Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

102 results about "Wood industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The wood industry or lumber industry is a—usually private—economic sector concerned with forestry, logging, timber trade, and the production of forest products, timber/lumber, primary forest and wood products (e.g. furniture) and secondary products like wood pulp for the pulp and paper industry. Some largest producers are also among the biggest timberland owners.

Natural resin formulations

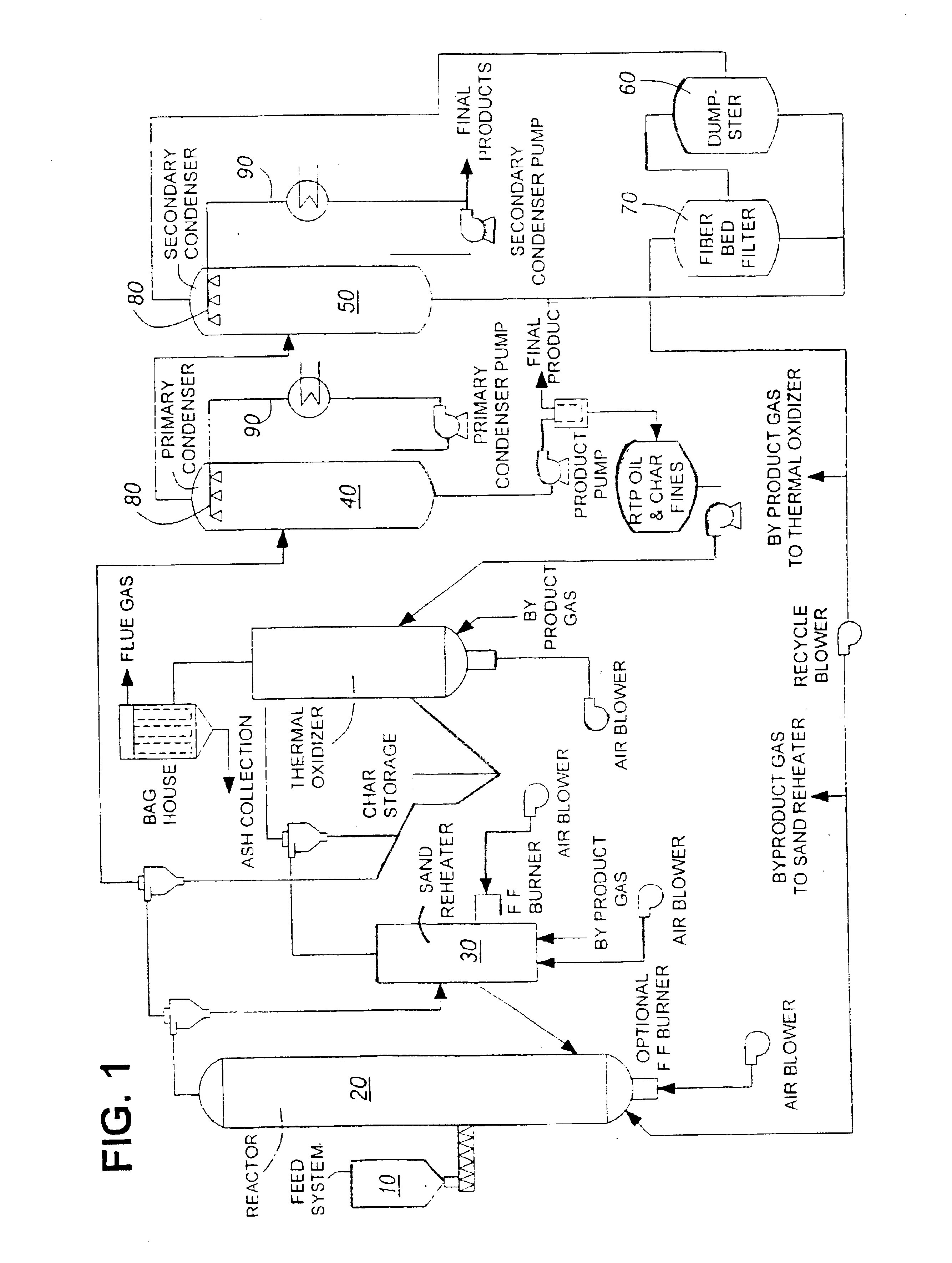

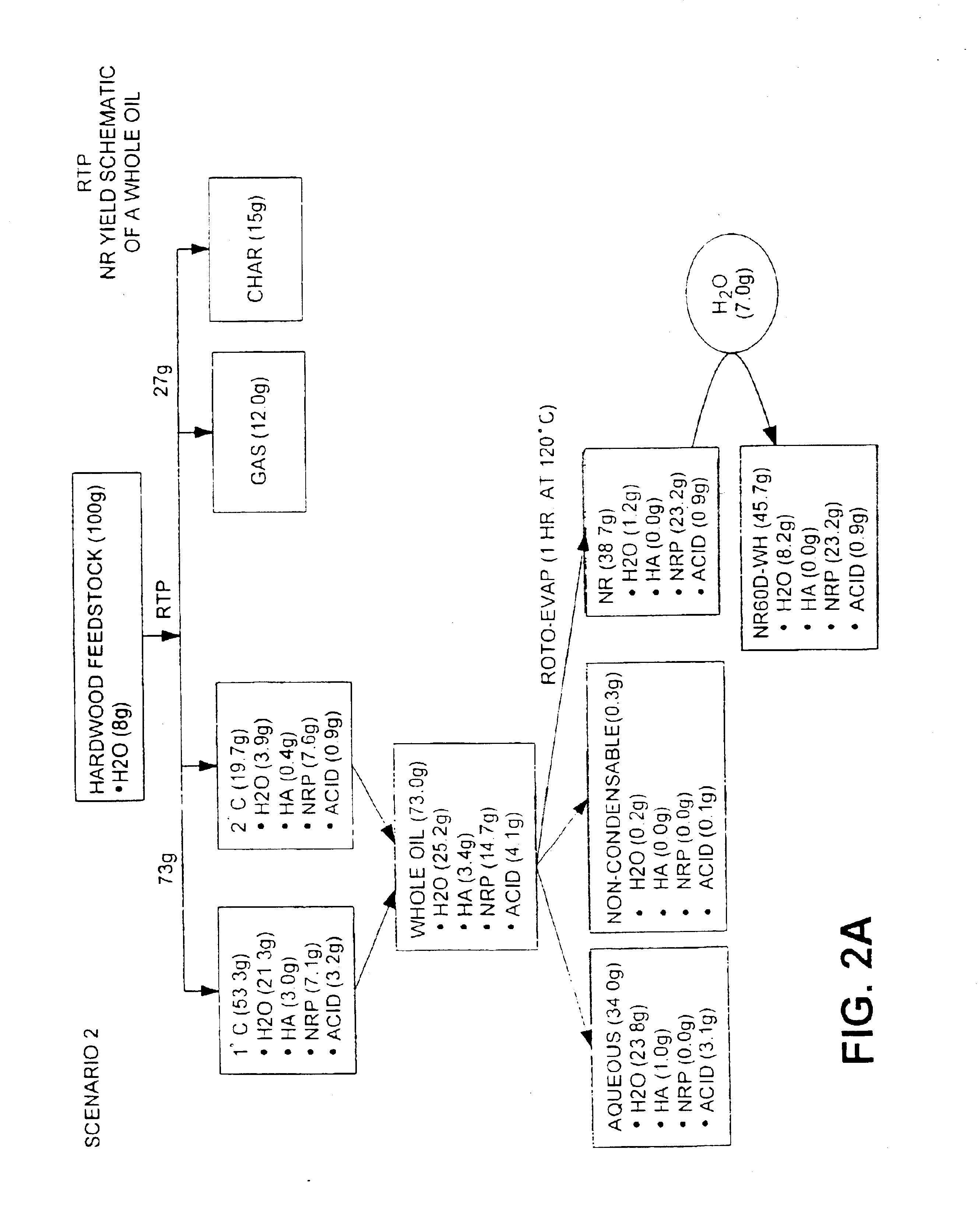

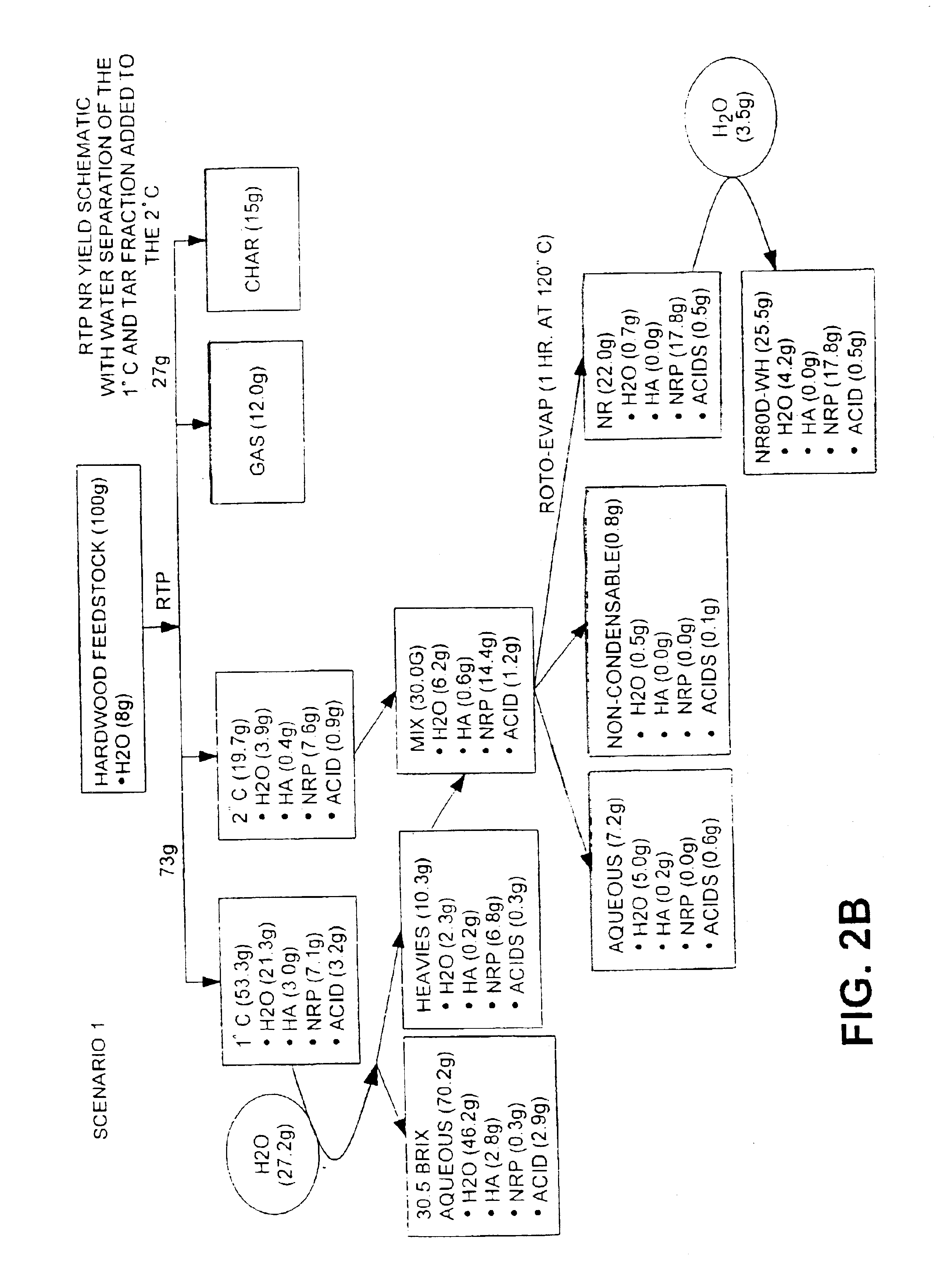

InactiveUS6844420B1Low viscosityImprove liquidityFatty oils/acids recovery from wasteBiofuelsNatural resinDistillation

This invention is directed to a method of preparing a natural resin by liquefying wood, bark, forest residues, wood industry residues, or other biomass using rapid destructive distillation (fast pyrolysis). Fast pyrolysis produces both vapors and char from biomass, and following removal of the char from the product vapors, a liquid pitch product is recovered and processed by distillation, evaporation, or a combination thereof, in order to obtain a natural resin which may be in either liquid or solid form. The natural resin comprises a total phenolic content from about 30% to about 80% (w / w), and is a highly-reactive ligninic compound that has been found to be suitable for use within resin formulations without requiring any further extraction or fractionation procedures. Resins comprising up to 60% natural resin have been prepared and tested in board production and found to exhibit similar properties associated with commercially available resins. The natural resin may substitute for phenol, or for both phenol and formaldehyde within phenol-containing resins. Similarly, the natural resin can replace a substantial part of the components within urea-containing resins.

