Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Fully stable combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

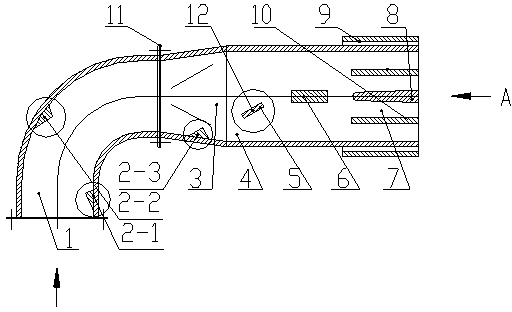

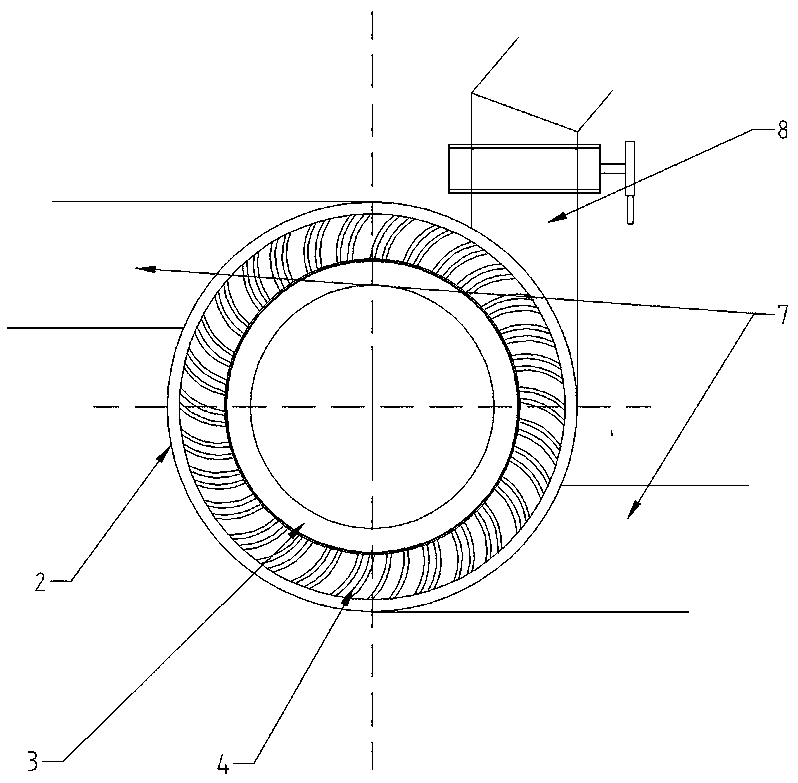

Small-sized annular combustion chamber with high-capacity heat intensity

ActiveCN102384489AGuaranteed uniformitySolve the problem of many oil leakage failuresContinuous combustion chamberCombustion chamberEngineering

The invention discloses a small-sized annular combustion chamber with high-capacity heat intensity, which comprises a combustion chamber casing, an oil supply component, an outer flame tube, an inner flame tube, a high-pressure turbine guider, an oil thrower wheel and an igniter, wherein the oil supply component is fixed on the combustion chamber casing; and the outer flame tube, the inner flame tube and the high-pressure turbine guider are fixedly connected with the combustion chamber casing. As an oil thrower wheel type baffling combustion chamber is adopted by the annular combustion chamber, and a radial combustion way is used, the axial size of the combustion chamber can be reduced, the size of the combustion chamber is reduced, and the heat capacity intensity of the combustion chamber can be effectively improved.

Owner:BEIJING POWER MACHINERY INST

Emergency released-torch burner

InactiveCN102620302AFully stable combustionReliable ignitionIncinerator apparatusGaseous fuel burnerStopped workCombustor

The invention discloses an emergency released-torch burner which comprises a nozzle pipe, the nozzle pipe is connected with a torch barrel by a flange, the upper end of the nozzle pipe is connected with a mixer, the top end of the mixer is provided with a flame holder, a windshield is arranged above the mixer, a firing barrel and an incandescent light which are supplied gas respectively through a fuel gas pipe thereof are arranged in the windshield, and a position close to the incandescent light is provided with a flame monitor. The emergency released-torch burner disclosed by the invention is simple in structure, easy to use, and reasonable in design; by using the burner, a torch system can satisfy the requirements of safe releasing under the conditions that the torch system starts and stops working and is in accident states and unstable working conditions; the burner is reliable in ignition, stabile and full in combustion, and uneasy to produce black smoke; and the incandescent light is not easy to go out, therefore, the service life of the emergency released-torch burner is prolonged, and the emergency released-torch burner is small in maintenance quantity, and uneasy to be damaged by people.

Owner:胜利油田盛运机械制造有限公司

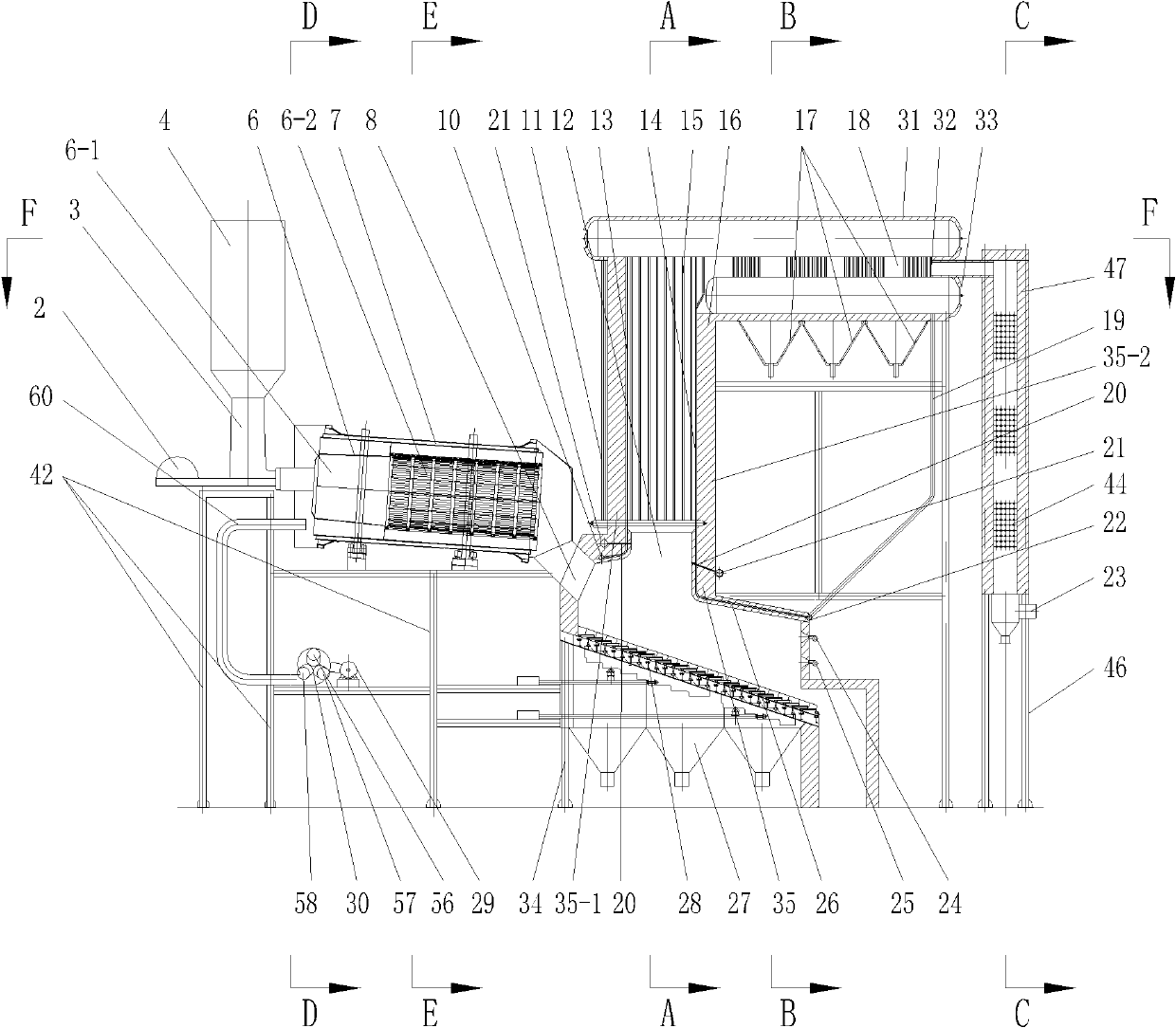

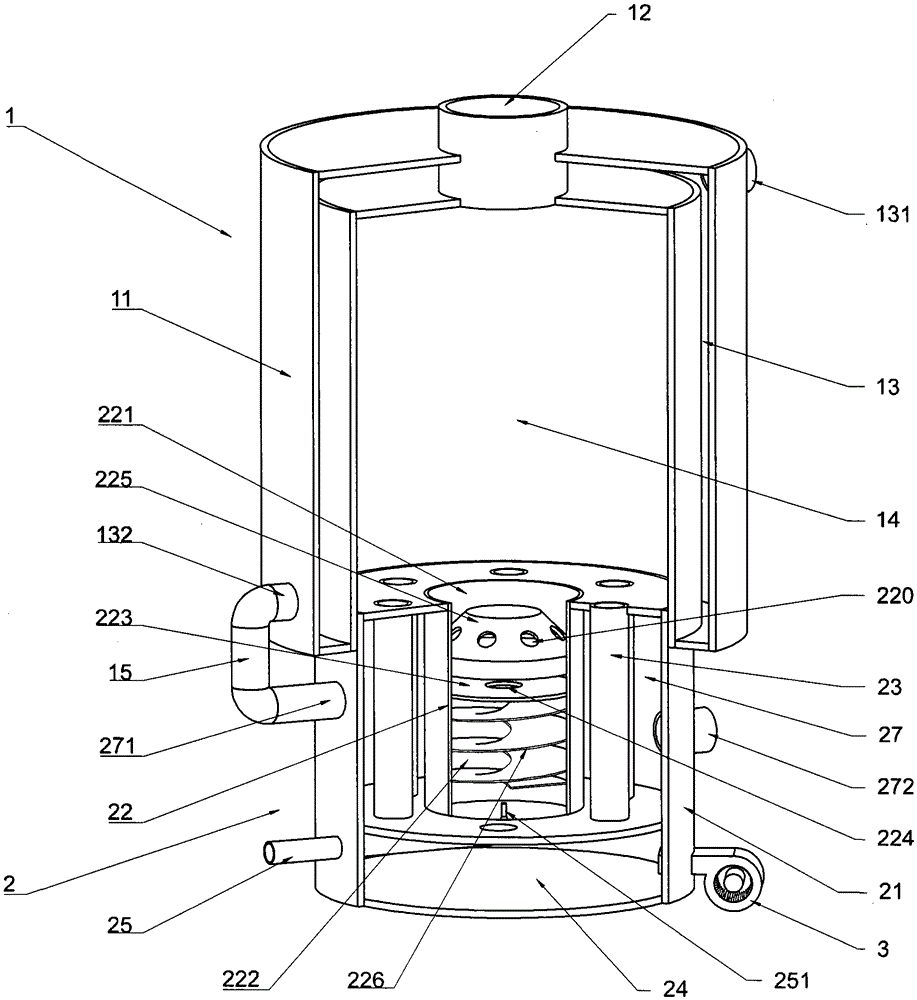

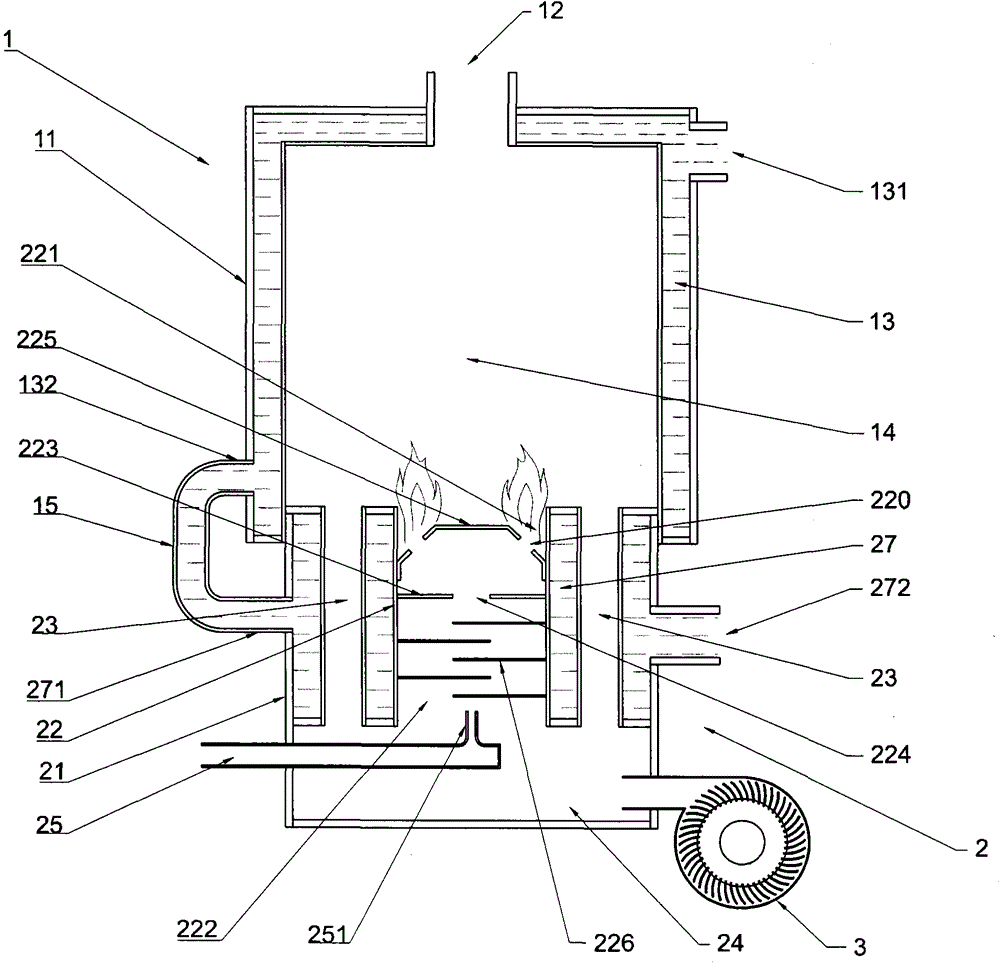

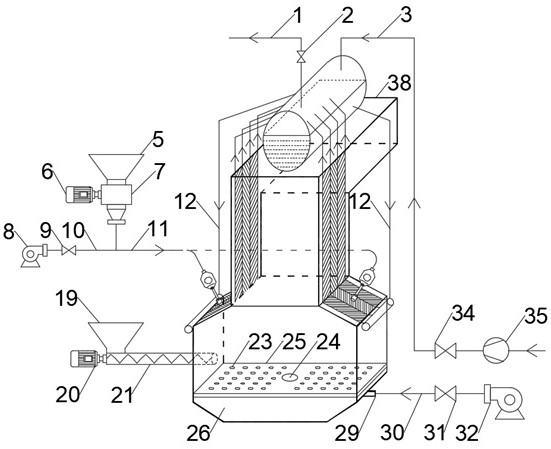

Three-dimensional hierarchical air supply combined waste incinerator

InactiveCN102168853ASmall granularityLow shape requirementIncinerator apparatusAir preheaterAir interface

The invention relates to a three-dimensional hierarchical air supply combined waste incinerator, in particular to a waste incinerator. The waste incinerator provided by the invention solves the problems of single function and narrow application range of the traditional waste incinerator. In the waste incinerator provided by the invention, the lower end of a feeding device is communicated with one end of a rotary drying pyrolysis device; the other end of the rotary drying pyrolysis device is communicated with a grate type incinerator; the feeding device and the rotary drying pyrolysis device are fixedly installed on a first bracket; two groups of secondary air spray pipes are both communicated with a secondary air main pipe; one group of the two groups of secondary air spray pipes is positioned above a rear arch and arranged on the outer side wall of a rear wall, and the other group of secondary air spray pipes are arranged at the lower end of a front wall; each group of secondary air spray pipes is communicated with a hearth; a high-temperature smoke interface is communicated with a horizontal flue through a pipeline; an intermediate-temperature smoke interface is communicated with a tail flue through a pipeline; and an air interface is communicated with the air outlet of an air preheater through a pipeline. The waste incinerator provided by the invention is used for incinerating waste.

