Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

575 results about "Injection point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Injection Points are designated places where operators can inject chemicals into a process stream to prevent or mitigate corrosion or cracking.

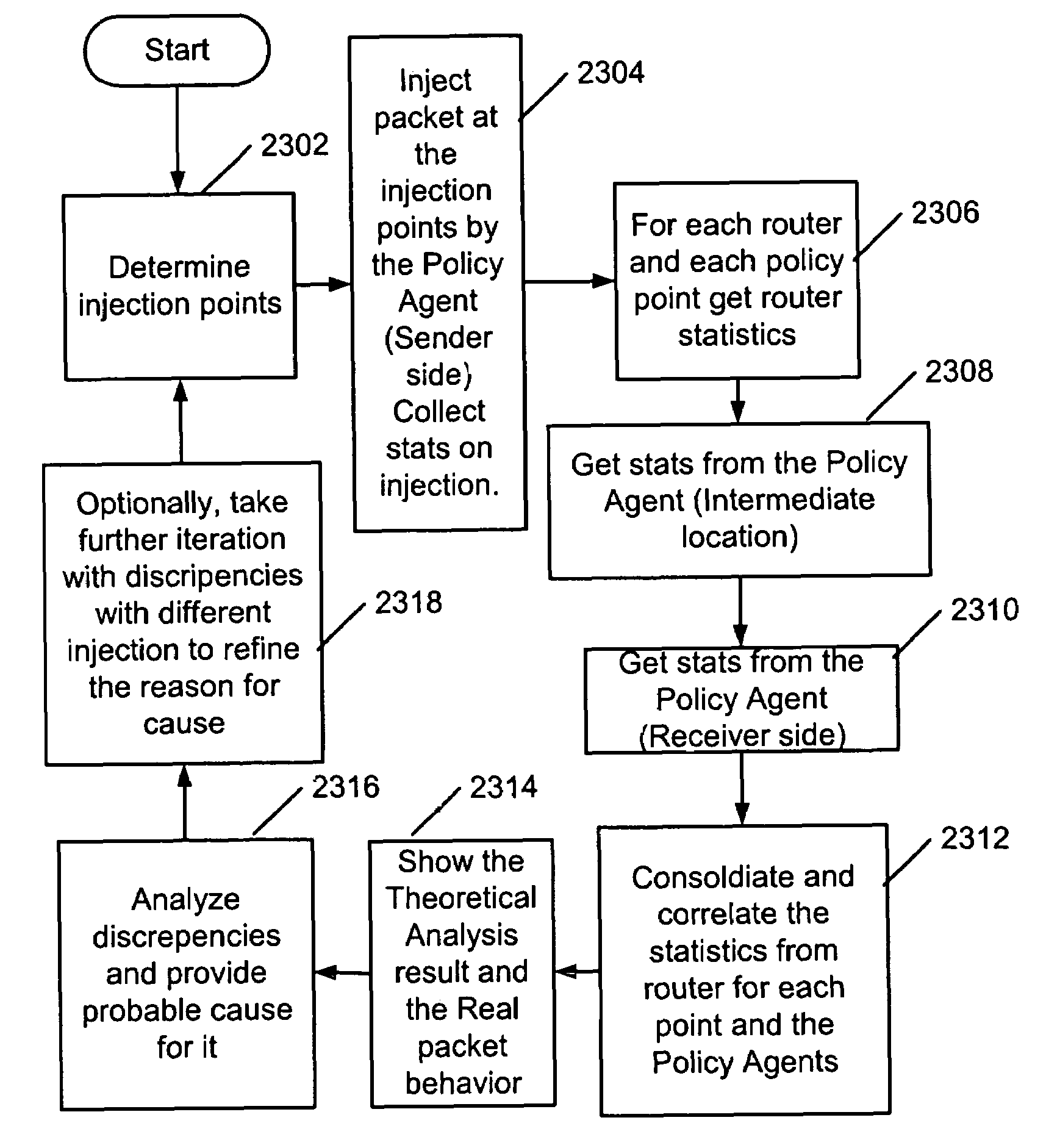

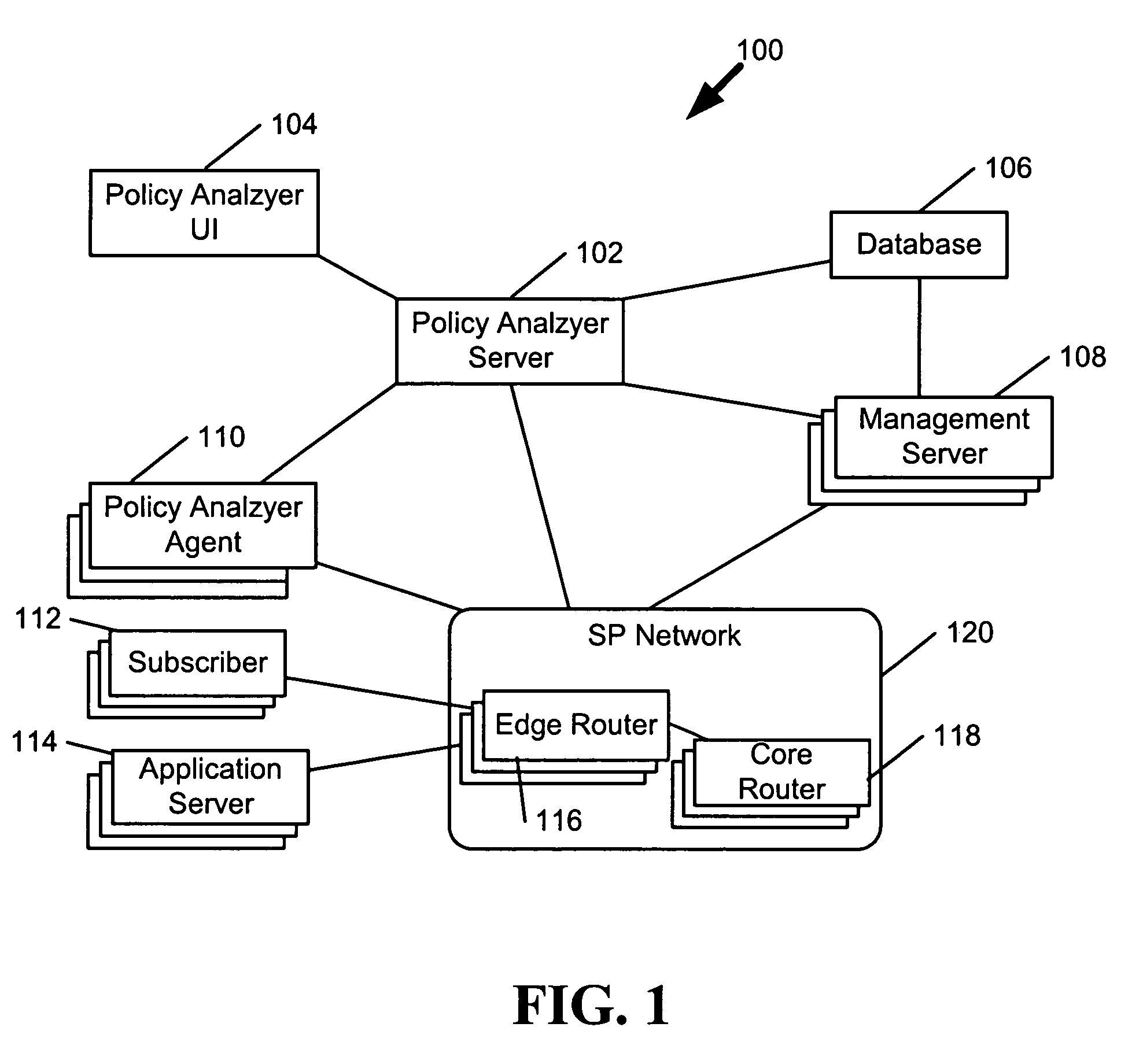

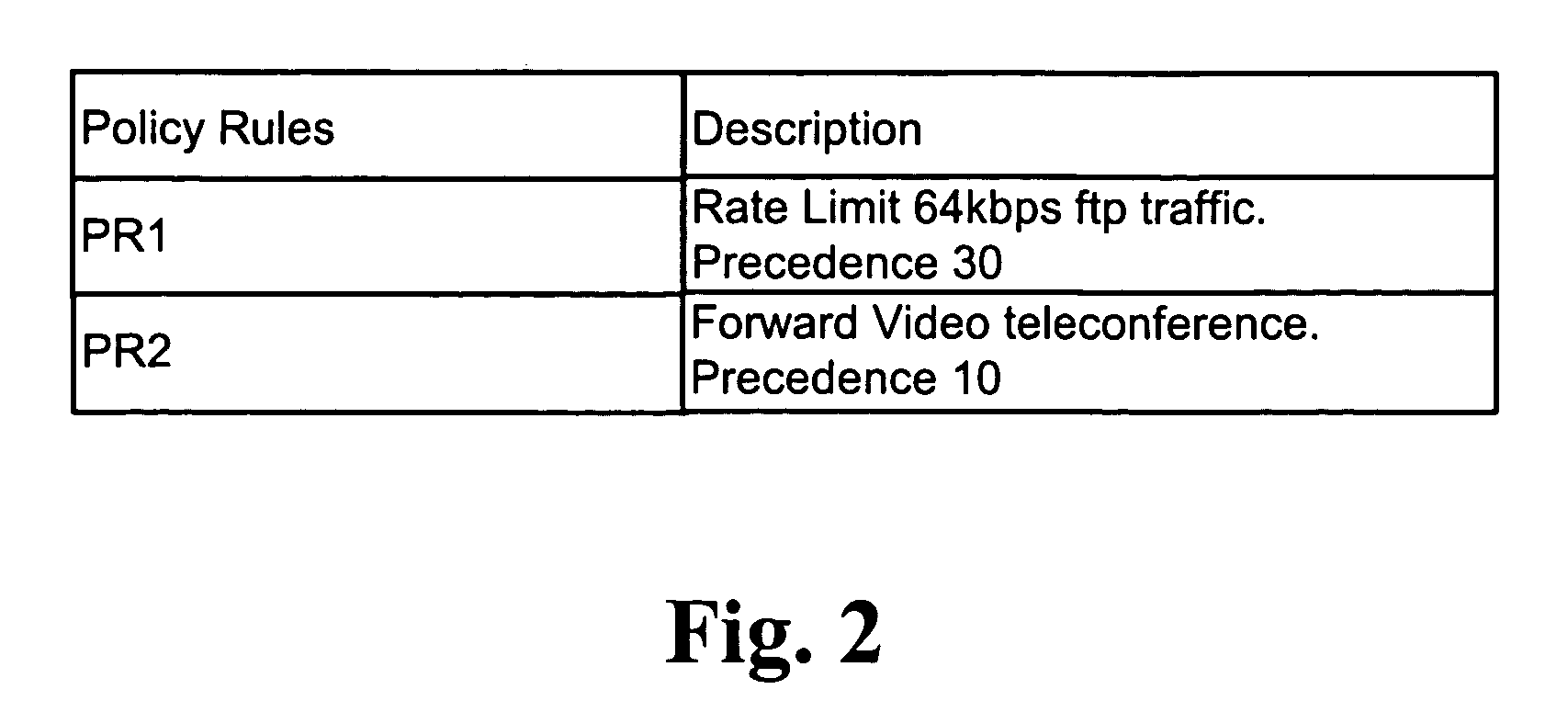

Policy analyzer

Owner:JUMIPER NETWORKS INC

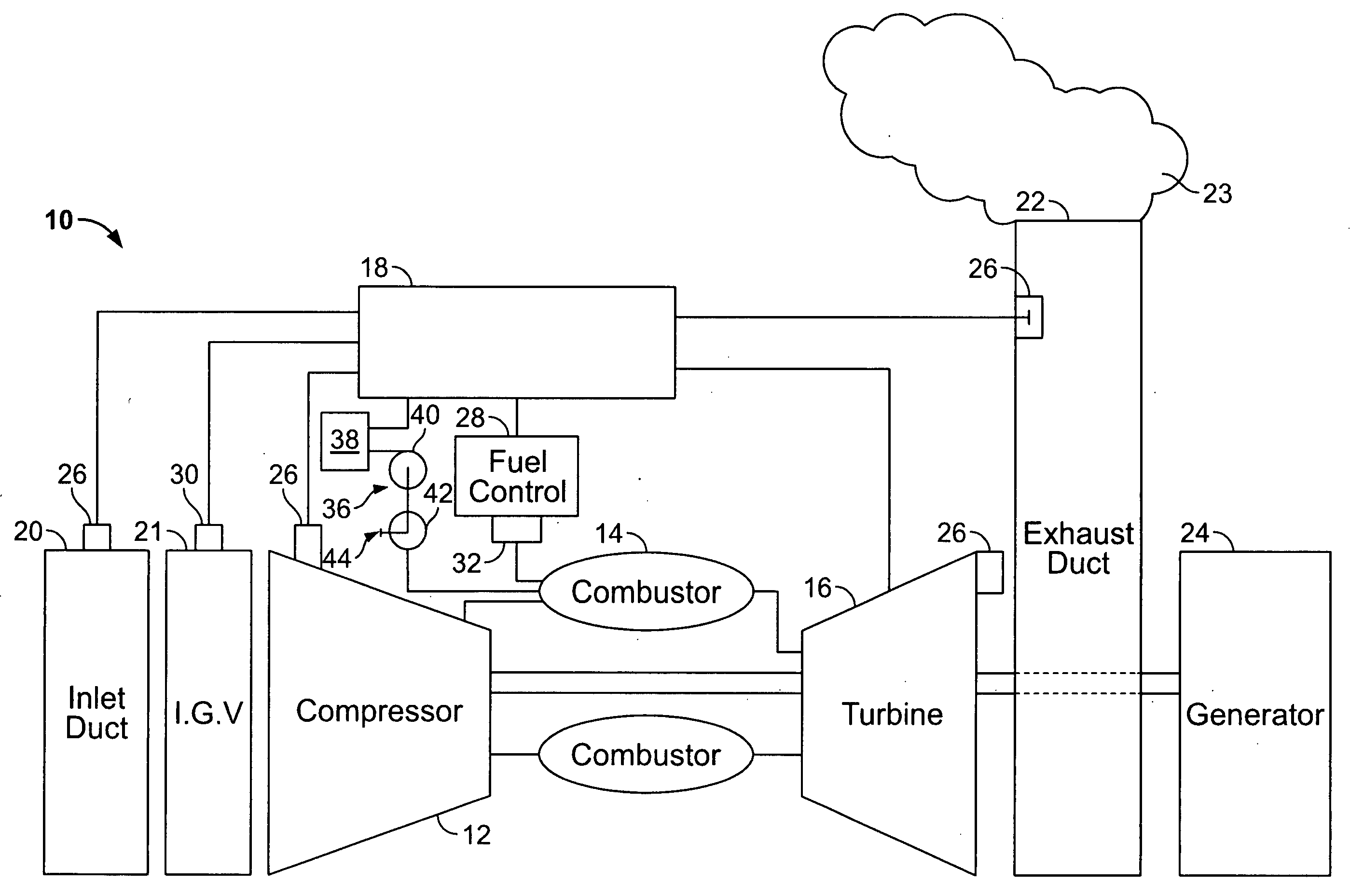

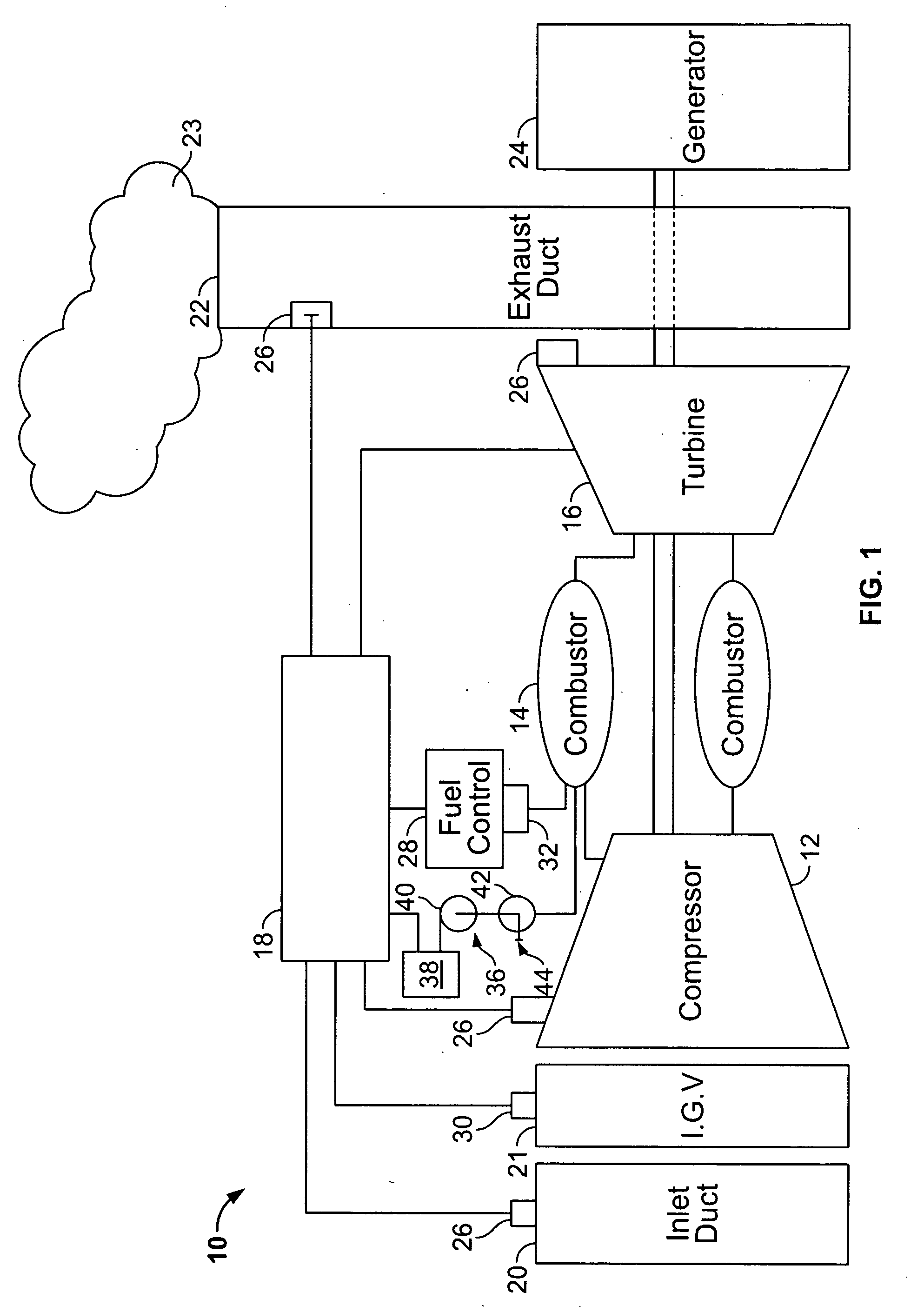

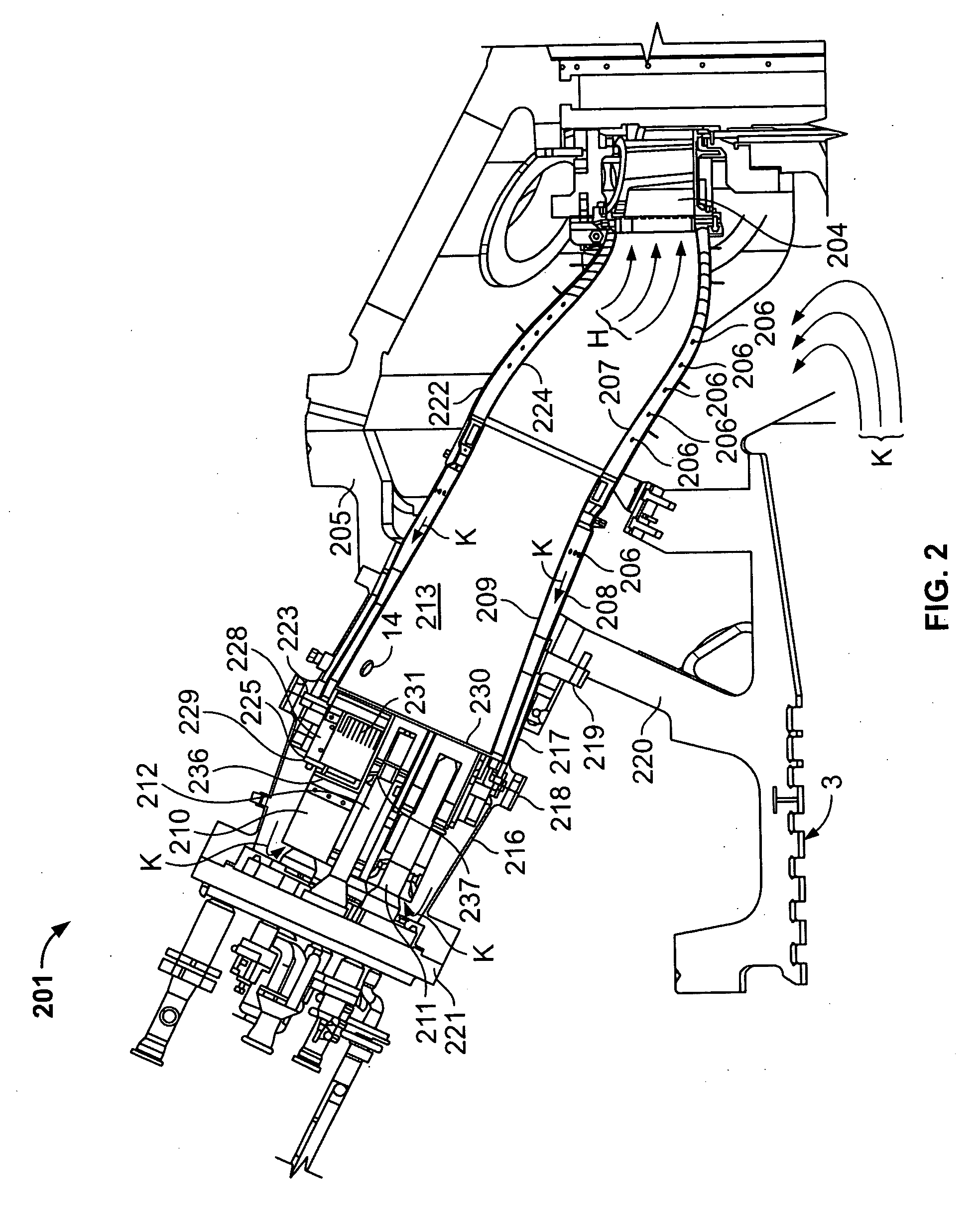

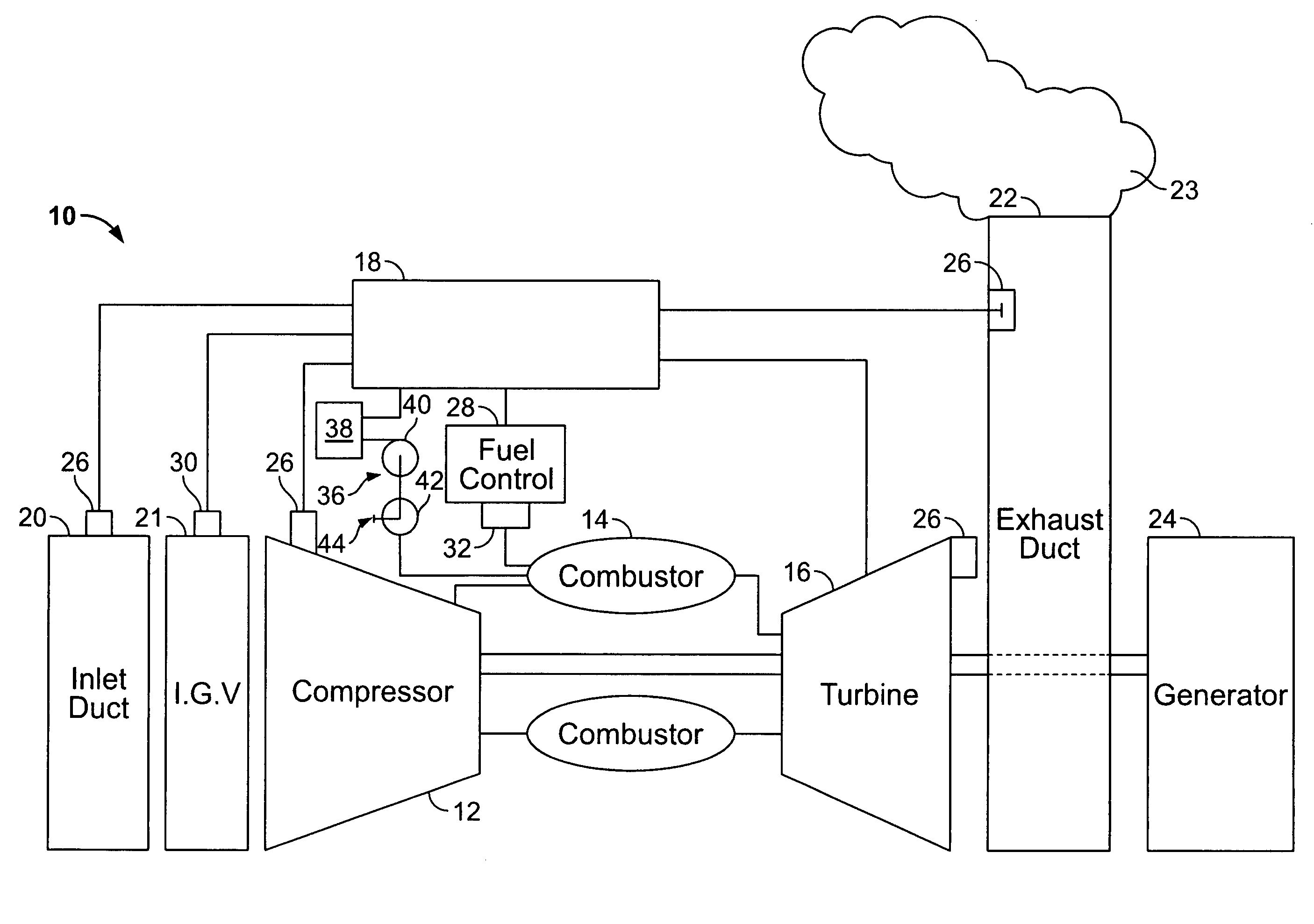

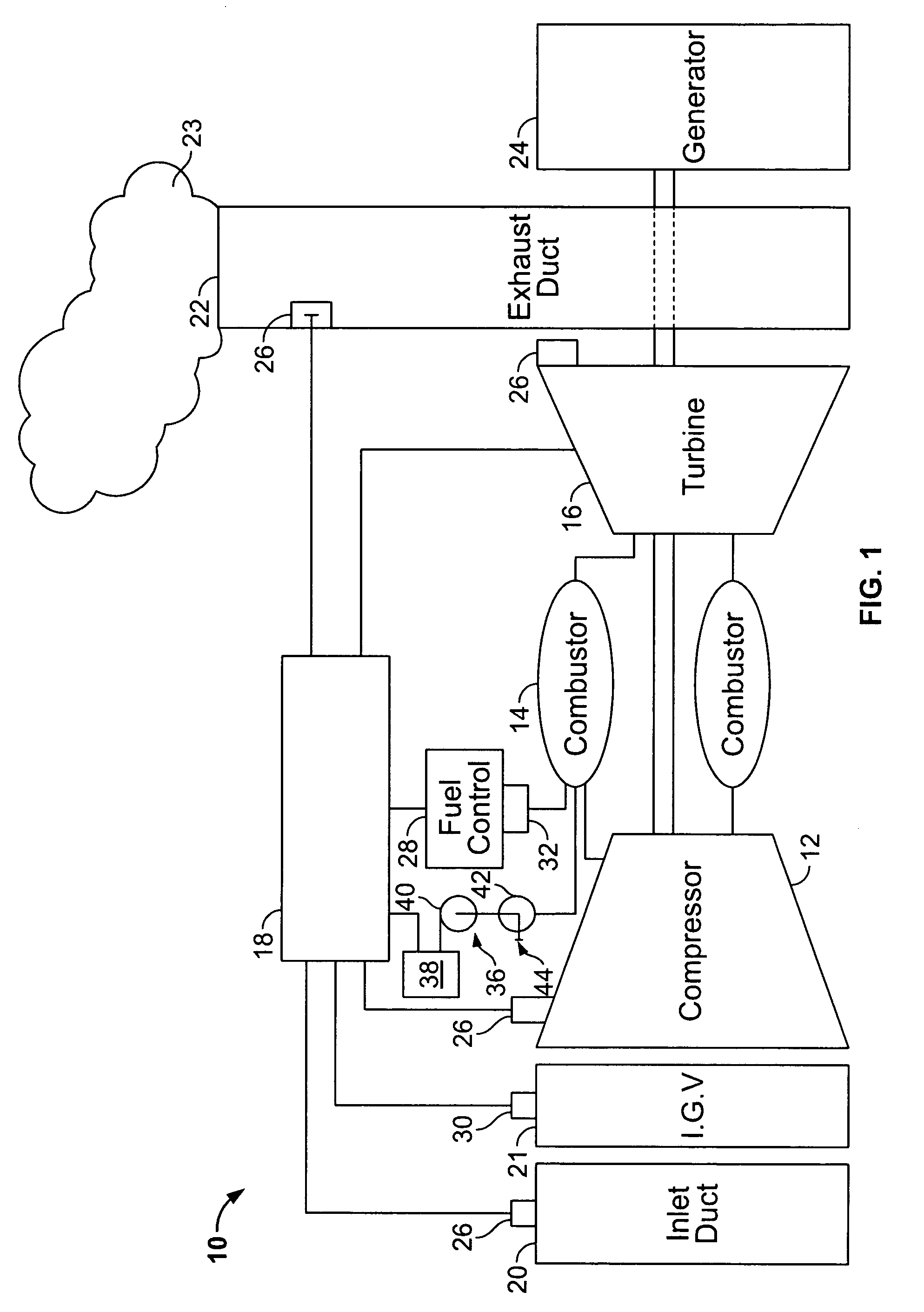

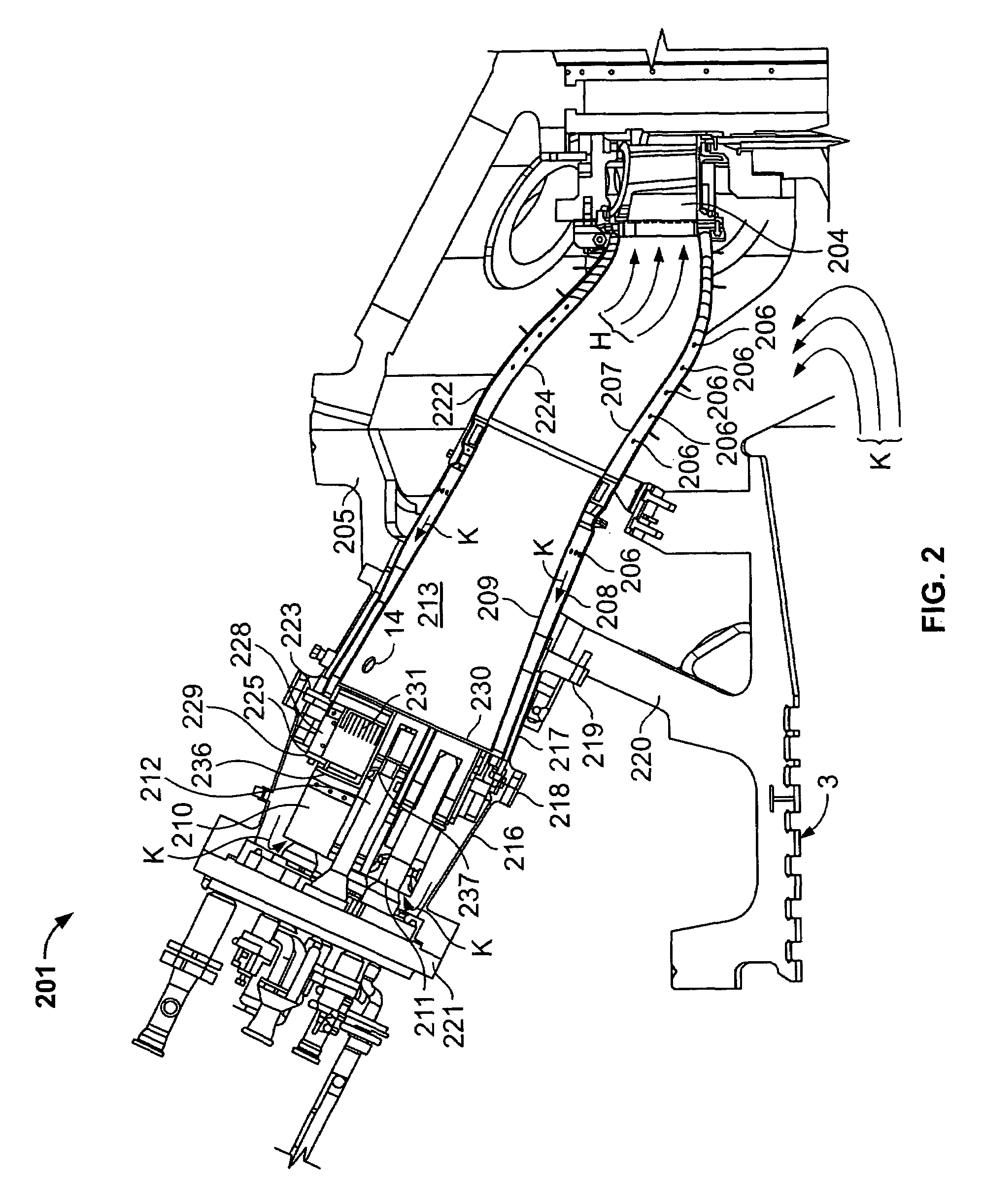

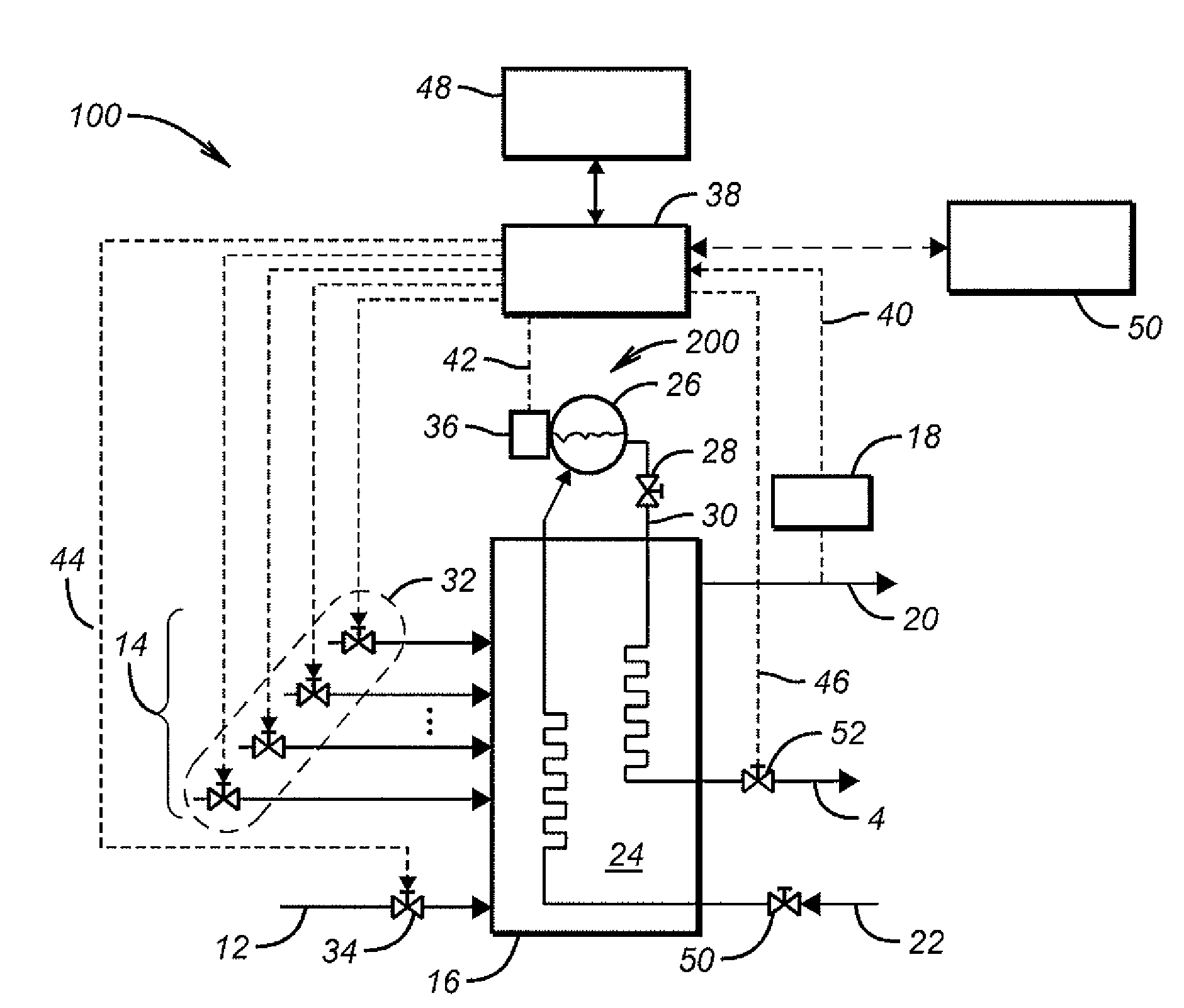

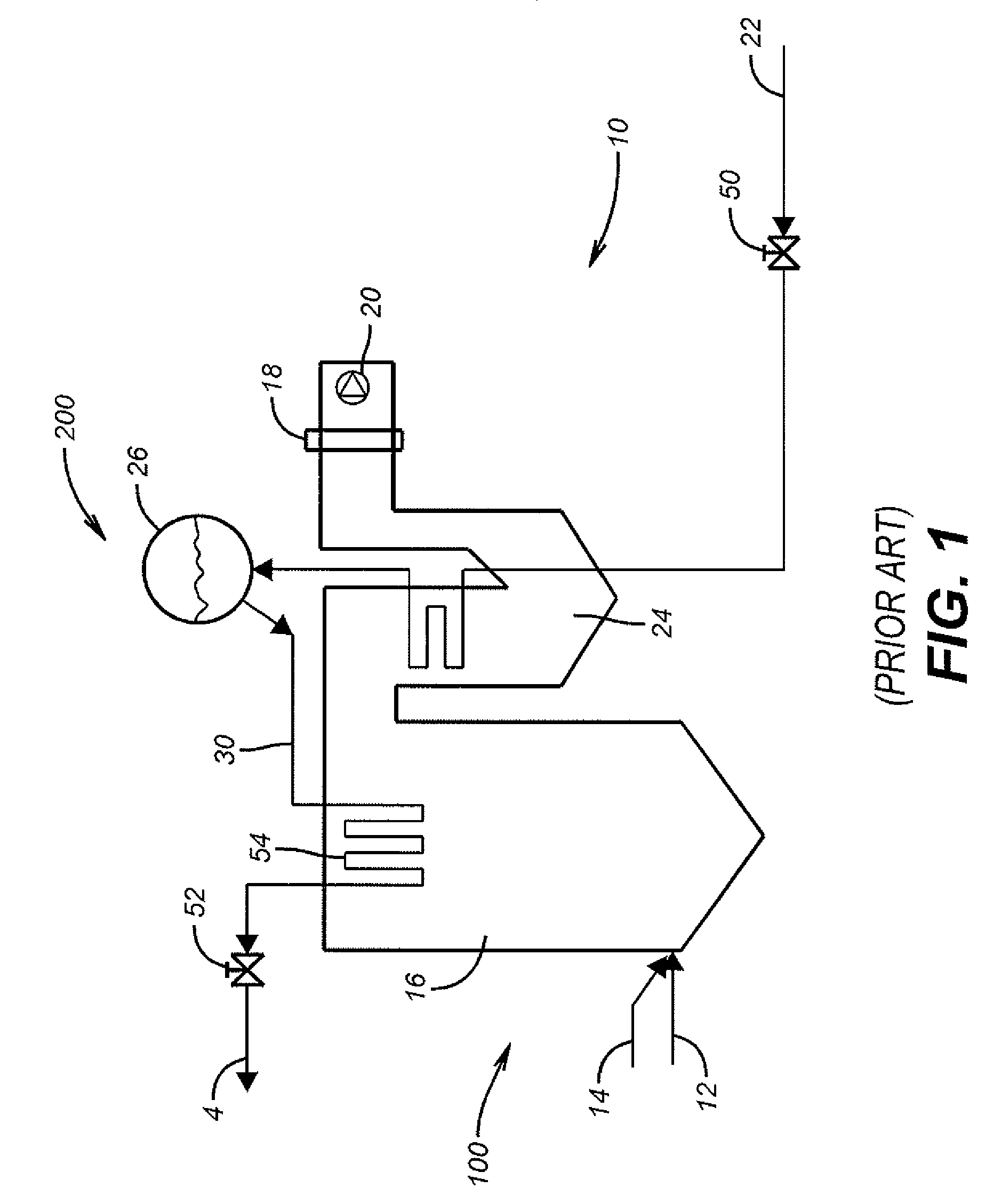

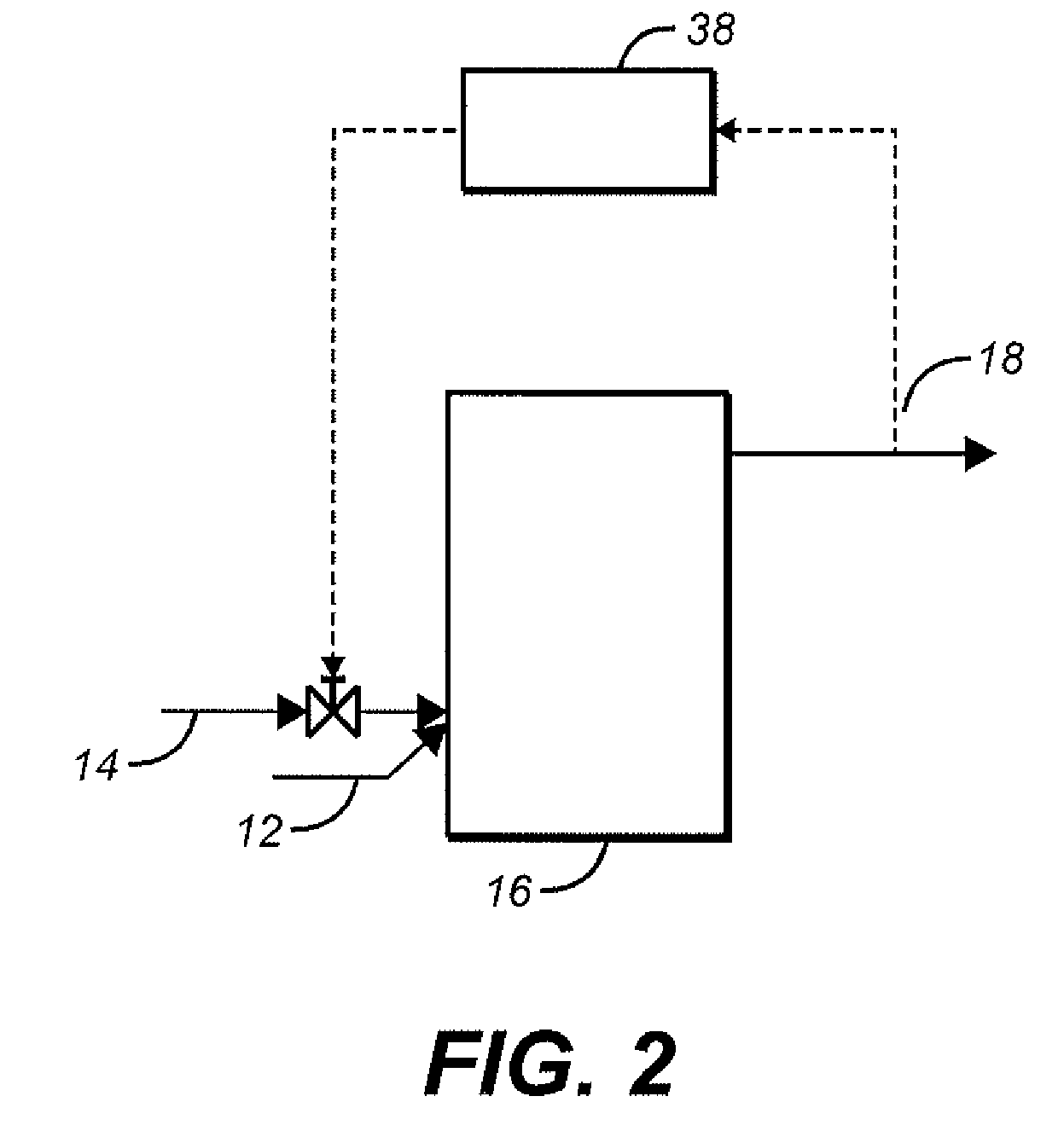

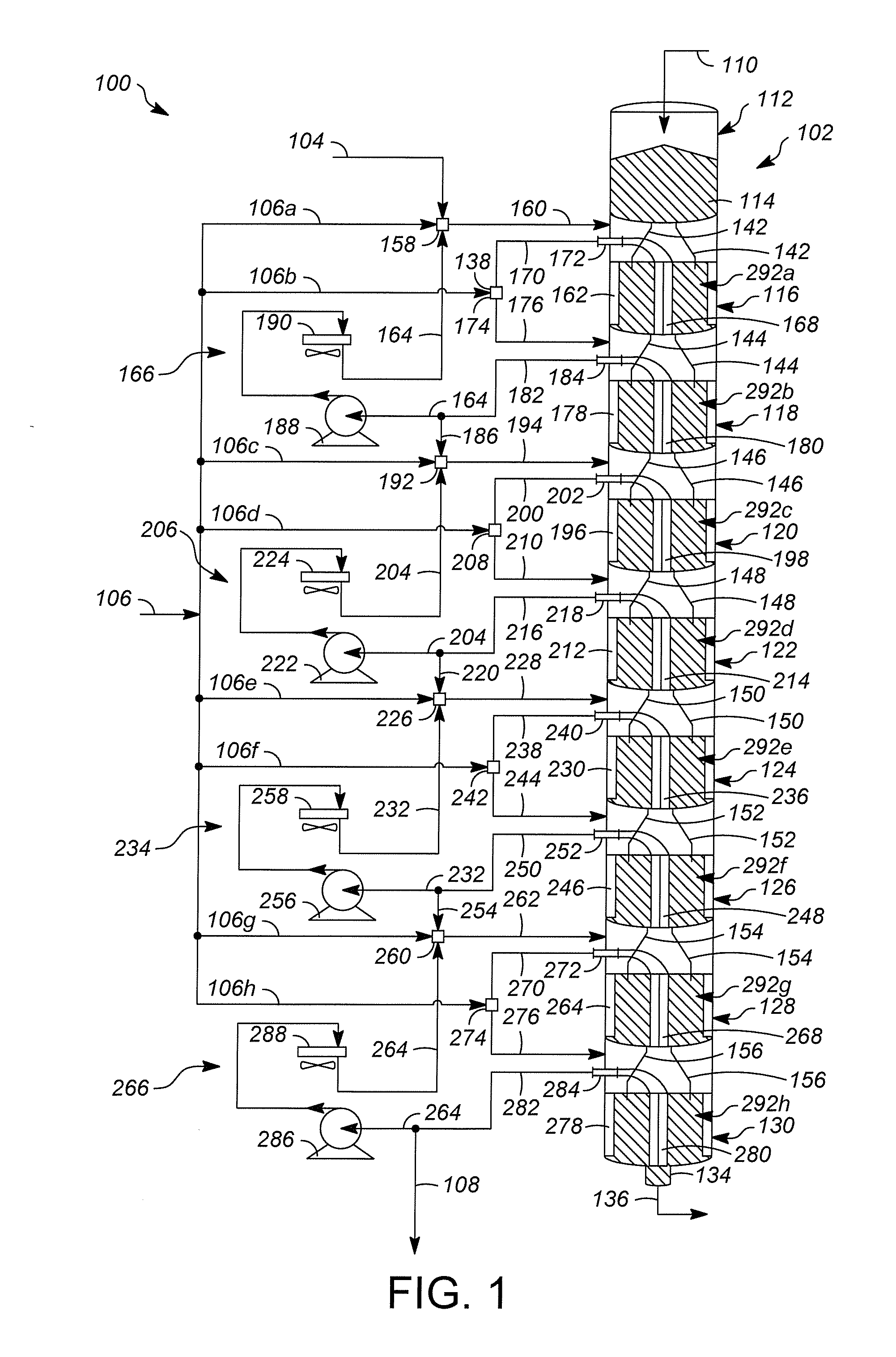

Methods and systems for low emission gas turbine energy generation

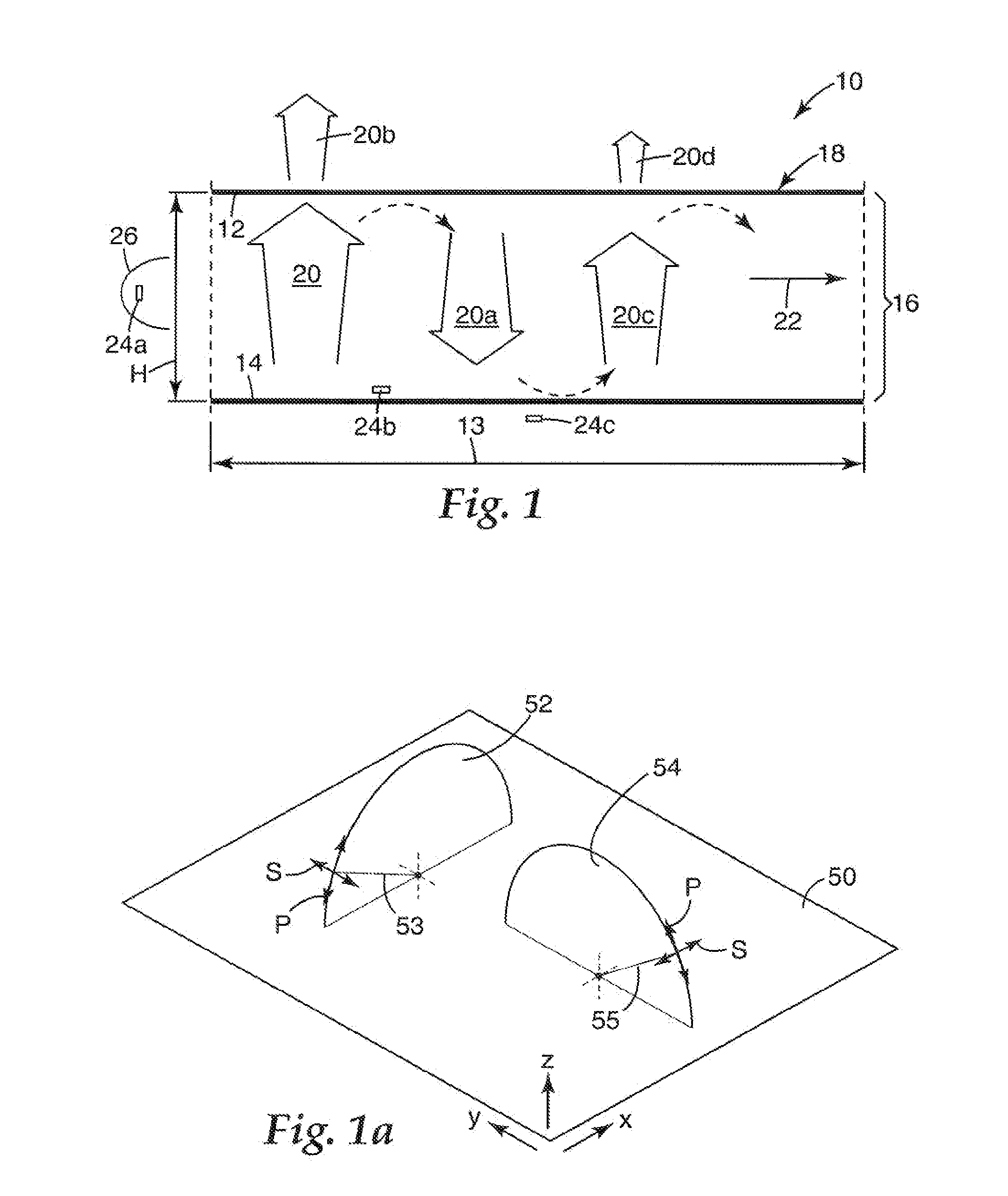

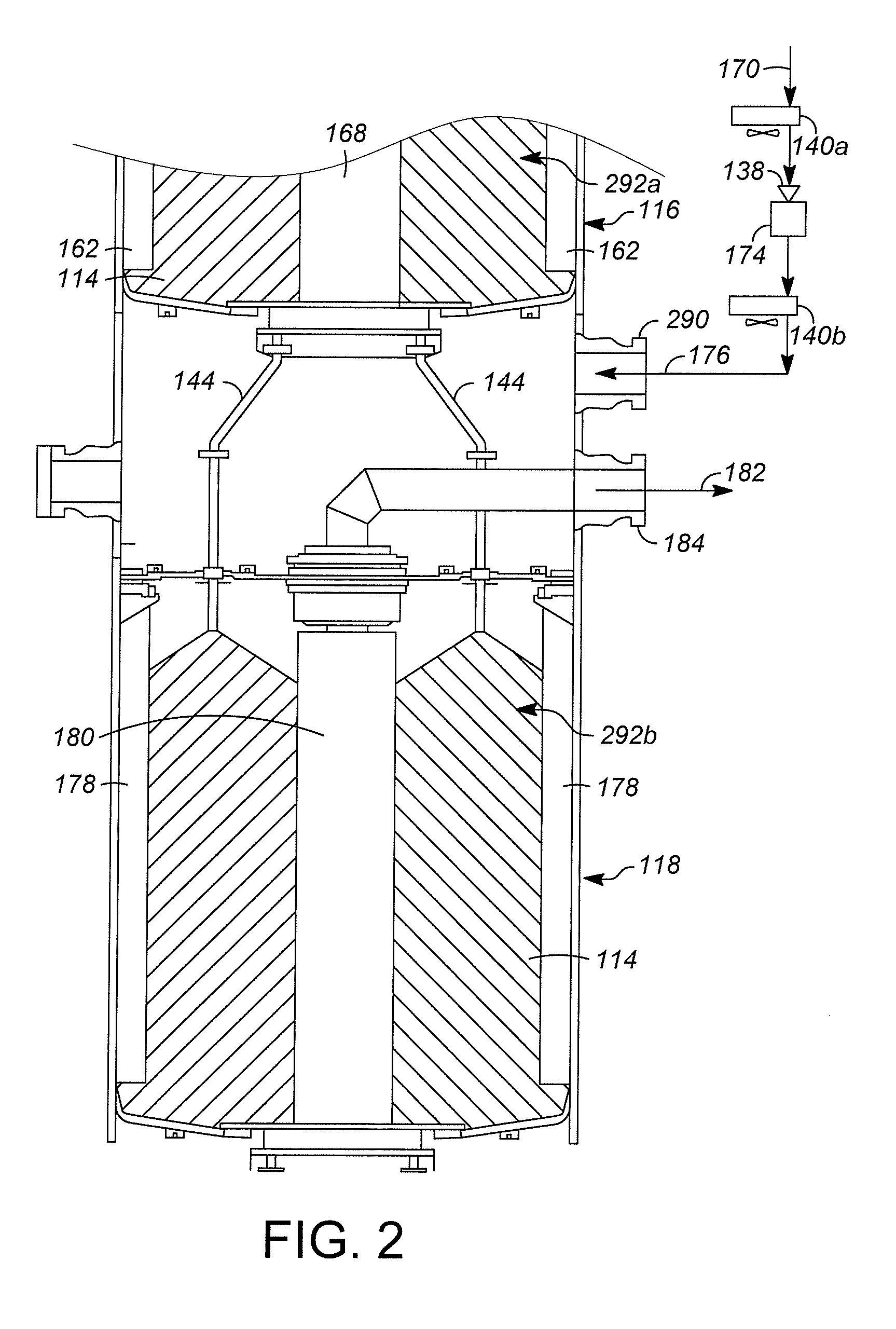

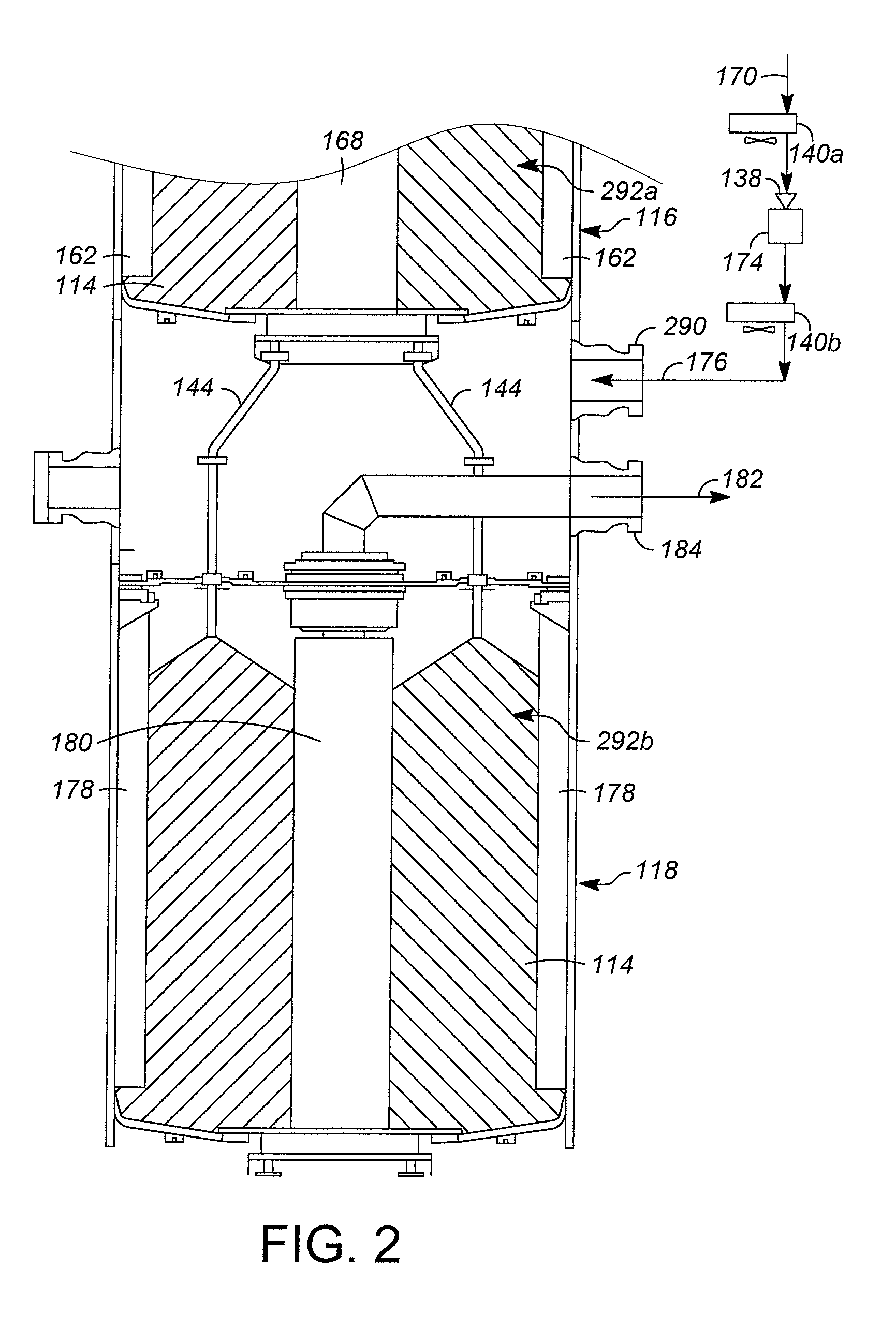

Methods and systems for a dry low NOx gas turbine engine system include a gas turbine engine including at least one dry low NOx combustor. The combustor includes a plurality of injection points wherein at least some of the injection points are configured to inject a fuel into the combustor at a plurality of different locations. The system includes a water source coupled to the combustor and operable to inject water into others of the plurality of injection points. The system also includes a control system that includes a sensor configured to measure an exhaust gas concentration of the turbine, a processor programmed to receive a signal indicative of the turbine exhaust gas concentration, and to automatically control the water injection using the received exhaust gas concentration signal. Such systems in use together can mitigate visible emissions from the exhaust stack.

Owner:GENERAL ELECTRIC CO

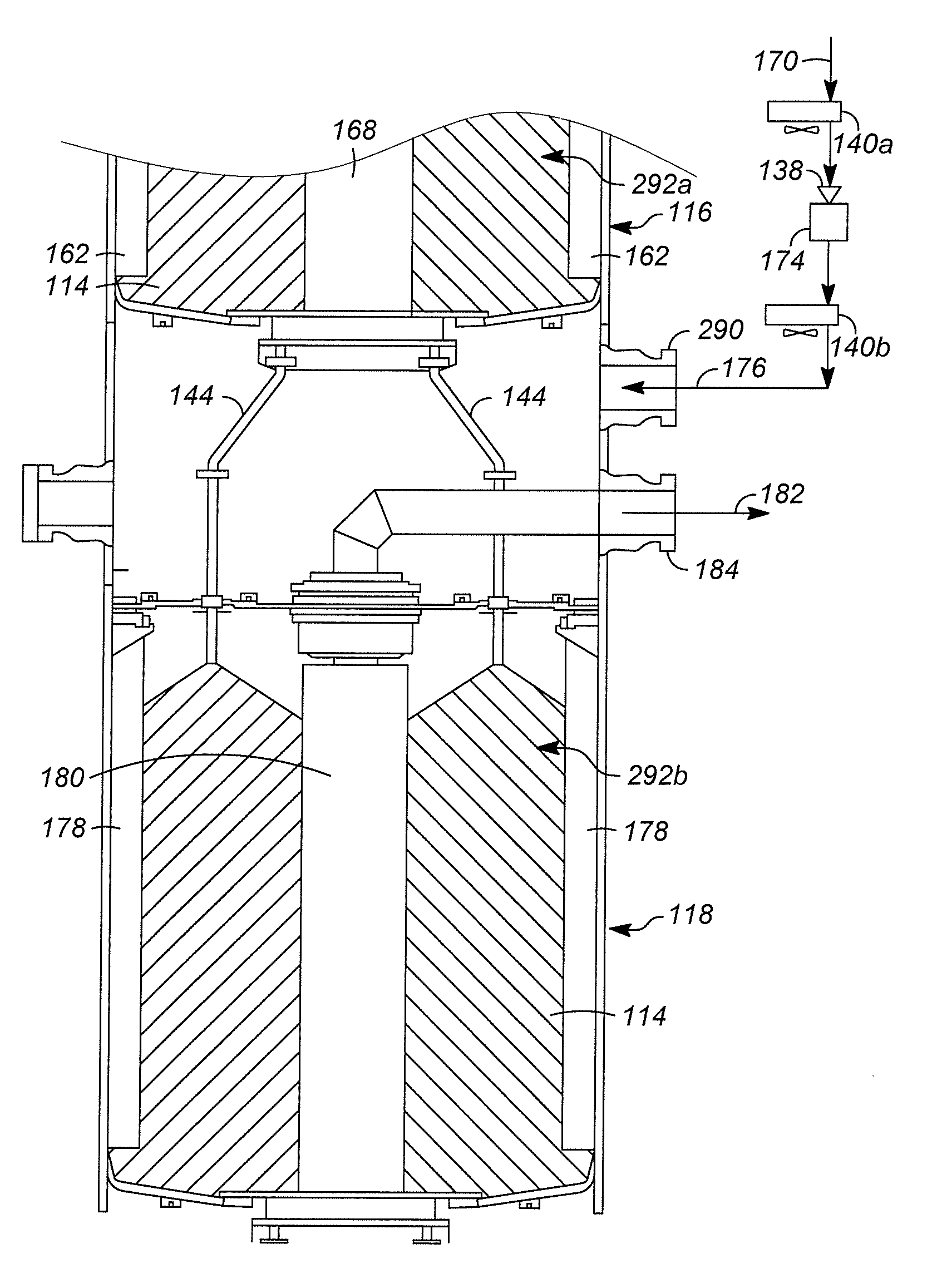

Systems for low emission gas turbine energy generation

