Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2928 results about "Biomass fuels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A biofuel is a fuel that is produced through contemporary processes from biomass, rather than a fuel produced by the very slow geological processes involved in the formation of fossil fuels, such as oil. Since biomass technically can be used as a fuel directly (e.g. wood logs), some people use the terms biomass and biofuel interchangeably.

Low emission energy source

Owner:BRIGHTSOURCE ENERGY

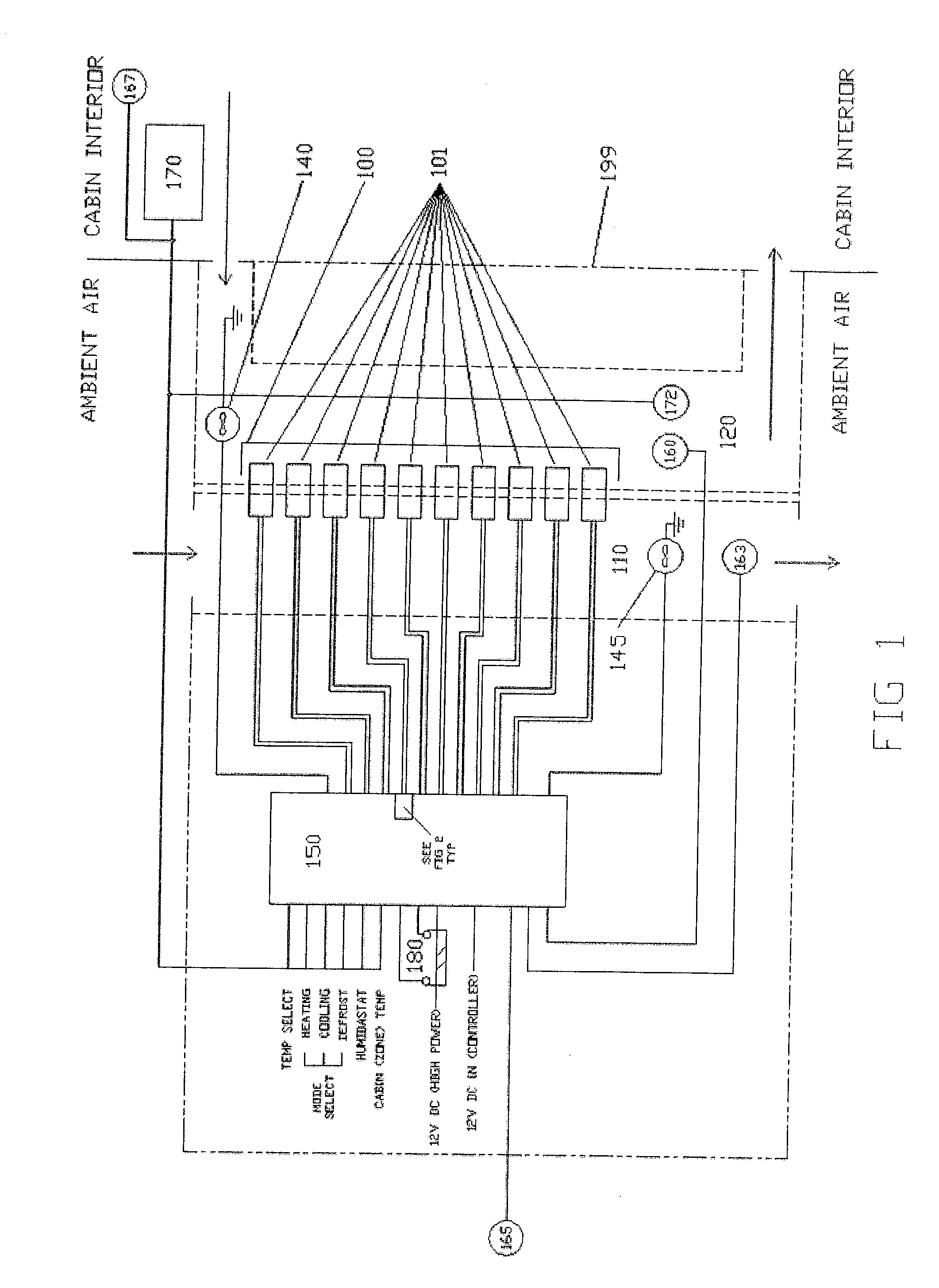

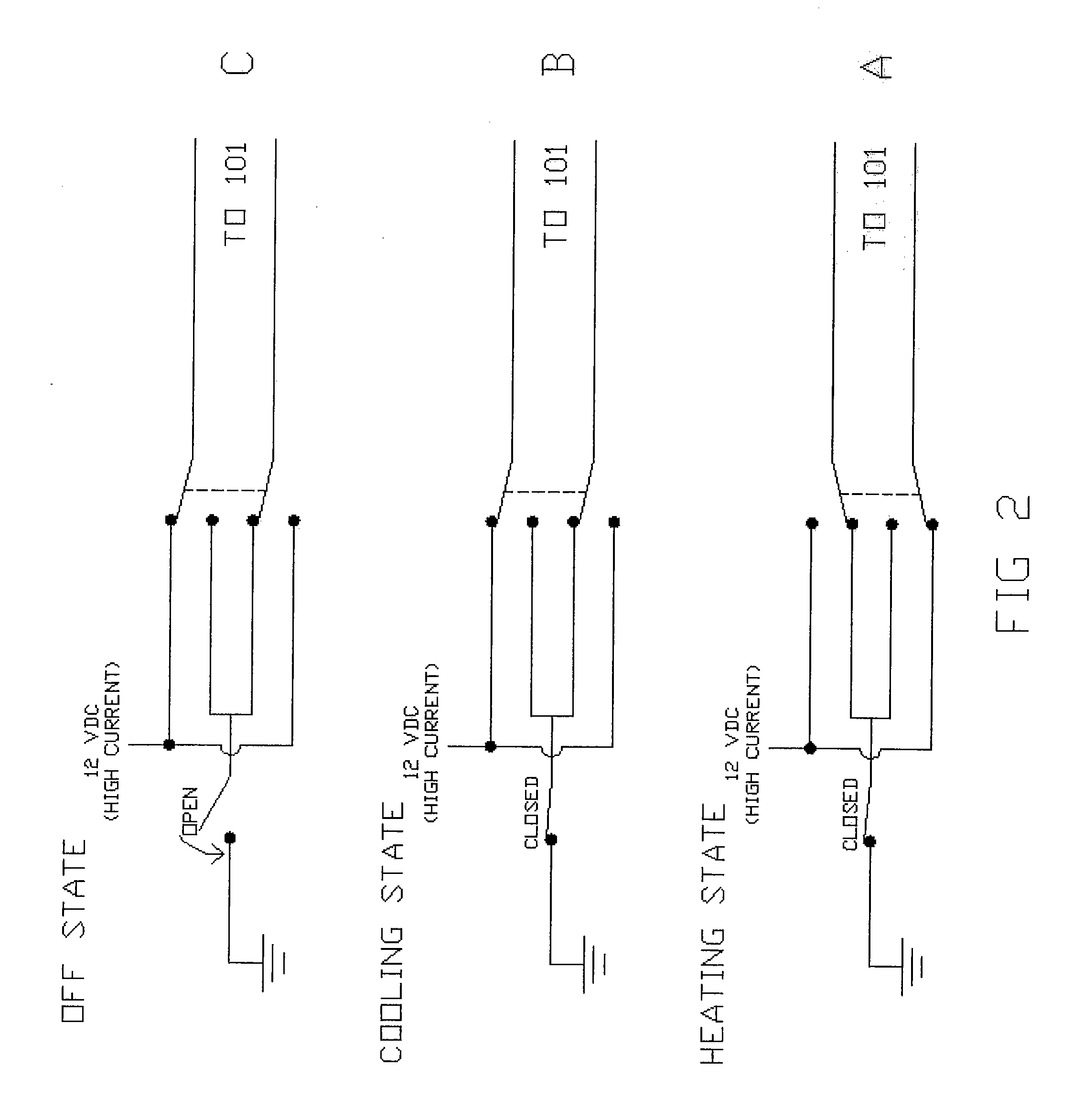

Regulating vehicle cabin environment and generating supplemental electrical current from waste heat

InactiveUS20070272290A1Reduce utilizationReduce weightInternal combustion piston enginesThermoelectric device with peltier/seeback effectNacelleElectrical devices

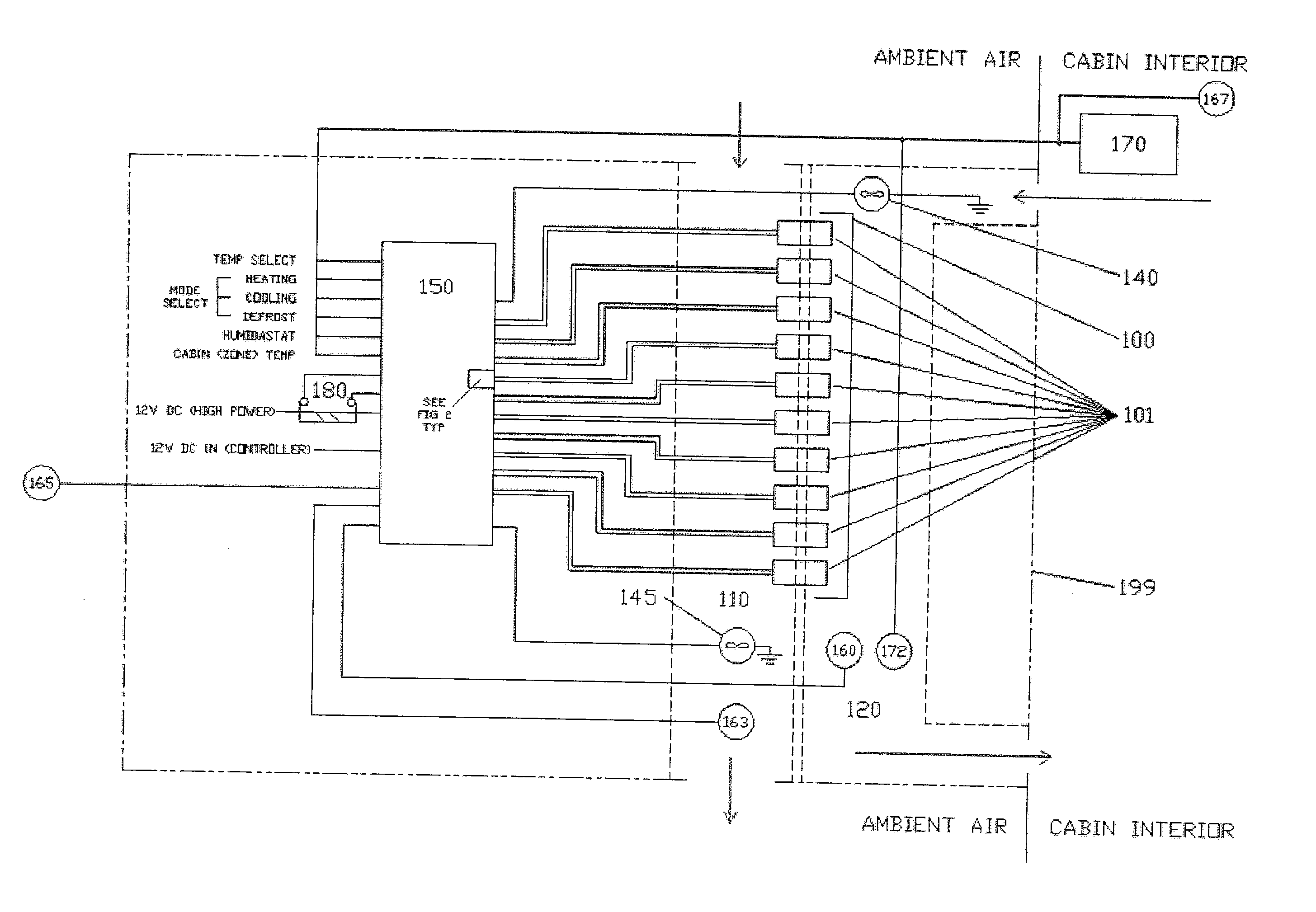

A method and system for environmental control and supplementary power generation in conventional and hybrid vehicle applications is presented. A thermoelectric heat pump function regulates vehicular interior temperature environments and uses the waste heat from a vehicles engine to power thermocouples and generate supplemental electrical current to power electrical devices. Thermocouples are used to gauge changes in temperature. The Peltier Effect is used to provide both primary cabin environmental control and supplementary power generation for motorized vehicle applications. Thermoelectric generators can be used for both primary internal climate control and supplementary power generation in the vehicular environment. Thermoelectric heat pumps' special characteristics are used to provide (a) primary cabin environment control including cooling, heating, dehumidifying, defrosting, pre-heating / pre-cooling and (b) supplemental DC power generation functions for conventional fossil fueled and / or biomass-fueled vehicles as well as emerging hybrid or all electric vehicle applications.

Owner:STATE OF FRANKLIN INNOVATIONS

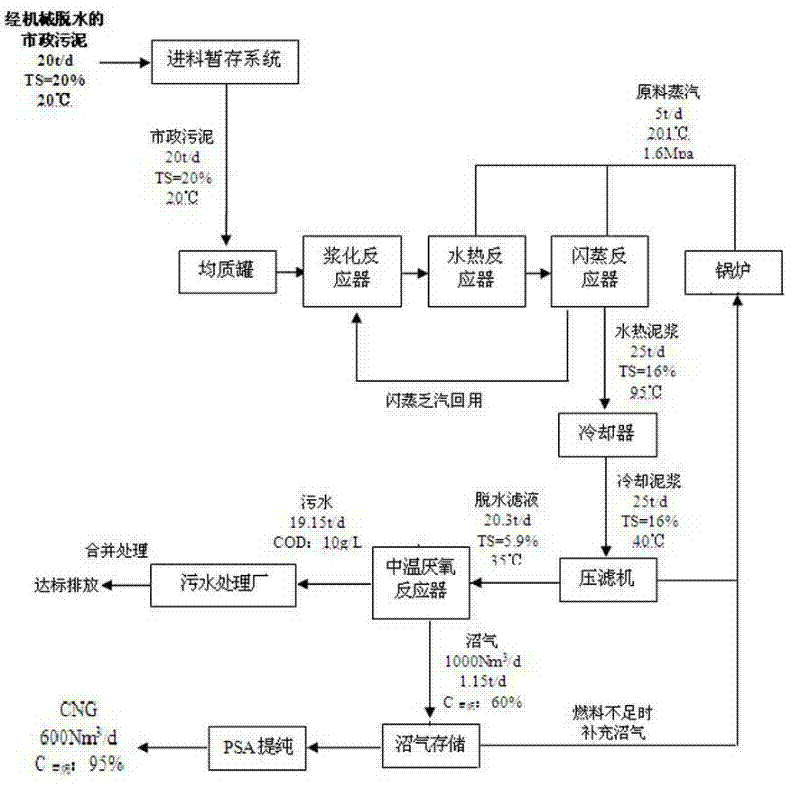

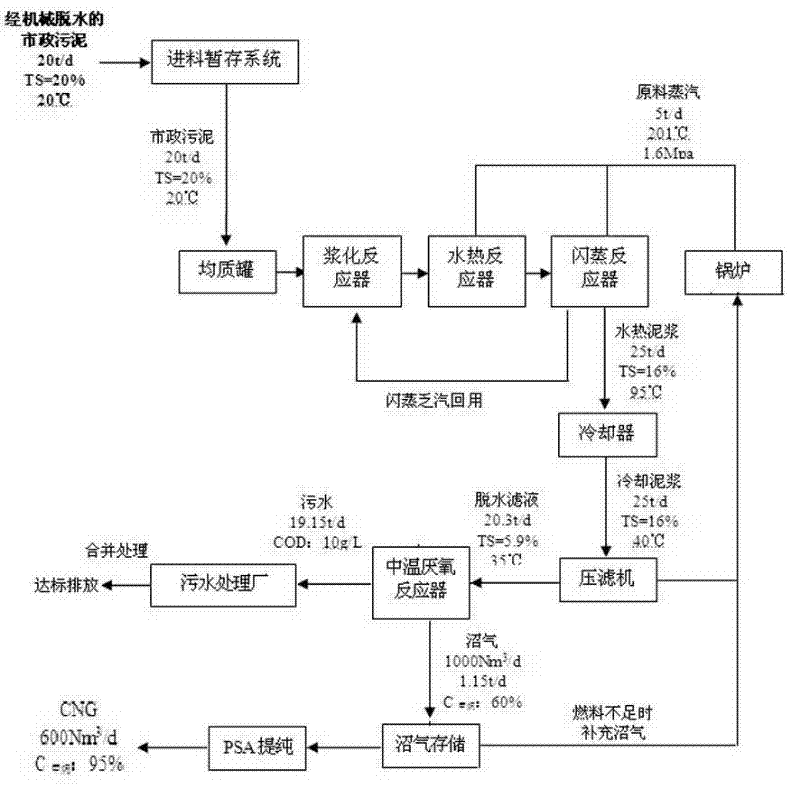

Sludge treatment process based on hydrothermal modification technology

InactiveCN102381820AAdvanced technologyHighlight energy savingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningAnaerobic reactorHigh pressure

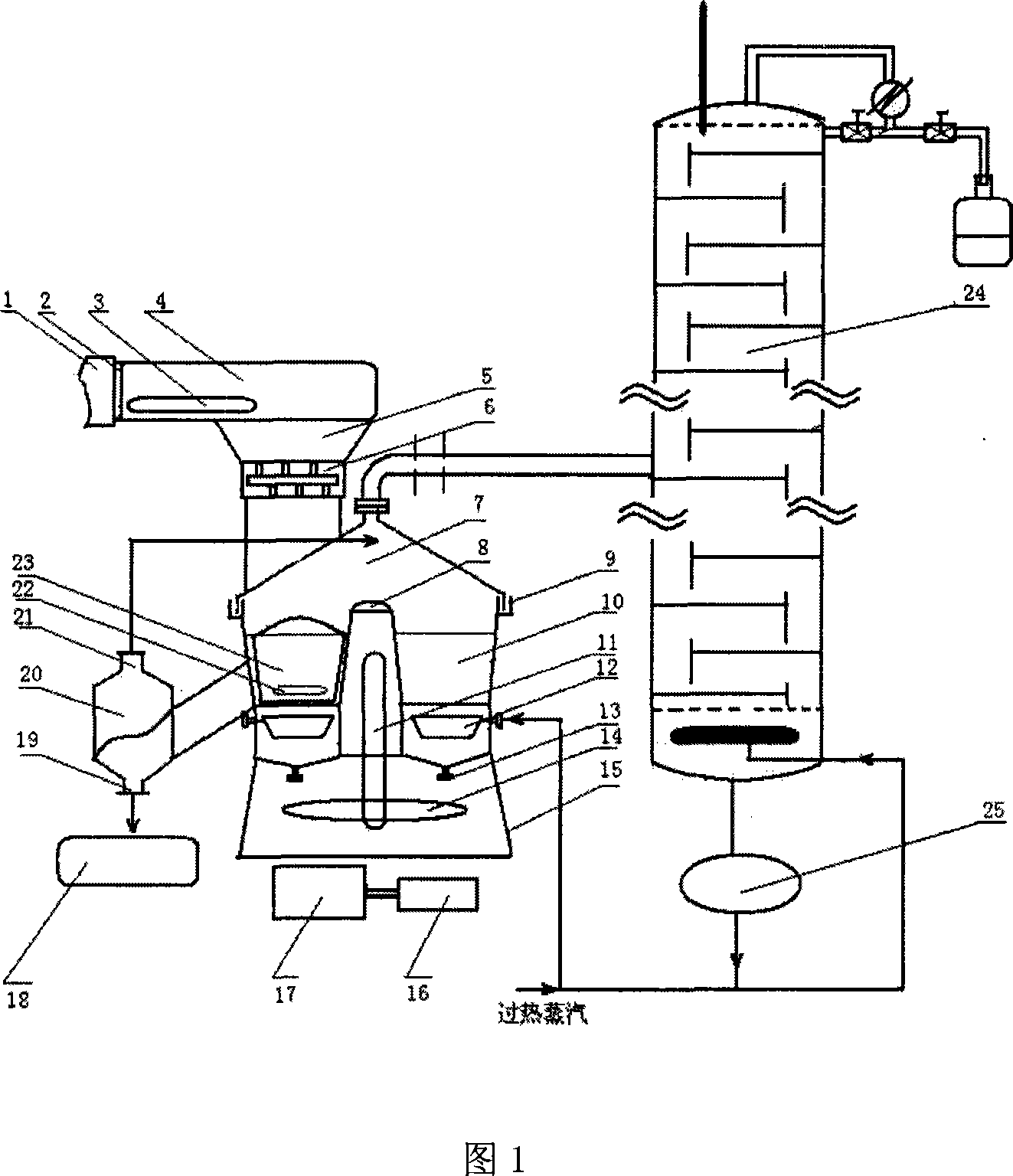

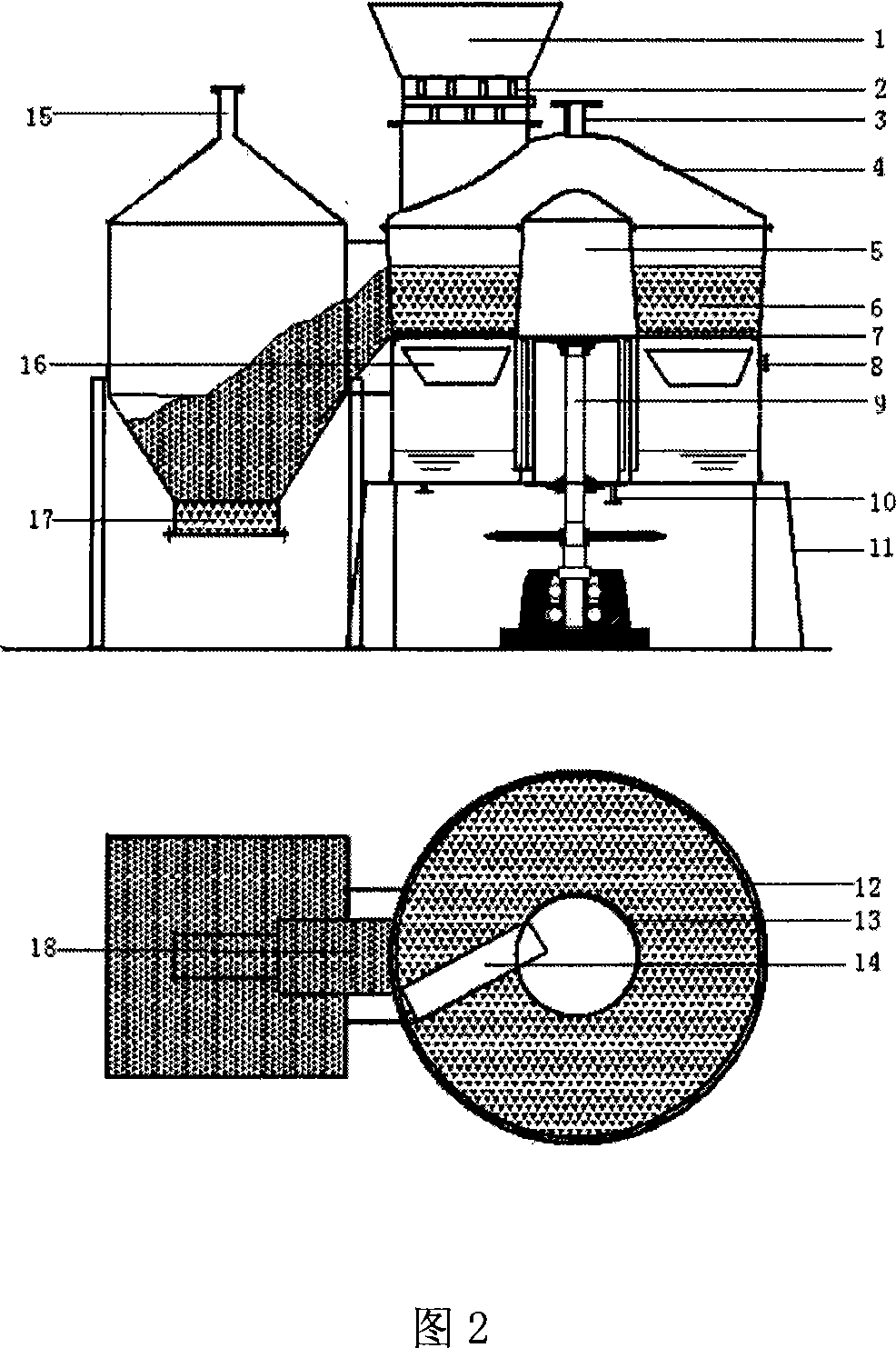

The invention relates to a sludge treatment process based on a hydrothermal modification technology. The sludge treatment process is carried out by comprising the following steps of: (1) temporarily storing the sludge which is subjected to mechanical dehydration and has the water content of 70-85% to a pretreatment unit and deodorizing the sludge; (2) introducing to a homogeneous device, fully mixing and homogenizing, introducing the homogenized sludge to a slurrying device, introducing the slurried sludge to a hydrothermal reactor for hydrothermal reaction, and introducing the hydrothermal sludge to a flash evaporator for decompression and flash evaporation; (3) cooling to 35-45 DEG C by using a cooler, then introducing to a high-pressure diaphragm pressure filter for pressure filtering and dehydration to obtain a dehydrated mud cake with the solid content of 35-45% and dehydrated filtrate; (4) introducing the dehydrated filtrate to an intermediate temperature anaerobic reactor, wherein the residence time is for 5.5-7.5d, the inlet water temperature is controlled below 40 DEG C, and the anaerobic reaction temperature is 30-40 DEG C; and (5) preparing a biomass fuel rod by using the dehydrated mud cake, and introducing the biomass fuel rod to a boiler to provide steam for the hydrothermal reactor and the flash evaporator. The sludge treatment process has the advantages of goodtreatment effect, obvious volume reduction effect, high harmless degree, recycling of methane, good economic benefit and the like.