Owner:HARBIN INST OF TECH

System for pyrolyzing and burning sludge at low temperature

InactiveCN101871649AReduce volumeLow investment costIncinerator apparatusExtrusion mouldingScrew conveyor

The invention discloses a system for pyrolyzing and burning sludge at low temperature, which comprises a sludge hopper, a dryer, a spiral conveyer, a low-temperature pyrolysis reactor, an extrusion moulding machine, an incinerator and a draught fan, wherein the spiral conveyer is used for conveying the sludge output from the sludge hopper to a feed inlet of the dryer; the low-temperature pyrolysis reactor is connected with a discharge port below the dryer; the extrusion moulding machine is connected with the discharge port of the low-temperature pyrolysis reactor; the incinerator is connected with the extrusion moulding machine through a conveyer and is provided with a waste heat boiler; the draught fan is connected with the waste heat boiler; and the upper part of the waste heat boiler is respectively connected with the dryer and the low-temperature pyrolysis reactor through waste heat input pipelines. After the dewatered sludge is dried and pyrolyzed at low temperature, the amount of the sludge entering the incinerator is reduced, thereby reducing the volume of the incinerator, greatly lowering the energy consumption and reducing the investment cost; the cost of manufacture, installation, operation and maintenance of an incinerator system is greatly reduced; and because the equipment investment is reduced, the system is convenient for dispersive treatment of sludge and has wide adaptability.

Owner:GUANGDONG CHANT GRP

Rich-lean separated pulverized coal burner

ActiveCN103267282AGuaranteed reflowStable combustionPulverulent fuel combustion burnersEngineeringHigh-temperature corrosion

Owner:HARBIN BOSHEN TECH DEV CO LTD

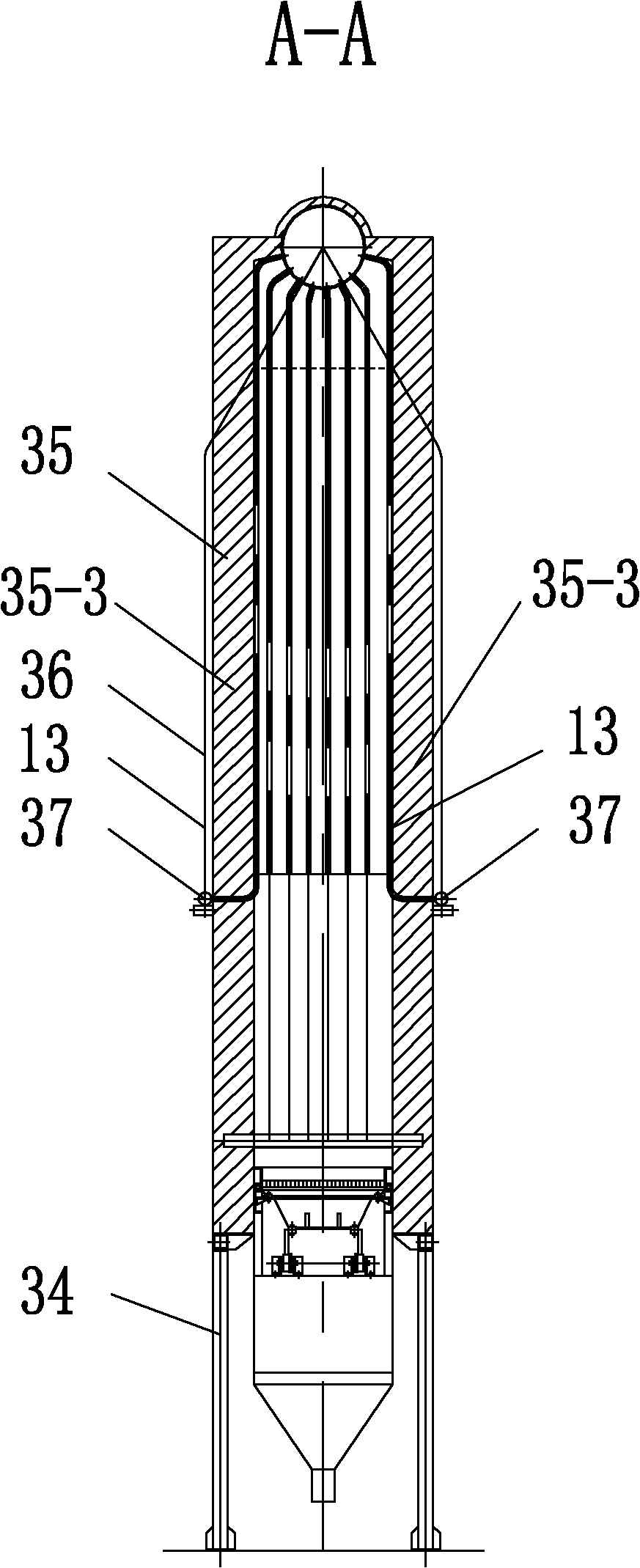

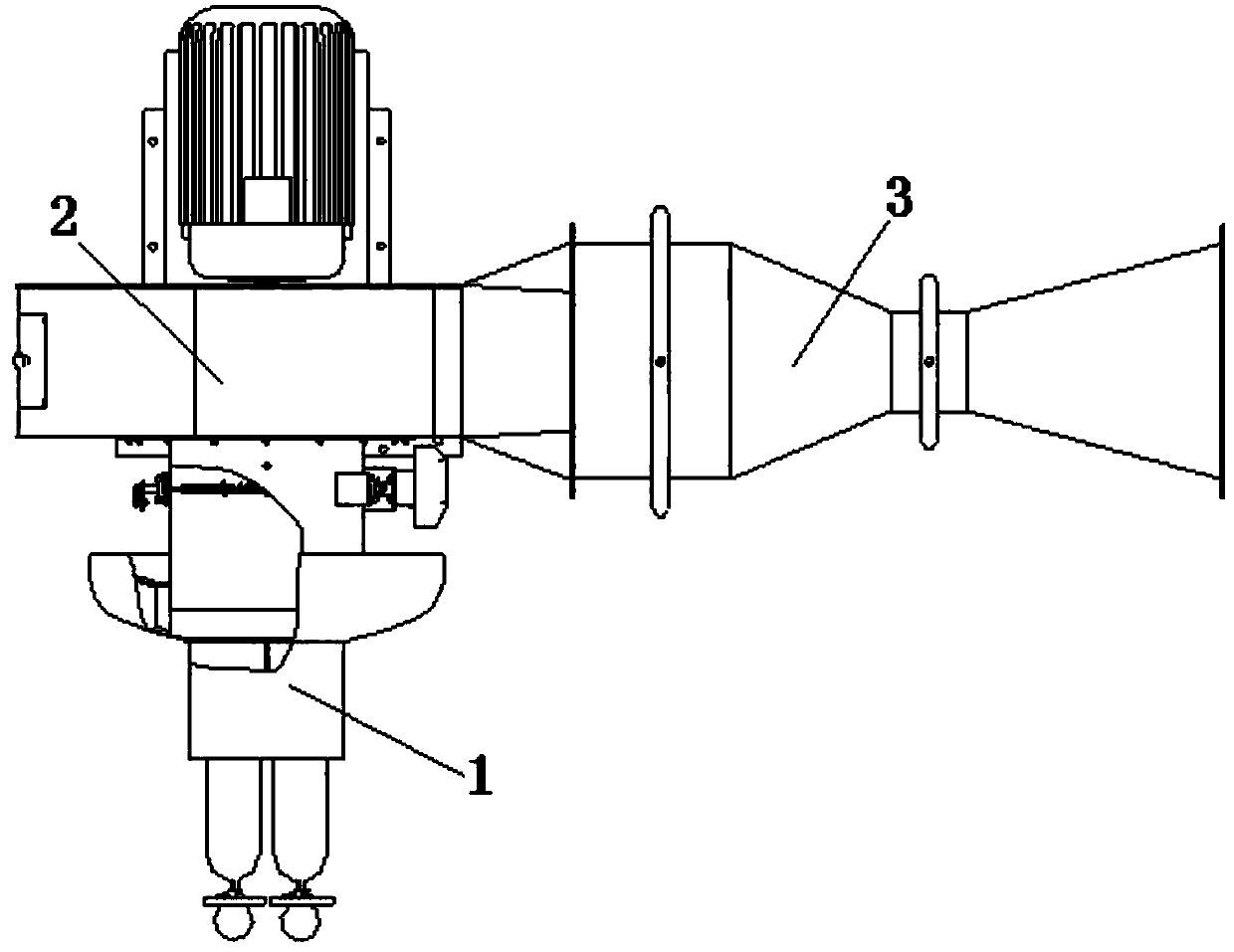

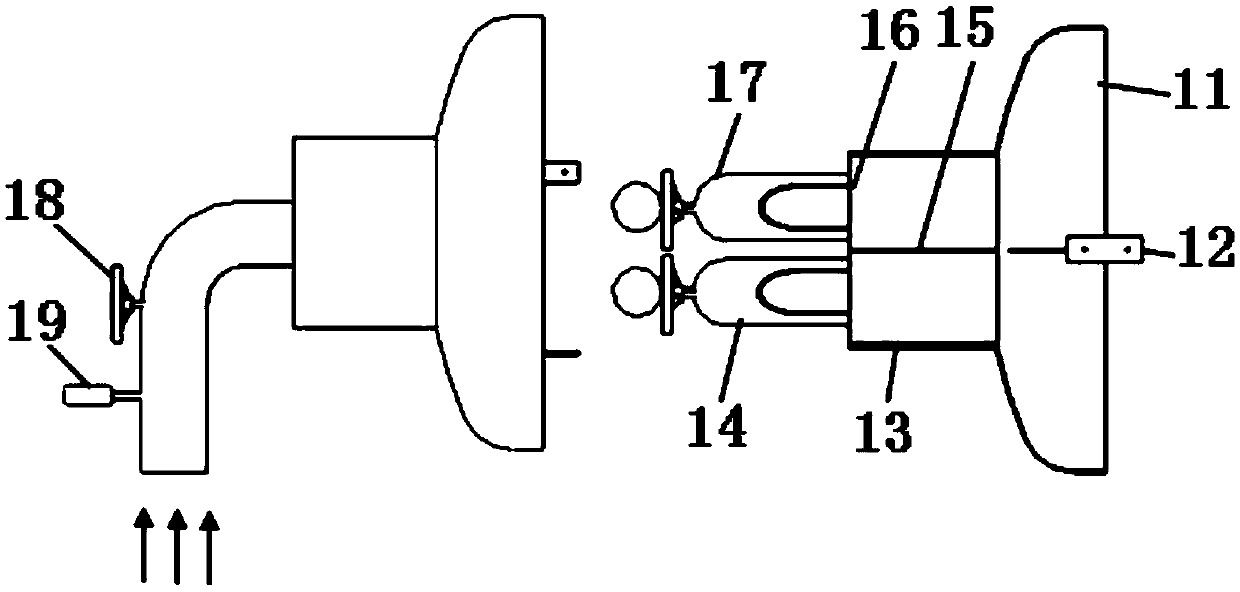

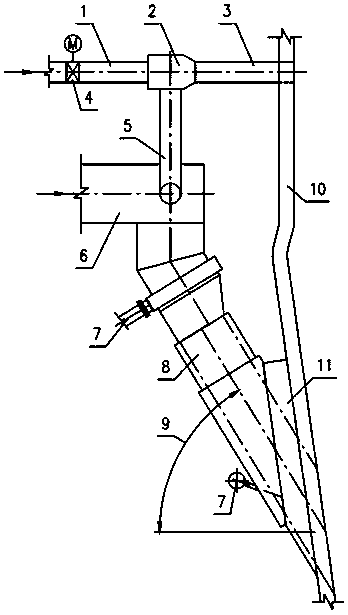

Blast furnace gas burning assisting device

ActiveCN104006394AIncrease contact areaExtension of timeIndirect carbon-dioxide mitigationIncinerator apparatusInlet channelThermal insulation

The invention relates to a blast furnace gas burning assisting device, and belongs to the technical field of gas emission treatment facilities. The inlet end of a cylindrical body of the device is composed of an air inlet channel in the center and an annular air inlet channel surrounding the air inlet channel. The outlet end of the device is composed of a flame stabilizing cone decreasing gradually and a flame spraying opening. A gradually-expanding cone section with a thermal insulation layer is arranged between the inlet end and the outlet end and the cone section is composed of an inner conical cylinder and an outer conical ring surrounding the outer side of the inner conical cylinder. The cone section is provided with a primary air pipe penetrating through the outer conical ring to be inserted into the inner conical cylinder, the outer end of the primary air pipe is communicated with the air and the inner end of the primary air pipe extends to form a nozzle with a necking section. A flow evening cavity extends towards the outer conical ring to form a backflow pipe, and the end of the backflow pipe is provided with an injection nozzle inserted into the primary air pipe and facing the center of the necking section. The blast furnace gas burning assisting device enables blast furnace gas entering the inner conical cylinder to be ignited reliably and burned stably.