Methods and systems for a dry low NOx gas turbine engine system include a gas turbine engine including at least one dry low NOx combustor. The combustor includes a plurality of injection points wherein at least some of the injection points are configured to inject a fuel into the combustor at a plurality of different locations. The system includes a water source coupled to the combustor and operable to inject water into others of the plurality of injection points. The system also includes a control system that includes a sensor configured to measure an exhaust gas concentration of the turbine, a processor programmed to receive a signal indicative of the turbine exhaust gas concentration, and to automatically control the water injection using the received exhaust gas concentration signal. Such systems in use together can mitigate visible emissions from the exhaust stack.

Owner:GE INFRASTRUCTURE TECH INT LLC

Real time optimization and control of oxygen enhanced boilers

InactiveUS7401577B2Easy to controlEasy to modifySolid fuel combustionCombustion measurementsCombustion chamberSteam pressure

An oxygen enriched boiler having a burner subassembly and a steam subassembly is disclosed. The burner subassembly has a fuel inlet, an oxidant inlet, a combustion chamber, a flue gas composition detector and a flue gas outlet. The fuel inlet provides fuel to the combustion chamber, the oxidant inlet provides an oxygen-enriched inlet stream to the combustion chamber, the combustion chamber burns the fuel and the flue gas composition detector measures at least one characteristic of the flue gas. The steam subassembly has a supply water inlet, a heat exchange zone, a water drum, a steam quality actuator and a steam outlet. The supply water inlet provides feed water to the heat exchange zone, the heat exchange zone transfers heat generated by combustion of the fuel to the water to generate steam, the water drum receives the heated water and steam from the heat transfer zone and maintains the water and steam at a selected steam pressure and water level, and the steam quality actuator regulates at least one characteristic of the steam. Flue gas characteristics, as well as other boiler performance variables, are monitored. At least one controller actuates on the oxidant injections to control combustion. The controller calculates the optimum oxidant distribution in real-time for a series of injection points to minimize undesired flue gas emissions while maintaining the desired steam conditions and boiler operating conditions.

