Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

513 results about "Destructive distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Destructive distillation is the chemical process of the decomposition of unprocessed material by heating it to a high temperature; the term generally applies to processing of organic material in the absence of air or in the presence of limited amounts of oxygen or other reagents, catalysts, or solvents, such as steam or phenols. It is an application of pyrolysis. The process breaks up or 'cracks' large molecules. Coke, coal gas, gas carbon, coal tar, ammonia liquor, and "coal oil" are examples of commercial products historically produced by the destructive distillation of coal.

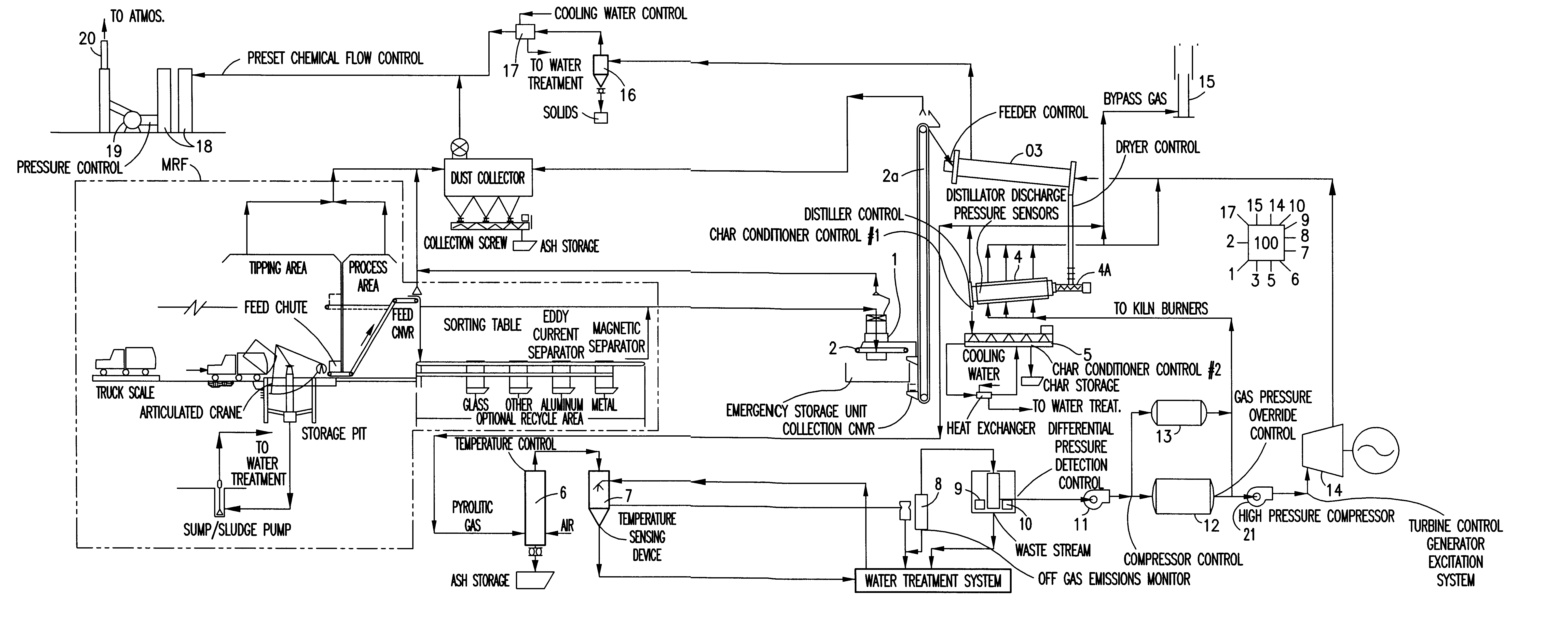

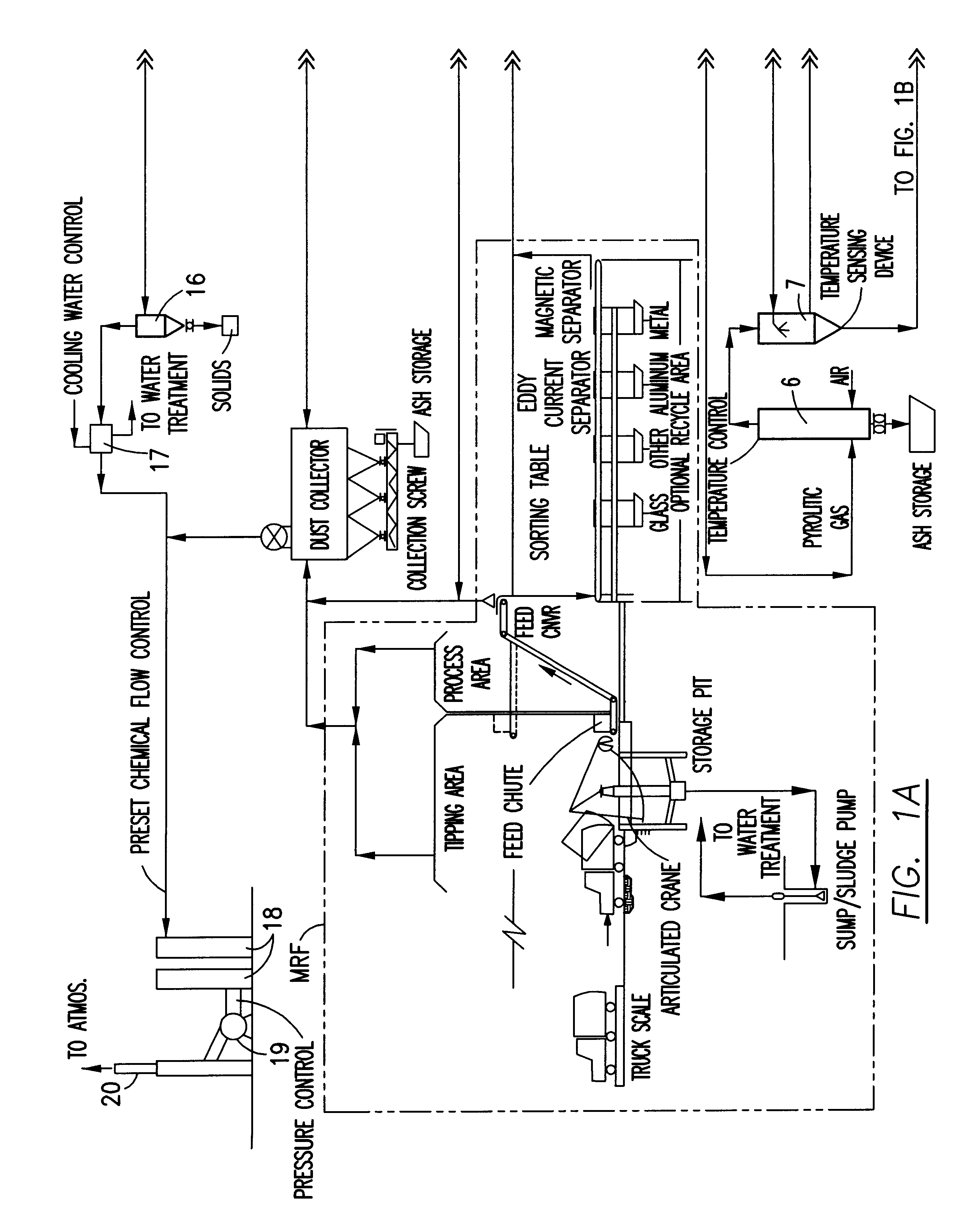

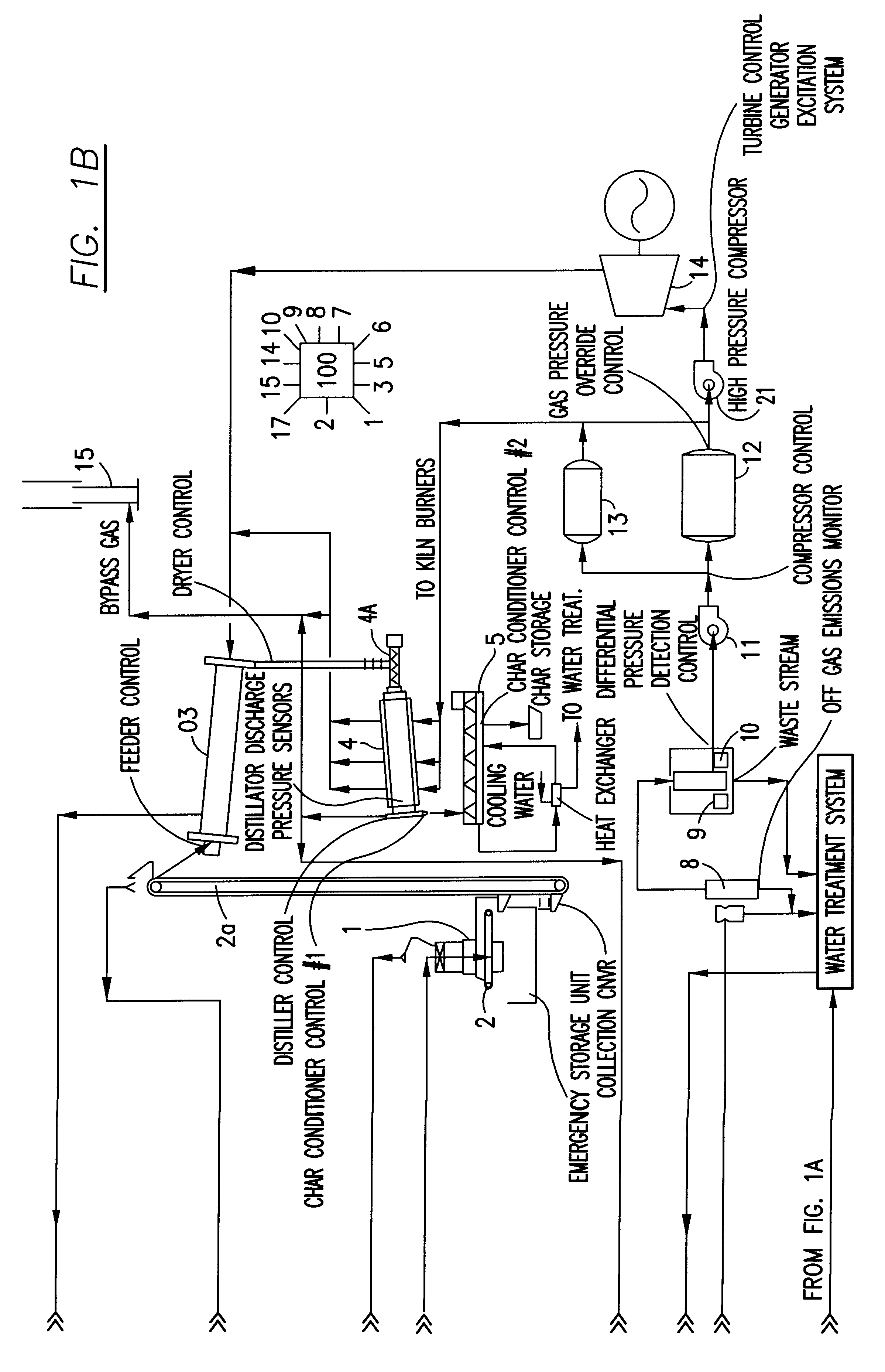

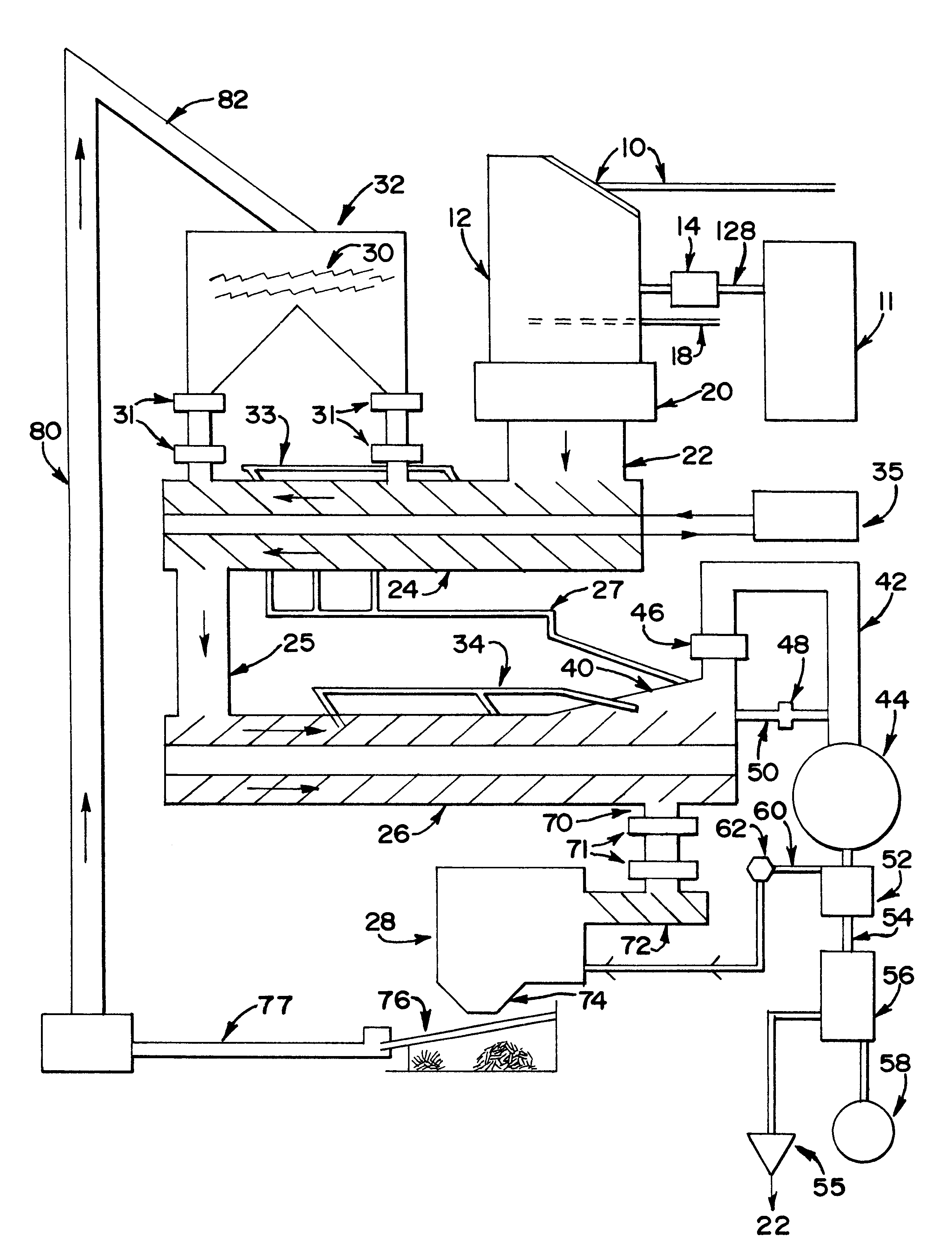

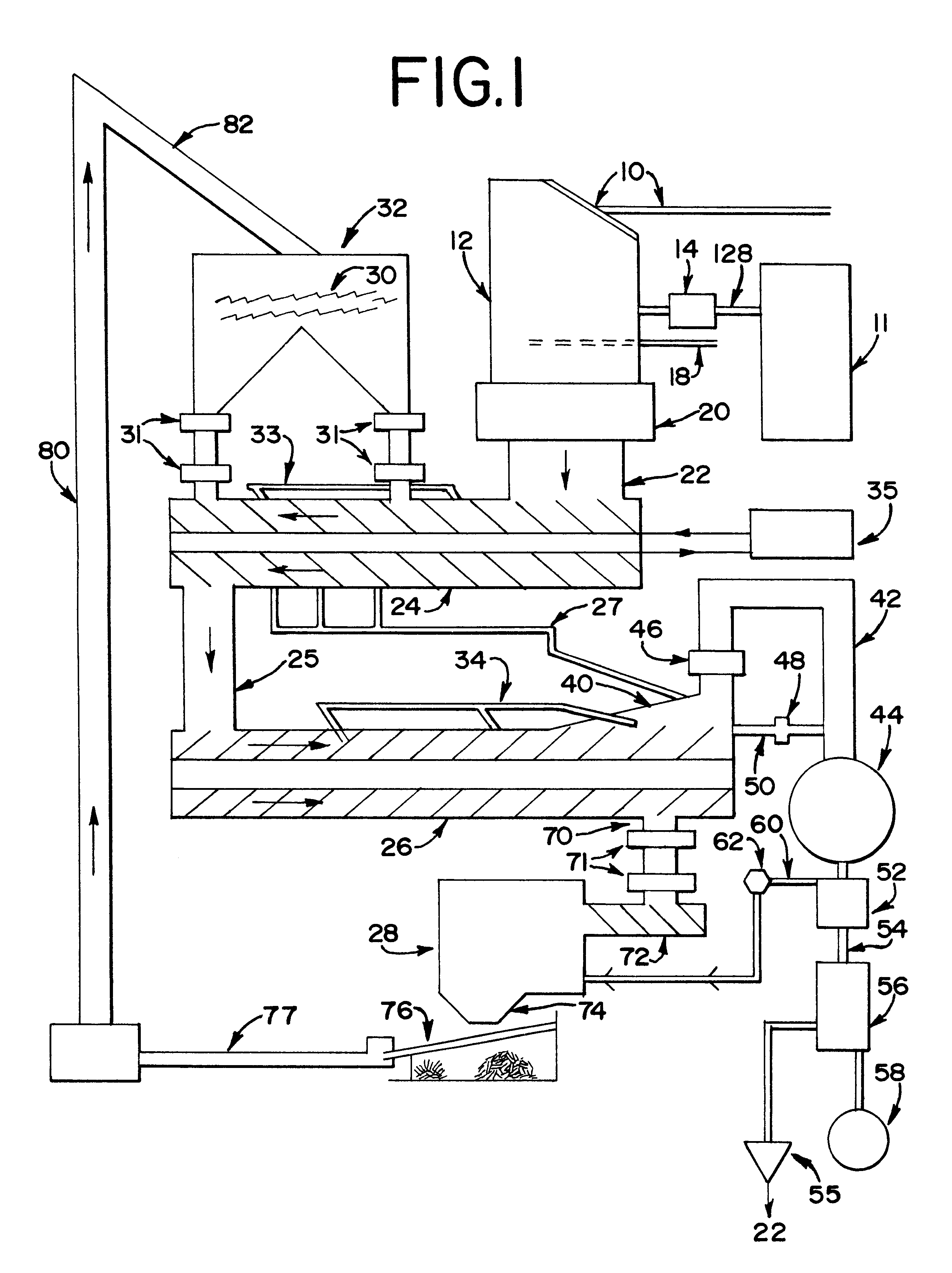

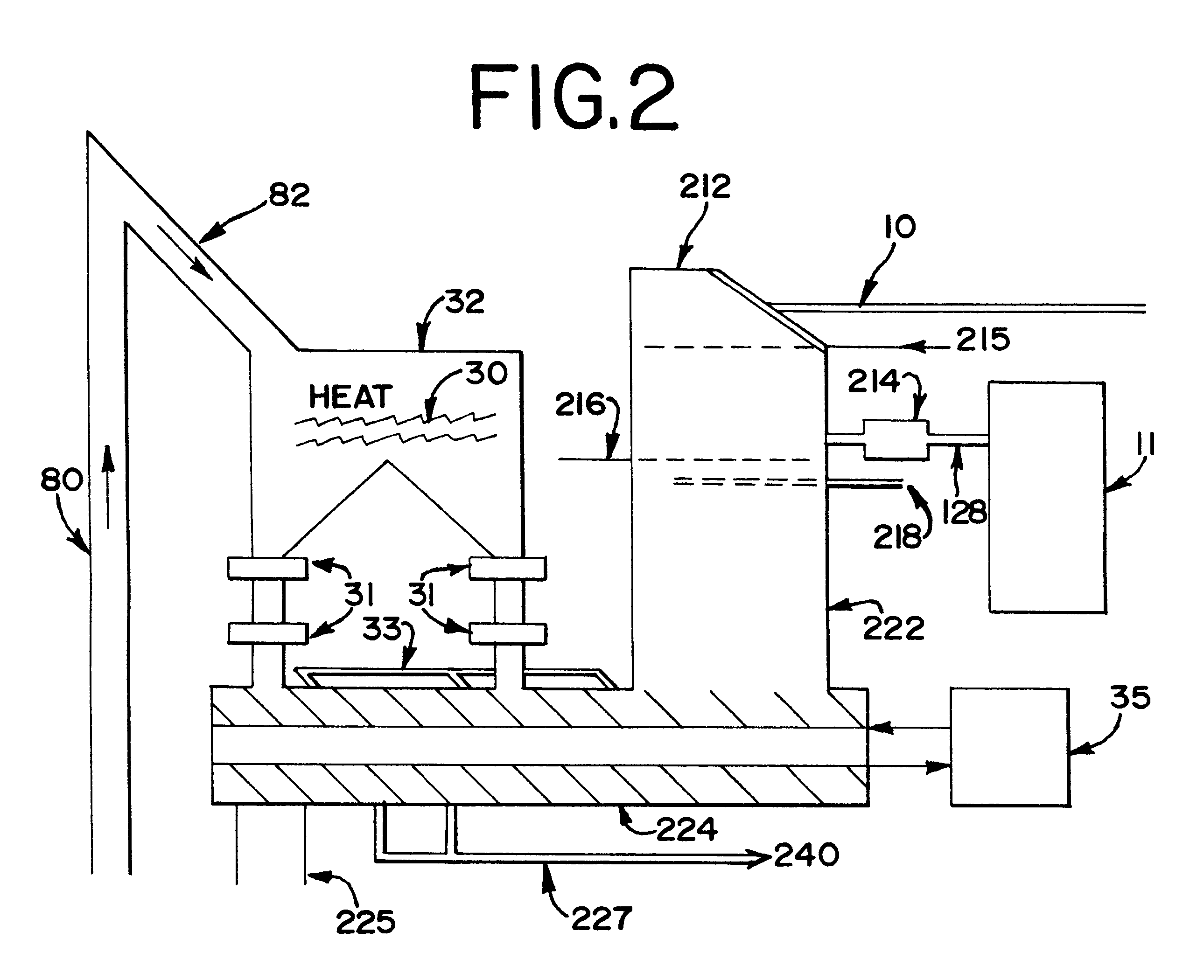

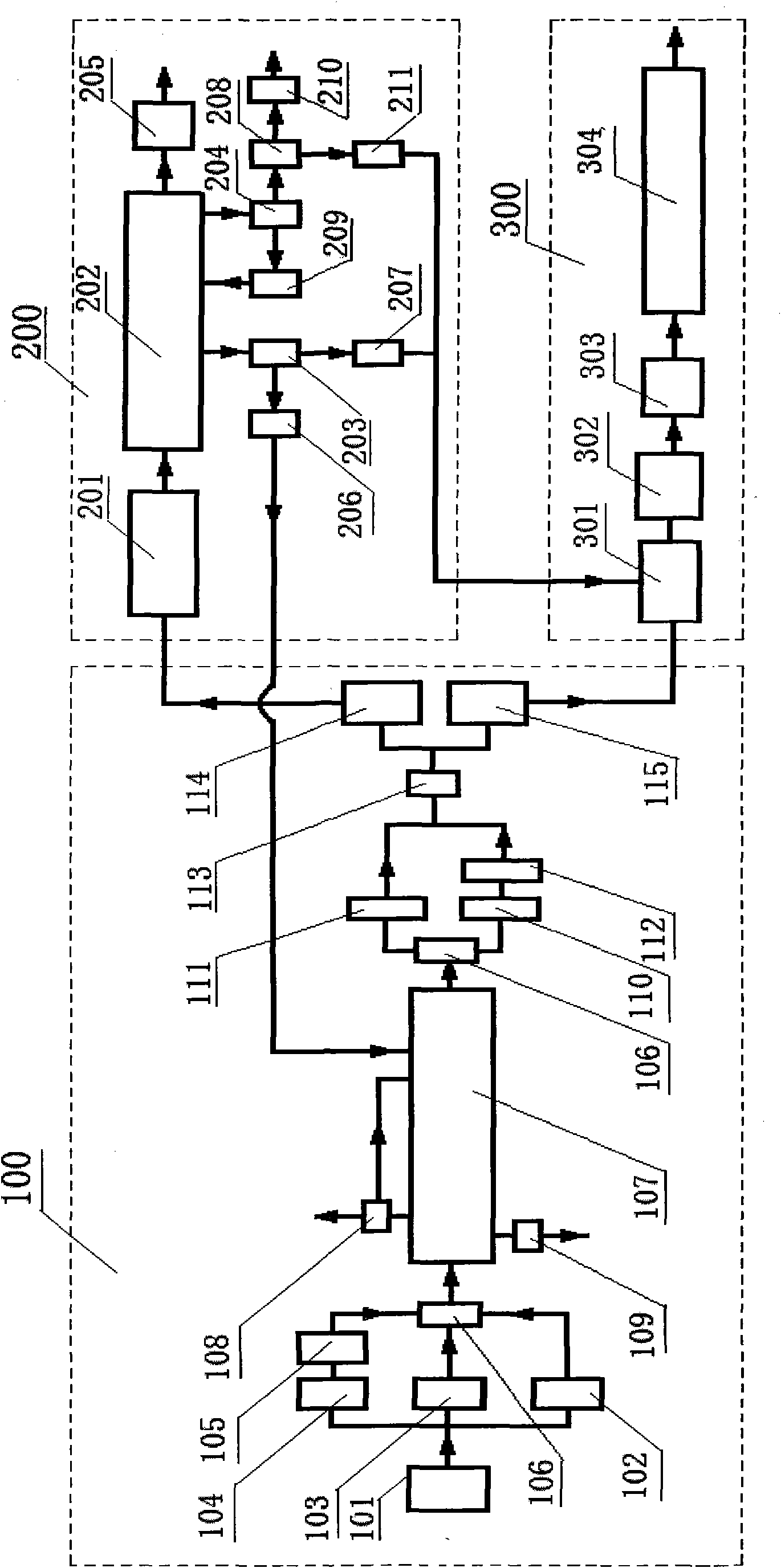

Integrated control and destructive distillation of carbonaceous waste

InactiveUS6182584B1High quantity and qualityEnhanced yield quantity and qualityHorizontal chamber coke ovensEmission preventionComputer control systemWaste stream

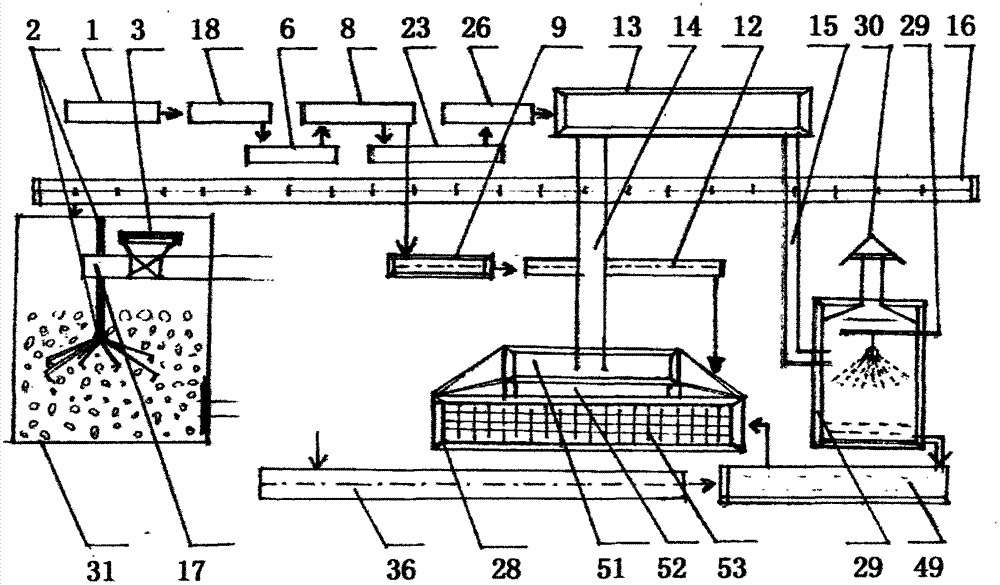

A system and process to provide integrated control for the pyrolytic composition of organic (biomass) waste products especially for municipal solid waste systems. The system includes integrated control that monitors biomass waste stream throughout the entire system and the products produced therefrom and includes presorting, controlling the amount of material processed in a continuous manner, shredding, removing moisture in a continuous process that is controlled and providing the waste stream to the distillation unit for pyrolytic action where it is converted into gaseous