Owner:南通海鹰机电集团有限公司

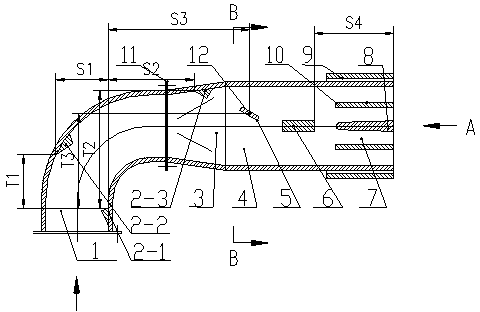

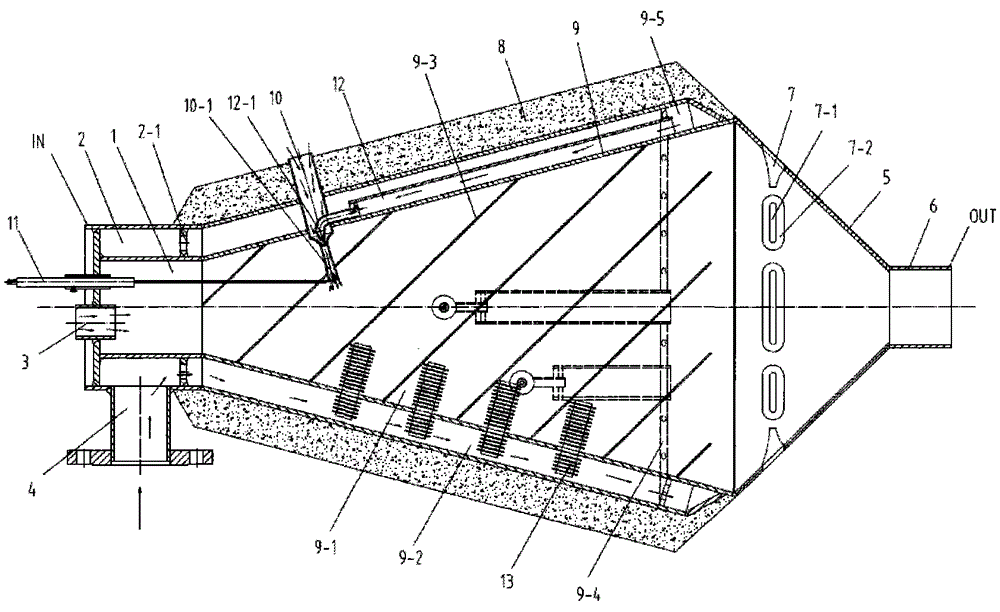

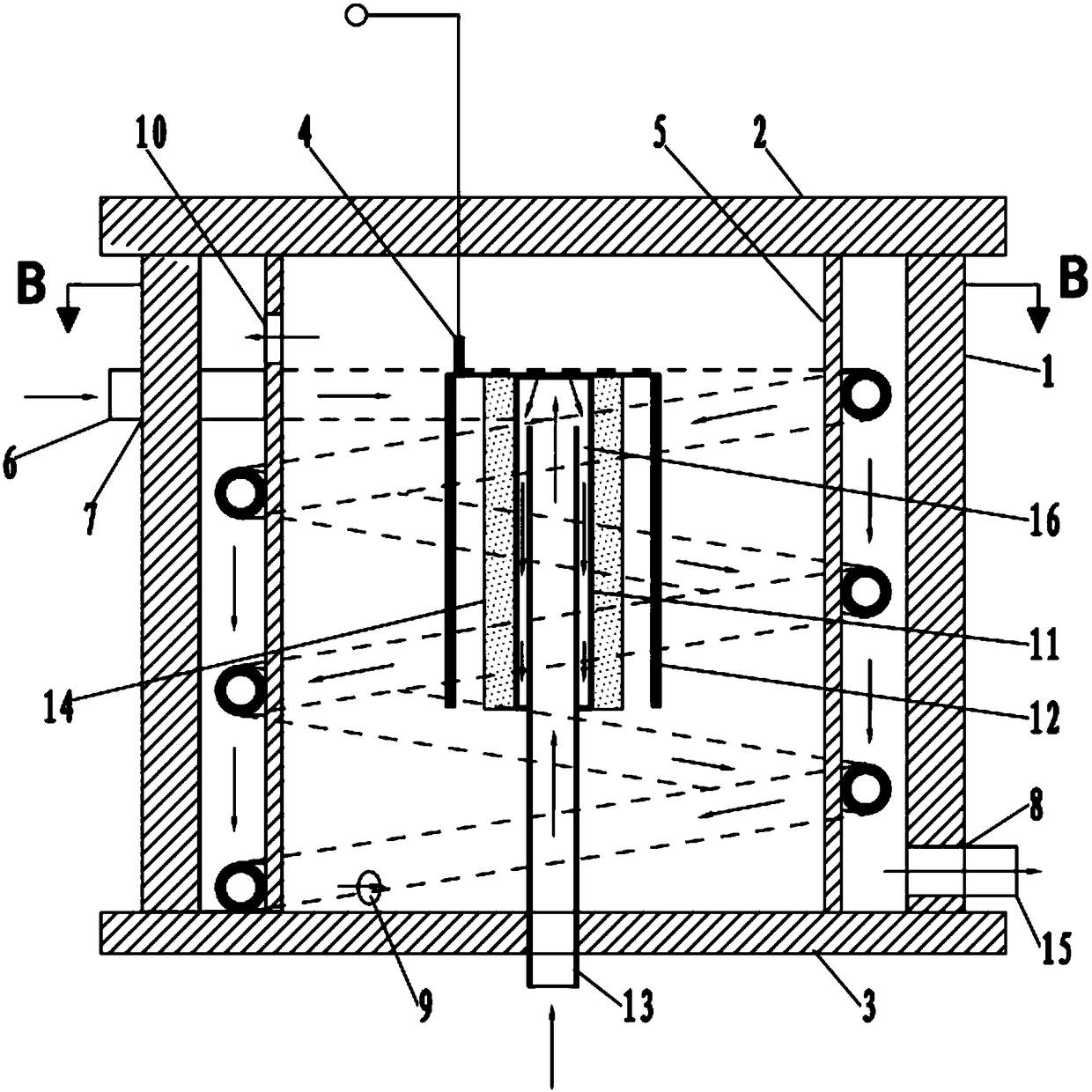

High-temperature air combustion intensifying device and method applicable to low heating value mixed garbage

ActiveCN102878569AIncineration is stable enoughFully stable combustionIncinerator apparatusCombustion chamberSlag

The invention discloses a high-temperature air combustion intensifying device and method applicable to low heating value mixed garbage, wherein a low-temperature preheater is arranged on the rear side of a U-shaped tail part flue; a garbage feeding opening is arranged on the side wall of the lower part of a furnace chamber; the side wall of the upper part of the furnace chamber is connected with the upper part of a cyclone separator; the bottom part of the cyclone separator is connected with the upper end of a back feeder; the lower end of the back feeder is connected with the side wall of the lower part of the furnace chamber; the upper end of the cyclone separator is connected with the upper part of the front side of a U-shaped combustion chamber; the lower end of the U-shaped combustion chamber is connected with the side wall of the lower part of the furnace chamber; the lower end of the furnace chamber is connected with the side wall of the lower part of the furnace chamber through a water-cooled cold slag sorting and back feeding device; and the upper part of the rear side of the U-shaped combustion chamber is connected with the upper part of the front side of the U-shaped tail part flue. The method utilizing the high-temperature air to intensify the low heating value garbage mixed combustion is more suitable for the domestic characteristics that the garbage has complicated components, high moisture and low heating value, has wider fuel application range, and is more sufficient and stable in combustion, the garbage can be purely combusted without the need of coal, the energy consumption is reduced, and the operating economy is improved.

Owner:ZHEJIANG UNIV

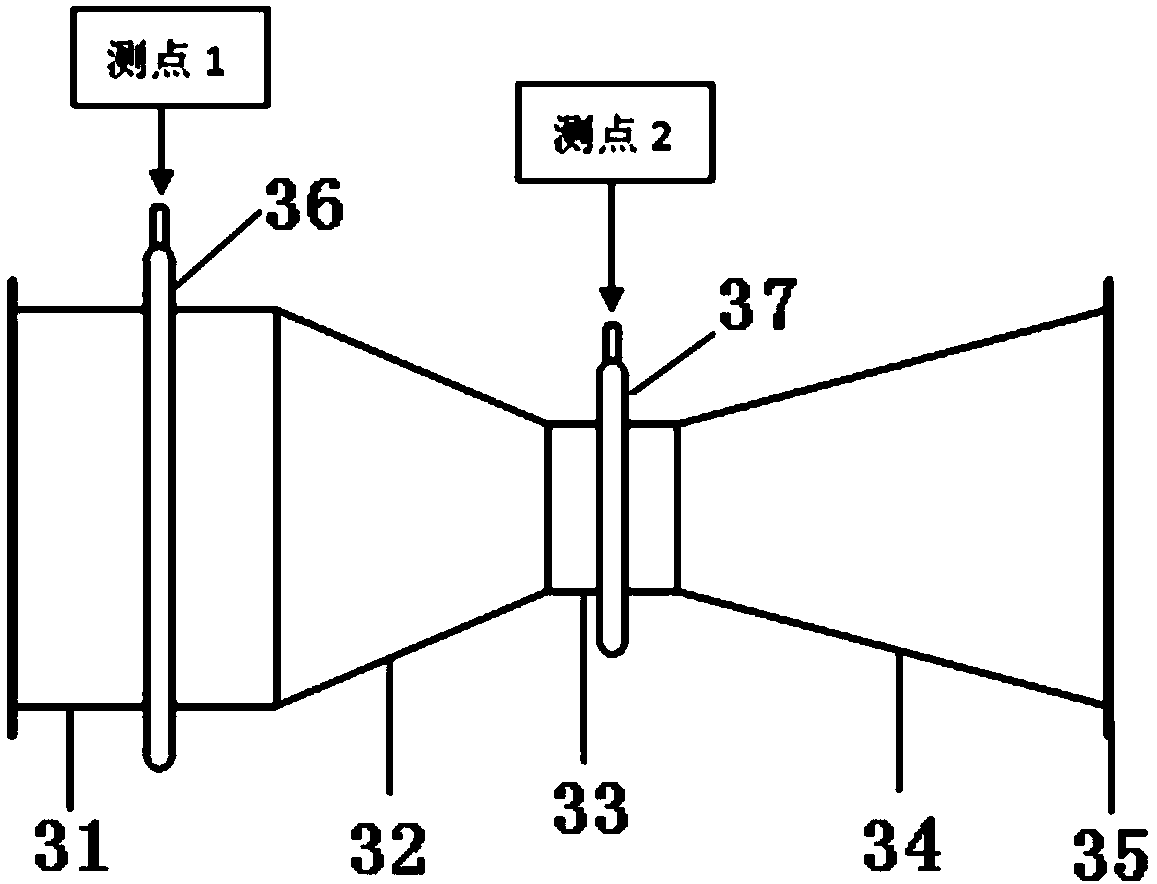

Combustor air distribution device and air distribution method

ActiveCN109539248AAchieve recyclingFully stable combustionBurnersAir supply regulationCombustorAir volume

The invention discloses a combustor air distribution device and an air distribution method. The combustor air distribution device comprises an air inlet device, an air blower and an air blower outputair volume detection device, wherein an outlet of the air inlet device communicates with the air blower, air blown by the air blower is conveyed to a combustor, a flow detection sensor is arranged onthe air inlet device, and is used for carrying out real-time detection on the flow of gas entering the air blower through the air inlet device, an air inlet is formed in the air blower and used for sucking fresh air, the air blower output air volume detection device is used for detecting the output air volume of the air blower in real time, namely the total air supply volume of the air distribution device, the air blower is provided with an air blower output air volume adjusting device, and is used for adjusting the output air volume of the air blower, the air inlet device comprises a combustible waste gas pipeline and / or a recycled smoke gas pipeline, and the air blower output air volume detection device is a venturi tube device. Thus, accurate air distribution is achieved, and the combustion efficiency and the stability are guaranteed.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

