Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1164 results about "Boiler furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Essentially, a furnace or boiler is the mechanism that produces the heat that your central heating system will then distribute to keep your home warm. A central heating system without a furnace and/or boiler wouldn’t be much of a heating system at all. 2: Furnaces (Giant Boxes of Fire)

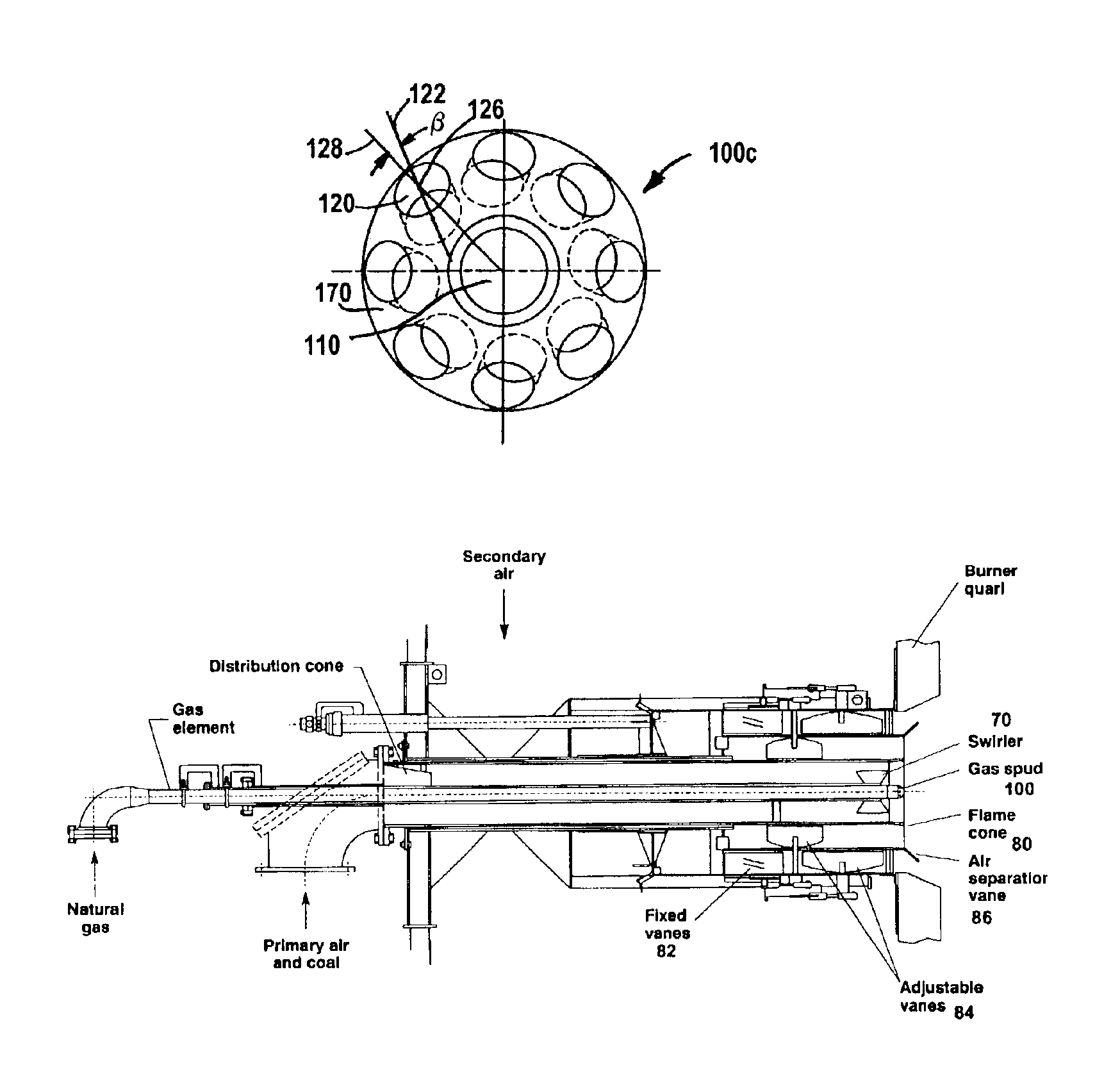

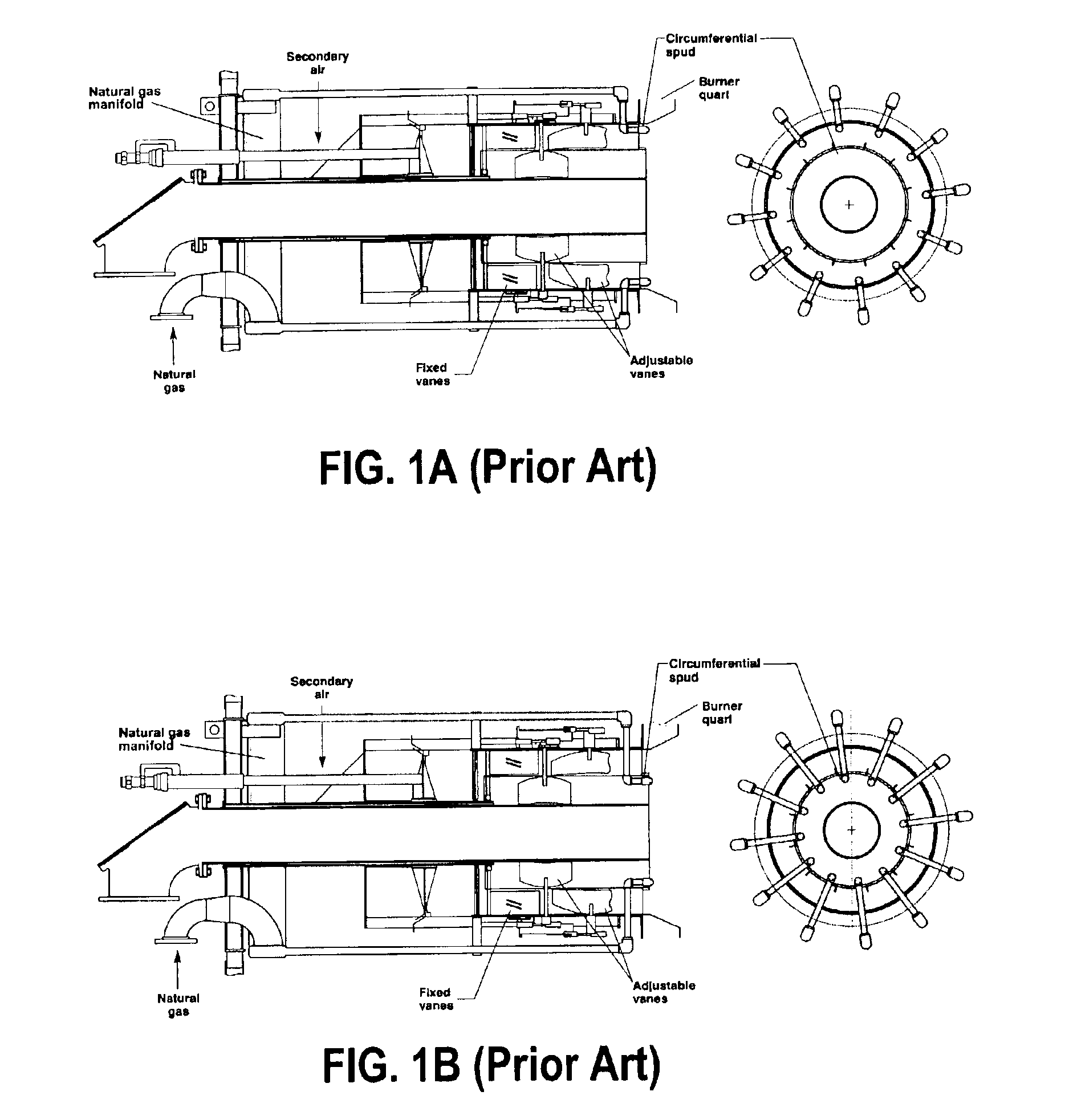

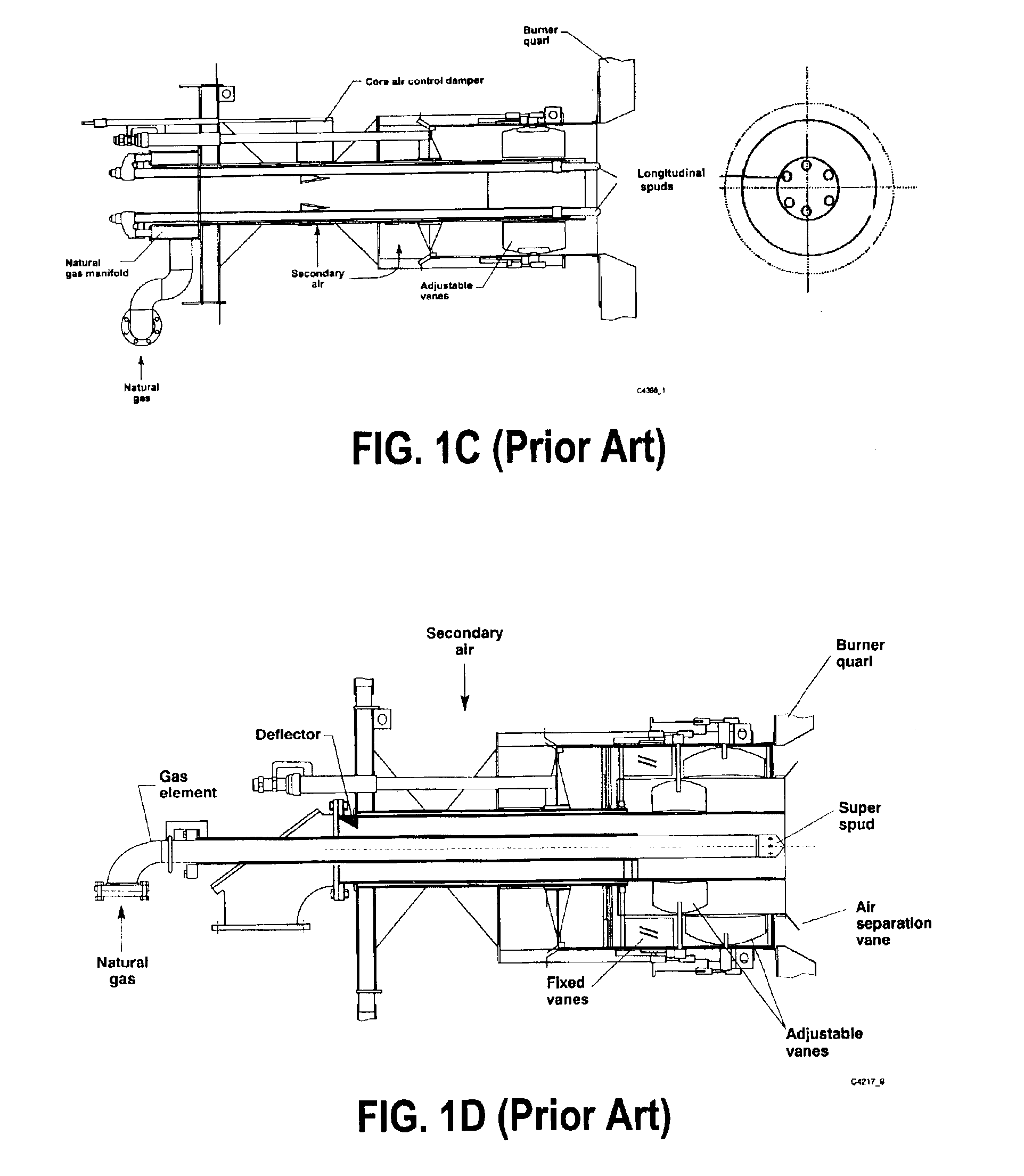

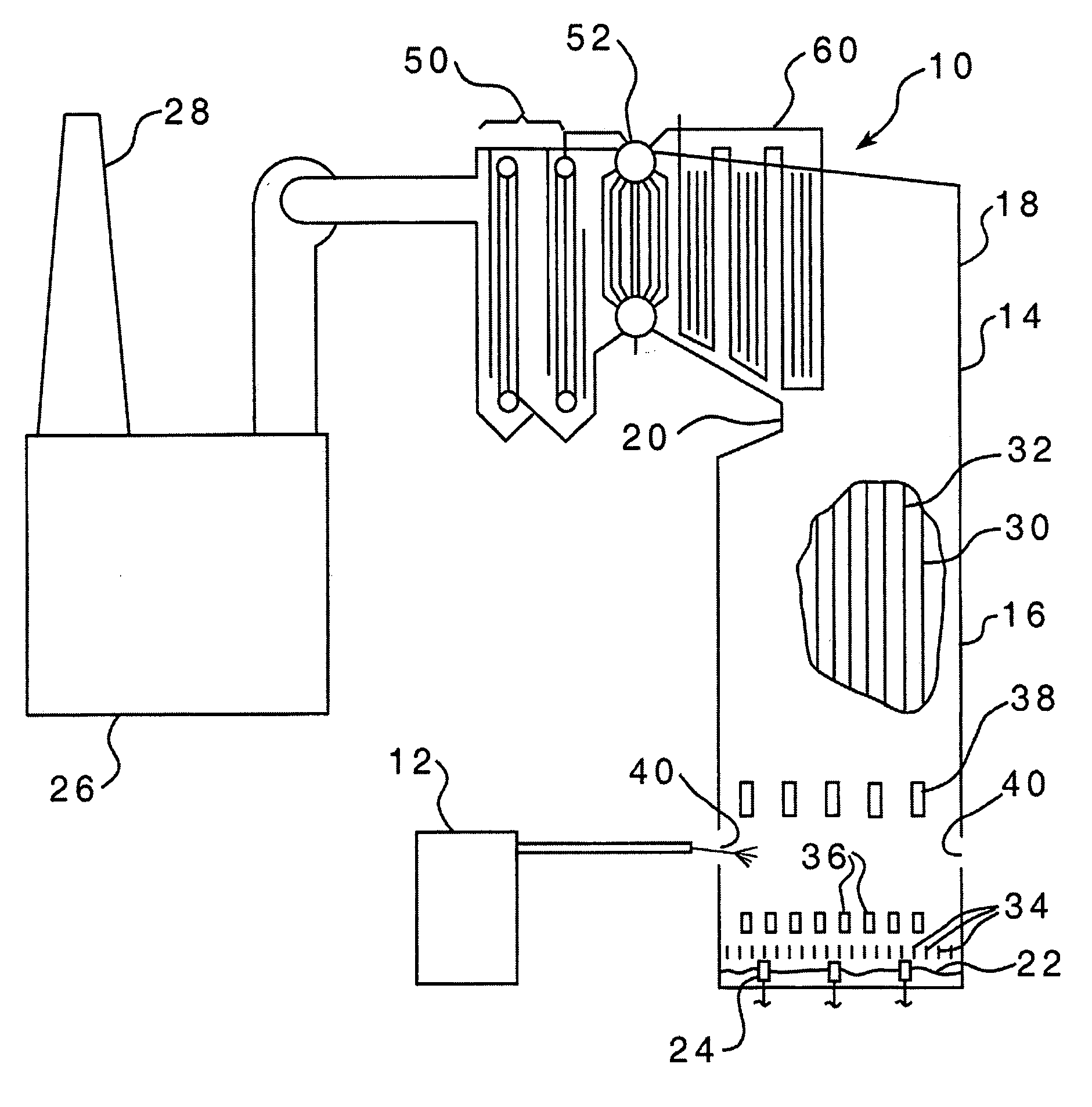

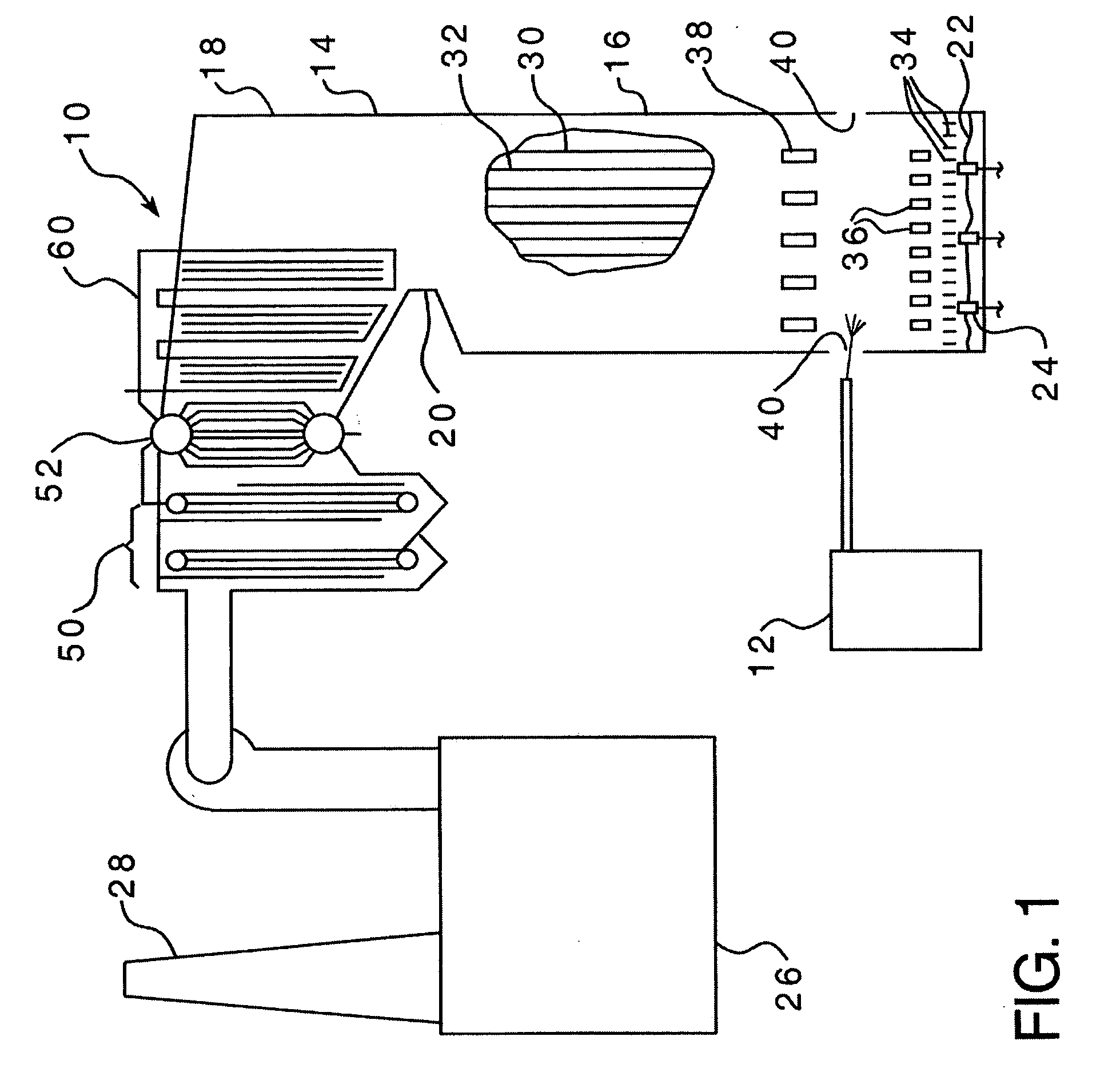

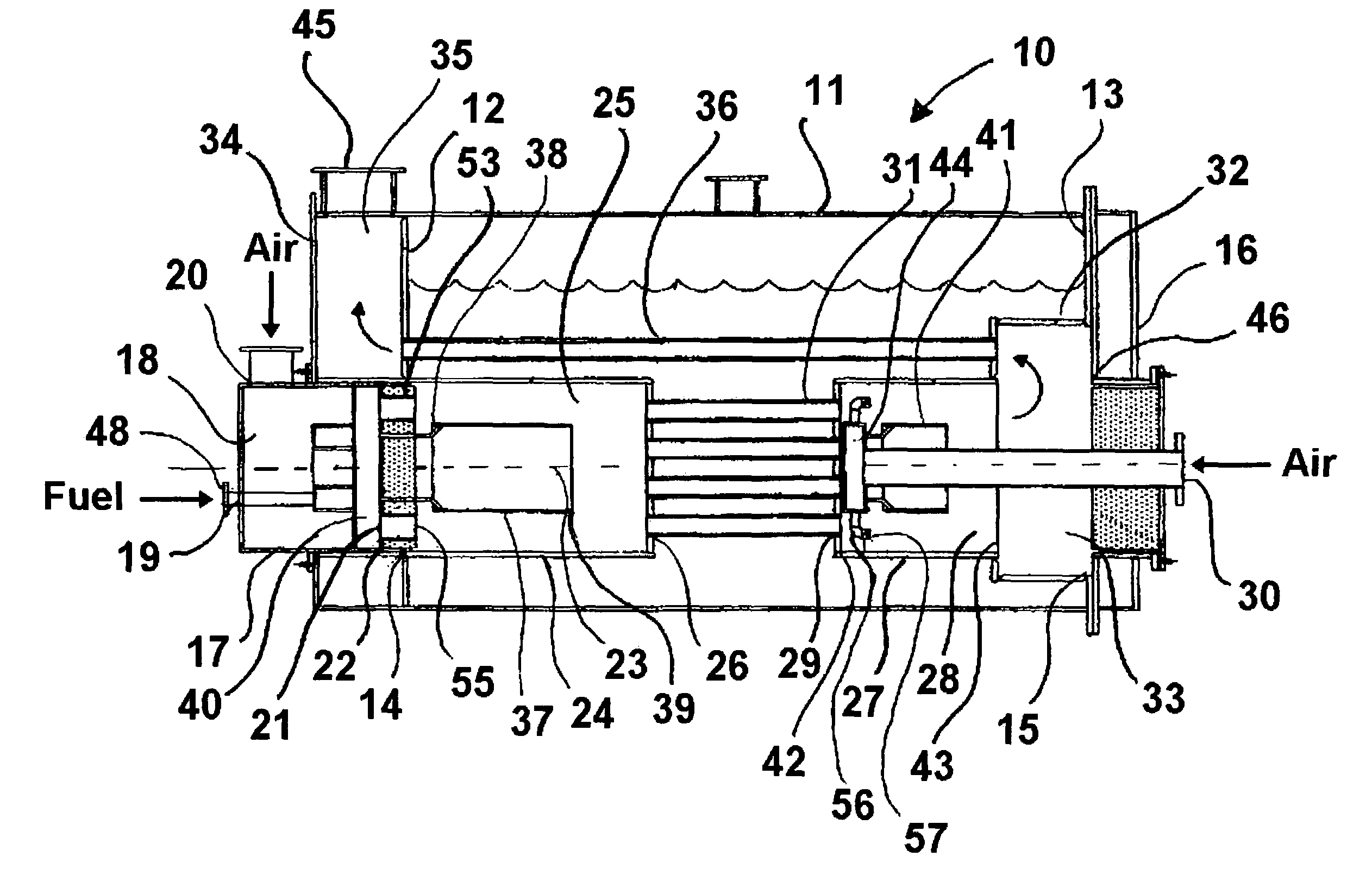

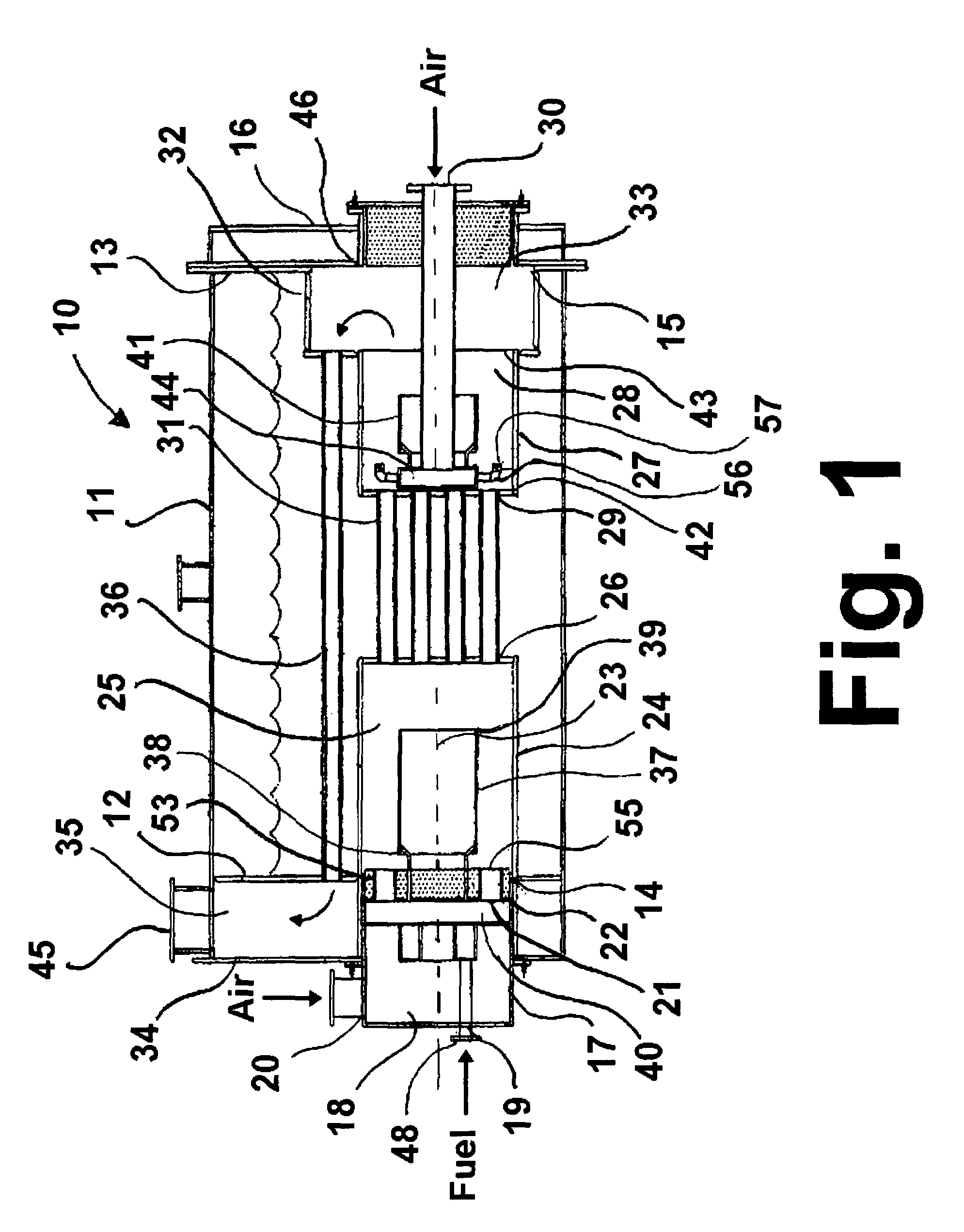

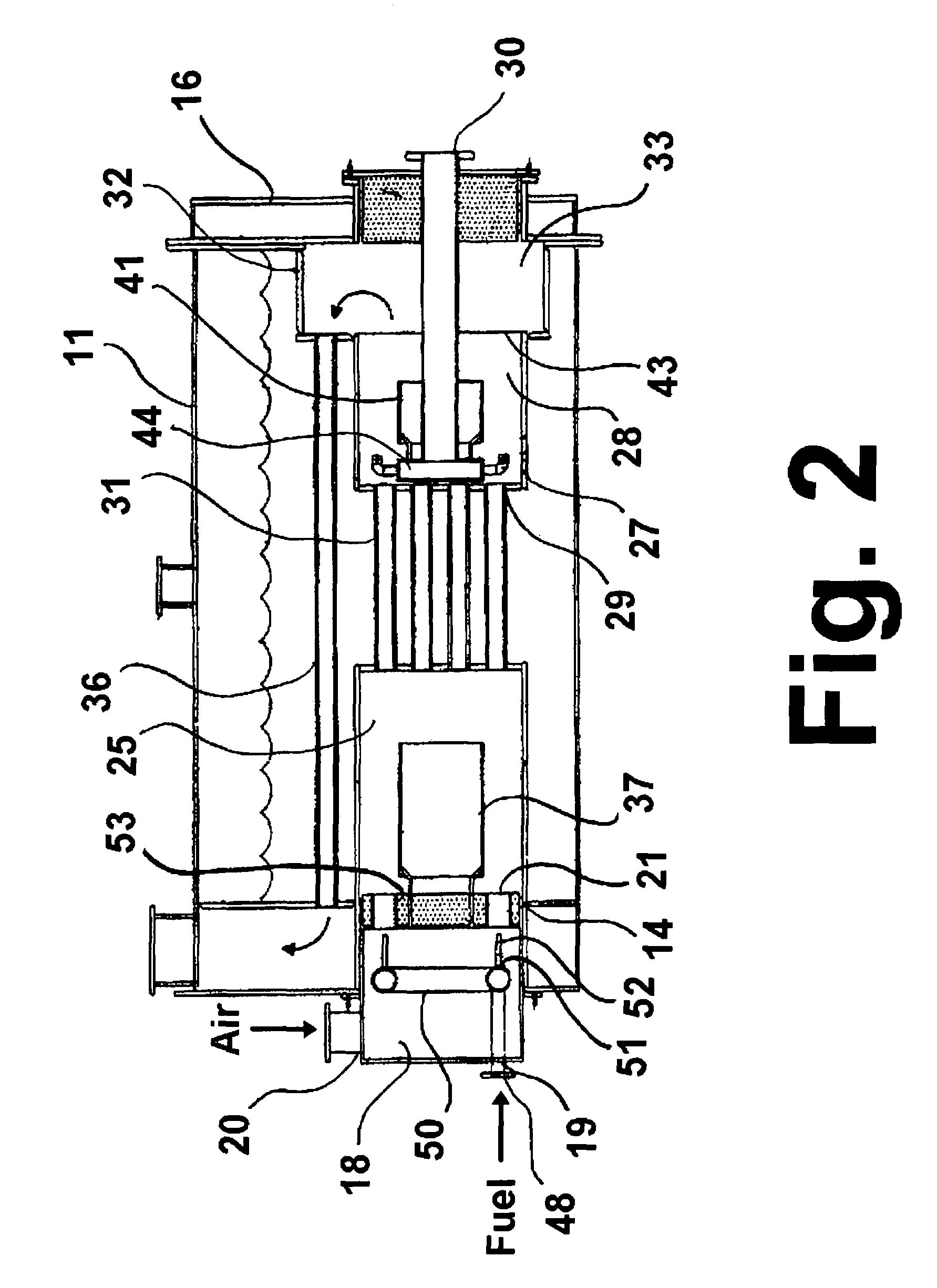

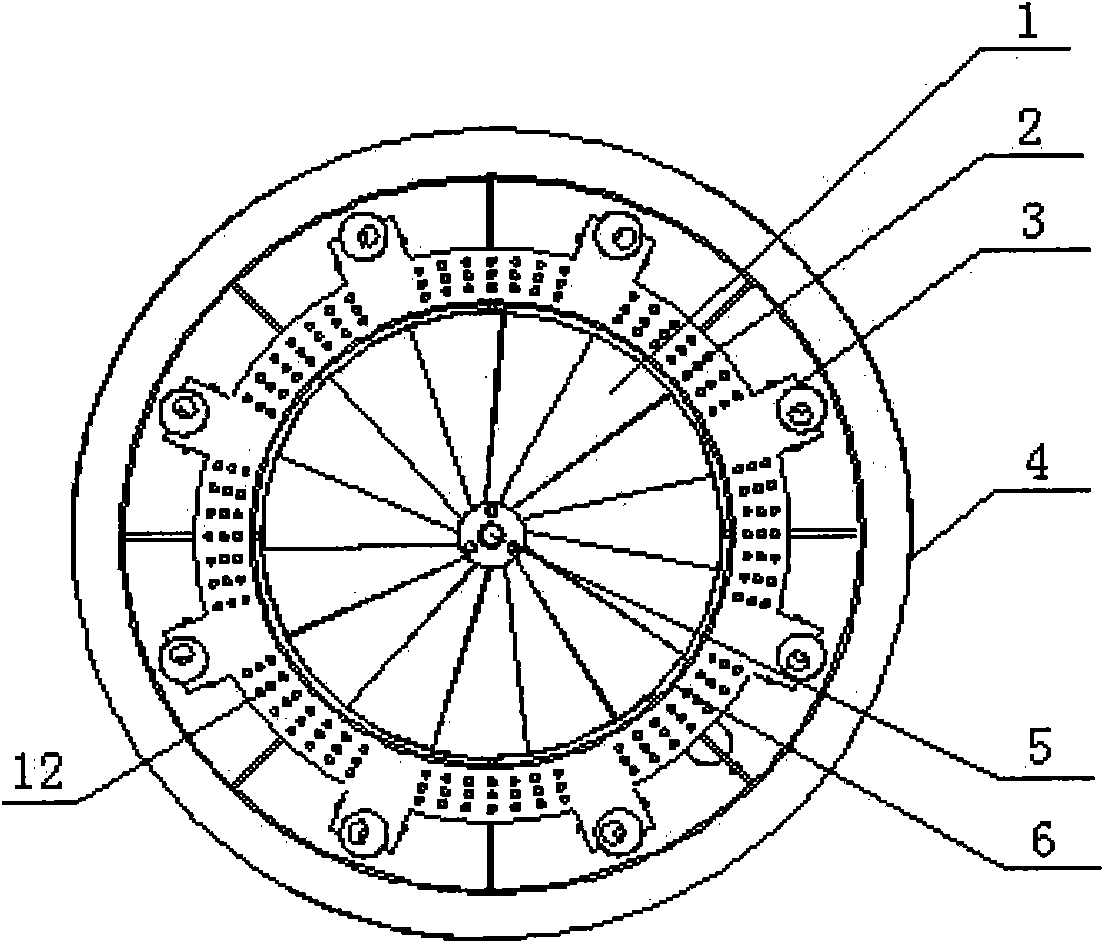

Dual fuel burner for a shortened flame and reduced pollutant emissions

InactiveUS6951454B2Emission reductionShorten the lengthCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelBoiler furnacePollutant emissions

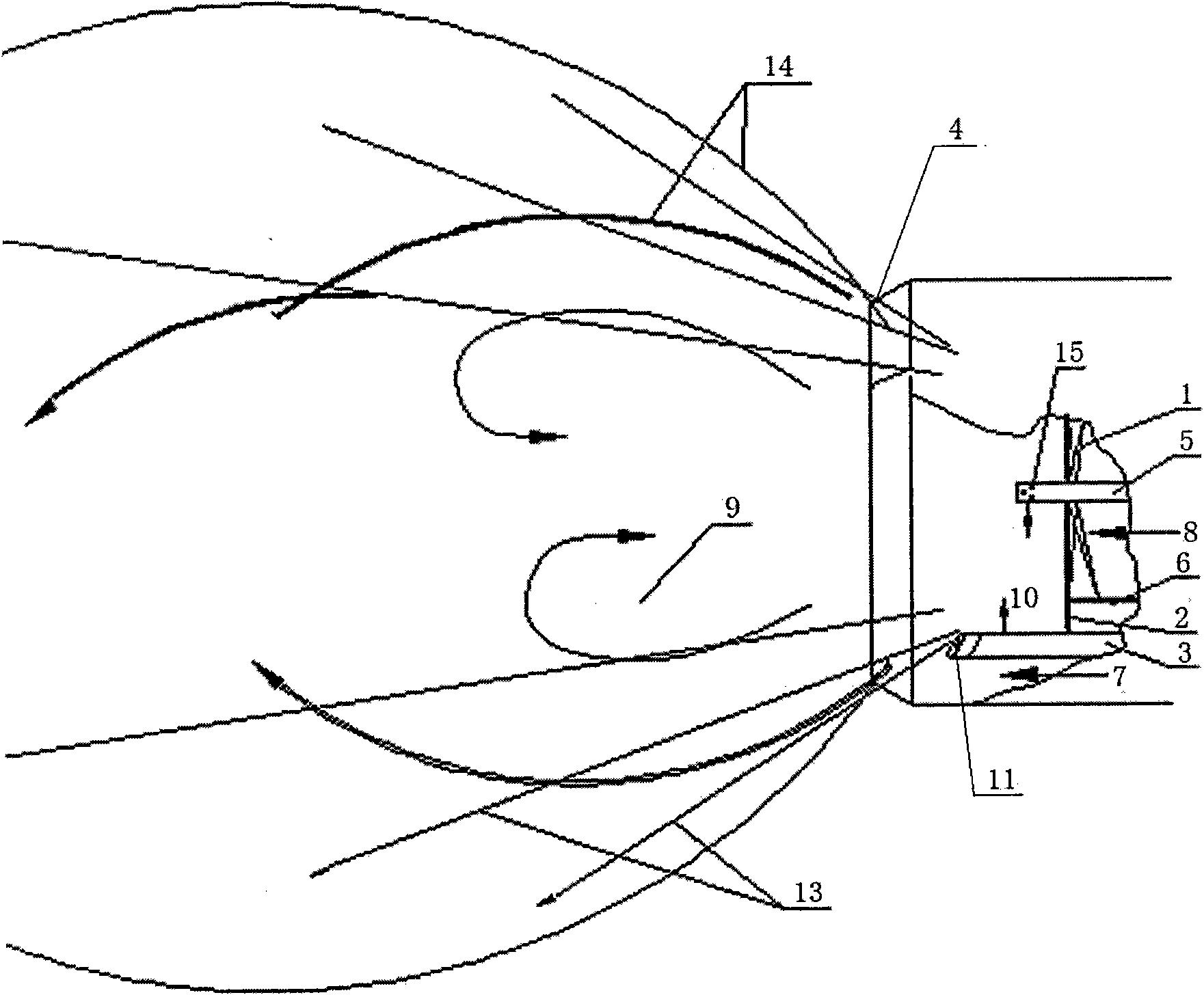

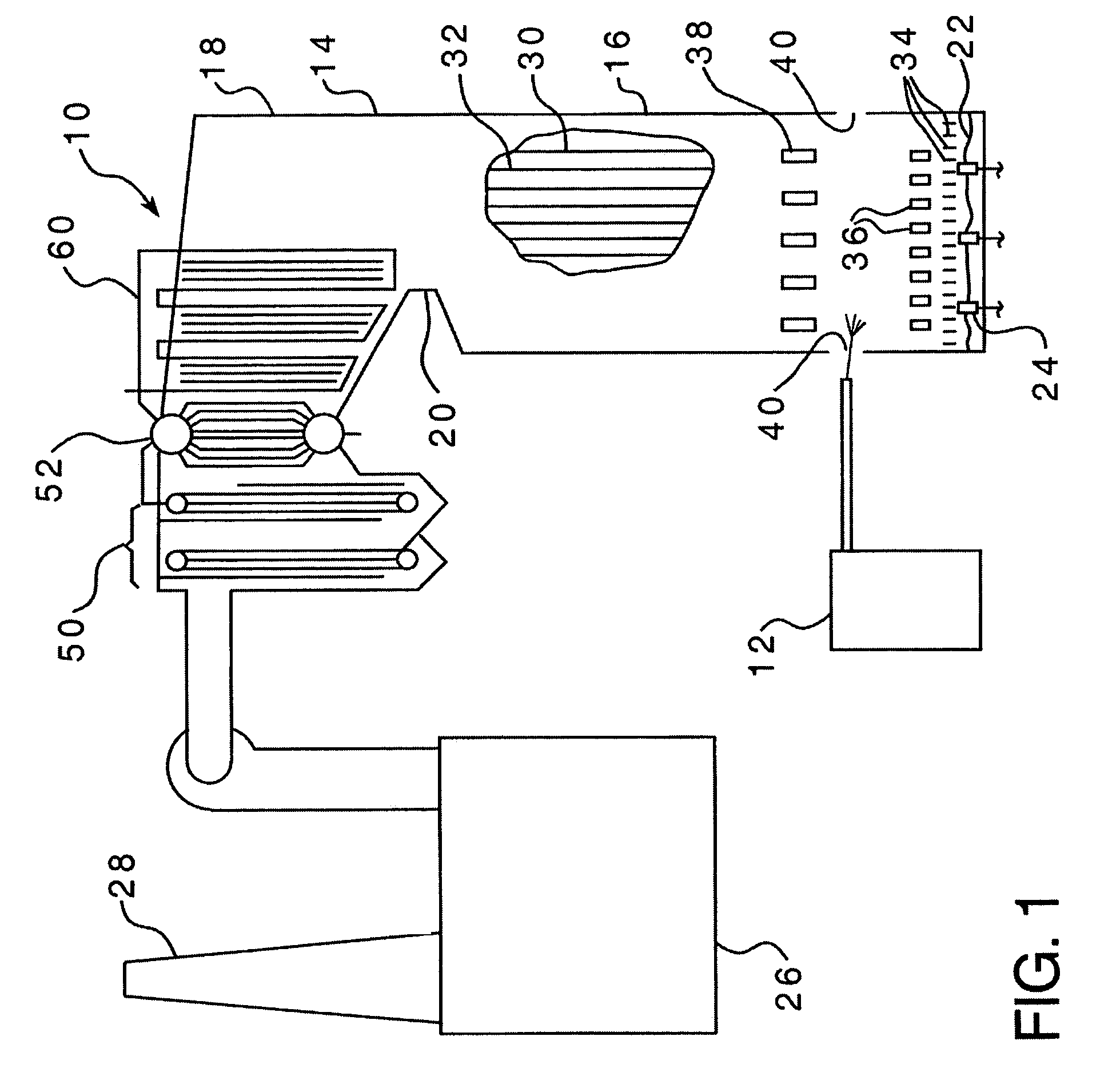

A dual fuel burner including an elongated supply pipe and a gas injector for a boiler furnace having a plurality of peripheral openings around a center opening. The peripheral openings are pitched radially away from the longitudinal axis of the gas injector and also pitched either clockwise or counter-clockwise, to impart a swirling motion to gaseous fuel exiting the injector through the openings. A first sleeve member is concentrically spaced about the supply pipe and the gas injector to form an inner annular passageway for