Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1872results about "Combustion using liquid and pulverulent fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

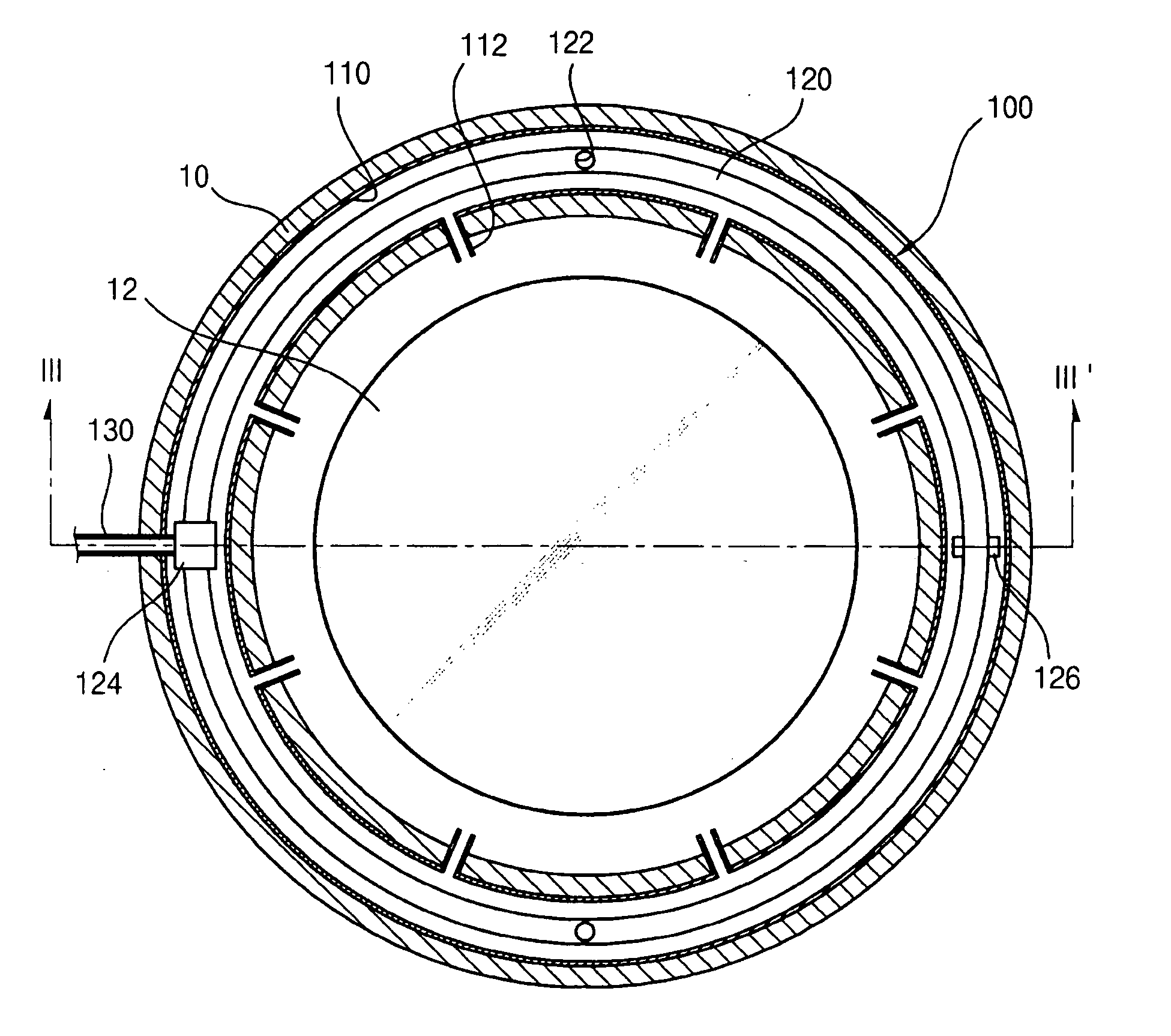

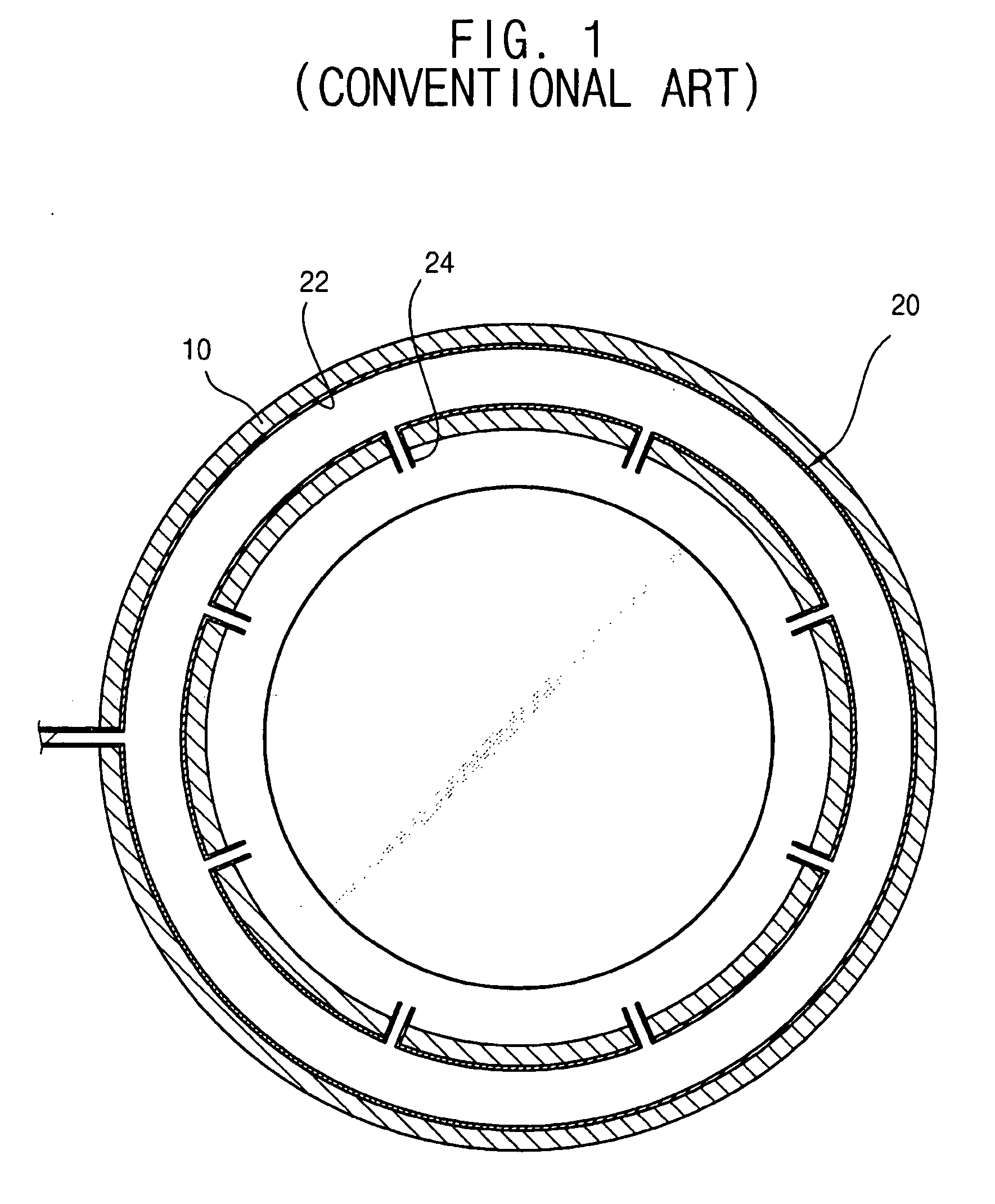

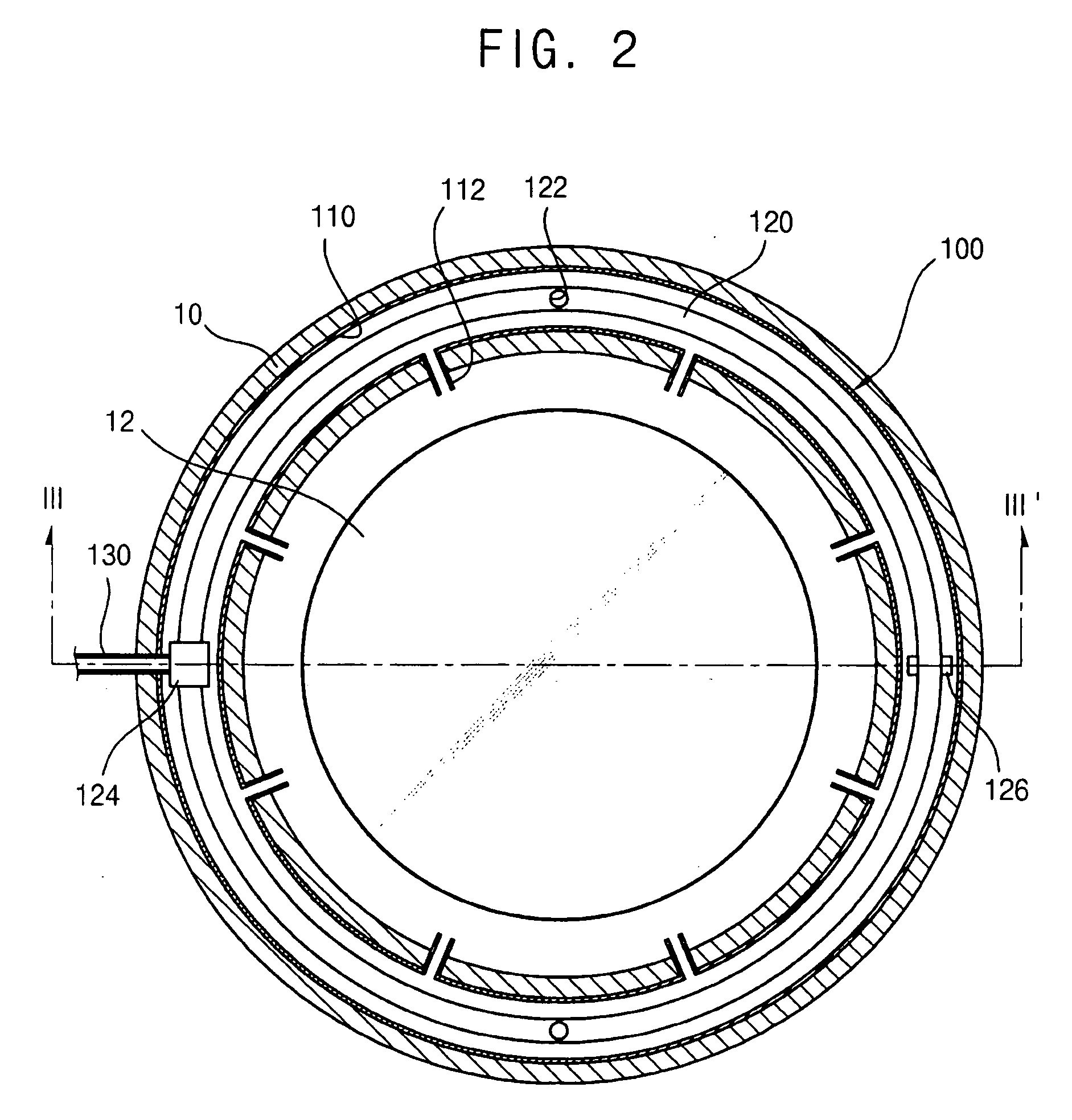

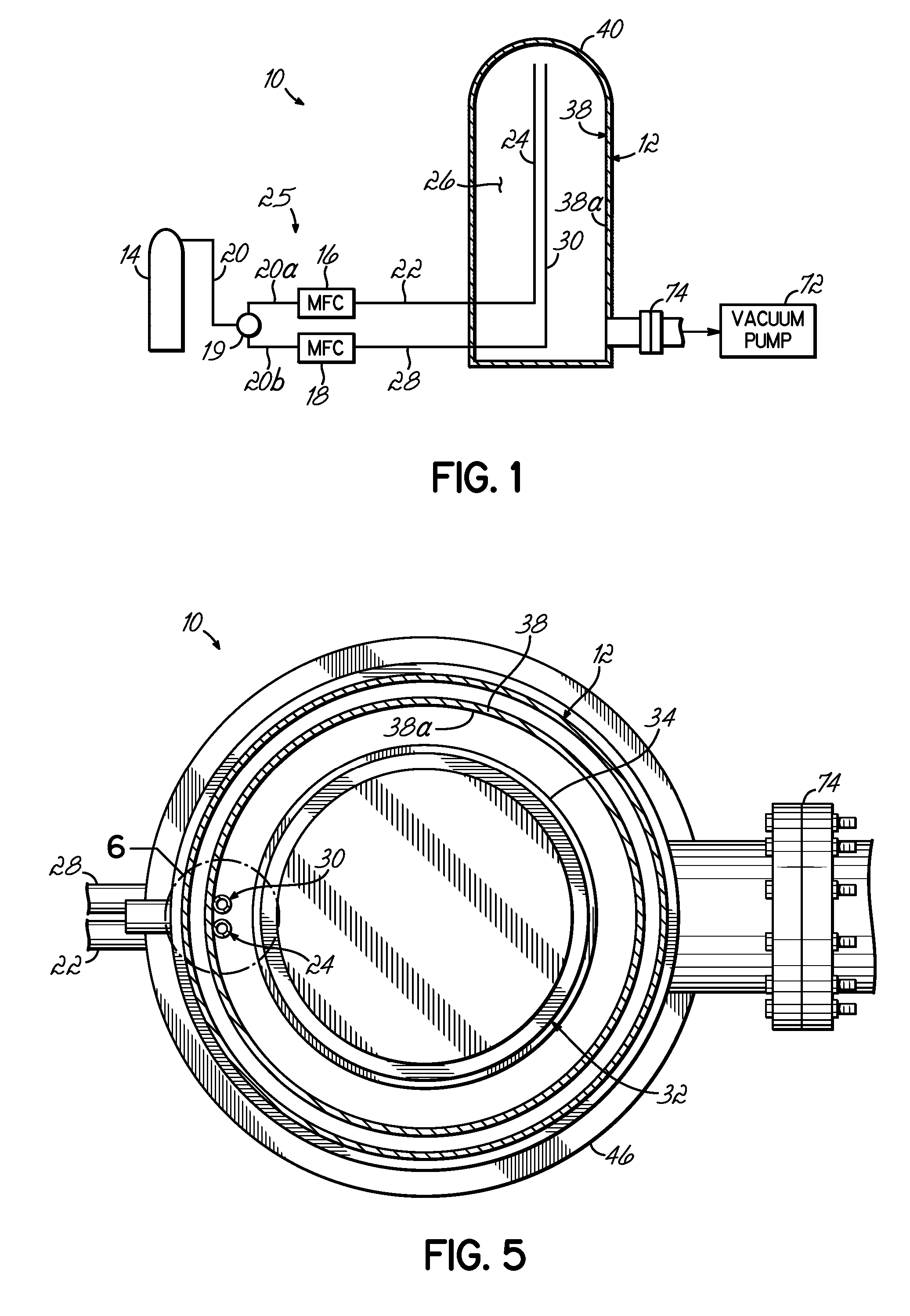

Gas supply device and apparatus for processing a substrate

InactiveUS20070087296A1Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelProcess engineeringGas supply

A gas supply device may include a first gas supply member that may be disposed in a chamber and around a substrate loaded in the chamber. The first gas supply member may include nozzles for providing a gas onto the substrate. A second gas supply member that may provide the gas supplied from at least one gas supply line to the first gas supply member.

Owner:SAMSUNG ELECTRONICS CO LTD

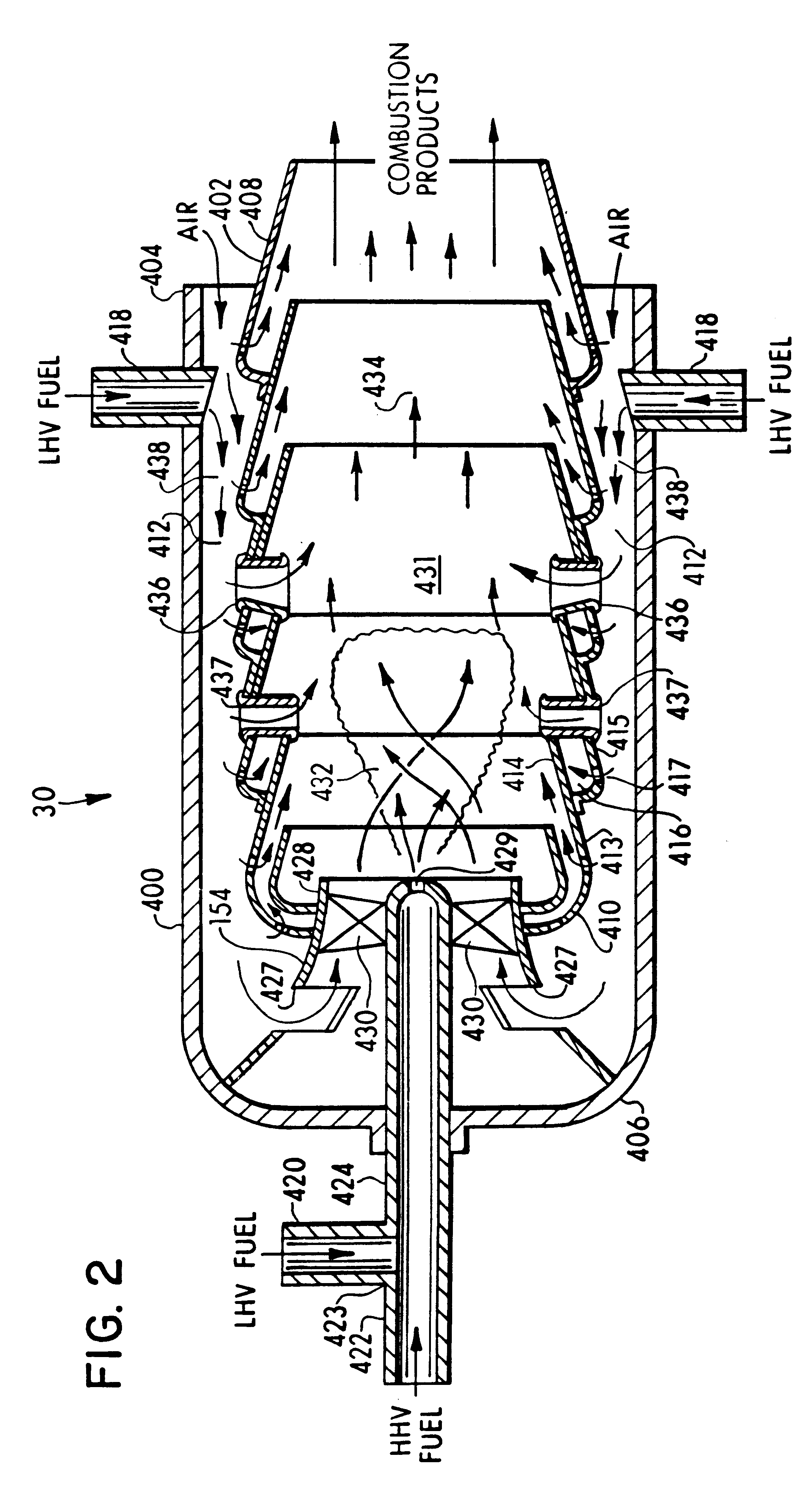

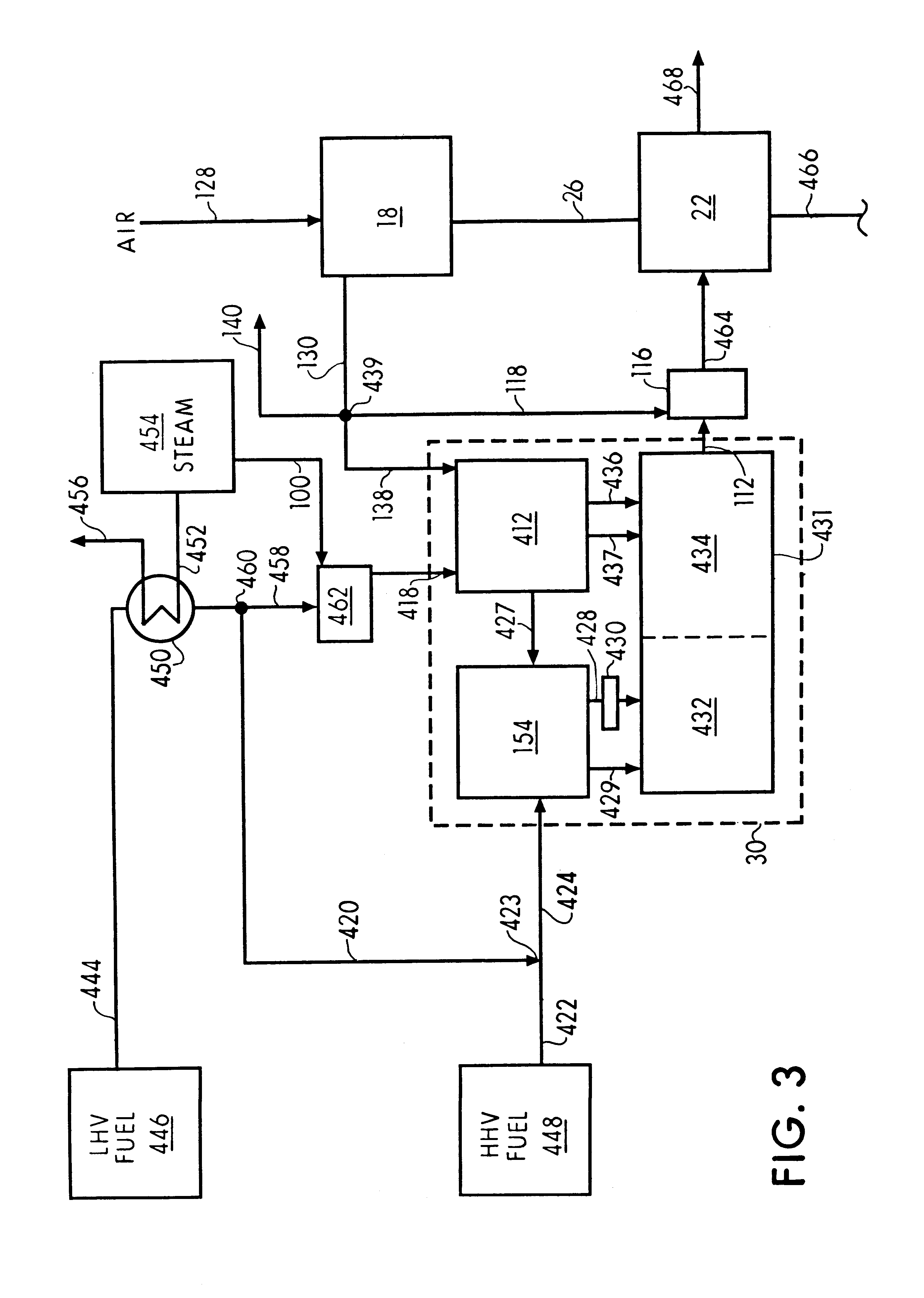

Staged combustion of a low heating value fuel gas for driving a gas turbine

A process is provided for combusting a low heating value fuel gas in a combustor to drive an associated gas turbine. A low heating value fuel gas feed is divided into a burner portion and a combustion chamber portion. The combustion chamber portion and a combustion air are conveyed into a mixing zone of the combustor to form an air / fuel mixture. The burner portion is conveyed into a flame zone of the combustor through a burner nozzle while a first portion of the air / fuel mixture is conveyed into the flame zone through a burner port adjacent to the burner nozzle. The burner portion and first portion of the air / fuel mixture are contacted in the flame zone to combust the portions and produce flame zone products. The flame zone products are conveyed into an oxidation zone of the combustor downstream of the flame zone while a second portion of the air / fuel mixture is also conveyed into the oxidation zone. The second portion is combusted in the oxidation zone in the presence of the flame zone products to produce combustion products. The combustion products are conveyed into the associated gas turbine and drive the gas turbine.

Owner:MARATHON OIL CO +1

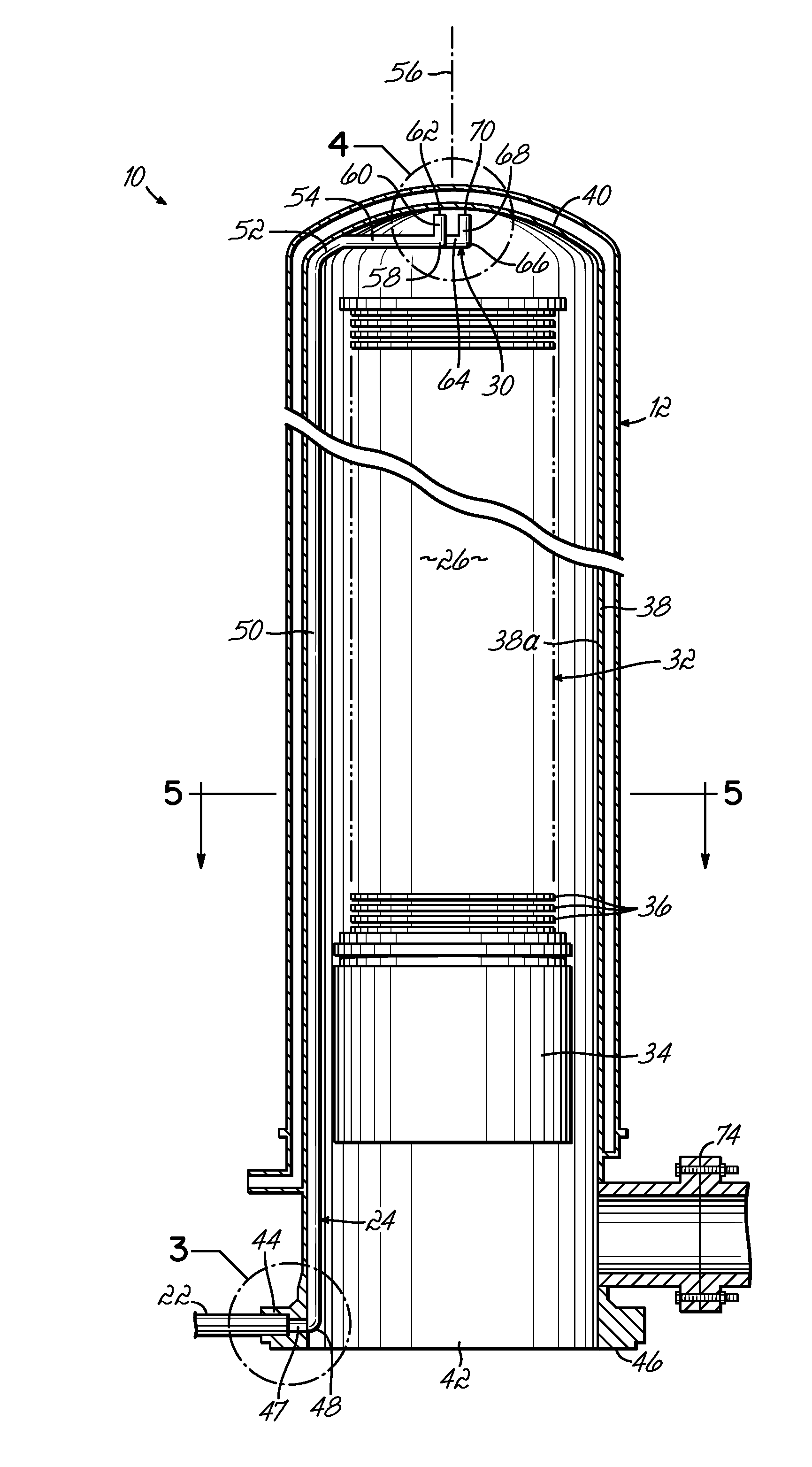

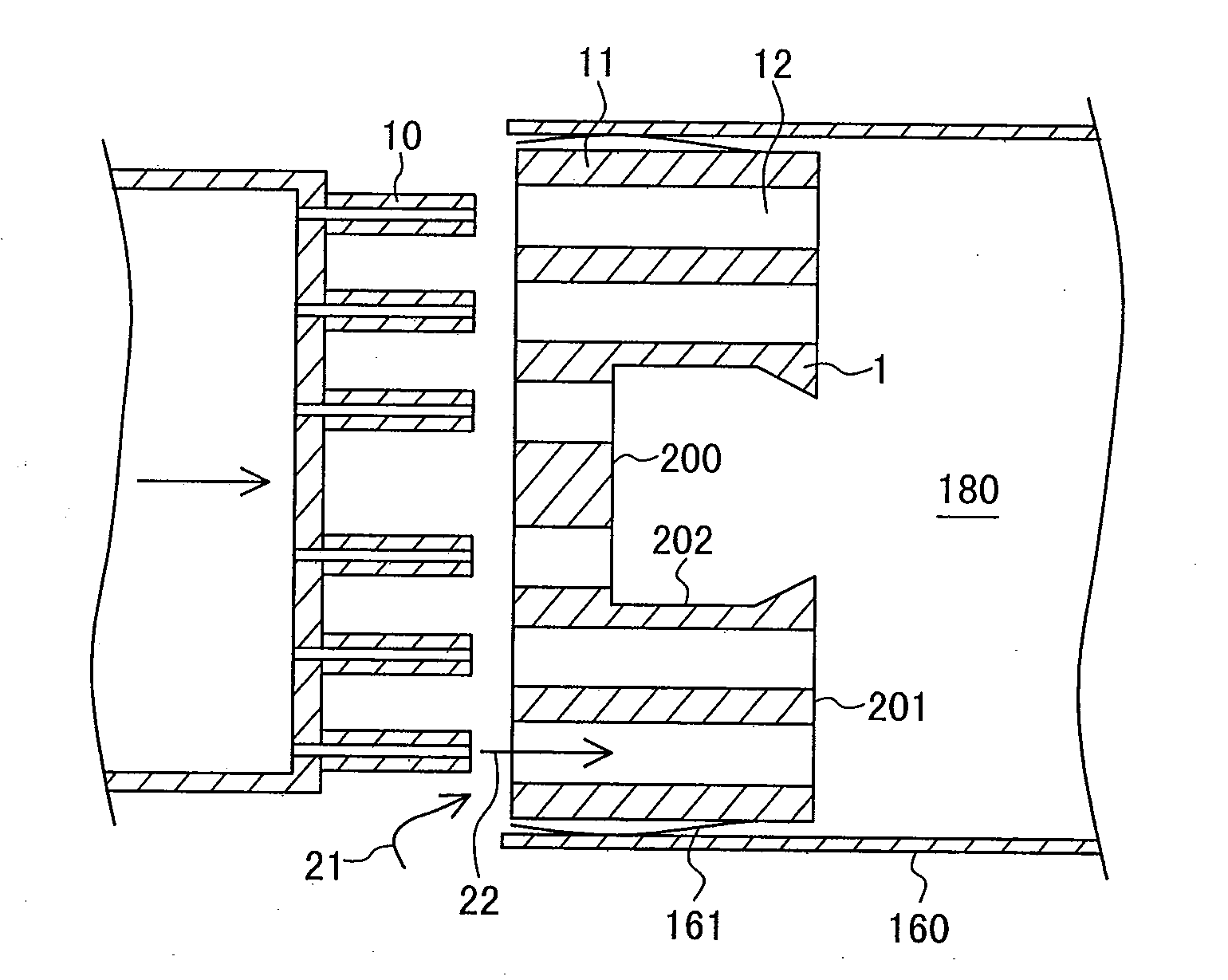

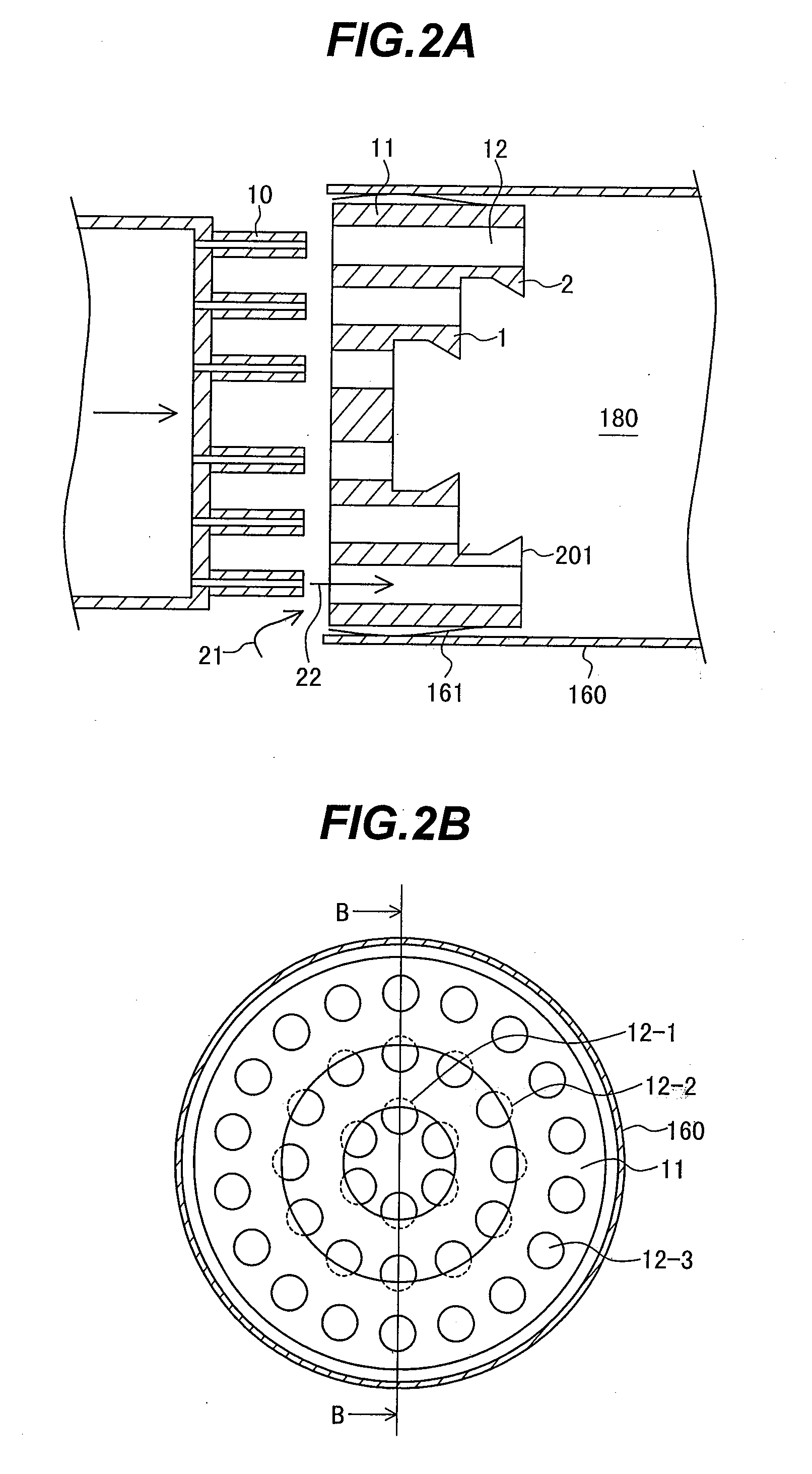

Thermal processing furnace, gas delivery system therefor, and methods for delivering a process gas thereto

InactiveUS7910494B2After-treatment apparatusCombustion using gaseous and pulverulent fuelProcess engineeringGas supply

A gas delivery system for supplying a process gas from a gas supply to a thermal processing furnace, a thermal processing furnace equipped with the gas delivery system, and methods for delivering process gas to a thermal processing furnace. The gas delivery system comprises a plurality of regulators, such as mass flow controllers, in a process gas manifold coupling a gas supply with a thermal processing furnace. The regulators establish a corresponding plurality of flows of a process gas at a plurality of flow rates communicated by the process gas manifold to the thermal processing furnace. The gas delivery system may be a component of the thermal processing furnace that further includes a liner that surrounds a processing space inside the thermal processing furnace.