Owner:AIR LIQUIDE AMERICA INC

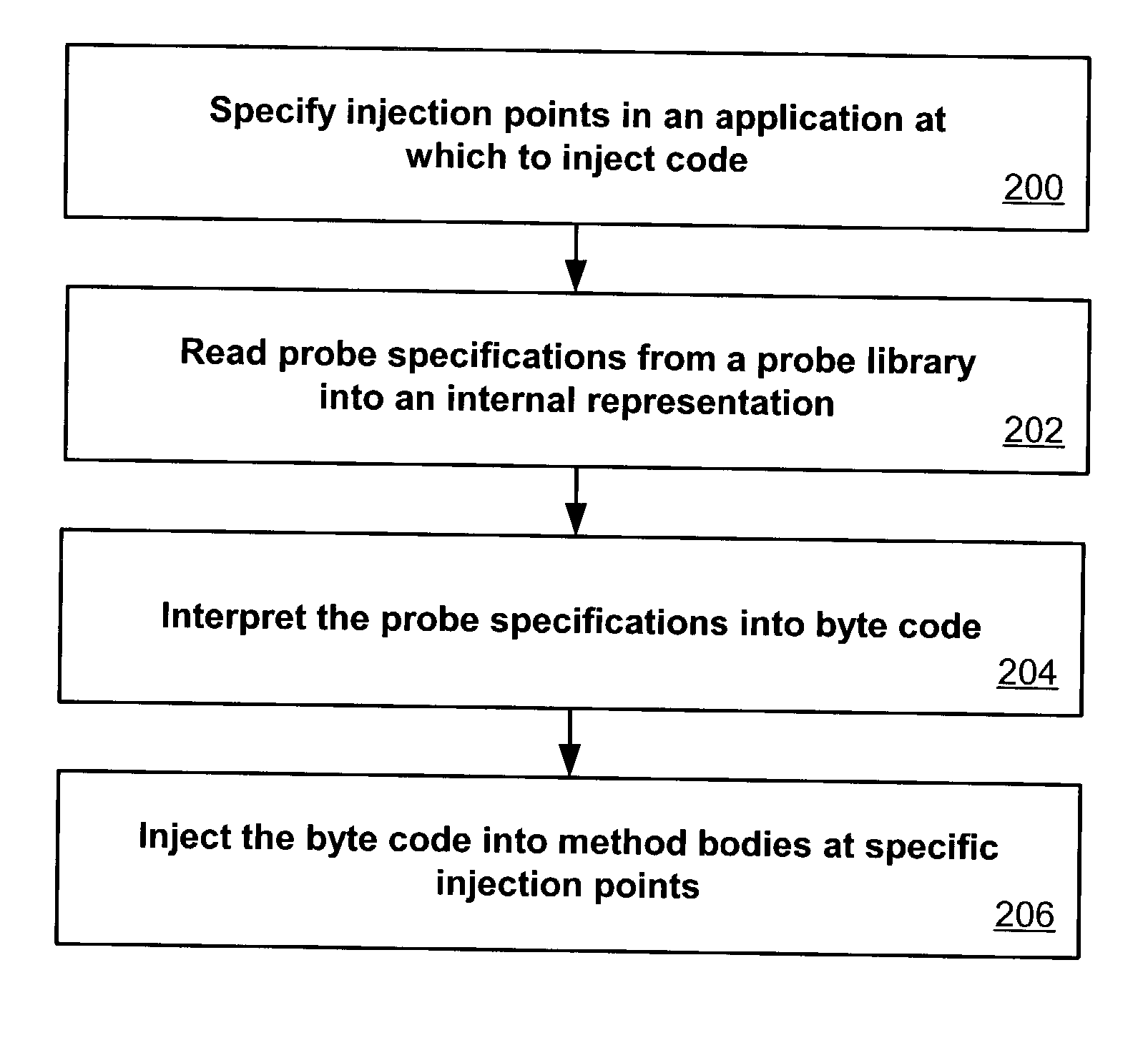

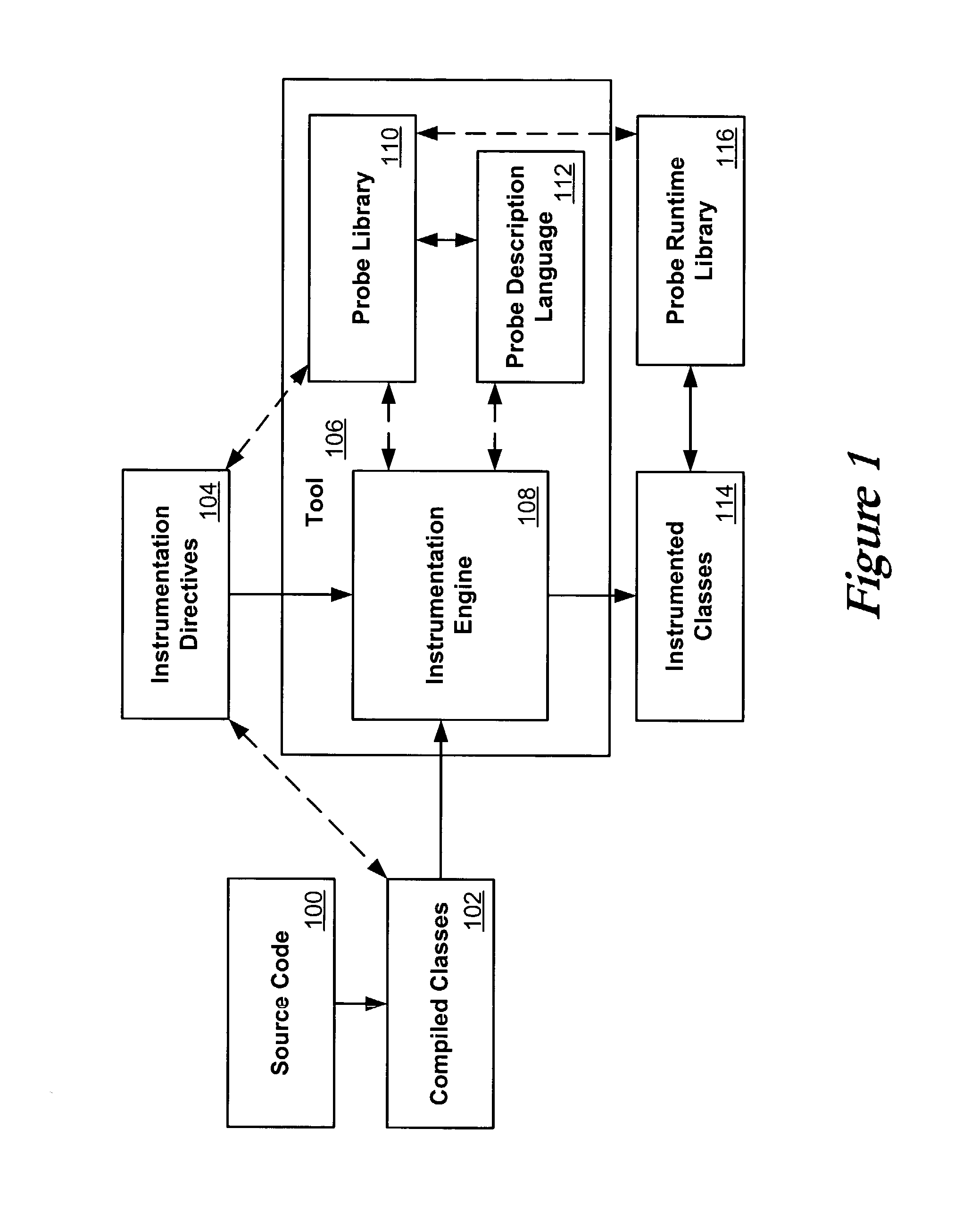

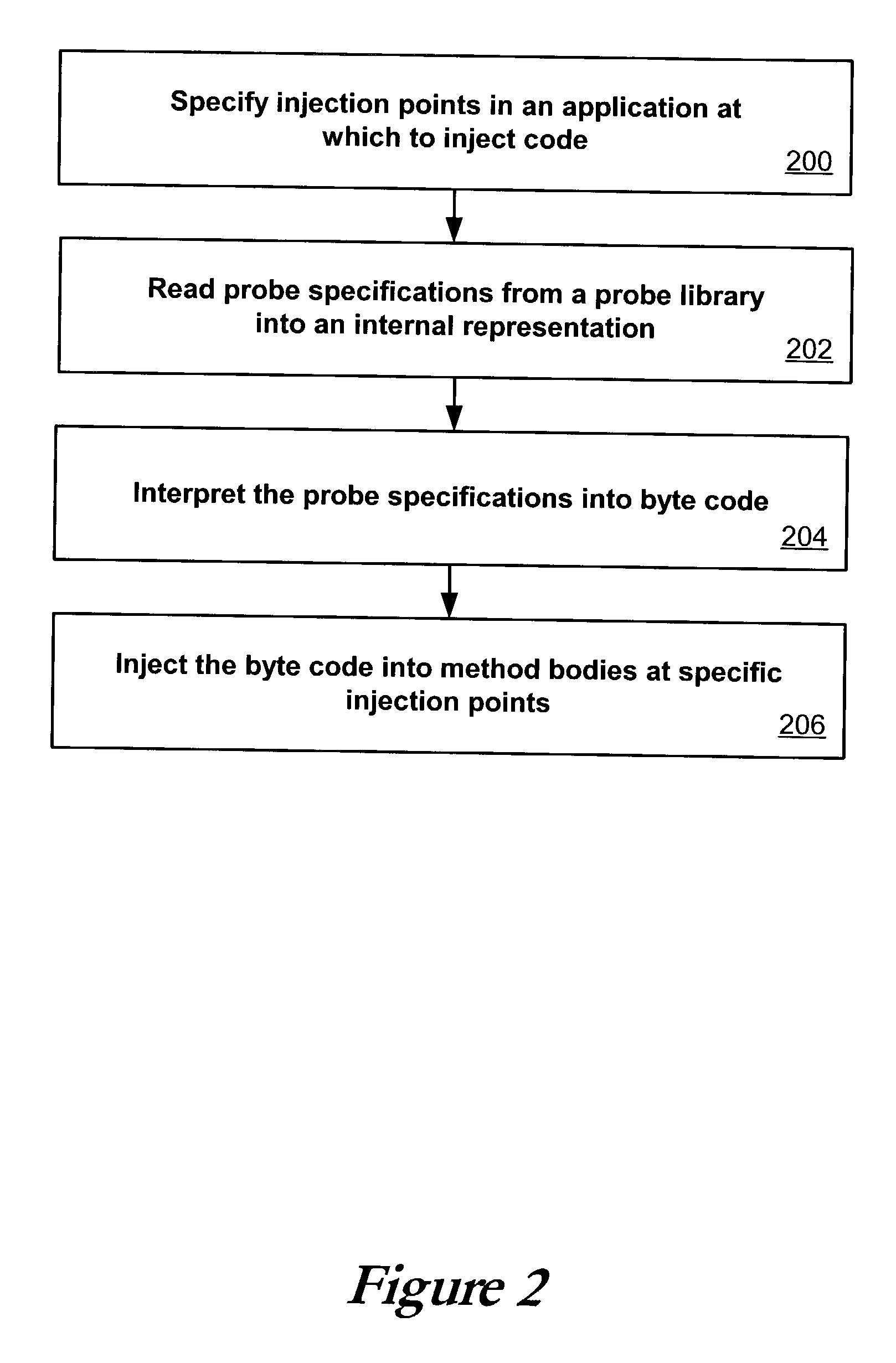

Flexible and extensible java bytecode instrumentation system

ActiveUS20030149960A1Error detection/correctionDigital computer detailsInjection pointCode injection

Code can be injected into a compiled application through the use of probes comprised of instrumentation code. Probes can be implemented in a custom high level language that hides low level instruction details. A directive file contains instructions on injecting a probe into a compiled application. An instrumentation engine reads these instructions and injects the probe into the compiled application at the appropriate injection points. Multiple probes can be used, and can be stored in a probe library. Each probe can inject code into the application at, for example, a package, class, method, or line of the compiled application. Calls can also be made to external runtime libraries. This description is not intended to be a complete description of, or limit the scope of, the invention. Other features, aspects, and objects of the invention can be obtained from a review of the specification, the figures, and the claims.

Owner:ORACLE INT CORP

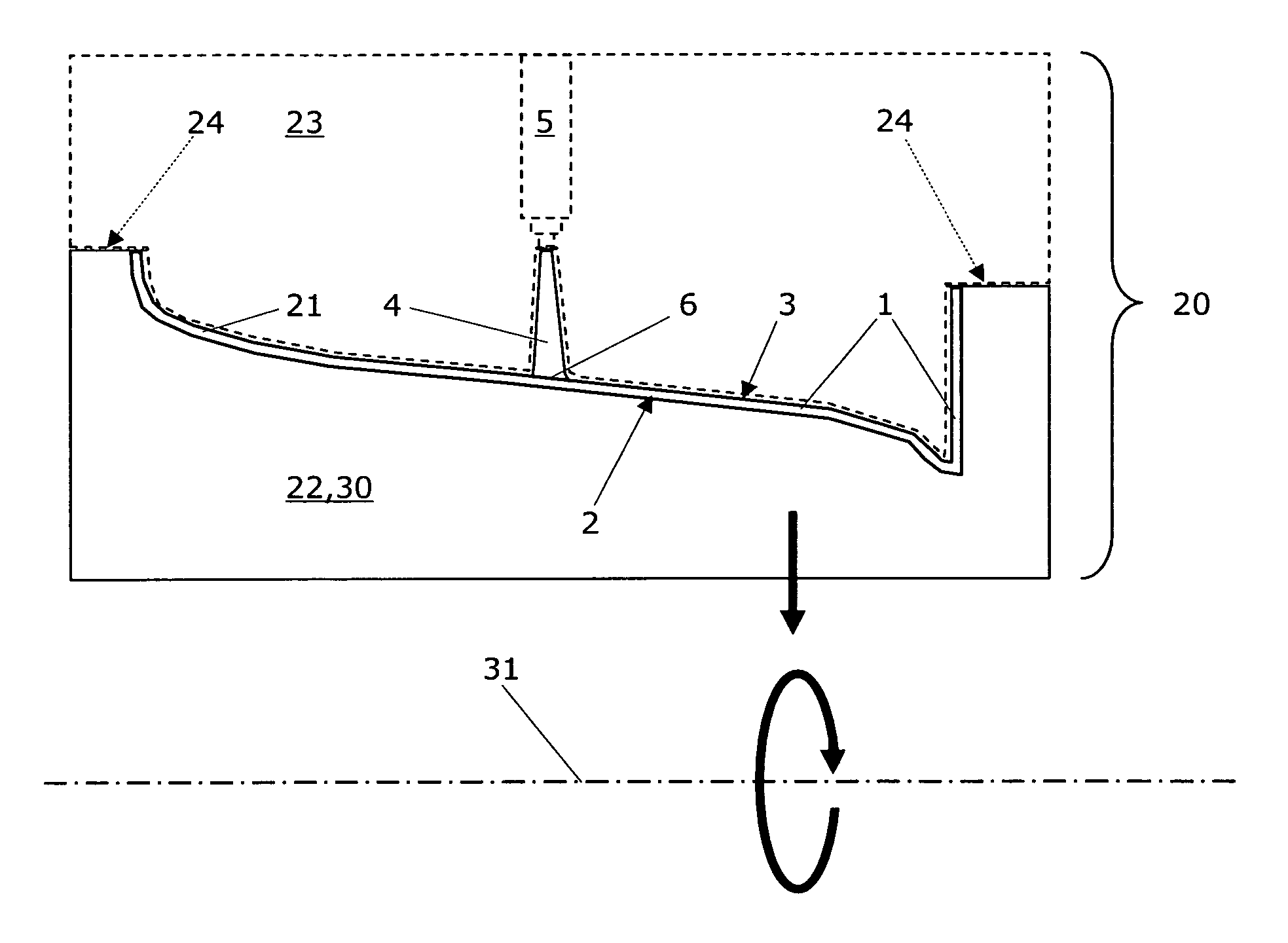

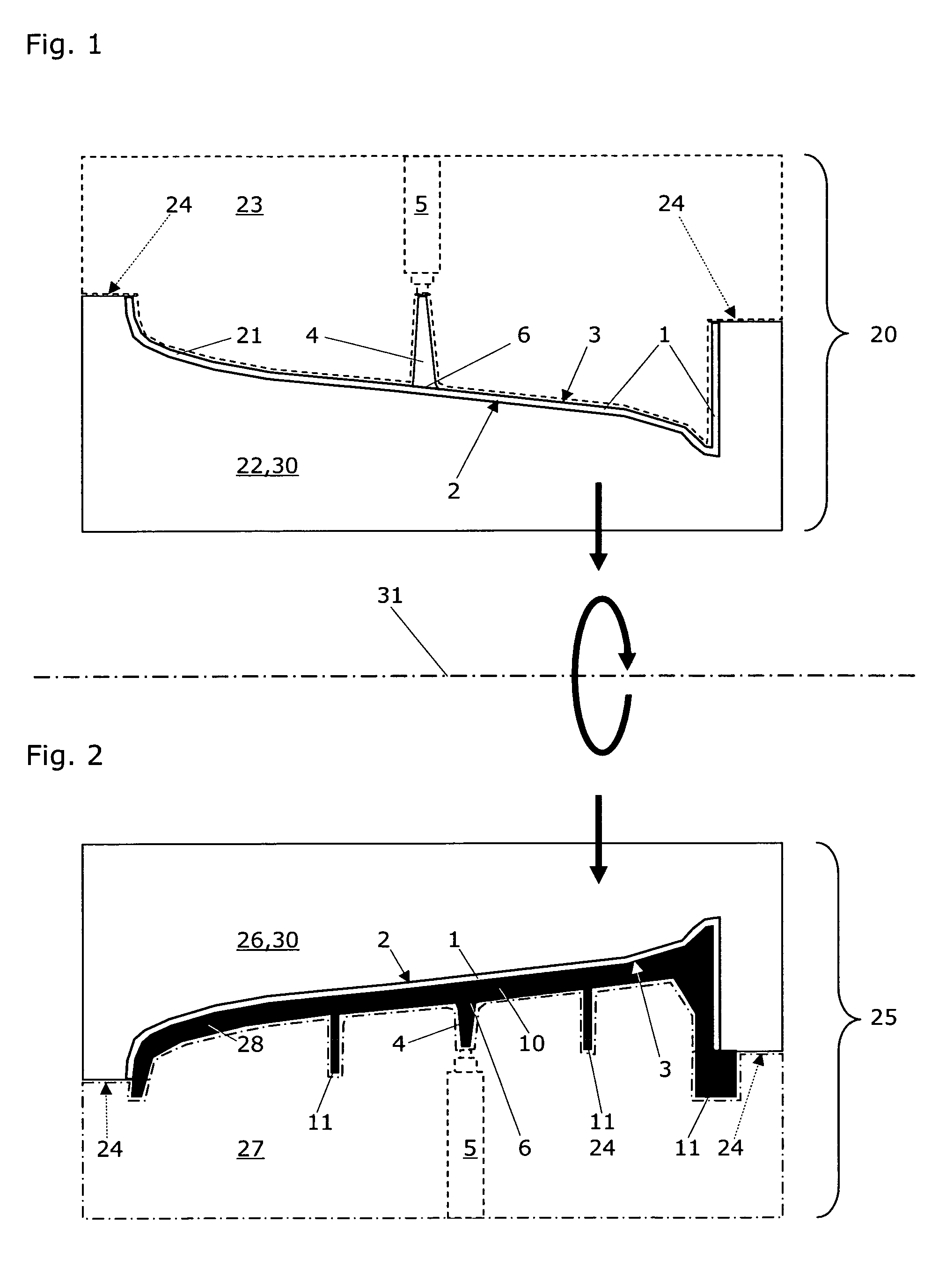

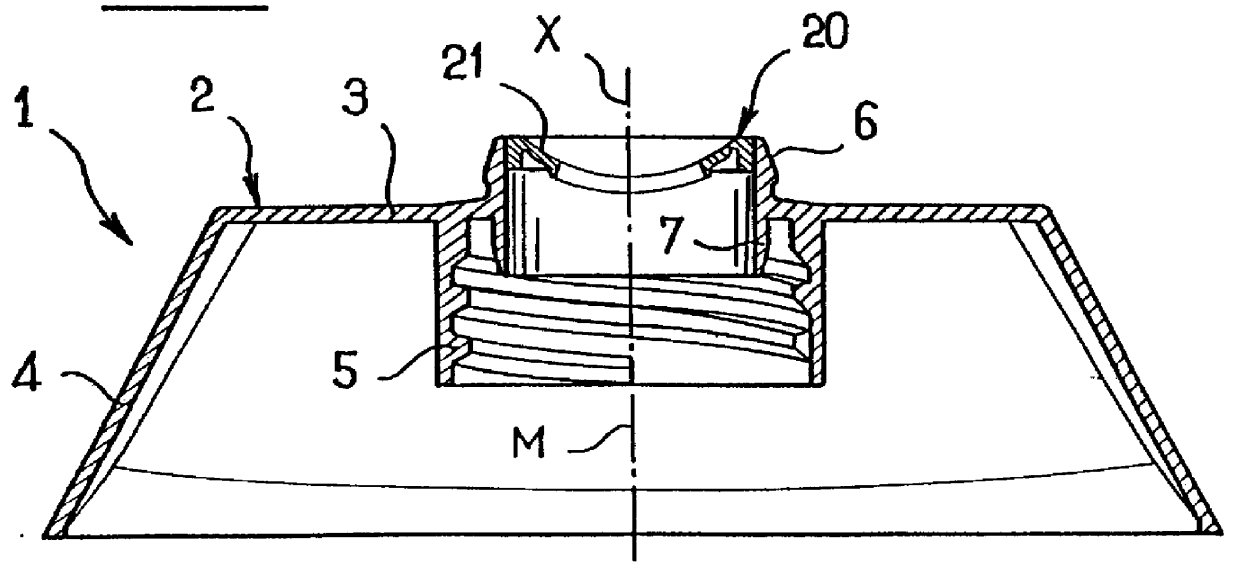

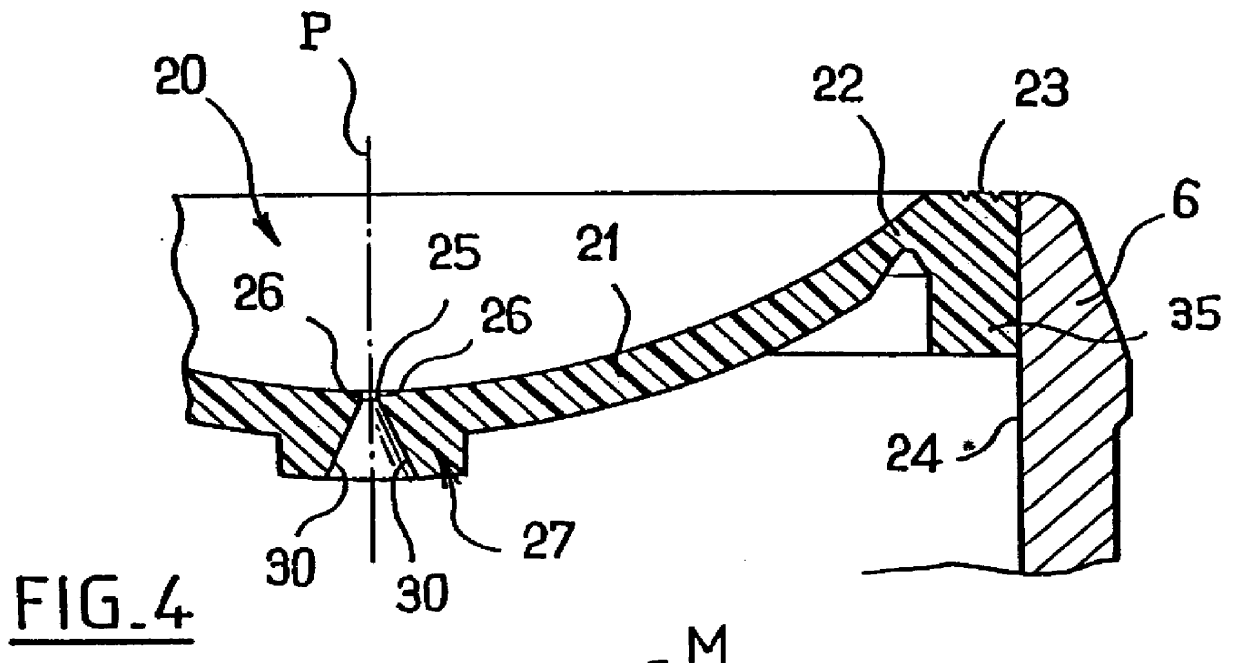

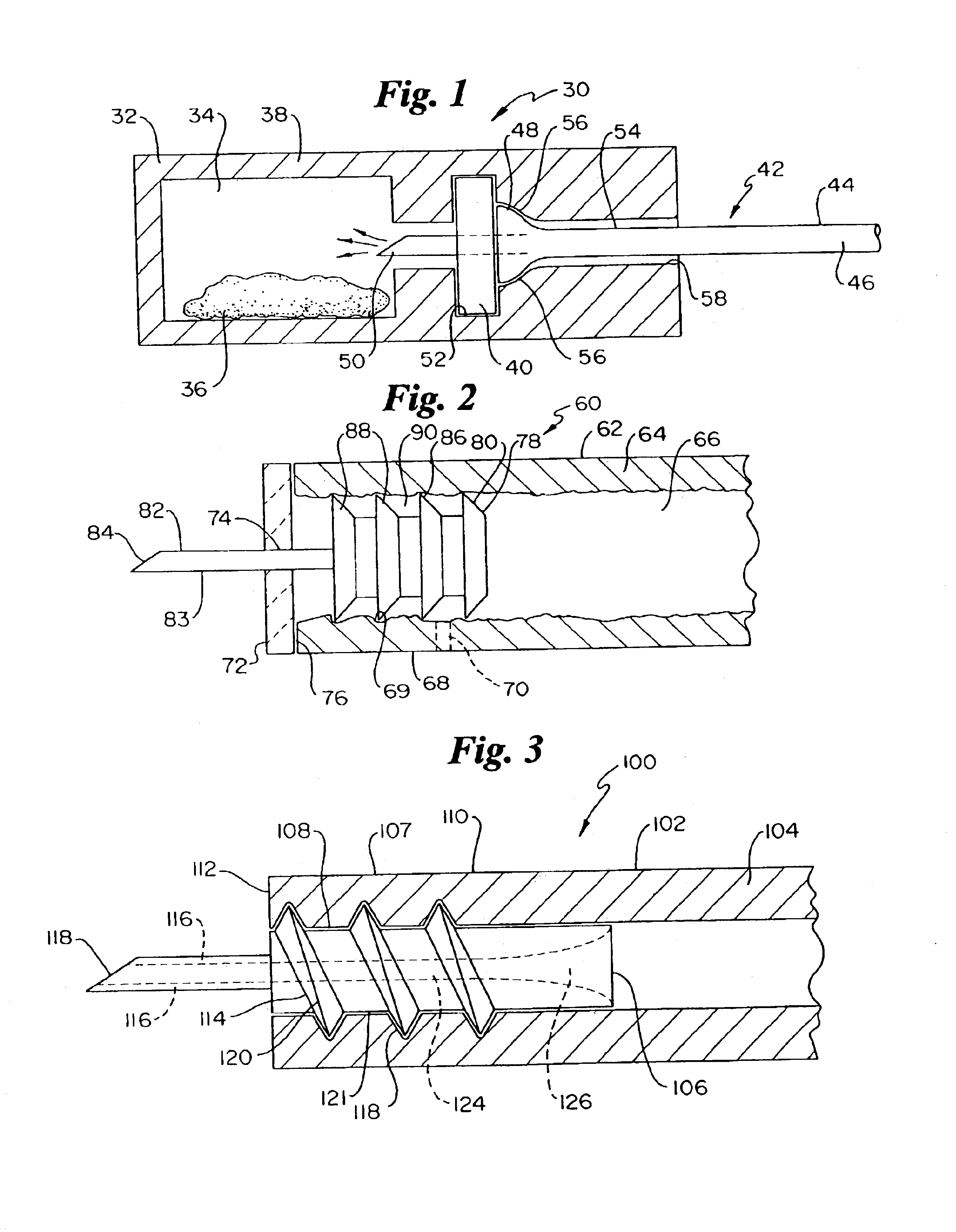

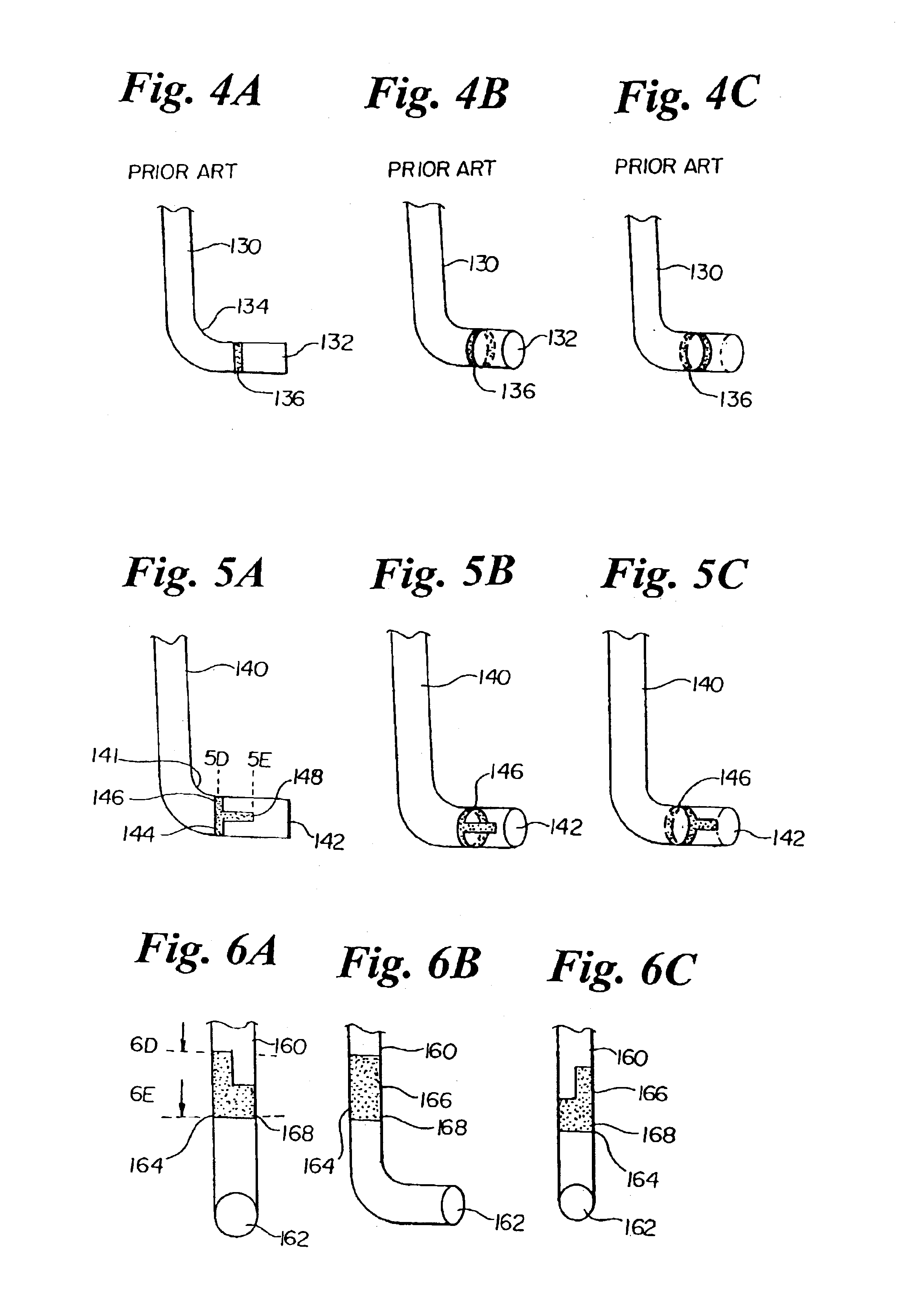

Injection molding method for manufacturing plastic parts

InactiveUS20060068206A1Quality improvementImprove replicationMouldsLayered productsInjection pointSingle injection

Disclosed is an injection molding method for manufacturing plastic parts from thermoplastically processible plastic molding materials with at least one exposed part (1) and at least one functional part (10), whereby the plastic molding material for the exposed part (1) comprises a transparent or translucent matrix with added effect pigments, and whereby the functional parts (10) can exhibit different physical and / or chemical plastic properties to the exposed parts (1). The injection molding method comprises the following steps: a) injection molding and solidification of the plastic molding material of the at least one exposed part (1) with an exposed surface (2) and a core surface (3) facing away from the latter in a first mold (20) with a first cavity (21); b) opening of the first mold (20) along a parting line or plane (24); c) closing of a second mold (25) with the at least one exposed part (1) in a second cavity (28); d) injection molding and solidification of the plastic molding material of the functional part (10) on the core surface (3) of the at least one exposed part (1); and e) opening of the second mold (25) and removal of the part. The injection molding method according to the invention is characterized in that for each exposed part (1)—to prevent irregularities such as flow marks and / or knit lines—a single injection nozzle (5) positioned to optimize the flow or at least two injection nozzles in a cascaded injection molding method are used, and that the plastic molding material for the exposed part (1) comprises at least one transparent polymer. The corresponding plastic parts manufactured by injection molding exhibit an exposed surface (2) and a core surface (3) facing away from the latter with at least one injection point (6), whereby the functional part (10) of the plastic part is injection molded onto the core surface (3) of the previously solidified exposed part (1).

Owner:EMS CHEM AG

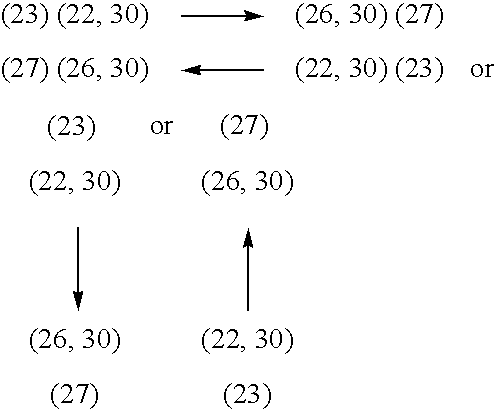

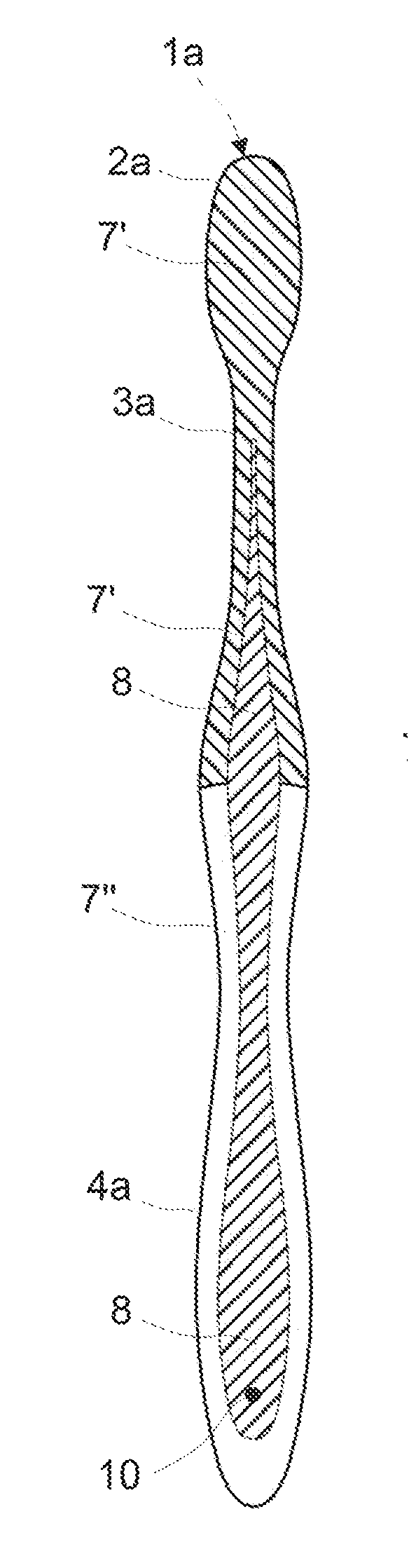

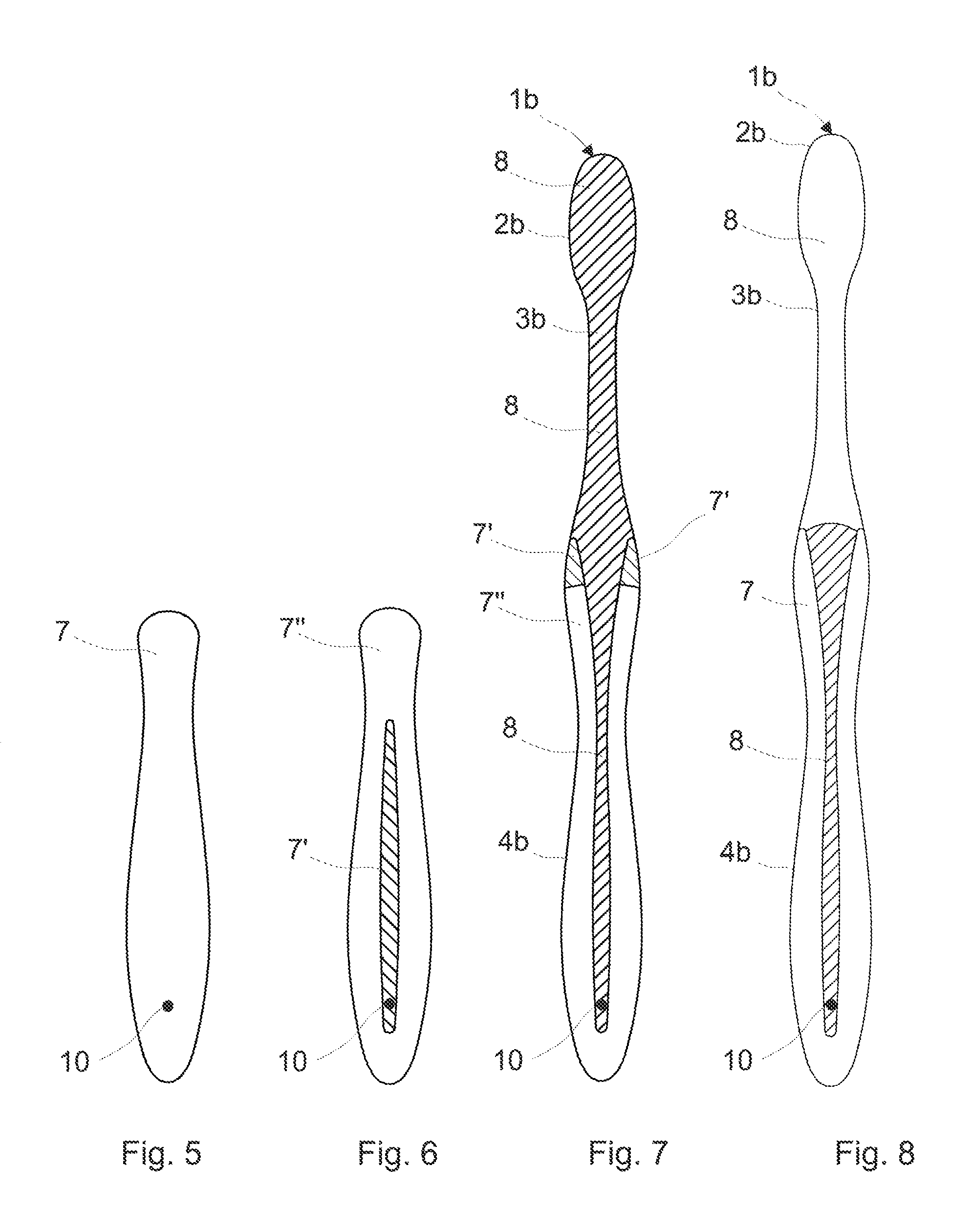

Method for producing a toothbrush, and toothbrush

InactiveUS20140173853A1High degreeFew method stepTravelling carriersHoldersThermoplasticInjection point

A grip body of a body care article, such as toothbrush, includes a grip part, a neck part and a head part. The grip body includes a first and a second material component of a thermoplastic plastic. The first and the second material component have a common injection point that is arranged outside a mould partition line formed by the mould partition.