conveying a mixture of primary air and pulverized coal to the furnace combustion zone. A second sleeve member is concentrically spaced about the first sleeve member to form an outer annular passageway for conveying secondary air to the furnace combustion zone, and a plurality of circumferentially spaced vanes mounted within the outer annular passageway for inducing a swirling motion to the secondary air discharging from the outer annular passageway into the furnace combustion zone.

Owner:THE BABCOCK & WILCOX CO

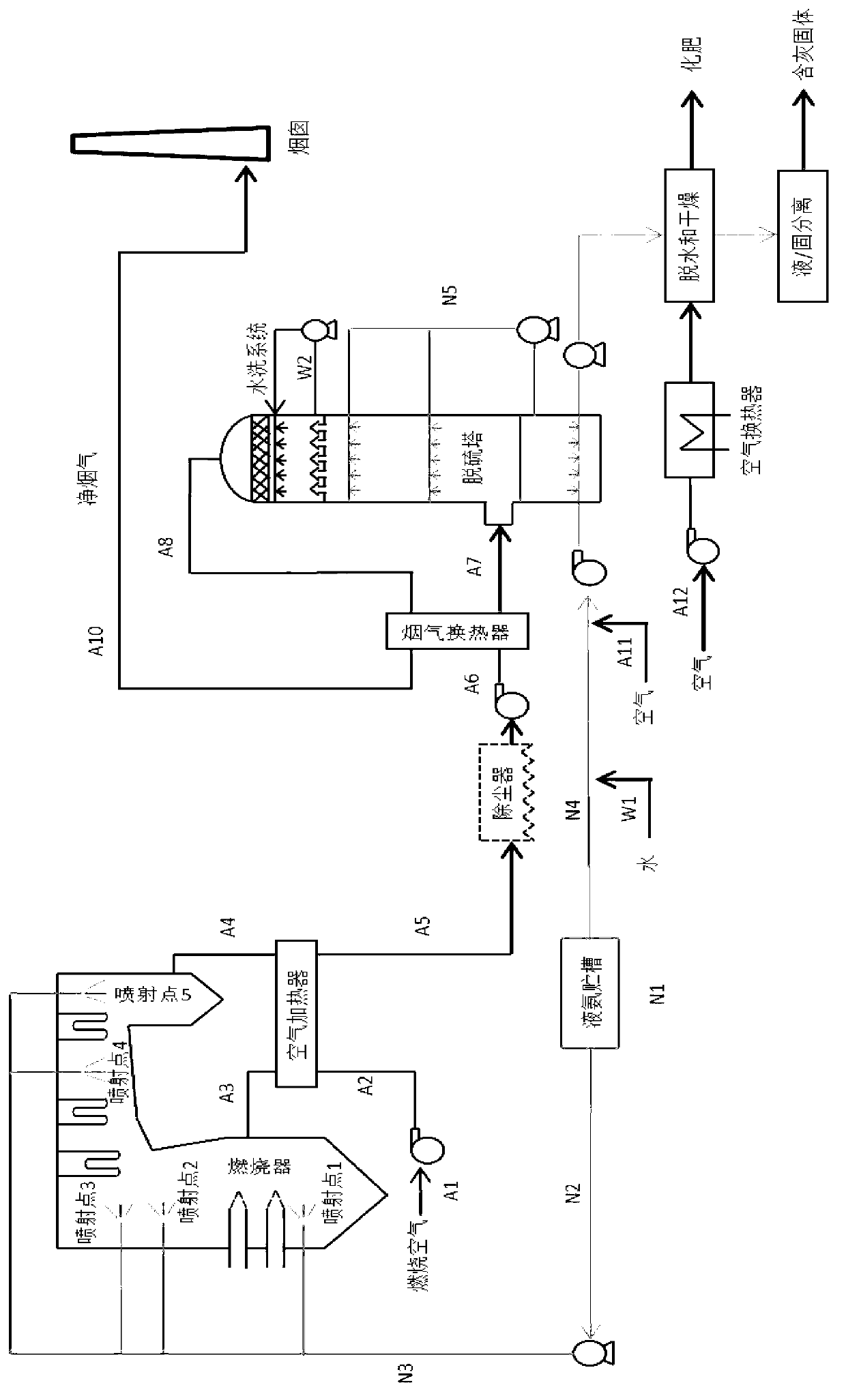

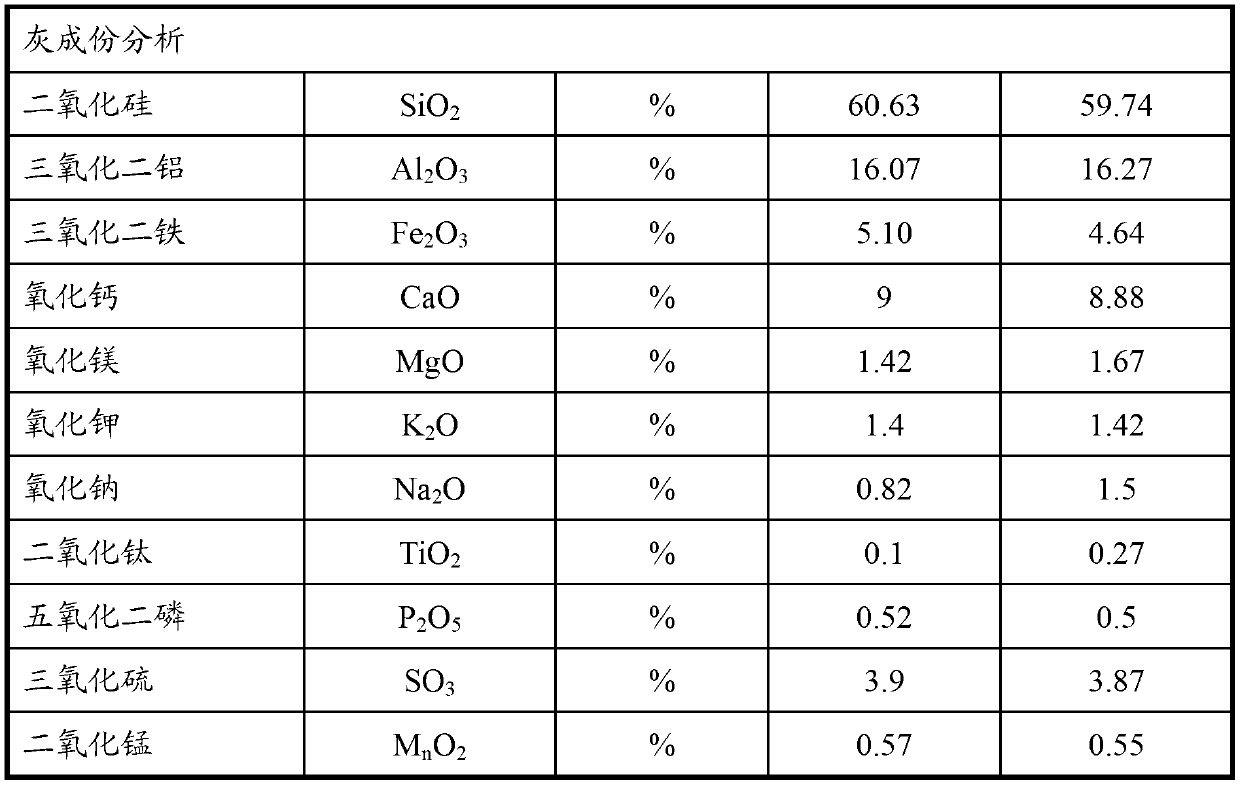

Method and device for combined removal of nitric oxide and sulfide in flue gas

InactiveCN103212284AGet rid of industrial designFully contactedDispersed particle separationAmmonium salt fertilisersBoiler furnaceFlue gas

The invention relates to a method for combined removal of nitric oxide and sulfide in flue gas. The method is characterized by comprising the following steps: spraying gasified ammonia into a furnace of a reaction boiler; reducing NOX in the flue gas to N2 by using a selective non-catalytic reduction method; sending the flue gas into a desulfurization tower; absorbing the SO2 in the flue gas by ammonia water added into the desulfurization tower; and discharging purified gas through a chimney. The invention also relates to a device for combined removal of nitrogen oxide and sulfide in flue gas. The device includes: (A) a combustion boiler used for the combustion of coal and provided with more than one ammonia injection points in the boiler furnace; (B) the desulfurization tower; and (C) an emptying device.