Owner:FUZHOU DEV ZONE SANSHUI ENVIRONMENTAL PROTECTION TECH

Low emission energy source

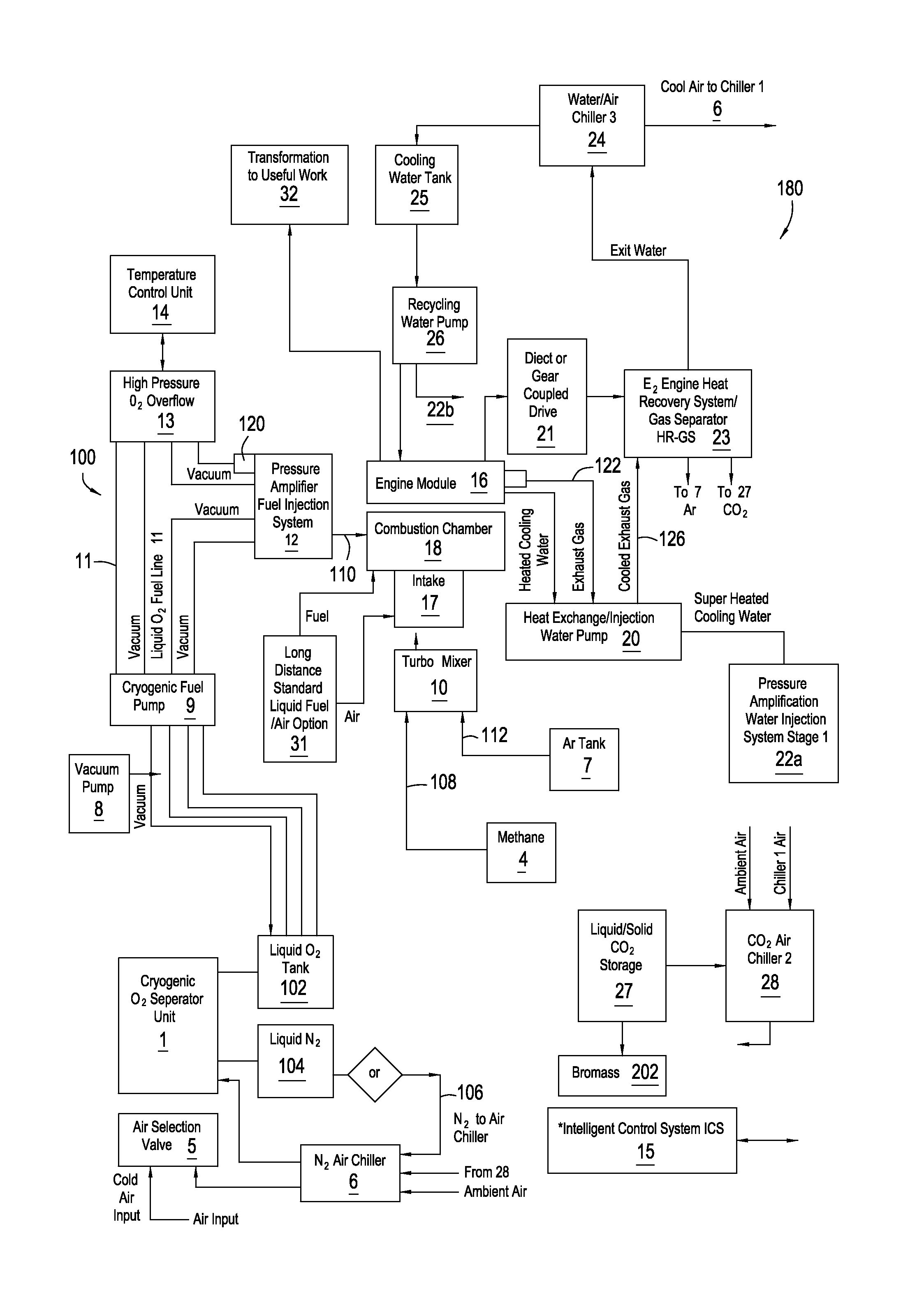

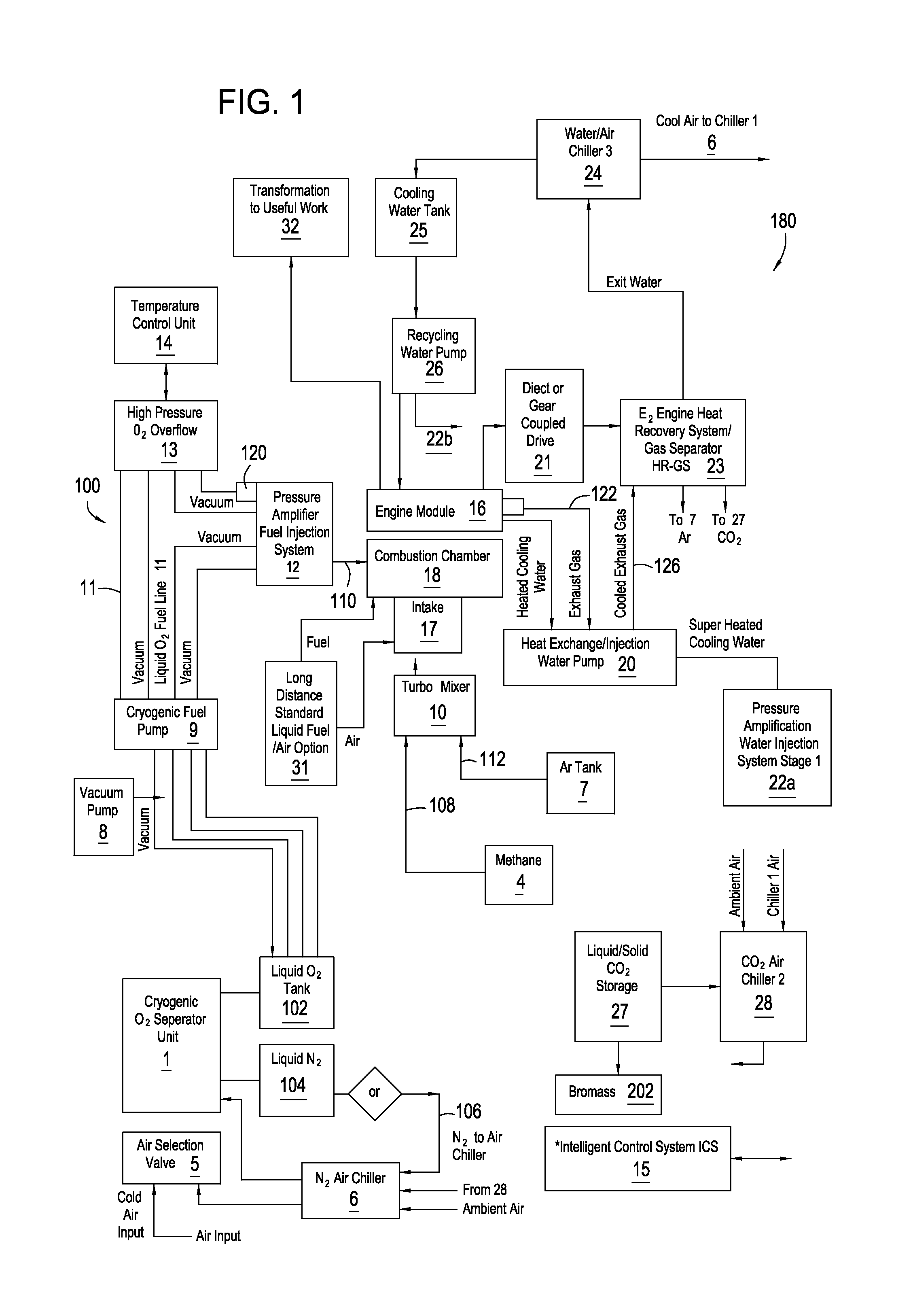

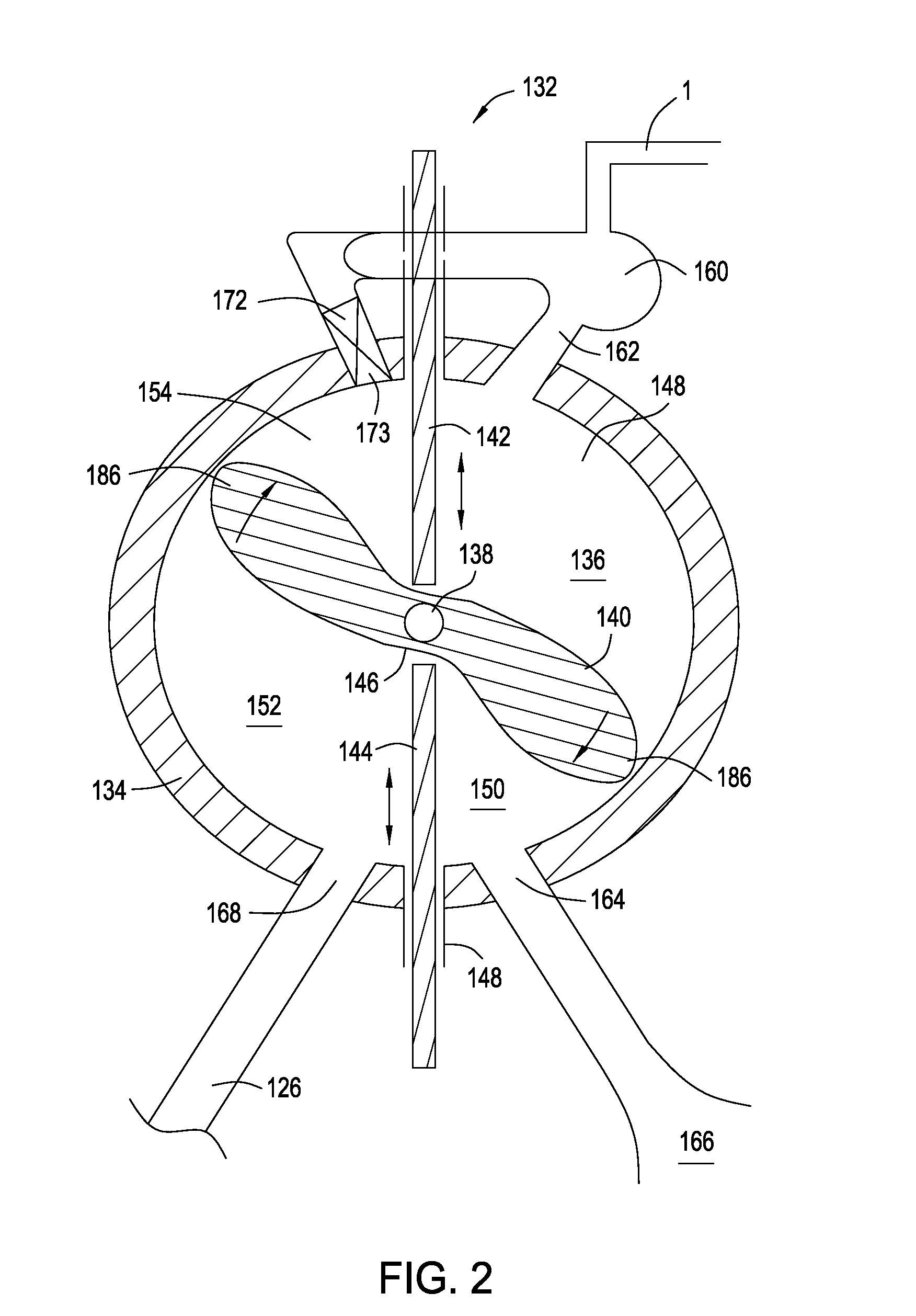

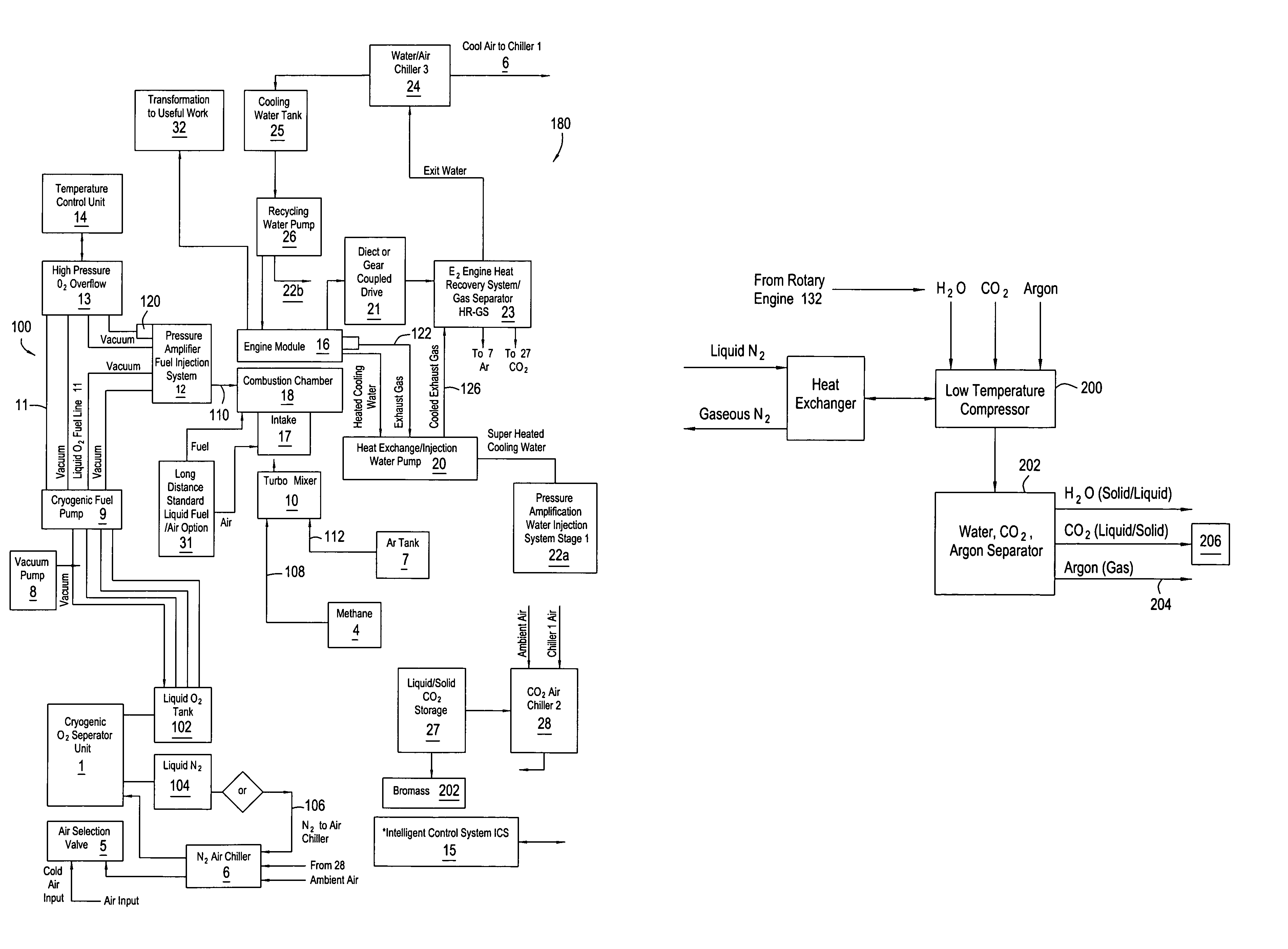

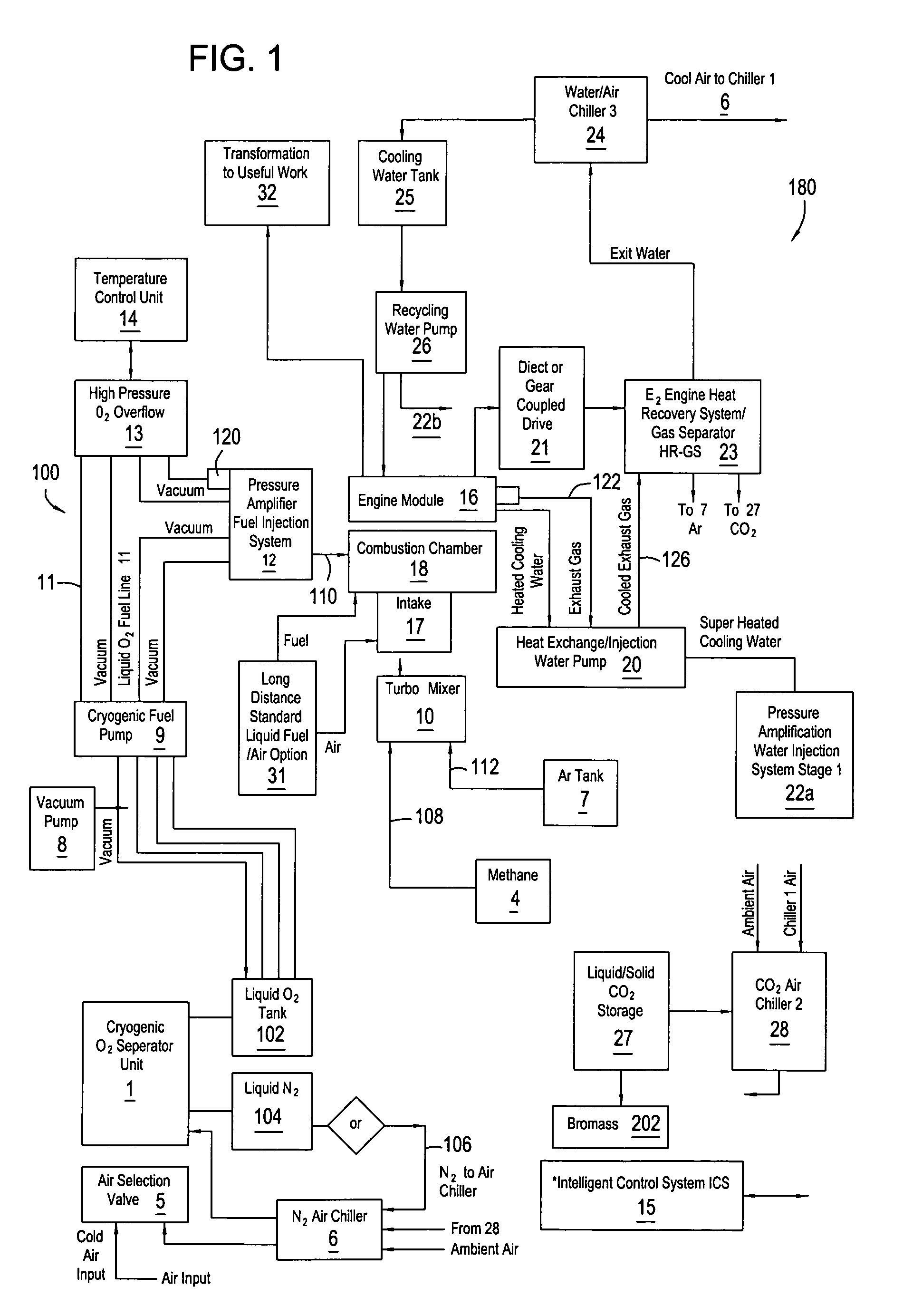

A power generator provides power with minimal CO2, NOx, CO, CH4, and particulate emissions and substantially greater efficiency as compared to traditional power generation techniques. Specifically nitrogen is removed from the combustion cycle, either being replaced by a noble gas as a working gas in a combustion engine. The noble gas is supplemented with oxygen and fuel, to provide a combustion environment substantially free of nitrogen or alternatively working in 100% oxygen-fuel combustion environments. Upon combustion, Very little to no nitrogen is present, and thus there is little production of NOx compounds. Additionally, the exhaust constituents are used in the production of power through work exerted upon expansion of the exhaust products, and the exhaust products are separated into their constituents of noble gas, water and carbon dioxide. The carbon dioxide may be used in conjunction with a biomass to accelerate the biomass growth and to recover the oxygen enriched air resulting from algae photosynthesis for enhancing the operation of the power generator using the as Biomass for processing into methanol / ethanol and biological oils as fuel for the power generator. The biomass fuel is seen as a solar fuel and may be used in conjunctions with other solar fuels like heated thermal oil and others, as well as clean fossil fuels to optimize to clean, and efficient operation of the power generator in various regulatory contexts.