fuel and a char residue. The gaseous fuel is scrubbed clean and monitored and stored and reused to provide heat to the system. The entire system may be self-sustaining and continuous with very little or no human intervention. An integrated real time computer control system includes sensors and measuring devices with all the major components to ensure integrated efficiency.

Owner:ENVIRONMENTAL SOLUTIONS & TECH

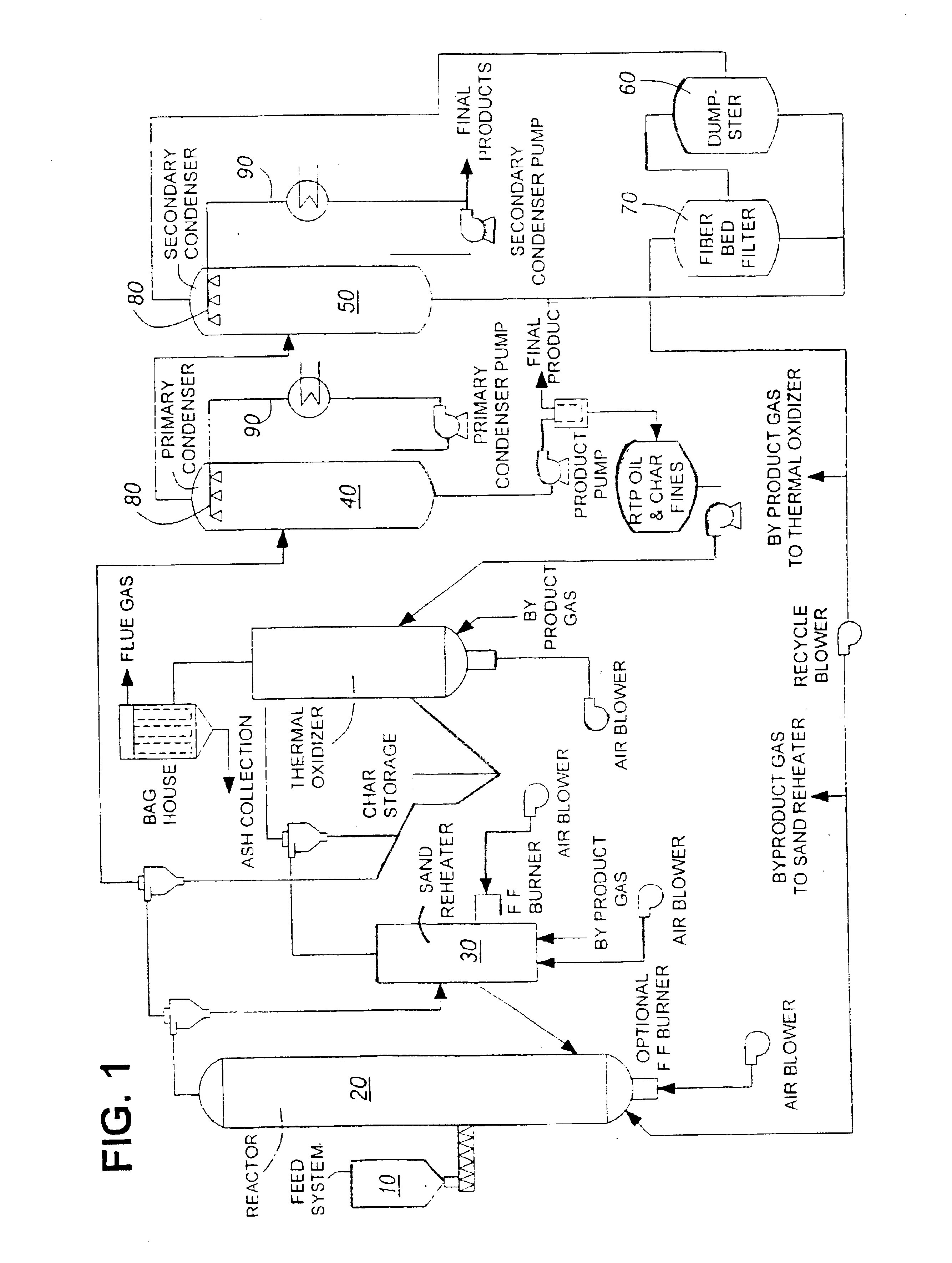

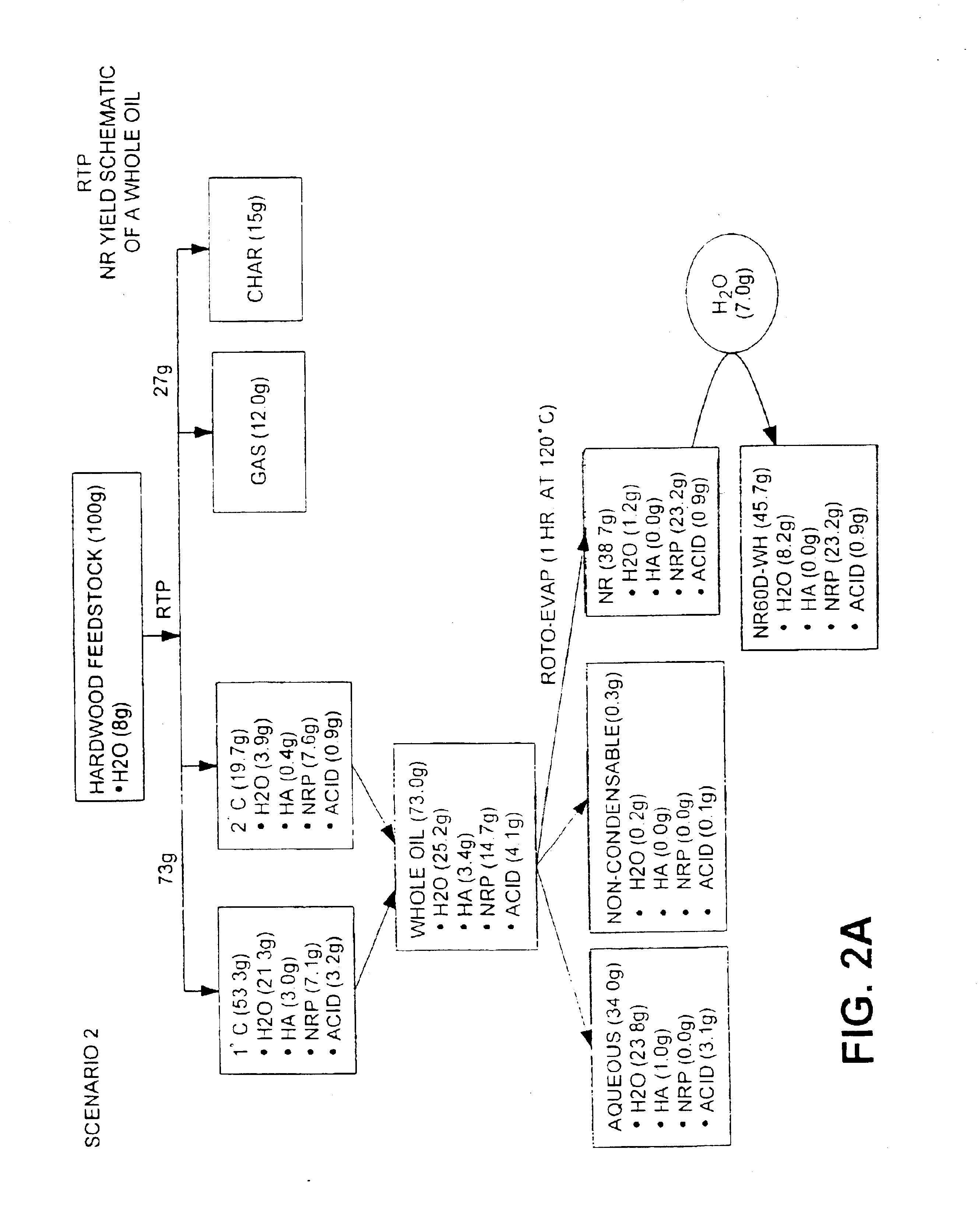

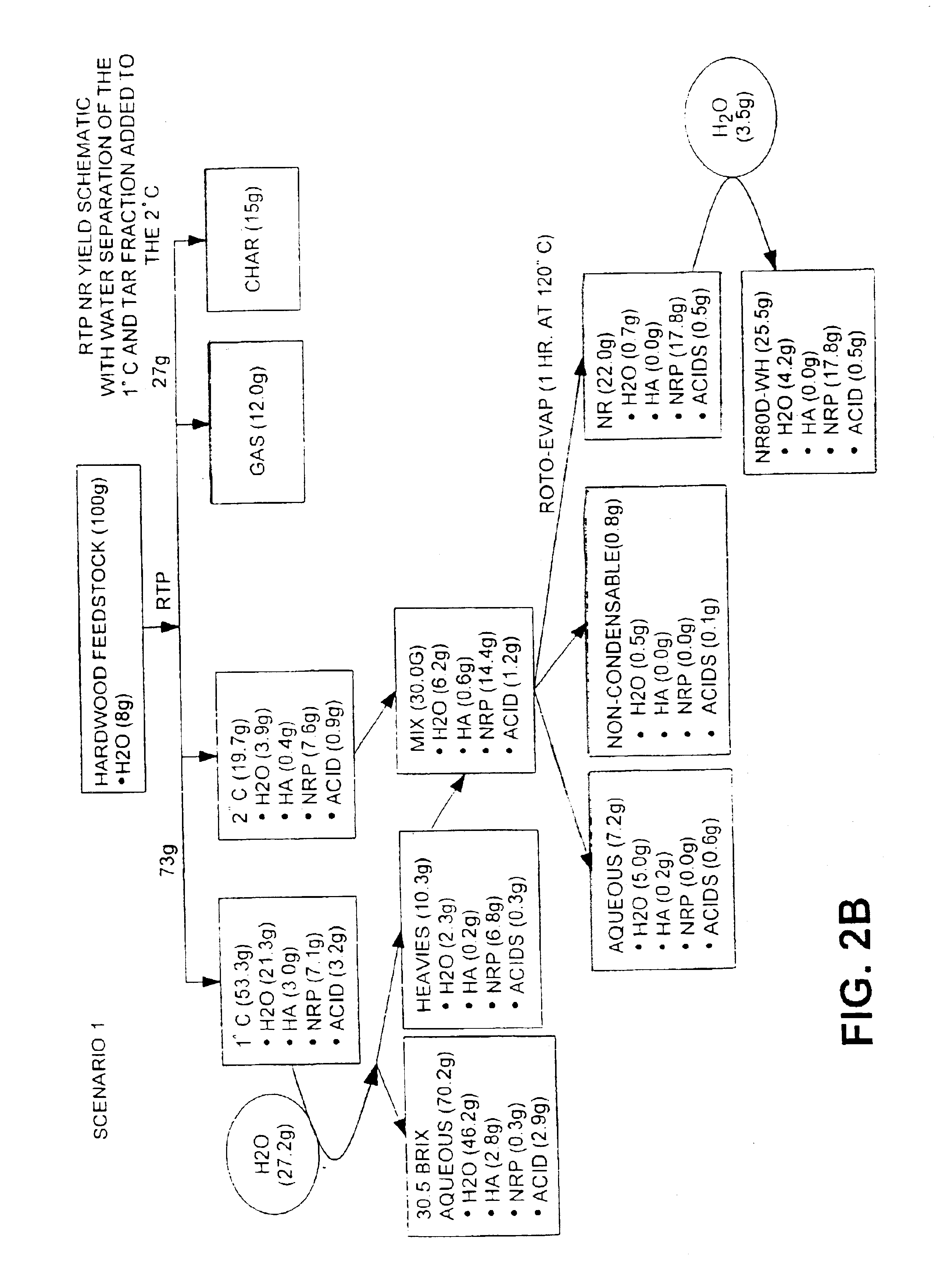

Natural resin formulations

InactiveUS6844420B1Low viscosityImprove liquidityFatty oils/acids recovery from wasteBiofuelsNatural resinDistillation

This invention is directed to a method of preparing a natural resin by liquefying wood, bark, forest residues, wood industry residues, or other biomass using rapid destructive distillation (fast pyrolysis). Fast pyrolysis produces both vapors and char from biomass, and following removal of the char from the product vapors, a liquid pitch product is recovered and processed by distillation, evaporation, or a combination thereof, in order to obtain a natural resin which may be in either liquid or solid form. The natural resin comprises a total phenolic content from about 30% to about 80% (w / w), and is a highly-reactive ligninic compound that has been found to be suitable for use within resin formulations without requiring any further extraction or fractionation procedures. Resins comprising up to 60% natural resin have been prepared and tested in board production and found to exhibit similar properties associated with commercially available resins. The natural resin may substitute for phenol, or for both phenol and formaldehyde within phenol-containing resins. Similarly, the natural resin can replace a substantial part of the components within urea-containing resins.