Owner:孙琦 +1

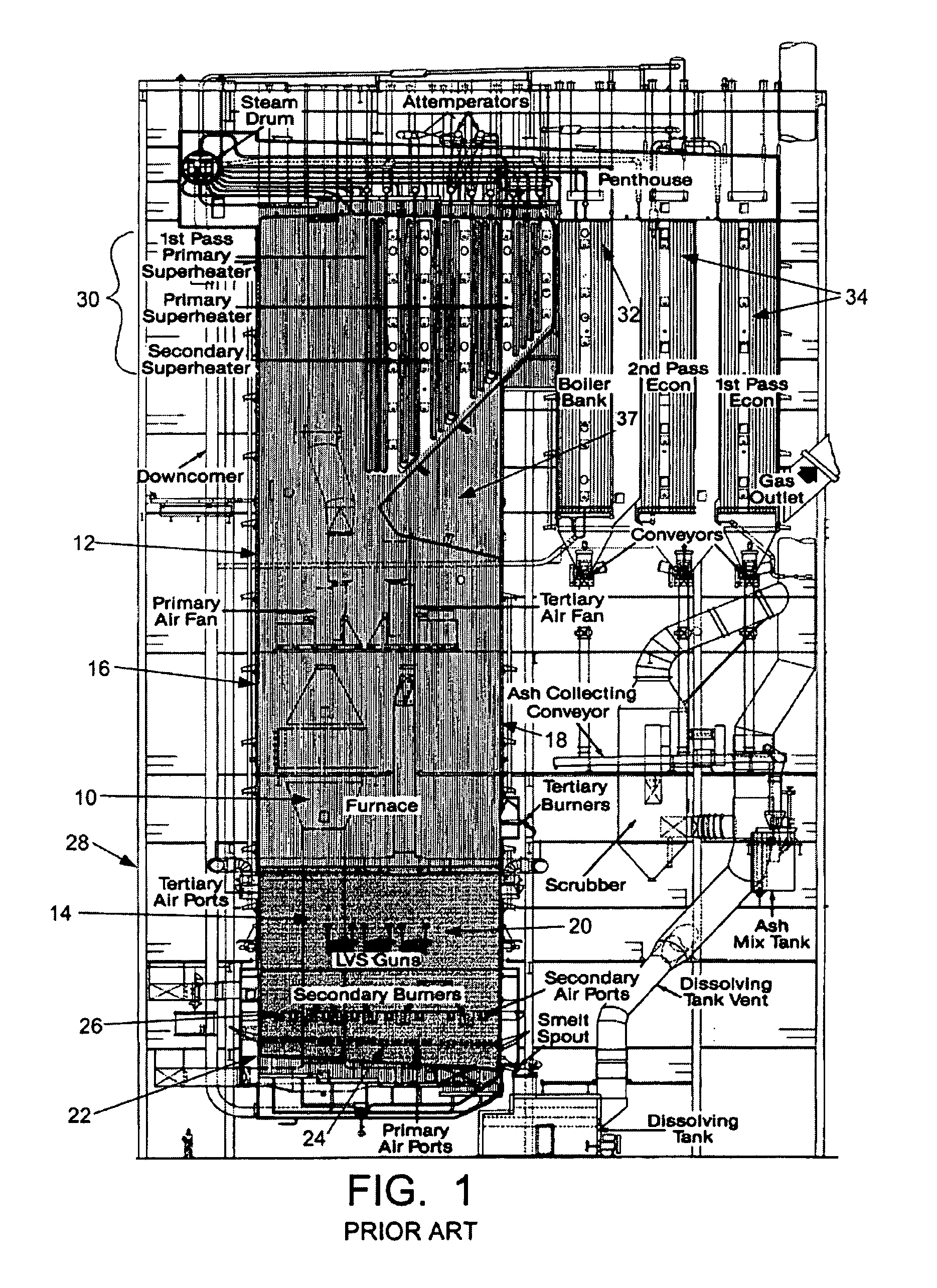

Method of determining individual sootblower effectiveness

ActiveUS20060065291A1Hollow article cleaningBoiler cleaning apparatusBoiler furnaceProcess engineering

A method of cleaning a heat transfer element within a boiler furnace is provided. The method includes the steps of allowing a furnace to operate and deposit ash on a heat transfer element, determining an efficiency rate for at least one cleaning element, and managing the cleaning element based on the efficiency rate.

Owner:INT PAPER CO

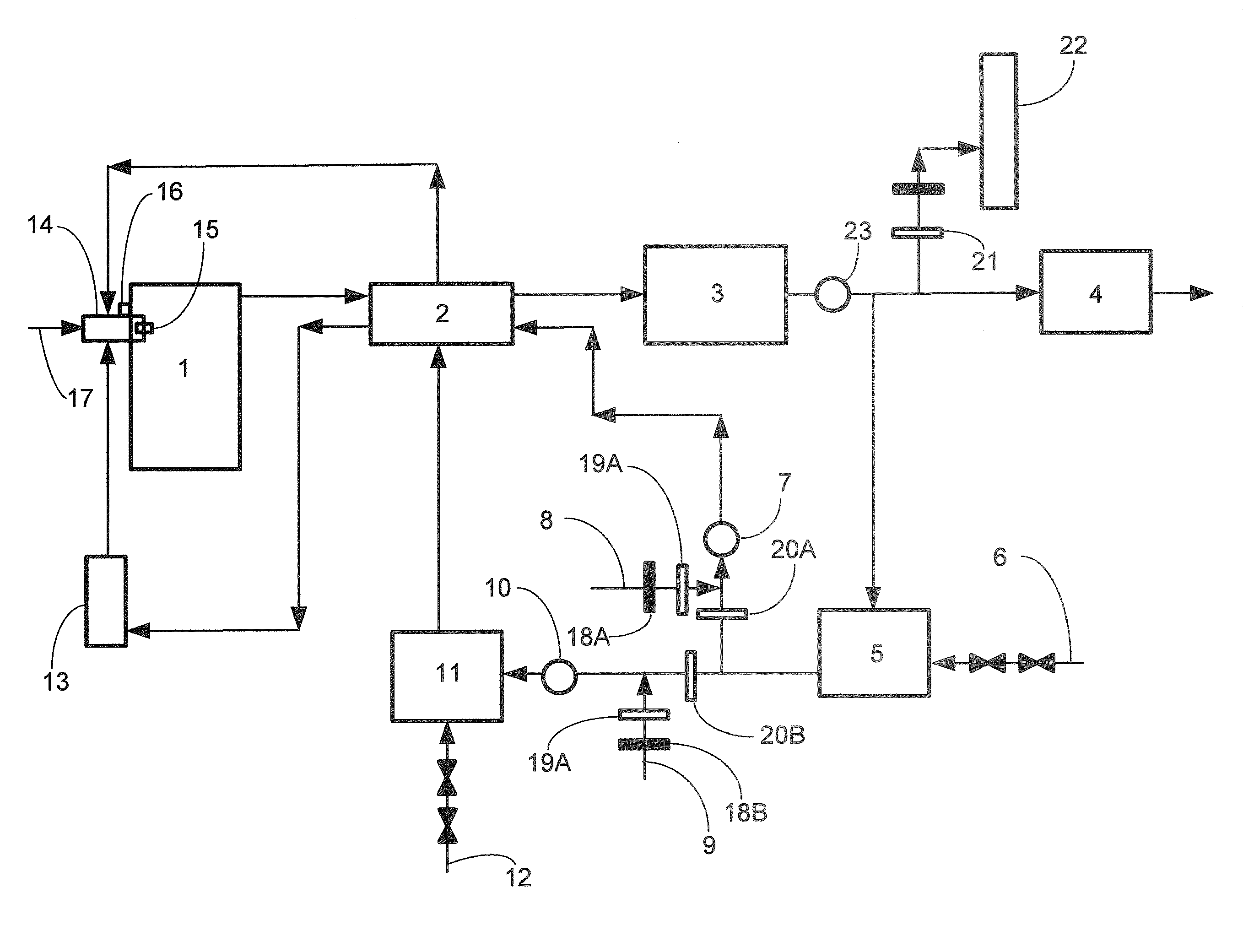

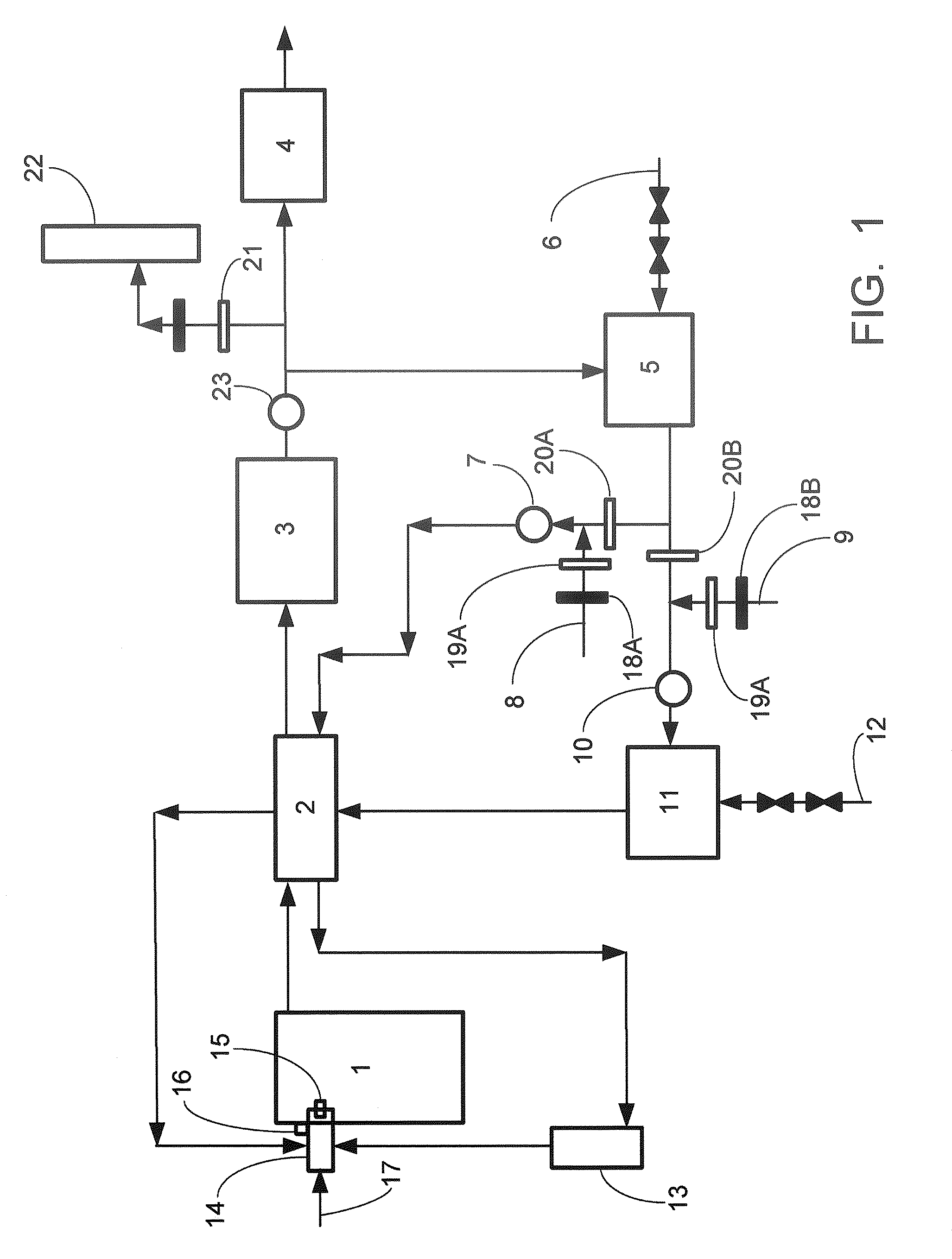

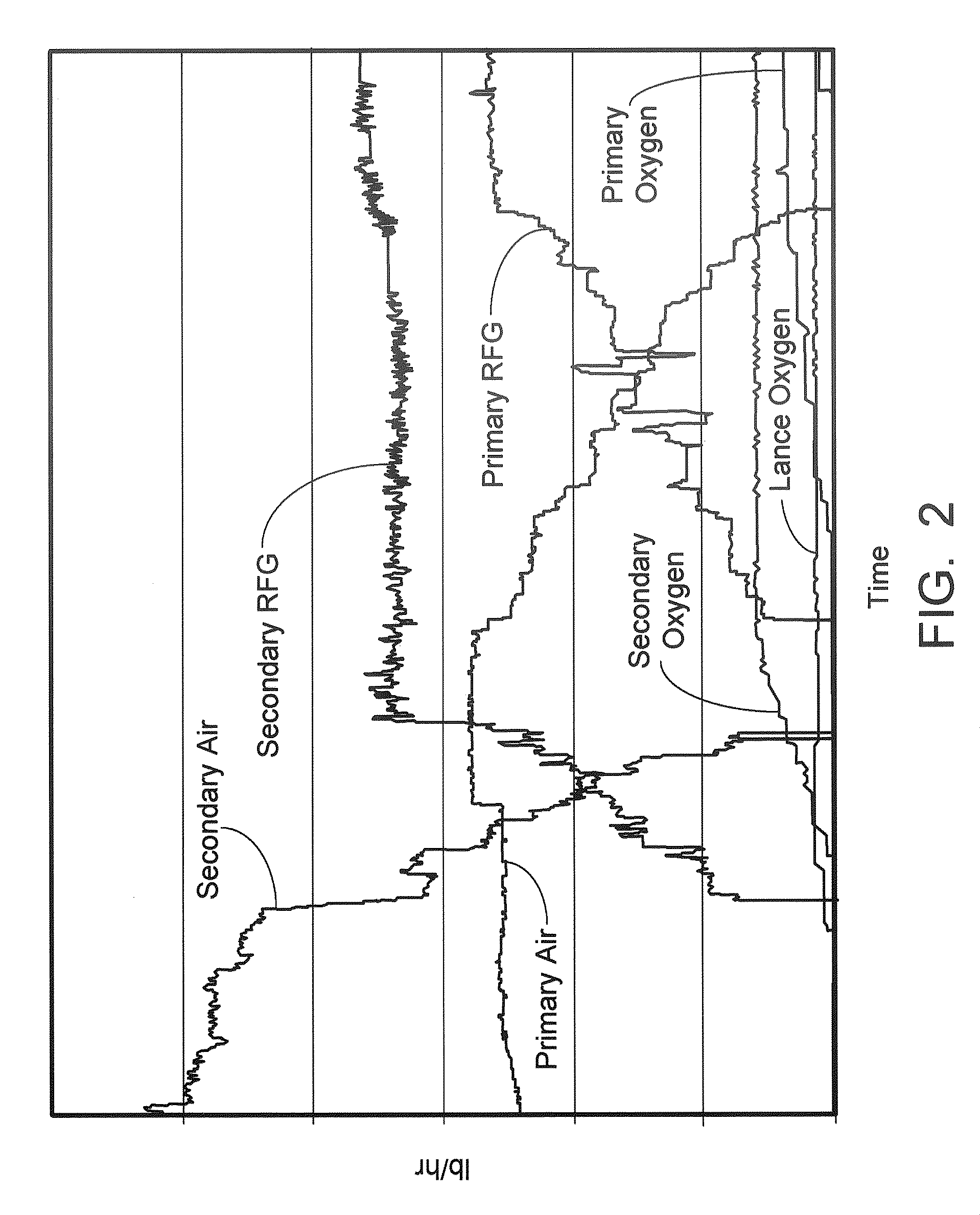

Oxy-combustion coal fired boiler and method of transitioning between air and oxygen firing

ActiveUS20090255450A1Easy to controlMinimize infiltrationLiquid carbonaceous fuelsPulverulent fuel combustion burnersBoiler furnaceCombustor

A new and unique boiler and method of transition between air and Oxy-combustion in a coal fired combustion process wherein near pure oxygen may be introduced to the boiler furnace in several locations including directly into the flame through the burner and / or directly into the furnace as nearly pure oxygen, and / or into the recycle flue gas streams to the burners, including both primary and secondary streams.