Owner:BRIGHTSOURCE ENERGY

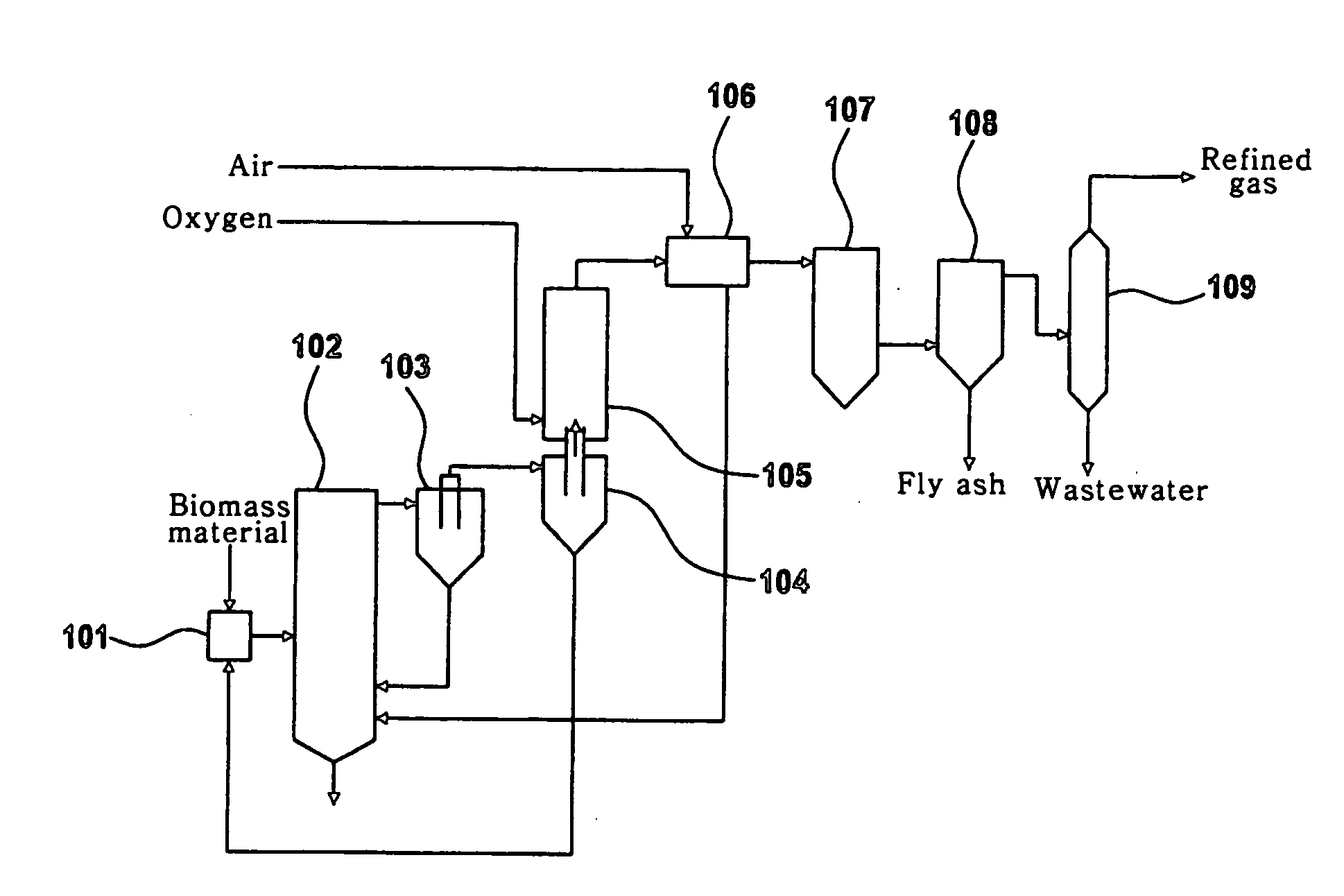

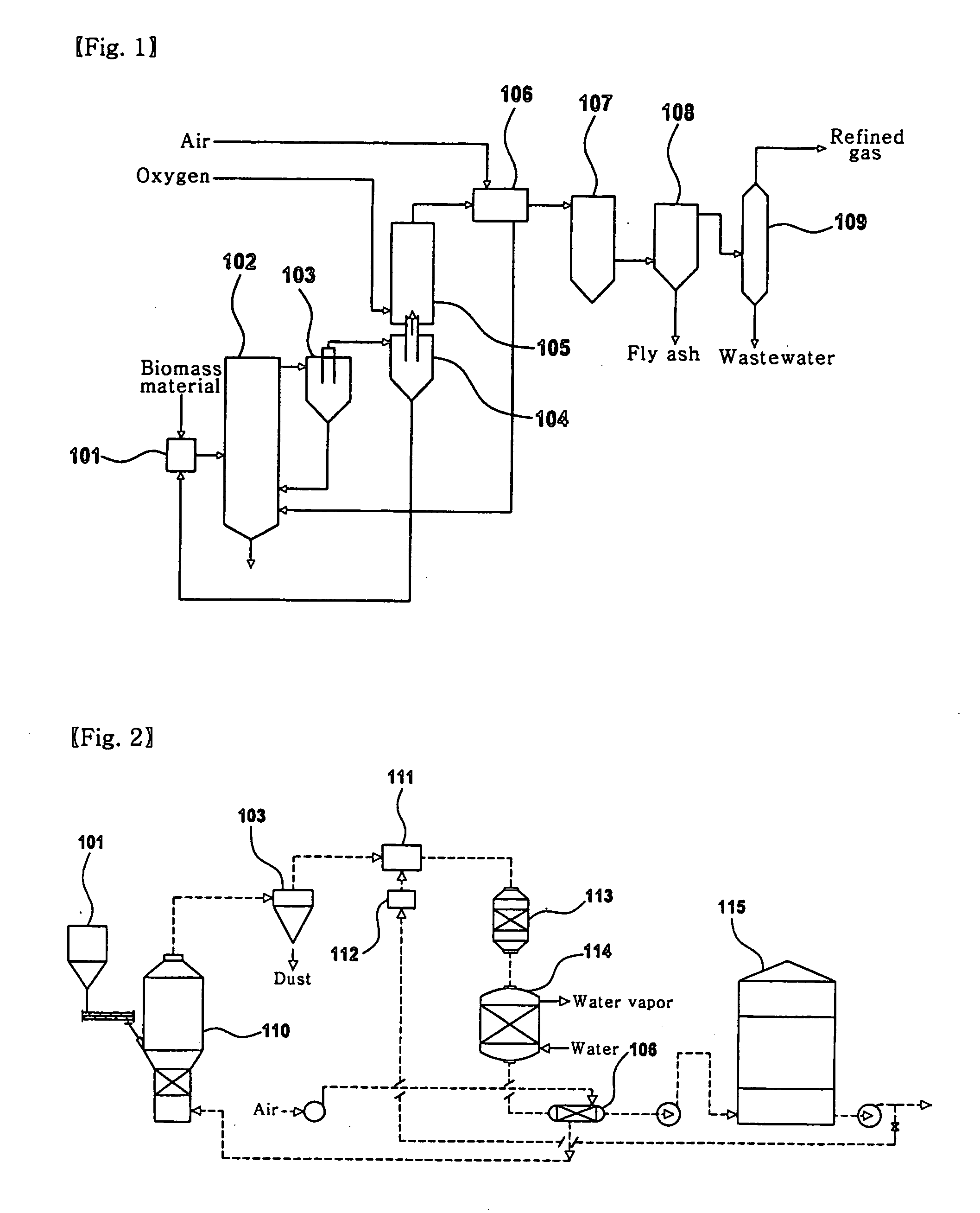

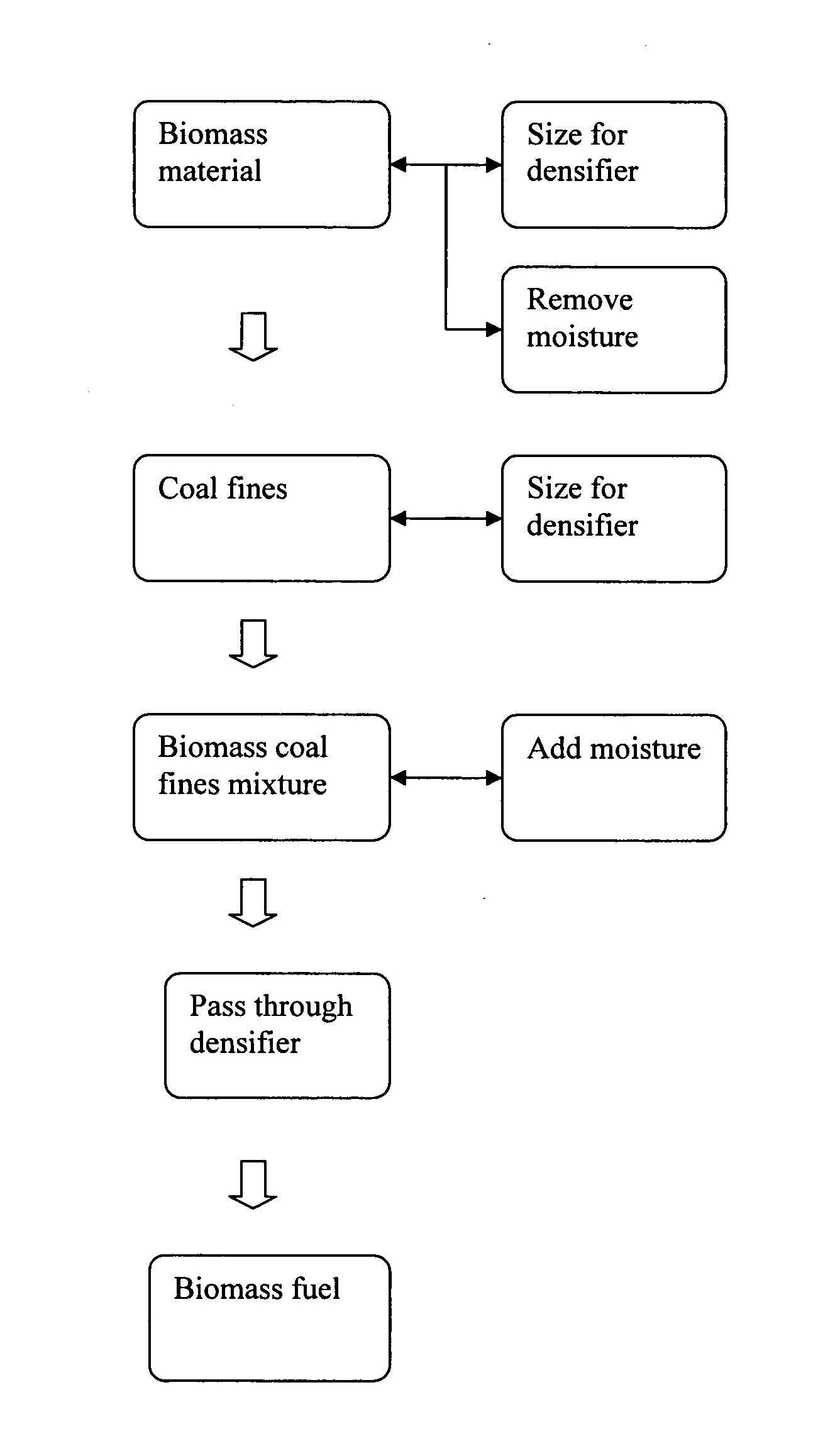

Apparatus of catalytic gasification for refined biomass fuel at low temperature and the method thereof

InactiveUS20070094929A1Low production costCompactCombustible gas catalytic treatmentLiquid hydrocarbon mixture productionCatalytic reformingFluidized bed

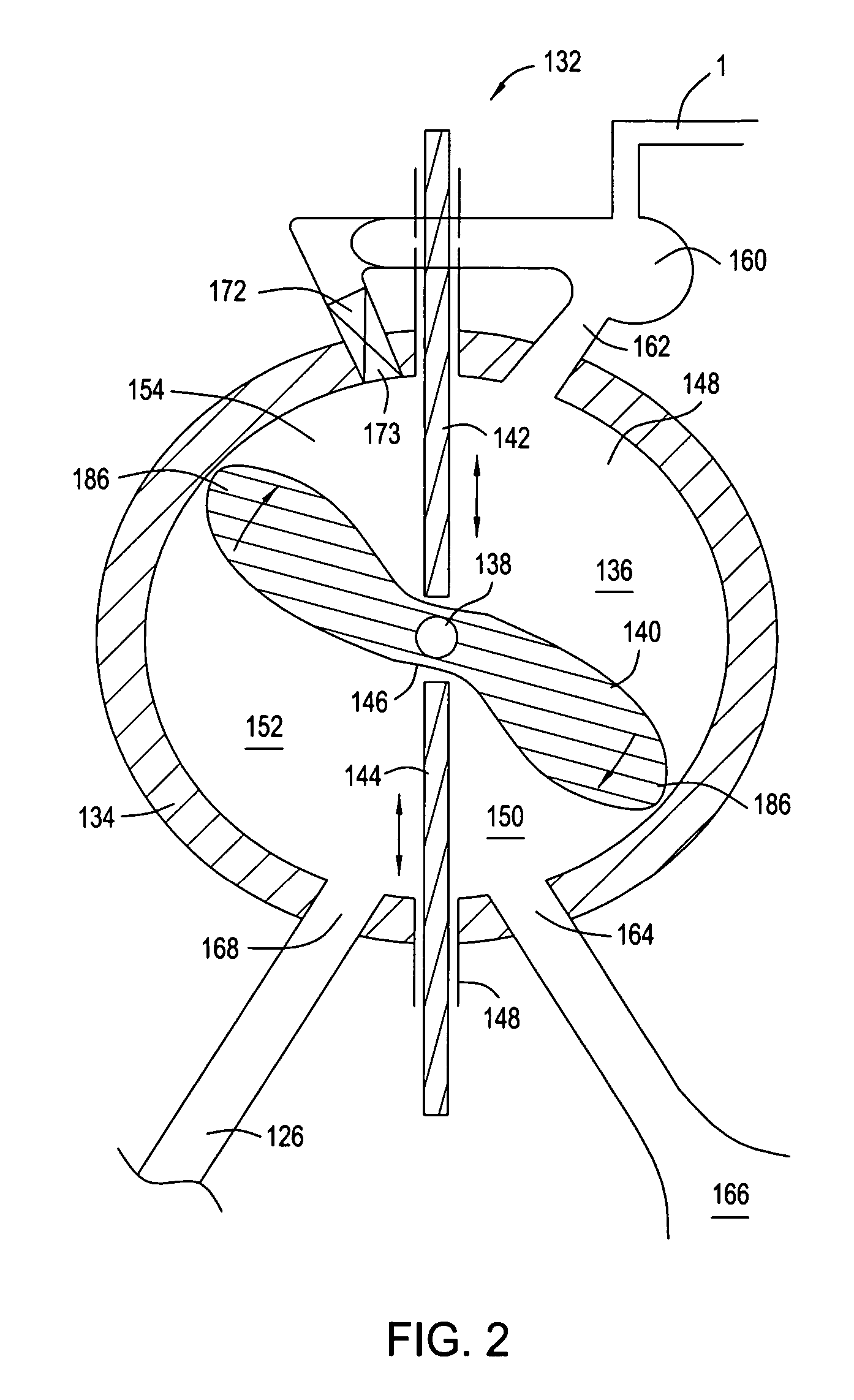

Disclosed is a gasification technique for converting biomass, which is difficult to treat, into clean gas fuel able to be burned in a cogeneration system. The gasification technique includes first stage fluidized-bed catalytic gasification, and second stage gasification of tar and catalytic reforming to convert nitrogen in tar, and HCN in a flammable gas into NH3, unlike conventional gasification techniques. In addition, since the temperature of a total gasification process is lower than a melting point of ash, powdery ash is generated and thus easily treated. Also, little heat is released due to the low process temperature, and therefore, a compact reactor may be designed to produce gas having a high caloric value. Further, the generated tar is recovered and reused in other processes, and the gas fuel contains a small amount of ammonia.

Owner:KOREA INST OF ENERGY RES

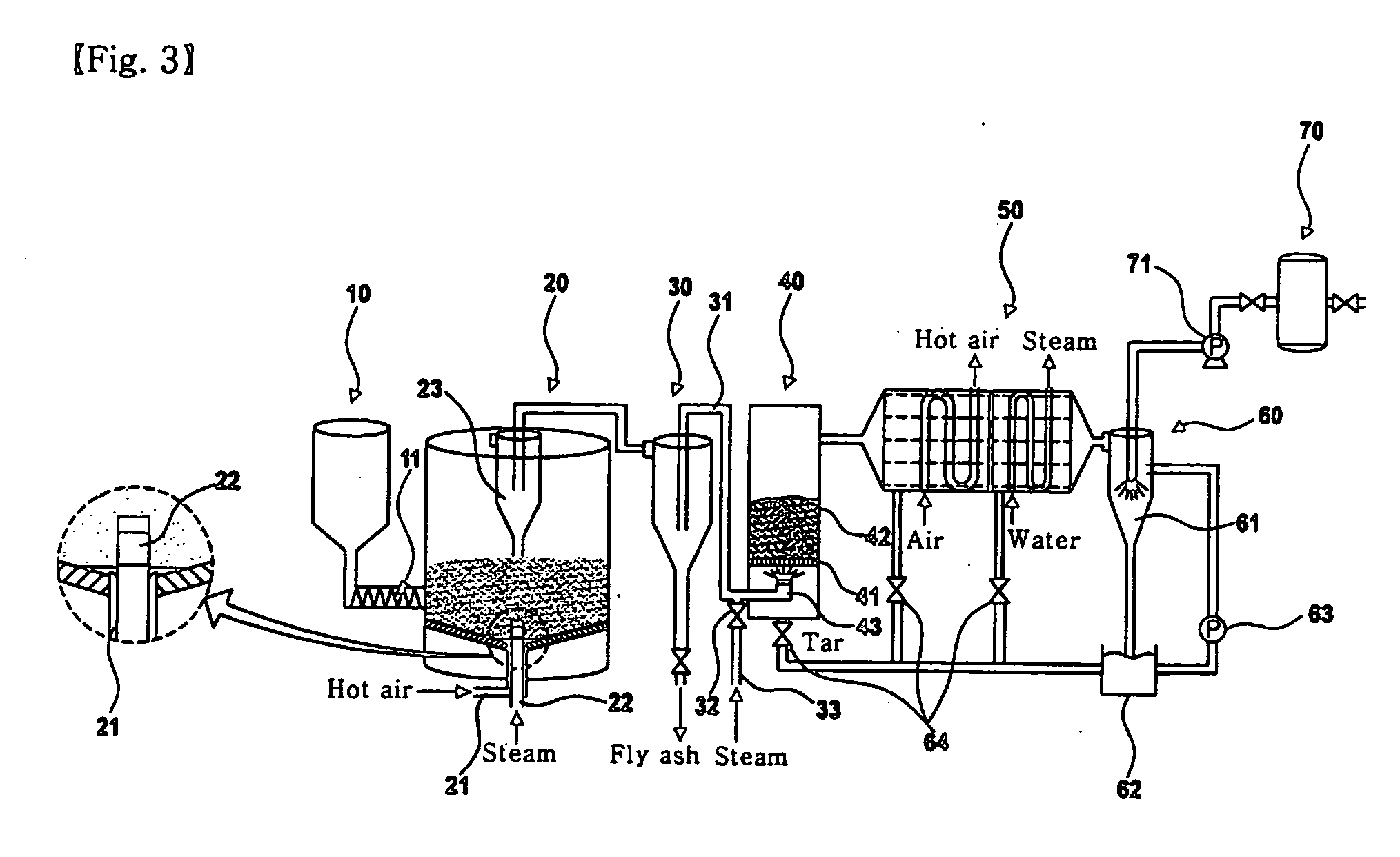

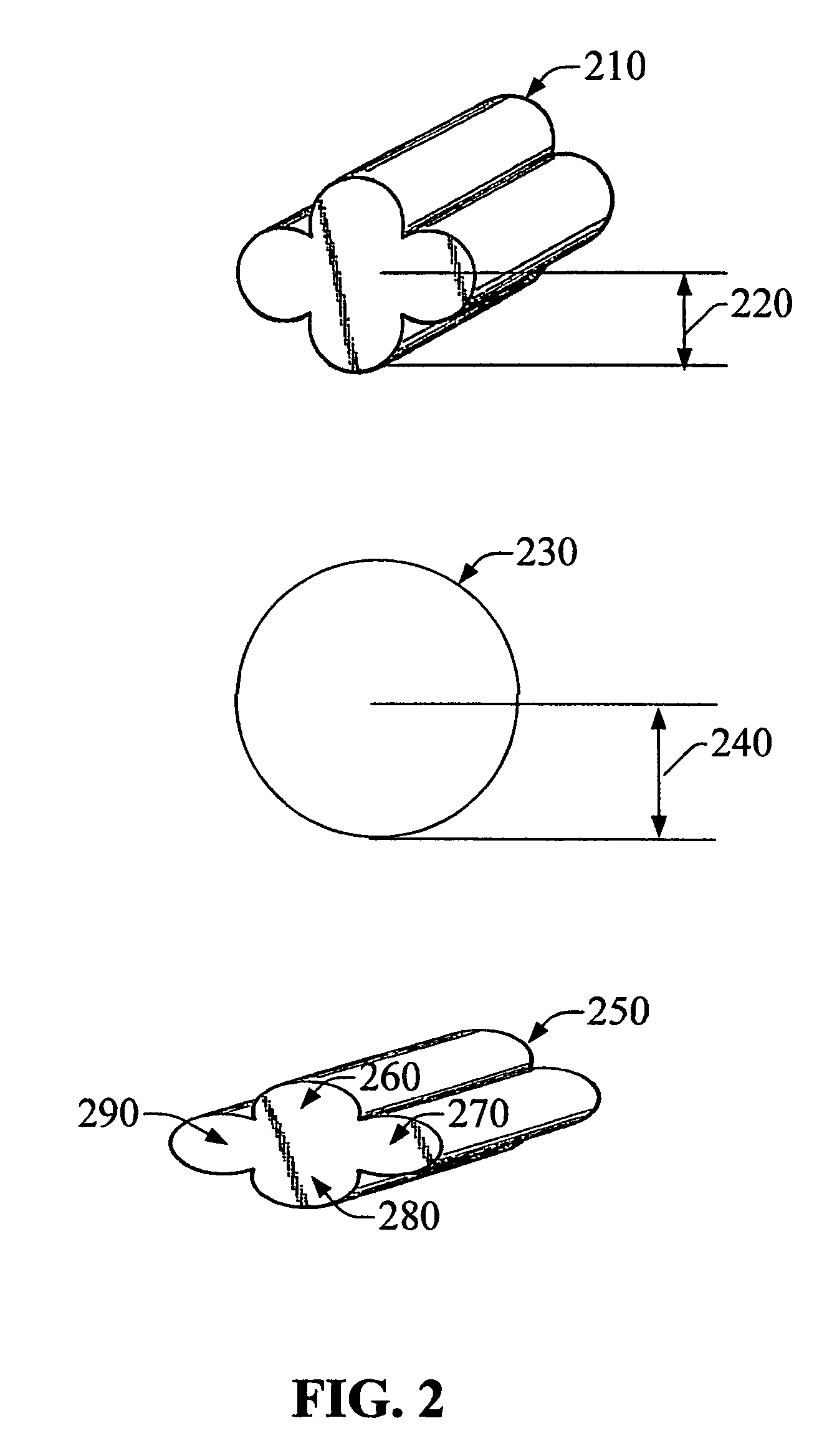

Method for producing a homogeneous biomass fuel for gasification applications

InactiveUS20070220805A1Smooth changeEasy to useBiofuelsSolid fuelsProcess engineeringVolumetric Mass Density

A method for producing a gasifier feedstock with uniform gasification characteristics from a number of biomass sources which each exhibit differences in their drying, pyrolysis, devolatization or gasification characteristics. The method allows biomass from a wide range and sources and with a wide range of gasification characteristics to be utilized within a gasifier without modification of the gasifier unit. The method produces a fuel pellet with controllable size, density and moisture content. The method smoothes any changes in calorific value which may exist between different feedstocks. It has been found that the gasification characteristics of a pellet formed in this way is strongly dependant upon the shape, moisture content and density of the pellet formed and less sensitive to the origin of the biomass feedstock.

Owner:ZEROPOINT CLEAN TECH

Water resistance, density, and durability of biomass fuels

InactiveUS20070261295A1Increased density and durabilityHigh densitySolid fuelsWaste based fuelCombustorAlternative fuels

Given the current world situation of fuel shortages and conflict over the finite amount of fuels available, it is very prudent to utilize every avenue available to increase the amount and quality of fuels available to use in power generation as well as other applications of steam. There are hundreds of thousands of tons of natural fuels, available for use here as well as other parts of the world. The BTU value of these waste materials is immeasurable. While most of these alternative fuels do not contain the highest BTU value, the amount of them available is beyond belief. The biggest drawback to alternative fuels has been the ease of utilization and quality of the product introduced into the combustors. Many years of testing and research by this individual have resulted in a variety of fuels that in addition to adding to the fuel supply of the world's consumers, will help to clean up the emission problems that are coming to the forefront of environmental concerns.

Owner:TOLMIE RICHARD W

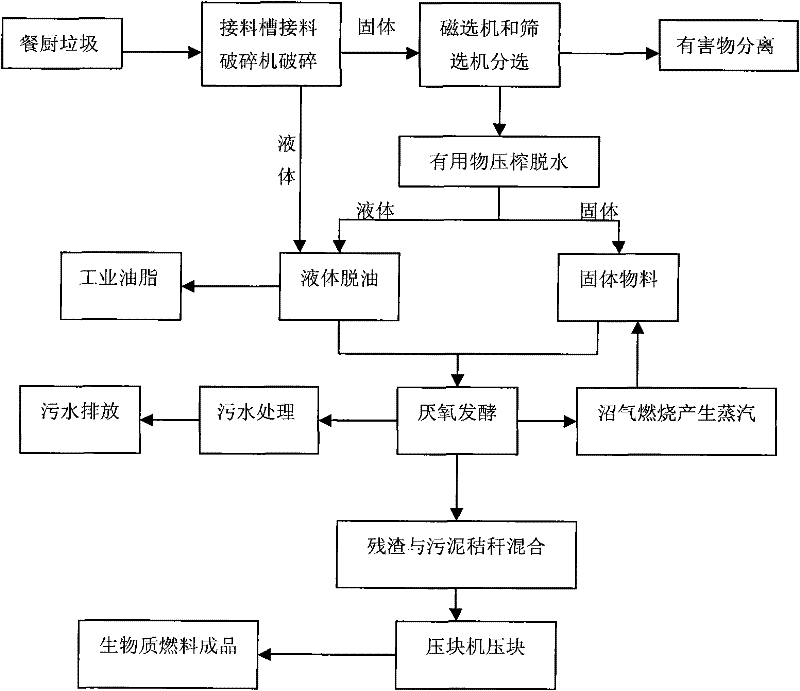

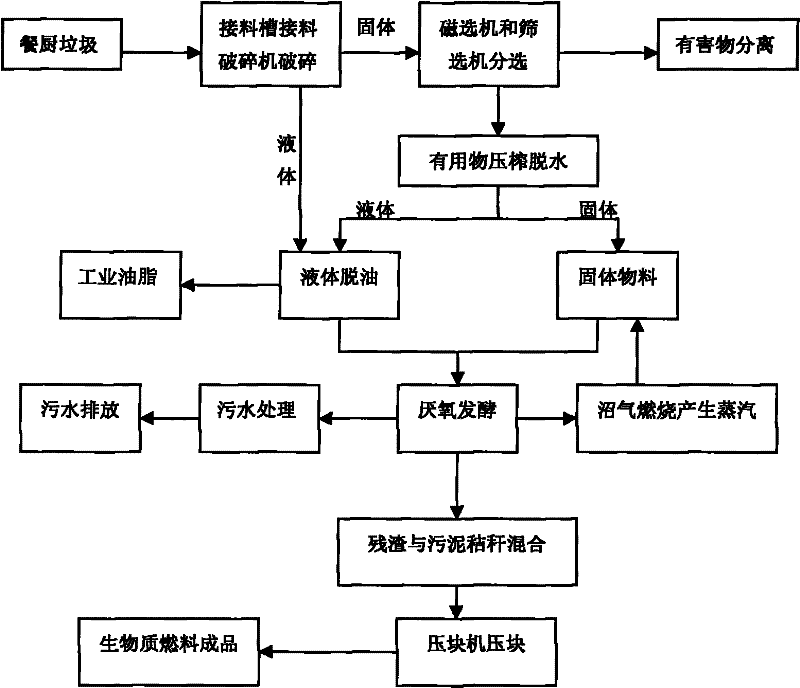

A method for preparing biomass fuel from kitchen waste

InactiveCN102268310AHarmlessAchieving processing powerFatty/oily/floating substances removal devicesSolid waste disposalSludgeSlurry

The invention relates to a method for recycling resources, in particular to a method for preparing biomass fuel from kitchen waste resources. The method for preparing biomass fuel from kitchen waste according to the present invention comprises sorting and crushing the kitchen waste, then dehydrating and deoiling, and anaerobically fermenting the solid materials in the kitchen waste after extracting the oil, and degrading the produced biogas Recycling, solid-liquid separation of the biogas slurry, the separated biogas residue is mixed with sludge, straw and other biomass materials, and dried and briquetted to make biomass fuel. The invention recycles kitchen waste and turns waste into treasure. It not only realizes the harmless and reduction treatment of kitchen waste, but also treats biomass waste such as sludge and straw, and the obtained products are completely burned without any waste. Secondary pollution, realize the comprehensive treatment of various wastes.

