Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2113 results about "Oil sludge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil sludge or black sludge is a solid or gel in motor oil caused by the oil gelling or solidifying, usually at temperatures higher than 100 degrees Celsius. Oil sludge can be a major contributor to internal combustion engine problems, and can require the engine to be replaced, if the damage is severe.

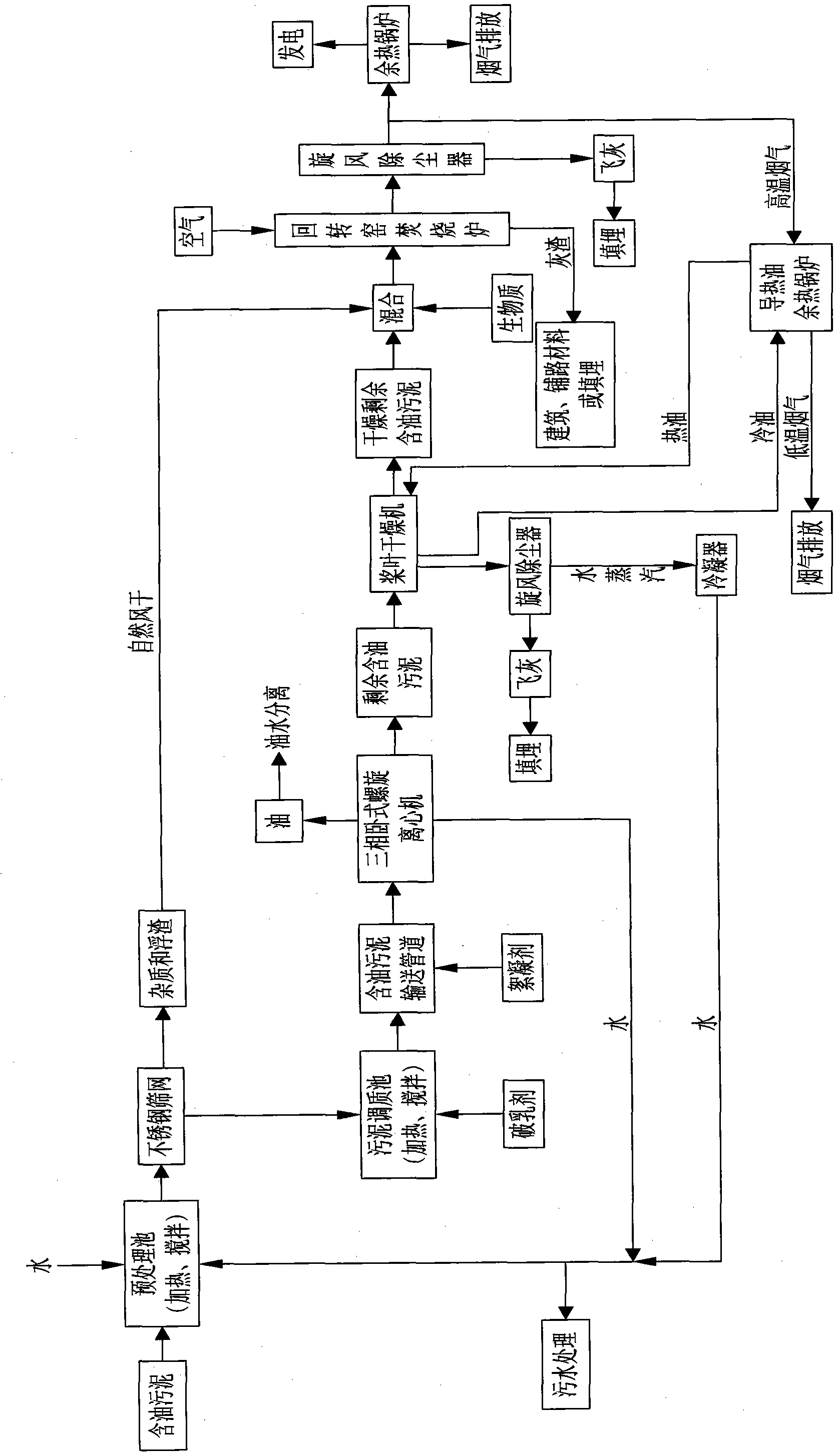

Oily sludge recycling and innocent comprehensive treatment process

InactiveCN102039301APromote resource utilizationEliminate secondary pollutionSolid waste disposalTreatment with plural serial refining stagesSlagOil sludge

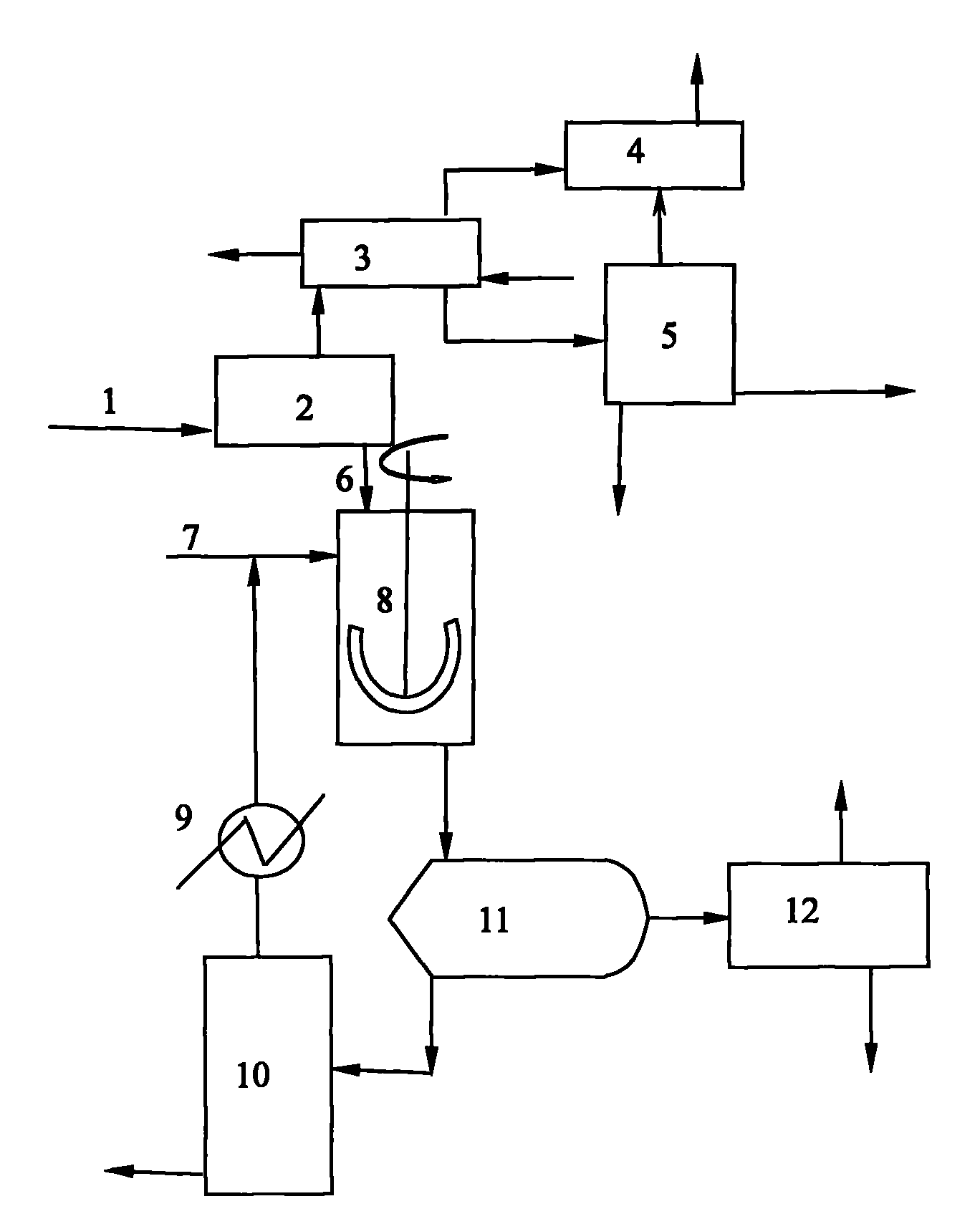

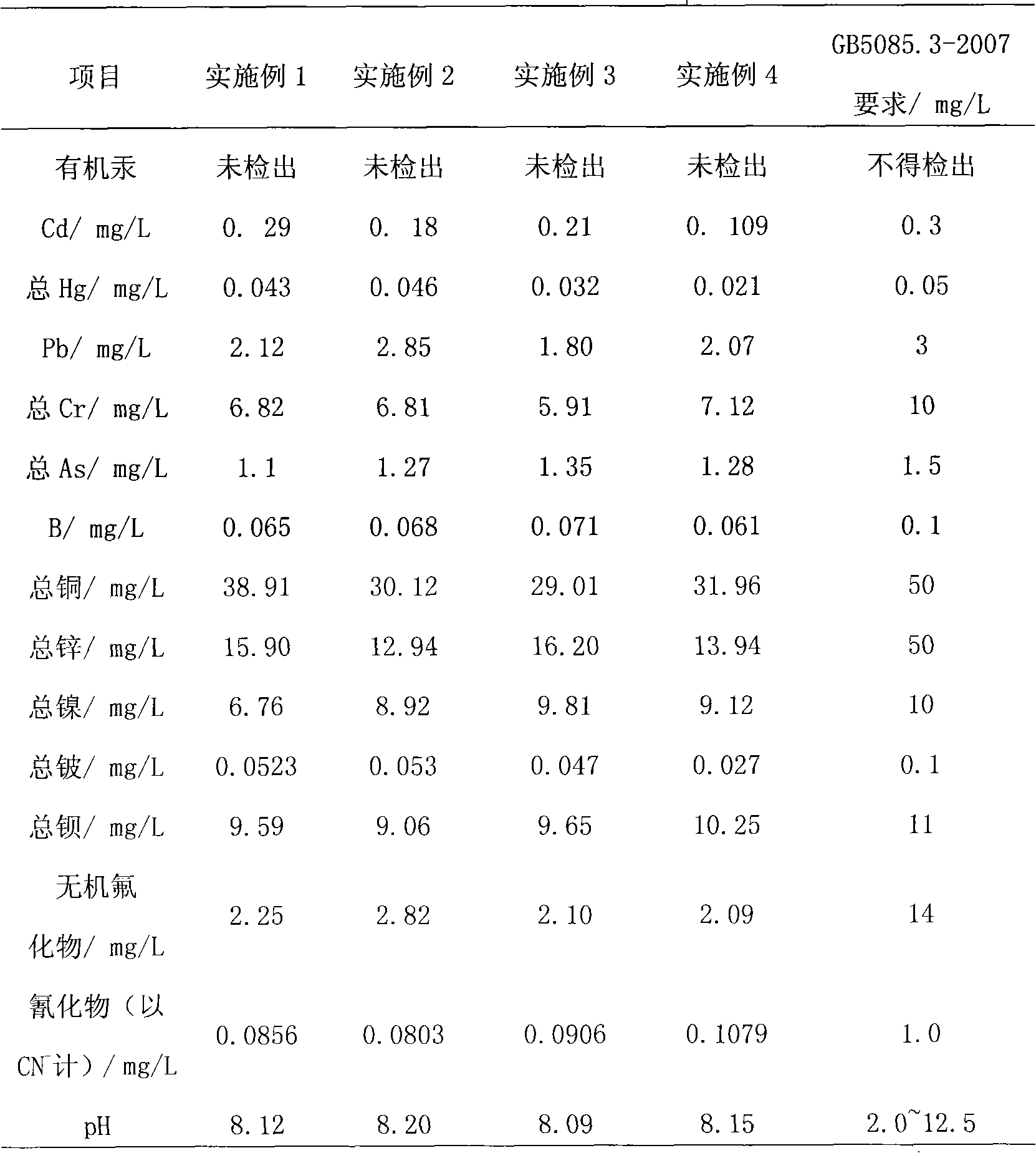

The invention provides an oily sludge recycling and innocent comprehensive treatment process, which comprises the following four steps of: 1, pretreating oily sludge: adding water into the oil sludge, heating and stirring to form fluidized sludge, and separating in a stainless steel screen; 2, conditioning the oily sludge, adding a demulsifier and a flocculant into the separated fluidized sludge for conditioning the oily sludge; 3, performing centrifugal separation on three phases of the oily sludge: introducing separated oil into an oil-water separation system for recovering crude oil, conveying separated water to the oily sludge pretreatment step for recycling, drying the separated residual oily sludge, and solid impurities and floating slag which are separated in the oily sludge pretreatment, and introducing the dried substances into a rotary kiln incinerator; and 4, performing mixed combustion on the residual oily sludge and biomass, performing high temperature incineration treatment after the residual oily sludge, the separated solid impurities and floating slag, and the biomass are mixed in a rotary kiln to remove the secondary pollution of the oily sludge, and recovering afterheat from high temperature flue gas.

Owner:KUNMING UNIV OF SCI & TECH

Acid based micro-emulsions of surfactants and solvents

InactiveUS6984610B2Organic detergent compounding agentsTransportation and packagingEmulsionOil sludge

Acid based micro-emulsions are disclosed comprising water, an acid blend, an anionic surfactant, a nonionic surfactant, a co-solvent, a solvent and an oxidizer. The micro-emulsions have particular utility in cleaning oil sludges and drilling mud residues from well cuttings, well formations and down hole and surface oil well drilling and production equipment.

Owner:INTEGRITY IND +1

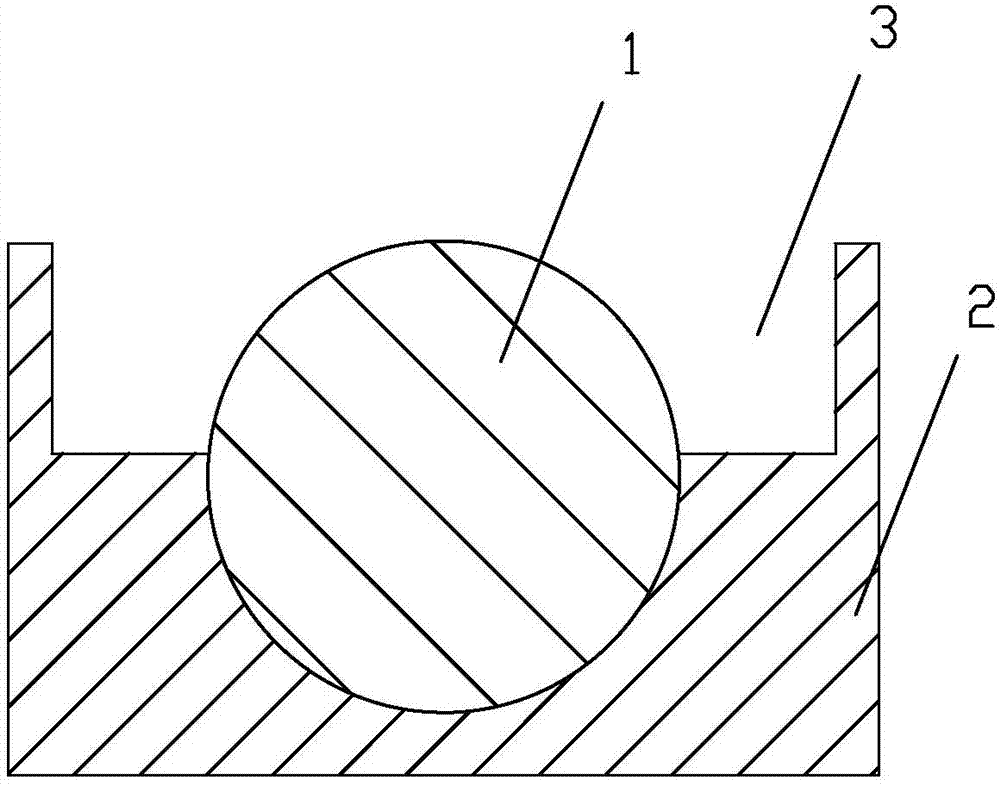

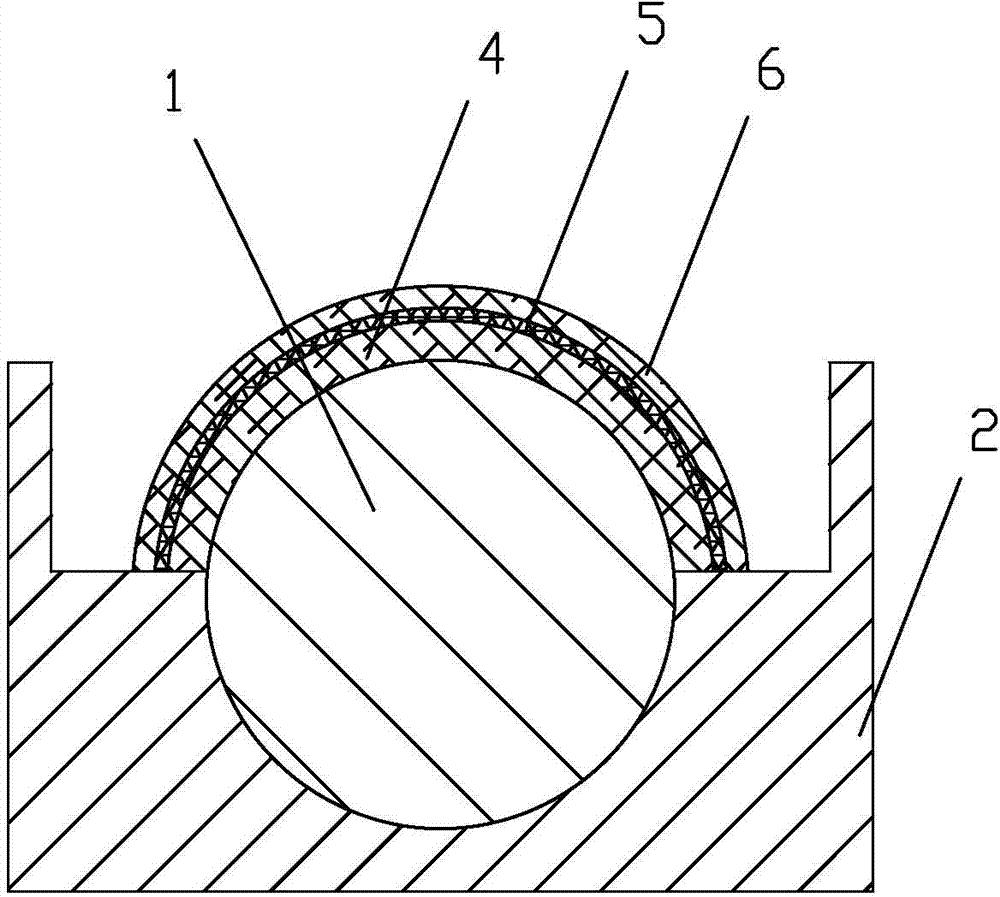

Sand consolidation and water plugging profile control agent made by oil sand

InactiveCN101451061ATo achieve the goal of emission reductionEnhanced overall recoveryDrilling compositionSealing/packingSlagGranularity

The invention relates to a sand-consolidating and water-blocking profile modifying agent for oil sludge sand. The profile modifying agent is prepared by mixing the following raw materials: oil sludge sand, 10 to 90 portions of consolidation agent or adding modifier, a consolidation accelerant or a consolidation retardant; the oil sludge sand is subjected to ball milling through a ball mill; part of large crude oil is separated off so as to reach the requirement of granularity of the profile control agent; therefore, the oil sludge sand with granularity of less than 200 meshes is less than 70 percent of the total mass of the oil sludge sand; and the consolidation agent is selected from one or a mixture of one or more of cement or cement clinker, steel slag, slag, pulverized coal ash, gypsum, lime and magnesia. In application, the profile control agent is prepared to a 1 to 20 percent suspension solution; and the suspension solution is injected into a deep part of stratum of an oilfield through profile modification equipment. The profile modifying agent fully utilizes mass oil sludge sand produced in the production process of various oilfields, realizes the aim of emission reduction; and the oil sludge sand is recycled and is used as the sand-consolidating and water-blocking profile modifying agent, thereby achieving the aim of consolidating sand, blocking water and improving extraction yield.