Owner:ENSYN RENEWABLES

Reactive polyurethane hot-melt adhesive for edge sealing in wood industry and preparation method thereof

InactiveCN103031100AHigh strengthLower melting temperaturePolyureas/polyurethane adhesivesPolyesterAdhesive cement

The invention discloses a reactive polyurethane hot-melt adhesive for edge sealing in wood industry, which is prepared from the following raw materials in percentage by weight: 10-30% of crystalline polyester polyol, 10-30% of amorphous polyester polyol, 8-15% of high-molecular-weight thermoplastic resin, 10-25% of diisocyanate, 1-8% of plasticizer, 10-30% of inorganic filler, 0.05-0.5% of antioxidant and 0.05-0.5% of ultraviolet absorbent. In addition, the invention also discloses a preparation method of the reactive polyurethane hot-melt adhesive. The adhesive disclosed by the invention has the advantages of extremely high drying speed, excellent initial bonding strength and final strength, high heat resistance, high storage stability, excellent environment friendliness, simple preparation technique, low cost and the like. The invention can well satisfy the requirements for edge sealing in wood industry, and is beneficial to industrialization of edge sealing production in wood industry.

Owner:嘉兴市恒泰化工科技有限公司

Environmental protection type adhesion agent for wood industry

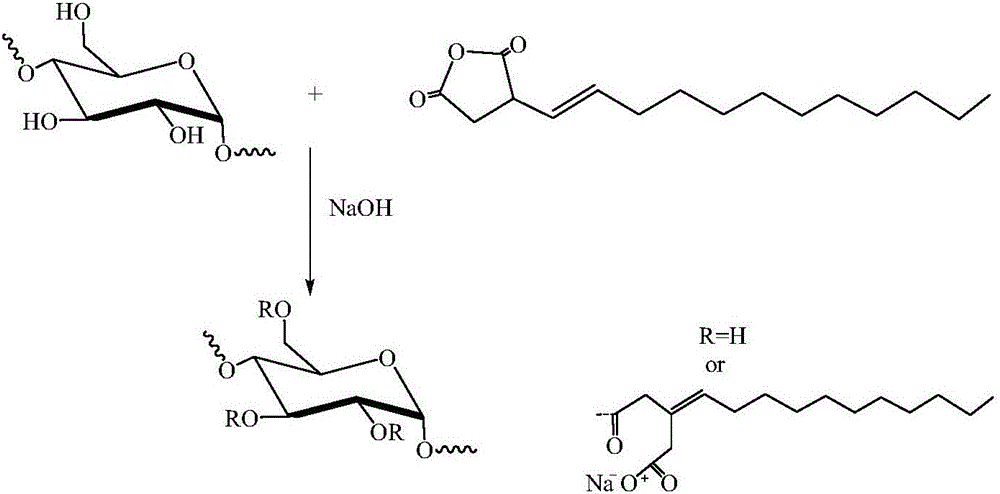

ActiveCN1912041AWide variety of sourcesThe source is non-toxicDomestic articlesUnsaturated alcohol polymer adhesivesAdhesivePolyvinyl alcohol

The invention discloses an environmental protection adhesive for timber industry, prepared of a formula comprising: PVA 5-10wt%, silica solution 10-20wt%, glycol 0.2-0.35wt%, polyacrylamide 0.03-0.05wt%, mildew- proof germicide 0-0.1wt%, fillings 10-12wt%, and water the rest. It does not use aldehyde-containing, hydroxybenzene-containing and organic volatile-containing matters as raw materials to form a formula, and the used raw materials have wide sources but no poisonous matters, and besides, these components can excellently cooperate with one another, therefore it has excellent performances of three-aldehyde glue and radically solves a series of problems caused by formaldehyde and organic volatile release.

Owner:河北为真竹木技术有限公司

High-temp alkali-resistant material and use therreof in ceramic filler

A high-temp. alkali-resistant material mainly contains MgO, SiO2 and Al2O3. Its primary crystal phase is forsterite and spinel. Its features are high resistance to alkali corrosion at high temp and use for preparing ceramic filler of heat-accumulating thermal oxidizer to treat organic waste gas in wood industry.

Owner:兰州瑞玛化机有限公司 +1

Adhesion agent for artificial board and method of producing the same

InactiveCN101402833ANo release issuesMeet environmental protection requirementsProtein adhesivesGlue/gelatin preparationNatural productAdhesive

The invention relates to an adhesive used for an artificial board and a preparation method thereof. The invention is characterized in that the artificial board consists of water, acid, chitosan, phenol and enzyme; the detail steps of the preparation technique are as follows: 70 to 100 portions of water, 0.01 to 6 portions of acid and 0.01 to 12 portions of flexible components are added into a stainless steel kettle; the temperature is between 10 and 80 DEG C; a stirring machine is started for uniformly mixing at a speed of 400r / min; 0.01 to 45 portions of phenol are added for stirring; the pH is adjusted to be 3 to 8; 1 to 10 portions of enzyme is added for continuously stirring; enzyme treatment time is between 0.1 minute and 48 hours; after the viscidity of the adhesive is 4 cups for 20 to 100 seconds, stirring is stopped; and then an opening is sealed for storage. The adhesive used for the artificial board does not contain formaldehyde, has no poison and smells during the production and use processes, does not release harmless gases, is safe and environmental friendly; the used chitosan is natural product which can be decomposed and recycled; in the invention, biocatalysis and biological transformation technologies are applied to wood industry; and bio-enzyme catalytic polymerization is adopted for preparing the adhesive and can be carried out under normal temperature and pressure.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

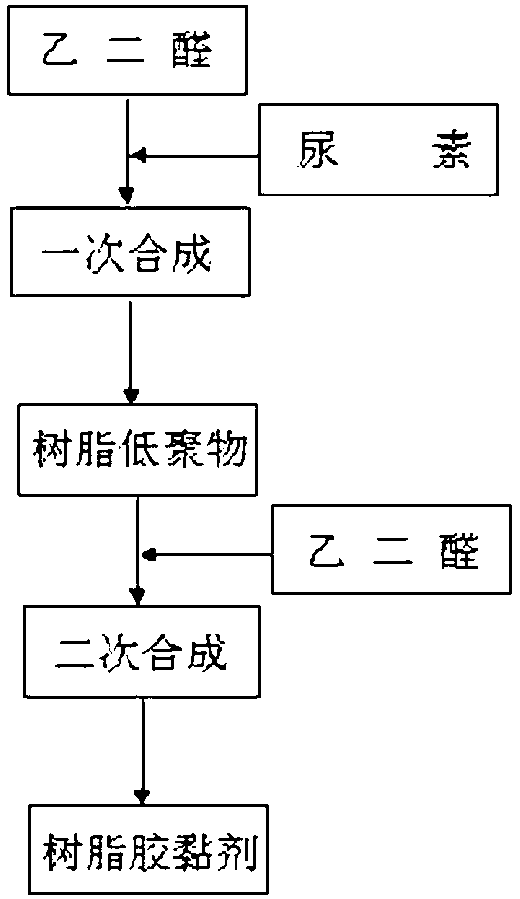

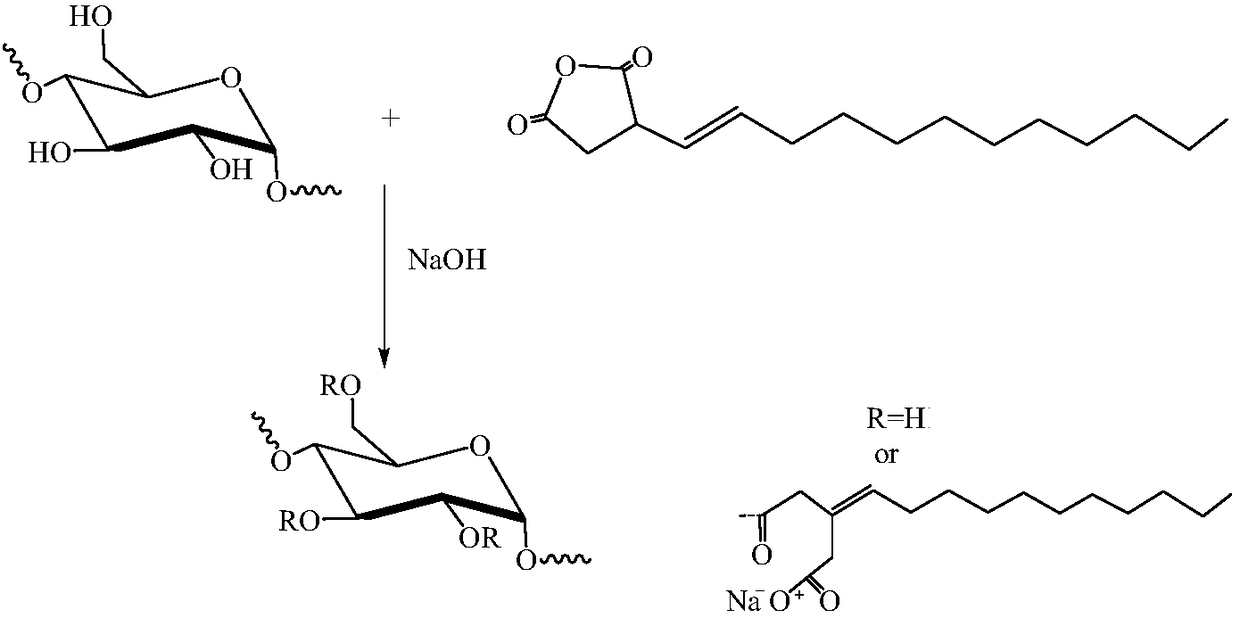

Resin adhesive free from formaldehyde release as well as preparation method and application thereof

InactiveCN103305168AStable structureImprove performanceAldehyde/ketone condensation polymer adhesivesOligomerGlyoxal

The invention discloses a resin adhesive free from formaldehyde release as well as a preparation method and an application thereof. The resin adhesive free from formaldehyde release is a urea-glyoxal resin adhesive, and is prepared from urea and glyoxal at a mol ratio of 1:(1-2) through stepwise synthesis. The preparation method comprises the following steps of: raw material preparation, primary synthesis and secondary synthesis, and specifically comprises step of weighing raw materials, dividing glyoxal into two parts, adding urea to the first part of glyoxal and reacting to obtain glyoxal-urea resin oligomer, adding the second part of glyoxal to the oligomer and reacting, and cooling and treating to obtain a target object. The application is the application of the resin adhesive free from formaldehyde release in artificial board production in wood industry, clothing manufacturing and paper-making production. The resin adhesive free from formaldehyde release is stable in structure, free from formaldehyde release and excellent in performance, and is applicable to production of artificial board, in particular of plywood and chipboard, as well as to clothing manufacturing, paper making and other fields.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Process of utilizing wood plastic composite for manufacturing formaldehyde-free bending glued parts

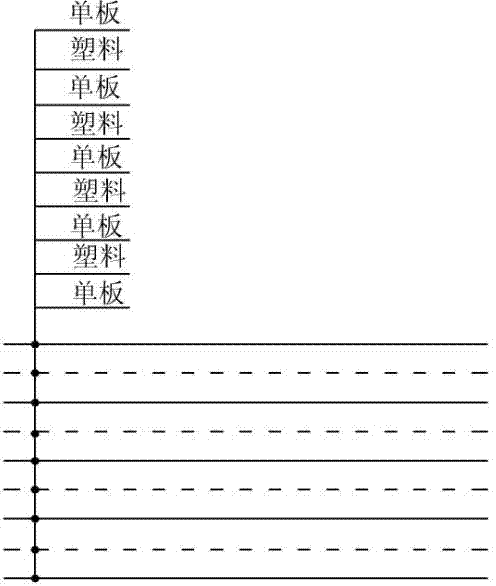

ActiveCN103538124AImprove bending performanceImprove the bending performance, can improve the utilization rate of woodWood veneer joiningEngineeringFurniture industry

The invention relates to a new process of utilizing single-board / plastic film composite for manufacturing formaldehyde-free bending glued furniture parts. A plastic film serves as bonding material, a wooden single board serves as a basic unit, rolling hole processing is performed on a single board gluing face, tree type, thickness and specification of the single board are selected according to product usage, and a blank can be assembled, the board blank is placed in a special die to heat and press in high frequency, the board blank is bent, glued and formed, the plastic film is solidified after being cooled, and formaldehyde-free bending glued furniture parts are obtained. The process is simple and low in producing cost; the products are free of pollution and recyclable during manufacture, processing and usage, and has the advantages of environment protection, energy efficiency and efficiency, an environment friendly, safe and healthy consumption concept of the wood industry and the furniture industry can be met, and the process has extensive application value.

Owner:FUJIAN AGRI & FORESTRY UNIV

Method for preparing wax oil floor

InactiveCN105291236ASimple processAvoid local uneven moisture contentWood working apparatusCoatingsPerilla oilTurpentine

The invention relates to the field of furniture wood industries, in particular to a method for preparing a wax oil floor. Firstly, linseed oil, stillingia oil, perilla oil, pine oil, castor oil, rosin modified resins and beeswax which each account for 10%-30% of the total content of semi-finished wax oil are mixed and subjected to high-temperature polymerization at the temperature of 280-300 DEG C; turpentine is added into a polymerized mixture for dilution and filtering to form the semi-finished wax oil; a dryer is added into the diluted and filtered semi-finished wax oil for concoction, and after the concoction is finished, finished wax oil is formed; then the finished wax oil is smeared to the floor, and finally after the wax oil on the floor is blown dry, the wax oil floor is formed. The process is simple, the wax oil floor with the indexes identical to foreign indexes can be produced, the floor without harmful substances such as formaldehyde and benzene is achieved, and the requirement of environmental protection is met.