Owner:董雅清

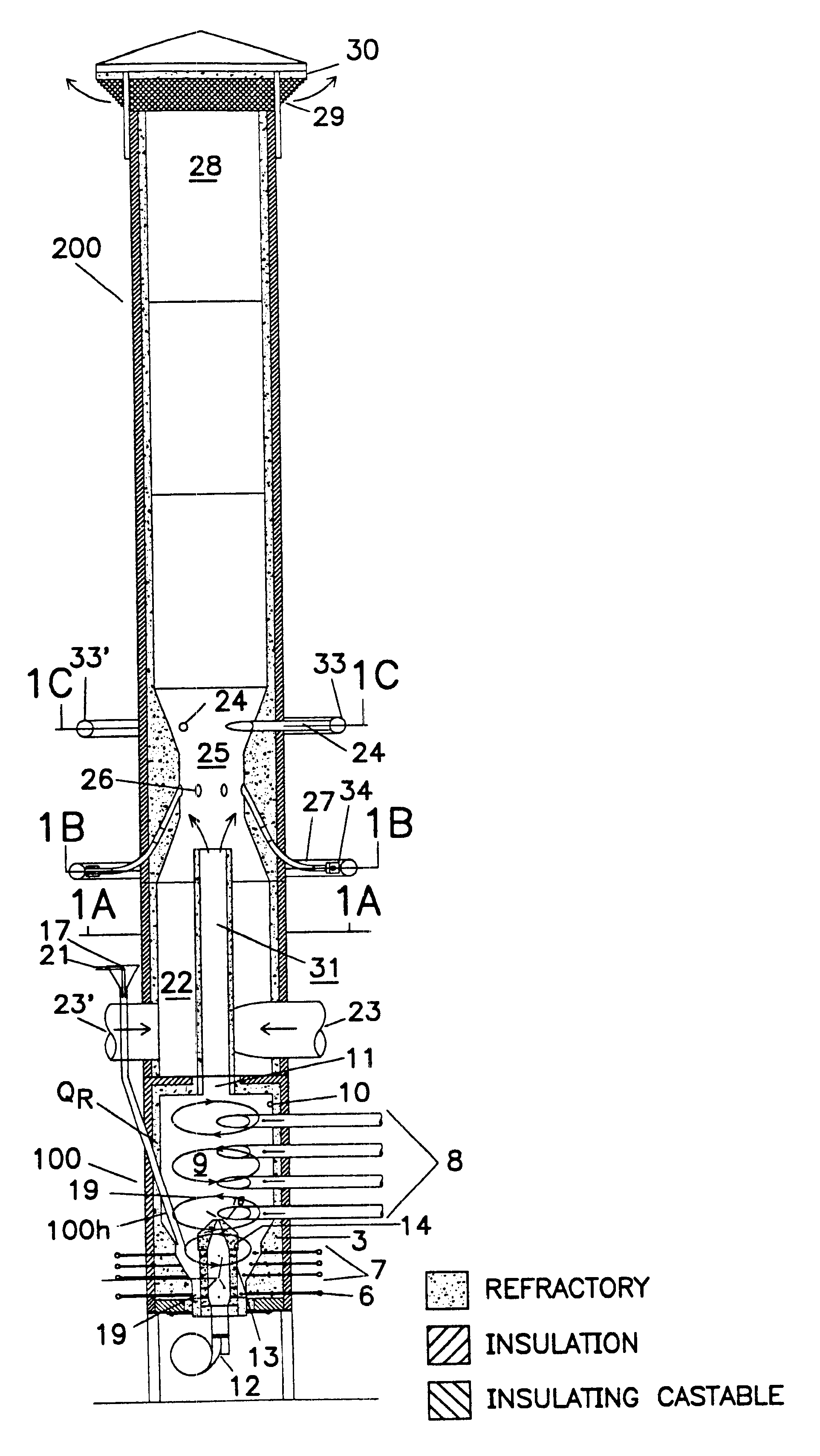

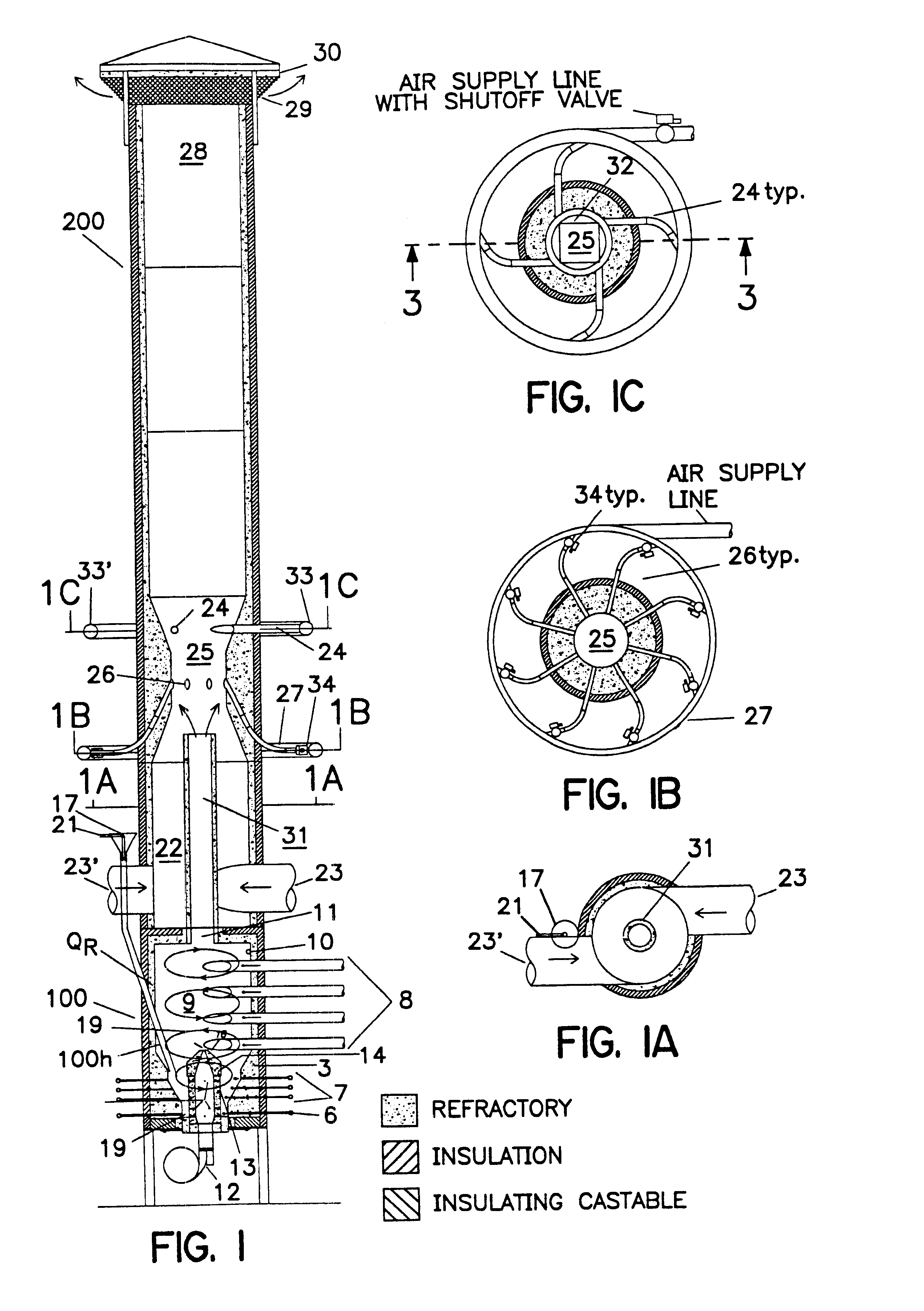

Combustors and burners with high turndown ratio

InactiveUS6363868B1Improve efficiencyIncrease flexibilityFuel supply regulationSolid waste disposalParticulatesCombustion chamber

Various smoke and combustible gas combustors (200, 300) are disclosed, and also disclosed are systems (100, 200) combining gas combustor with inventive burner. Such a burner (100 or 100') provides combustion of a particulate fuel such as sawdust, and many types of varying moisture content biomass fuels such as poultry litter. The combustors and burners exhibit a high turndown ratio ["TDR"].The smoke or combustible gas combustors (200, 300) are combined synergistically with such a burner (100, 100'), or combined with another suitable burner, so as to provide high temperature burner output gases to the combustor, which has coaxial inner and outer combustion chambers (352, 356) inlet tuyere(s) connected to the inner combustion chamber for introducing combustible smoke or other gases to be burned into the inner combustion chamber at one end thereof with cyclonic flow, and in which combustion air is mixed with combustible smoke or other gases to form a gas stream moving through the inner combustion chamber with cyclonic movement. A preheat tube (331) within the combustible gas heating chamber receives heated exhaust gases from the burner, and communicates with the inner combustion chamber exit through a plurality of apertures (364) for controlled flow of said heated exhaust gases into the gas stream and so heating same by mixing the exhaust gases with the stream of air and combustible gases.

Owner:INDEPENDENT STAVE

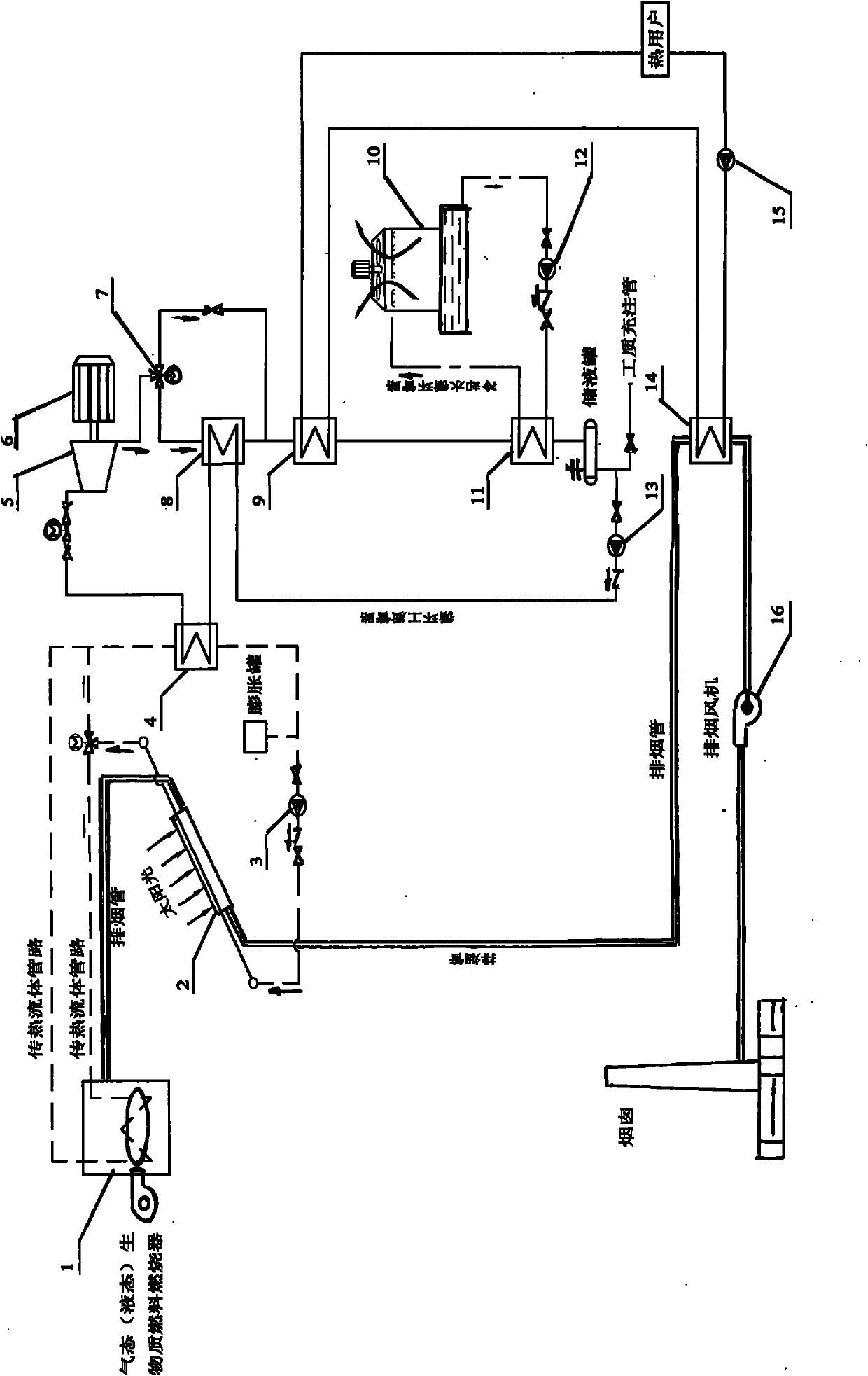

Low temperature solar energy-biomass energy combined heat and power system

InactiveCN101949369ARealize heatingReduce generationSolar heating energyFrom solar energyOrganic Rankine cycleEngineering

The invention relates to a low temperature solar energy-biomass energy combined heat and power system and a generating process. The system comprises a heat transfer fluid (such as heat transfer oil, ionic liquid, and water) circulation loop, a working medium circulation loop of an organic Rankine cycle, a heating furnace smoke discharge pipeline, a hot water heating loop and a cooling water loop. A heating furnace is used for supplementing heat for the heat transfer fluid or used as a standby heat source, and the heating surface uses dimethyl ether, heavy oil, biomass or low-grade cheap fuel made from the biomass; propane (R290), pentafluoropropane (R245fa) and the like are used as circulation working media; the exhaust heat regeneration quantity of the organic Rankine cycle can be adjusted according to the heating demand of a user; and a solar concentrator of the system is a solar concentration and waste heat recovery integrated vacuum flat-plate concentrator with a heat regenerating measure at the bottom, and the waste heat of exhaust smoke of the heating furnace can be recovered while fully using solar energy. The system can directly and efficiently convert a large quantity of low-grade biomass fuel and low-density solar energy into electric energy and supplies heat to users at the same time.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing formed fuel by using agriculture castoff

A process for producing molded fuel by using agricultural waste belonging to a solid-fuel technology field and the objective is to resolve the problem of waste utilization. The technical scheme is showed as follows: straw, sawdust, wood chips, rice crust, bagasse and other agricultural waste and liquid waste of paper are used as raw materials to produce molded fuel by drying, grinding, mixing, and so on. The invention produces molded fuel with agriculture waste and liquid waste of paper as raw materials, not only saving raw materials costs, but also reducing pollution emissions. And the adhesion of some materials in liquid waste of paper are used without heating block, thus no heating loss, but also reducing the abrasion of mechanical equipment and heat loss of raw materials caused by heating. In addition, liquid waste of paper contains 3 to 5 percent of alkaline substances, which can enhance the activity of combustion. Molded fuel produced by using the process provided by the invention which is characterized in flammability, high heat value, non-polluting, low cost, and so on.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Organically clean biomass fuel

An organically clean biomass fuel formed of mixture of a powder, which may be either dried, cellulosic product, wood charcoal powder, and / or a combination of the two, and a fluid, which may be vegetable oil, vegetable alcohol or a combination of the two. A centrifugal machine dries moist, cellulosic product and extracts black liquor. A grinder transforms the dried, cellulosic product into powder. Gum may be extracted from the vegetable oil or vegetable alcohol. A batch mixer or vibrating vessel mixes the powder and the fluid together; the fluid moisturizes the powder. Depending upon the relative amount of the fluid as compared to powder, the mixture will either be in a liquid cream state or a doughy state. If the latter, the mixture may be pressed into briquettes or ingots.

Owner:ECOEM

Kitchen waste and food waste treatment process and kitchen waste and food waste treatment system

The invention discloses a kitchen waste and food waste treatment process and a kitchen waste and food waste treatment system. The process comprises steps as follows: mixtures of kitchen waste and food waste are sorted by an automatic sorting table and put into a pre-treatment pulverizer for pulverizing; a liquid-phase mixture obtained through the automatic sorting table and an oil-water mixture separated from the pulverizer enter oil-water separating equipment for oil-water separation; a water phase separated from the oil-water separating equipment is filtered and is discharged as life irrigating water finally; an oil phase enters biological separating equipment for biological separation, and biological oil is prepared finally. The kitchen waste and the food waste pulverized by the pre-treatment pulverizer are taken as nutrition sources and are put into a polypide cultivation production line for saprophagous polypide cultivation, adult polypides enter a dryer for drying treatment and are processed and produced into feedstuff for poultry, fish and the like, polypide waste and residues are degraded, a part of a degraded material is used for generating electricity in a biomass fuel mode, and the other part is packed and transported outwards in an organic fertilizer mode for use.