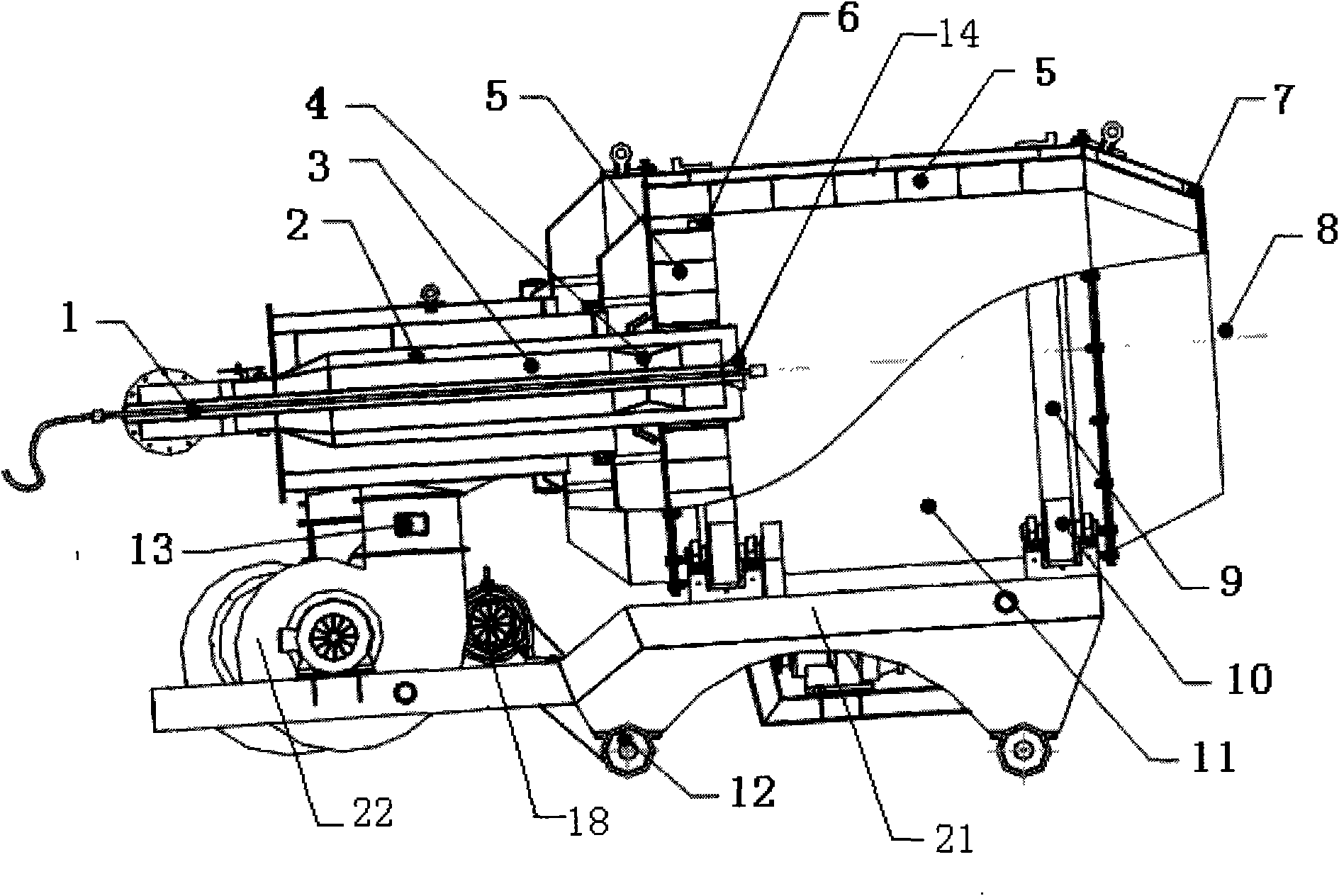

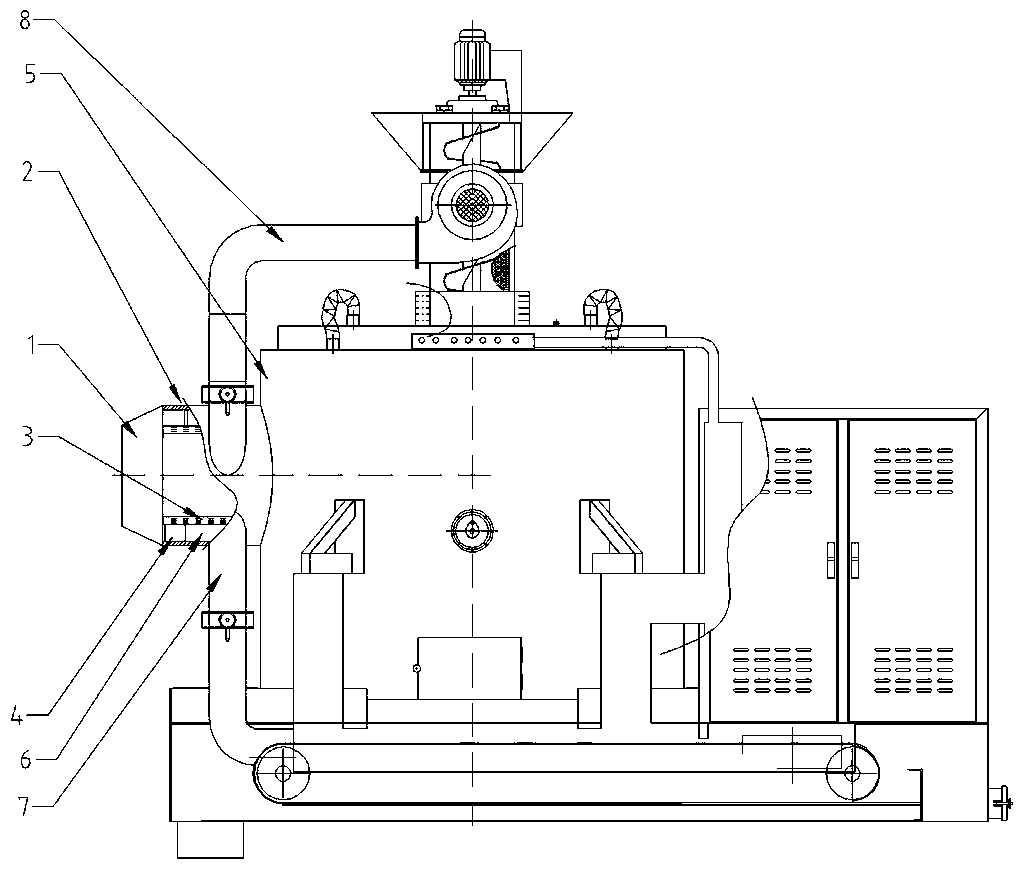

Multifunction coal dust combustor

InactiveCN101650027AFully stable combustionEasy to burnPulverulent fuel combustion burnersAutomatic controlCombustion chamber

The invention discloses a multifunction coal dust combustor of the technical field of road construction and maintenance machinery, comprising a traveling chassis, a combustion furnace, an air and coaldust regulating mechanism, a drive mechanism, a blower, an automatic ignition device and an electric control system, wherein the air and coal dust regulating mechanism consists of an electromotion air valve, a pipeline, a flap valve and a Venturi pipe; an air outlet is connected with the combustion furnace; the pipeline comprises an automatic ignition device channel, a dense coal dust channel, athin coal dust channel, a secondary air channel and a third air channel which are arranged in sequence from inside to outside; the outlet end of the dense coal dust channel is connected with the Venturi pipe; the outlet of the Venturi pipe is provided with a bluff body; and the flap valve is arranged on the inlet ends of the dense coal dust channel and the thin coal dust channel. The multifunctioncoal dust combustor has high degree of automation, sufficient combustion and high efficiency, thereby lowering demands on coal quality, and long service life and can realize the functions of automatic rotation of a combustion chamber, automatic travel of the whole combustor, automatic ignition, air oil automatic regulation and temperature automatic control.

Owner:HENAN ROADY ROAD MACHINERY

gas boiler burner

The invention relates to the technical field of burners, in particular to a gas boiler burner. The gas boiler burner comprises a boiler body and a burner body. The boiler body comprises a boiler shell. A heating cavity is formed in the boiler shell. The boiler shell is provided with a discharge port. The discharge port is communicated with the heating cavity. The burner body comprises a burner shell. A cylinder is arranged on the upper portion in the burner shell. A first mixing chamber is formed on the lower portion in the burner shell. A combustion chamber is arranged on the upper portion in the cylinder. A second mixing chamber is arranged on the lower portion in the cylinder. The combustion chamber is communicated with the heating cavity. A combustion plate with a plurality of combustion holes is arranged in the combustion chamber. A plurality of air passages are arranged in the cylinder or on the periphery of the cylinder. The first mixing chamber is connected with a gas pipe and an air boosting device. The burner shell and the boiler shell are connected with each other. The gas boiler burner has the advantages of being reasonable in structural arrangement, long in service life, more sufficient in combustion and the like.

Owner:NINGBO DUOBEI MACHINERY IND

Horizontal type double-flue industrial coal powder boiler

The invention relates to an industrial coal powder boiler which is characterized by comprising a transversely arranged cylindrical boiler casing, wherein a front end plate and a back end plate are respectively arranged at the front part and the rear part in the boiler casing; two precombustion chambers abreast and axially penetrate the middle part of the front end plate, the outlet ends of the two precombustion chambers are respectively communicated with ends of two horizontal boiler flues abreast and transversely arranged in the boiler casing and other ends of the two boiler flues are respectively communicated with the back end plate; a front smokebox is formed between the front end of the boiler casing and the front end plate, the rear end of the boiler casing and the back end plate are divided into an upper part and a lower part through a partition board and a rear smokebox and a smoke collection chamber are respectively formed at the lower part and the upper part; a water wall circuit is vertically arranged in the rear smokebox and a chimney is communicated at the top of the smoke collection chamber; and a group of two-pass smoke pipes communicated with the front smokebox and the rear smokebox is axially arranged at the lower parts in the middles of the two boiler flues and a group of three-pass smoke pipes communicated with the front smokebox and the smoke collection chamber is axially arranged at the upper parts of the two boiler flues. The invention can be widely used in any situation where the small and medium-sized industrial coal powder boilers are required.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

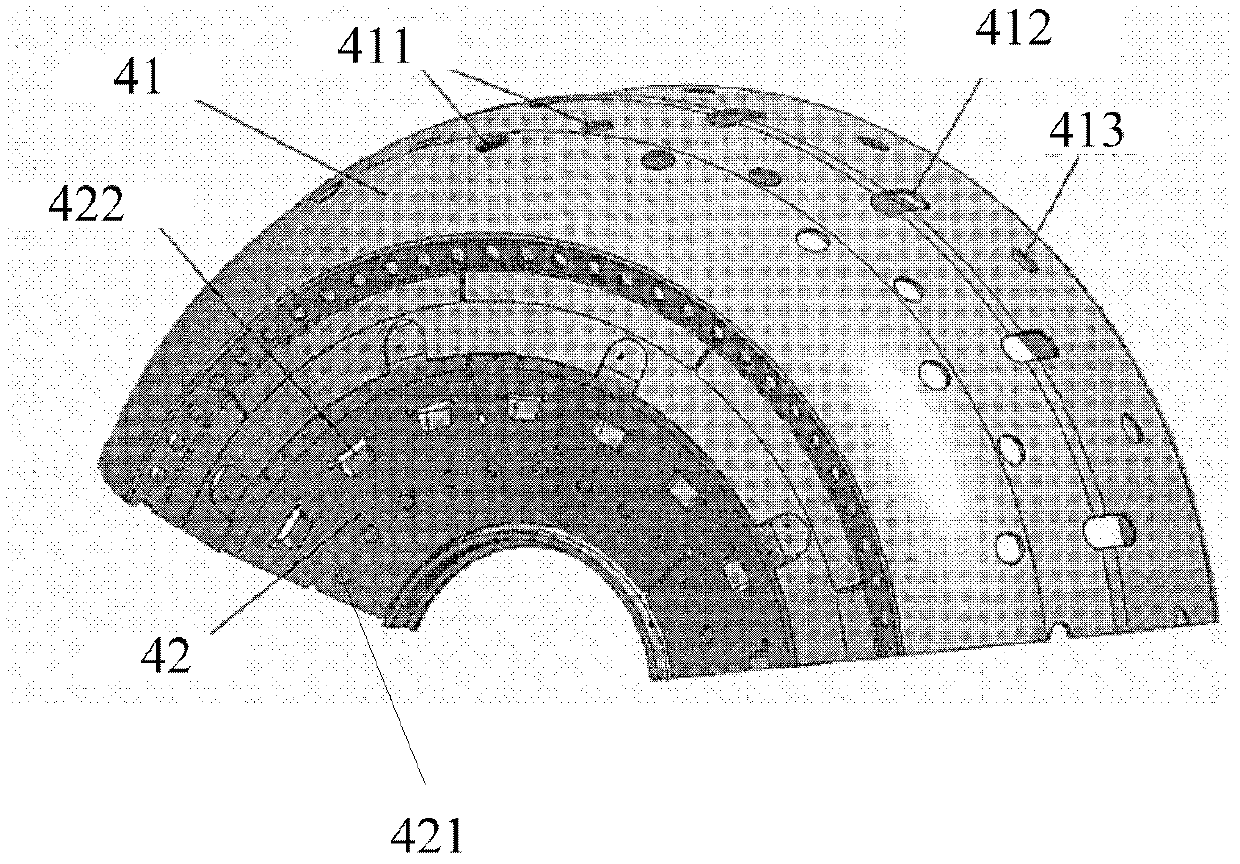

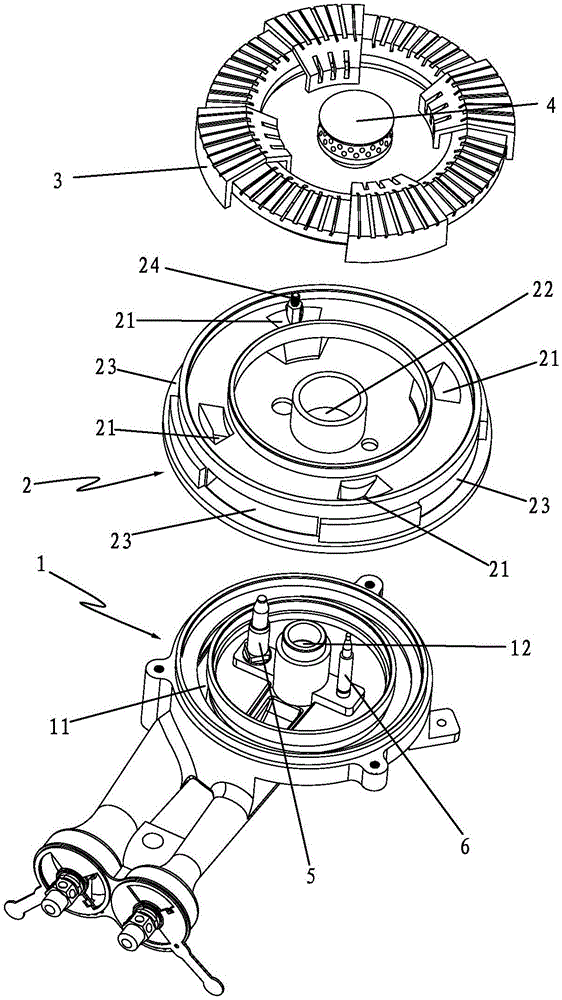

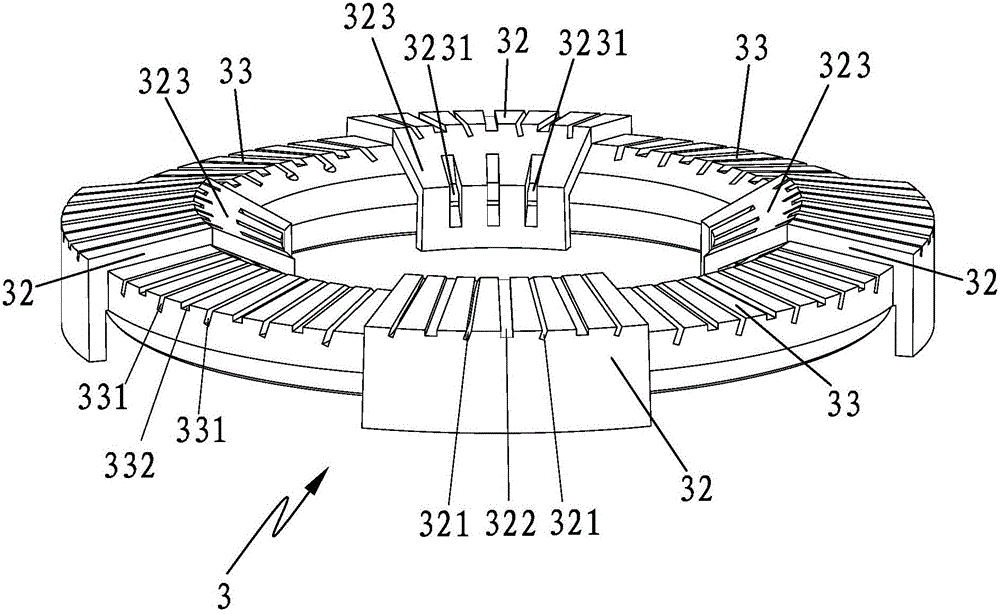

Burner of gas cooker

ActiveCN106765107AFully stable combustionExpanded Stereo Supplement CapabilitiesDomestic stoves or rangesStoves/ranges topsCombustorEngineering

The invention discloses a burner of a gas cooker. The burner comprises a burner head, and an outer ring gas groove, a central gas groove, an outer ring gas ejection pipe which communicates with the outer ring gas groove, and a central gas ejection pipe which communicates with the central gas groove are arranged on the burner head; a fire cover seat is arranged at the upper end of the burner head; an outer ring fire cover which communicates with the outer ring gas groove and a central fire cover which communicates with the central gas groove are arranged at the upper end of the fire cover seat; an annular groove which communicates with the outer ring gas groove is formed in the lower end of the outer ring fire cover; a plurality of bosses are arrayed on the circumference of the upper end of the outer ring fire cover; grooves are formed between the adjacent bosses; a plurality of first strip-shaped fire grooves which penetrate through the space in the direction from the ring outer sides to ring core sides of the bosses are formed in the upper surfaces of the bosses; a plurality of second strip-shaped fire grooves which penetrate through the space in the direction from the ring outer sides to ring core sides of the grooves are formed in the upper surfaces of the grooves; and the bottoms of the first strip-shaped fire grooves and the bottoms of the second first strip-shaped fire grooves communicate with the annular groove. According to the burner, the three-dimensional supplementation capability of secondary air is high, and stable combustion is facilitated.