Owner:江苏徐家木业有限公司 +1

Environment-friendly adhesive as well as preparation method and application thereof

The invention belongs to the technical field of adhesive production, and particularly relates to an environment-friendly adhesive and a method for preparing the environment-friendly adhesive by using silkworm cocoon waste silk glue. The preparation method of the environment-friendly adhesive comprises the following steps: (1) collecting wastewater generated after boiling silkworm cocoons, cooling to room temperature, then filtering by using an ultrafiltration membrane, and recovering a trapped liquid so as to obtain a silk glue concentrated solution, or concentrating by 10-12 times in vacuum or at normal pressure under the condition of lower than 80 DEG C so as to obtain a silk glue concentrated solution; (2) carrying out modified treatment on the silk glue concentrated solution obtained in the step (1) so as to obtain the silk glue concentrated solution subjected to modified treatment; and (3) concentrating the silk glue concentrated solution subjected to modified treatment at a normal pressure or in vacuum under the condition of lower than or equal to 80 DEG C so as to obtain a sticky flowable material which is the environment-friendly adhesive. The environment-friendly adhesive prepared by the method can be widely applied to wood industries or plant fiber molding industries, is safe and environment-friendly and does not release harmful substances such as formaldehyde which are harmful to human bodies in a using process.

Owner:郝飞麟

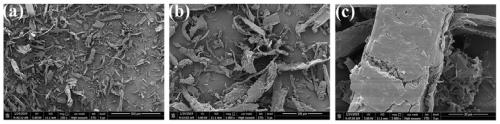

Polyethylene glycol wood powder composite phase change material (PCM) and preparation method and applications thereof

ActiveCN109825254AAchieve the purpose of reusingReduce usageHeat-exchange elementsFiberMaterials preparation

The invention belongs to the technical field of biology based phase change materials, and especially relates to a polyethylene glycol wood powder composite phase change material (PCM) and a preparation method and applications thereof. The polyethylene glycol wood powder composite phase change material (PCM) is composed of polyethylene glycol and wood powder. The preparation method comprises following steps: heating and melting polyethylene glycol, adding wood powder into melted polyethylene glycol under stirring, evenly mixing under heating and stirring, and finally subjecting the mixture to vacuum adsorption to obtain the polyethylene glycol wood powder composite phase change material. Waste leftover materials in the wood industry are processed to obtain ultrafine wood powder and wood fibers, which are used to prepare the phase change material; natural renewable biological resources are used to prepare the phase change material; the wastes are recovered and reutilized; and the using amount of nonrenewable fossil resources and mineral resources is reduced in phase change material preparation. The prepared phase change material has the advantages of high enthalpy change value and good heat stability.

Owner:SOUTH CHINA AGRI UNIV

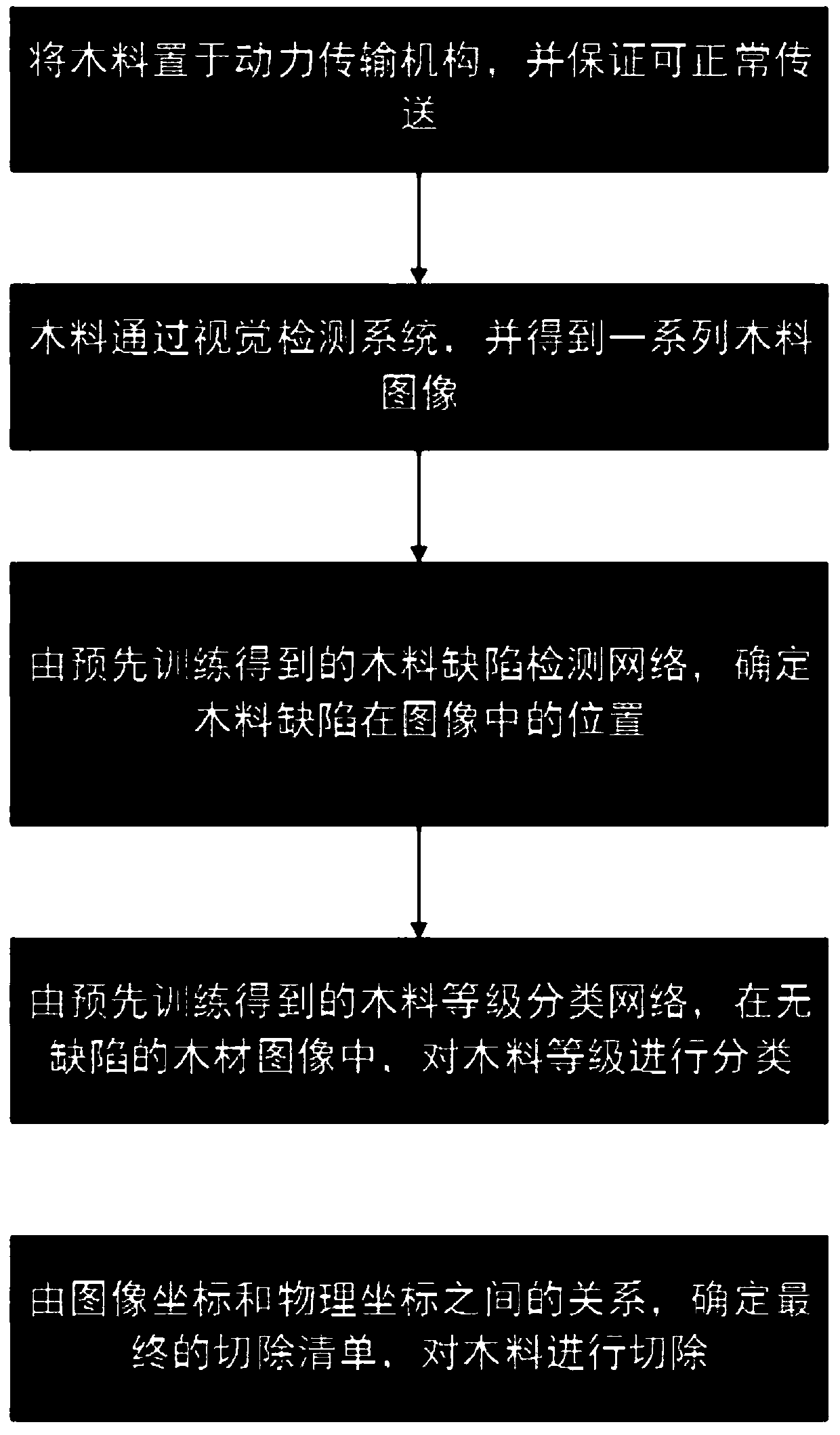

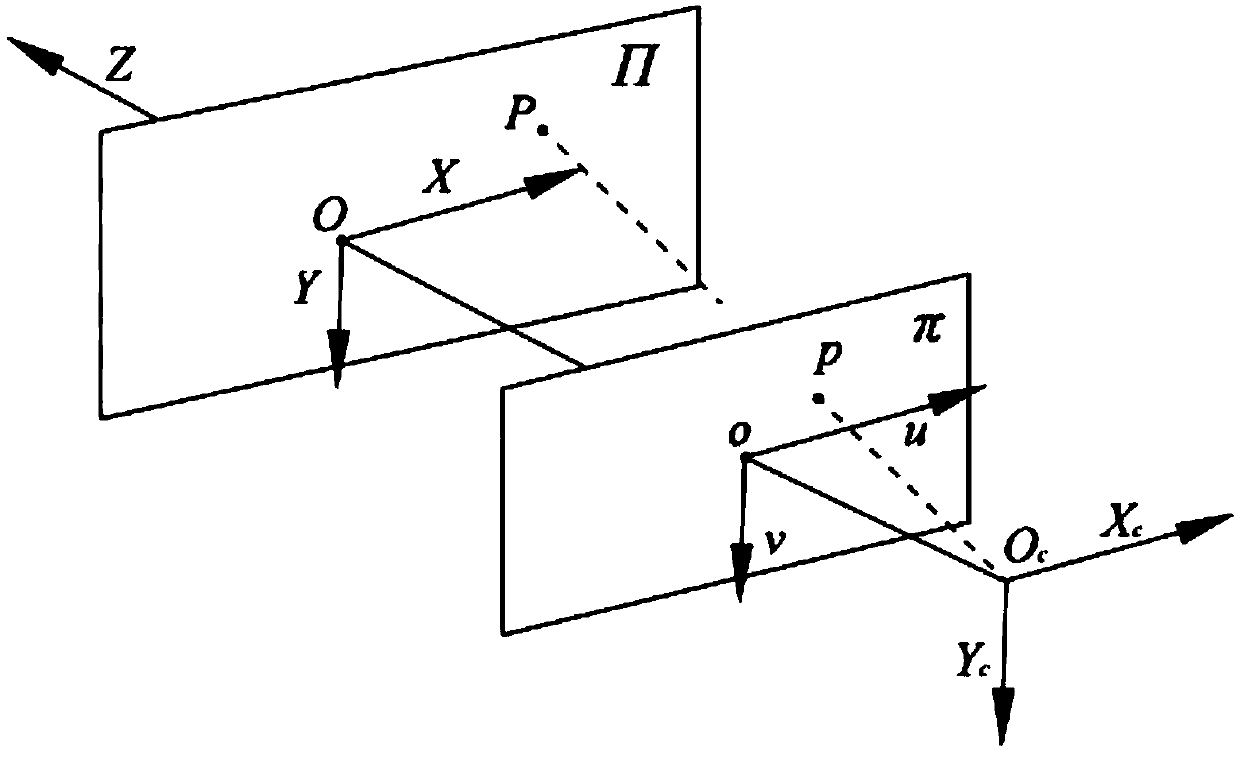

Intelligent detection method for wood optimizing cut-off saw based on deep learning

InactiveCN109557104AImprove processing efficiencyIncrease the level of automationOptically investigating flaws/contaminationNeural architecturesFault toleranceImaging processing

Owner:临沂众为智能科技有限公司 +2

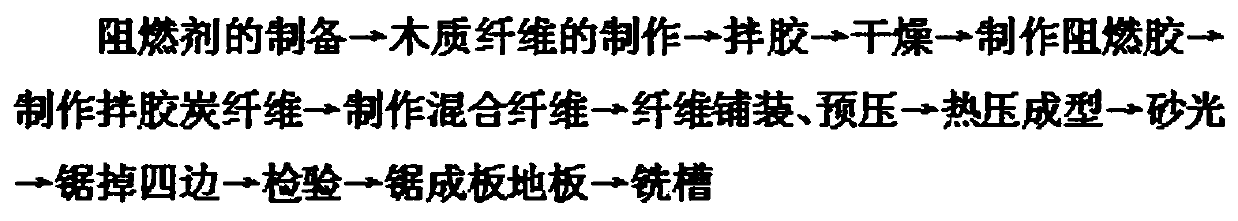

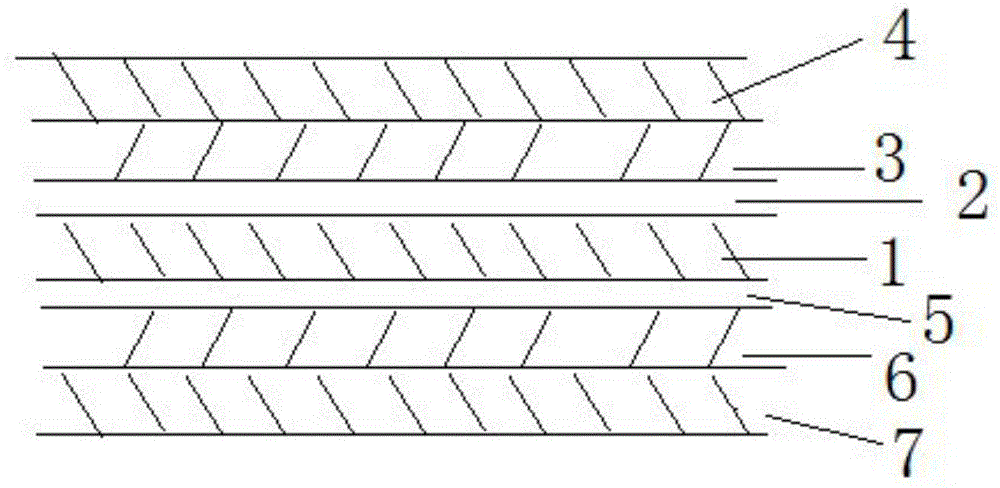

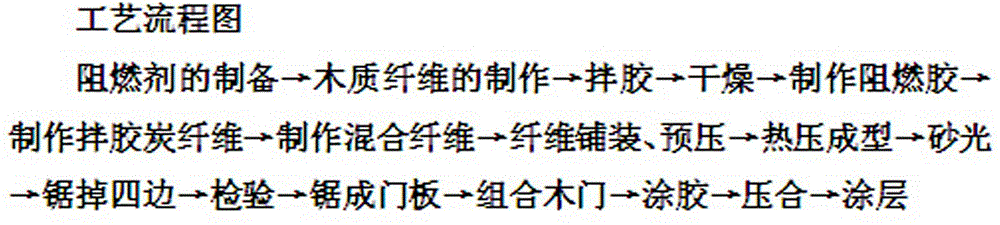

Manufacturing method for environment-friendly energy-saving fireproof antimagnetic and antistatic floor

The invention discloses a manufacturing method for an environment-friendly energy-saving fireproof antimagnetic and antistatic floor. The method comprises the steps that fire retardants, wood fibers, carbon fibers, urea-formaldehyde glue, waterproofing agent of paraffin, chemical addition agents and the like are adopted, and an environment-friendly energy-saving fireproof anti-magnetic-radiation and antistatic density board is formed at a time through high temperature and high pressure after preparation of the fire retardants, fiber glue mixing and layered pavement. The method has the advantages that 1, the mechanical property is improved; 2, the good fireproof performance is achieved and meets the standard of the level B or the level C of GB8264; 3, the anti-electromagnetic, anti-radiation, antistatic and electric conduction functions are achieved; 4, the formaldehyde emission is lower than the national standard; 5, sufficient reuse of three-remains waste wood of forests and industrial waste-grade carbon fibers is achieved, the waste material is changed into the things of value, a large number of forest resources are saved, the cost is reduced, and the environment is protected effectively.