Owner:THE BABCOCK & WILCOX CO +1

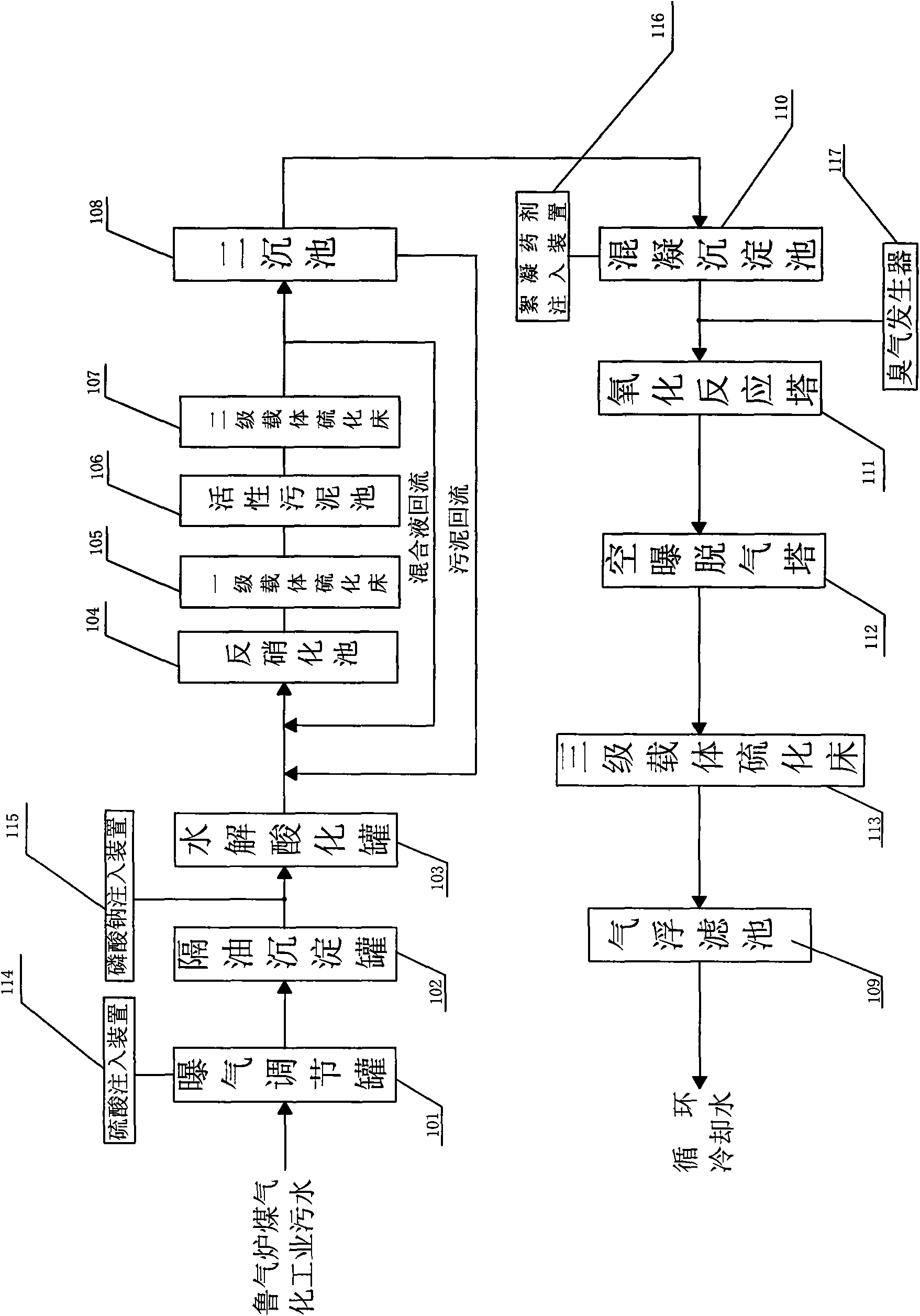

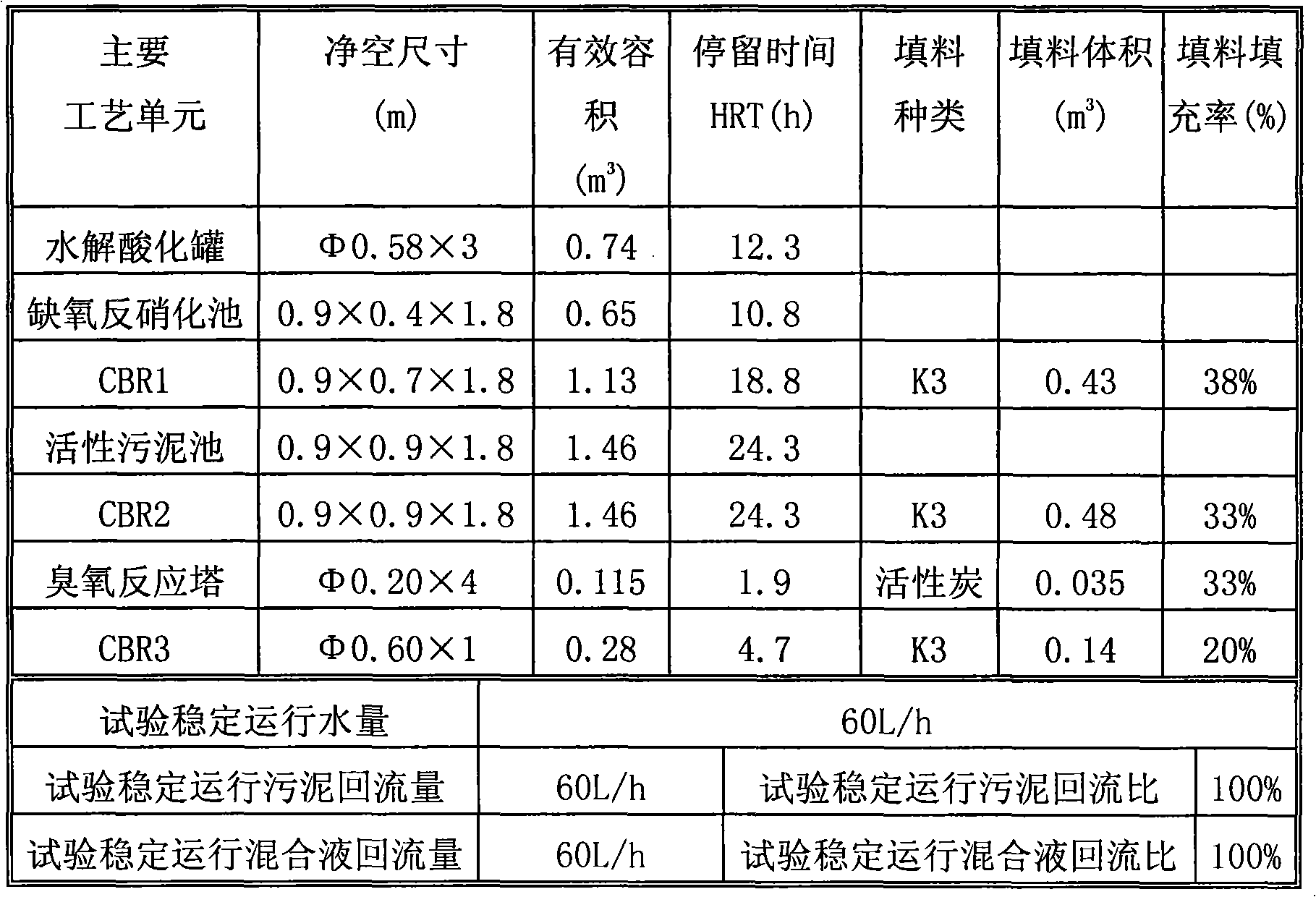

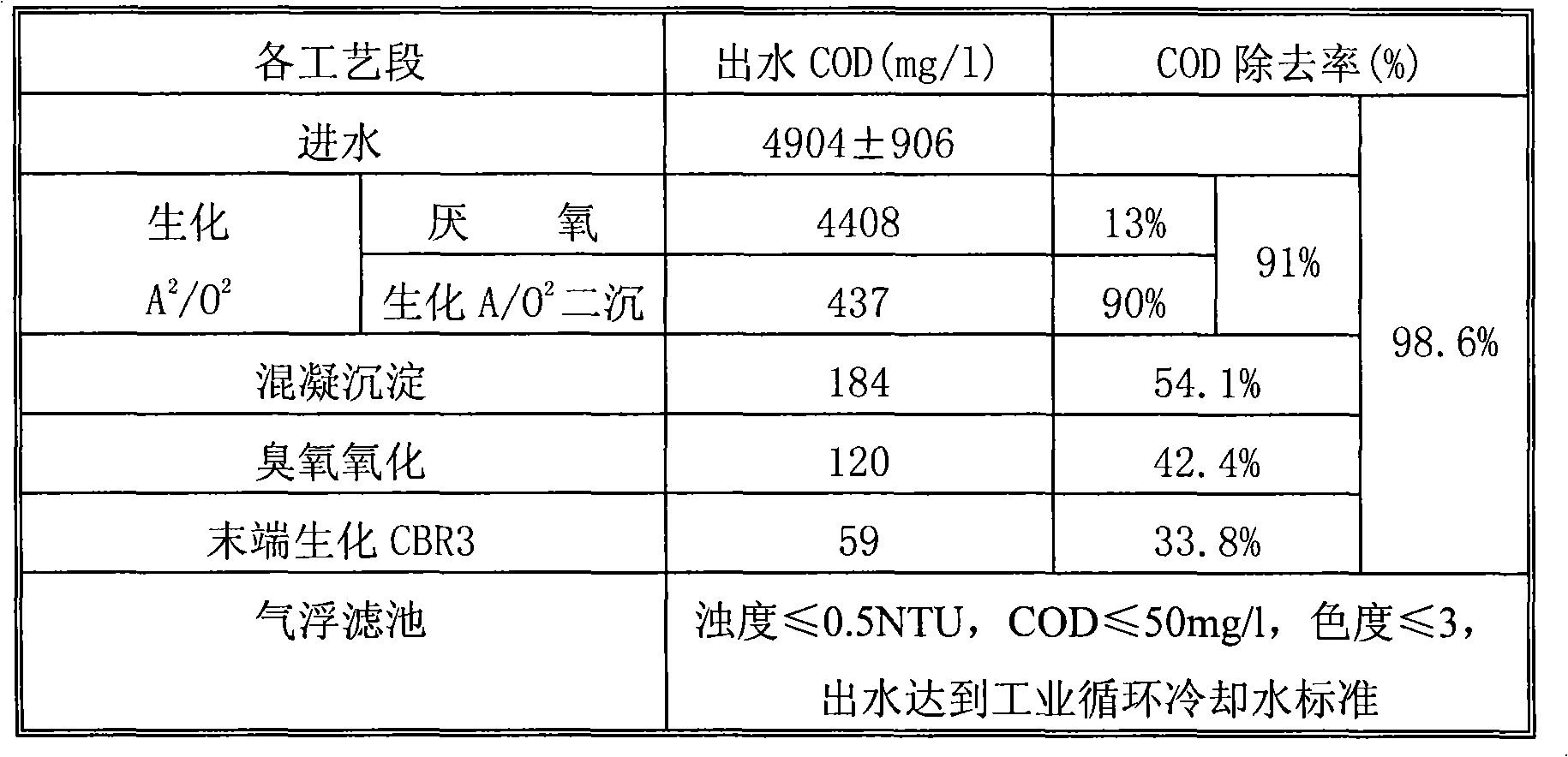

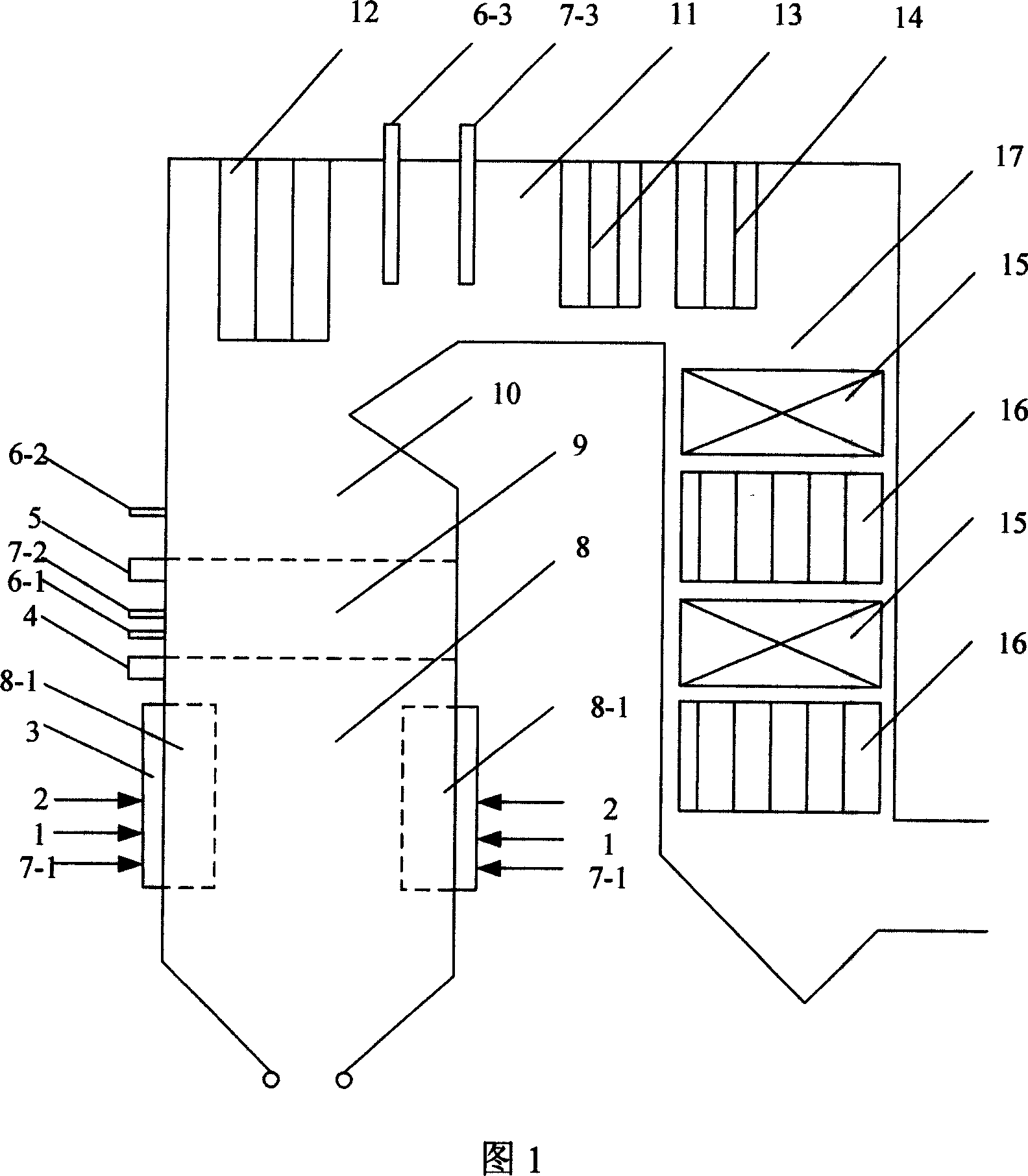

Lurgi furnace coal gasification wastewater treatment and reuse technology

ActiveCN101607777AImprove impact resistanceGuaranteed uptimeTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentCoal gasification wastewaterActivated sludge

The invention discloses a Lurgi furnace coal gasification wastewater treatment and reuse technology, comprising the steps of adopting aeration adjustment, oil separation and sedimentation, hydrolysis acidification, denitrification treatment, first order carrier fluidized bed decarburization, residual COD removement with activated sludge, second order carrier fluidized bed ammonia / nitrogen removement, sludge-water separation, precipitation, oxidation reaction, residual ozone removement, organic waste removement and floating filter treatment to treat the coal gasification wastewater of a Lurgi furnace coal gasification factory and obtaining water which can be reused. The invention has simple operation and low process cost and the treated effluent can be used as the cooling water of boiler furnaces, thus fully recycling the treated Lurgi furnace coal gasification wastewater.

Owner:DASMART ENVIRONMENTAL SCI & TECH (BEIJING) CO LTD

Feedforward signal control method in boiler steam temperature automatic control system

InactiveCN102012017AImprove qualityReduce steam temperature fluctuationsSuperheating controlSteam pressureAutomatic control

The invention discloses a feedforward signal control method in a boiler steam temperature automatic control system, which is used for improving quality of boiler steam temperature control. The technical scheme comprises the following steps of: measuring boiler furnace pressure, boiler steam pocket pressure (or steam-water separator pressure), boiler overheater outlet steam pressure, and boiler reheater outlet steam pressure; and calculating by utilizing the signals to form a combustion disturbing signal, an overheat steam flow disturbing signal, a reheat steam flow disturbing signal, an overheat steam temperature control system feedforward signal and a reheat steam temperature control system feedforward signal in turn. The method can effectively improve the quality of boiler steam temperature control, reduces steam temperature fluctuation caused by combustion disturbance and steam flow disturbance, does not need any additional hardware equipment, only needs increasing a little of software control logic, has low cost and cannot reduce the system reliability.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method of decreasing release of nitrogen oxide in the pulverized-coal fired boiler and its used boiler

InactiveCN101021327AEmission reductionIncrease burn rateLighting and heating apparatusBoiler furnaceCombustor

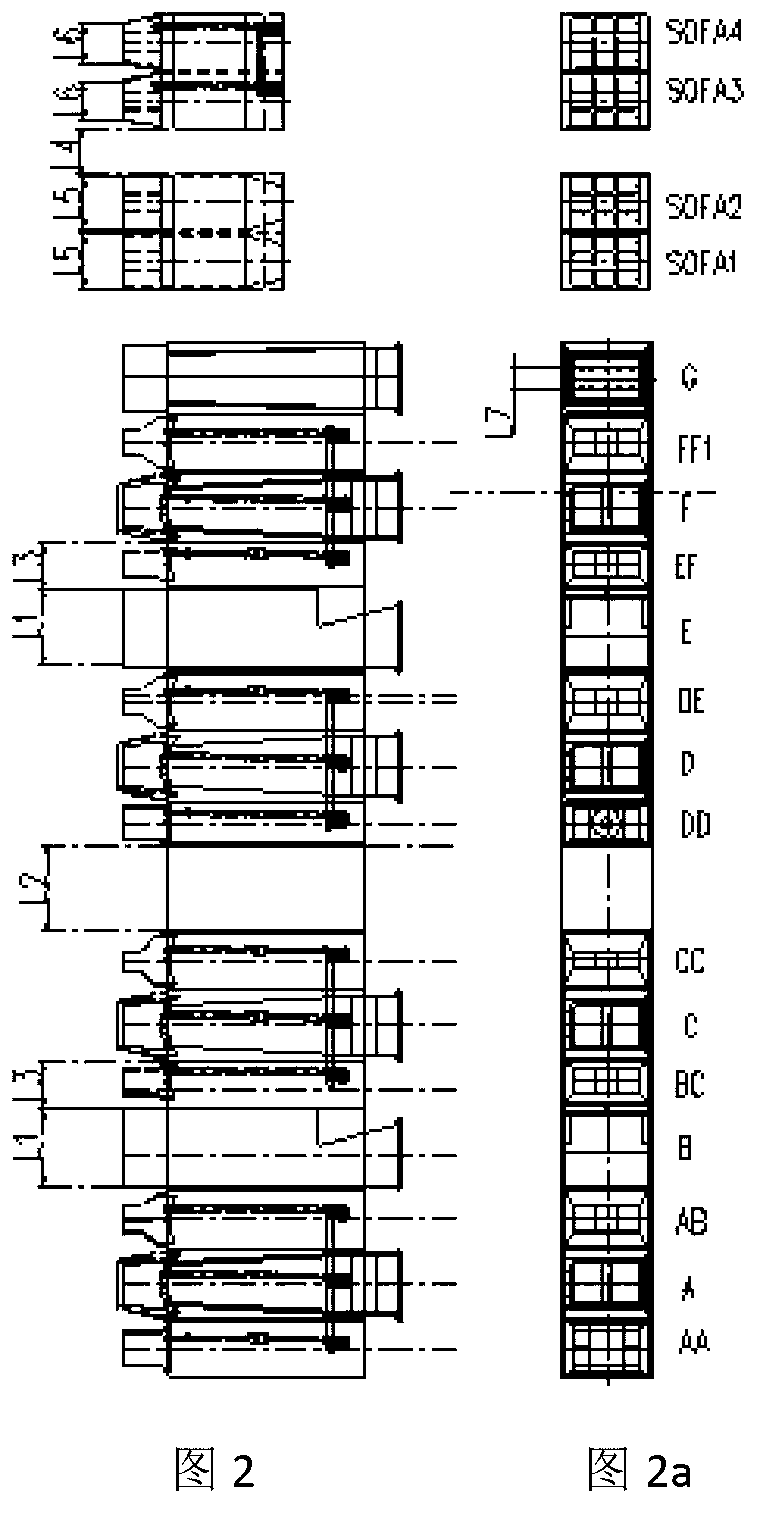

The present invention relates to a method capable of reducing nitrogen oxide discharge for coal powder boiler and boiler using said method. Said invention is characterized by that said boiler is composed of boiler furnace cavity, horizontal flue and tail flue, and the furnace cavity interior is divided into main combustion zone, reduction zone and burning zone. The method for reducing discharge adopts the coal powder boiler with main combustion zone, reduction zone, burning zone, near combustor zone, horizontal flue and tail flue, makes the amino reducing agent be sprayed into reduction zone, burning zone and horizontal flue and make the hydrocarbyl reducing agent be sprayed into main combustion zone and reduction zone or main combustion zone, reduction zone and horizontal flue. Said method can effectively reduce NOx discharge by 60%-80%.

Owner:HARBIN INST OF TECH

Super low NOx, high efficiency, compact firetube boiler

ActiveUS6971336B1Reduce nitrogen oxide emissionsReducing NO<sub>Furnace-tube steam boilersCombustion enginesCombustion chamberBoiler furnace

A firetube boiler furnace having two combustion sections and an in-line intermediate tubular heat transfer section between the two combustion sections and integral to the pressure vessel. This design provides a staged oxidant combustion apparatus with separate in-line combustion chambers for fuel-rich primary combustion and fuel-lean secondary combustion and sufficient cooling of the combustion products from the primary combustion such that when the secondary combustion oxidant is added in the secondary combustion stage, the NOx formation is less than 5 ppmv at 3% O2.

