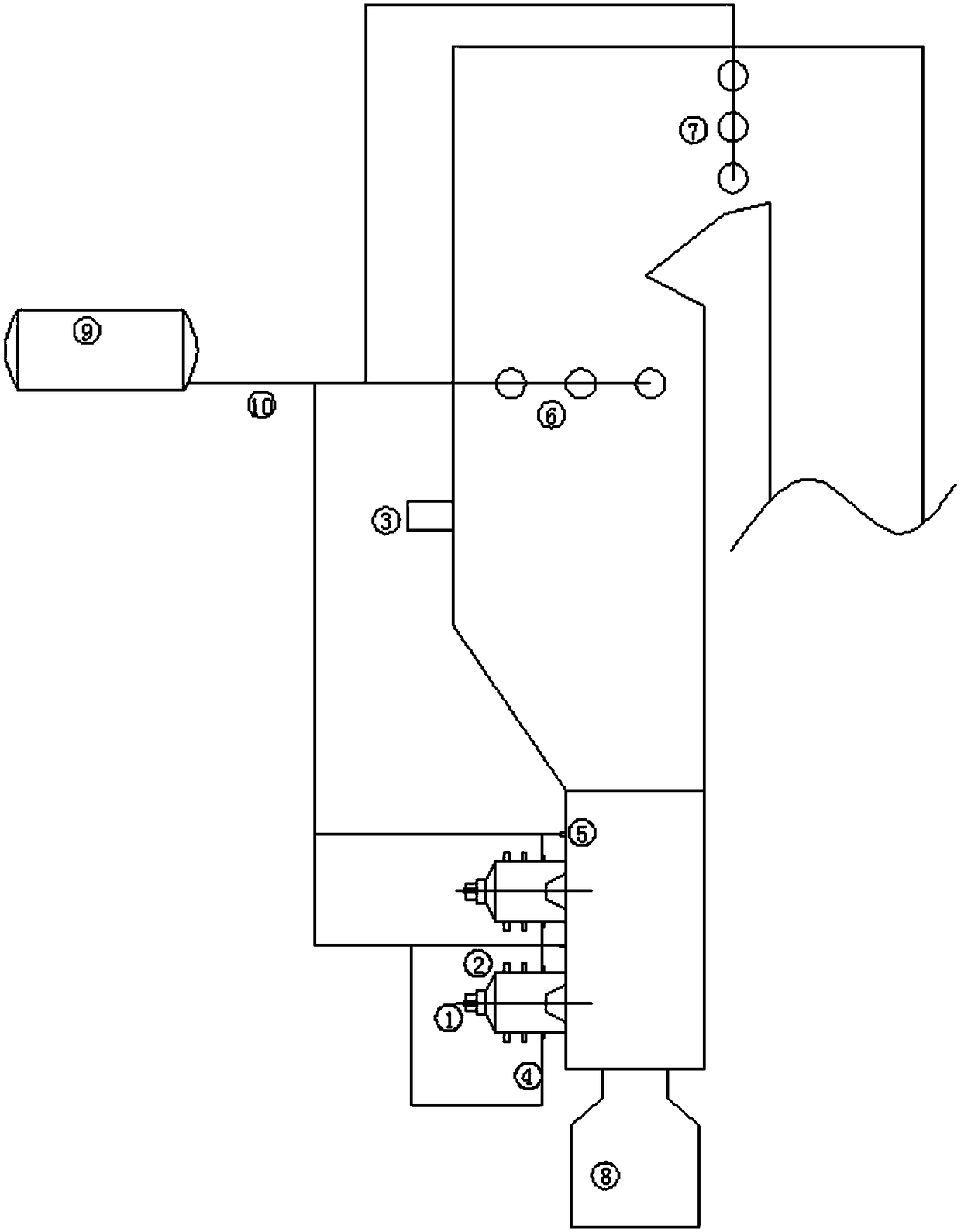

[0034] The present invention as figure 1 As shown, the cyclone furnace is equipped with two rows of cyclone burners; the primary air of the cyclone burner enters from the axial direction of the cyclone through the primary air inlet 1, and the secondary air of the cyclone burner enters from the cyclone through the secondary air inlet 2. The side wall of the cylinder enters tangentially, and part of the secondary air enters the furnace from the graded air inlet 3 on the upper part of the cyclone furnace furnace as graded wind; the first nozzle 4 of the amino reducing agent is arranged on the cylinder wall of the cyclone cylinder burner, and the amino reduction The second nozzle 5 of the agent is arranged on the side wall of the furnace above the cyclone burner; the first nozzle of the SNCR is arranged in the upper part of the furnace, and the second nozzle of the SNCR is arranged in the top flue of the furnace; the slag pool at the bottom of the cyclone furnace 8, and communicat...

Embodiment 2

[0038]Step 1: The coal powder is carried by the primary air, and enters the cyclone burner axially from the cyclone burner through the primary air inlet 1, and the secondary air enters the cyclone burner from the side wall of the cyclone burner through the secondary air inlet 2, At the same time, part of the secondary air enters the furnace interior through the grading air inlet 3 as the grading air;

[0039] Step 2: The pulverized coal entering the cyclone burner is ignited in the high-temperature reduction zone of the cyclone burner, and after burning, it forms liquid slag and flue gas carrying fly ash; the classified wind reduces the oxygen content in the combustion zone of the furnace, making the furnace The internal local area is in a reducing atmosphere as a whole, creating conditions for injecting the amino reducing agent; open the first nozzle 4 of the amino reducing agent or the second nozzle 5 of the amino reducing agent, and reduce the ammonia gas or urea and other a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com