Owner:ENSYN RENEWABLES

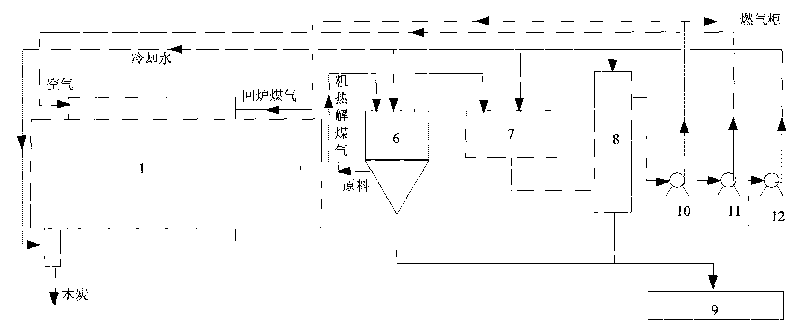

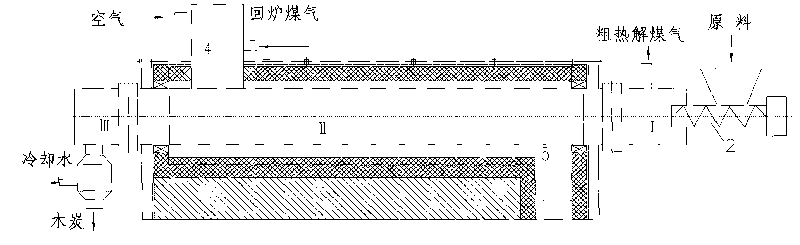

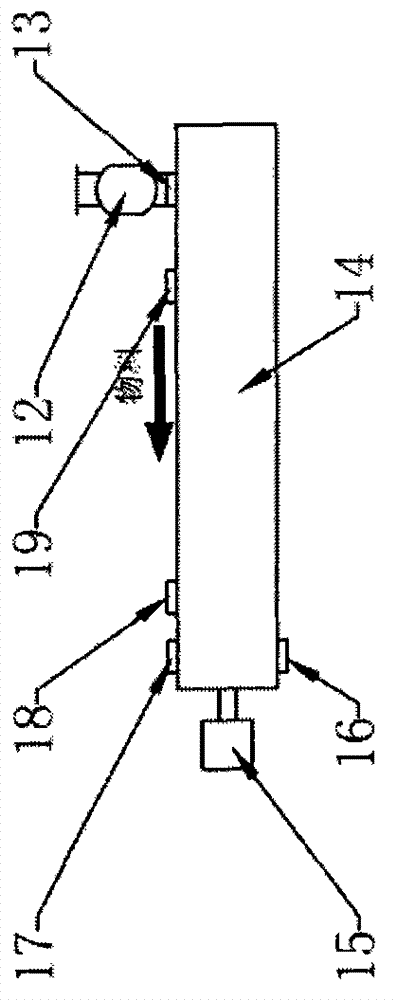

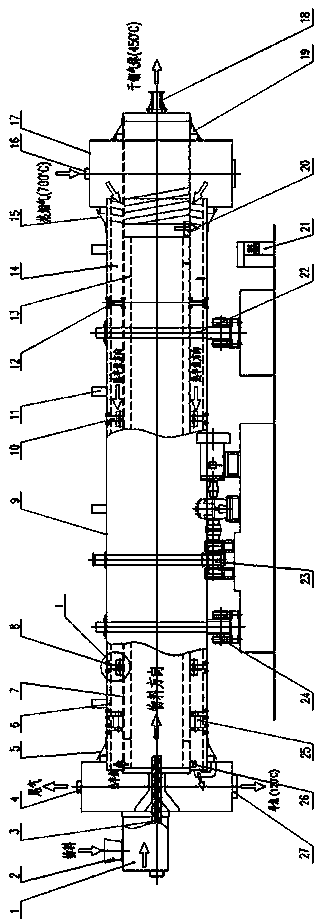

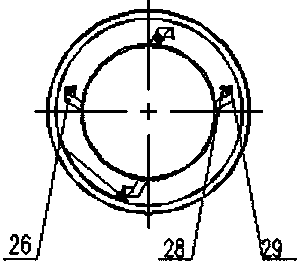

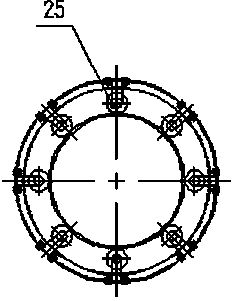

Process for internally heated continuous preparing biomass pyrolysis gasification gas and rotary furnace utilized by same

ActiveCN101693848ASmall footprintProvide continuous and stableBiofuelsSpecial form destructive distillationThermal energyDecomposition

The invention discloses a process for integrally heated continuous preparing biomass pyrolysis gasification gas and a rotary furnace utilized by the same. At a furnace tail cooling section, red charcoal at a temperature of 600-800 DEG C after pyrolyzing and destructive distilling reacts with steam generated by cooling spray water on the lower portion in the furnace so as to absorb large quantities of heat and simultaneously generate water gas and semi-water gas. Heat generated by burning recycled gas and air is used for maintaining pyrolysis temperature of biomass material layers and providesenough heat for further, pyrolysis, destructive distillation and steam decomposition reaction. By aid of the heat, biomass inside the furnace is pyrolyzed and destructively distilled to generate large quantities of volatile matters, and the biomass is gradually heated to decompose destructive gas with high heat value. The rotary furnace utilizes a three-section design: a first section is a furnace head preheating section, which is mainly used for preheating and drying raw materials, a second section is a rotary furnace body pyrolysis section, which is mainly used for pyrolysis and destructivedistillation and is a core operation portion of the furnace, and a third section is a furnace tail cooling section, which is mainly used for cooling charcoal. Prepared gas is high in heat value, and devices occupy small space.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

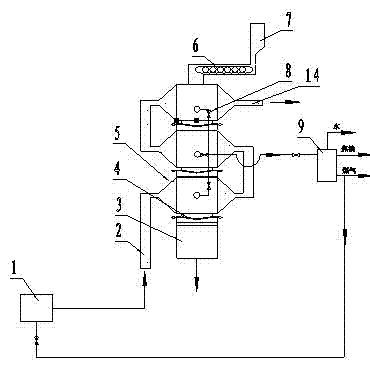

Microwave pyrolysis apparatus for waste tires

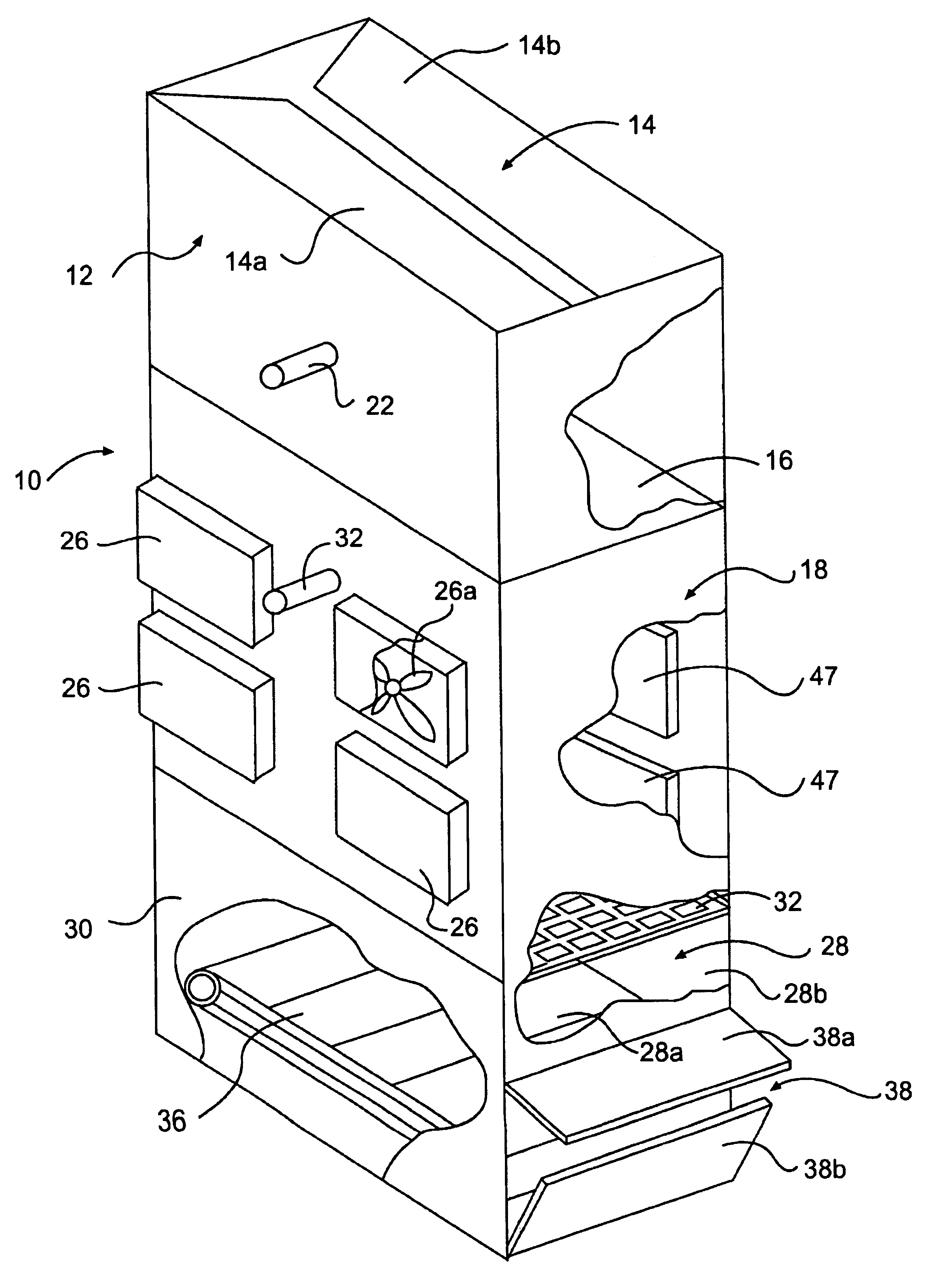

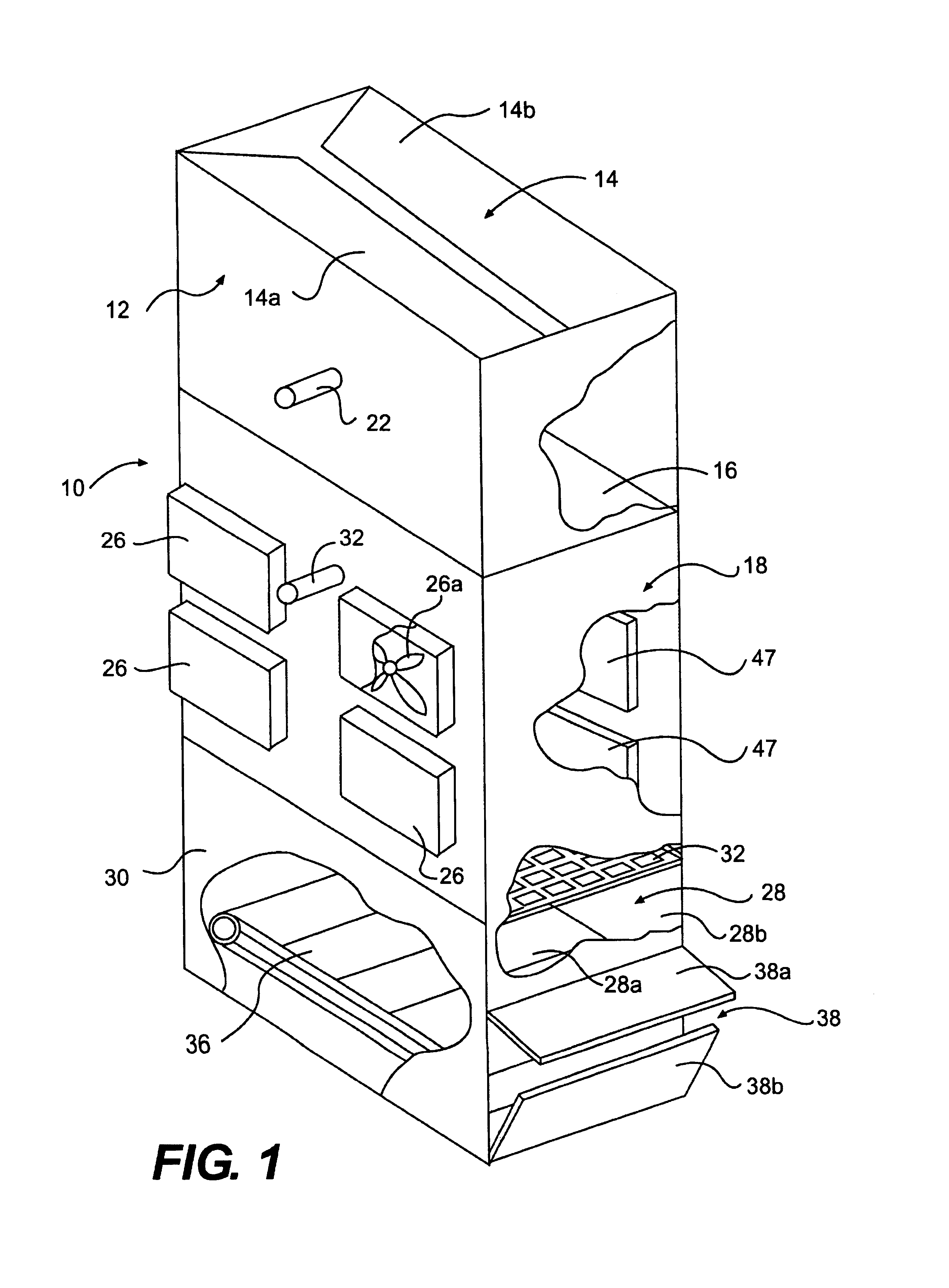

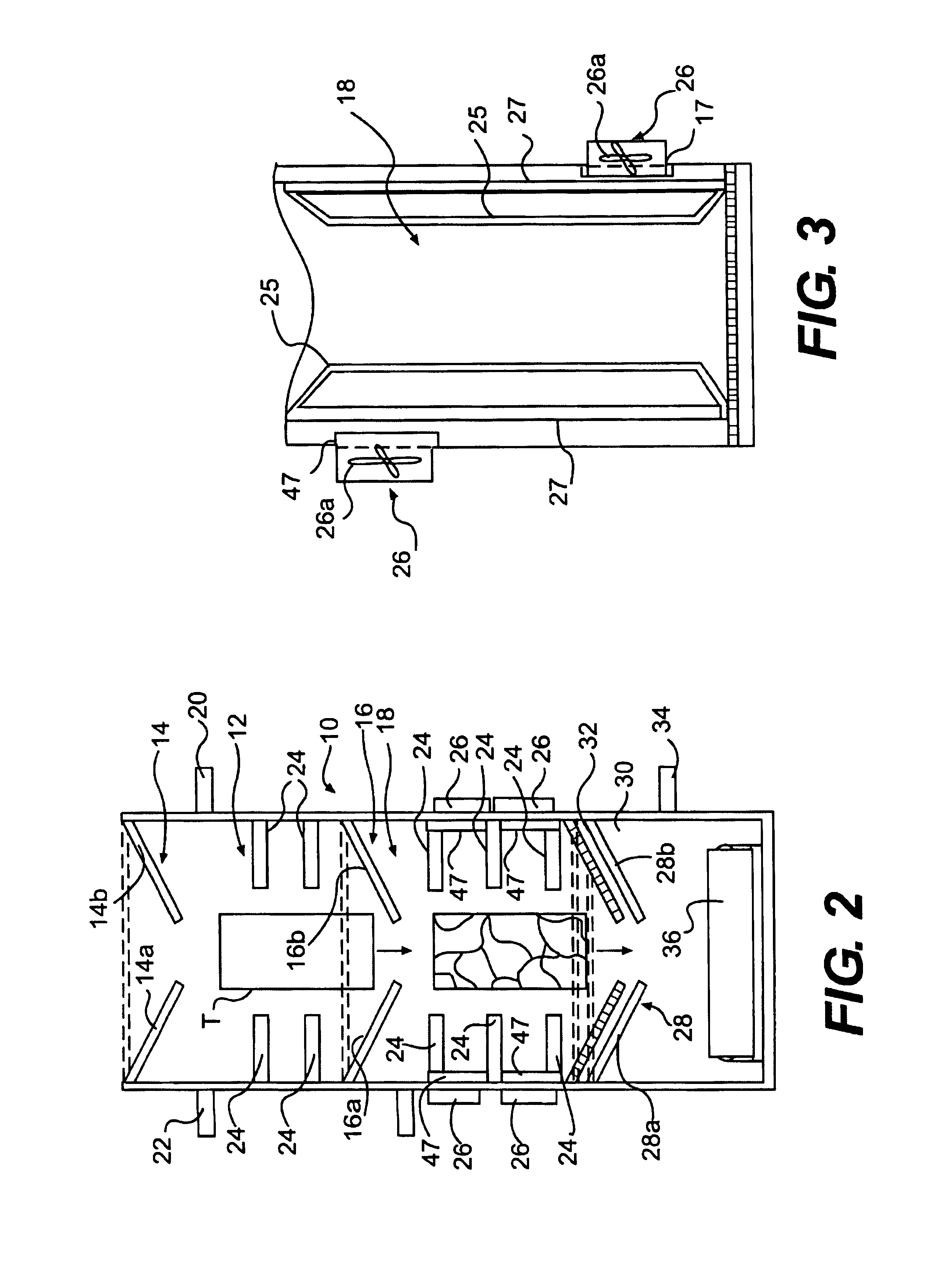

InactiveUS7101464B1Electrical coke oven heatingCombustible gas coke oven heatingMicrowave pyrolysisDistillation

A microwave distillation apparatus provides destructive distillation of whole waste tires. The apparatus includes a housing including a plurality of vertically arranged chambers. A preheat chamber provides preheating of a whole waste tire received therein. An irradiation chamber, located below the preheat chamber and thermally coupled to the preheat chamber such that heat generated in the irradiation chamber creates heat convection currents in the preheat chamber, receives a preheated whole waste tire from the preheat chamber. A microwave energy supply supplies microwave energy to the irradiation chamber to provide destructive distillation of a tire received in that chamber. A cooling chamber, located below the irradiation chamber, receives by-products of the destructive distillation therefrom and provides delivery of the by-products from the housing.

Owner:PRINGLE JOE A MR +1

Processing method and system to convert garbage to oil

InactiveUS6387221B1Improve rendering capabilitiesIncrease speedCombustible gas coke oven heatingDirect heating destructive distillationPetroleum productHydrocotyle bowlesioides

Garbage and waste of all types that includes or comprises organic matter, particularly including medical waste, plastics, paper, food waste, animal by-products, and the like, can be economically recycled into petroleum products, including oil. Machinery performs a method that mimics natural processes but accomplishes the task in minutes, at rates of about 15 tons per day in a typical processing machine, rather than taking hundreds of thousands of years in nature. The process and apparatus of the invention may chop the waste into small pieces, under negative pressure if appropriate, and then pass the waste into first and then second augers for compression and heating. Destructive distillation occurs, in which large molecular weight hydrocarbons and petrochemicals are heated by hot oil passing through the hollow shaft and by circulating hot, dense, hard material, such as steel balls or fragments or hard rock pieces and such, under pressure with steam, to produce low molecular weight hydrocarbons. The volatile hydrocarbons are released through a pressure relief valve, into a column of catalyst material, and then to a heat exchanger, which cools the gases to condensation temperatures of water and oil. Gases remaining, such as methane, are passed to a furnace or other use, and the water and oil are separated. The hot items used to put heat into the compressed material in the first stage auger are retrieved after processing is completed and then reheated and cycled back into the first stage auger.

Owner:WASTE PROCESSORS INC TOM BECVAR TRACEY MUSGROVE & HIMSELF

Method for extracting Chinese-style flue-cured tobacco fragrance cigarette juice for electronic cigarette

ActiveCN104041935ASuitable for needsCigarette tobacco smell strongTobacco treatmentTobacco devicesFlavorLiquid smoke

The invention discloses a method for extracting Chinese-style flue-cured tobacco fragrance cigarette juice for an electronic cigarette. The method comprises the following steps: 1, blending flue-cured tobacco type tobacco leaves, tobacco shreds or tobacco powder; 2, applying cigarette feed liquid or materials with high sugar content on the tobacco leaves, tobacco shreds or tobacco powder; 3, performing destructive distillation on the tobacco leaves, tobacco shreds or tobacco powder by different temperature sections; 4, collecting fractions. The fractions collected by the method can directly serve as electronic cigarette juice, and cigarette essence perfume having characteristic flavor, or edible essence perfume also can be added to enrich the styles of the electronic cigarette tobacco juice; the electronic cigarette juice collected by the method has the style characteristic and flavor similar to those of a Chinese-style cigarette, the satisfaction is good, the fragrance is harmonious, and the taste is pure and mild.