Owner:深圳市德力骏塑胶机械有限公司

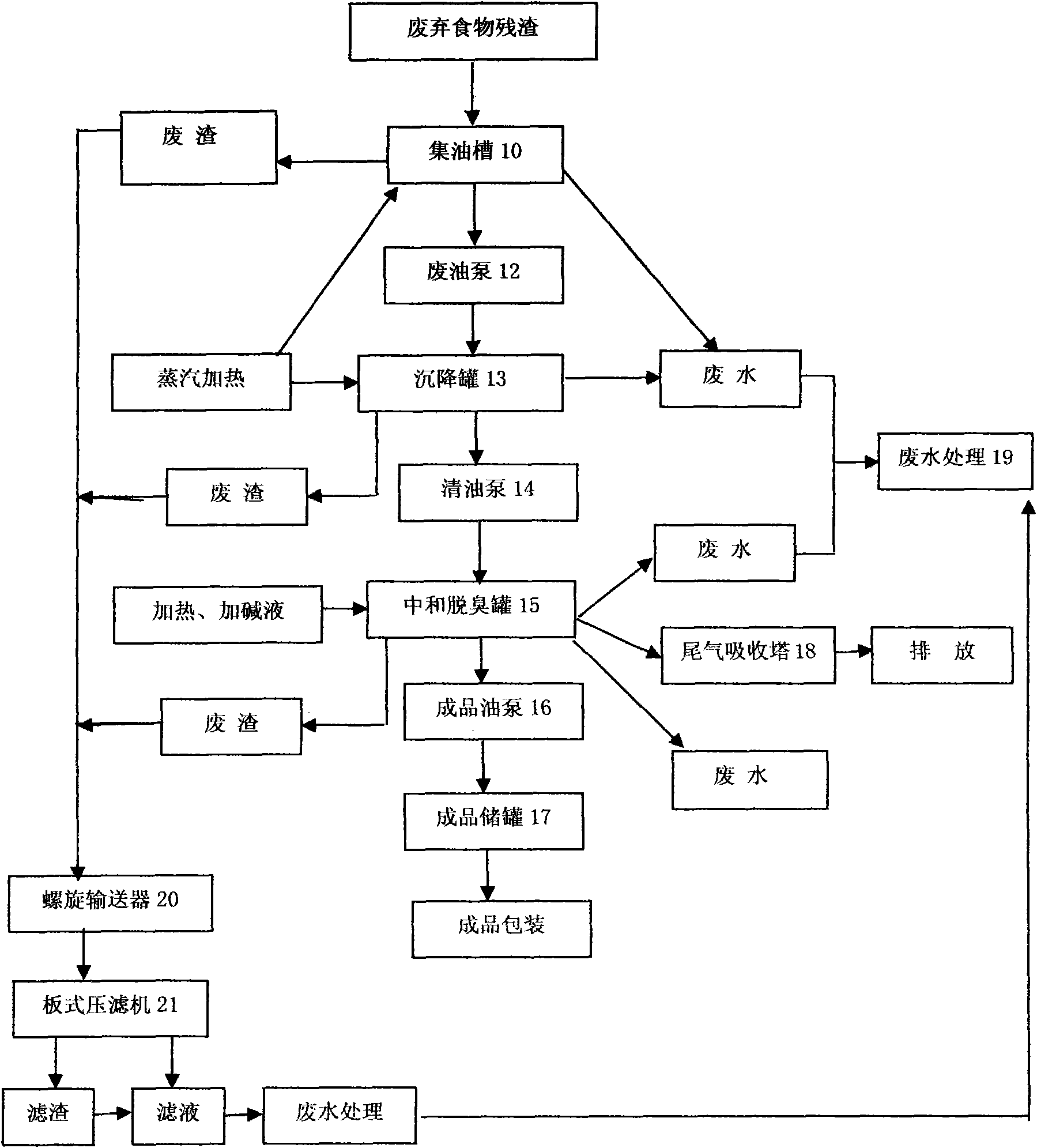

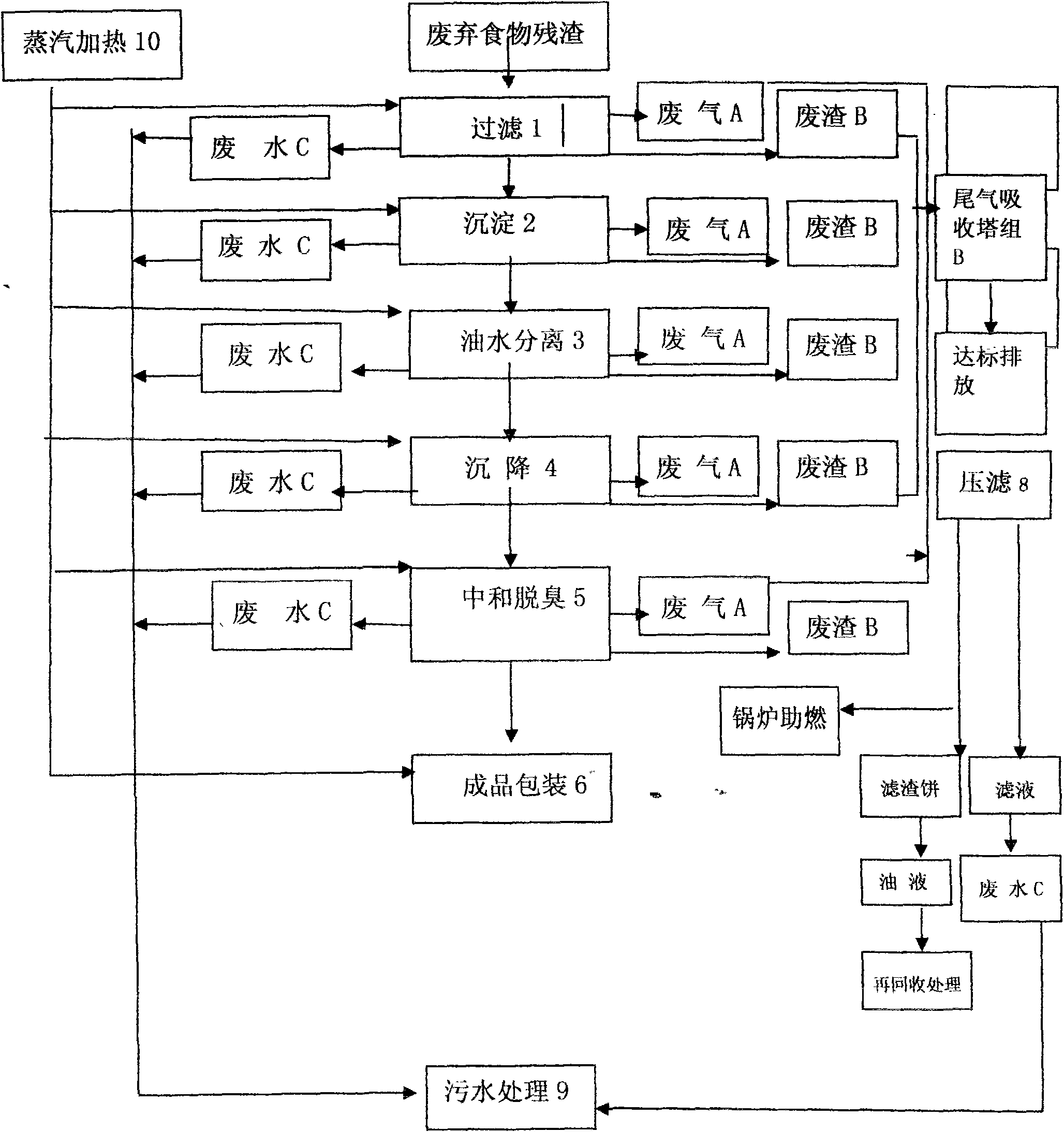

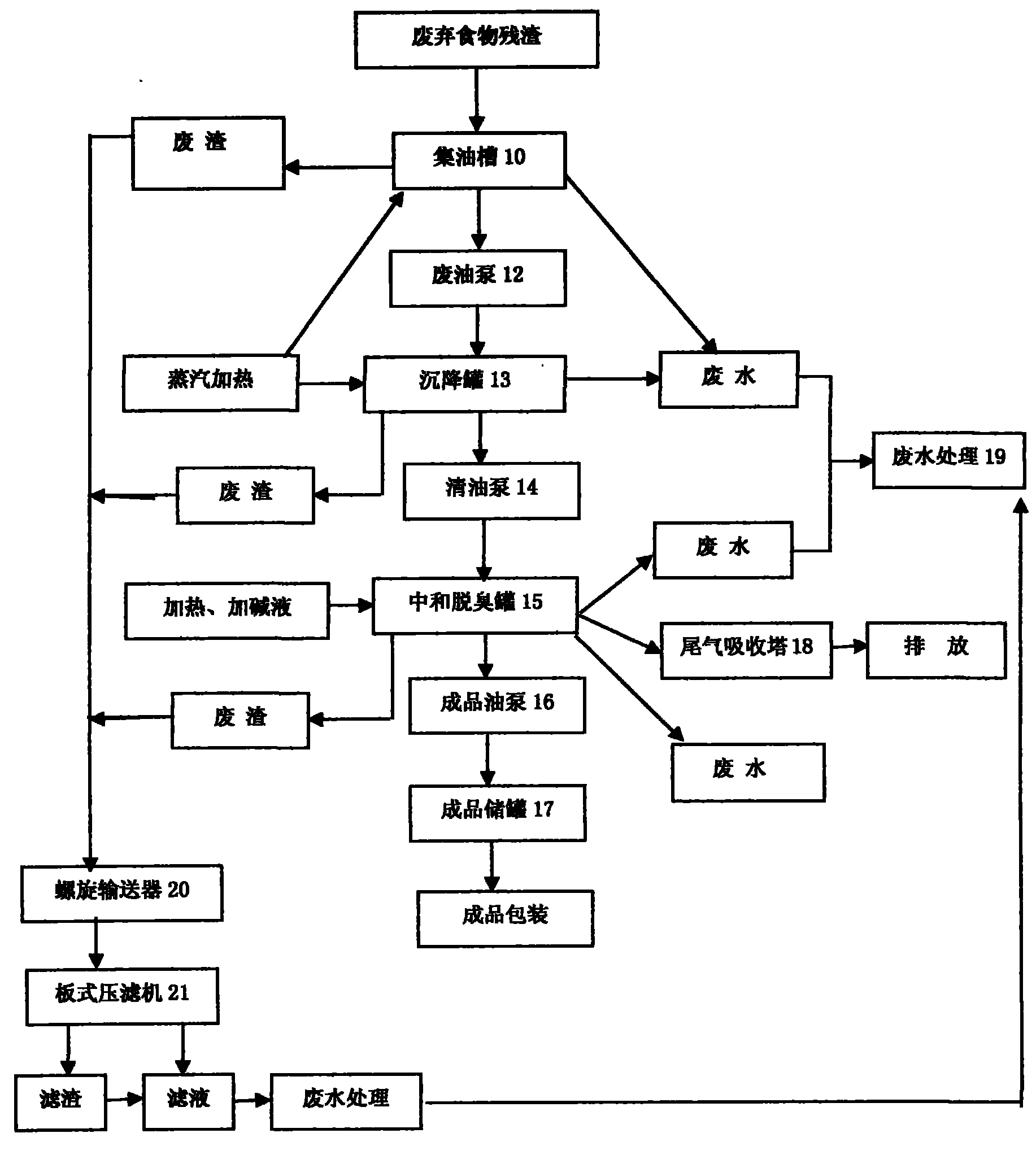

Industrialized treatment facility and method for catering wastes

InactiveCN102051267AAvoid secondary pollutionRealize recycling of resourcesFatty oils/acids recovery from wasteFatty/oily/floating substances removal devicesChemical treatmentBiodiesel

The invention discloses an industrialized treatment facility and method for catering wastes. The facility is composed of a filter, an oil-water separator, an oil sump, a sedimentation tank, a neutralization and deodorization tank, a storage tank, a tail gas absorption system, a waste water treatment system and a waste residue treatment system, wherein the filter and the oil-water separator are arranged in the oil sump, the oil sump, the sedimentation tank, the neutralization and deodorization tank and the storage tank are sequentially communicated; a waste water pump is arranged between the oil sump and the sedimentation tank, and a boiled oil pump is arranged between the sedimentation tank and the neutralization deodorization tank; and the tail gas absorption system is respectively communicated with the filter, the oil-water separator, the sedimentation tank and the neutralization and deodorization tank. The production process in the invention comprises six procedures of solid-residue separation, oil-water separation, neutralization and deodorization, tail gas purification, sewage treatment and waste residue treatment. In the invention, catering wastes are subjected to physical and chemical treatment under the close condition, and no waste gas, waste residue or waste water is discharged; separation, deodorization, decolourization and other technologies are utilized to separate waste oil from the catering wastes, and the waste oil is used for producing industrial production raw materials of biodiesel, lubricating grease and the like; and 'three wastes' produced in the production process are recycled by adopting chemical and physical methods, thus biomass fuel, reuse water for life and purified air are obtained. The invention thoroughly avoids secondary pollution in waste oil refining and separating process and realizes recycling of waste water, waste gas and waste residue.

Owner:XIAN ZHONGRUN ENVIRONMENTAL PROTECTION TECH

Method for preparing biomass fuel by utilizing obsolete fungus stick of edible fungus

InactiveCN101712903ARealize comprehensive utilizationLow costBiofuelsSolid fuelsEcological environmentAdditive ingredient

In recent years, with the rapid growth of the traditional edible fungus industry all over China, the pollution and the hazard generated to the entironment and the edible fungus industry per se by a large number of obsolete fungus sticks (slags) after the primary planting of edible fungi also become bigger and bigger, and the innocent treatment and the research development in the aspect of reutilization on the obsolete fungus sticks in the industry also become more and more, wherein the research of preparing the biomass fuel by taking the obsolete fungus sticks is an important research direction. The invention provides a method for preparing the biomass fuel by taking the obsolete fungus sticks and the fungus slags of the edible fungi as the main materials; the method has low cost and belongs to the field of waste comprehensive development and deep utilization. In the invention, the obsolete fungus sticks and the fungus slags of the edible fungi are used as the main materials, wherein the weight proportion is higher than 50 percent; the mixture ratio of other auxiliary materials is simple and varied and most of auxiliary materials is crop wastes; then the main ingredients and the auxiliary materials are extruded to be formed and then dried, thereby preparing the biomass fuel. In the invention, the biomass fuel can be processed into products with different density and shapes by adopting common biomass fuel forming equipment in the market. The products of the invention have high heat value and do not have smoke or stink; under the simple conditions, common peasant households can prepare and use the biomass fuel on the spot; the biomass fuel is a novel environment-friendly fuel. In the edible fungus scale planting areas, waste utilization is effectively realized, and pollution sources can be thoroughly eliminated.

Owner:北京普仁生态技术有限公司

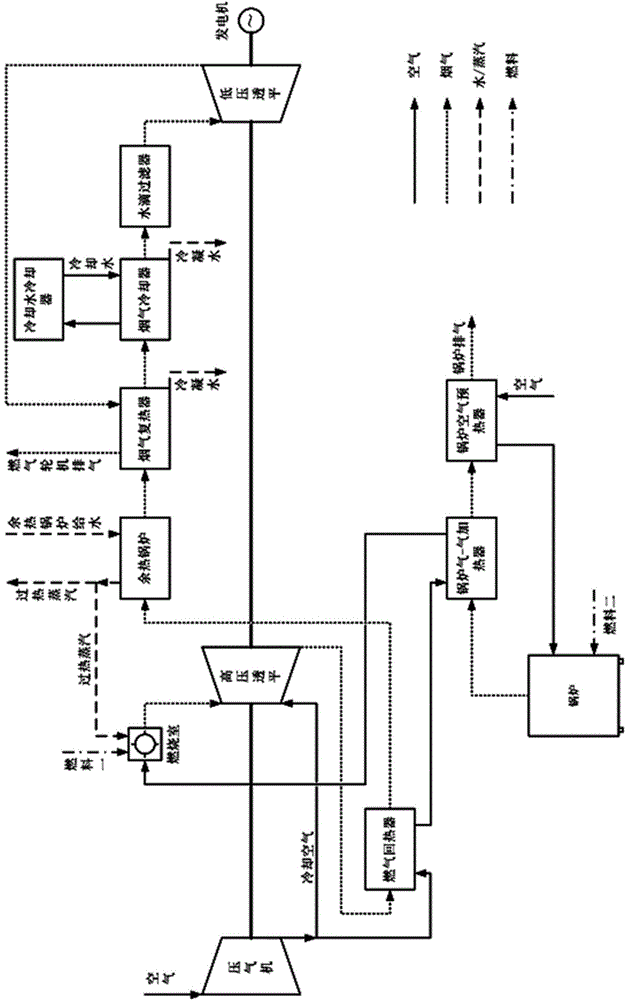

Dual-fuel steam injection direct-inverse gas turbine combined cycle

ActiveCN104533621ACombined Cycle Efficiency ImprovementEmission reductionTurbine/propulsion engine coolingGas turbine plantsSystem integrationBrayton cycle

The invention relates to a clean fuel and biomass fuel dual-fuel steam injection direct-inverse gas turbine combined cycle. A backheating type steam injection-inverse gas turbine combined cycle form is adopted for a gas turbine, and clean fuel is adopted for the gas turbine; flue gas produced when biomass fuel burns in a boiler indirectly heats the air entering a combustion chamber of the gas turbine first and then preheats the air entering the boiler, wherein the steam cyclically produced by the gas turbine can be used for supplying heat to the outside. According to the dual-fuel steam injection direct-inverse gas turbine combined cycle, the gradient utilization principle of energy is utilized, an external combustion method and the advanced steam injection direct-inverse Brayton cycle are organically combined through system integration, the energy utilization efficiency of the biomass fuel can be substantially improved, the proportion of the biomass fuel to the clean fuel is adjustable, and self-balance of water consumption and water recovery for steam injection can be achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

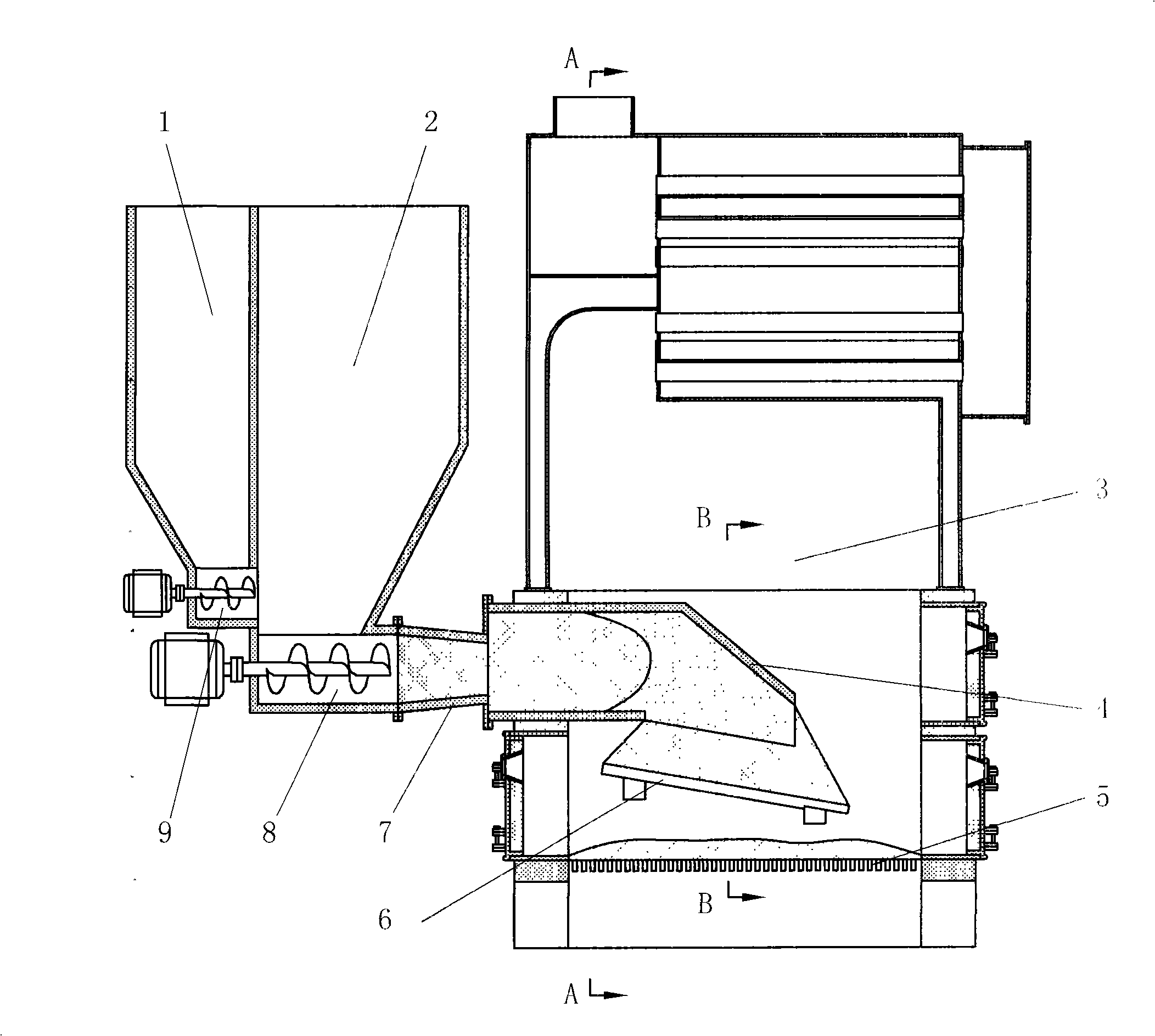

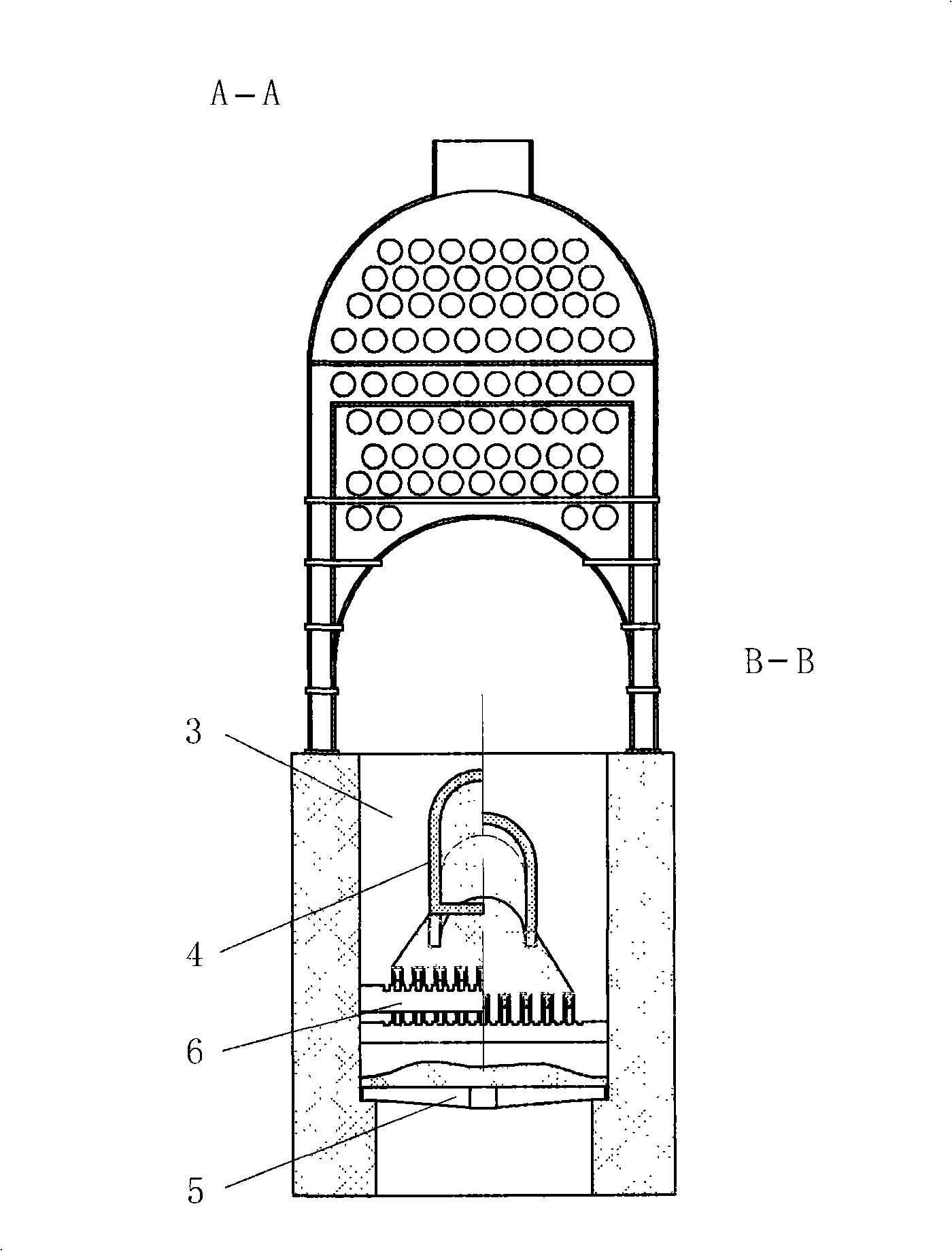

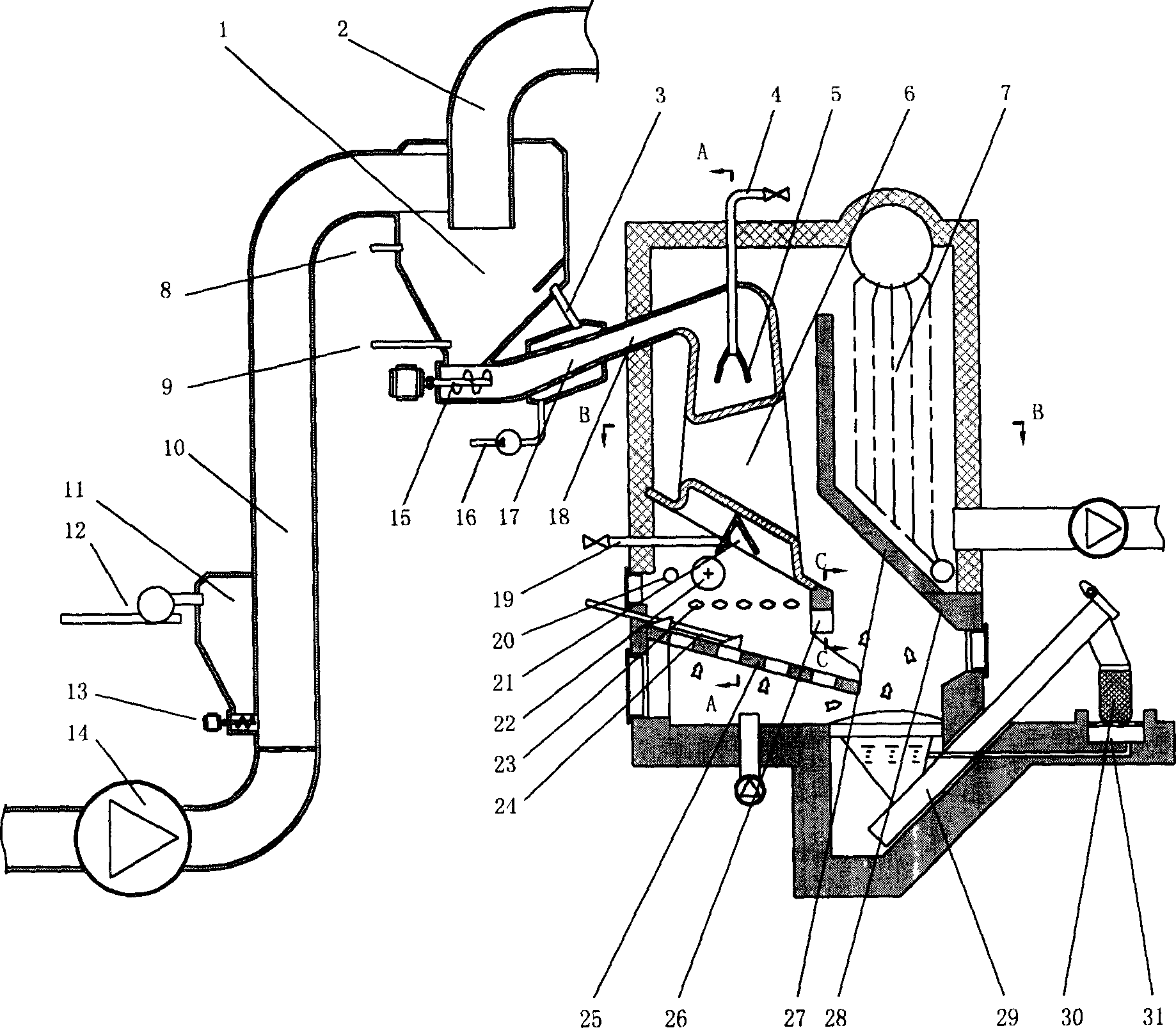

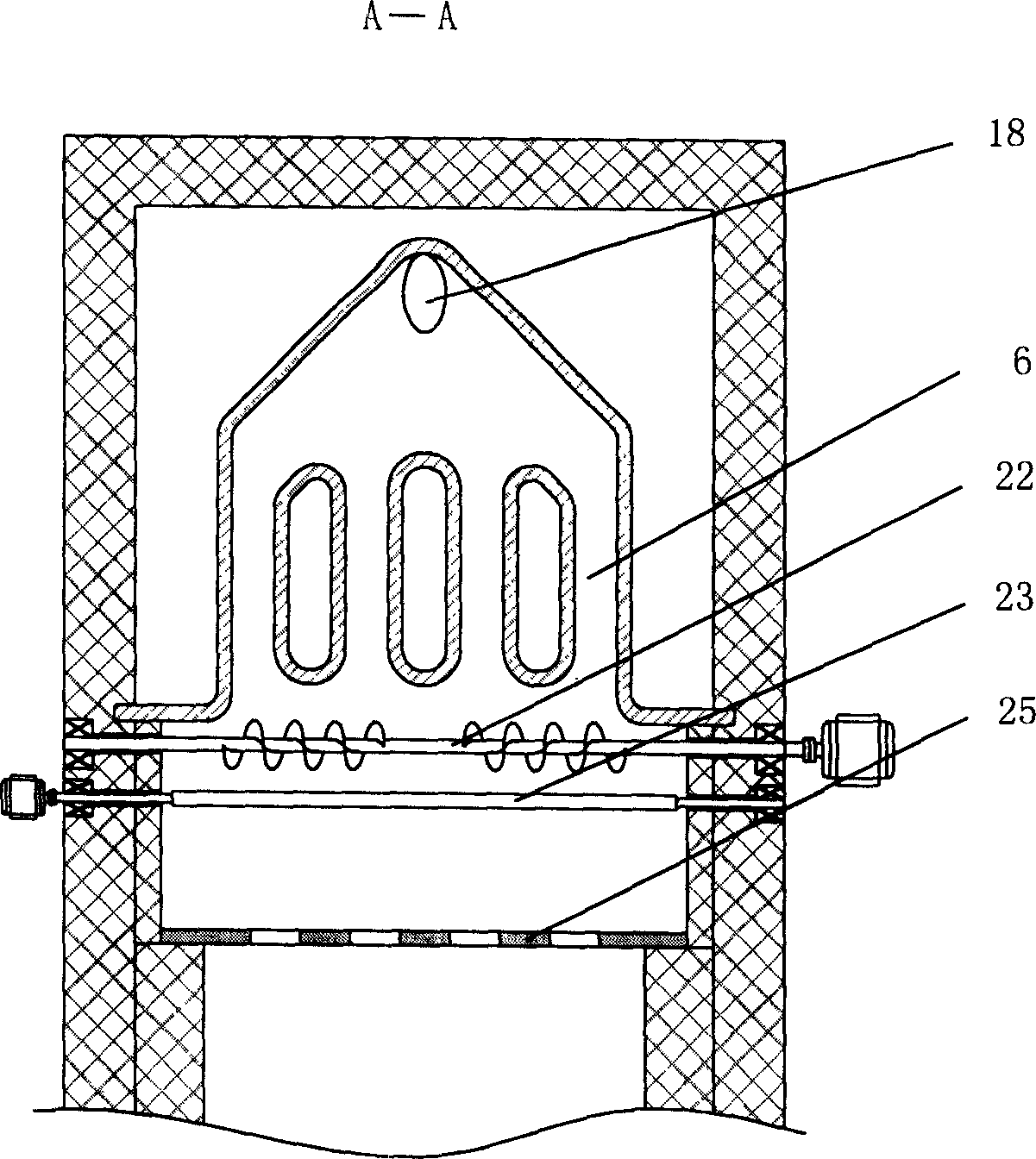

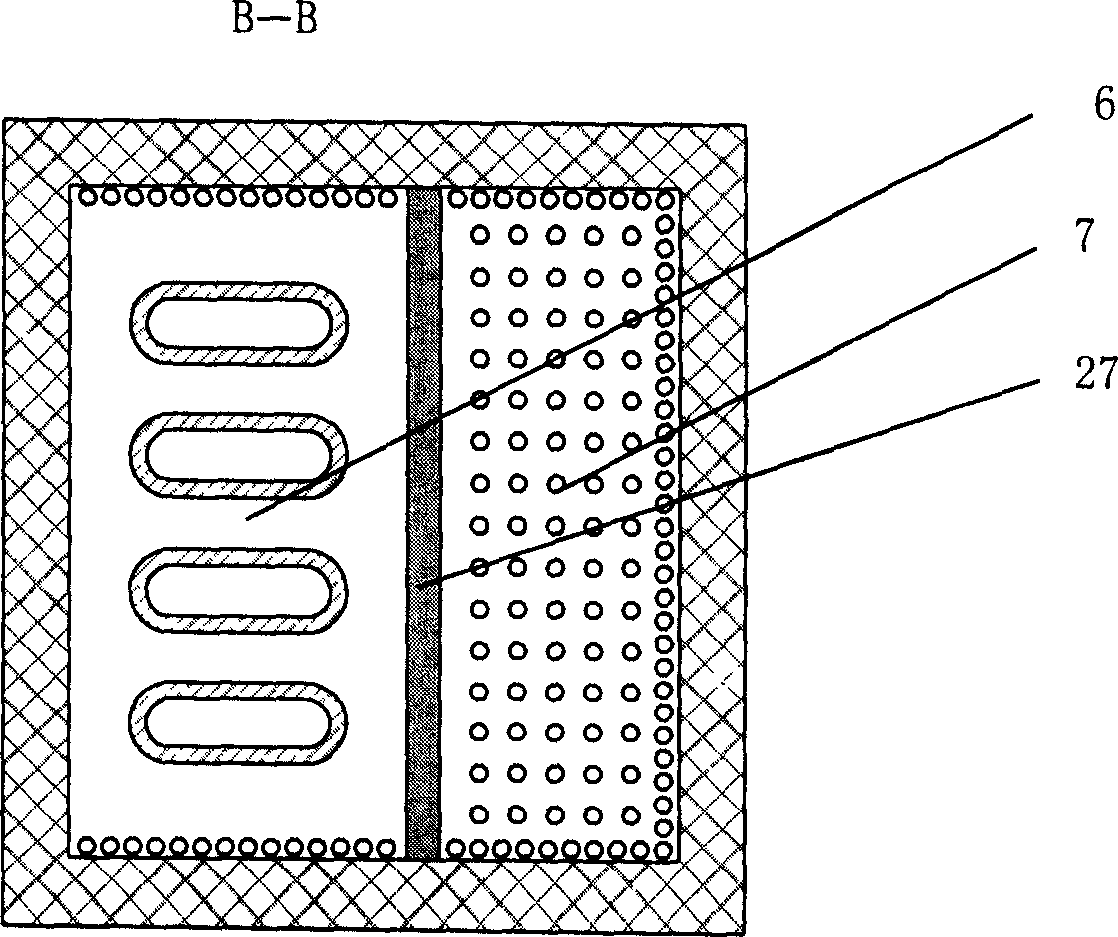

Biomass vaporizing combustion coupled type cyclone boiler

InactiveCN101625117ABurn fullyGuaranteed gasification effectChemical industrySolid fuel combustionCycloneCombustion chamber