Owner:TOKYO ELECTRON LTD

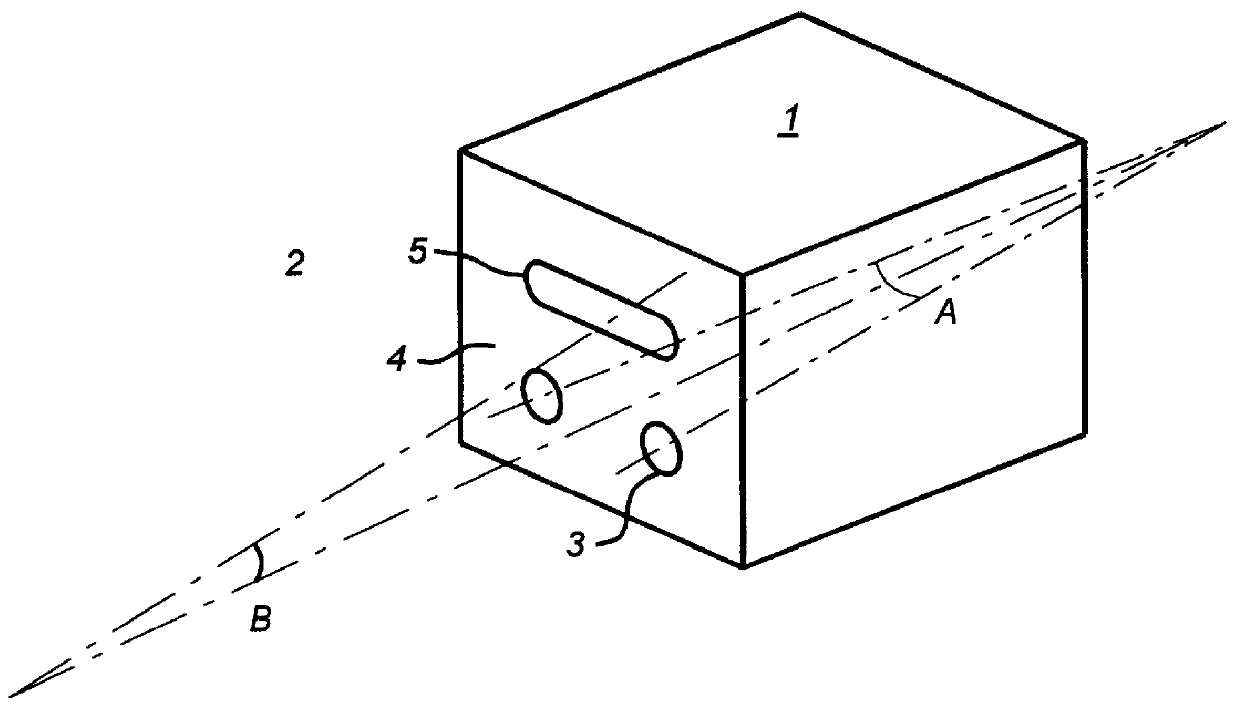

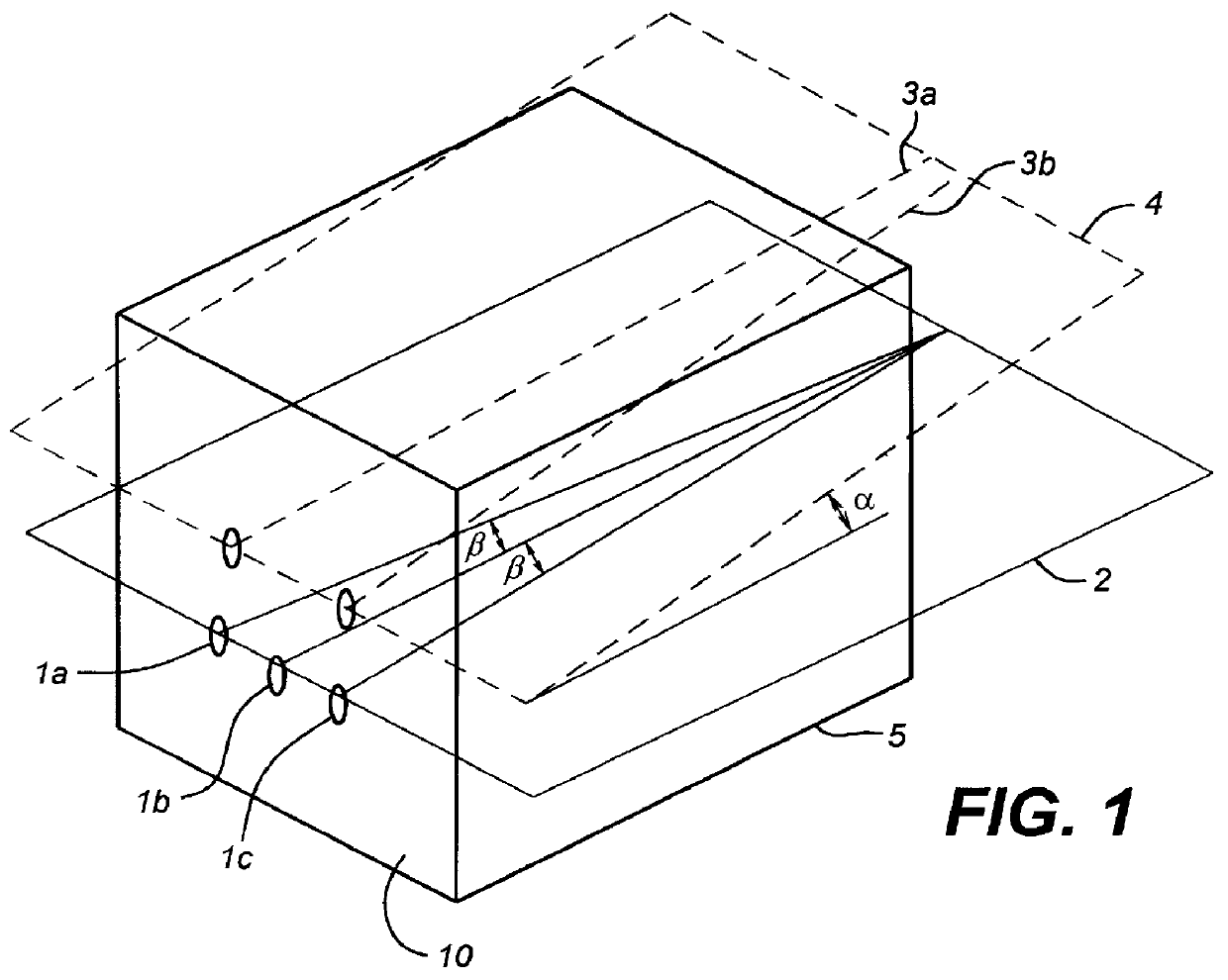

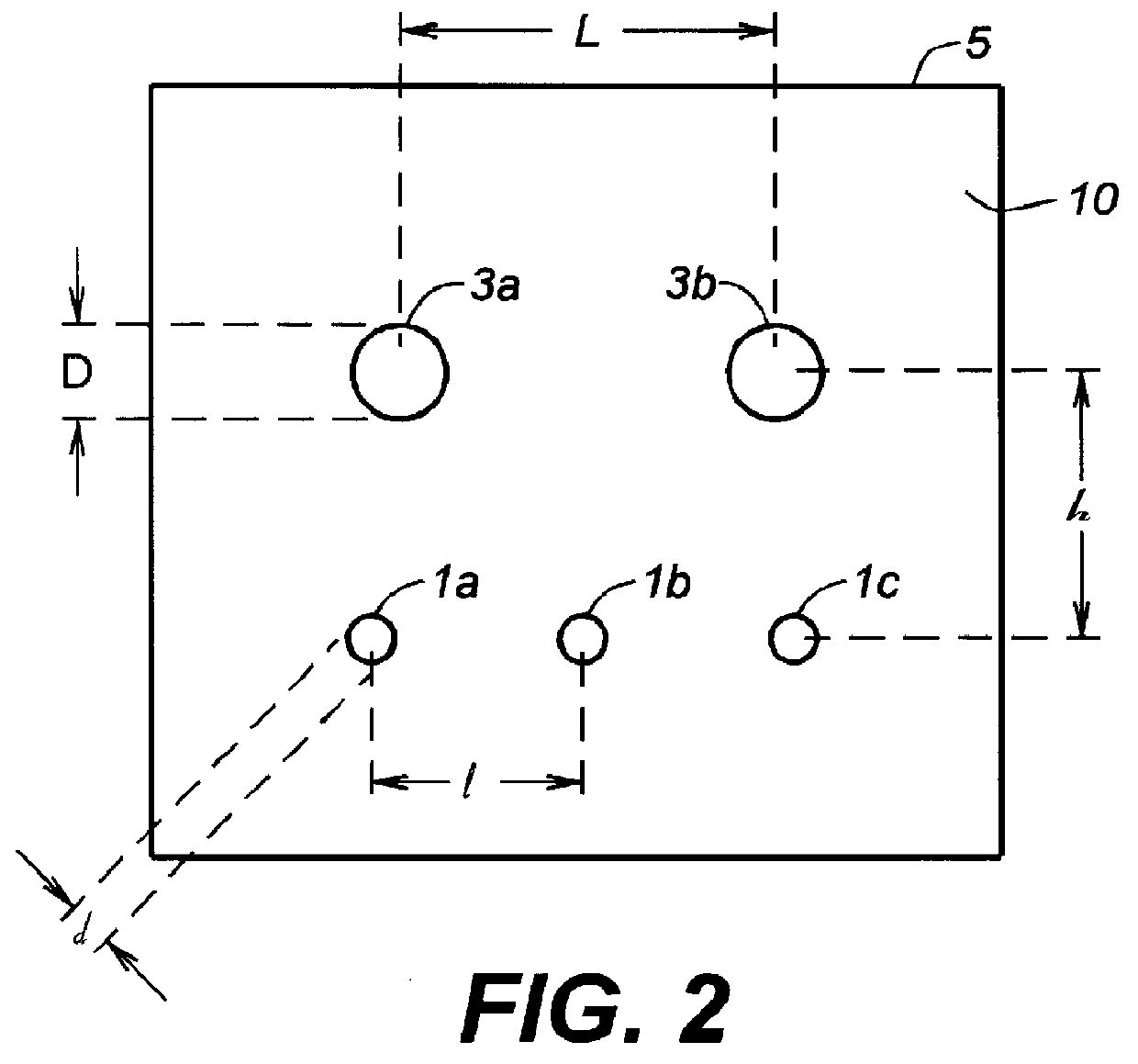

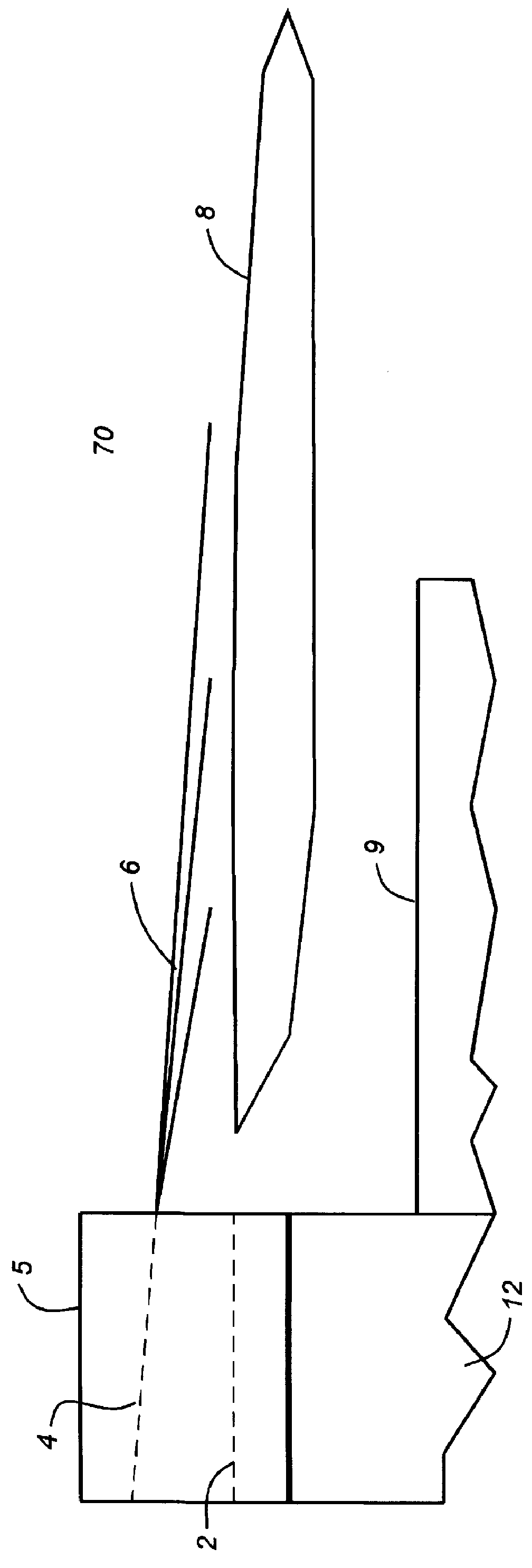

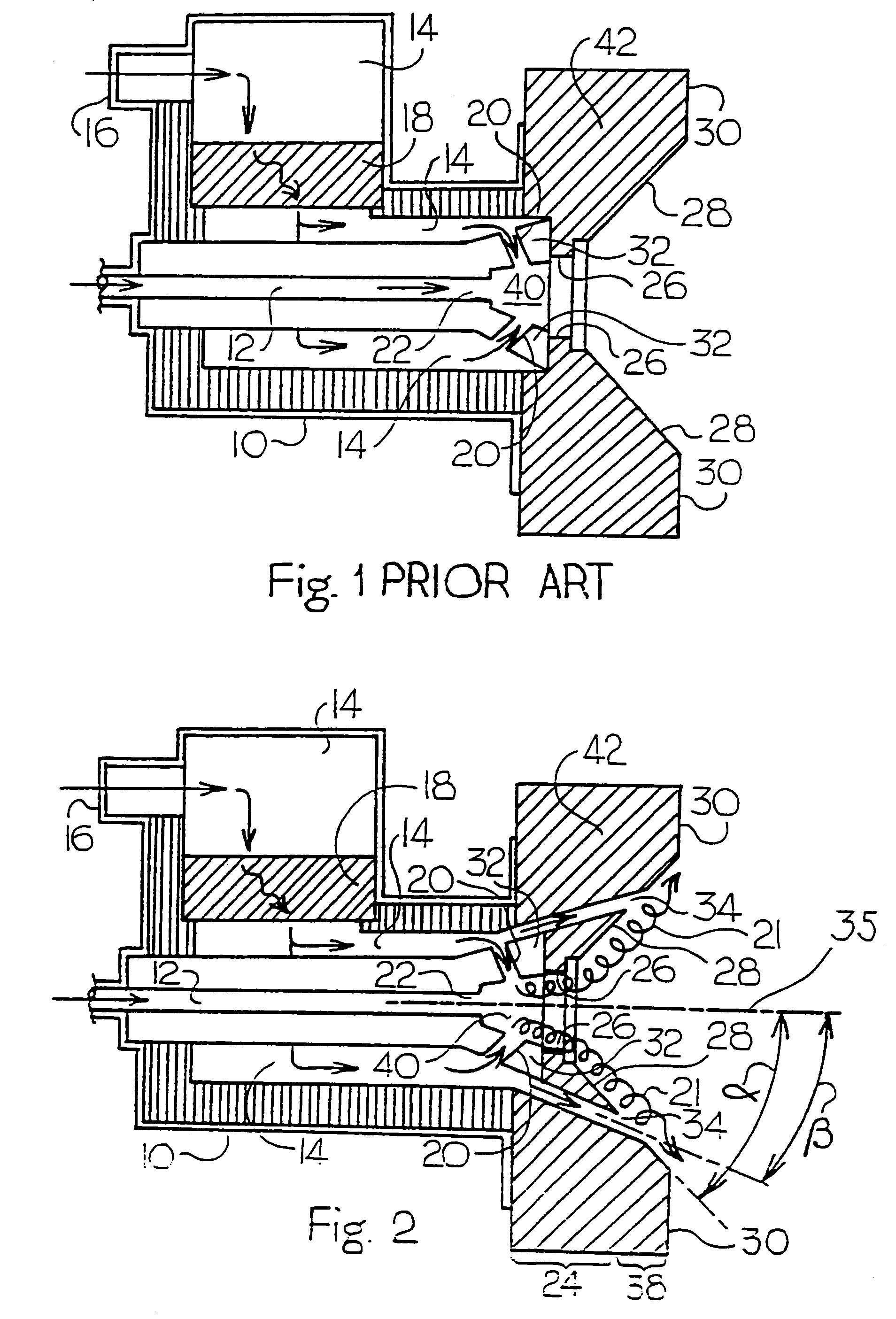

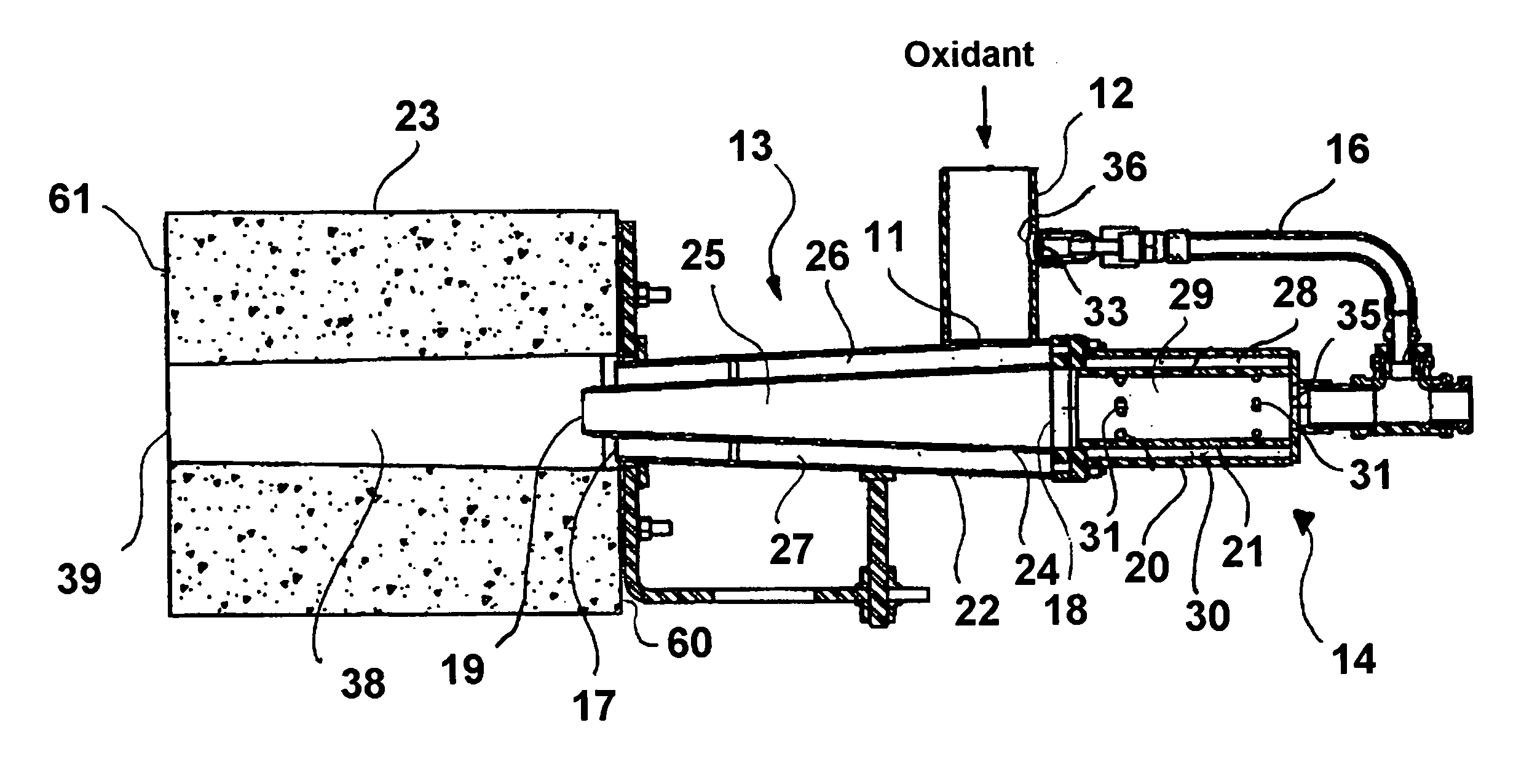

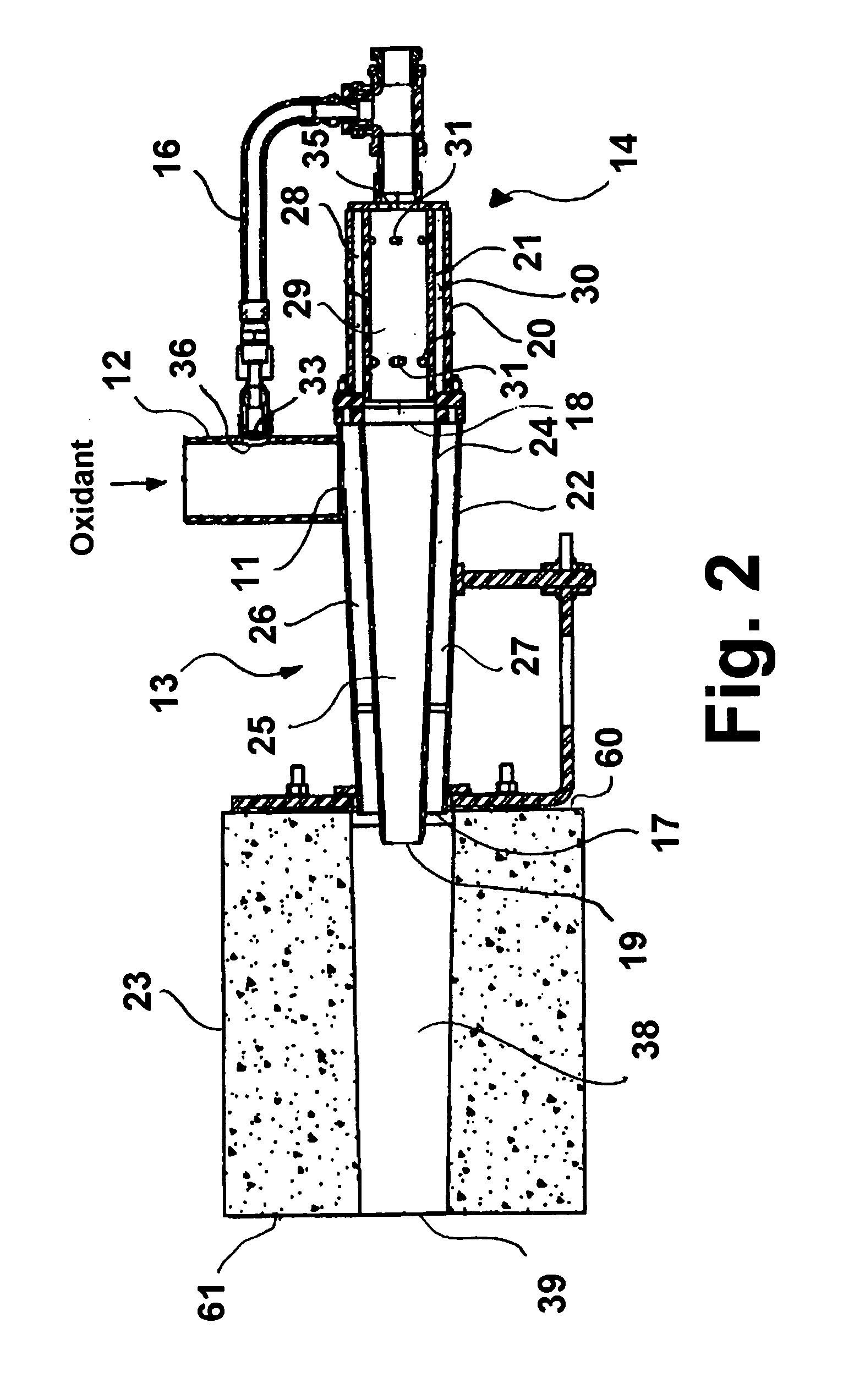

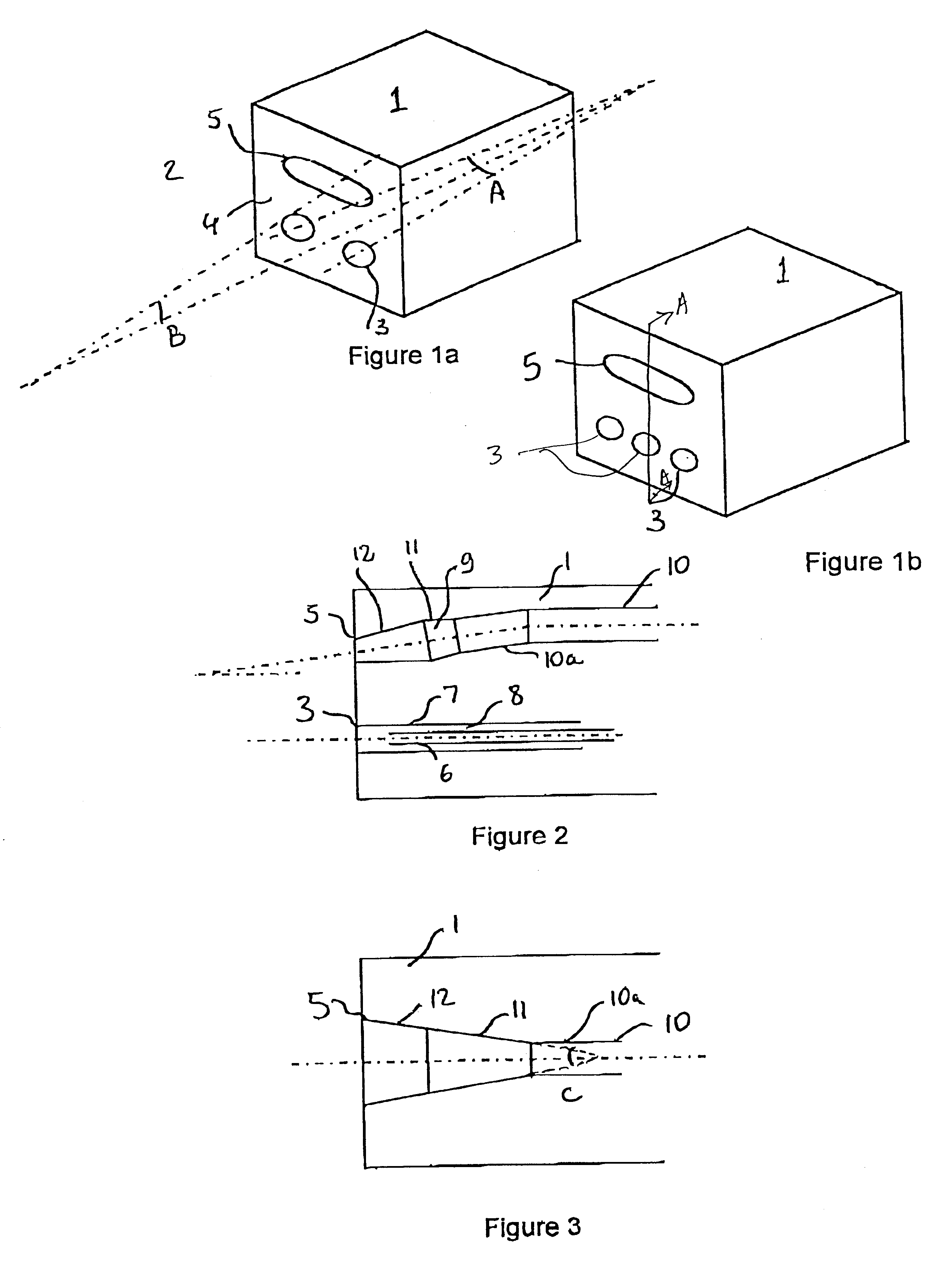

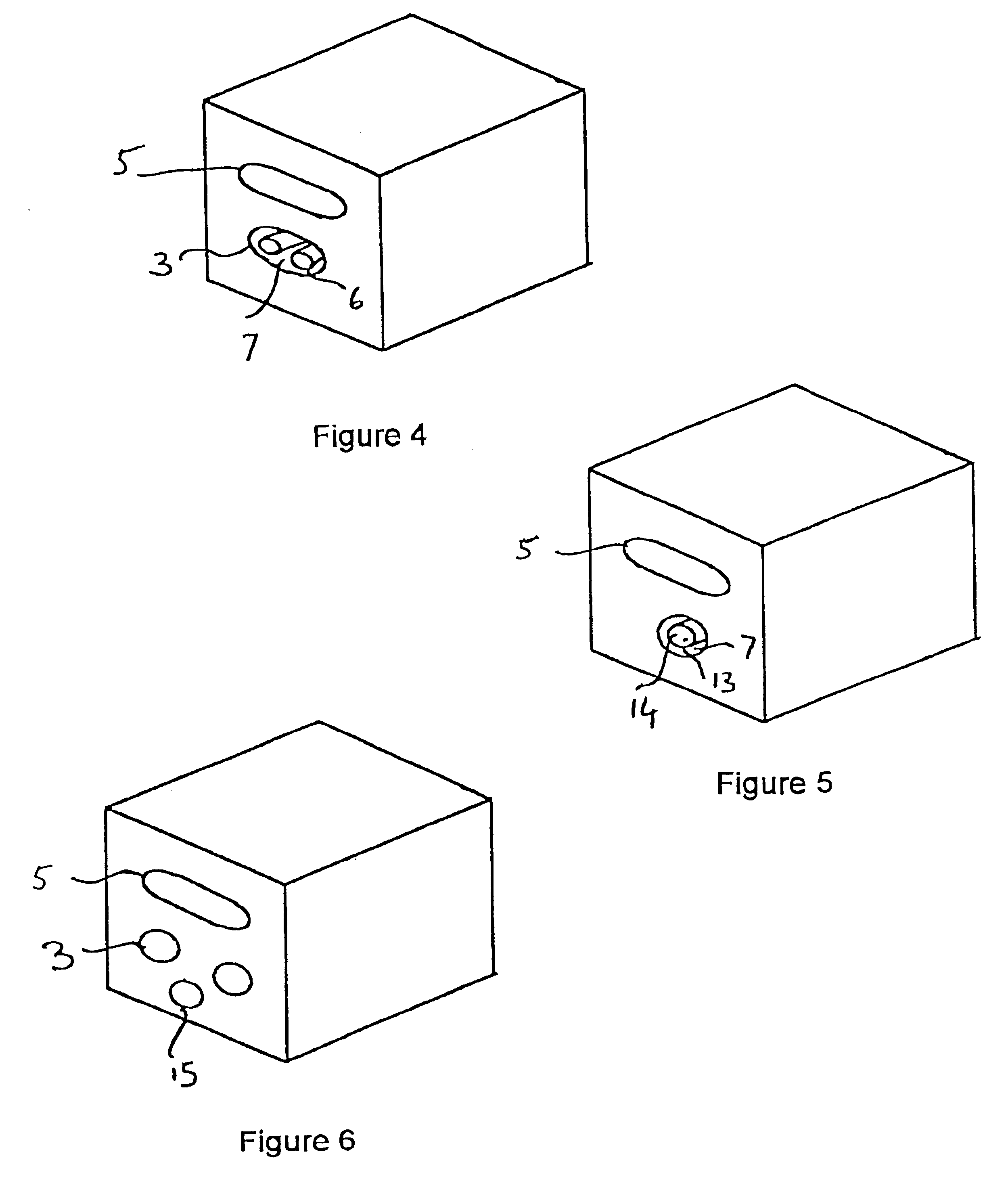

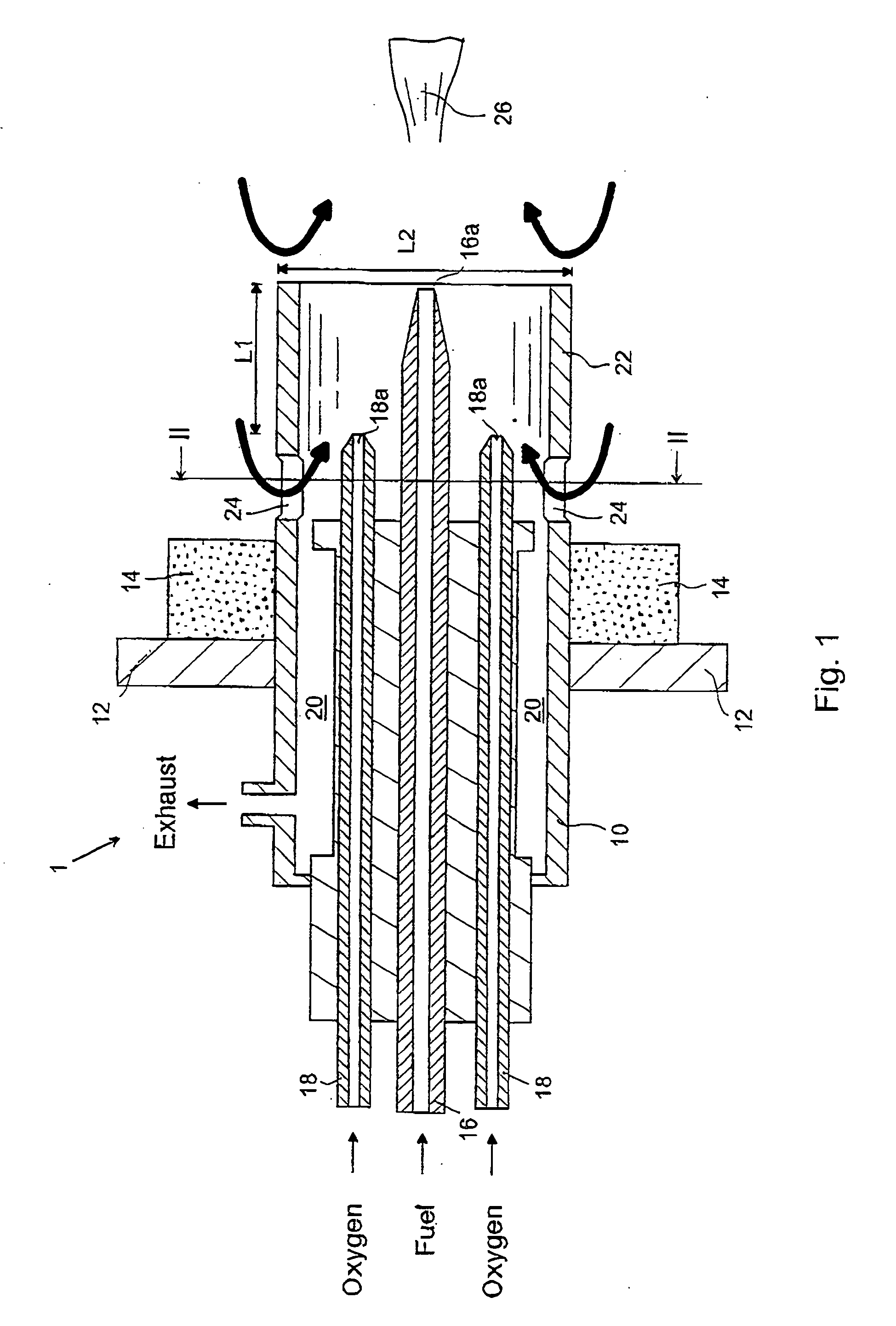

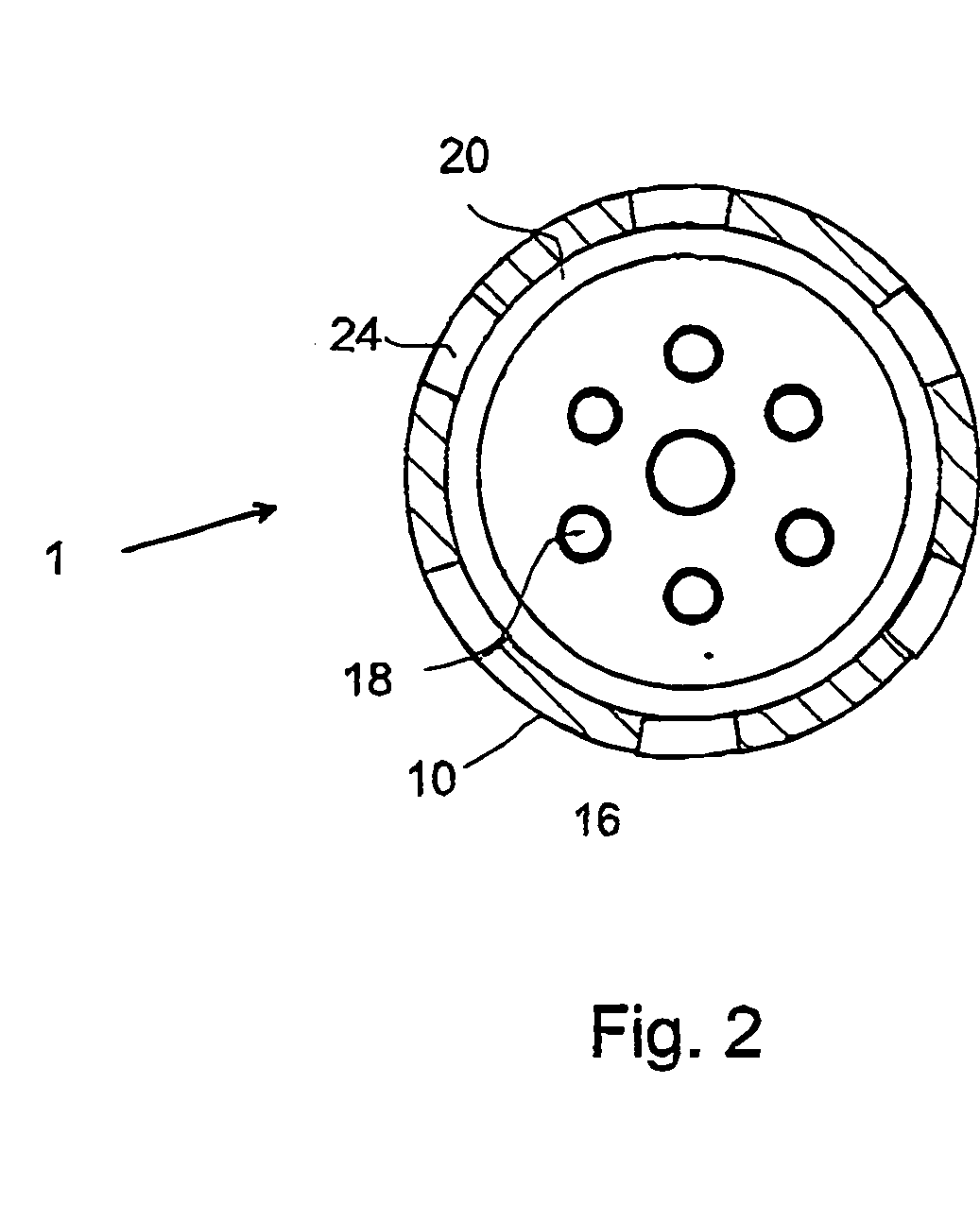

Combustion process and apparatus therefore containing separate injection of fuel and oxidant streams

InactiveUS6074197AReduce nitrogen oxide emissionsAvoid chemical reactionsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCombustion chamber

A burner assembly having improved flame length and shape control is presented, which includes in exemplary embodiments at least one fuel fluid inlet and at least one oxidant fluid inlet, means for transporting the fuel fluid from the fuel inlet to a plurality of fuel outlets, the fuel fluid leaving the fuel outlets in fuel streams that are injected into a combustion chamber, means for transporting the oxidant fluid from the oxidant inlets to at least one oxidant outlet, the oxidant fluid leaving the oxidant outlets in oxidant fluid streams that are injected into the combustion chamber, with the fuel and oxidant outlets being physically separated, and geometrically arranged in order to impart to the fuel fluid streams and the oxidant fluid streams angles and velocities that allow combustion of the fuel fluid with the oxidant in a stable, wide, and luminous flame. Alternatively, injectors may be used alone or with the refractory block to inject oxidant and fuel gases. The burner assembly affords improved control over flame size and shape and may be adjusted for use with a particular furnace as required.