Owner:CHINA TOBACCO SHANDONG IND

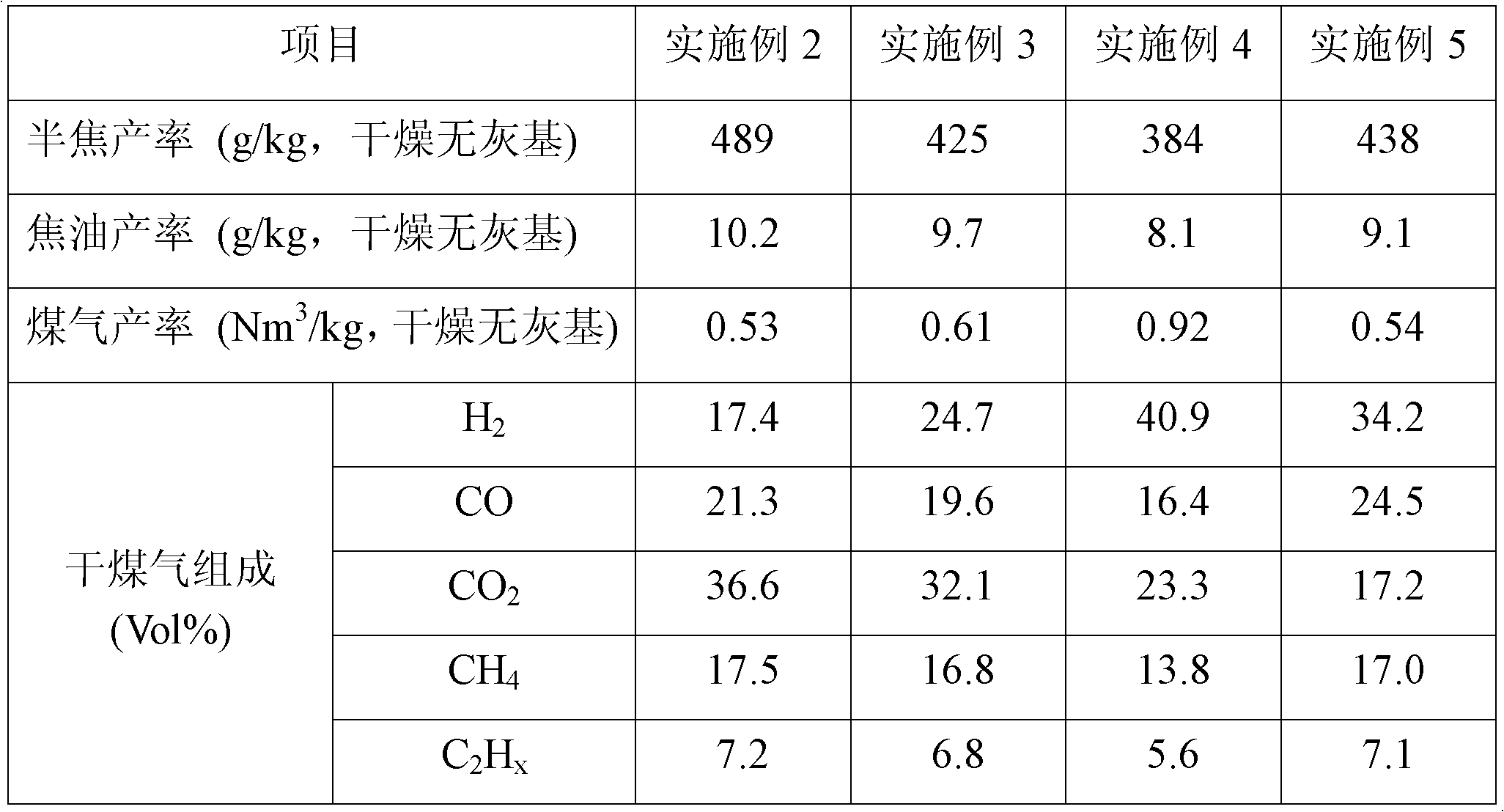

Method for preparing semicoke, empyreumatic oil and coal gas by pyrolyzing coal

InactiveCN102010728AIncrease production capacityFast heatingCoke quenchingDirect heating destructive distillationHeat carrierTar

The invention discloses a method for preparing semicoke, empyreumatic oil and coal gas by pyrolyzing coal. The method is characterized in that a heating mode of solid thermal carriers is adopted in the pyrolysis process; the semicoke generated in the pyrolysis process and large-particle semicoke in a heat carrier mixture are separated as products by a size grading method, and the empyreumatic oiland coal gas with a medium heat value are produced as byproducts, wherein a pyrolysis system mainly comprises a heat carrier storage bin, a mixer, a pyrolysis reactor, a solid grading separator and araising pipe burning reactor. In the invention, the heating rate of coal is improved, the destructive distillation time is shortened, the single burner production capacity is improved, and the coal of combination grain is taken as production raw materials, the raw material adaptability and the utilization factor are high and the method provided by the invention is suitable for various lignite andbitumite.

Owner:DALIAN UNIV OF TECH

Passivation process and passivation system of active coke

InactiveCN101781596AImprove stabilityReduce production process costsSolid fuelsBiochemical engineeringDestructive distillation

The invention provides a passivation process and a passivation system of active coke. The process mainly comprises: firstly, carrying out rehydration and cooling treatment on quenched active coke which is from the destructive distillation pyrolyzation treating process; then feeding the rehydrated active coke into a passivation react zone for low-temperature oxidation passivation treatment; and finally, cooling the coke which is treated by rehydration and low-temperature oxidation passivation to the normal temperature. Therefore, the coke has greatly-increased stability, and can not self-ignite under the conditions of long-distance transport and long time of being exposed to the environment; and simultaneously, the invention has the advantages that the cost of production technology is low, the system operation has simplicity, stability and high practicability and the production process has less pollution, thus the invention can be used in the process of large-scale active coke passivation industrial production.

Owner:HUNAN HUAYIN ENERGY TECH

Method for preparing radioactive <124>I ions

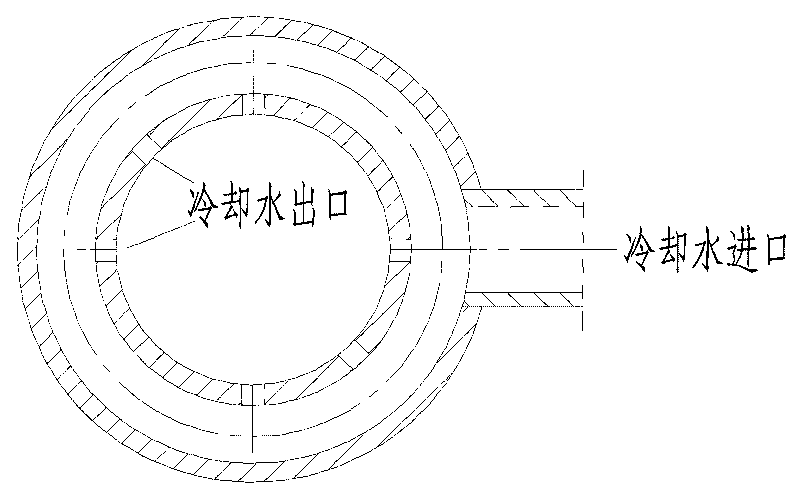

ActiveCN103771341ANo leaksImprove radiation effectIodineAlkali metal iodidesAngle of incidenceDistillation

The invention discloses a method for preparing radioactive <124>I ions. The preparation method comprises the following steps: a, taking aluminium oxide powder and tellurium dioxide powder in a mass ratio of 1:18-22, uniformly mixing the powder, and pressing the obtained mixture into a tellurium target with a thickness of 50-60 mg / cm<2>; b, placing the prepared tellurium target in a circular accelerator, and irradiating the tellurium target 2-3 h by Te (p, n) <124>I, wherein the incident p particle beam intensity is 18-20 mu A, the energy is 18.5-20 MeV, and the angle of incidence is 6-10 DEG; meanwhile, cooling the tellurium target by using water in the process of irradiating, and after the irradiating is completed, placing the tellurium target to cool 4-6 h; c, placing the tellurium target in a quartz distillation tube of a destructive distillation device to distill, meanwhile, controlling the temperature to 750 DEG C so as to heat the tellurium target, so that radioactive <124>I ions are escaped, and collecting the radioactive <124>I ions. The problems that radionuclide <124>I prepared in the prior art is low in yield and low in recovery rate are solved.

Owner:MITRO BIOTECH CO LTD

Method for preparing rubber packing from modified oil shale semicoke

The invention relates to a method for preparing rubber packing from modified oil shale semicoke. The method is characterized by comprising the following steps: 1) performing superfine crushing on oil shale semicoke after destructive distillation; 2) roasting in a high-temperature furnace, performing air insulation heat preservation, and performing furnace cooling so as to obtain carbonized oil shale semicoke; 3) modifying the carbonized oil shale semicoke superfine powder by using a surface modifier so as to obtain modified oil shale semicoke powder, wherein the addition amount of the surface modifier accounts for 2% of the mass of the powder, the modification temperature is the room temperature, and the modification time is 30 minutes; 4) smelting the modified oil shale semicoke, rubber, carbon black, zinc oxide, stearic acid, an antioxidant, liquid paraffin, sulfur and a promoter in a smelting machine at certain temperature; and 5) cooling, and molding by using a press vulcanizer. Organic matter residues in the oil shale semicoke can be sufficiently utilized, wastes can be turned into wealth, environment pollution caused by air storage can be eliminated, the carbonized oil shale semicoke powder is uniform in surface carbonization, solid in wrapping, good in organic matter compatibility, stable in performance, simple in process and low in cost. Various indexes of mechanical properties of testing samples can meet national standards.

Owner:JILIN UNIV

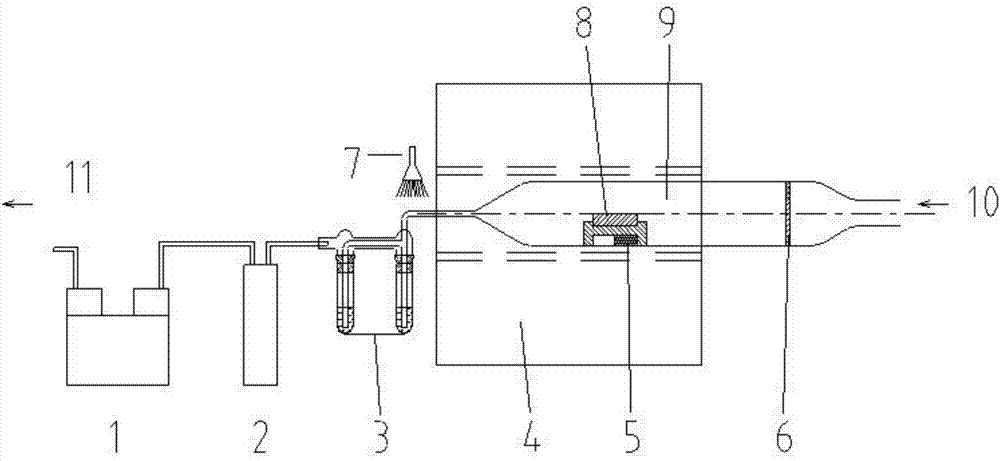

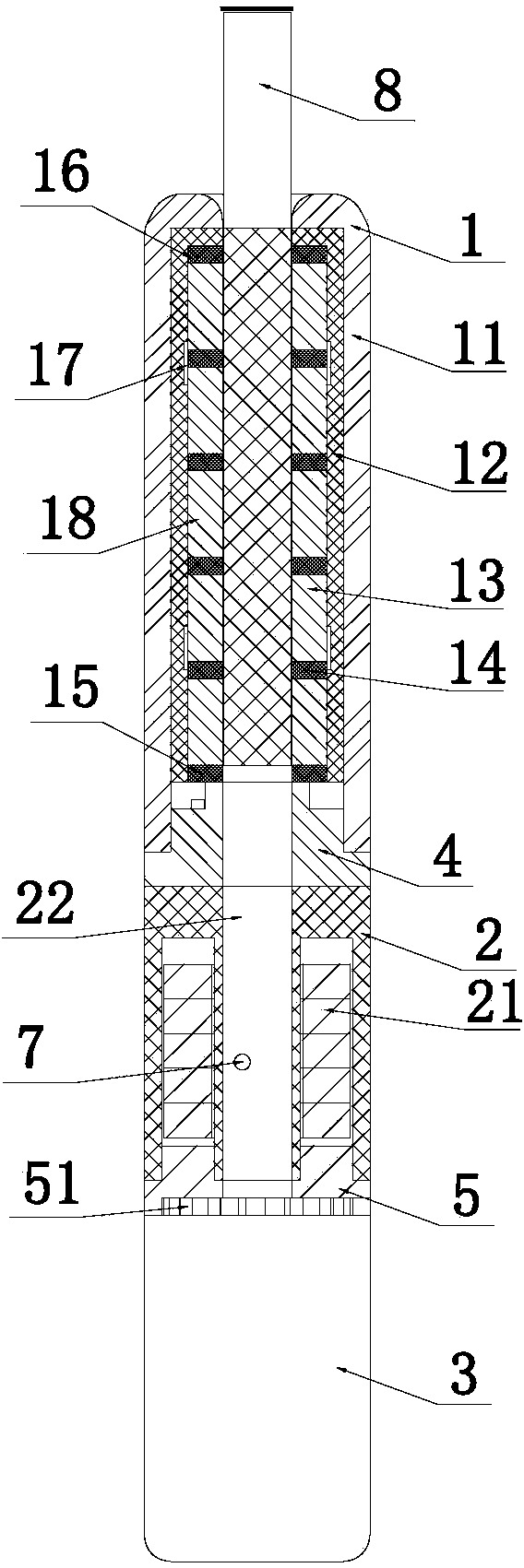

Sectional heating control device for non-burning cigarettes

InactiveCN103720057AEnsure characteristic feelingHarm reductionTobacco devicesControl systemBurn cigarette

The invention relates to a sectional heating control device for non-burning cigarettes. The sectional heating control device comprises a sectional heater and a control system, the sectional heater comprises multiple hollow heating elements, an insulating and heat insulating washer is arranged between every two adjacent hollow heating elements, the hollow heating elements and the insulating and heat insulating washers form a tubular whole, the tubular whole is hollow to from a heating chamber for accommodating tobacco products, one end of the heating chamber is a cigarette inlet, and the other end of the heating chamber is communicated with outside air through an air flow passage. The control system comprises a controller and a power supply, the power supply is connected with the controller which comprises a CPU (central processing unit) and power regulators, the CPU is connected with the power regulators which are connected to the hollow heating elements respectively, and the CPU controls the hollow heating units to heat in axial sequence. Through an electric heating mode, aroma components in the cigarettes can be removed by destructive distillation, and harm of the cigarettes to human bodies is reduced.

Owner:CHINA TOBACCO ZHEJIANG IND

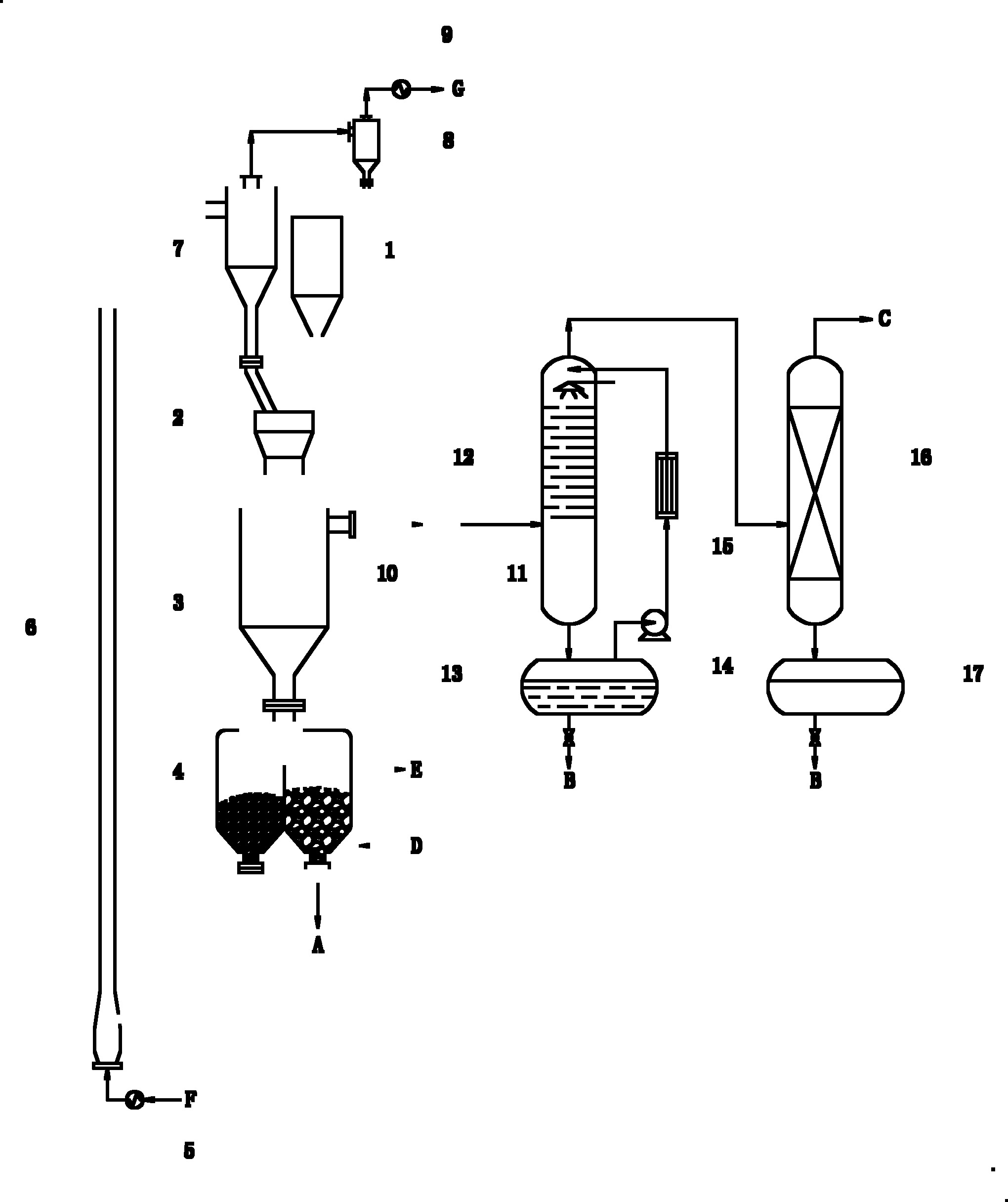

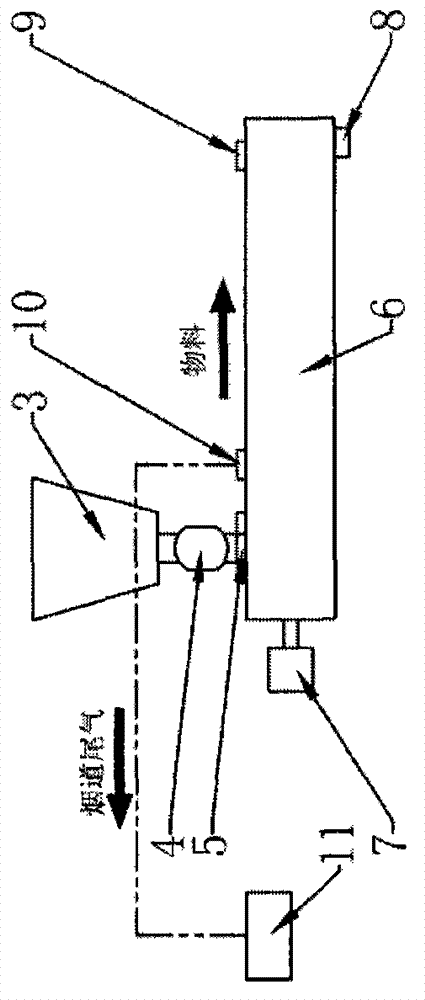

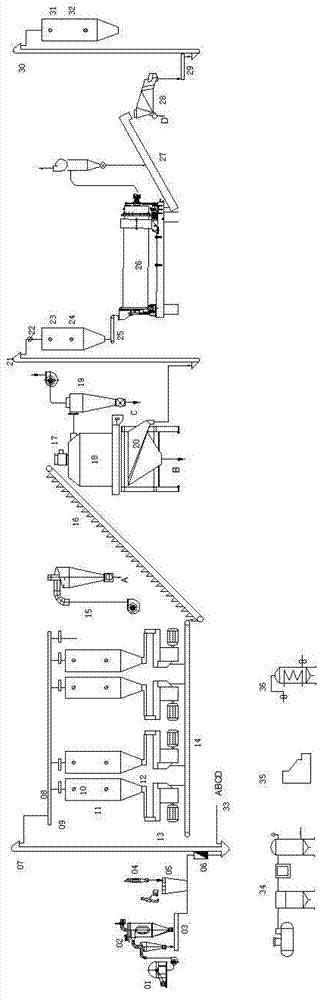

Apparatus and process for destructive distillation and cracking of biomass

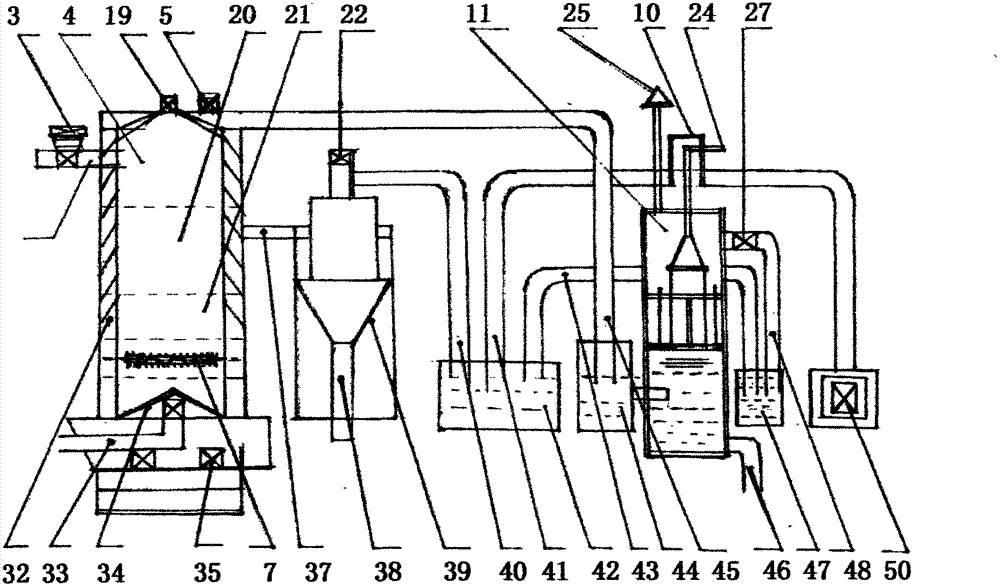

ActiveCN102816575AShort processReduce energy consumptionMechanical conveying coke ovensCombustible gas coke oven heatingReactive distillationProcess engineering

The invention discloses an apparatus and a process for destructive distillation and cracking of biomass, belonging to the technical field of industrial processing apparatus structures and processes for mechanical products. The apparatus comprises an input part, a reaction vessel part, a control part and a processing output part. Self-balancing of energy in the process of production is realized through utilization of the destructive distillation and cracking process for biological garbage. According to the invention, the destructive distillation and cracking process for biomass has the advantages of short process flow, little equipment and low energy consumption, and the apparatus has the advantages of safe and convenient operation, easy maintenance and repair, etc.