Owner:ZHONGSHAN INSE GROUP

Gas boiler burner

The invention relates to the technical field of burners, in particular to a gas boiler burner. The gas boiler burner comprises a boiler body and a burner body. The boiler body comprises a boiler shell. A heating cavity is formed in the boiler shell. The boiler shell is provided with a discharge port. The discharge port is communicated with the heating cavity. The burner body comprises a burner shell. A cylinder is arranged on the upper portion in the burner shell. A first mixing chamber is formed on the lower portion in the burner shell. A combustion chamber is arranged on the upper portion in the cylinder. A second mixing chamber is arranged on the lower portion in the cylinder. The combustion chamber is communicated with the heating cavity. A combustion plate with a plurality of combustion holes is arranged in the combustion chamber. A plurality of air passages are arranged in the cylinder or on the periphery of the cylinder. The first mixing chamber is connected with a gas pipe and an air boosting device. The burner shell and the boiler shell are connected with each other. The gas boiler burner has the advantages of being reasonable in structural arrangement, long in service life, more sufficient in combustion and the like.

Owner:NINGBO DUOBEI MACHINERY IND

A blast furnace gas accompanying burning device

ActiveCN104006394BIncrease contact areaExtension of timeIndirect carbon-dioxide mitigationIncinerator apparatusInlet channelThermal insulation

The invention relates to a blast furnace gas burning assisting device, and belongs to the technical field of gas emission treatment facilities. The inlet end of a cylindrical body of the device is composed of an air inlet channel in the center and an annular air inlet channel surrounding the air inlet channel. The outlet end of the device is composed of a flame stabilizing cone decreasing gradually and a flame spraying opening. A gradually-expanding cone section with a thermal insulation layer is arranged between the inlet end and the outlet end and the cone section is composed of an inner conical cylinder and an outer conical ring surrounding the outer side of the inner conical cylinder. The cone section is provided with a primary air pipe penetrating through the outer conical ring to be inserted into the inner conical cylinder, the outer end of the primary air pipe is communicated with the air and the inner end of the primary air pipe extends to form a nozzle with a necking section. A flow evening cavity extends towards the outer conical ring to form a backflow pipe, and the end of the backflow pipe is provided with an injection nozzle inserted into the primary air pipe and facing the center of the necking section. The blast furnace gas burning assisting device enables blast furnace gas entering the inner conical cylinder to be ignited reliably and burned stably.

Owner:南通海鹰机电集团有限公司

Cylindrical porous jetting-type miniature liquid combustor and combustion method thereof

The invention relates to a miniature liquid fuel combusting device, and discloses a cylindrical porous jetting-type miniature liquid combustor. The cylindrical porous jetting-type miniature liquid combustor comprises a combustion chamber, an upper sealing plate, a lower sealing plate and an air inlet pipeline, the upper sealing plate and the lower sealing plate are used for sealing the combustionchamber, the combustion chamber is provided with a first air inlet and a second air exhaust, and one end of the air inlet pipeline penetrates through the first air inlet and extends into the combustion chamber; the combustion chamber is internally provided with a feeding pipeline and a cumbustor body, one end of the feeding pipeline is located inside the combustor body, the bottom of the combustorbody is connected with the middle of the feeding pipeline, and the other end of the feeding pipeline penetrates through the lower sealing plate. The invention further provides a combustion method ofthe cylindrical porous jetting-type miniature liquid fuel combustor. The miniature liquid fuel combustor and the combustion method thereof have the advantages that the superficial area of liquid fuelis increased, so that the liquid fuel is sufficiently mixed with air, and meanwhile, evaporation of the liquid fuel is accelerated at the same time so that combustion can be stably and efficiently conducted.

Owner:SOUTH CHINA UNIV OF TECH

Method for recovering polymerized phosphate by mixed combustion of phosphorus-containing waste

ActiveCN107062273AFully stable combustionSave energyIncinerator apparatusInorganic phosphatePhysical chemistry

The invention relates to a method for recovering polymerized phosphate by mixed combustion of phosphorus-containing waste. The method comprises the steps that the phosphorus-containing waste and natural gas are directly mixed and burnt through an incineration spray gun; the consumption amount of the phosphorus-containing waste ranges from 1 m<3> / h to 6 m<3> / h, the consumption amount of the natural gas ranges from 50 m<3> / h-500 m<3> / h, and the combustion temperature ranges from 600 DEG C to 850 DEG C; and the phosphorus-containing waste is firstly dried in flames after being atomized, organic matter solid particles are formed and move along with the flame airflow, incineration is continued, organic phosphorus is changed into inorganic phosphate, then the solid density is increased, the particles are precipitated gradually from the flames or the high-temperature airflow, the automatic separation function is achieved, the particles are separated from a high temperature area, and the product melting is reduced.

Owner:ZHENJIANG JIANGNAN CHEM

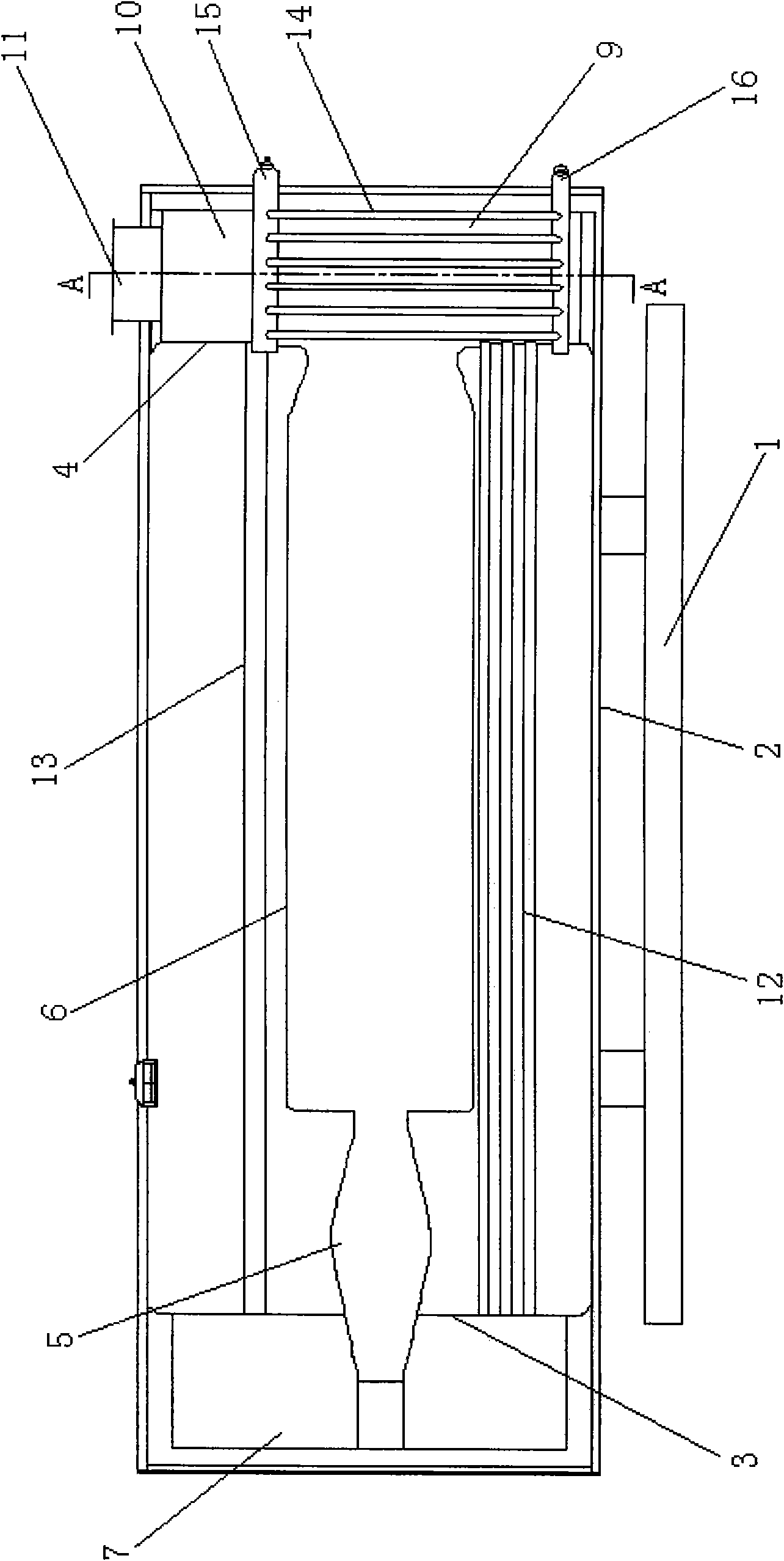

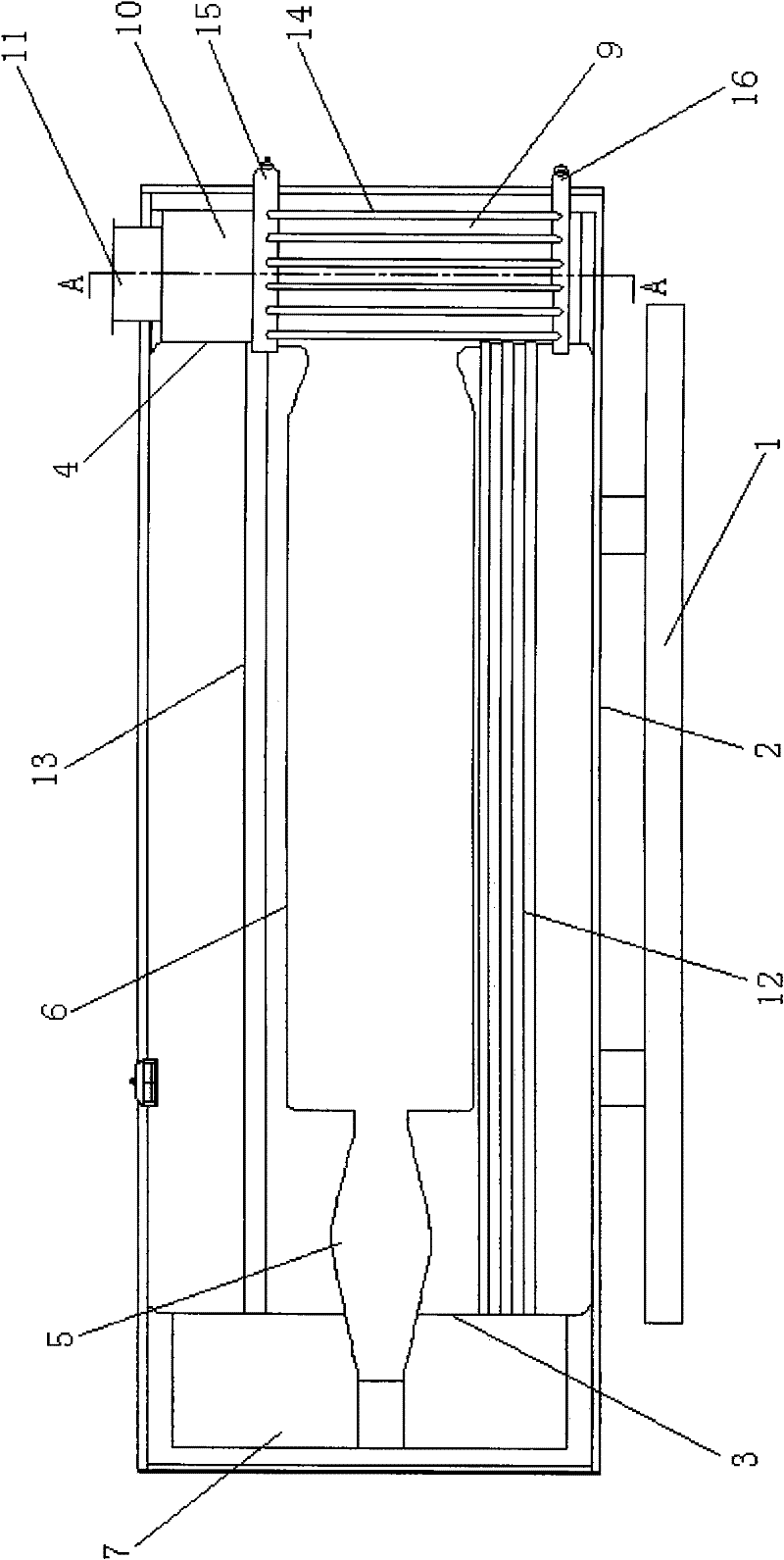

Water-cooling gas furnace core and vacuum hot water boiler comprising same

PendingCN114484435AFully stable combustionUniform flameCombustion technology mitigationWater heatersThermodynamicsFlue gas

The embodiment of the invention provides a water-cooling gas furnace core and a vacuum gas-fired hot water boiler comprising the same. The water-cooling gas furnace core comprises a first clamping flange, a heat exchange tube cluster and a second clamping flange, the heat exchange tube cluster is arranged between the first clamping flange and the second clamping flange to jointly form a wall face restraining smoke circulation, the heat exchange tube cluster at least comprises a first heat exchange tube cluster and a radiation heat dissipation tube cluster, and the first heat exchange tube cluster and the radiation heat dissipation tube cluster are arranged on the wall face. And a heat exchange medium is packaged in the heat exchange tube cluster. According to the embodiment, the average heat exchange coefficient can be increased, deep cooling of high-temperature flue gas is achieved, ultralow NOx emission is guaranteed, and meanwhile the heat utilization efficiency is greatly improved.