Owner:AIR LIQUIDE AMERICA INC +1

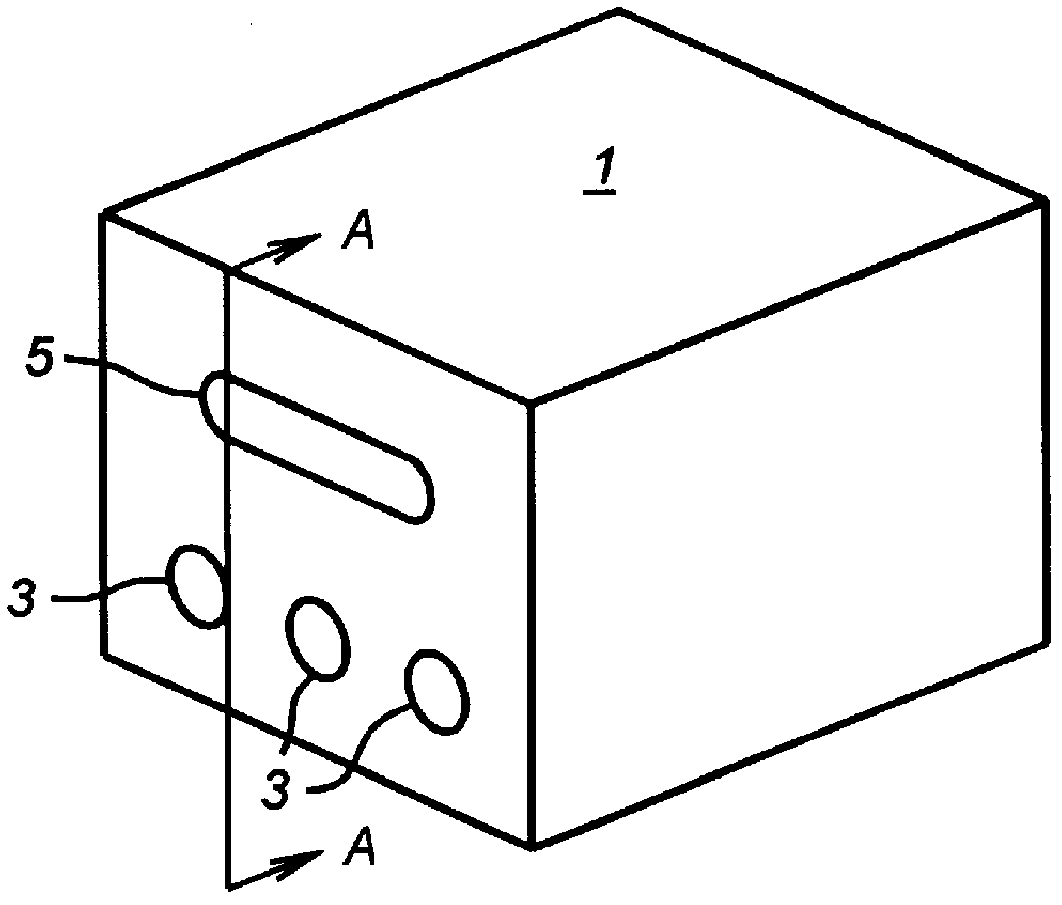

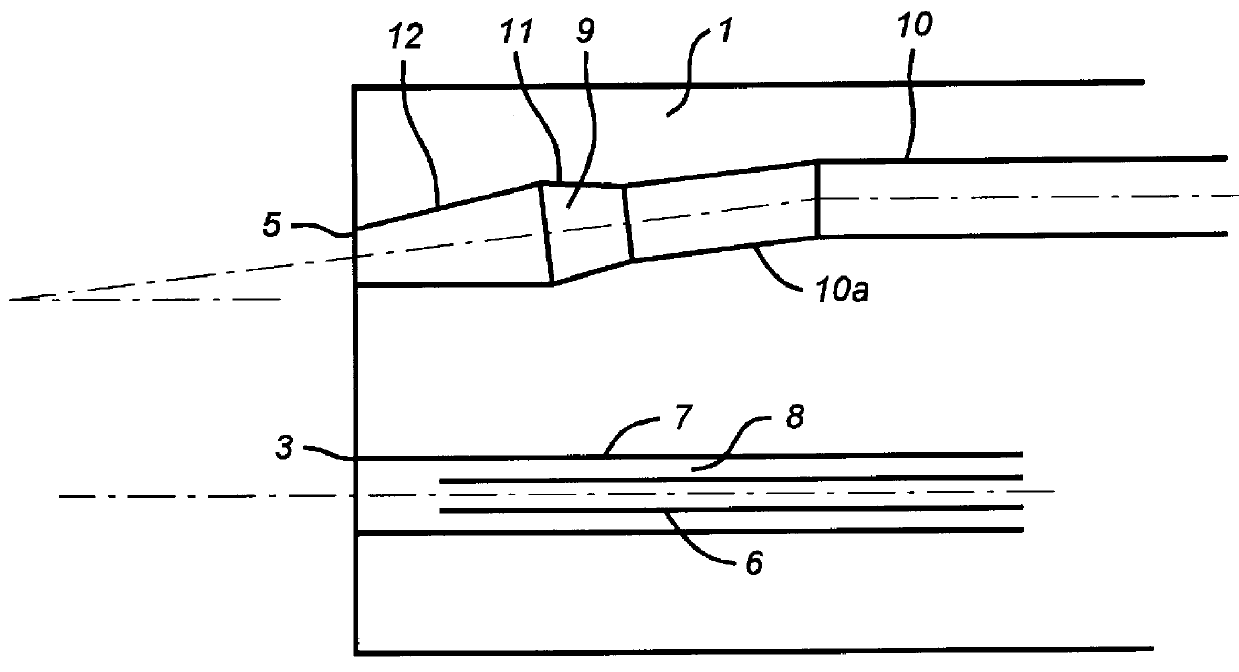

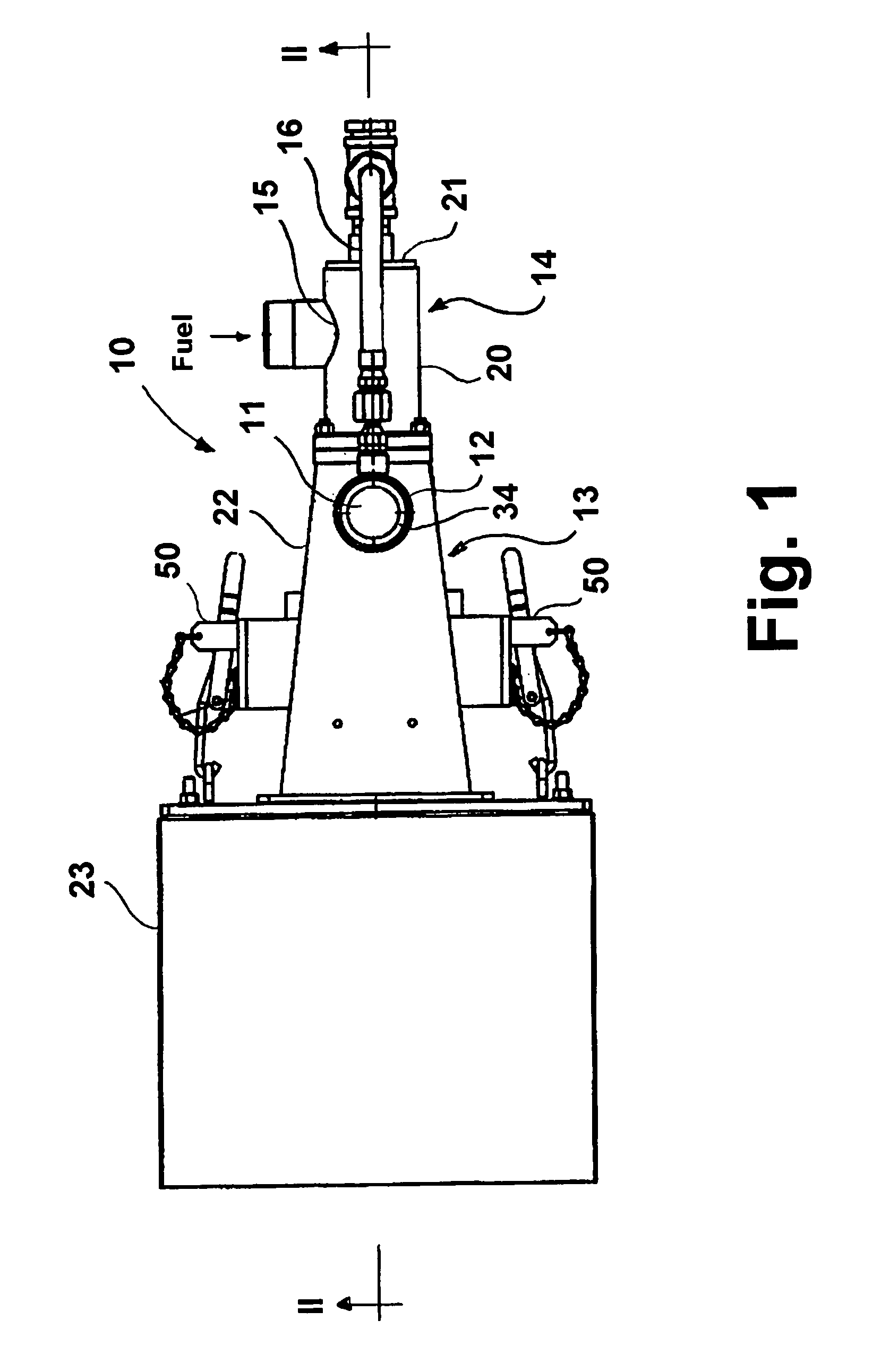

Refractory block for use in a burner assembly

InactiveUS6068468ACombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCombustion chamber

A burner assembly having improved flame length and shape control is presented, which includes in exemplary embodiments at least one fuel fluid inlet and at least one oxidant fluid inlet, means for transporting the fuel fluid from the fuel inlet to a plurality of fuel outlets-, the fuel fluid leaving the fuel outlets in fuel streams that are injected into a combustion chamber, means for transporting the oxidant fluid from the oxidant inlets to at least one oxidant outlet, the oxidant fluid leaving the oxidant outlets in oxidant fluid streams that are injected into the combustion chamber, with the fuel and oxidant outlets being physically separated, and geometrically arranged in order to impart to the fuel fluid streams and the oxidant fluid streams angles and velocities that allow combustion of the fuel fluid with the oxidant in a stable, wide, and luminous flame. Alternatively, injectors may be used alone or with the refractory block to inject oxidant and fuel gases. The burner assembly affords improved control over flame size and shape and may be adjusted for use with a particular furnace as required.

Owner:AIR LIQUIDE AMERICA INC +1

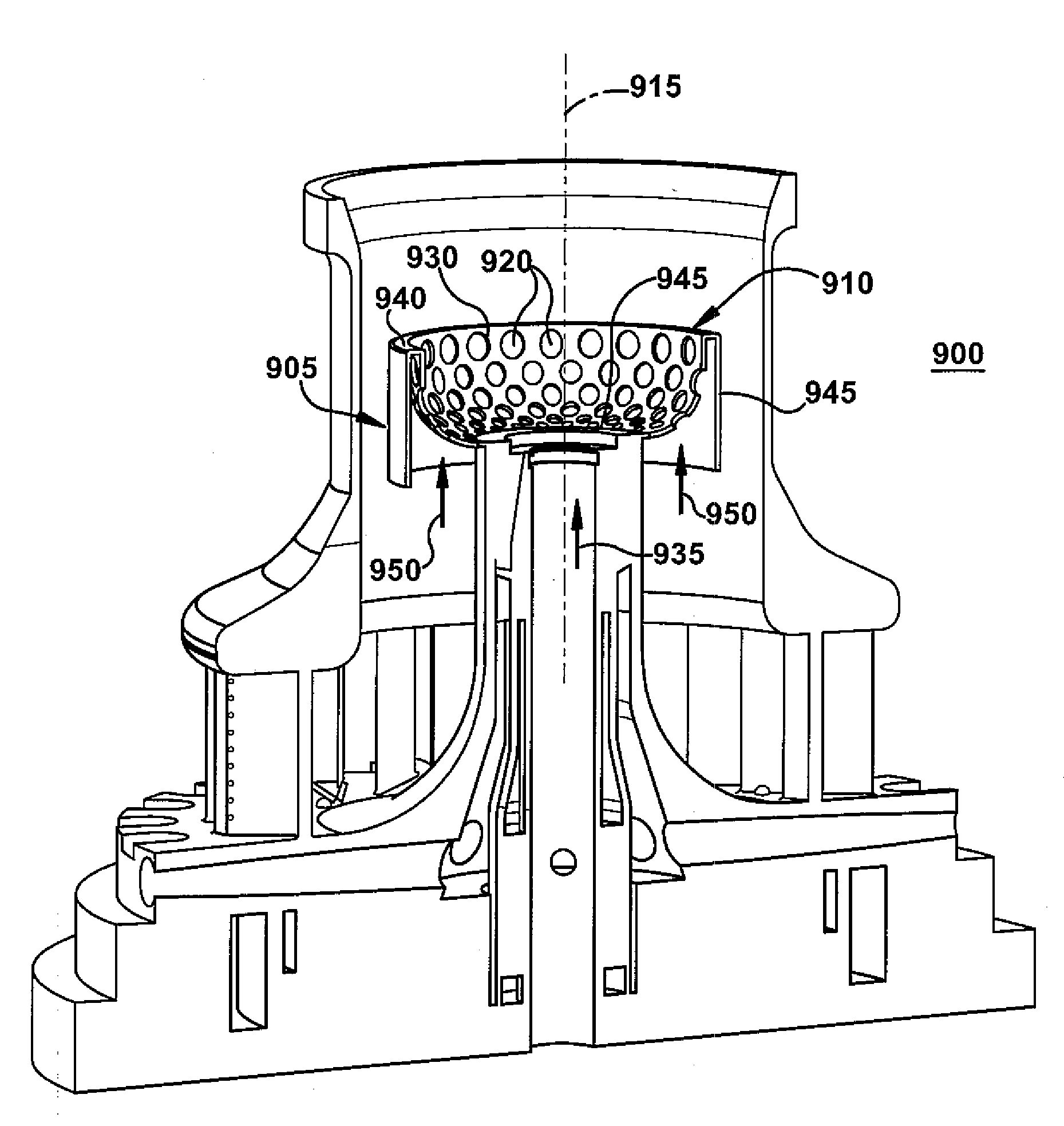

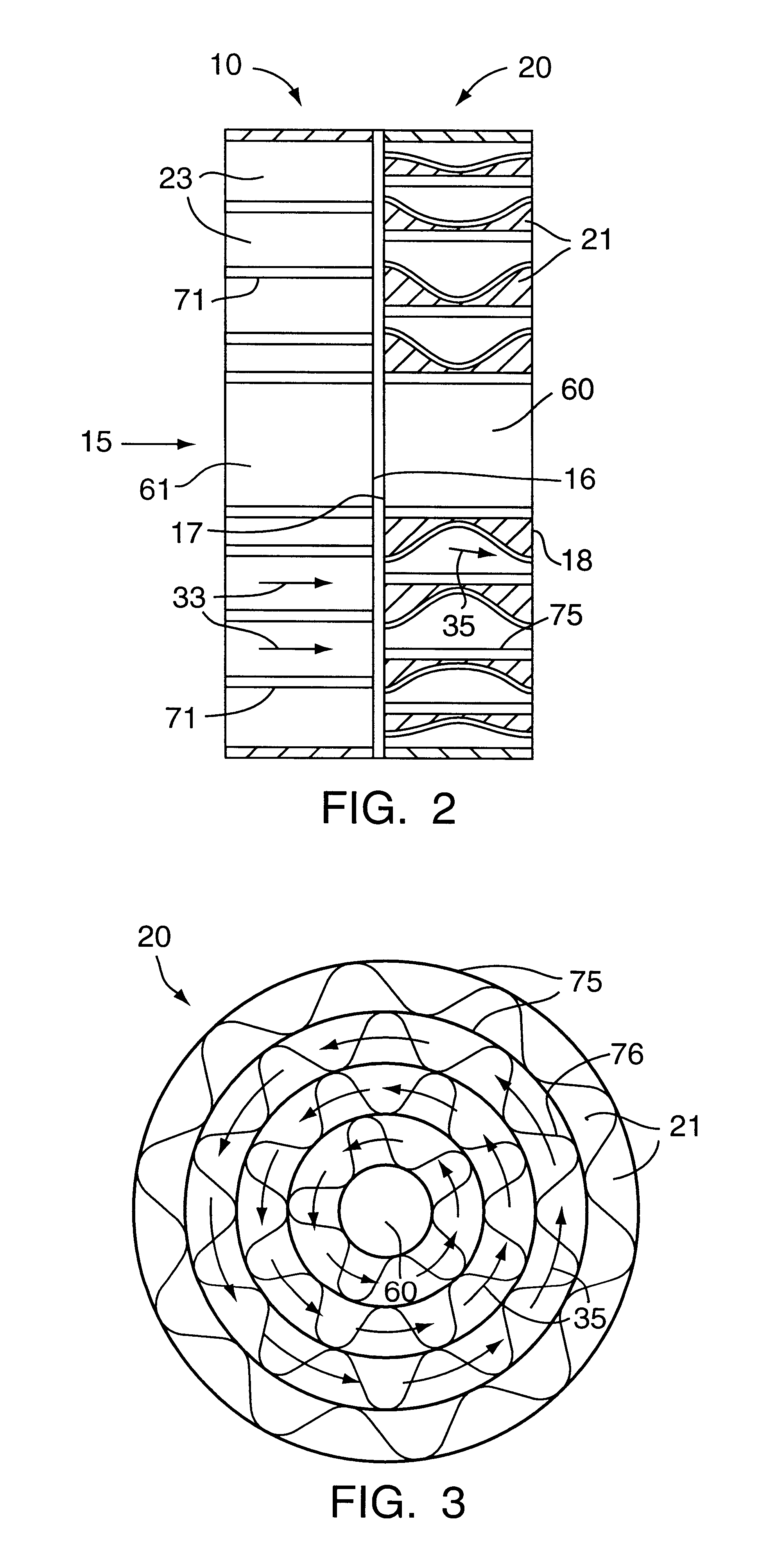

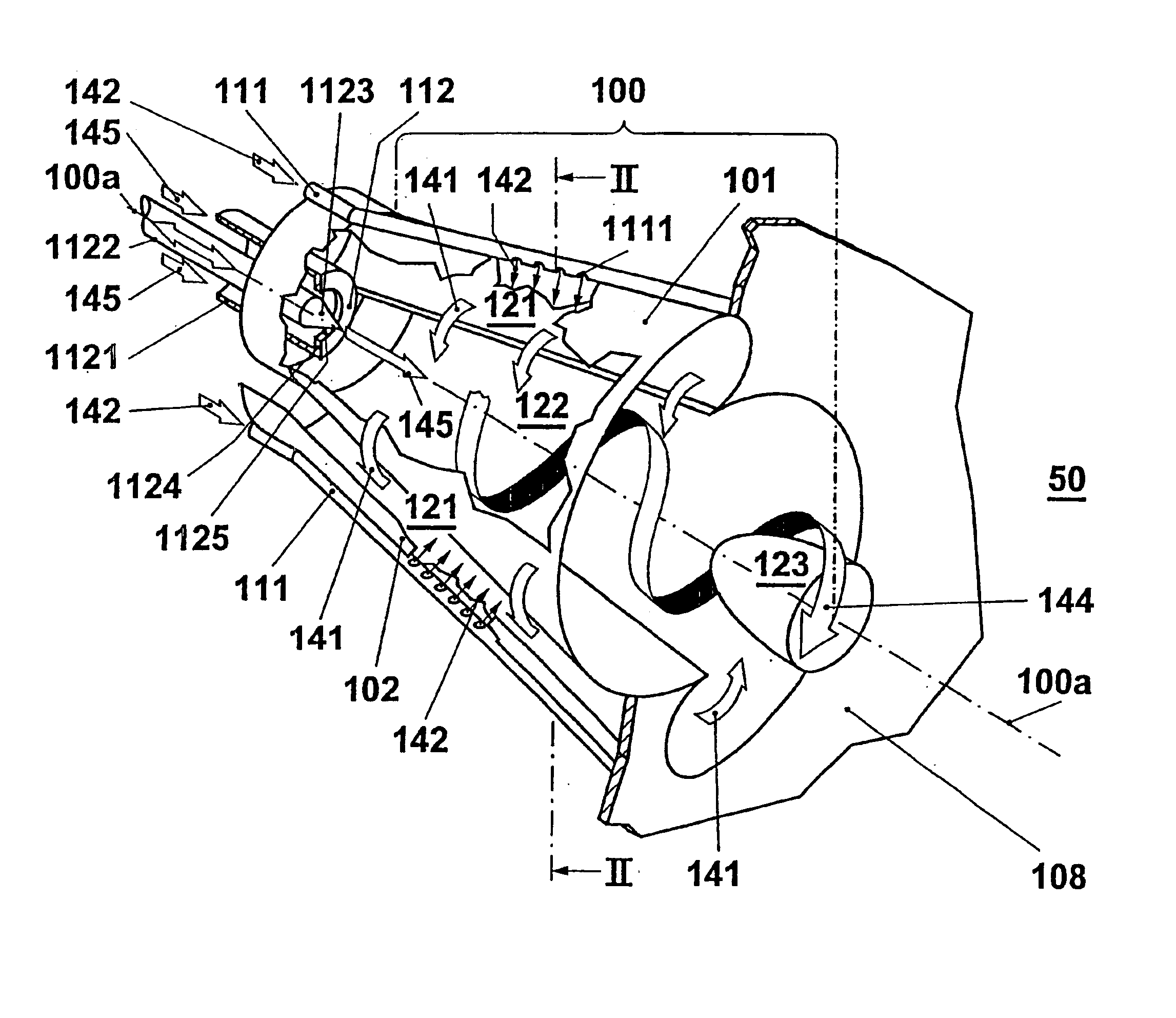

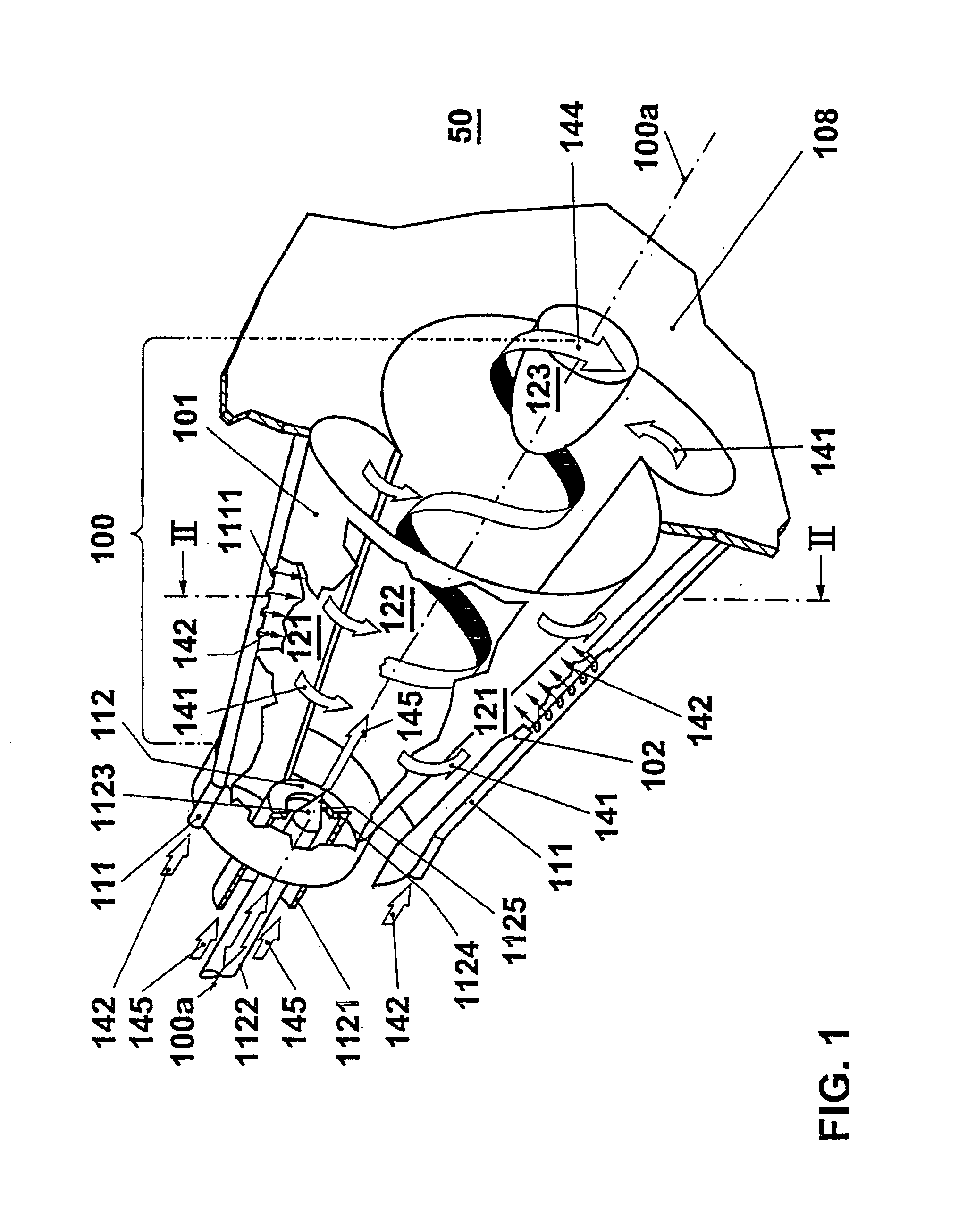

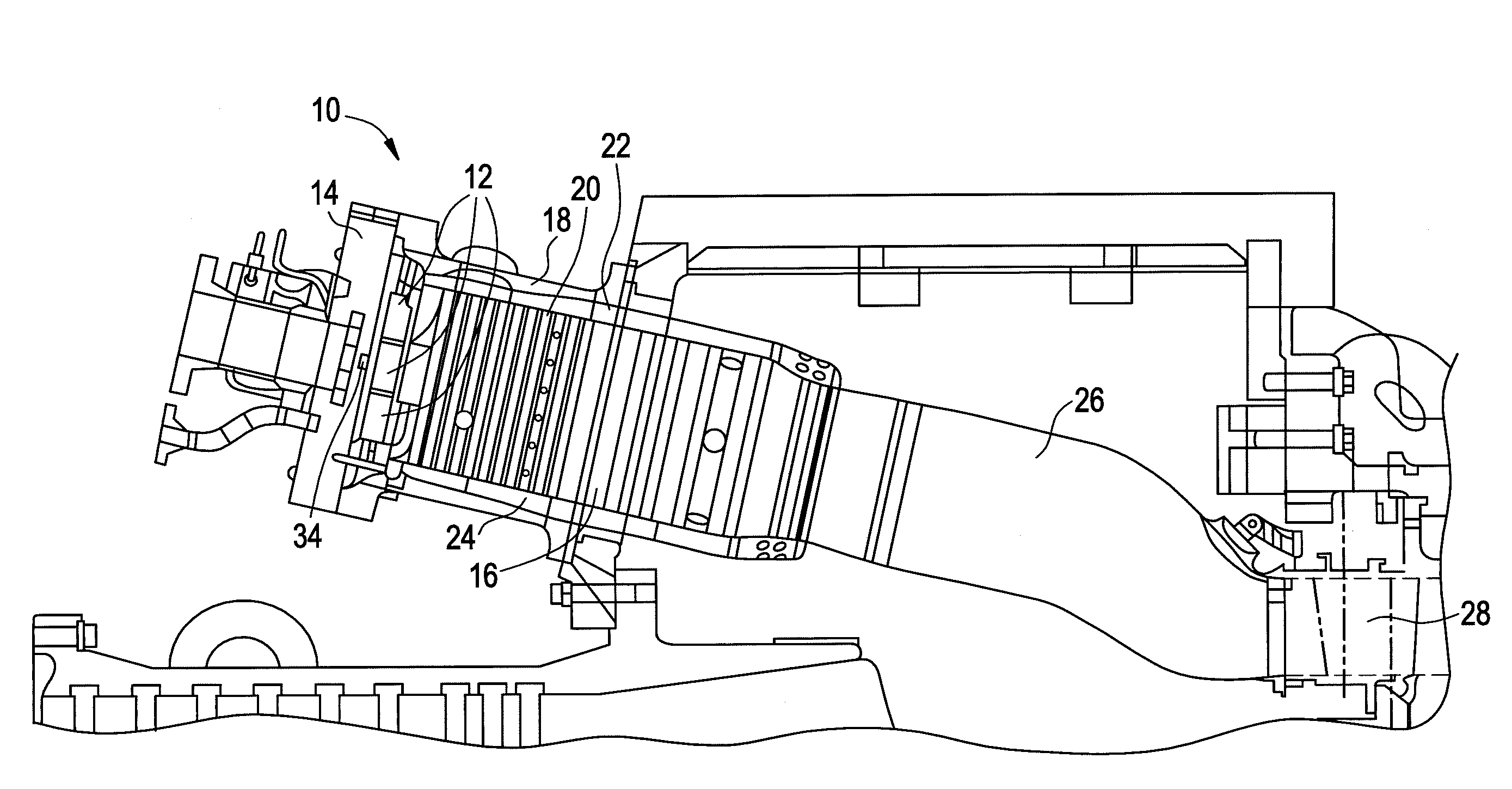

Lean premixed, radial inflow, multi-annular staged nozzle, can-annular, dual-fuel combustor

InactiveUS20090111063A1Stable combustionEmission reductionCombustion using gaseous and pulverulent fuelContinuous combustion chamberCombustorNuclear engineering

A lean premixed, radial inflow, multi-annular staged nozzle for creating three independent combustion zones within a can-annular, dual-fuel gas turbine combustor is provided. The nozzle includes a pilot zone fueled by a gas pilot nozzle and center cartridge; a flame holder zone fueled by an inner main gas fuel; a main flame zone fueled by an outer main gas fuel; a main radial swirler for mixing a portion of incoming air to the nozzle with the inner main gas fuel supply and the outer main gas fuel supply; an endcover; and means for controlling the ratio of an inner main gas fuel supplied and an outer main gas fuel supplied.

Owner:GENERAL ELECTRIC CO

Swirling flashback arrestor

InactiveUS6179608B1Performance maximizationPipeline systemsGaseous fuel burnerEngineeringGas turbines

A structure is disclosed that will quench a flame front during a flashback event in a gas turbine while simultaneously providing a mixing function during normal operations. The device disclosed consists of two monoliths one upstream of the other. In the basic embodiment of the invention the downstream monolith acts as a mixer while the combination of the upstream monolith and the downstream monolith act as the flashback arrestor. Other embodiments of the device also allow the downstream monolith to be a flameholder.

Owner:PRECISION COMBUSTION

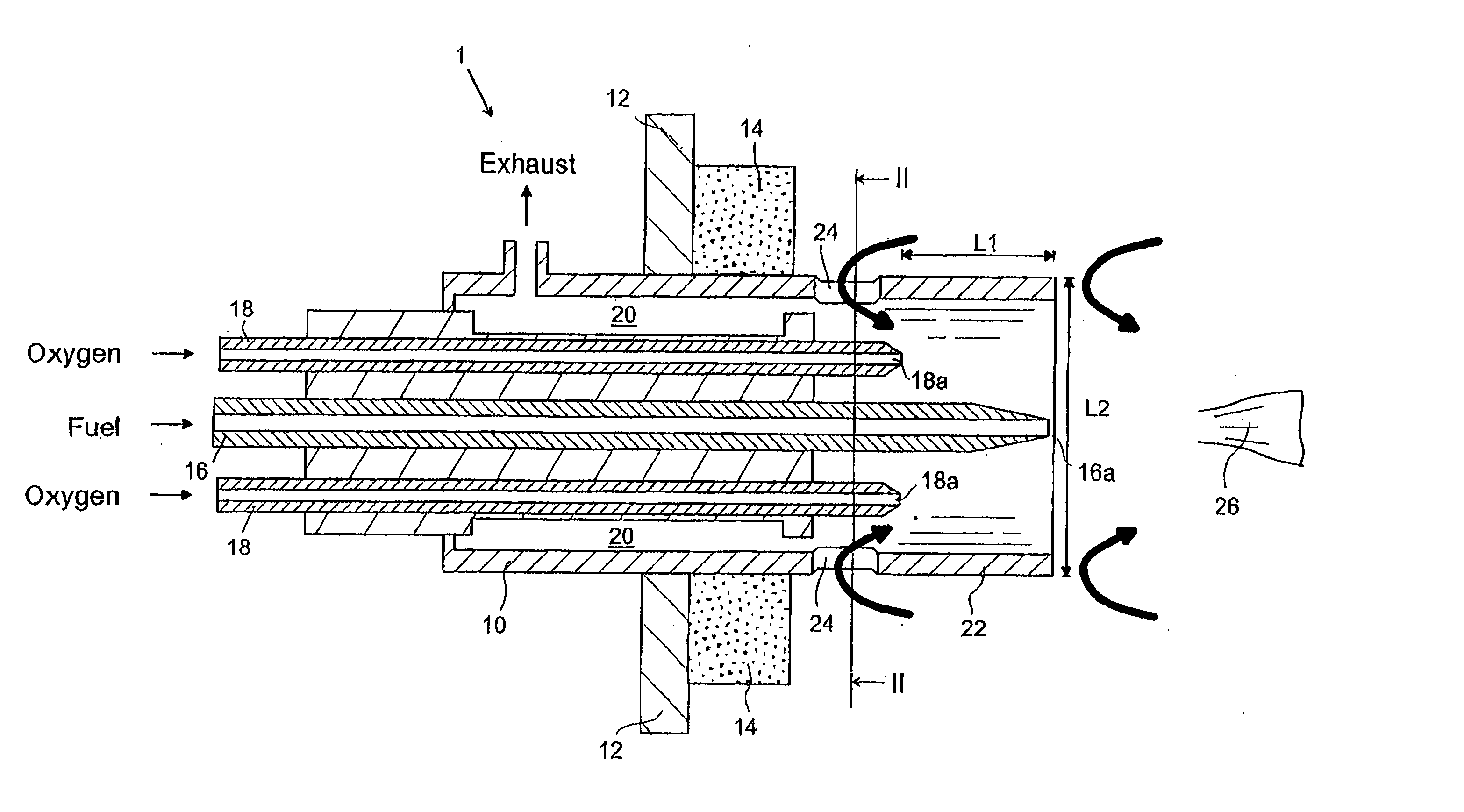

Self-cooled oxygen-fuel burner for use in high-temperature and high-particulate furnaces

InactiveUS6210151B1Avoiding particulate inspiration.TheControl expansionIndirect carbon-dioxide mitigationGaseous fuel burnerParticulatesVolatiles

A self-cooled oxidant-fuel burner consisting novel fuel and oxidant nozzles and three compartment refractory burner block design is proposed. The new oxidant-fuel burner can fire in high-temperature (2200° F. to 3000° F.) and high-particulate (or high process volatiles / condensates) furnaces without over-heating or causing chemical corrosion damage to it's metallic burner nozzle and refractory burner block interior. Using various embodiments of nozzle and block shape, the burner can offer a traditional cylindrical flame or flat flame depending on the heating load requirements. The new features of this burner include unique fuel nozzle design for the streamline mixing of fuel and oxidant streams, a controlled swirl input to the oxidant flow for desired flame characteristics, a controlled expansion of flame envelope in the radial and axial dimensions, and efficient sweeping of burner block interior surface using oxidant to provide convective cooling and prevent any build up of process particulates. In addition, a relatively thick wall metallic nozzle construction with heat conduction fins enable efficient heat dissipation from the nozzle tip and providing a maintenance free burner operation.

Owner:AIR LIQUIDE AMERICA INC +1

Oxidizing oxygen-fuel burner firing for reducing NOx emissions from high temperature furnaces

InactiveUS6171100B1Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFurnace temperatureEquivalence ratio

Burner firing method and device are presented where an oxidizing oxygen-fuel burner is fired at an angle to the reducing air-fuel burner flame to reduce overall NOx emissions from high temperature furnaces. The oxidizing oxy-fuel burner stoichiometric equivalence ratio (oxygen / fuel) is maintained in the range of about 1.5 to about 12.5. The reducing air-fuel burner is fired at an equivalence ratio of 0.6 to 1.00 to reduce the availability of oxygen in the flame and reducing NOx emissions. The oxidizing flame from the oxy-fuel burner is oriented such that the oxidizing flame gas stream intersects the reducing air-fuel flame gas stream at or near the tail section of the air-fuel flame. The inventive methods improve furnace temperature control and thermal efficiency by eliminating some nitrogen and provide an effective burnout of CO and other hydrocarbons using the higher mixing ability of the oxidizing flame combustion products. The simultaneous air-fuel and oxy-fuel burner firing can reduce NOx emissions anywhere from 30% to 70% depending on the air-fuel burner stoichiometric ratio.