Owner:上海清平环保科技有限公司

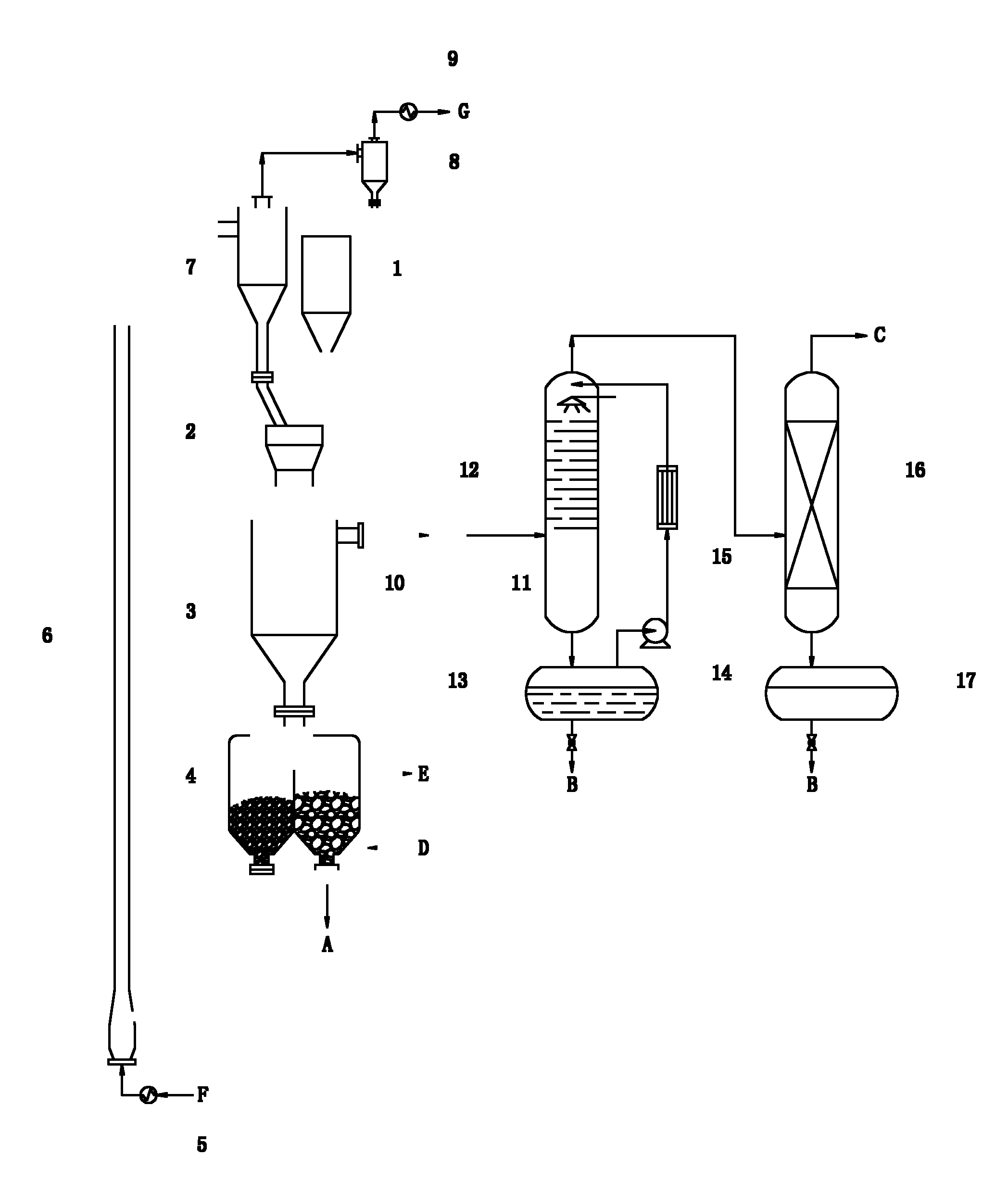

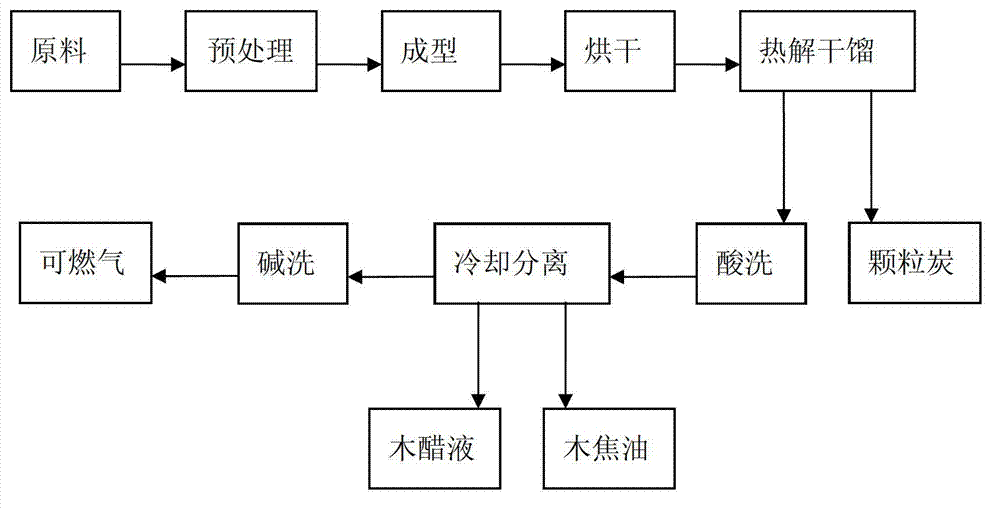

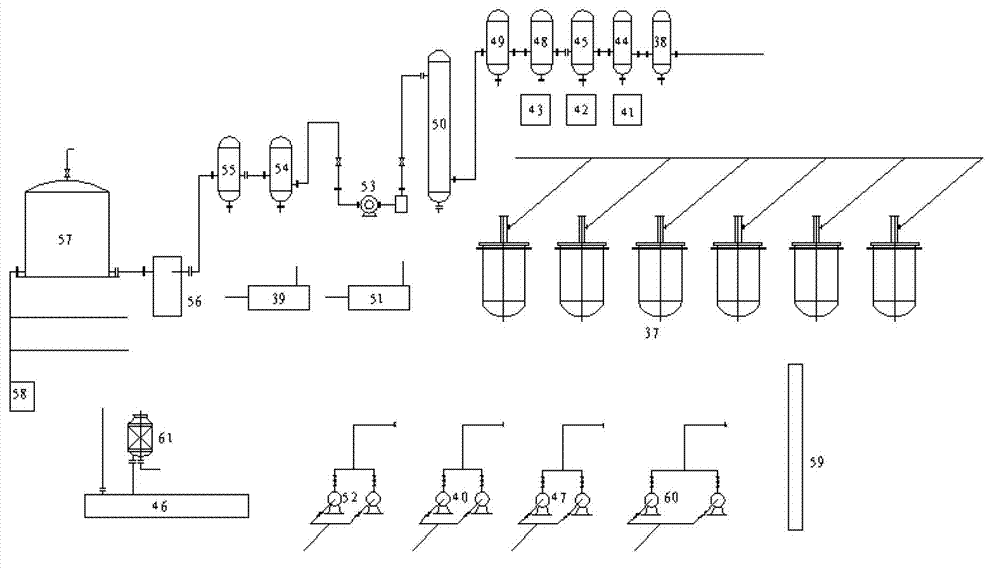

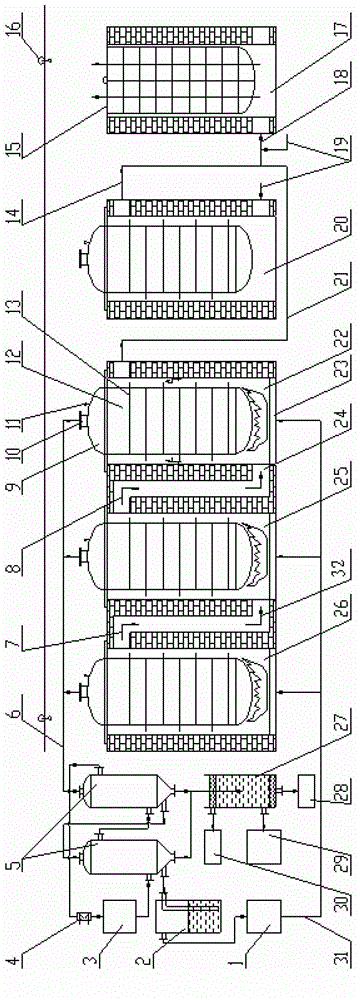

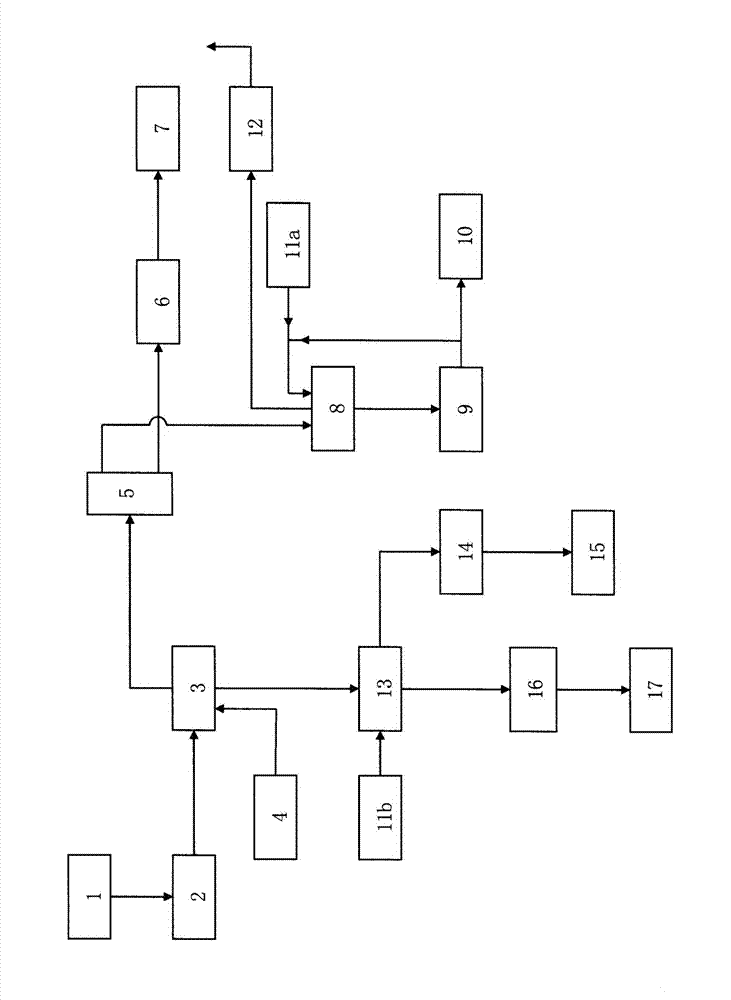

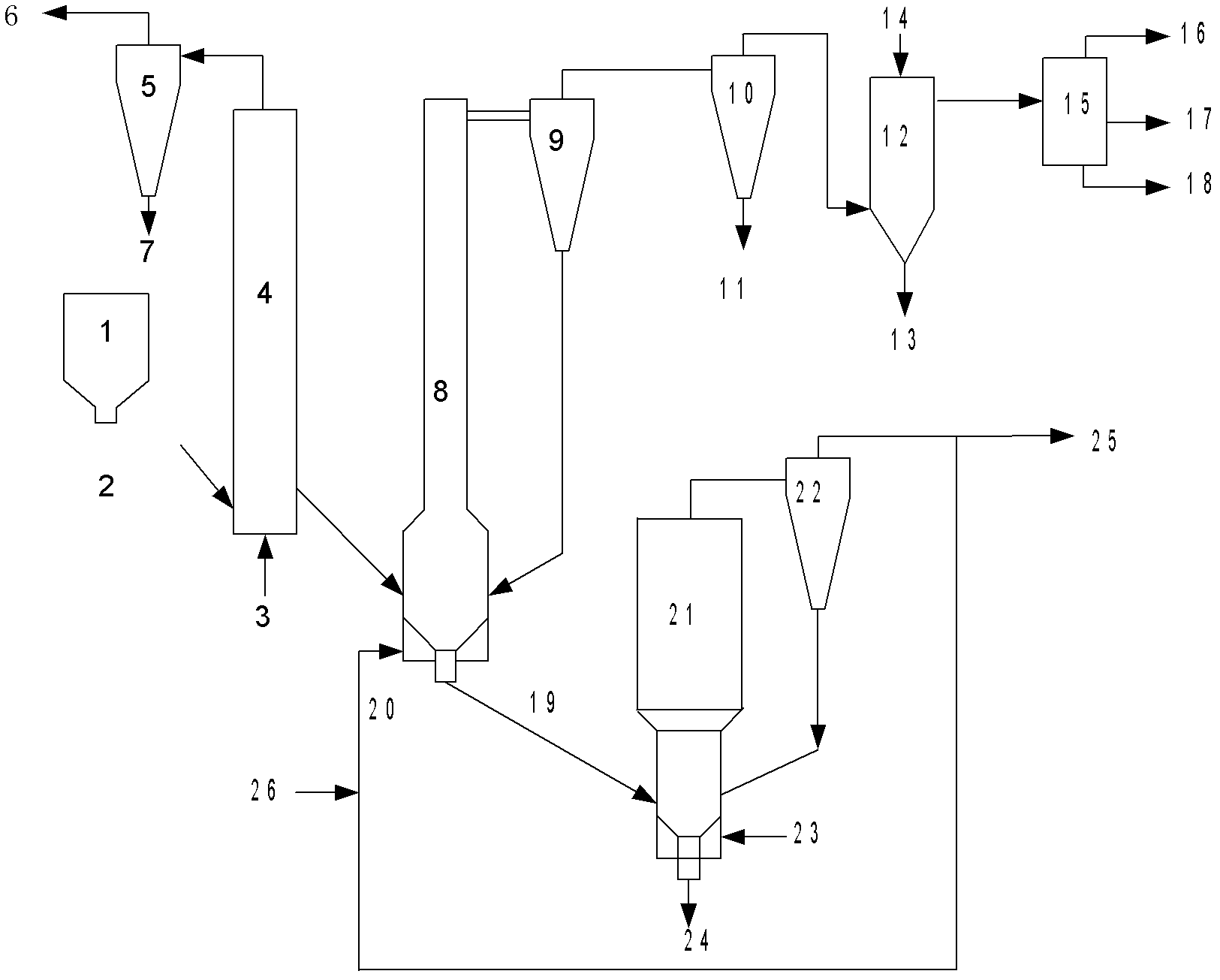

Process for industrially producing carbon, gas, oil and electricity through biomass energy forming and destructive distillation

ActiveCN102776009AReduce the chance of crackingExtended service lifeBiofuelsPyroligneous acid productionAcid washingMoisture

The invention discloses a process for industrially producing carbon, gas, oil and electricity through biomass energy forming and destructive distillation. The process comprises the following steps of: raw material pretreatment: crushing raw materials; forming: pressing the crushed raw materials into formed particles in a certain shape; drying: controlling the moisture content in the formed particles at 3%-5%; destructive distillation: thermo-chemically converting the dried formed particles into granular carbon, gas and liquid under the condition of air isolation or in the presence of little air; acid washing: performing acid washing on the gas produced through the destructive distillation; cooling and separation: cooling the acid-washed gas and performing gas-liquid separation on the gas and the condensed liquid, and then performing wood tar-pyroligneous separation on the cooled liquid; and alkali washing: performing alkali washing on the cooled gas. The process is capable of converting the biomass raw materials into high-grade good-quality fuels and industrial raw materials.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Technology of preparing synthetic gas using non agglomerating or weak agglomerating coal fluidized destructive distillation

ActiveCN1912070AIncrease profitHigh yieldCombined combustion mitigationGasification with fuel pre-distillationLiquid productWater vapor

The invention discloses a process for making synthetic gas by non-adhesive or low-adhesiveness coal fluidized carbonization, comprising the steps of: crushing non-adhesive or low-adhesiveness coal into fine coal; feeding the fine coal into a carbonization reactor and producing coal gas, tar steam and semicoke; cooling the coal gas and tar steam, and extracting the coal gas and coal tar; feeding the semicoke into a coal gas generator to react with oxygen gas and water steam to produce generated coal gas and coal ash; feeding the generated coal gas into a CO conversion reactor to regulate composition of the synthetic gas and act as synthetic methanol gas. And the utilization ratio of raw materials can be 100%. And the oil yield of fine coal fluidized carbonization is high. And the produced semicoke can completely turn into generated coal gas, and finally only coal ash is left. And the yield of liquid products by carbonization and liquid products synthetized by synthetic gas is higher than that of liquid products by coal liquefaction.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND

Large-scale brown coal quality-improving process and apparatus

InactiveCN102757833AImprove utilizationComprehensive utilization of product quality improvementSolid fuelsSpecial form destructive distillationBrown coalMicrowave

The invention belongs to the technical field of brown coal quality improving, and relates to a large-scale brown coal quality-improving process and a large-scale brown coal quality-improving apparatus. According to the invention, an interrelated large-scale continuous brown coal quality-improving system is composed of three modules which are a tunnel internal-heat drying module, an external-heating microwave destructive distillation module, and a powdery brown coal molding and drying module. Because of large-amount water discharging, a brown coal block large-capillary framework is collapsed, so that the brown coal is naturally broken into small blocks and powder without mechanical disruption. The small-block brown coal is subjected to destructive distillation under high-temperature hot wind external heating and microwave coupling, until the blocks turn into semi-coke; water-containing coal gas, water-containing coal tar, anhydrous gas, and anhydrous coal tar are respectively obtained by destructive distillation. With a binder of the water-containing coal tar and coal tar pitch (one or a mixture thereof), the powdery brown coal is subjected to kneading and aging; the material is processed into granules by using a vacuum extrusion granulator; and the particles are processed by using a low-temperature microwave drying device, so that high-quality brown coal particles with high strength, low moisture absorption, and high heat value are obtained. The brown coal particles can endure long-distance transportation.

Owner:周灿旭

Household up-draft biomass gasification device

InactiveCN101560411ASettlement requires ignition,Resolution timeCombined combustion mitigationGasification with fuel pre-distillationRadiation lossTar

The invention discloses a household up-draft biomass gasification device, which has an upright cylinder structure and is characterized in that the household up-draft biomass gasification device comprises a destructive distillation chamber arranged at the upper section thereof, a main gasification chamber arranged at the middle section thereof and an ash chamber arranged at the lower section thereof; all the sections are respectively separated by a heat storage grille and a heat storage grate; and the main gasification chamber is enclosed by a radiation cylinder on the periphery. The household up-draft biomass gasification device has no need of an external firing heat source, fast firing speed and high temperature of the gasification center, remarkably reduces tar content, reduces radiation loss of a furnace body, and has high gasification efficiency, long fire banking time of the gasification furnace, simple and compact structure, convenient operation and low operating cost.

