Method for synchronously recovering mercuric chloride, metal salt and active carbon in spent catalyst

A mercuric chloride and waste catalyst technology, applied in chemical instruments and methods, mercuric halide, separation methods, etc., can solve problems such as environmental pollution and scarcity of raw materials for new catalyst production, achieve high utilization rate, solve scarcity of raw materials, and restore activated carbon void effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

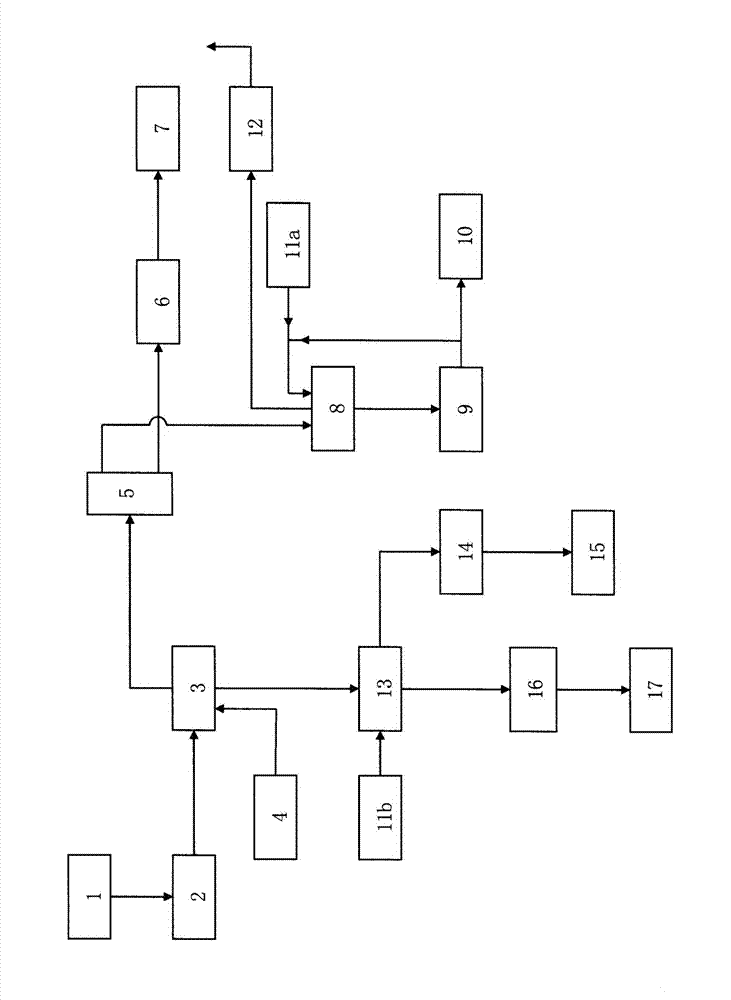

Method used

Image

Examples

Embodiment 1

[0027] A batch of spent catalyst replaced from the converter, the main technical indicators:

[0028] Specific surface: 130m 2 / g

[0029] Mercury chloride content: 5.7%

[0030] Other metal chlorides (BaCl 2 , KCl) content: 13.0%

[0031] Water content: 3.4%

[0032] Carbon tetrachloride absorption rate: 25%

[0033] Bulk density: 610g / l

[0034] Particle size: 3~8mm

[0035] With the method for synchronous recovery of mercuric chloride, metal salt and gac provided by the present invention to reclaim the valuable elements therein, carry out according to the following sequence of steps:

[0036] (1) Drying of waste catalyst

[0037] Put the waste catalyst 1 into the drier 2, the drier 2 is a vertical reactor, and dry it below 80°C until the water content of the waste catalyst 1 is below 0.3%;

[0038] (2) Recovery of mercuric chloride

[0039] Put the dried waste catalyst in the retort 3 whose outer wall is uniformly heated to a temperature of 480°C with an electric ...

Embodiment 2

[0046] A batch of spent catalyst replaced from the converter, the main technical indicators:

[0047] Specific surface: 170m 2 / g

[0048] Mercury chloride content: 3.2%

[0049] Other metal chlorides (BaCl 2 , KCl) content: 15.4%

[0050] Water content: 2.0%

[0051] Carbon tetrachloride absorption rate: 27%

[0052] Bulk density: 592g / l

[0053] Particle size: 3~8mm

[0054] With the method for synchronous recovery of mercuric chloride, metal salt and gac provided by the present invention to reclaim the valuable elements therein, carry out according to the following sequence of steps:

[0055] (1) Drying of waste catalyst

[0056] Put the waste catalyst 1 into the drier 2, the drier 2 is a vertical reactor, and dry it below 80°C until the water content of the waste catalyst 1 is below 0.3%;

[0057] (2) Recovery of mercuric chloride

[0058] Put the dried waste catalyst in the retort 3 whose outer wall is evenly heated to 560°C with electric heating bands, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com