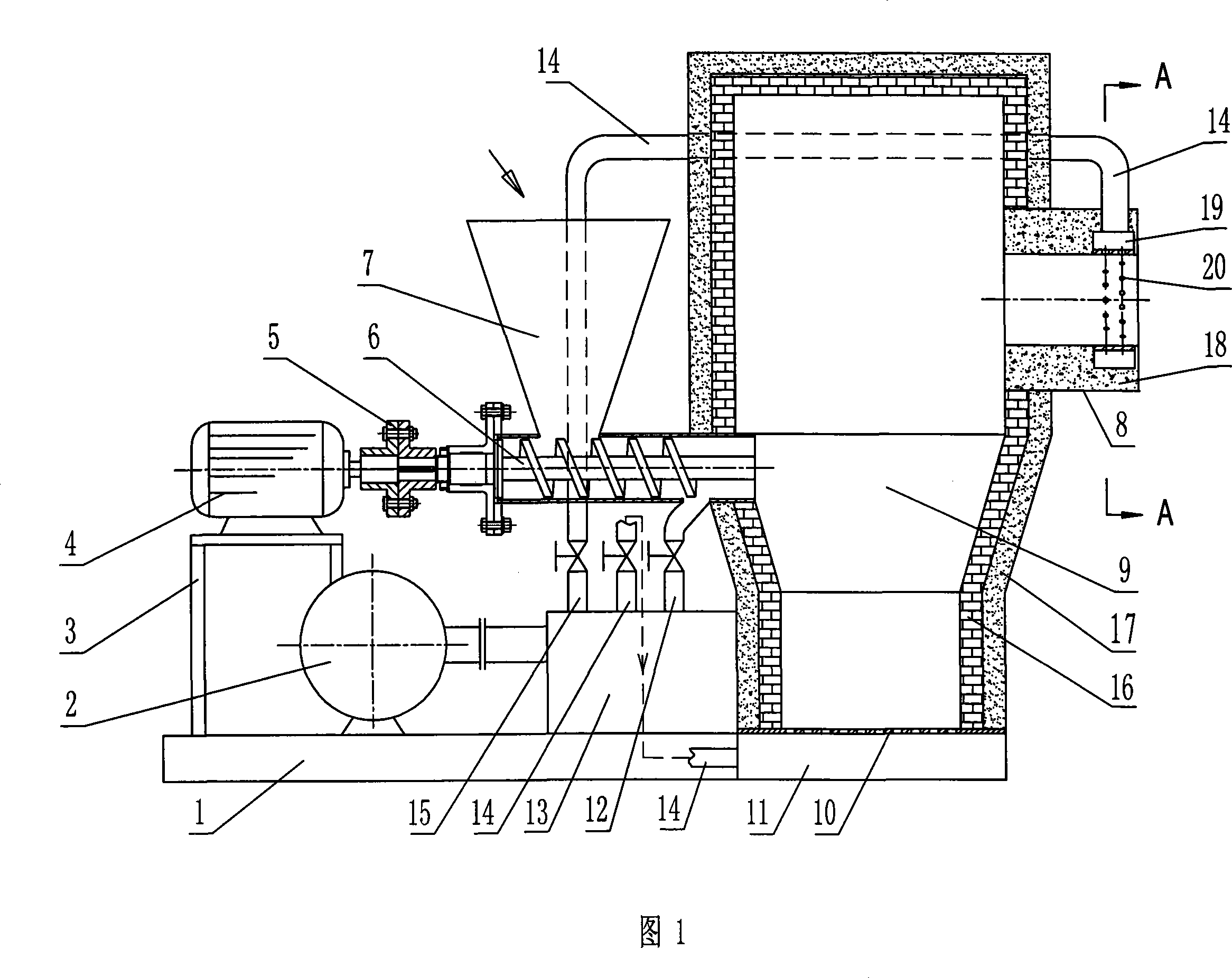

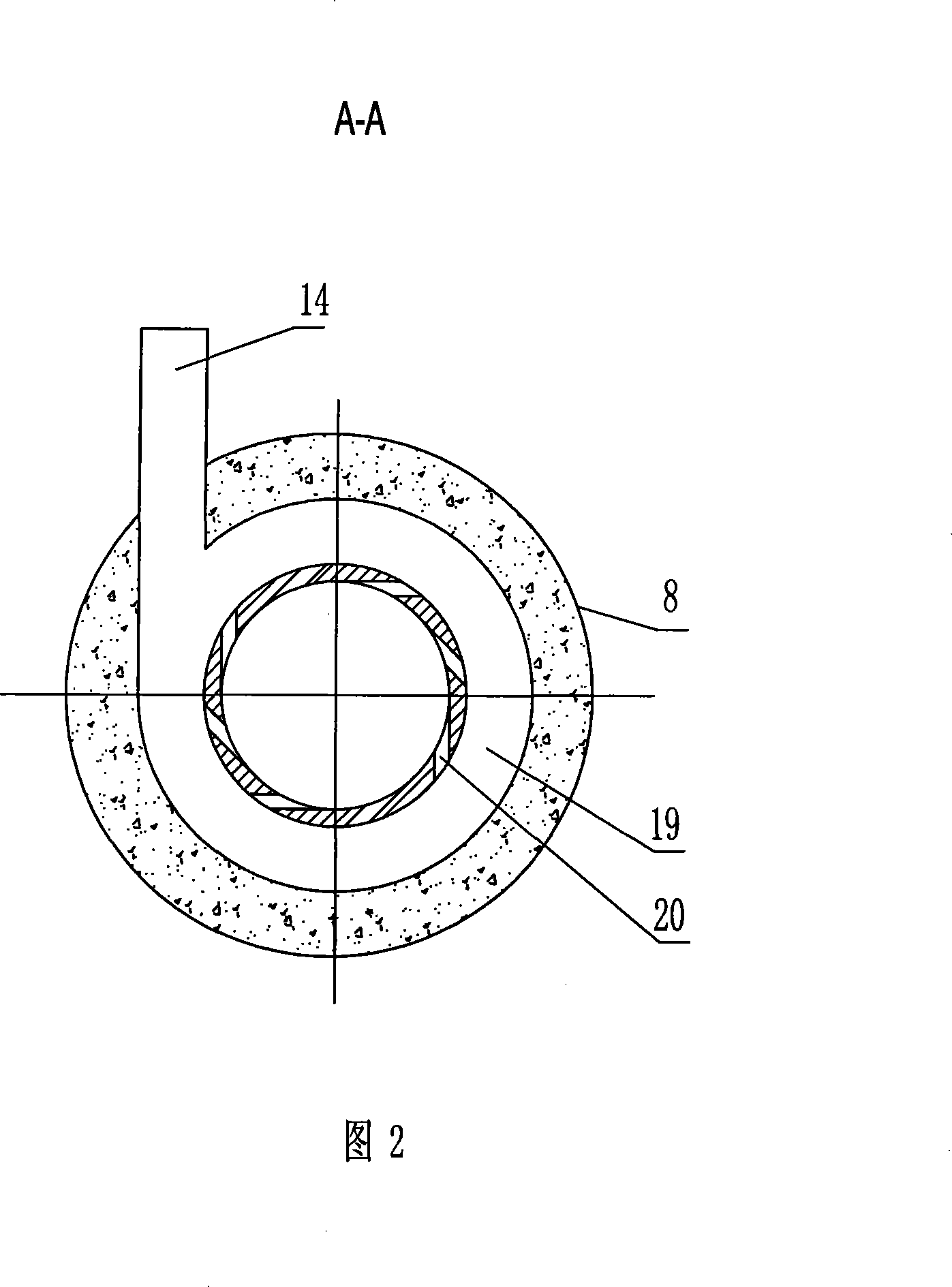

The invention relates to a biomass vaporizing combustion coupled type cyclone boiler, solving the problems of low thermal efficiency, high tar content in vaporizing gas, easy scorification of a high-temperature heating surface and the like existing in the current biomass boiler, and comprising a jacketed type boiler body and a feeding device thereof, a primary air fan, a secondary air fan, a water circulating pump, an ash slurry pond and a flue water fog deduster. The invention has the technical points that the secondary air fan is connected with the jacket of the boiler body, and an atomizing nozzle is arranged on the inner side of an outer boiler wall; secondary air and water vapour tangential jet holes are distributed on the circumference of an inner boiler wall; one end of a small spiral feeder of the feeding device is connected with the inner cavity of a vaporizing combustion chamber, and the other end is connected with the secondary air fan by a feeding air valve; the vaporizing combustion chamber and a complete combustion chamber are communicated. The invention has reasonable structure design and stable operation and strengthens effects of heat transfer and fuel vaporization, which can increase the transformation efficiency of biomass energy and heat values of biomass fuel vaporizing products, and thus, the biomass fuel is completely and sufficiently burnt, thereby saving energy, increasing the heat efficiency of the boiler, protecting environment and reducing environmental pollution.

Owner:辽宁玺丰新能源科技有限公司

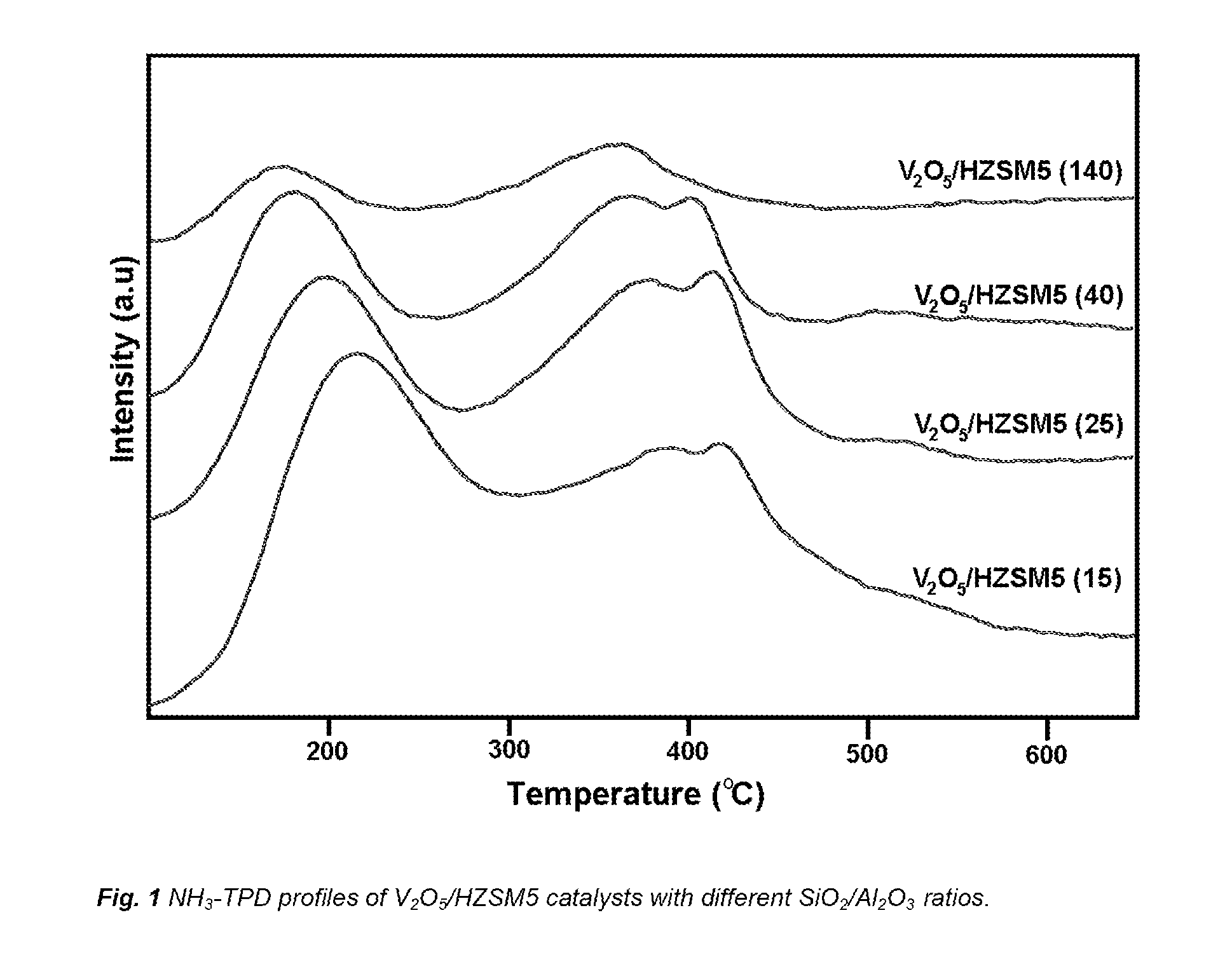

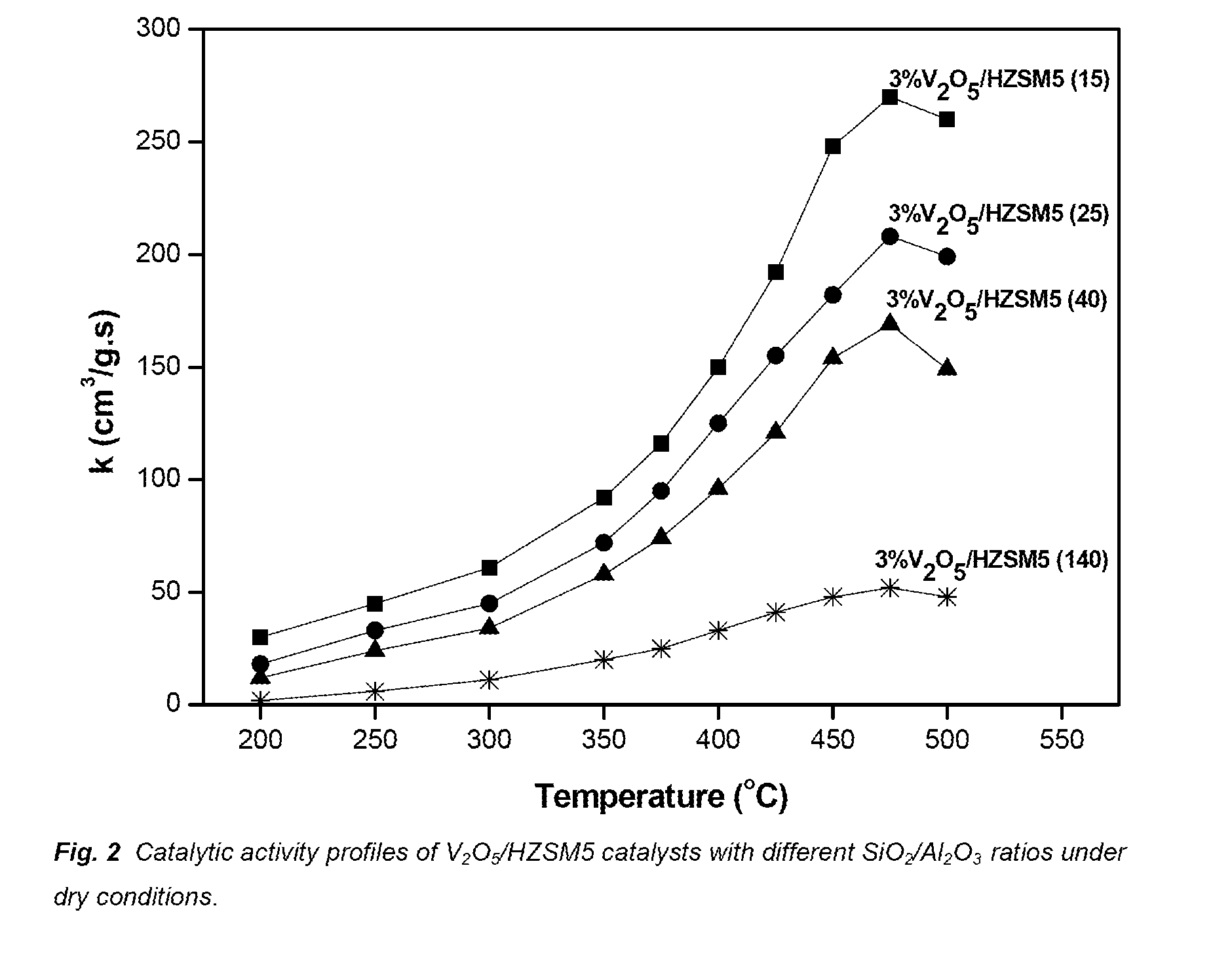

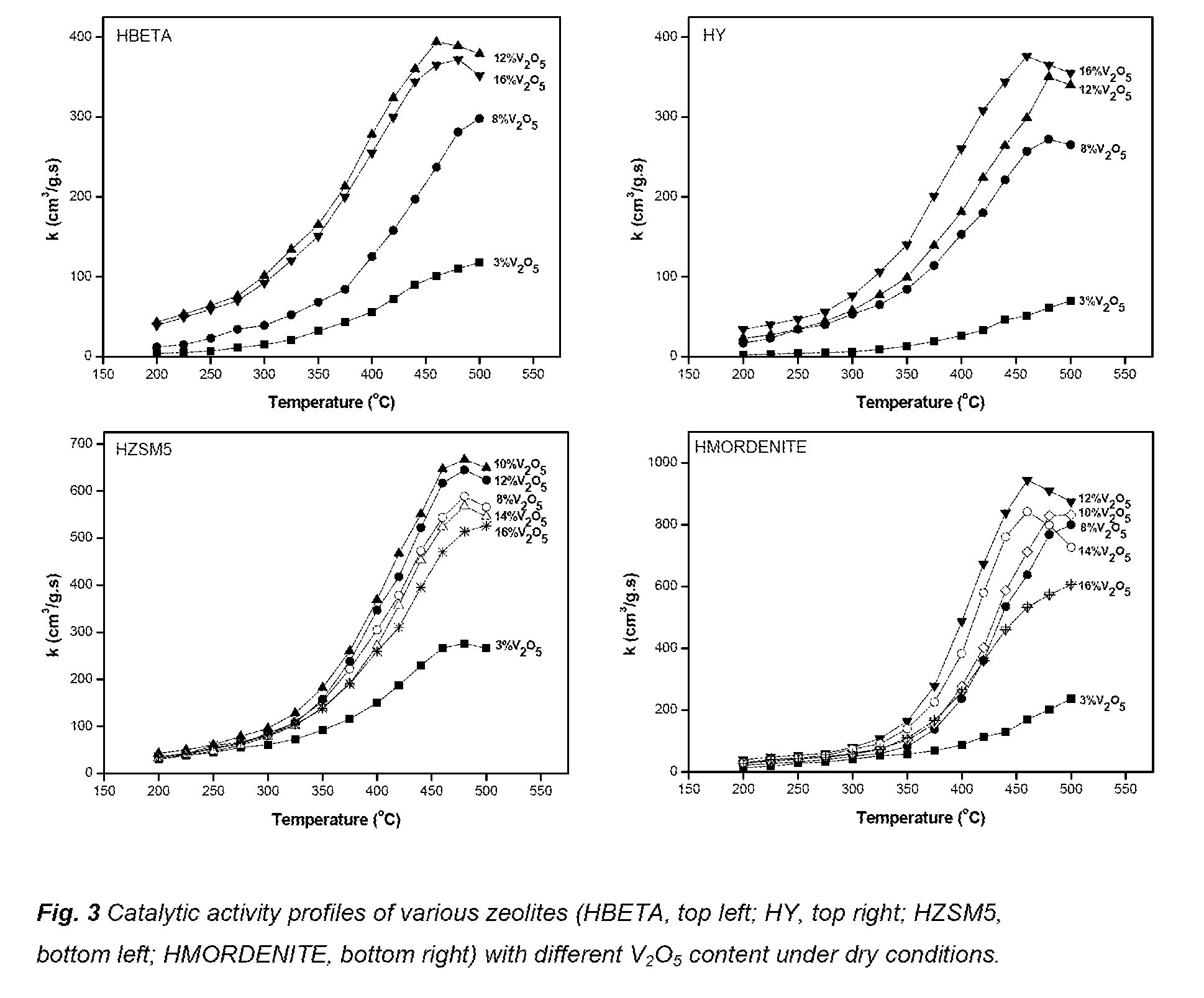

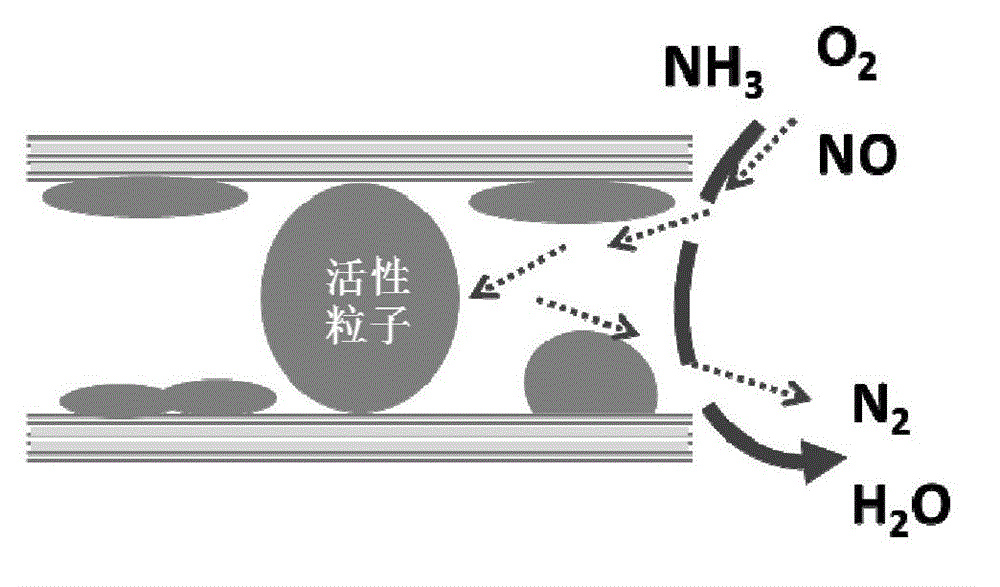

Vanadia-supported zeolites for scr of no by ammonia

The catalytic behaviour of vanadia-supported zeolite catalysts with different SiO2 / Al2O3 ratios was tested for the SCR of NO with ammonia. The SCR activity was found to be directly correlated to the total acidity of the catalysts. On the surface of these zeolites the V2O5 was highly dispersed and amorphous in nature. After the impregnation with vanadium and subsequent poisoning with potassium oxide not much change in micro-pore structure of HZSM5 was observed by N2 adsorption studies. Interestingly, potassium-doped HZSM5 and HMORDENITE catalysts showed high resistance to deactivation because of the unique nature of the material exhibiting higher surface area and acidity than the conventional V2O5—WOx / ZrO2 or TiO2 catalysts. Consequently, a possible application of these alkali-tolerant SCR catalysts in biomass fired power plants can be envisaged.