Owner:HARBIN SHENGSHI HUALIN TECH

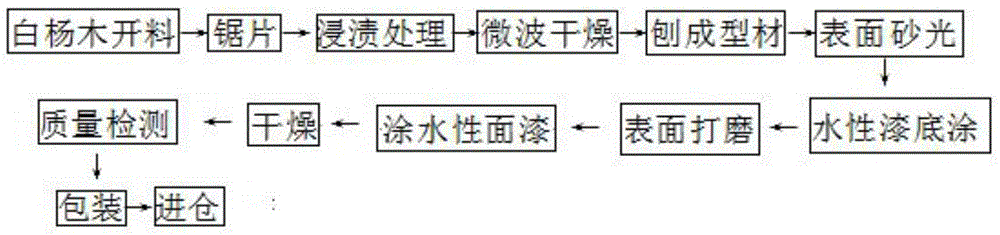

White poplar wood frame strip and manufacturing method thereof

InactiveCN104924372AGood physical and mechanical propertiesHigh densityRadiation/waves wood treatmentSynthetic resin layered productsPulp and paper industryWater soluble

The invention provides a white poplar wood frame strip and a manufacturing method thereof. The manufacturing method comprises the following steps: adopting a water-soluble impregnant, uniformly spraying or soaking an impregnation liquid on a white poplar wood sheet subjected to cutting and sawing to carry out impregnation treatment; carrying out microwave drying on the impregnated white poplar wood sheet; and carrying out section bar processing on the white poplar wood sheet by a planing machine. The white poplar wood frame strip which takes white poplar as a basic raw material is green and environmentally-friendly, low-carbon and attractive, novel and practical, and nationally initiative, so that fast-growing white poplar man-made forest in China becomes the main theme of raw materials in wood industry, and a strong industrial chain of research and development, production, marketing and export is realized. Due contribution is made for new normal development and sustainable development of Chinese economy.

Owner:付成永

Method for extracting squalene by treating eucalyptus urophylla with complex enzyme method

InactiveCN103664461AReduce usageExtend the industrial chainHydrocarbon purification/separationHydrocarbonsPapermakingWood industry

The invention discloses a method of treating eucalyptus urophylla to extract squalene by a complex enzyme method. The method comprises the following steps: (1), preparing materials; (2), carrying out complex enzyme treatment; (3), extracting; (4), carrying out molecular distillation; and (5), collecting squalene. The method disclosed by the invention has the advantages that usage amount of a solvent can be reduced, extracting and separating steps are simpler and industrial production needs are satisfied; and meanwhile, an industry chain of the wood industry and papermaking-pulping can be prolonged, and economic value of the eucalyptus urophylla is improved.

Owner:WUHAN SHUTAI TECH

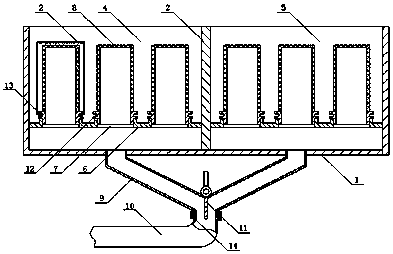

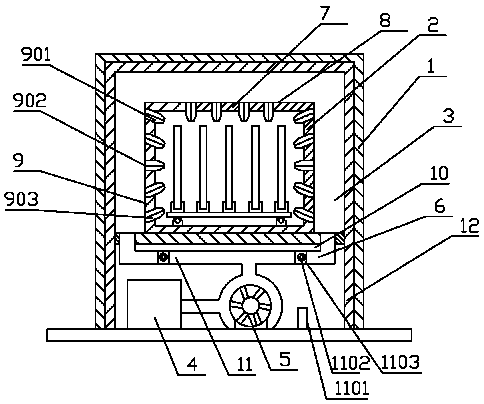

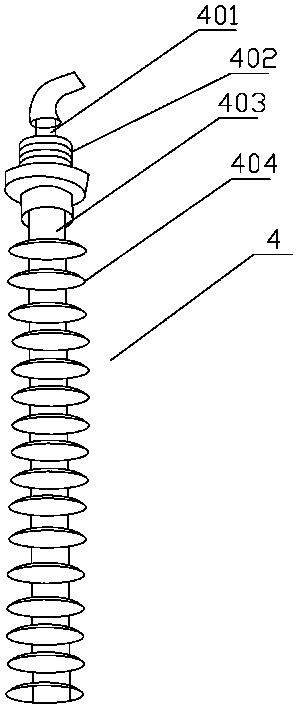

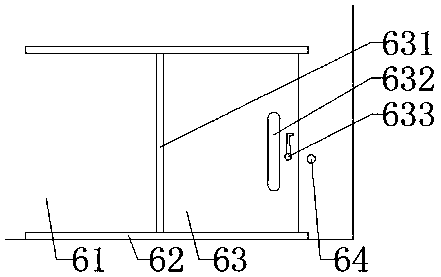

Bag dust collecting tank for wood industry

InactiveCN107648946ASimple structureReasonable designDispersed particle filtrationEngineeringMechanical engineering

A cloth bag dust removal box for wood industry according to the present invention belongs to the field of dust removal, and includes a box body and a dust removal bag. The chamber, the left chamber and the lower part of the right chamber are fixed with horizontal plates, and the horizontal plates are evenly distributed with circular sockets, and the circular cages with bottom openings are inserted and installed on the circular sockets. The cages are covered with dust-removing cloth bags, and the bottoms of the left chamber and the right chamber are provided with branches connected to the main pipe, and switching paddles are provided at the triangular connection between the branch road and the main pipe. A cloth bag dedusting box for wood industry of the present invention has the characteristics of simple structure, reasonable design, convenient use, can replace the cloth bag in the process of use, does not affect the continuity of dust removal work, etc., and divides the dedusting box into two separate Each chamber works alternately, and the dust bag in the other chamber can be removed for cleaning while one chamber is working.

Owner:湖州市新庭吉家居科技有限公司

Water glue powder for wood industry, and production method for water glue powder

InactiveCN105062382ALow costEasy to transportMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPolyvinyl acetatePolyvinyl alcohol

The invention discloses a water glue powder for the wood industry, and a production method for the water glue powder. The water glue powder can completely replace glue and a filling material which are used in a plywood production process. The water glue powder is a solid powder, and can be directly used after being uniformly mixed with water of which the weight is twice of that of the water glue powder, without adding other filling materials; the water glue powder is low in manufacturing cost, environment-friendly, long in shelf life and easy to transport, and is prepared from the following components in parts by weight: 8-20 parts of polyvinyl acetate, 20-30 parts of starch, 0.01-0.05 part of an antioxidant, 2-5 parts of stearic acid, 5 parts of melamine, 10 parts of polyvinyl alcohol, 15-25 parts of oxidized starch, 0.5 part of borax and 7-15 parts of attapulgite.

Owner:HUAIAN ZHENNONG HIGH POLYMER MATERIALS CO LTD

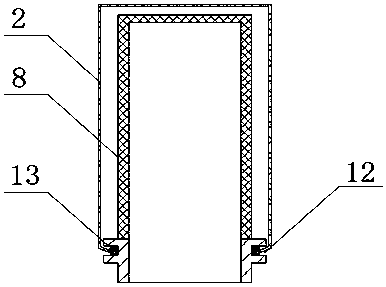

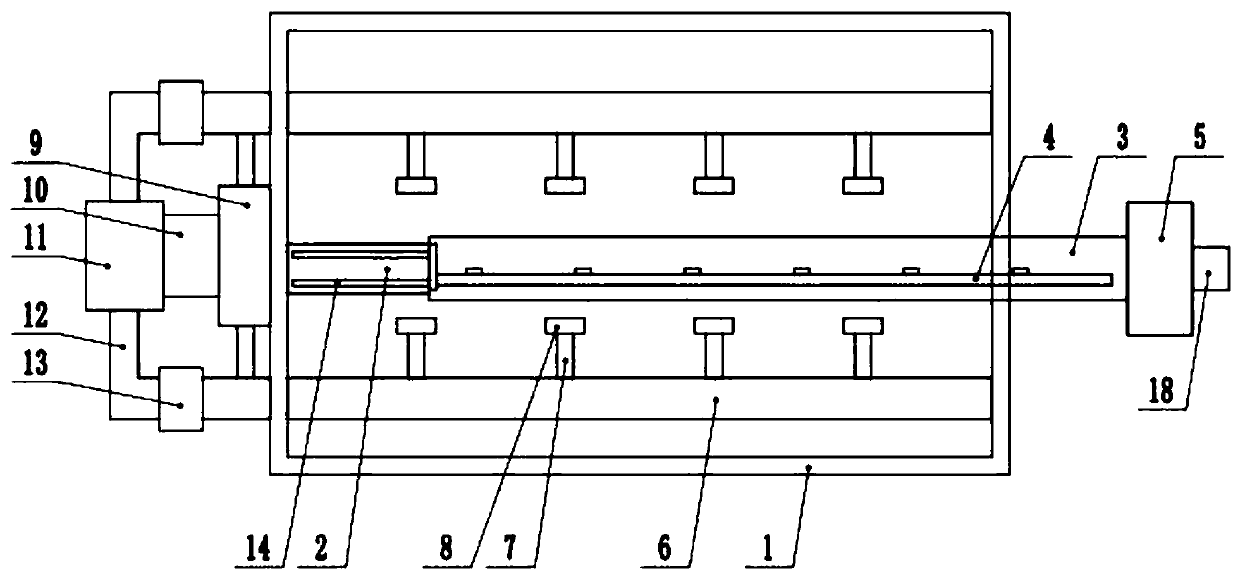

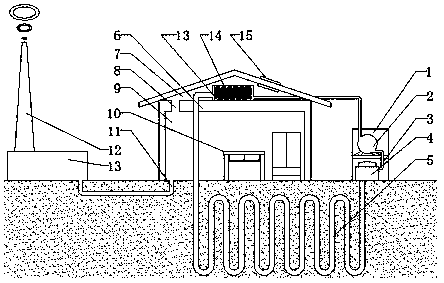

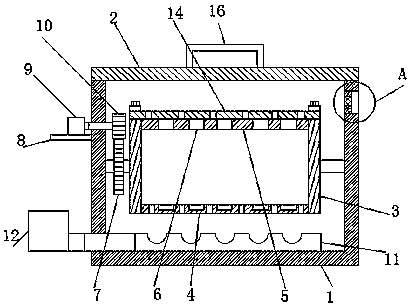

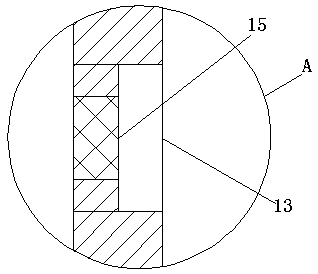

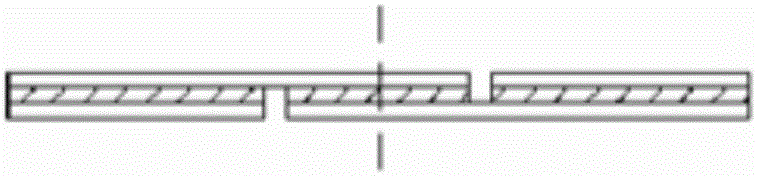

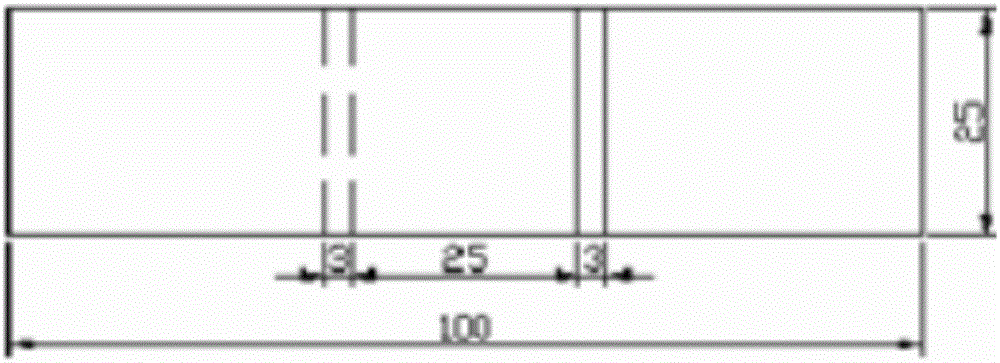

Panel drying device for wood industry

PendingCN108344260AWill not emitImprove drying effectDrying gas arrangementsDrying chambers/containersHigh resistanceElectrical resistance and conductance

The invention belongs to the technical field of wood industry processing, in particular to a panel drying device for wood industry. The panel drying device for wood industry comprises an outer room body, an inner room body and a hot air circulating system, wherein a hot air flowing space is formed between the inner room body and the outer room body; the hot air circulating system comprises a stainless steel heating tube with a fin, a fan and an air duct; the stainless steel heating tube is arranged on the inner side of the outer room body; the stainless steel heating tube with the fin is composed of a high resistance electric heating alloy wire, a connecting screw, an electric heating tube and a heat-dissipating fin; the high resistance electric heating alloy wire is arranged on the uppersurface of the connecting screw; the connecting screw is connected to the electric heating tube; the electric heating tube is arranged in the heat-dissipating fin; and an air guide tube unit for guiding hot air into the inner room body to dry panels is arranged on the inner room body. By generating and introducing hot air to the hot air flowing space by means of the hot air circulating system to dry the panels placed in the inner room body all around, the panel drying device for wood industry is good in drying effect and high in work efficiency. The electric heating efficiency is high by adopting the stainless steel heating tube with the fin.