Owner:三木舜锅炉(江苏)有限公司

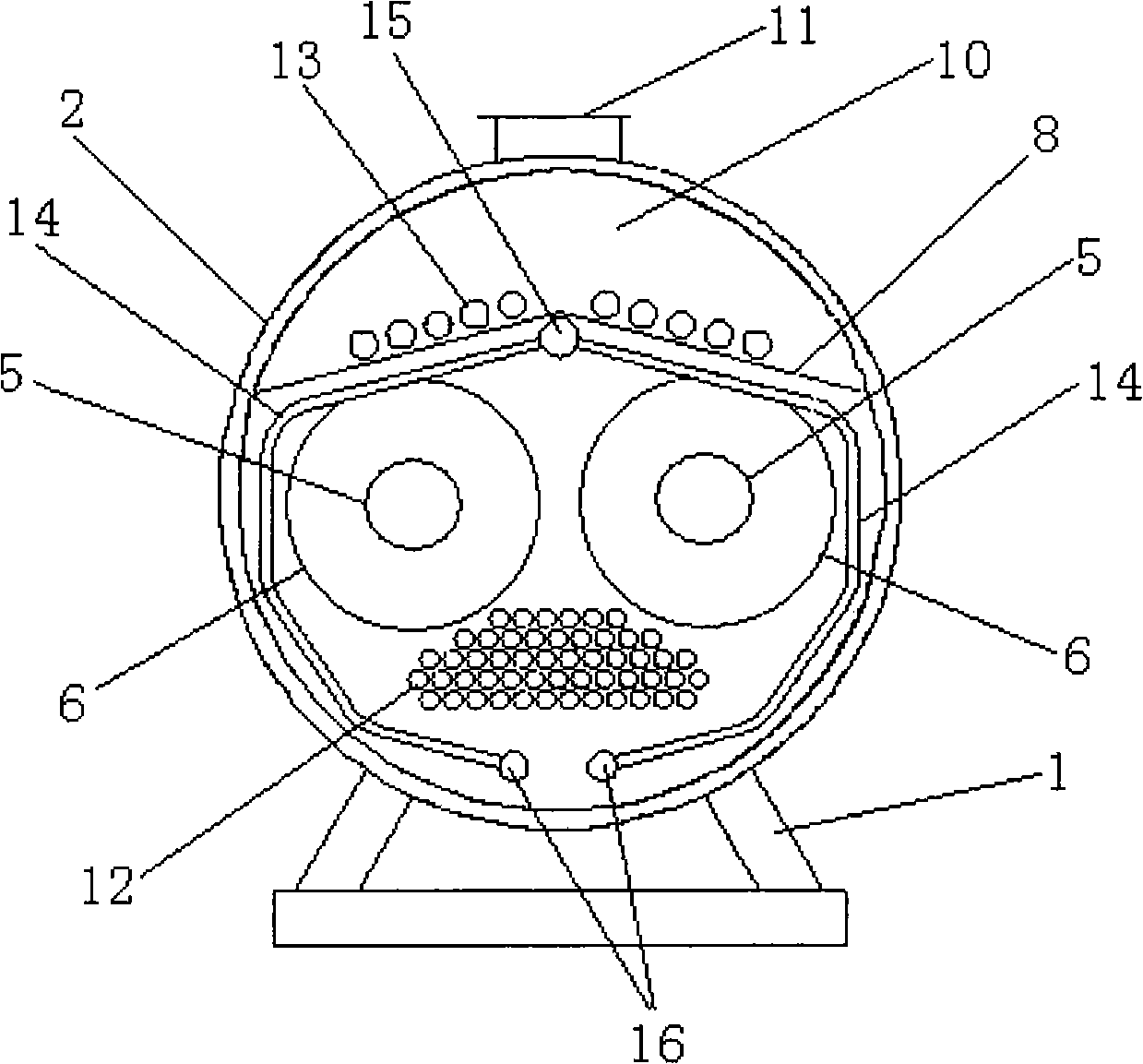

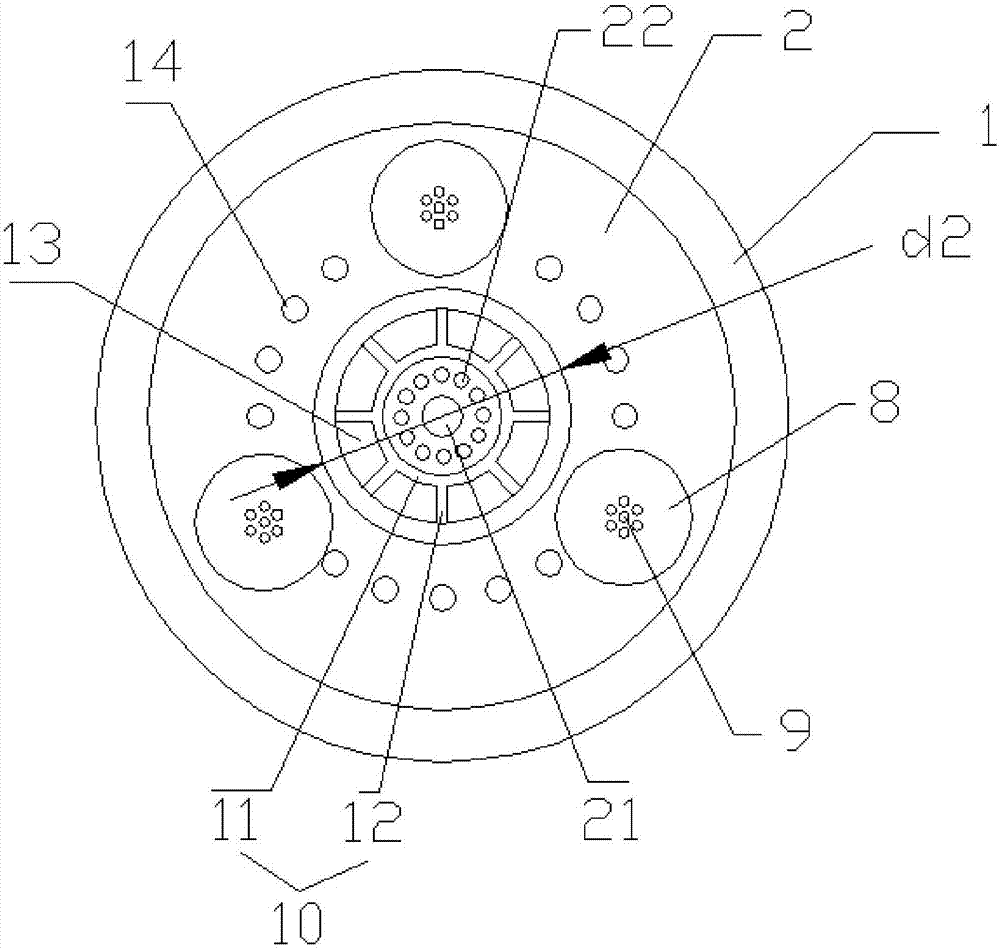

Combustion control system of a biomass combustion furnace

InactiveCN105674251BEasy to implementImprove control effectCombustion apparatusCombustion regulationControl systemBiomass combustion

The invention discloses a combustion control system for a biomass combustion furnace. The combustion control system comprises a furnace body, a blower and an air supplying tank (1), wherein the air supplying tank is in a drum shape with a cover arranged at the top part and the sealed bottom and is arranged at the bottom of a hearth in the furnace body; a plurality of air exhaust holes are formed in the top cover of the air supplying tank; an air inlet (2) is formed in the side wall of the air supplying tank and is connected with the blower through an air inlet tube (3); the air exhaust holes are formed in two rings; 12 outer ring air exhaust holes (4) are formed in an outer ring and in the circumferential direction of the air supplying tank in a halving manner; and 6 inner ring air exhaust holes (5) are formed in an inner ring and in the circumferential direction of the air supplying tank in the halving manner. The combustion control system for the biomass combustion furnace is easy in implementation and is beneficial to improving the biomass combustion efficiency.

Owner:CHANGSHA UNIVERSITY

Horizontal type double-flue industrial coal powder boiler

ActiveCN101576317BAchieving large-scale use requirementsImprove efficiencyWater heatersSteam boilersThermodynamicsProcess engineering

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

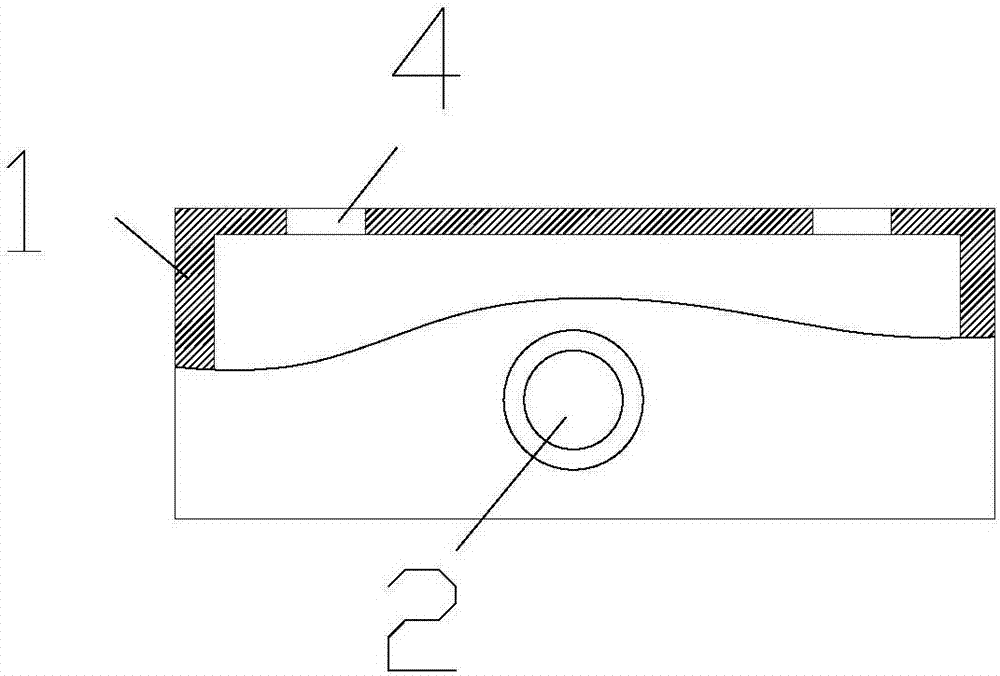

Nozzle of straw burner

InactiveCN110118353AHigh flame temperatureReduce material requirementsSolid fuel combustionCombustion apparatusWater jacketNozzle

The invention relates to a nozzle of a straw burner. The nozzle is composed of a high-temperature resisting nozzle head, a nozzle outer barrel and a water jacket inner barrel. The water jacket inner barrel is concentrically sleeved with the nozzle outer barrel. Cyclone flow deflectors are mounted in an annular gap between the end, close to the high-temperature resisting nozzle head, of the water jacket inner barrel and the nozzle outer barrel. According to the nozzle of the straw burner, the designed water jacket inner barrel can be used for reducing requirements for the material of the nozzleinner barrel, and the fire spray temperature of the nozzle can be made higher.

Owner:郴州华峰能源科技有限公司

A burner protected by inert gas

The invention belongs to the field of burner application, and is a burner protected by an inert gas, a burner protected by an inert gas, including a casing, a spray chamber is provided in the casing, and a spray device is provided in the spray chamber , the spray block is provided with a filling device, the spray block is provided with a heat absorbing device, the lower side of the housing is provided with an air spray chamber, and the air spray chamber is provided with an air spray device, which is used for oil mist and The air is mixed, and the right side of the housing is provided with an adjusting cavity, and an adjusting device is arranged in the adjusting cavity. The invention can atomize the liquid combustion oil and clean the oil accumulated on the lower side of the device, and can also prevent static electricity generation, and can automatically adjust the length of the combustion pipeline by the size of the sprayed flame, and can protect the temperature of the combustion oil from exceeding Standard, inert gas can be passed into the device, so that the atomized combustion oil can be completely excluded from the device.