Owner:AIR LIQUIDE AMERICA INC +1

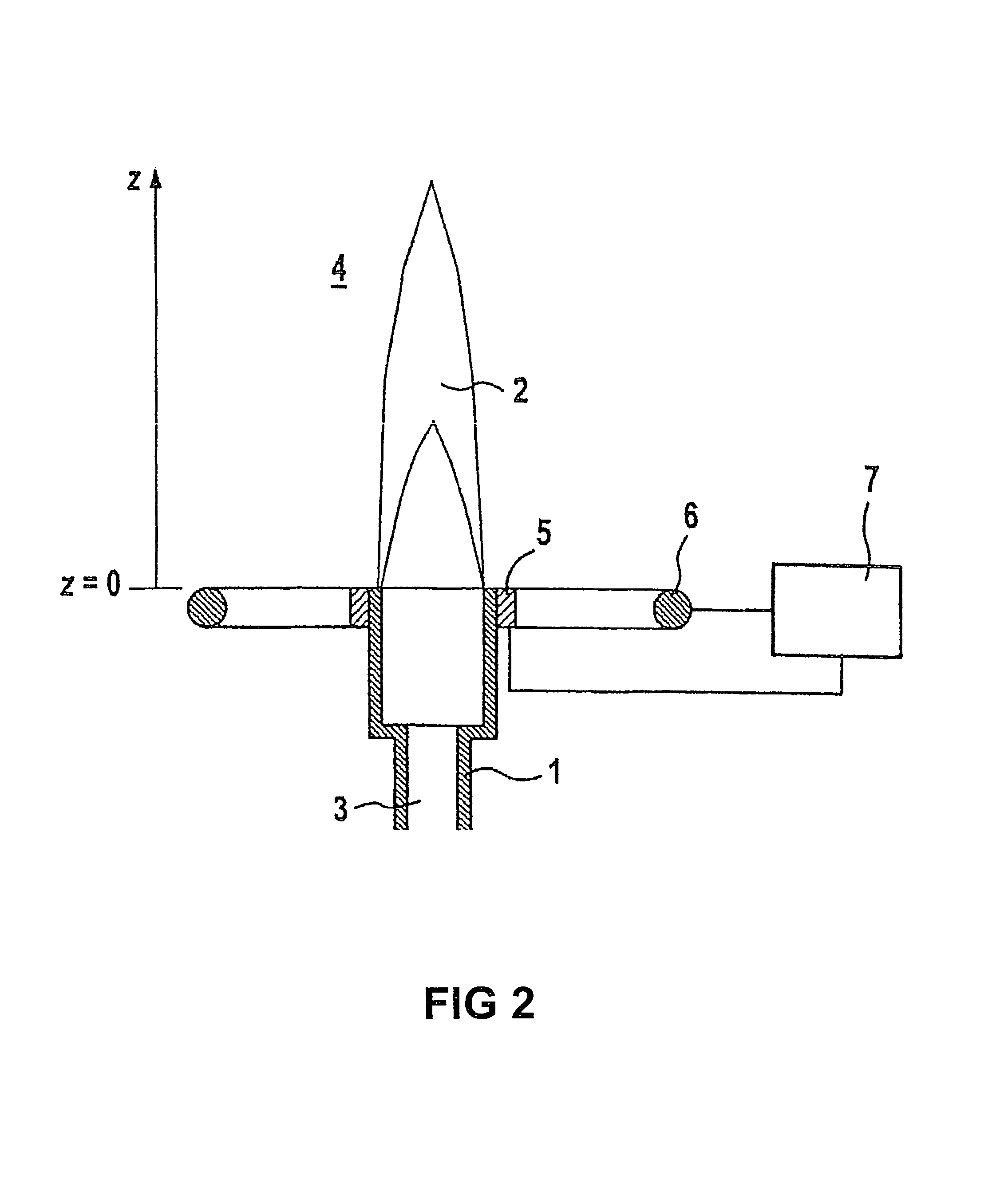

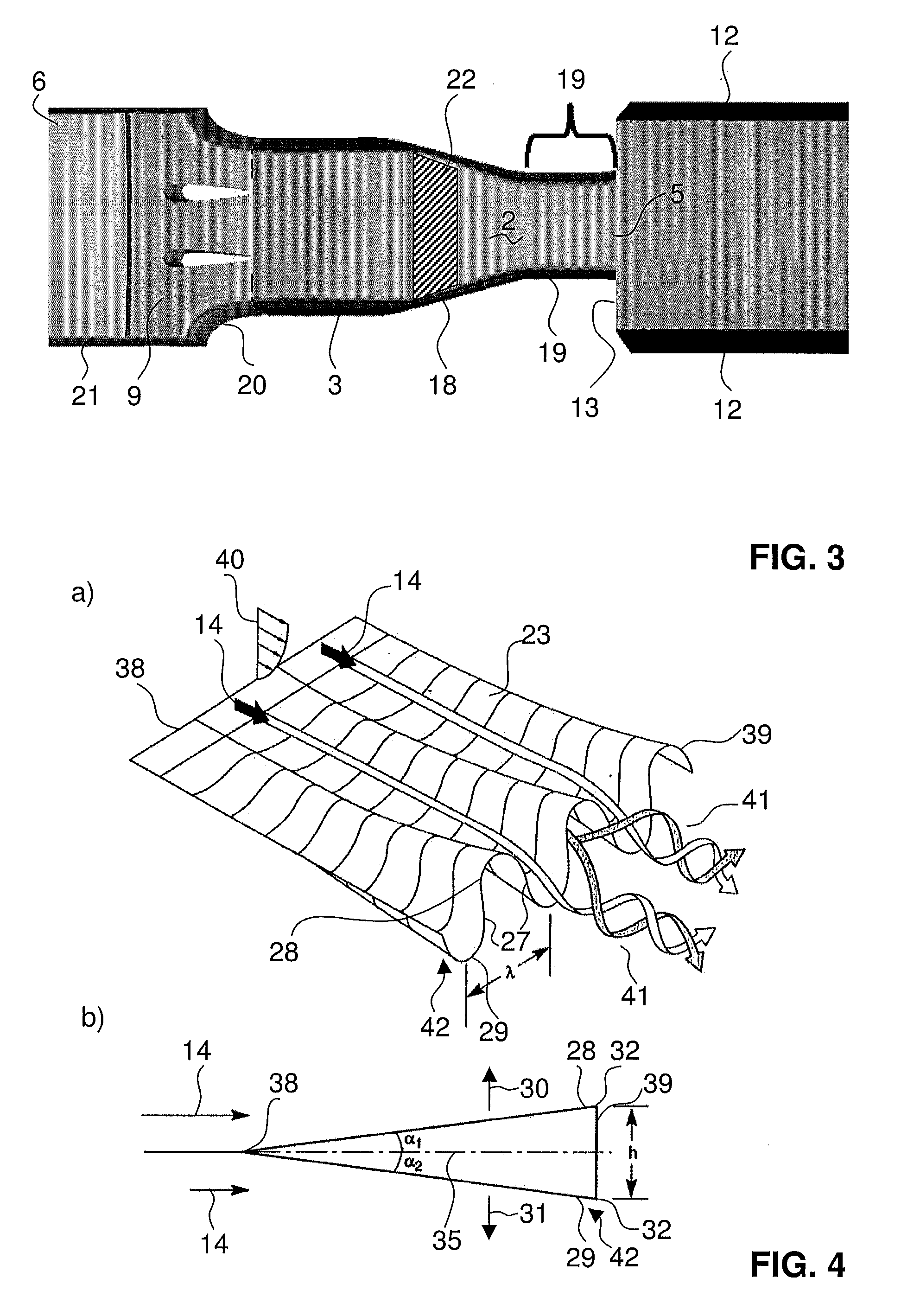

Process for operation of a burner with controlled axial central air mass flow

InactiveUS6901760B2Reduce the amount requiredAffect intensityCombustion using gaseous and pulverulent fuelContinuous combustion chamberCombustorEngineering

Owner:ANSALDO ENERGIA SWITZERLAND AG

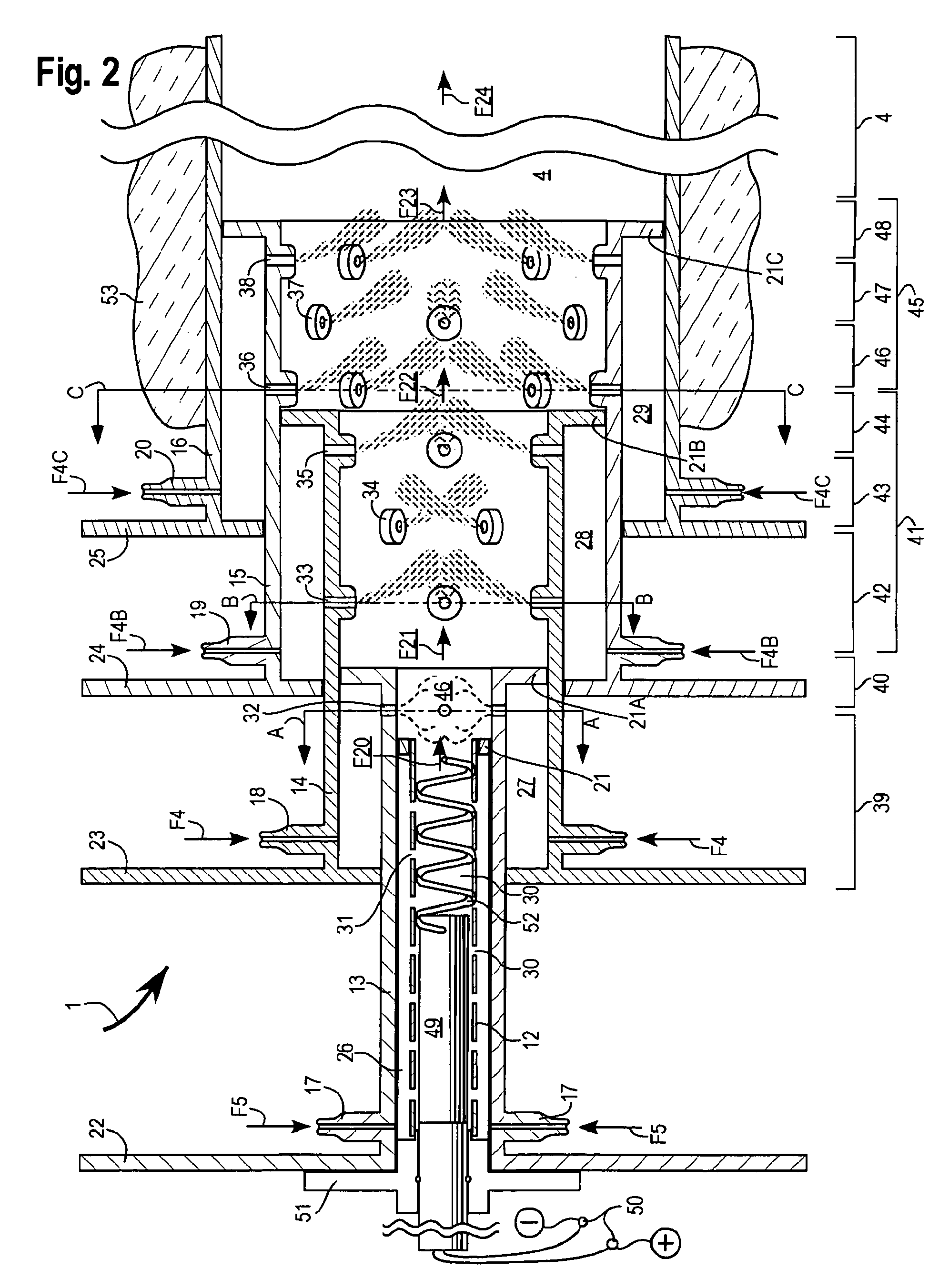

Method and device for influencing combustion processes involving combustibles

InactiveUS7137808B2Increase influenceEconomical and simpleCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorHazardous substance

A method and device are for influencing combustion processes, and include an electrical device. The electrical device engages with the flame front so that the electrical field thus produced, only penetrates areas of the flame front in which a stabilizing and harmful-substance-reducing effect is produced. The electrodes of the burner are arranged outside the region of the flame in the associated device.

Owner:SIEMENS AG

Combustion equipment and burner combustion method

InactiveUS20080268387A1Reduce nitrogen oxide emissionsIncrease flow rateCombustion using gaseous and pulverulent fuelContinuous combustion chamberCombustion chamberCombustor

Combustion equipment of a coaxial jet combustion scheme is provided that includes: a burner plate in which fuel and air are mixed with each other while the fuel and air pass through an air hole; a burner plate extension which is a portion of the burner plate and extends toward a combustion chamber side spaced apart from the air hole; and a protrusion disposed on the combustion chamber side of the burner plate extension so as to protrude in a direction where flow of the fuel moves. In the combustion equipment, a gap between opposite portions of the protrusion is greater than a diameter of the air hole and a flame source forming area is defined between the burner plate, the burner plate extension and the protrusion. The combustion equipment of a coaxial jet combustion scheme can achieve a further reduction in NOx emissions.

Owner:HITACHI LTD

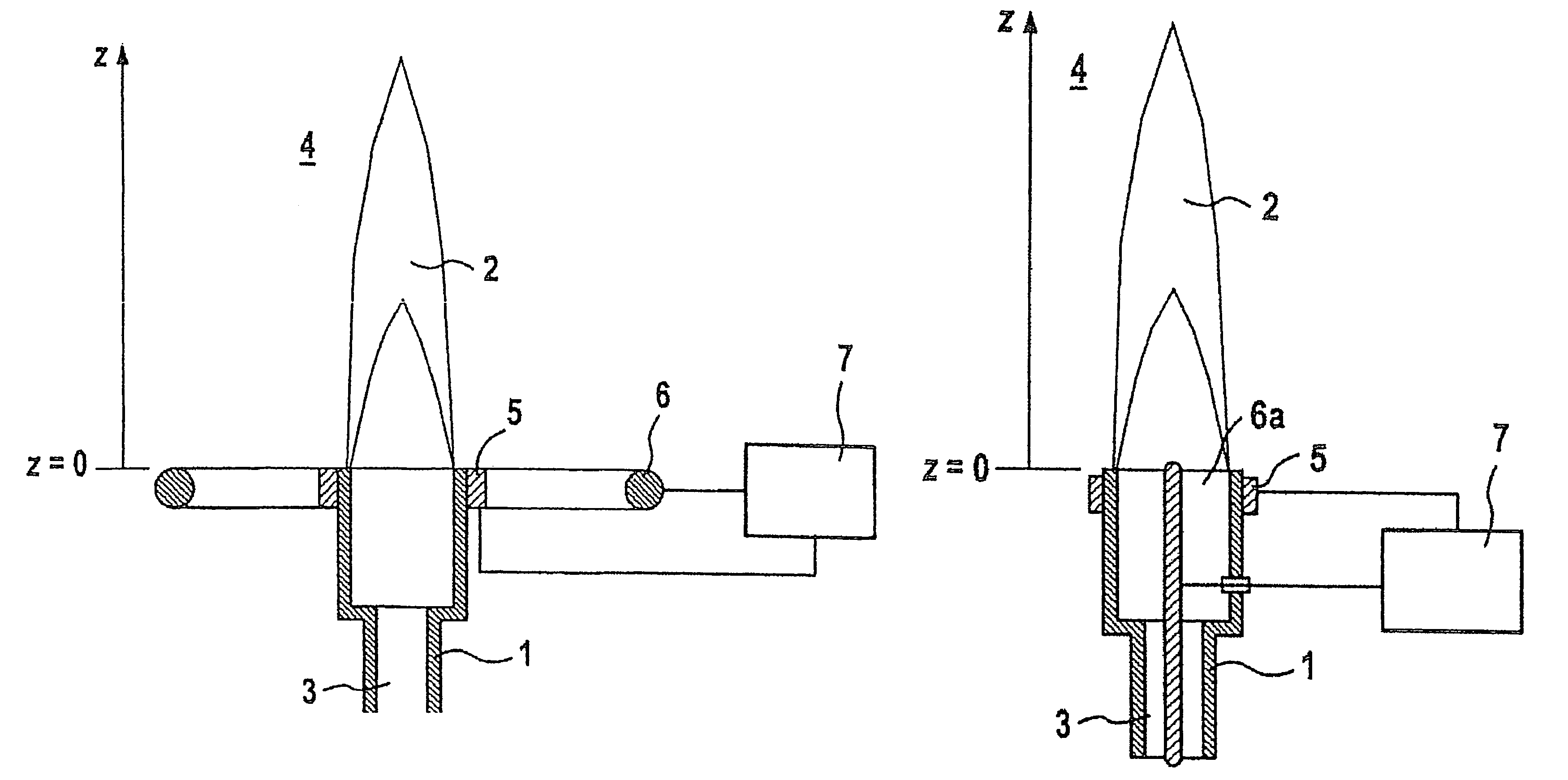

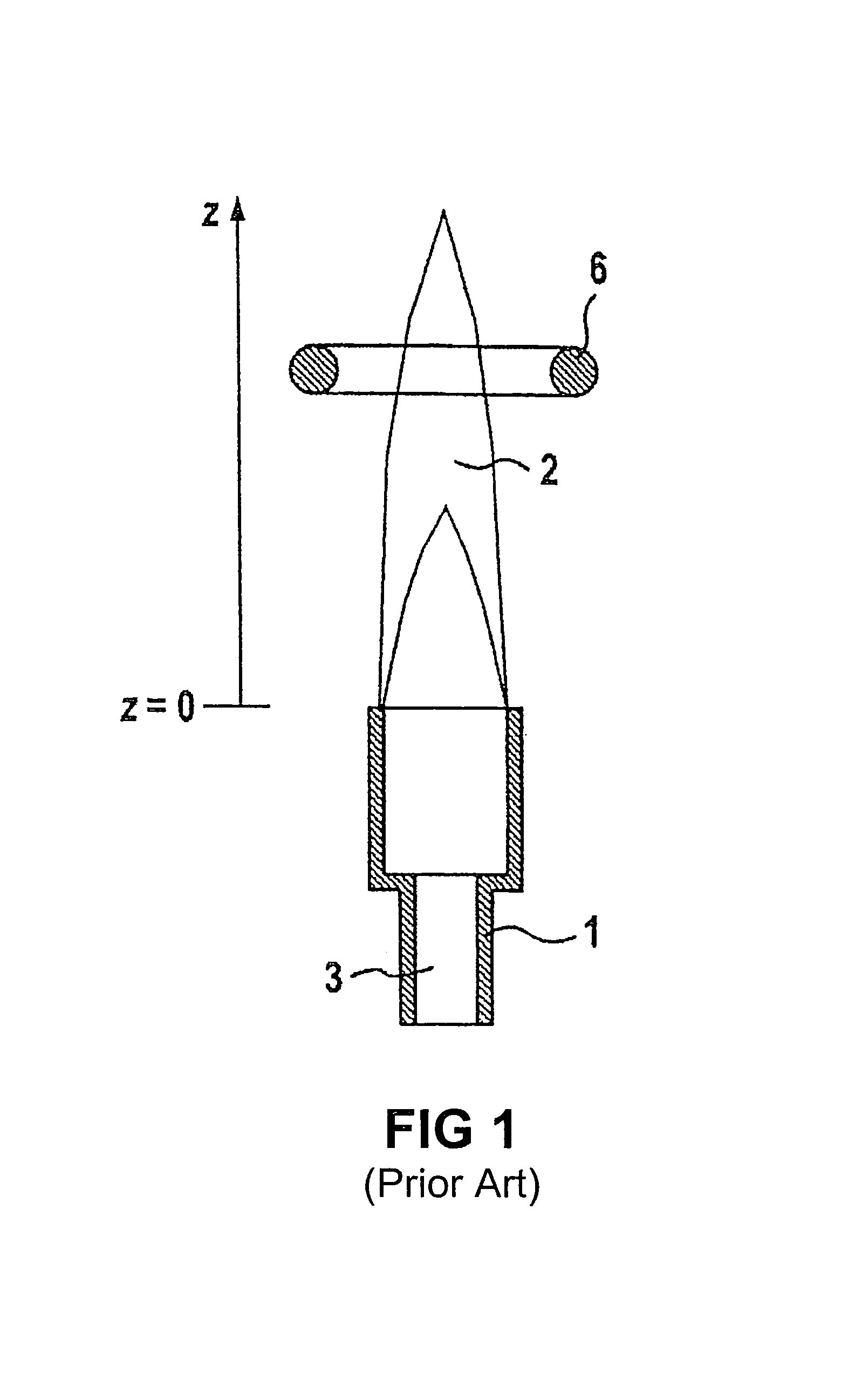

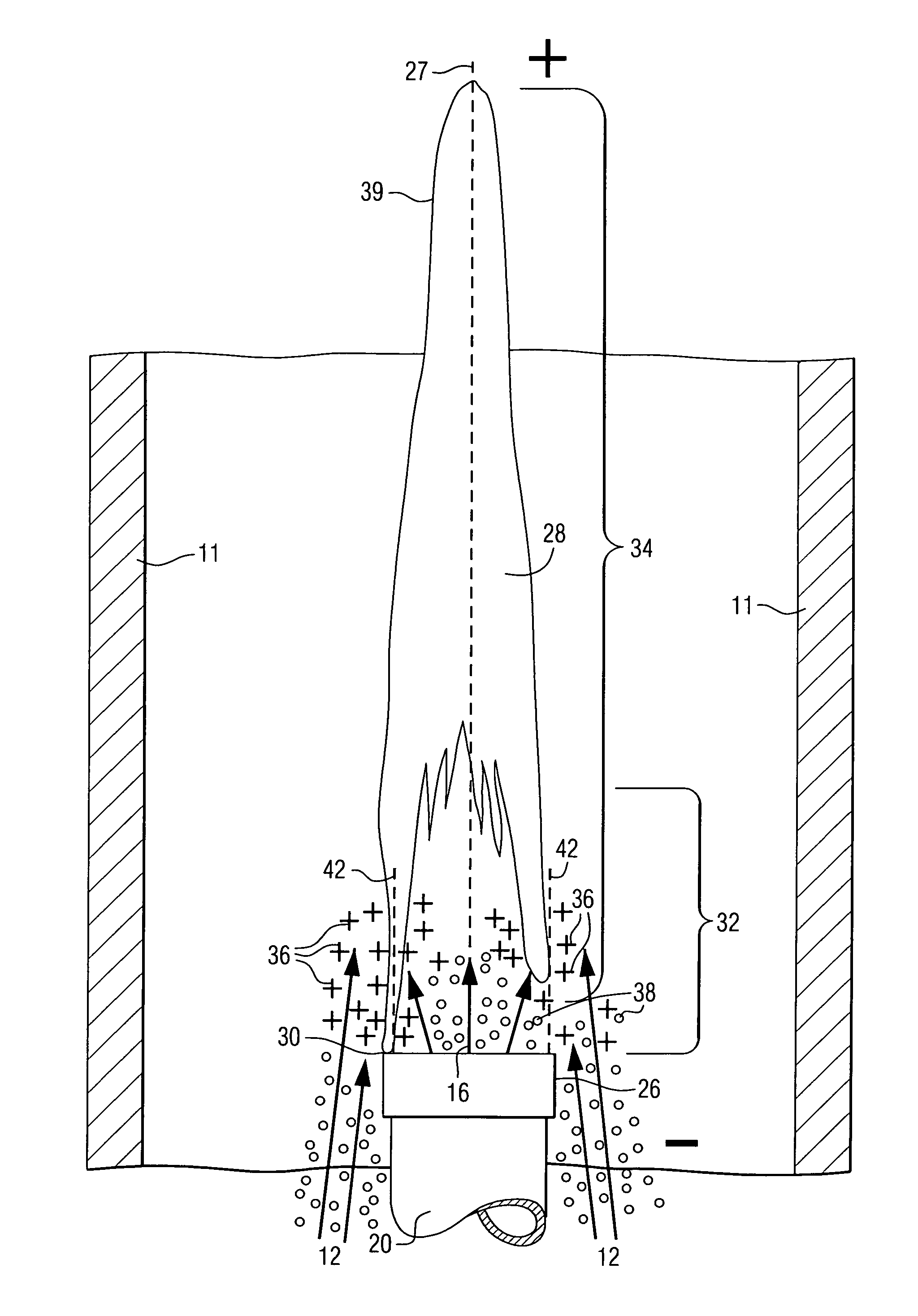

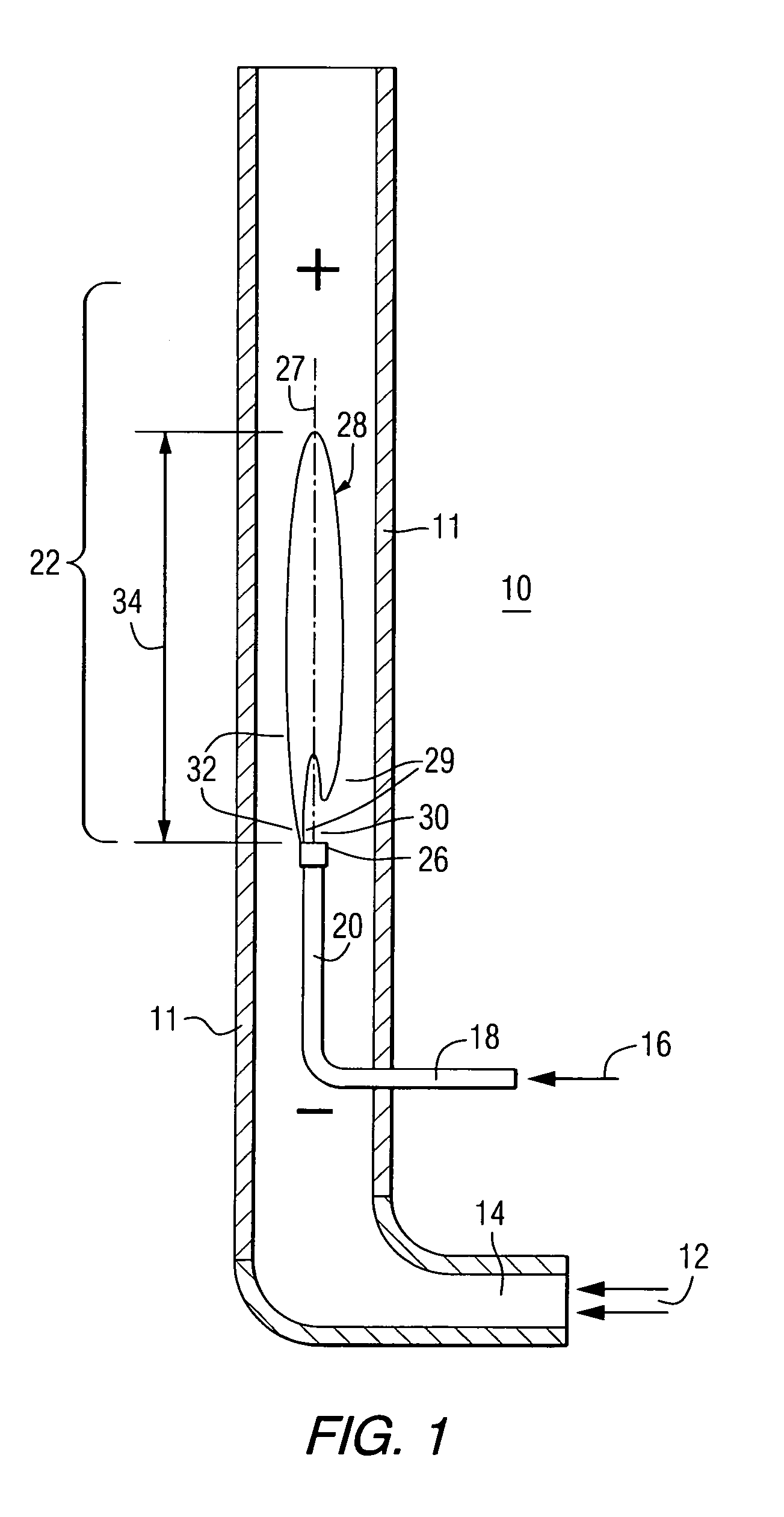

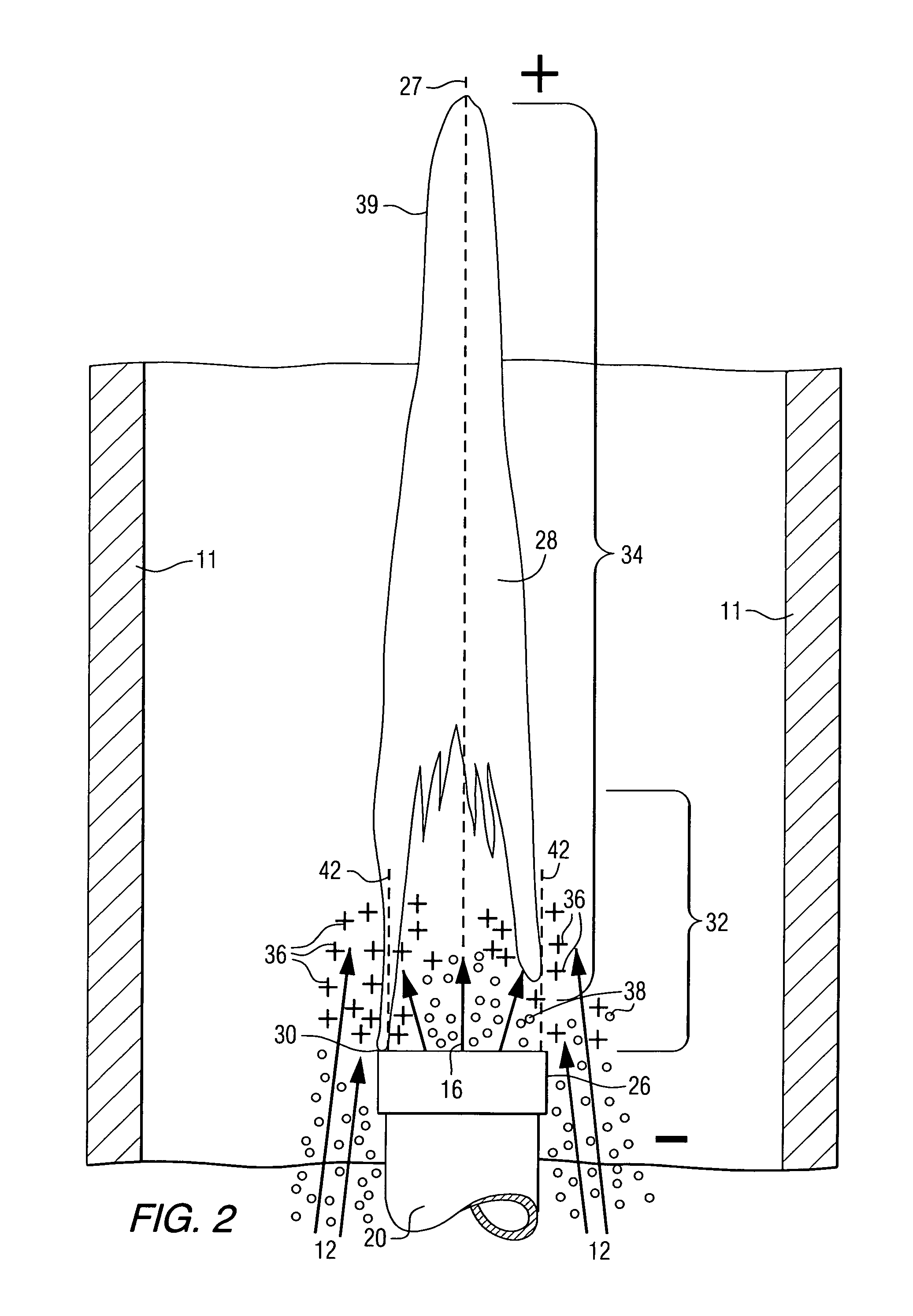

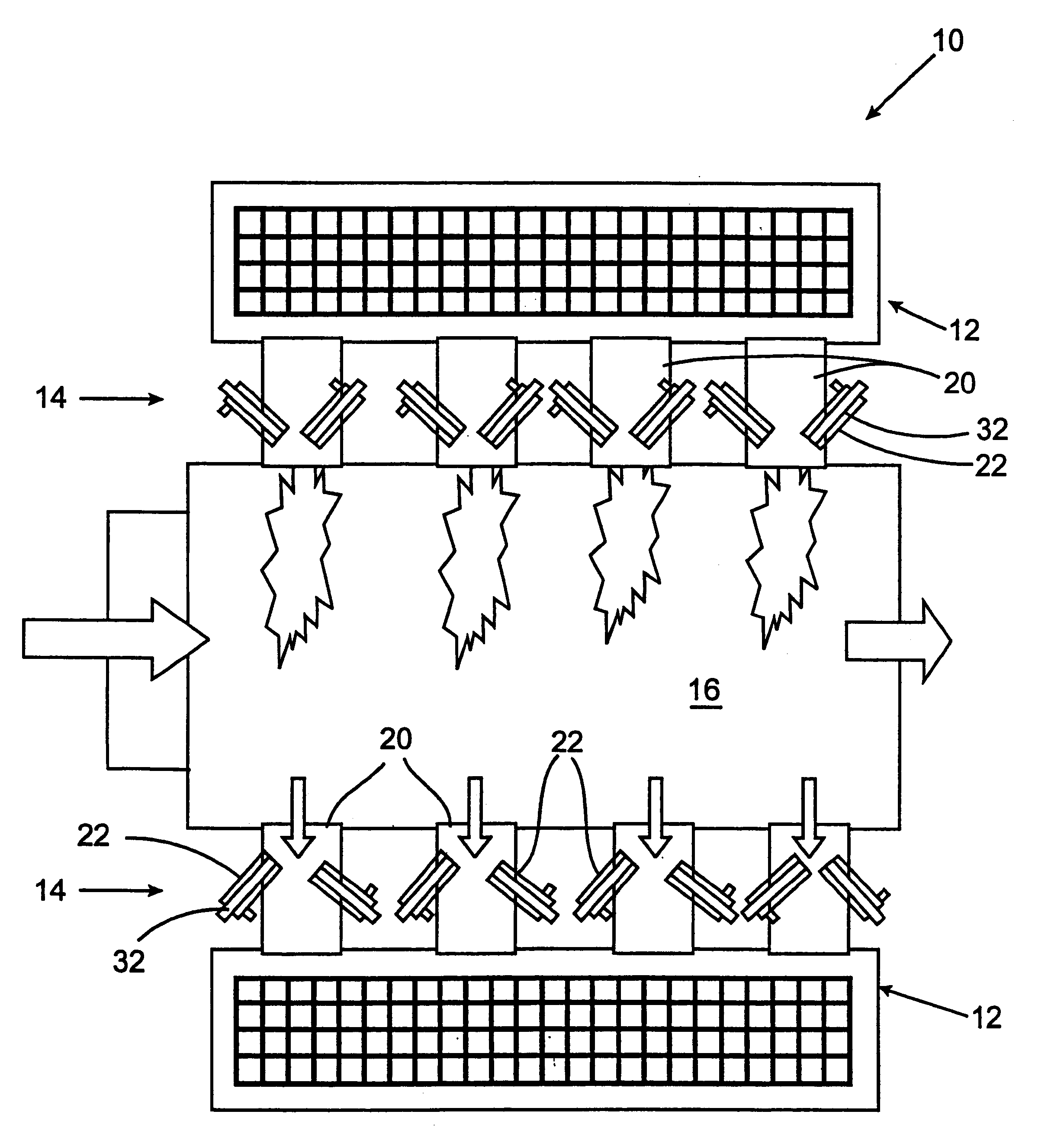

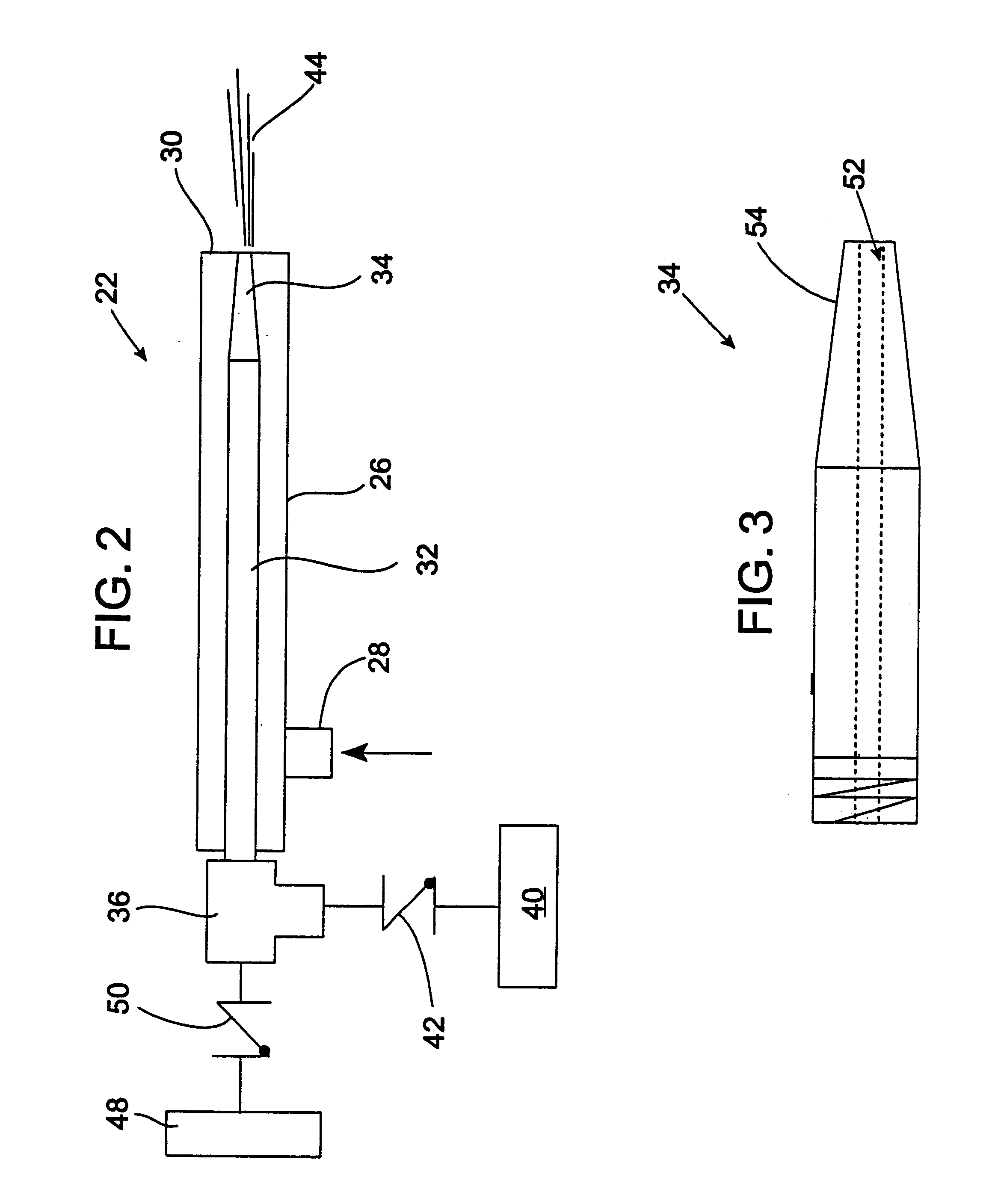

Electric flame control using corona discharge enhancement

InactiveUS7243496B2Increased ionizationPromote combustionTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionElectricityCombustor

A method of operating a combustor (10), to provide intimately mixed hot combusted gas (44) for a gas turbine (46), includes feeding gaseous oxidant (12) and gaseous fuel (16) into the combustor (10) near a combustion flame (28) which has a tip end (39) and a root end (29), where corona discharge occurs through adjustment of an electric field (34), and where the corona discharge causes ionized particles (36) to form and also causes intimate turbulent mixing of the gases.