Owner:安徽喜阳阳新能源科技有限公司

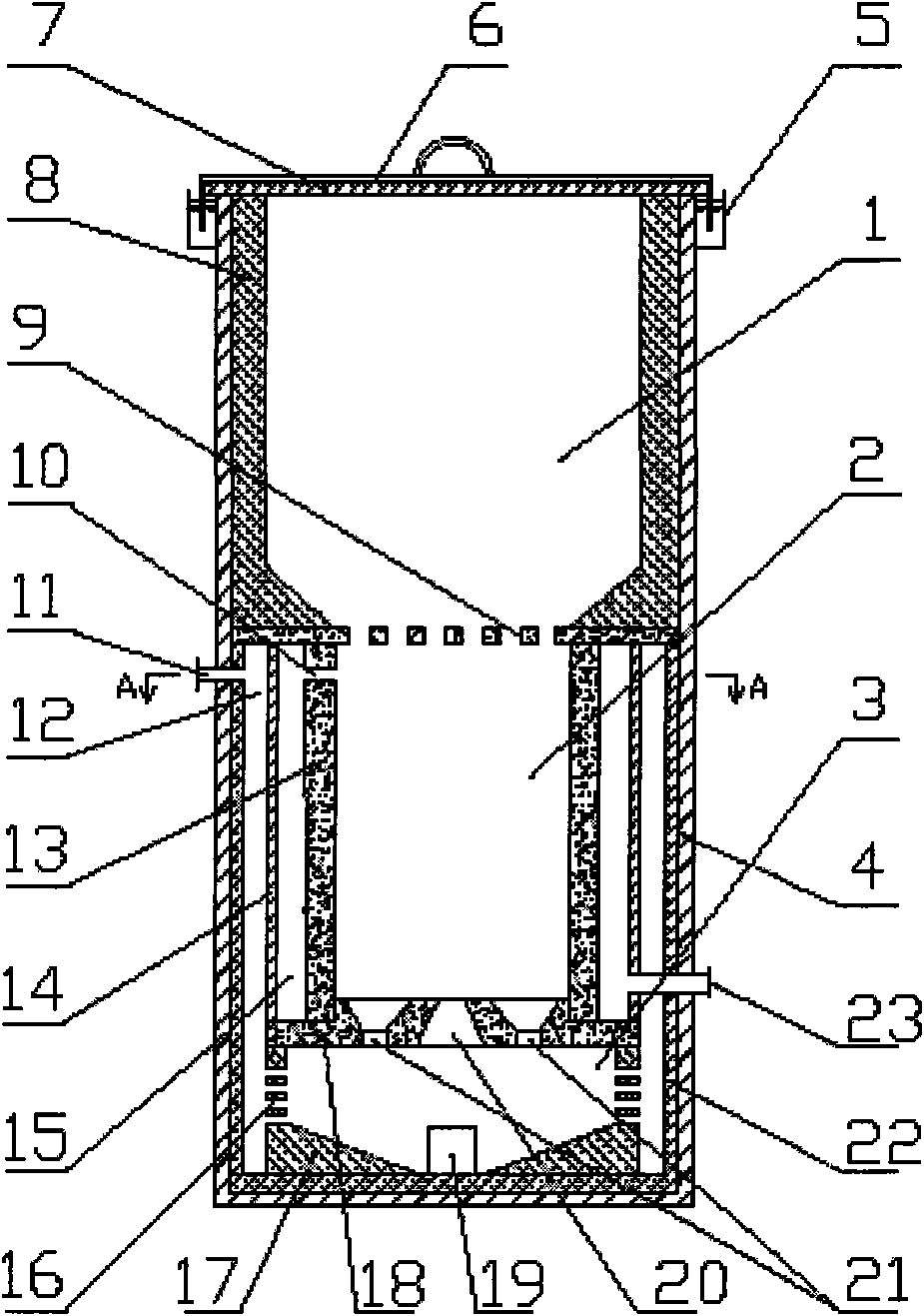

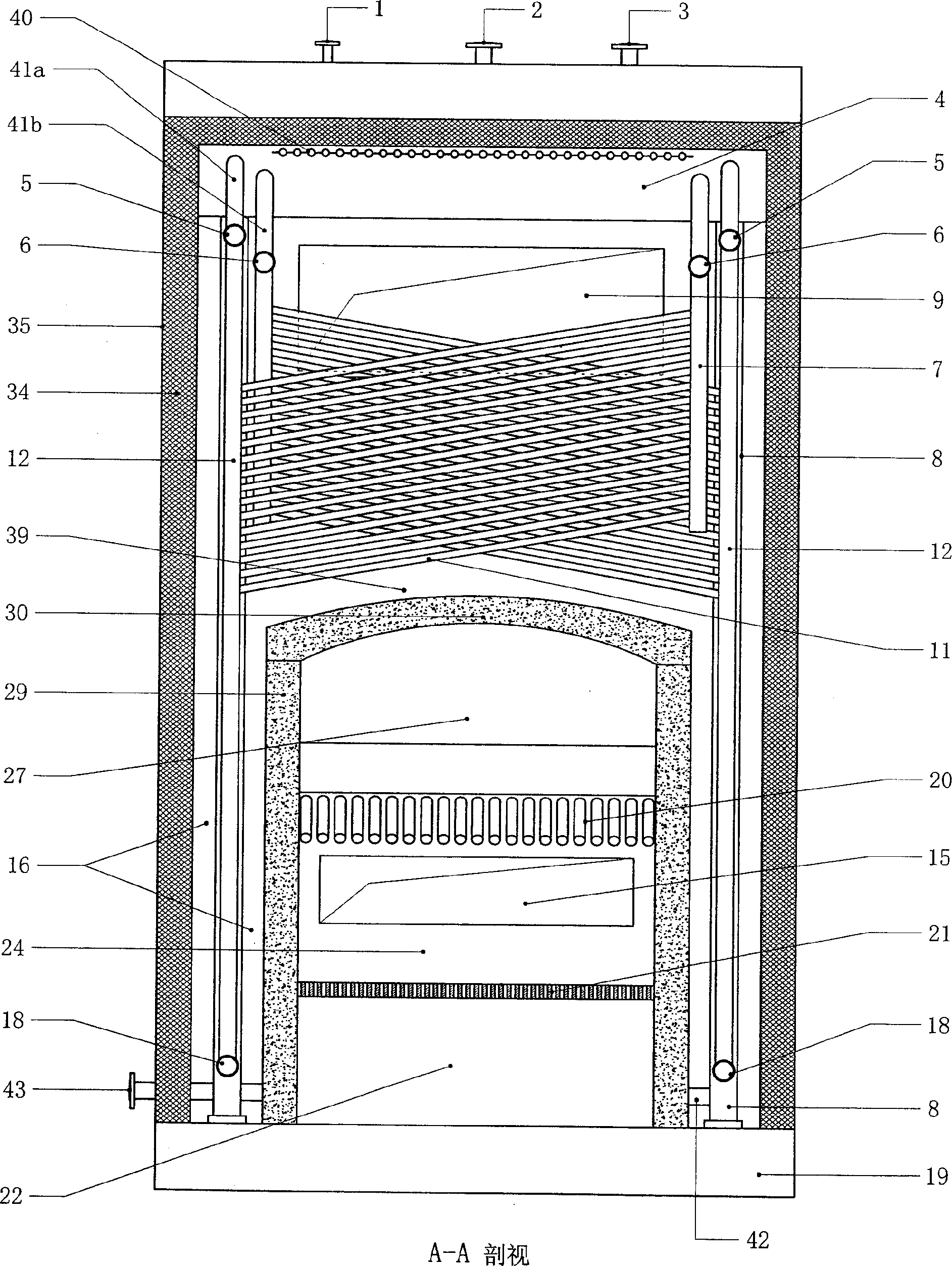

Carbonizing system and carbonizing process of wood materials

ActiveCN102911683AQuality improvementIncrease the heat exchange areaBiofuelsEnergy inputCooling chamberAgricultural residue

The invention discloses a carbonizing system of wood materials. The carbonizing system of wood materials comprises a carbonizing device and a by-product recovery device, wherein the carbonizing device comprises a reaction vessel and a reaction chamber for putting the reaction vessel; the reaction vessel comprises a material shelf and a destructive distillation kettle for putting the material shelf; the destructive distillation kettle is composed of a destructive distillation kettle body and a destructive distillation kettle cover; an exhaust hole and a temperature measuring hole are arranged on the destructive distillation kettle cover; the reaction chamber comprises a calcining chamber with a combustion area, a carbonizing chamber, a pre-heating chamber which are sequentially arranged, a drying chamber and a cooling chamber for pre-treatment and post-treatment of wood materials respectively. The pre-heating chamber, the carbonizing chamber and / or the exhaust hole on the destructive distillation kettle cover in the calcining chamber are connected with the by-product recovery device. The system is suitable for carbonizing production of all wood materials such as tree wood, hard weed tree, bamboo material, forestry and agricultural residues (straw, shell, sawdust and on the like). The invention is scientific and rational in process, none in emission and pollution, short in production period and low in cost, thereby being suitable for popularization and application.

Owner:BLUESTAR BEIJING CHEM MACHINERY

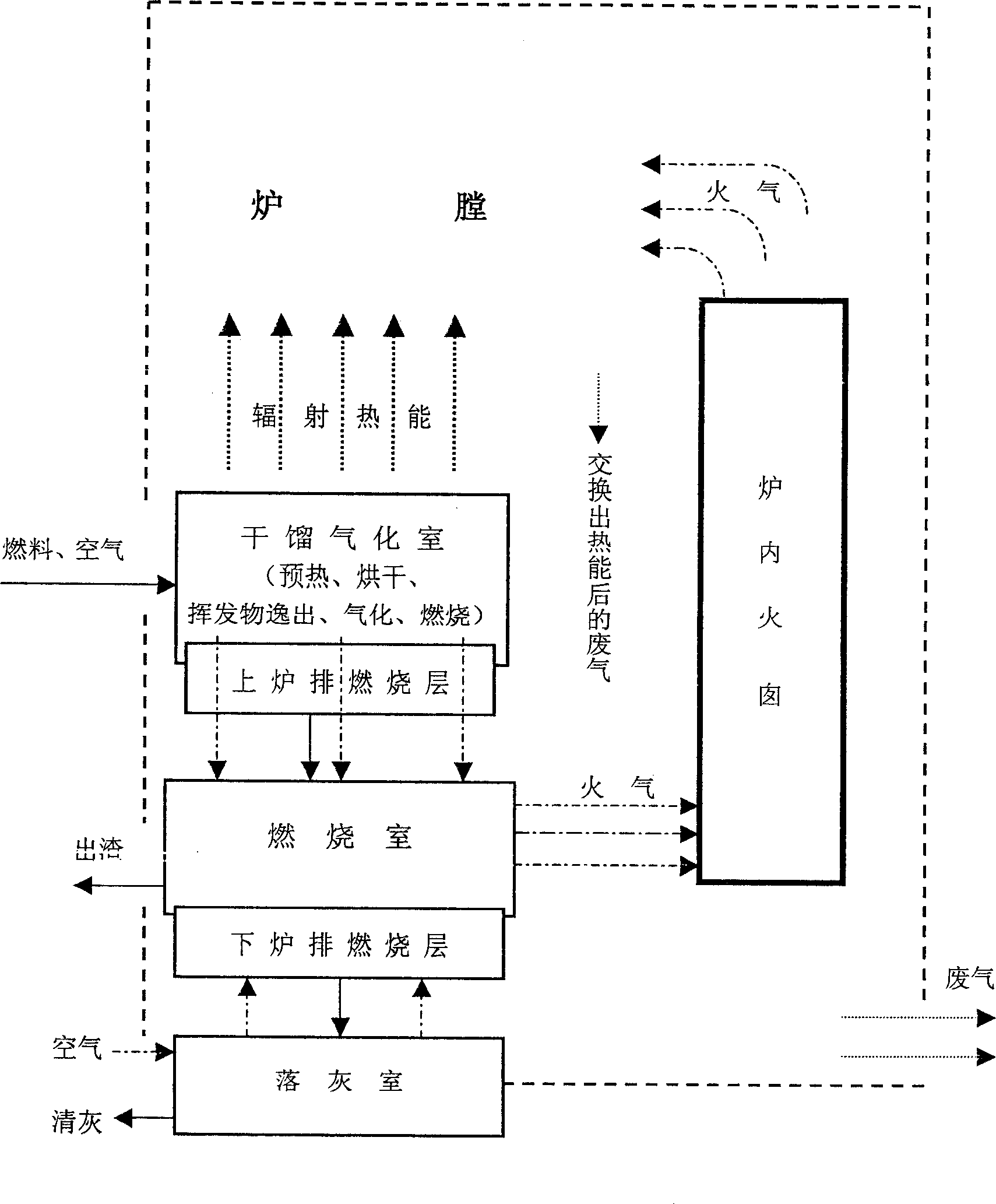

Smokeless burning technique and equipment with fire fontanel being setup inside furnace

InactiveCN1916490AAchieve clean combustionImprove combustion efficiencySolid fuel combustionCombustion apparatusCombustion chamberEngineering

A smokeless combustion device with fire stack in furnace consists of destructive distillation gasification combustion chamber, the second combustion chamber, top fire grate, bottom fire grate, fire stack in furnace, firepot, heated surface and fender. The extensive fuel materials such as raw coal, bulk coal, section coal, wood, straw and agricultural wastes can be used as fuel material of said device.

Owner:周开根

Method for synchronously recovering mercuric chloride, metal salt and active carbon in spent catalyst

InactiveCN102962033AIncrease profitSolve the scarcityPhysical/chemical process catalystsCalcium/strontium/barium chloridesMetal saltsRaw material

The invention discloses a method for synchronously recovering mercuric chloride, metal salt and active carbon in a spent catalyst. The method is orderly implemented through the steps of spent catalyst drying, mercuric chloride recovery, complex perforation of active carbon and metal salt recovery, wherein mercuric chloride in the spent catalyst is recovered through destructive distillation in combination with condensation and aqueous solution absorption; deposits in the micropores of the active salt are displaced through hot water soaking in combination with bubbling by introducing air, thereby realizing the purpose of recovering the pores of the active carbon; and then the active carbon is recovered through drying and the metal salt is recovered through filtering; in the whole process, no pollutant is generated and discharged and the utilization rate of water is also extremely high; valuable elements in the spent catalyst are all recovered; and the valuable elements in the spent catalyst which is used in production previously and contains mercuric chloride, metal salt and active carbon are utilized, thereby achieving the purposes of solving the problems of scarce raw materials for new catalyst production and environmental pollution caused by inappropriate spent catalyst disposal; as a result, the method is obvious in economic benefit, environmental benefit and social benefit.

Owner:那风换

Vibrating turning mixed flow type complete-alternation granule wax shale destructive distillation method and device

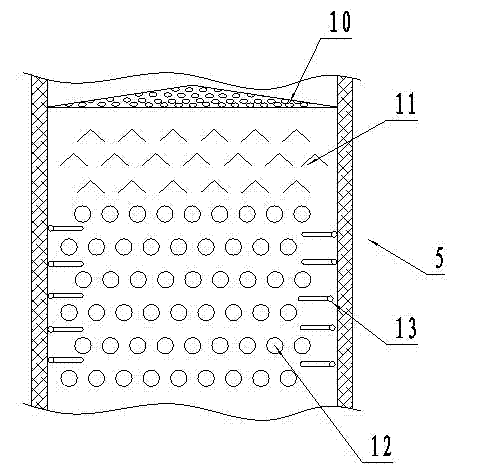

InactiveCN101343544ASimple structureEasy to operateLiquid hydrocarbon mixture productionSpecial form destructive distillationWaxMixed flow

The invention relates to carbonization process and the device thereof which can treat short grain oil shale. A multilayer vibrated bed is used to convey material, a thermal cycling gas is used as gas heat carrier, and the material is carbonized under the working condition of repeated material interflow. The material and the gas heat carrier are not only vertically but also transversely contacted in a retort oven, the carbonization intensity is high, the time is short, and the oil yield is higher than 90 percent. The device has the advantages of simple structure, convenient operation, low investment and high efficiency.