Owner:浙江浔园家居股份有限公司

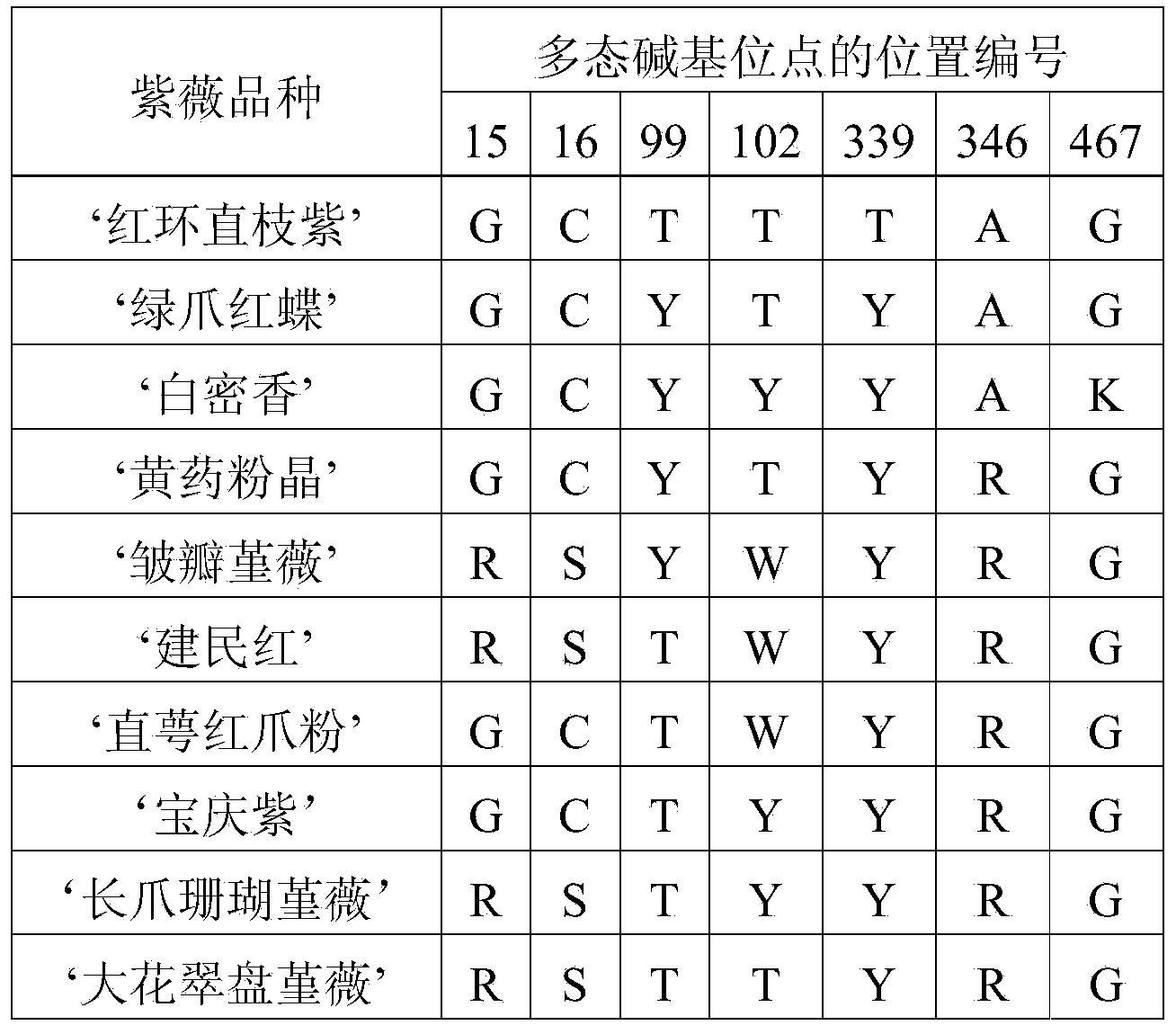

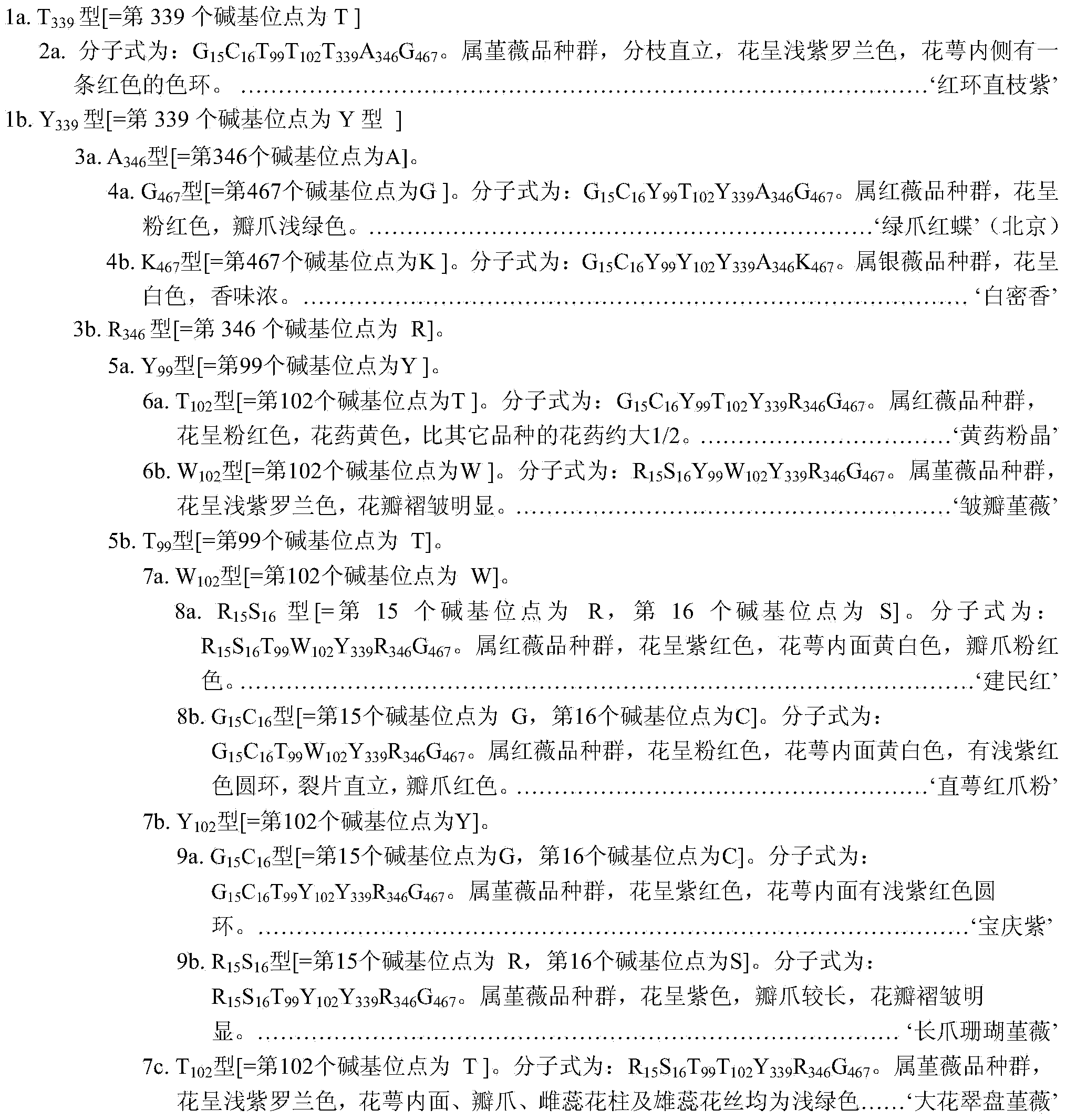

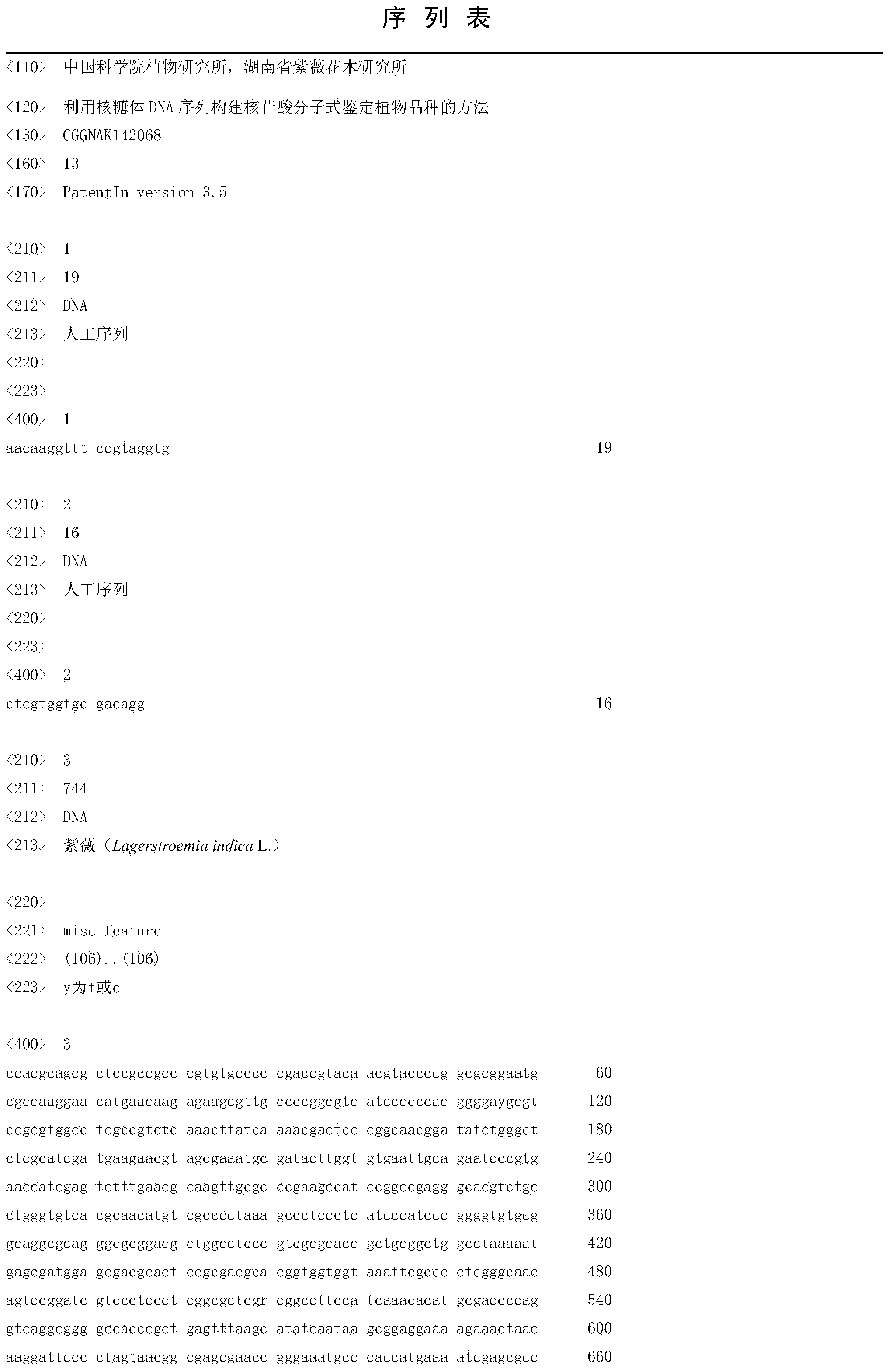

Method for building nucleotide formula to identify plant variety by using ribosome deoxyribonucleic acid (DNA)

InactiveCN103757114ASpeed up breedingIncrease productivityMicrobiological testing/measurementRibosomal DNASingle strand dna

The invention discloses a method for identifying plant variety, and provides a method for identifying crape myrtle variety. The method comprises the following steps: 1) carrying out polymerase chain reaction (PCR) amplification by taking a genome deoxyribonucleic acid (DNA) of to-be-detected crape myrtle as a template and using a primer composed of two single-chain DNA molecules shown in a sequence 1 and a sequence 2, so as to obtain a PCR product; 2) sequencing the PCR product, and listing the nucleotide formulas of the to-be-detected crape myrtle according to the sequencing result; 3) comparing the nucleotide formulas obtained in the step 2) with corresponding nucleotide formulas of a plurality of crape myrtle varieties, so as to determine the variety of the to-be-detected crape myrtle. An experiment proves that the method is accurate, and simple and fast to operate, the production efficiency and the quality monitoring level of related enterprises can be improved, and the defects of the traditional method are effectively compensated. In addition, identification of a non-flowering phase (for example, a seedling stage) is simultaneously achieved. The method has important significance on facilitation of development of new variety breeding of the crape myrtle, crape myrtle flower and wood industries and urban garden greening, and environmental protection.