Owner:DANMARKS TEKNISKE UNIV

Biomass particle fuel and preparation method thereof

InactiveCN104927961AQuality improvementImprove qualitySolid fuelsWaste based fuelOrganic matterCow dung

The invention relates to the technical field of biomass fuel, in particular to biomass particle fuel and a preparation method thereof. The biomass particle fuel and the preparation method are characterized in that cow dung, biogas residues, sawdust, yellow mud and corn straw are pre-fermented to change the structure layer of the biomass raw materials and form a compact structure, high-content organic matter is formed, and organic matter components are increased; drainage oil is poured into the organic matter, high-speed stirring is used to allow microscopic biochemical reaction between the drainage oil and the fermented materials, and organic matter mass and quality are increased; the stirred mixture is fermented to further convert the organic matter so as to increase the combustible substances in the organic matter and improve the quality of the organic matter; combustion improver is added and extrusion forming is performed to allow the prepared biomass particle fuel to be good in quality.

Owner:广西稳德福能源科技有限公司

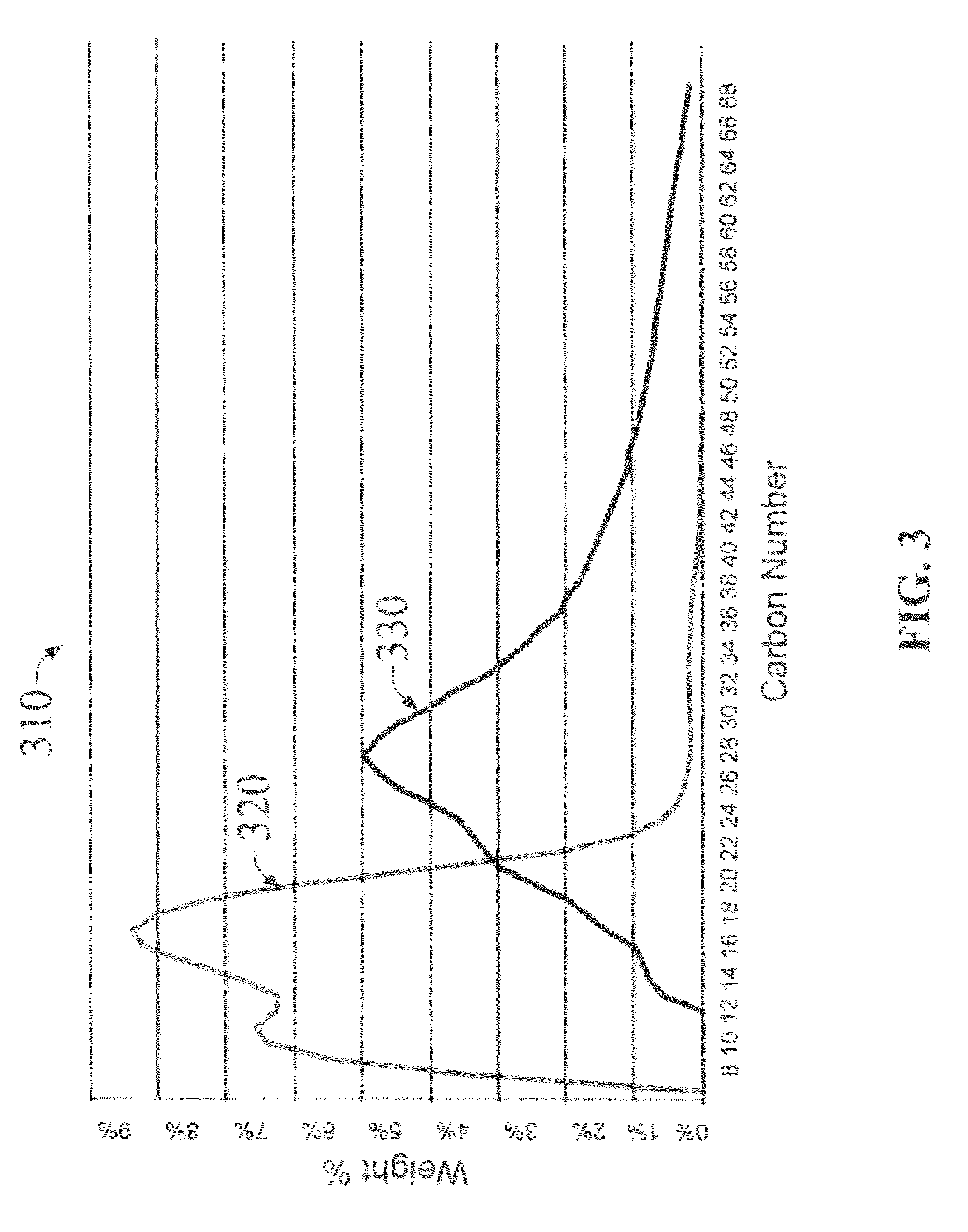

Catalytic process for the direct production of hydrocarbon fuels from syngas

ActiveUS8394862B1High selectivityImprove its cetane contentOrganic compound preparationOxygen compounds preparation by reductionSyngasProcess engineering

A unique process and catalyst is described that operates efficiently at low pressures for the direct production of a high cetane diesel type fuel or diesel type blending stock from stoichiometric mixtures of hydrogen and carbon monoxide. This invention allows for, but is not limited to, the economical and efficient production high quality diesel type fuels from small or distributed fuel production plants that have an annual production capacity of less than 100 million gallons per year by eliminating traditional hydrocracking and other costly upgrading processes. This catalytic process is ideal for distributed diesel fuel production plants such as biomass to fuel production plants and stranded natural gas to diesel fuel production plants, and other applications that require optimized economics based on supporting distributed feedstock resources.

Owner:GREYROCK TECH LLC

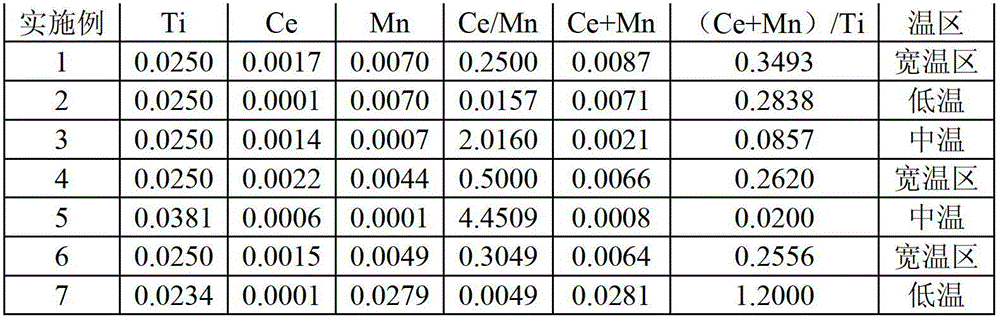

Medium/low-temperature core-shell denitration catalyst and preparation method and application thereof

ActiveCN102941083AStrong resistanceStrong anti-poisoningDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsManganeseCerium

The invention discloses a medium / low-temperature core-shell denitration catalyst and a preparation method and application thereof, belonging to the technical field of air pollution control. Main raw materials consist of a titanium-based nano tube, soluble salt of cerium and soluble salt of manganese, wherein a carrier shell of the catalyst is formed by the titanium-based nano tube, and an active nanoparticle core is formed by oxides of cerium and manganese. The molar ratio of the total amount of cerium and manganese to the amount of titanium is (0.02-0.12):1, the molar ratio of cerium to manganese is more than 0.5 or less than 0.25, and when the molar ratio of cerium to manganese is between 0.25 and 0.5, the catalyst has good activity in a medium-temperature zone, a low-temperature zone and a medium / low-temperature zone. The preparation method comprises the steps of soaking the titanium-based nano tube in an organic solvent, adding the soluble salt of cerium and the soluble salt of manganese, impregnating, drying and roasting, thereby obtaining the medium / low-temperature core-shell denitration catalyst. The catalyst has broad application prospects in treatment of waste gases with high contents of solid toxic components, such as exhaust gas of industrial furnaces, flue gas of power plants using biomass fuels and the like.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

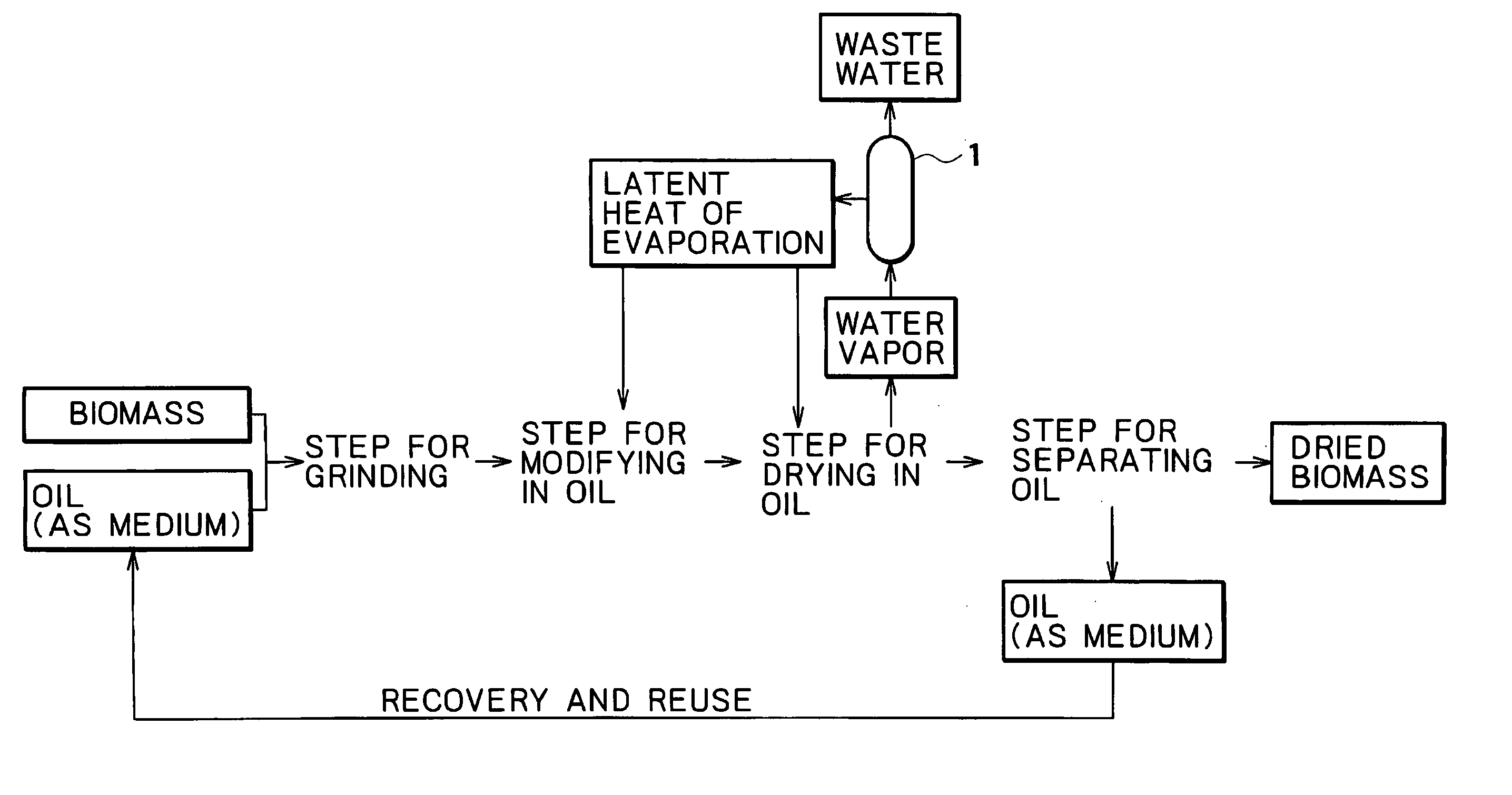

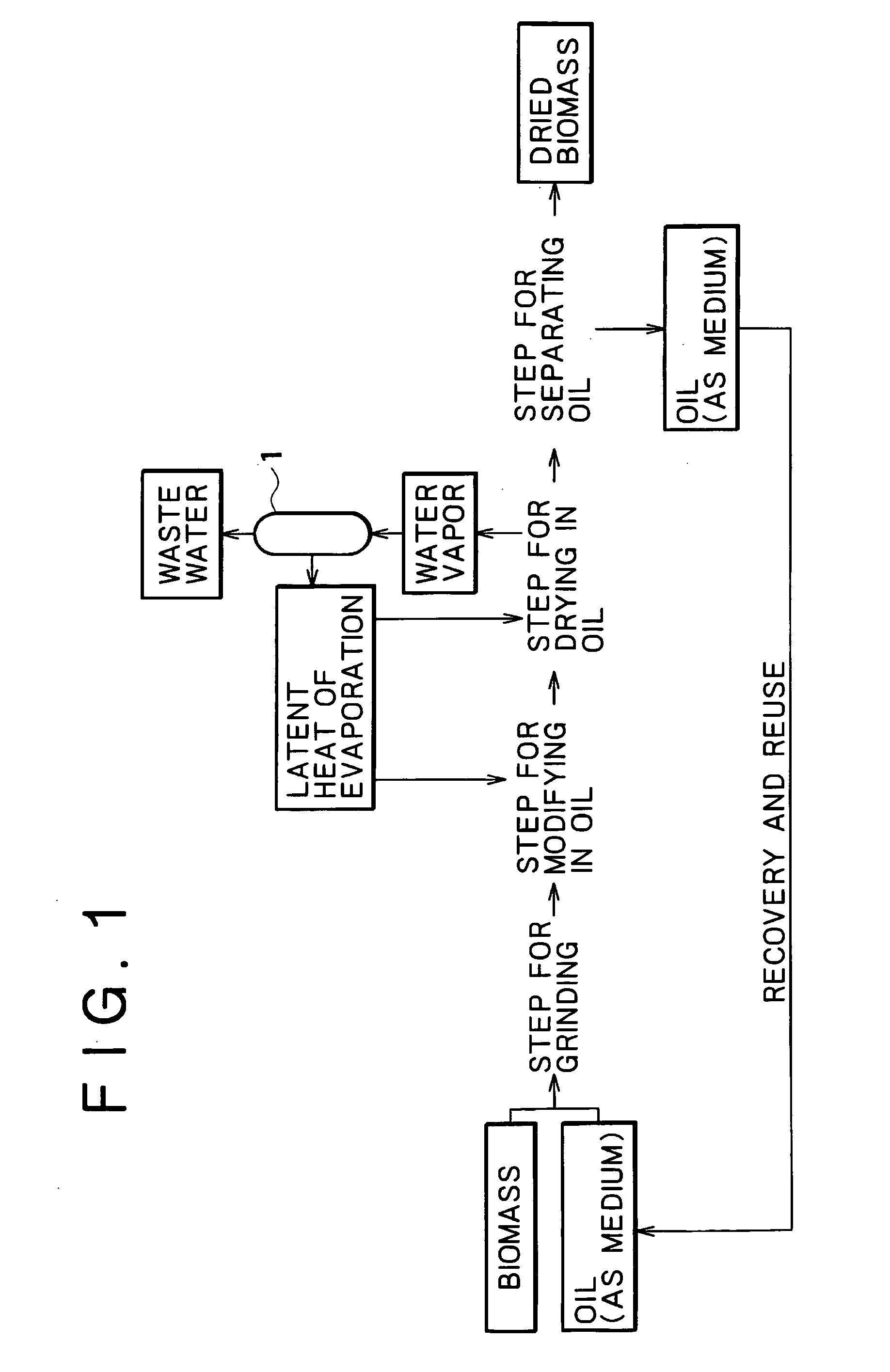

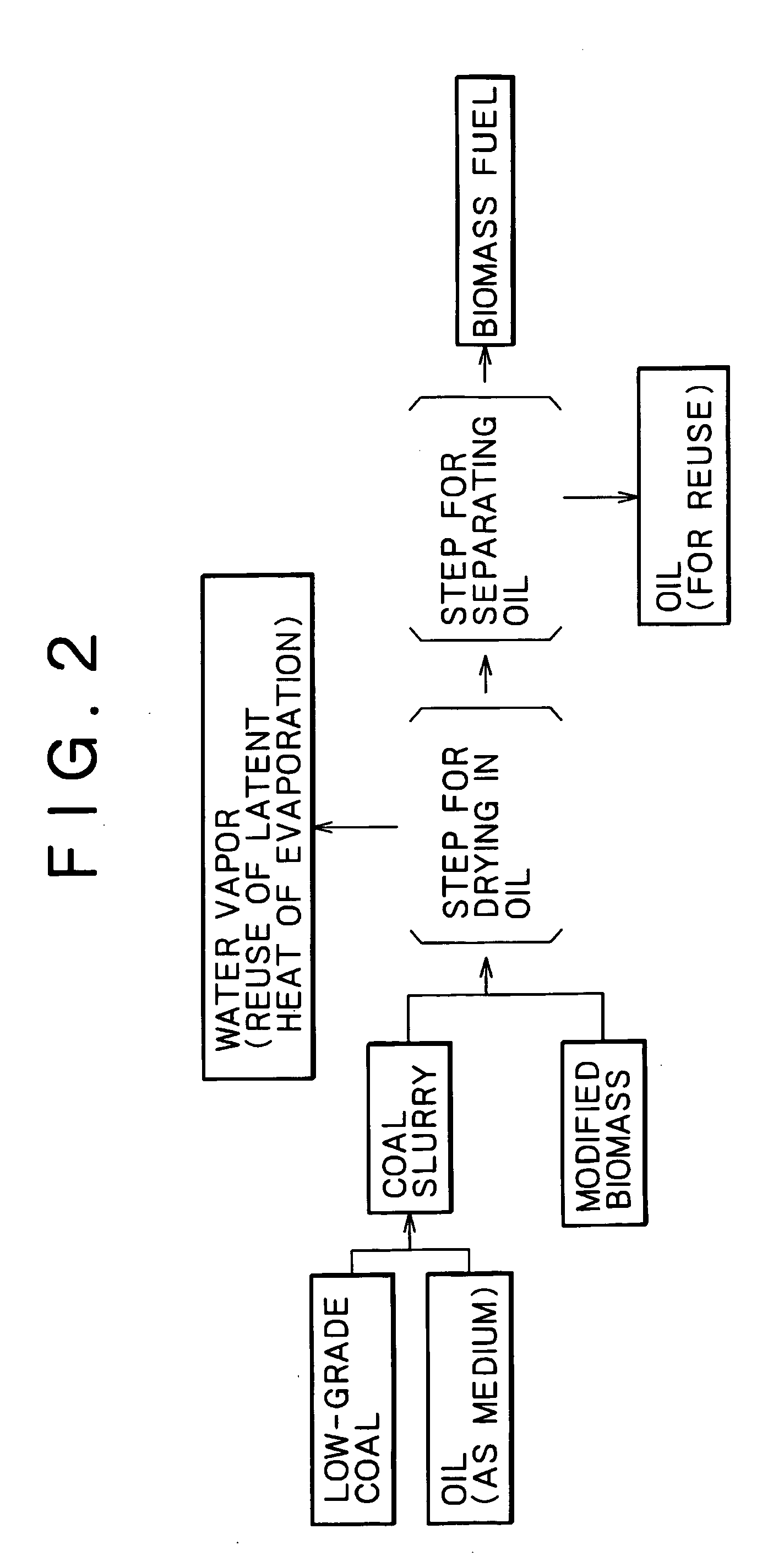

Method for drying plant-derived biomass and method for producing biomass fuel

Disclosed herein is an economical method for efficiently drying the plant-derived biomass for which there has been no established method for disposal and reuse. This drying method does not impair the value of plant-derived biomass as a fuel. Disclosed also herein is a method for producing a biomass fuel from the plant-derived biomass which has been dried by the aforesaid method. The drying method consists of dehydrating (drying) plant-derived biomass in oil with heating and modifying it simultaneously. Drying in this way partly decomposes the plant-derived biomass, thereby yielding a good constituent for biomass fuel.

Owner:KOBE STEEL LTD

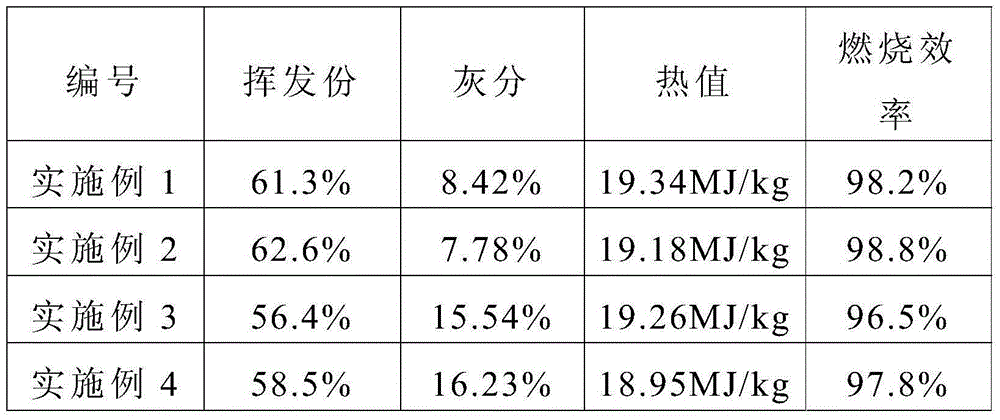

Preparation method for biomass fuel

The invention relates to a preparation method for a biomass fuel and belongs to the technical field of biomass fuels. The method comprises the steps of preparing the following raw materials: 35-45% of rice husks, 35-45% of straws, 1-1.5% of oxidizing agent, 2-3.5% of combustion improver, 8-12% of binder and 12-15% of bulking agent; crushing rice husks and straws, uniformly mixing the crushed rice husks and the crushed straws with the oxidizing agent and the combustion improver, adding the bulking agent, mixing the bulking agent with the above materials, and finally adding the binder to obtain granular products. The biomass fuel can be fully combusted. Meanwhile, the combustion product of the biomass fuel is rich in a variety of elements and can be used as an agricultural fertilizer. Therefore, the cyclic utilization of the biomass fuel is realized and the environment is prevented from being polluted.