Owner:GAS TECH INST

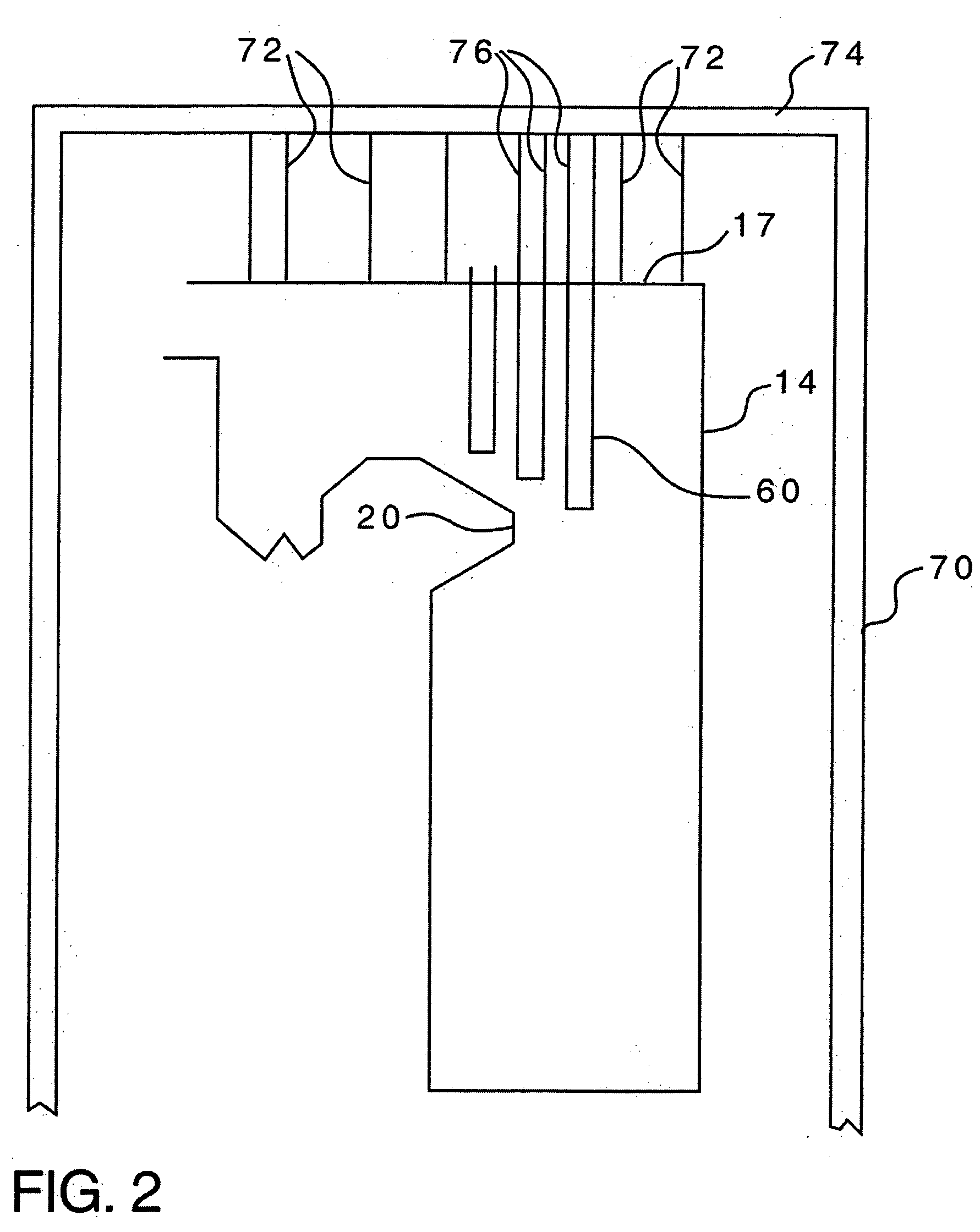

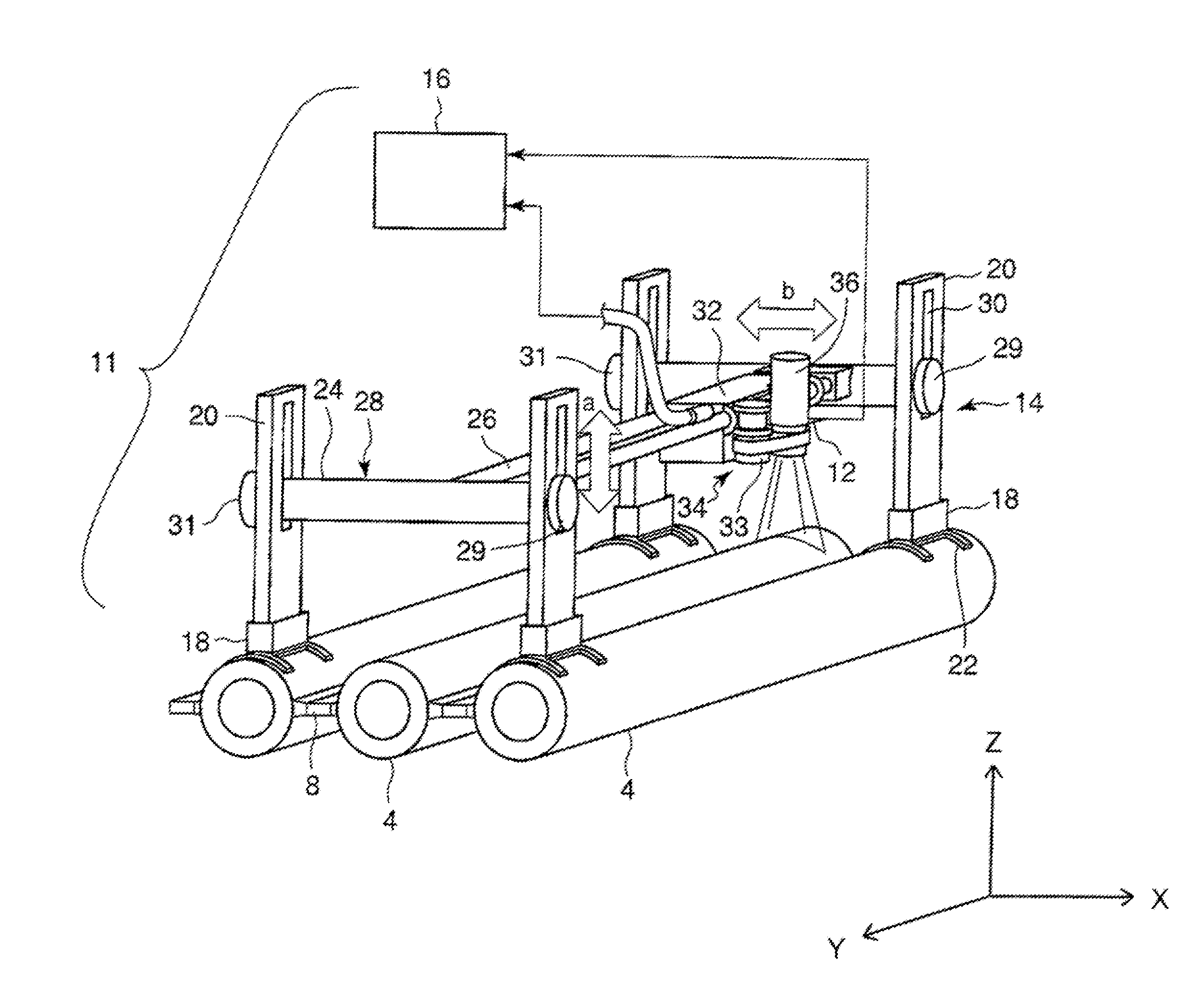

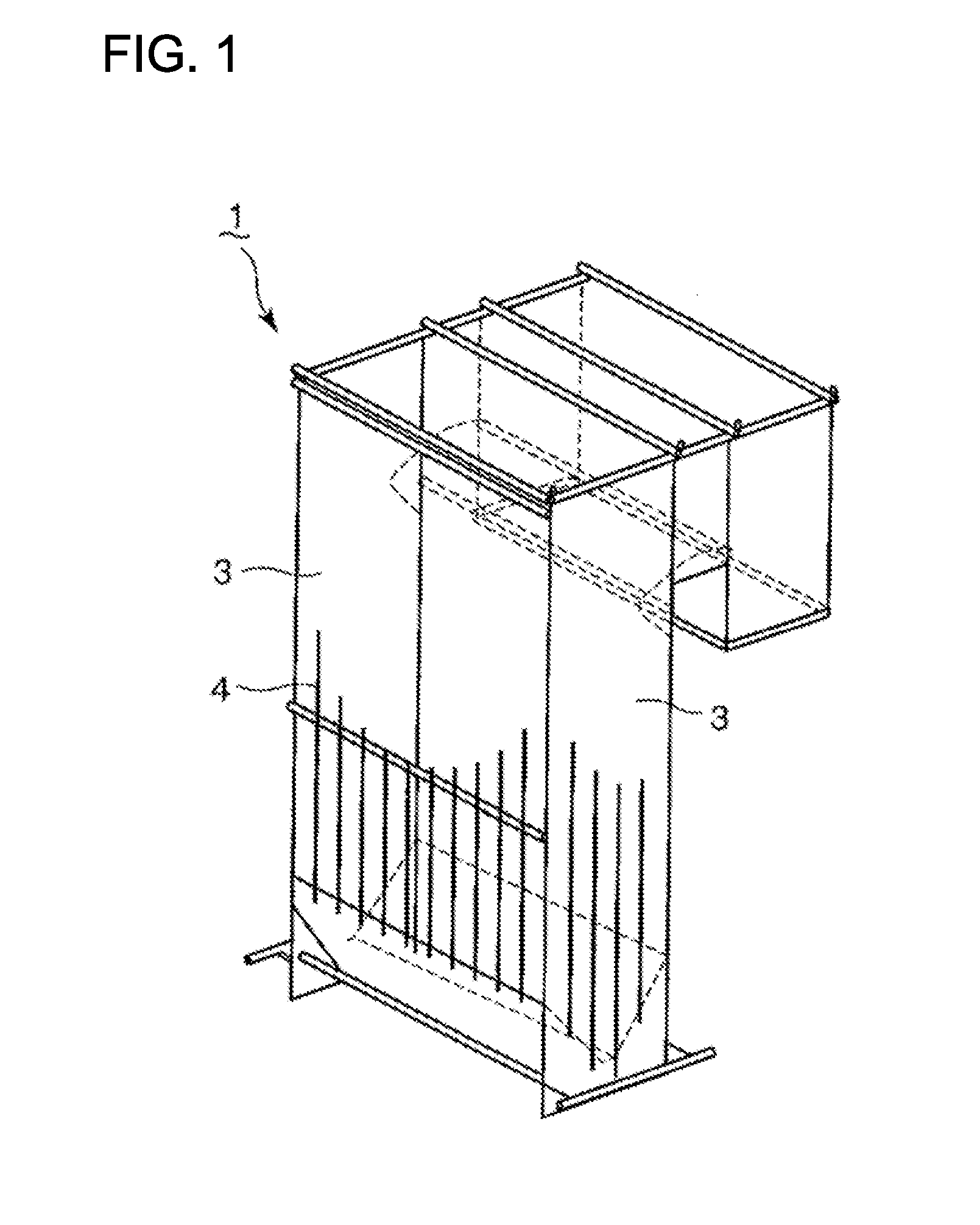

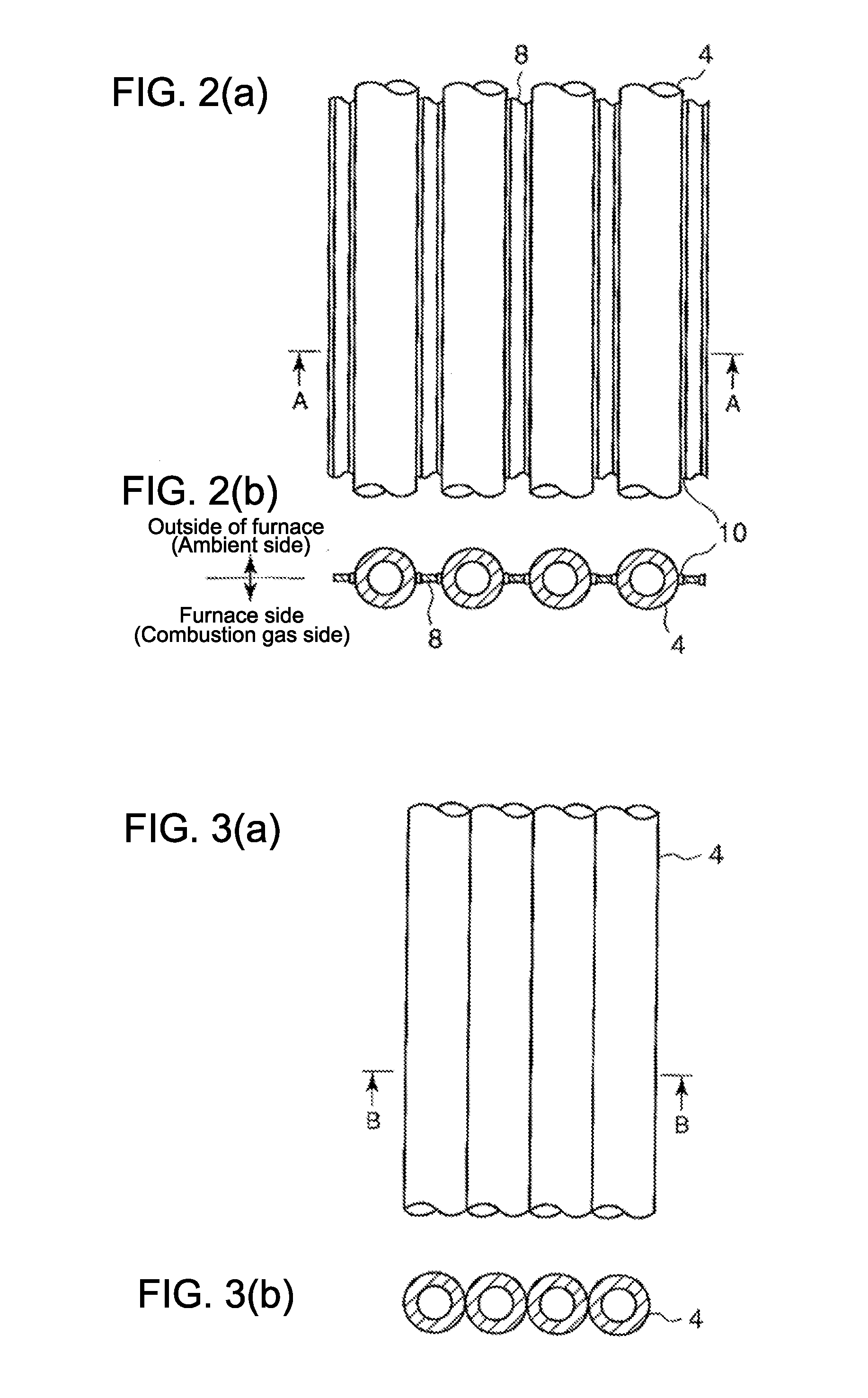

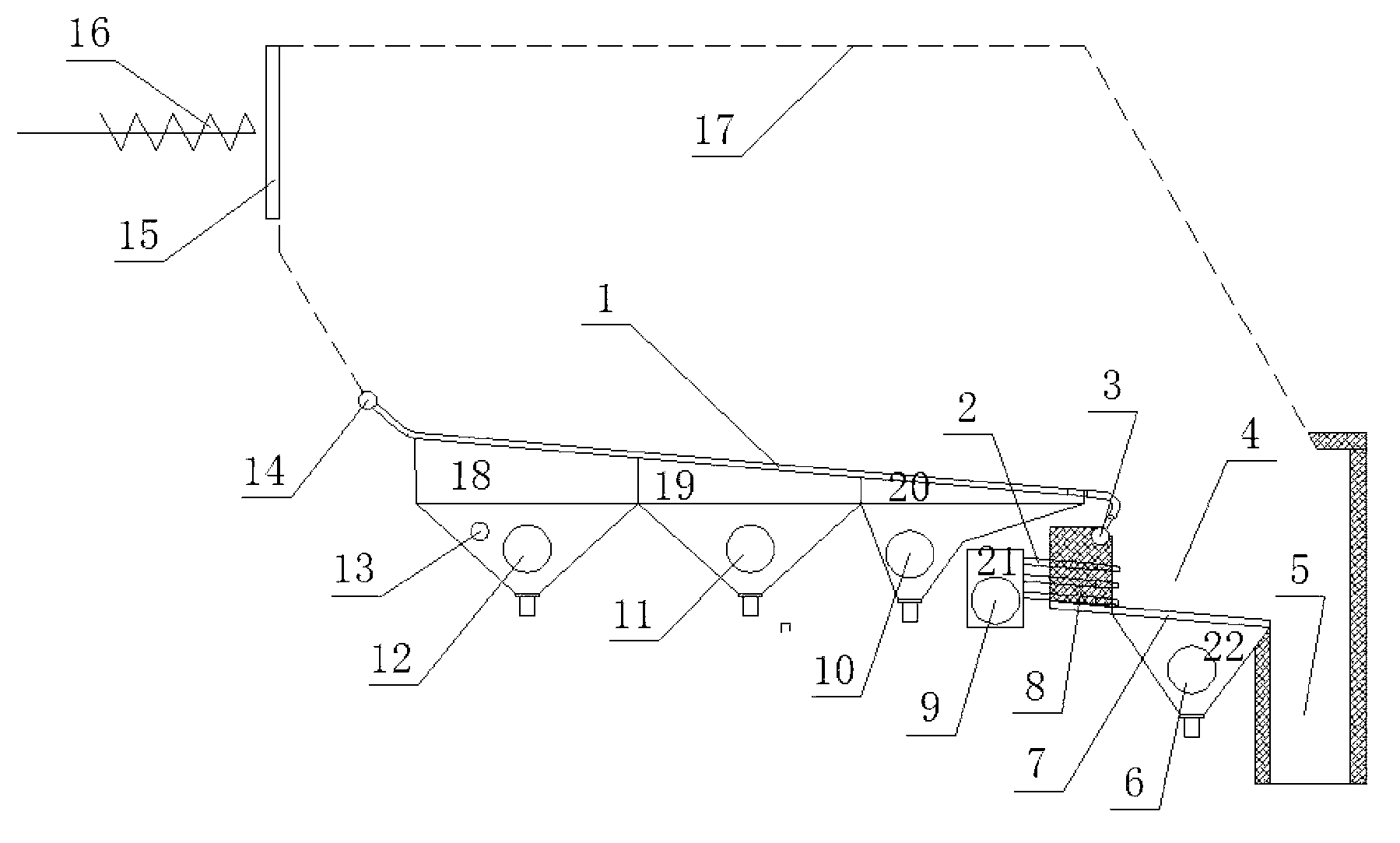

Inspection device and inspection method for boiler furnace water wall tubes

ActiveUS20110279828A1Reduce wall thicknessEnsure correct executionMaterial analysis by optical meansUsing optical meansBoiler furnaceLaser light

There are provided an inspection device and an inspection method for boiler furnace water wall tubes, which can inspect reduced wall thickness conditions of multiple water wall tubes, extending in an up-down direction along inner wall surfaces of a boiler furnace and arranged adjacent to each other, accurately and efficiently over a wide range based on surface shapes of the water wall tubes measured by a laser displacement sensor. A scanner 14 including columns 20 placed upright and fixed by magnets onto the surfaces of multiple water wall tubes 4 extending the up-down direction on the inner wall surfaces of the boiler furnace, a support frame 28 fixed to the columns 20 to support a displacement sensor 12 producing laser light to be irradiated onto the surface of a water wall tube 4, and a moving mechanism 31 for moving the displacement sensor 12 in the axial direction of the water wall tube 4 relative to the support frame 28. A signal processing unit 16 is also provided for calculating the amount of reduced wall thickness of the water wall tube 4 from a difference between the cross-sectional surface shape of the water wall tube 4 based on a signal from the displacement sensor 12 and a reference shape without reduction in wall thickness in order to evaluate a reduced wall thickness condition.

Owner:MITSUBISHI POWER LTD

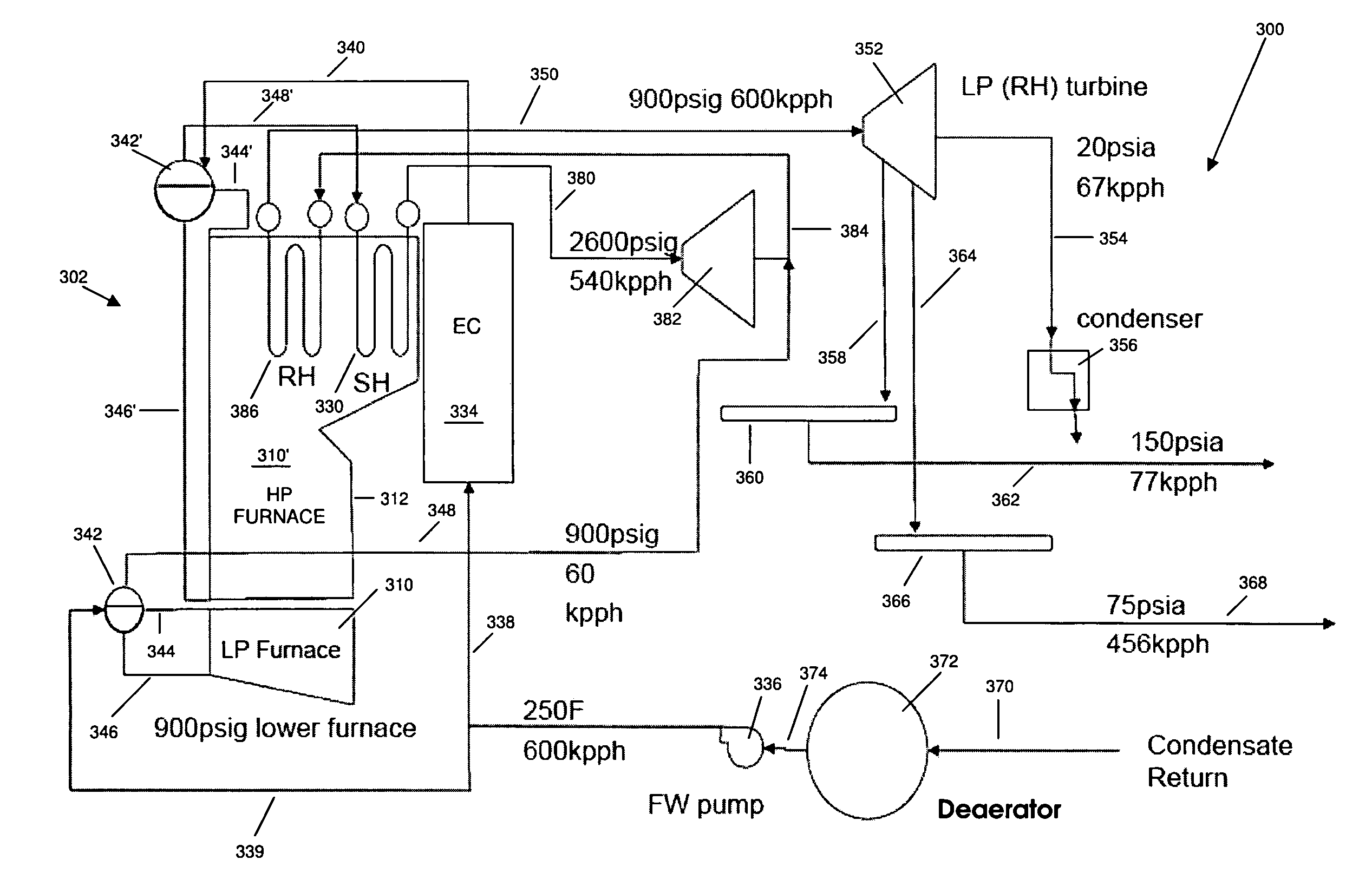

Enhanced steam cycle utilizing a dual pressure recovery boiler with reheat

InactiveUS20090241860A1Increase generationThe material is lowSuperheating controlFood processingBoiler furnaceEngineering

An enhanced steam cycle utilizing a dual pressure recovery boiler with reheat allows a large increase in electrical generation with various turbine cycles while overcoming traditional lower furnace material limitations. A dual pressure designed recovery boiler furnace is provided with a lower furnace and an upper furnace. The lower furnace is operated at a lower temperature to prevent or reduce corrosion of the lower furnace wall tubes caused by the reducing environment. The lower furnace can be either a low pressure natural circulation steam generating (drum) system or economizer. Unlike the lower furnace, the upper furnace is not exposed to a reducing environment and is therefore not as susceptible to severe corrosion rates. The upper furnace is operated at higher temperatures and pressures which permit implementation of higher efficiency reheat steam cycles. The upper furnace thus operates as a high pressure natural circulation steam generating (drum) system, or as a once-through supercritical steam generating system. The dual pressure recovery boiler can thus be coupled to a variety of condensing, non-condensing or a combination of condensing and non-condensing turbine cycles to provide a large increase in electrical generation.

Owner:THE BABCOCK & WILCOX CO

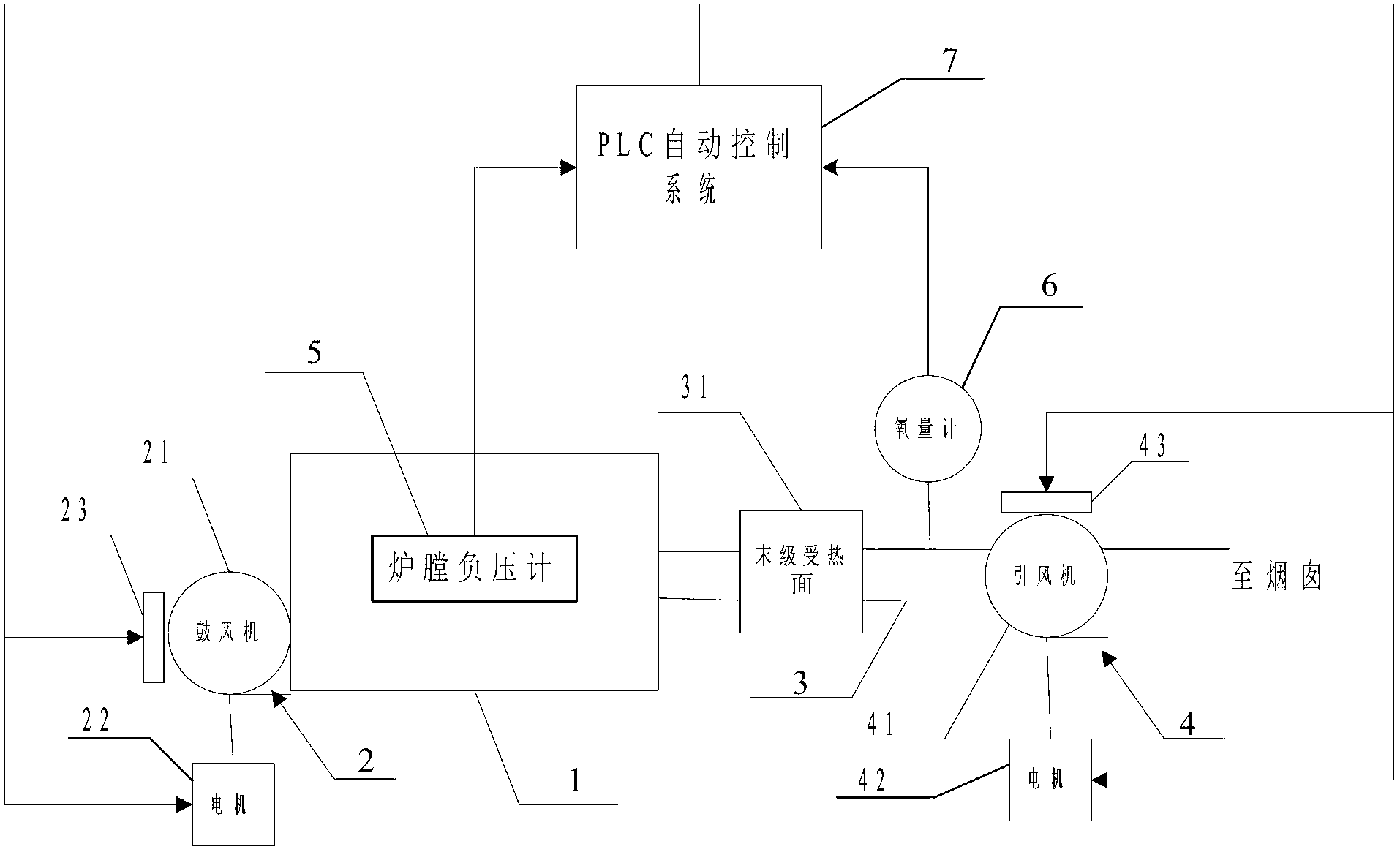

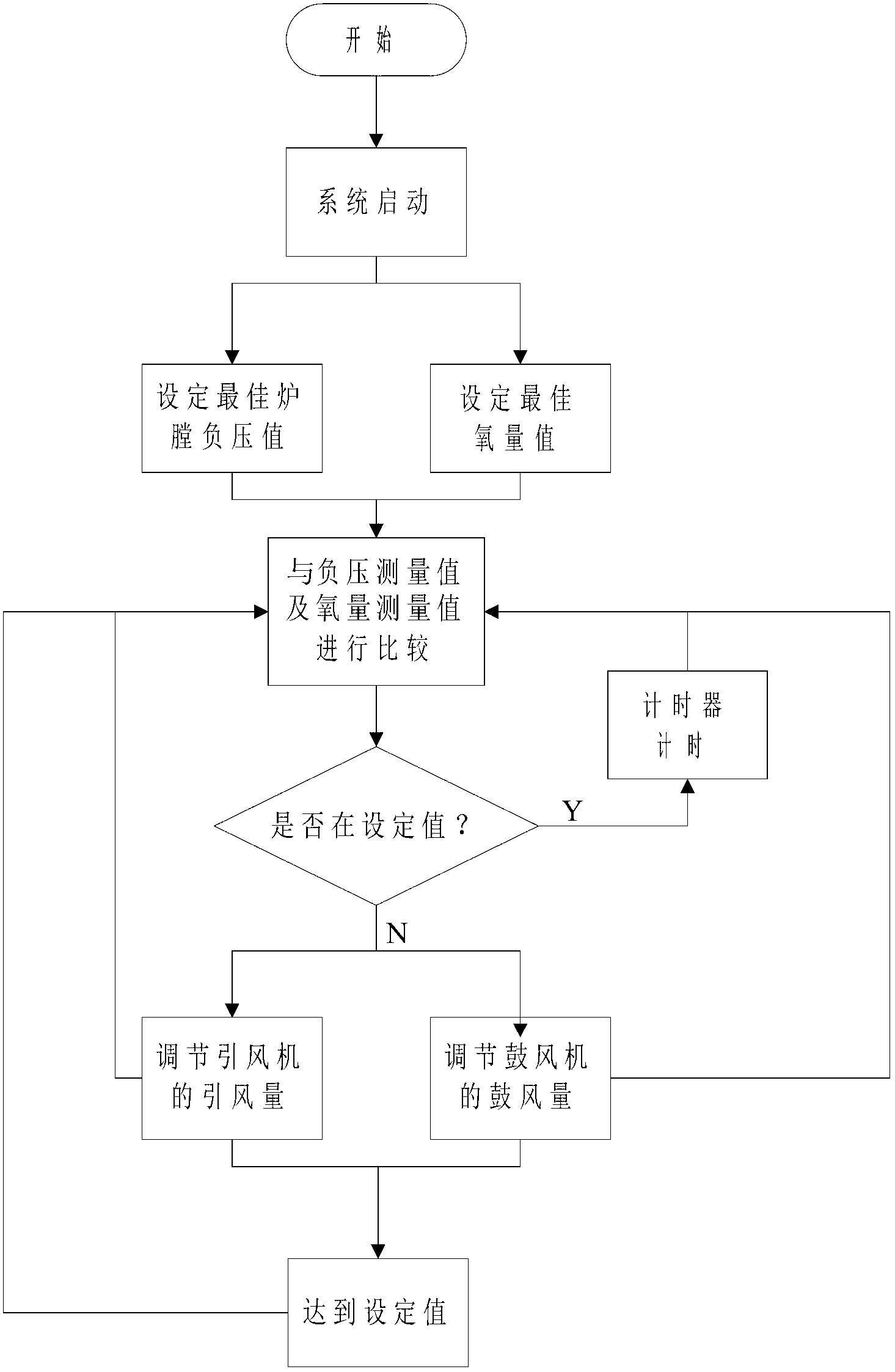

Air distribution optimized automatic control system and control method thereof of boiler

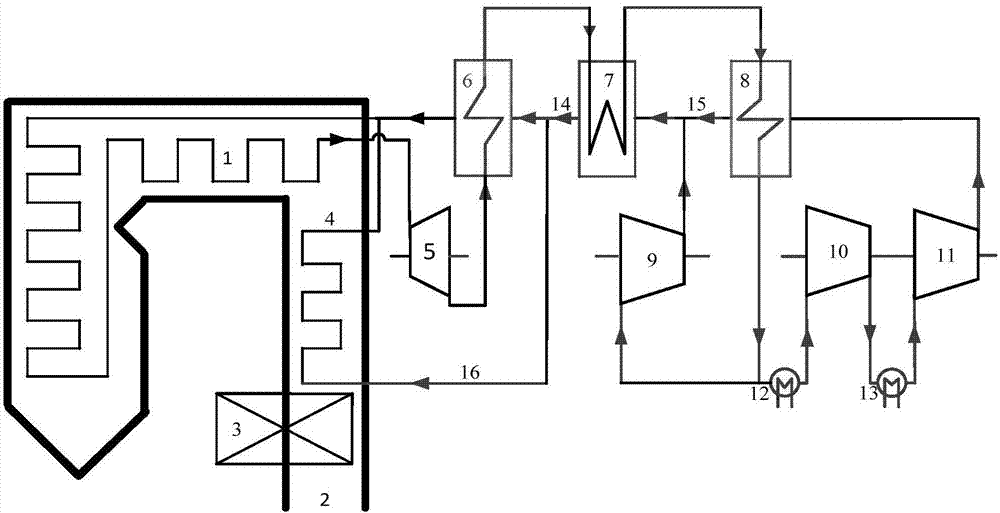

The invention provides an air distribution optimized automatic control system and a control method thereof of a boiler. The system comprises a boiler furnace, a blower, a boiler rear smoke channel, an induced draft fan, a depressimeter, an oxymeter and a PLC (programmable logic controller) automatic control system; the PLC automatic control system is used for setting a furnace negative pressure set value and an oxygen content set value; the depressimeter and the oxymeter are respectively used for measuring a negative pressure in the boiler furnace to obtain a negative pressure measured value and an oxygen content in the boiler rear smoke channel to obtain an oxygen content measured value; the PLC automatic control system receives the negative pressure measured value and the oxygen content measured value and compares the negative pressure measured value and the oxygen content measured value with the furnace negative pressure set value and the oxygen content set value, then sends an instruction according to a comparative result to adjust an induced draft volume of the induced draft fan and a blast volume of the blower; thus the negative pressure in the boiler furnace and the oxygen content in the boiler rear smoke channel behind a boiler last-stage heating surface are adjusted to the set values, so that the boiler always runs under the economic condition; and automatic adjustment of the oxygen content or automatic adjustment of the furnace negative pressure can also be adopted independently.