Owner:SHANDONG UNIV

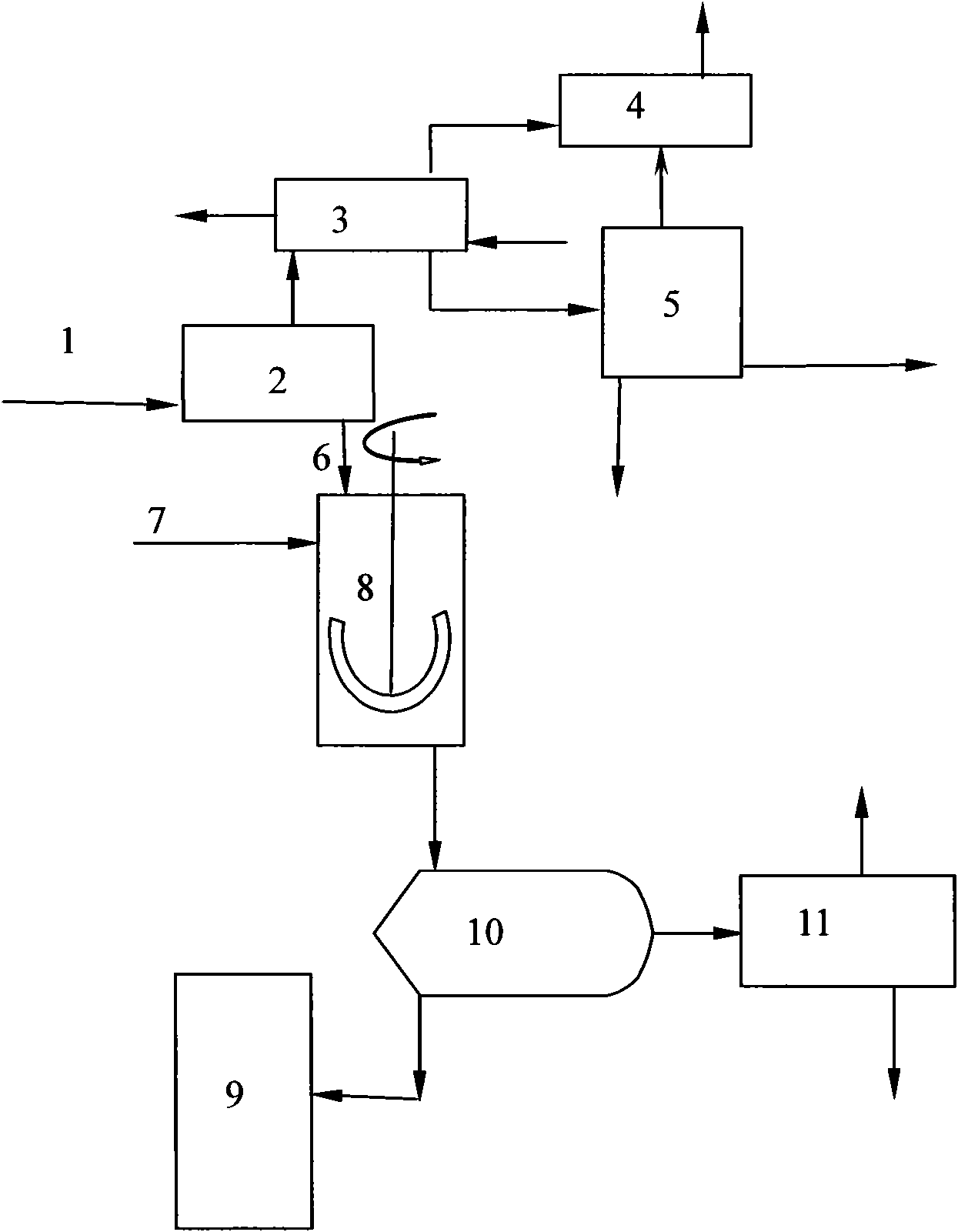

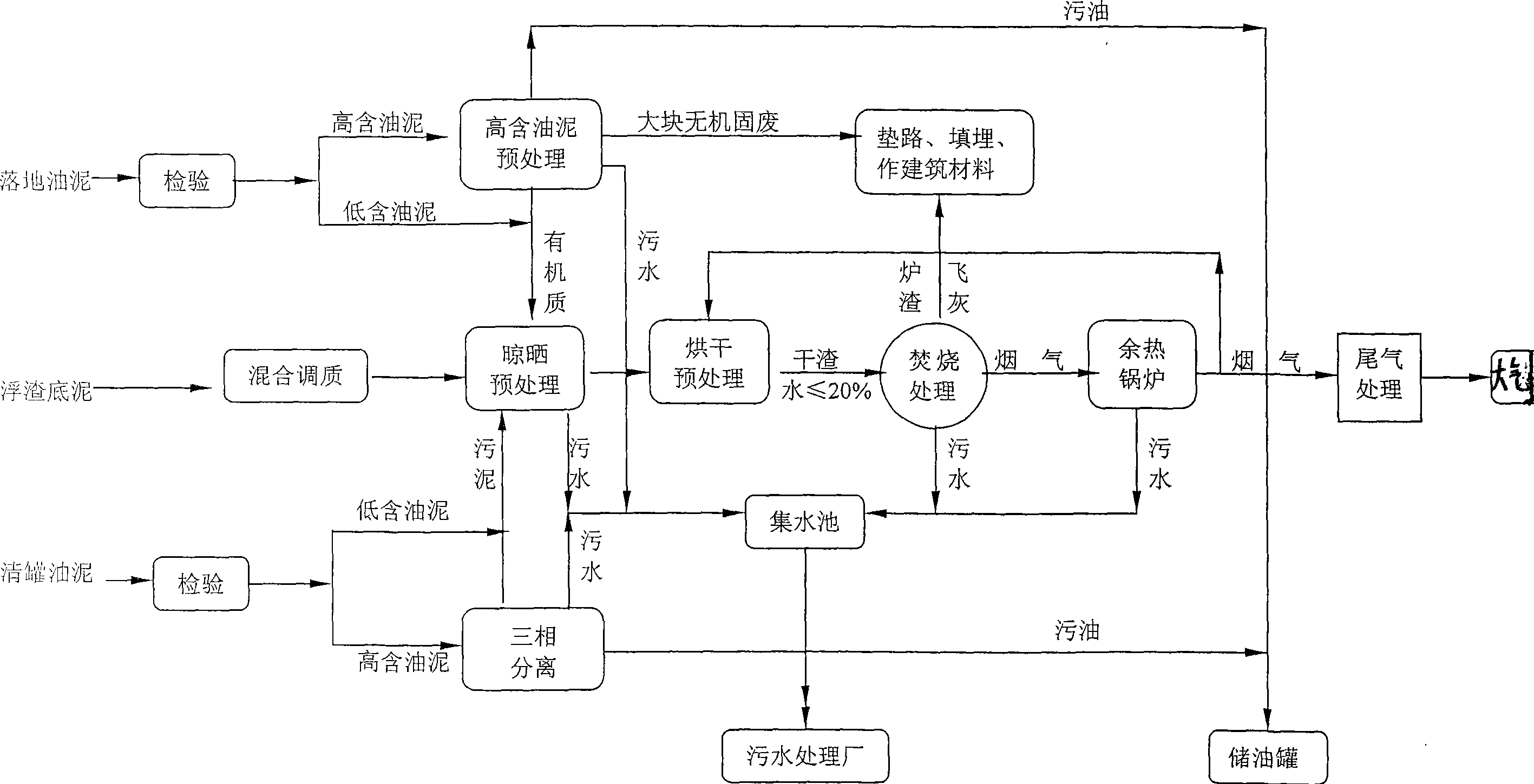

Novel process for comprehensively treating oily sludge of oil field

ActiveCN101602566AAvoid secondary pollutionHarmlessSludge treatment by de-watering/drying/thickeningSolid particleSlurry

The invention provides a novel process for comprehensively treating oily sludge of an oil field, which comprises processes for separating oil, water and sludge from the oily sludge. The process is characterized in that the processes for separating oil, water and sludge comprise a first process of fluidizing and pre-treating sludge, a second process of hardening and tempering the sludge, and a third process of mechanically separating the oily sludge; water separated through the processes can be used as process water to a circulating water recycling process; the separated cleaned oil enters an oil chamber of an oil-water separation device; and solid particles, namely the centrifuged sludge, are discharged through a screw conveyer. The process has the recovery ratio reaching 95 percent for recovering effluent oil to the utmost extent; and the treated sludge has water content less than 60 percent and oil content less than 2 percent, and can be used for underlaying a road of a well site or carrying out subsequent depth treatment. The process cyclically utilizes wastewater, prevents secondary pollution of sewage and slurry, and has large treatment capacity, wide treatment range, advanced technical proposal, high automatic degree, low operation cost, simple operation and clean production.

Owner:北京惠博普能源技术有限责任公司

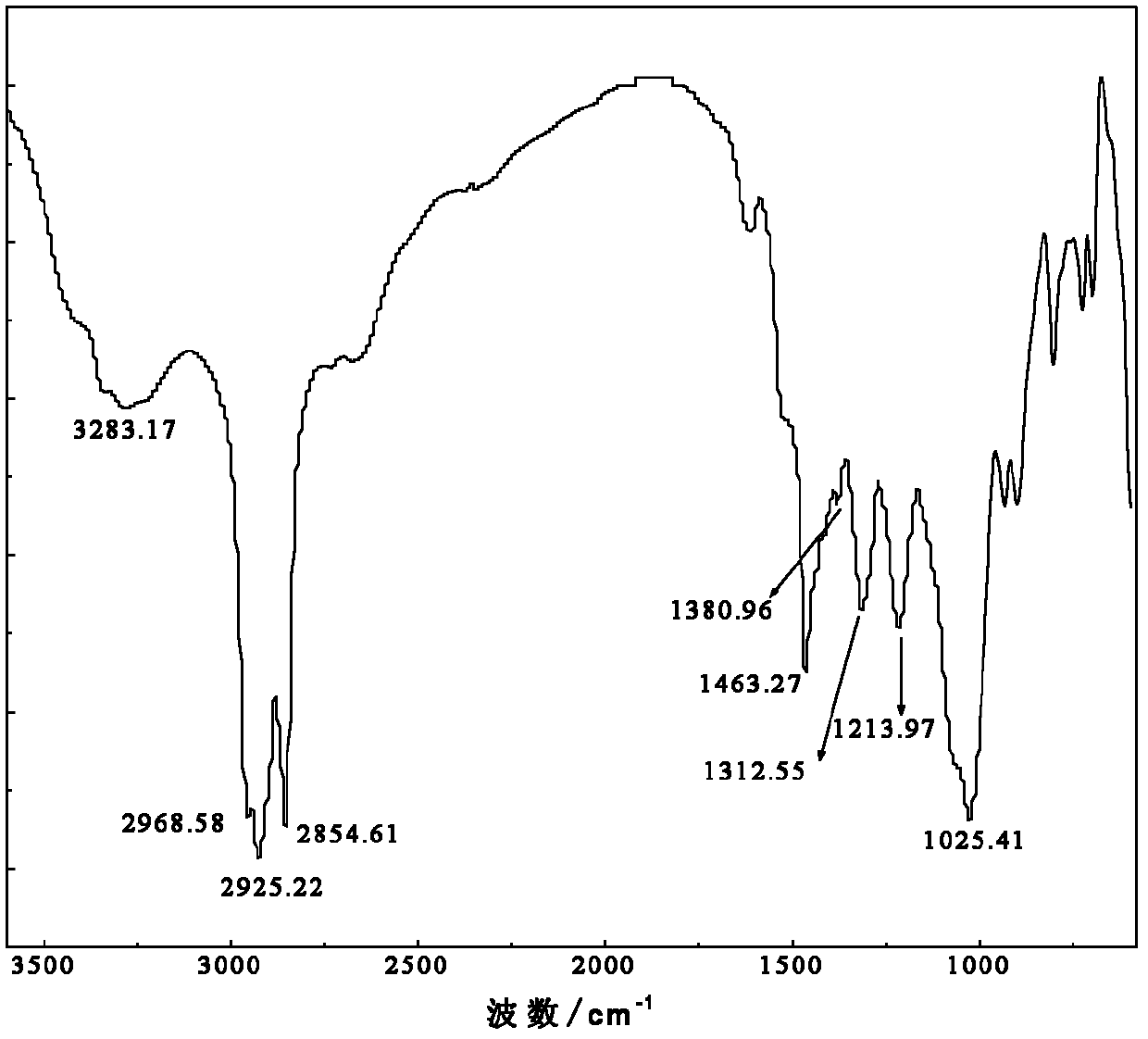

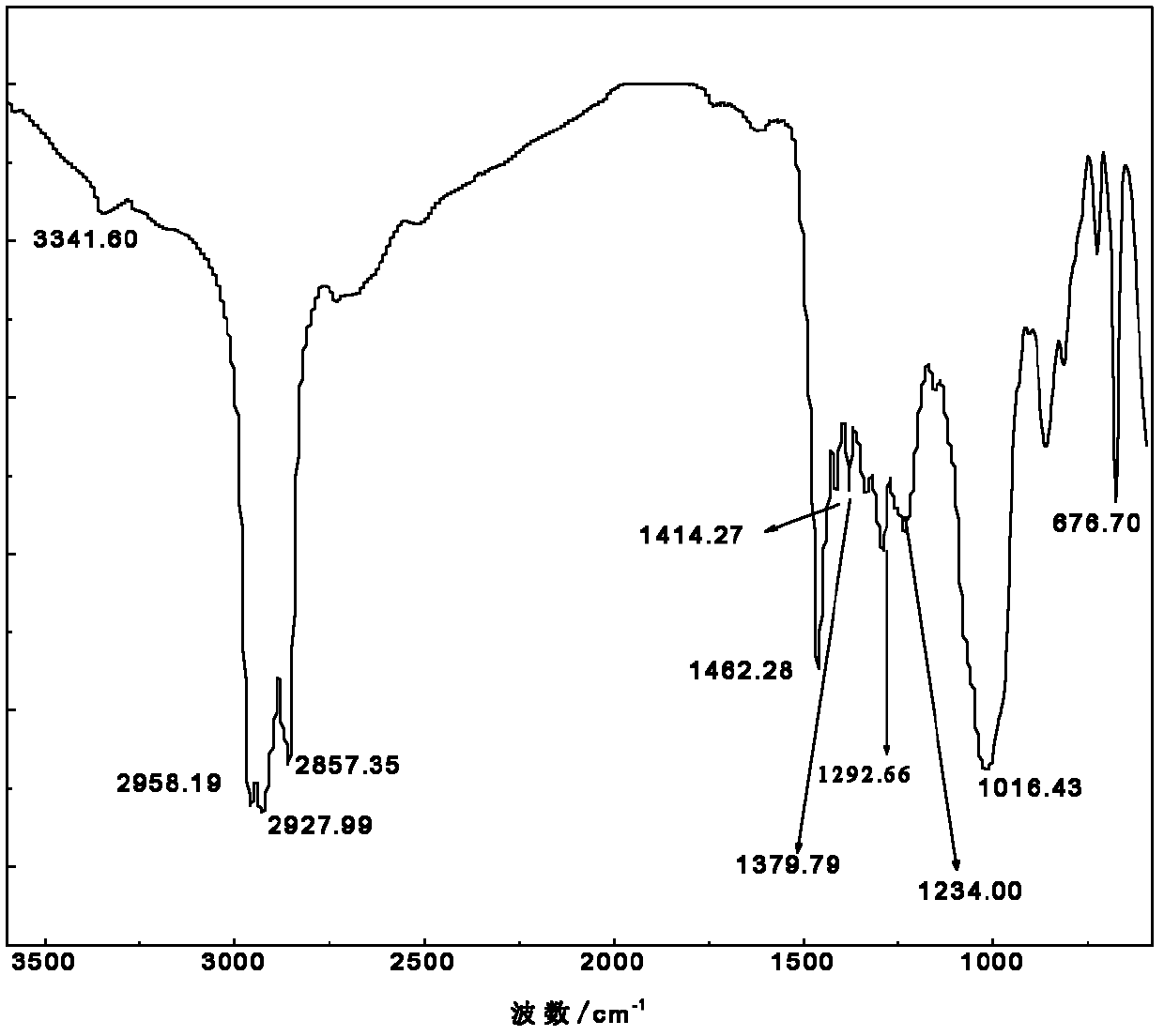

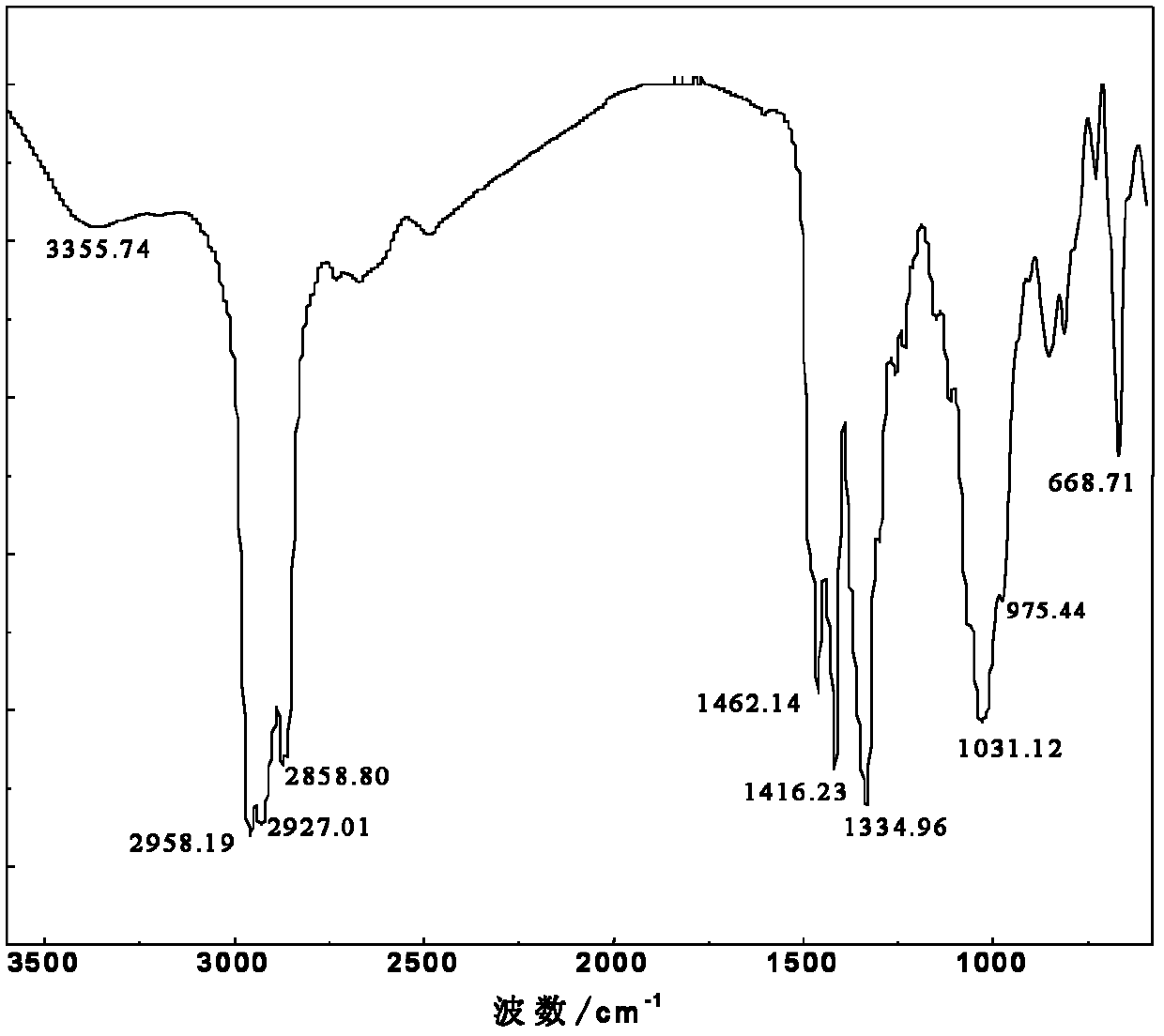

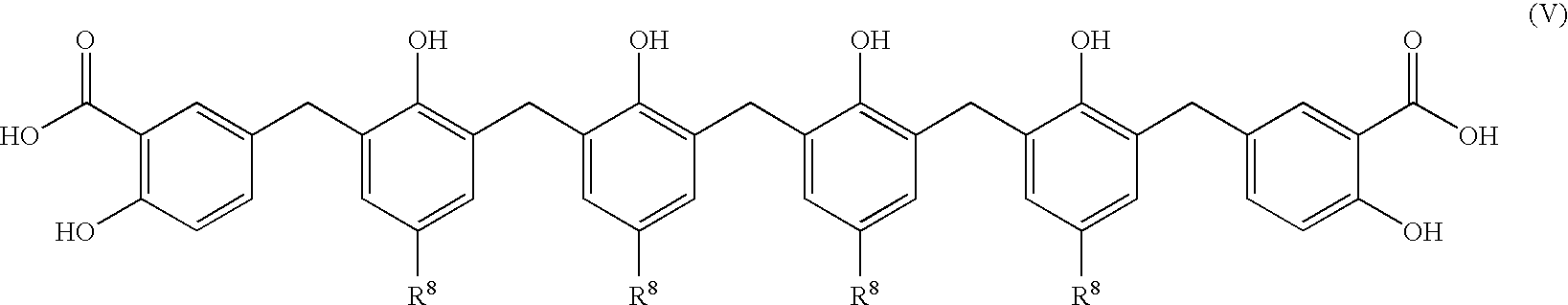

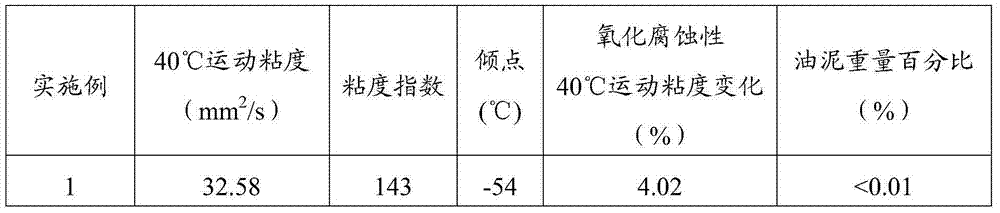

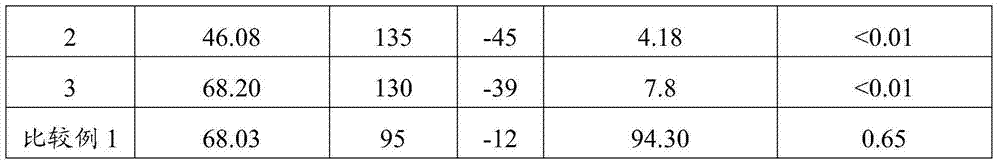

Extreme pressure antiwear additive and preparation method and application thereof

InactiveCN102504913AModerate chemical activityGood oil solubilityGroup 5/15 element organic compoundsAdditivesSolubilityOil sludge

The invention provides an extreme pressure antiwear additive and a preparation method and application thereof; the extreme pressure antiwear additive has a general formula structure as shown in the specification, wherein R1, R2 and R3 in the formula is respectively alkyl groups, aryl groups or aralkyl of a C4-C20 linear chain or branched chain. The extreme pressure antiwear additive provided by the invention is formed by reacting phosphorus oxychloride, C1-C20 alcohols, organic amine and benzotriazole. The extreme pressure antiwear additive provided by the invention can be applied to lubrication oil and lubricating grease with 0.1-2.0wt% of recommended dosage. The extreme pressure antiwear additive provided by the invention has moderate chemical activity, good oil solubility, very good compatibility with other addition agents, no peculiar smell and good thermal oxidation stability, and can effectively reduce the abrasion of devices and oil sedimentation as well as generation of oil sludge. After applied to gear oil, the extreme pressure antiwear additive has excellent antiwear performance and thermal oxidation stability; and simultaneously the extreme pressure antiwear additive can be applied to a lubricating grease and automatic transmission liquid and hydraulic oil of automobiles.