Owner:TRISA HLDG AG

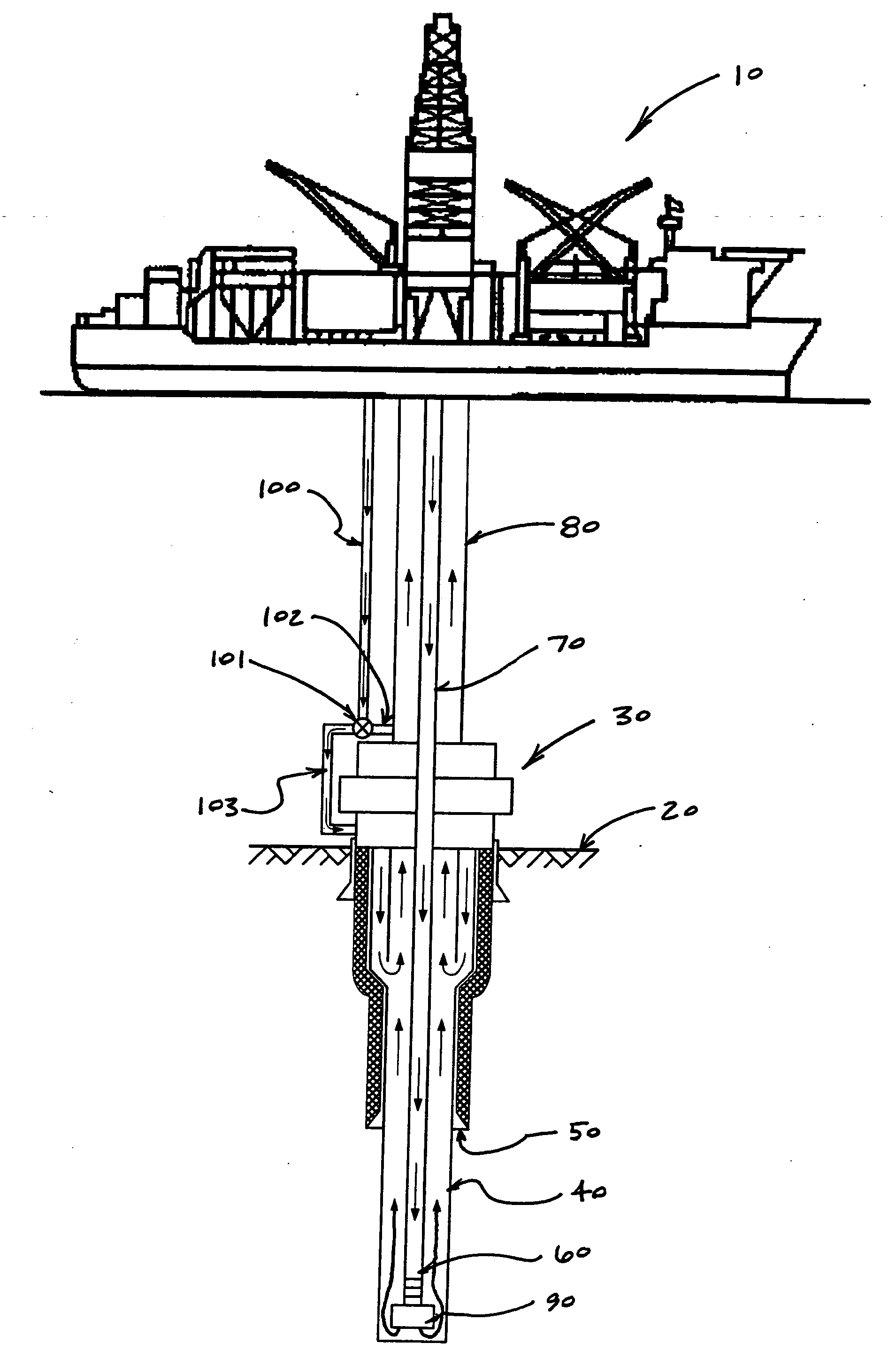

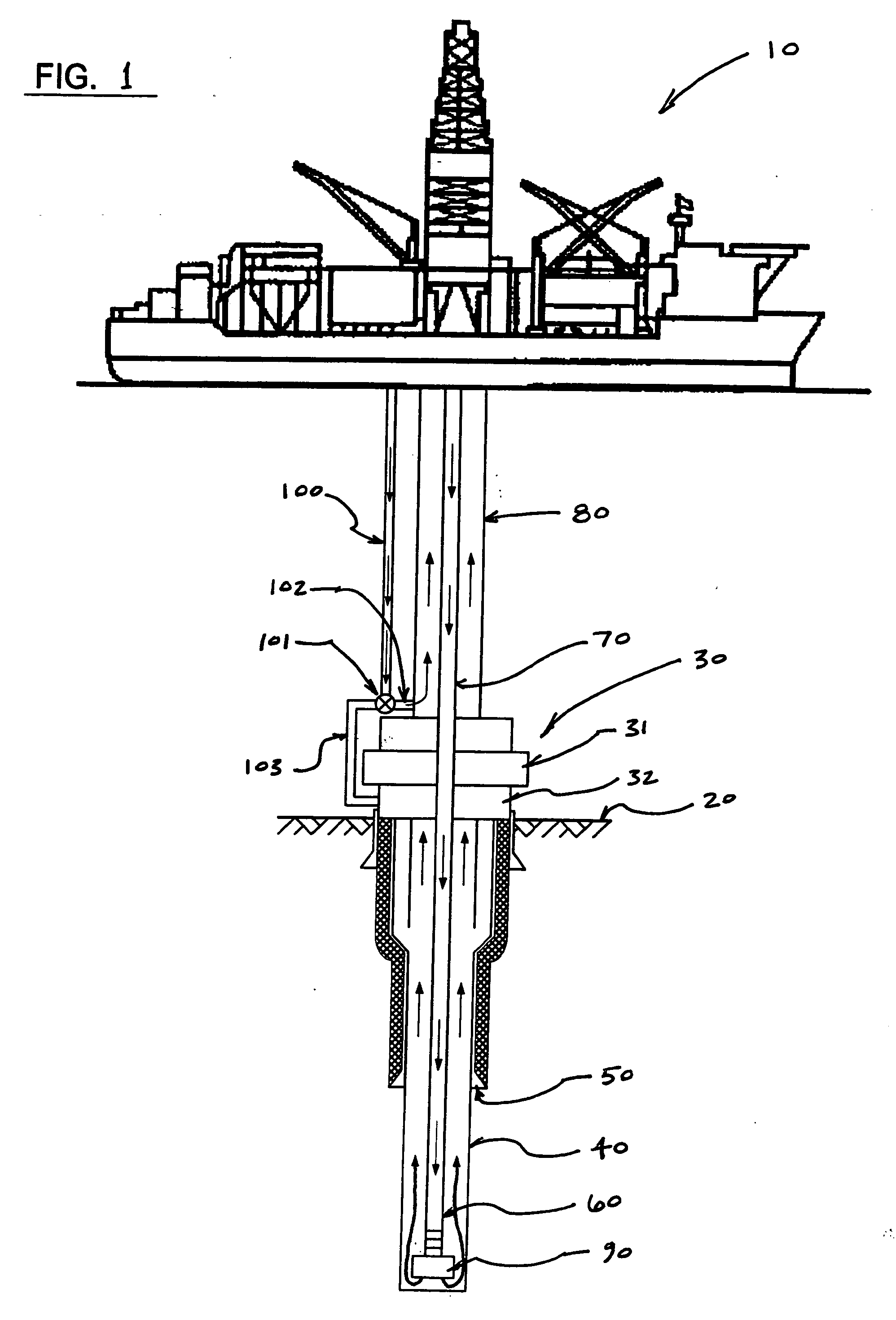

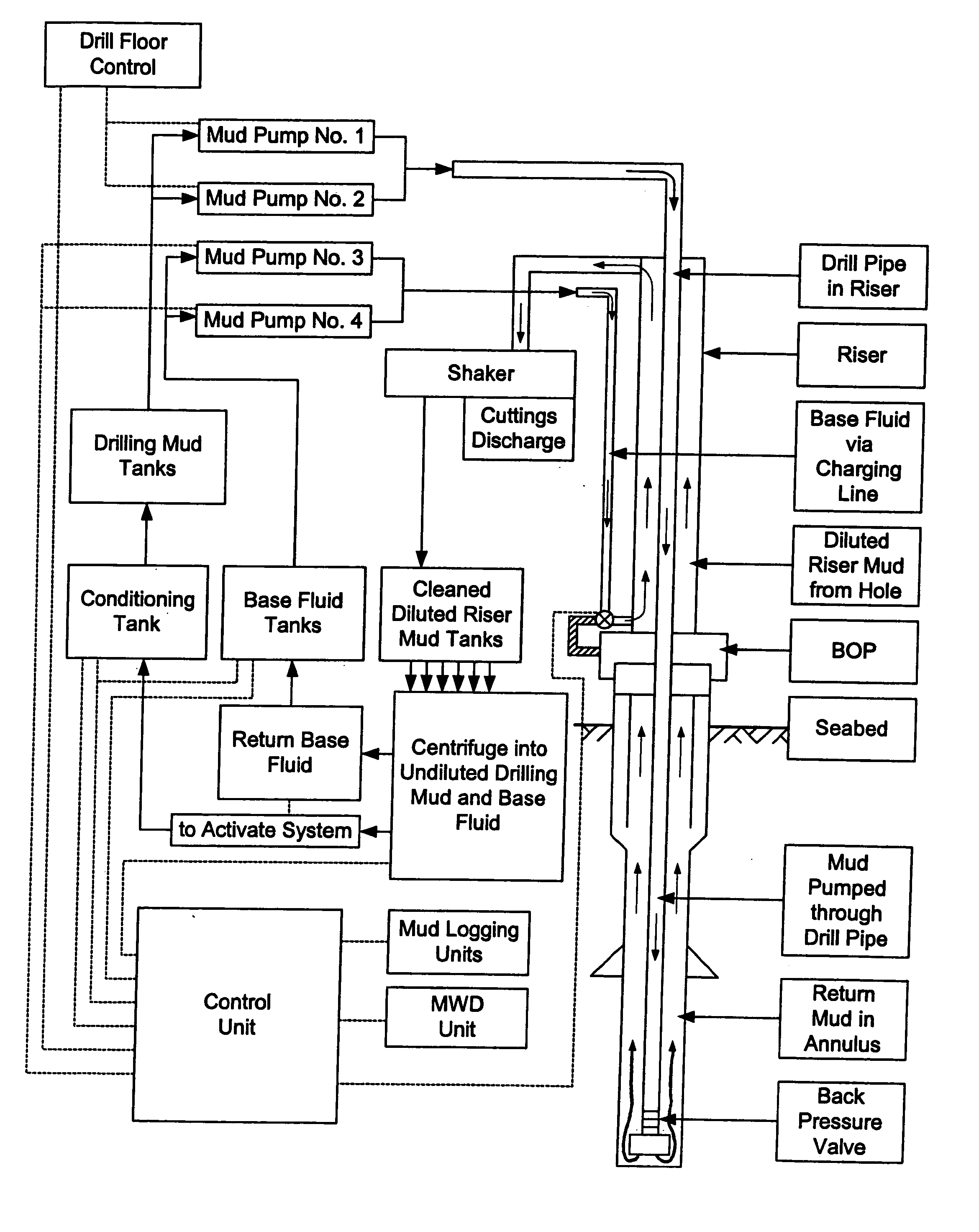

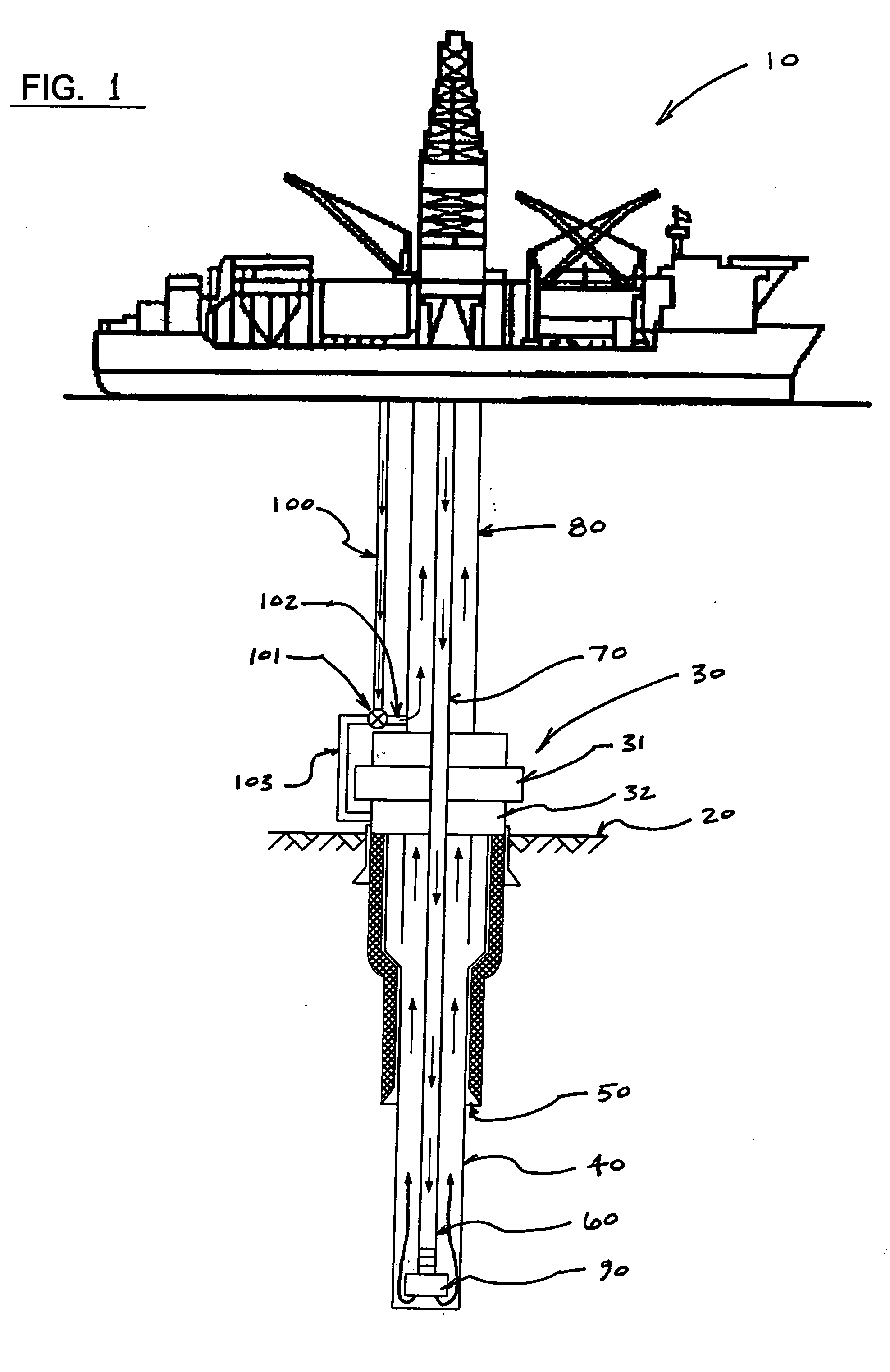

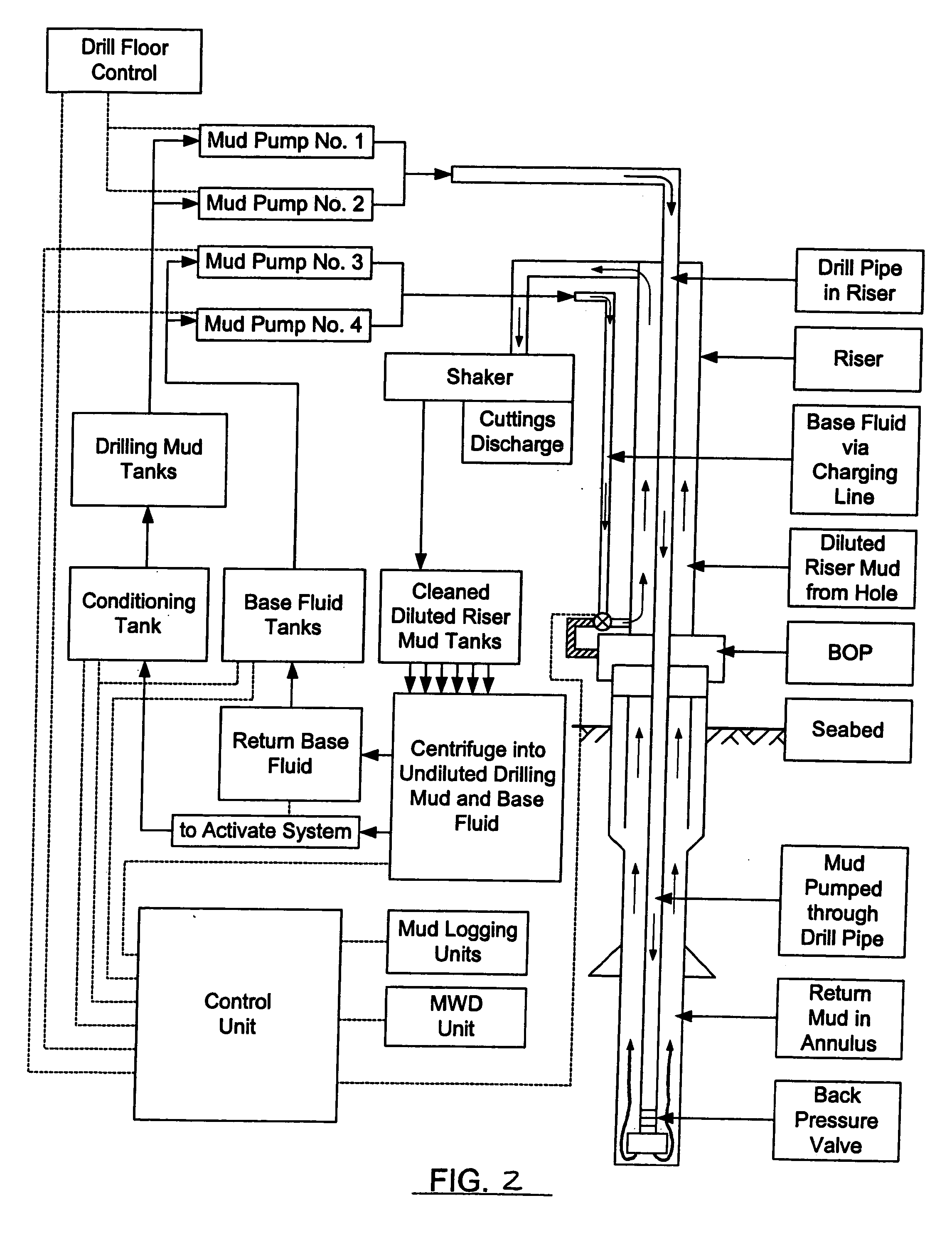

Dual Gradient Drilling Method And Apparatus With An Adjustable Centrifuge

A method and system for controlling drilling mud density in drilling operations. The mud required at the wellhead is combined with a base fluid of a different density to produce diluted mud in the riser. By combining the appropriate quantities of drilling mud with base fluid, riser mud density at or near the density of seawater may be achieved, thereby permitting greater control over the pressure in the wellbore and various risers. Blowout preventers may also be used in combination with the process to control these pressures. Concentric risers are disclosed, wherein an annulus defined within one riser is utilized to carry the different density base fluid to the injection point for injection into the drilling mud, while an annulus defined within another riser is utilized to carry the combination fluid and cuttings back to the drilling rig. Cuttings are separated in the usual manner at the surface. The diluted mud is passed through a centrifuge system to separate drilling mud from the different density base fluid. The centrifuge system may also be utilized to separate the recovered drilling fluid into a substantially barite portion and a substantially drilling fluid portion, wherein the two portions are stored locally at the rig and recirculated during drilling operations.

Owner:DUAL GRADIENT SYST

Method for varying the density of drilling fluids in deep water oil and gas drilling applications

A method and system for controlling drilling mud density in drilling operations. The mud required at the wellhead is combined with a base fluid of a different density to produce diluted mud in the riser. By combining the appropriate quantities of drilling mud with base fluid, riser mud density at or near the density of seawater may be achieved, thereby permitting greater control over the pressure in the wellbore and various risers. Blowout preventers may also be used in combination with the process to control these pressures. Concentric risers are disclosed, wherein an annulus defined within one riser is utilized to carry the different density base fluid to the injection point for injection into the drilling mud, while an annulus defined within another riser is utilized to carry the combination fluid and cuttings back to the drilling rig. Cuttings are separated in the usual manner at the surface. The diluted mud is passed through a centrifuge system to separate drilling mud from the different density base fluid. The centrifuge system may also be utilized to separate the recovered drilling fluid into a substantially barite portion and a substantially drilling fluid portion, wherein the two portions are stored locally at the rig and recirculated during drilling operations.

Owner:DUAL GRADIENT SYST

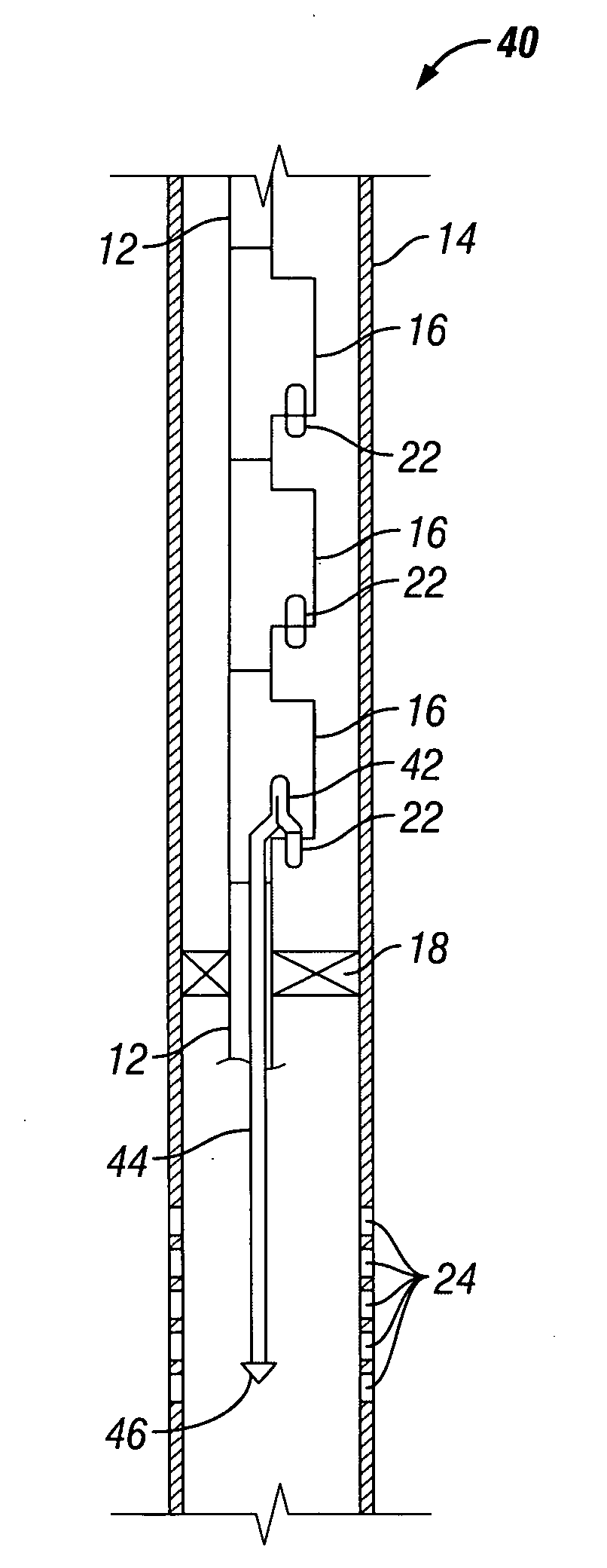

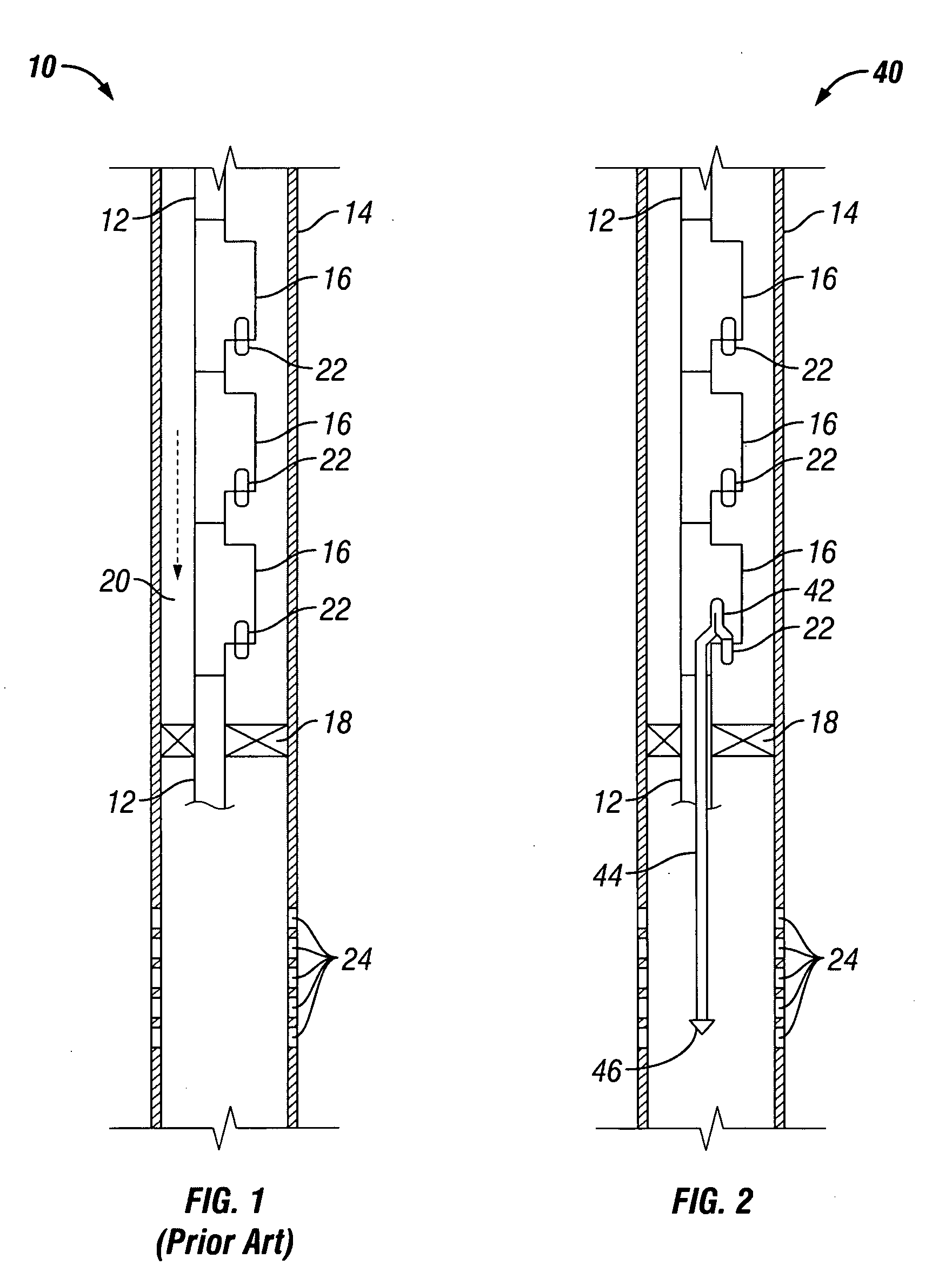

System and method for thru tubing deepening of gas lift

ActiveUS20090255684A1Blowout preventionFluid removalWell/borehole valve arrangementsProduction packerInjection point

The present disclosure is directed to a gas lift system adapted to provide a gas injection point to a deeper location in a wellbore. A turn-over suspension mandrel can be landed inside a side pocket mandrel and connected to a gas lift valve on one end and a coil on the other end. A length of production tubing can extend from the side pocket mandrel. The production tubing can include a production packer to seal the annulus between the tubing and the well casing. The turn-over suspension mandrel can be constructed such that gas entering the gas lift valve is directed down through the coil and into the wellbore beneath the production packer. A plug can be placed at the bottom of the coil in order to prevent blowouts during installation of the gas lift system. An alternative embodiment of the present disclosure provides a coil and plug hung from a gas lift valve of a pack-off assembly.