Owner:一百分(盐城)传媒科技有限公司

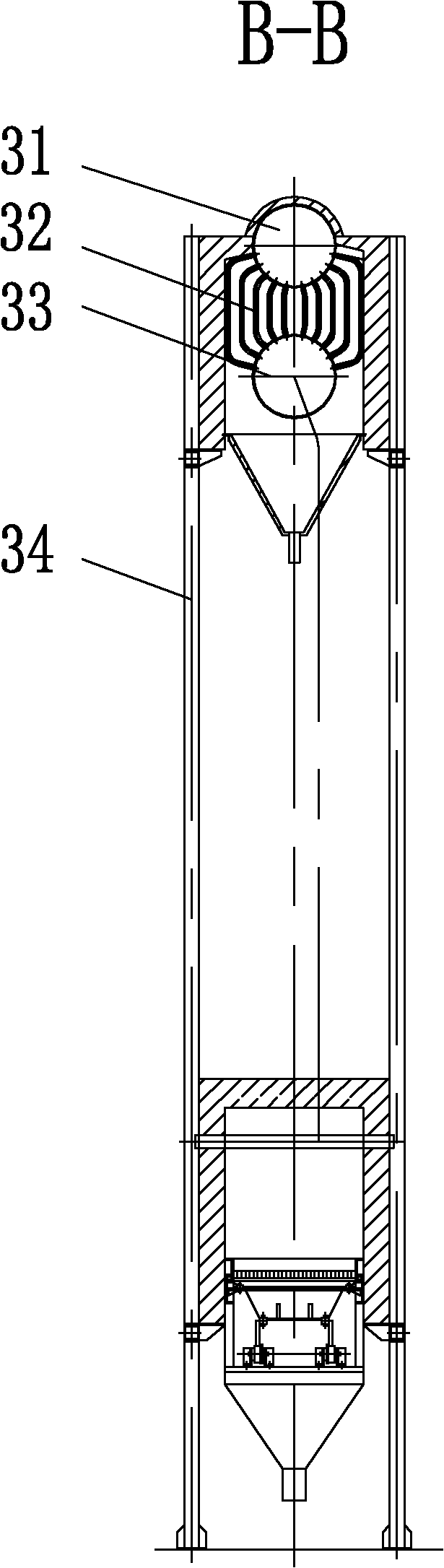

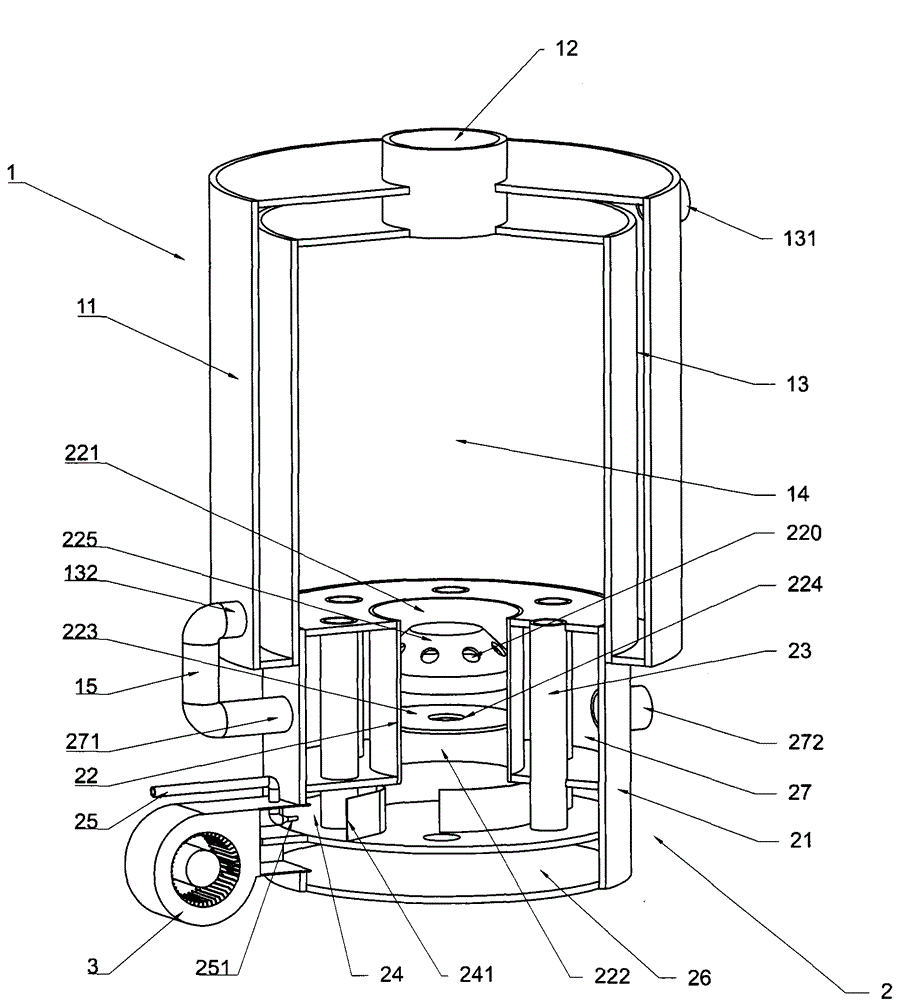

A return type compressor and its engine

ActiveCN111692134BIncreased compression capacityFully stable combustionPump componentsGas turbine plantsControl theoryCylinder (engine)

The invention discloses a reflux compressor and its engine, comprising a U-shaped sleeve rotor, the U-shaped sleeve rotor comprising an inner cylinder, an outer cylinder and an annular cylinder connected between the inner cylinder and the outer cylinder Bottom; the U-shaped sleeve rotor opening side is provided with an end cover, and an inner channel stator and an outer channel stator are arranged between the end cover and the U-shaped sleeve rotor, wherein the inner channel stator is arranged on In the middle part of the inner cylinder, the outer duct stator is arranged between the inner cylinder and the outer cylinder; a low-pressure compressed air section is formed between the inner cylinder and the inner duct stator; the inner cylinder and the inner duct A high-pressure compressor section is formed between the stators of the outer duct; the airflow flows back into the high-pressure compressor section after passing through the low-pressure compressor section, and then is discharged after reflowing; the present invention can improve the compressor's compressor capacity, thereby increasing the power of the engine, and The axial dimension of the engine can be shortened.

Owner:NANCHANG HANGKONG UNIVERSITY +1

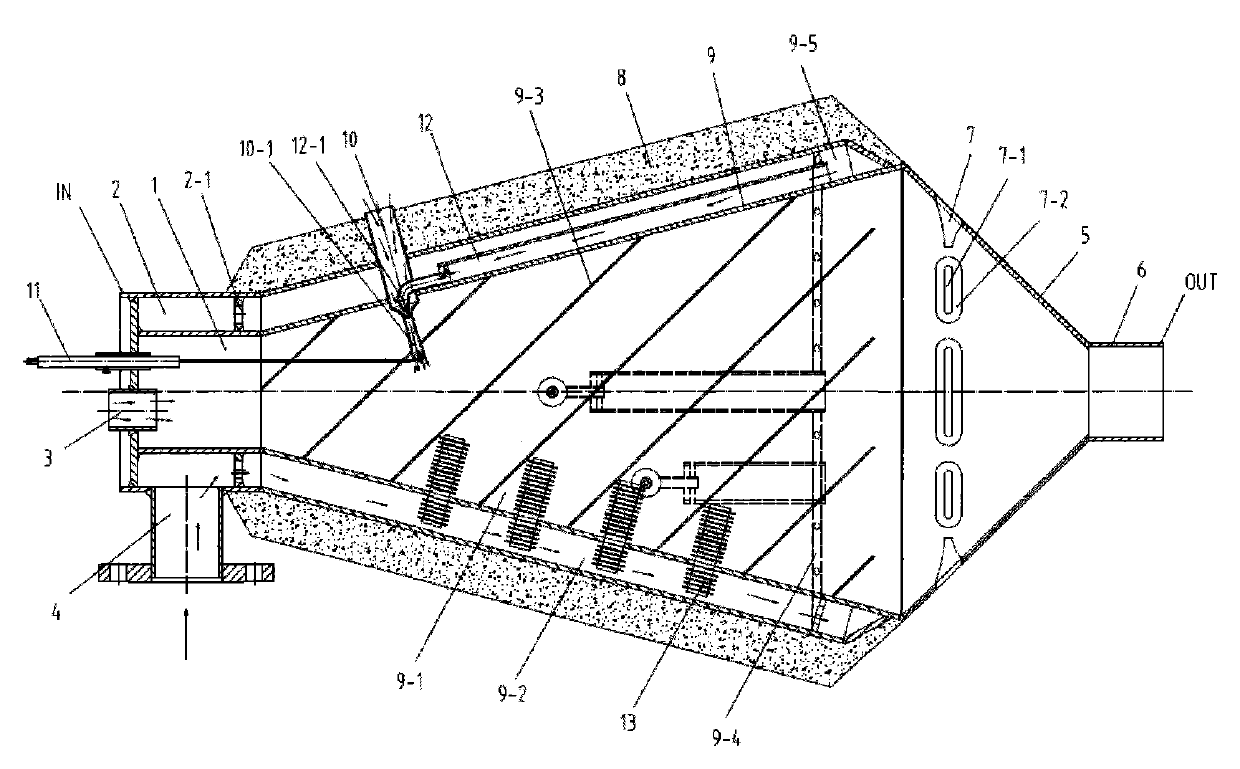

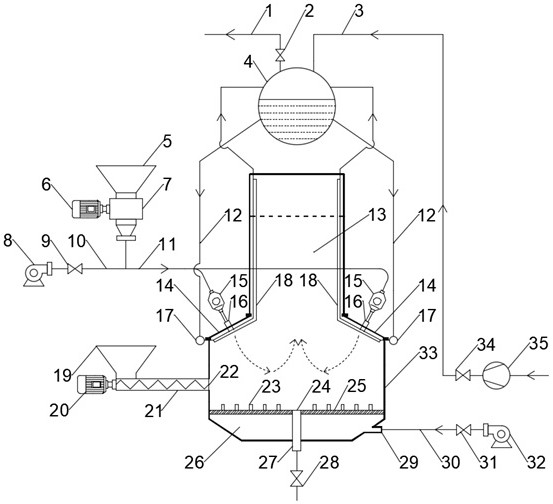

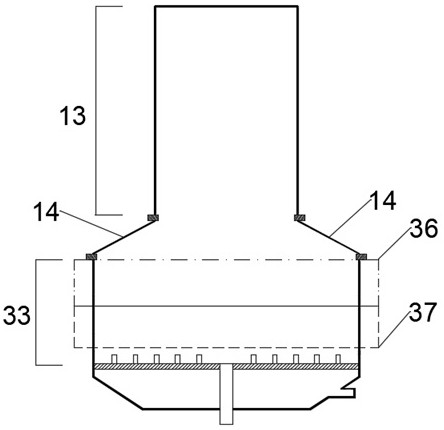

A Circulating Fluidized Bed/Bubbling Fluidized Bed Coupled Pressurized Oxygen-enriched Combustion Device

ActiveCN109297015BReduce volumeLow investment costFluidized bed combustionIndirect carbon-dioxide mitigationFurnace temperatureHearth

The invention discloses a circulating fluidized bed / bubbling fluidized bed coupled pressurized oxygen-enriched combustion device. The circulating fluidized bed / bubbling fluidized bed coupled pressurized oxygen-enriched combustion device comprises a circulating fluidized bed / bubbling fluidized bed coupled hearth, an air chamber, an air distribution plate, a cyclone separator, a return feeder, an external heat exchanger, a buried pipe heating face and a screen type heating face; the hearth adopts graded air supply and graded coal supply, the buried pipe heating face is arranged in the dense-phase zone, a lean-phase zone outlet is connected to the cyclone separator, the cyclone separator is used for separating solid materials in smoke gas in the hearth outlet, and the materials enter the return feeder and the external heat exchanger. The device is suitable for combustion of solid fuel under pressurizing and high inlet oxygen concentration, and advantages of a bubbling fluidized bed and acirculating fluidized bed can be achieved. The buried pipe heating face with the high capacity utilization rate is arranged on the bubbling and fluidizing area of the lower portion of the hearth, thelimited arrangement of the heating face can be effectively solved, and through graded coal supply, graded air supply and graded return feeding, the furnace temperature and in-furnace temperature distribution can be effectively controlled.

Owner:SOUTHEAST UNIV

Fluidized bed industrial boiler combusting wood industry waste and combustion heat exchange method of fluidized bed industrial boiler

PendingCN112013382AFully stable combustionEasy to control temperatureFluidized bed combustionApparatus for fluidised bed combustionFluidized bedHearth

The invention relates to the technical field of boilers, in particular to a fluidized bed industrial boiler for combusting wood industry waste and a combustion heat exchange method of the fluidized bed industrial boiler. The fluidized bed industrial boiler comprises a hearth, an arch part and an uptake flue which communicate with one another in sequence; the hearth communicates with a first material conveying mechanism, and the first material conveying mechanism is used for conveying first-kind biomass particles to a lower area of the hearth; the arch part is provided with a large-size end anda small-size end, the large-size end is connected to the hearth, and the small-size end is connected to the uptake flue; and the arch part communicates with a second material conveying mechanism, andthe second material conveying mechanism is used for conveying second-kind biomass particles to an upper area of the hearth, wherein the particle size of the first-kind biomass particles is millimeterlevel or above, and the particle size of the second-kind biomass particles is micron level. Partitioned stable and sufficient combustion and effective combustion heat utilization of the biomass particles with different particle sizes are achieved.

Owner:JIANGSU UNIV +1

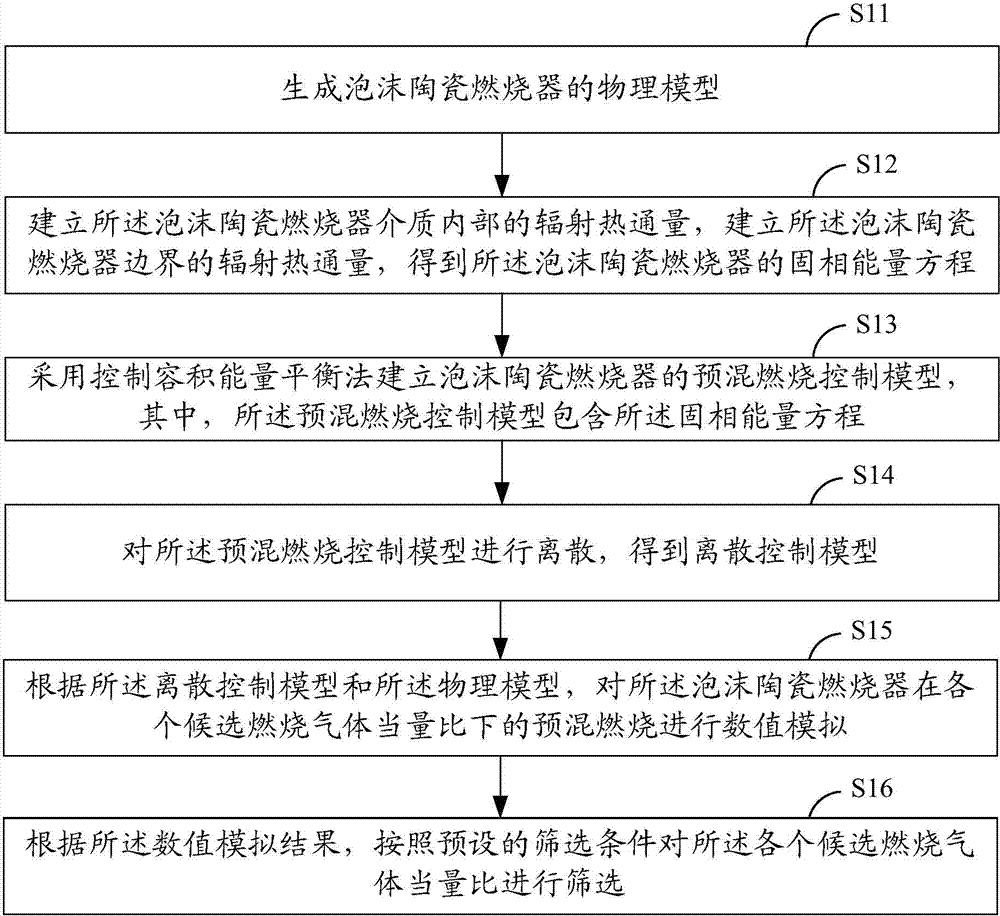

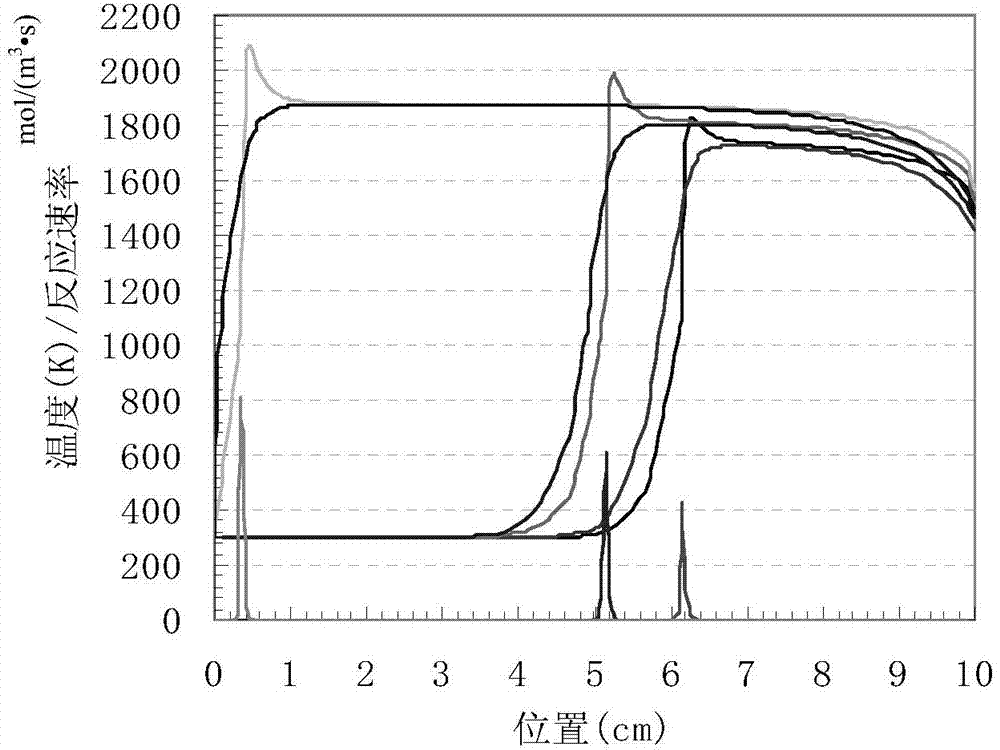

Method for screening equivalence ratios of combustion gas of foamed ceramic burner