Owner:天津市金岛润滑科技股份有限公司

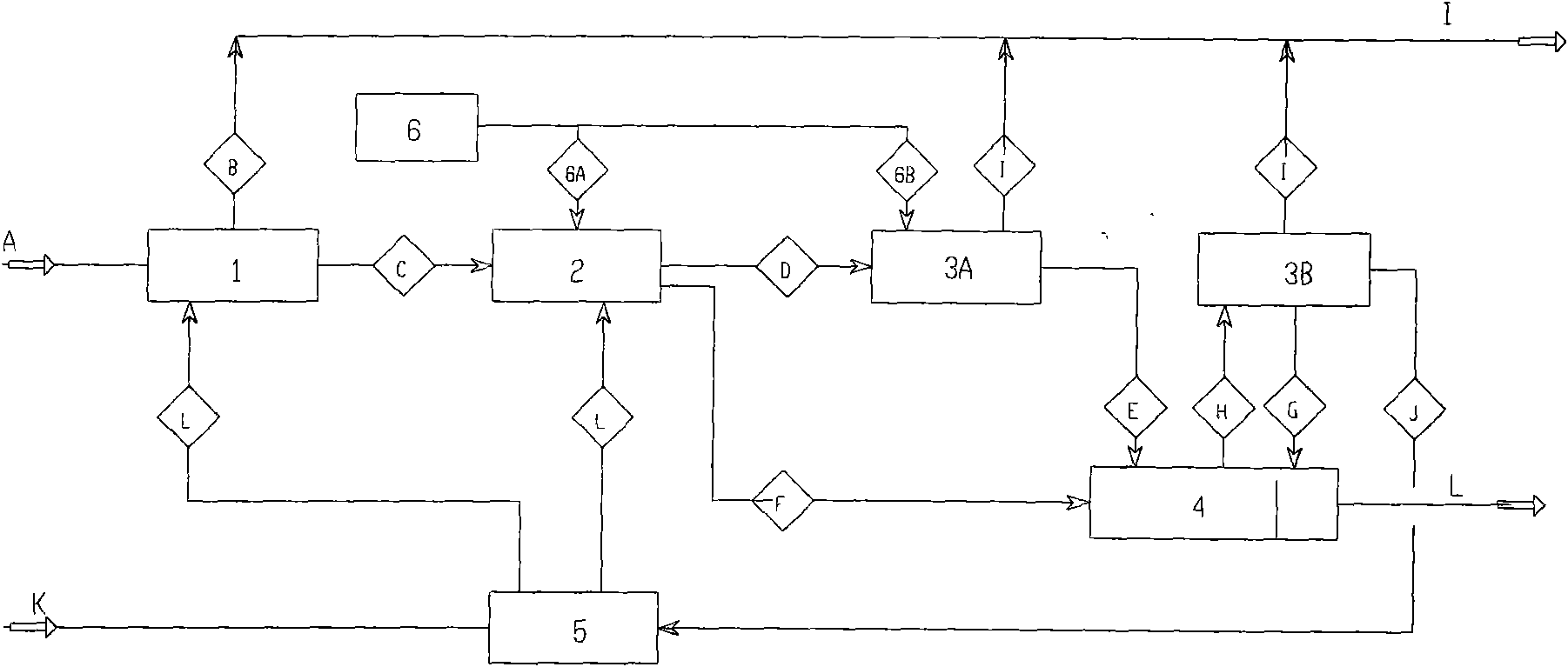

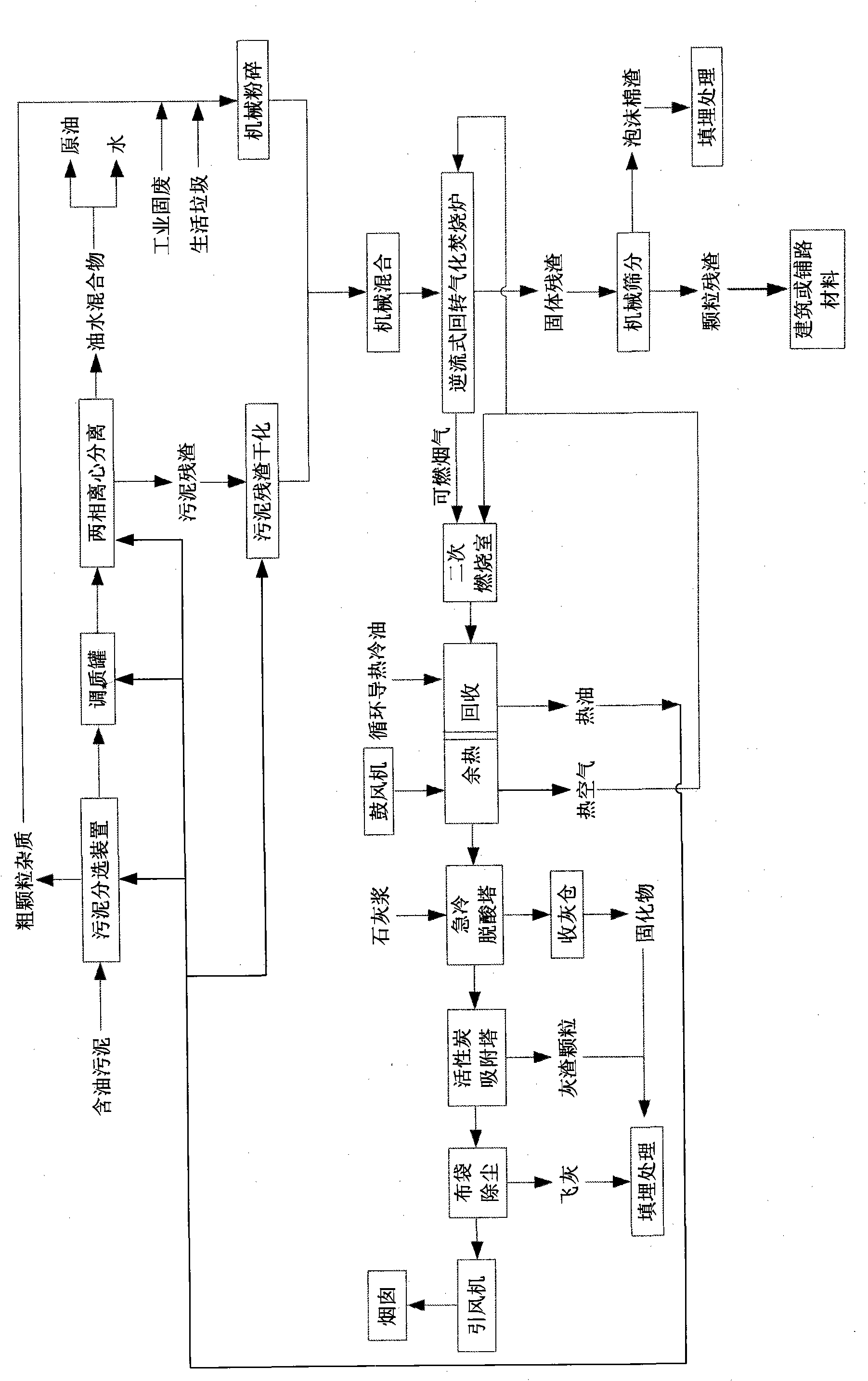

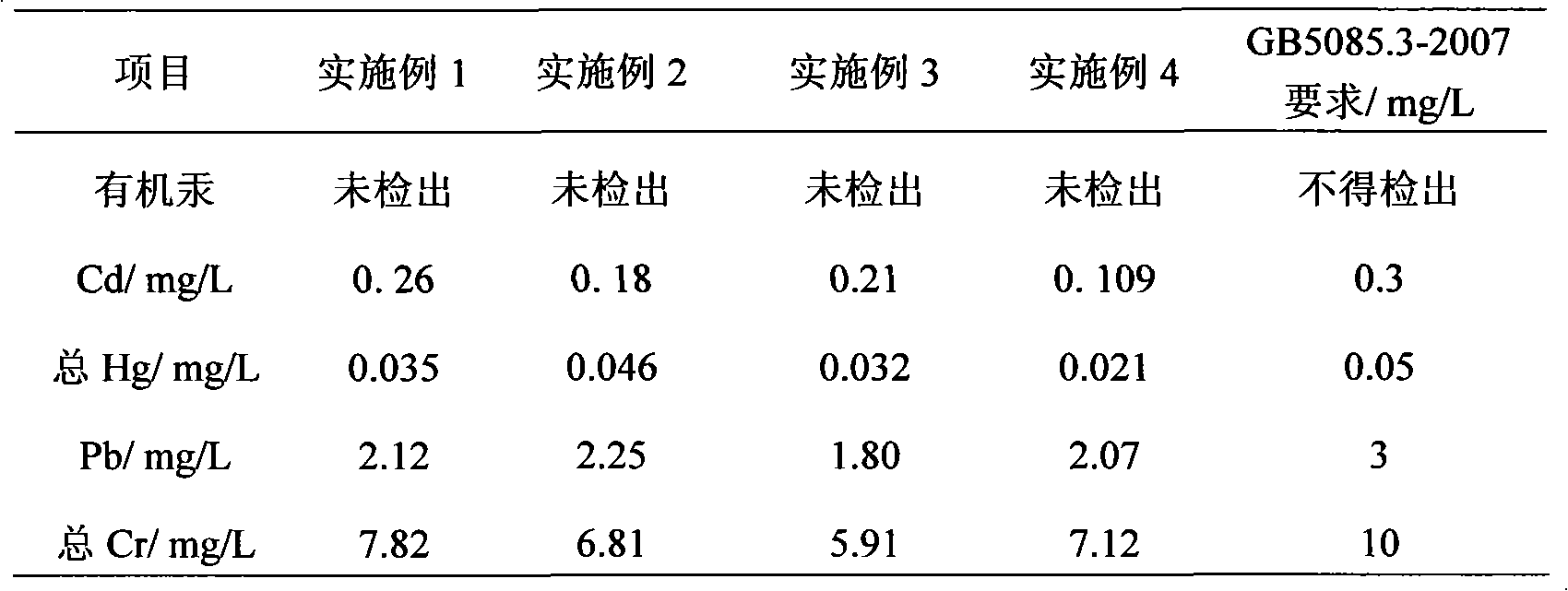

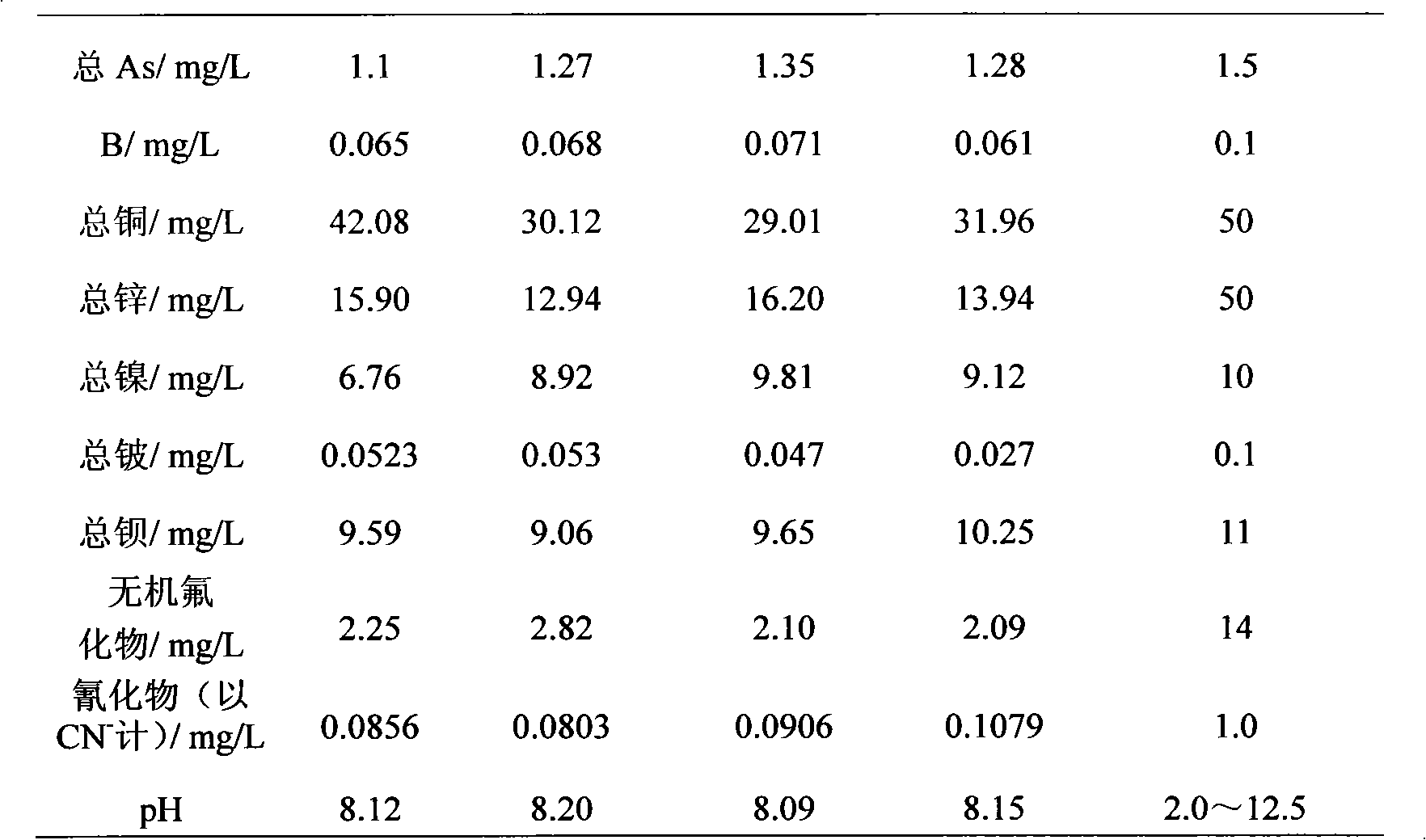

Combined treatment method for oilfield solid waste

InactiveCN101963358AHigh recovery rateLess investmentIncinerator apparatusCombustion chamberOil sludge

The invention provides a new combined treatment process for oilfield solid waste (oil sludge, industrial solid waste and household garbage). In the process, liquid-solid separation is performed on the oil sludge of an oilfield by adopting a conditioning-centrifugal separation process; the separated liquid enters oil-water separation equipment constructed on the oilfield for recovering crude oil; the oil recovery rate is up to 65 to 90 percent; after drying separated solid residue, the separated solid residue and pre-crushed industrial solid waste and household garbage are mixed and enter a countercurrent-type rotary gasification incinerator; combustible components in the oilfield solid waste are decomposed and gasified into combustible gases which are combusted partially in the incinerator; the combustible gases are combusted completely in a secondary combustion chamber; high-temperature smoke gas afterheat is recovered by a conduction oil afterheat boiler and air preheating equipment; and low-temperature smoke gas of which the afterheat is recovered is harmlessly exhausted after being treated by a sharp-quenching deacidification tower, an activated carbon adsorption tower and a bag-type dust remover. The process realizes the purposes of decrement, harmlessness and resources of oilfield solid waste treatment.

Owner:KUNMING UNIV OF SCI & TECH

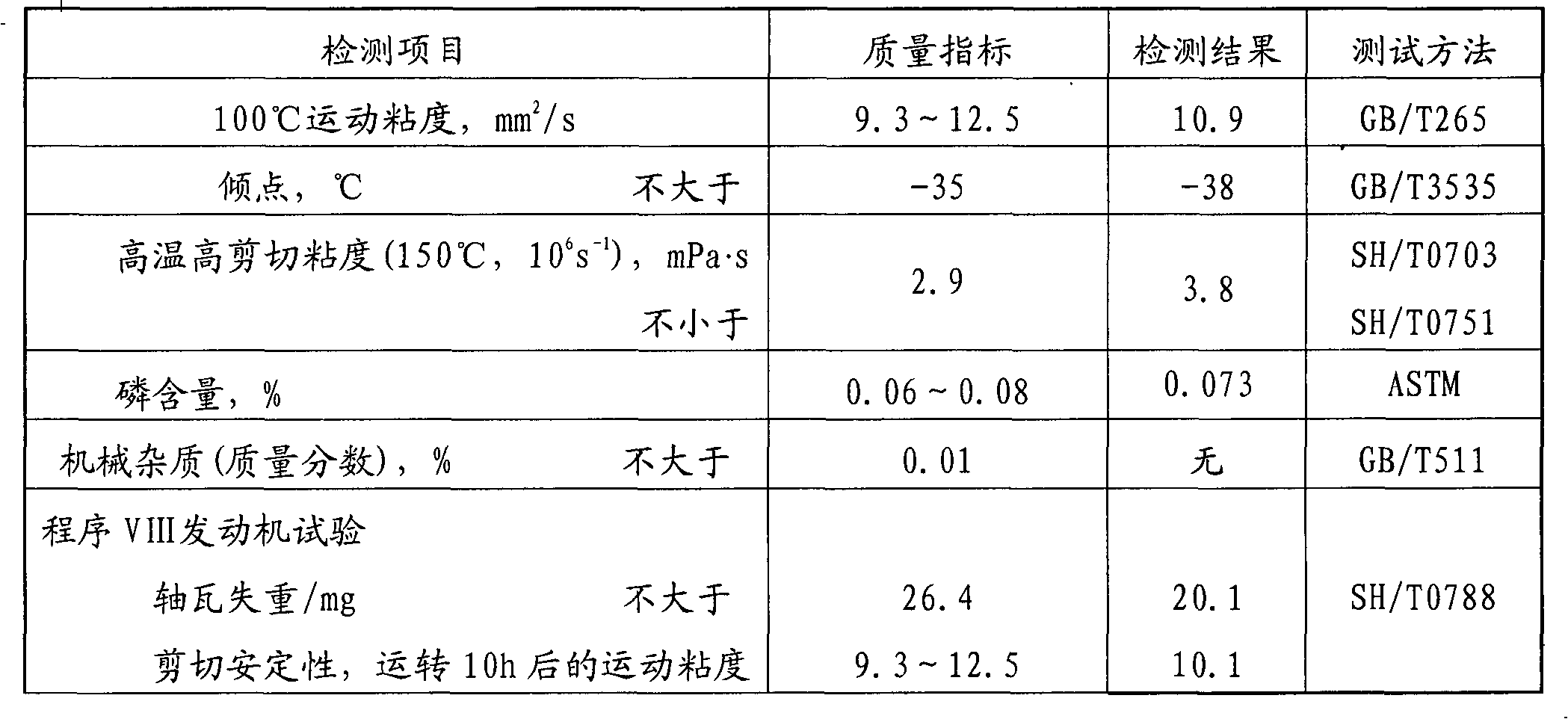

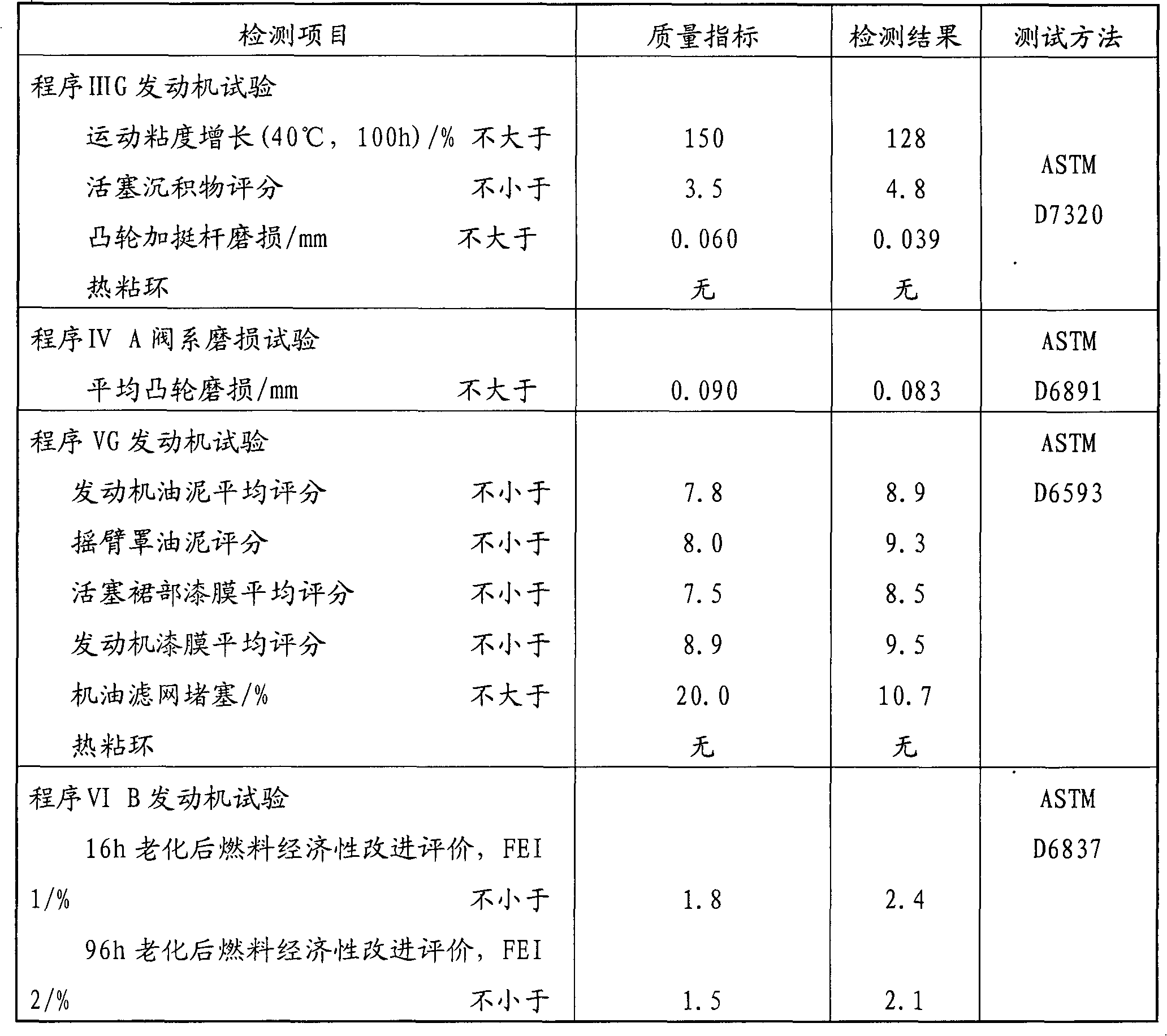

Energy-efficient long-life gasoline engine oil

InactiveCN101982534AReduce sulfur and phosphorus contentImprove carrying capacityLubricant compositionEcological environmentOil sludge

The invention discloses energy-efficient long-life gasoline engine oil prepared from the following components: synthetic base oil, a composite antioxygen, a metal cleaning agent, an ashless dispersant, a nano-level friction improver, a viscosity improver and a pour point reducer. The gasoline engine oil provided by the invention has the following advantages: requirements of API SM, ILSAC GF-4 and SAEJ300 are met and the service life is long; the complete synthetic base oil features low pour point, high viscosity index, good economy of fuel, degradability and reduced harm to the ecological environment; the phenol type antioxygen is combined with ZDDP, the anti-oxygen and antifriction properties are good and the catalyst poisoning in a tail gas processing unit is prevented; the acid neutralization capacity is good, the cleaning dispersibility is good and the oil sludge and carbon deposit are prevented from being generated; and the nano-level friction improver is added, the frictional factor is low, and the oil film features high carrying capacity and can automatically repair abraded surface and lengthen the service life of the engine.