Owner:BAKER HUGHES INC

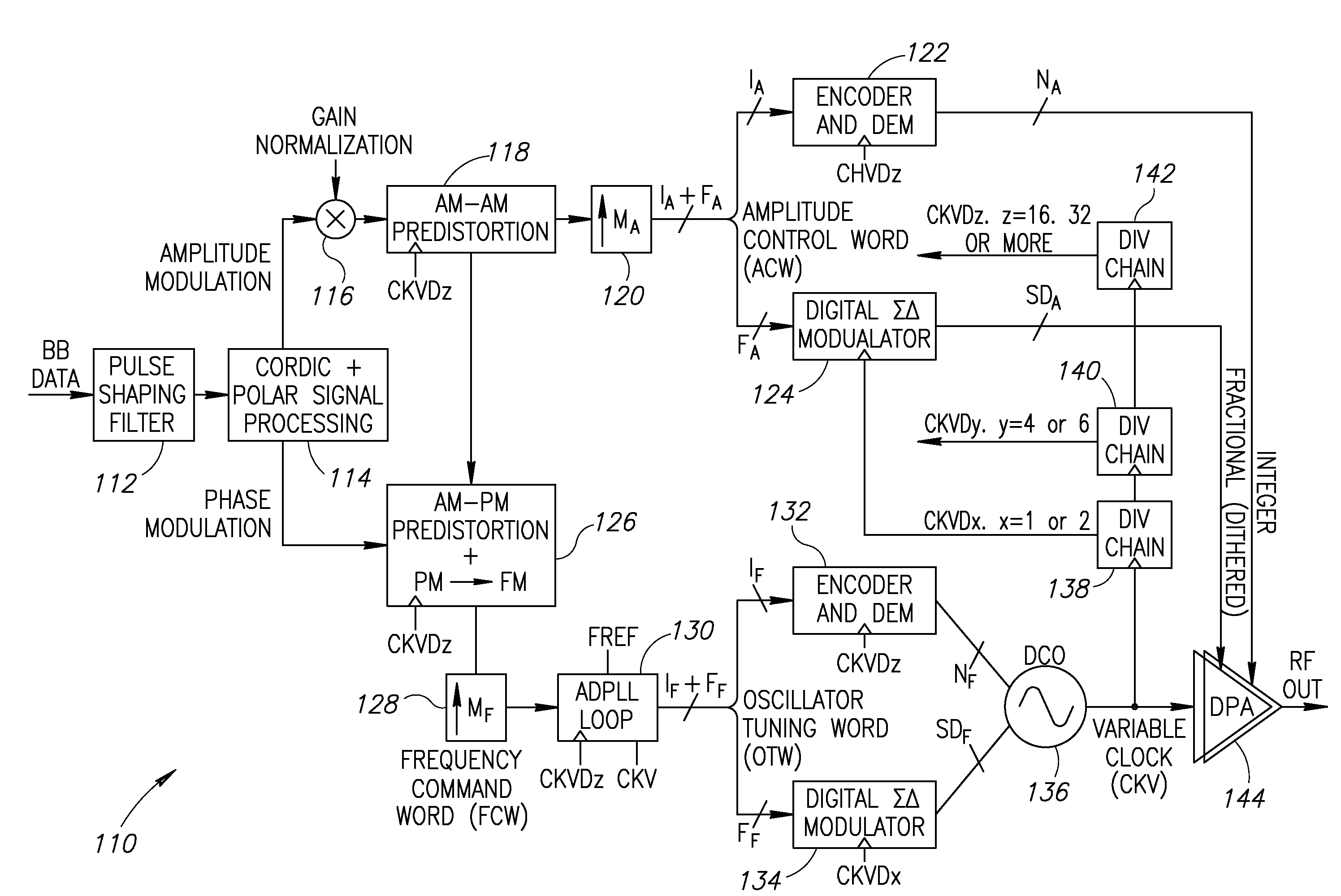

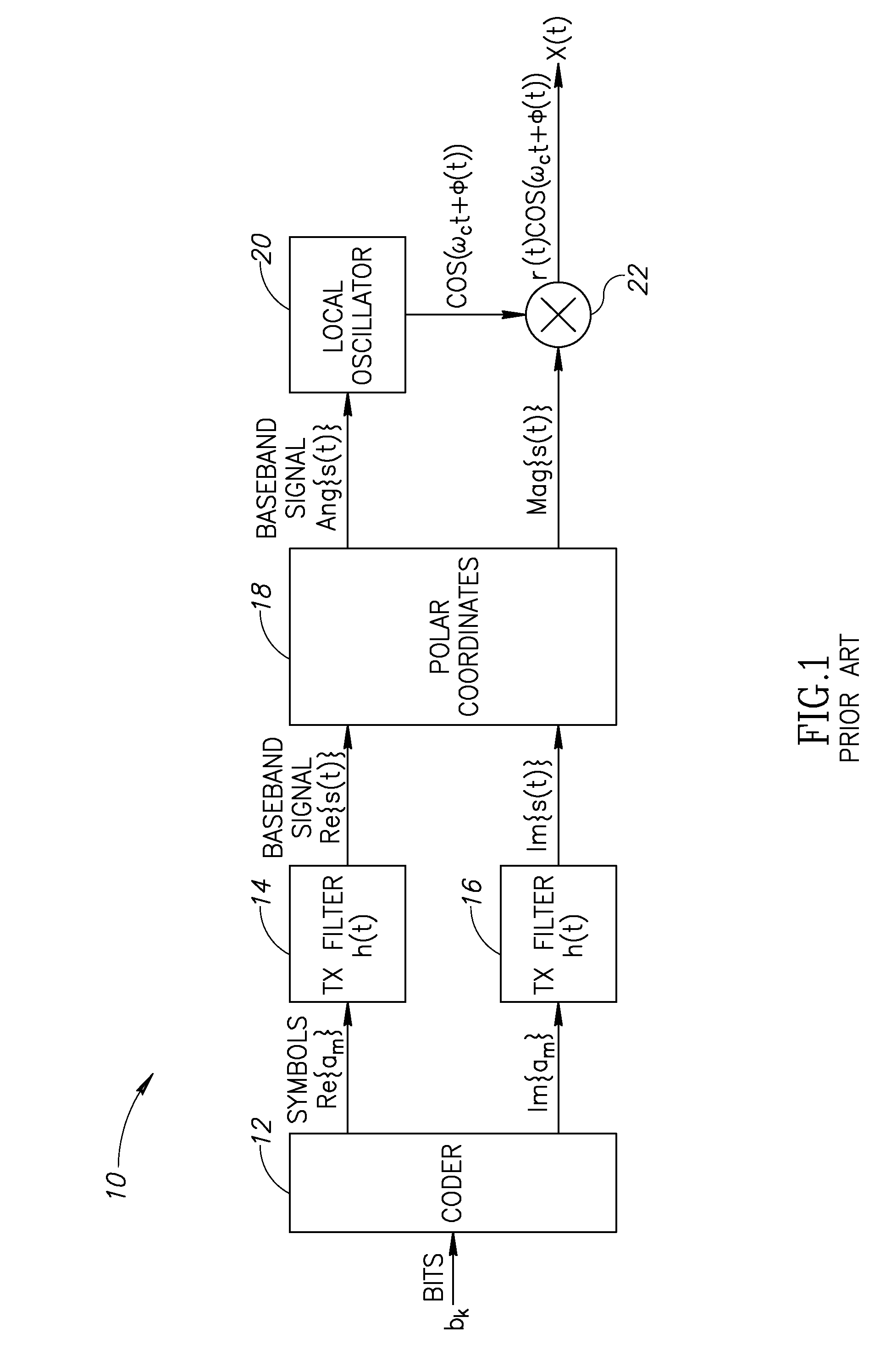

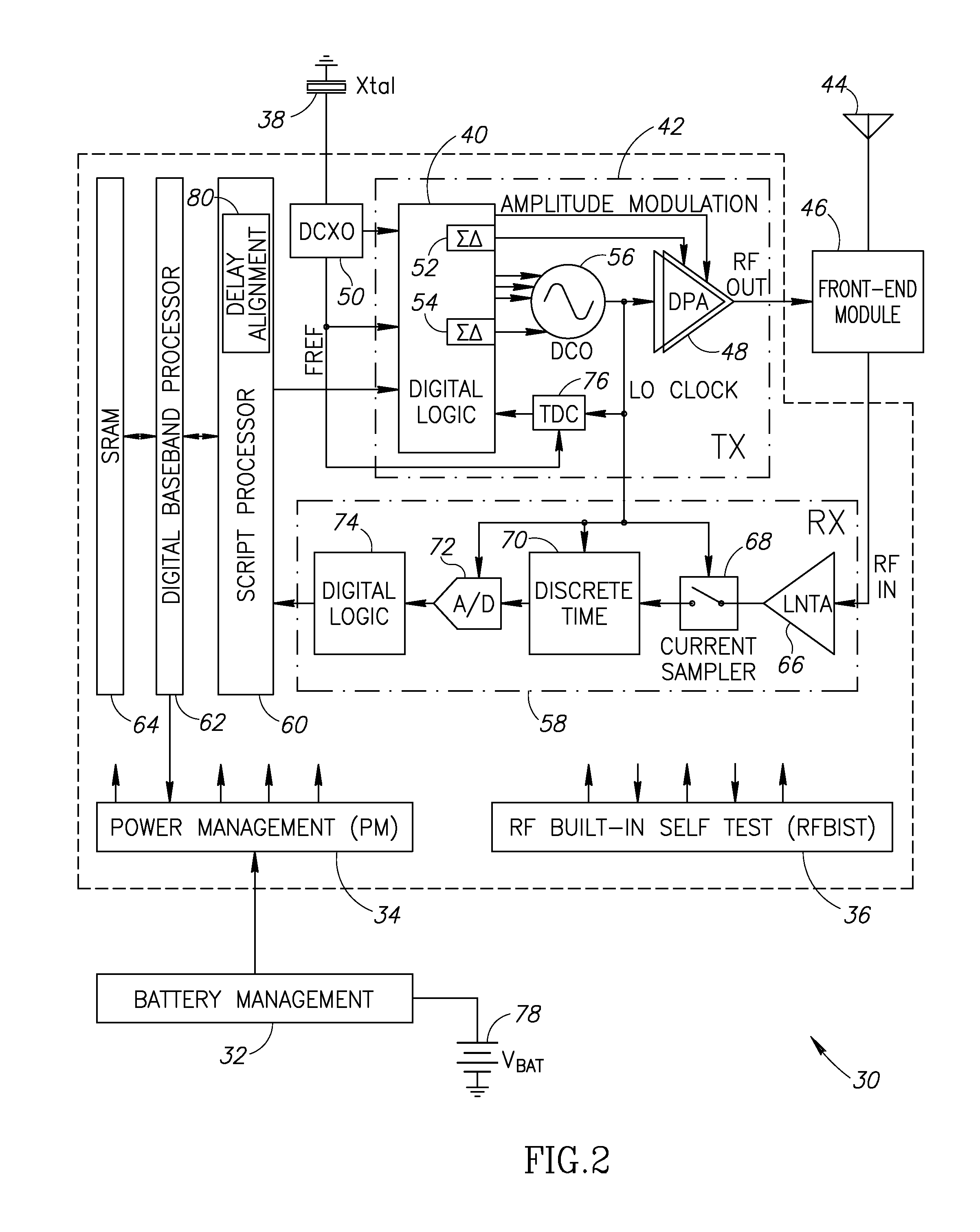

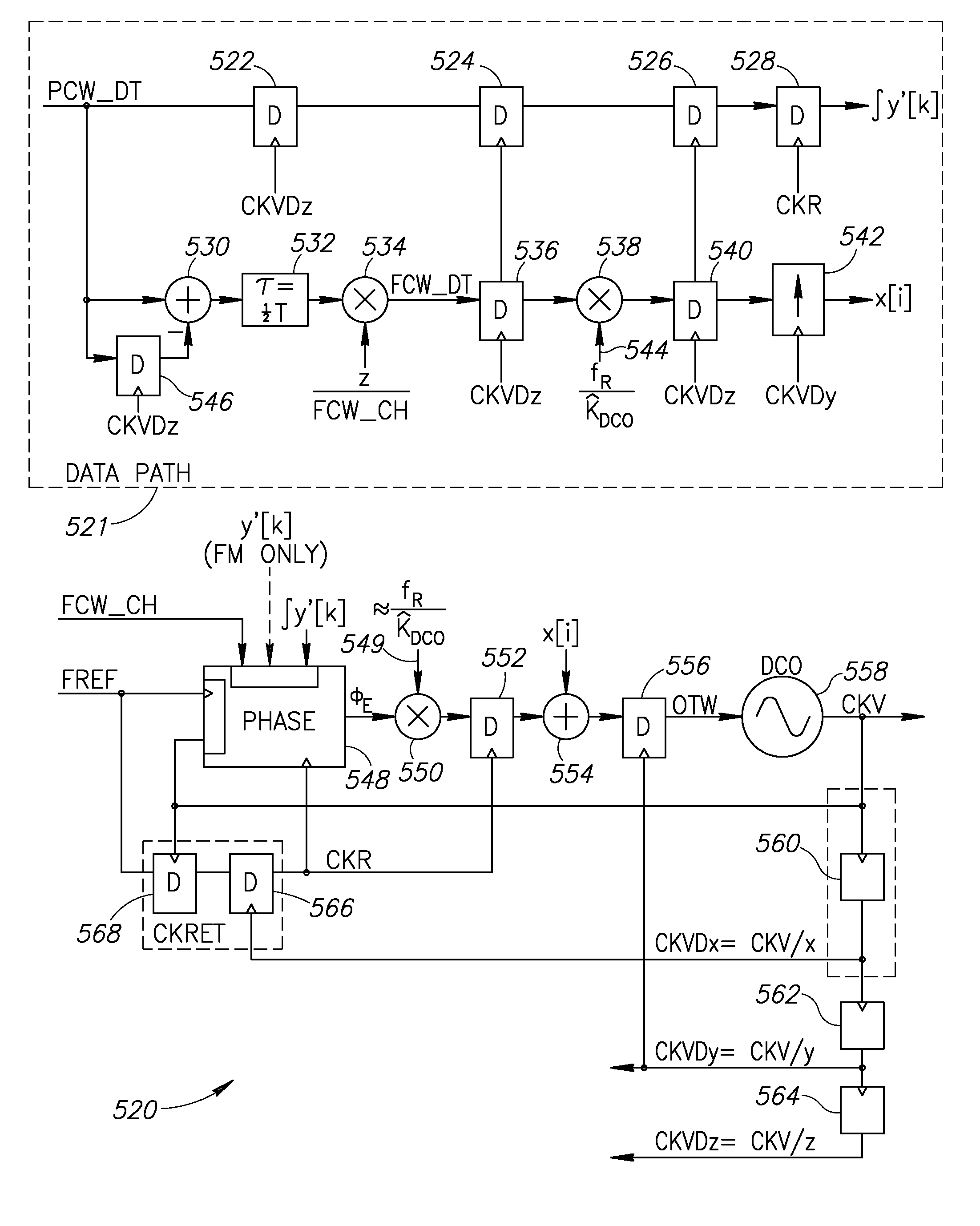

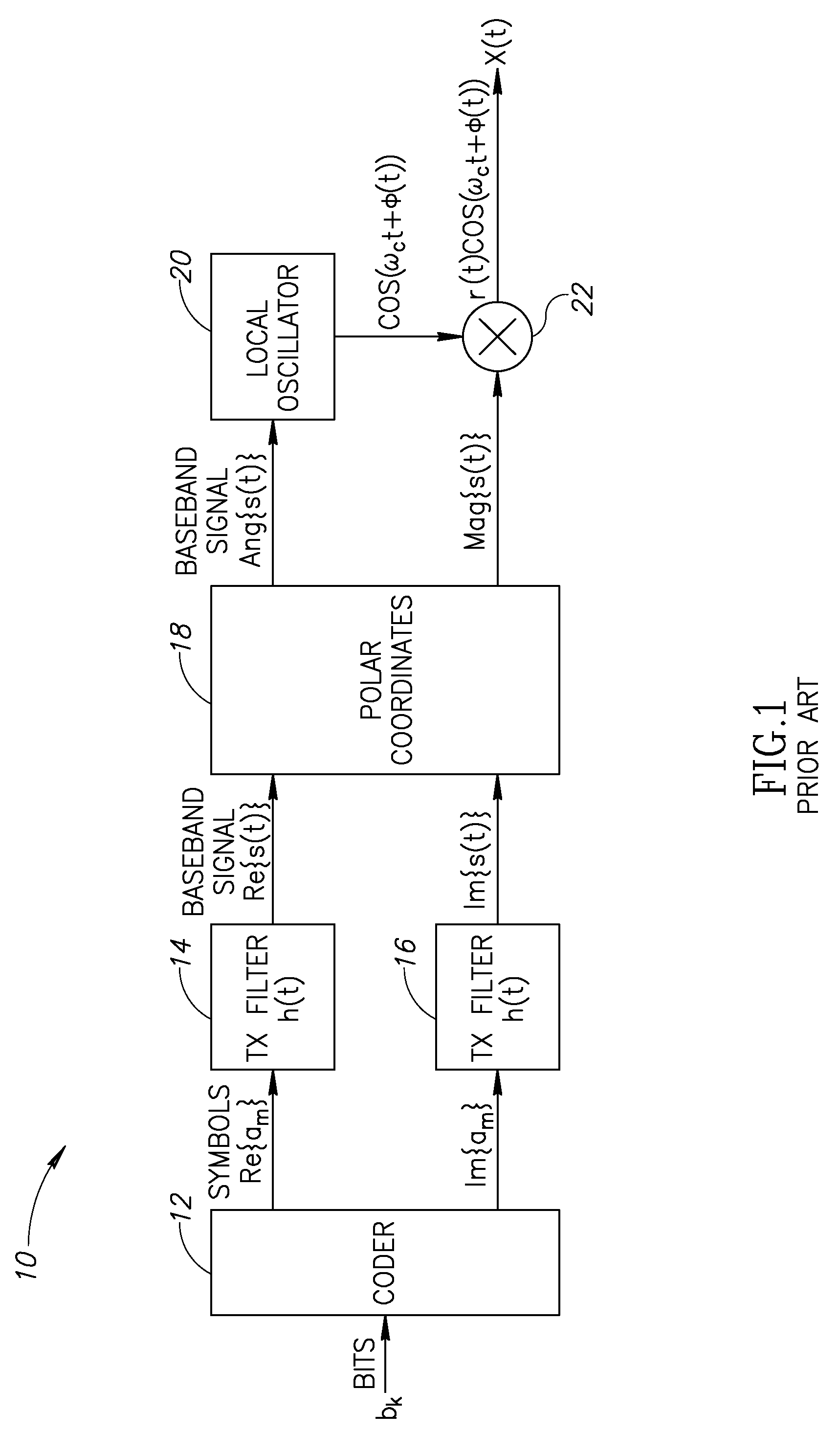

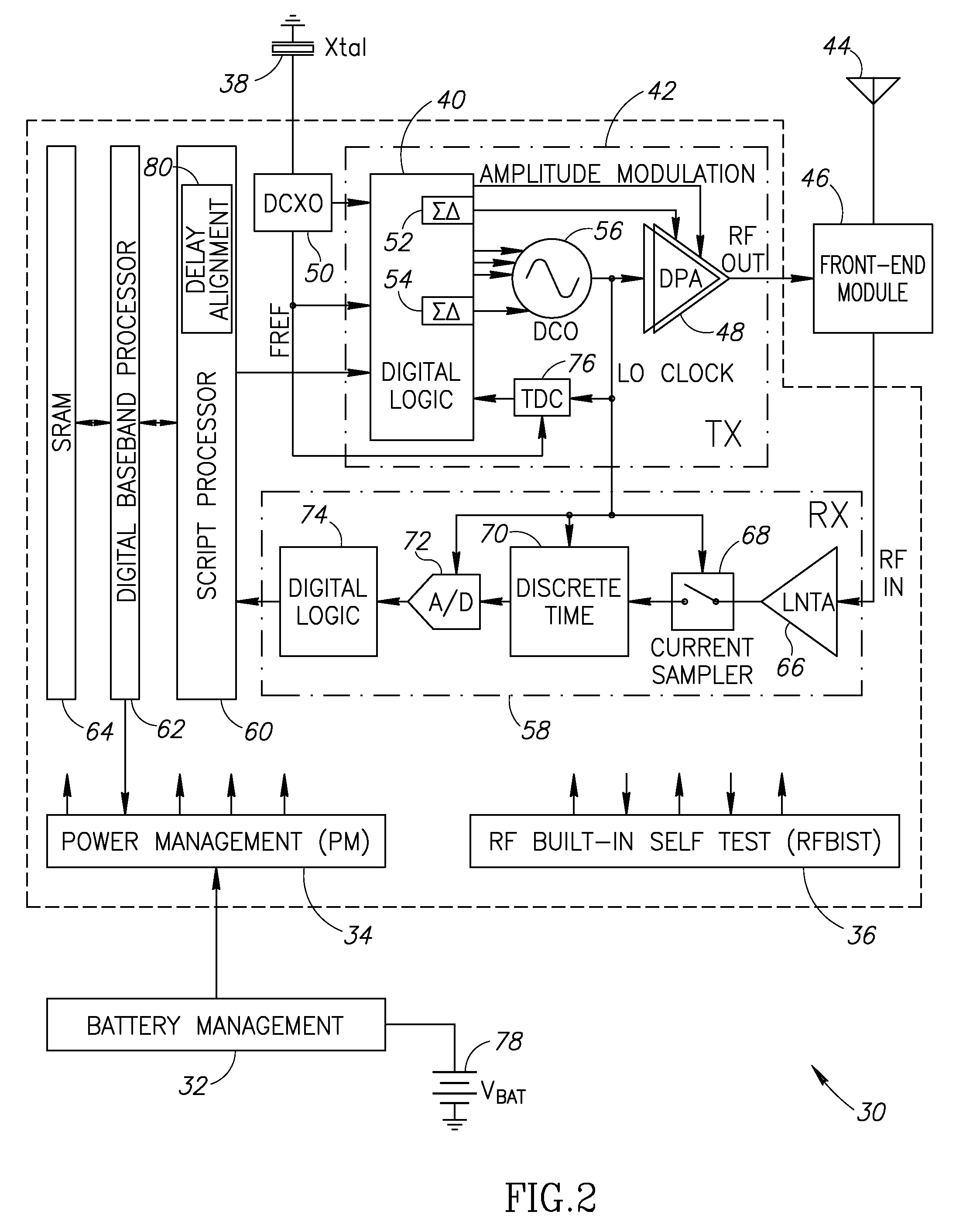

Precise delay alignment between amplitude and phase/frequency modulation paths in a digital polar transmitter

ActiveUS20070189417A1Achieve alignmentHigh phase modulation accuracy requirementSimultaneous amplitude and angle modulationModulation with suppressed carrierAudio power amplifierNanosecond

A novel apparatus for and method of delay alignment between amplitude and phase / frequency modulation paths in a digital polar transmitter. The invention provides a fully digital delay alignment mechanism where better than nanosecond alignment is achieved by accounting for processing delays in the digital circuit modules of the transmitter and by the use of programmable delay elements spread across several clock domains. Tapped delay lines compensate for propagation and settling delays in analog elements such as the DCO, dividers, quad switch, buffers, level shifters and digital pre-power amplifier (DPA). A signal correlative mechanism is provided whereby data from the amplitude and phase / frequency modulation paths to be matched is first interpolated and then cross-correlated to achieve accuracy better than the clock domain of comparison. Within the ADPLL portion of the transmitter, precise alignment of reference and direct point injection points in the ADPLL is provded using multiple clock domains, tapped delay lines and clock adjustment circuits.

Owner:TEXAS INSTR INC

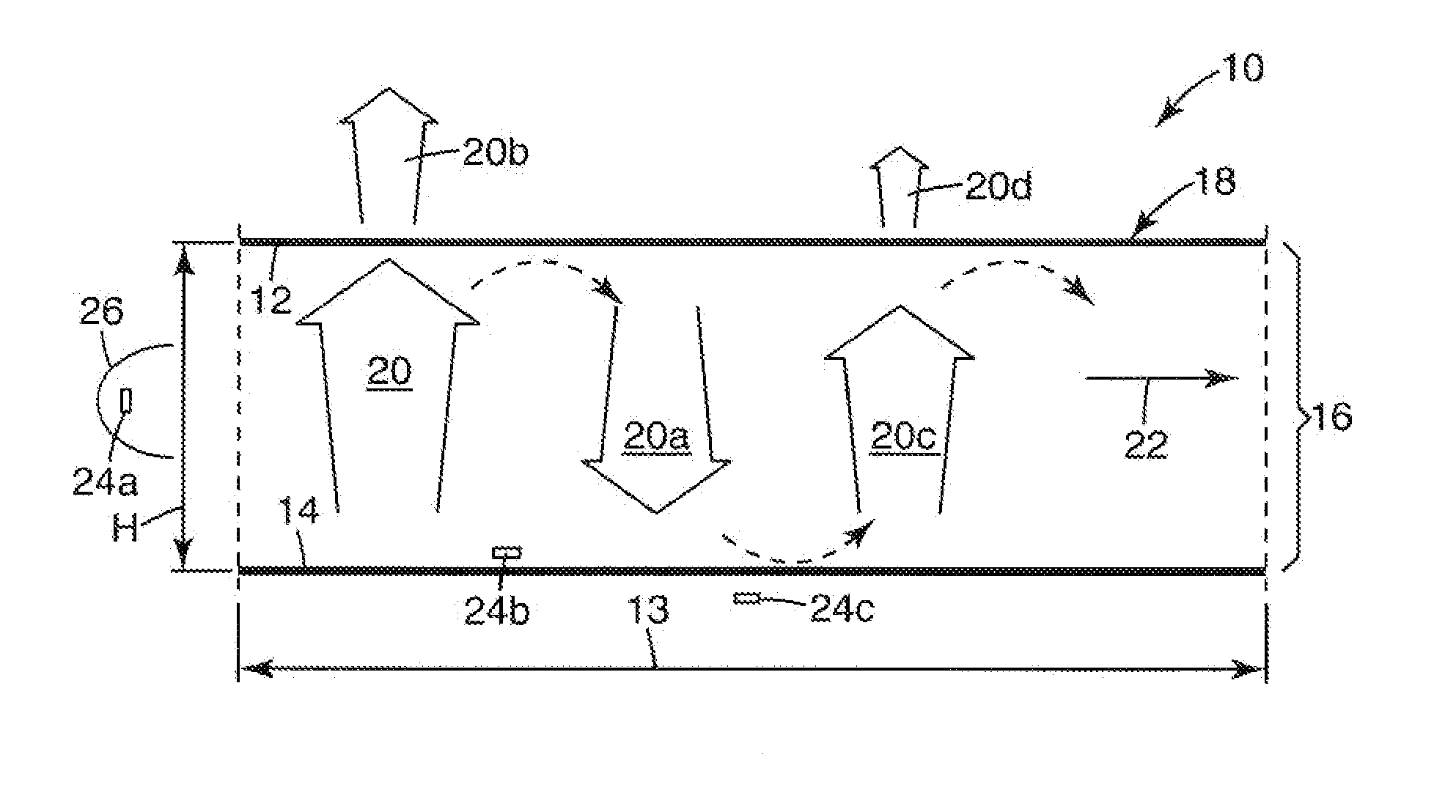

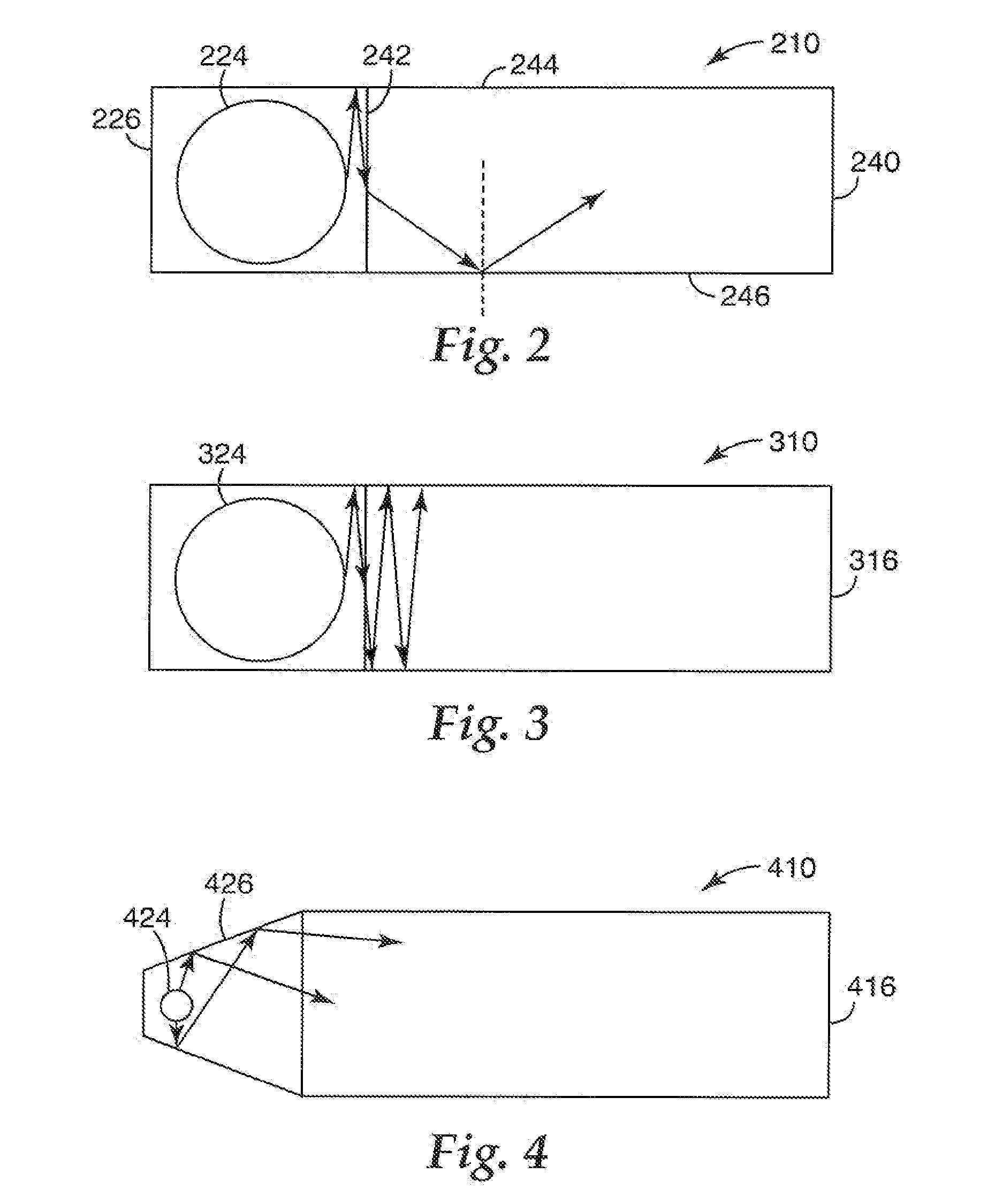

Recycling backlights with semi-specular components

ActiveUS20100238686A1Improve output performanceHollow light guidesIlluminated signsBack reflectorInjection point

A hollow light-recycling backlight has a “semi-specular” component providing a balance of specularly and diffusely reflected light improving the uniformity of the light output. The component may be arranged on the reflectors (1021), (1014) or inside the cavity (1016). This balance is achieved by designing the component's “transport ratio” defined by (F−B) / (F+B), (F and B are the amounts of incident light scattered forwards and backwards respectively by the component in the plane of the cavity) to lie in a certain range. Furthermore, the product of the front and back reflector “hemispherical” reflectivities should also lie in a given range. Alternatively, the “cavity transport value”, a measure of how well the cavity can spread injected light from the injection point to distant points in the cavity should lie in a further range and the “hemispherical” reflectivity of the back reflector should be >0.7.

Owner:3M INNOVATIVE PROPERTIES CO

Gas phase olefin polymerizations using dual donor catalyst systems

InactiveUS6900281B2Wide molecular weight distributionImprove tactical performanceGas phaseElectron donor

A gas-phase olefin polymerization process in a plug flow reactor uses a catalyst system containing a magnesium halide supported titanium-containing component, an organoaluminum component, and at least one external electron donor component; in the process a first external donor component is added to the reactor at an injection point axially near an injection point for the supported transition metal containing component, and at least a second external donor component is added to the reactor axially downstream from the injection point for the first external donor component.

Owner:INEOS TECH USA

Delay alignment in a closed loop two-point modulation all digital phase locked loop

InactiveUS20070189431A1Easy to adjustAchieve alignmentSimultaneous amplitude and angle modulationPulse automatic controlNanosecondAudio power amplifier

A novel apparatus for and method of delay alignment in a closed loop two-point modulation all digital phase locked loop (ADPLL). The invention provides a fully digital delay alignment mechanism where better than nanosecond alignment is achieved by accounting for processing delays in the digital circuit modules of the transmitter and by the use of programmable delay elements spread across several clock domains. Tapped delay lines compensate for propagation and settling delays in analog elements such as the DCO, dividers, quad switch, buffers, level shifters and digital pre-power amplifier (DPA). A signal correlative mechanism is provided whereby data from the amplitude and phase / frequency modulation paths to be matched is first interpolated and then cross-correlated to achieve accuracy better than the clock domain of comparison. Within the ADPLL portion of the transmitter, precise alignment of reference and direct point injection points in the ADPLL is provided using multiple clock domains, tapped delay lines and clock adjustment circuits.

Owner:TEXAS INSTR INC

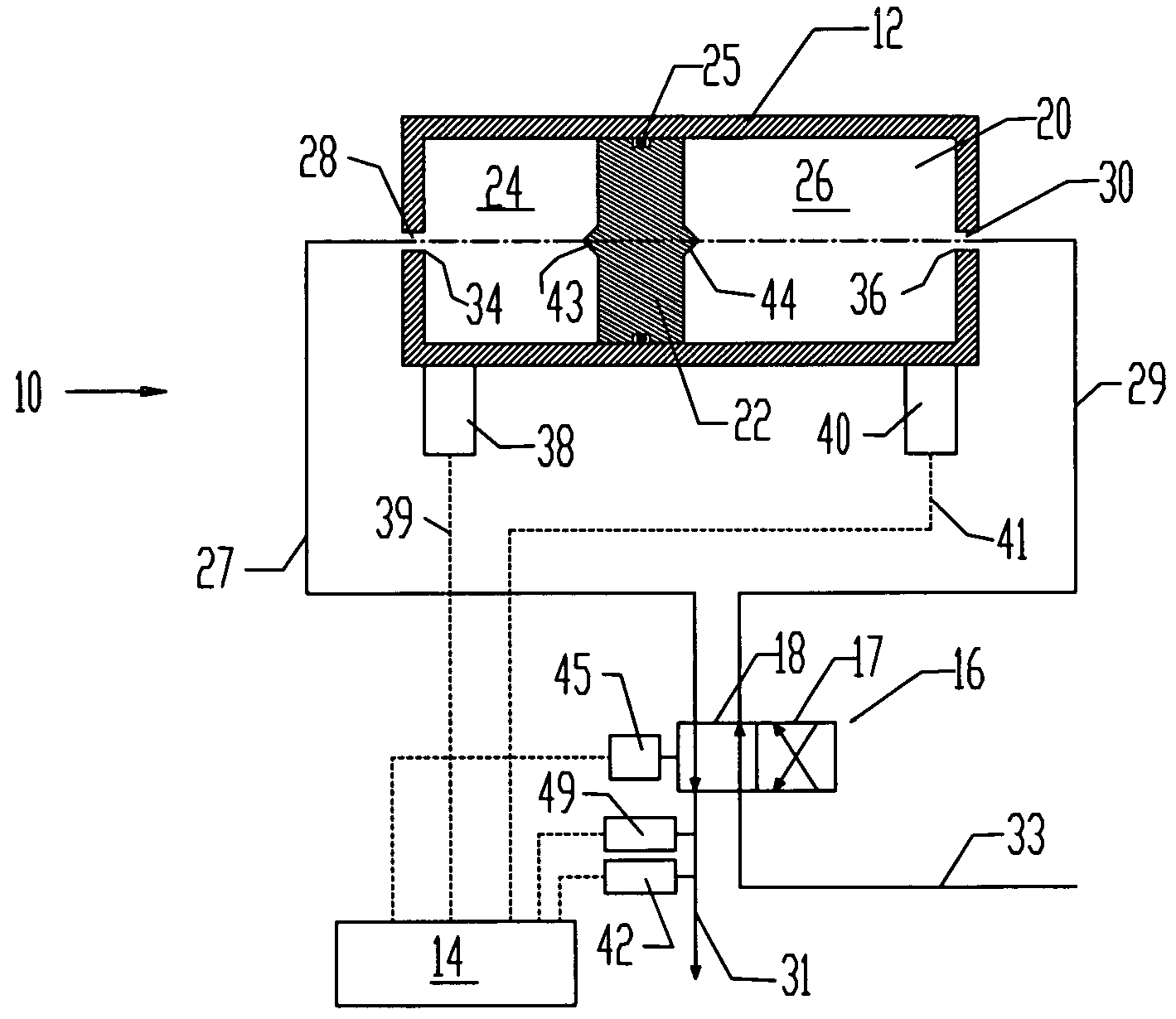

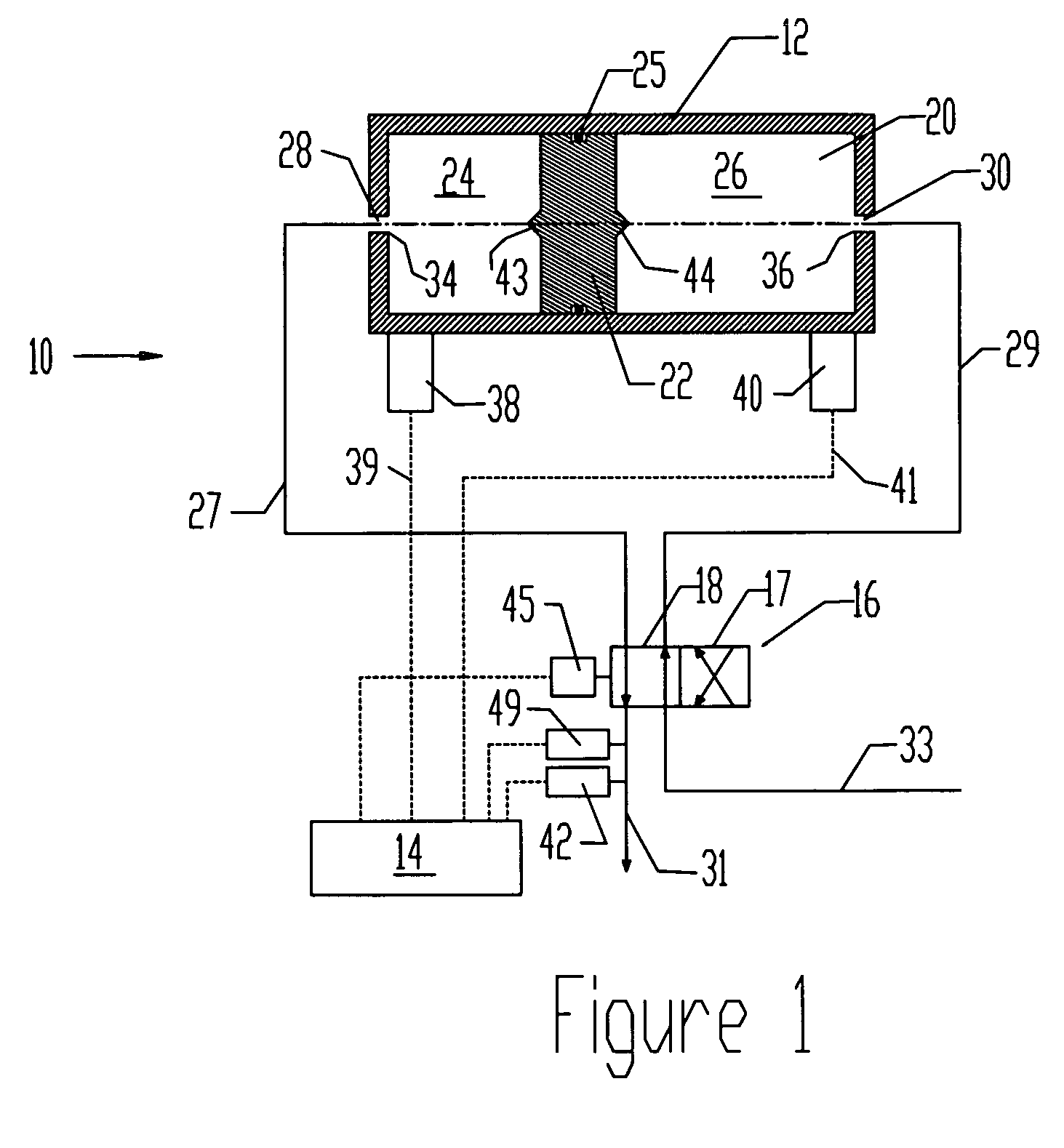

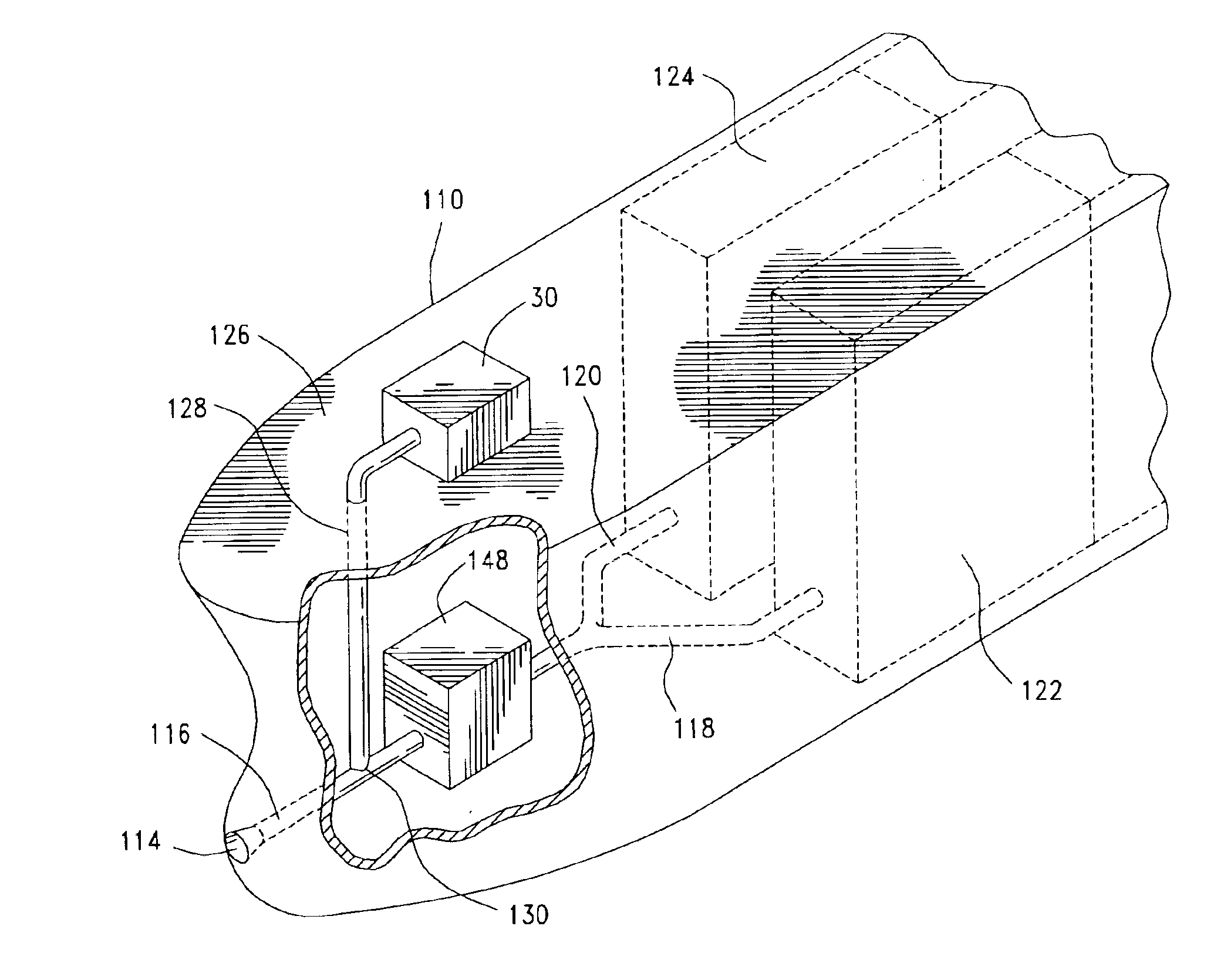

Fluid injection system

InactiveUS6973936B2Increase flow rateReduce flow rateTime indicationPower operated devicesLine tubingControl system

A fluid injection system controls the distribution of fluid from a supply line to a selected well at an adjustable rate. A fluid barrier divides a cylinder into first and second chambers. A multi-position valve comprises a first position for passing fluid from the supply line into the first chamber to displace fluid from the second chamber back through the valve to an injection point, and a second position for passing fluid from the supply line to the second chamber to displace fluid from the first chamber back through the valve to the injection point. A control system in communication with a position sensor times displacement of the fluid barrier to selected positions, and selectively adjusts a variable valve opening to adjust flow rate, switch between the first and second positions, and periodically increase the valve opening for cleaning.