Owner:SIEMENS ENERGY INC

Method of retrofitting a furnace to provide oxygen enrichment

An oxygen enrichment system is provided which uses the existing air / fuel burners of a regenerative furnace to distribute additional oxygen to the burners for increased efficiency, and reduced nitrous oxide emissions. The centrally positioned cooling air lances in the burners of a regenerative furnace are modified to deliver oxygen when the burners are firing for oxygen enrichment. During the burmer firing cycle, oxygen is delivered from an oxygen supply through the oxygen lance to provide a central oxygen jet. The fuel is delivered concentrically around the oxygen jet. During the non-firing cycle of the burner, cooling air or other cooling fluid is delivered from the cooling air supply through the oxygen jet for cooling the offside of the furnace.

Owner:AIR LIQUIDE AMERICA INC

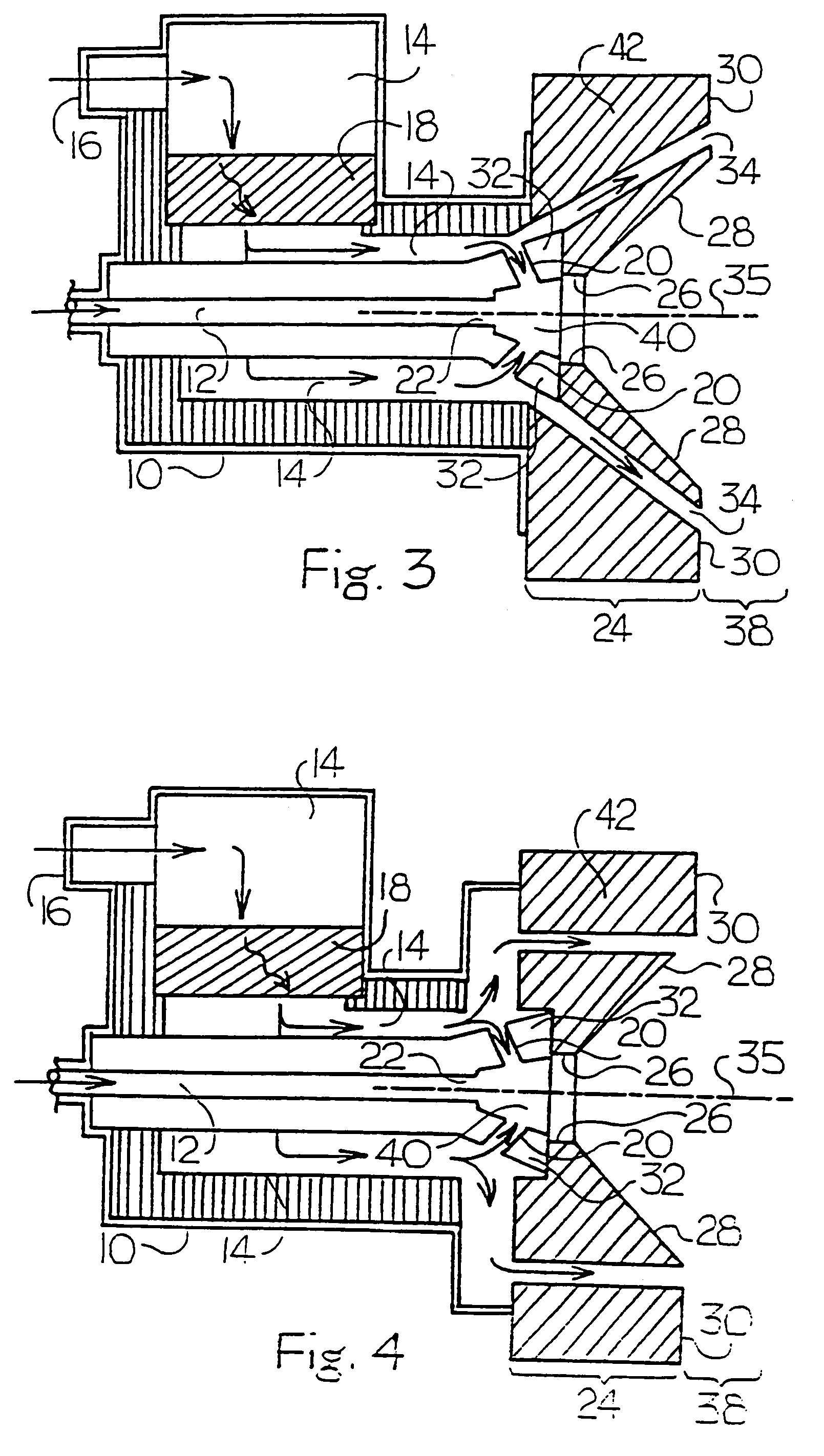

Air staged low-NOx burner

InactiveUS7175423B1Reduce the production of nitrogen oxidesReduce nitrogen oxide emissionsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorEngineering

An apparatus and method for using staged air combustion. The apparatus includes a burner body (10) secured to a port block (42), and a fuel passageway (12) extending through the burner body (10), terminating in a fuel nozzle (22), which injects fuel into the burner throat (40). Primary air jets (20) are configured to inject primary air into a primary combustion region (24), which is normally in the burner throat (40). A dish with a dish surface (28) is connected to the burner throat (40); the dish surface (28) extending in a divergent angle with respect to a burner centerline (35). Secondary air jets (34) are connected to the air passageway (14) and extend through the port block (42). The secondary air jets (34) inject secondary air into a secondary combustion region (38), which may be at the dish surface (28) or the hot face (30) of the burner.

Owner:BLOOM ENG

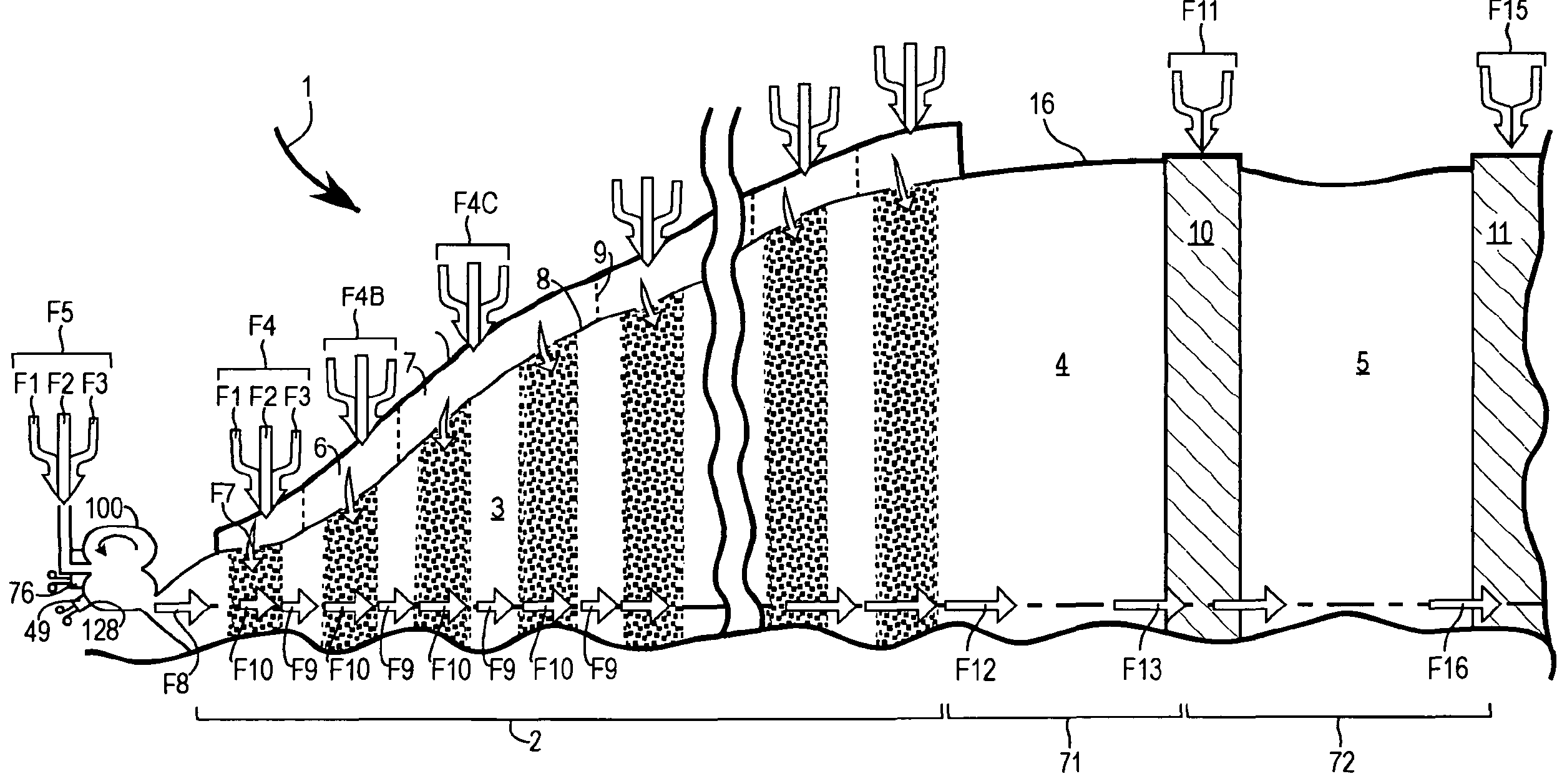

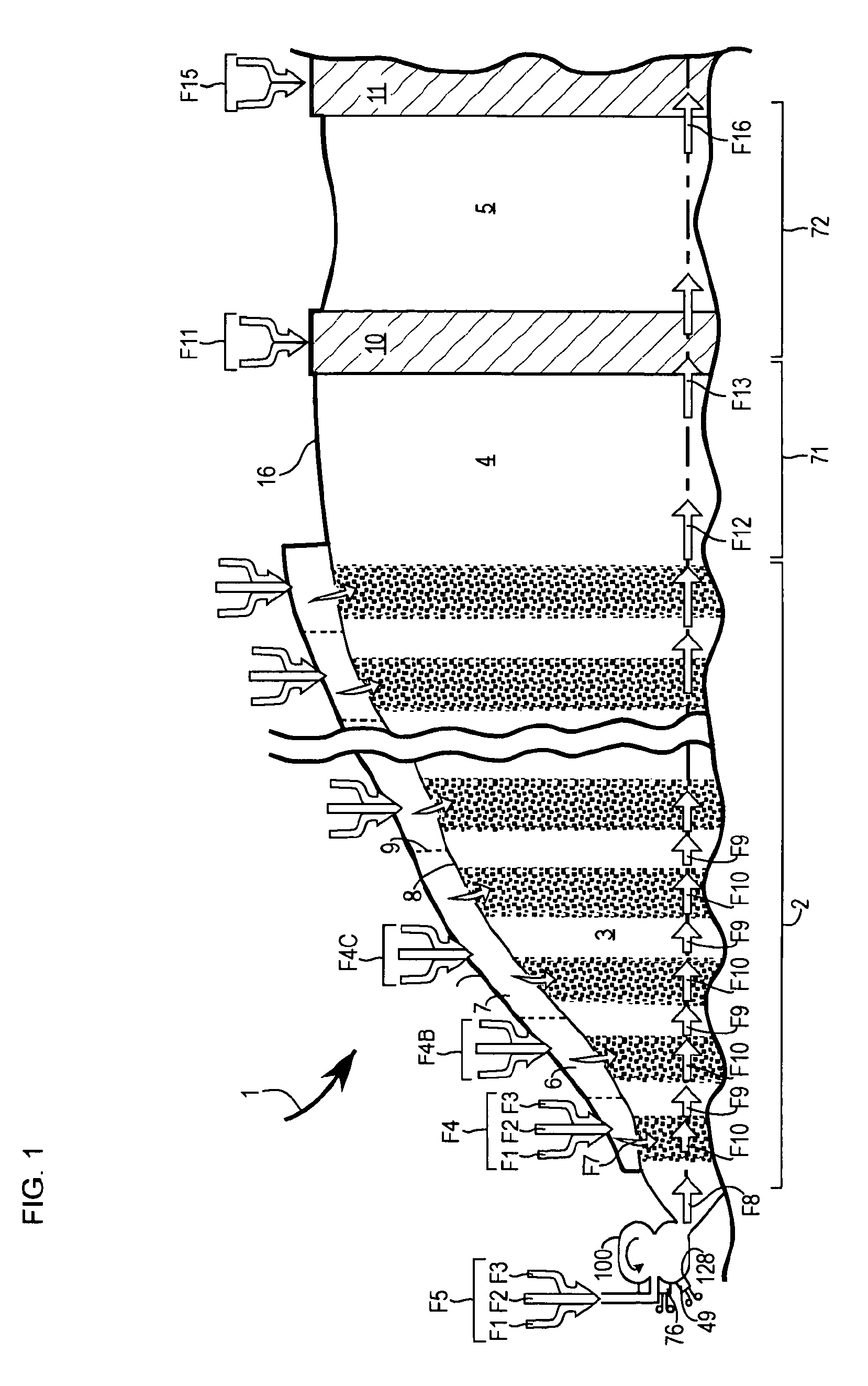

Low emissions combustion apparatus and method

ActiveUS7788897B2Well mixedImprove stabilityGas turbine plantsIndirect carbon-dioxide mitigationCombustionDiluent

Clean combustion and equilibration equipment and methods are provided to progressively deliver, combust and equilibrate mixtures of fuel, oxidant and aqueous diluent in a plurality of combustion regions and in one or more equilibration regions to further progress oxidation of products of incomplete combustion, in a manner that sustains combustion while controlling temperatures and residence times sufficiently to reduce CO and NOx emissions to below 25 ppmvd, and preferably to below 3 ppmvd at 15% O2.

Owner:VAST HLDG LLC

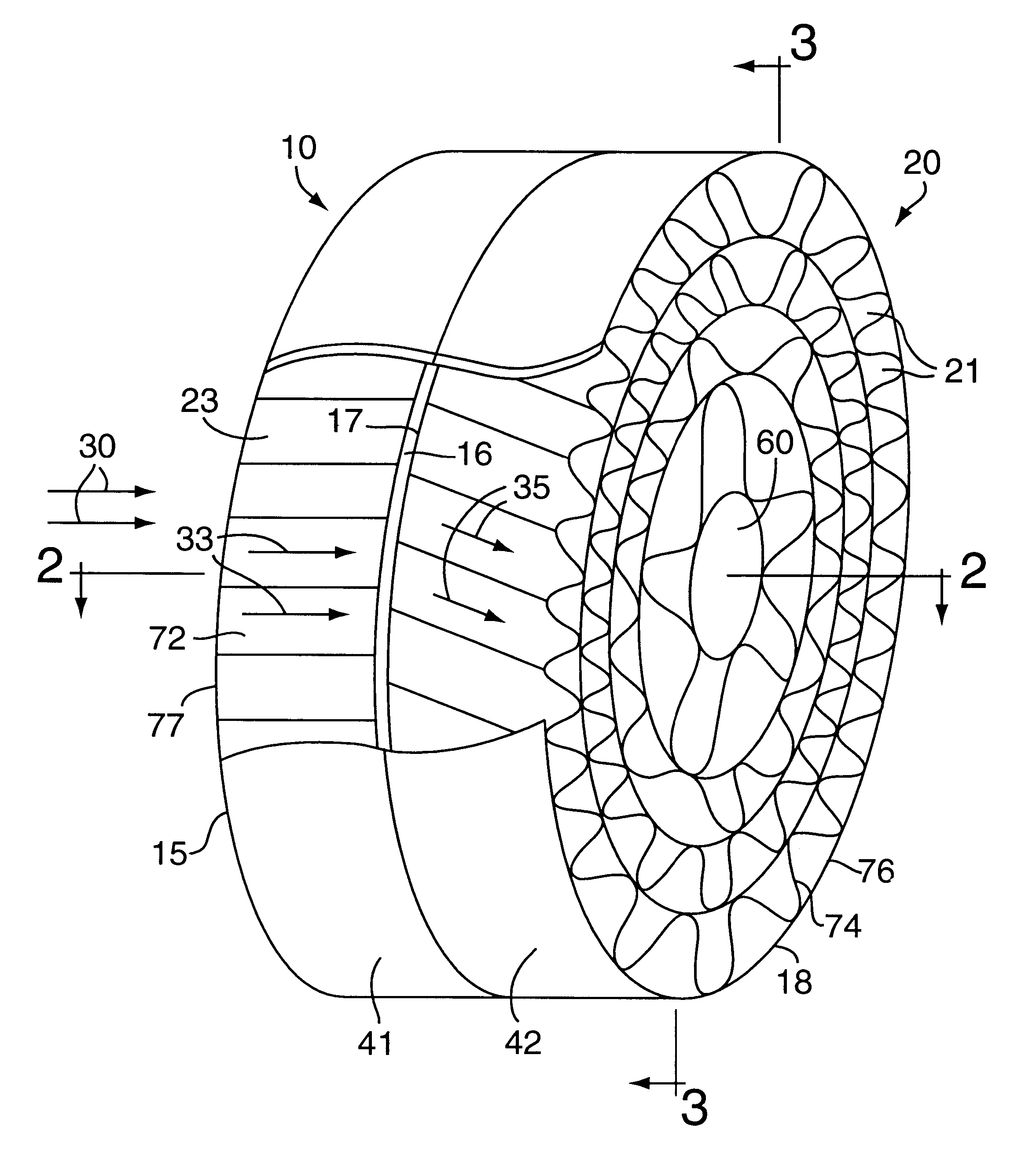

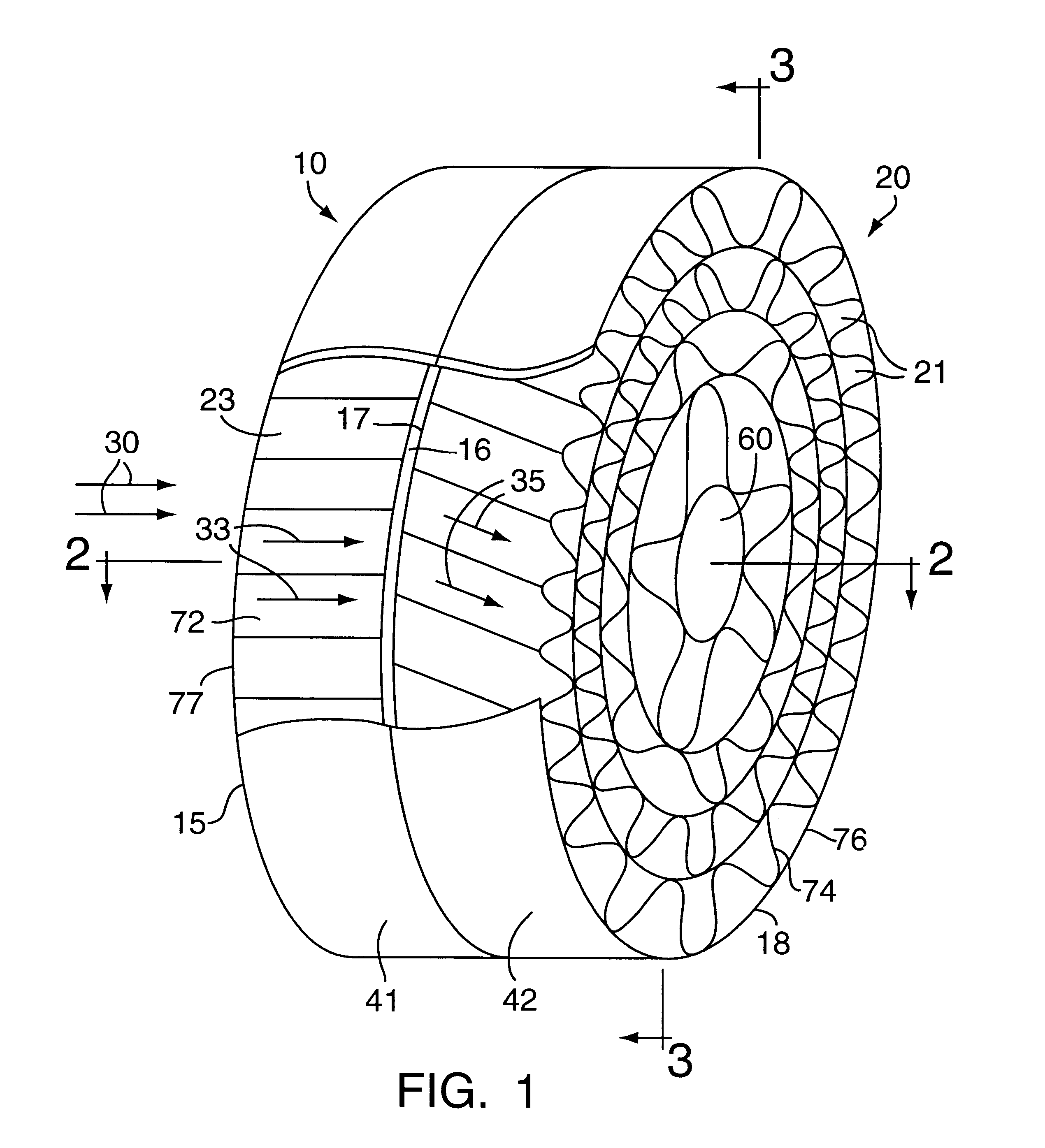

Slotted injection nozzle and low NOx burner assembly

InactiveUS6866503B2Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorEngineering

A nozzle comprising a nozzle body having an inlet face, an outlet face, and an inlet flow axis passing through the inlet and outlet faces, and two or more slots extending through the nozzle body from the inlet face to the outlet face. Each slot has a slot axis and the slot axis of at least one of the slots is not parallel to the inlet flow axis of the nozzle body. In another embodiment, the nozzle comprises a nozzle body having an inlet face, an outlet face, and an inlet flow axis passing through the inlet and outlet faces, and two or more slots extending through the nozzle body from the inlet face to the outlet face, each slot having a slot axis, wherein none of the slots intersect other slots and all of the slots are in fluid flow communication with a common fluid supply conduit. The nozzles may be used to inject secondary fuel in a burner system having a central burner combusting a primary fuel surrounded by secondary fuel injection nozzles.

Owner:AIR PROD & CHEM INC

Diluent shroud for combustor

Owner:GENERAL ELECTRIC CO

High-heat transfer low-NOx combustion system

ActiveUS6939130B2Lower NO<sub>xIncrease brightnessCombustion using gaseous and pulverulent fuelBurner safety arrangementsCombustion systemVertical plane

Owner:GAS TECH INST

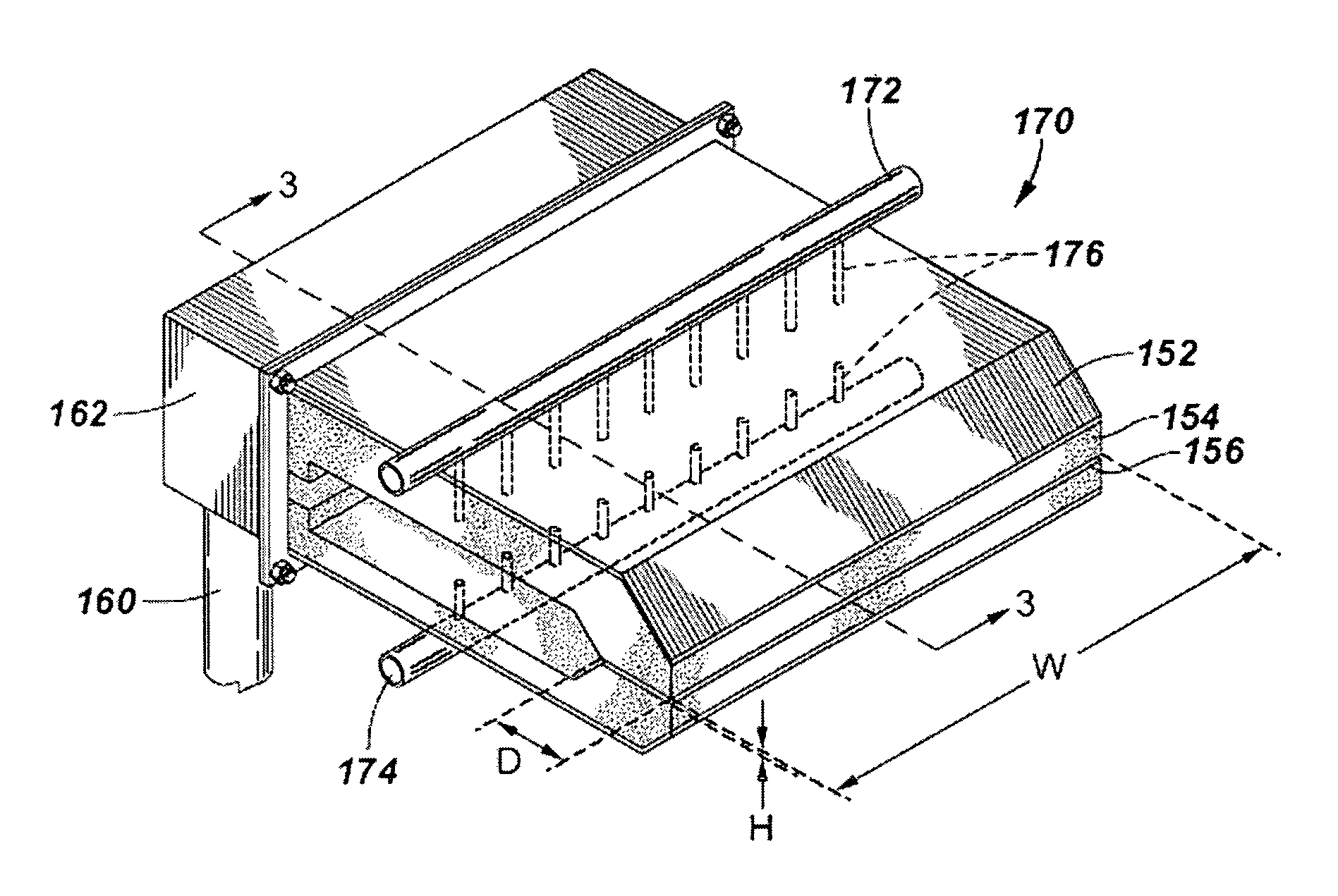

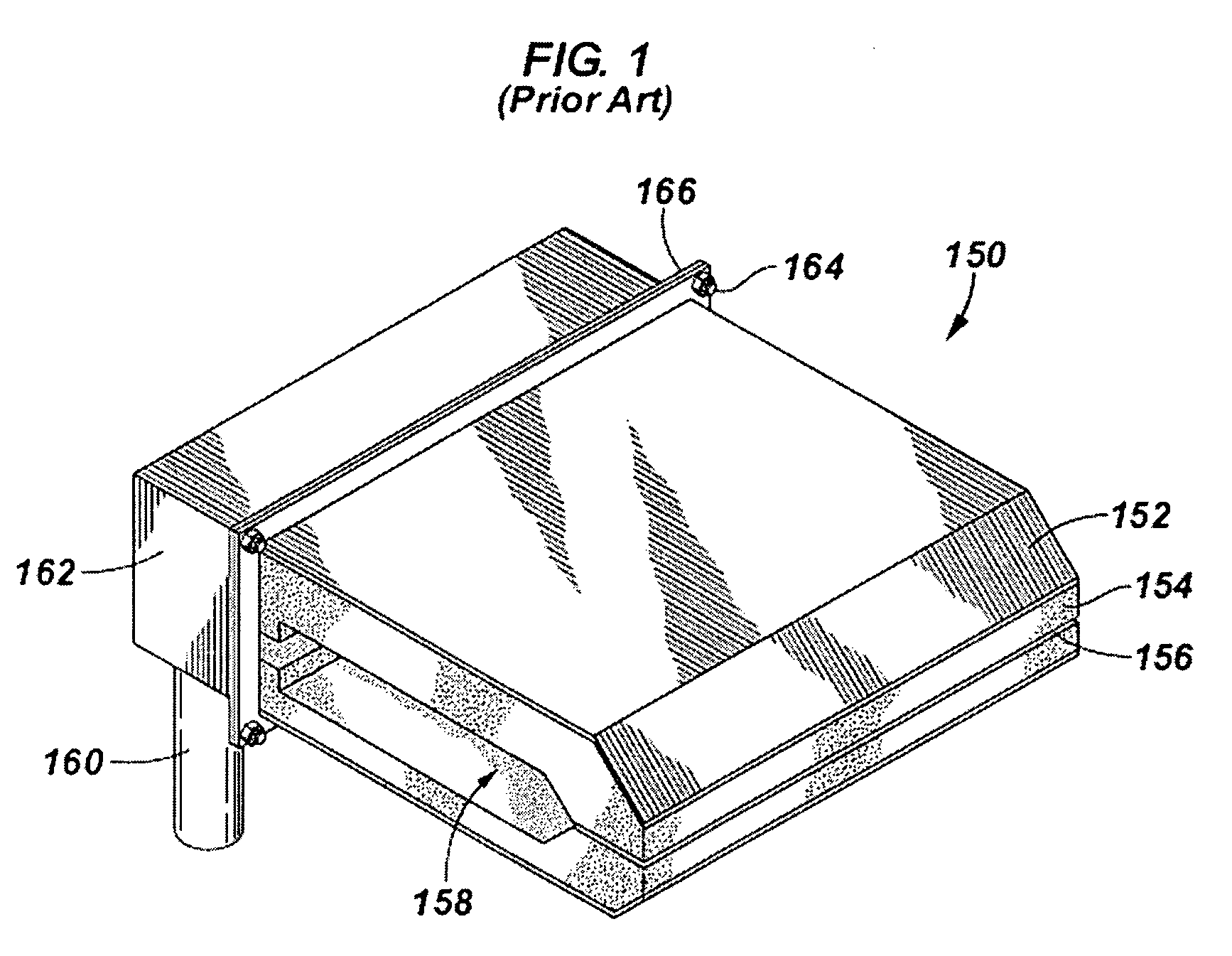

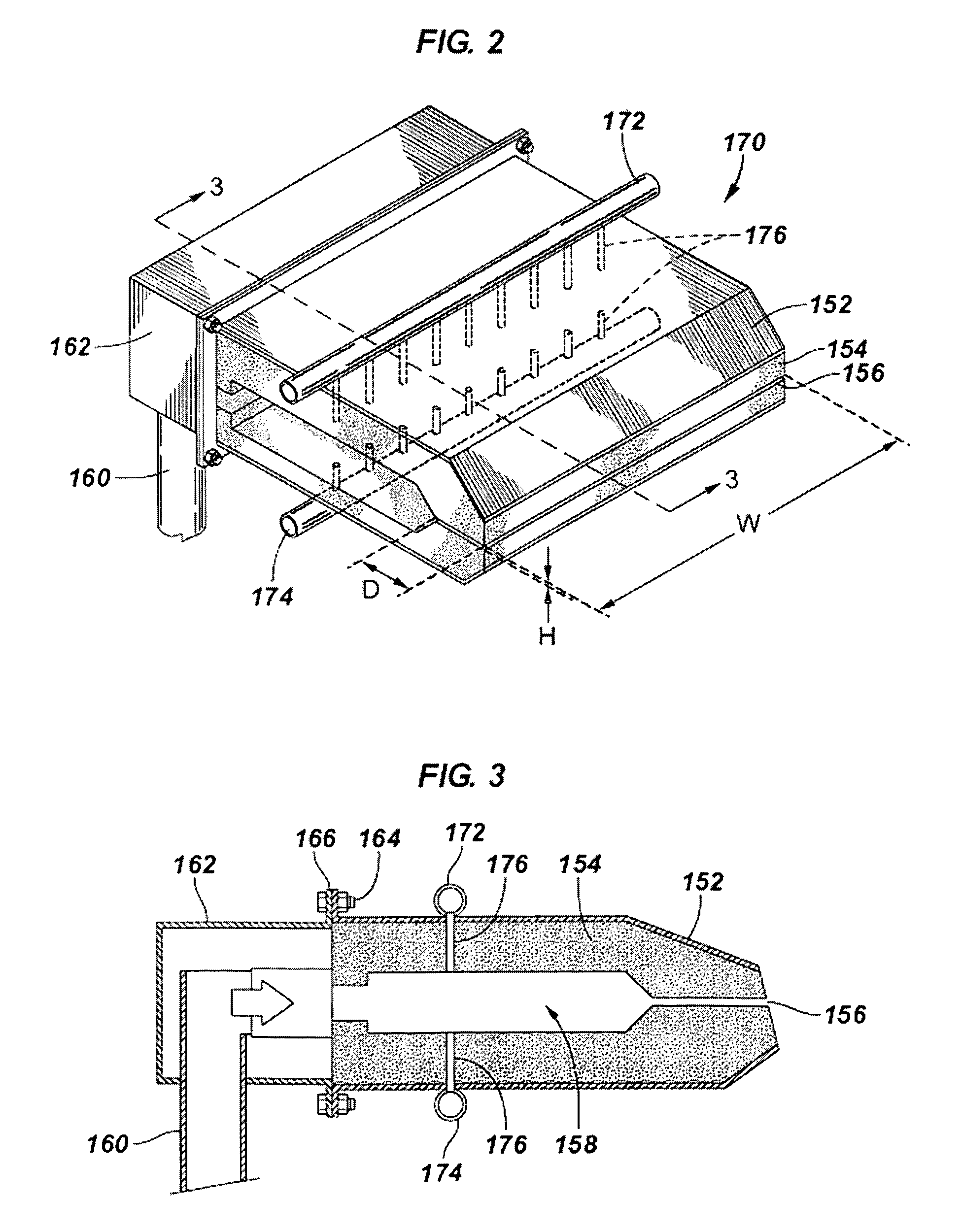

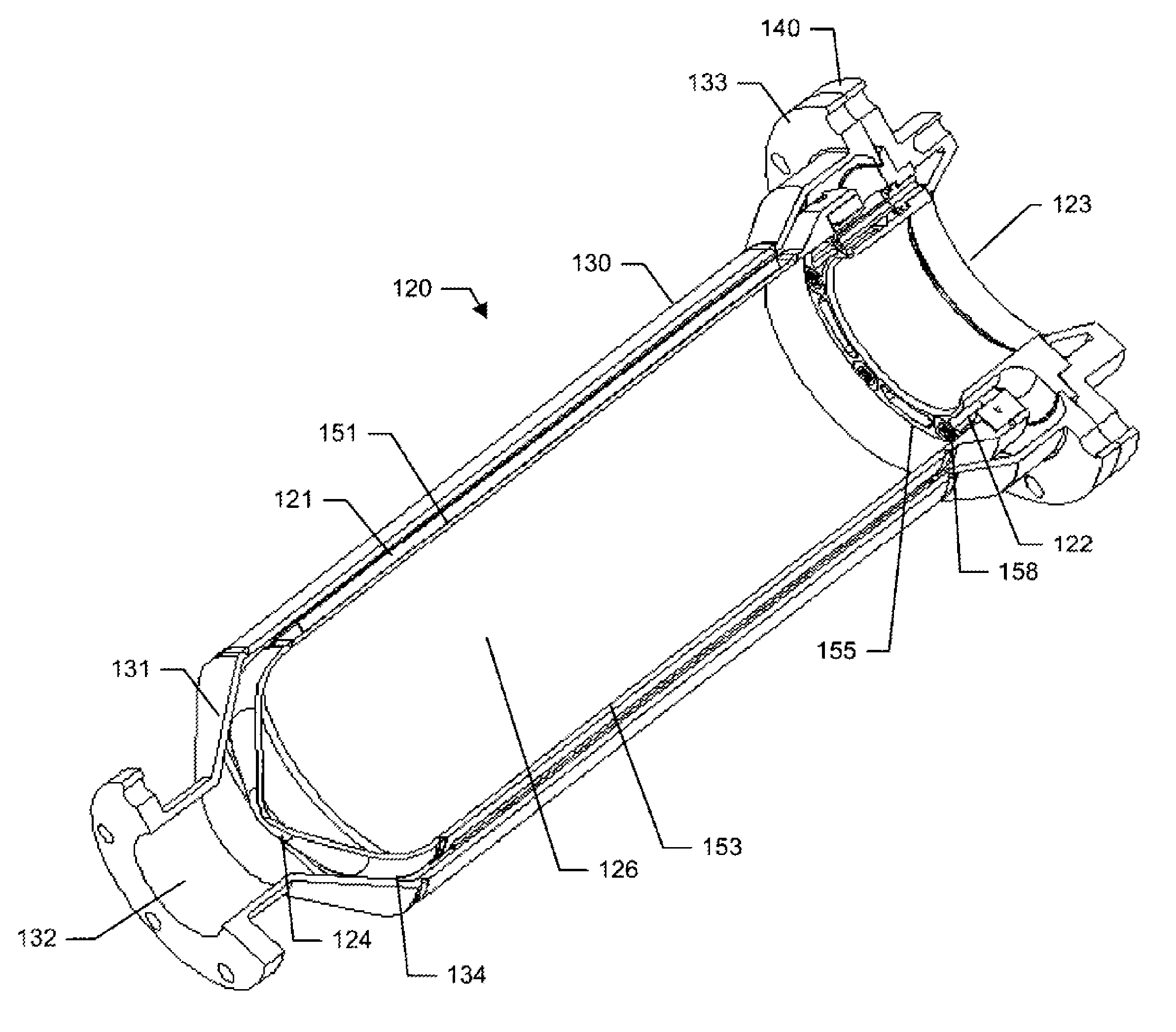

Burner apparatus and methods for making inorganic fibers

Inorganic fiber production burner apparatus and methods of use are disclosed. One burner includes a refractory block adapted to be in fluid connection with sources of primary oxidant and fuel, the refractory block having a fuel and primary oxidant entrance end and a flame exit end, the flame exit end having a substantially rectangular flame exit having a width greater than its height, the refractory block defining a combustion chamber and a second chamber fluidly connecting the combustion chamber and the flame exit end; and an oxygen manifold fluidly connected to the combustion chamber and adapted to route oxygen to the combustion chamber through a plurality of passages through the refractory block. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:JOHNS MANVILLE CORP

Combustion process and apparatus therefore containing separate injection of fuel and oxidant streams

InactiveUS6331107B1Reduce nitrogen oxide emissionsAvoid chemical reactionsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCombustion chamber

A burner assembly having improved flame length and shape control is presented, which includes in exemplary embodiments at least one fuel fluid inlet and at least one oxidant fluid inlet, means for transporting the fuel fluid from the fuel inlet to a plurality of fuel outlets, the fuel fluid leaving the fuel outlets in fuel streams that are injected into a combustion chamber, means for transporting the oxidant fluid from the oxidant inlets to at least one oxidant outlet, the oxidant fluid leaving the oxidant outlets in oxidant fluid streams that are injected into the combustion chamber, with the fuel and oxidant outlets being physically separated, and geometrically arranged in order to impart to the fuel fluid streams and the oxidant fluid streams angles and velocities that allow combustion of the fuel fluid with the oxidant in a stable, wide, and luminous flame. Alternatively, injectors may be used alone or with the refractory block to inject oxidant and fuel gases. The burner assembly affords improved control over flame size and shape and may be adjusted for use with a particular furnace as required.