Owner:GUANGDONG SANVO CHEM IND TECH

Preparation and application of biological carbon immobilized microbial agent

ActiveCN106148318AImprove removal efficiencyKeep aliveContaminated soil reclamationMicroorganism based processesMicroorganismMicrobial agent

The invention relates to preparation and application of a biological carbon immobilized microbial agent. The method comprises the following steps of: sequentially performing seed solution culture and liquid fermentation culture to microorganisms capable of degrading petroleum to obtain fermentation liquid; performing mixed adsorption to the fermentation liquid and biological carbon to prepare the biological carbon immobilized microbial agent. The invention further provides application of the biological carbon immobilized microbial agent to soil polluted by oily sludge and sand and petroleum. By immobilizing the microorganisms having a function of degrading petroleum and then remedying the soil polluted by oily sludge and sand and petroleum, the petroleum removal efficiency is remarkably improved and the removal rate is improved by 20 to 30 percent as compared with remediation by solely using microorganisms. The invention uses agricultural wastes such as corncobs as precursors to prepare carriers, the cost is low, a great amount of microbial agent is easily obtained and simultaneously the reclamation of wastes is realized.

Owner:山东百科利生态科技有限公司

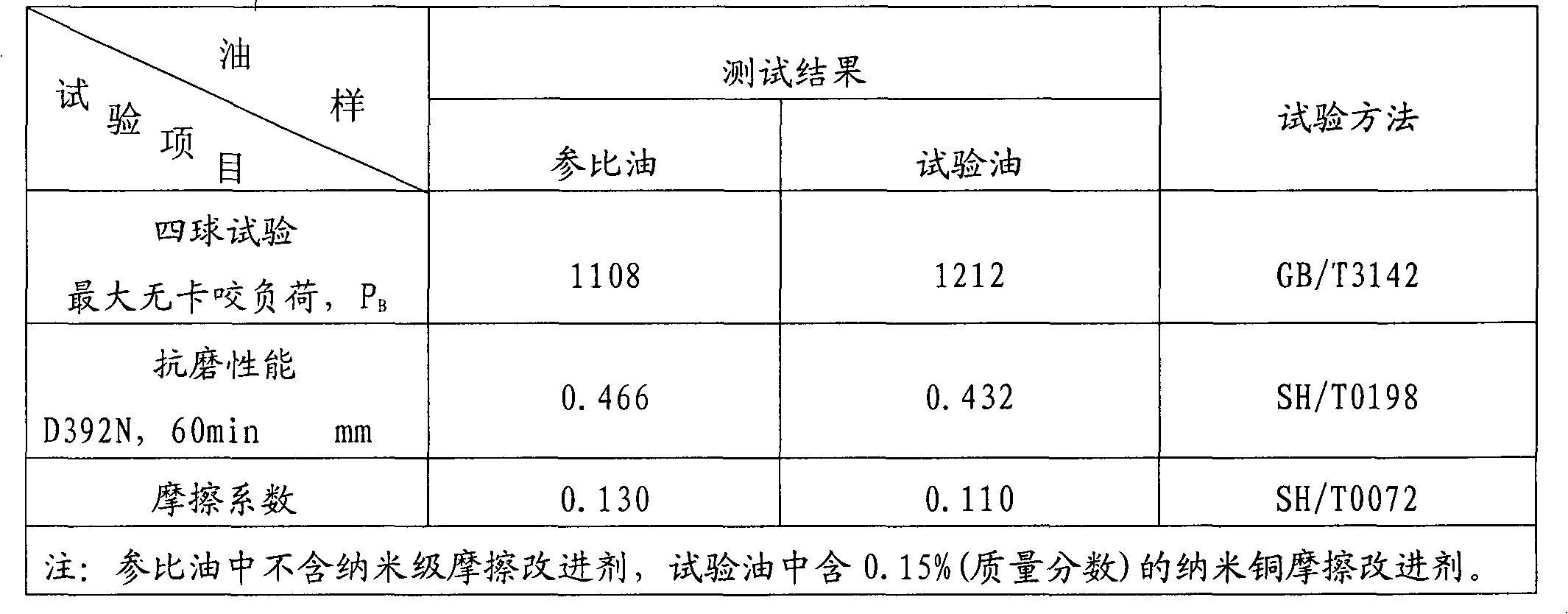

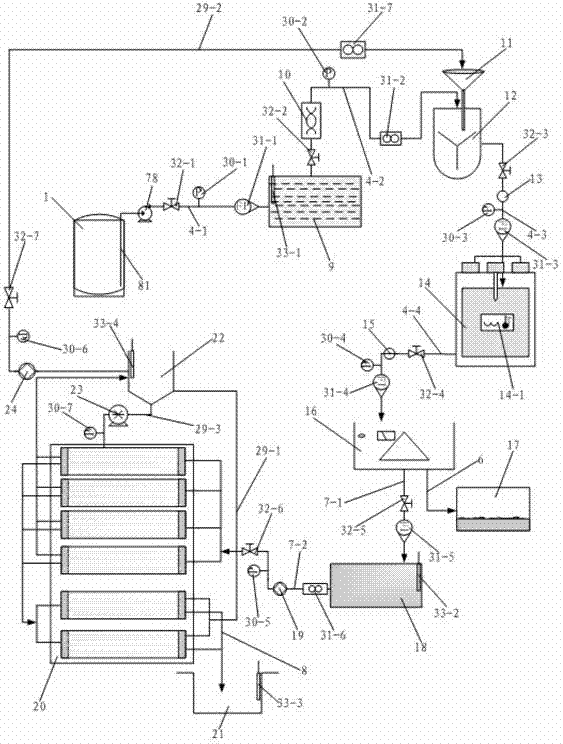

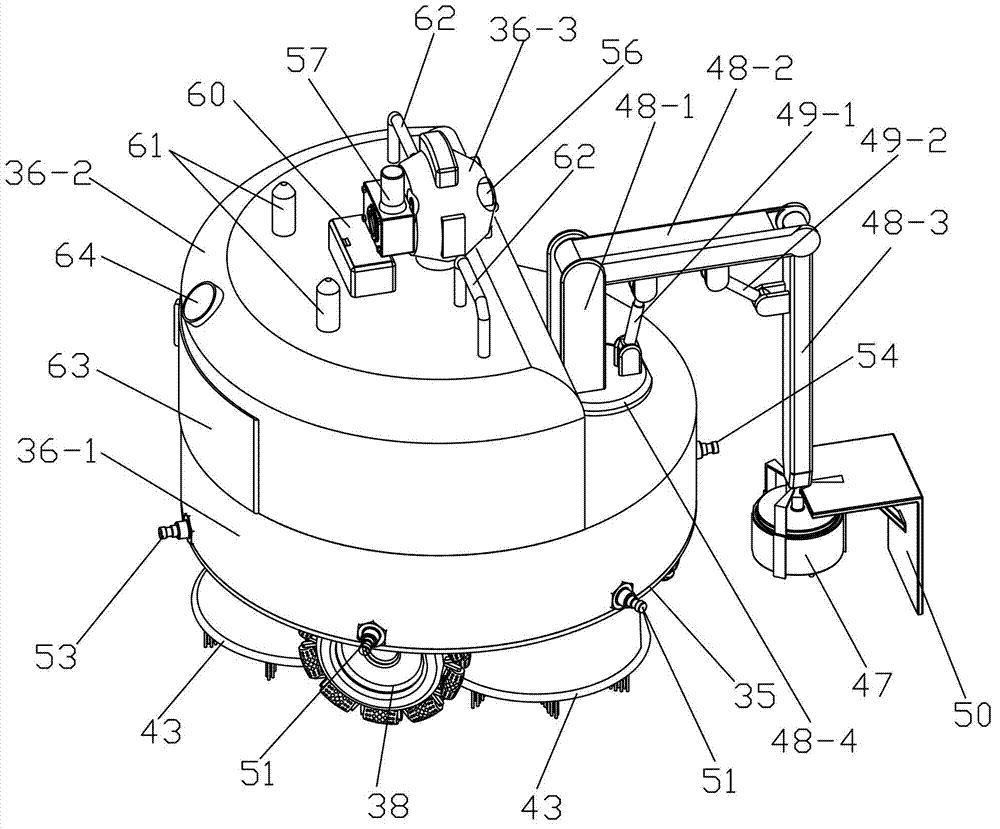

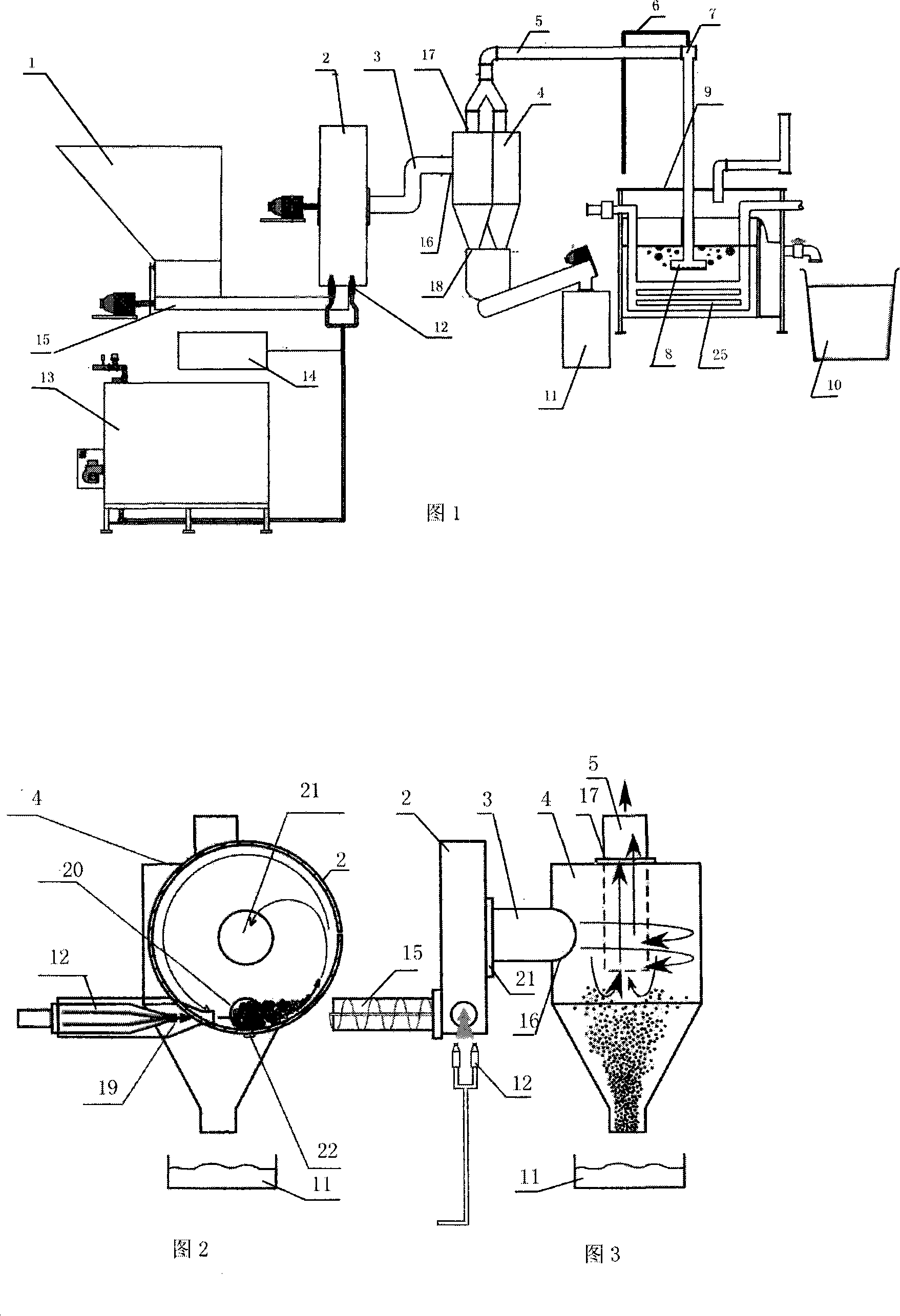

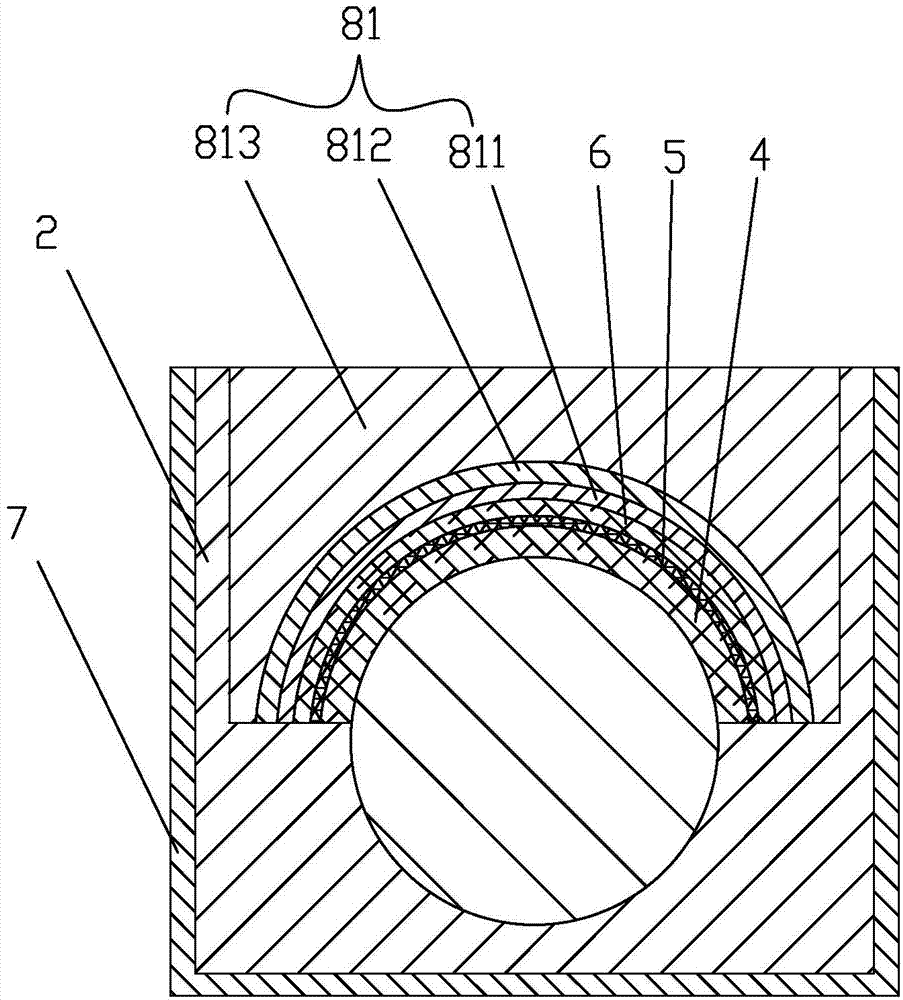

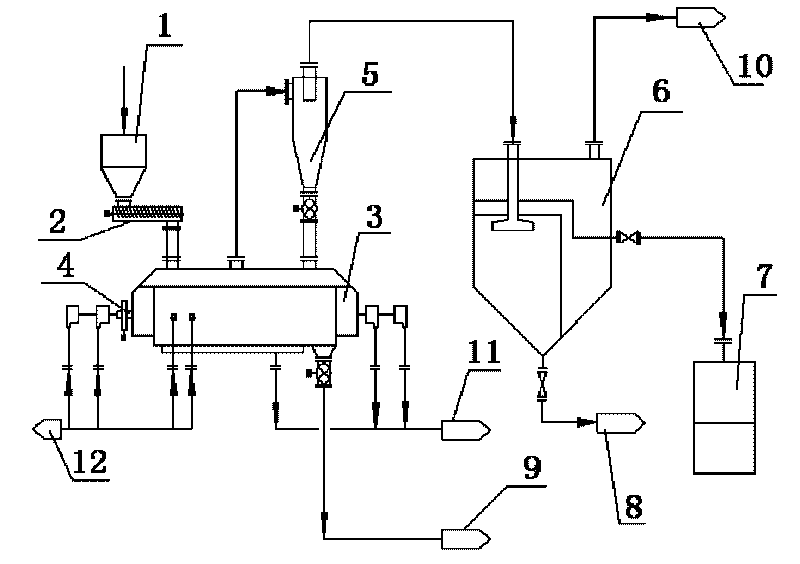

Oil sludge cleaning and processing system for oil tank

InactiveCN102825040ARealize all-round cleaningCompact structureSludge treatmentHollow article cleaningUltrafiltrationResource utilization

The invention discloses an oil sludge cleaning and processing system for an oil tank. The oil sludge cleaning and processing system comprises a cleaning system, an oil sludge processing system and an integrated control system, wherein the cleaning system comprises a cleaning robot, an electric hydraulic pump, a water pump, an inert gas storage tank and a screw pump; the cleaning robot comprises a machine body, a traveling unit, a cleaning unit, a robot cleaning control unit, a sensing and communication unit and a robot power supply unit; the oil sludge processing system comprises an oil sludge processing device, an oil sludge processing control system and an oil sludge processing power supply device; the oil sludge processing device comprises a stirring machine, an ultrasonic emulsion breaking device, a centrifuge and an ultrafiltration system, as well as an oil sludge storage pool, a sludge pool, a centrifugal liquid storage tank, a concentration tank and a filtrate pool; a funnel is arranged on the stirring machine; and the integrated control system comprises an integrated control computer and a communication circuit module. The oil sludge cleaning and processing system disclosed by the invention has the advantages of reasonable design and high degree of intelligentization, and can realize comprehensive cleaning of the oil tank, good safety, fast oil sludge processing speed and resource utilization of oil sludge, and further reduce environmental pollution and waste of resources.