Owner:XIAOCHANG XINBO AGRI DEV CO LTD

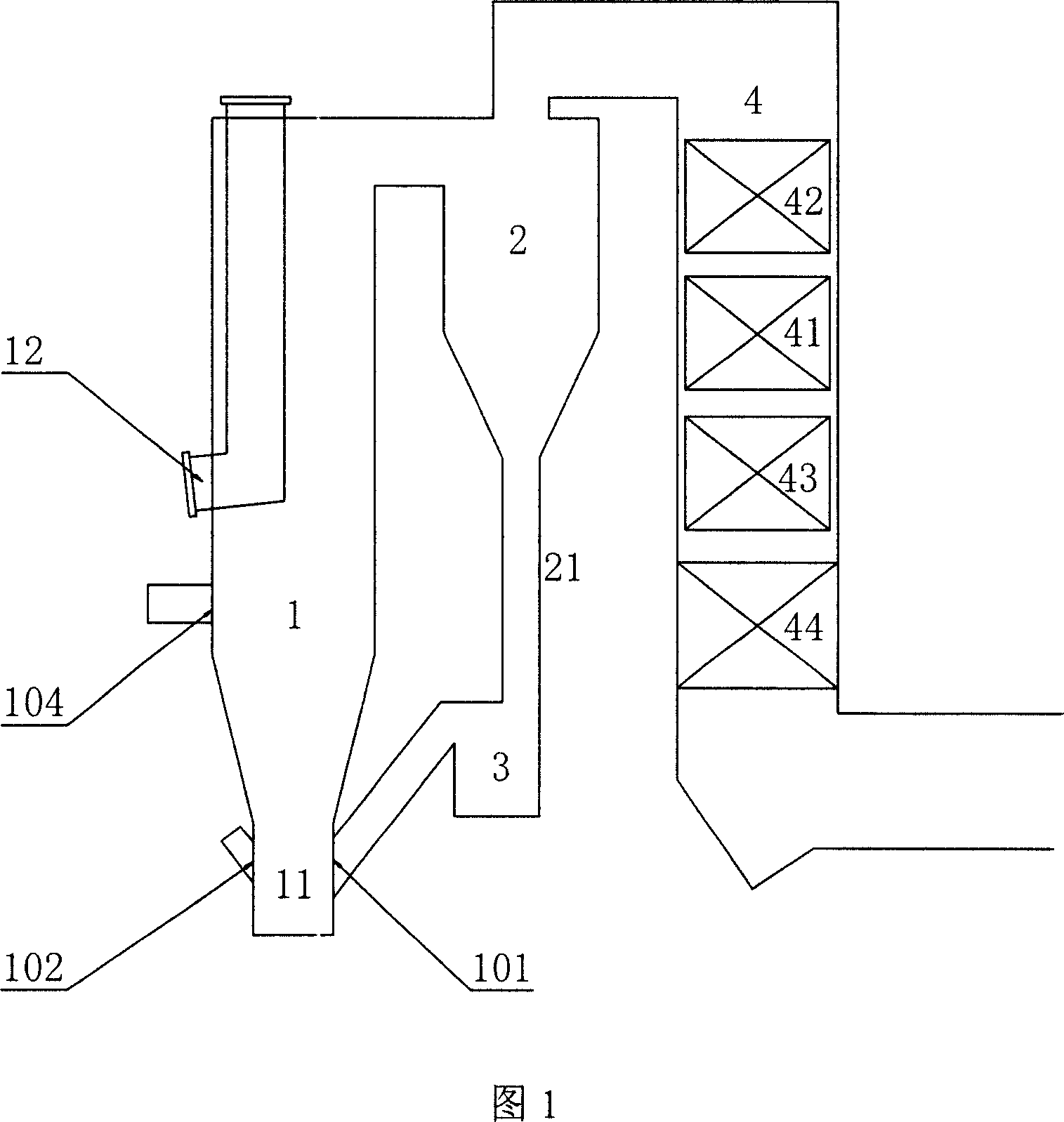

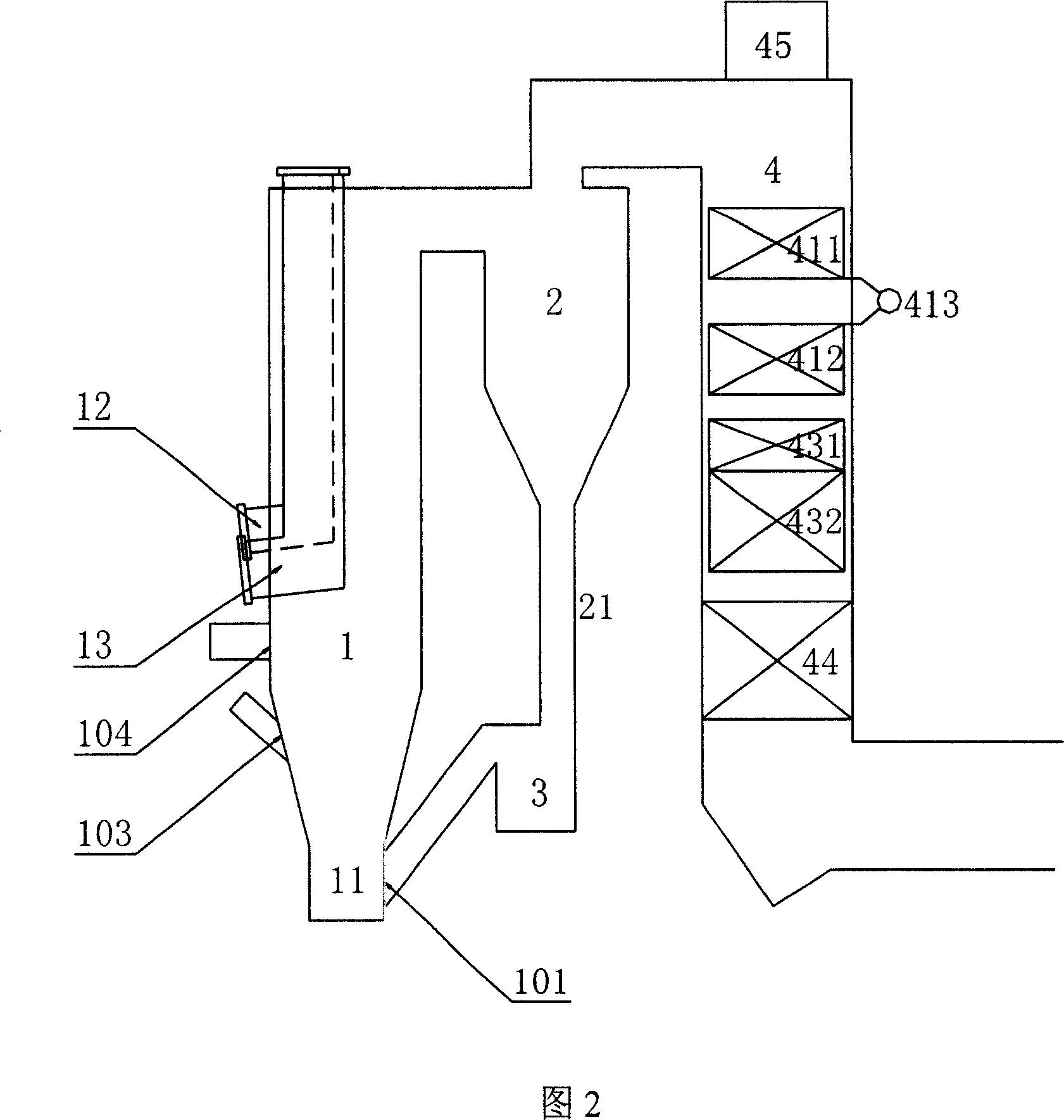

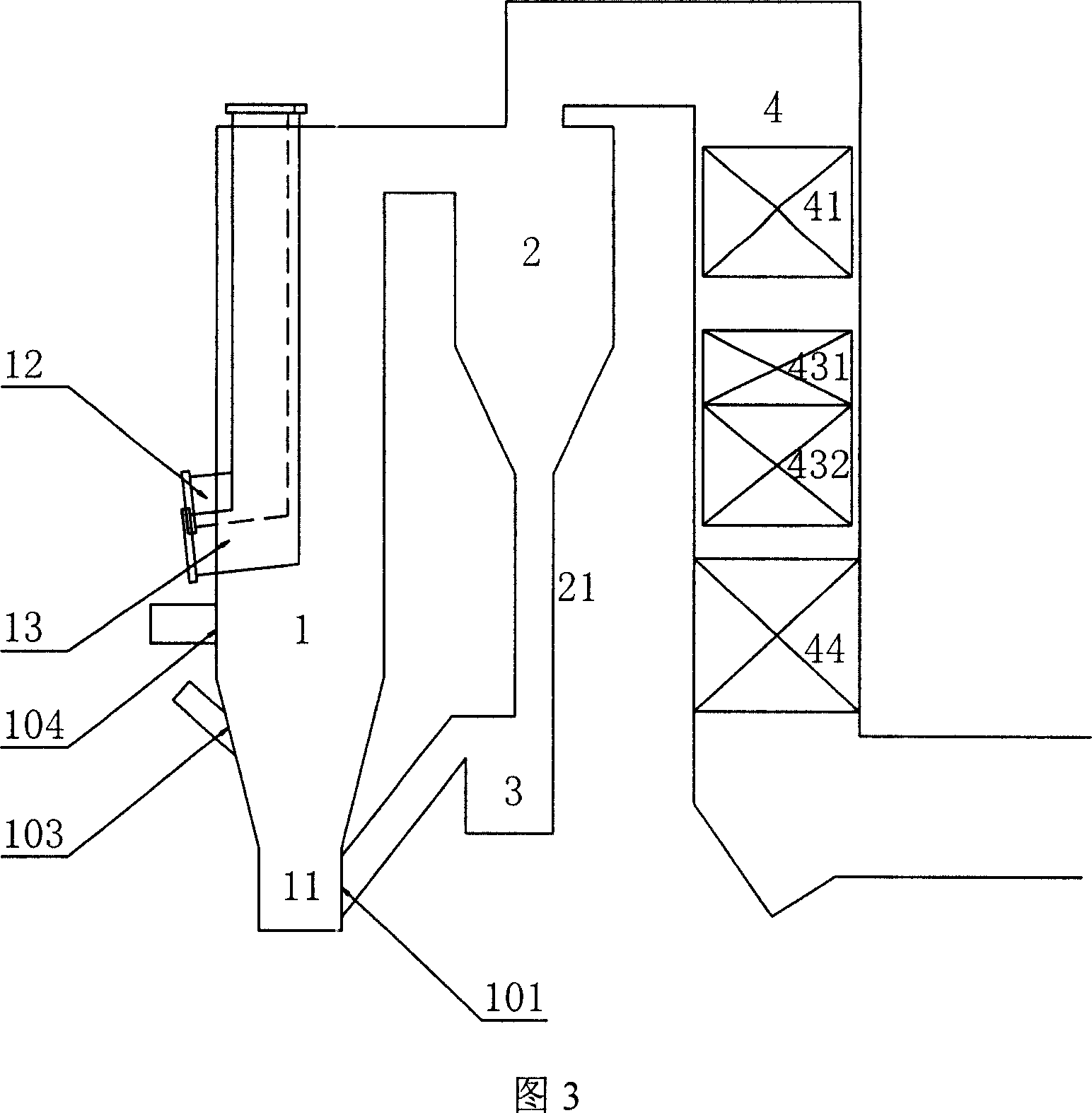

Biomass circulating fluid bed burning method and biomass circulating fluid bed boiler

ActiveCN101113816AReduce the temperatureImprove working environmentFluidized bed combustionApparatus for fluidised bed combustionTemperature controlSuperheater

The invention discloses a biological circulation fluidized bed combustion method and a biological fueled circulation fluidized bed boiler; the fluidized bed boiler comprises a boiler cavity, a clutch, a material refeeder, a tail chimney, wherein, the boiler cavity is provided with a superheater high temperature section, and the tail chimney is provided with a superheater low temperature section. Through the arrangement of heating surfaces of the boiler cavity and the tail chimney and other auxiliary measures, the temperature of the upper part of the boiler cavity is controlled at 550 to 800 DEG C, the outlet steam temperature of the tail heating surface is controlled at 350 to 400 DEG C, so as to solve the problem that: the temperature distribution of the boiler cavity is unreasonable, and the material concentration of the lower part of the boiler cavity is too low when the biological fuels are combusted in the circulation fluidized bed based on the stable fire, complete consumption of biological fuels , so that the temperature distribution in the boiler cavity tends to be equalized and the boiler cavity can be prevented from clinkering, and the accumulated ashes on the heating surfaces can also be prevented from being clinkered, furthermore, the boiler output capacity can be ensured, and a high steam parameter can also be achieved to ensure the generation efficiency.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Method and system for continuously separating ethanol and utilizing residual heat based on solid-state fermentation material

InactiveCN101235391AReduce labor intensityMeet the needs of modern large-scale industrial productionBiofuelsEnergy inputDistillationSeparation technology

The invention relates to a method and a system for continuously separating alcohol and utilizing residual heat on the basis of solid state fermentation material, which belongs to the technical field of biomass fuel alcohol. The method mainly comprises the following steps: tight-line pumping, feeding into tower, distributing, stripping alcohol, discharging residue, utilizing residual heat and the like. The system achieves residual heat reutilization through the following two approaches which comprises firstly, looping back residual liquid to outer cylinder clamp ferrules of a closed ring groove rotating disc stripping tower, heating up material and closed tunnel outer clamp ferrules preheating fermentation material, secondly, complementing solid state distillation steam consumption through electrically heating. The alcohol-residue continuous separation technique and closed ring groove rotating disc alcohol stripping tower which are proposed by the invention are suitable for stripping alcohol in solid state fermentation products of sugar or starch such as sweet sorghum stalks and the like, which achieves a goal of automatically feeding and discharging, and continuously separating alcohol and residue, and the method of the invention effectively utilizes reactor residual liquid hidden heat, which complements partial steam gas, and achieves the superiorities of high net energy ratio of solid state fermentation path sweet sorghum alcohol and low environmental load.

Owner:TSINGHUA UNIV

Method and apparatus for biomass ebullition, gasification and combustion

InactiveCN101196296AGuaranteed uptimeImprove combustion performanceFluidized bed combustionApparatus for fluidised bed combustionCombustion chamberDirect combustion

The invention relates to a biomass boiling gasification burning method and device, which is characterized in that: blow the biomass fuel from a material inlet of a gasification firebox to the gasification firebox; the biomass fuel boils under the action of a primary flow raising from the bottom of the gasification firebox; then the biomass fuel burns incompletely under boiling status after lighted up to generate with high temperature combustible gas which can be discharged by a gas burner for direct burning. The boiling gasification burning device comprises a feeding mechanism, an air supply mechanism and the gasification firebox; a gas burner for discharging high temperature fuel gas is arranged at middle upper section of the side wall of the gasification firebox; a discharging opening of the feeding mechanism is positioned on the side wall of the gasification firebox lower than the gas burned and is communicated with the gasification firebox; a wind arrangement device is arranged at bottom of the gasification firebox; the air supply mechanism provides the gasification firebox with the primary flow through the wind arrangement device, which is communicated with the discharging opening of the feeding mechanism through the a feeding air pipe.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI

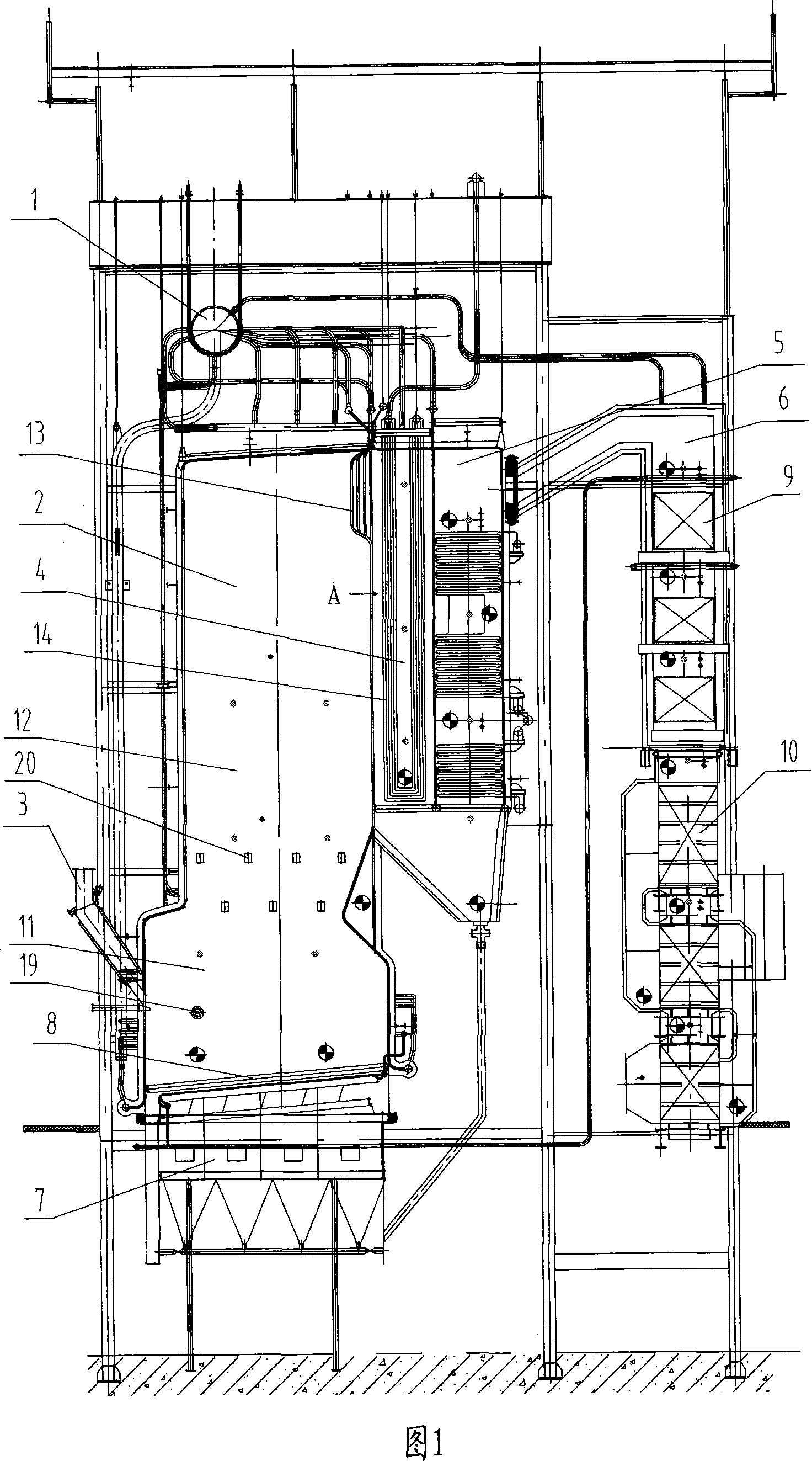

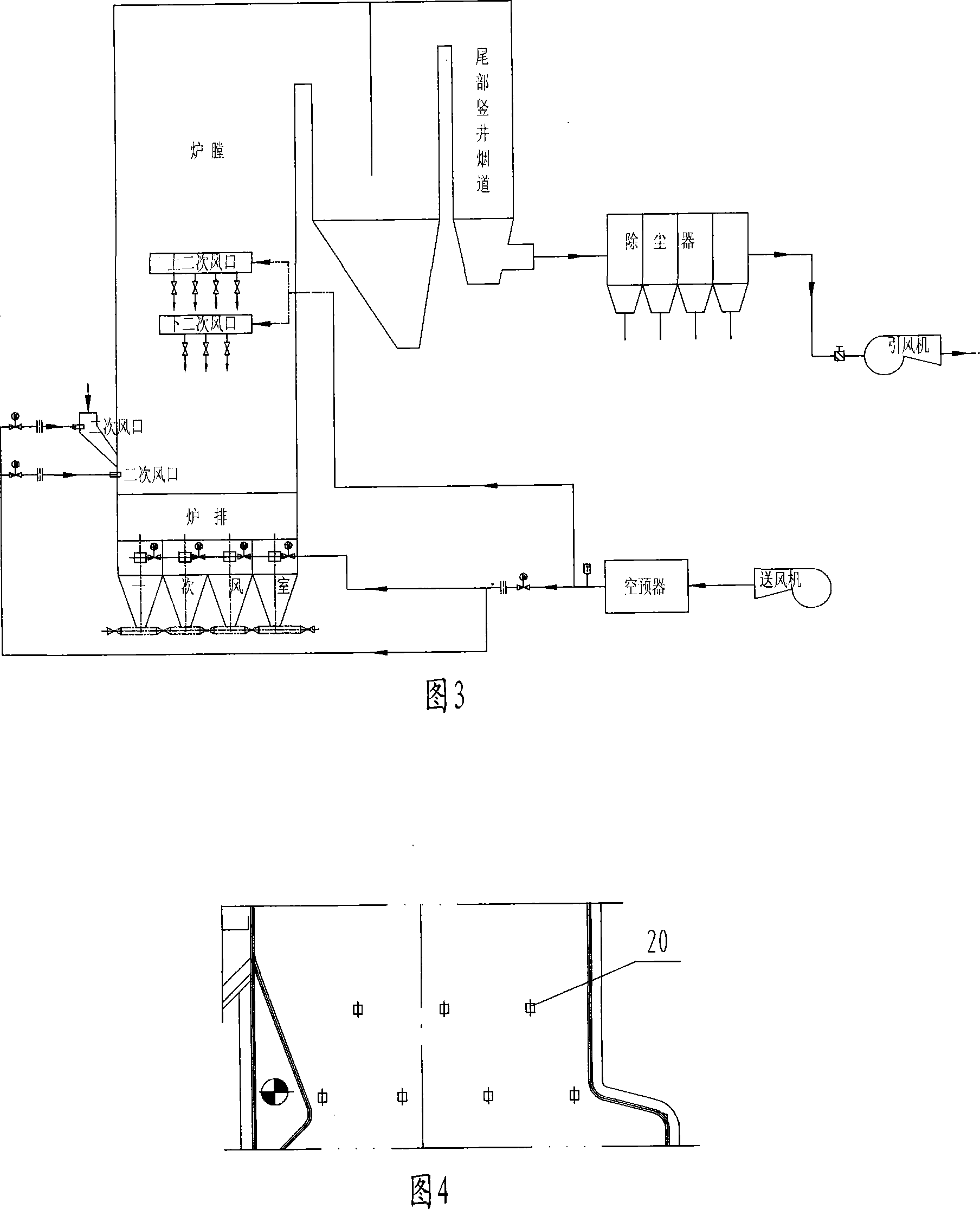

Biomass fuel boiler

ActiveCN101105336ABurn fullyNot corrodedIndirect carbon-dioxide mitigationWater heatersAir preheaterEngineering

The invention discloses a biomass fuel boiler based on the original coal burning boiler. A primary air chamber, secondary air ports respectively equipped in a feed pipe and in a furnace cavity below the feed pipe, and a plurality of air ports equipped at the left and right sides of the furnace cavity and staggeredly arranged are connected with an air preheater, and a regulating baffle is respectively provided in each air ports. The invention realizes complete combustion of biomass fuel with suspension combustion as main combustion manner and grate firing as auxiliary combustion manner. As an improvement, the cross-sectional area of the combustion zone in the furnace cavity is larger than the burnout zone; a dregs condensing pipe equipped with a cooling water passage is provided at the inlet port of a first smoke flue; superheaters are disposed at different positions of the boiler in accordance with the type of biomass fuel; a vertical shaft smoke flue at tail portion is sequentially connected with a dust remover and an induced fan; and an adjacent furnace heating device is respectively equipped in the furnace cavity and the lower header tanks of the water-cooled wall of the first and second smoke flues. The invention can prevent high temperature corrosion, assure heat exchange efficiency and storage bin safety, shorten starting time, and prolong service life.

Owner:CHINA WESTERN POWER INDAL

Biomass fuel thermal decomposition vaporization combustion method and apparatus

InactiveCN101294707AReduce resistanceReduce the effect of dustIncinerator apparatusLump/pulverulent fuel feeder/distributionCombustionPropeller

A gasification and combustion device for biomass fuel pyrogenation is provided with the technical proposal as follows: a pyrogenation device is added in the hearth of a boiler and is composed of a pyrogenation cylinder and a pyrogenation furnace, and a material feeding device is arranged out of the hearth. The biomass fuel is pushed forward by a main spiral propeller and is gradually compressed when passing through a fuel passage to improve the degree of compaction and prevent pyrogenation gas from escaping, the biomass fuel is pushed to move on by the subsequent fuel after entering the pyrogenation cylinder, and gradually falls on the pyrogenation furnace bed to come into contact with oxygen for being ignited, the pyrogenation cylinder is heated by flame after ignition, the biomass fuel in the pyrogenation cylinder is heated to a temperature being higher than that of pyrogenation, the biomass fuel carries out gas-solid separation, the gas can only escape from the flame on the pyrogenation furnace bed, and the combustible component therein is subjected to forced ignition, the flame goes up to the upper part of the hearth along the latearal face of the pyrogenation cylinder and is burnt out, at the same time the pyrogenation cylinder is heated for the continuous pyrogenation reaction therein, and the solid on the pyrogenation furnace bed is broken to pieces, and falls or continuously burns on the pyrogenation furnace bed.

Owner:韩枫

Boiler capable of producing jointly oil, gas and carbon and heat-energy by pyrolyzing biological fuels

InactiveCN1814699AImprove qualityReduce pyrolysis energy consumptionBiofuelsLiquid hydrocarbon mixture productionProcess engineeringThermal water

This invention relates to a boiler pyrolyzing biomass fuels to generate biooil, combustible gas, active carbon and heat energy composed of a supplying system, an outer pyrolysis device, a heat exchange pyrolysis device and a boiler, in which, its supplying system can dewater, degas, rise the temperature to let its energy density the maximum, the outer heat pyrolysis device can quickly pyrolyze the prepared fuels to generate pyrolysis steam at 900deg.C to be used by the heat exchange device to pyrolyze biomass materials without O2 to generate semi-coke used in producing active carbon.

Owner:韩枫

Municipal refuse handling method and equipment

The invention relates to a municipal refuse handling method and equipment. The handling method includes the steps of squeezing for water removal, magnetic separation sorting, first-stage smashing, blasting separation, second-stage smashing, biomass fuel adding, pelletizing and particle burning heating and steam generation or power generation; and the handling equipment comprises a feeding conveying device, a magnetic separation conveying device, a material collecting hopper, a discharging plate, a magnetic separation device, an air blower, a mixing and stirring machine, a refuse water removal roller press, a biomass particle machine, a refuse smashing machine and a smokeless burning device. According to the municipal refuse handling method and equipment, the refuse handling process is simple, a bonding assistant does not need to be added during pelletizing, and manufactured municipal refuse combustible particles are smooth in surface, compact in structure, higher in calorific value, high in drying degree and free of pollution during burning.

Owner:黎汉东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com