Owner:INST OF BOTANY CHINESE ACAD OF SCI +1

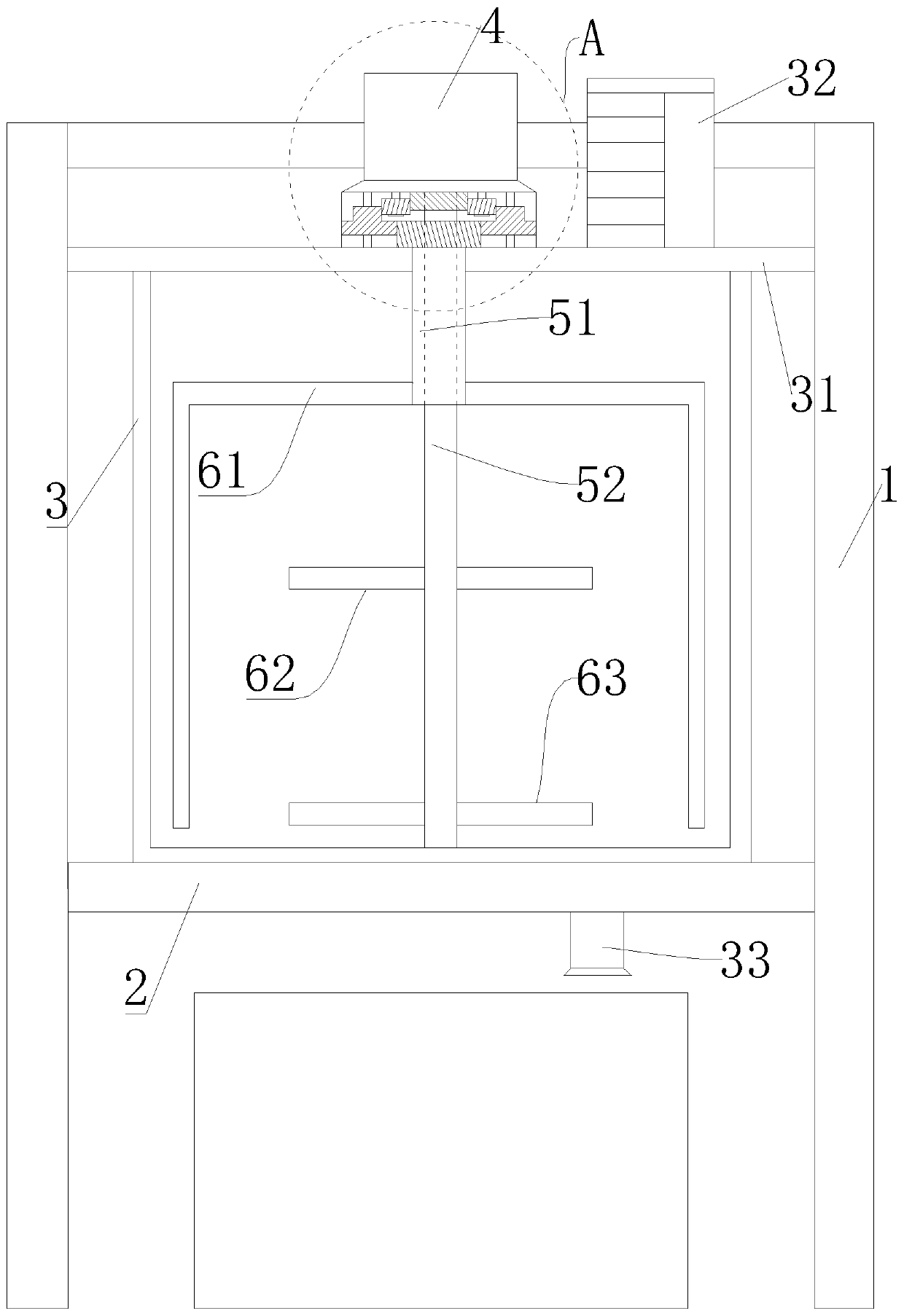

Wood industry plate drying device

InactiveCN110686469AEasy to moveAchieve recyclingDrying solid materials without heatDrying gas arrangementsHot blastMechanical engineering

The invention discloses a wood industry plate drying device, and relates to the technical field of wood industry processing. The device comprises a drying box, wherein a drying mechanism and a plate placing mechanism are arranged in the drying box, and a circulation drying mechanism is arranged outside the drying box; the plate placing mechanism comprises fixed side plates fixedly arranged on thetwo sides of the interior of the drying box, and a placement rack is arranged between the two fixed side plates; sliding side plates are fixedly connected to the two sides of the placement rack, and the end parts of the sliding side plates are fixedly connected with an end plate; and the drying mechanism comprises an air return pipe and a hot air pipe arranged in the drying box, and the end part of the hot air pipe is fixedly provided with an air exhaust head. According to the drying device, the wood industry board can be conveniently moved into the drying box through arranging the plate placing mechanism, the plate can be dried through arranging the drying mechanism, and wet hot air in the drying box can be dried through arranging the drying device, so that cyclic utilization of the hotair is achieved, and the energy saving performance is high.

Owner:江苏傲森博林家具有限公司

Method for producing urea formaldehyde resin adhesive

InactiveCN102190997ALow costSimple production processMonocarboxylic acid ester polymer adhesivesAldehyde/ketone condensation polymer adhesivesAluminium hydroxideFragility

The invention relates to a method for producing a urea formaldehyde resin adhesive. The product produced by the method is a main adhesive used in wood industries at home and abroad and can be used for adhering plate materials, veneers and building decorative plates. The urea formaldehyde resin adhesive has the advantages of no color or oyster white color, high curing speed, high transparency, high operability, rich and readily available raw materials, no pollution to the surfaces of wood materials and simple production process. The urea formaldehyde resin adhesive has the defects of high fragility, lower water resistance and adhesive strength compared with those of phenolic resin and low durability. In the method, the defects are shrunk to minimum and the advantages are maintained by a certain process. The urea formaldehyde resin adhesive is prepared from the raw materials such as liquid urea formaldehyde resin with content of 60 percent, polyhexenyl acetate, ammonium sulfate, wood powder, melamine glue formaldehyde resin, aluminium hydroxide and formaldehyde.

Owner:段全义

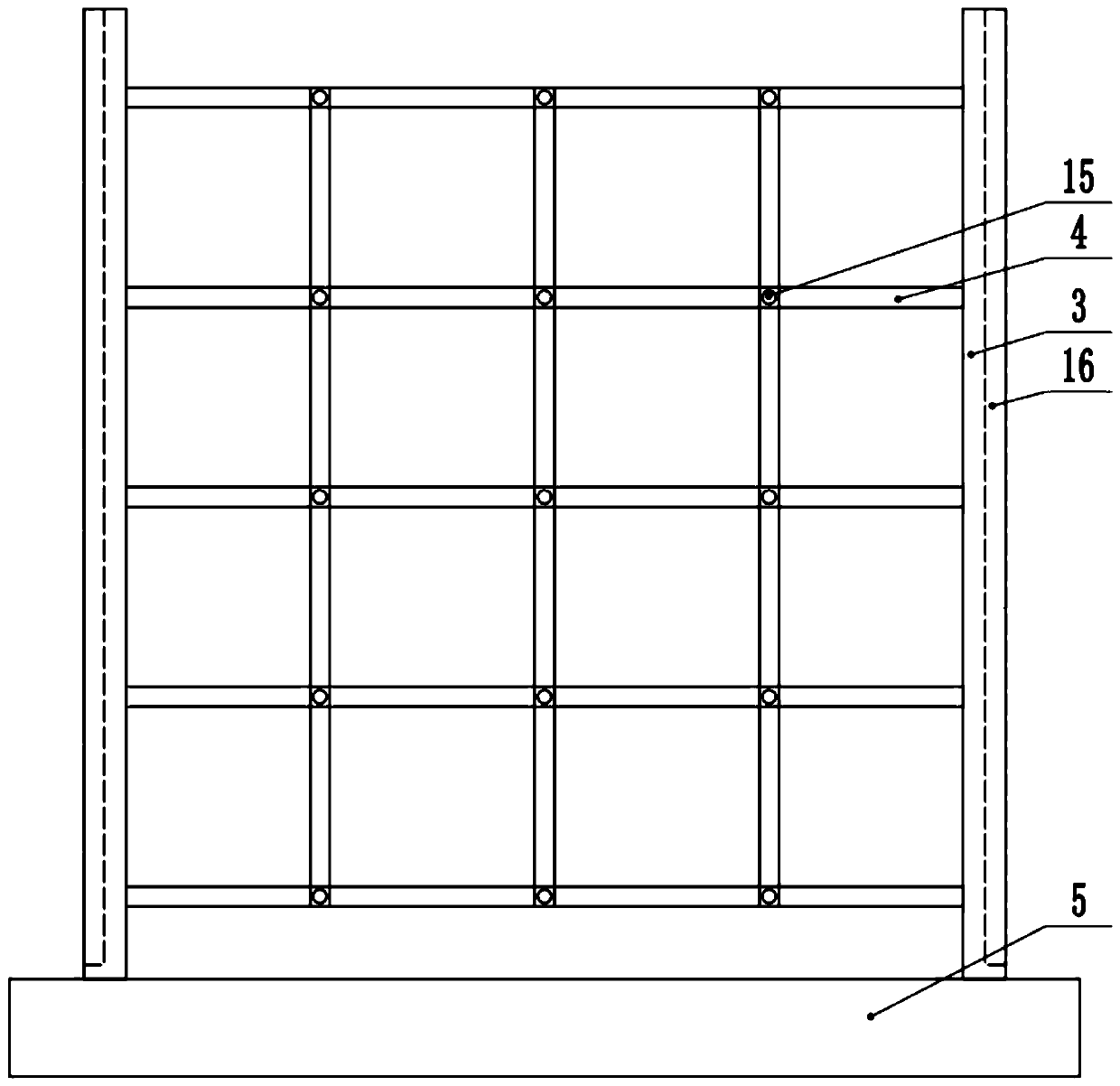

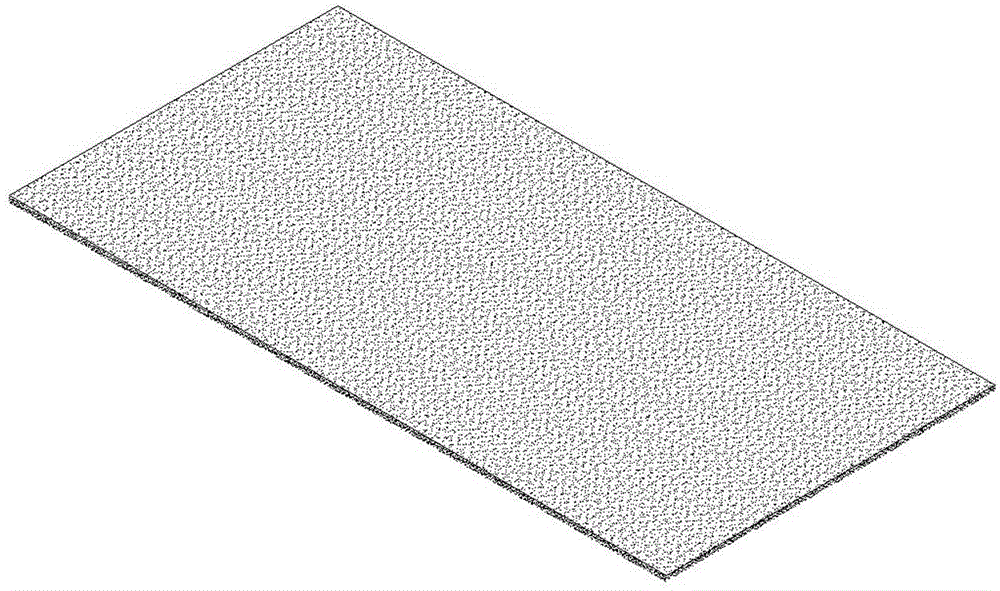

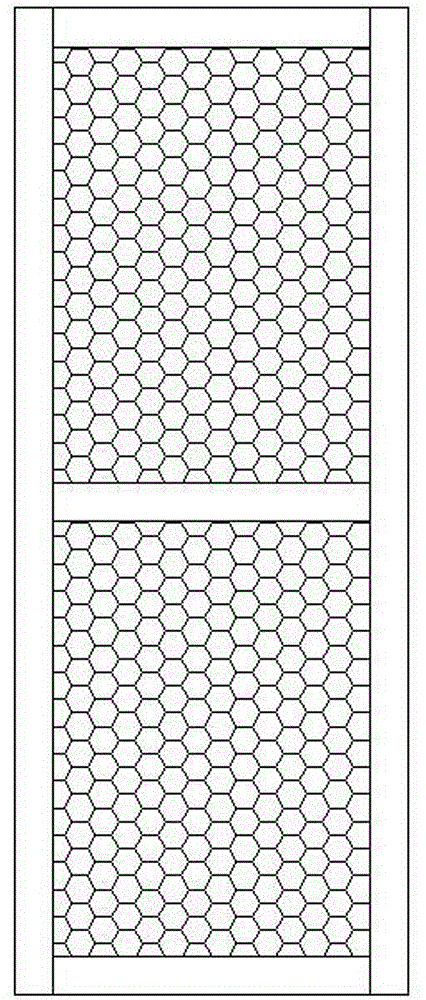

Manufacturing method for environment-friendly energy-saving fireproof anti-electromagnetic radiation composite door

InactiveCN105328755AFull reuseSave resourcesFlat articlesDomestic articlesElectromagnetic radiationFire retardant

The invention discloses a manufacturing method for an environment-friendly energy-saving fireproof anti-electromagnetic radiation composite door. The method comprises the steps that fire retardants, wood fibers, carbon fibers, urea-formaldehyde glue, waterproofing agent of paraffin, chemical addition agents and the like are adopted, and an environment-friendly energy-saving fireproof anti-electromagnetic radiation antistatic density board is formed at a time through high temperature and high pressure after preparation of the fire retardants, fiber glue mixing and layered pavement. The method has the beneficial effects that 1, the mechanical property is improved; 2, the good fireproof performance is achieved and meets the standard of the level B or the level C of GB8264; 3, the anti-electromagnetic radiation antistatic and electric conduction functions are achieved; 4, the formaldehyde emission is lower than the national standard; 5, sufficient reuse of three-remains waste wood of forests and industrial waste-grade carbon fibers is achieved, the waste material is changed into the things of value, a large number of forest resources are saved, the cost is reduced, and the environment is protected effectively.