Owner:周利坤

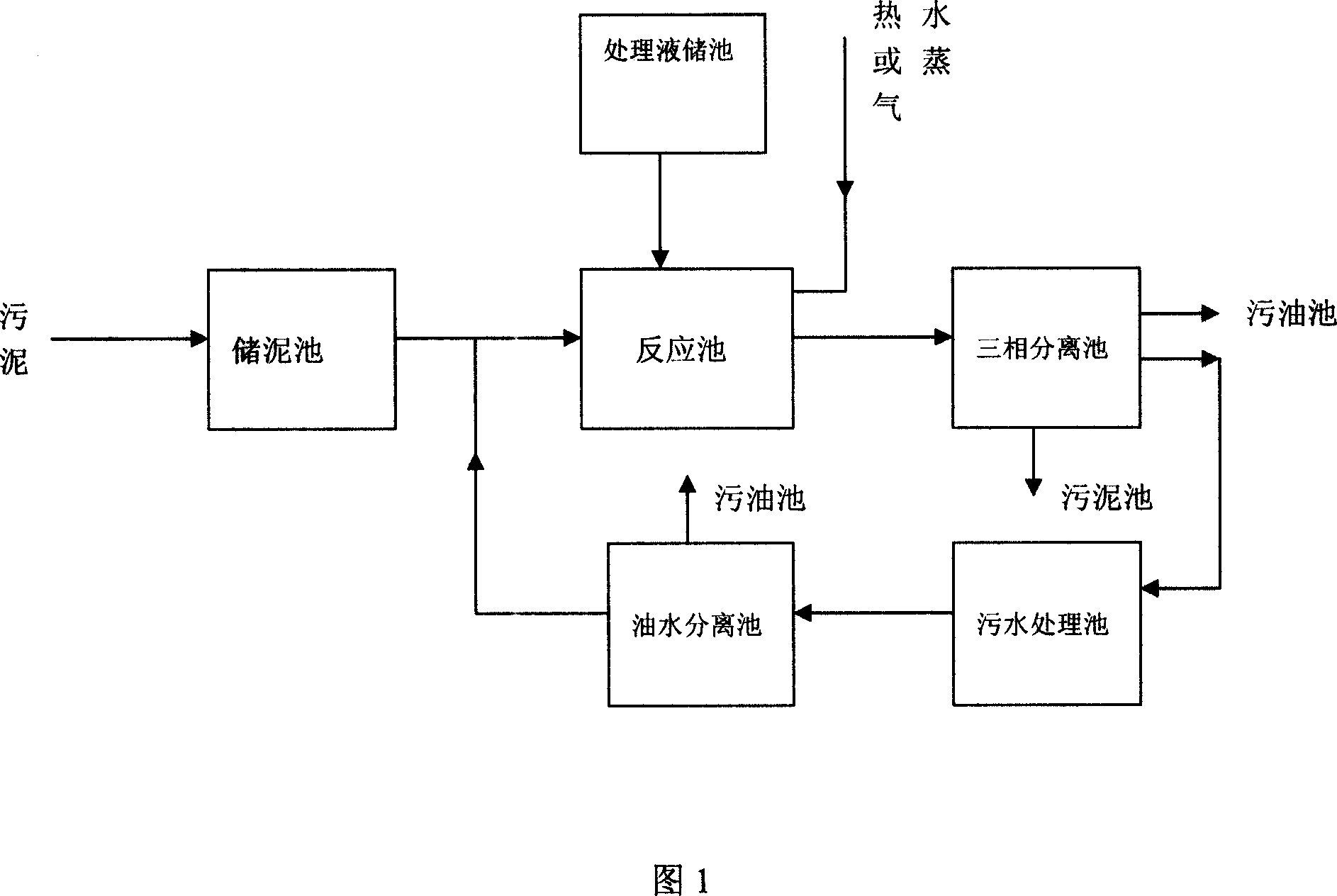

Process of treating oil-containing sludge

ActiveCN101088942ANo pollution in the processEfficient recyclingSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningOil sludgeSewage

The present invention relates to oil-containing sludge treating process, which includes the following steps: pumping oil-containing sludge into sewage reacting tank and adding water while stirring; adding treating solution; heating and stirring to separate oil from sludge; adding coagulant while stirring to react for 2-30 min, adding polyacrylamide, stirring and solid-liquid separating into three layers; collecting oil, water and sludge separately; and collecting the sludge with oil content less than 1 wt% in the sludge collecting tank and further solidification or draining. The present invention has the advantages of recovering oil, reducing environmental pollution, low cost, etc.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

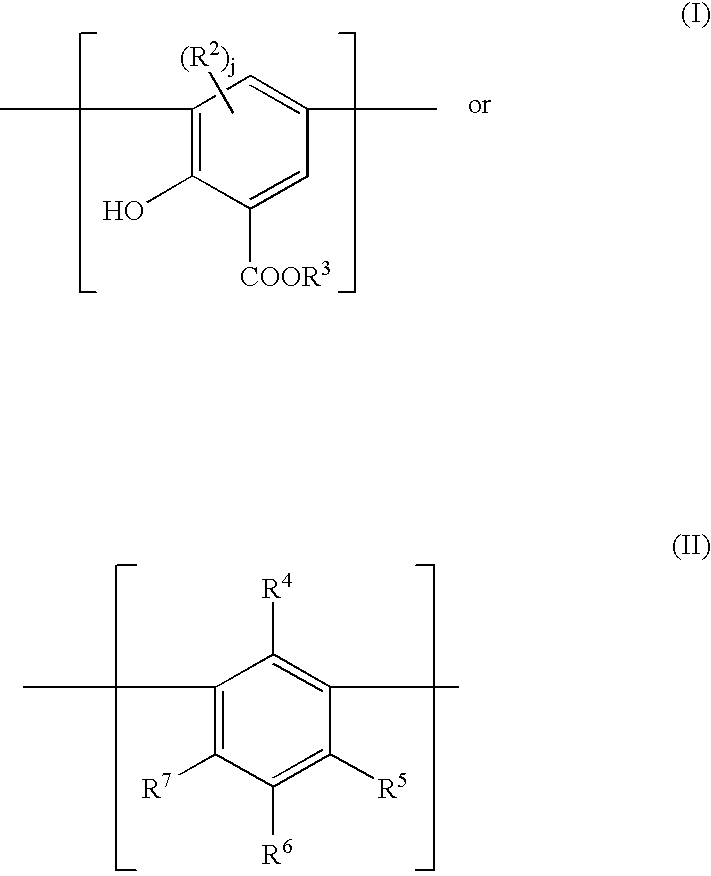

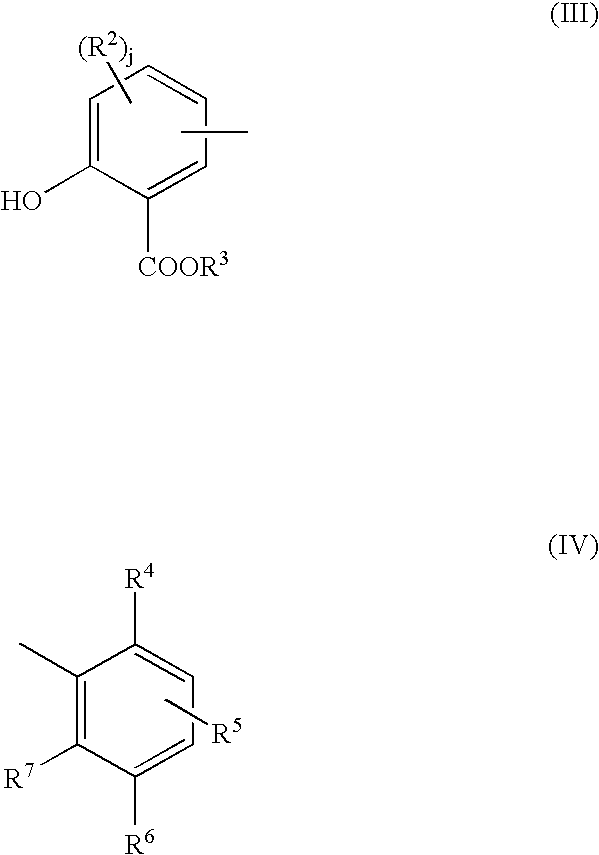

Lubricated part having partial hard coating allowing reduced amounts of antiwear additive

InactiveUS20070197407A1Reduce wearReduces clogged filtersVacuum evaporation coatingSputtering coatingBorideSulfide

A lubricated part composition containing (a) a part with at least a partial hard surface coating of average thickness less than about 25 micrometres, said coating containing at least one moiety selected from the group consisting of silicides, nitrides, carbides, borides, oxides, sulphides and mixtures thereof; (b) a detergent selected from at least one of the group consisting of a phenate salt, a sulphonate salt, a salixarate salt and mixtures thereof; and (c) an oil of lubricating viscosity. The invention further relates to the use of the composition to decrease engine wear, decrease sludge formation, filter plugging, decrease sulphur emissions and decrease phosphorus emissions.

Owner:THE LUBRIZOL CORP

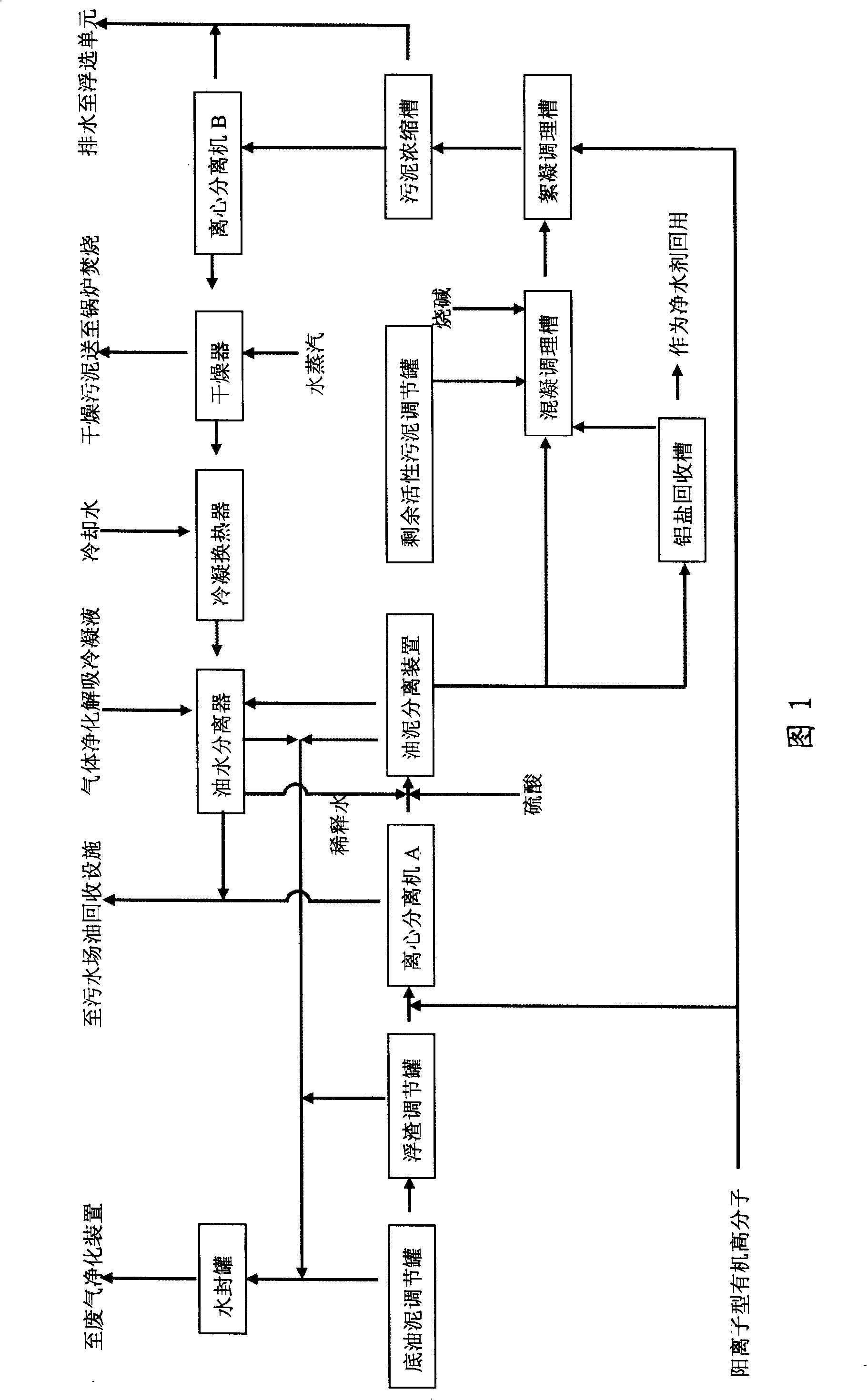

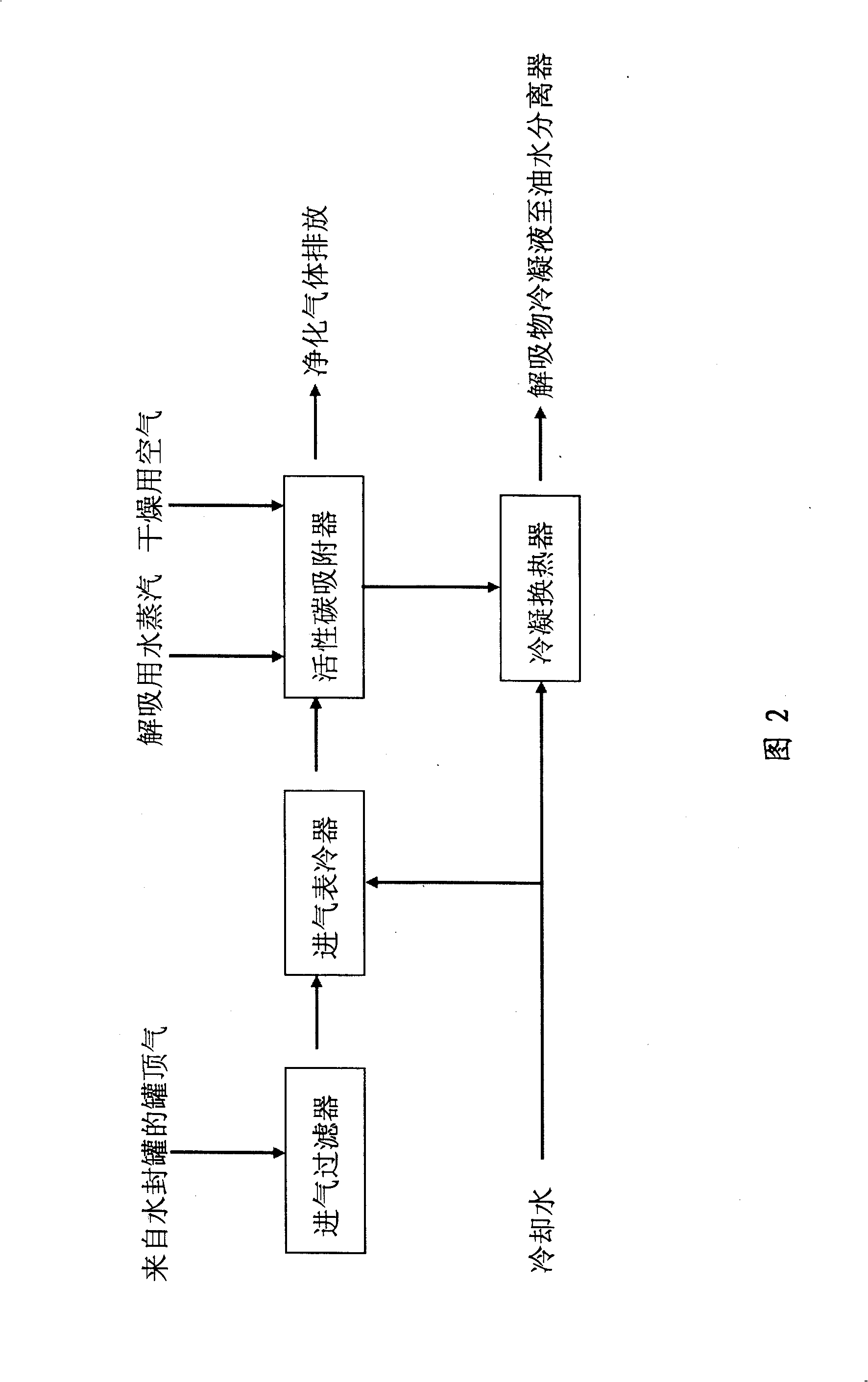

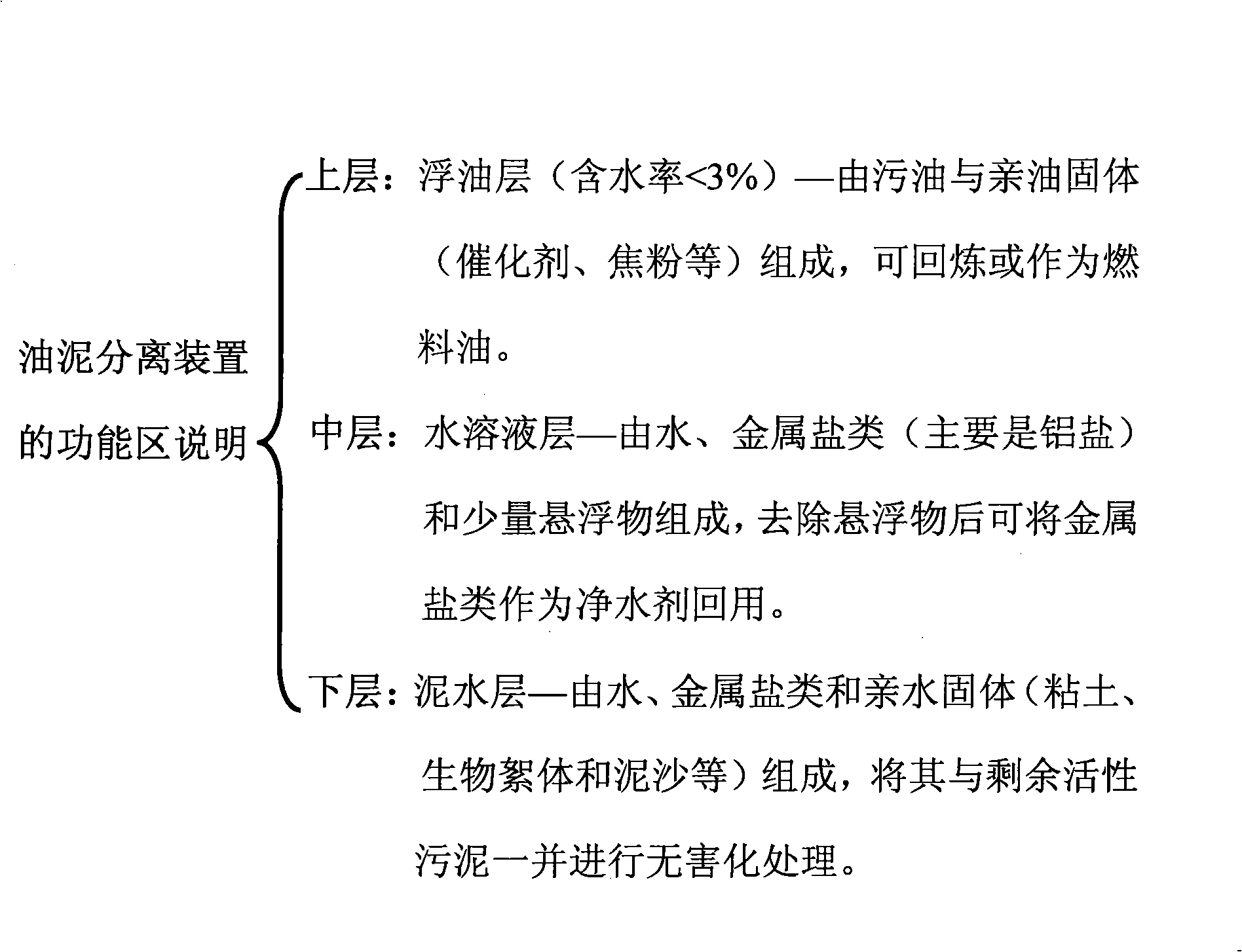

Method for innocent treatment of bottom oil sludge, scruff and active sludge in petro-chemical industry

InactiveCN101343137ASave resourcesReduce pollutionSludge treatment by de-watering/drying/thickeningIncinerator apparatusChemical industryActivated sludge

The invention discloses a method of harmless treatment to residual activated sludge produced by bottom sludge, scum and biochemical treatment units in the petrochemical industry, which comprises: emulsion breaking to the bottom sludge and scum; separation of oil, water and mud of products after emulsion breaking; and recovery of dirty oil at the upper part and sedimentation of mud-water mixture at the lower part, recovery of clear liquor at the upper part, and treatment of coagulation conditioning, flocculation conditioning, sludge concentration, sludge dewatering, sludge drying and sludge incineration to mud-water mixture at the bottom part and the residual activated sludge sequentially. The method can effectively recycle useful oil substances and aluminum-containing compounds in the bottom sludge and scum, purify possibly released malodorous gases in mud produced in the process of storage and disposal, and carry out the treatment such as sludge conditioning, dewatering and drying sequentially to the residual mass hazardous wastes after the recycling treatment, then utilize the current boilers in enterprises to implement the direct incineration treatment. The method has advantages of simple operation and running, safety and reliability, complete resource recovery, controllable water removal, and maximally reducing the environmental pollution.

Owner:罗德春

Dirty oil mud separating method and device

InactiveCN101239770ANo secondary pollutionEasy to handleSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningWater vaporOil sludge

The present invention relates to a petroleum processing method and equipment, especially to an oil-bearing sludge separating method and equipment, provides a simple, economical, practical, environment-protecting and pollution-free oil-bearing sludge processing method and equipment, and the method comprises the following procedures: heating the water vapor to the superheated steam with temperature above 500 DEG C with a superheated steam boiler; injecting the superheated steam to the oil-bearing sludge with a speed of 2 mach, the oil-bearing sludge is crushed to small particles after instant colliding; separating the water component and the oil component which are evaporated and sublimed instantly with a cyclone separator; dropping the temperature and fluidifying through water spraying; and extracting the oil product up to standard by the separating of the oil-water separating pot, above 95% oil component in the oil-bearing sludge can be recovered and the oil content of the residue is lower than 5%, the petroleum processing method has the advantages of guaranteeing the quality of the recovered oil product, simple operation and maintenance, broad application that can be applied to varies types of oil-bearing sludge and oil-bearing sand, excellent economic benefit and low cost, the equipment is used for processing the oil-bearing sludge that is generated in the crude oil exploration and exploitation, crude oil transportation and the petroleum refinery wastewater treatment.