Owner:WATSON RICHARD R

Standpipe distributor for short time contact of hydrocarbon compounds with particles

InactiveUS6143253ACompact and convenientSmall and convenientCatalytic crackingFluidised-bed furnacesParticle flowJet flow

An arrangement for the controlled production of an essentially linear array of hydrocarbon feed injection jets reduces required clearances and elevation while facilitating modification of the contacting locating a feed distributor containing a linear array of jets at a standpipe junction point to provide choke point for particle flow control. The flow properties of the extended particle layer are controlled by adjusting the density of the particles above the choke point created by the upper part of the standpipe inside diameter and the top of the distributor. Steam or another fluidization medium may be added to the particles directly above the distributor for this purpose. This invention can also modify the particle or feed injection characteristics by changing the projection of the distributor into the standpipe to adjust the flow area over the choke point and by the use of bottom slides or baffles to change the flow area size and configuration. Location of the distributor at a standpipe junction will also typically allow the placement of the distributor at a lower location in the process which eliminates the need to add vessel height for supplying pressure drop for the particle discharge point. The distributor arrangement also fits compactly into most common standpipe junctions. Thus, the arrangement of this invention solves the problem of inserting an extended array of feed injection points into a fluidized particle contacting process without providing a large amount of clearance or additional vessel height.

Owner:UOP LLC

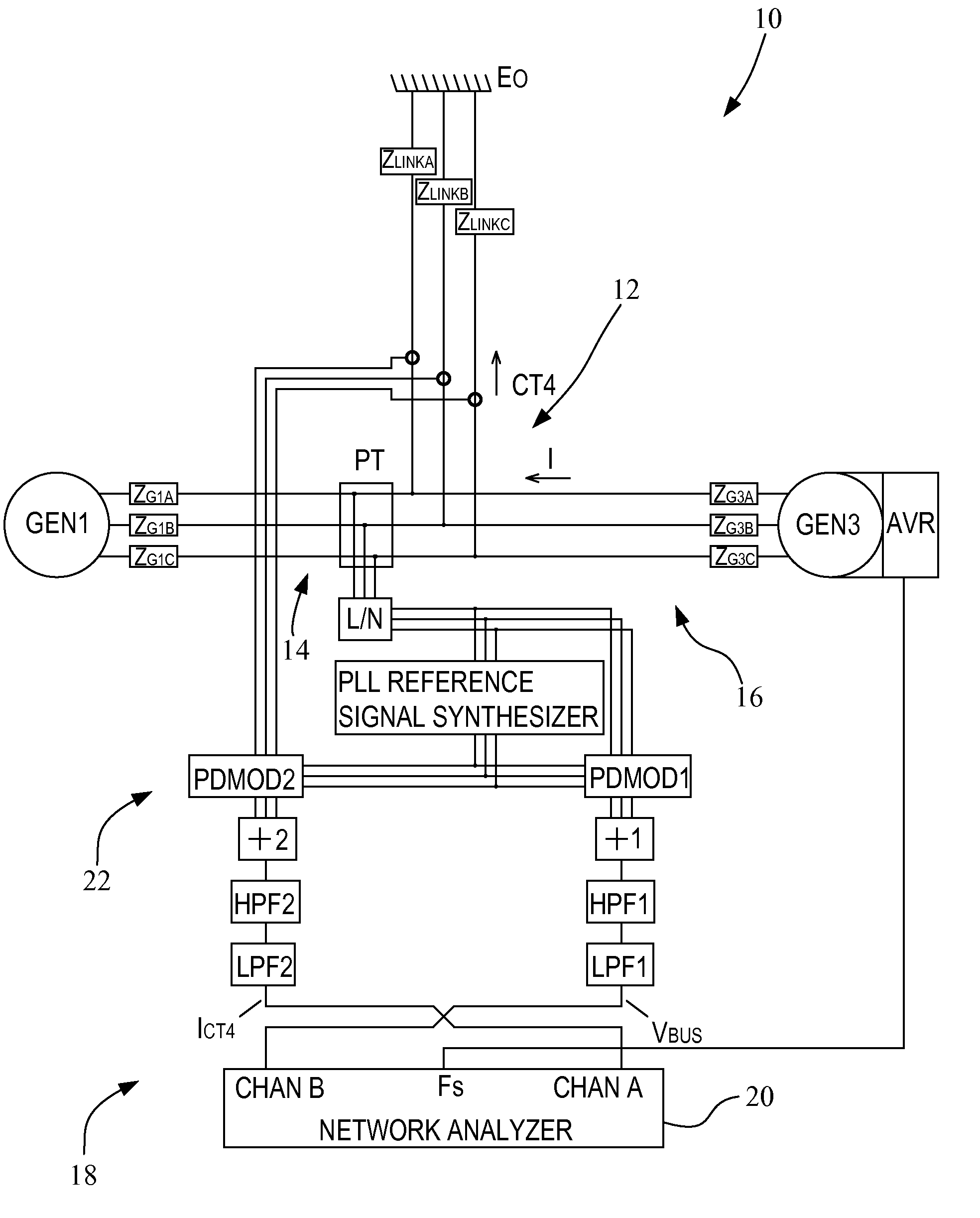

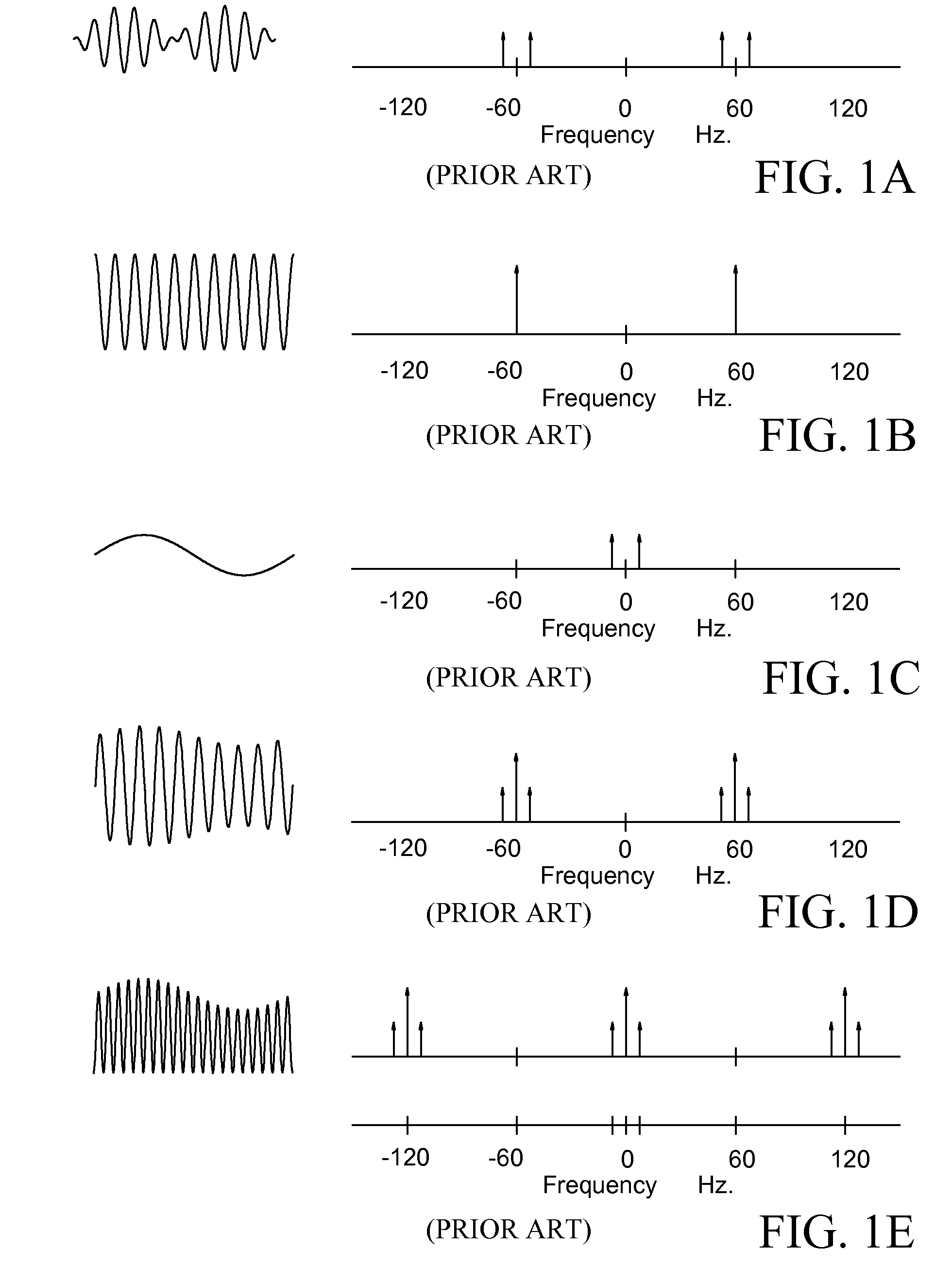

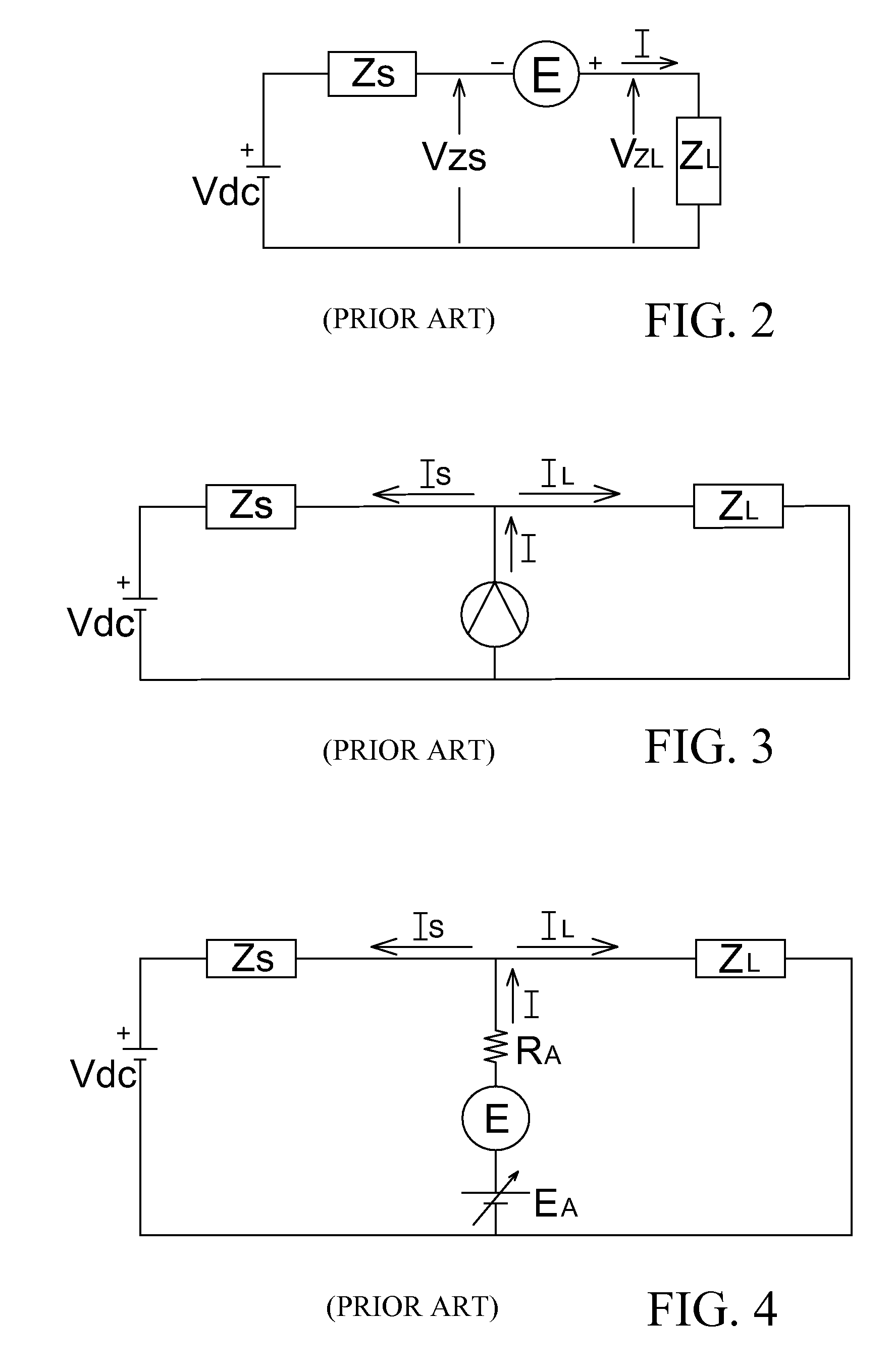

Method for measuring stability margin at a node of a polyphase power grid

InactiveUS20070241759A1Avoid oscillatory instabilityAvoid instabilityDc network circuit arrangementsElectric devicesPower gridInjection point

A method for measuring a stability margin at a node of a polyphase power grid injects suppressed-carrier stimulus into a node of the power grid by low-level amplitude modulation of the output voltage of a pre-exiting generator connected to the node. Response signals are obtained and product demodulated on a per-phase basis and summed in three-phase groups. Demodulated and summed responses contain signals that represent the suppressed-carrier impedance upstream and downstream of the stimulus injection point, and are processed to determine the stability margin at the node.

Owner:WILLIAMS MICHAEL LAMAR

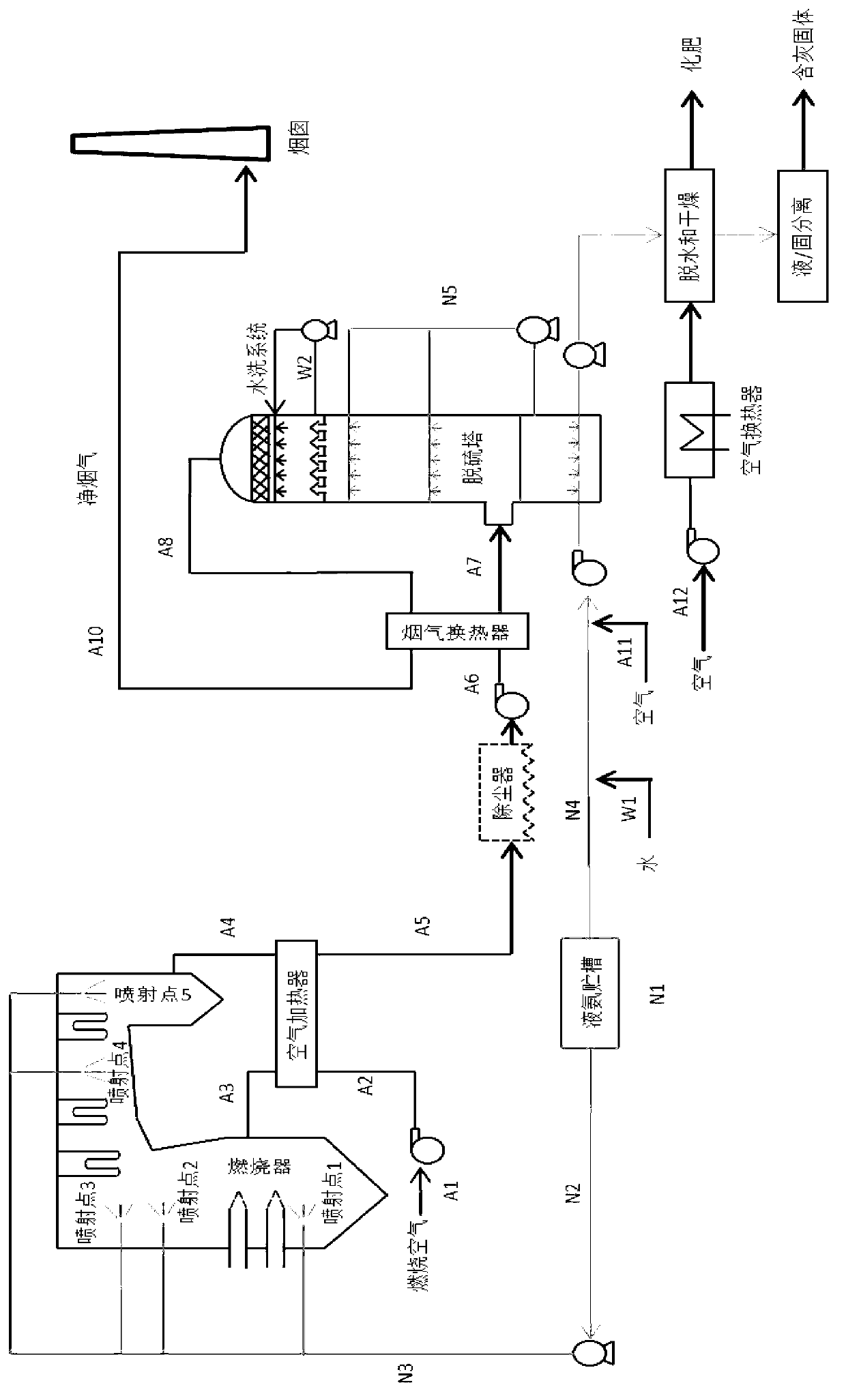

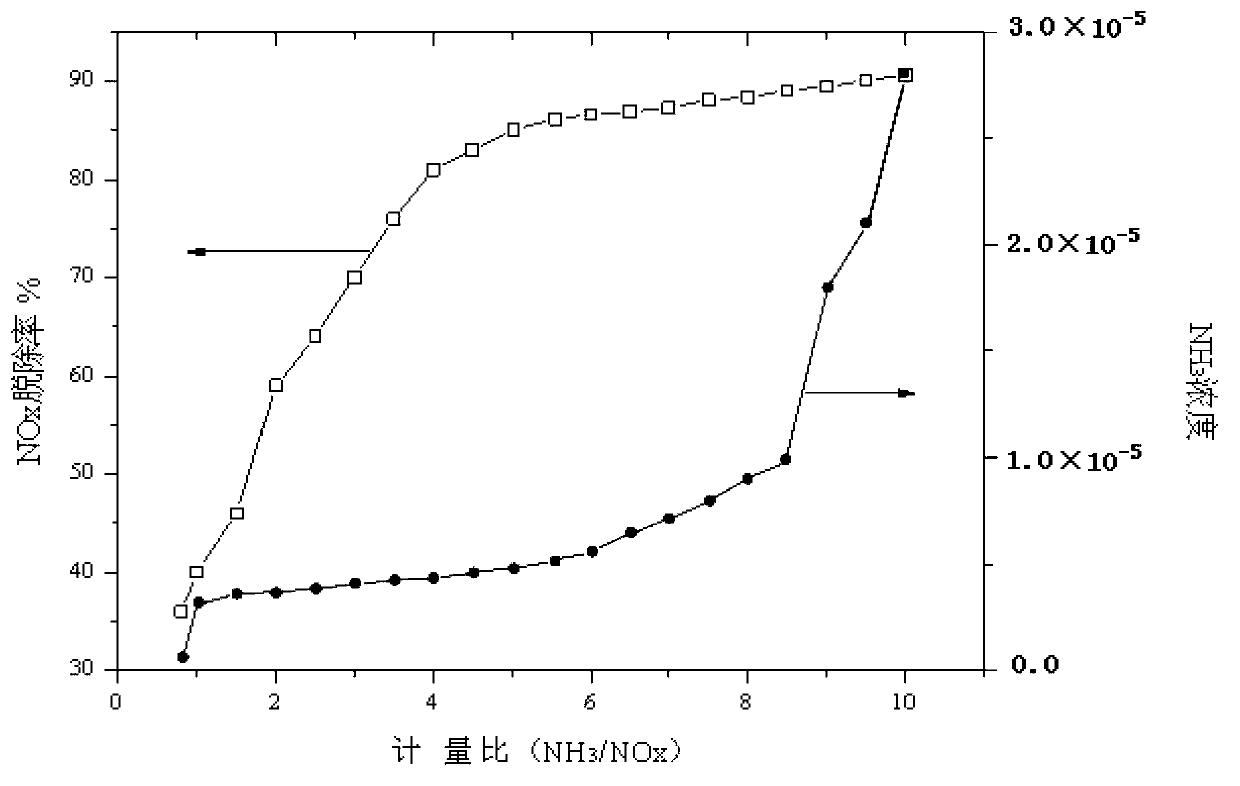

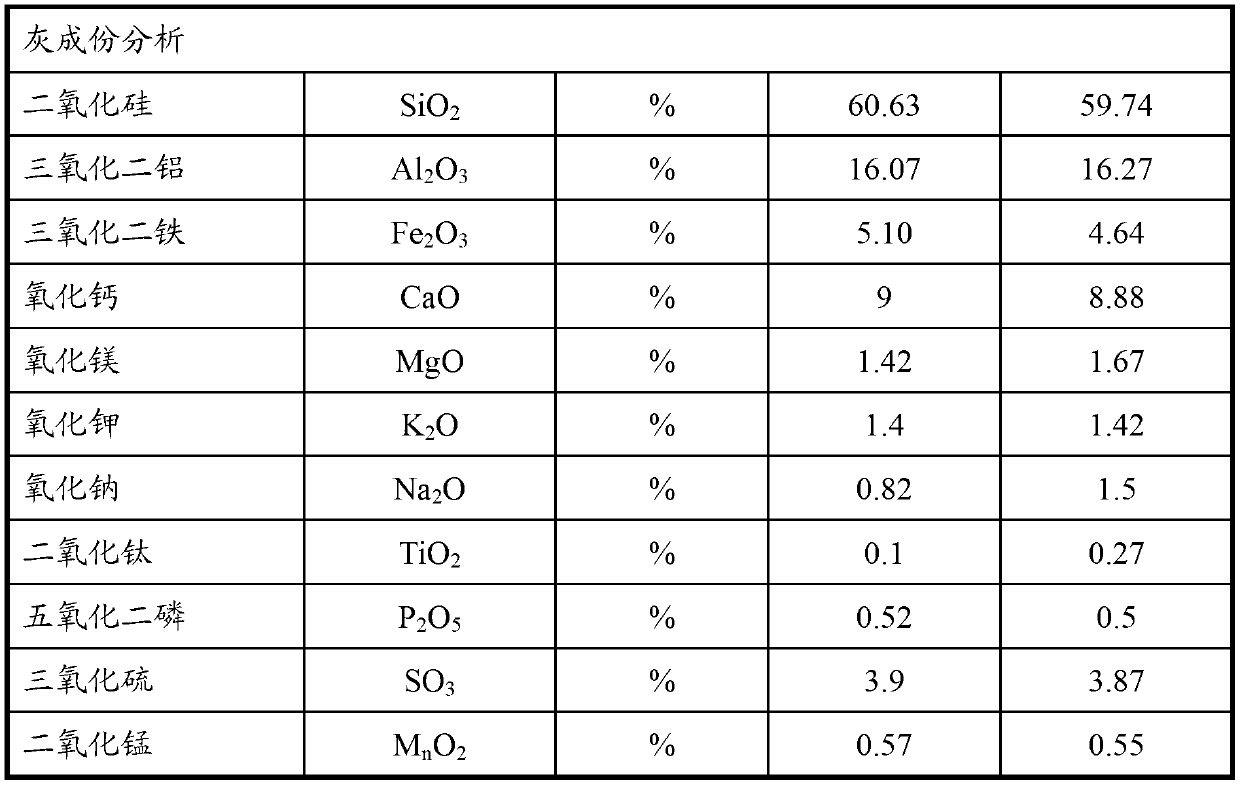

Method and device for combined removal of nitric oxide and sulfide in flue gas

InactiveCN103212284AGet rid of industrial designFully contactedDispersed particle separationAmmonium salt fertilisersBoiler furnaceFlue gas

The invention relates to a method for combined removal of nitric oxide and sulfide in flue gas. The method is characterized by comprising the following steps: spraying gasified ammonia into a furnace of a reaction boiler; reducing NOX in the flue gas to N2 by using a selective non-catalytic reduction method; sending the flue gas into a desulfurization tower; absorbing the SO2 in the flue gas by ammonia water added into the desulfurization tower; and discharging purified gas through a chimney. The invention also relates to a device for combined removal of nitrogen oxide and sulfide in flue gas. The device includes: (A) a combustion boiler used for the combustion of coal and provided with more than one ammonia injection points in the boiler furnace; (B) the desulfurization tower; and (C) an emptying device.

Owner:孙琦 +1

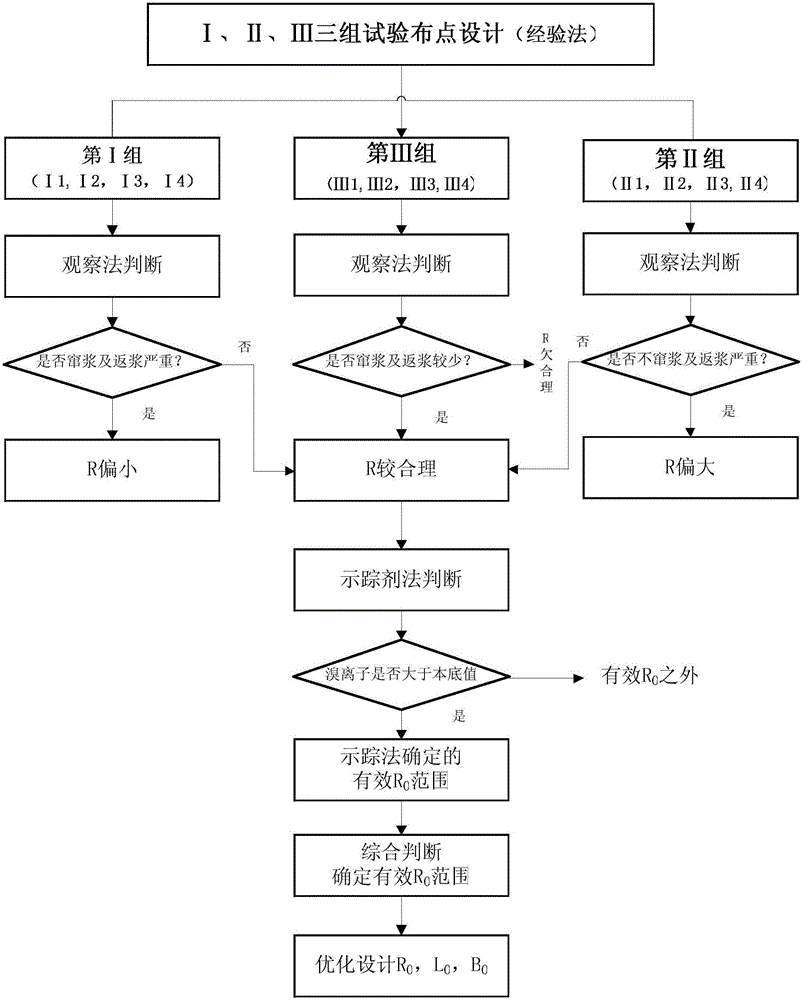

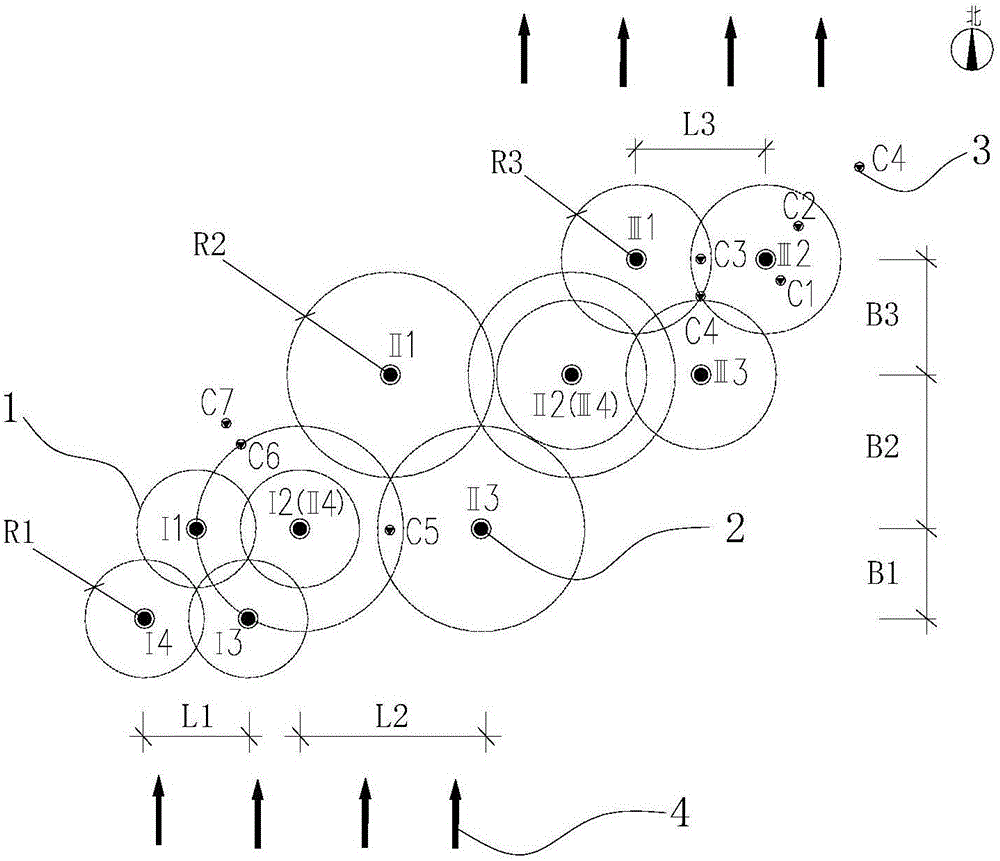

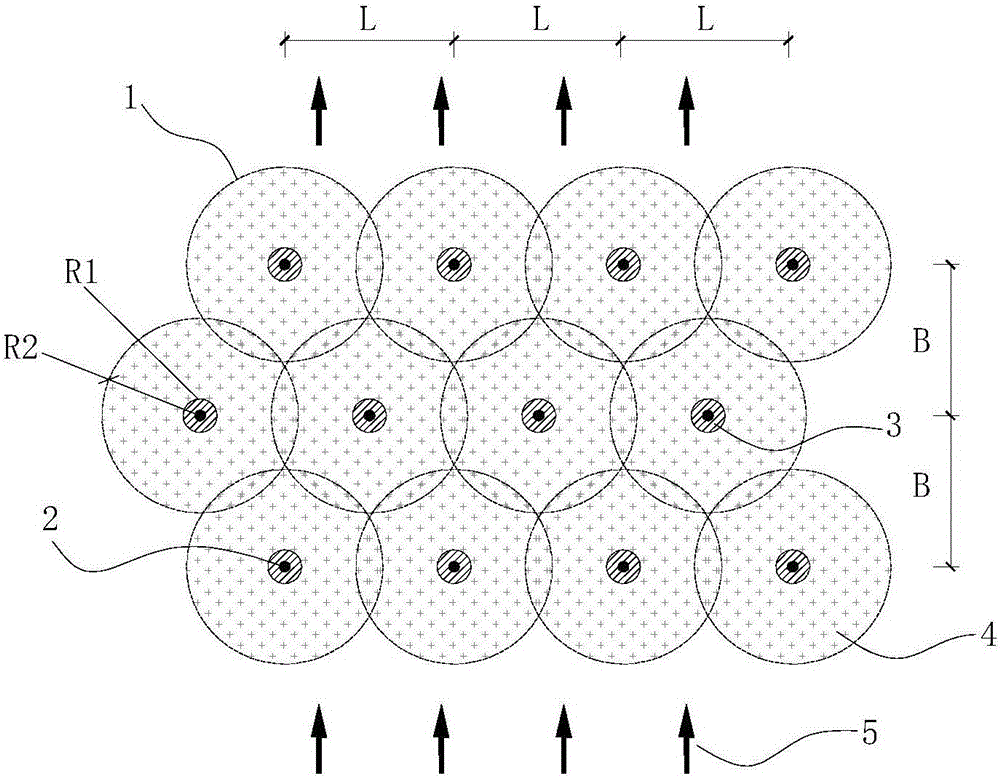

Method for determining in situ injection repair diffusion radiuses of contaminated soil and underground water

ActiveCN105973759ASolve the problem of back slurryEasy to operateConstructionsContaminated soil reclamationHigh pressureInjection test

The invention discloses a method for determining in situ injection repair diffusion radiuses of contaminated soil and underground water. According to the method, points are distributed according to a triangle method, pitch-row is designed to be perpendicular to the flowing direction of the underground water, array pitch is in the flowing direction of the underground water, and the flow expansion of a repair reagent in the underground water within the reaction effective time is taken into account. The method comprises three steps: firstly, observation method: the repair reagent and a definite proportion of bromide ion serving as tracers are simultaneously injected into an aqueous stratum in the condition of high pressure whirl spraying injection. The diffusion of the reagent is judged by observing the phenomena of grout return and grout leaking between adjacent injection points; secondly, bromide ion tracer method: after the completion of injection, underground water depth setting rapid sampling is performed, the concentration of the tracers is rapidly detected in field, and the concentration of the bromide ion in the underground water is compared with a background value; thirdly, bromide ion tracer method and observation method: the optimum diffusion radiuses are determined through synthetic judgment. The method is applied to optimal design of diffusion radiuses and hole arrangement parameters and monitoring of injection effect in soil and underground water in situ injection tests and repair construction.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

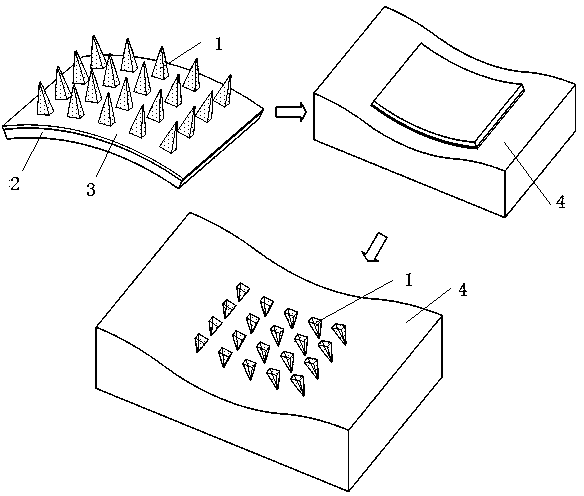

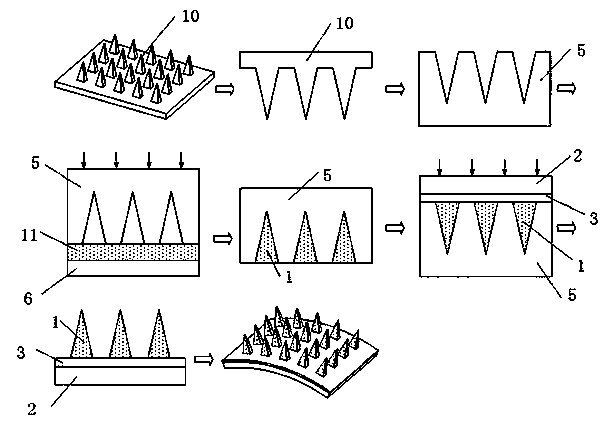

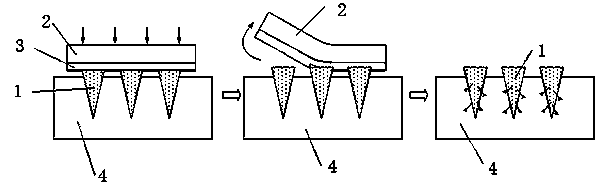

Separable microneedle system and manufacturing method thereof

ActiveCN104069585AHigh mechanical strengthSmooth piercingMicroneedlesMedical devicesInjection pointMicro-needle

The invention relates to the technical field of the microneedles for the medical cosmetology and in particular relates to a separable microneedle system and a manufacturing method thereof. The separable microneedle system comprises a microneedle and a substrate; the microneedle is detachably fixed on the substrate; when the microneedle penetrates into the skin, the microneedle is separated from the substrate so that the microneedle is remained in the skin. The separable microneedle system has the beneficial effects that the microneedle is made of a biocompatible and degradable material, has enough mechanical strength so as to smoothly pierce the skin and can be remained in the skin for procedural degradation; active substances are stable in activity in the microneedle is made of the biocompatible and degradable material, so that the medicine can be released controllably for a long time in the injection point; the microneedle substrate can be made of a flexible material, the hard microneedle can be separated from the flexible substrate, and after the microneedle penetrates into the skin, the microneedle is removed and the separated microneedle is continuously remained in the skin so that the internal active substances can be controllably dissolved and released.