Owner:HARBIN SHENGSHI HUALIN TECH

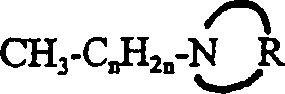

Microbicidal compositions and methods using combinations of propiconazole and N-alkyl heterocycles and salts thereof

InactiveCN1374834AAvoid attackEasy to controlBiocideDead animal preservationBiotechnologyLeather industry

An improved microbicide propiconazole, (RS)-1-[2-(2,4-dichlorophenyl)-4-propyl-1,3-dioxolane-2-ylmethyl] -1H-Method of microbicidal efficacy of 1,2,4-triazole. In this method, propiconazole and a synergist, an N-alkyl heterocyclic compound, a salt thereof or a mixture thereof, are applied to a matrix or aqueous system that is prone to microorganisms. The dosage of N-alkyl heterocyclic compound, its salt or its mixture can effectively improve the microbicidal activity of the microbicide. N-alkyl heterocyclic compounds have the structure of formula (I), CH3-CnH2n- (I), where the parameter n is 5-17, and the heterocyclic ring defined as (II) is a substituted or unsubstituted 4-8 membered ring. The present invention describes microbicidal compositions wherein propiconazole and an N-alkyl heterocyclic compound, a salt thereof, or a mixture thereof are present in a total amount effective to control the growth of at least one microorganism. Methods of controlling microbial growth on various substrates and in various aqueous systems are also described. In the leather industry, wood industry, paper industry, textile industry, agricultural industry, coating industry and industrial process water, the microbicidal composition of propiconazole and N-alkyl heterocyclic compounds, their salts or their mixtures is particularly useful. Microbicides.

Owner:BUCKMAN LAB INT INC

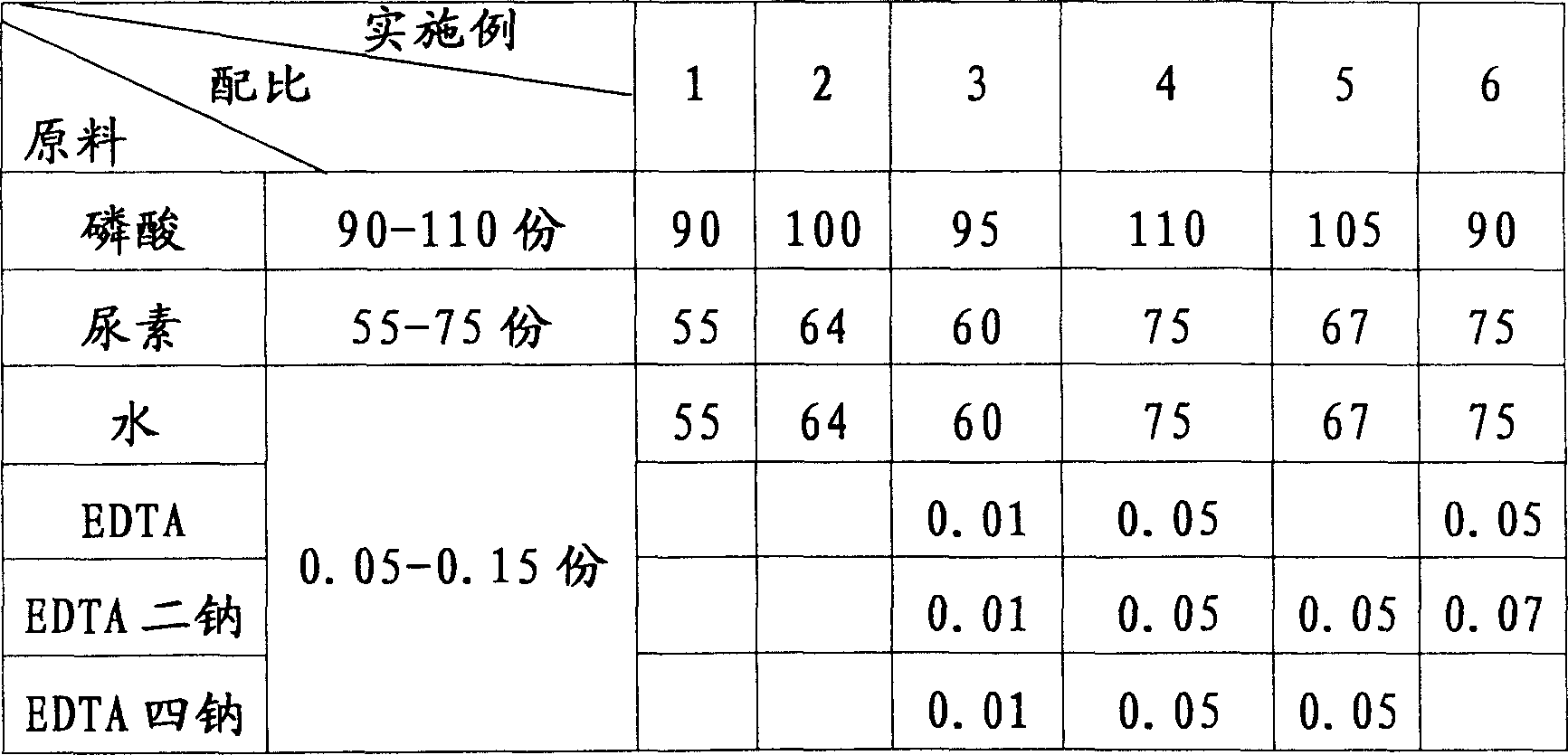

Free formaldehyde trapping agent and process for preparing same

A method for production of free formaldehyde catching agent is characterized in that it consists of the following raw materials and parts by weight: 90-110 parts of phosphorus acid, 55-75 parts of carbamide, 55-75 parts of water and 0.05-0.15 parts of catalyst; its process flow comprises first adding the total phosphorus acid and the total carbamide prepared into the autoclave, stirring, then adding the catalyst and water of the same parts by weight as the carbamide simultaneously, heating to 120-130 DEG C, preserving heat, when PH arrives at 6.0-6.5, naturally cooling to less than 40 DEG C, then obtaining the target product by adjusting PH to 7.0-7.5 with ammonia. The catching agent obtained by this method can be widely used in production that needs urea formaldehyde condensate glue such as timber industry, and it is excellent in that its raw materials are easy to get, its process is simple, its cost is low and its elimination factor for aldehyde is high.

Owner:ZHEJIANG FORESTRY UNIVERSITY

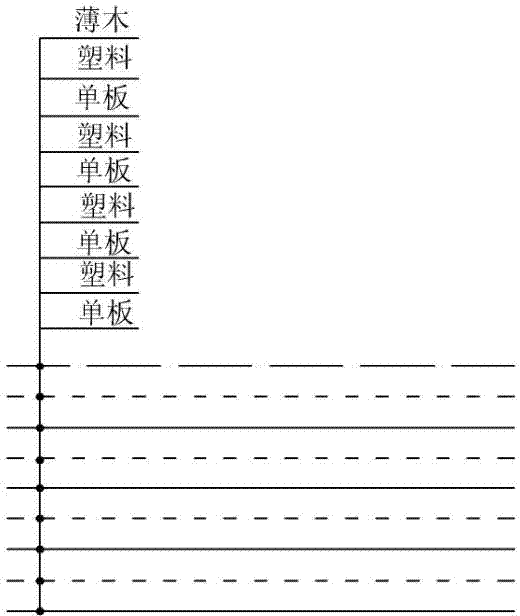

China fir dense furniture profile and processing method

InactiveCN105397876AGuarantee friendlinessSolve pollutionWood treatment detailsWood veneer joiningMaterials preparationAdhesive

The invention belongs to the technical field of base material preparation of wood processing and furniture production, and particularly relates to a China fir dense furniture profile and a processing method. A plastic film replaces an adhesive to prepare the dense furniture profile; the thickness of China fir sheets is 8-12 mm, the width is selected according to the specification of the furniture profile, and the sheets are subjected to microwave softening treatment, then assembled to be put into a home-made pressurization mold and pressurized and glued into the dense furniture profile under the certain hot-pressing conditions. The processing method ensures that the base material is free of aldehyde and environmentally friendly, and the processing method is a processing technology capable of efficiently improving the additional value of middle cutting wood of fast-growing China firs. The consumption concepts of environmental protection, safety and health in the current wood industry and furniture industry are met, and the application fields are wide.

Owner:FUJIAN AGRI & FORESTRY UNIV

High-temperature curing type esterified modified tapioca starch adhesive and preparation method thereof

ActiveCN106590468BImprove performanceHigh bonding strengthNon-macromolecular adhesive additivesStarch derivtive adhesivesAdhesiveUltraviolet lights

The invention provides a high-temperature cured type esterification modified cassava starch adhesive and a preparation method thereof and belongs to the technical field of adhesive preparation. At present, raw materials of adhesives generally used in the wood industry are non-renewable. The high-temperature cured type esterification modified cassava starch adhesive is mainly prepared from, by weight, 80-100 parts of modified cassava starch adhesive, 7-12 parts of isocyanate, 0.5-1.5 parts of antioxygen, 0.5-2 parts of flame retardant, 0.02-0.2 part of light stabilizer and 0.5-1 part of ultraviolet light absorber, wherein the modified cassava starch adhesive comprises cassava starch, polyvinyl alcohol, sodium dodecyl sulfate and dodecenyl succinic anhydride. The high-temperature cured type esterification modified cassava starch adhesive is moderate in viscosity, stable in storing and slow in layering. The preparation process is simple and easy to operate. The consumed time is short. The high-temperature cured type esterification modified cassava starch adhesive is excellent in water resistant performance and bonding strength, and industrial production is likely to be realized.

Owner:NORTHEAST FORESTRY UNIVERSITY

Efficient wood industry board drying device

InactiveCN109341255AImprove drying efficiencyDry comprehensiveDrying gas arrangementsDrying chambers/containersEngineeringWood industry

The invention discloses an efficient wood industry board drying device. The efficient wood industry board drying device comprises a top-opened drying box, the top of the drying box is rotationally connected with a box cover matched with the opening of the drying box through hinges, the two opposite inner side walls of the drying box are rotationally connected with connecting plates through rotating shafts, the bottom ends of the side walls, close to each other, of the two connecting plates are jointly and fixedly connected with a first mesh plate, the top ends of the side walls, close to eachother, of the two connecting plates are jointly and fixedly connected with a limiting plate, a row of square holes which are uniformly distributed are formed in the top of the limiting plate, a row ofgrooves corresponding to the row of square holes are formed in the top of the first mesh plate, limiting mechanisms corresponding to the limiting plate are arranged at the tops of the two connectingplates, and a first straight gear fixedly sleeves the outer side wall of one rotating shaft. According to the efficient wood industry board drying device, a wood industry board needing to be dried isrotated by 360 degrees so that the wood industry board can be more comprehensively dried by hot air, and then the drying efficiency of the wood industry board is greatly improved.

Owner:柳州市恒茂木业有限公司

Novel adhesive for wood industry

ActiveCN104277751AImprove adhesionNot easy to fall offNon-macromolecular adhesive additivesMacromolecular adhesive additivesPotassium persulfateEpoxy

The invention discloses a novel adhesive for wood industry. The adhesive is prepared from the following components in parts by weight: 2-3 parts of sodium hexametaphosphate, 3-4 parts of polyether polyol, 1-2 parts of aluminic acid ester, 5-6 parts of sodium hexametaphosphate, 4-5 parts of hydroxyethyl saponin gum, 1-2 parts of dibutyl phthalate, 2-3 parts of potassium persulfate, 2-3 parts of caprolactam, 6-7 parts of an epoxy resin emulsion and 2-3 parts of a penetrant JFC. The novel adhesive for wood industry disclosed by the invention is strong in adhesive force, difficult to fall, easily available in raw materials and good in weather resistance.