Owner:张贺新

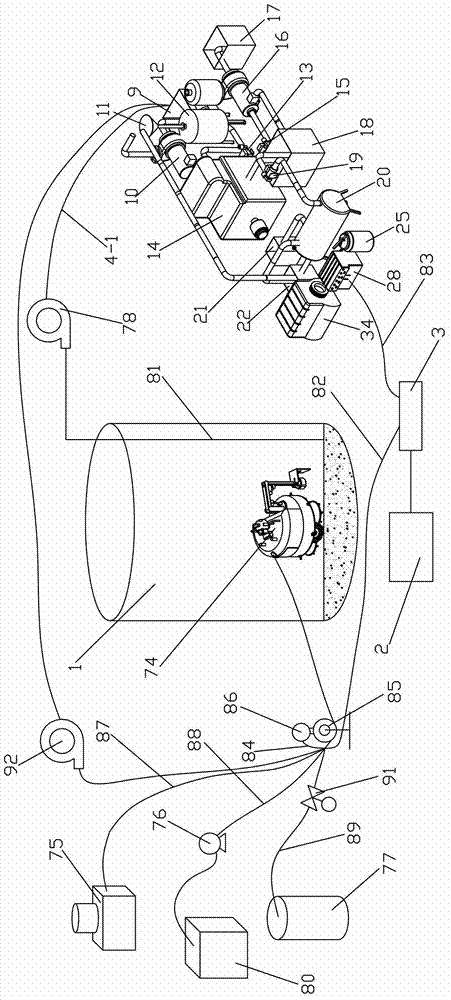

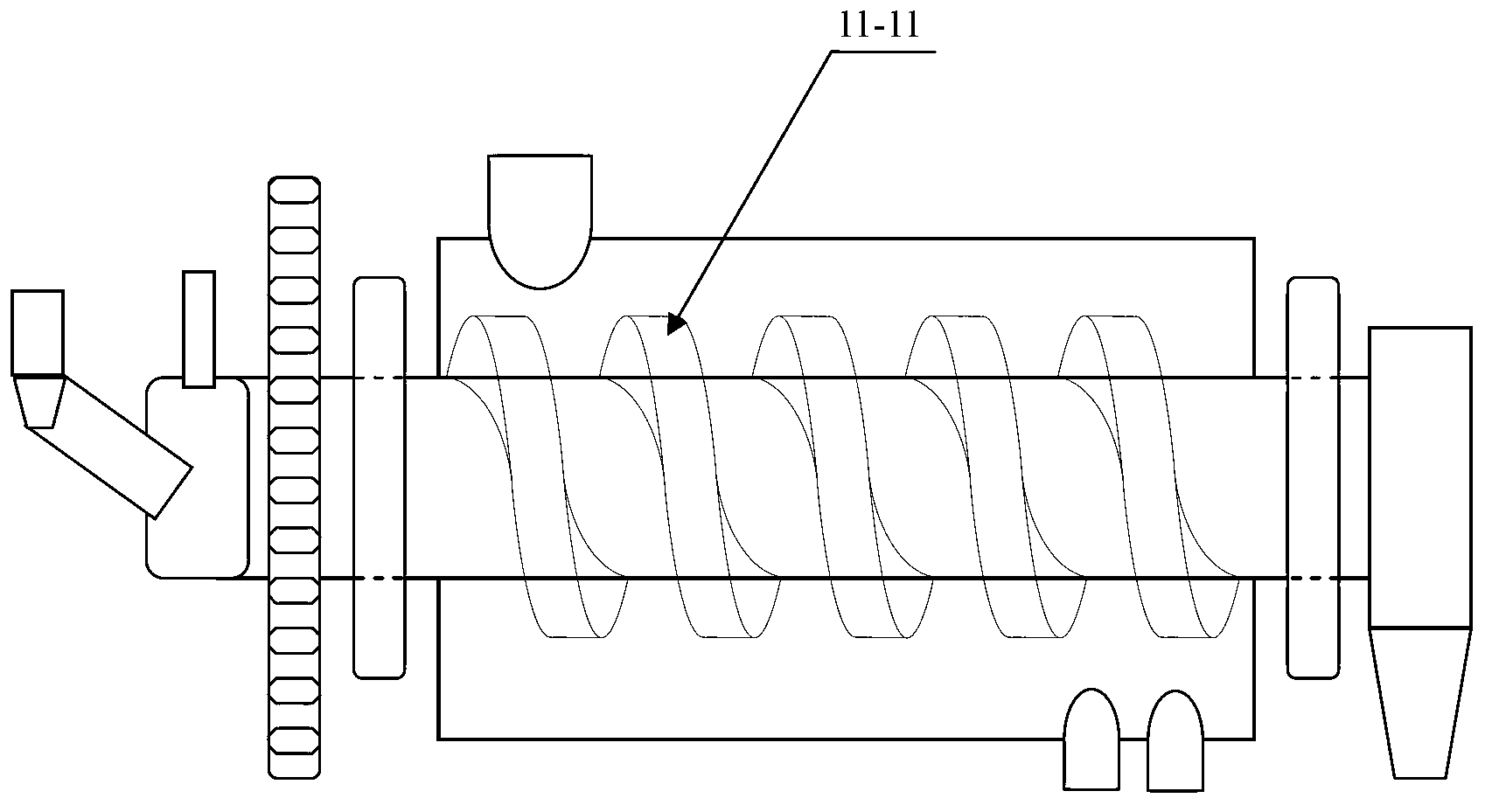

Low-temperature carbonization apparatus and method for oil sand, oil sludge, oil shale and biomass

ActiveCN103160301AIncrease profitReduce energy consumptionDirect heating destructive distillationBiofuelsCarbonizationOil shale gas

The invention discloses a low-temperature carbonization apparatus and method for oil sand, oil sludge, oil shale and biomass. The apparatus comprises a delivery apparatus, a storage bin, a metering apparatus, a drying furnace and a surge bin. The method comprises the following steps: drying, preheating, carbonizing, and cooling. The core of the invention is an external heating type rotary carbonization furnace which realizes the pyrolysis of oil sand, oil shale, oil sludge (oil sludge on the ground, oil sludge at the bottom of a tank and oil-containing sludge from oil refinery) and biomass, and the product is high in purity and low in loss. The invention effectively solves the problems of solid materials such as adhesion, wall accretion and the like in the pyrolysis process by material returning. The technology provided by the invention is simple in process and reliable and stable in operation, and has obvious advantages in the treatment of small particle materials such as oil shale, oil sand, oil sludge (oil sludge on the ground, oil sludge at the bottom of a tank and oil-containing sludge from oil refinery), biomass and the like.

Owner:何建祥

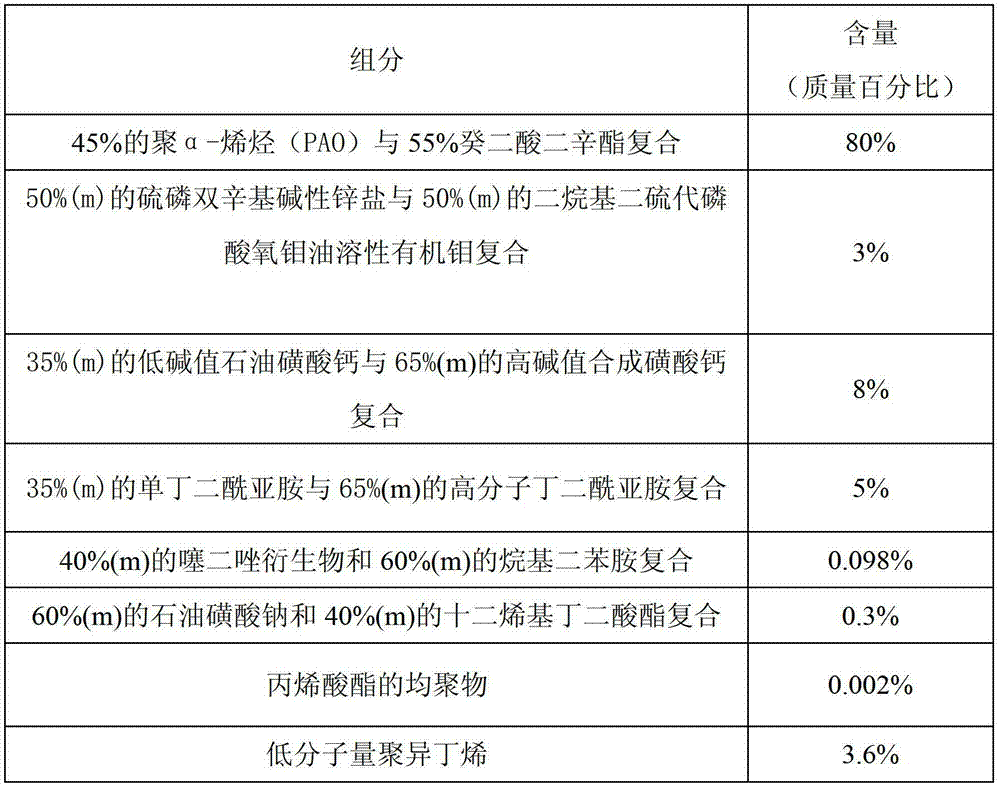

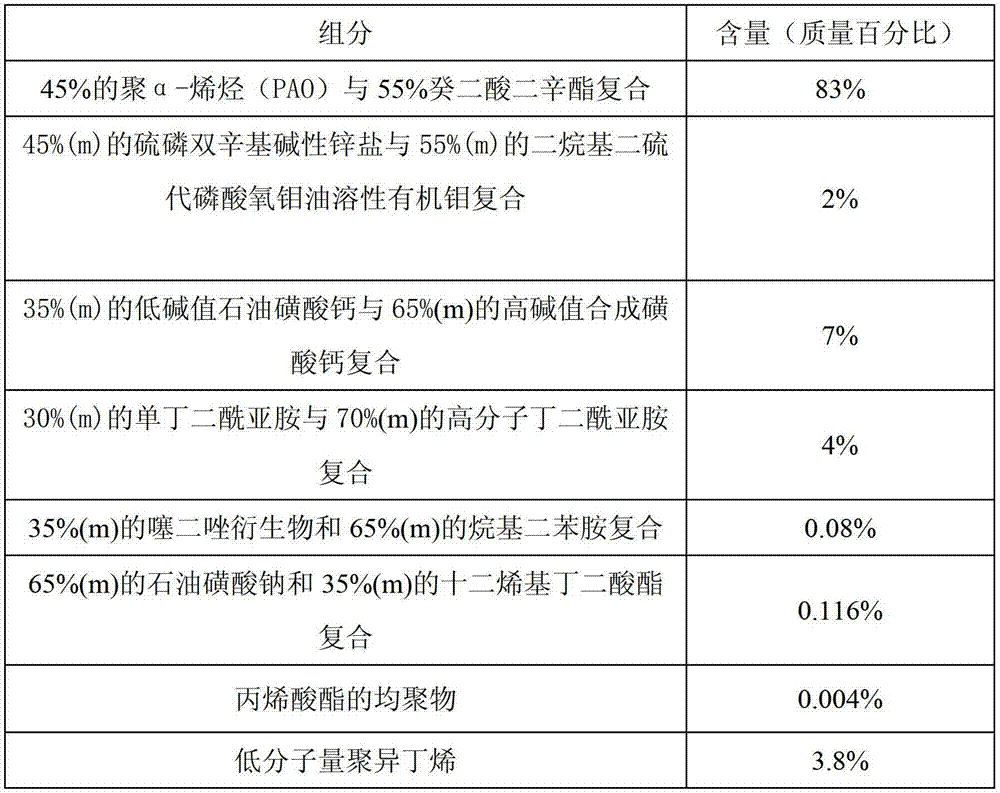

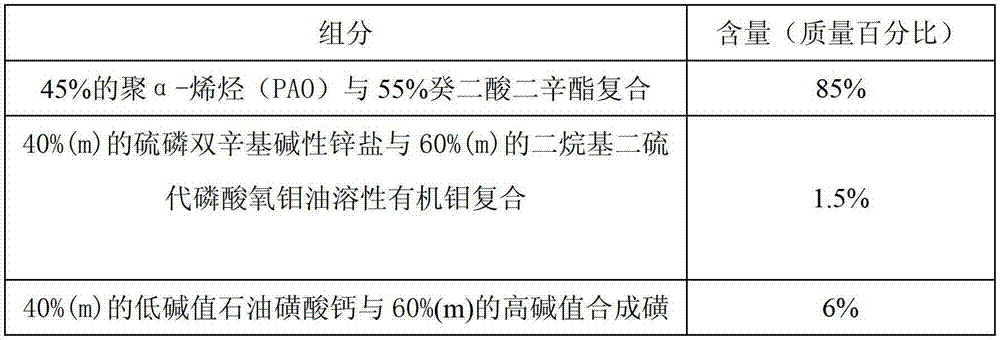

Environment-friendly and energy-saving gasoline engine lubricating oil

The invention discloses environment-friendly and energy-saving gasoline engine lubricating oil, which is composed of composite base oil, a composite oxidation and a corrosion inhibitor, a composite metal detergent, a composite ashless dispersant, a metal passivator, an antirusting agent, an antifoaming agent and a viscosity index improver, wherein the base oil is compounded from poly-alpha-olefin (PAO) and dioctyl sebacate. With the adoption of the gasoline engine lubricating oil, energy conservation, long oil change period, and reduction for waste oil, waste gas and particulate matters are realized, biodegradability is high compared with the traditional lubricating oil, the fuel economy of an engine is improved, the service life of the engine is prolonged, and the generation of oil sludge and carbon deposition in the engine can be inhibited; and the base oil technical requirements of quality grade specifications SG, SH, SJ, SL, SM and SN of gasoline engine lubricating oil, and the performance requirements of multi-grade oil with viscosity grades 0W, 5W, 10W, 15W, 20W and the like can be met.

Owner:广西谛恒生物能源投资有限公司

Process for treating oily sludge

ActiveCN101823824AEasy extractionImprove extraction abilitySludge treatment by de-watering/drying/thickeningLiquid carbonaceous fuelsTemperature controlTreatment effect

The invention relates to a process for treating oily sludge and is particularly applicable to the oily sludge generated in the wastewater treatment process of an oil refinery. The process has the following steps of: after performing anhydration treatment on centrifugally dehydrated oily sludge in rotary-type anhydration treatment equipment under certain negative pressure and temperature control to destroy a water, oil and solid stabilizing system of the oily sludge, evaporating part of oil and water in the oily sludge, and performing solvent extraction treatment on coke generated after the anhydration. Solid residue obtained after treatment reaches the solid emission standard; the wastewater generated in the process can reach standard after biochemical treatment and is discharged; the extracted oil can be used as fuel or used for refining; and an extractant can be regenerated and recycled. The process has main characteristics of high sludge anhydrating and extracting speed, high efficiency, good effect, mild operating condition, little energy consumption, good sludge treatment effect and simple equipment operation and maintenance.

Owner:PETROCHINA CO LTD

Process for separating treating mud containing oil

InactiveCN1724421AEasy to handleMeet the requirements of backfillSludge treatmentFatty/oily/floating substances removal devicesDemulsifierOil sludge

A process for reclaiming the oily sludge includes such steps as proportionally mixing it with water and separating agent prepared proportionally from sulfuric acid, demulsifier and water, stirring at 70-95 deg. C, laying aside to form oil, water and mud phases, and conventional separation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for processing oil sludge

The invention relates to a method for processing oil sludge, and is suitable for processing ground crude oil in oil field, and a whole technology does not impacted by the loading. According to the existence state of oil, sand and water in oil-containing sludge, by the steps of heating, adding drug, homogenizing, aerating, depositing and centrifuging at high speed, the existence distribution state of oil, sand and water can be changed, the sand-in-oil phenomenon in the original oil sludge is gradually changed to sand-in-water, and the inclusion viscosity of the crude oil to sediment is reduced. Through settlement, oil sludge can be separated before entering into a centrifuge, the loading of the high speed centrifuge is reduced, processing amount of a device is increased, and the unit energy consumption is reduced. The separated sediment surface as well as the internal oil content are reduced to the lowest limitation. The unit treatment process parameter can be freely adjusted according to the oil-containing sludge processing requirement, the method has certain adaption capability; the process is simple and smooth, the operation and management are convenient, recovered crude oil and processed sediment can reach the standard in a stable manner, and a system employs the combination of automatic mode and manual operation.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Manufacturing method of simulation tree mould

The invention discloses a manufacturing method of a simulation tree mould. The method comprises the following steps: manufacturing a mould clamping fixture, and making a simulation tree by mixed resin; manufacturing an upper mould, namely, laying oil sludge on the ground, leveling the laid oil sludge, enabling half of the simulation tree to be embedded into the oil sludge, defining a frame made of the oil sludge around the simulation tree to form a pouring tank, coating the simulation tree with a layer of vaseline, coating the vaseline layer with a silica gel layer, covering the silica gel layer by an abrasive cloth layer, pouring silica gel into the pouring tank to form a second silica gel layer, manufacturing a box body, removing the oil sludge around the simulation tree, framing the simulation tree by the box body, injecting filler into the box body, forming a filling layer on the second silica gel layer, and standing still until the layer is cured; manufacturing a lower mould, wherein the method of manufacturing the lower mould is the same as that of manufacturing the upper mould. With the method, the manufacturing cost of the simulation tree mould is very low, and thus the method is suitable for popularization.

Owner:李东礼

Treatment method of oily sludge

ActiveCN102050556AReduce volumeReduce quality problemsThermal non-catalytic crackingSludge treatment by de-watering/drying/thickeningTherapeutic effectOil sludge

The invention relates to a treatment method of oily sludge, which is particularly suitable for oily sludge generated during the sewage treatment process of a refinery plant. The method comprises the following steps: after centrifugal dewatering, the oily sludge is dehydrated through rotary dehydration equipment under the control of a certain negative pressure and a certain temperature, so as to destroy the water, oil and solid stable system in the oily sludge; parts of oil and water in the oily sludge are distilled out; the coke generated after dehydration is extracted with a solvent; after extraction, the material undergoes the solid-liquid separation; the separated liquid phase is delivered to a delayed coking device; the separated solid phase is dehydrated to form the residues that meet the discharge standards for solids; and the wastewater generated during the process is biochemically treated and then discharged after reaching the discharge standards. The invention is mainly characterized in that the sludge treatment process is short, the speeds and the efficiencies of sludge dehydration and extraction are high, the effect is good, the operational condition is moderate, the energy consumption is reduced, the oily sludge treatment effect is good, and the operating maintenance of the equipment is simple.

Owner:PETROCHINA CO LTD

Method for synthesizing and using oil sludge falling to the ground

InactiveCN101050049AEfficient recyclingEliminate pollutionSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesOil sludgeMineral oil

This invention relates to a method for utilizing the mixtures of crude oil and soil. The method adopts thermochemical washing, dehydration / drying treatment, and incineration on different kinds of mixtures of crude oil and soil. Recovered mineral oil and wastewater can be utilized. Petroleum sludge is sent to an incinerator for incineration, and the flue gas generated during incineration is used to heat waste heat boiler to produce steam, which is a heat source for production and living. The method has such advantages as simple process, easy application, low running cost, effective recovery and utilization of mineral oil, no environmental pollution, clean production, and high profit.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

Air compressor oil and preparation method thereof

InactiveCN104263481AGuaranteed safe operationAvoid cloggingLubricant compositionGas compressorAntioxidant

The invention provides air compressor oil which comprises the following components in parts by weight: 75-94 parts of synthetic hydrocarbon base oil, 5-20 parts of synthetic ester base oil and 1-5 parts of functional additive, wherein the functional additive comprises a purification dispersant, an antiwear agent, a metal deactivator, an antirust agent, an antioxidant, a pour point depressant, a demulsifying agent and an anti-foaming agent. The invention provides a preparation method of the air compressor oil. The preparation method comprises the step of mixing the synthetic hydrocarbon base oil, the synthetic ester base oil and the functional additive at the temperature of 60-80DEG C to obtain the air compressor oil. According to the air compressor oil provided by the invention, the synthetic oil is used as the base oil and the compound type functional additive is added, so that the air compressor oil provided by the invention has low oil sludge property. In addition, the air compressor oil provided by the invention also has the advantages of better thermal oxidation stability, low-temperature fluidity and higher viscosity index, and the use requirement of an air compressor is met.

Owner:CHINA PETROLEUM & CHEM CORP

Combined treatment method for oil-containing sludge

ActiveCN103241913AReduce lossesImprove economySludge treatment by de-watering/drying/thickeningResource utilizationPetrochemical

The invention relates to a combined treatment technology for oil-containing sludge, which is particularly suitable for oil-containing sludge which is generated in sewage treatment processes of petrochemical plants. The method comprises: adding a texturizer into the oil-containing sludge for texturizing treatment, adding an oil displacement agent for uniformly mixing, mechanically dehydrating the oil-containing sludge to reduce a water content to 50-90%, then sending the oil-containing sludge into squeezing equipment for squeezing, mixing mud cakes after squeezing with a mixed extractant, uniformly stirring for extraction, sending a mixture into a solid-liquid separator after extraction, introducing a separated liquid into a rectifying tower for regenerating the extractant, and mixing separated solid residue after dried with coal to used as a fuel. The treatment technology of the invention has advantages of low energy consumption for oil-containing sludge treatment, and fast extraction speed, can recover oil in the oil-containing sludge, and can implement resource utilization and harmlessness treatment of the oil-containing sludge.