Owner:AIR LIQUIDE AMERICA INC

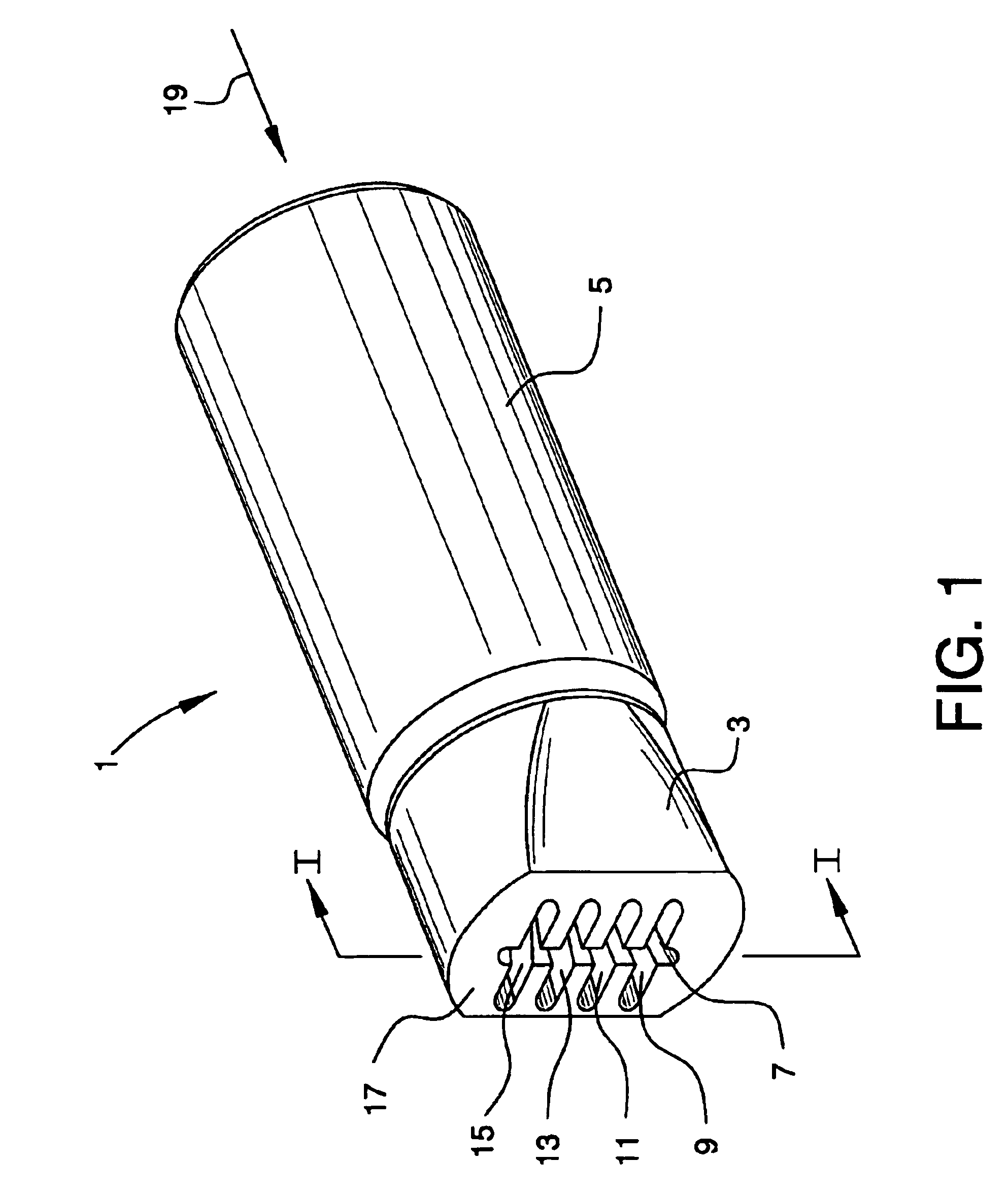

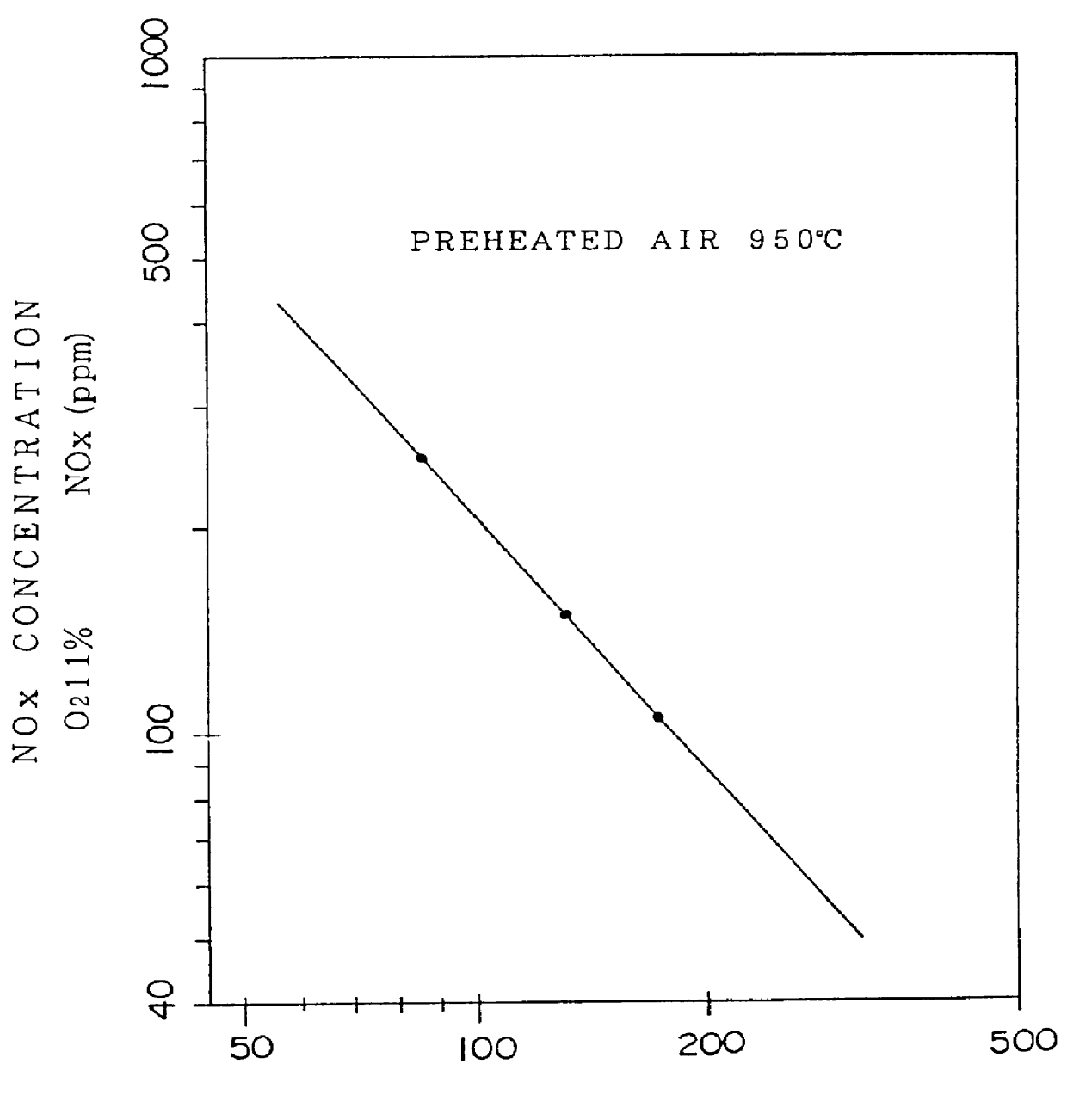

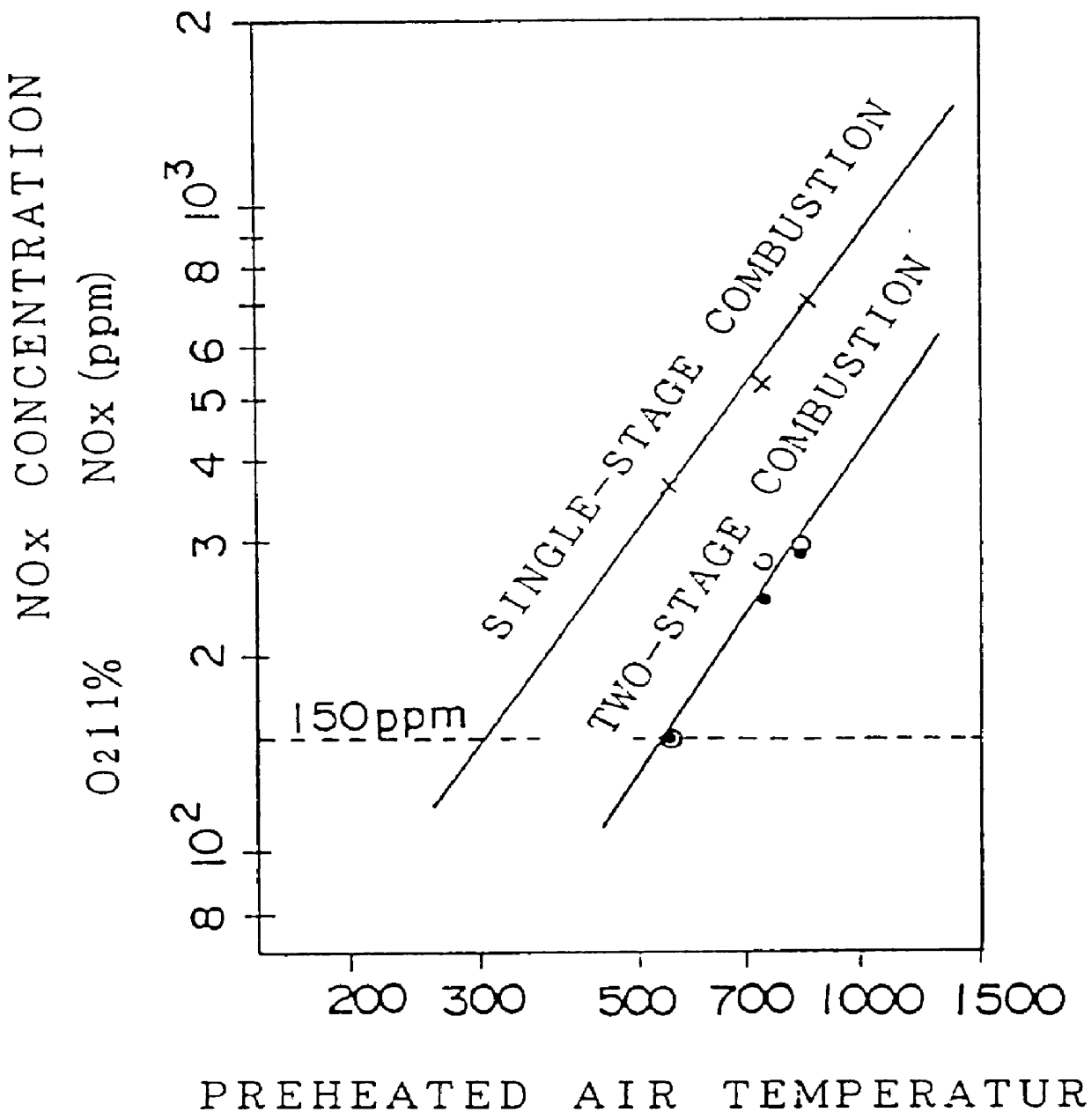

Radiant tube burner

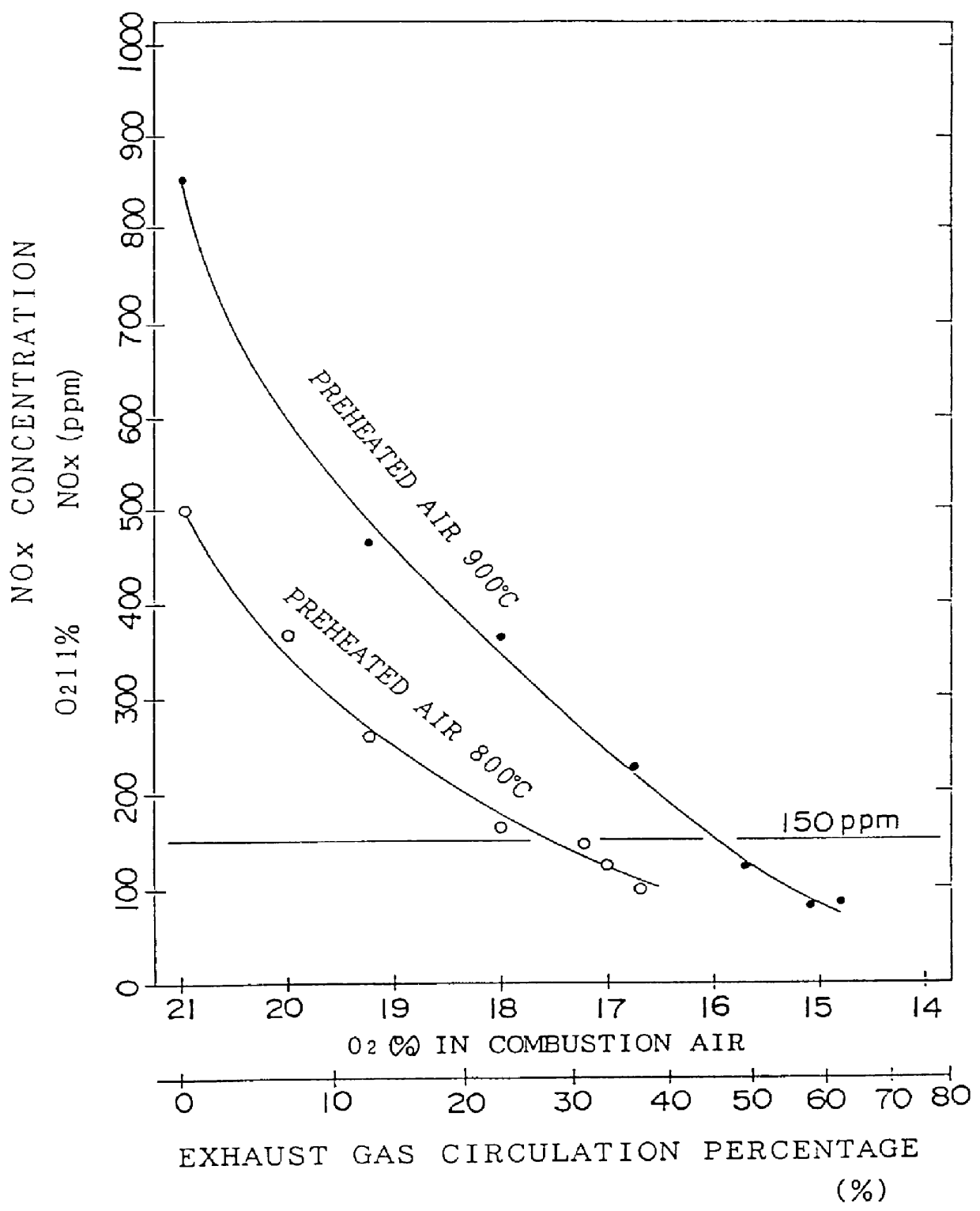

PCT No. PCT / JP95 / 01916 Sec. 371 Date May 23, 1996 Sec. 102(e) Date May 23, 1996 PCT Filed Sep. 22, 1995 PCT Pub. No. WO96 / 09496 PCT Pub. Date Mar. 28, 1996With respect to a radiant tube burner to be used for heating a heating furnace or the like, to suppress the generation of NOx accompanying combustion, to make the structure thereof fit for a radiant tube burner equipment, to simplify the control of a fuel supply system and an air supply system, and to prevent the coking. Furthermore, to provide a combustion control scheme appropriate to a radiant tube burner. For these purposes, the present invention placed the respective tips of a fuel nozzle, e.g., pilot burner joint-use nozzle (11), and an air throat (13) in the end of a radiant tube (3) and moreover has a combustion air injection port (33) of the air throat (13) provided to be deviated in contact with or near to the inner circumferential wall surface of the radiant tube (3). In addition, a control device (307) for making a burner burn alternately.