InactiveCN103615720AFully stable combustionHigh precisionGaseous fuel burnerCombustion regulationEnergy balancingEquivalence ratio

The invention provides a method for screening equivalence ratios of combustion gas of a foamed ceramic burner. The method includes the steps that a physical model of the foamed ceramic burner is generated; the radiant heat flux inside media of the foamed ceramic burner is established by the adoption of a diffusion approximation method, the radiant heat flux on the boundary of the foamed ceramic burner is established through a double-flux method, and a solid phase energy equation of the foamed ceramic burner is obtained; a premixed combustion control model of the foamed ceramic burner is established by the adoption of a volume control energy balance method; the premixed combustion control model is disjointed, so that a discrete control model is obtained; numerical simulation is conducted on premixed combustion of the foamed ceramic burner under all the candidate combustion gas equivalence ratios according to the discrete control model and the physical model; all the candidate combustion gas equivalence ratios are screened on the basis of a preset screening condition according to a numerical simulation result. By the aid of the method, the combustion characteristic inside the burner can be obtained accurately, and the best combustion gas equivalence ratio can be screened out.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

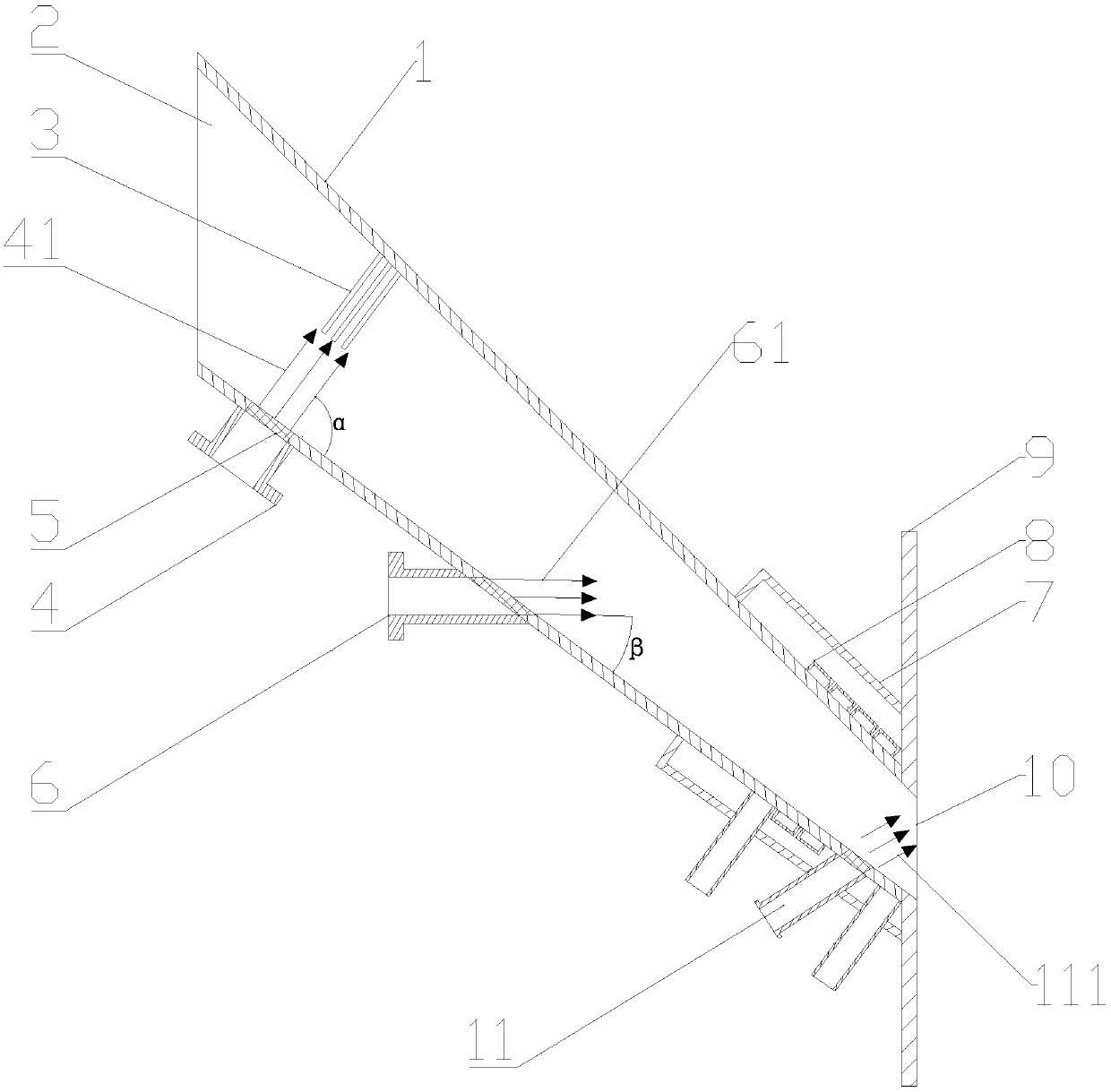

Feeding semi-pyrolysis device and method for household waste incineration boiler

PendingCN109959015AImprove energy efficiencyReduce generationIncinerator apparatusBoiler furnaceIncineration

The invention relates to a feeding semi-pyrolysis device and method for a household waste incineration circulating fluidized bedboiler. The feeding semi-pyrolysis device for the household waste incineration boiler comprises a boiler front feeding part and a semi-pyrolysis part. The head of a screw feeder (6) of the boiler front feeding part is connected with a feeding chute (8), and the feeding chute is connected into a boiler wall (10) to enter a boiler furnace in the mode of forming an included angle between the feeding chute and the horizontal plane. The included angle refers to a chute angle (9). The semi-pyrolysis part comprises a hot air duct (1), an air evacuating device (2), a boiler-in pipeline (3) and an air evacuating pipeline (5). The air evacuating device is installed betweenthe hot air duct and the boiler-in pipeline. Boiler hot air is connected into the hot air duct. The boiler-in pipeline enters a boiler furnace lean-phase zone through a boiler wall opened hole. One end of the air evacuating pipeline is connected with the air evacuating device, and the other end of the air evacuating pipeline is connected with the head of the screw feeder. A ventilation door (4) isinstalled on the hot air duct in front of the air evacuating device. According to the feeding semi-pyrolysis device for the household waste incineration boiler, materials can be burnt more stably andsufficiently in the waste circulating fluidized bedboiler and exhausting standards are met.

Owner:SHANGHAI ELECTROMECHANICAL DESIGN & RES INST CO LTD

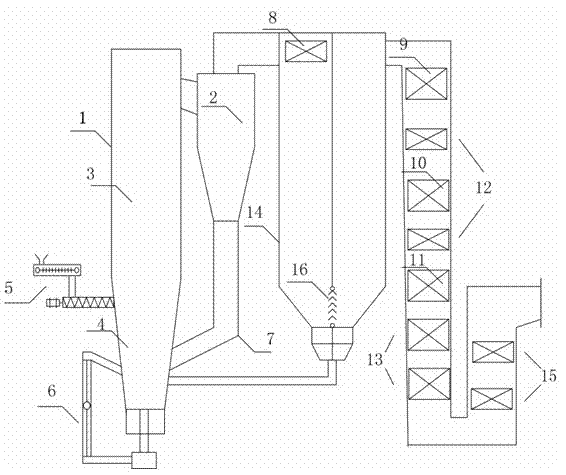

S-shaped regenerative chamber type regenerative burner nozzle

InactiveCN104791796AImprove straightnessGood dispersionIndirect carbon-dioxide mitigationGaseous fuel burnerHeating furnaceLower face

The invention discloses a regenerative burner nozzle and relates to the technical field of burning of heating furnaces, quenching furnaces, forging furnaces, casting ladle preheating devices and heat treatment furnaces. The regenerative burner nozzle is formed in an integral casting mode and divided into a burner nozzle body 13 and a regenerative chamber 14. The burner nozzle body 13 is divided into a spraying segment 9, a burning segment 10 and a mixing segment 11, wherein the spraying segment 9 is cylindrical, the burning segment 10 is in the shape of a sector and is connected with a guiding burner nozzle body 1, dispersion of mixed gas is facilitated, and the burning effect is enhanced. The mixing segment 11 is cylindrical and is connected with an air channel 12 and a fuel pipe 8, and a sector-shaped end 2 is adopted on the other side of the air channel 12. Any angle can be formed between the fuel pipe 8 and the central axis of the burner nozzle. The regenerative chamber 14 is in the shape of a quadrangular prism, partition plates 3 are arranged in a vertical alternating mode so that the regenerative chamber can be partitioned to be in the shape of S, the number of the partition plates 3 ranges from 1 to 5, gas resistance can be increased if the number of the partition plates 3 is too large, and accordingly, gas flowing speed will be reduced. The regenerative chamber 14 is filled with heat accumulation mediums 5, the upper face and the lower face of the regenerative chamber 14 are provided with a heat accumulation medium outlet / inlet 4, and installation and maintenance are facilitated. The side, the tail of which is close to the partition plates 3, of the regenerative chamber 14 is provided with an air pipe port 7, a sector-shaped segment 6 is arranged on the inner side of the air pipe port 7, and gas can be dispersed evenly.

Owner:UNIV OF JINAN

Boiler dropping tube

InactiveCN109654526ASimple structureReduce manufacturing costFluidized bed combustionFuel feeding arrangementsHeat conductingEngineering

The invention discloses a boiler dropping tube. The boiler dropping tube comprises a dropping tube, a first air channel, a second air channel, a separation assembly and a hollow heat conducting tube,wherein the dropping tube is obliquely arranged on the sidewall of a boiler, the upper end and lower end of the dropping tube are separately provided with a feeding port and a discharging port and thedischarging port is connected with the inside of the boiler; the first air channel is located at the lower sidewall of the dropping tube and close to the position of the feeding port; the first air channel provides a first airflow blowing into the dropping tube; the second air channel is located at the middle and lower portion of the lower sidewall of the dropping tube and provides a second airflow blowing into the dropping tube; the separation assembly is provided with a plurality of separating rods, wherein the separating rods are located on the flow path of the first airflow, and one end of each separating rod is fixed on the upper sidewall of the dropping tube; the hollow heat conducting tube is provided with a water inlet and a water outlet and spirally wound on the lower end of theouter wall of the dropping tube. According to the boiler dropping tube, the fuel combustion is more stable and sufficient, the turbulent smoke generated by the explosion is reduced, the fuel accumulation in the dropping tube is avoided, and the fuel delivery efficiency is improved.

Owner:国祯美洁 (安徽)生物质热电有限公司

Backflow type air compressor and engine

ActiveCN111692134AIncreased compression capacityFully stable combustionPump componentsGas turbine plantsPhysicsStator

The invention discloses a backflow type air compressor and an engine. The backflow type air compressor comprises a U-shaped sleeve rotor, wherein the U-shaped sleeve rotor comprises an inner barrel, an outer barrel and an annular barrel bottom connected between the inner barrel and the outer barrel; an end cover is arranged on the opening side of the U-shaped sleeve rotor, an inner duct stator andan outer duct stator are arranged between the end cover and the U-shaped sleeve rotor, the inner duct stator is arranged in the middle of the inner barrel, and the outer duct stator is arranged between the inner barrel and the outer barrel. A low-pressure air compression section is formed between the inner barrel and the inner duct stator, and a high-pressure air compression section is formed between the inner barrel and the outer duct stator. Air flow flows back into the high-pressure air compression section after passing through the low-pressure air compression section, and then is discharged after flowing back again. The air compression capacity of the air compressor can be improved, the power of the engine is further improved, and the axial size of the engine can be shortened.

Owner:NANCHANG HANGKONG UNIVERSITY +1

A kind of fast and high-efficiency aerosol fire extinguishing agent and preparation method thereof

ActiveCN105597259BHigh fire extinguishing efficiencyEasy to igniteFire extinguisherCombustionAlcohol

The invention relates to a rapid and efficient aerosol fire extinguishing agent and a preparation method thereof and belongs to the field of fire protection engineering. With the total mass of raw materials of the aerosol fire extinguishing agent being 100%, the aerosol fire extinguishing agent is prepared from, by mass, 60-80% of an antioxidant, 10-30% of a combustible agent, 0-15% of a modifier and 1-5% of an adhesive. The preparation method of the aerosol fire extinguishing agent includes the steps that firstly, the antioxidant, the combustible agent and the modifier are dried at 50-80 DEG C and then mixed evenly; then, the adhesive dissolved in ethyl alcohol or acetone is added, granulation is carried out with a screen after full and even mixing, and the granulated material is dried at 50-80 DEG C; then, the dried material is subjected to compression moulding forming with a mould, and the aerosol fire extinguishing agent is obtained. The aerosol fire extinguishing agent is easy to ignite, high in combustion speed, capable of generating a large amount of fire extinguishing matter within a short time, full and stable in combustion and high in fire extinguishing efficiency. According to the preparation method, the process is simple, the raw materials are easy to obtain, and the preparation cost is low.

Owner:HUBEI HAISHAN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com