Owner:PETROCHINA CO LTD

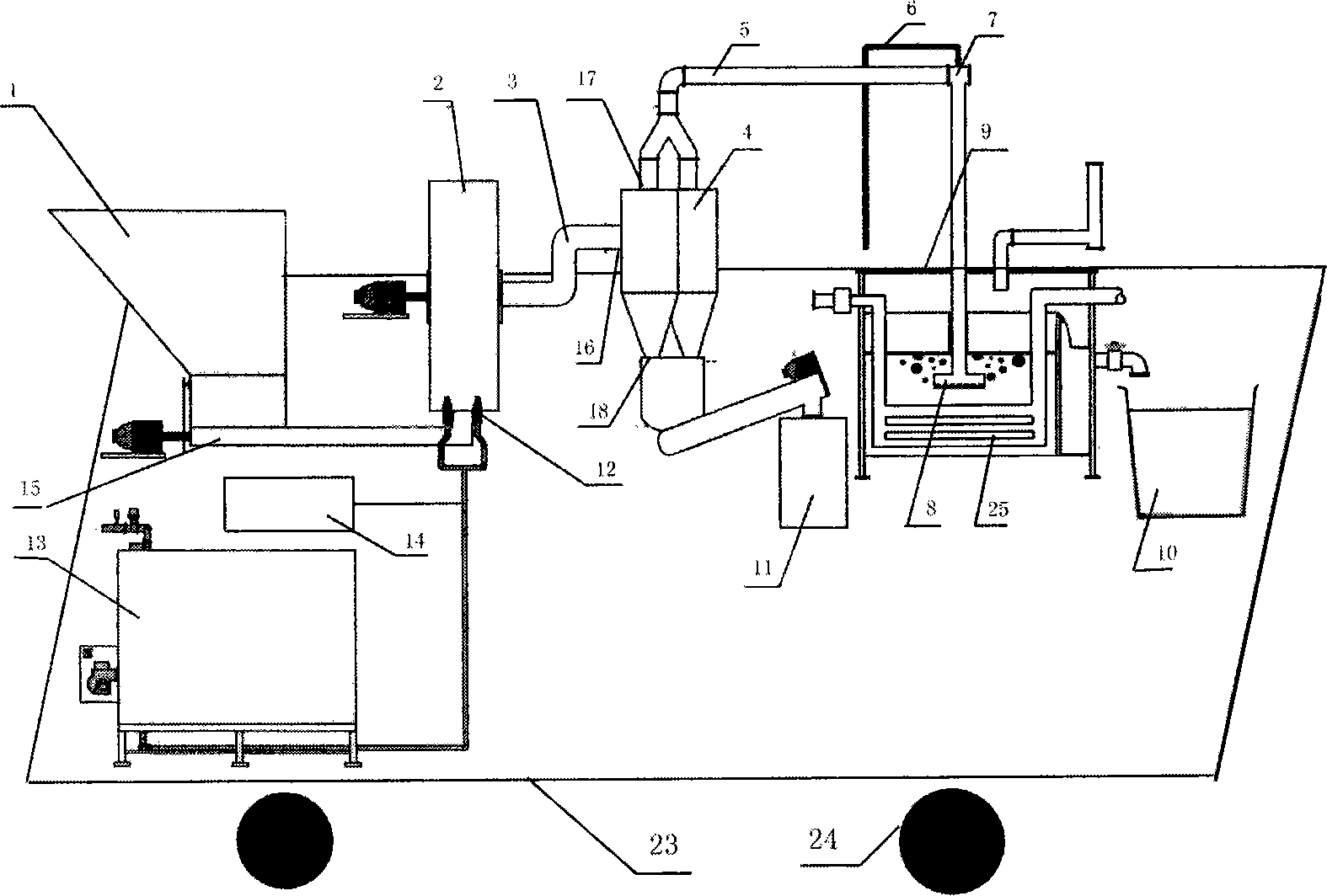

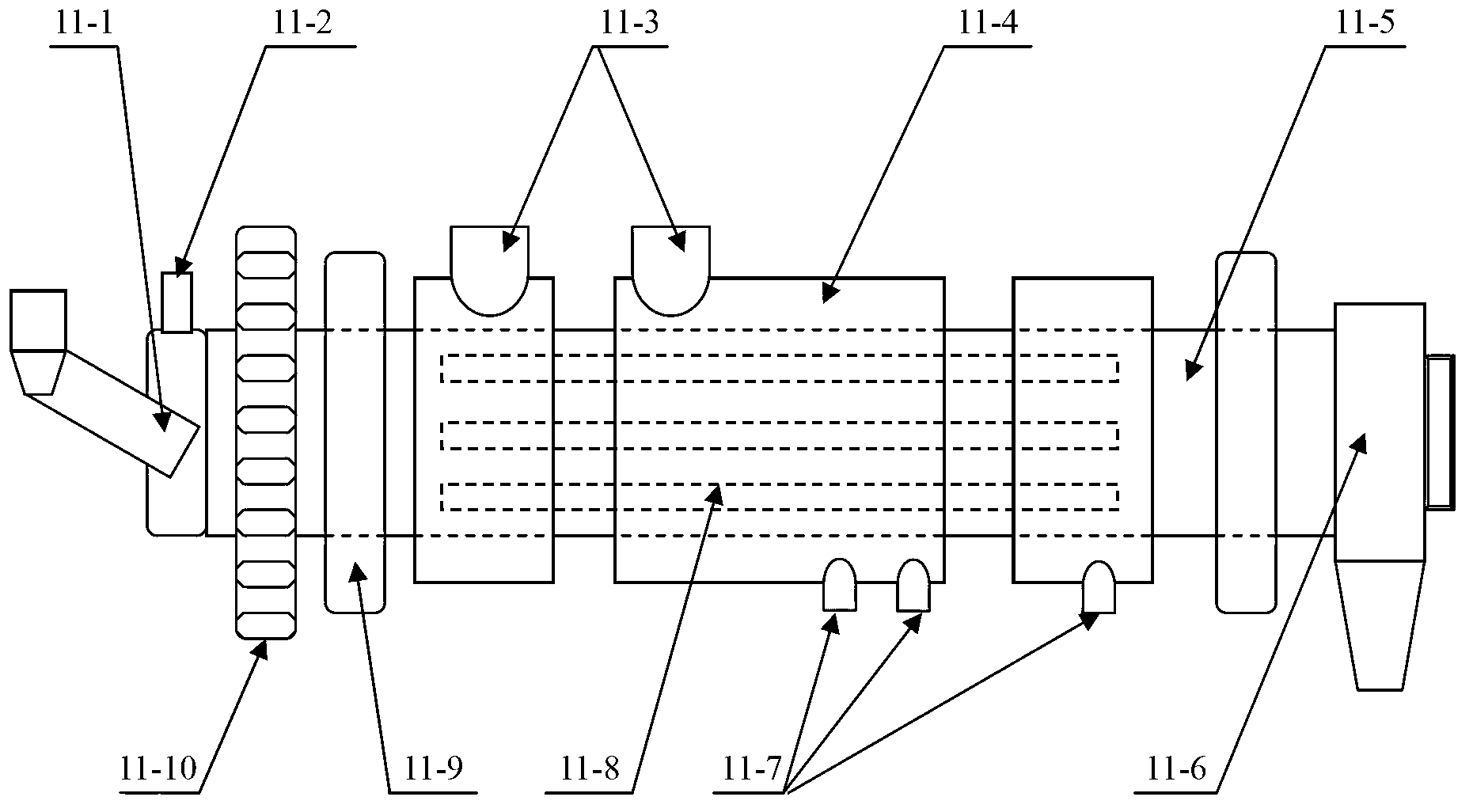

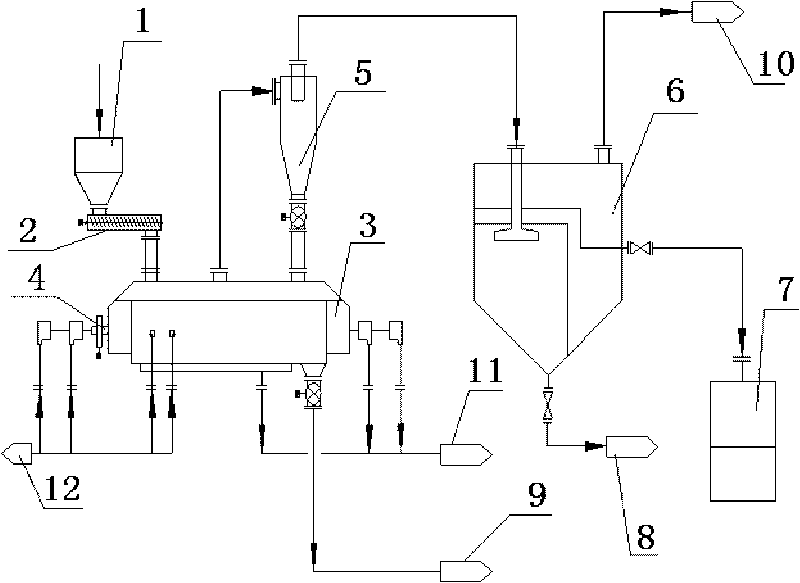

Oil field oil sludge drying treatment combined device and oil sludge drying treatment technique

ActiveCN101759344ARealize resourcesAchieve reductionSludge treatment by de-watering/drying/thickeningOil fieldOil sludge

The invention relates to an oil field oil sludge drying treatment method, in particular to an oil field oil sludge drying treatment combined device and an oil sludge drying treatment technique, being technically characterized in that oil sludge with the moisture content of about 80% is firstly added into a sludge hopper from an oil sludge inlet, and the wet sludge is sent into a paddle dryer by the sludge hopper through a lower screw conveyer; a hollow shaft of the paddle dryer as well as a hollow blade and a dimple jacket which are arranged on the hollow shaft are internally communicated with a high temperature heating medium, so that the sludge can be treated by drying; oil-water mixed steam with moisture evaporated out from the paddle dryer enters the cyclone separator, and trace sludge dust enters the cyclone separator, so that gas-solid separation can be carried out; the trace sludge dust returns back into the paddle dryer, and the purified moisture enters an oil-water separator for cooling and separating oil and gas; and the oil is recovered into an oil storage tank. The oil field oil sludge drying treatment combined device and the oil sludge drying treatment technique have the advantages of shrinkage, harmlessness and reclamation.

Owner:XIAN CHANGQING TECH ENG

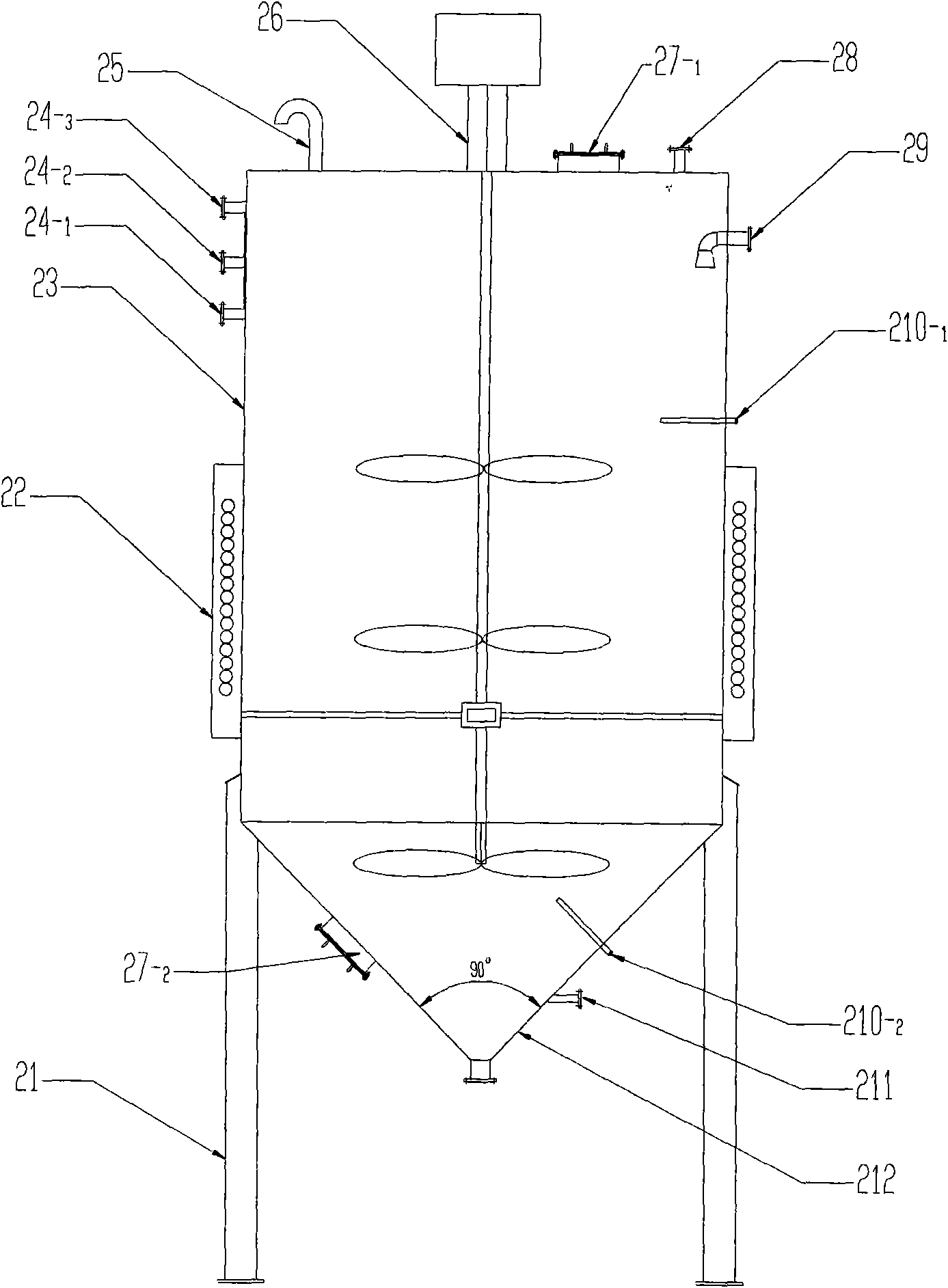

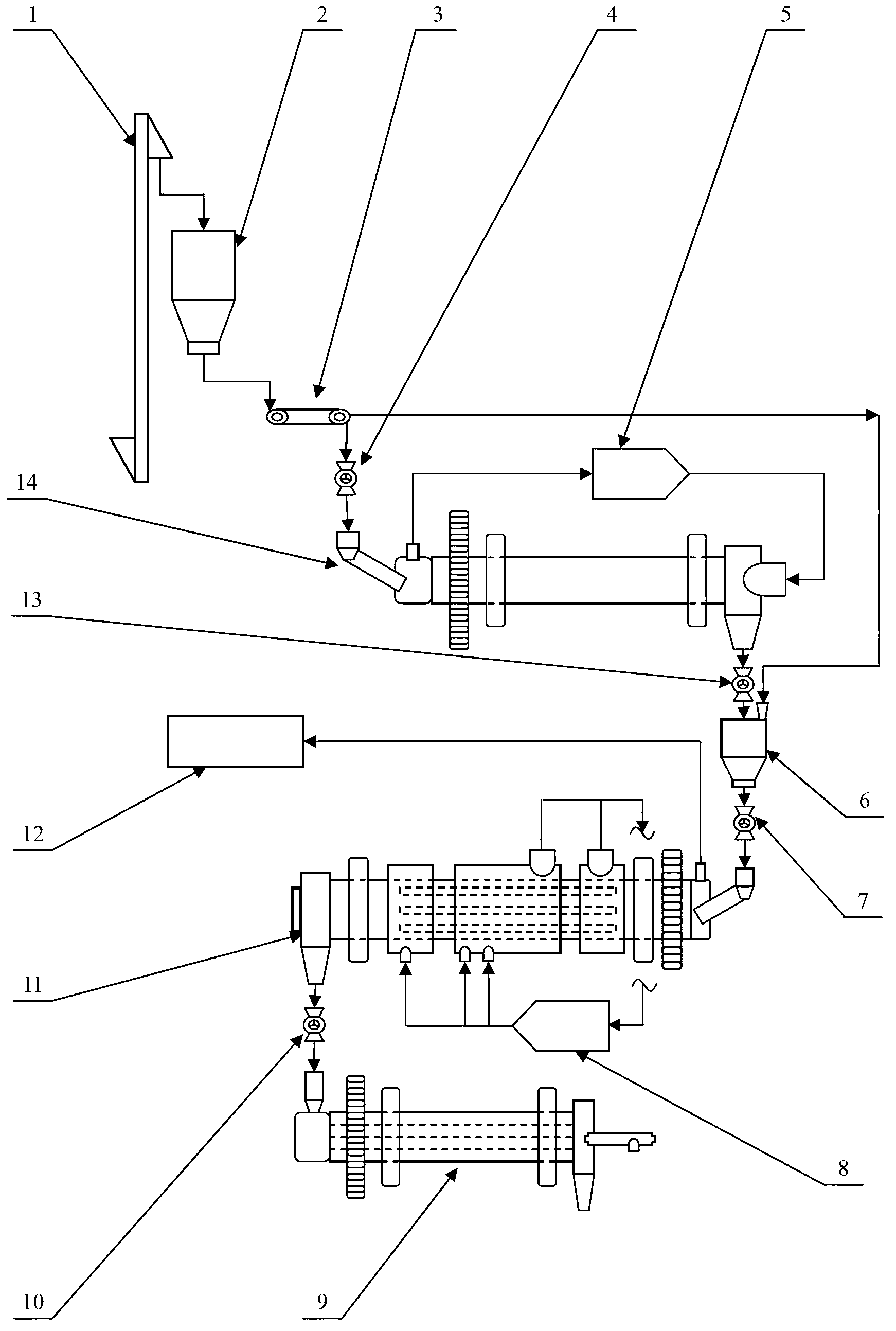

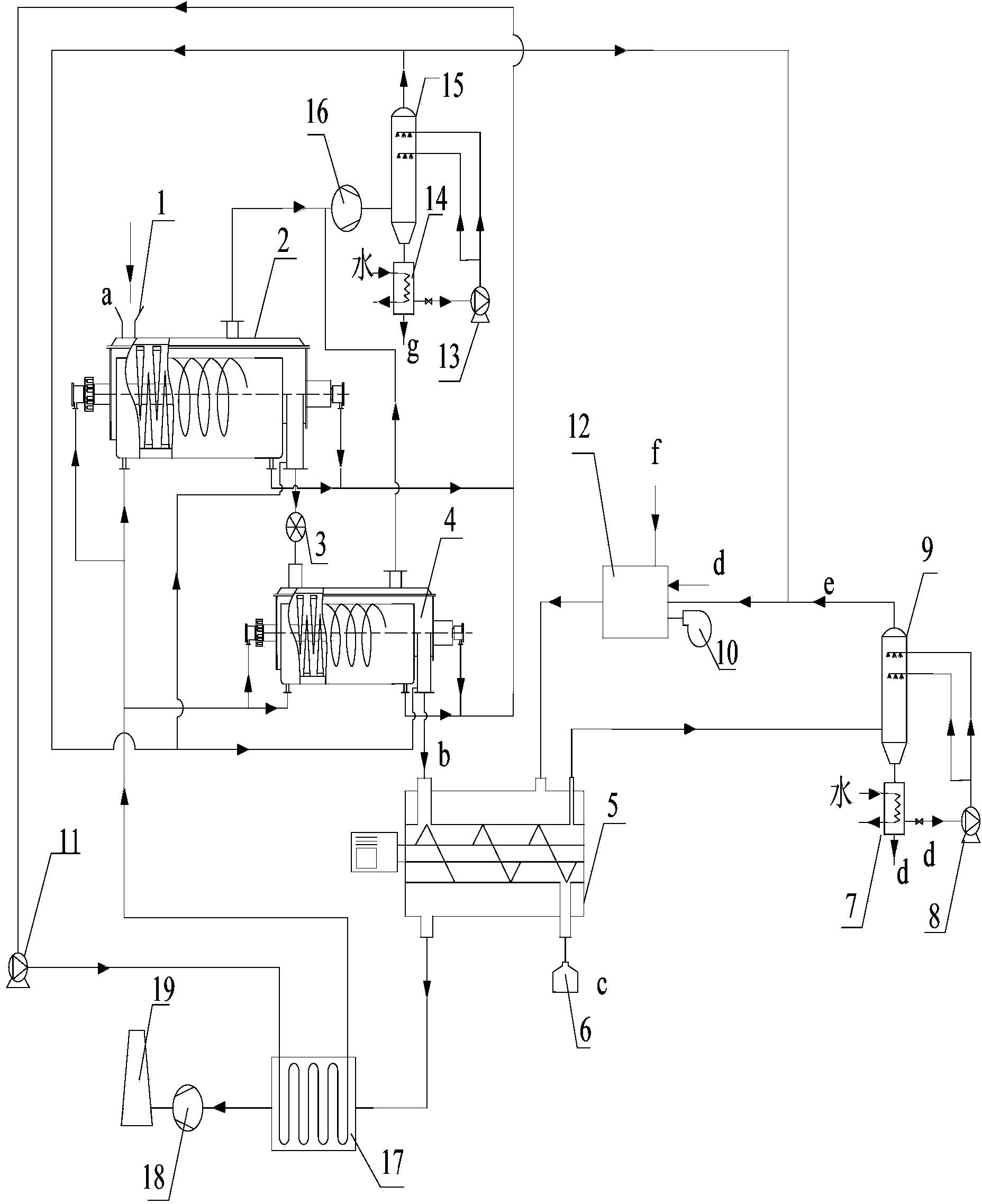

High-efficiency oil sludge pyrolysis oil making method and system

InactiveCN104261649AReduce moisture contentPrevent deflagrationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesAtmospheric airOil sludge

The invention discloses a high-efficiency oil sludge pyrolysis oil making method and system and belongs to the technical field of solid waste recycling and environment. Crude oil sludge is subjected to deep drying and breaking treatment by virtue of a two-stage blade-type dryer and then enters a spiral pyrolyzing furnace, and produced pyrolysis gas is subjected to spray cooling to obtain an oil product; noncondensing gas and part of pyrolysis oil which are produced in a drying and pyrolysis process are fed into a burning furnace to be burned, and high temperature smoke produced during burning is used for providing heat for a pyrolysis furnace; smoke at an outlet of a jacket of the pyrolysis furnace passes through a heat conduction oil heat exchanger to recycle waste heat and then is discharged into the air; and the heat conduction oil after being heated provides heat for the blade-type dryer. Therefore, the high-efficiency oil sludge pyrolysis oil making method and system are safe and reliable, drying pyrolysis efficiency is high, the oil product in the sludge can be recycled, gradient utilization of energy is realized, and oil sludge recycling and harmless treatment is realized.