Owner:吴启成

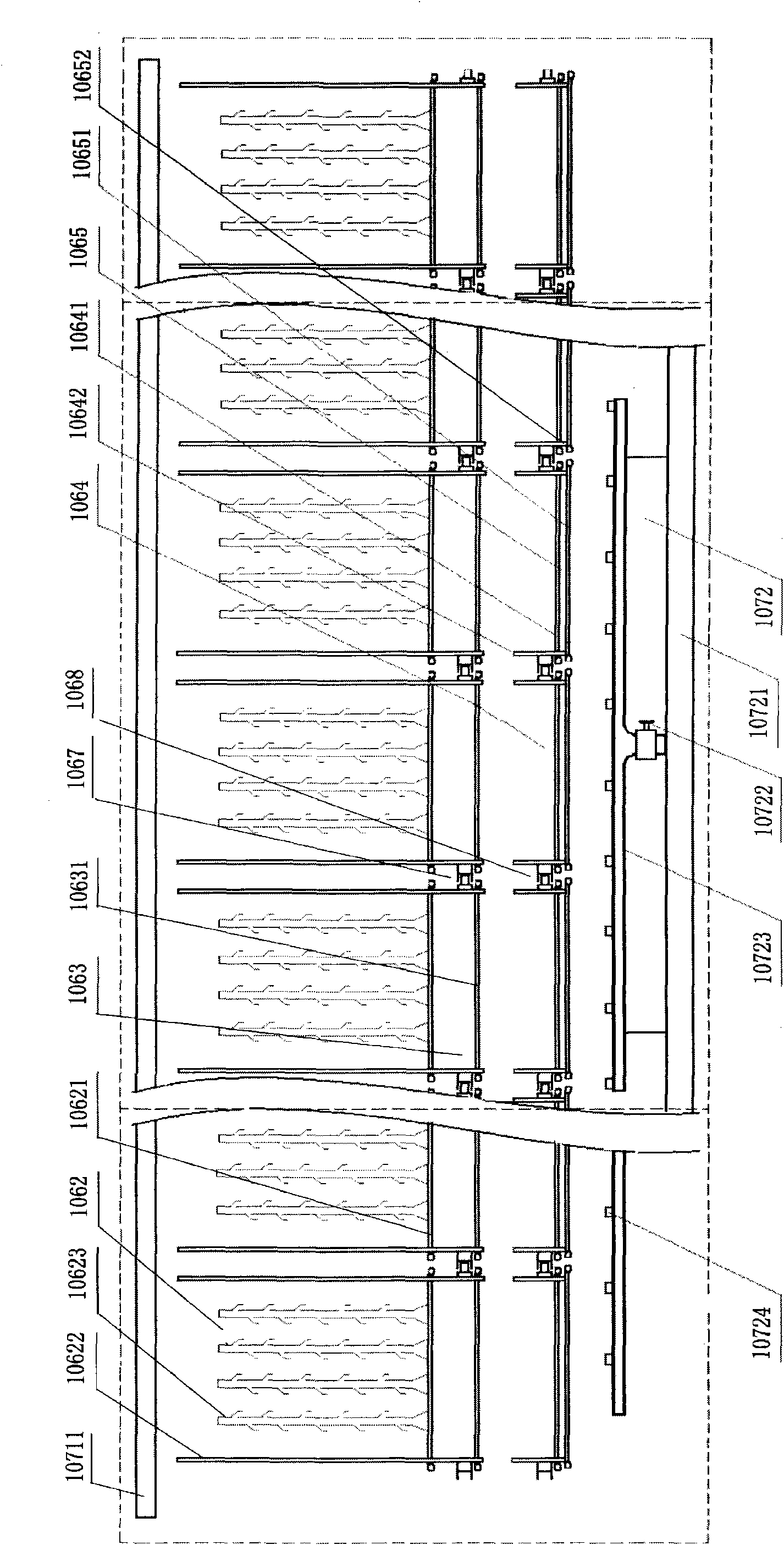

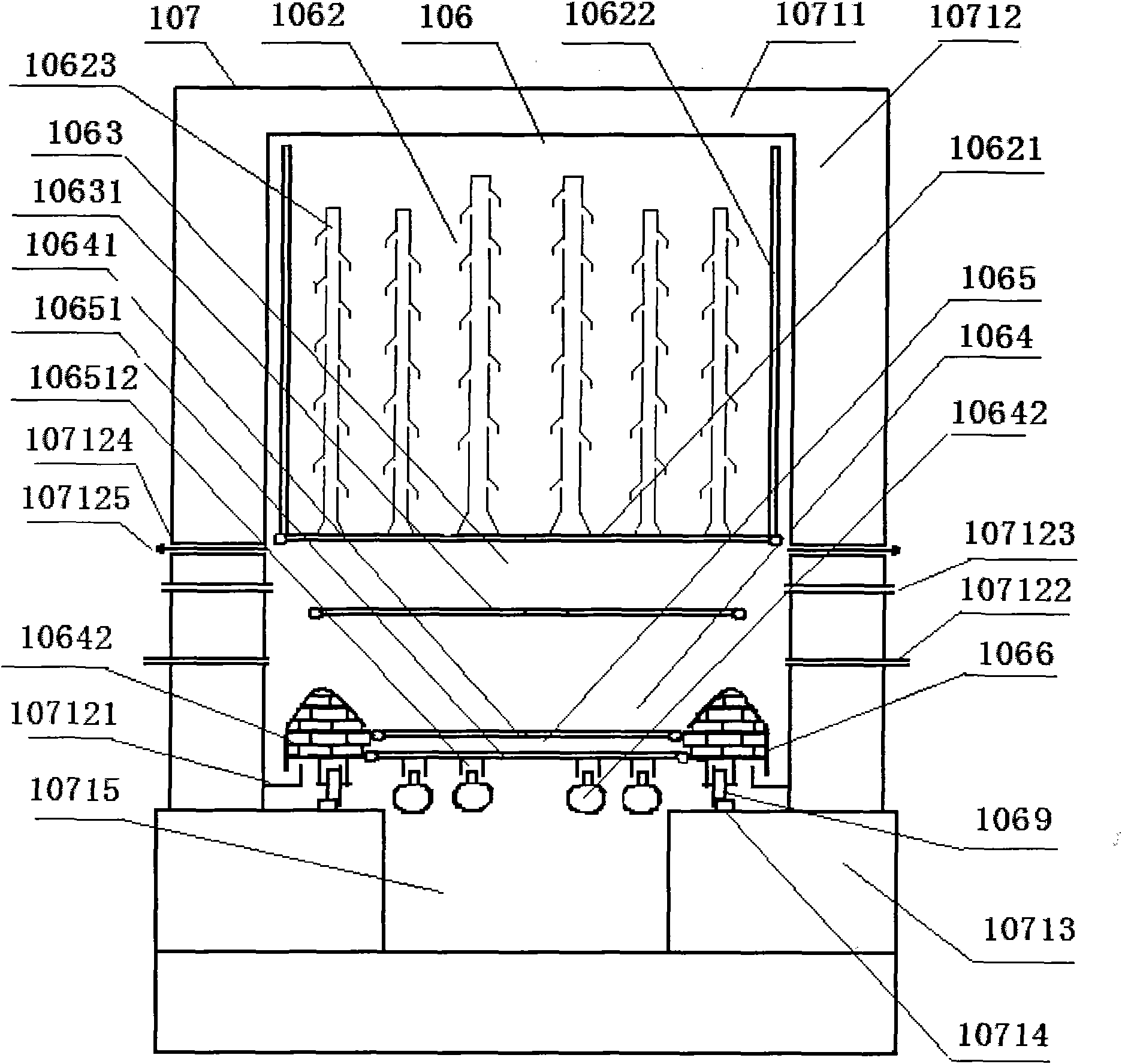

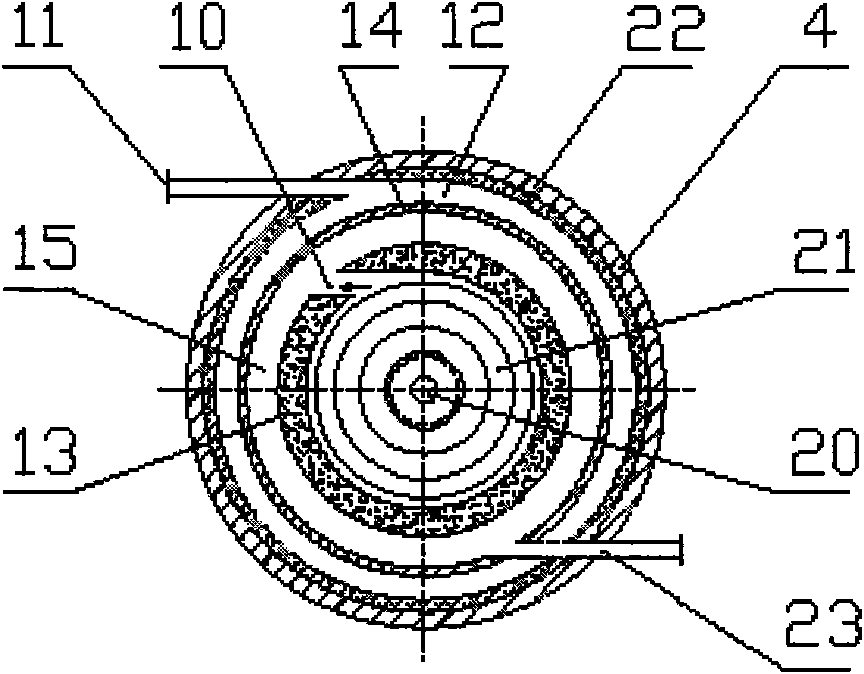

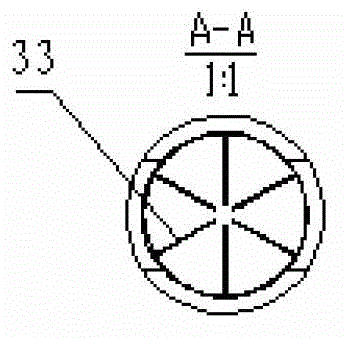

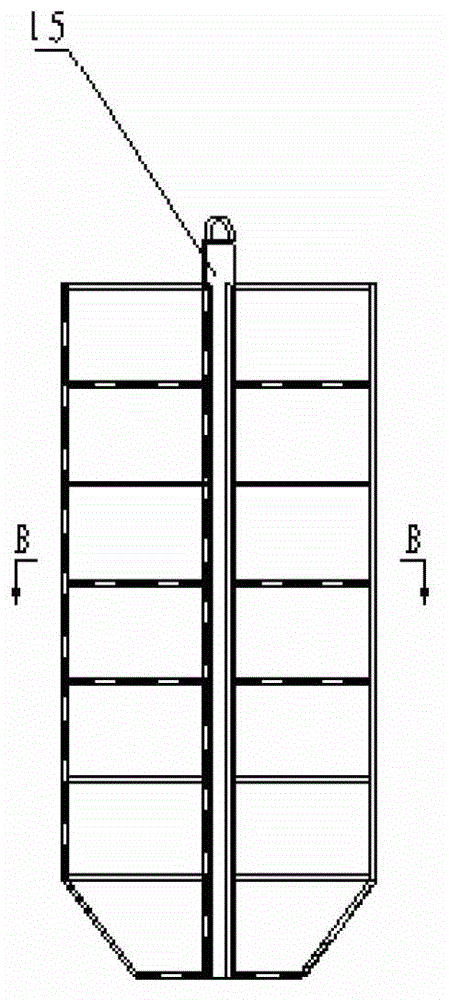

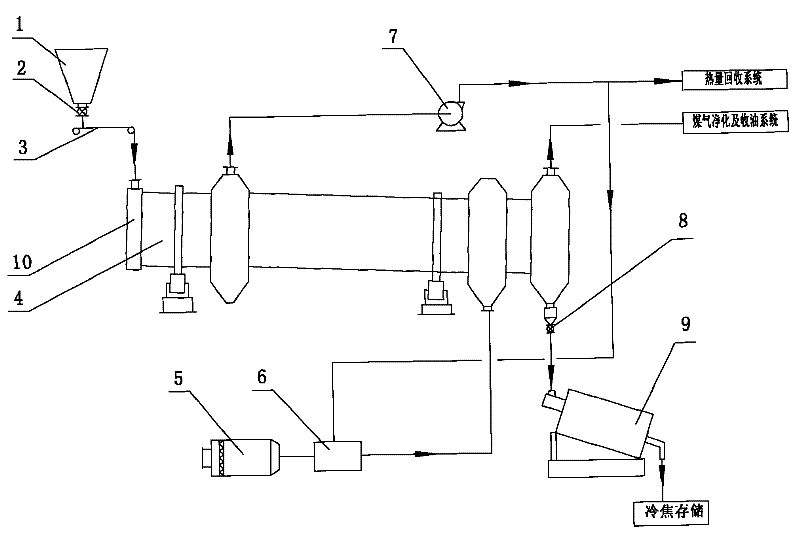

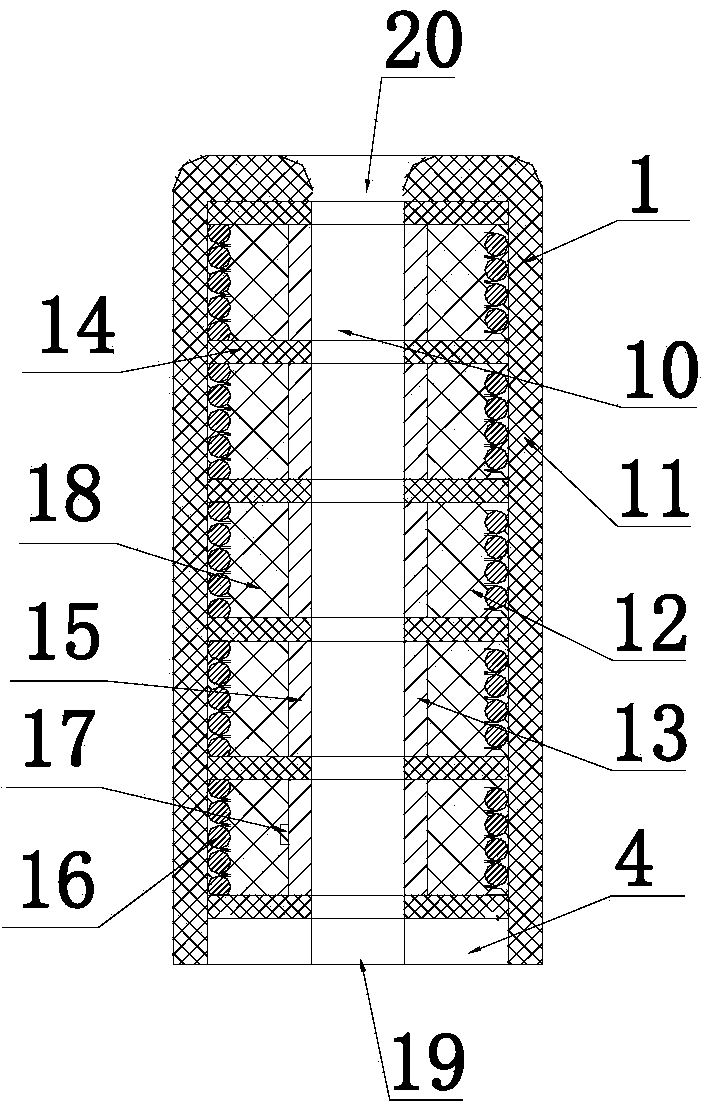

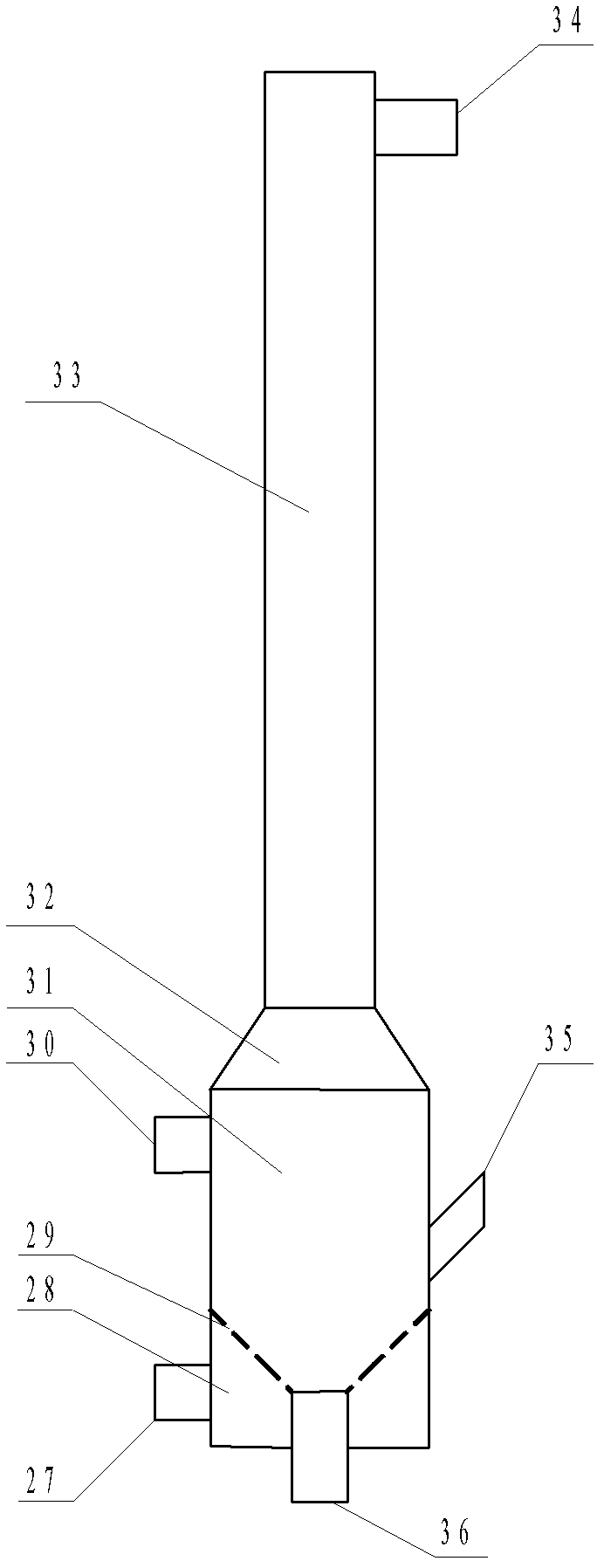

Single-stage fine coal multi-pipe rotary low-temperature destructive distillation technology and system

ActiveCN102358840AImprove thermal efficiencyEasy to handleIndirect heating destructive distillationSpecial form destructive distillationSingle stageSpiral blade

The invention discloses a single-stage fine coal multi-pipe rotary low-temperature destructive distillation technology and a system. The single-stage fine coal multi-pipe rotary low-temperature destructive distillation technology adopts a multi-pipe rotary destructive distillation machine to carry out low-temperature destructive distillation of fine coal. Multiple destructive distillation pipes for dispersing fine coal are arranged in the multi-pipe rotary destructive distillation machine. Spiral blades are arranged in the destructive distillation pipes and have the effects of diversion and disturbance on coal. The single-stage fine coal multi-pipe rotary low-temperature destructive distillation technology and the system can enhance destructive distillation effects, can increase destructive distillation effective areas, have the advantages of large fine coal treatment amount, small destructive distillation gas treatment amount, low content of tar and dust, and high calorific value of gas, can realize recovery of chemical raw materials such as coal tar and the like produced in low-temperature destructive distillation of soft coal and low-order fine coal as completely as possible, can improve a comprehensive utilization rate of coal, and can realize production of semicoke powder and high-calorific value gas from soft coal and low-order fine coal through low-temperature destructive distillation.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Multilayer rotary kiln based small granular material destructive distillation method

ActiveCN103952165ALow running costGuaranteed concentrationEnergy inputIndirect heating destructive distillationGranularityFlue gas

The invention relates to a multilayer rotary kiln based small granular material destructive distillation method. The method comprises the following steps: adding oil shale granules (with the granularity of 0-20mm) with the water content of below 5% to a bunker from a kiln head, sending to the inner cylinder of a rotary kiln by a spiral conveying device, heating the material in the inner cylinder to 500DEG C through the circulation of high temperature hot flue gas (with the temperature of 700DEG C) from a hot blast stove in an annular channel between an outer cylinder and the inner cylinder to pyrolyze the oil shale material in order to generate a destructive distillation gas and semicoke, and carrying out purifying recovery on the destructive distillation gas to obtain gas and shale oil; and adding the semicoke into the annular channel from the inner cylinder, allowing the semicoke to run along a direction opposite to the material running direction in order to carry out heat exchange of the material in the inner cylinder and absorb the waste heat of the semicoke, discharging parts of the semicoke from the stove, and adding a small amount of the semicoke to the inner cylinder for the mixing of the small amount of the semicoke with a normal temperature mixture in order to further utilize the waste heat of the semicoke. The method has the advantages of simple technology, low energy consumption, no pollution, high product quality, realization of the industrial large-scale production, and easy large-area popularization.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Method for extracting Chinese style mixed-fragrance cigarette juice for electronic cigarette

The invention discloses a method for extracting Chinese-style mixed-fragrance cigarette juice for an electronic cigarette. Tobacco leaves, tobacco shreds or tobacco powder of flue-cured tobacco, burley tobacco and aromatic tobacco are mixed, cigarette feed liquid or at least one of cocoa powder, licorice, honey and blackcurrant extracts is added, the mixture is subjected to destructive distillation by different temperature sections, and fractions are collected. The fractions collected by the method can directly serve as electronic cigarette juice, and cigarette essence perfume having characteristic flavor, or edible essence perfume also can be added to enrich the styles of the electronic cigarette juice; the electronic cigarette juice collected by the method has the style characteristic and flavor similar to those of a Chinese style blended type cigarette, mildness and sweetness of VIRGINIA and pungency and appetizing of an aired cigarette are realized, and the aftertaste is pure.

Owner:CHINA TOBACCO SHANDONG IND

Electromagnetic wave heating device for non-burning cigarettes

The invention relates to an electromagnetic wave heating device for non-burning cigarettes. The device comprises an outer shell, a heat insulation sleeve and a heater. A cigarette inlet allowing tobacco products to be inserted in is formed at the front end of the outer shell, an air inlet is formed at the rear end of the outer shell connectively, the heater is arranged in the outer shell, an electromagnetic wave heating element is adopted as the heater and comprises a coil and an inner heating sleeve, the coil and the inner heating sleeve are matched to realize heating, the heat insulation sleeve is arranged between the coil and the inner heating sleeve, insulation washers are arranged at two ends of the electromagnetic wave heating element respectively, the inner heating sleeve is hollow to form a heating cavity for accommodating the tobacco products, the front end of the heating cavity is communicated with the cigarette inlet, and the rear end of the heating cavity is communicated with the air inlet. By the device, aroma components in the cigarettes can be removed by destructive distillation through an electromagnetic wave heating mode in stead of directly burning the cigarettes, harm of the cigarettes to human bodies is reduced, and a consumer is ensured to obtain a tobacco feature feeling.

Owner:CHINA TOBACCO ZHEJIANG IND

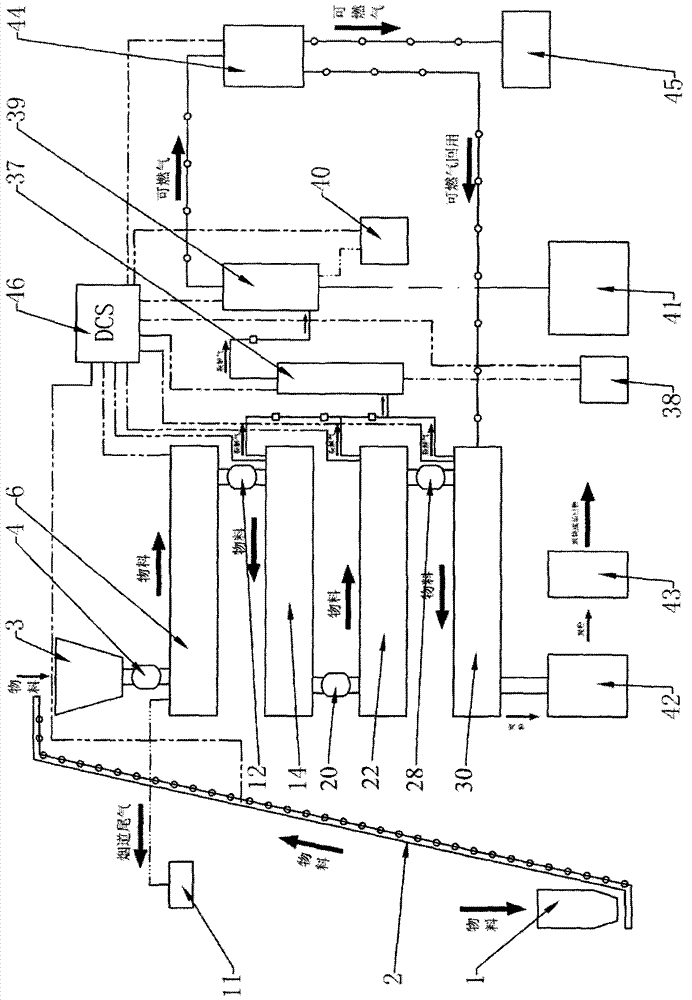

Method for integrative sorting and destructive distillation pyrolysis and gasification of household refuse without discharge of dioxin

InactiveCN102816578AAvoid it happening againAvoid harmDirect heating destructive distillationEnergy inputBrickResource utilization

The invention provides a method for integrative sorting and destructive distillation pyrolysis and gasification of household refuse without discharge of dioxin. According to the method, an automatic garbage integrative sorting system, a feeding charging system, a destructive distillation pyrolysis and gasification furnace system, an exhaust gas purifying device, an ash removing device and a combustible gas power generation system are used in the method; problems in treatment of household refuse are thoroughly overcome, for example, generation of dioxin is avoided and pollution of waste water, exhaust gas and waste residues is reduced; plastic garbage in hybrid municipal solid waste is sorted out for preparation of plastic particles by using the automatic garbage integrative sorting system; after drying, rest garbage is converted into combustible gas and is used to prepare the renewable resource tar through integrative treatment of destructive distillation pyrolysis and gasification, waste residues are used for brick making, waste water is recycled after treatment, and exhaust gas is purified and discharged after the exhaust gas reaches the standard. When the method provided by the invention is used for treating garbage, generation and harm of dioxin are avoided, no waste water, waste residues and wastes are discharged, harmlessness and full resource utilization are realized in reality, and recycling economy of treating wastes with wastes and turning the waste into the valuable is achieved.