Owner:厦门薇针医药科技有限公司

Flow reducer member, in particular for a receptacle containing a cosmetic, and a method of manufacture

InactiveUS6152324ALow costReliable manufacturingPower operated devicesMouldsInjection pointEngineering

A dispenser head for dispensing a fluid includes a dispenser endpiece of rigid or semi-rigid thermoplastic material and a flow reducer member of elastically deformable thermoplastic material secured to the endpiece. The member includes at least one slot whose edges are suitable for moving apart under the effect of thrust from the fluid while it is being dispensed. A method of making the dispenser head includes making the flow reducer member by injection molding from one or more injection points situated on one or both sides of the slot.

Owner:LOREAL SA

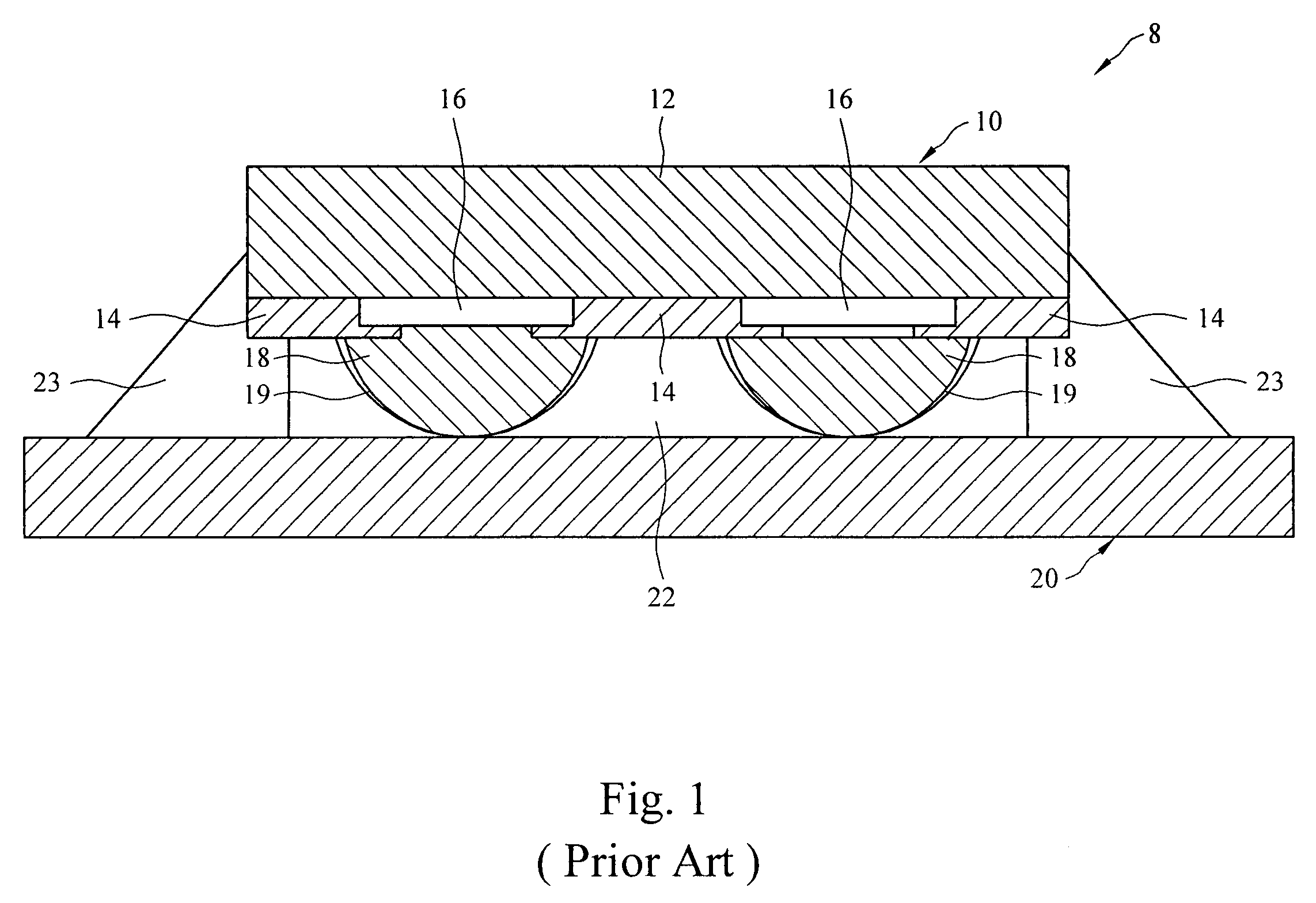

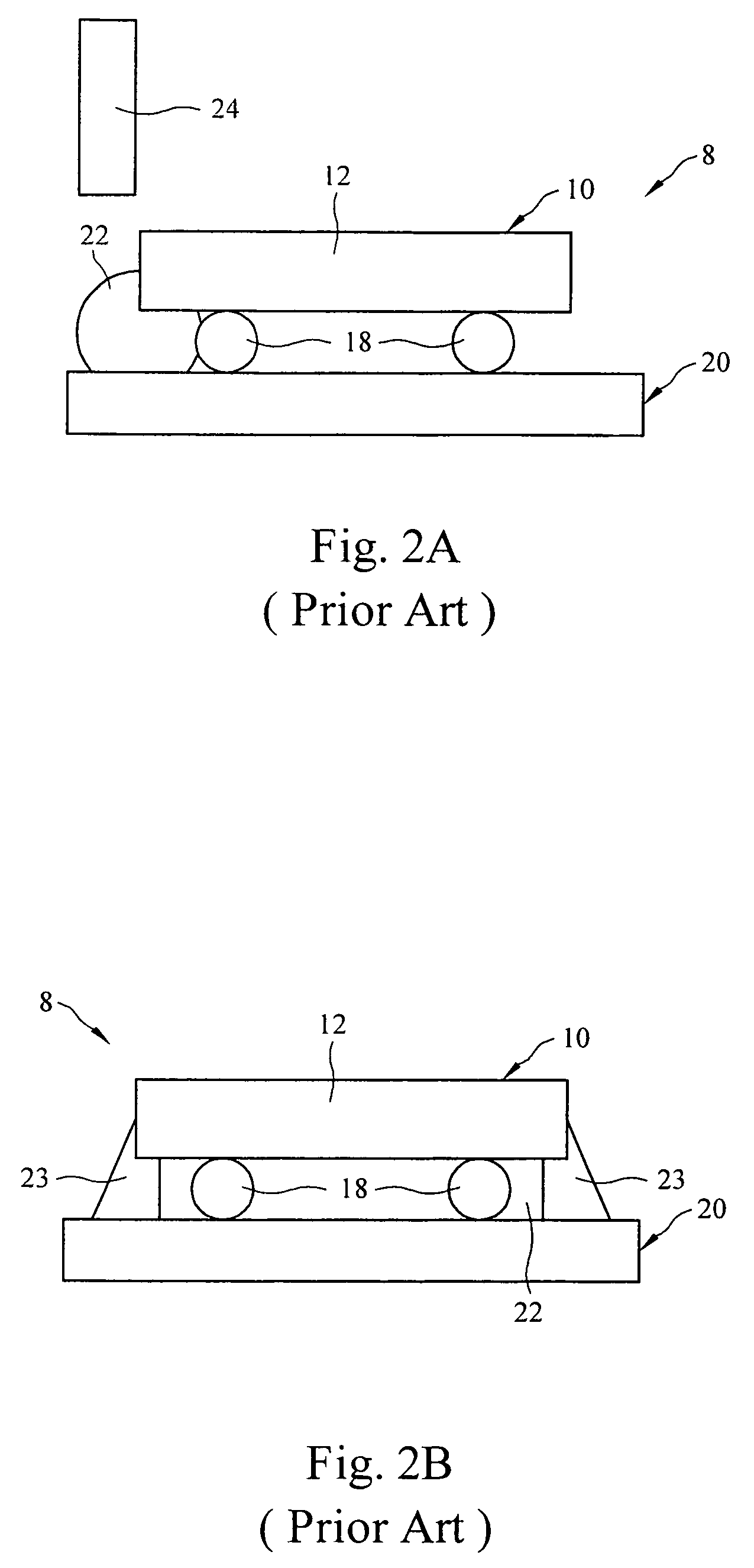

IC chip package structure and underfill process

ActiveUS7148560B2Relieve pressurePrevents orSemiconductor/solid-state device detailsSolid-state devicesMultiple injectionInjection point

A novel integrated circuit (IC) chip package structure and underfill process which reduces stress applied to corners of a flip chip in an IC package structure during the application of an adhesive material between the flip chip and a carrier substrate is disclosed. The process includes providing a dam structure on a carrier substrate; attaching solder bumps of an inverted flip chip to the carrier substrate; injecting an adhesive material between the flip chip and the carrier substrate at multiple injection points located along adjacent edges of the flip chip; and injecting a sealant material around the adhesive material. During application of the adhesive material and the sealant material to the IC package structure in the underfill process, the dam structure reduces stress applied to the corners of the flip chip. This prevents or at least reduces de-lamination of dielectric layers on the flip chip.

Owner:TAIWAN SEMICON MFG CO LTD

Ballast water ozone injection method and system

InactiveUS6869540B2Method securityAuxillariesSelf-bailing equipments/scuppersOzone generatorInjection point

A method to treat ballast water comprises injecting ozone into water loading into a sea faring vessel prior to charging the water into a ballast tank; and charging the ozone injected water into the ballast tank. A system for treating ballast water comprises a sea faring vessel including at least one ballast tank; an ozone generator that generates ozone, a ballast water conduit that uptakes water through a loading port of a sea faring vessel and conducts the water to load the ballast tank; and an ozone feed line that injects ozone from the generator into water in the conduit at an injection point located upstream to an intersection of the conduit with the ballast tank.

Owner:NUTECH O3 INC

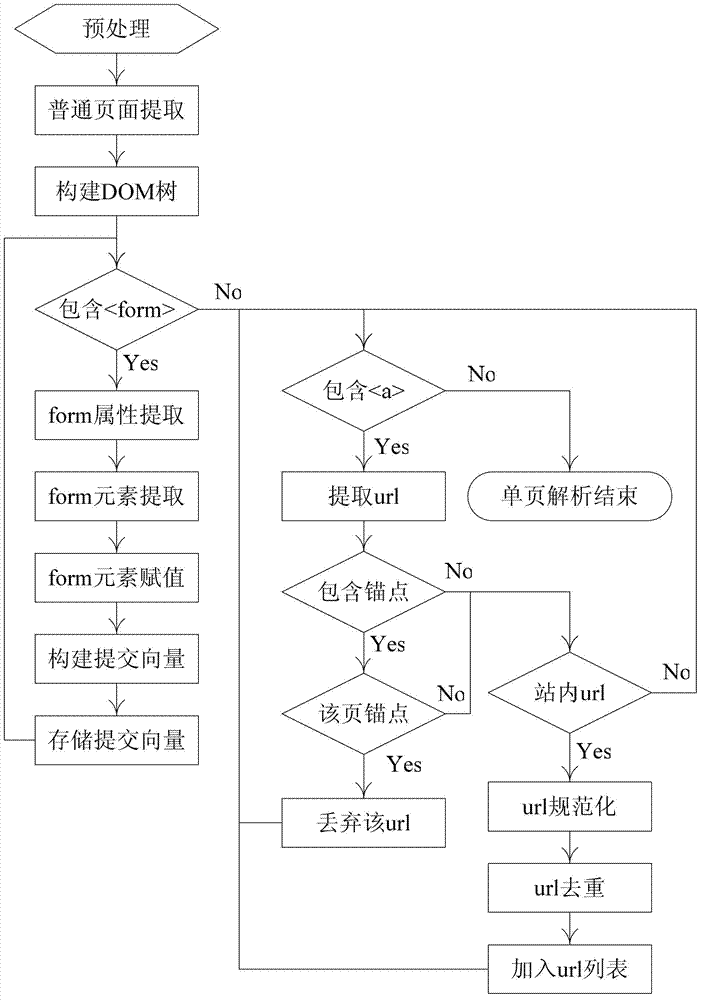

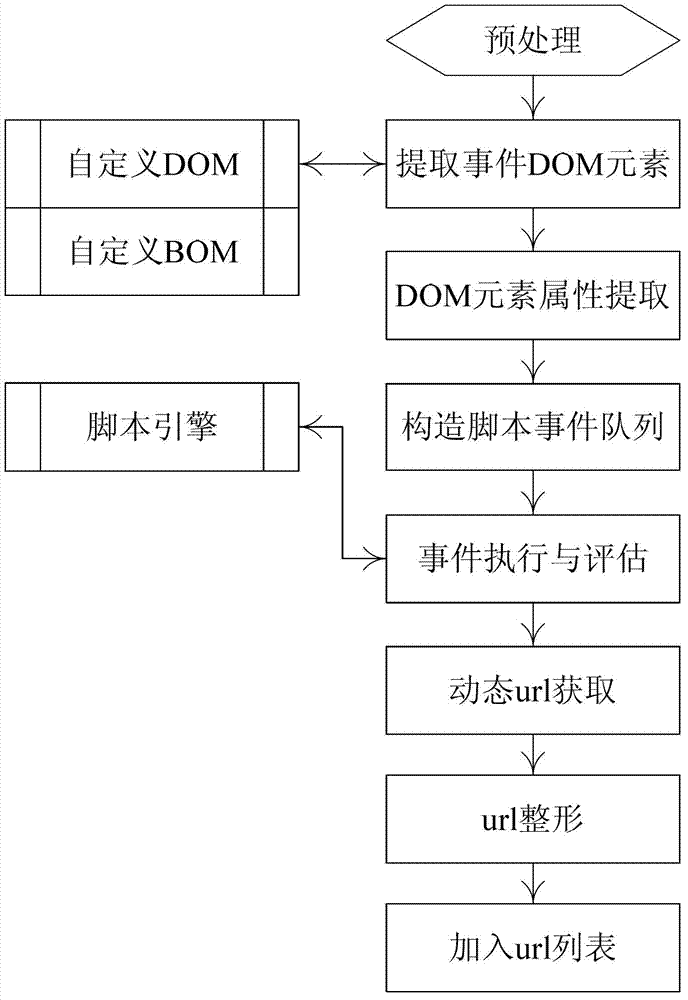

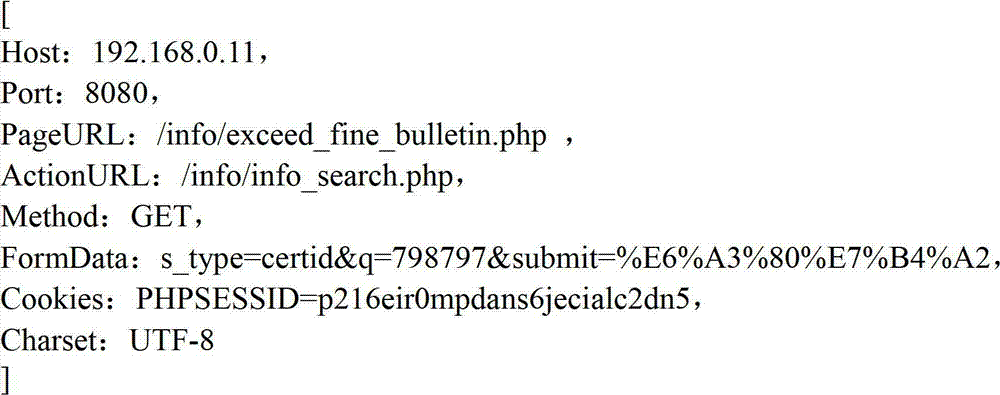

Injection point extracting method in SQL (Structured Query Language) injection vulnerability detection

InactiveCN102831345AIncrease the analysis processSolve the problem of false positivesComputer security arrangementsSoftware testing/debuggingFiltrationSQL injection

The invention discloses an injection point extracting method in SQL (Structured Query Language) injection vulnerability detection, which is used for solving the technical problem of poor accuracy of the traditional method in the SQL injection vulnerability detection under a Web environment. According to the technical scheme, the injection point extracting method comprises the steps of: firstly, preprocessing a downloaded webpage, dividing the webpage into a simple webpage and a complex webpage, extracting a data injection point of the simple webpage, extracting a data injection point of the complex webpage, extracting a test case through constructing the test case, analyzing service response, and establishing a decision rule of an SQL injection vulnerability. According to the invention, starting from obtaining the data injection points of a Web application system, through constructing the targeted test case, the used test case is used for carrying out character string, numerical value, annotation and delay testing according to the types and the parameter compositions of the data injection points, thus the test of the injection vulnerability caused by simple filtration of URL (Uniform Resource Locator) parameters and table submitted data is effectively dealt; and through analysis response, the established decision rule of the SQL injection vulnerability is improved in testing accuracy.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

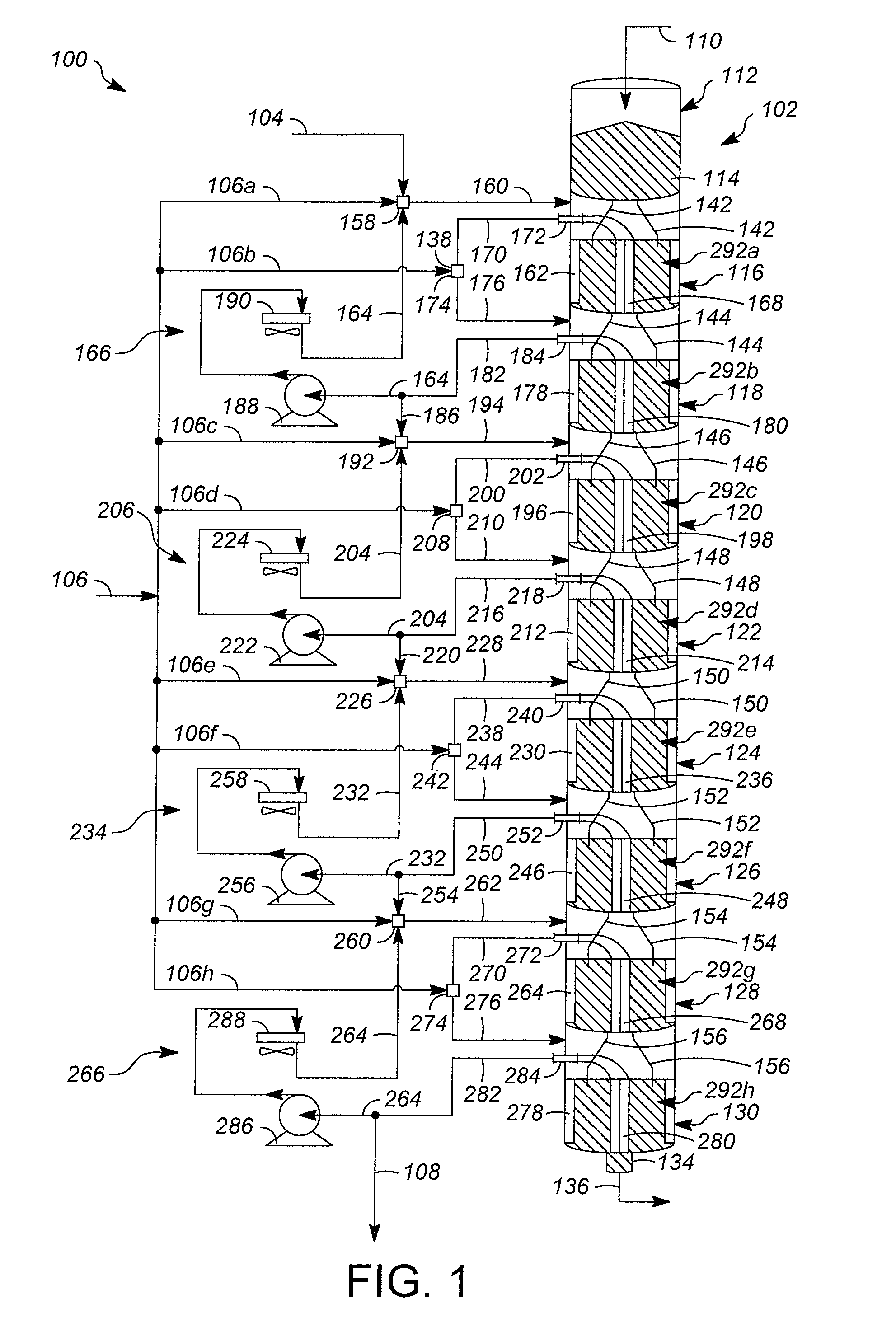

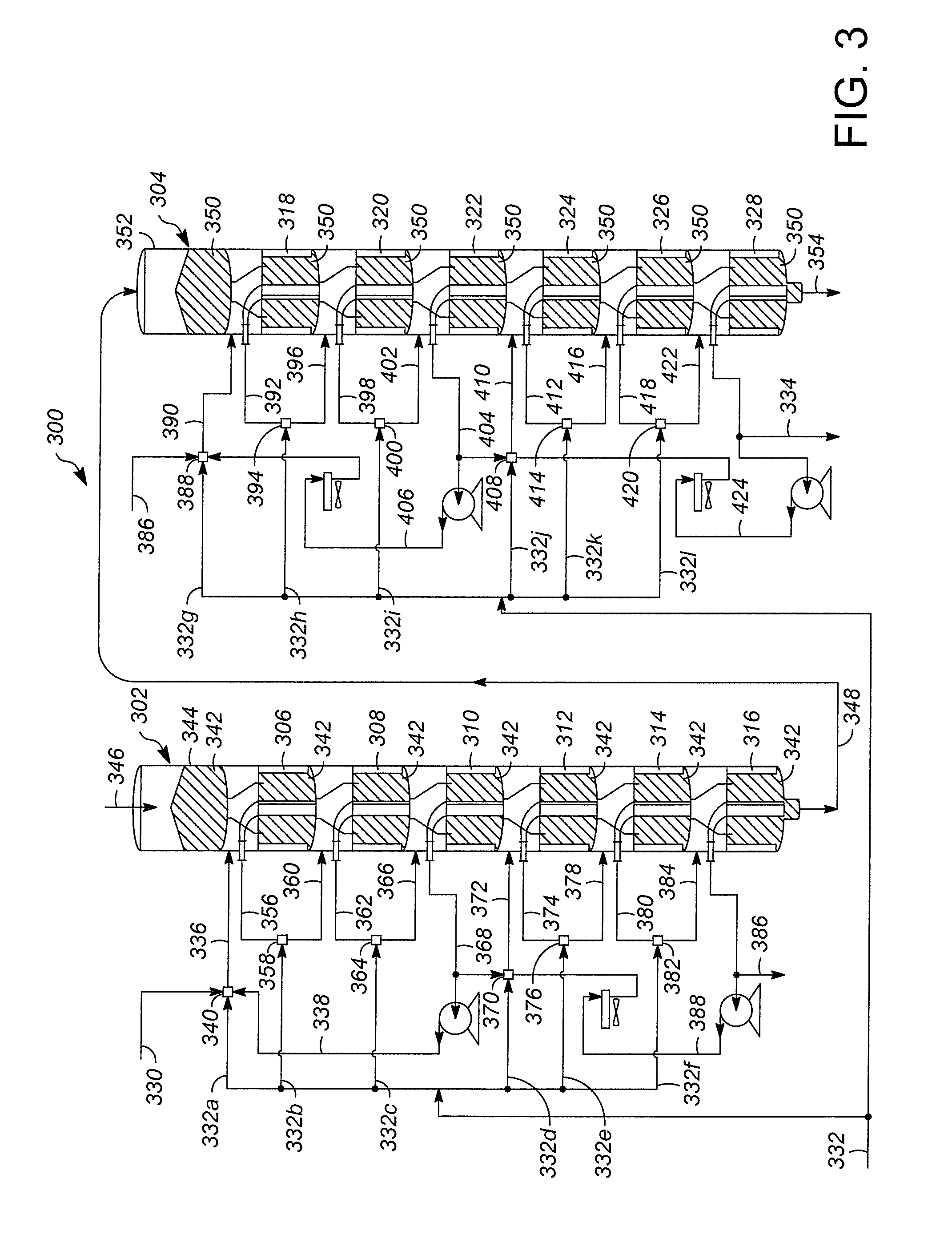

Solid catalyst hydrocarbon alkylation using stacked moving bed radial flow reactors

Systems and processes for the alkylation of a hydrocarbon are provided that utilize a plurality of moving bed radial flow reactors. An olefin injection point can be provided prior to each reactor by providing a mixer that mixes olefin with a hydrocarbon feed, or with the effluent stream from an upstream reactor, to produce a reactor feed stream. Catalyst can be provided from the reaction zone of one reactor to the reaction zone of a downstream reactor through catalyst transfer pipes, and can be regenerated after passing through the reaction zones of the reactors. The moving bed radial flow reactors can be stacked in one or more reactor stacks.

Owner:UOP LLC

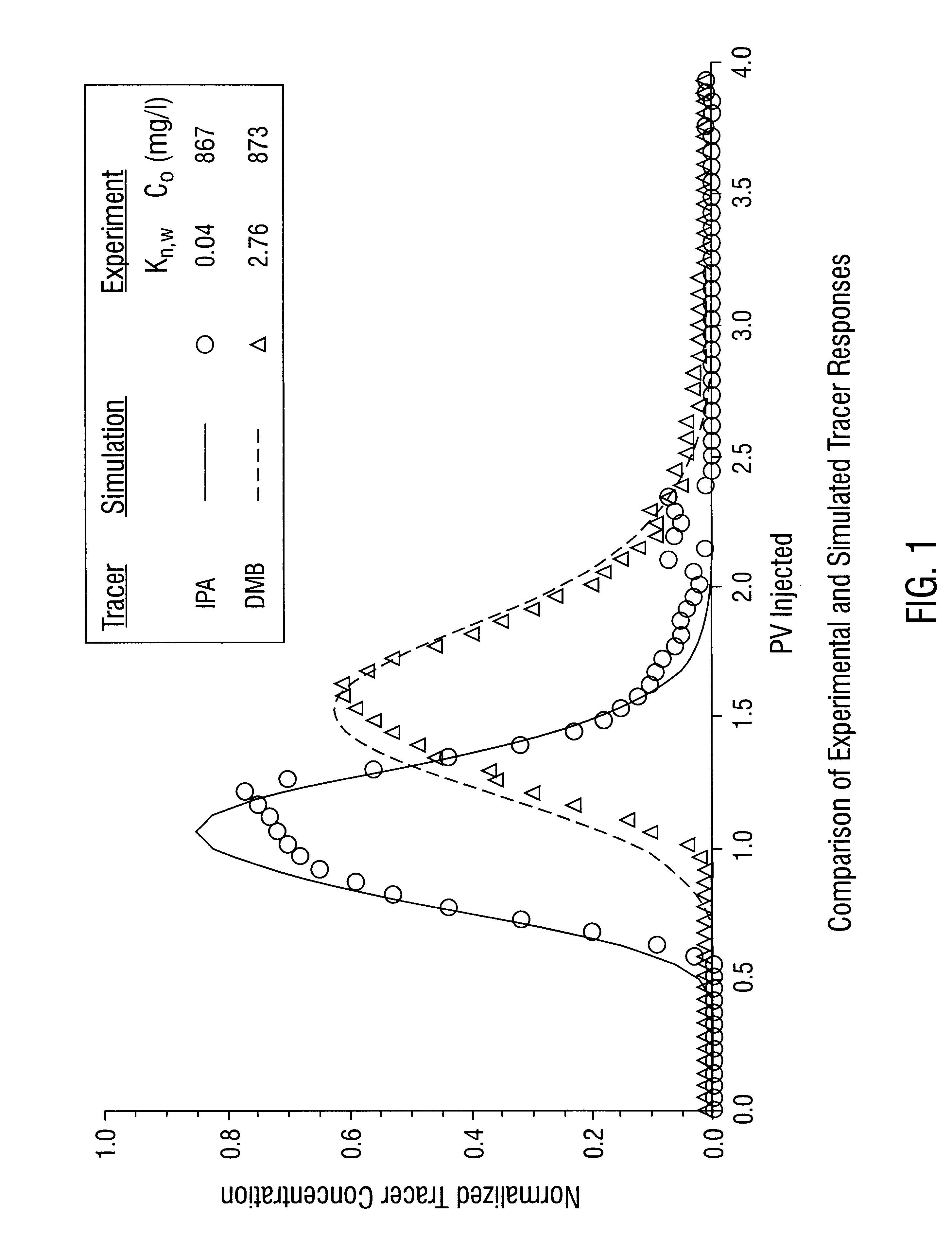

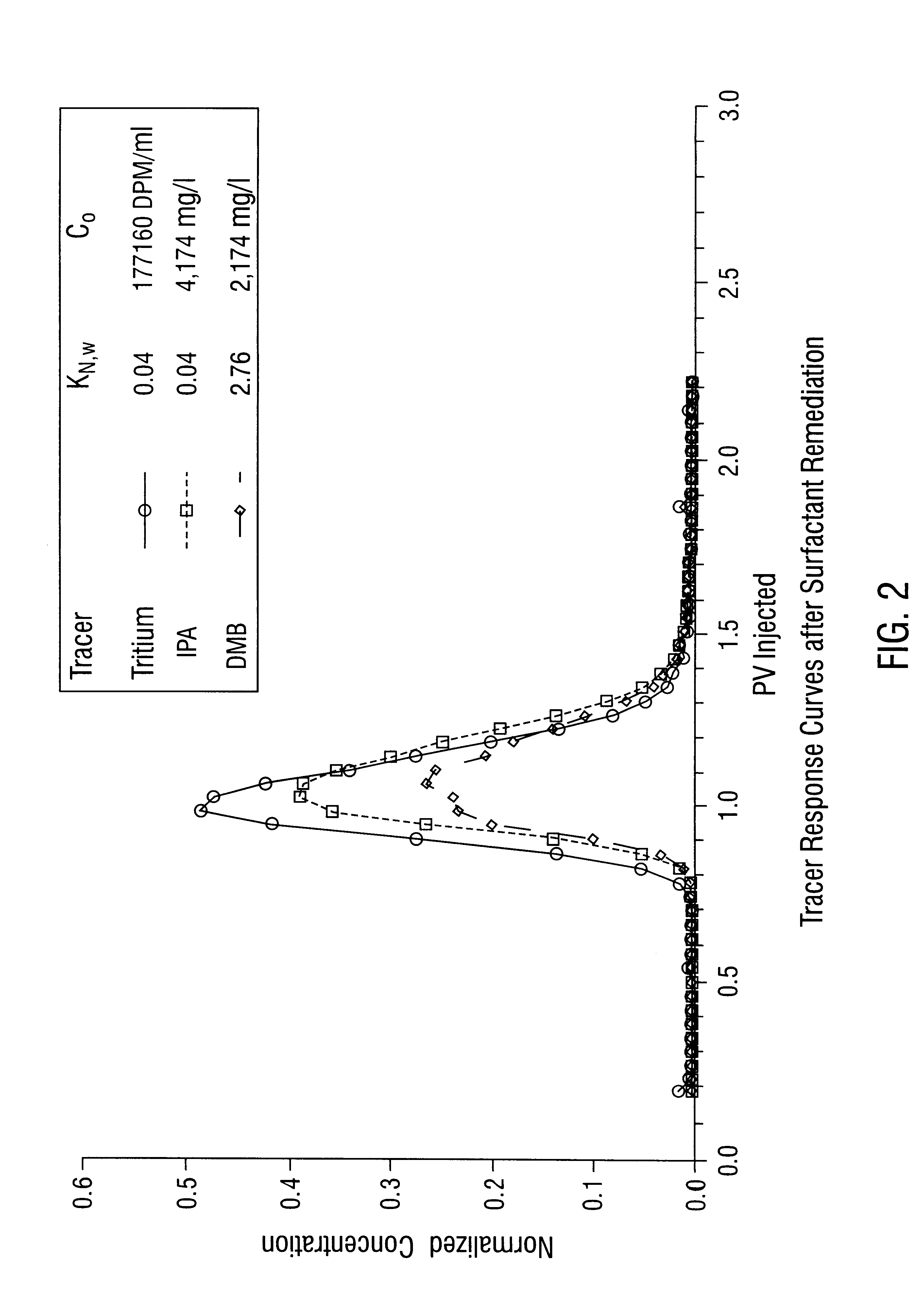

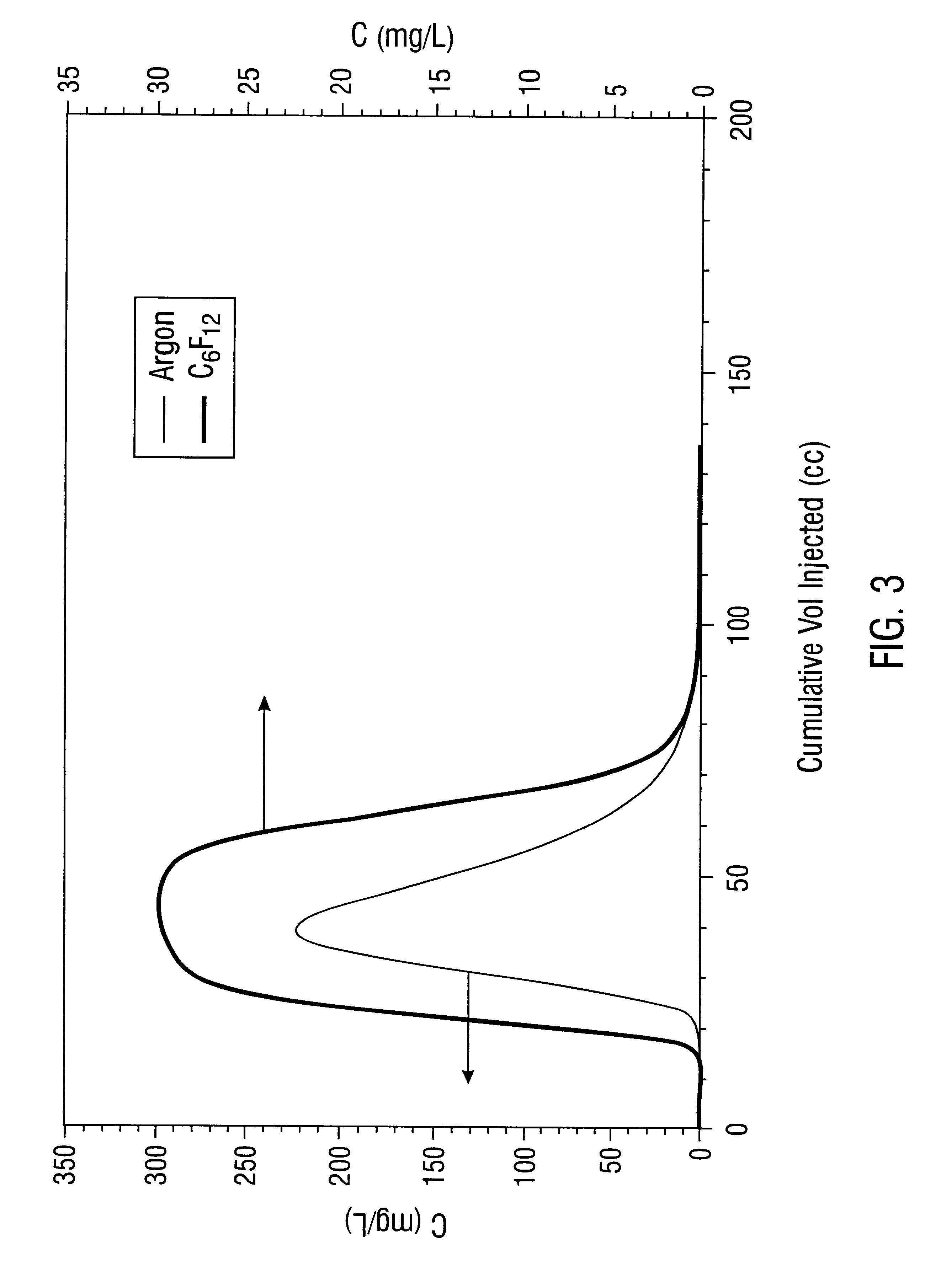

Characterization of organic contaminants and assessment of remediation performance in subsurface formations