Owner:SOUTHEAST UNIV

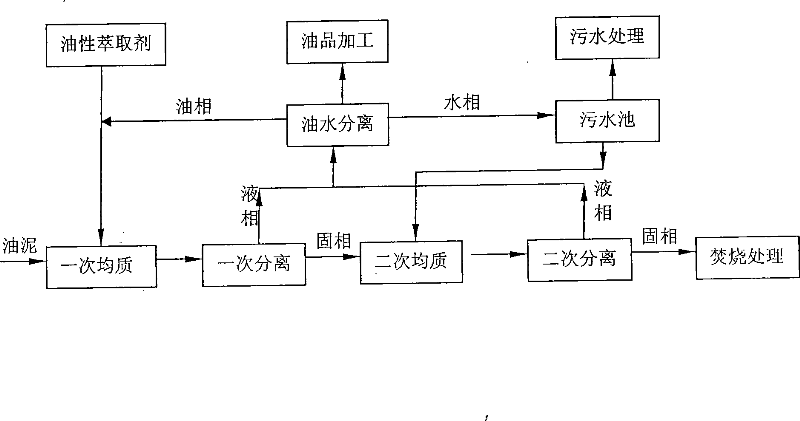

Oil soil treatment technique for tank cleaning

InactiveCN101041541AHigh recovery rateEfficient recyclingSludge treatmentMultistage water/sewage treatmentSoil treatmentAdhesive

The invention discloses a disposing craft of tank-cleaning oil sludge, which comprises the following steps: putting tank-cleaning oil sludge into one and two grade homogeneous machine; adding into extracting agent at finite ratio; heating; stirring; proceeding once and twice solid-liquid separation in centrifuge; leading into water-oil separating tank; proceeding settling segregation; separating out of oil, wastewater and sand; proceeding continuous extraction; handling; discharging; burning; biological degrading; or using as process-type adhesive.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

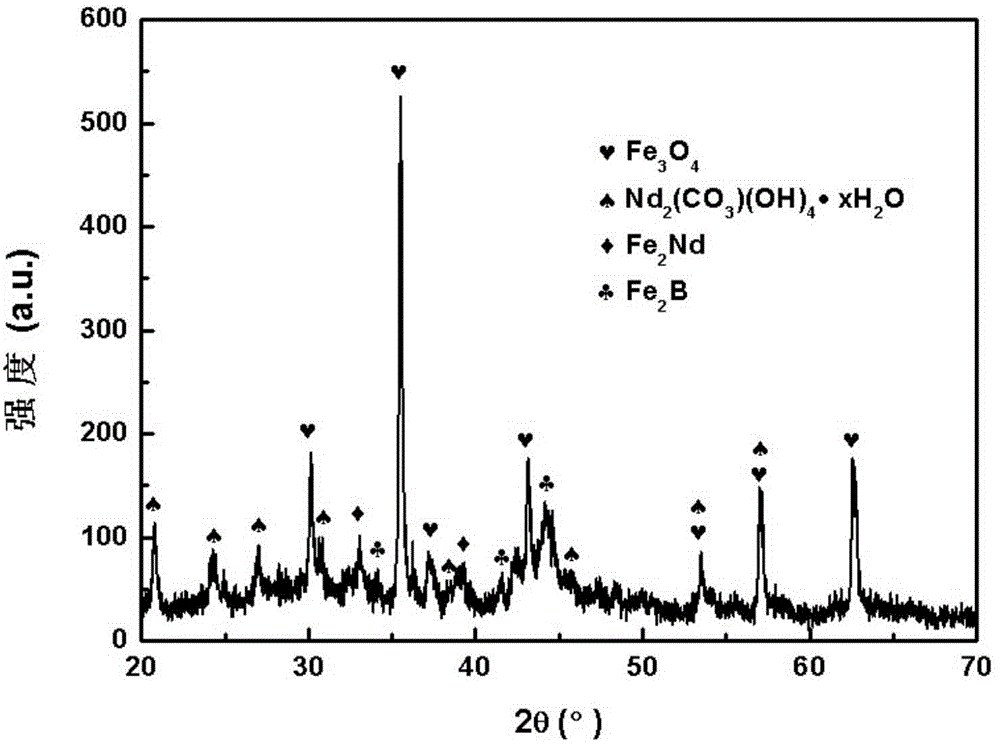

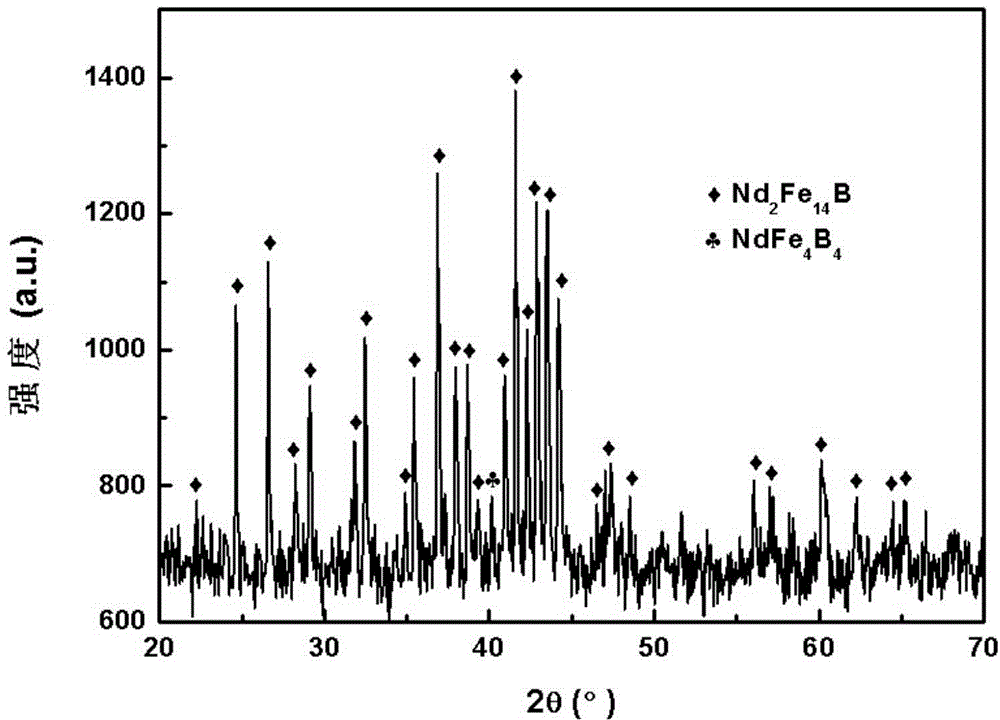

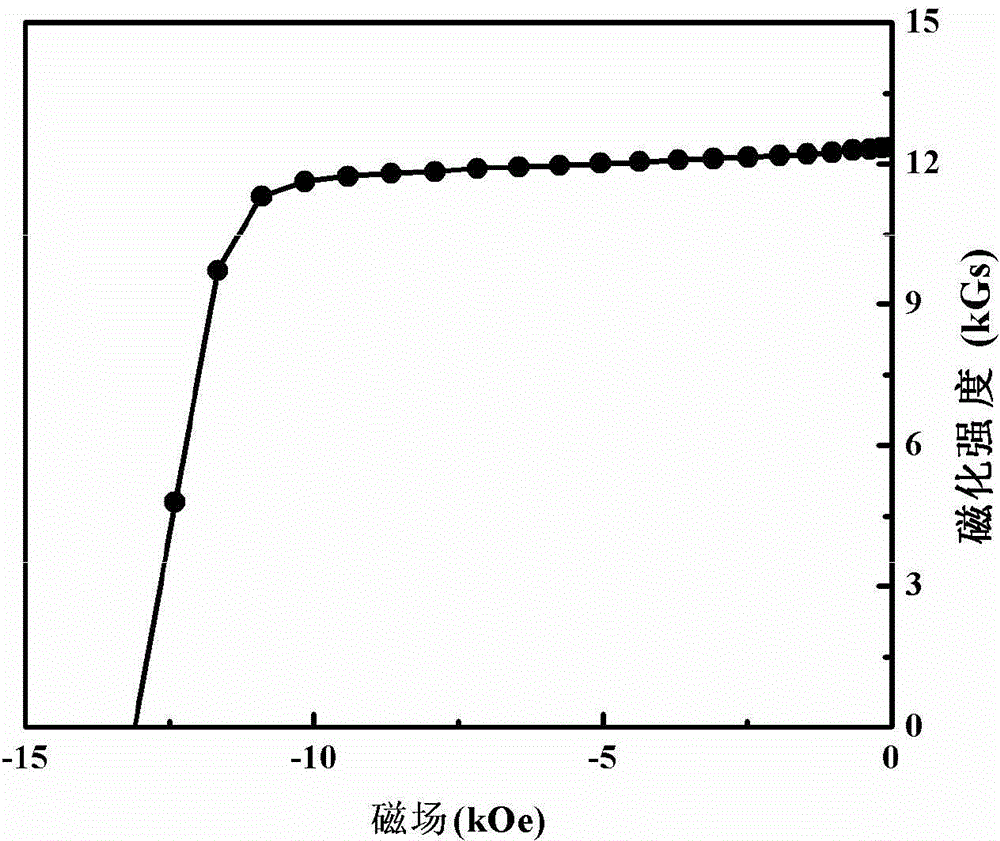

Short-process method for preparing high-performance sintered NdFeB magnet by utilizing sintered NdFeB oil sludge waste material

ActiveCN104690270AReduce the energy consumption of millingShort processInductances/transformers/magnets manufactureRecycling and recovery technologiesScrapEnvironmentally friendly

The invention discloses a short-process method for preparing a high-performance sintered NdFeB magnet by utilizing a sintered NdFeB oil sludge waste material, and belongs to the technical field of recycling of the sintered NdFeB oil sludge waste material. The method comprises the following steps: (1) distillation of organics in oil sludge, (2) ultrasonic washing of oil sludge powder, (3) calcium reduction and diffusion, (4) ultrasonic rinsing and drying under a magnetic field, (5) powder mixing and sintering, and the like. The short-process method has the advantages that when the sintered NdFeB oil sludge waste material is taken as a raw material, the regenerative high-performance sintered NdFeB magnet can be directly obtained; a vacuum stepped heating method is adopted in an oil sludge distillation process, so that most organics can be effectively removed; magnetic field ultrasonic treatment is adopted in an oil sludge powder washing process, so that residual organics can be effectively removed; through an addition of nanometer powder, the maximum magnetic energy product of the obtained regenerative high-performance sintered NdFeB magnet can reach 35.26 MGOe. The method is short in process, efficient, environmentally friendly, and high in rare earth recycling rate.

Owner:BEIJING UNIV OF TECH

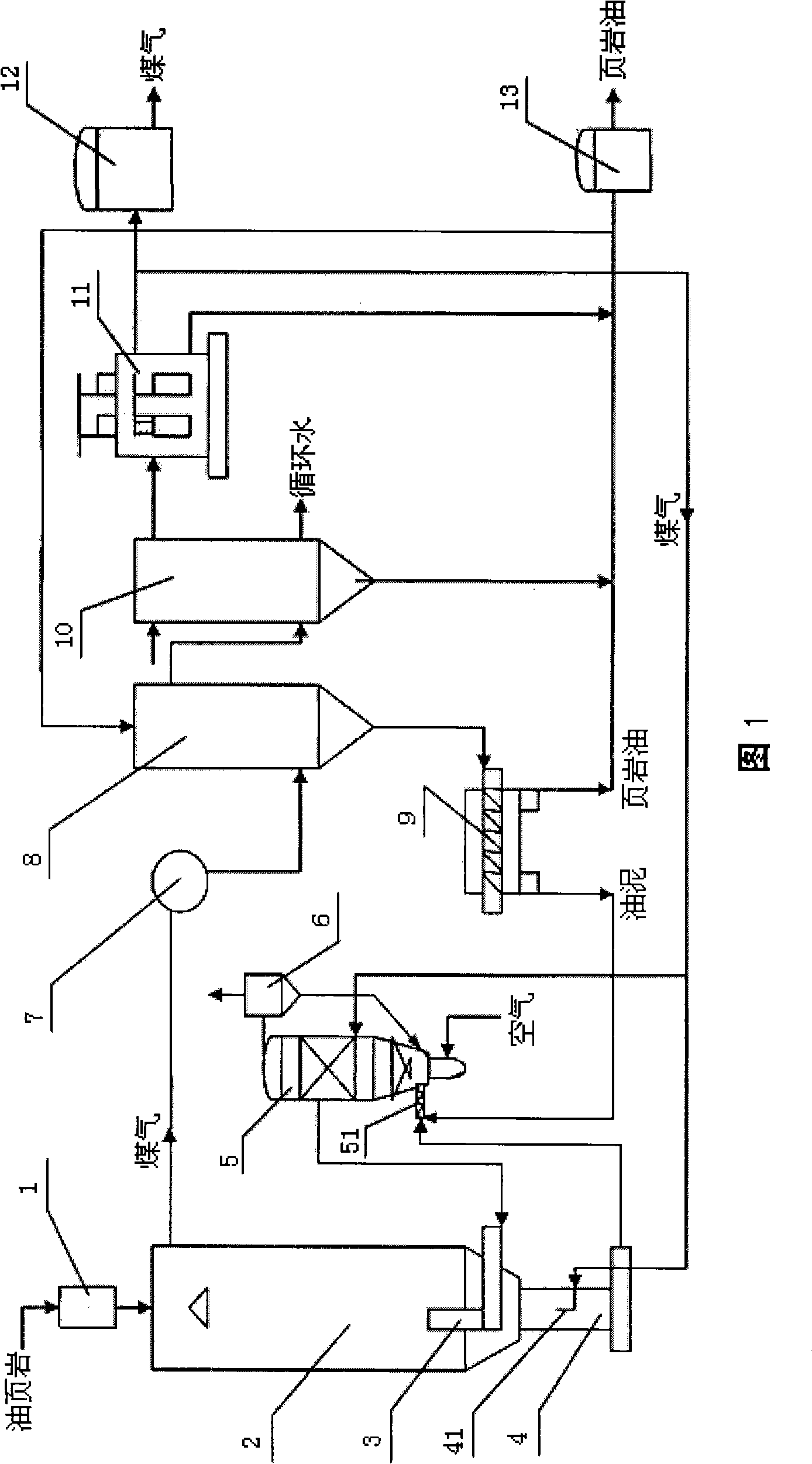

Full cycle dry distillation process and system for producing shale oil from oil shale (coal)

InactiveCN101280201AHigh calorific valueAchieve separationSpecial form destructive distillationDistillationOil sludge

The invention provides a full cycle dry distillation process and a system which use oil shale (coal) to produce shale oil; the technological process includes that the distillation of the oil shale is processed in an oil shale distillation system which is composed of an oil shale input storage tank, a non-oxygen coal-gas heating retort and a semi-coke discharge device to generate pyrogenous coal gas and the semi-coke; the pyrogenous coal gas is separated and purified by a pyrogenous coal gas multi-stage purifying system composed of a coal gas collecting pipe, an oil-washing tower, an intercooling tower and an electrical oil trap; the obtained coal gas is preheated by a coal gas preheating system composed of a fluidized bed combustion furnace, a spiral feeder and a duster collector and then is fed into the non-oxygen coal-gas heating retort for the dry distillation of the oil shale; the oil product separated from the oil-washing tower, the intercooling tower and the electrical oil trap is purified and collected through an oil product purifying and collecting system so that the shale oil product is obtained; the semi-coke and the sludge generated during the dry distillation and purification process are used as the materials for the preheating of the coal gas. The dry distillation process in the invention can effectively realize the functions of dry distillation, dust separation and combusting the semi-coke and sludge generated during the process of dry distillation for the preheating of the coal gas; thereby, the sources is utilized sufficiently and the environmental protection requirement is fulfilled.

Owner:ZHUHAI TOP ENERGY TECH

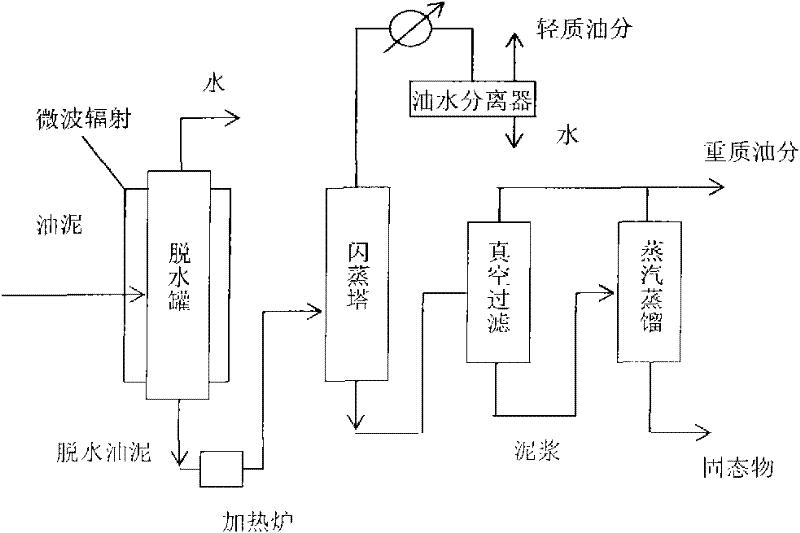

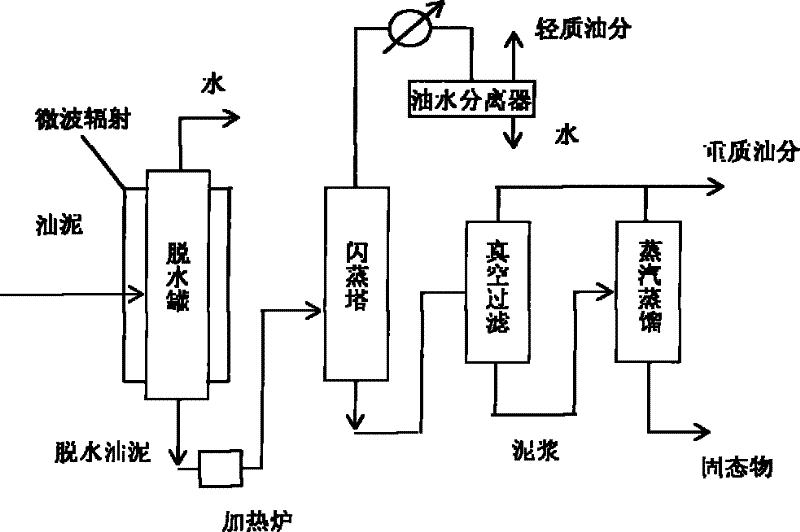

Method for treating oil sludge

ActiveCN102452776AImprove processing efficiencySmall scaleSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningFull recoveryOil sludge

The invention discloses a method for treating oil sludge. The method realizes oil sludge integrated treatment by utilization of microwave demulsification dehydration, heat treatment flash evaporation and steam distillation. Concretely, the method comprises the following steps of 1, carrying out a microwave pretreatment demulsification dehydration process on oil sludge to reduce water content of the oil sludge, 2, heating the oil sludge subjected to the microwave pretreatment demulsification dehydration process to a temperature of 100 to 300 DEG C in an oxygen-free environment, feeding the heated oil sludge into a separating column, carrying out a heat treatment flash evaporation process, through condensation, recovering a light oil component and water separated by the heat treatment flashevaporation, and taking out sludge comprising a heavy oil component and solids from the separating column, and 3, carrying out solid-liquid separation of the sludge in the bottom of the separating column, recovering the heavy oil component as a coking or catalytic cracking raw material, and carrying out a steam distillation process on the solids to further recover an oil component from the solids. The method can realize full recovery of various valuable components of oil sludge and has good industrial application economical efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

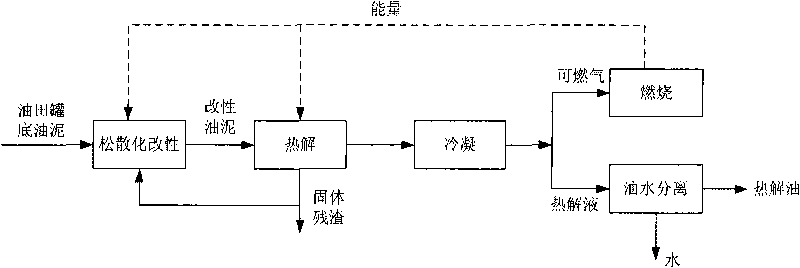

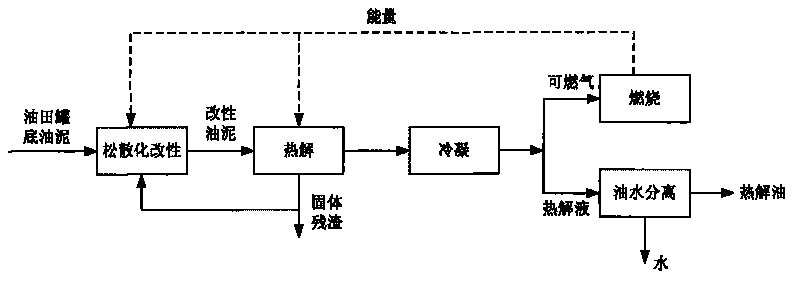

Reclamation treatment method of oil field tank bottom oil sludge

InactiveCN101759339AEnhanced mass transferGuaranteed uptimeSludge treatment by pyrolysisByproduct vaporizationResource recoveryOil field

The invention discloses an oil sludge treatment method which comprises the following steps of: first, carrying out loose modification on oil field tank bottom oil sludge, then carrying out pyrolysis, and obtaining solid residue and gas product; condensing the gas product and obtaining pyrolysis liquid and combustible gas; and carrying out oil-water separation on the pyrolysis liquid, and obtaining pyrolysis oil. The reclamation treatment method of oil field tank bottom oil sludge can effectively recover oil resource in the oil sludge, realizes self-heat-supply of a system and high-efficiency recovery utilization of energy, and achieving the aim of harmless treatment of the oil sludge. Compared with other treatment technologies, the technology has the advantages of stable and reliable operation, high oil resource recovery rate, strong adaptability and low secondary pollution, thus being a reclamation treatment technology of oil field tank bottom oil sludge which is worth popularizing.

Owner:TSINGHUA UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com