Owner:NIPPON KOKAN KK +1

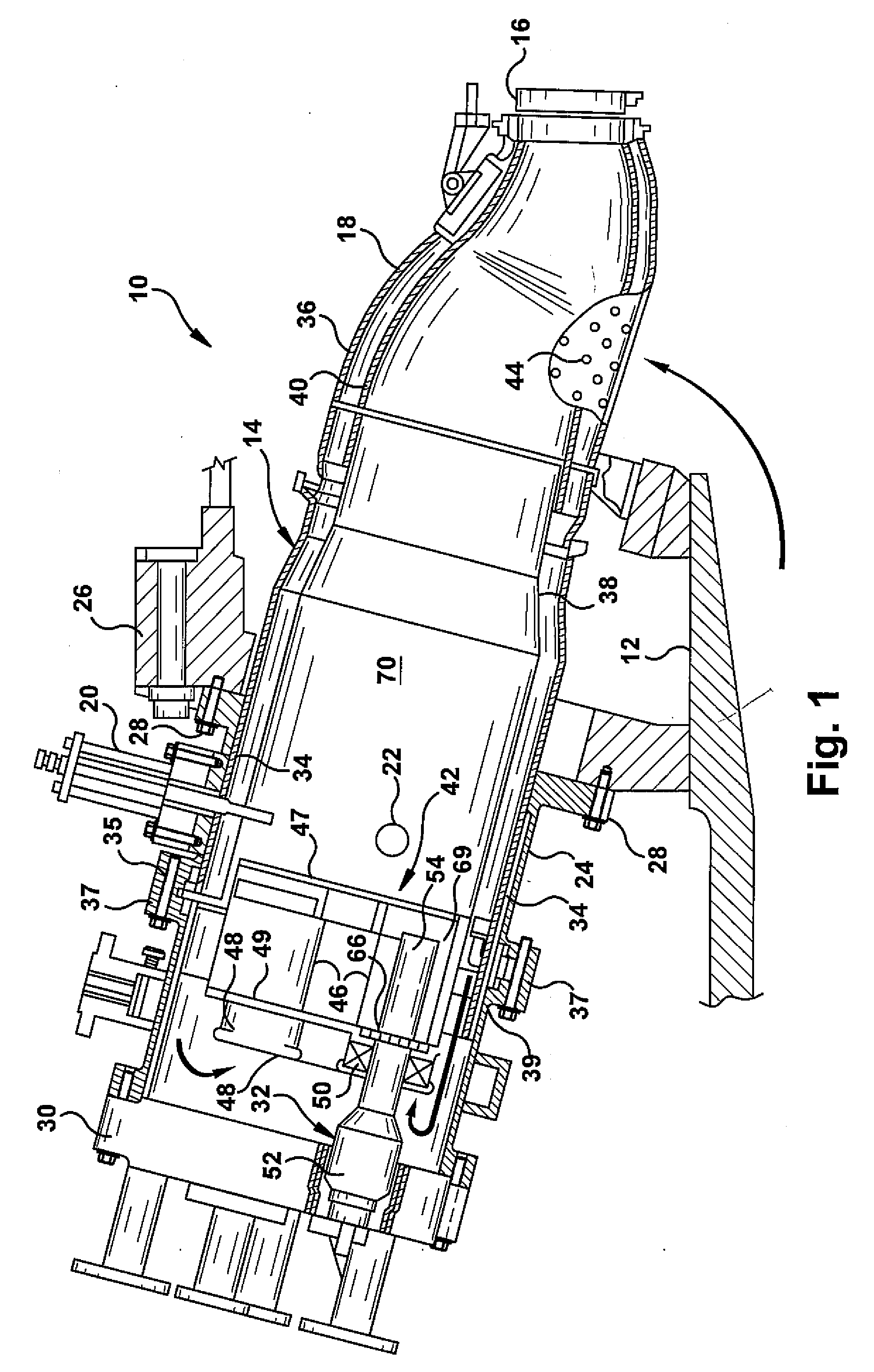

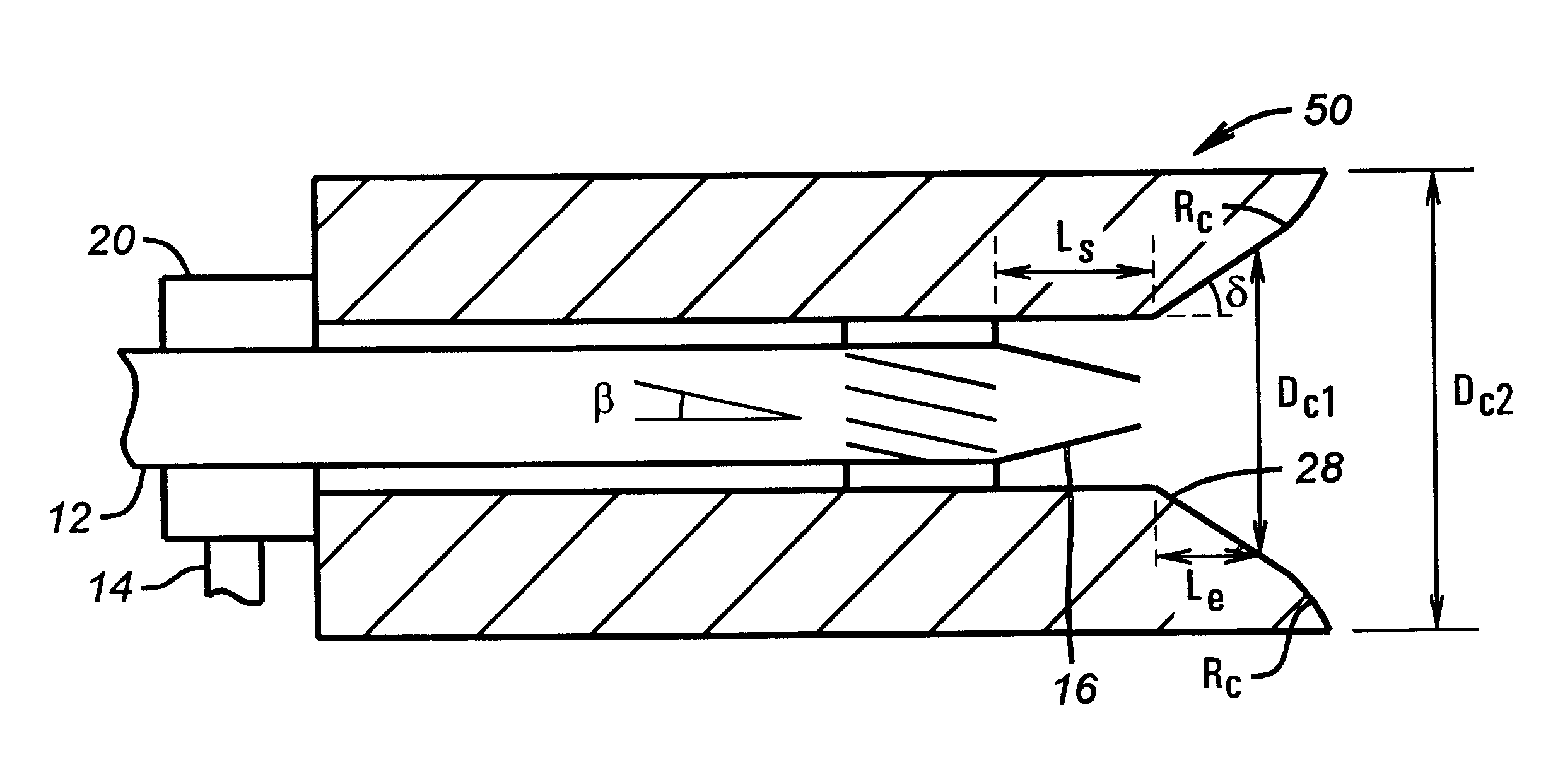

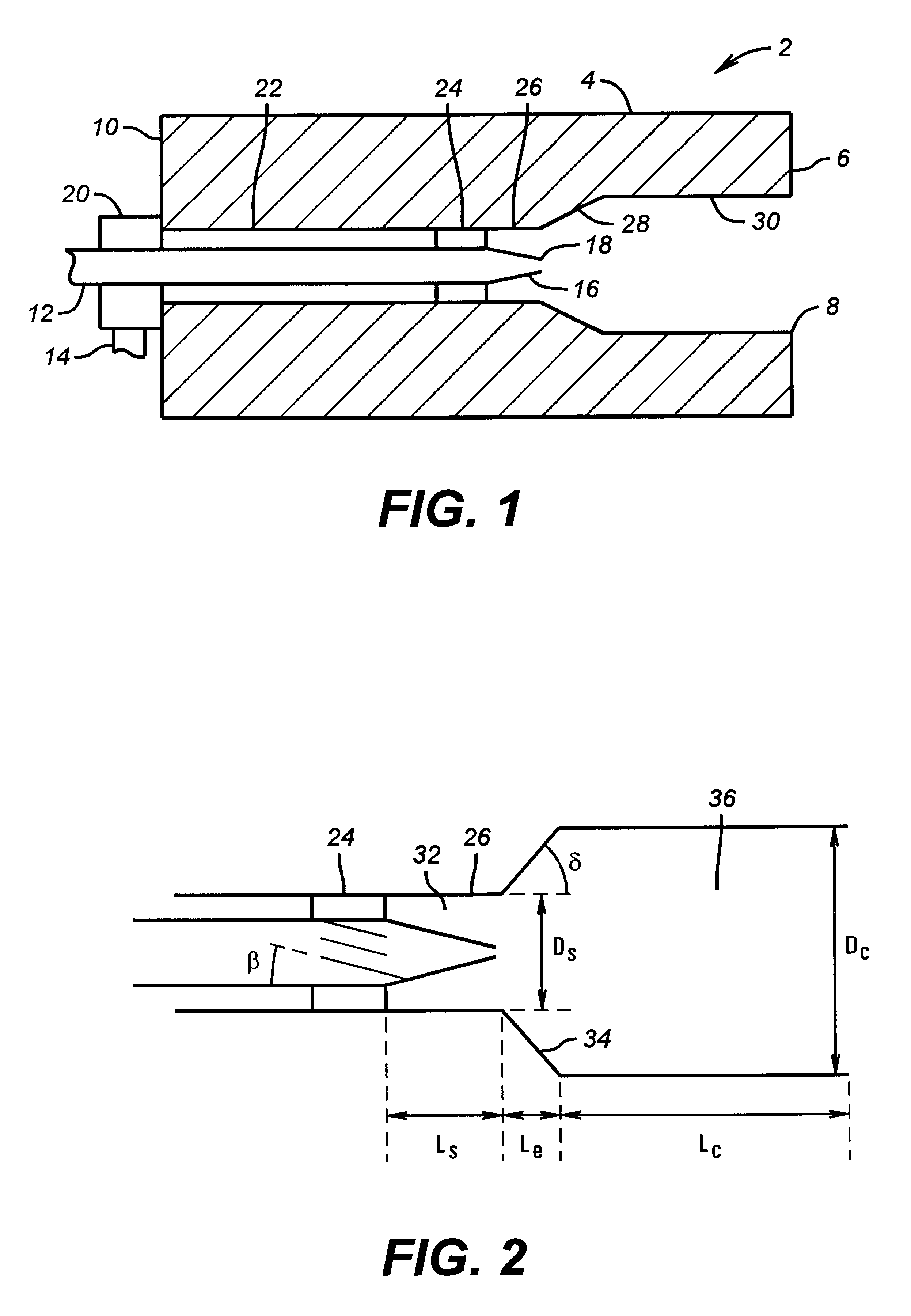

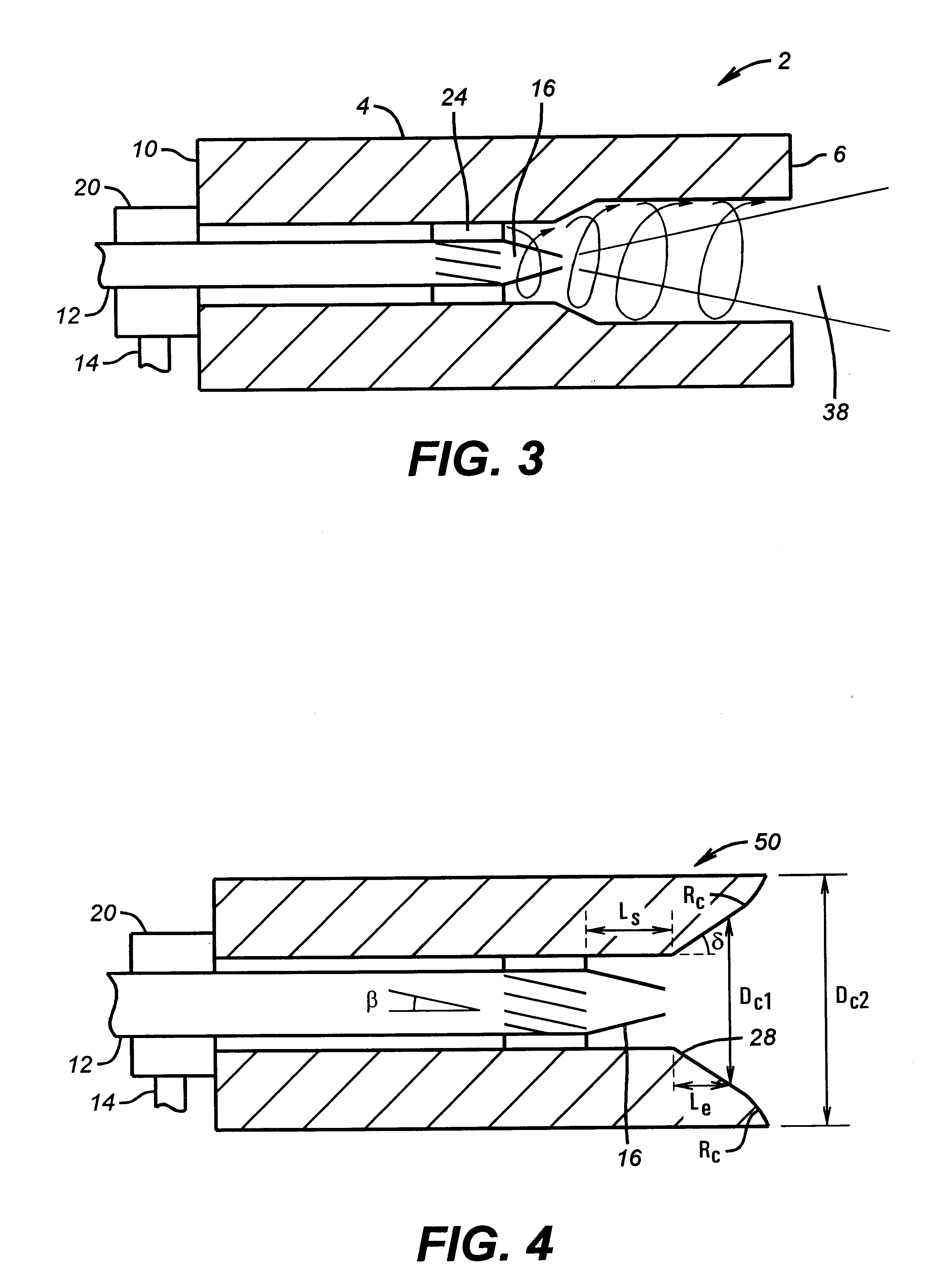

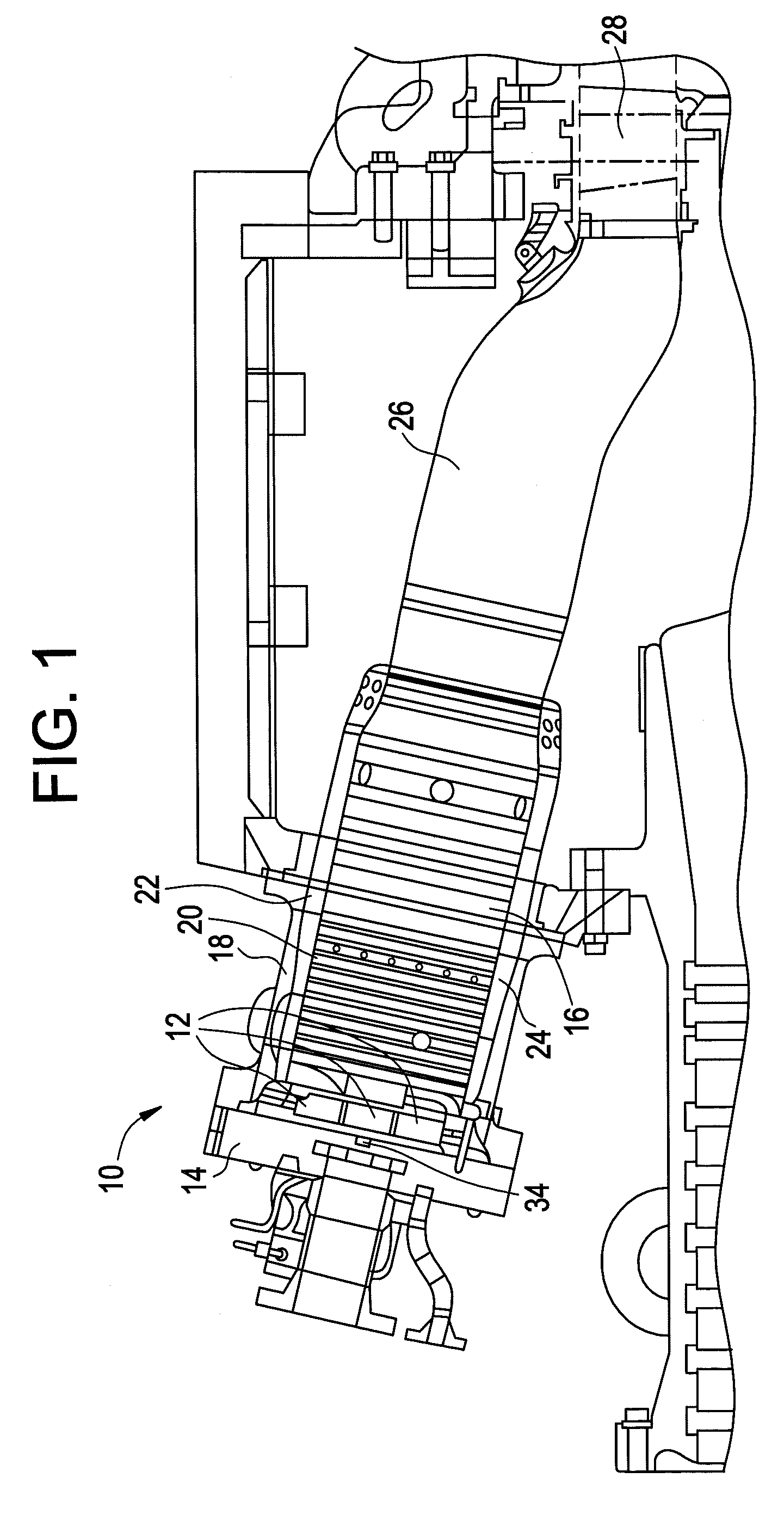

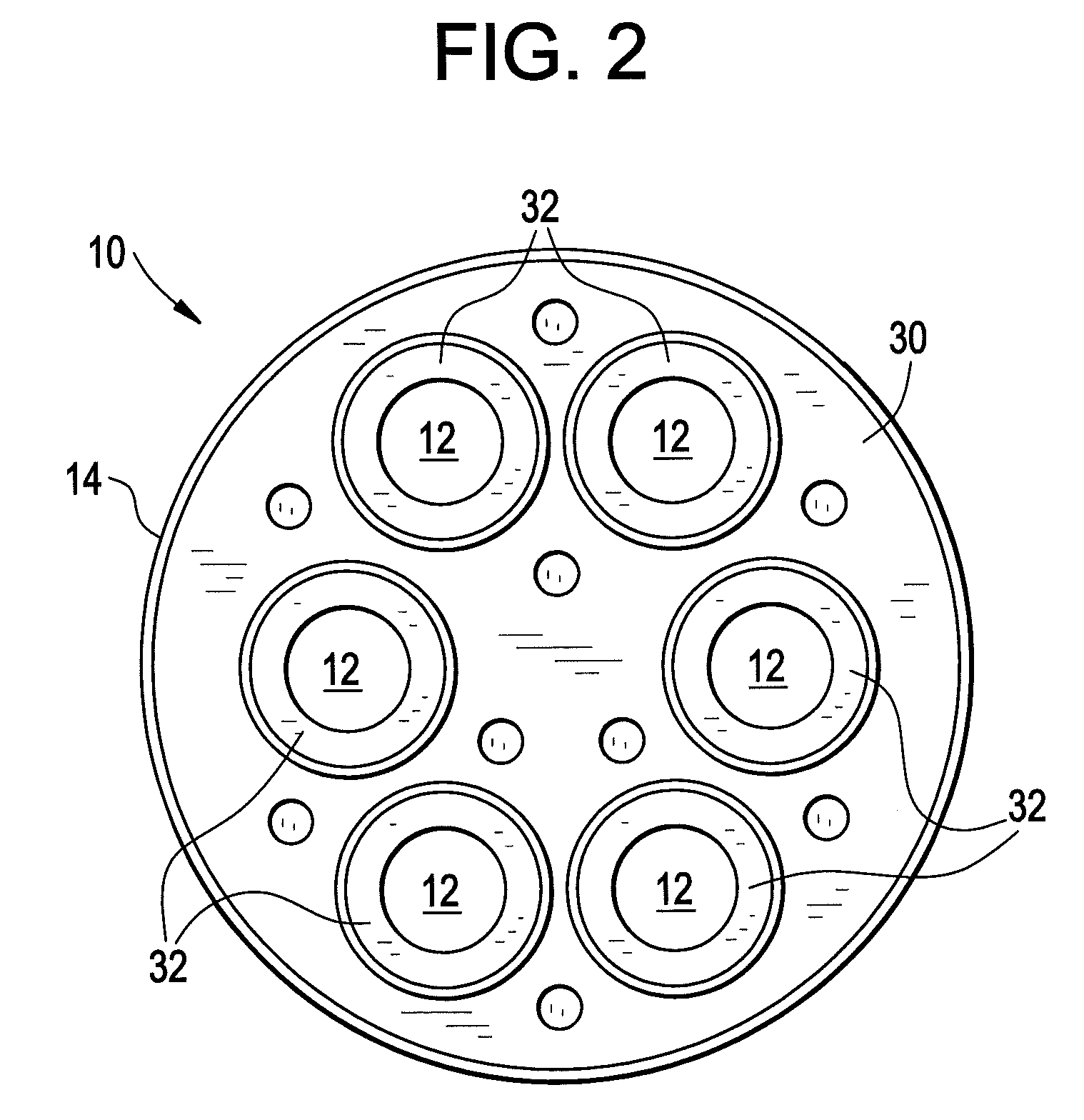

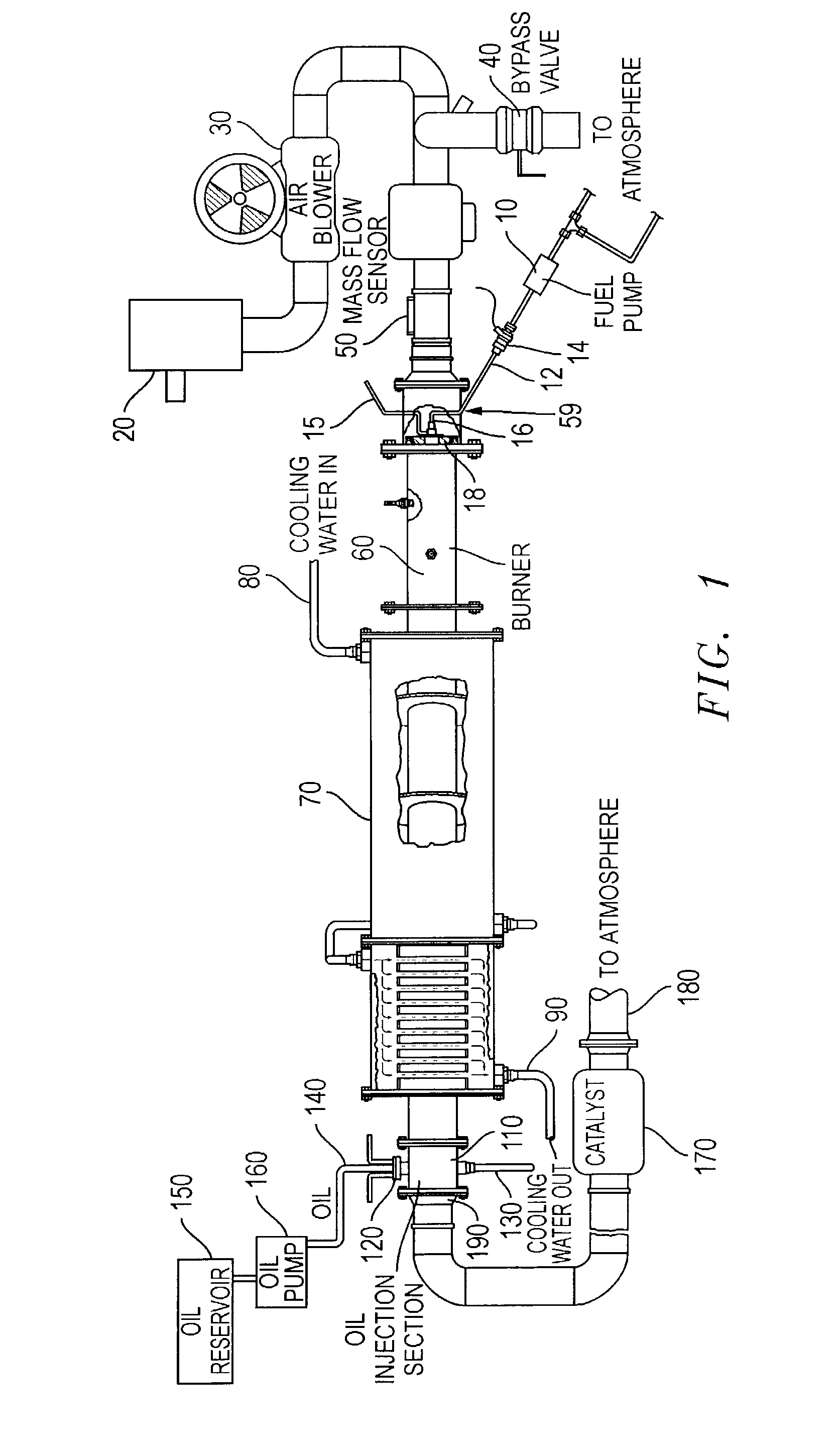

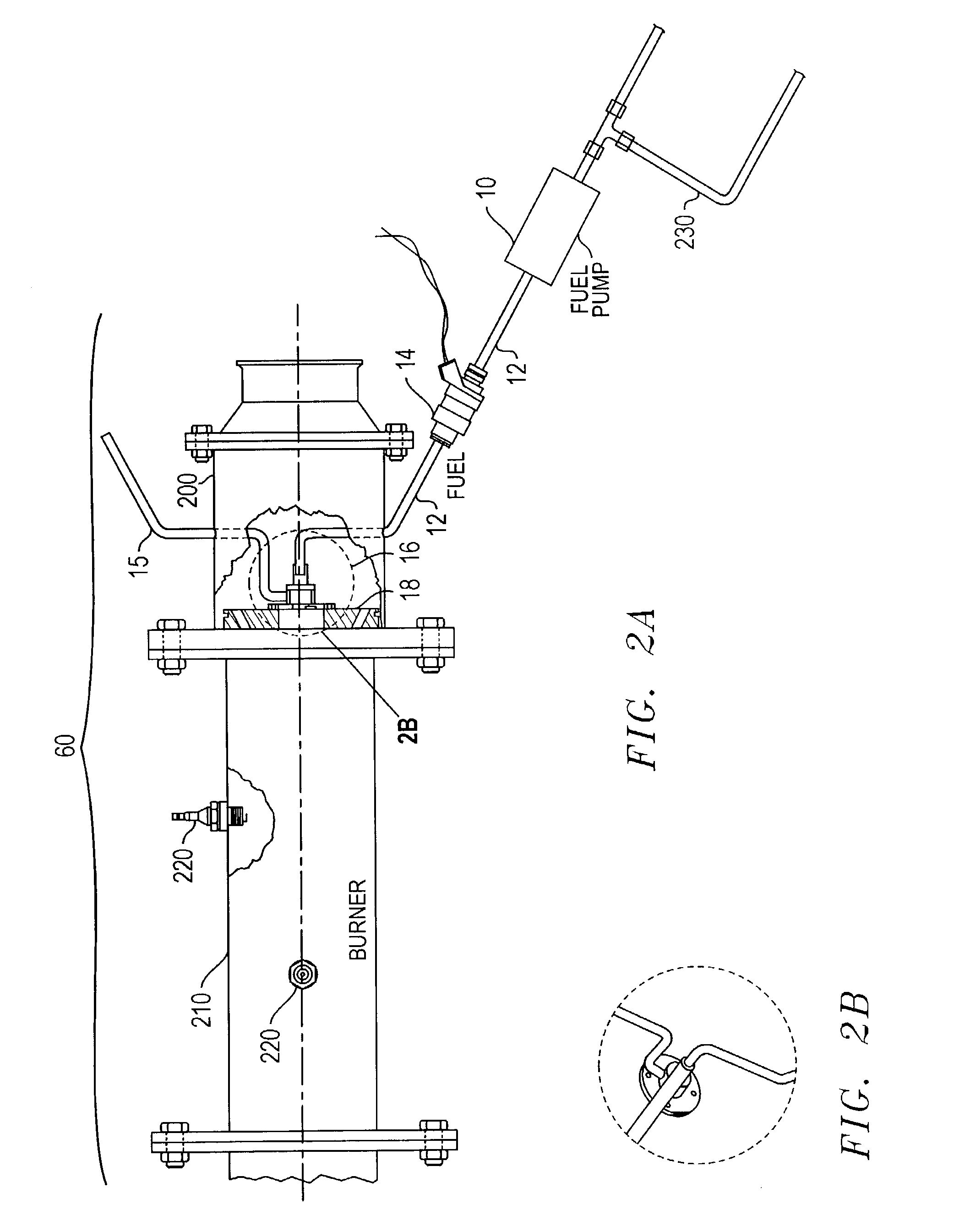

Method and apparatus for testing catalytic converter durability

InactiveUS20030079520A1Internal combustion piston enginesExhaust apparatusCombustorChemical measurement

The present application relates in general to an apparatus and to methods for testing the performance of an automotive catalytic converter under conditions simulating those which occur in motor vehicles over extended driving conditions. The application provides a novel swirl plate and a novel fuel injector which enable the burner to run stoichiometric for extended periods of time.

Owner:SOUTHWEST RES INST

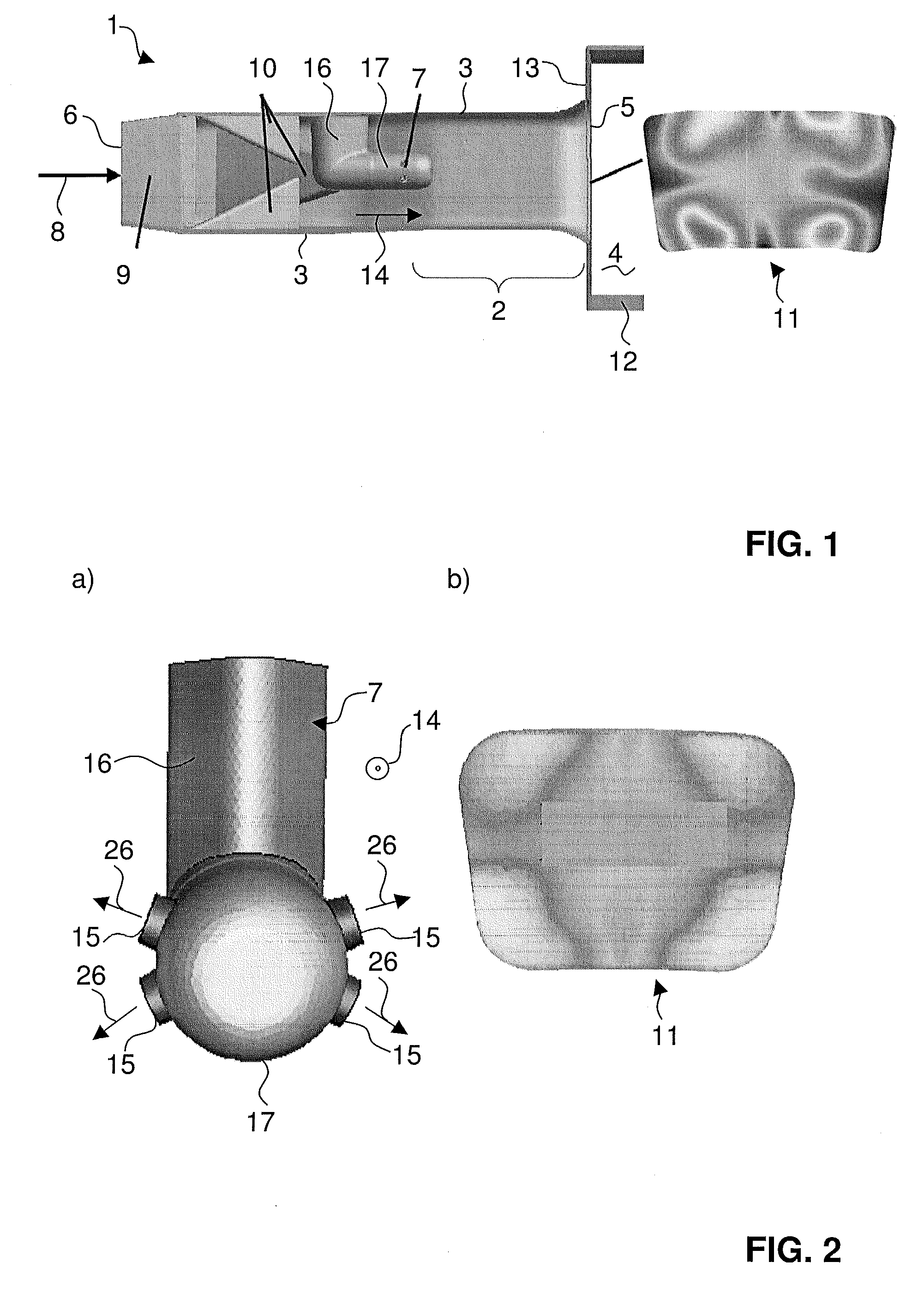

Reheat burner injection system

The disclosure relates to a burner for a combustion chamber of a gas turbine, with an injection device for the introduction of at least one gaseous and / or liquid fuel into the burner, wherein the injection device has at least one body which is arranged in the burner with at least one nozzle for introducing the at least one fuel into the burner, the at least one body being configured as a streamlined body which has a streamlined cross-sectional profile and which extends with a longitudinal direction perpendicularly or at an inclination to a main flow direction prevailing in the burner. The at least one nozzle has its outlet orifice at or in a trailing edge of the streamlined body, and with reference to a central plane of the streamlined body, the trailing edge is provided with at least two lobes extending in opposite transverse directions.