Owner:严大春

Oil sludge treating system and method

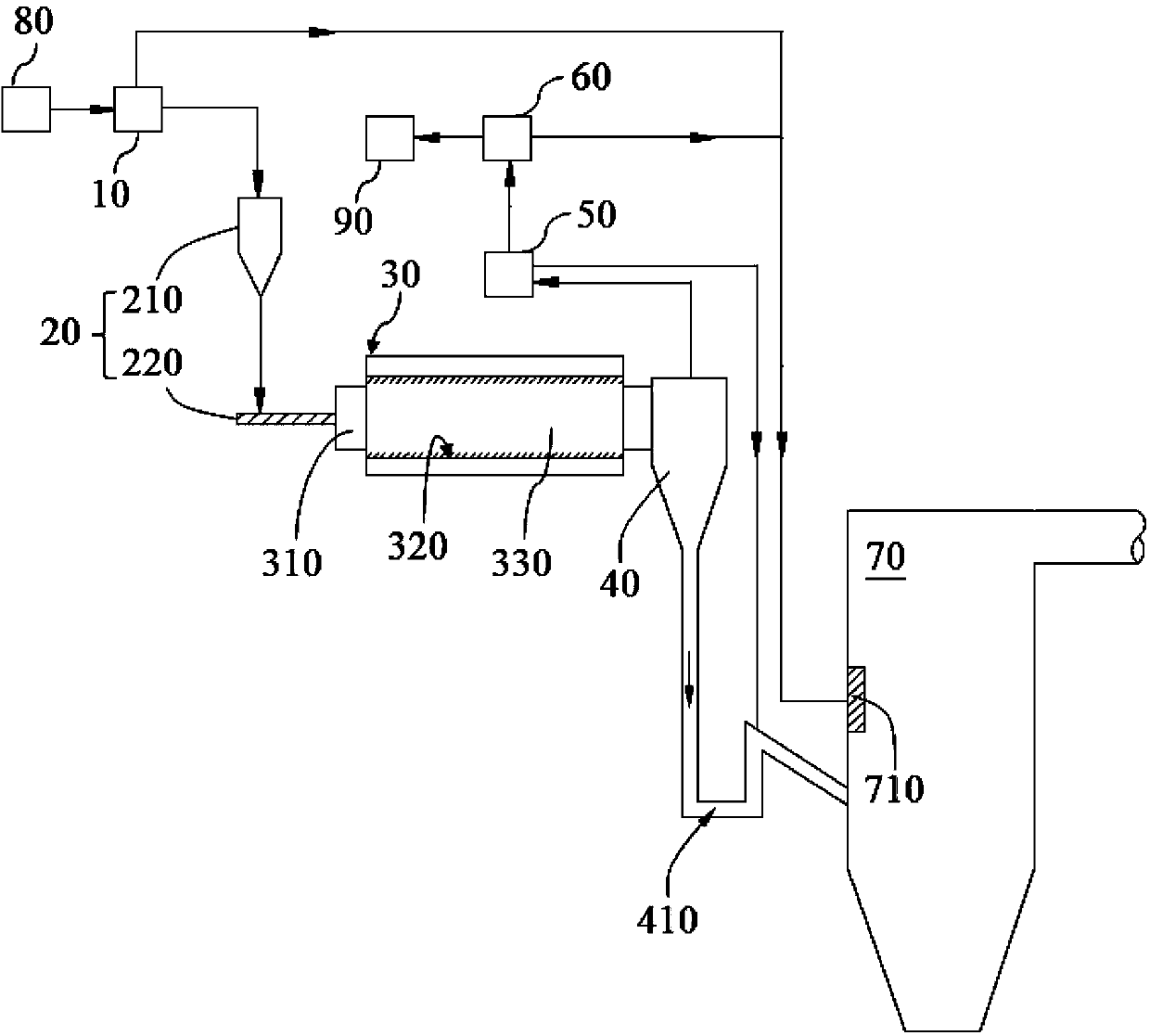

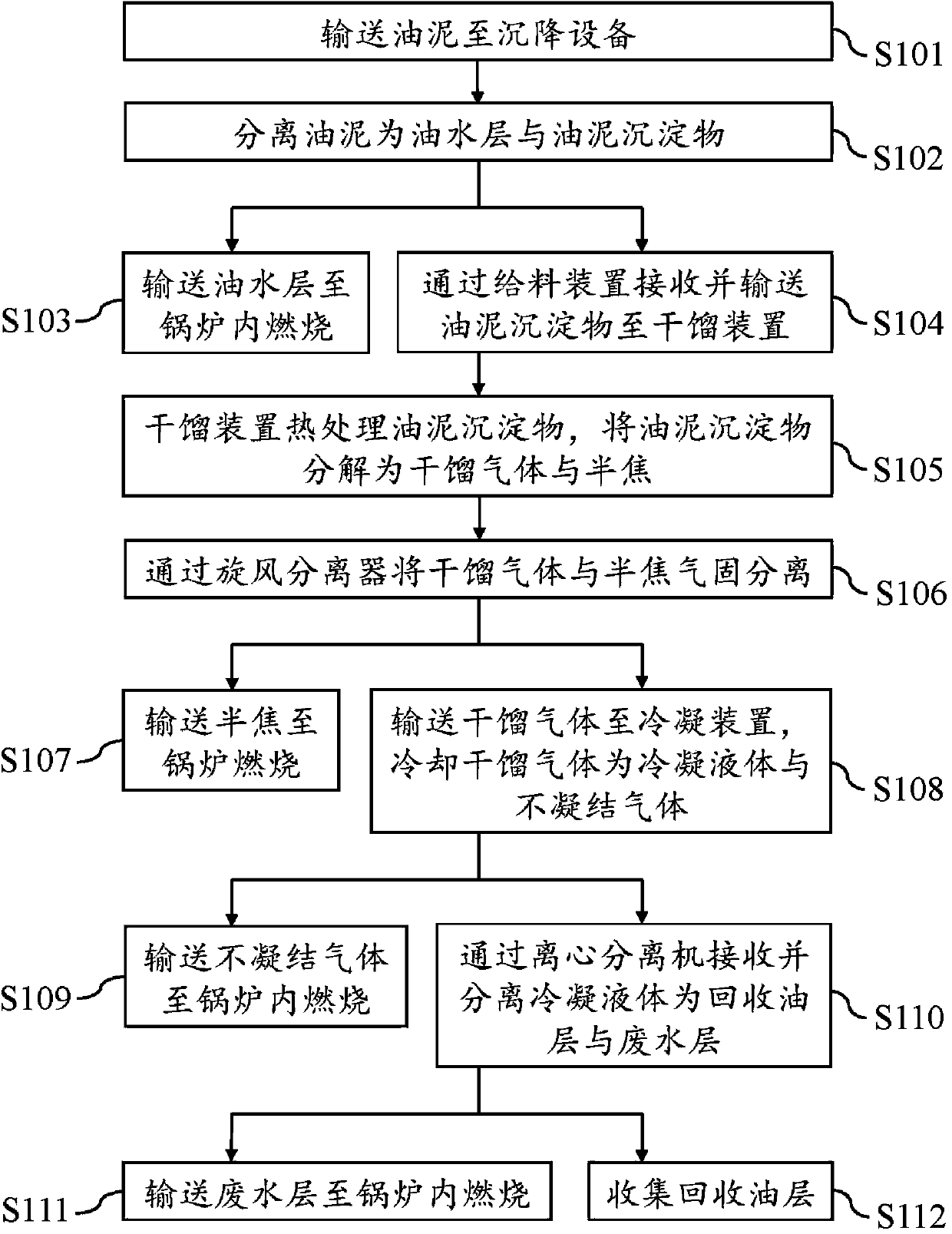

InactiveCN103420555AEasy to separateCompliance with emission standardsSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisCombustionEnergy recovery

The invention discloses an oil sludge treating system and method. The oil sludge treating system comprises a sedimentation device, a feeding device, a destructive distillation device, a cyclone separator, a condensation device, a centrifugal separator and a boiler. Oil sludge is divided into an oil-water layer and an oil sludge sediment through the sedimentation device; the oil sludge sediment is conveyed to the destructive distillation device through the feeding device, and is decomposed into destructive distillation gas and semicoke through the destructive distillation device; gas-solid separation is conducted through the cyclone separator; then the destructive distillation gas is cooled to be condensed fluid and non-condensable gas through the condensation device; the condensed fluid is divided into a recovered oil layer and a waste water layer through the centrifugal separator; finally the recovered oil is collected for later use. In addition, in the treating process, the oil-water layer, the semicoke, the non-condensable gas and the waste water layer are conveyed to the boiler for combustion. Therefore, the oil sludge treating system has functions of pollutant treatment and energy recovery, and is high economical efficiency.

Owner:中国大唐集团科学技术研究总院有限公司

Large-scale low-order brown coal upgrading tower

InactiveCN102199437AWell formedEasy to manufactureDirect heating destructive distillationIndirect heating destructive distillationCombustion chamberGas transfer

The invention relates to a large-scale low-order brown coal upgrading tower, which is used for solving the problem of the industrial destructive distillation of low-order brown coal. The large-scale low-order brown coal upgrading tower comprises a tower body, a combustor, a coal bunker and a screw feeder, wherein the coal bunker and the screw feeder are positioned on the top of the tower body, and a carbocoal outlet is formed on the lower part of the tower body; the tower body consists of a plurality of unit towers which are arranged longitudinally in a laminated mode; a uniformly-distributed plate, an anti-wearing tile and a heating pipe are arranged in each unit tower from top to bottom; high-temperature flue gas discharged from the combustor enters the heat pipe in each unit tower sequentially from bottom to top from an S-shaped high-temperature flue; each unit tower is provided with a gas transfer pipe; a gas valve is arranged on the transfer pipe; and the unit tower positioned on the uppermost part is provided with a discharge flue. The upgrading tower consists of a plurality of unit towers, so the structure is convenient to manufacture and mount, and products are easy to form. Due to the adoption of a continuous production mode, the large-scale low-order brown coal upgrading tower is suitable for large-scale industrial production, is simple in equipment and easy to implement, and provides an effective path for the utilization of the low-order brown coal.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

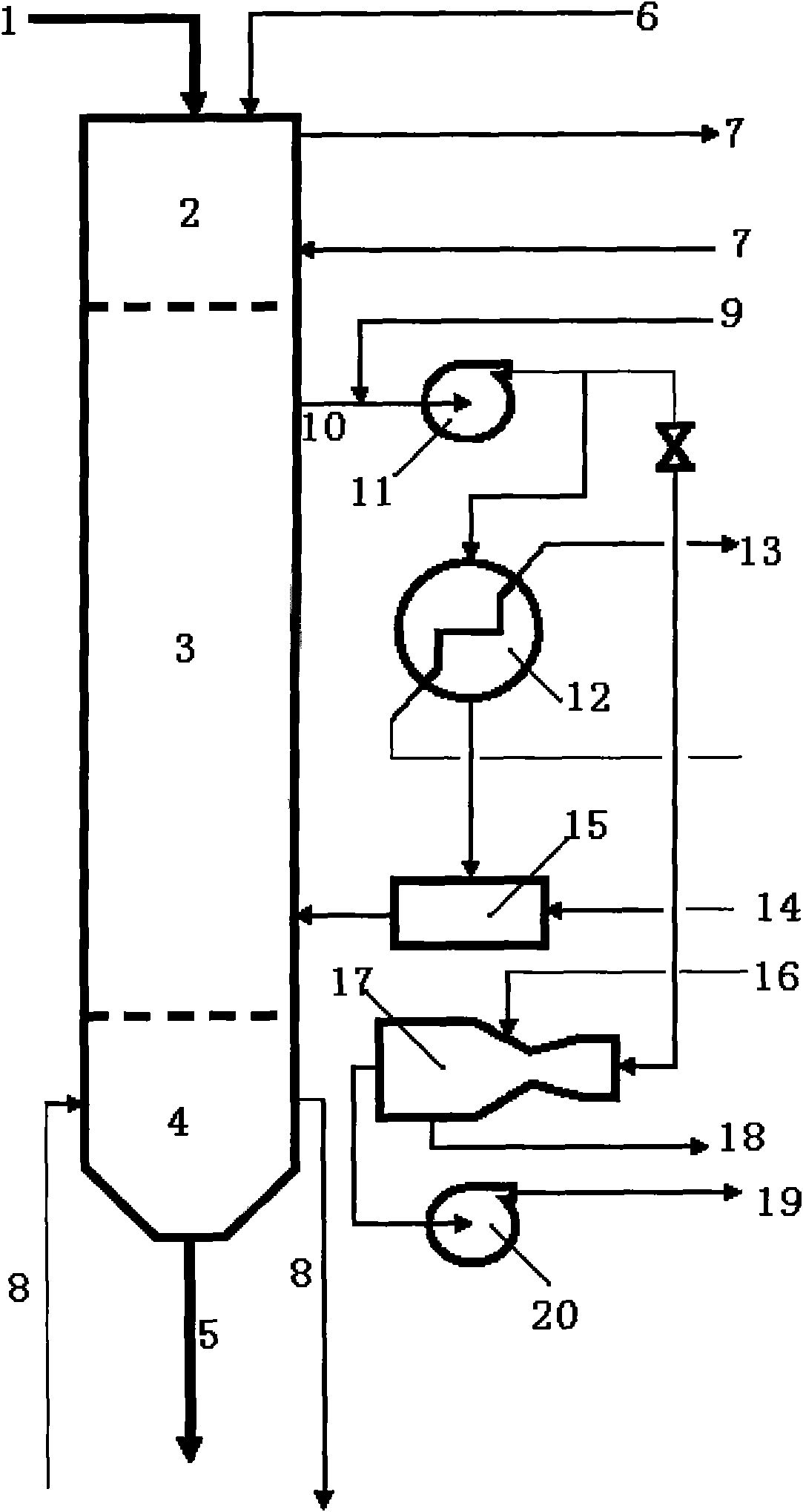

Fluidized bed low-temperature destructive distillation system and low-temperature destructive distillation method of low-rank coal

InactiveCN103160299AExtended stayHigh solid contentDirect heating destructive distillationSpecial form destructive distillationPartial hydrogenationHydrogen atmosphere

The invention provides a fluidized bed low-temperature destructive distillation system and a low-temperature destructive distillation method of low-rank coal. According to the method, a mixed gas of hot coal gas produced by a gasification furnace and circulation cold coal gas is adopted as a hot carrier and a fluidizing gas of a destructive distillation reaction. A hydrogen atmosphere of coal gas can provide a partial hydrogenation effect, such that obtained tar has the advantages of high light component content, good quality, high thermal efficiency, and high yield. Also, with the method, a two-stage low-temperature destructive distillation reactor is adopted, such that the retention time of solid particles in the reactor is increased, destructive distillation effect is improved, high solid content in the bed can be maintained, and operation stability can be maintained. The invention also provides a low-temperature destructive distillation reactor. The low-temperature destructive distillation reactor is the two-stage low-temperature destructive distillation reactor, such that the retention time of solid particles in the reactor is increased, and destructive distillation effect is improved. With the two-stage low-temperature destructive distillation reactor, high solid content in the bed can be maintained, and operation stability can be maintained.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM +1

Method for preparing rhodium chloride hydrate by recovering rhodium from dead rhodium catalyst of oxo synthesis

ActiveCN102923796AAvoid Entrainment LossAvoid overheatingRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsCooking & bakingSorbent

The invention discloses a method for preparing rhodium chloride hydrate by recovering rhodium from dead rhodium catalysts of oxo synthesis. The method is characterized by comprising: adding a certain amount of silica solid adsorbent in the dead rhodium catalysts of the oxo synthesis reactions, placing the mixture into a high-temperature furnace to perform destructive distillation baking through a certain temperature control program, adding a certain amount of concentrated hydrochloric acid into residue obtained through the destructive distillation baking, leading enough amount of ozone into the mixture by controlling the certain temperature until no charcoal grey particle exists in a system, and performing filtering washing to obtain coarse chlororhodic acid solution; and removing plasma impurities including Fe, Ni, Ca and the like in the chlororhodic acid solution by means of a well-known ion exchange method, and performing concentrating and drying to obtain the rhodium chloride hydrate.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

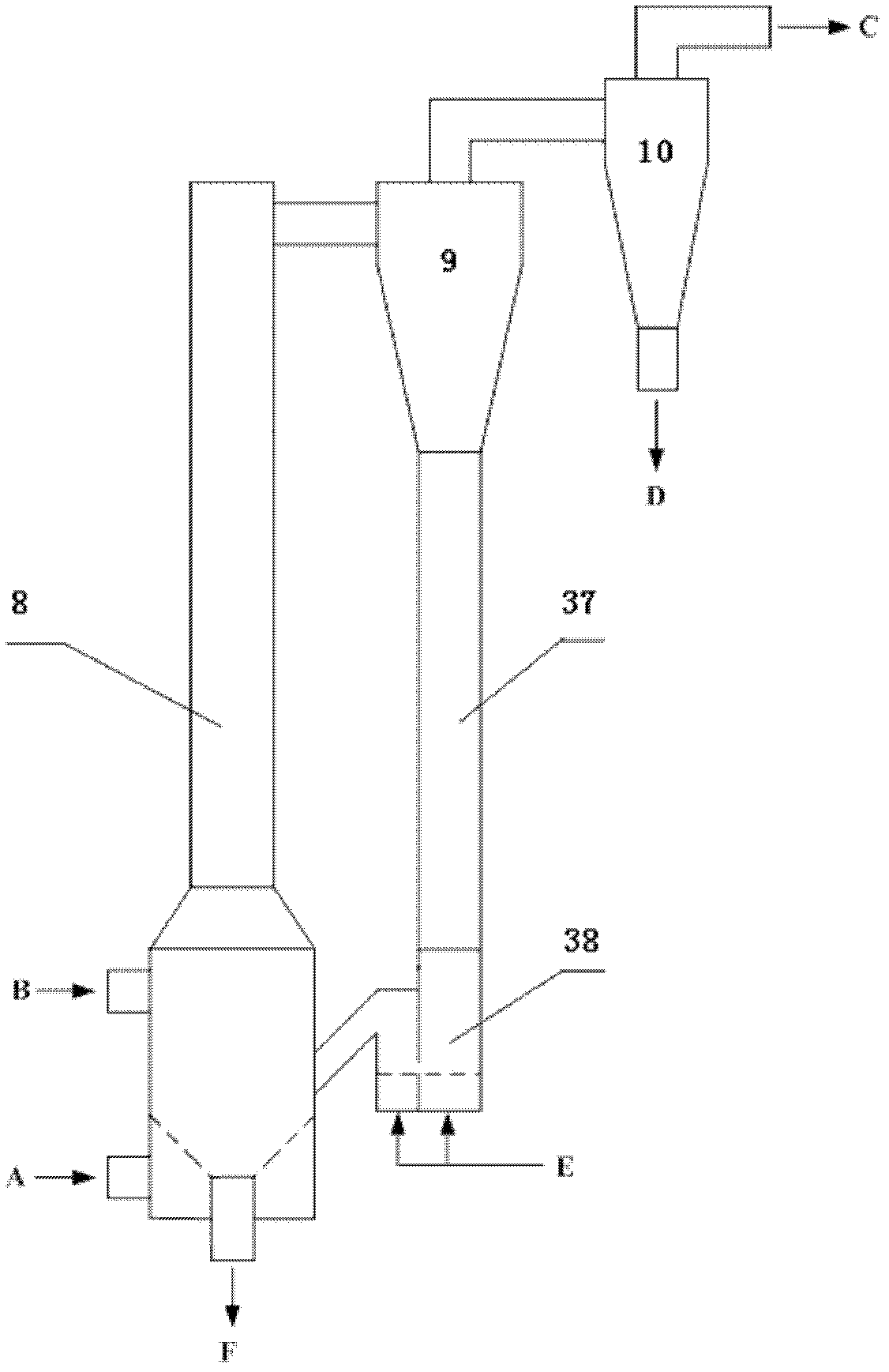

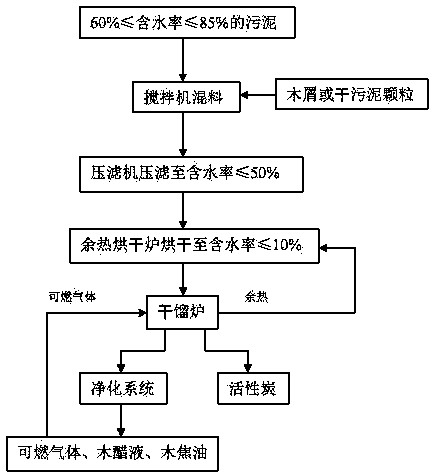

Process and device for sludge pyrolysis

InactiveCN103466912AImprove heating efficiencyIncrease furnace capacityCombination devicesSludge treatment by de-watering/drying/thickeningSludgePollution

The invention relates to a process and device for sludge pyrolysis. The device is characterized by comprising a gas retort, a waste heat drying oven, a deodorization system, a purification system and a control system. A combustor is arranged on the lower portion of the hearth of the gas retort, and the hearth of the gas retort is connected with the waste heat drying oven. Wood chips or dry sludge particles are added to sludge to be mixed evenly, filter pressing is carried out, and sludge pressing blocks are manufactured. The sludge pressing blocks are pre-dried in the waste heat drying oven, and are contained in the inner kettle of the gas retort for carbonization, gas generated by the carbonization is separated by the purification system, and combustible gas is manufactured for heating the gas retort. Destructive distillation solid residues are used for the filtering and deodorization of combustion tail gas in the gas retort. A low-temperature carbonization technology is adopted, harmless utilization and recycling utilization are carried out on the sludge, the combustible gas generated in the low-temperature carbonization process can be used for heating the gas retort, resources are cyclically utilized and recycled, energy consumption in sludge treatment is reduced, the pollution of the sludge treatment on environment is reduced, secondary products with a high added-value are produced, and economic benefits and social benefits are achieved.

Owner:JIANGSU ZHAOSHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com