Owner:SHENZHEN INST OF SPECIAL EQUIP INSPECTION & TEST

Acoustic soot blower, and method for operating the same

The sonic soot blower includes a sonic wave oscillator that oscillates sonic waves by compressed air or steam, a frequency-regulating portion that varies the frequencies of the sonic waves oscillated by the above-described sonic wave oscillator, a resonance tube that resonates the oscillated sonic waves, and a horn that amplifies the same, wherein powdery dust adhered to members installed inside a boiler furnace, etc., are removed, and are prevented from adhering to the above-described members. The above-described frequency-regulating portion is a gas mixer which is connected to the upstream side of the sonic wave oscillator and is provided with two or more gas conducting flow channels for conducting a compressive gas whose temperatures and / or densities are different from each other, or a slide mechanism that varies the length of the above-described resonance tube. Since the sonic soot blower is able to oscillate sonic waves while regulating the oscillation frequency so as to be suited to the operating conditions of the boiler, it becomes possible to effectively remove ash from the heat transmission tubes and to effectively prevent the same from adhering thereto over a wide range of operating conditions of soot blower-installed equipment (such as a boiler).

Owner:MITSUBISHI HITACHIPOWER SYST LTD

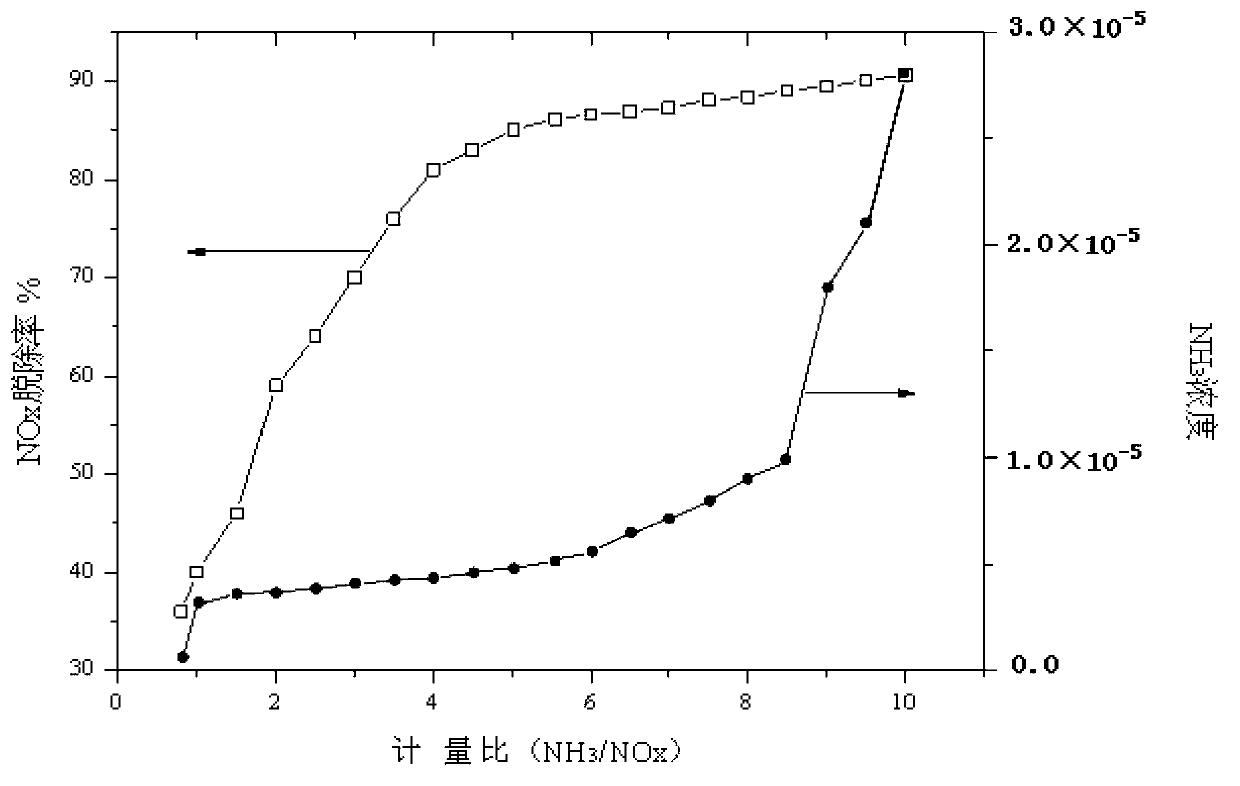

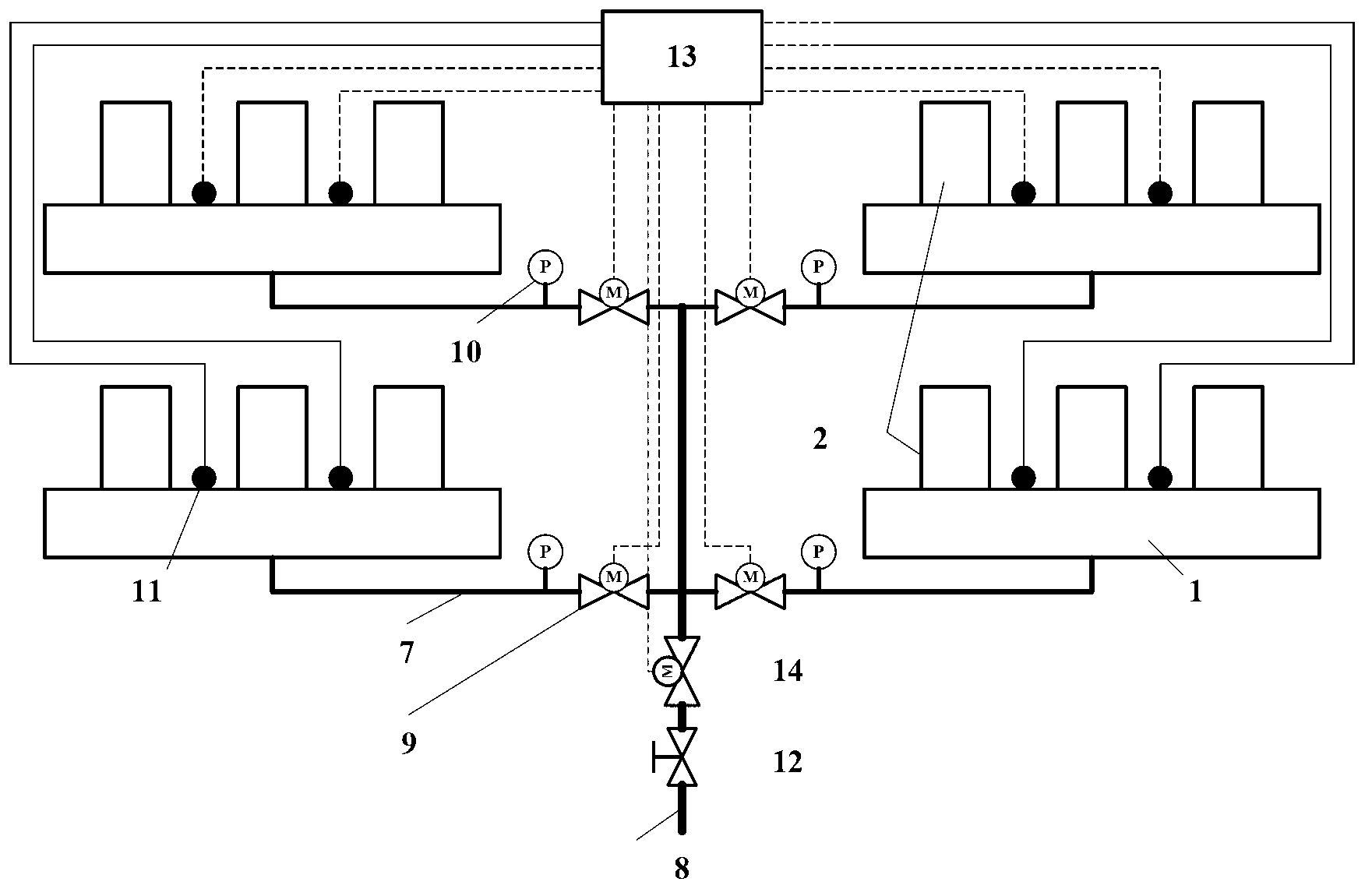

SNCR-SCR combined denitration system and method based on ammonia nitrogen molar ratio detection and regulation

InactiveCN105169917AFlexible operationImprove denitrification efficiencyDispersed particle separationAir preheaterCorrosion

The invention belongs to the technical field of controlling atmospheric pollutants exhausted by coal-fired boilers, and particularly relates to an SNCR-SCR combined denitration system and method based on ammonia nitrogen molar ratio detection and regulation. The system comprises an ammonia-containing storage tank, an air preheater, an SNCR reaction zone, an SCR reaction zone, a first detection system, a second detection system, a third detection system and a control system, wherein the SNCR reaction zone is arranged in a boiler furnace, the SCR reaction zone is arranged in a boiler flue, and the first detection system, the second detection system and the third detection system are connected with the control system. The combined denitration system can achieve full-load denitration operation, is high in denitration efficiency and solves the problem of corrosion and deposition of ammonium bisulfate in follow-up equipment.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

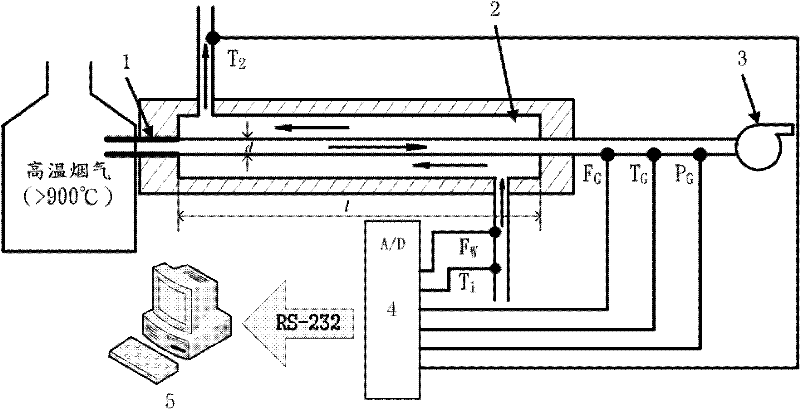

Apparatus of measuring power station boiler furnace gas temperature and measuring method thereof

InactiveCN102252780AAvoid contactExtended service lifeTemperature measurement of flowing materialsMeasurement deviceEngineering

An apparatus of measuring power station boiler furnace gas temperature and a measuring method thereof, which belong to the thermal power technology field, are disclosed. The apparatus comprises: a high temperature resistant ceramic sampling tube, a water-cooled pipe heat exchanger, an air inducing apparatus, temperature, pressure and flow measuring components, a digital to analog converter, and a data processing computer. The high temperature resistant ceramic sampling tube forms a sealing connection with a water-cooled pipe heat exchanger a screw mouth. A cooling water honeycomb duct forms a sealing connection with the pipe heat exchanger. The air inducing apparatus is arranged in the position of a pipe heat exchanger gas exit and is used as a power supply for gas flow. The temperature measuring component, the pressure measuring component and the flow measuring component are respectively arranged in the positions of exits and entrances of a gas pipe and the cooling water duct of the water-cooled pipe heat exchanger, and acquisition data is output to a control module to be recorded. In the invention, based on a water-cooled pipe heat exchanger principle, heat exchange between a little constant volume gas in a furnace and the cooling water is used and a real time temperature of the gas in the furnace can be obtained by inversely analyzing cooling water heat variation and the heat of the tail gas.

Owner:SHANGHAI JIAO TONG UNIV

Low-NOx combustor with internal reflux of flue gas and homogeneous combustion and gas configuration method thereof

ActiveCN102012025AReduce generationAvoid local high temperatureGaseous fuel burnerIndustrial gasCombustor

Owner:SHANGHAI NUOTE FEIBO COMBUSTION EQUIP CO LTD

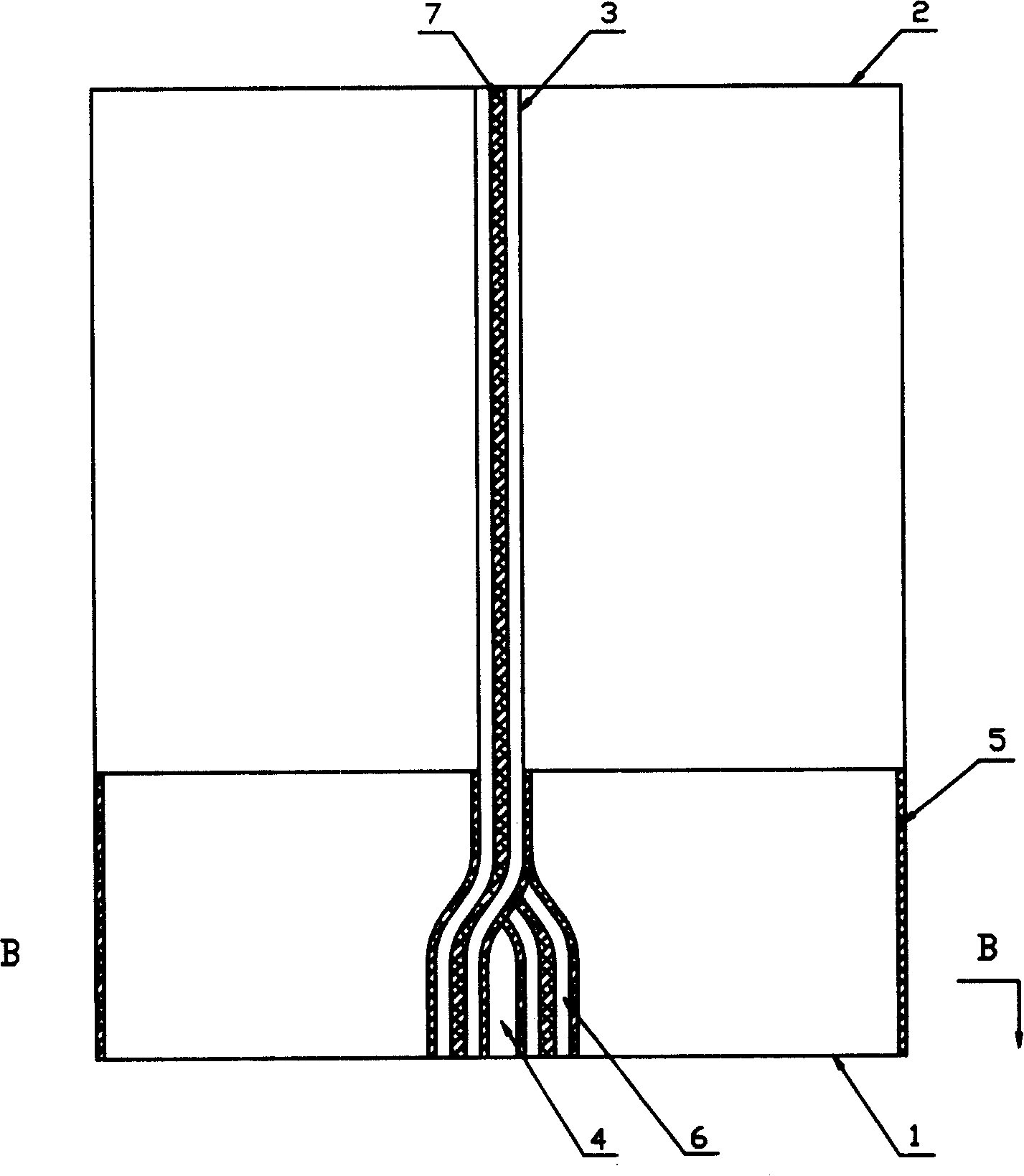

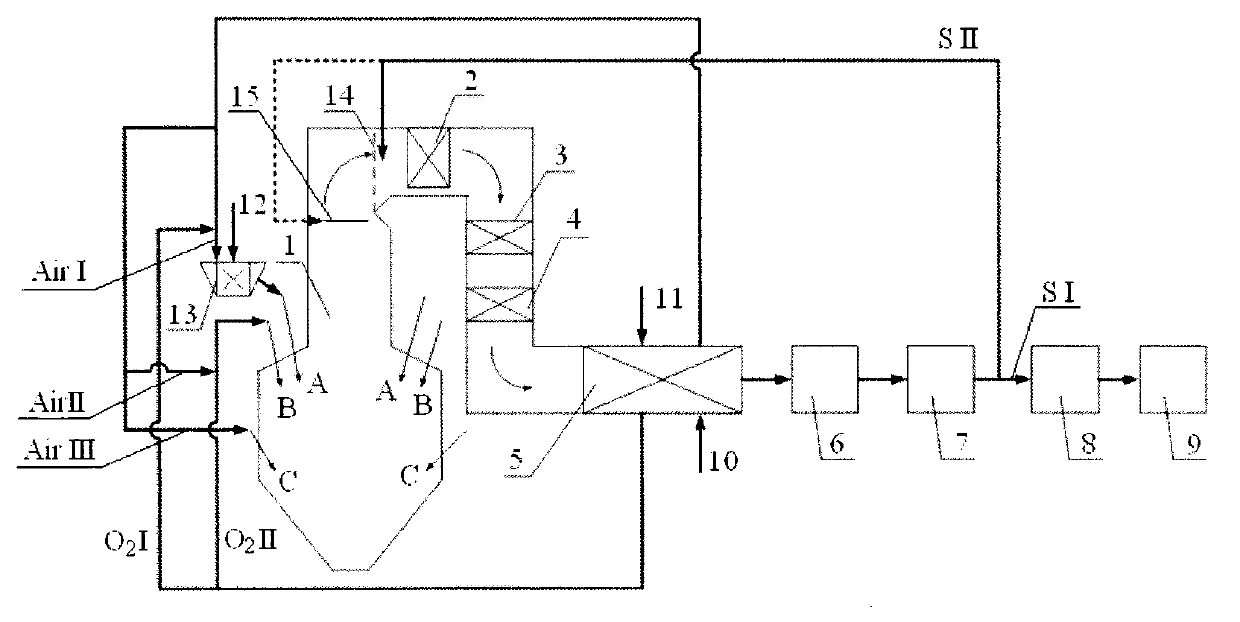

Circulating fluid bed boiler furnace possessing heating screen

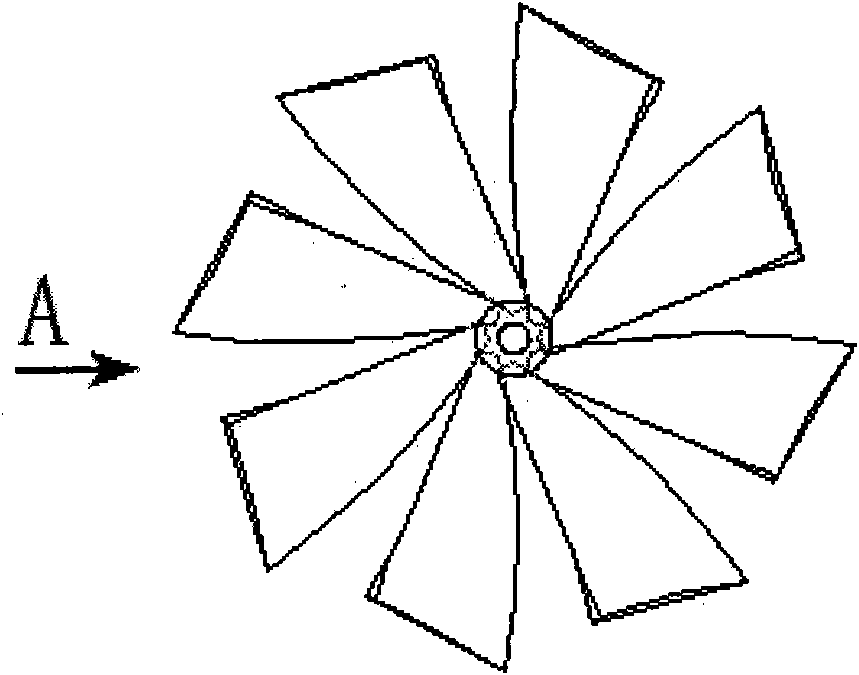

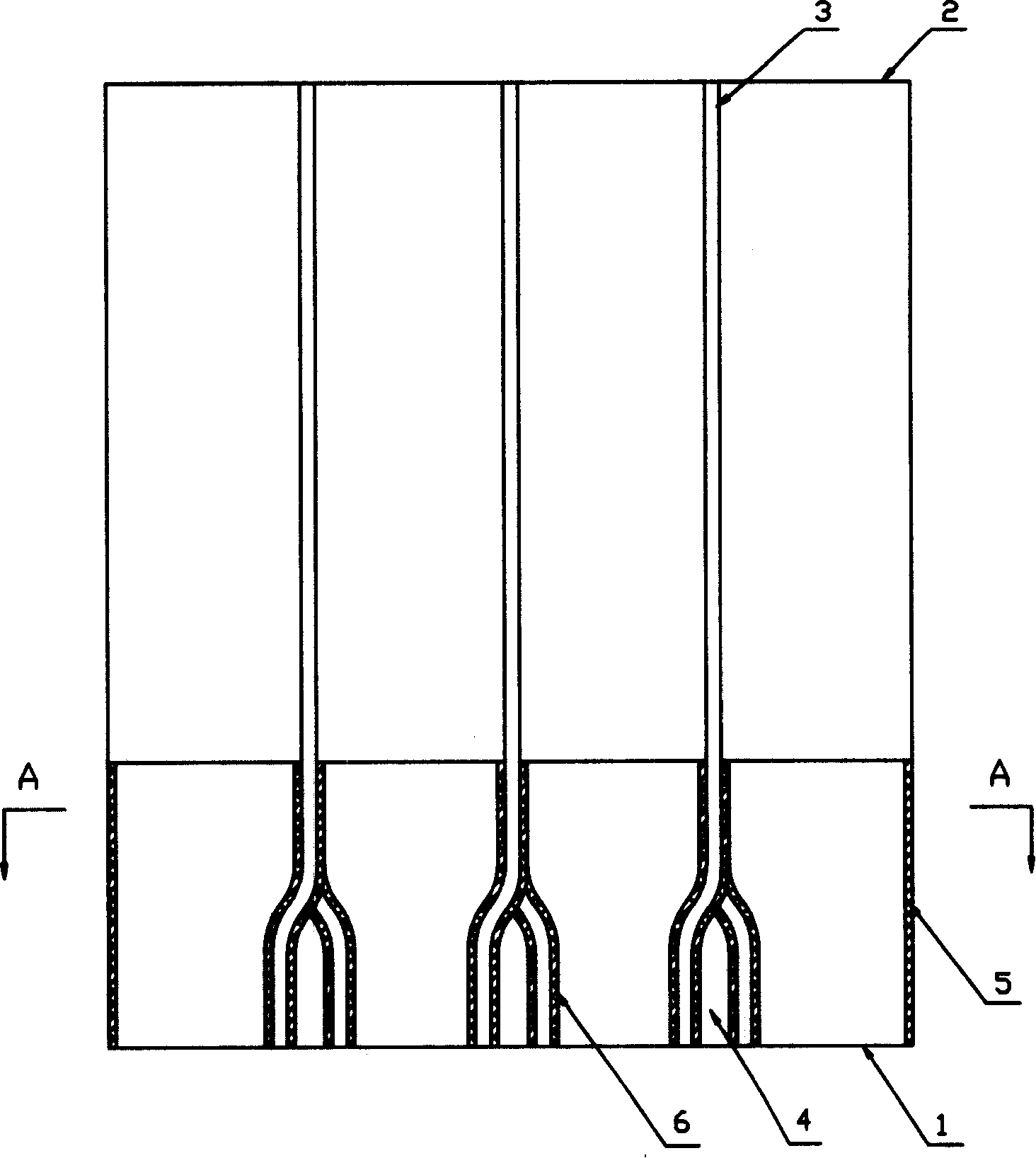

ActiveCN101240893AGuaranteed concentrationEmission reductionSteam boilersBoiler furnaceFluidized bed