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

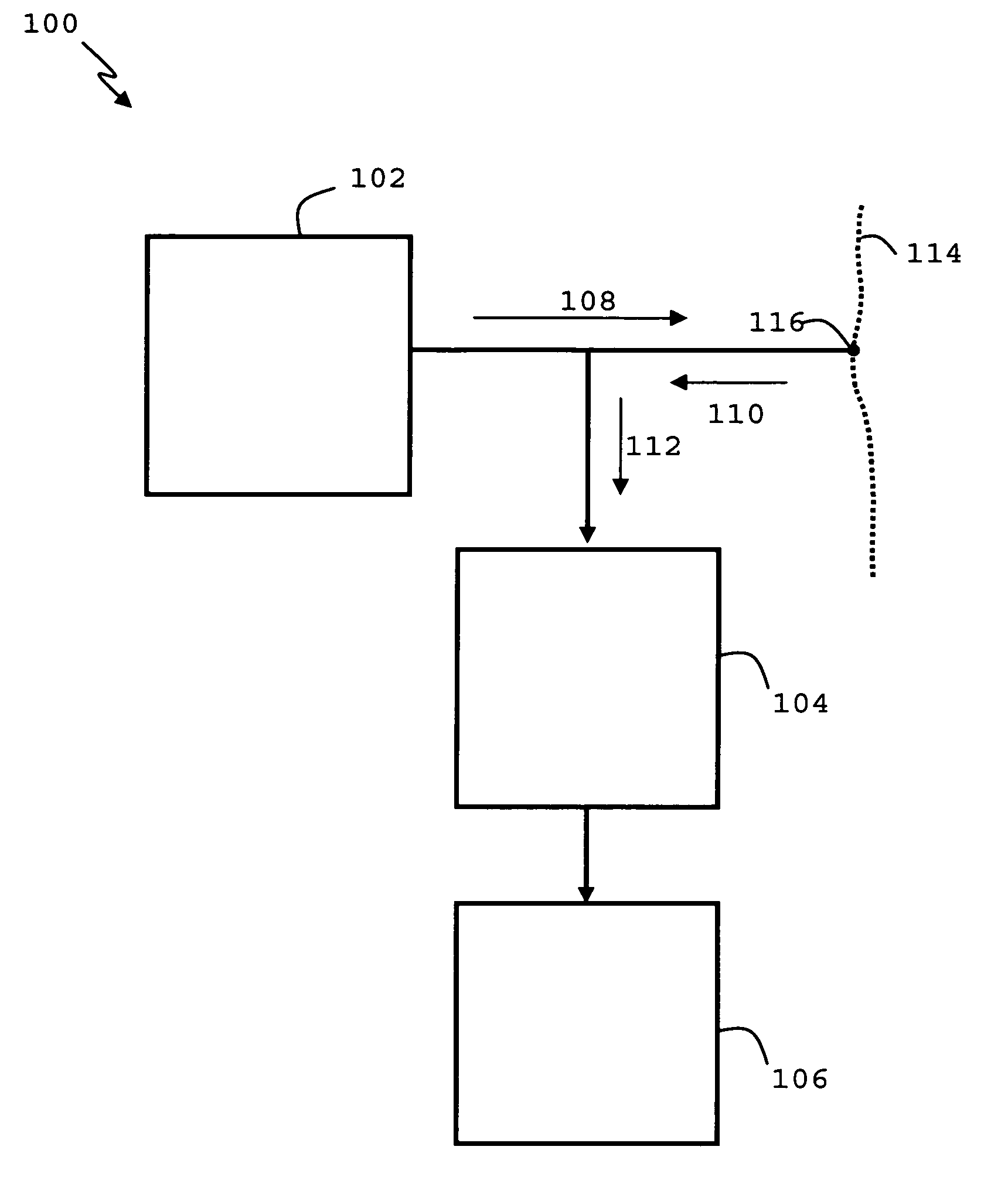

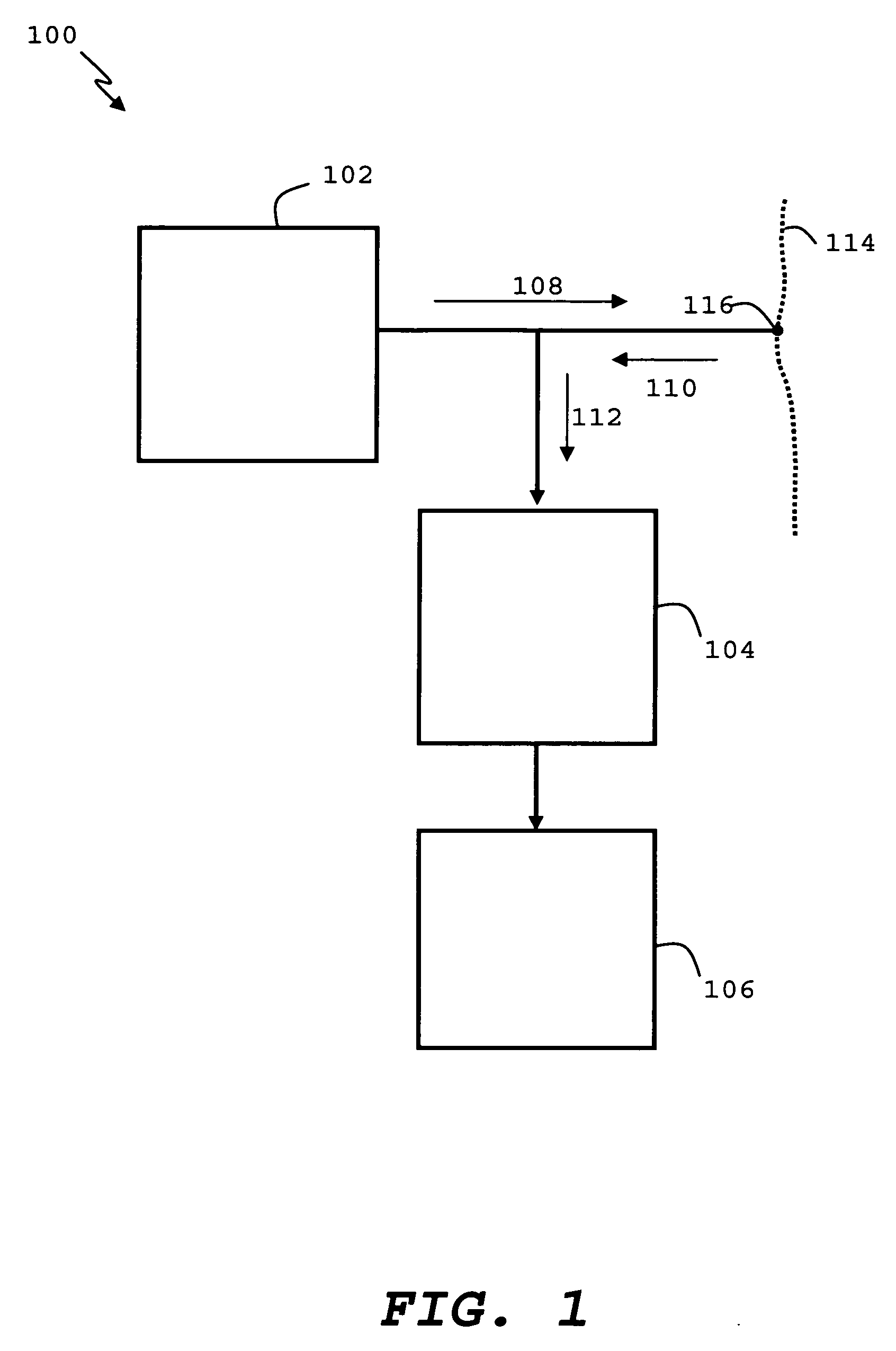

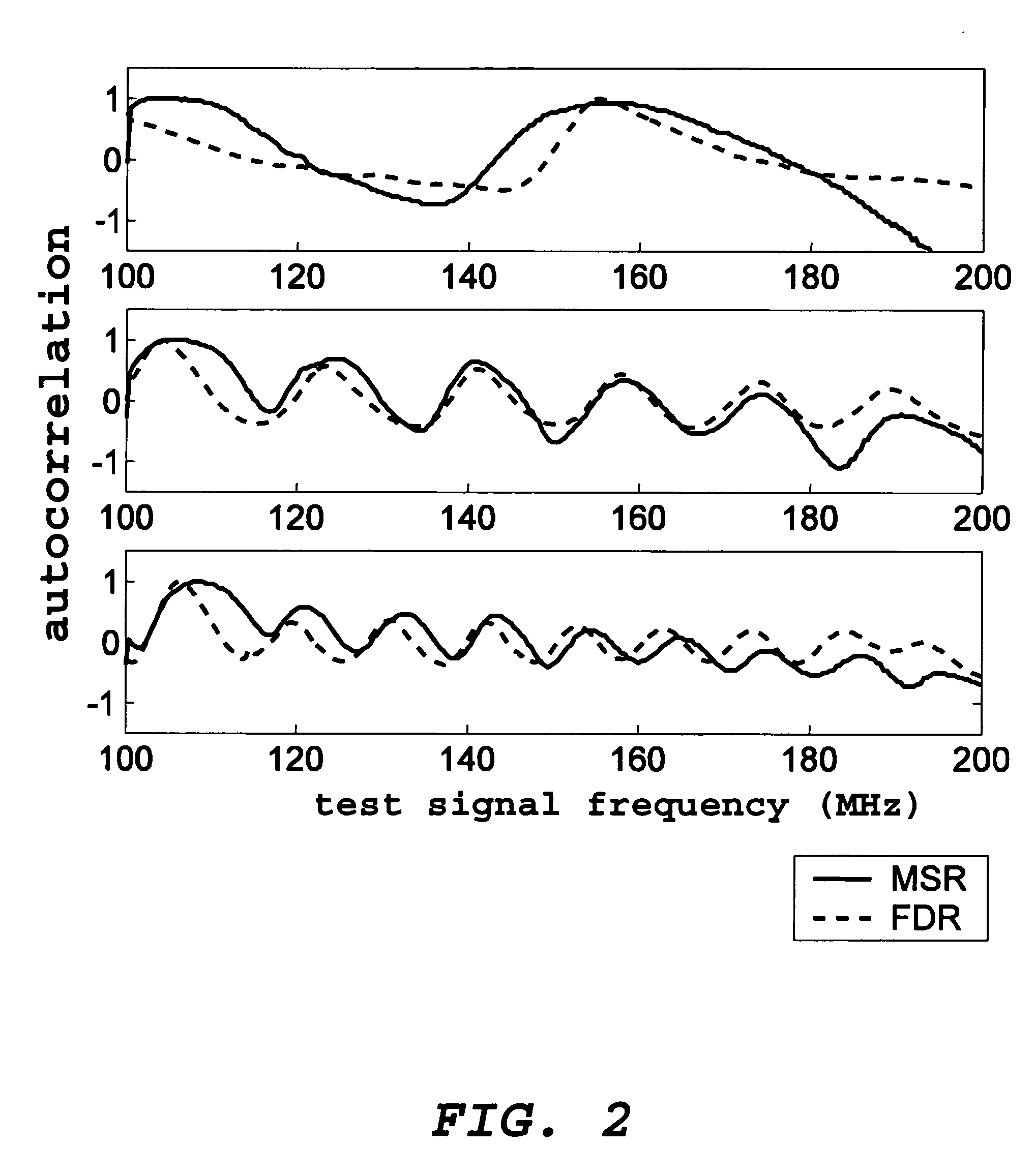

Apparatus and method for testing a signal path from an injection point

ActiveUS20060087323A1Accurately determine characteristicAccurately determineFault location by pulse reflection methodsTesting/calibration of speed/acceleration/shock measurement devicesInjection pointEngineering

The invention includes an apparatus and method for testing an electronic signal path. The apparatus includes a signal generator (102) configured to inject a test signal into the electronic signal path at an injection point when coupled to the signal path. The apparatus further includes a detector (104) coupled to the signal generator and configured to receive a combined signal at the injection point when coupled to the electronic signal path and determine an autocorrelation of the combined signal. The apparatus further includes an analyzer coupled to the detector and configured to determine a characteristic of the electronic signal path from the autocorrelation. The method includes injecting (902) a test signal into the electronic signal path an injection point, receiving (904) a combined signal from the electronic signal path at the injection point, determining (906) an autocorrelation of the combined signal, and estimating (908) a characteristic of the electronic signal path from the autocorrelation.

Owner:UNIV OF UTAH RES FOUND

Solid catalyst hydrocarbon conversion process using stacked moving bed reactors

InactiveUS20110152591A1Catalytic naphtha reformingHydrocarbon oil crackingReactor systemInjection point

Systems and processes for hydrocarbon conversion are provided that utilize a plurality of moving bed reactors. The reactors may be moving bed radial flow reactors. Optional mixers that mix a portion of a second hydrocarbon feed with the effluent stream from an upstream reactor, to produce reactor feed streams may be employed, and the reactor feed streams may be introduced at injection points prior to each reactor. Catalyst can be provided from the reaction zone of one reactor to the reaction zone of a downstream reactor through catalyst transfer pipes, and can be regenerated after passing through the reaction zones of the reactors. The moving bed reactors can be stacked in one or more reactor stacks.

Owner:UOP LLC

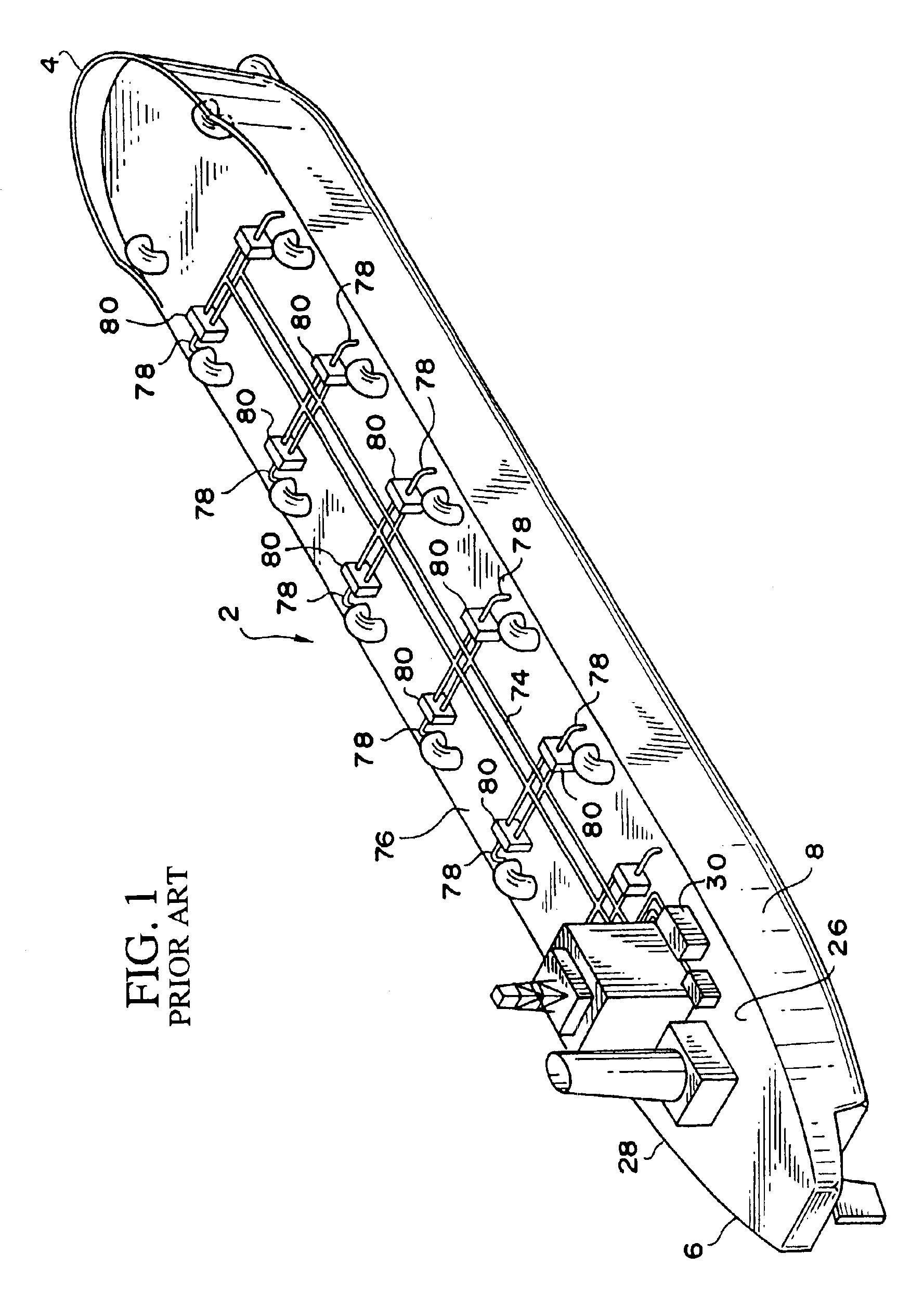

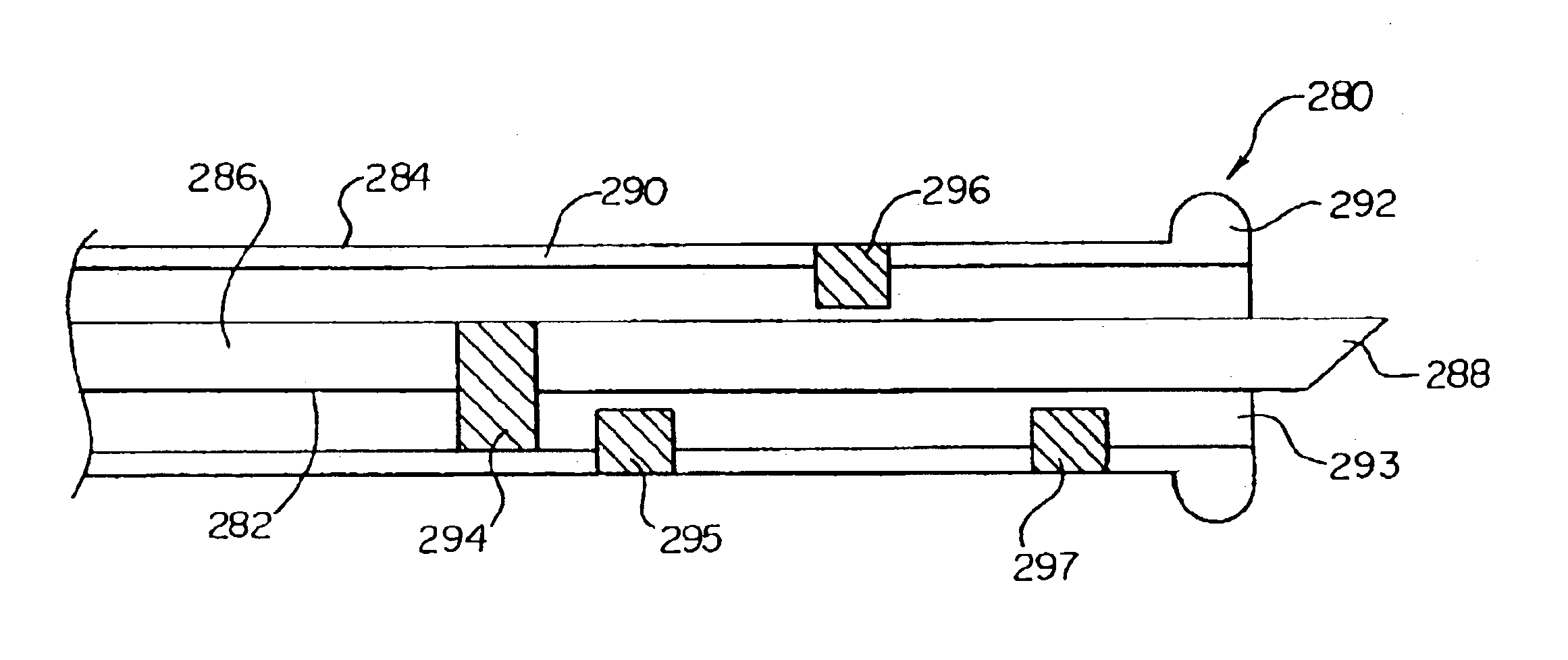

Infusion devices and method

InactiveUS6939322B2Less sharpReduce cuttingUltrasonic/sonic/infrasonic diagnosticsGuide needlesCardiac muscleInjection point

Myocardial revascularization catheters and methods are provided herein. Catheters in accord with the present invention may include an outer shaft and an inner shaft where the inner shaft may be slidably and rotatably disposed in the outer shaft and the distal movement of the inner shaft may be arrested by the engagement of stops and catches located within the inner and outer shaft Methods in accord with the current invention may include providing a therapeutic, providing a radiopaque contrast media, injecting the therapeutic through a lumen into the myocardium of the heart, and injecting the radiopaque contrast media through a lumen into myocardium of the heart. In this example, the location of the injection the radiopaque material may be chosen to indicate the injection point of the injection of the therapeutic.

Owner:BOSTON SCI SCIMED INC

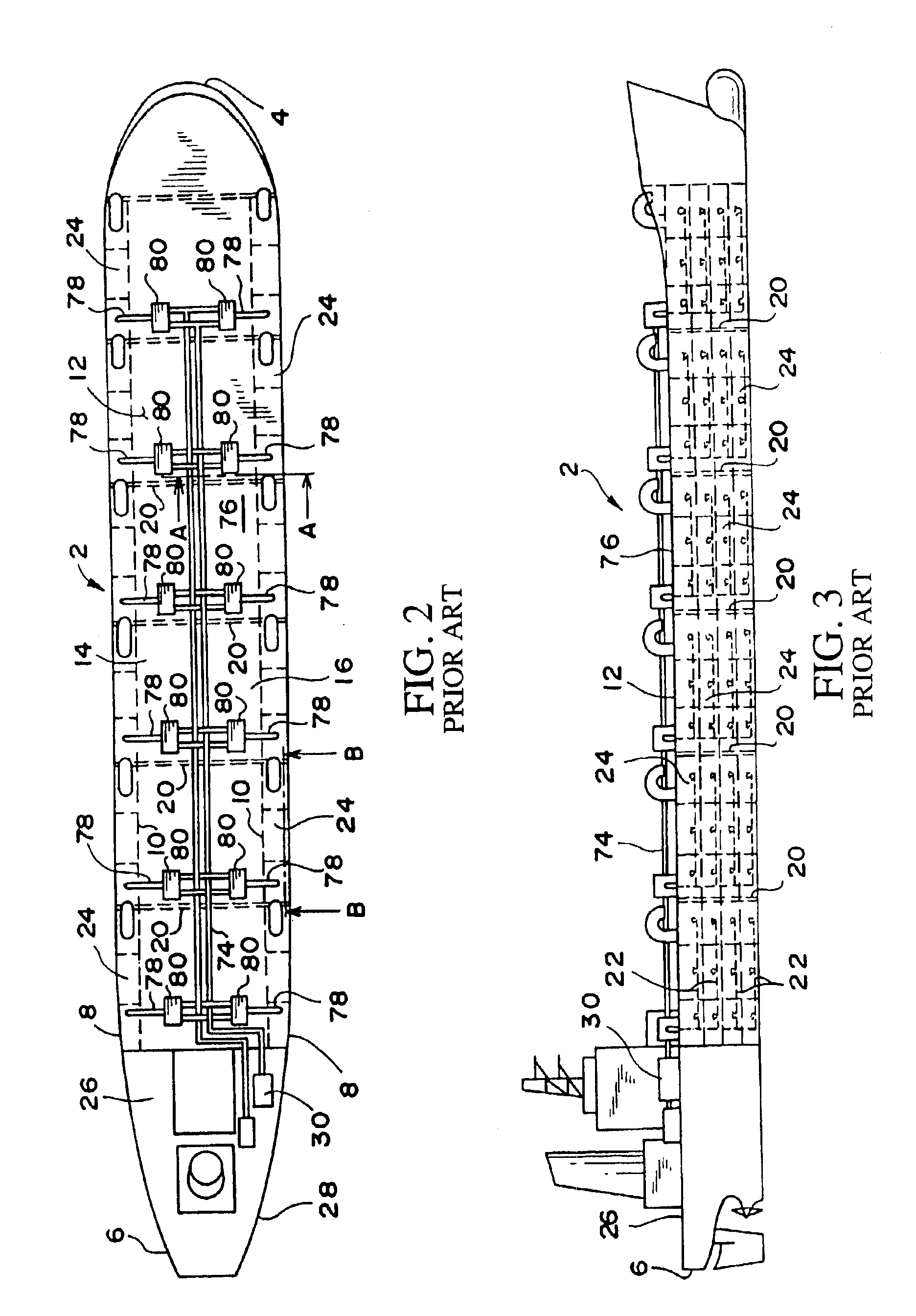

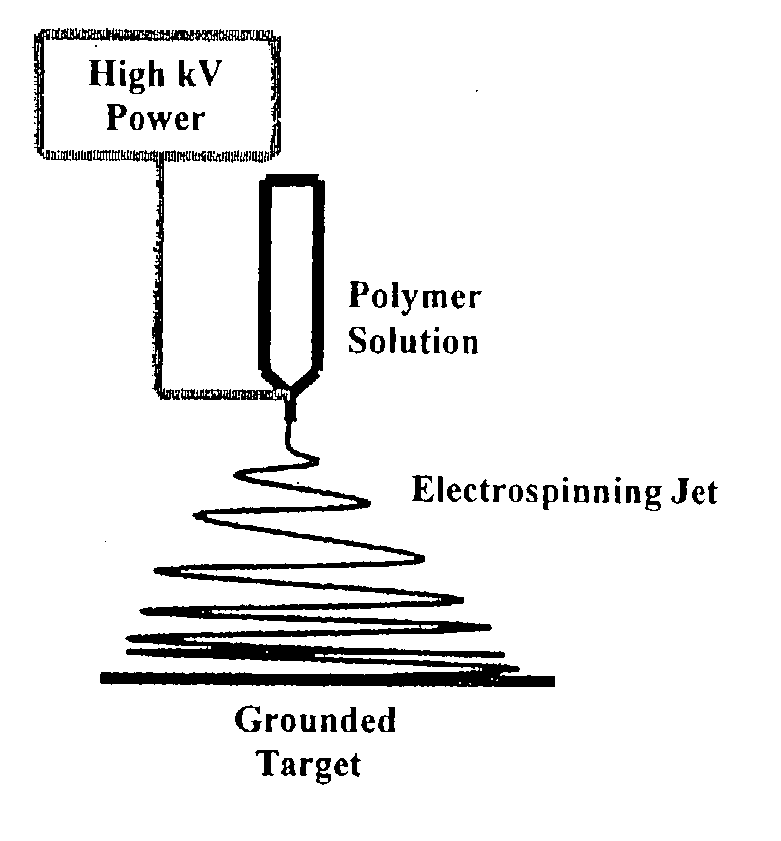

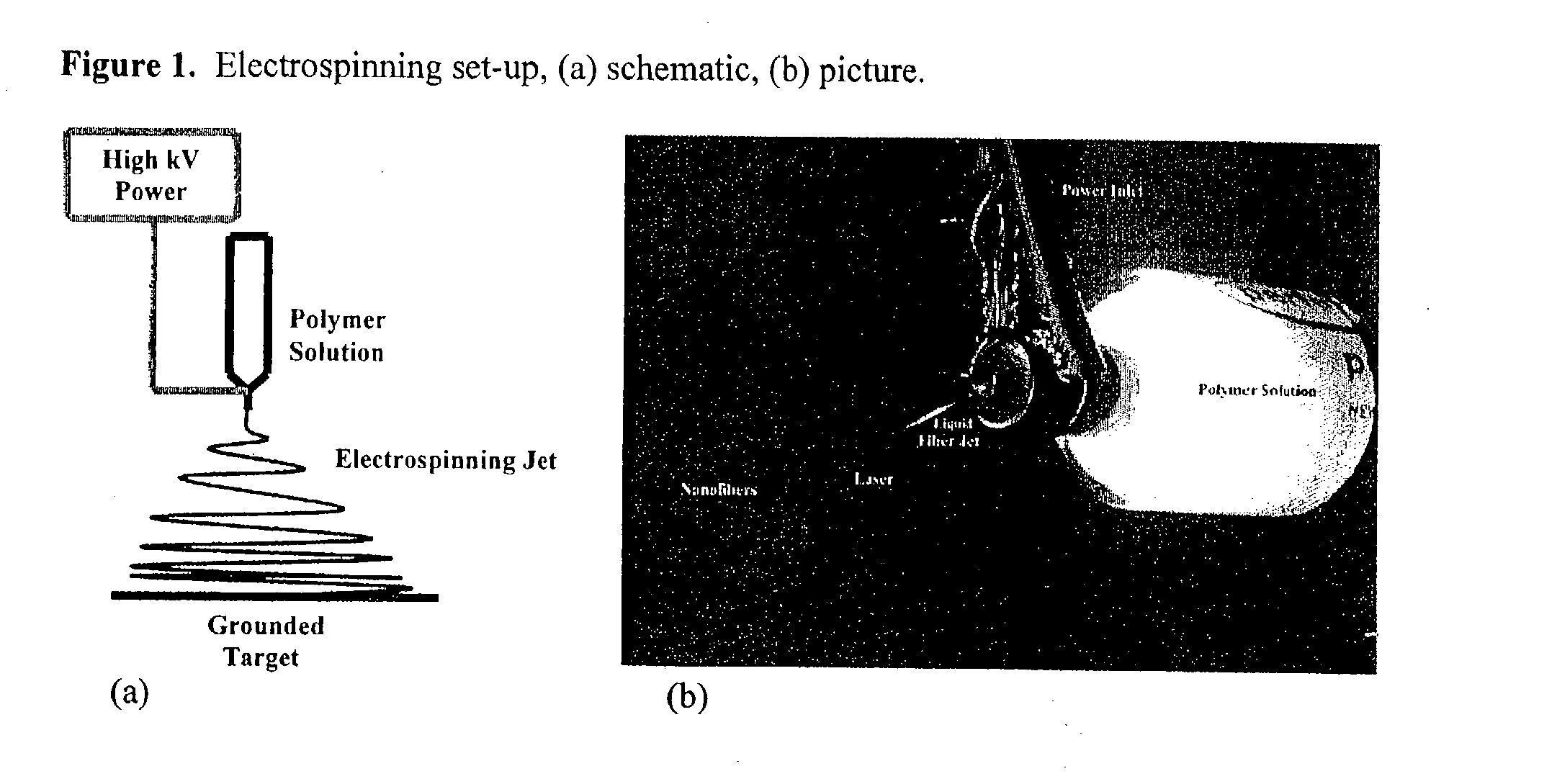

Production of nanowebs by an electrostatic spinning apparatus and method

InactiveUS20050048274A1Raise the ratioLarge throughputElectro-spinningPaper/cardboard layered productsFiberMoisture capacity

A method for producing a webbed fibrillar material includes providing a polymer material including a solvent; injecting the polymer material into an electric field toward an electrically charged target; controlling at least one process parameter to produce the webbed fibrillar material having one or more desired characteristics; and collecting the webbed fibrillar material from the target. The process parameter may be selected from the group consisting of an electric field strength, a temperature, a solution viscosity of the polymer material, a distance between an injection point and the target, a solvent type, a relative concentration of the solvent and polymer material, a molecular weight of the molecules of the polymer material, an environmental temperature, an environmental humidity, and a drying time of the injected polymer material.

Owner:UNIVERSITY OF DELAWARE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com