Owner:珠海鼎力工贸有限公司

High-temperature cured type esterification modified cassava starch adhesive and preparation method thereof

ActiveCN106590468AImprove performanceIncrease responsivenessNon-macromolecular adhesive additivesStarch derivtive adhesivesAdhesiveUltraviolet lights

The invention provides a high-temperature cured type esterification modified cassava starch adhesive and a preparation method thereof and belongs to the technical field of adhesive preparation. At present, raw materials of adhesives generally used in the wood industry are non-renewable. The high-temperature cured type esterification modified cassava starch adhesive is mainly prepared from, by weight, 80-100 parts of modified cassava starch adhesive, 7-12 parts of isocyanate, 0.5-1.5 parts of antioxygen, 0.5-2 parts of flame retardant, 0.02-0.2 part of light stabilizer and 0.5-1 part of ultraviolet light absorber, wherein the modified cassava starch adhesive comprises cassava starch, polyvinyl alcohol, sodium dodecyl sulfate and dodecenyl succinic anhydride. The high-temperature cured type esterification modified cassava starch adhesive is moderate in viscosity, stable in storing and slow in layering. The preparation process is simple and easy to operate. The consumed time is short. The high-temperature cured type esterification modified cassava starch adhesive is excellent in water resistant performance and bonding strength, and industrial production is likely to be realized.

Owner:NORTHEAST FORESTRY UNIVERSITY

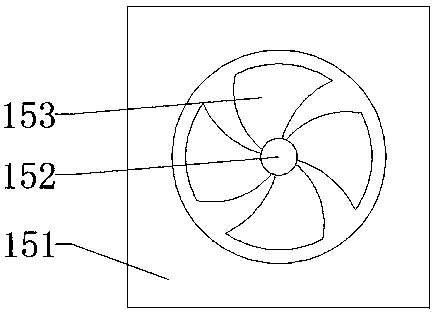

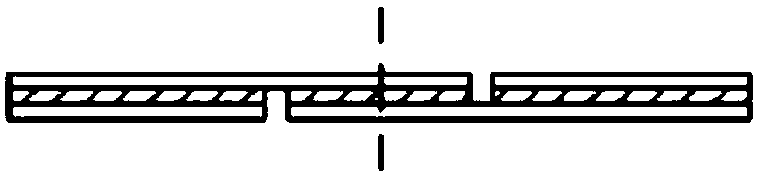

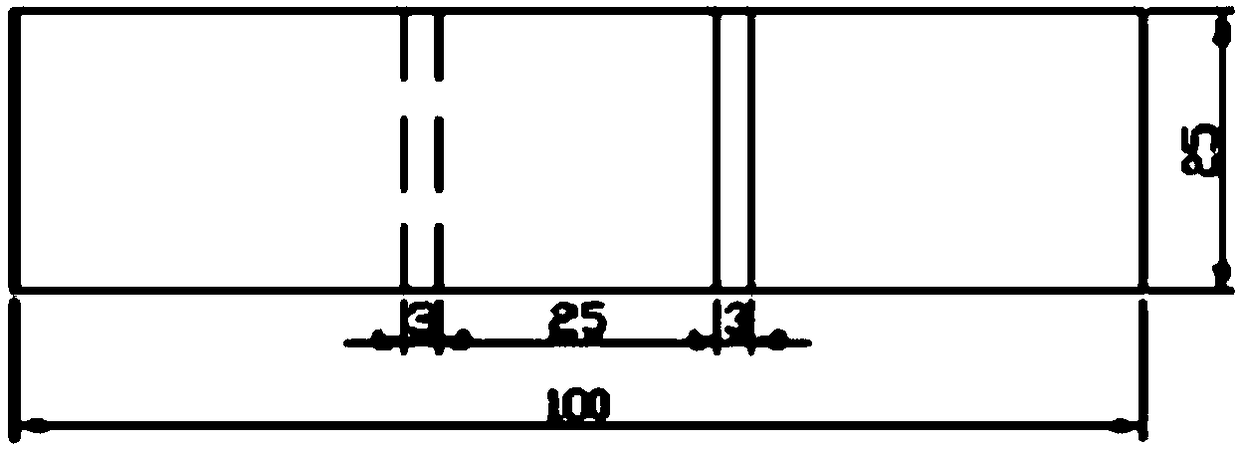

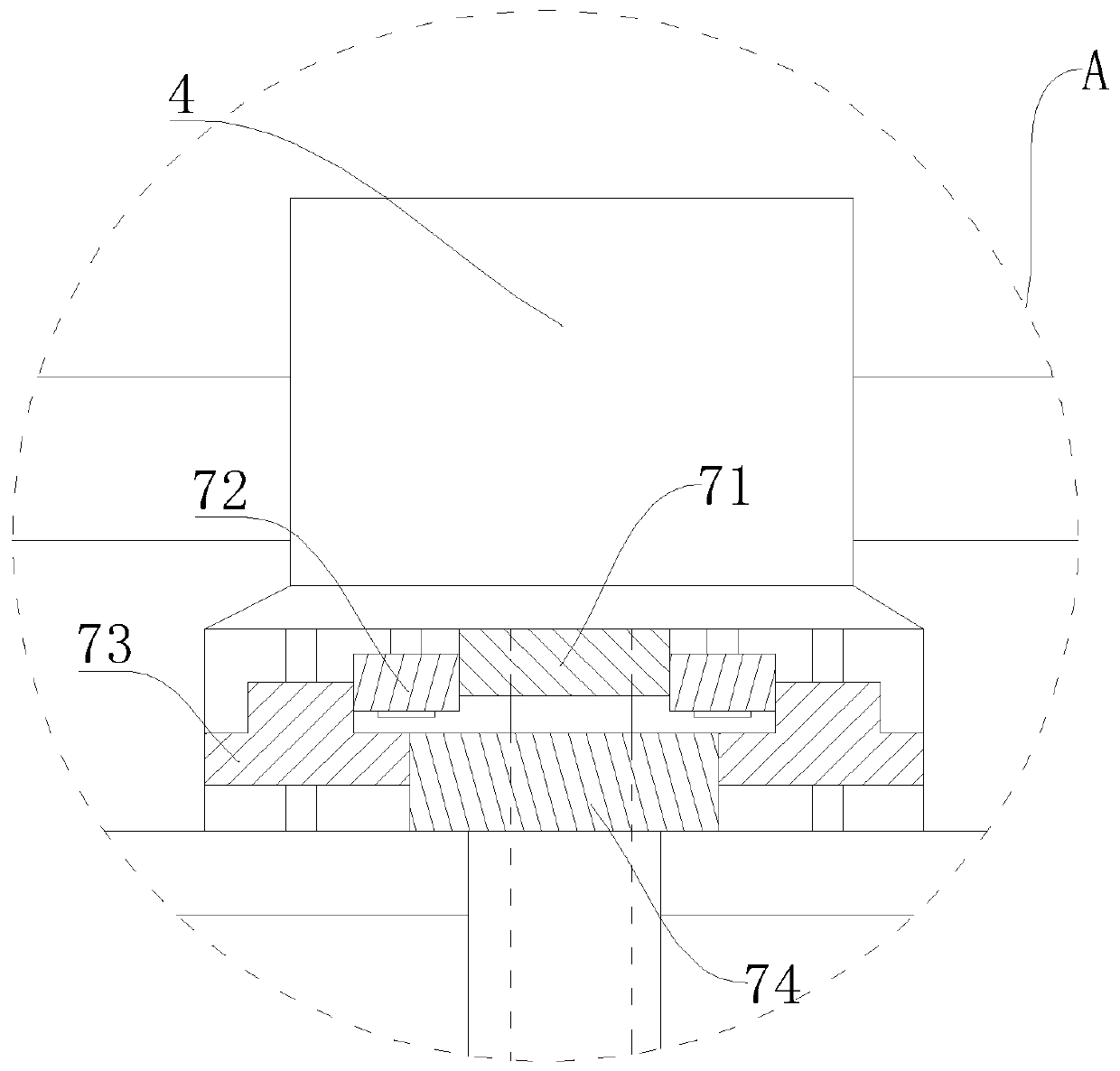

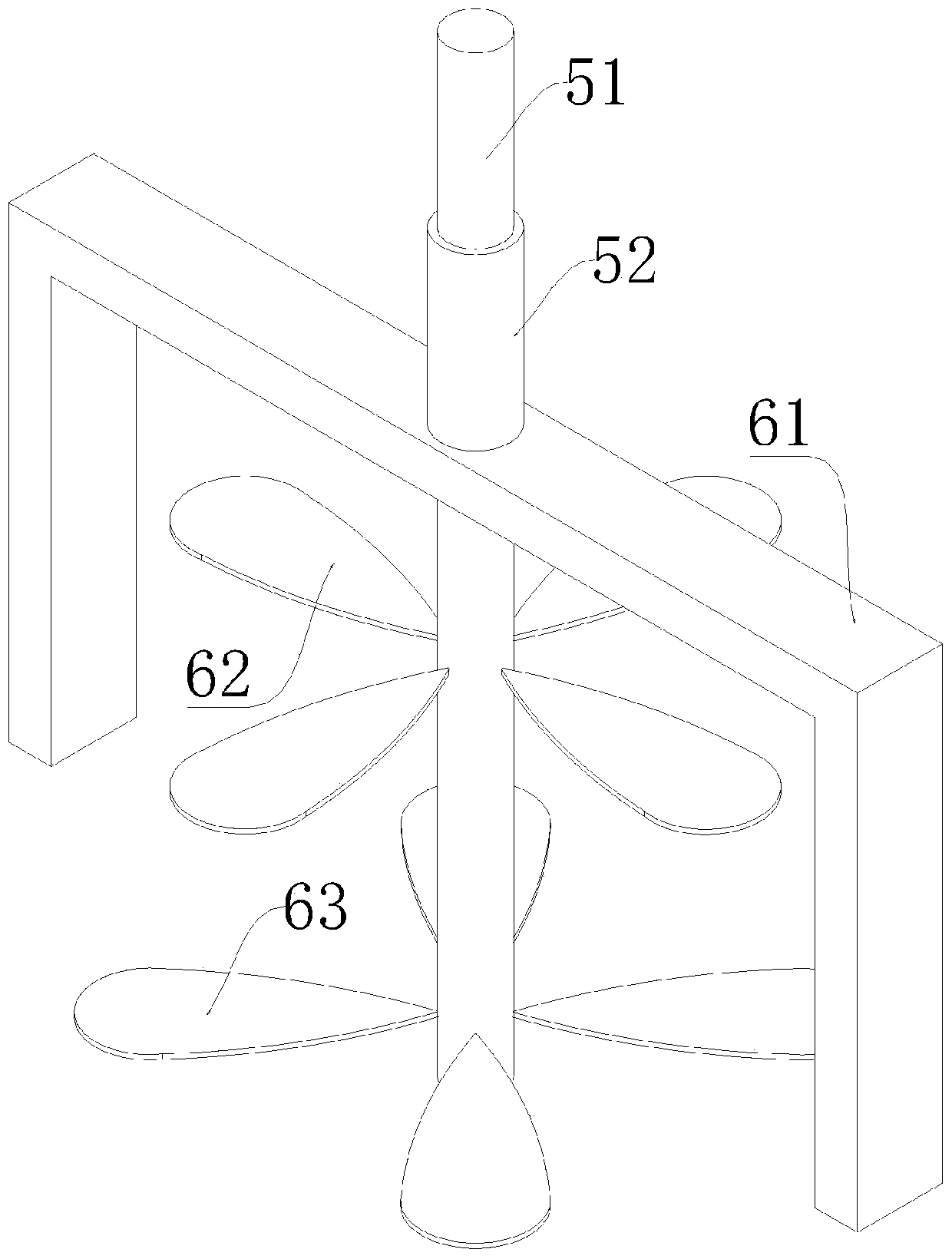

Bidirectional stirring device for wood industry glue

InactiveCN110813146AImprove stirring efficiencyNo partial oxidation due to prolonged stirringRotary stirring mixersTransportation and packagingAdhesive glueElectric machinery

The invention discloses a bidirectional stirring device for wood industry glue, wherein the bidirectional stirring device comprises a rack, and a support plate is arranged in the rack; a stirring barrel is arranged on the supporting plate, and a vertically-arranged motor is arranged in the center of the upper portion of the stirring barrel; a bidirectional gear mechanism is arranged below the motor and is connected with a first stirring rod; the first stirring rod is sleeved with a second stirring rod connected with the bidirectional gear mechanism; a first fan-shaped stirring blade and a second fan-shaped stirring blade are respectively arranged at the middle part and the lower end of the first stirring rod; inverted U-shaped stirring blades are arranged at the lower end of the second stirring rod; a barrel cover is arranged at the top of the stirring barrel; the bidirectional gear mechanism is mounted on the barrel cover; a feeding hopper is arranged on the barrel cover; a discharging pipe penetrating through the supporting plate is arranged below the stirring barrel; the second stirring rod is shorter than the first stirring rod. The bidirectional stirring device has the advantages that the stirring efficiency is relatively high, the stirring time is relatively short, and local oxidation of glue cannot be caused.

Owner:冯国防

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com