Owner:ANSALDO ENERGIA SWITZERLAND AG

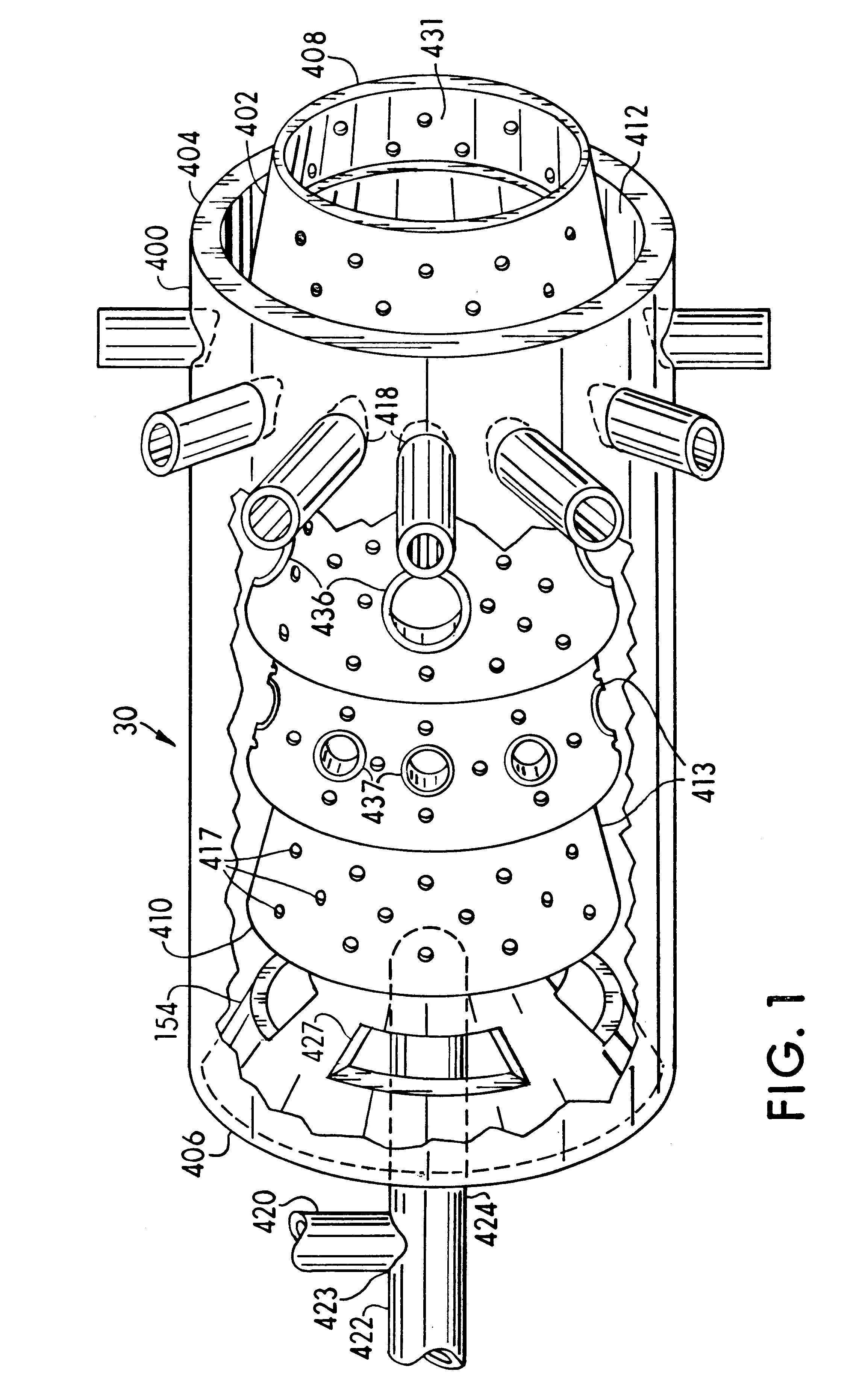

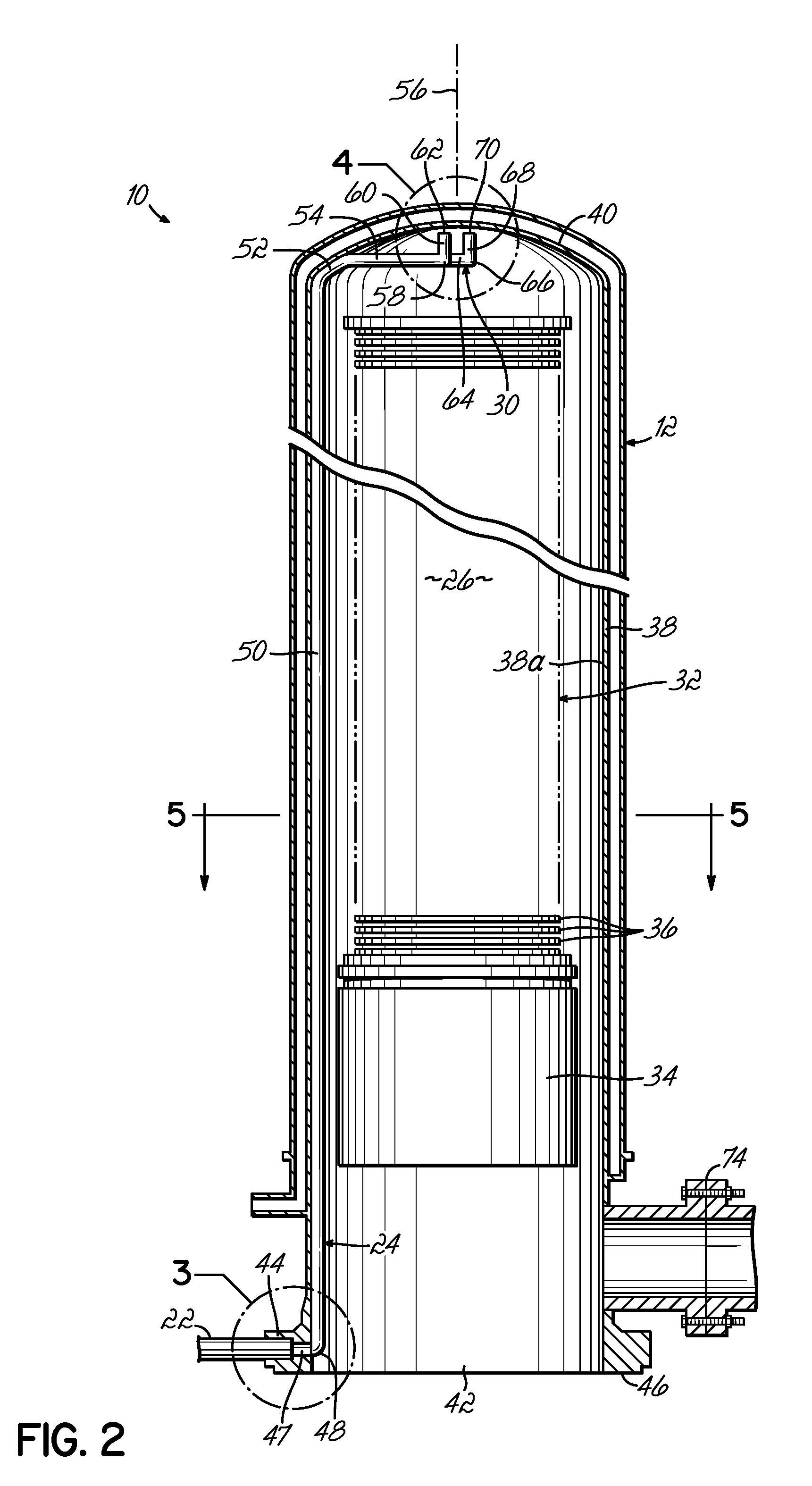

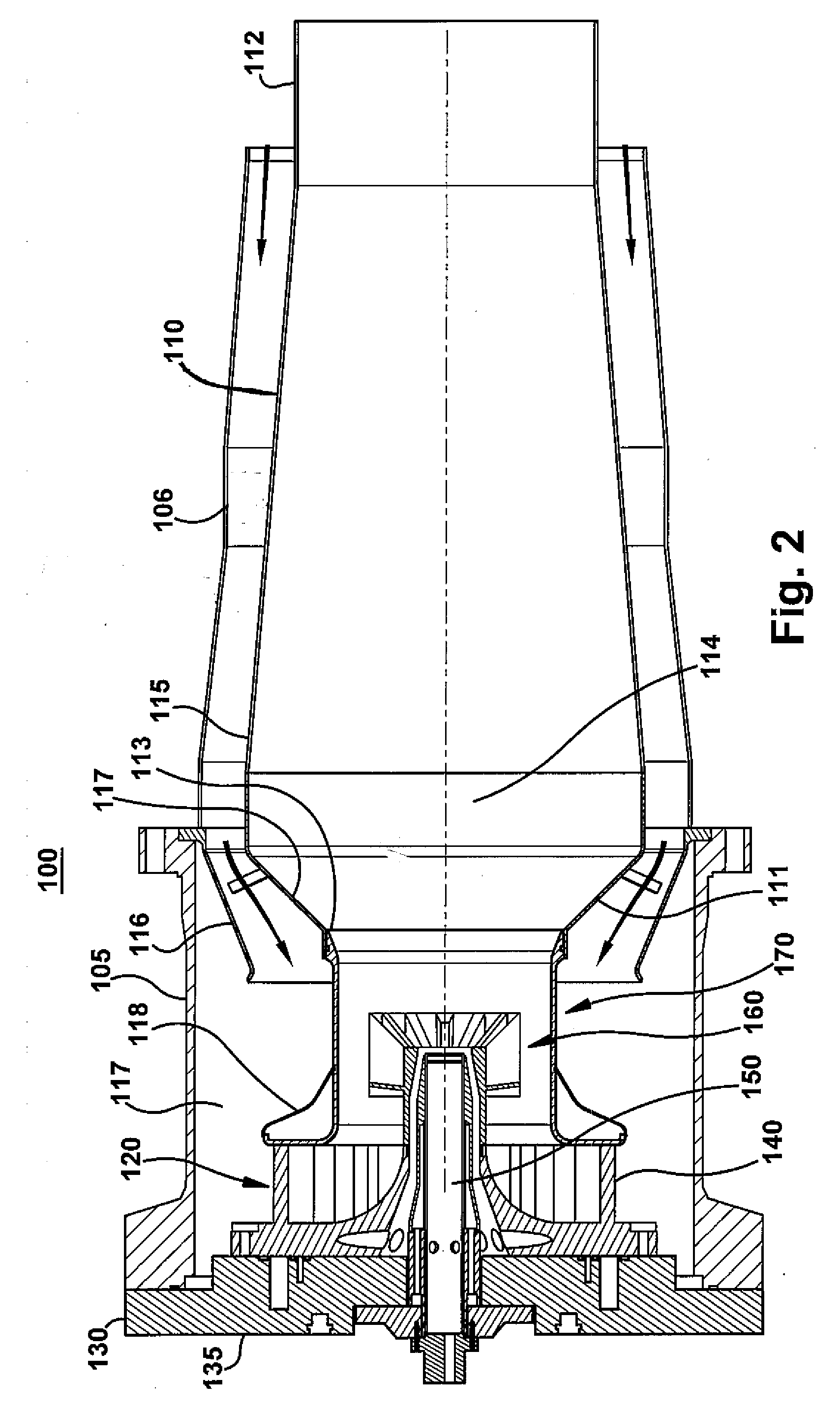

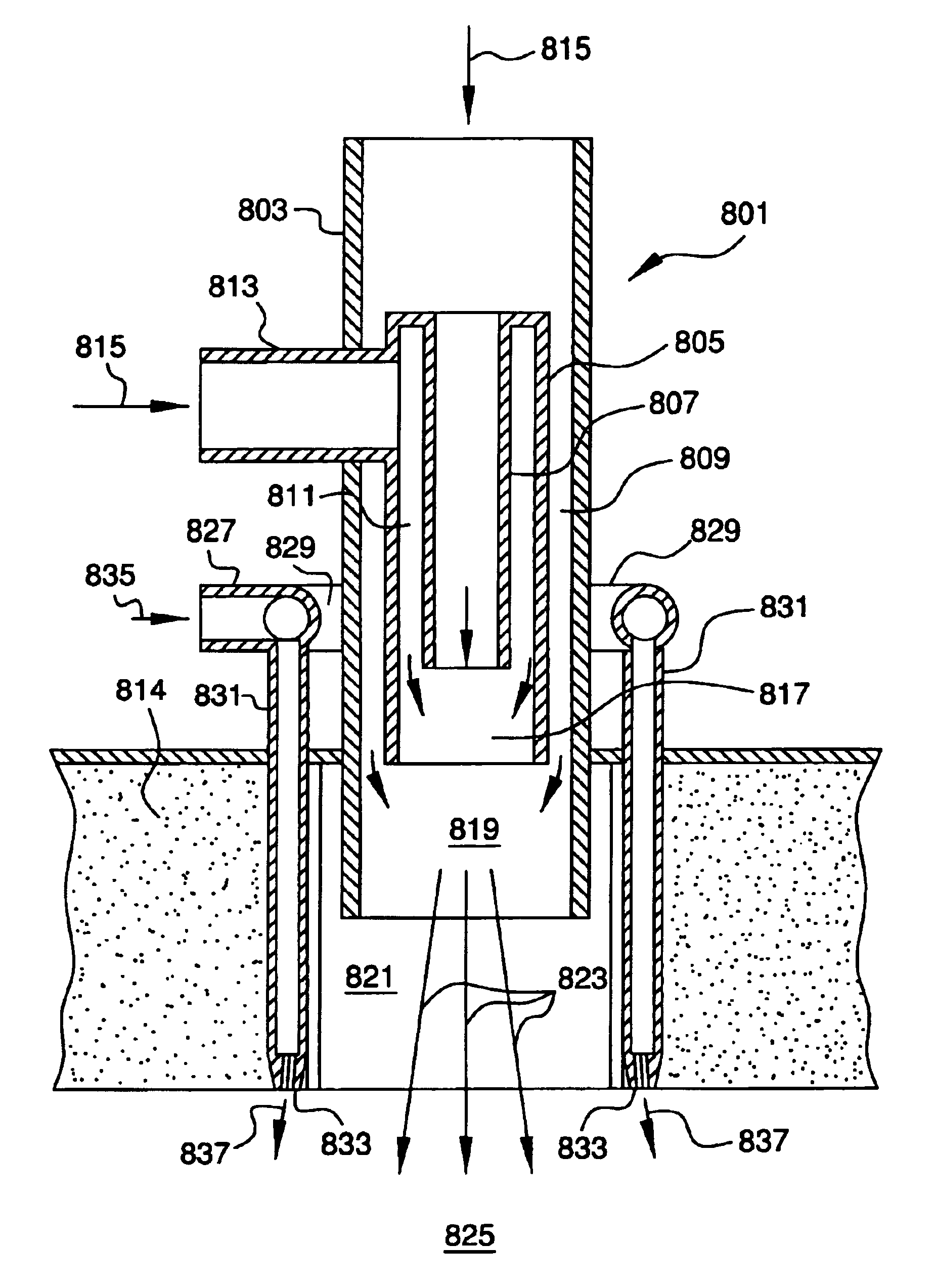

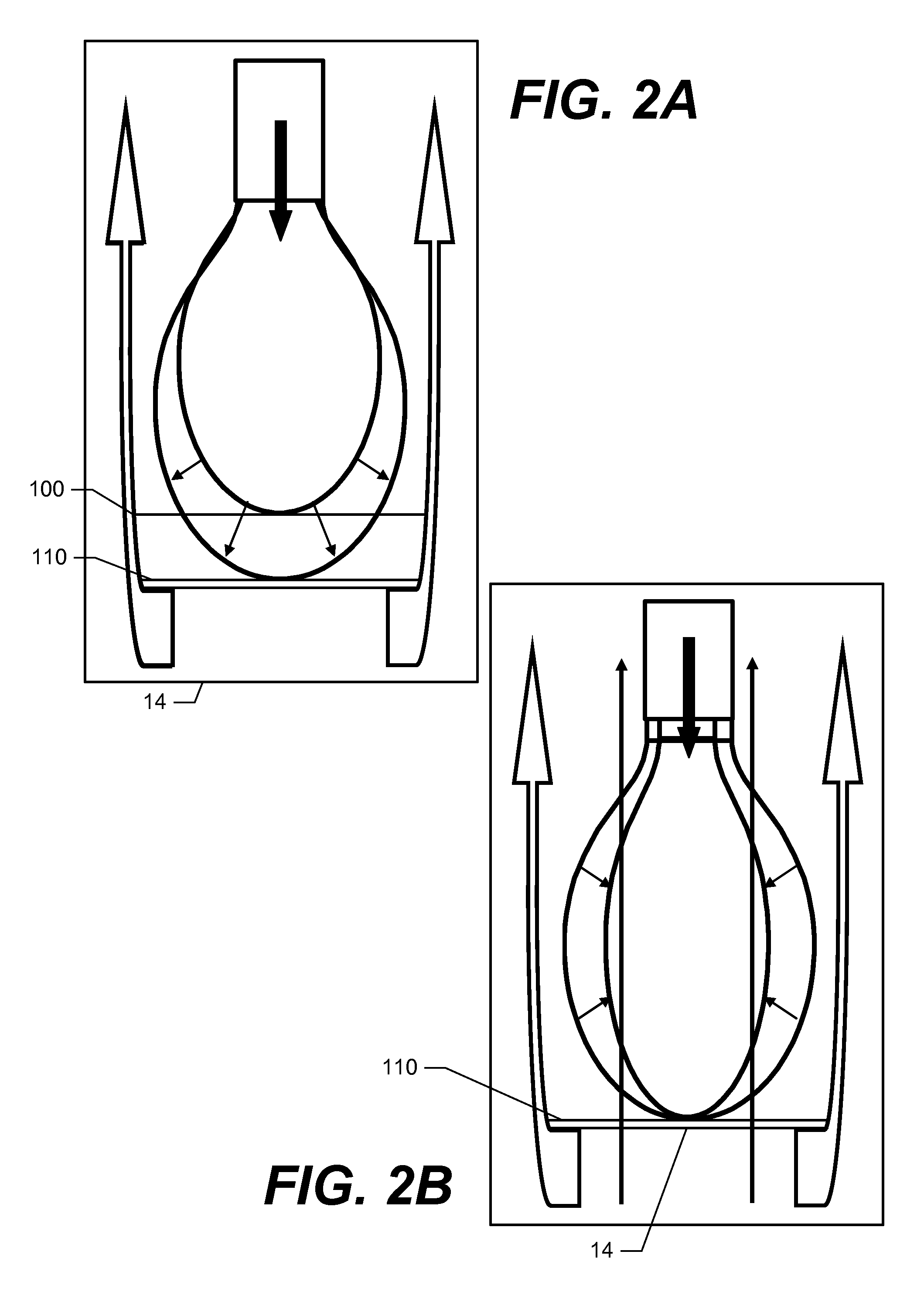

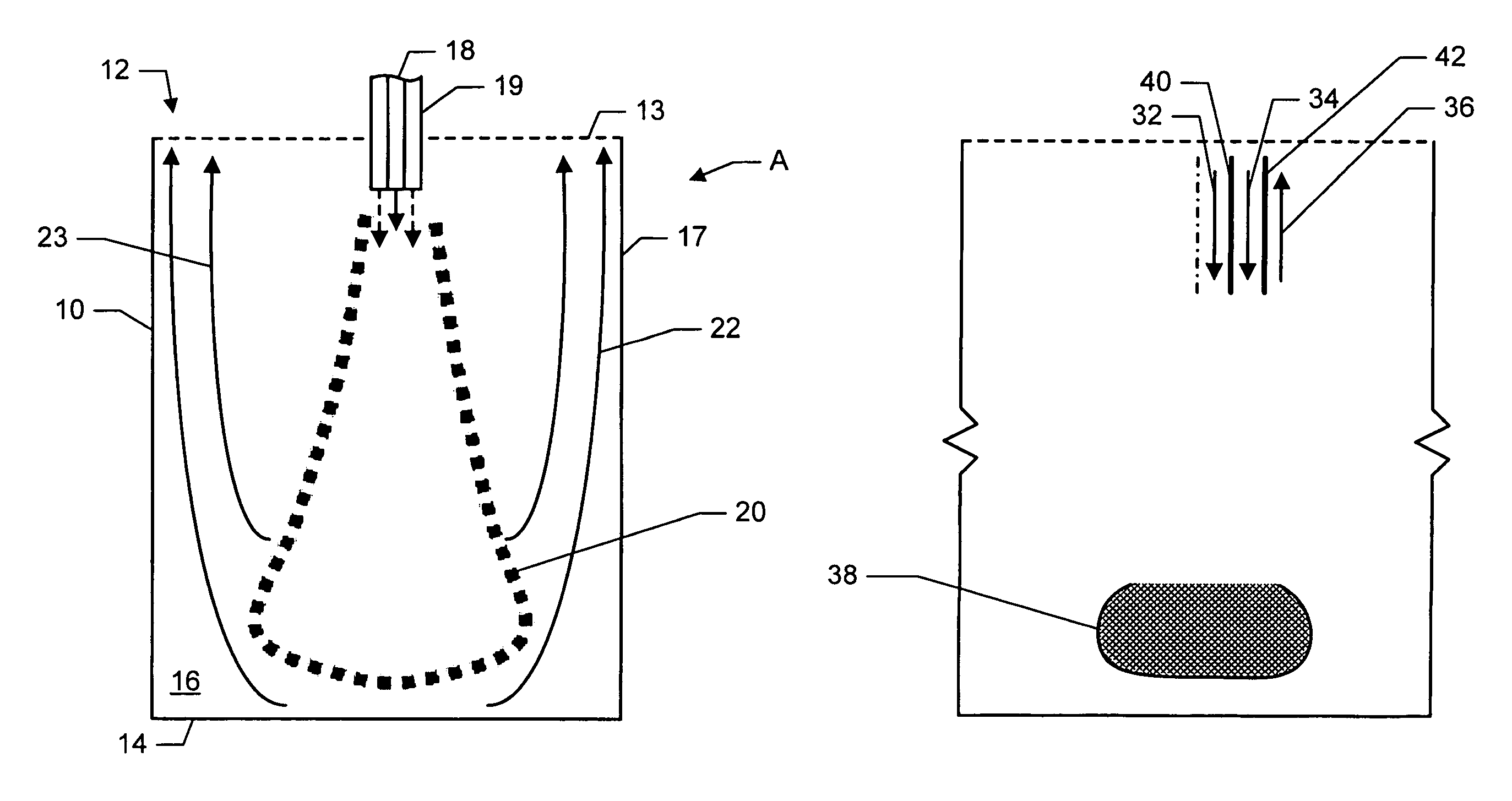

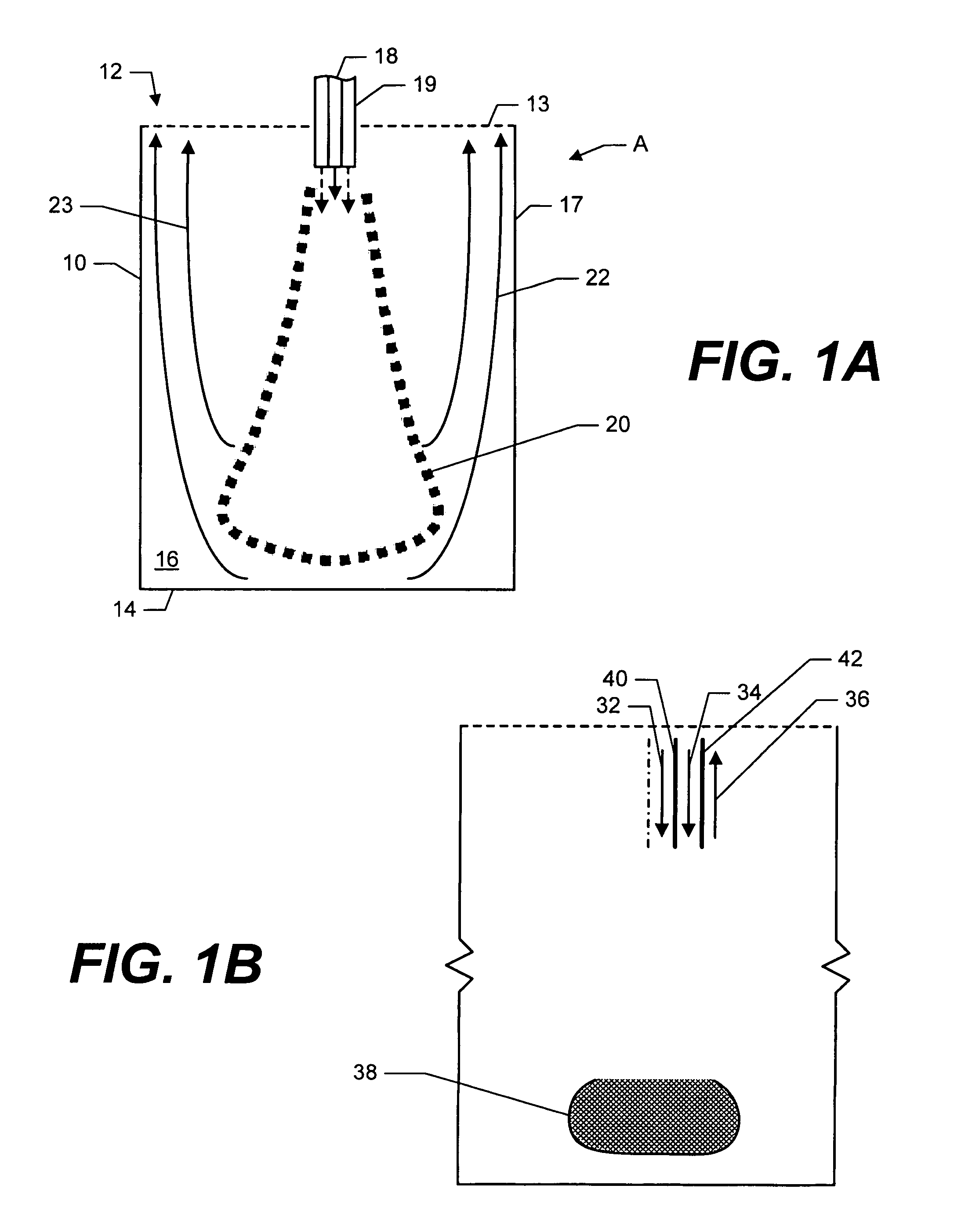

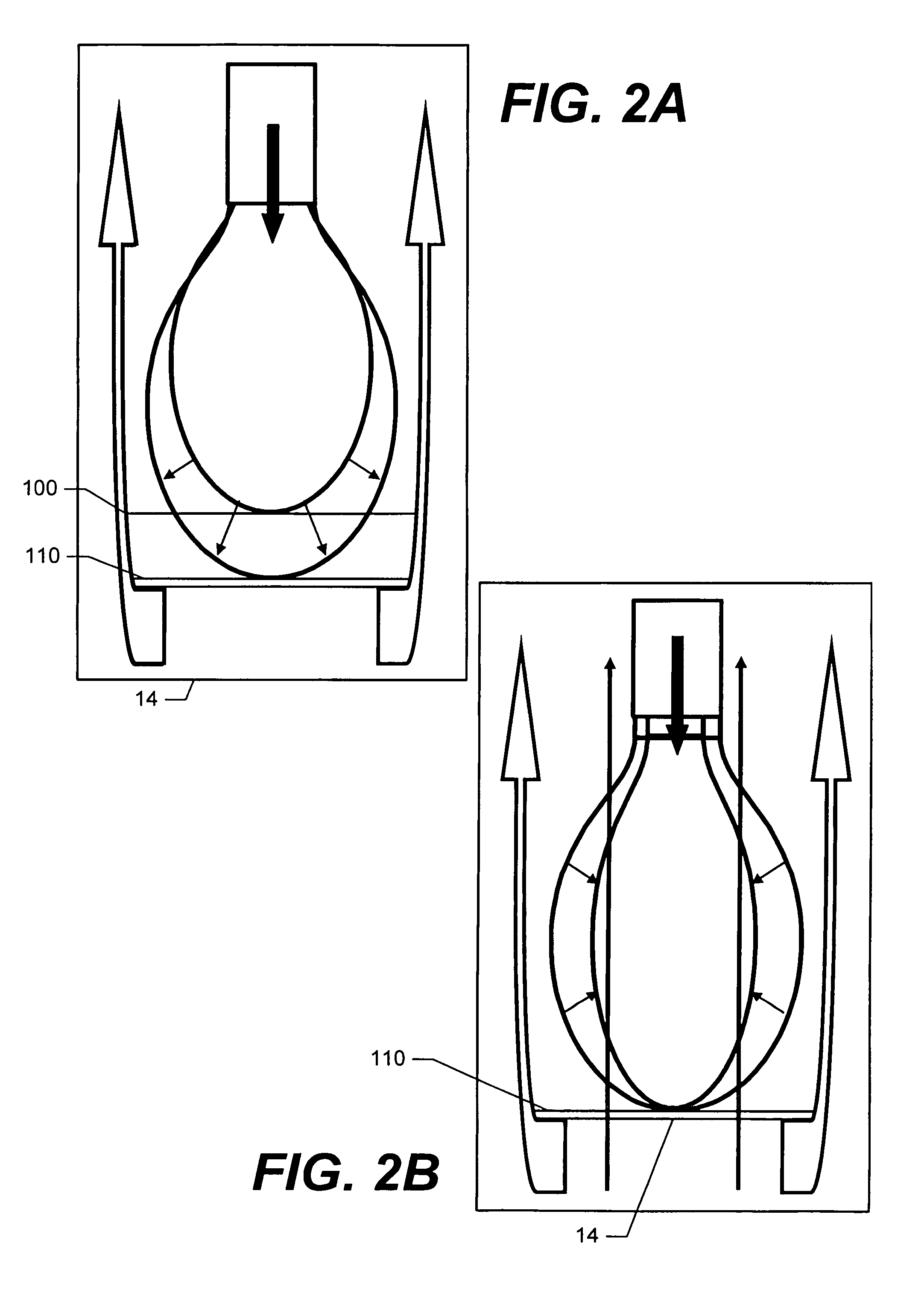

Stagnation point reverse flow combustor for a combustion system

InactiveUS7168949B2Combustion using gaseous and pulverulent fuelContinuous combustion chamberStagnation pointCombustion system

A combustor assembly includes a combustor vessel having a wall, a proximate end defining an opening and a closed distal end opposite said proximate end. A manifold is carried by the proximate end. The manifold defines a combustion products exit. The combustion products exit being axially aligned with a portion of the closed distal end. A plurality of combustible reactant ports is carried by the manifold for directing combustible reactants into the combustion vessel from the region of the proximate end towards the closed distal end.

Owner:GEORGIA TECH RES CORP

Method and apparatus for heat treatment

InactiveUS20050239005A1High degreeCombustion using gaseous and pulverulent fuelPulsating combustionCombustorCost effectiveness

A method and an apparatus for heat-treatment of materials, preferably metals, are provided. The method comprises the following steps: providing and maintaining a flame by supplying a burner with fuel and gas containing at least 80 percent by volume oxygen; creating an oxygen-hot exhaust mixture by recirculating exhausts from the flame to the gas containing oxygen by means of an ejector effect; mixing the oxygen-exhaust mixture and the fuel; and providing a secondary recirculation by recirculating exhausts from the flame to the oxygen-exhaust-fuel mixture. The method and apparatus allow for extremely low NOx emissions and high efficiency, resulting in an environmentally friendly and at the same time cost effective process.

Owner:LINDE AG

Stagnation point reverse flow combustor

InactiveUS7425127B2Combustion using gaseous and pulverulent fuelContinuous combustion chamberStagnation pointCombustor

A method for combusting a combustible fuel includes providing a vessel having an opening near a proximate end and a closed distal end defining a combustion chamber. A combustible reactants mixture is presented into the combustion chamber. The combustible reactants mixture is ignited creating a flame and combustion products. The closed end of the combustion chamber is utilized for directing combustion products toward the opening of the combustion chamber creating a reverse flow of combustion products within the combustion chamber. The reverse flow of combustion products is intermixed with combustible reactants mixture to maintain the flame.

Owner:GEORGIA TECH RES CORP

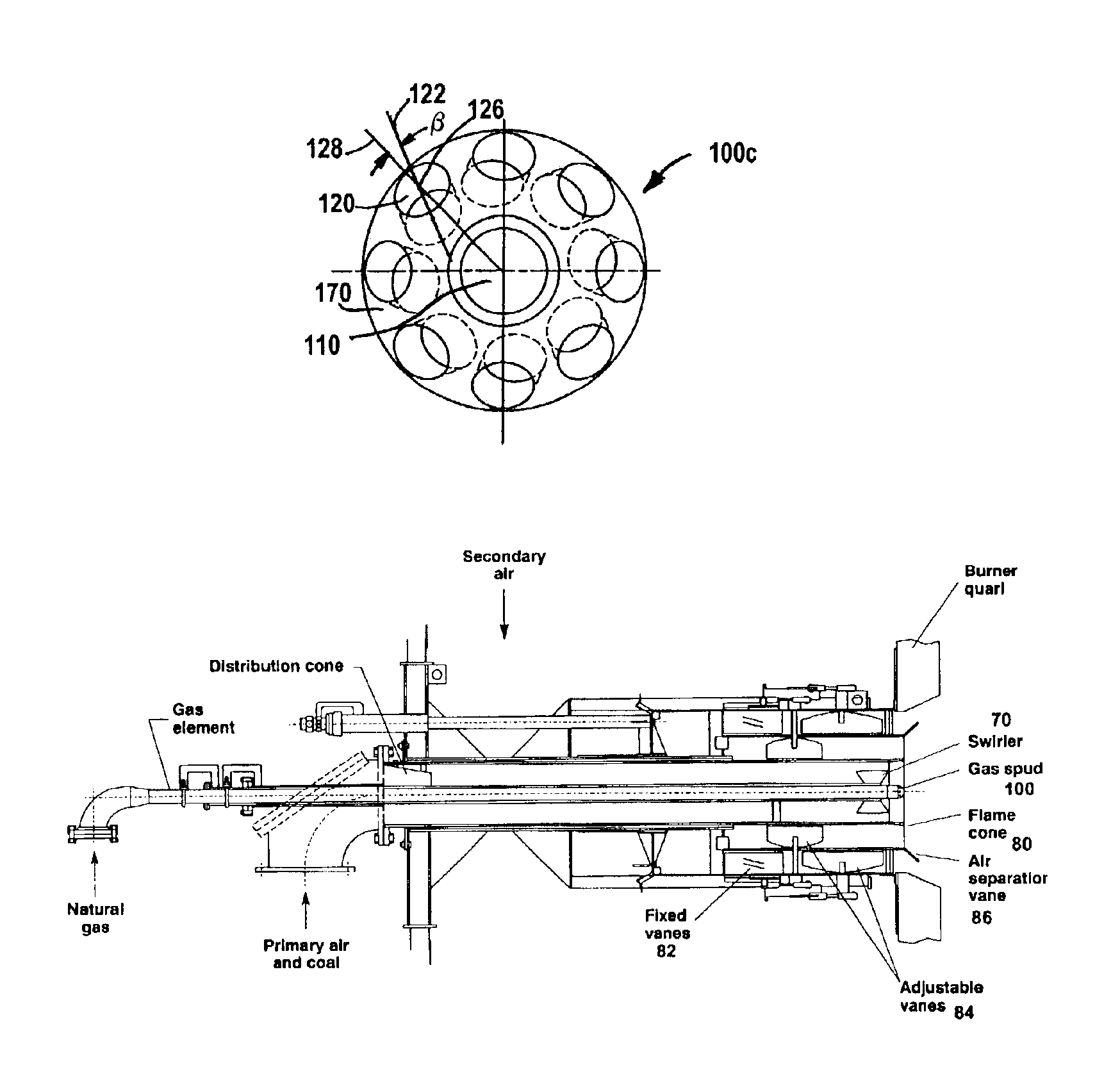

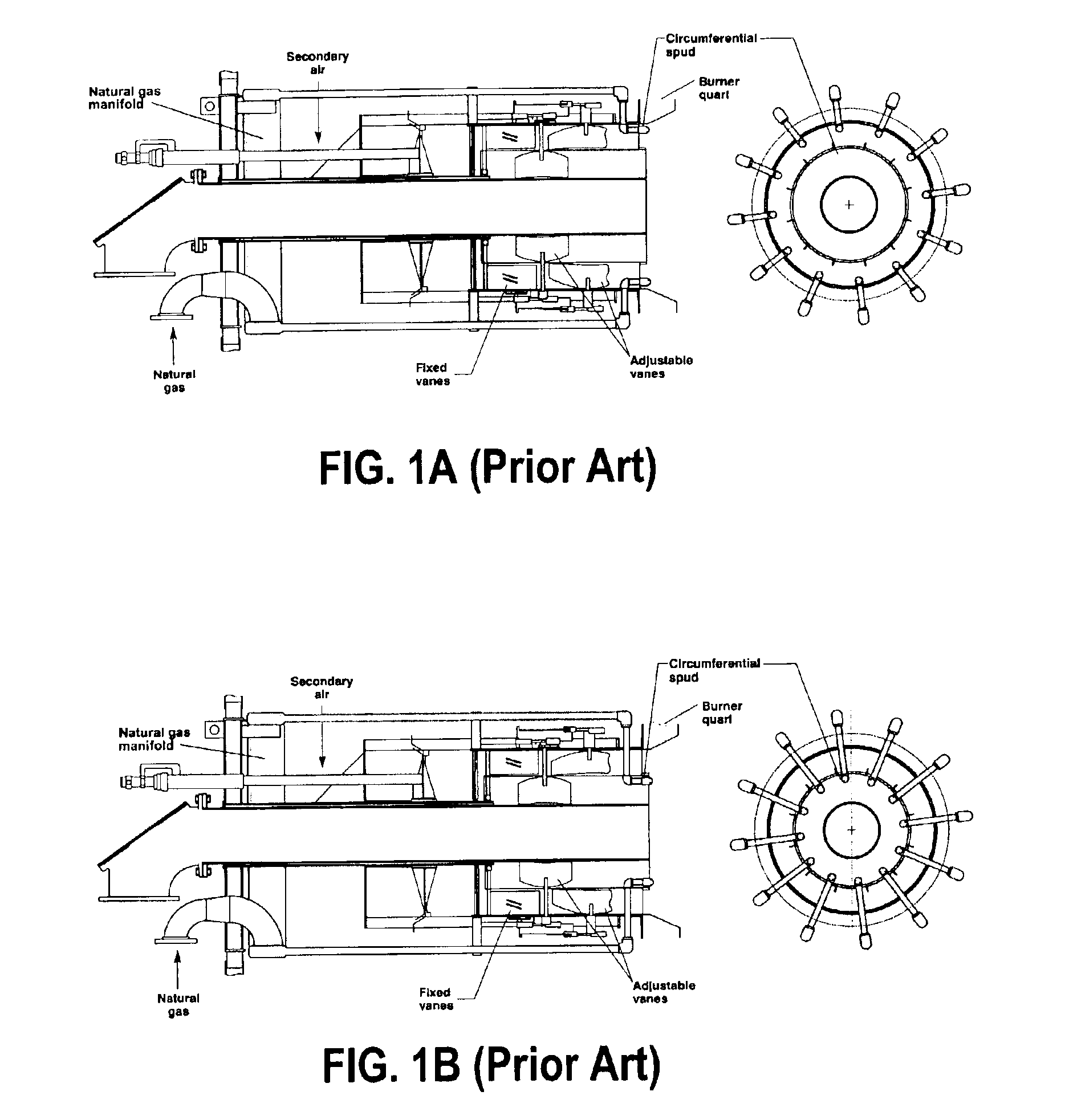

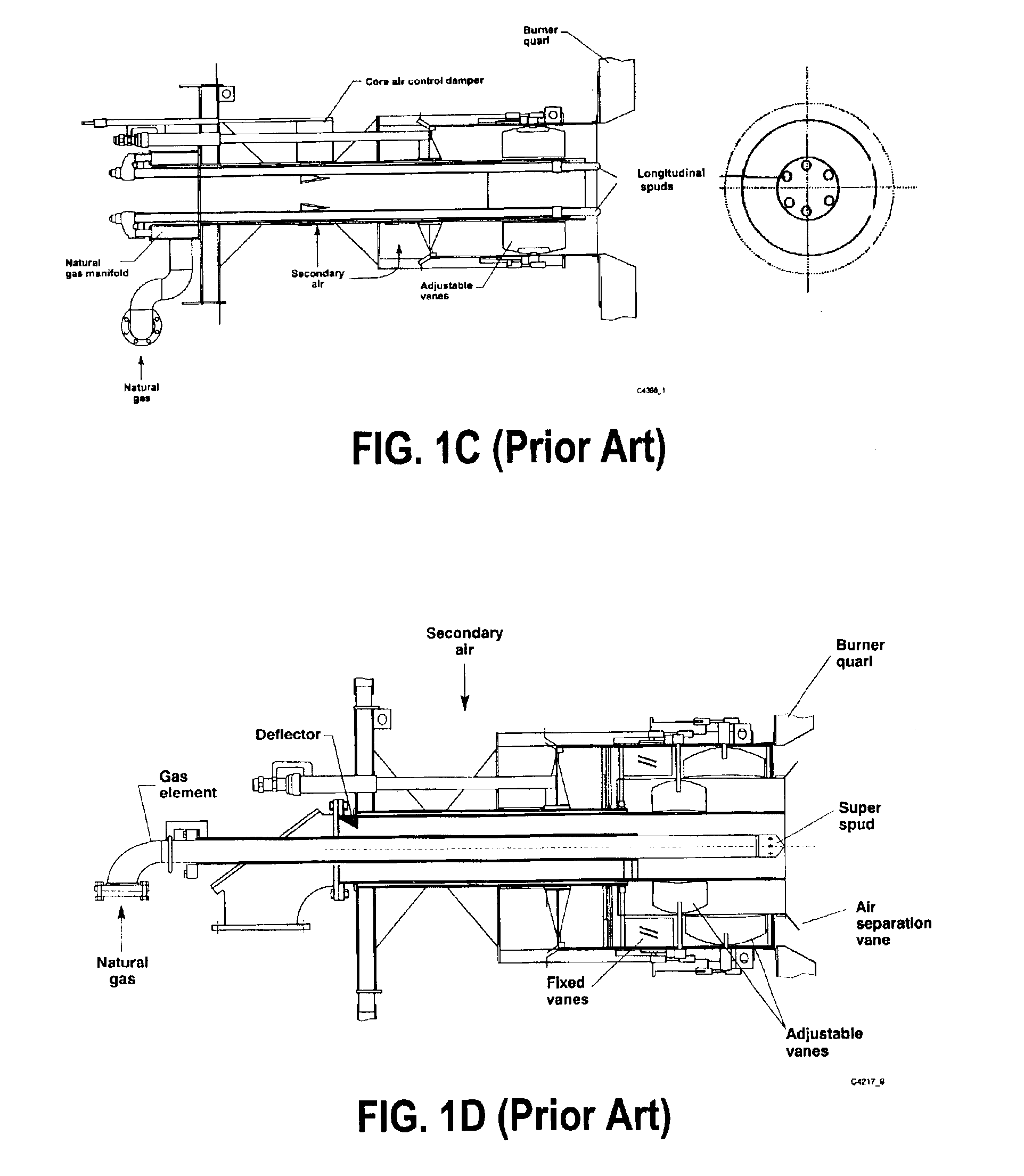

Dual fuel burner for a shortened flame and reduced pollutant emissions

InactiveUS6951454B2Emission reductionShorten the lengthCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelBoiler furnacePollutant emissions

A dual fuel burner including an elongated supply pipe and a gas injector for a boiler furnace having a plurality of peripheral openings around a center opening. The peripheral openings are pitched radially away from the longitudinal axis of the gas injector and also pitched either clockwise or counter-clockwise, to impart a swirling motion to gaseous fuel exiting the injector through the openings. A first sleeve member is concentrically spaced about the supply pipe and the gas injector to form an inner annular passageway for conveying a mixture of primary air and pulverized coal to the furnace combustion zone. A second sleeve member is concentrically spaced about the first sleeve member to form an outer annular passageway for conveying secondary air to the furnace combustion zone, and a plurality of circumferentially spaced vanes mounted within the outer annular passageway for inducing a swirling motion to the secondary air discharging from the outer annular passageway into the furnace combustion zone.

Owner:THE BABCOCK & WILCOX CO

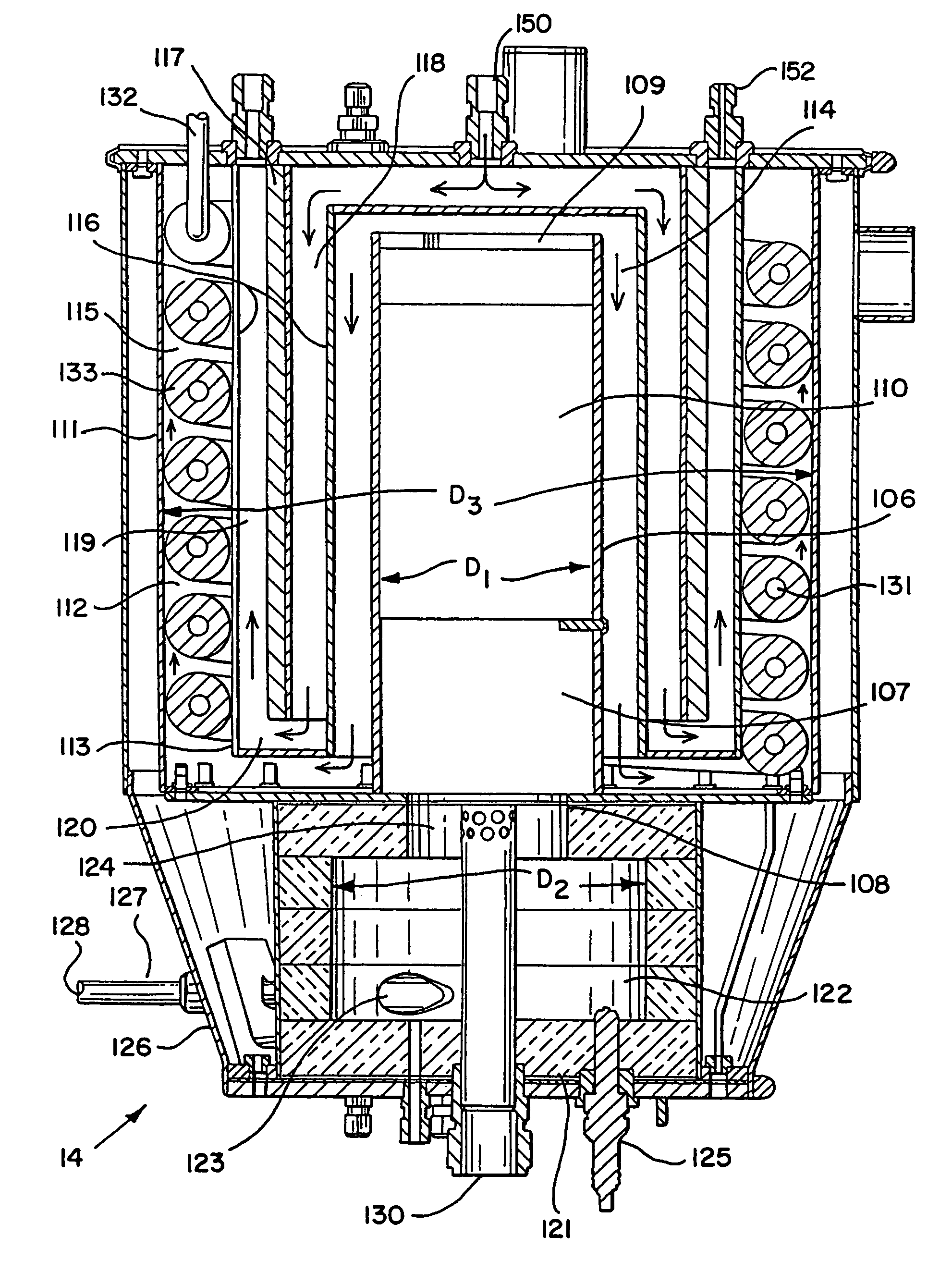

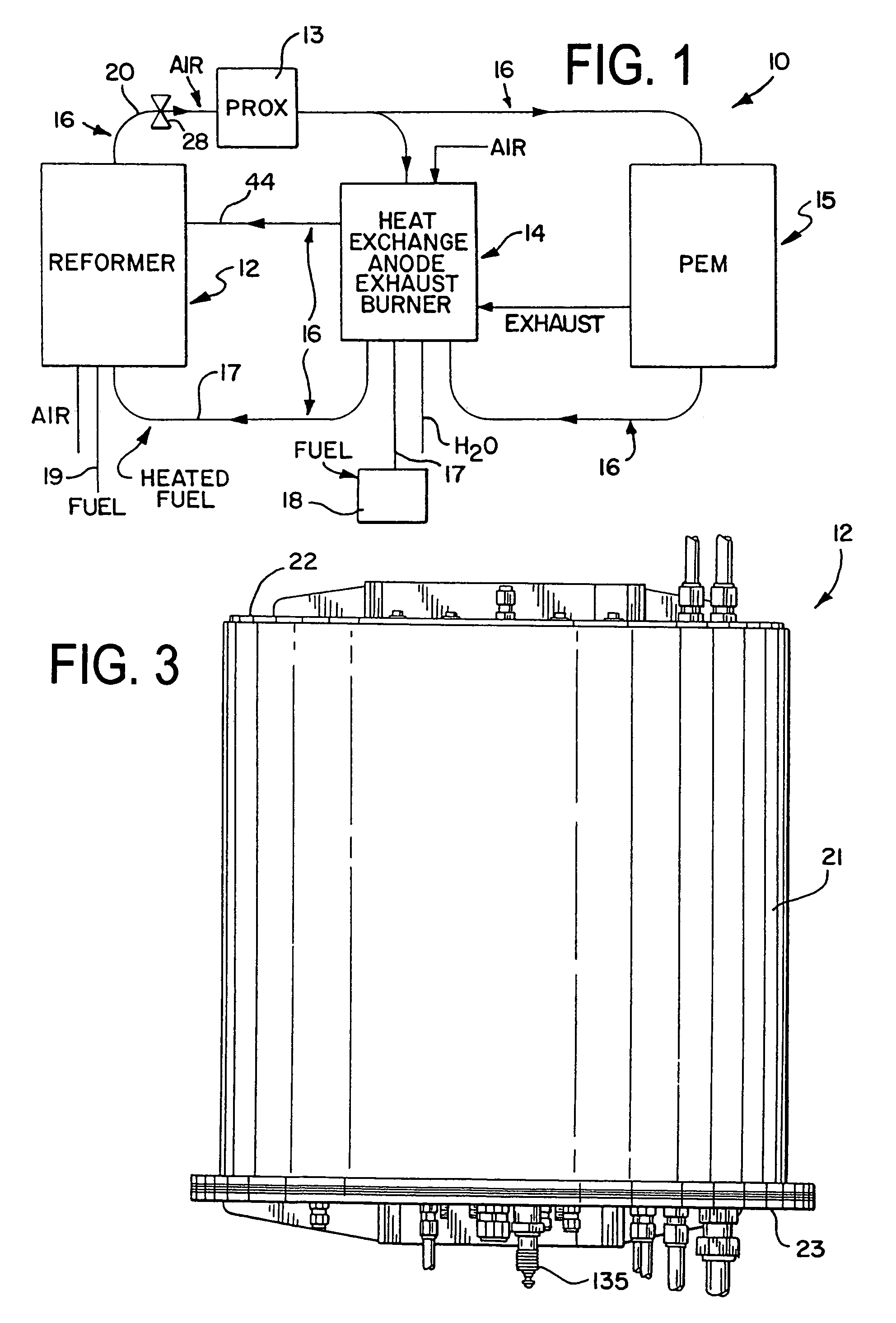

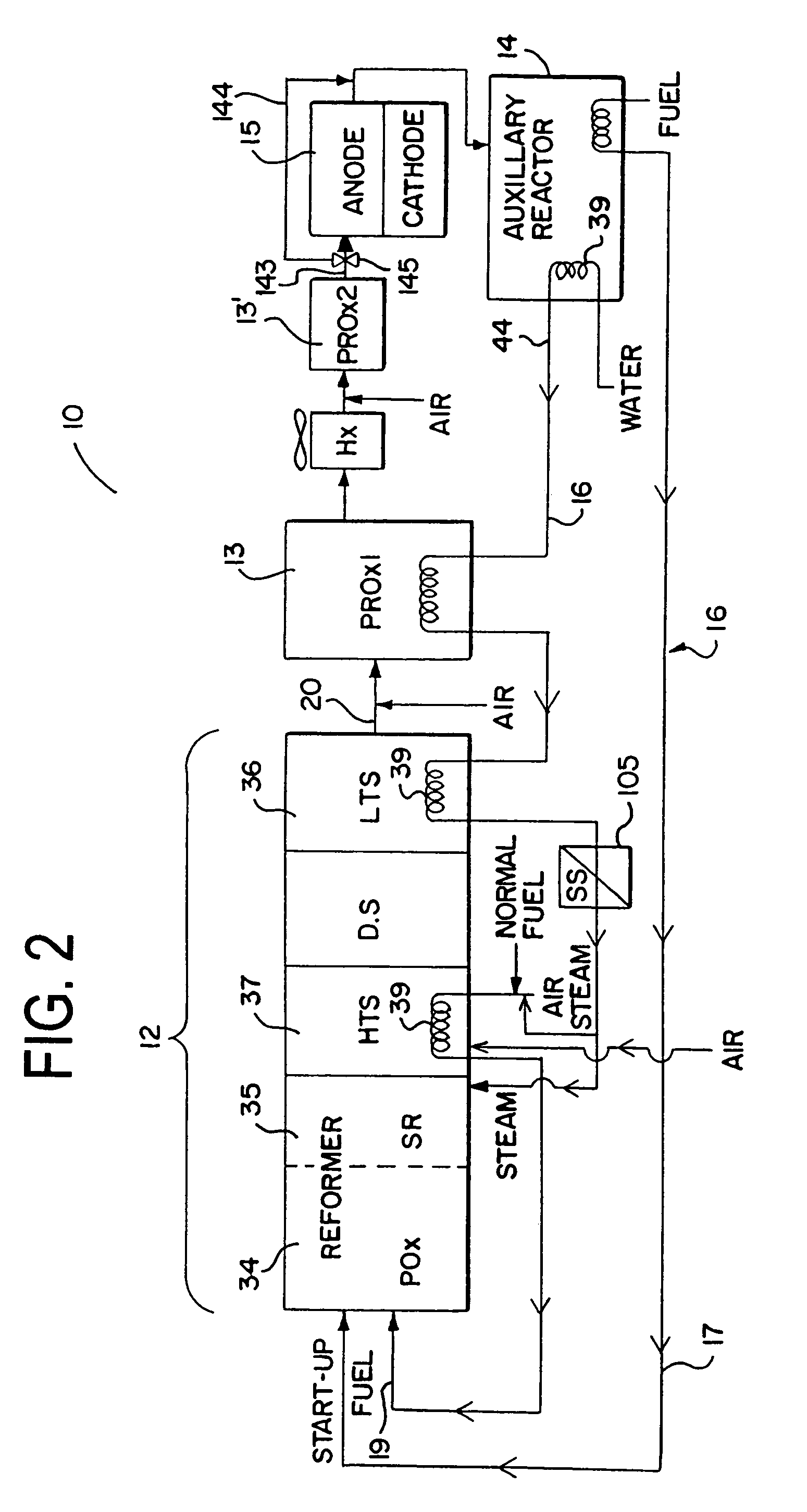

Auxiliary reactor for a hydrocarbon reforming system

InactiveUS6986797B1Thermal non-catalytic crackingFluidized bed combustionCombustorNuclear engineering

An auxiliary reactor for use with a reformer reactor having at least one reaction zone, and including a burner for burning fuel and creating a heated auxiliary reactor gas stream, and heat exchanger for transferring heat from auxiliary reactor gas stream and heat transfer medium, preferably two-phase water, to reformer reaction zone. Auxiliary reactor may include first cylindrical wall defining a chamber for burning fuel and creating a heated auxiliary reactor gas stream, the chamber having an inlet end, an outlet end, a second cylindrical wall surrounding first wall and a second annular chamber there between. The reactor being configured so heated auxiliary reactor gas flows out the outlet end and into and through second annular chamber and conduit which is disposed in second annular chamber, the conduit adapted to carry heat transfer medium and being connectable to reformer reaction zone for additional heat exchange.

Owner:POWERTAP HYDROGEN FUELING CORP

Compression-molded vegetable wax-based candle

InactiveUS20050158679A1Simple methodBurn cleanCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelParaffin waxCompression molding

Prilled wax particles are formed from a vegetable wax-based composition. After compression, a predominantly paraffin wax-based composition is optionally poured over the vegetable wax-based composition to form an encased candle. The method of the present invention offers the possibility to incorporate a high fragrance load to the candle.

Owner:CHEN QIN +4

Popular searches

Semiconductor/solid-state device manufacturing Chemical vapor deposition coating Combustion using lump and gaseous fuel Combustion apparatus Combustion using lump and liquid fuel Combustion using liquid and gaseous fuel Combustion using lump and pulverulent fuel Hydrogen/synthetic gas production Hydrogen Hydrocarbon from carbon oxides

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com