The present invention provides a circulating fluidized bed boiler furnace having heated screen, the heated screen is set between the furnace grid plate and the ceiling which height is identical to the furnace, the heated screen is made of membrane panel, membrane panel pipe has working substance un-down, the upper of the heated screen is vertical, the lower has space connected the front and the back screen formed by pipe; the heated screen is one or more plates. The circulating fluidized bed boiler furnace having heated screen gives space to the material cycle when the furnace provides extending heated surface, ensuring the uniformity of the material concentration, temperature and heat transfer; secondary air inlets in the center of the furnace, fullu burning, and has lower NOx drainage.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

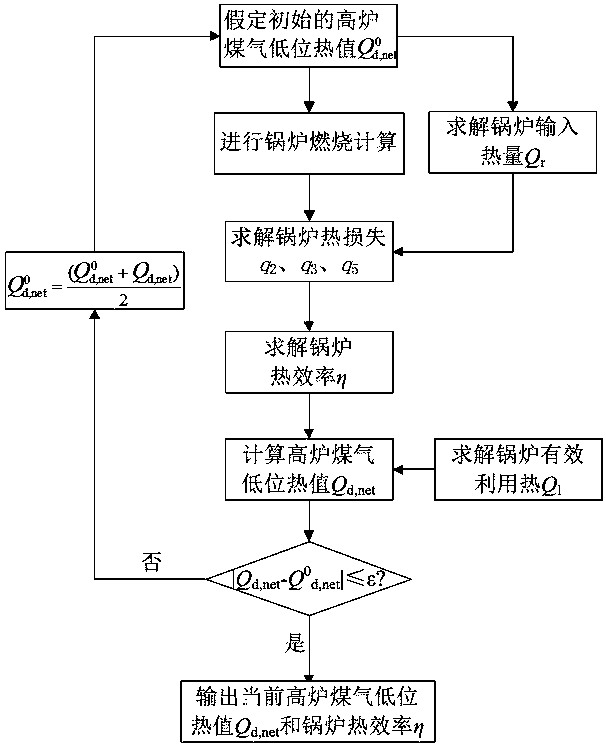

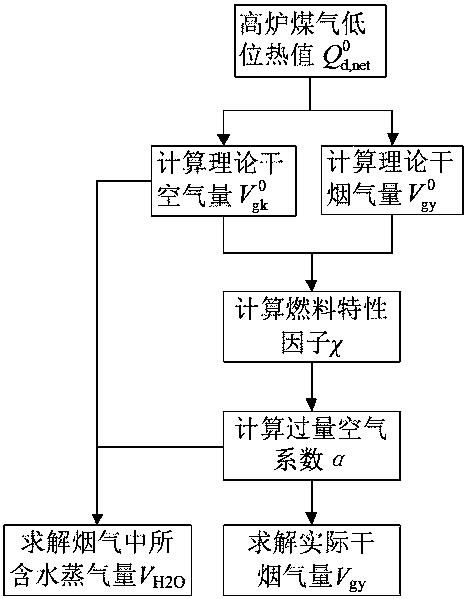

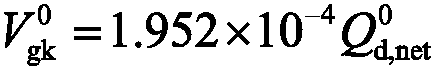

Blast furnace gas boiler furnace-entering gas thermal value and boiler heat efficiency on-line monitoring method

ActiveCN107796851AOnline identification of low calorific valueHigh implementabilityMaterial heat developmentFuel testingBoiler furnaceOriginal data

The invention relates to a blast furnace gas boiler furnace-entering gas thermal value and boiler heat efficiency on-line monitoring method, which comprises the following steps of collecting online operation data of a machine set in real time, wherein the online operation data includes smoke gas oxygen content, smoke gas CO content, exhausted smoke temperature, furnace-entering blast furnace gas flow rate, boiler evaporation quantity, environment temperature; solving the input data of effective utilization heat of a boiler; preprocessing the obtained original data to obtain effective data; obtaining the furnace-entering gas thermal value and the boiler heat efficiency of a blast furnace gas boiler according to the obtained effective data. The lower calorific value of blast furnace gas canbe recognized on line and is used for online monitoring of the boiler thermal efficiency; reliable basis can be provided for boiler performance analysis and combustion regulation; important practicalsignificance is realized; the blast furnace gas thermal value and the boiler thermal efficiency are obtained completely through online calculation on boiler operation parameters; off-line data collection and any manual parameter input are not needed; the operation can be realized completely through the online data collection of the machine set; good implementation performance is realized.

Owner:JIANGSU MARITIME INST

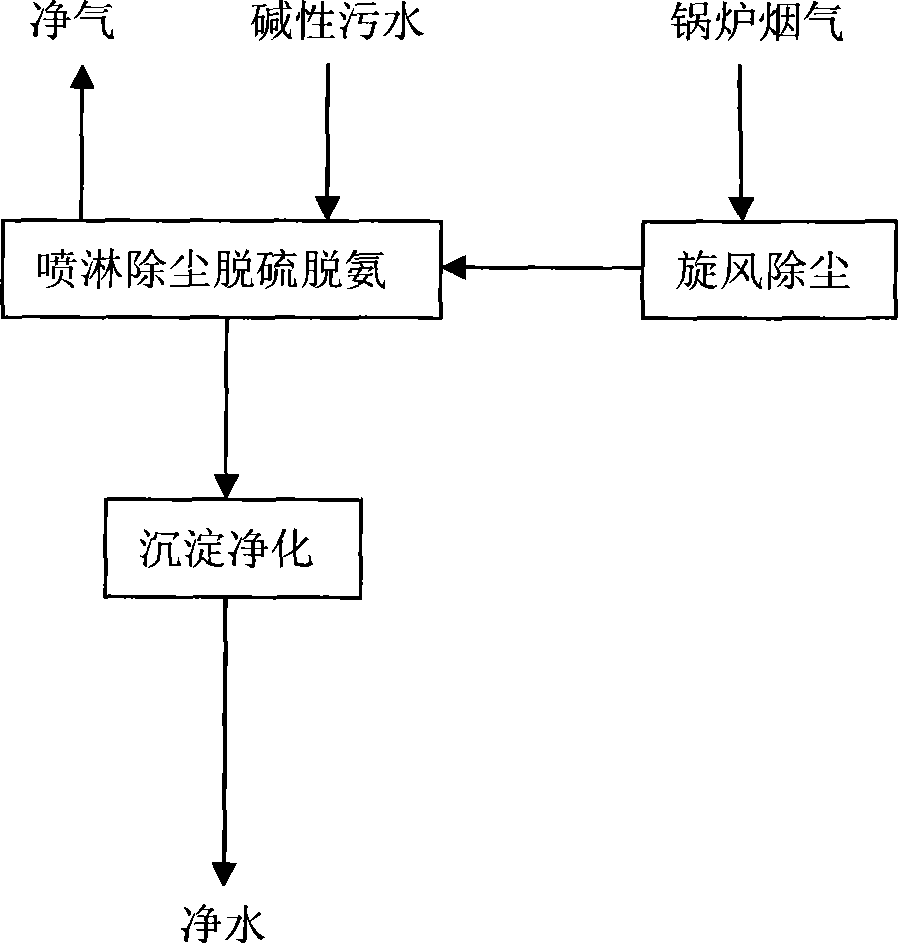

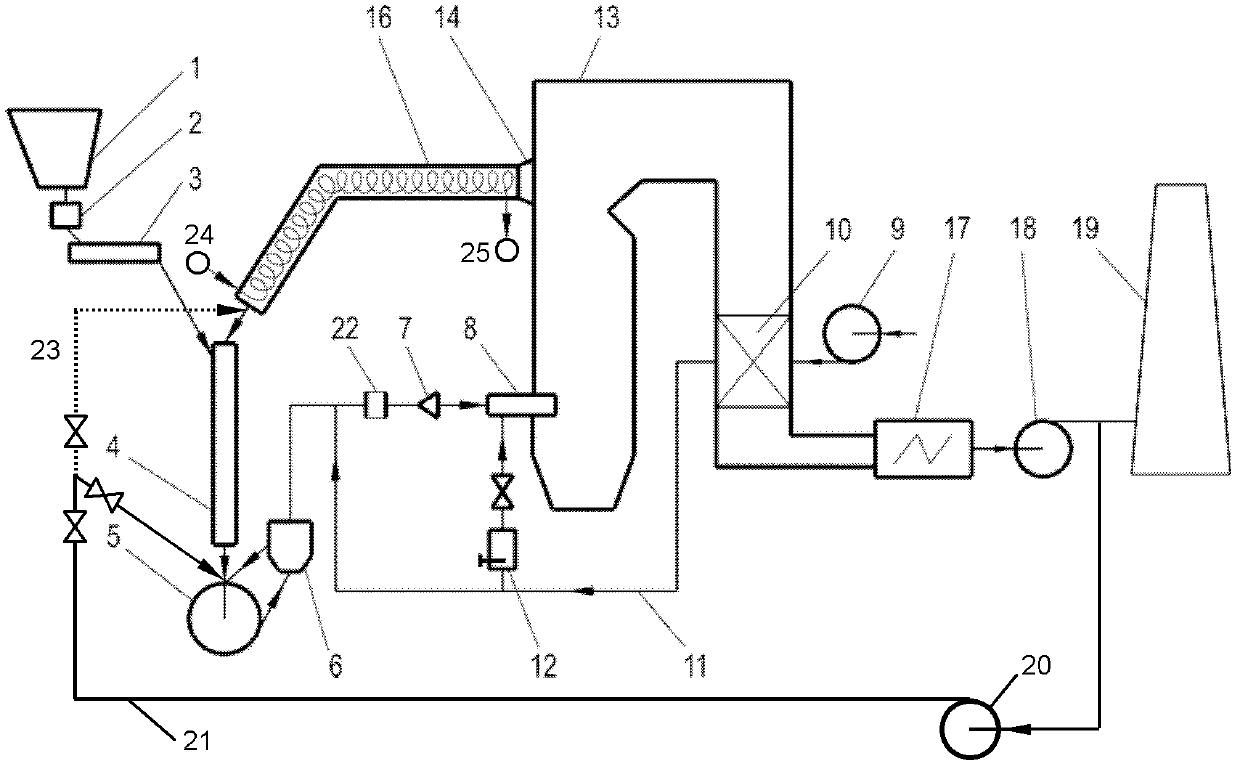

Method for processing waste water/gas from tungsten smelting and a device thereof

InactiveCN101530737AReduce consumptionSave waterDispersed particle separationWater/sewage treatment by neutralisationCycloneAir volume

The invention relates to a method for processing waste water / gas from tungsten smelting and a device thereof. The method is to directly implement the processing of the waste water / gas by utilizing alkali waste water, which is generated by extracting ammonium tungstate from tungsten ores by an ion exchange method, and by utilizing smoke gas generated by a boiler furnace, and the method comprises the following steps of: cyclone dust removal, spray dust removal, desulfurization, deamination, controlling the temperature of the primarily dust-removed smoke gas of the boiler furnace in a range from 140-200 DEG C, diffusing from bottom to top the air quantity of 13000-18000 m<3> / H and controlling the flow quantity from top to bottom in a range from 13-15 m<3>H, spraying the alkali waste water for exchange absorption for removing fine particle dusts and SO2 in the smoke gas and free ammonia in the alkali waste water, exhausting net gas after the spraying absorption to the air and discharging purified water after deposition; the device for realizing the method for processing waste water / gas from tungsten smelting comprises; a water pump, a multitubular cyclone dust extractor, a dust-removing desulfurization deamination nitrogen column and a water processing pond. The invention has the advantages of simple technological steps, small investment of the device, easy operation, low processing cost and primary standard exhaust of the waste water / gas.

Owner:FUJIAN JINXIN TUNGSTEN

CCD-based intelligent soot blowing system for formed soot and bonded slag on boiler heating surface

ActiveCN106093062AGet thickness in real timeEliminate environmental problemsLighting and heating apparatusOptically investigating flaws/contaminationImaging processingBoiler furnace

The invention discloses CCD-based intelligent soot blowing system for formed soot and bonded slag on a boiler heating surface. The system comprises an image acquiring system, an image processing system, a soot blowing controlling system and a soot blowing executing system; the image acquiring system is arranged on a boiler wall and used for acquiring two-dimensional images and transmitting and storing the images to a computer through a receiving and storing device; the image processing system is used for conducting three-dimensional reconstruction and colorimetric temperature measurement on the two-dimensional images to obtain the thickness of a soot slag layer and the relative temperature of the heating surface; the soot blowing controlling system is used for conducting fuzzy processing on the thickness of the soot slag layer and the relative temperature of the heating surface and sending out an instruction; the soot blowing executing system conducts targeted intelligent soot blowing according to the instruction. According to the system, the heating surface is partitioned according to a soot blower, the thickness of the soot slag layer and the relative temperature of the heating surface are taken as input variables of fuzzy control, and therefore the whole boiler heating surface is accurately monitored; soot blowing is conducted on the local heating surface as needed, therefore, soot blowing loss is reduced, and the overall heat efficiency of a boiler is improved.

Owner:SOUTH CHINA UNIV OF TECH

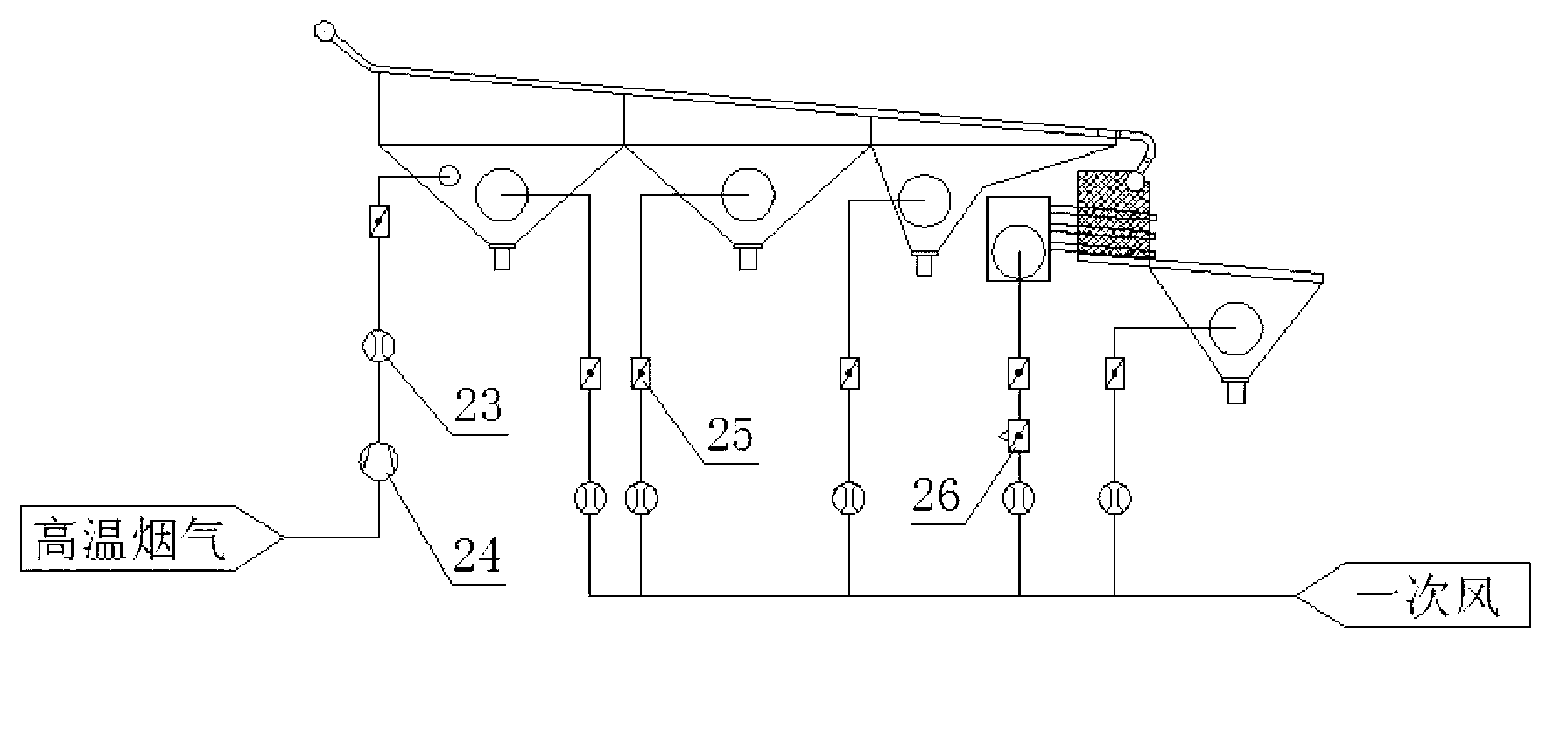

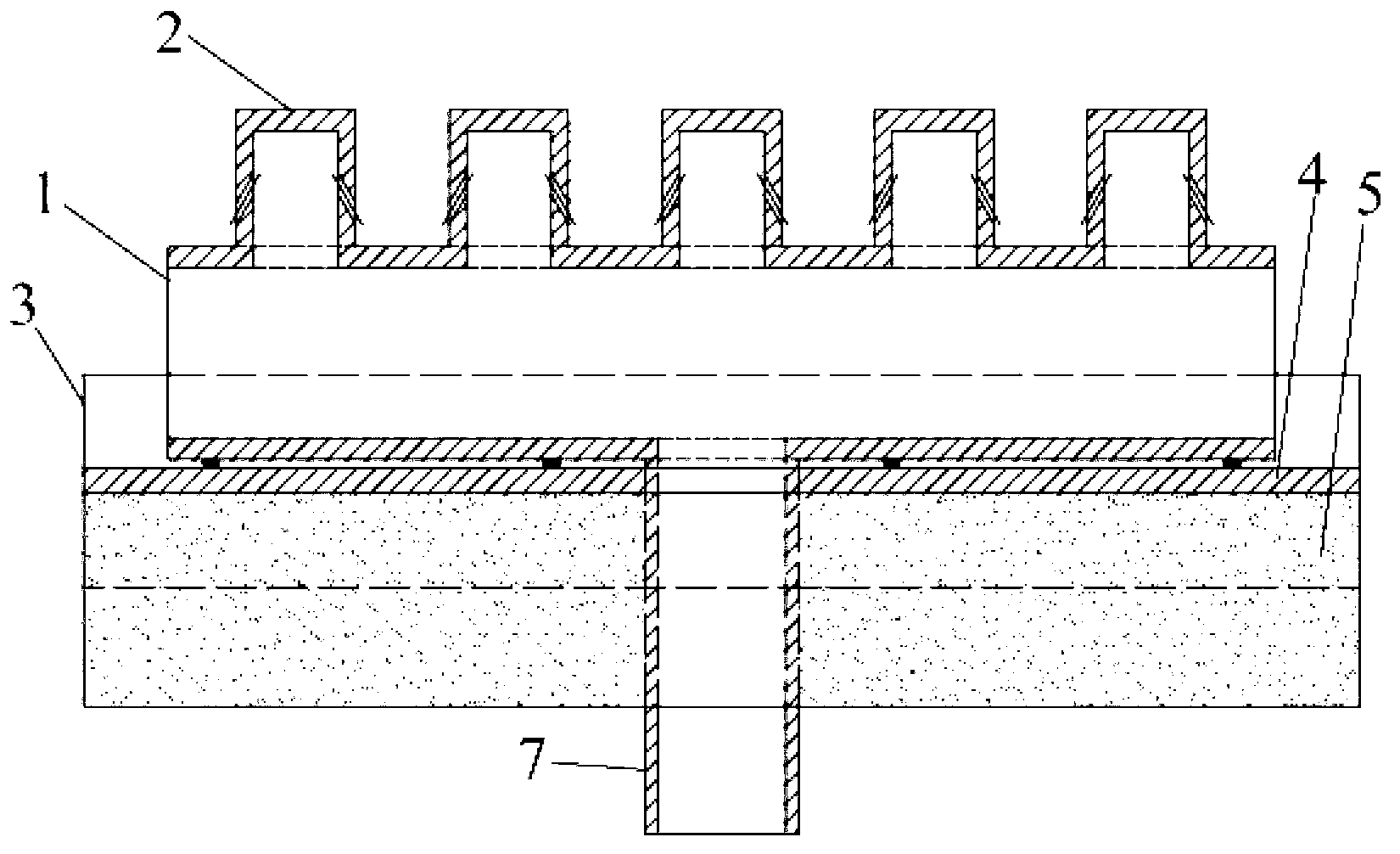

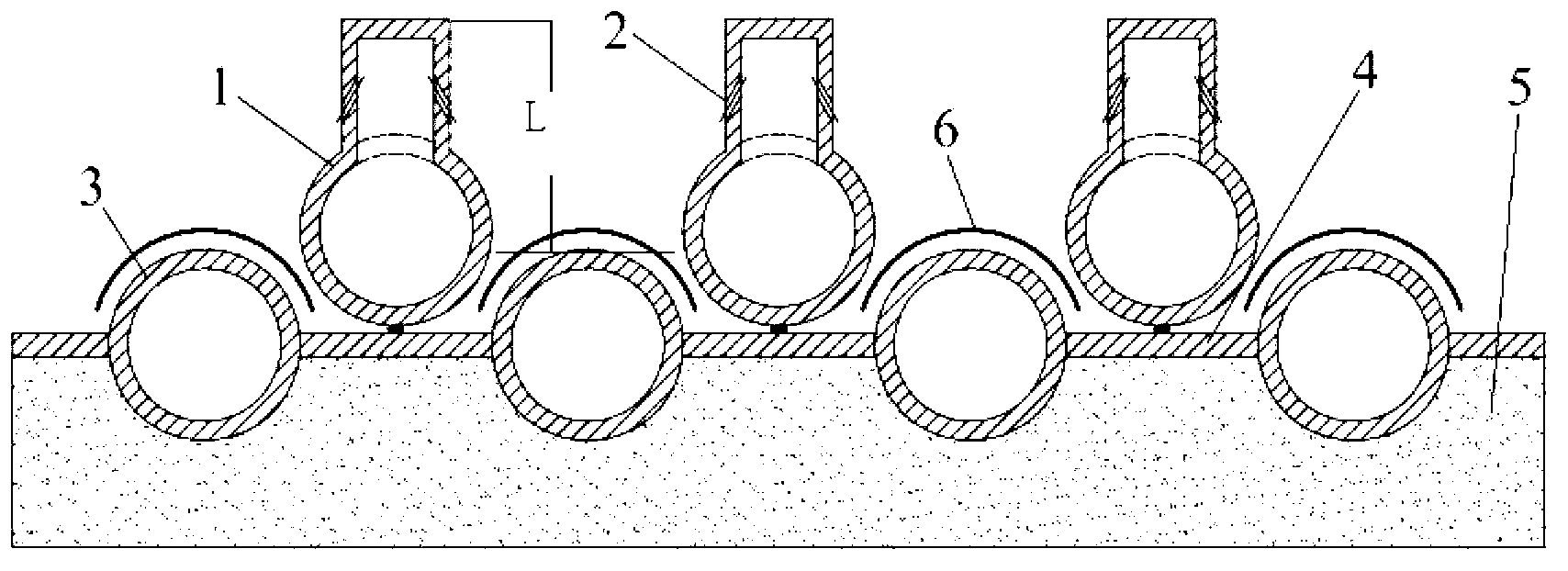

Direct fired pulverizing system of smoke drying lignite coal fan mill

ActiveCN102889607AGuaranteed temperatureReduce ventilationDrying gas arrangementsLump/pulverulent fuel preparationBoiler furnaceProcess engineering

The invention discloses a direct fired pulverizing system of a smoke drying lignite coal fan mill, which comprises a high temperature furnace smoke pipe and a hot wind mixer, wherein the high temperature furnace smoke pipe is formed by arranging a cluster of circular pipes in parallel to form a flue; the circular pipes are located in a vapor-water circulating system of a power plant; an outlet of the high temperature furnace smoke pipe is communicated with a down drying tube; an inlet is communicated with a hot smoke pumping port of a boiler furnace; the hot wind mixer is connected between a classifier and a pulverized coal distributer; the other route of the hot wind device is connected to the hot wind mixer; and a coal inlet of the fan coal mill is further connected with a cool smoke pumping port of the boiler flue. The direct fired pulverizing system of the smoke drying lignite coal fan mill has the advantages of safety in operation, simple structure, low investment and being capable of effectively utilizing heat energy of high-quality smoke.

Owner:SHANGHAI YUANMENG ELECTRIC POWER ENERGY TECH CONSULTING CENT

Efficient segmentation control combustion method and system for biomass boiler with charcoal combustion cell

InactiveCN103017145AEasy to removeIncrease the drying medium temperatureSolid fuel combustionCombustion apparatusSlagHearth

The invention discloses an efficient segmentation control combustion method and system for a biomass boiler with a charcoal combustion cell, and belongs to the technical field of the fire grate combustion of a biomass direct-combustion power generation boiler. A water cooling vibration fire grate is arranged on the bottom of a hearth; a smoke and air mixing box and a plurality of primary air bellows are arranged below the water cooling vibration fire grate; the charcoal combustion cell is arranged below the front end of the water cooling vibration fire grate; the bottom of the charcoal combustion cell is provided with a fixed fire grate; and the front end of the charcoal combustion cell is provided with a slag well. The external moisture of biomass fuel is removed in the drying area of the water cooling vibration fire grate; then, the biomass fuel is moved to the pyrolysis combustion area of the fire grate to generate a great quantity of volatile component to enter the hearth; when the volatile component of the biomass fuel is almost burnt, residual fixed carbon covered by ash is vibrated into the charcoal combustion cell; in the falling process, the residual fixed carbon covered by ash is overturned and collided to remove surface ash; oxygen is directly diffused to the surface of the charcoal to react with the charcoal; and the ash slag is blown into the slag well. According to the invention, the biomass fuels of different types and moistures can be subjected to efficient segmentation control combustion on the fire grate of the boiler.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method of managing the cleaning of heat transfer elements of a boiler within a furnace

A method of cleaning a heat transfer element within a boiler furnace is provided. The method includes the steps of allowing a furnace to operate and deposit ash on a heat transfer element, determining an efficiency rate for at least one cleaning element, and managing the cleaning element based on the efficiency rate.

Owner:INT PAPER CO

Low-nitric-oxide direct-current pulverized coal combustor adaptive to meager coal boiler

ActiveCN103267279AReduce generationReduce carbon contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorJet flow

The invention relates to a low-nitric-oxide direct-current pulverized coal combustor adaptive to a meager coal boiler, which can achieve stable and economical combustion, and also reduces nitric oxide emission to the lowest level, so that the low-nitrogen combustion modifying technique of the meager coal boiler is improved. The low-nitric-oxide direct-current pulverized coal combustor adaptive to the meager coal boiler comprises main combustor groups which are arranged on four corners of a hearth of the meager coal boiler in a four-angle tangential circle combustion mode, are matched with a water-cooling wall high-temperature-prevention corrosion system of the hearth, and are identical in structure; each main combustor group comprises pulverized coal combustors arranged at intervals and secondary air spray ports; the upper parts of the main combustor groups are provided with corresponding separation burnout air groups; a layer of precombustion chamber back flow combustor is arranged in each n-layer of pulverized coal combustors; the jet flow rotation direction of the main combustor groups is the anticlockwise direction; the rotation direction of secondary air ports close to the upper parts of the precombustion chamber back flow combustors is the clockwise direction, and the imaginary tangential circle diameter is greater than the imaginary tangential circle diameter of the main combustors; separation burnout air groups include upper groups and lower groups; and the jet flow of the lower groups is in an imaginary tangential circle mode, and the jet flow of the upper groups is in an opposed combustion mode.

Owner:STATE GRID CORP OF CHINA +1

Carbon-free low-nox liquid fuel oxygen transport rector for industrial water tube boilers

ActiveUS20150176487A1Combustion using gaseous and pulverulent fuelSemi-permeable membranesSmall dropletLiquid fuel

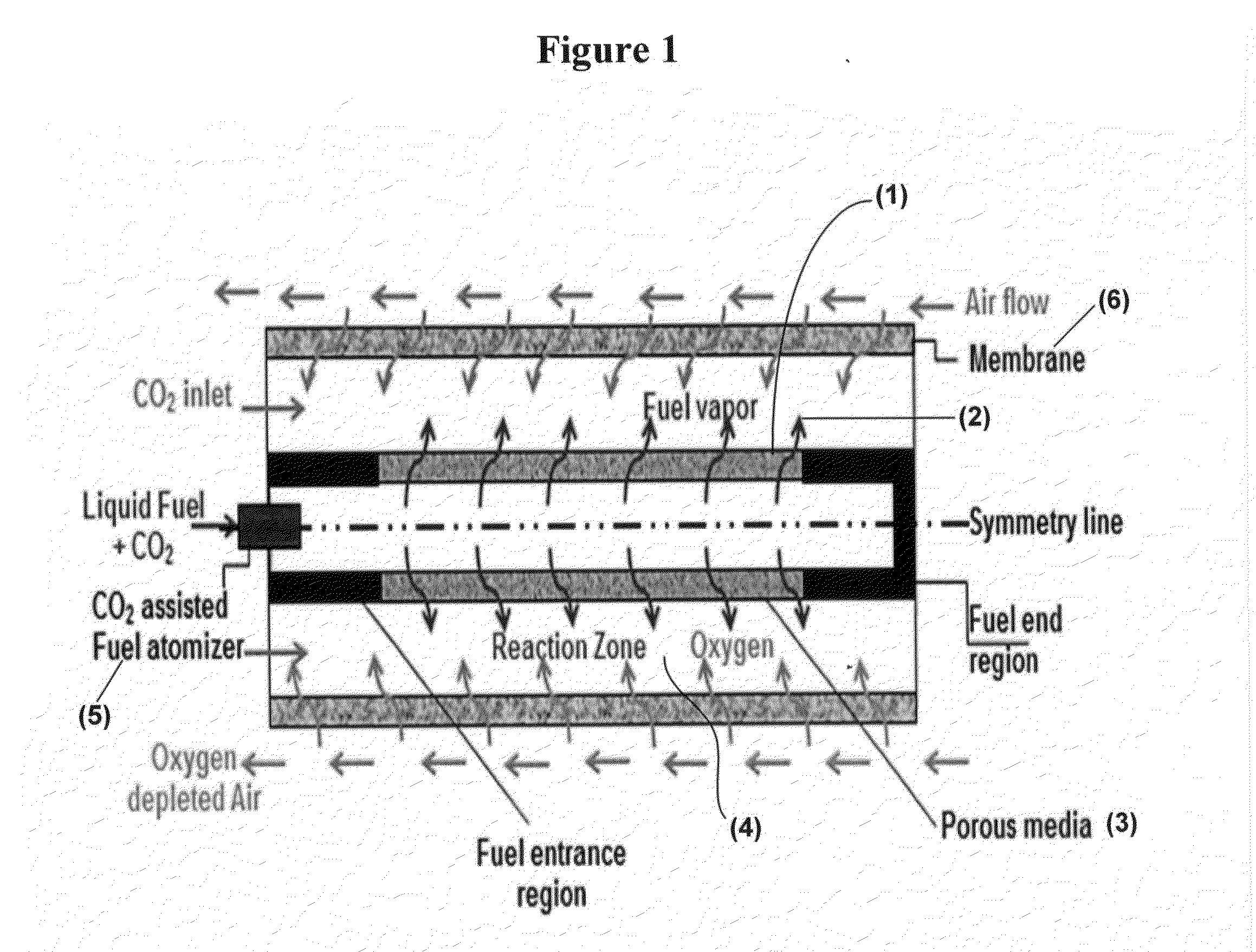

An oxygen transport reactor for boiler furnaces and gas turbine combustors that utilizes a liquid fuel that is oxidized as a gaseous fuel in a membrane reactor. A liquid fuel is introduced by vaporizing the fuel inside a porous pipe surrounded by an annulus reaction zone which is surrounded by an annulus air zone. An oxygen transport membrane separates the annulus reaction zone containing the porous vaporized fuel and sweeping CO2 from the air feed side zone. Oxygen is transported from the outer annulus through the membrane to the annulus reaction zone containing the vaporized fuel and sweeping CO2. Fuel is first cracked to very small droplets in the intake fuel atomizer utilizing part of the intake CO2 then completely vaporized inside the porous pipe utilizing the heat coming from the surrounding reaction zone. The oxygen transport reactor is applicable for carbon free boiler furnaces and gas turbine combustors which utilize oxygen transport reactors for combined oxygen separation and combustion.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Soot-blowing control device and method for boiler furnace based on heat flow online measurement

InactiveCN101975400AImprove accuracyImprove real-time performanceBoiler controlData acquisitionEngineering

Owner:SOUTHEAST UNIV

Supercritical carbon dioxide brayton cycle system

InactiveCN106870037ASimple structurePromote absorptionCombustion processIndirect carbon-dioxide mitigationAir preheaterGas compressor

The invention discloses a supercritical carbon dioxide brayton cycle system belonging to the field of power station energy conservation. The supercritical carbon dioxide brayton cycle system mainly comprises a boiler furnace heating face, a boiler tail heating face, an air preheater, a boiler tail flue, a cycle working medium bypass pipeline, a high temperature regenerator, a medium temperature regenerator, a low temperature regenerator, a working medium turbine, a high-temperature gas compressor, an intercooling gas compressor and a cooler. The boiler furnace heating face is rearranged, a high-temperature regenerator bypass is arranged, thus the requirement of newly designed supercritical carbon dioxide cycle heat exchange is matched, cycle efficiency is improved, the utilization performance of low temperature smoke is improved, and heat absorption capacity distribution of the air preheater is improved and is optimized to be the same as the designed heat exchange capacity, corresponding to the air preheater, in coal steam cycle basically. Intercooling compression technology is adopted, cycle efficiency is improved, and the heat exchange interval of the cooler is optimized, thereby being matched with a water cooling system. In addition, the supercritical carbon dioxide brayton cycle system is simple in structure and high in operating efficiency and has good application prospects in engineering.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

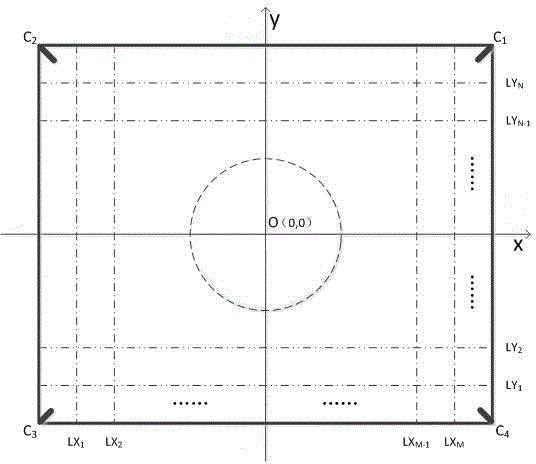

Balance control method for temperature field of utility boiler furnace

InactiveCN103557535AEvenly filledImprove combustion efficiencyCombustion regulationFurnace temperatureProportion integration differentiation

The invention discloses a balance control method for the temperature field of a utility boiler furnace. The balance control method comprises the following steps: (1) building a furnace section reference coordinate system; (2) respectively arranging temperature measurement devices in the cross direction and the longitudinal direction of the furnace section; (3) acquiring the temperature values of all measurement paths; (4) making a fitted curve between the temperature and the coordinates of the furnace section measurement paths; (5) meshing the furnace section; (6) building a two-dimensional temperature field of the furnace section; (7) calculating the center coordinates of the two-dimensional temperature field of the furnace section; (8) adopting a PID (Proportion Integration Differentiation) controller to achieve control correction calculation of the furnace temperature field; (9) calculating the control corrections of the opening degrees of four corner jet fuel air doors of the boiler; (10) implementing the temperature field balance control method in a DCS (Decentralized Control System). The balance control method has the advantages that pulverized coal is sufficiently burnt out during boiler combustion, the flame center is in the center of the furnace, the temperature field of the furnace is uniformly distributed and the combustion efficiency and stability of the furnace are improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Pneumatic dust cleaning device of boiler

The invention relates to a pneumatic dust cleaning device for cleaning accumulated dust in a coal-fired boiler furnace arch and a horizontal flue. The accumulated dust piling friction is overcome and a dust accumulation layer is in the fluidization state by utilizing pneumatic (steam-driving), moving beds and fluidization theory, and ultimately the accumulated dust flows back to a hearth or is raised by the fume to be discharged through a cold dust funnel and a tail part flue, thereby achieving the dust cleaning effect. The dust cleaning device consists of components of dust blowing tubes, dust blowing nozzles (hoods), a wearing plate, dust blowing medium conveying pipelines, adjusting valves, a temperature measuring device, a control system and the like, wherein the dust blowing tubes are clung to a wall-surrounding tube film and arranged regionally, then flexible control in dust blowing in different areas is realized; and the distances and the relative angles of the dust blowing nozzles and wall-surrounding tubes can be selected according to demands. By utilizing the pneumatic dust cleaning device, the accumulated dust in the coal-fired boiler furnace arch and the horizontal flue can be effectively eliminated, a heated surface is kept clean, the efficiency of the boiler is improved, and the safety in operation of the boiler is ensured.

Owner:XIAN THERMAL POWER RES INST CO LTD

Micro oxygen rich combustion W flame boiler and CO2 emission reduction system

ActiveCN103104910AReduce energy consumptionReduce investmentDirect carbon-dioxide mitigationIndirect carbon-dioxide mitigationBoiler furnaceUnit mass

The invention discloses a micro oxygen rich combustion W flame boiler and a CO2 emission reduction system, which is characterized in that anthracite or low-volatile coal is introduced in the W flame boiler furnace for fully combusting, the formed flue gas is divided into two strands through a heat exchange zone and a gas-gas heat exchanger after cooling, one strand is taken as a recycling flue gas; air and oxygen are simultaneously heated in the gas-gas heat exchanger, the heated air is divided into three strands, oxygen is divided into two strands, a first strand of oxygen and a first strand of air are mixed and introduced in a furnace arch primary air pipeline, a second strand of oxygen and a second strand of air are mixed and introduced in a furnace arch secondary air pipeline, and a third air is introduced in a back and forth wall secondary air pipeline. The invention combines the micro oxygen rich combustion technology and the W flame boiler, the desulphurization, denitration and capture with lower cost can be realized, and zero discharge can be realized. The pure oxygen amount required by fuel combustion with unit mass under a micro oxygen rich combustion mode is obviously reduced by comparing with oxygen rich combustion, and energy consumption and cost of air separation oxygen preparation can be greatly reduced.

Owner:SHANGHAI BOILER WORKS

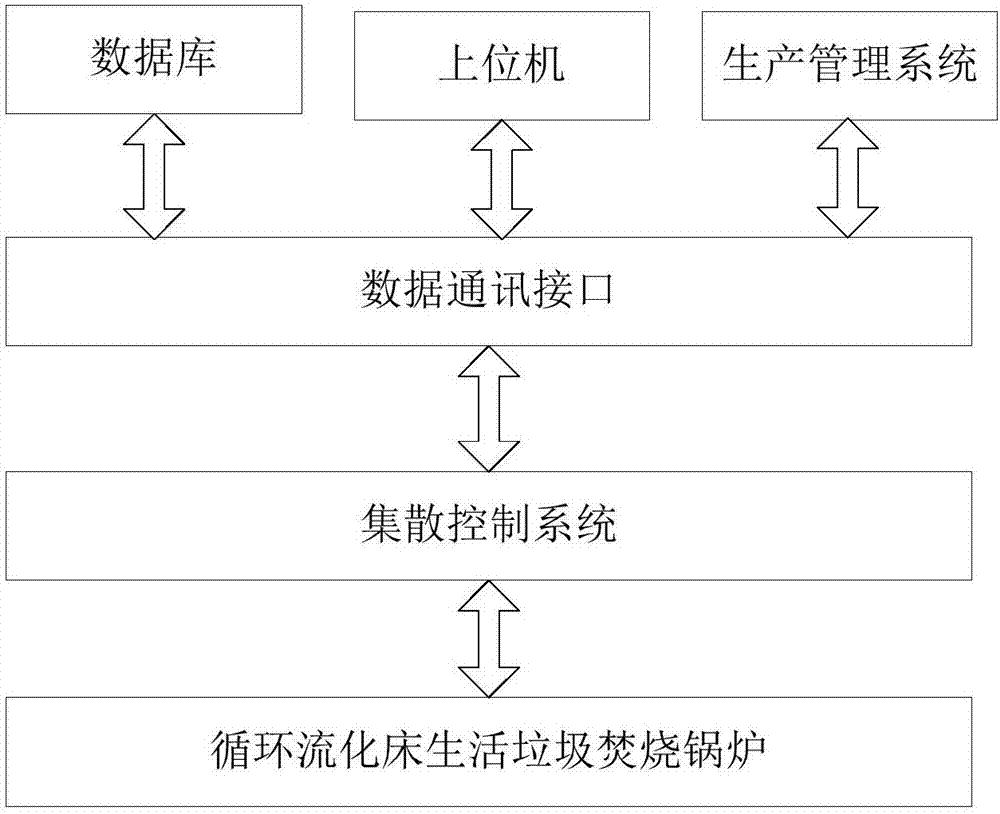

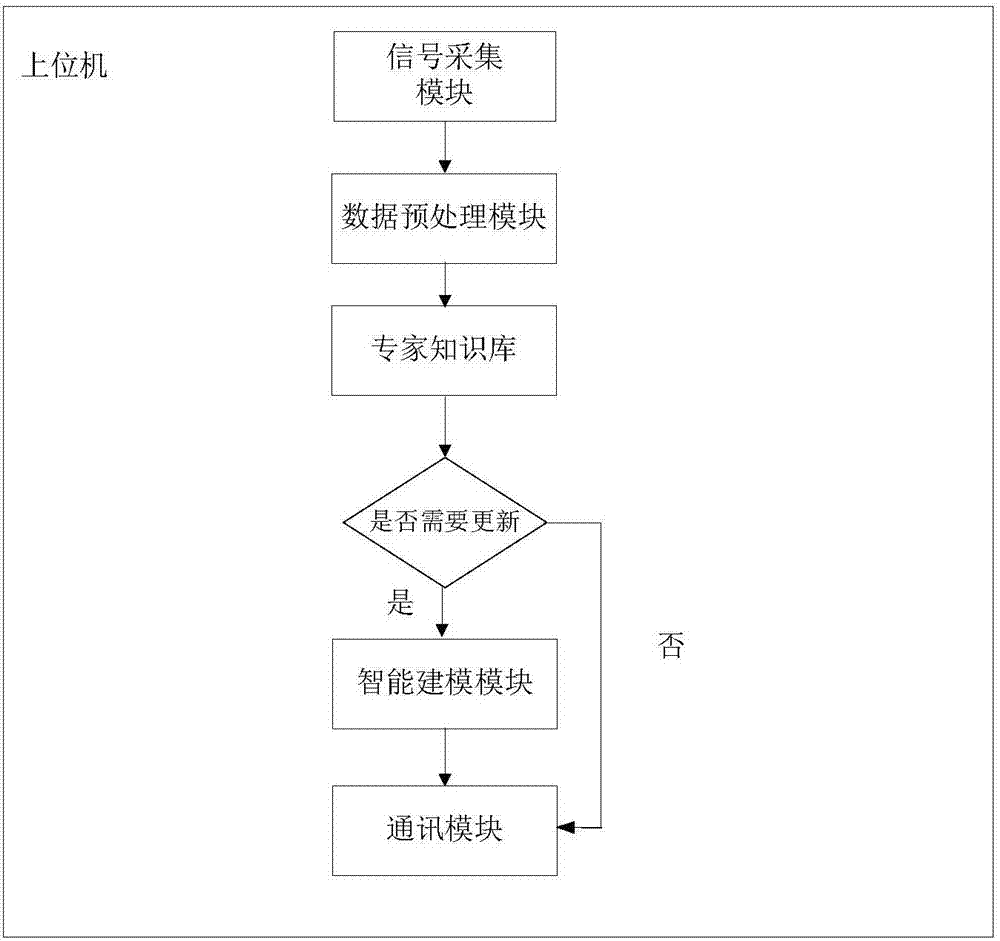

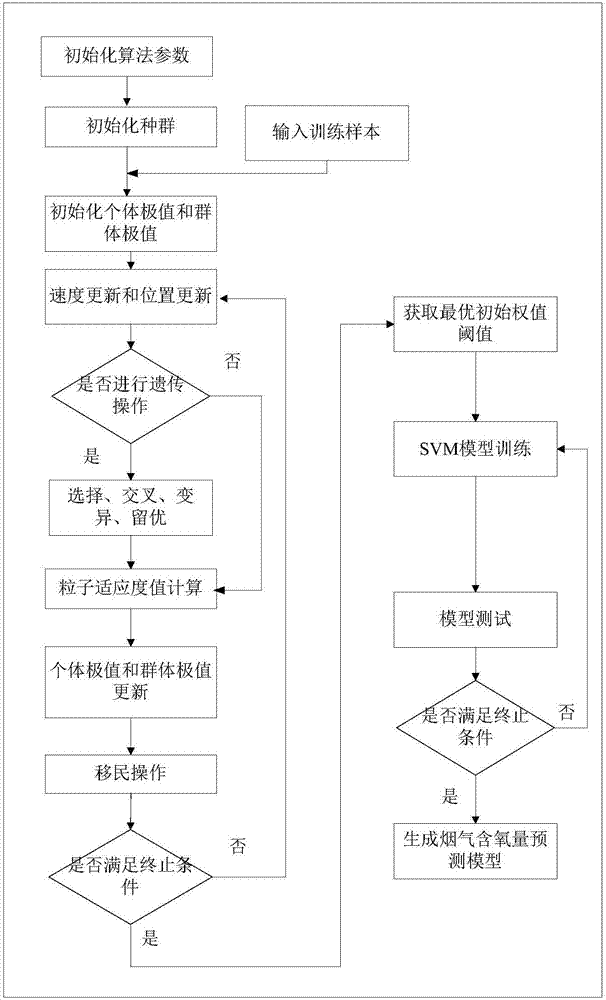

Prediction system of circulating fluidized bed household garbage burning boiler furnace outlet flue gas oxygen content and method thereof

ActiveCN107016455AImprove generalization abilityImprove build efficiencyForecastingCharacter and pattern recognitionEngineeringParticle swarm algorithm

The invention discloses a real-time prediction system of a circulating fluidized bed household garbage burning boiler furnace outlet flue gas oxygen content and a method thereof. An integration modeling method of a support vector machine algorithm and a multi-population genetic particle swarm optimization algorithm is used. A rapid, economic and adaptive updating system and a method are constructed so as to predict a boiler furnace outlet flue gas oxygen content in real time, and tedious and complex mechanism modeling work is avoided. A nonlinear dynamical characteristic of a SVM algorithm, a generalization capability and a real-time prediction capability are used to represent a dynamical change characteristic of a flue gas oxygen content. A particle swarm optimization algorithm is used to optimize a SVM algorithm punishment parameter C and a nuclear parameter g so as to increase a generalization capability of a model. A genetic operator and a multi-population migration mechanism are introduced so as to accelerate a convergence speed of a particle swarm algorithm, increase a diversity of a particle swarm optimization algorithm solution, reduce a possibility for particle swarm algorithm optimization calculation to get into local optimum and increase a global search capability and a local search capability of the algorithm.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com